Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

943 results about "Fine structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

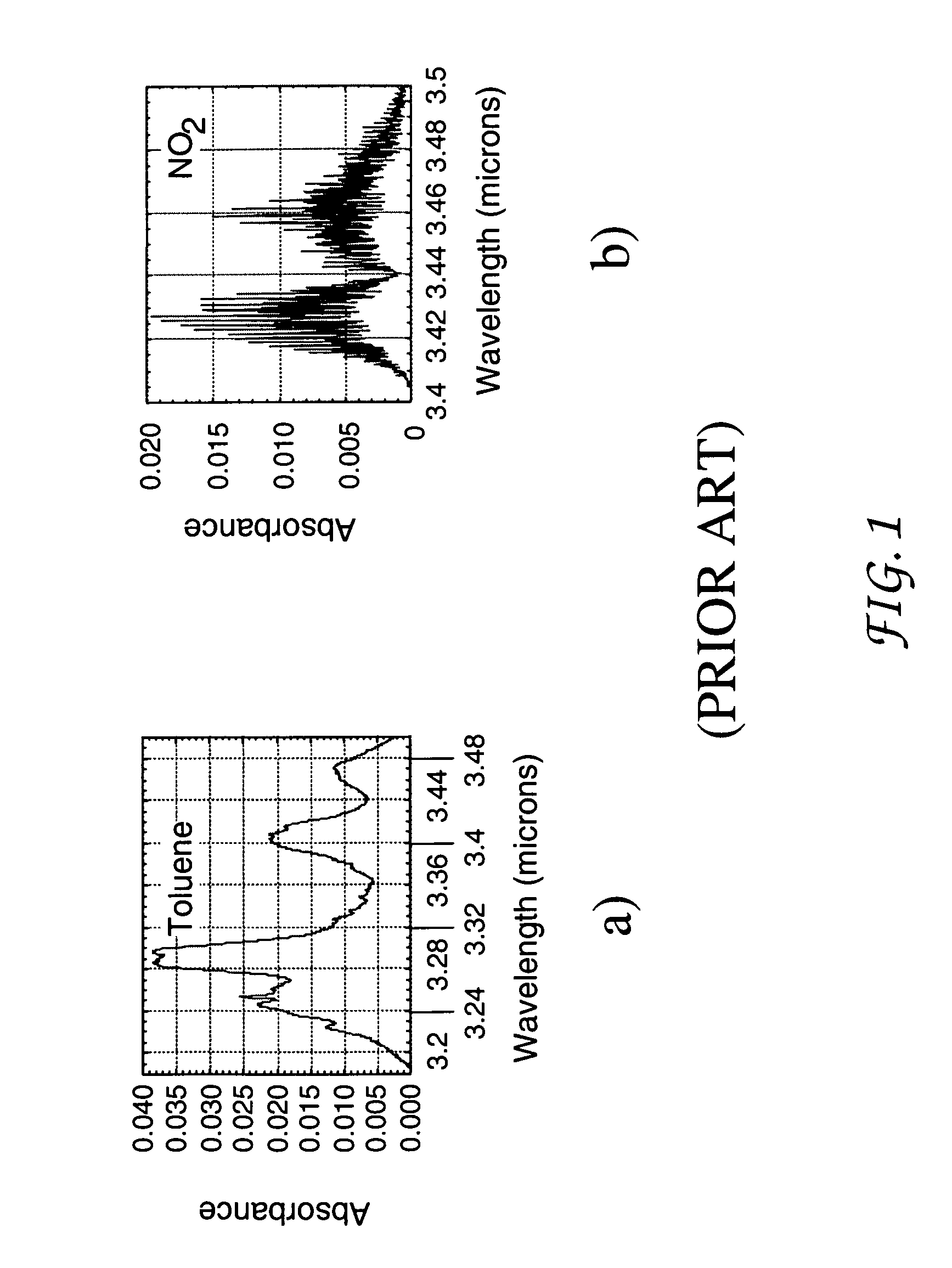

In atomic physics, the fine structure describes the splitting of the spectral lines of atoms due to electron spin and relativistic corrections to the non-relativistic Schrödinger equation. It was first measured precisely for the hydrogen atom by Albert A. Michelson and Edward W. Morley in 1887 laying the basis for the theoretical treatment by Arnold Sommerfeld, introducing the fine-structure constant.

Carbon-Based Fine Structure Array, Aggregate of Carbon-Based Fine Structures, Use Thereof and Method for Preparation Thereof

ActiveUS20080095694A1Long and strong aggregateEasy alignmentMaterial nanotechnologyLayered productsFine structureStrong interaction

An aggregate of carbon-based fine structures in which a plurality of carbon-based fine structures are collected, wherein respective carbon-based fine structures are oriented in the same direction. The above aggregate of carbon-based fine structures is an aggregate of a plurality of carbon-based fine structures in a state they are pulled by one another with strong interaction, and has such a length that allows the improvement of the handleability and workability thereof.

Owner:NIPPON SANSO CORP

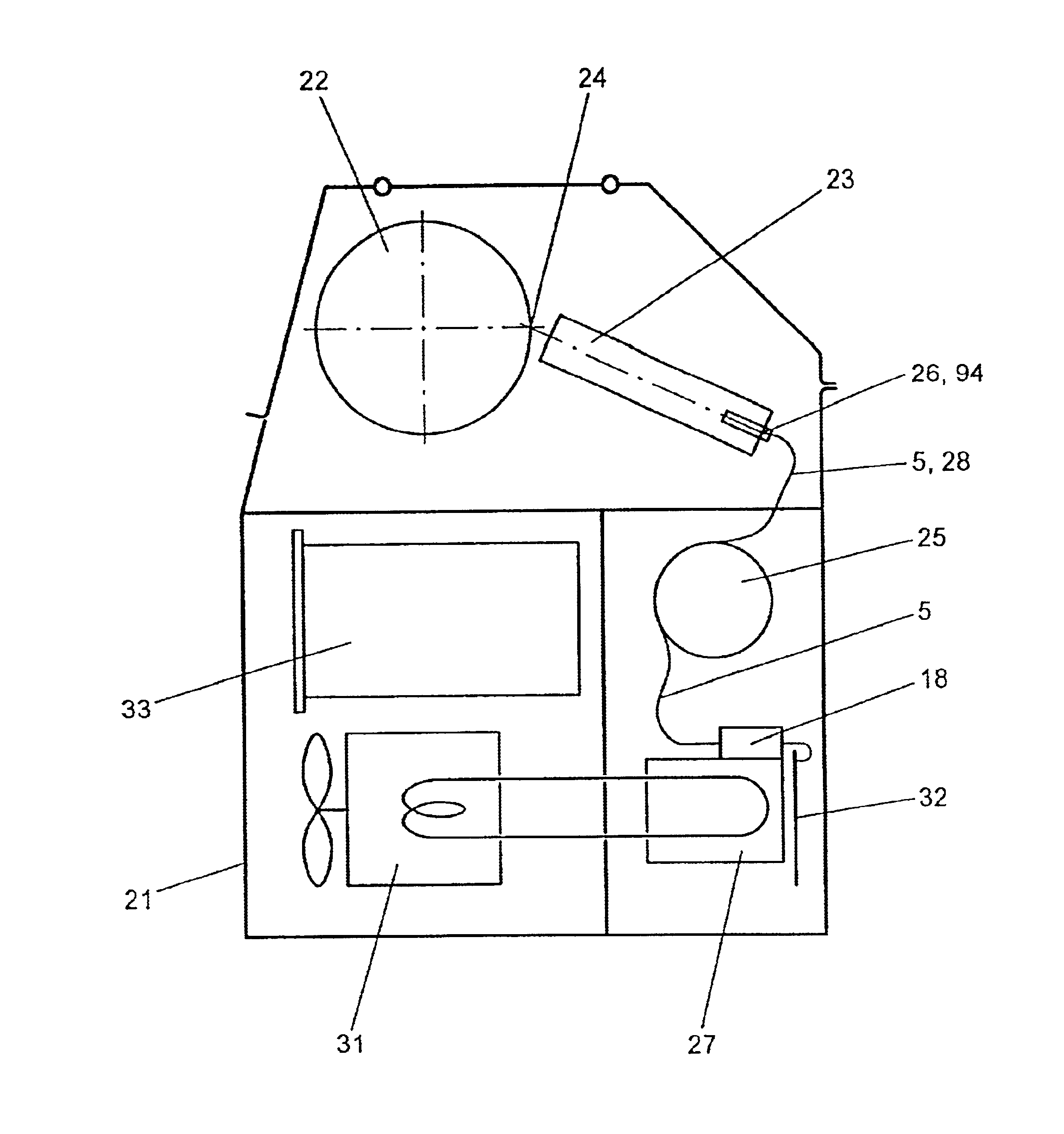

Multi-tactile display haptic interface device

InactiveUS20030210259A1Input/output for user-computer interactionCosmonautic condition simulationsFine structureTouch Perception

A tactile array is integrated with a large scale force-feedback device. Under software control, the large scale force-feedback device provides large scale shape information while the tactile display provides fine structures and surface texture. In a virtual reality environment, the concept of a "tactile map" is employed. A tactile map provides surface details and is rendered by the tactile array. Tactile maps may be based on actual object surface properties, or they may be arbitrarily generated based on the application. In operation, the effect of colliding with a object is produced and the point of contact is noted. The corresponding location on the tactile map is identified, and the surface features are rendered on the tactile array. Moving the point of contact changes the corresponding portion of the tactile map being rendered.

Owner:THE HENRY M JACKSON FOUND FOR THE ADVANCEMENT OF MILITARY MEDICINE INC

Tunable light source for use in photoacoustic spectrometers

InactiveUS6975402B2The process is compact and efficientOptical signal transducersColor/spectral properties measurementsFiberFine structure

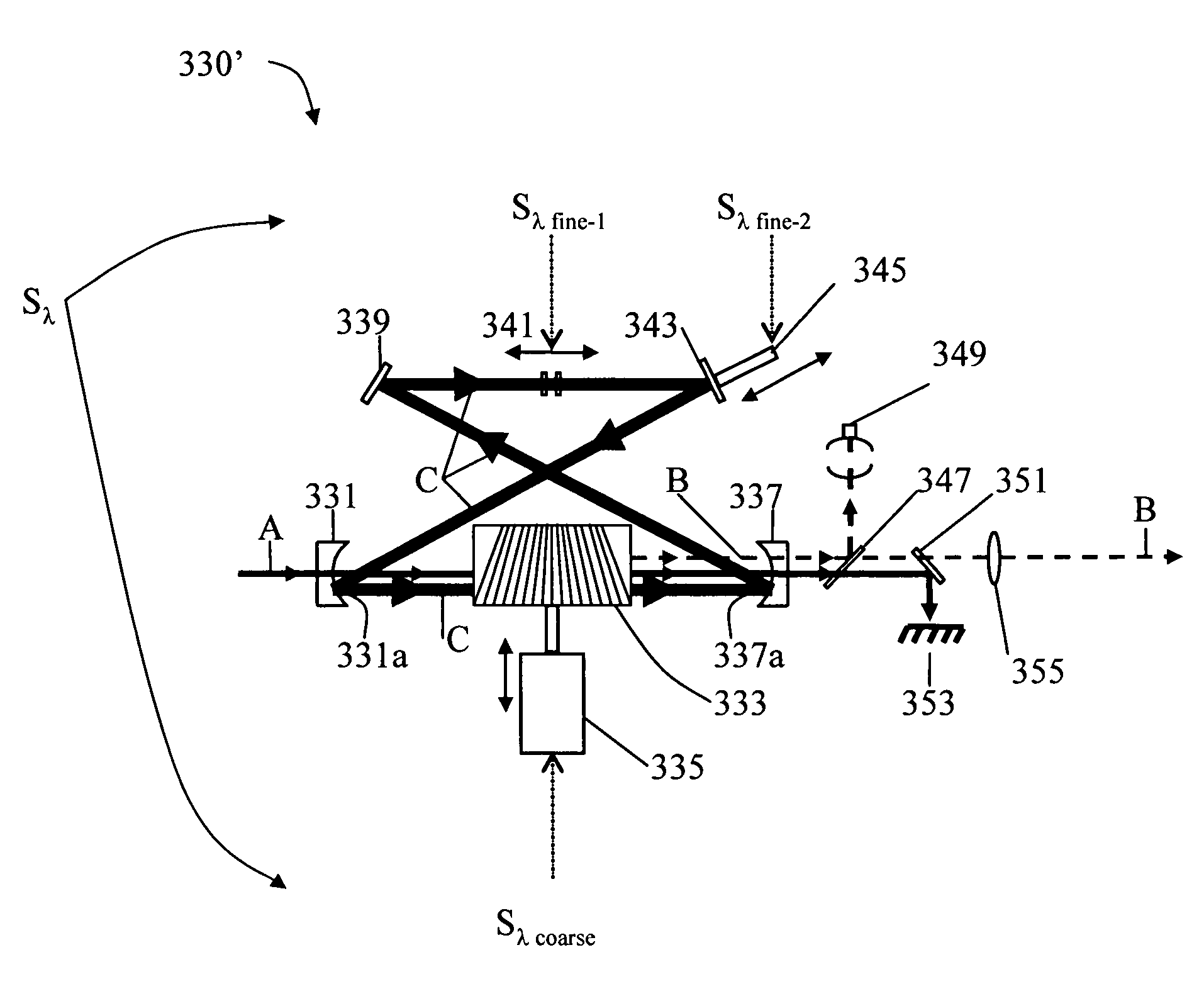

The present invention provides a photoacoustic spectrometer that is field portable and capable of speciating complex organic molecules in the gas phase. The spectrometer has a tunable light source that has the ability to resolve the fine structure of these molecules over a large wavelength range. The inventive light source includes an optical parametric oscillator (OPO) having combined fine and coarse tuning. By pumping the OPO with the output from a doped-fiber optical amplifier pumped by a diode seed laser, the inventive spectrometer is able to speciate mixtures having parts per billion of organic compounds, with a light source that has a high efficiency and small size, allowing for portability. In an alternative embodiment, the spectrometer is scanned by controlling the laser wavelength, thus resulting in an even more compact and efficient design.

