Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1700 results about "Directional solidification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

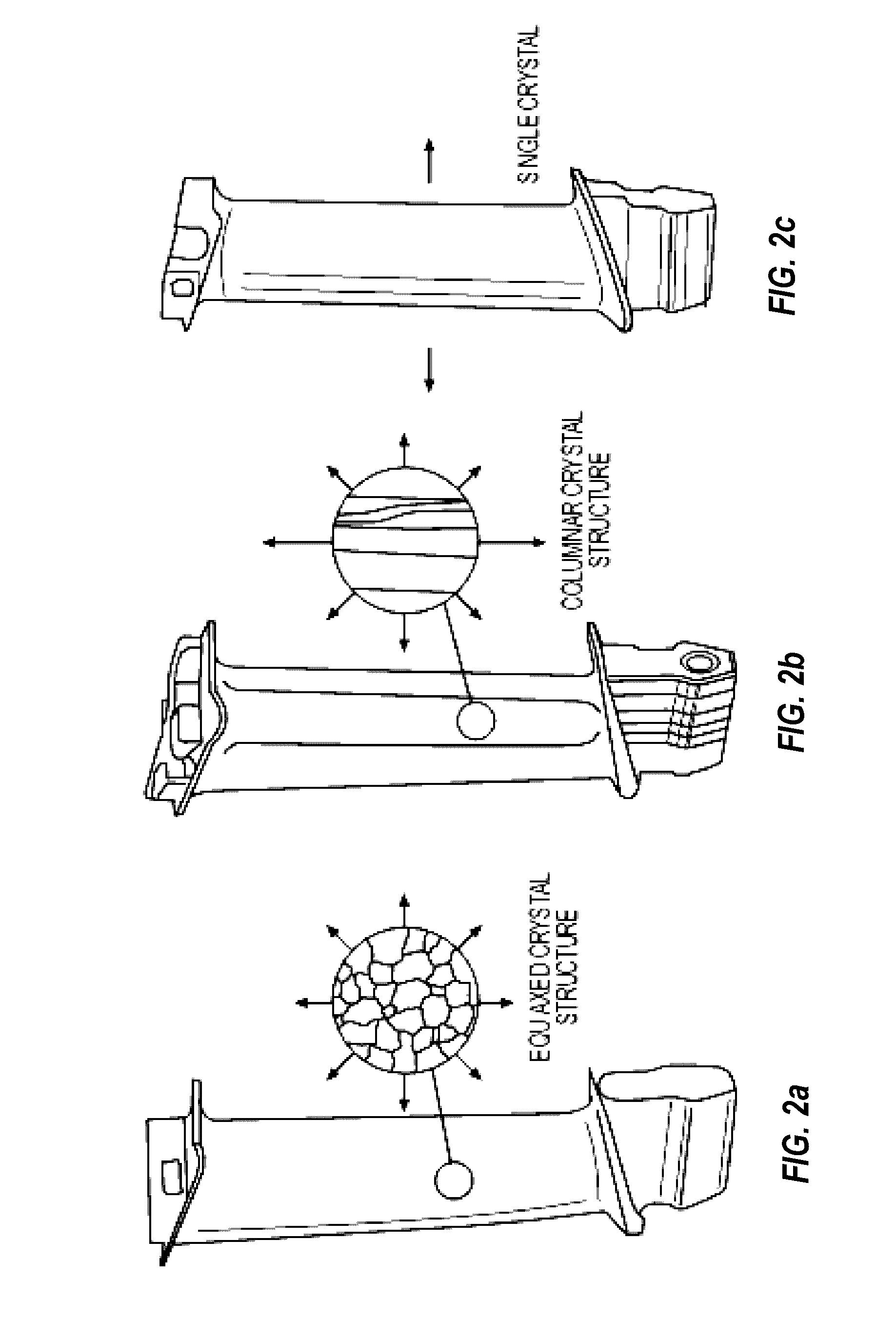

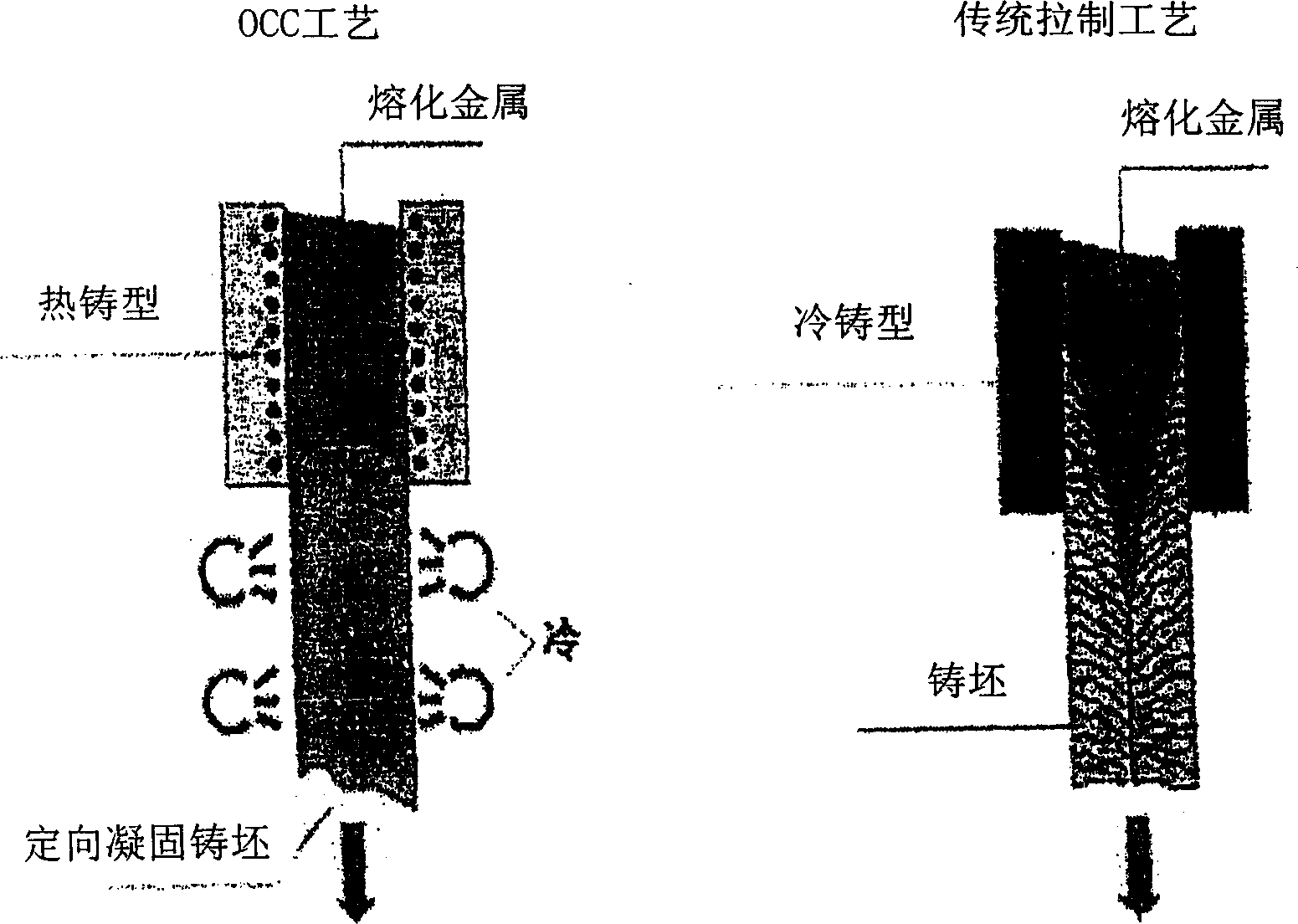

Directional solidification (DS) and progressive solidification are types of solidification within castings. Directional solidification is solidification that occurs from farthest end of the casting and works its way towards the sprue. Progressive solidification, also known as parallel solidification, is solidification that starts at the walls of the casting and progresses perpendicularly from that surface.

Systems and methods for additive manufacturing and repair of metal components

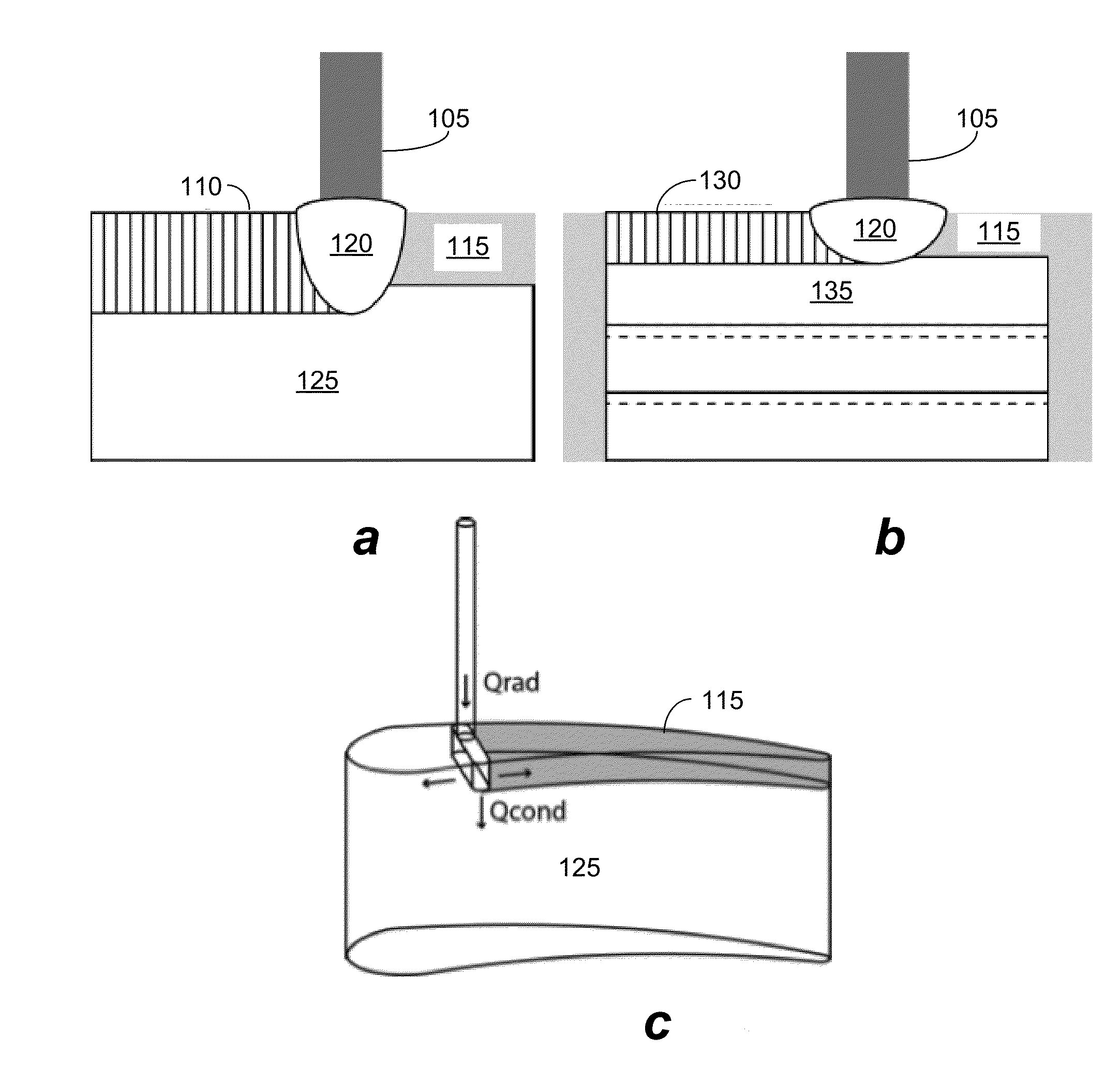

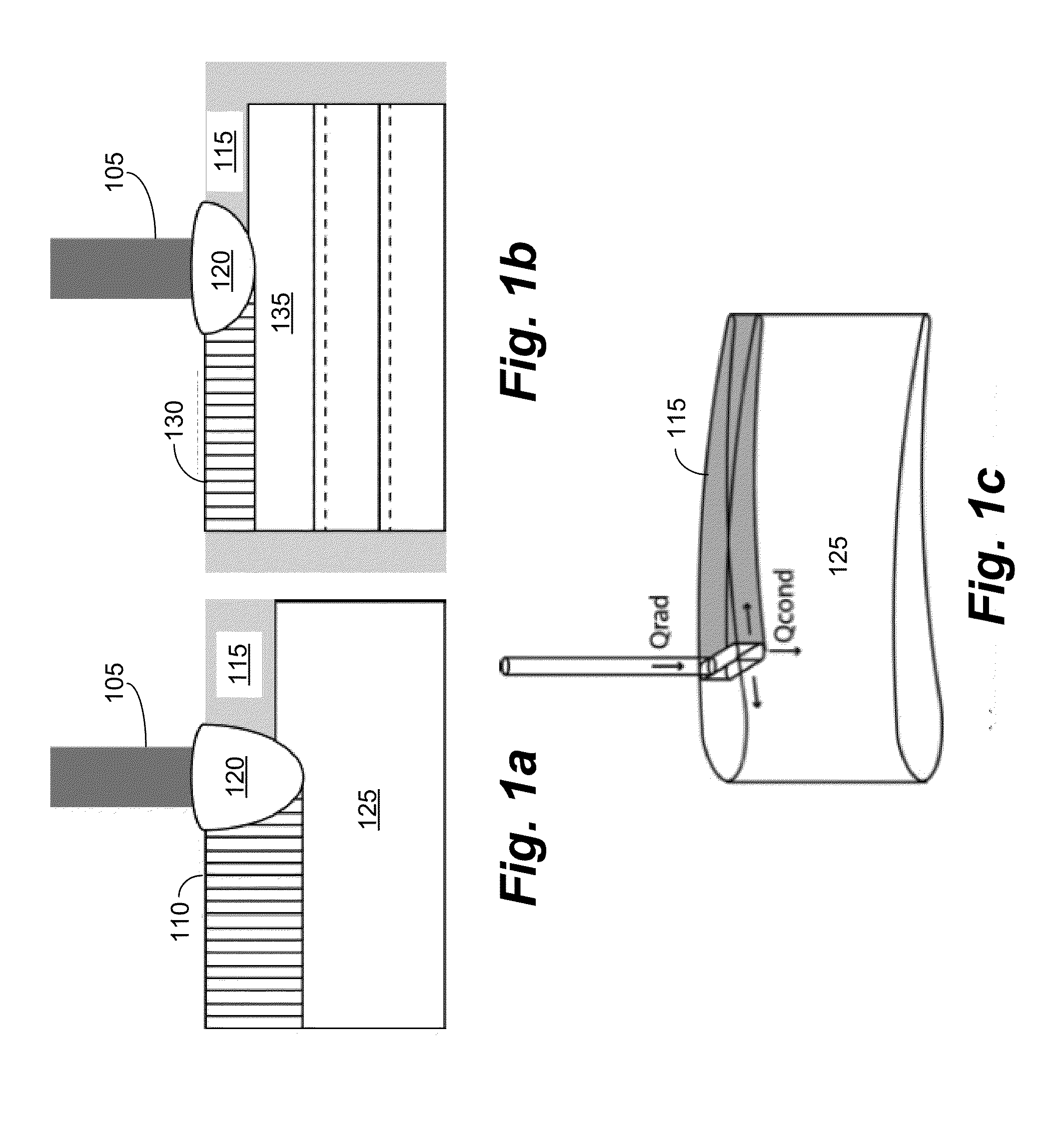

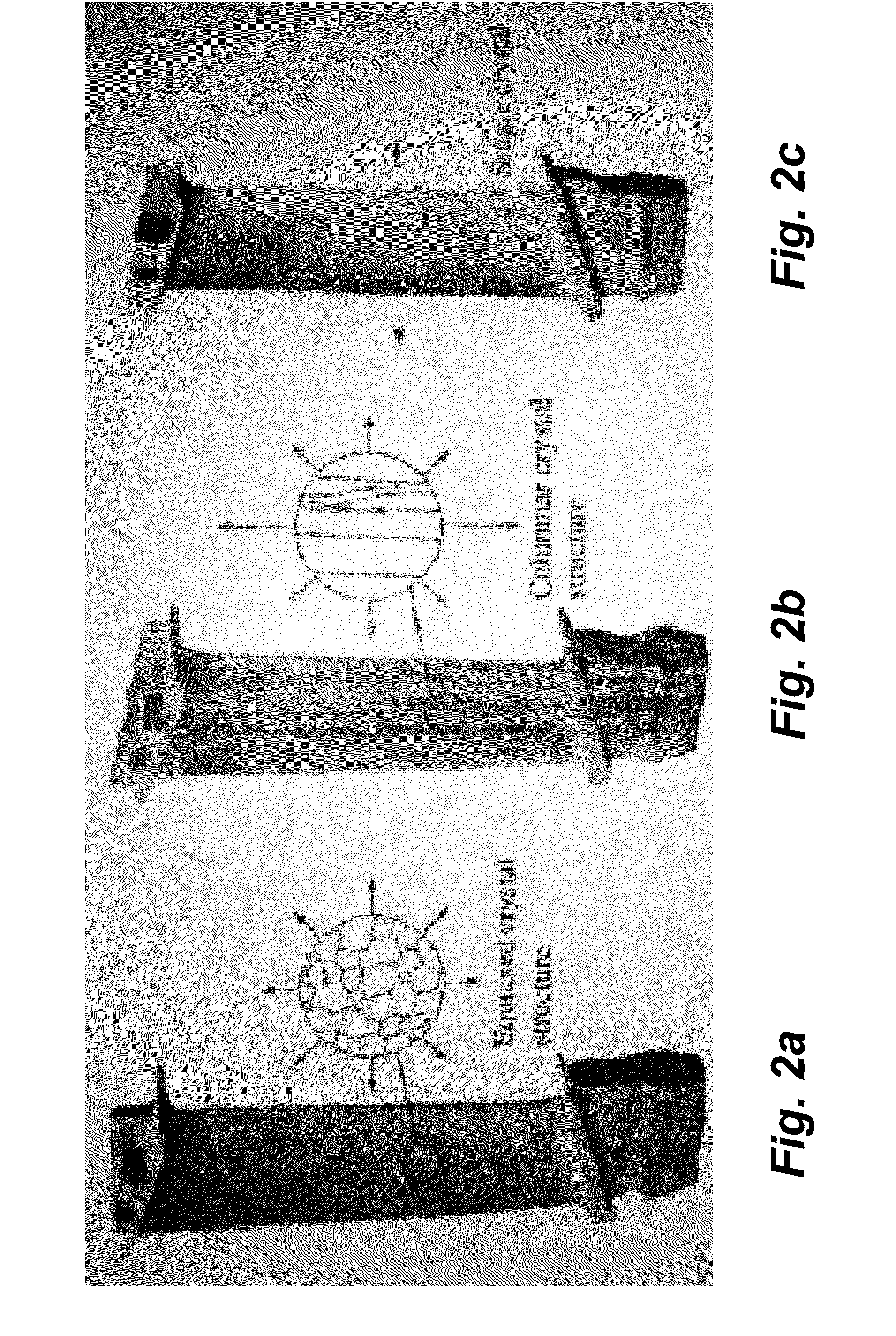

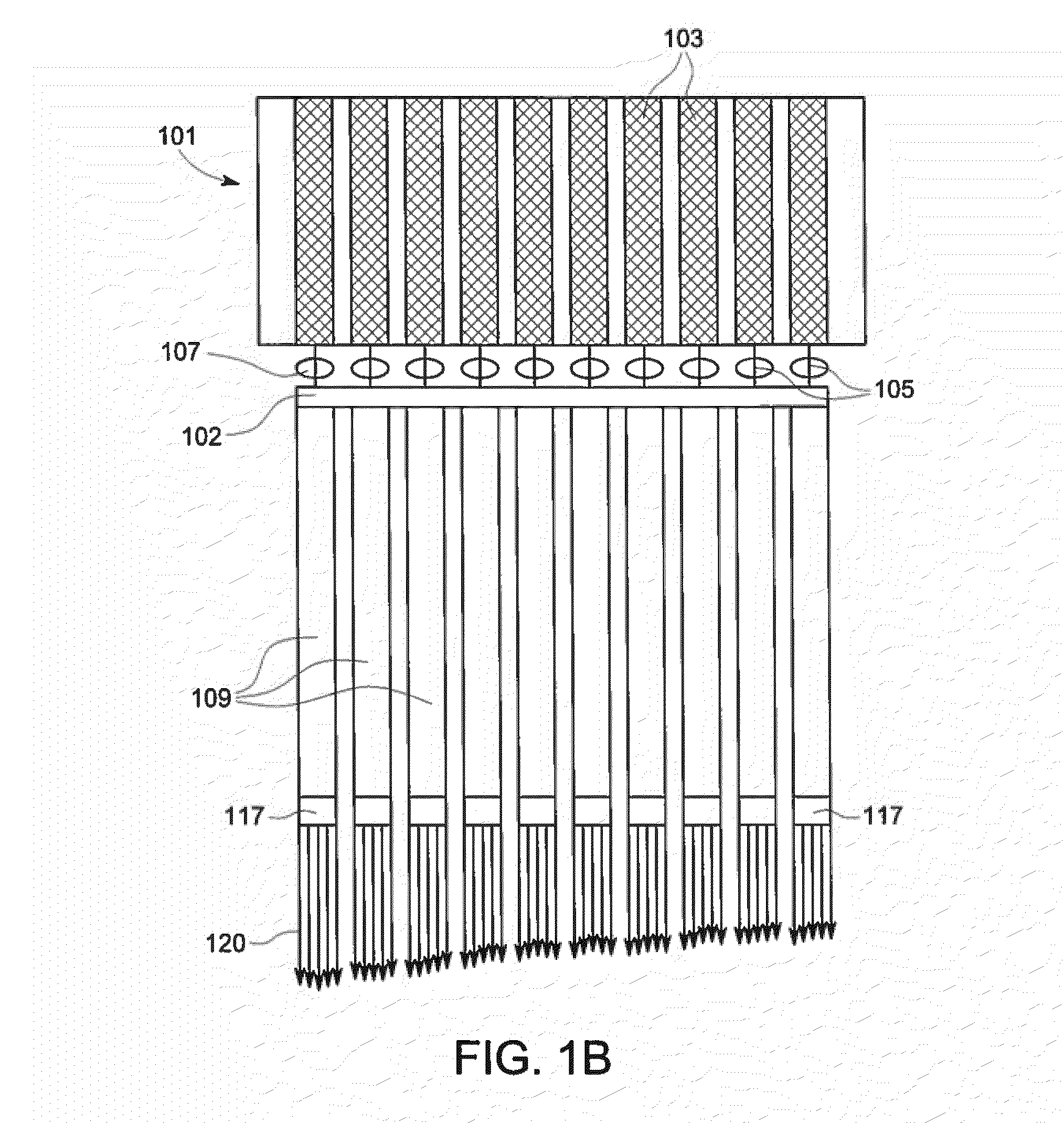

Scanning Laser Epitaxy (SLE) is a layer-by-layer additive manufacturing process that allows for the fabrication of three-dimensional objects with specified microstructure through the controlled melting and re-solidification of a metal powders placed atop a base substrate. SLE can be used to repair single crystal (SX) turbine airfoils, for example, as well as the manufacture functionally graded turbine components. The SLE process is capable of creating equiaxed, directionally solidified, and SX structures. Real-time feedback control schemes based upon an offline model can be used both to create specified defect free microstructures and to improve the repeatability of the process. Control schemes can be used based upon temperature data feedback provided at high frame rate by a thermal imaging camera as well as a melt-pool viewing video microscope. A real-time control scheme can deliver the capability of creating engine ready net shape turbine components from raw powder material.

