Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1670results about "Dough-sheeters/rolling-machines/rolling-pins" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

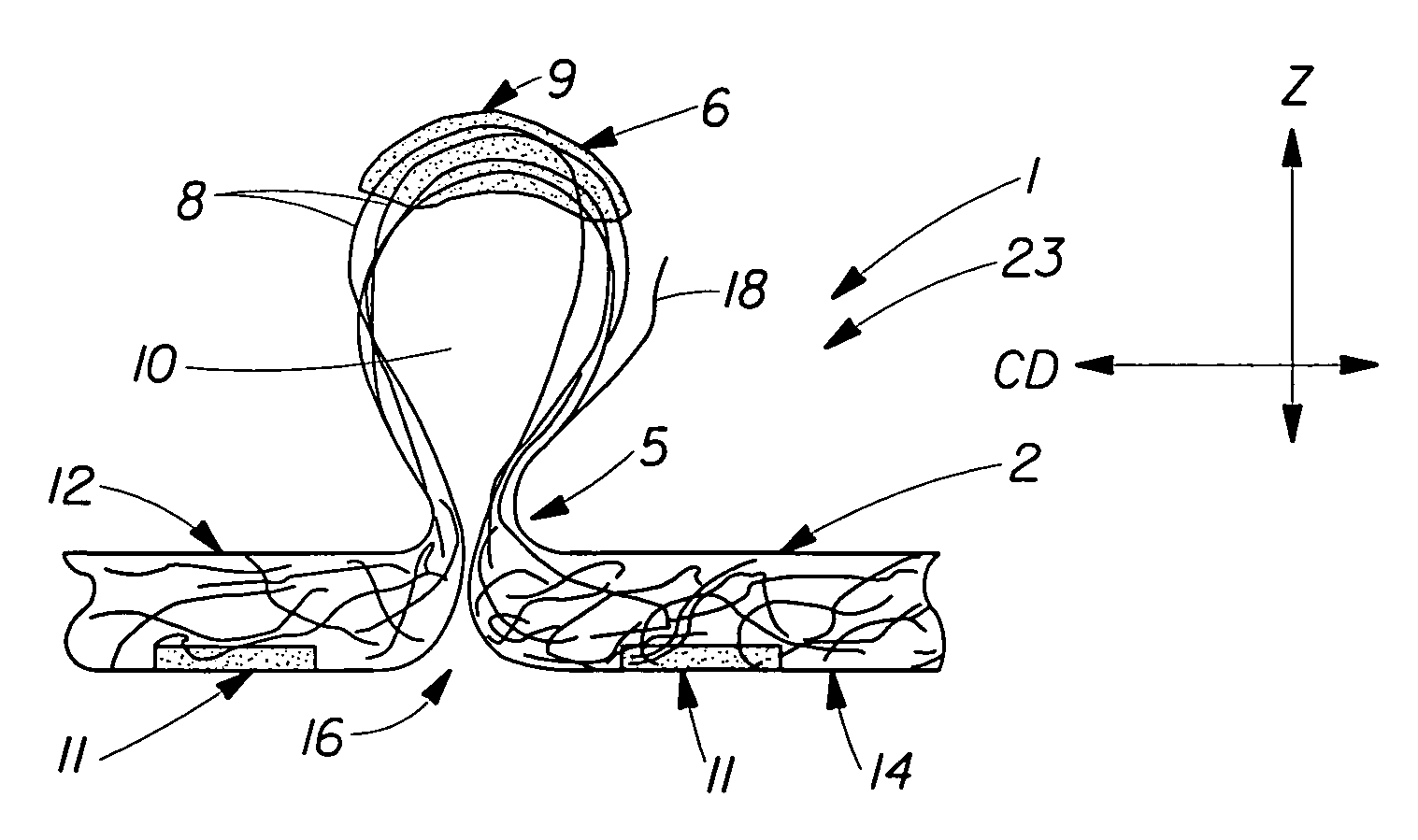

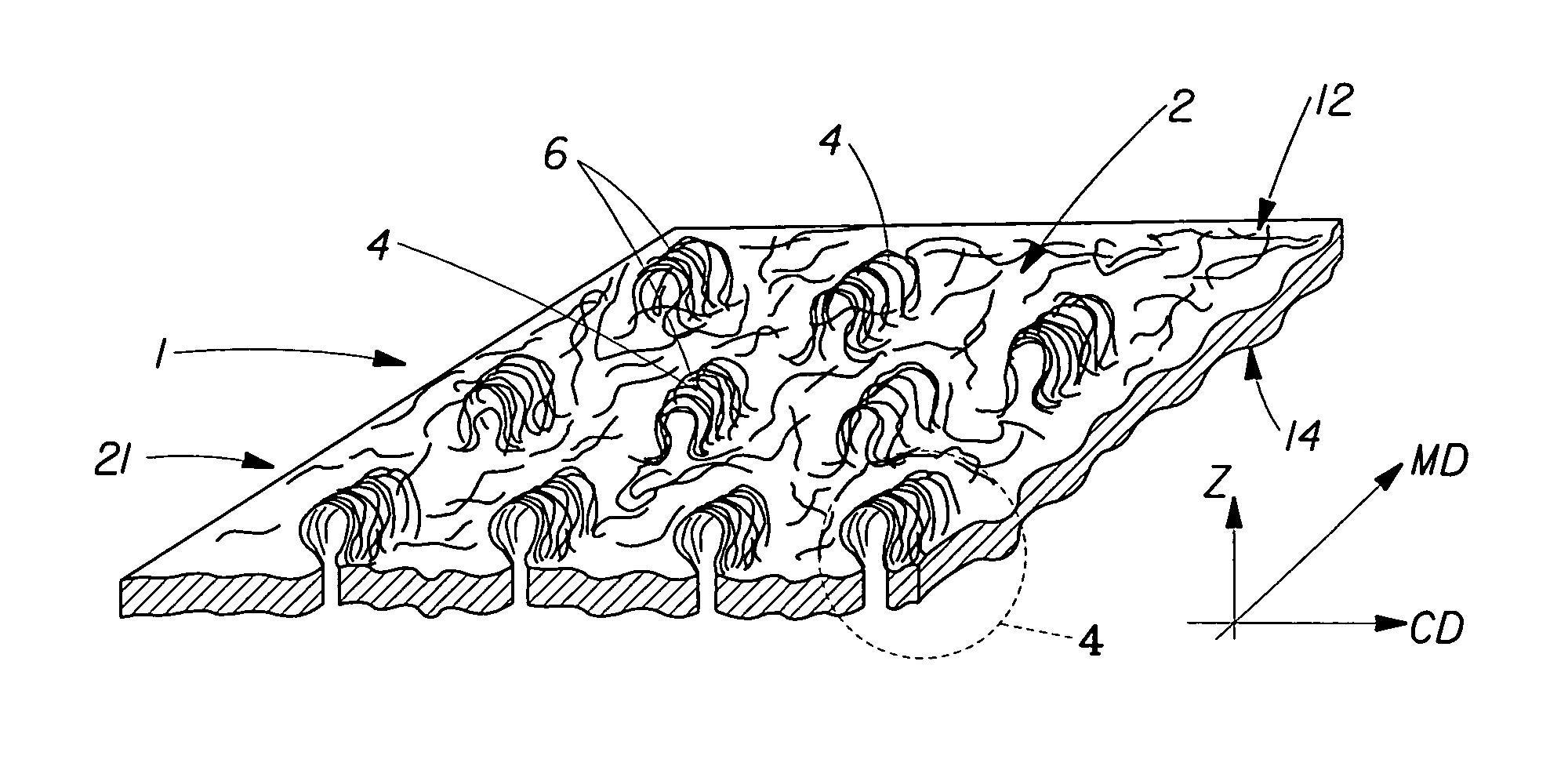

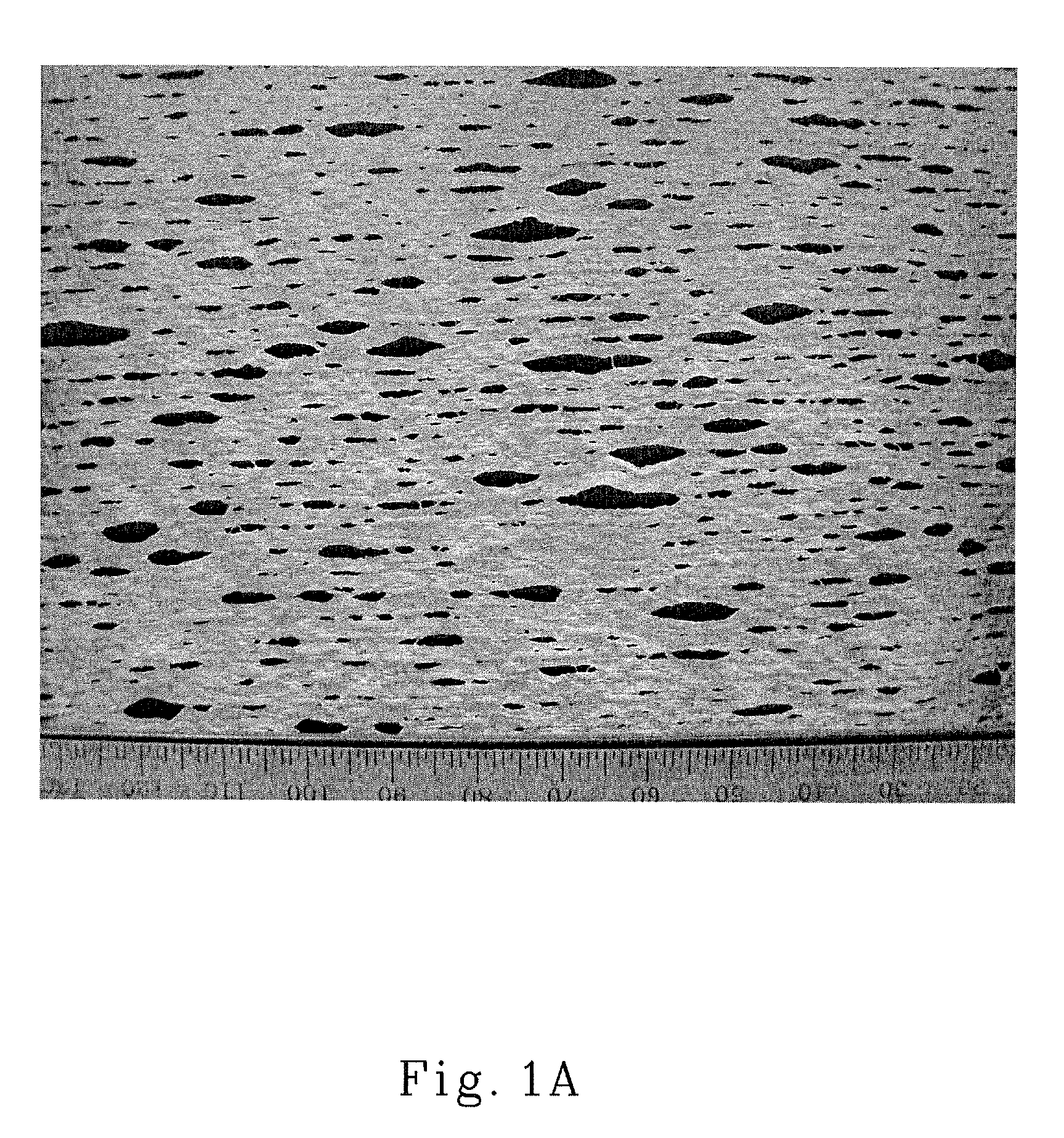

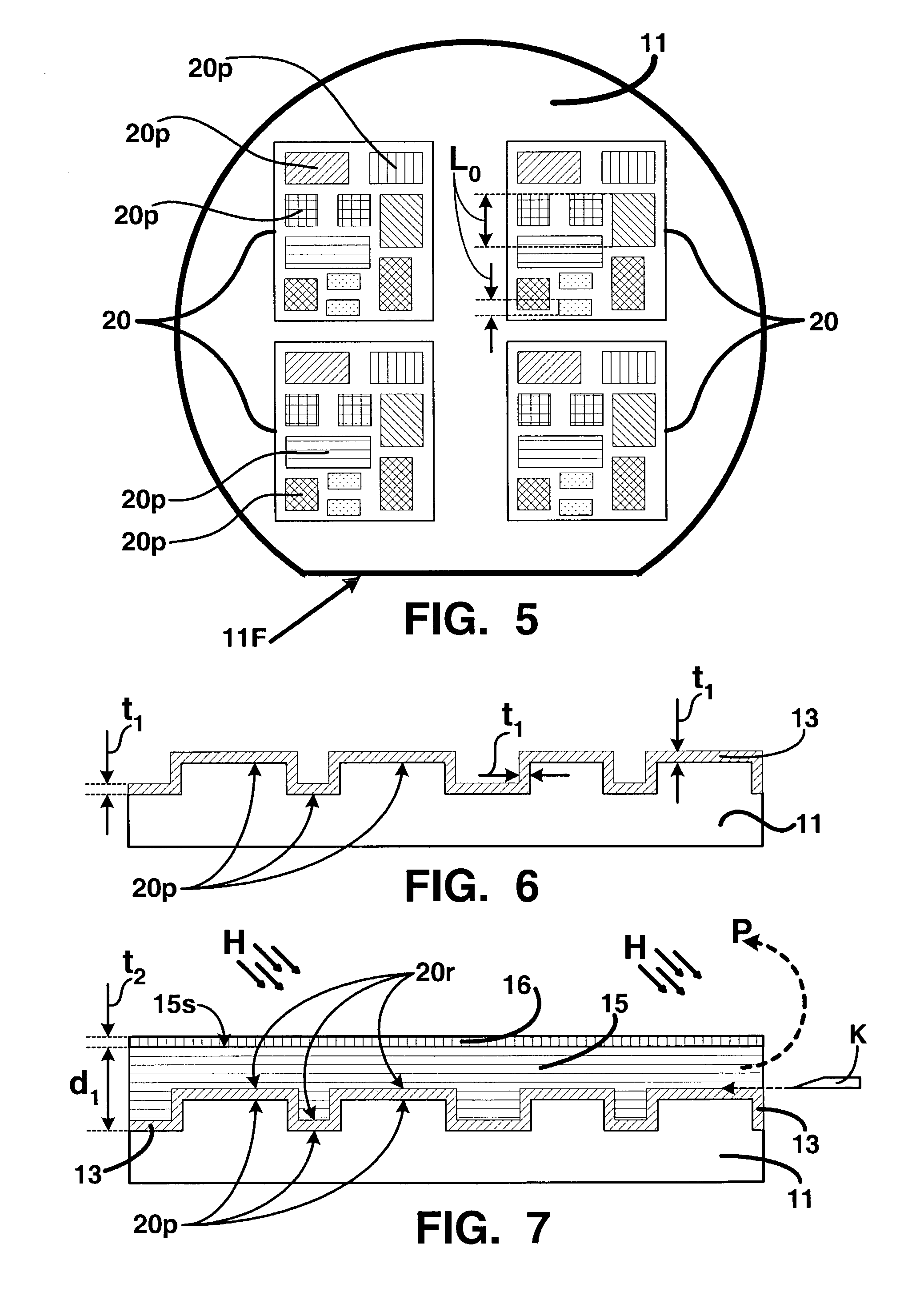

Tufted fibrous web

A fibrous web having a first surface and a second surface. The fibrous web has a first region and at least one discrete second region, the second region being a discontinuity on the second surface and being a tuft comprising a plurality of tufted fibers extending from the first surface. The tufted fibers define a distal portion, the distal portion comprising portions of the tufted fibers being bonded together. Bonding can be thermal melt-bonding. In another embodiment the second surface of the web can have non-intersecting or substantially continuous bonded regions, which also can be thermal melt-bonding.

Owner:PROCTER & GAMBLE CO

Tufted fibrous web

A fibrous web having a first surface and a second surface. The fibrous web has a first region and at least one discrete second region, the second region being a discontinuity on the second surface and being a tuft comprising a plurality of tufted fibers extending from the first surface. The tufted fibers define a distal portion, the distal portion comprising portions of the tufted fibers being bonded together. Bonding can be thermal melt-bonding. In another embodiment the second surface of the web can have non-intersecting or substantially continuous bonded regions, which also can be thermal melt-bonding.

