Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6985 results about "Thermal conduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

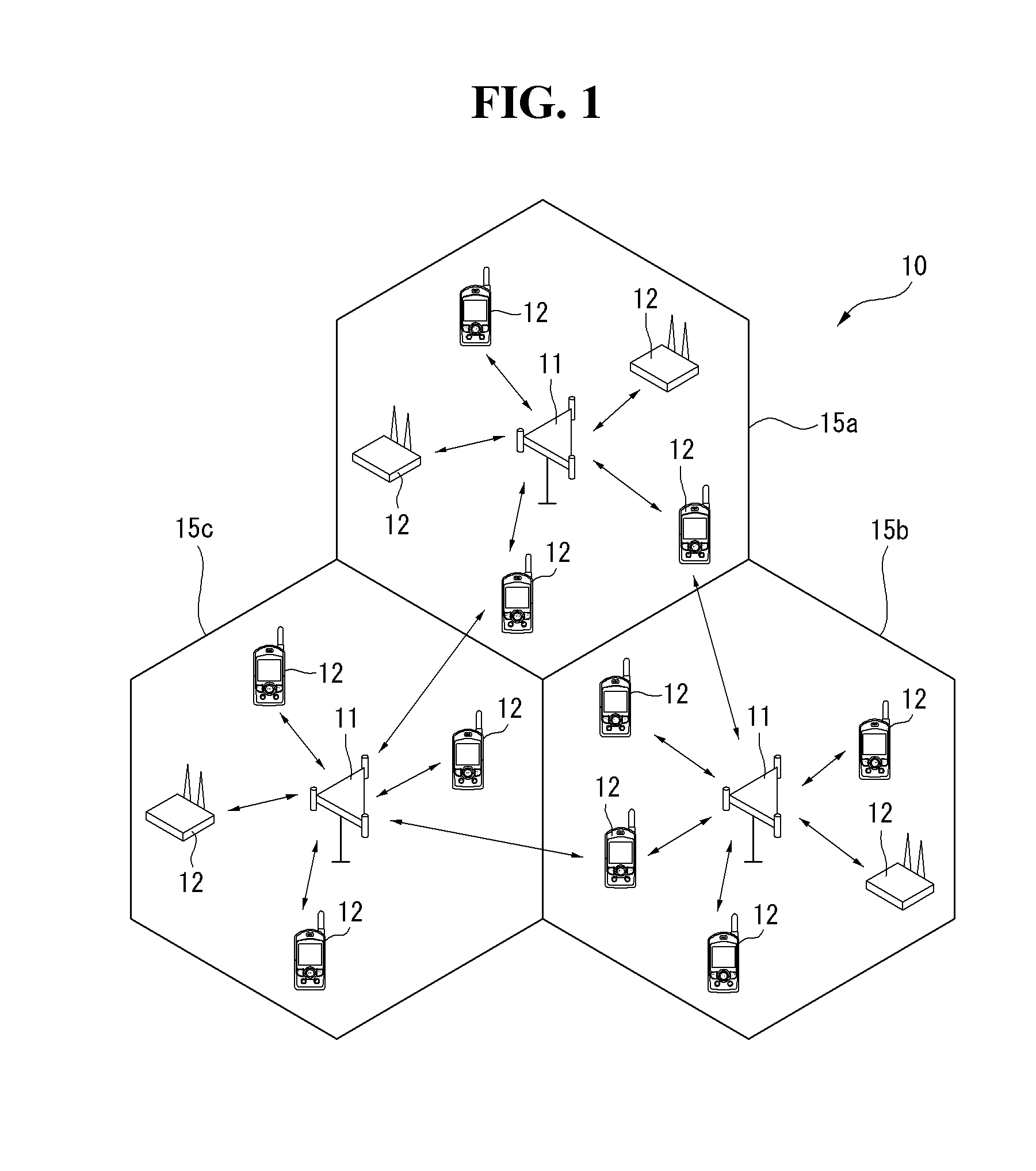

Thermal conduction is the transfer of heat internal energy by microscopic collisions of particles and movement of electrons within a body. The microscopically colliding particles, that include molecules, atoms and electrons, transfer disorganized microscopic kinetic and potential energy, jointly known as internal energy. Conduction takes place in all phases of solids, liquids, gases and waves. The rate at which energy is conducted as heat between two bodies is a function of the temperature difference temperature gradient between the two bodies and the properties of the conductive interface through which the heat is transferred.

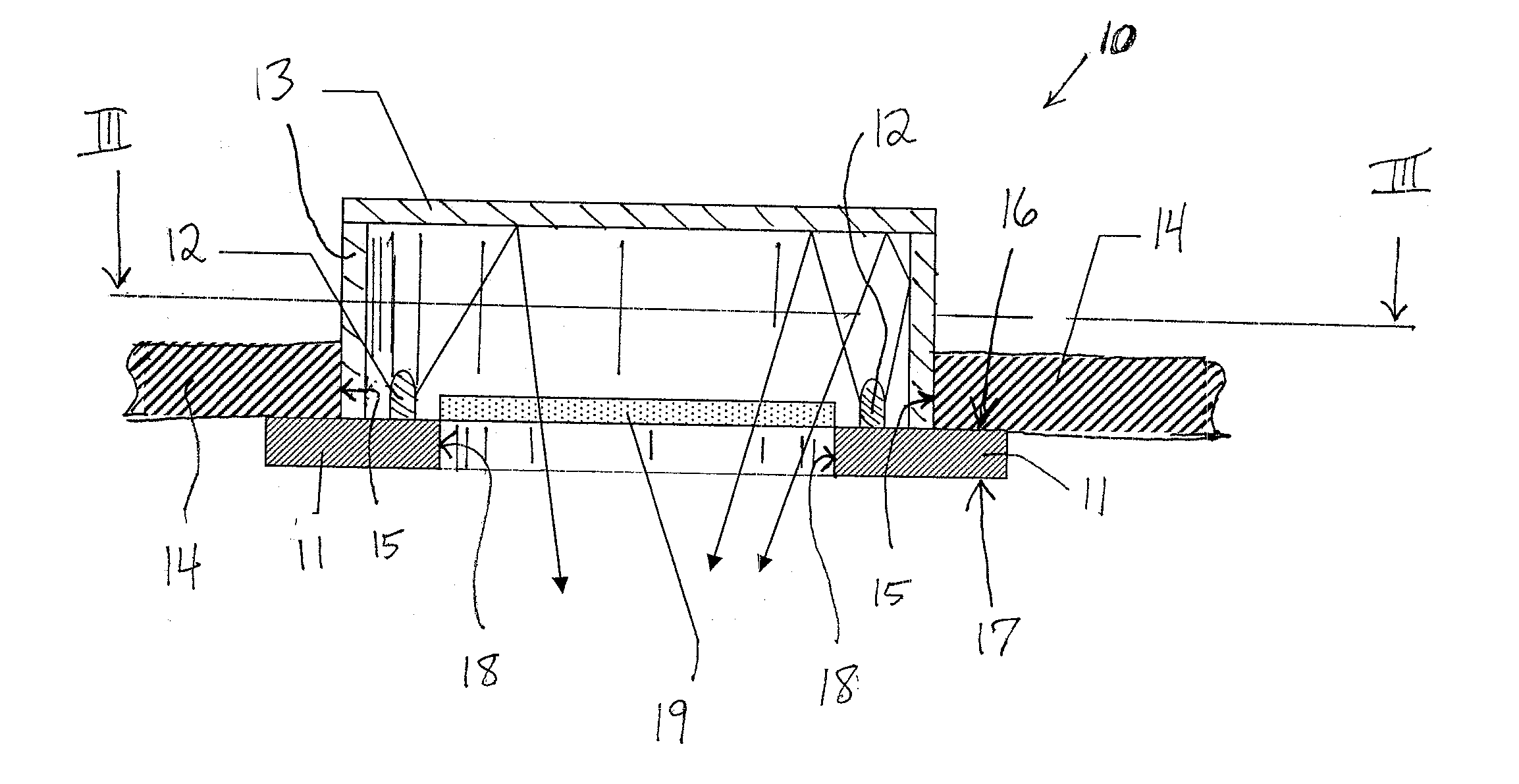

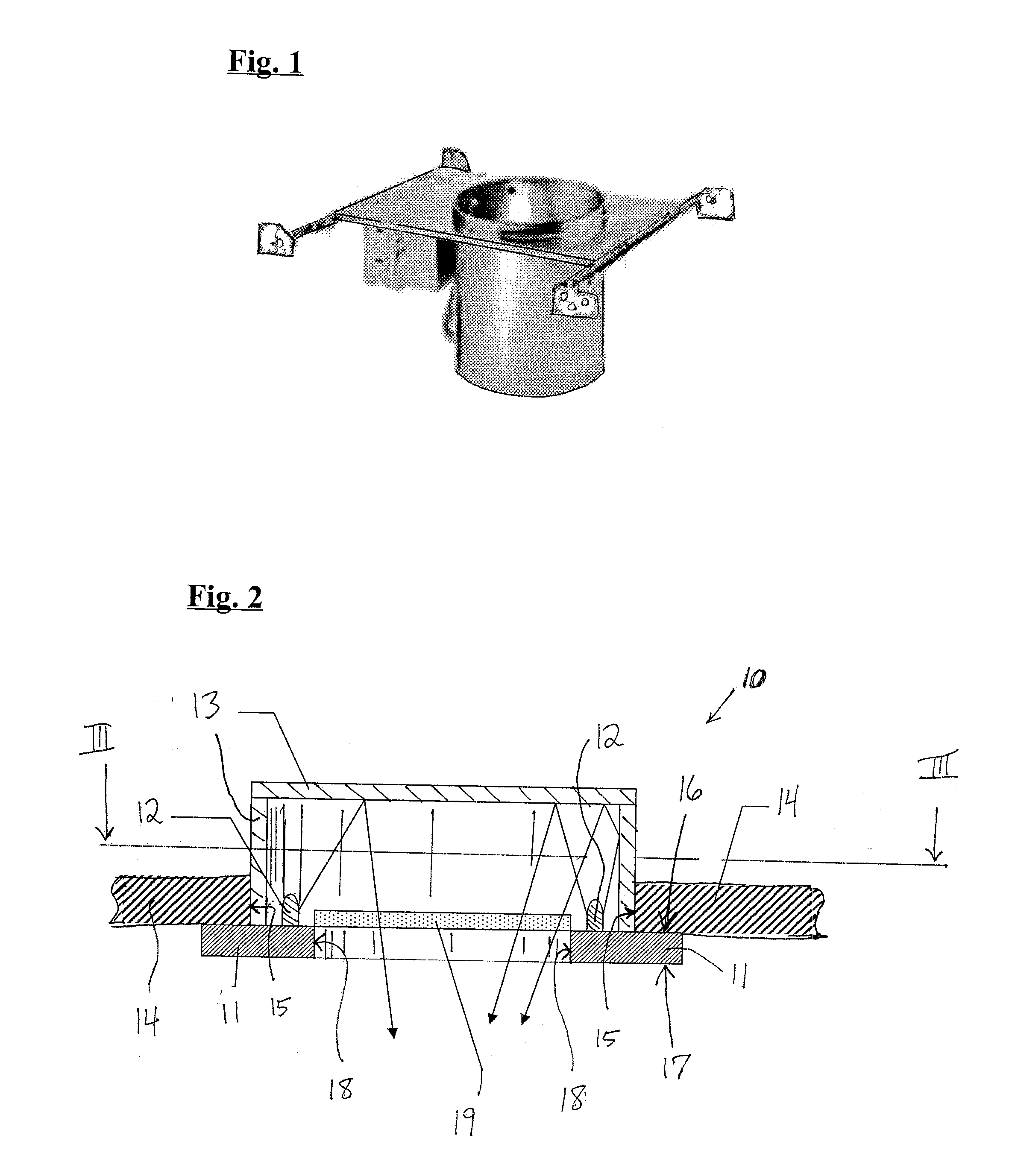

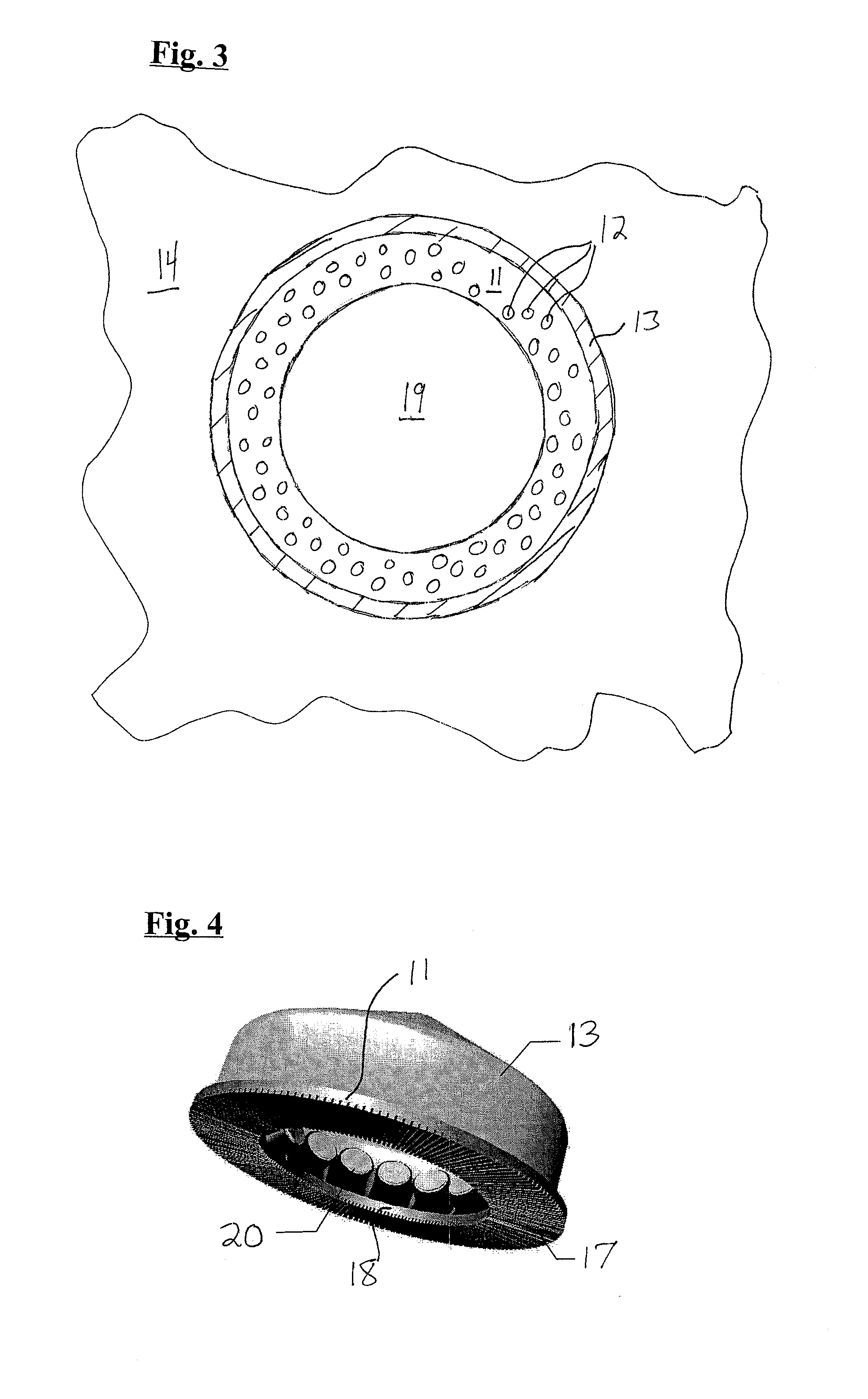

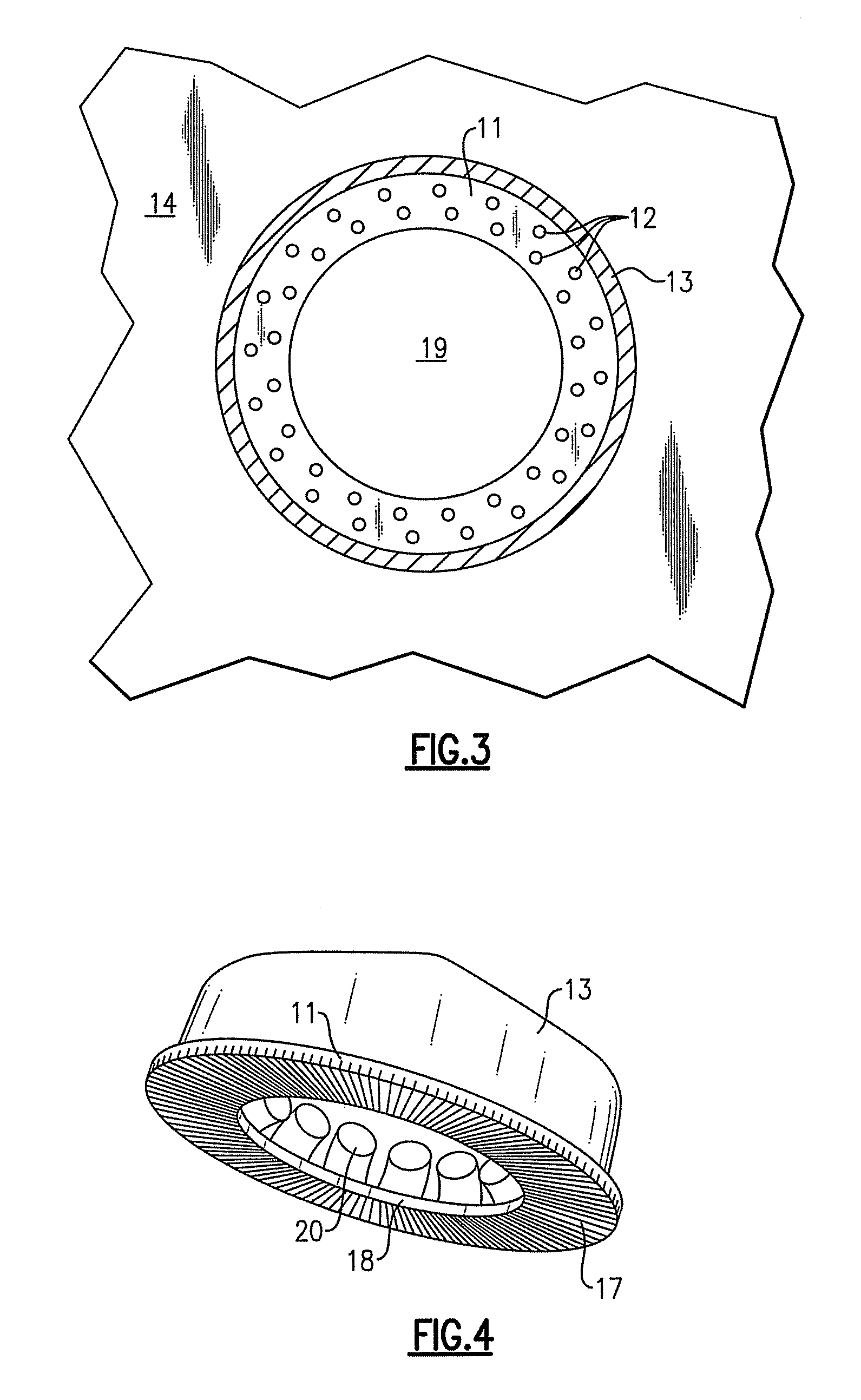

Lighting device

ActiveUS20070263393A1Reduce glareEfficient transferMechanical apparatusPoint-like light sourceEffect lightEngineering

Owner:IDEAL IND LIGHTING LLC

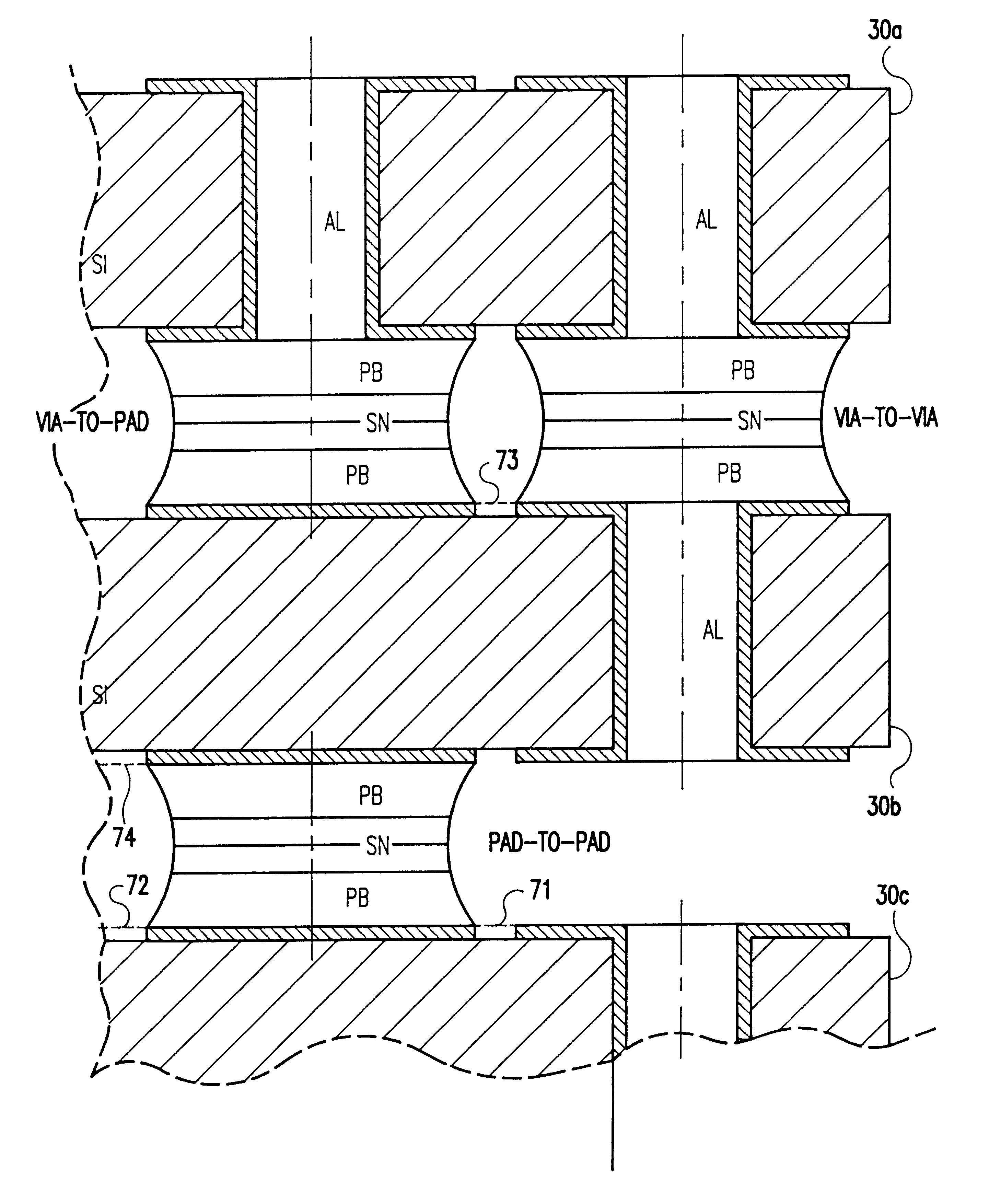

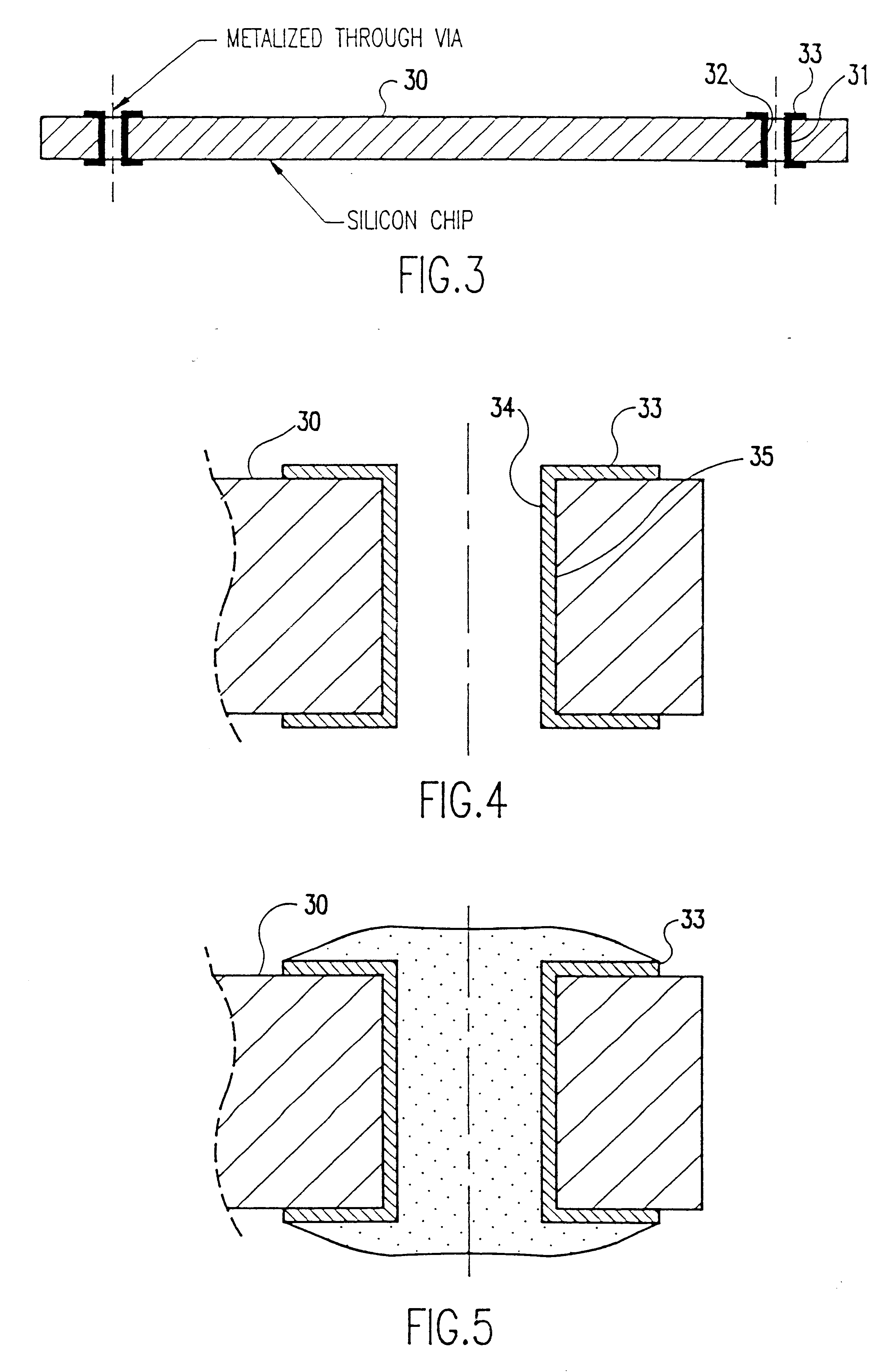

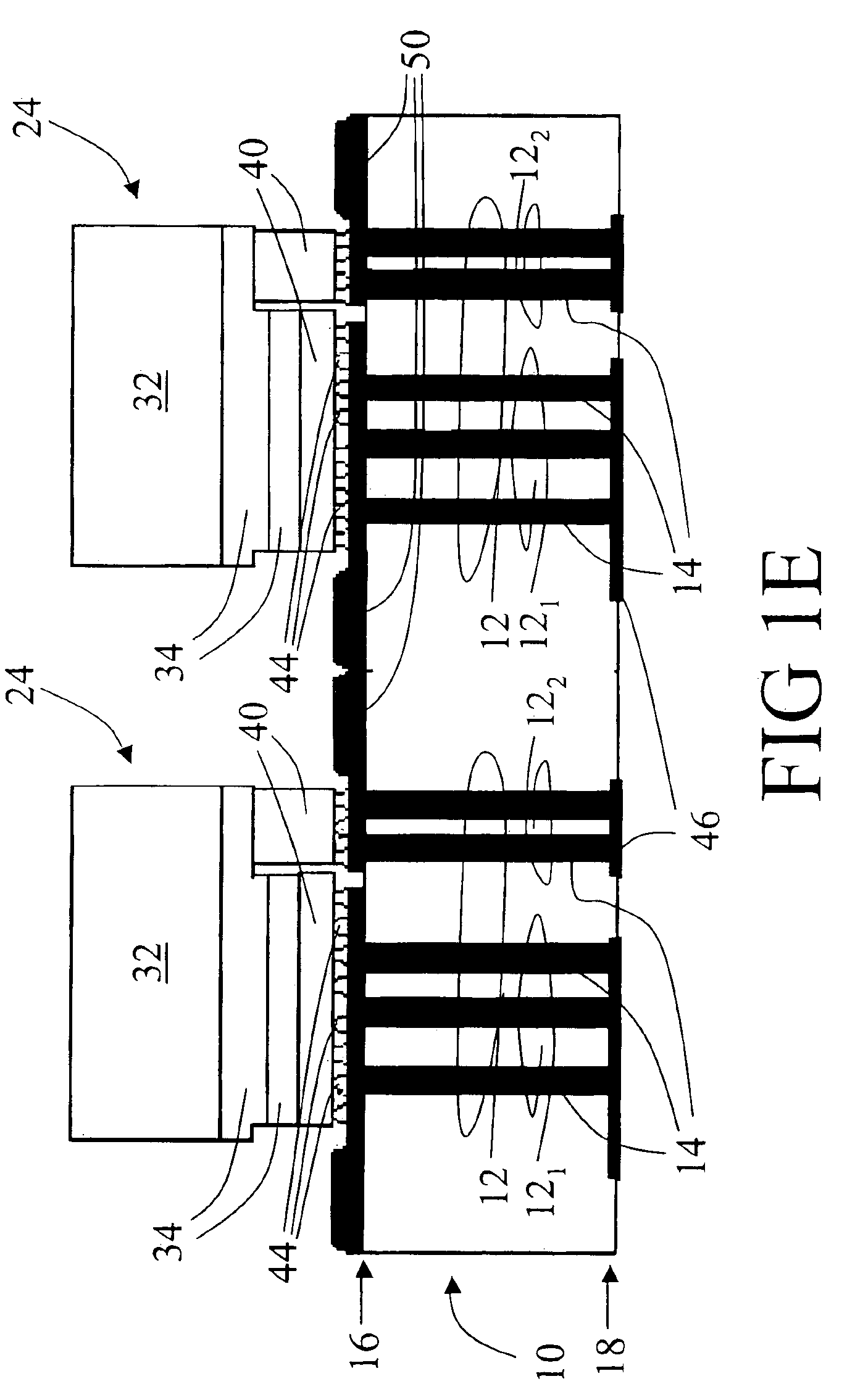

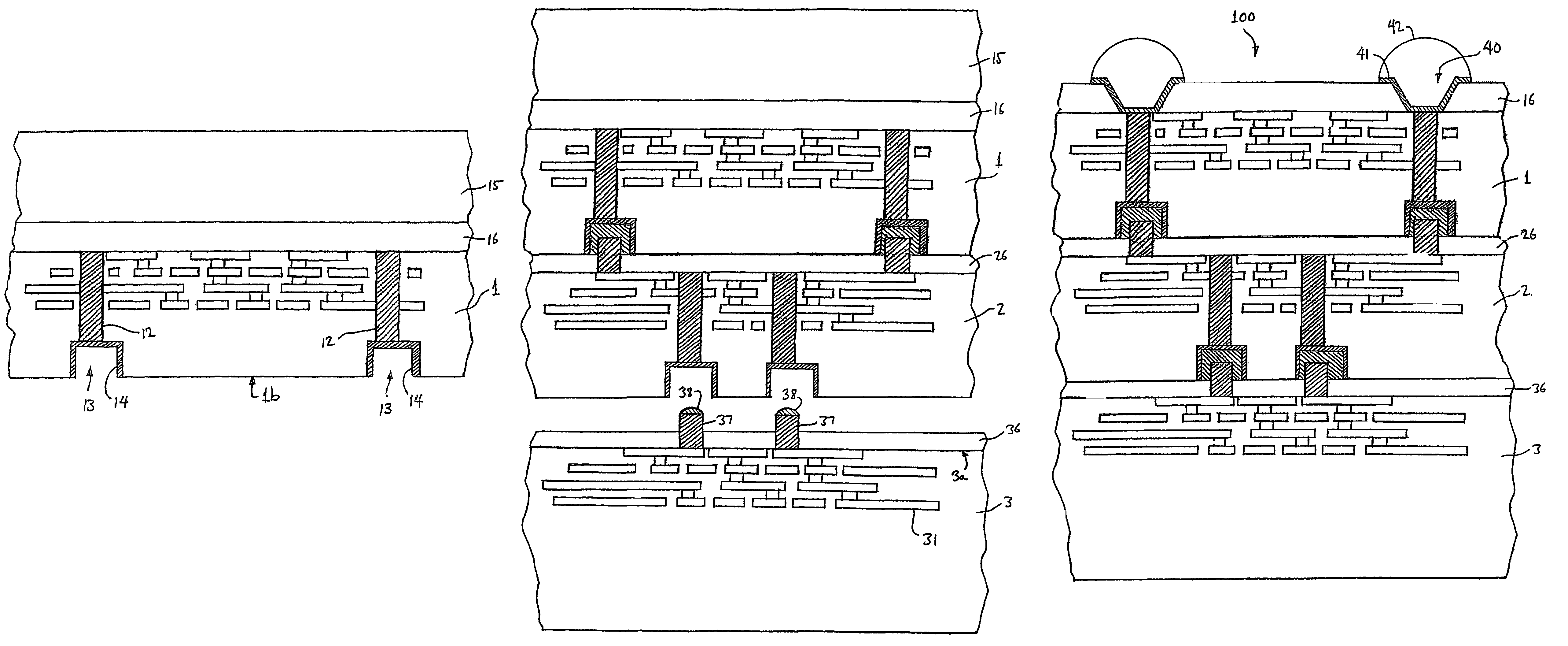

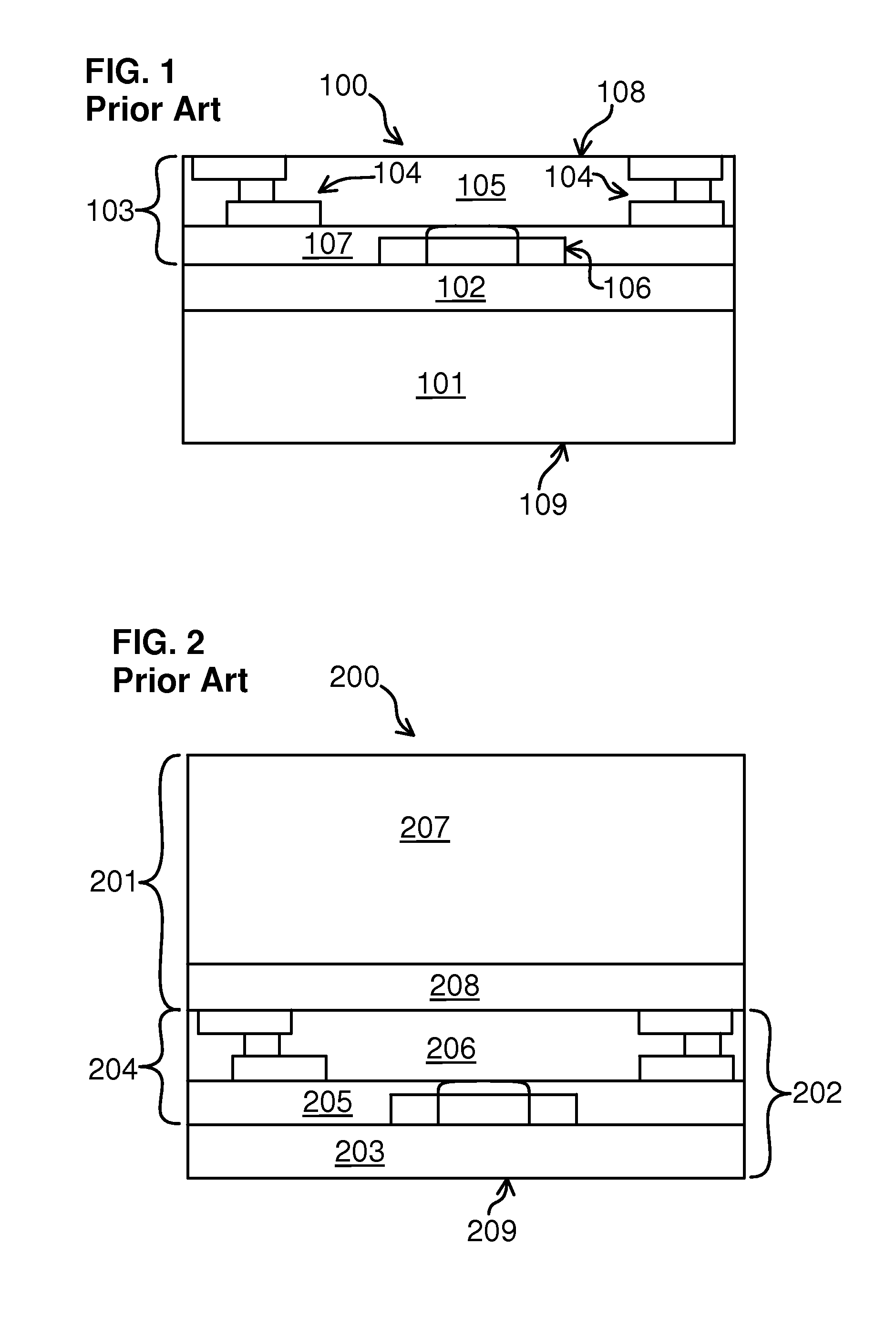

High density integrated circuit packaging with chip stacking and via interconnections

InactiveUS6236115B1Reduced connection exposureLarge capacitySemiconductor/solid-state device detailsSolid-state devicesEngineeringThermal expansion

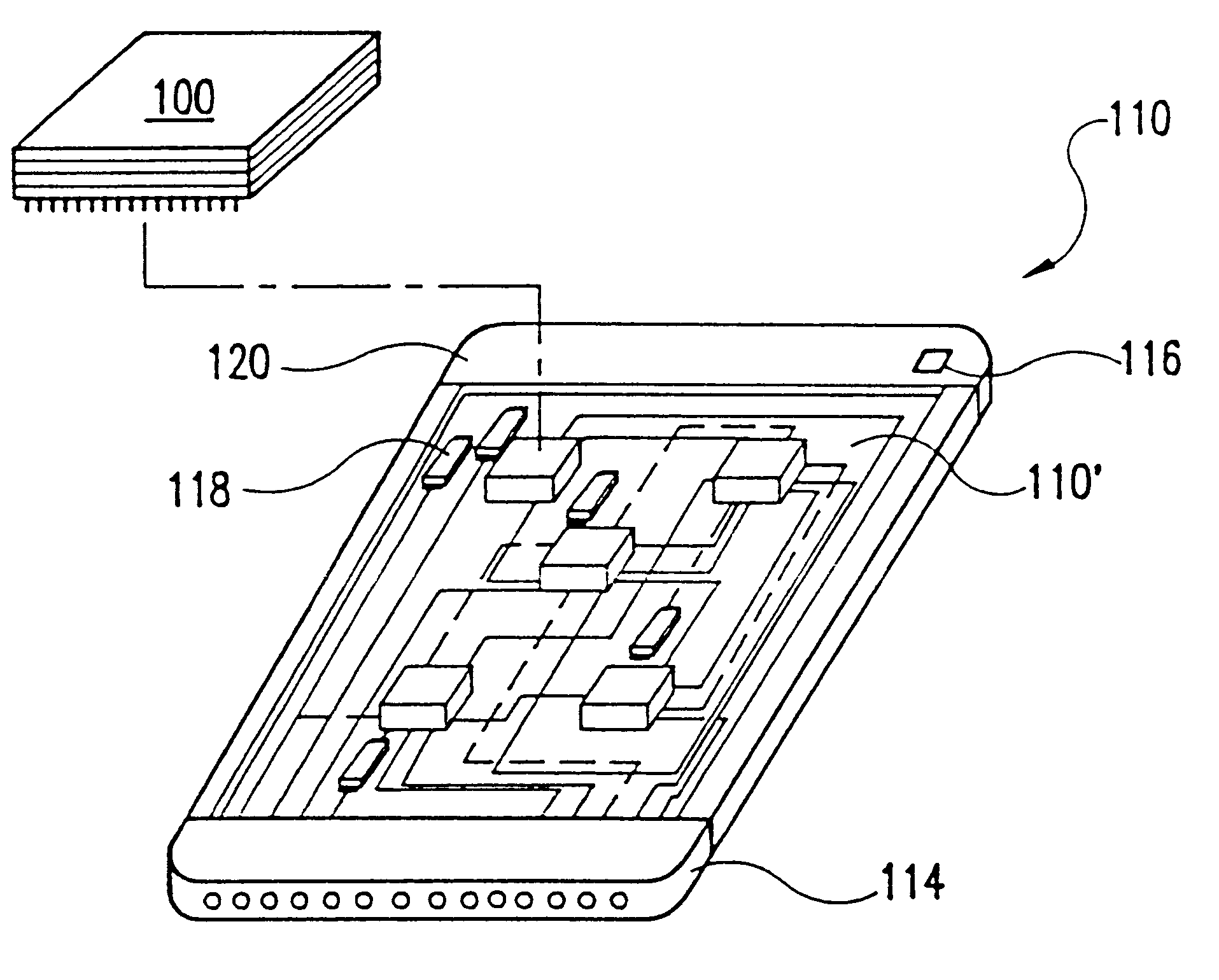

Chip stacks with decreased conductor length and improved noise immunity are formed by laser drilling of individual chips, such as memory chips, preferably near but within the periphery thereof, and forming conductors therethrough, preferably by metallization or filling with conductive paste which may be stabilized by transient liquid phase (TLP) processes and preferably with or during metallization of conductive pads, possibly including connector patterns on both sides of at least some of the chips in the stack. At least some of the chips in the stack then have electrical and mechanical connections made therebetween, preferably with electroplated solder preforms consistent with TLP processes. The connections may be contained by a layer of resilient material surrounding the connections and which may be formed in-situ. High density circuit packages thus obtained may be mounted on a carrier by surface mount techniques or separable connectors such as a plug and socket arrangement. The carrier may be of the same material as the chip stacks to match coefficients of thermal expansion. High-density circuit packages may also be in the form of removable memory modules in generally planar or prism shaped form similar to a pen or as a thermal conduction module.