Owner:SANDIA NAT LAB

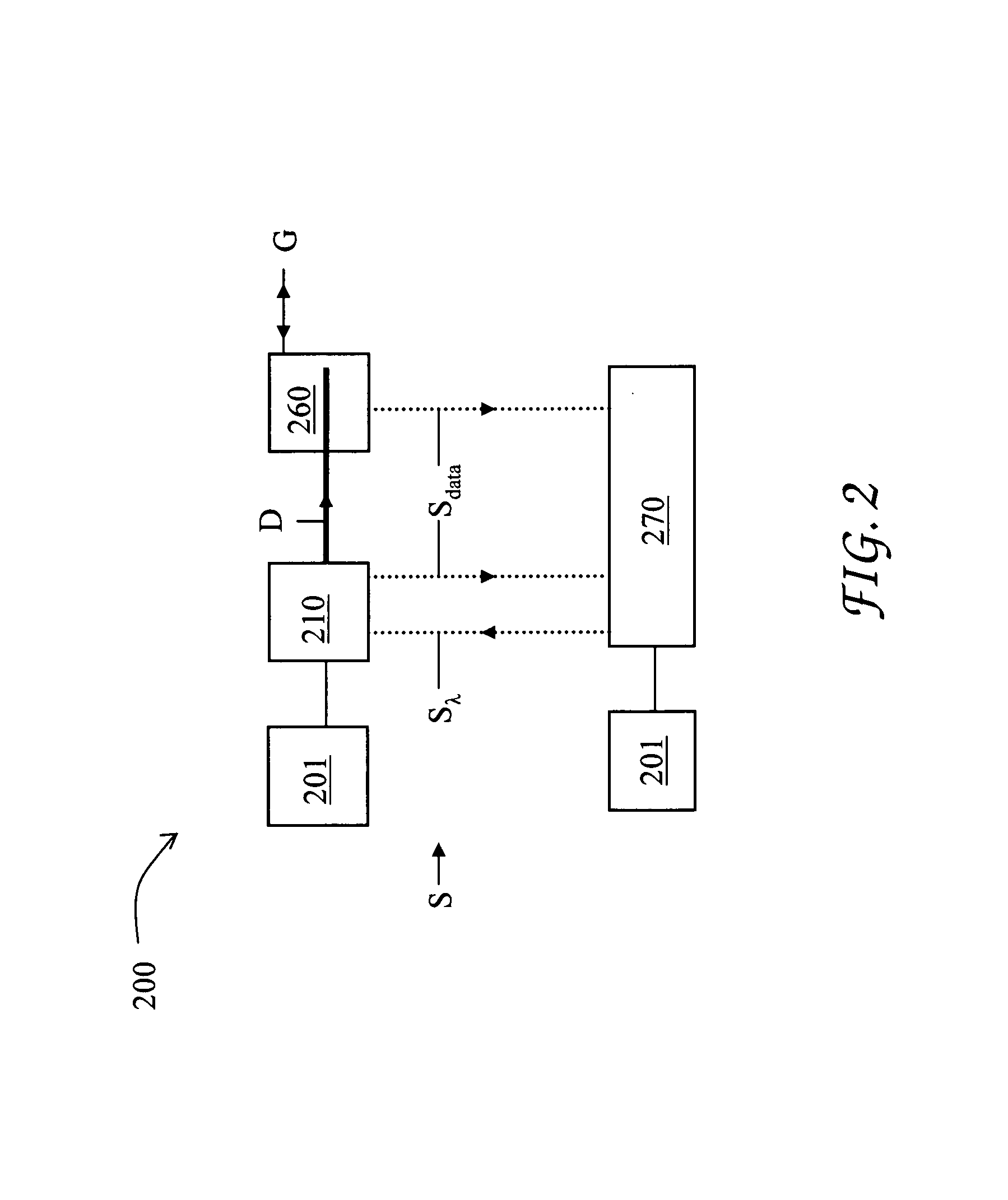

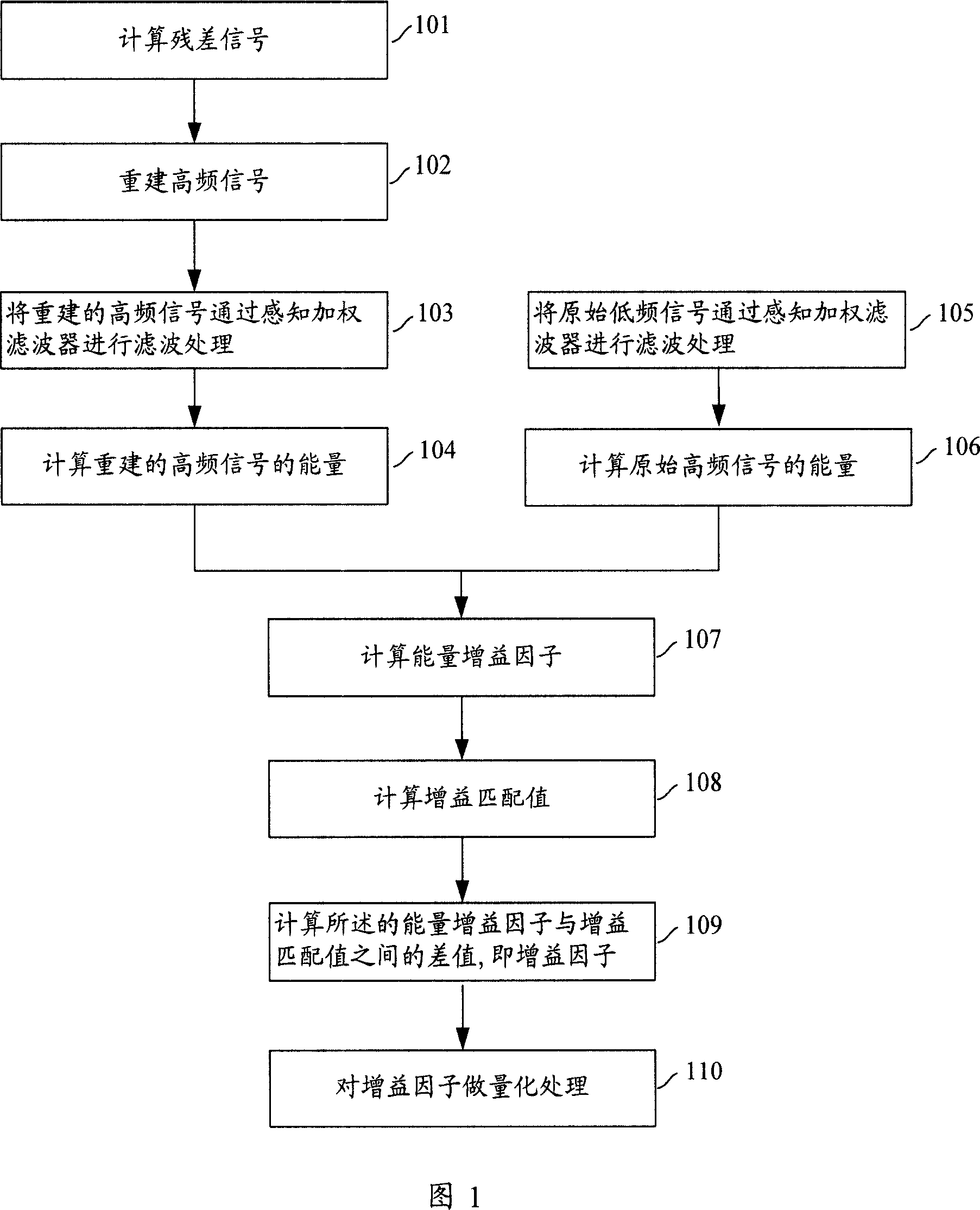

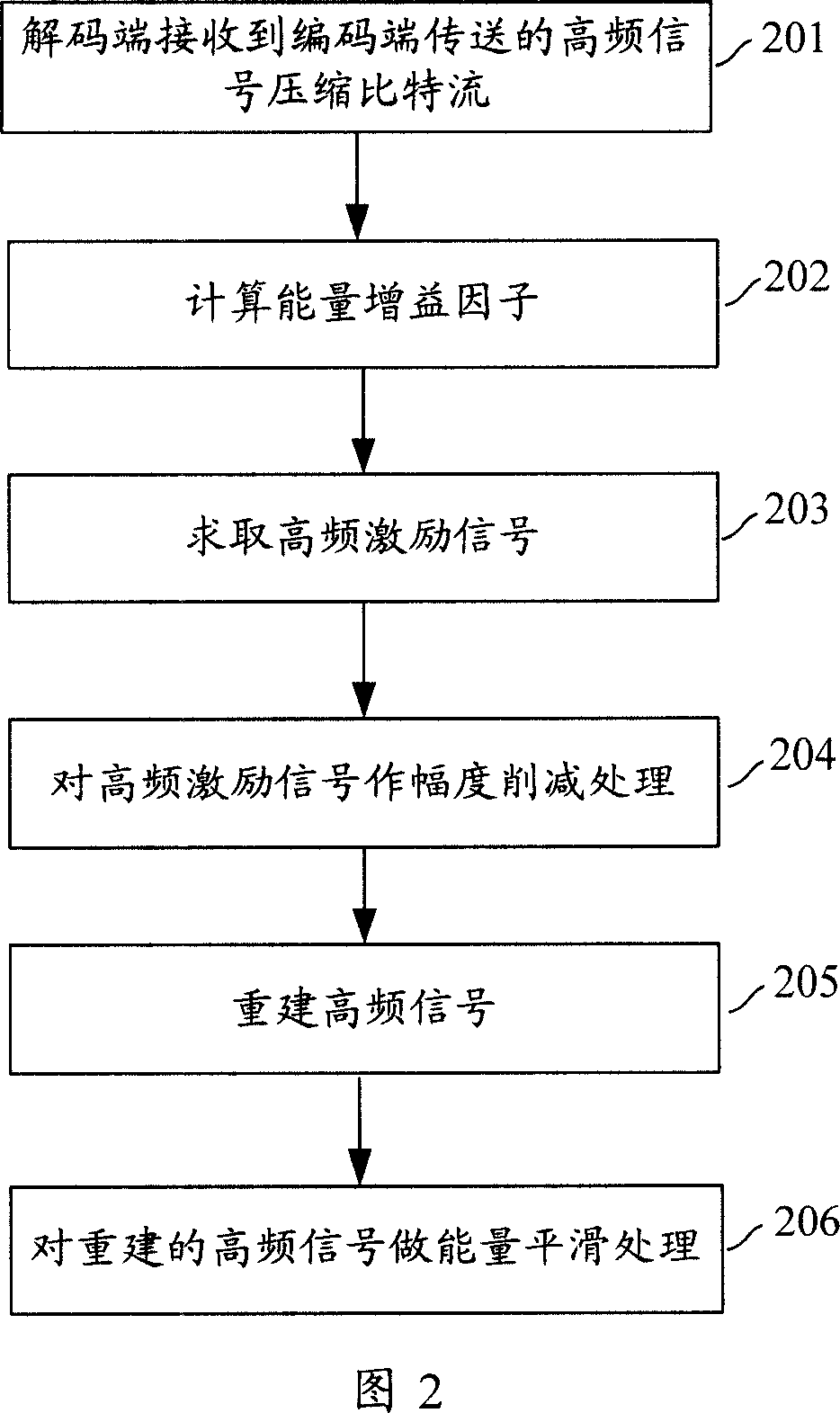

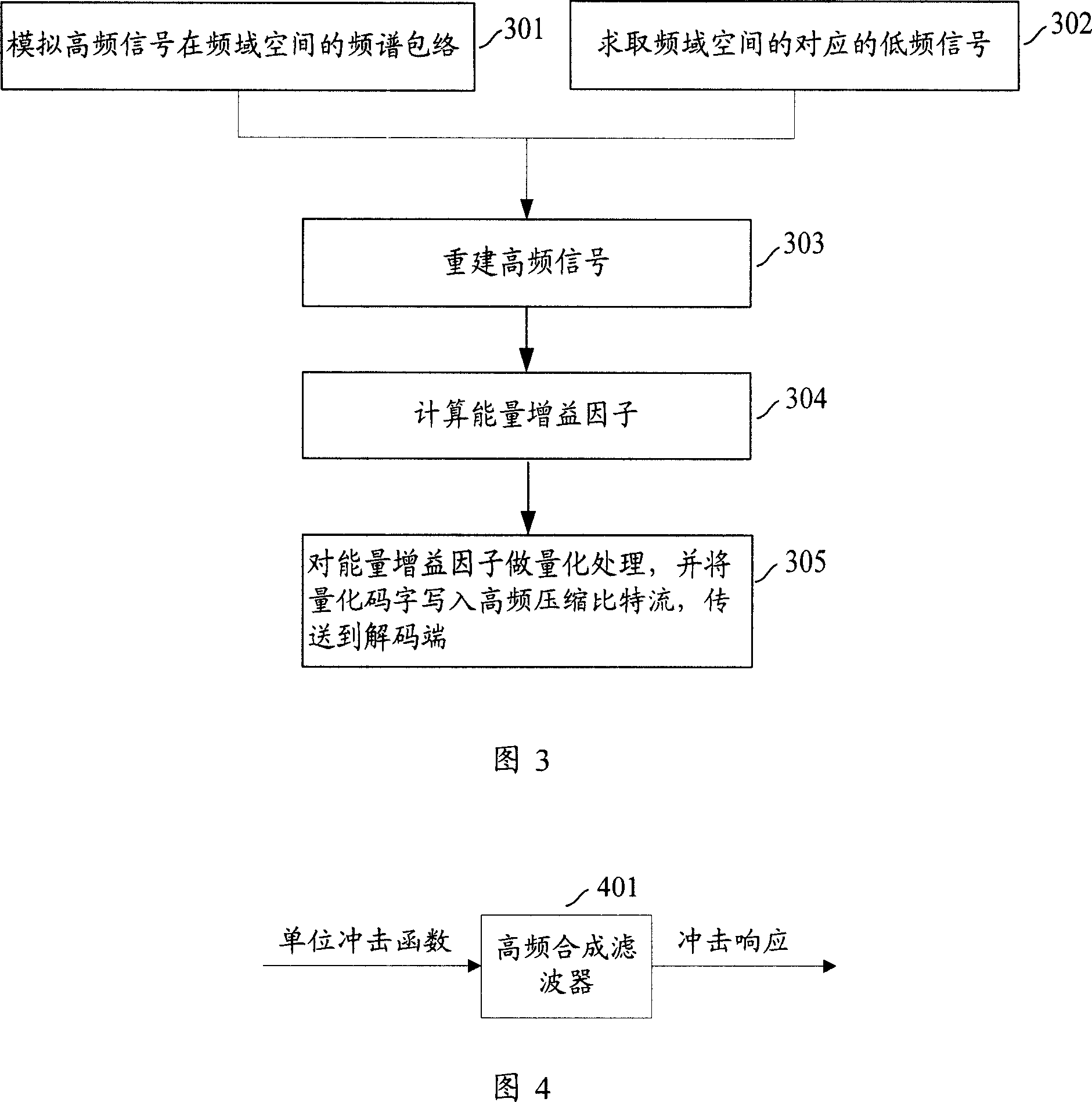

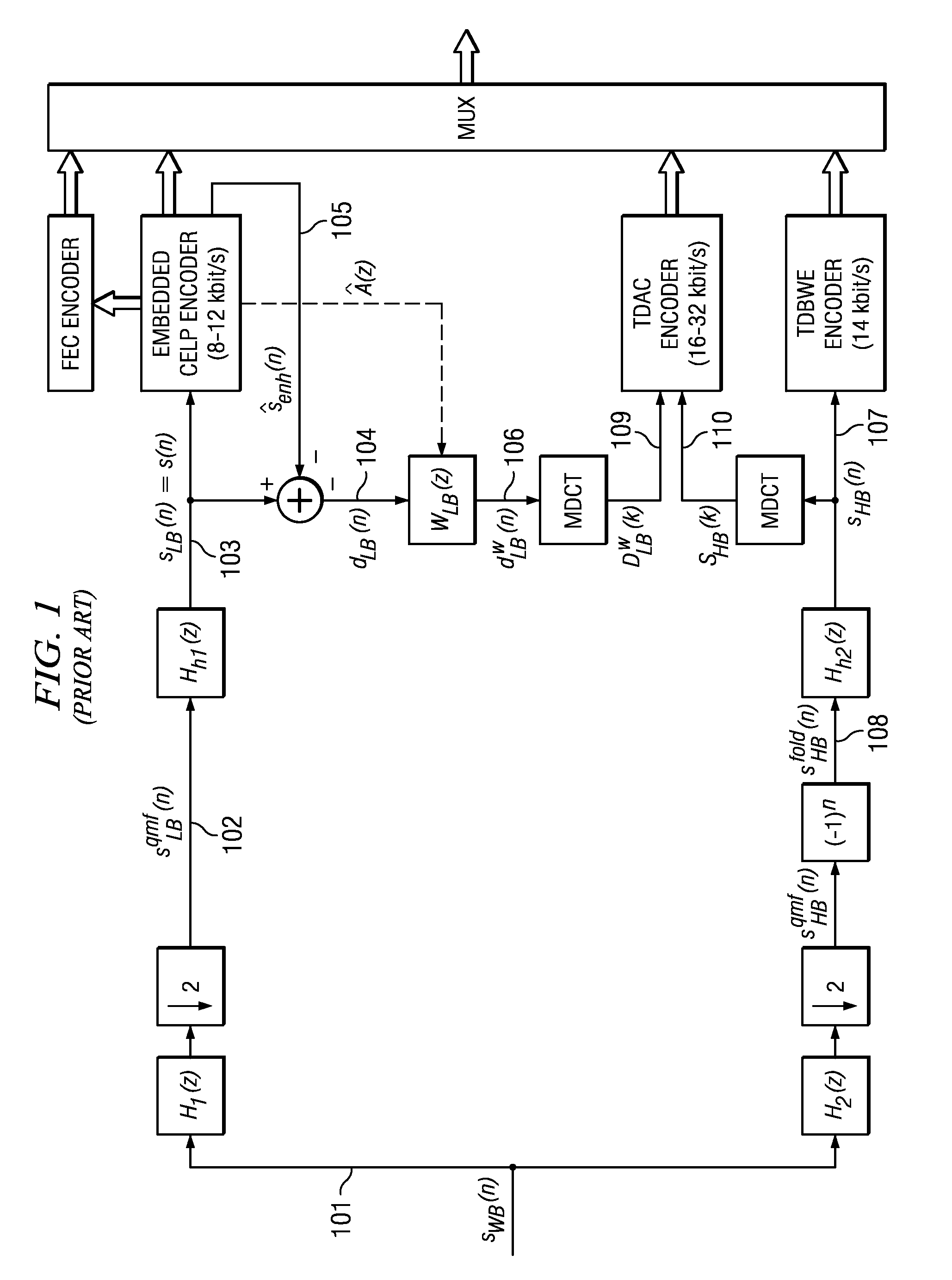

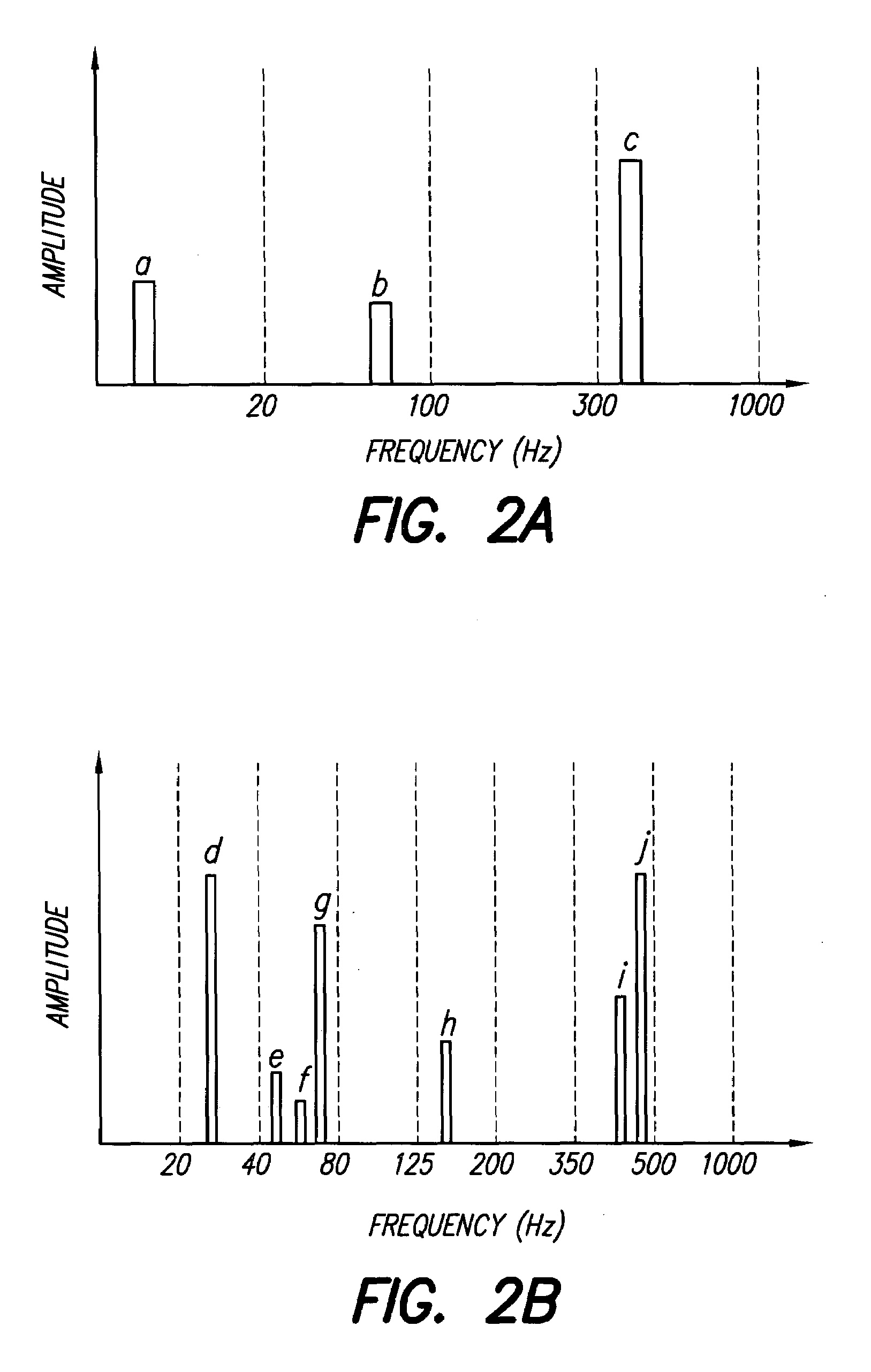

Band-width spreading method and system for voice or audio signal

The invention discloses a method and system for speech or audio signal bandwidth expansion, which comprises: A. to simulate spectral envelope of the high-frequency signal components in the speech or audio signal. B. to make a synthesis of the said spectrum envelope and the low-frequency signal components corresponding to the high-frequency signal components in the frequency and spatial domain to obtain the reset high-frequency signal components. The invention also discloses the method and system to realize the said bandwidth expansion, the technical scheme offered by which has the advantage of less bit number of coding that can be adaptively adjusted based on the type features of the signals. Besides, by extracting spectrum envelope of the high-frequency signal components, the invention makes the fine structure acted on the low-frequency signal components corresponding frequency and spatial domain to guarantee the correlation between the reset high-frequency signal spectrum and the harmonization of the high-frequency signal spectrum lopped during coding.

Owner:HUAWEI TECH CO LTD +1

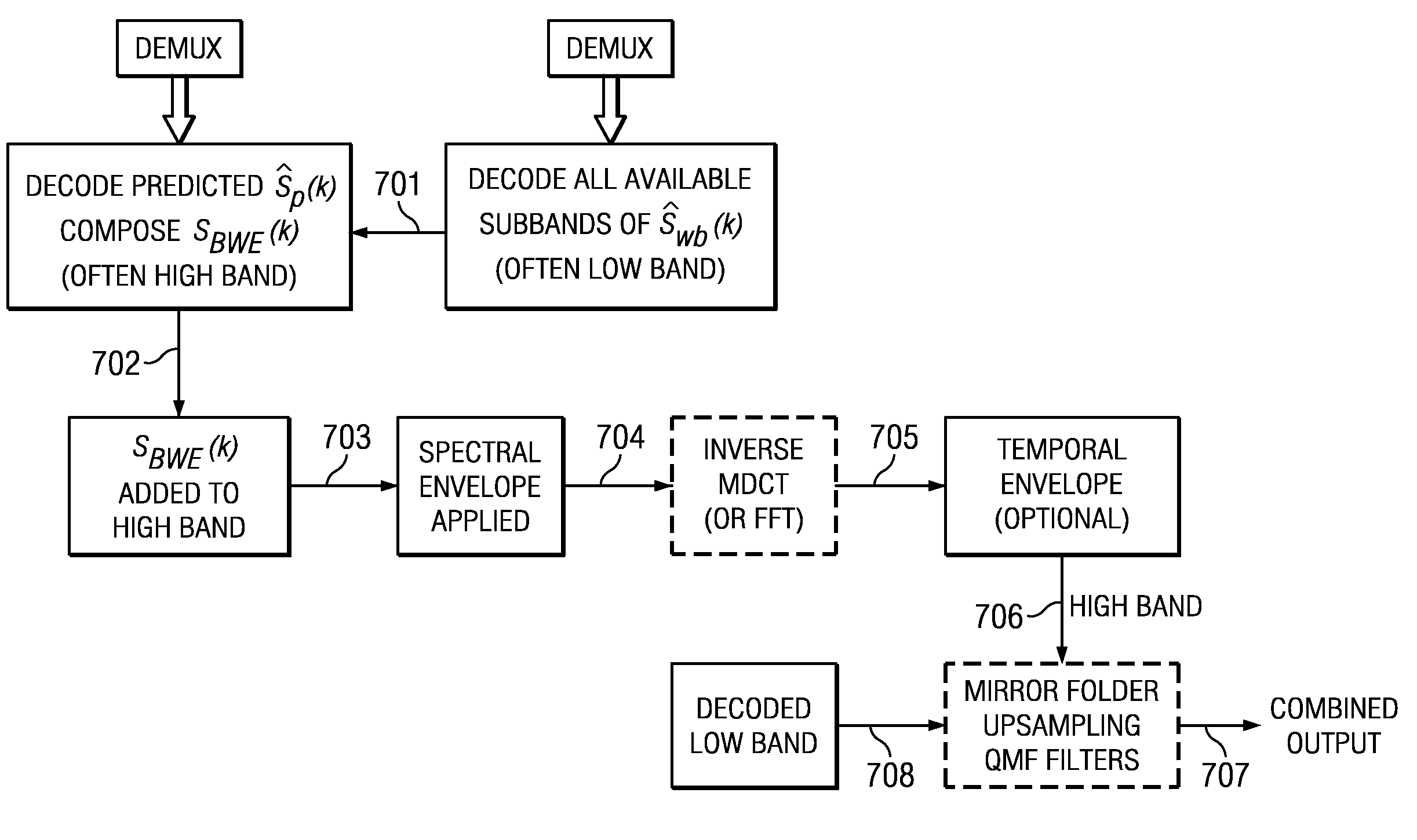

Adaptive Frequency Prediction

ActiveUS20100063802A1Error minimizationSimple structureSpeech analysisDigital computer detailsFine structureFrequency spectrum

In one embodiment, a method of transceiving an audio signal is disclosed. The method includes providing low band spectral information having a plurality of spectrum coefficients and predicting a high band extended spectral fine structure from the low band spectral information for at least one subband, where the high band extended spectral fine structure are made of a plurality of spectrum coefficients. The predicting includes preparing the spectrum coefficients of the low band spectral information, defining prediction parameters for the high band extended spectral fine structure and index ranges of the prediction parameters, and determining possible best indices of the prediction parameters, where determining includes minimizing a prediction error between a reference subband in high band and a predicted subband that is selected and composed from an available low band. The possible best indices of the prediction parameters are transmitted.

Owner:HUAWEI TECH CO LTD

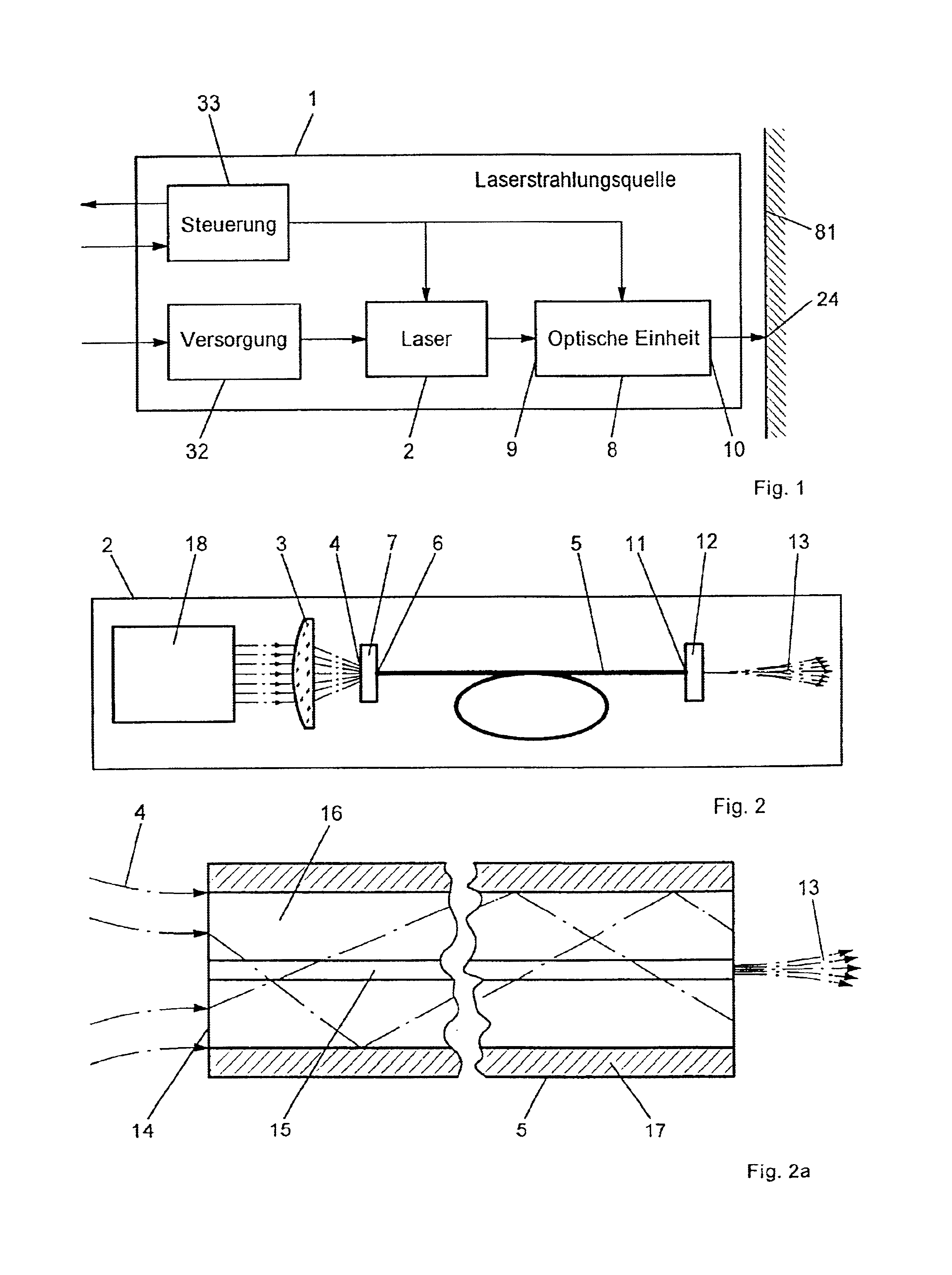

Laser radiation source

InactiveUS6888853B1High densityHigh energyInking apparatusLaser using scattering effectsFine structureOptoelectronics

A system and method for selectively process material on a processing surface of a printing form to create a fine structure or pattern for images or text. At least one fiber laser comprising a pump source and a laser fiber is provided. A laser gun is mounted adjacent the printing form and has at least a focusing optics. The fiber laser outputs a laser beam which is diffraction-limited to permit the focusing optics to focus the laser beam onto the processing surface of the printing form as a spot having a spot size sufficiently small to process the processing surface to create the fine structure or pattern images or text.

Owner:HELL GRAVURE SYST

Printable Medium for the Etching of Silicon Dioxide and Silicon Nitride Layers

InactiveUS20080121621A1High viscosityGood printabilityDecorative surface effectsFinal product manufactureFine structureEtching

The present invention relates to a novel printable etching medium having non-Newtonian flow behaviour for the etching of surfaces in the production of solar cells and to the use thereof. In particular, the invention relates to corresponding particle-containing compositions by means of which extremely fine structures can be etched very selectively without damaging or attacking adjacent areas.

Owner:MERCK PATENT GMBH

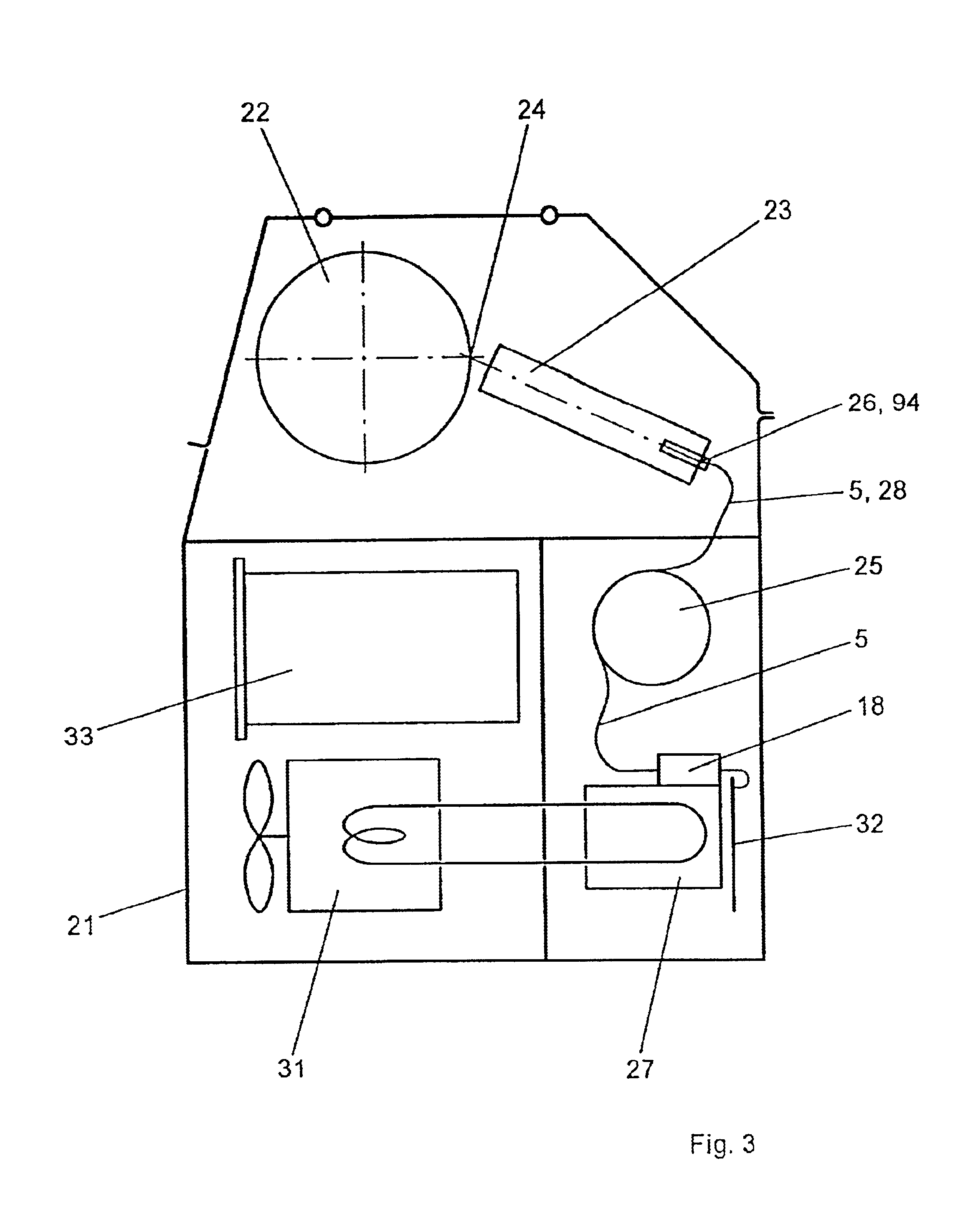

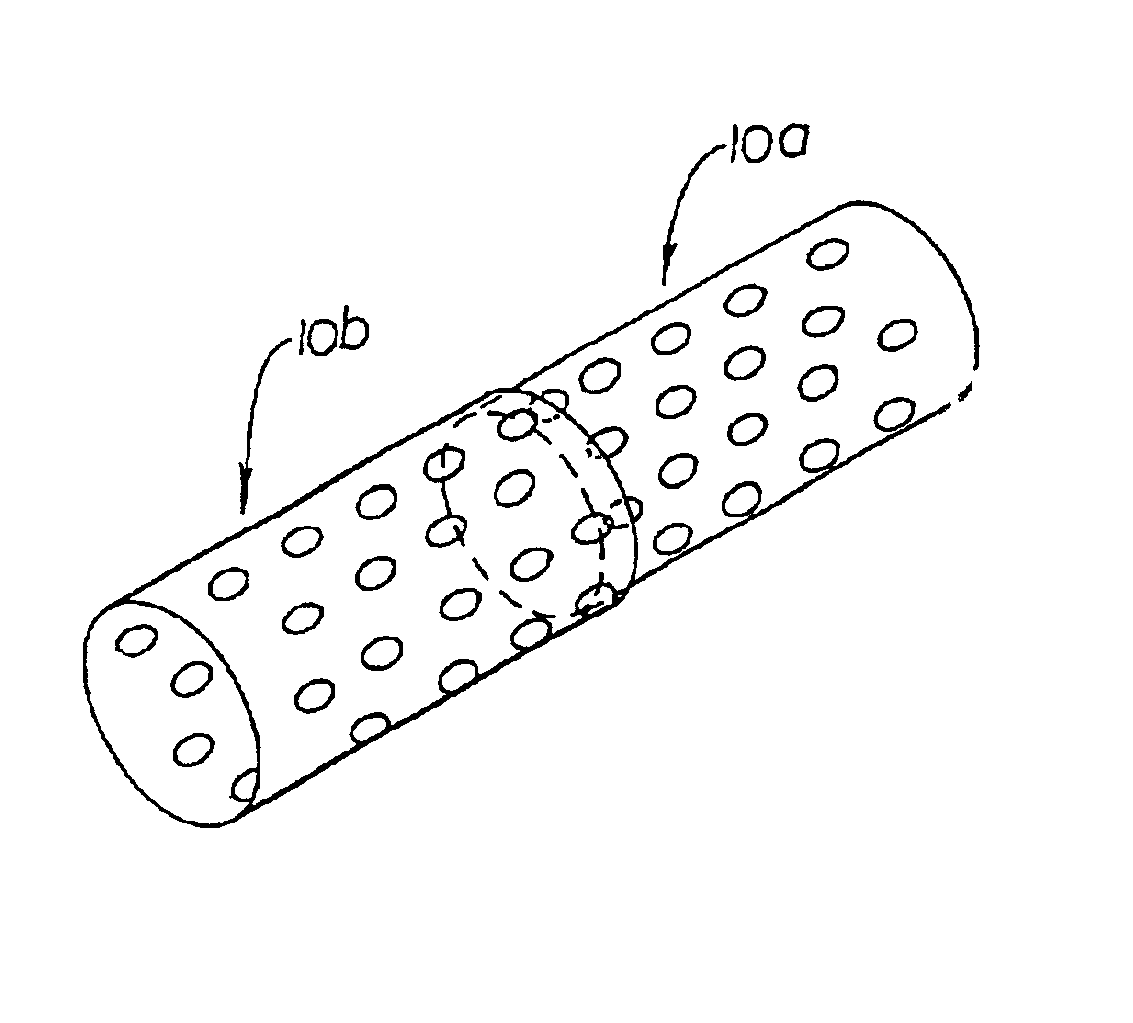

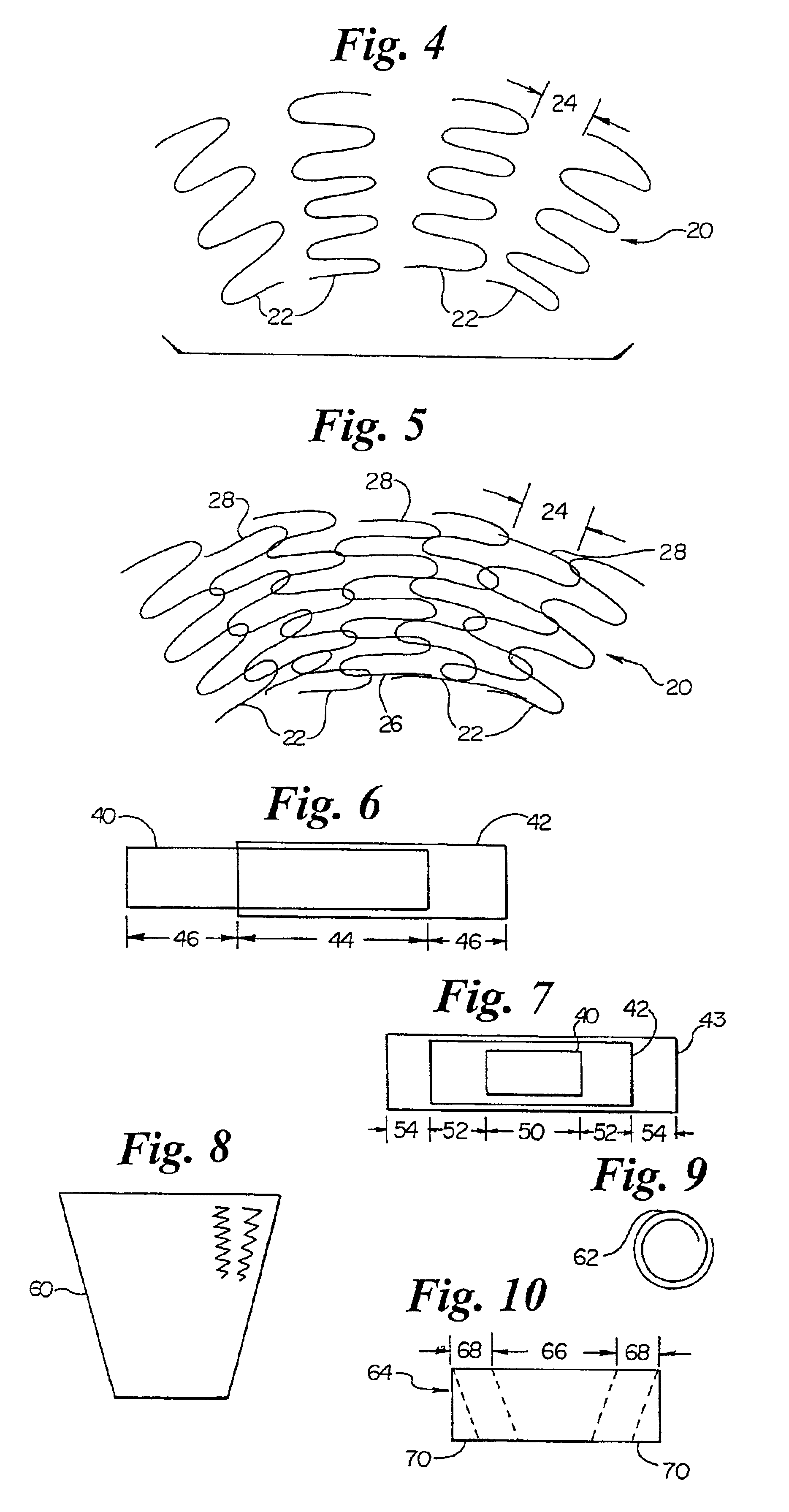

Micro structure stent configurations

Owner:BOSTON SCI SCIMED INC

Method for preparing metal titanium or titanium alloy super-oleophobic surface

InactiveCN102021628AImprove stabilityReduce resistanceSurface reaction electrolytic coatingSpecial surfacesFine structureTitanium alloy

The invention discloses a method for preparing a metal titanium or titanium alloy super-oleophobic surface. The method comprises the following steps of: performing primary anodic oxidation treatment on metal titanium or titanium alloy to obtain a roughened surface with a microstructure; forming a titanium dioxide nanotube array film on the surface with microstructure through secondary anodic oxidation so as to obtain a composite fine structured micro-nanostructure; and modifying with a low-surface-energy substance to obtain the super-oleophobic surface and the super-hydrophobic and super-oleophobic surface. The metal titanium or titanium alloy surface has super-oleophobic and super-hydrophobic characteristics for multiple kinds of organic liquid, the static contact angle is greater than 155 degrees; the rolling angle is less than 10 degrees; meanwhile, the surface also shows superior super-oleophobic and super-hydrophobic characteristics for pure water and aqueous solution of acid, alkali and salt.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

