Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

963results about How to "Reduce glare" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

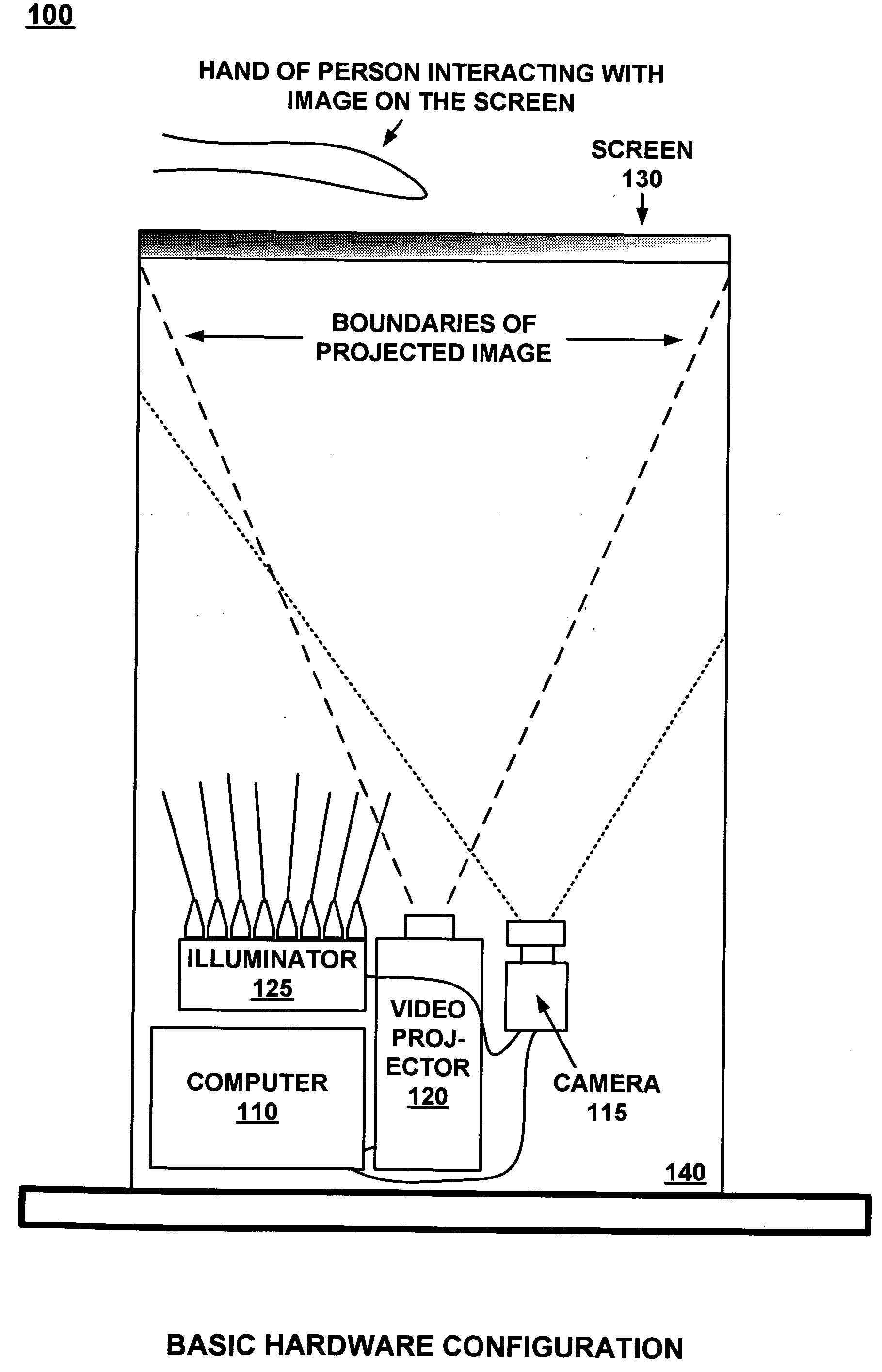

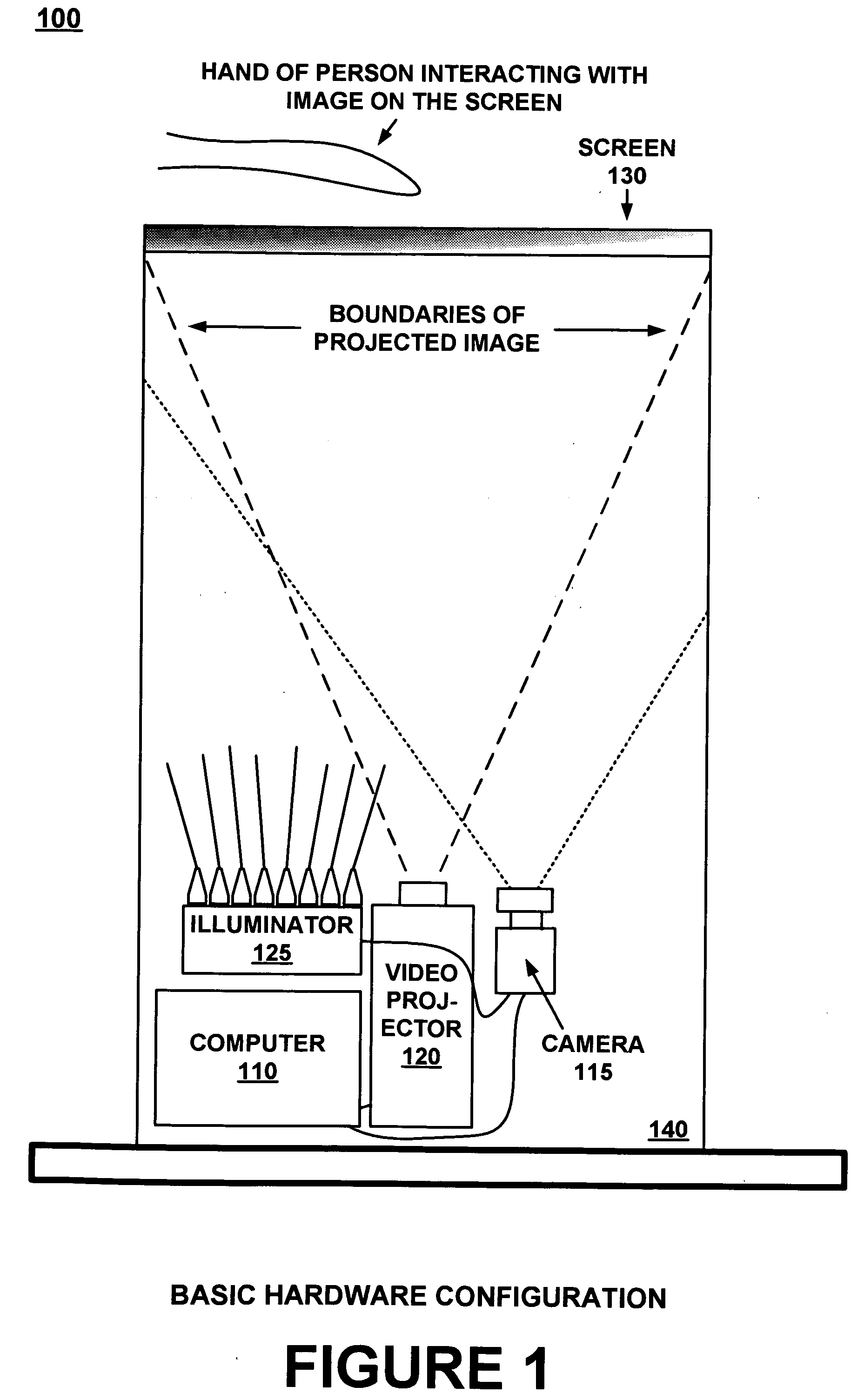

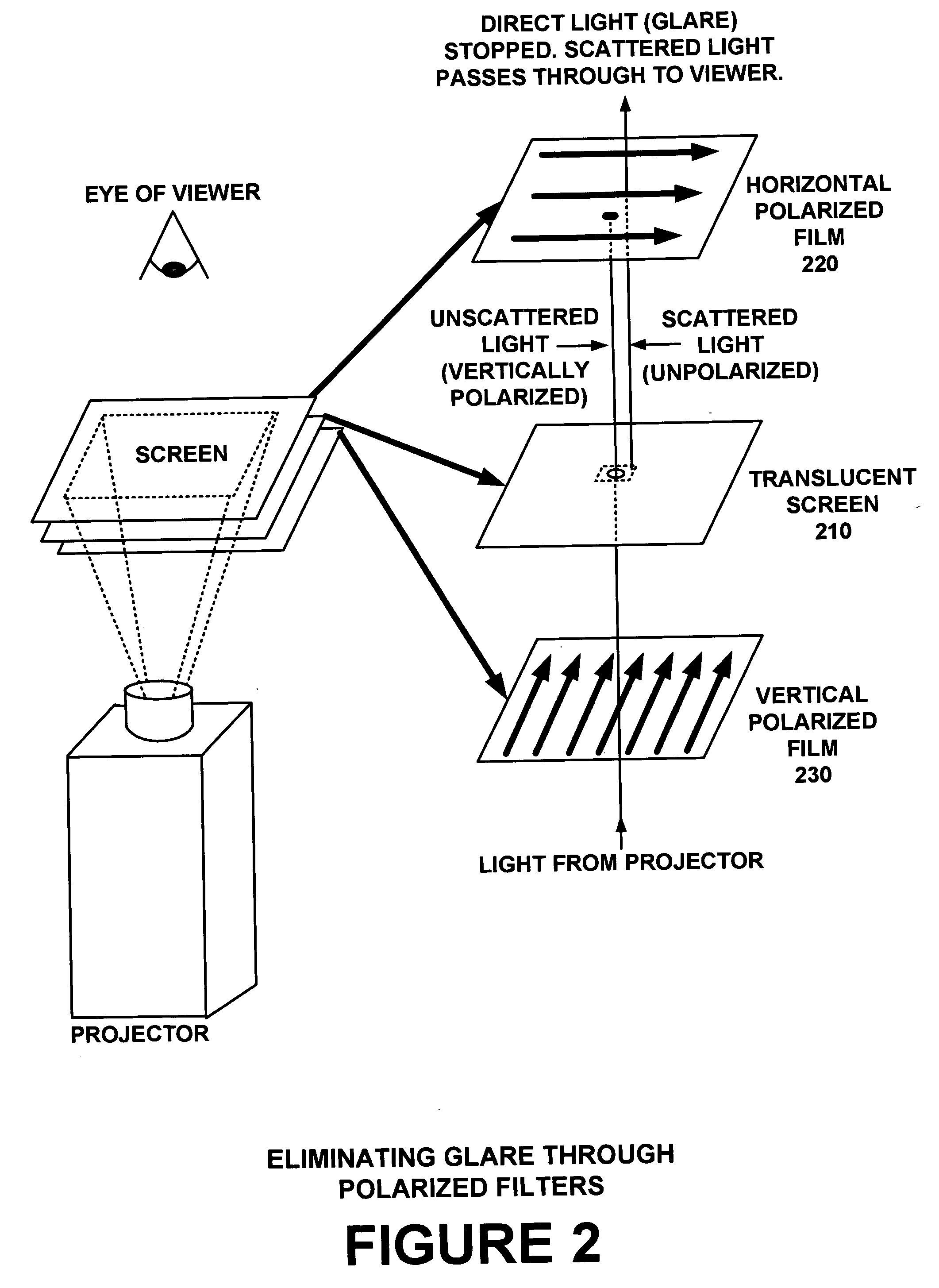

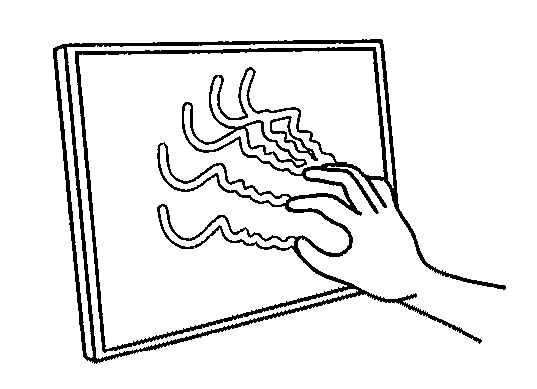

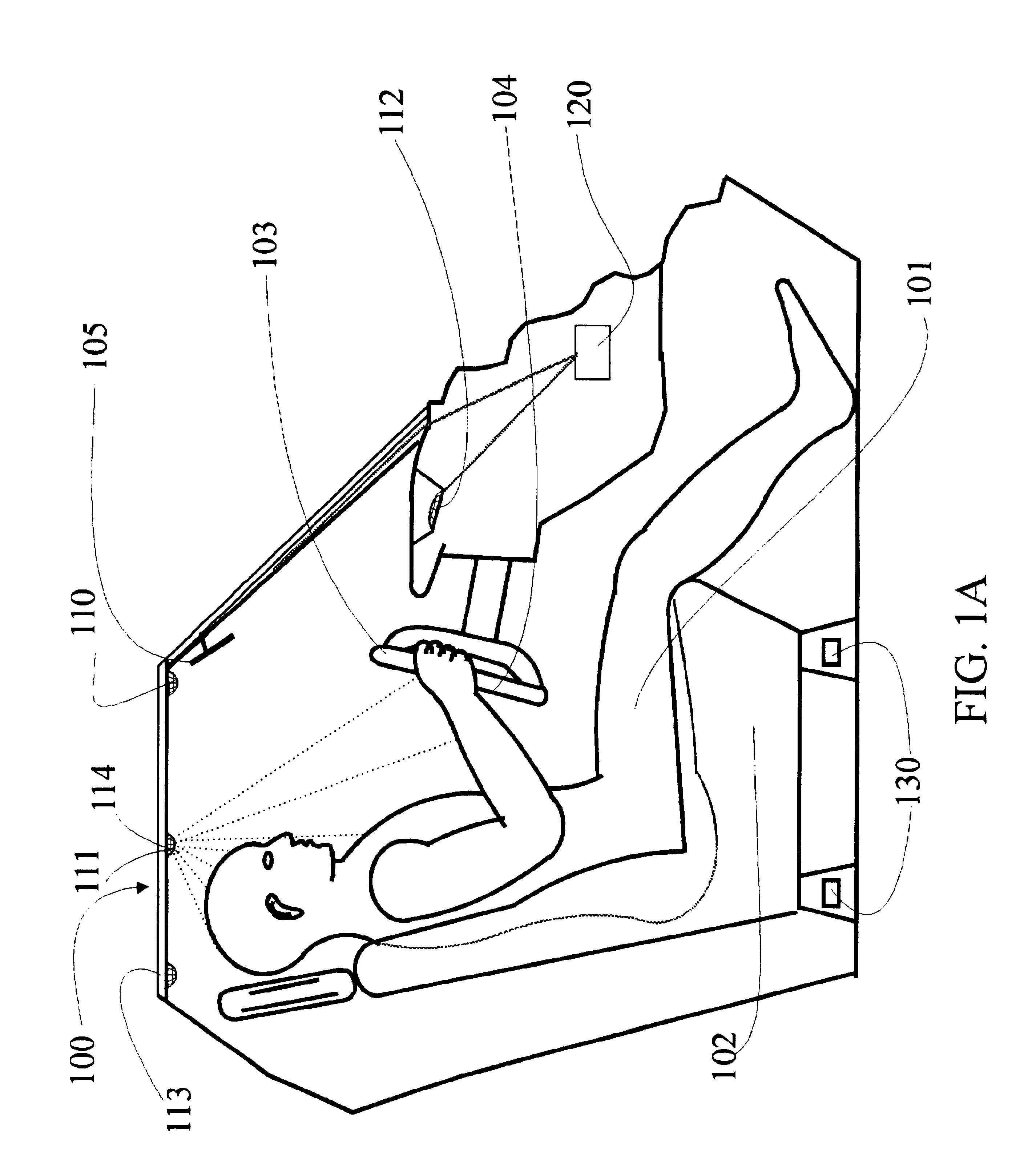

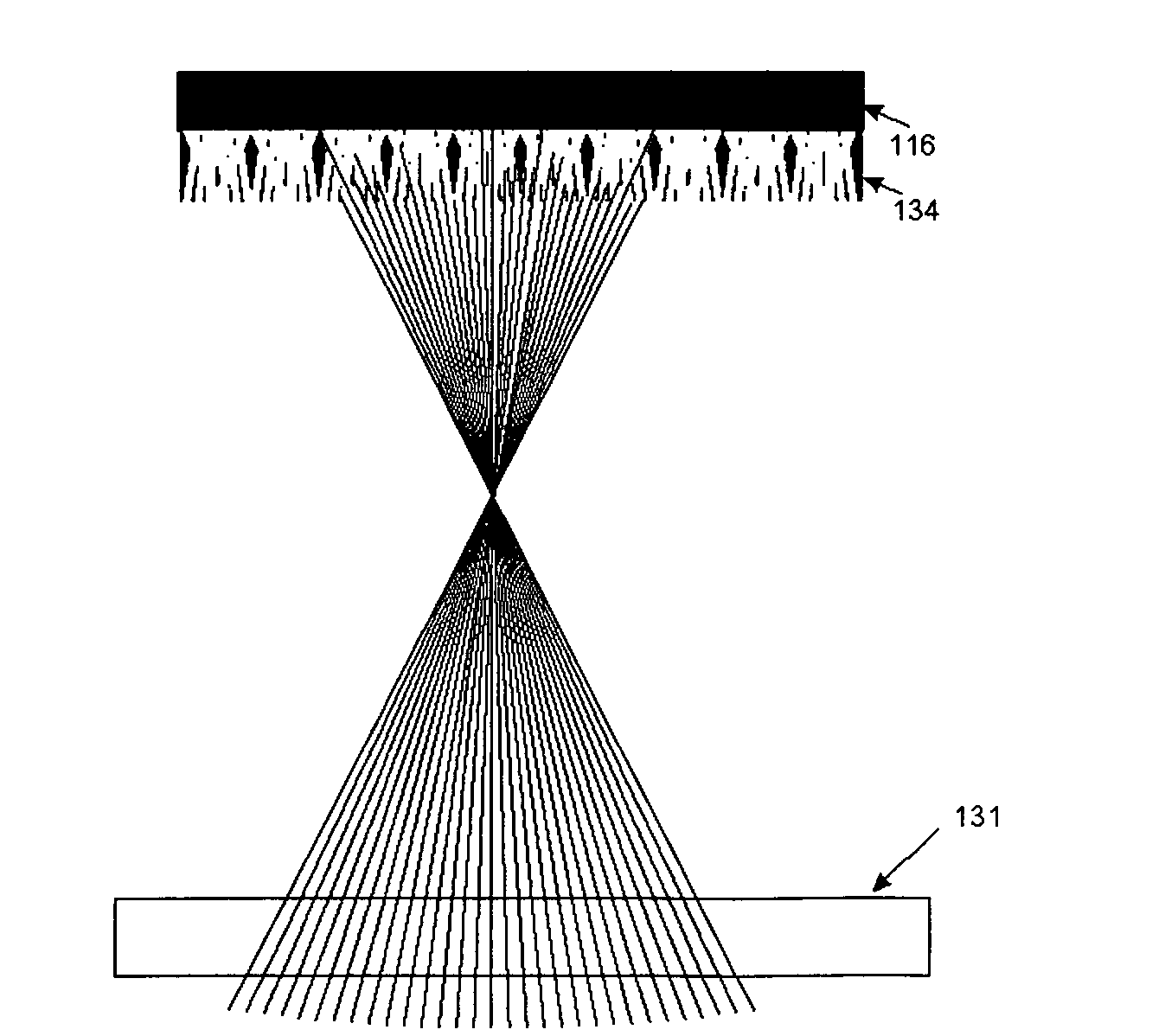

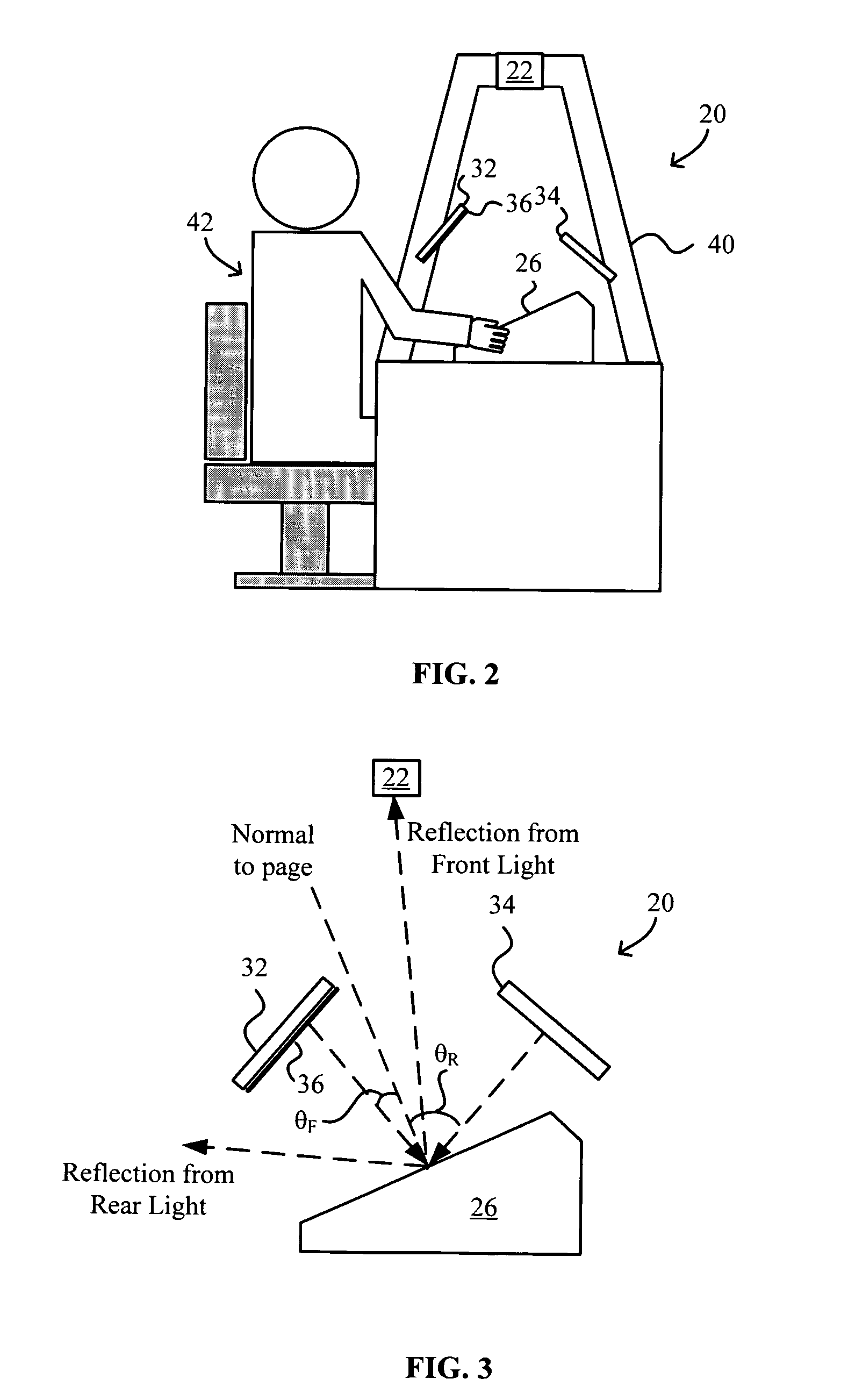

Self-contained interactive video display system

InactiveUS20050122308A1Reduce glareReduce glare effectInput/output for user-computer interactionTelevision system detailsFlat panel displayComputer graphics (images)

A self-contained interactive video display system. A flat-panel display screen displays a visual image for presentation to a user on a front side of the flat-panel display screen. A first illuminator illuminates the flat-panel display screen with visible light. A second illuminator illuminates an object. A camera detects interaction of an illuminated object with the visual image, wherein the camera is operable to view the object through the flat-panel display screen. A computer system directs the projector to change the visual image in response to the interaction.