Owner:INT BUSINESS MASCH CORP

High density integrated circuit packaging with chip stacking and via interconnections

InactiveUS6187678B1Reduced connection exposureLarge capacitySemiconductor/solid-state device detailsSolid-state devicesThermal expansionPrism

Chip stacks with decreased conductor length and improved noise immunity are formed by laser drilling of individual chips, such as memory chips, preferably near but within the periphery thereof, and forming conductors therethrough, preferably by metallization or filling with conductive paste which may be stabilized by transient liquid phase (TLP) processes and preferably with or during metallization of conductive pads, possibly including connector patterns on both sides of at least some of the chips in the stack. At least some of the chips in the stack then have electrical and mechanical connections made therebetween, preferably with electroplated solder preforms consistent with TLP processes. The connections may be contained by a layer of resilient material surrounding the connections and which may be formed in-situ. High density circuit packages thus obtained may be mounted on a carrier by surface mount techniques or separable connectors such as a plug and socket arrangement. The carrier may be of the same material as the chip stacks to match coefficients of thermal expansion. High-density circuit packages may also be in the form of removable memory modules in generally planar or prism shaped form similar to a pen or as a thermal conduction module.

Owner:IBM CORP

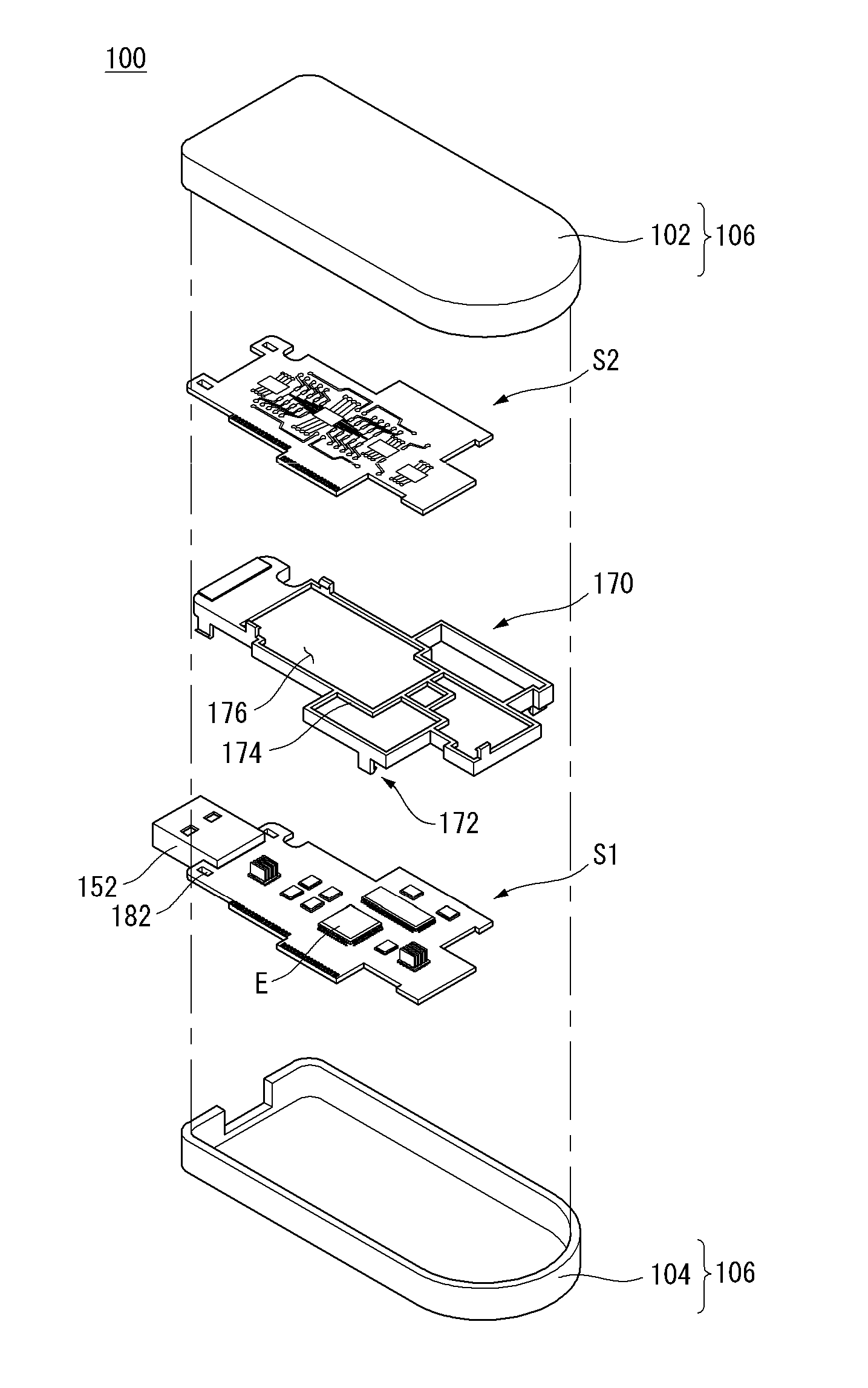

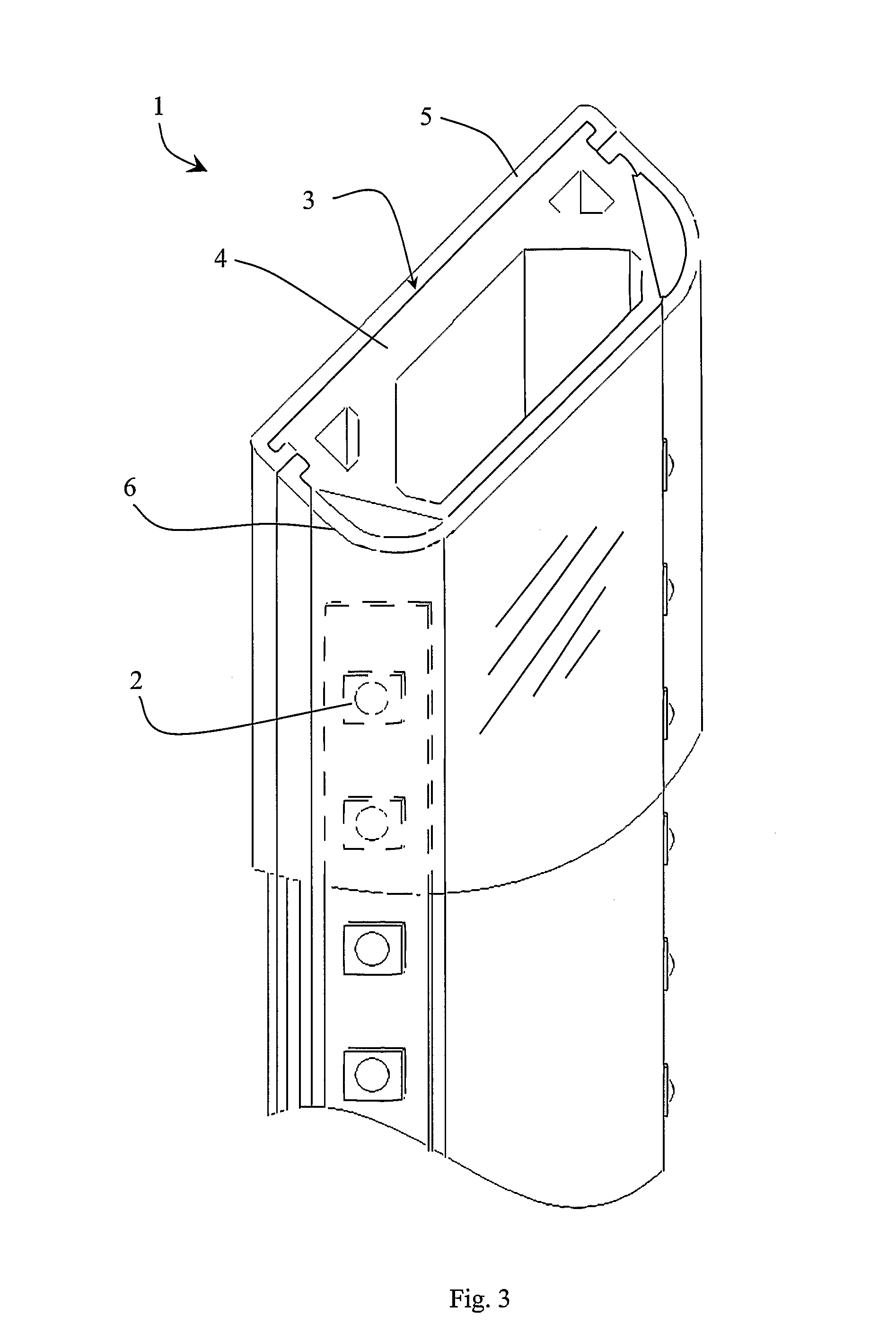

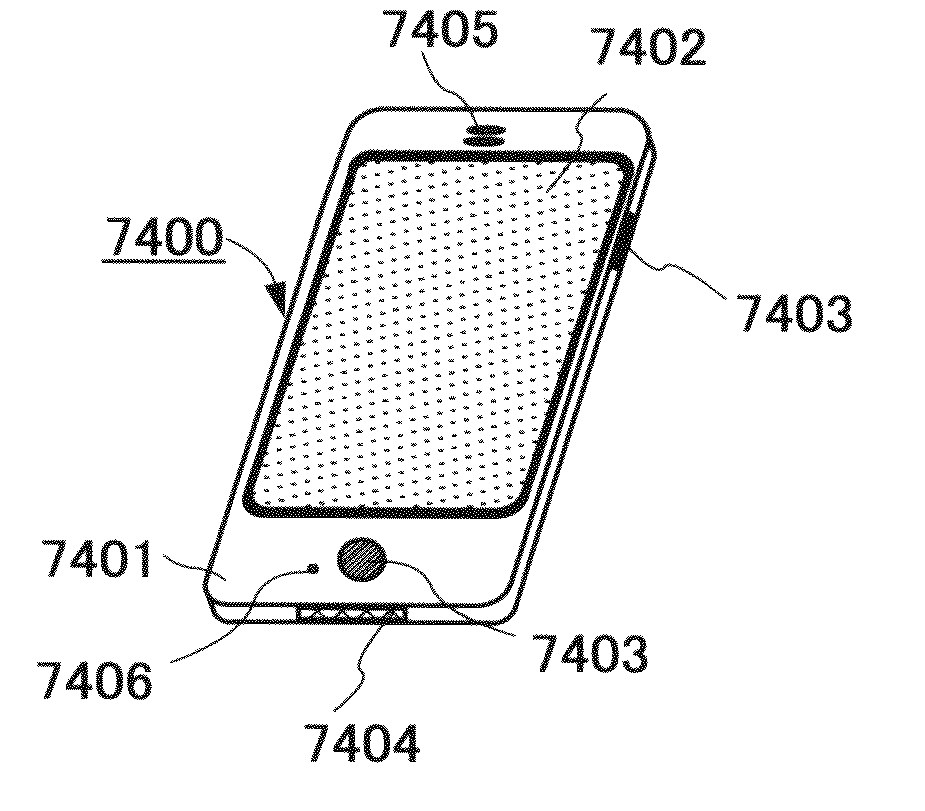

Mobile terminal

InactiveUS20110188207A1Efficient transferMinimized in sizeDigital data processing detailsSemiconductor/solid-state device detailsData interchangeElectrical and Electronics engineering

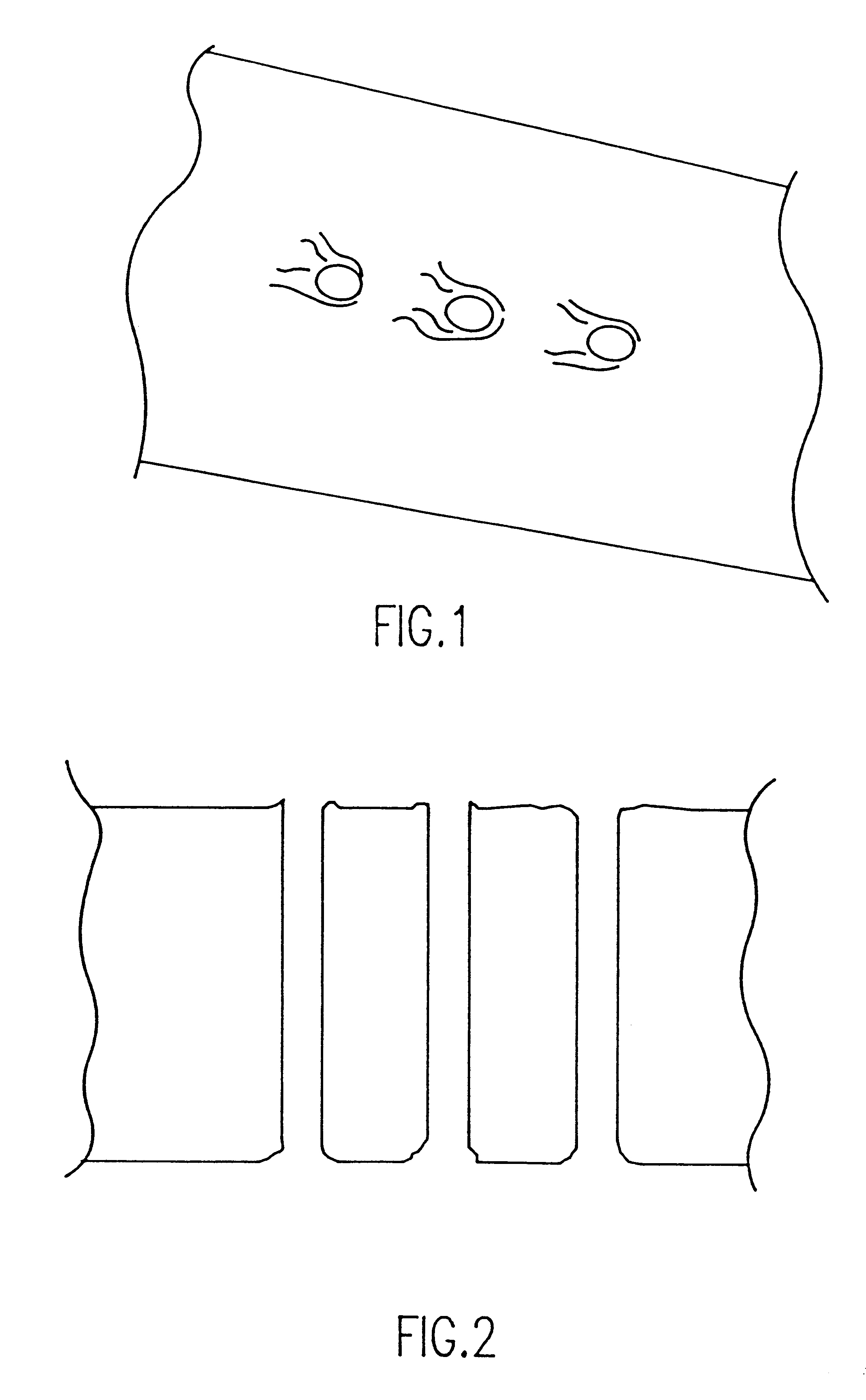

A mobile terminal is provided. The mobile terminal comprises at least one element, a connector selectively connected to another device to provide a data exchange path between the at least one element and the other device, and a thermal conduction frame having one side coming into contact with the at least one element and the other side coming into contact with the connector to transfer heat generated from the at least one element to the connector. The connector is connected to the element included in the mobile terminal and the other device through the thermal conduction frame to effectively transfer heat generated from the element to the other device through the connector.

Owner:LG ELECTRONICS INC

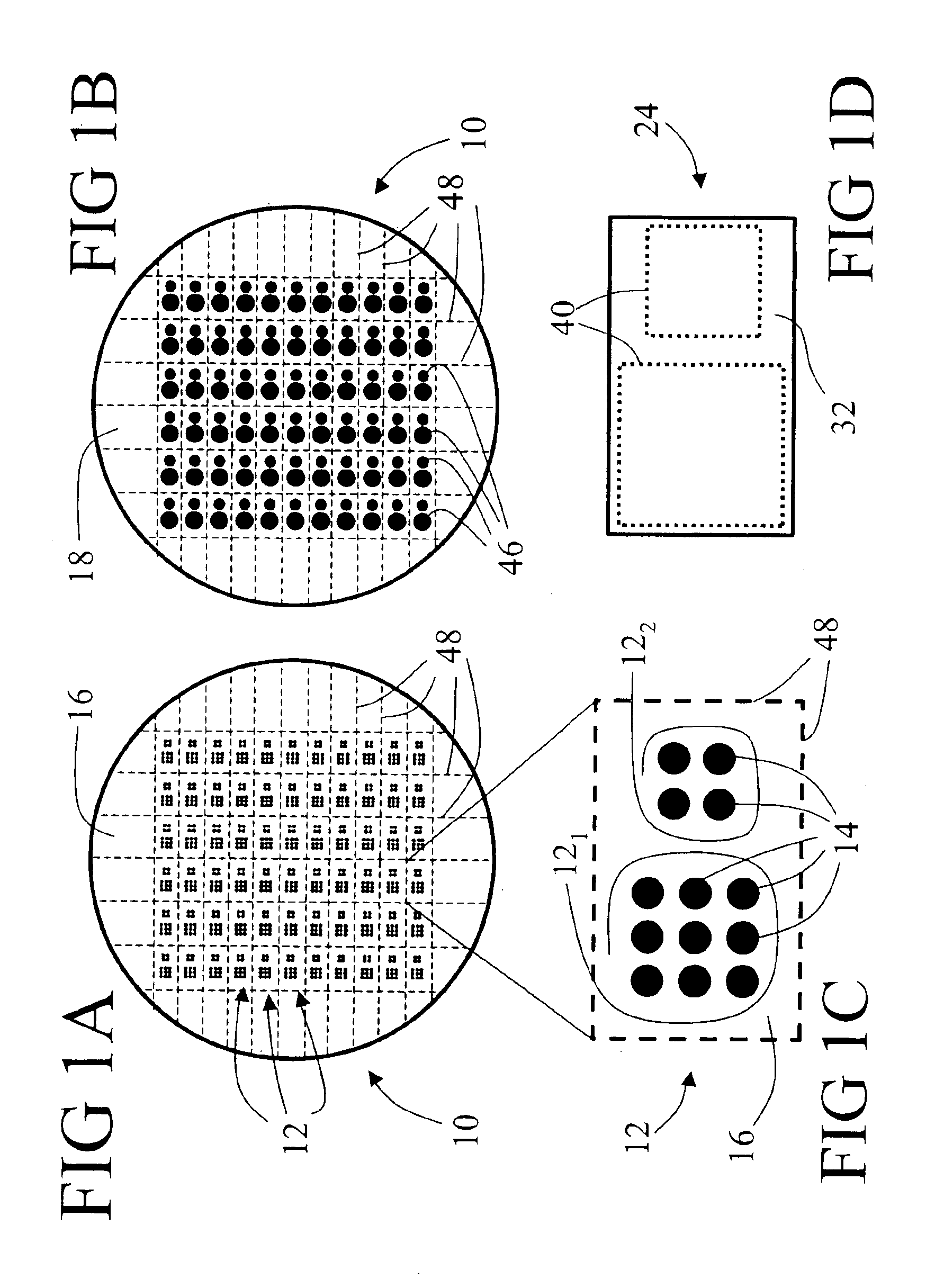

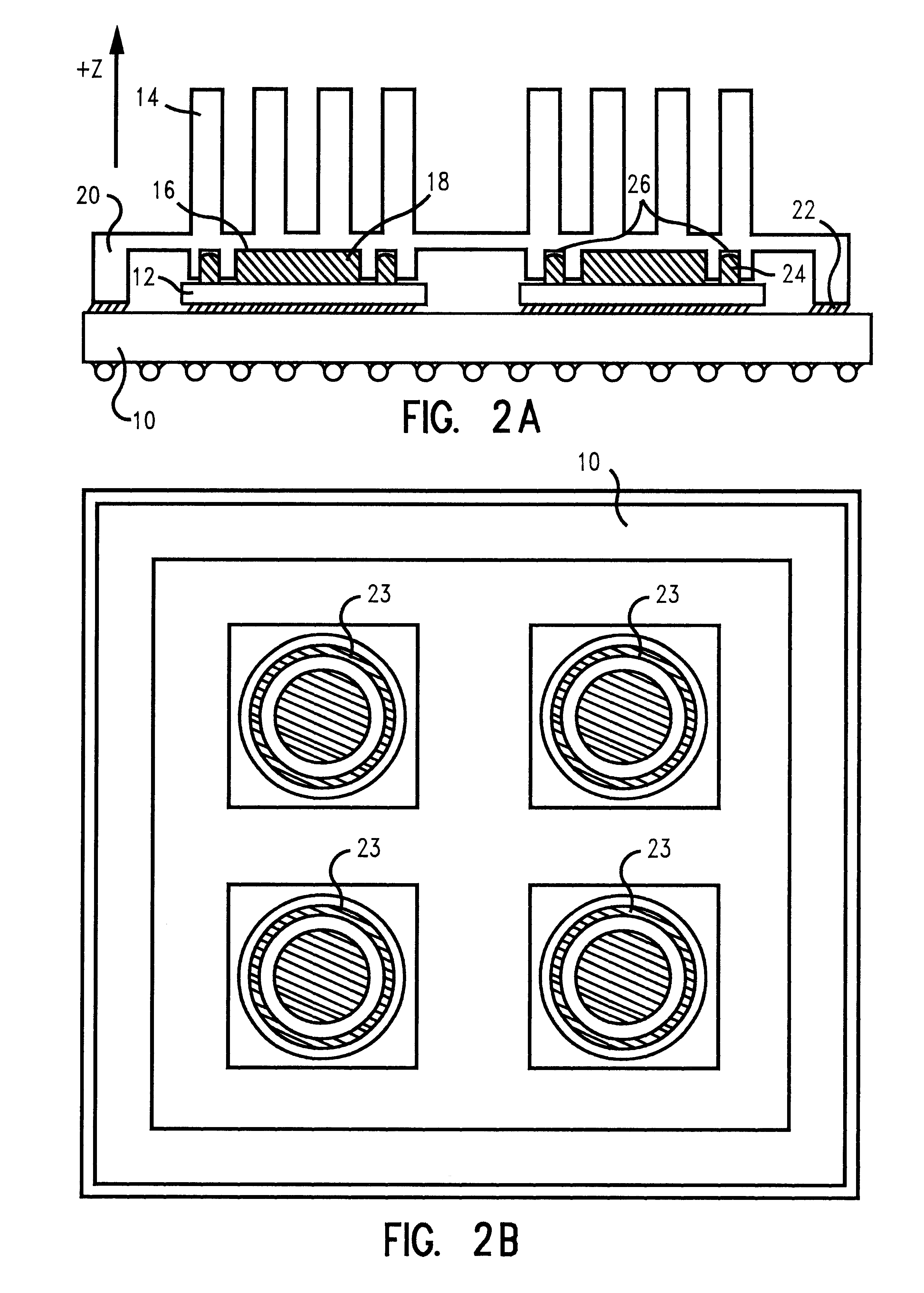

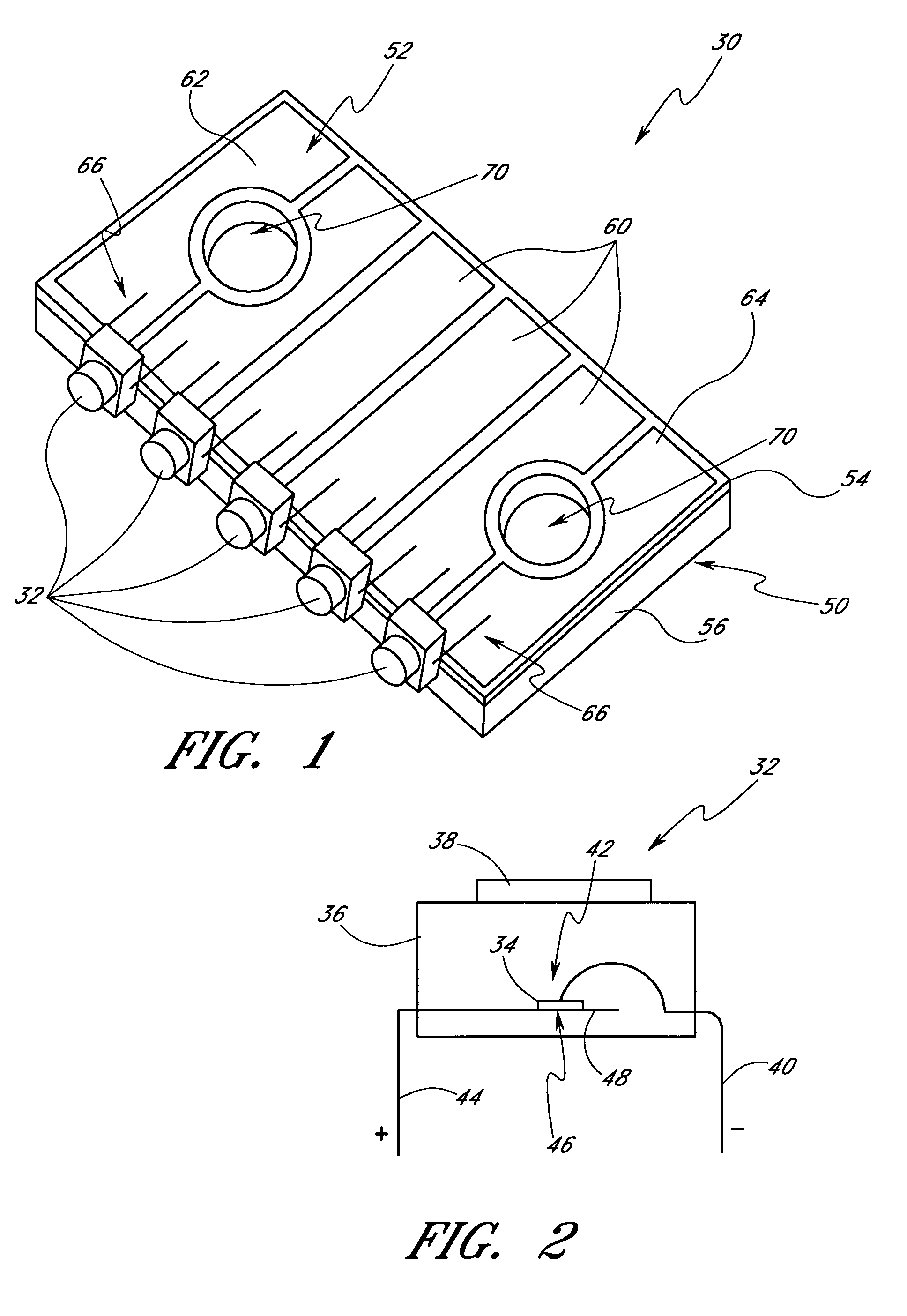

LED power package

InactiveUS6964877B2Solid-state devicesSemiconductor/solid-state device manufacturingSurface mountingEngineering

Surface mount light emitting diode (LED) packages each contain a light emitting diode (LED) die (24). A plurality of arrays of openings are drilled into an electrically insulating sub-mount wafer (10). A metal is applied to the drilled openings to produce a plurality of via arrays (12). The LED dice (24) are flip-chip bonded onto a frontside (16) of the sub-mount wafer (10). The p-type and n-type contacts of each flip-chip bonded LED (24) electrically communicate with a solderable backside (18) of the sub-mount wafer (10) through a via array (12). A thermal conduction path (10, 12) is provided for thermally conducting heat from the flip-chip bonded LED dice (24) to the solderable backside (18) of the sub-mount wafer (10). Subsequent to the flip-chip bonding, the sub-mount wafer (10) is separated to produce the surface mount LED packages.