Owner:THE PROCTER & GAMBLE COMPANY

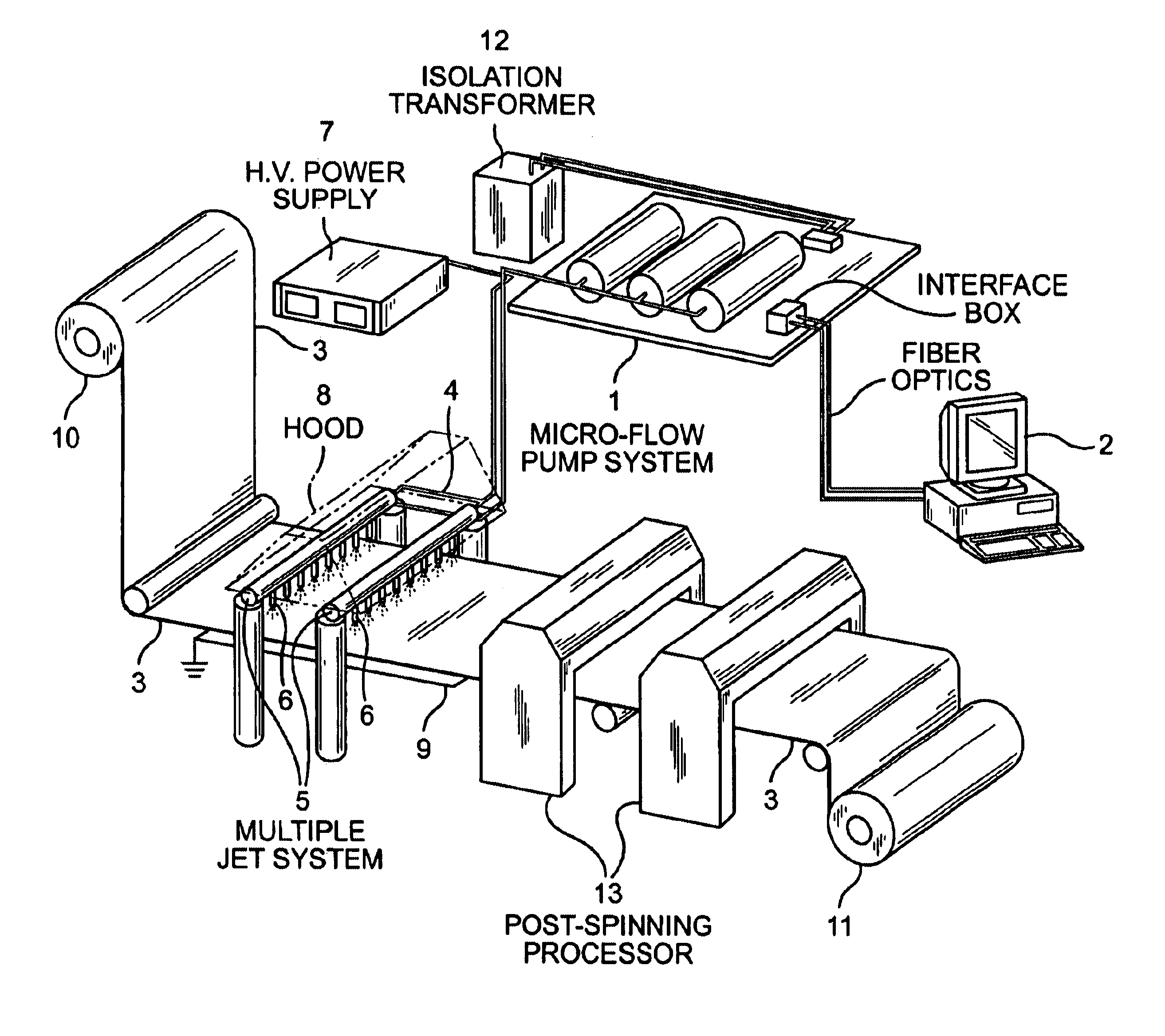

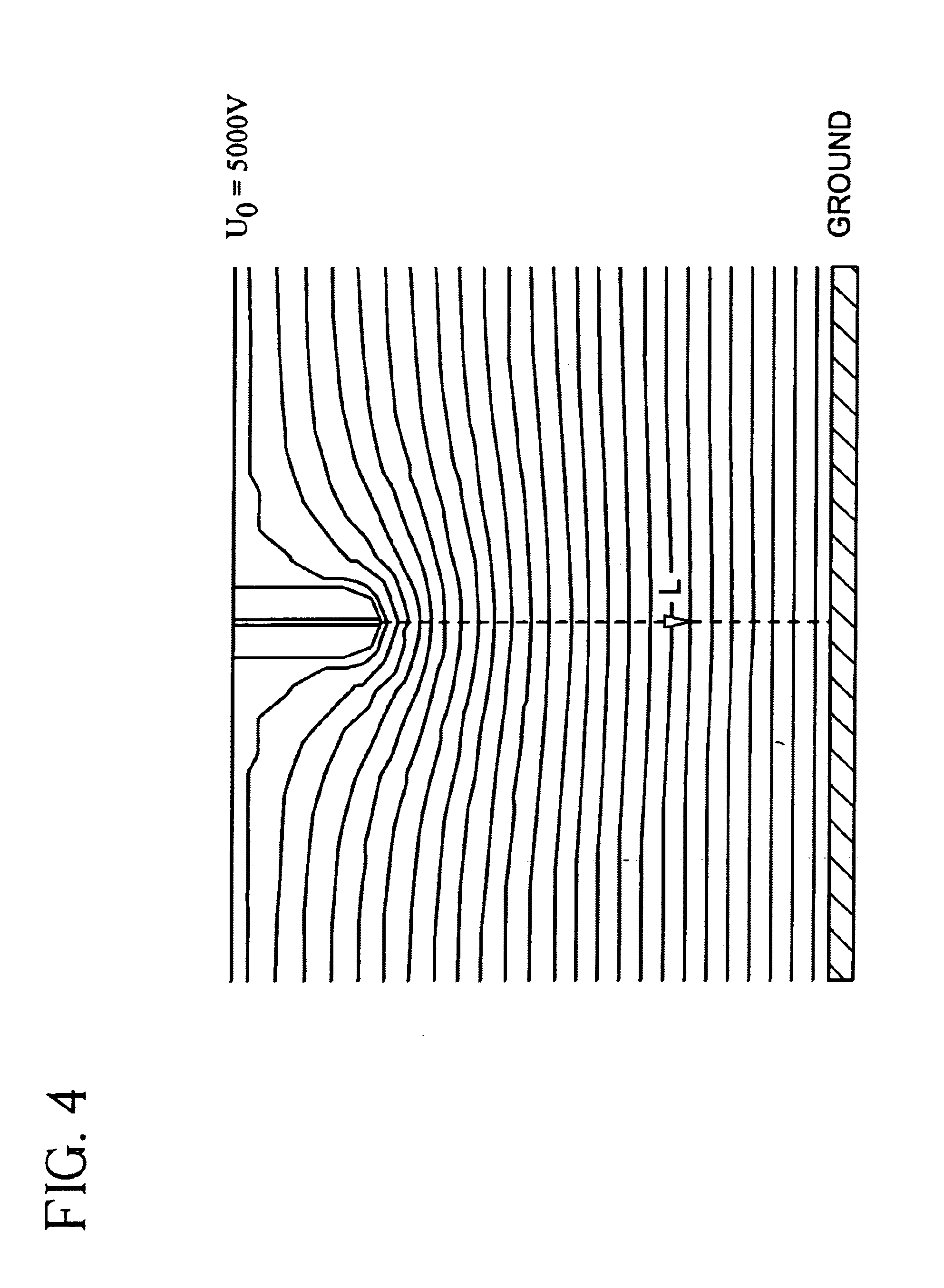

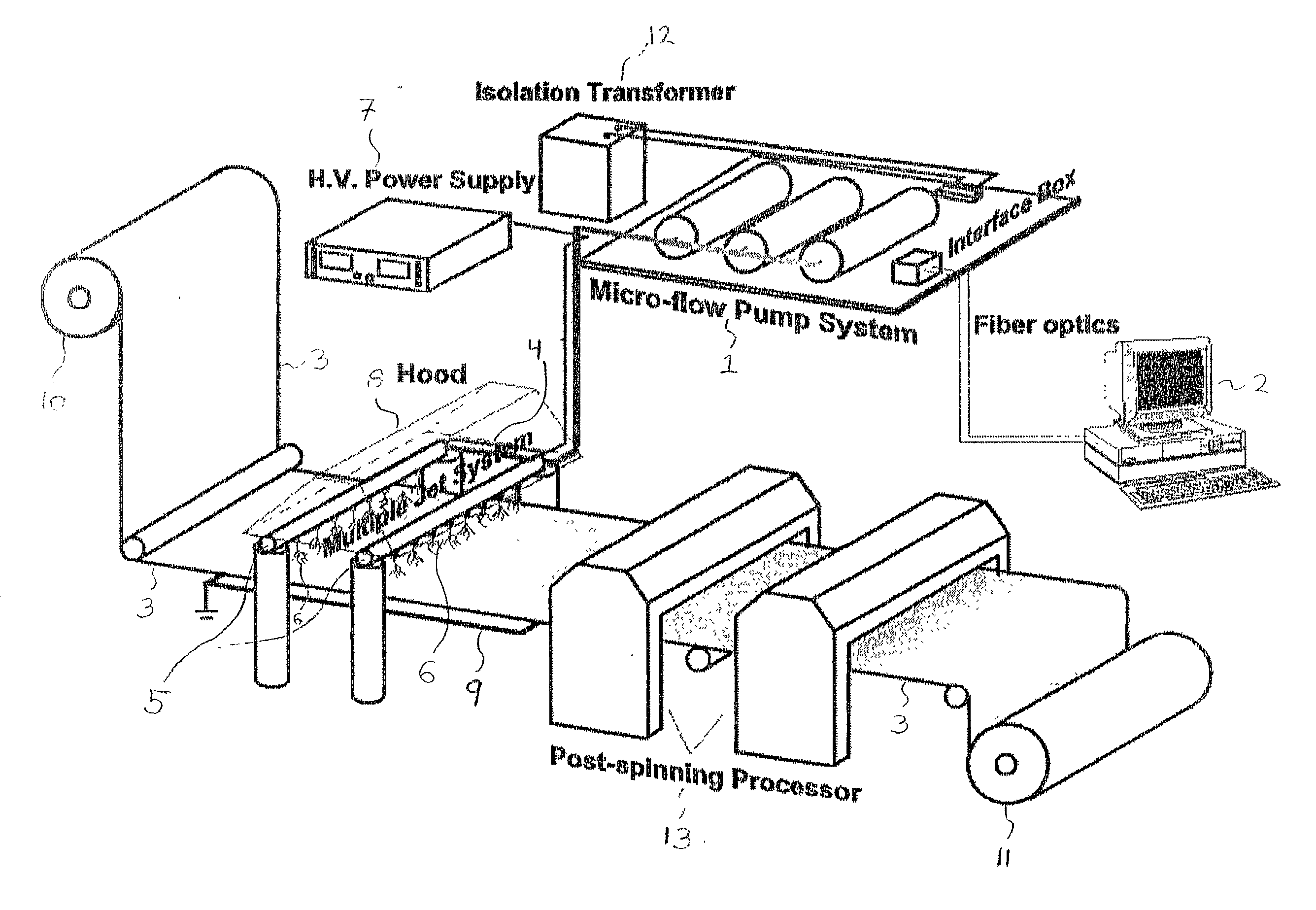

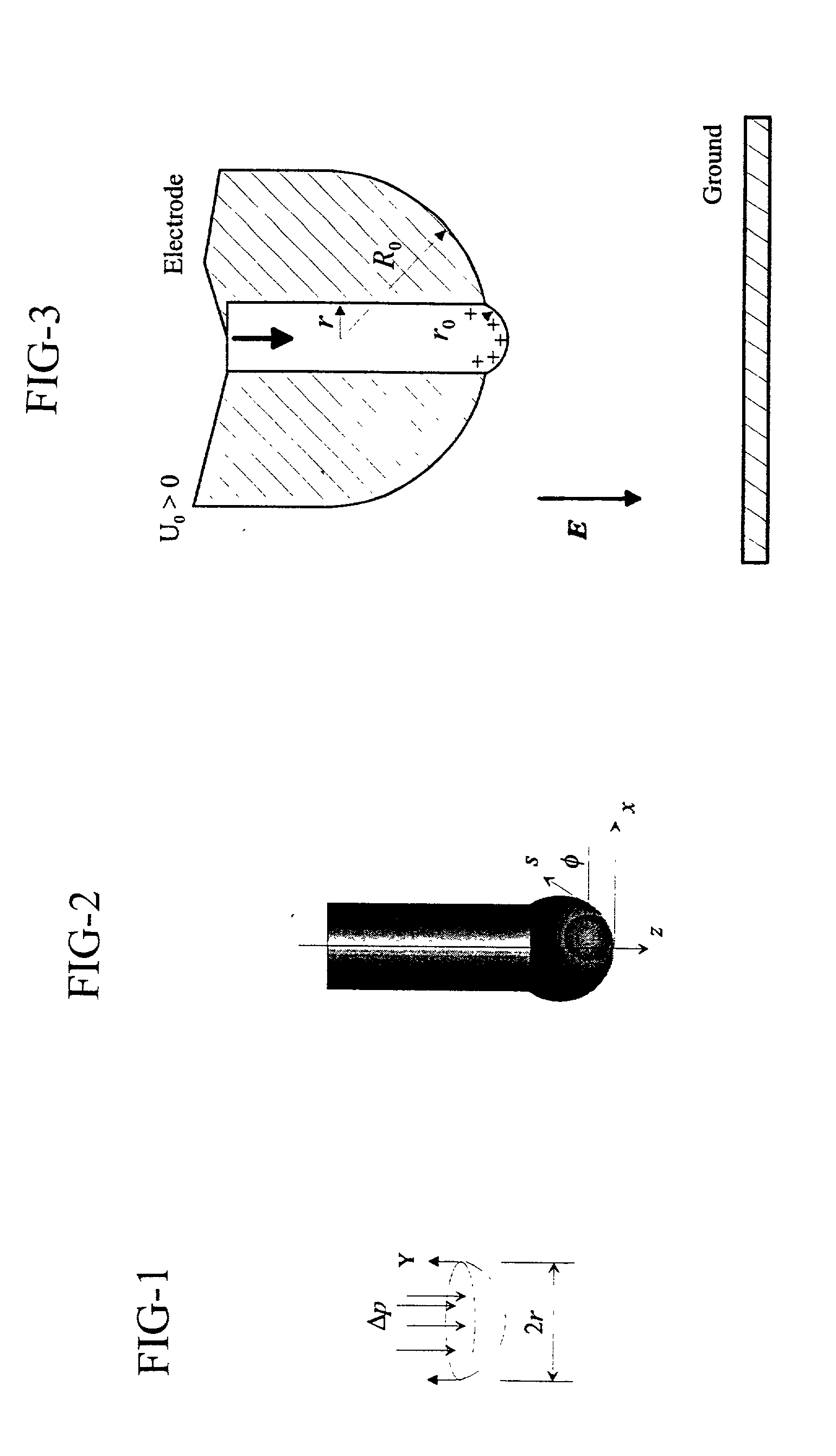

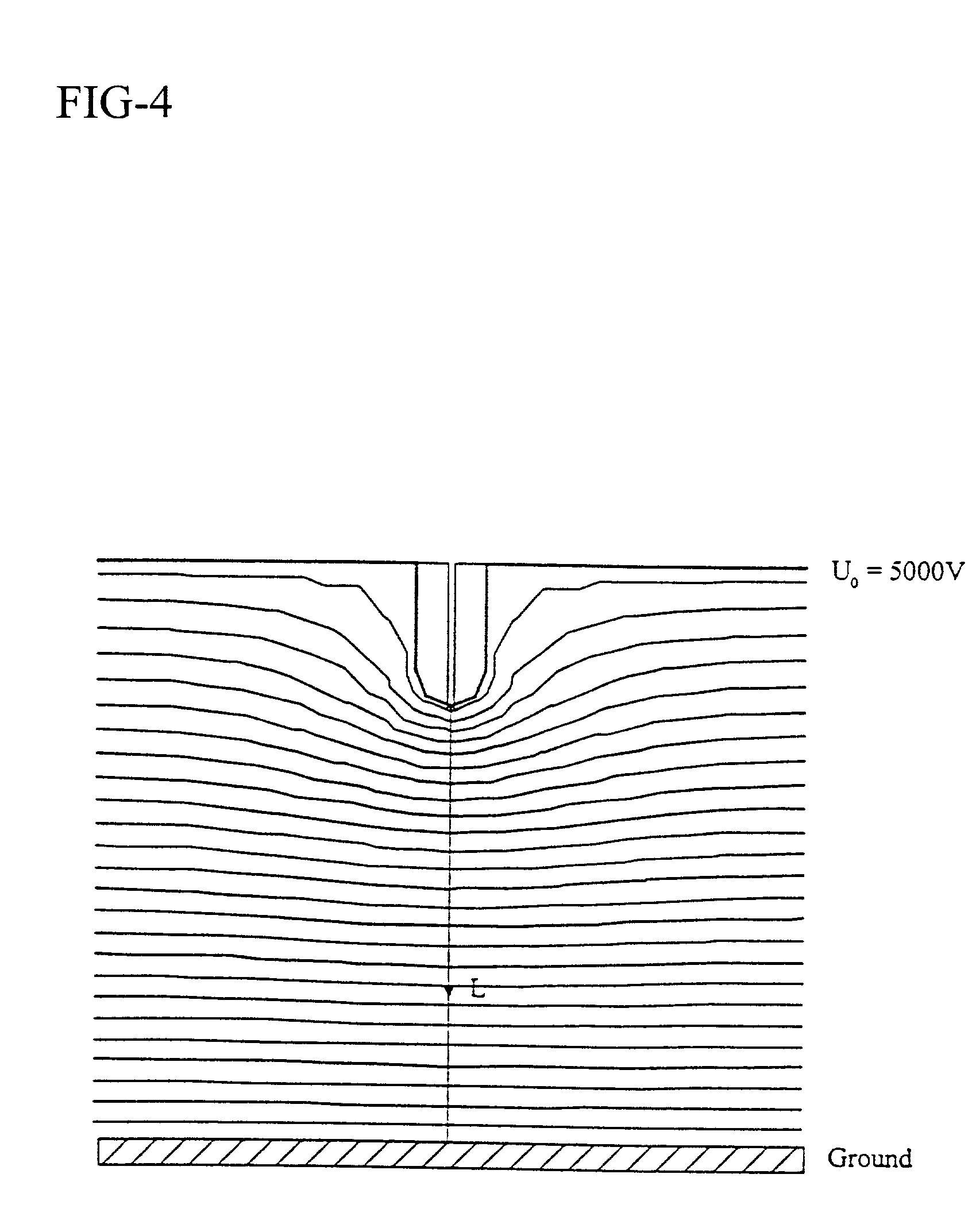

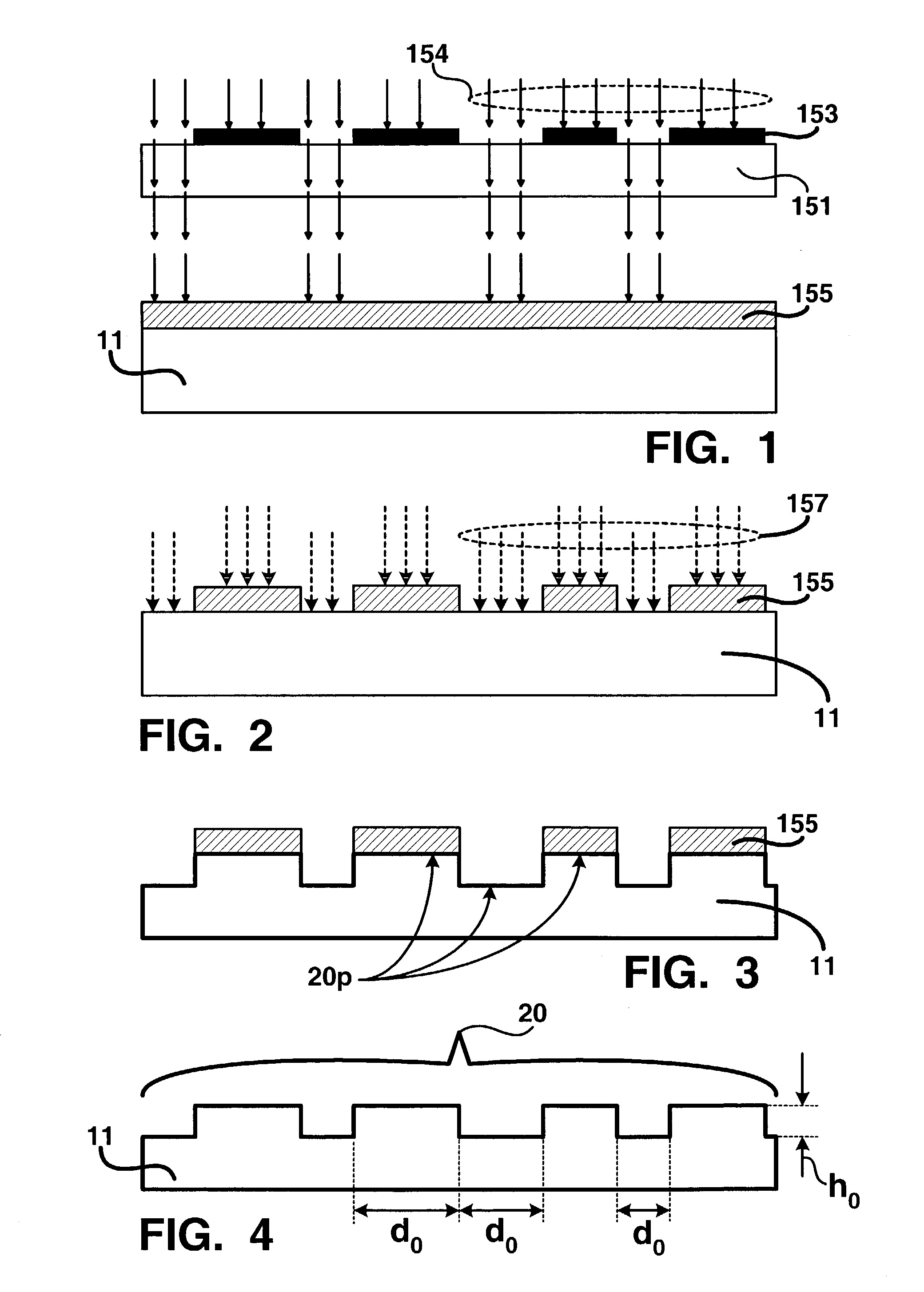

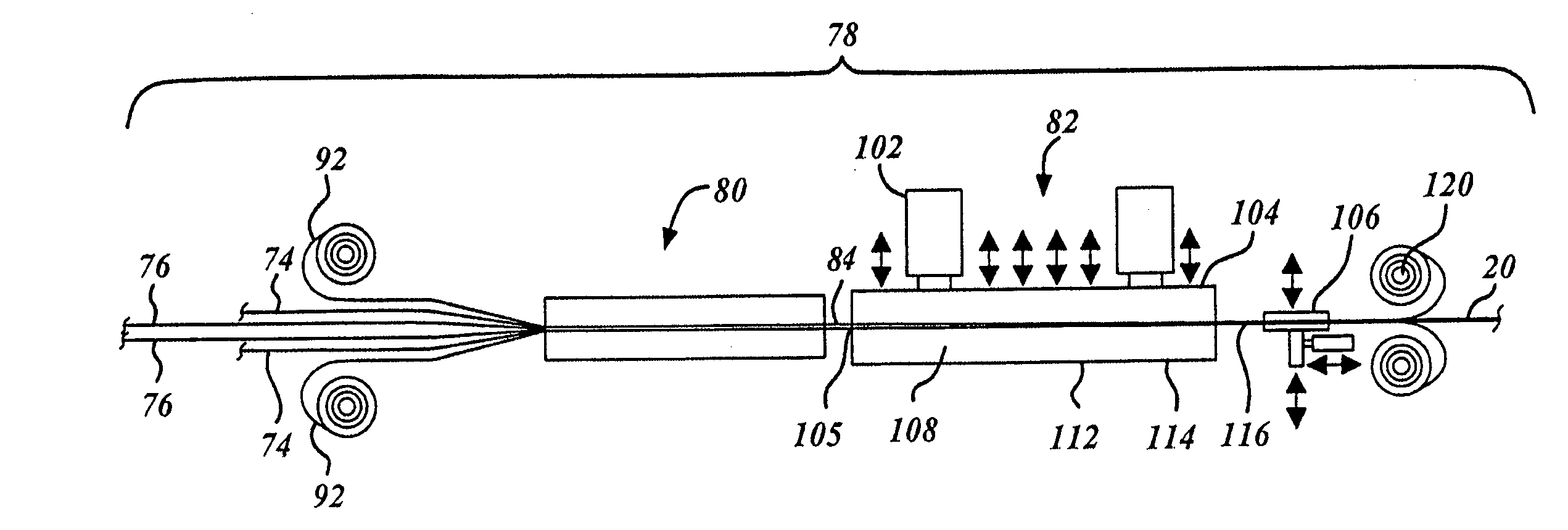

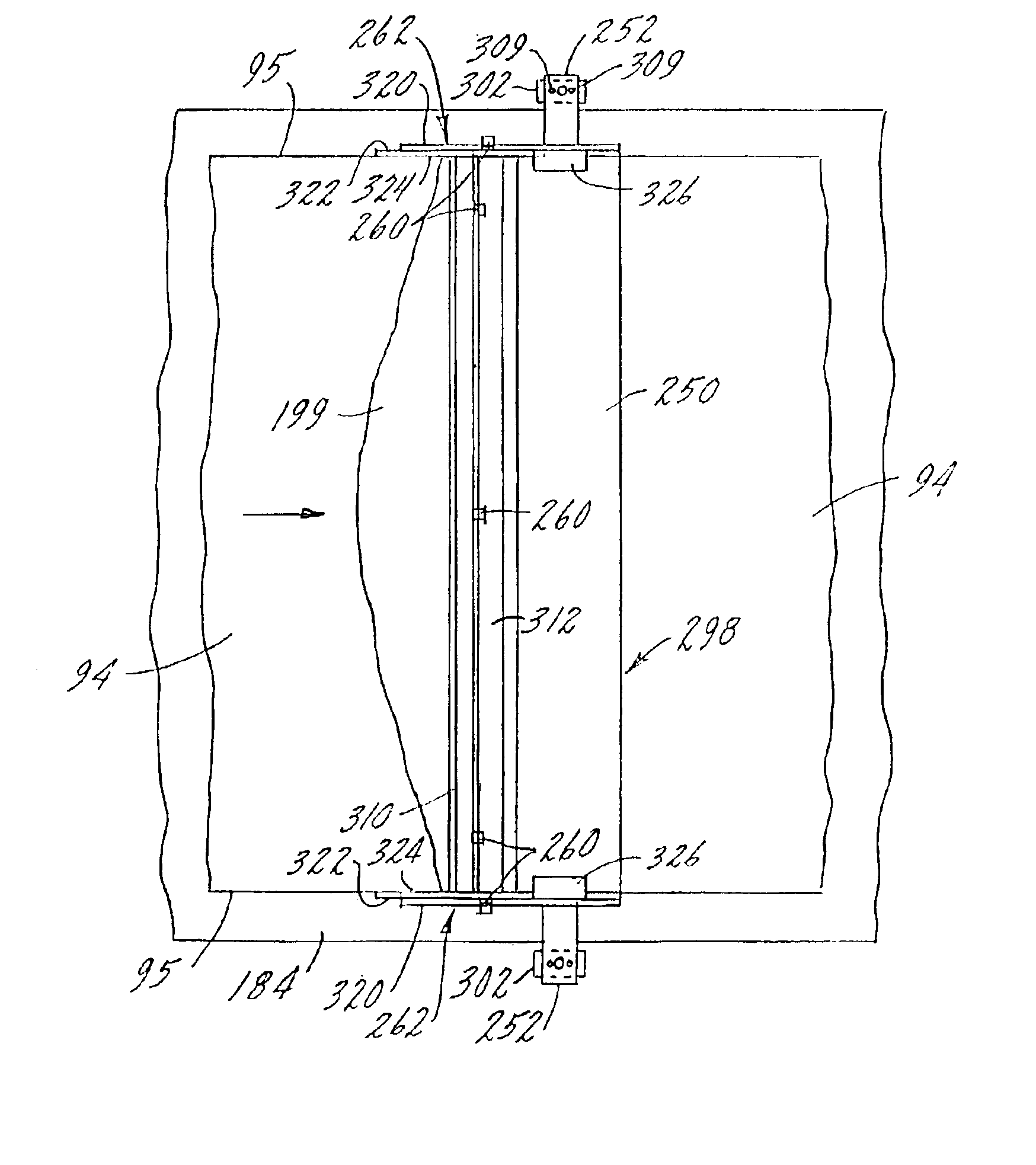

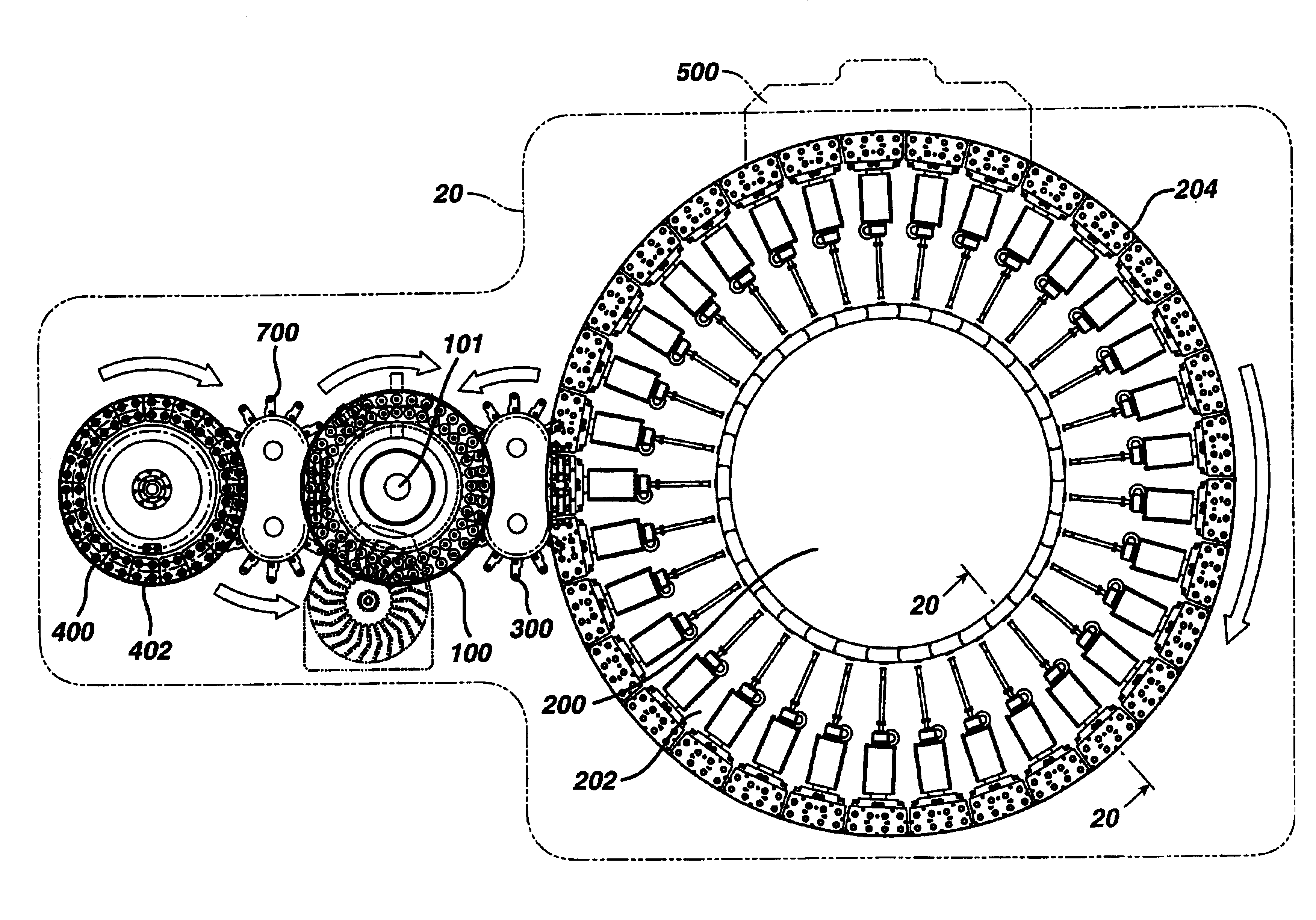

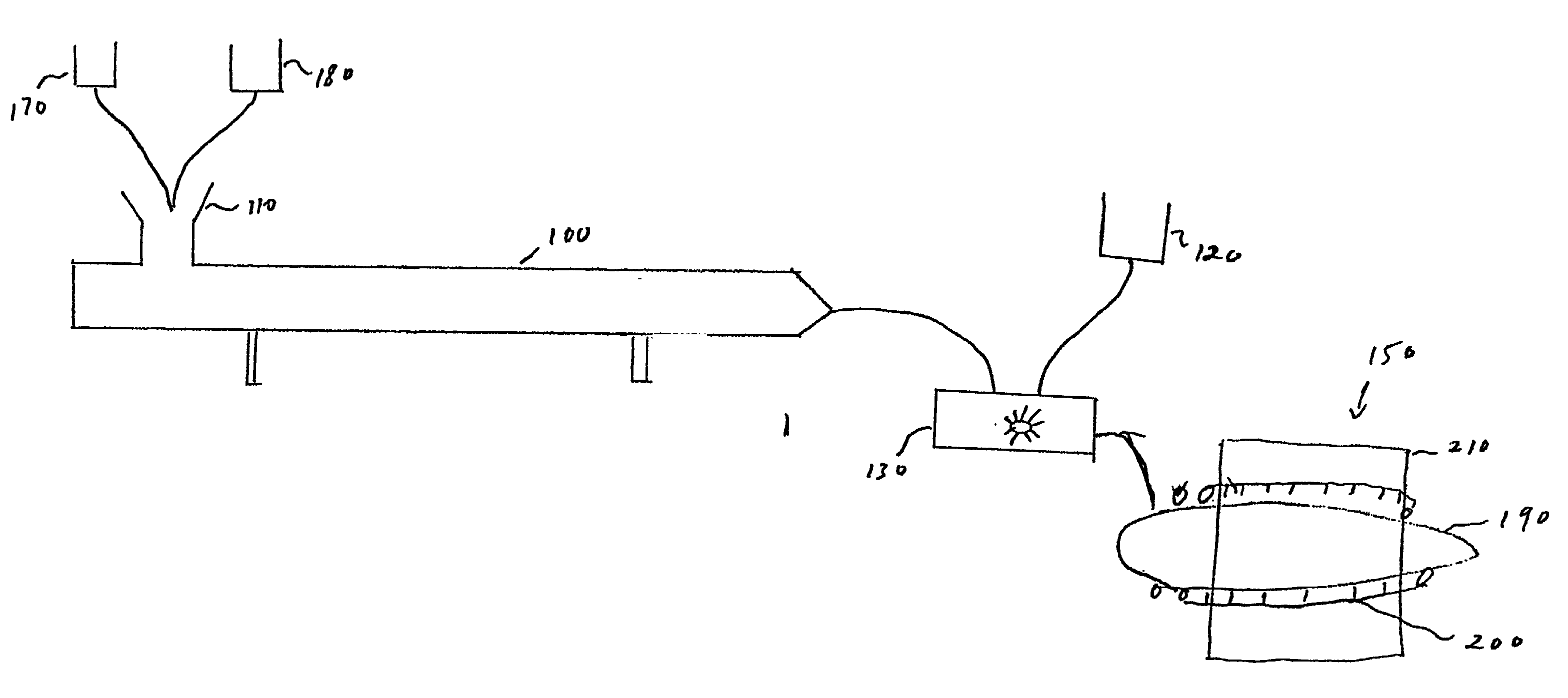

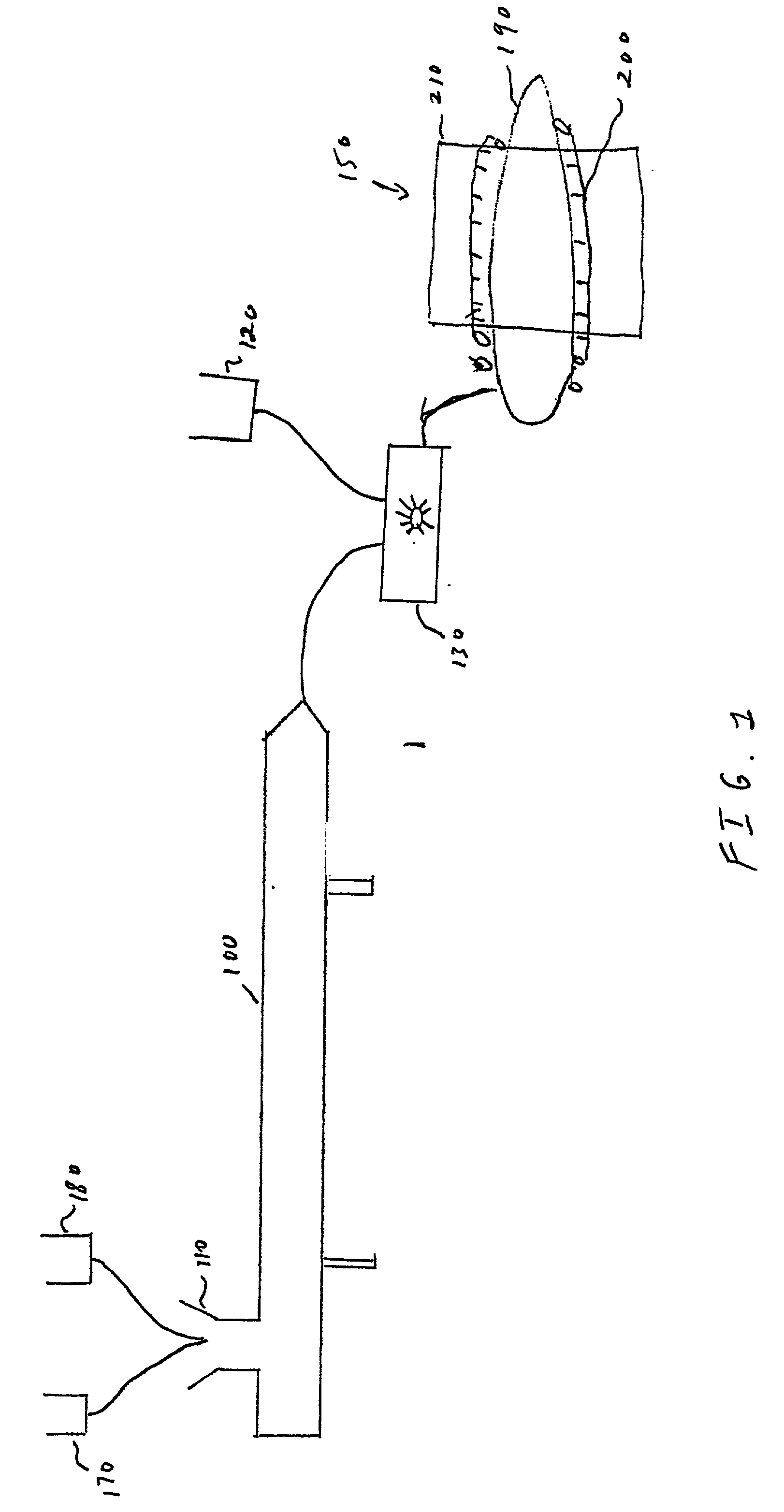

Apparatus and methods for electrospinning polymeric fibers and membranes

InactiveUS6713011B2Easy to controlLarge specific surface areaElectric discharge heatingConfectioneryFiberElectrospinning

An apparatus and method for electrospinning polymer fibers and membranes. The method includes electrospinning a polymer fiber from a conducting fluid in the presence of a first electric field established between a conducting fluid introduction device and a ground source and modifying the first electric field with a second electric field to form a jet stream of the conducting fluid. The method also includes electrically controlling the flow characteristics of the jet stream, forming a plurality of electrospinning jet streams and independently controlling the flow characteristics of at least one of the jet streams. The apparatus for electrospinning includes a conducting fluid introduction device containing a plurality of electrospinning spinnerets, a ground member positioned adjacent to the spinnerets, a support member disposed between the spinnerets and the ground member and movable to receive fibers formed from the conducting fluid, and a component for controlling the flow characteristics of conducting fluid from at least one spinneret independently from another spinneret.