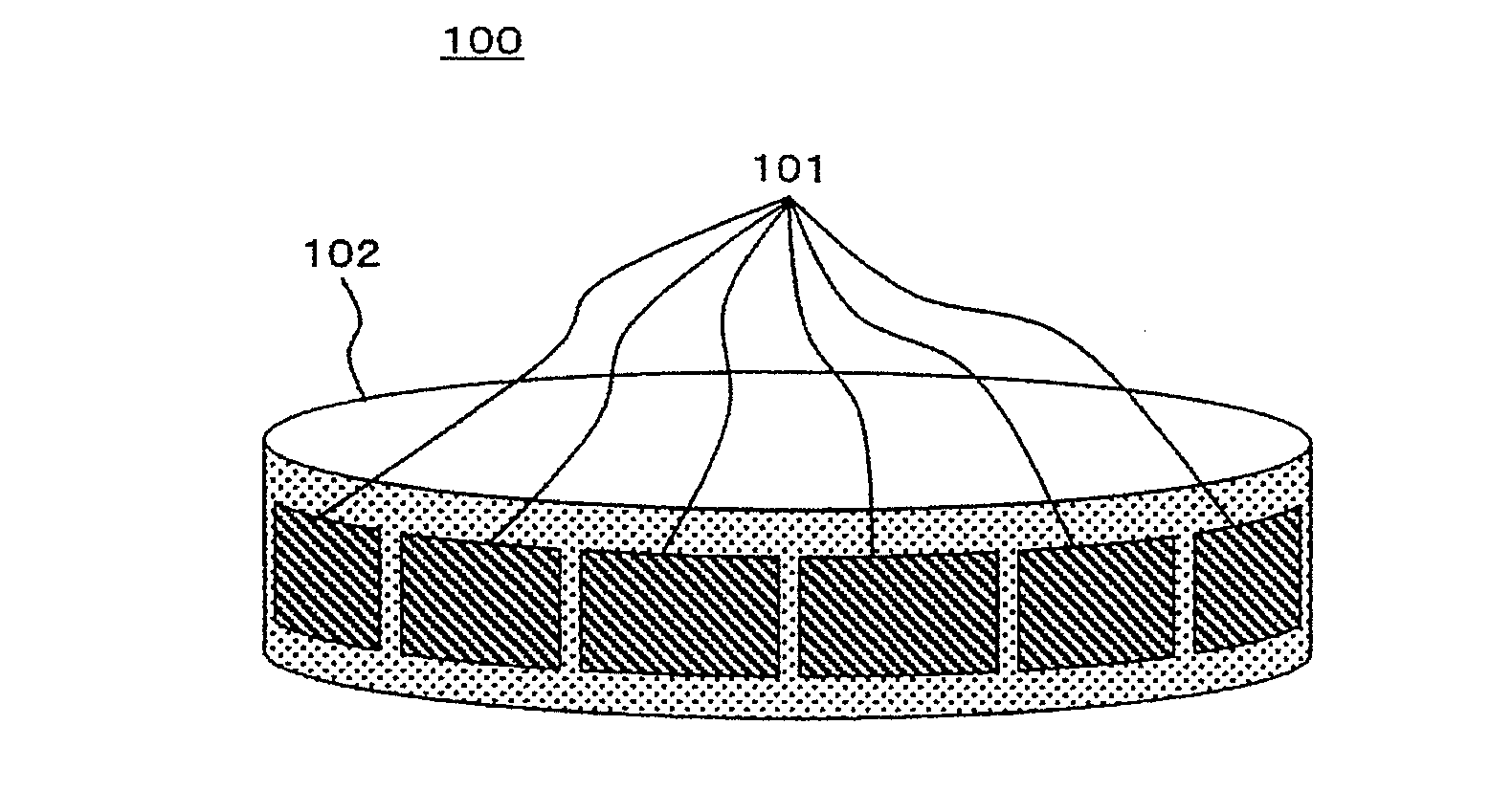

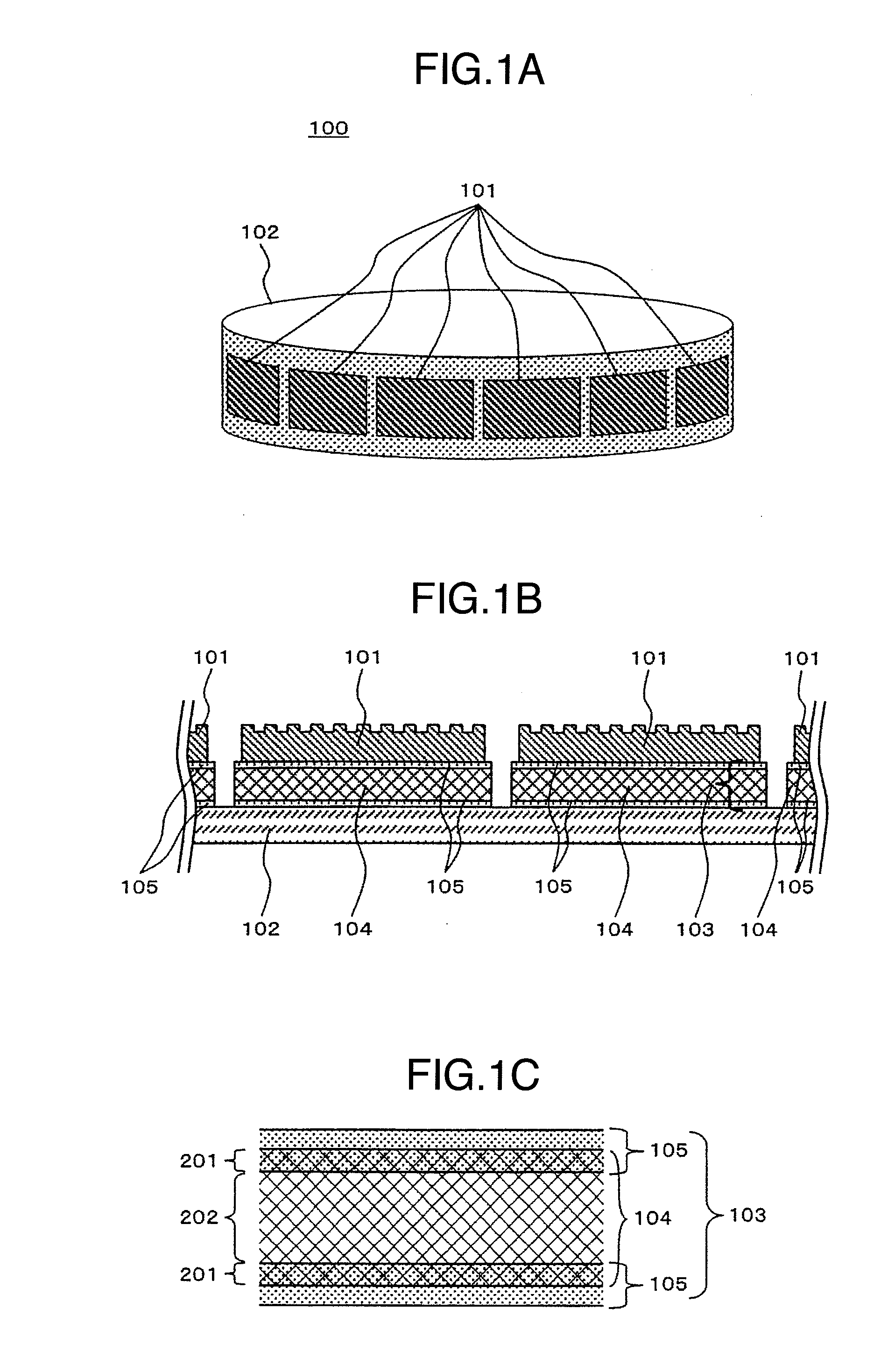

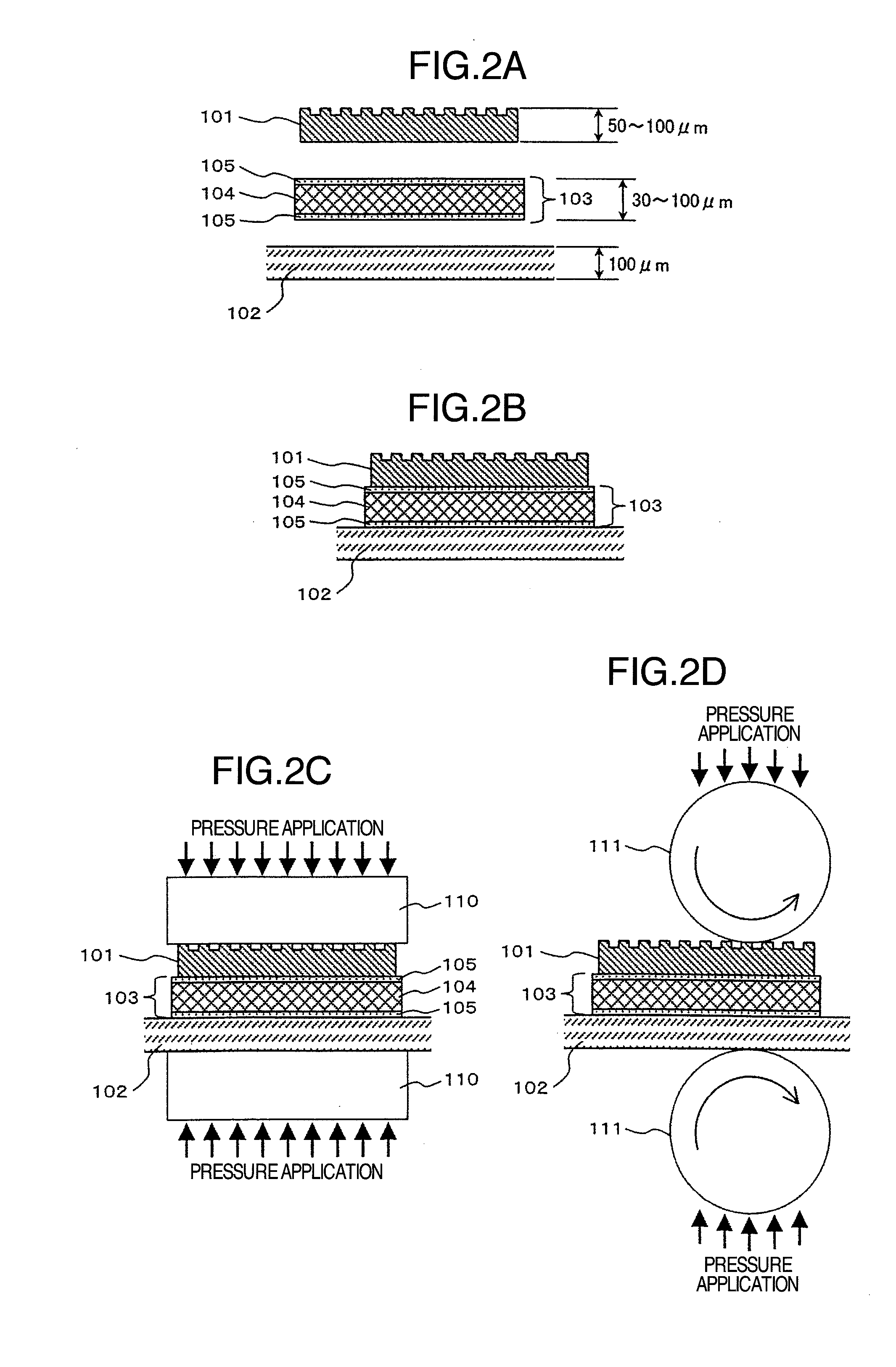

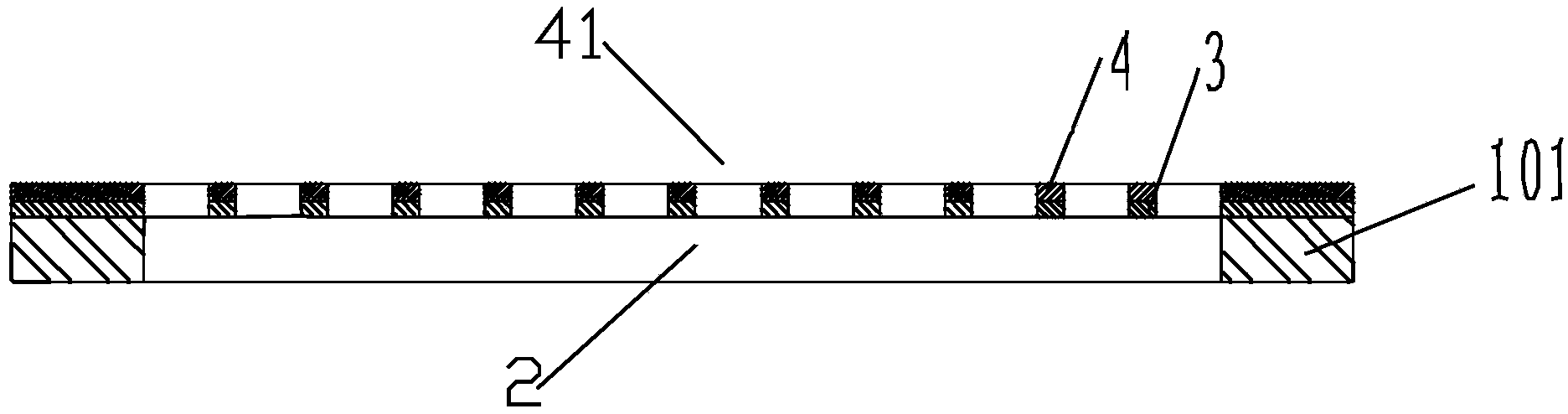

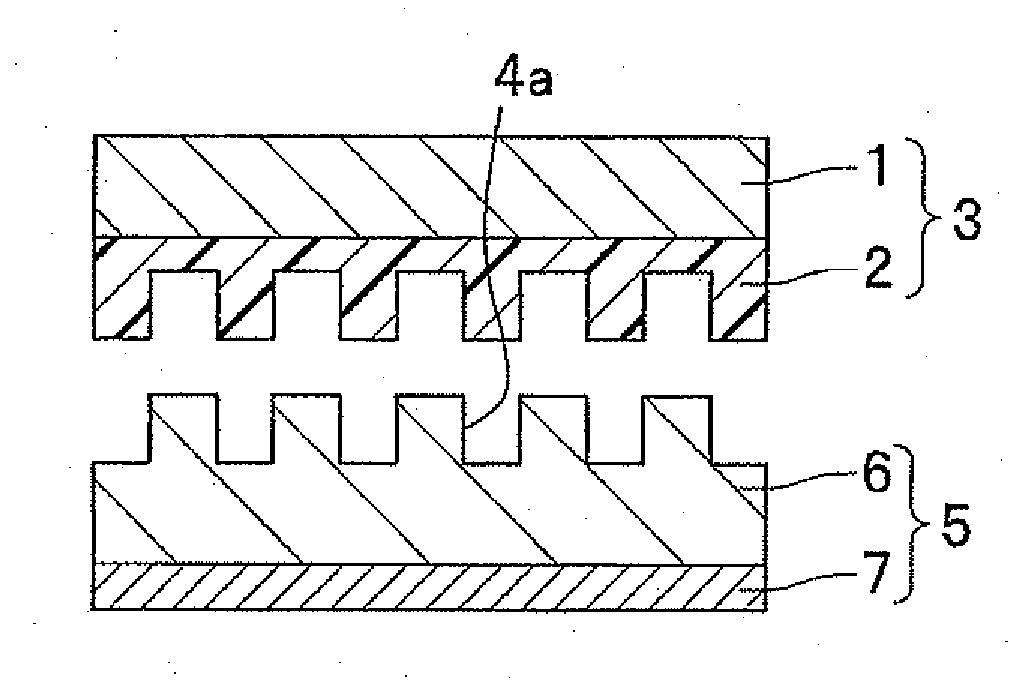

Belt-shaped mold and nanoimprint system using the belt-shaped mold

InactiveUS20090087506A1High aspect ratioFormed rapidly and stablyNanoinformaticsConfectioneryFine structureTransfer system

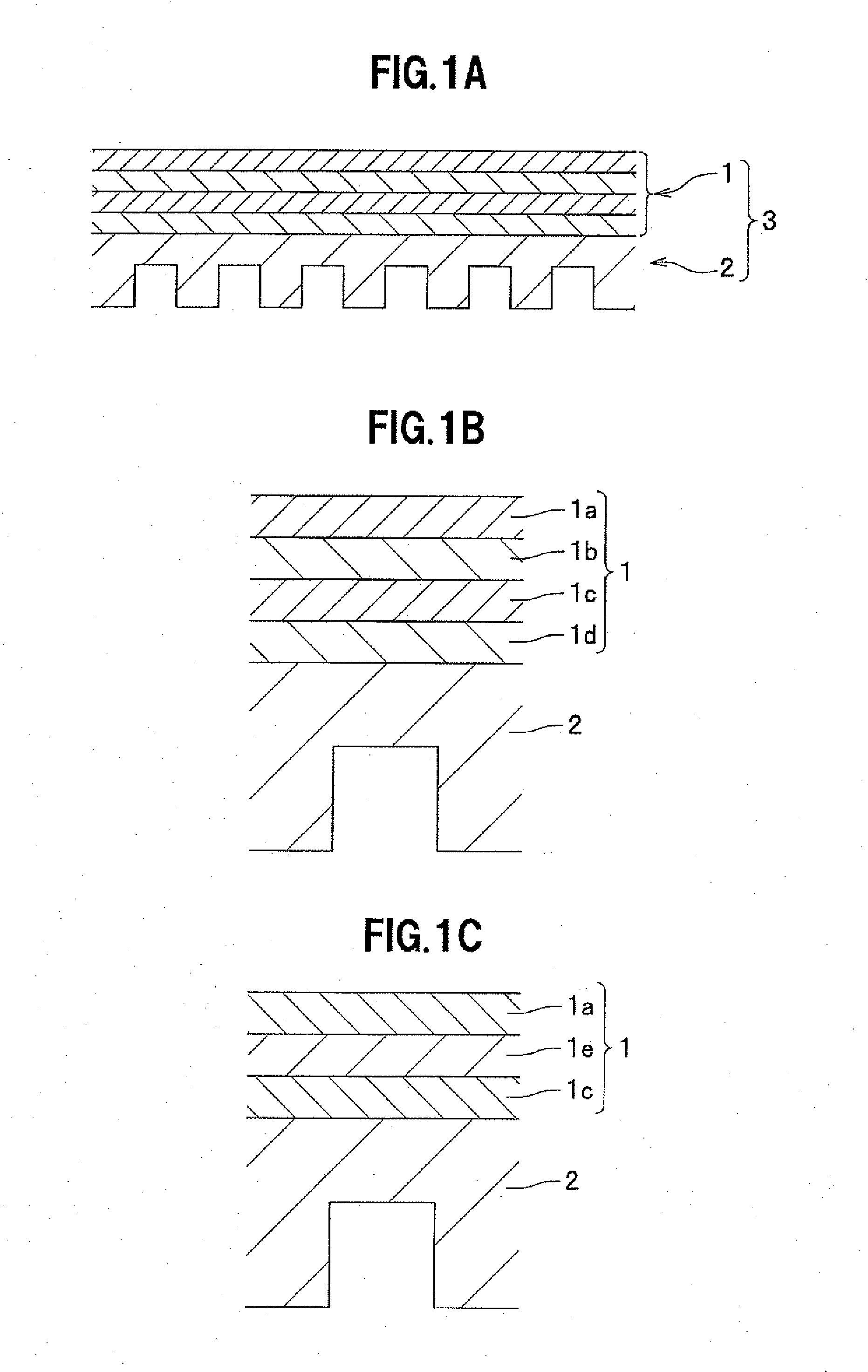

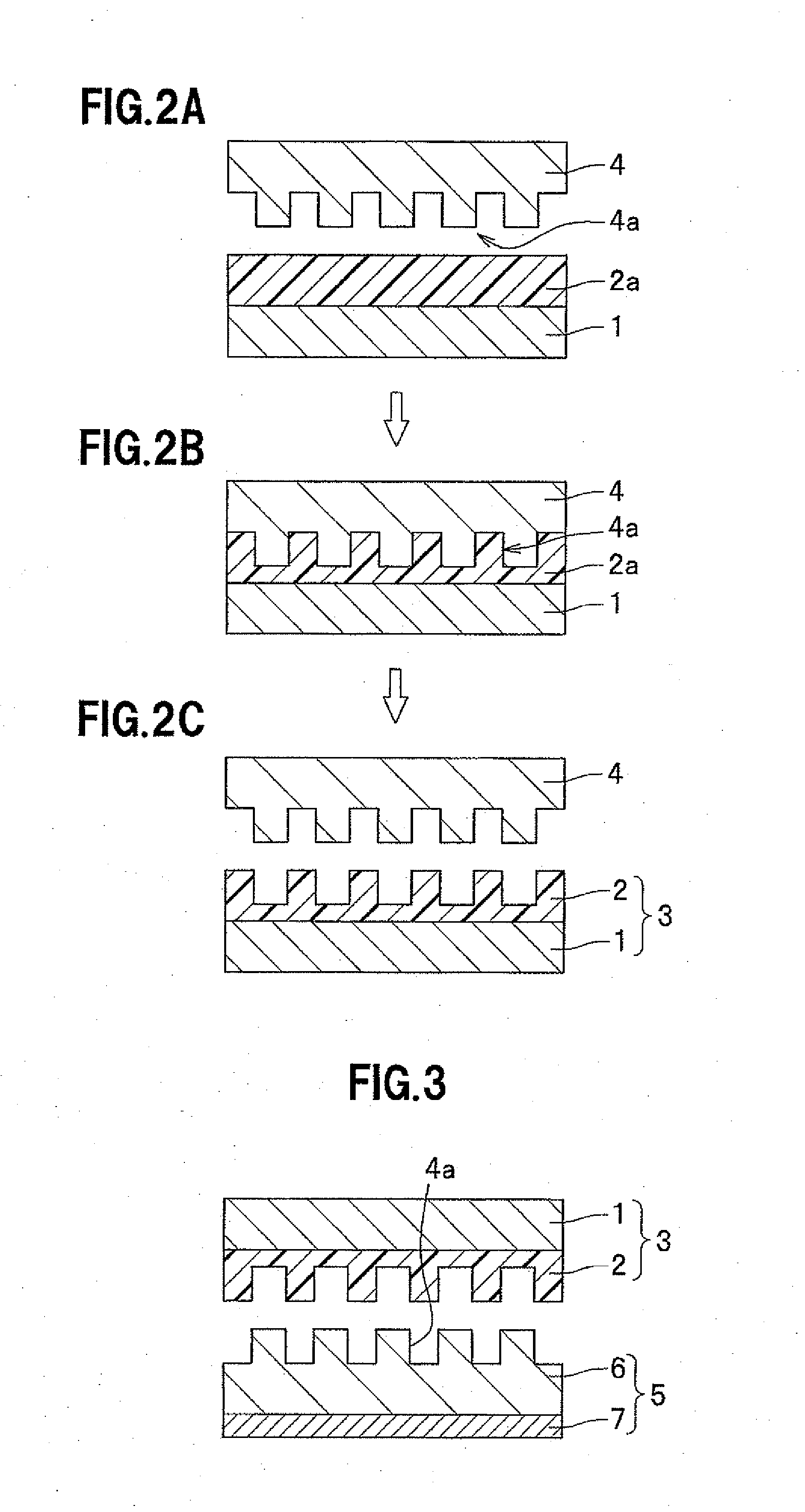

There is provided a fine pattern transfer, belt-shaped mold, with which a fine structure having a high aspect ratio can be formed rapidly and stably using nanoimprinting, and a fine pattern transfer system (a nanoimprint system) that employs this mold. According to the present invention, a nanoimprint mold includes: a belt-shaped support member; a plurality of stampers, for each of which a fine convex-and-concave pattern, to be transferred, is formed on one surface; and an adhesive member, to which the belt-shaped support member and the stampers are to be securely adhered, wherein the adhesive member includes a porous member and adhesive layers, which are deposited on either face of the porous member, for impregnating one part of the porous member, and wherein, for the porous member, a porous area that is not impregnated with the adhesive layers, is provided and positioned so as to sandwich the porous member between portions impregnated with the adhesive layers.

Owner:HITACHI LTD

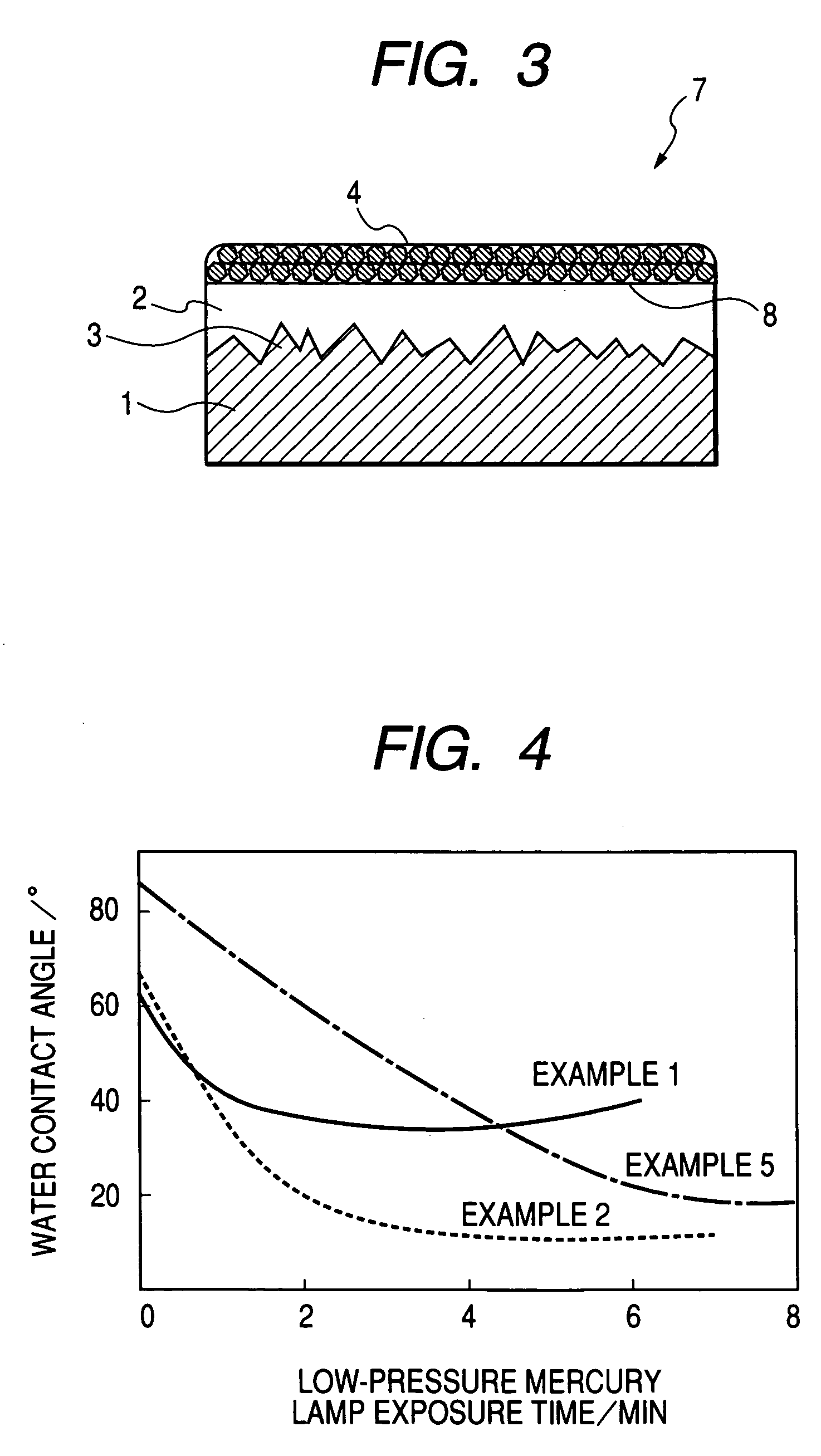

Substrate, conductive substrate, fine structure substrate, organic field effect transistor and manufacturing method thereof

A substrate is provided which comprises an organic resin layer on a base material, wherein the base material has an average surface roughness of not less than 1.2 nm but no more than 5 nm and a maximum height of a surface unevenness of not less than 0.1 μm but no more than 1.0 μm; the organic resin layer has an average surface roughness of not more than 1 nm and a maximum peak height of a surface unevenness of not more than 30 nm; and at least a part of a surface of the organic resin layer comprises a hydrophilic region.