Owner:MICROSOFT TECH LICENSING LLC

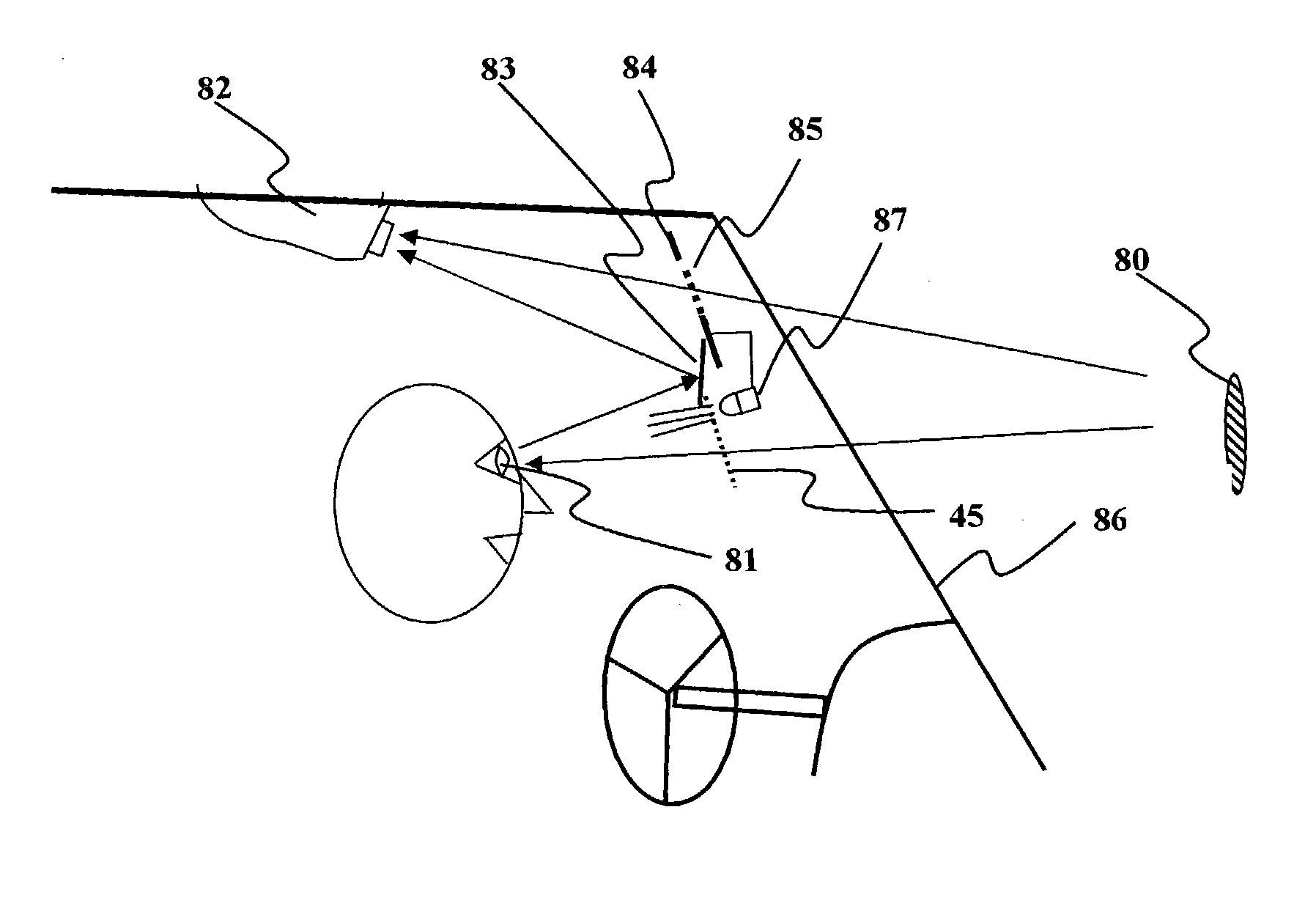

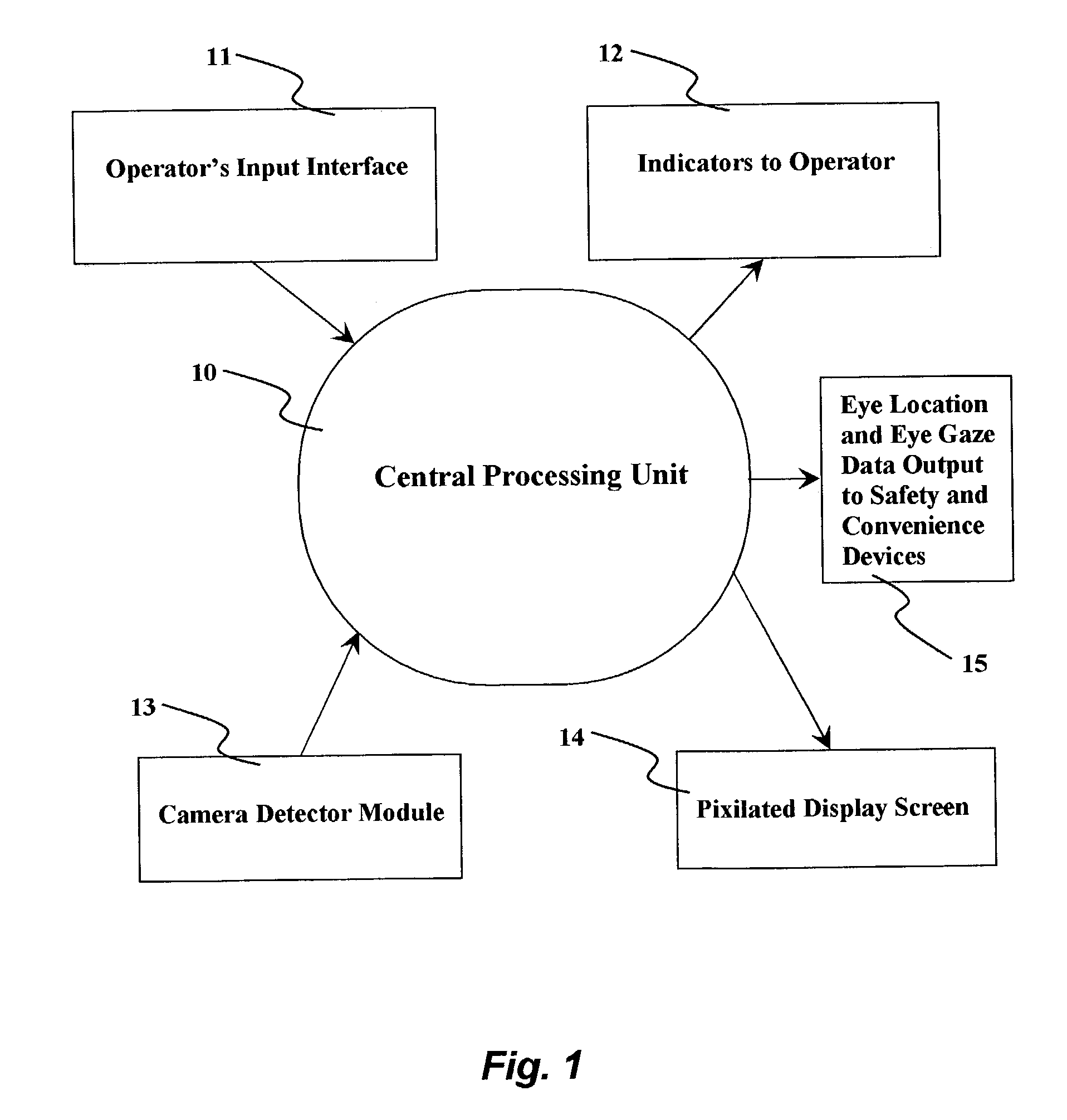

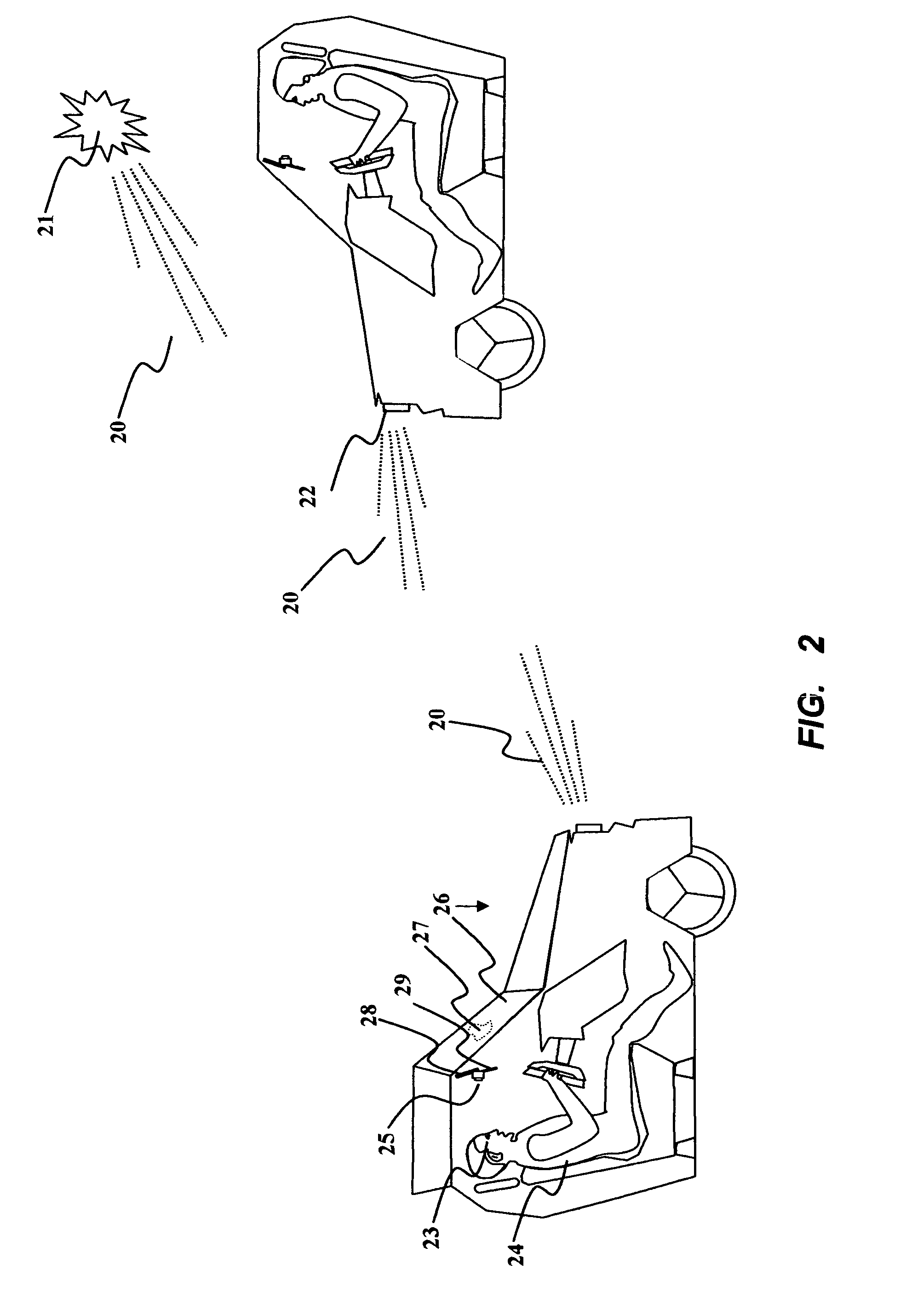

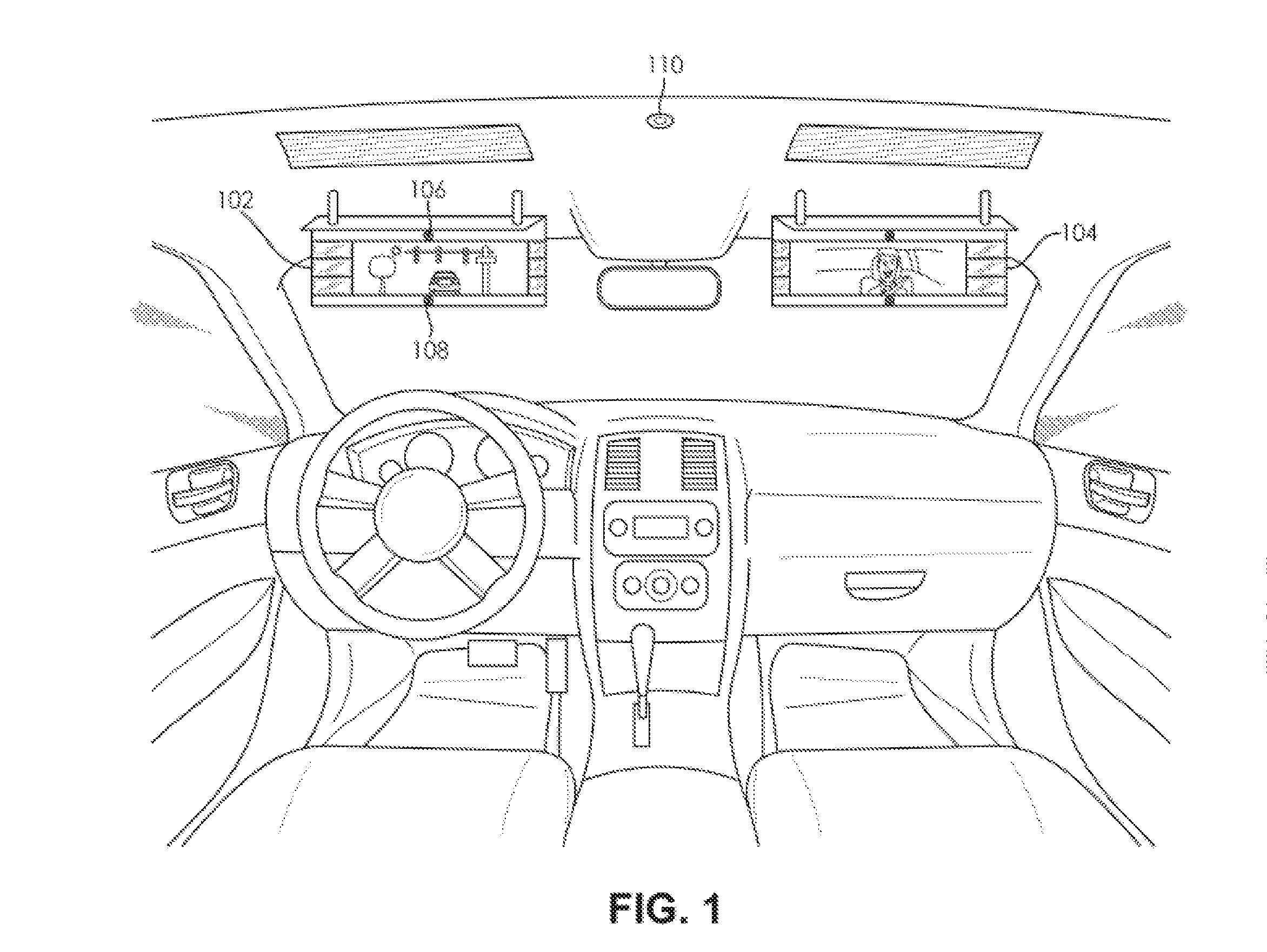

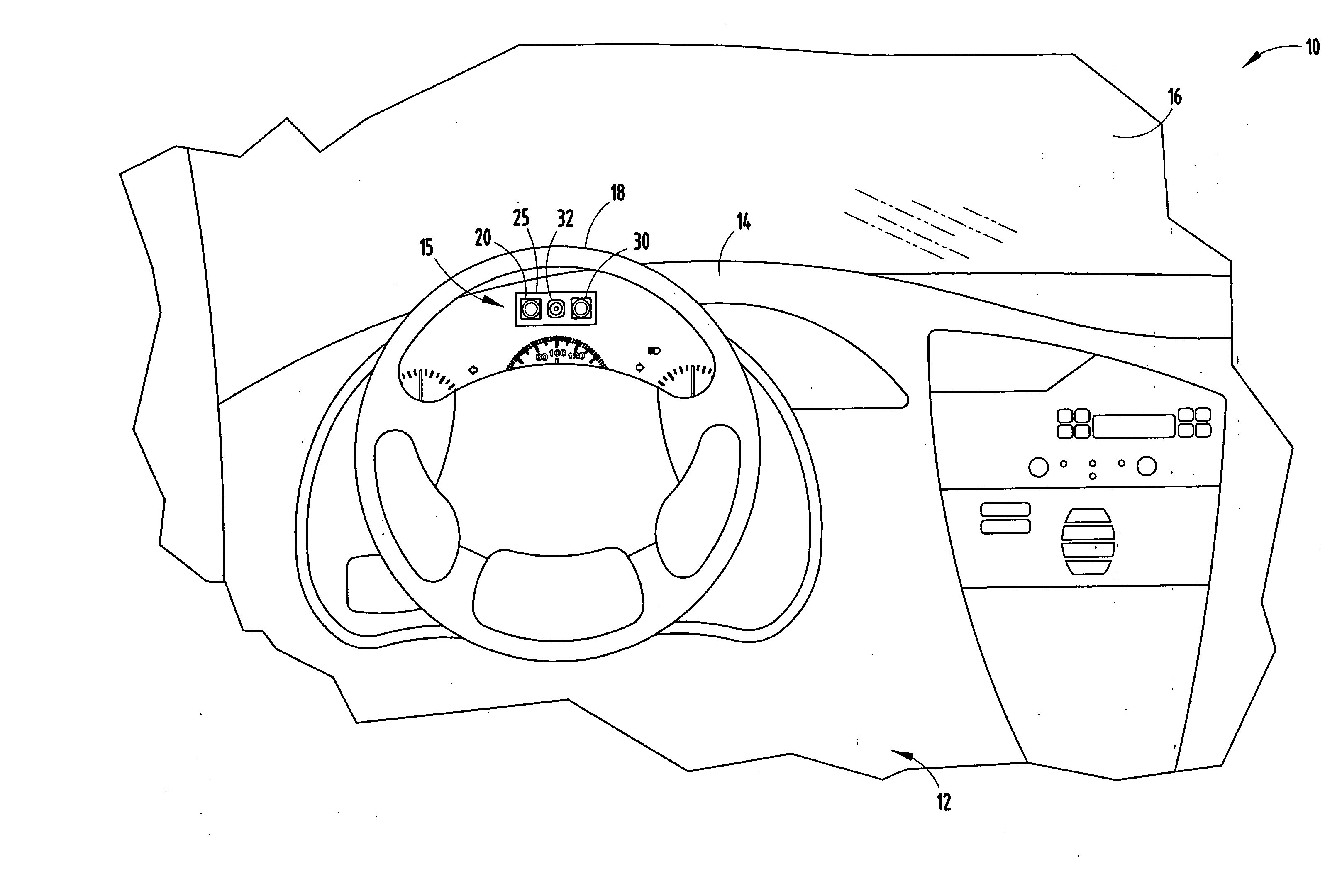

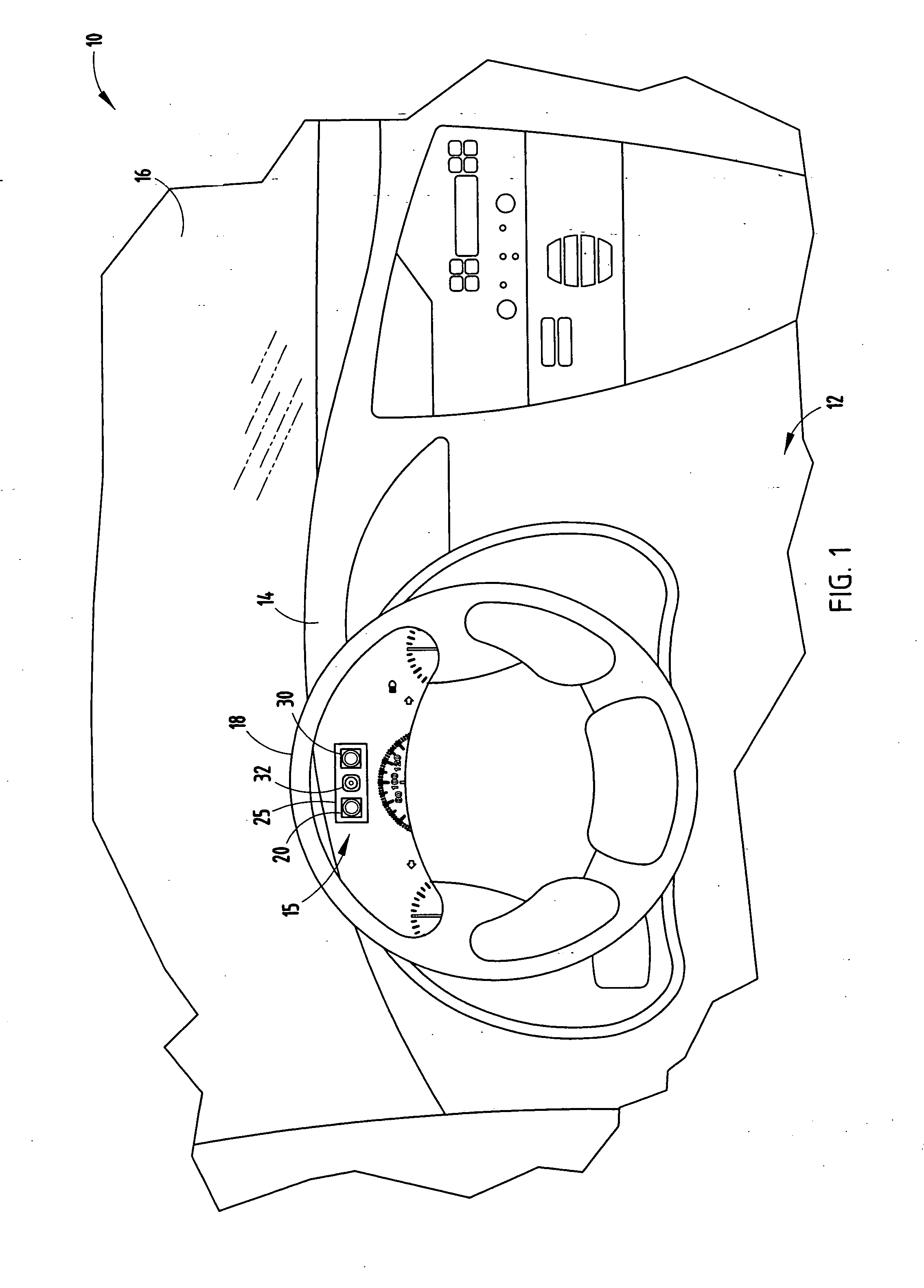

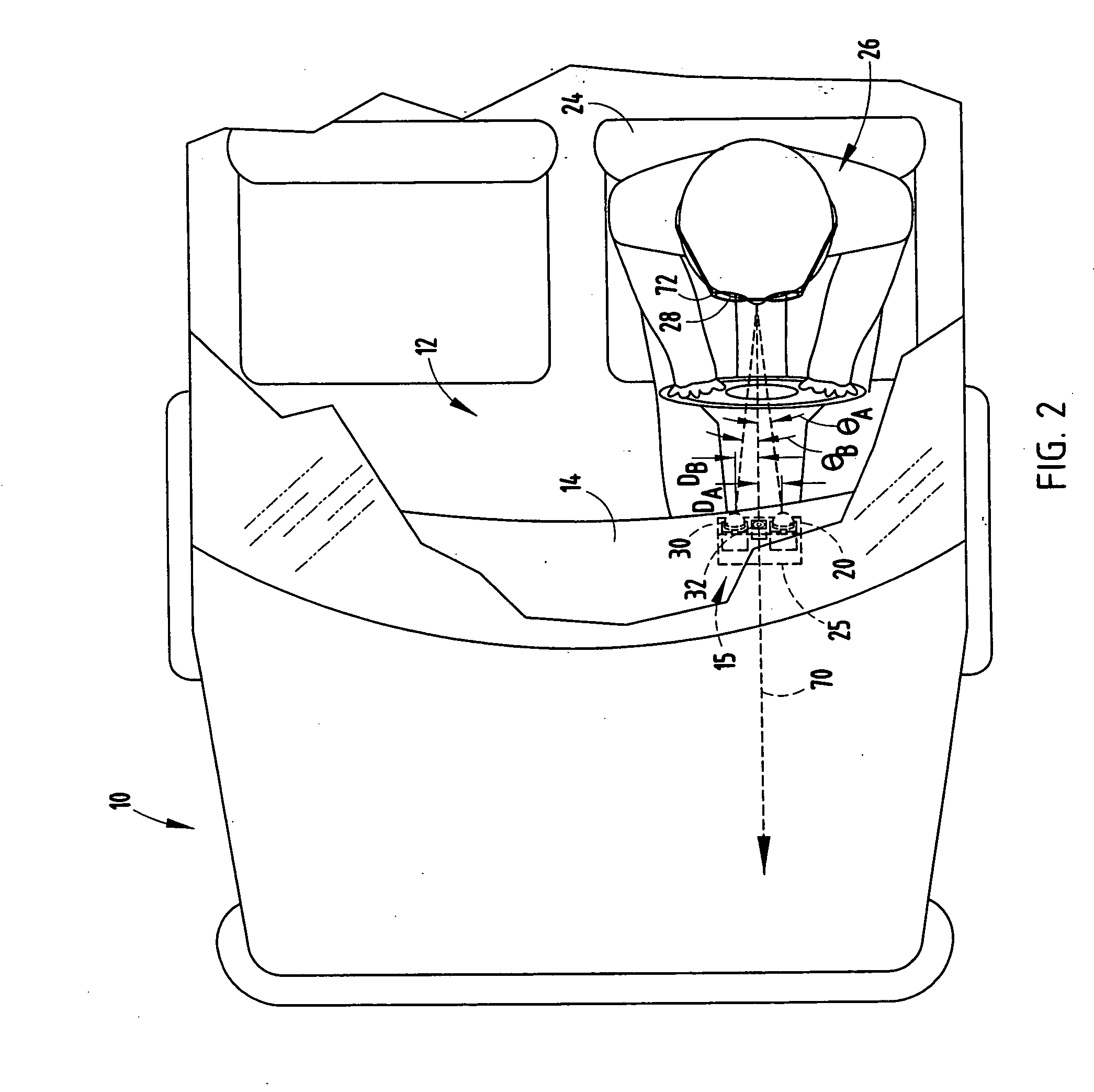

Enhanced vision for driving

InactiveUS7199767B2Reduce glareImprove viewing effectPhotometry using reference valueInstruments for comonautical navigationDriver/operatorLight source

A system for imposing a filter between a vehicle driver's eyes and a source of light including at least one detector facing inward into a compartment in the vehicle toward a likely position of the head of the vehicle driver and arranged to obtain images of the eyes of the driver and a processor coupled to the detector(s) and arranged to determine the location of the driver's eyes based on analysis of the images obtained by the detector(s) and to obtain information about objects exterior of the vehicle providing sources of light from the images obtained by the detector(s) based on reflections off of the driver's eyes, i.e., the position of such objects. A filter, such as a pixelated screen, is imposed between the sources of light and the driver's eyes based on the location of the driver's eyes and the information about the exterior objects providing the sources of light.