Owner:RES FOUND THE

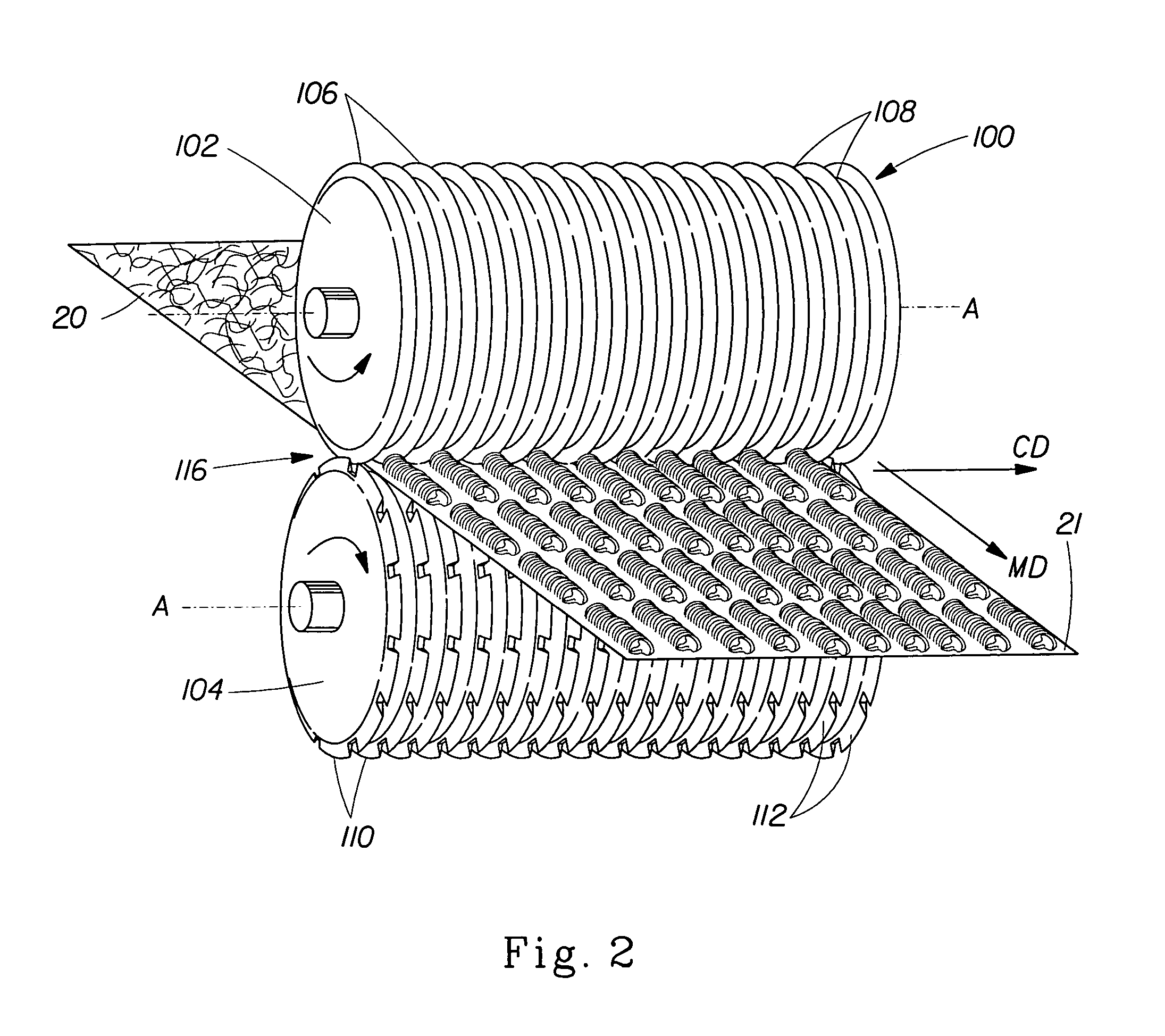

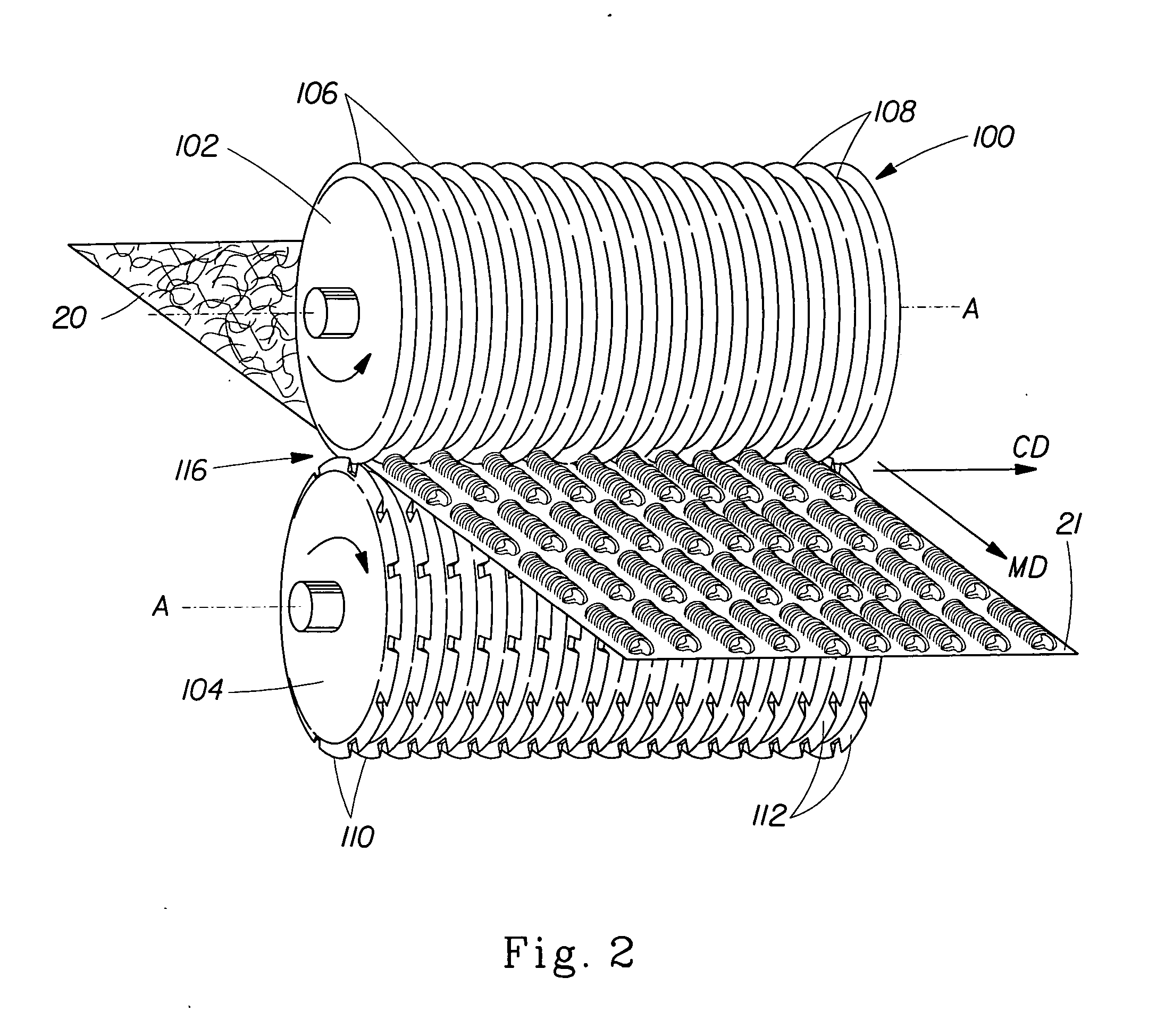

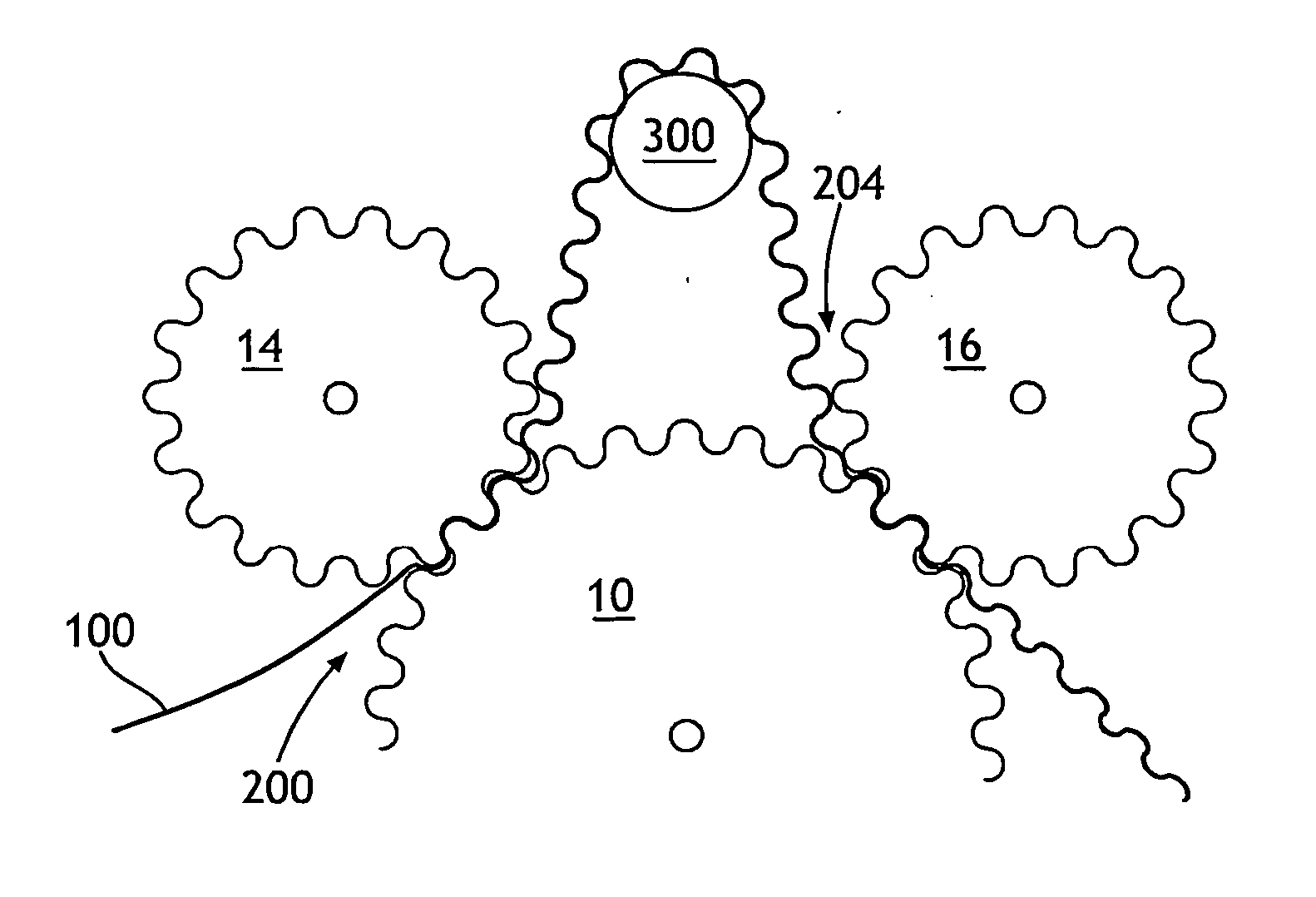

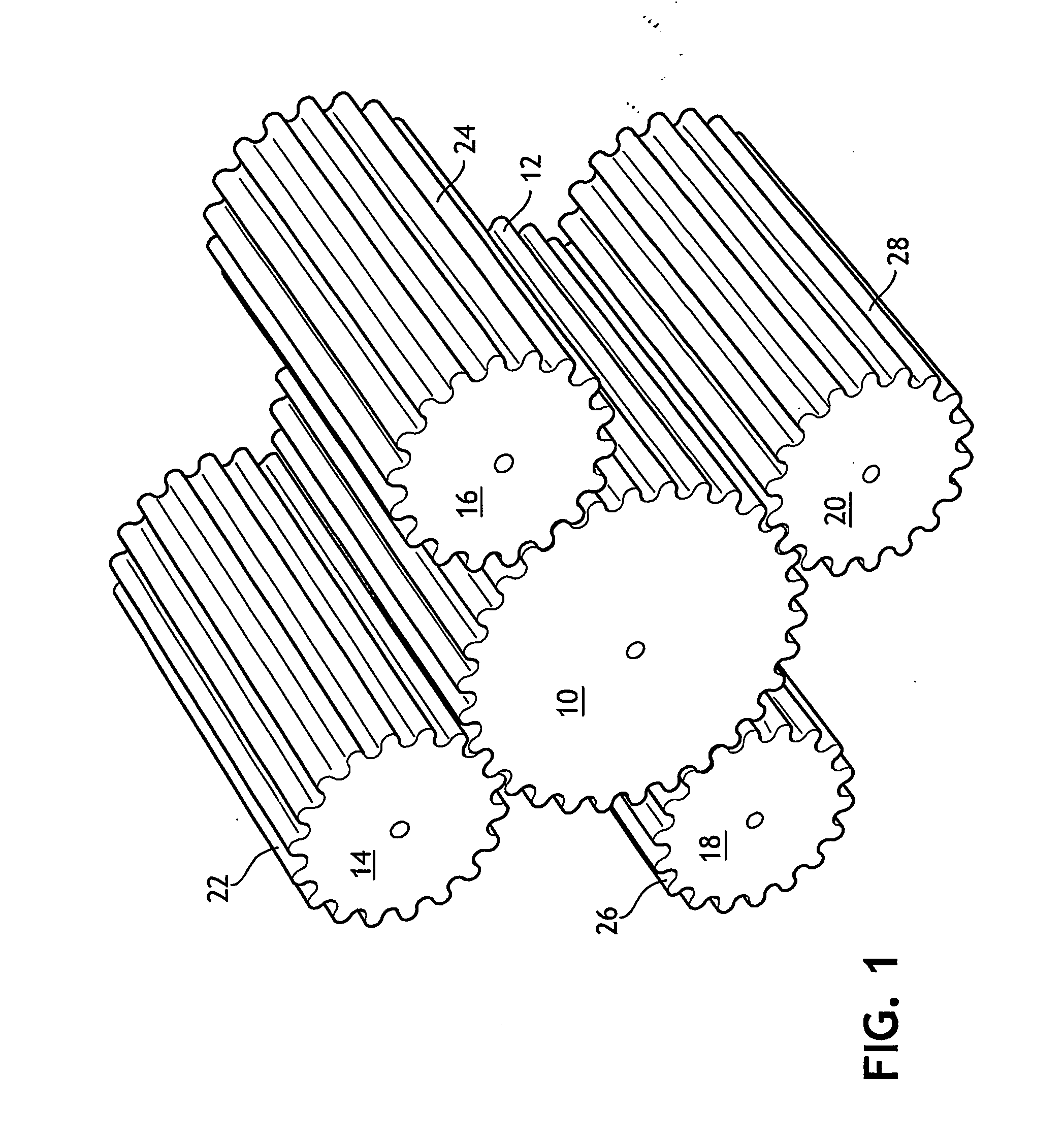

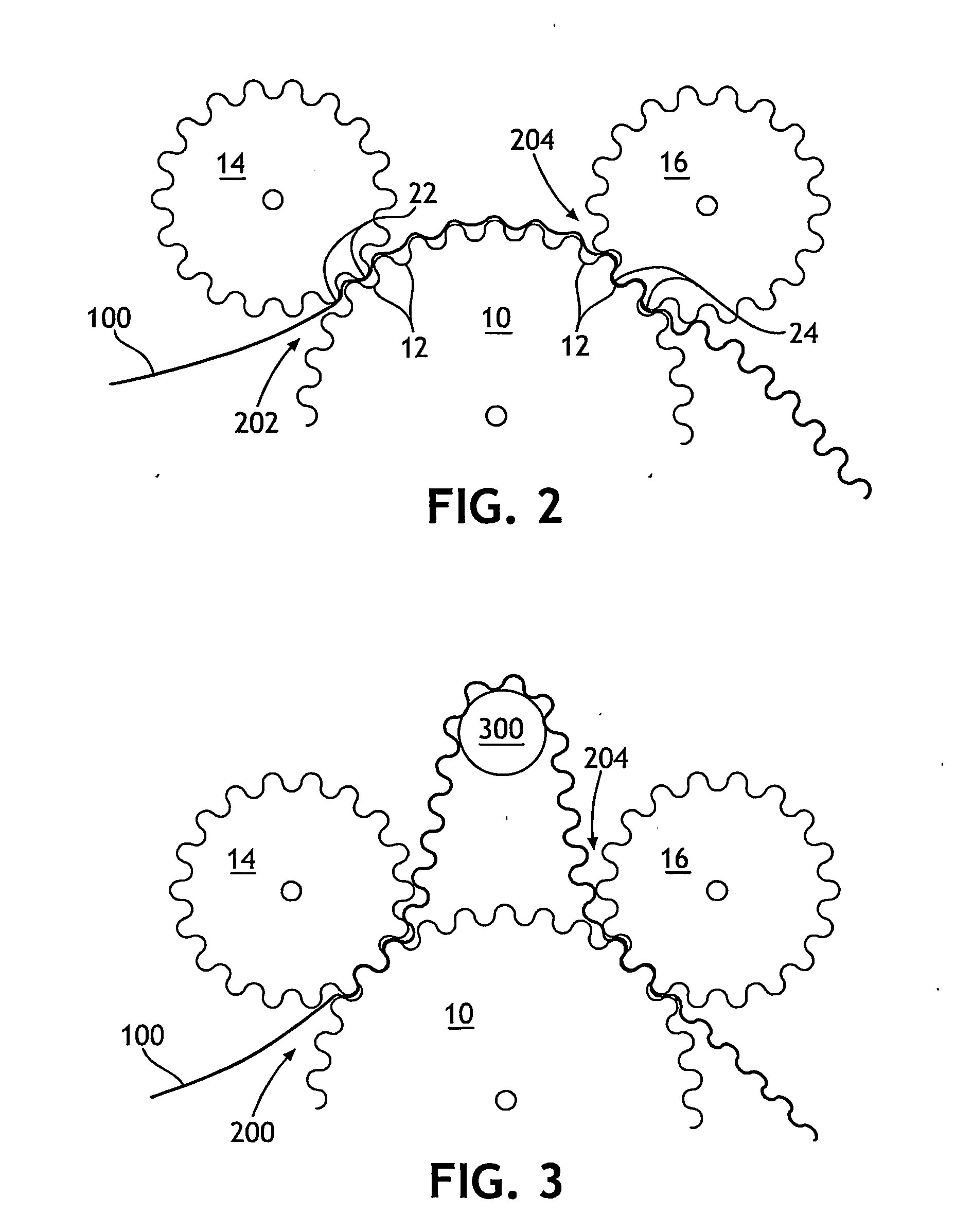

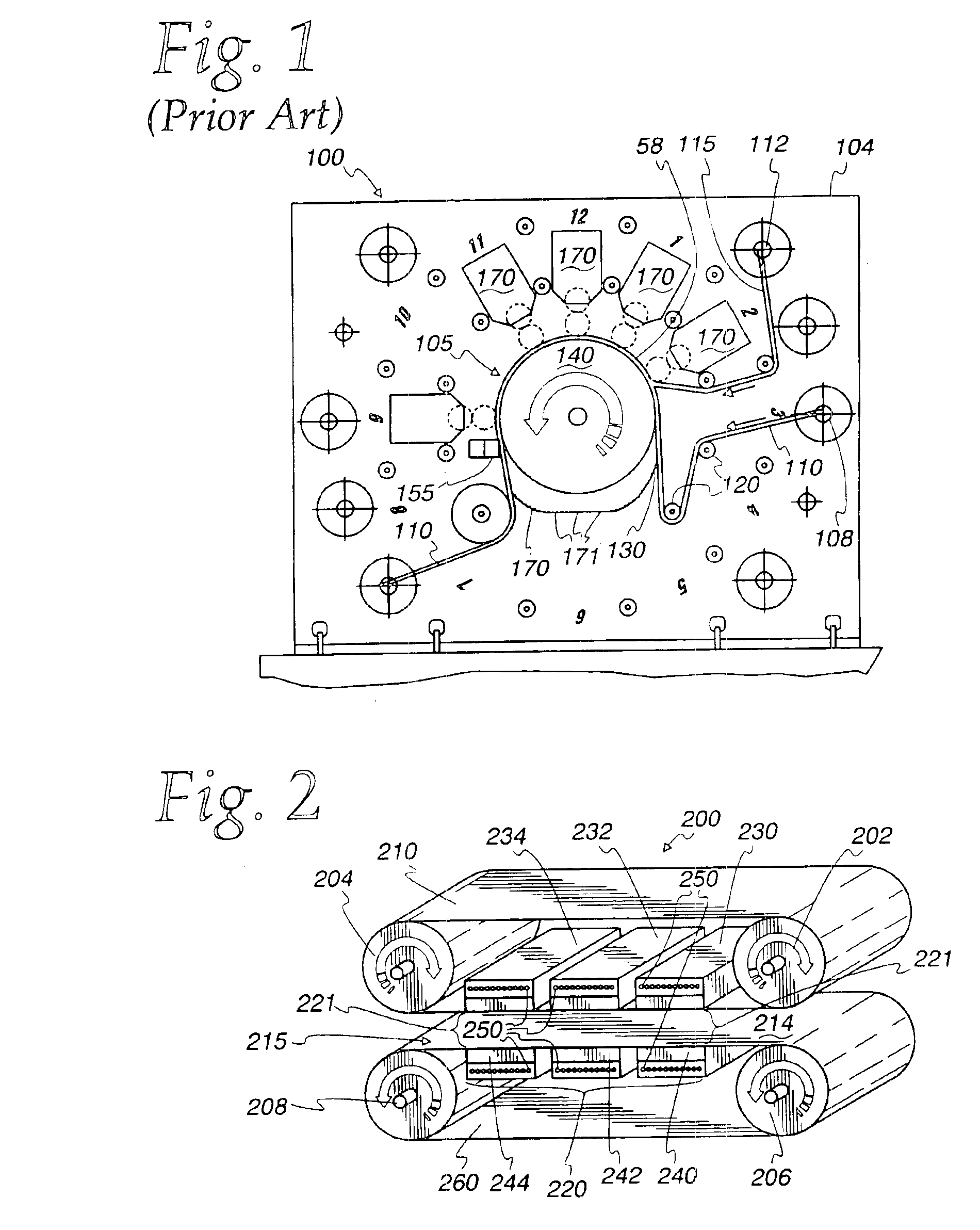

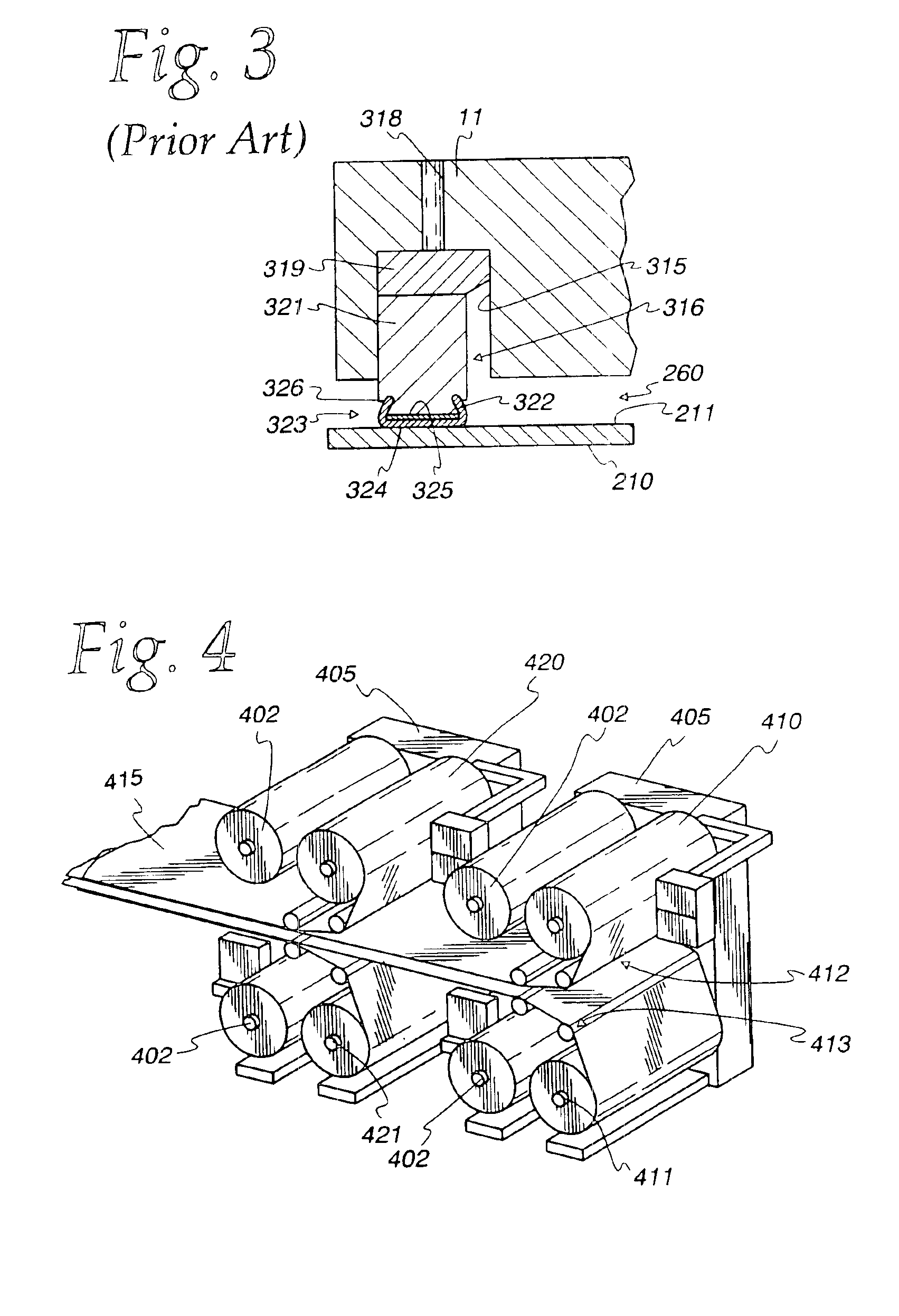

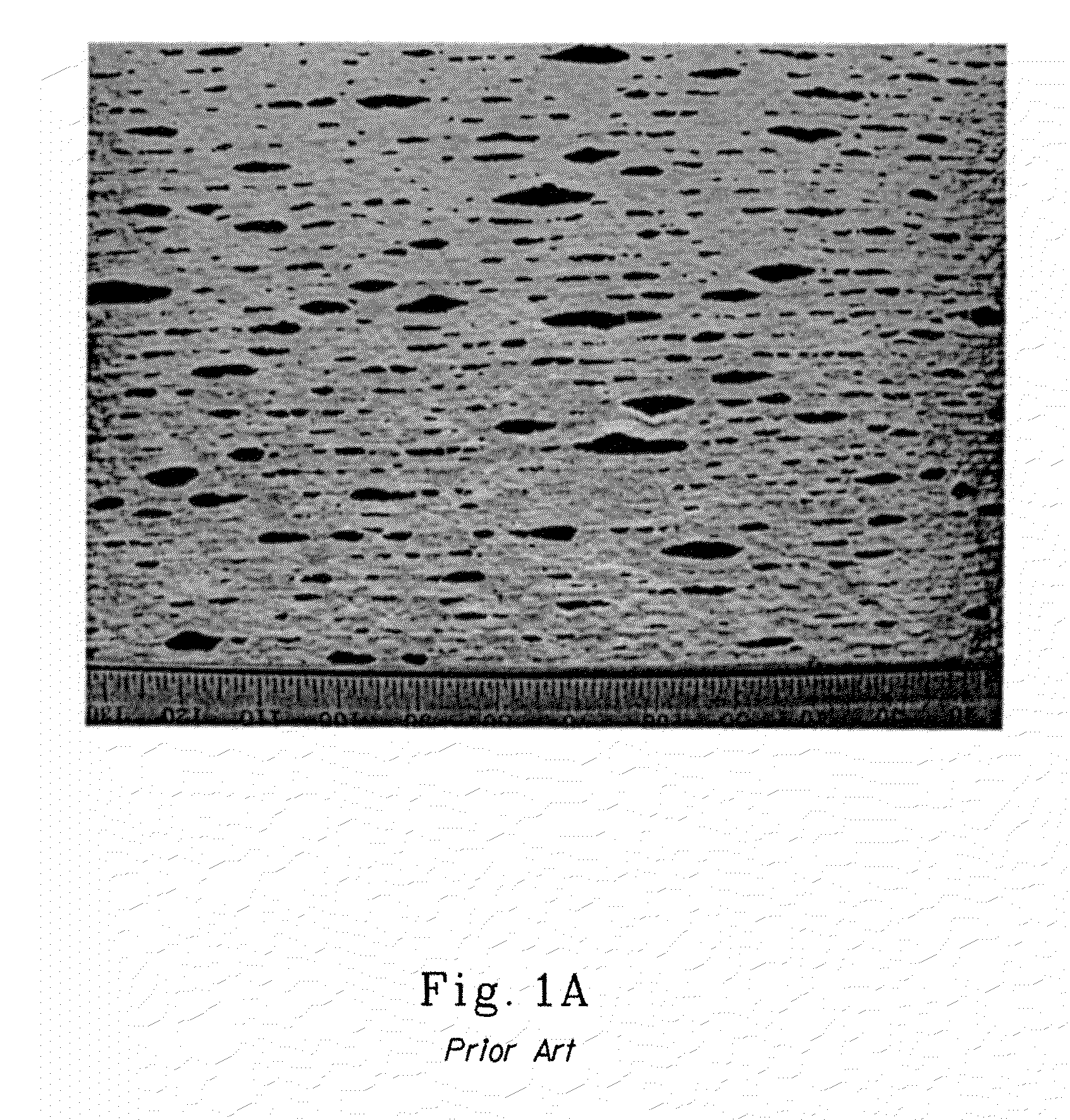

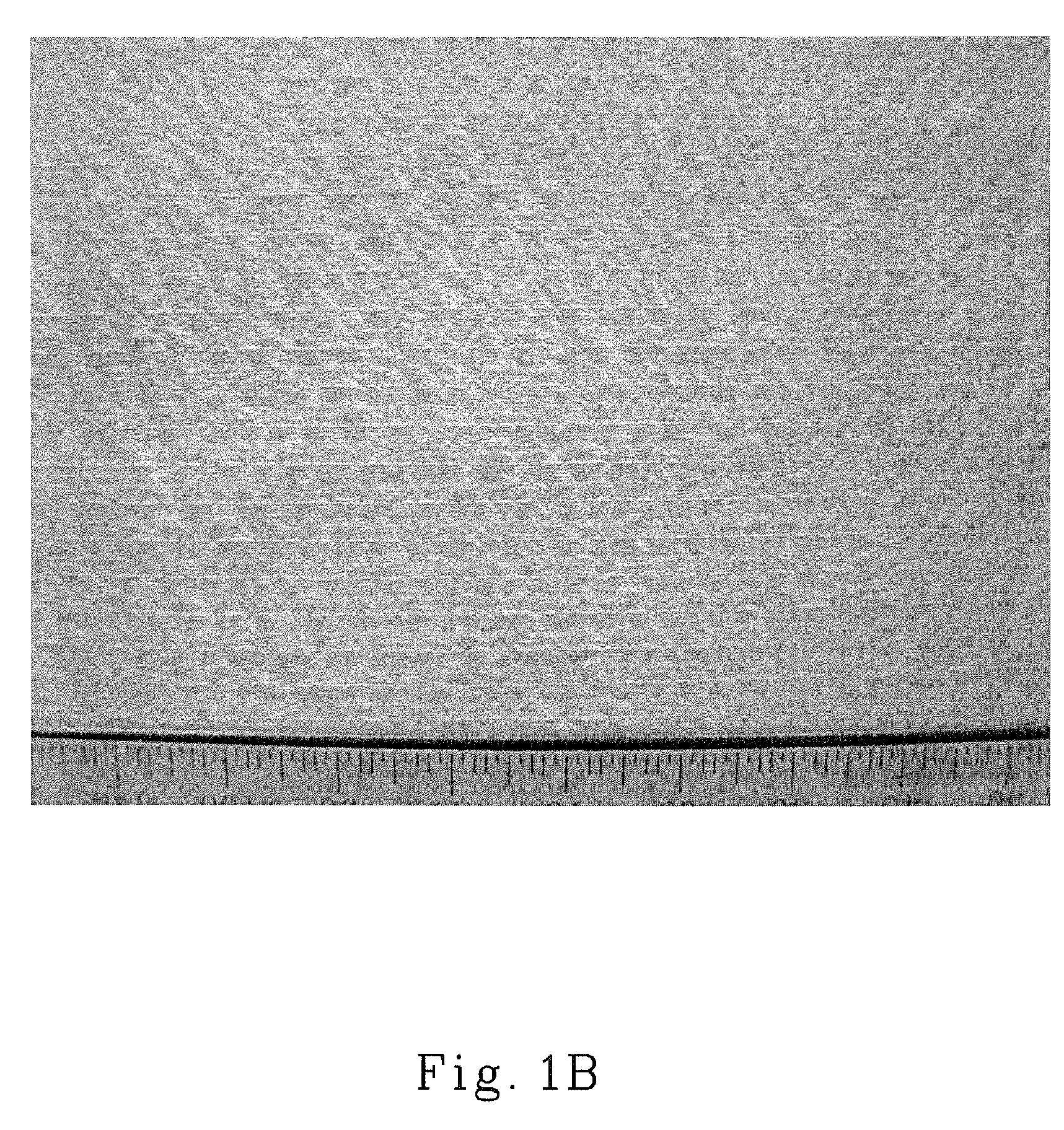

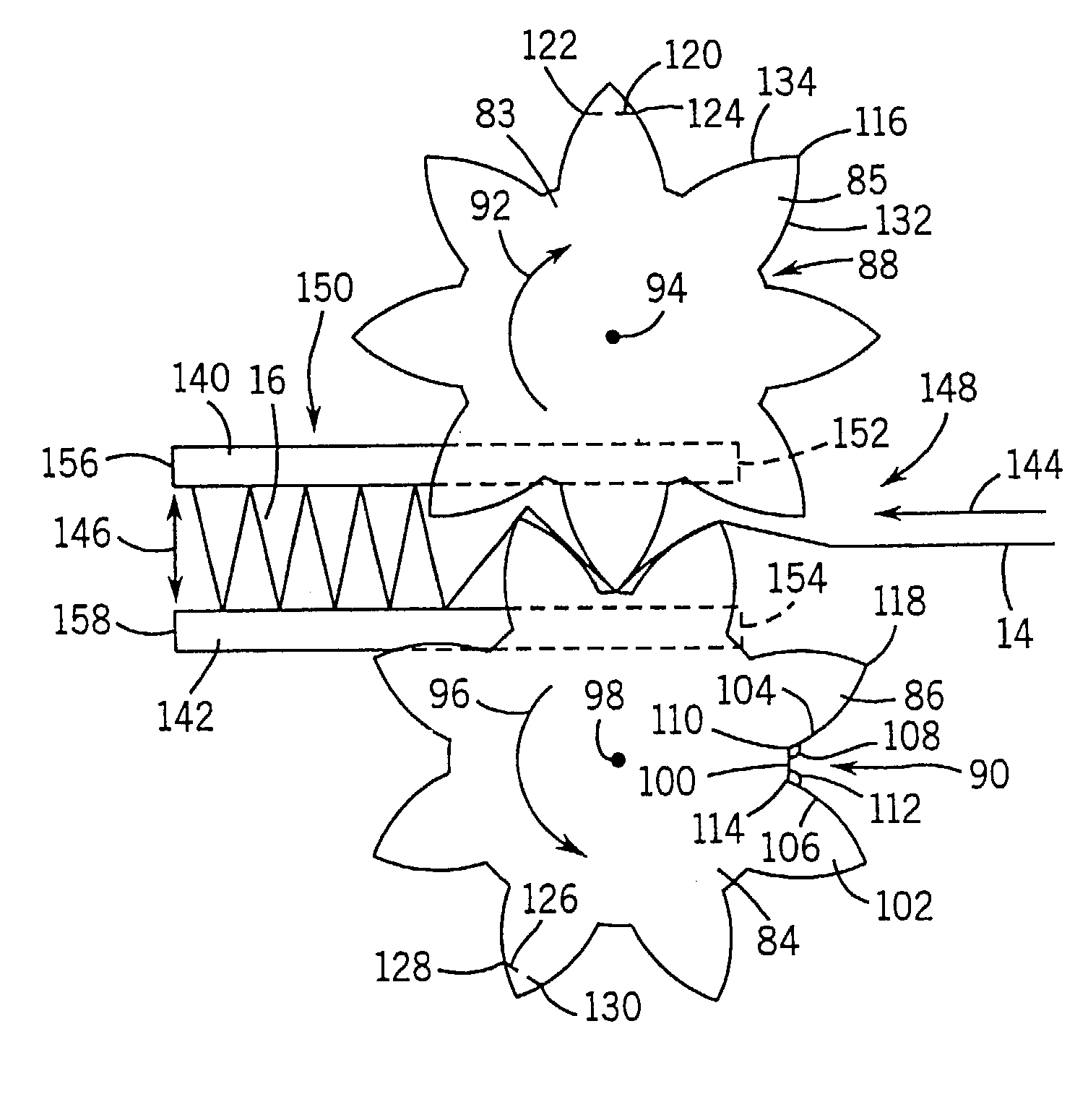

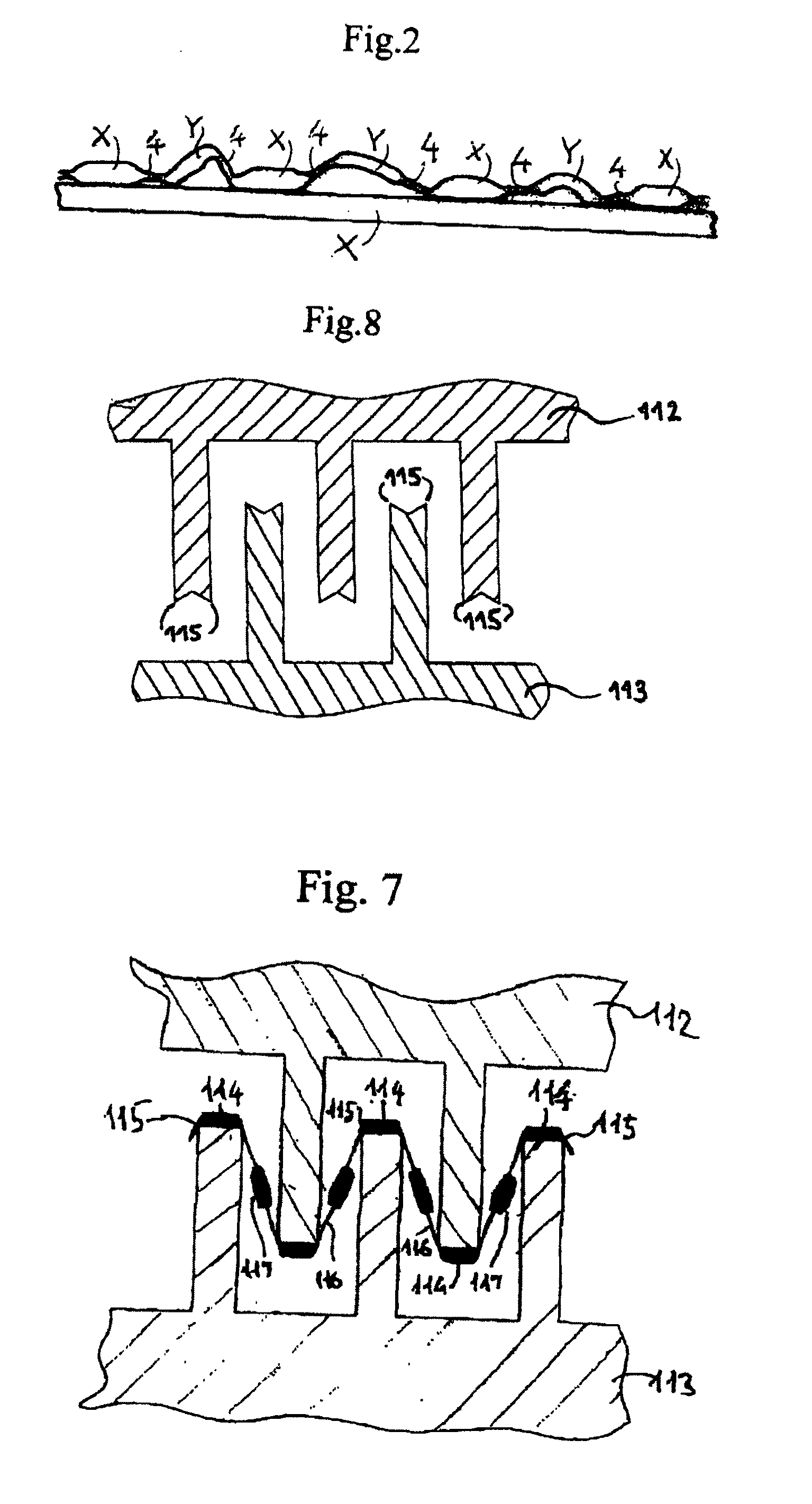

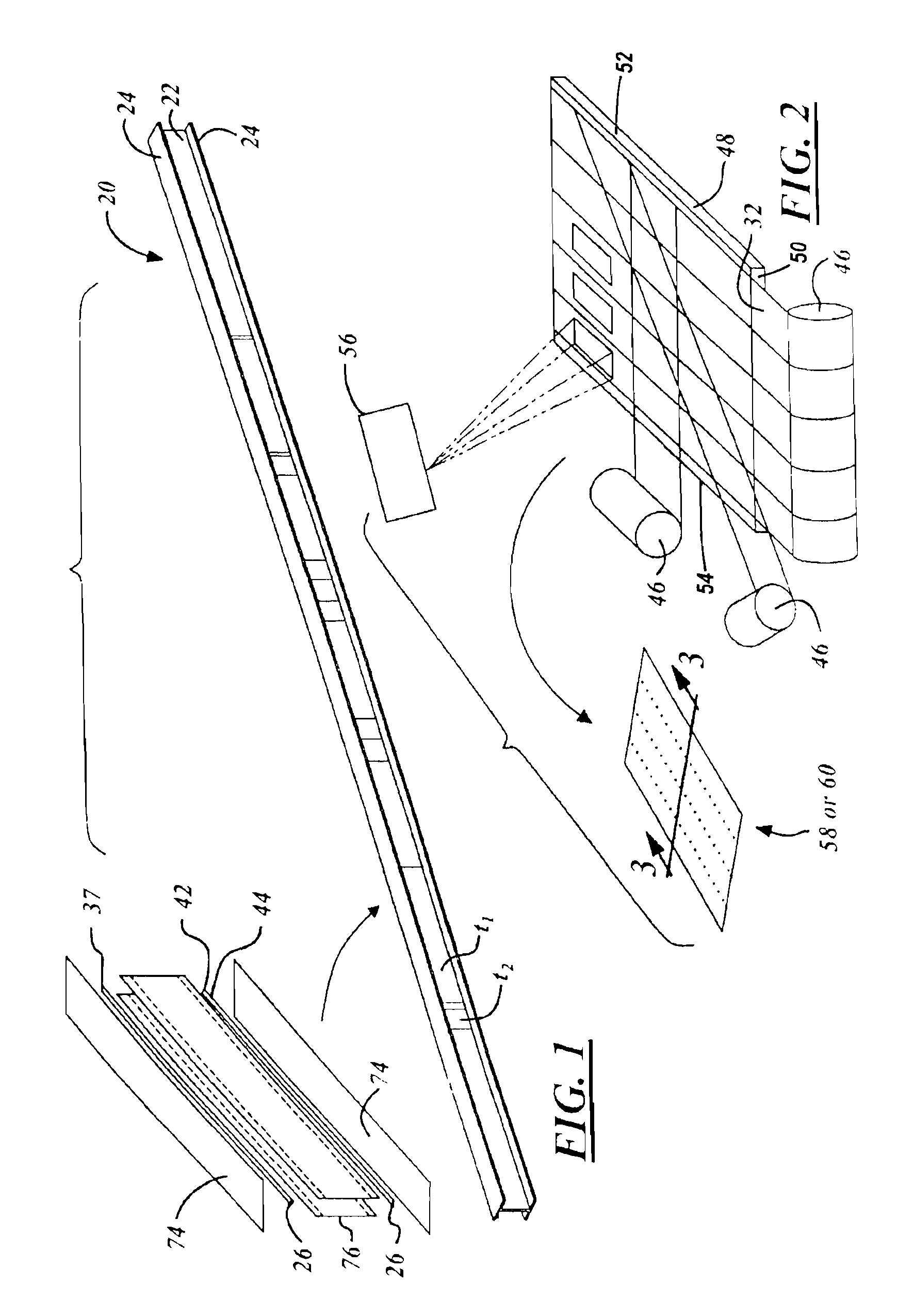

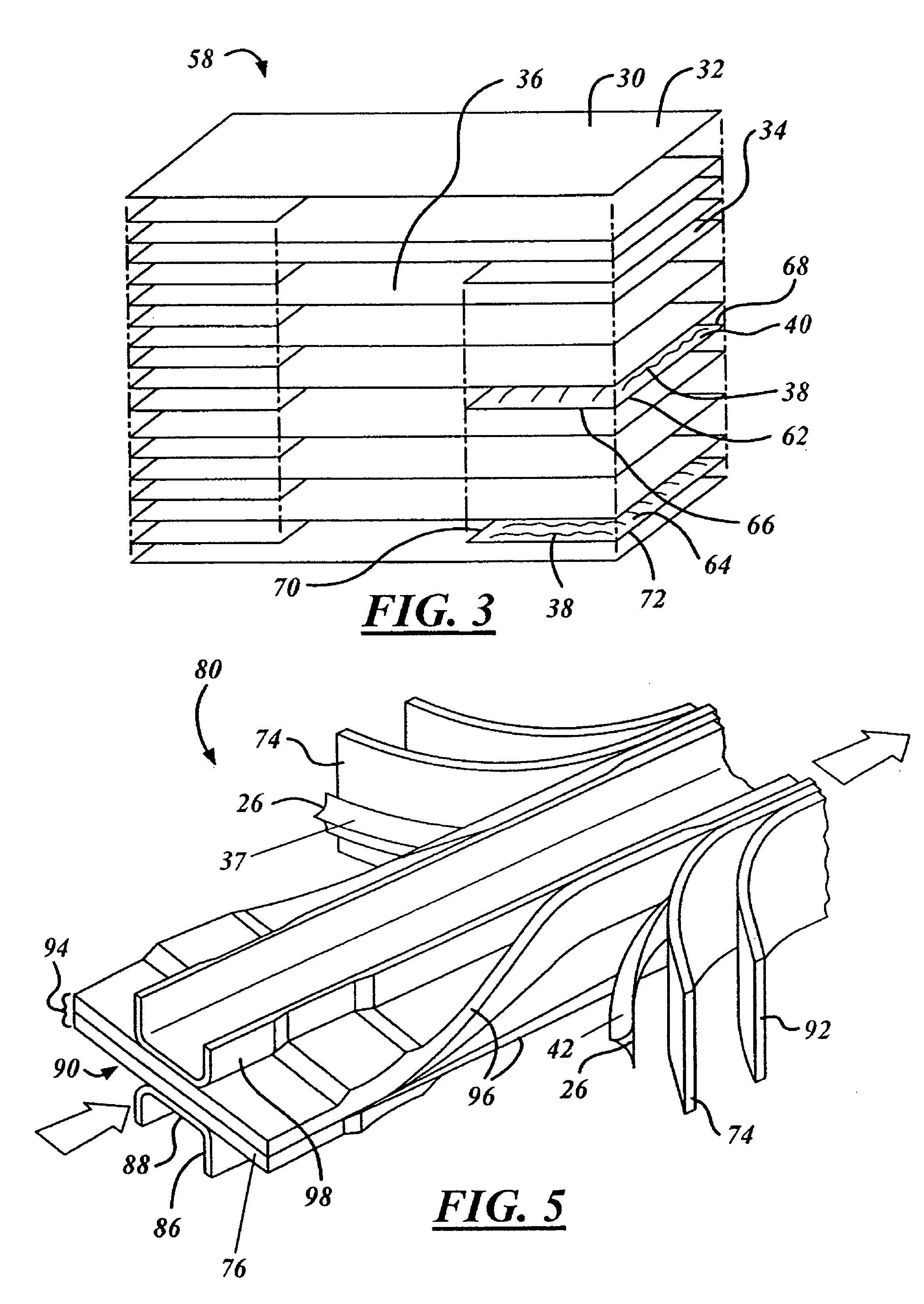

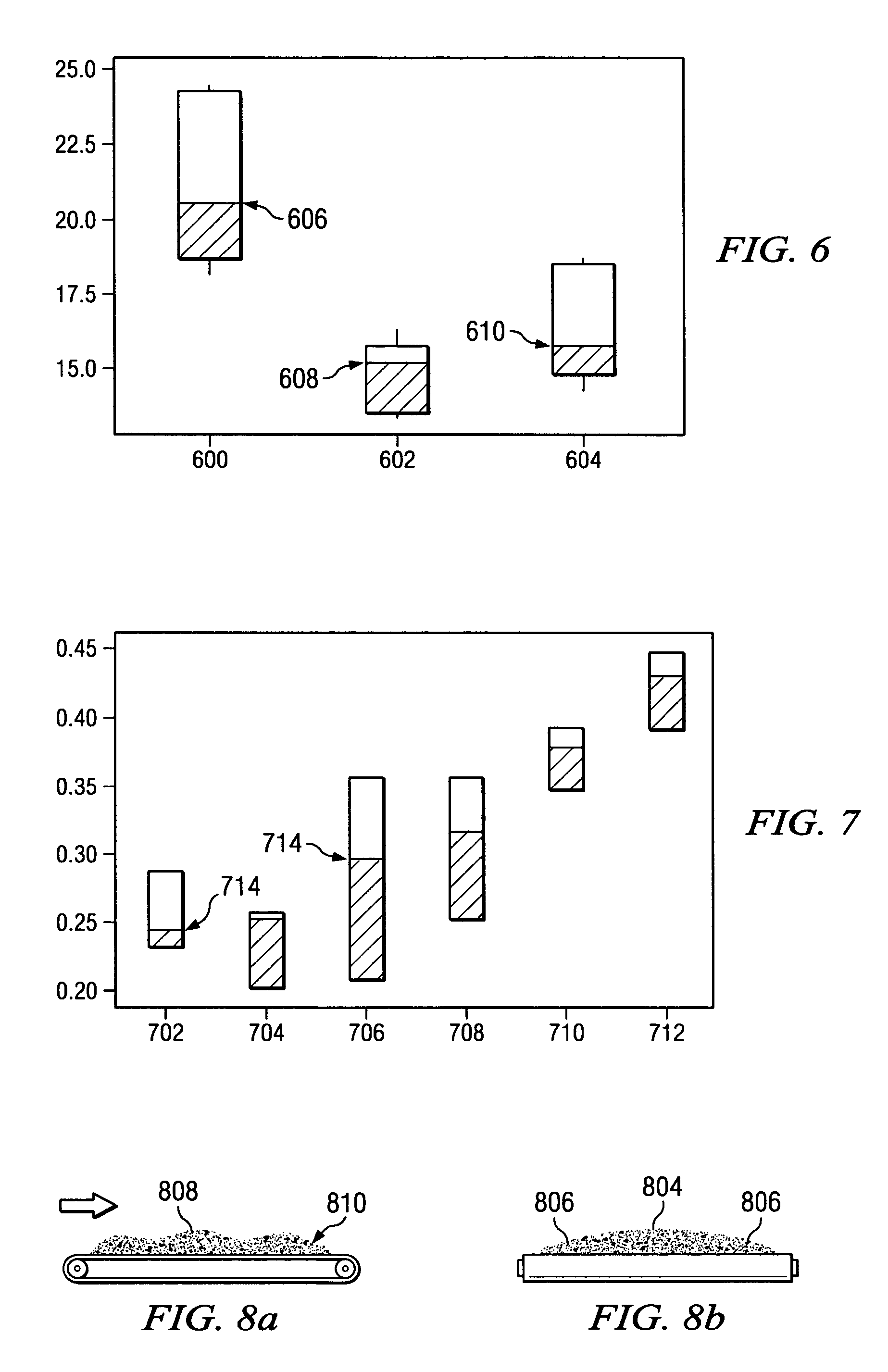

Device and process for treating flexible web by stretching between intermeshing forming surfaces

InactiveUS20060151914A1Increase flexibilityWidely vary degree of stretchDough-sheeters/rolling-machines/rolling-pinsConfectioneryPersonal Care ProductBiomedical engineering

A series of nips (200, 202, 204, 412, 414) formed by intermeshing grooves (22, 24, 26, 28) provides for a higher degree of stretch, particularly for lightweight webs (100) by stretching in stages in multiple grooved nips. The ability to adjust the degree of stretch at each nip can provide a high degree and variability of stretch with reduced web damage compared to a single step application of the same stretch. Improvements to the manufacture of lightweight components of personal care products such as diaper backing components are obtained.