Owner:CANON KK

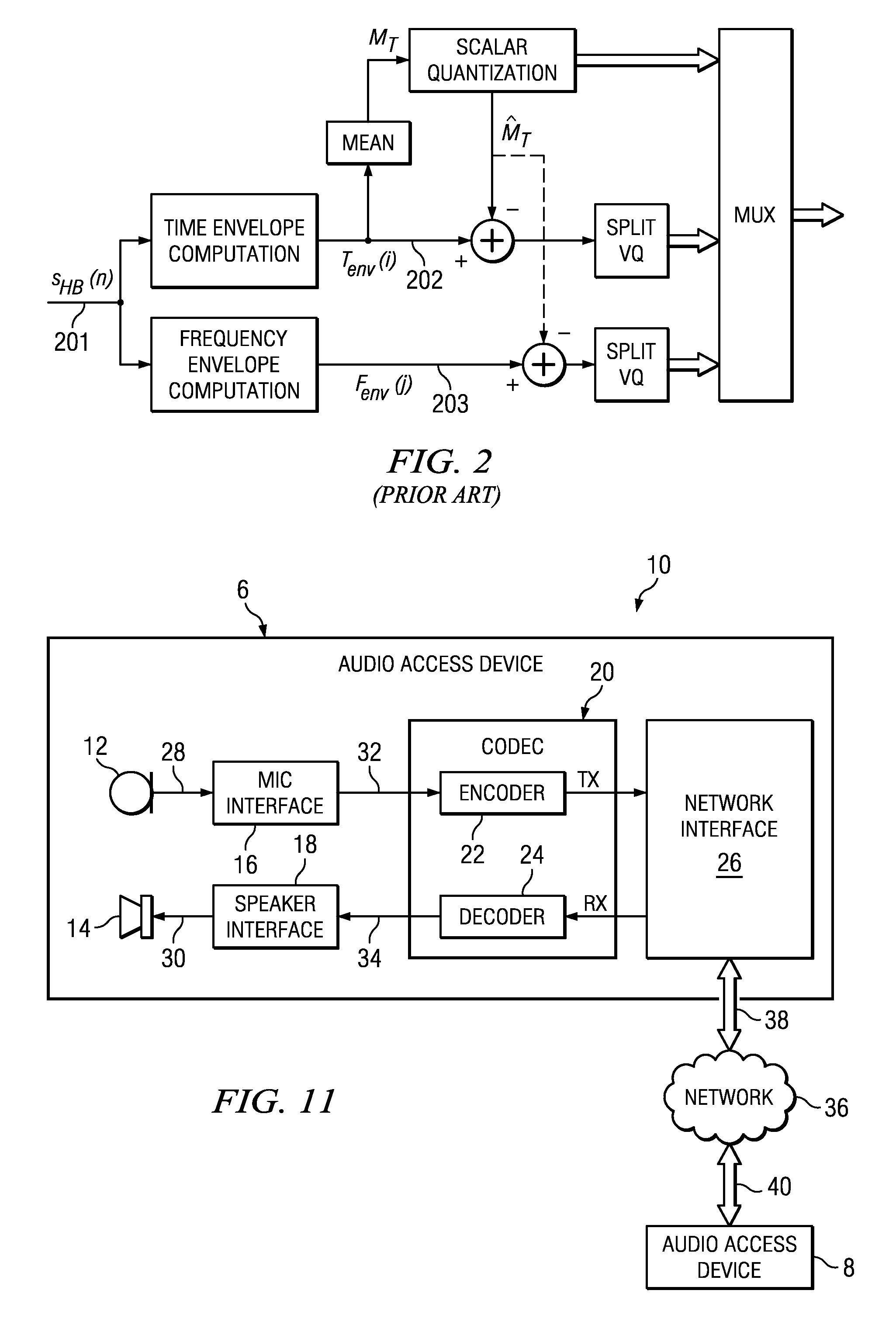

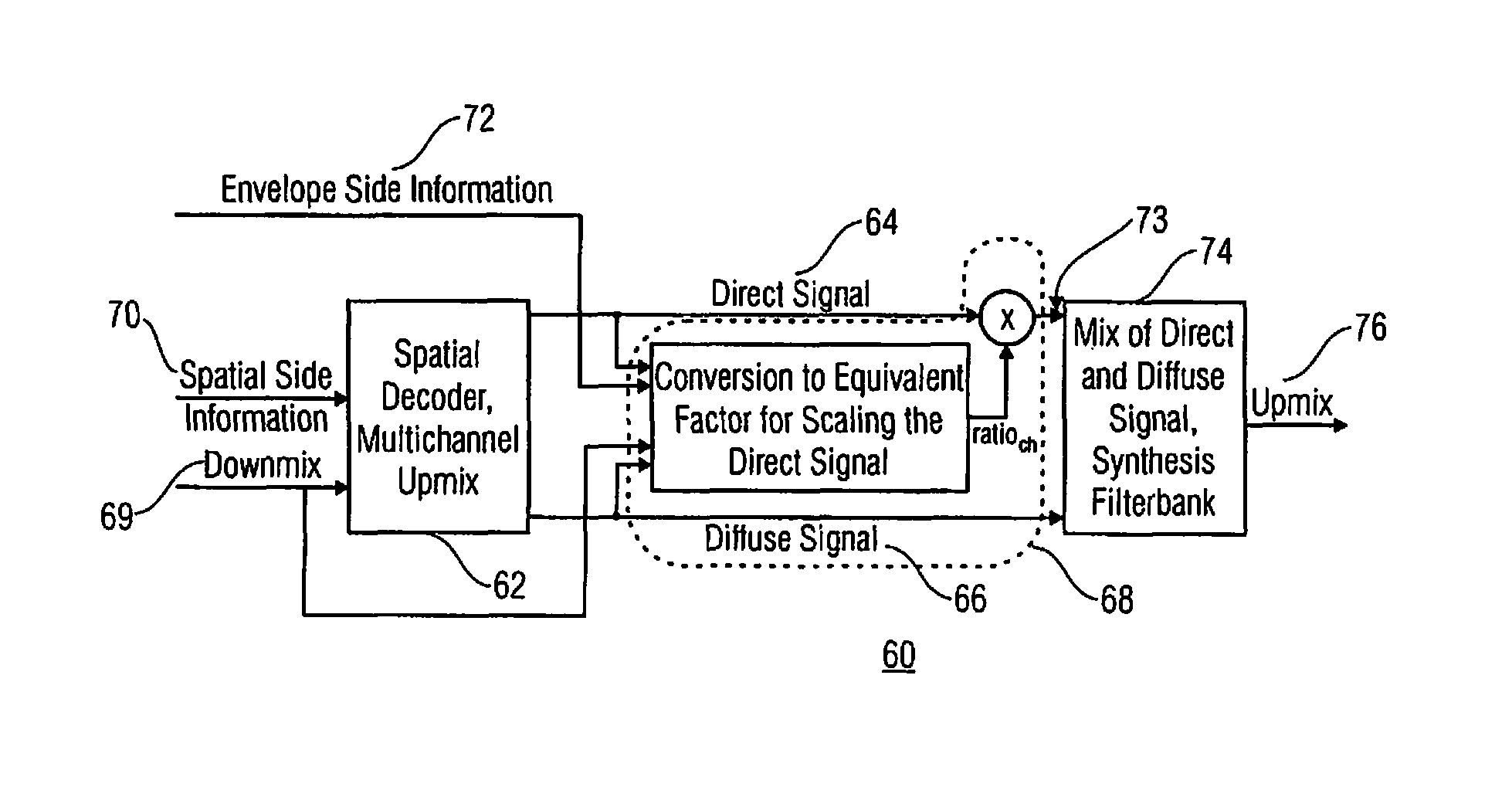

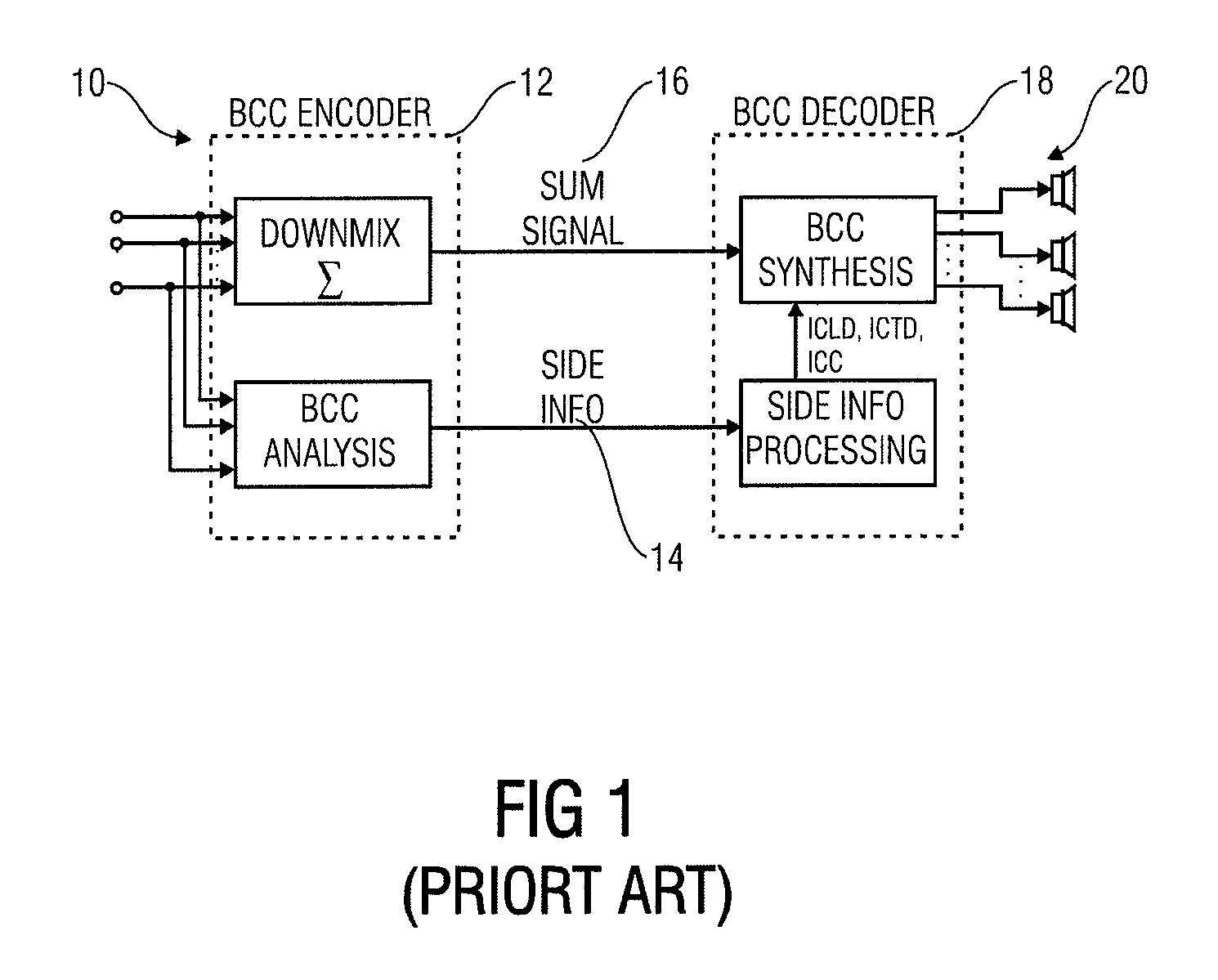

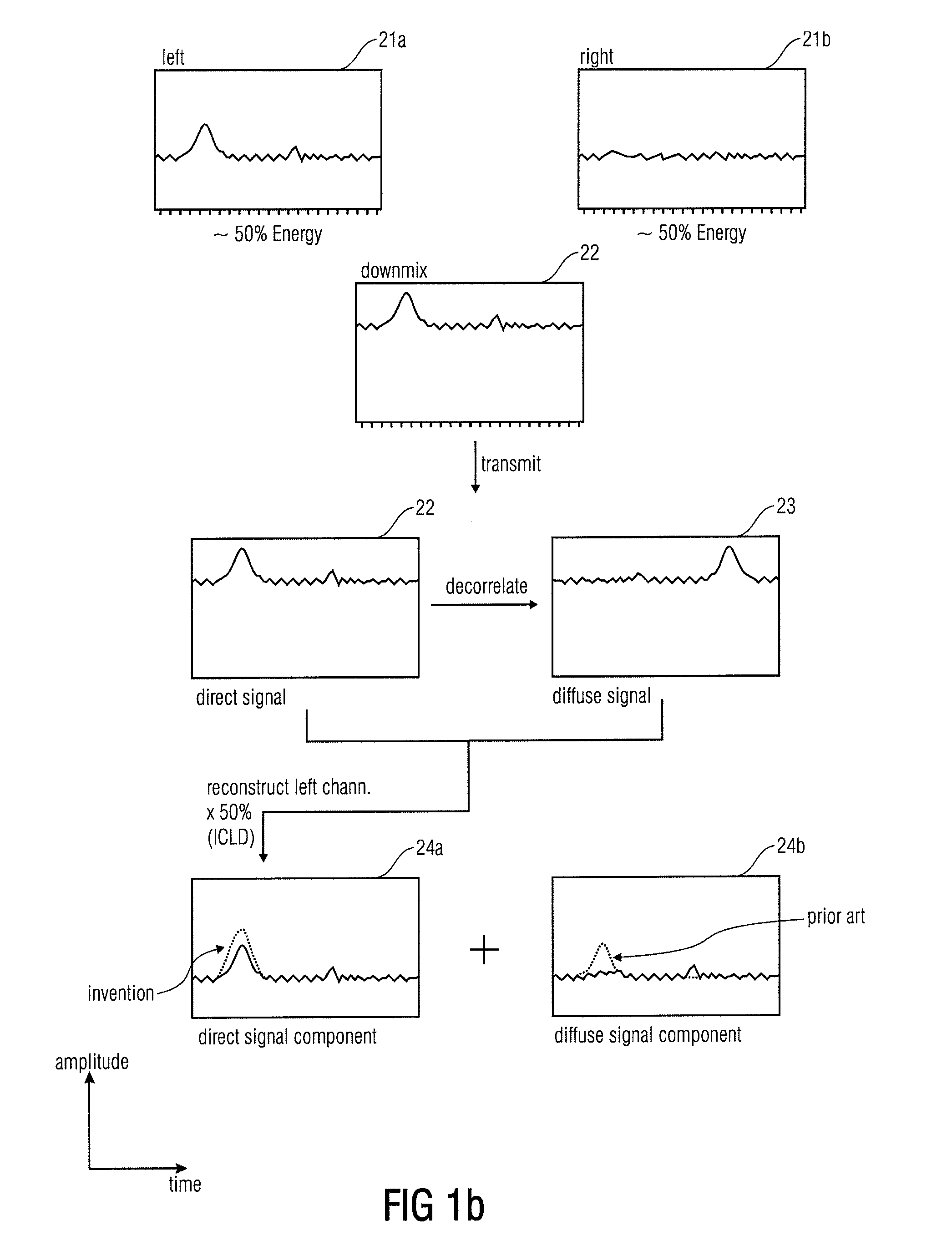

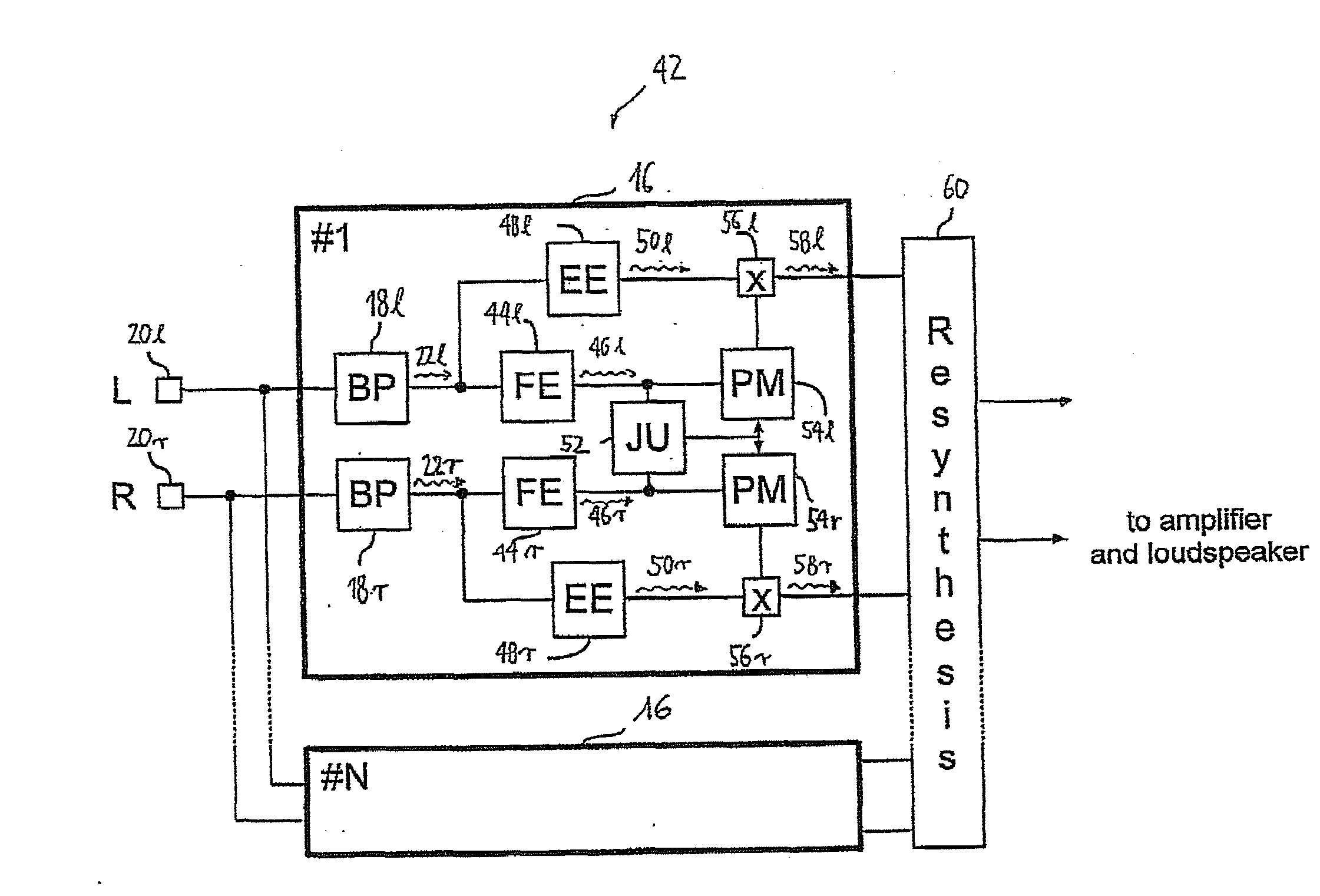

Enhanced method for signal shaping in multi-channel audio reconstruction

ActiveUS8116459B2Enhanced signal shapingQuality improvementPiezoelectric/electrostrictive transducersSpeech analysisFine structureComputer science

The present invention is based on the finding that a reconstructed output channel, reconstructed with a multi-channel reconstructor using at least one downmix channel derived by downmixing a plurality of original channels and using a parameter representation including additional information on a temporal fine structure of an original channel can be reconstructed efficiently with high quality, when a generator for generating a direct signal component and a diffuse signal component based on the downmix channel is used. The quality can be essentially enhanced, if only the direct signal component is modified such that the temporal fine structure of the reconstructed output channel is fitting a desired temporal fine structure, indicated by the additional information on the temporal fine structure transmitted.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

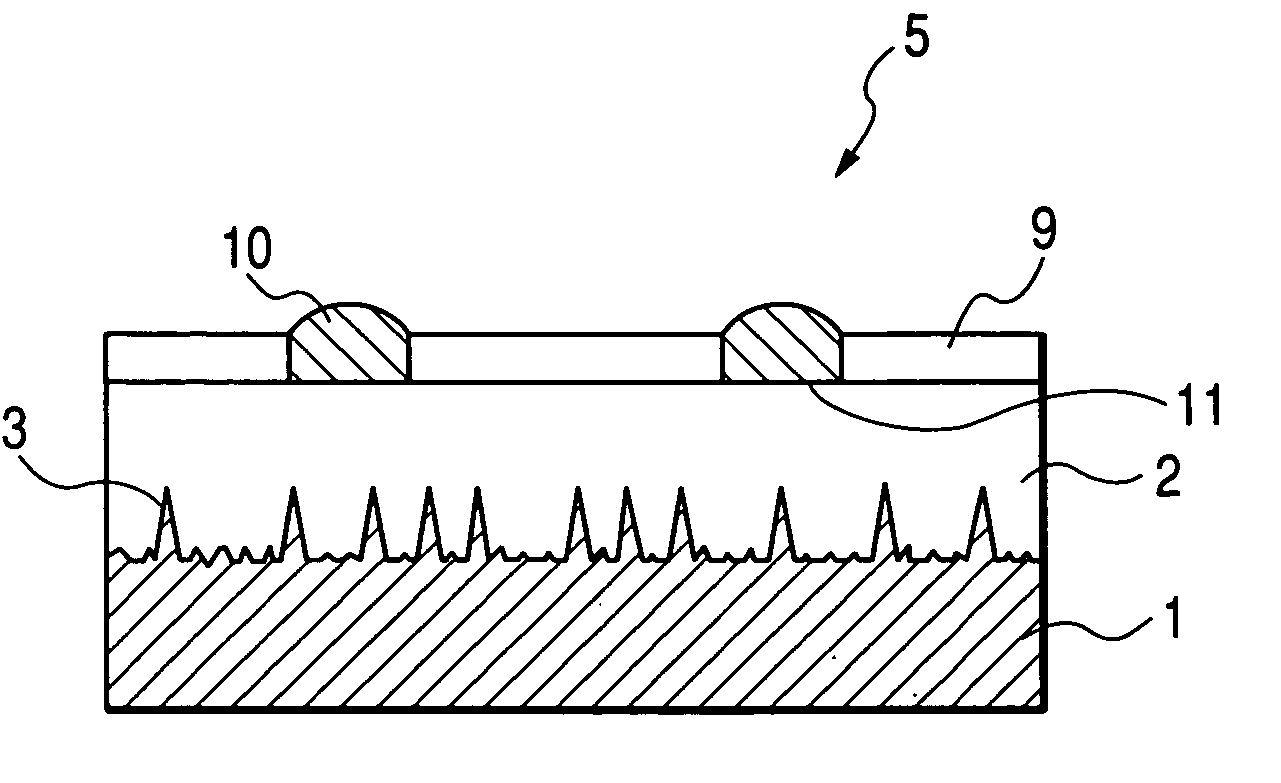

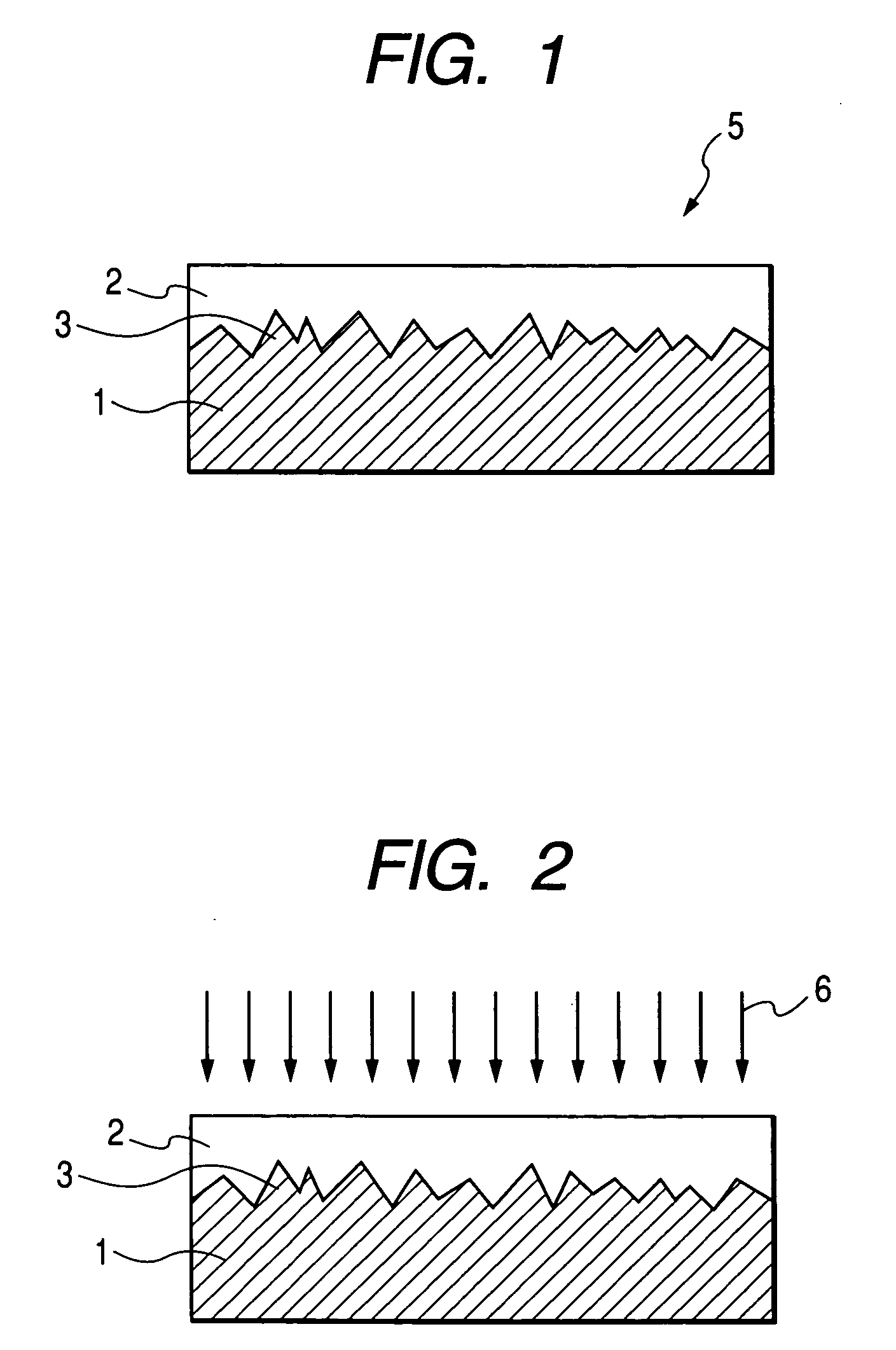

Interposer and method for producing the same and electronic device

InactiveUS20080241997A1Easily realizedServiceably miniaturizedSemiconductor/solid-state device detailsSolid-state devicesFine structureElectrical conductor

An interposer includes a substrate made of an inorganic material; a through wiring including conductors embedded in through holes; and an upper wiring and (or) a lower wiring. The through wiring, the upper wiring and the lower wiring are respectively formed on preliminary wiring patterns that are additionally simultaneously or sequentially formed on layers made of an insulating material applied to at least wiring forming parts of the substrate, and are formed with a metal mold itself used for forming the preliminary wiring patterns or layers made of a wiring material applied by a printing operation, a plating operation or a deposition on the preliminary wiring patterns formed on the layers of the insulating material by transferring a fine structure pattern of the metal mold.

Owner:SHINKO ELECTRIC IND CO LTD

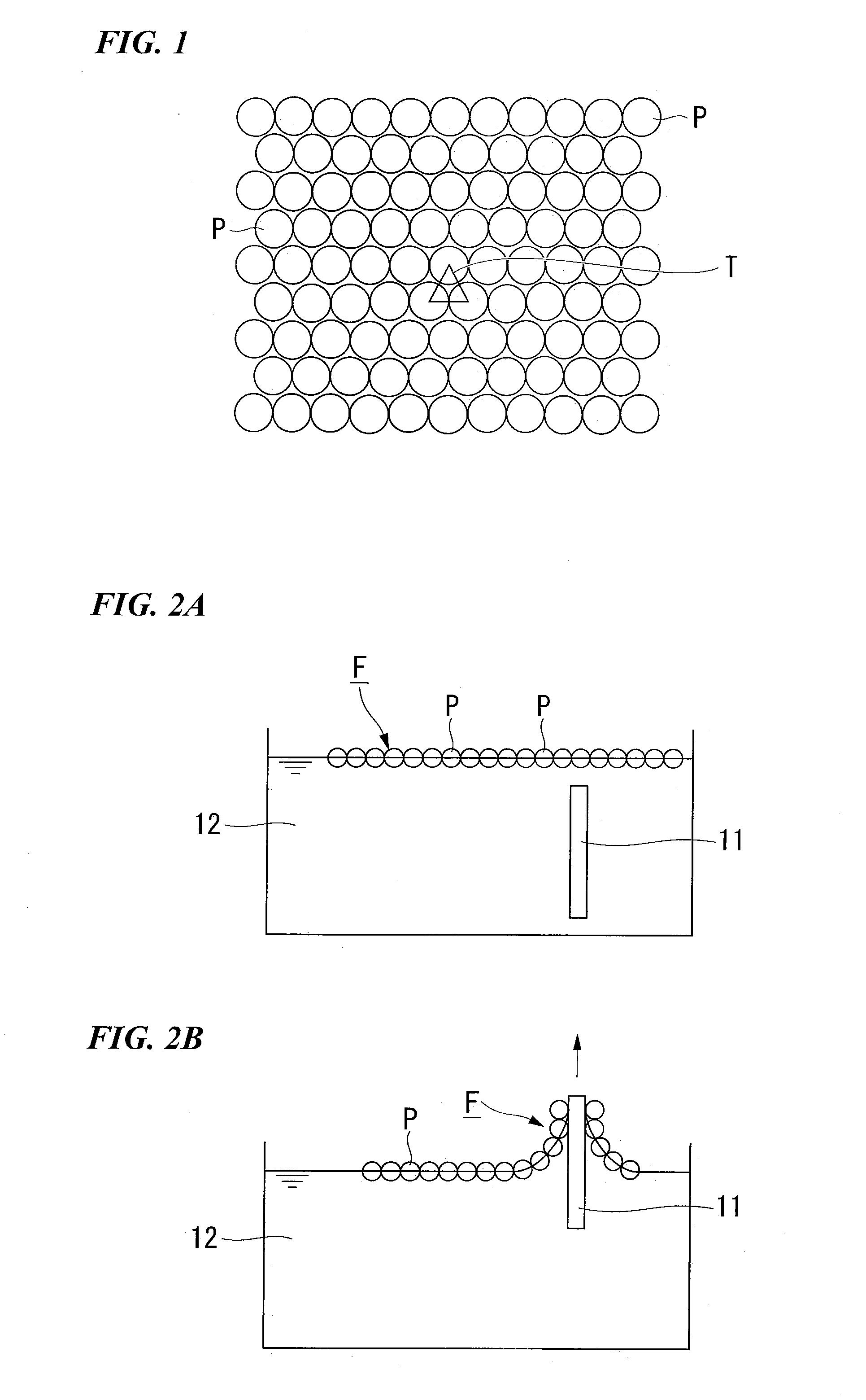

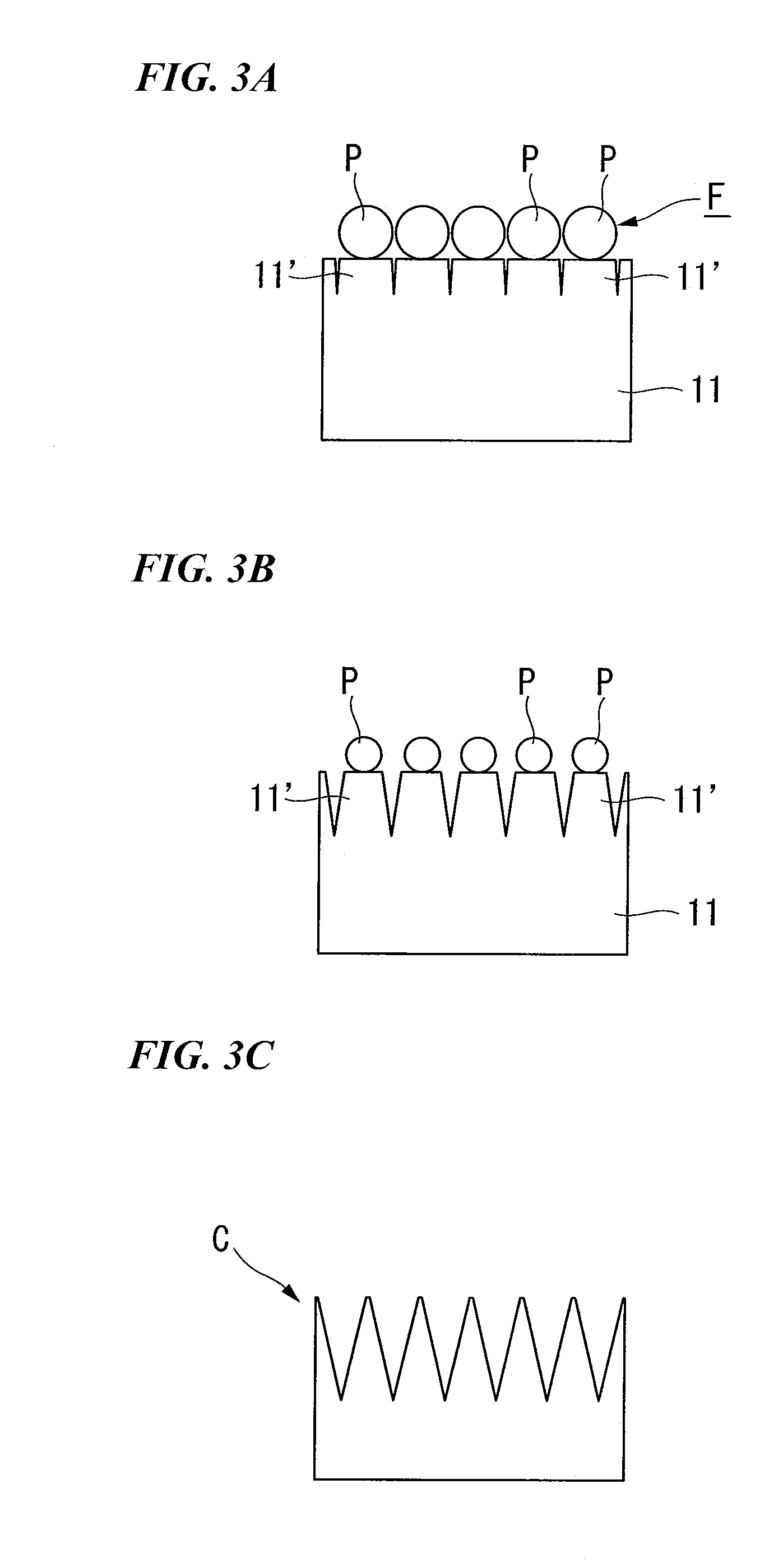

Monoparticulate-film etching mask and process for producing the same, process for producing fine structure with the monoparticulate-film etching mask, and fine structure obtained by the production process

ActiveUS20090274873A1Improve accuracySimple structureMaterial nanotechnologyNanoinformaticsFine structureMicro structure

A micro structure which is preferred as an original plate of an antireflection, a mold of nano imprint or injection molding is obtained by a single particle film etching mask on which each particle is precisely aligned and closest packed in two dimensions. A single particle film etching mask is produced by a drip step wherein a dispersed liquid in which particles dispersed in a solvent are dripped onto a liquid surface of a water tank, a single particle film formation step in which a single particle film which consists of the particles by volatizing a solvent is formed, and a transfer step in which the single particle film is transferred to a substrate. The single particle film etching mask on which particles are closest packed in two dimensions, has a misalignment D(%) of an array of the particles that is defined by D(%)=|B−A|×100 / A being less than or equal to 10%. However, A is the average diameter of the particles, and B is the average pitch between the particles in the single particle film.