Owner:PROLIGHT OPTO TECH

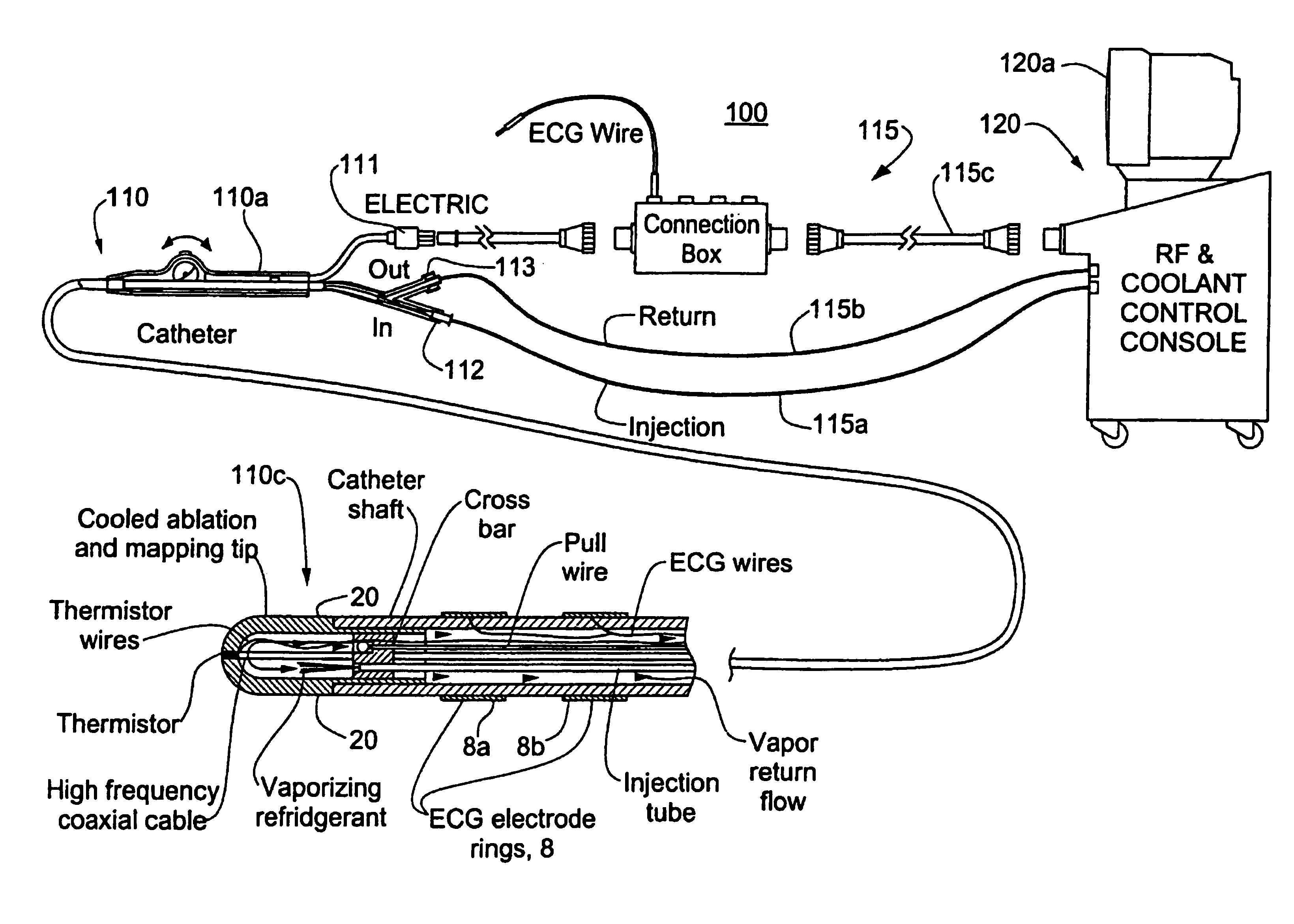

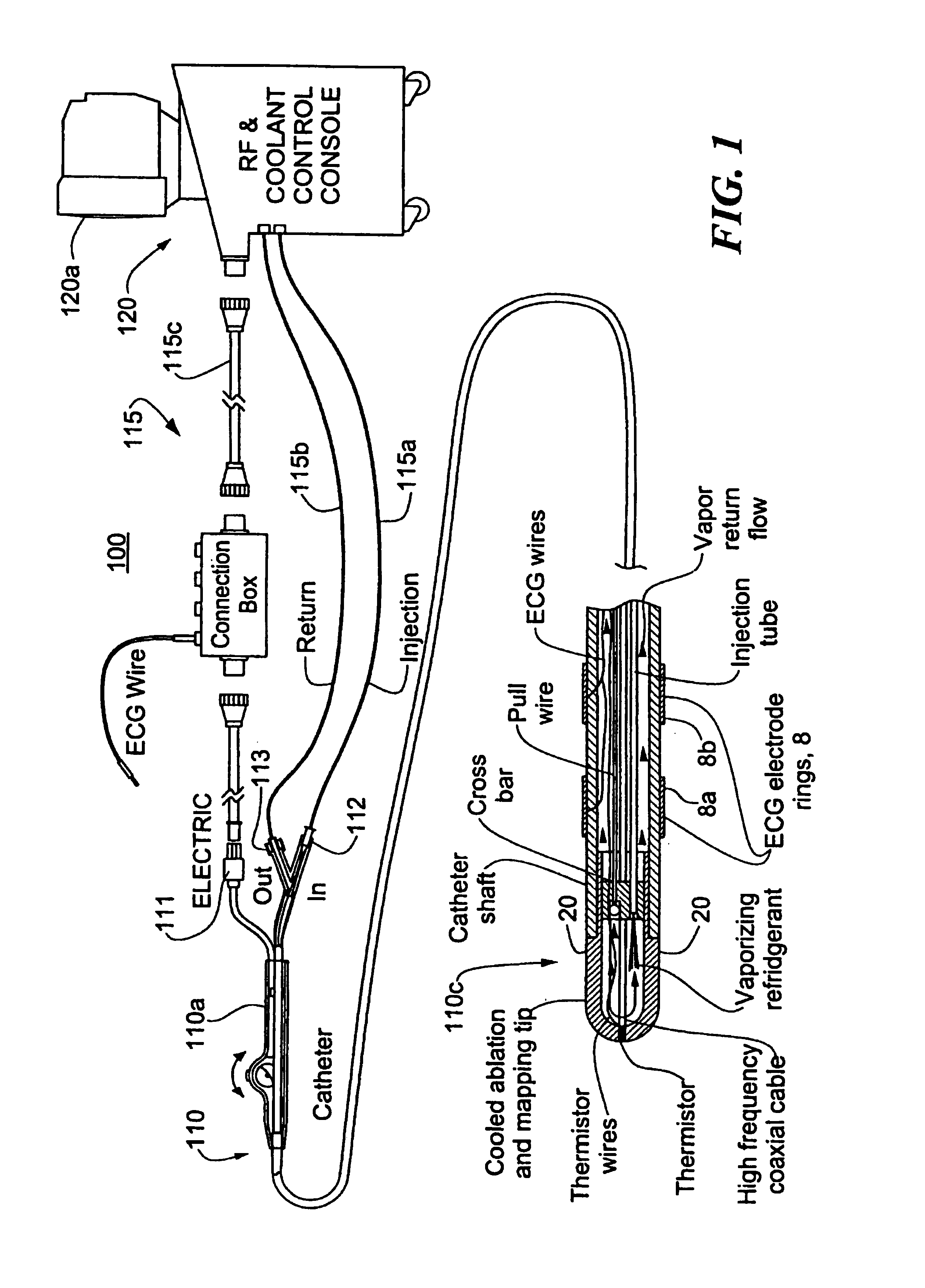

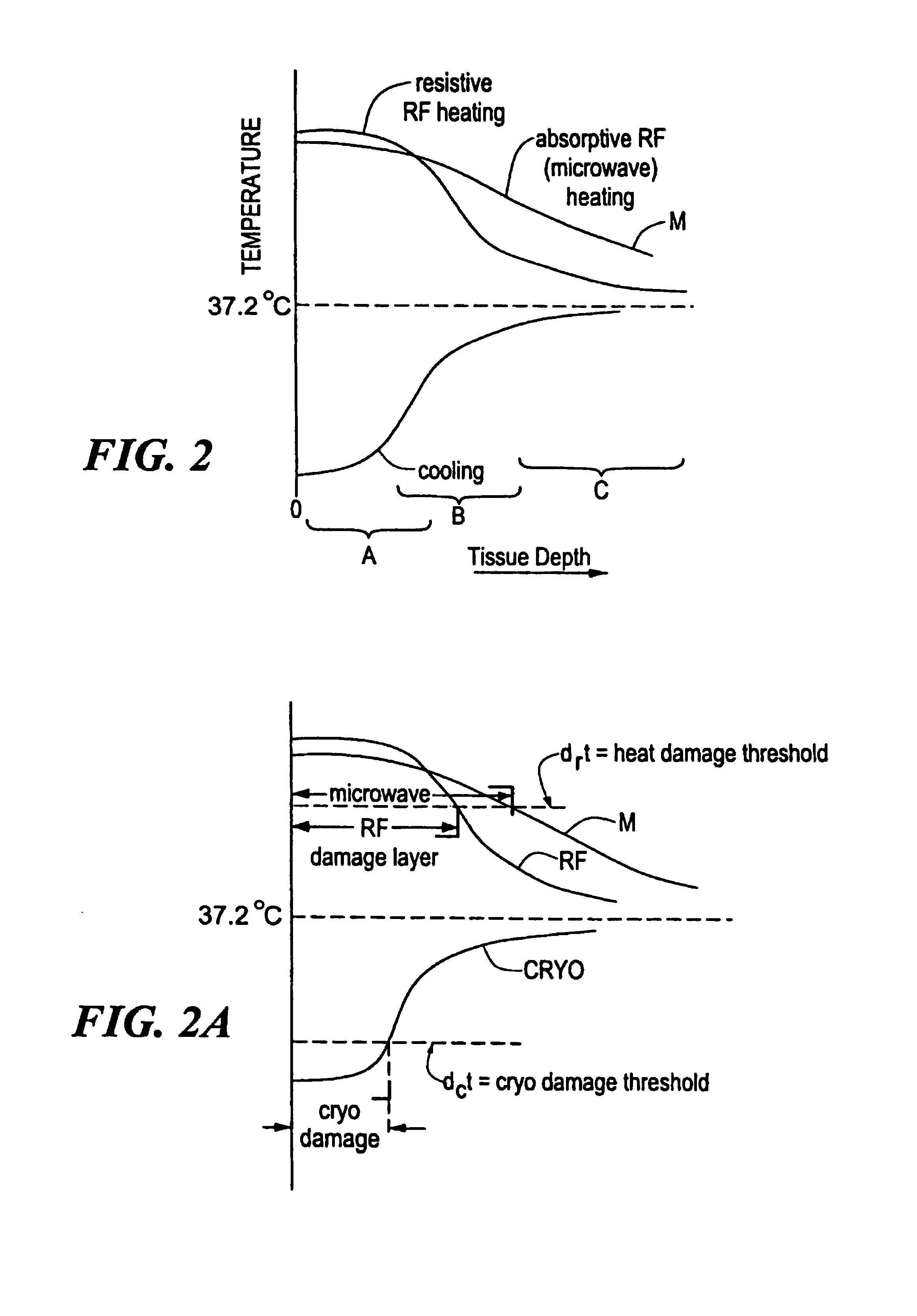

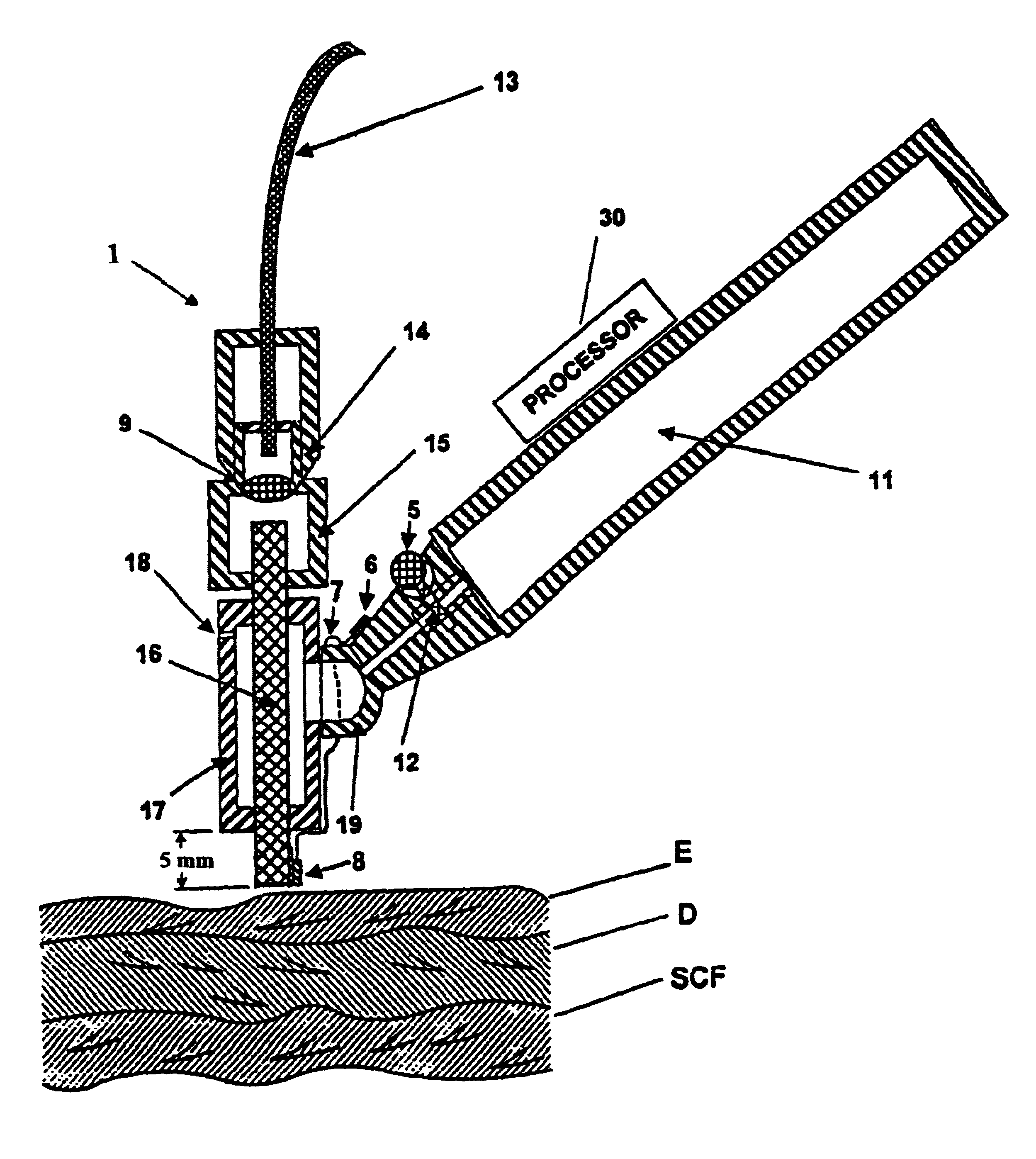

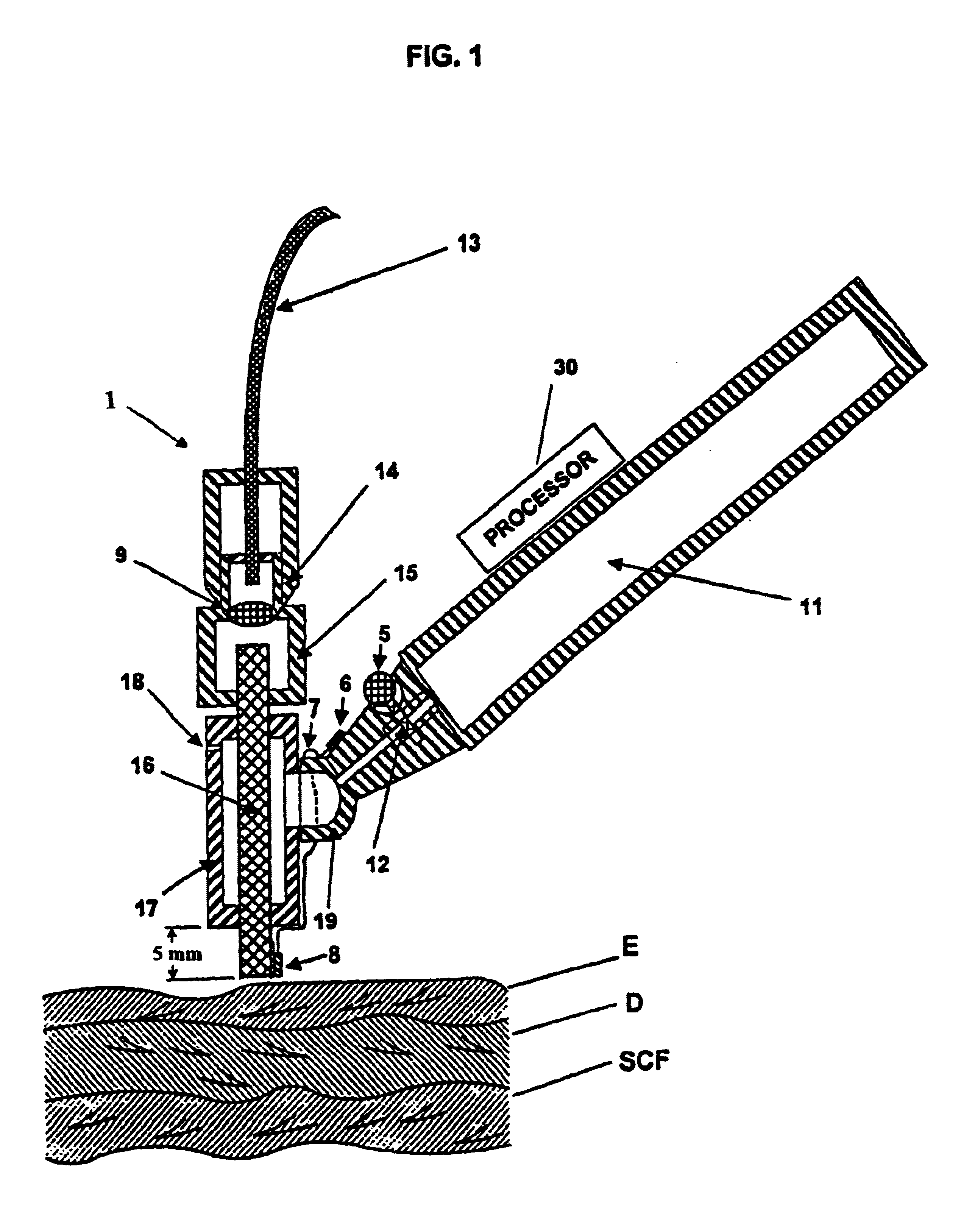

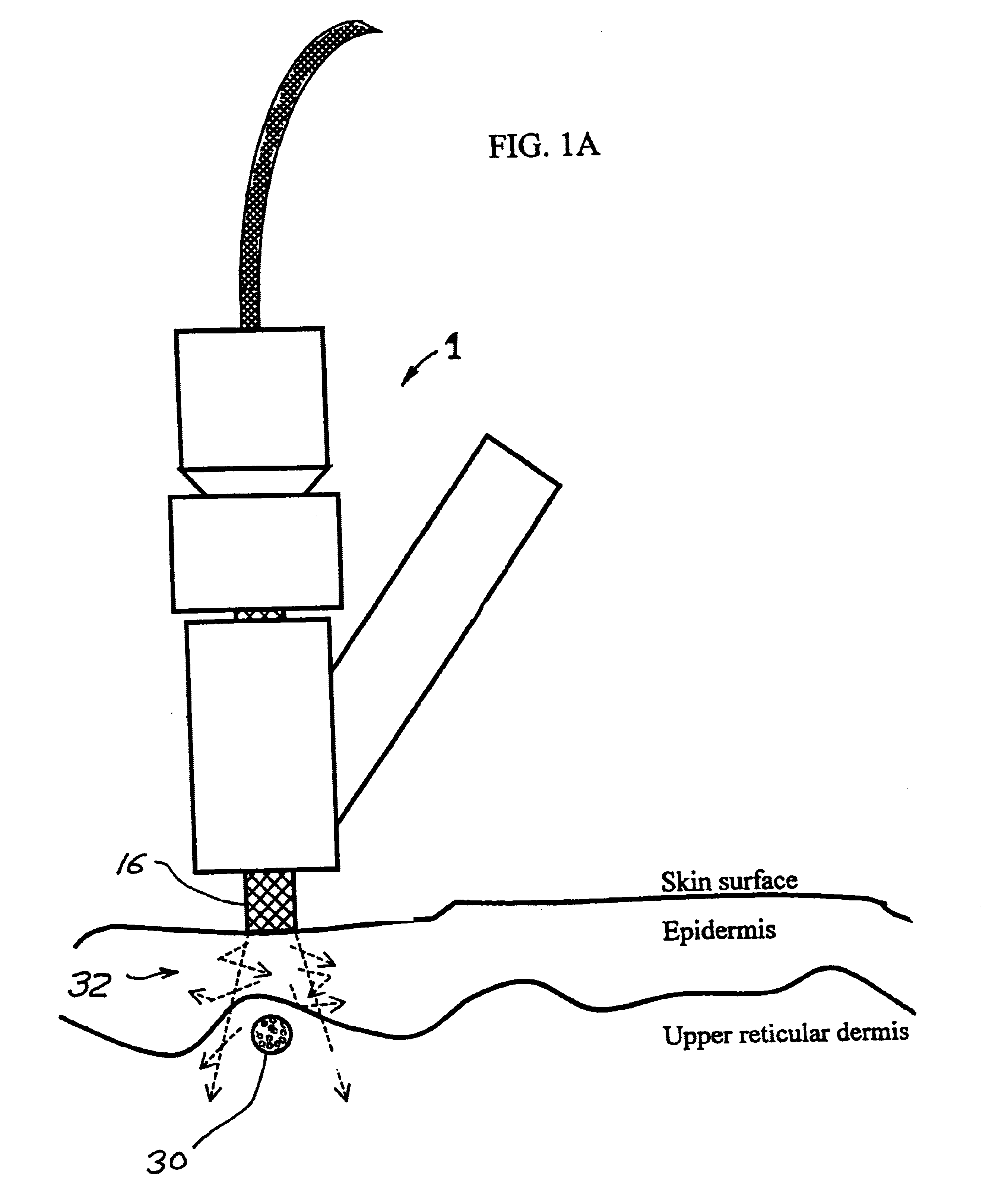

Catheter with cryogenic and heating ablation

InactiveUS7097641B1Improve versatilityEnhancing speed and placement lesionCatheterSurgical instruments for heatingTissue remodelingCelsius Degree

A catheter includes a cryoablation tip with an electrically-driven ablation assembly for heating tissue. The cryoablation tip may be implemented with a cooling chamber through which a controllably injected coolant circulates to lower the tip temperature, and having an RF electrode at its distal end. The RF electrode may be operated to warm cryogenically-cooled tissue, or the coolant may be controlled to conductively cool the tissue in coordination with an RF treatment regimen, allowing greater versatility of operation and enhancing the lesion size, speed or placement of multi-lesion treatment or single lesion re-treatment cycles. In one embodiment a microwave energy source operates at a frequency to extend beyond the thermal conduction depth, or to penetrate the cryogenic ice ball and be absorbed in tissue beyond an ice boundary, thus extending the depth and / or width of a single treatment locus. In another embodiment, the cooling and the application of RF energy are both controlled to position the ablation region away from the surface contacted by the electrode, for example to leave surface tissue unharmed while ablating at depth or to provide an ablation band of greater uniformity with increasing depth. The driver or RF energy source may supply microwave energy at a frequency effective to penetrate the ice ball which develops on a cryocatheter, and different frequencies may be selected for preferential absorption in a layer of defined thickness at depth in the nearby tissue. The catheter may operate between 70 and minus 70 degrees Celsius for different tissue applications, such as angioplasty, cardiac ablation and tissue remodeling, and may preset the temperature of the tip or adjacent tissue, and otherwise overlay or delay the two different profiles to tailor the shape or position where ablation occurs or to speed up a treatment cycle.

Owner:MEDTRONIC CRYOCATH LP

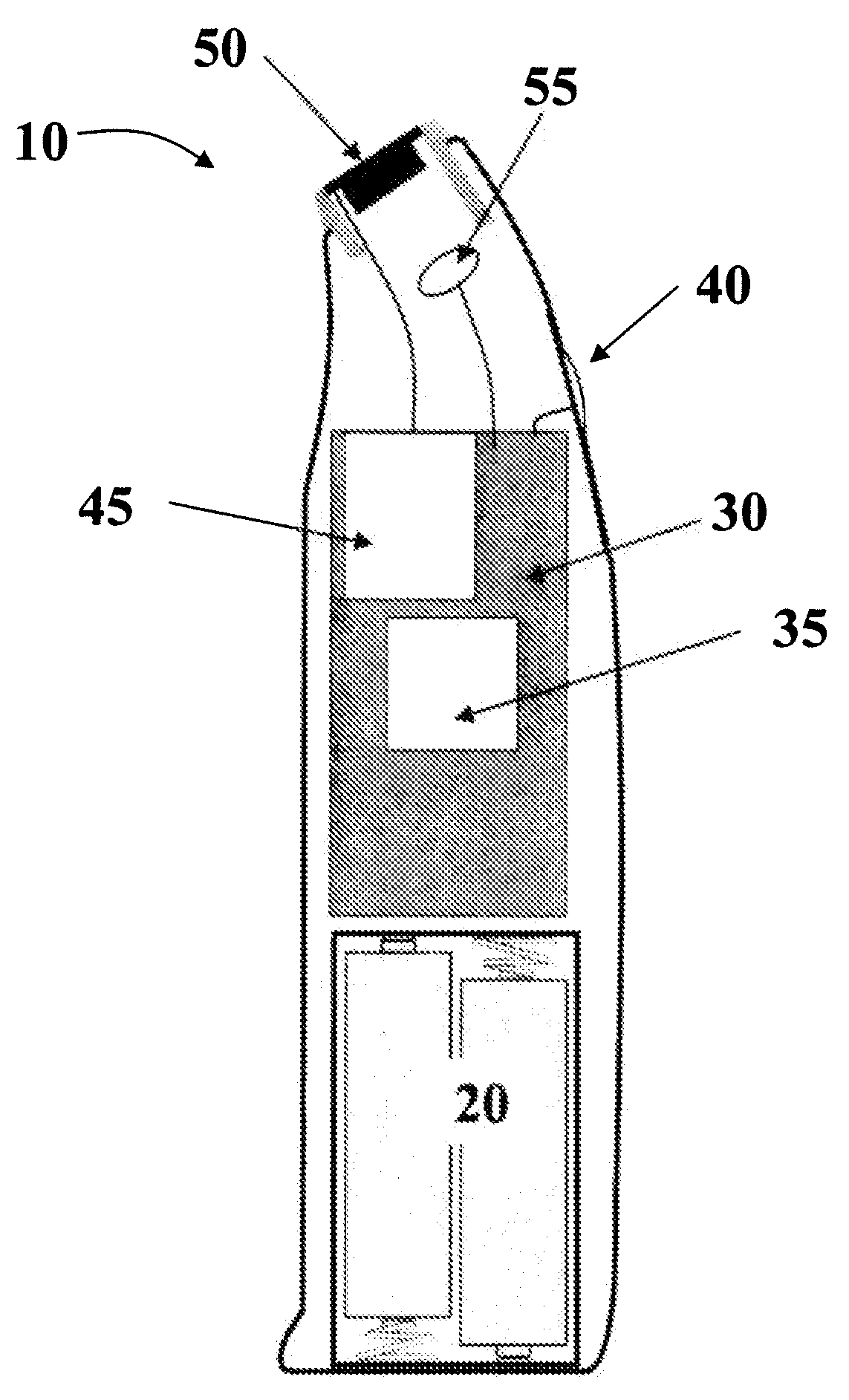

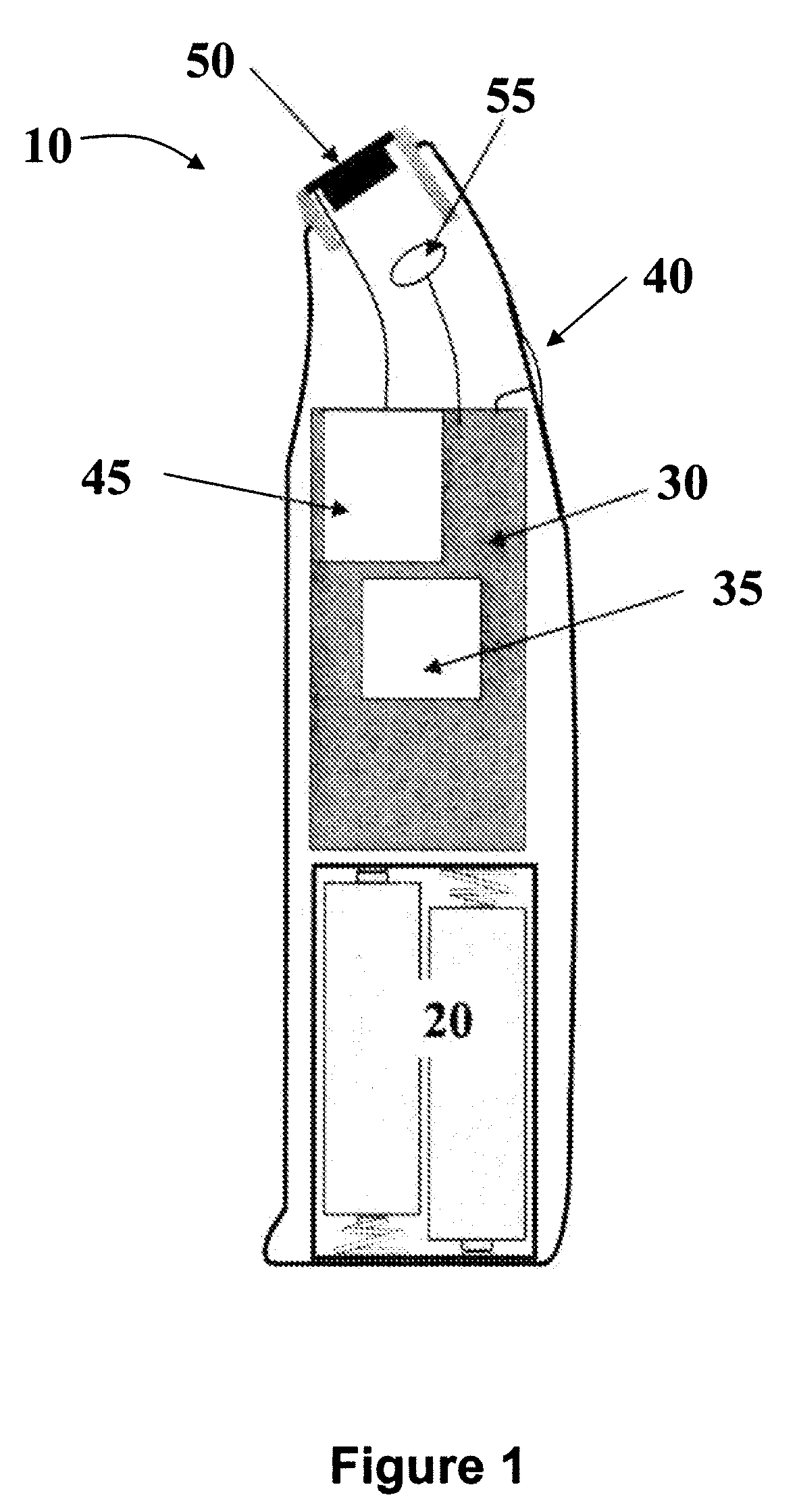

Devices and Methods for Treatment of Skin Conditions

InactiveUS20080139974A1Removing fine wrinkleClean skinUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyWrinkle skinHand held

Devices and methods for the treatment of skin conditions and lesions are disclosed herein. A compact hand held device that can be safely used by those suffering from skin conditions, such as acne, warts, cold blisters, blemished skin, or fine wrinkles. The devices employ the application of ultrasound energy and heat for the treatment of skin conditions and lesions. Typically, the peak temperatures employed are about 40° C. to about 70° C. by the devices, are achieved in less than about 20 second, and maintained for less than about 40 second. Ultrasound absorption and thermal conduction transfers heat from the device to the skin and causes a biological response that accelerates acne clearing, treats blemished skin, itching, or fine wrinkles. The total heat transferred is low enough to prevent burns.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

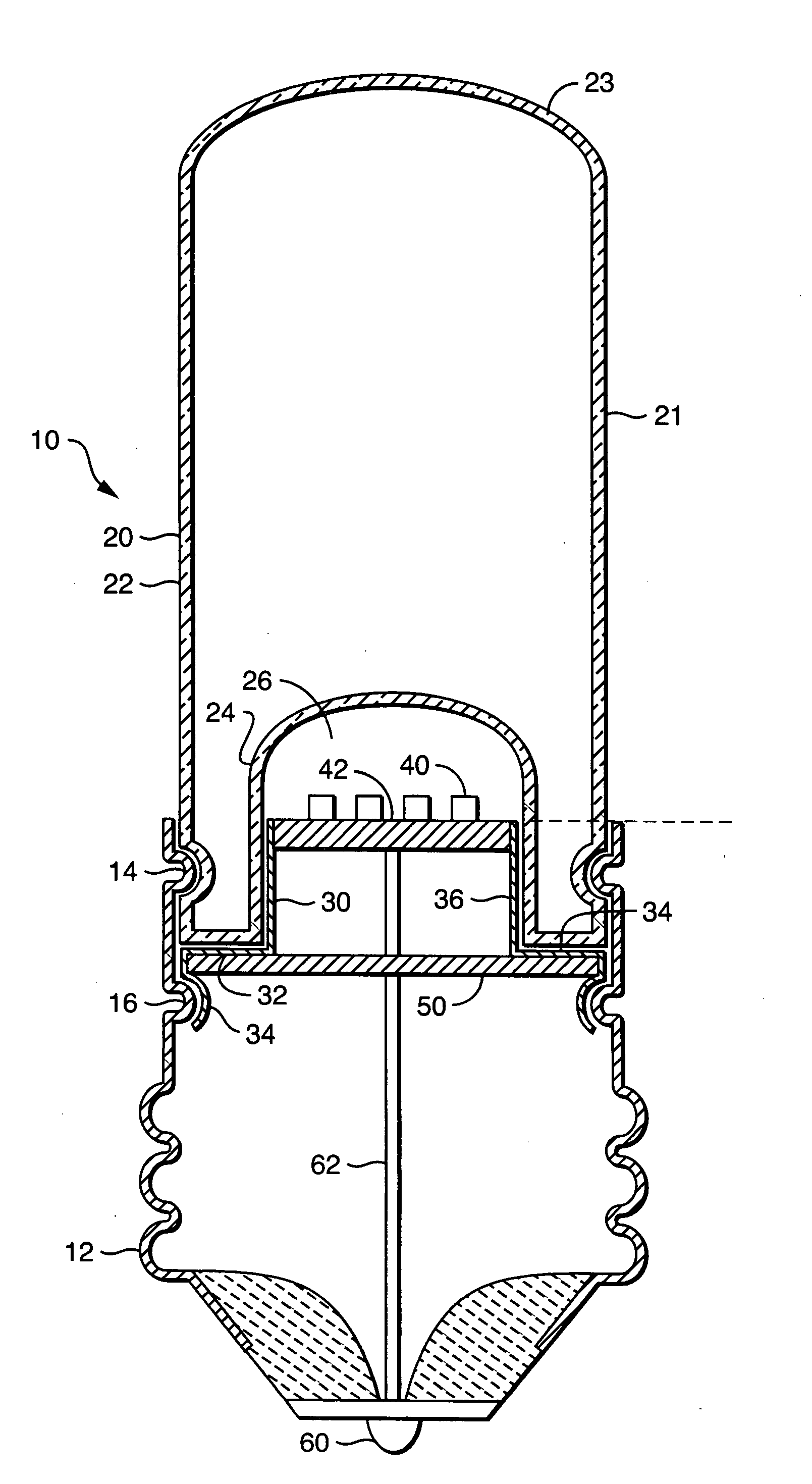

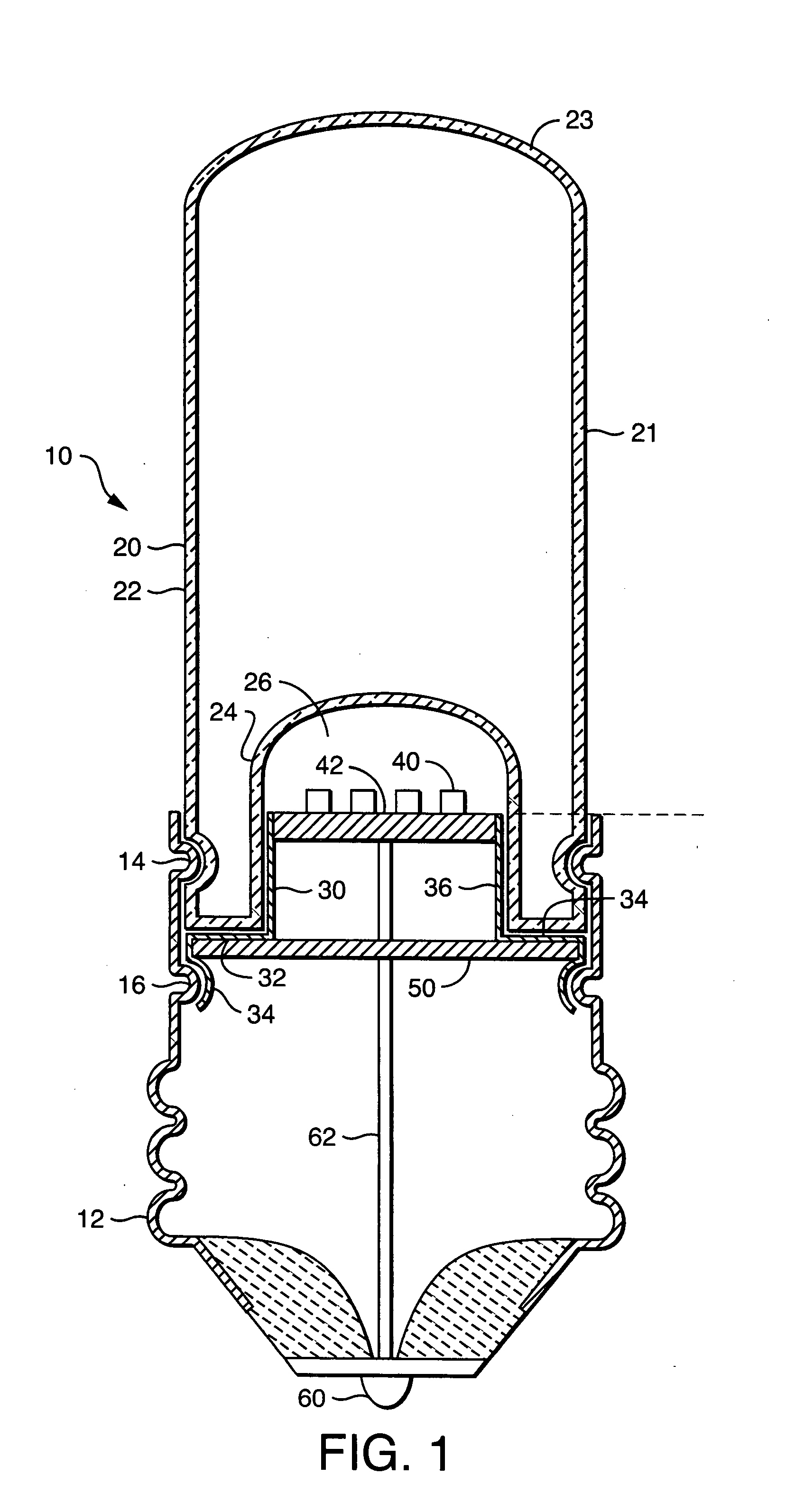

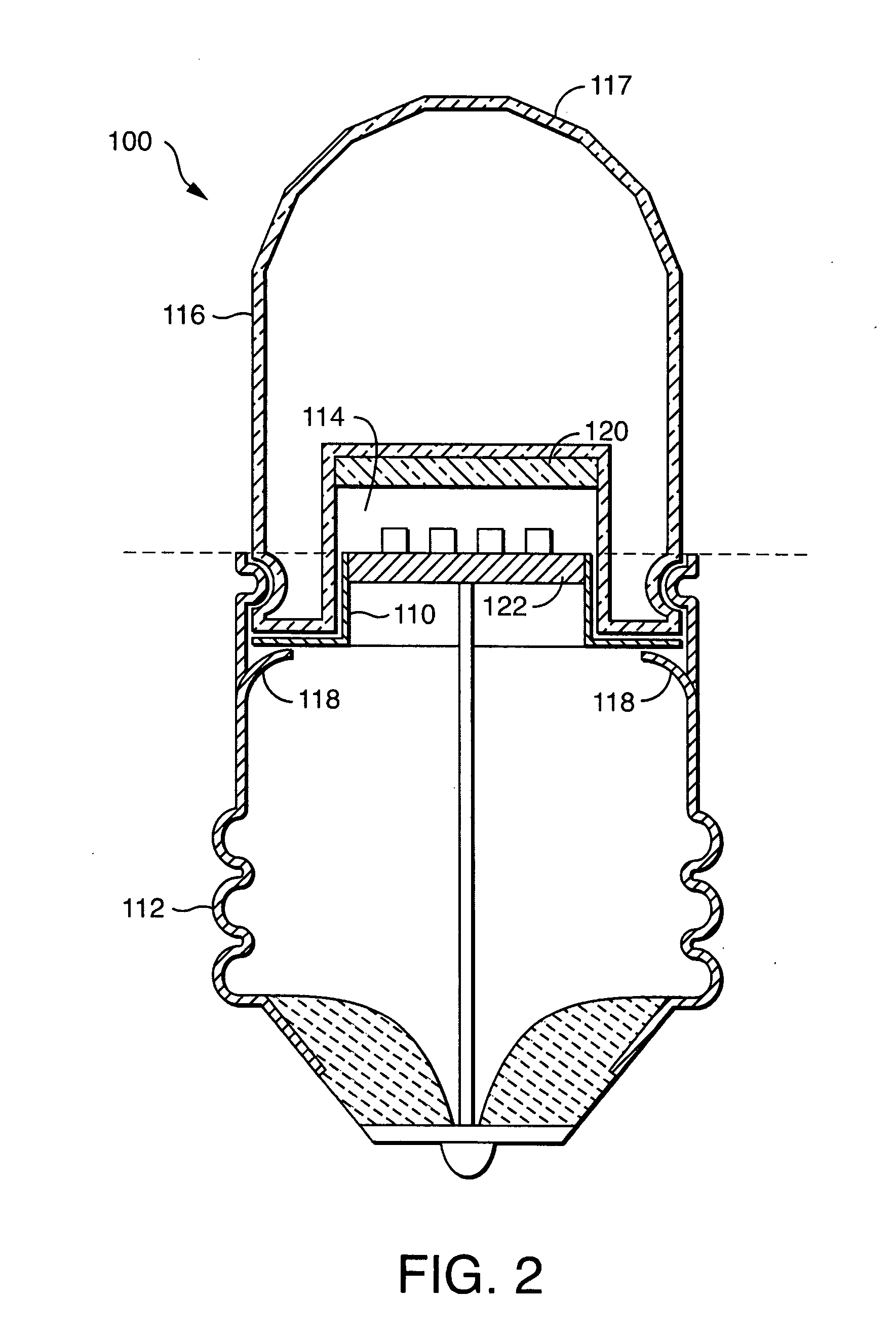

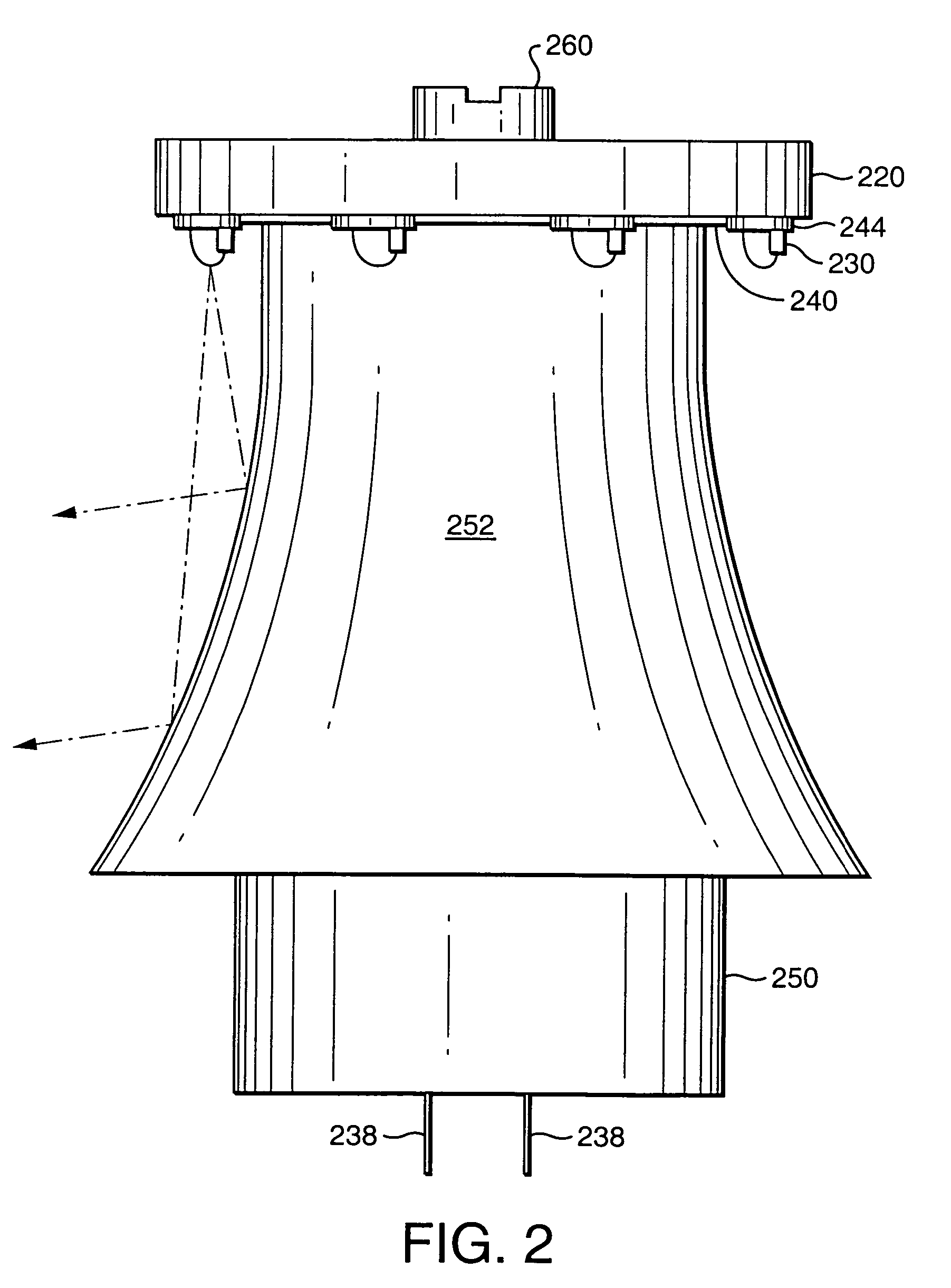

LED lamp with heat sink optic

An LED lamp may be made with a heat sink optic. The lamp has a base having a first electrical contact and a second electrical contact for receiving current. At least one LED is mounted on a thermally conductive support; that supports electrical connections for the LED and provides thermal conduction of heat from the LED to the optic. The LED support mounted in the base and electrically coupled through the first electrical contact to electrical current. The light transmissive, and heat diffusing optic has an external an internal wall defining a cavity with the LED positioned in the cavity. The optic is in thermal contact with the LED support and mechanically coupled to the base. The snap together structure enables rapid manufacture while allowing numerous variations.