Owner:KIMBERLY-CLARK WORLDWIDE INC

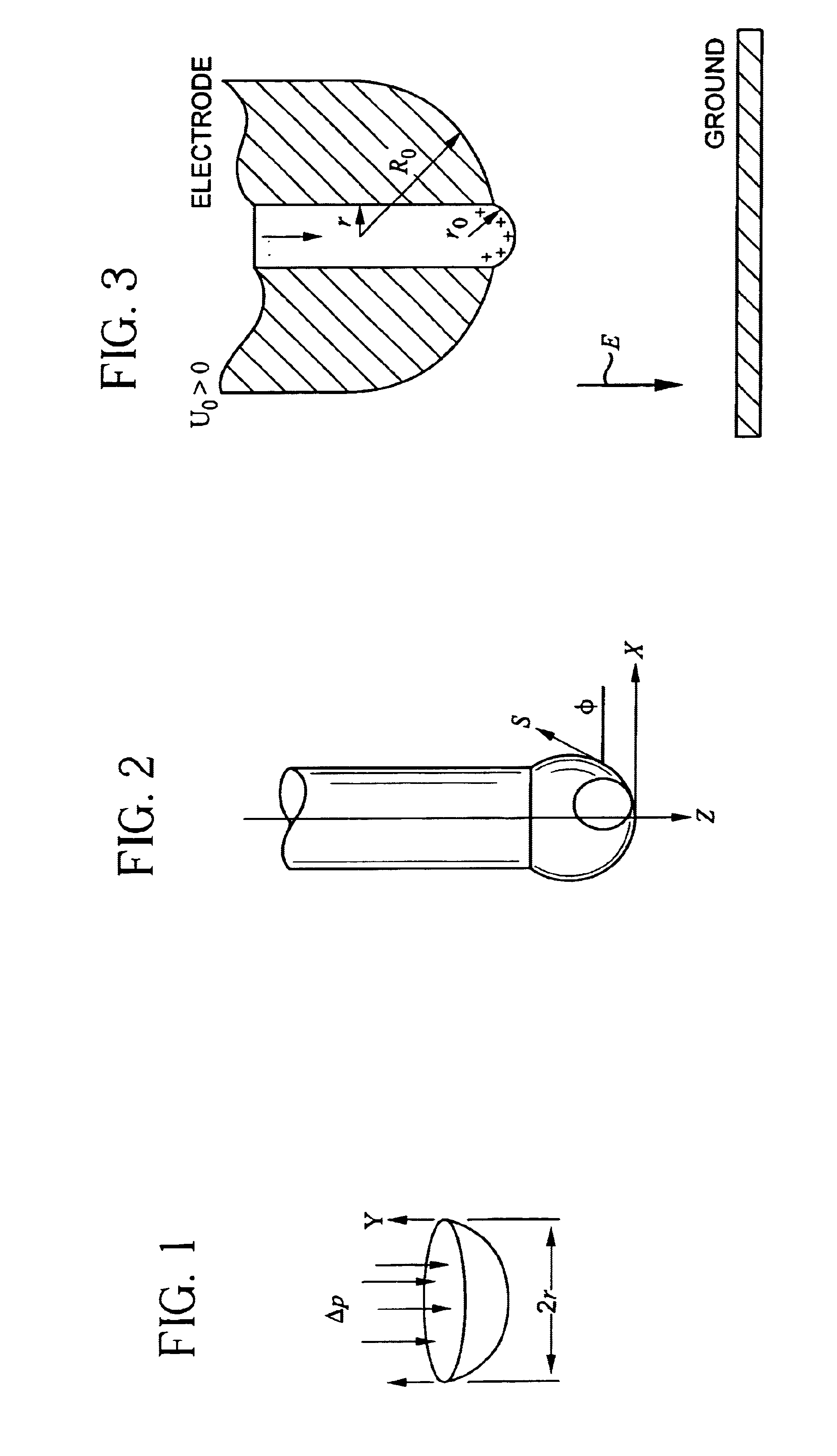

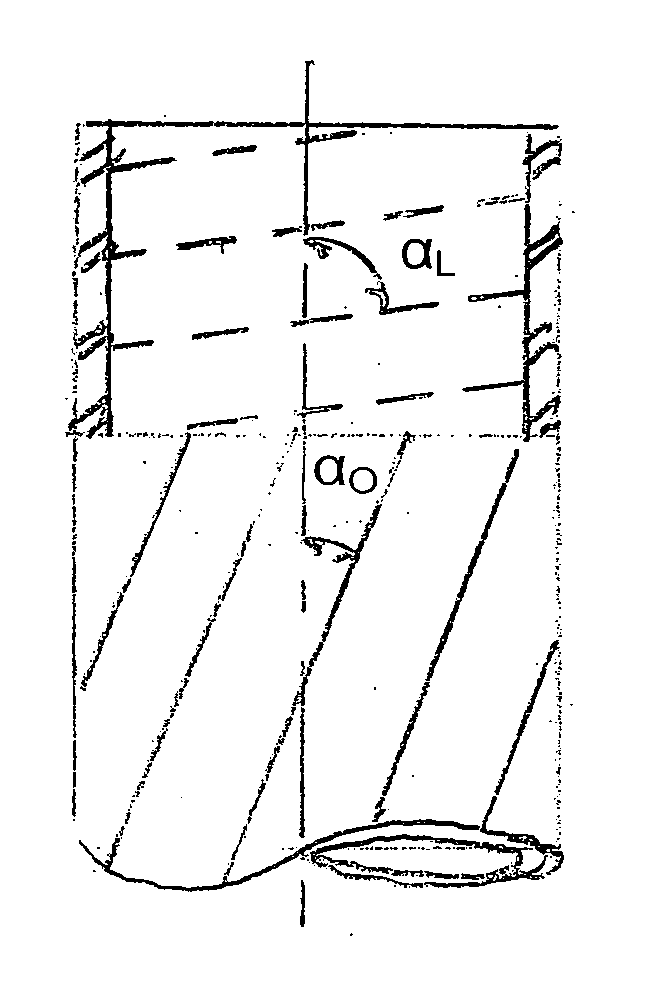

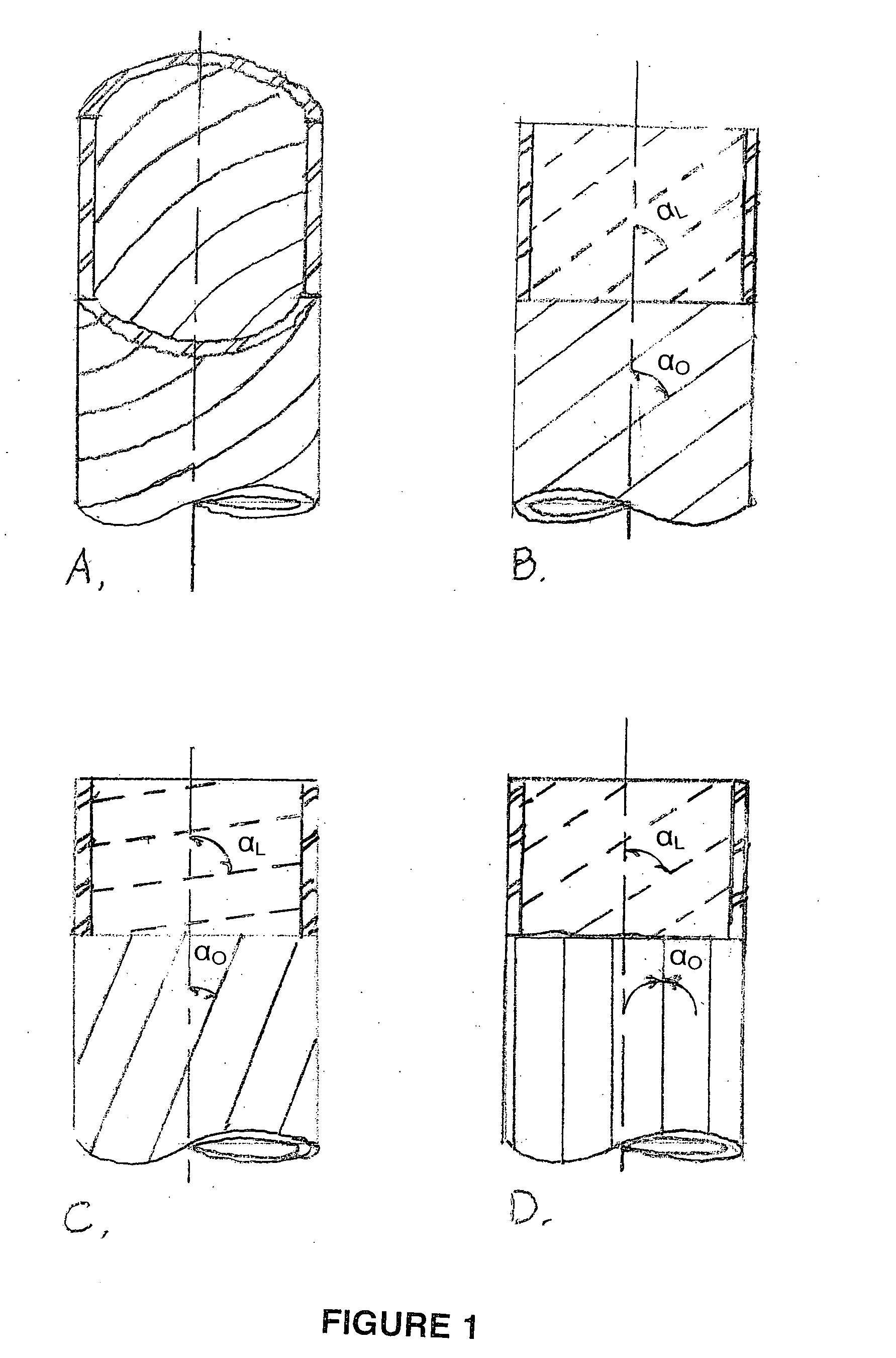

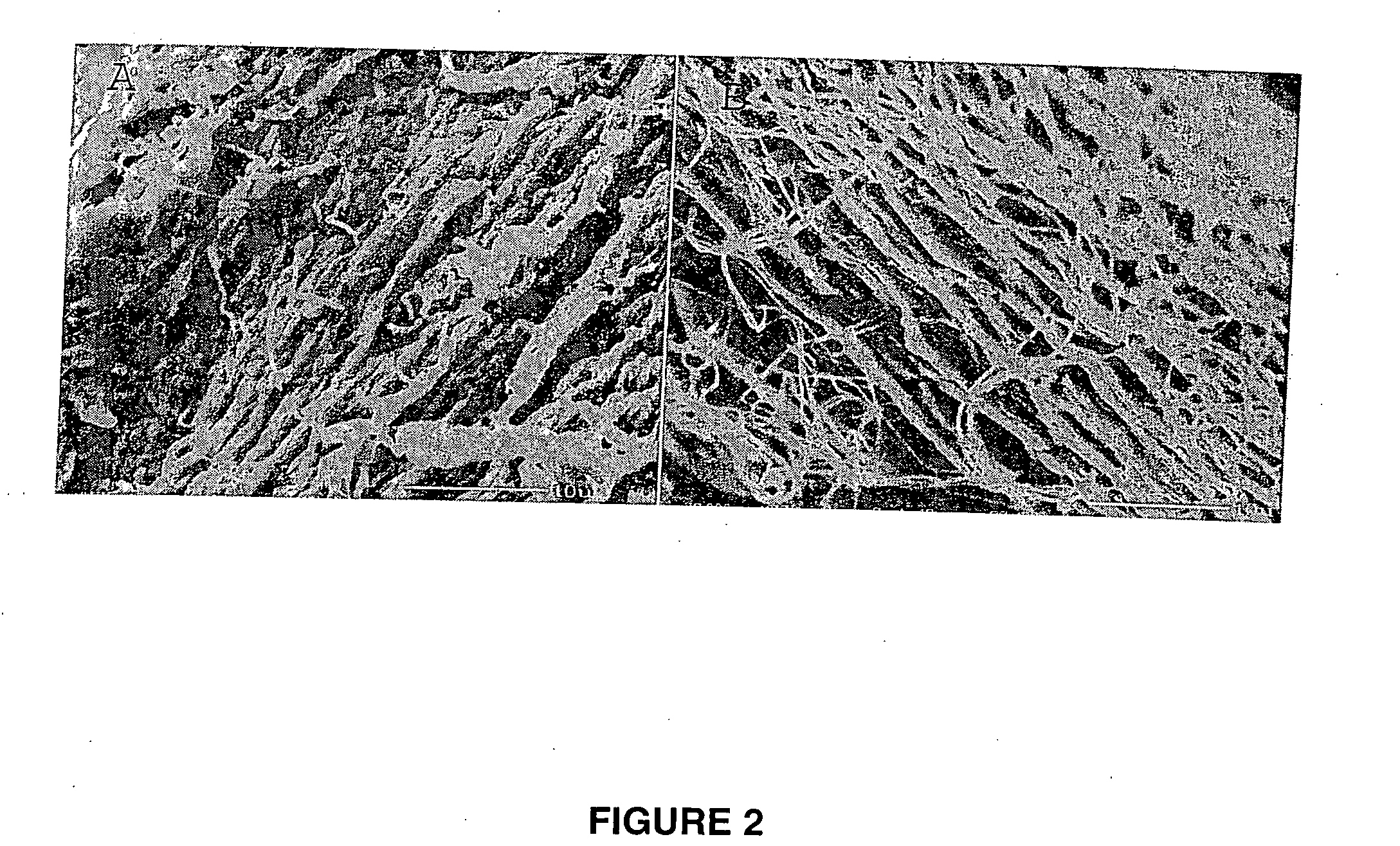

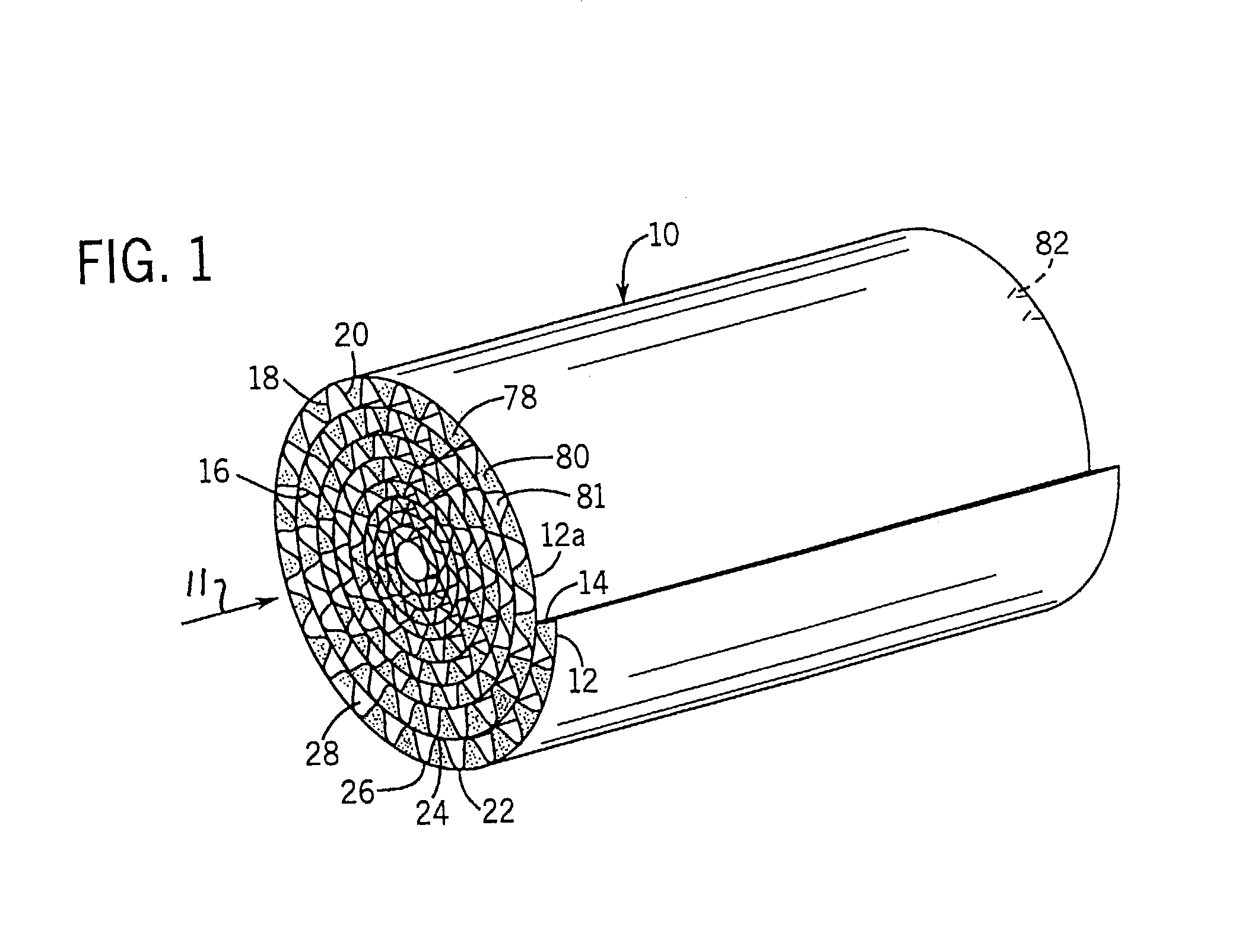

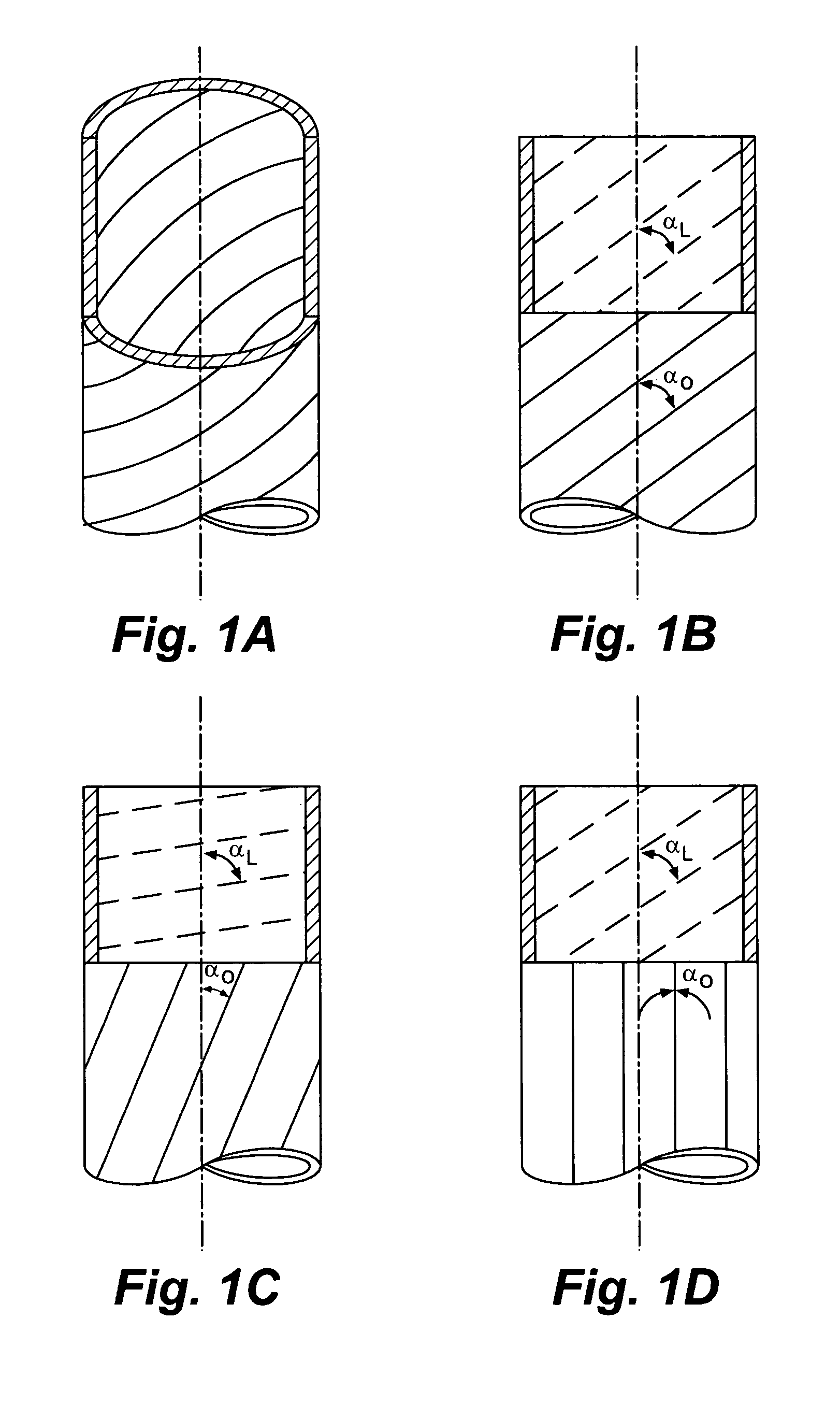

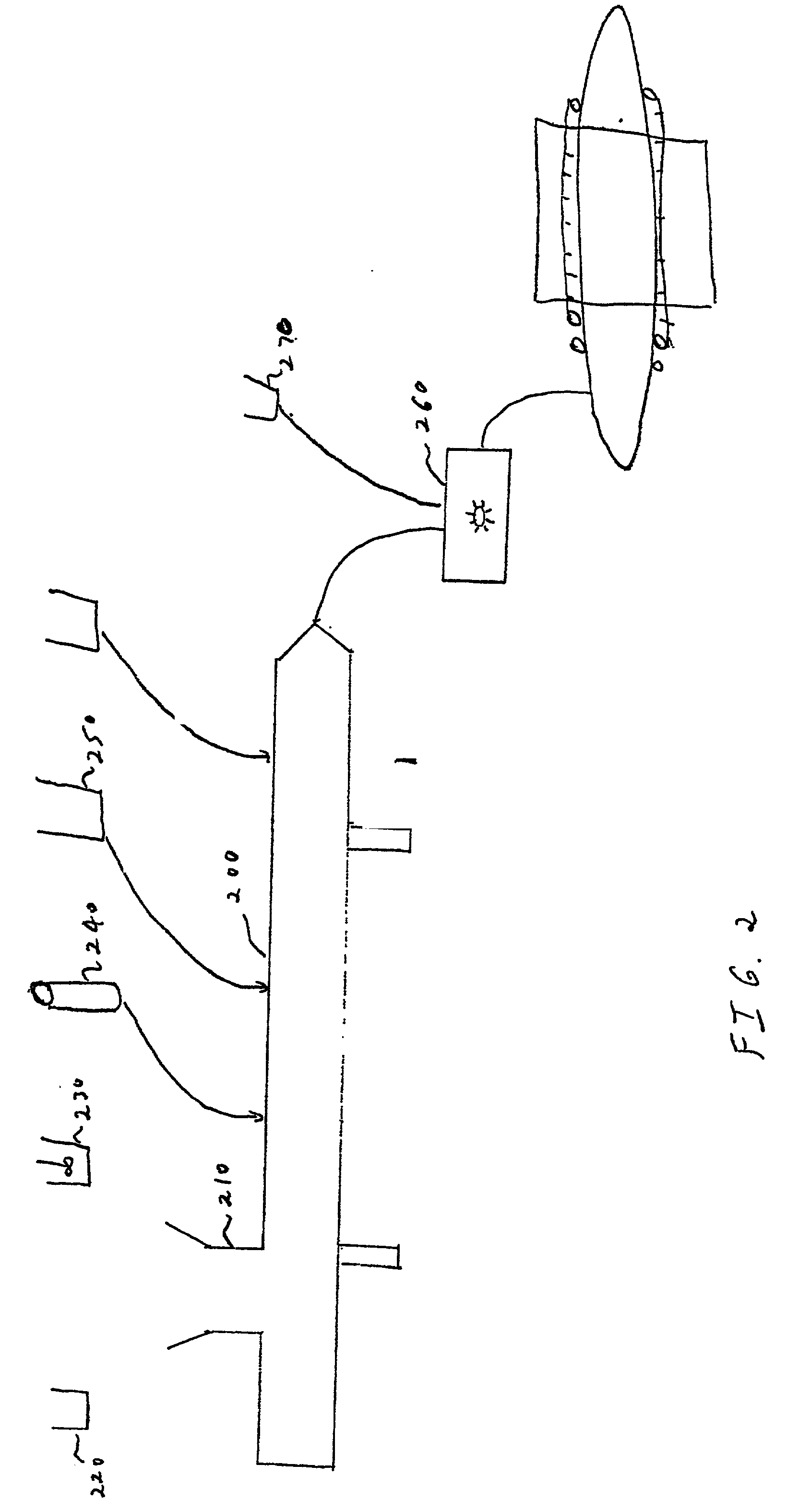

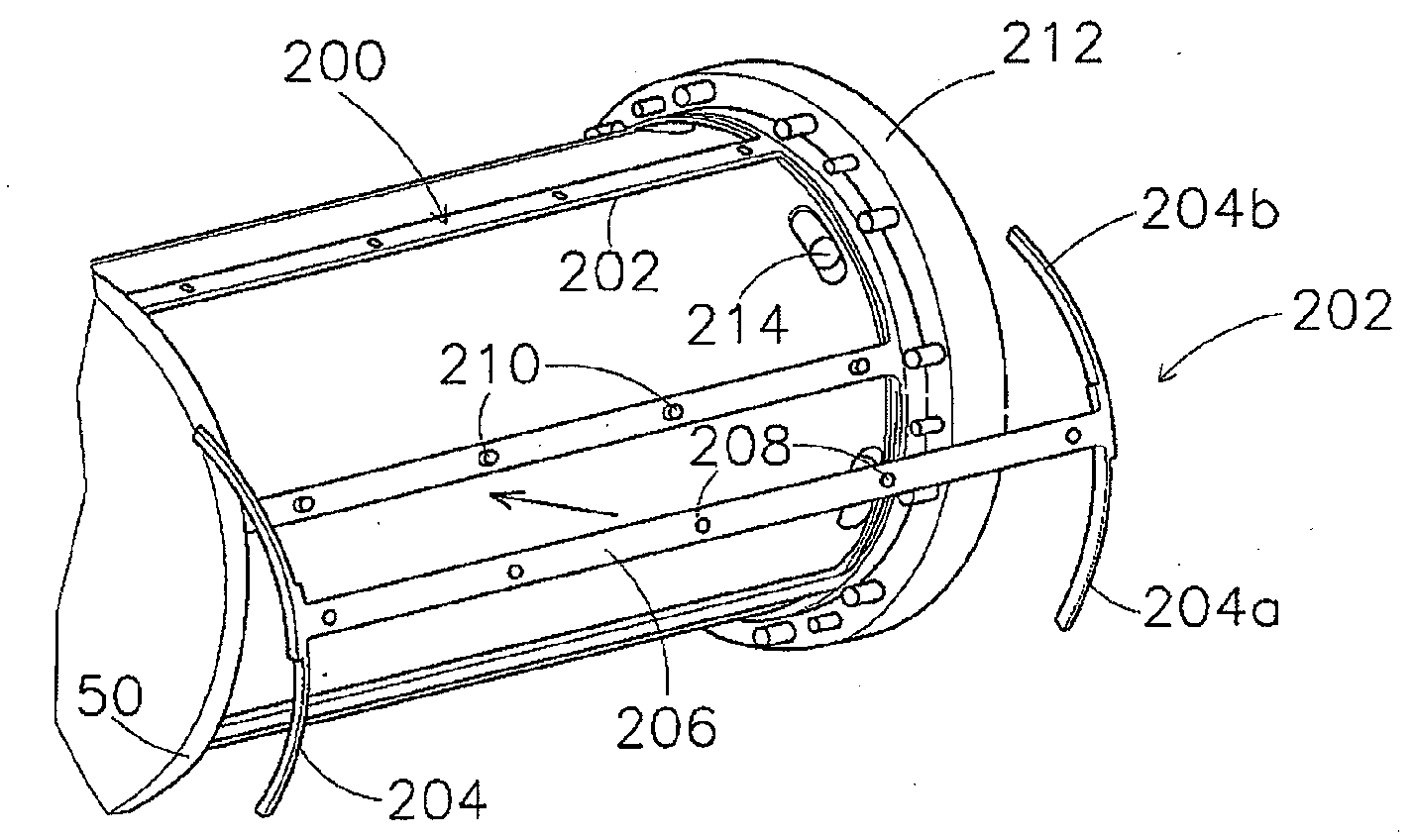

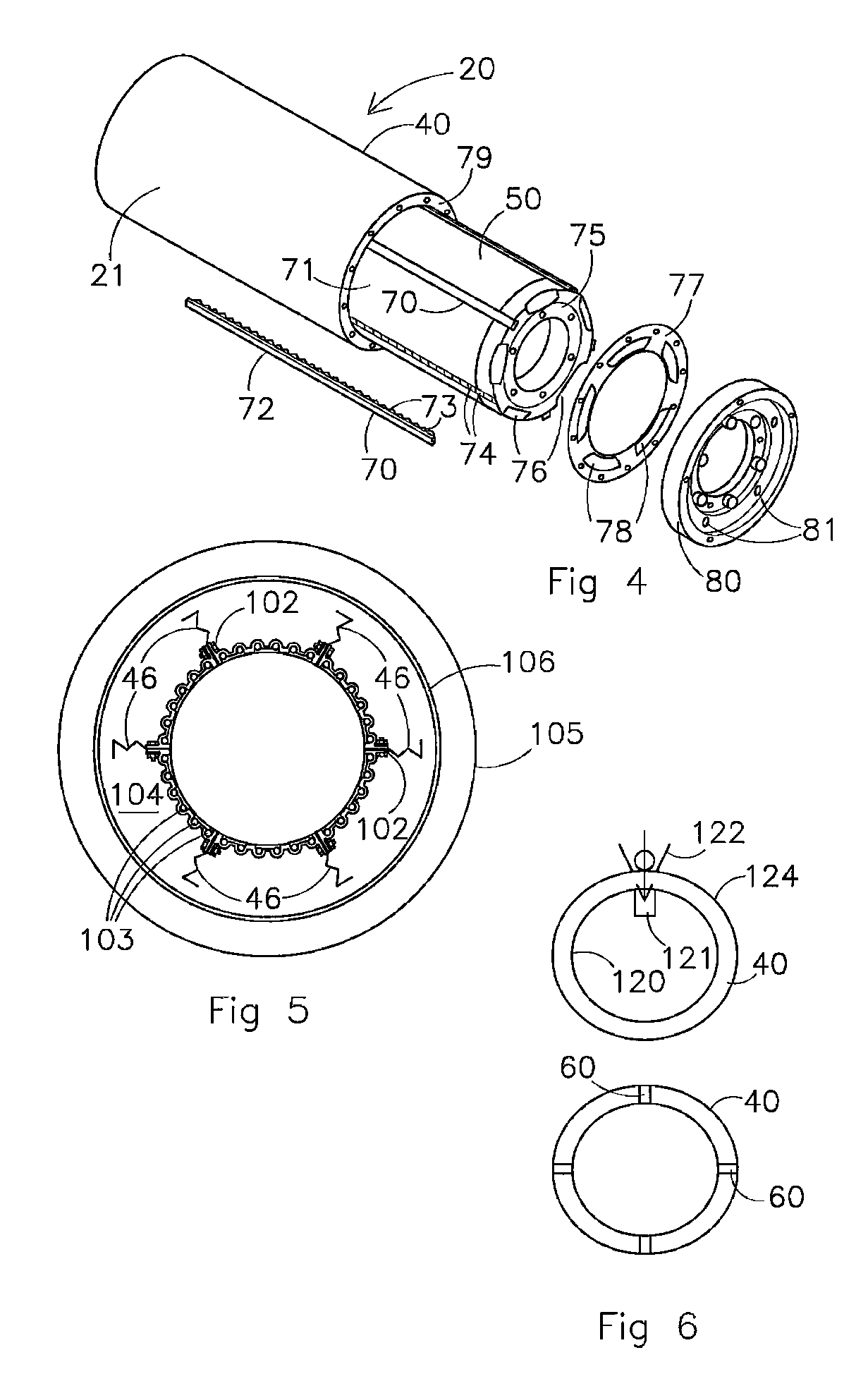

Tissue scaffold having aligned fibrils, apparatus and method for producing the same, and artificial tissue and methods of use thereof

ActiveUS20050009178A1Improve structural strengthMinimal immunological responsePeptide/protein ingredientsHollow filament manufactureFiberRadial position

A tubular tissue scaffold is described which comprises a tube having a wall, wherein the wall includes biopolymer fibrils that are aligned in a helical pattern around the longitudinal axis of the tube where the pitch of the helical pattern changes with the radial position in the tube wall. The scaffold is capable of directing the morphological pattern of attached and growing cells to form a helical pattern around the tube walls. Additionally, an apparatus for producing such a tubular tissue scaffold is disclosed, the apparatus comprising a biopolymer gel dispersion feed pump that is operably connected to a tube-forming device having an exit port, where the tube-forming device is capable of producing a tube from the gel dispersion while providing an angular shear force across the wall of the tube, and a liquid bath located to receive the tubular tissue scaffold from the tube-forming device. A method for producing the tubular tissue scaffolds is also disclosed. Also, artificial tissue comprising living cells attached to a tubular tissue scaffold as described herein is disclosed. Methods for using the artificial tissue are also disclosed.

Owner:UNIVERSITY OF SOUTH CAROLINA

Apparatus and methods for electrospinning polymeric fibers and membranes

An apparatus and methods for electrospinning polymer fibers and membranes are described. The methods include in one aspect electrospinning a polymer fiber from a conducting fluid containing the polymer in the presence of a first electric field established between a conducting fluid introduction device and a ground source and modifying the first electric field with a second electric field to form a jet stream of the conducting fluid. In another aspect the methods include forming an electrospinning jet stream of the conducting fluid and electrically controlling the flow characteristics of the jet stream. In yet another aspect the methods include forming a plurality of electrospinning jet streams of the conducting fluid and independently controlling the flow characteristics of at least one of the jet streams. The apparatus for electrospinning includes a conducting fluid introduction device containing a plurality of electrospinning spinnerets for delivering the conducting fluid, a ground member positioned adjacent to the spinnerets, a support member disposed between the spinnerets and the ground member and movable to receive fibers formed from the conducting fluid, and a means for controlling the flow characteristics of conducting fluid from at least one spinneret independently from the flow characteristics of conducting fluid from another spinneret. An improved conducting fluid introduction device which includes a plurality of spinnerets, each for independently delivering a controlled quantity of conducting fluid at a controlled pressure or flow rate, the spinnerets being charged at an electric potential and being disposed relative to each other to normally interfere with the electric field produced by adjacent spinnerets, each of the spinnerets having a tip at which conducting fluid exits configured to have an electrostatic field strength at each tip stronger than the liquid surface tension at each of the tips is also described.