Owner:SPERO YECHEZKAL EVAN

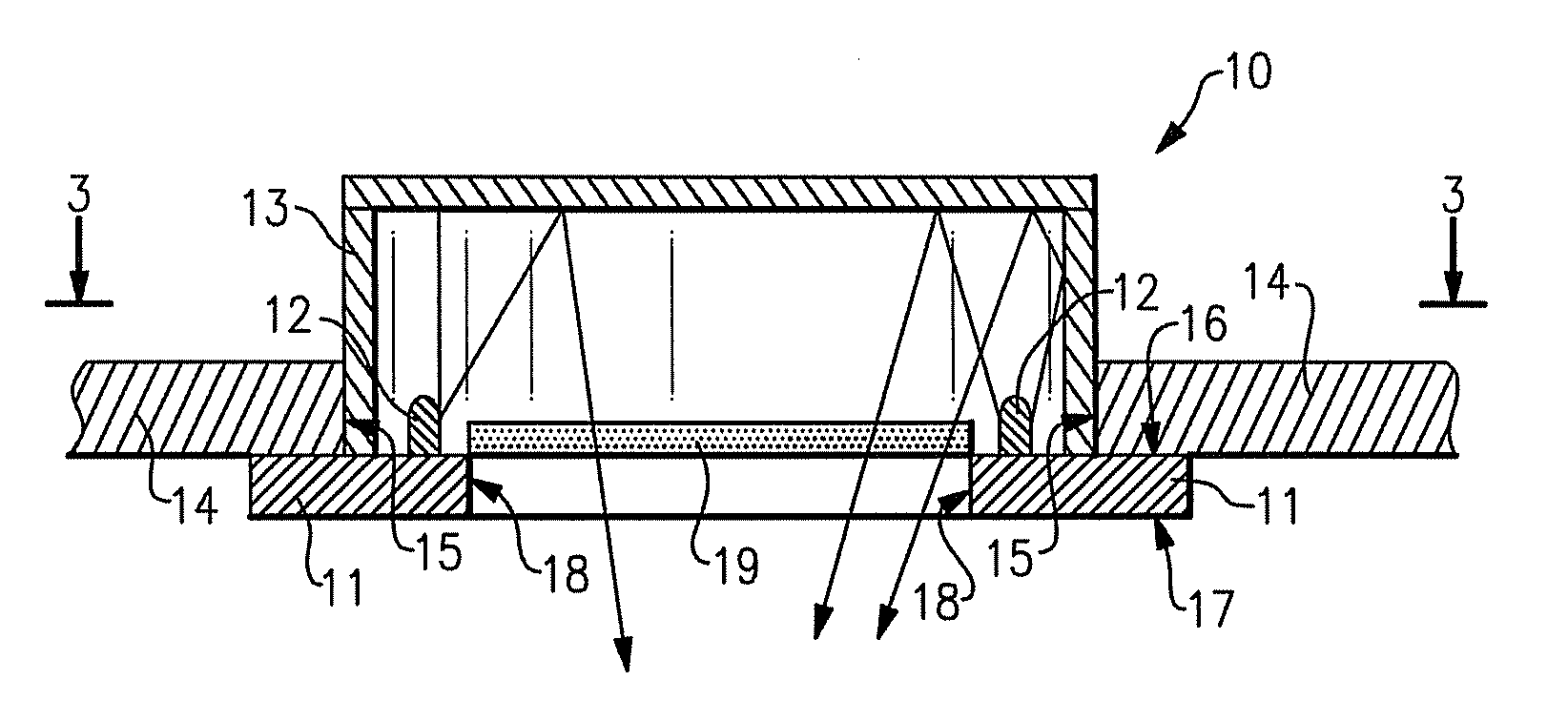

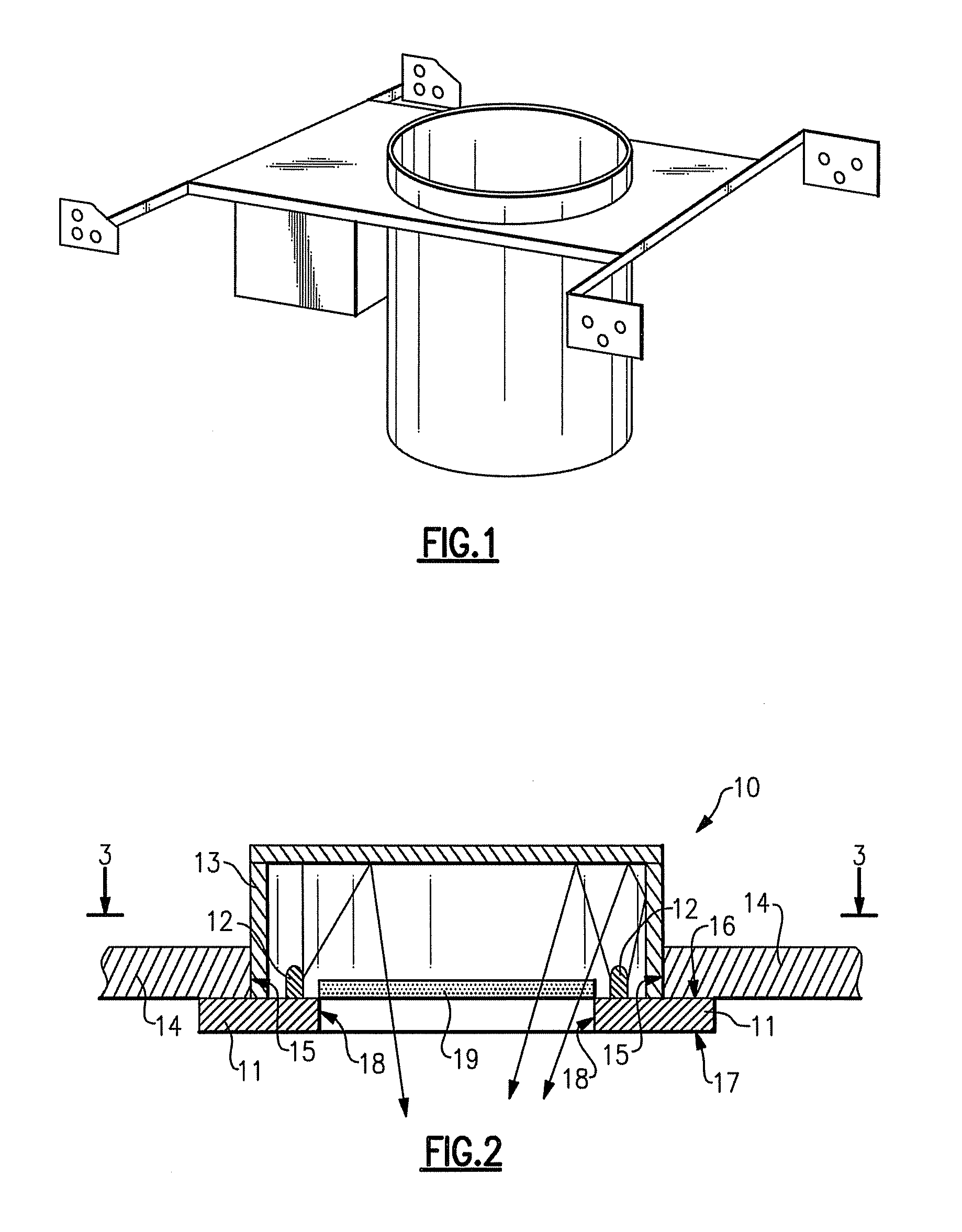

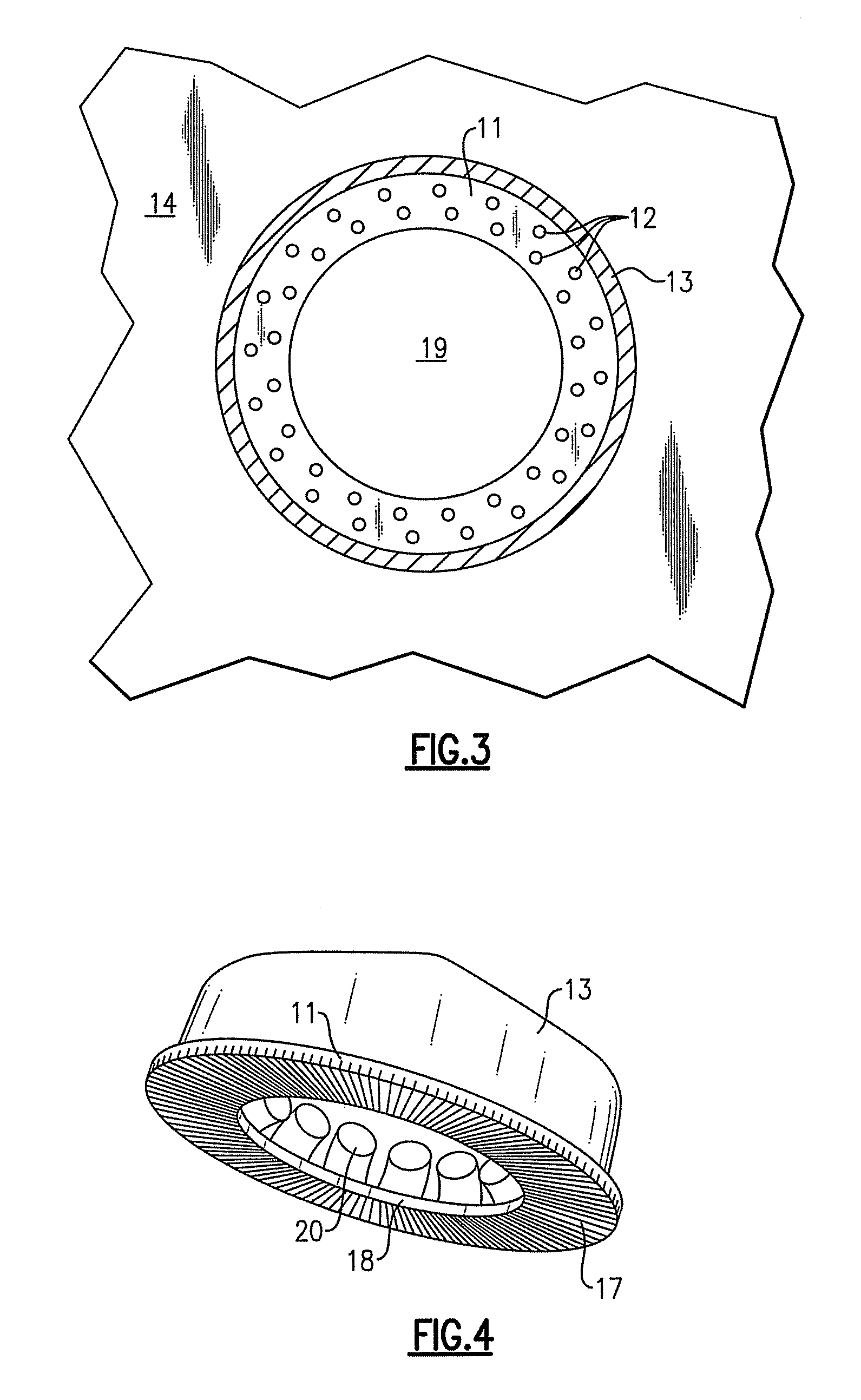

Lighting device

ActiveUS7722220B2Reduce glareEfficient transferMechanical apparatusPoint-like light sourceEffect lightEngineering

First, second and third lighting devices each comprise a thermal conduction element, solid state light emitters and a reflective element. In the second device, the conduction element defines an opening; and the emitters and reflective element are mounted on a first side of the conduction element. In the third device, the conduction element defines an opening; a first portion of a first side of the conduction element is in contact with a contact region of a construction surface; and the emitters and reflective element are mounted on the first side. A fourth device comprises a conduction element and emitters; a first portion of a first side of the conduction element is in contact with a contact region of a construction surface; the emitters are mounted on a second portion of the first side of the conduction element; and a second side of the conduction element is exposed to ambient air.