Owner:OSRAM SYLVANIA INC

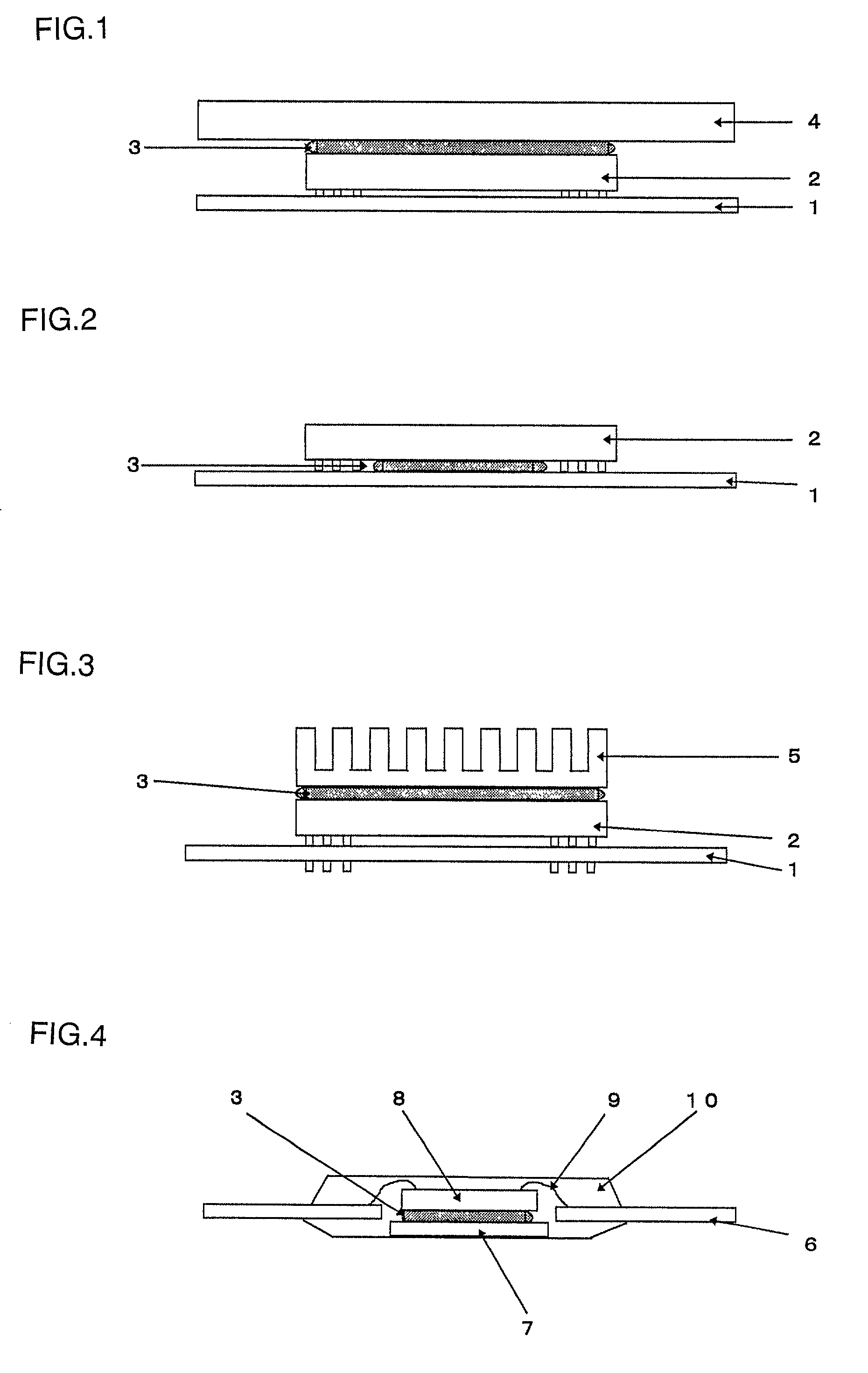

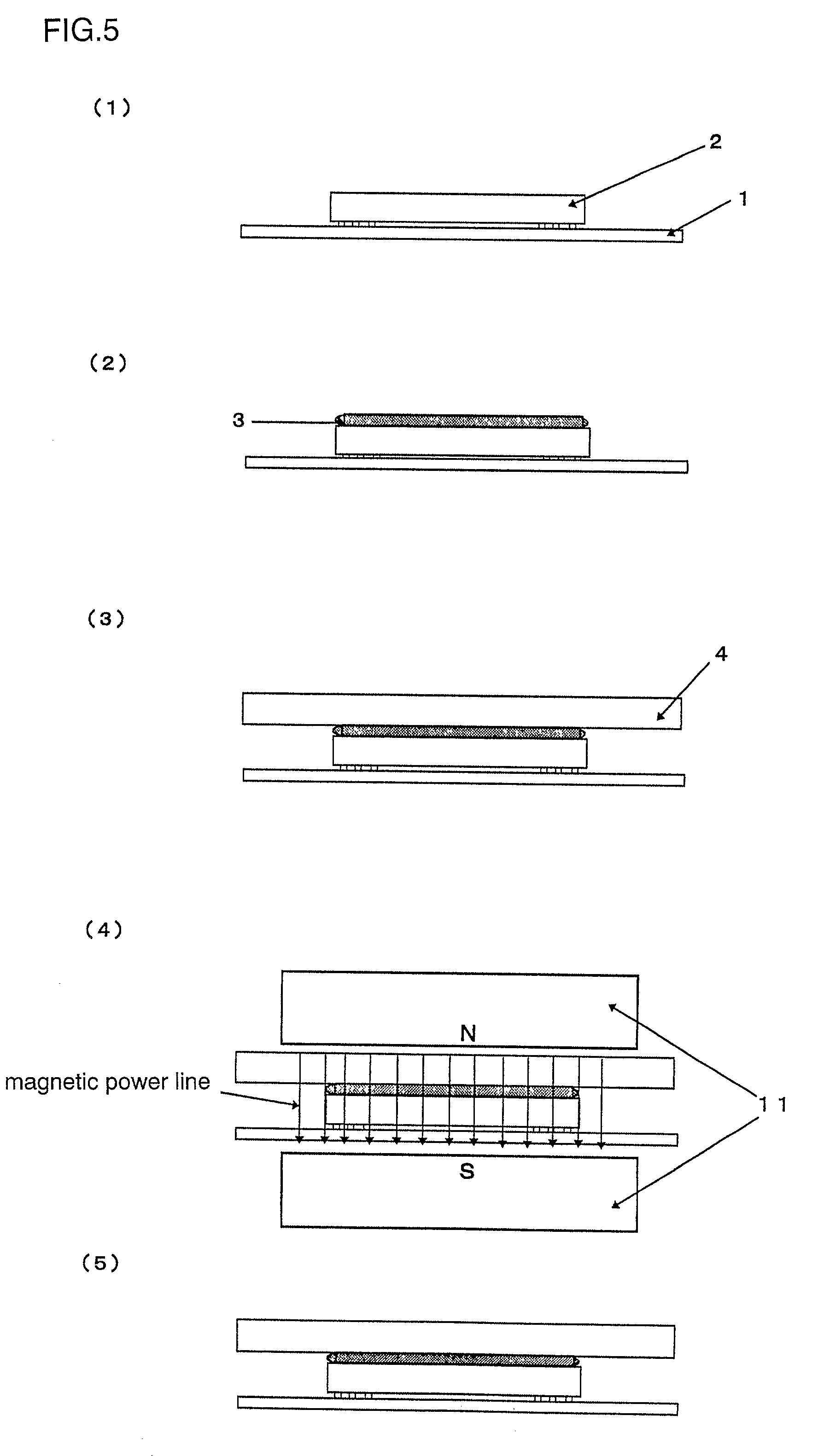

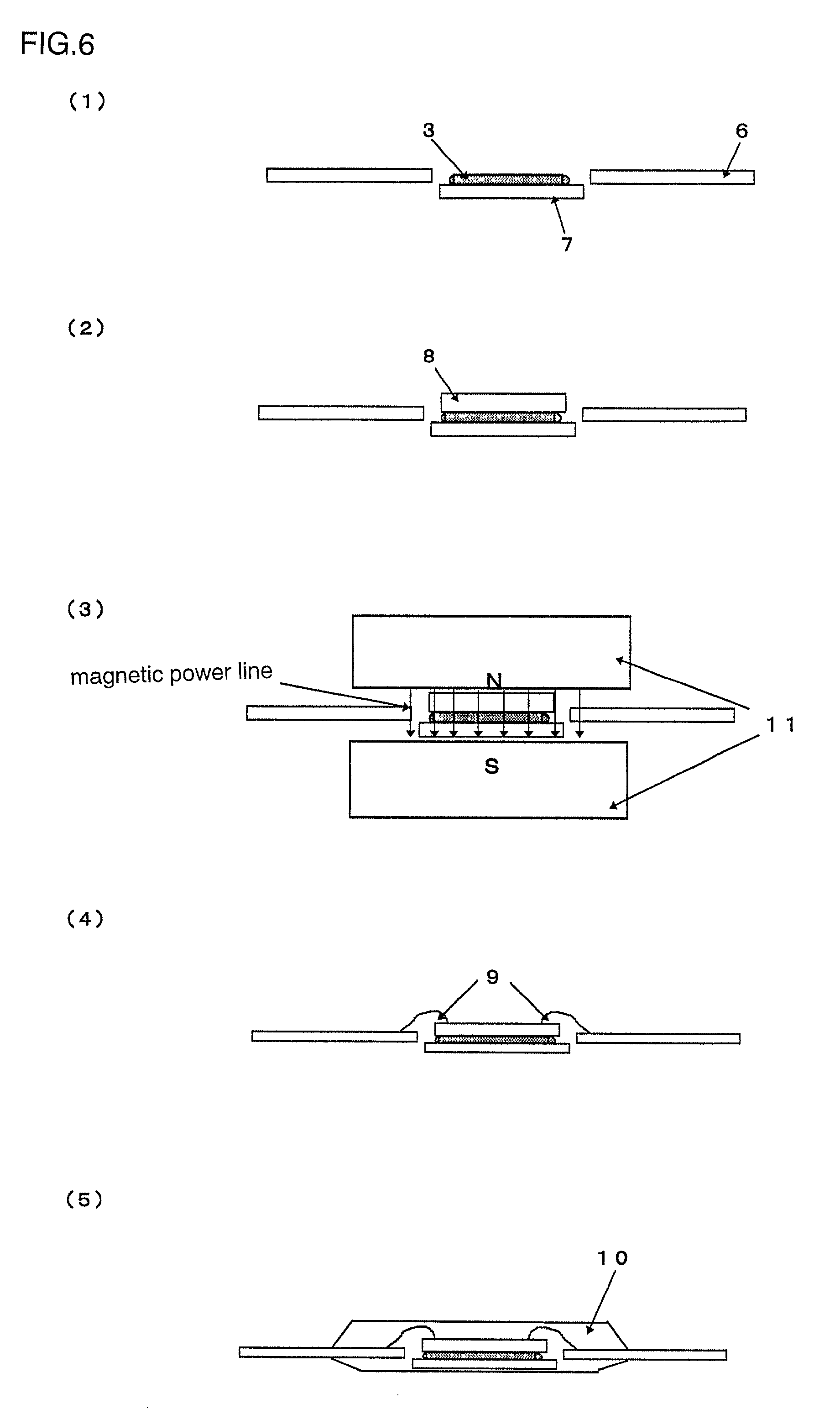

Adhesion method and electronic component

InactiveUS20010004131A1Efficiently dissipatedEnhanced radiationAdhesive processesLamination ancillary operationsAdhesiveBoron nitride

The present invention provides an adhesion method of improving the heat conduction in a fixed direction by using a heat conductive adhesive made by blending boron nitride powder and adhesive polymer and adhering by orienting boron nitride powder in the heat conductive adhesive to the fixed direction under the magnetic atmosphere and an electronic component for effectively dissipating heat generated from semiconductor device 2, power source 4, light source or other components used for the electric products, and an electronic component excellent in radiation.

Owner:POLYMATECH CO LTD

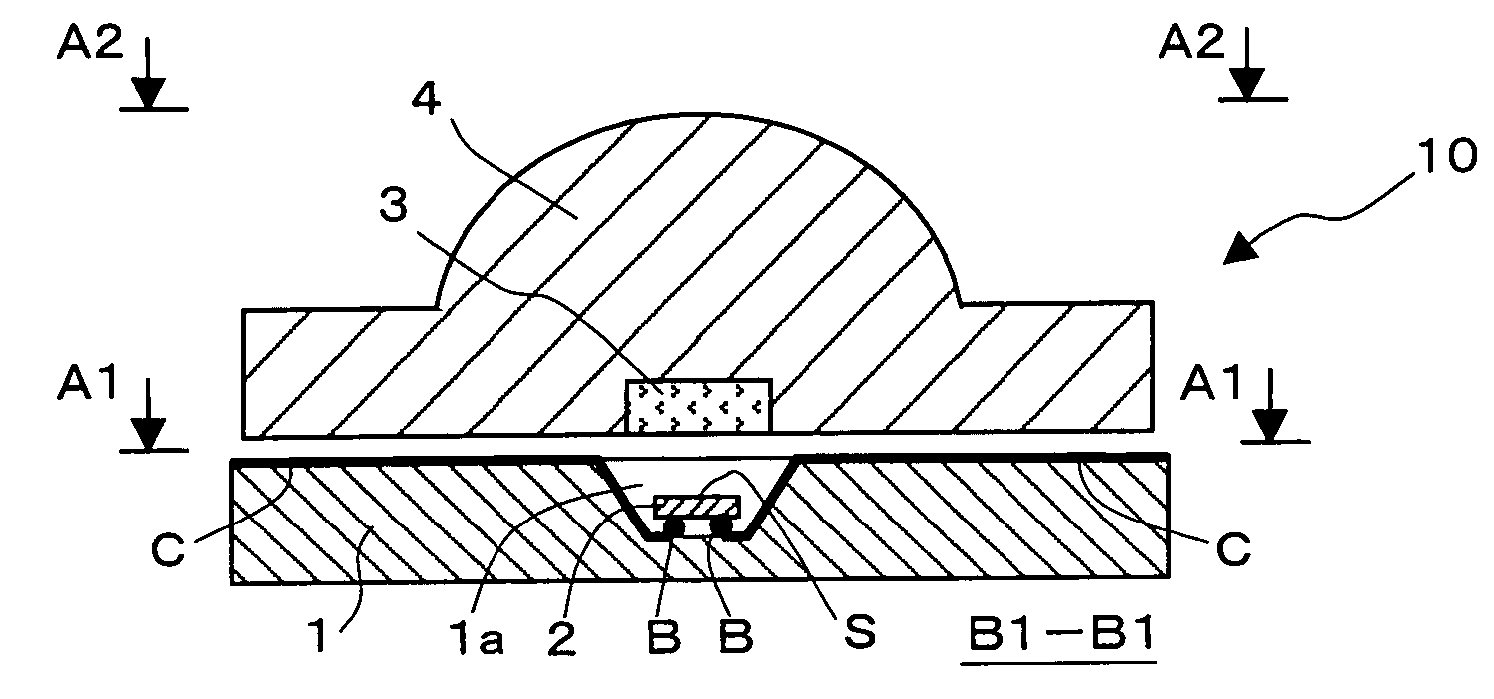

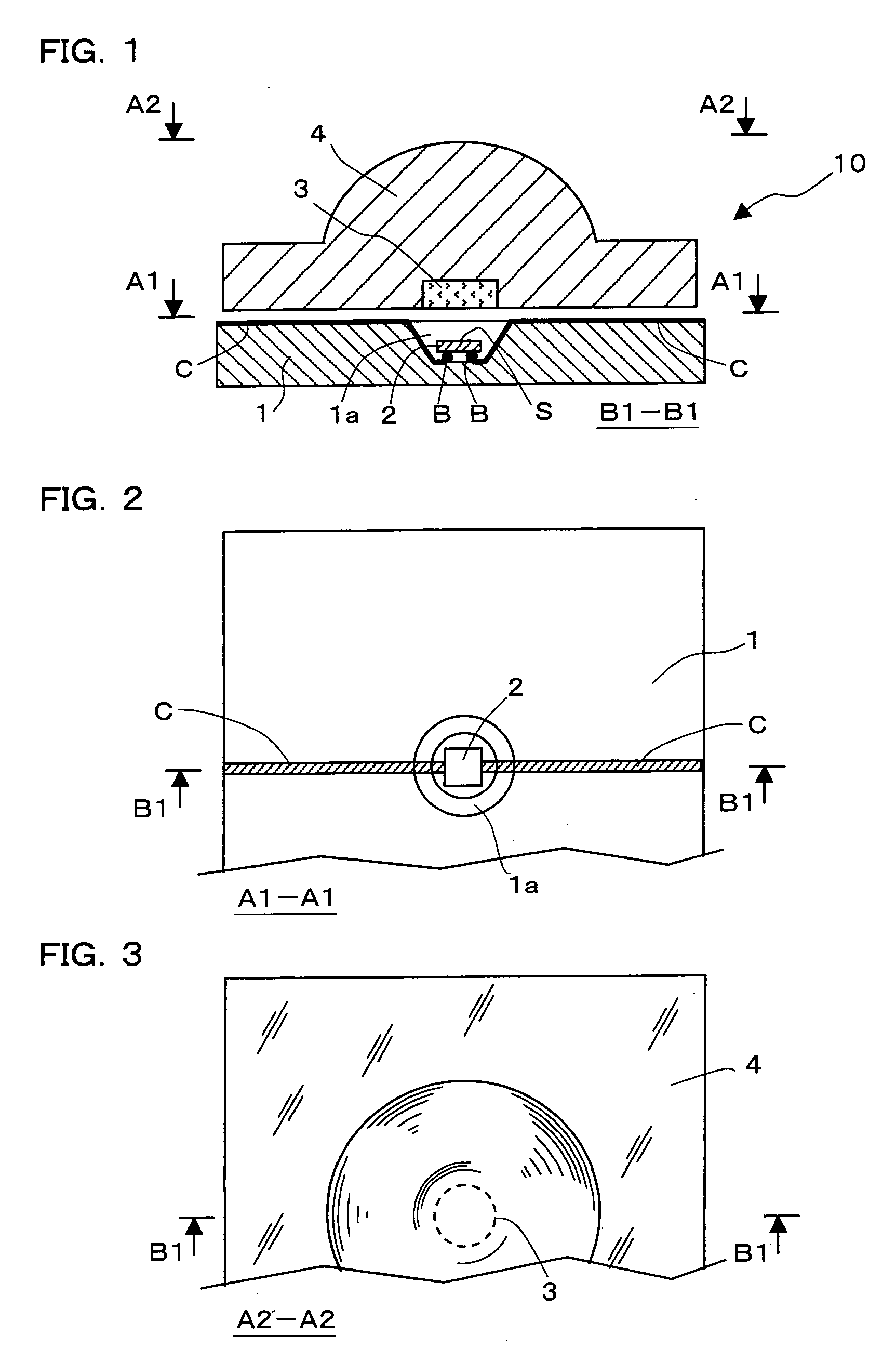

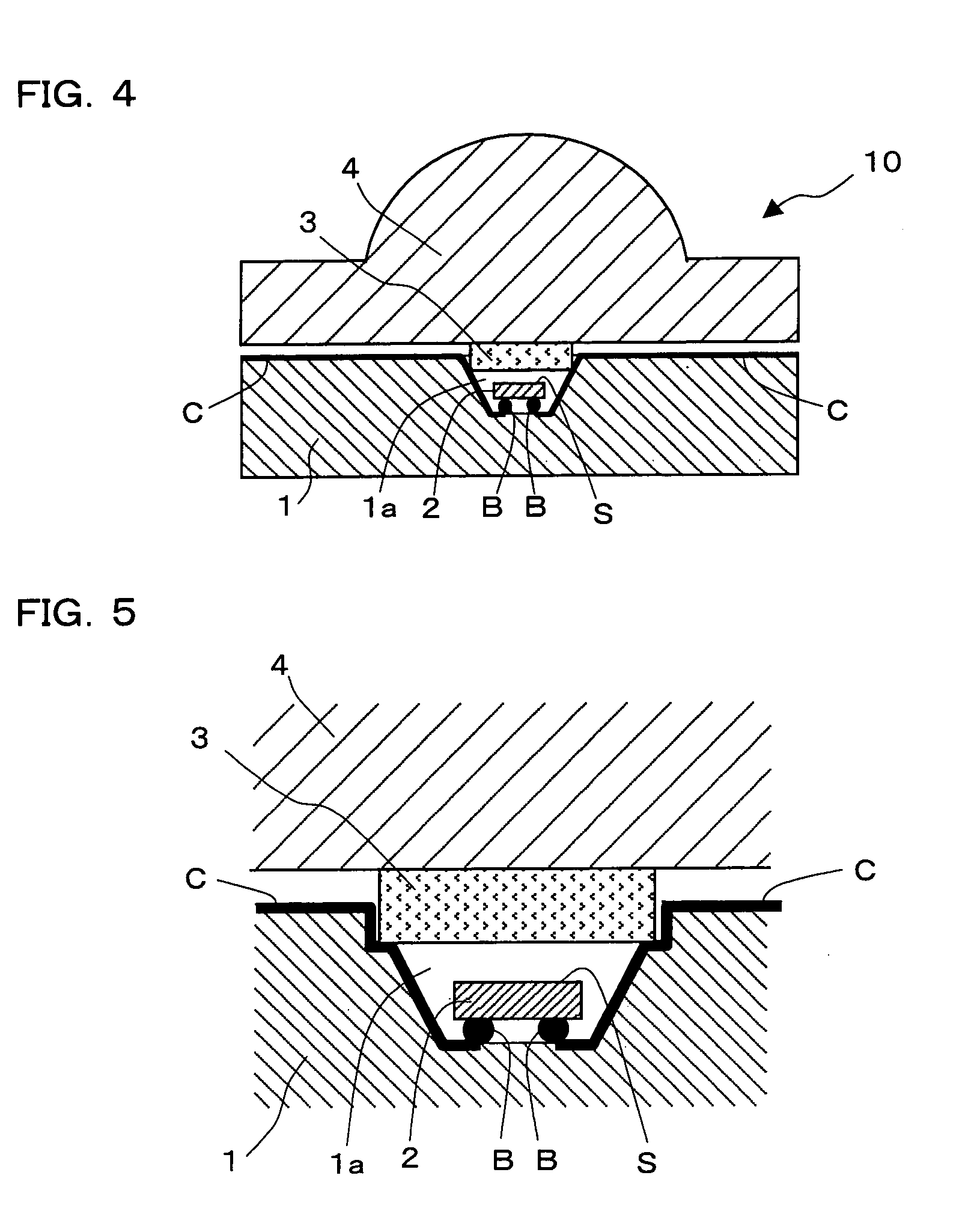

Light emitting device using led

InactiveUS20040190304A1Extended service lifeEffective coolingDischarge tube luminescnet screensLighting heating/cooling arrangementsLength waveLight emitting device

A light-emitting device (10) using an LED is proposed. This light-emitting device (10) is provided with a packaging substrate (1), a light-emitting element (2) which is mounted on this packaging substrate (1) with its face down, a fluorescent member (3) that is arranged face to face with a light-extracting surface (S) of the light-emitting element (2) without contacting the light-emitting element (2) and an optical member (4) which receives light that has been emitted from the light-emitting element (2) and made incident thereon through the fluorescent member (3), and aligns the incident light toward the outside of the device. Light, emitted from the light-emitting element (2), is made incident on the fluorescent member (3) to excite the fluorescent material so that the fluorescent material re-emits light having a wavelength different from that of the incident light. Those light rays, emitted from the light-emitting element (2), which have not been absorbed by the fluorescent member (3) and have passed through the fluorescent member (3) and those light rays that have been emitted from the fluorescent material are made incident on the optical member (4) and are aligned. Because the fluorescent member (3) is not made in contact with the light-emitting element (2), it does not receive the heat from the light-emitting element (2) through heat conduction, and consequently becomes less susceptible to degradation due to heat. Moreover, with the face-down mounting structure, the fluorescent member (3) and the optical member (4) can be placed closer to the light-emitting element (2) as long as they dose not contact the light-emitting element (2). Consequently, the service life of the fluorescent material or the fluorescent-material-mixed resin that tends to deteriorate can be lengthened, lights can be extracted more efficiently, and light rays can be properly aligned in a predetermined direction.

Owner:MATSUSHITA ELECTRIC WORKS LTD

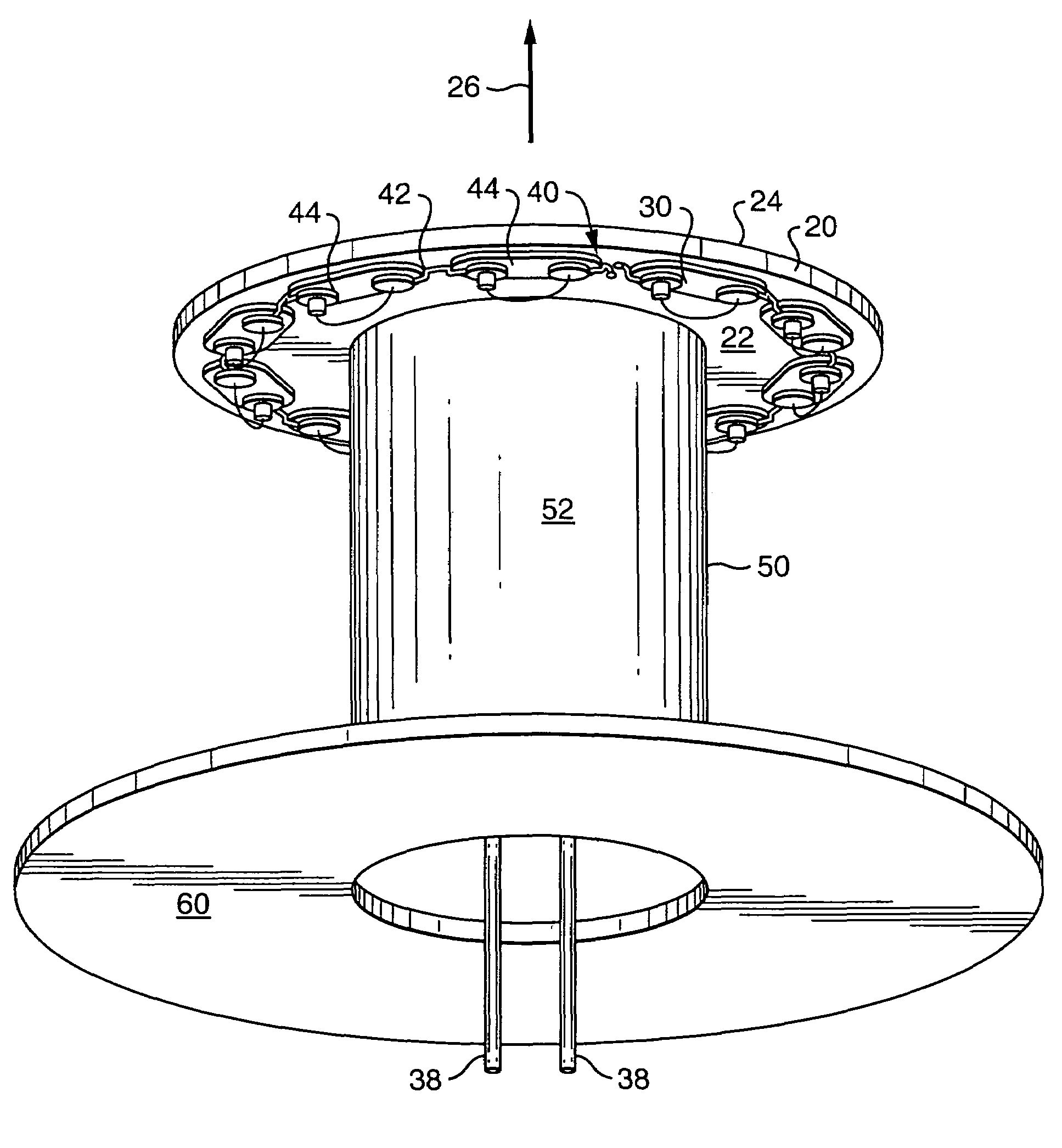

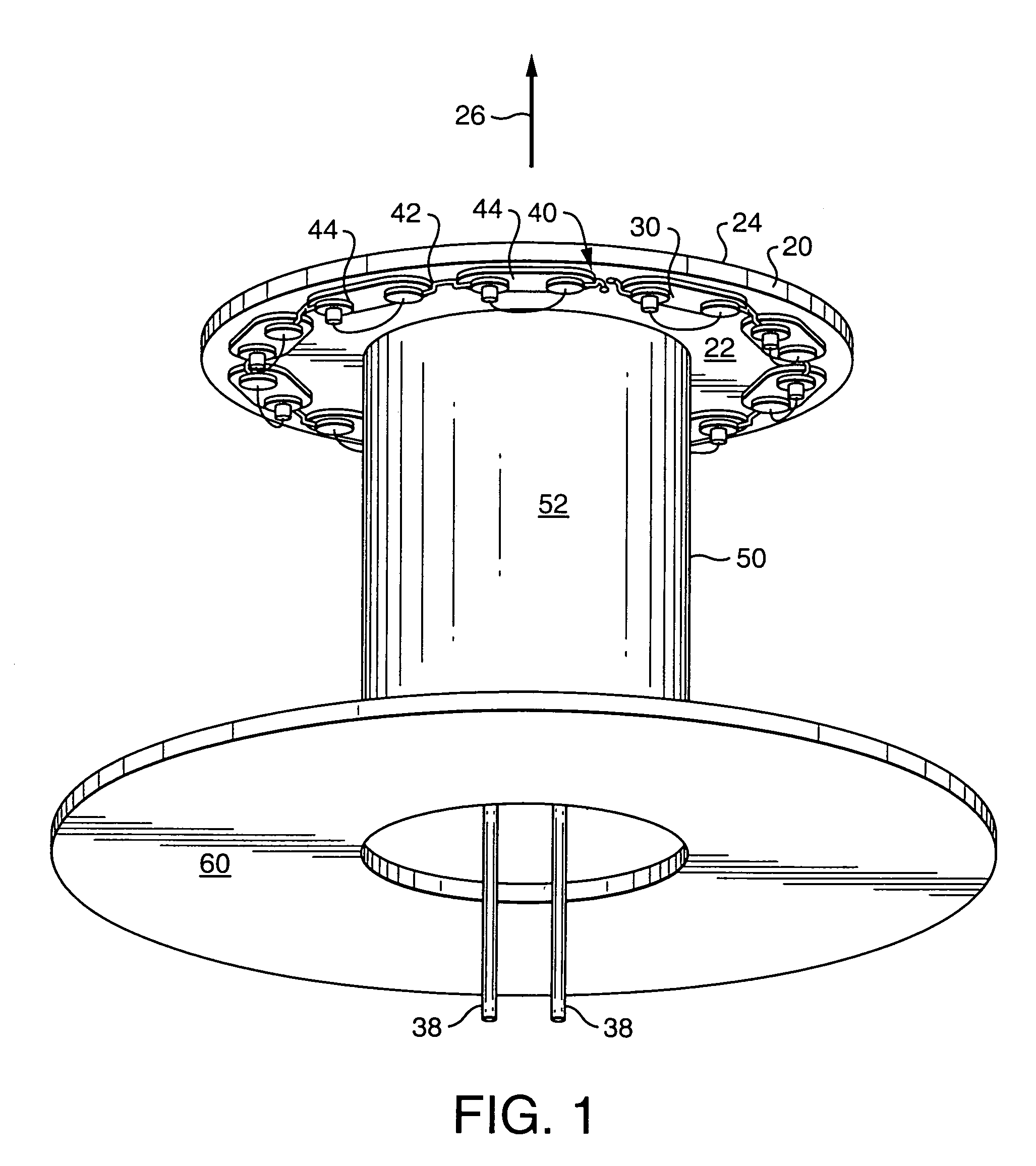

Lighting device

ActiveUS7722220B2Reduce glareEfficient transferMechanical apparatusPoint-like light sourceEffect lightEngineering

First, second and third lighting devices each comprise a thermal conduction element, solid state light emitters and a reflective element. In the second device, the conduction element defines an opening; and the emitters and reflective element are mounted on a first side of the conduction element. In the third device, the conduction element defines an opening; a first portion of a first side of the conduction element is in contact with a contact region of a construction surface; and the emitters and reflective element are mounted on the first side. A fourth device comprises a conduction element and emitters; a first portion of a first side of the conduction element is in contact with a contact region of a construction surface; the emitters are mounted on a second portion of the first side of the conduction element; and a second side of the conduction element is exposed to ambient air.

Owner:IDEAL IND LIGHTING LLC

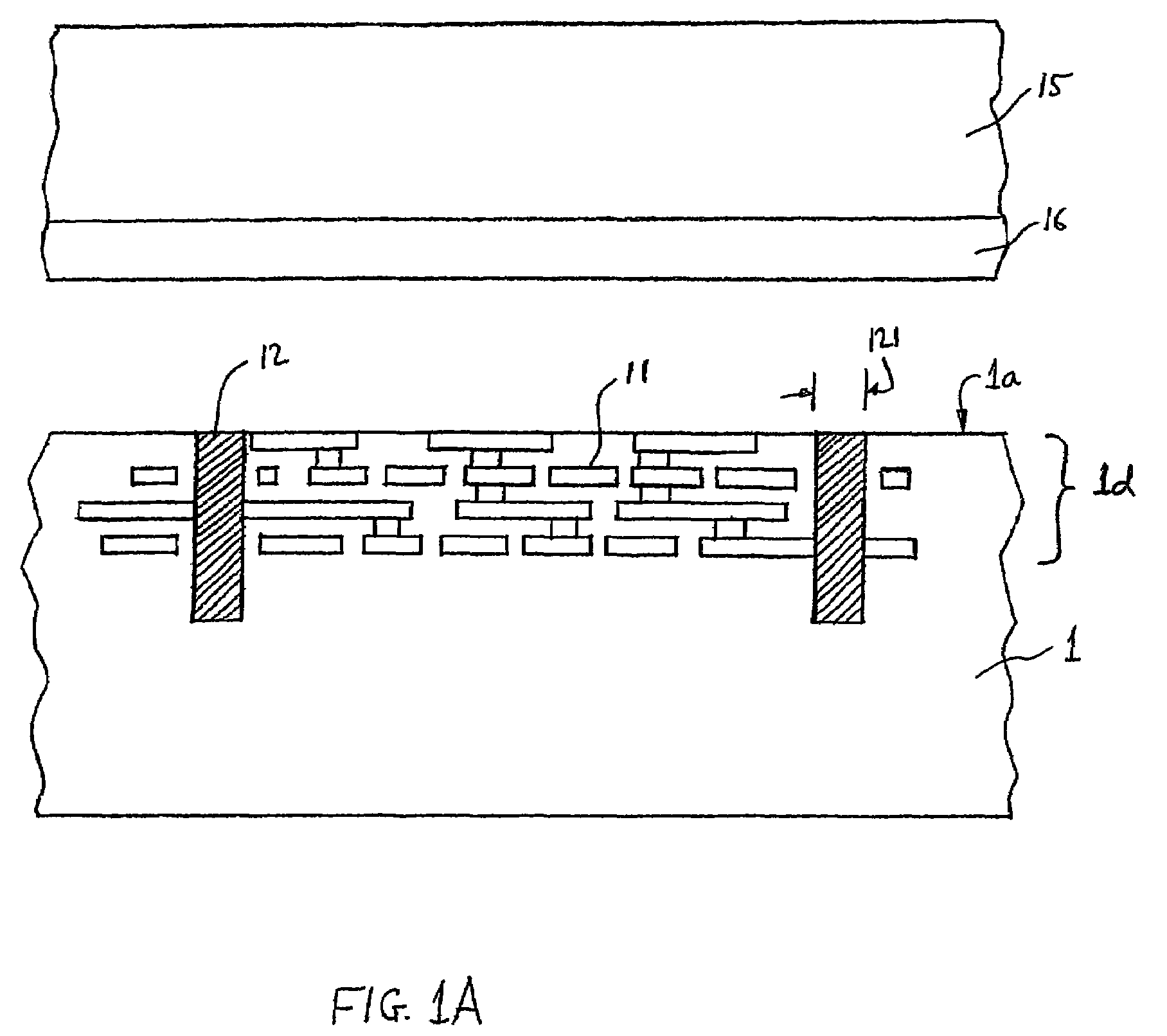

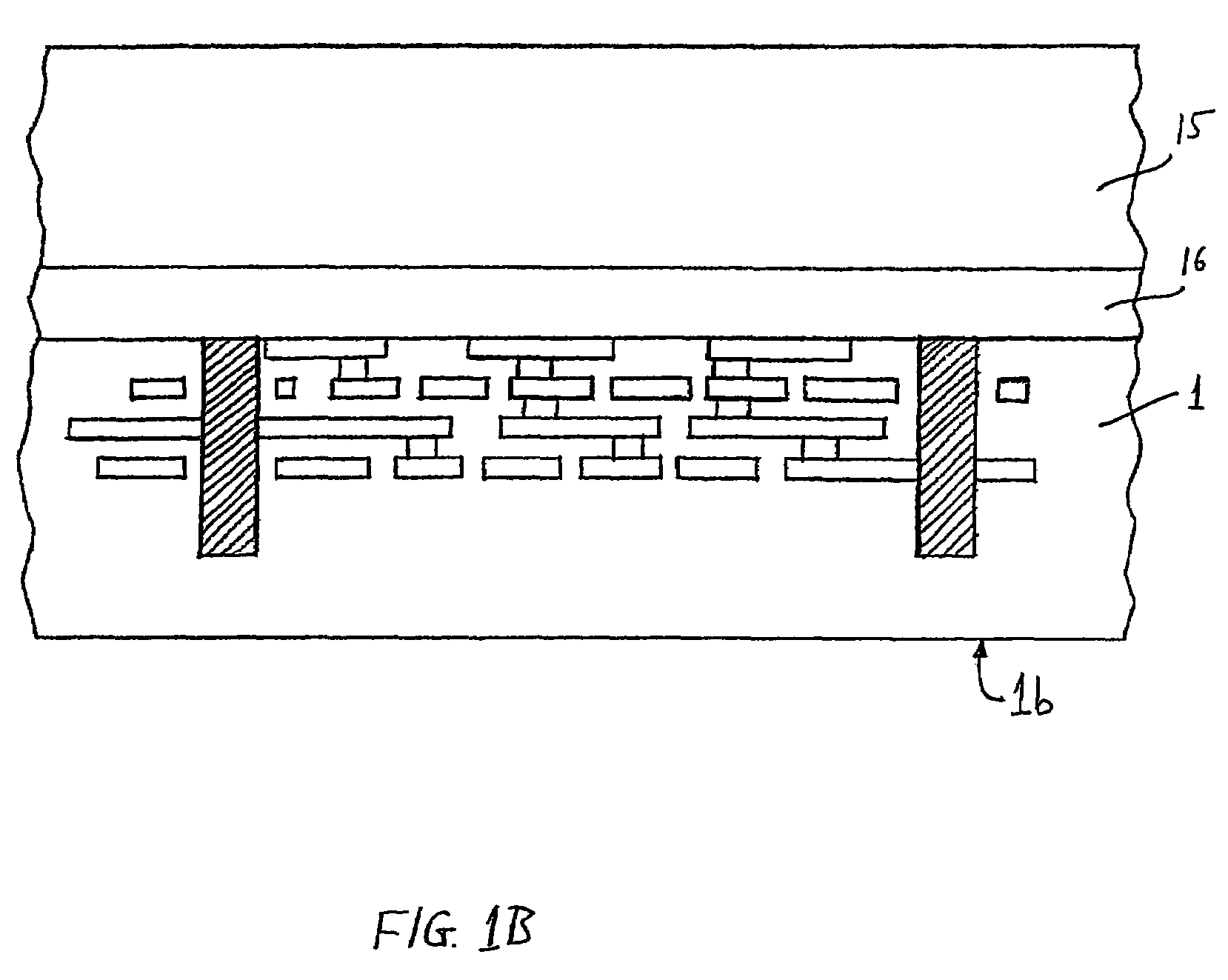

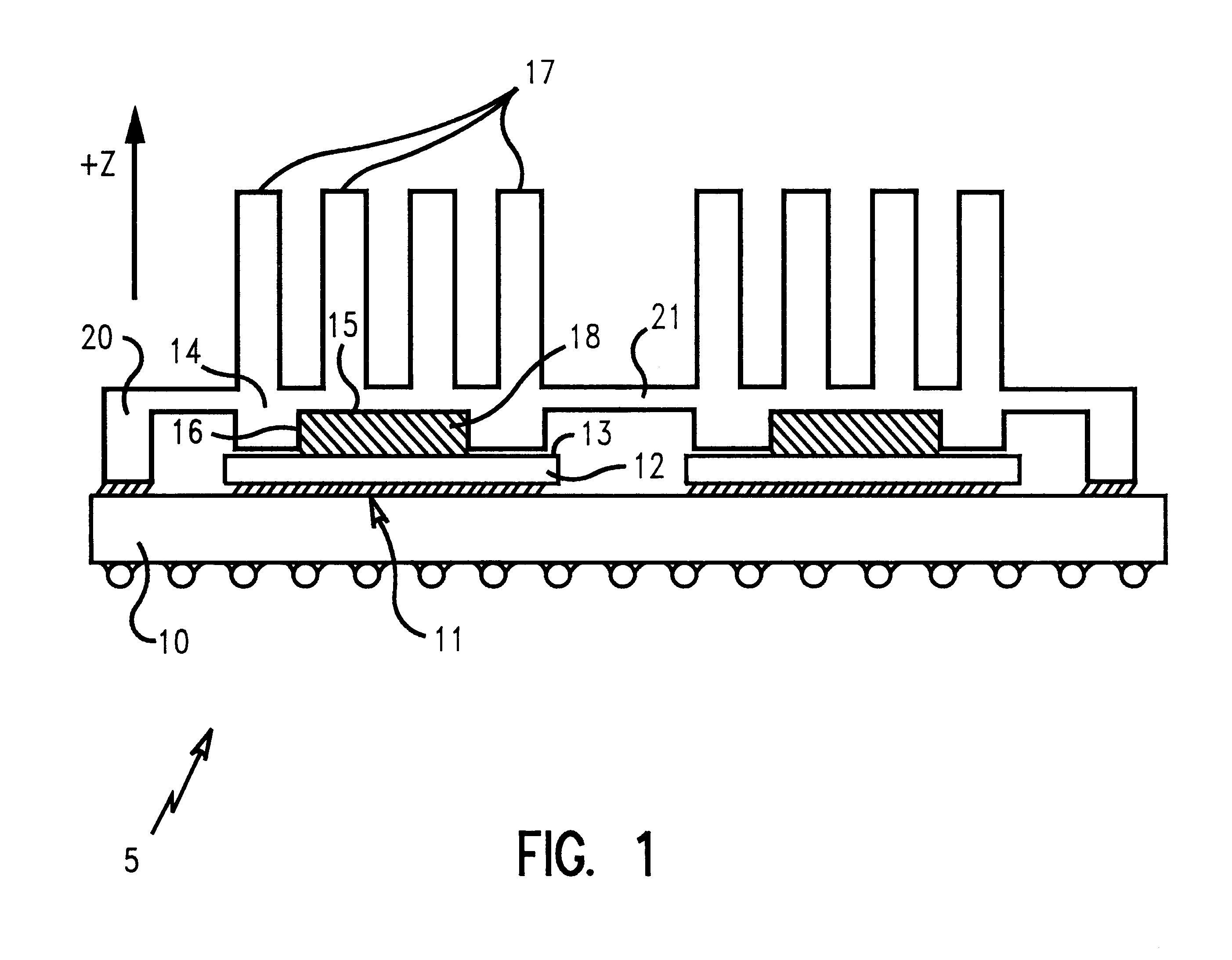

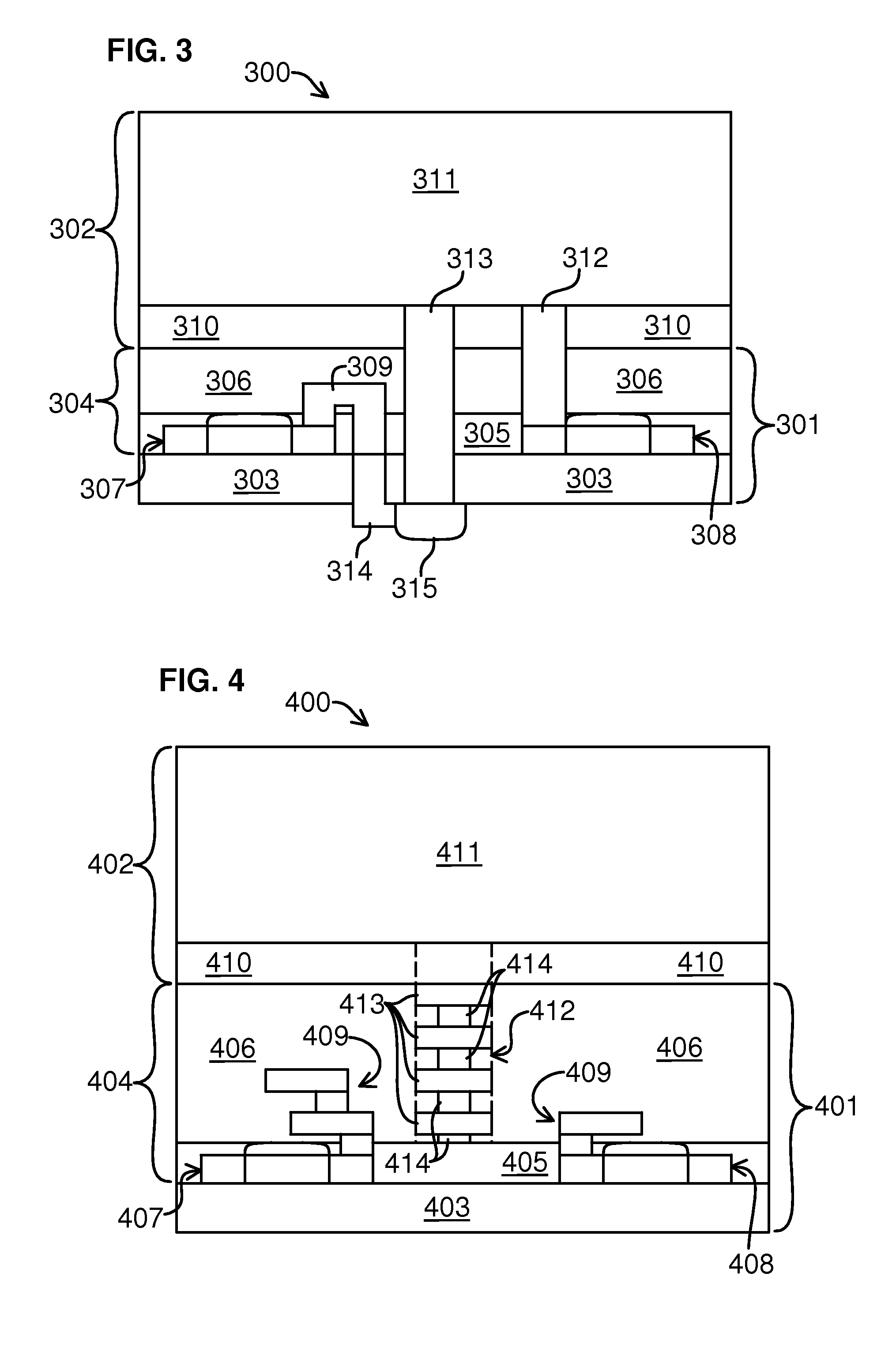

Three-dimensional device fabrication method

InactiveUS7354798B2Semiconductor/solid-state device detailsSolid-state devicesConduction pathwayElectrical connection