Owner:RES FOUND THE

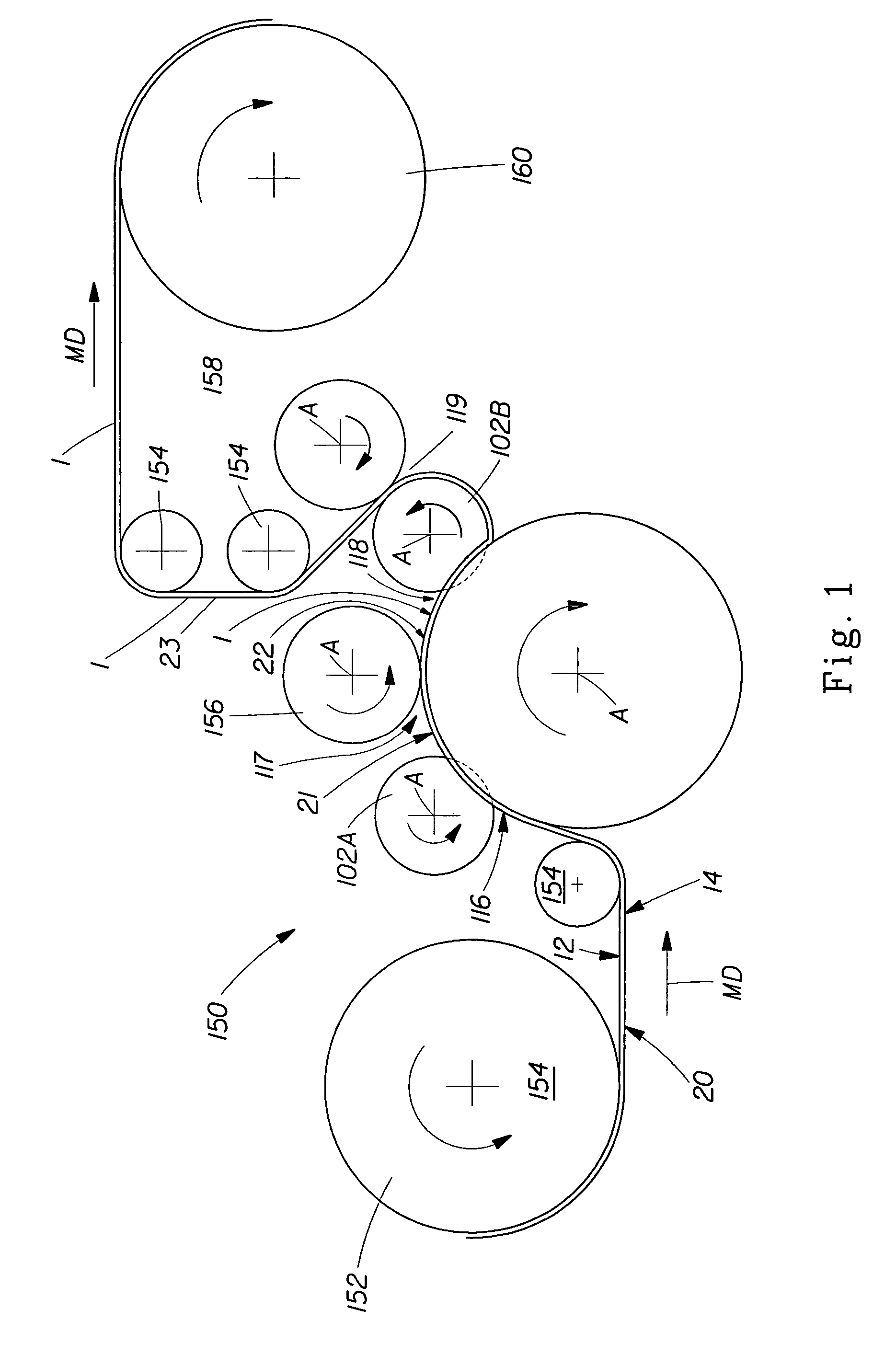

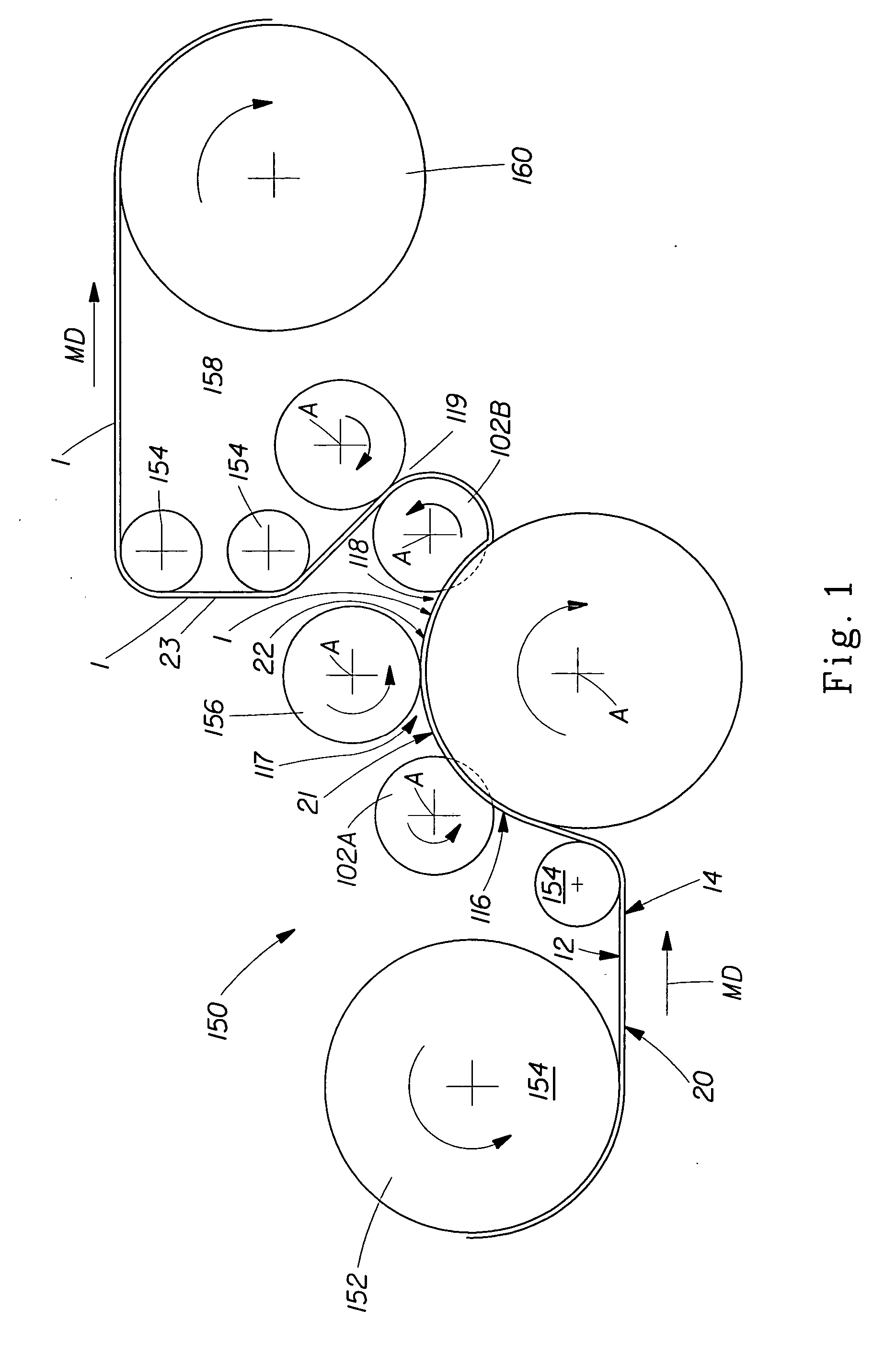

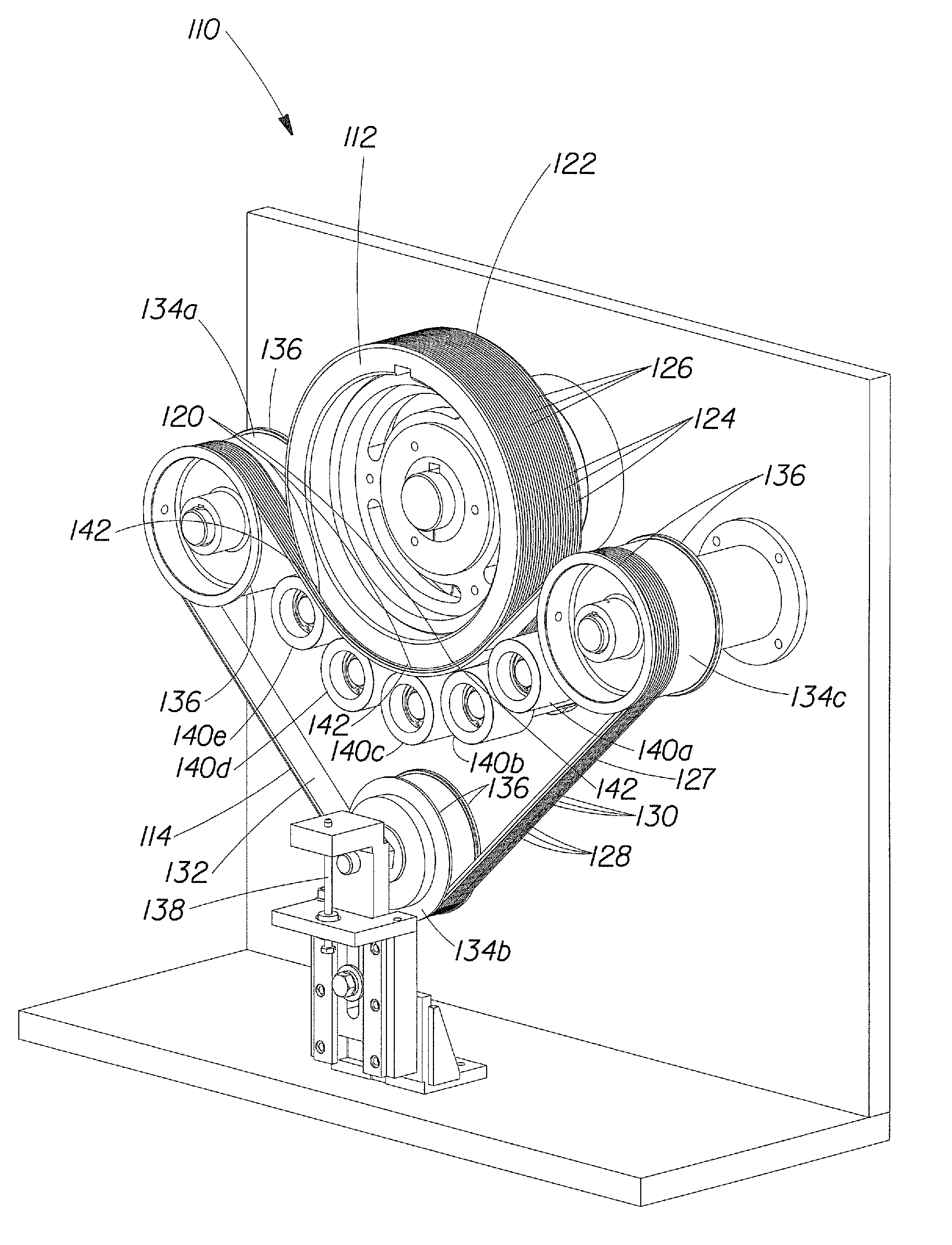

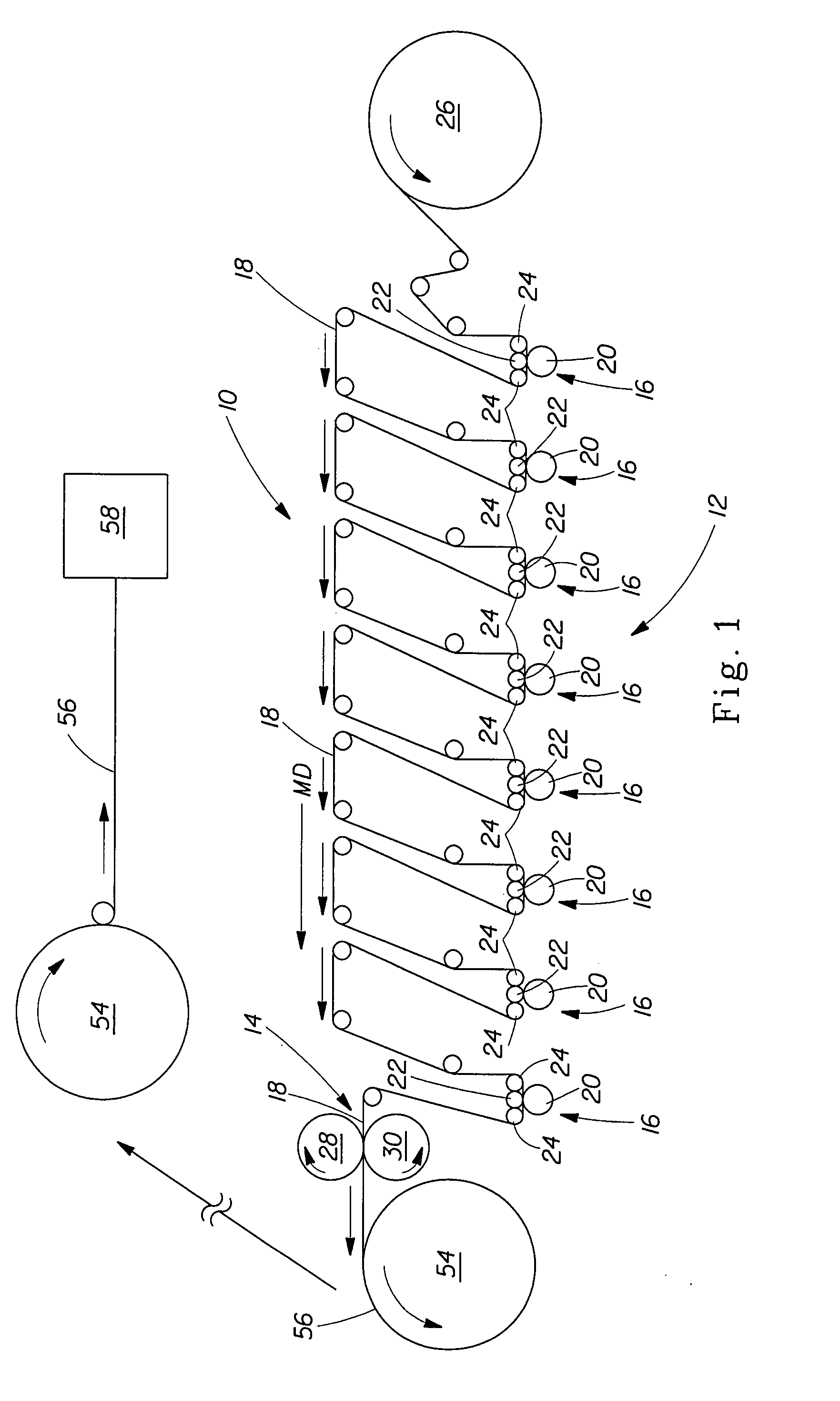

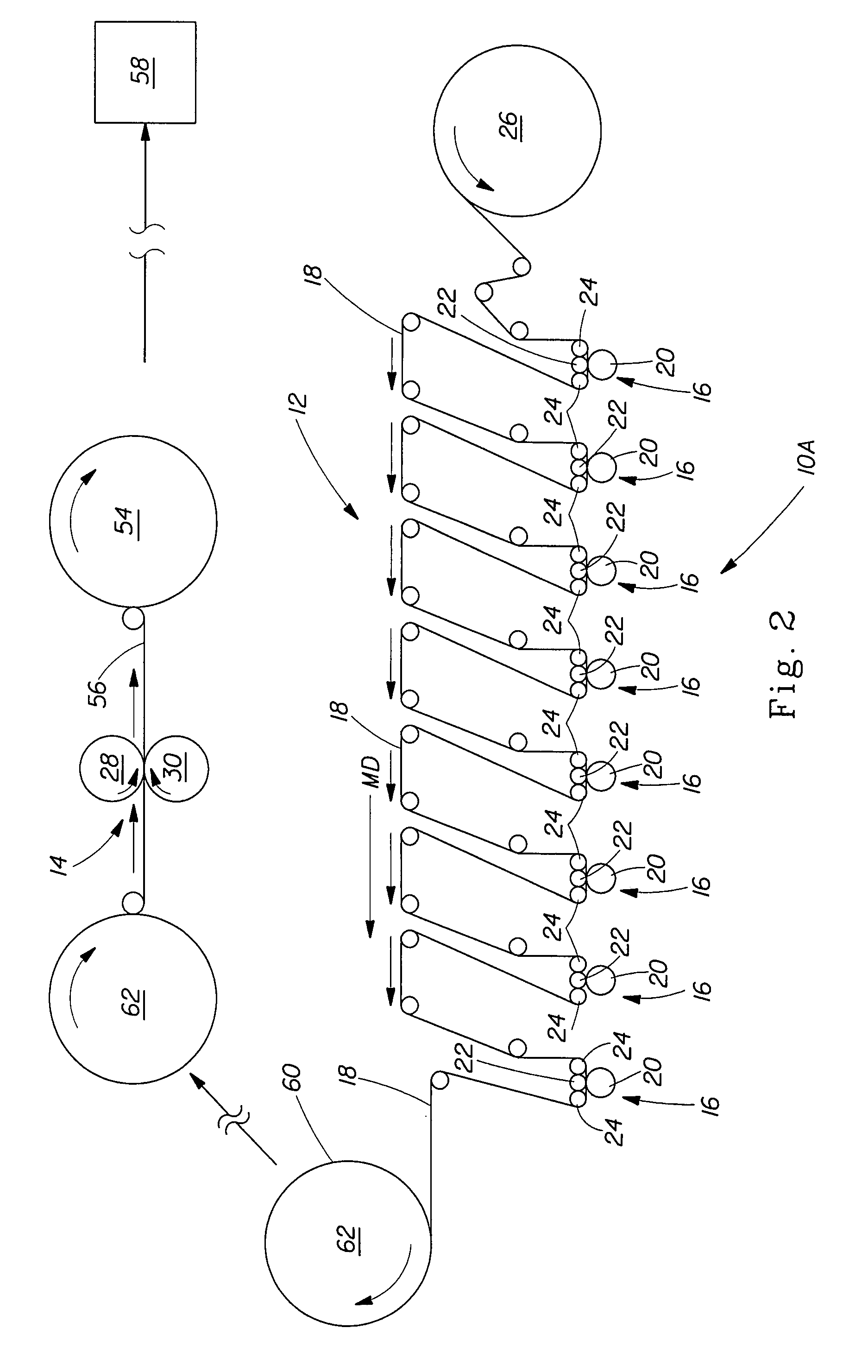

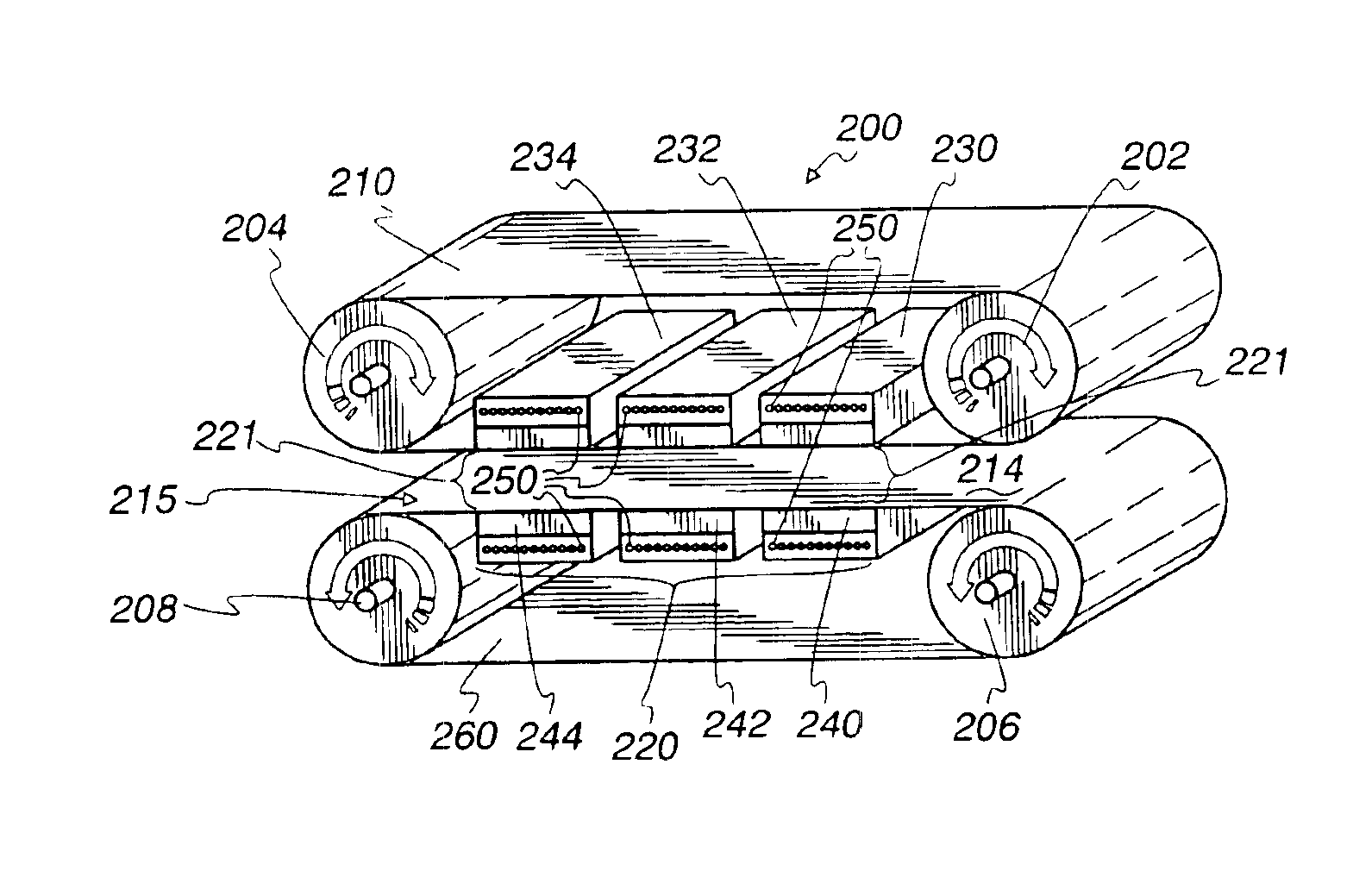

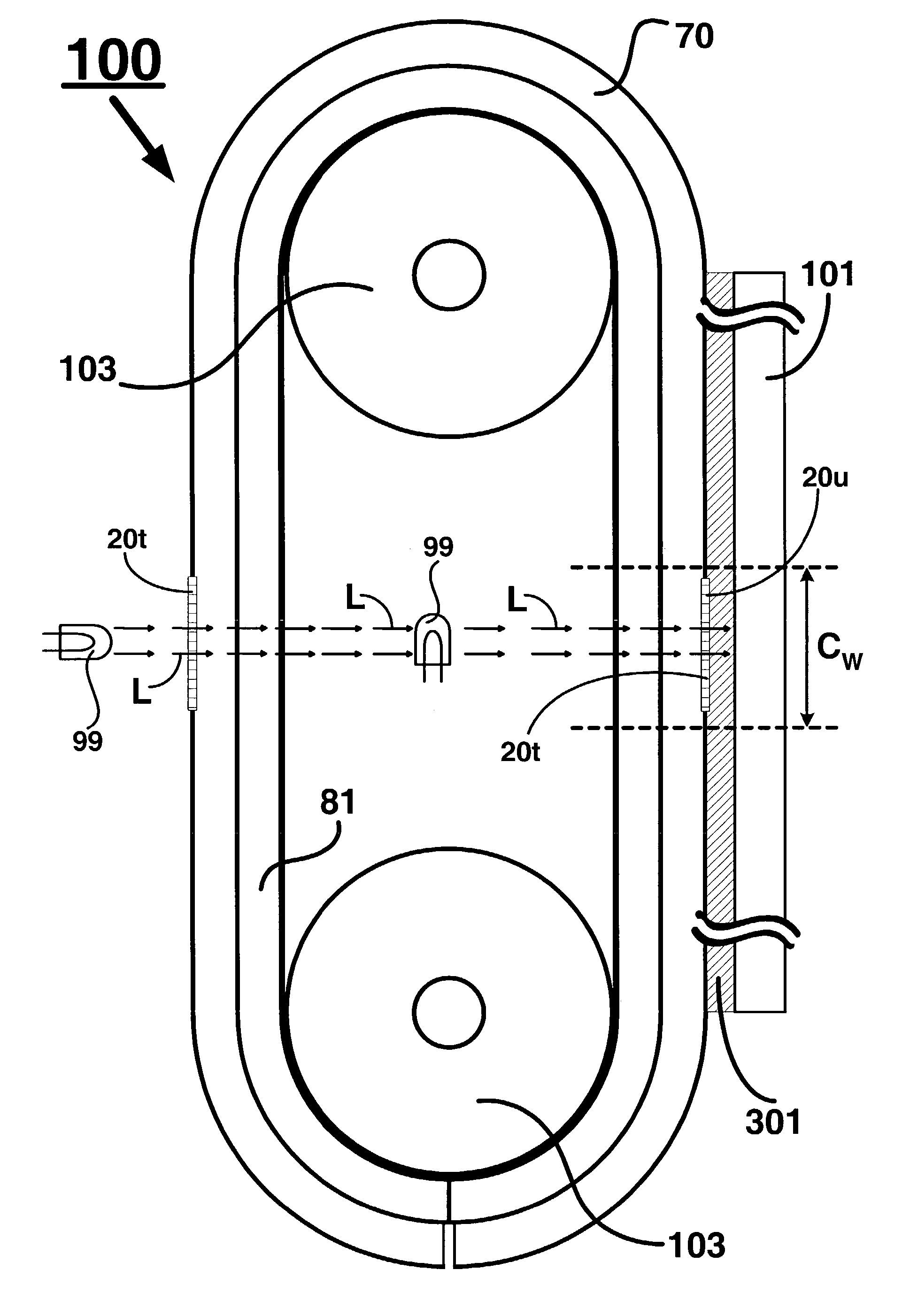

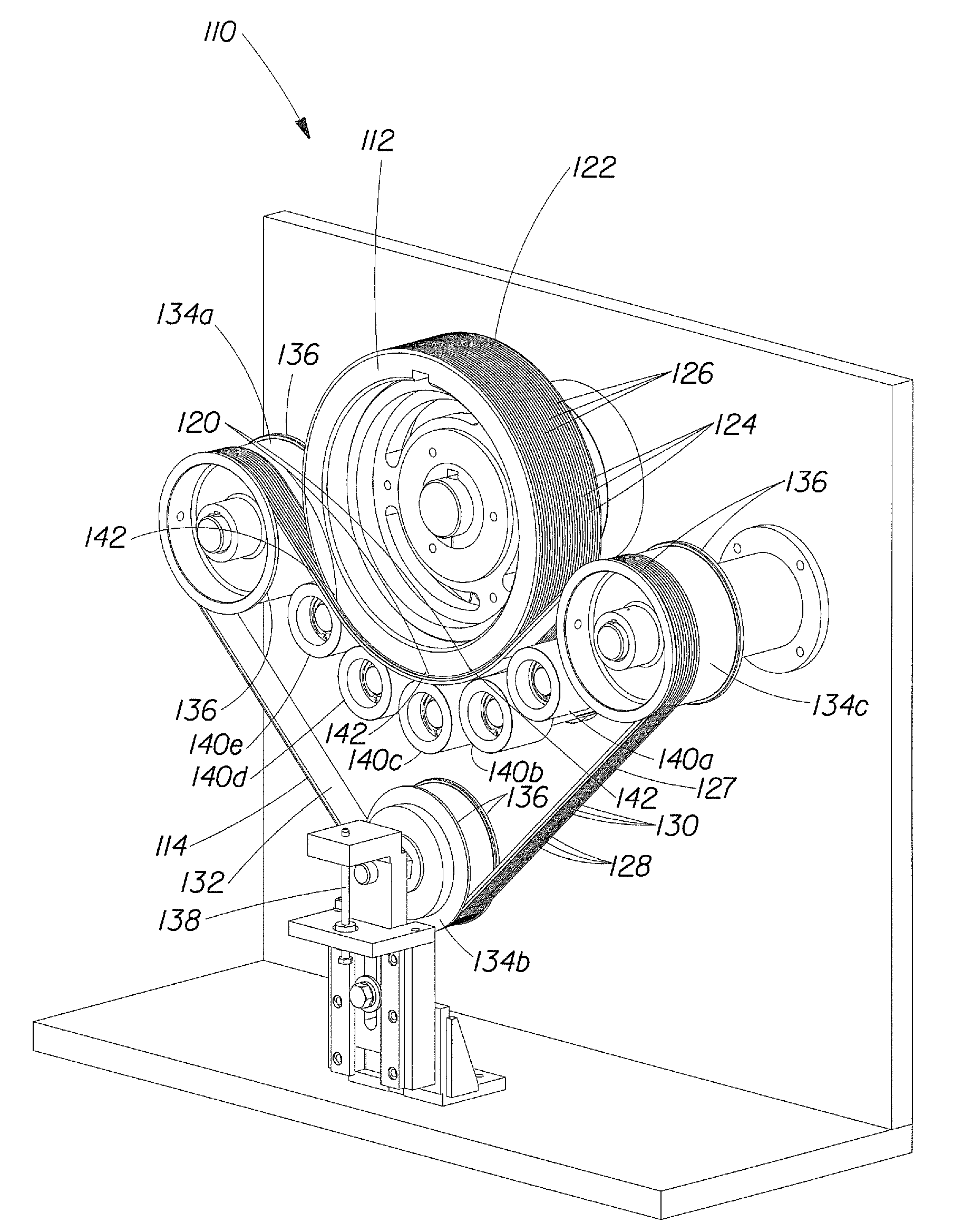

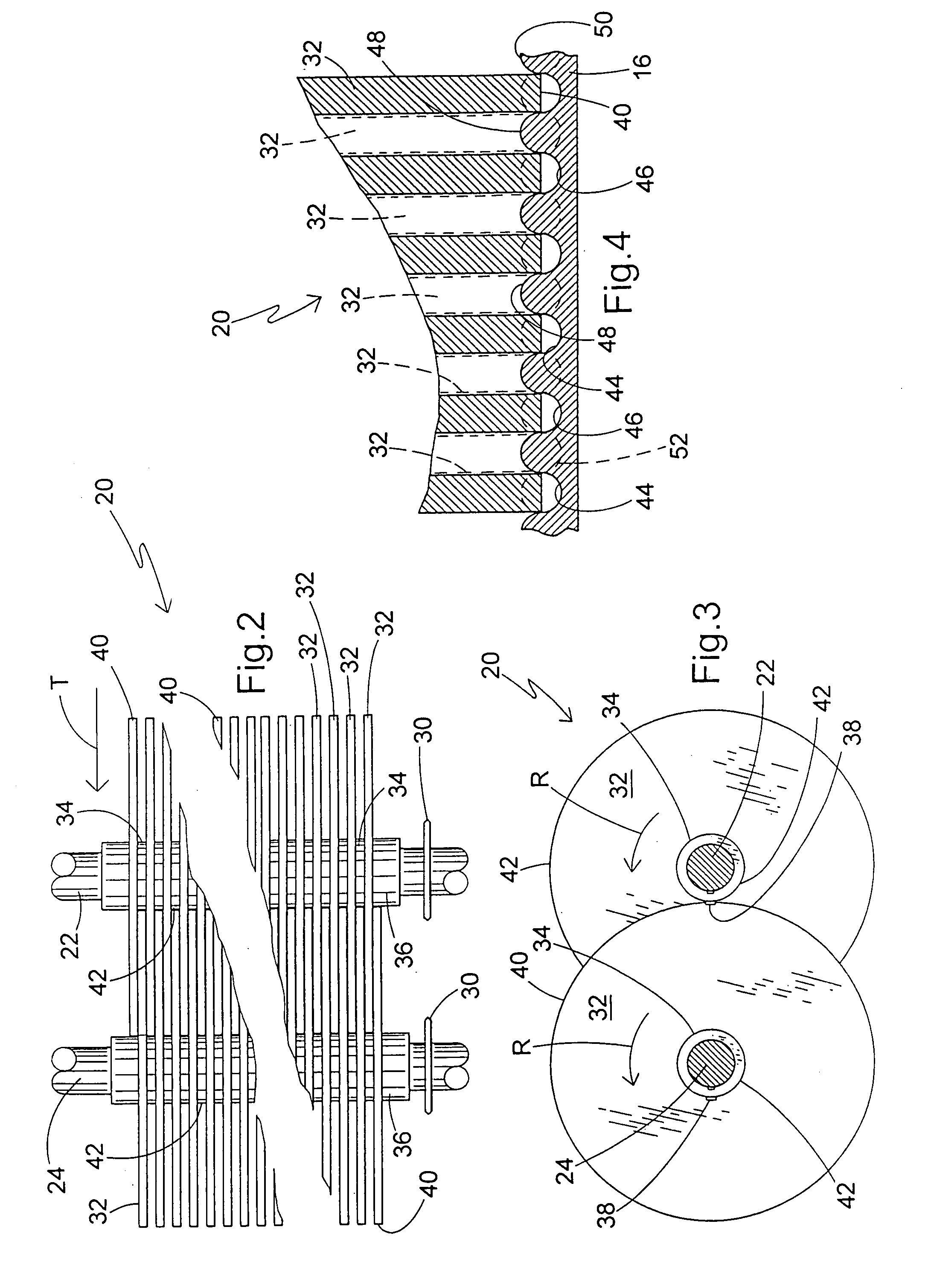

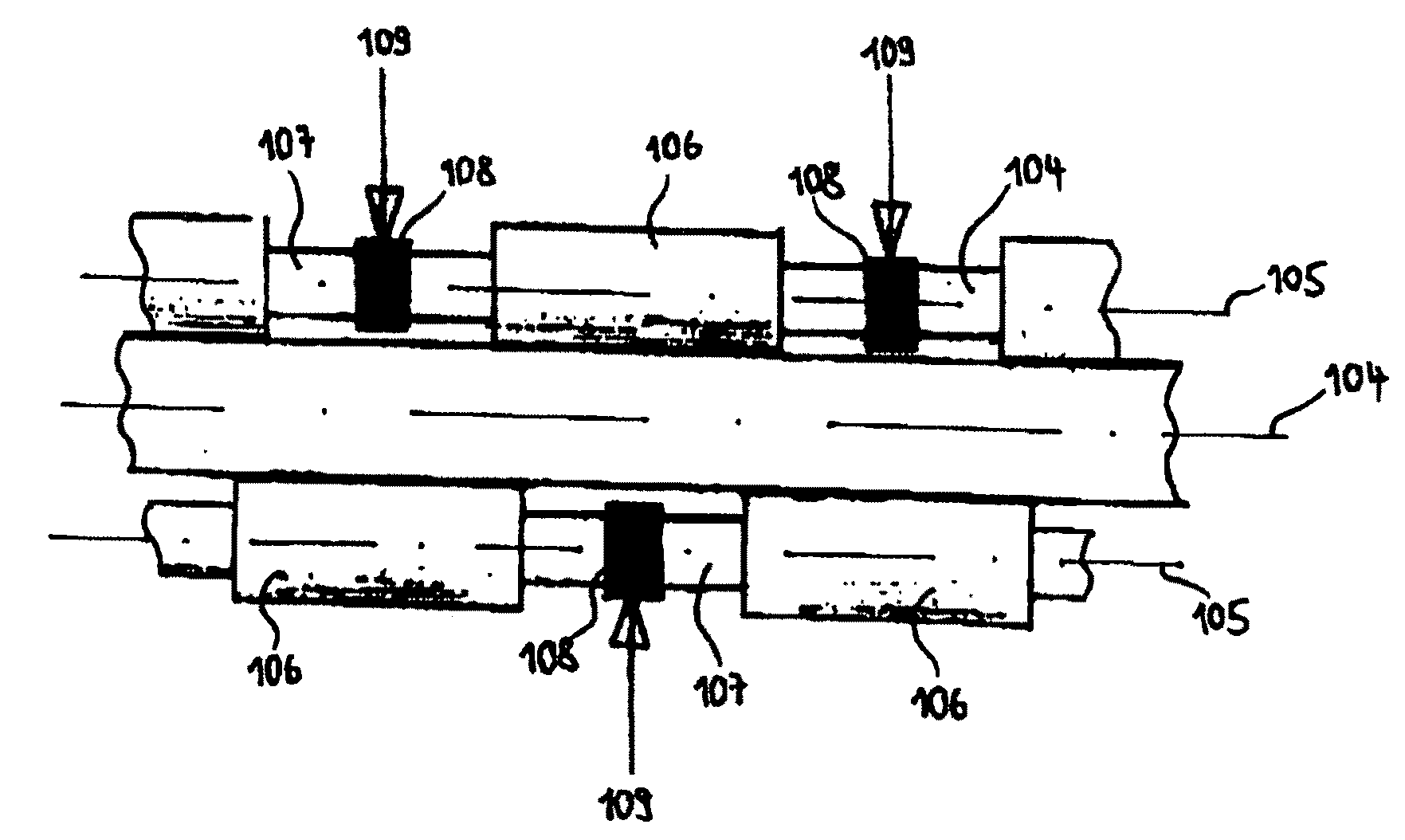

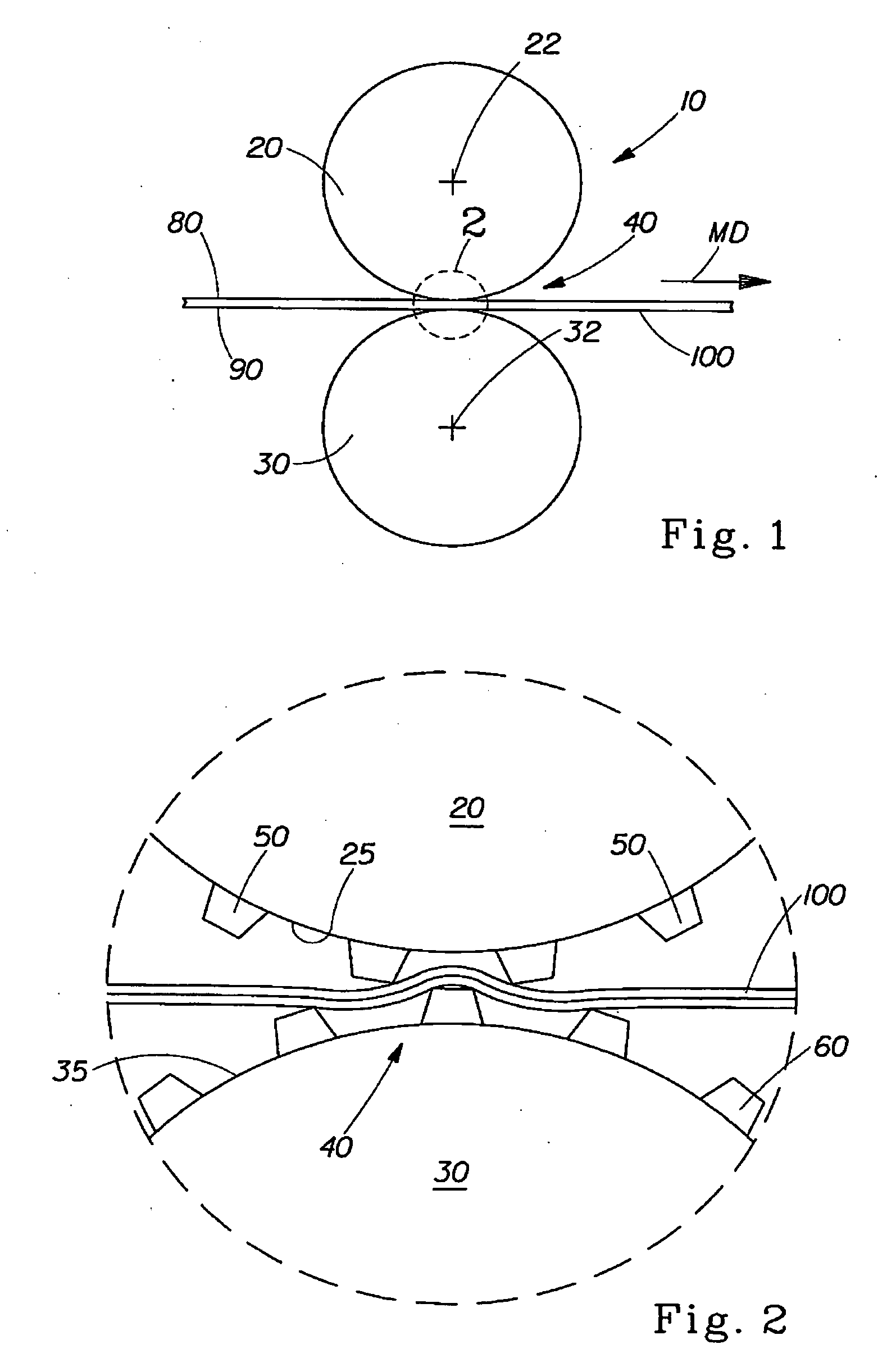

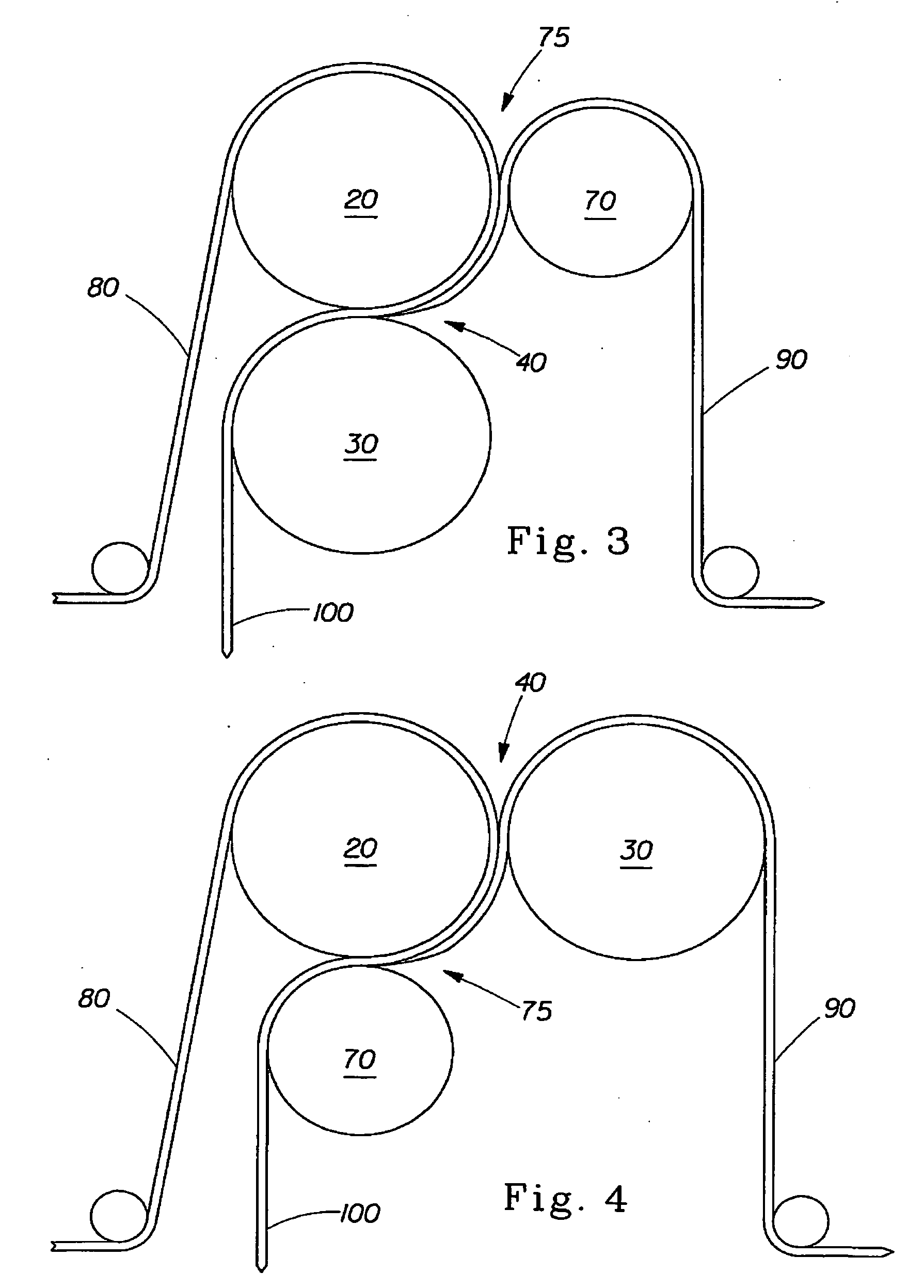

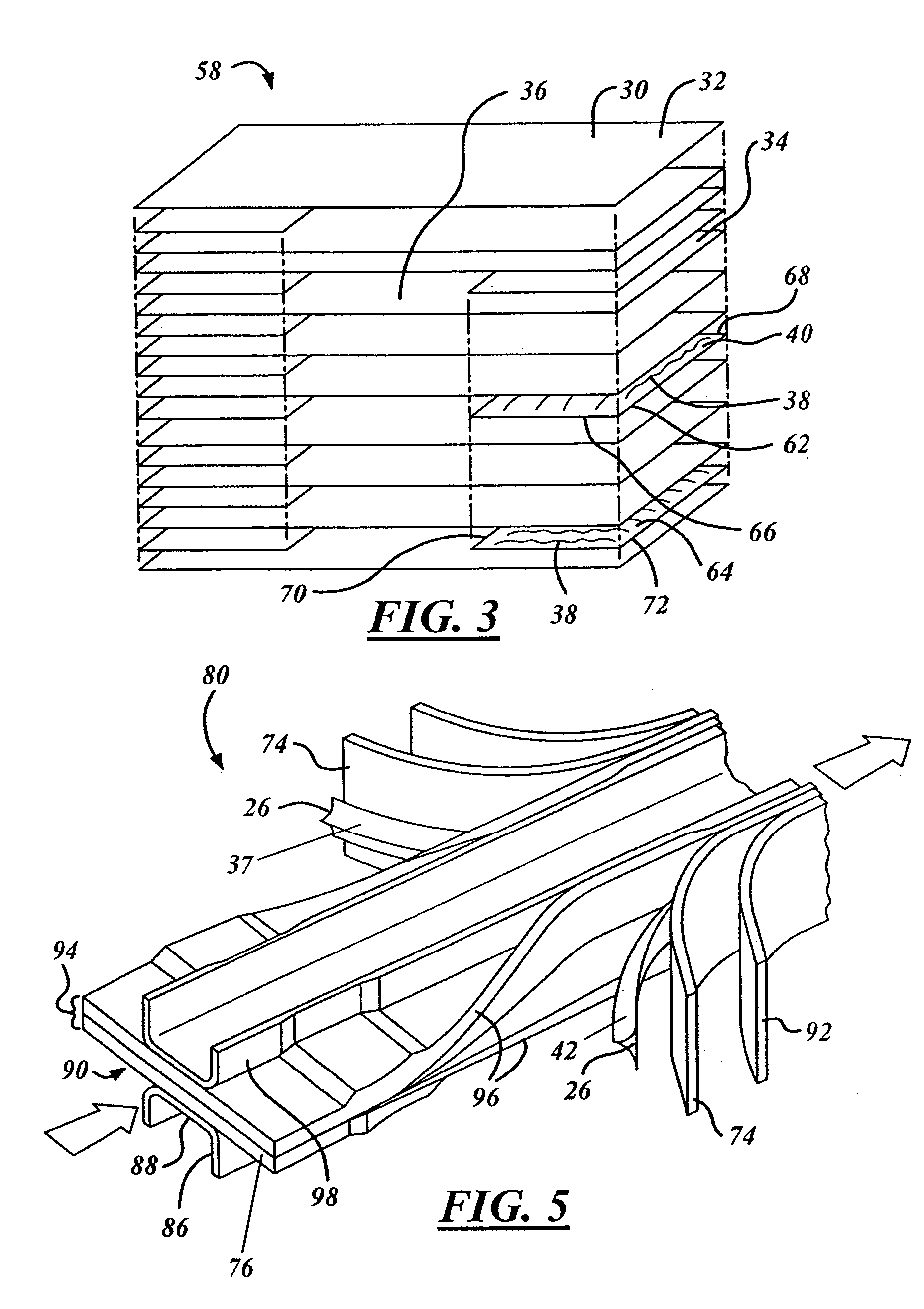

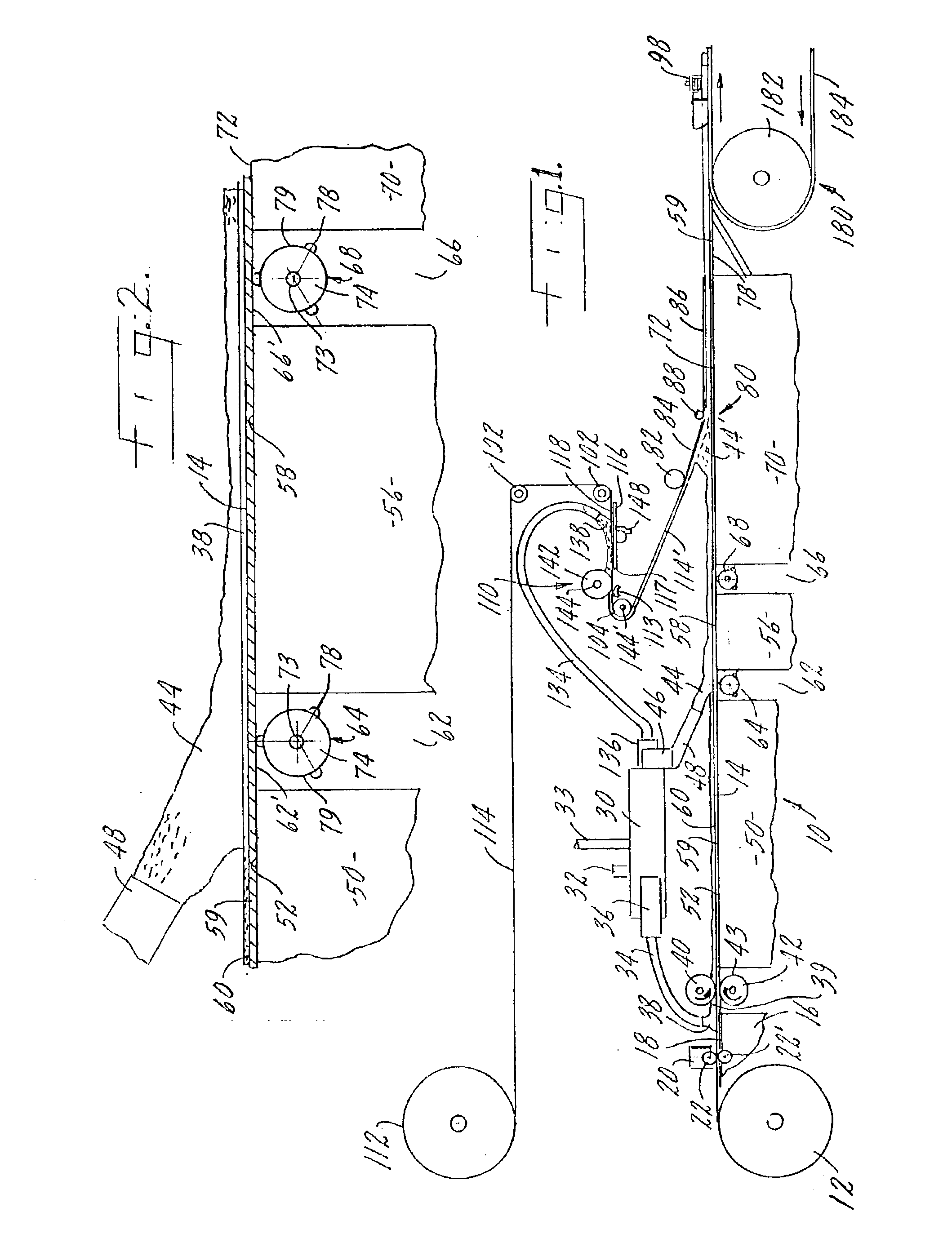

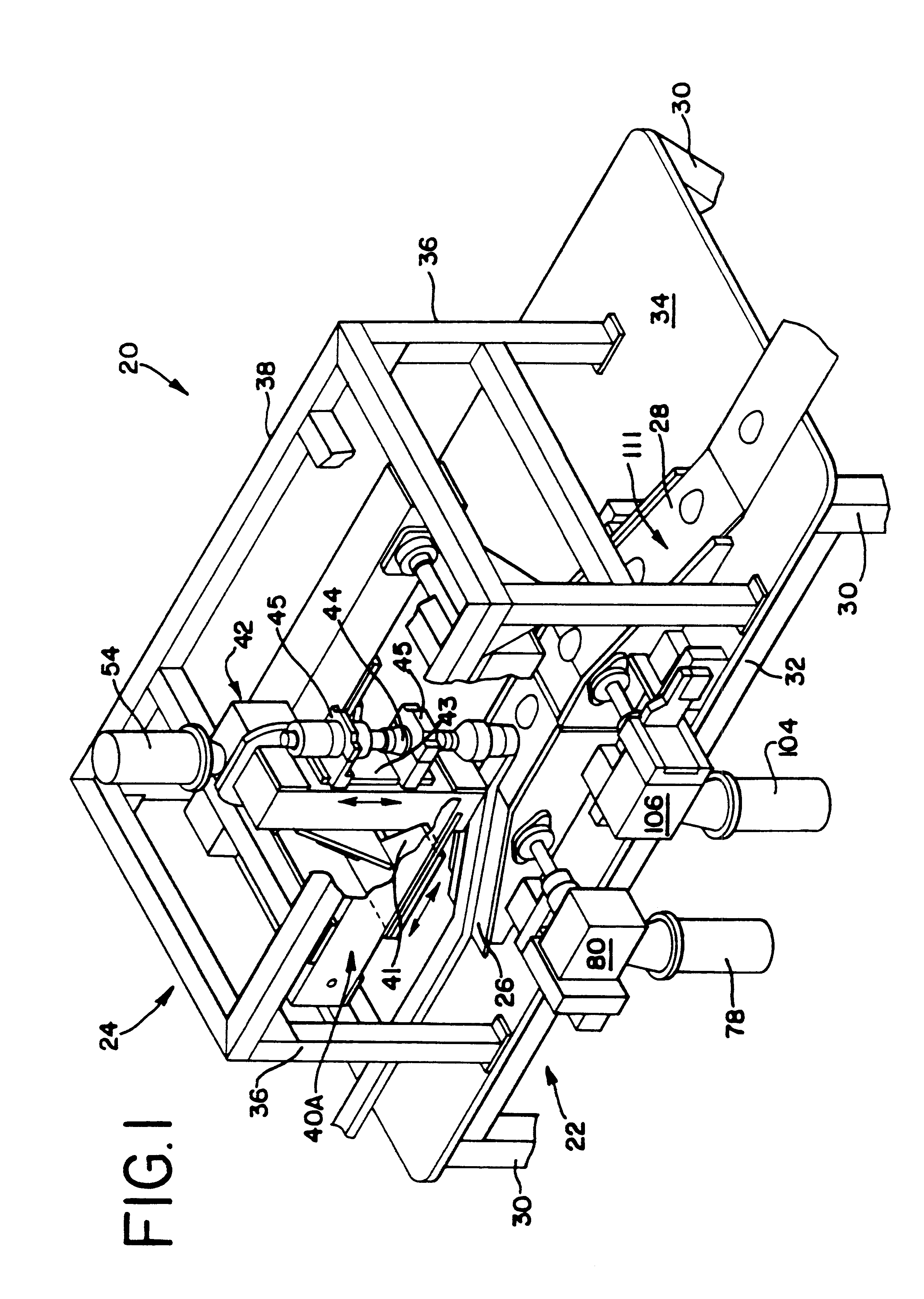

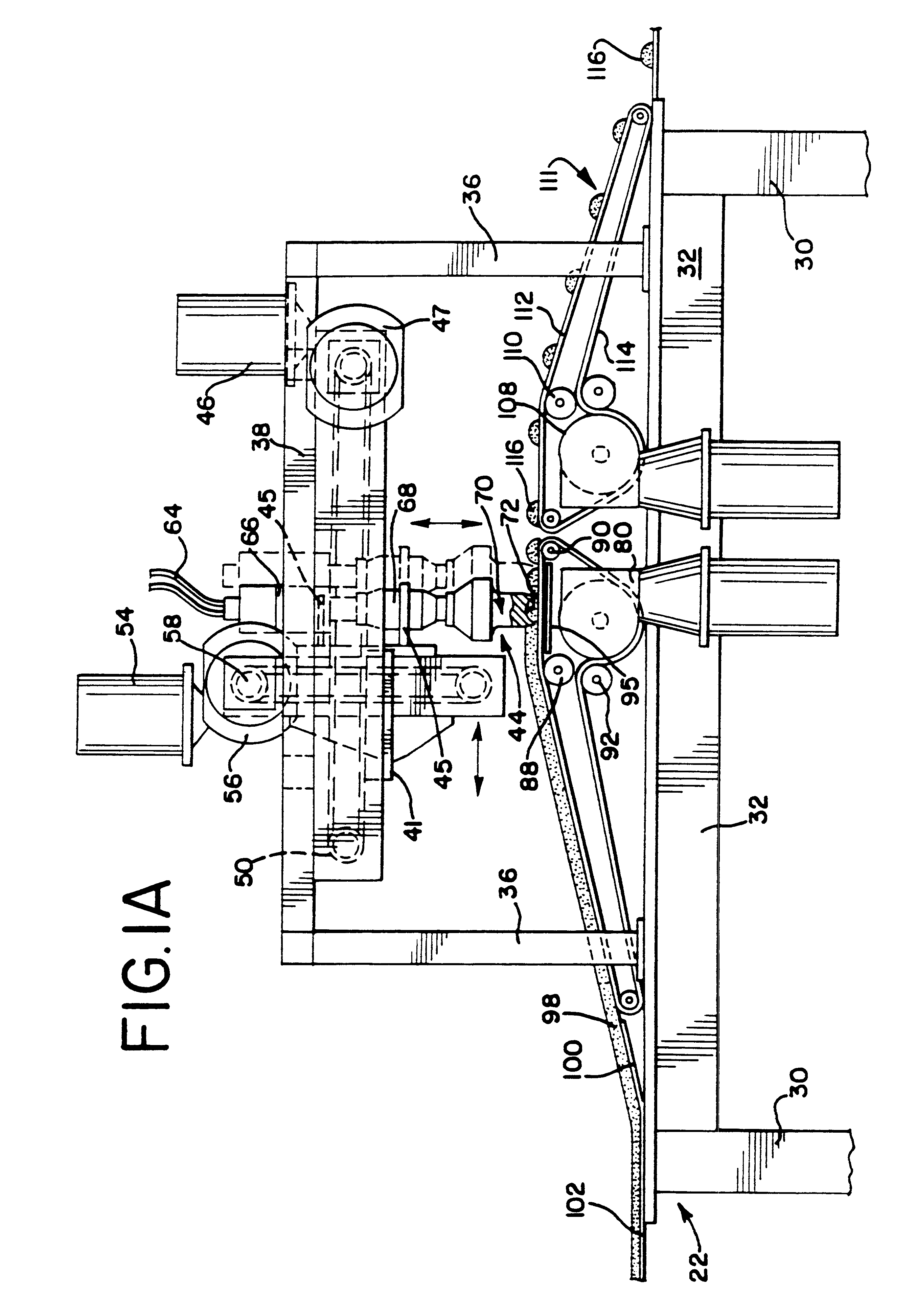

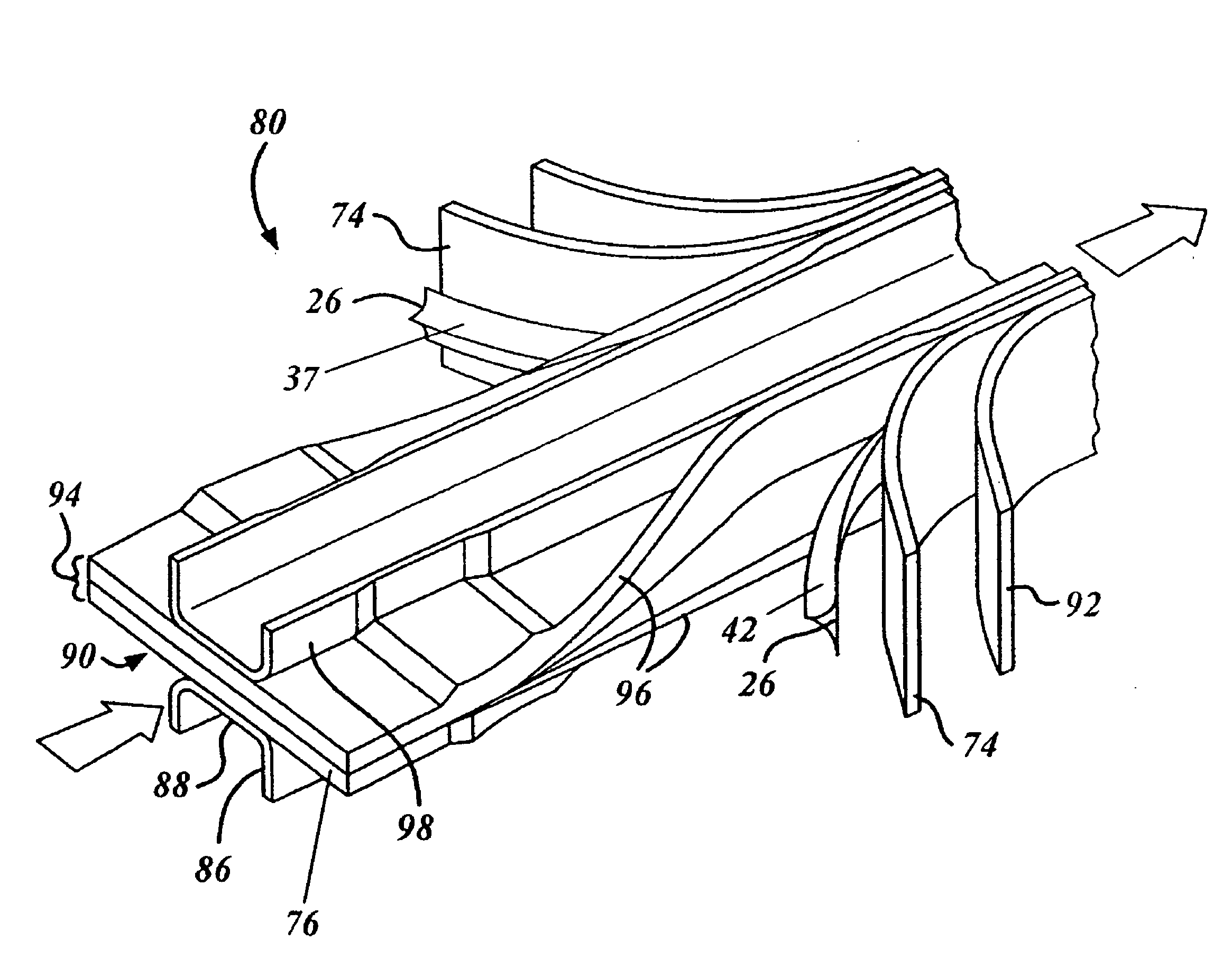

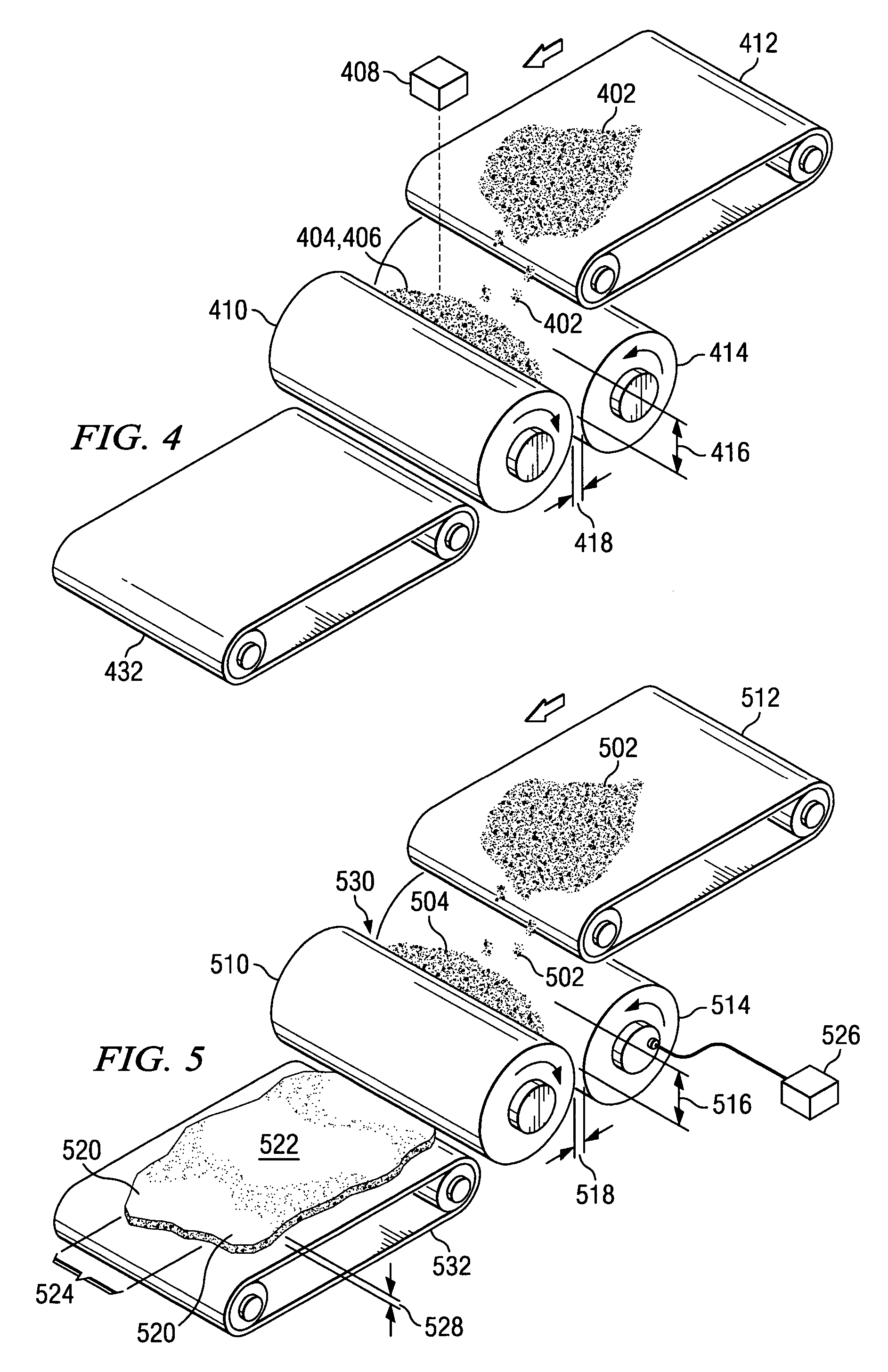

Method and Apparatus for Incrementally Stretching a Web

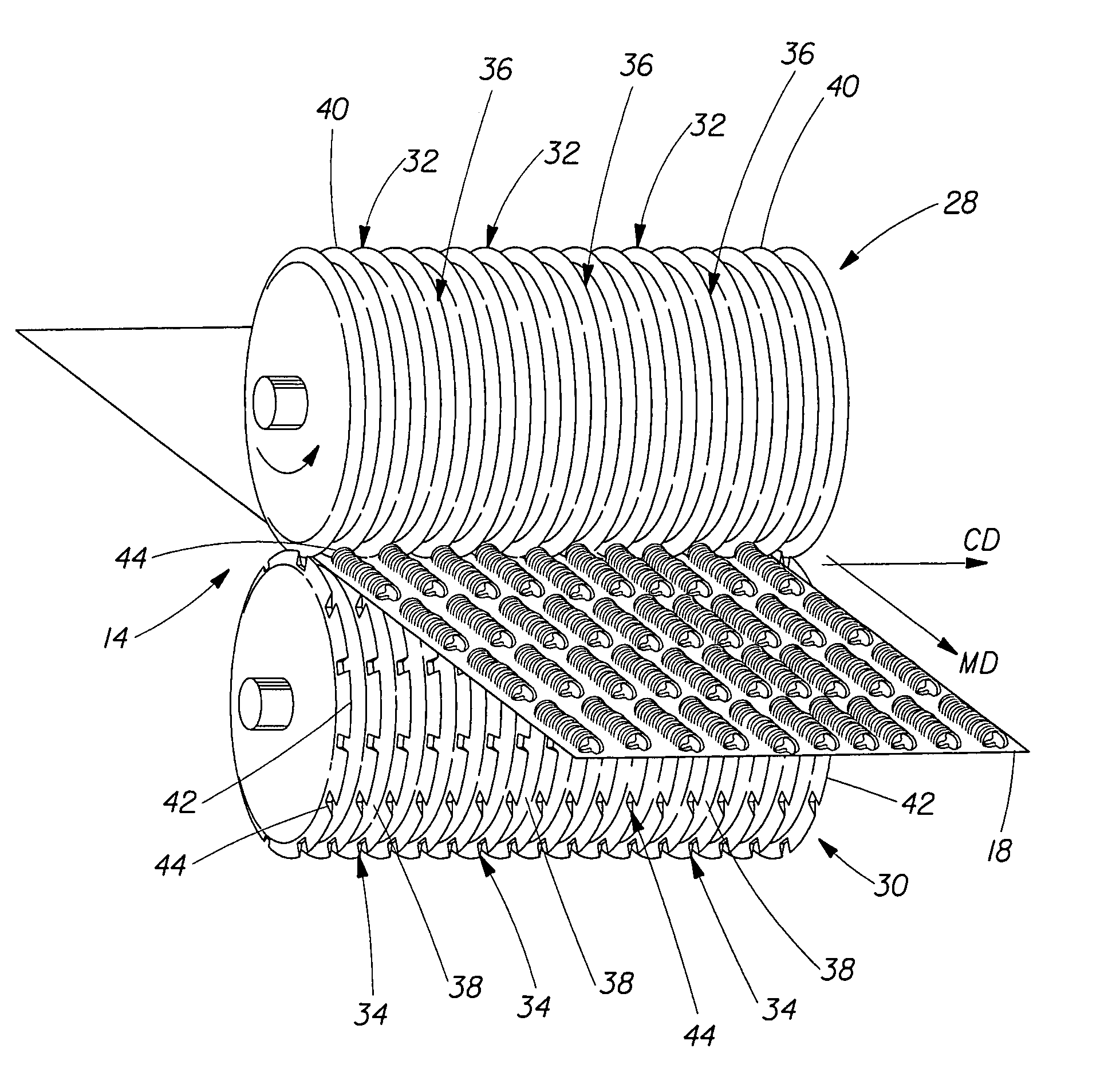

ActiveUS20080224351A1Increase path lengthIncrease line speedDough-sheeters/rolling-machines/rolling-pinsConfectioneryEngineeringBiological activation

A method and apparatus is provided which uses activation members for incrementally stretching a web at a low strain rate. The activation members include an activation belt and a single activation member wherein the activation belt and single activation member comprise a plurality of teeth and grooves that complement and engage one another at a depth of engagement in a deformation zone. The depth of engagement can be controlled to increase linearly over at least a portion of the deformation zone such that a web interposed between the activation belt and the single activation member in the deformation zone is incrementally stretched at a low rate of strain.

