Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

103 results about "Melt pool" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A full melt pool means the wax has been heated long enough to reach the edge of the container. This usually occurs in about 1-2 hours. A full melt pool should be 1/8 to 1/4 inch deep which will allow the fragrance to disperse more completely into the room.

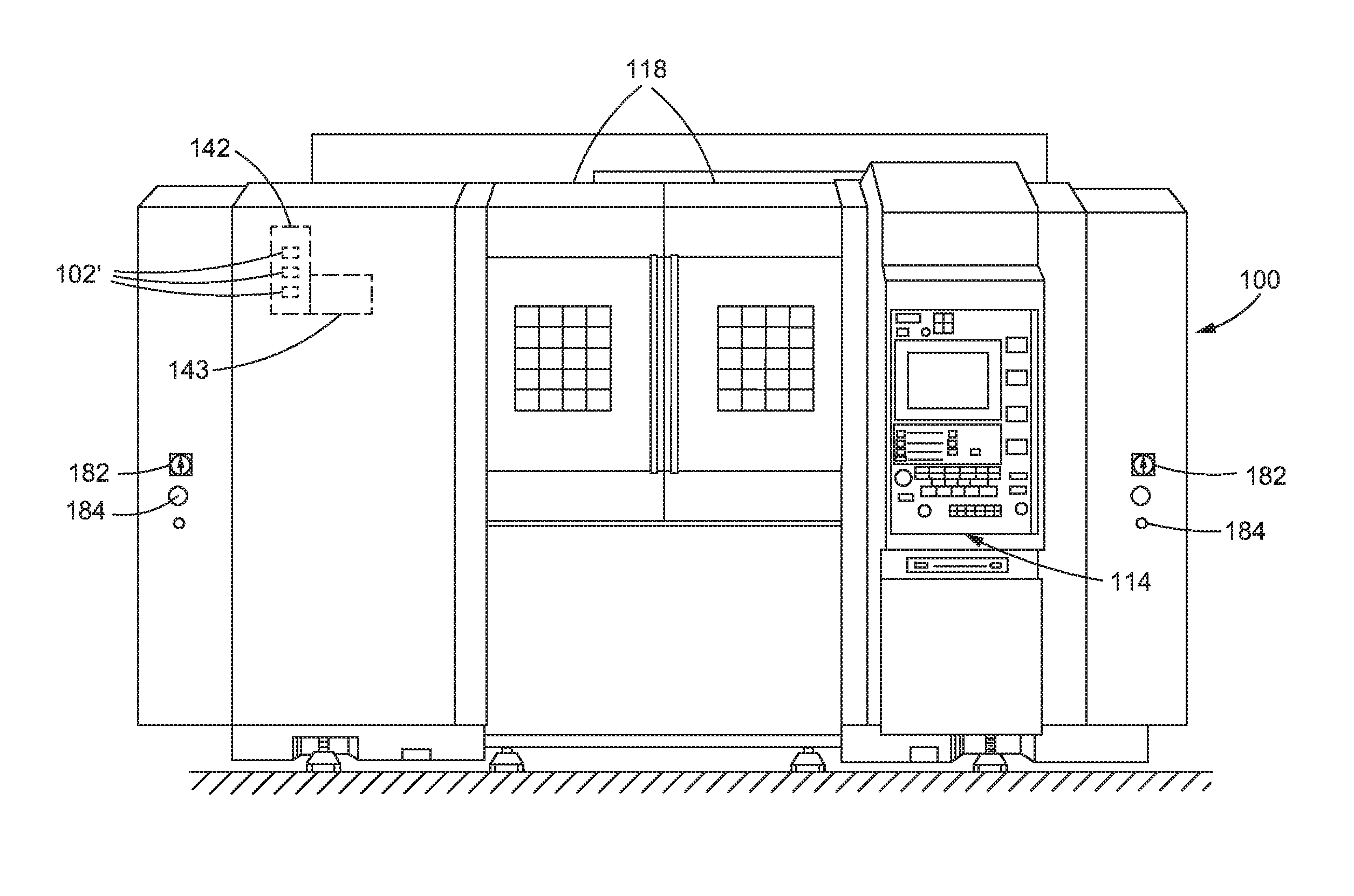

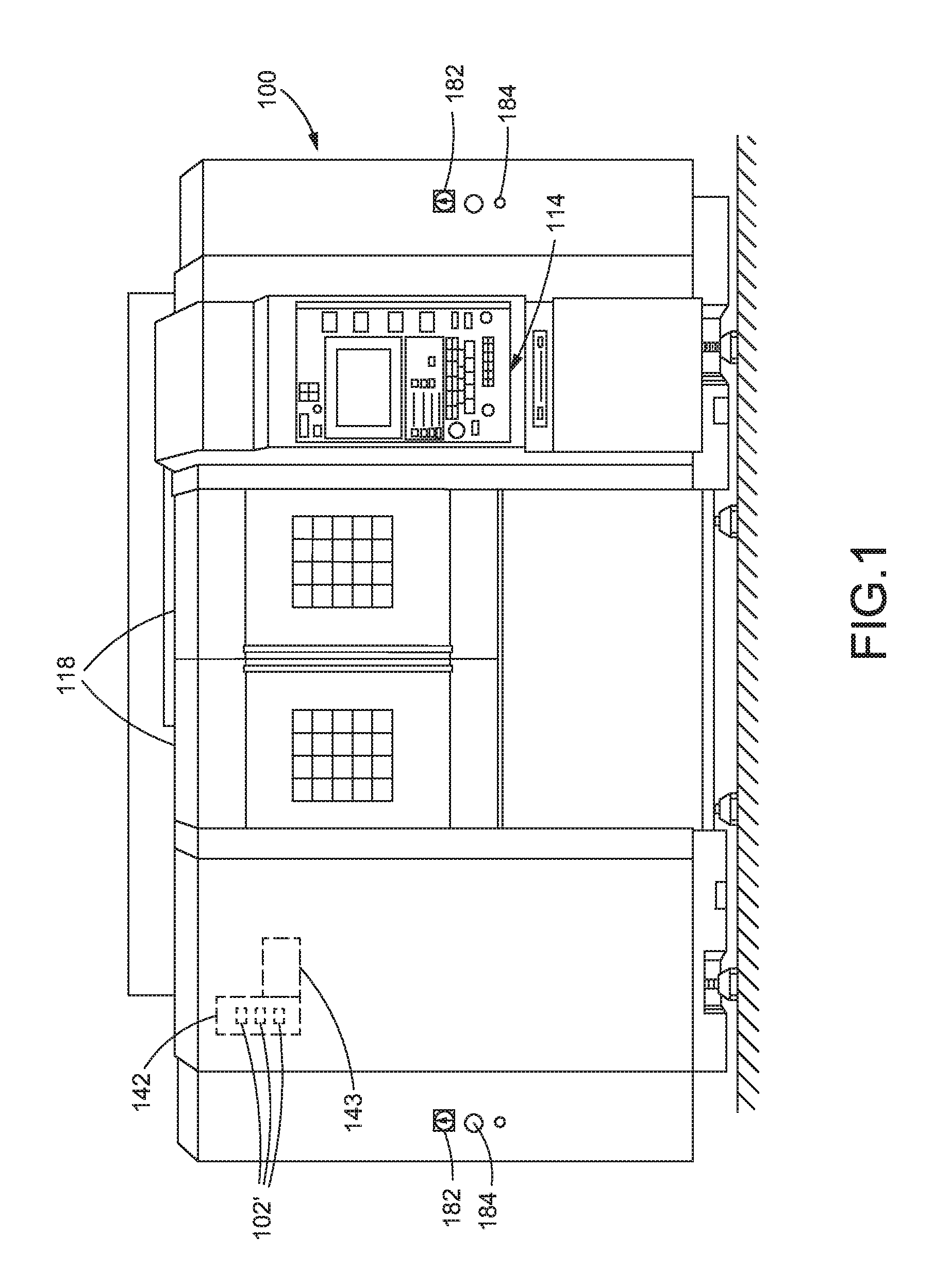

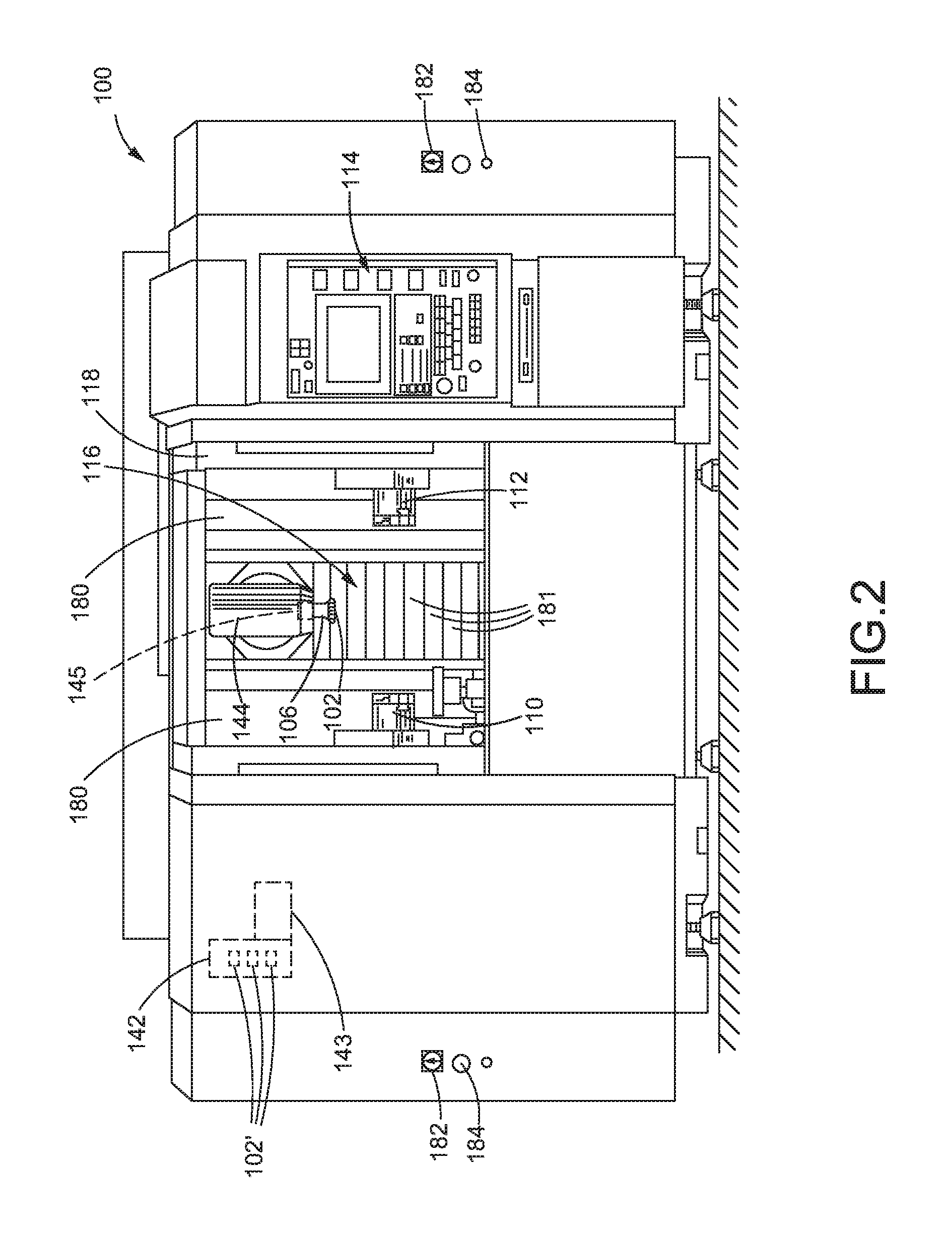

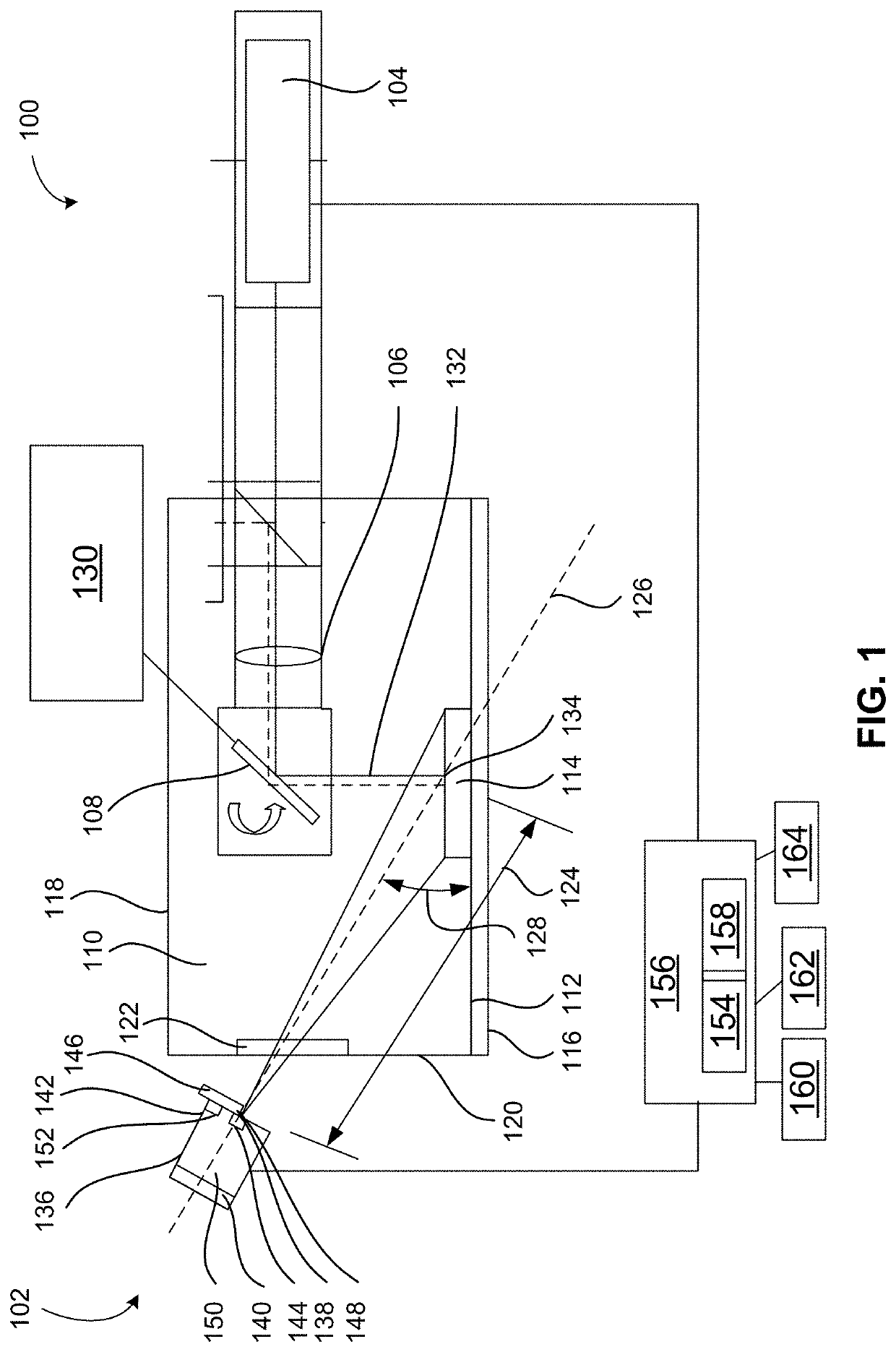

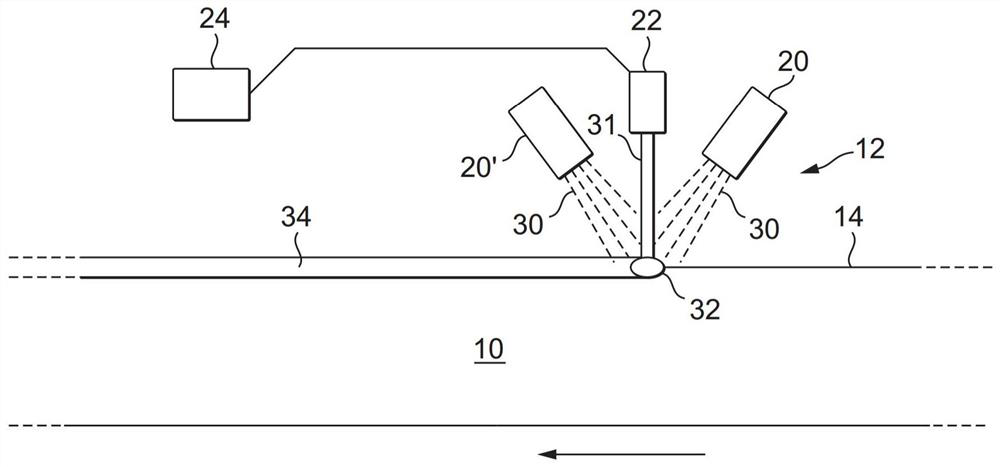

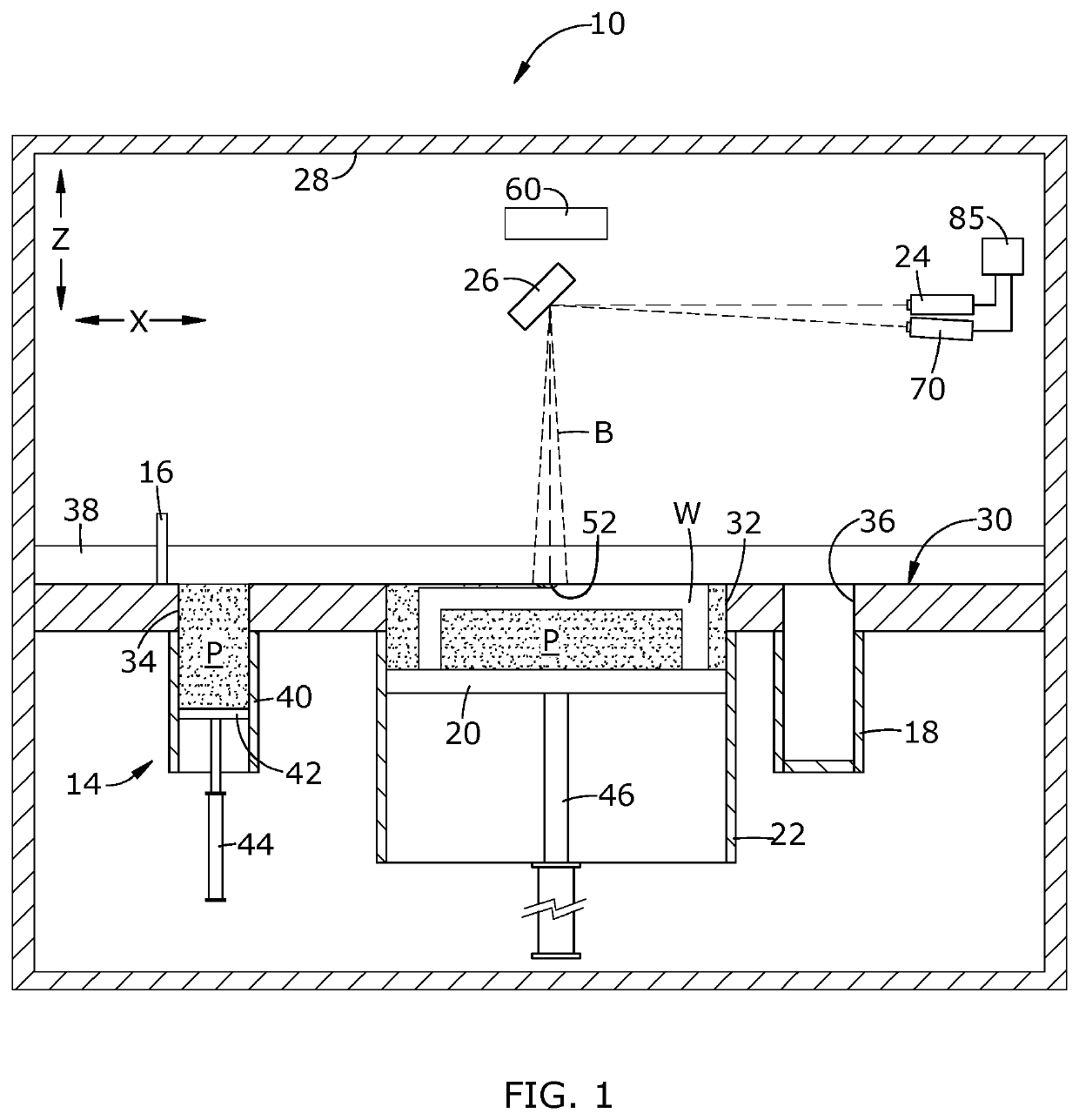

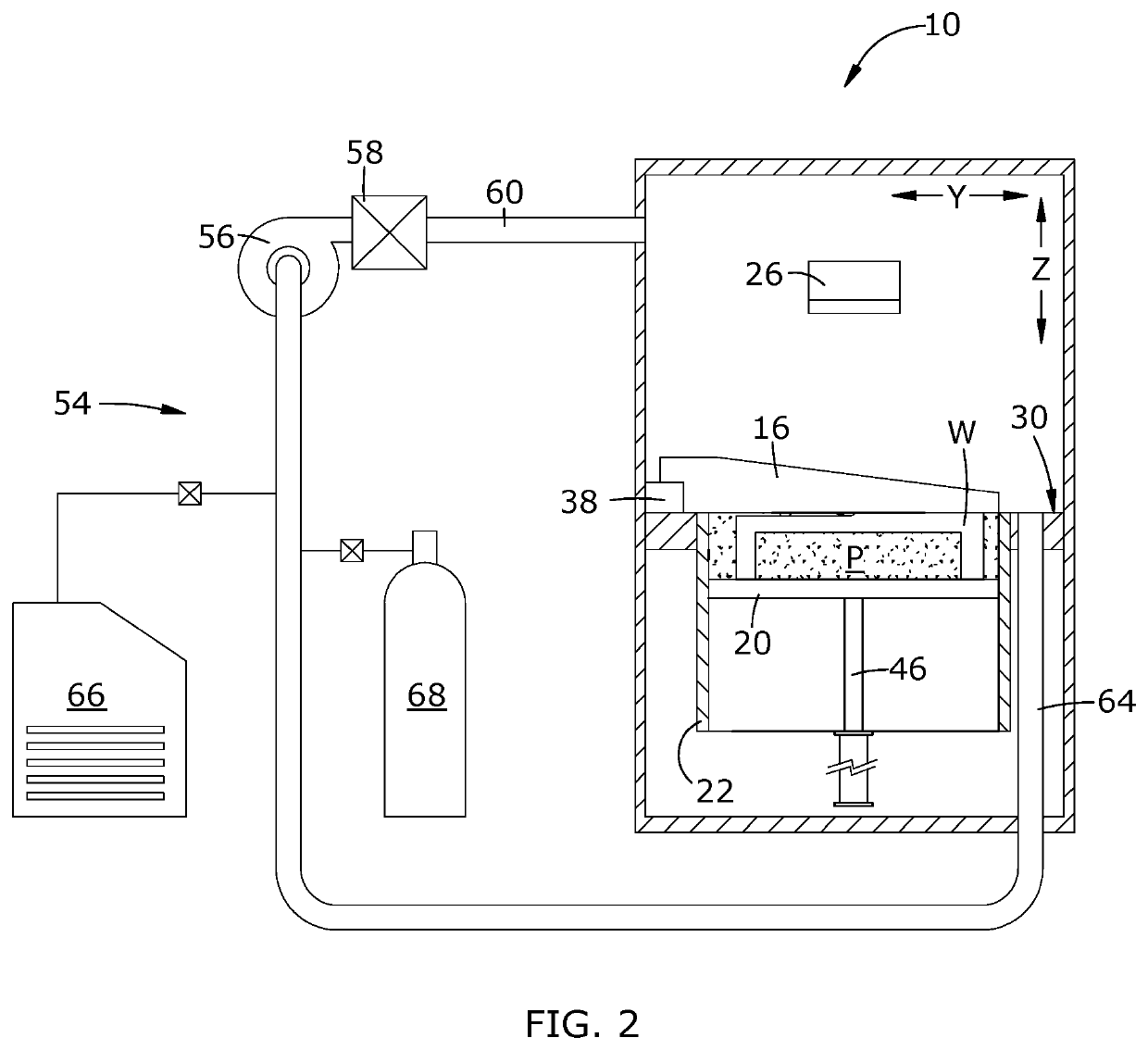

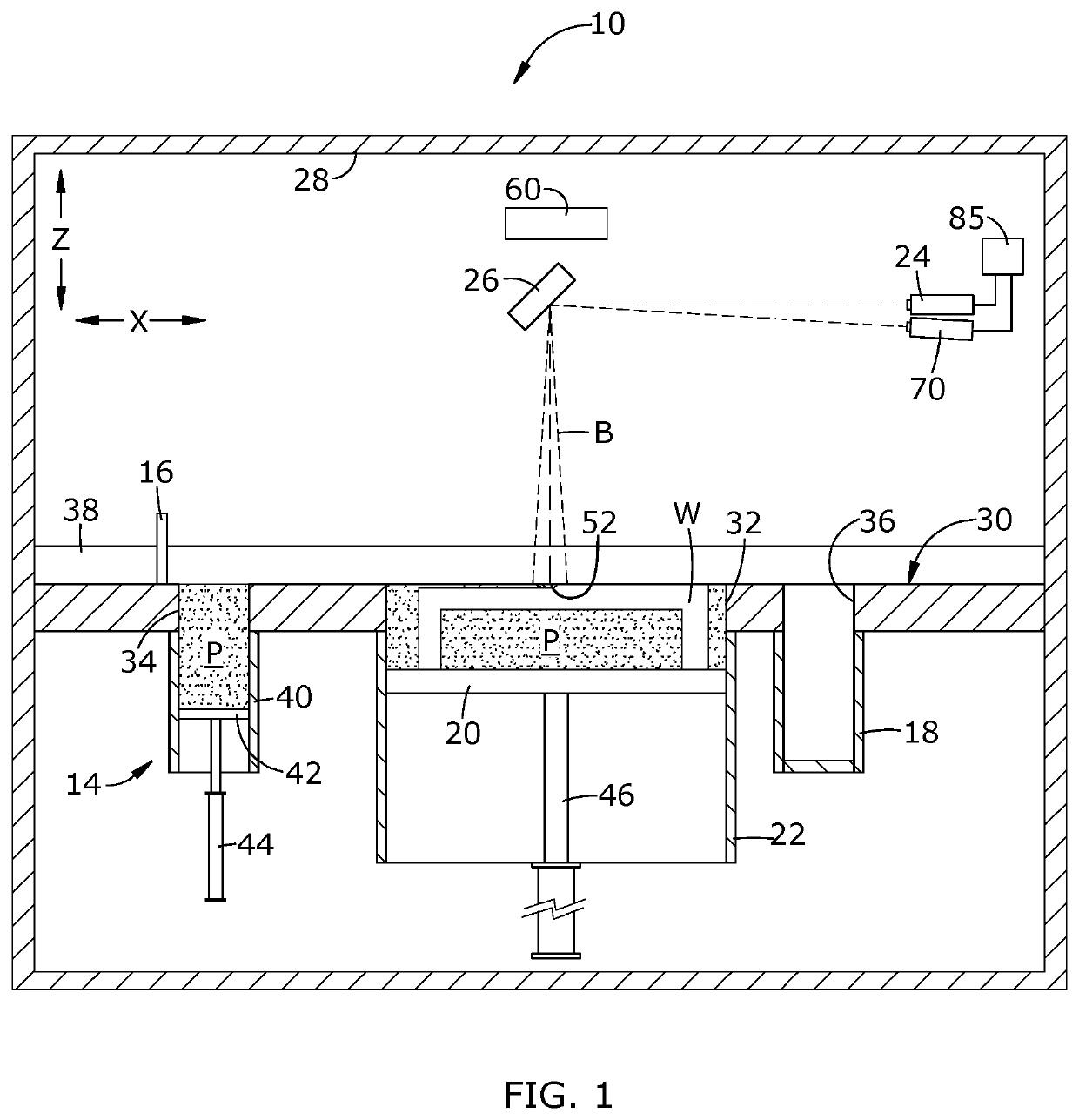

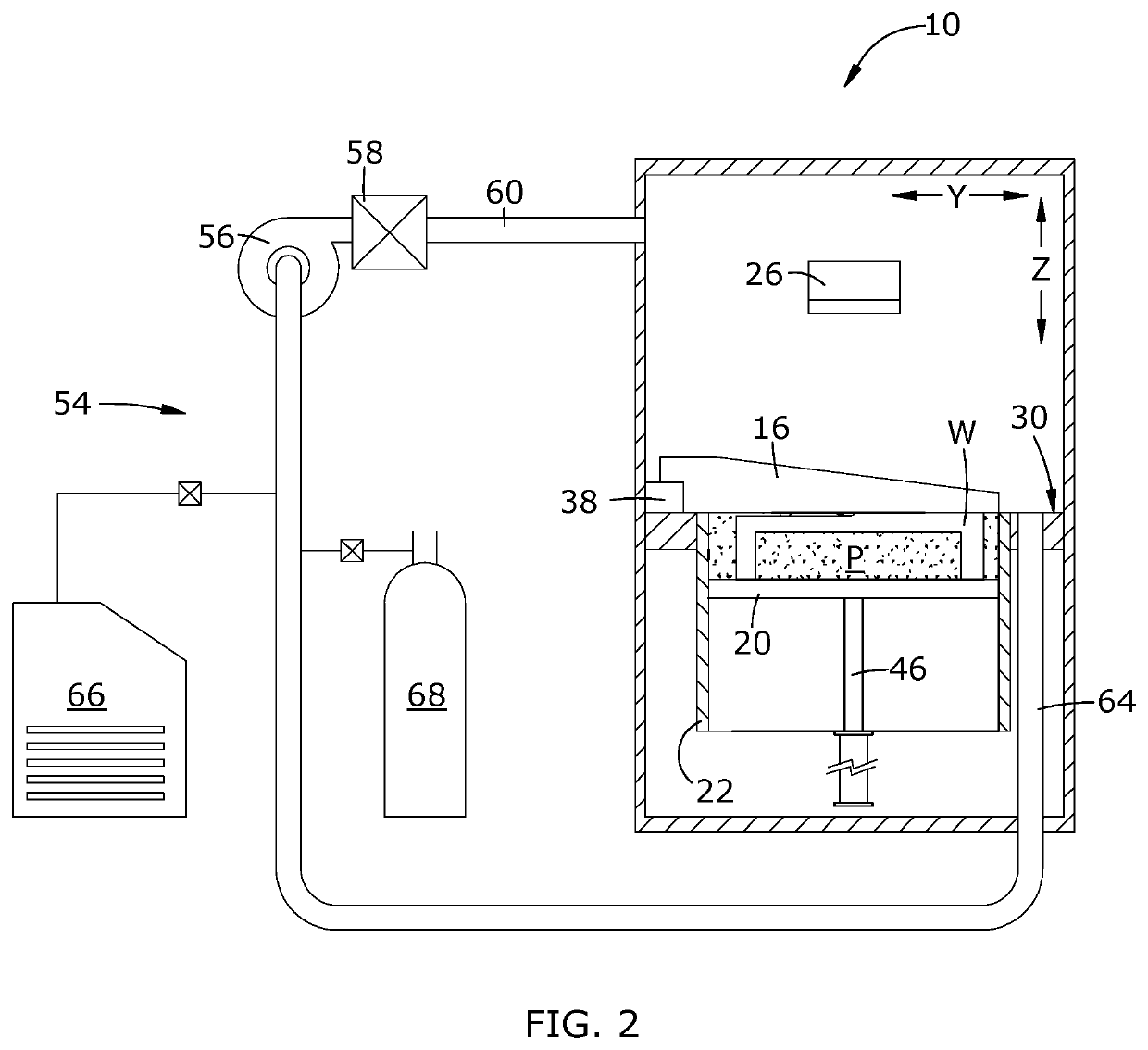

Machine Tool System and Method for Additive Manufacturing

InactiveUS20170008127A1Additive manufacturing apparatusLaser beam welding apparatusLeading edgeSpray nozzle

Methods and apparatus for performing additive manufacturing processes using a machine tool may include controlling an orientation of a processing head to control the tangential angle of a fabrication energy beam, a feed powder nozzle, or both. The orientation of a non-circular energy beam may be control to more evenly distribute the energy beam across a width of a tool path. Additionally or alternatively, the orientation of the feed powder nozzle may be controlled to project toward a powder target that is spaced from a beam target. The powder target may be directed to a trailing edge of a beam spot formed by the energy beam to increase the amount of powder incorporated into a melt pool formed by the energy beam. Alternatively, the powder target may be directed to a leading edge of the beam spot to provide a self-correcting feature to address thickness errors formed in previous layers of added material.