Owner:OJI PAPER CO LTD

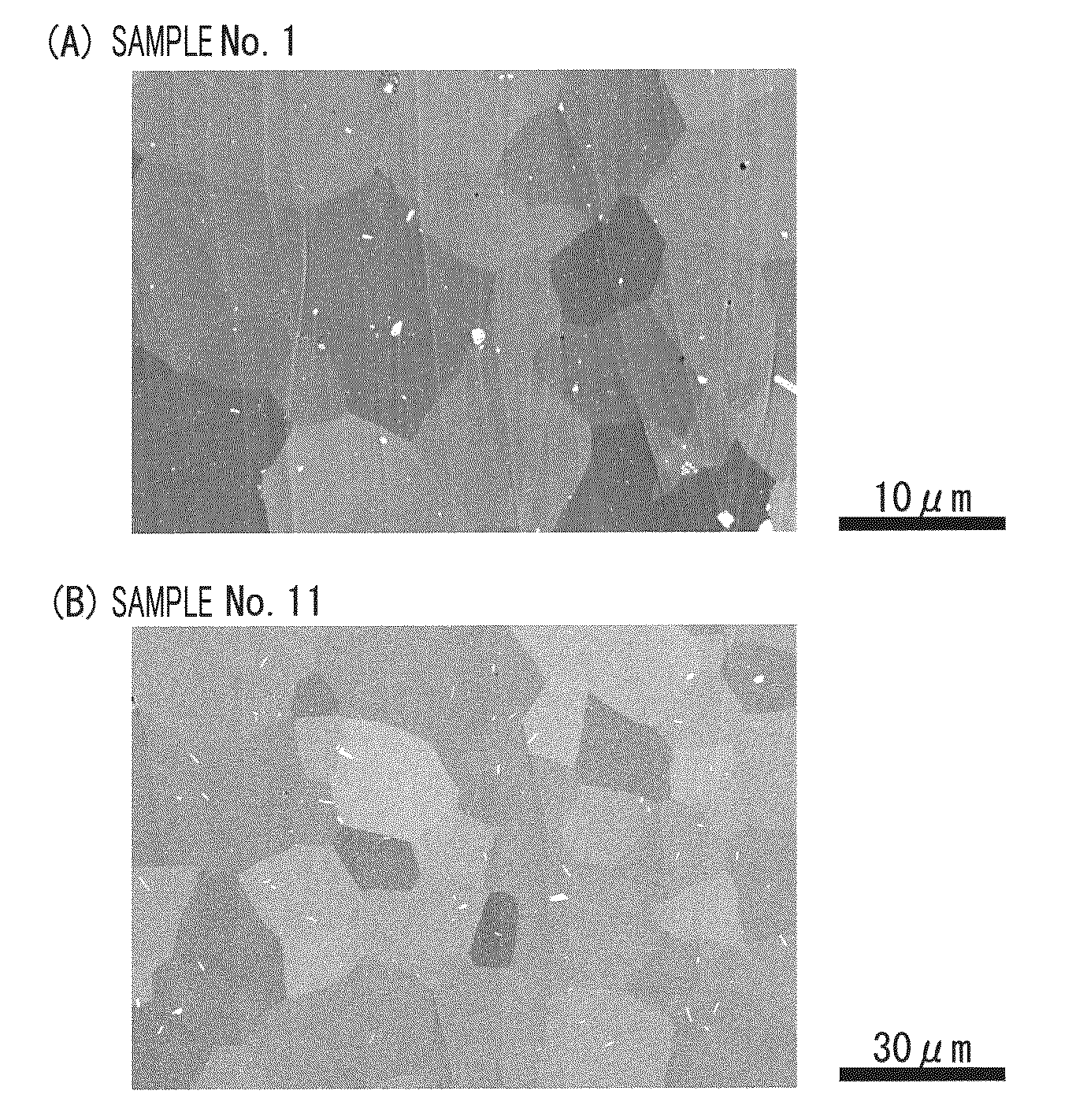

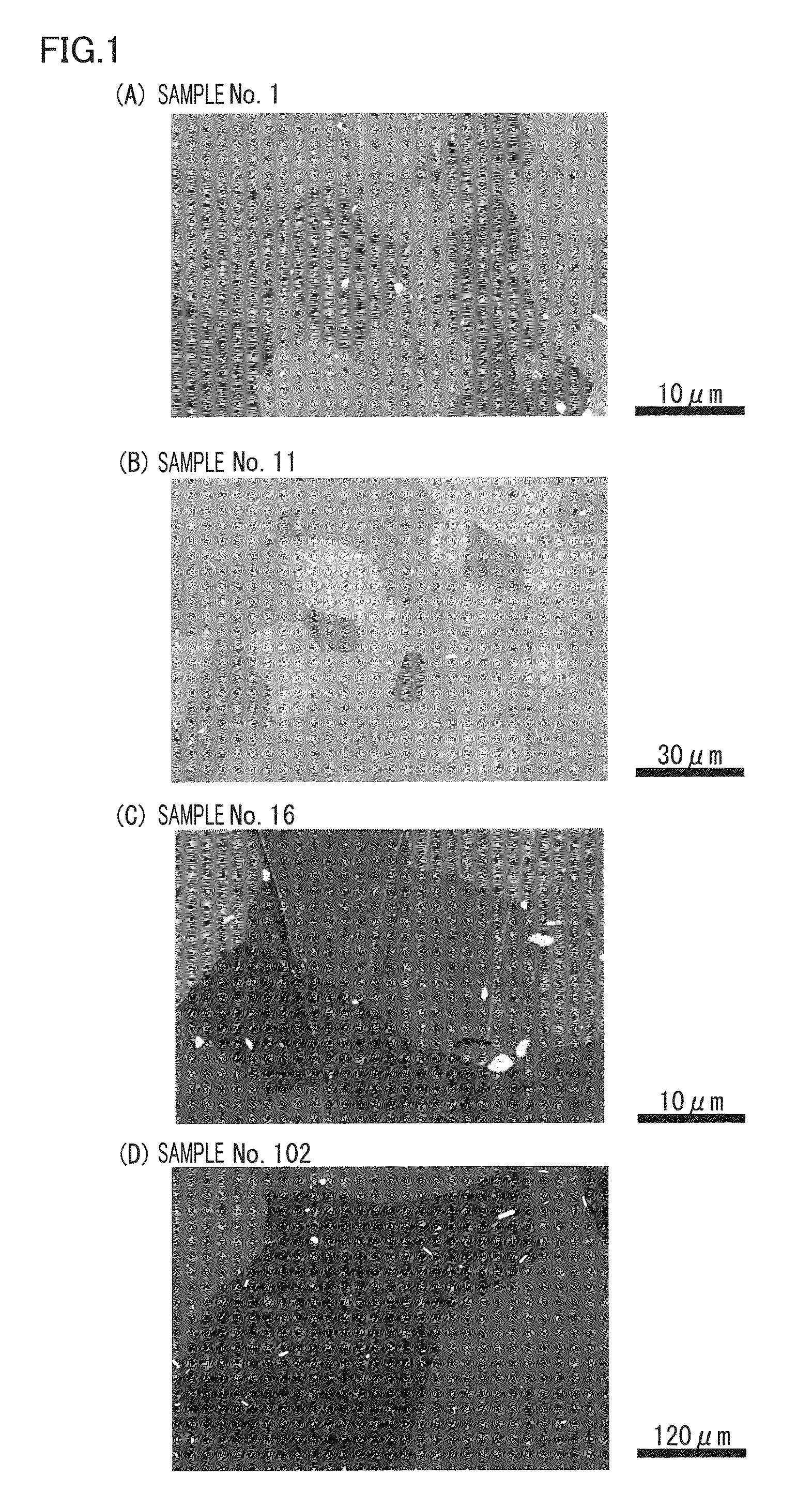

Aluminum alloy wire, and aluminum alloy twisted wire, covered electrical wire and wire harness using the same

ActiveUS20130264115A1High strengthHigh elongationSingle bars/rods/wires/strips conductorsConductive materialFine structureCable harness

An aluminum (Al) alloy wire, which is an extra fine wire having a wire diameter of 0.5 mm or less, contains, in mass %, Mg at 0.03% to 1.5%, Si at 0.02% to 2.0%, at least one element selected from Cu, Fe, Cr, Mn and Zr at a total of 0.1% to 1.0% and the balance being Al and impurities, and has an electrical conductivity of 40% IACS or more, a tensile strength of 150 MPa or more, and an elongation of 5% or more. By producing the extra fine wire from an Al alloy of a specific composition containing Zr, Mn and other specific elements, though the extra fine wire is extra fine, it has a fine structure with a maximum grain size of 50 μm or less and is superior in elongation.

Owner:SUMITOMO ELECTRIC IND LTD +2

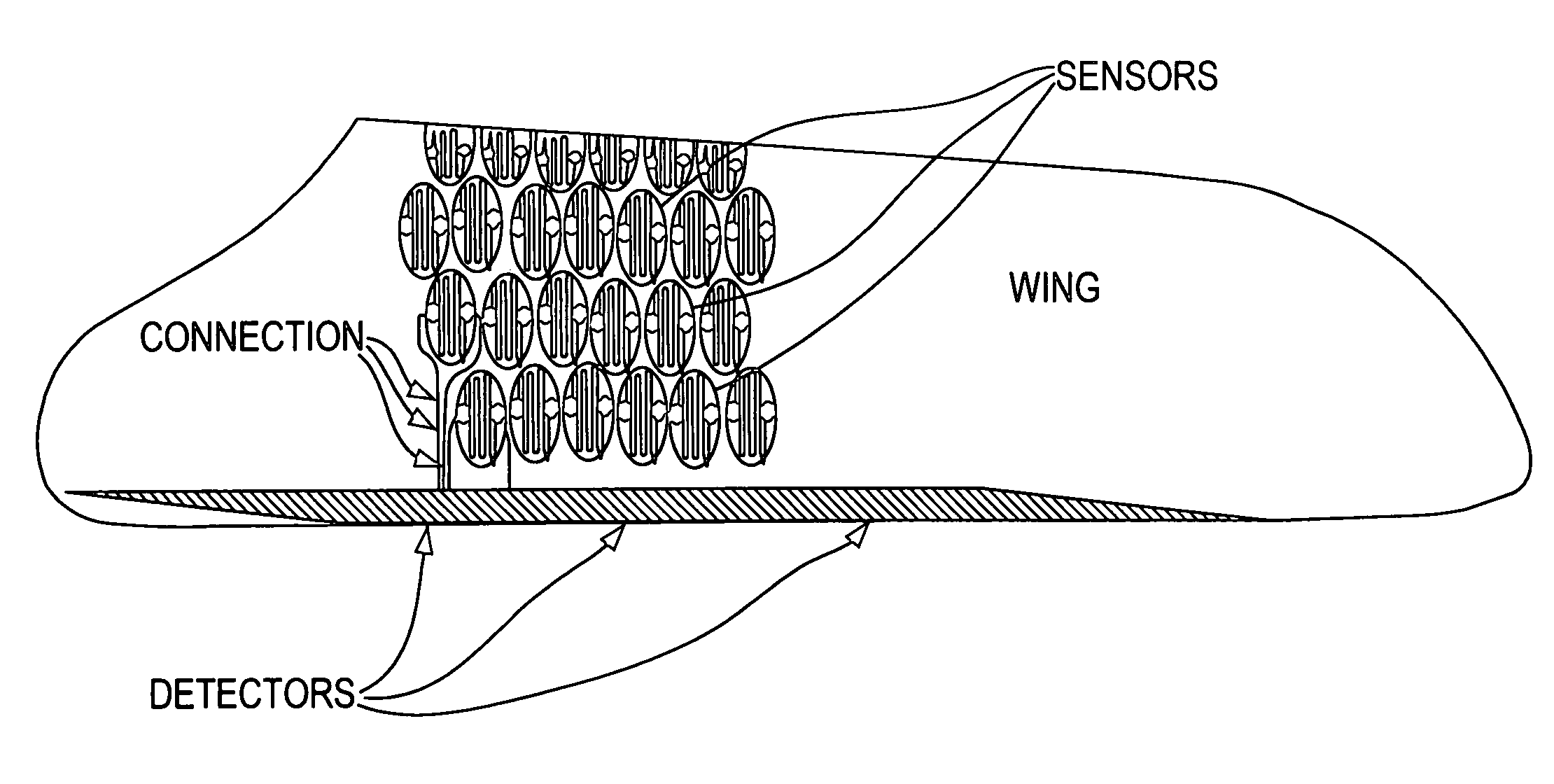

Method and apparatus for strain-stress sensors and smart skin for aircraft and space vehicles

InactiveUS6986287B1Wide rangeChange pressureForce measurementUsing electrical meansFine structureStress sensor

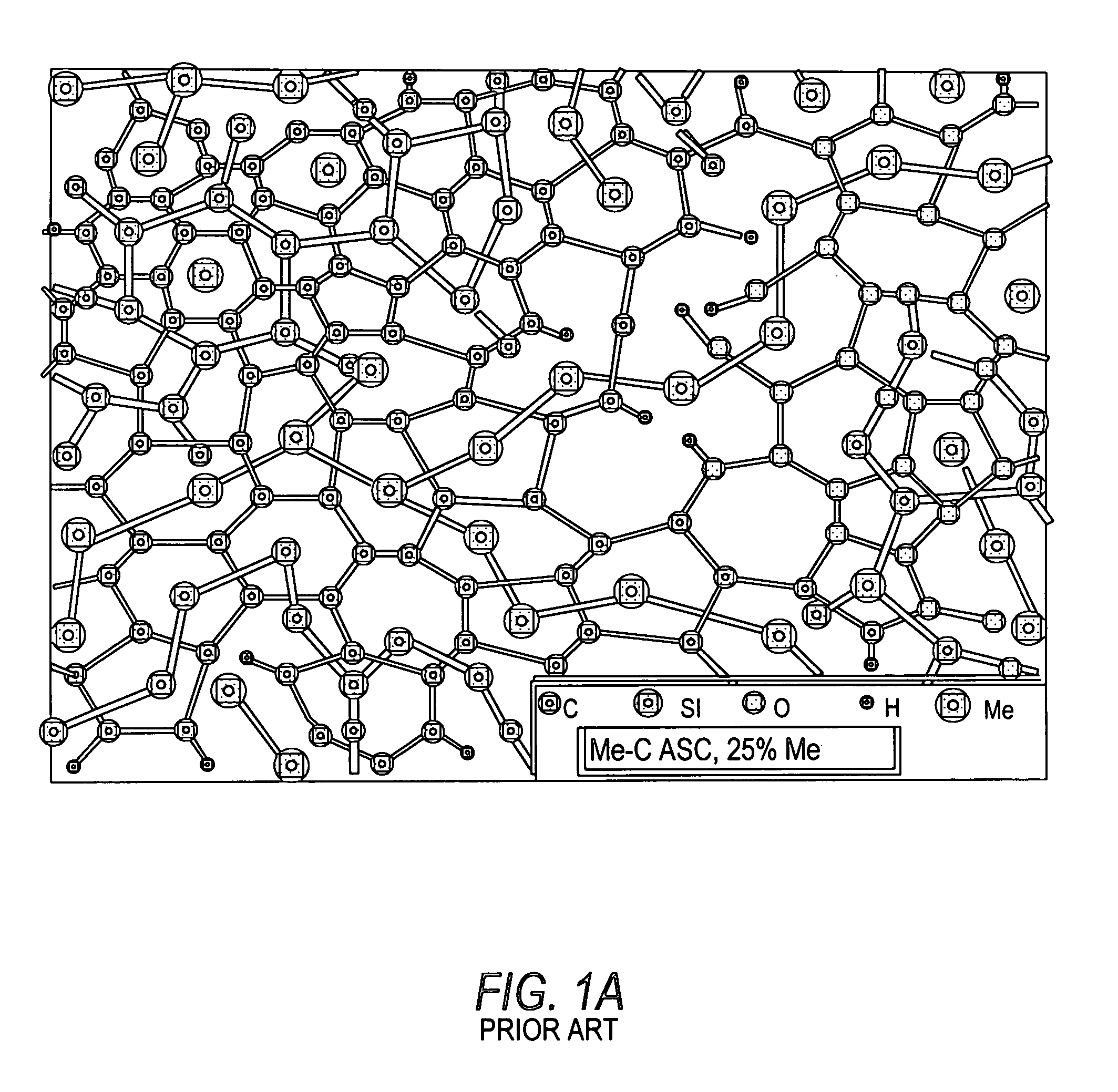

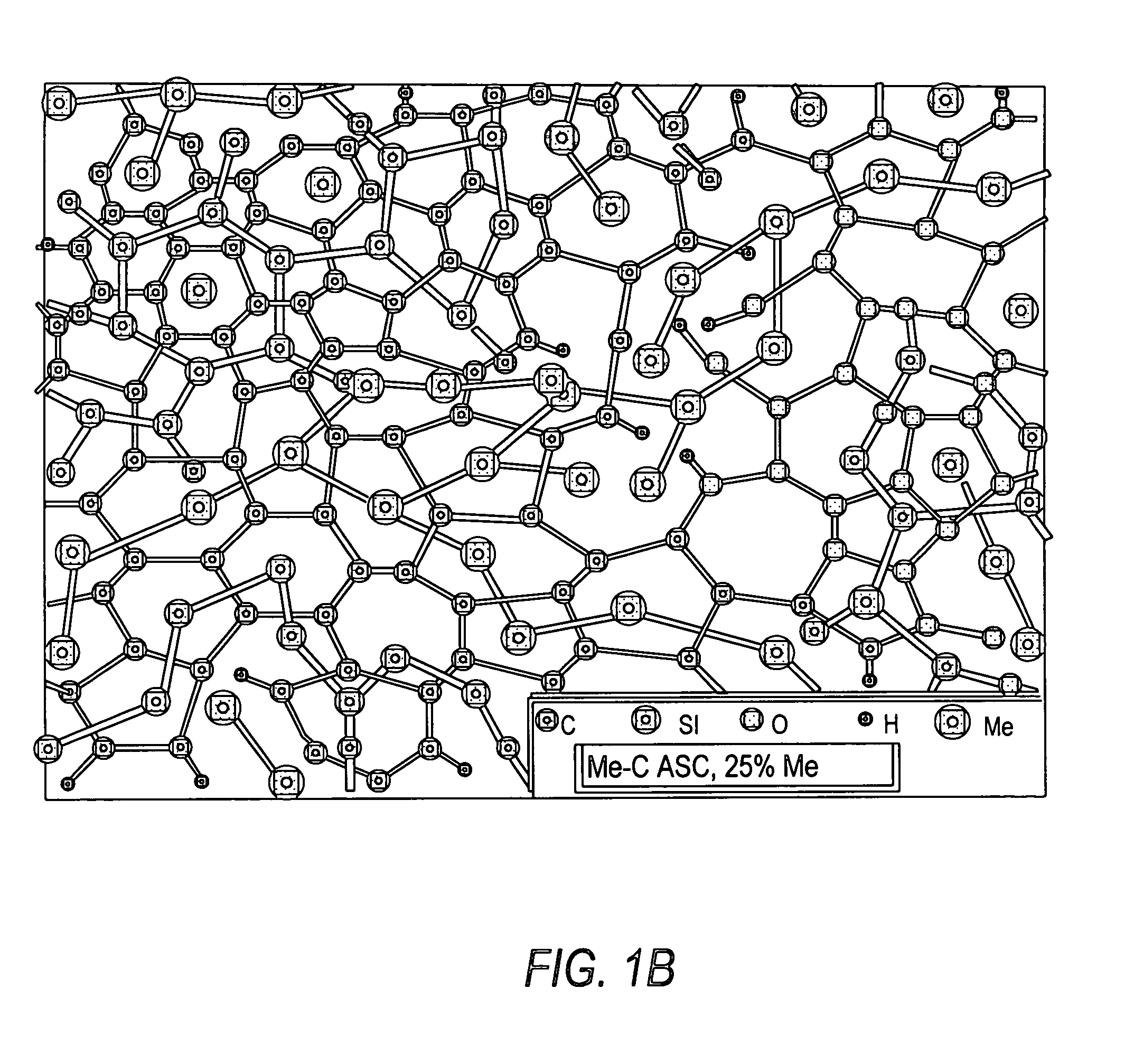

A new family of multifunctional smart coatings based on of stabilized diamond-like metal-carbon atomic scale composites and diamond-like atomic-scale composite (DL ASC) materials. Based on a unique combination of the coating fine structure, properties of the coating / substrate interface, and the mechanical and electrical properties of the coating, the disclosed smart coatings would integrate various high resolution sensors and interconnections, and the sensor would diagnose dangerous stress distribution in the coated subject with no distortion in real time, while these diamond-like coatings would simultaneously provide environmental protection of the coated surface and improve its aerodynamic quality.

Owner:NANODYNAMICS INC

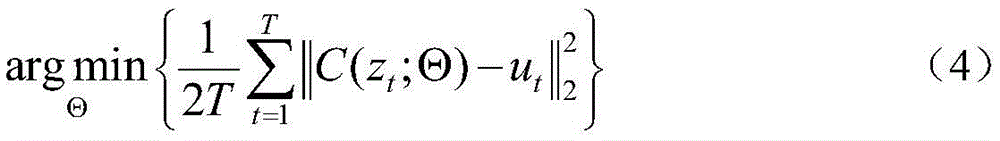

Fast magnetic resonance imaging method and device based on deep convolution neural network

ActiveCN107182216AIncrease the multiple of under-collectionImproving Imaging AccuracyImage enhancementDiagnostic recording/measuringFine structurePrior information

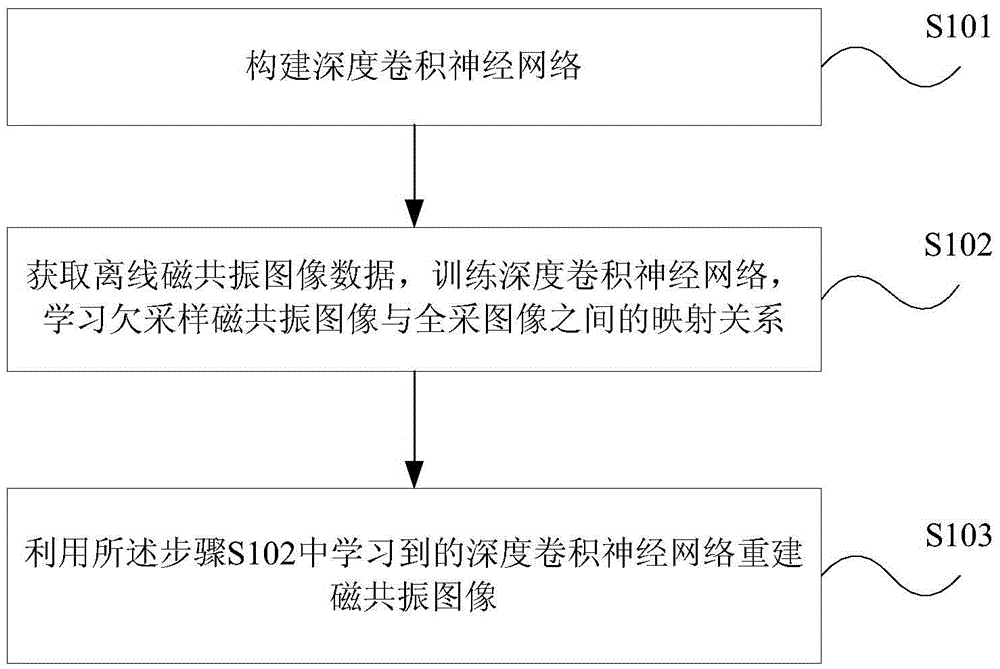

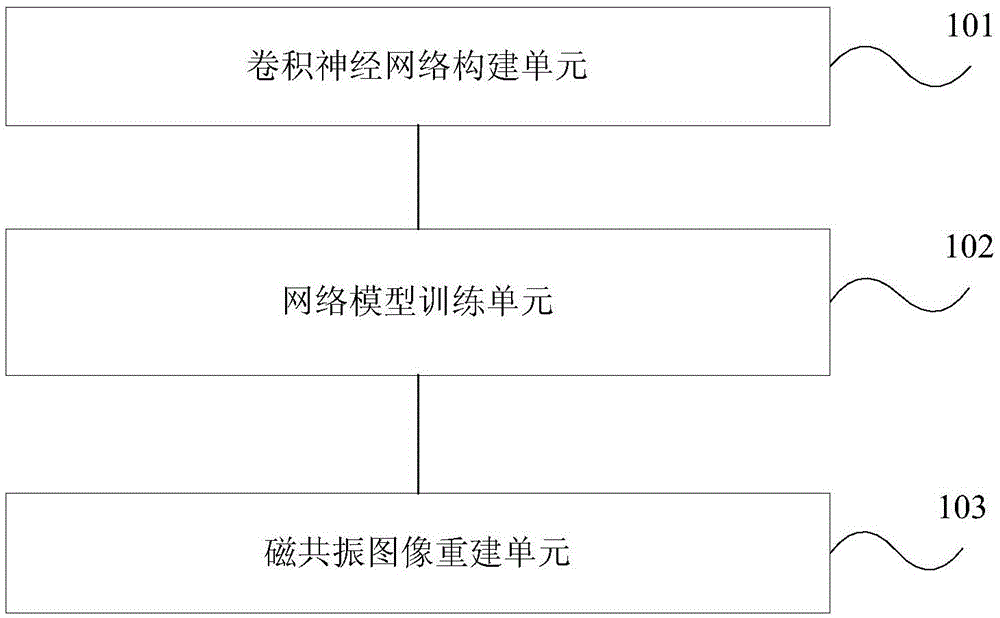

The invention provides a fast magnetic resonance imaging method and device based on a deep convolution neural network. The fast magnetic resonance imaging method comprises steps of constructing a deep convolution neural network, obtaining an offline magnetic resonance image data, training the deep convolution neural network, learning a mapping relation between an undersampled magnetic resonance image and a full sampled image, using a deep convolution neural network learned through the S2 to reconstruct a resonance image. The fast magnetic resonance imaging method and device based on deep convolution neural network learn an offline deep convolution neural network through using substantial sampled magnetic resonance data, learns a mapping relation between the sampled magnetic resonance image and the full sampled image, fully uses offline substantial the magnetic resonance images to develop the prior information, enables the offline network to recover more fine structure and image characteristics from the undersampled resonance data and improves the magnetic resonance multiple and the imaging accuracy.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