Owner:THE PROCTER & GAMBLE COMPANY

Apparatus and process for producing a web substrate having indicia disposed thereon and elastic-like behavior imparted thereto

Owner:THE PROCTER & GAMBLE COMPANY

Process and apparatus for embossing precise microstructures and embossing tool for making same

InactiveUS6908295B2Maintain pressureReduce frictionConfectionerySolid-state devicesEngineeringPlastic property

A process and apparatus for embossing thermoplastic products having precise microstructured surfaces including using a continuous press having upper and lower belts with the embossing pattern(s); feeding thermoplastic material through the press where heat and pressure are applied to form the embossed pressure microstructure, and cooling the embossed material, all while maintaining pressure. A continuous embossing tool is provided by welding segments together, the welds including interface material at the weld joint which is of a different material than the segment material to increase the tensile strength.

Owner:AVERY DENNISON CORP

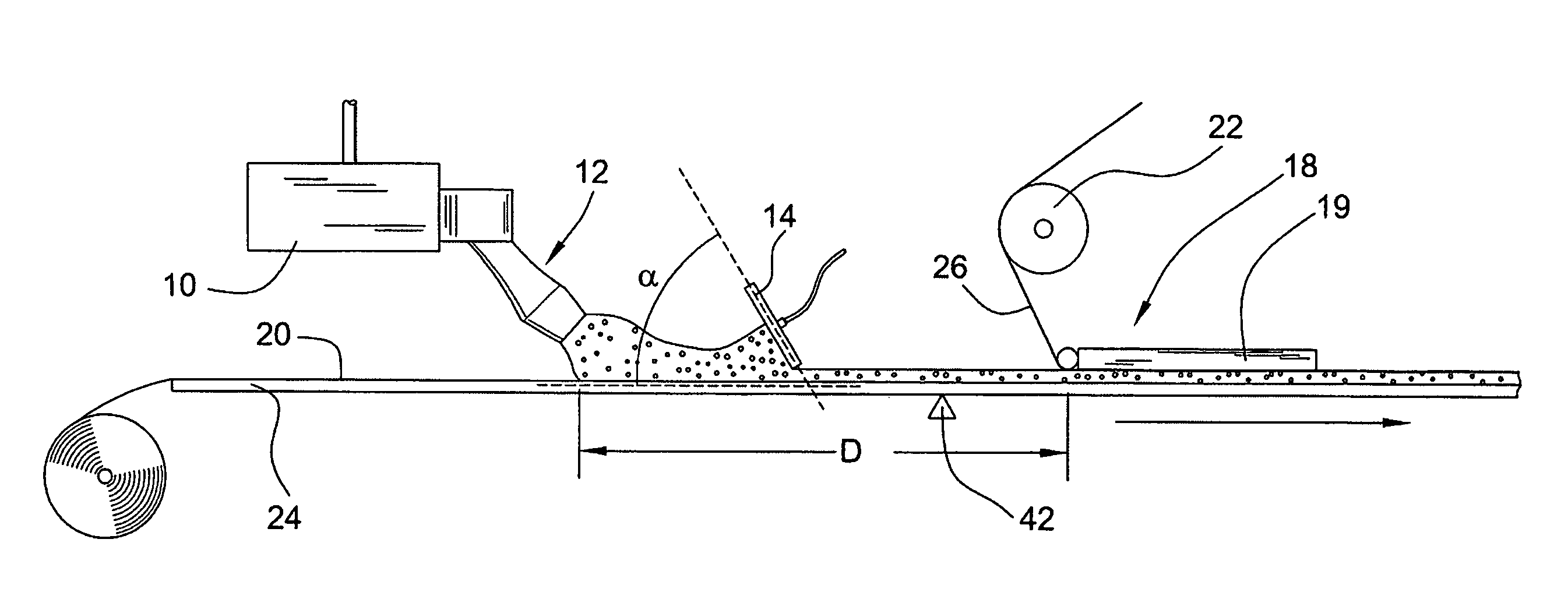

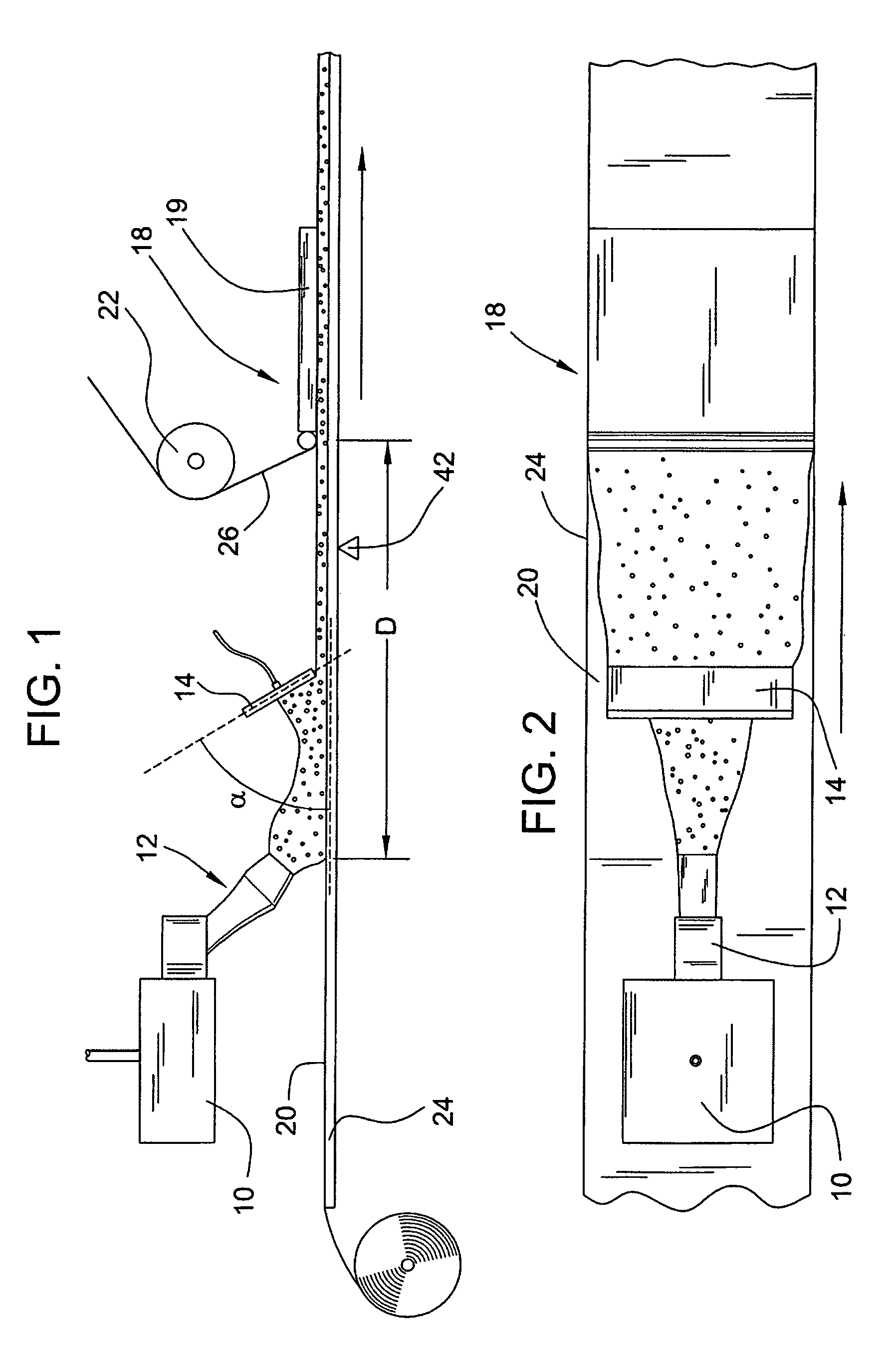

Slurry spreader for cementitious board production

InactiveUS7364676B2Increase productionSubstantial eliminationConfectioneryPress rollersCement boardEngineering

The invention provides a board forming system comprising a forming table comprising a belt with a surface for conveying a backing layer; a mixer fitted with a mechanism capable of depositing cementitious slurry material over a top surface of the backing layer; and a slurry spreader positioned downstream of the mixer, wherein a portion of the slurry spreader comprises a plurality of apertures which are connected to a source of pressurized fluid. The slurry spreader is configured such that the pressurized fluid flows out of the slurry spreader through the apertures so as to provide a continuous film of fluid across an outer surface of the slurry spreader. The slurry spreader is positioned such that it can contact at least a portion of the cementitious slurry after the slurry exits the discharge and before the slurry is spread across the width of the backing layer such that the thickness of the slurry is approximately equal to the desired slurry thickness for board formation. The invention further provides methods for forming cementitious board comprising the use of the slurry spreader.

Owner:UNITED STATES GYPSUM CO

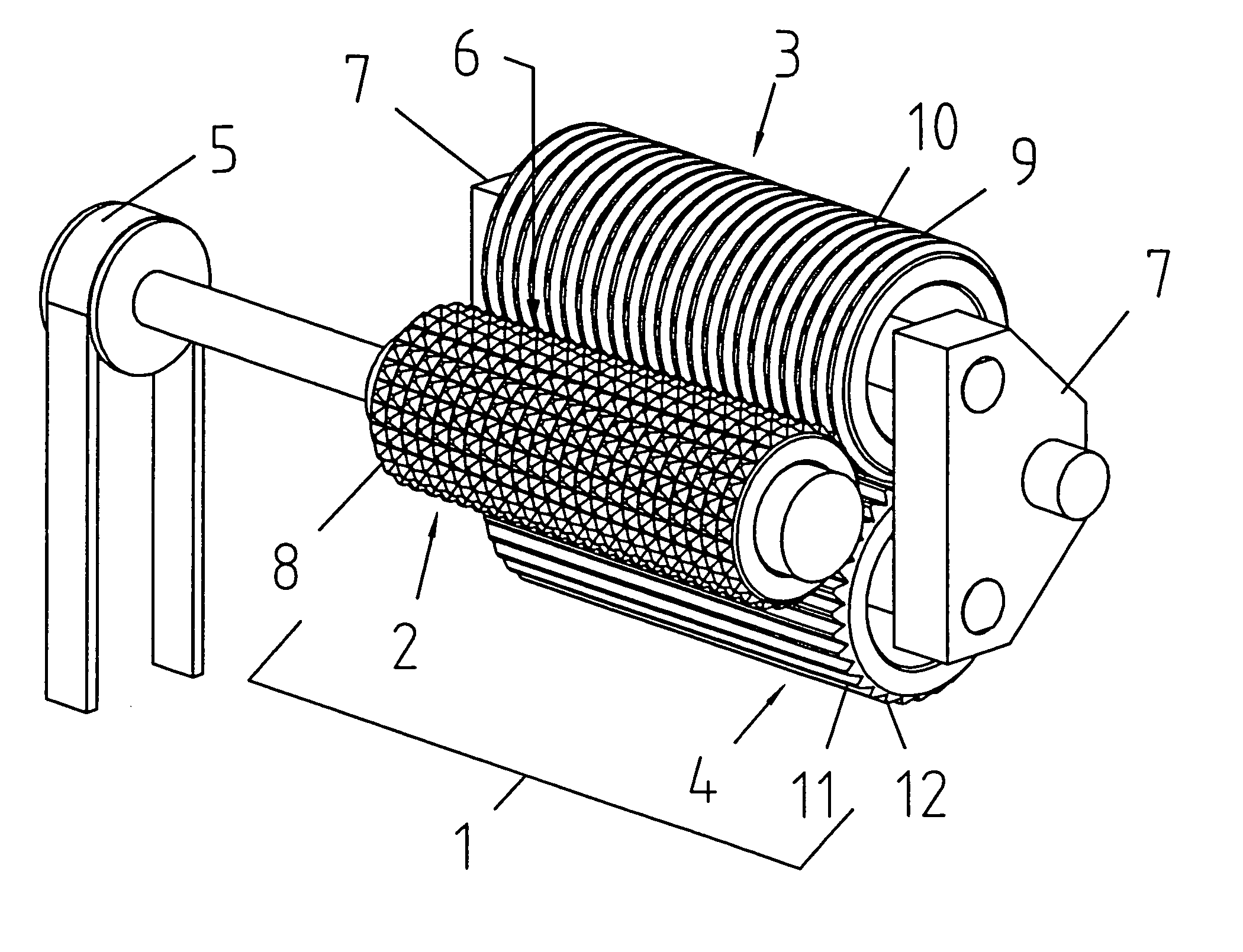

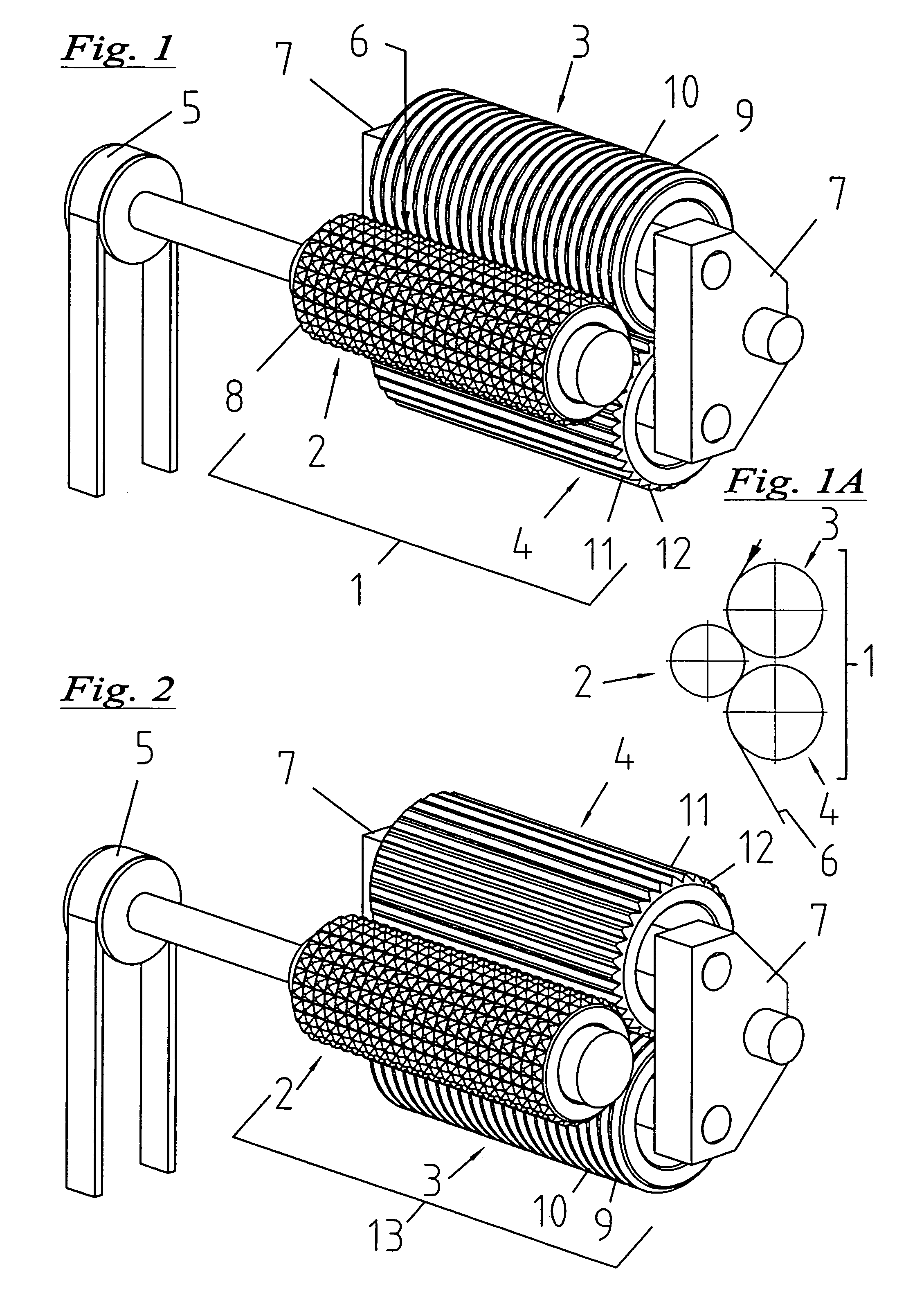

Device for treating flat material

InactiveUS7147453B2Not easy to copyImprove accuracyMechanical working/deformationDough-sheeters/rolling-machines/rolling-pinsEngineeringMechanical engineering

The invention relates to a device for embossing and / or glazing films. The device for embossing includes a first and second embossing roll, through which flat material can be fed under pressure, in order to create a pattern. An additional embossing roll is connected downstream of the second embossing roll, this additional embossing roll interacting with the first or preceding embossing roll. The patterned flat material may be fed between these embossing rolls, in order to be embossed again with essentially the same pattern. In a simplified embodiment, only a total of two rolls are used. In order to achieve as precise an embossing as possible, with special effects, the first driven embossing roll is provided with teeth, while at least one other embossing roll comprises rings or longitudinal ribs, or is smooth.

Owner:BOEGLL GRAVURES SA

Apparatus for embossing a flexible substrate with a pattern carried by an optically transparent compliant media

An apparatus for embossing a flexible substrate with an optically transparent compliant media is disclosed. The complaint media includes an optically transparent imprint stamp with an imprint pattern therein. The flexible substrate is coated with a photopolymer material. The compliant media can be connected with an optically transparent belt material to form an embossing belt or connected with an optically transparent cylinder to from an embossing drum. A coated side of the flexible substrate is urged into contact with the imprint stamp and the imprint pattern is embossed in the photopolymer material and an ultraviolet light passing through the compliant media contemporaneously cures the photopolymer material during the embossing.

Owner:APPLIED MATERIALS INC

Method and apparatus for incrementally stretching a web

ActiveUS8021591B2Easy to adjustIncrease path lengthDough-sheeters/rolling-machines/rolling-pinsConfectioneryEngineeringMechanical engineering

Owner:PROCTER & GAMBLE CO

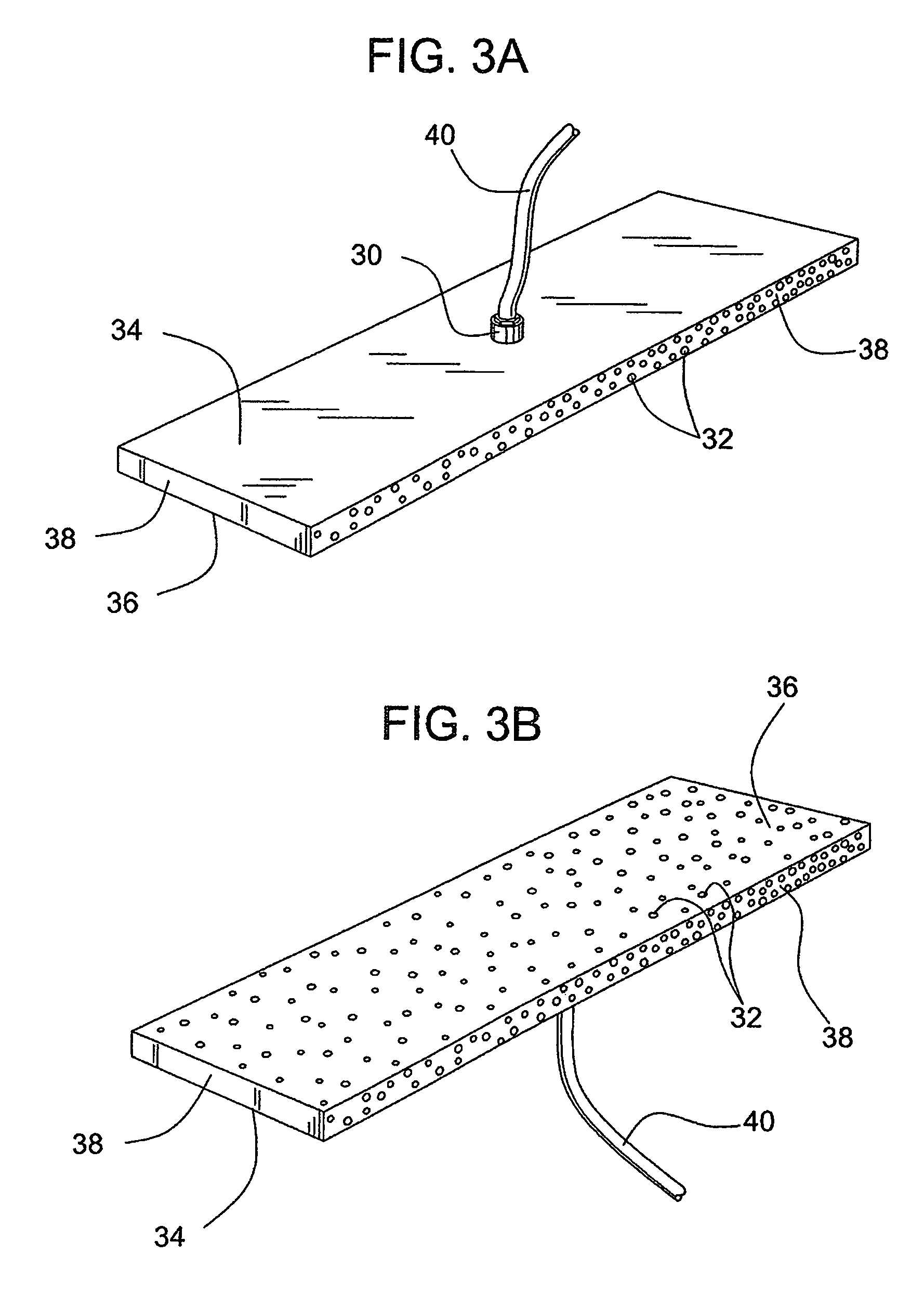

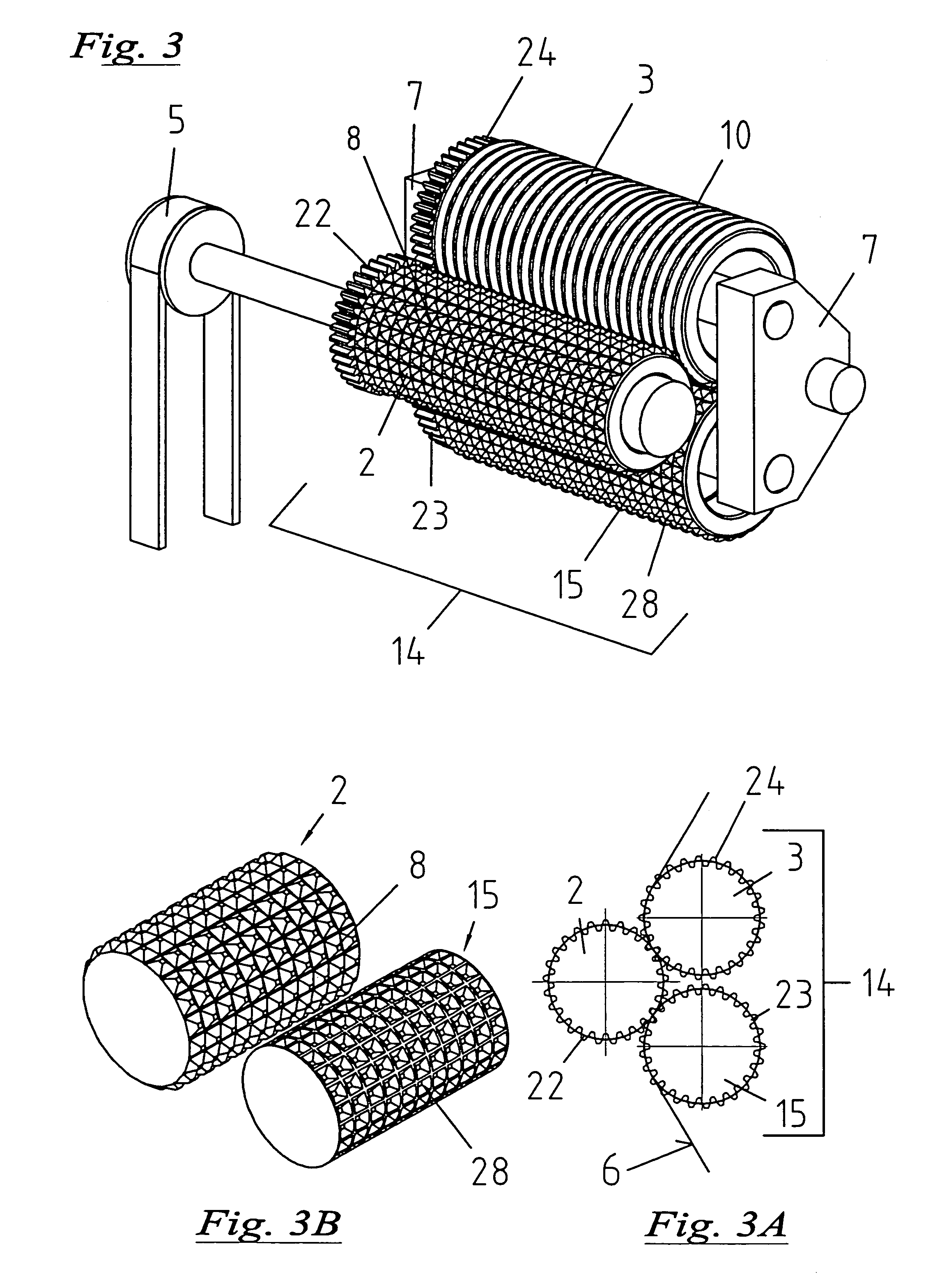

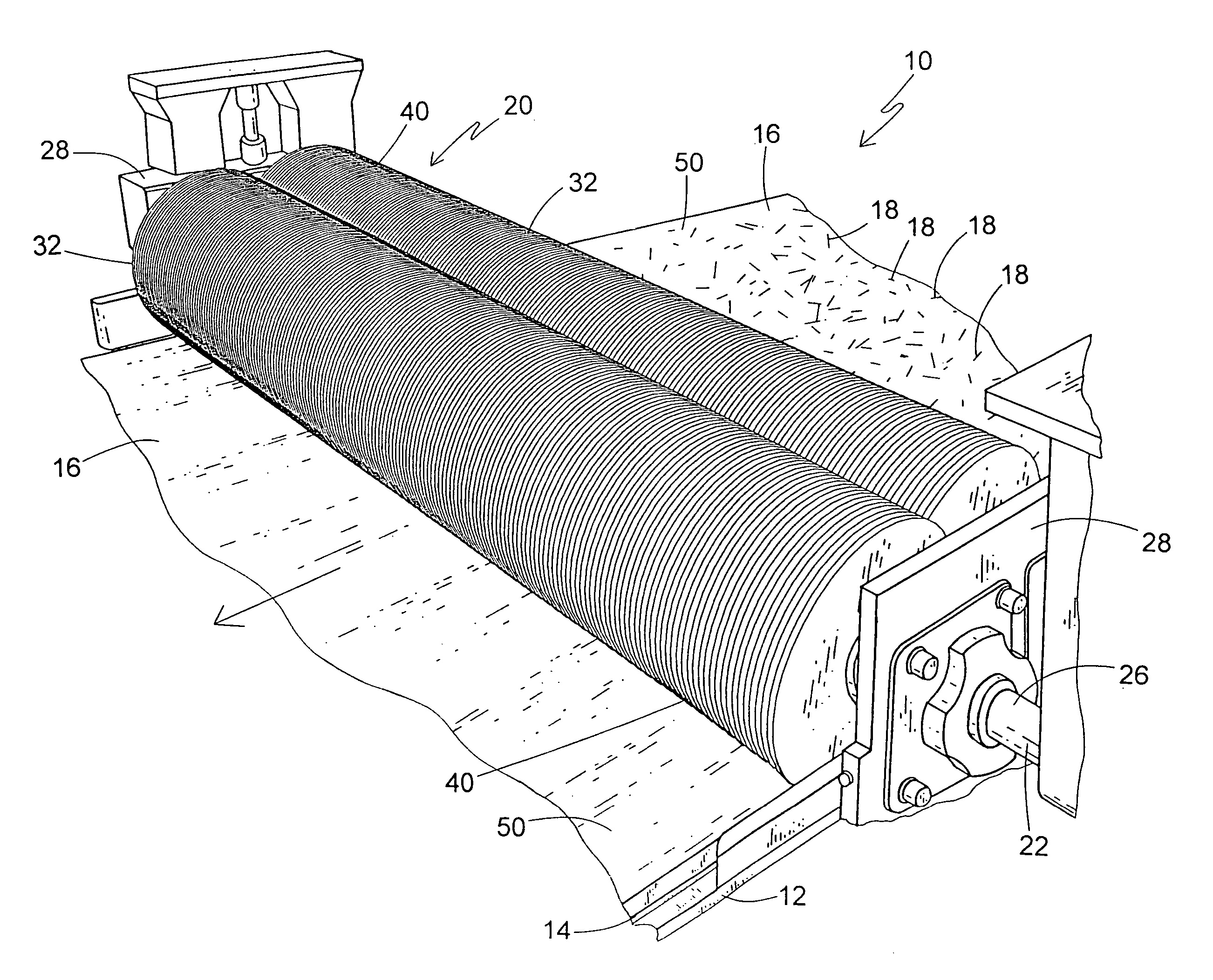

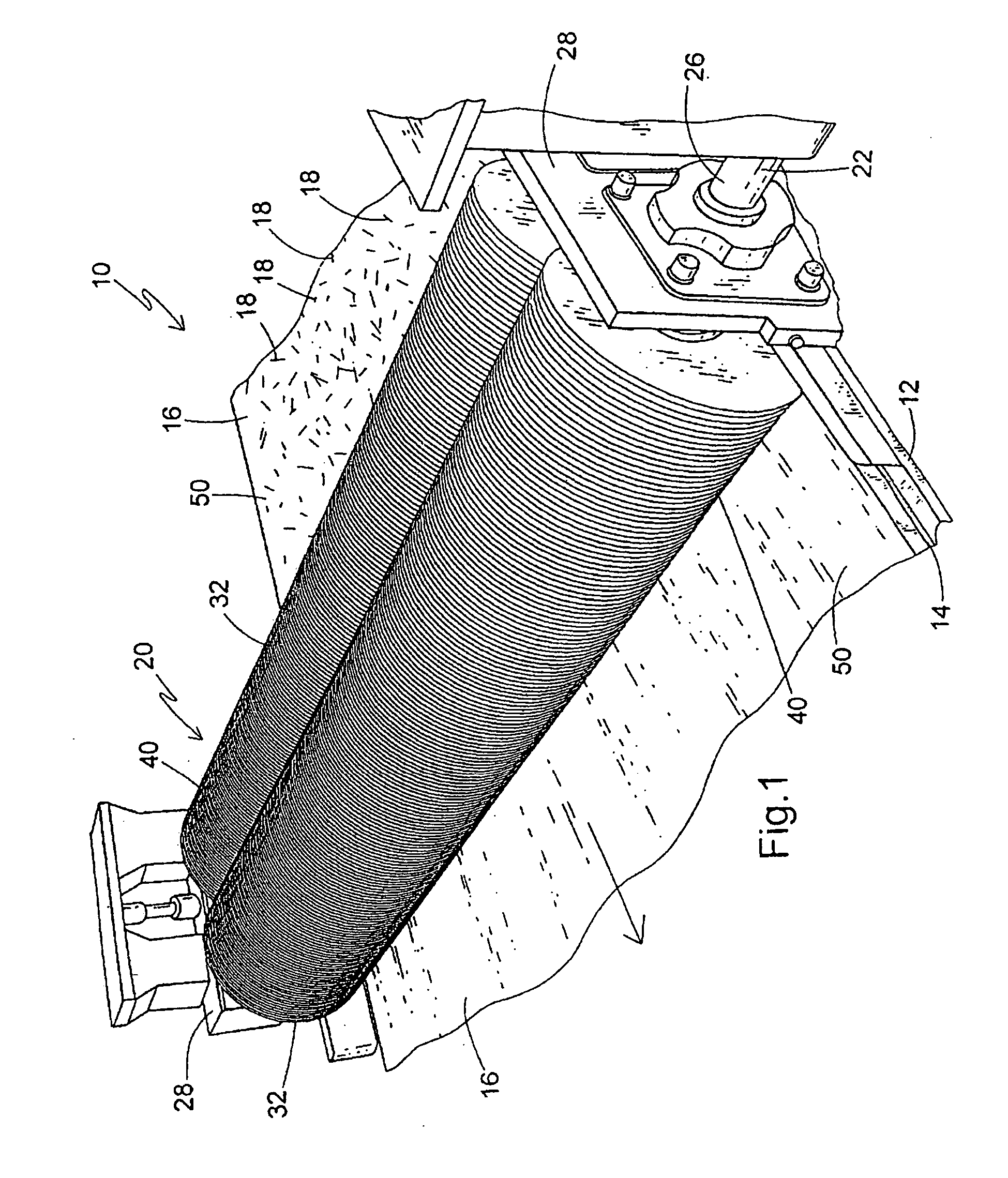

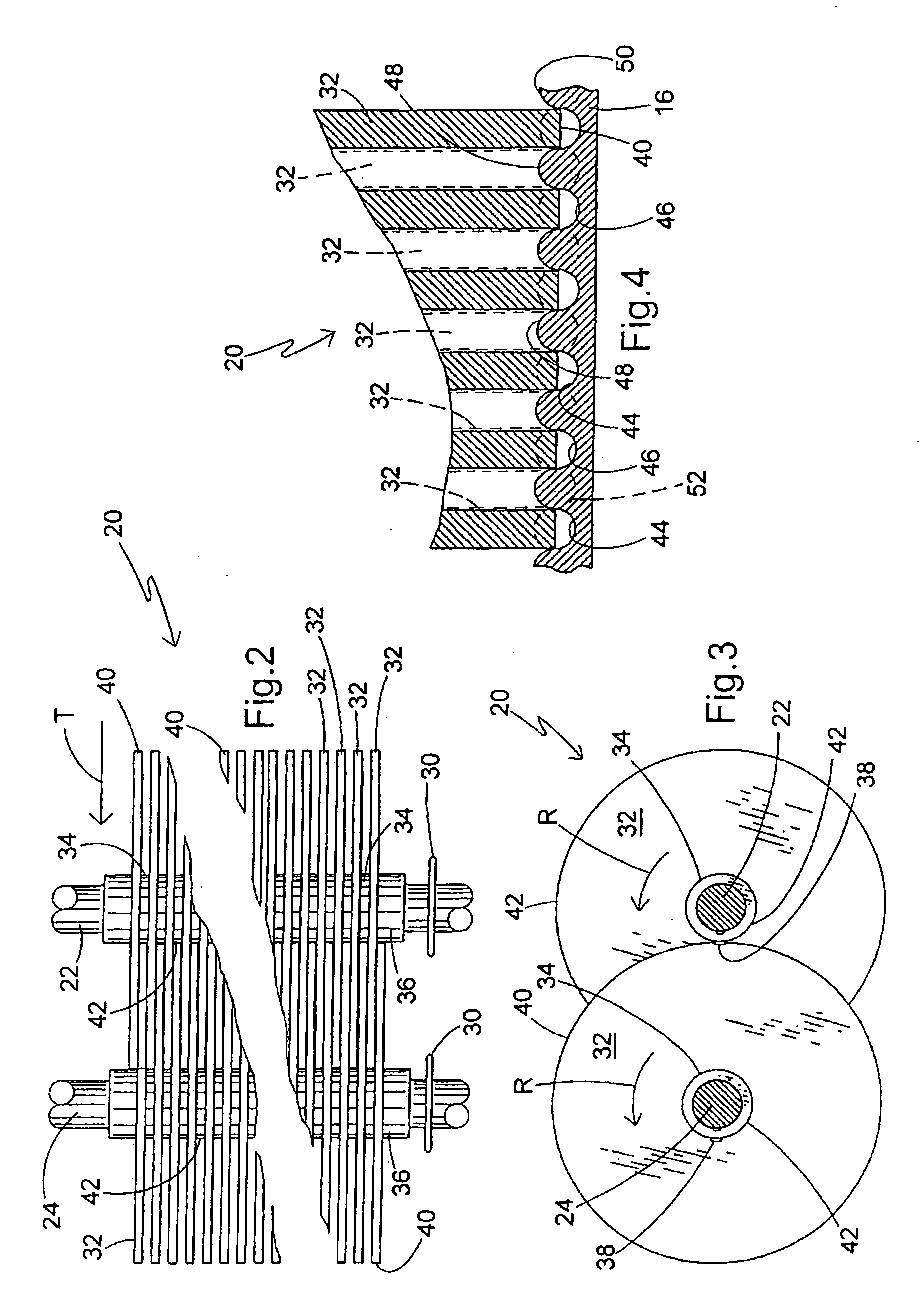

Embedment device for fiber-enhanced slurry

ActiveUS20050064055A1Reduces board line downtimePrevent buildupTransportation and packagingRotary stirring mixersFiberProduction line

An embedment device for use in a structural panel production line wherein a slurry is transported on a moving carrier relative to a support frame, and chopped fibers are deposited upon the slurry, includes a first elongate shaft secured to the support frame and having a first plurality of axially spaced disks, a second elongate shaft secured to the support frame and having a second plurality of axially spaced disks, the first shaft being disposed relative to the second shaft so that the disks intermesh with each other. The intermeshing relationship enhances embedment of the fibers into the slurry and also prevents clogging of the device by prematurely set slurry particles.

Owner:UNITED STATES GYPSUM CO

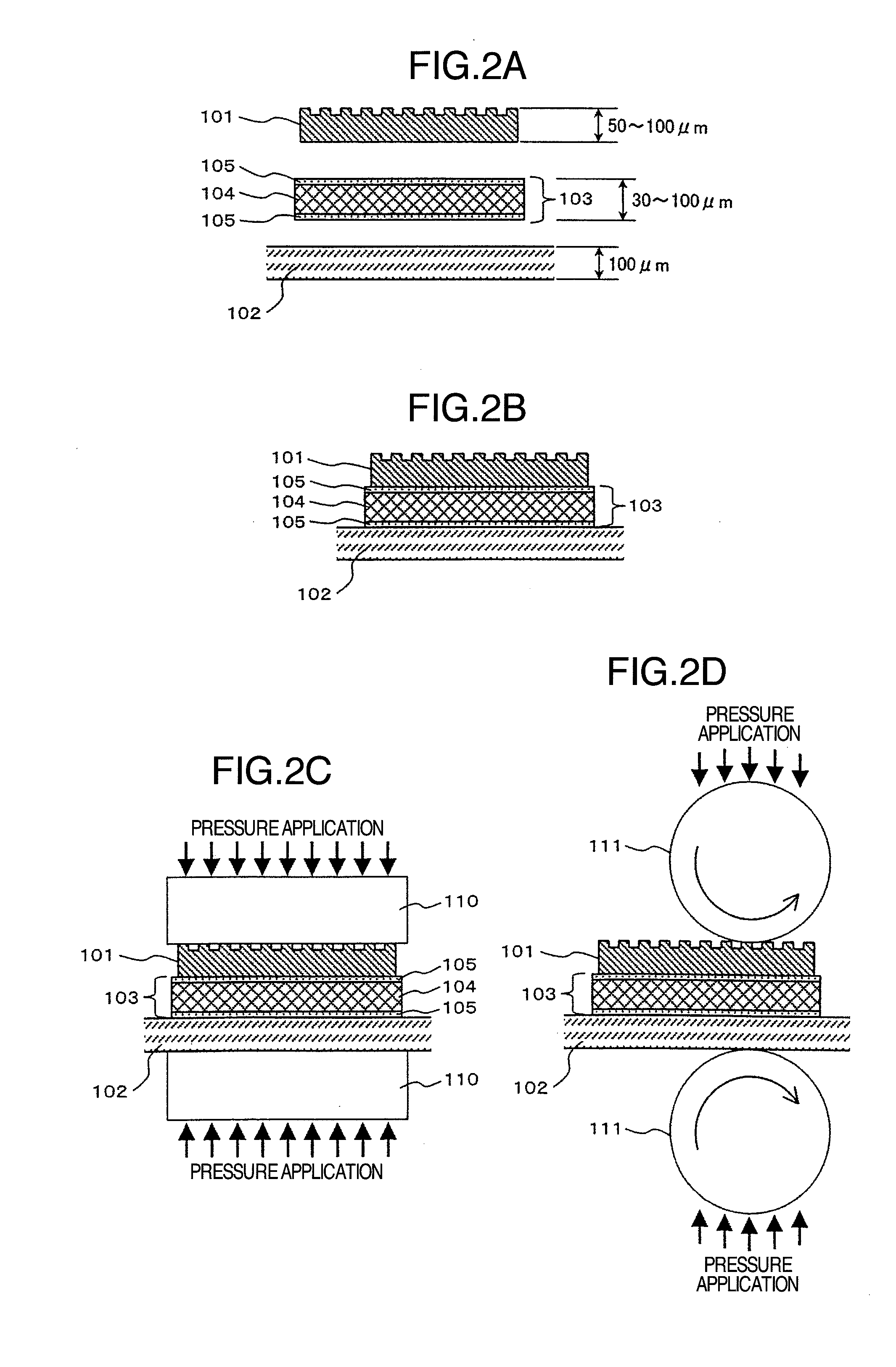

Filter and forming system

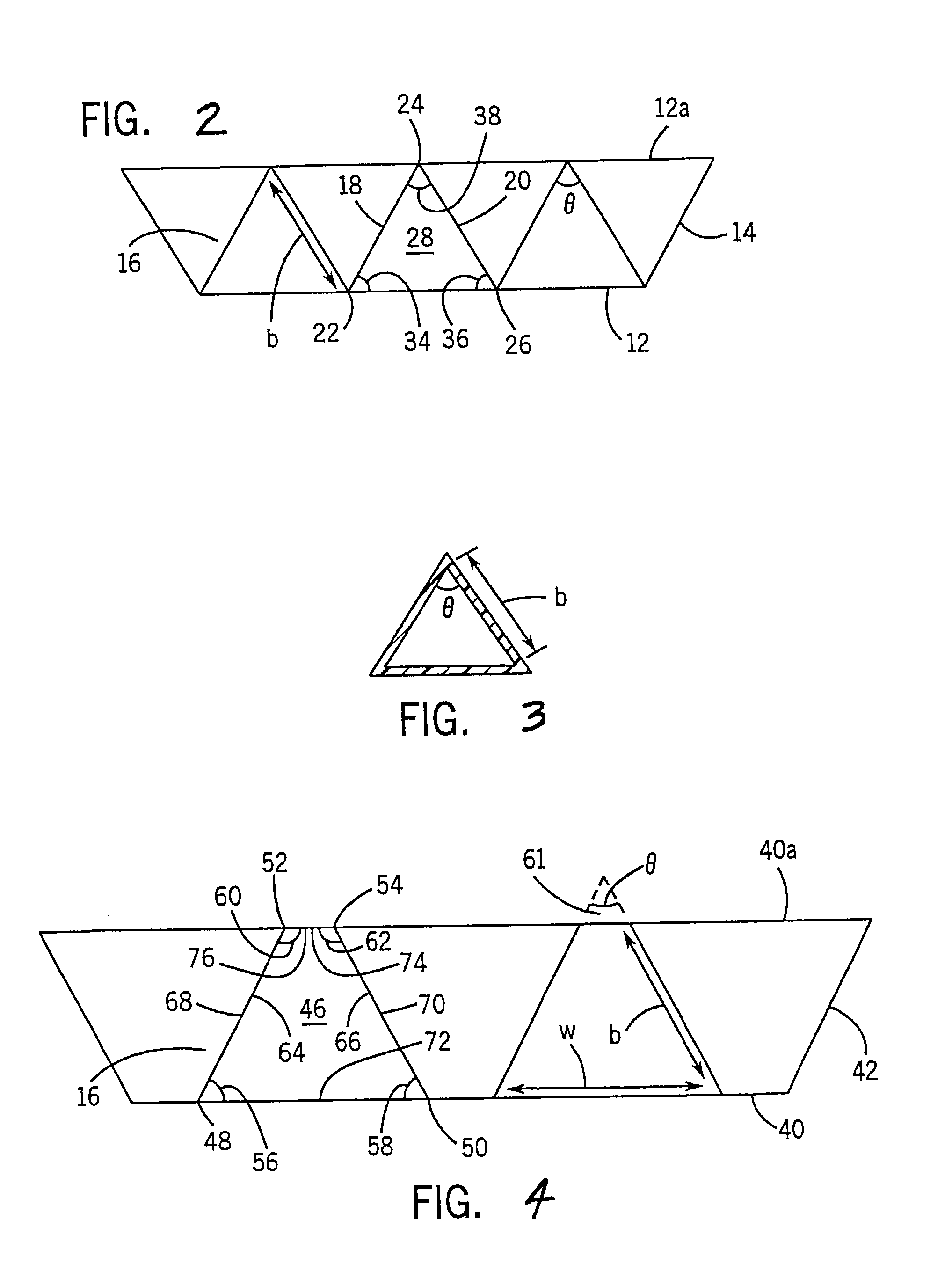

InactiveUS6946012B1More laminar flowShort pleat heightMechanical working/deformationDispersed particle filtrationFilter mediaEngineering

A filter includes first and second sheets of filter media, the second sheet being pleated and forming with the first sheet a plurality of axially extending flow channels having lateral cross-sectional shapes with two adjacent included angles each greater than 45° and less than 75°. Forming apparatus and methods are provided.

