Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1387 results about "Thermal break" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A thermal break or thermal barrier is an element of low thermal conductivity placed in an assembly to reduce or prevent the flow of thermal energy between conductive materials. The opposite of a thermal barrier is a thermal bridge.

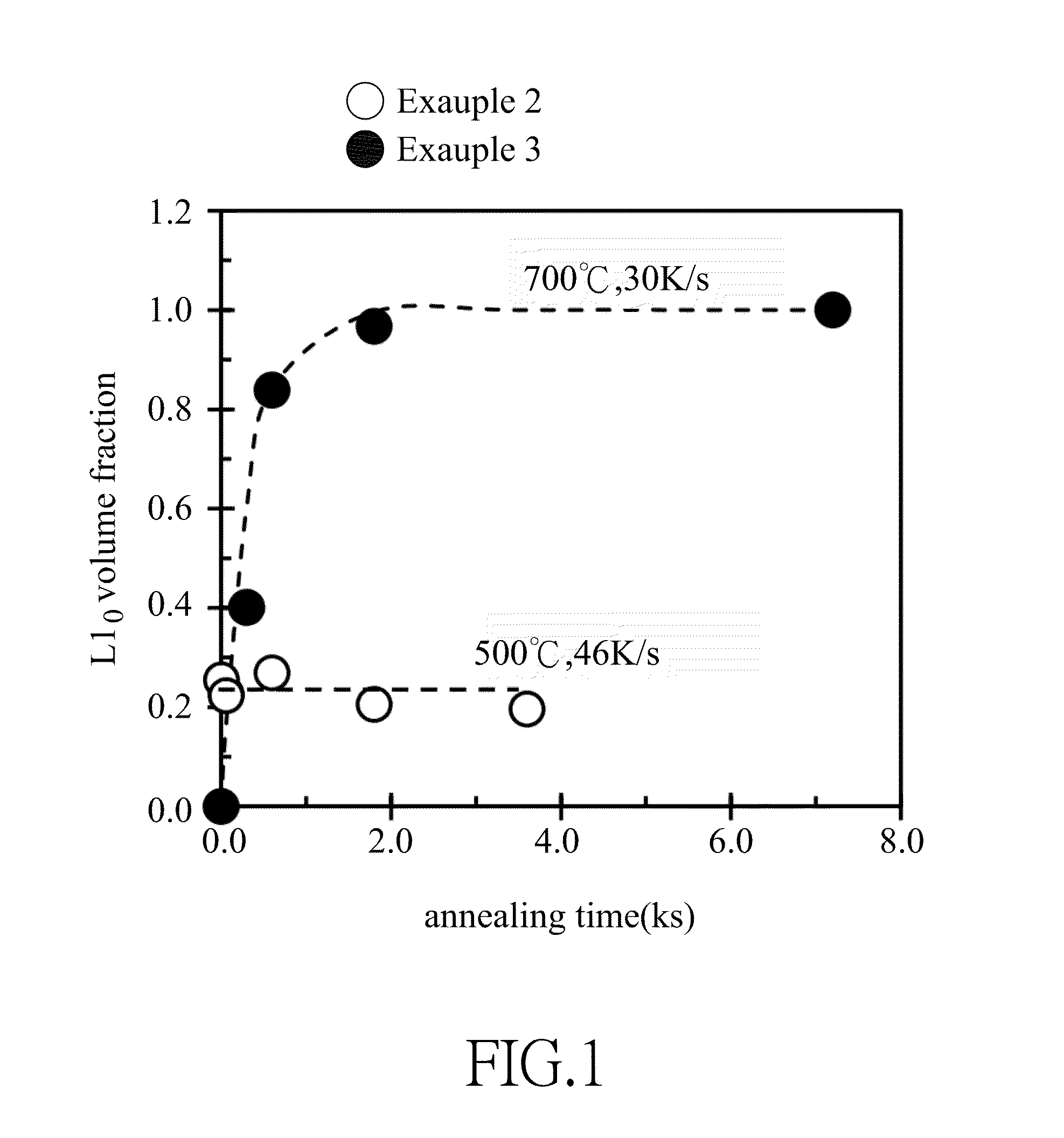

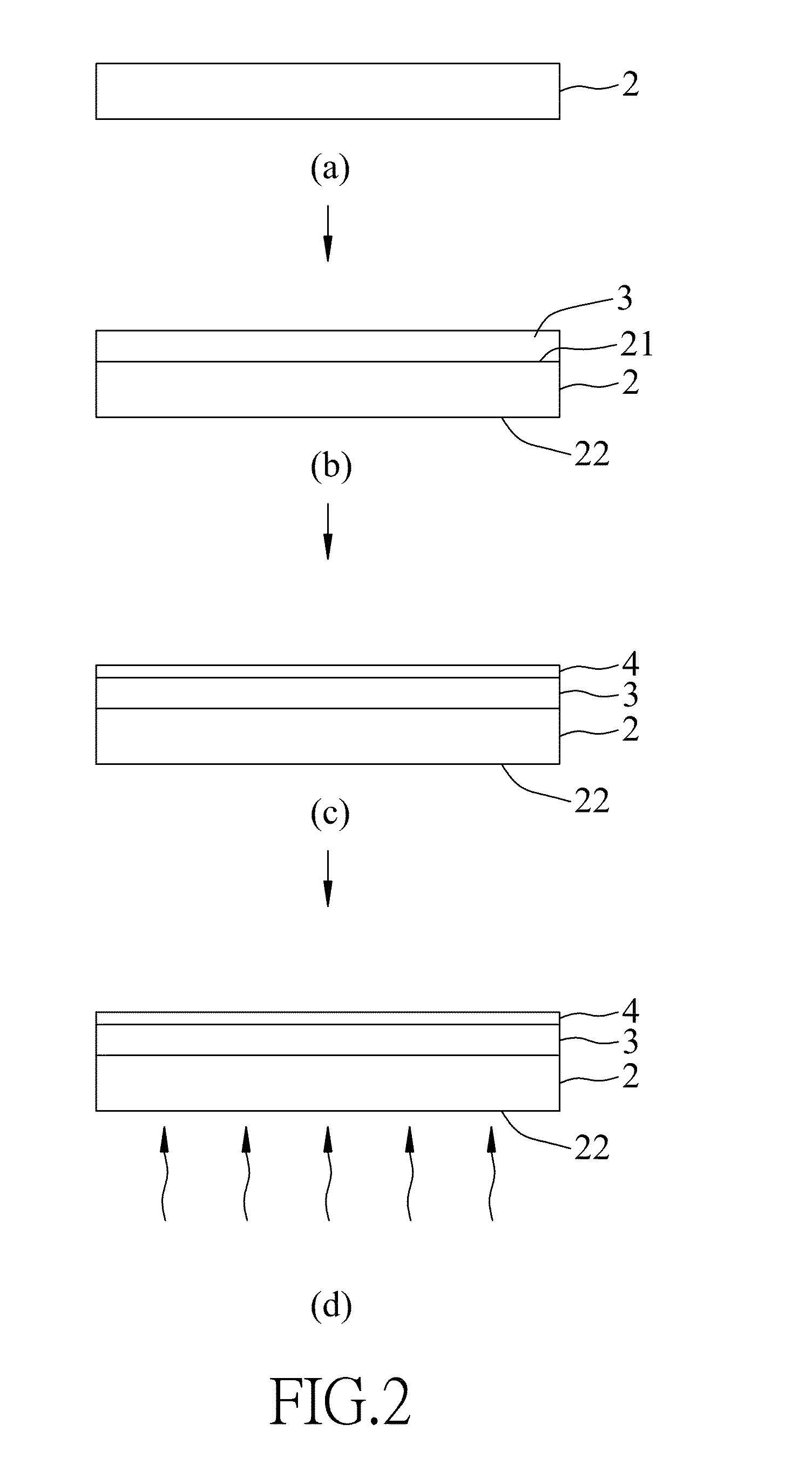

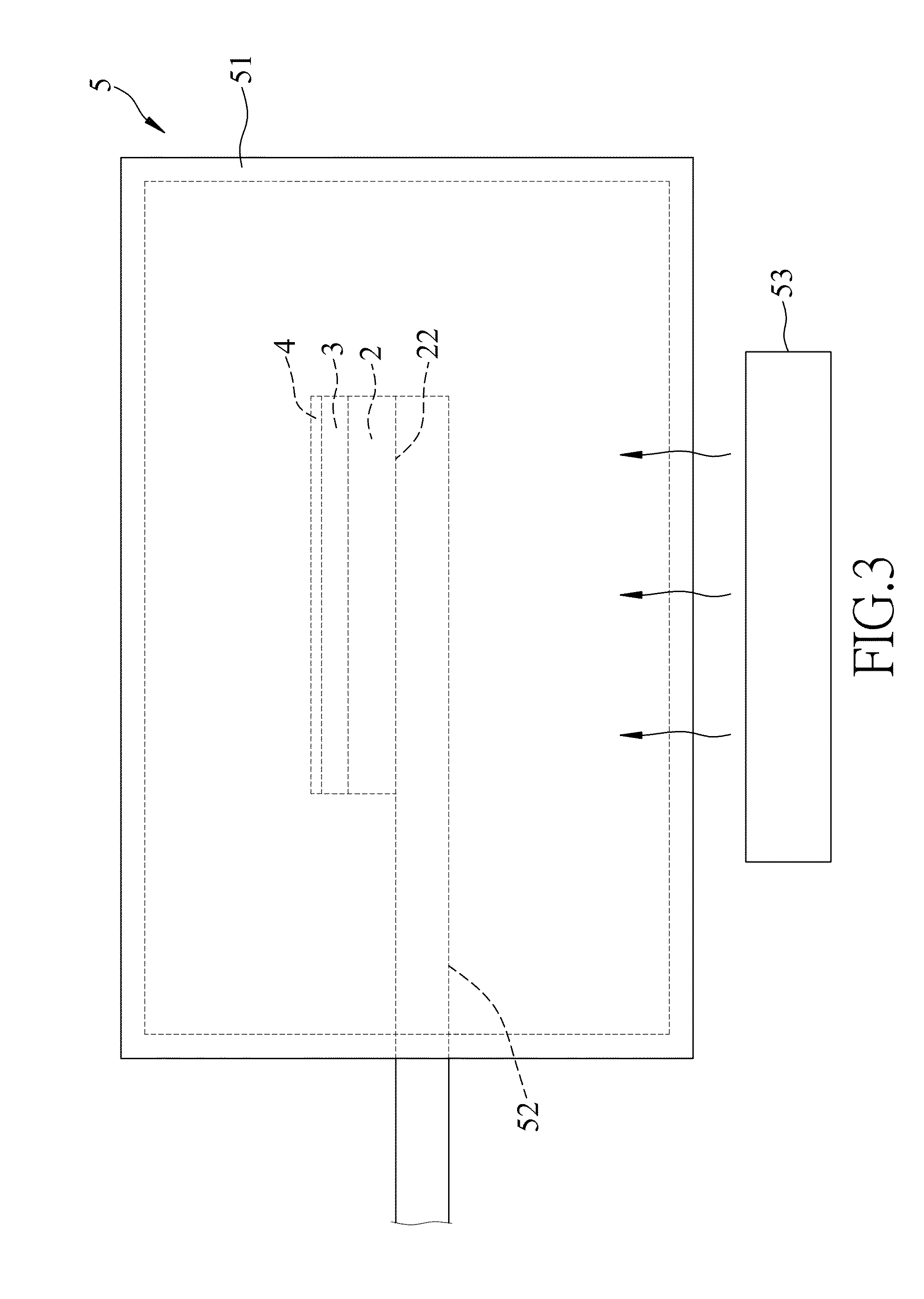

Method for making an ordered magnetic alloy

ActiveUS20140366990A1Rapid thermal expansionOvercomes drawbackChemical vapor deposition applicationHeat treatment applicationIn planeMetal

A method for making an ordered magnetic alloy includes (a) providing a thermally conductive base having opposite first and second surfaces; (b) forming a thermal barrier layer on the first surface of the thermally conductive base; (c) forming a disordered magnetic alloy layer on the thermal barrier layer, the disordered magnetic alloy layer being made from a disordered alloy which contains a first metal selected from Fe, Co, and Ni, and a second metal selected from Pt and Pd; and (d) after step (c), applying a transient heat to the thermally conductive base to cause rapid thermal expansion of the thermally conductive base, which, in turn, causes generation of an in-plane tensile stress in the disordered magnetic alloy layer.

Owner:NATIONAL TSING HUA UNIVERSITY

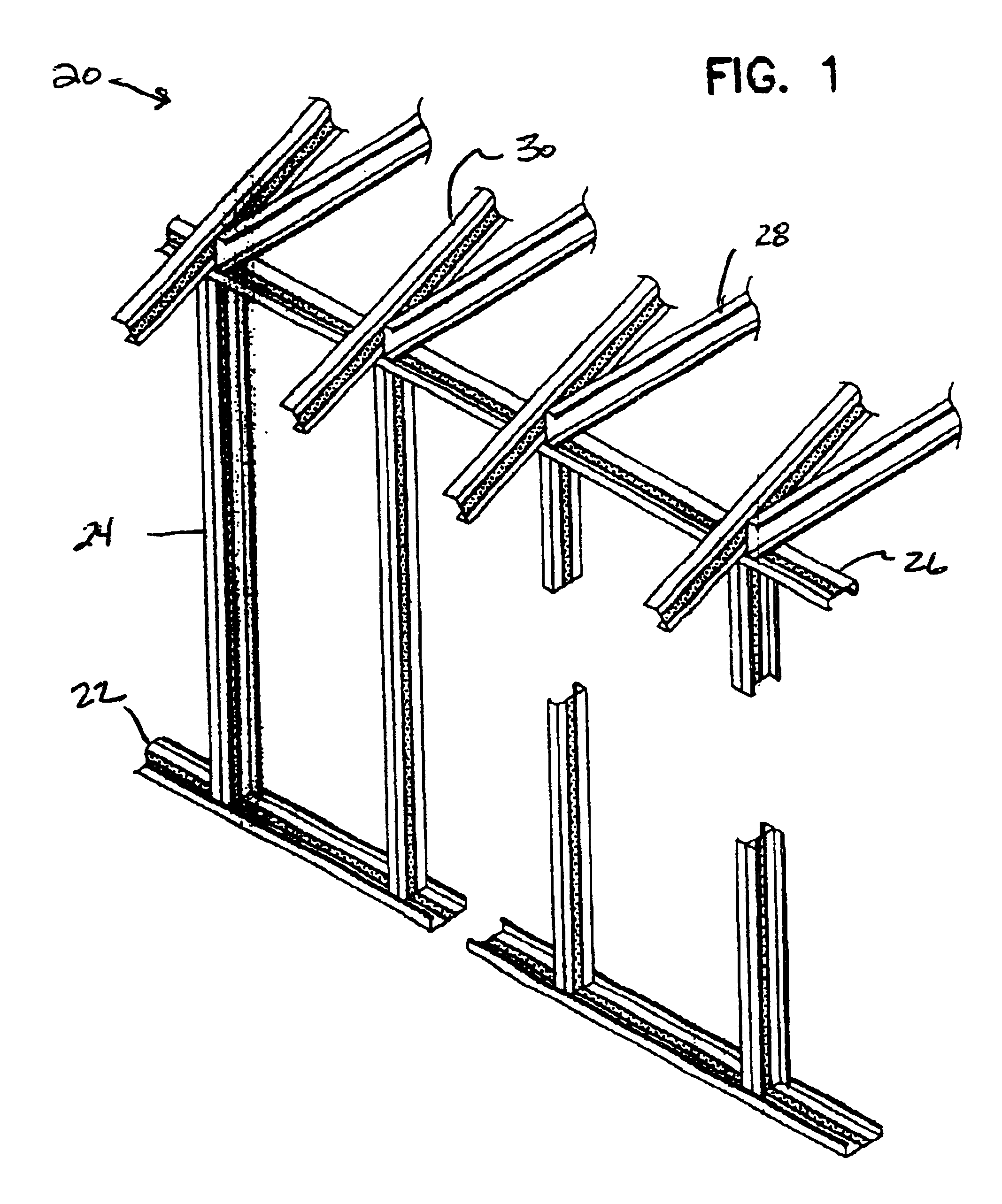

Insulated stud panel and method of making such

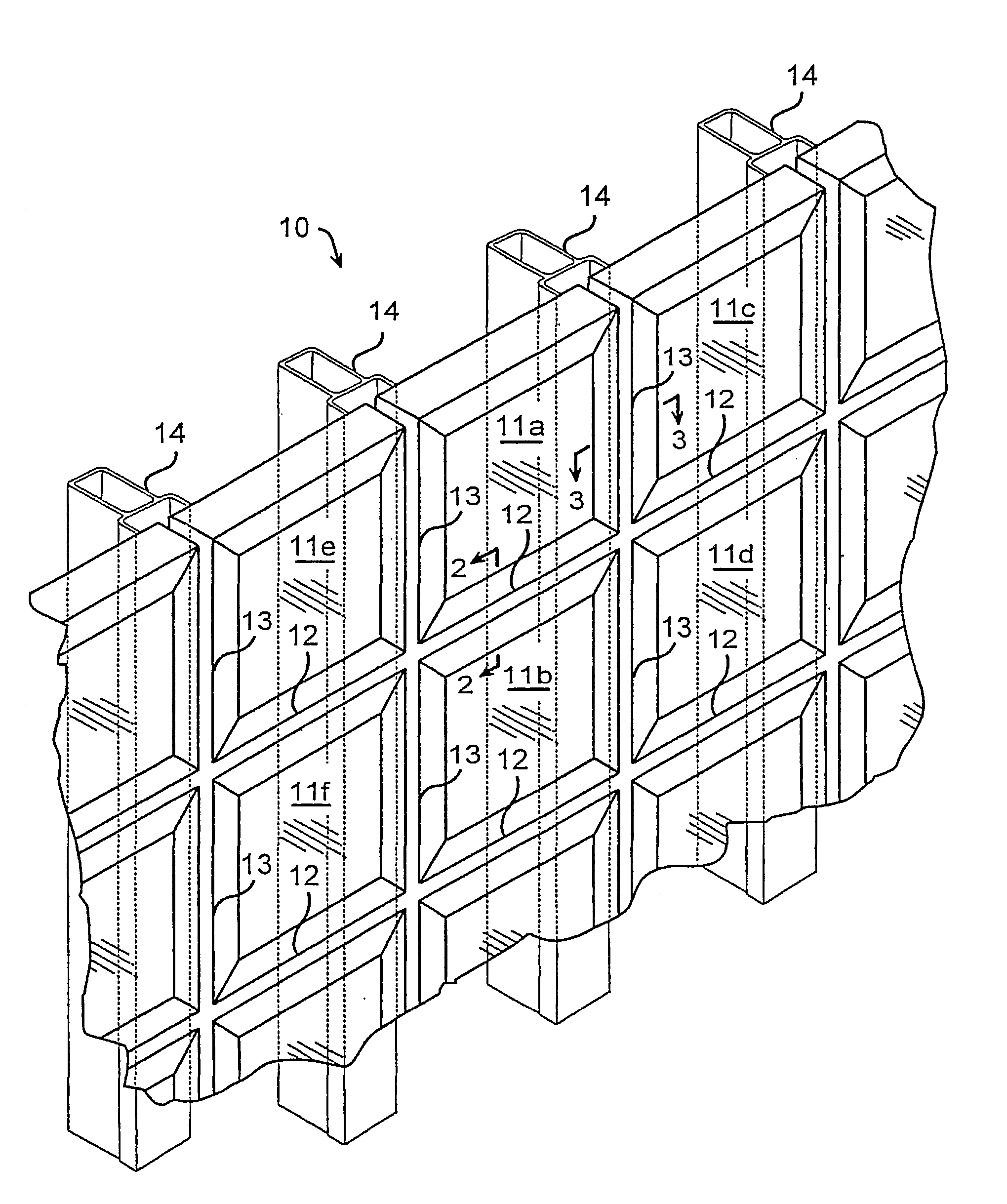

A stud panel and method of making a stud panel where interior sheathing may be a temporary piece of transparent plastic or a permanent panel of sheet rock so as to retain insulation in place and minimize scarfing. The stud panel may include studs having through holes extending in a length direction of the stud panel such that insulation in adjacent inner regions separated by such studs interlock with each other and contribute to a structural integrity of the stud panel. The stud panel may include a space between inner studs and one of the exterior and interior sheathing so as to provide a thermal and sound break between the exterior and inner sheathing so as to minimize heat, air and sound transfer between the exterior and interior sheathing. A method of making the stud panel is further disclosed, where such a method may include the step of incrementally introducing insulation from a closed end of an inner region to an open end of an inner region and may further include the step of automatically introducing insulation into the inner regions of the stud panel.

Owner:HAGEN HANS T JR +1

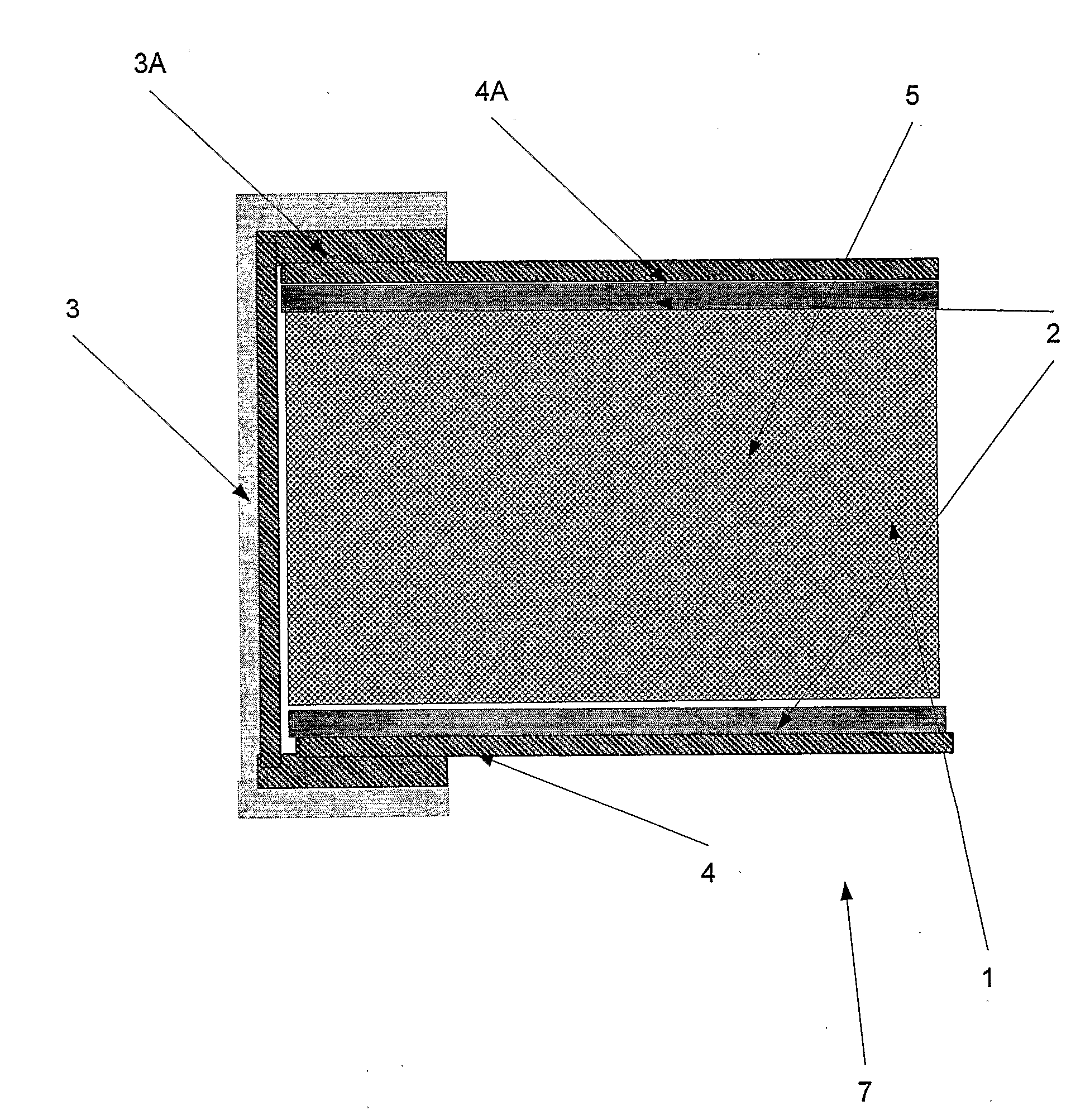

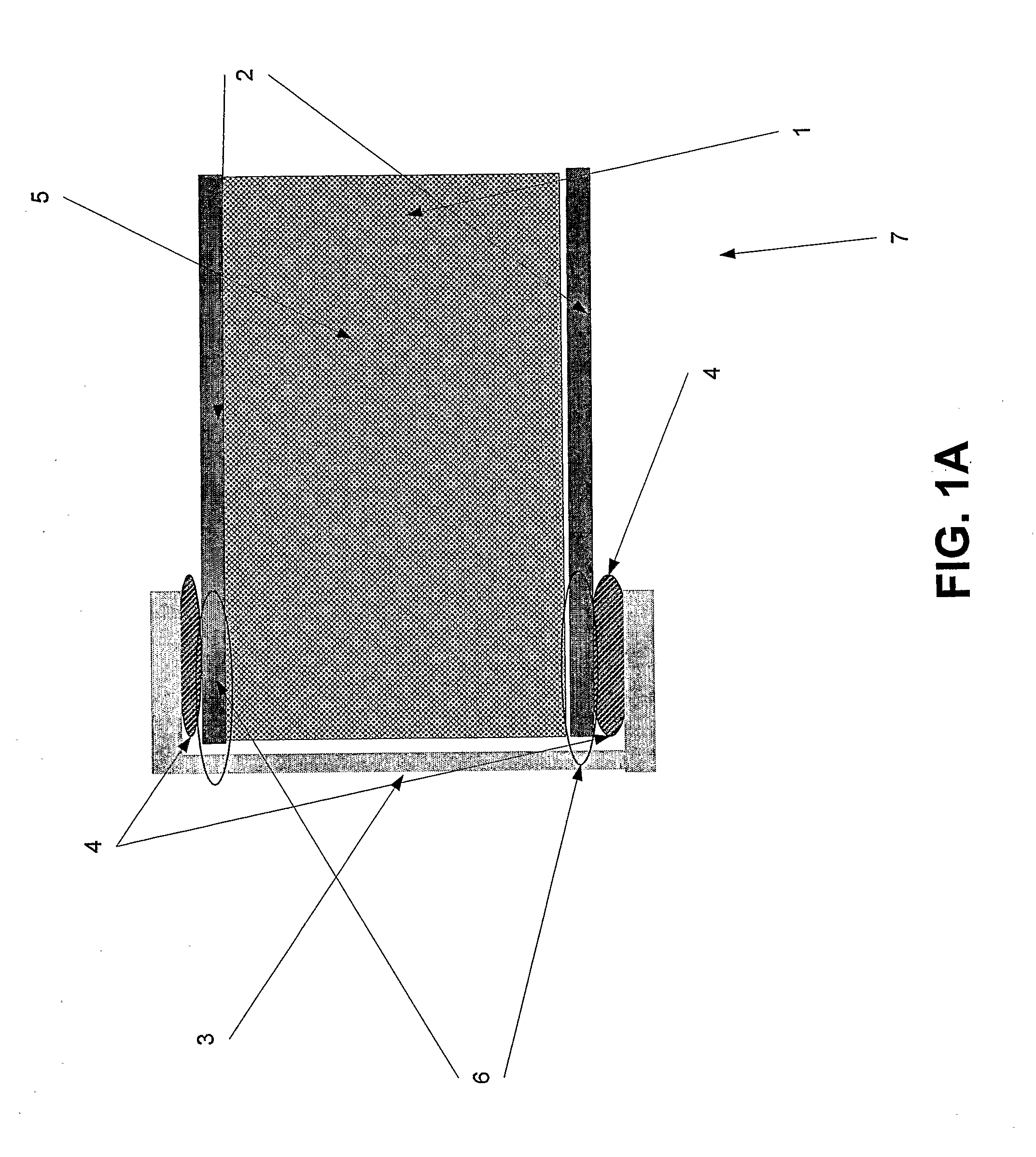

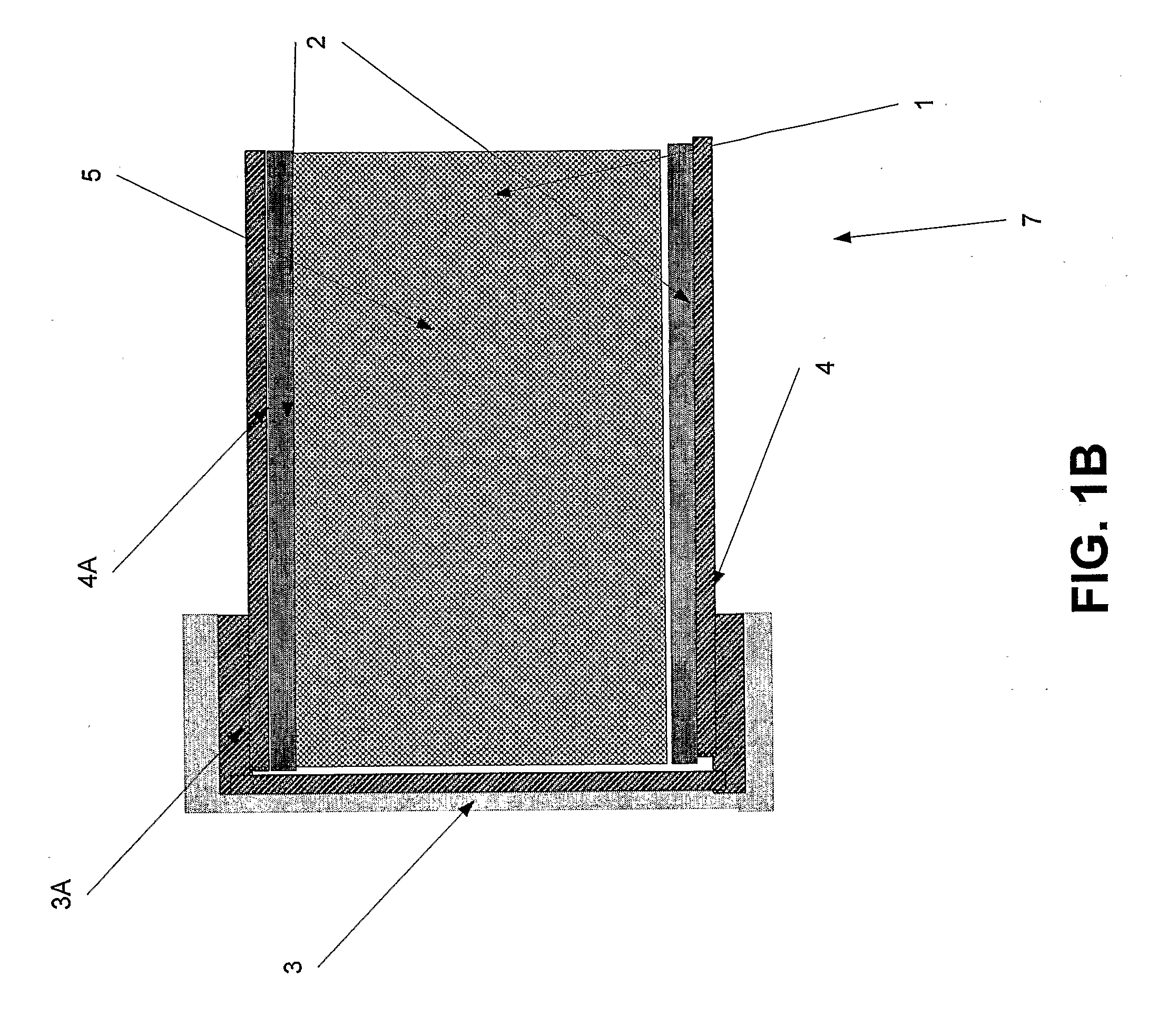

Evacuated Thermal Insulation Panel

InactiveUS20090031659A1Easy accessMaterial nanotechnologyFunctional valve typesThermal insulationWater vapor

A sealed vacuum thermal insulation panel having a thermal barrier that comprises a core made of thermal insulation material and two panel walls made of a barrier material substantially impermeable to atmospheric gases and water vapors. The two panel walls covers opposite sides of the core. The sealed panel further comprises at least one lateral strip of substantially impermeable to atmospheric gases and water vapor. The lateral strip is adapted to sealably enfold the edges of the obverse side of the two panel walls. Additionally, the sealed panel further comprises at least one sealing strip, each comprising sealing material. The sealing strip is adapted to sealably join the edges to the inner side of the lateral strip.

Owner:THERMOVAC LTD

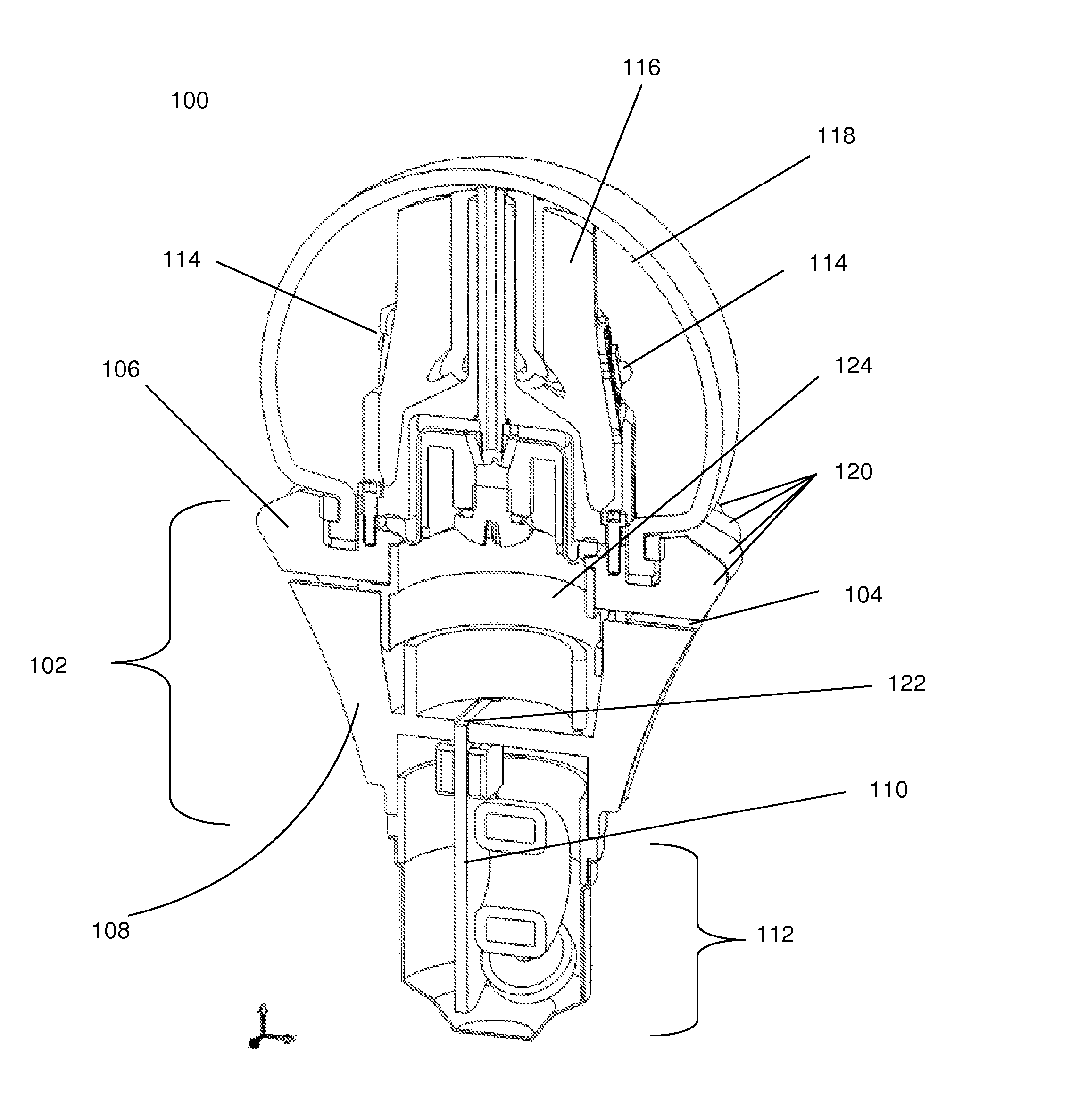

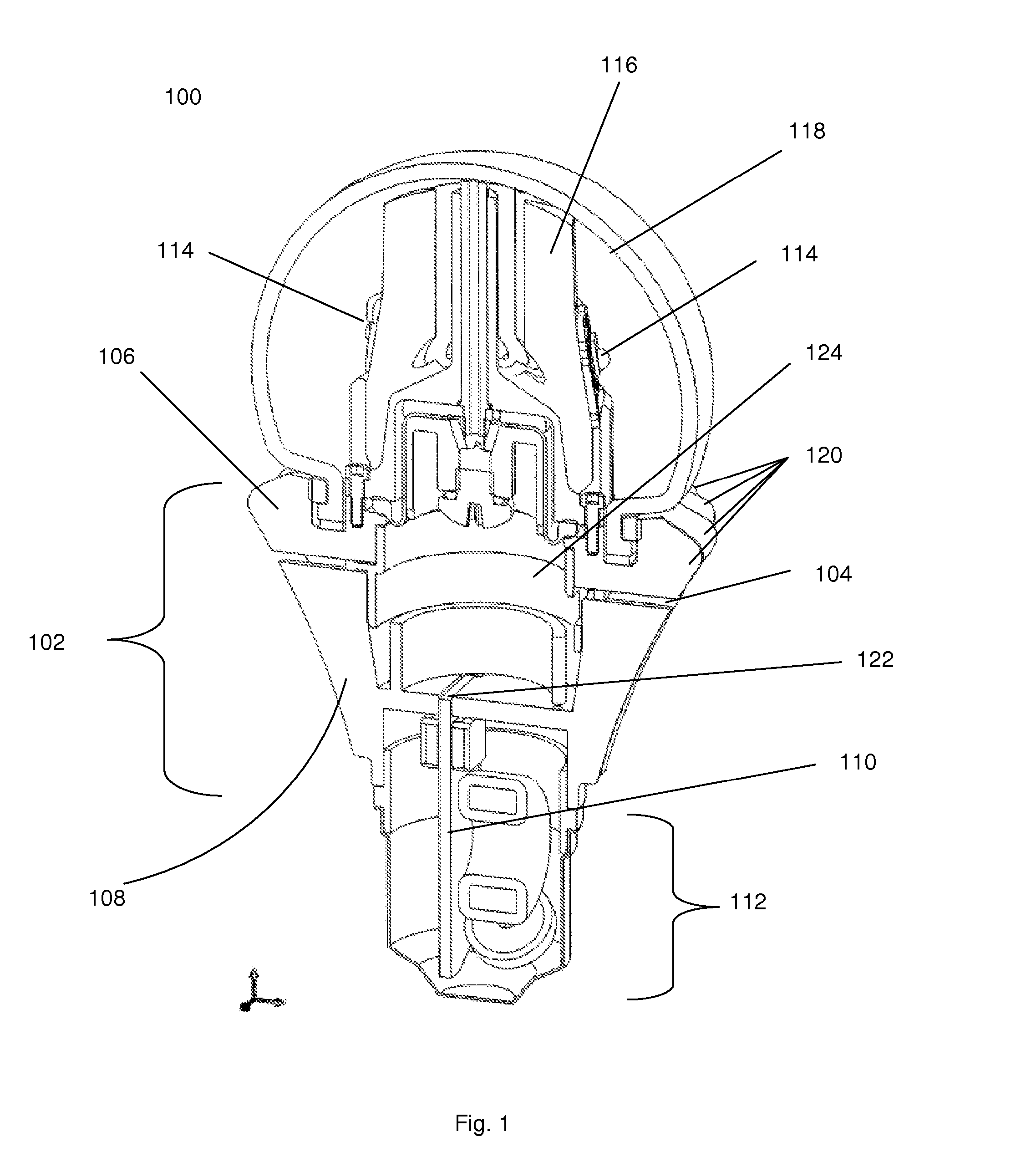

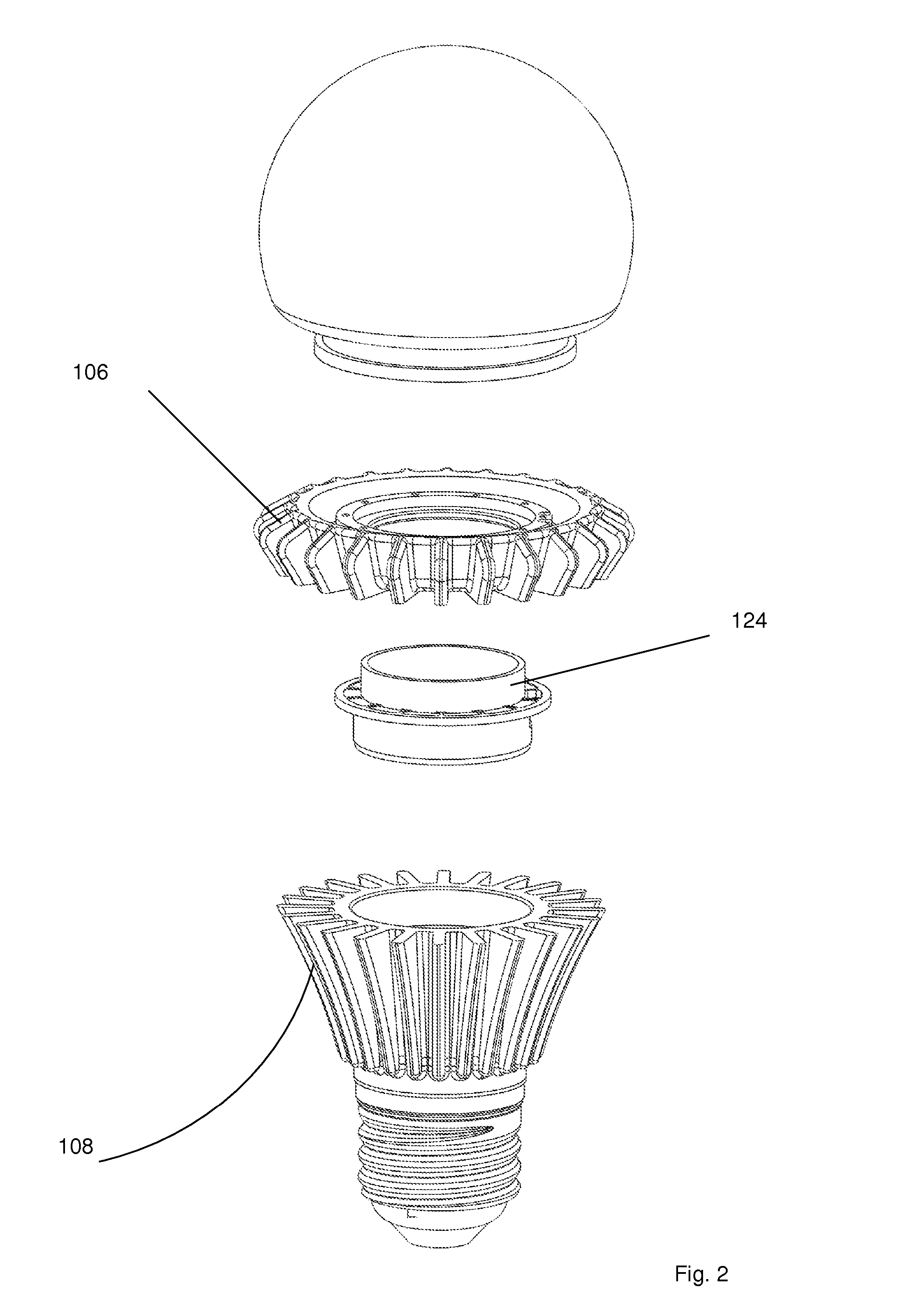

Partitioned heatsink for improved cooling of an LED bulb

InactiveUS8740415B2Point-like light sourceLighting heating/cooling arrangementsDriver circuitThermal break

A light emitting diode (LED) bulb has a shell. An LED is within the shell. The LED is electrically connected to a driver circuit, which is electrically connected to a base of the LED bulb. The LED bulb also has a heatsink between the shell and base. A thermal break partitions the heatsink into an upper partition adjacent the shell and a lower partition adjacent the base.