Owner:GEORGIA TECH RES CORP

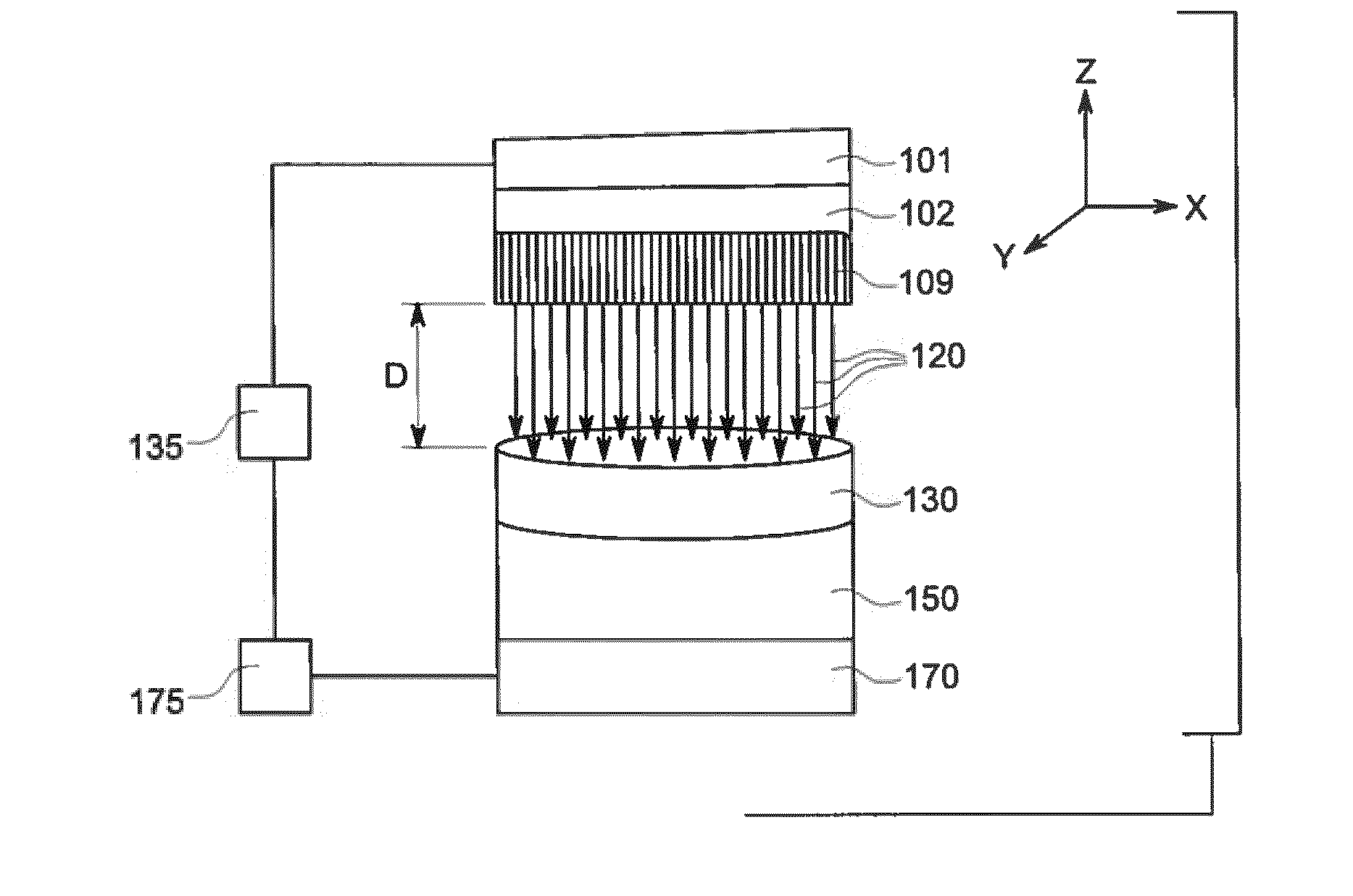

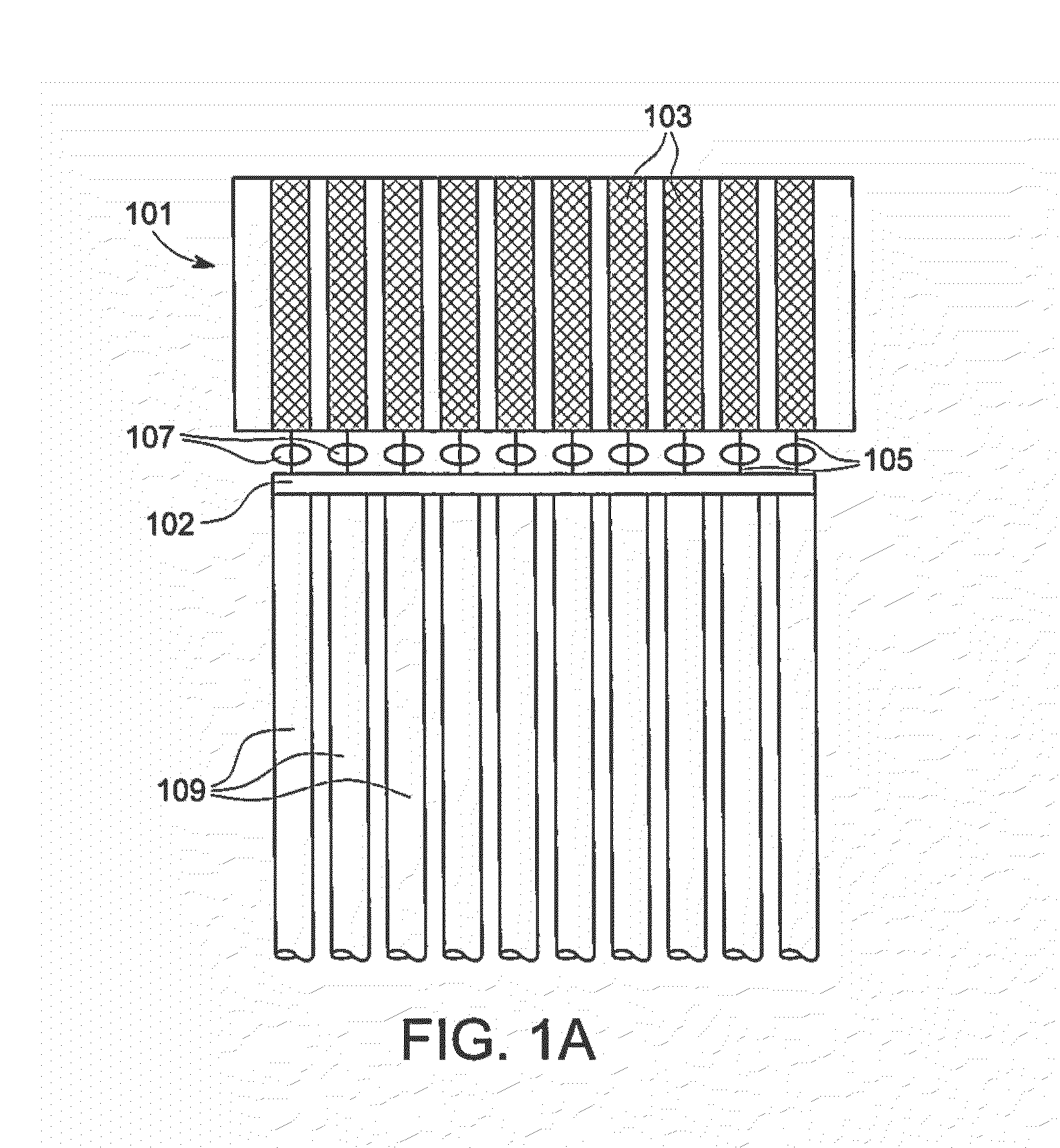

Control of solidification in laser powder bed fusion additive manufacturing using a diode laser fiber array

A method of method of forming or repairing a superalloy article having a columnar or equiaxed or directionally solidified or amorphous or single crystal microstructure includes emitting a plurality of laser beams from selected fibers of a diode laser fiber array corresponding to a pattern of a layer of the article onto a powder bed of the superalloy to form a melt pool; and controlling a temperature gradient and a solidification velocity of the melt pool to form the columnar or single crystal microstructure.

Owner:GENERAL ELECTRIC CO

Systems and methods for additive manufacturing and repair of metal components

Scanning Laser Epitaxy (SLE) is a layer-by-layer additive manufacturing process that allows for the fabrication of three-dimensional objects with specified microstructure through the controlled melting and re-solidification of a metal powders placed atop a base substrate. SLE can be used to repair single crystal (SX) turbine airfoils, for example, as well as the manufacture functionally graded turbine components. The SLE process is capable of creating equiaxed, directionally solidified, and SX structures. Real-time feedback control schemes based upon an offline model can be used both to create specified defect free microstructures and to improve the repeatability of the process. Control schemes can be used based upon temperature data feedback provided at high frame rate by a thermal imaging camera as well as a melt-pool viewing video microscope. A real-time control scheme can deliver the capability of creating engine ready net shape turbine components from raw powder material.

Owner:GEORGIA TECH RES CORP

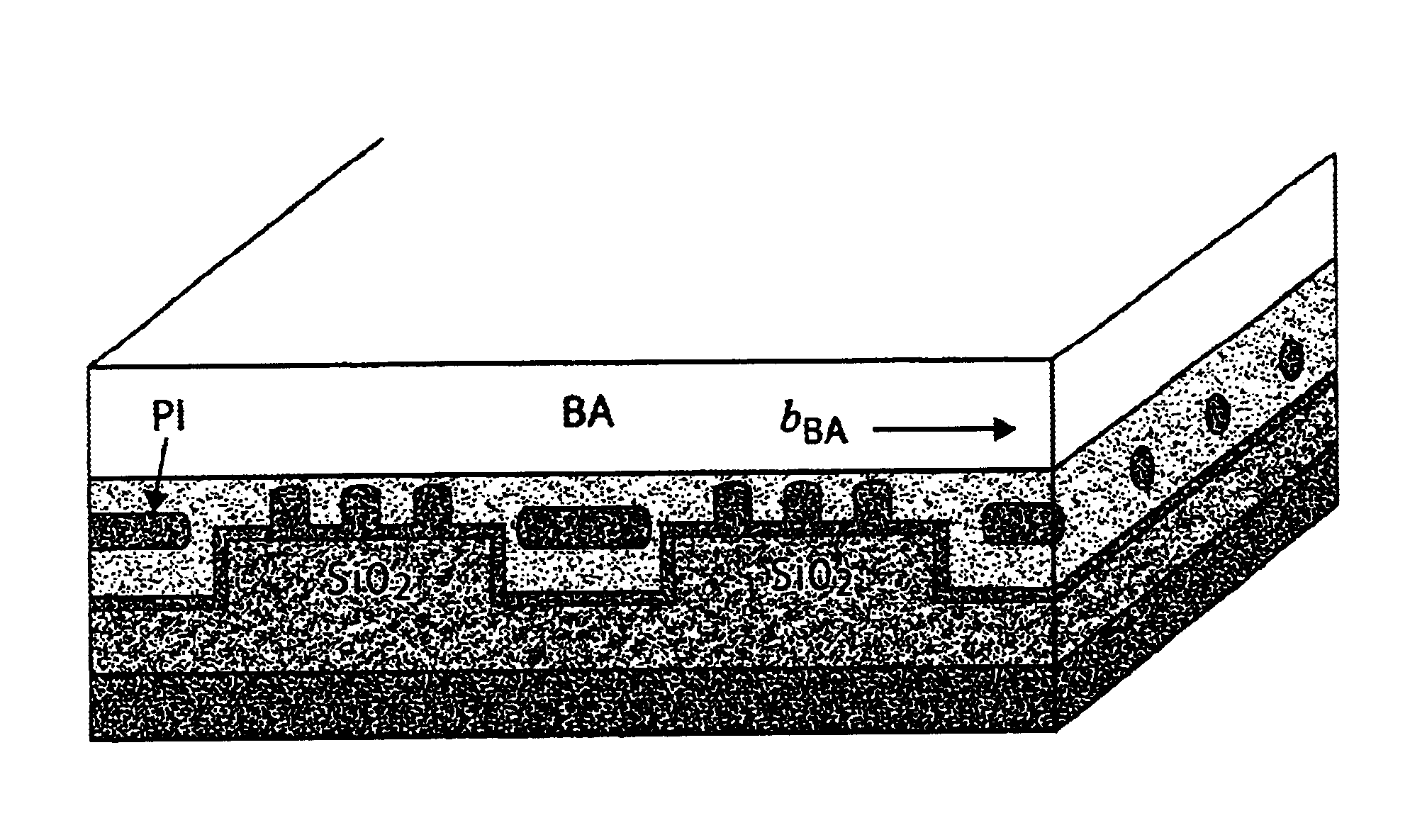

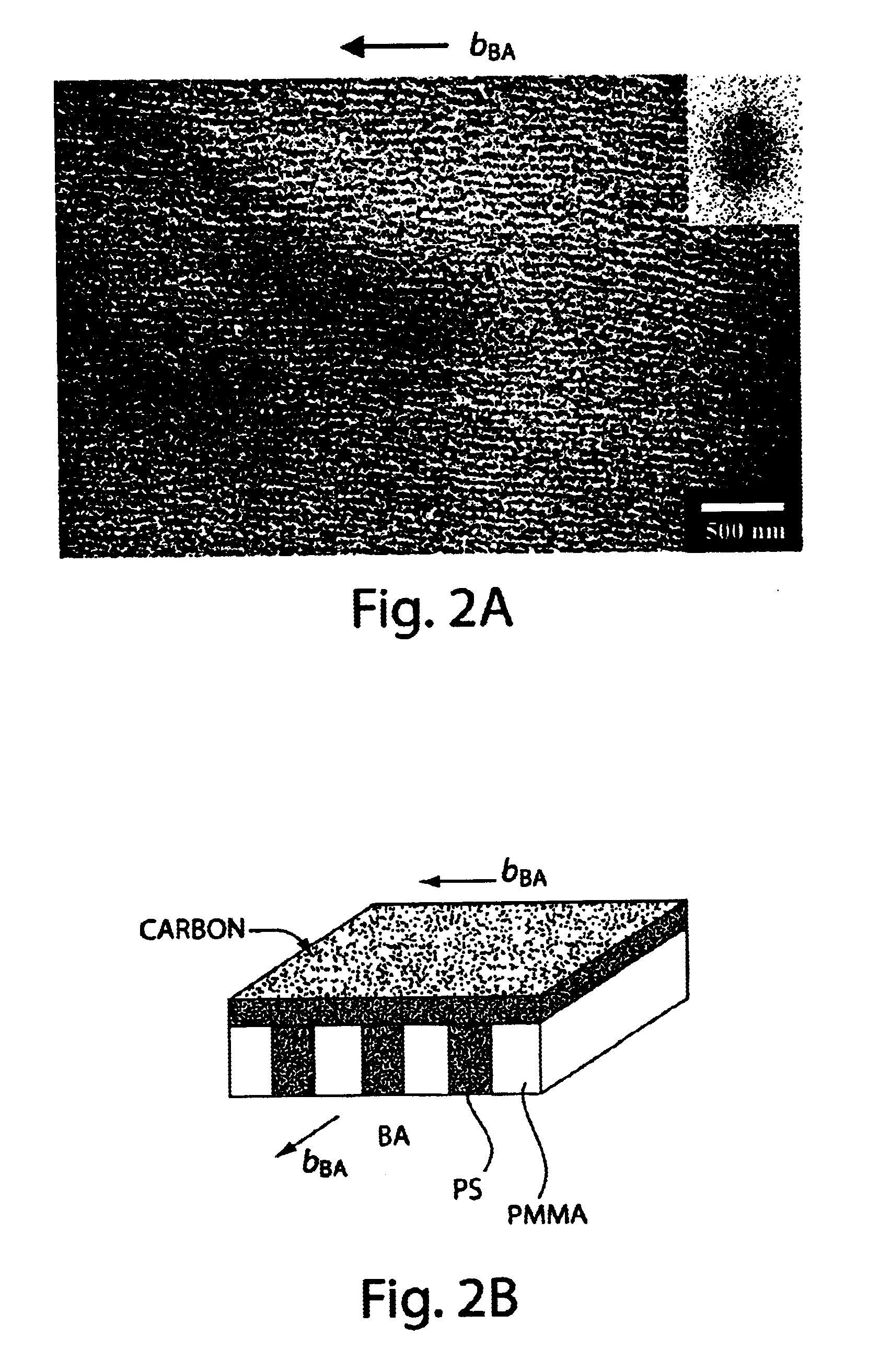

Large area orientation of block copolymer microdomains in thin films

InactiveUS6893705B2Free from defectIndividual molecule manipulationPhotomechanical apparatusIn planeDirectional solidification

A method and apparatus for orientation of block copolymer microdomains via rapid solidification. Rapid solidification from a solvent may include directional solidification and / or epitaxy to form patterns of microdomains in a film of block copolymer. Microdomains may include various structures formed by components of a block copolymer, such as vertical lamellae, in-plane cylinders, and vertical cylinders, and may depend on film thickness. Orientation of structures in microdomains may be controlled to be approximately uniform, and spatial arrangement of microdomains may be controlled.

Owner:MASSACHUSETTS INST OF TECH

Method for producing monocrystalline metal or semi-metal bodies

InactiveUS20090047203A1Cheap methodCost effective productionPolycrystalline material growthSiliconVertical gradientCrucible

Owner:SCHOTT AG

High energy beam area-selecting fusing method and device capable of controlling temperature gradient in shaping area

ActiveCN104959604AEnsure directional solidification conditionsReal-time monitoring of temperature gradientsAdditive manufacturing apparatusTemperature controlHeat flow

The invention discloses a high energy beam area-selecting fusing method and device capable of controlling temperature gradient in a shaping area, and a temperature measurement module and a temperature control module are added to a shaping assembly of the device. When the device is used for manufacturing high-energy beam additive, the temperature gradient interval in a molten pool can be calculated in real time utilizing the boundary temperature, acquired by the temperature measurement module, of a shaping area, proper hot-fluid conditions can be applied to the shaping area through the temperature control module to control temperature gradient intervals of the molten pool and the shaping area, so the molten pool can always satisfy conditions of directional solidification, high precision and performance directional solidified metal members and monocrystalline metal members having different sizes and structures can be efficiently manufactured. By adopting the high energy beam area-selecting fusing method and device capable of controlling the temperature gradient in a shaping area, not only the temperature gradient of the shaping area can always satisfy directional solidification conditions, but also the temperature gradient distribution in stages of a shaping process can be flexibly changed according to actual process needs, so various of functional / structural gradient members can be manufactured.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for producing silicon for use in solar cells

InactiveUS6090361AAvoid energy wasteAvoid material lossPolycrystalline material growthSiliconElectrical batteryZone melting

Method for producing highly purified silicon for use in solar cells by a single solidification purification, pouring silicon into a mold and gradually fractionally solidifying it while solidifying the liquid surface, followed by purifying the solidified silicon by zone melting or continuous casting using an electromagnetic mold, or by zone melting in combination with continuous casting, and optionally causing directional solidification to concentrate impurities, leaching and recycling.