Owner:FLEETGUARD INC

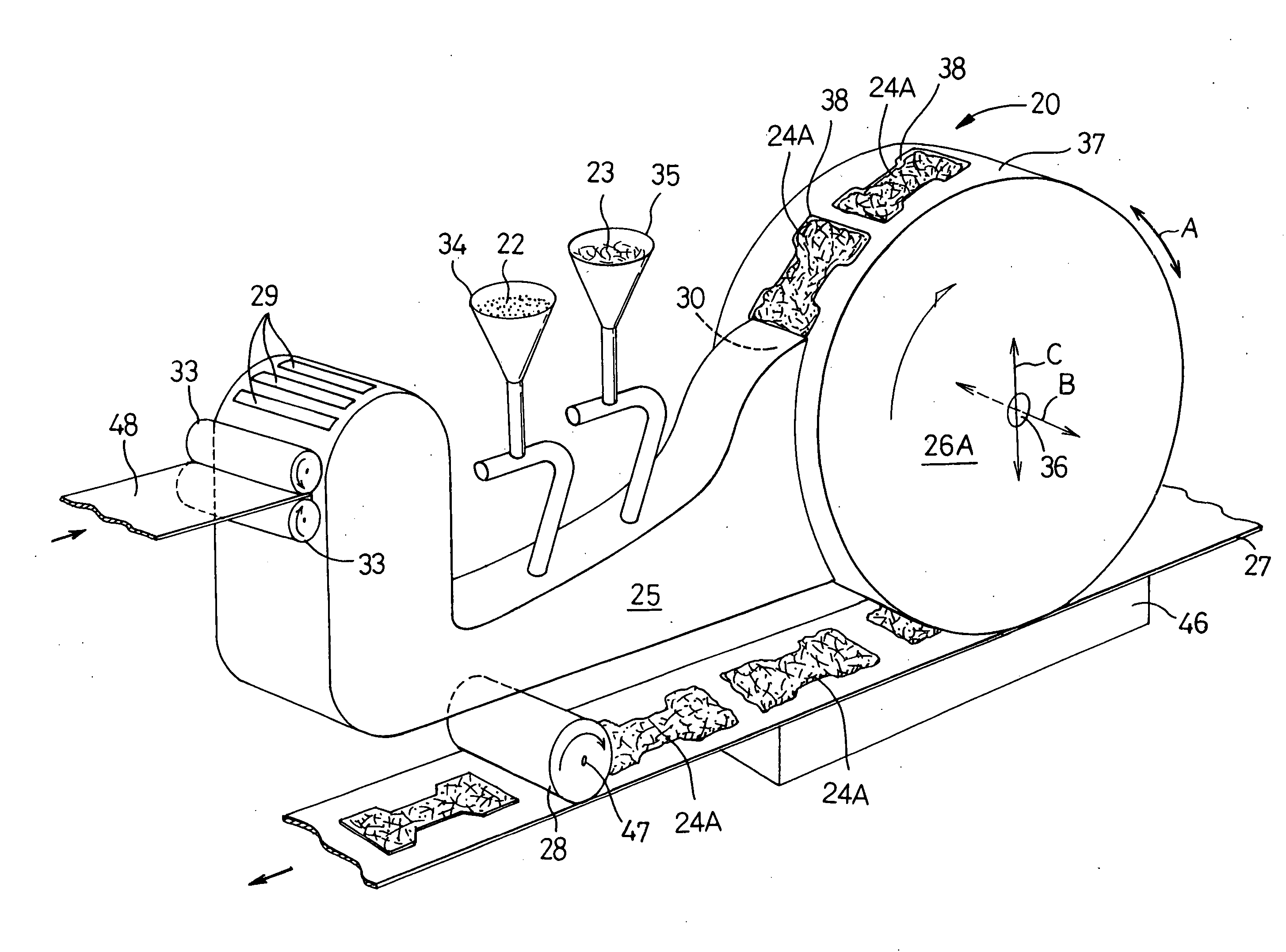

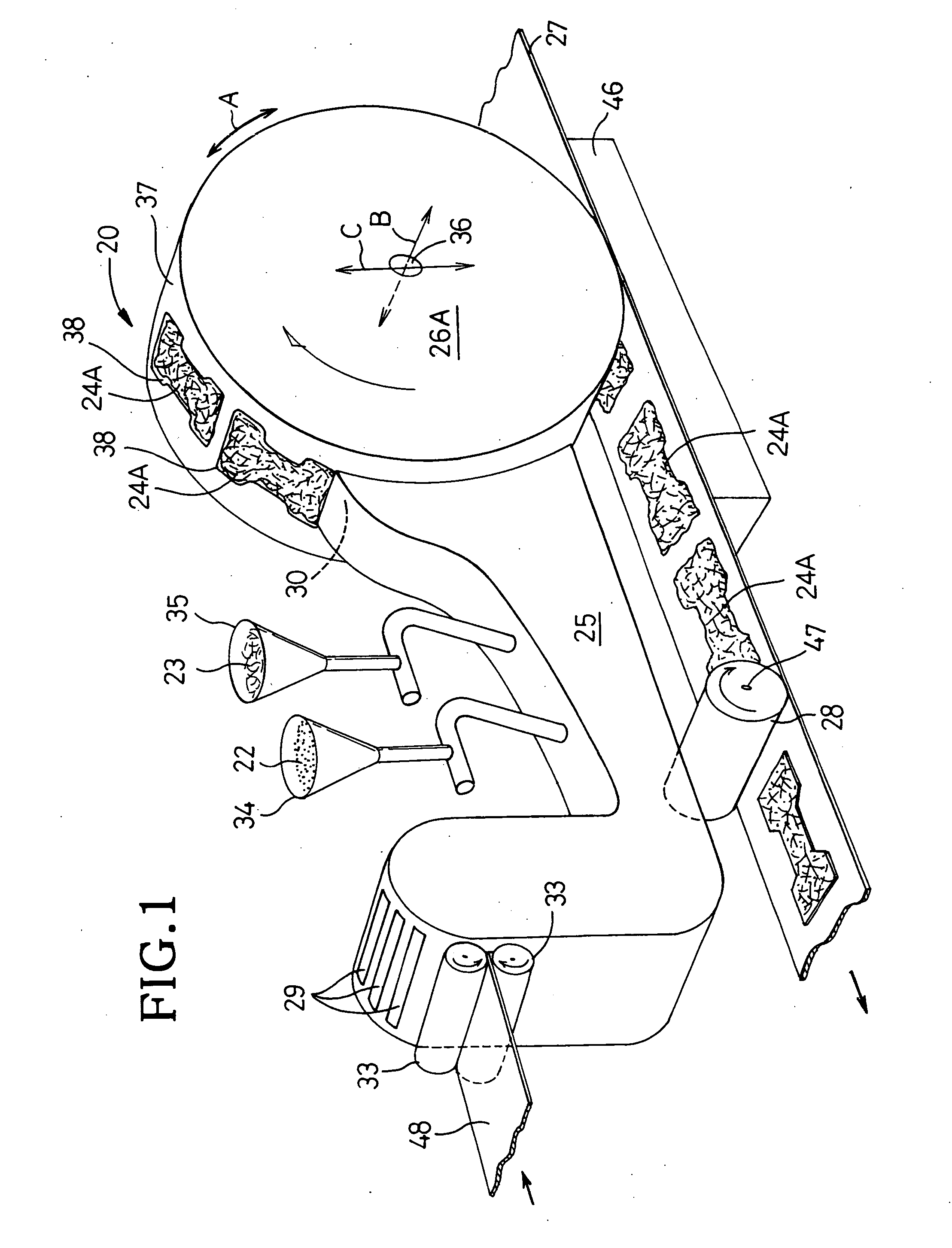

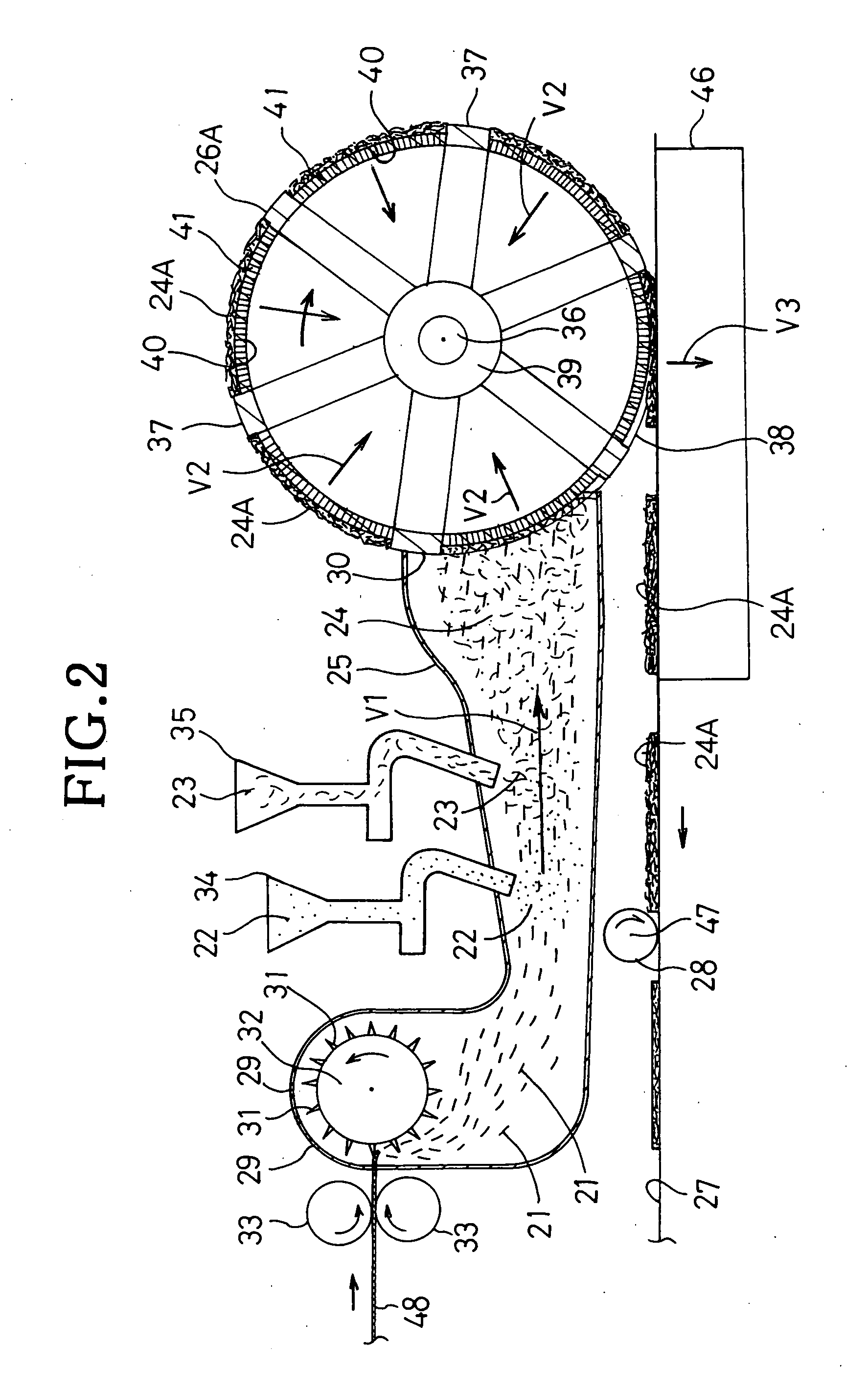

Liquid absorbent material molding drum

InactiveUS20060105075A1Uniform stiffnessEffective absorptionDough-sheeters/rolling-machines/rolling-pinsConfectioneryEngineeringAbsorbent material

Here is disclosed a liquid-absorbent material molding drum for making liquid-absorbent materials to be incorporated in disposable diapers or the like. A molding depression is formed on its bottom with a plurality of protrusions each protruding outward in a diametrical direction of the drum and being relatively long in a circumferential direction of the drum. These protrusions are continuously arranged in the circumferential direction but distanced one from another by a predetermined dimension in an axial direction of the drum.

Owner:UNI CHARM CORP

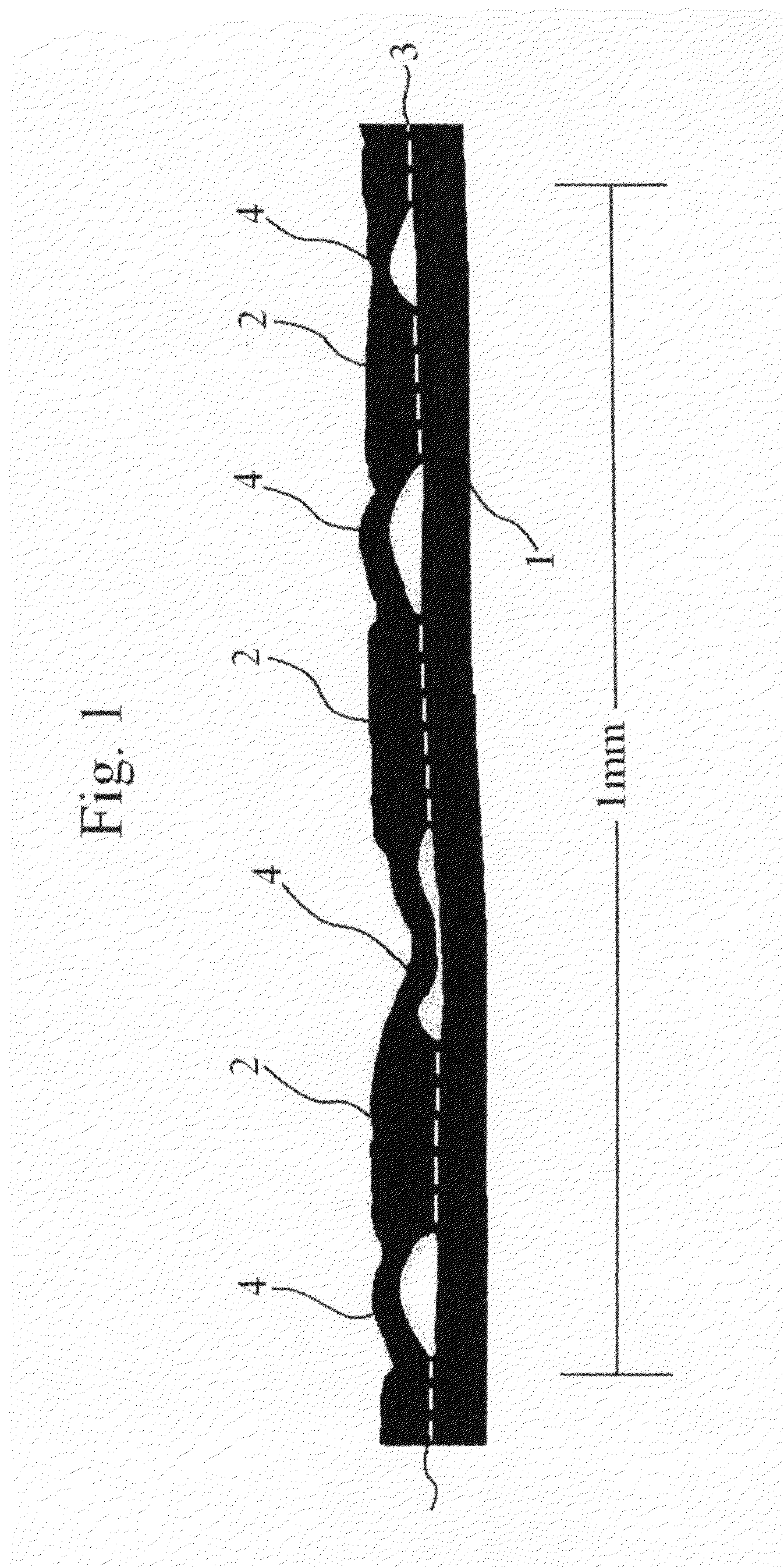

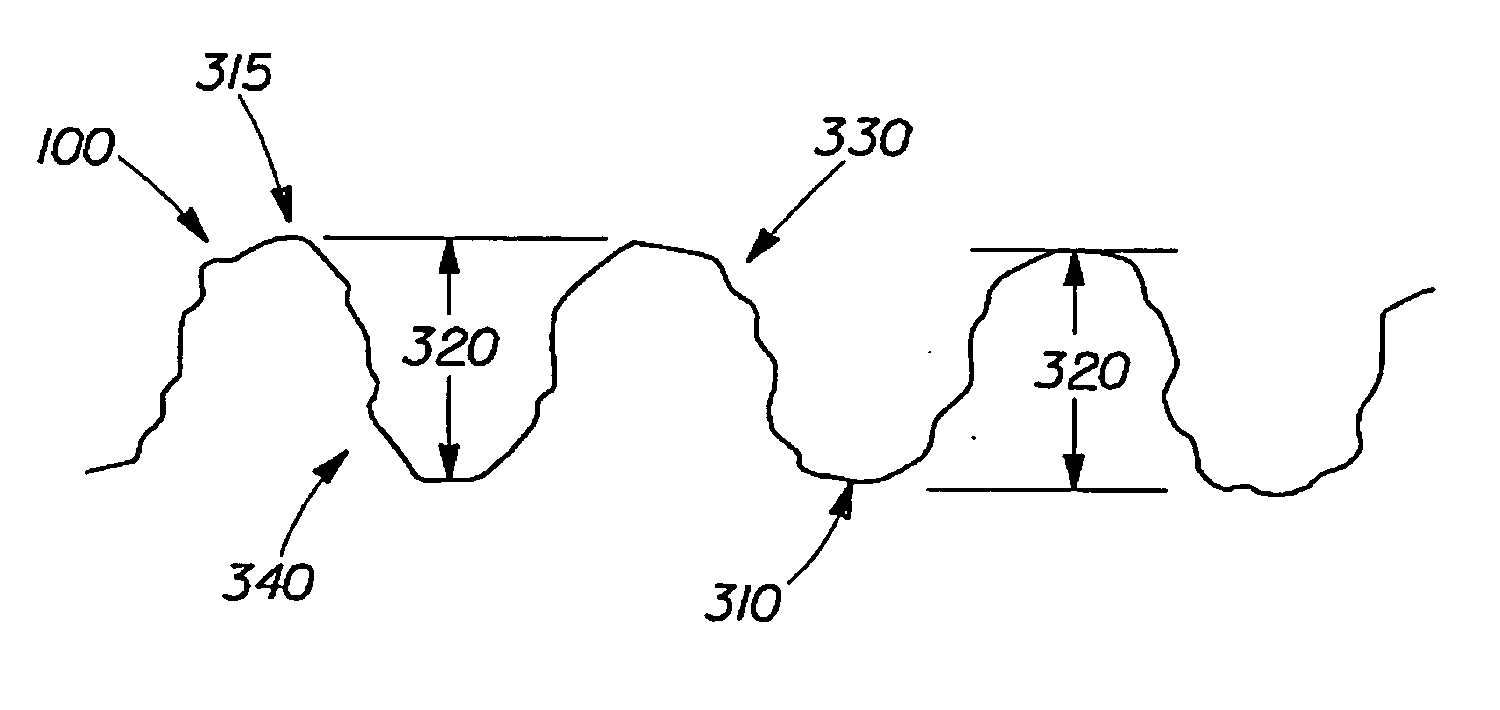

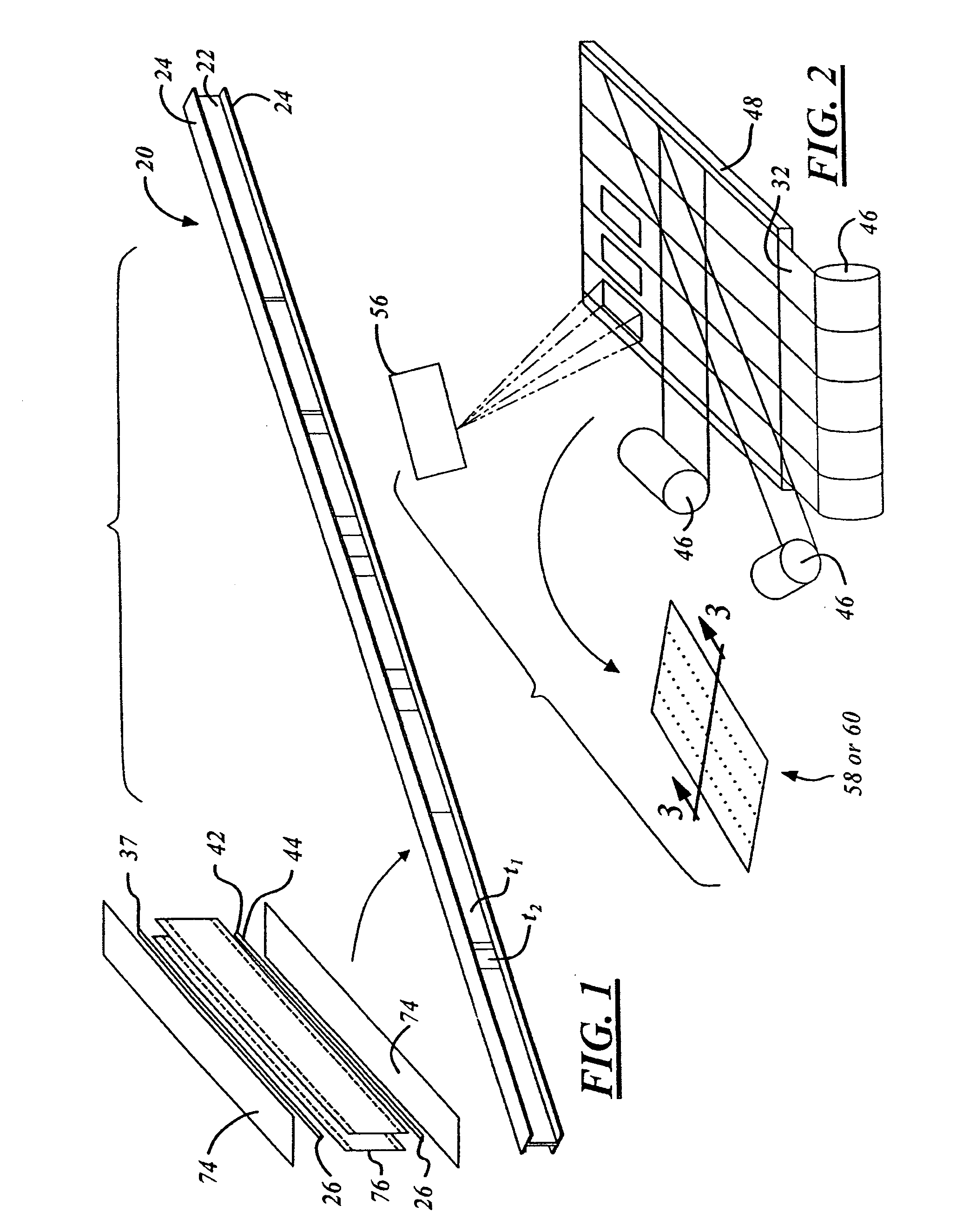

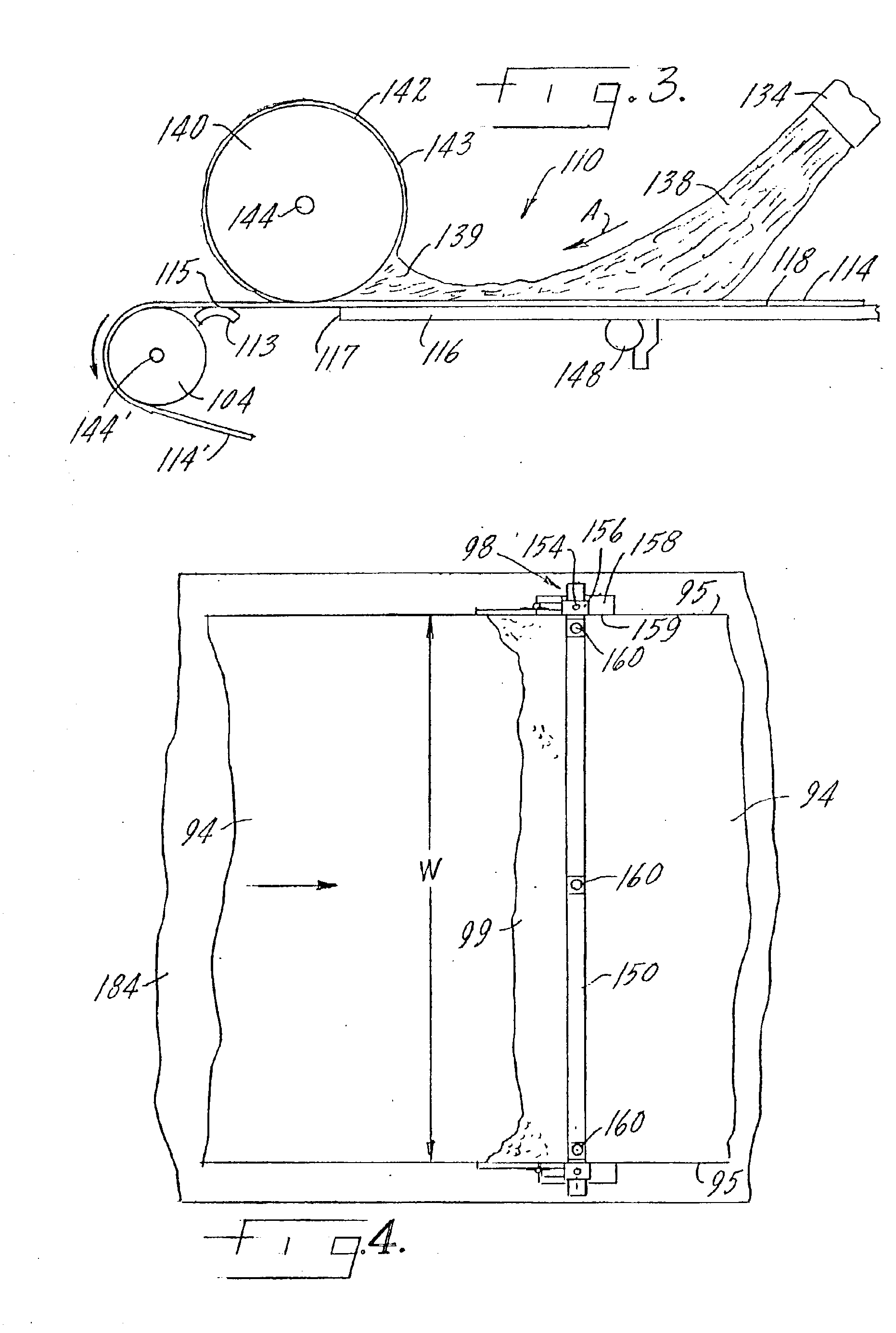

Crosslaminate of oriented films and methods and apparatus for manufacturing same

ActiveUS20090233041A1Improvement of tear propagation resistanceImprove aestheticsConfectioneryPress rollersEngineeringUltimate tensile strength

A crosslaminate is formed from two oriented plies of thermoplastic polymer material, arranged so that their orientation directions cross one another, the plies being heat sealed together. Each ply is semi-fibrillated, that is consist of linear thin regions of biaxially oriented material and thicker linear bosses between the thinner regions. The webs are sealed primarily through bonds formed at the intersection of the bosses (thicker regions). The array of bosses has a division less than 2 mm. The laminate has improved aesthetic and strength properties. A method for forming the crosslaminate involves segmental stretching of the material to form the thinner regions, and apparatus comprising intermeshing grooved stretching rollers having sharp-edged crests is described.

Owner:THE GLAD PROD CO

Embossing process including discrete and linear embossing elements

InactiveUS20060278355A1Non-fibrous pulp additionNatural cellulose pulp/paperEngineeringRandom pattern

An apparatus for producing an embossed product including a first embossing member having a plurality of discrete embossing elements disposed in a first non-random pattern having at least one first single pattern unit. The total area of the distal ends of the discrete embossing elements in the first single pattern unit is less than about 5.0 cm2. The apparatus also includes a second embossing member having a plurality of linear embossing elements disposed in a second non-random pattern having at least one second single pattern unit. The total area of the second distal ends in the second single pattern unit is less than about 10 cm2. The second non-random pattern is coordinated with the first non-random pattern such that when engaged with each other the first single pattern unit and the second single pattern unit make up an embossing pattern single pattern unit.

Owner:THE PROCTER & GAMBLE COMPANY

Novel fabrication process for thermoplastic composite parts

ActiveUS20070175571A1Mechanical working/deformationArtificial flowers and garlandsManufacturing technologyEngineering

A fabrication method of forming a thermoplastic composite laminate material with tailored and varying thickness in a continuous process. This process utilizes automated equipment or hand lay-up to collate parts or components into a multi-layer stack. Each stack contains all plies, including ply build-up areas, tacked in the proper location to maintain orientation and location. The consolidation tooling contains all necessary part features and is coordinated to the customized multiple ply stacks to form a single integrated thermoplastic composite laminate potentially having areas of differing thickness from these multiple ply stacks.

Owner:THE BOEING CO

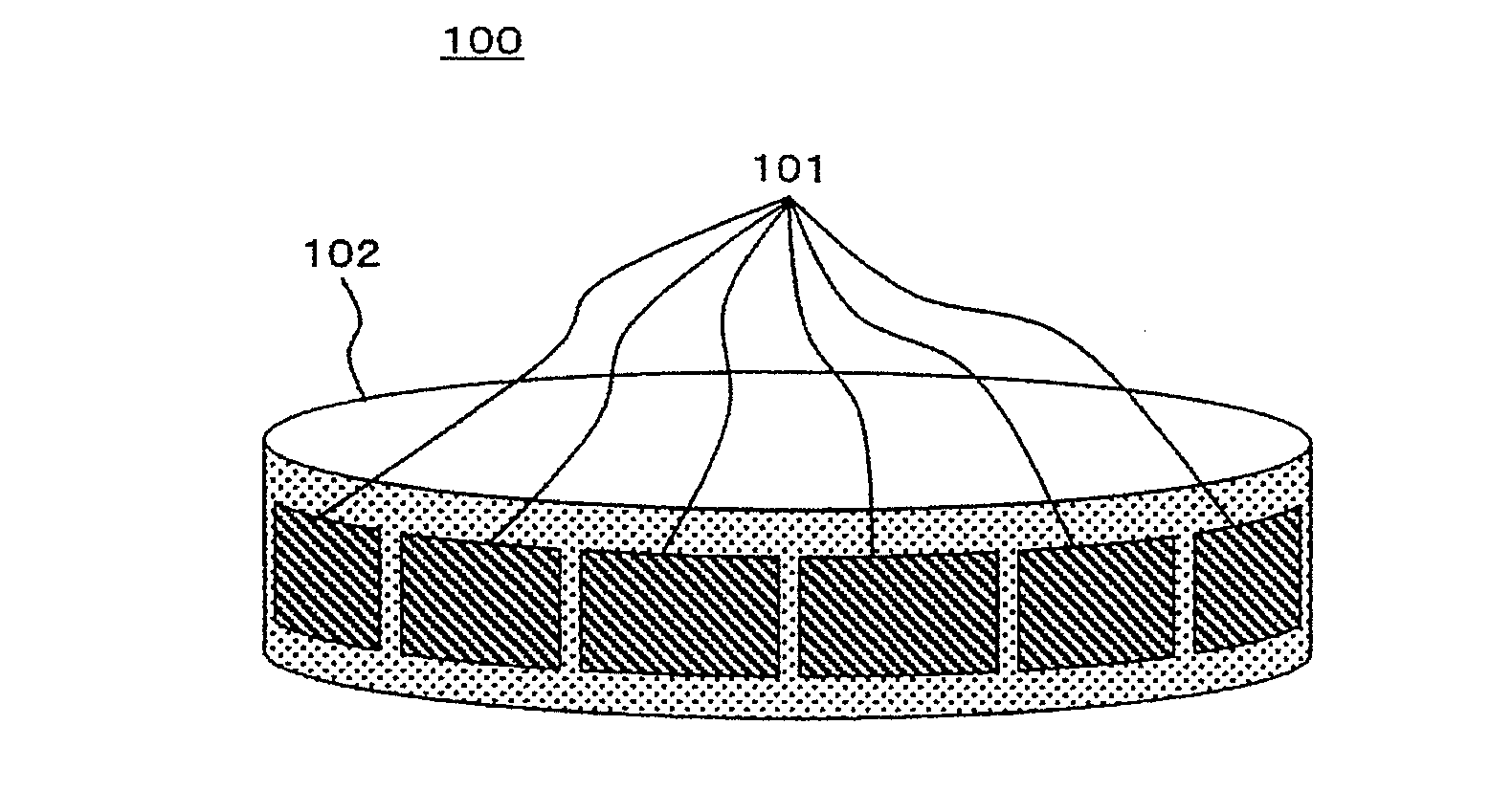

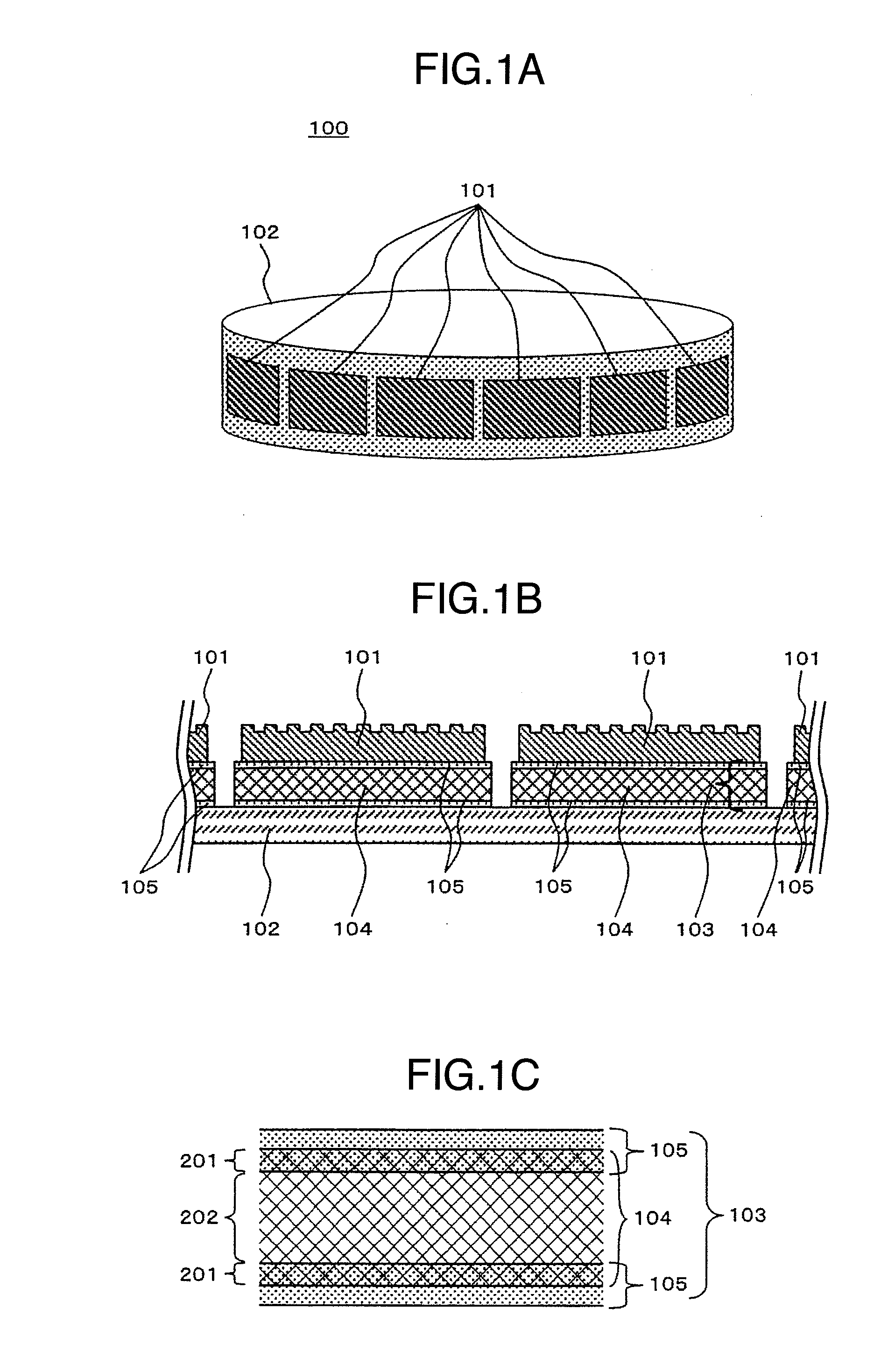

Belt-shaped mold and nanoimprint system using the belt-shaped mold

InactiveUS20090087506A1High aspect ratioFormed rapidly and stablyNanoinformaticsConfectioneryFine structureTransfer system

There is provided a fine pattern transfer, belt-shaped mold, with which a fine structure having a high aspect ratio can be formed rapidly and stably using nanoimprinting, and a fine pattern transfer system (a nanoimprint system) that employs this mold. According to the present invention, a nanoimprint mold includes: a belt-shaped support member; a plurality of stampers, for each of which a fine convex-and-concave pattern, to be transferred, is formed on one surface; and an adhesive member, to which the belt-shaped support member and the stampers are to be securely adhered, wherein the adhesive member includes a porous member and adhesive layers, which are deposited on either face of the porous member, for impregnating one part of the porous member, and wherein, for the porous member, a porous area that is not impregnated with the adhesive layers, is provided and positioned so as to sandwich the porous member between portions impregnated with the adhesive layers.

Owner:HITACHI LTD

Gypsum board forming device

A gypsum board forming device having a gypsum forming station including two laterally disposed edger shoes, and at least one laterally disposed edger bar clamping element on the edger bar. In one embodiment a laterally extending forming plate extends over the top surface of the formed gypsum board, the forming plate including a plurality of micropore conduits through which pressurized water is supplied to provide a film of smoothing water over the top surface of the gypsum board. In another embodiment the edger shoes have a flapper mechanism for retaining unset slurry skimmed off the surface of the gypsum board by the edger bar.