Owner:SWITCH BULB CO INC

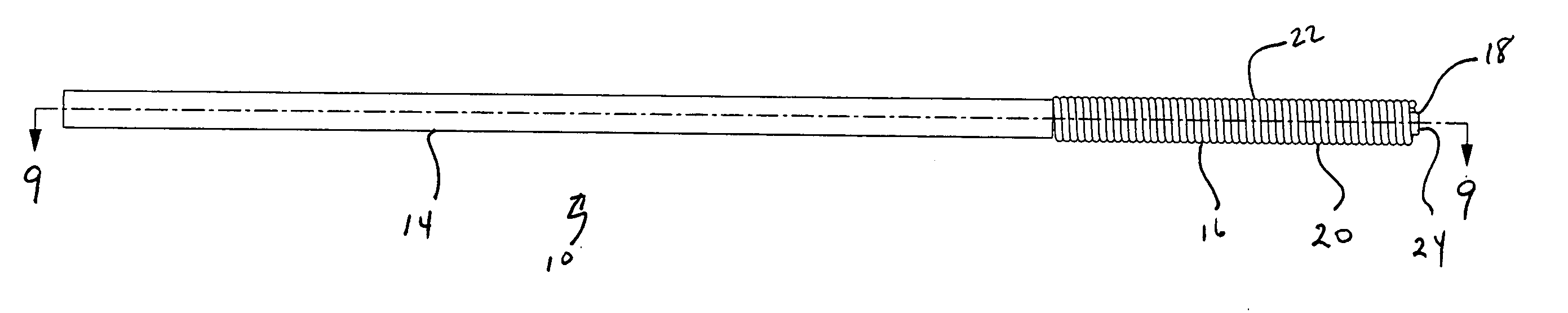

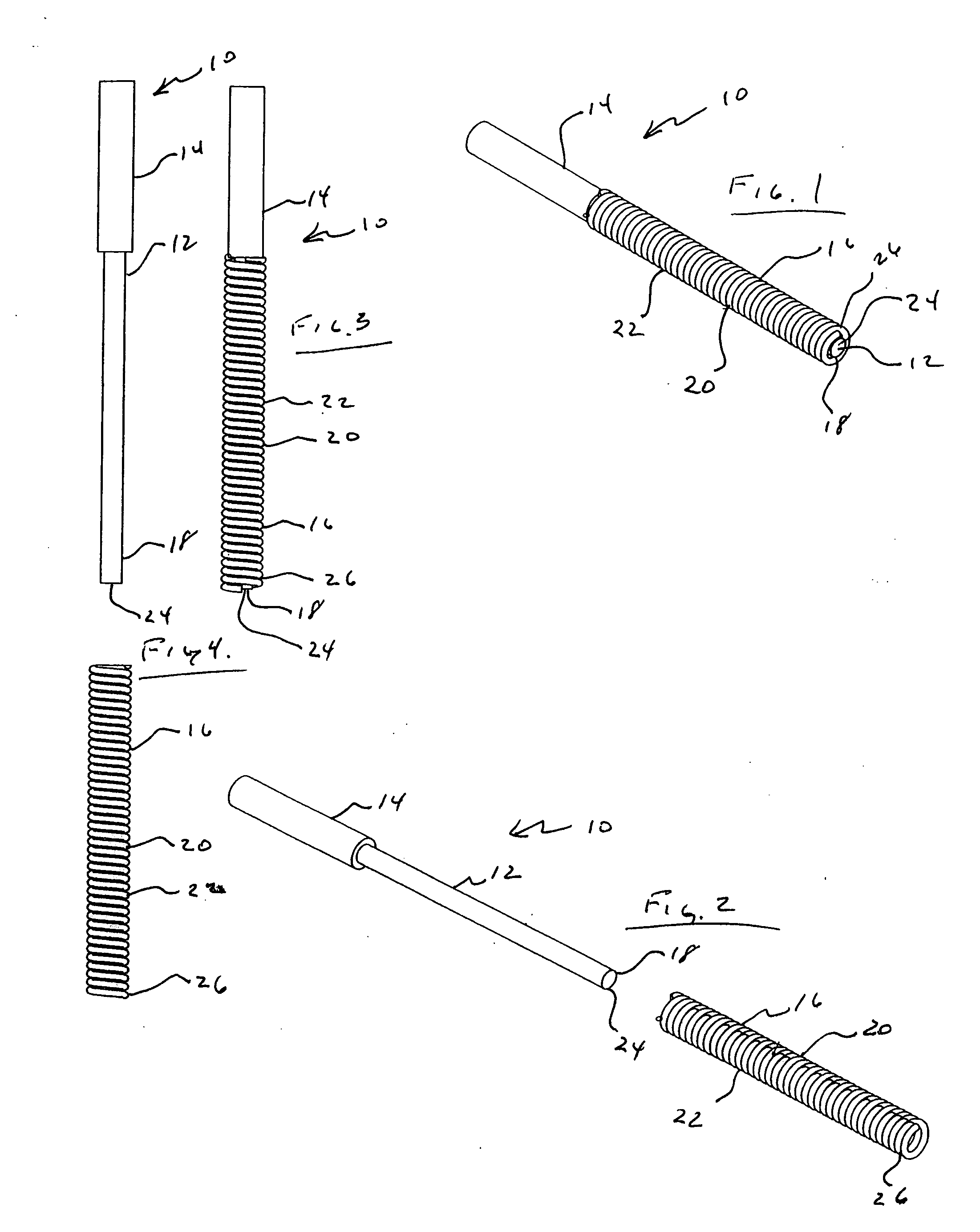

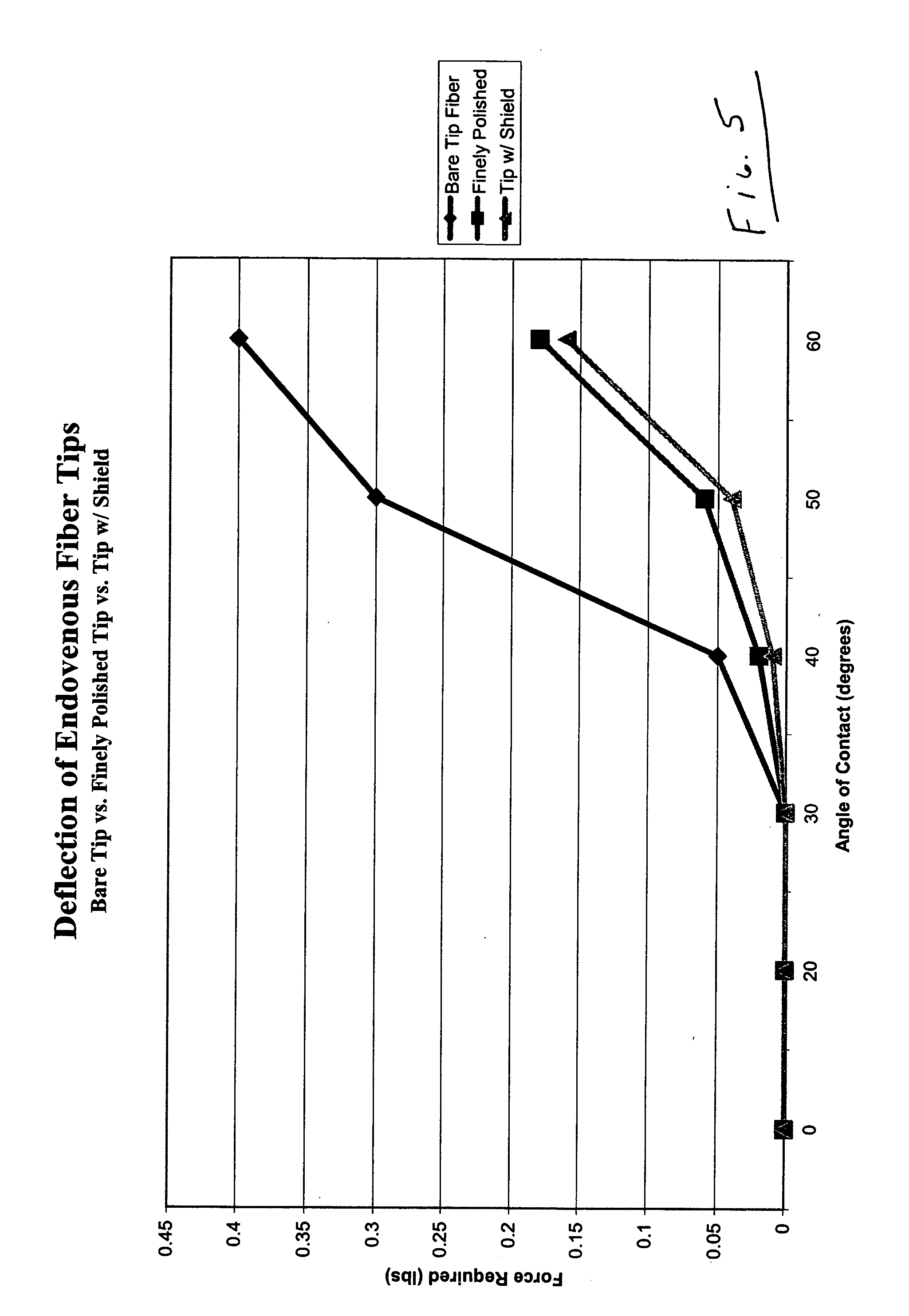

Laser fiber for endovenous therapy having a shielded distal tip

InactiveUS20070179486A1Increase awarenessReduce riskDiagnosticsSurgical instrument detailsVeinThermal break

An endovenous laser fiber optic member for endovenous laser therapy of peripheral veins of the body including a heat resistant insulative tip shield covering the distal end of the laser fiber optic. The tip shield may have echogenic qualities to increase ultrasound reflectivity. The tip shield also improves deflectability of the distal end and acts as a thermal break.

Owner:VASCULAR SOLUTIONS

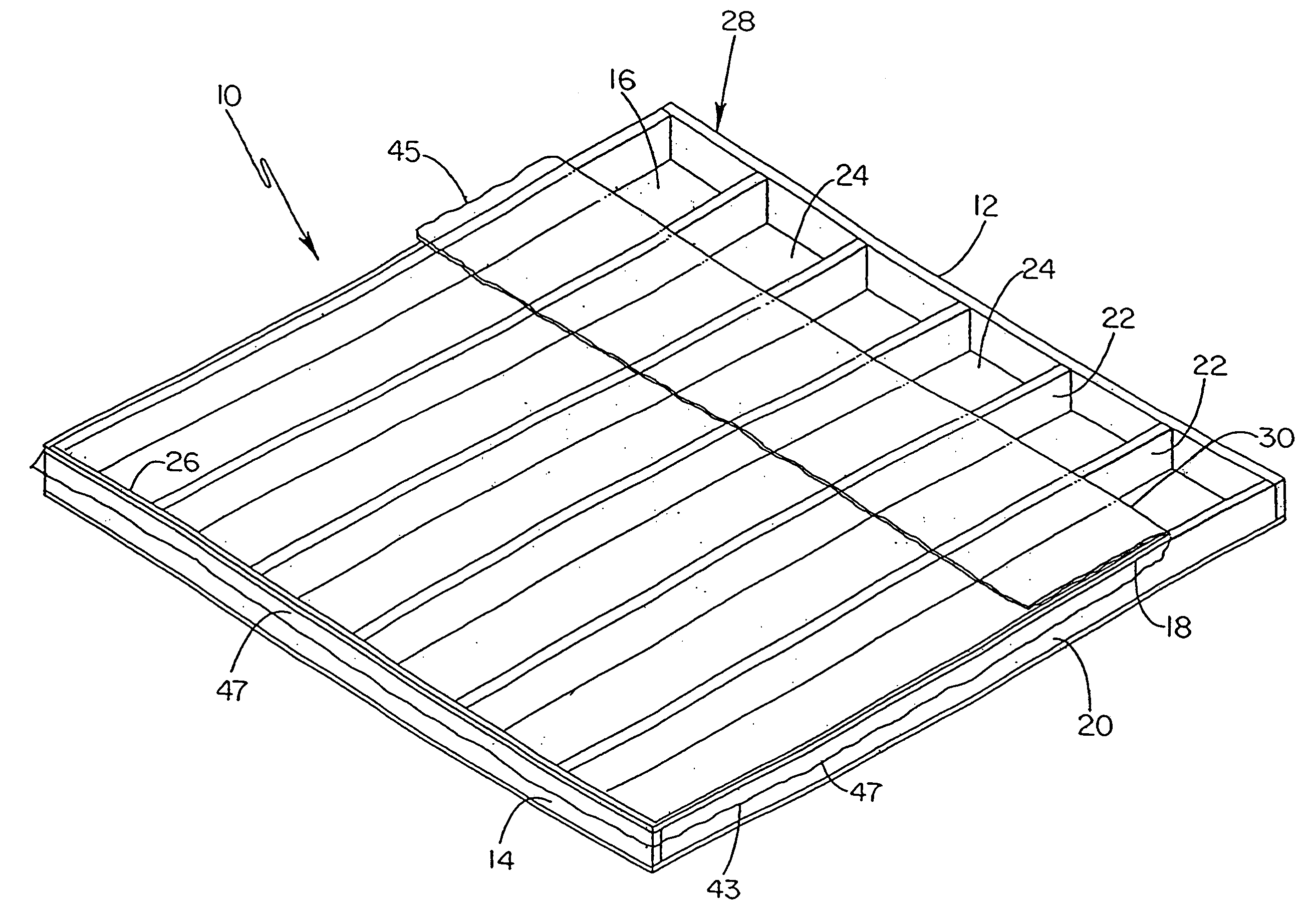

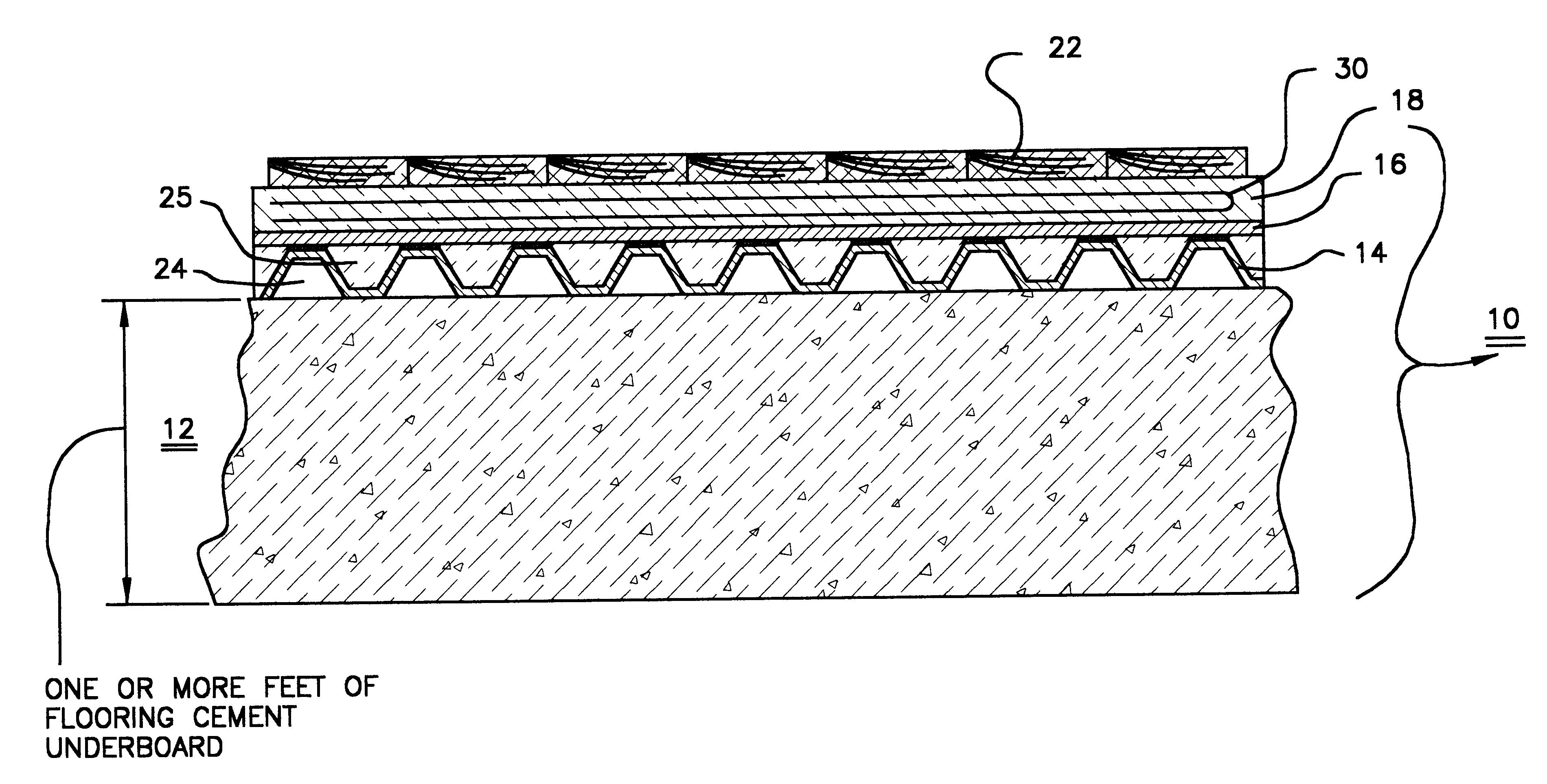

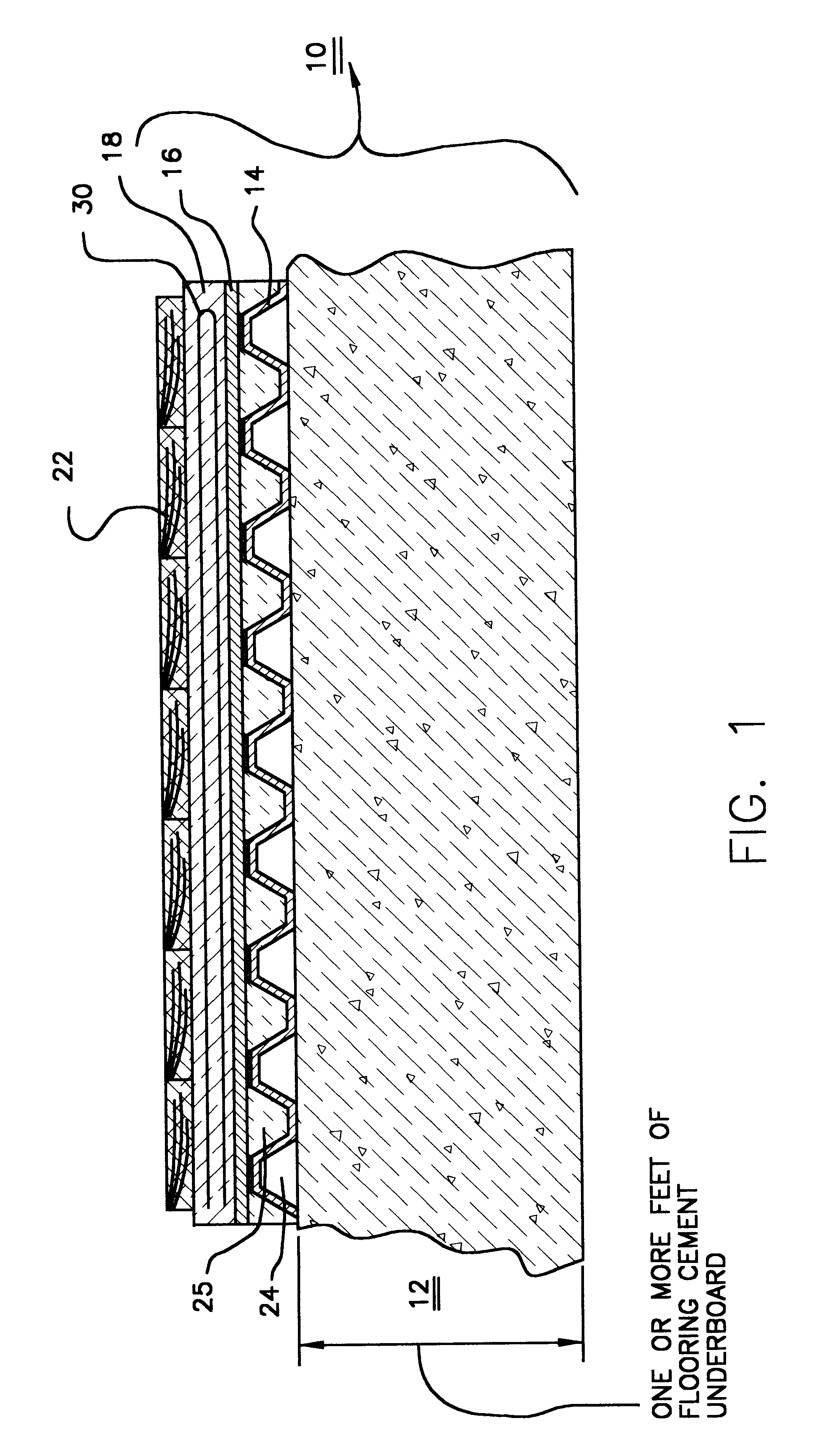

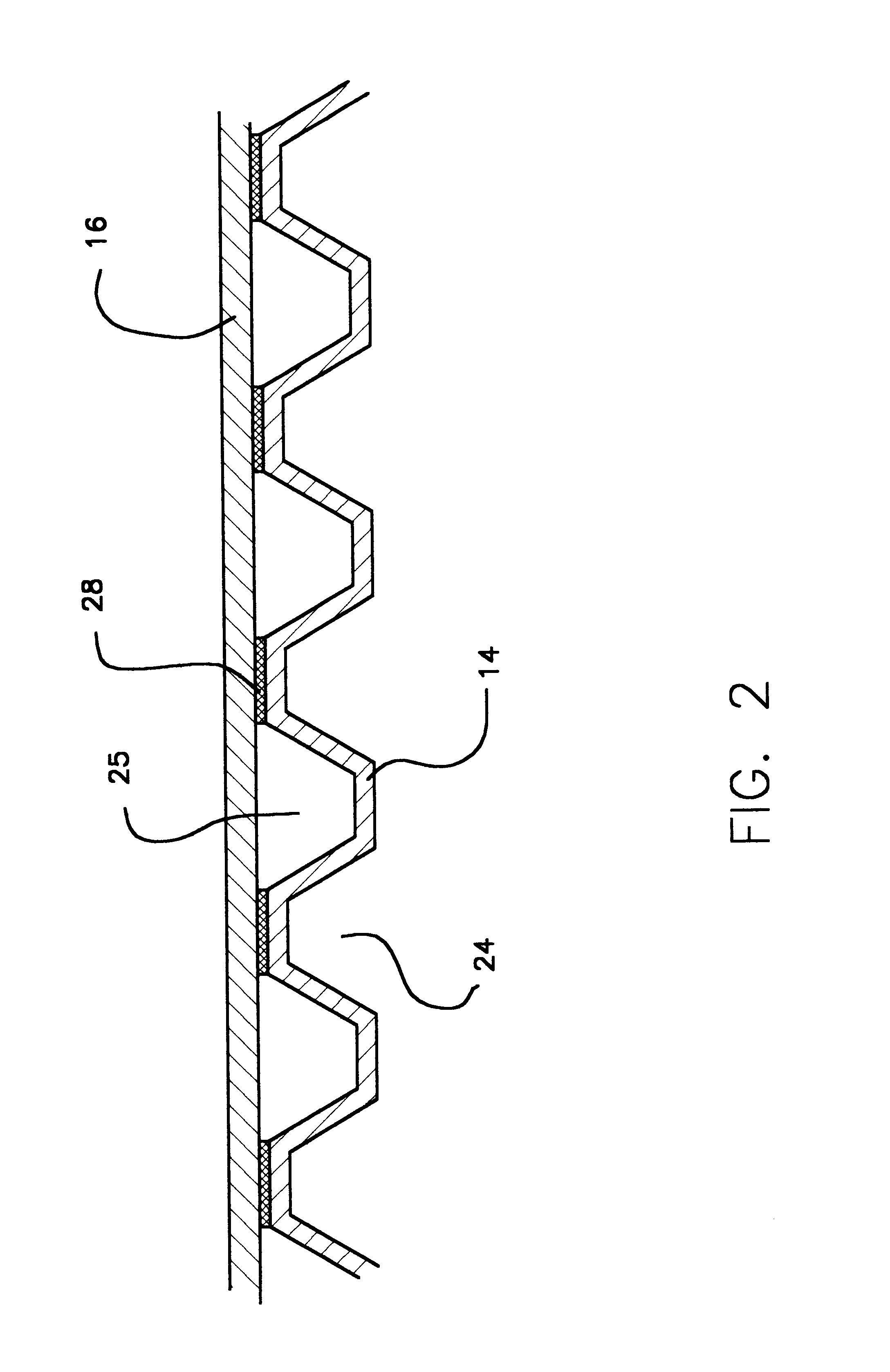

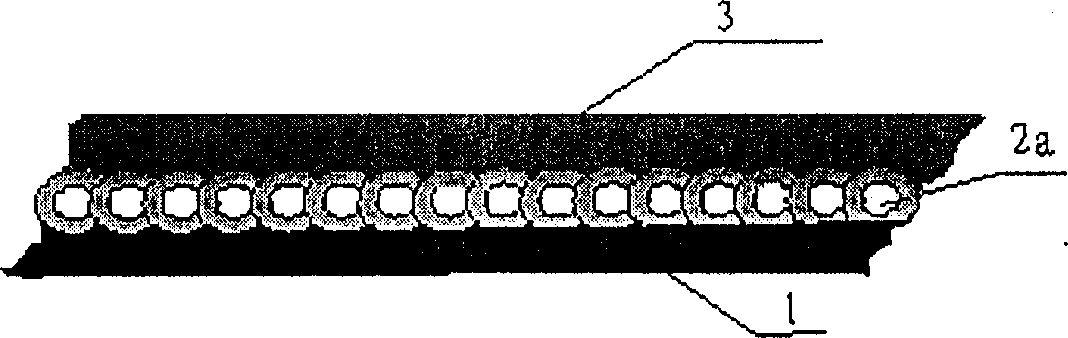

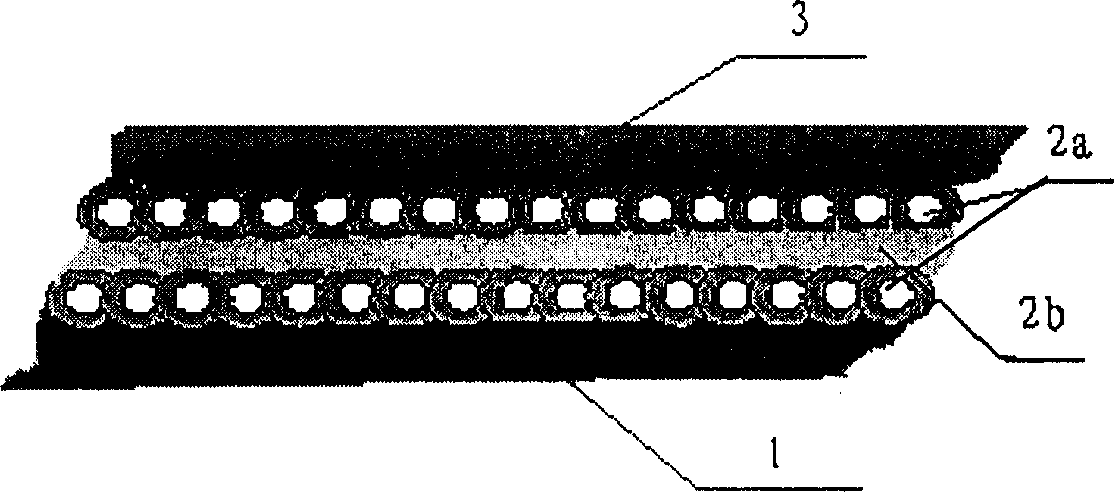

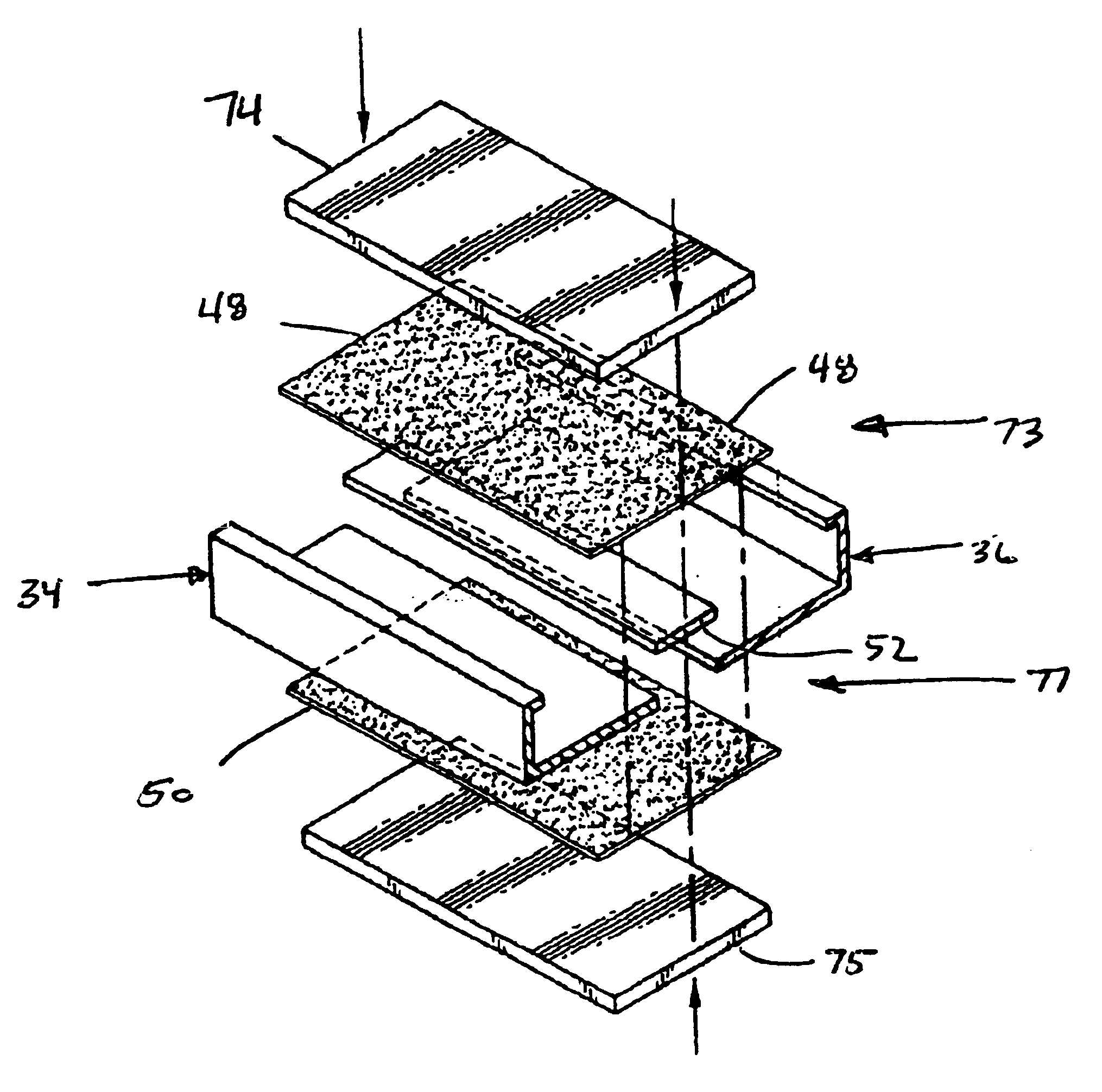

Radiant floor heating system with reflective layer and honeycomb panel

InactiveUS6188839B1Prevent heat lossPrevents dispersal (and hence waste)Fluid heatersLayered productsThermal breakHoneycomb

A radiant floor heating system and method of installation is provided, the system of the present invention being disposed within a solidified cement or under board. A panel member having a laminated reflective material which serves as a thermal break is placed upon the hardened cement or under board. The panel member may be comprised of any substance to which the reflective material may be secured such as a honeycombed plastic panel to which the reflective material layer is laminated. A heating element is disposed on the reflective material. Thereafter, both the heating element and the reflective layer are coated with a layer of thin set or cement. The heating element may include a heated wire element which is unwound off a roll, or the heating element may be meshed within a web of material which is cut to match the dimensions of the floor and then disposed on top of the reflective layer. After the thin set or cement dries with the heating element embedded within, marble or other types of tiles may be laid as flooring.

Owner:PENNELLA RONALD J

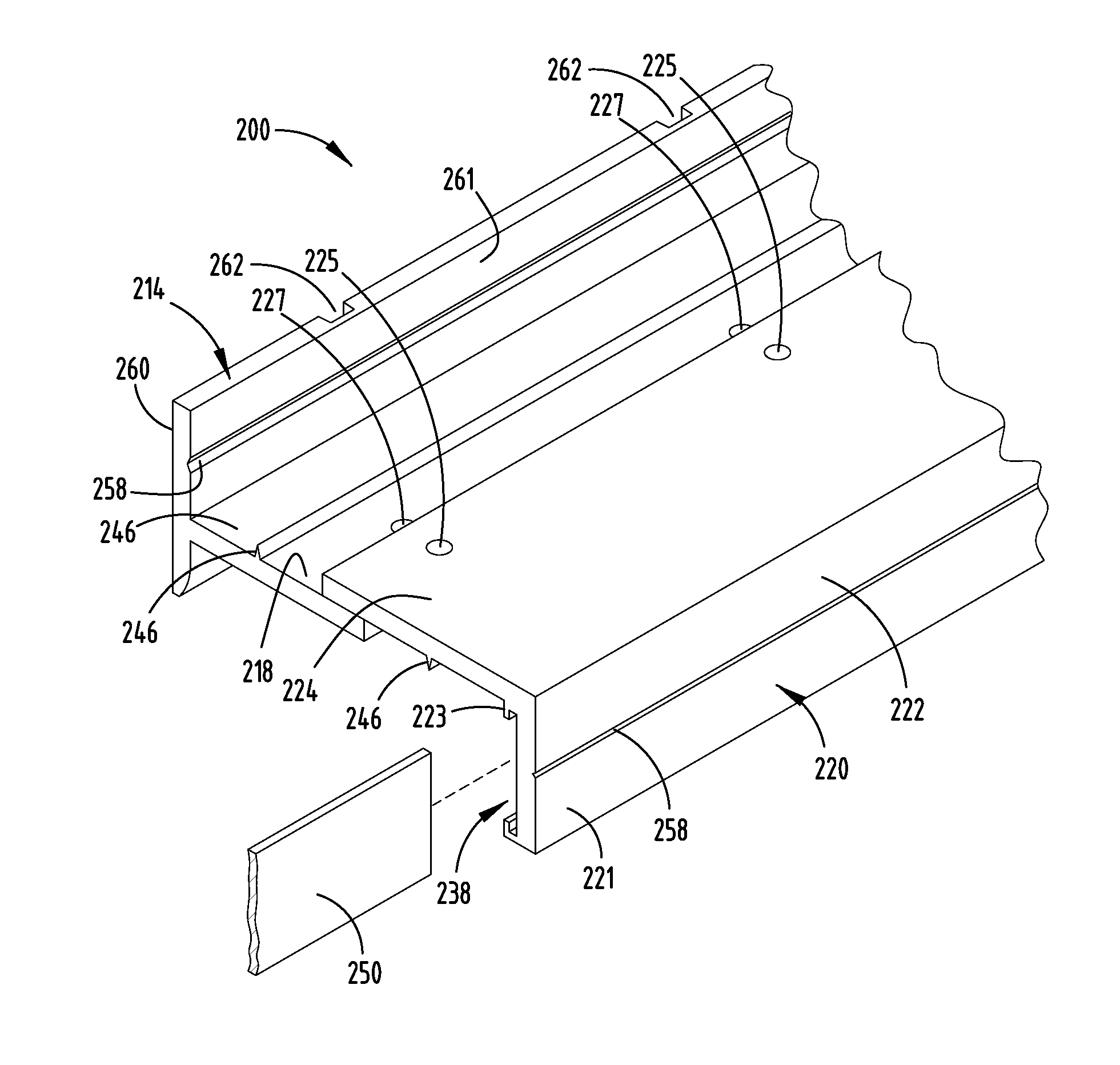

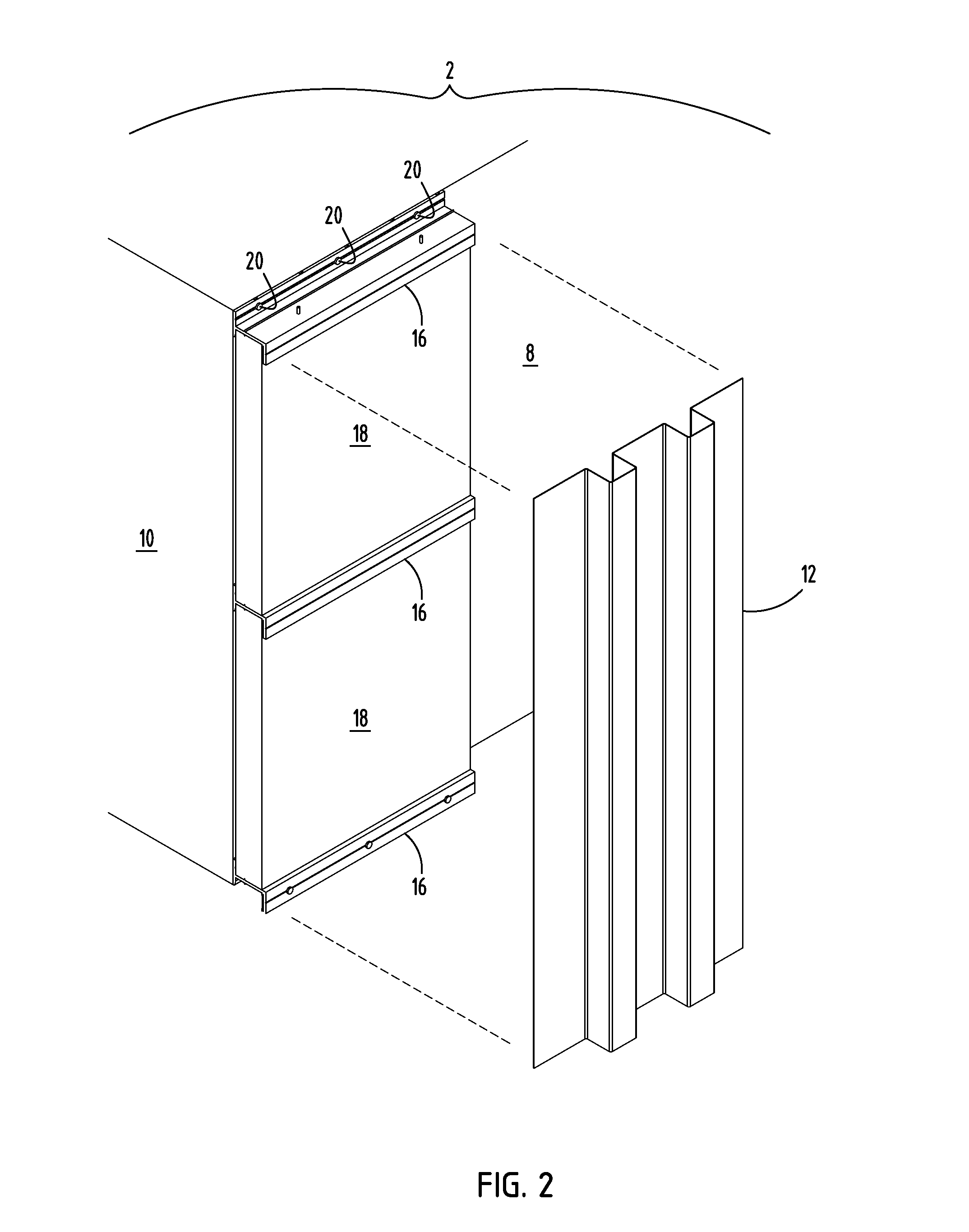

Polymer-based bracket system for exterior cladding

A system for supporting exterior panels or cladding units on a building substrate. The system includes a plurality of polymeric bracket members, wherein each of the polymeric bracket members further includes an anchor section, adapted to be coupled to the building substrate, and a support section adapted to couple to the exterior cladding unit. In assembly, as disposed between the building substrate and the exterior cladding units, the polymeric bracket members provide a thermal break from the exterior cladding units to the building substrate.