Owner:DMG MORI SEIKI ADVANCED SOLUTIONS

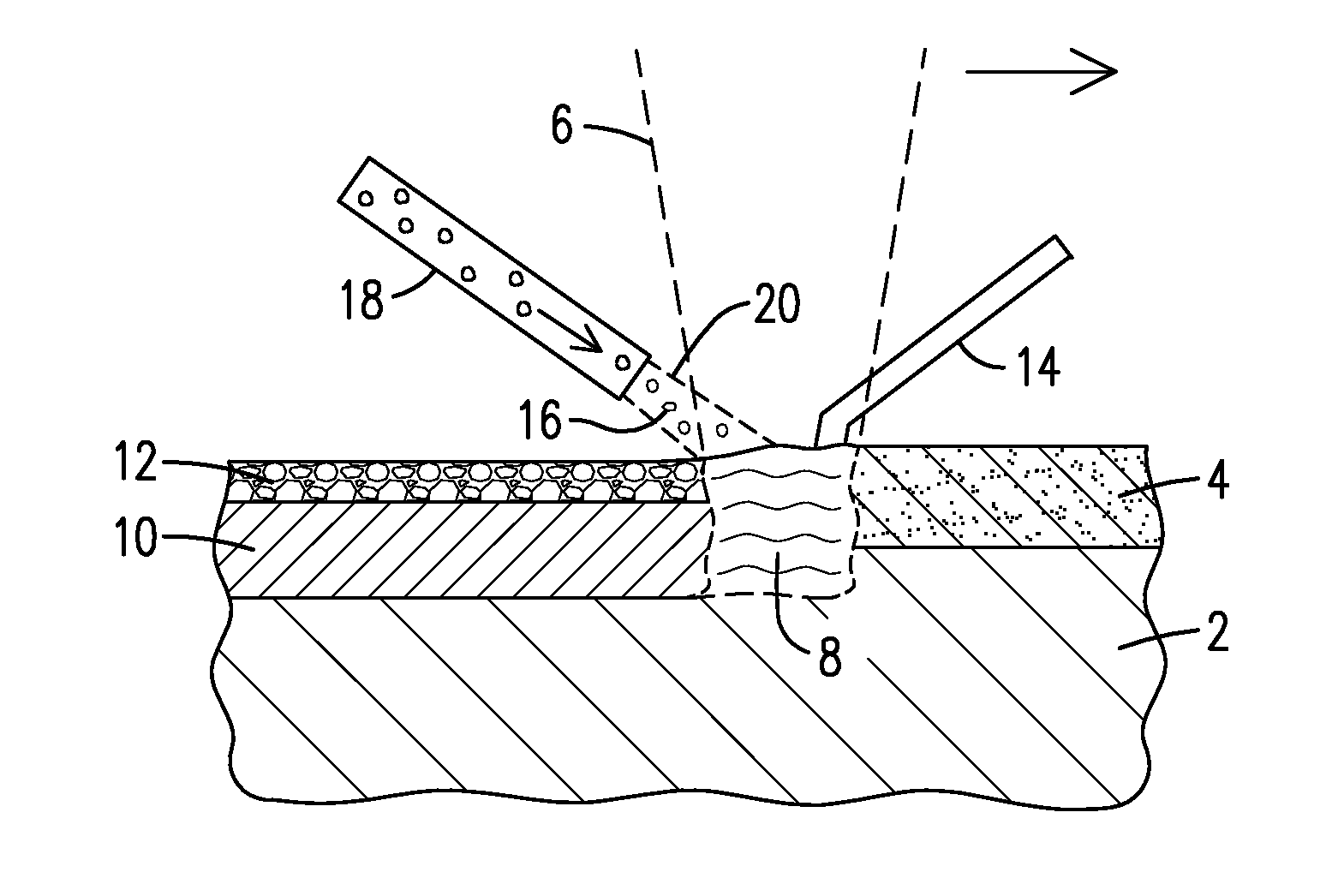

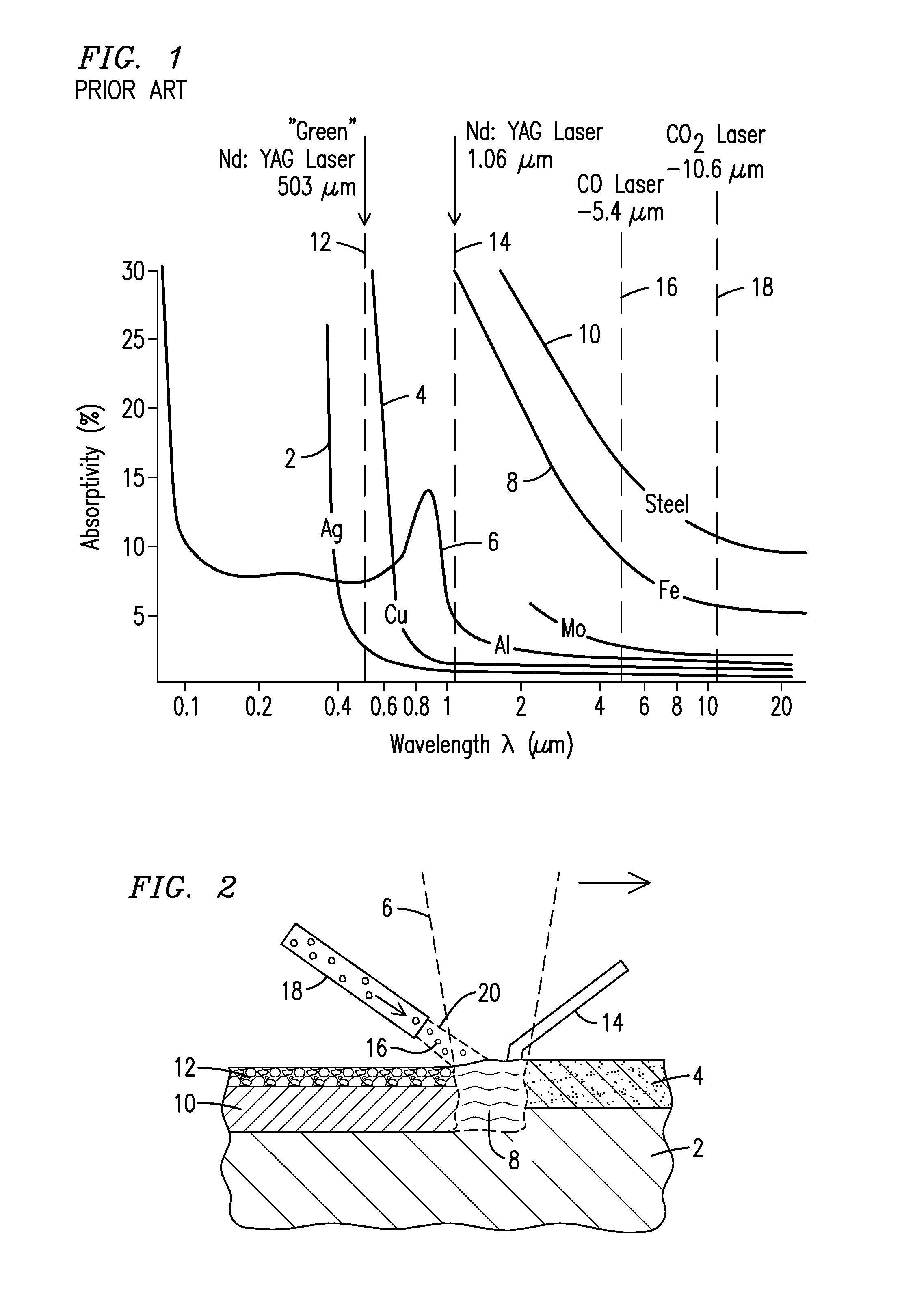

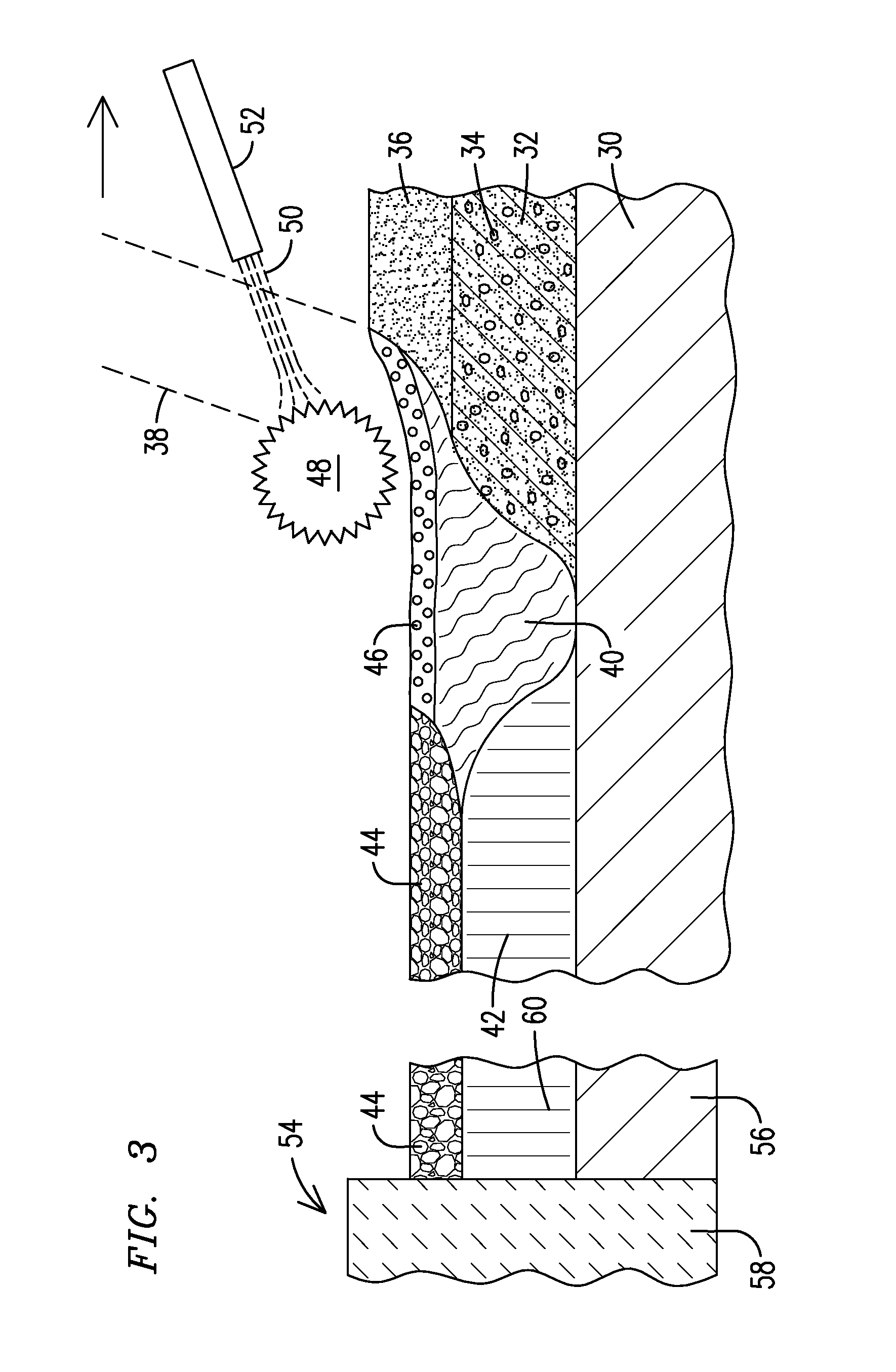

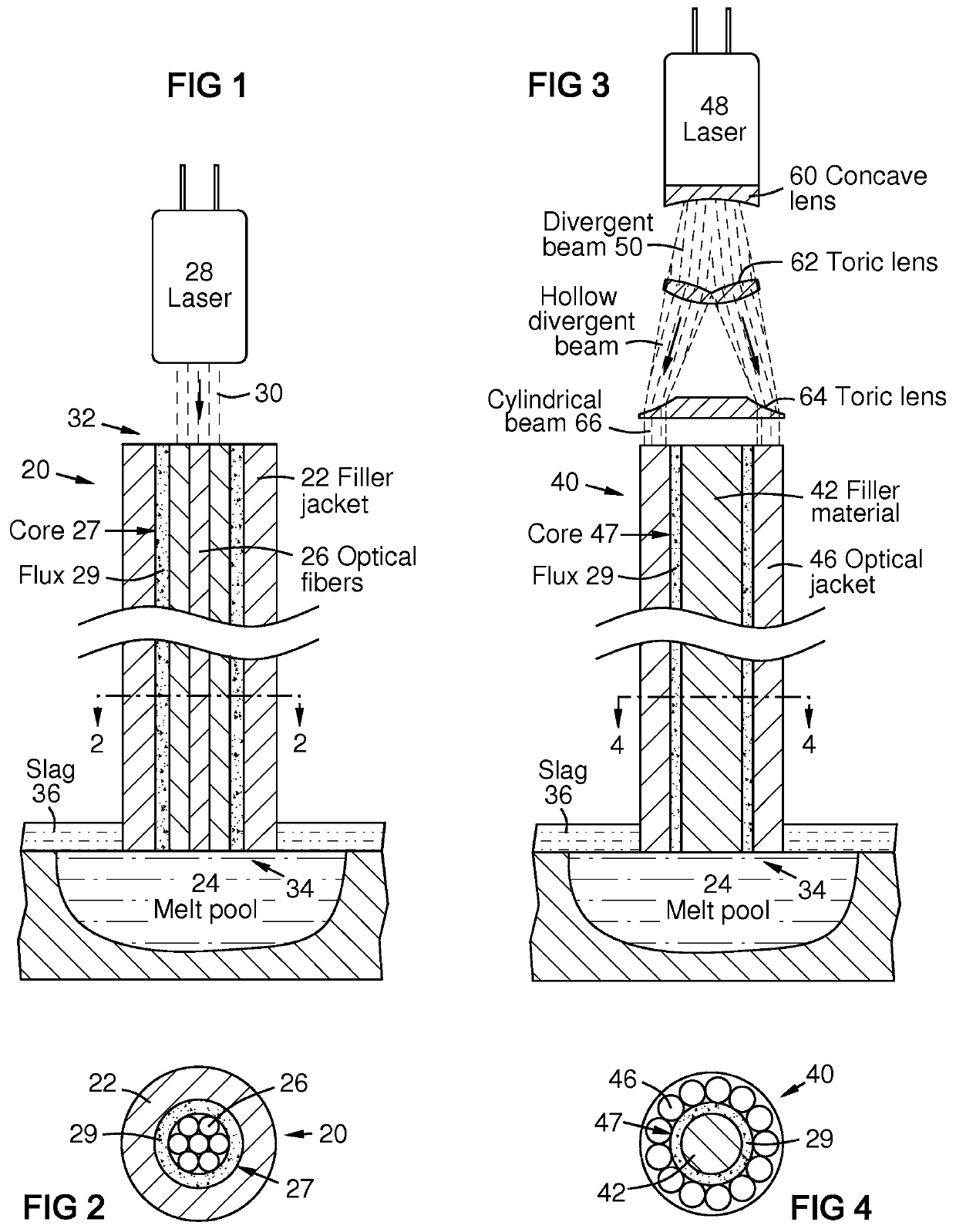

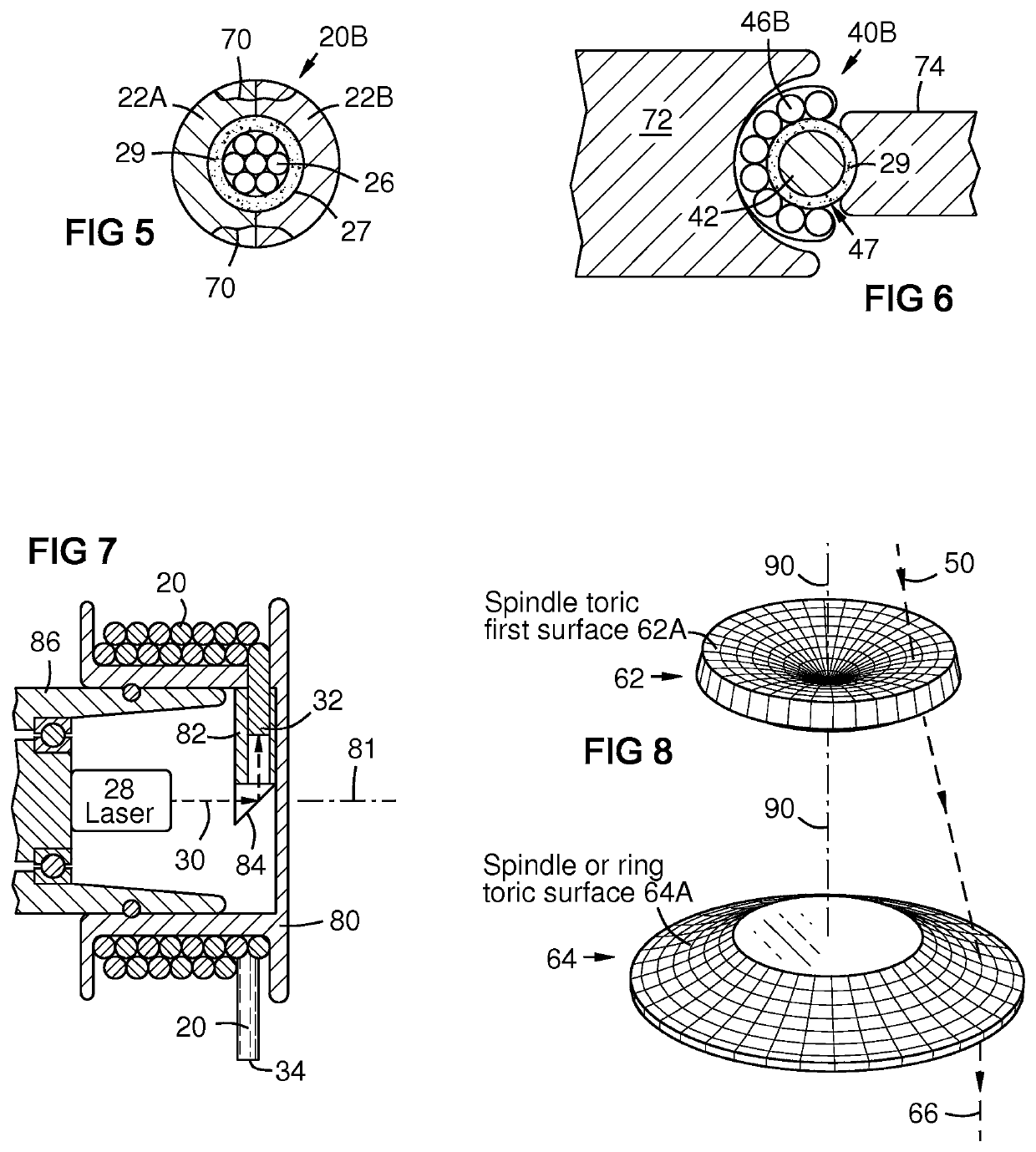

Laser metalworking of reflective metals using flux

Methods for laser processing of reflective metals. A reflective metal (2) is heated by applying a laser beam (6) to a layer of flux (4) in contact with the reflective metal, in which the flux is a powdered flux composition. The laser beam (38) may be applied to a powdered flux composition (36) such that thermal energy absorbed from the laser beam is transferred to a reflective-metal filler material (32) situated on a support material (30), and the powdered flux composition and the reflective-metal filler material melt to form a melt pool (40) which solidifies to form a metal layer (42) covered by a slag layer (44).

Owner:SIEMENS ENERGY INC

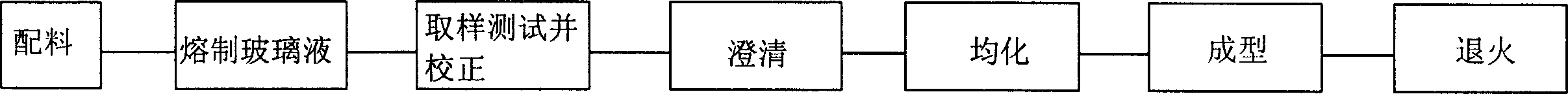

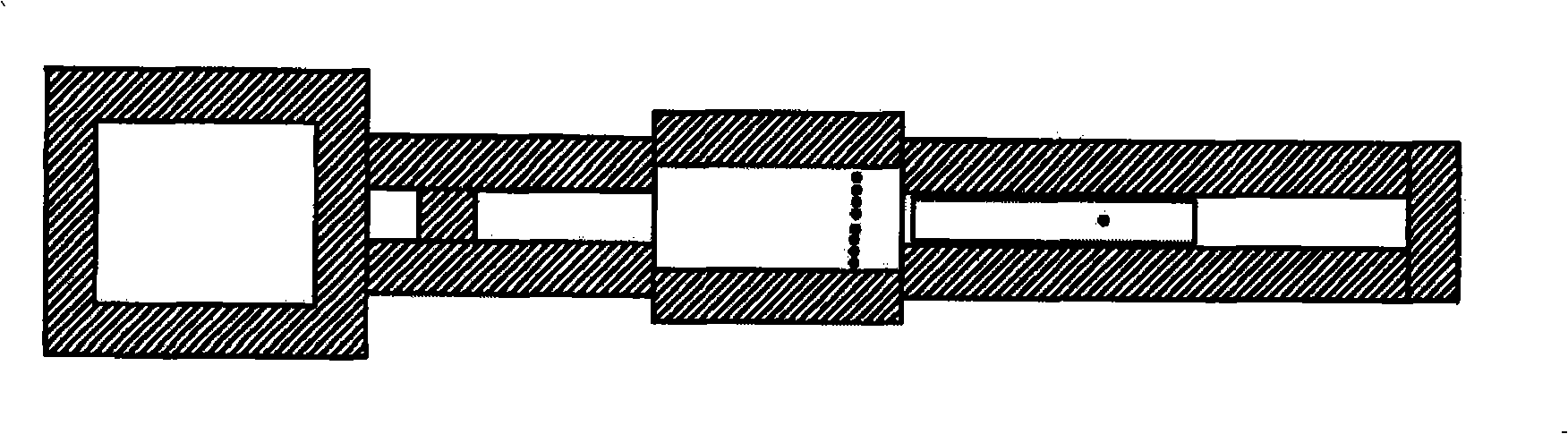

Environmental protective heavy flint optical glass in high refractive index, and high dispersion, and producing method and equipment

ActiveCN1915875AHigh refractive indexSpeed up the production processGlass furnace apparatusControl systemMetallurgy

This invention provides a method for producing environmentally friendly heavy-flint optic glass with high refractivity and high color dispersion. The heavy-flint optic glass is composed of: SiO2 20-44 wt.%, TiO2 22-34 wt.%, Nb2O5 5-22 wt.%, Na2O 7-18 wt.%, BaO 9-17 wt.%, K2O 0-9 wt.%, CaO 0-3 wt.%, ZrO2 0-3 wt.%, SrO 0-0.5 wt.% and Sb2O3 0-0.5 wt.%. The method comprises (1) mixing the raw materials uniformly; (2) melting in a tank furnace at 1150-1300 deg.C to obtain glass liquid with uniform refractivity; (3) clearing, homogeneizing and molding the glass liquid into glass stripes; (4) annealing in an annealing furnace. The equipment comprises a tank furnace and an annealing furnace. The melting pool of the tank furnace is connected with an automatic burning control system. The heavy-flint optic glass dose not contains pollutive components such as PbO, As2O3 and GdO. The method can reduce the times of high-temperature melting and improve the optic permeability.

Owner:CDGM OPTICAL GLASS

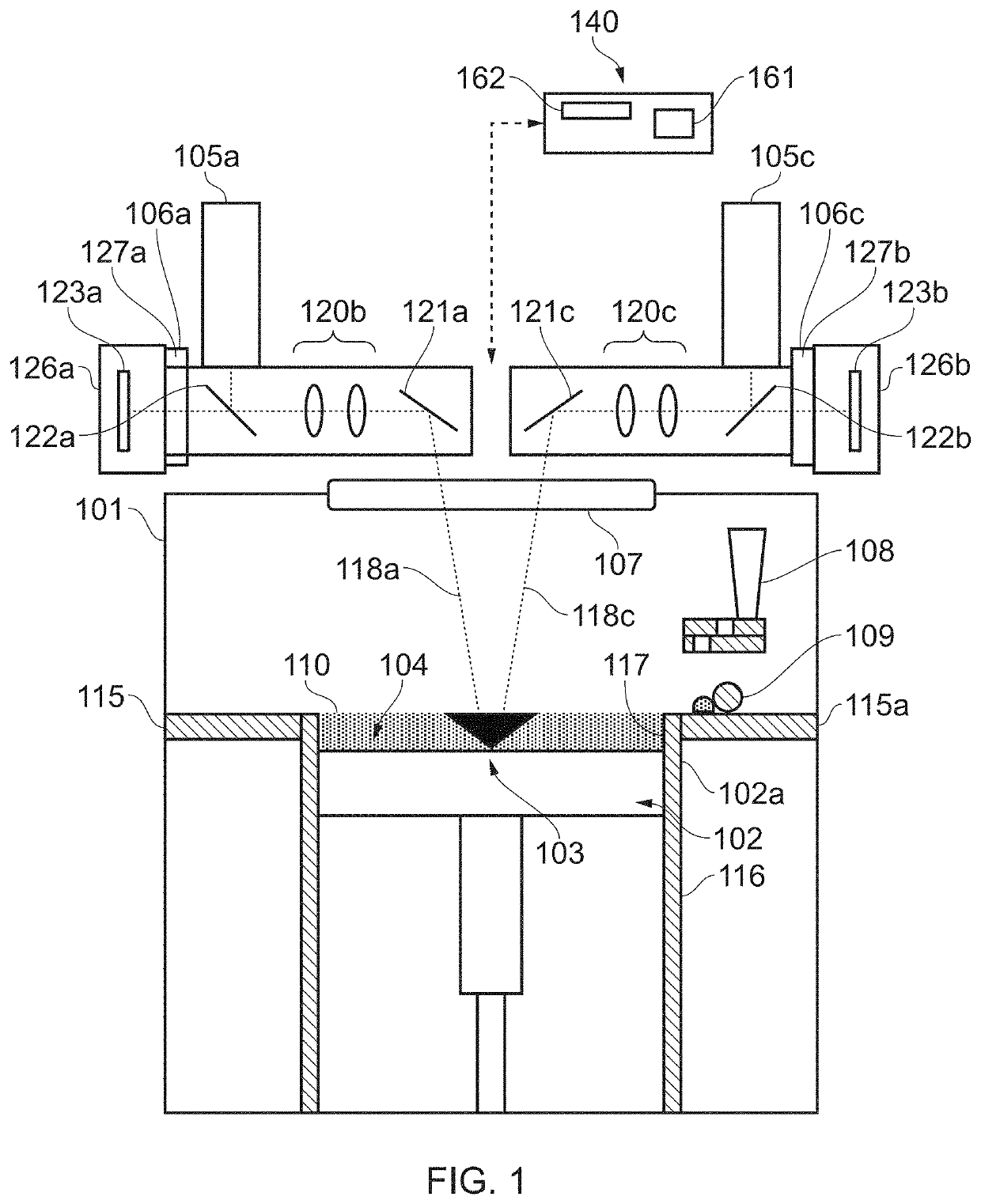

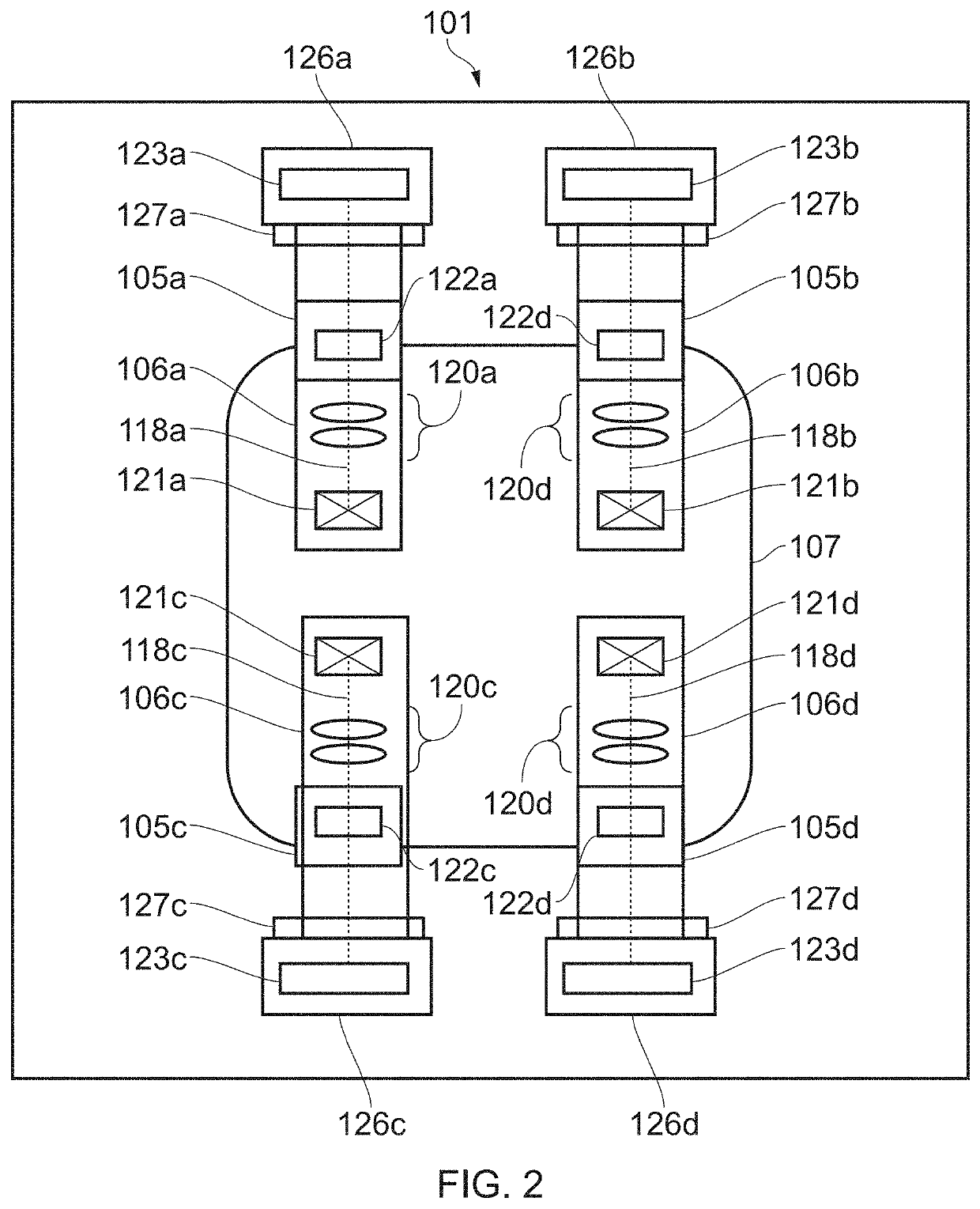

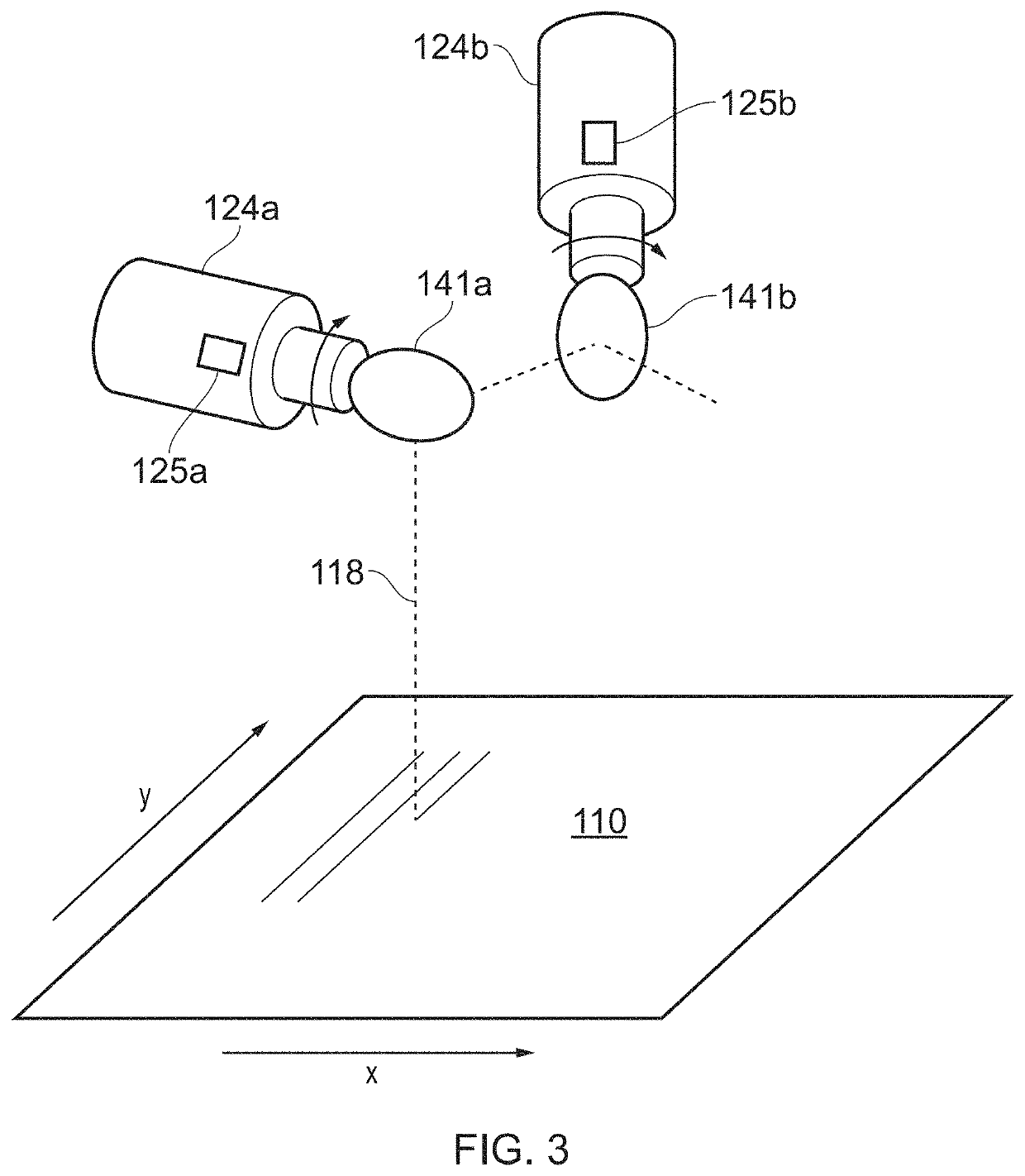

Additive layer manufacturing methods

InactiveUS20170197278A1More equi-axe grain structureReduce stress buildupTurbinesAdditive manufacturing apparatusBeam sourceEngineering