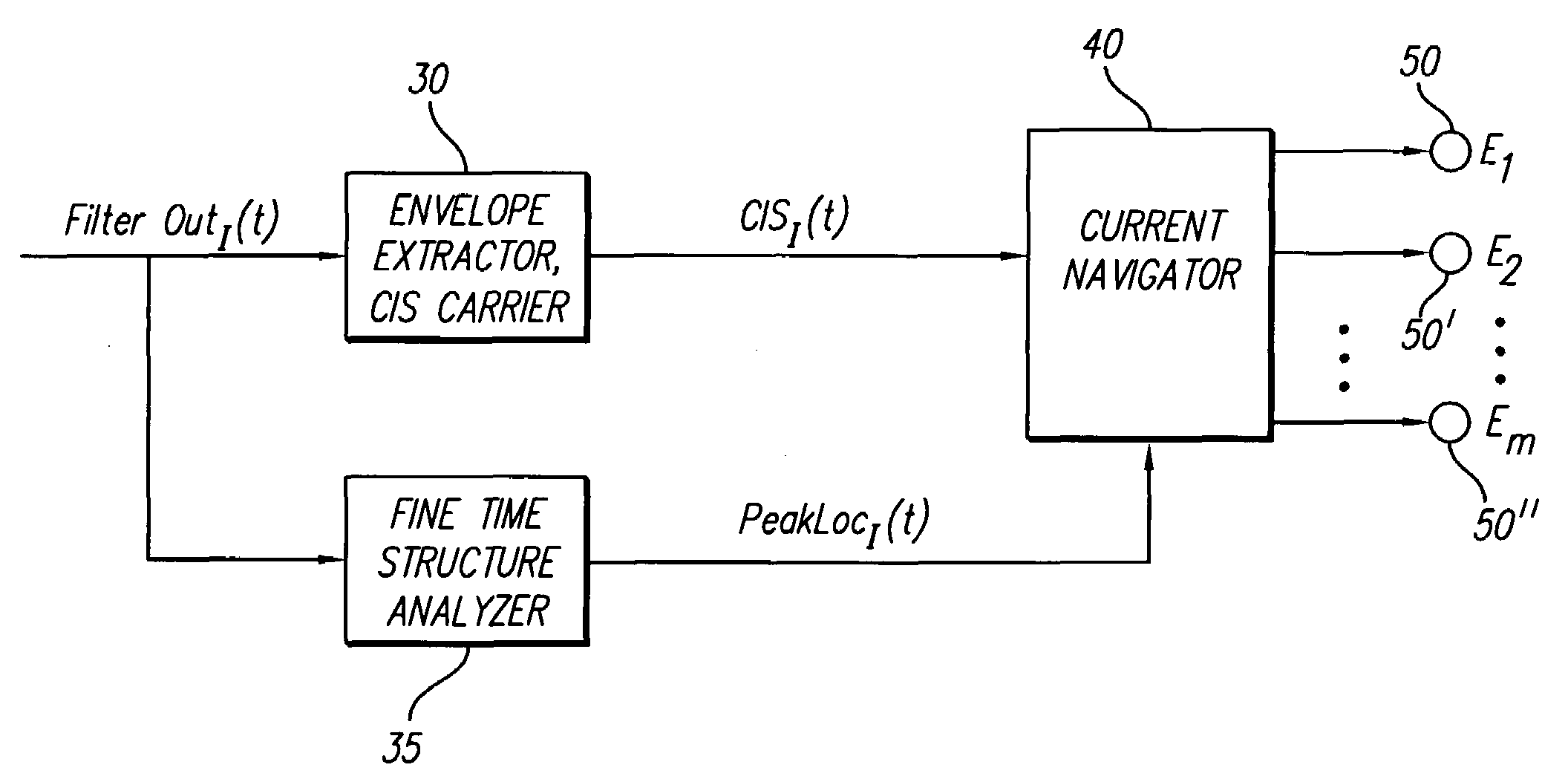

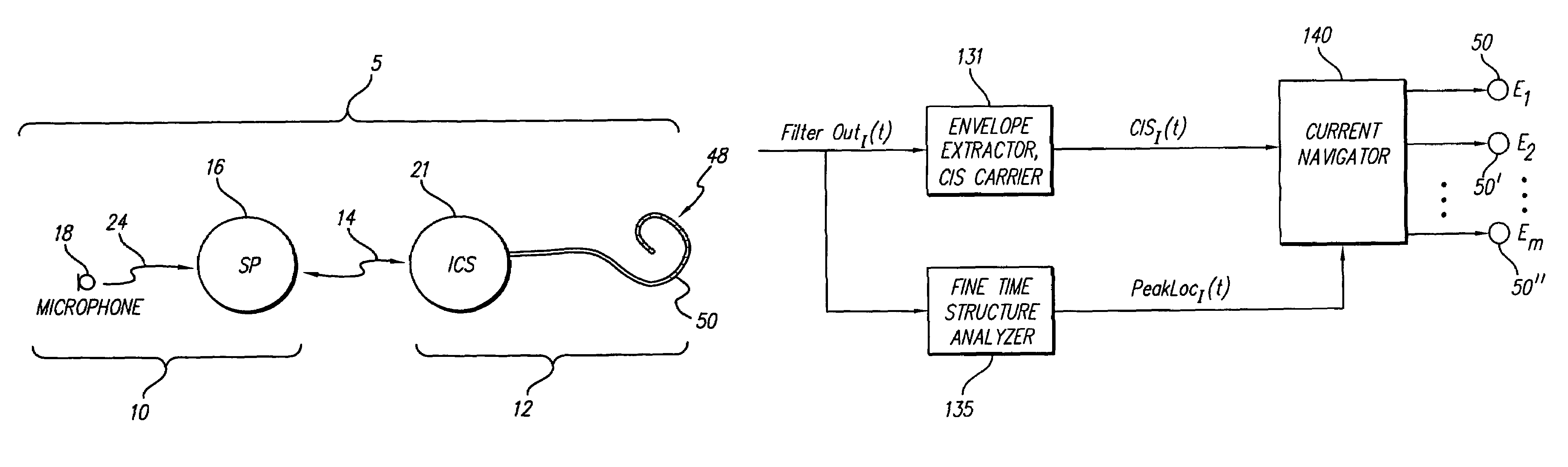

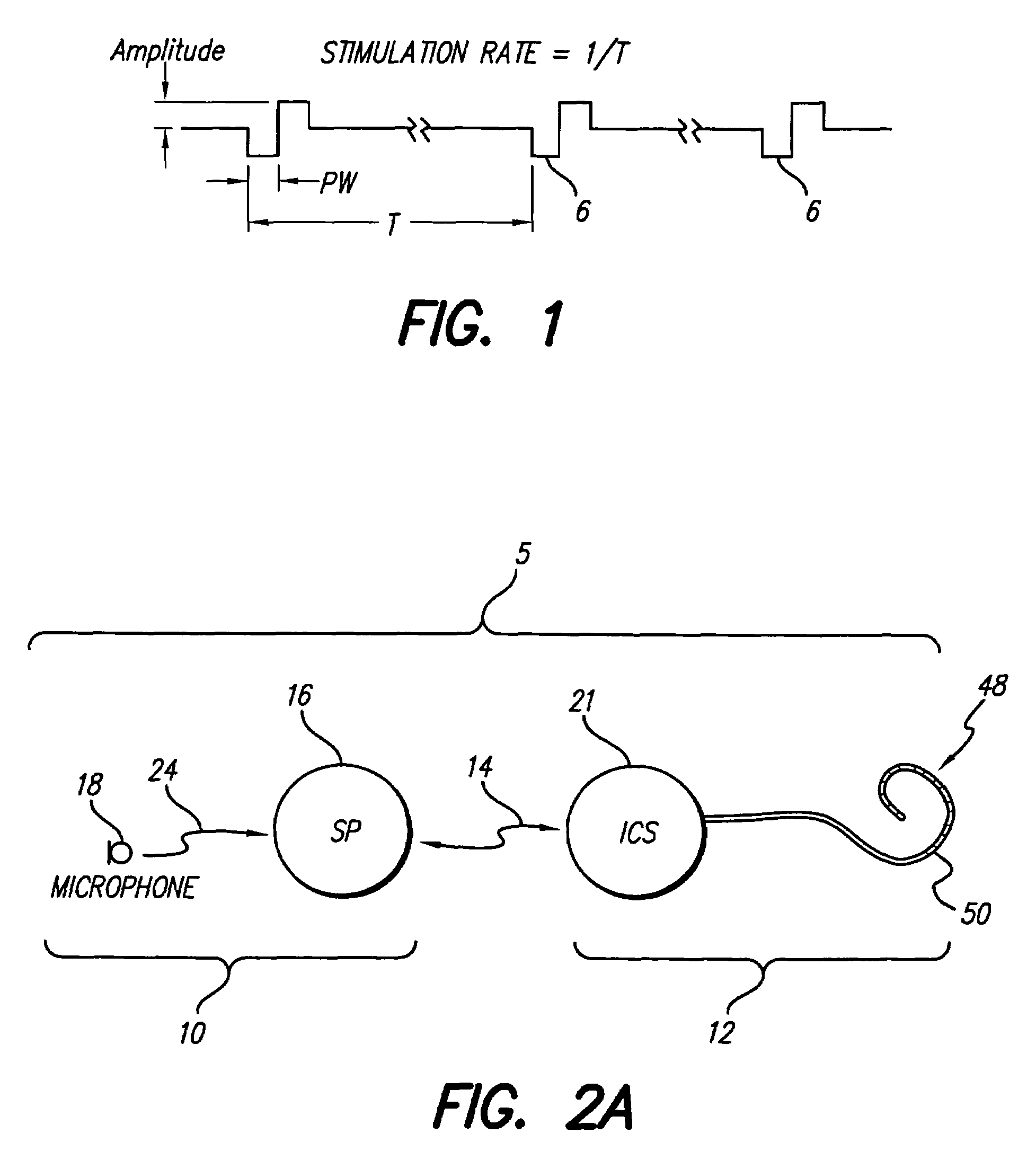

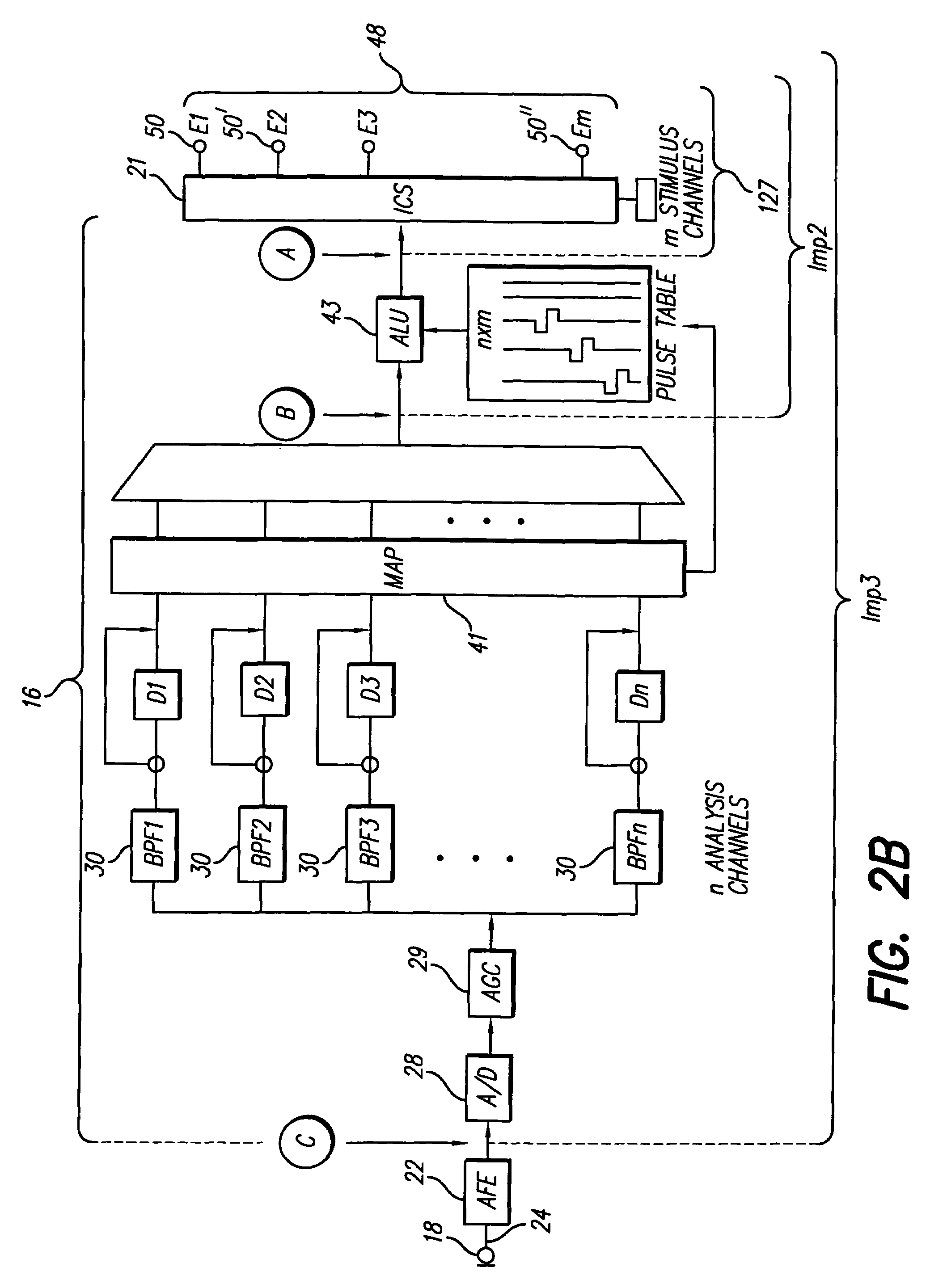

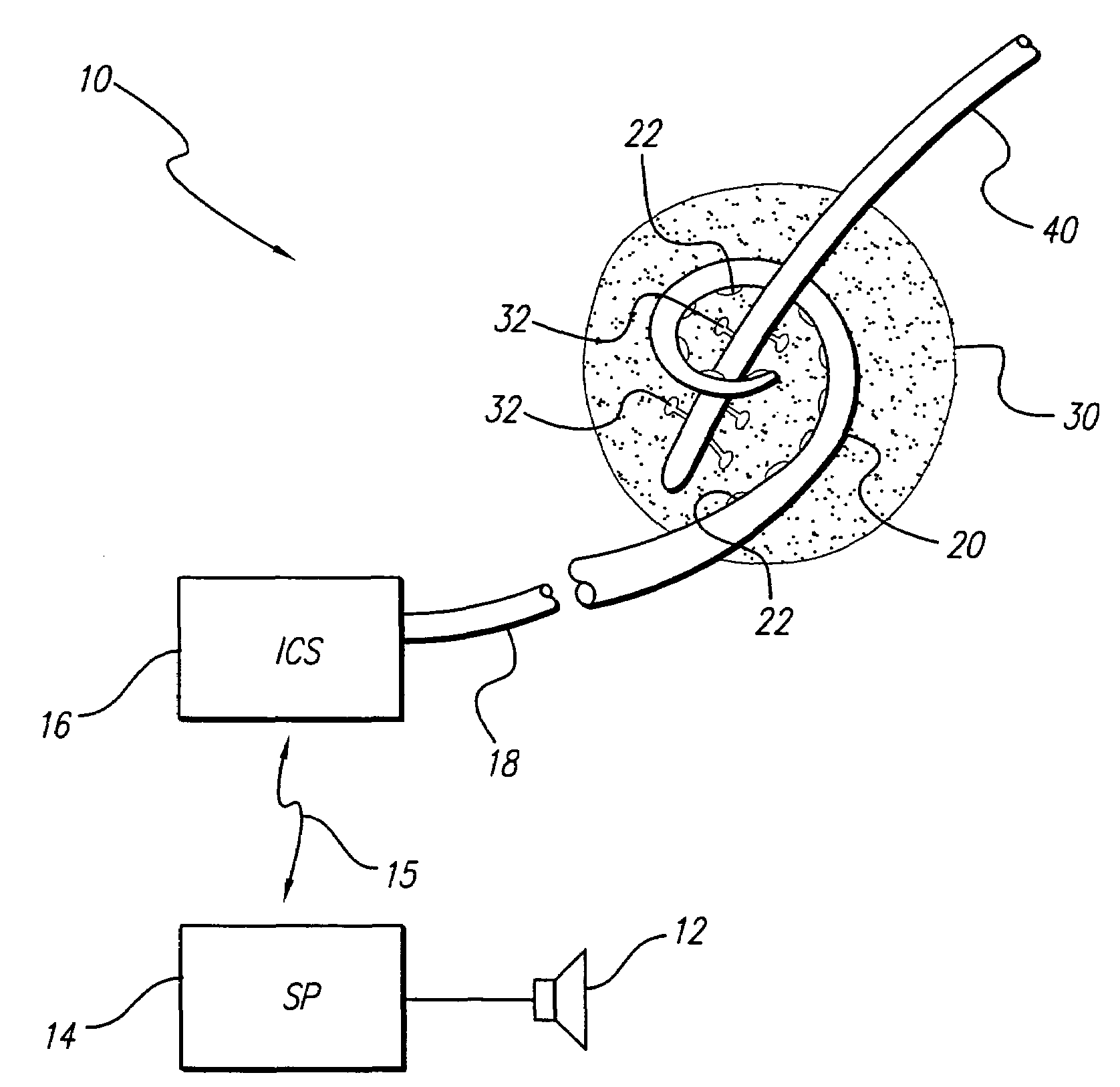

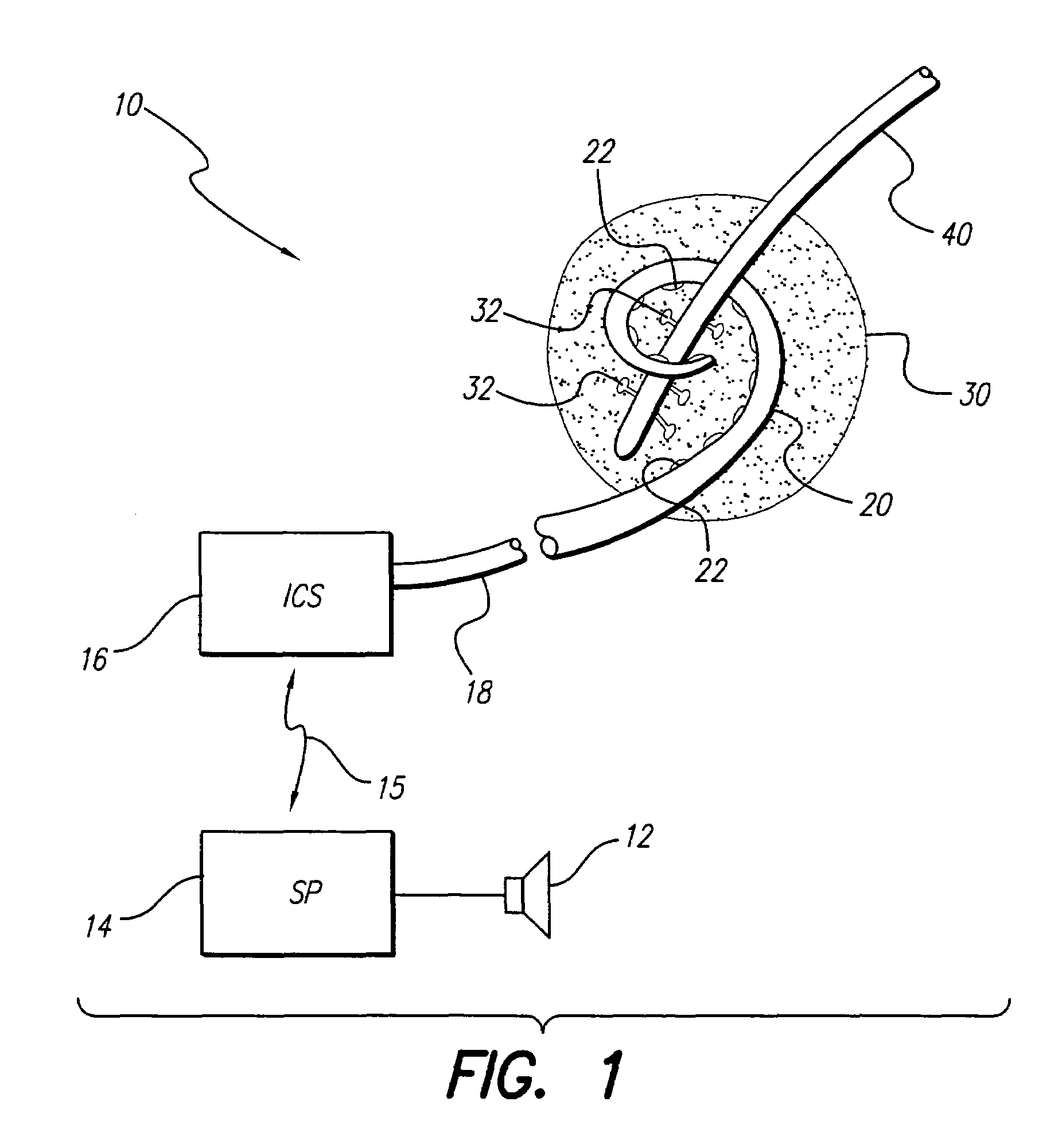

Method of using non-simultaneous stimulation to represent the within-channel fine structure

The present invention provides a cochlear stimulation system and method for capturing and translating FTS in incoming sounds and delivering this information spatially to the cochlea. An embodiment of the system may comprise an FTS estimator / analyzer and a current navigator. An embodiment of the method of the invention can comprise: analyzing the incoming sounds within a time frequency band, extracting the slowly varying frequency components and estimating the FTS to obtain a more precise dominant FTS component within a frequency band. After adding the fine structure to the carrier to identify a precise dominant FTS component in each frequency band (or stimulation channel), a stimulation current is steered to the precise spatial location on the cochlea that corresponds to the dominant FTS component, the steering accomplished by delivering non-simultaneous stimuli through at least two electrodes.

Owner:ADVANCED BIONICS AG

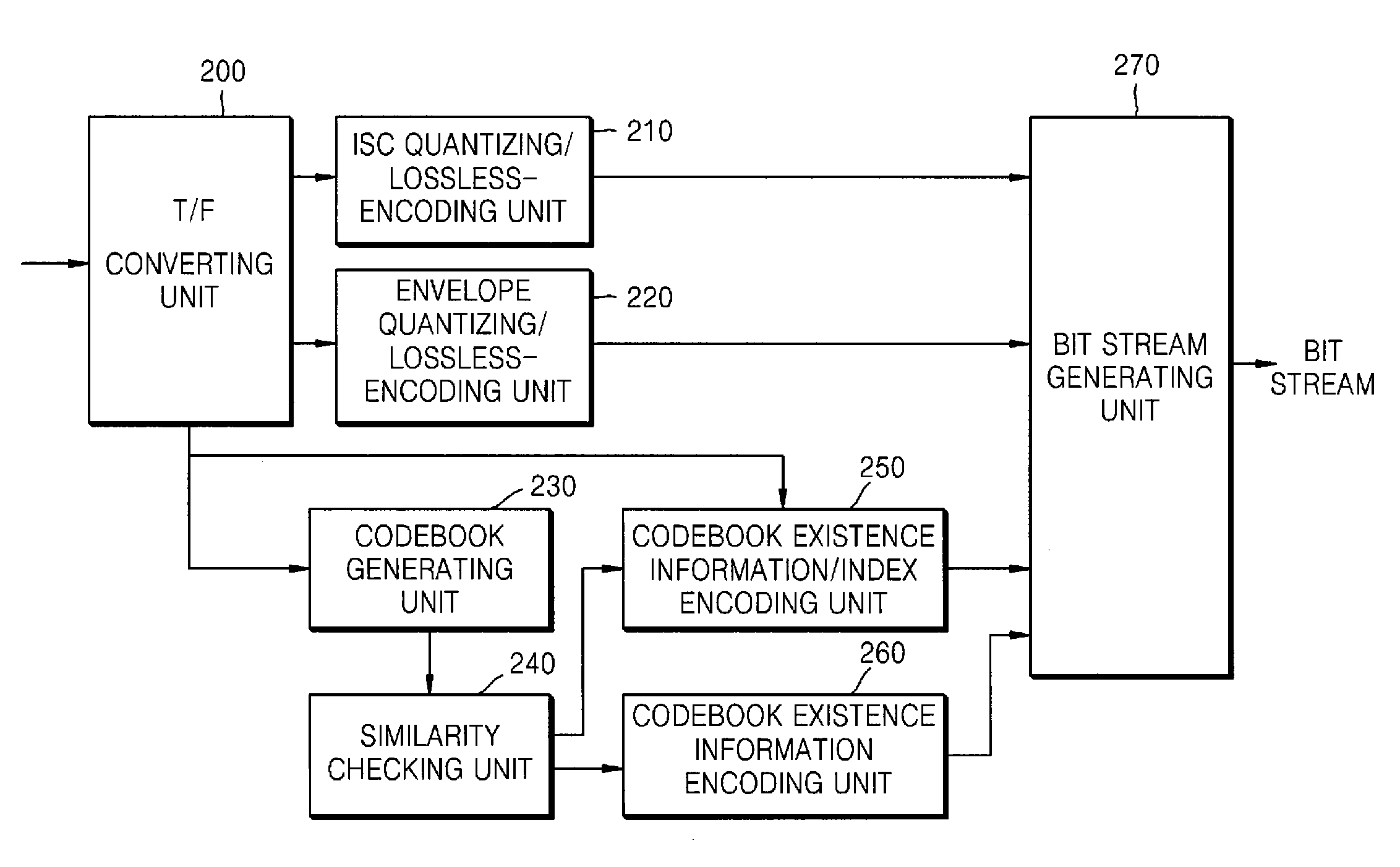

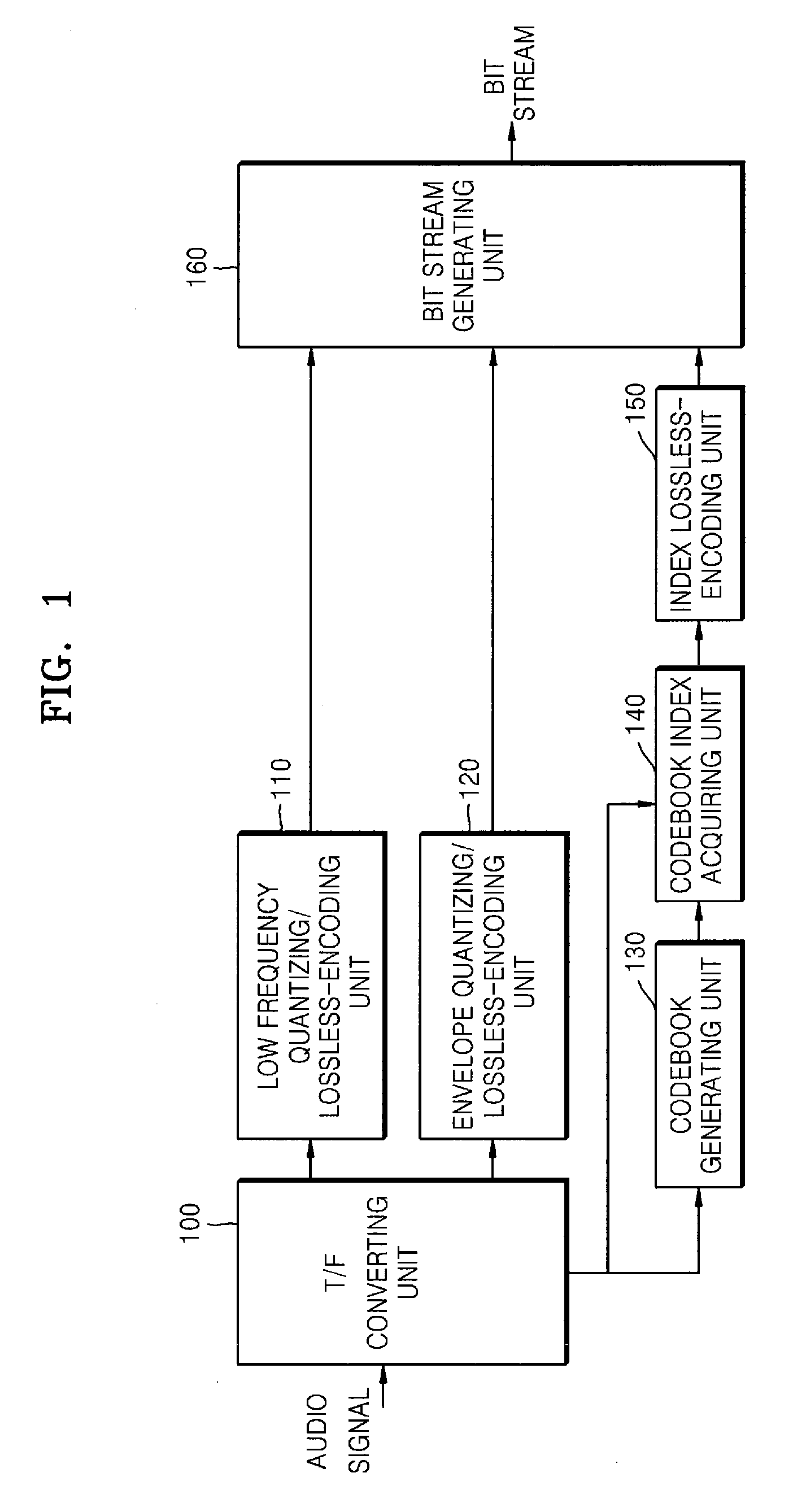

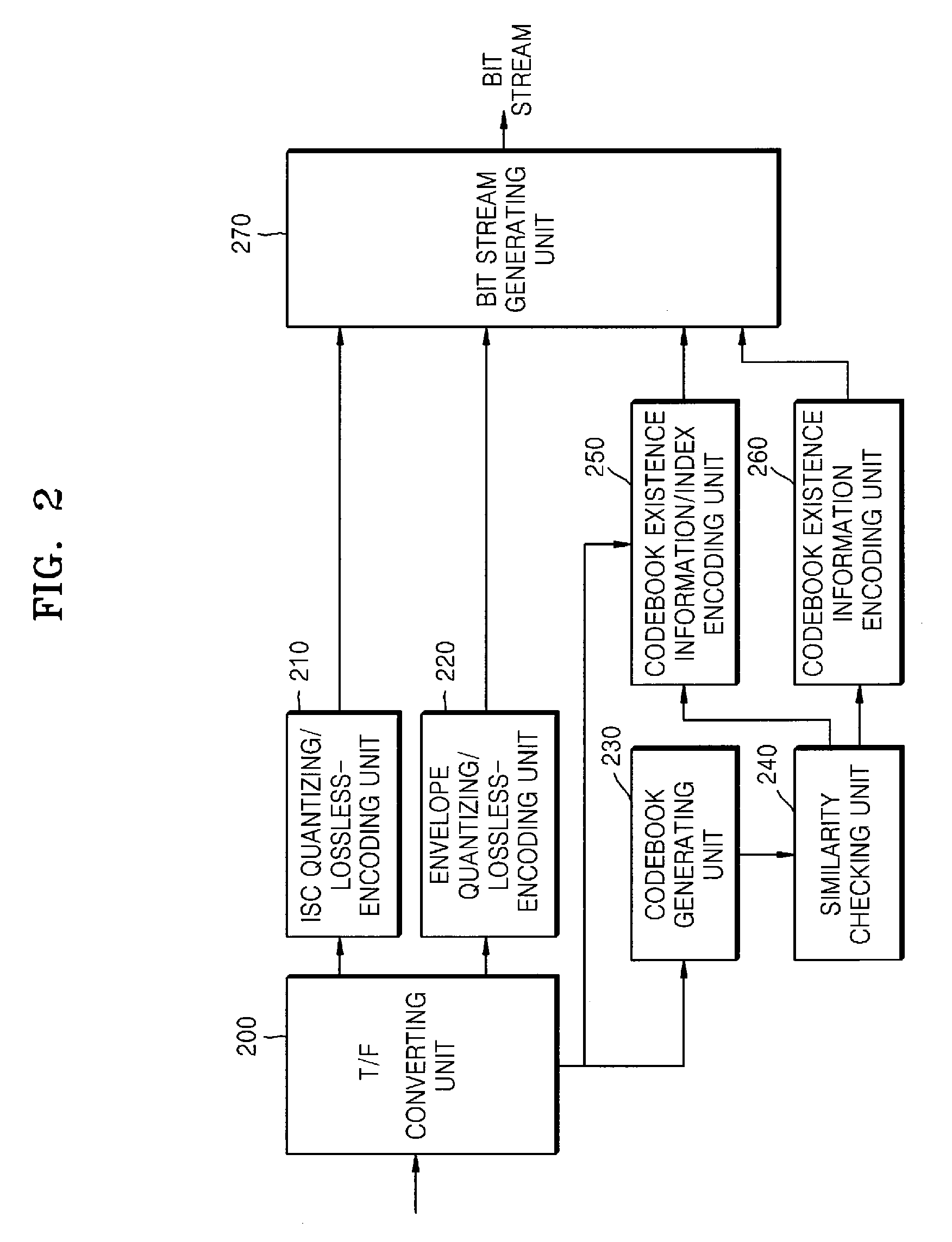

Method and apparatus to encode/decode low bit-rate audio signal

InactiveUS20070016411A1Components is relatively effectiveReduce frequency bandwidthSpeech analysisFine structureENCODE

A method and apparatus to encode / decode a low bit-rate audio signal. The method of encoding a low bit-rate audio signal, includes quantizing and losslessly-encoding a specific frequency component of an audio signal in a frequency domain, generating codebooks using the audio signal in the frequency domain, detecting an envelope of a frequency component of the audio signal other than the specific frequency component in a specific band unit and quantizing and losslessly-encoding the detected envelope of the other frequency component, selecting a codebook that is most similar to the other frequency component of the audio signal to be encoded from among the generated codebooks and determining a codebook index (fine structure), losslessly-encoding the determined codebook index, and generating a bit stream using the specific frequency component, the envelope of the other frequency component, and the determined codebook index. The method of decoding a low bit-rate audio signal, includes restoring and dividing a bit stream into a specific frequency component and a frequency component other than the specific frequency component, losslessly-decoding and inversely quantizing the specific frequency component, restoring codebook index information and envelope information about the other frequency component, generating codebooks using the specific frequency component which is inversely quantized, and restoring the other frequency component using the restored codebook index information and the restored envelope information about the other frequency component.