Owner:ADVANCED ARCHITECTURAL PROD

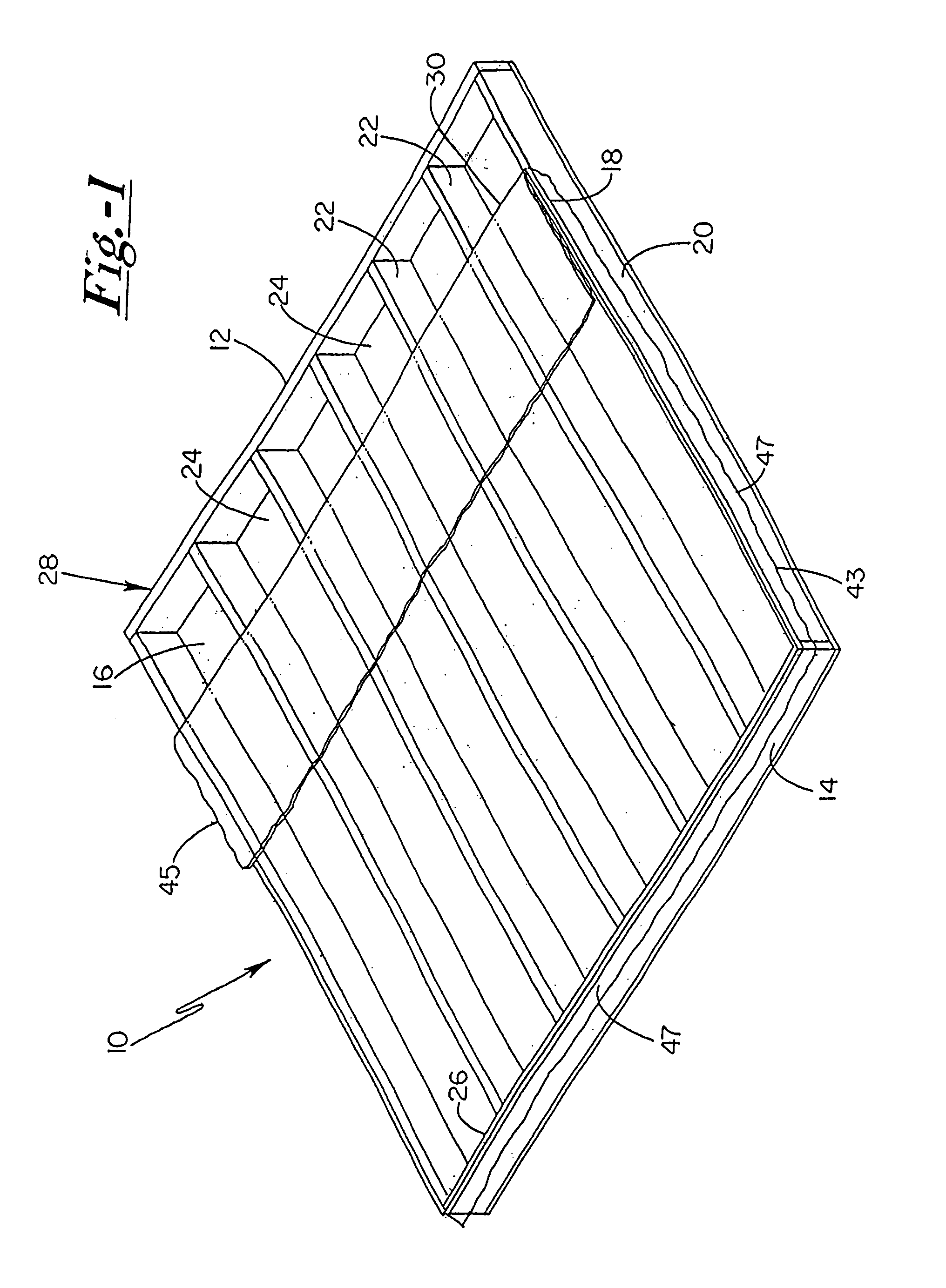

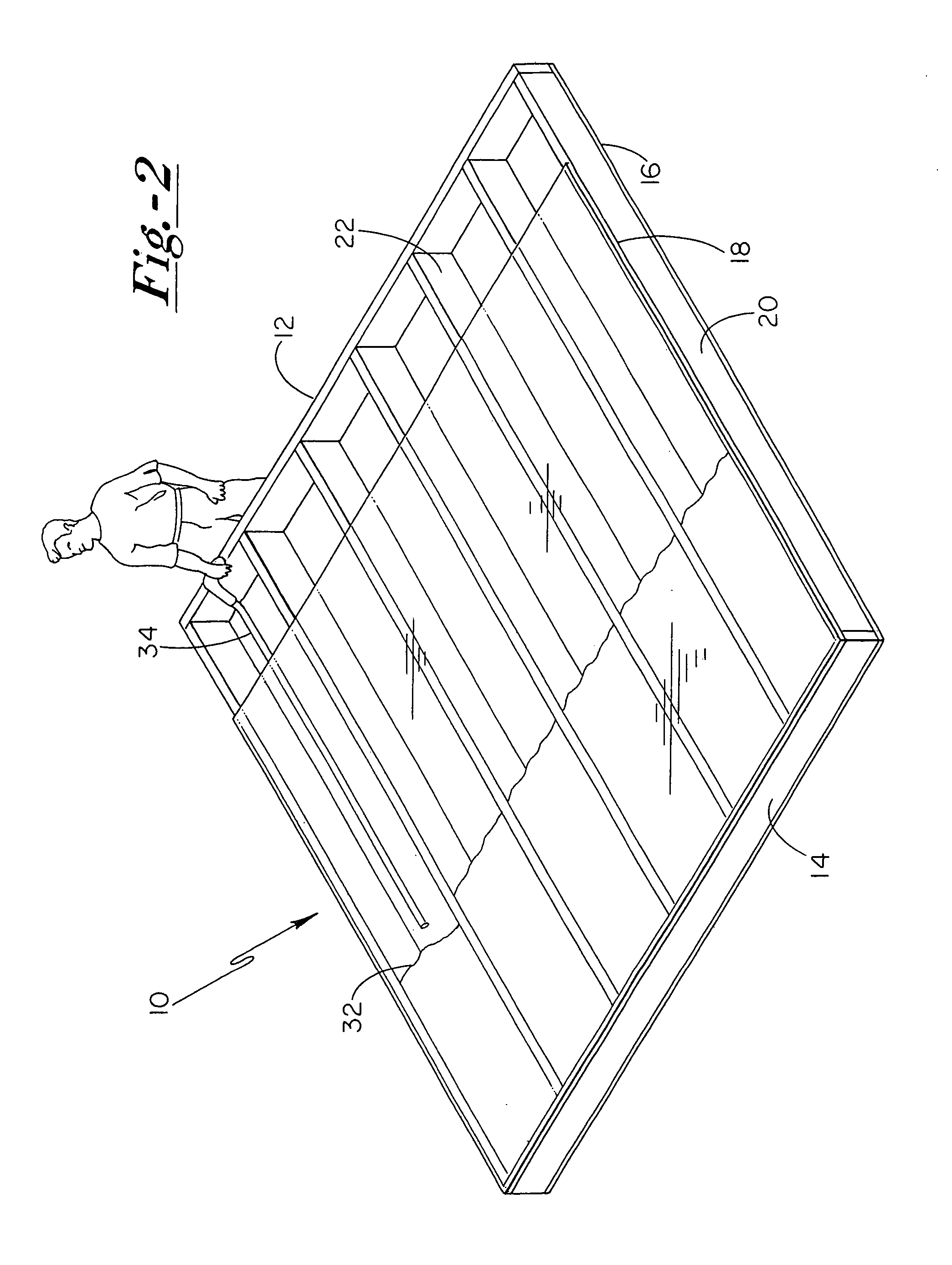

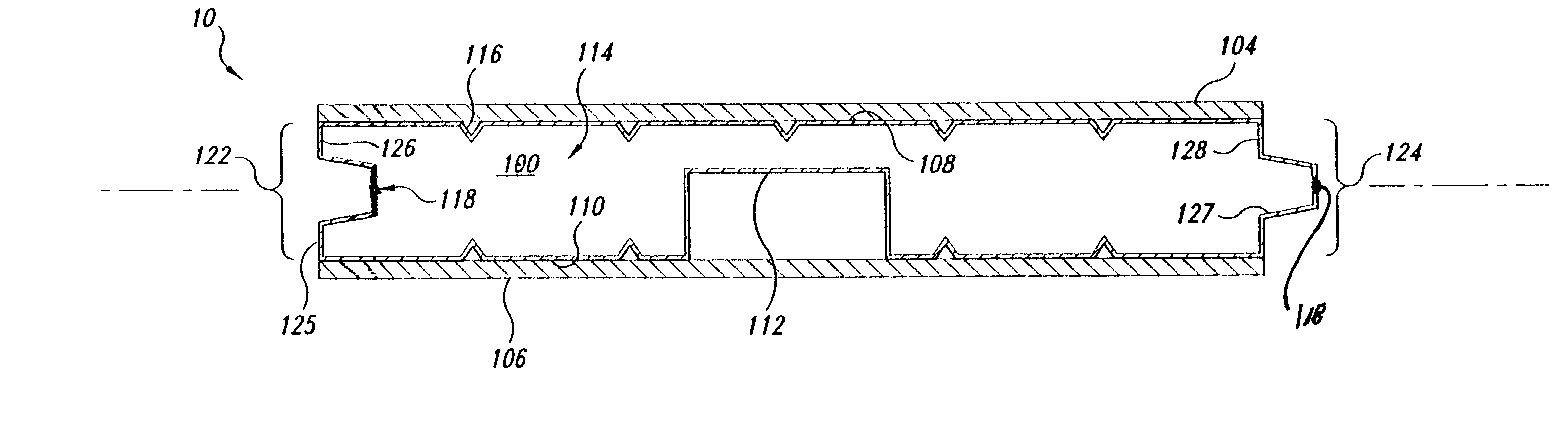

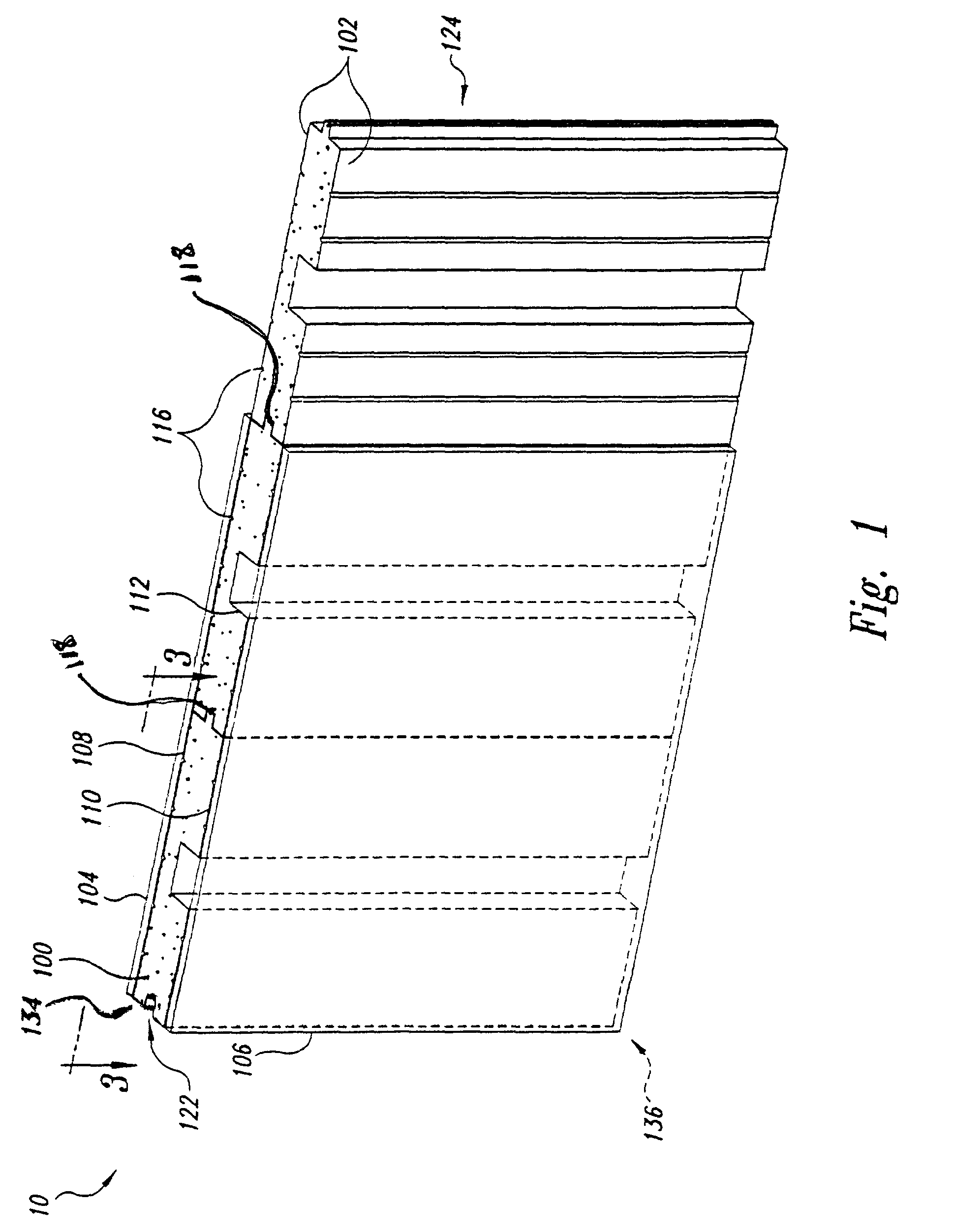

Insulated asymmetrical directional force resistant building panel with symmetrical joinery, integral shear resistance connector and thermal break

InactiveUS7107731B2Improve structural performanceEasy and less-expensive to manufactureBuilding roofsWallsThermal breakStructural load

A structural building system including an improved, structural-load-bearing, building component, such as a building panel, having front and back sections, an insulating core, integral symmetrical joinery, a thermal break, and at least one shear resistance connector The panel is asymmetrical about one axis, and is designed to be directionally positioned with respect to the maximum anticipated force. A shear resistance connector array may be positioned between the front and back sections or may be integral to the front or back section. A face sheet may span one or more than one building panel, and provides structural support to the building system.

Owner:OUTDOOR VENTURE A CORP OF +1

Polymer-based bracket system for metal panels

A system for supporting exterior panels on a substrate of a building structure. The system has a plurality of polymeric bracket members, and each of the bracket members have at least one anchor section, at least one web section and at least one support section. The polymeric bracket members provide a thermal break from the exterior panel to the substrate of the building structure. A plurality of exterior cladding units are held in place by the bracket members. A plurality of vents are disposed between the panels and the exterior panels, and a plurality of vents are also disposed between the panels and the substrate, thereby forming a ventilation system.

Owner:ADVANCED ARCHITECTURAL PROD

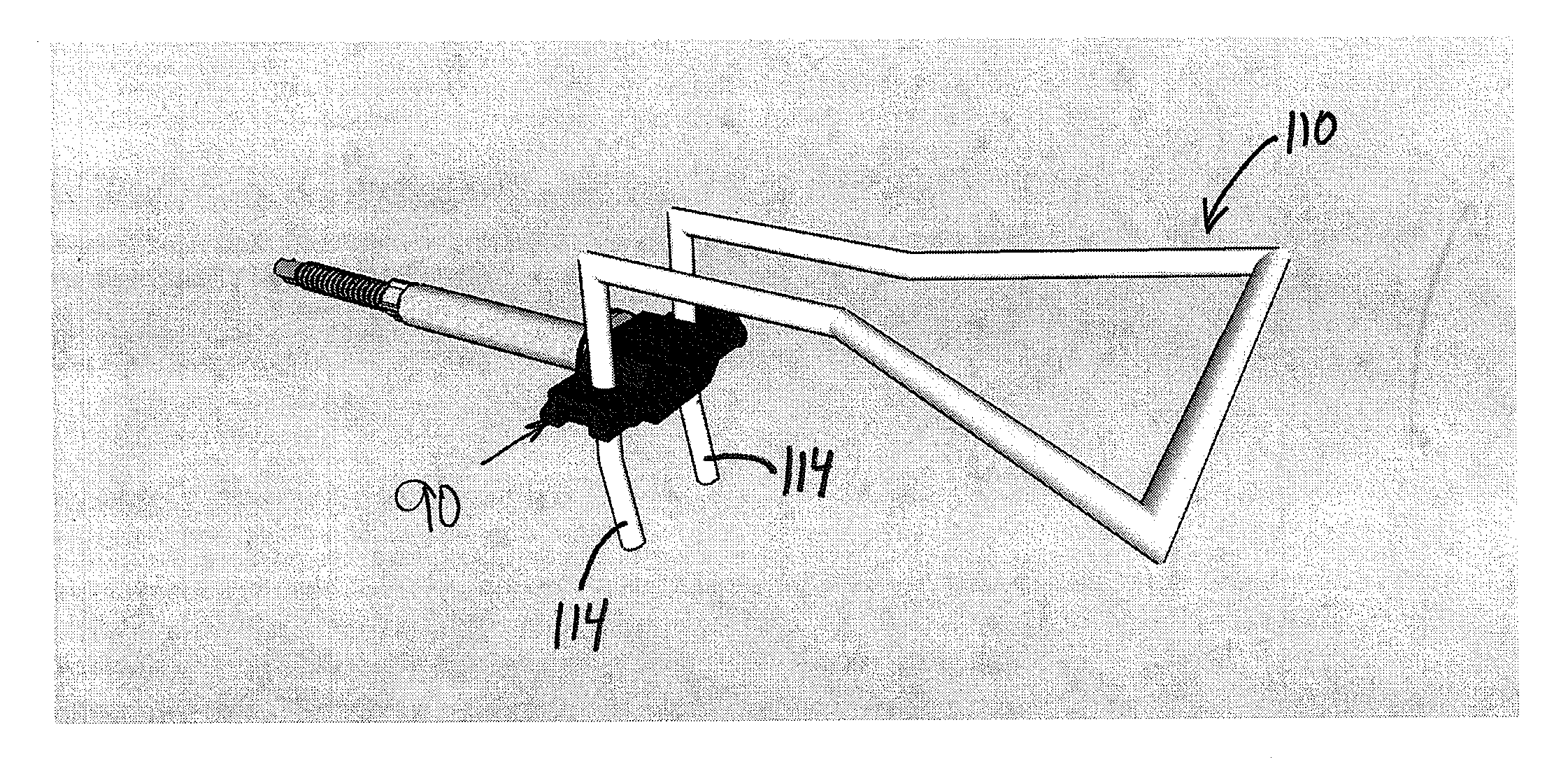

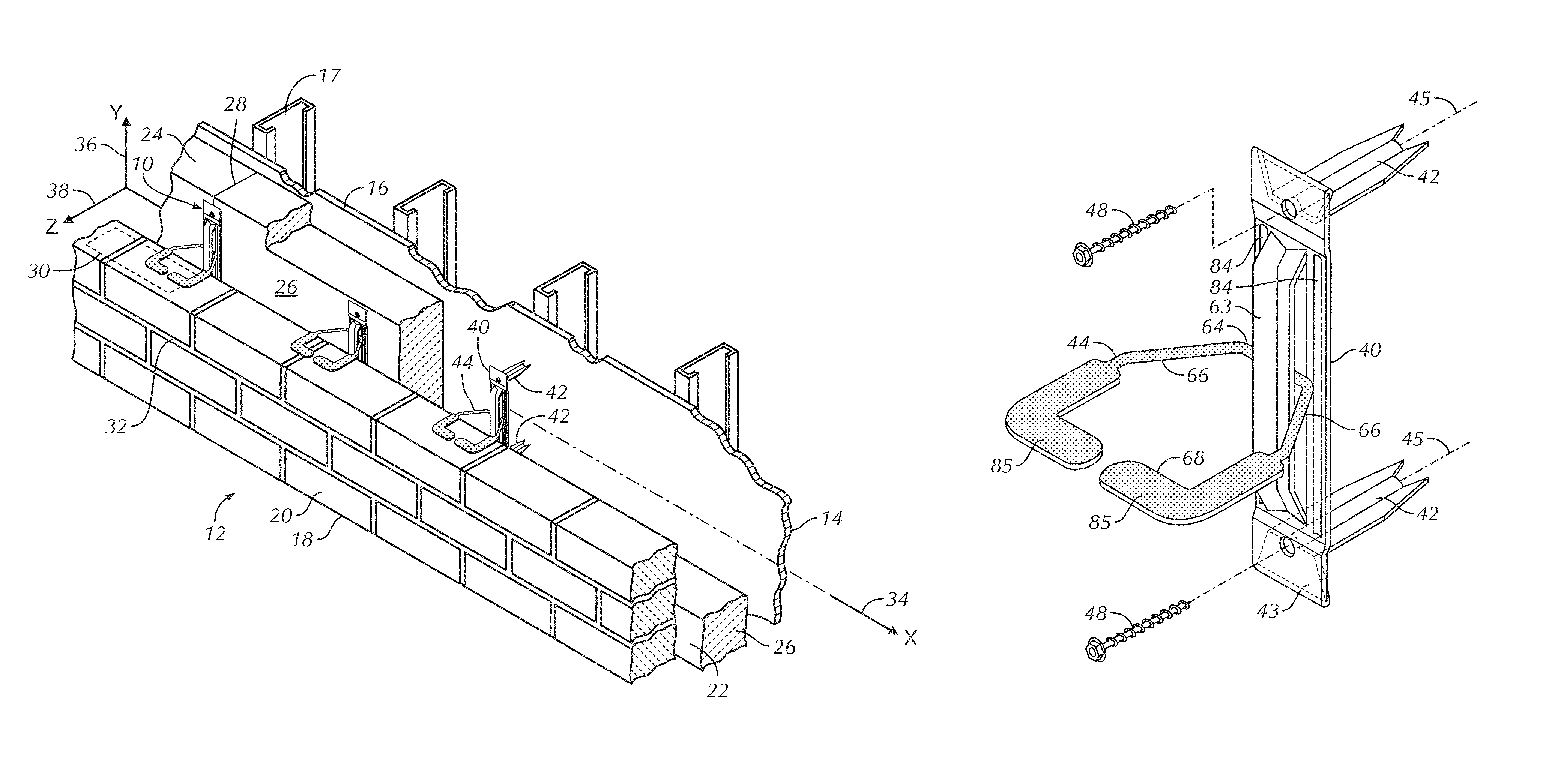

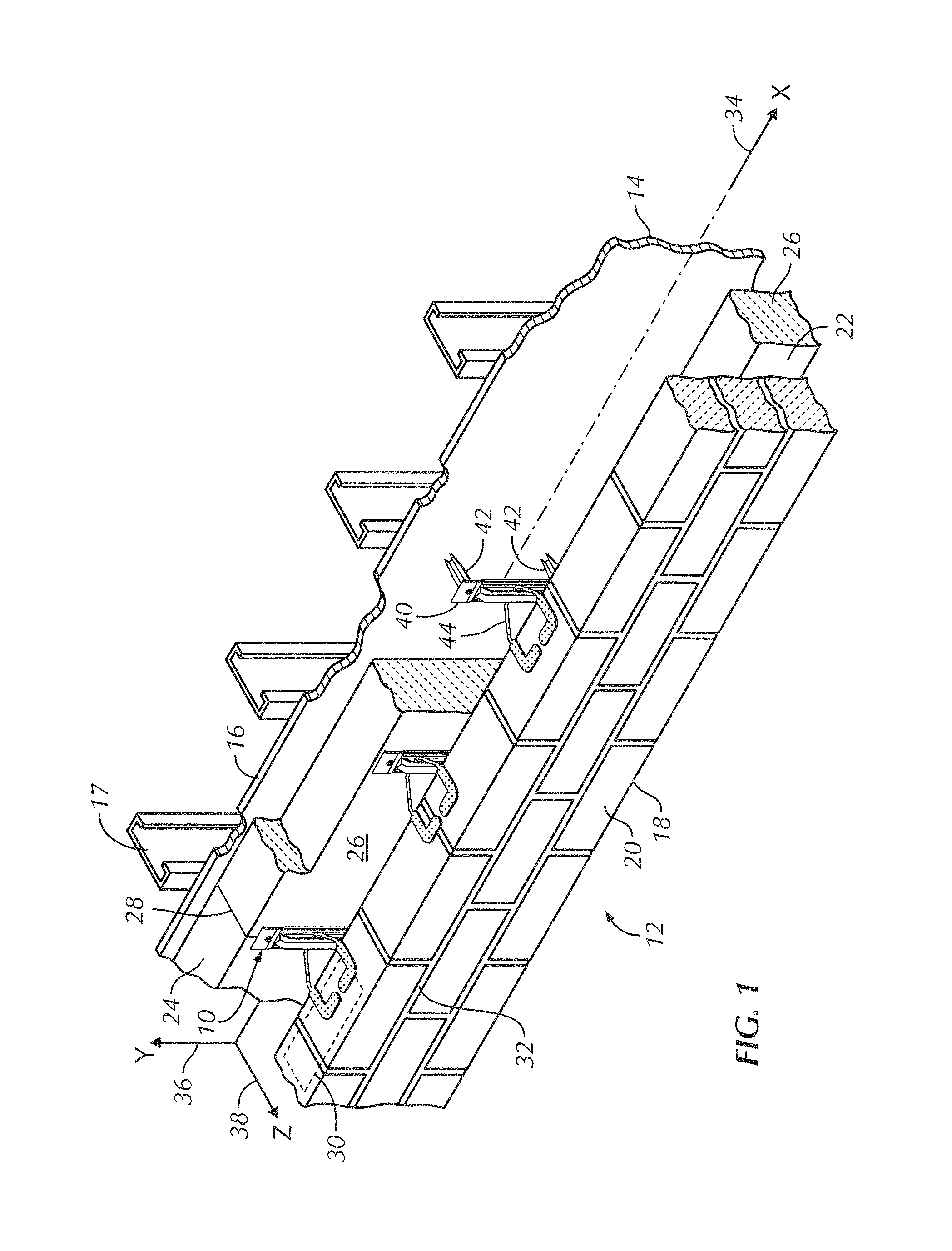

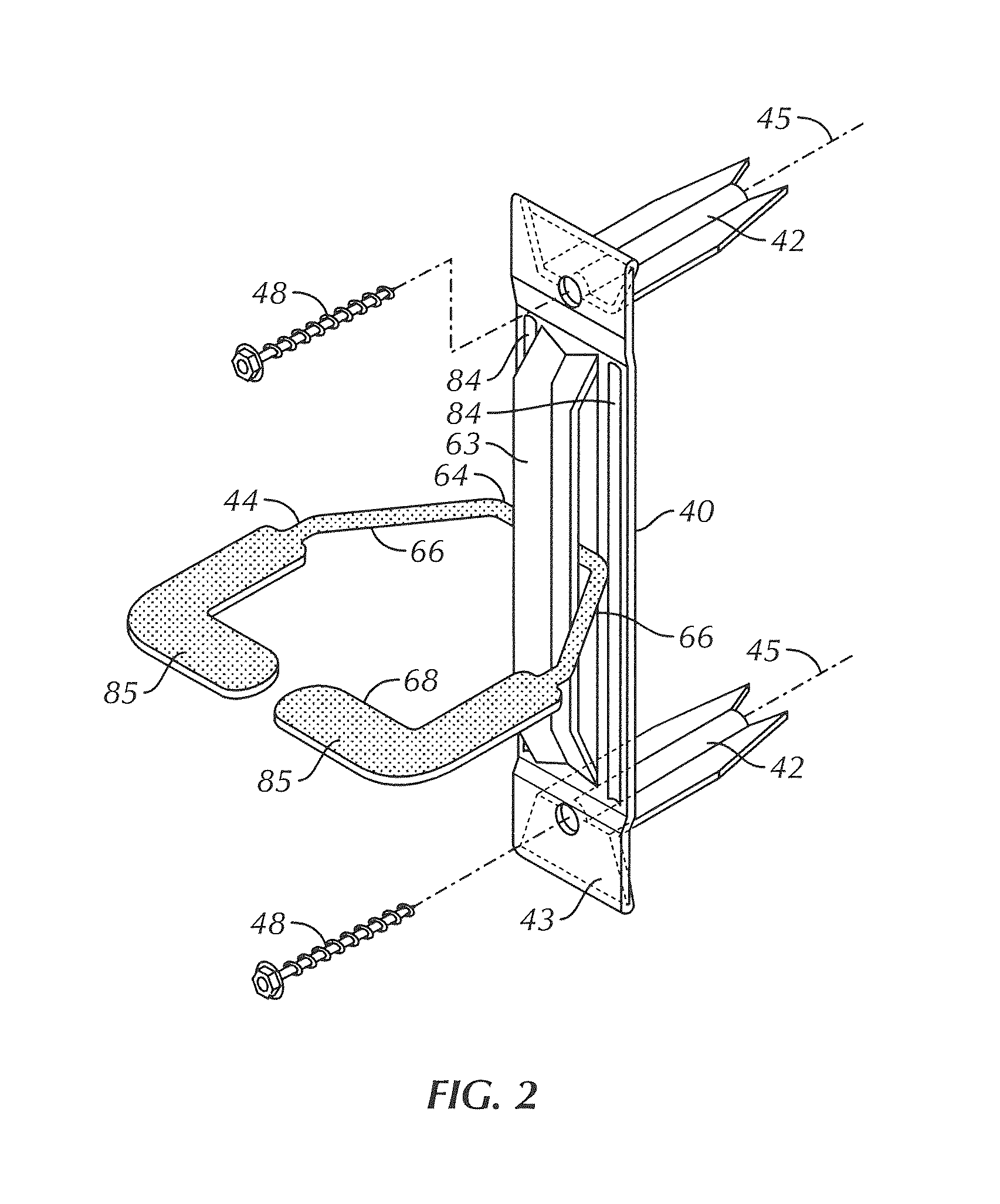

Thermal clip attachment apparatus for masonry anchors and methods thereof

A thermal clip attachment apparatus and methods for using the thermal clip attachment with a masonry veneer anchor system are disclosed. The thermal clip attachment may be a composite piece that attaches to the part of a stud that protrudes from an inner structural supportive wall after the stud is advanced into the wall. The thermal clip attachment serves as a thermal break between the stud and an outer masonry veneer wall. Further, the thermal clip attachment also serves as an attachment point for a wire tie, which allows a positive lateral load connection to be established between the outer masonry veneer wall and the inner structural supportive wall.

Owner:MECHANICAL PLASTICS CORP

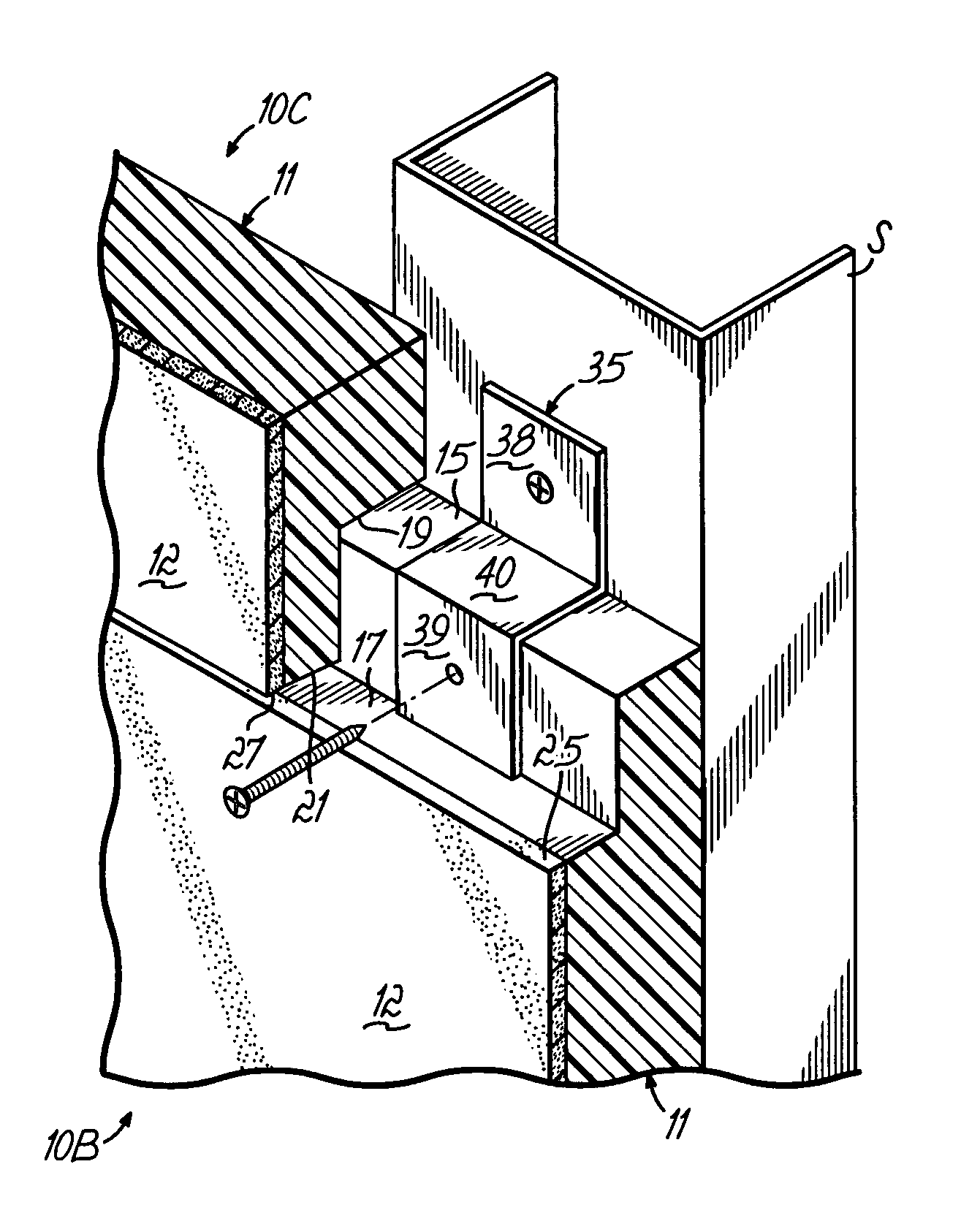

Adhesion Enhanced Insulated Framing Member

InactiveUS20120011793A1Resist delaminatingReduce necessityAdhesive processesConstruction materialThermal breakEngineering

The present invention relates to the construction arts, in particular a new implementation for a framing member or structural support apparatus for bearing the loads required for walls, roofs, ceilings, and floors. Further a formed insulated layer with enhanced adhesion characteristics provides a thermal break within the framing member serves to increase the insulation value and enhance the structural value of the apparatus.

Owner:EARTHCORE WORLDWIDE

High-speed aircraft large-area interlayer heat protection and insulation structure and forming method thereof

ActiveCN103287568AImprove efficiencyAvoid destructionLayered productsFuselage insulationAdhesive cementInsulation layer

The invention discloses a high-speed aircraft large-area interlayer heat protection and insulation structure and a forming method thereof, belonging to the field of aerospace aircraft surface layer thermal-protection structures. The interlayer heat protection and insulation structure comprises a grid rib support layer, a heat insulation layer and an outer skin heat protection layer which are sequentially laid from bottom to top on the upper surface of a base of a metal supporting structural part, wherein the grid rib support layer is composed of an inner skin and a plurality of grids; the rib height of the grids is 10mm-12mm, and the sectional width of ribs is 2mm; the heat insulation layer is composed of an aerogel composite material laid in the grid rib support layer; the surface of the heat insulation layer is coated with an adhesive, and then an upper skin heat-protection layer is laid on the surface of the heat insulation layer. The heat protection and insulation structure is applicable to a large-area interlayer between the metal base and a surface layer material of a body of a control cabinet, a load cabinet or an instrument cabinet of a high-speed aircraft, and has the properties of ablation resistance, high-temperature airflow scouring resistance, low thermal conduction, light weight and the like, can meet long-time heat protection and insulation requirements, has good application prospect, and is beneficial to popularization and implementation.