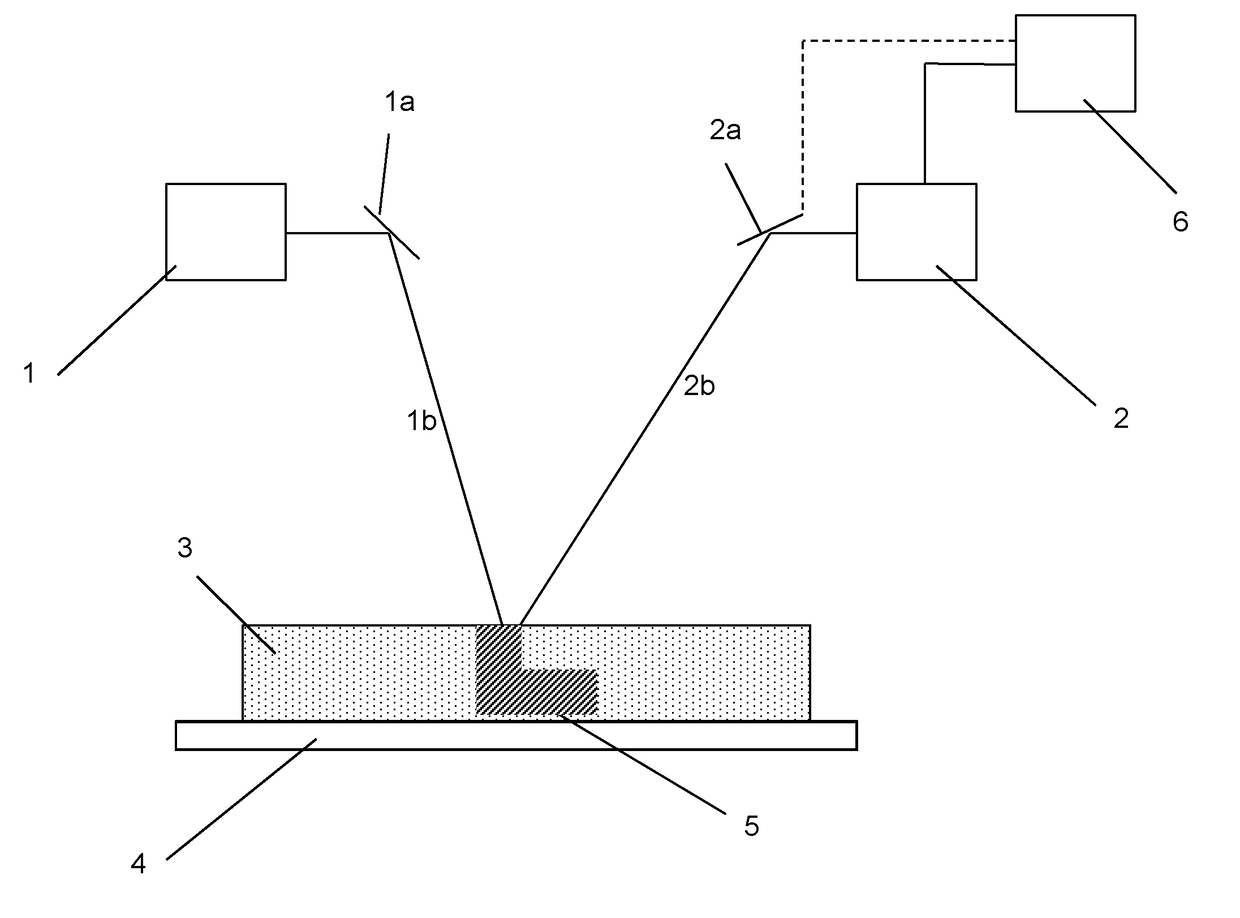

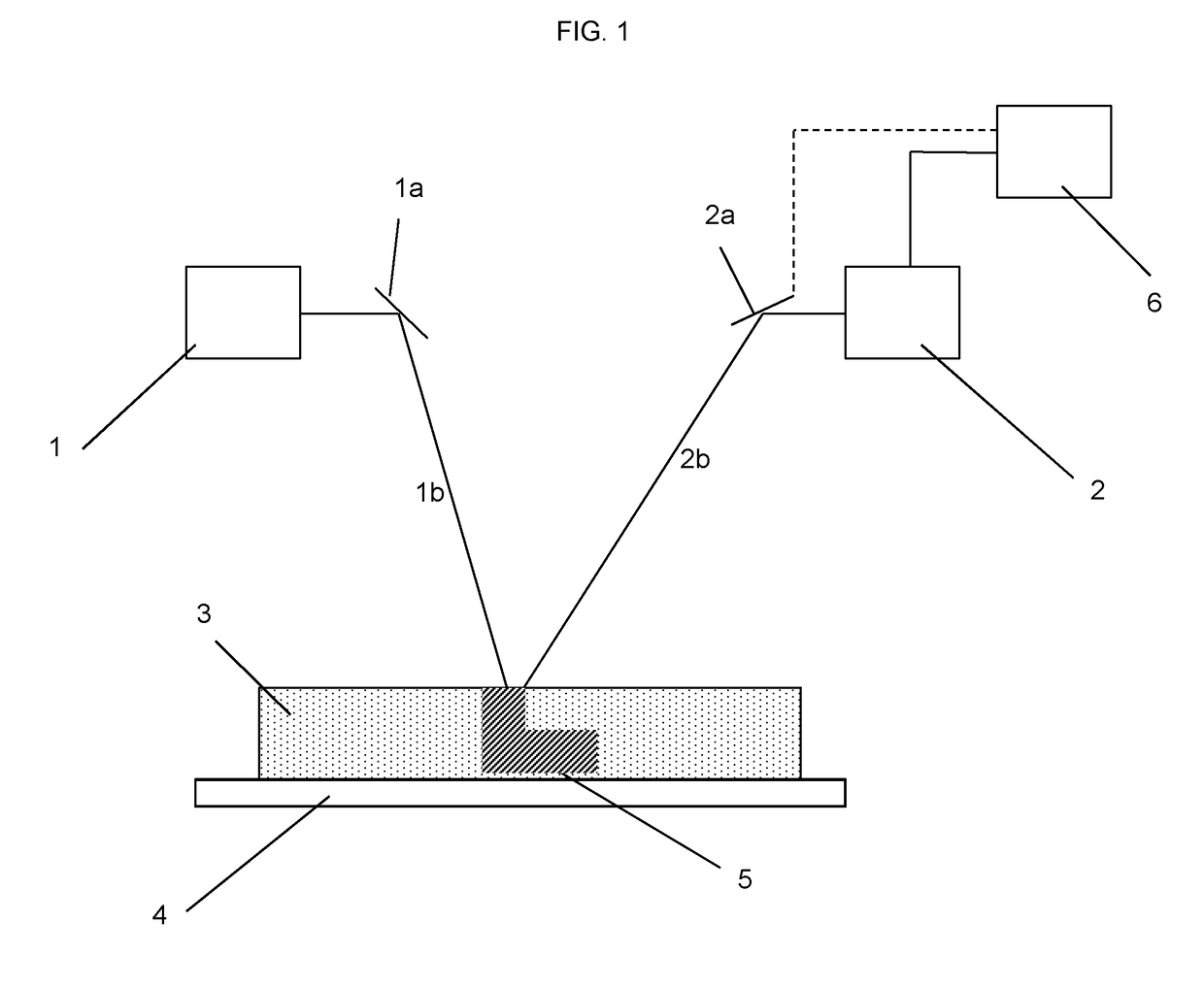

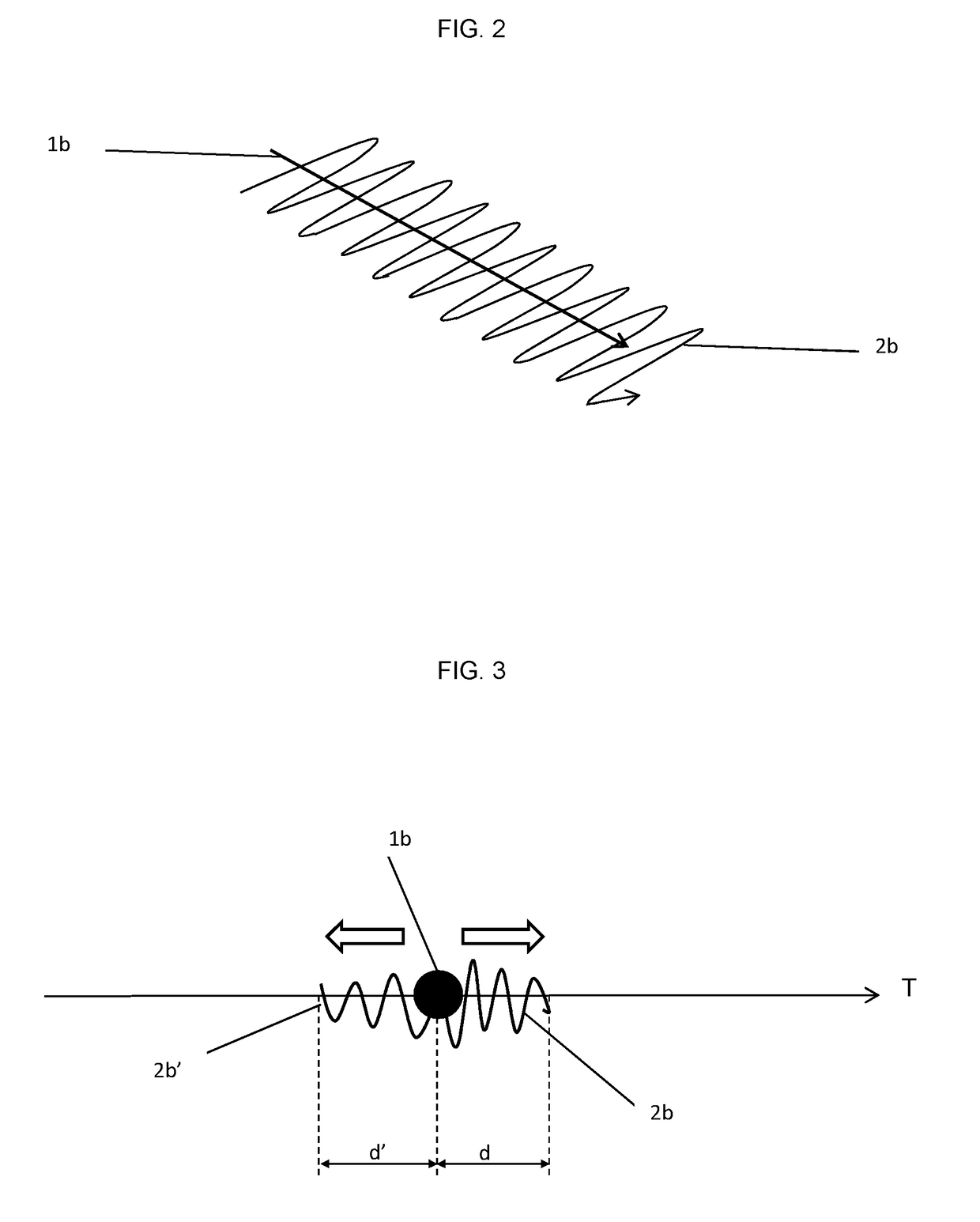

An apparatus and method for performing an ALM process is described. A first energy beam source (1) provides an energy beam (1b) which selectively melts a substrate powder (3) into a melt pool. A second energy beam source (2) provides an energy beam (2b) to heat condition substrate powder proximate to the melt pool. The path of the second energy beam (2b) is controlled by a controller (6) to oscillate independently of the path followed by the first energy beam (1b). The method may be applied to control and optimise heating and cooling rates of the sintered substrate during the ALM process enabling its microstructure to be controlled to suit the end use of the product and reduce the occurrence of residual stresses and consequent crack propagation.

Owner:ROLLS ROYCE PLC

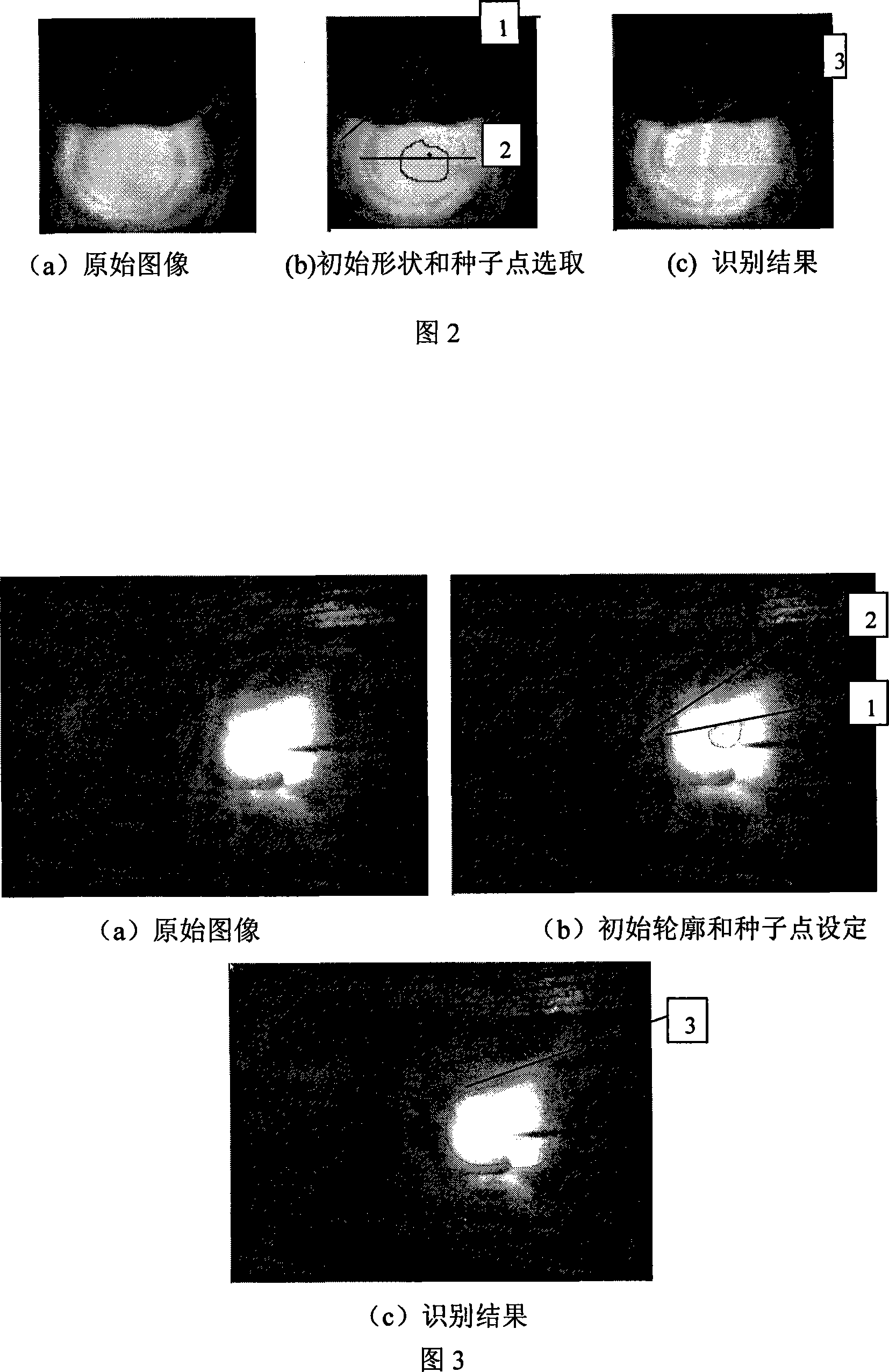

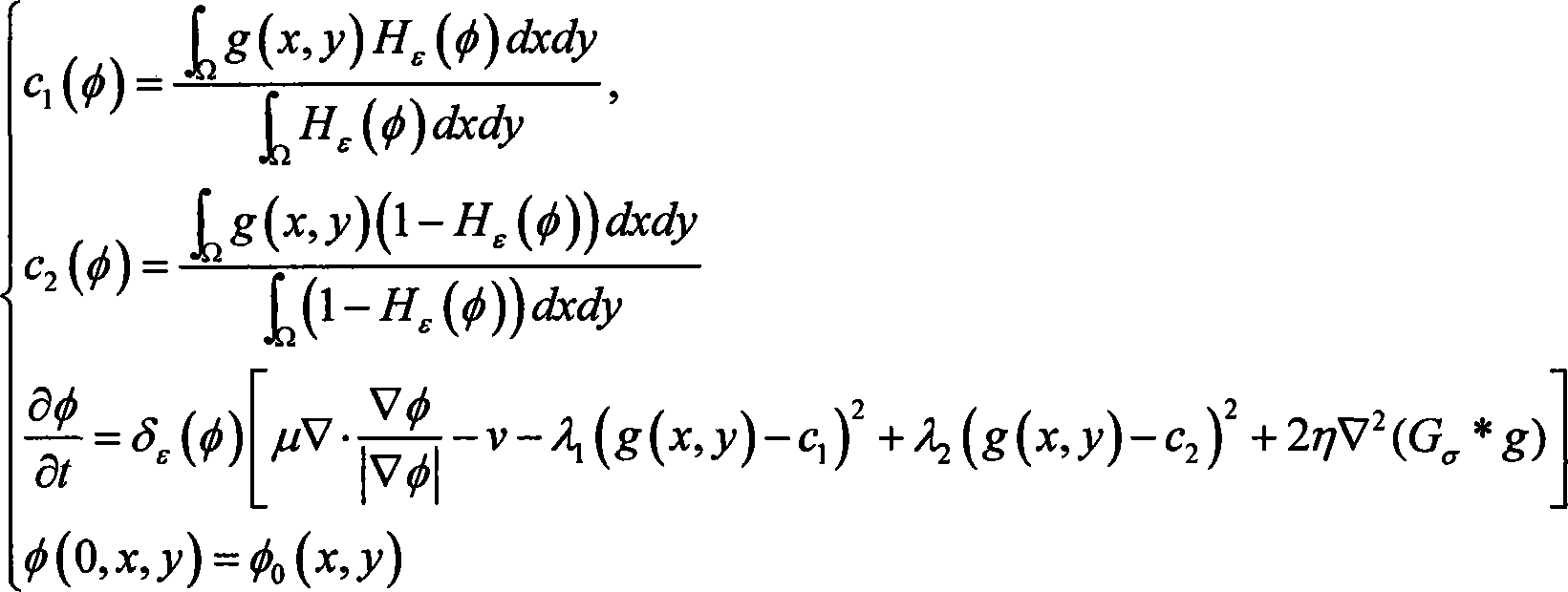

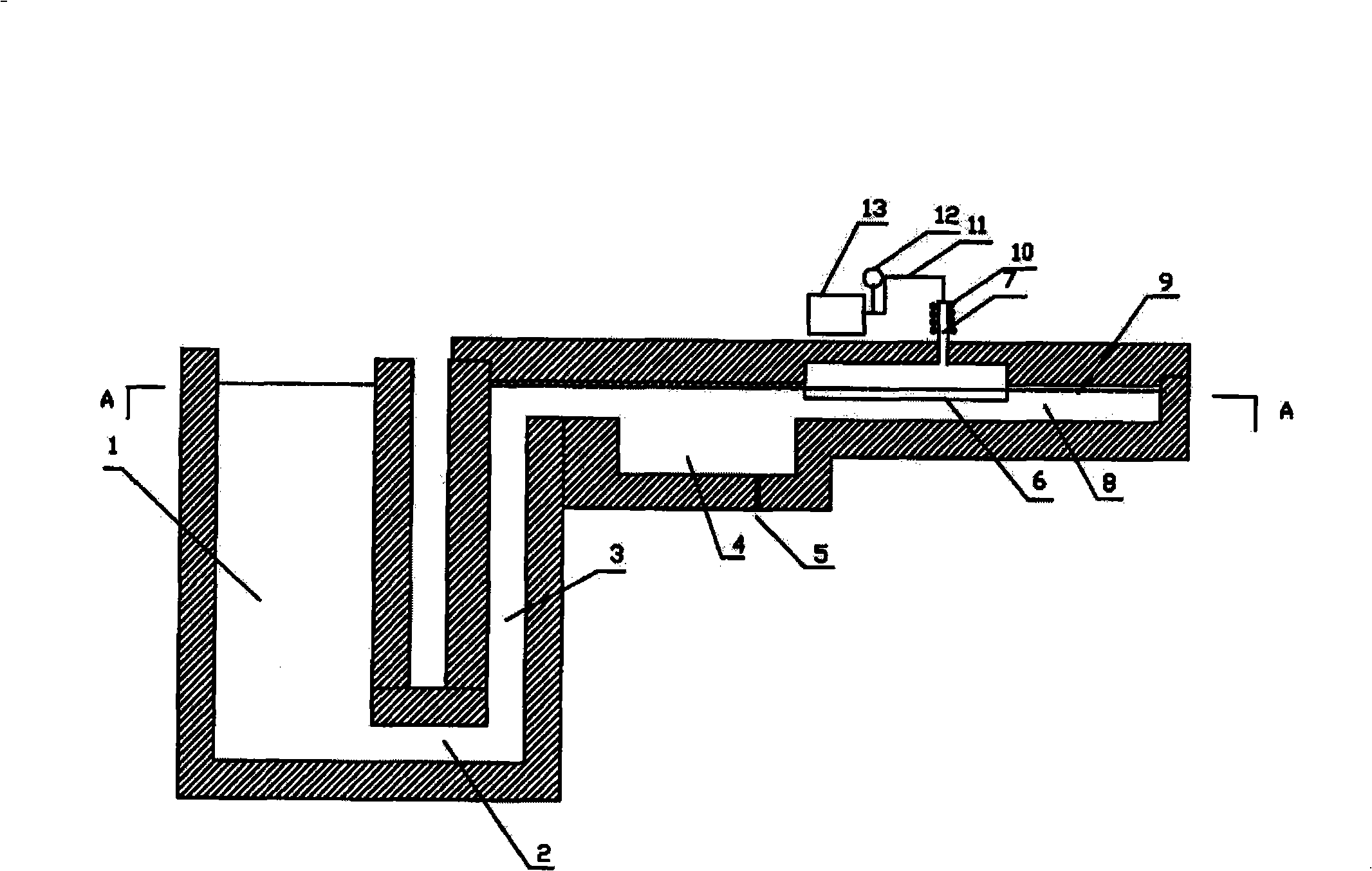

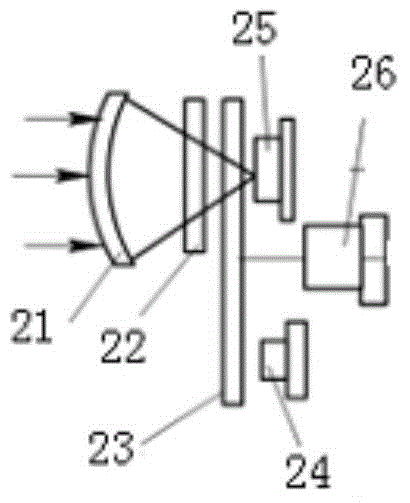

Welding image identification method

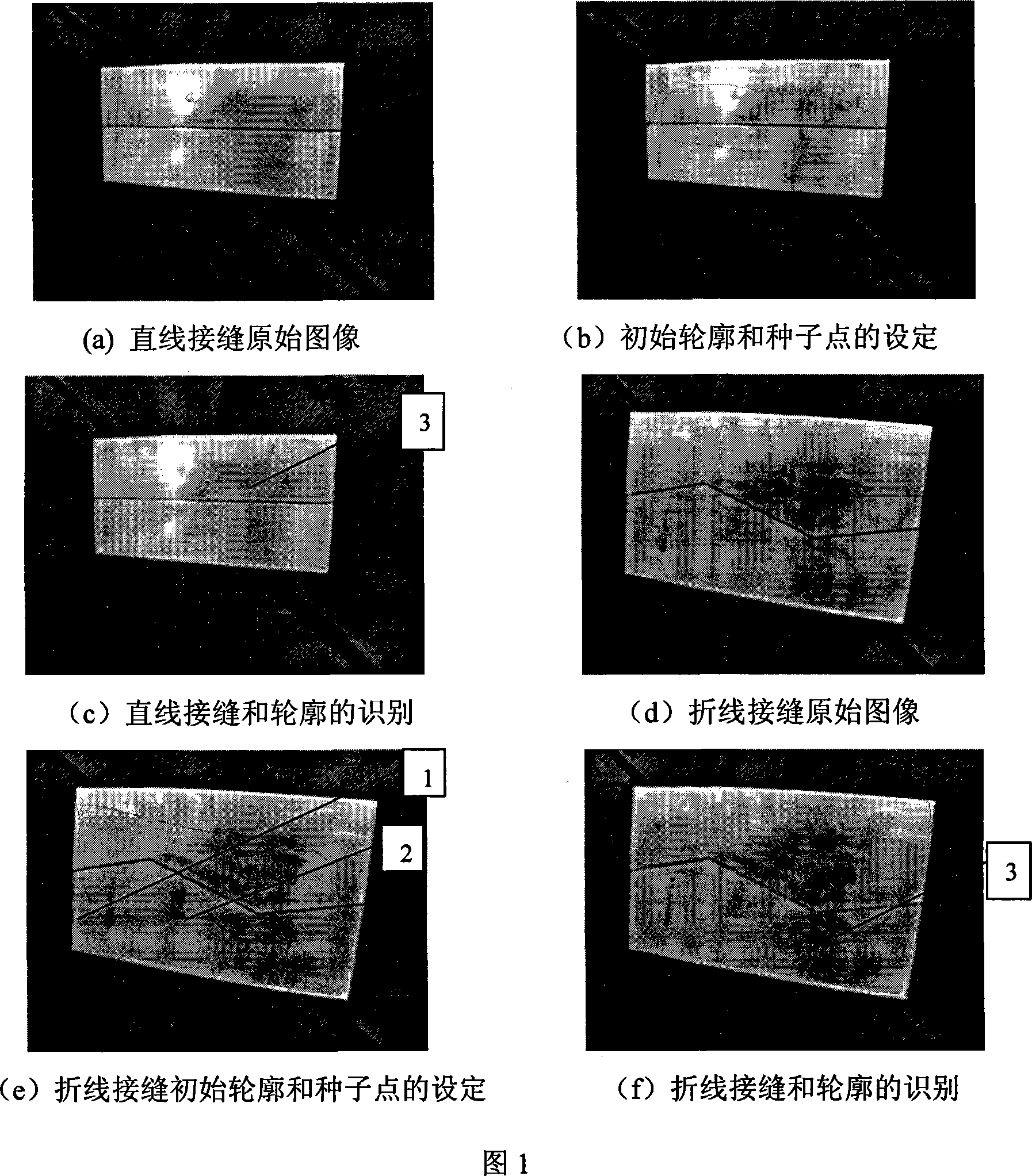

The utility model relates to a identification method of weld image based on the experiences known in the prior art, comprising: a weld seam image is acquired by a charge-coupler (CCD) and the image is processed using the C-V segmentation method; for the image to be welded, the initial contour is acquired using a CCD video camera under irradiation of general indoor light source; for the melting pool image in the welding process, the initial contour is acquired through a dimmer and filter system and used as the dividing and gradually evolved using the C-V segmentation method, thereby the actual edge shape and contour information of the pre-weld joint and the melting pool during welding process can be acquired The utility model can acquire the coordinate and the contour information of the pre-weld joint image as well as the contour information and the size information of the melting pool image, which can be use in automatic welding system or the welding robot path planning, the joint tracing and correction, penetration control and forming quality control, molding quality control, and has good applicability in the more technical fields of intelligent welding based on vision sensing technology.

Owner:JIANGSU UNIV

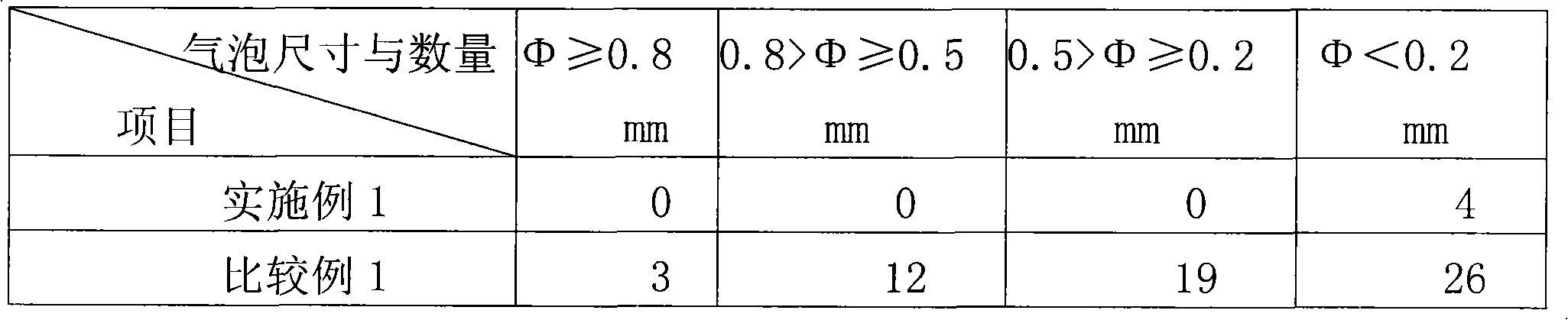

Fine clarifying method of electric melting furnace and device

InactiveCN101538111AHigh viscosityIncrease surface tensionGlass furnace apparatusQuality levelOptical glass

The invention provides a fine clarifying method applicable to an electric melting furnace and a device; a clarifying pool is connected with a rising channel of the electric melting furnace; the viscosity of molten glass is kept less than 102.0-103.0dPa.s, the area of the clarifying pool is 20-50 percent of the area of a melting pool, and the depth of the clarifying pool is 300-800mm; the rear part of the clarifying pool is connected with a pressure-reducing cover; the viscosity of the molten glass in the pressure-reducing cover is about 103.0-104.0dPa.s, so as to lead the partial pressure in the pressure-reducing cover to be small than the partial pressure in the molten glass; the gas remained in the molten glass overflows; a material-supplying channel is connected with the rear part of the pressure-reducing cover; by further temperature-reducing adjustment of the material-supplying channel, so as to achieve the needed viscosity of a forming machine or a material-supplying device; by the technique for fine clarifying and the device, the diameter of the bubble of the glass product is smaller than 0.2mm, the quantity of the bubble is smaller than or equal to 5 for every 1000g of glass, thus achieving the melting quality level of optical glass.

Owner:WUHAN UNIV OF TECH

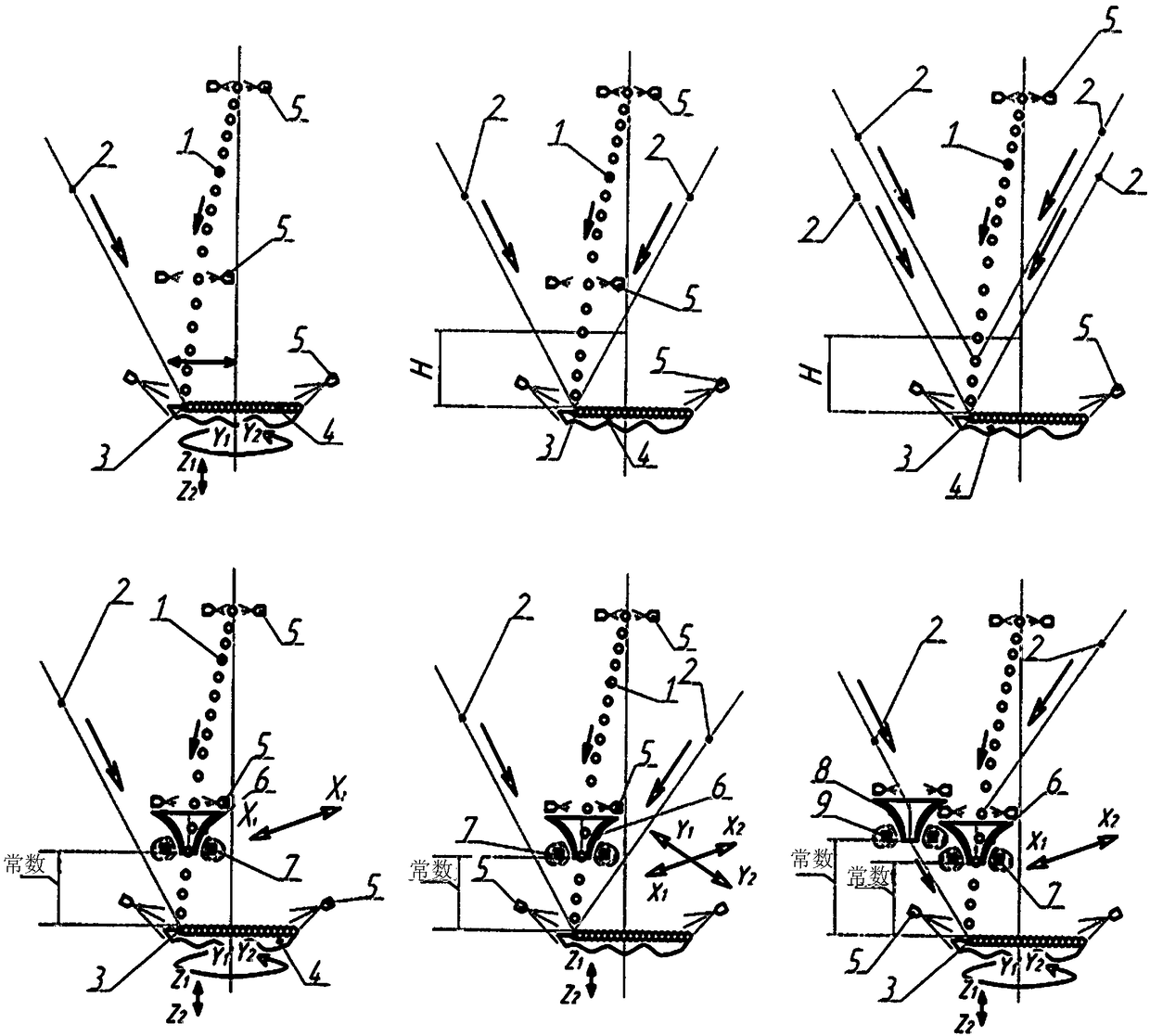

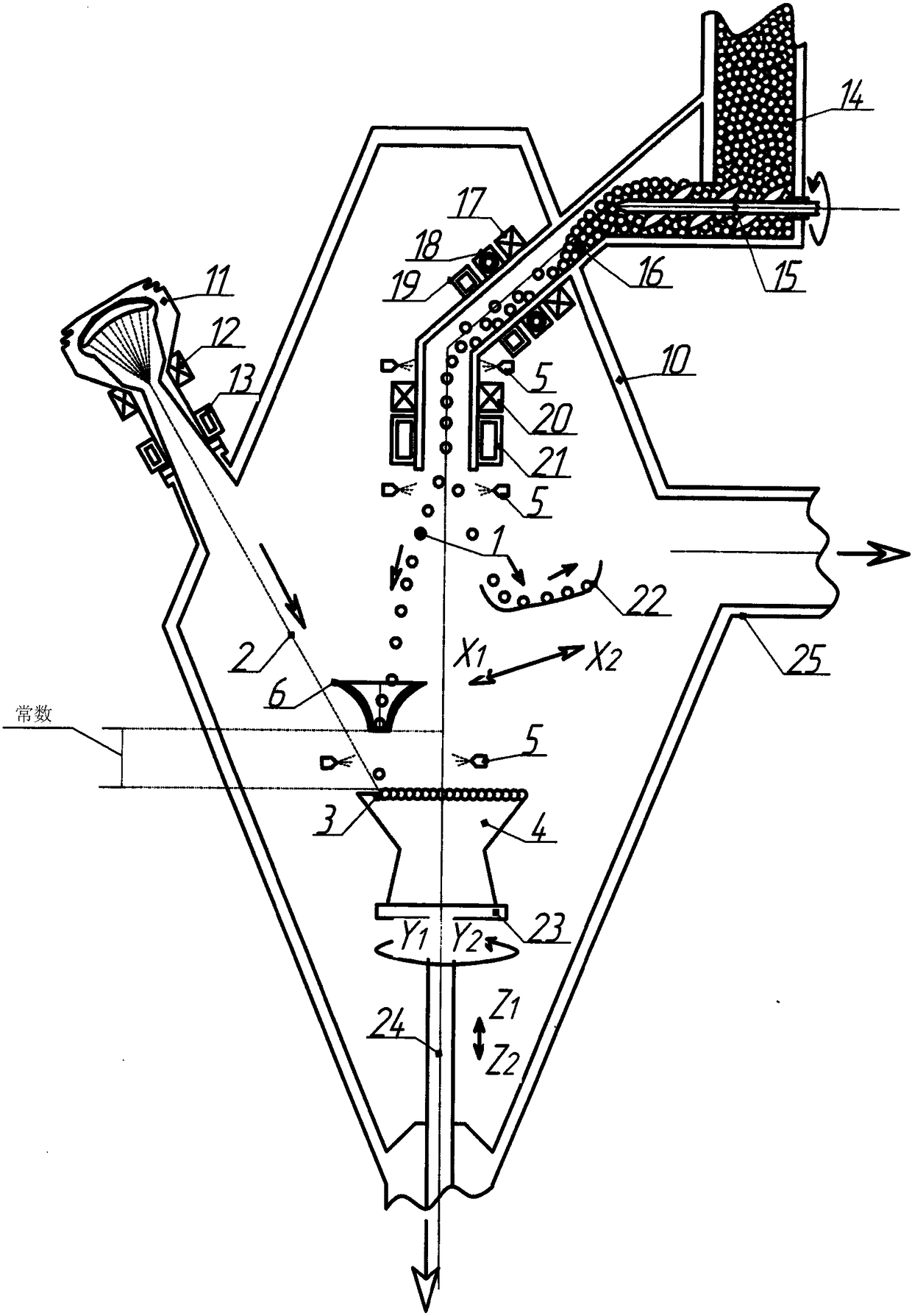

Method and device for the additive manufacturing of components

ActiveCN108136500AReduce consumptionImprove accuracyAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringLaser beams

The invention relates to the field of the additive manufacturing of components, which are formed by the direct deposition of a substance, in the form of granules of a metal or non-metal, which passesfrom a reservoir into a melt bath, produced by the thermal energy of a laser or electron beam, and subsequently crystallizes. The granules enter the melt bath without the intervention of a gas stream,the path and rate of travel of said granules changing while they are in flight under the effect of an electromagnetic field. The granules travel within a chamber, falling into the melt bath from above from a reservoir, from which they are fed at a set speed by the rotation of an adjustable screw feed, and passing through a system of electromagnetic devices, which control the path of the granulesby means of electromagnetic fields. The coordinates of this path are tracked by sensors, which transmit a signal to a computer, wherein the flight path of the granules is adjusted by control via the electronic devices and the delivery speed and volume of the substance is adjusted by adjusting the rotation of the screw feed. The invention increases the efficiency of the production cycle, reduces the dimensions of the equipment and increases the accuracy and speed with which material is delivered for the manufacture of a component, while enabling adjustment of the amount, temperature, path and fraction of said material and increasing the strength of the component.

Owner:阿迪鲁特有限责任公司

Method for monitoring laser melting pool in real time

InactiveCN104677503AEasy accessEasy to handlePyrometry using electric radation detectorsLaser beam welding apparatusThermodynamicsDisplay device

The invention discloses a method for monitoring a laser melting pool in real time and relates to the technical field of temperature monitoring in a laser re-melting process. A device for realizing the method comprises a bracket, an infrared probe, an alarming device and a control box, wherein the bracket is arranged on a main shaft; the infrared probe used for acquiring temperature information of the laser melting pool and the alarming device are arranged on the bracket; the control box is used for processing the temperature information acquired by the infrared probe and is provided with a displayer; a control circuit is arranged in the control box, is connected with a power switch of a temperature field through a relay and comprises a central controller, and a measured temperature analytical model displayer, a data storage module, a communication module and a power module which are respectively connected with the central controller; the communication module is connected with an upper computer. The method has the advantage that great convenience is brought to the acquisition and analysis of the temperature field in the laser re-melting process.