Owner:SAMSUNG ELECTRONICS CO LTD

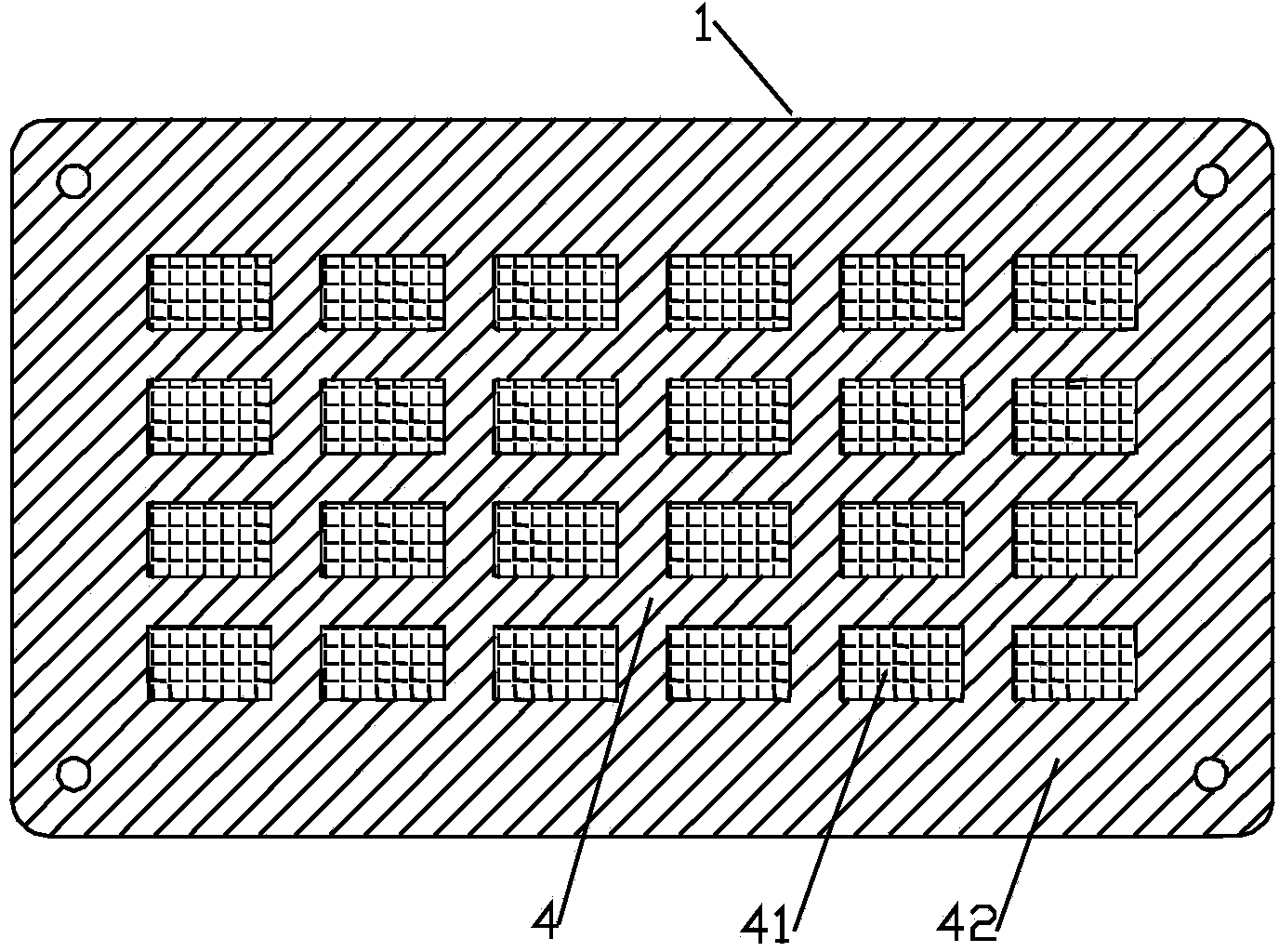

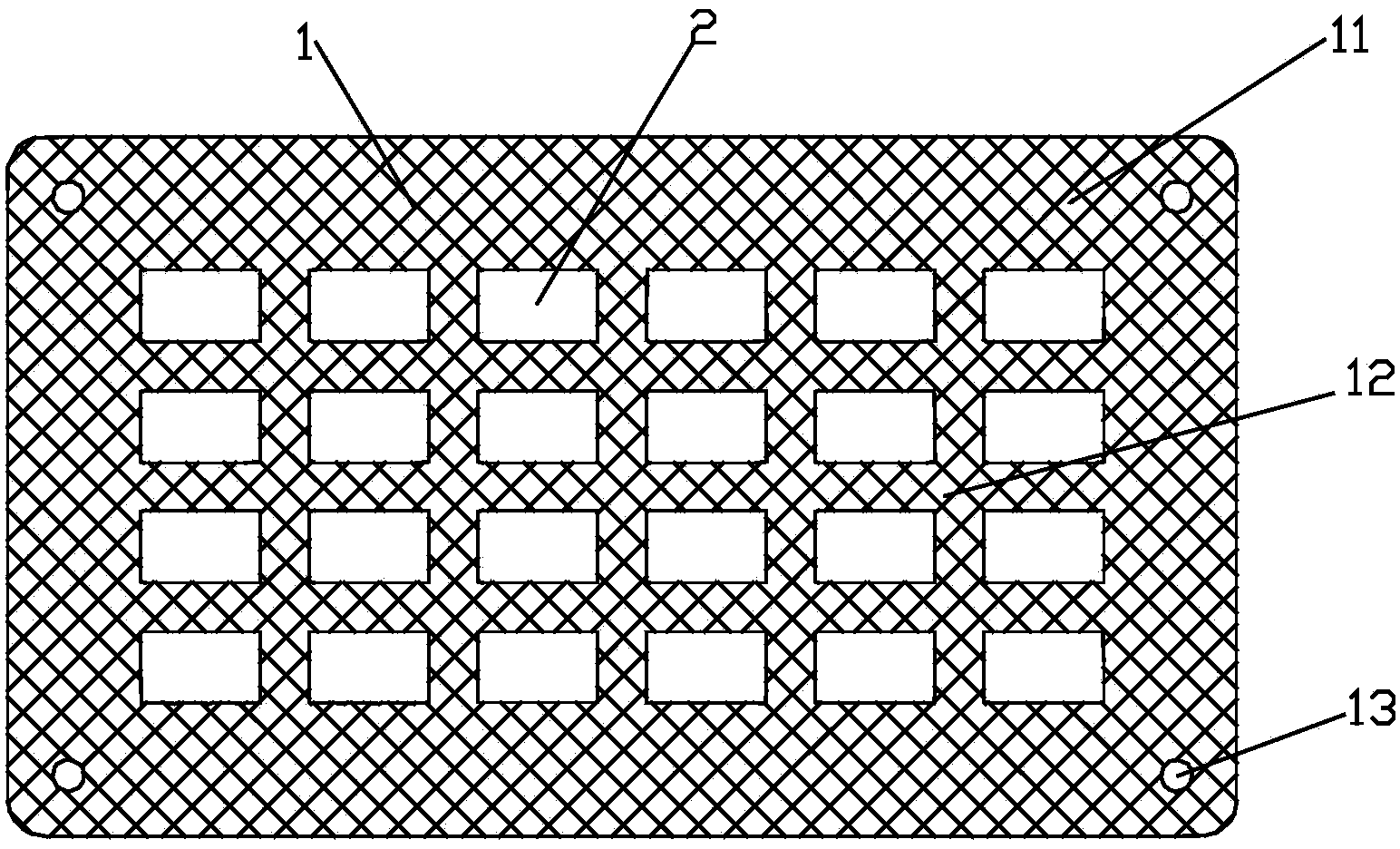

Novel fine metal mask plate for producing organic light emitting diode (OLED) display panel and fabrication method of novel fine metal mask plate

ActiveCN103451598AHigh strengthSave the process of welding to the frameVacuum evaporation coatingPhotomechanical apparatusInvar alloyFine structure

The invention discloses a novel fine metal mask plate for producing an organic light emitting diode (OLED) display panel and a fabrication method of the novel fine metal mask plate. The novel fine metal mask plate comprises a border formed by a plurality of through holes formed in a metal substrate, wherein a layer of fine mask is electroformed on the upper surface of the border, so that the fine mask and the border are combined into a whole; the fine mask divides a pattern area and a border area, on which a part with a fine structure is formed; the through holes in the pattern area and the border correspond to each other. The fabrication method comprises the following steps: A, preparing the metal substrate, namely carrying out rough shape cutting on an invar alloy plate or a stainless steel plate, so as to accord with the design size and form the metal substrate; B, fabricating the fine mask, namely coating a photoresist layer on the metal substrate, developing required patterns on the photoresist layer on the metal substrate, and orderly electroforming a metal substrate layer and a metal layer with a low coefficient of thermal expansion, so as to form the fine mask of the mask plate; and C, etching the substrate, namely dividing the pattern area on the refine mask, etching off the metal substrate in a district corresponding to the back part of the pattern area by a chemical etching method, so as to form the through holes, and leaving an external border and an internal partition frame, so that the external border and the internal partition frame jointly support the fine mask.

Owner:ZHONGSHAN XINNUO MICROELECTRONICS CO LTD

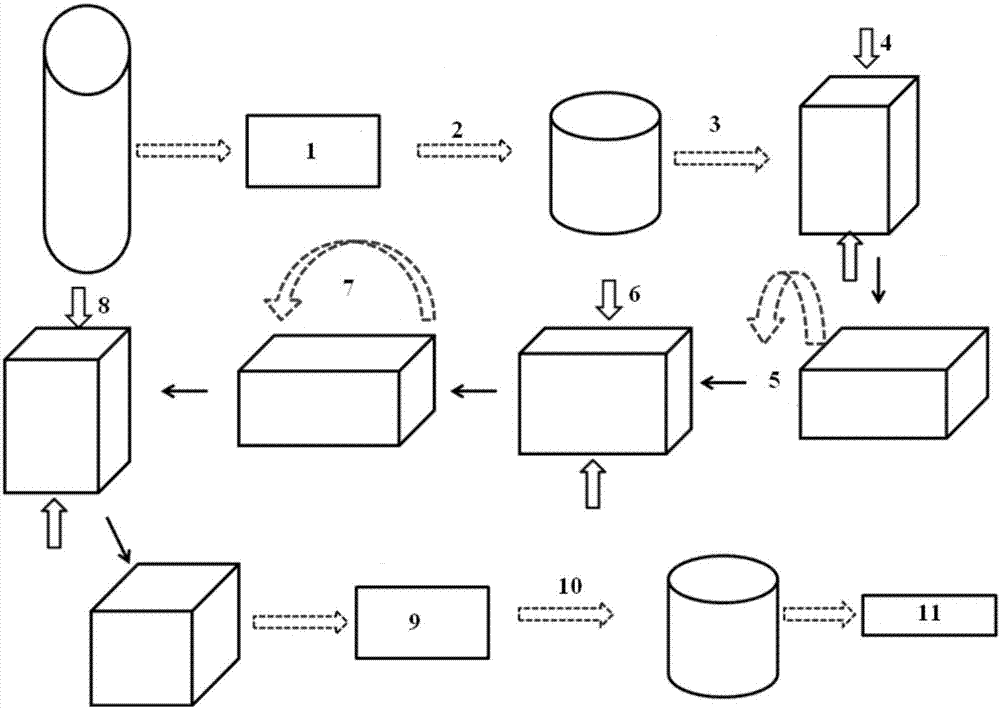

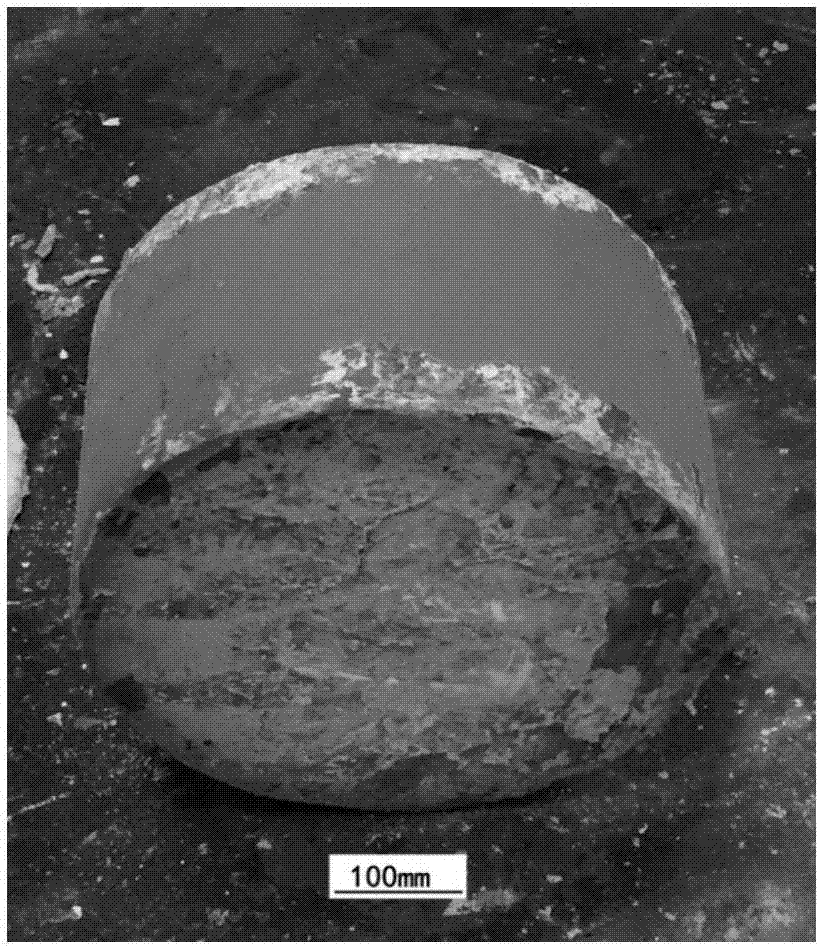

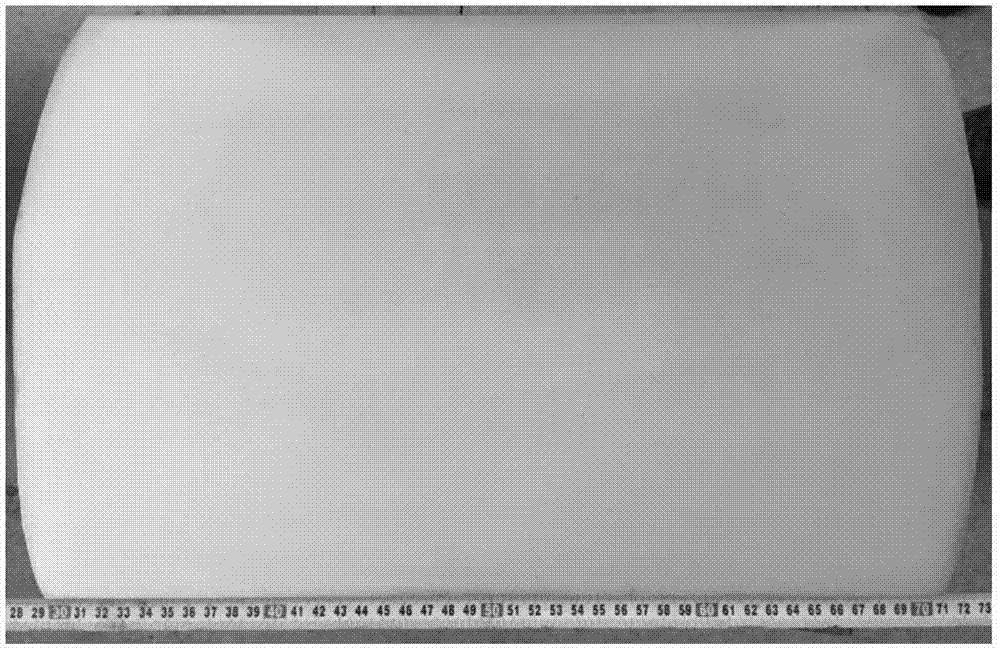

Multidirectional forging method for high-alloyed high-temperature alloy sheared billet/biscuit

ActiveCN106862447AAccurately measure uniformityGuaranteed uniformityMetal-working apparatusFine structureUltra fine

The invention relates to a forging method, in particular to a multidirectional forging method for obtaining a high-alloyed high-temperature alloy sheared billet / biscuit with the uniform and fine structure. The multidirectional forging method includes the following steps that (1) high-temperature homogenizing treatment is conducted on a low-segregation and high-purity controlled directional solidification ingot blank; (2) the controlled directional solidification ingot blank is subjected to upsetting and cogging; (3) the upset blank is forged into a cuboid blank; (4) multidirectional forging is conducted on the cuboid blank; (5) the blank subjected to multidirectional forging for multiple cycles is subjected to finishing, so that a shear billet / biscuit of the required size is obtained; and (6) the obtained shear billet / biscuit is subjected to physical and chemical testing. The multidirectional forging method is not only suitable for preparation of uniform and ultra-fine-grain high-alloyed nickel-based high-temperature alloy sheared billets for aviation, spaceflight and vessels, but also can be popularized to a steel mill to product high-speed steel and hot-working die steel, and the prepared ultra-fine-grain shear billets have the characteristic of uniform structure.

Owner:CENT IRON & STEEL RES INST

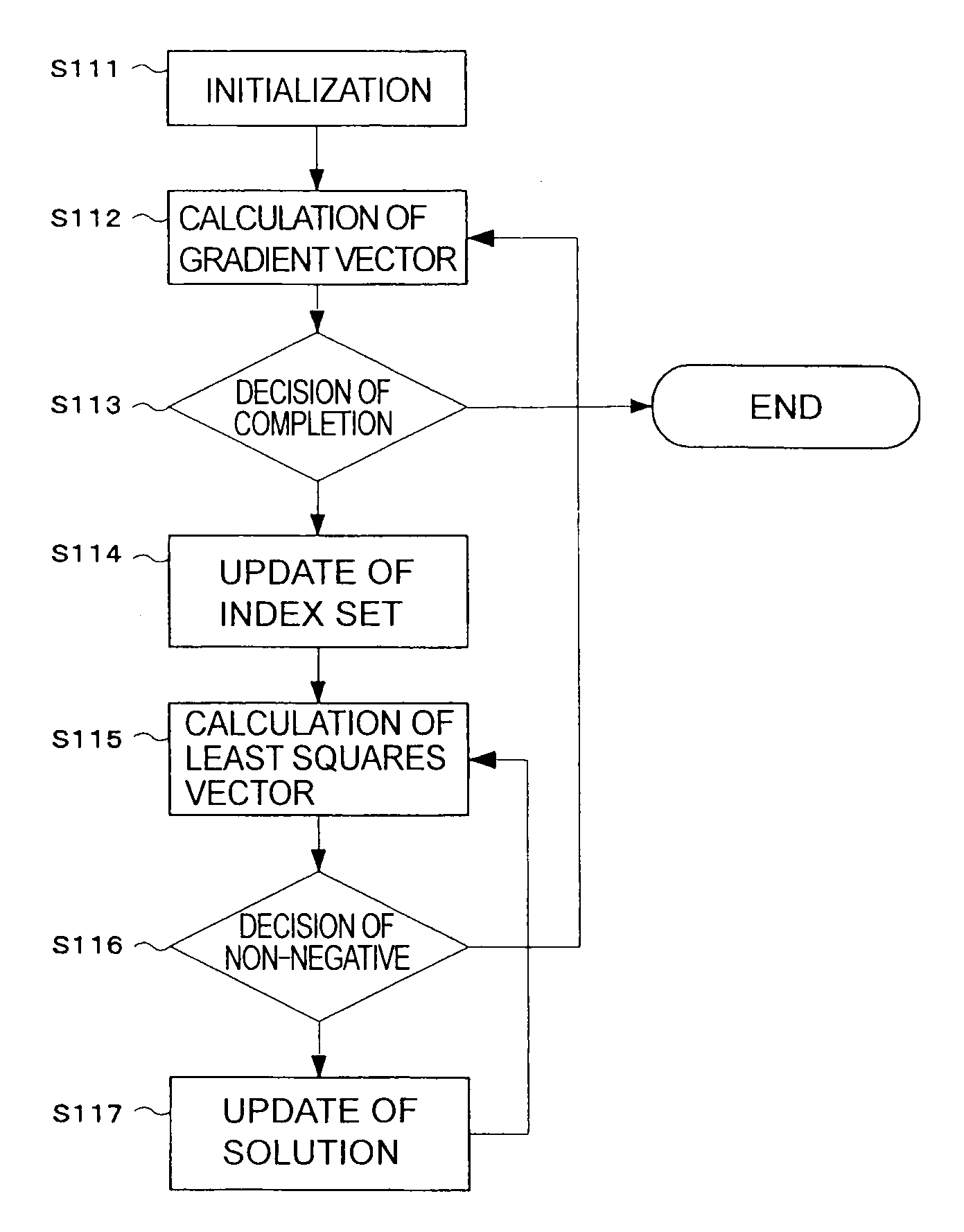

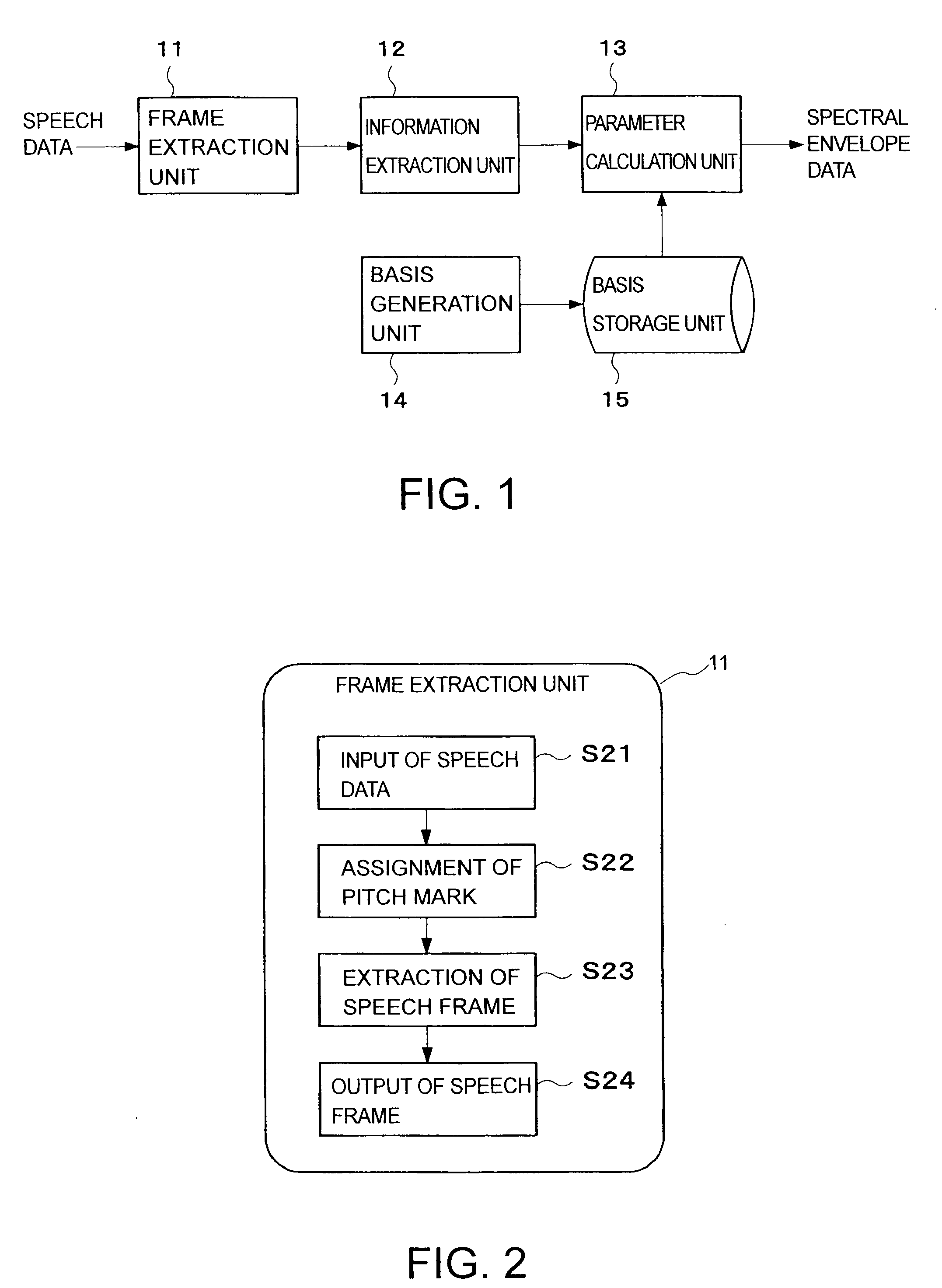

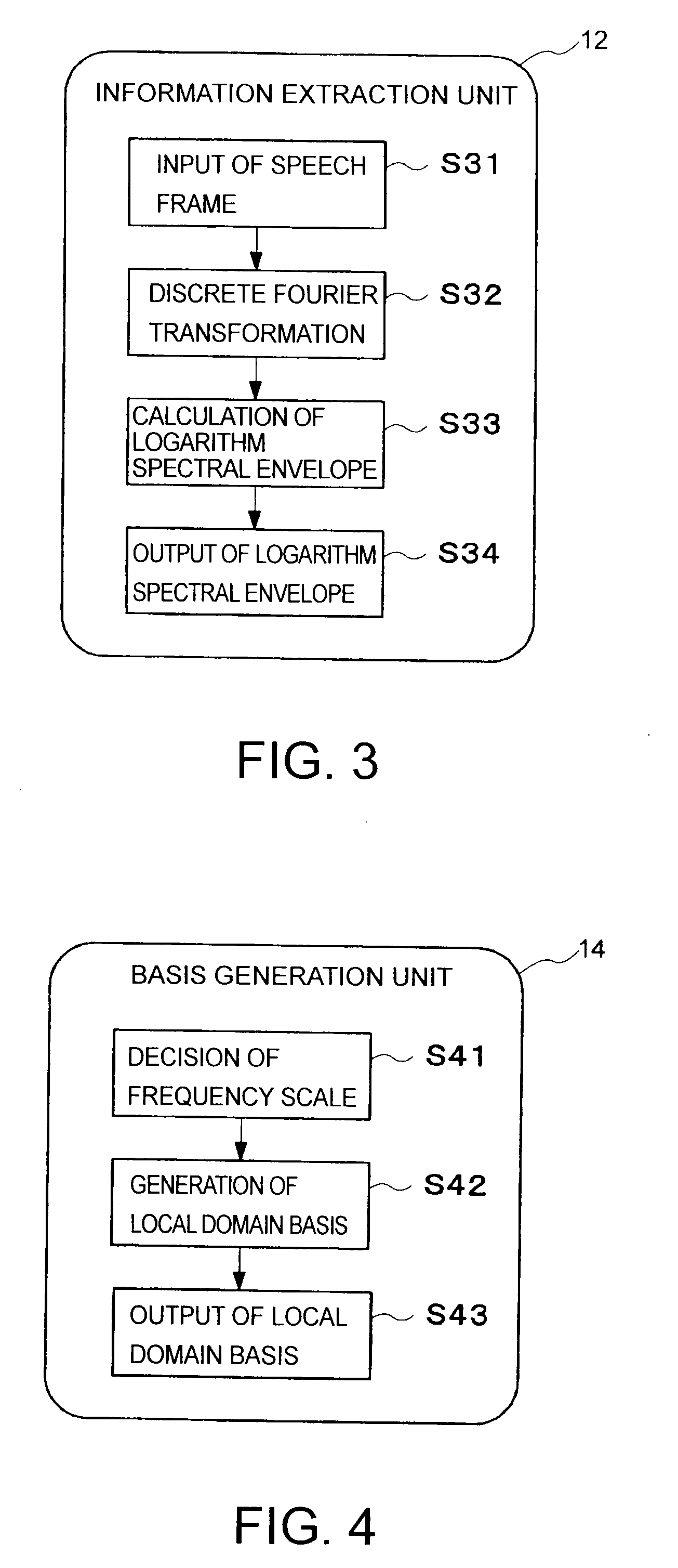

Speech processing apparatus and speech synthesis apparatus

ActiveUS20090144053A1Quality improvementEasy execution of processingSpeech synthesisFine structureFrequency spectrum

An information extraction unit extracts spectral envelope information of L-dimension from each frame of speech data. The spectral envelope information does not have a spectral fine structure. A basis storage unit stores N bases (L>N>1). Each basis is differently a frequency band having a maximum as a peak frequency in a spectral domain having L-dimension. A value corresponding to a frequency outside the frequency band along a frequency axis of the spectral domain is zero. Two frequency bands of which two peak frequencies are adjacent along the frequency axis partially overlap. A parameter calculation unit minimizes a distortion between the spectral envelope information and a linear combination of each basis with a coefficient by changing the coefficient, and sets the coefficient of each basis from which the distortion is minimized to a spectral envelope parameter of the spectral envelope information.