Owner:北京玻钢院复合材料有限公司

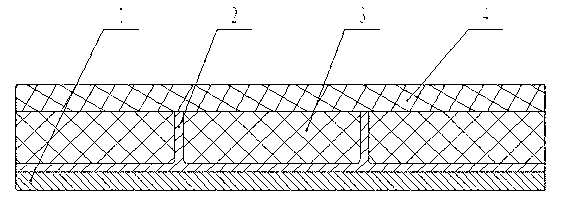

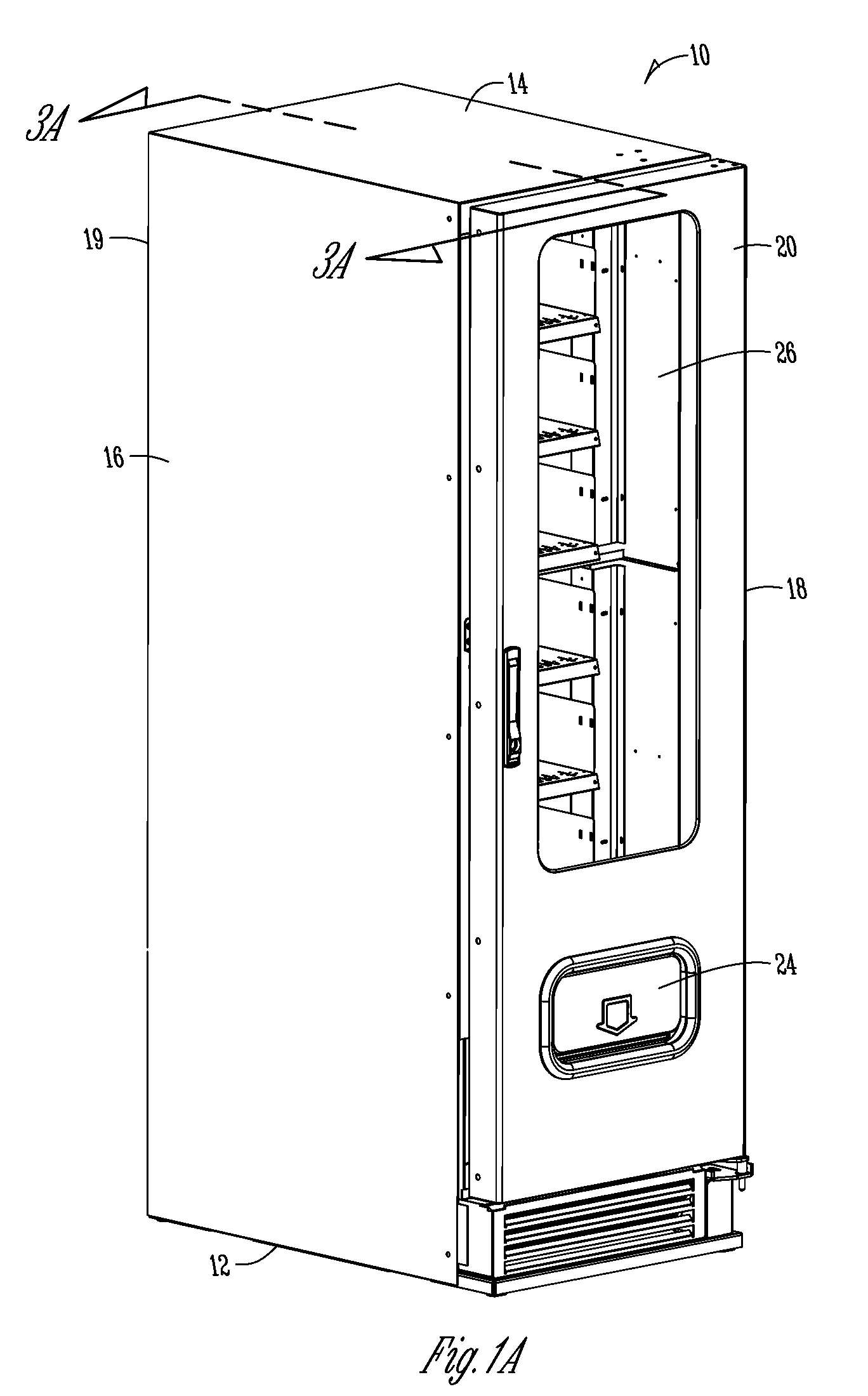

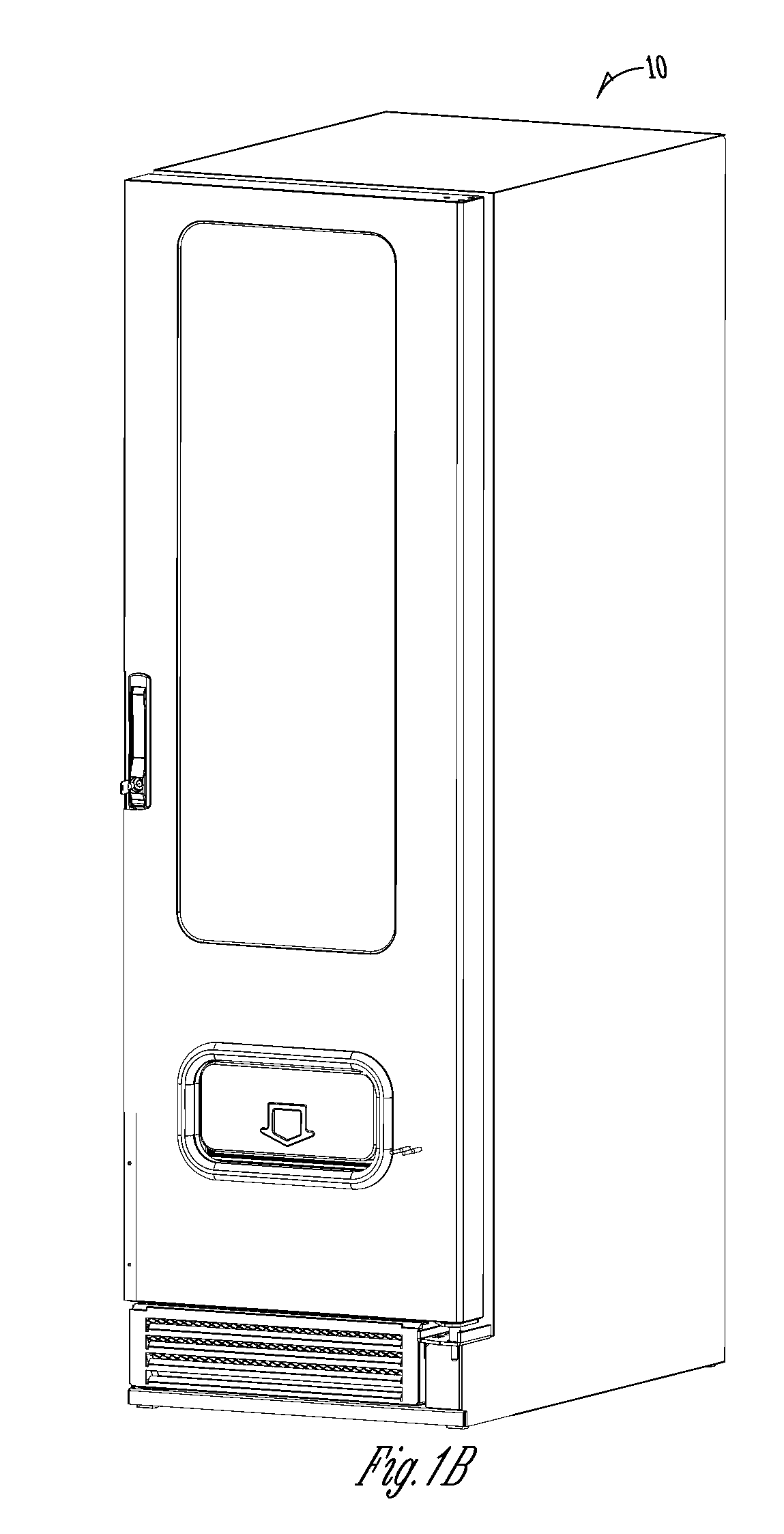

Apparatus and method for single or multiple temperature zone(s) in refrigerated vending machine

ActiveUS20090090734A1Efficiently configured (or reconfiguredEfficient and economical stepKitchen cabinetsSpecial data processing applicationsThermal breakEngineering

An automated vending machine that can be selectively configured to include one or several temperature zones. A single refrigeration system and universal interior allows easy and economical assembly into a one, two, or three temperature zone machine. Thermal breaks and dividers are used to partition zones, when needed. The basic vending machine cabinet, dispensers, and controls are not changed between configurations. In one aspect, a universal air duct can be used for all three configurations, with minor changes.

Owner:FAWN ENG

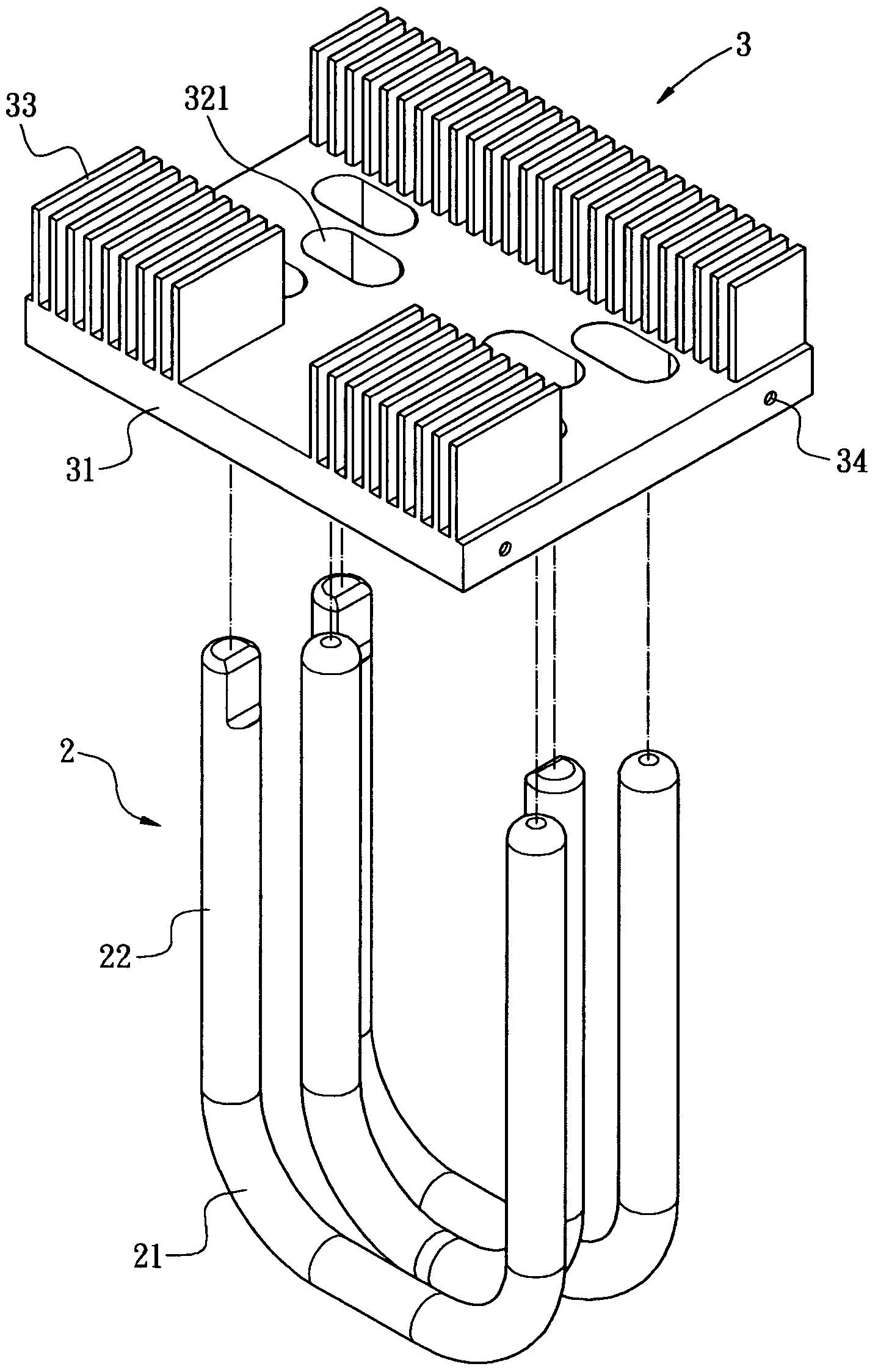

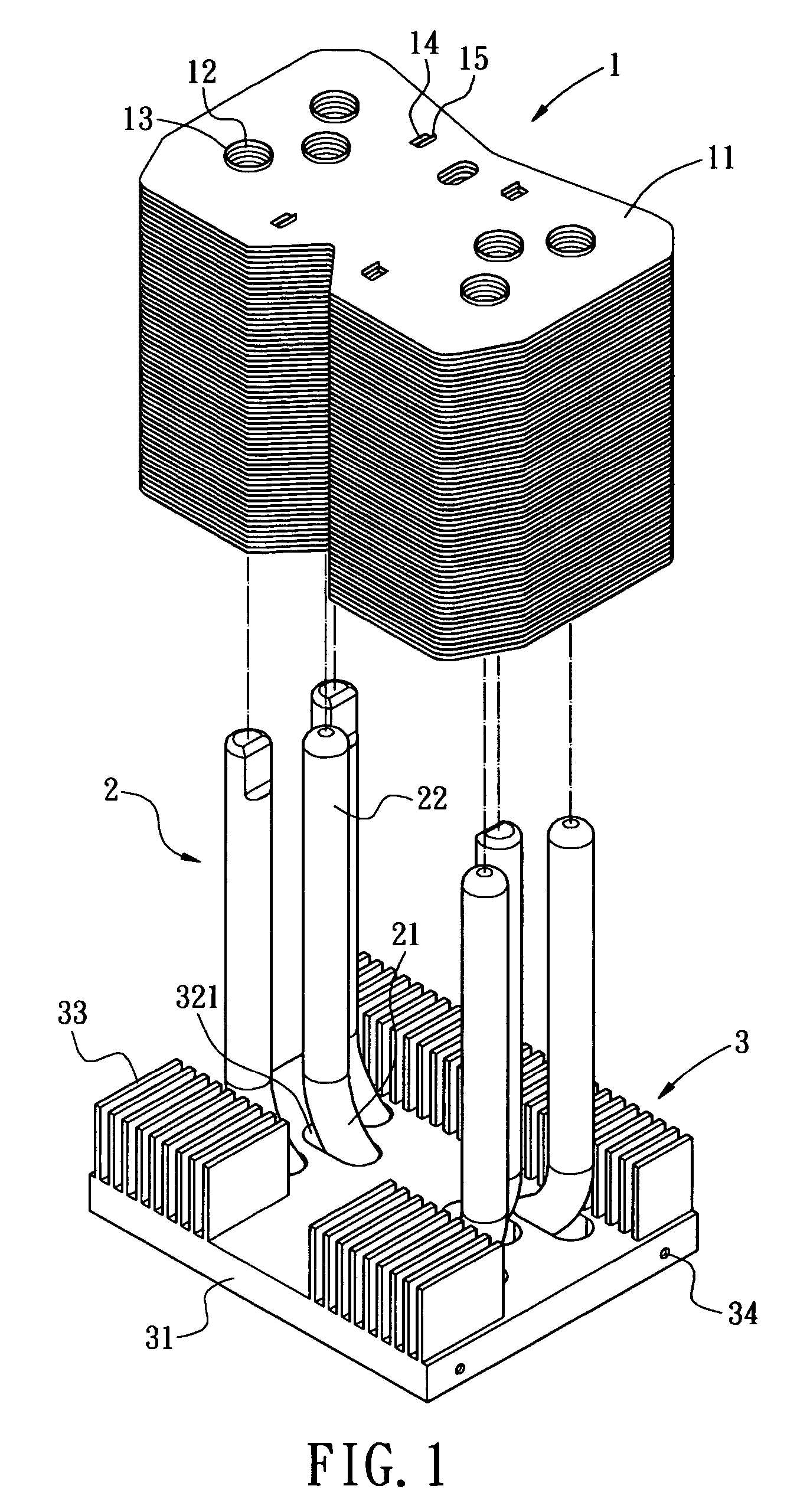

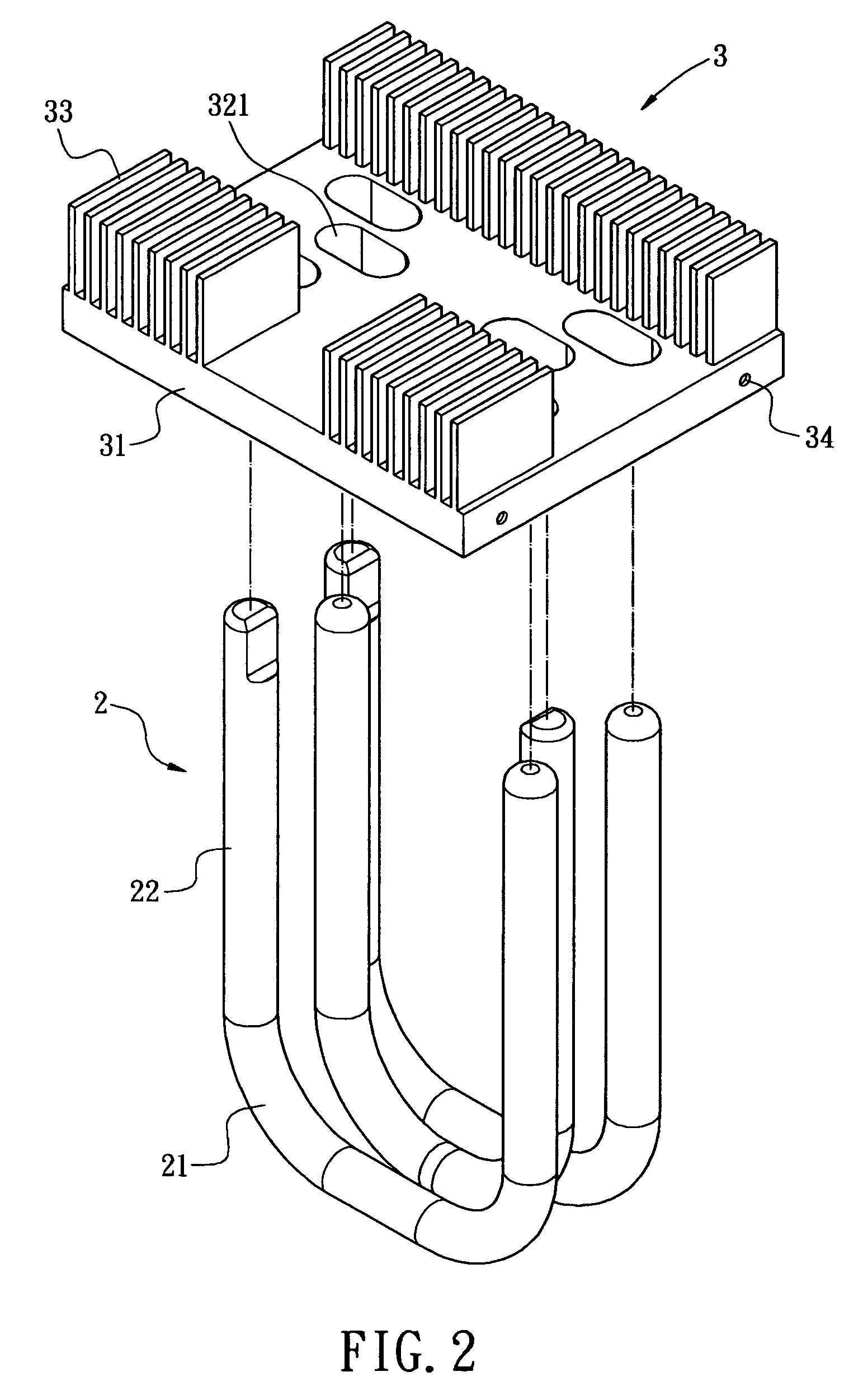

Thermal structure for electric devices

InactiveUS7245494B2Digital data processing detailsSemiconductor/solid-state device detailsThermal breakElectrical devices

A thermal module includes a thermal body, at least one thermal tube, and a holding part. The thermal tube includes a heat receiving portion and condenser terminals connecting with the thermal body, wherein the heat receiving portion has a plane. The holding part includes a plate body with trenches therein, wherein the trenches has through holes and a connecting part formed between the through holes. The through holes are used for receiving and holding the heat receiving portion of the thermal tube. The connecting part are connected with a top surface of the heat receiving portion. Thus, thermal transfer is speed up, and the thermal module is assembled without a thermal treatment which causing a copper reduction reaction, resulting in improvement of thermal conduction, reduction of cost, and manufacturing time saving.

Owner:CPUMATE INC +1

Polymer-based bracket system for exterior cladding

A system for supporting exterior panels or cladding units on a building substrate. The system includes a plurality of polymeric bracket members, wherein each of the polymeric bracket members further includes an anchor section, adapted to be coupled to the building substrate, and a support section adapted to couple to the exterior cladding unit. In assembly, as disposed between the building substrate and the exterior cladding units, the polymeric bracket members provide a thermal break from the exterior cladding units to the building substrate.

Owner:ADVANCED ARCHITECTURAL PROD

Veneer tie and wall anchoring systems with in-cavity thermal breaks

ActiveUS8667757B1Prevents pulloutReduce openingConstruction materialCovering/liningsCross-linkThermal break

Thermally-isolating veneer ties and anchoring systems employing the same are disclosed. A thermally-isolating coating is applied to the veneer tie, which is interconnected with a sheetmetal surface-mounted wall anchor. The thermally-isolating coating is selected from a distinct grouping of materials, that are applied using a specific variety of methods, in one or more layers and cured and cross-linked to provide high-strength adhesion. The thermally-coated veneer ties provide an in cavity thermal break that severs the thermal threads running throughout the cavity wall structure, reducing the U- and K-values of the anchoring system by thermally-isolating the metal components.

Owner:HOHMANN & BARNARD INC

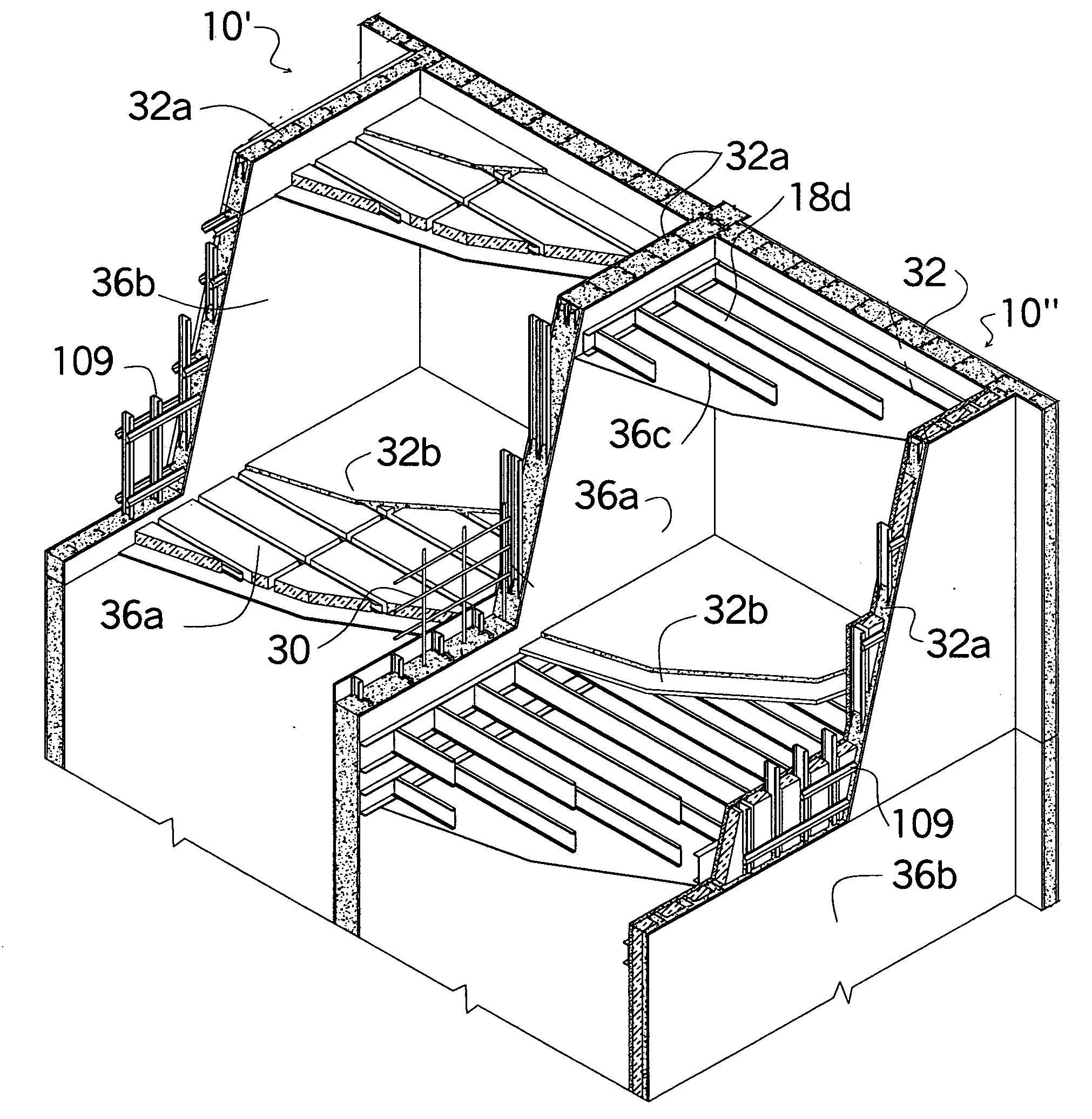

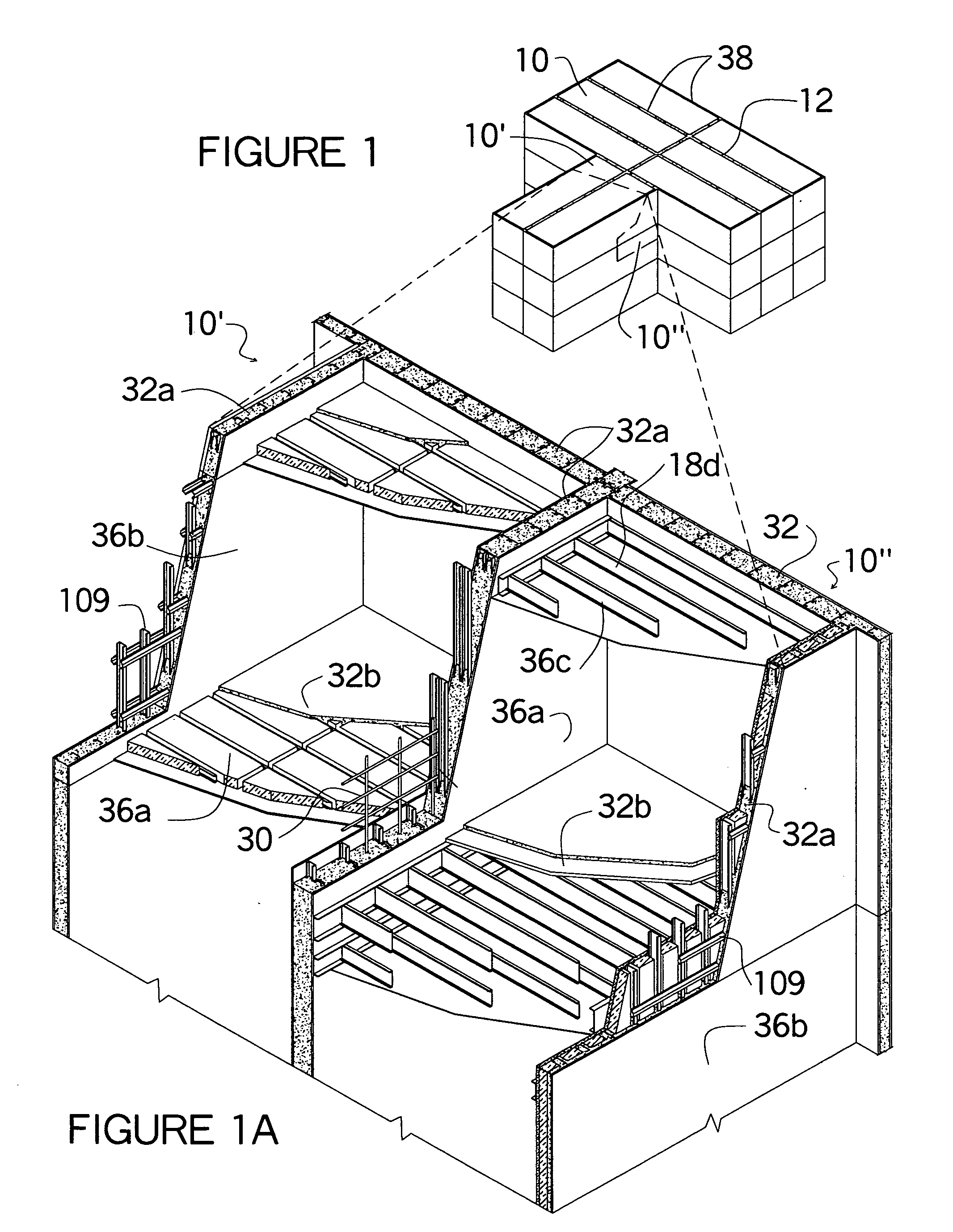

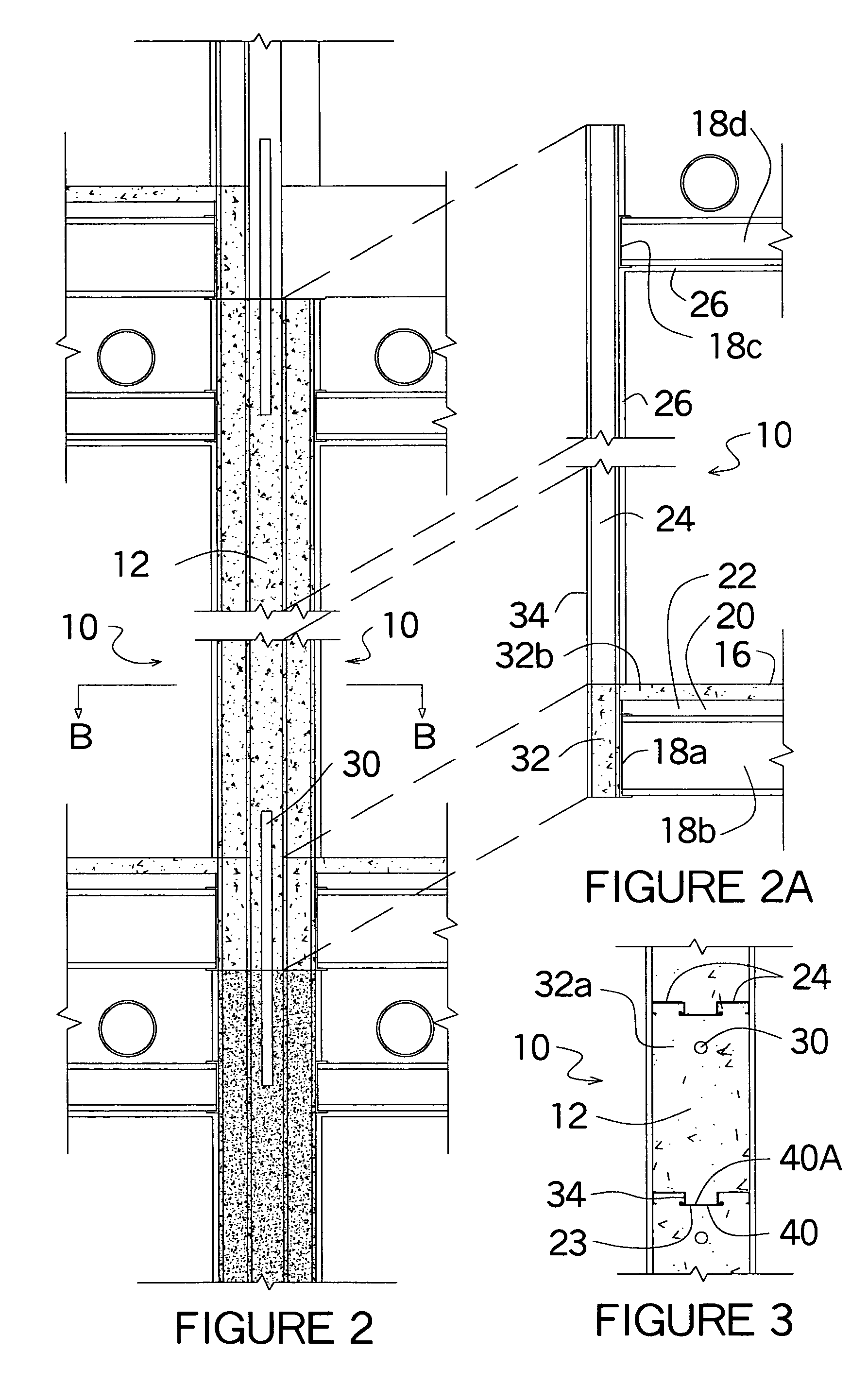

Modular building construction employing concrete mold assembly

A modular building construction where each module consists of self-contained molds to allow concrete to form within the walls of each module as well as between the modules when two or more modules are placed together. The structural load capacities of the modules are transmitted directly into the concrete within the wall without bearing directly on the module below. The forming structure for the modules can be fabricated either using wood or metal construction. The exterior and interior wall finishes are the resulting structure of the molds. Since the molds are self-contained the walls can consist of, either drywall, rigid insulation, thin brick or siding just to name a few. The interior forming structure can extend into the concrete footing or above or to adjacent modules to structurally secure the modules together. The modules can be built with a flooring structure as well as ceiling. The interior walls as well as the floor and ceiling also function as wall supporting braces. The exterior walls have many different forming molds to accommodate many different construction situations. Some forming structures are formed with a thermal break between the exterior and interior forming structure. The thermal break allows the wall to also be used as a heating or cooling distribution system. Different types of connectors are described allowing for the connectors to be hidden. Several methods are shown how the electrical distribution can be provided within a concrete wall by using the forming structure within the mold. A ribbed concrete mold can be formed for a poured-in-place wall as well as for a floor and roof system. Temporary floor bracing can be used when pouring the flooring system, or only just the concrete beams can be poured and the floor can be poured later. The flooring system can be used as concrete wall or as a roof structure.

Owner:LEBLANG DENNIS

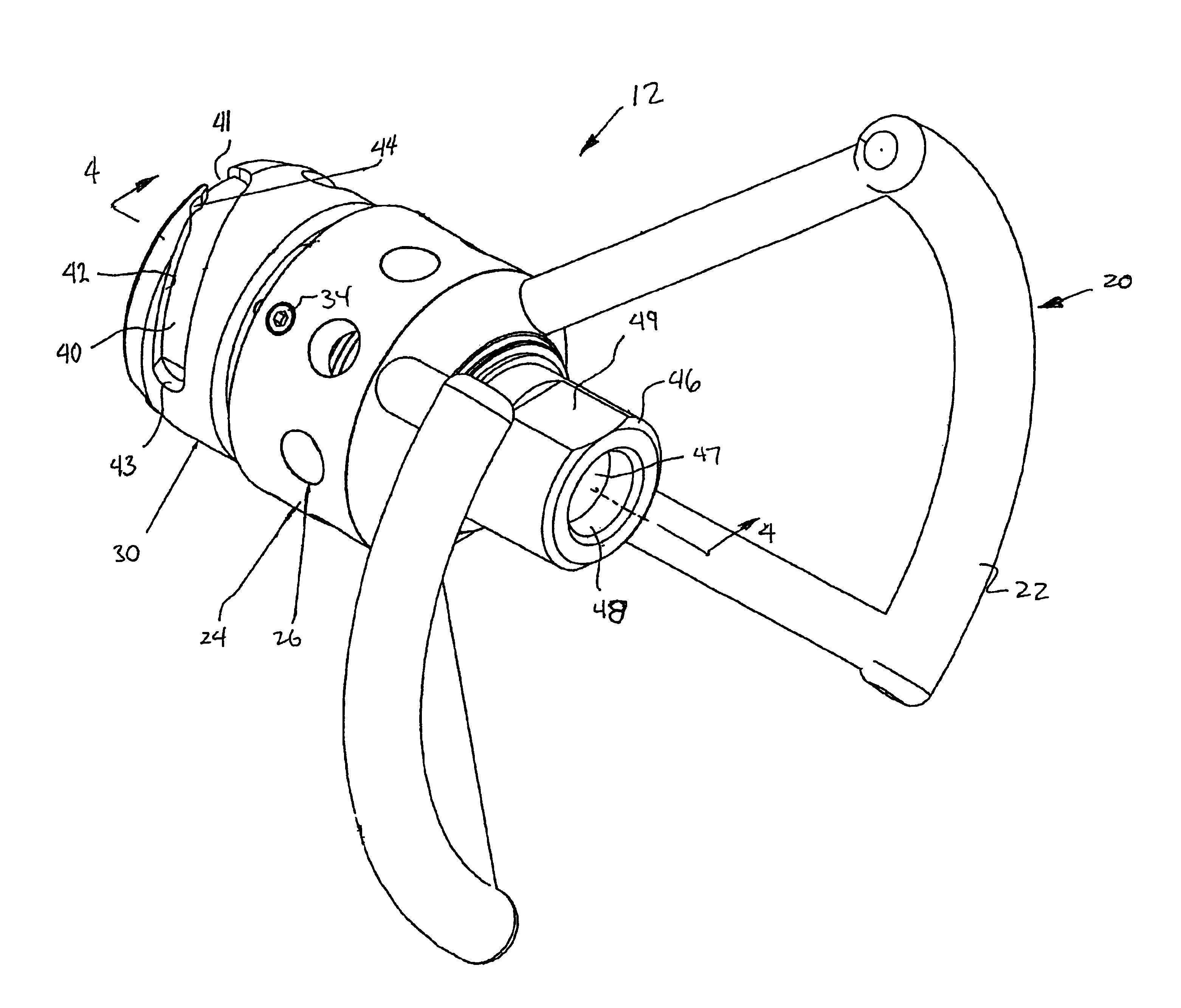

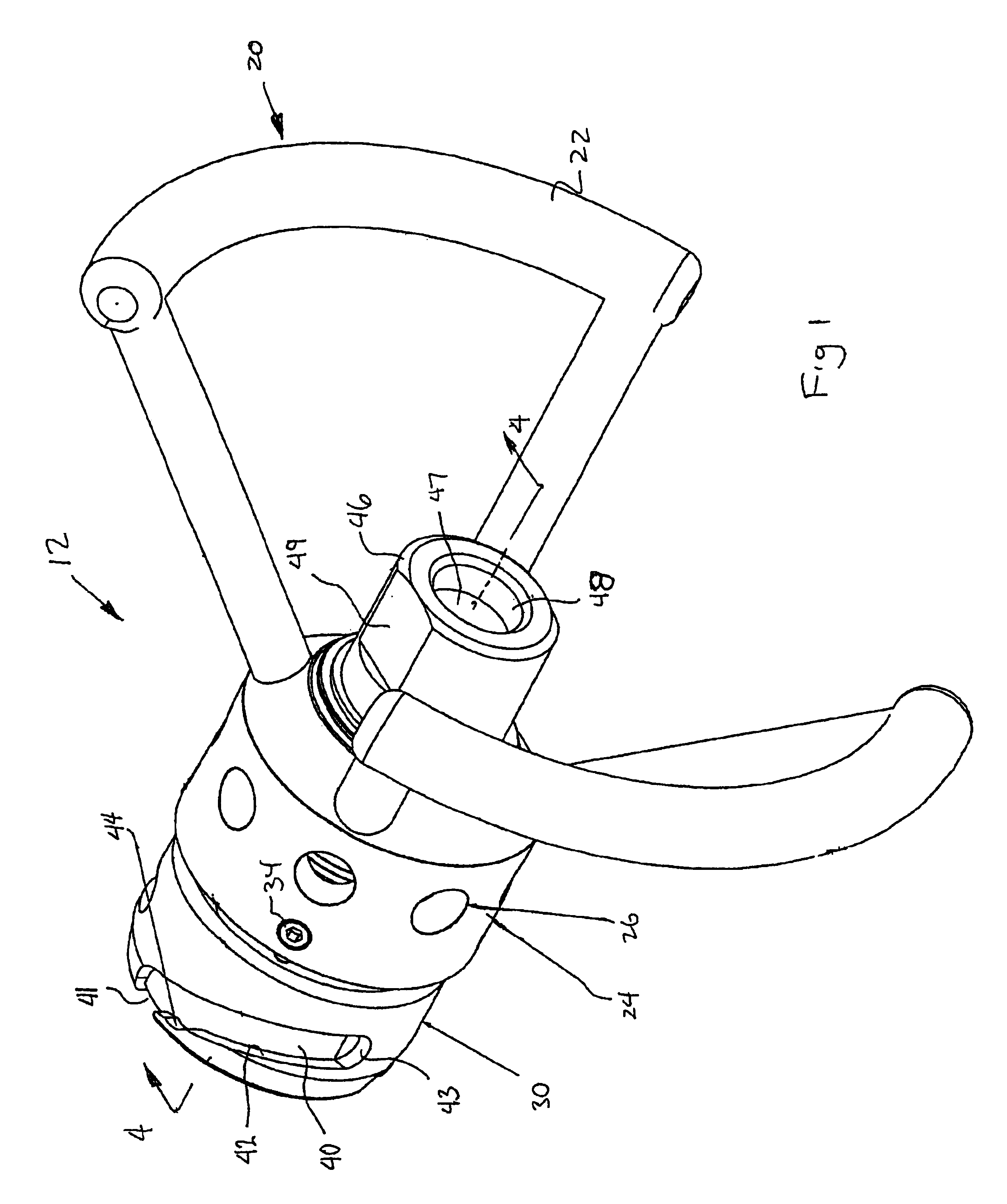

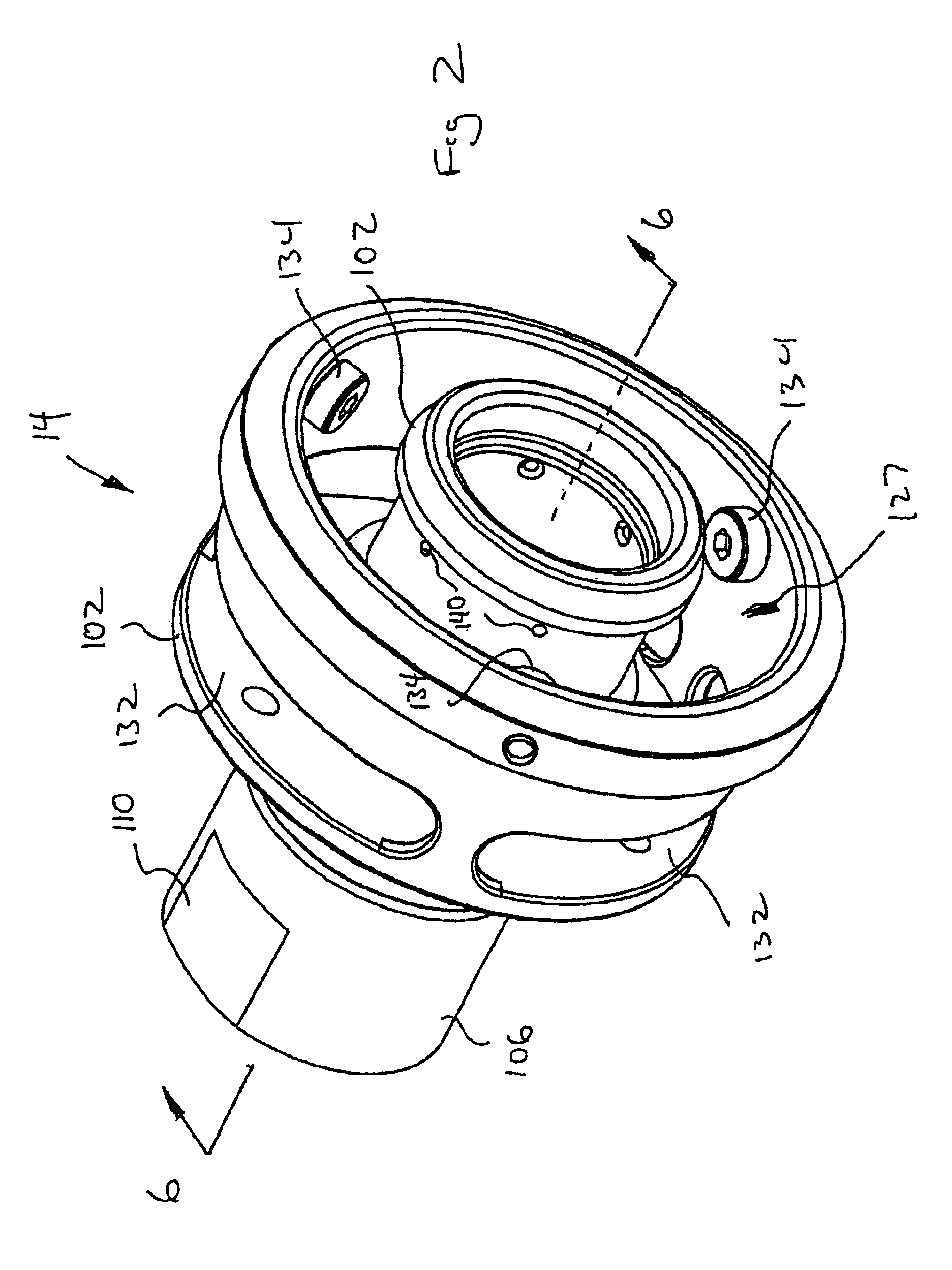

Cryogenic coupling device

ActiveUS6945477B2Prevent overflowSmall sizeVessel mounting detailsSpray nozzlesThermal breakCoupling

A cryogenic coupling device includes a valved receptacle and a valved nozzle. Rollers in an outer collar of the receptacle are received in helical channels along a collar of the nozzle. A notch or detent in each of the channels provides a vent position to vent fluid before the nozzle is fully disconnected from the receptacle. Interface seals on the nozzle include first and second annular seals that function as ice and containment scrapers, as well as fluid seals. The nozzle has a rotatable handle assembly, isolated from the fluid path, which provides easy connect and disconnect of the nozzle from the receptacle. The handle assembly includes a thermal break, and is easily removable from the nozzle, along with other parts of the nozzle and receptacle, for service and maintenance.