Owner:徐州盛高矿山机械制造有限公司

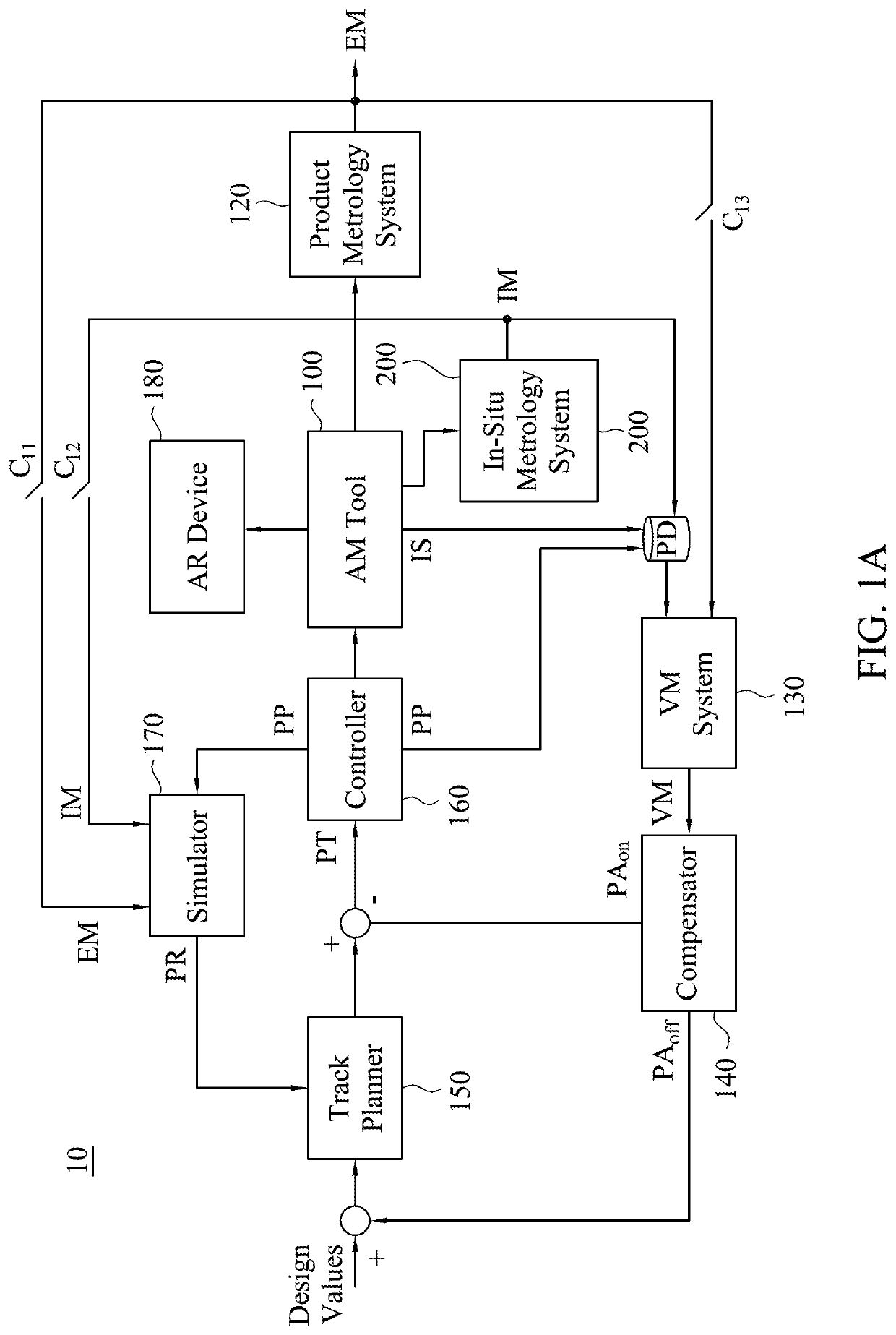

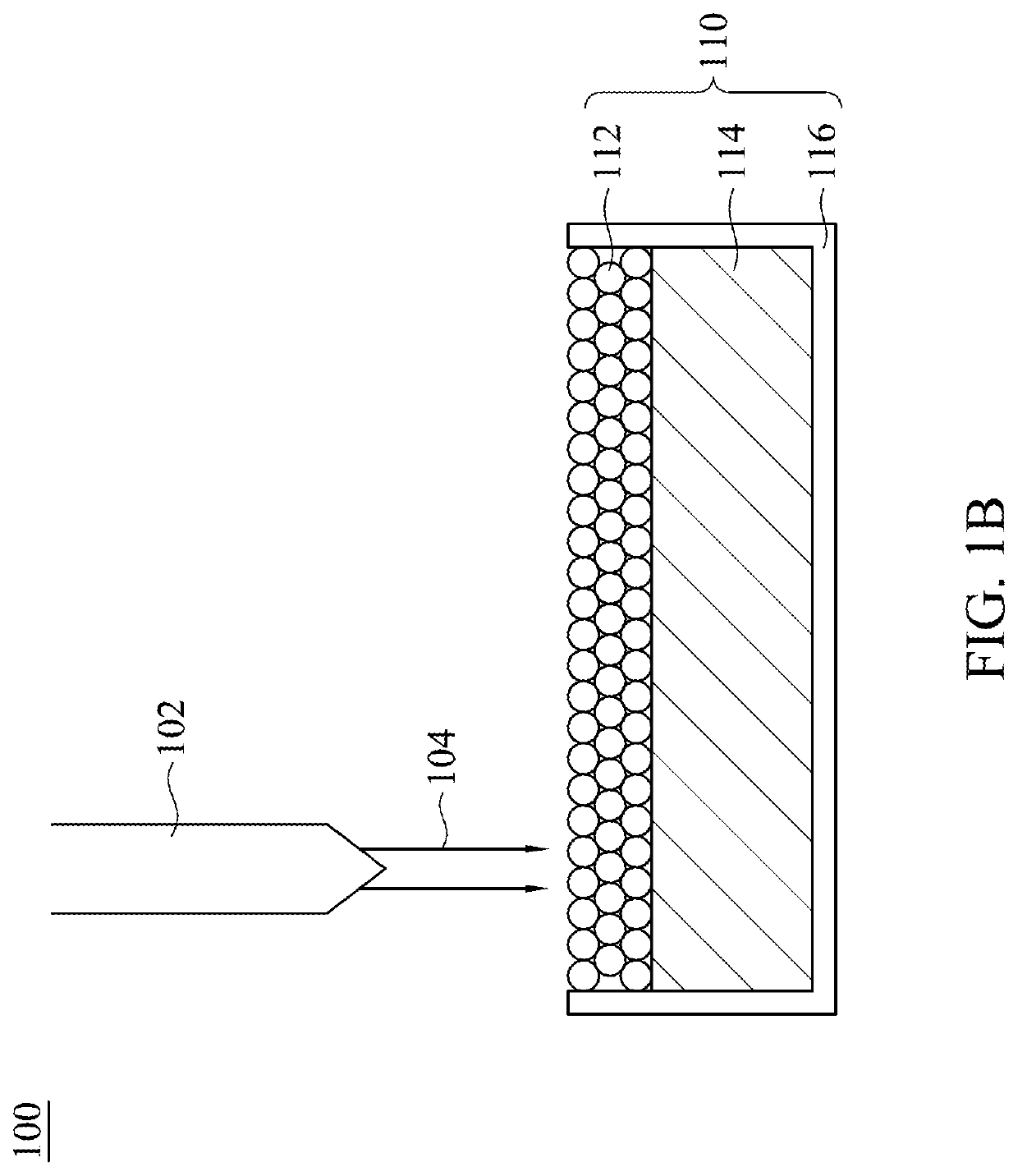

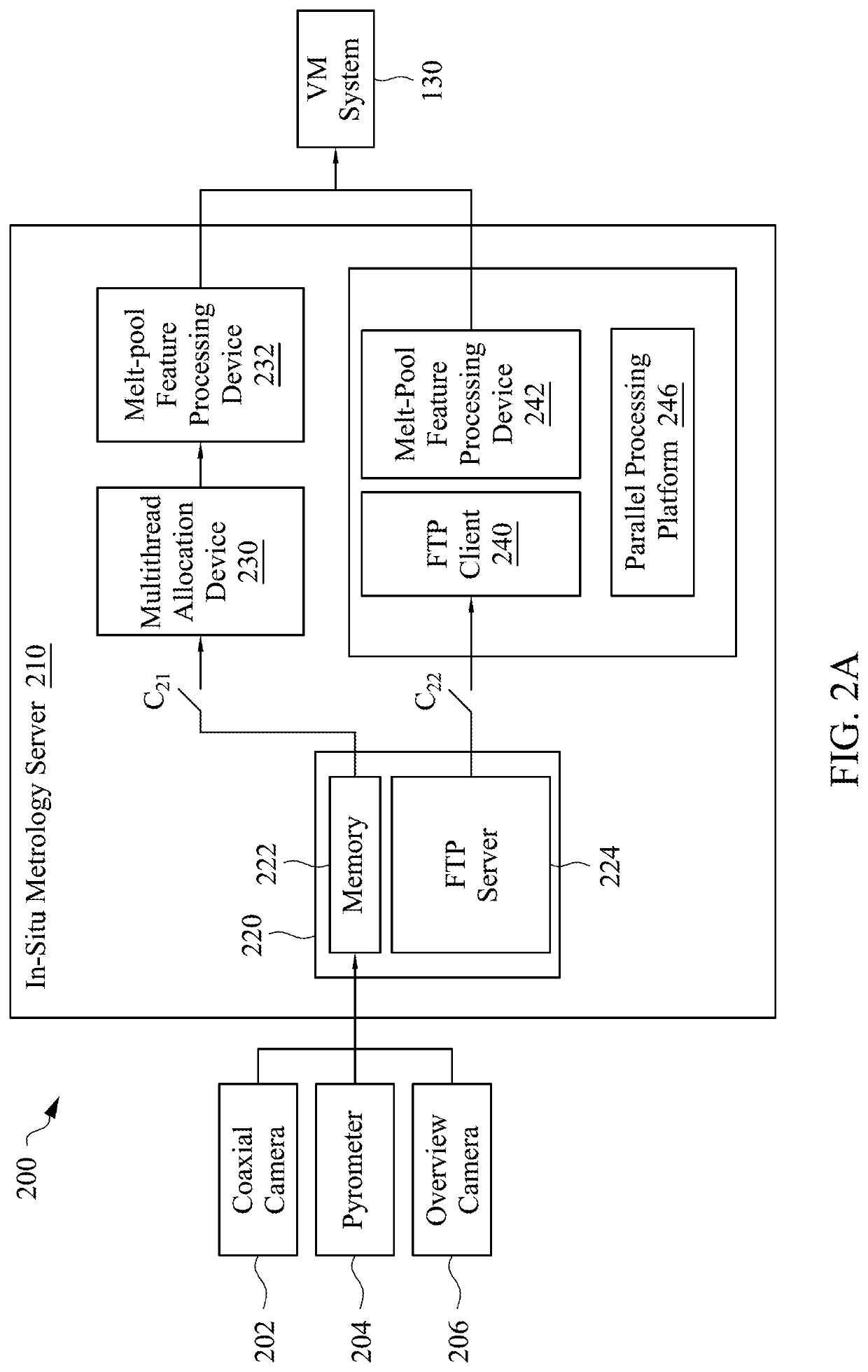

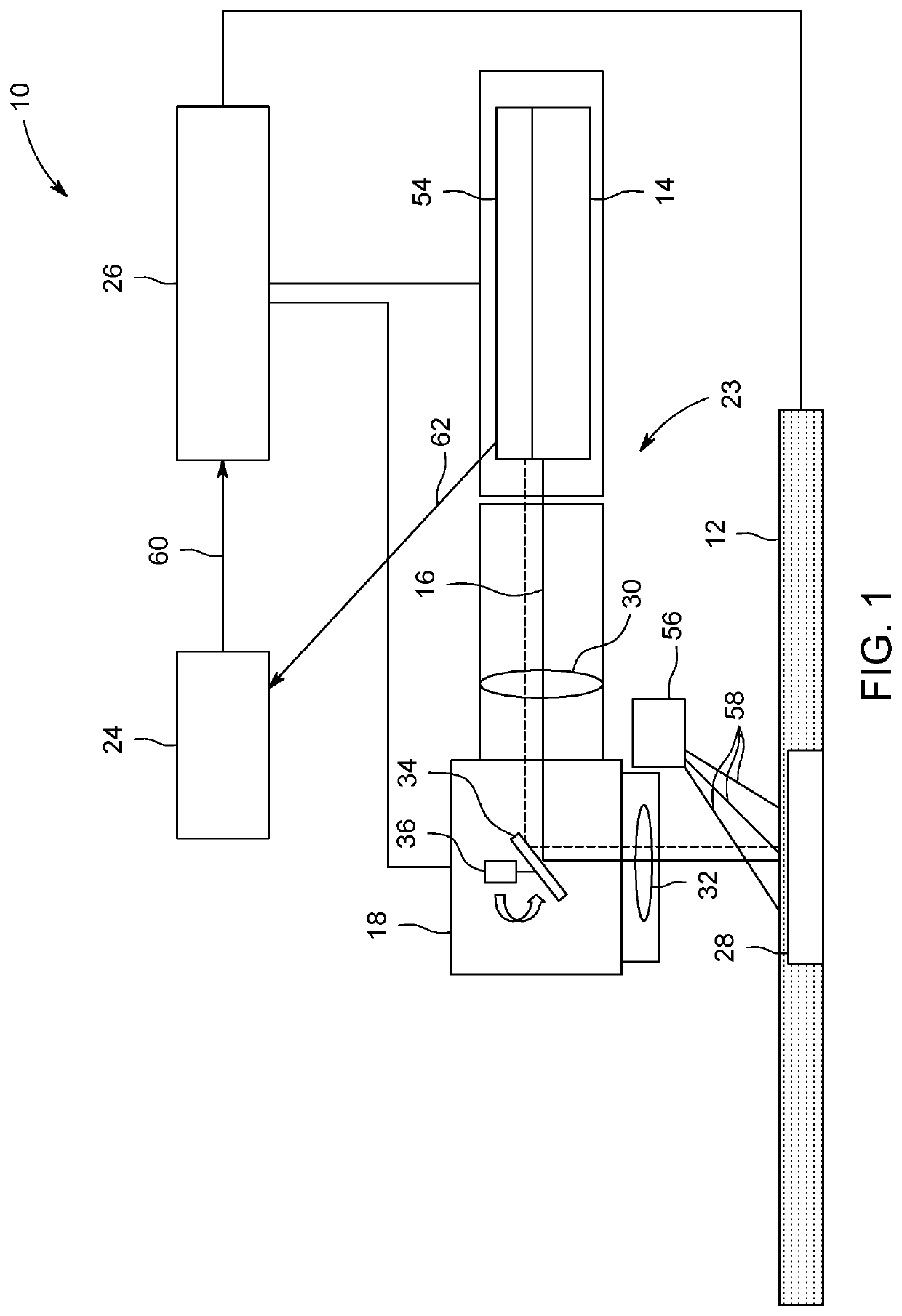

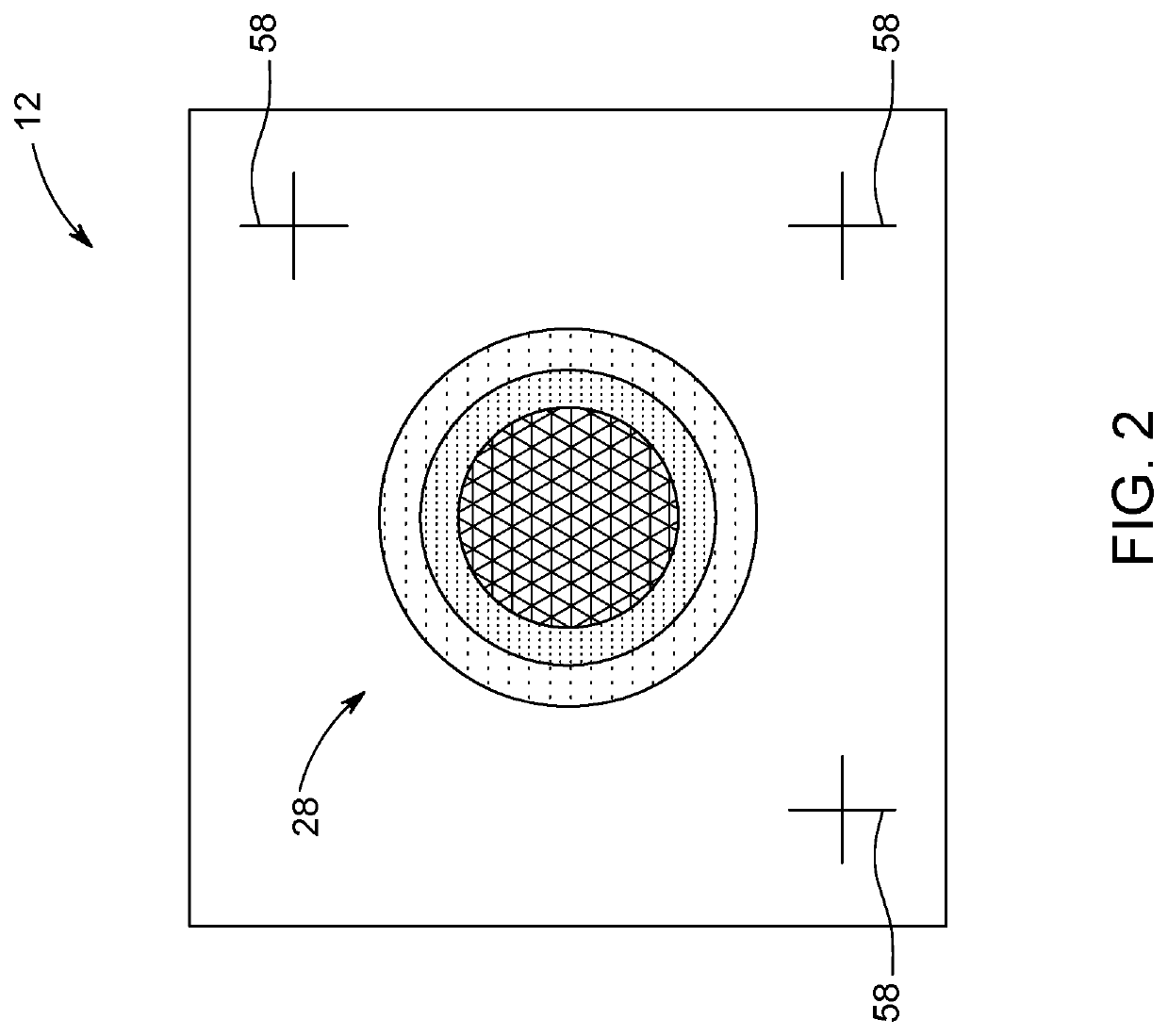

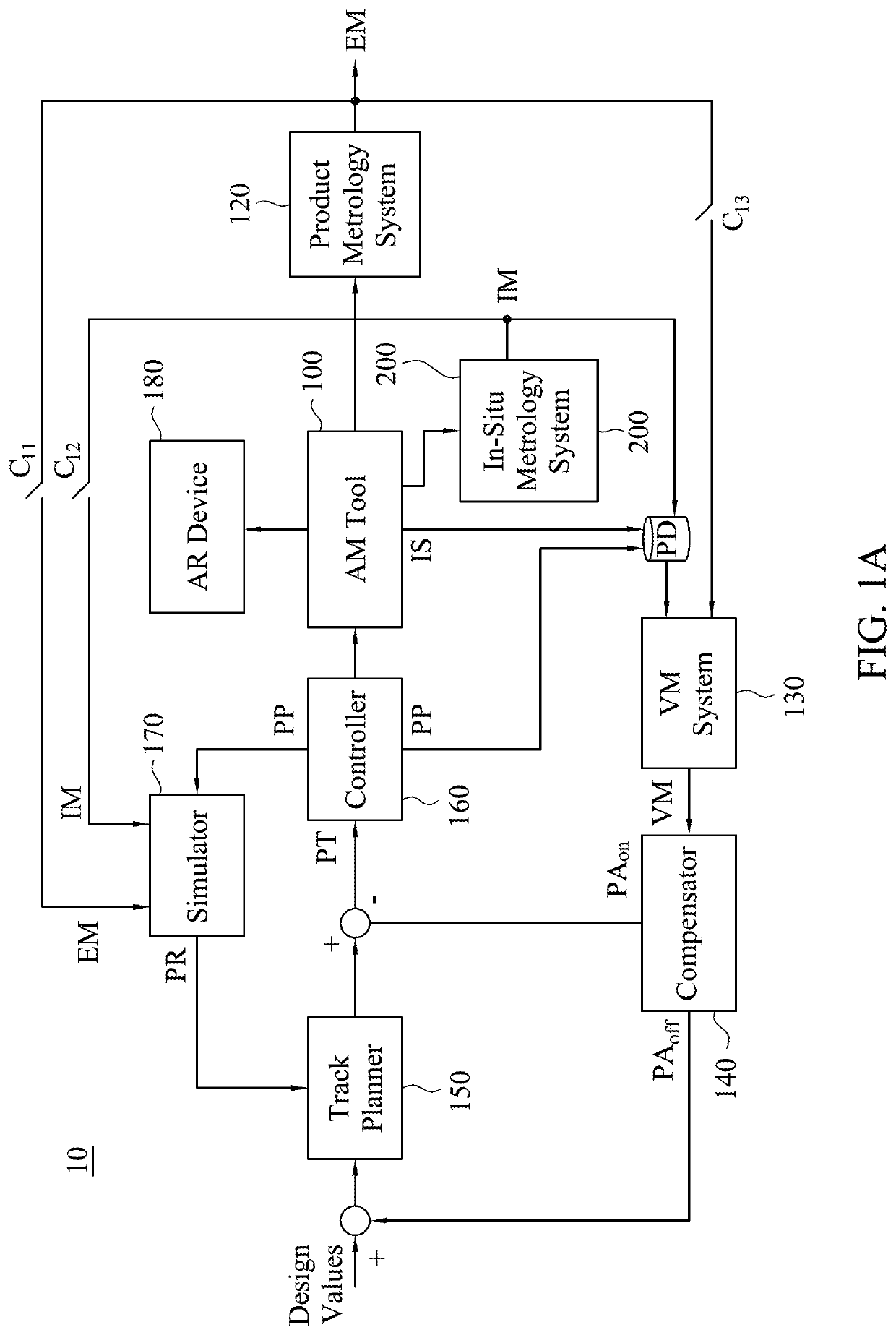

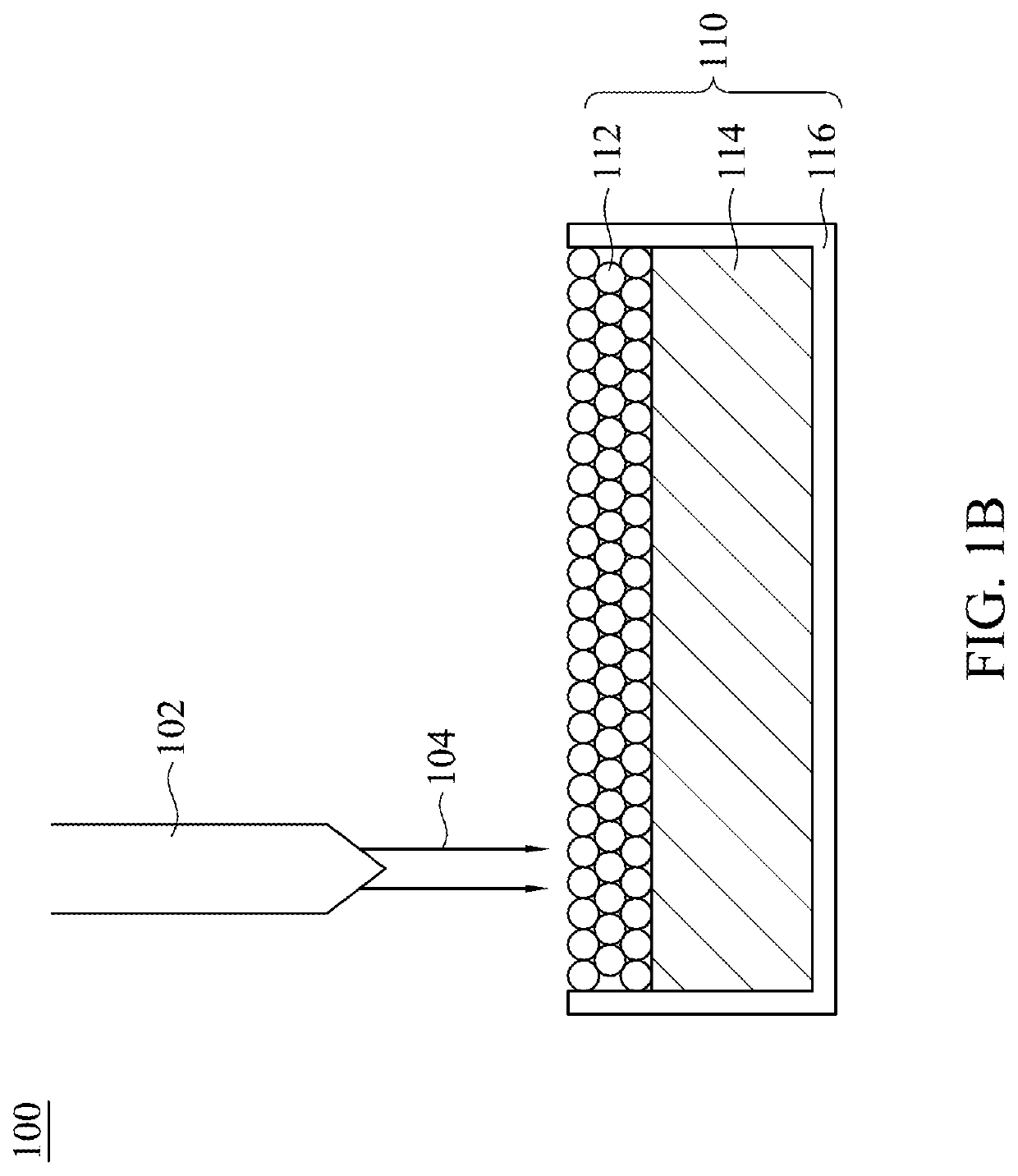

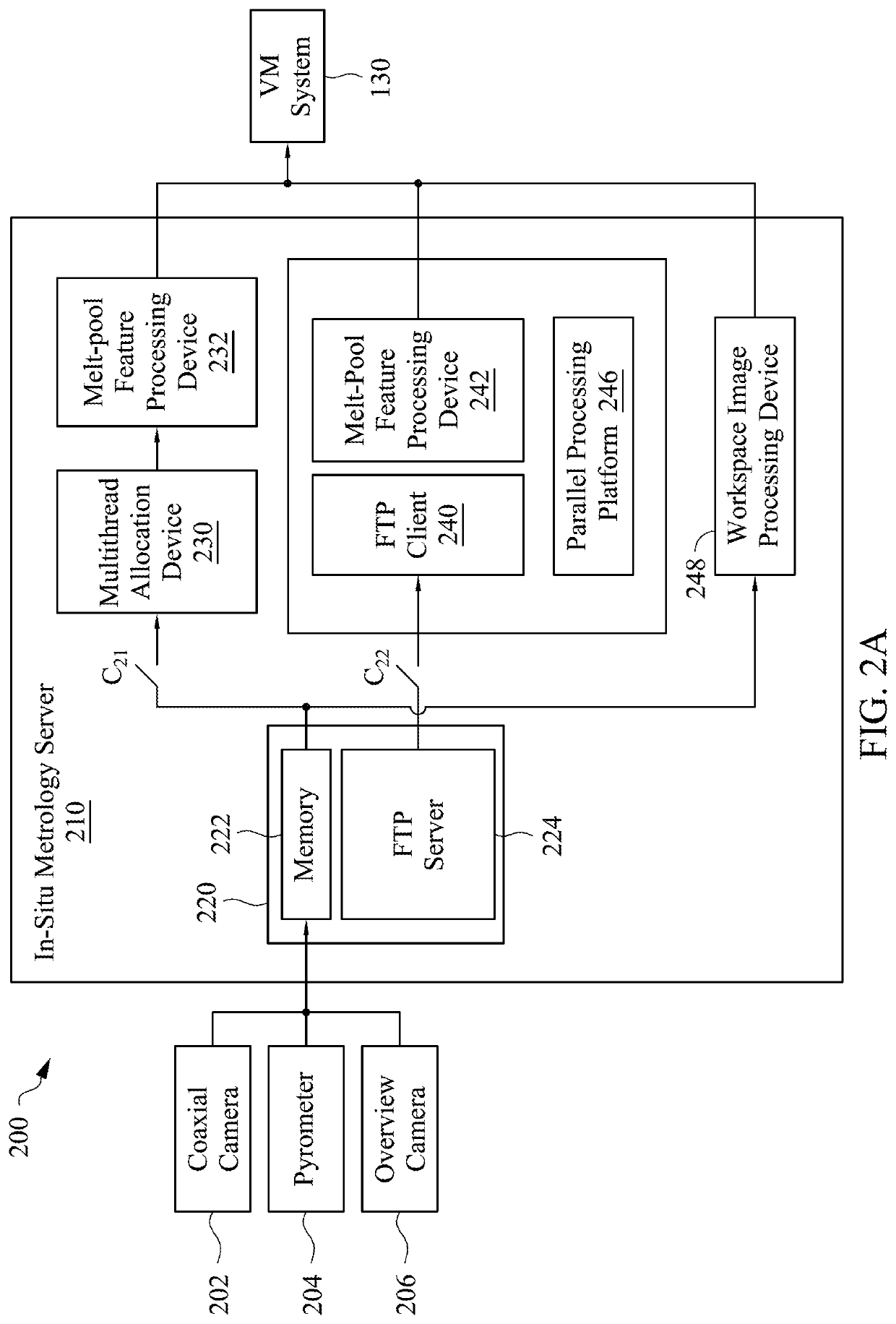

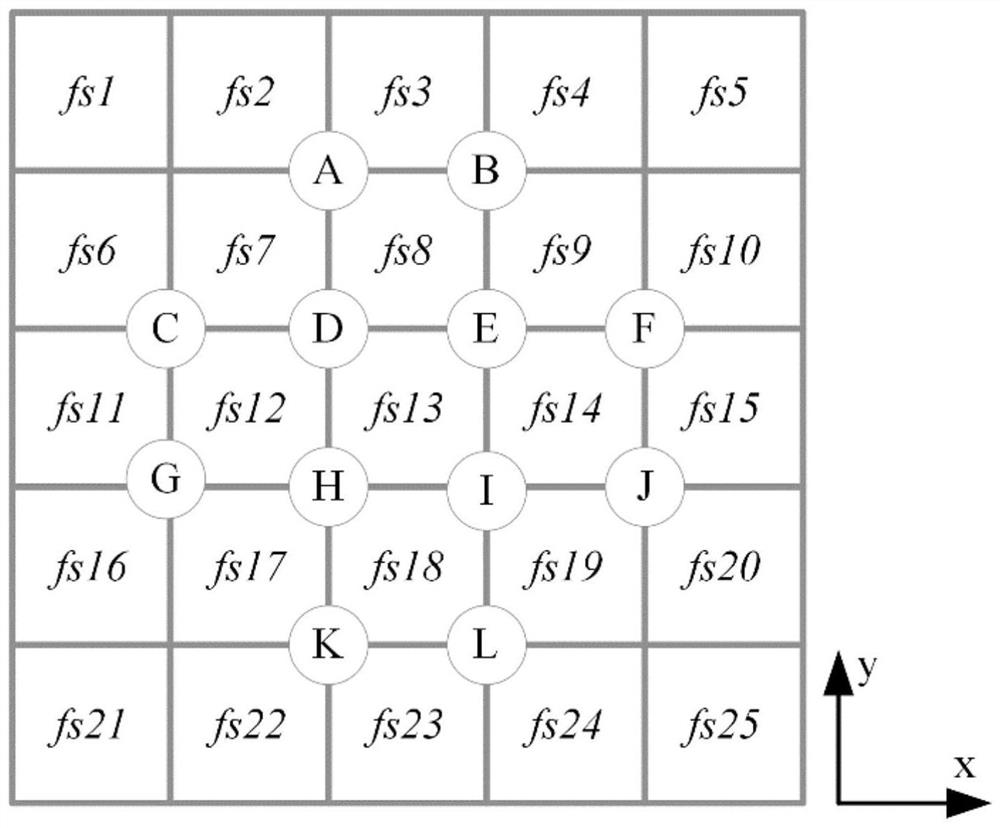

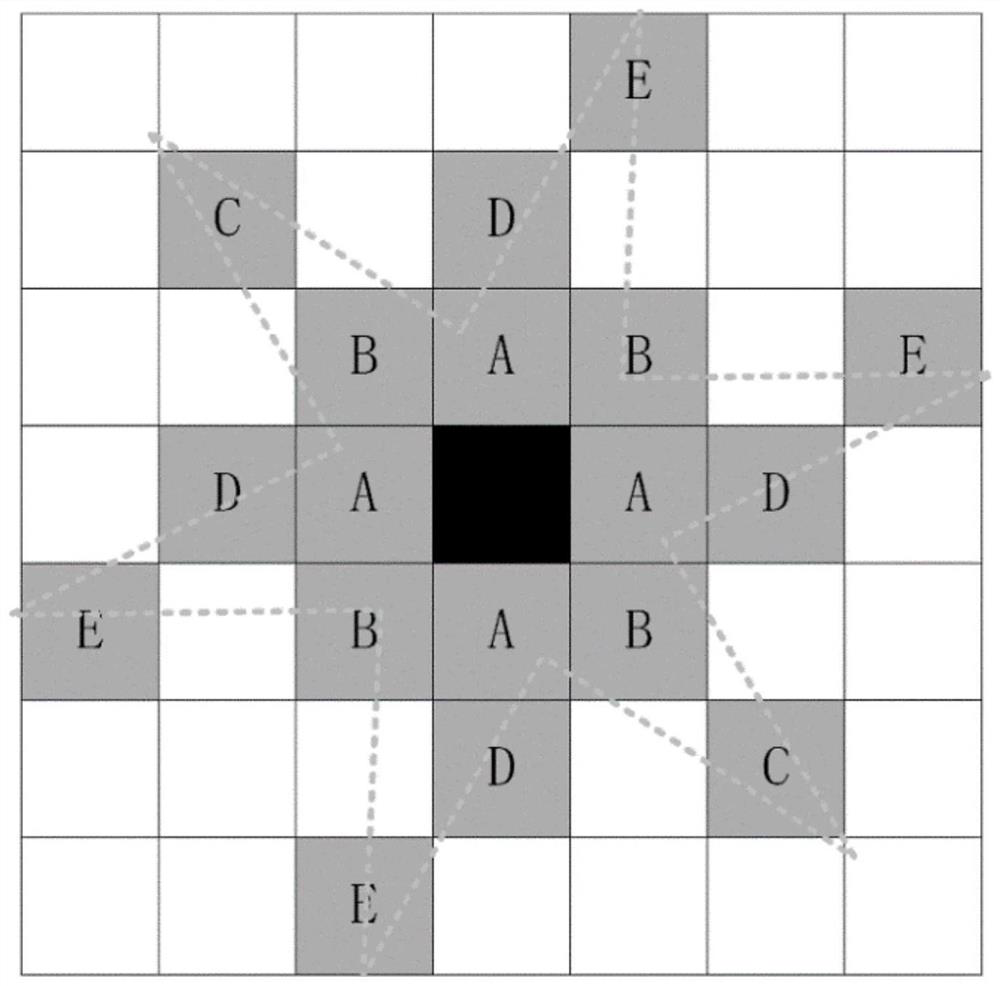

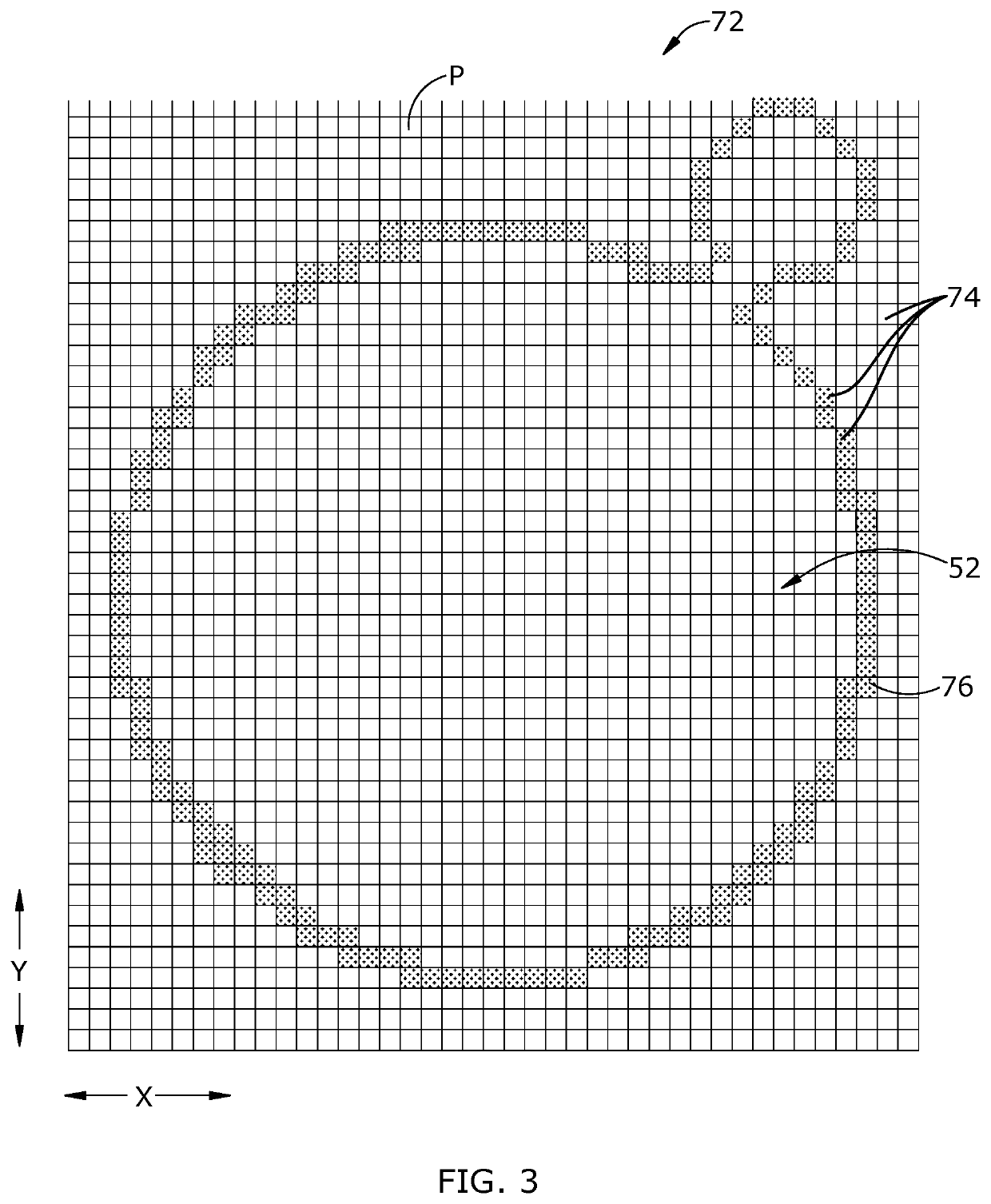

Additive manufacturing system and method and feature extraction method

ActiveUS20200147893A1Obtaining product qualityIncrease productionProgramme controlAdditive manufacturing apparatusFeature extractionPowder bed

An additive manufacturing (AM) system, an AM method, and an AM feature extraction method are provided. The AM system includes an AM tool, a product metrology system, an in-situ metrology system, a virtual metrology (VM) system, a compensator, a track planner, a controller, a simulator and an augmented reality (AR) device. The simulator is used to find feasible parameter ranges, while the AR device is used to support operations and maintenance of the AM tool. The product metrology system, the in-situ metrology system and the VM system are integrated to estimate the variation of material on a powder bed of the AM tool. The compensator is used for compensating the process variation by adjusting process parameters. The product metrology system is used to measure the quality of products. The in-situ metrology system is used to collect features of melt pools on the powder bed.