Owner:IDEAL IND LIGHTING LLC

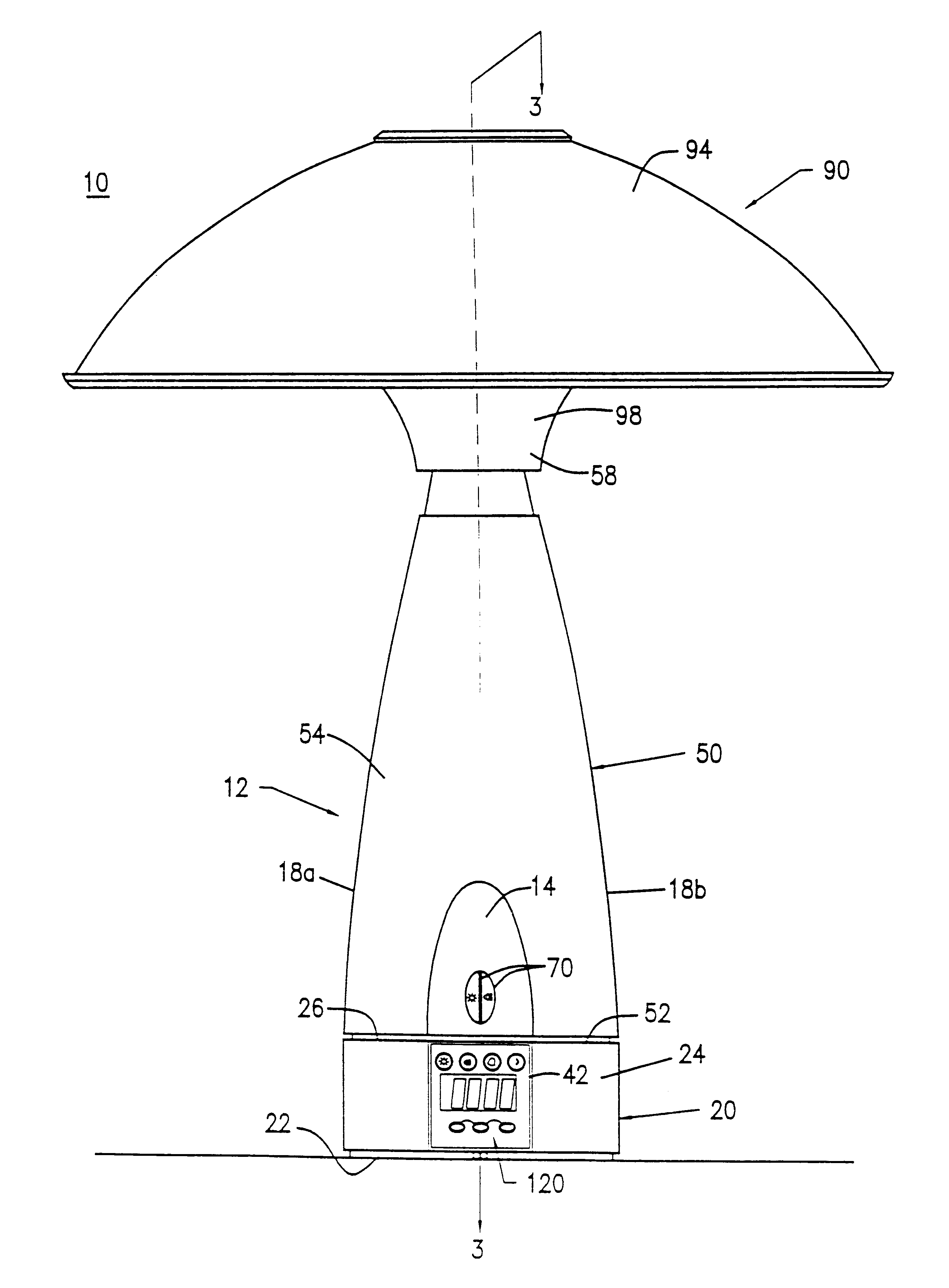

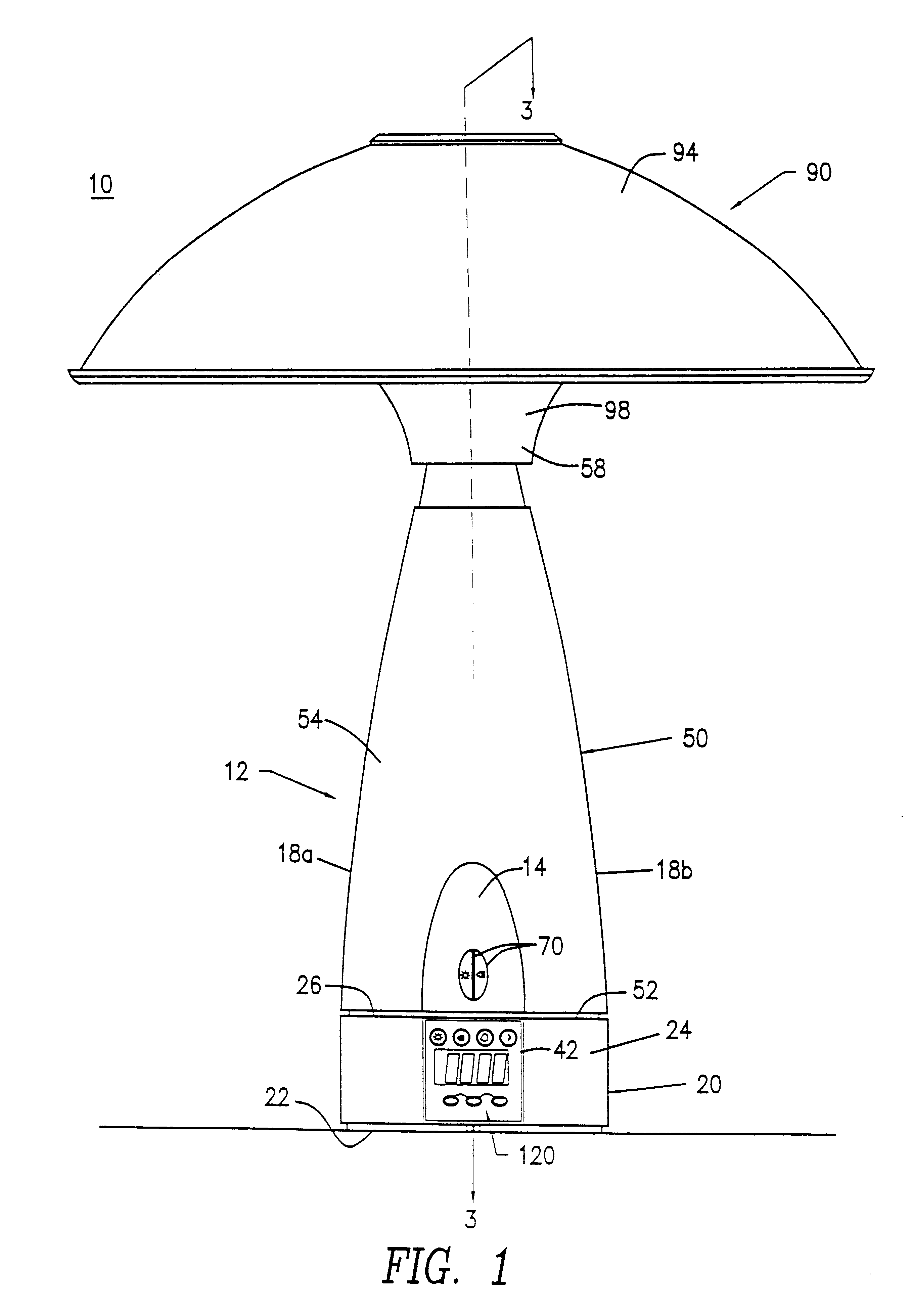

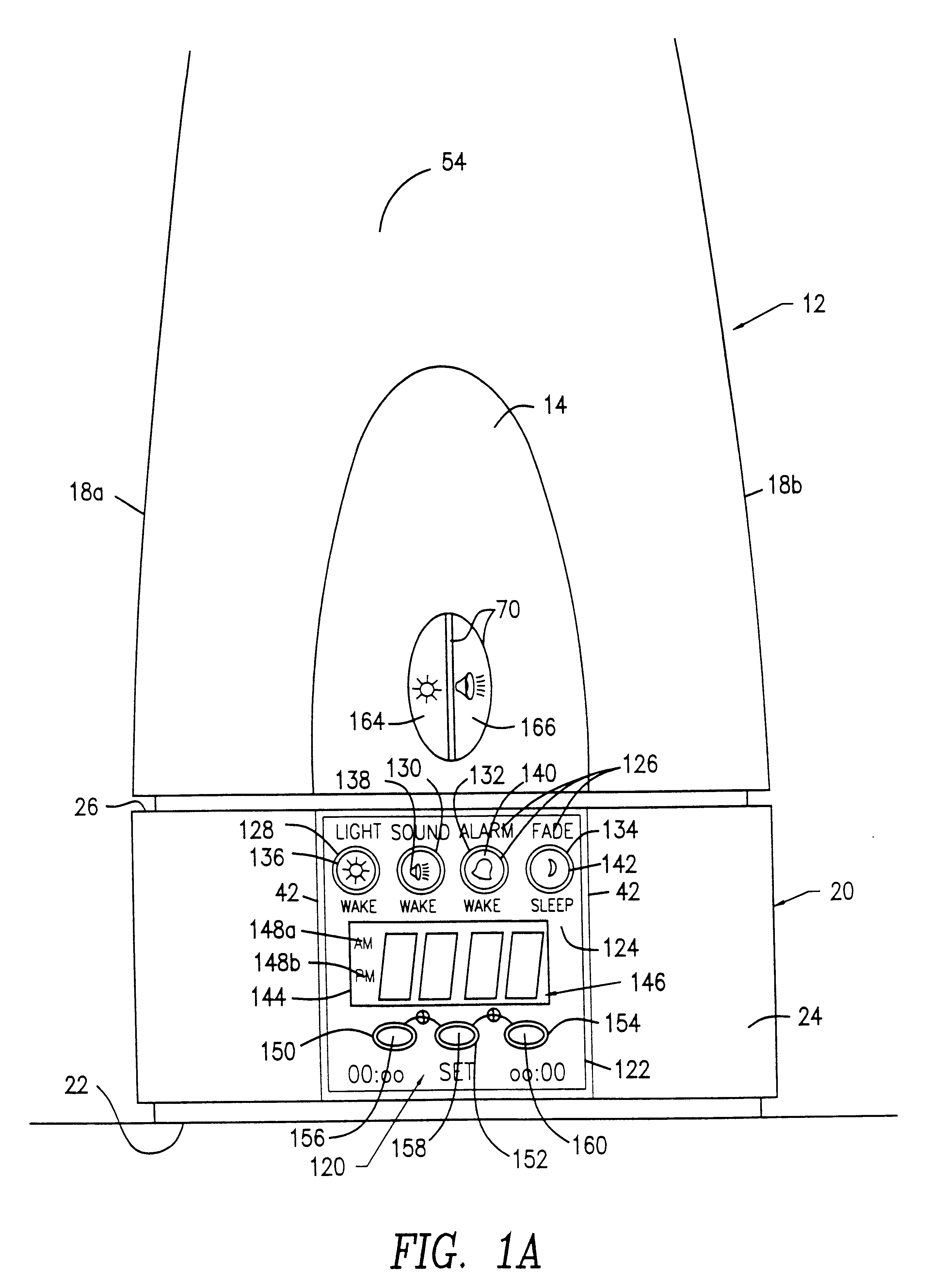

Lamp and alarm clock with gradually increasing light or sounds

InactiveUS6236622B1No pressureReduce glareVisual indicationAcoustic time signalsCycle controlEffect light

A lighting fixture having a lamp and alarm clock with a wake-up cycle and sleep cycle with gradually increasing and decreasing light and sounds. The lighting fixture includes at least one lamp for emitting light in the wake-up cycle and in the sleep cycle. The lighting fixture also includes at least one speaker for emitting sound in the wake-up cycle and in the sleep cycle. The lighting fixture further includes a dimmer switch for dimming the light and wake-up cycle control buttons for setting and controlling a wake-up cycle having a light control button for setting the time when the wake-up cycle control buttons activates the light mode and gradually increases the lamp brightness emitted from the at least one lamp; and sound control buttons for setting and controlling the time when the wake-up cycle control buttons activates the sound mode and gradually increases the sound intensity emitted from the at least one speaker; and sound selection switches for selecting one of multiple pre-set sounds for the sound mode of the wake-up cycle, or for full time operation as background sound.

Owner:VERILUX

Adaptive/anti-blinding headlights

InactiveUS6144158AReduce glareImprove eyesightVehicle headlampsSolid-state devicesLight beamClassical mechanics

This invention relates to the production of a beam of light comprised of many microbeams, controlled by incoming radiation, employing a sensor to determine the location of light sources forward of the apparatus and using that information to control the intensity, and / or the angular position, of one or more narrow-angle microbeams, which are part of a large number of beams comprising the overall output beam.

Owner:SENSCI CORP

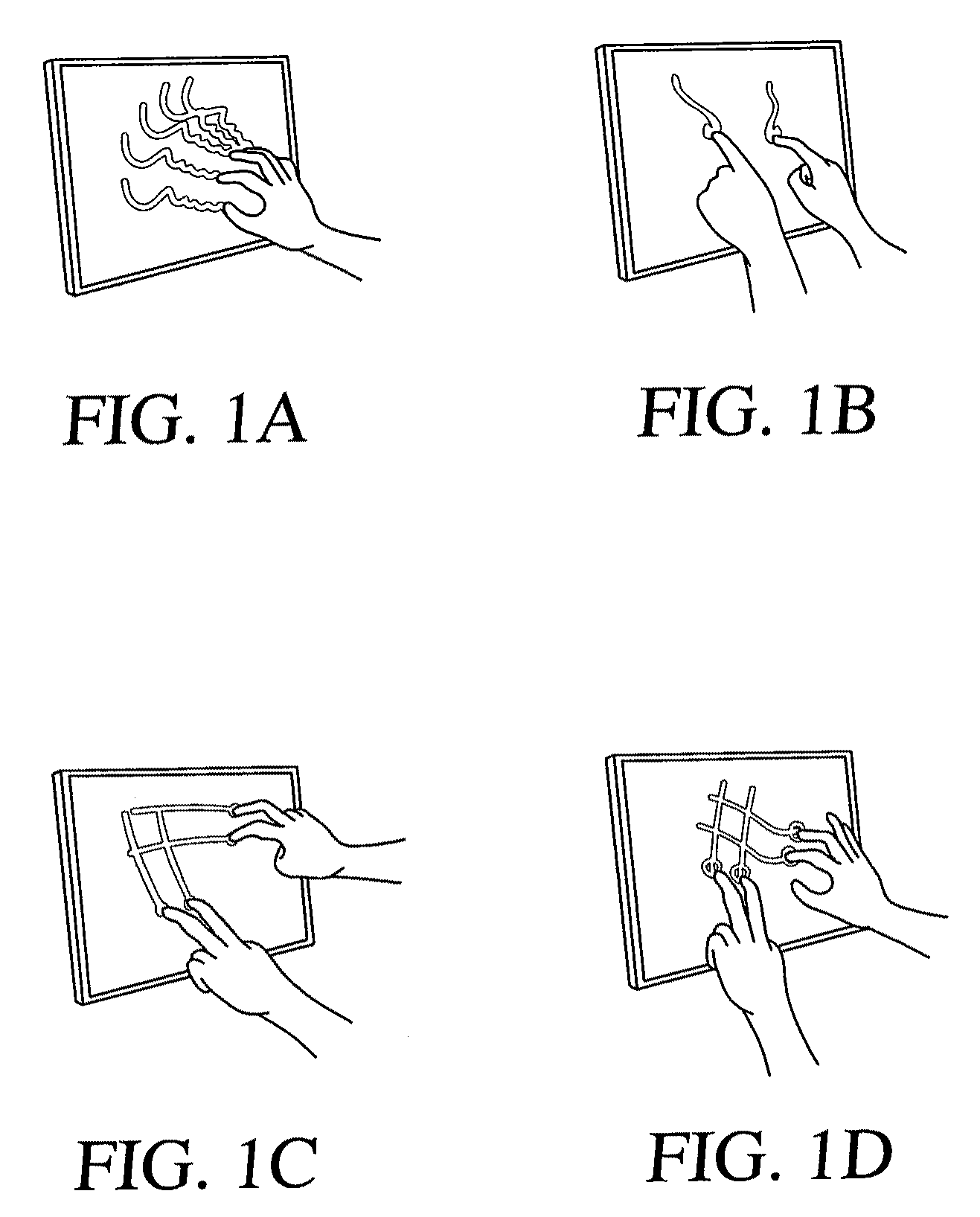

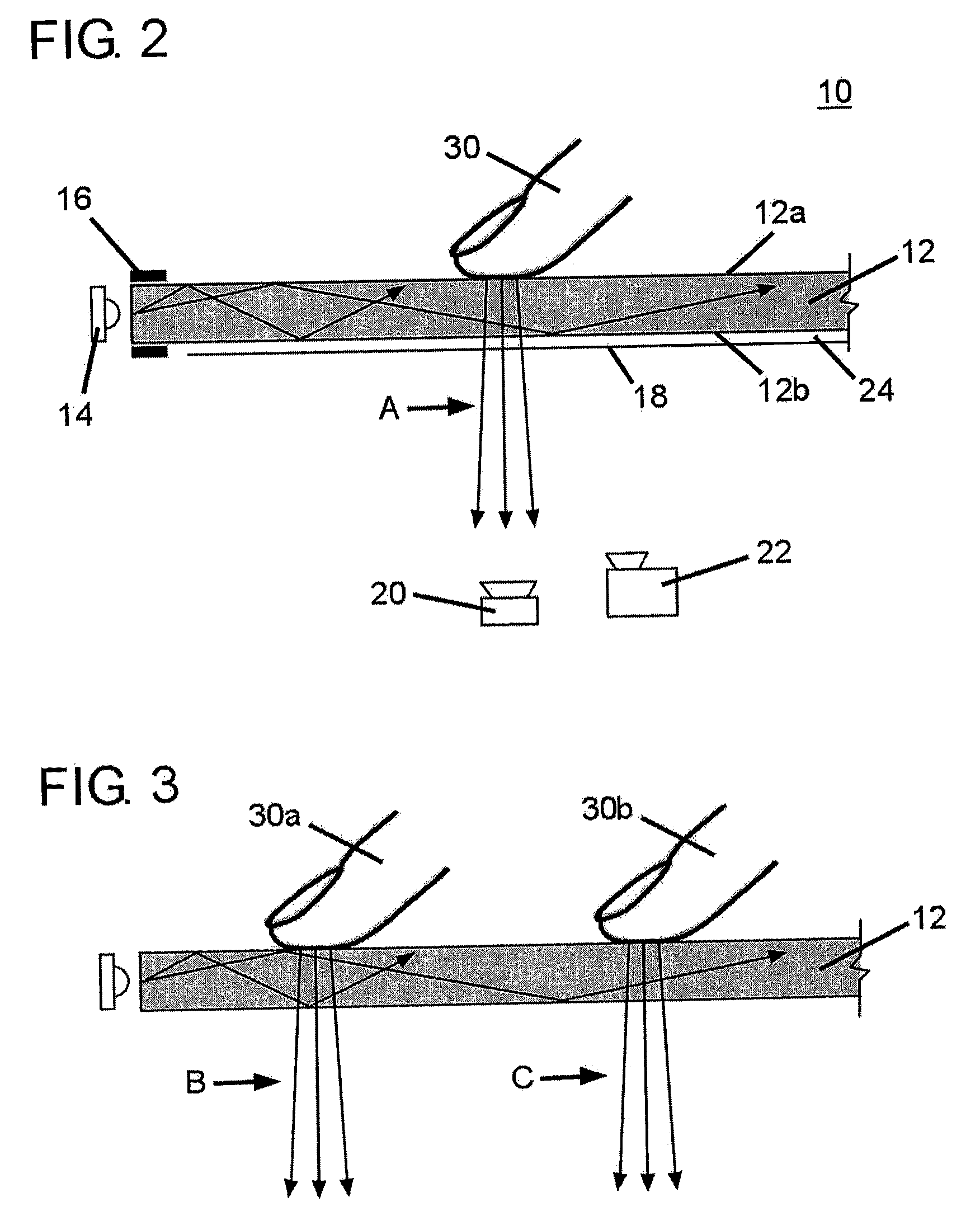

Multi-touch sensing through frustrated total internal reflection

InactiveUS20080179507A2Simple and inexpensive and scalableCut surfaceBeam/ray focussing/reflecting arrangementsMaterial analysis by optical meansMulti inputTotal internal reflection