Owner:PARKER INTANGIBLES LLC

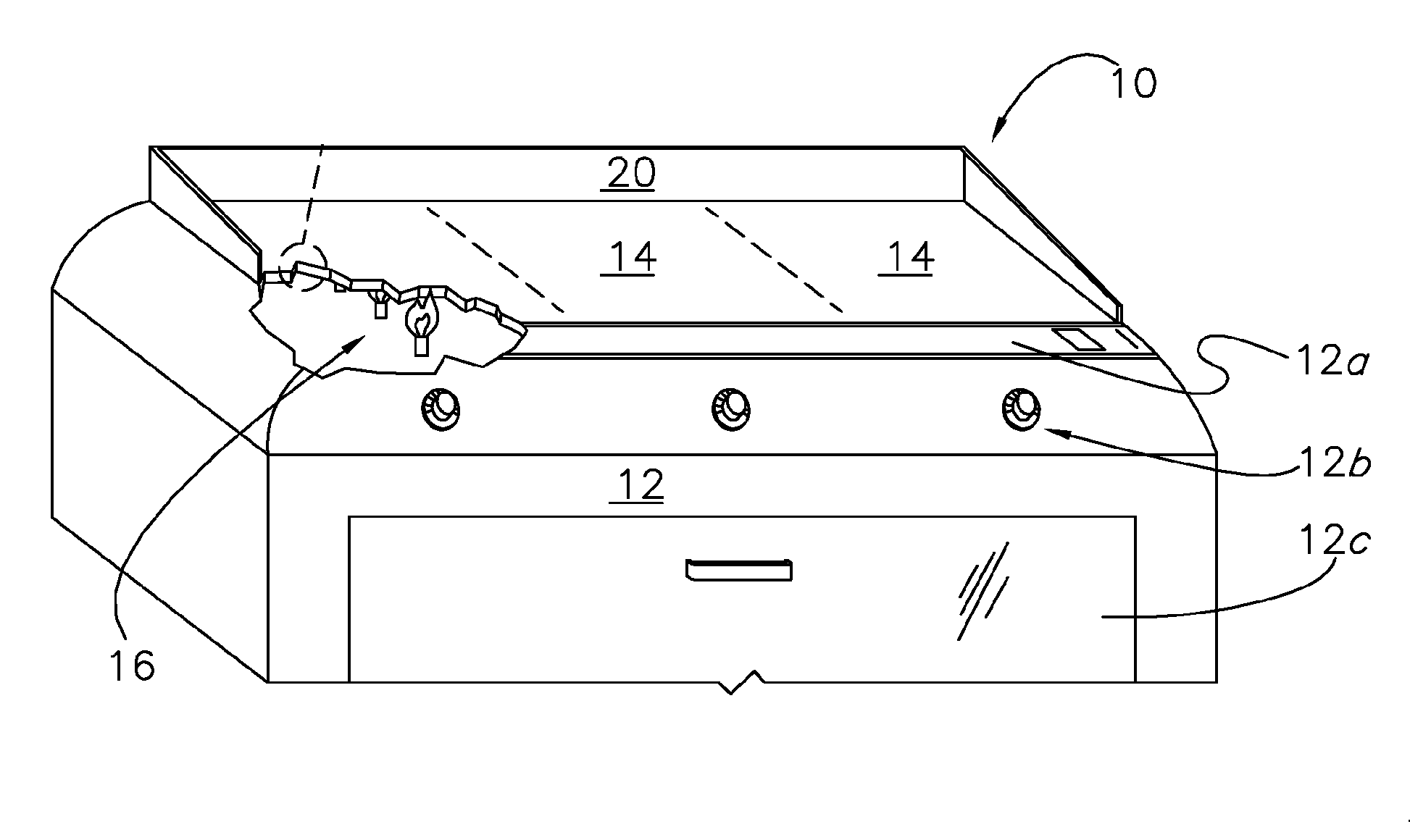

Multi-zone composite cooking griddle with unitary thermally conductive plate

InactiveUS20100199857A1Easy constructionEasy to manufactureCooking-vessel materialsRoasters/grillsThermal breakEngineering

A composite cooking structure adapted for use as a griddle top, presenting a plurality of thermally autonomous cooking zones when engaged by at least one heat source, and having a multi-layered configuration, including an uppermost hard planar member for presenting a cooking surface, a unitary thermally conductive planar member defining at least one thermal break for improving heat distribution within a zone and reducing thermal bleeding among adjacent zones, and preferably a lowermost hard planar member for improving the structural capacity of the structure, wherein the members are preferably metallurgically bonded and the thermal breaks cooperatively define the zones.

Owner:PREMARK FEG L L C

Themally insulating and reducing composite paint and its preparing process and application

InactiveCN1396219AGood heat insulation and heat reduction effectConjugated diene hydrocarbon coatingsSpecial surfacesAntistatic agentThermal radiation

A composite coated layer for thermal insulating and heat reflecting is composed of a thermal insualting layer on the surface of a substrate and a heat reflecting layer on the said thermal insulating laye. The thermal insulating layer contains filming agent, hollow microbeads arranged by one or more layers, thermal insulating filler and / or stress reducing material. The reflecting layer contains filming agent, antiageing agent, antistatic agent and reflecting pigment.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

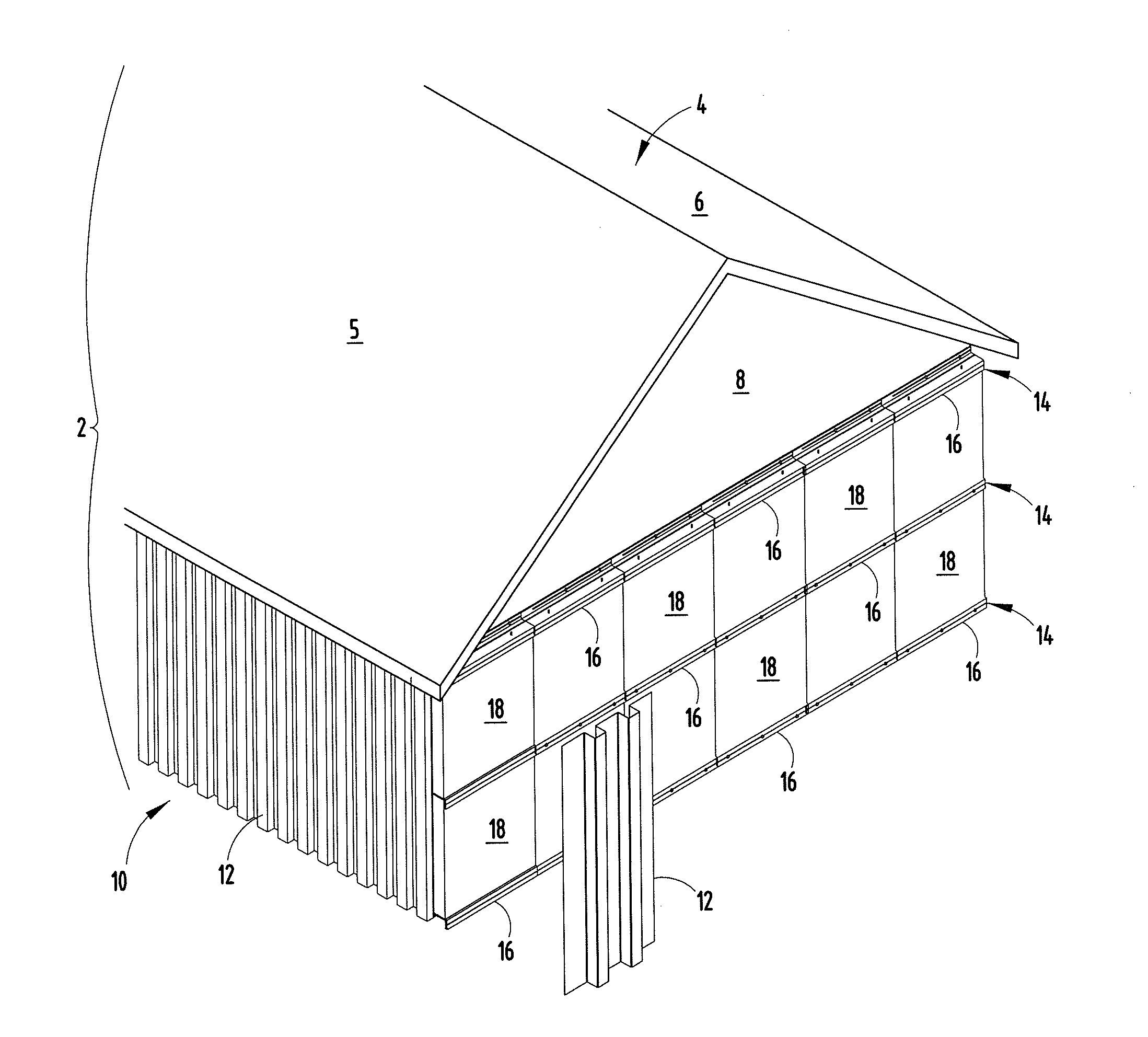

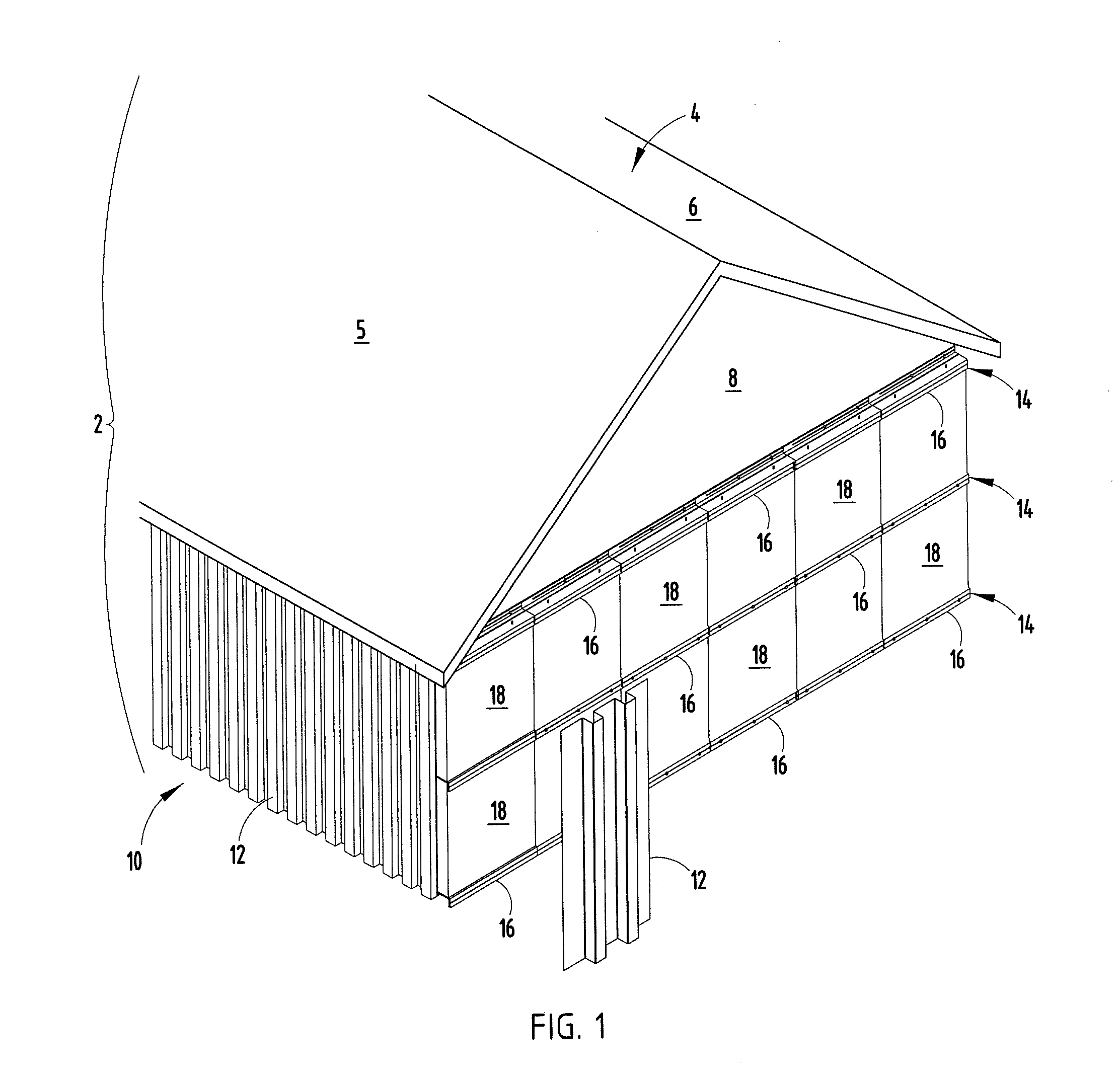

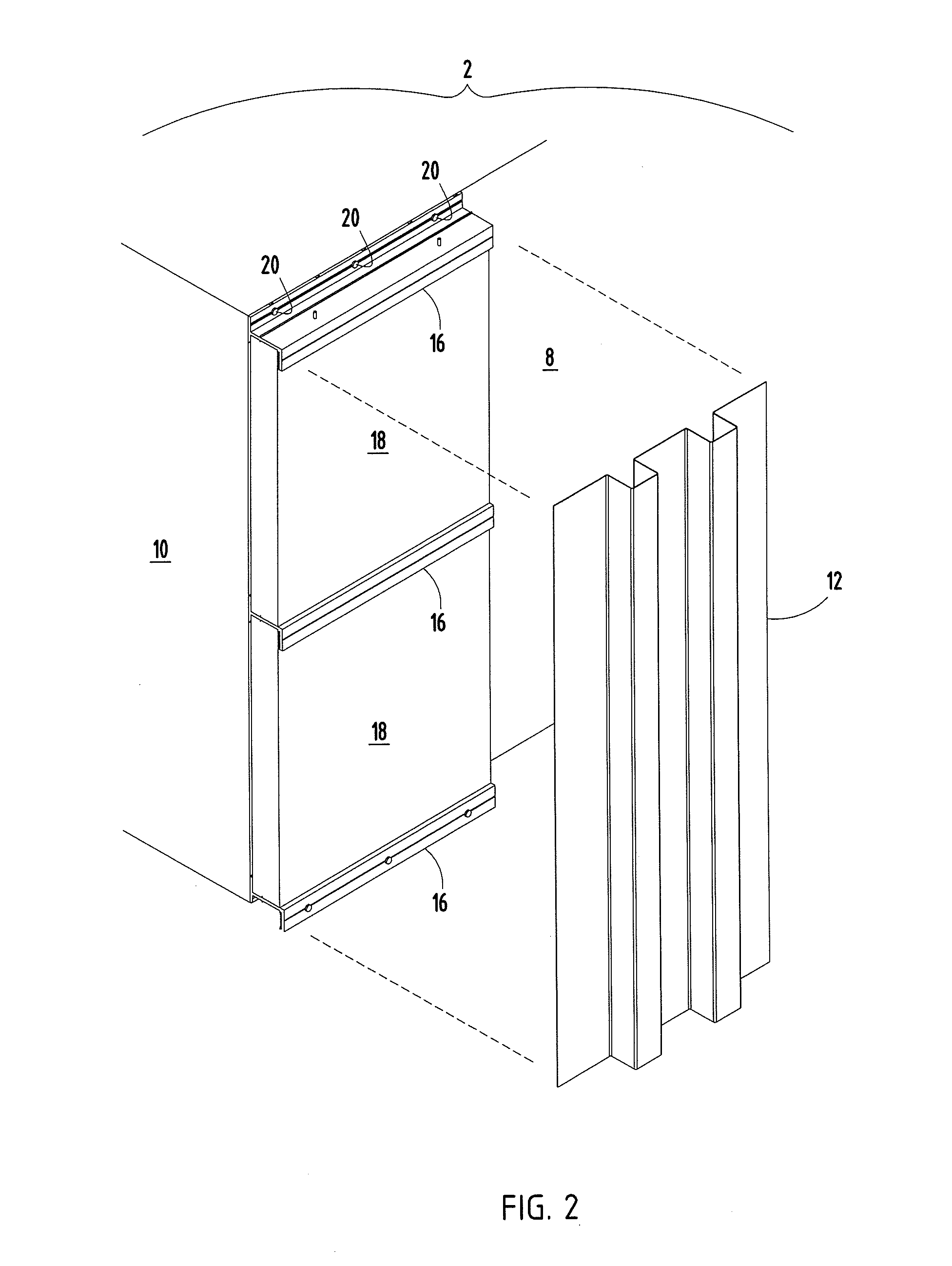

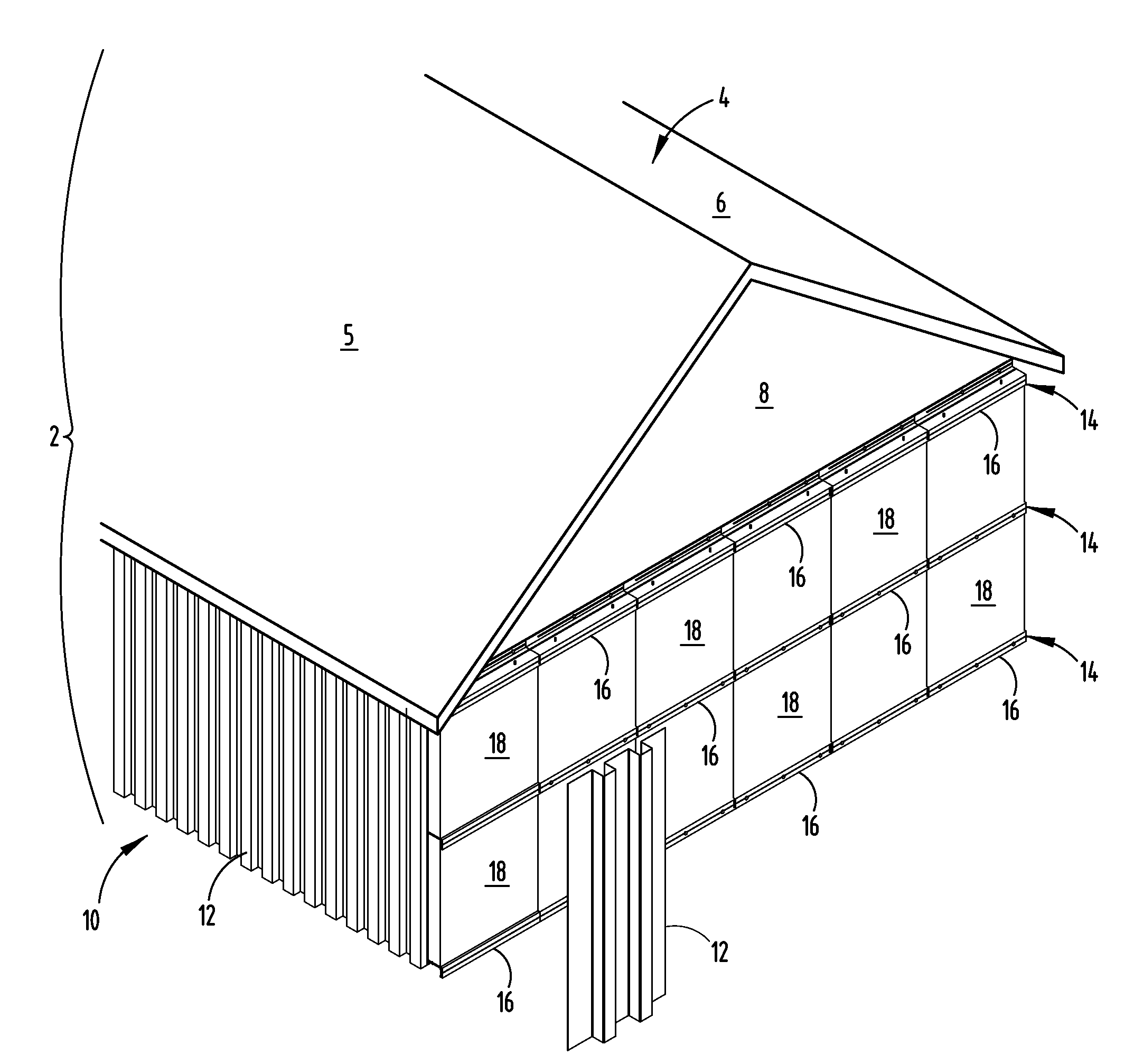

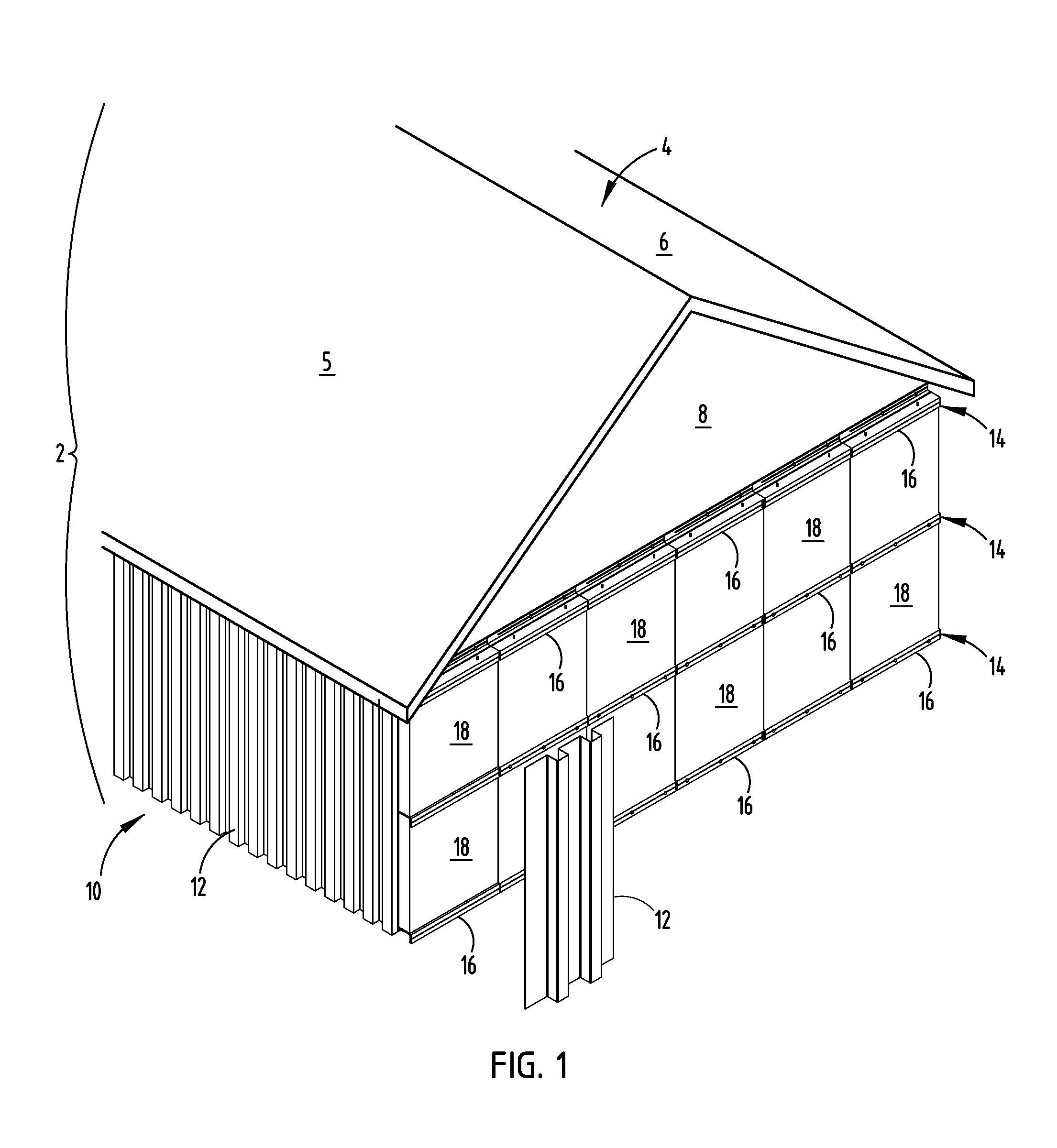

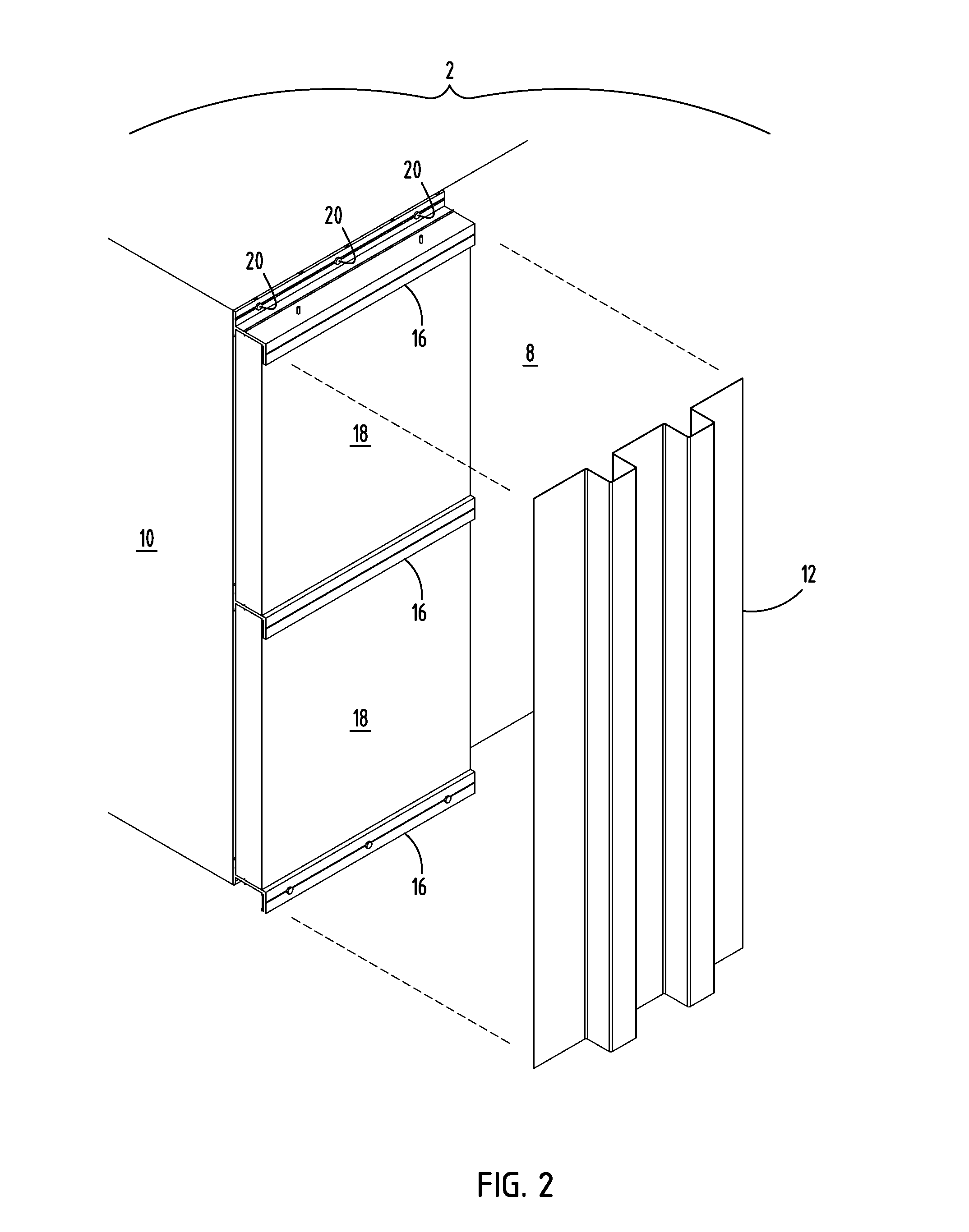

Suntrap self-regulating solar greenhouse

InactiveUS20070062105A1Climate change adaptationRenewable energy machinesThermal energyThermal break

A self-regulating solar-heated-and-cooled greenhouse consisting of a thermally-insulated opaque shell, generally formed by a floor supporting east, north, and west-oriented walls supporting a northerly-facing sloping roof, leaving the southern exposure of said shell “open”, said shell incorporating means of regulating the admission or expulsion of air to the greenhouse. Said “open” south face to be sealed-over by a solar energy collecting system comprised of two parallel light-admitting curtain-wall systems, generally vertical in orientation and planar in configuration, with a space between said wall systems forming an enhanced thermal break and of sufficient distance so as to effect periodic maintenance, and incorporating means of regulating admission or expulsion of air to the greenhouse. Said greenhouse further incorporating means of directing excess thermal energy collected during daylight hours into appropriate storage systems either within or without the confines of said greenhouse, and further incorporating means of providing insulation for the south-facing solar-wall systems at night or during inclement weather.

Owner:STEVENS MICHAEL MAURICE

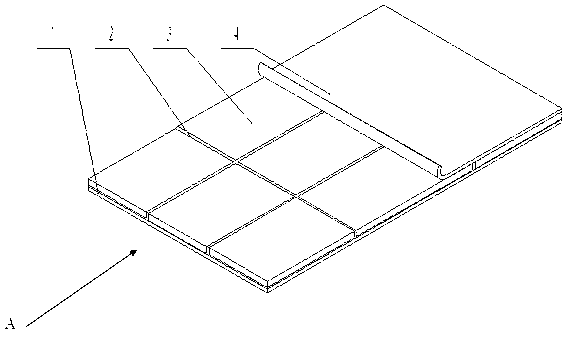

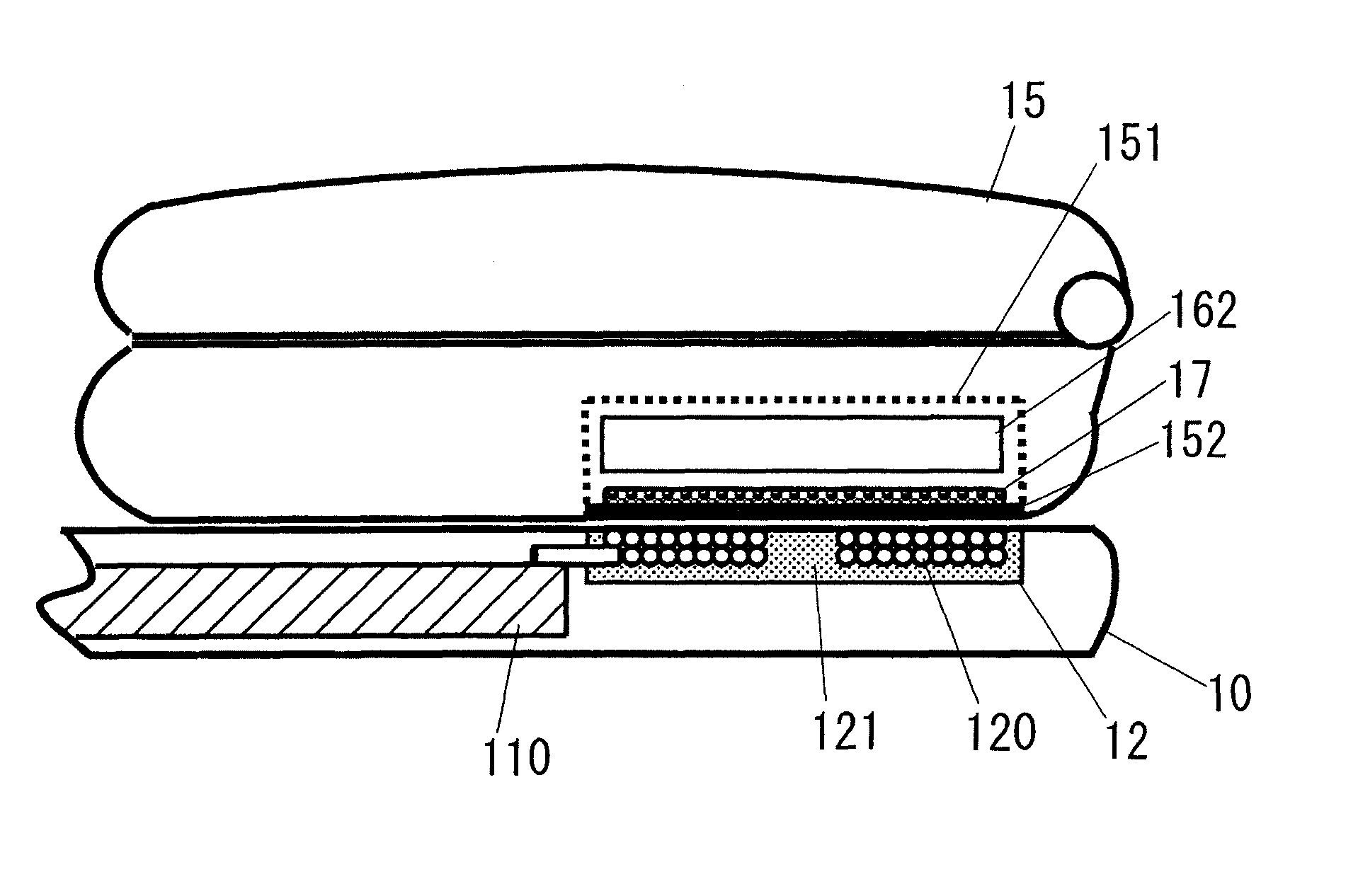

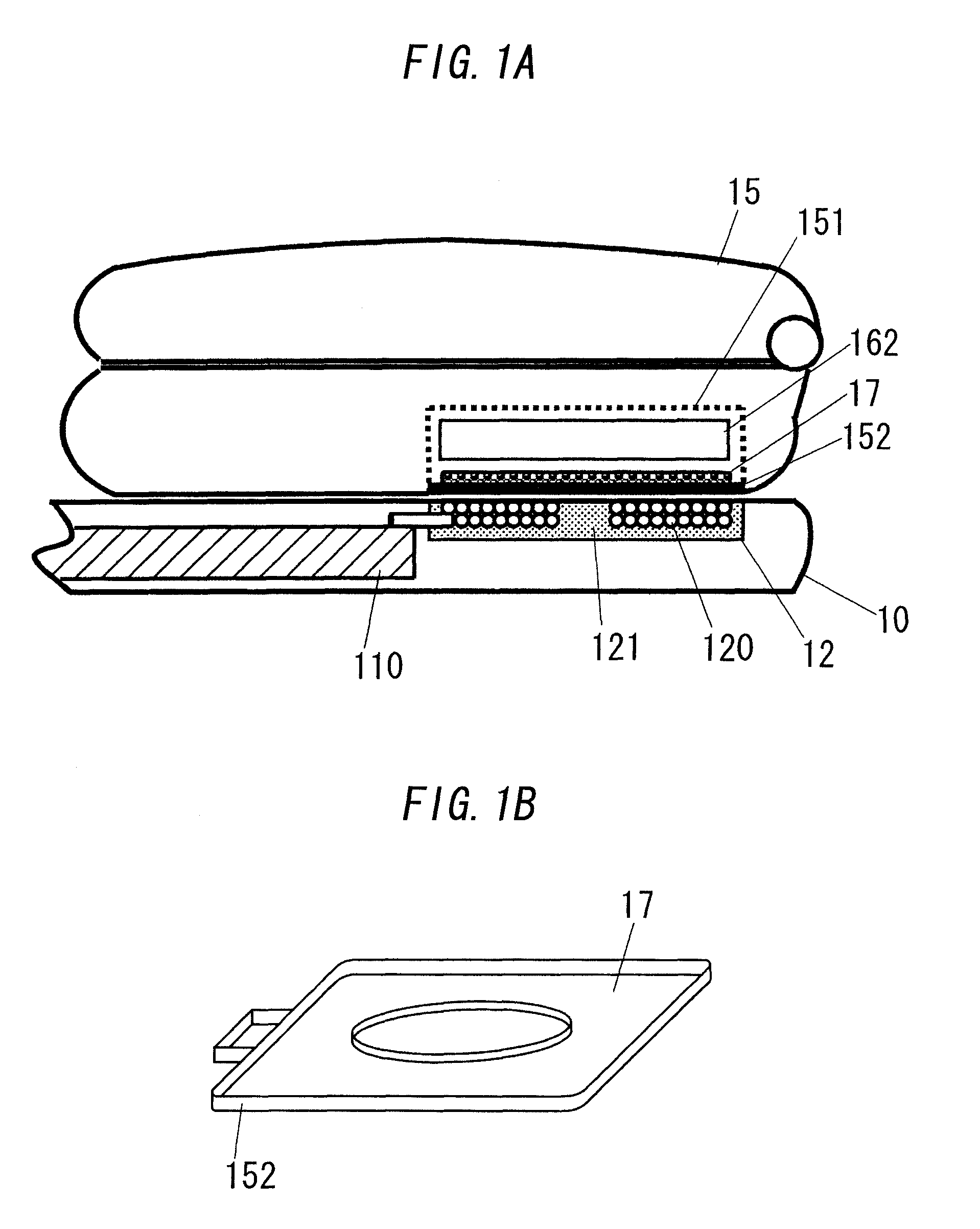

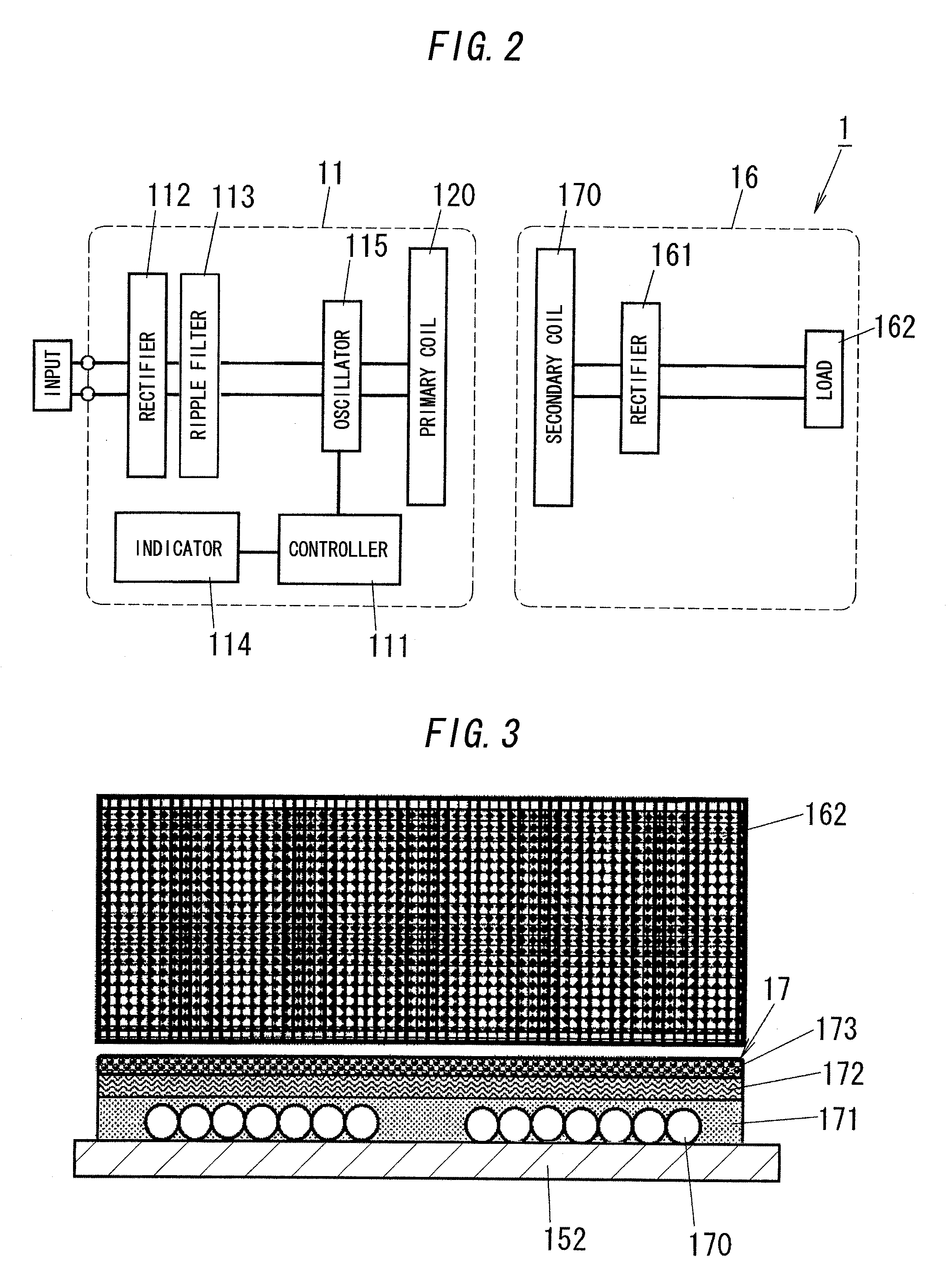

Contactless power transmission apparatus and a method of manufacturing a secondary side thereof

InactiveUS8421574B2High power transmission efficiencyReduce the impact of noiseBatteries circuit arrangementsTransformersElectric power transmissionInsulation layer

According to a first aspect, a secondary side of contactless power transmission apparatus includes: a holding member which is physically separated from a primary side; a magnetic layer; a shield layer for shielding electromagnetic noise; and a heat insulation layer. The secondary coil is a planar coil and supported by the holding member, and at least the magnetic layer is laminated on one side of the planar coil and unified with the planar coil. According to a second aspect, the secondary side of the apparatus includes a plurality of magnetic layers. Each permeability of the magnetic layers is different from each other, and each of the magnetic layers forms a magnetic path with the primary side.