Owner:NAT CHENG KUNG UNIV

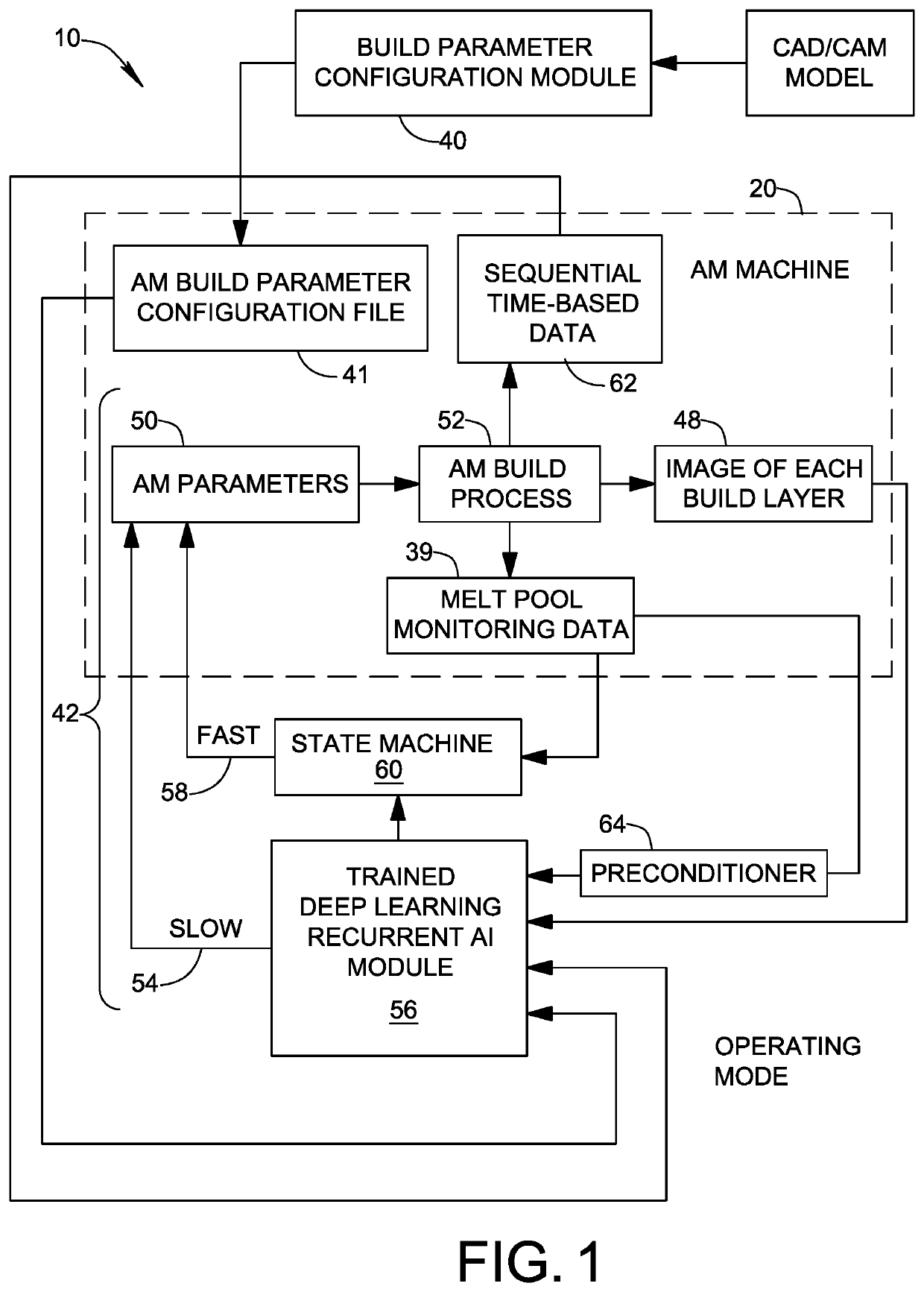

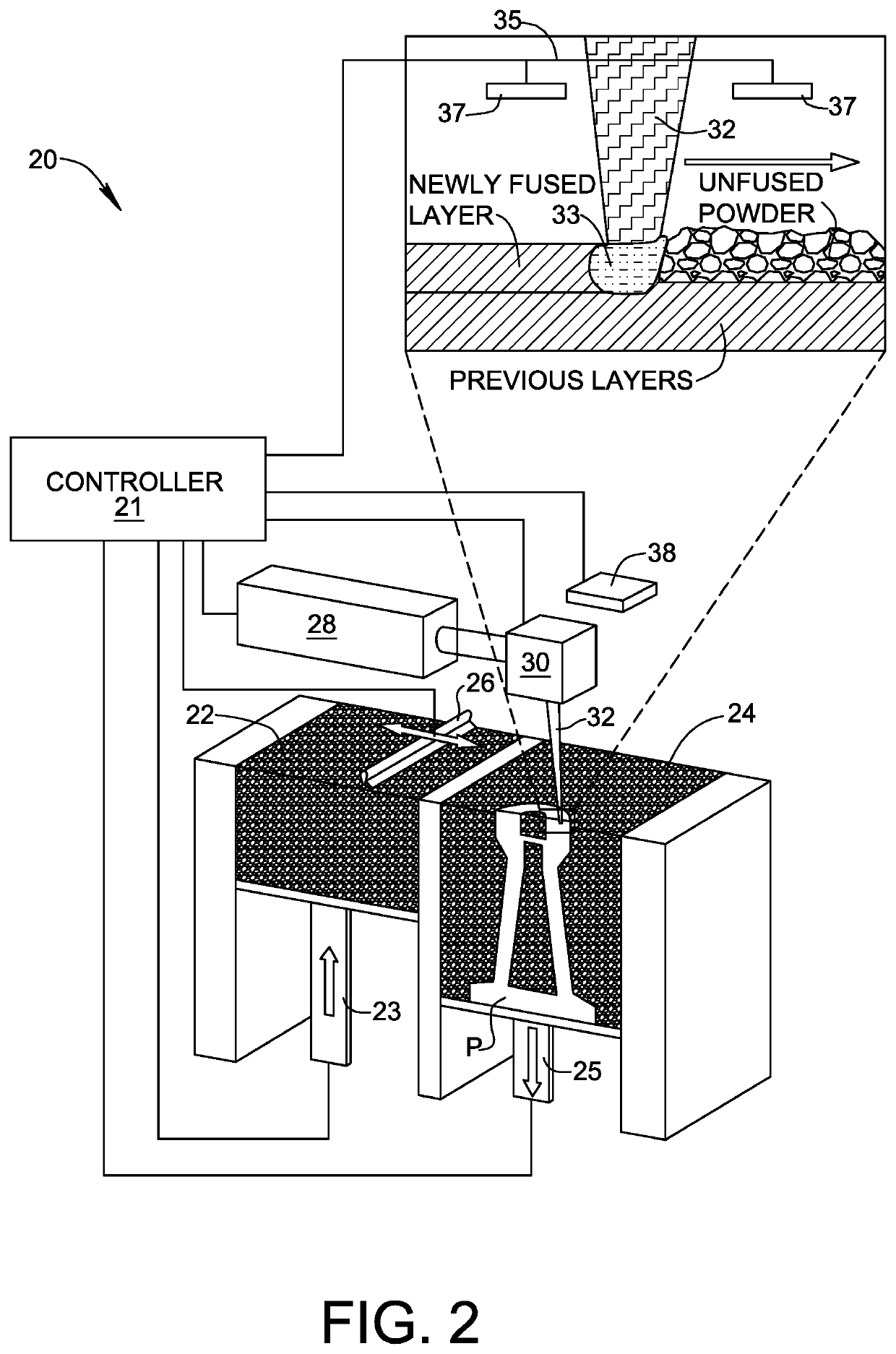

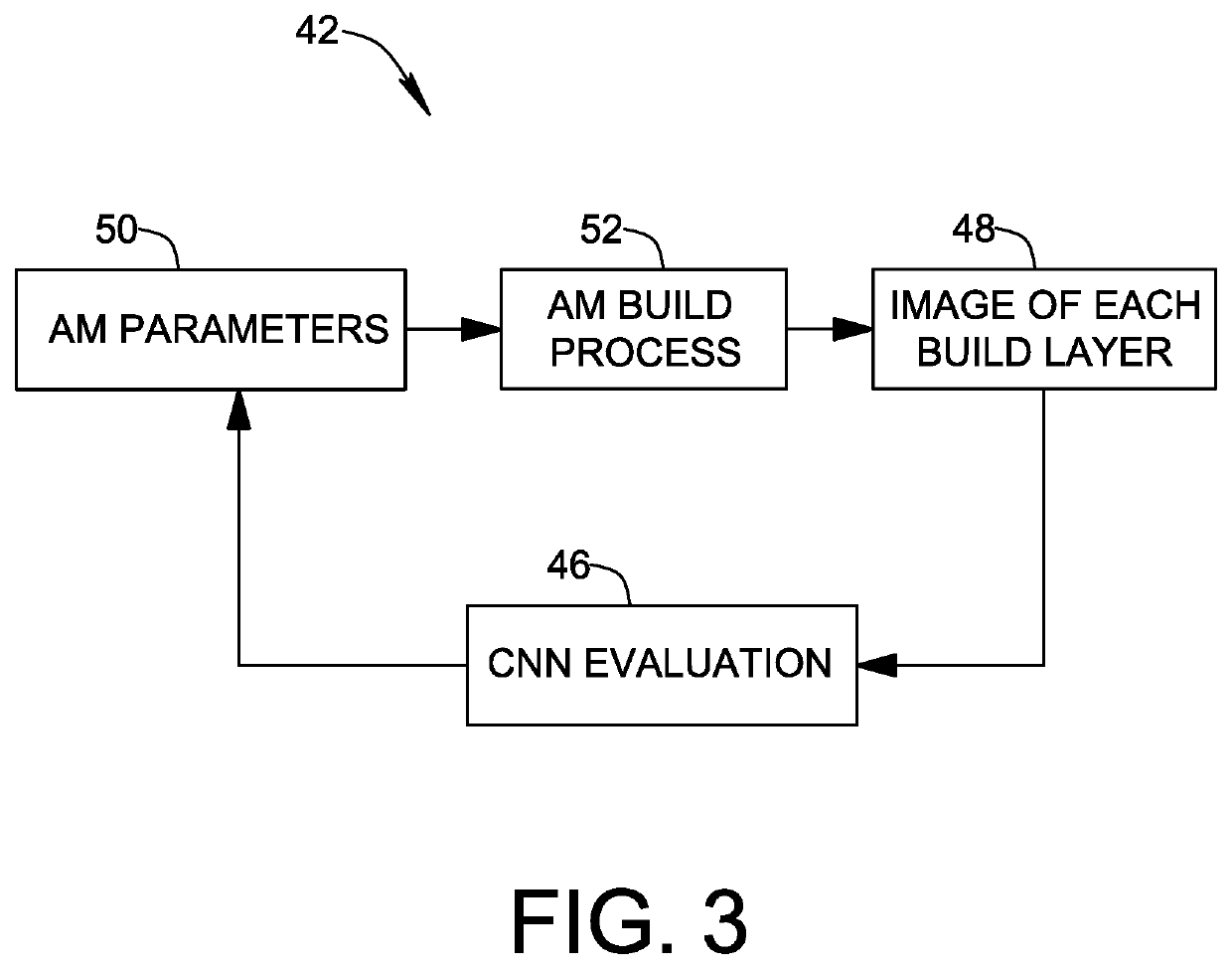

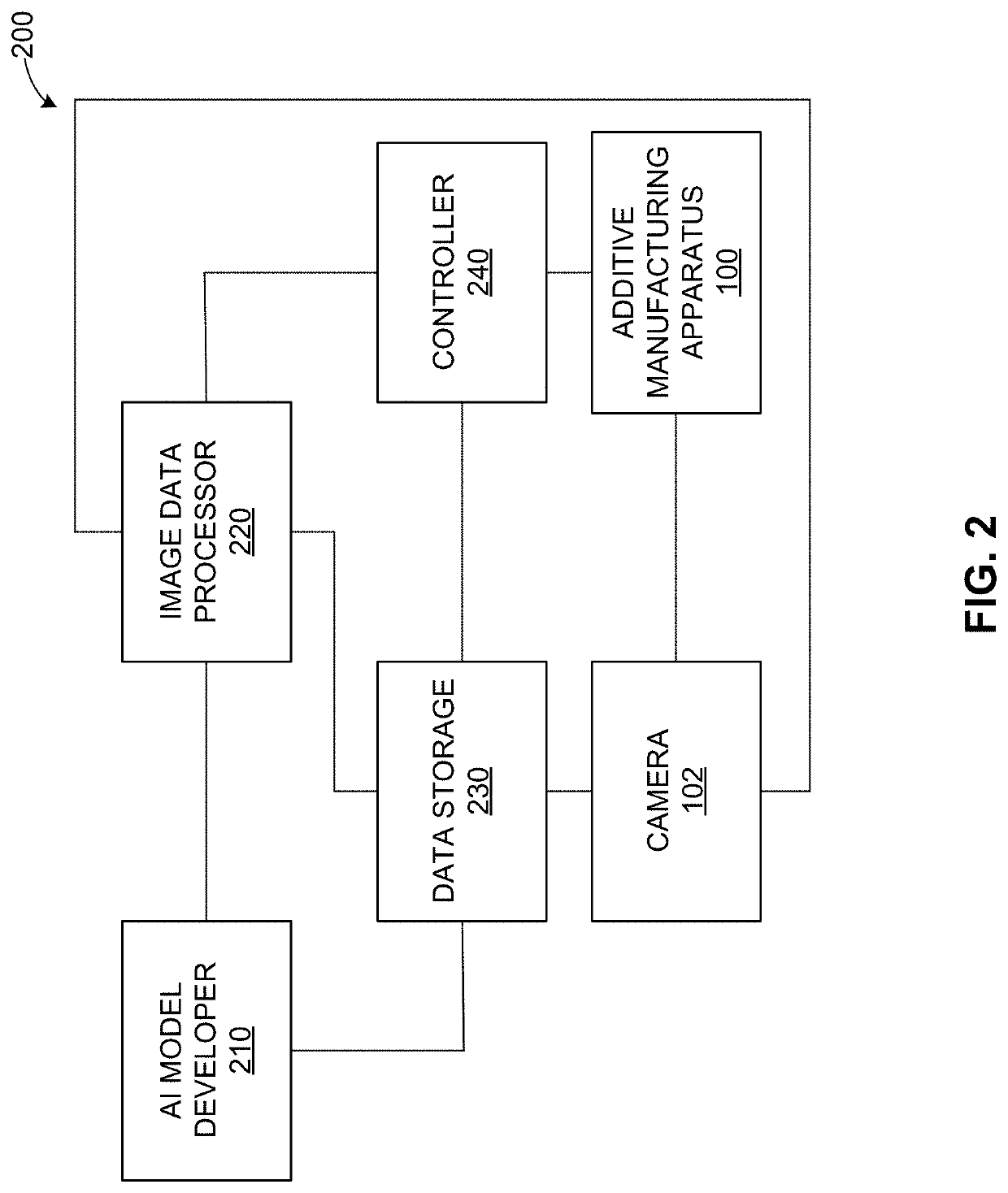

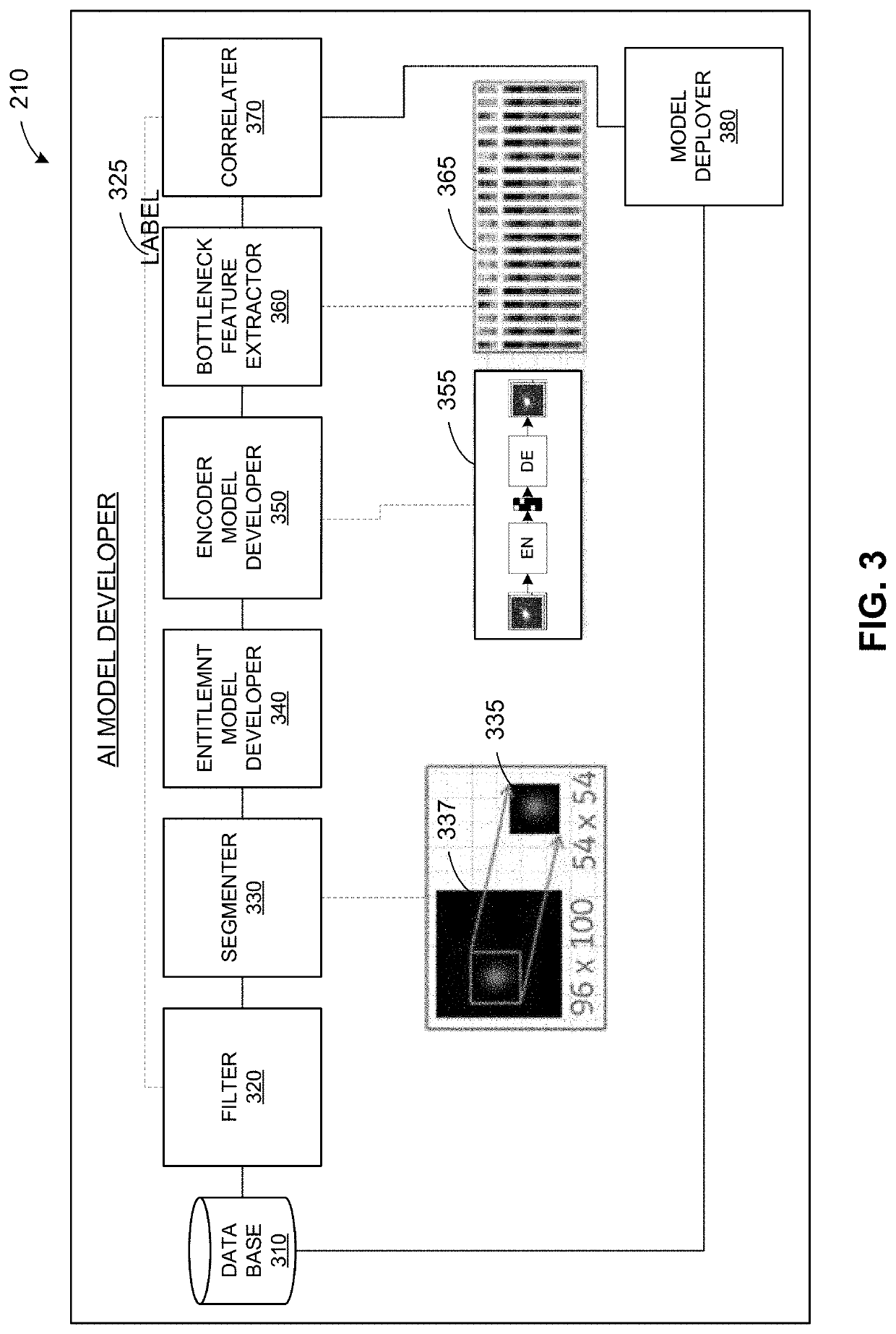

Convolutional neural network evaluation of additive manufacturing images, and additive manufacturing system based thereon

An additive manufacturing system uses a trained artificial intelligence module as part of a closed-loop control structure for adjusting the initial set of build parameters in-process to improve part quality. The closed-loop control structure includes a slow control loop taking into account in-process build layer images, and may include fast control loop taking into account melt pool monitoring data. The artificial intelligence module is trained using outputs from a plurality of convolutional neural networks (CNNs) tasked with evaluating build layer images captured in-process and images of finished parts captured post-process. The post process images may include two-dimensional images of sectioned finished parts and three-dimensional CAT scan images of finished parts.