Owner:MICROSOFT TECH LICENSING LLC

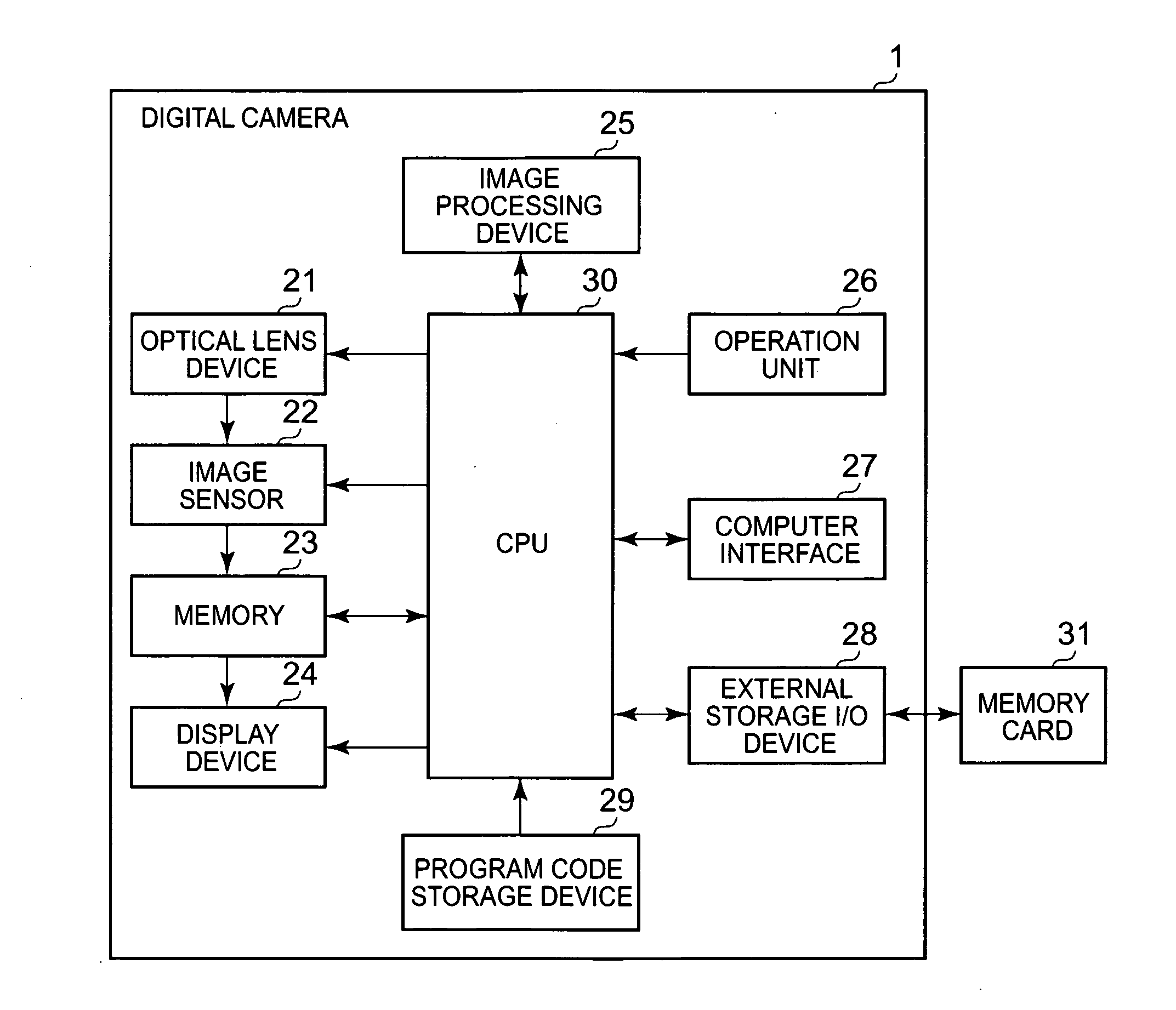

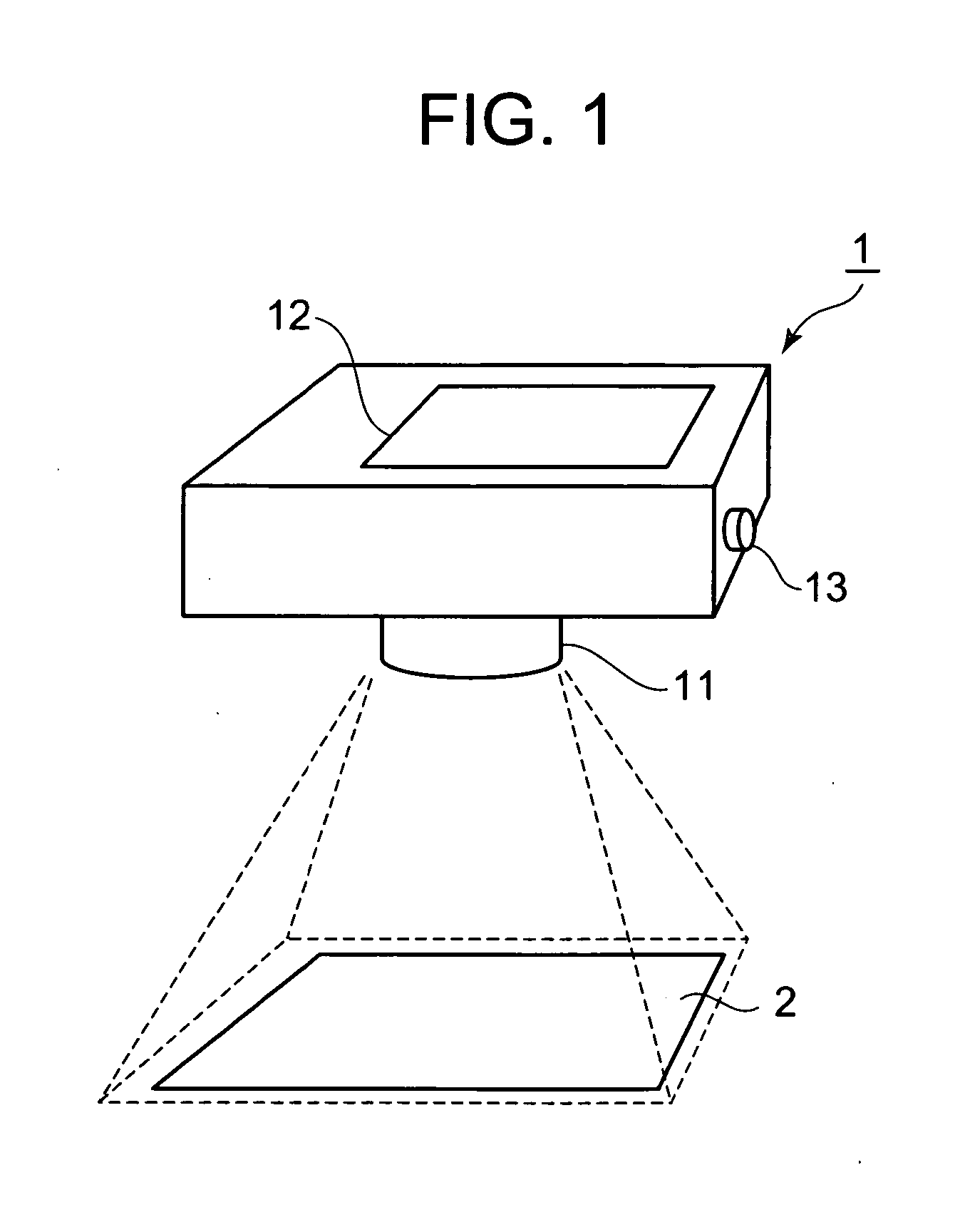

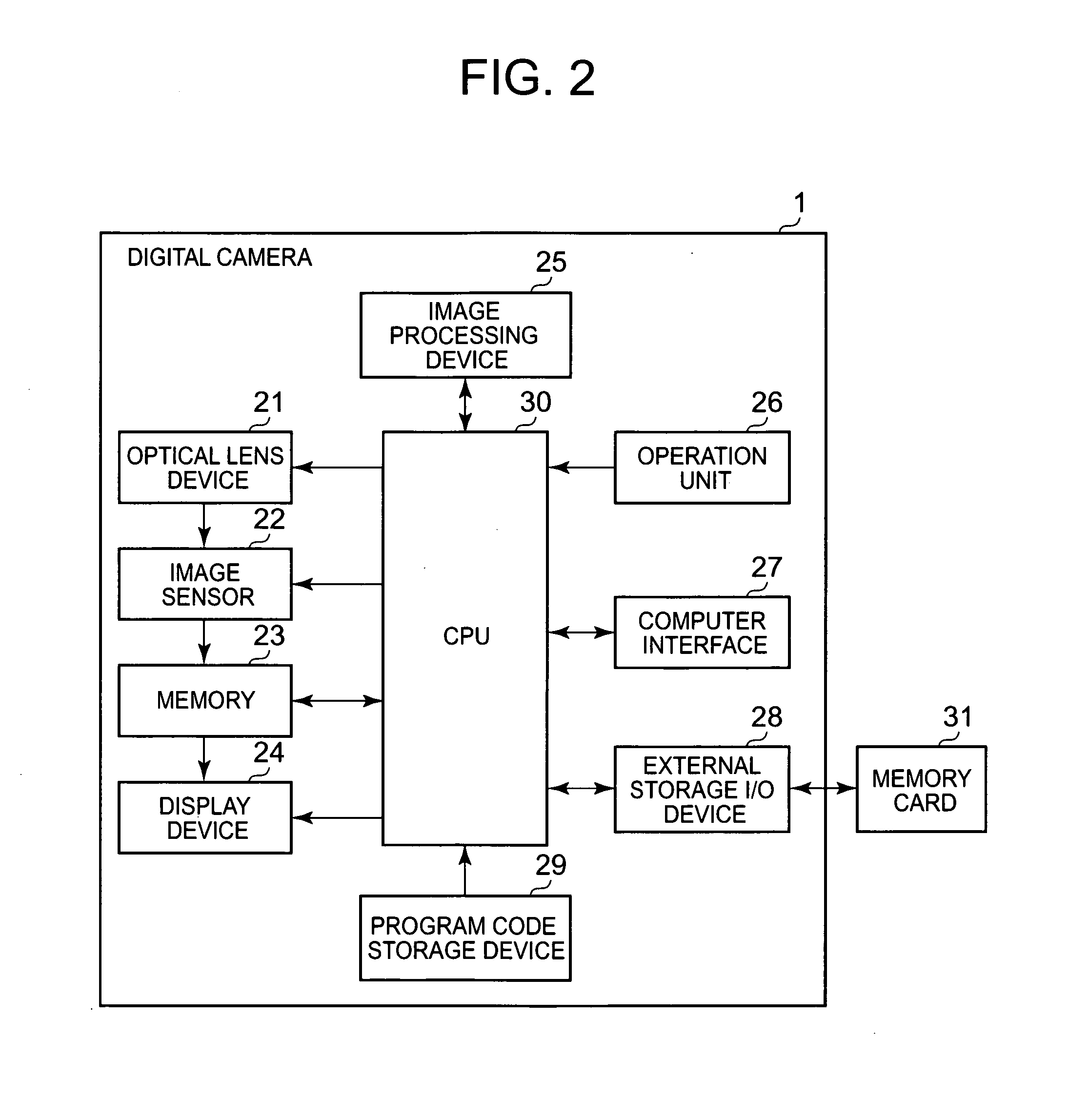

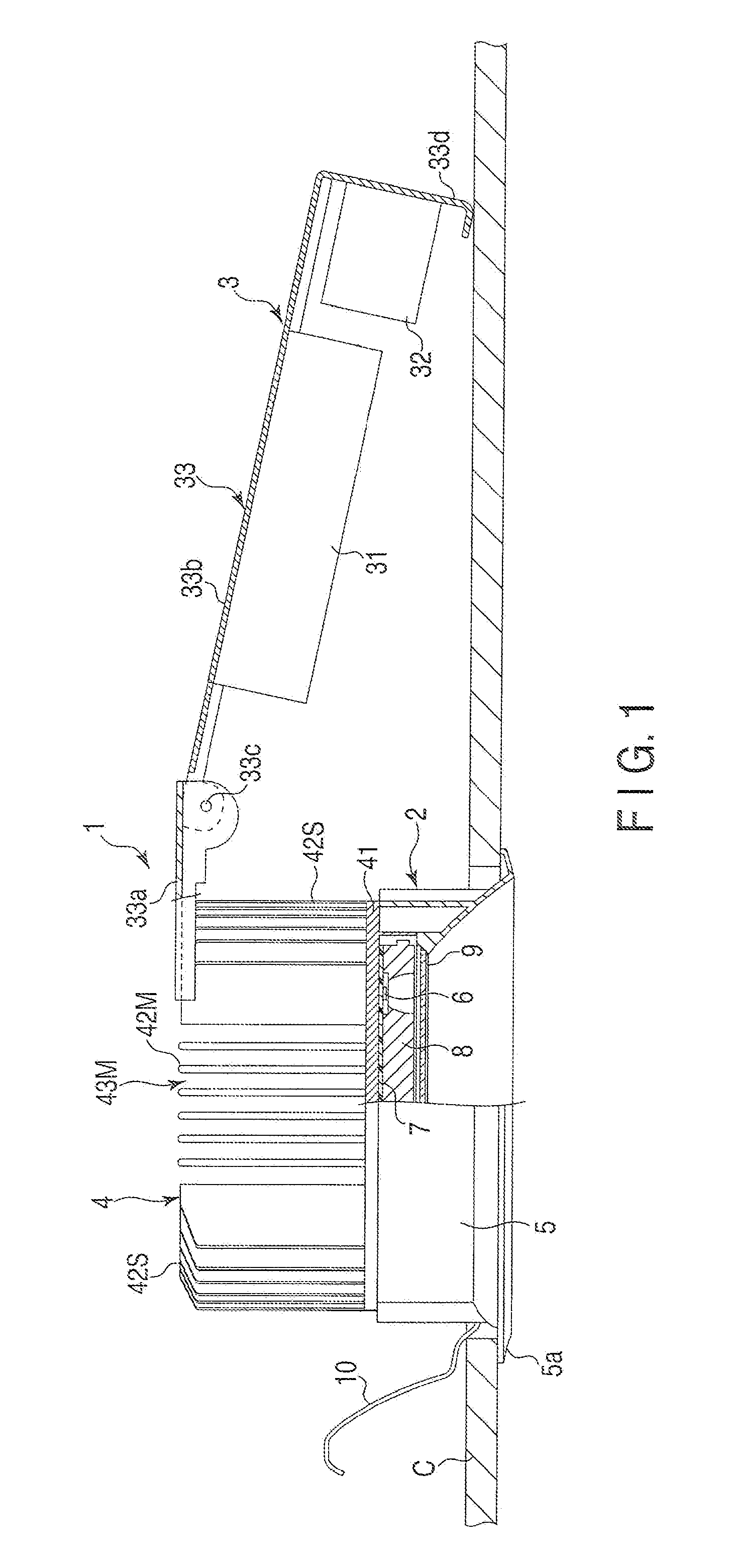

Image capture apparatus, image processing method for captured image, and recording medium

InactiveUS20060222260A1Slow changeReduce glare effectsImage enhancementCharacter and pattern recognitionImaging processingPaper document

A digital camera (1) shoots a document plural times from different directions to obtain a plurality of images. An image processing device included in the digital camera (1) corrects the keystone distortion of each image to generate an image which seems as if the document were shot from in front of it. The image processing device synthesizes the images by addition-averaging the pixel values of each pixel in the plurality of corrected images. Even if captured images are illuminated by glare from a light because a document made of glossy paper is shot, the influence of the glare is reduced by addition-averaging the pixel values of each pixel in the plurality of images.

Owner:CASIO COMPUTER CO LTD

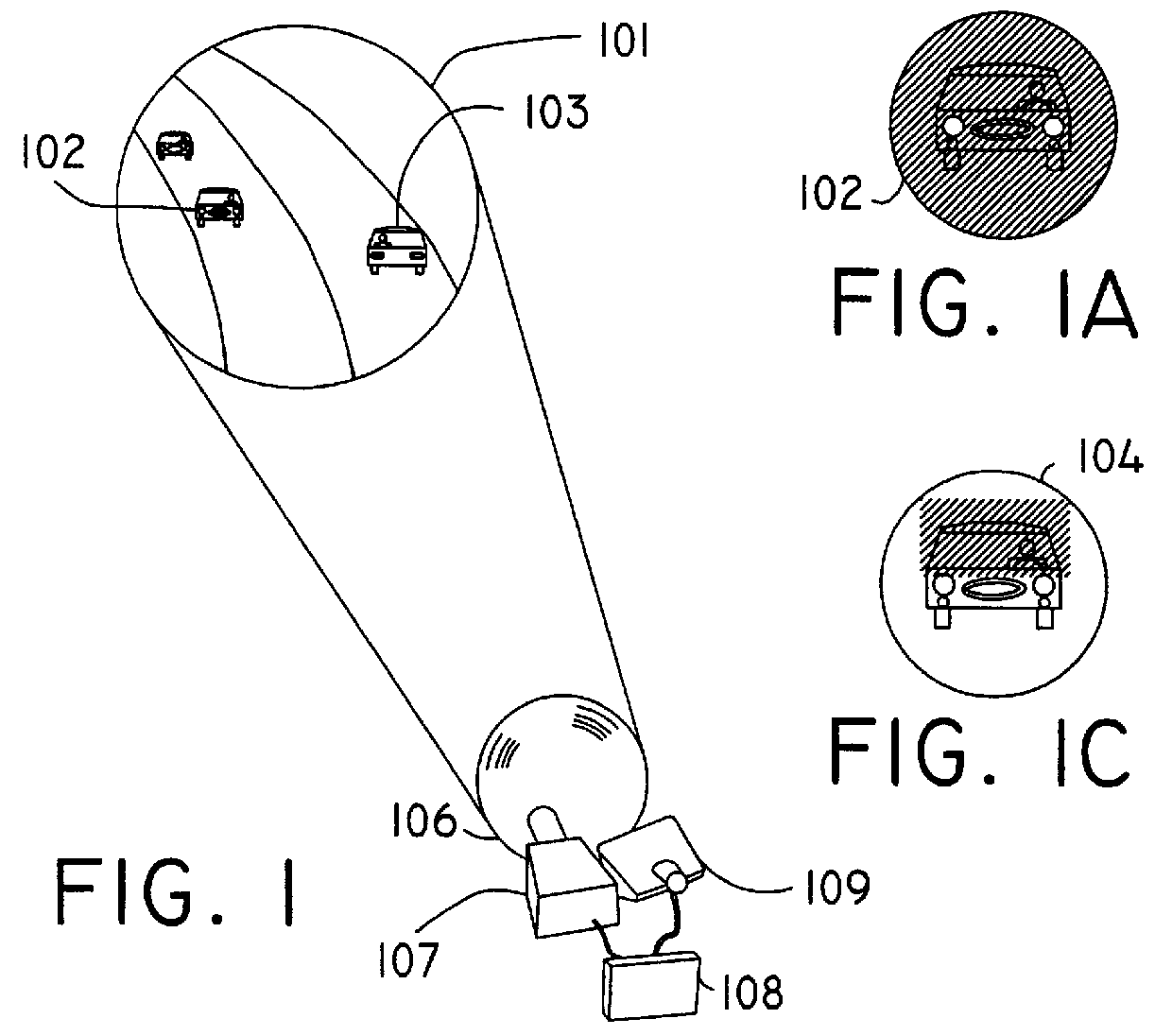

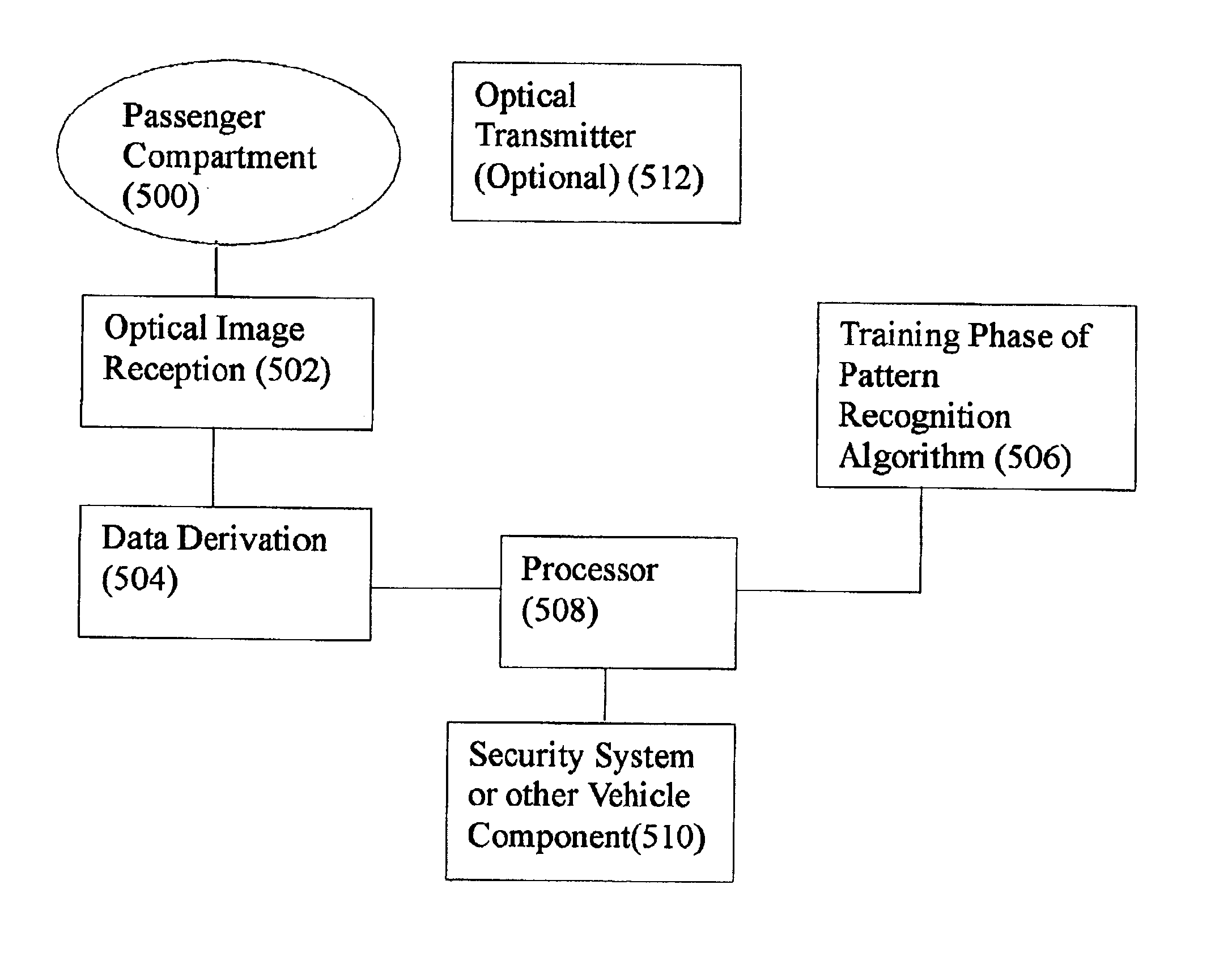

Vehicular monitoring systems using image processing

InactiveUS6856873B2Accurate identificationReduce glareVehicle seatsDigital data processing detailsImaging processingMonitoring system

Vehicular monitoring arrangement for monitoring an environment of the vehicle including at least one active pixel camera for obtaining images of the environment of the vehicle and a processor coupled to the active pixel camera(s) for determining at least one characteristic of an object in the environment based on the images obtained by the active pixel camera(s). The active pixel camera can be arranged in a headliner, roof or ceiling of the vehicle to obtain images of an interior environment of the vehicle, in an A-pillar or B-pillar of the vehicle to obtain images of an interior environment of the vehicle, or in a roof, ceiling, B-pillar or C-pillar of the vehicle to obtain images of an interior environment of the vehicle behind a front seat of the vehicle. The determined characteristic can be used to enable optimal control of a reactive component, system or subsystem coupled to the processor. When the reactive component is an airbag assembly including at least one airbag, the processor can be designed to control at least one deployment parameter of the airbag(s).