Owner:PANASONIC CORP

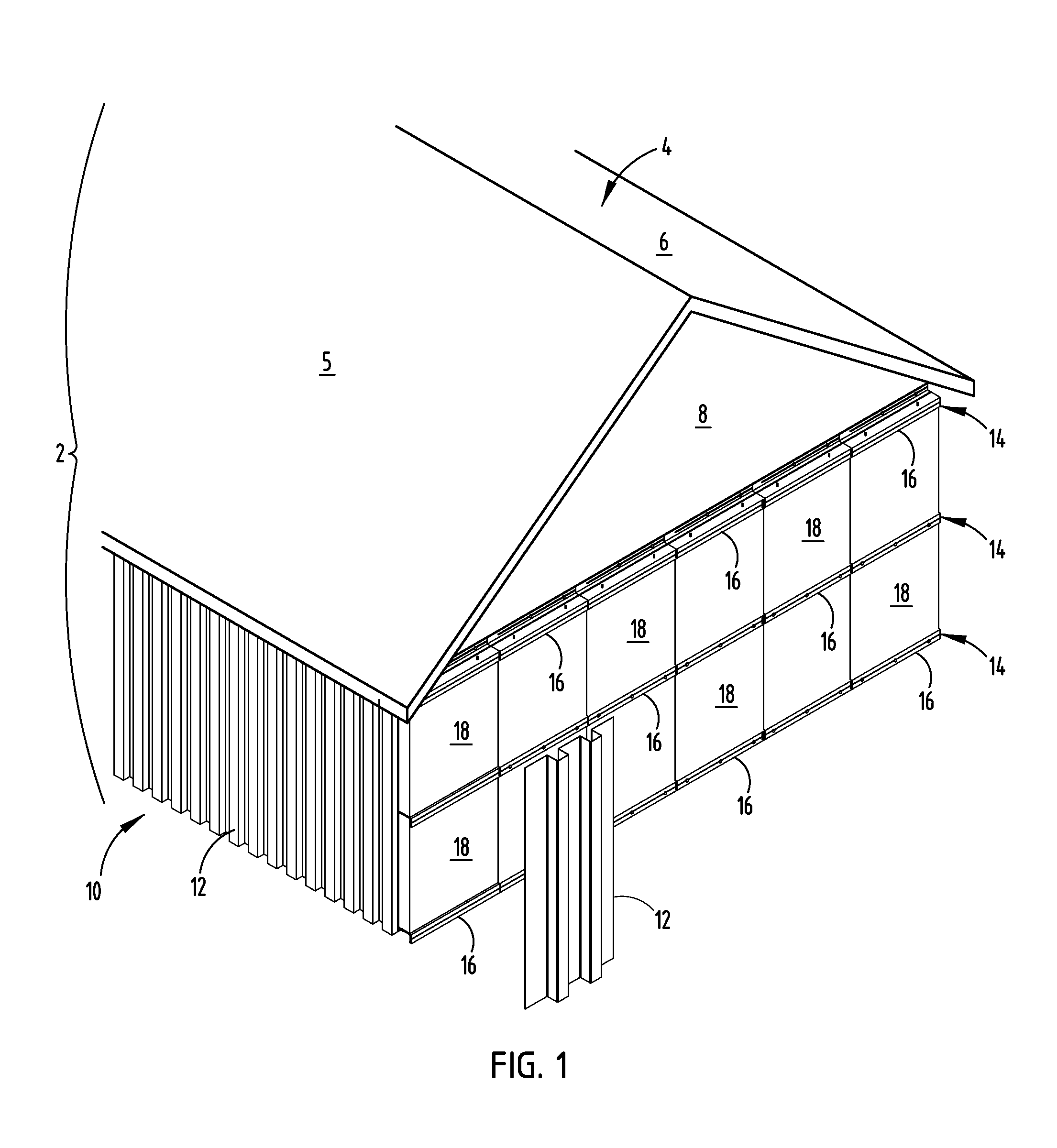

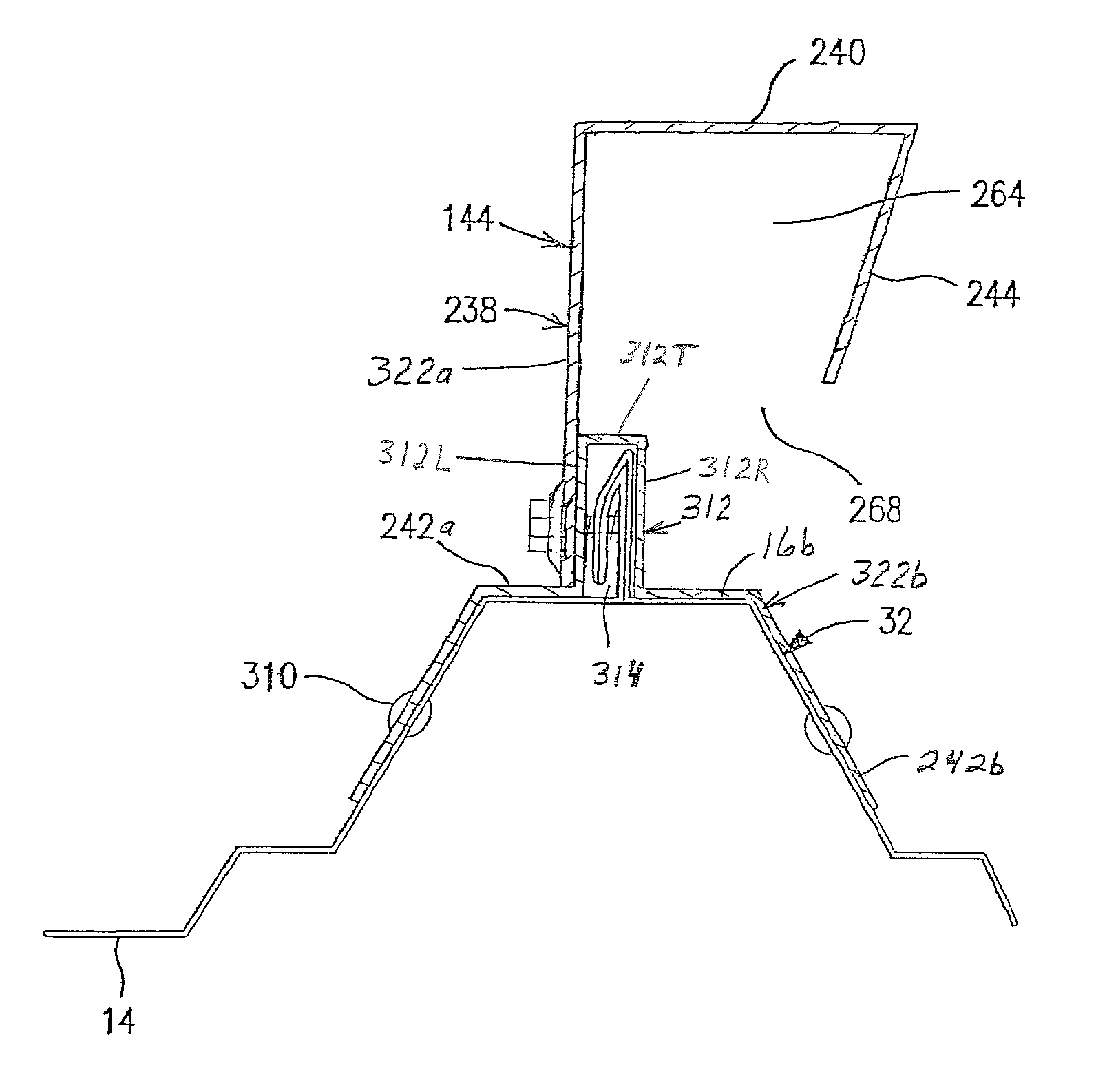

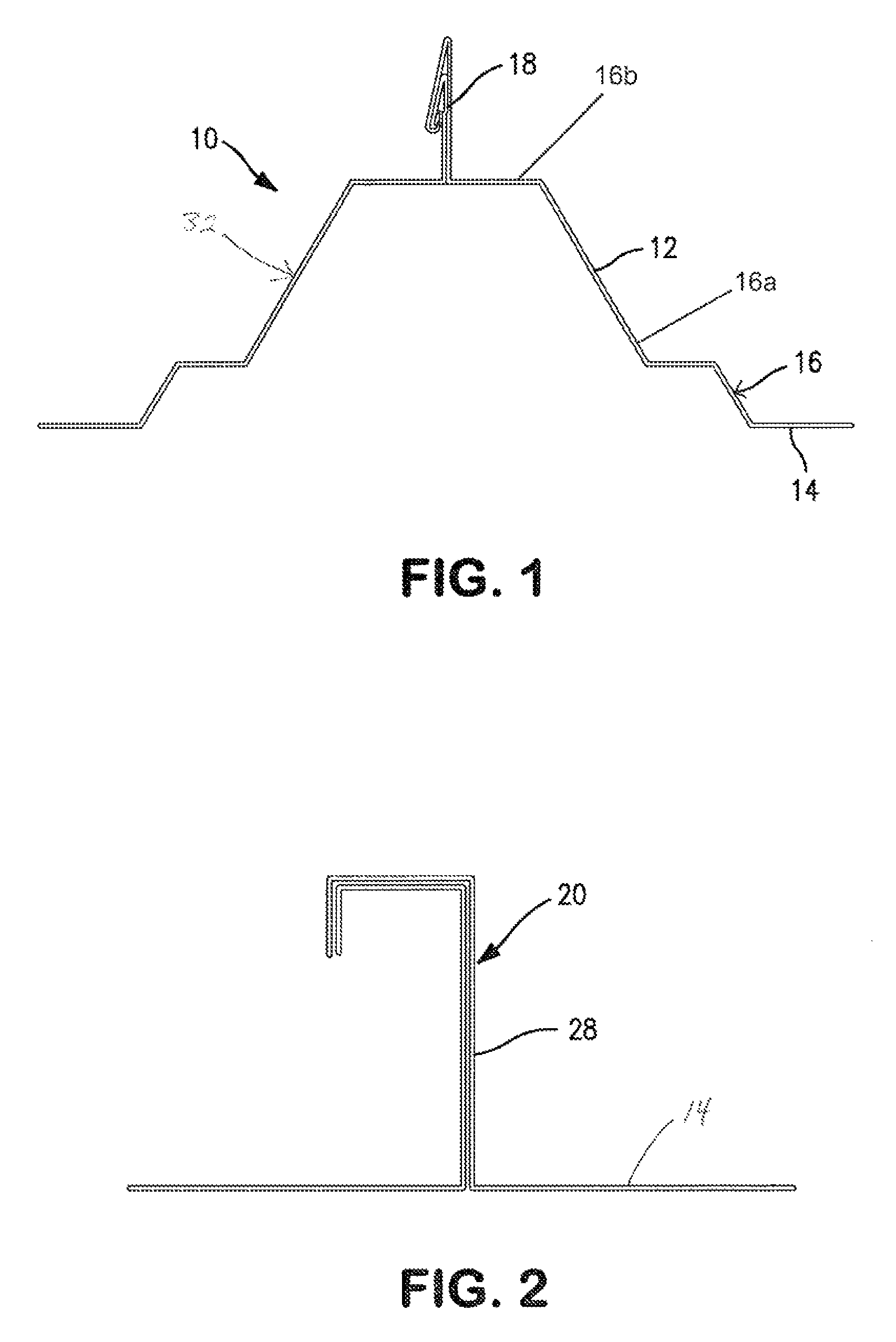

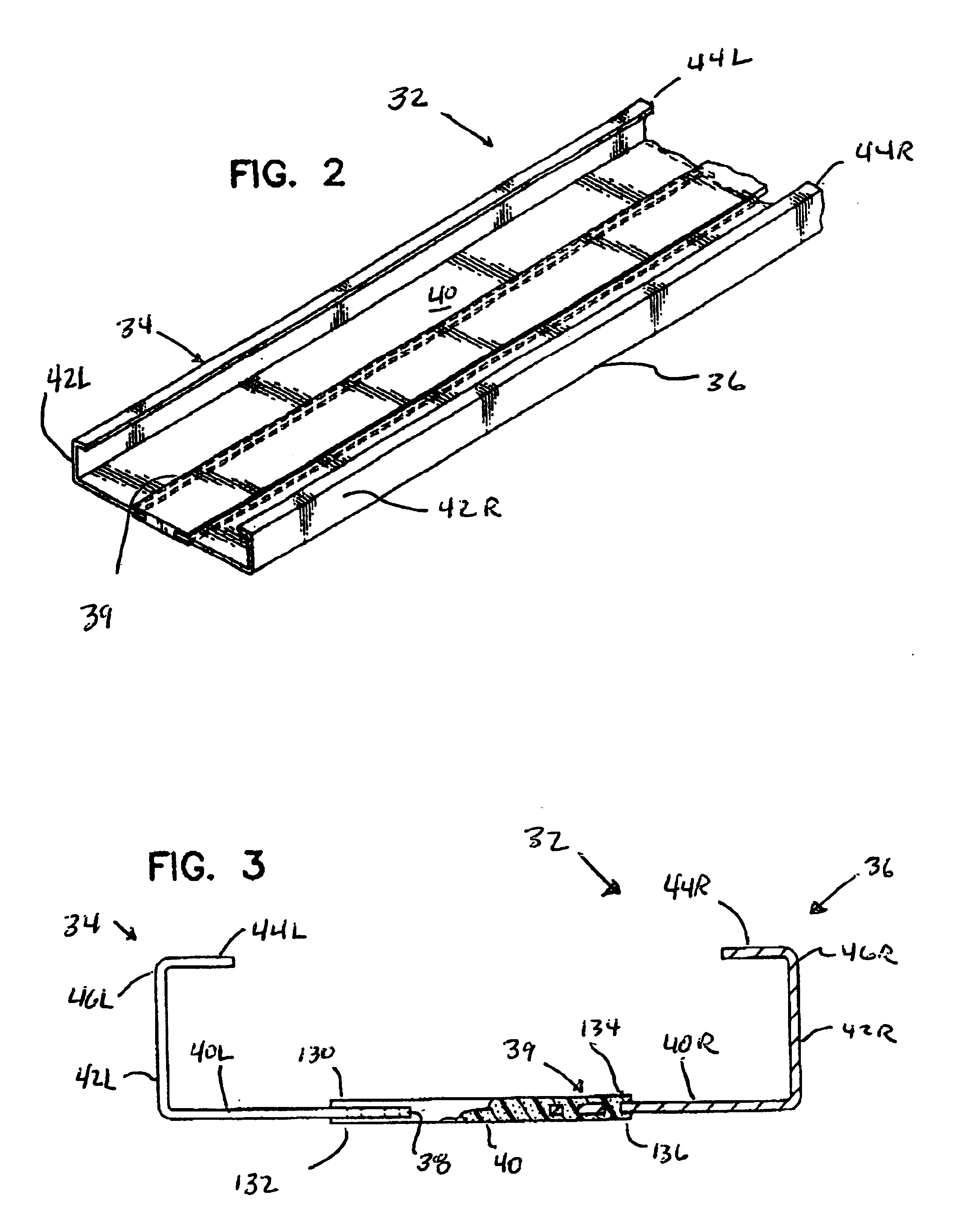

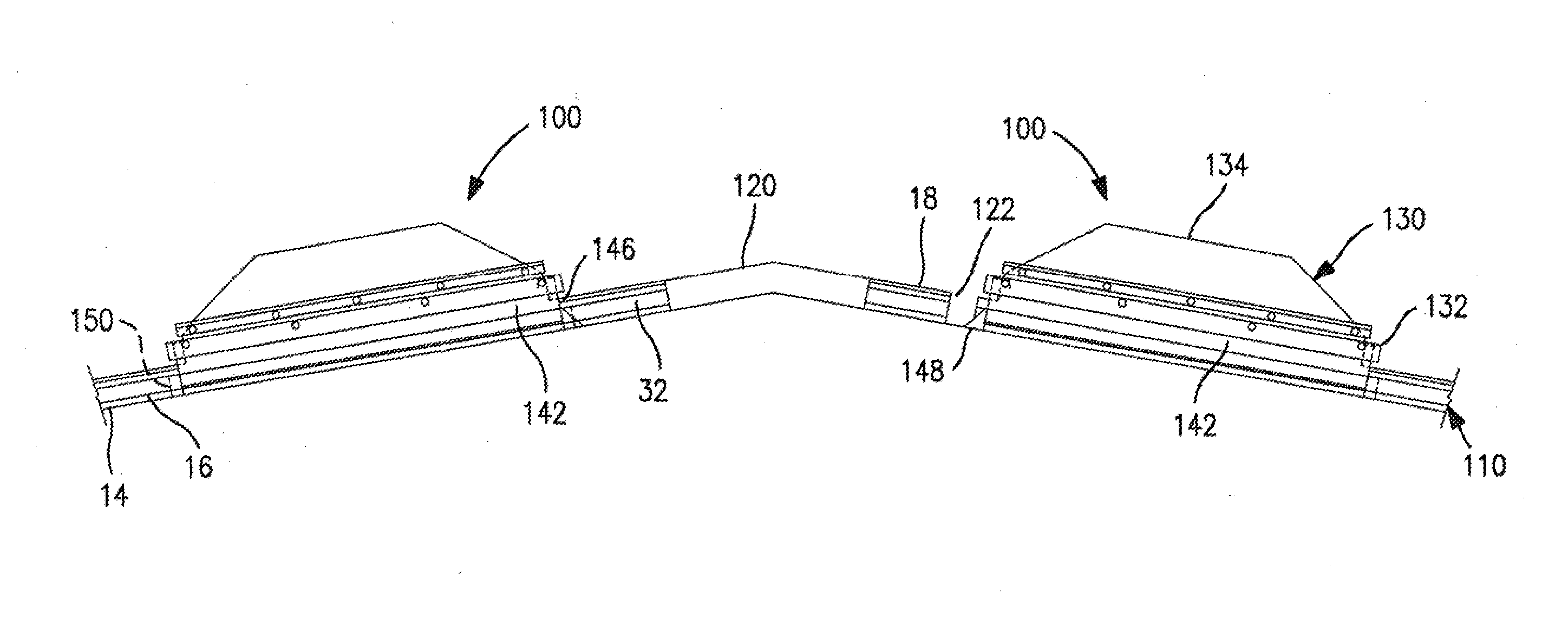

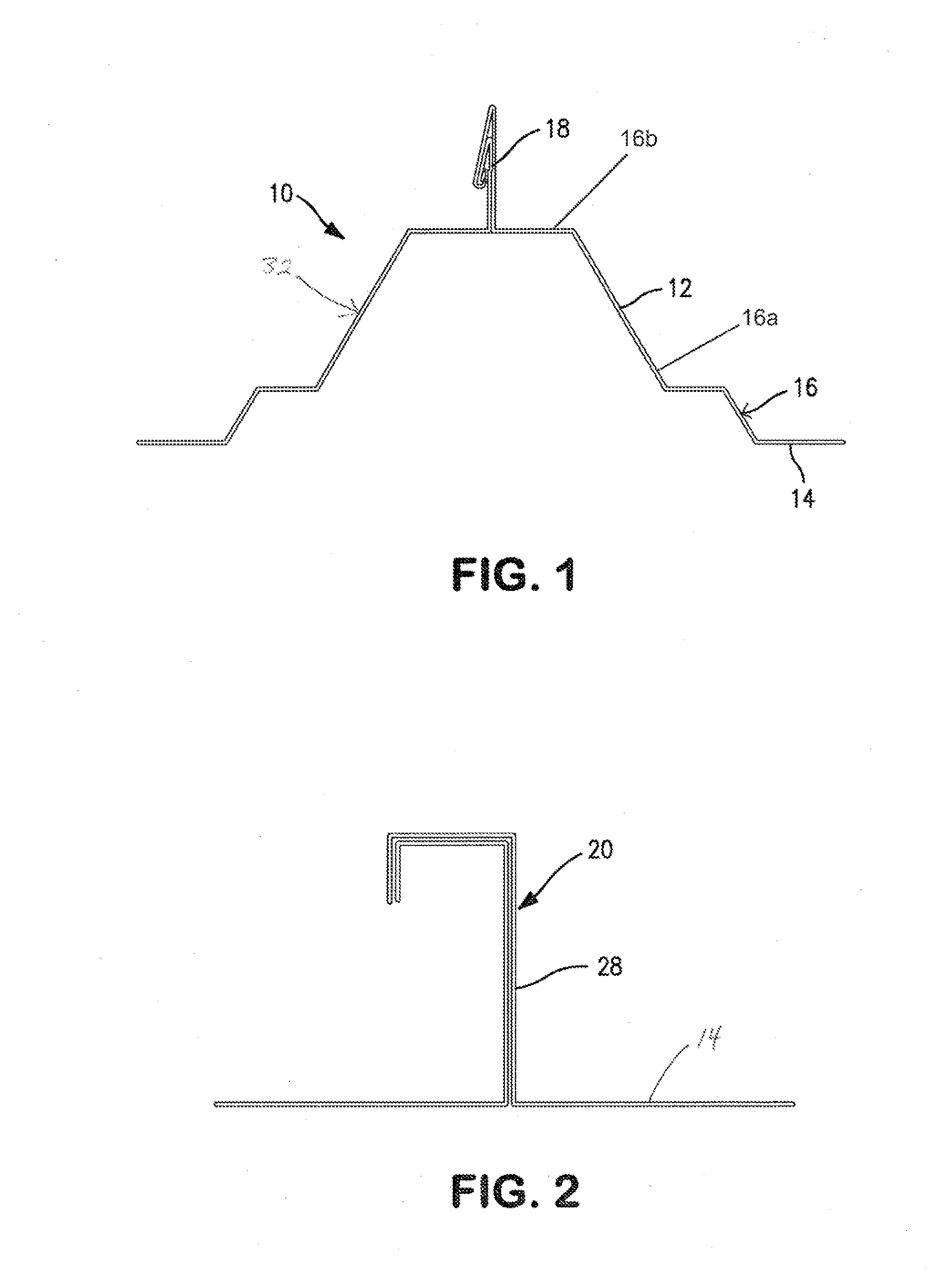

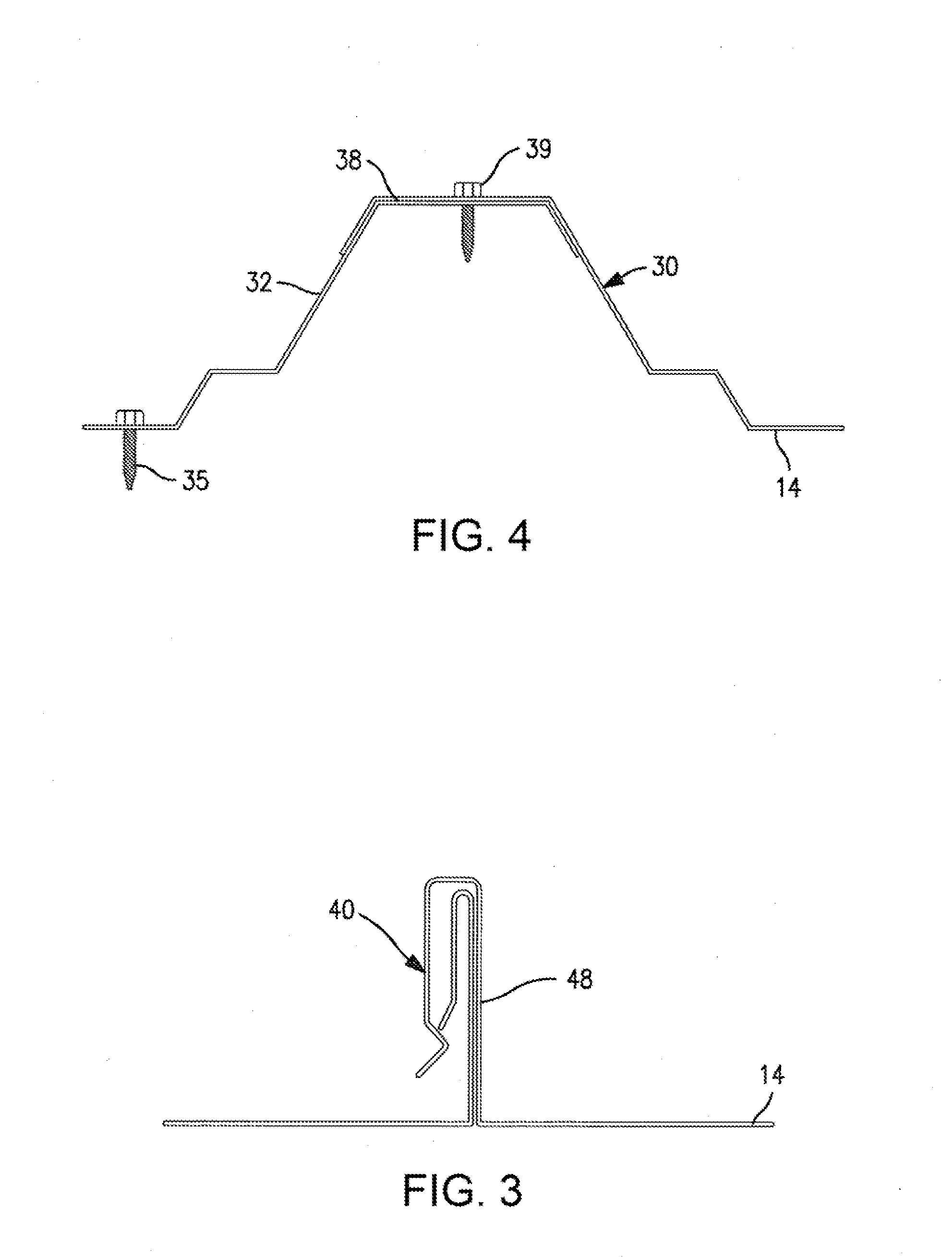

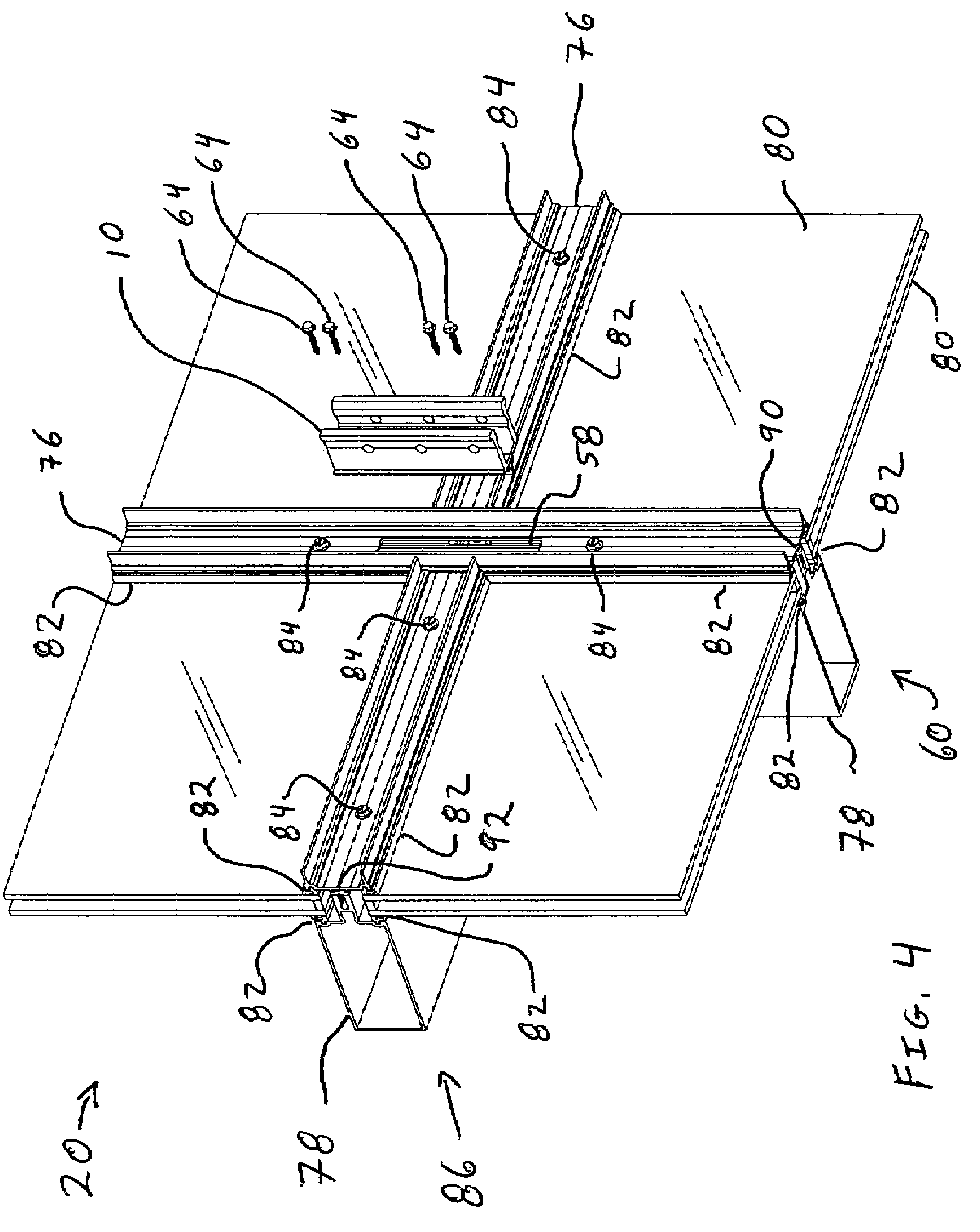

Support structures on roofs

ActiveUS9534390B2Reduce the numberReduced structureRoof covering using slabs/sheetsSky-lights/domesThermal breakEngineering

Metal panel roofs, and load support structures for supporting loads on such roofs. Side rails provide primary support for loads on such roofs. The side rails can be fabricated from sheet metal or can be extruded. A side rail includes a standing seam cavity which is lowered, and covers, the standing seam. Side walls of the standing seam cavity. An upstanding web extends up from the cavity, and lower shoulders may extend laterally, optionally downwardly, from the walls which define the cavity, on either one side, or both sides, of the cavity. Building roof insulation can extend up through an aperture in the roof, surrounded by such load support structure, and extend up to the top of the side rail, thus providing a thermal break between the load support structure elements and the space surrounded by the load support structure.