A method is described for fabricating a three-dimensional integrated device including a plurality of vertically stacked and interconnected wafers. Wafers (1, 2, 3) are bonded together using bonding layers (26, 36) of thermoplastic material such as polyimide; electrical connections are realized by vias (12, 22) in the wafers connected to studs (27, 37). The studs connect to openings (13, 23) having a lateral dimension larger than that of the vias at the front surfaces of the wafers. Furthermore, the vias in the respective wafers need not extend vertically from the front surface to the back surface of the wafers. A conducting body (102) provided in the wafer beneath the device region and extending laterally, may connect the via with the matallized opening (103) in the back surface. Accordingly, the conducting path through the wafer may be led underneath the devices thereof. Additional connections may be made between openings (113) and studs (127) to form vertical heat conduction pathways between the wafers.

Owner:IBM CORP

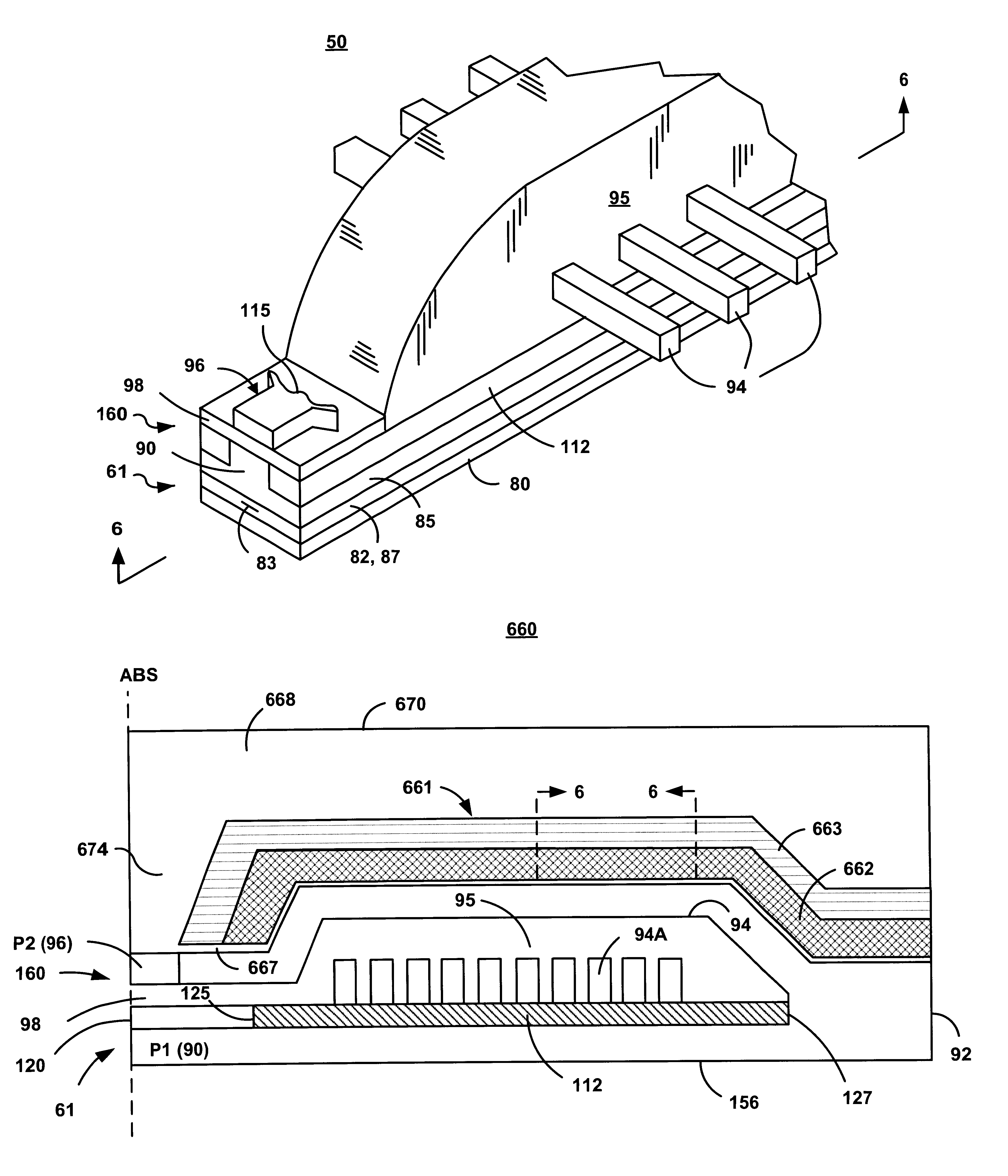

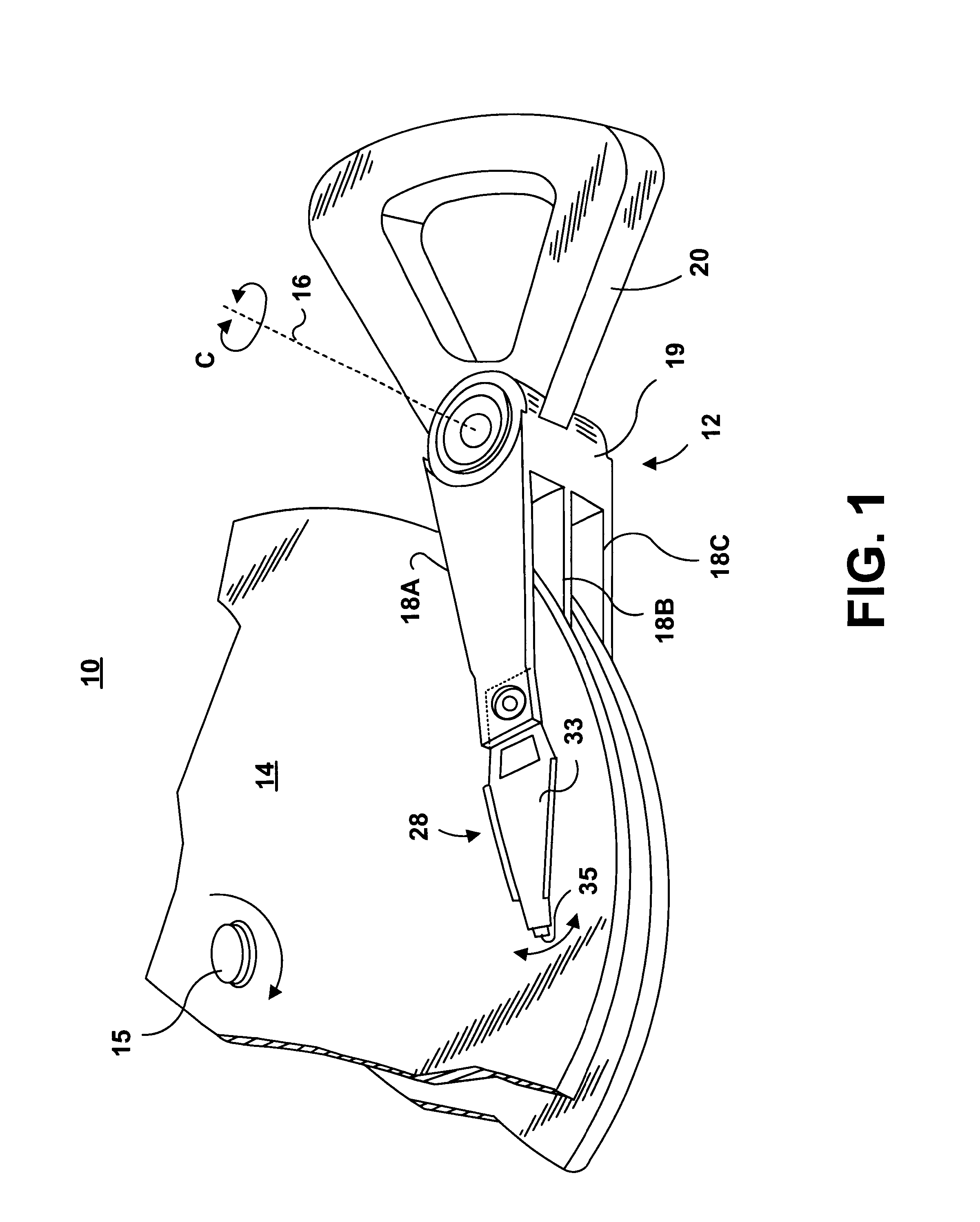

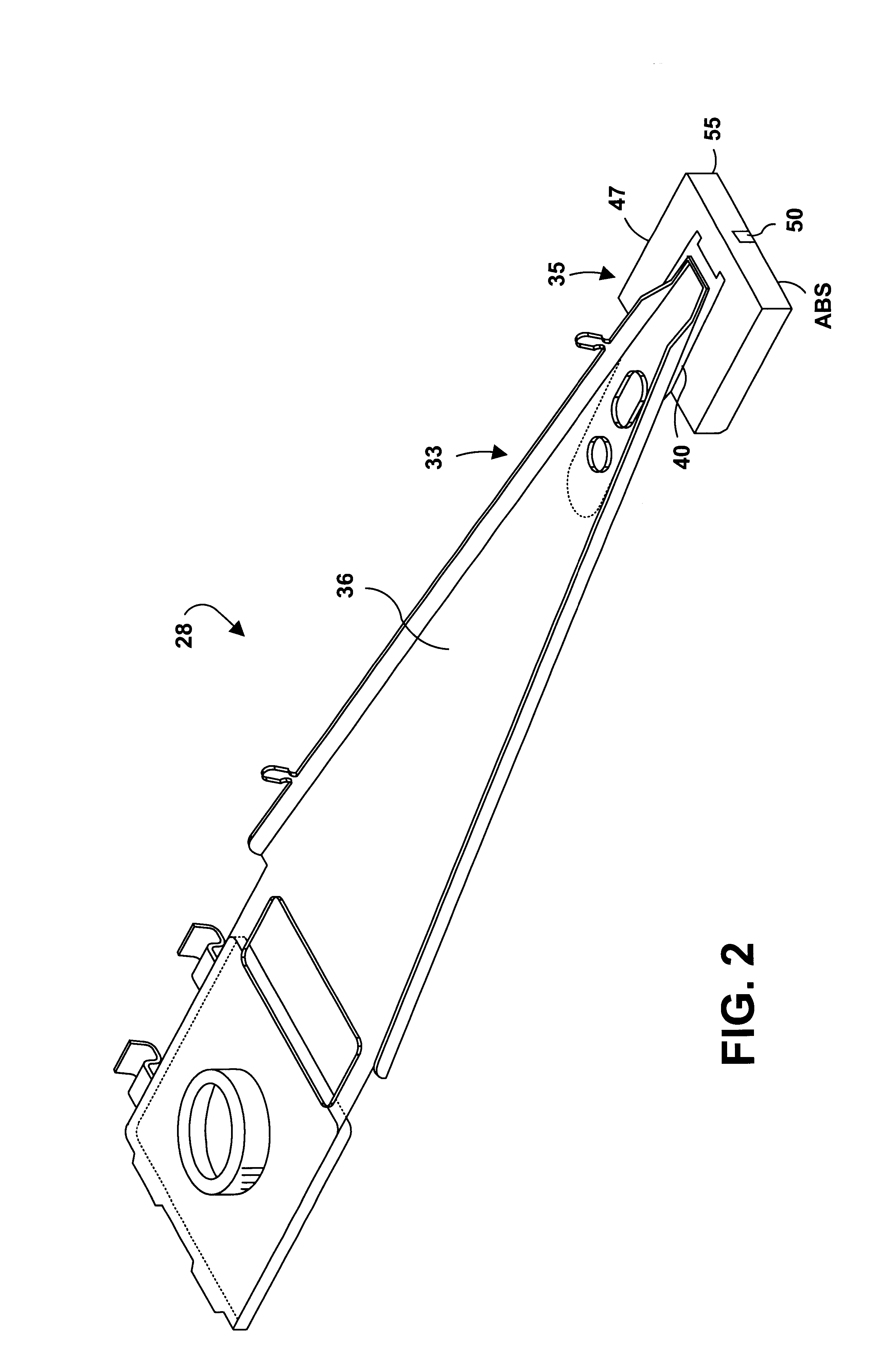

Hybrid diffuser for minimizing thermal pole tip protrusion and reader sensor temperature

InactiveUS6859343B1Reduces reader sensor temperatureImprove thermal conductivityManufacture head surfaceRecord information storageInvarInsulation layer

An enchance recording head design provides conduction and mechanical restraint control in order to minimize the pole tip protrusion and the head temperature resulting from the thermal heating of the magnetic recording head during operation. In one embodiment, the recording head includes a hybrid diffuser formed within an insulation layer, at a predetermined distance from the head write section. The hybrid diffuser is comprised of a thermal conduction layer with high thermal conductivity, such as gold or copper, and a mechanical restraint layer having near zero CTE, such as a 60-80% face-centered-cubic NiFe (Invar) material. The hybrid diffuser is recessed from the ABS to prevent the delamination of the hybrid diffuser due to the otherwise displacement incompatibility between the inner insulating layer and the hybrid diffuser at the ABS.

Owner:WESTERN DIGITAL TECH INC

Tissue cooling rod for laser surgery

A laser treatment device and process with controlled cooling. The device contains a cooling element with high heat conduction properties, which is transparent to the laser beam. A surface of the cooling element is held in contact with the tissue being treated while at least one other surface of the cooling element is cooled by the evaporation of a cryogenic fluid. The cooling is coordinated with the application of the laser beam so as to control the temperatures of all affected layers of tissues. In a preferred embodiment useful for removal of wrinkles and spider veins, the cooling element is a sapphire plate. A cryogenic spray cools the top surface of the plate and the bottom surface of the plate is in contact with the skin. In preferred embodiments the wavelength of the laser beam is chosen so that absorption in targeted tissue is low enough so that substantial absorption occurs throughout the targeted tissue. In a preferred embodiment for treating large spider veins with diameters in the range of 1.5 mm, Applicants use an Er:Glass laser with a wavelength of 1.54 microns.< / PTEXT>

Owner:RELIANT TECH INC

LED light source assembly

ActiveUS7093958B2IntensiveImprove cooling effectPoint-like light sourceLighting support devicesElectricityHigh concentration

A compact LED light source providing intensive LED positioning along with thermal dissipation can be made with a heat conductive plate supporting a plurality of LEDs mounted on the plate and in thermal contact with the plate. The plate further supports electrical circuitry providing electrical connection to the LEDs. A heat conductive stem mechanically supports the plate and may provide a thermal conduction path from the plate away from the LEDs. A high concentration of LED can then be conveniently mounted and held in close proximity for increased optical system intensity, while providing a thermal exit path for the associated increase in heat concentration.

Owner:SUZHOU LEKIN SEMICON CO LTD

Thermal enhancement approach using solder compositions in the liquid state

InactiveUS6281573B1Lower resistanceThermal mismatchPrinted electric component incorporationSemiconductor/solid-state device detailsThermal energyThermal coefficient

Solder compositions are introduced to interface between an IC chip and its associated heat exchanger cover. The solder compositions have a solidus-liquidus temperature range that encompasses the IC chip operational temperature range. The solder composition has the desired property of absorbing and rejecting heat energy by changing state or phase with each temperature rise and decline that result from temperature fluctuations associated with the thermal cycles of the integrated circuit chips. A path for high thermal conduction (low thermal resistance) from the IC chip to the heat exchanger to the ambient air is provided by an electronic module cover, configured as a cap with a heat exchanger formed or attached as a single construction, and made of the same material as the substrate, or made with materials of compatible thermal coefficients of expansion to mitigate the effects of vertical displacement during thermal cycling. The cap-heat exchanger cover is constructed to be compliant, and to contact both the IC chip and substrate.

Owner:IBM CORP

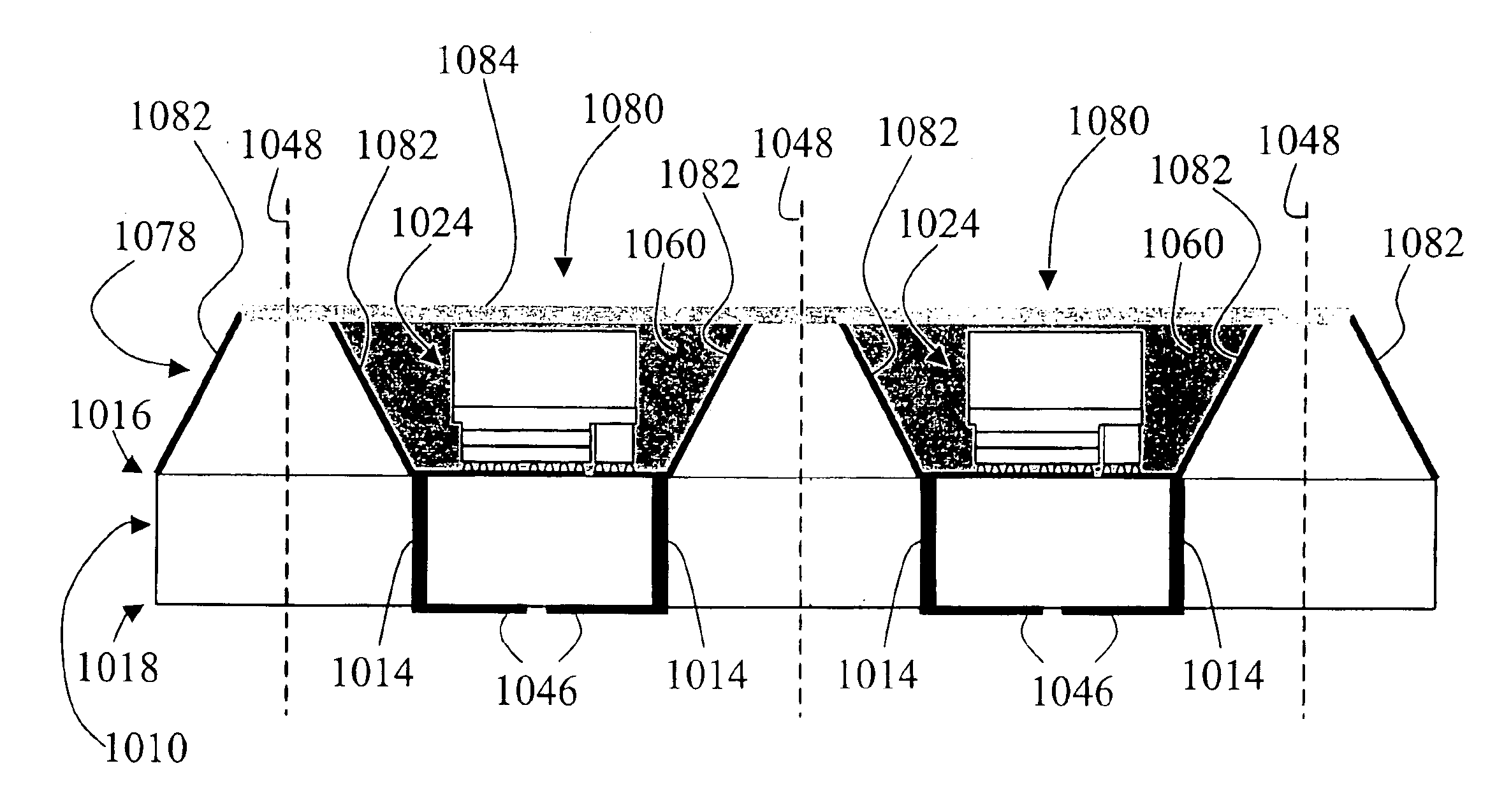

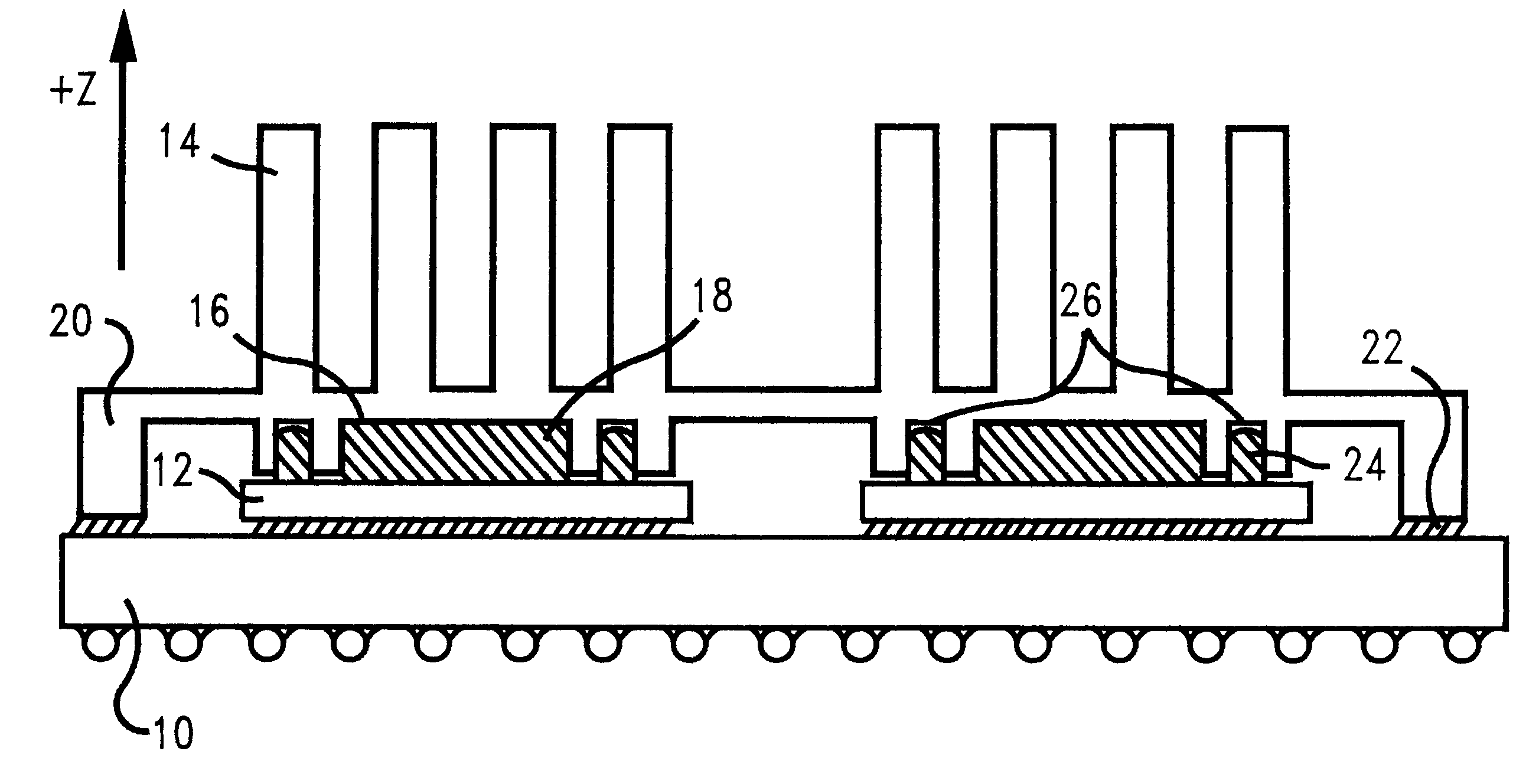

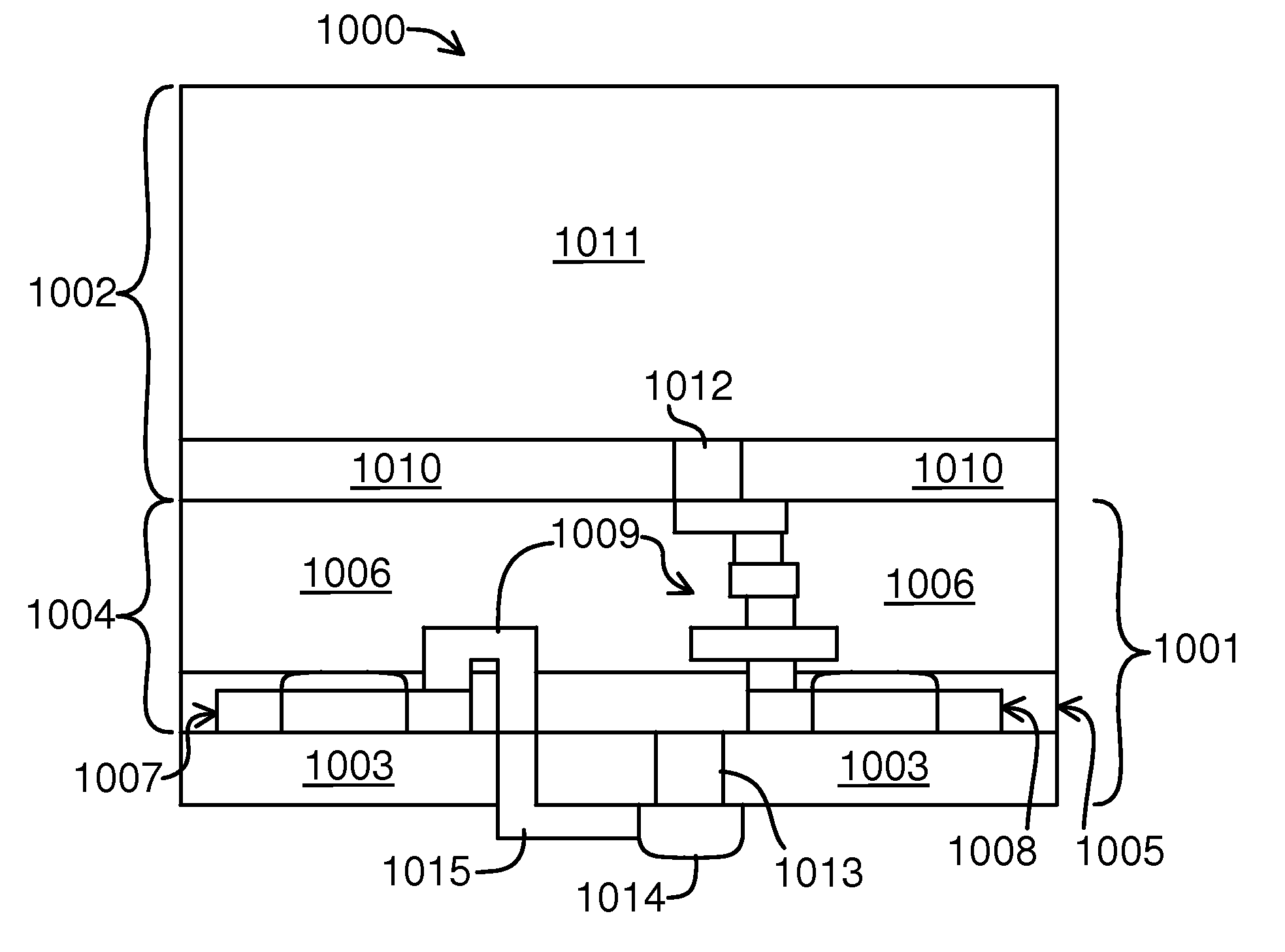

Thermal Conduction Paths for Semiconductor Structures

ActiveUS20120146193A1Semiconductor/solid-state device detailsSolid-state devicesSemiconductor structureThermal contact

A thermal path is formed in a layer transferred semiconductor structure. The layer transferred semiconductor structure has a semiconductor wafer and a handle wafer bonded to a top side of the semiconductor wafer. The semiconductor wafer has an active device layer formed therein. The thermal path is in contact with the active device layer within the semiconductor wafer. In some embodiments, the thermal path extends from the active device layer to a substrate layer of the handle wafer. In some embodiments, the thermal path extends from the active device layer to a back side external thermal contact below the active device layer.

Owner:QUALCOMM INC

Display cabinet illumination

An illuminator has two lines of LEDs on inwardly-directed faces of an elongate body which forms a mullion for a display cabinet. Heat conduction through the body to outer surfaces provides the durable effect of anti-sweat heating to prevent condensation in doors of the cabinet.