Owner:KAWASAKI STEEL CORP

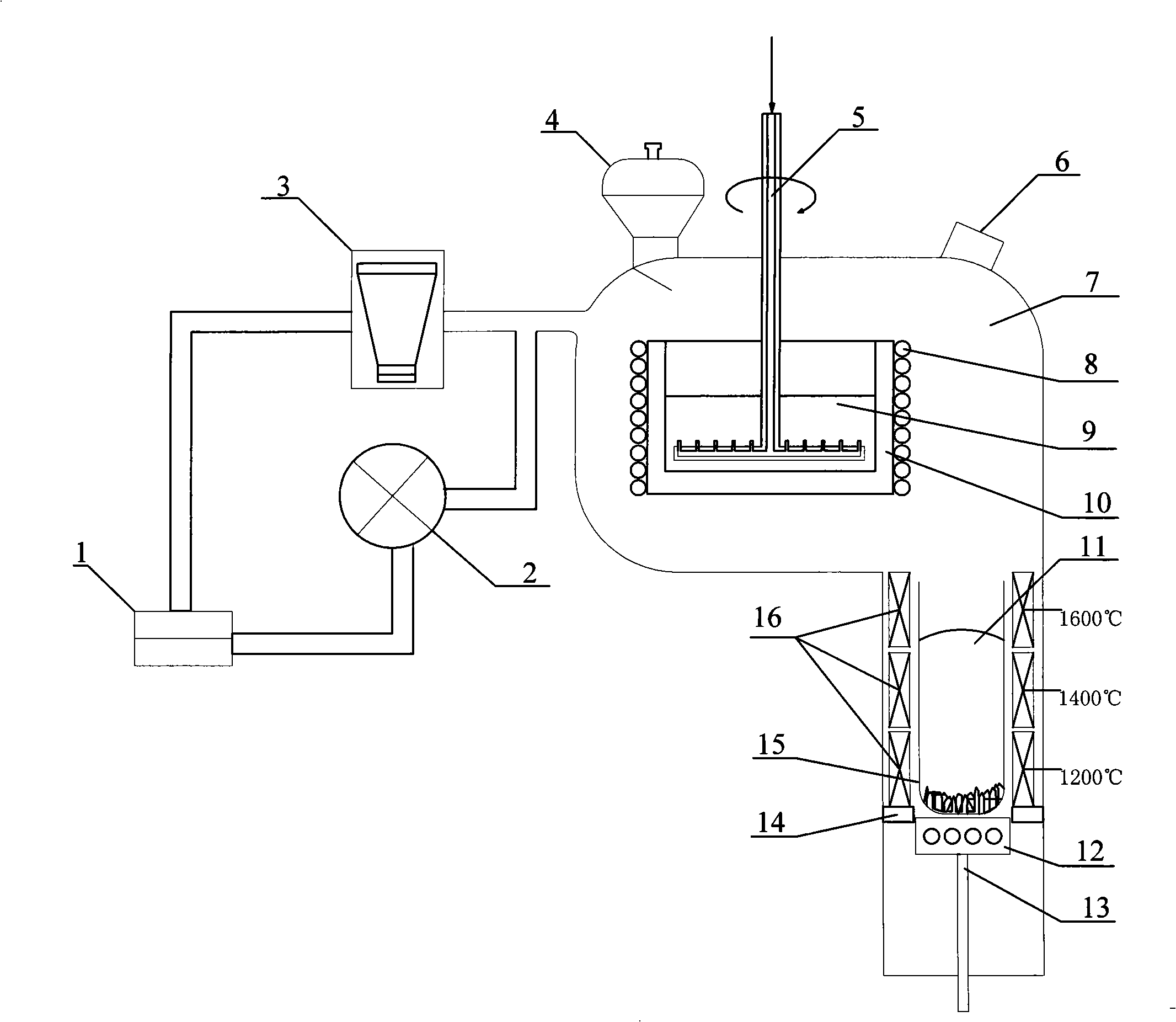

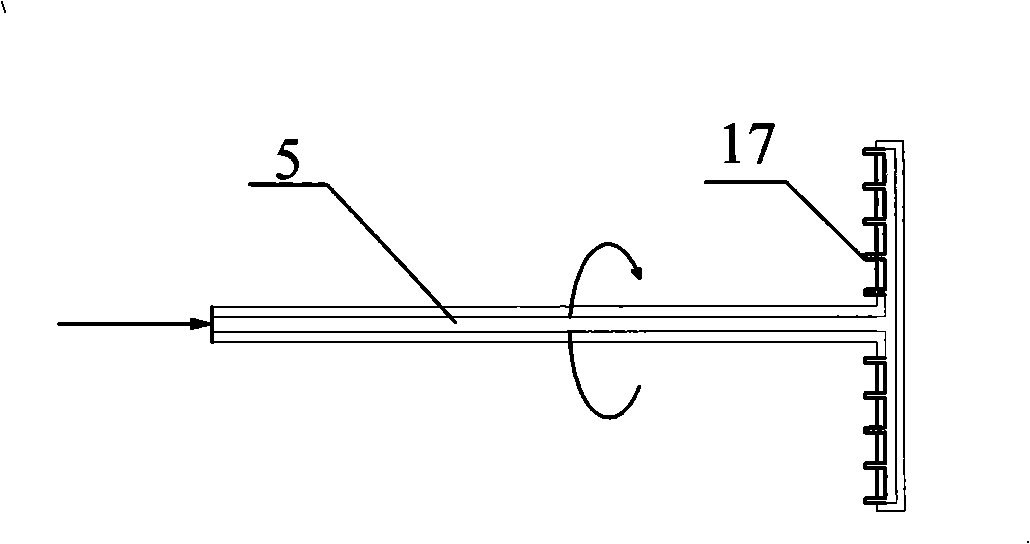

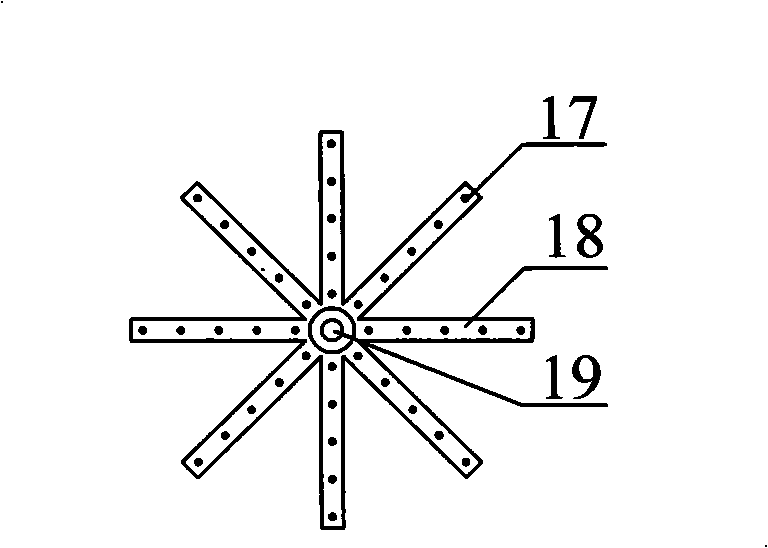

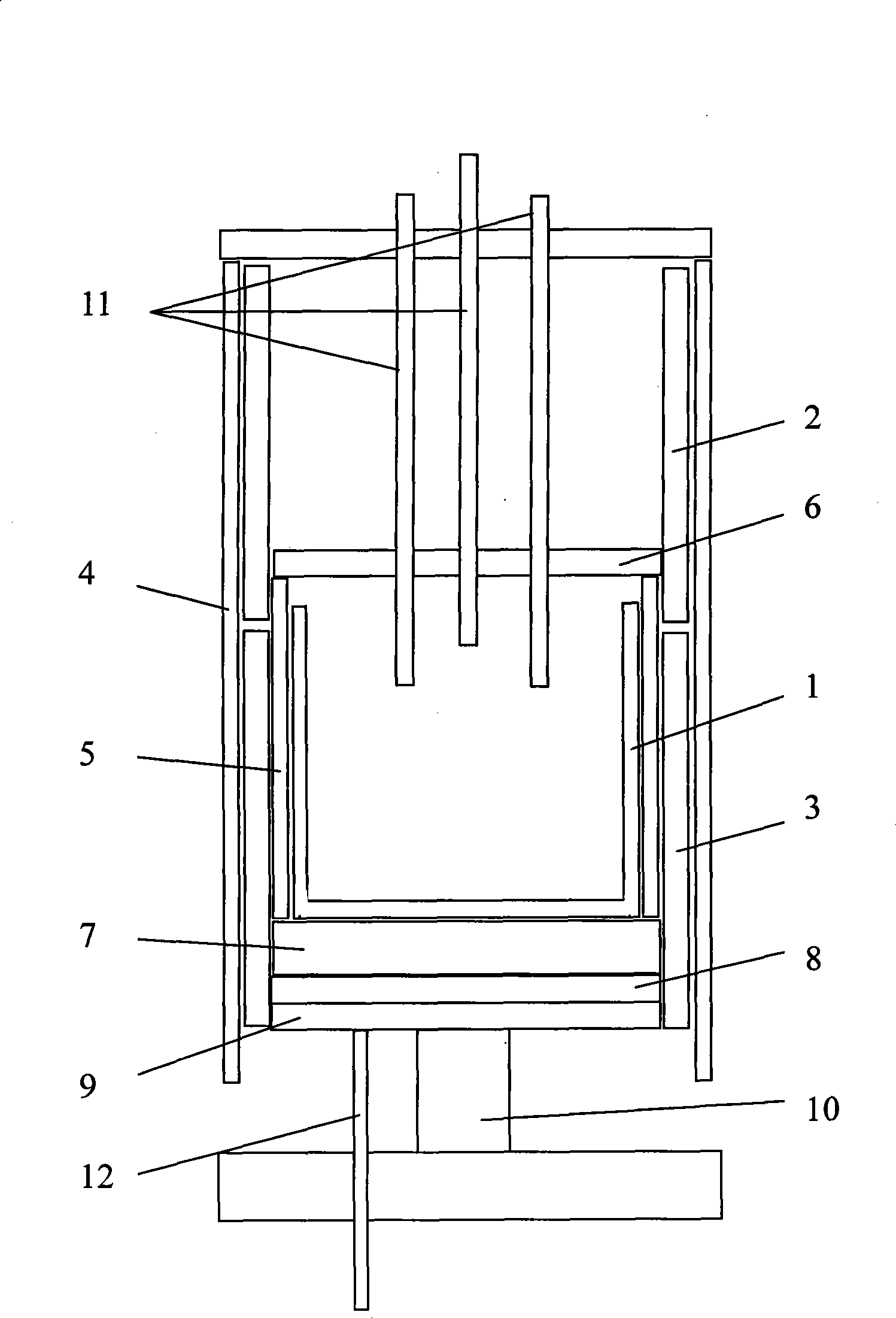

Purification apparatus and method for solar energy level polysilicon

Disclosed are a purification device as well as a purification method of solar-grade polysilicon, relating to a polysilicon, which provides a purification device and a purification method of solar-grade polysilicon characterized by low cost, high purity, simple process, easy operation and suitability for large-scale production. The purification device is equipped with a vacuum system, a melting system and a directional solidification system; wherein the vacuum system is provided with a mechanical rotary vane pump, a lobed element pump and an oil diffusion pump, and the melting system is provided with a vacuum chamber, a secondary feeder, an observation window, a rotary ventilation device which can be raised and lowered, an induction coil and a graphite crucible; and the directional solidification system is disposed at the lower part of the vacuum chamber and is equipped with an electric resistance-wire heating and holding furnace, a graphite mold, a holding furnace frame, a water-cooled copper tray and an elevating lever which can control speed. The metal silicon is treated by induction heating to be molten, the oxidizing gas is fed under conditions of low vacuum and high temperature to remove boron, and then under conditions of high temperature and high vacuum to remove phosphorus, and finally the molten silicon solution is poured into a directional mold to strictly conduct directional solidification to remove metal impurities.

Owner:XIAMEN UNIV

Method for manufacturing polycrystalline silicon used for solar battery

InactiveCN101122047ASolve environmental problemsPolycrystalline material growthFinal product manufactureSilicon monoxideElectrical battery

A method of preparing a polycrystalline silicon for solar batteries adopts combined means of silicon monoxide disproportionation, acid dipping separation and vacuum melting and processes by the following procedures: (1) the silicon monoxide is made from chemical pure industrial silicon and high purity sand quartz. (2) the high purity silicon is obtained by disproportionation of the silicon monoxide. (3)impurities boron and phosphorus in the silicon are removed by soaking with aquafortis. (4) the high purity silicon is further purified by melting of a vacuum electro beam furnace, and parts with impurities heavily gathered in a cast ingot are cut. (5) nitrogen or nitrogen plus hydrogen is fed into a plasma furnace for melting, so as to further remove the rest boron, phosphorus and other impurities, and conduct directional solidification. (6)the outer skin and parts with impurities heavily gathered of the cast ingot are cut, and finally the high purity silicon which is above 6N pure and applicable to solar batteries is obtained. The invention rejects the technical route of the Siemens method, prevents environment pollution, improves safety of production, and is good for promotion and application in China.

Owner:李绍光

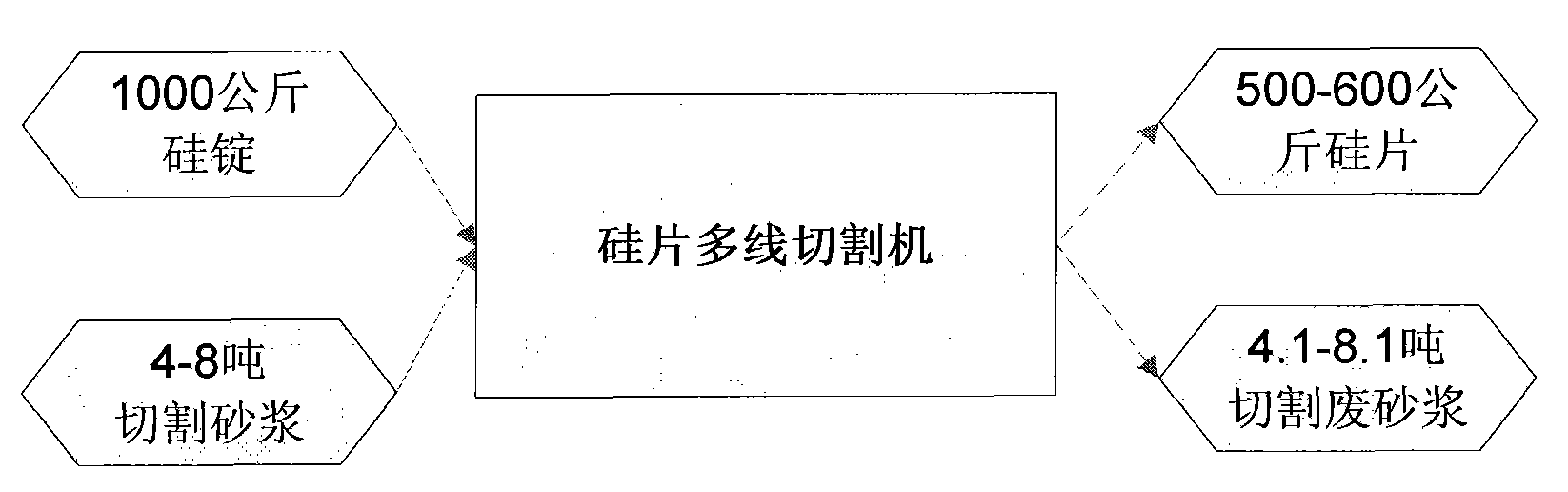

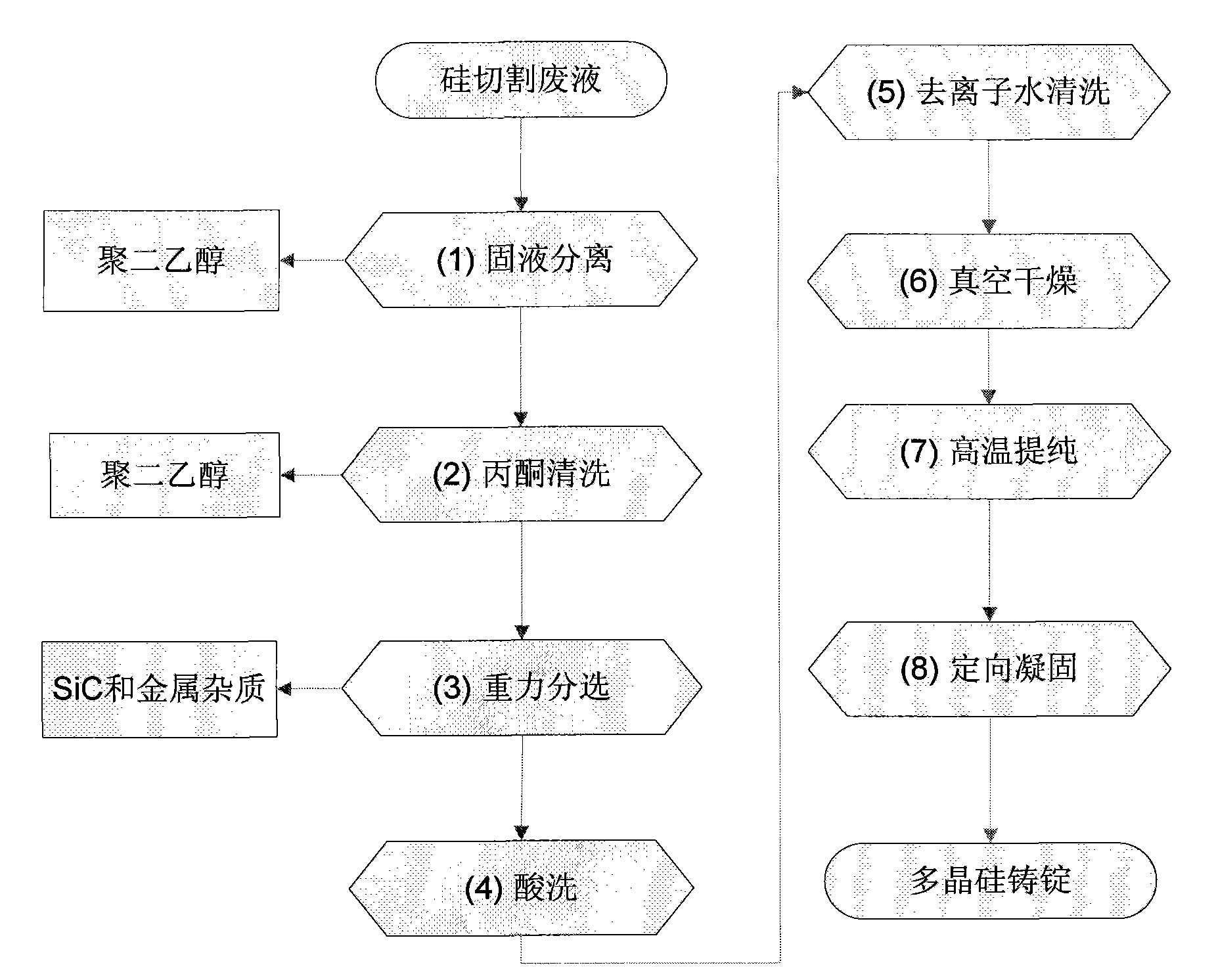

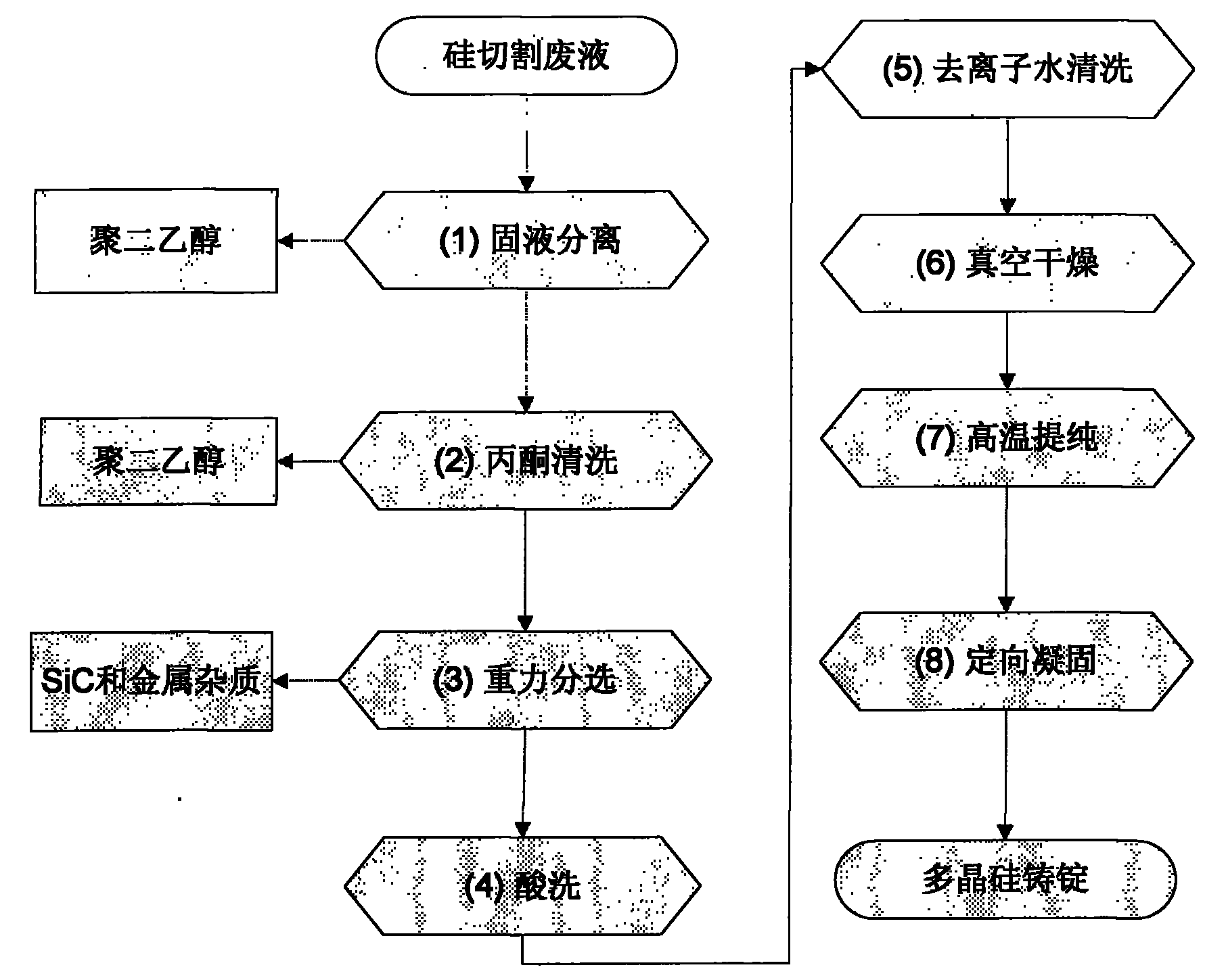

Method for recovering polysilicon ingots, carborundum powder and polyethylene glycol from cutting waste mortar

InactiveCN101792142AHigh yieldMultistage water/sewage treatmentSilicon compoundsPotassiumPolyethylene glycol

The invention discloses a method for recovering polysilicon ingots, carborundum powder and polyethylene glycol from cutting waste mortar. The recovering method comprises the following steps shown as an attached diagram, wherein the high temperature purification comprises the following steps of: mixing the prepared silicon micro powder with a fluxing agent according to the weight ratio of 1: 0.5-5 into lumps, carrying out high temperature treatment in a high temperature vacuum furnace with the treatment temperature range of 1450-1800 DEG C and the treatment time range of 1-10h; and then carrying out directional solidification on melting-state high purity silicon subjected to the high temperature treatment to obtain the polysilicon ingots; wherein the fluxing agent is selected from one or any mixture of silica, alumina, calcium oxide, magnesium oxide, potassium oxide, sodium oxide, calcium fluoride, magnesium fluoride, sodium fluoride, sodium chloride, potassium chloride and calcium chloride. The invention has the advantages that: the yields of carborundum and polyethylene glycol are high and can reach more than 70-80 percent; and the recovered polysilicon ingots reach the purity of 6-7N and completely satisfy of the requirement for preparing silicon slices of silicon solar cell.