Owner:T&M INVENTIONS

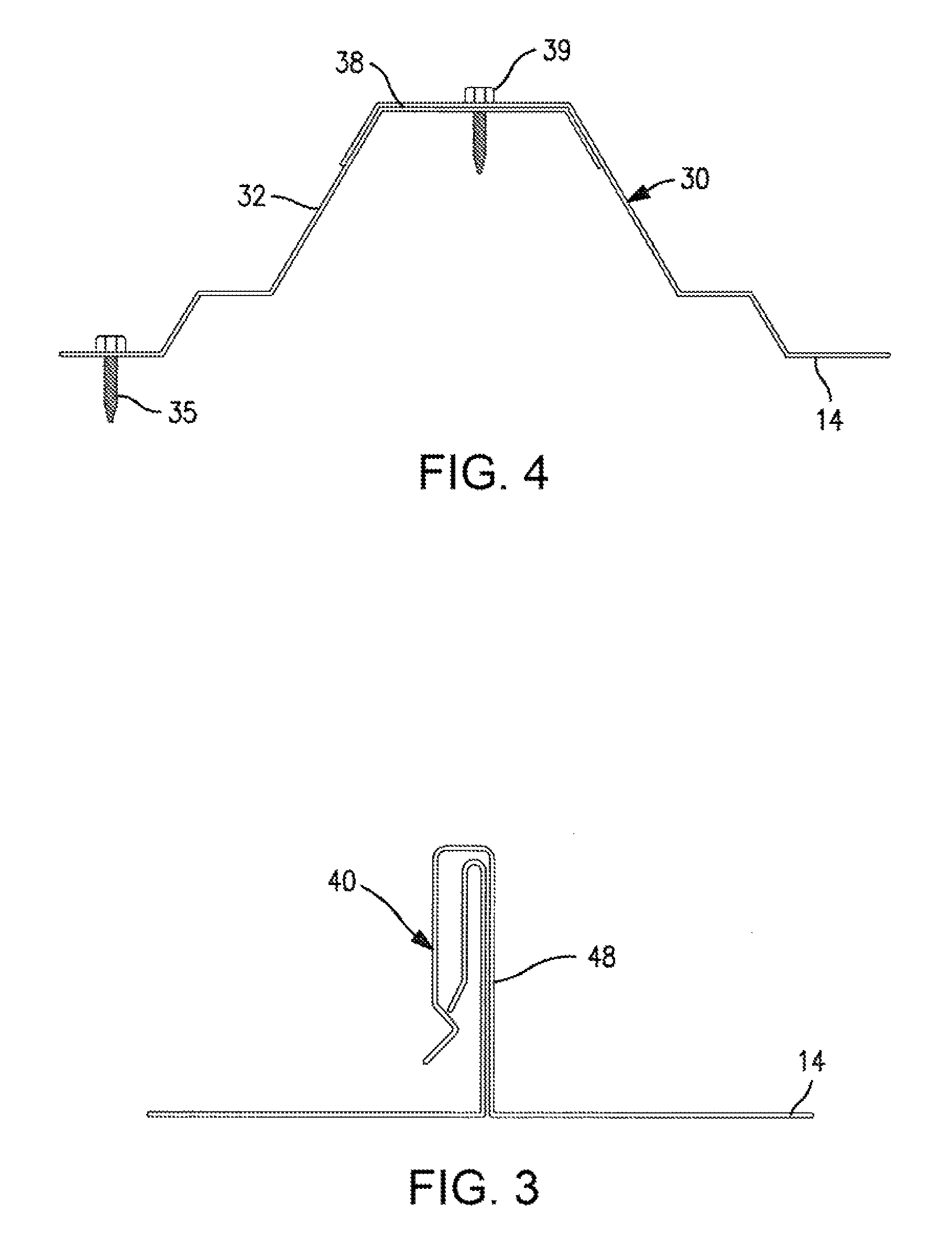

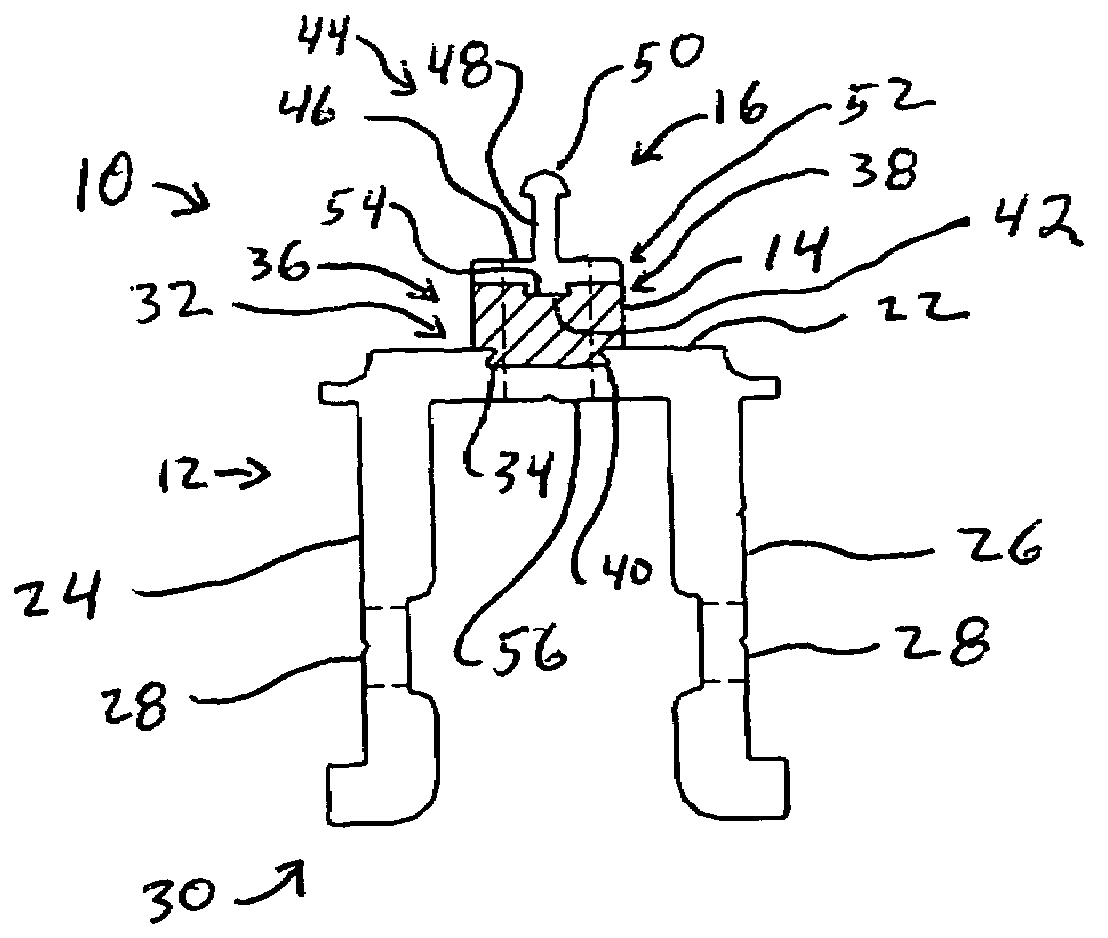

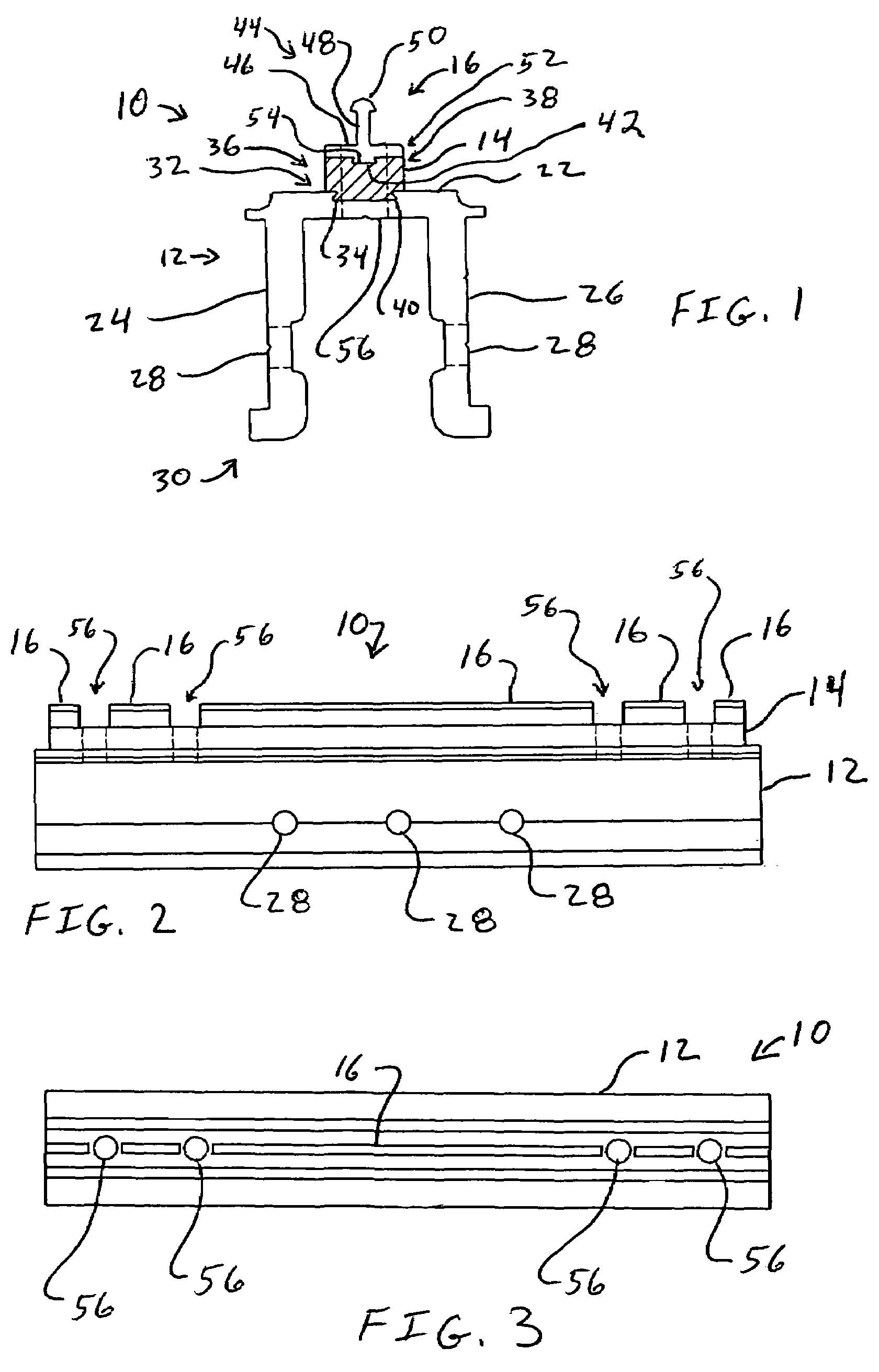

Members with a thermal break

Members formed from thermally conductive components which have a gap therebetween. The gap is bridged and the conductive components integrated into a composite member by a reinforced polymer. This provides a thermal break which inhibits the flow of heat between the conductive components of the member. This construction also blocks the transfer of sound and other vibrations between the conductive components of the member. The construction also mitigates the formation of condensation on an artifact fixed to one of the components.

Owner:YARROW BAY INDS

Support structures on roofs

ActiveUS20140260068A1Reduce the numberReduced structureRoof covering using slabs/sheetsSky-lights/domesThermal breakEngineering

Metal panel roofs, and load support structures for supporting loads on such roofs. Side rails provide primary support for loads on such roofs. The side rails can be fabricated from sheet metal or can be extruded. A side rail includes a standing seam cavity which is lowered, and covers, the standing seam. Side walls of the standing seam cavity. An upstanding web extends up from the cavity, and lower shoulders may extend laterally, optionally downwardly, from the walls which define the cavity, on either one side, or both sides, of the cavity. Building roof insulation can extend up through an aperture in the roof, surrounded by such load support structure, and extend up to the top of the side rail, thus providing a thermal break between the load support structure elements and the space surrounded by the load support structure.

Owner:T&M INVENTIONS

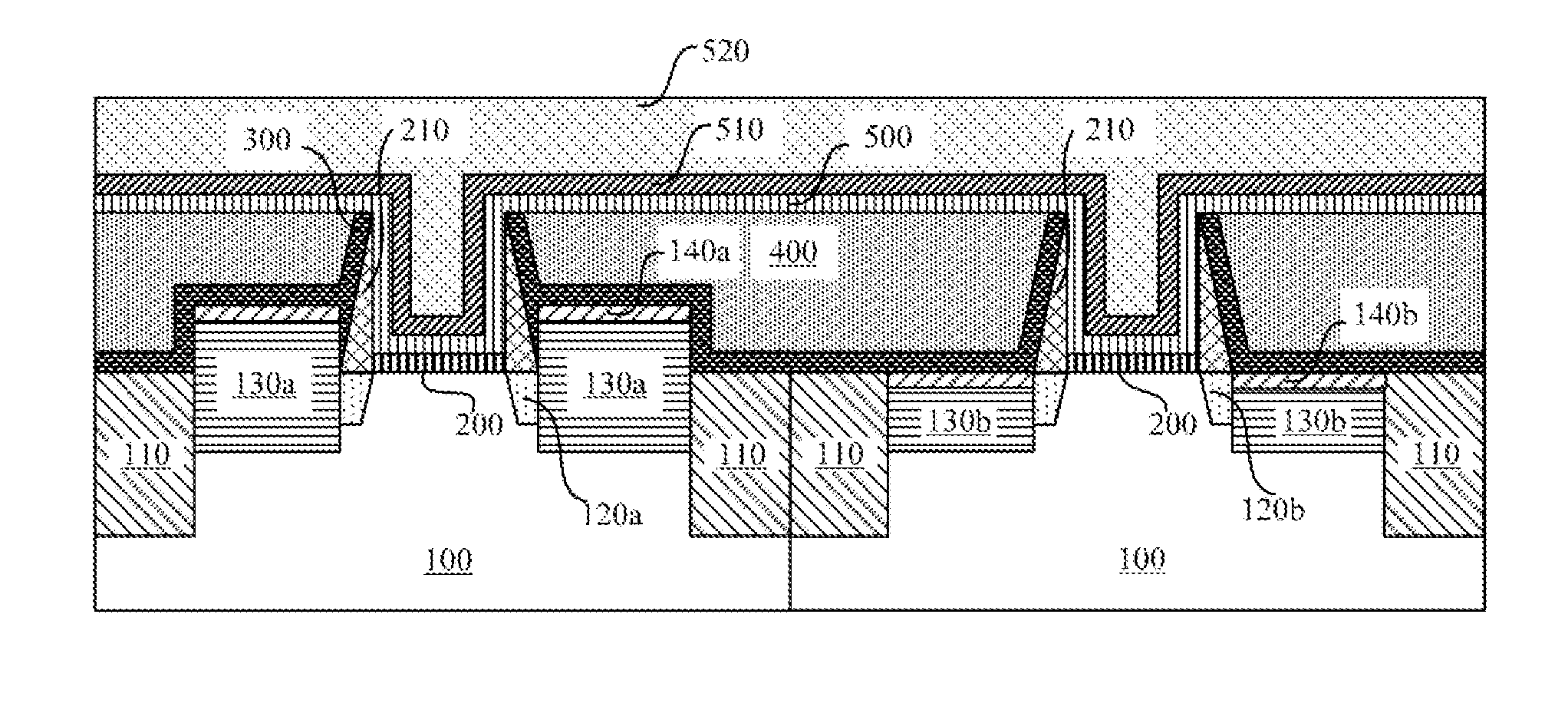

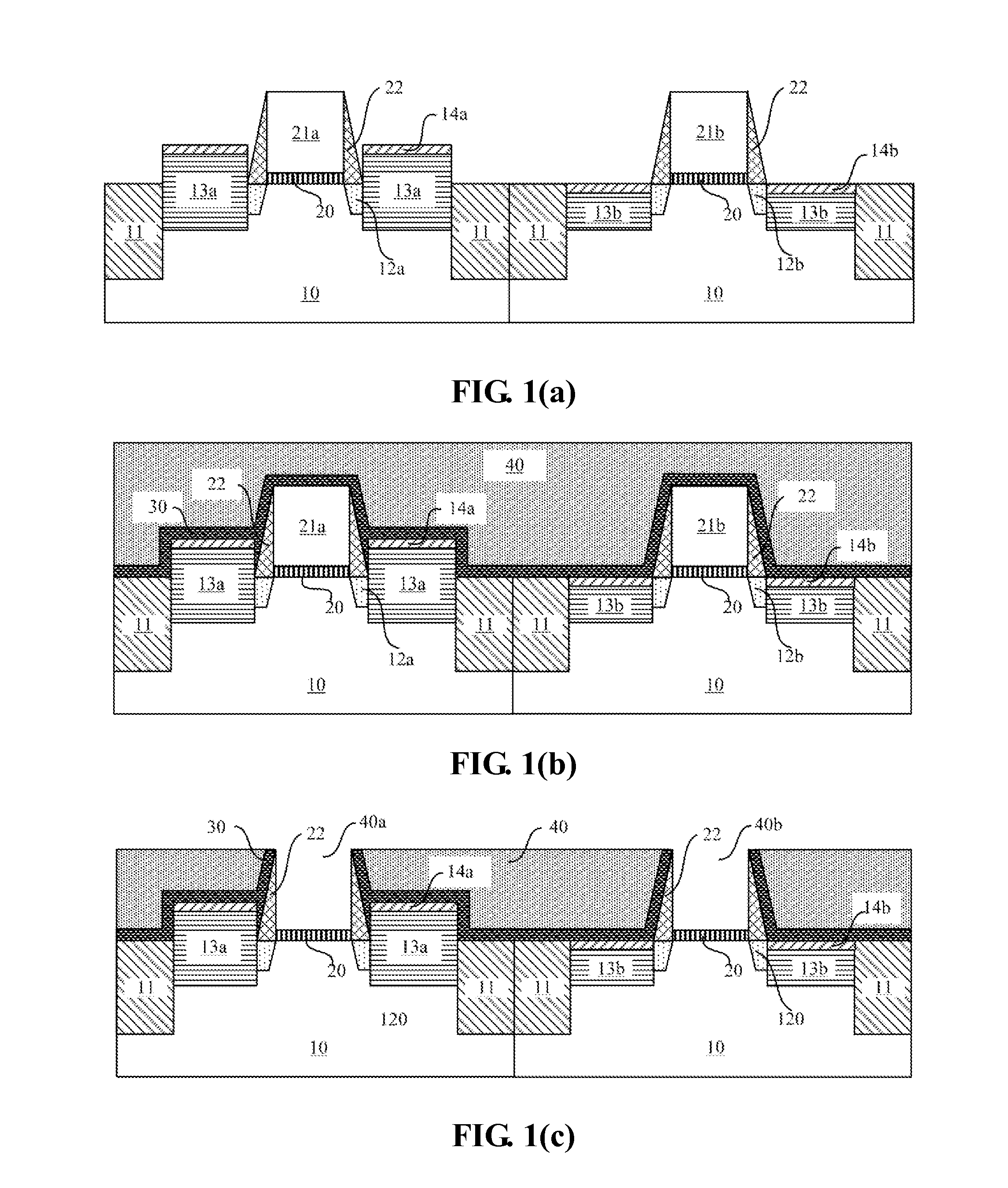

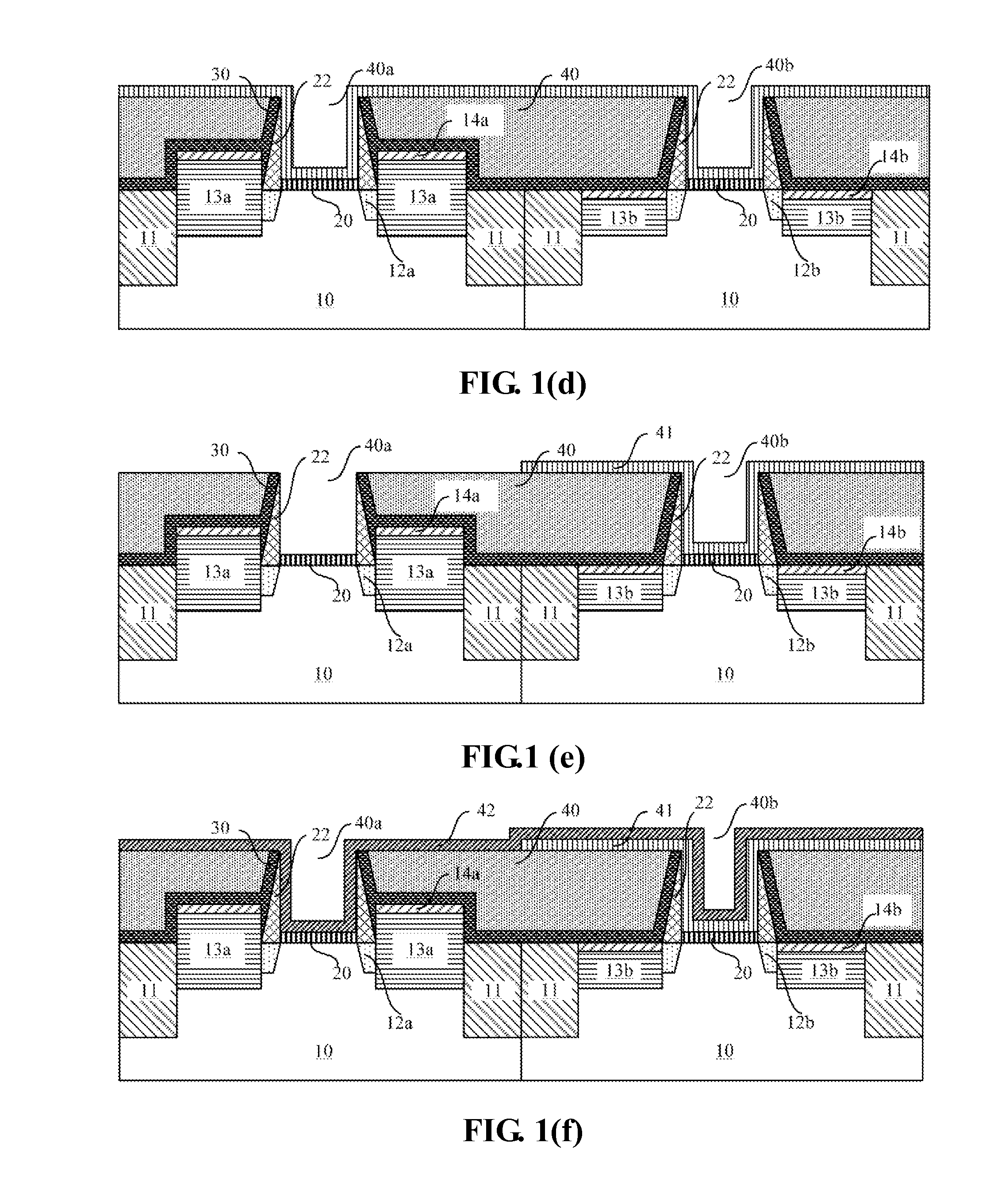

Dual-metal gate CMOS devices and method for manufacturing the same

InactiveUS20150102416A1Easy to manufactureSimple processTransistorSolid-state devicesCMOSThermal break

A method for manufacturing a dual metal CMOS device comprising: forming a first type metal work function modulation layer in the first gate trench and the second gate trench; forming a second type work function metal diffusion source layer in the first gate trench and the second gate trench; forming a heat isolation layer that shields the region of the first type device; and thermally annealing the regions where the first type device and the second type device are located.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

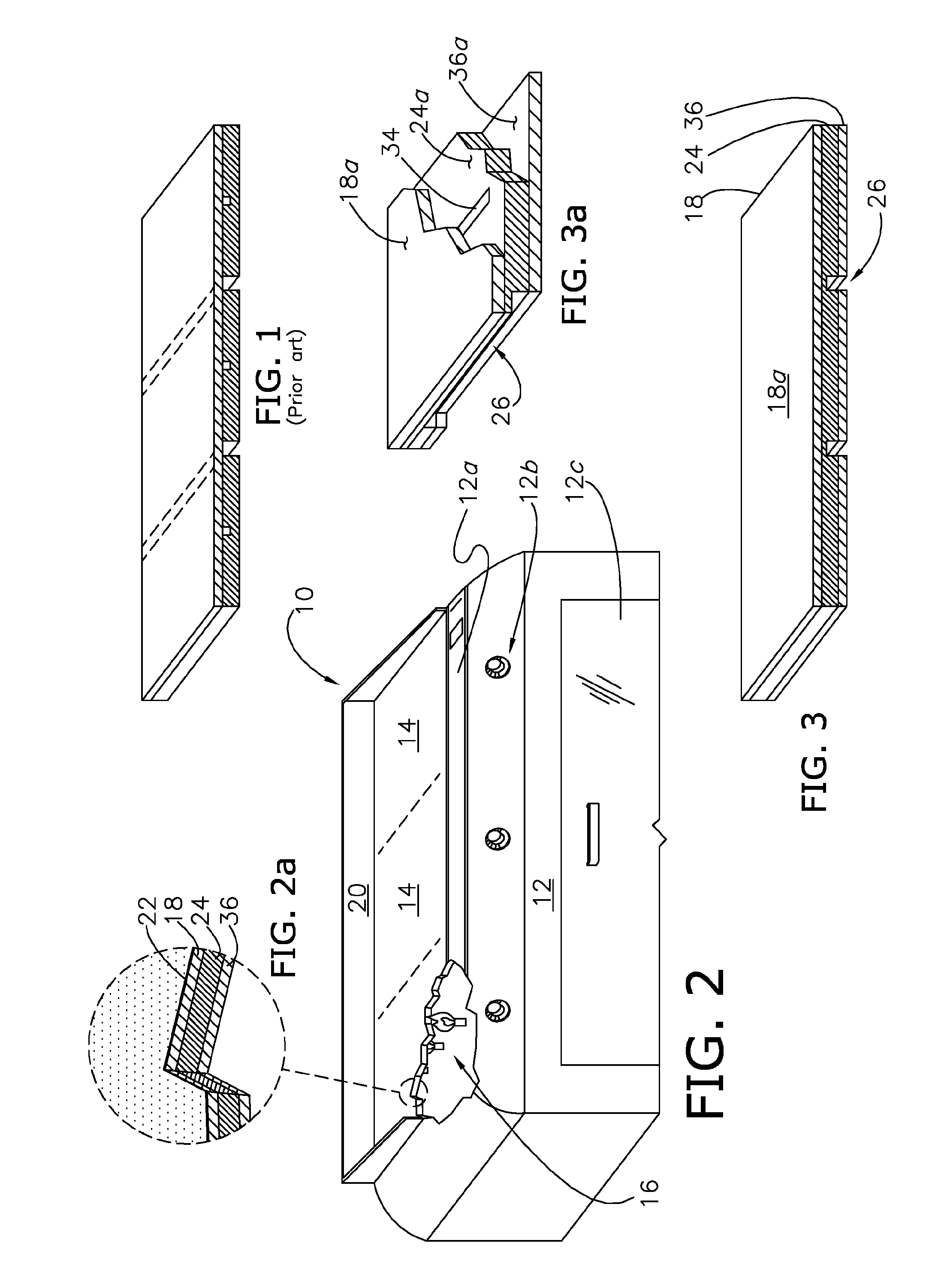

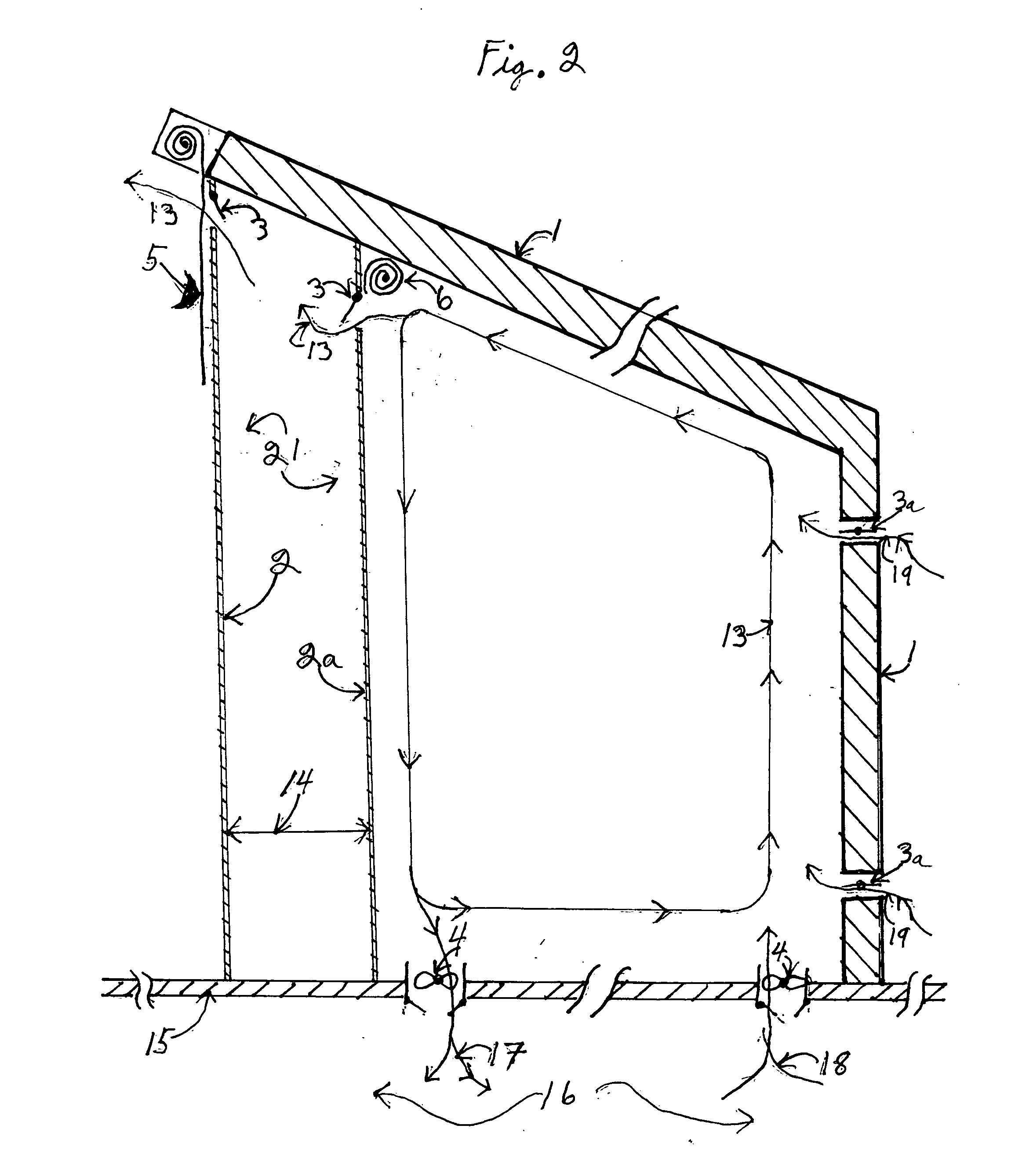

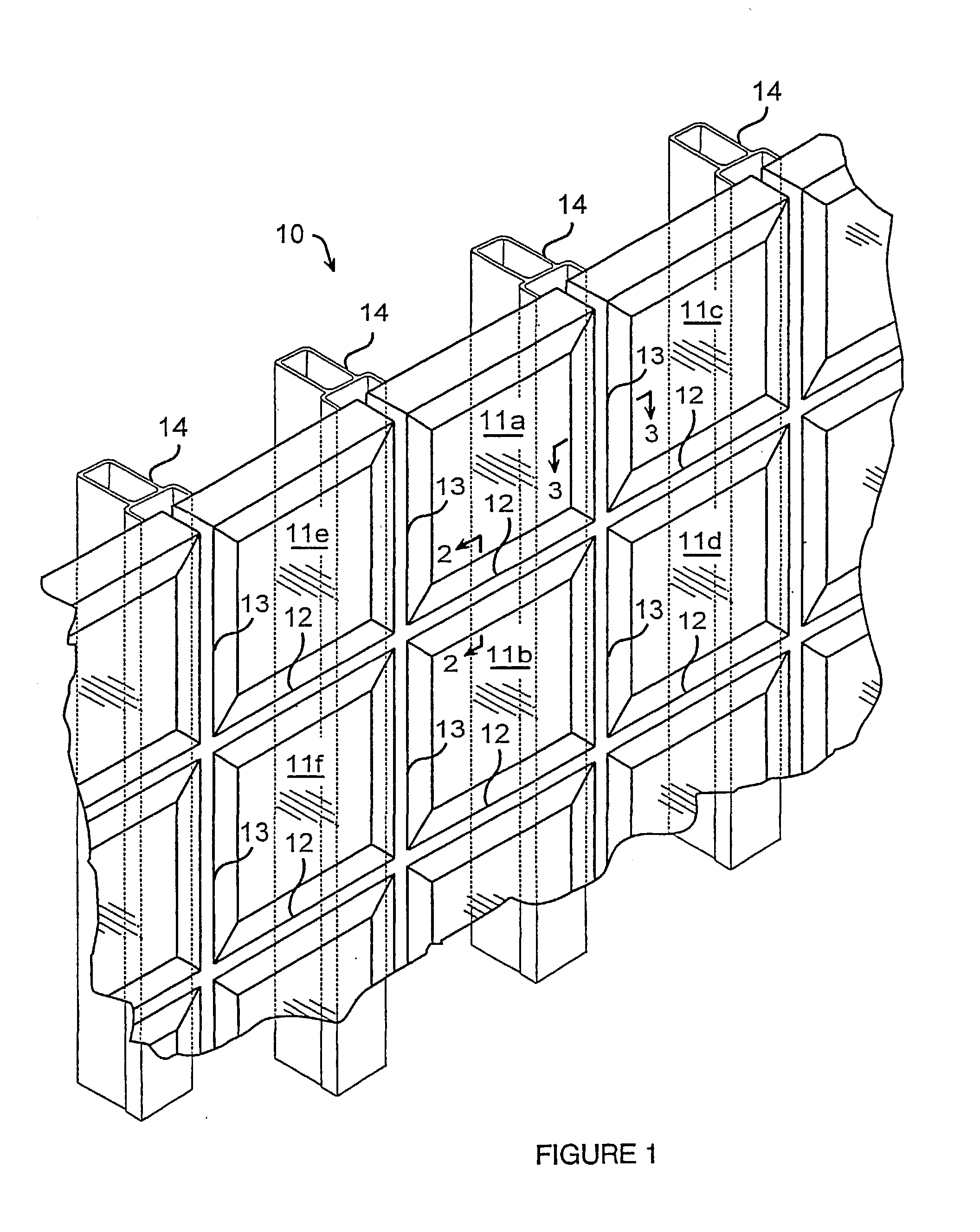

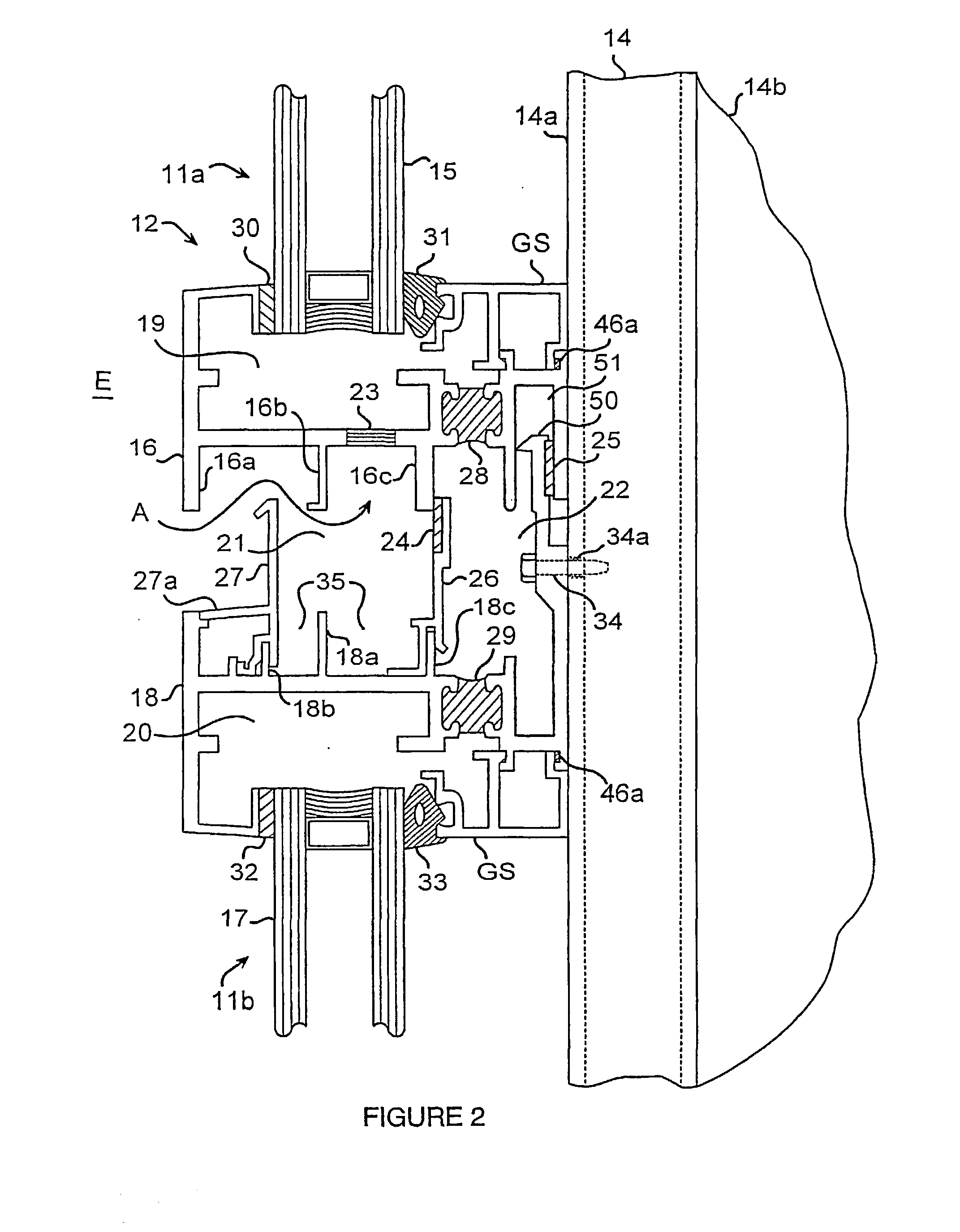

Enhanced curtain wall system

When assembled to a building support structure to form a curtain wall system of adjoining panels, a preferred embodiment of the enhanced airloop wall system as shown in FIG. 2 comprises panel frame segments (e.g., upper frame segment) that, when assembled, form interconnected inner and outer airloop segments (e.g., inner loop segment) that separate and improve water seal and air seal functions and improve sealing performance, a circuitous path (e.g., "A") at an enlarged air opening into an airloop to pressure equalize and limit water entry into the airloop, a two point fastener support of each panel assembly to allow interfloor deflections under seismic or other loads without excessive loads on the panel assembly, a structural hook-like protrusion for resisting building outward loads on panels separate from fasteners, a splitter in a drainage cavity in the outer airloop that creates a dual drainage path and a surface upon which droplets can collect. In addition, one or more panel frames are partially composed of thermal breaks to increase the resistance to heat transfer between the building interior and the exterior environment E, and clip-on panel frame elements allow easier panel assembly installation and replacement.