Owner:NUALIGHT

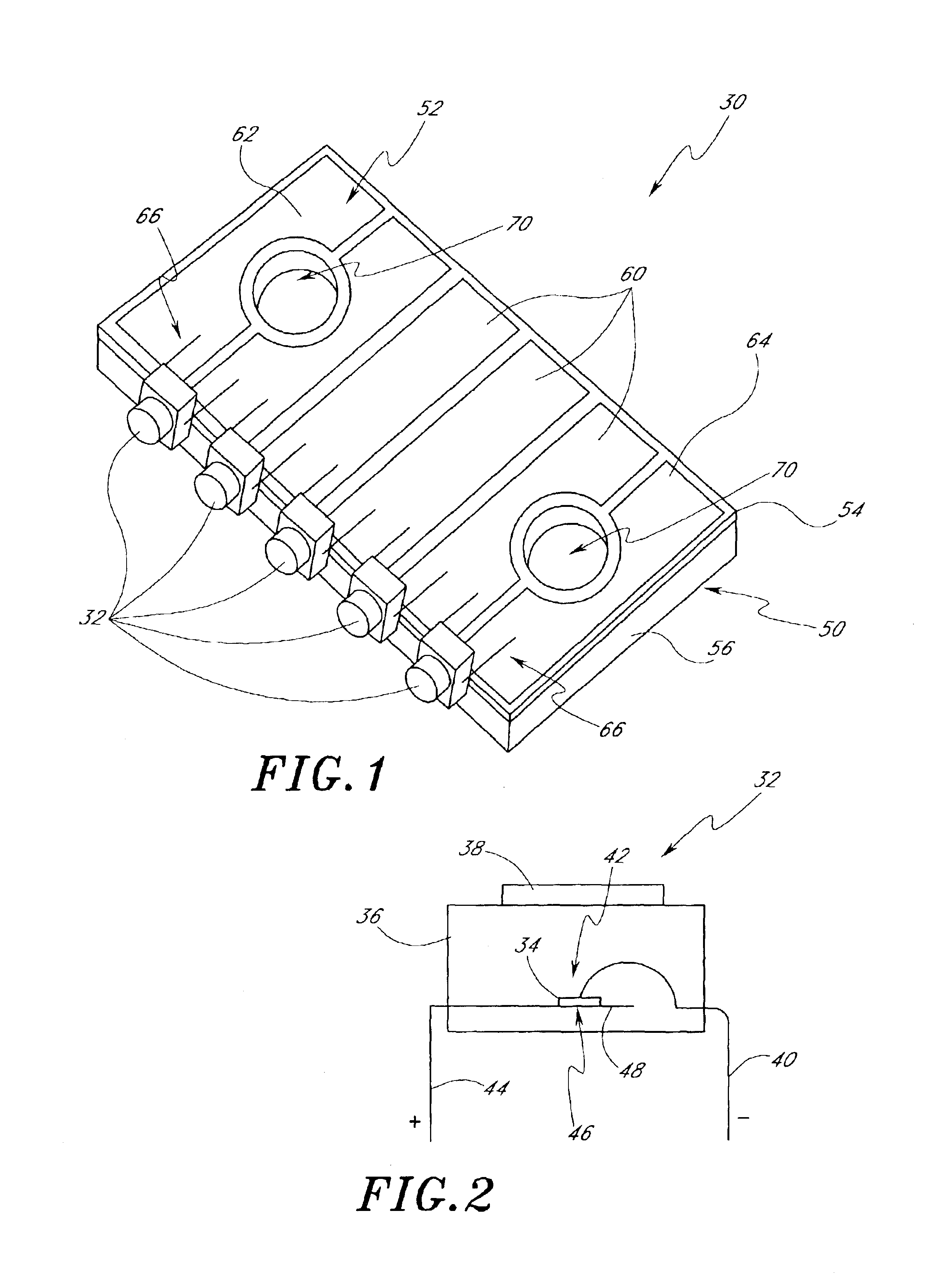

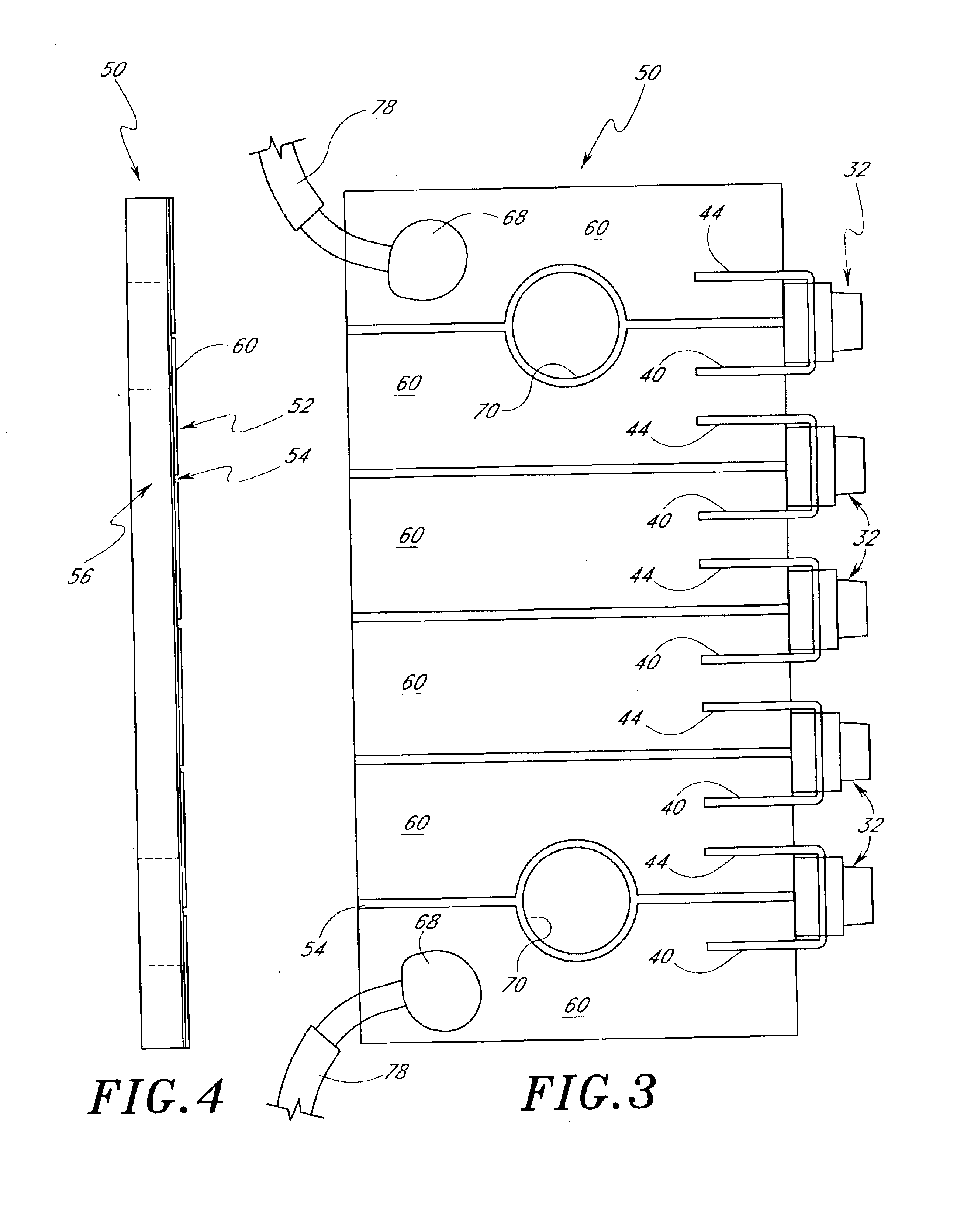

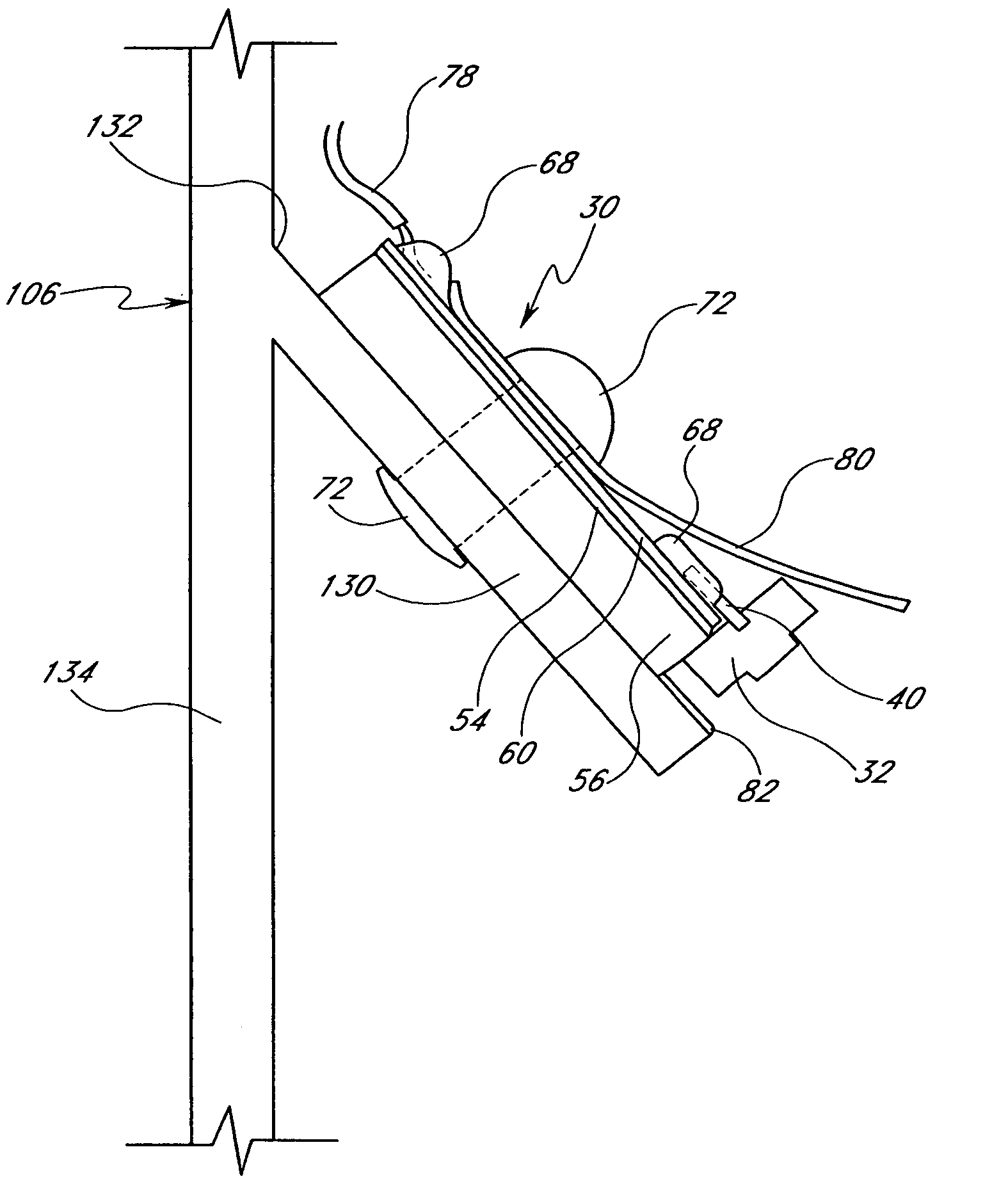

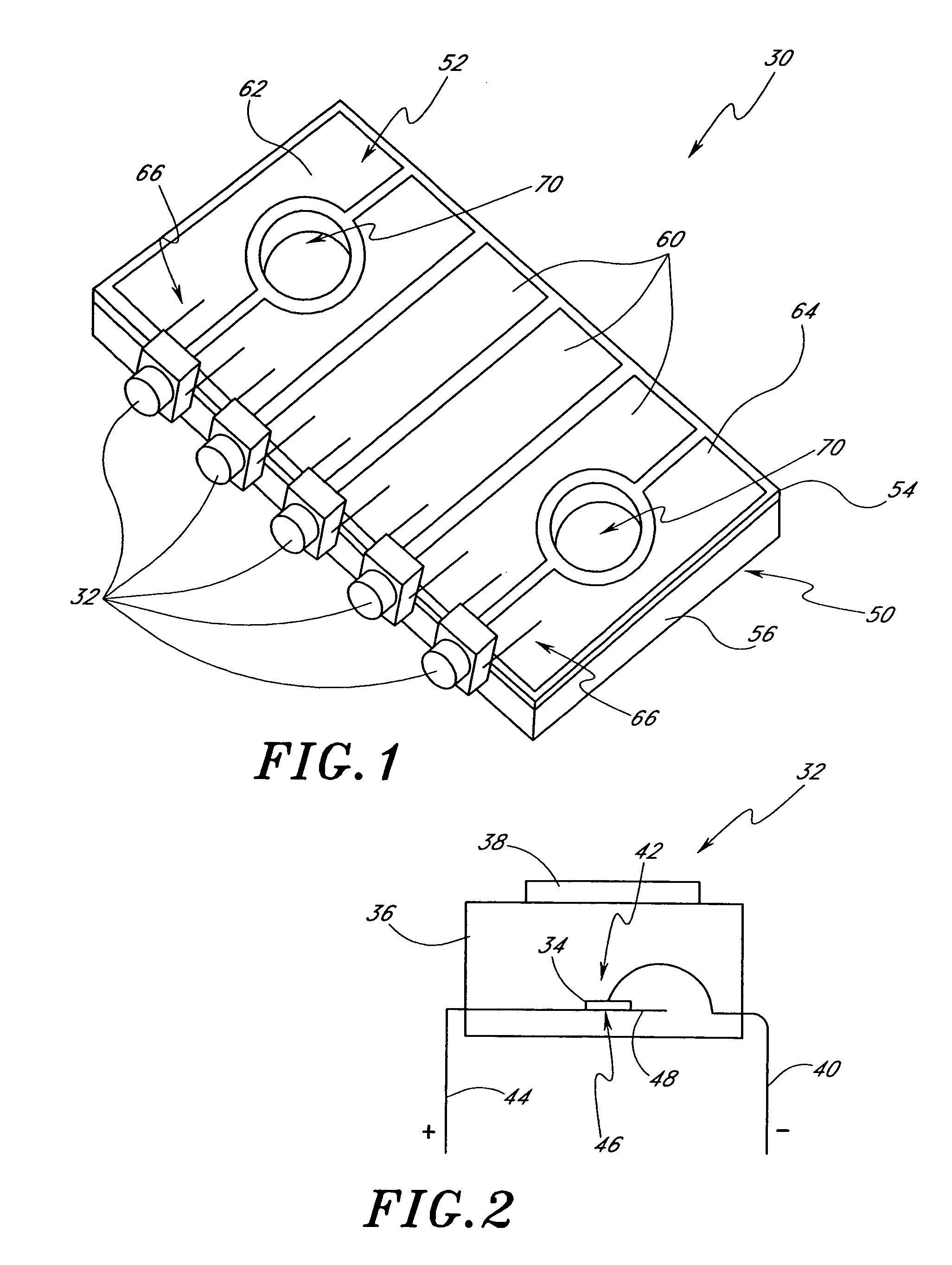

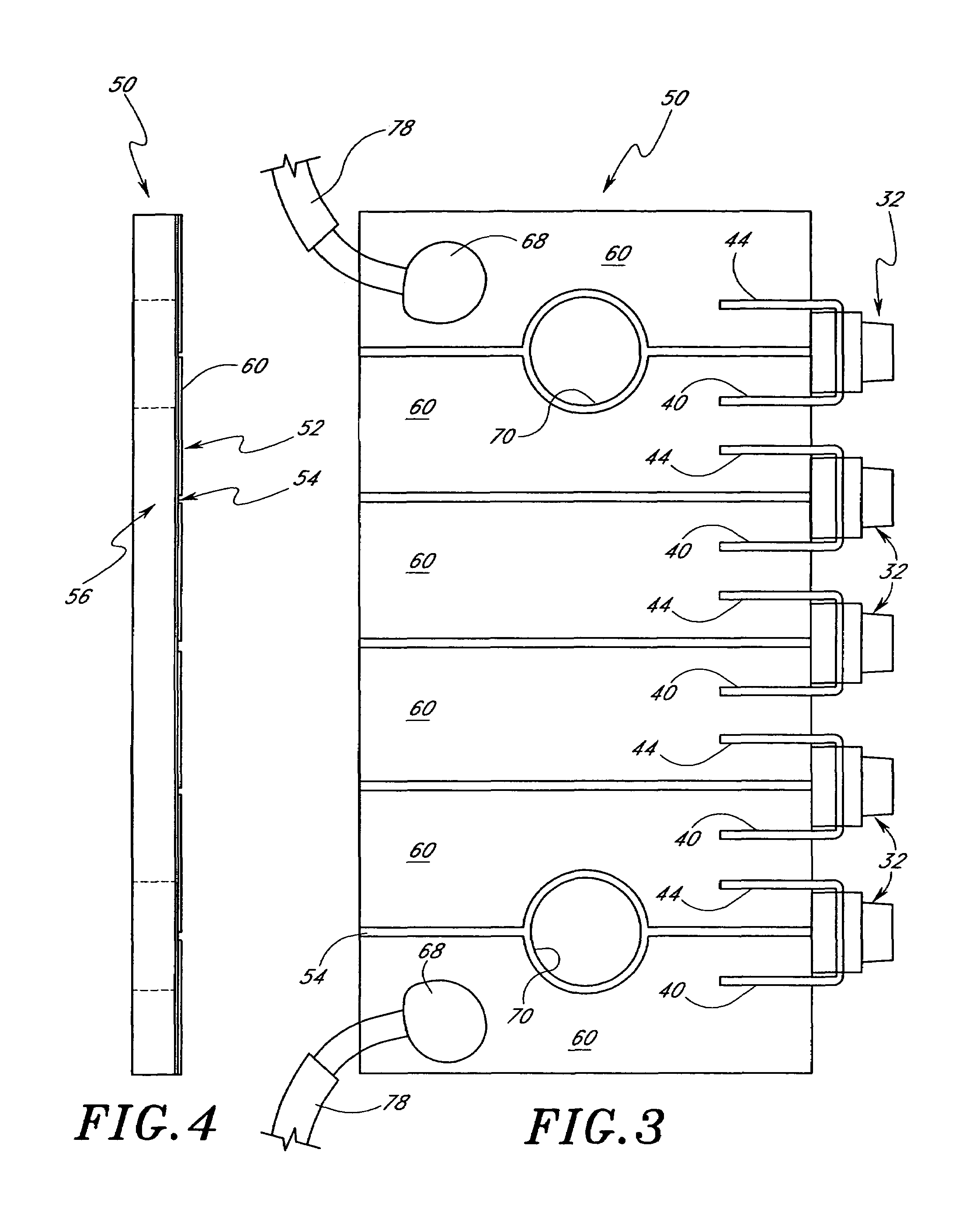

Mounting arrangement for light emitting diodes

A modular light emitting diode (LED) mounting configuration is provided including a light source module having a plurality of pre-packaged LEDs arranged in a serial array. The module includes a heat conductive body portion adapted to conduct heat generated by the LEDs to an adjacent heat sink. As a result, the LEDs are able to be operated with a higher current than normally allowed. Thus, brightness and performance of the LEDs is increased without decreasing the life expectancy of the LEDs. The LED modules can be used in a variety of illumination applications employing one or more modules.

Owner:DIAMOND CREEK CAPITAL LLC

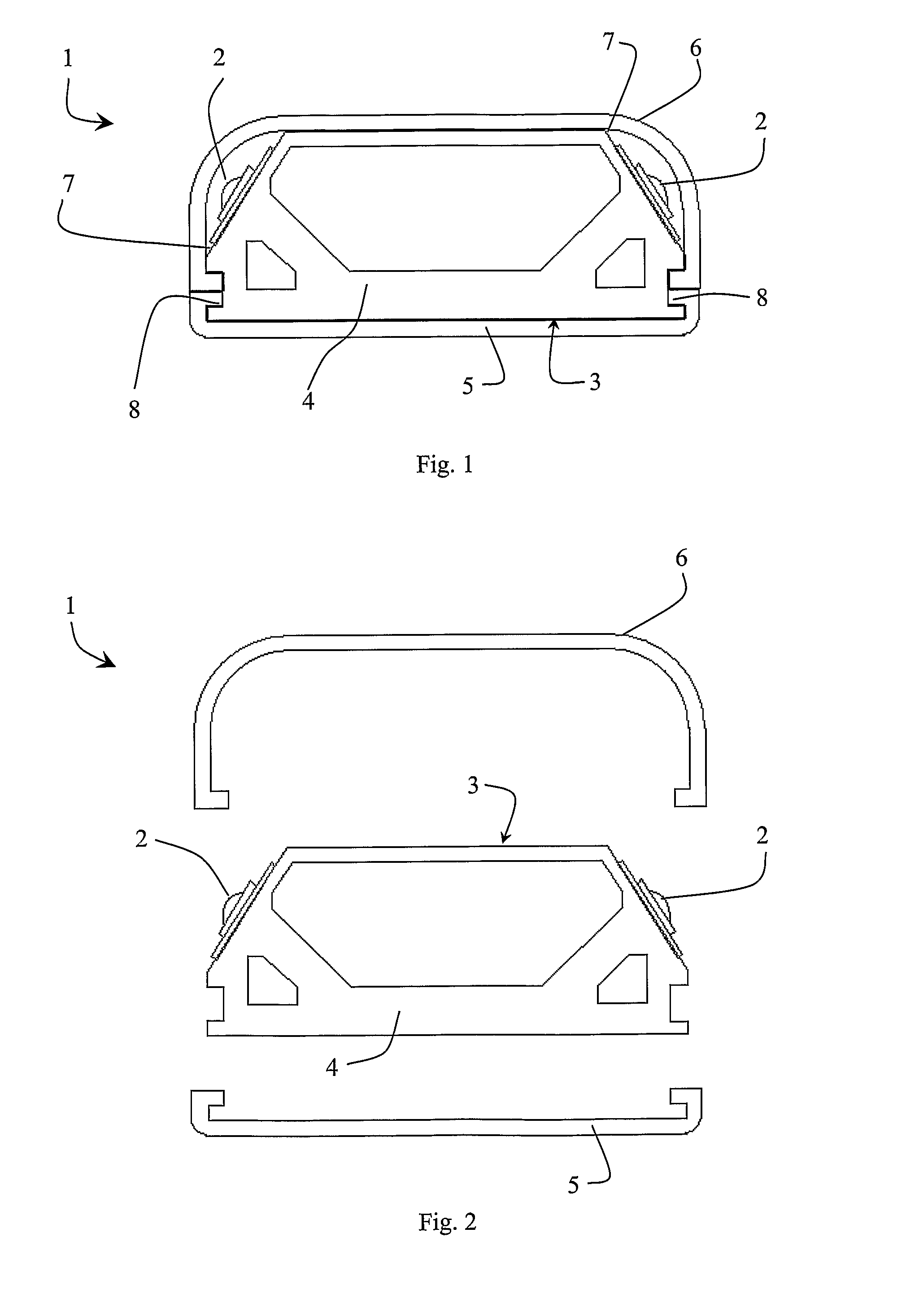

Sealing structure, device, and method for manufacturing device

ActiveUS20140252386A1Avoid heat conductionLow heat resistanceSolid-state devicesSemiconductor/solid-state device manufacturingSealantBiomedical engineering

Provided is a device in which heat conduction from a sealant to a functional element is suppressed and whose bezel is slim. The sealing structure includes a first substrate, a second substrate whose surface over which a sealed component is provided faces the first substrate, and a frame-like sealant which seals a space between the first substrate and the second substrate with the first substrate and the second substrate. The second substrate includes a groove portion between the sealant and the sealed component. The groove portion is in a vacuum or includes a substance whose heat conductivity is lower than that of the second substrate.

Owner:SEMICON ENERGY LAB CO LTD

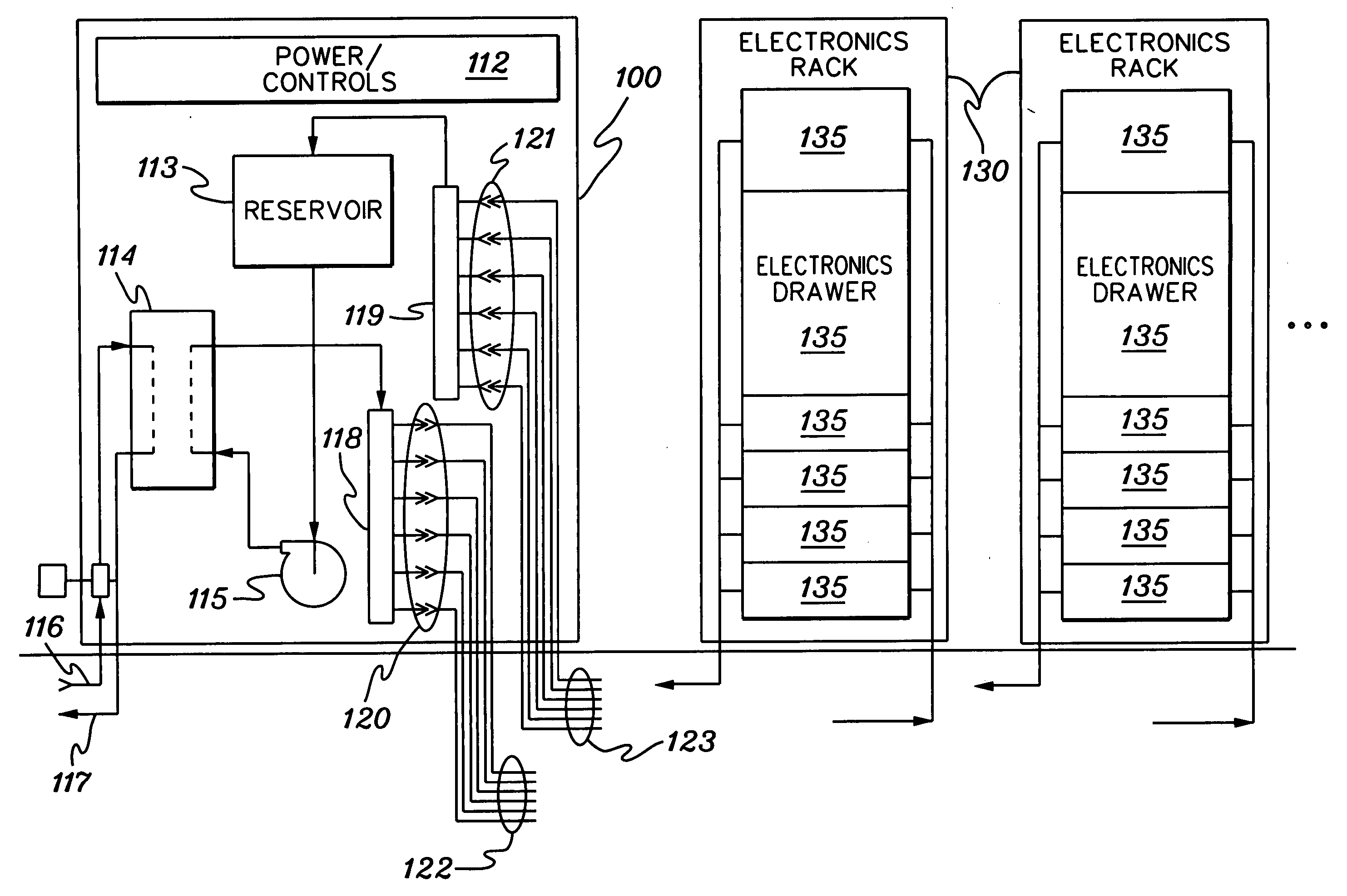

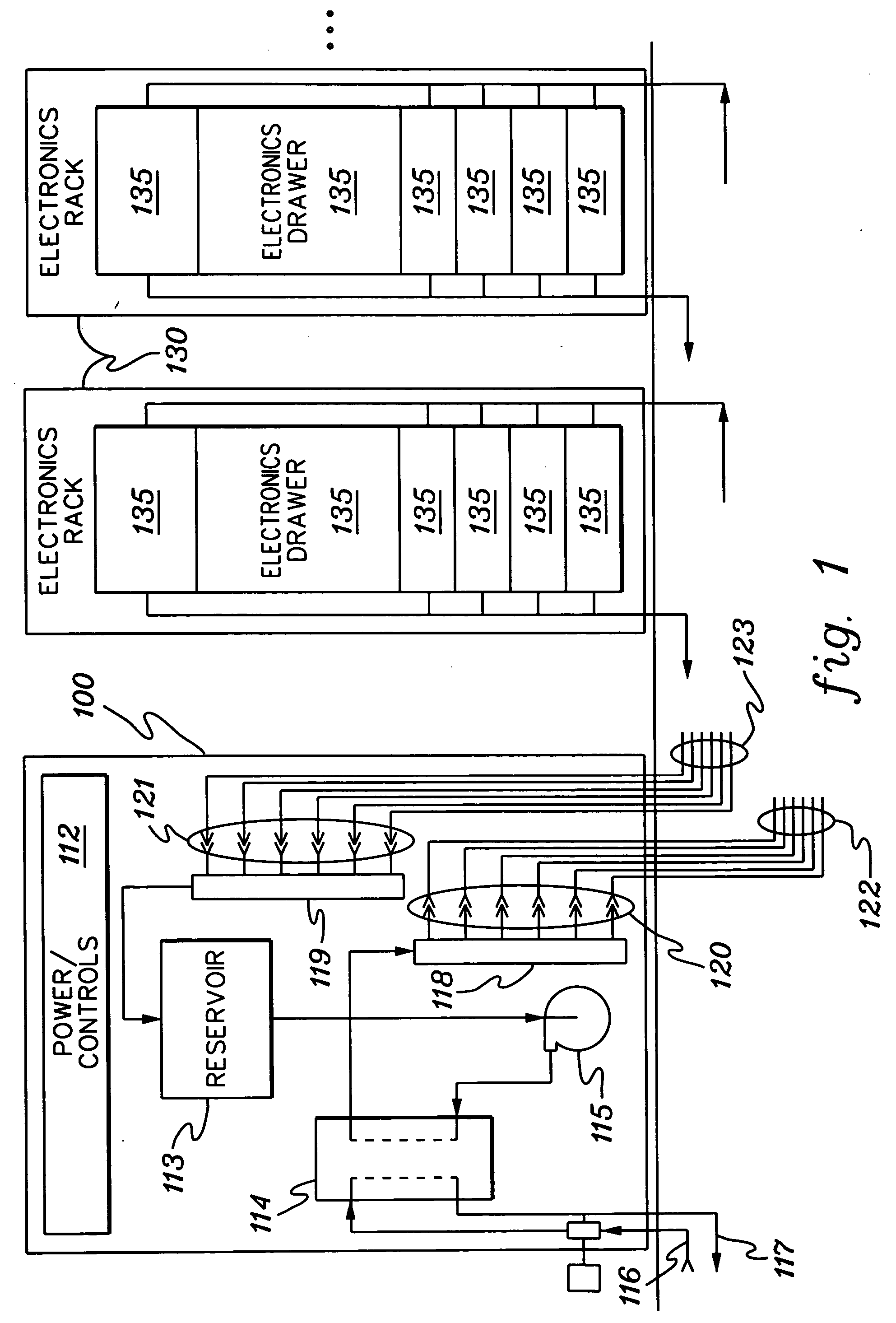

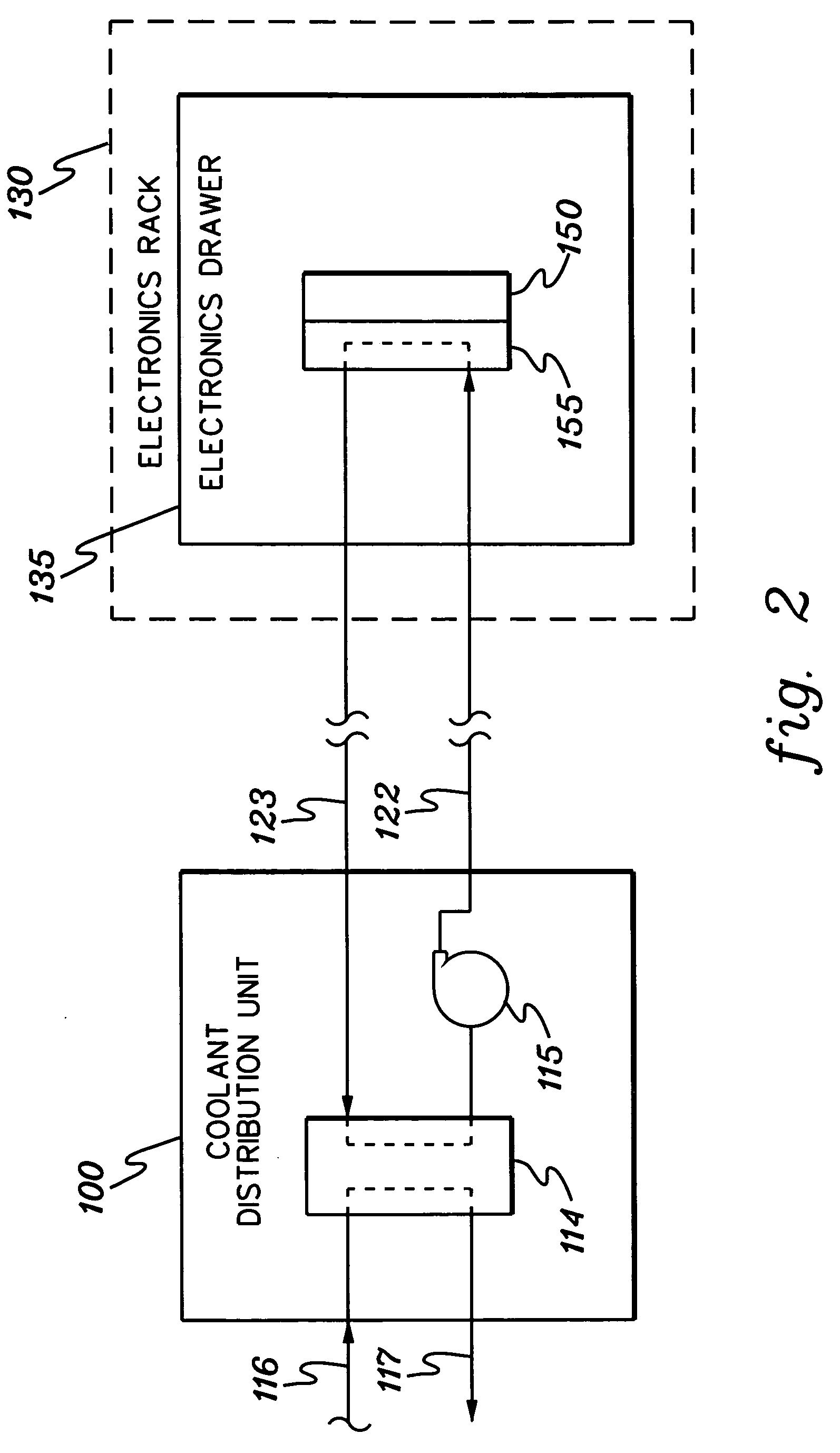

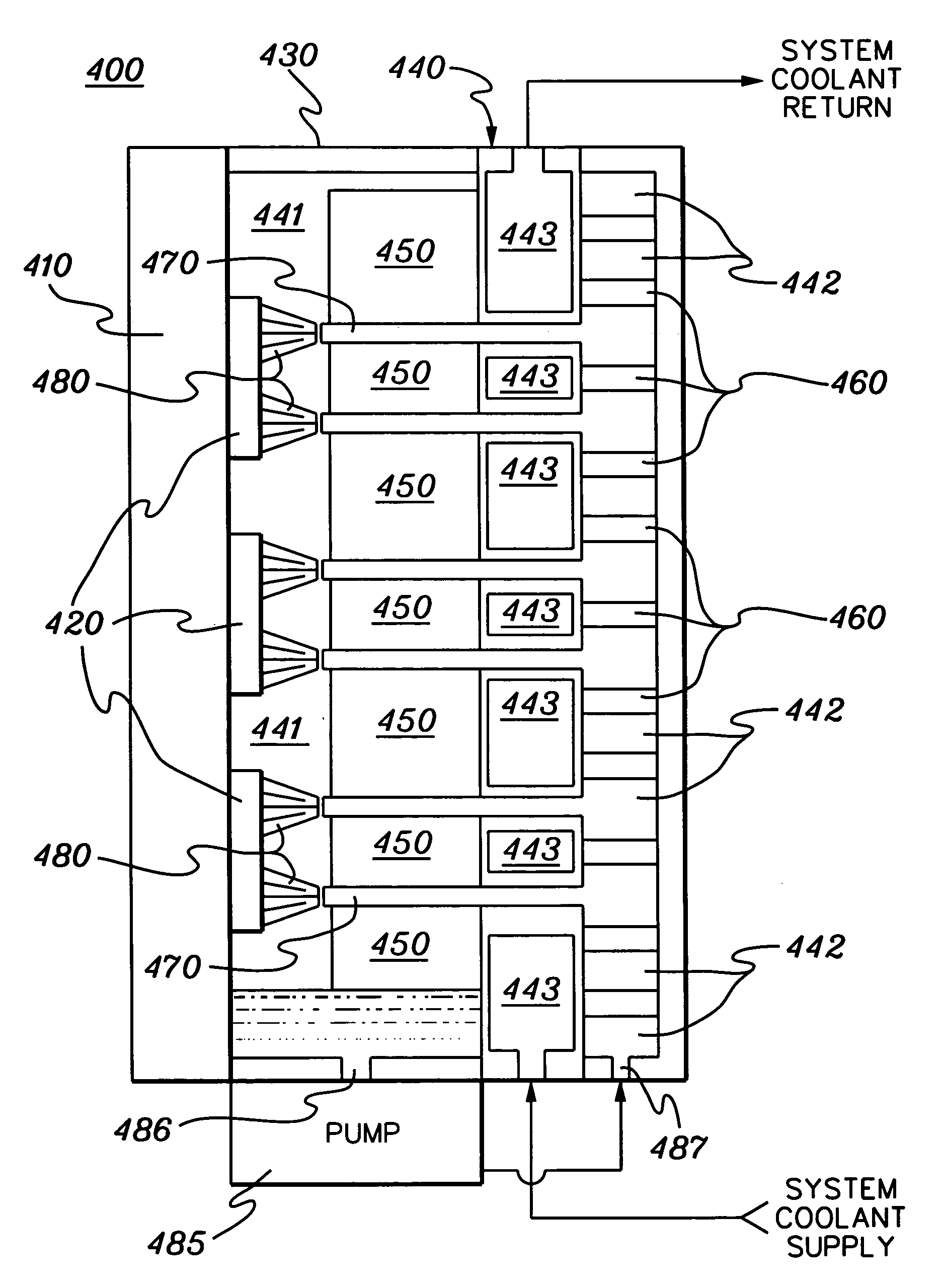

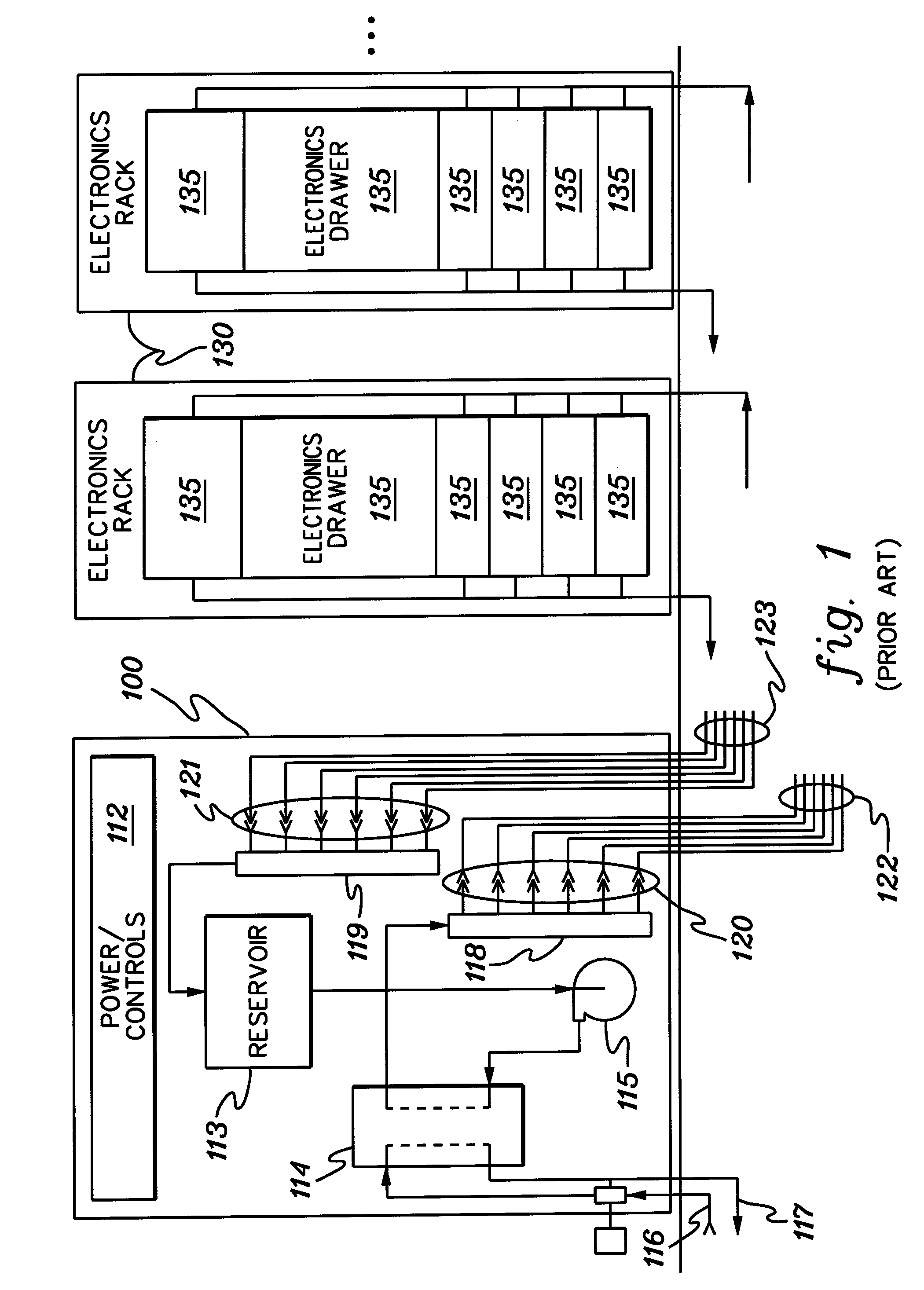

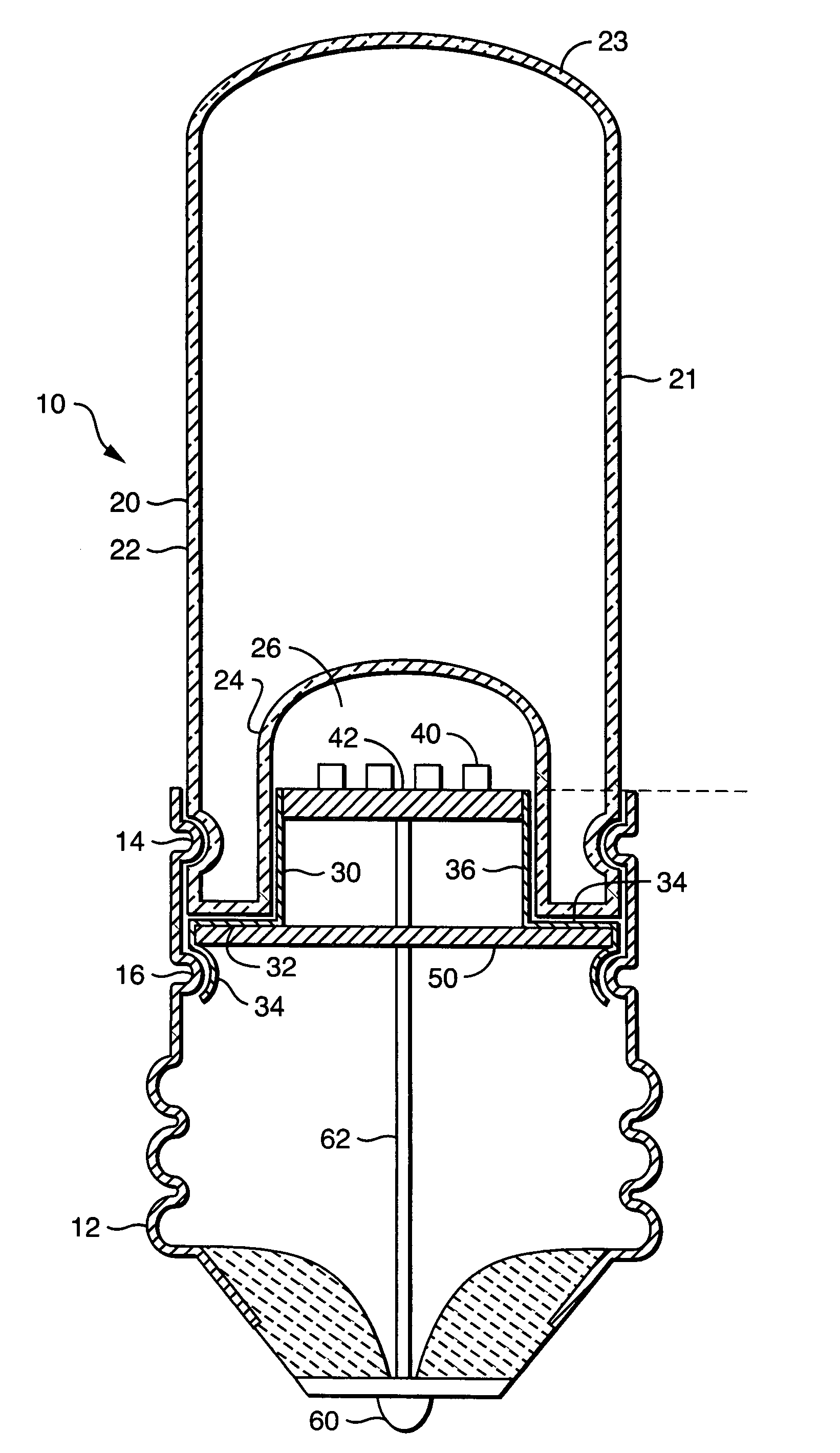

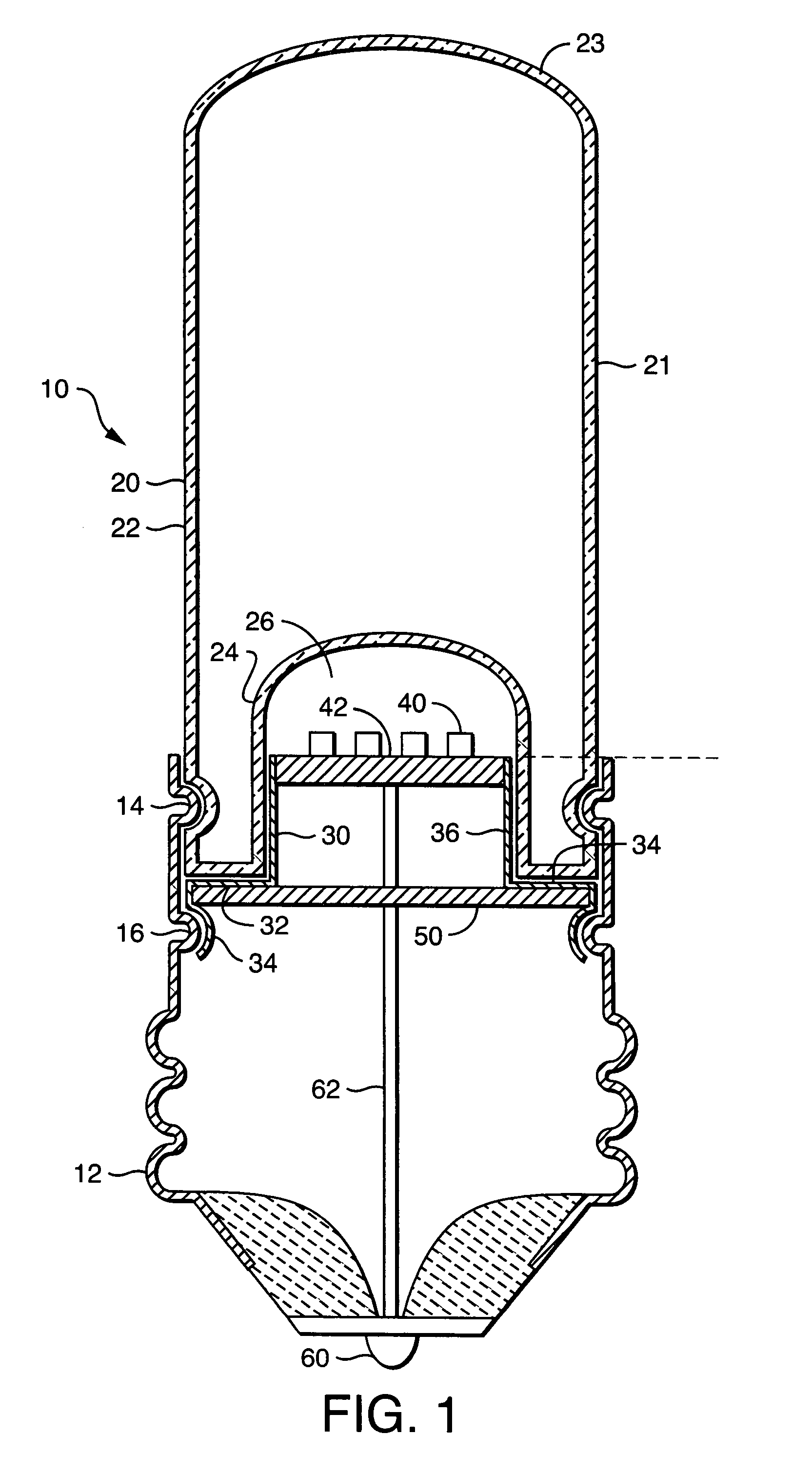

Cooling apparatus and method for an electronics module employing an integrated heat exchange assembly

A cooling apparatus for an electronics assembly having a substrate and one or more electronics devices includes an enclosure sealably engaging the substrate to form a cavity, with the electronics devices and a heat exchange assembly being disposed within the cavity. The heat exchange assembly defines a primary coolant flow path and a separate, secondary coolant flow path. The primary coolant flow path includes first and second chambers in fluid communication, and the secondary flow path includes a third chamber disposed between the first and second chambers. The heat exchange assembly provides a first thermal conduction path between primary coolant in the first chamber and secondary coolant in the third chamber, and a second thermal conduction path between primary coolant in the second chamber and secondary coolant in the third chamber. The heat exchange assembly further includes coolant nozzles to direct primary coolant towards the electronics devices.