Owner:BPB LTD

Tissue scaffold having aligned fibrils and artificial tissue comprising the same

ActiveUS7338517B2Sufficient structural strength to withstand pressureMinimal immunological responsePeptide/protein ingredientsDough-sheeters/rolling-machines/rolling-pinsFiberFibril

Owner:UNIVERSITY OF SOUTH CAROLINA

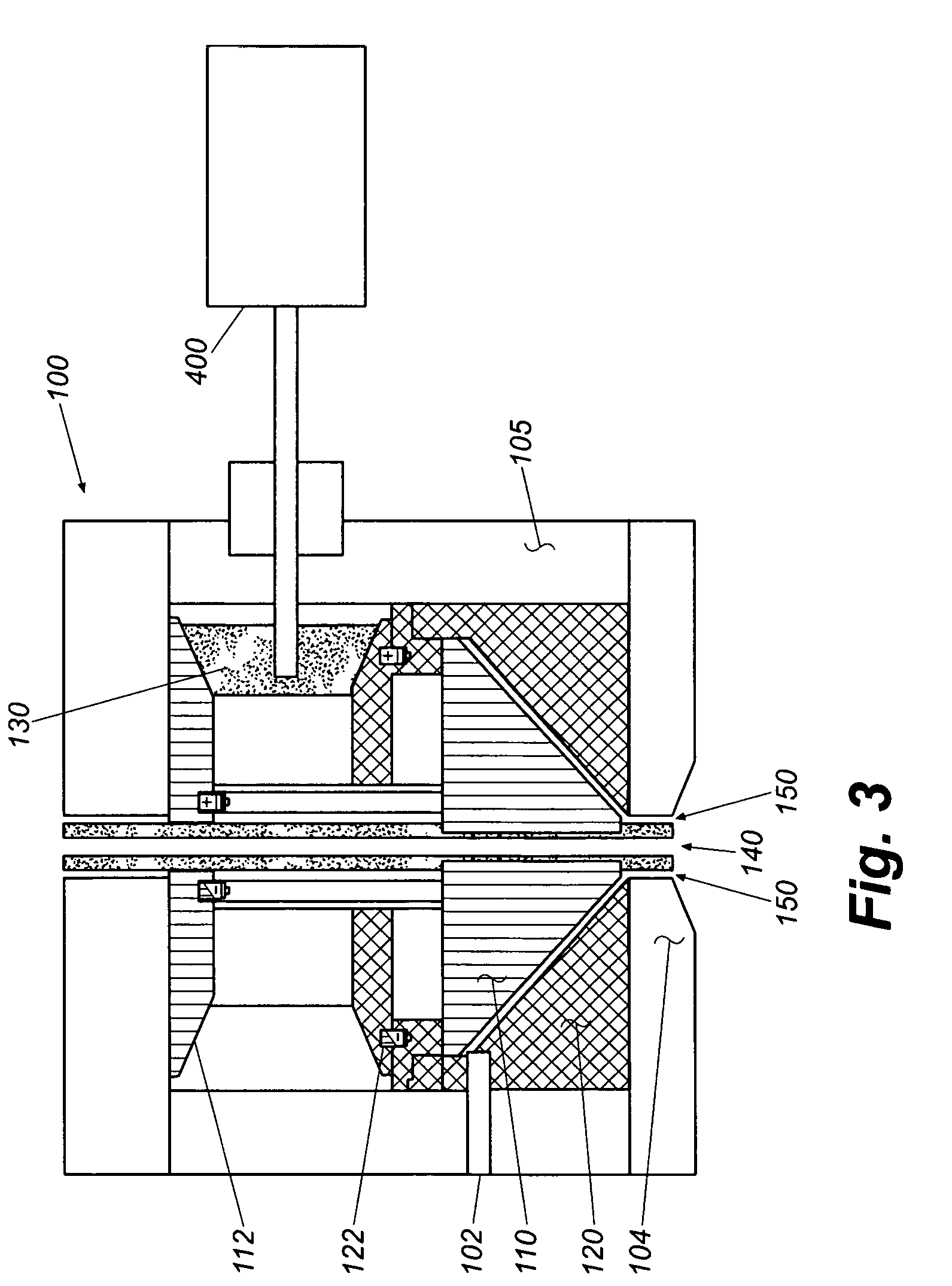

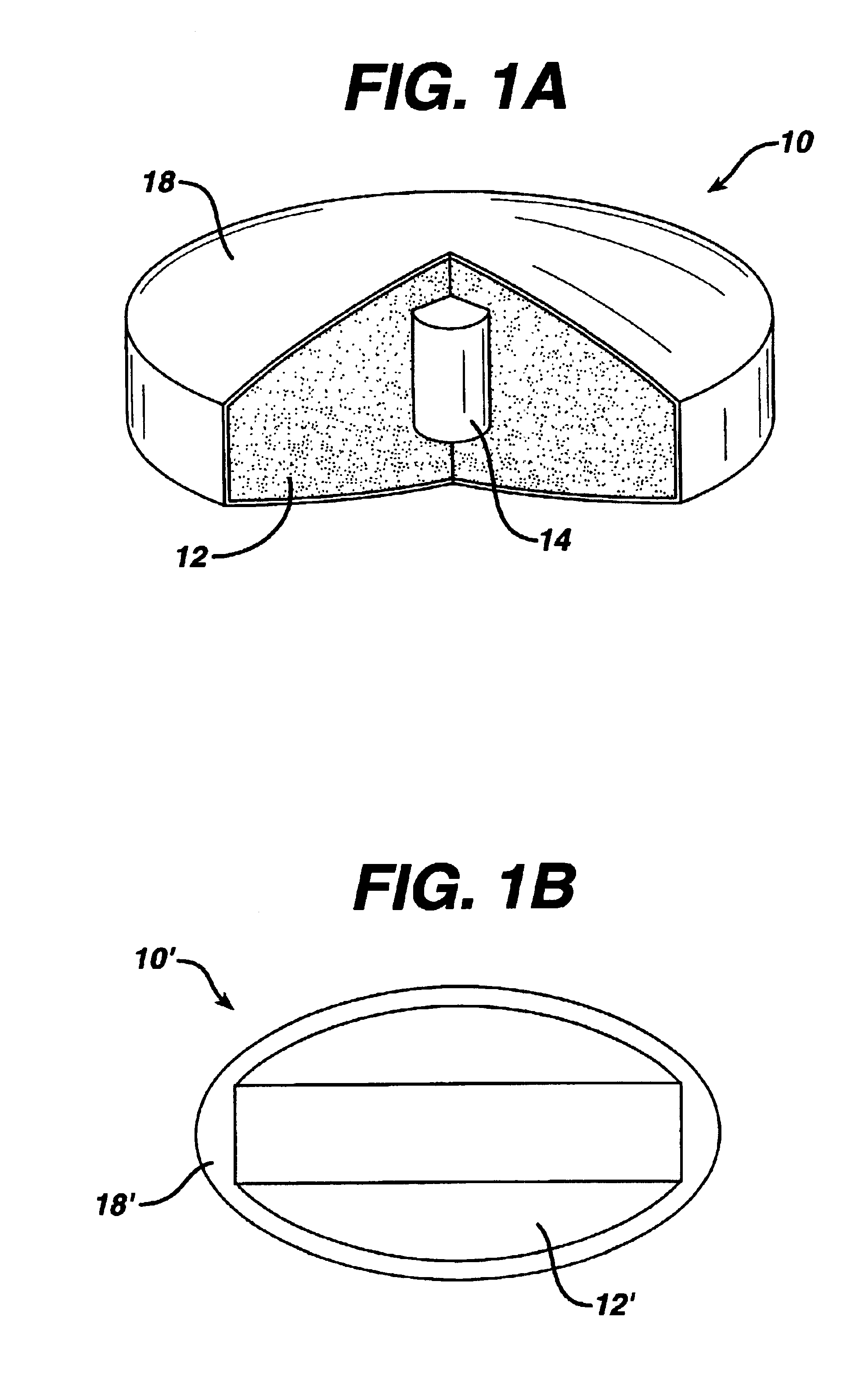

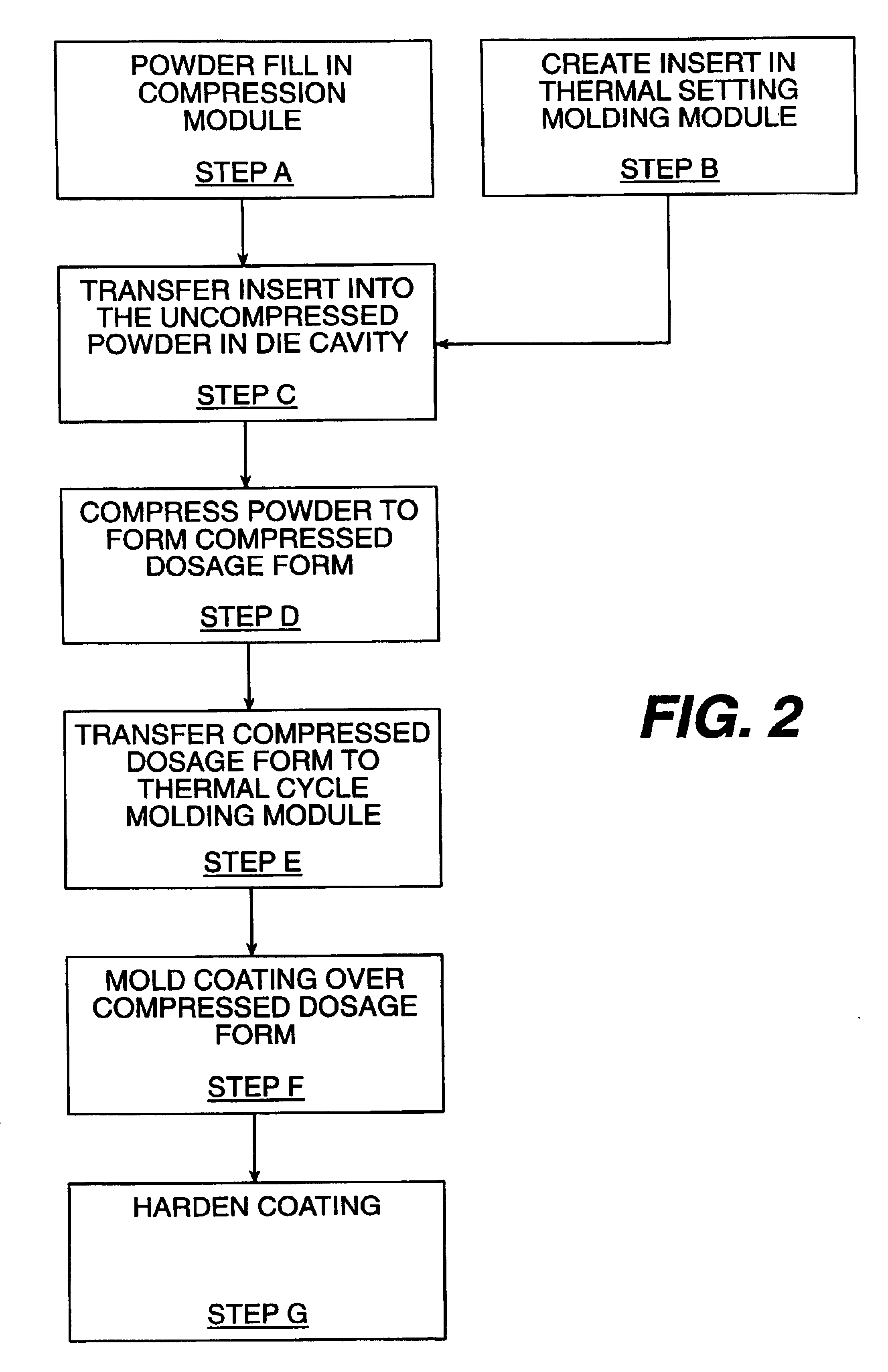

Apparatus for manufacturing dosage forms

InactiveUS6837696B2Organic active ingredientsTurning machine accessoriesComputer moduleBiomedical engineering

Systems, methods and apparatuses for manufacturing dosage forms, and to dosage forms made using such systems, methods and apparatuses are provided. Novel compression, thermal cycle molding, and thermal setting molding modules are disclosed. One or more of such modules may be linked, preferably via novel transfer device, into an overall system for making dosage forms.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

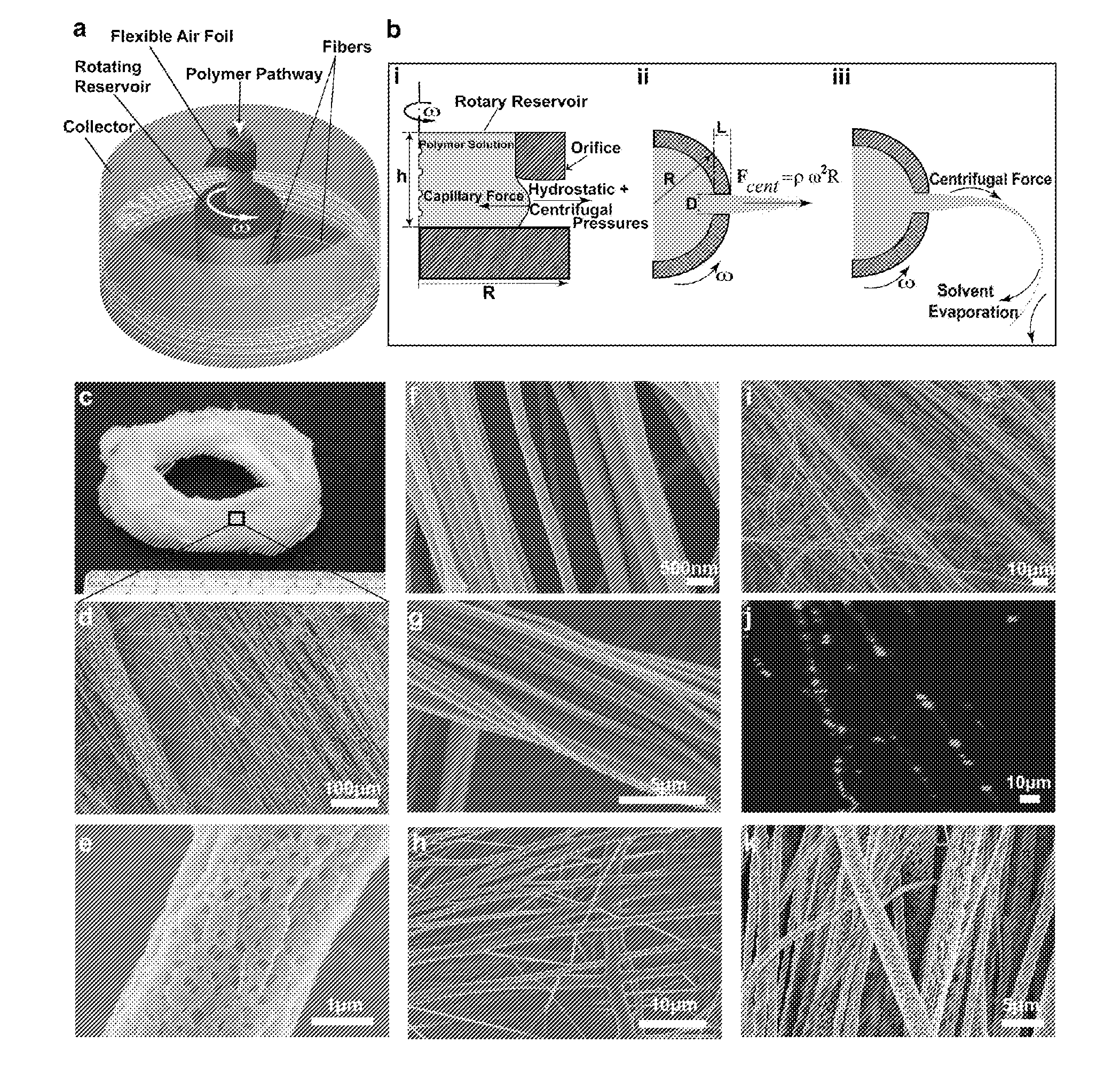

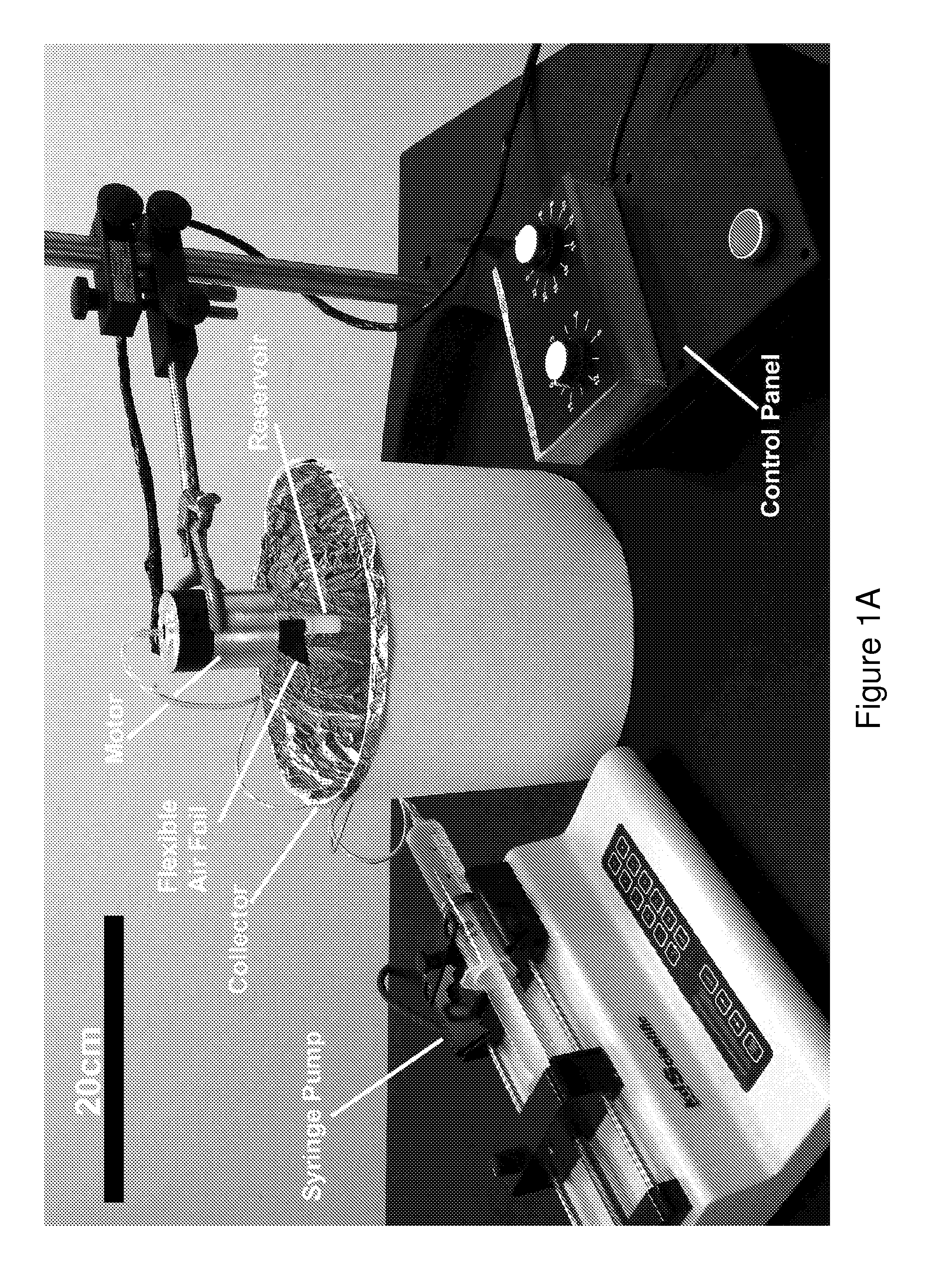

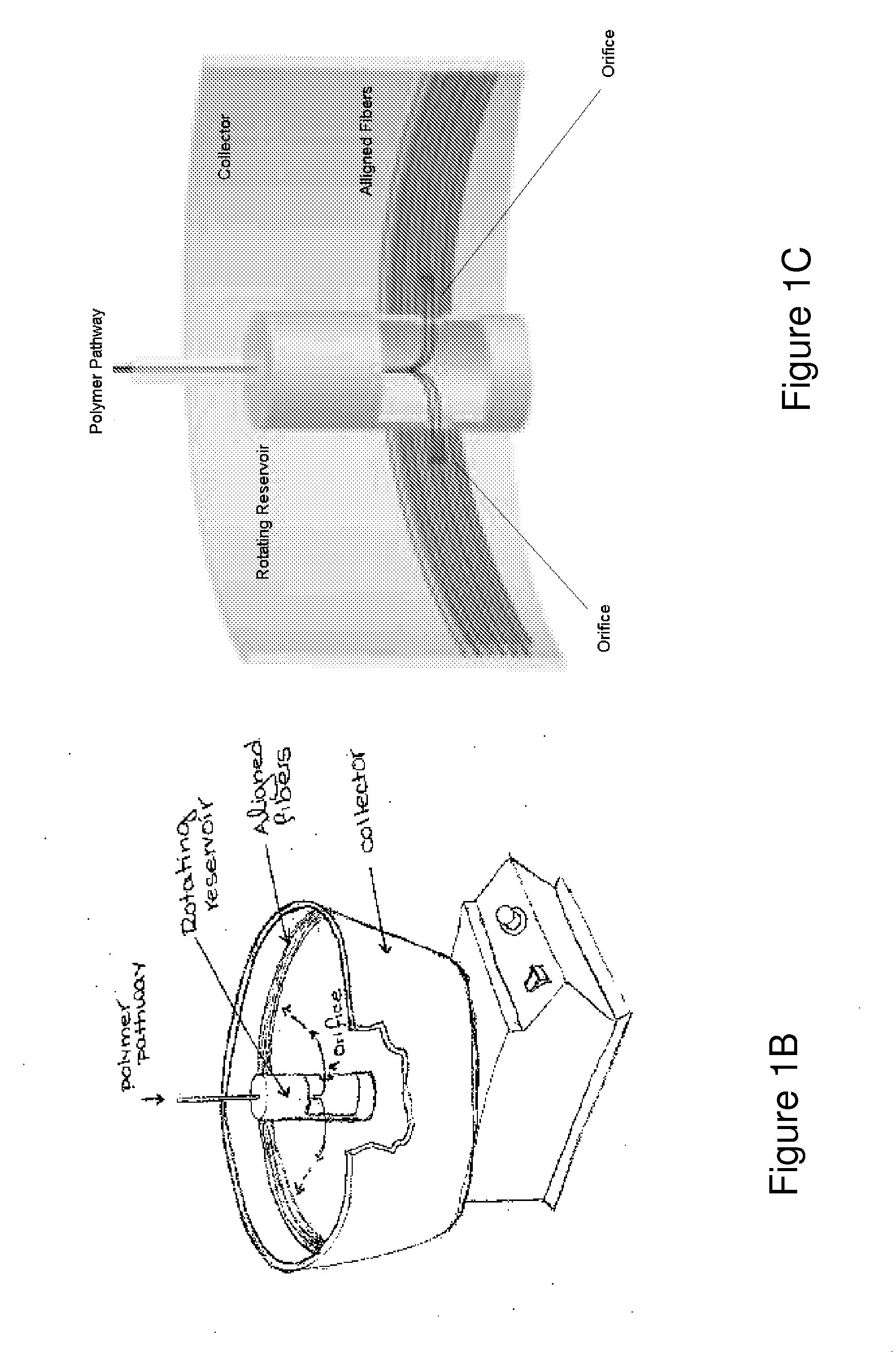

Methods and devices for the fabrication of 3D polymeric fibers

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

Process and apparatus for making a thermoset foam

InactiveUS20020171164A1Avoid squeezingAvoid deathDough-sheeters/rolling-machines/rolling-pinsConfectioneryPolymer scienceExtrusion

A thermosetting foam, preferably a polyurethane foam is prepare by mixing all the components in one or more extruders and directing the chemical streams to a mixing head where the catalyst is added. Thus, the reaction can be controlled in a facile manner, whereby clogging of the extrusion head is avoided.

Owner:JOHNS MANVILLE INT INC

Mould member for moulding three-dimensional products, system and methods of manufacturing a mould member

ActiveUS20090134544A1Difficult to processReduce riskMouldsArtificial flowers and garlandsCavity wallMaterials science

A mould member for moulding three-dimensional products from a mass of one or more food starting materials, which are suitable for consumption, in particular human consumption, comprises a body having a porous structure and a plurality of mould cavities, which mould cavities each have a mould cavity wall defined by the body and an opening in a surface of the body, wherein the body comprises at least one essentially fluid tight barrier.

Owner:STORK TITAN

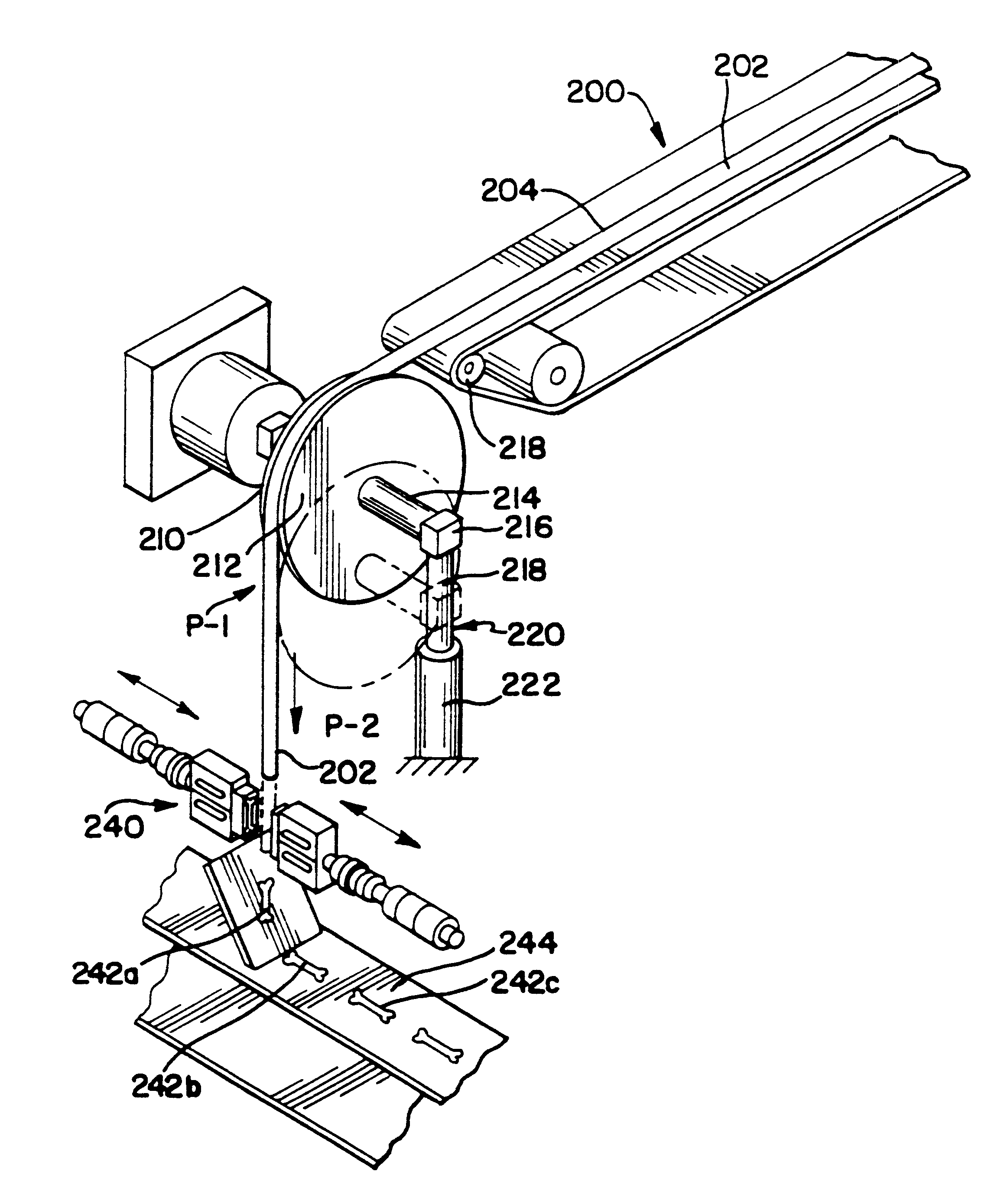

Ultrasonic forming of confectionery products

The invention provides for the manufacture of food products. In one preferred form, methods and apparatus are provided for cutting individual confectionery products from a slab or strip of product material into a product with a particular silhouette. In another form, the invention provides methods and apparatus for both cutting and forming individual confectionery products from strips or ropes. The process can be used for simply forming products from pre-cut segments or other blanks of confectionery material, including imparting a relatively precise texture, finish or detail to such products. The products may, but need not, be subsequently enrobed in chocolate or another coating. In still other embodiments, the confectionery material may comprise grains of a puffed cereal. In some instances, a matrix of plasticizable material holds the grains together and the confectionery material may also include, in addition to the puffed cereal, candied fruit bits, dry fruits, nuts, or the like. In some cases, the puffed cereal may be held together by surface contact between adjacent grains instead of being held by the matrix.

Owner:MARS INC

Fabrication process for thermoplastic composite parts

ActiveUS7807005B2Mechanical working/deformationArtificial flowers and garlandsThermoplastic compositesMechanical engineering

A fabrication method of forming a thermoplastic composite laminate material with tailored and varying thickness in a continuous process. This process utilizes automated equipment or hand lay-up to collate parts or components into a multi-layer stack. Each stack contains all plies, including ply build-up areas, tacked in the proper location to maintain orientation and location. The consolidation tooling contains all necessary part features and is coordinated to the customized multiple ply stacks to form a single integrated thermoplastic composite laminate potentially having areas of differing thickness from these multiple ply stacks.

Owner:THE BOEING CO

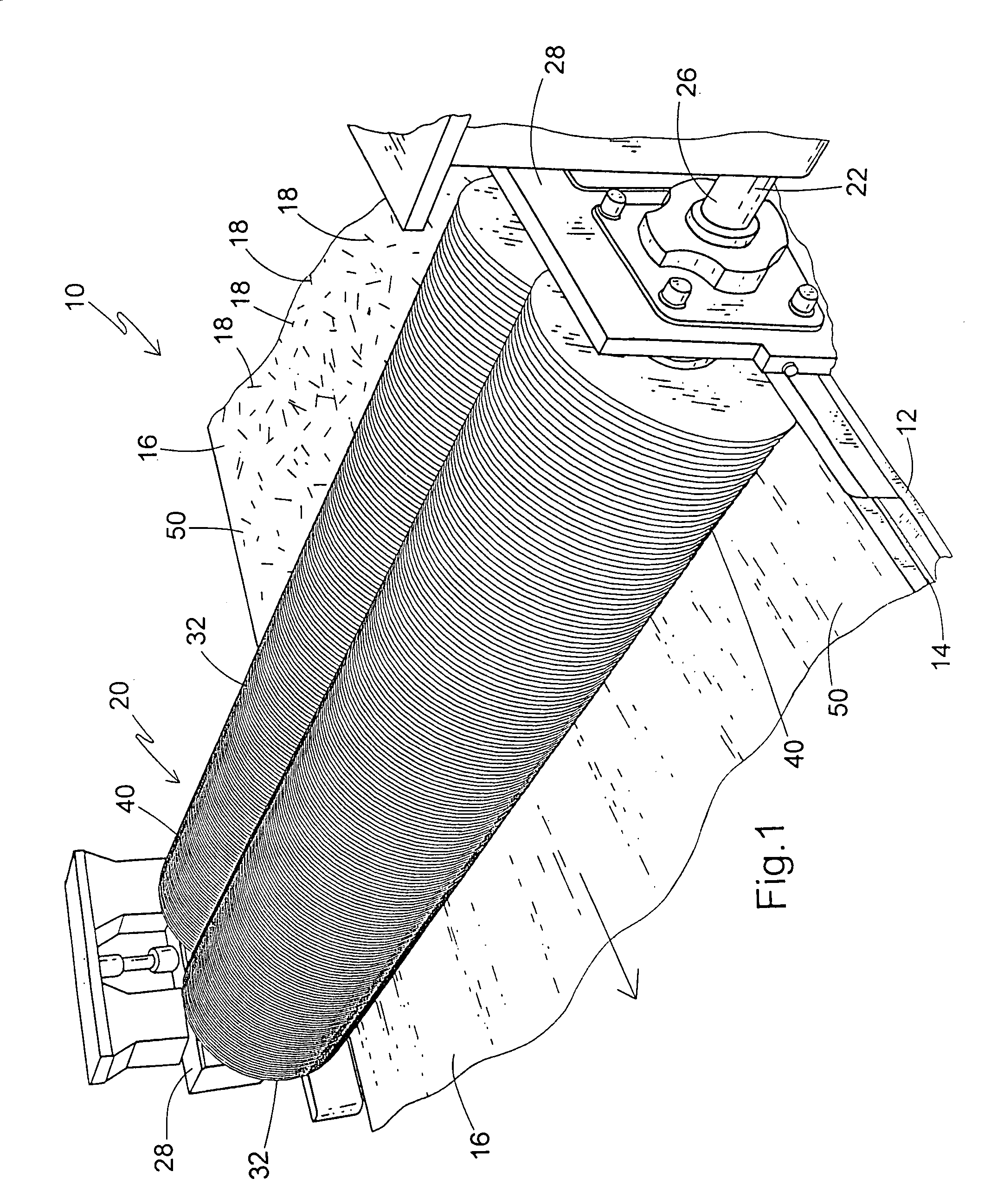

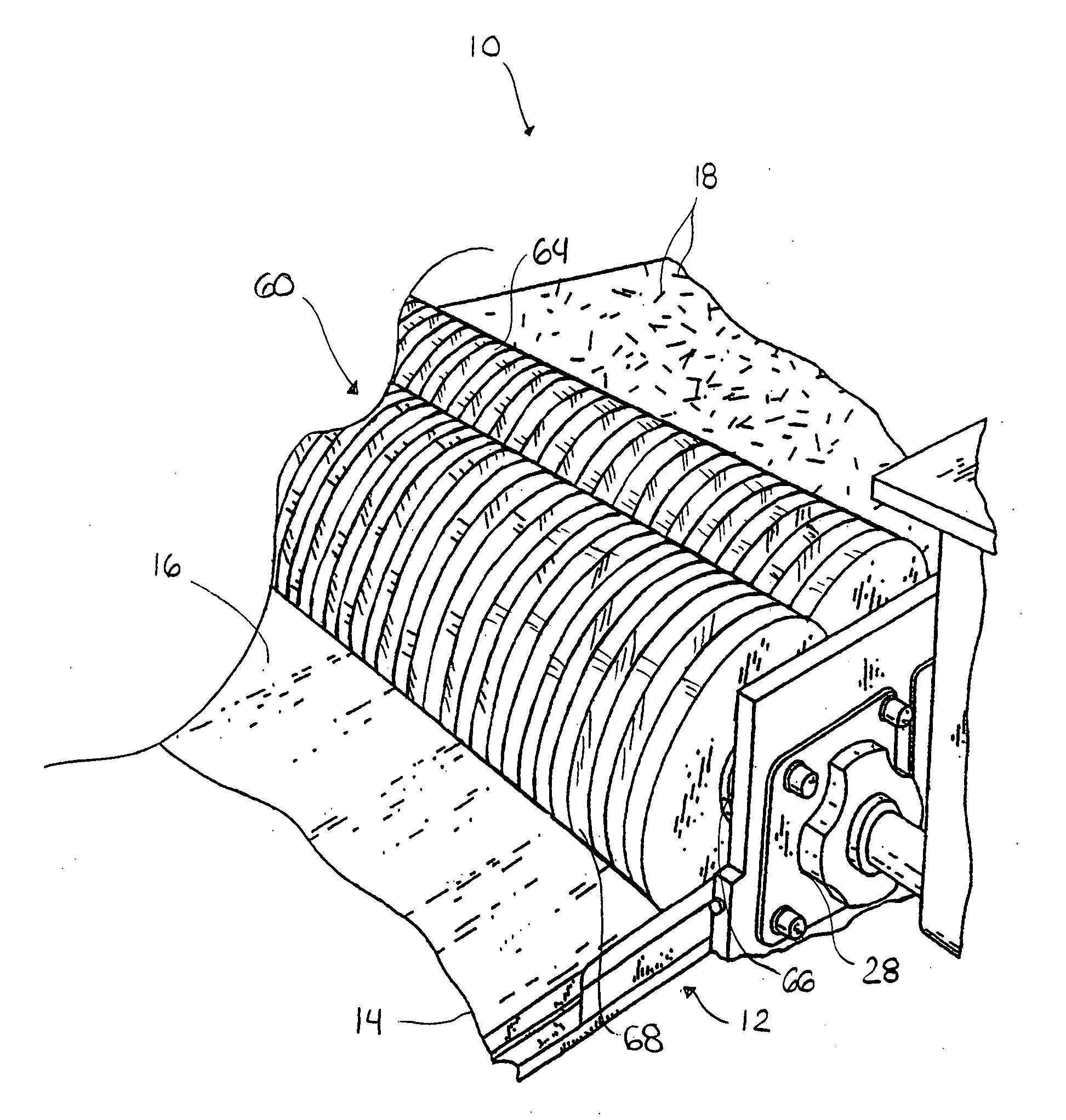

Embedment roll device

ActiveUS20070110838A1Reduces board line downtimePrevent buildupRotary stirring mixersTransportation and packagingEngineeringMechanical engineering

An embedment device includes a first integrally formed elongate shaft rotatably secured to the support frame and having a first plurality of axially spaced disks axially fixed to the first shaft, a second integrally formed elongate shaft rotatably secured to the support frame and having a second plurality of axially spaced disks axially fixed to the second shaft, the first shaft being disposed relative to the second shaft to be horizontally aligned and so that the disks intermesh with each other, and wherein, when viewed from the side, peripheries of the first and second pluralities of disks overlap each other.

Owner:UNITED STATES GYPSUM CO

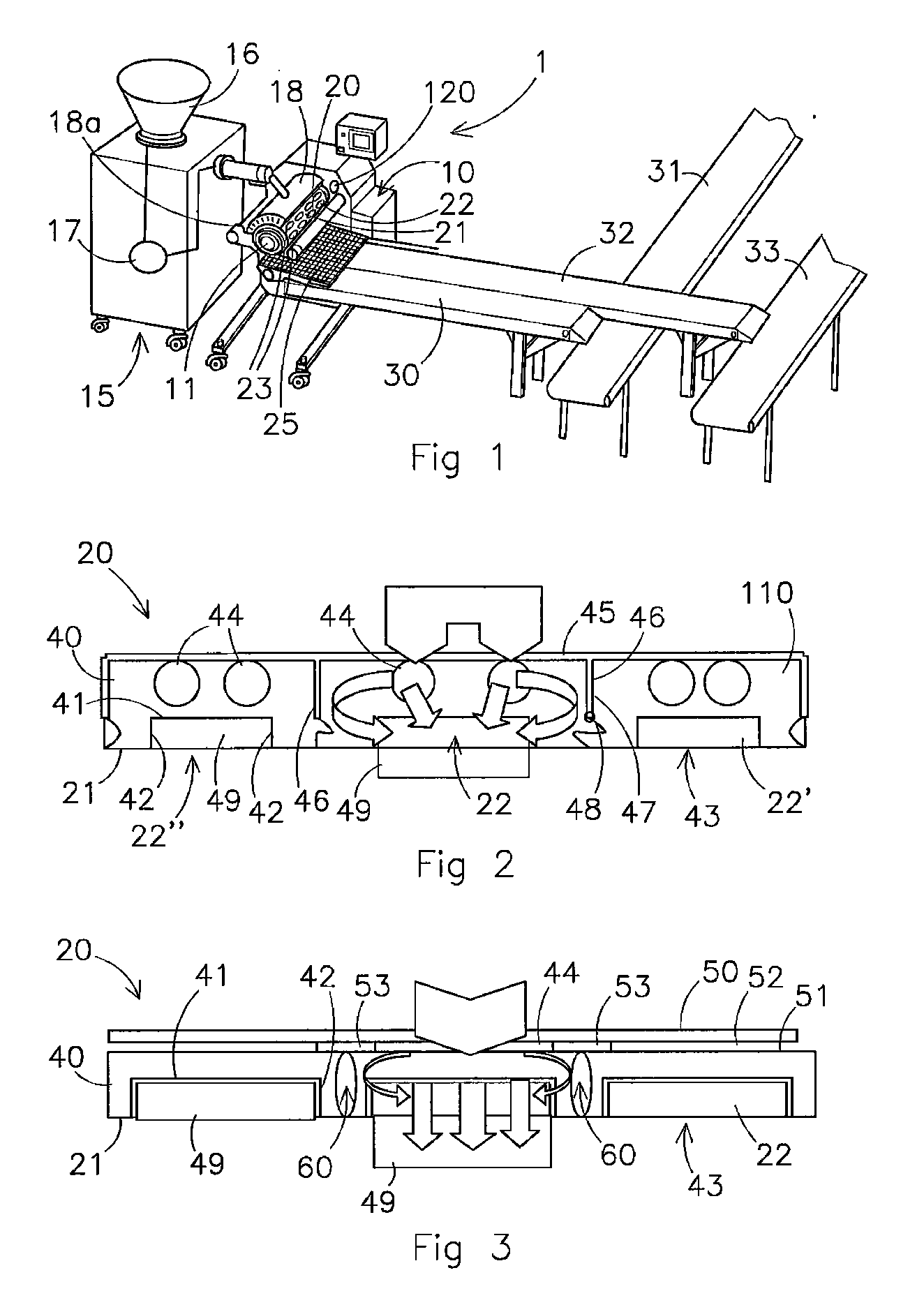

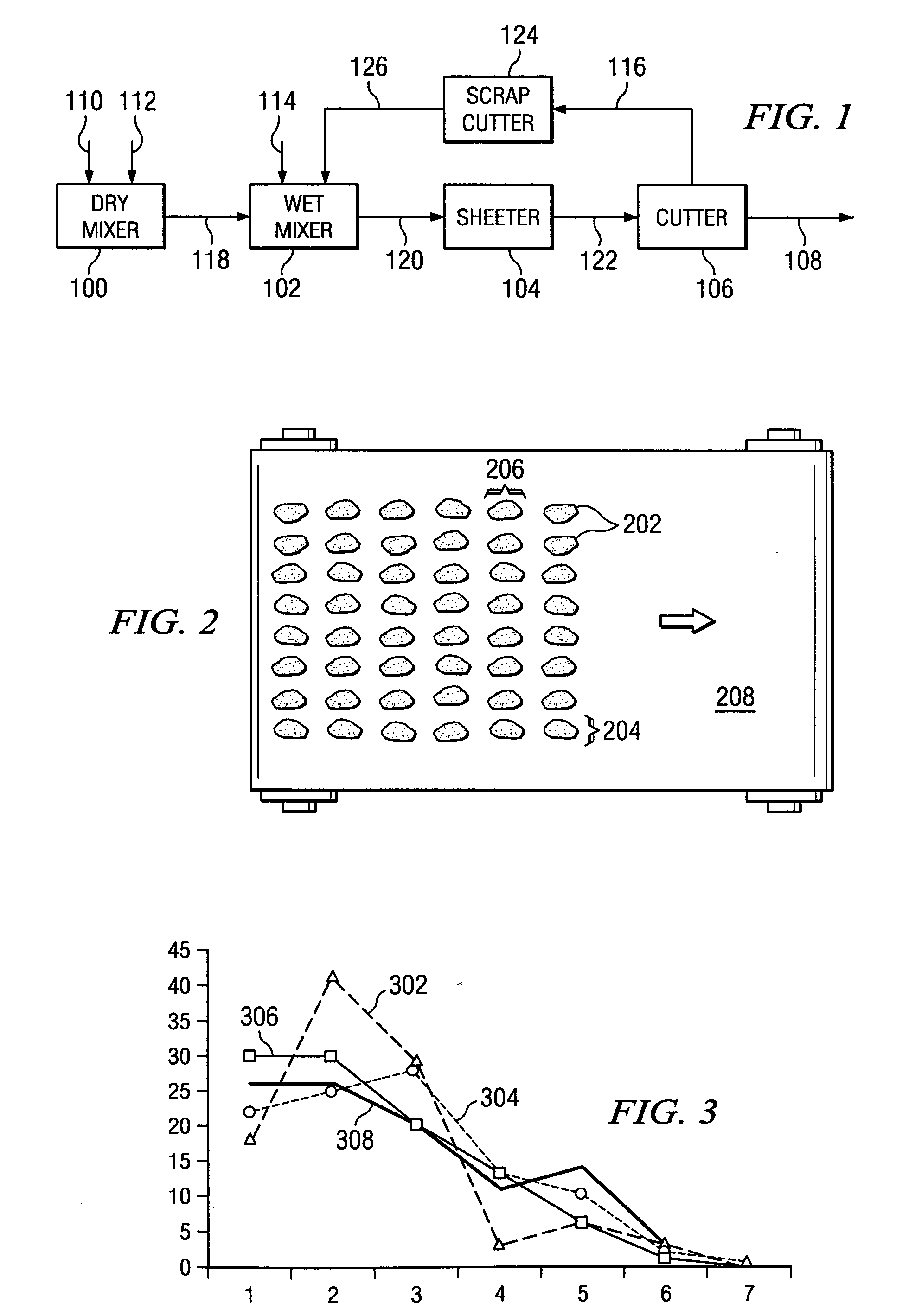

Method for sheeting and processing dough

InactiveUS20060034988A1Improve consistencyGood composition uniformityDough treatmentDough-sheeters/rolling-machines/rolling-pinsAdditive ingredientEngineering

An improved method to produce a dough sheet having improved uniform properties in a high-speed manufacturing environment. In accordance with one embodiment of the present invention, the dough sheeting system comprises improved control of dough particles in the sheeter nip, and improved control of dough properties across the width of the dough sheet including, but not limited to, uniform thickness, uniform work input, uniform moisture content, uniform emulsifier content, and uniform dry ingredient content. In a preferred embodiment, the improvements described herein enable the high-speed production of stackable chip products. Improved mixing and control of process conditions in dry and wet upstream mixers enable such production.

Owner:FRITO LAY NORTH AMERICA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com