Owner:唐康宁

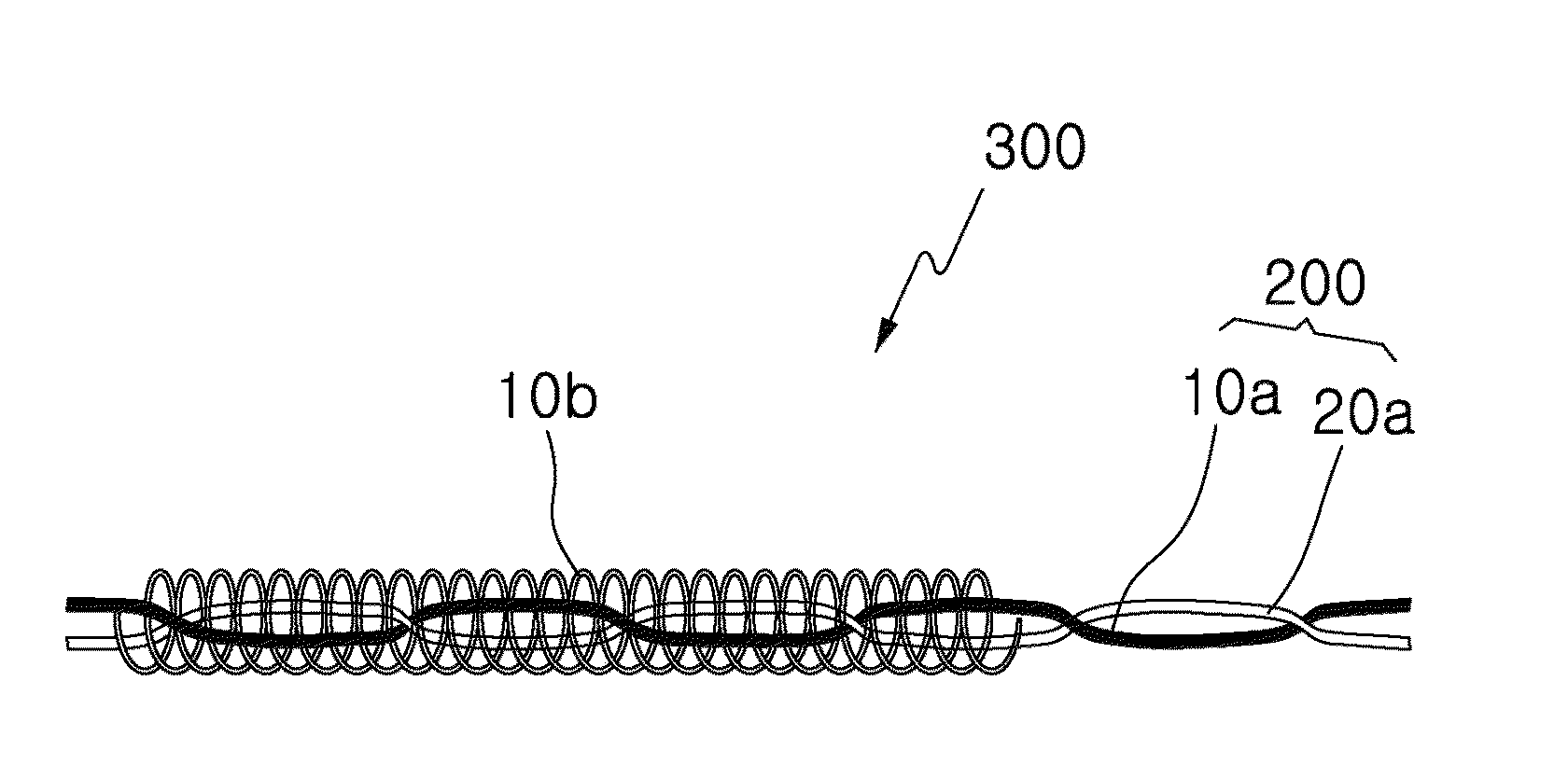

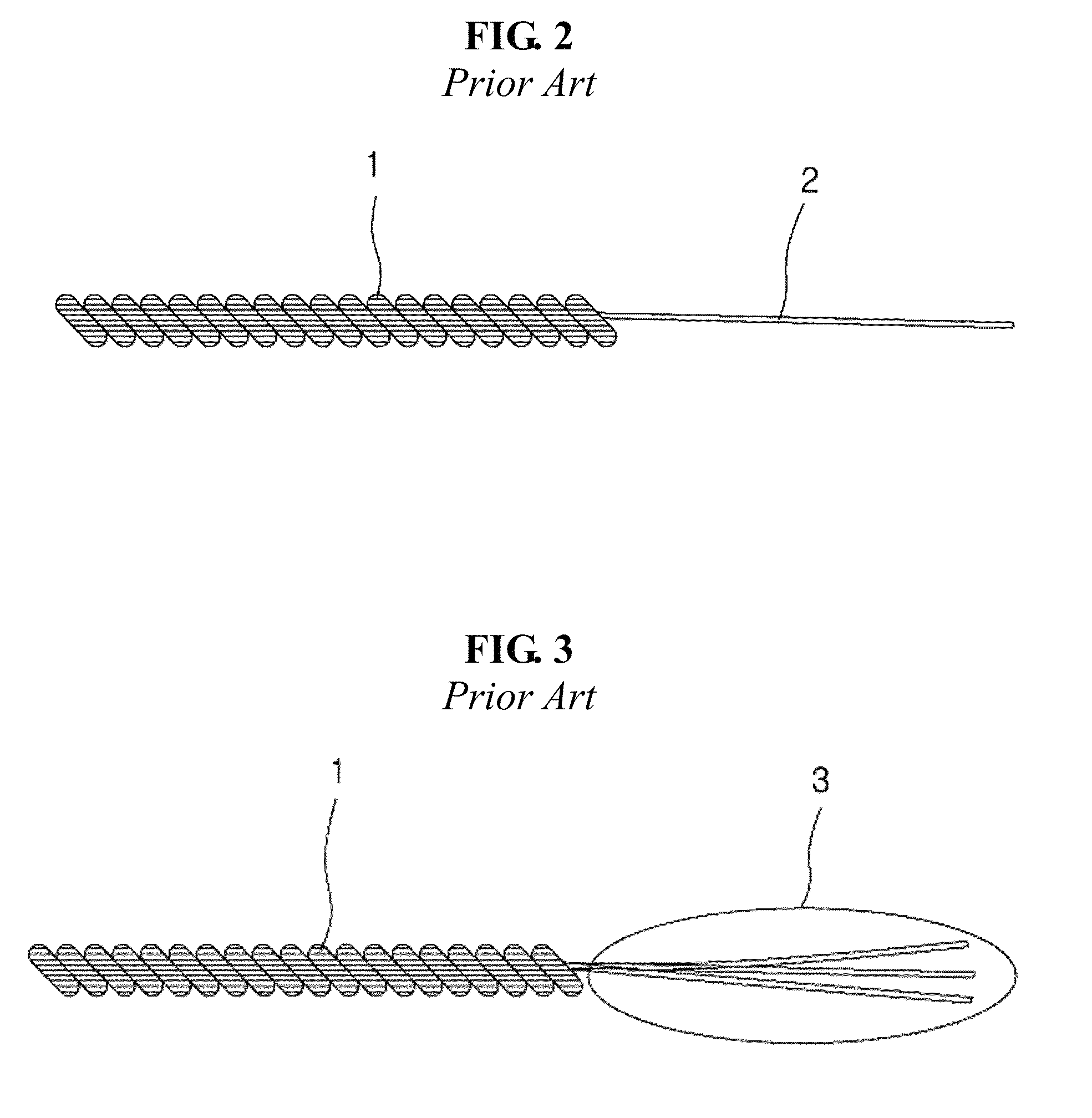

Silver yarn, plied yarn silver yarn, functional fabric using same, and method for producing same

ActiveUS8549829B2Effect andHighly effective in preventing electromagnetic waves and static electricityWeft knittingYarnWire rodYarn

The present invention relates to plied silver yarn using silver wire as thread, wherein the silver wire is entirely made of silver (Ag) or a silver alloy, to achieve antimicrobial properties and conductivity, as well as to functional fabric using same and to a method for producing same. The plied silver yarn of the present invention uses, as a core yarn, any one of at least one strand of silver wire and fiber yarn made from natural fiber or synthetic fiber, and uses the other as winding yarn covering the core yarn, wherein said one strand of silver wire is produced by casting a silver alloy containing pure silver or copper into a wire rod through directional solidification, and making the wire rod into a microfiber having a diameter of 0.015 to 0.05 mm through a pulling process.

Owner:AMOGREENTECH CO LTD

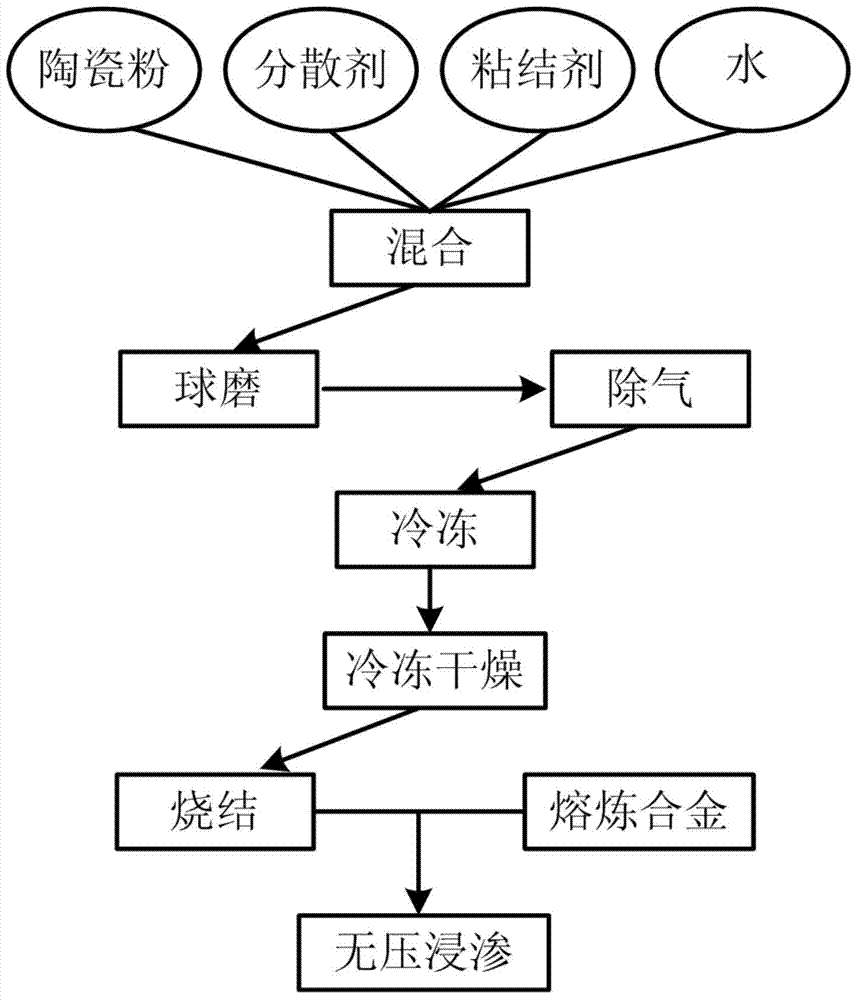

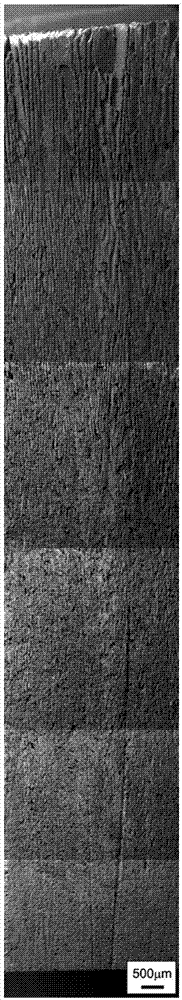

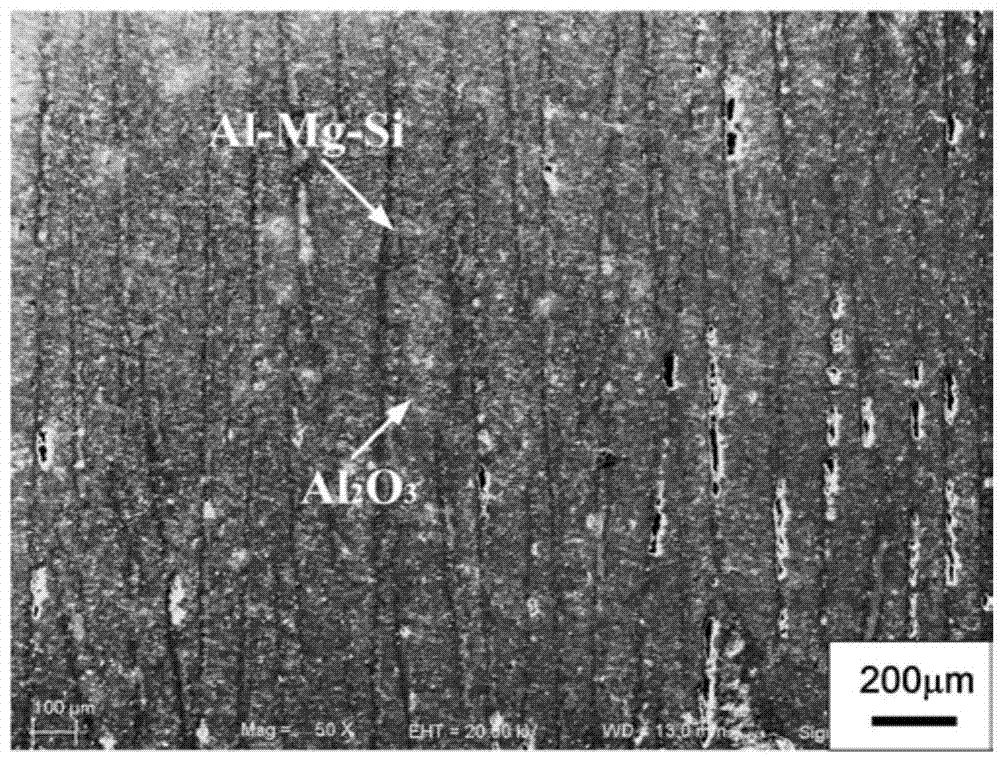

High-strength lamellar Al-based metal ceramic composite material and preparation method thereof

InactiveCN103895285ANot easy to sinterEasy to manufactureCeramicwareMetal layered productsWater basedMass ratio

The invention discloses a high-strength lamellar Al-based metal ceramic composite material and a preparation method thereof, aiming at solving the problems of high preparation cost, complex operation, single type of reinforcement ceramic and low strength. The high-strength lamellar Al-based metal ceramic composite material, i.e., high-strength lamellar structure Al-Si-Mg / (Al2O3, SiC, TiC) composite material comprises ceramic powder and Al-Si-Mg alloy. The volume fraction of ceramic powder is 20%-40vol%; the volume fraction of Al-Si-Mg alloy is 80%-60vol%; the mass ratio of aluminum in the Al-Si-Mg alloy is 75-84wt%; the mass ratio of silicon is 10-15wt%; the mass ratio of magnesium is 6-10wt%. The preparation method of the high-strength lamellar Al-based metal ceramic composite material comprises the following steps: preparation of water-based ceramic slurry; directional solidification; freezing and drying; sintering of blanks; smelting of alloy; and non-pressure infiltration.

Owner:JILIN UNIV

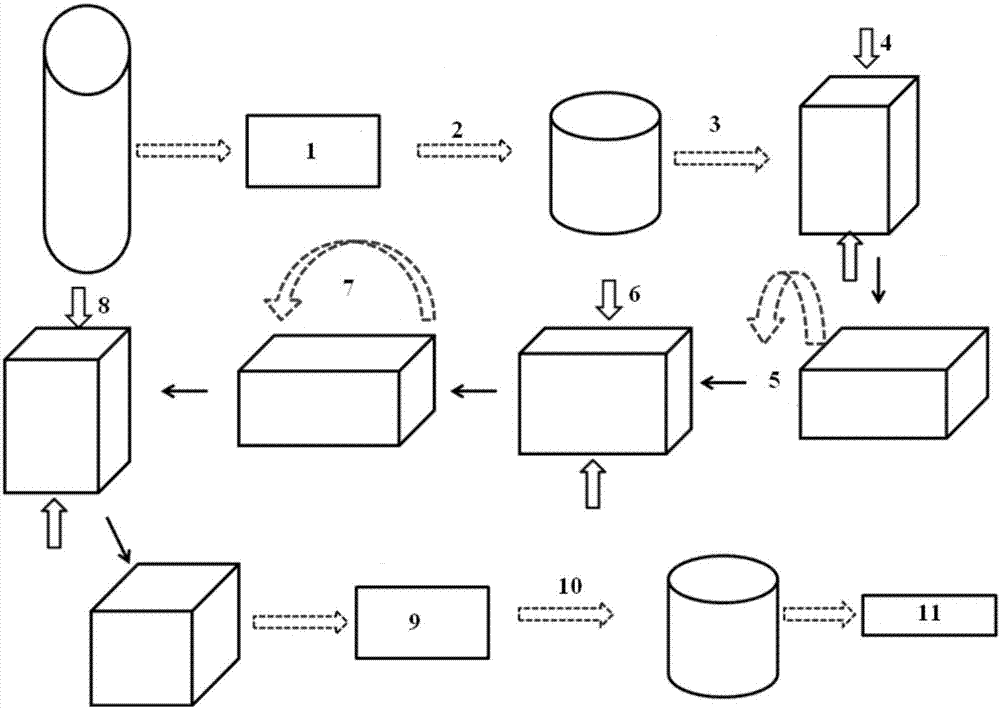

Multidirectional forging method for high-alloyed high-temperature alloy sheared billet/biscuit

ActiveCN106862447AAccurately measure uniformityGuaranteed uniformityMetal-working apparatusFine structureUltra fine

The invention relates to a forging method, in particular to a multidirectional forging method for obtaining a high-alloyed high-temperature alloy sheared billet / biscuit with the uniform and fine structure. The multidirectional forging method includes the following steps that (1) high-temperature homogenizing treatment is conducted on a low-segregation and high-purity controlled directional solidification ingot blank; (2) the controlled directional solidification ingot blank is subjected to upsetting and cogging; (3) the upset blank is forged into a cuboid blank; (4) multidirectional forging is conducted on the cuboid blank; (5) the blank subjected to multidirectional forging for multiple cycles is subjected to finishing, so that a shear billet / biscuit of the required size is obtained; and (6) the obtained shear billet / biscuit is subjected to physical and chemical testing. The multidirectional forging method is not only suitable for preparation of uniform and ultra-fine-grain high-alloyed nickel-based high-temperature alloy sheared billets for aviation, spaceflight and vessels, but also can be popularized to a steel mill to product high-speed steel and hot-working die steel, and the prepared ultra-fine-grain shear billets have the characteristic of uniform structure.