Owner:AMERICAN VEHICULAR SCI

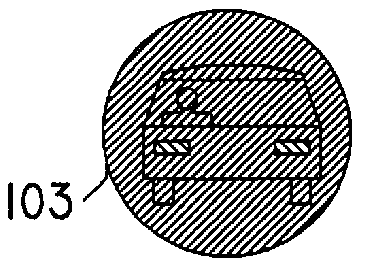

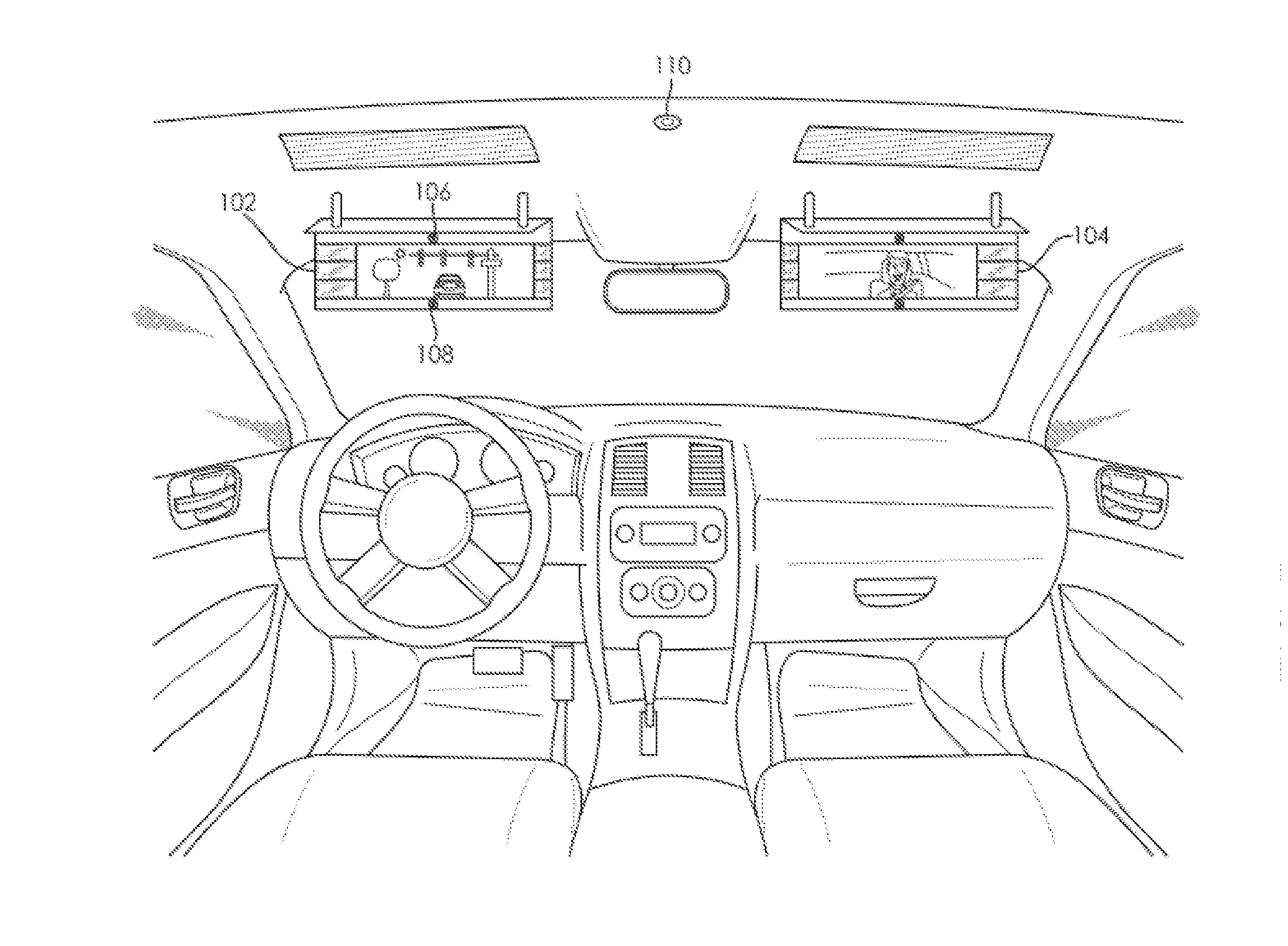

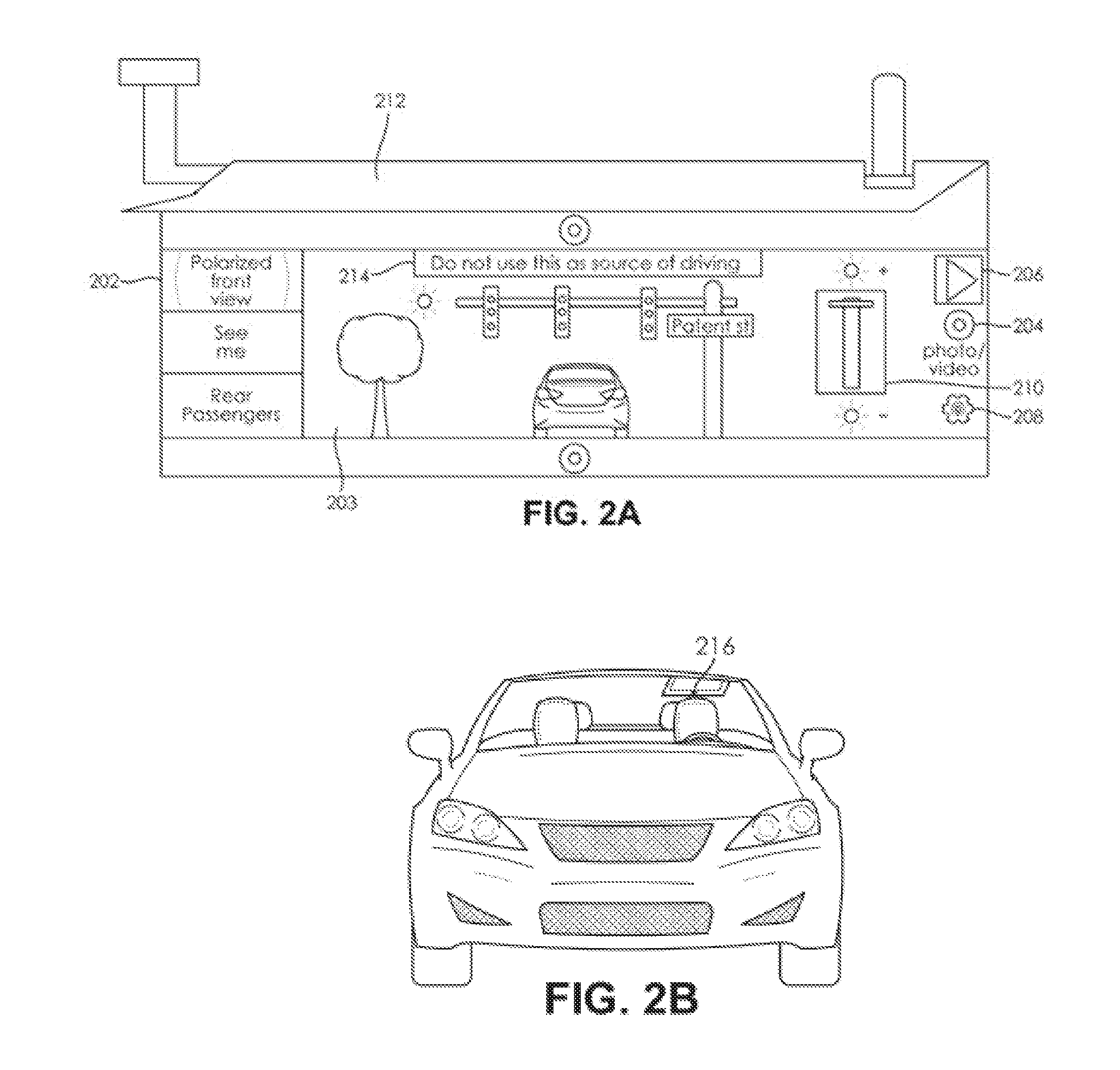

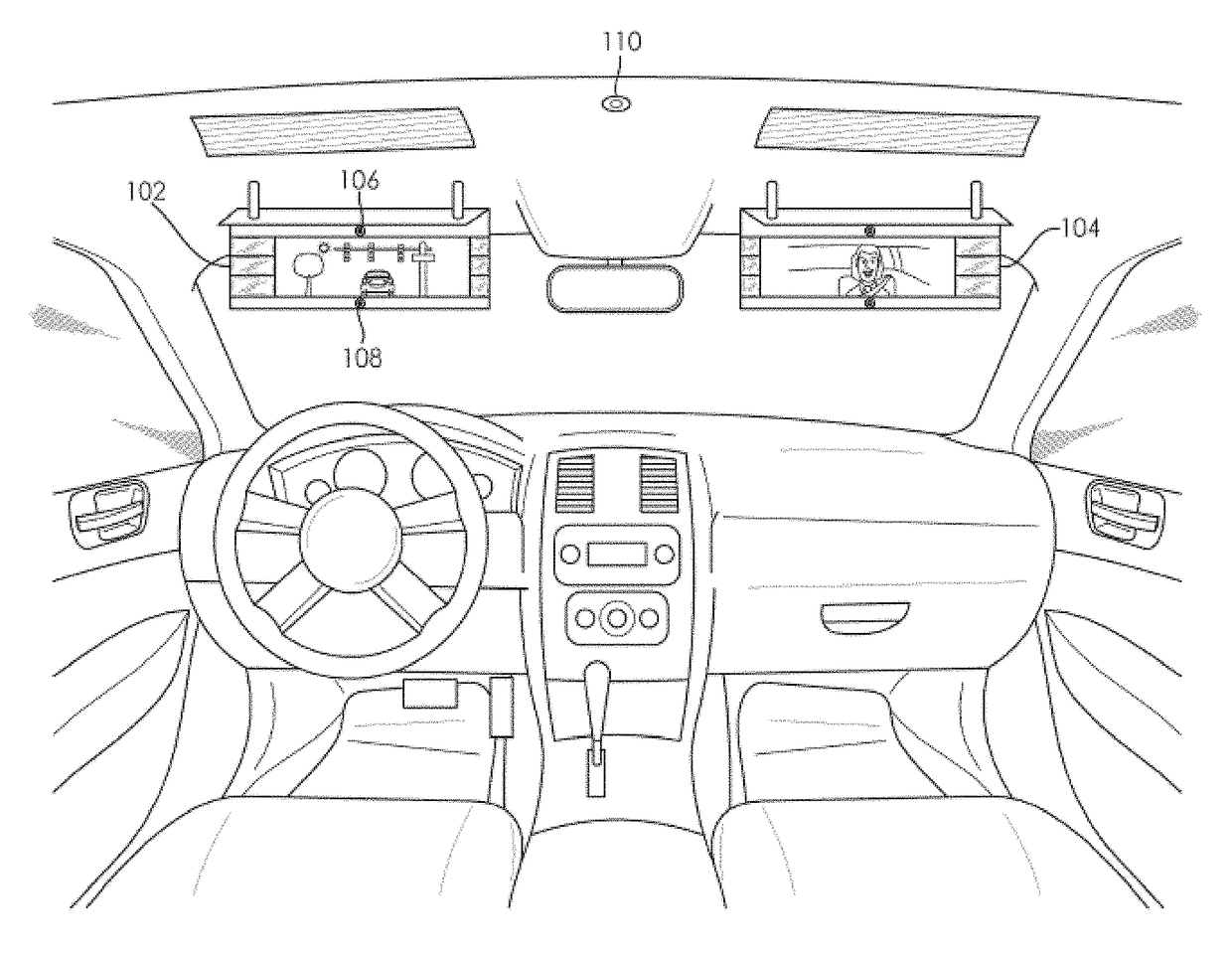

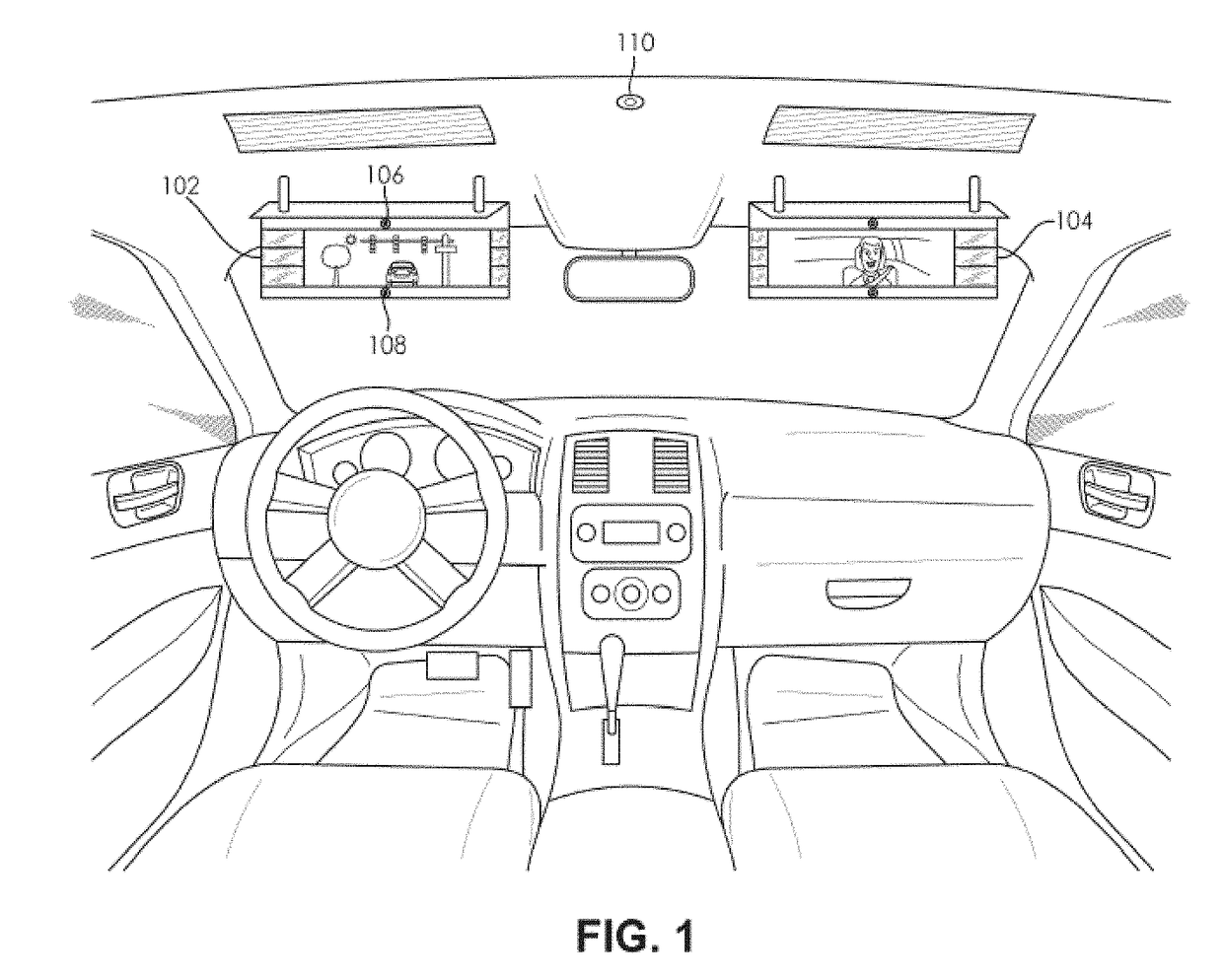

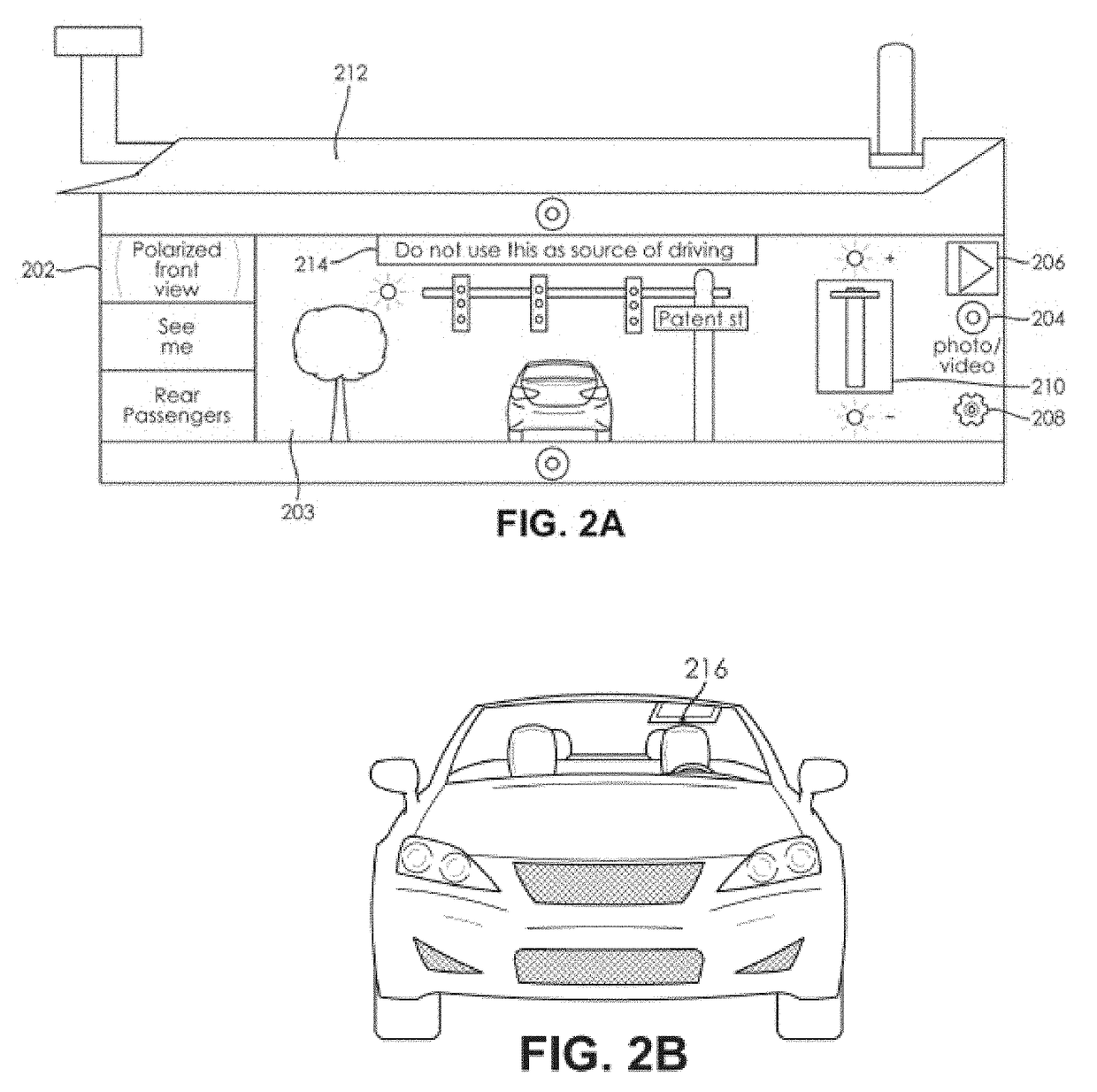

Smart vehicle sun visor

ActiveUS20170013188A1Reduce glareEliminate glareInput/output for user-computer interactionTelevision system detailsDistractionVisibility

A vehicle sun visor system with a touch screen display is configured to display video feed from one or more cameras. A front facing polarized and / or photochromic camera shows the area of view which is normally blocked by the deployed sun visor, allowing the user to view traffic lights, road signs, etc. without the distraction of glare. Software image processing may also be used to reduce glare and improve visibility. In addition, the sun visor system also has a “see-me” camera which allows the user to use the screen as a mirror, and one or more rear-view cameras which can be used to see the passenger area of a vehicle through the touch-screen display. Any of the cameras may be used to take photos or videos, which may be viewed on the display and transmitted wirelessly to other electronic devices or cloud storage.