Owner:MOOG INC

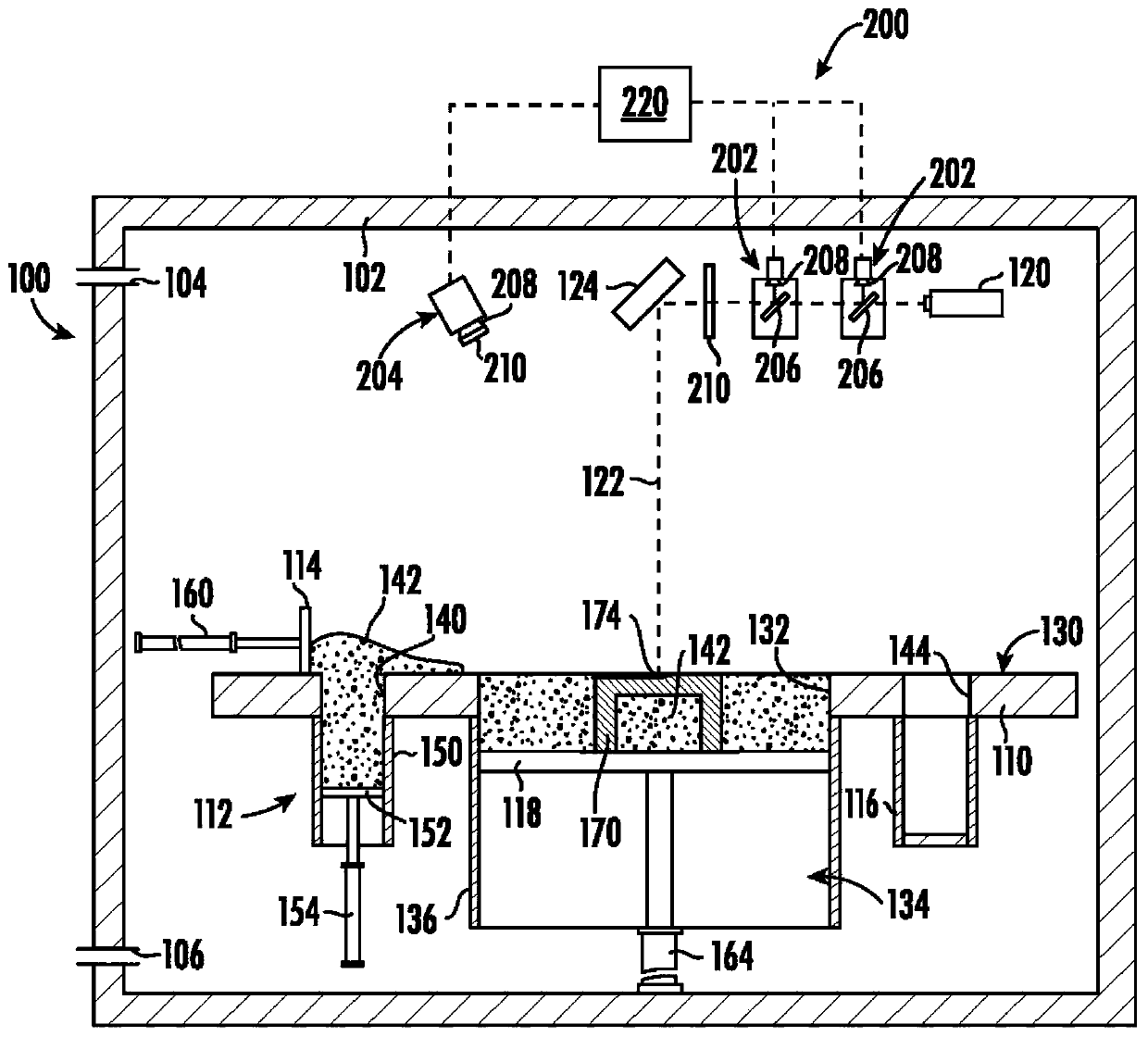

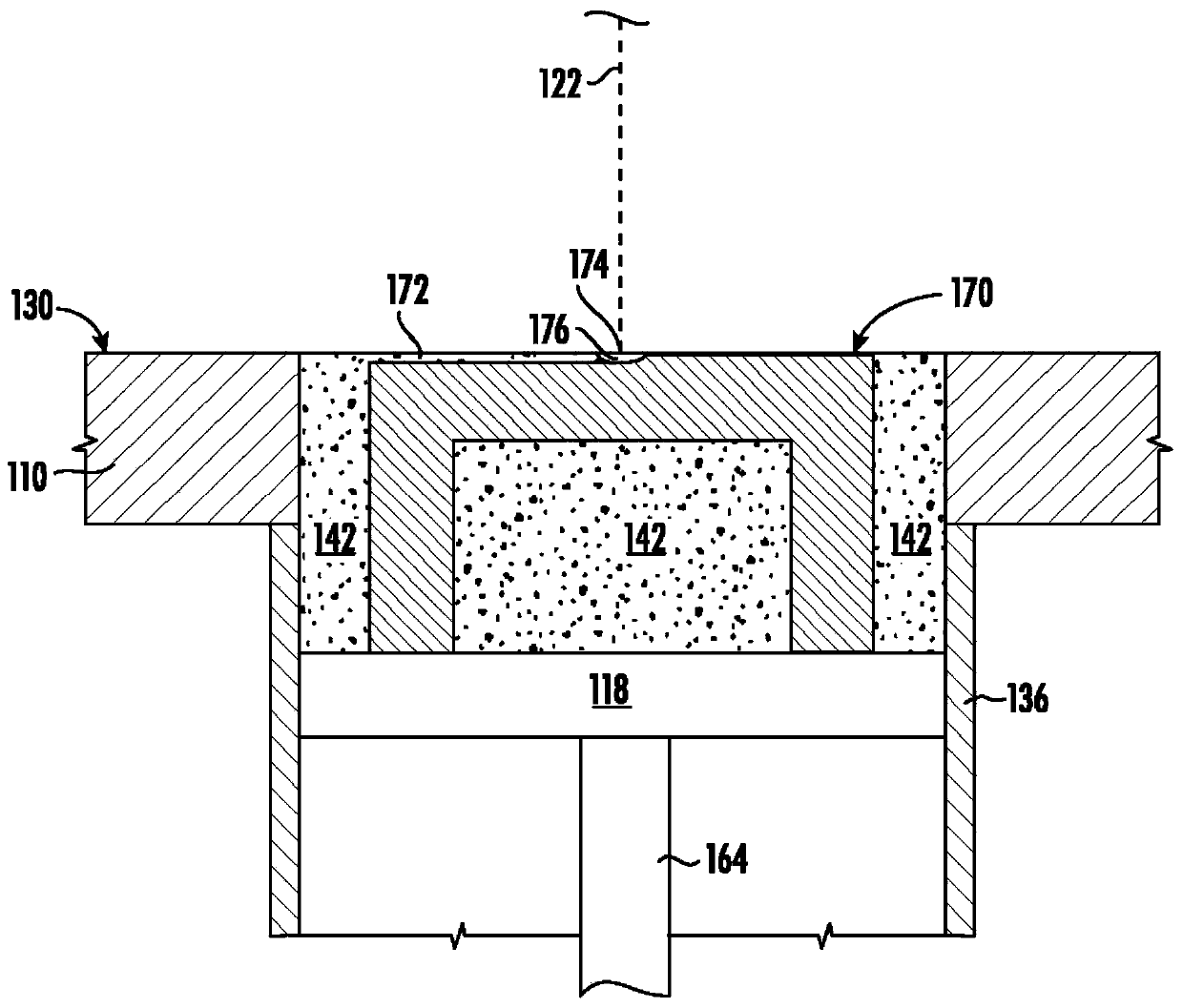

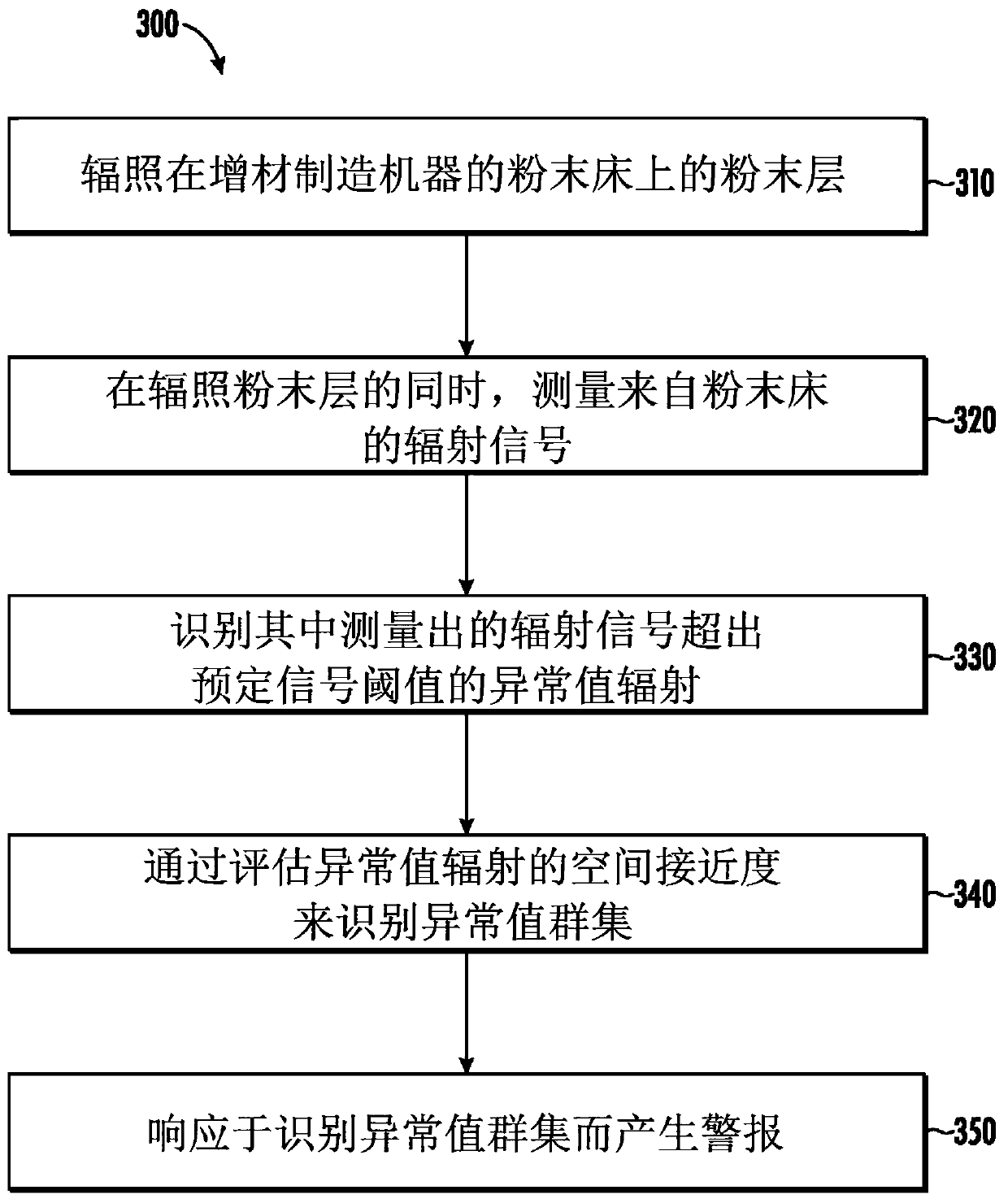

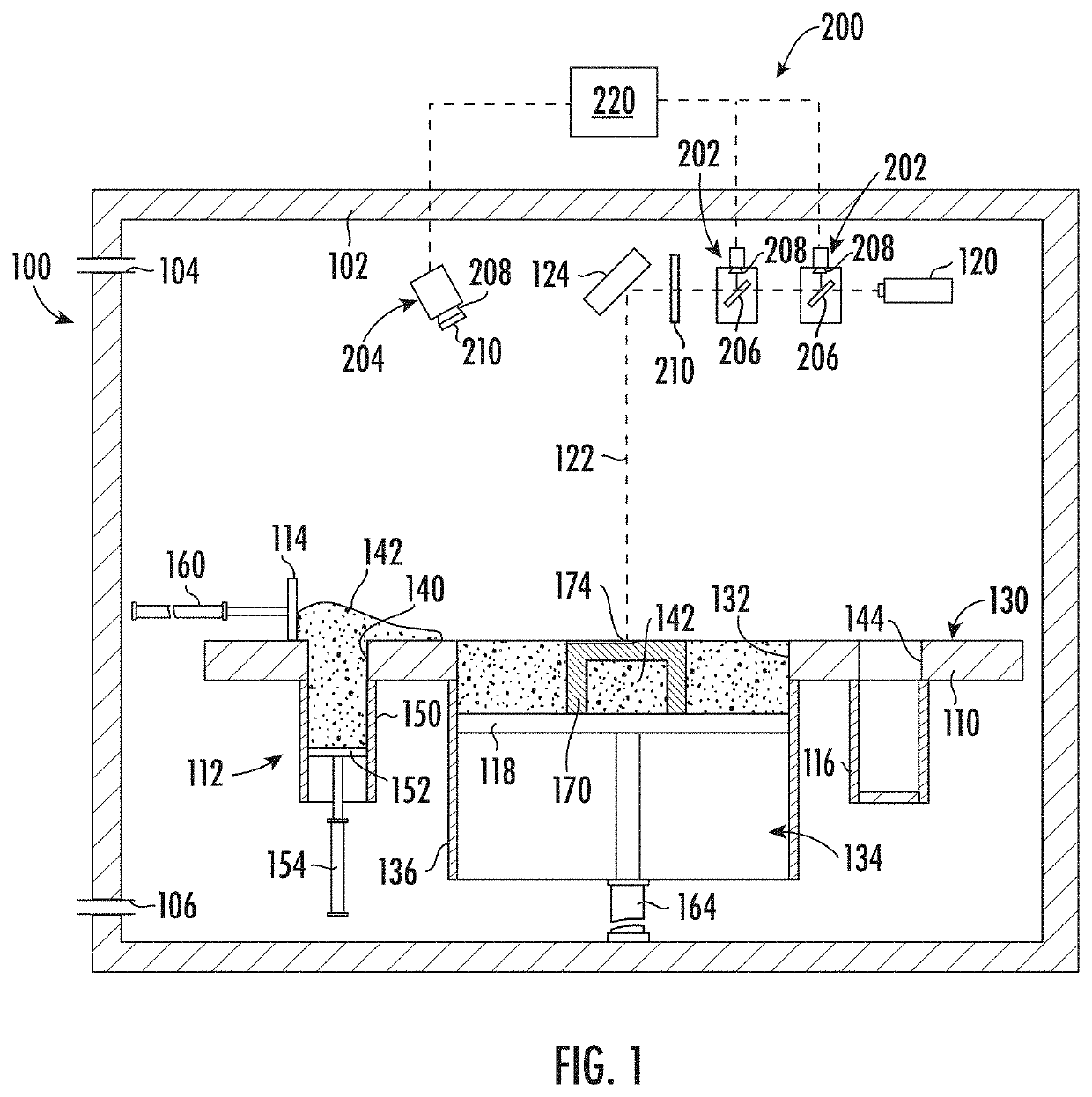

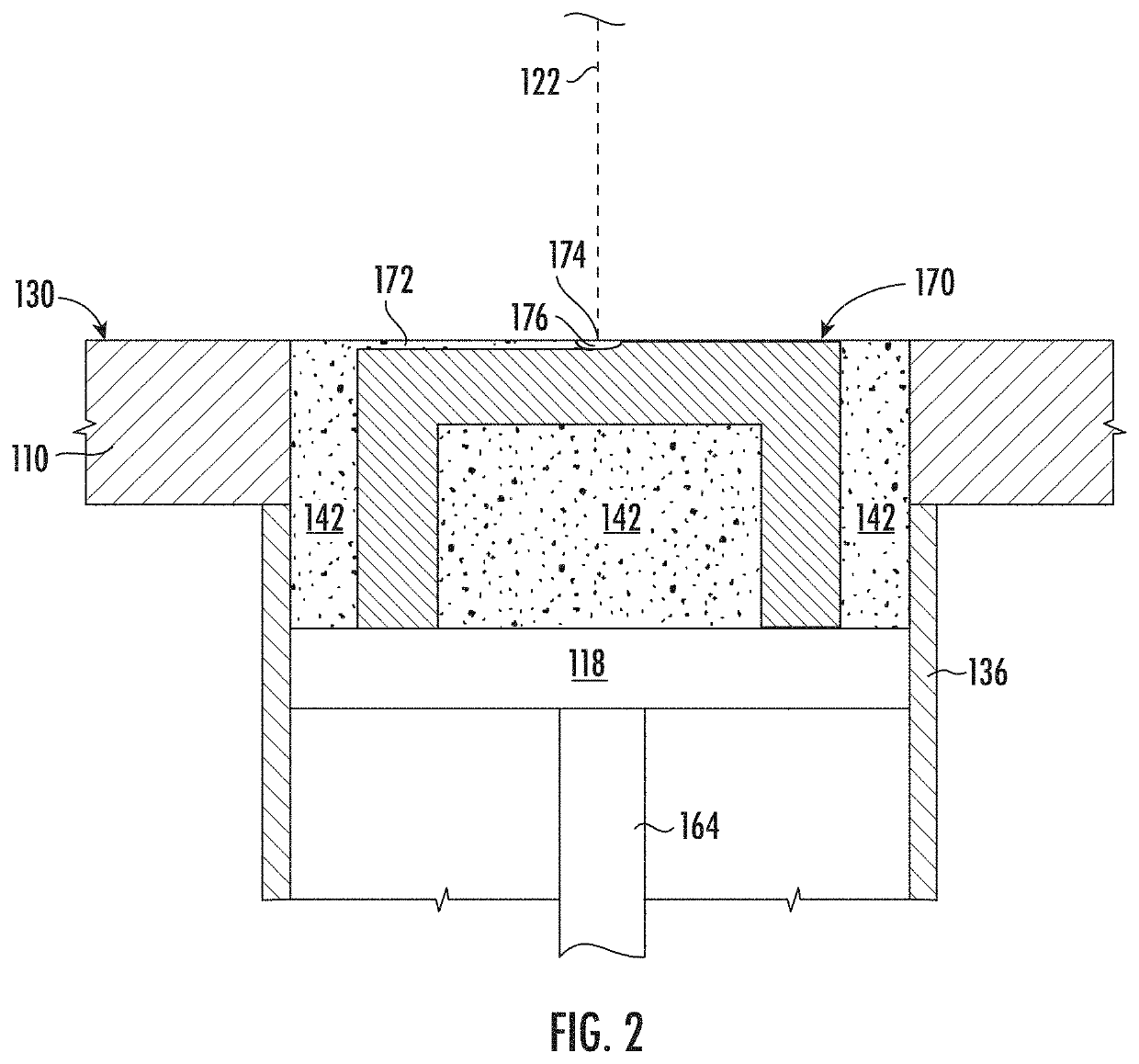

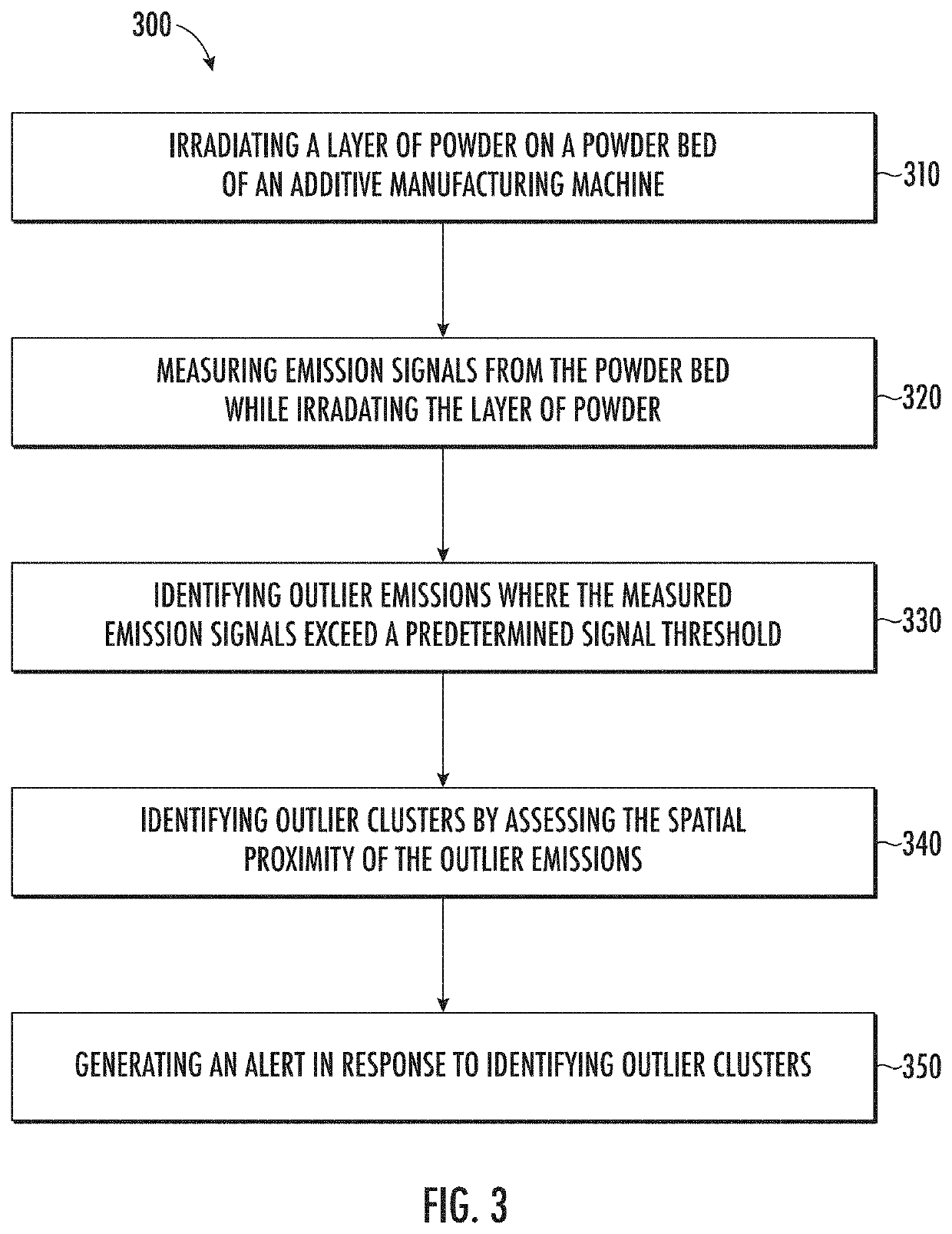

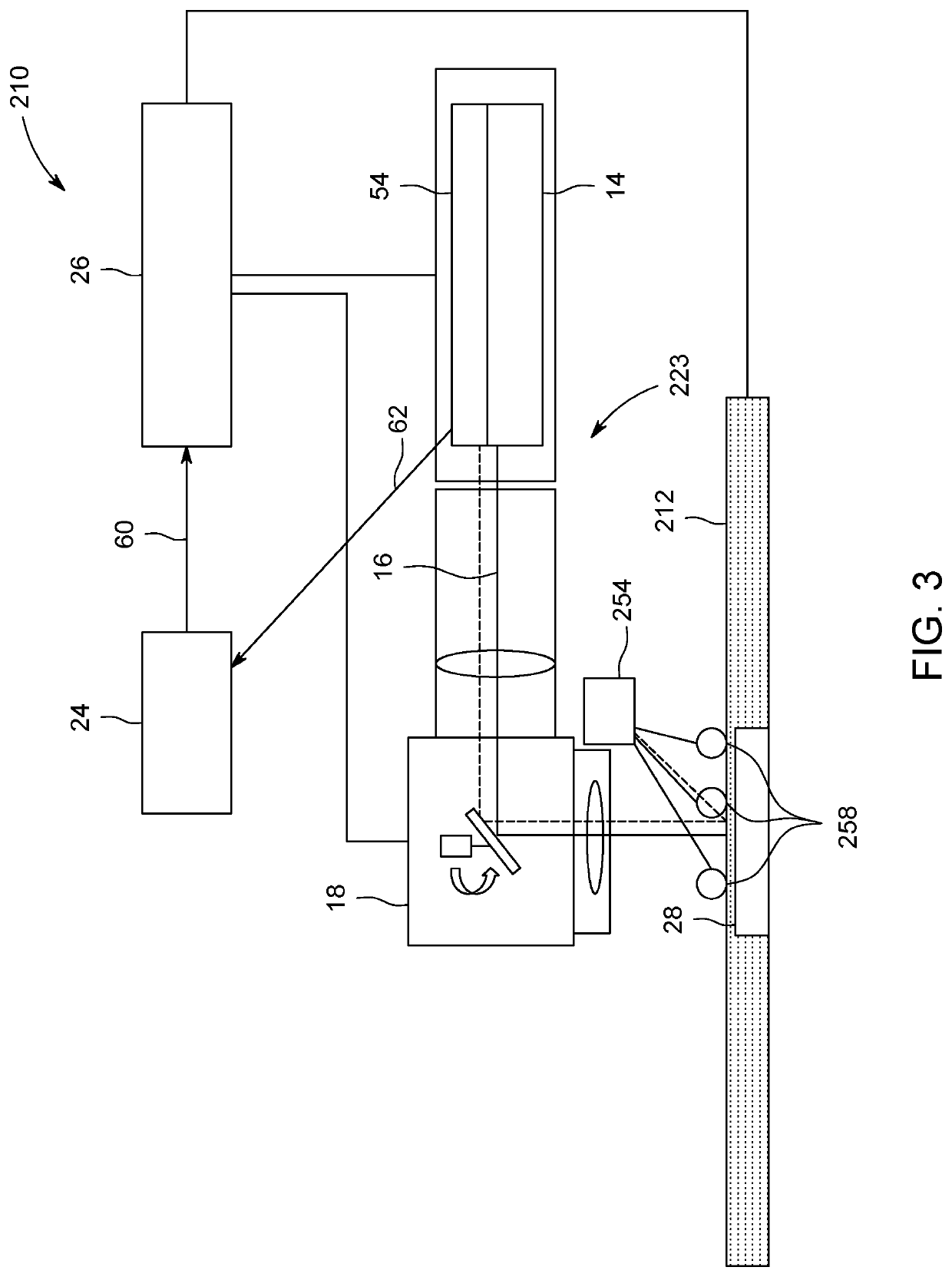

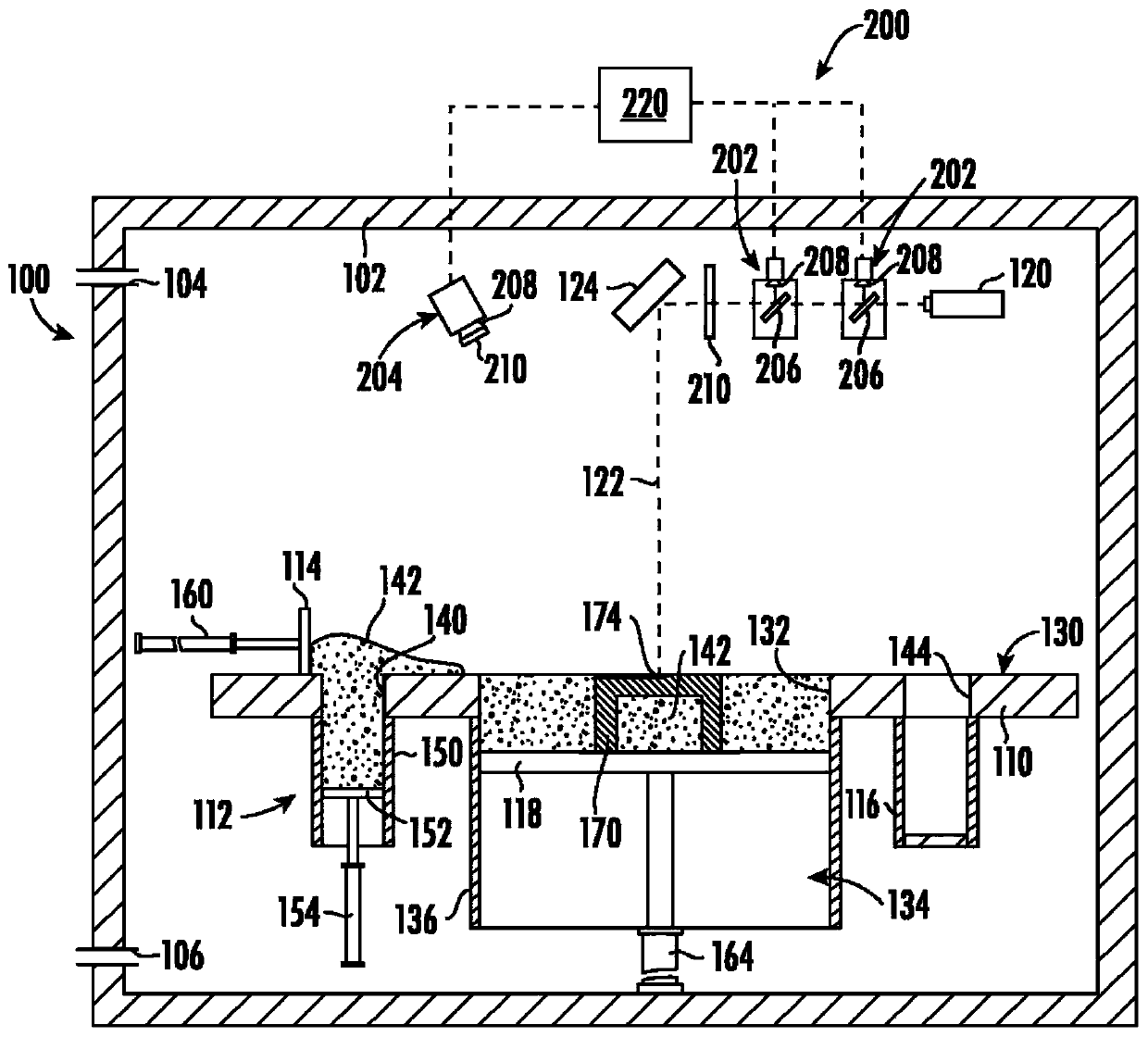

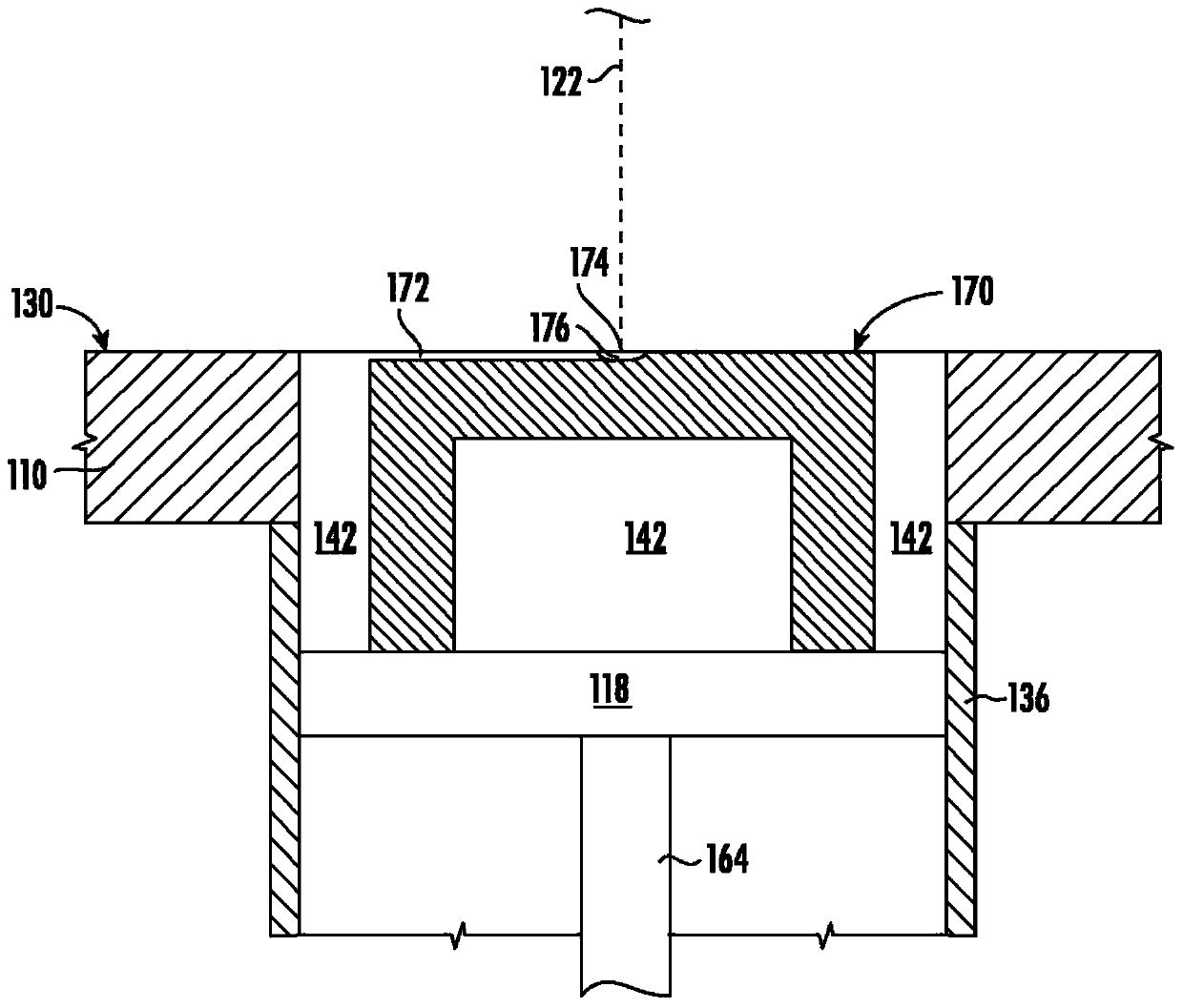

Melt pool monitoring system and method for detecting errors in additive manufacturing process

A system (100) and method (300) of monitoring a powder (142)-bed additive manufacturing process is provided where a layer of additive powder (142) is fused using an energy source (120) and electromagnetic emission signals are measured by a melt pool monitoring system (200) to monitor the print process. The measured emission signals (250) are analyzed to identify outlier emissions (254) and clusters of outliers are identified by assessing the spatial proximity of the outlier emissions (254), e.g., using clustering algorithms, spatial control charts, etc. An alert may be provided or a process adjustment may be made when a cluster is identified or when a magnitude of a cluster exceeds a predetermined cluster threshold.

Owner:GENERAL ELECTRIC CO

Systems and methods for compression, management, and analysis of downbeam camera data for an additive machine

PendingUS20210283717A1Additive manufacturing apparatusIncreasing energy efficiencyData compressionProcess engineering

An example additive manufacturing apparatus includes an energy source to melt material to form a component in an additive manufacturing process, a camera aligned with the energy source to obtain image data of the melted material during the additive manufacturing process, and a controller to control the energy source during the additive manufacturing process in response to processing of the image data. The controller adjusts control of the energy source based on a correction determined by: applying an artificial intelligence model to image data captured by a camera during an additive manufacturing process, the image data including an image of a melt pool of the additive manufacturing process; predicting an error in the additive manufacturing process using an output of the artificial intelligence model; and compensating for the error by generating a correction to adjust a configuration of the energy source during the additive manufacturing process.

Owner:GENERAL ELECTRIC CO

Melt Pool Monitoring System and Method for Detecting Errors in an Additive Manufacturing Process

ActiveUS20200147725A1Additive manufacturing apparatusCeramic shaping apparatusCluster algorithmPowder bed

A system and method of monitoring a powder-bed additive manufacturing process is provided where a layer of additive powder is fused using an energy source and electromagnetic emission signals are measured by a melt pool monitoring system to monitor the print process. The measured emission signals are analyzed to identify outlier emissions and clusters of outliers are identified by assessing the spatial proximity of the outlier emissions, e.g., using clustering algorithms, spatial control charts, etc. An alert may be provided or a process adjustment may be made when a cluster is identified or when a magnitude of a cluster exceeds a predetermined cluster threshold.

Owner:GENERAL ELECTRIC CO

Systems and methods for additive manufacturing in-build assessment and correction of laser pointing accuracy

ActiveUS10814427B2Manufacturing platforms/substratesIncreasing energy efficiencyEngineeringMechanical engineering

An additive manufacturing system includes a laser device, a build plate, a first scanning device, and an alignment system. The laser device is configured to generate a laser beam. The build plate has a position relative to the laser device. The first scanning device is configured to selectively direct the laser beam across the build plate. The laser beam generates a melt pool on the build plate. The alignment system includes a fiducial marks projector configured to project a plurality of fiducial marks across the build plate. Each fiducial mark has a location on the build plate. The alignment system also includes an optical detector configured to detect the location of each of the fiducial marks on the build plate. The alignment system is configured to detect the position of the build plate relative to the laser device.

Owner:GENERAL ELECTRIC CO

Improvements in or relating to on-axis melt pool sensors in an additive manufacturing apparatus

PendingUS20220168813A1Prevent dip in intensity of signalCompensate for misalignmentAdditive manufacturing apparatusIncreasing energy efficiencyOptical axisOptic system

A method of aligning an on-axis melt pool sensor in an additive manufacturing apparatus. The method includes scanning a first laser beam along a first scan path across a working surface using a first optical train to generate a melt pool along the first scan path and scanning a field of view of an on-axis sensor along a second scan path across the working surface using a second optical train for steering a second laser beam. The first and second scan paths intersect. An adjustment to be made to an alignment of the field of view of the on-axis sensor with an optical axis of the second optical train is determined from a variation in the signal generated by the on-axis sensor as the field of view is scanned along the second scan path.

Owner:RENISHAW PLC

Additive manufacturing system and method and feature extraction method

ActiveUS20200247064A1Obtaining product qualityIncrease productionManufacturing platforms/substratesManufacturing enclosuresFeature extractionPowder bed

An additive manufacturing (AM) system, an AM method, and an AM feature extraction method are provided. The AM system includes an AM tool, a product metrology system, an in-situ metrology system, a virtual metrology (VM) system, a compensator, a track planner, a controller, a simulator and an augmented reality (AR) device. The simulator is used to find feasible parameter ranges, while the AR device is used to support operations and maintenance of the AM tool. The product metrology system, the in-situ metrology system and the VM system are integrated to estimate the variation of material on a powder bed of the AM tool. The compensator is used for compensating the process variation by adjusting process parameters. The product metrology system is used to measure the quality of products. The in-situ metrology system is used to collect features of melt pools on the powder bed.

Owner:NAT CHENG KUNG UNIV

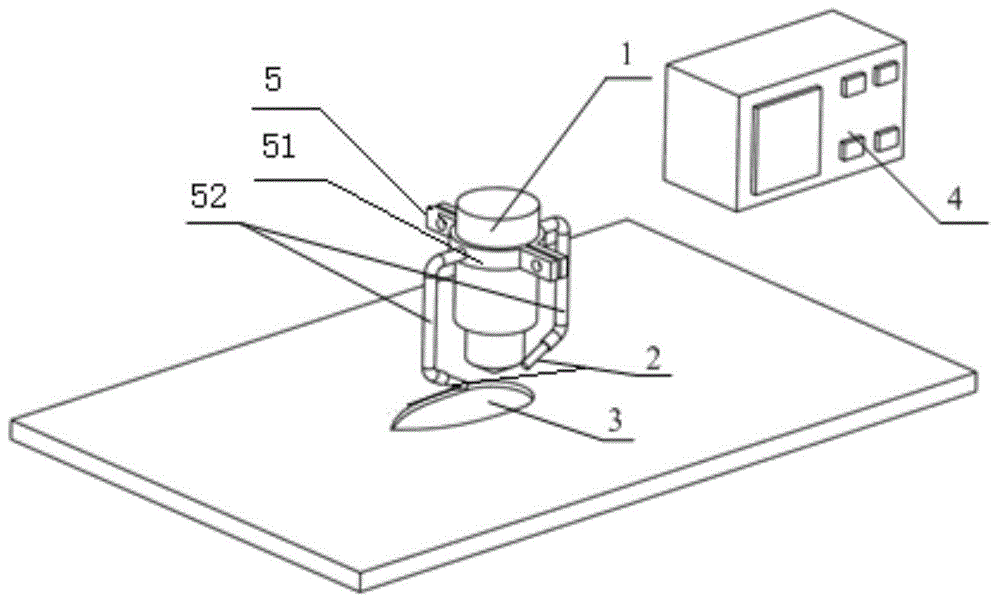

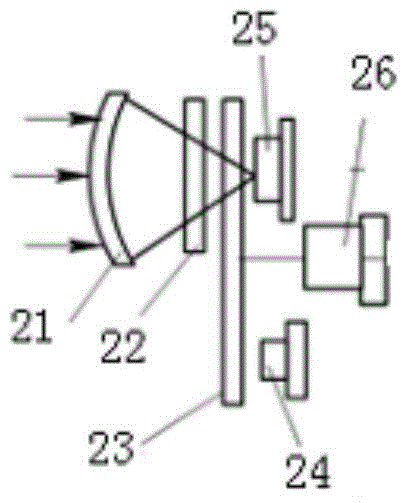

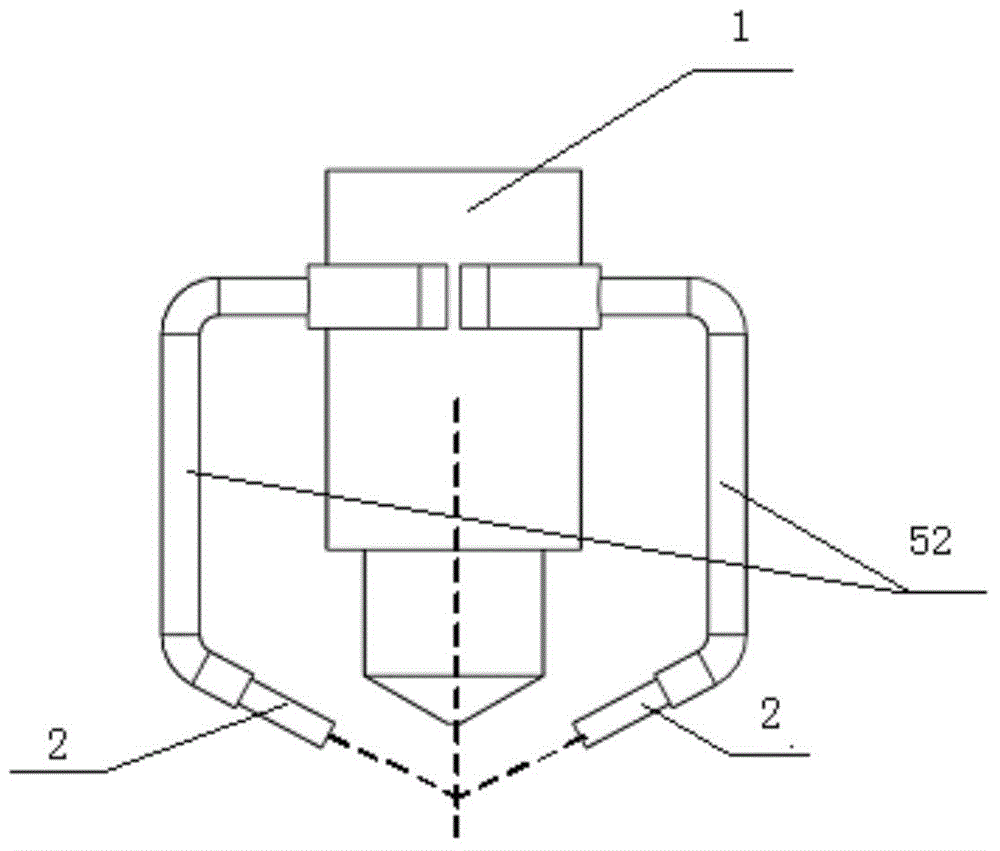

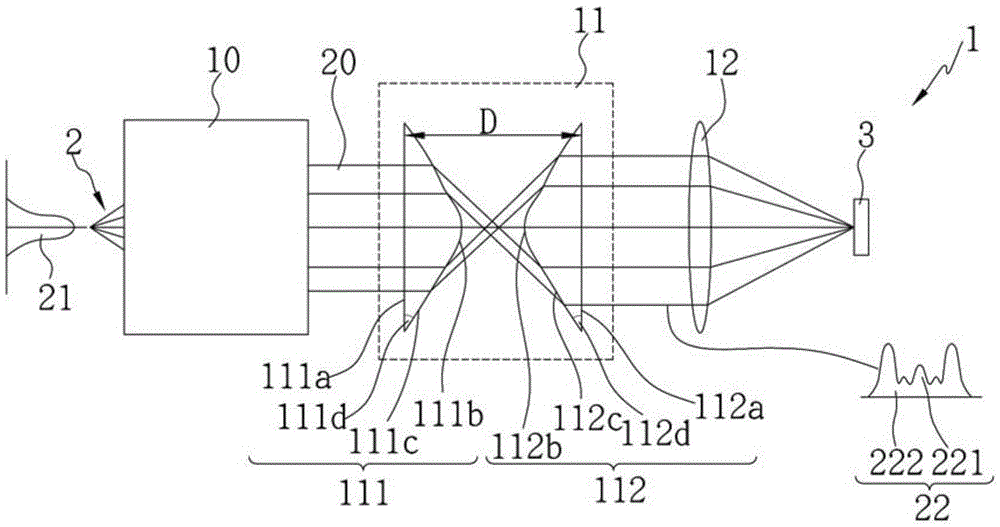

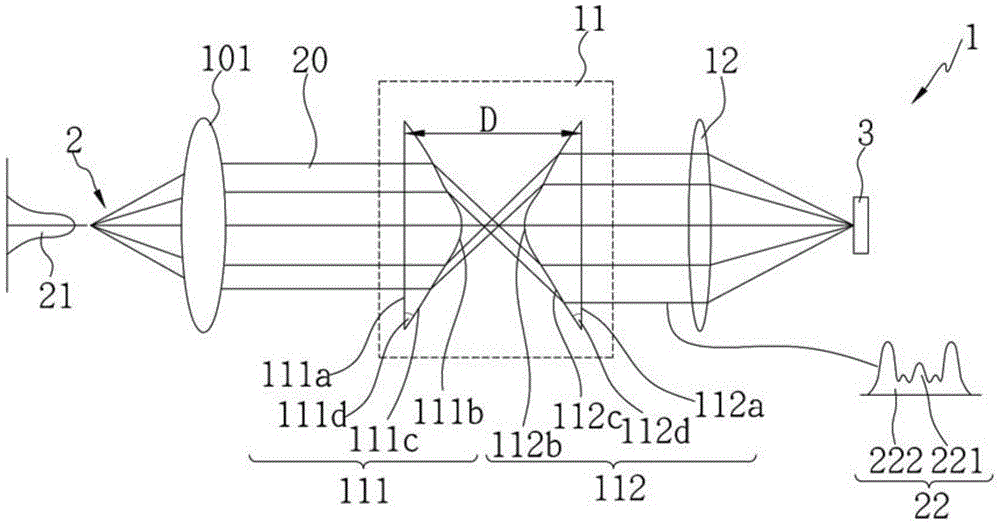

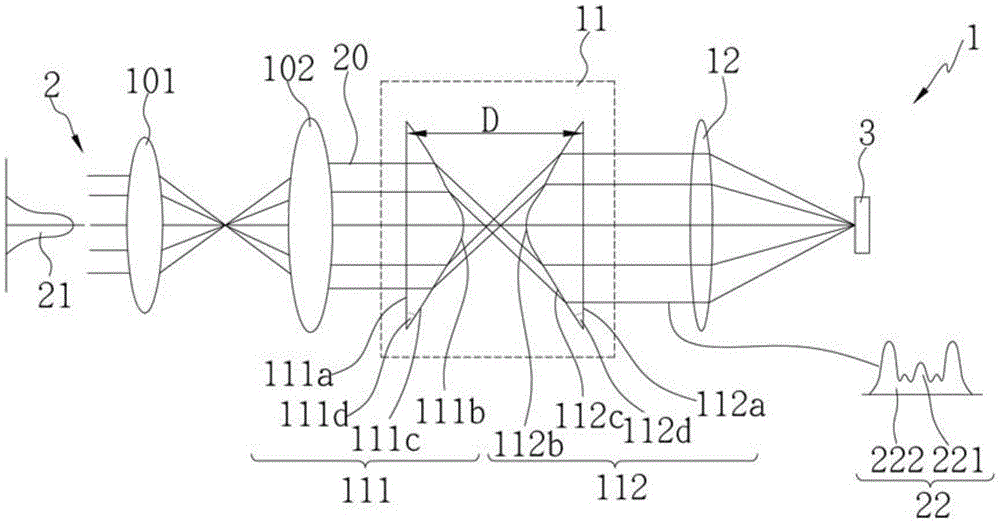

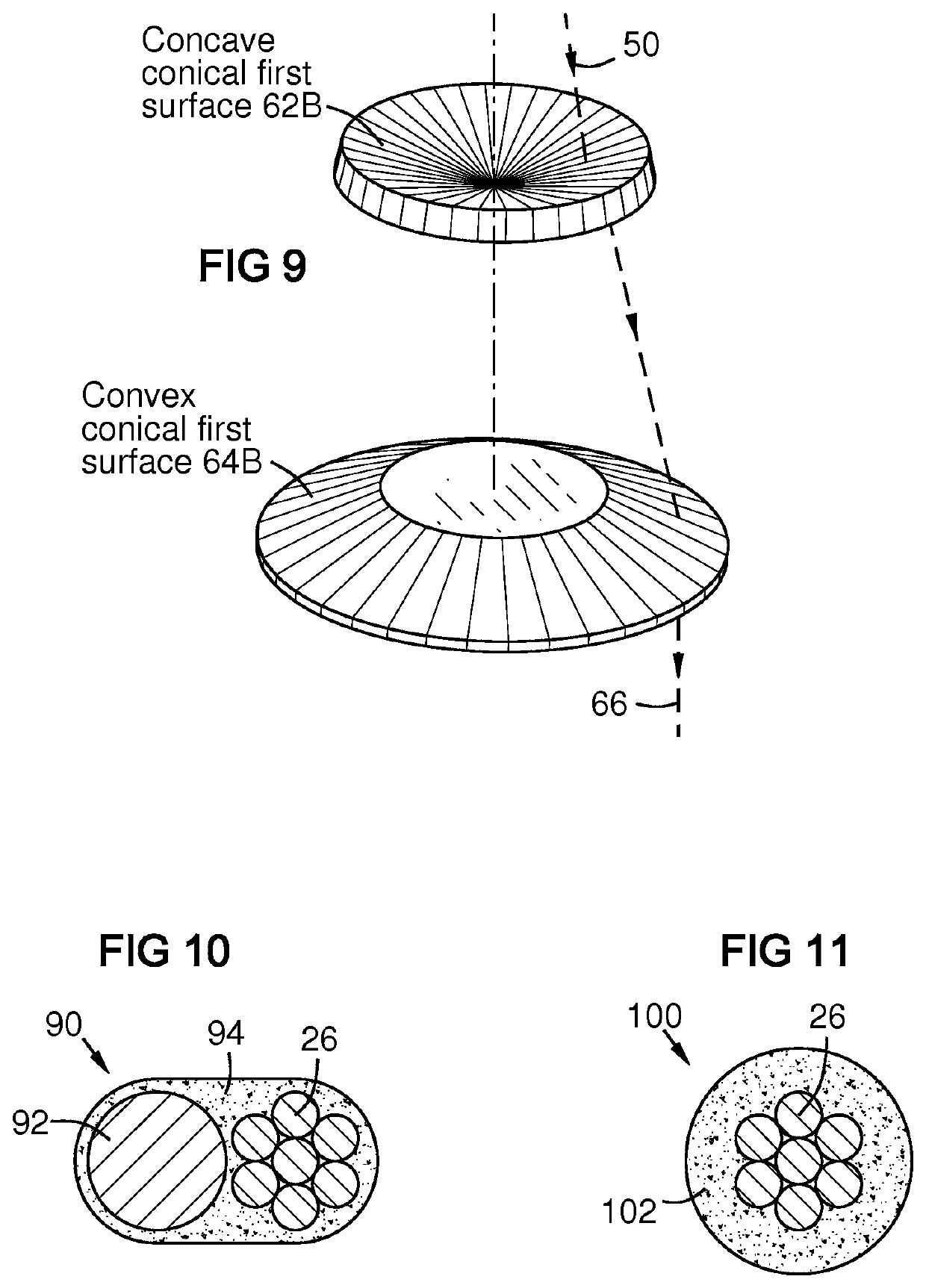

Device for heating to generate uniform motlen pool

ActiveCN106814459AAvoid the problem of gasification splashReduce overlapLaser beam welding apparatusOptical elementsEngineeringAxicon

This disclosure provides a device for heating to generate a uniform molten pool, including: a source unit for generating an energy beam; a beam expanding / reducing unit positioned in an energy path of the energy beam for adjusting the diameter of the energy beam; a flat-top conical lens set positioned in the energy path and including at least two flat-top axicons, with the beam expanding / reducing unit positioned between the source unit and the flat-top conical lens set; and a focusing lens positioned in the energy path, with the flat-top conical lens set between the beam expanding / reducing unit and the focusing lens, and the energy beam being focused by the focusing lens. This disclosure generates a uniform molten pool to prevent vaporization splash due to overheating of the material during melting.