Owner:CENT IRON & STEEL RES INST

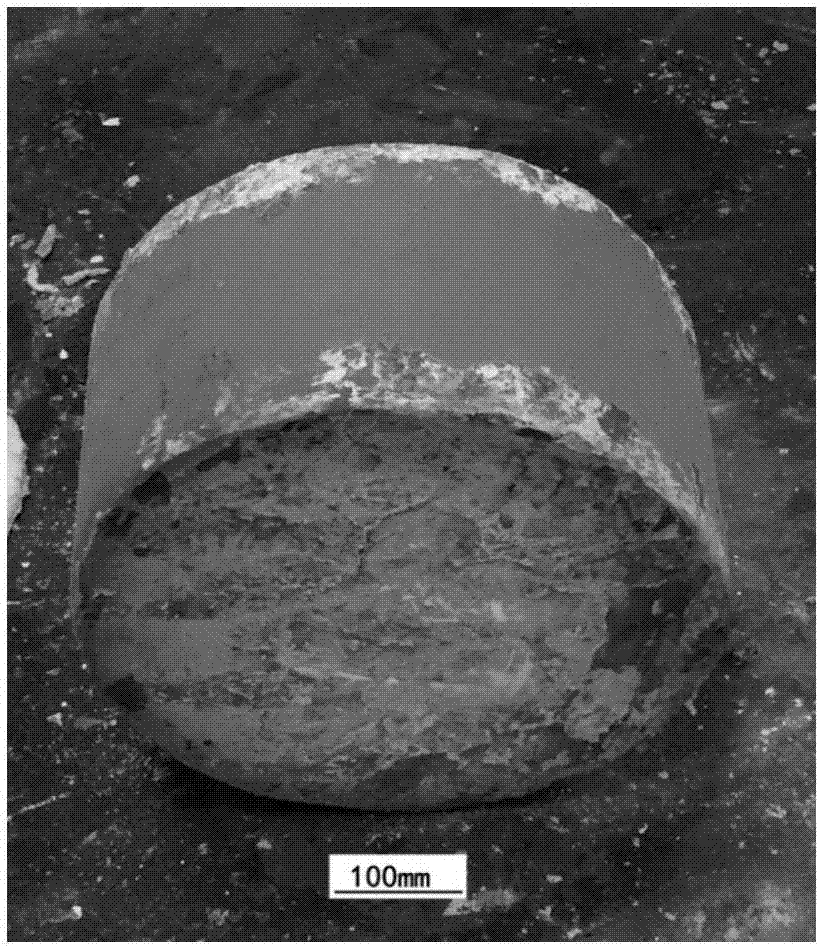

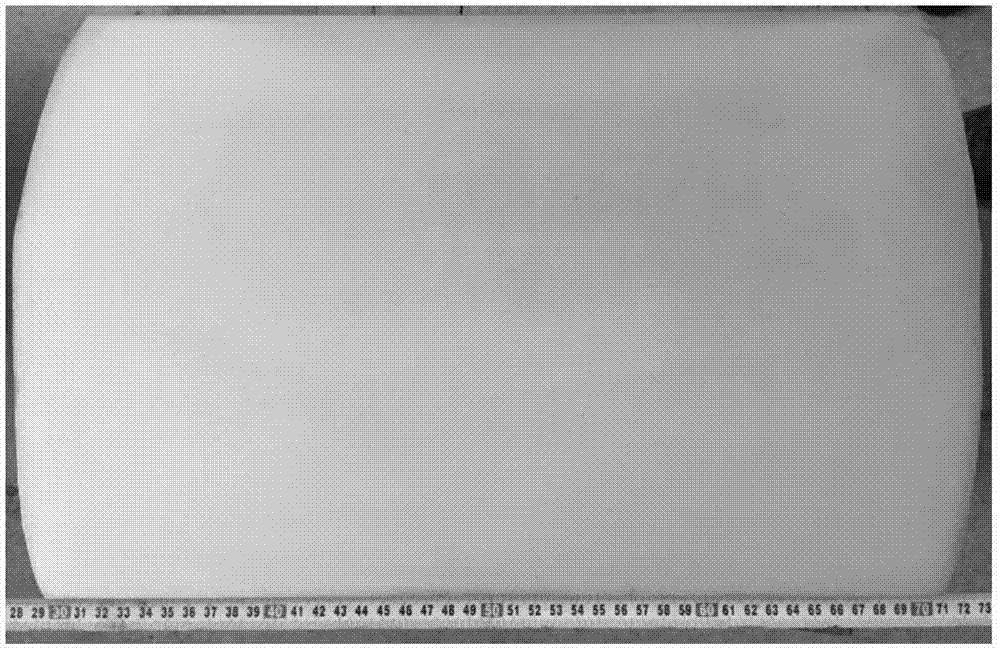

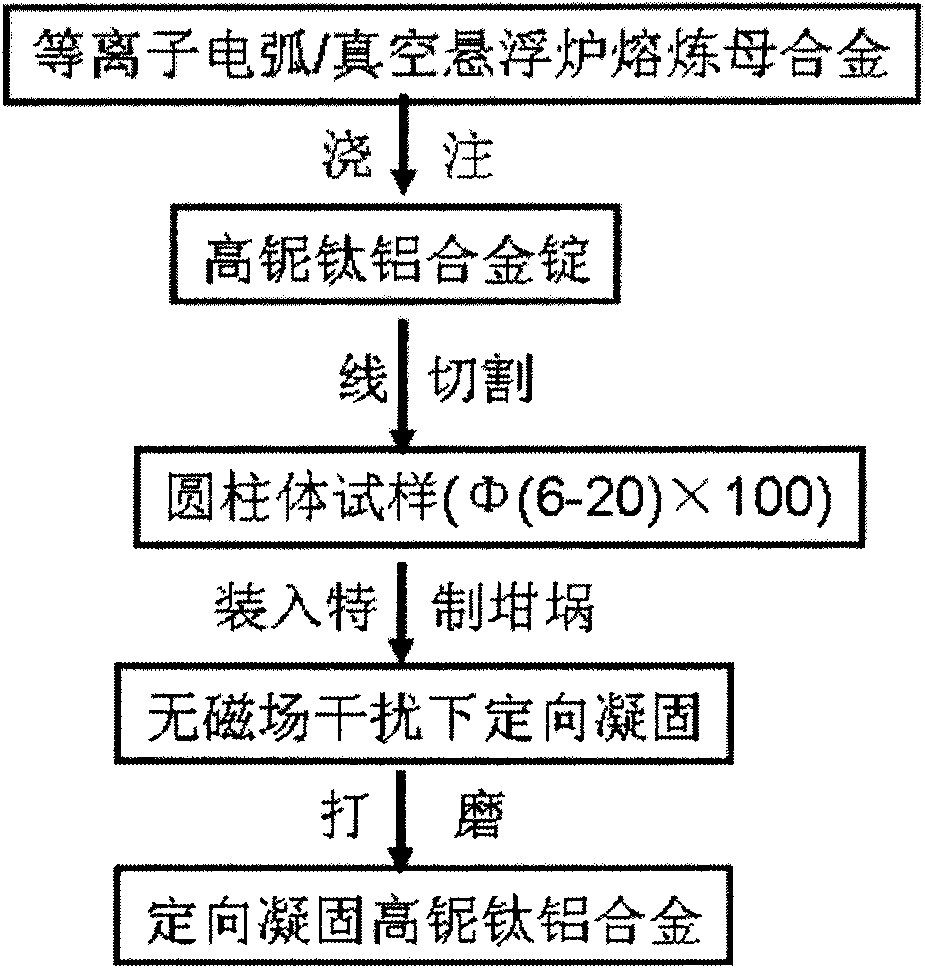

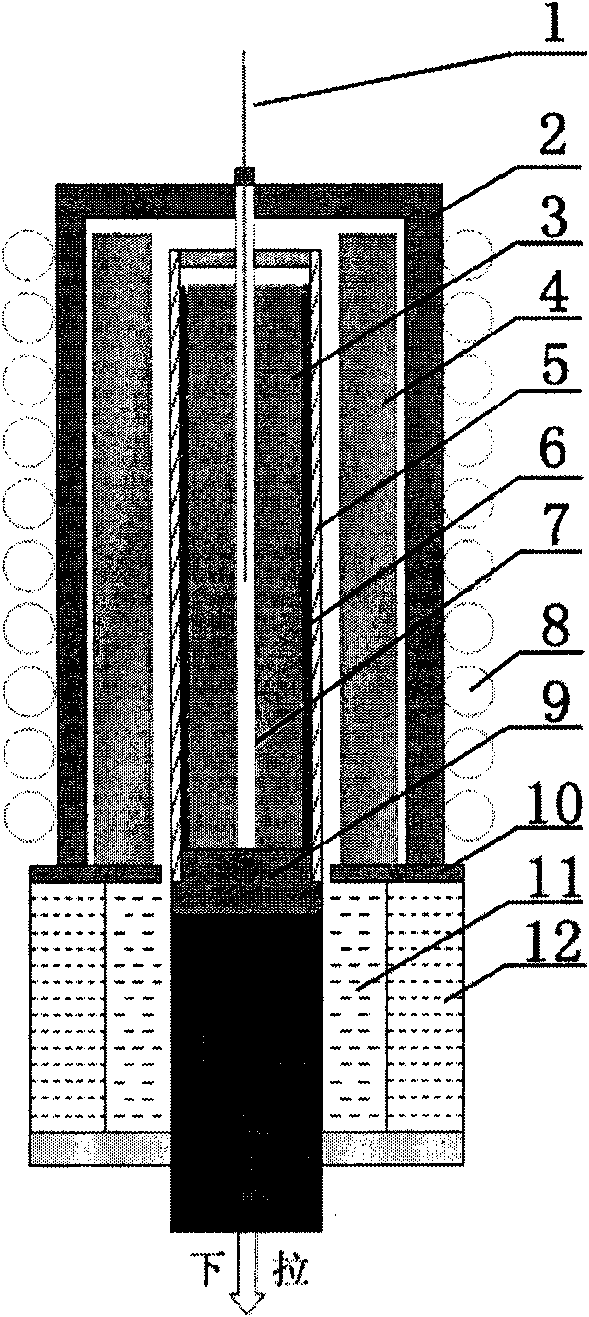

Preparation method of directional solidification high-niobium TiAl-base alloy

ActiveCN101875106AHigh melting pointImprove room temperature performanceMetallic materialsZone melting

The invention discloses a preparation method of a directional solidification high-niobium TiAl-base alloy, which belongs to the field of metal material preparation. The high-niobium TiAl-base alloy contains Ti, Al, Nb, W, Mn, C, B and Y, and the atomic percentage is: (43-49) Ti-(45-46) Al-(6-9) Nb-(0-0.5) (W and Mn)-(0-0.5) (C and B)-(0-0.5) Y, an as-cast master alloy rod which is smelted by plasma arc or vacuum suspension is taken as a raw material, a high-purity alumina ceramic tube with a coating layer of which the main component is yttrium oxide is used as a crucible, Ga-In-Sn alloy liquid is cooling liquid, and the directional solidification high-niobium TiAl-base alloy is successfully prepared by using an improved zone-melting and directional solidification system. The processing technology is simple and reliable, the directional solidification effect is obvious, and the method has universal applicability. The directional solidification high-niobium TiAl-base alloy which is prepared by the directional solidification method has comprehensive and good high temperature performance and room temperature ductility and has wide application prospect in terms of high temperature structural materials.

Owner:UNIV OF SCI & TECH BEIJING

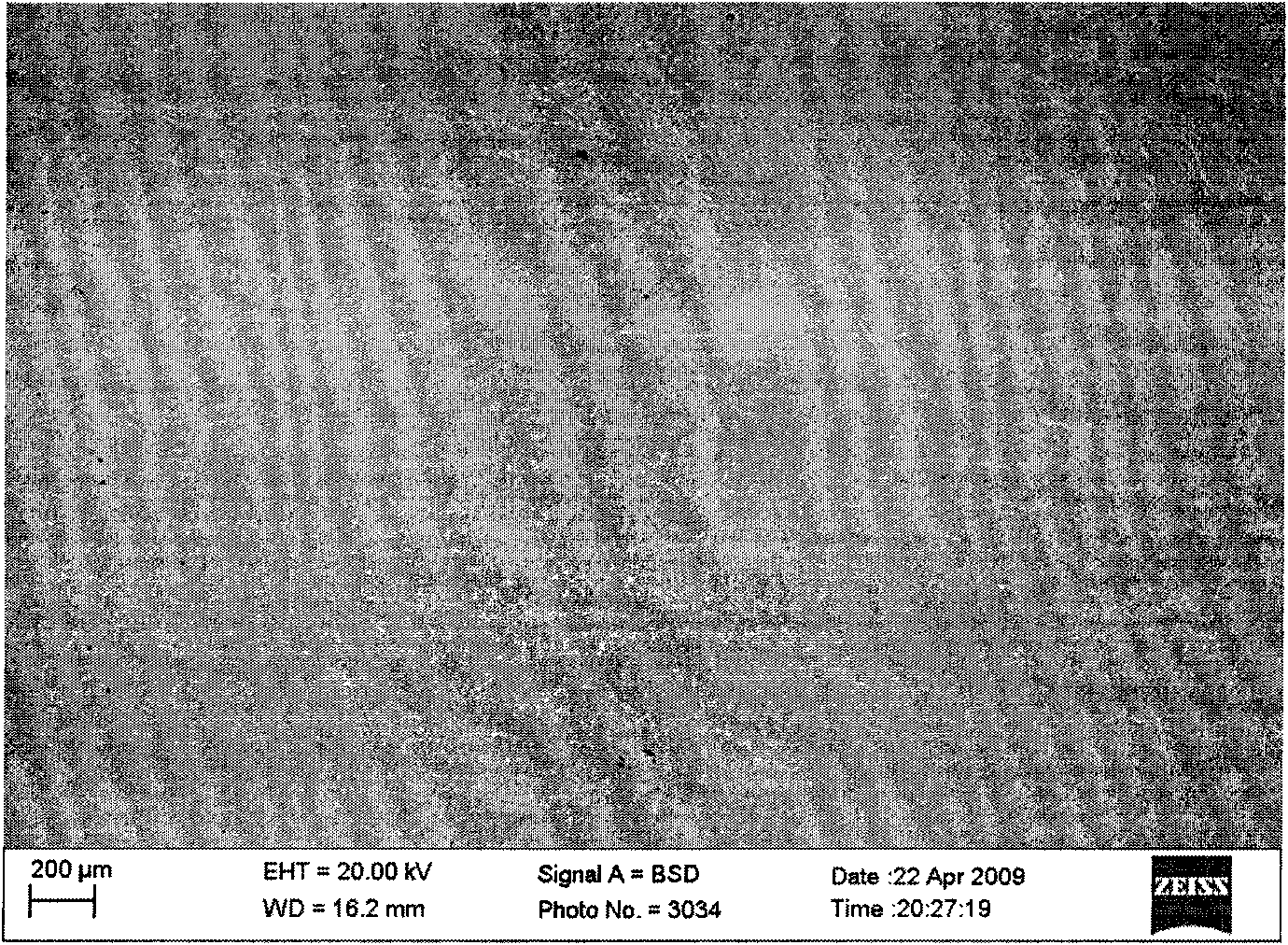

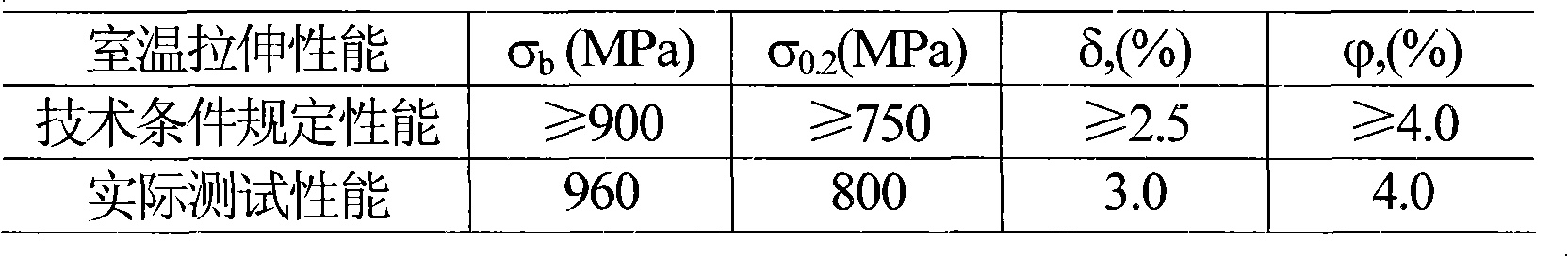

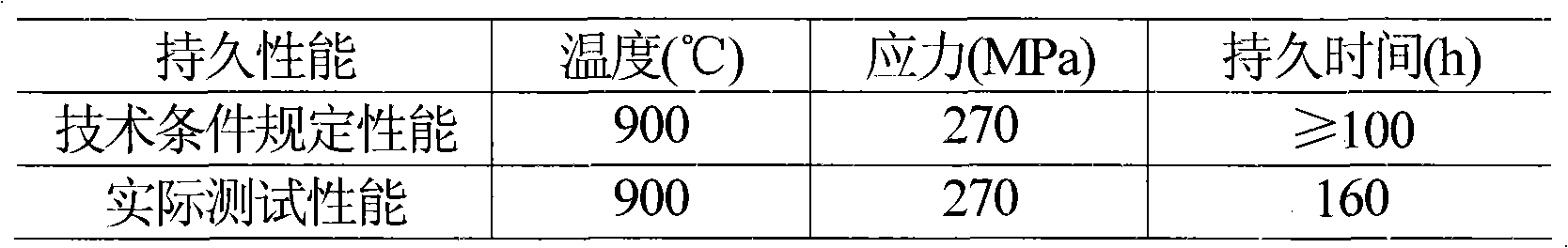

Directional solidification heat corrosion resistant nickel base cast superalloy and preparation method thereof

InactiveCN101294250AImprove performanceElimination of lateral grain boundariesLiquid metalInduction furnace

The invention relates to a directional-freezing heat-proof corrosion-resistant nickel base cast superalloy with low cost and excellent performance. The cast superalloy has the chemical composition range by weight percentage as follows: C is 0.04 to 0.09; Cr is 14.5 to 15.3; Co is 9.0 to 9.9; W is 4.7 to 5.9; Mo is 1.6 to 2.3; Al is 2.8 to 3.3; Ti is 4.2 to 5.0; Hf is 0.3 to 0.6; Ta is 0.3 to 1.5; B is 0.06 to 0.10; Y (adding quantity) is 0.015; Mn is less than or equals to 0.2; Si is less than or equals to 0.2; P is less than or equals to 0.008; S is less than or equals to 0.008; Fe is less than or equals to 0.5; the other weight percentage is composed of Ni. A vacuum induction furnace is adopted to smelt master alloy, and the directional-freezing is performed in a liquid-metal-cooled (LMC) furnace to prepare columnar grain alloy; the vacuum degree of a directional furnace is less than or equals to 5*10<-4>mmHg, the casting temperature ranges from 1480 to 1570 DEG C, the drawing velocity is 3 to 15mm / min, the temperature gradient is 95 to 145 DEG C / cm, and the temperature of melting tin ranges from 250 to 350 DEG C. The invention provides the heat-proof corrosion-resistant superalloy, which contains Ta, does not contain alloying elements that are Re (with low cost), Nb, Zr and Ce, and has a stable microstructure. Compared with cheC88 Y-BN, the tensile-strength (using Delta (b) and Delta0.2 to represent) is increased more than 30 percent, the plasticity is improved obviously, the lasting temperature is risen by 30 DEG C under the same stress condition, and the cast superalloy is applied to manufacture turbine blades of a combustion turbine which is used under 930 DEG C.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Production method of large polycrystalline ingot

ActiveCN102021650AIncrease production capacityIncrease profitPolycrystalline material growthSingle crystal growth detailsCooking & bakingShielding gas

The invention relates to the technical field of ingot casting of solar energy batteries, in particular to a production method of a large polycrystalline ingot. Silicon nitride and water are mixed uniformly through electric mixing for 15-30 minutes, and the mixture is used as a coating liquid, the coating liquid is uniformly coated on the inner surface of a crucible after the crucible is preheated, and then high-temperature baking is carried out on the crucible, a silicon material is loaded in the baked crucible, and then charging is carried out on the crucible loaded with the silicon material, shielding gas-argon passes through a polycrystalline furnace after vacuumizing is carried out on the polycrystalline furnace, the polycrystalline furnace is heated to melt the silicon material, and then, the melted silicon material is gradually crystallized from the bottom part to the top part through directional solidification, and then discharging is carried out after gradual cooling is carried out through high-temperature annealing, the crucible is disassembled after the discharged polycrystalline ingot is cooled at room temperature, so as to obtain the polycrystalline silicon ingot which is sliced to prepare the battery. The large charging amount is realized, the capacity of the casting ingot is improved, the utilization rate of the polycrystalline ingot is improved, the cost is reduced, the requirements of a high-load slicer are met, and the crystal quality is kept to be unchanged.

Owner:TRINA SOLAR CO LTD

High-strength and high-conductivity CuAg alloy material and preparation method thereof

InactiveCN101643866AImprove as-cast structureSemiconductor/solid-state device detailsSolid-state devicesElemental compositionFiber

The invention discloses a high-strength and high-conductivity CuAg alloy material with a continuous fiber tissue and a preparation method thereof. The material consists of Cu, Ag, etc. Cu and Ag alloyingot with a columnar structure is obtained by a directional solidification technology, and continuous fibrous tissue structure is obtained by the technologies of extruding, drawing, etc. The components of the alloy material are as follows: 5-10wt% of Ag and balance of Cu. The preparation method of the CuAg alloy comprises the following steps: (1) preparing chemical composition; (2) vacuumizing asmelting room and a directional solidification room; (3) smelting the alloy; (4) directionally solidifying; (5) hot extruding; (6) hot processing; and (7) drawing wire or rolling. The material is applicable to slide contact material such as a middle-load and low-load switch, a breaker, a contactor, a micromotor slip ring, a commutating sheet, and the like, high-pulse magnetic field conductor material, an integrated circuit lead wire frame, a fish torpedo lead wire, an electric conduction reed, etc.

Owner:KUNMING INST OF PRECIOUS METALS

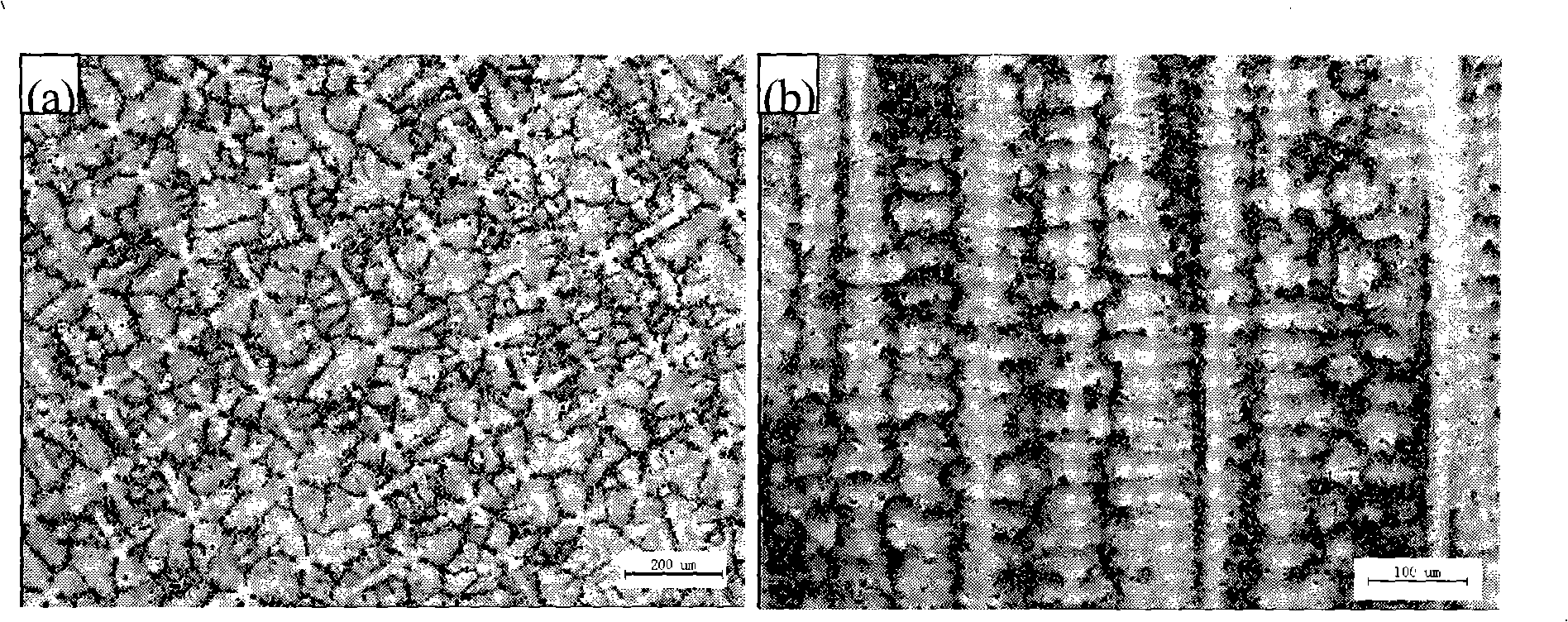

Preparation method of casting columnar multi-crystal silicon with large crystal grains in single crystal direction

ActiveCN101654805AReduce grain boundary densityLow elimination efficiencyPolycrystalline material growthSingle crystal growth detailsCrucibleSingle crystal

The invention discloses a preparation method for casting columnar multi-crystal silicon with large crystal grains in the same crystal direction, which comprises the following steps: (1) sequentially putting single-crystal silicon blocks, silicon raw materials and doped elements in a crucible; (2) heating the crucible to melt the silicon raw materials and the doped elements on the single-crystal silicon blocks, wherein all single-crystal silicon block can not be completely melted; and (3) starting heat exchange from the bottom of the crucible, and using the single-crystal silicon blocks as seedcrystals for induced growth and directional solidification to form the multi-crystal silicon. The columnar multi-crystal silicon with large crystal grains can effectively reduce the crystal boundarydensity in the materials and basically solves the problem of the reduction of the battery efficiency caused by the existence of a large number of crystal boundaries in the prior common process of casting the multi-crystal silicon; and meanwhile, the crystal grains in the multi-crystal silicon prepared by the invention have the same crystal direction, so that the high-efficiency alkaline wool making technology in the preparation process of batteries can be used, thereby improving the absorption efficiency of batteries for light.

Owner:ZHEJIANG UNIV

Production method of oriented high-silicon-steel thin plates

The invention relates to a production method of oriented high-silicon steel thin plates, which belongs to the technical field of metal material production. The process comprises the following steps of: 1. obtaining cylindrical crystals grown in (100) directions by adopting a directional solidification method, and wherein the solidification rate is controlled between 0.6 and 15 mm / min and the temperature gradient is controlled between 60 and 400K / cm; 2. heating plate blanks at the heating temperature between 800 DEG C and 1300 DEG C, and then hot rolling the plate blanks to obtain sheet steel of 1.0-4.0mm; 3. carrying out annealing heat treatment and acid washing on the hot rolled plate blanks, and warm rolling the hot rolled plate blanks to obtain 0.4-0.8mm; and 4. carrying out heat treatment on warm rolled plates, and carrying out multiple cold rolling and secondary recrystallization annealing to obtain the oriented high-silicon steel. The production method has the advantages that the directional solidification method is utilized for controlling organization and crystal grain orientation from the material production source, a cold rolling method is used for producing alloy oriented plate materials, and the soft magnetic performance of the high-silicon steel is greatly improved. Produced cold rolled thin plates have good plate shapes.