Owner:ADVANCED BUILDING SYST

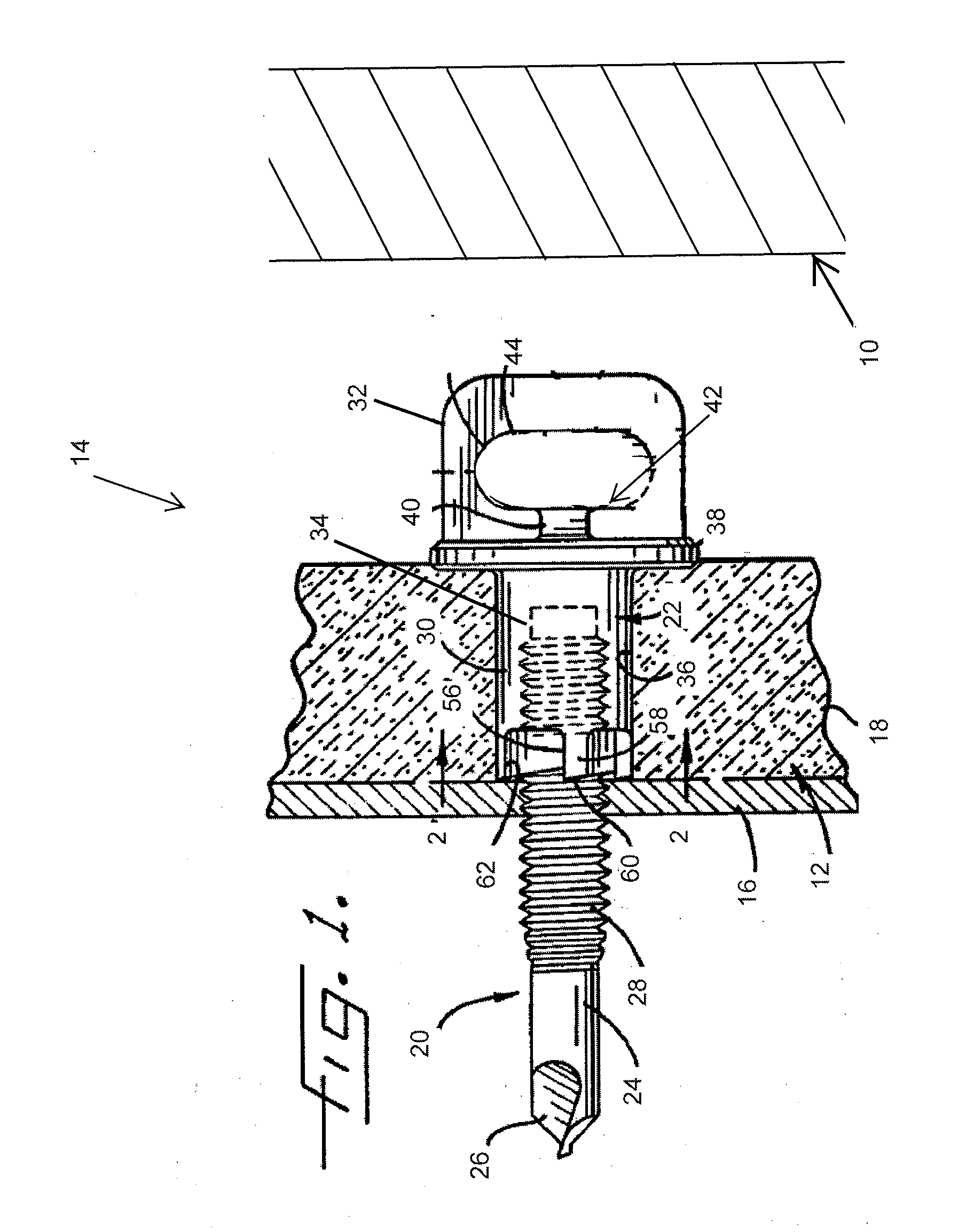

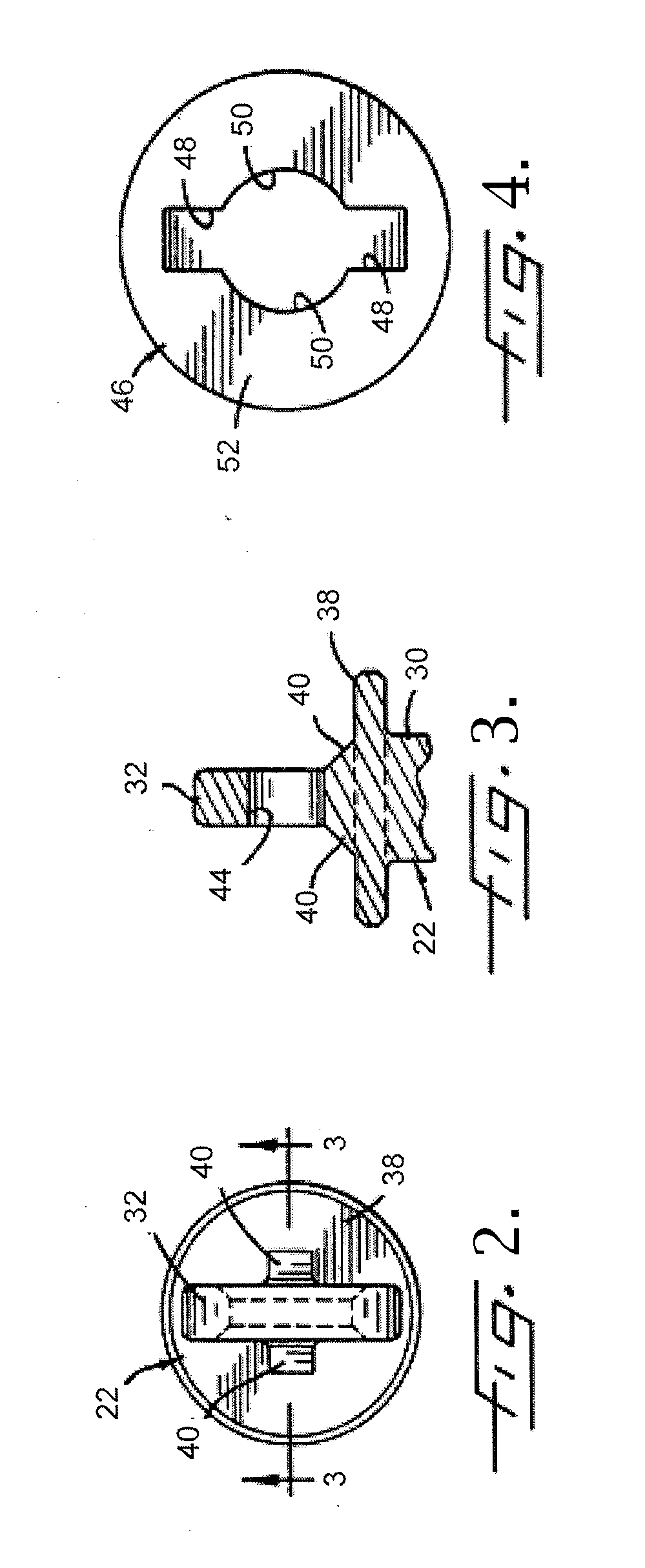

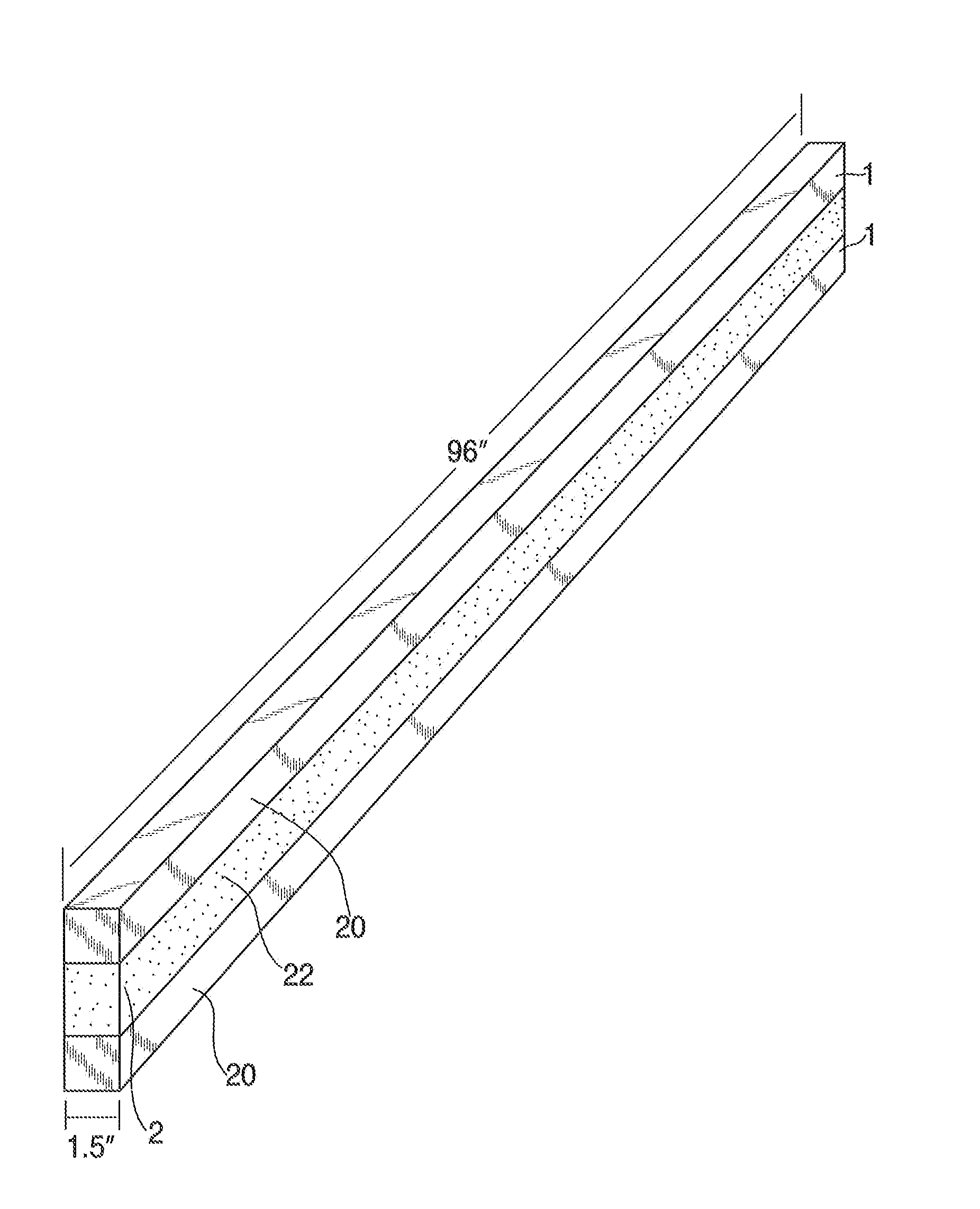

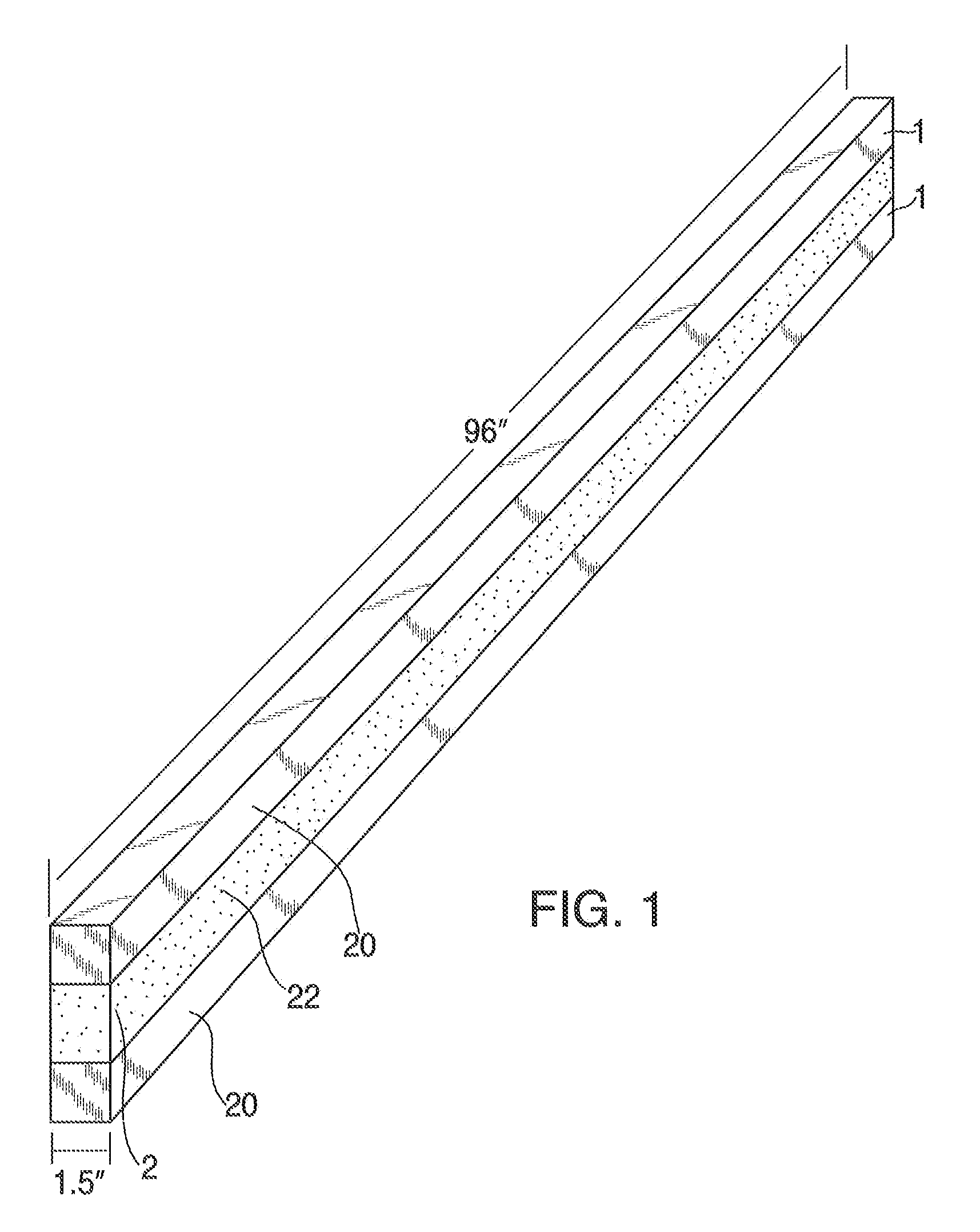

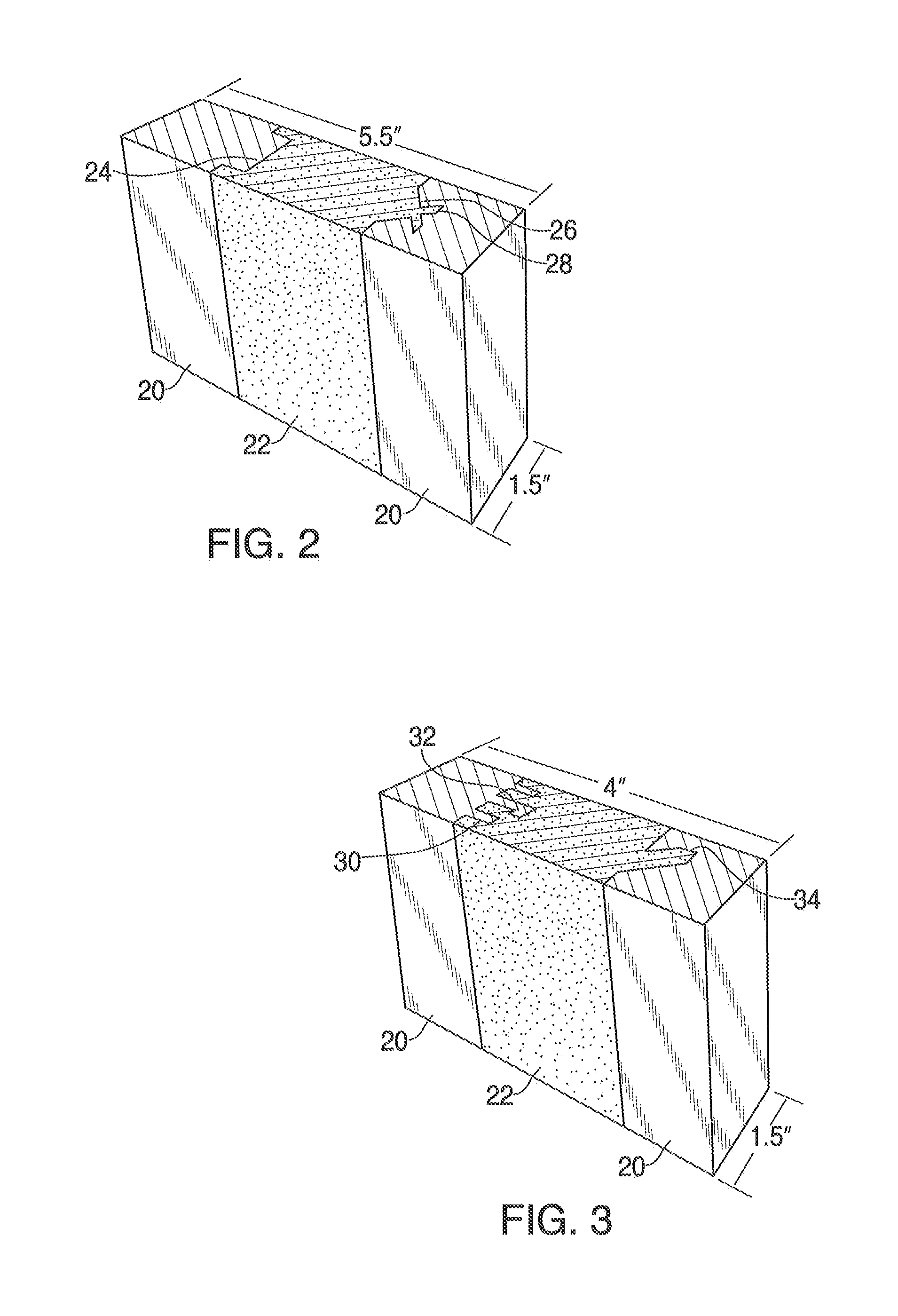

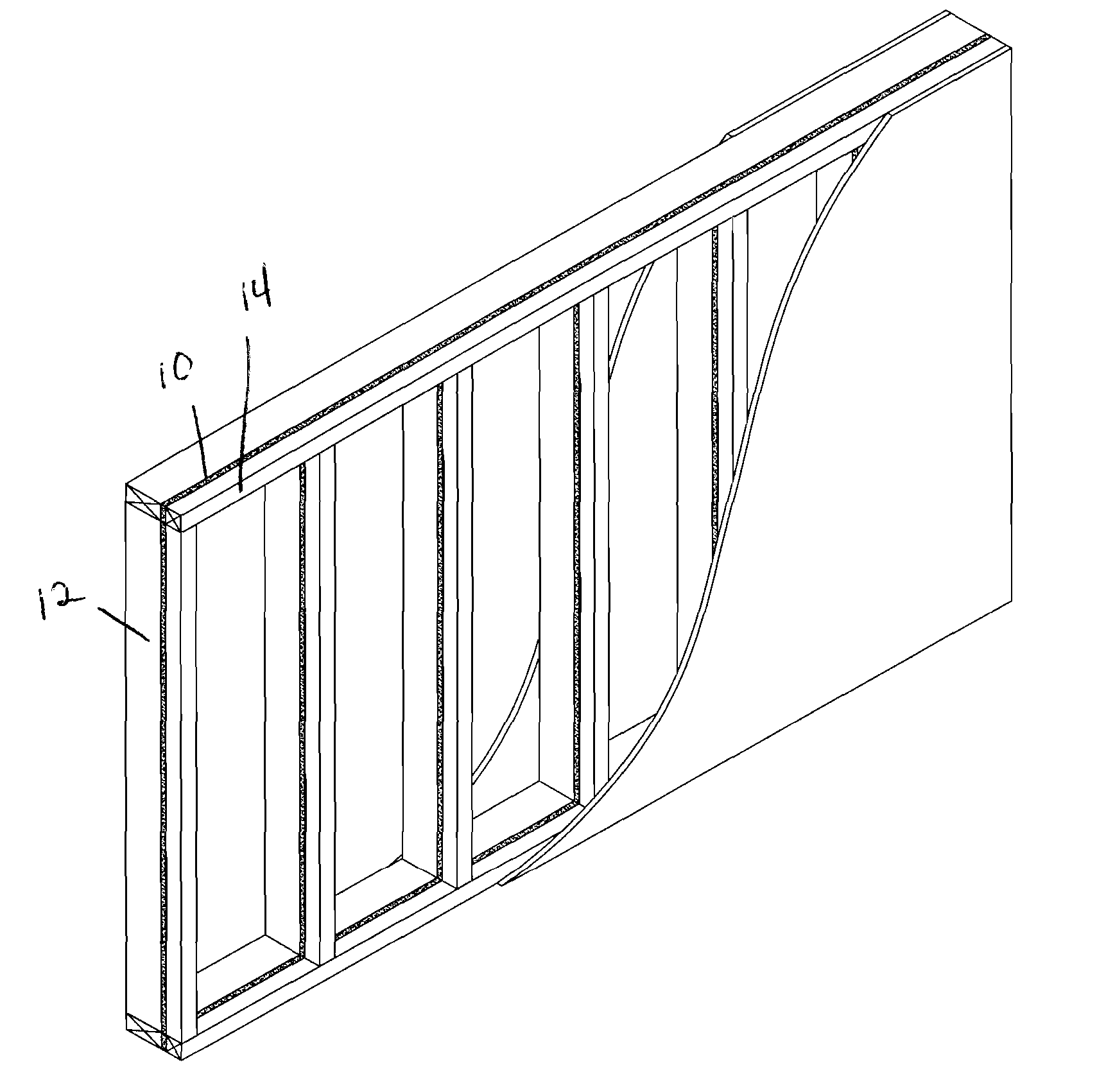

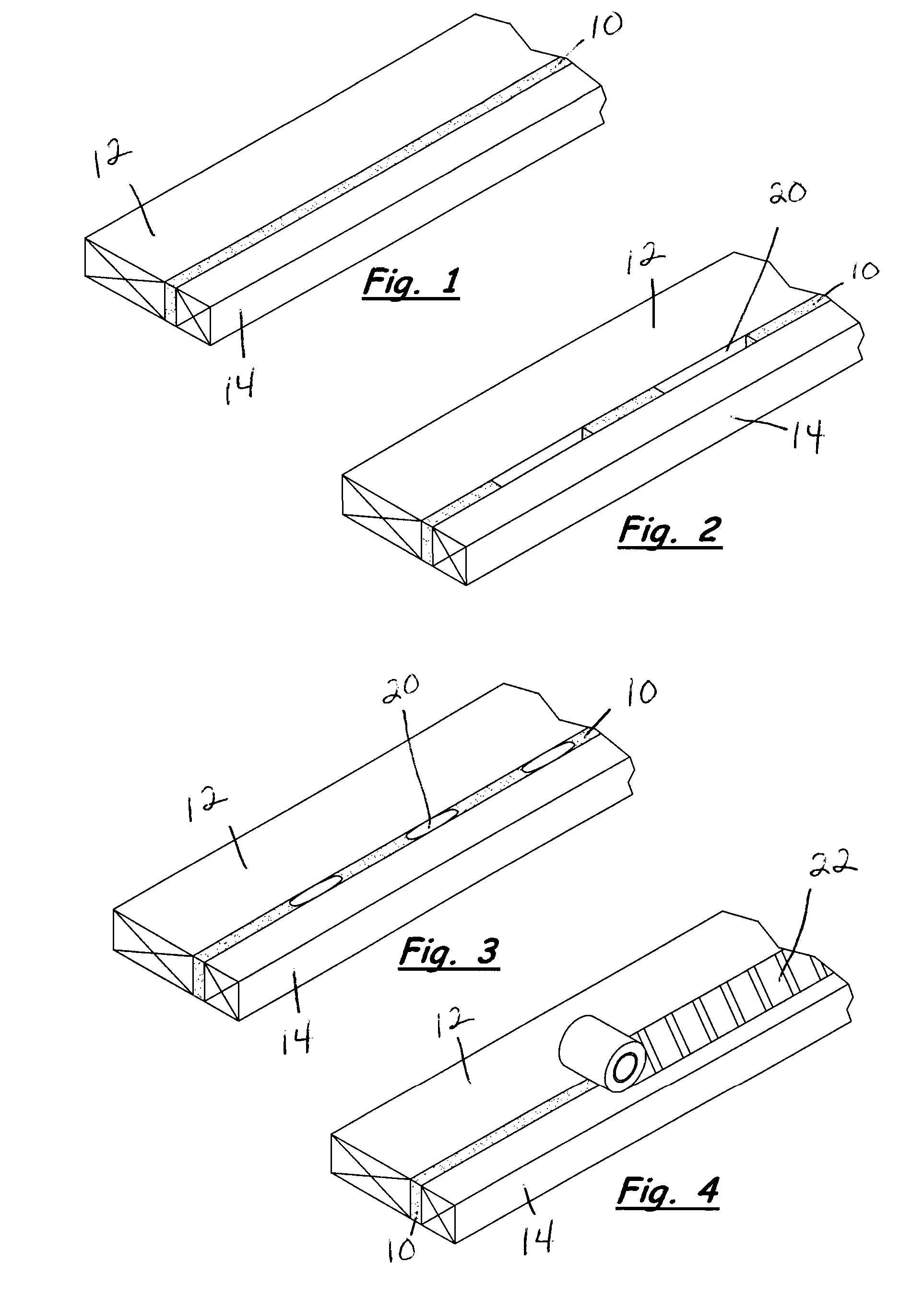

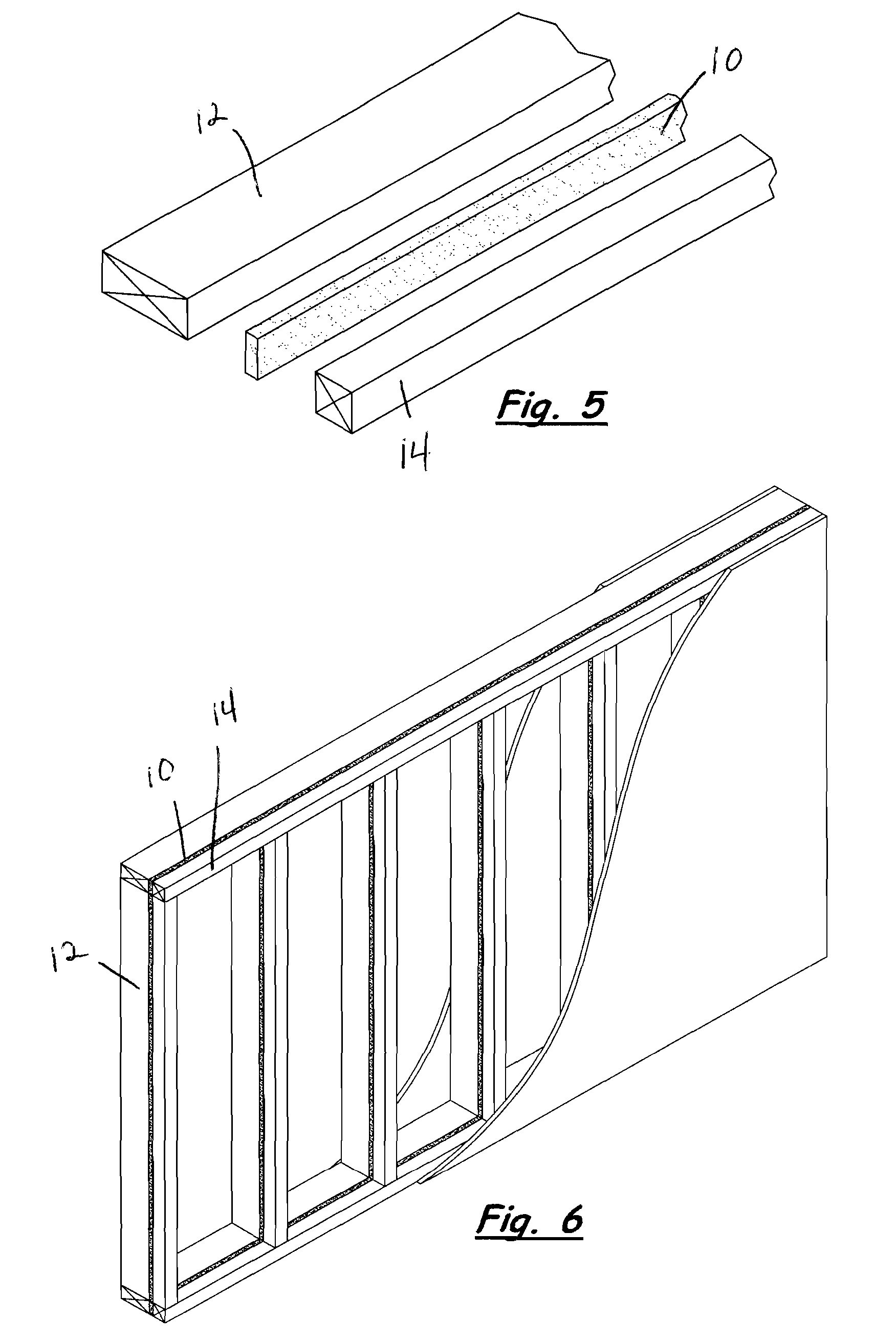

Wall Stud with a Thermal Break

ActiveUS20110239573A1Reduce installation costsStructural integrity remainsLiquid surface applicatorsWallsThermal breakWall stud

Insulating material is sandwiched between one edge of a structural 2×4 and one edge of a structural 2×2 to form a 2×6 wall stud with a thermal break. While shapes, sizes and compositions of the structural members can vary, the insulated wall stud has the advantage of being the size of conventional lumber reducing installation cost.

Owner:LOCKHART STACY L

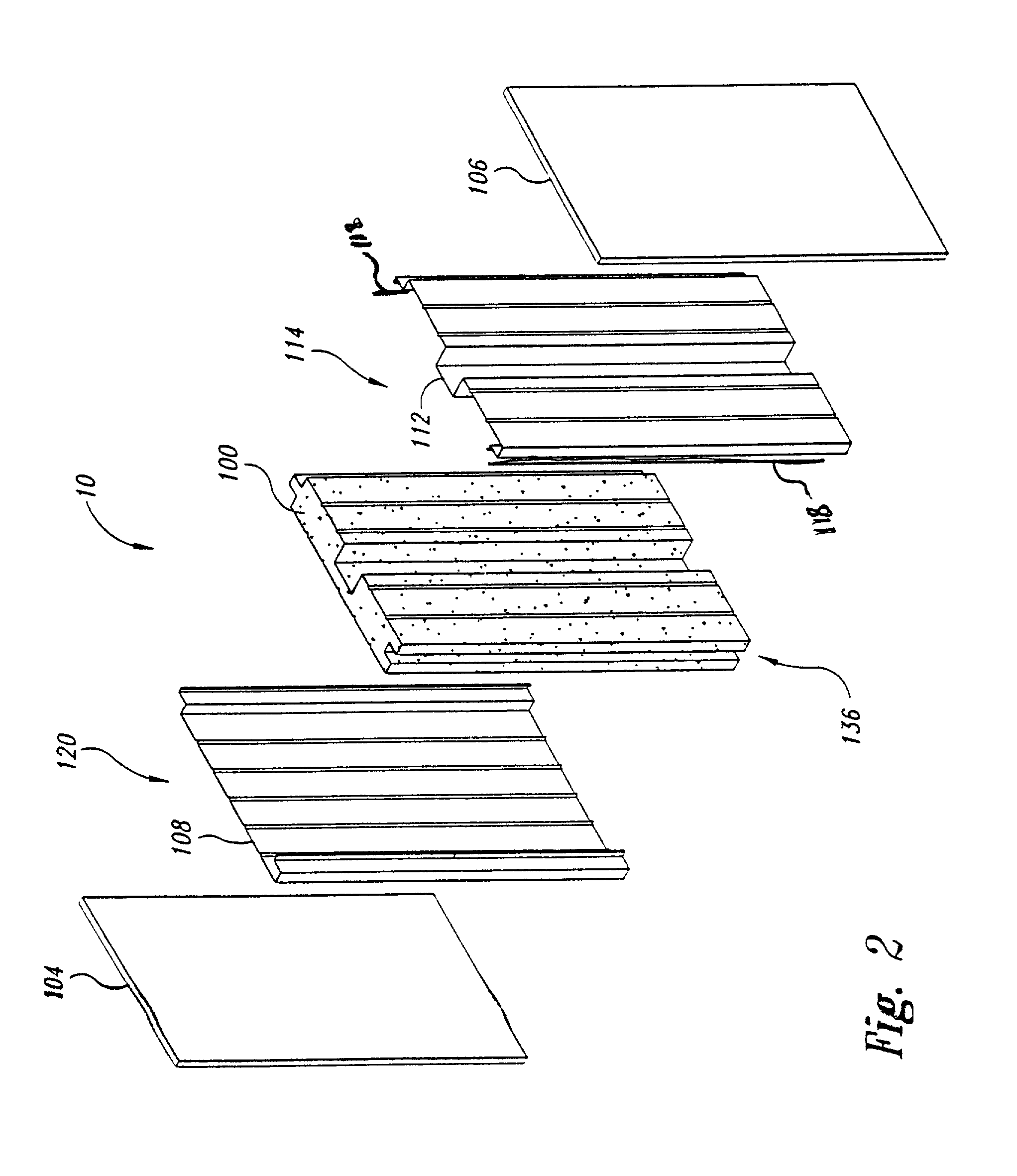

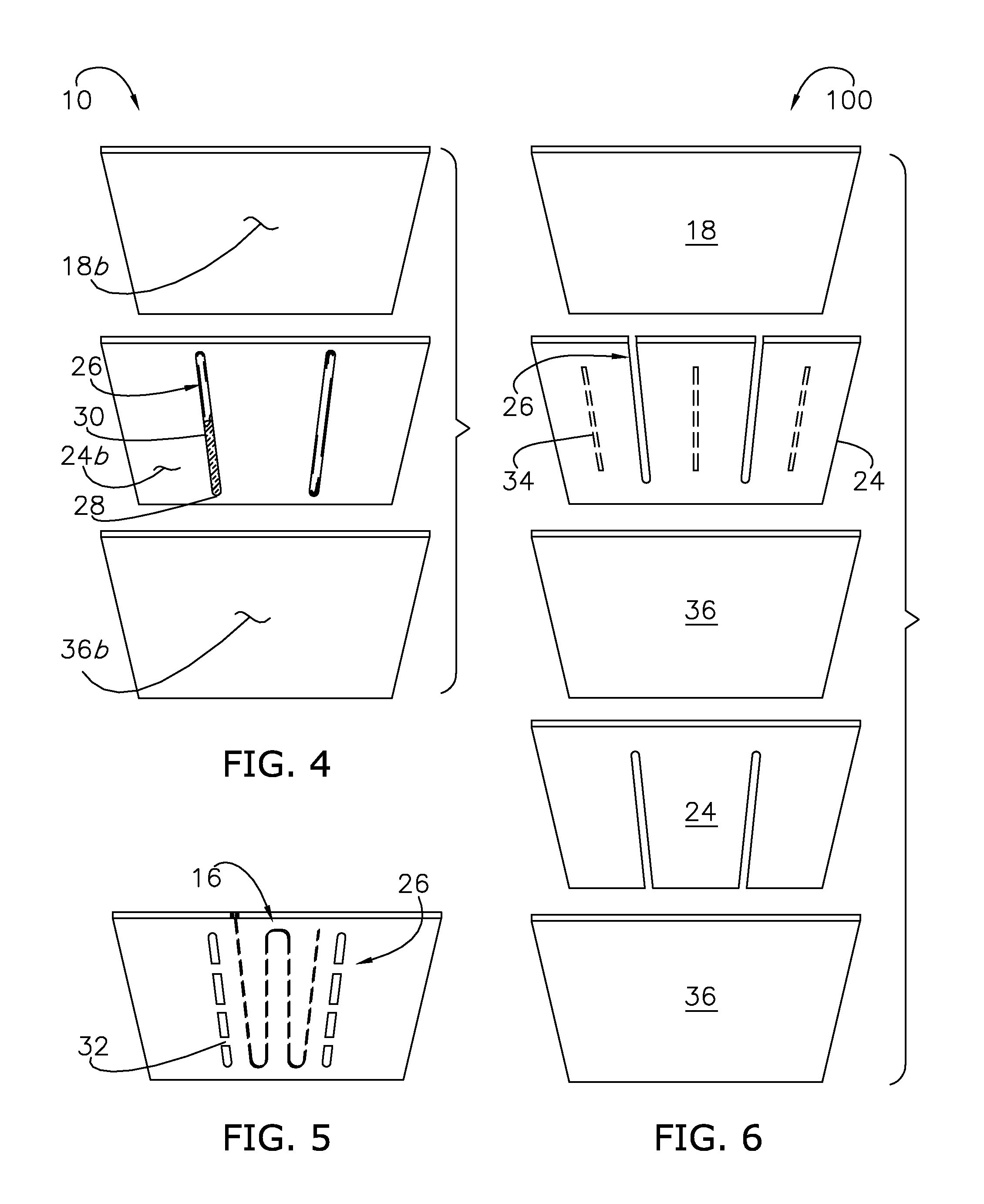

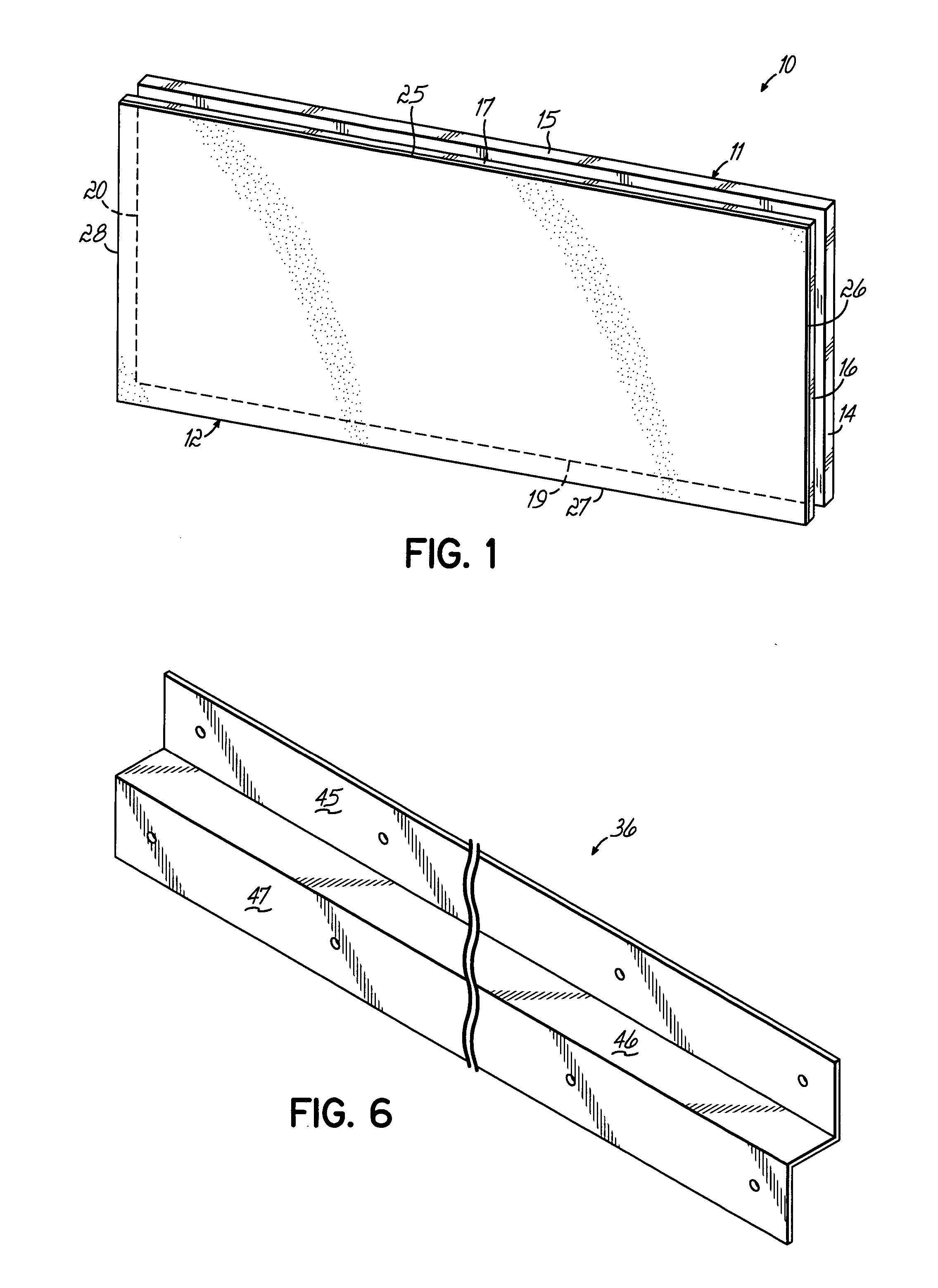

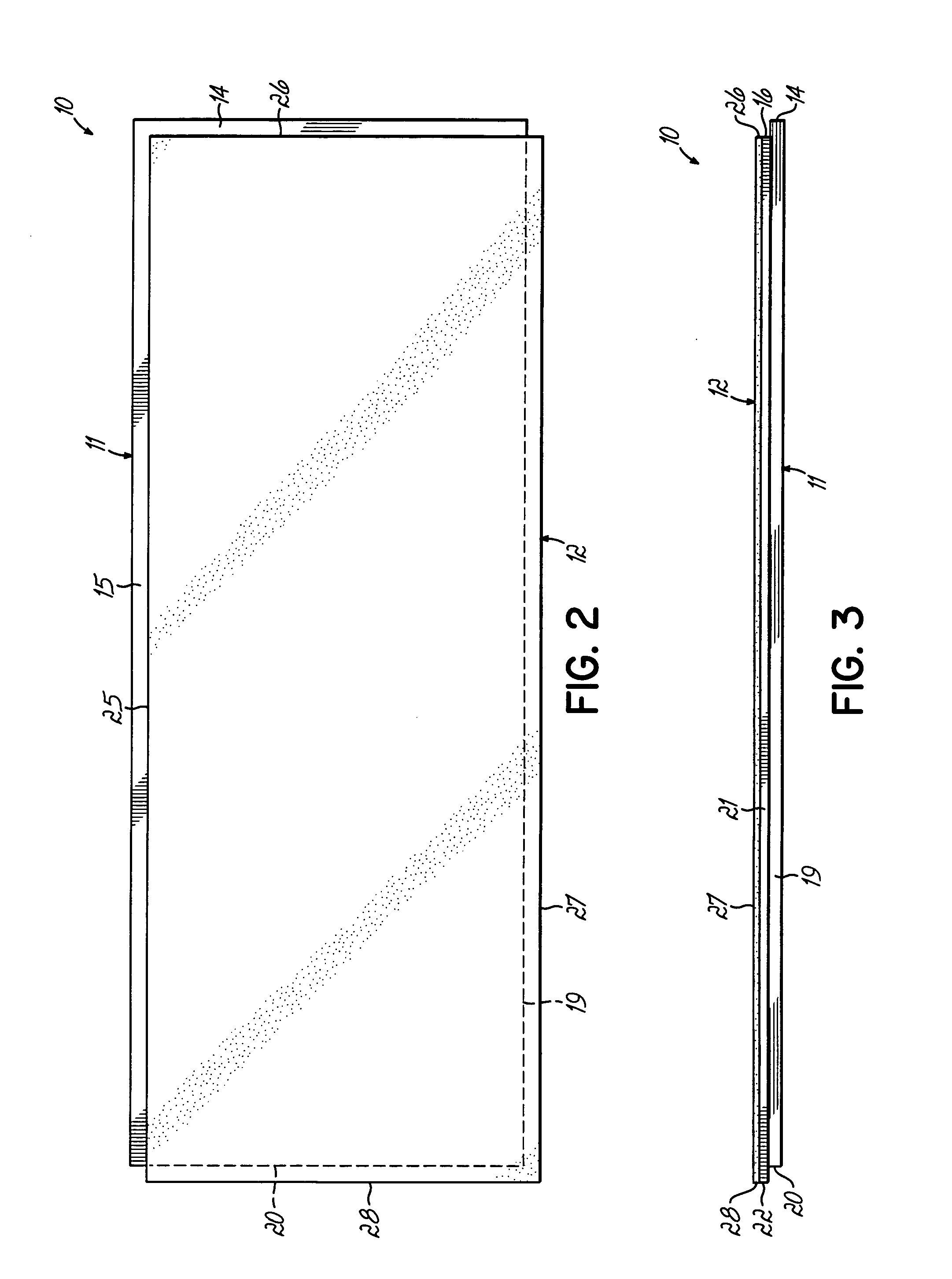

Insulated sheathing panels

An insulated sheathing panel comprises an insulating member and a facing. The insulating member has two adjacent edges formed by a portion of its thickness extending beyond two corresponding adjacent edges of said facing. Two other adjacent edges of said insulating member in the said relative thickness portion are recessed within two corresponding edges of said facing. When the panels are applied to a stud wall, their edges are ship-lapped, with edges of the facings in abutted relation so there is not thermal break at the panel seam. “Z”-shaped clips or elongated bars are used to secure panels to the stud wall. The panel facings are finished and no vapor barrier is required. Methods are included.

Owner:CRAWFORD RICHARDS H

Thermally broken sunshade anchors

ActiveUS7600350B2Reduce the heating effectPhotovoltaic supportsBuilding roofsThermal breakEngineering

A thermally broken sunshade anchor can attach a sunshade to a mullion of a curtain wall of a building structure. The thermally broken sunshade anchor has a body for connection to the sunshade, a wall attachment member for attachment to the curtain wall, and a thermal break between the body and the wall attachment member. The thermal break is positioned adjacent a thermal break location portion of the body and adjacent a thermal break location portion of the wall attachment member. The thermal break resists heat transfer such that the body and the wall attachment member are substantially thermally isolated from each other by the thermal break. The thermal break can be formed by pour and debridge processes.

Owner:YKK AP AMERICA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com