Owner:IND TECH RES INST

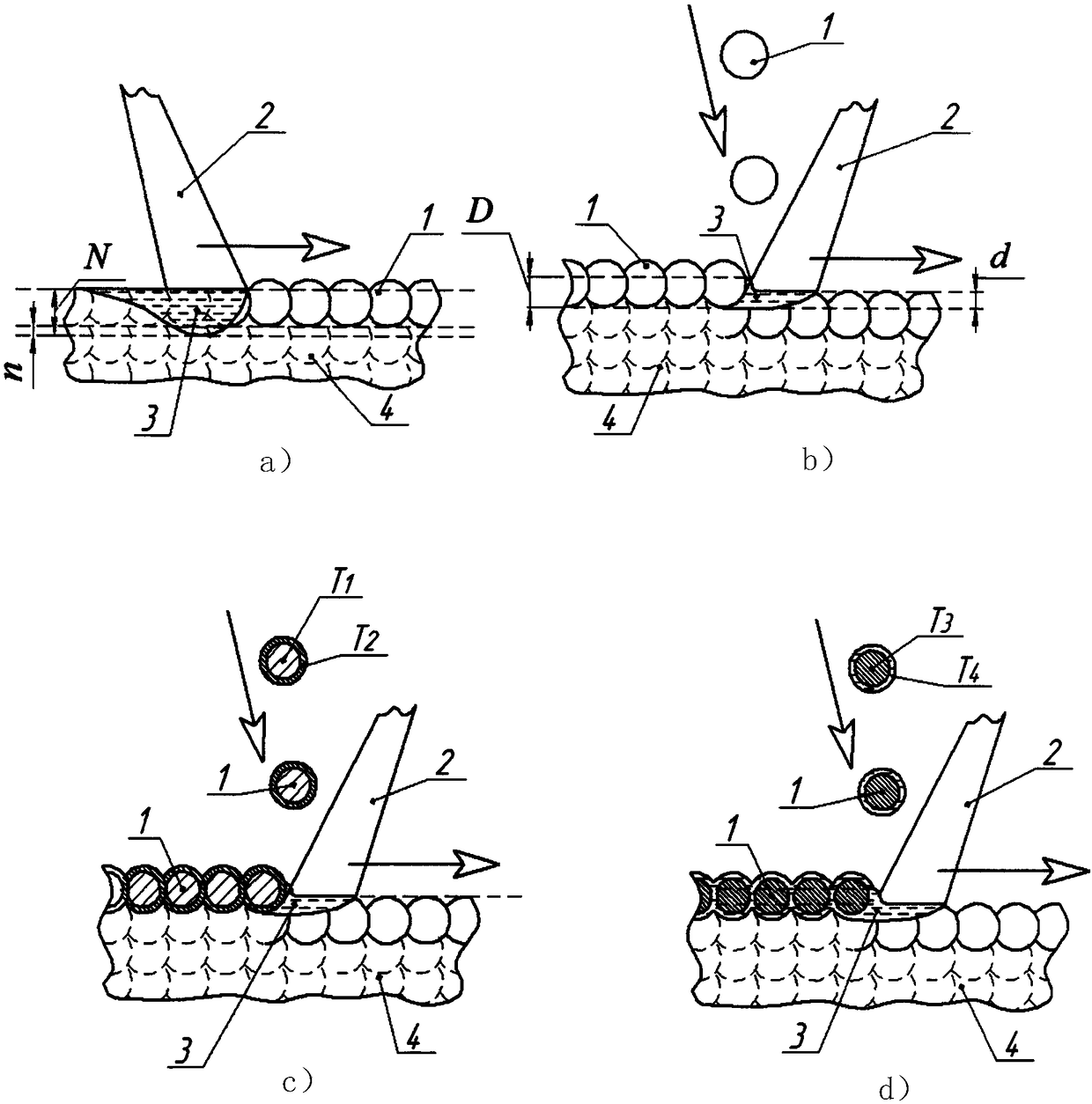

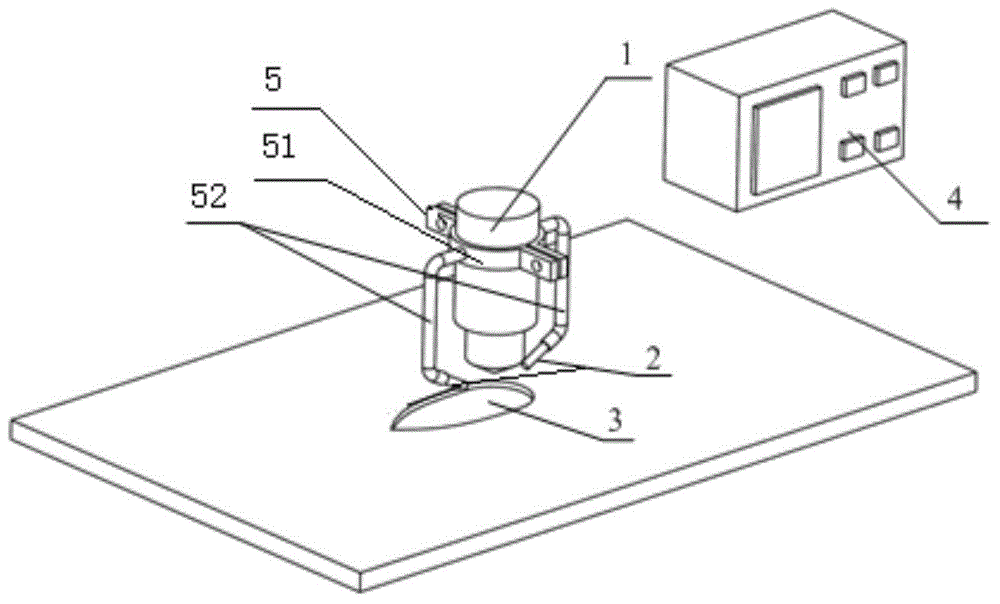

Method for promoting intracrystalline distribution of fine particles in laser shock melting and injecting process

ActiveCN111485235ARealize intragranular distributionIncrease temperatureMetallic material coating processesThermal breakThermal insulation

A method for promoting intracrystalline distribution of fine particles in the laser shock melting and injecting process controls the ratio of the temperature of the fine particles injected into a melting pool to the temperature of the melting pool in the laser shock melting and injecting process by coating a to-be-modified material with a thermal insulation layer, performing preheating, using negative defocusing technological parameters and the like, thereby promoting the intracrystalline distribution of the fine particles in the laser shock melting and injecting process, meanwhile promoting the formation of a laser shock effect and improving the injection rate of the fine particles, and the method has the advantage of being easy to implement.

Owner:JIANGSU UNIV

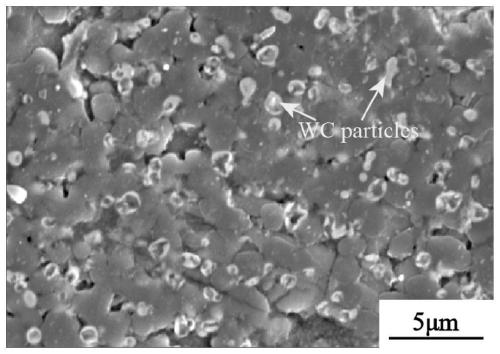

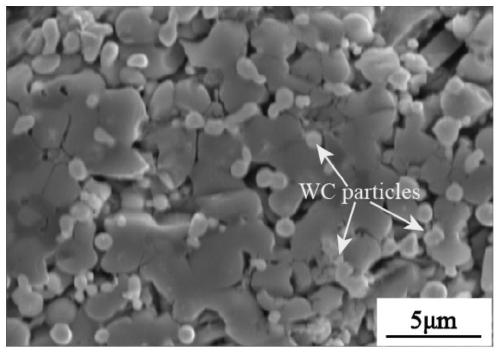

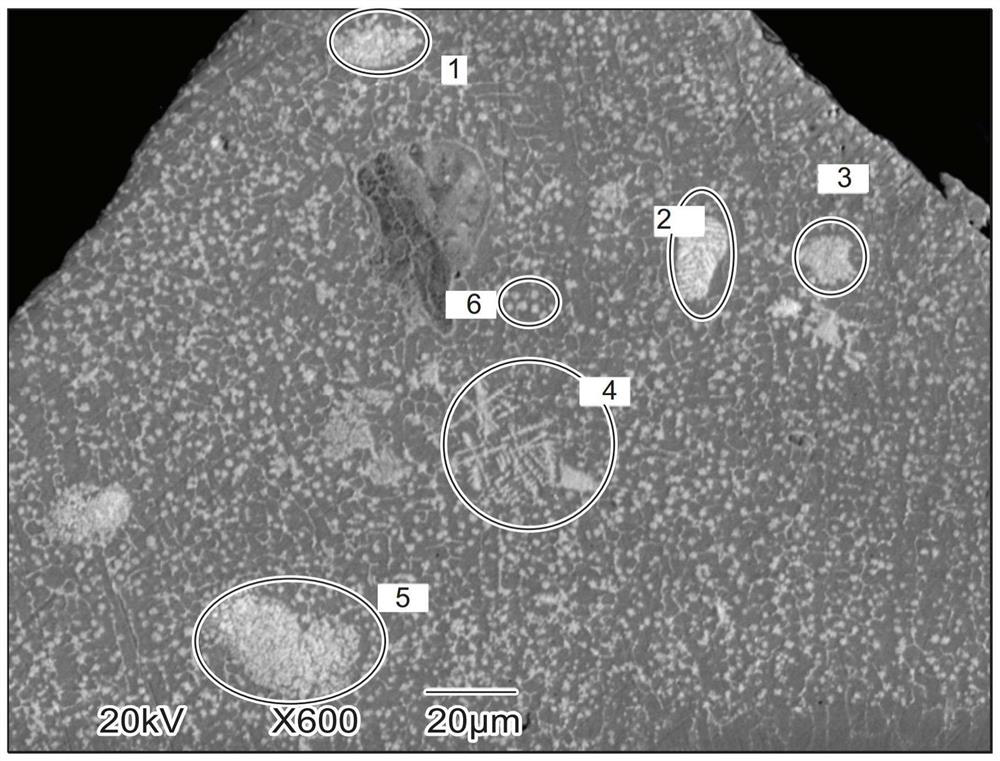

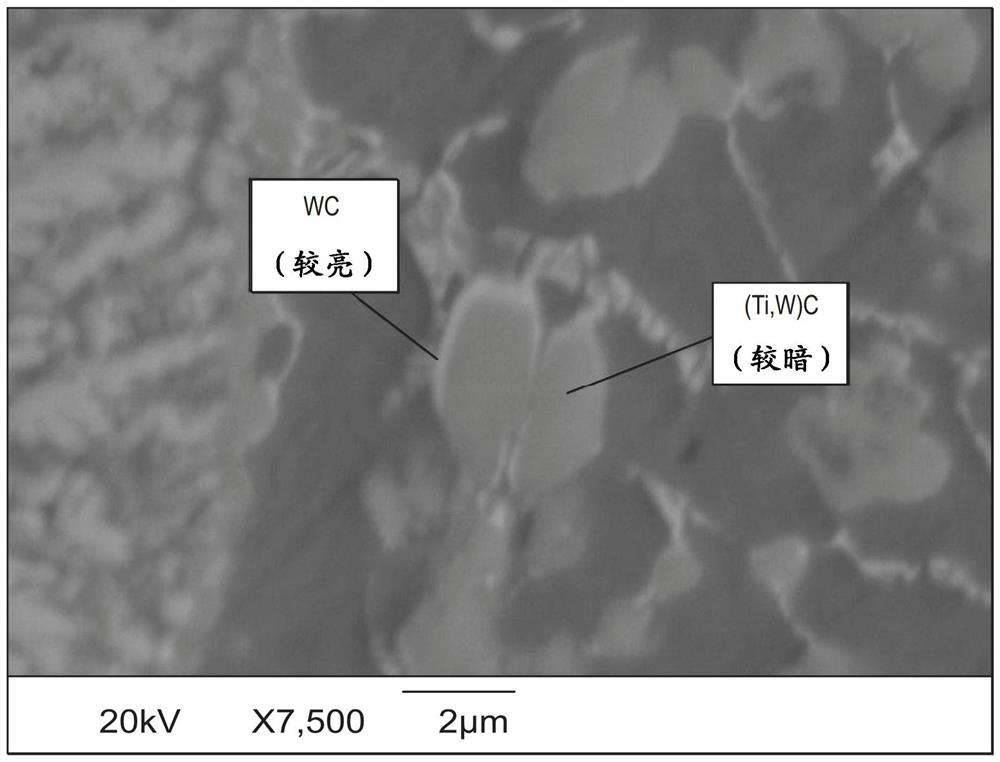

Carbide material for cutting devices and associated method of manufacture

The invention provides a carbide material for cutting devices and an associated method of manufacture. There is provided a carbide material (34) comprising Tungsten Carbide of 60 to 85 weight%, Titanium Carbides of 10 to 25 weight% and preferably a metal matrix of 0.5 to 20 weight% comprising Fe and optionally at least one or both of the metals Co or Ni. There is also provided a device comprisinga ferrous substrate and such a carbide material and a method of manufacturing a device, the method comprising mixing powders comprising Carbon, Tungsten and a scavenger material such as Titanium, placing the mixed powders proximal a ferrous substrate (10), impinging an energy source (31) onto the powdered materials to create a melt pool (32) formed of the powders and the material of the substrate,and allowing the melt pool to solidify to form a carbide material (34) substantially free from Iron Tungsten carbides of (W, Fe)6 C and (W, Fe)12 C type.

Owner:C4有限公司

Equipment for monitoring laser melting pool in real time

The invention discloses equipment for monitoring a laser melting pool in real time and relates to the technical field of temperature monitoring in a laser re-melting process. A device comprises a bracket, an infrared probe, an alarming device and a control box, wherein the bracket is arranged on a main shaft; the infrared probe used for acquiring temperature information of the laser melting pool and the alarming device are arranged on the bracket; the control box is used for processing the temperature information acquired by the infrared probe and is provided with a displayer; a control circuit is arranged in the control box, is connected with a power switch of a temperature field through a relay and comprises a central controller, and a measured temperature analytical model displayer, a data storage module, a communication module and a power module which are respectively connected with the central controller; the communication module is connected with an upper computer. The equipment has the advantage that great convenience is brought to the acquisition and analysis of the temperature field in the laser re-melting process.

Owner:徐州盛高矿山机械制造有限公司

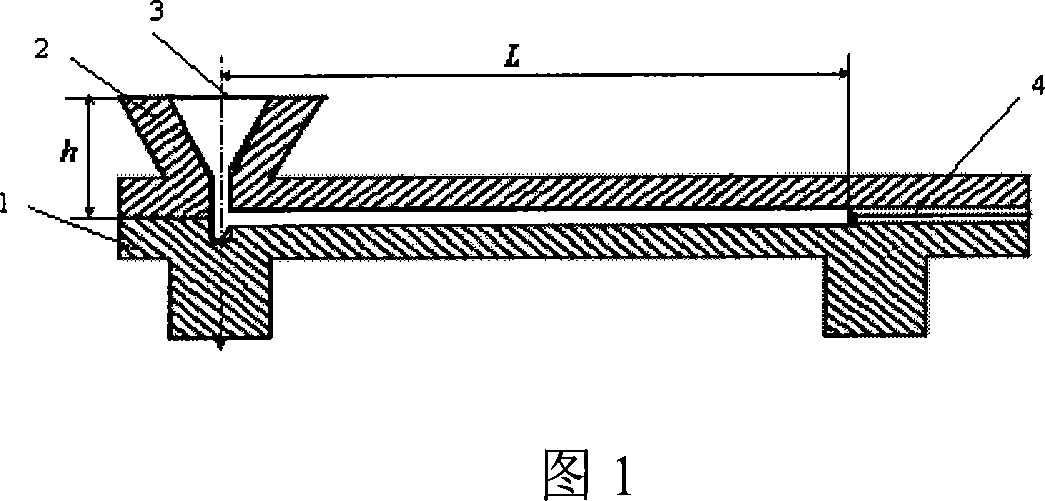

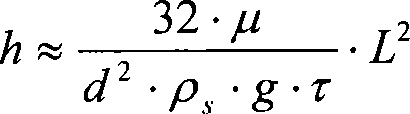

Rapid measuring method and apparatus for viscosity coefficient of dross

This invention discloses one resides sticky rapid rest method and its device, which comprises the following steps: measuring melt pool resides temperature; drilling the resides into funnel; the funnel exit end sets one level tube to test melt resides level tube flow length; according to the measured flow length to get relative temperature melt resides sticky degrees on standard curve.

Owner:CENT SOUTH UNIV

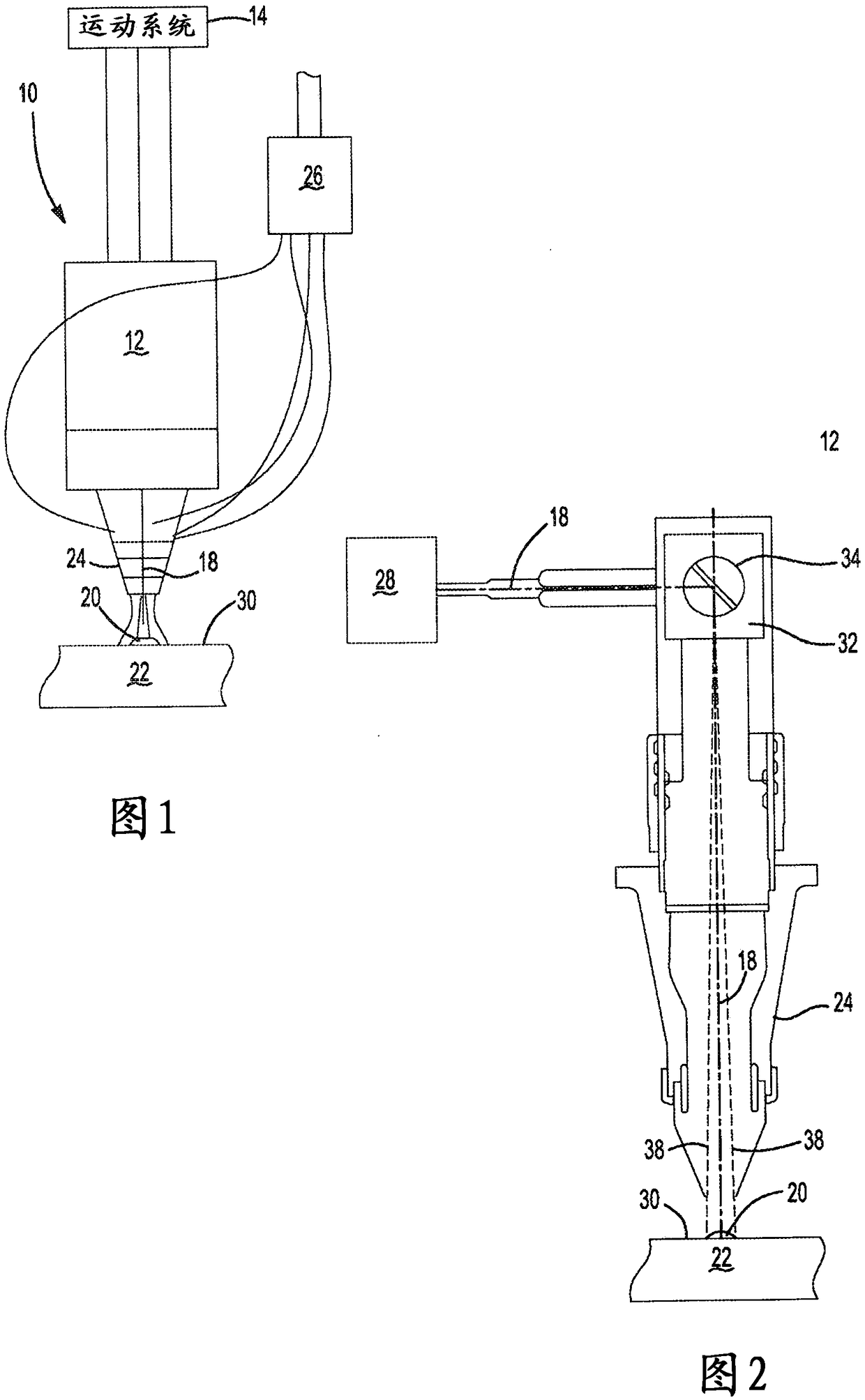

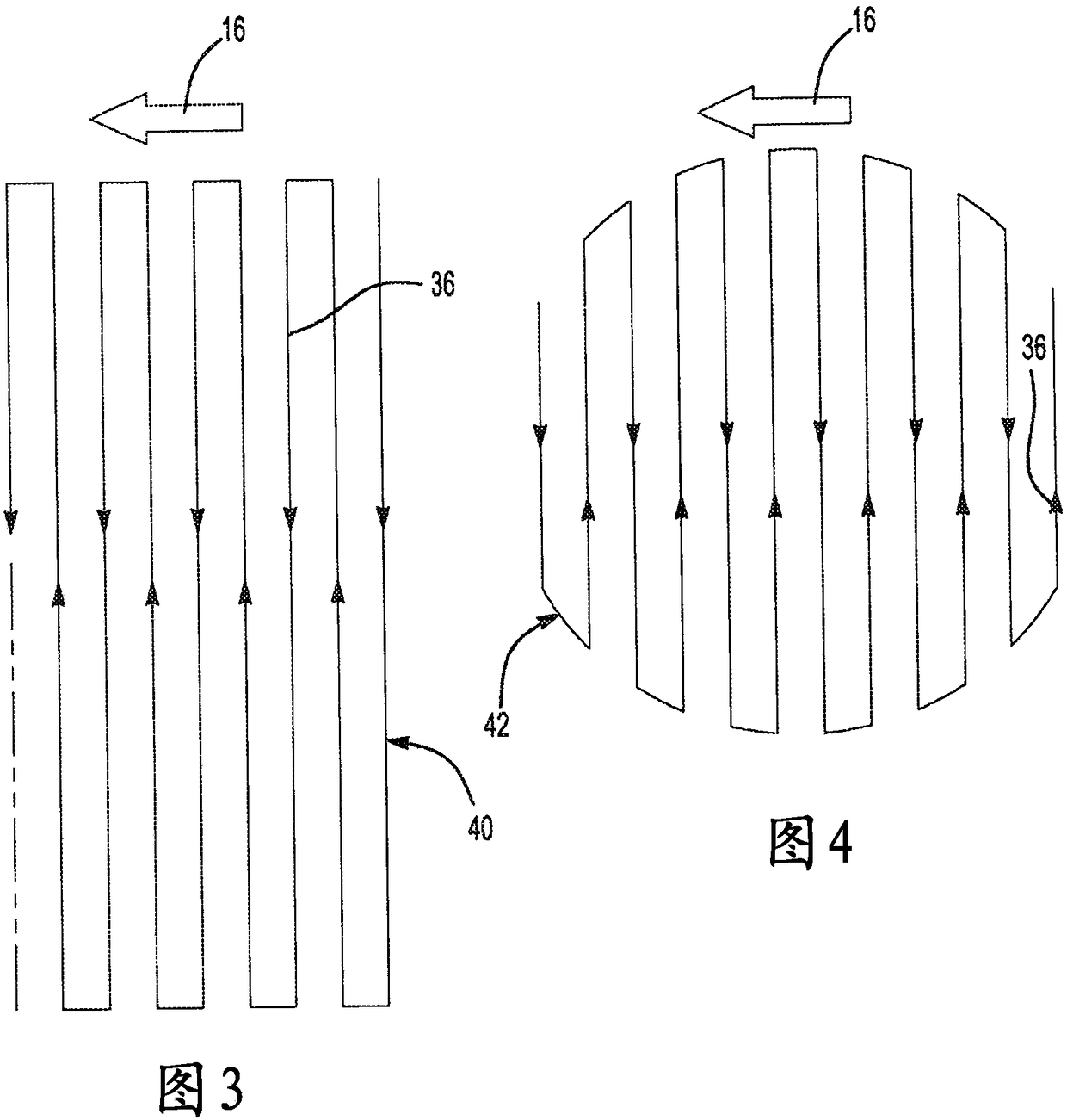

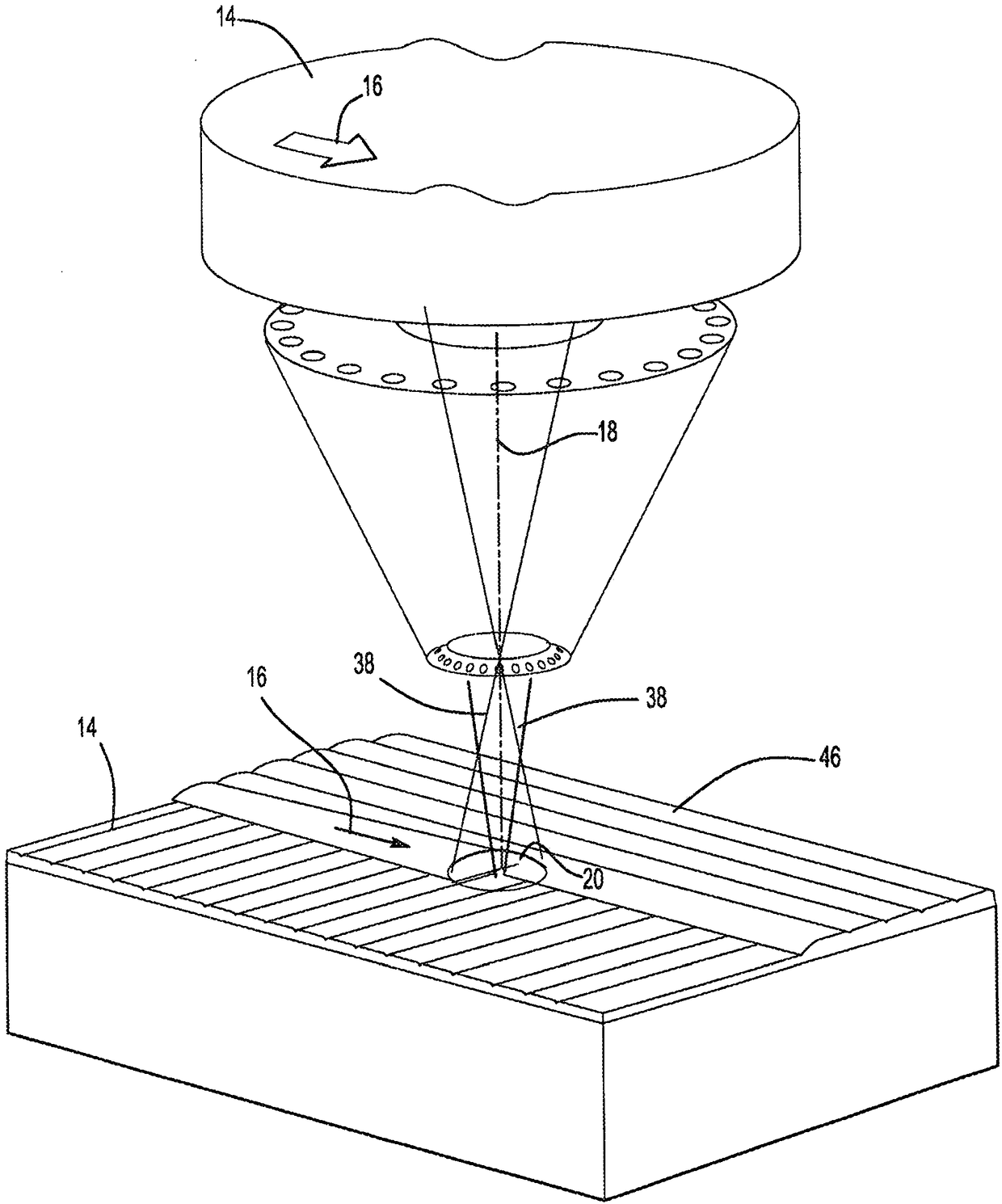

Nozzle with laser scanning head for direct metal deposition

InactiveCN108136541ADeposition processing improvedReduced Power RequirementsAdditive manufacturing apparatusLaser beam welding apparatusLaser scanningSpray nozzle

An apparatus for performing direct material deposition upon a substrate for generating a three dimensional object includes a motion system for moving an head. The head includes a laser for generatinga laser beam and a laser scanner for directing the laser beam at the substrate for generating a melt pool at the substrate. A nozzle delivers material into the melt pool generated by the laser beam for forming a bead of material upon the substrate. The laser scanner is cooperable with the motion system, which is moveable along a first path while the laser scanner is simultaneously moveable along asecond path for progressively generating a bead of material deposited upon the substrate.

Owner:DM3D TECH

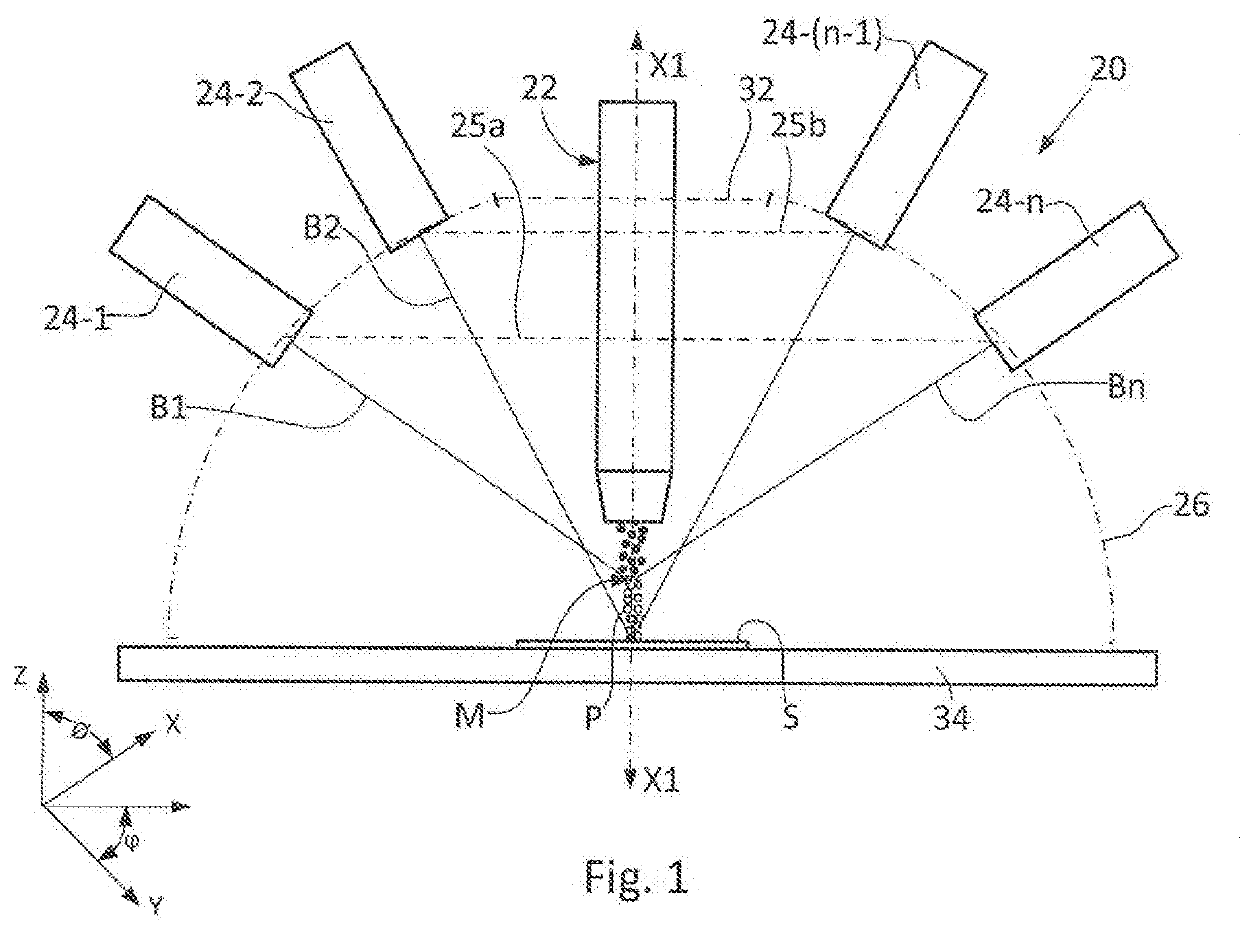

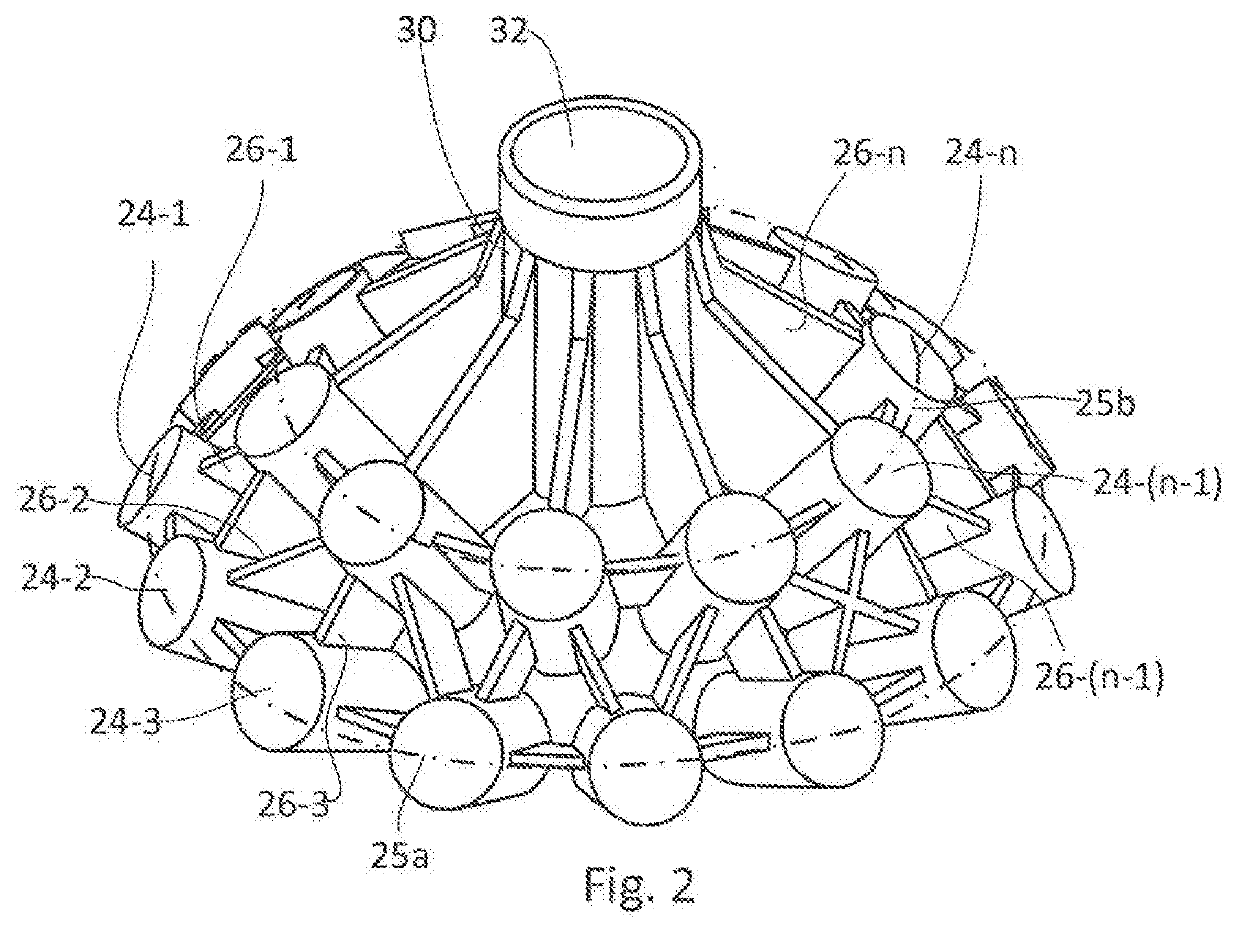

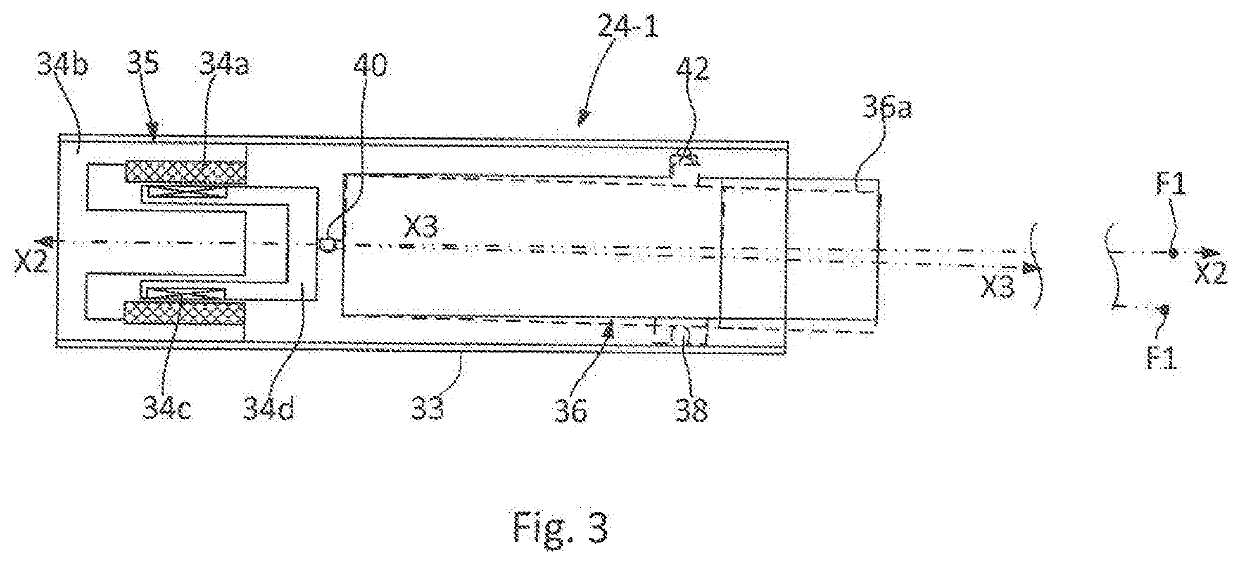

Method and apparatus for 3D laser printing by heating/fusing metal wire or powder material with controllable melt pool

PendingUS20210283718A1Additive manufacturing apparatusIncreasing energy efficiencyOptical axisMetallic materials

An apparatus for 3D laser printing and a method for fusing a metal material with control of a melt pool on a substrate are provided. The apparatus contains a metal wire or powder feed unit and a plurality of laser sources symmetrically arranged on the surface of an imaginary hemisphere. Each laser source contains a laser with a laser beam focusing lens that focuses the laser beam in a focal point at a given distance from the focusing lens. The laser source is also provided with CPU / GPU-controlled devices for independently shifting each laser or a group of lasers along the optical axis and / or for tilting the lasers relative to the longitudinal axis of the source housing so that heating or fusing can be performed by placing the focal points of the lasers selectively at any point of the material or on a substrate for forming and controlling the melt pool.