Owner:UNIV OF SCI & TECH BEIJING

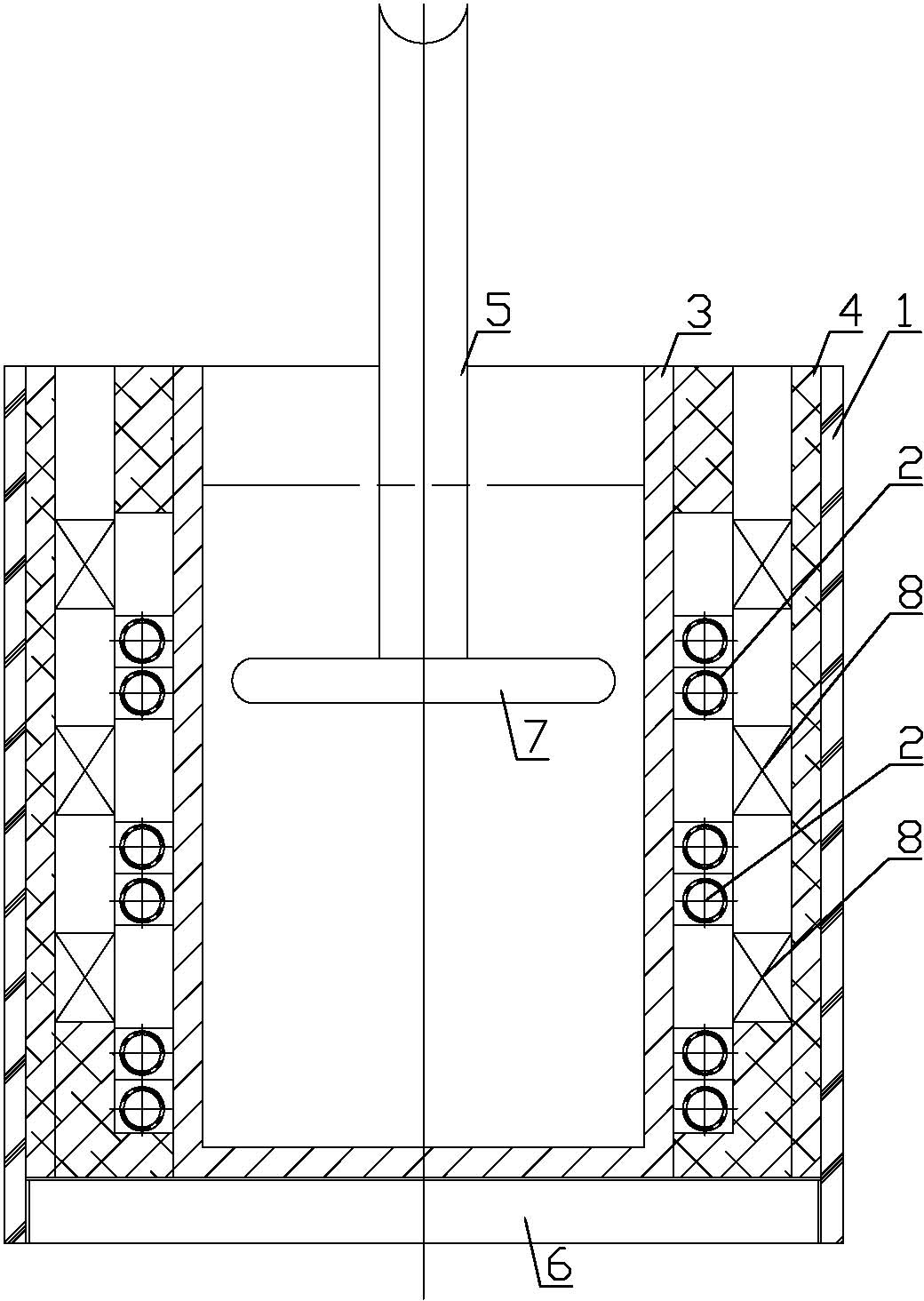

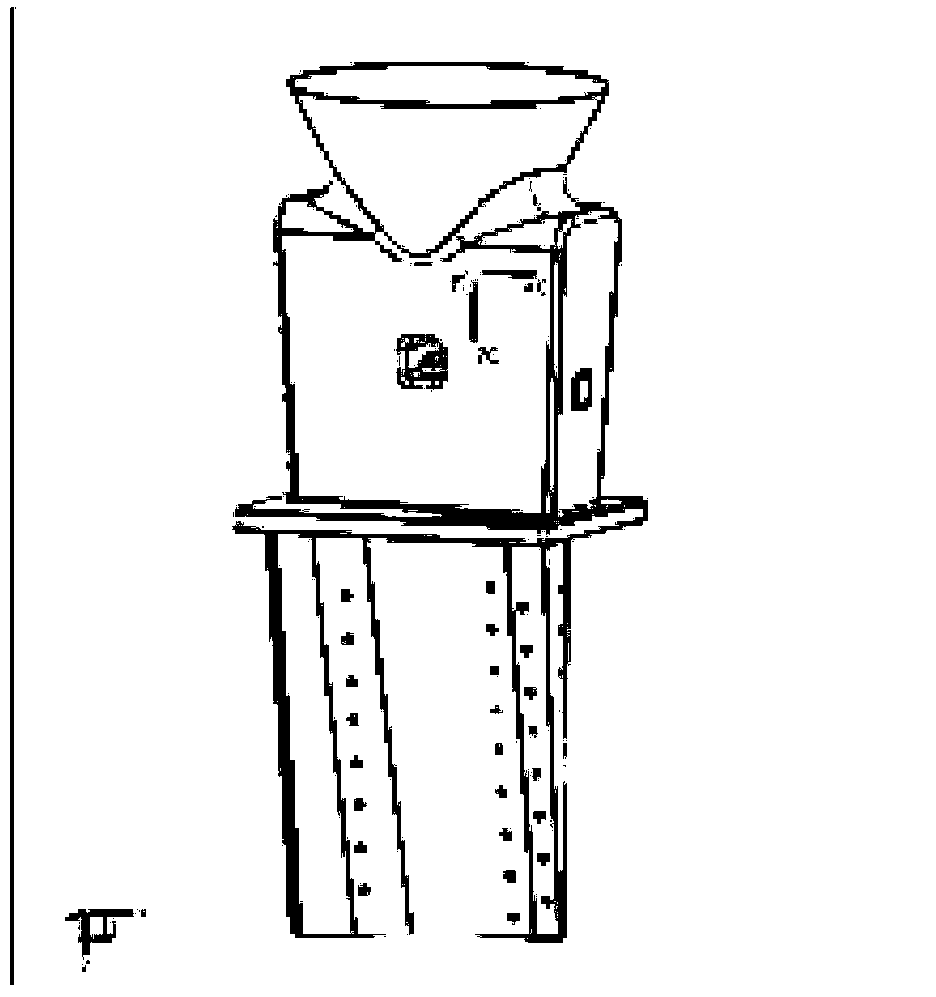

Method for purifying and ingot casting multi-temperature zones silicon material and apparatus thereof

InactiveCN101423220AAvoid coolingAvoid heatingAfter-treatment apparatusPolycrystalline material growthElectrical resistance and conductanceCrucible

The invention provides a method and a device used for purifying and ingot-casting of multi-temperature area silicon material; the silicon material is added into a crucible after a fluxing medium is added; the silicon material is inductively heated, fused and vacuum-smelted; furthermore, oxidative gas is added to carry out the reaction; subsequently, temperature reducing and directional solidification are carried out to the silicon material to form silicon ingots by crystallization. The device comprises a crucible system, a lifting device, an induction heater and a resistance heater; the induction heater is arranged on the upper surface of the resistance heater so as to respectively form an induction heating area and a resistance heating area; the lifting device is arranged on the lower surface of the resistance heating area and can move up and down in the induction heating area and the resistance heating area; and the crucible system is arranged on the lifting device. The method and the device can be used for purifying and ingot-casting the silicon ingot with high purity and high purification efficiency, can complete the whole process in one furnace body and can save the time and energy resource.

Owner:PROPOWER RENEWABLE ENERGY SHANGHAI

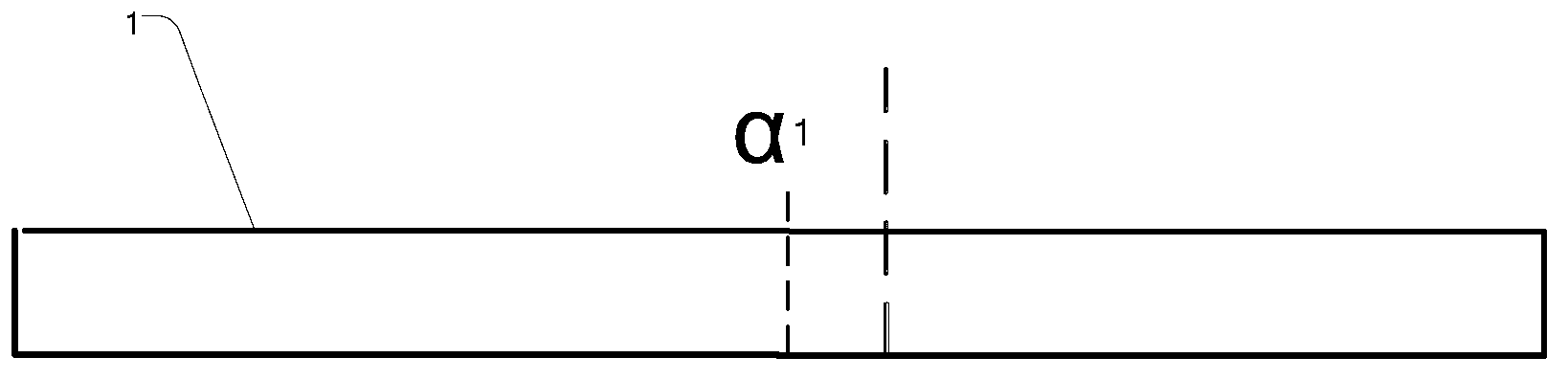

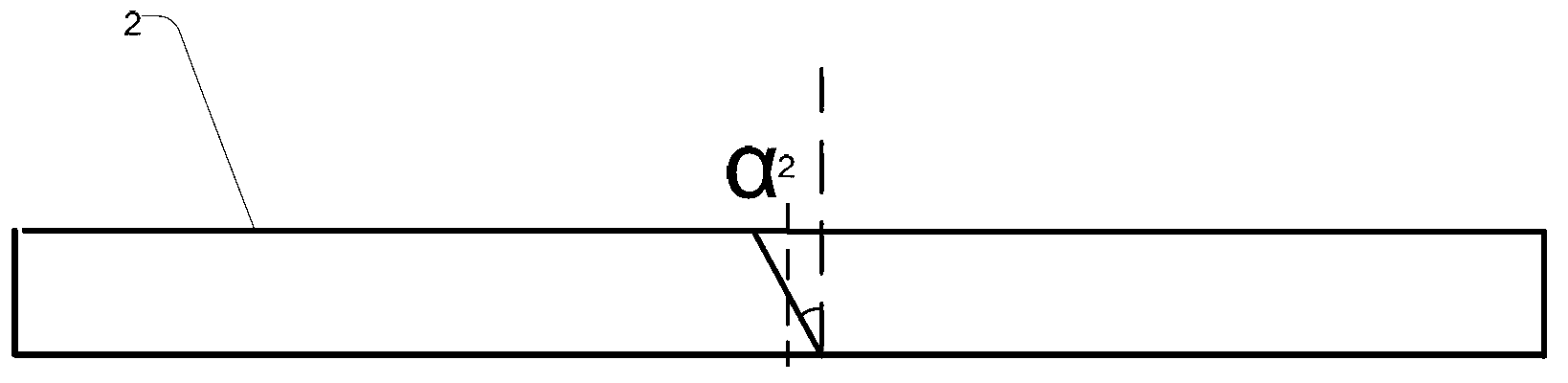

Seed crystal splicing method used for monocrystal-like silicone cast ingot

ActiveCN103060892AReduce generationPromote growthPolycrystalline material growthFrom frozen solutionsSolar batteryDislocation

The invention discloses a seed crystal splicing method used for monocrystal-like silicone cast ingot, and used for directional solidification method monocrystal-like silicone cast ingot. Seed crystal layers are formed by seed crystal closely arrayed. An alpha angle is formed between the tangential direction of at least one of spliced surfaces of every two blocks of seed crystal and the normal direction of a plane at the bottom of a crucible, wherein 0 degree < alpha <90 degrees. The seed crystal splicing method that the splicing surface is tangent to the normal direction of the plane at the bottom of the crucible, and the splicing surface does not coincides with the normal direction of the plane at the bottom of the crucible is adopted. The shape of the seed crystal is changed to reduce dislocation source and even the generation of polycrystalline grain boundaries, all-momocrystal is achieved, and monocrystal-like with less dislocation source grows. Therefore, dislocation defect of silicon slices is reduced, monocrystal area proportion is increased, photoelectric conversion efficiency of a solar battery is improved, the service life of the battery is prolonged, and therefore the performance of a photovoltaic device is improved.