Owner:BE TOPNOTCH LLC

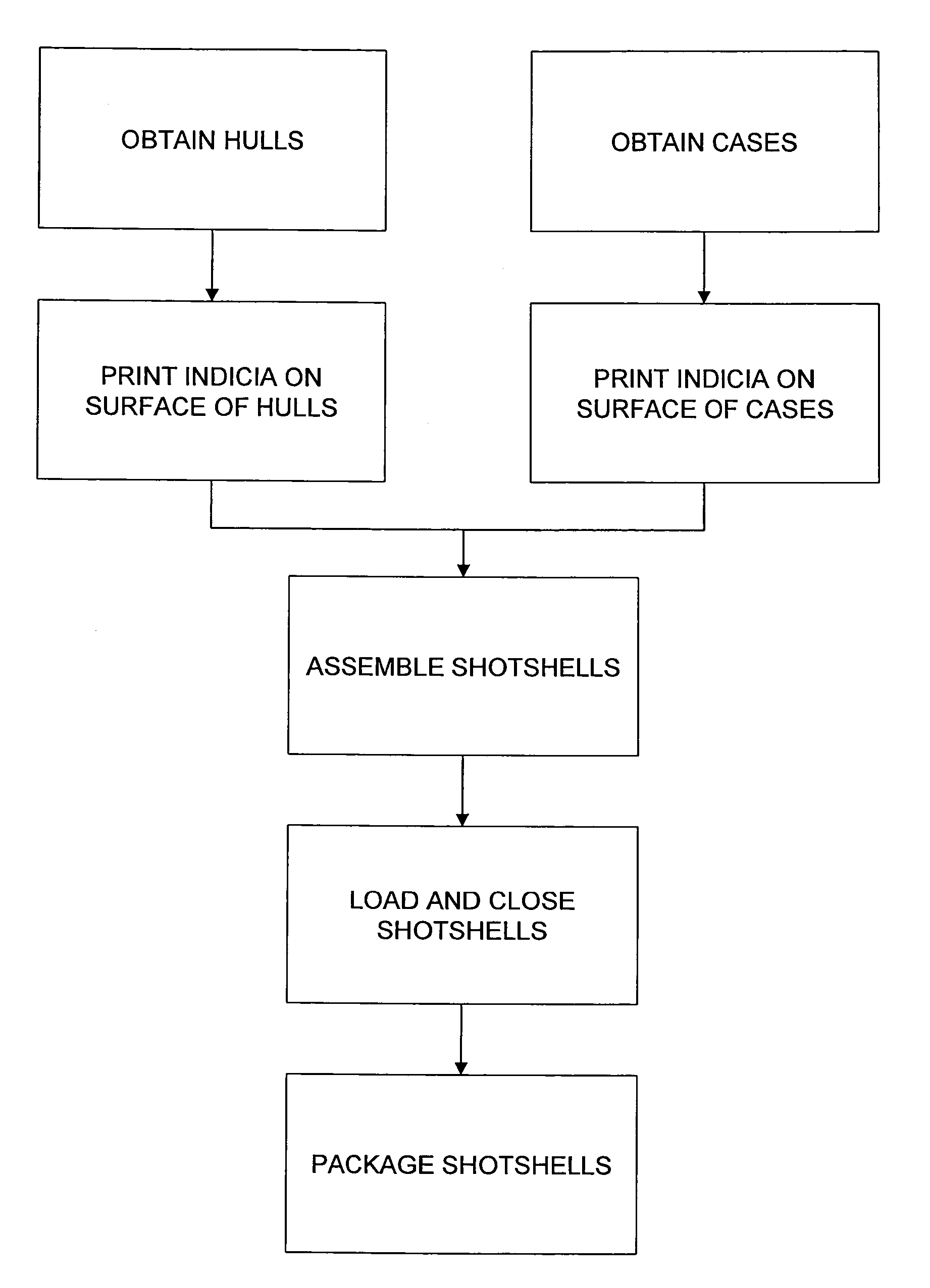

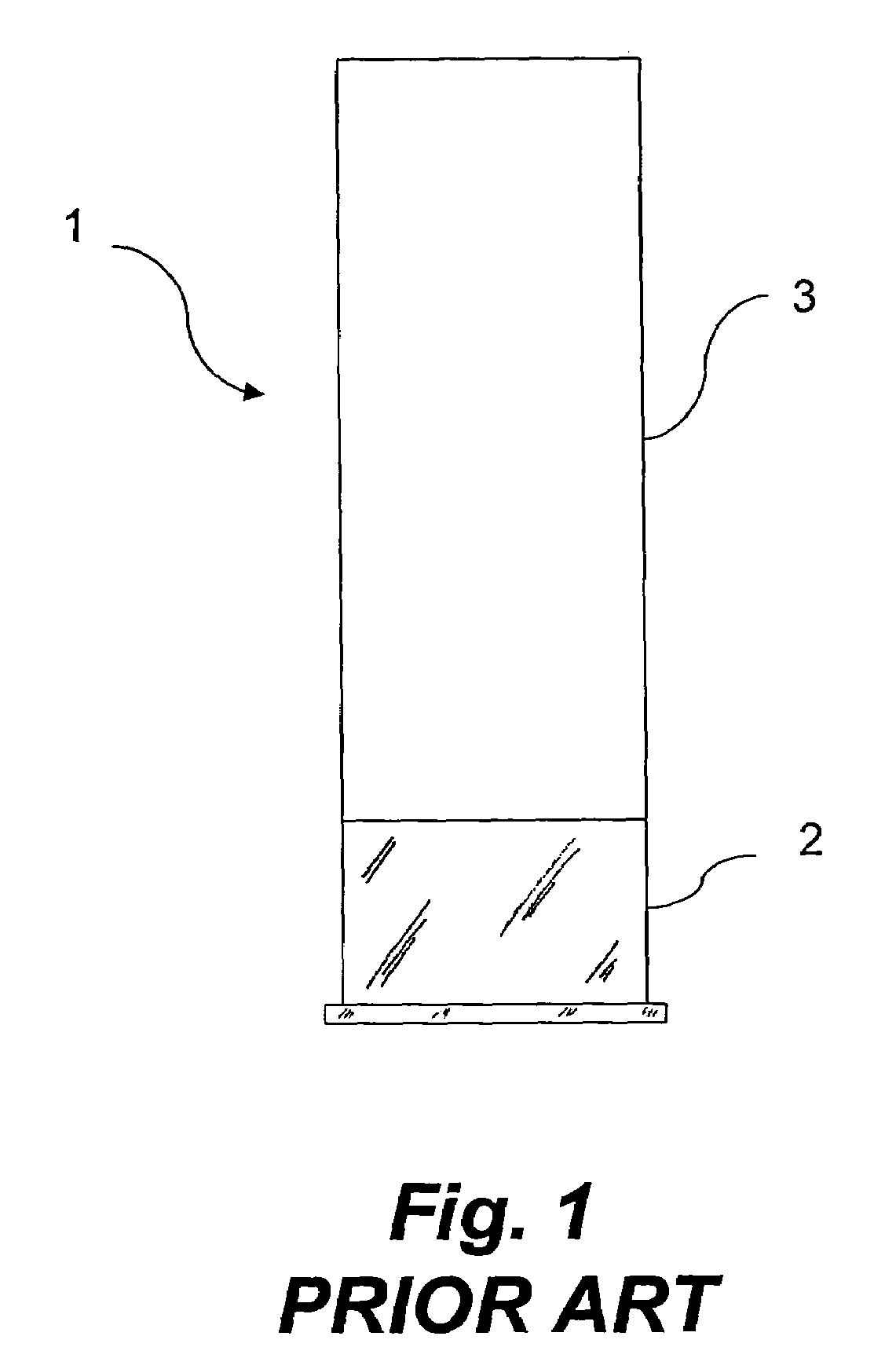

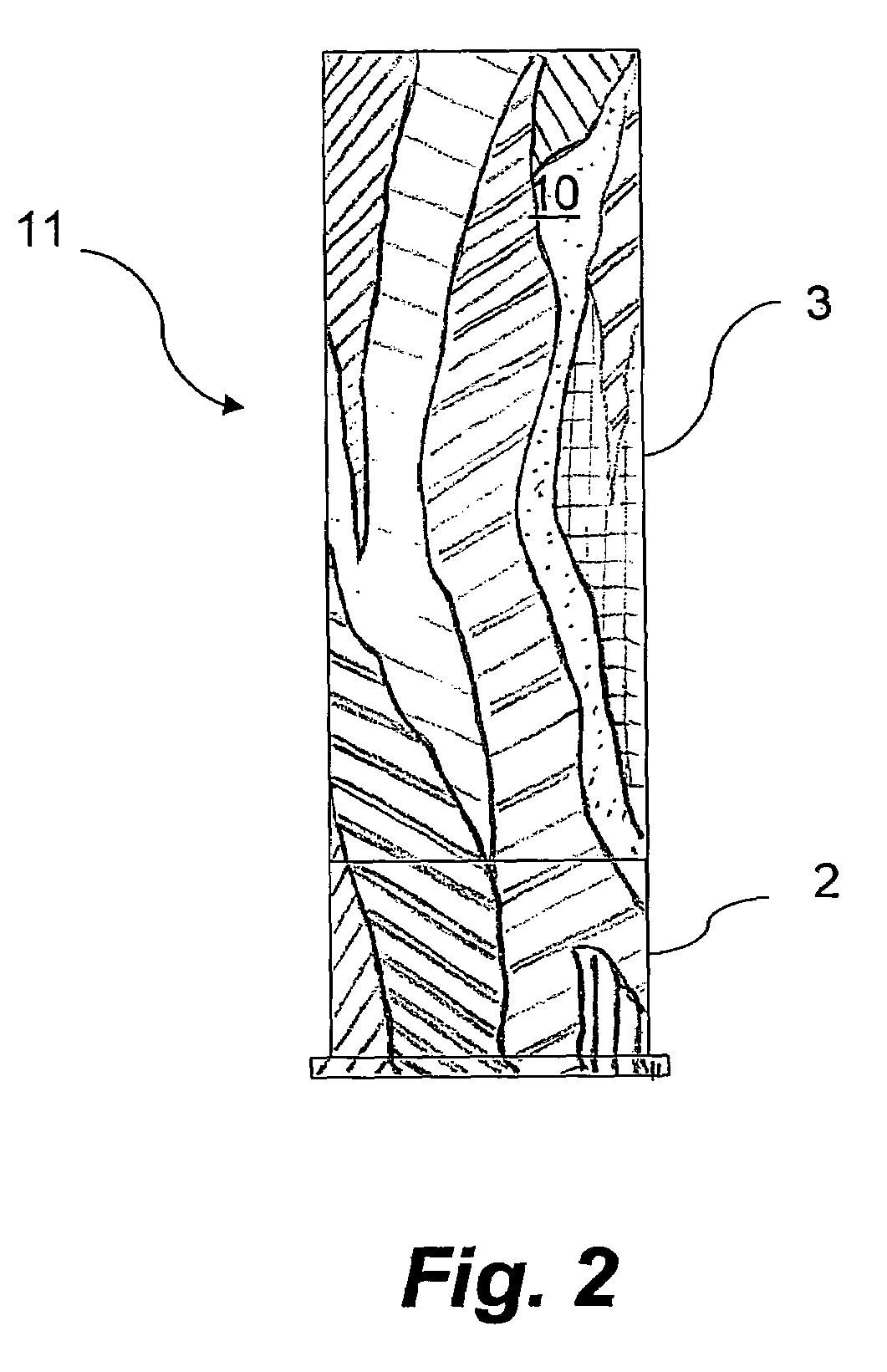

Ammunition having surface indicia and method of manufacture

InactiveUS7014284B2Improved adhesion to surfaceReduce glareShotgun ammunitionTypewritersBiomedical engineeringHeat transfer

Ammunition, such as shotshells used in waterfowl hunting, have indicia applied to substantially all of the external surface to reduce glare normally a problem in conventional ammunition. The indicia, such as a camouflage pattern, is applied either through the use of inkjet printing directly on the shotshell surface or through the application of a heat transfer sleeve to which the indicia has been previously applied. The process of applying the camouflage pattern may be incorporated into the manufacture of the ammunition or may be operable as a standalone process used for pre-manufactured ammunition.

Owner:MORTON WILLIAM BILL +2

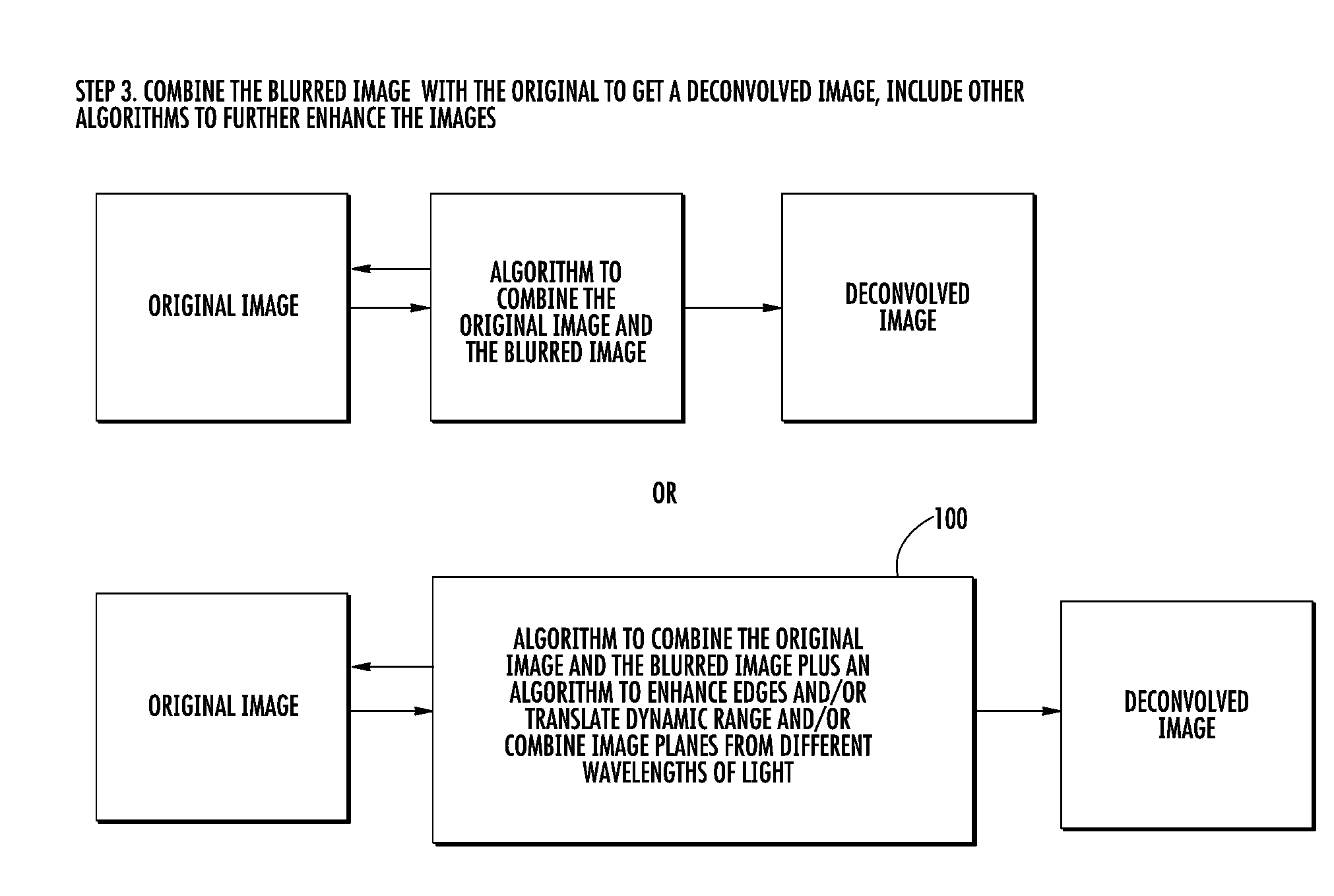

Apparatus and Method for Reducing Glare in Images

InactiveUS20090273843A1Reduce contrastReduce glareTelevision system detailsColor television detailsComputer visionComputer science