Owner:IBM CORP

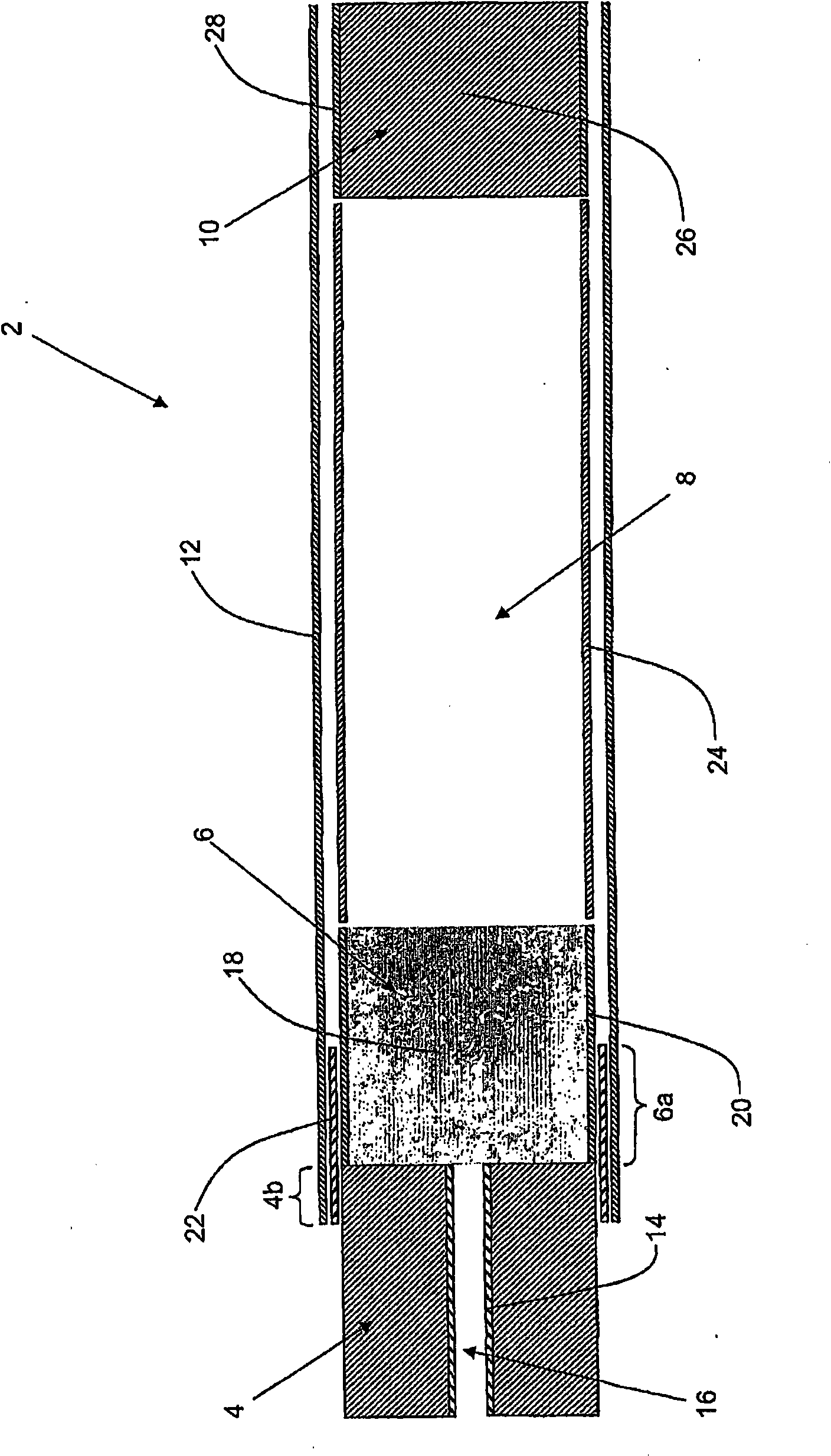

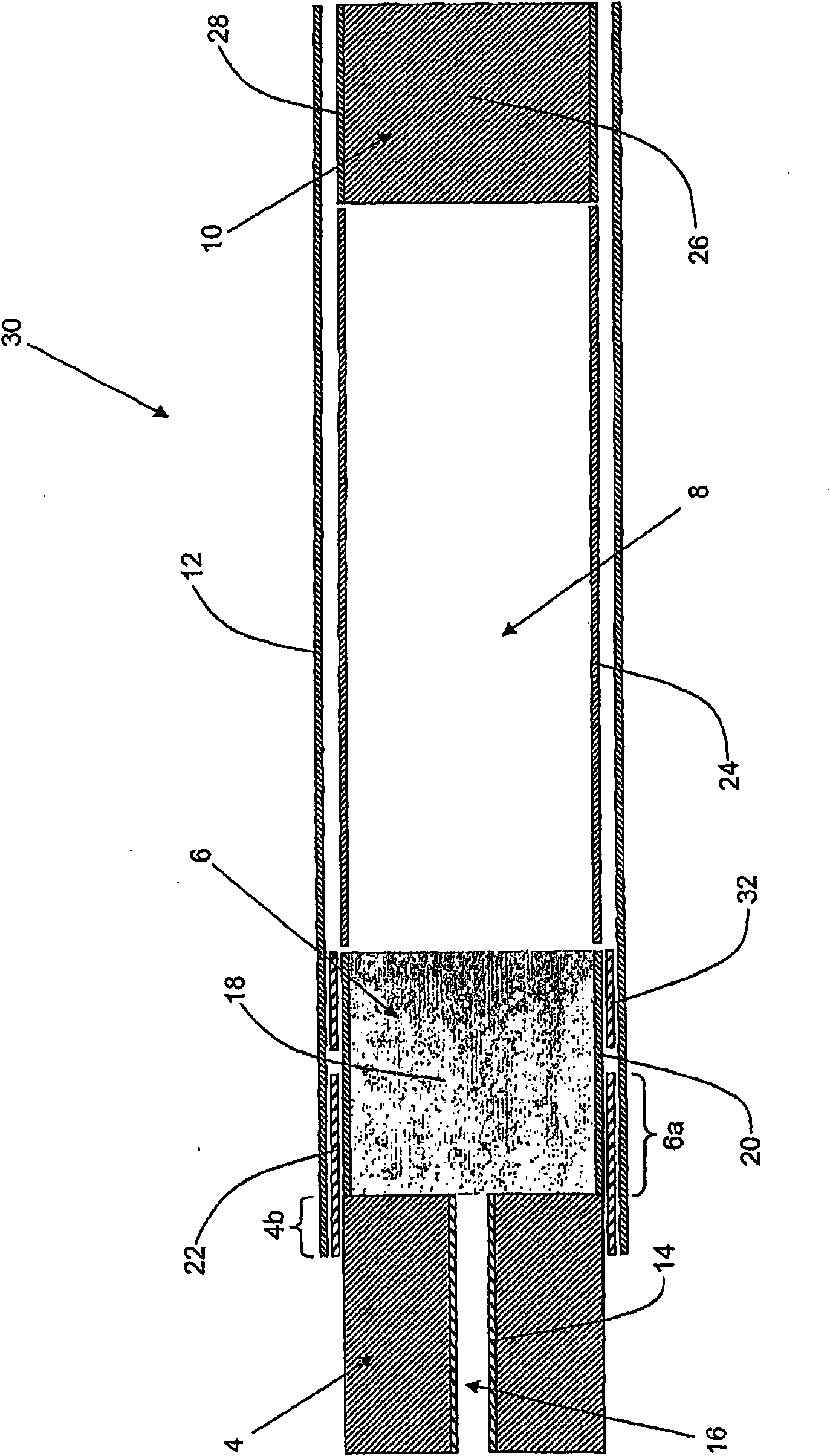

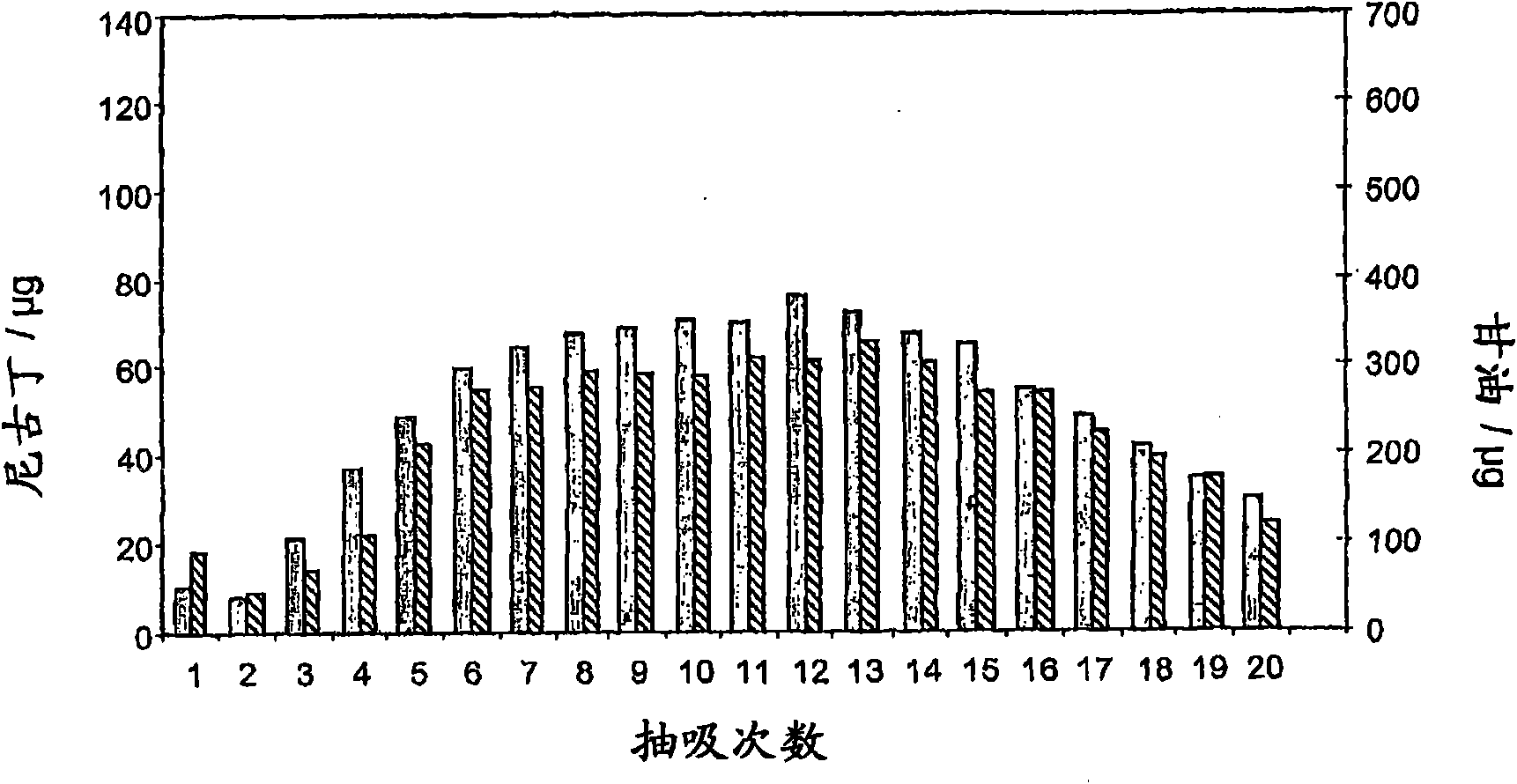

Distillation-based smoking article

Owner:PHILIP MORRIS PROD SA

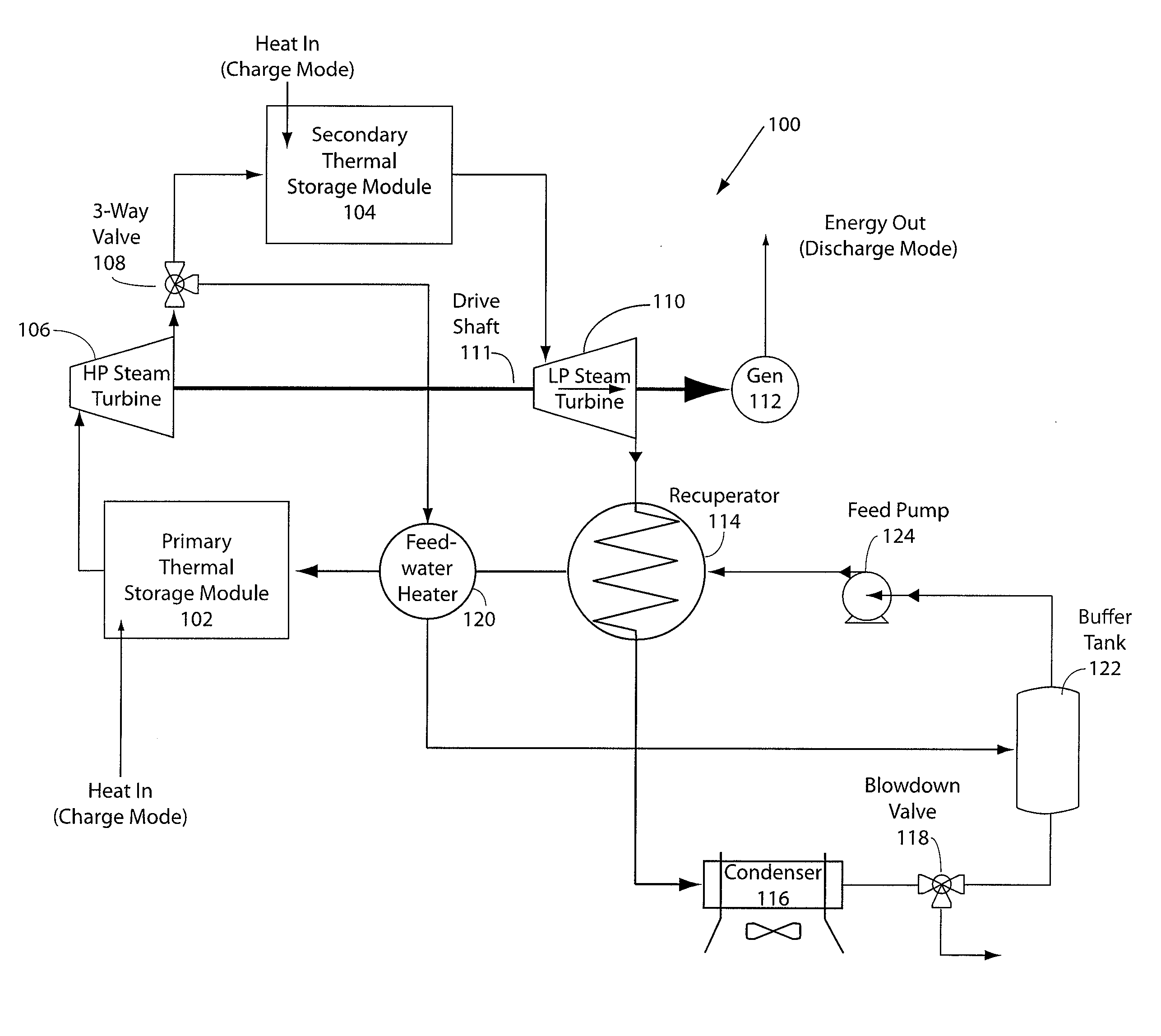

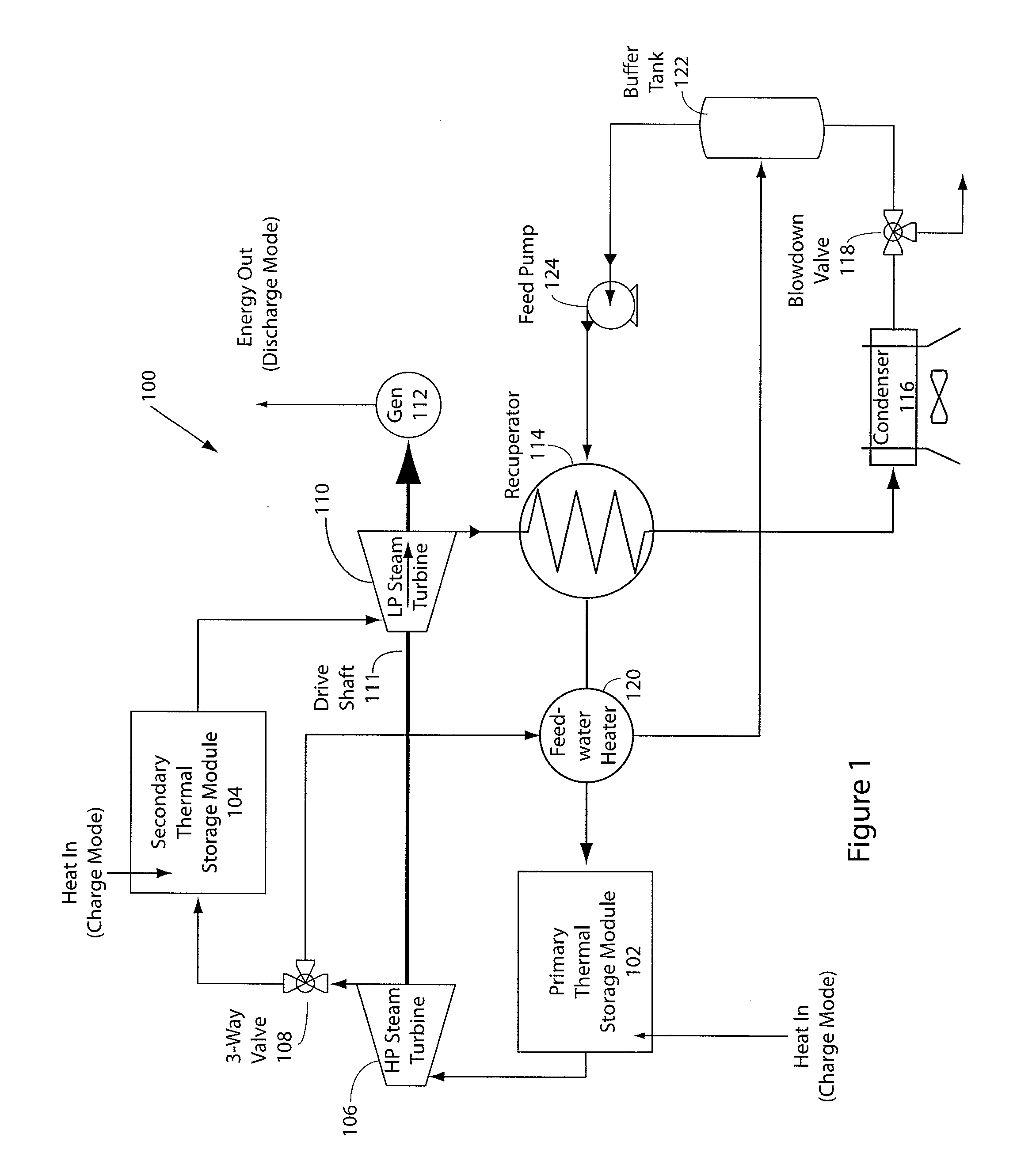

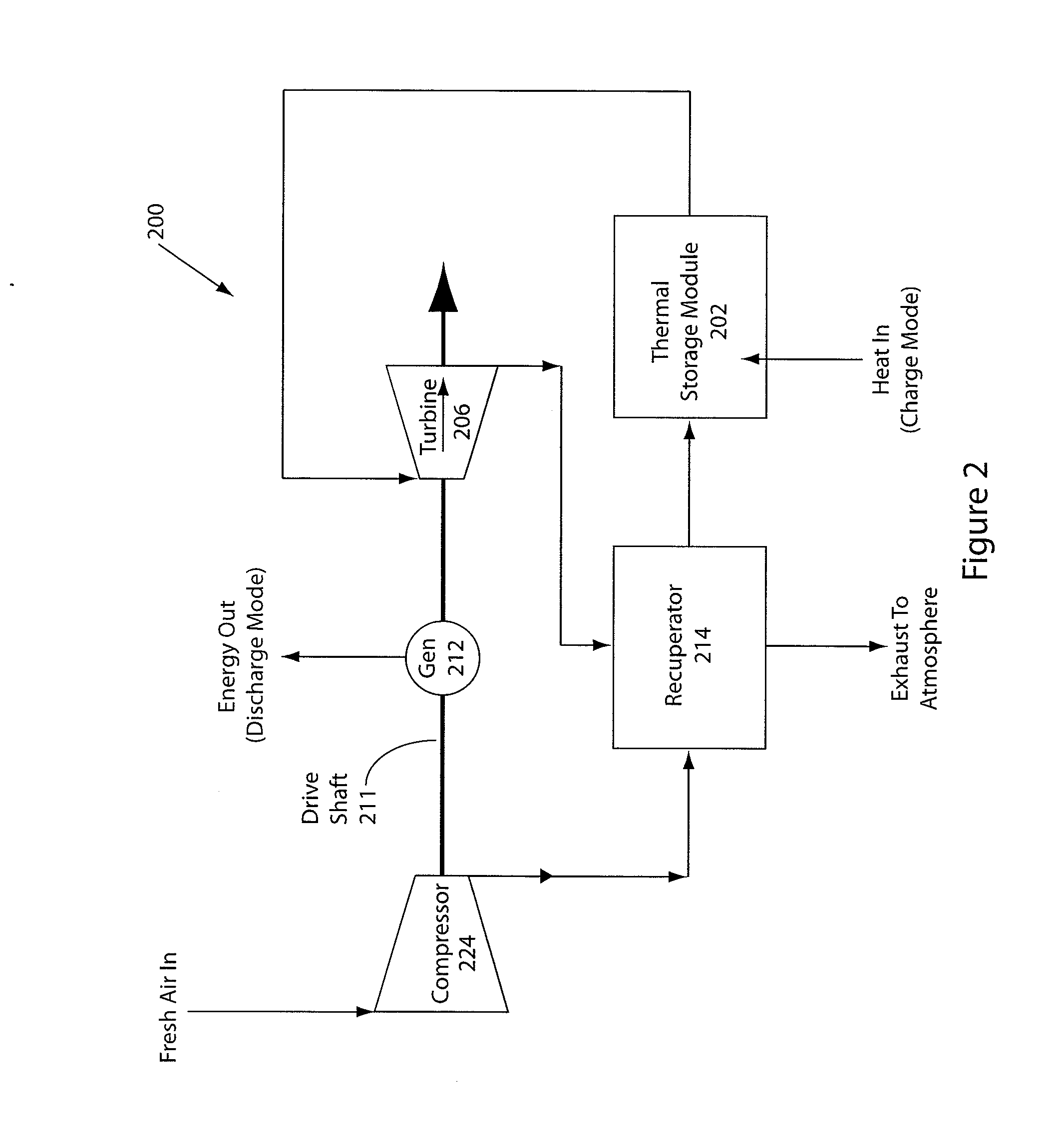

System and method for thermal energy storage and power generation

A thermal energy storage system is proposed in which the latent heat of fusion of common salts is used to store energy within a selectable temperature range, extending both above and below the melting / freezing temperature zone of the salt mixture. The salt mixture occupies interstitial void spaces in a solid endostructure. The solid material remains in the solid state throughout the thermal cycling of the energy storage system, and preferably has properties of thermal conduction and specific heat that enhance the behavior of the salt mixture alone, while being chemically compatible with all materials in the storage system. The storage system is capable of accepting and delivering heat at high rates, thereby allowing power generation using a suitable energy transfer media to power a turbine of an electric generator or a process heat need to provide a relatively local, dispatchable, rechargeable thermal storage system, combined with a suitably sized generator.

Owner:WOODWARD GOVERNOR CO

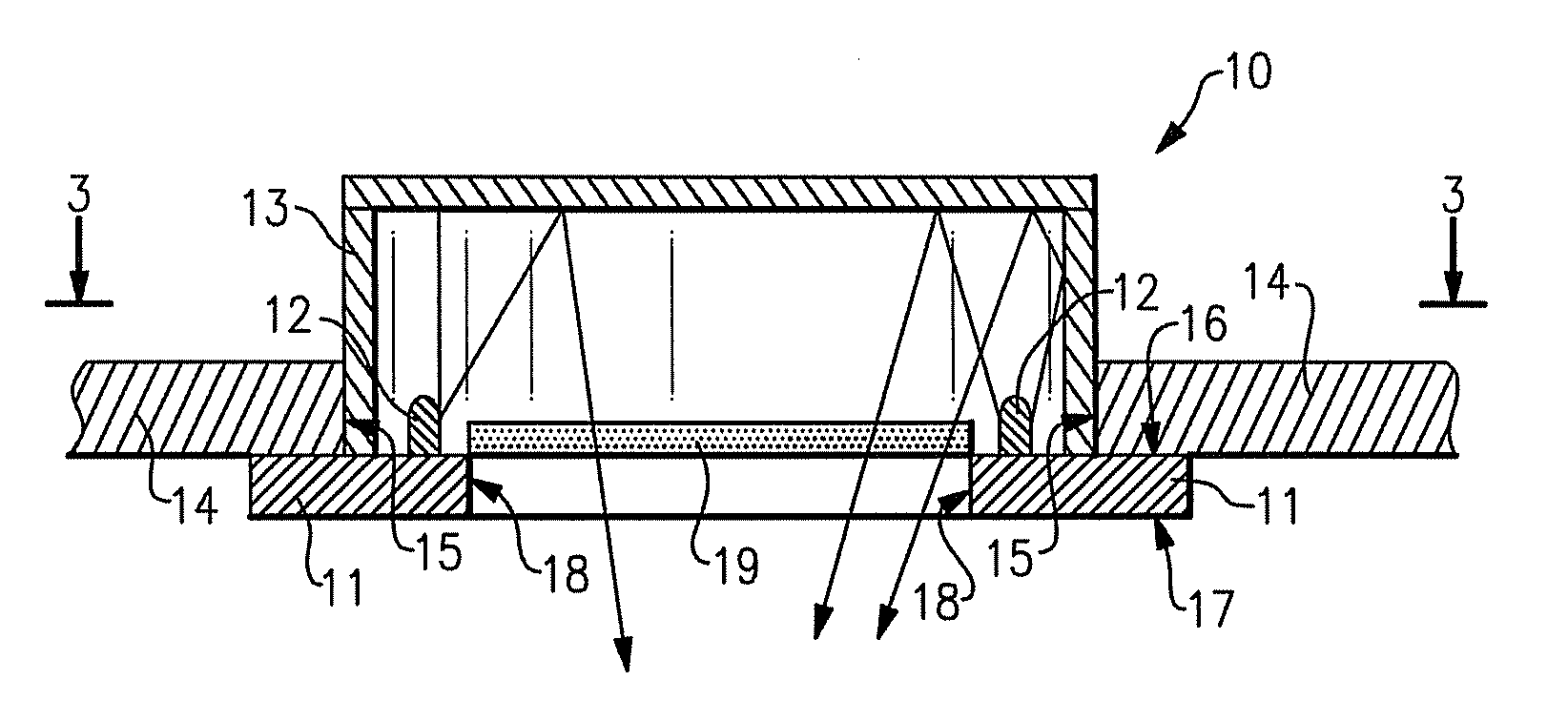

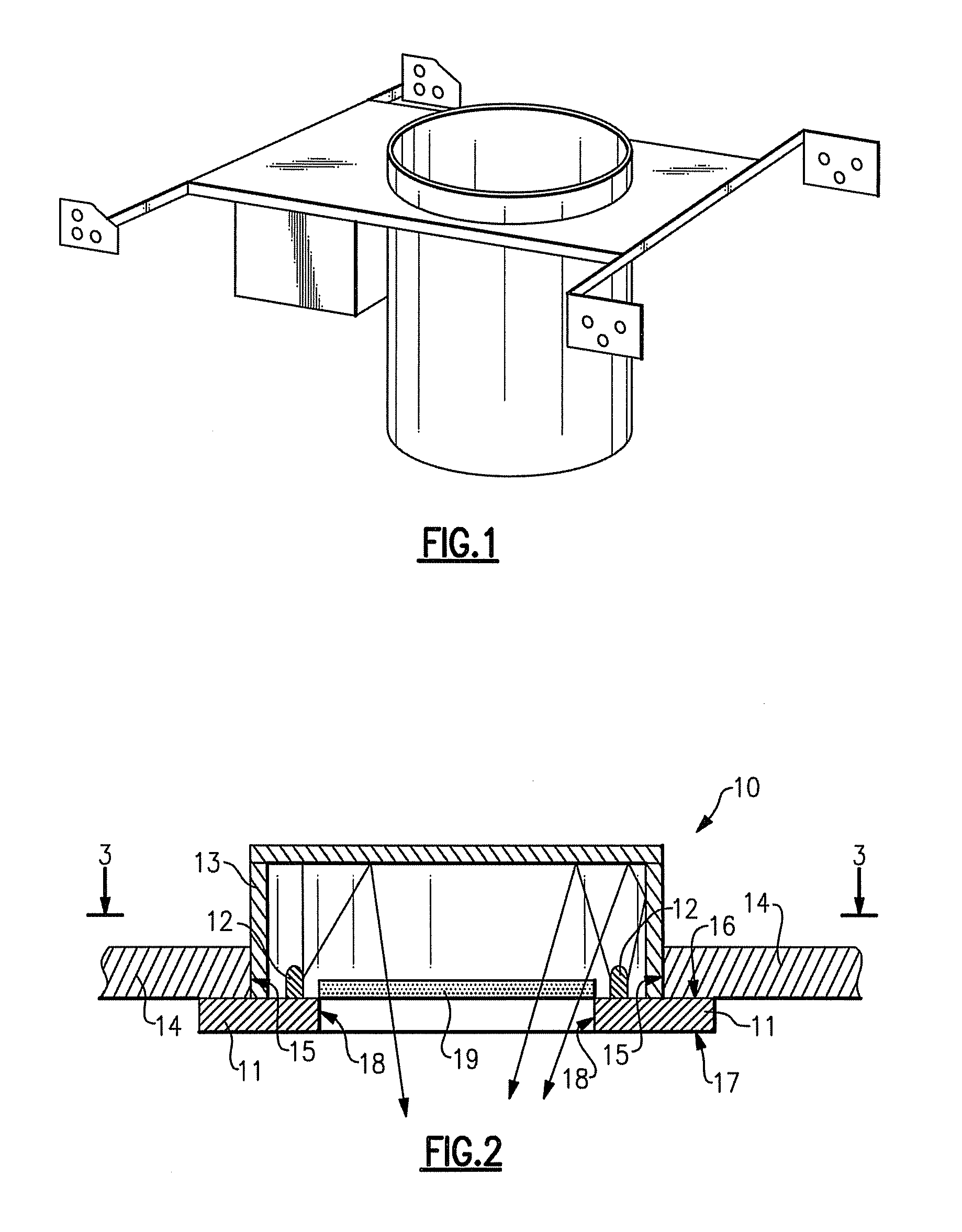

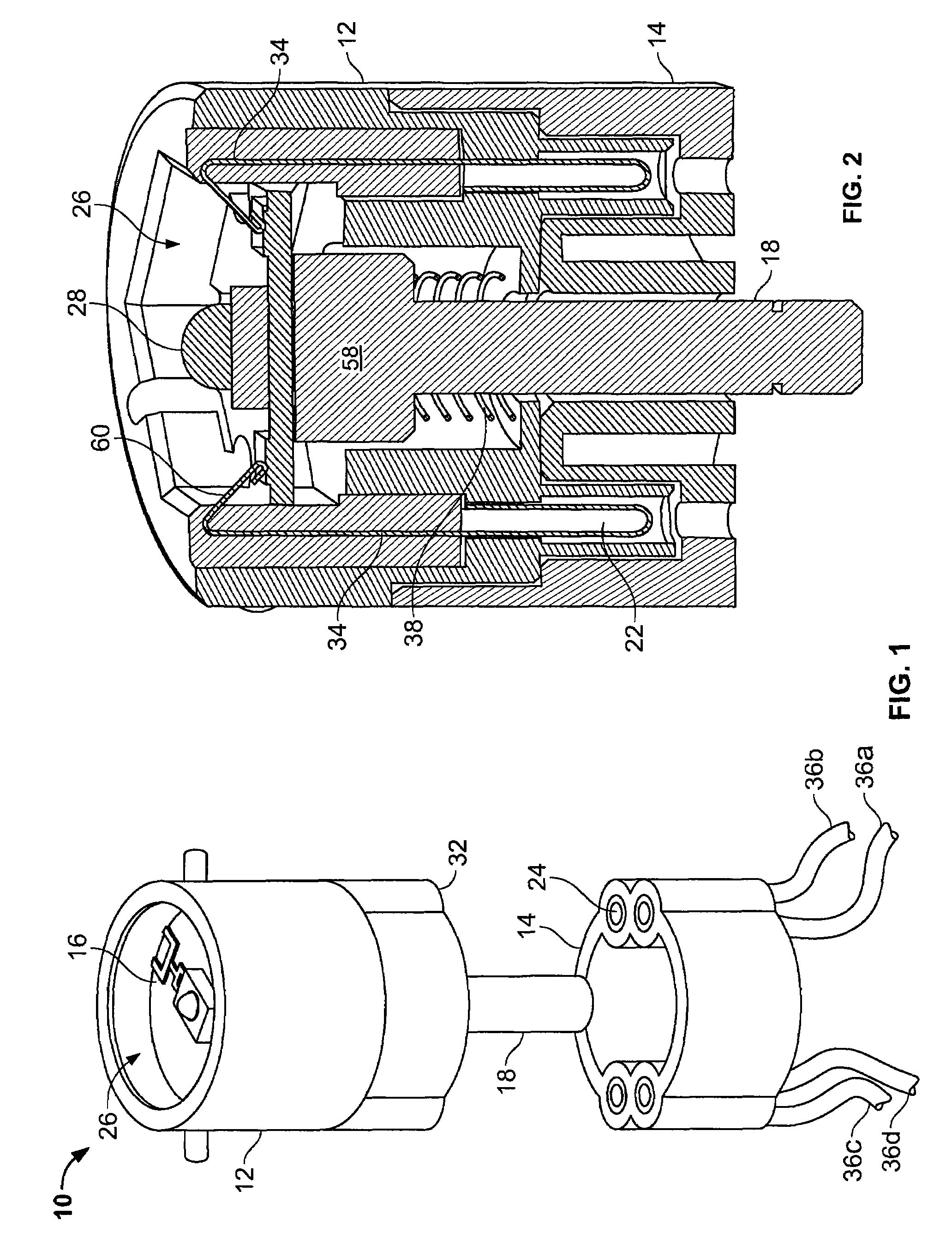

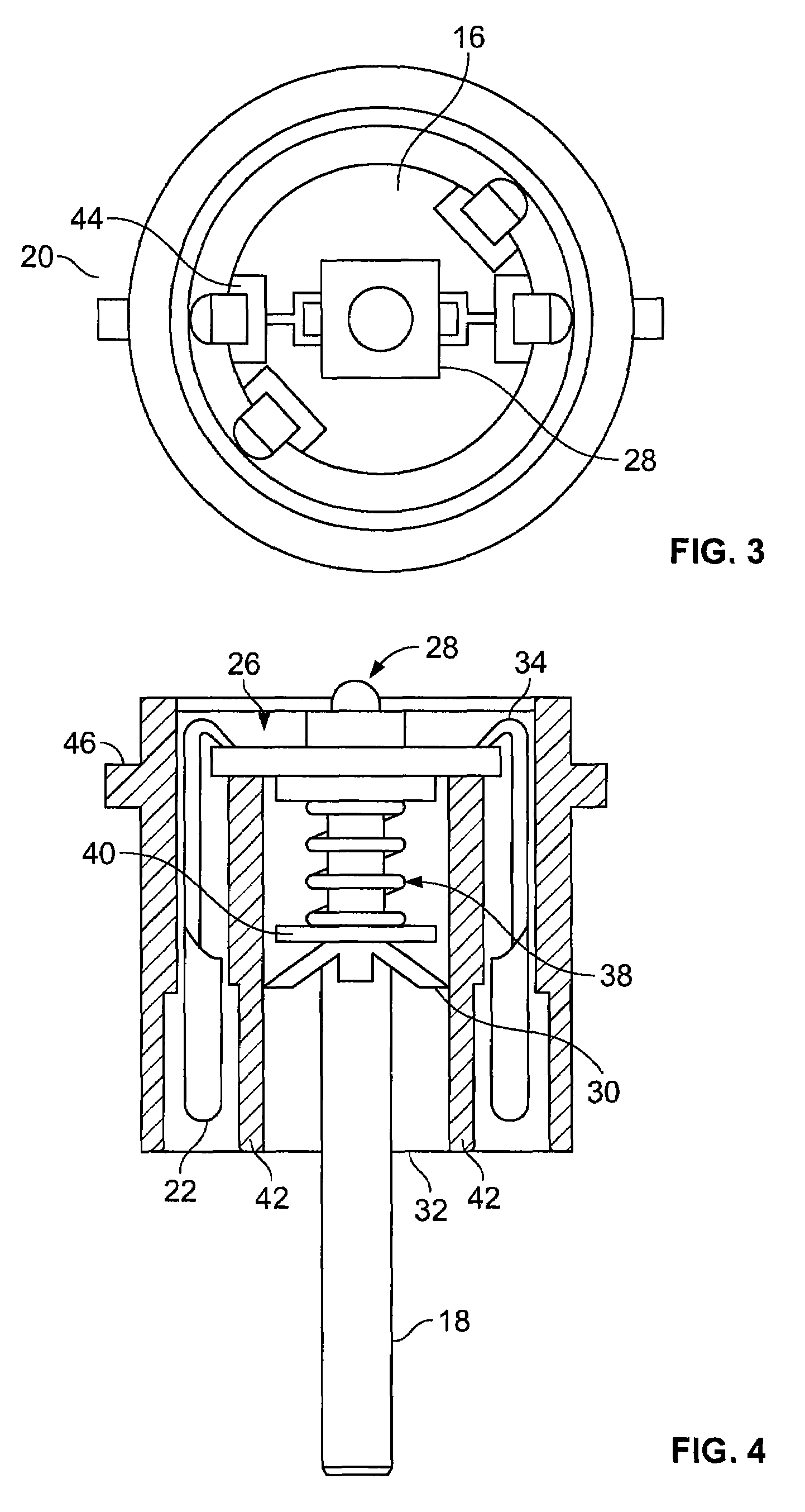

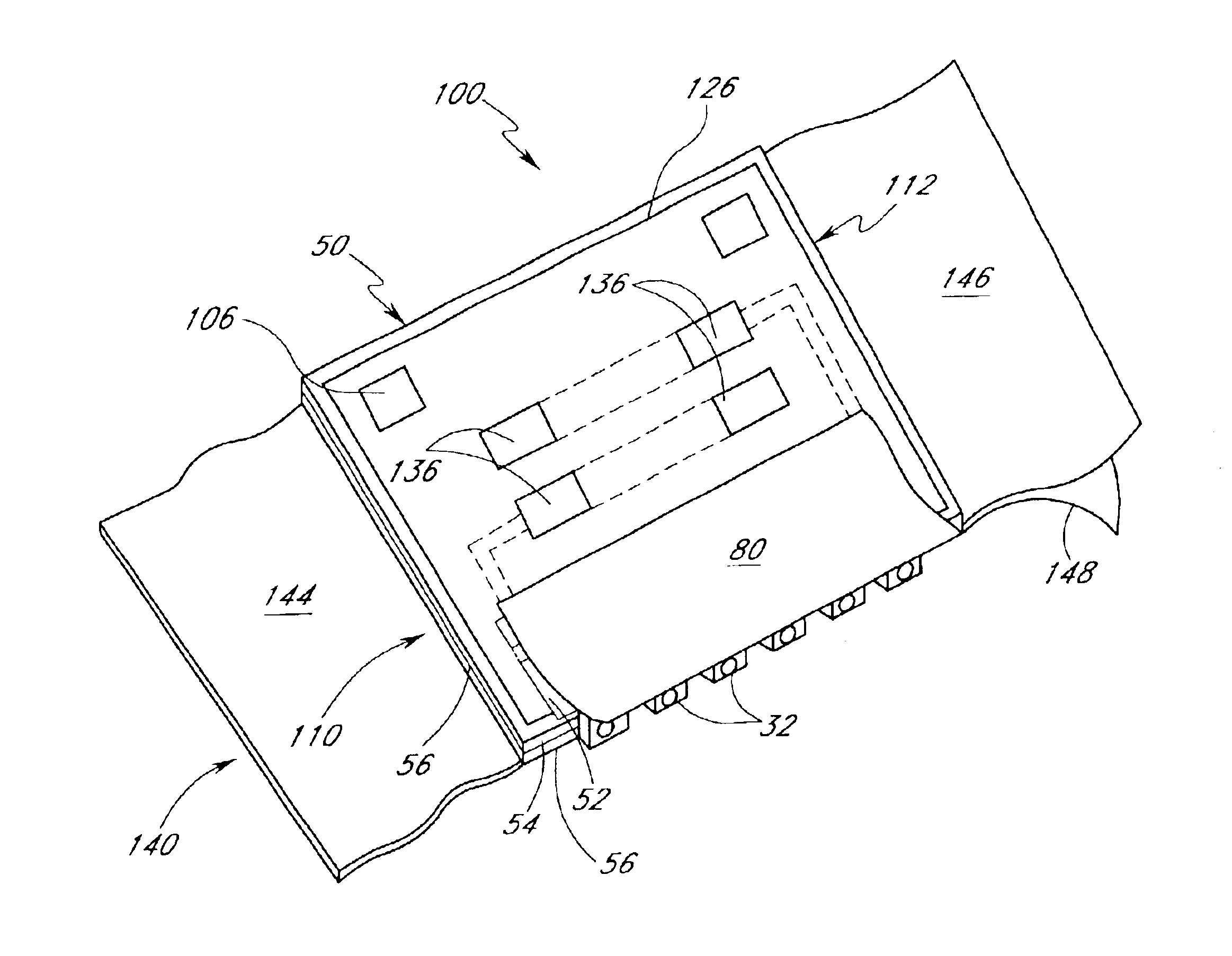

LED connector assembly with heat sink

A universal mounting supports high intensity LEDs in a lighting fixture with heat removal and electrical connection facilities. A holder includes a peripheral sidewall defining a cavity for accepting a printed circuit board assembly. A support member supports the printed circuit board assembly along the peripheral sidewall. Electrical contact elements are provided the printed circuit board. A thermal conduction member is in thermal communication with the printed circuit board assembly. The receptacle portion removably engages with the holder portion. A plurality of contact sockets conductively engages the electrical contact elements of the holder portion to interconnect the contact elements to external wires. An aperture in the receptacle portion accepts the thermal conduction member, wherein the thermal conduction member passes through the aperture and into a space for dissipating heat from the printed circuit board.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