Owner:DOGRU JOHN MEHMET ULGAR +1

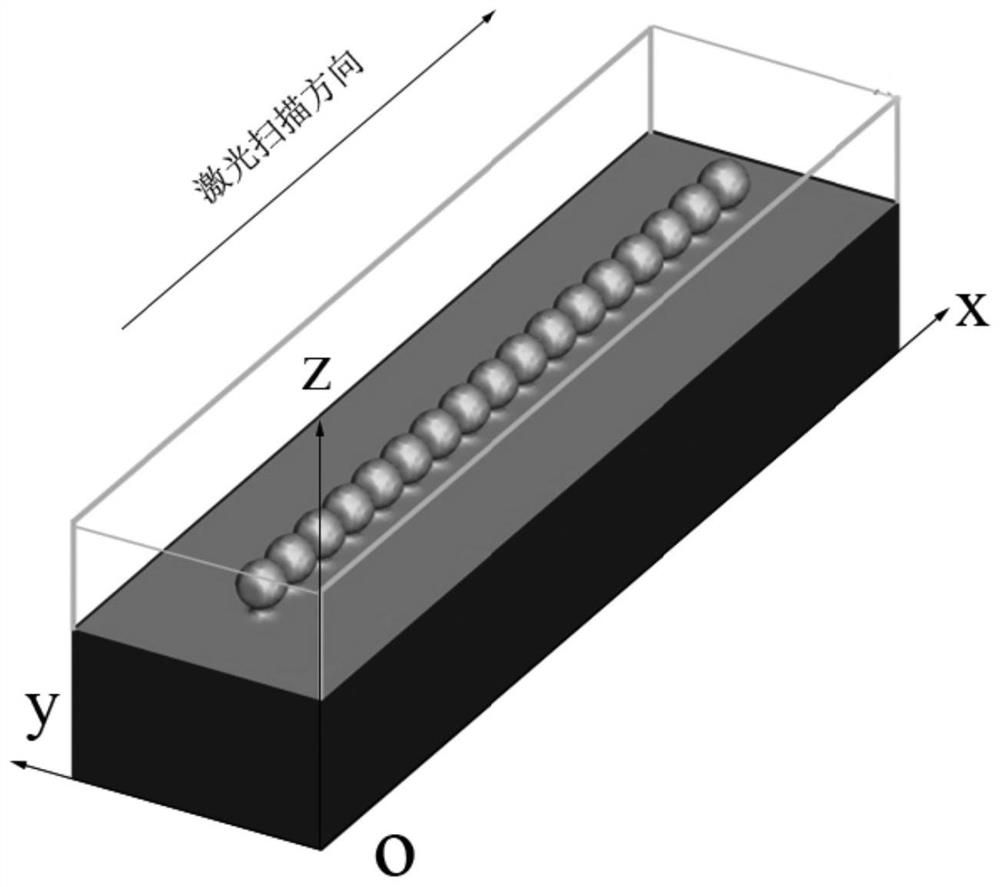

Numerical simulation method for microstructure evolution of magnesium alloy selective laser melting

InactiveCN113807033AAccurate Quantitative PredictionAccurate Quantification of Evolutionary ProcessesGeometric image transformationDesign optimisation/simulationSelective laser meltingMg alloys

The invention provides a numerical simulation method for microstructure evolution of magnesium alloy selective laser melting, which comprises the following steps of: simulating laser scanning by adopting a Gaussian surface heat source model; obtaining a flow field and a temperature field of a selective laser melting pool; applying a VOF method to track a free interface; selecting a specific two-dimensional section in a macroscopic geometric model to perform microstructure simulation calculation; respectively establishing an equiaxed crystal nucleation model in the molten powder and a nucleation model of columnar crystals epitaxially grown on the edge of the melting pool; respectively establishing a solid-phase solute diffusion model and a liquid-phase solute diffusion model; determining a growth kinetic model of dendritic crystals, and performing iterative calculation according to a cellular capture rule; and storing the data obtained by calculation, and carrying out visualization processing. The method can accurately and quantitatively predict the microstructure evolution process of the magnesium alloy in the selective laser melting process.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

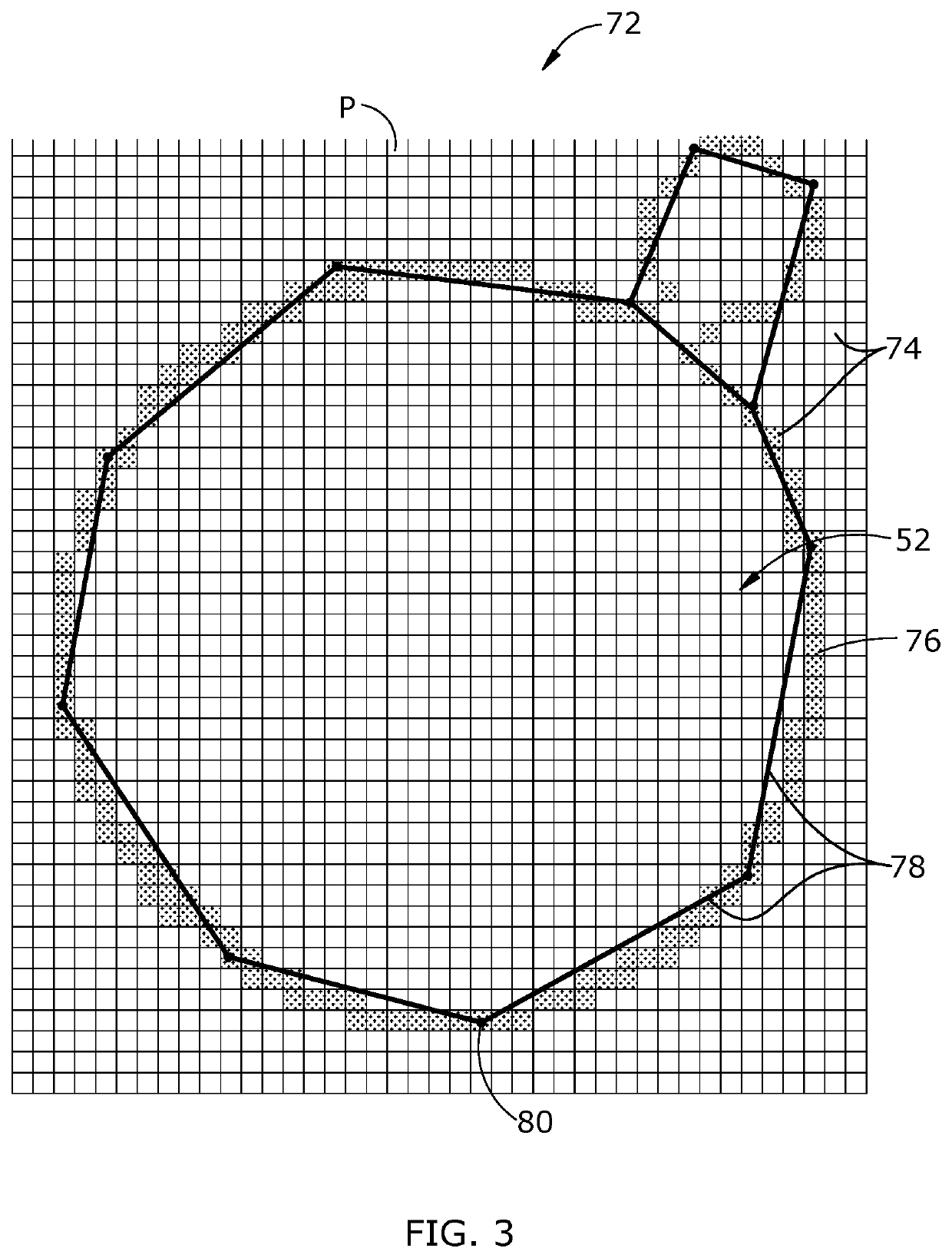

Method for melt pool monitoring using algebraic connectivity

ActiveUS20200189196A1Image enhancementAdditive manufacturing apparatusAlgebraic connectivityProcess engineering

A method of controlling an additive manufacturing process in which a directed energy source is used to selectively melt material to form a workpiece, forming a melt pool in the process of melting, the method comprising: using an imaging apparatus to generate an image of the melt pool comprising an array of individual image elements, the image including a measurement of at least one physical property for each of the individual image elements; from the measurements, mapping a melt pool boundary of the melt pool; computing a algebraic connectivity of the melt pool; and controlling at least one aspect of the additive manufacturing process with reference to the algebraic connectivity.

Owner:GENERAL ELECTRIC CO

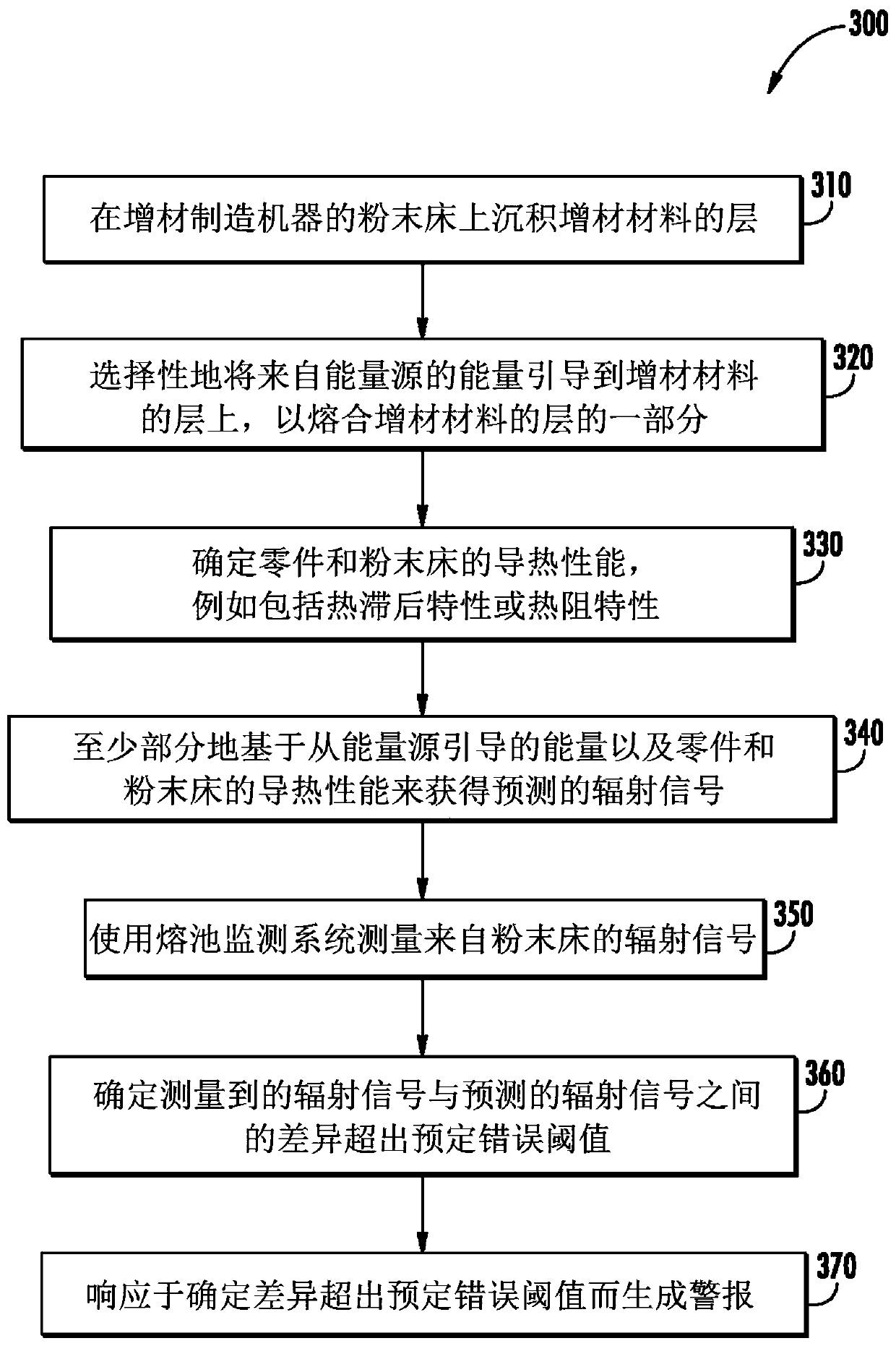

Method for detecting errors and compensating for thermal dissipation in an additive manufacturing process

ActiveCN111168997AManufacturing platforms/substratesIncreasing energy efficiencyPowder bedElectromagnetic radiation

Owner:GENERAL ELECTRIC CO

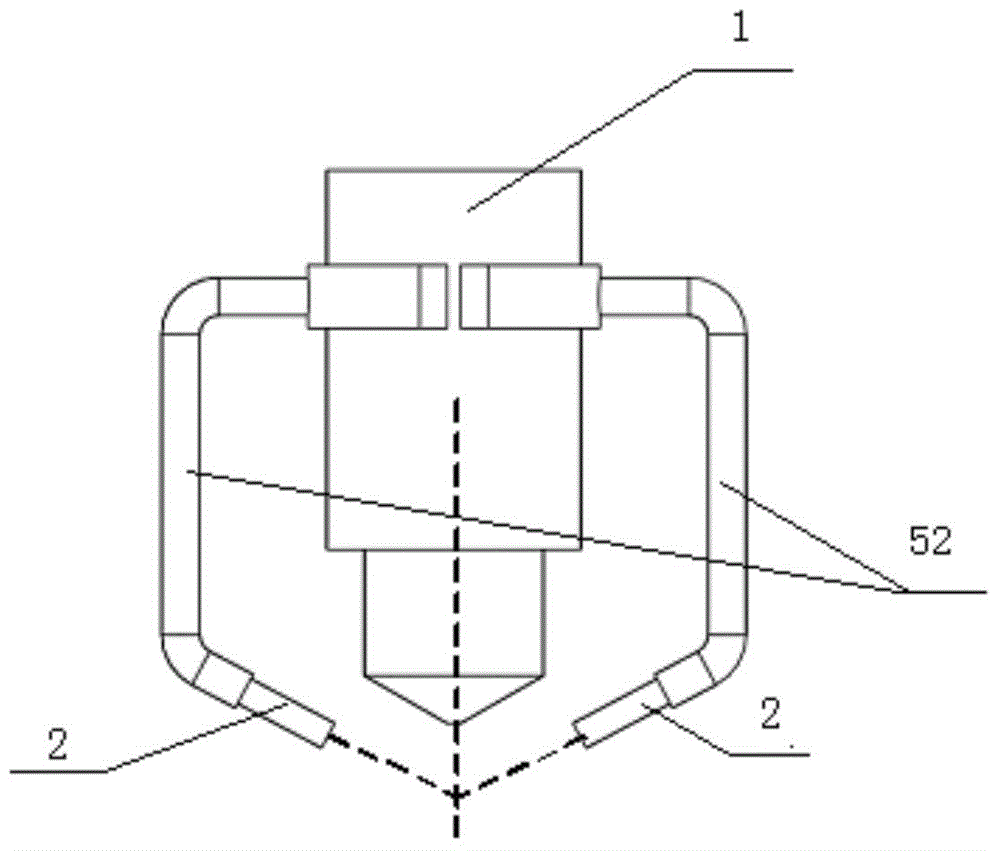

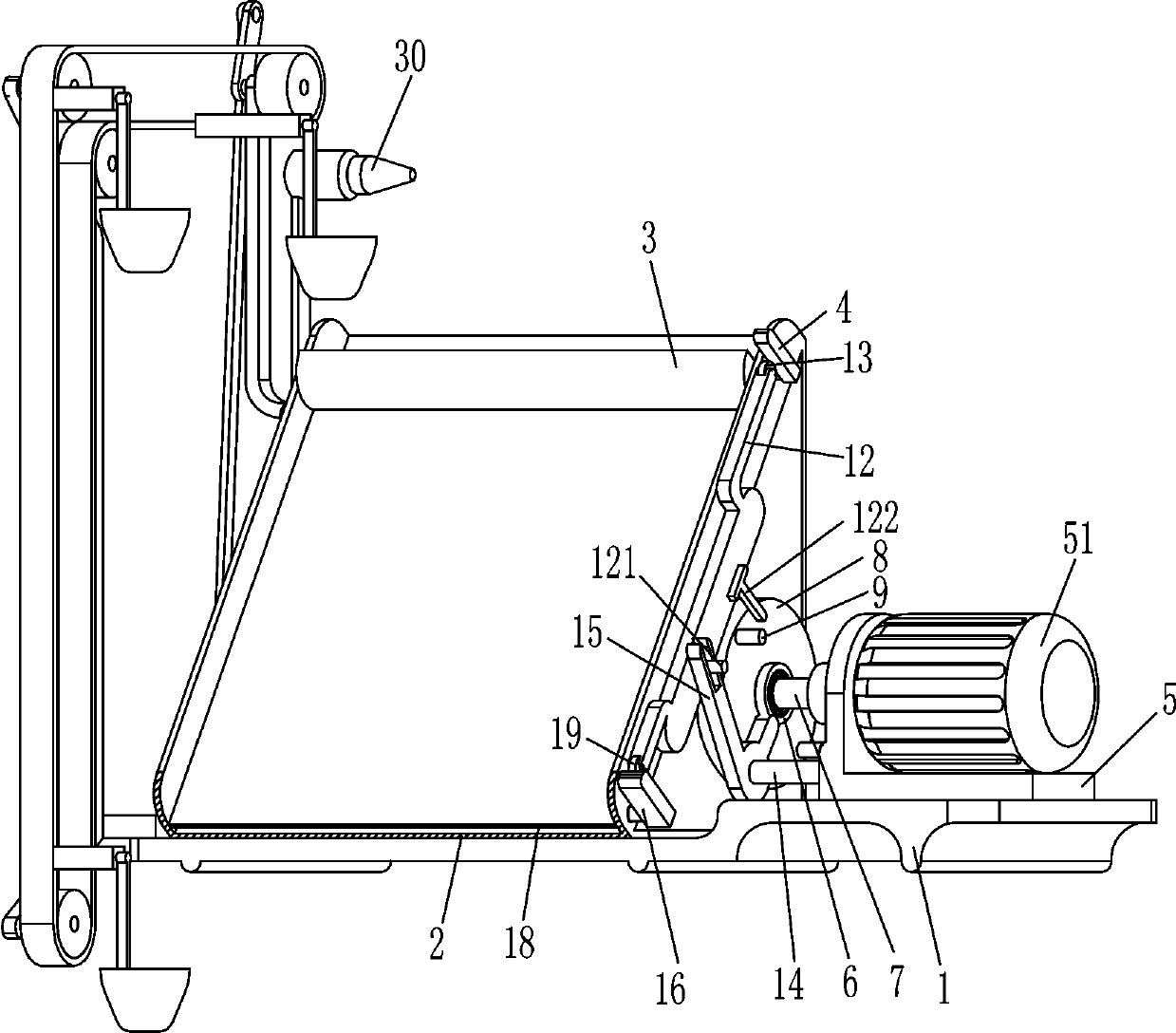

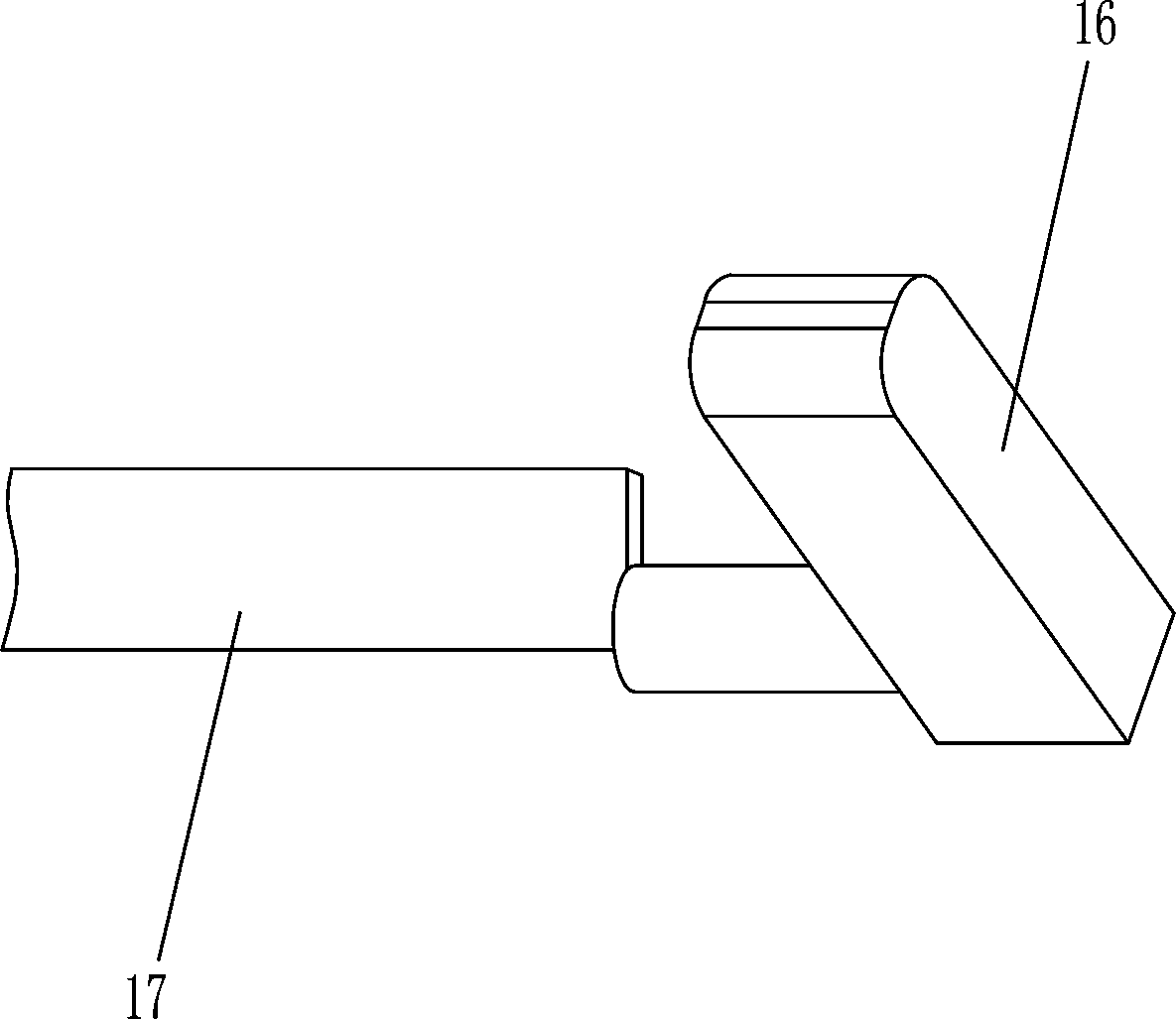

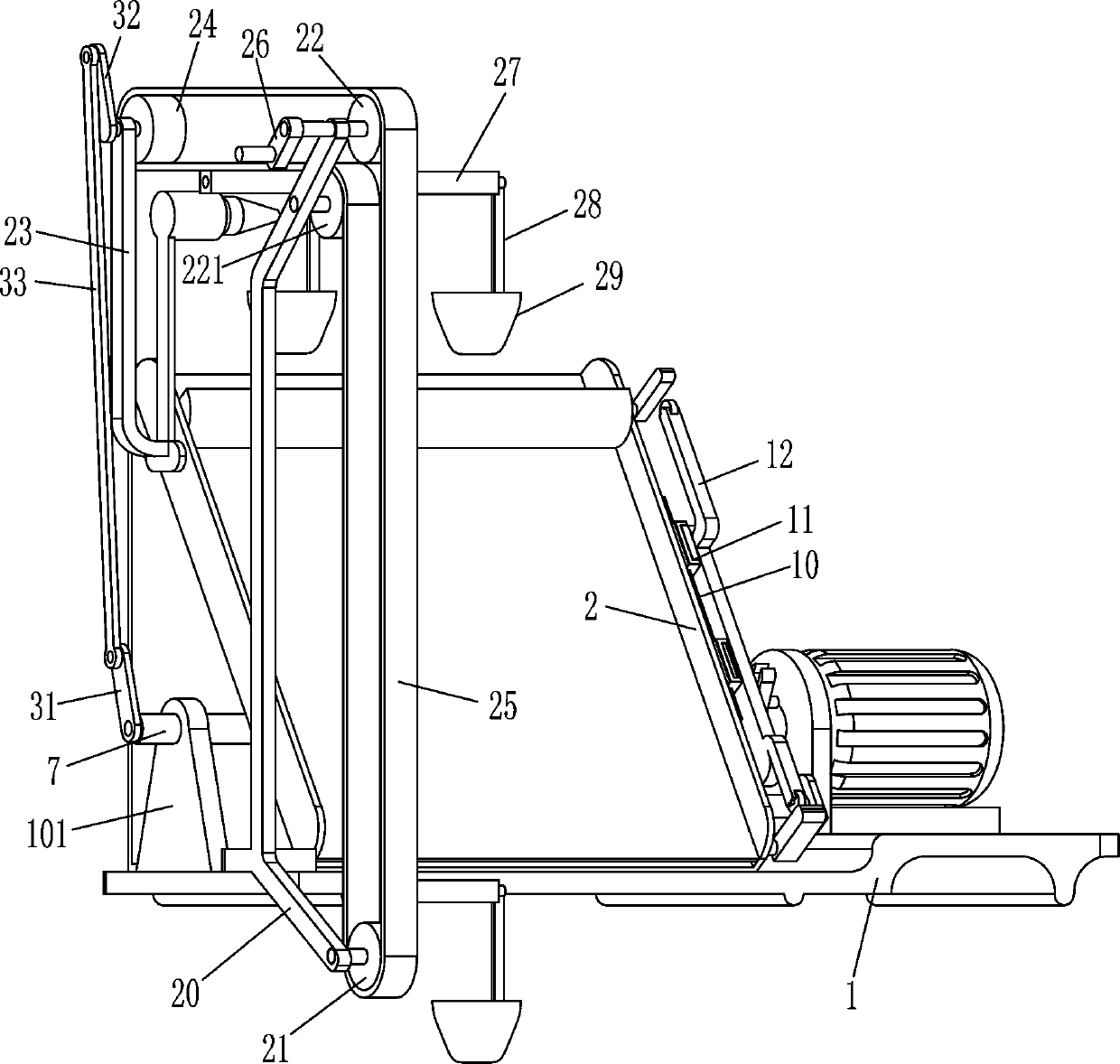

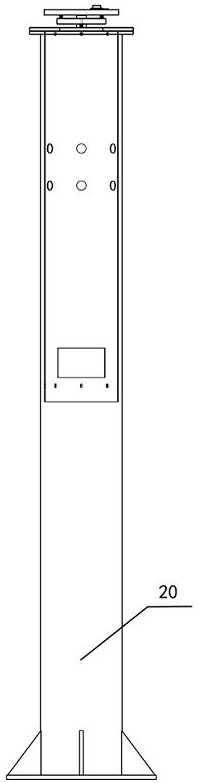

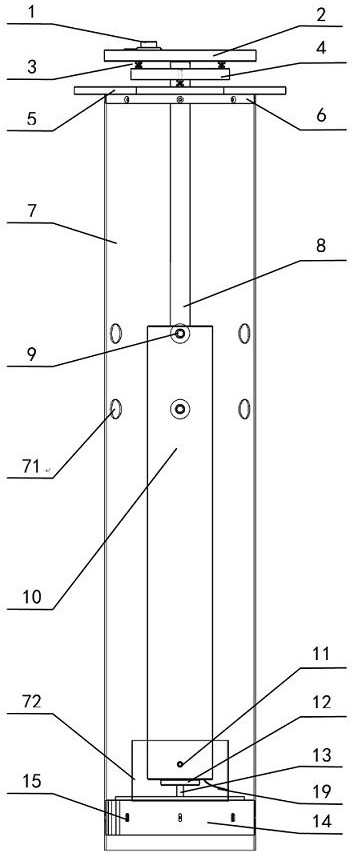

Lead plate manufacturing device used in cooperation with lead melting pool

ActiveCN111408703AEasy to manufactureIncrease productivityCasting plantsElectric machineryIndustrial engineering

The invention relates to a lead plate manufacturing device, in particular to a lead plate manufacturing device used in cooperation with a lead melting pool. The technical objective of the lead plate manufacturing device is to provide the lead plate manufacturing device which can rapidly manufacture lead plates in batches and can be used in cooperation with the lead melting pool. The lead plate manufacturing device used in cooperation with the lead melting pool comprises a base, a supporting seat, a forming hopper, a material uniformizing hopper, a first swinging piece, a mounting seat and thelike, wherein the supporting seat is fixedly connected to the upper side of the base, the forming hopper is fixedly connected to the upper side of the base, the material uniformizing hopper is movablyconnected to the upper portion of the forming hopper, the first swinging piece is fixedly connected to one end of the material uniformizing hopper, and the mounting seat is fixedly connected to the upper side of the base. According to the lead plate manufacturing device, lead water can be automatically conveyed to the forming hopper to manufacture the lead plates only by starting a motor, the process can be cyclically repeated, and the tedious and complex manual means are not needed.

Owner:邱德钡

Optically conductive filler for laser processing

ActiveUS11344975B2Additive manufacturing apparatusIncreasing energy efficiencyLaser processingPhysical chemistry

Owner:SIEMENS ENERGY INC

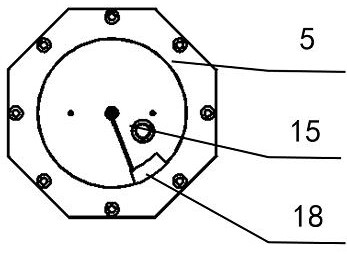

Large-dip-angle self-leveling device

ActiveCN113513677ARealize automatic levelingEquipped with leveling overrun alarm functionStands/trestlesIncline measurementEpoxyMeasuring instrument

The invention relates to a large-dip-angle self-leveling device. The large-dip-angle self-leveling device comprises a mounting base platform arranged on a mounting stand column and a supporting cylinder connected with the mounting base platform. A leveling plate is arranged at the top of the mounting base platform, and a leveling platform is arranged on the leveling plate. A spirit bubble indicator and a control circuit board are arranged on the leveling platform. A balance weight connecting rod is arranged in the supporting cylinder, one end of the balance weight connecting rod is connected with the leveling platform, and the other end of the balance weight connecting rod is connected with a balance weight. A four-core cable penetrates through the balance weight connecting rod and the balance weight. Observation windows are symmetrically arranged at the lower part of the supporting cylinder. A melting pool is arranged at the bottom in the supporting cylinder, and special hot melt adhesive is contained in the melting pool. A heating pipe is inserted into the special hot melt adhesive and is connected with the balance weight through an epoxy resin heat insulation sleeve. One end of the four-core cable is connected with the control circuit board, and the other end is connected with the heating pipe. The large-dip-angle self-leveling device is low in cost, high in leveling reliability and suitable for installation of instruments and equipment needing to be kept in a horizontal state in the working process of the measuring instruments.

Owner:NORTHWEST INST OF ECO ENVIRONMENT & RESOURCES CAS

Method for melt pool monitoring using machine learning

InactiveUS20200189199A1Image enhancementAdditive manufacturing apparatusReference imageProcess engineering

A method of controlling an additive manufacturing process in which a directed energy source is used to selectively melt material to form a workpiece, forming a melt pool in the process of melting. The method includes: using an imaging apparatus to generate an image of the melt pool comprising an array of individual image elements, the image including a measurement of at least one physical property for each of the individual image elements; using a software machine learning algorithm to classify each image as acceptable or unacceptable; and controlling at least one aspect of the additive manufacturing process with reference to the image classification.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com