Owner:TOSHIBA DIGITAL SOLUTIONS CORP

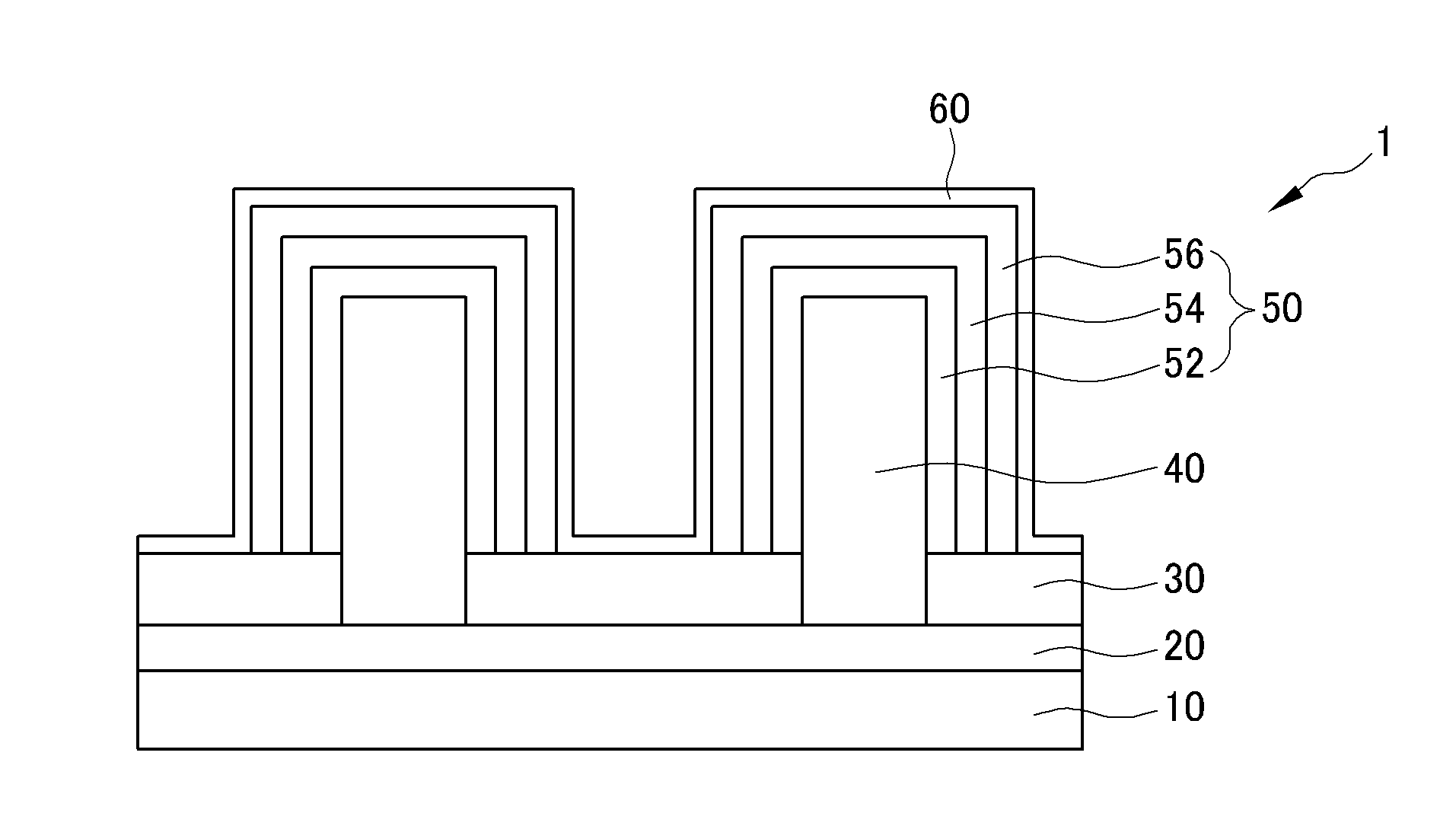

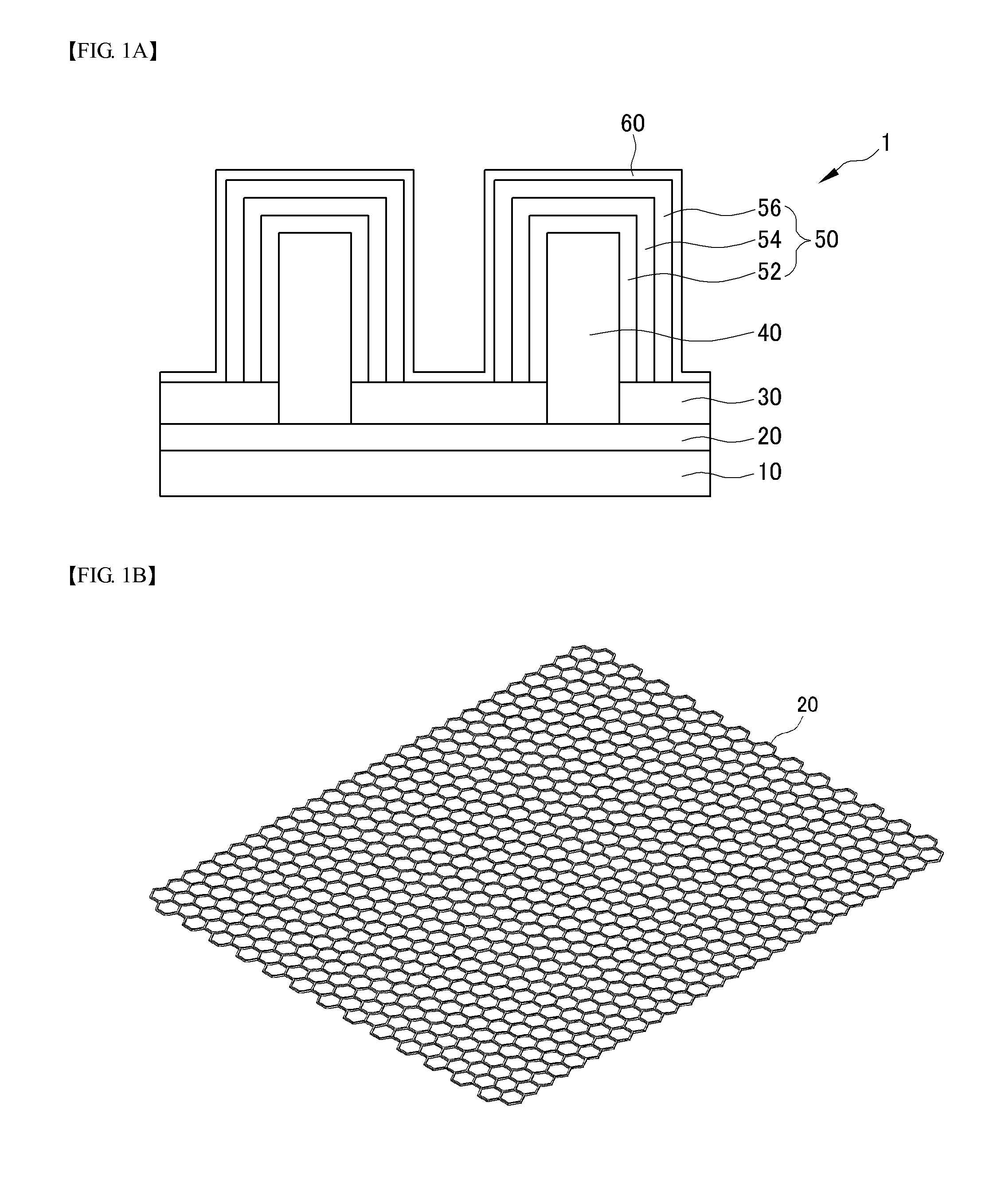

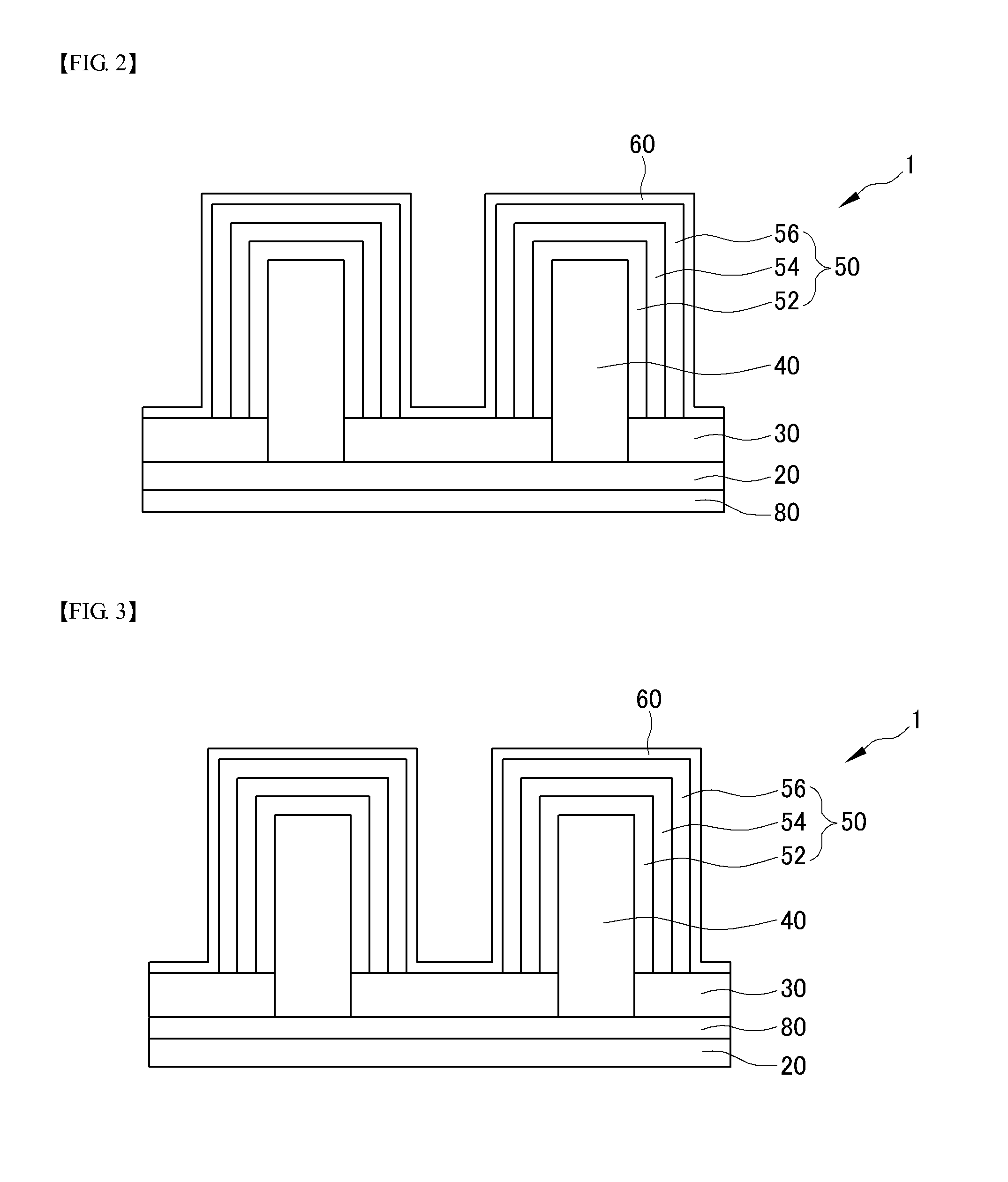

Light-emitting element and method for manufacturing same

ActiveUS20130187128A1Improve efficiencyGood electrical conductivitySemiconductor/solid-state device manufacturingNanoopticsOptoelectronicsFine structure

The present invention provides a light-emitting element comprising: a carbon layer comprising a graphene; a plurality of fine structures having grown toward the upper side of the carbon layer; and a light-emitting structure layer formed on the surface of the fine structures

Owner:SEOUL NAT UNIV R&DB FOUND

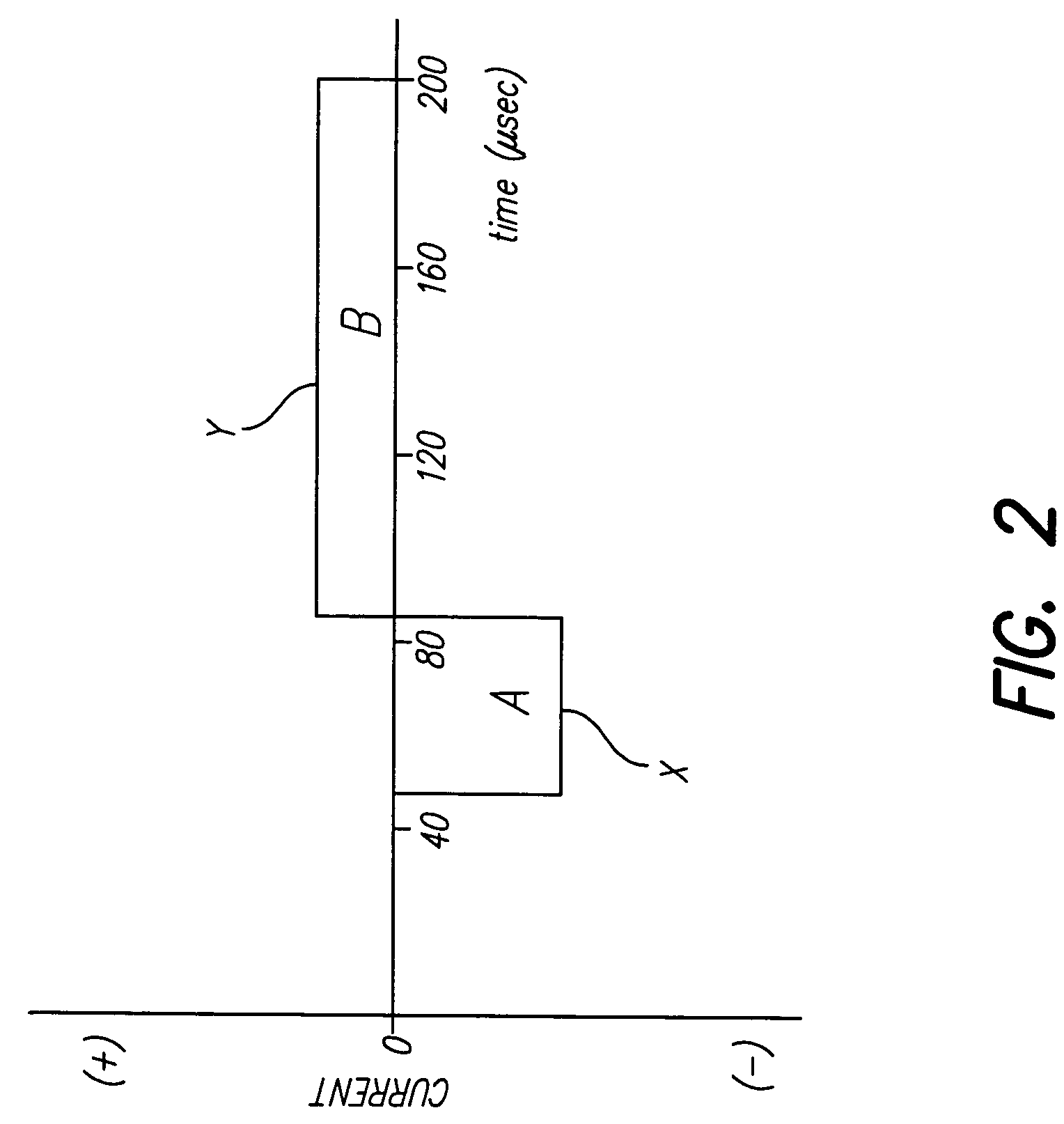

Method and system to convey the within-channel fine structure with a cochlear implant

The present invention provides a cochlear stimulation system and method for capturing and translating fine time structure (“FTS”) in incoming sounds and delivering this information spatially to the cochlea. The system comprises a FTS estimator / analyzer and a current navigator. An embodiment of the method comprises analyzing the incoming sounds within a time frequency band, extracting the slowly varying frequency components and estimating the FTS to obtain a more precise dominant FTS component within a frequency band. After adding the fine structure to the carrier to identify a precise dominant FTS component in each analysis frequency band (or stimulation channel), a stimulation current may be “steered” or directed, using the concept of virtual electrodes, to the precise spatial location (place) on the cochlea that corresponds to the dominant FTS component. This process is simultaneously repeated for each stimulation channel and each FTS component.

Owner:ADVANCED BIONICS AG

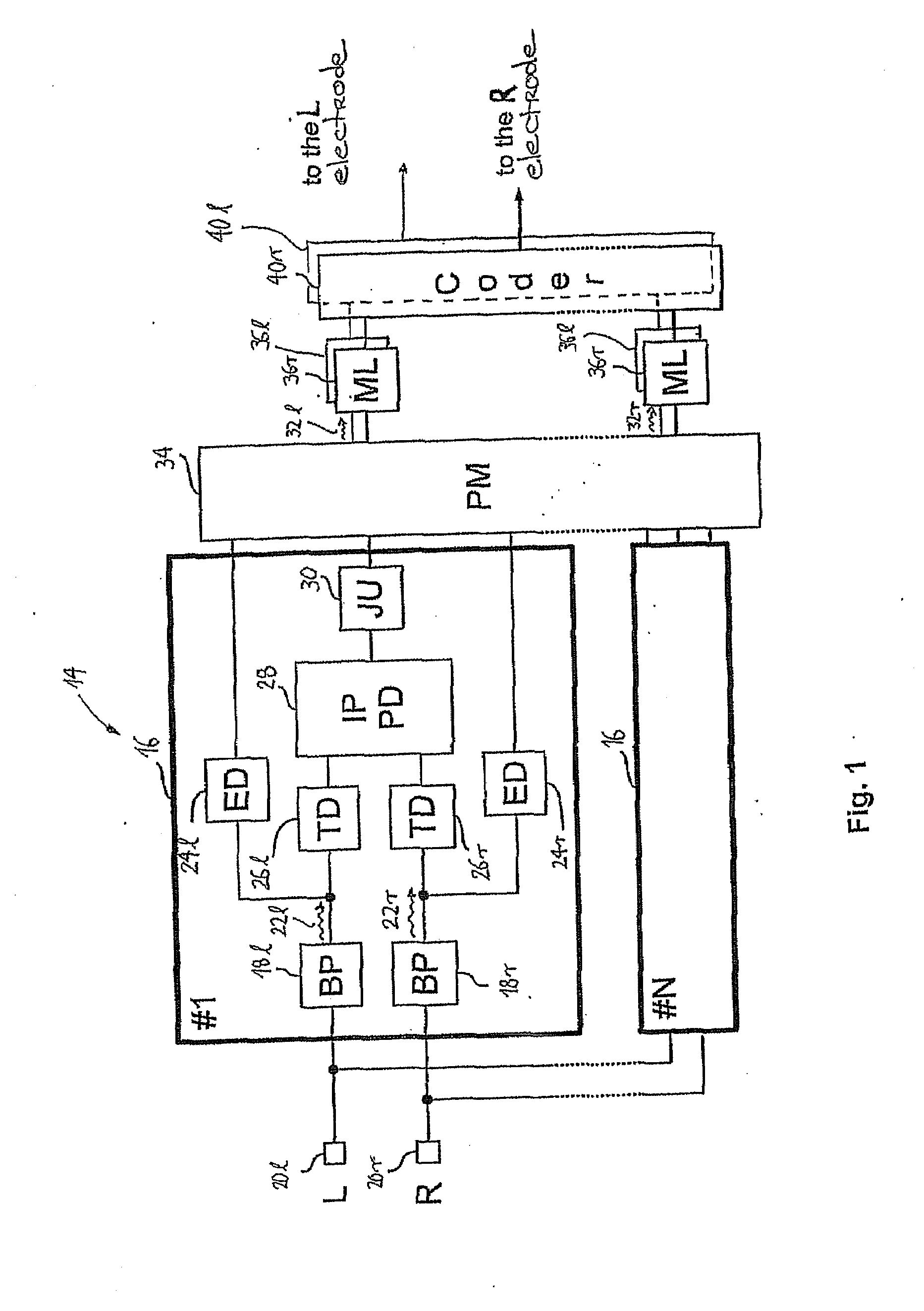

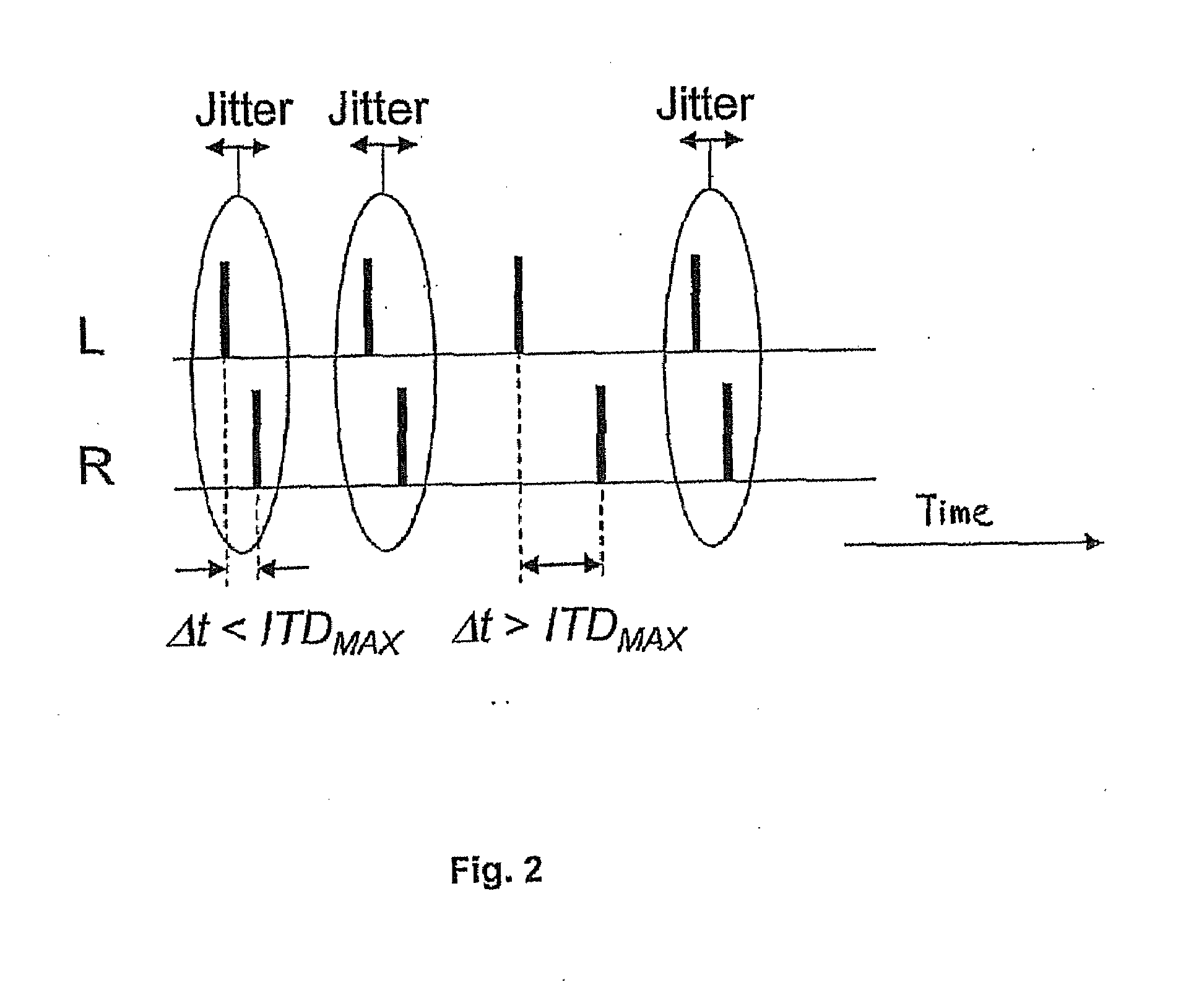

Binaural Stimulation in Neural Auditory Prostheses or Hearing Aids

ActiveUS20080319509A1Avoid time-overlapElectrotherapyImplantable hearing aidsInteraural time differenceFine structure

The present invention discloses of binaural stimulation in a neural auditory prosthesis. Binaural acoustic signals are generated that represent sound associated with a user's left and right ears respectively. Based on the binaural acoustic signals, corresponding binaural stimulation signals are generated for electrical stimulation of auditory nerve tissue of the user, wherein the binaural stimulation signals each include a fine structure component with periodic characteristics and interaural time difference (ITD) information. A phase jitter component is added to the binaural stimulation signals to reduce the periodic characteristics of the fine structure component while preserving the interaural time difference (ITD) information.

Owner:MED EL ELEKTROMEDIZINISCHE GERAETE GMBH

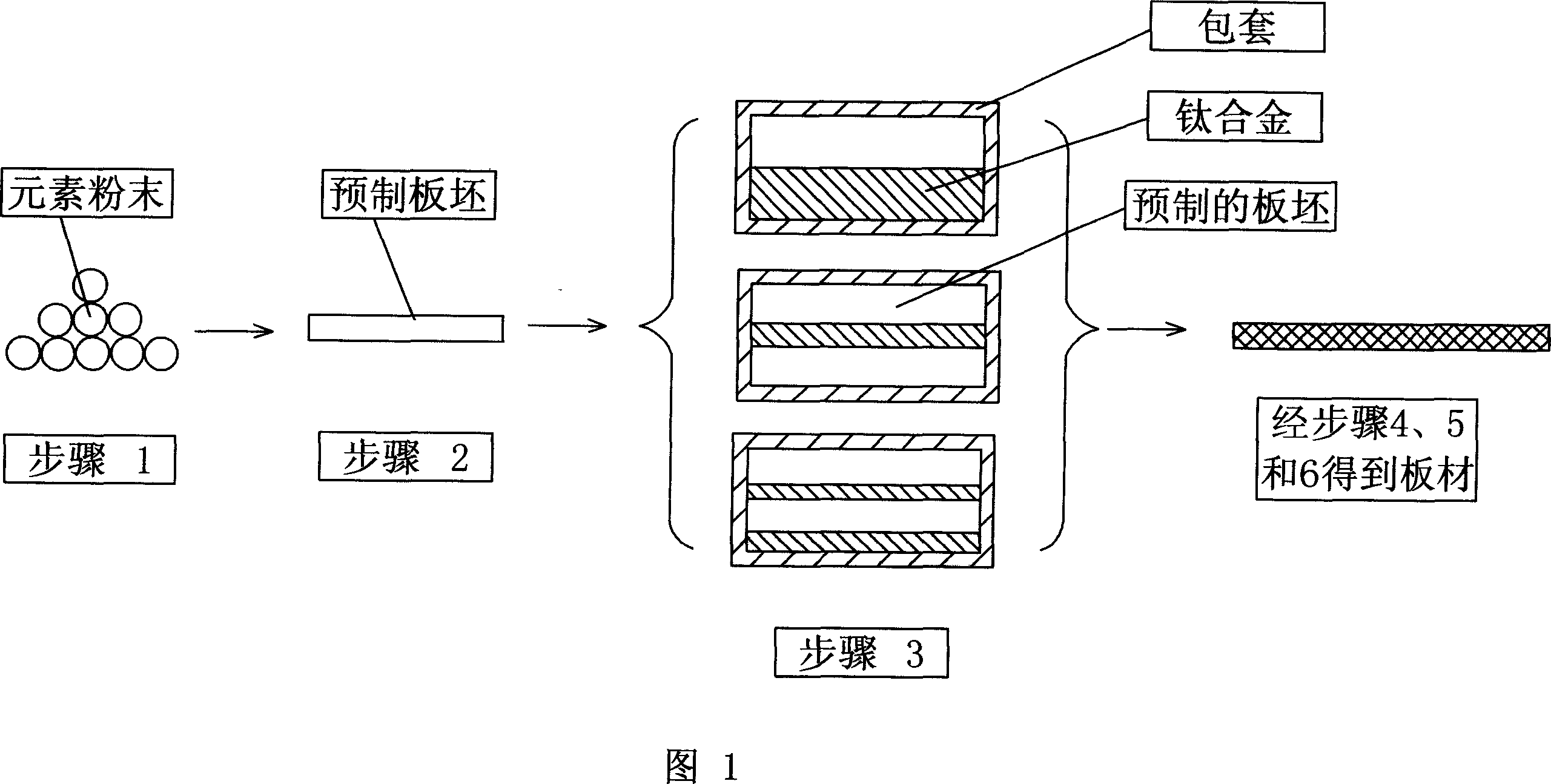

Method for preparing TiAl alloy clad plate by element powder

InactiveCN101011739AThe overall thickness is thinImprove mechanical propertiesFine structureTitanium alloy

The invention relates to the making of TIAl alloy compound plate using element powders, which mixes the element powders like Ti, Al and others in proportion evenly, getting the plate blank after cold rolling or compression, combining the blank and Ti alloy plate with certain thickness for heat compression or hot isostatic treatment to get the compound board. It makes the board with finer structure, thin board, with better comprehensive mechanic feature, being able to make high performance and big size compound board.

Owner:HARBIN INST OF TECH

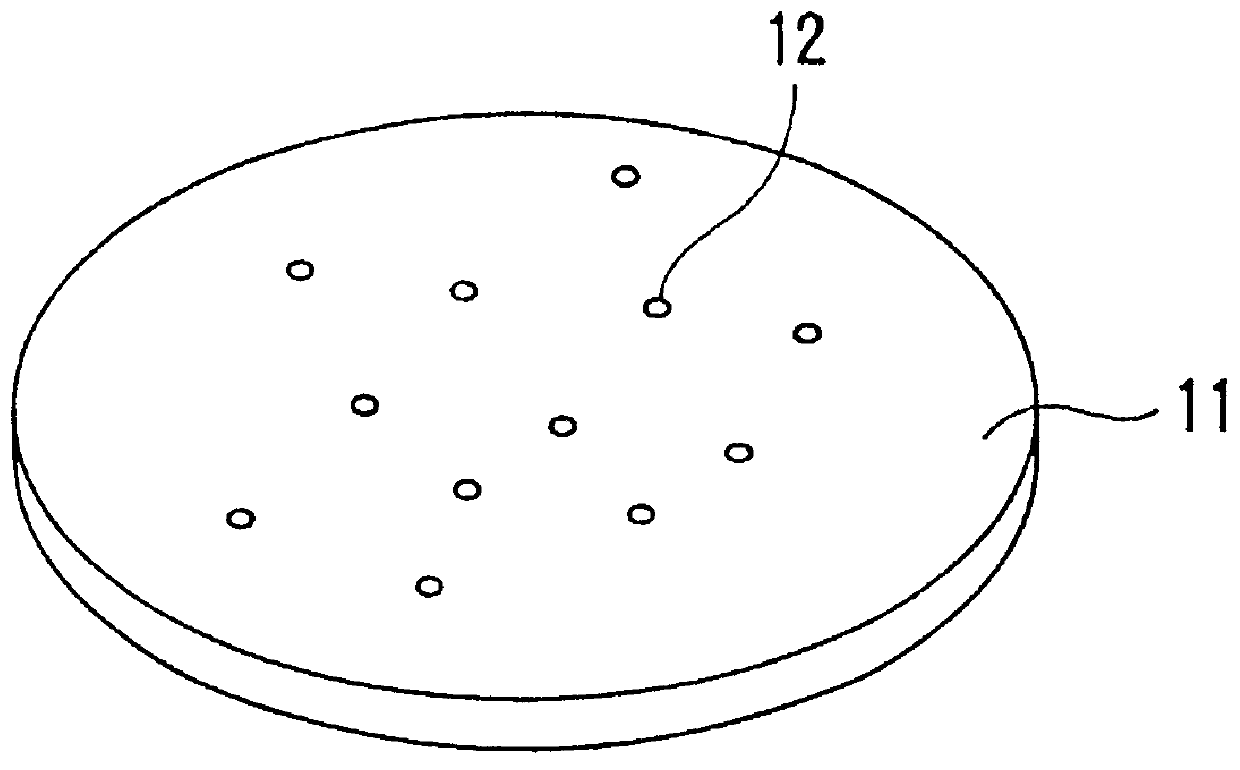

Ultra-fine microfabrication method using an energy beam

InactiveUS6010831ADecorative surface effectsSemiconductor/solid-state device manufacturingFine structurePositional Technique

An ultra-fine microfabrication method using an energy beam is based on the use of shielding provided by nanometer or micrometer sized micro-particles to produce a variety of three-dimensional fine structures which have not been possible by the traditional photolithographic technique which is basically designed to produce two-dimensional structures. When the basis technique of radiation of an energy beam and shielding is combined with a shield positioning technique using a magnetic, electrical field or laser beam, with or without the additional chemical effects provided by reactive gas particle beams or solutions, fine structures of very high aspect ratios can be produced with precision. Applications of devices having the fine structures produced by the method include wavelength shifting in optical communications, quantum effect devices and intensive laser devices.

Owner:EBARA CORP +1

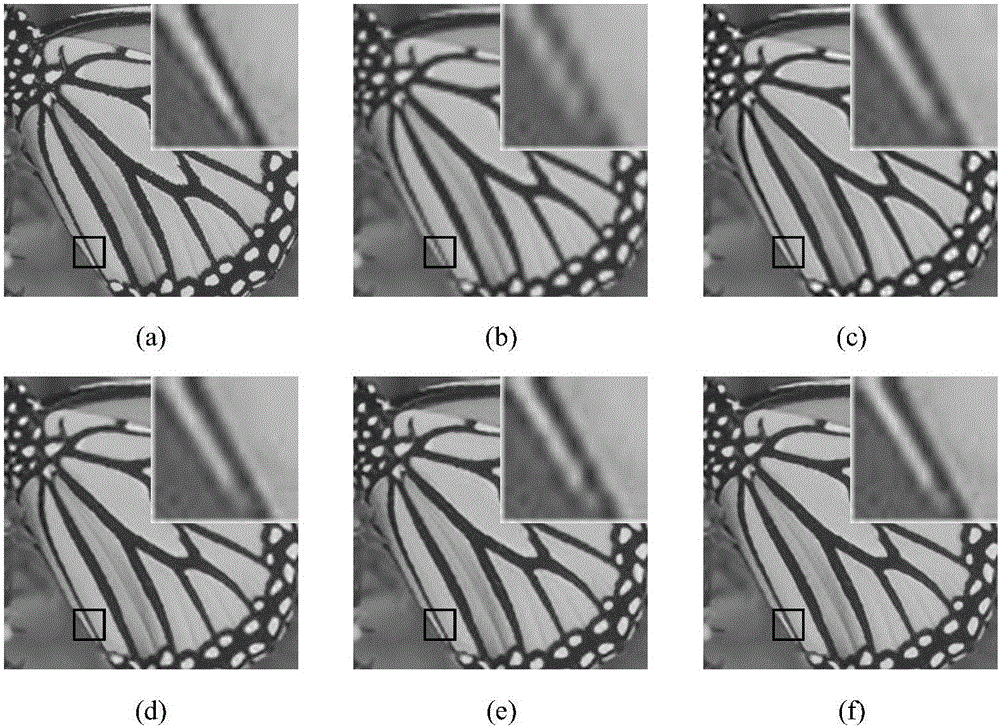

Single image super-resolution reconstruction method combining depth learning and gradient transformation

ActiveCN106204489AAdvantages of subjective visual effectsHigh objective evaluation parameter valueImage enhancementImage analysisFine structureReconstruction method

The invention discloses a single image super-resolution reconstruction method combining depth learning and gradient transformation. The method comprises the steps that a super-resolution method based on depth learning is used to carry out upsampling on an input low-resolution image to acquire an upsampling image; a gradient operator is used to carry out gradient-extracting on the upsampling image; a depth convolutional neural network is used to convert extracted gradient; a cost function is reconstructed by using the input low-resolution image and the converted gradient as constraints; a gradient descent method is used to optimize the reconstructed cost function to acquire a final output high-resolution image. According to the single image super-resolution reconstruction method provided by the invention, the reconstructed image has a fine structure in the subjective visual effect, is free of artificial effect, and has a high objective evaluation parameter value. The invention provides the effective single image super-resolution reconstruction method.

Owner:SICHUAN UNIV

System and method for using a multi-contact electrode to stimulate the cochlear nerve or other body tissue

InactiveUS7317944B1Preserving temporalPreserving spatial resolutionHead electrodesDiagnostic recording/measuringFine structurePatient retention

A system and method for preserving temporal and spatial resolution in complex sounds for poor performing patients having high stimulation thresholds is described. The system and method employs two or more adjacent electrode contacts to deliver concurrent stimulation. This concurrent delivery of stimuli creates a high current field intensity that overlaps between individual current fields generated by the two or more adjacent electrodes and which individual fields are summed to create an overlapping field that has a higher current field intensity than a single current emanating from an individual electrode. The use of this method reduces or eliminates the need to increase either the stimulus current amplitude or to increase the pulse width, both of which may cause loss of system resolution, i.e., loss of fine structure information that is used to resolve complex sounds such as music.

Owner:ADVANCED BIONICS AG

Stamper for transferring fine pattern and method for manufacturing thereof

An object of the present invention is to provide a stamper for transferring fine pattern and a method for manufacturing the stamper, the stamper has a fine structure layer to improve a continuous transferring property of the resinous stamper, and to allow accurate and continuous transferring. In order to achieve the above object, the present invention provides a stamper for transferring fine pattern, including: a fine structure layer on a supporting substrate, in which the fine structure layer is a polymer of a resinous compound whose principal component is silsesquioxane derivative having a plurality of polymerizable functional groups.

Owner:HITACHI HIGH-TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com