Cooling apparatus and method for an electronics module employing an integrated heat exchange assembly

A cooling apparatus for an electronics assembly having a substrate and one or more electronics devices includes an enclosure sealably engaging the substrate to form a cavity, with the electronics devices and a heat exchange assembly being disposed within the cavity. The heat exchange assembly defines a primary coolant flow path and a separate, secondary coolant flow path. The primary coolant flow path includes first and second chambers in fluid communication, and the secondary flow path includes a third chamber disposed between the first and second chambers. The heat exchange assembly provides a first thermal conduction path between primary coolant in the first chamber and secondary coolant in the third chamber, and a second thermal conduction path between primary coolant in the second chamber and secondary coolant in the third chamber. The heat exchange assembly further includes coolant nozzles to direct primary coolant towards the electronics devices.

Owner:INT BUSINESS MASCH CORP

Embossed heat spreader

ActiveUS8081474B1Increase surface areaImprove rigiditySemiconductor/solid-state device detailsSolid-state devicesComputer moduleEngineering

One embodiment of the present invention sets forth a heat spreader module for dissipating thermal heat generated by electronic components. The assembly comprises a printed circuit board (PCB), electronic components disposed on the PCB, a thermal interface material (TIM) thermally coupled to the electronic components, and a heat spreader plate thermally coupled to the TIM. The heat spreader plate includes an embossed pattern. Consequently, surface area available for heat conduction between the heat spreader plate and surrounding medium may be increased relative to the prior art designs.

Owner:GOOGLE LLC

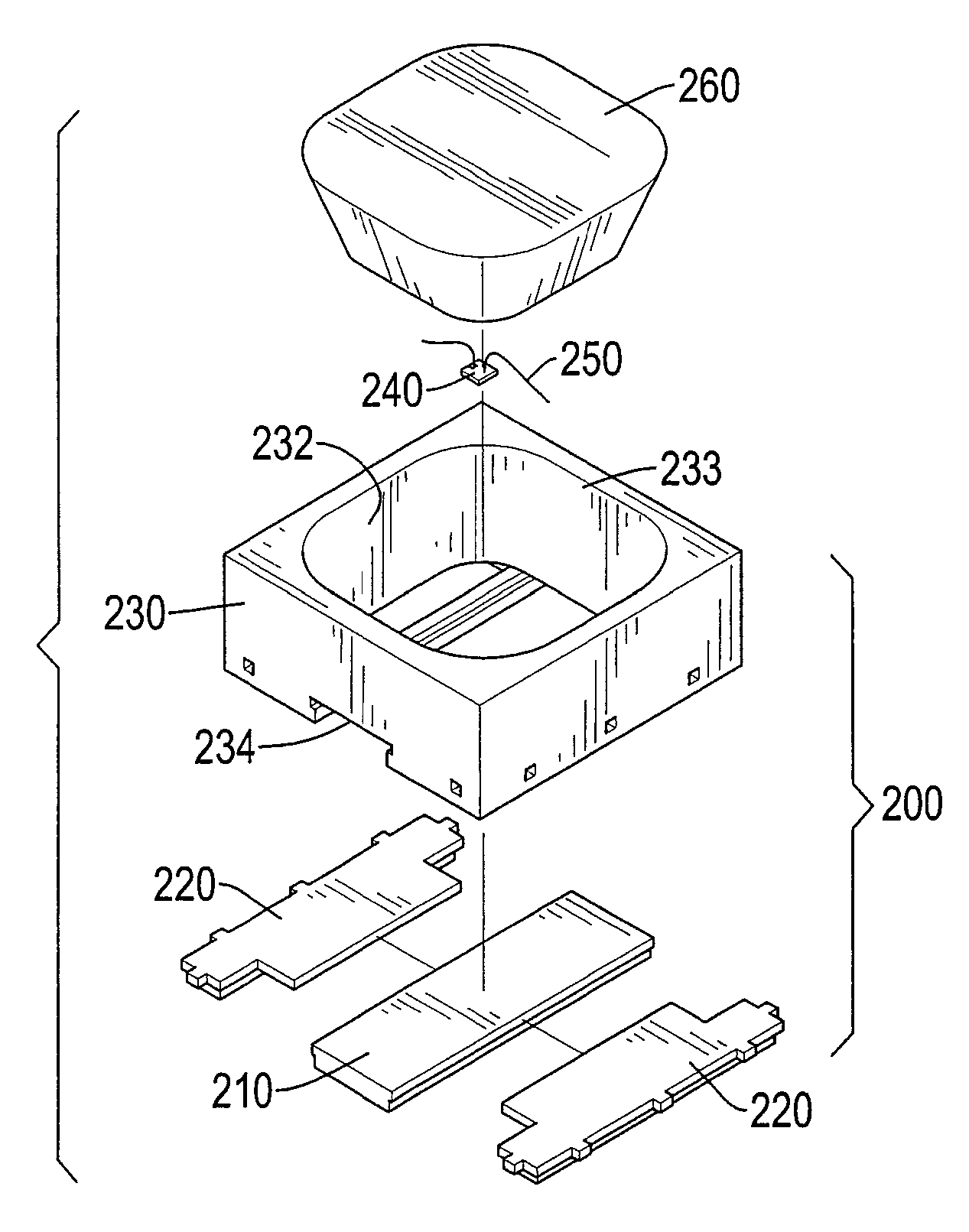

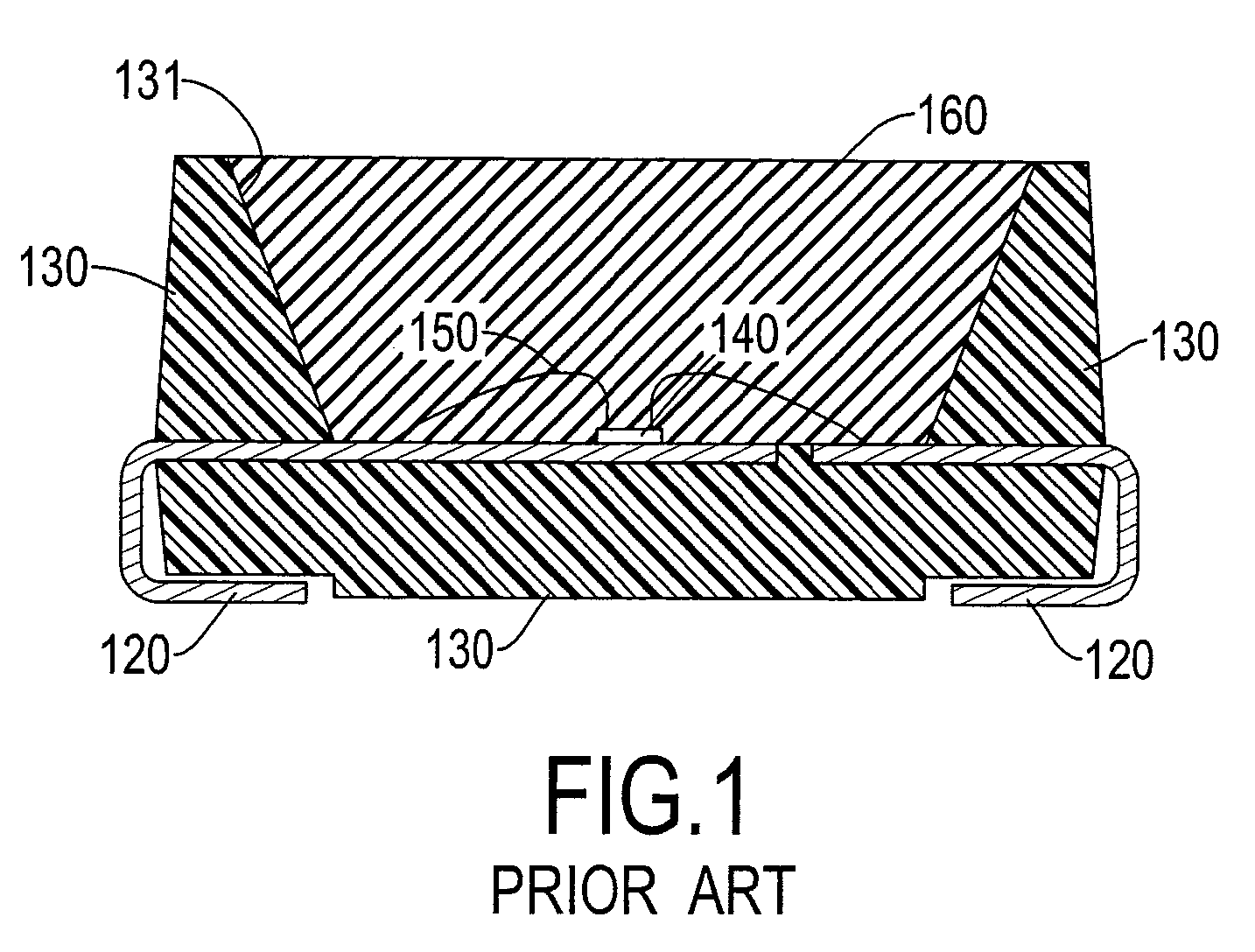

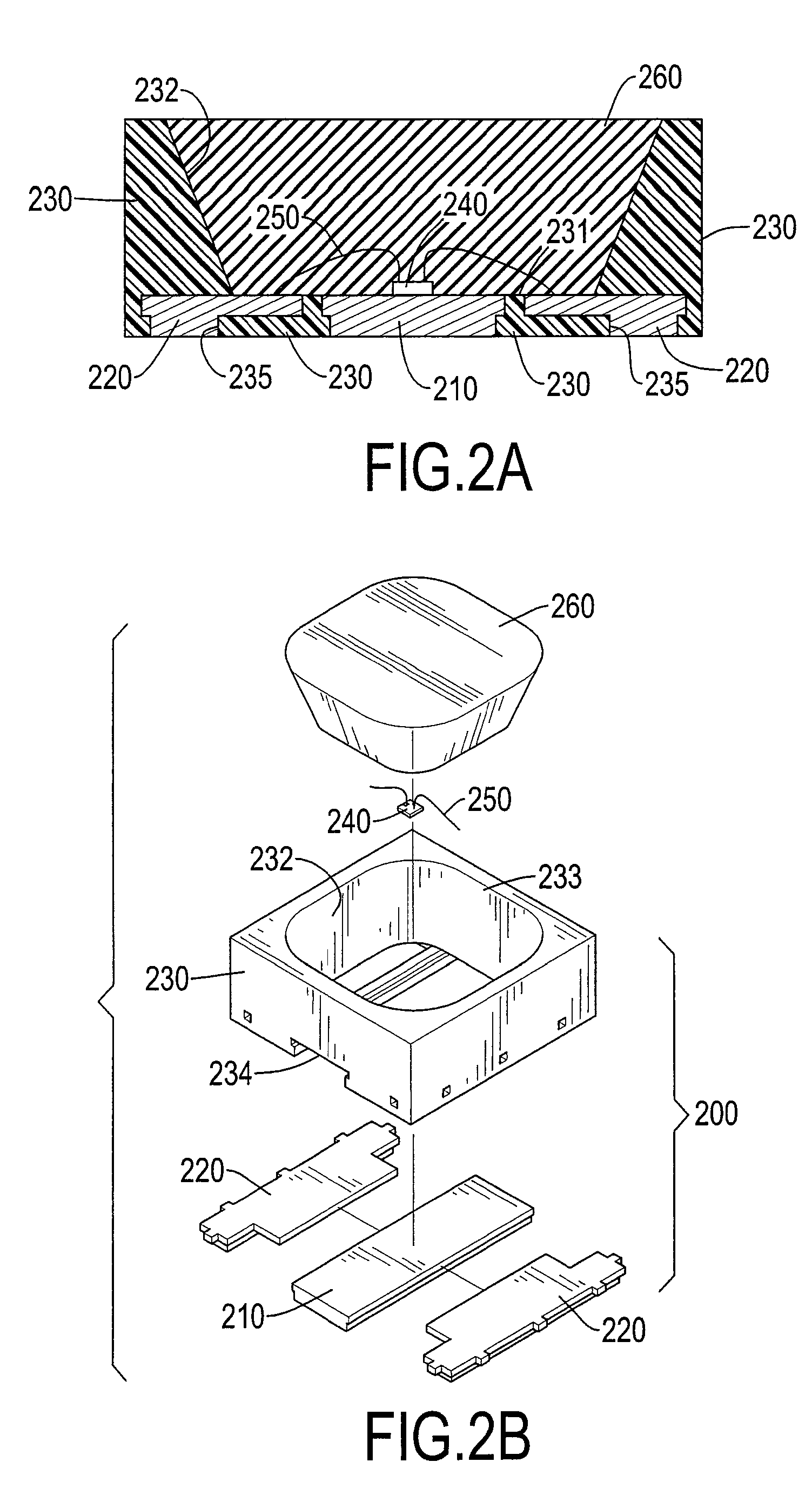

Package for a high-power light emitting diode

InactiveUS20080258162A1Improve thermal efficiencyBroaden applicationSolid-state devicesSemiconductor devicesEngineeringSealant

A package for a high-power light emitting diode (LED) has a packaging substrate, at least one LED chip, at least one pair of conductive wires and an encapsulant. The packaging substrate has a reflective base with a recess, a dissipating board and at least one pair of electrodes. The electrodes and dissipating board are mounted in the reflective base and have upper surfaces. The LED chip is adhered to the dissipating board. The conductive wires connects electrodes of the LED chip and the electrodes. The encapsulant is transparent and fills the recess of the reflective base. Most heat from the LED chip is conducted via the dissipating board, thereby improving thermal conduction efficiency and allowing more powerful or numerous LED chips in the package. Therefore, the package provides different pass ways for conducting heat and electricity to improve heat conduction of the LED.

Owner:KOUNG CHIA YIN +1

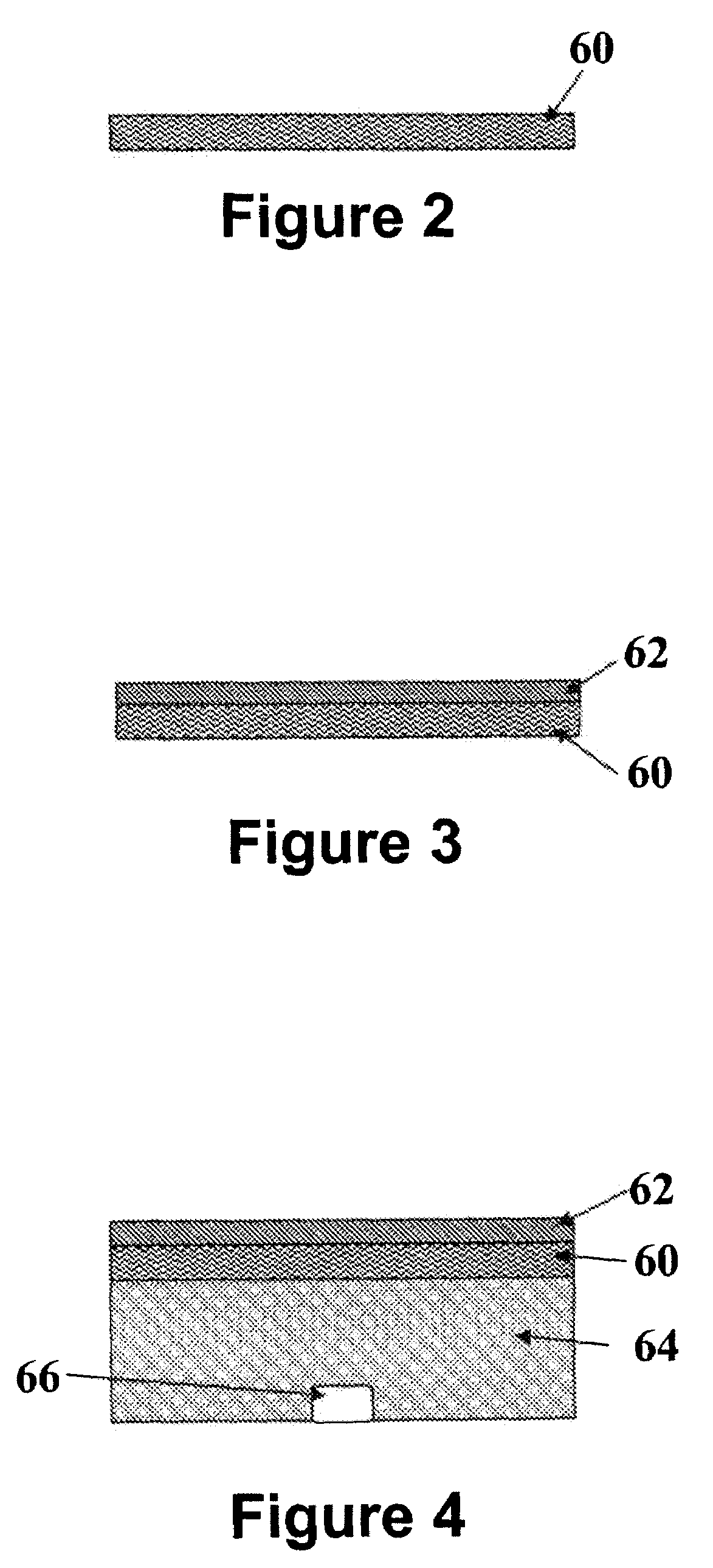

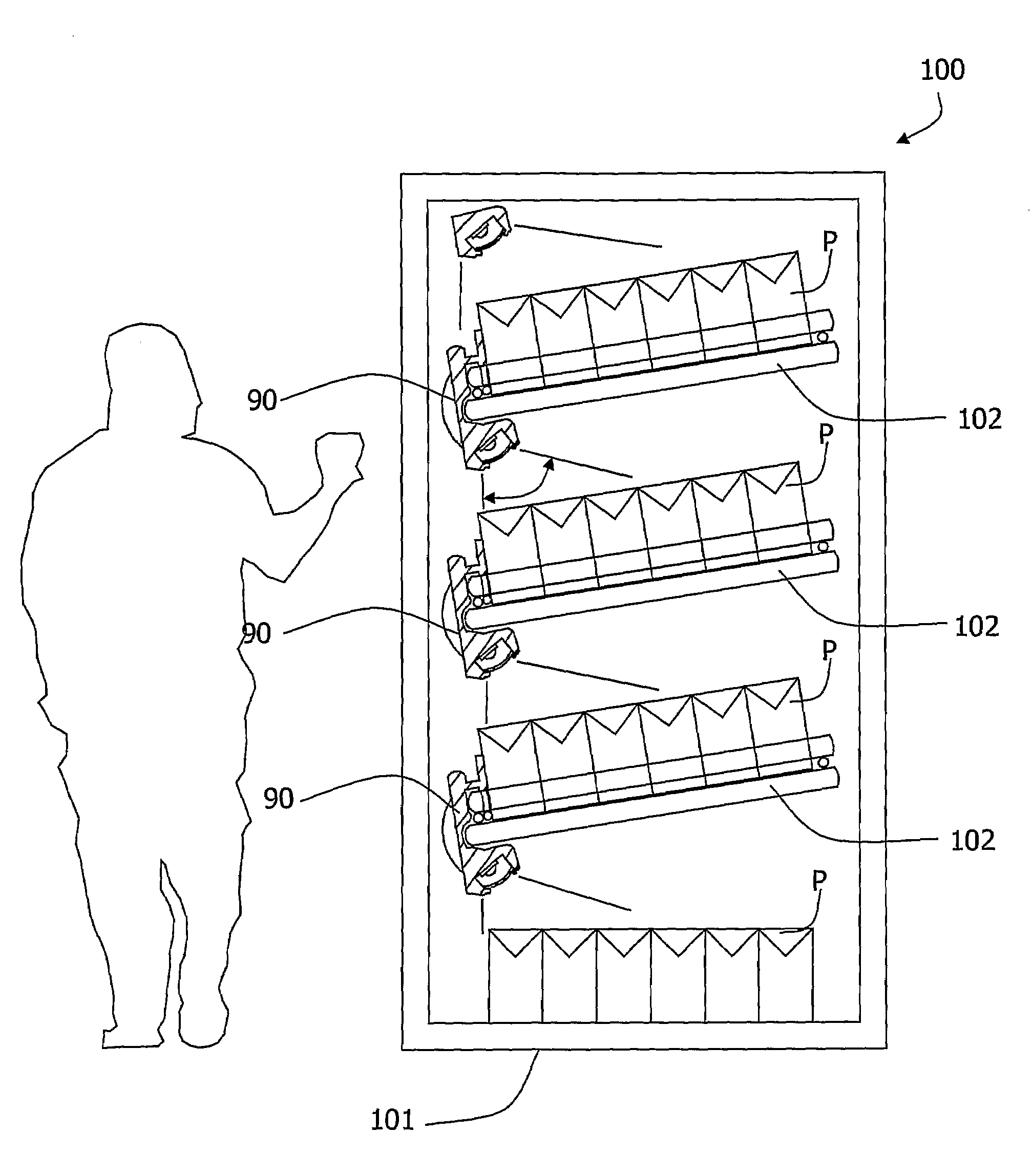

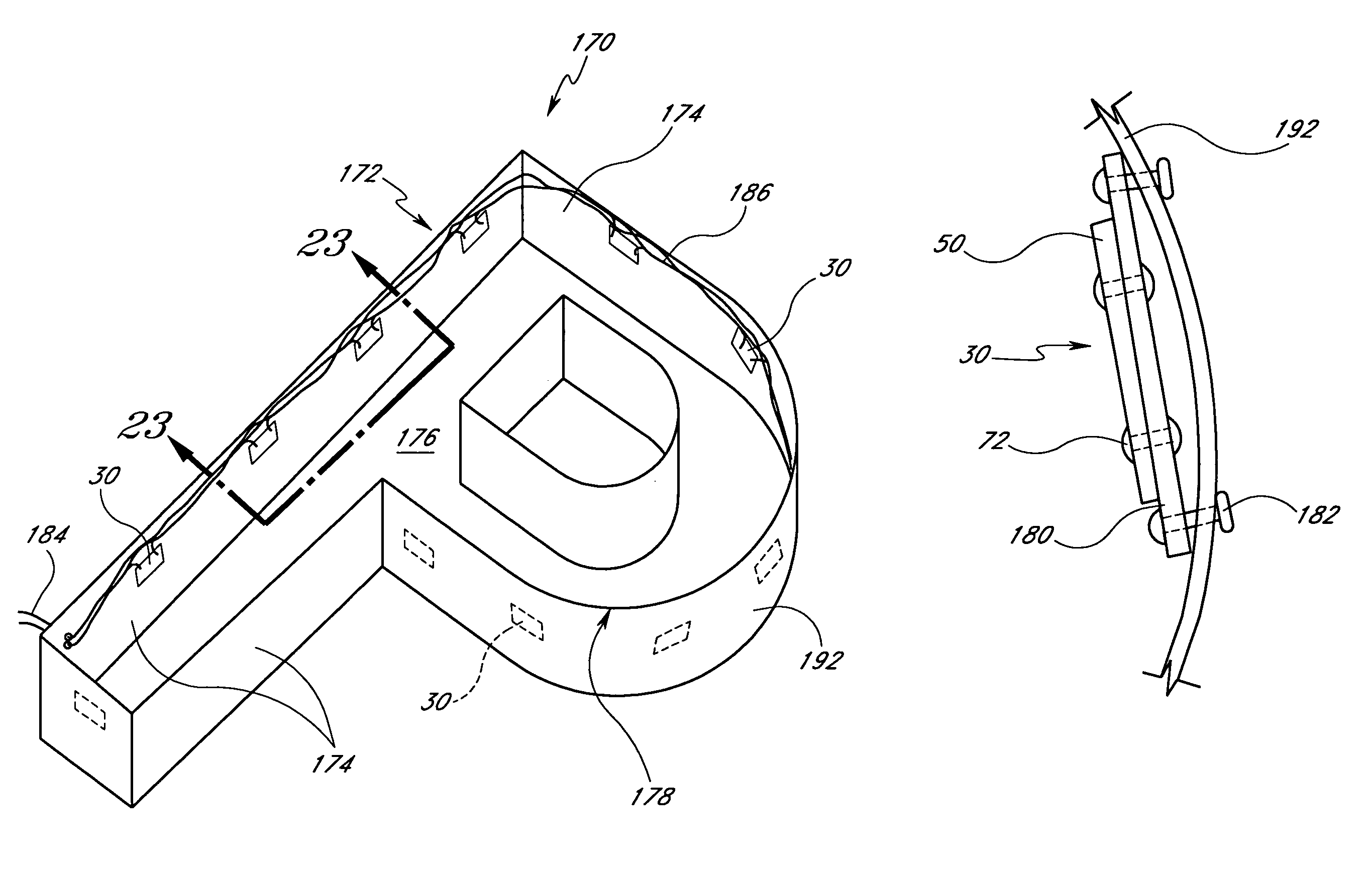

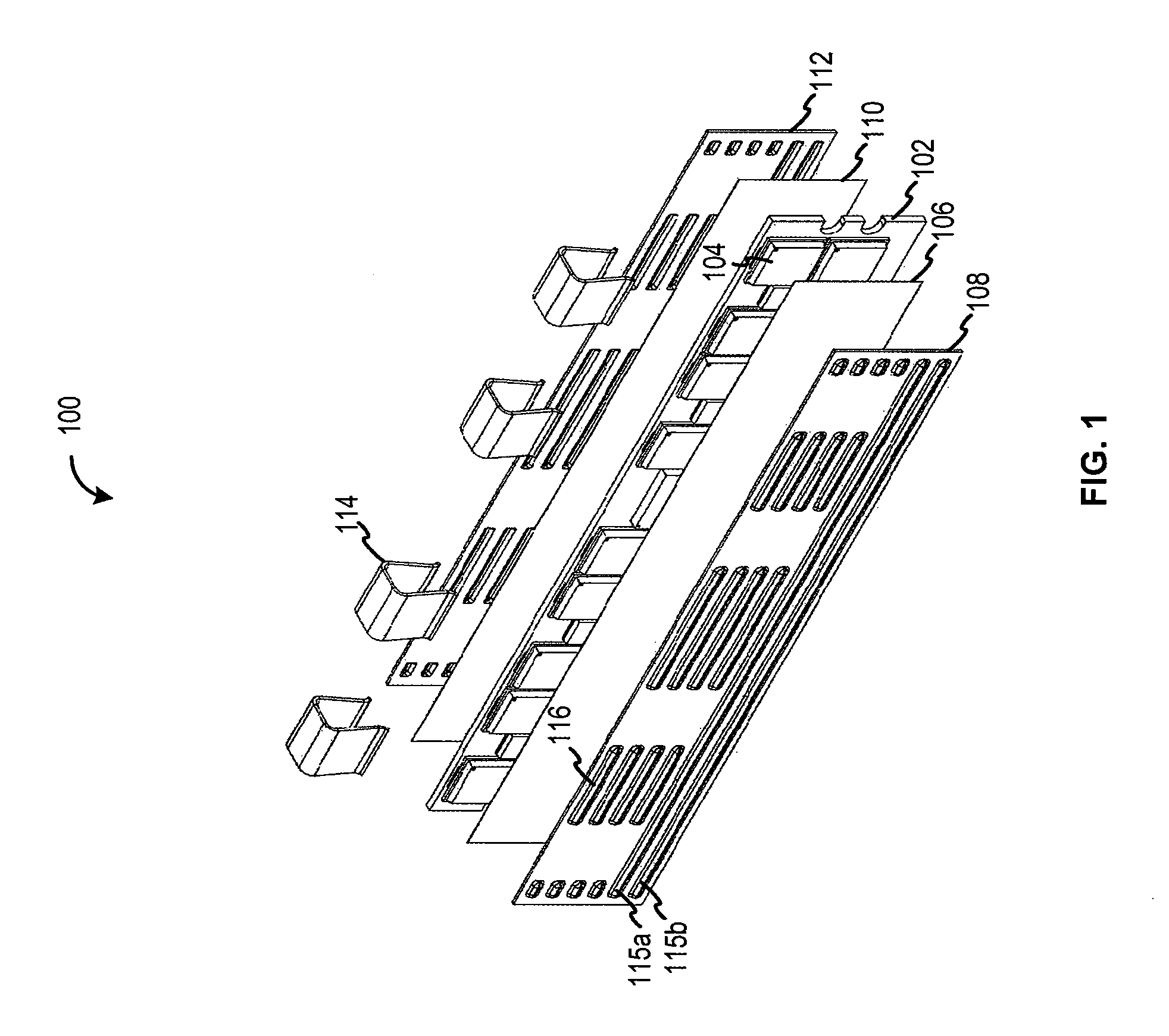

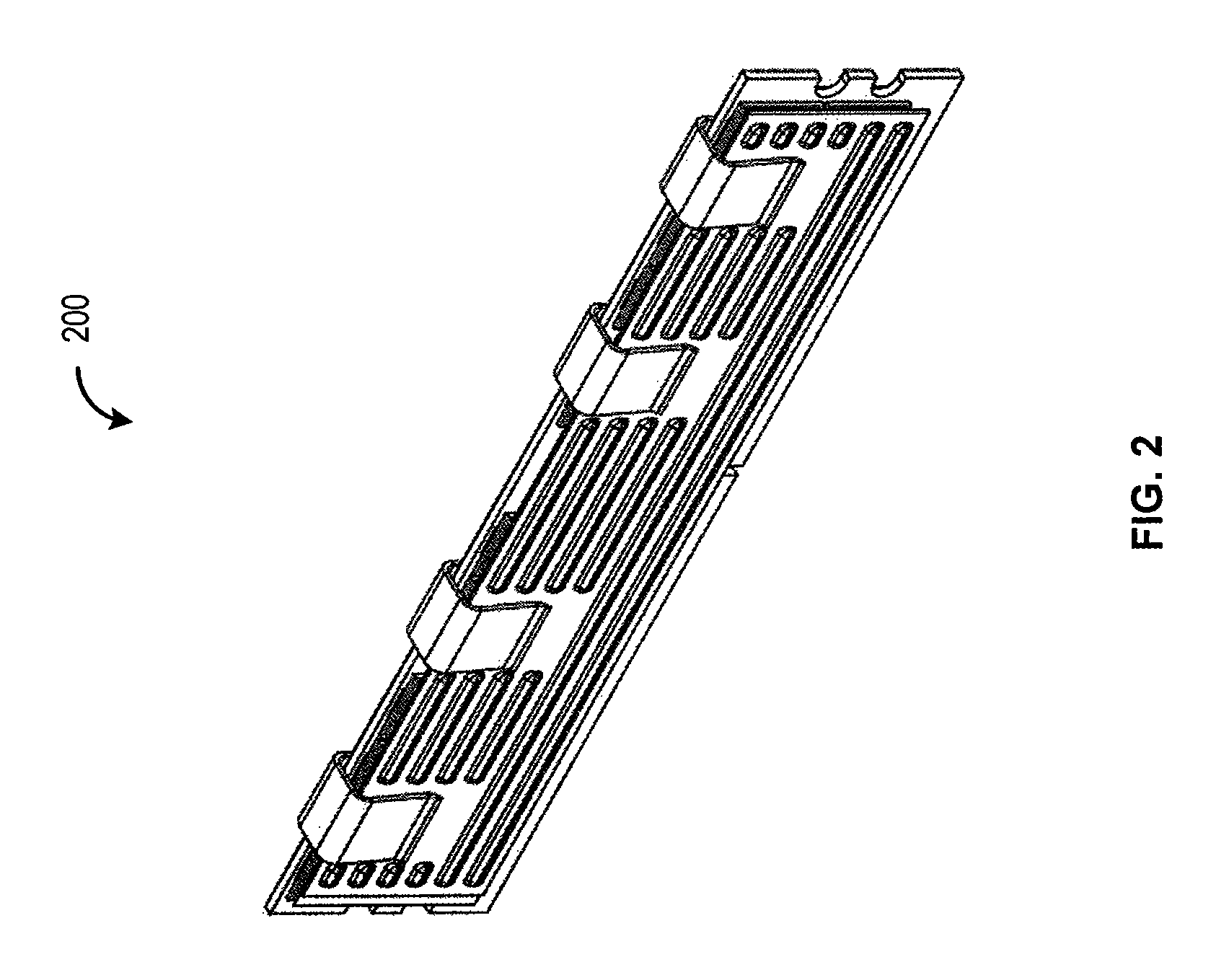

Modular mounting arrangement and method for light emitting diodes

InactiveUS6846093B2Increase brightnessLighting support devicesPoint-like light sourceModularityComputer module

A modular light emitting diode (LED) mounting configuration is provided including a light source module having a plurality of pre-packaged LEDs arranged in a serial array. The module includes a heat conductive body portion adapted to conduct heat generated by the LEDs to an adjacent heat sink. A heat conductive adhesive tape connects the LED module to the mount surface. As a result, the LEDs are able to be operated with a higher current than normally allowed. Thus, brightness and performance of the LEDs is increased without decreasing the life expectancy of the LEDs. A plurality of such LED modules can be pre-wired together in a substantially continuous fashion and provided in a dispenser, such as a roll or box. Thus, to install a plurality of such LED modules, a worker simply pulls modules from the dispenser as needed, secures the appropriate number of modules in place, and connects the assembled modules to a power source.

Owner:DIAMOND CREEK CAPITAL LLC

Mounting arrangement for light emitting diodes

A modular light emitting diode (LED) mounting configuration is provided including a light source module having a plurality of pre-packaged LEDs arranged in a serial array. The module includes a heat conductive body portion adapted to conduct heat generated by the LEDs to an adjacent heat sink. As a result, the LEDs are able to be operated with a higher current than normally allowed. Thus, brightness and performance of the LEDs is increased without decreasing the life expectancy of the LEDs. The LED modules can be used in a variety of illumination applications employing one or more modules.

Owner:DIAMOND CREEK CAPITAL LLC

LED lamp with heat sink optic

An LED lamp may be made with a heat sink optic. The lamp has a base having a first electrical contact and a second electrical contact for receiving current. At least one LED is mounted on a thermally conductive support; that supports electrical connections for the LED and provides thermal conduction of heat from the LED to the optic. The LED support mounted in the base and electrically coupled through the first electrical contact to electrical current. The light transmissive, and heat diffusing optic has an external an internal wall defining a cavity with the LED positioned in the cavity. The optic is in thermal contact with the LED support and mechanically coupled to the base. The snap together structure enables rapid manufacture while allowing numerous variations.

Owner:OSRAM SYLVANIA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com