Owner:JIANGXI SAI WEI LDK SOLAR HI TECH CO LTD

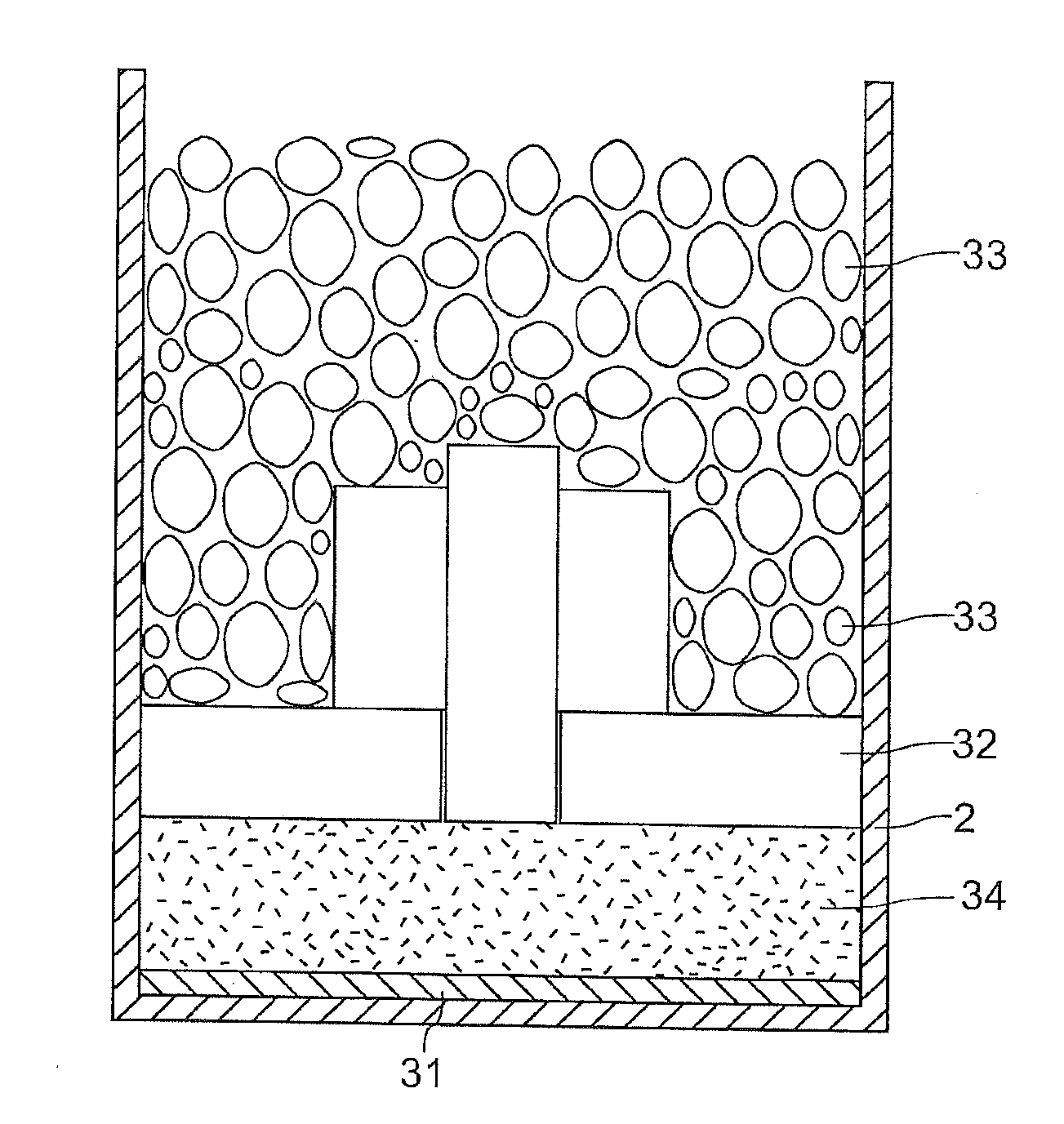

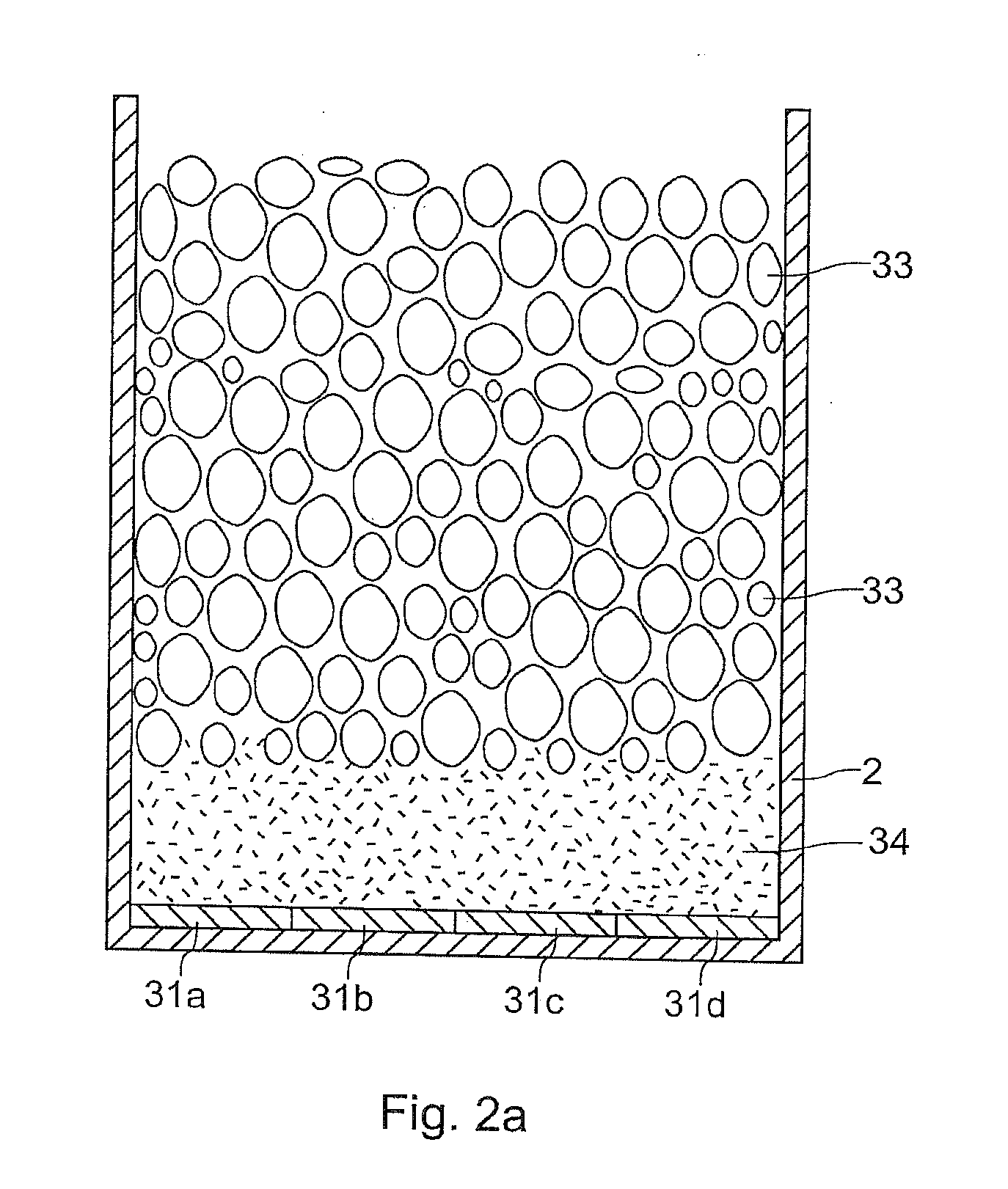

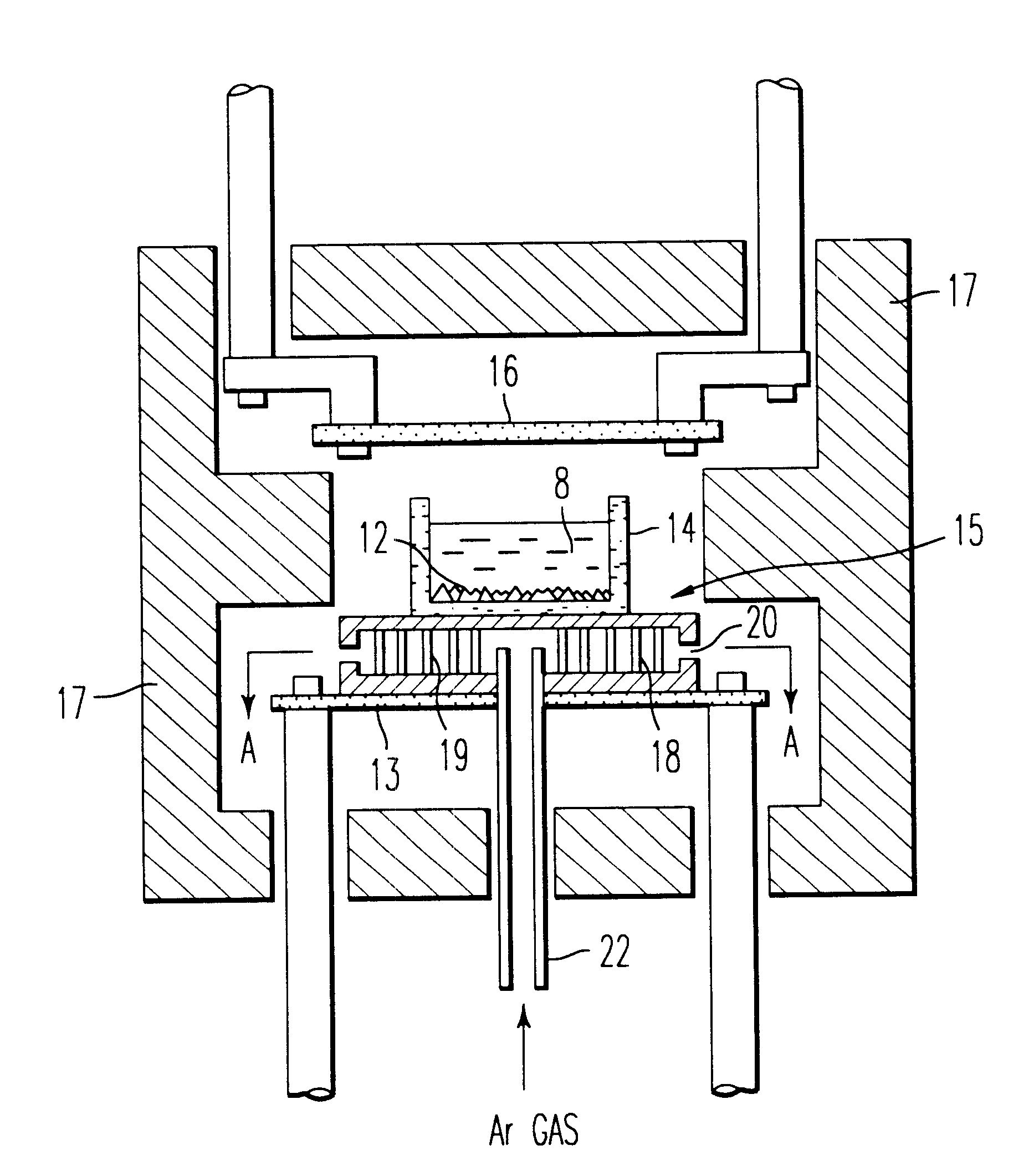

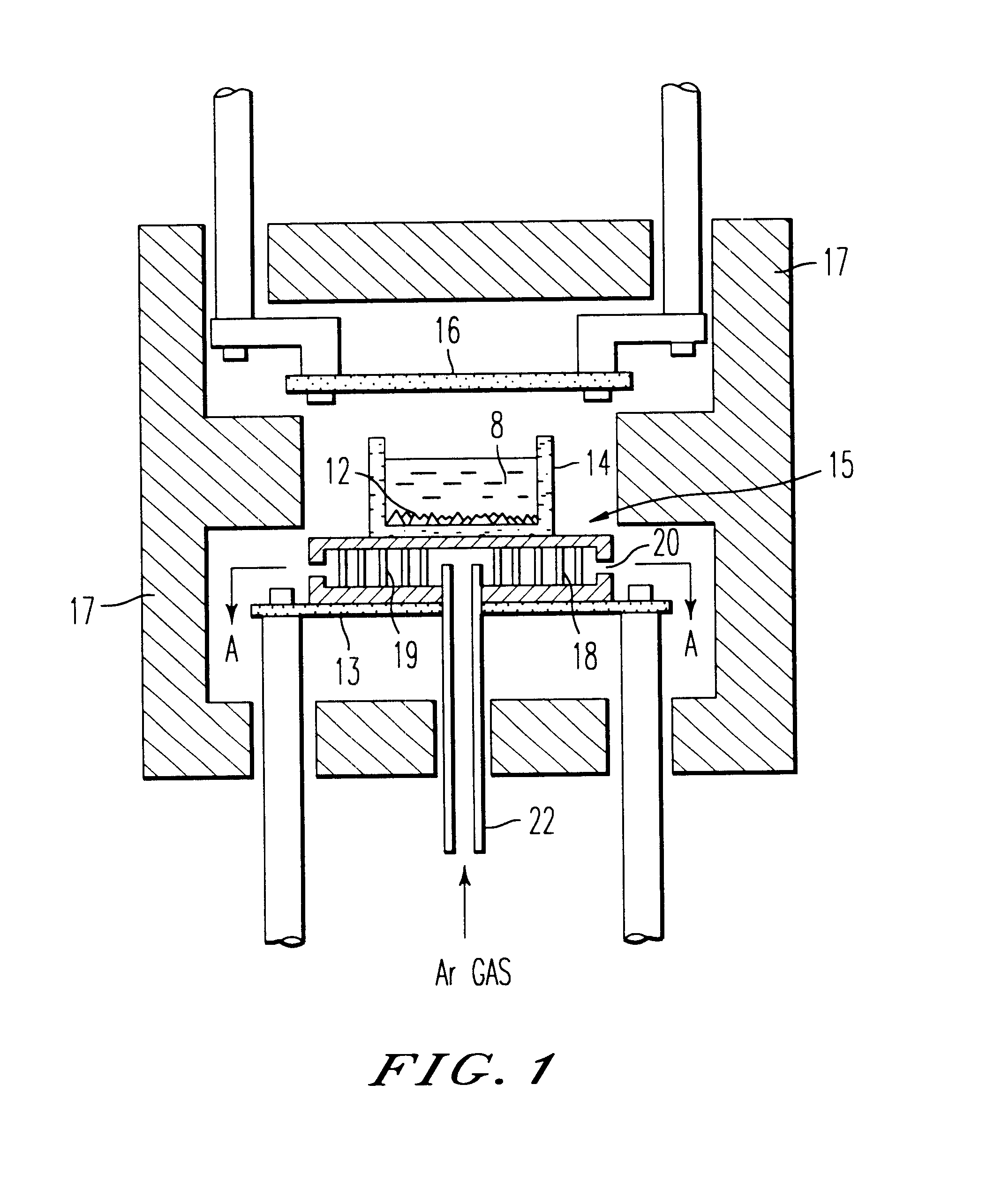

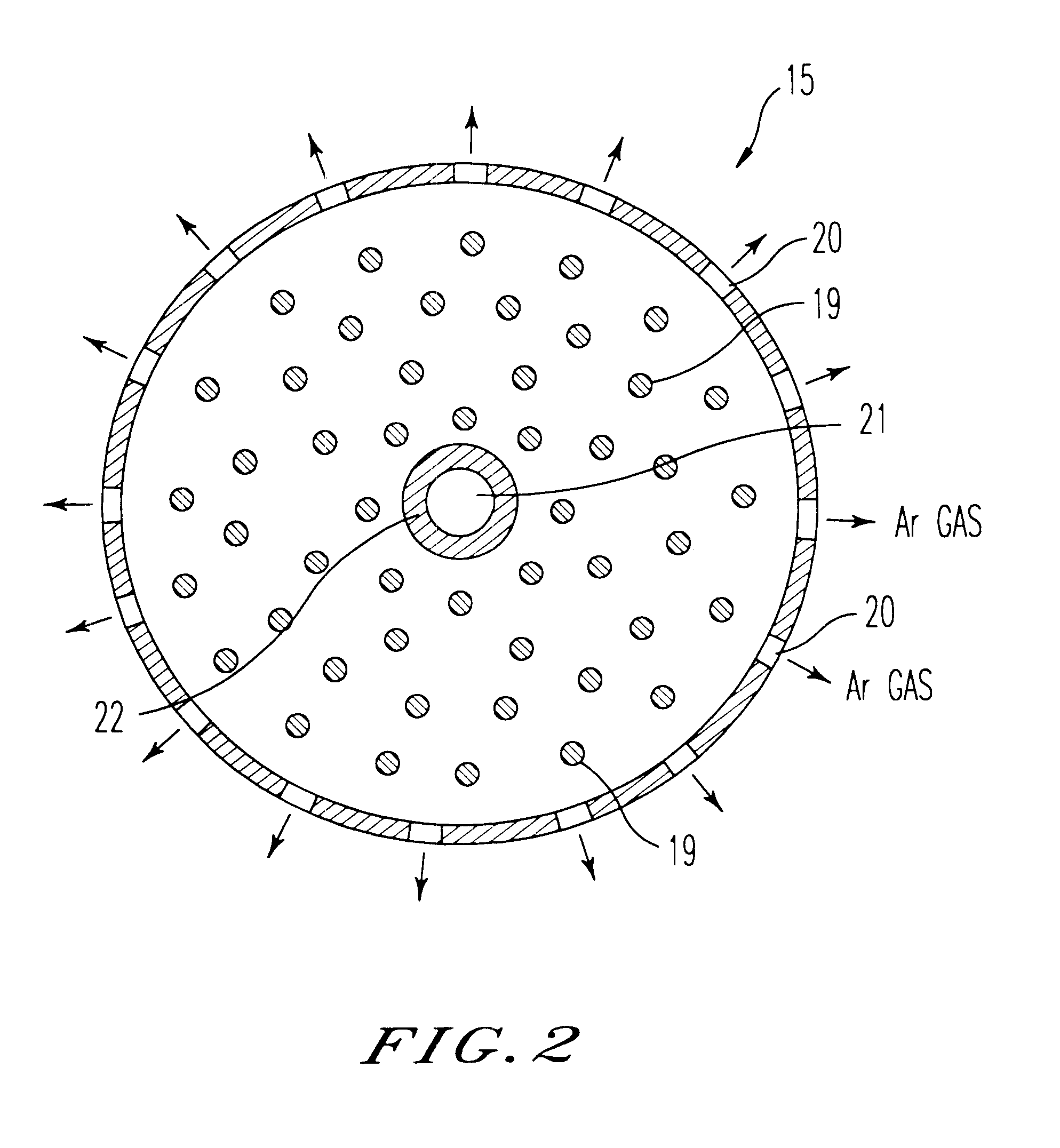

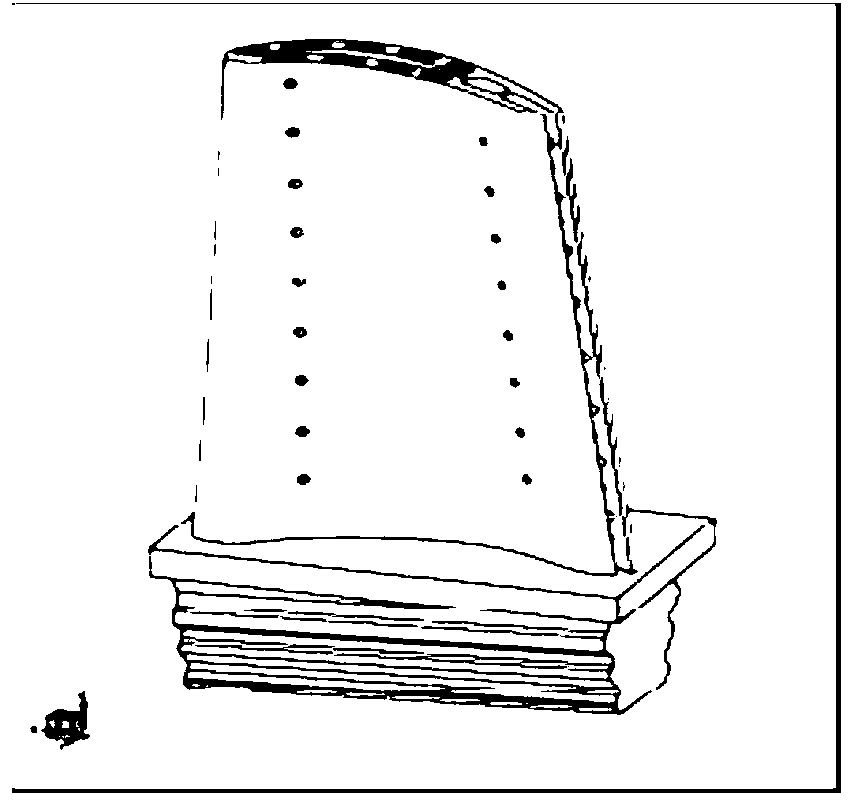

Method for producing silicon ingot having directional solidification structure and apparatus for producing the same

A method for producing a silicon ingot having a directional solidification structure comprising the steps of: placing a silicon raw material into a crucible of a melting device constructed by mounting a chill plate on an underfloor heater, mounting a crucible with a large cross-sectional area on the chill plate, providing an overhead heater over the crucible, and surrounding the circumference of the crucible with a heat insulator; heat-melting the silicon raw material by flowing an electric current through the underfloor heater and overhead heater; chilling the bottom of the crucible by halting the electric current through the underfloor heater after the silicon raw material has been completely melted to form a molten silicon; chilling the bottom of the crucible by flowing an inert gas through the chill plate; and intermittently or continuously lowering the temperature of the overhead heater by intermittently or continuously decreasing the electric current through the overhead heater, and an apparatus for producing the silicon ingot.

Owner:MITSUBISHI MATERIALS CORP

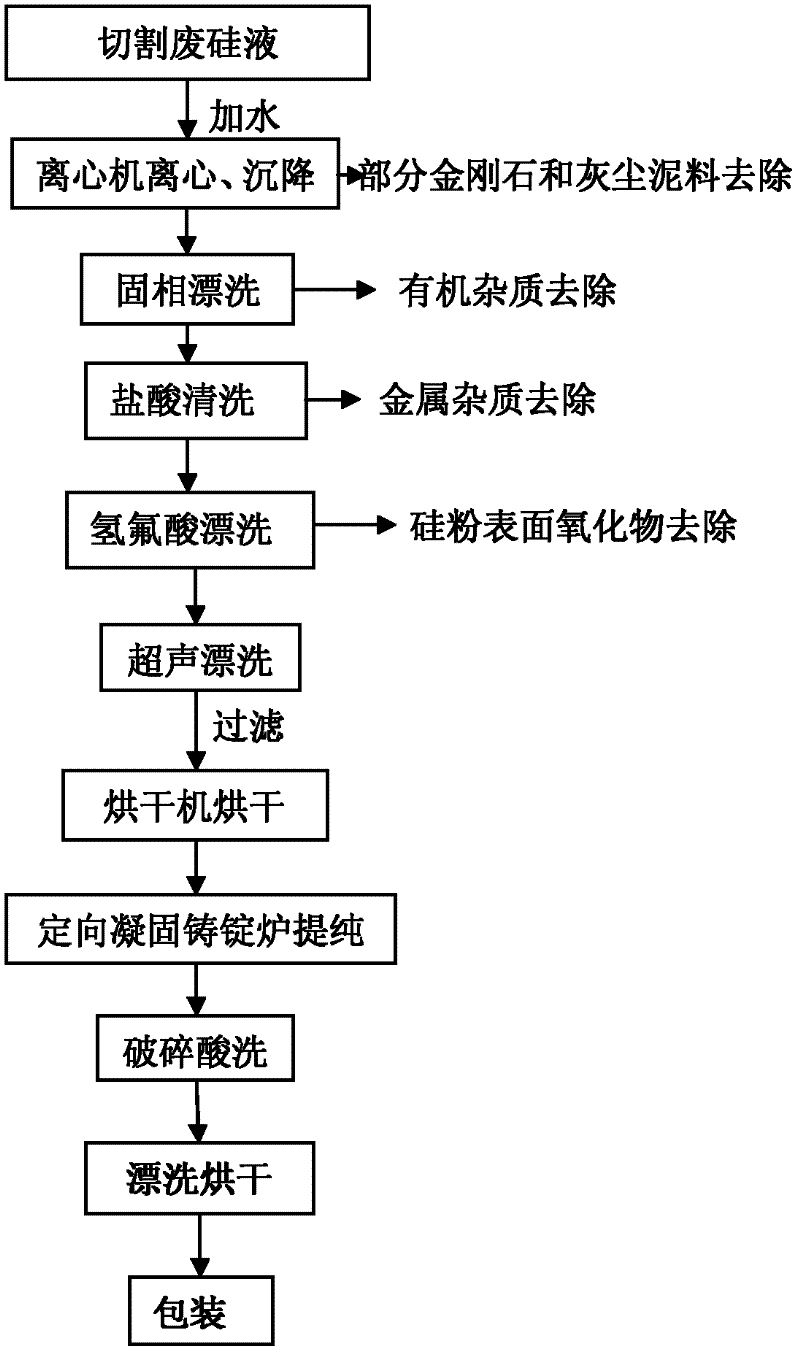

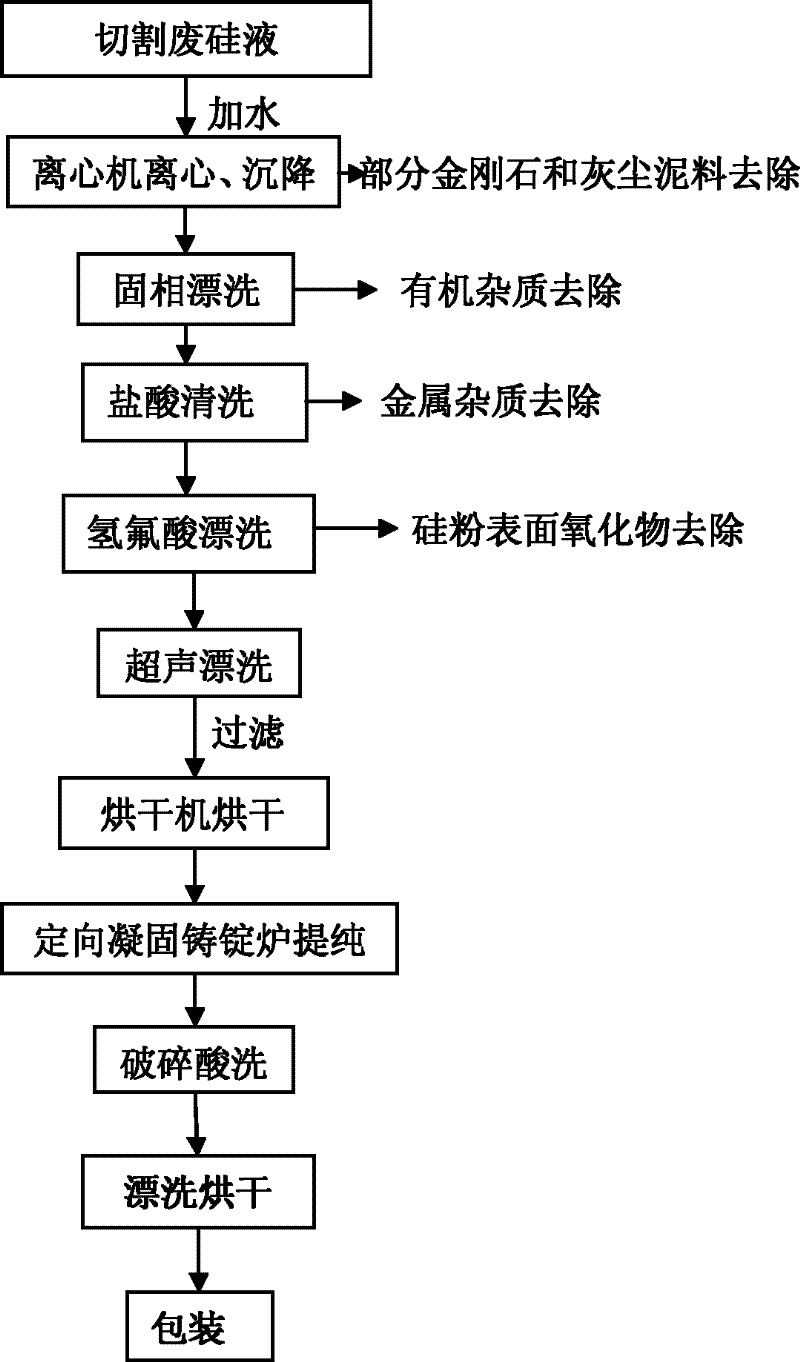

Method for recovering silicon material from waste materials in cutting crystalline silicon by diamond wire

The invention discloses a method for recovering silicon material from waste materials in cutting crystalline silicon by a diamond wire. The method is characterized by comprising the following steps of: feeding the collected waste materials to a centrifugal machine to centrifuge and settle, thus obtaining silicon material sediment; carrying out solid-phase rinsing on the silicon material sediment to remove organic matter type impurities and part of diamond powder from residual liquid in solid, thus obtaining silicon powder with certain purity; pickling the solid-phase silicon powder with hydrochloric acid to remove metal impurities; after rinsing the silicon powder subjected to hydrochloric acid pickling with pure water, rinsing the silicon powder with hydrofluoric acid to remove oxide from the surface of the silicon powder; carrying out ultrasonic rinsing and drying on the silicon material rinsed with hydrofluoric acid; carrying out directional solidification, ingot casting and purification on the dried silicon material, thus obtaining a solar grade silicon material; and at last, carrying out packaging after smashing, pickling, rinsing and drying the silicon material. The method is simple and convenient, the equipment cost is low, the operation is easy to control, the treatment recovery rate is high and the overall recovery rate can achieve over 99.99%.

Owner:ZHENJIANG HUANTAI SILICON TECH

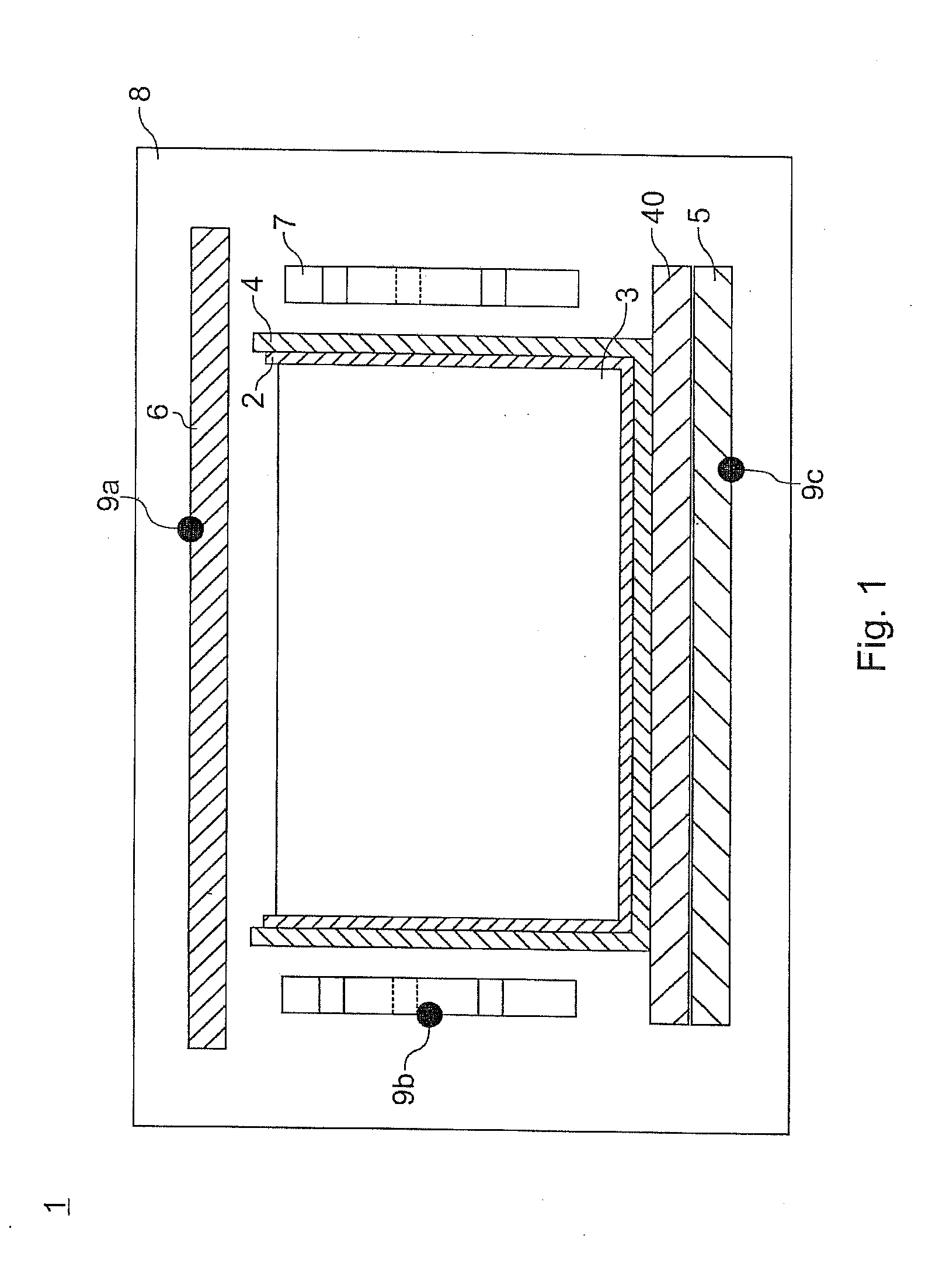

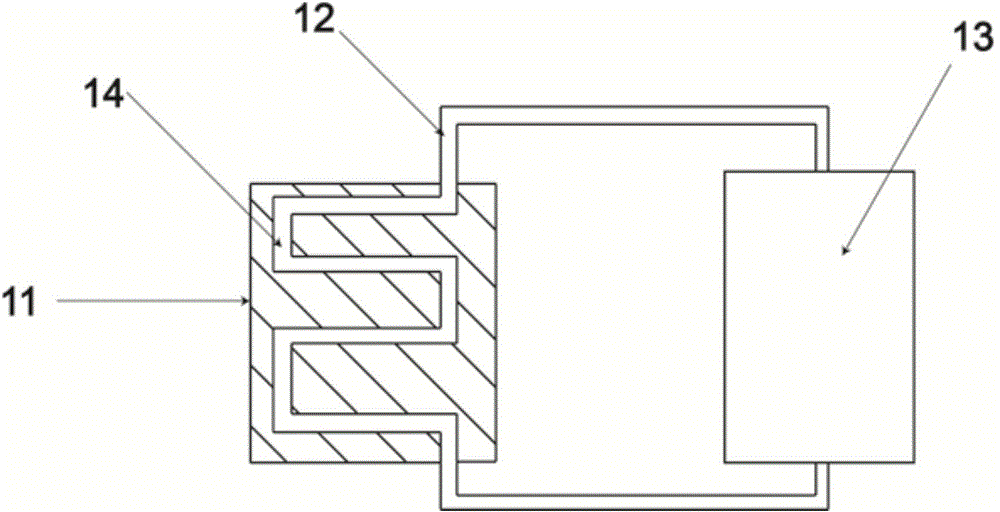

Braze alloy for high-temperature brazing and methods for repairing or producing components using a braze alloy

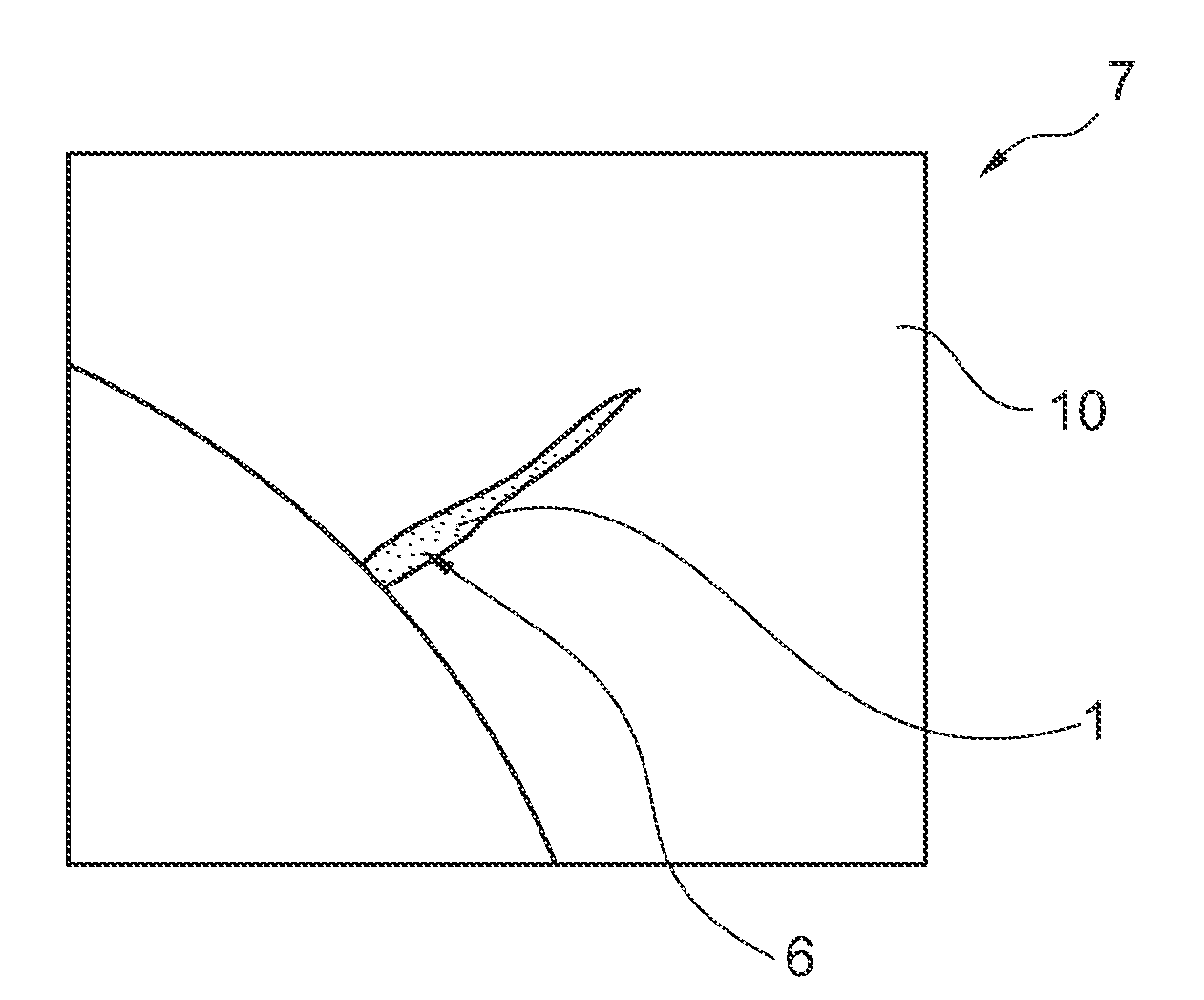

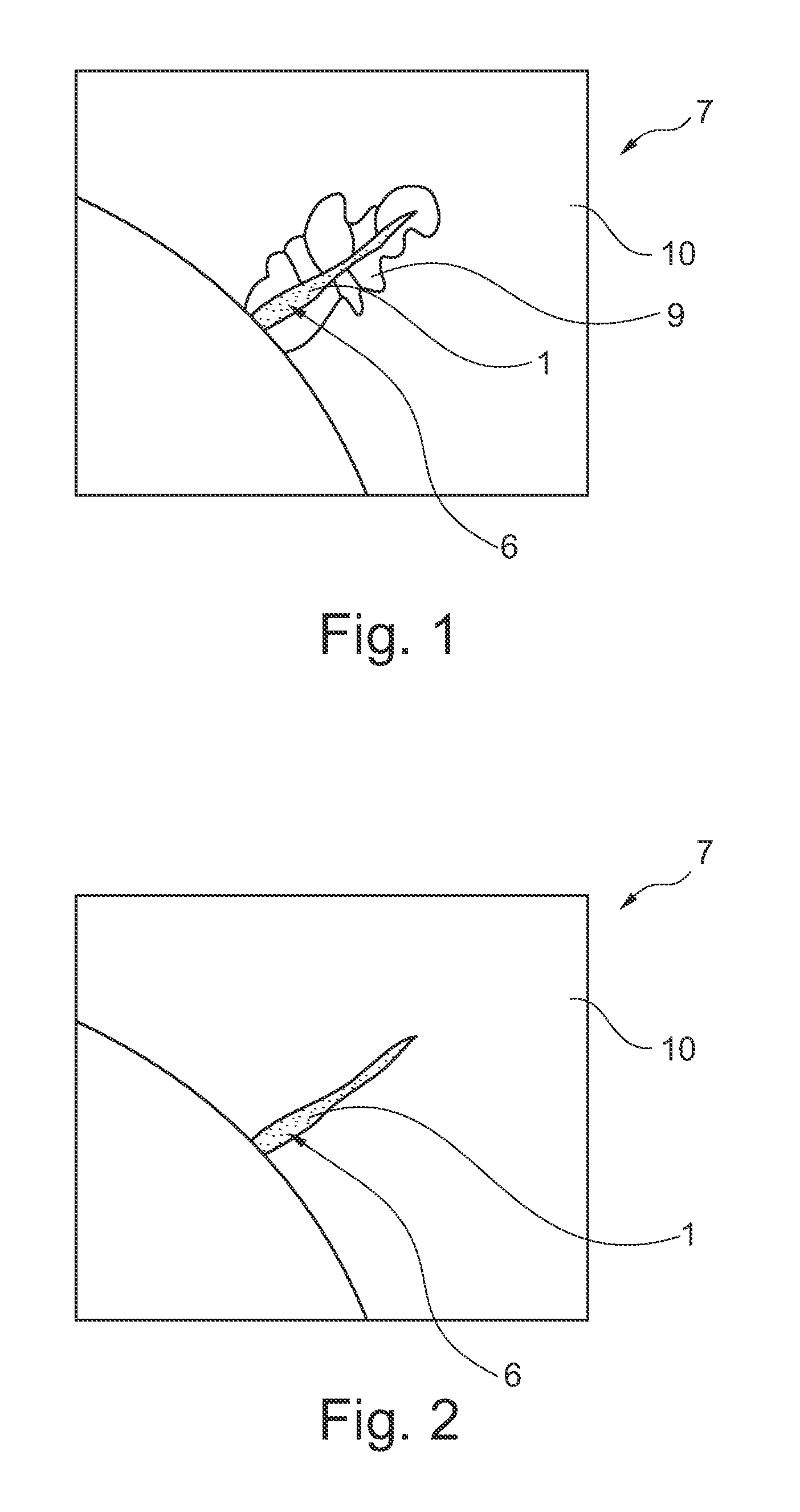

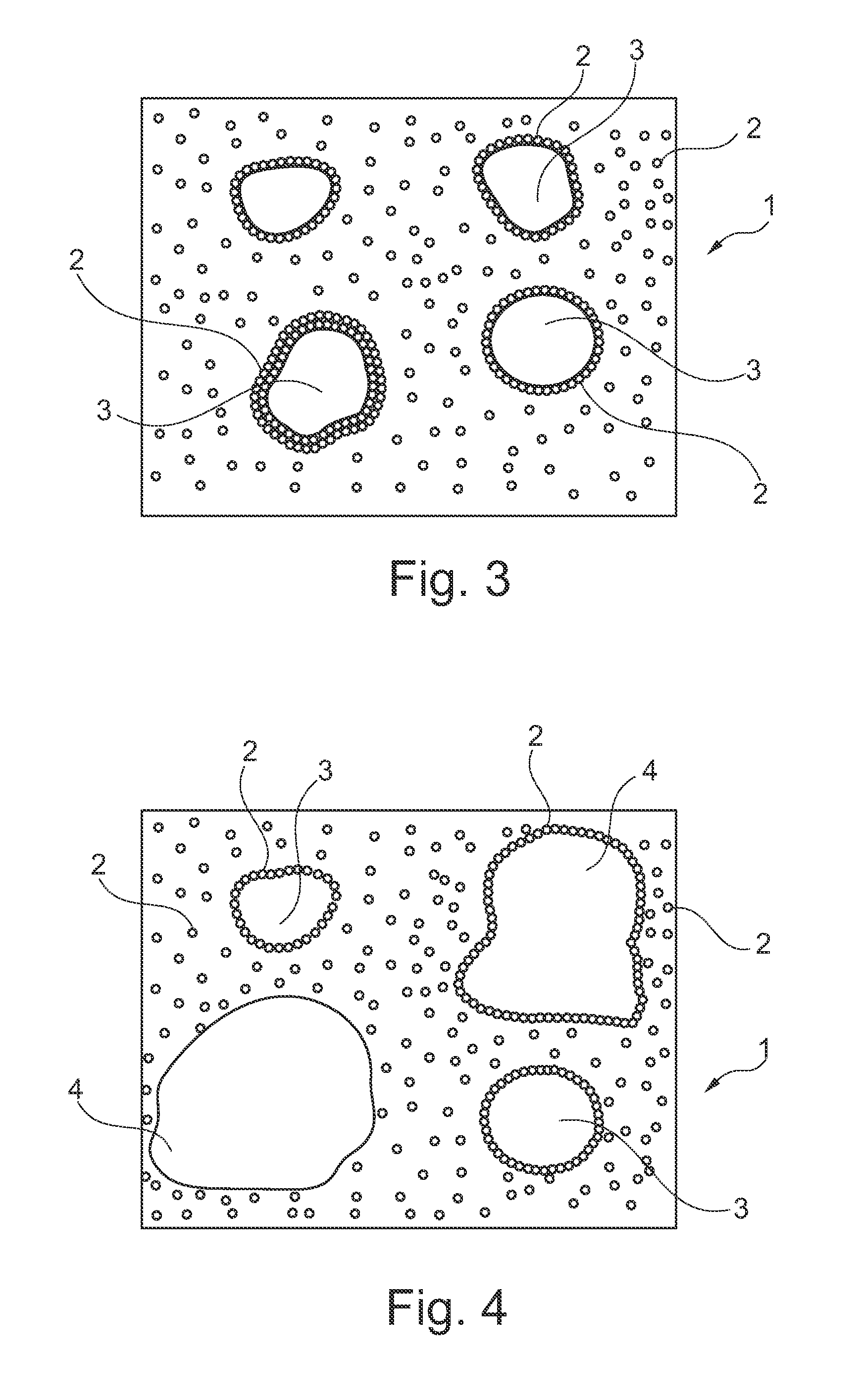

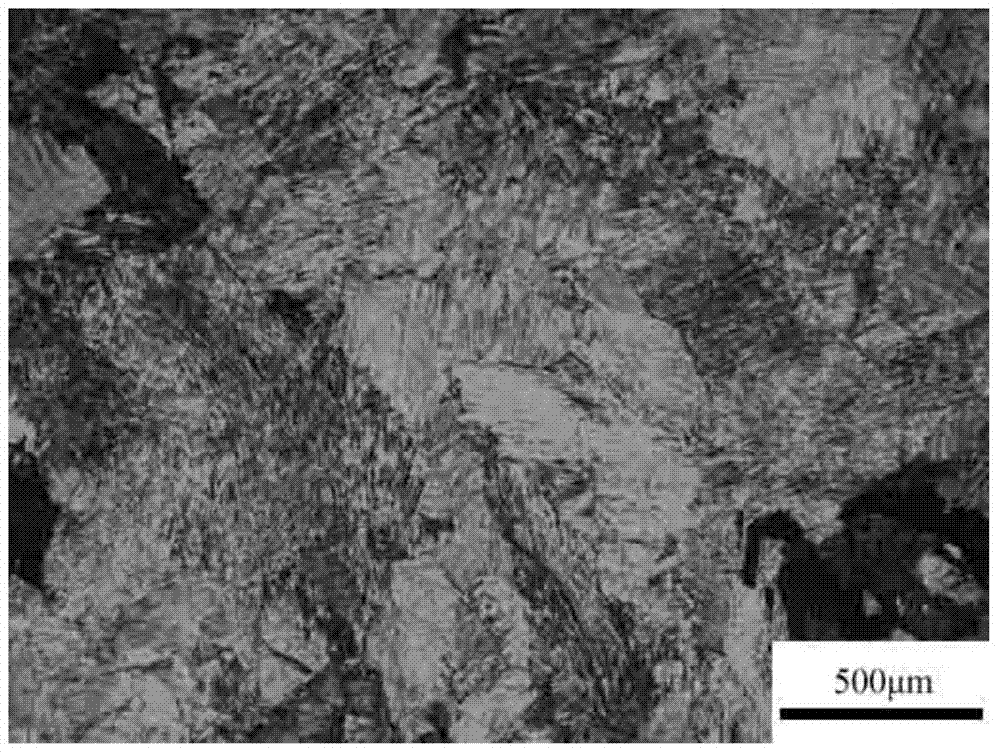

In a Ni-based, Co-based, or Ni—Co-based braze alloy (1) for high-temperature brazing of components (7) of modular structure and for repairing damaged components (7) which are formed of single crystal or directionally solidified superalloys using said braze alloy (1), the braze alloy has a first metallic powder component (2) having particle sizes in the nanometer range and a second metallic powder component (3) having particle sizes in the micrometer range. The surface of the particles of the second powder component (3) is thinly coated with particles of the first powder component (2). The braze alloy (1) additionally includes grain boundary stabilizing elements as alloying elements. In addition, melting point depressants can be present in the braze alloy (1) in a commercially common quantity or with a considerably increased proportion. Both the melting temperature of the braze alloy (1) and the probability of recrystallization are advantageously reduced.

Owner:ANSALDO ENERGIA IP UK LTD

Directional TiAl-based alloy and preparation method thereof

ActiveCN103789598AImprove high temperature mechanical propertiesKeep low densityDirectional solidificationMaterials science

The invention discloses directional TiAl-based alloy and a preparation method thereof. According to the atomic percentage, TiAl alloy components are expressed as Ti-(40-50)Al-aNb-bCr-cMo-dV-eMn, wherein in the formula, a, b, c, d, e are atomic percentages, a+b+c+d+e is less than or equal to 10, and the balance is Ti. The method for preparing the columnar crystal TiAl-based alloy includes the following steps that mother alloy is smelted through vacuum induction suspension, and a mother alloy cast rod is prepared through vacuum suction casting; an optical floating zone crystal growth system is adopted, argon is used as protection gas, the flow speed is 3-3.6L / min, the width of a regional heating zone is 6-6.7mm, heat treatment is performed on the TiAl-based alloy cast rod, the heating temperature is controlled to be 1250-1350 DEG C, the drawing speed is in the range of 3-13 micrometers per second, and the columnar crystal TiAl-based alloy is prepared. Compared with a directional solidification technology, in the preparation method, peritectic reaction is omitted, and therefore peritectic segregation is avoided; the problem that refractory metal and alloy, such as tungsten and molybdenum, with direction tissue cannot be prepared through the direction solidification technology can also be solved.

Owner:NANJING UNIV OF SCI & TECH

Fe-Ga series magnetostriction material and its producing process

InactiveCN1392616AEfficient use ofLow costMagnetostrictive material selectionRoom temperatureSingle crystal

This invention relates to a magnetic material. The components of material are Fe100-x-yGaxMyQ where x=10-40, M is Al, Be, Cr, In, Cd, Mo, Ge, y=0-15, Q is C, N, O additional doping. Main points of its technique are according to the requirement of the invented material components to smelt the mother alloy in a magnetic suspension over or vacuum induction furnace, to process monocrystal or polycrystal oriented materials with the high-temperature gradient quick directional solidification or czochralski or Bridgeman method under 1000-1200 deg.C for 1-48 hours then cool to 750-600 deg.C in the furnace and keep temp. for 0.2-48 hours, then quenching with water, or cool furnace to room temperature with different cooling speed for 750 to 600 deg.C or apply 500-20000 e magnetic field in the cooling process.

Owner:UNIV OF SCI & TECH BEIJING

Method for Purifying High-purity Aluminum by Directional Solidification and Its Melting Furnace

ActiveCN102277505ATemperature controlQuality improvementStirring devicesCrucible furnacesDirectional solidificationMelting furnace

Owner:乌鲁木齐众航新材料科技有限公司

Manufacturing method of ceramic mold of monocrystal turbine blade

ActiveCN103464690AImprove heat transfer performanceSolve complex and uncontrollable heat transfer problemsFoundry mouldsCeramic shaping apparatusLeading edgeTurbine blade

The invention discloses a manufacturing method of a ceramic mold of a monocrystal turbine blade. The integral ceramic mold with a special spiral crystal selector is designed and manufactured according to grain orientation requirements of the monocrystal turbine blade. When orientated solidification is used for manufacturing the monocrystal blade, the thickness of a shell at an abrupt change in a section (such as a connecting part between a blade body and a marginal plate) is increased, and the heat transfer capacity is reduced, so that crystal defects such as stray crystals are caused easily. On the premise that the casting strength requirements are met, with the adoption of topological optimization and design of a heat transfer passage, the heat transfer capacity of the mold is improved, and a temperature gradient on the leading edge of a solid-liquid interface during the orientated solidification is increased, so that the whole blade can obtain a good monocrystal organization.

Owner:XI AN JIAOTONG UNIV +1

Method for improving temperature distribution in process of single crystal casting solidification

InactiveCN101537484APromote growthSmooth scalabilityPolycrystalline material growthFrom frozen solutionsElectrical conductorGraphite

The invention discloses a method for improving temperature distribution in a process of single crystal casting solidification, relating to the field of high-temperature alloy directional solidification. In a process of preparing molten mould casting ceramic mould shell, and in a process of implanting a heat conductor into a casting to be solidified and transfer heat to the external, a position with thermal barrier is easy to occur. The heat conductor is graphite or SiC. Practical use shows that by applying the technology, an undercooling difference and an undercooling time difference in the casting can be greatly reduced, thereby the probability of generating stray crystals is obviously reduced, and the single crystal qualified rate of the casting is greatly enhanced.

Owner:JIANGSU UNIV

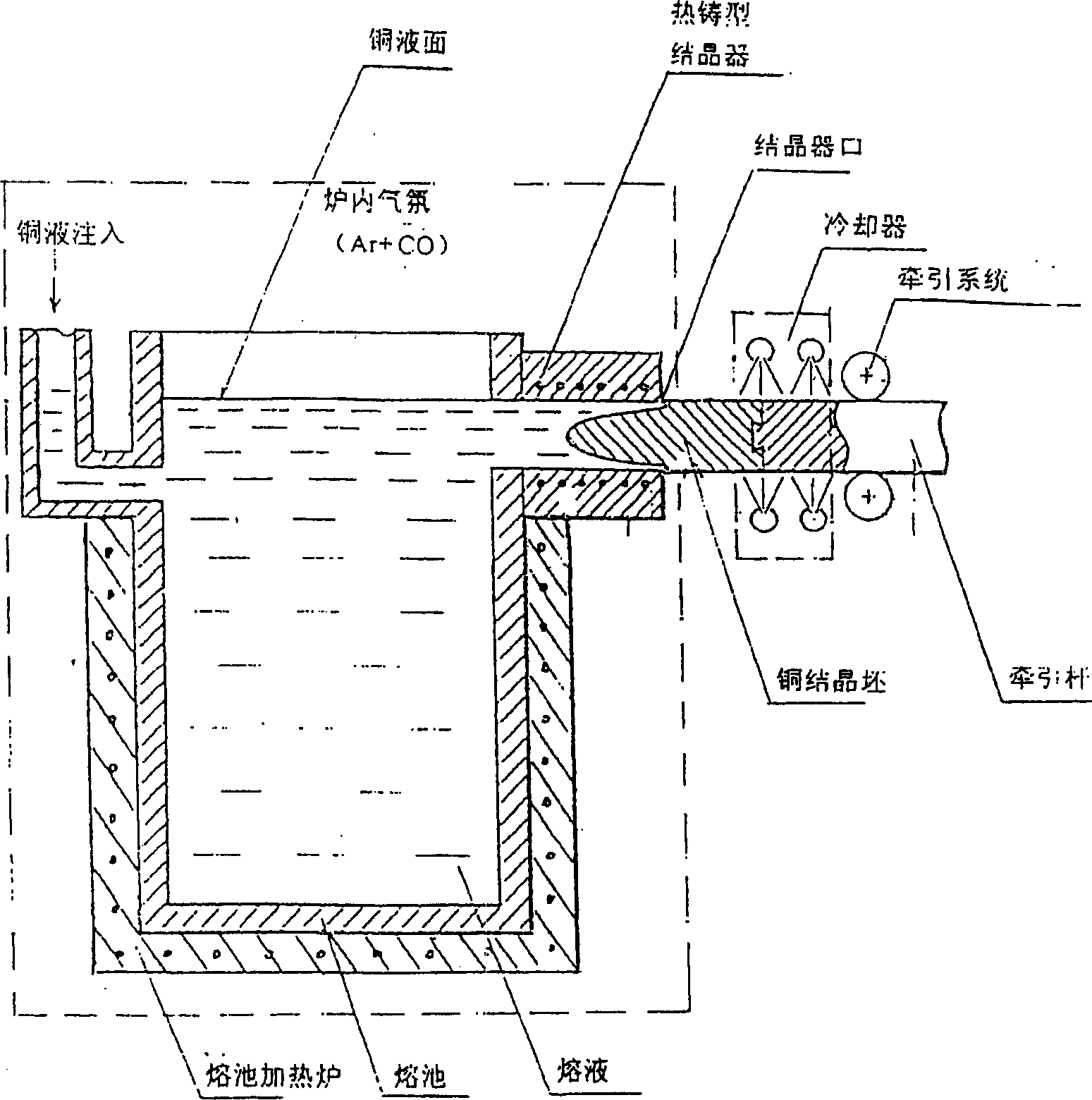

Control method and device for continuous metal monocrystal casting process

InactiveCN1810416ALow impurity contentRealize the display effectSingle crystalDirectional solidification

The metal monocrystal casting device consists of three work chambers formed with two vacuum isolating valves and their cooling and drawing system integrated together. The horizontal oriented solidifying continuous casting process are performed in a protecting atmosphere so as to obtain copper monocrystal with very low content of O, H and other impurity.

Owner:上海智诚电讯材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com