Owner:MITSUBISHI ELECTRIC RES LAB INC

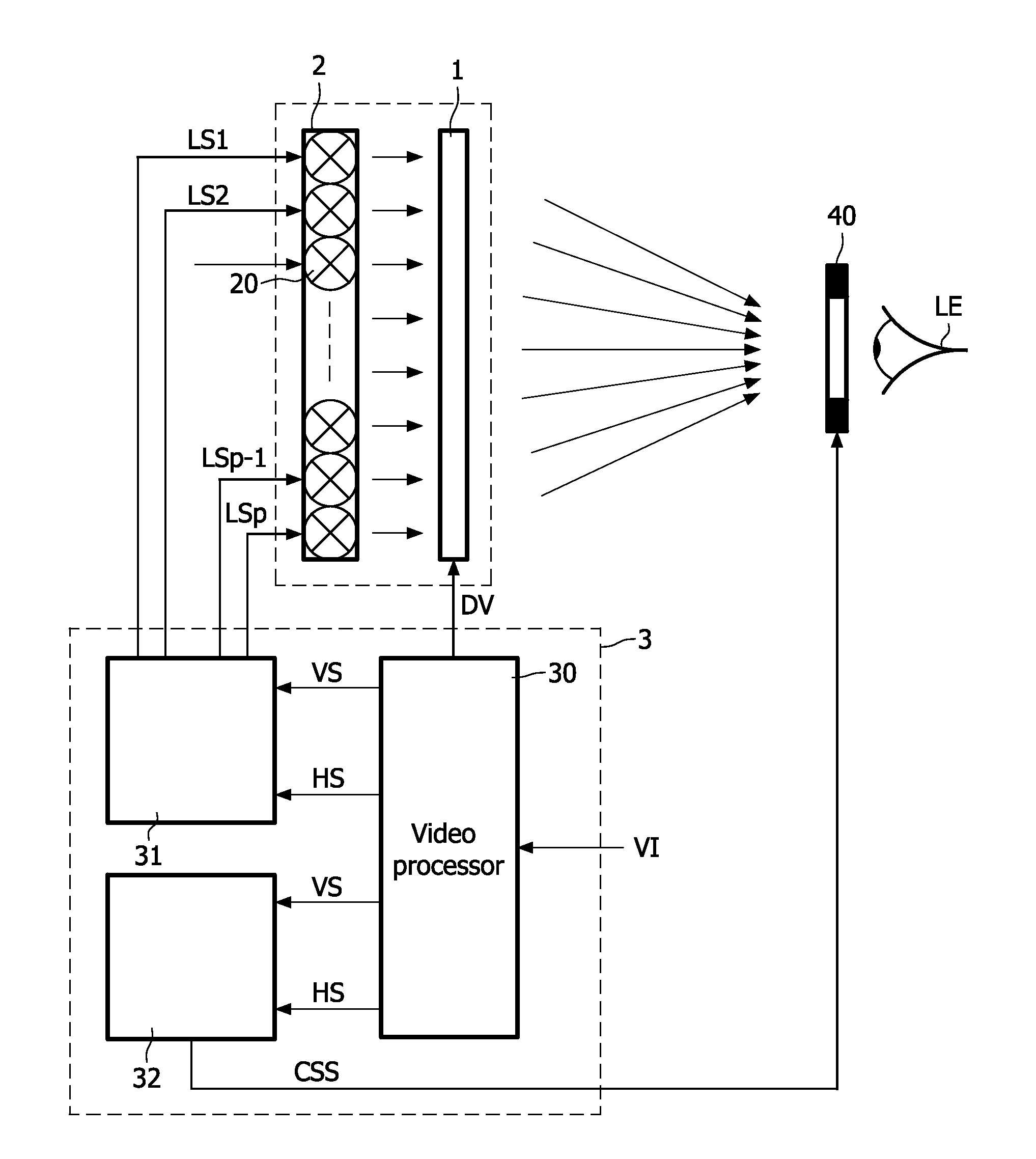

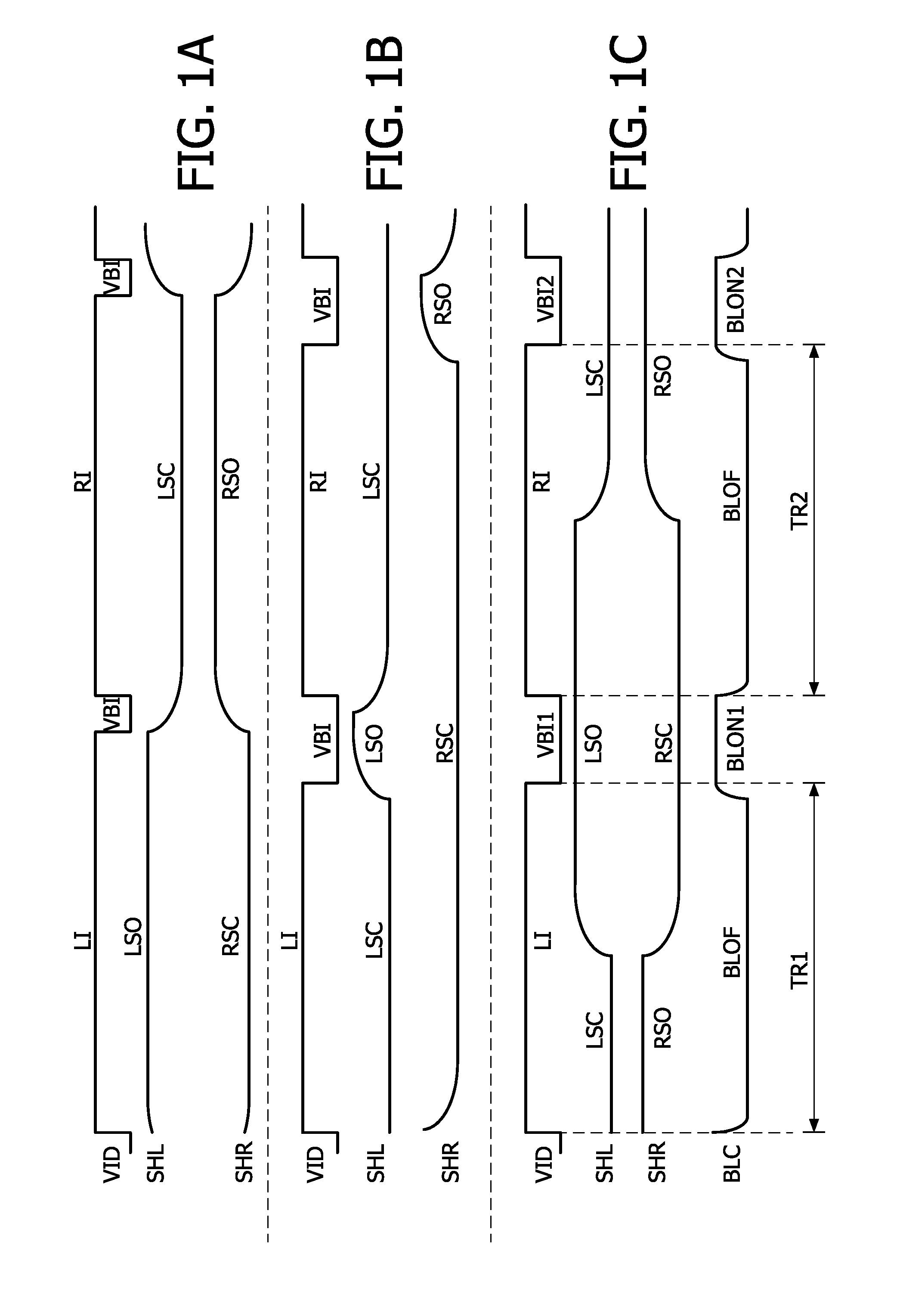

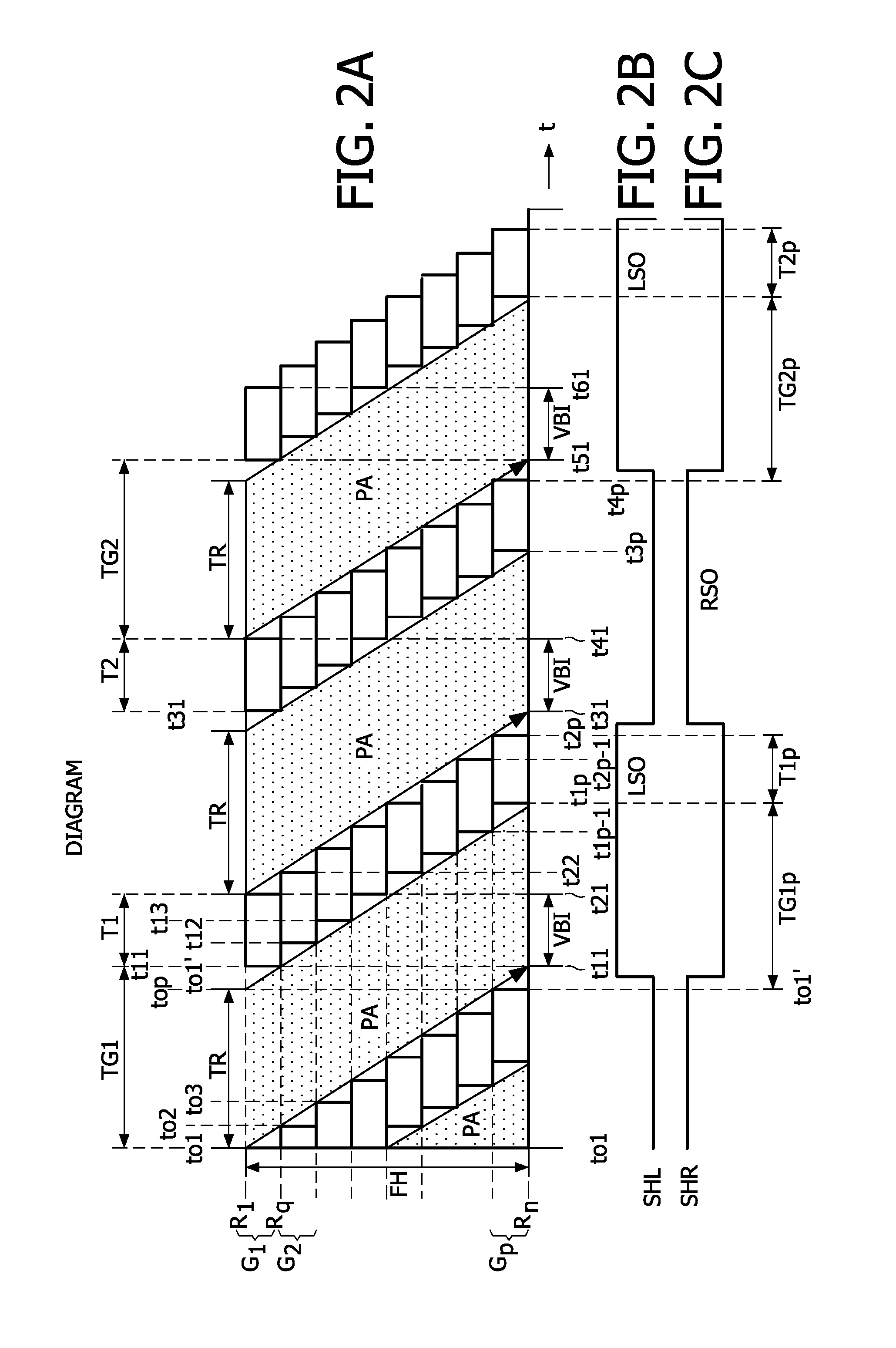

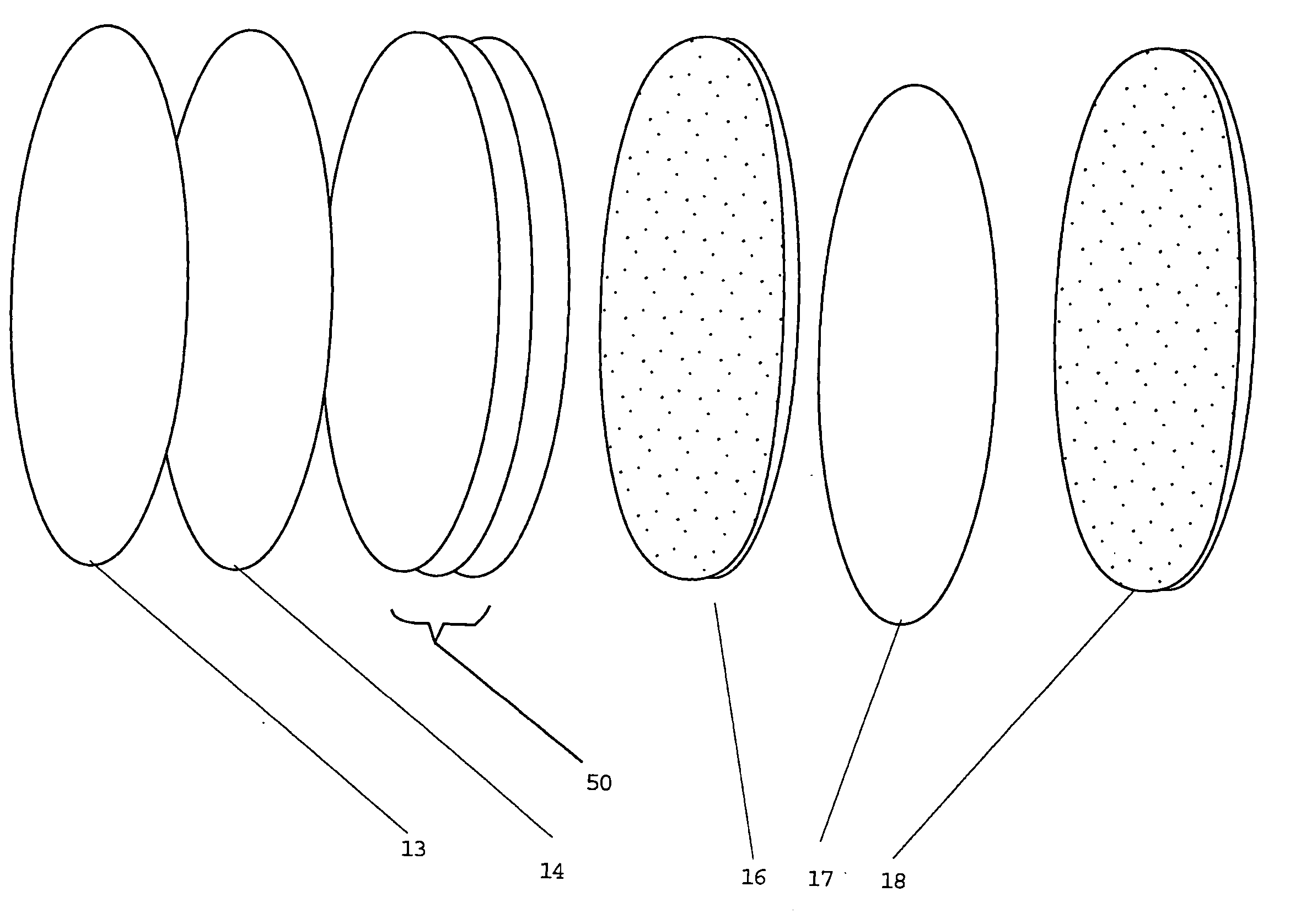

Stereocopic visualisation

InactiveUS20100289883A1Minimizing glareSlowly optical stateCathode-ray tube indicatorsColor television detailsEngineeringStereoscopic visualization

A LCD display system comprises a LC panel (1), a backlight unit (2) for illuminating the LC panel (1) or a portion thereof, and a controller (3). The controller: (i) controls the LC panel (1) to display a first image (LI) and a second image (RI) forming a stereoscopic pair, (ii) controls the backlight unit (2) to only illuminate the LC panel (1) or the portion thereof during a first period in time (BLON1; T1) after the pixels (10) of the LC panel (1) or the portion thereof have a stable optical state according to the first image (LI), and during a second period in time (BLON2; T2) after the pixels (10) of the LC panel (1) or the portion thereof have a stable optical state according to the second image (RI), and (iii) generates a control signal (CSS) for controlling a first one (40) of a pair of 3D shutter glasses (4) to be in a transmissive state for enabling viewing of the pixels (10) of the LC panel (1) or the portion thereof only during the first period in time (BLON1; T1) and a second one (41) of the pair of 3D shutter glasses (4) to be in a transmissive state for enabling viewing of the pixels (10) of the LC panel (1) or the portion thereof only during the second period in time (BLON2; T2).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

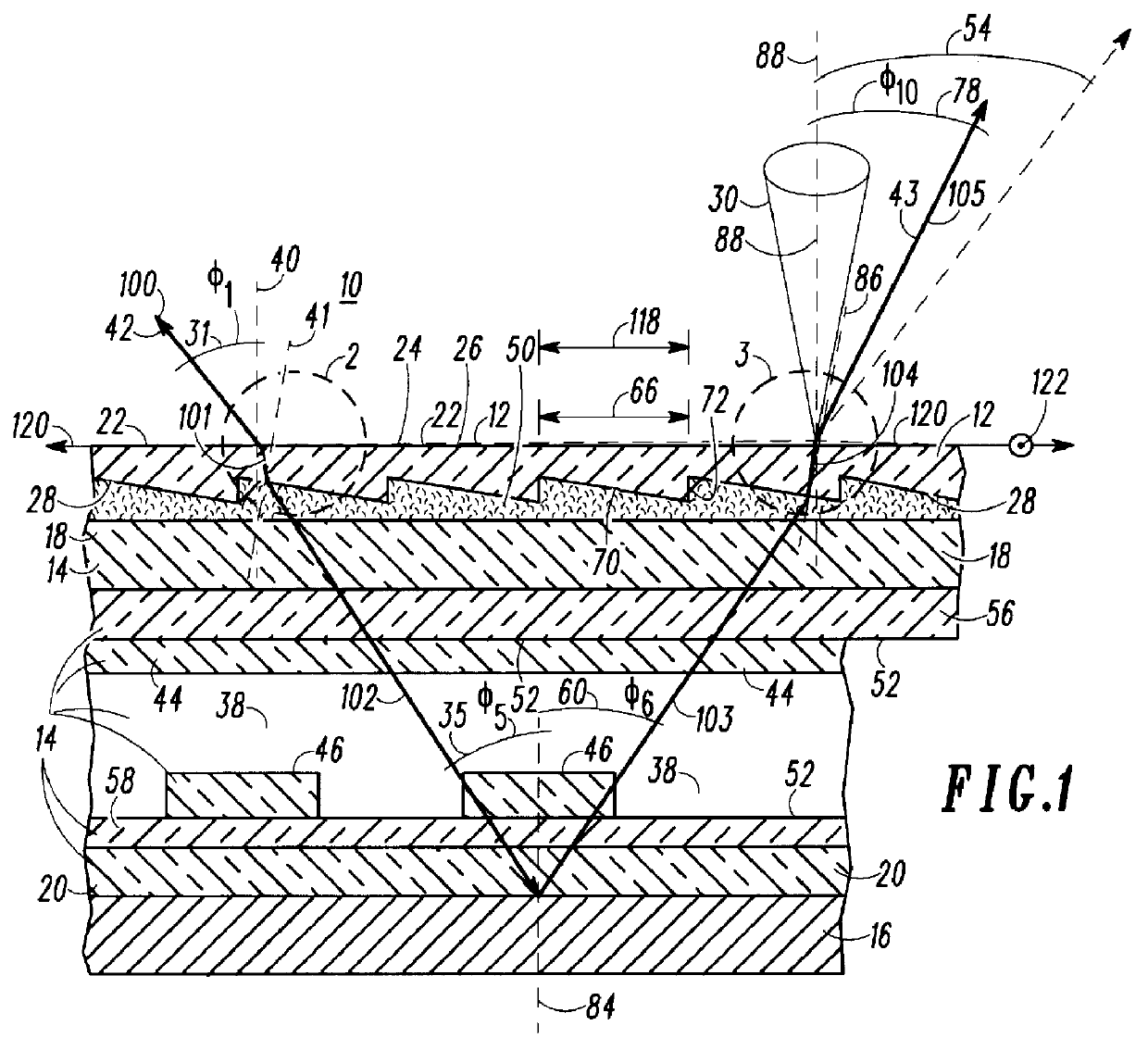

Optical display device having prismatic film for enhanced viewing

InactiveUS6166787AImprove visibilityImprove legibilityPrismsLaser detailsOptical propertyOptical interaction

The display device includes an optical cell having a cell front with at least one cell region being capable of an optically transmissive mode and an optically nontransmissive mode with reference to the cell front. The optical cell contains an optically active material responsive to an applied electrical field such that optical properties of the material are controllably changeable. A reflector may be optically coupled to the cell. A prismatic film including a prismatic surface is optically coupled to the optical cell. The prismatic surface preferably comprises a series of prisms. The prisms have first faces and second faces intersecting the first faces. The first faces are oriented to refract light obliquely intercepting the first faces and the second faces are oriented to minimize refractive, reflective, and optical interactions of the light with the second faces. The prismatic film, the cell, and the reflector optically cooperate such that light entering a display at an incident angle is emitted from the display at an exiting angle distinct from the incident angle for viewing of the display.

Owner:GOOGLE TECH HLDG LLC

Display rear passenger view on a display screen in vehicle

ActiveUS20170313248A1Reduce glareEliminate glareTelevision system detailsAntiglare equipmentIn vehicleEngineering

An automotive audio visual system includes a display screen on the vehicle, such as the central display screen on the vehicle's dashboard, and one or more rear cameras facing a rear passenger seat of the vehicle. The image or video feed from one or more rear cameras is displayed on the display screen in the vehicle, so that the front passengers can view the rear passenger area on the vehicle's display screen.

Owner:BE TOPNOTCH LLC

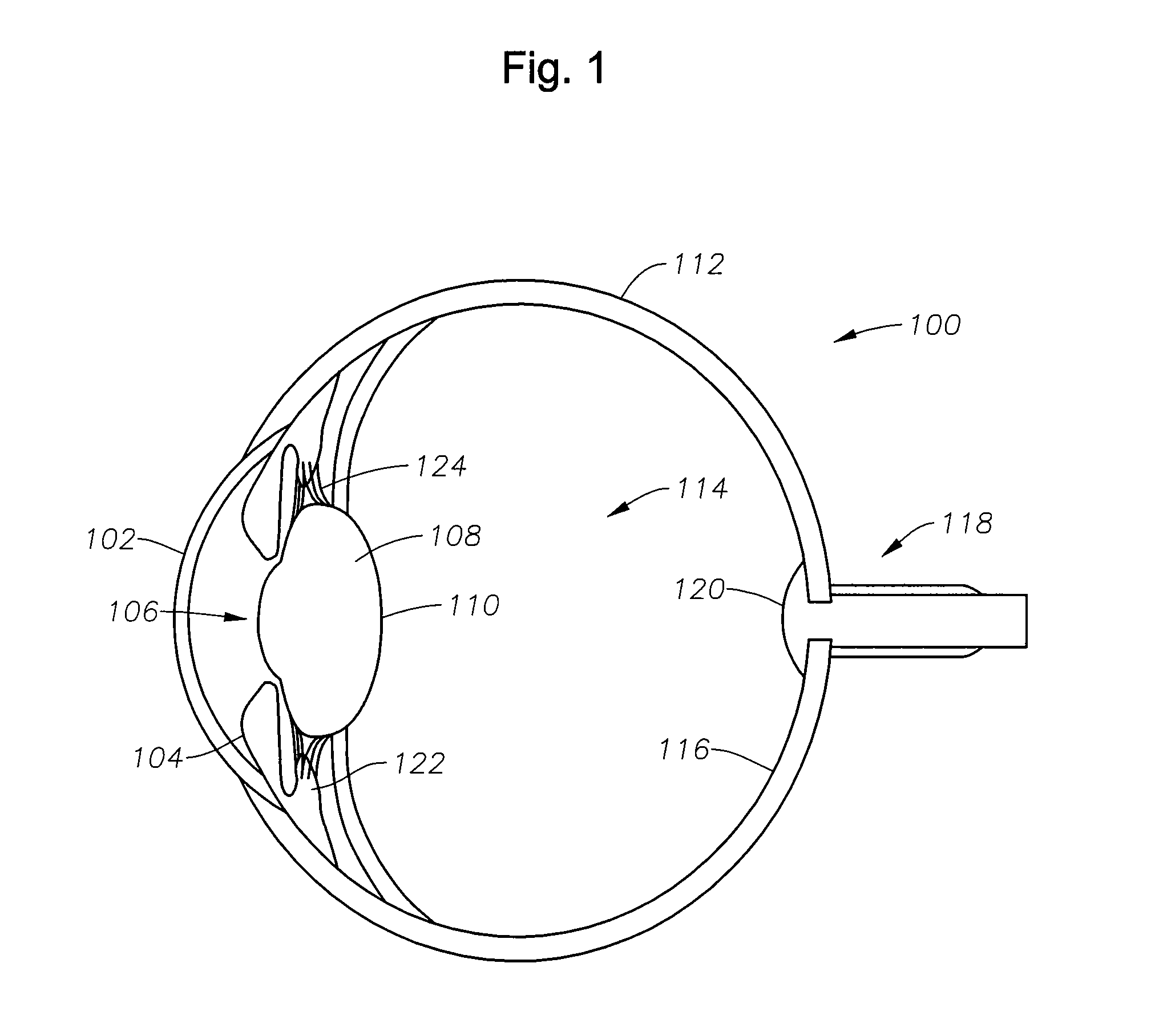

Rugate optical lens to prevent macular degeneration

InactiveUS20060092374A1Reduce decreaseWell-balanced light transmission profileOptical partsHueOptic lens

An improved lens with Rugate filter specifically designed to be worn in prescription and non-prescription glasses, contact lenses, intraocular lenses and sunglasses, and to provide protection against macular degeneration by reducing harmful visible blue light transmission and ocular photochemical damage. The lens at least includes a single lens layer with a Rugate filter deposited thereon to selectively block visible blue light. Other layers may be added including a polarizing layer, dielectric layer and / or color tint in a lens sandwich configuration, to additionally give a high degree of UVA and UVB protection, color contrast, and glare reduction. The Rugate filter is a stop band which yields an exceptional light transmission profile under all light conditions, thereby maximizing protection as well as clarity of vision. In the multi-layer embodiment, all of the lens layers provide comprehensive protection for preventing macular degeneration, cataracts and other ocular injuries, yet maintain a balanced light transmission profile for visual acuity.

Owner:HIGH PERFORMANCE OPTICS

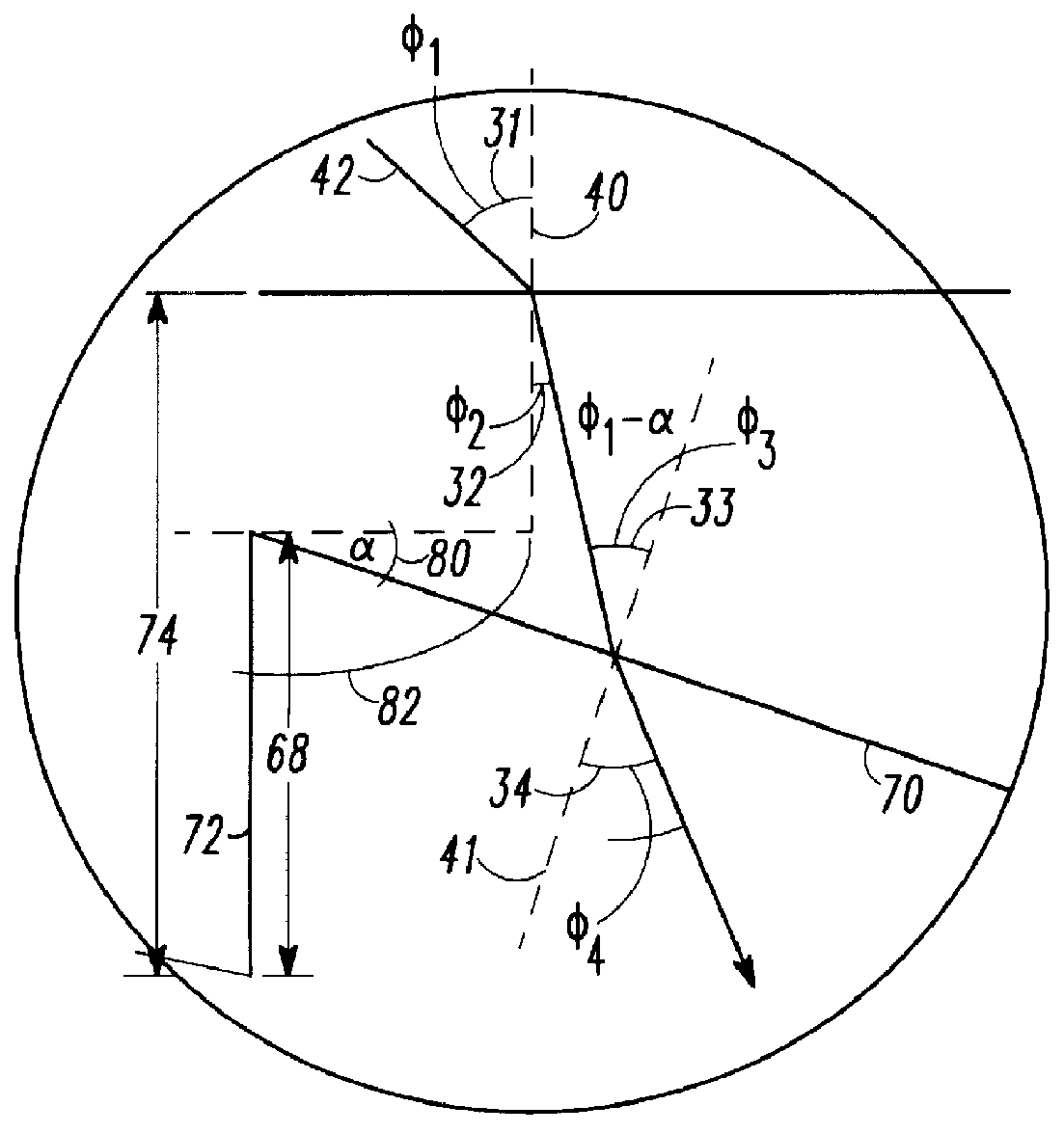

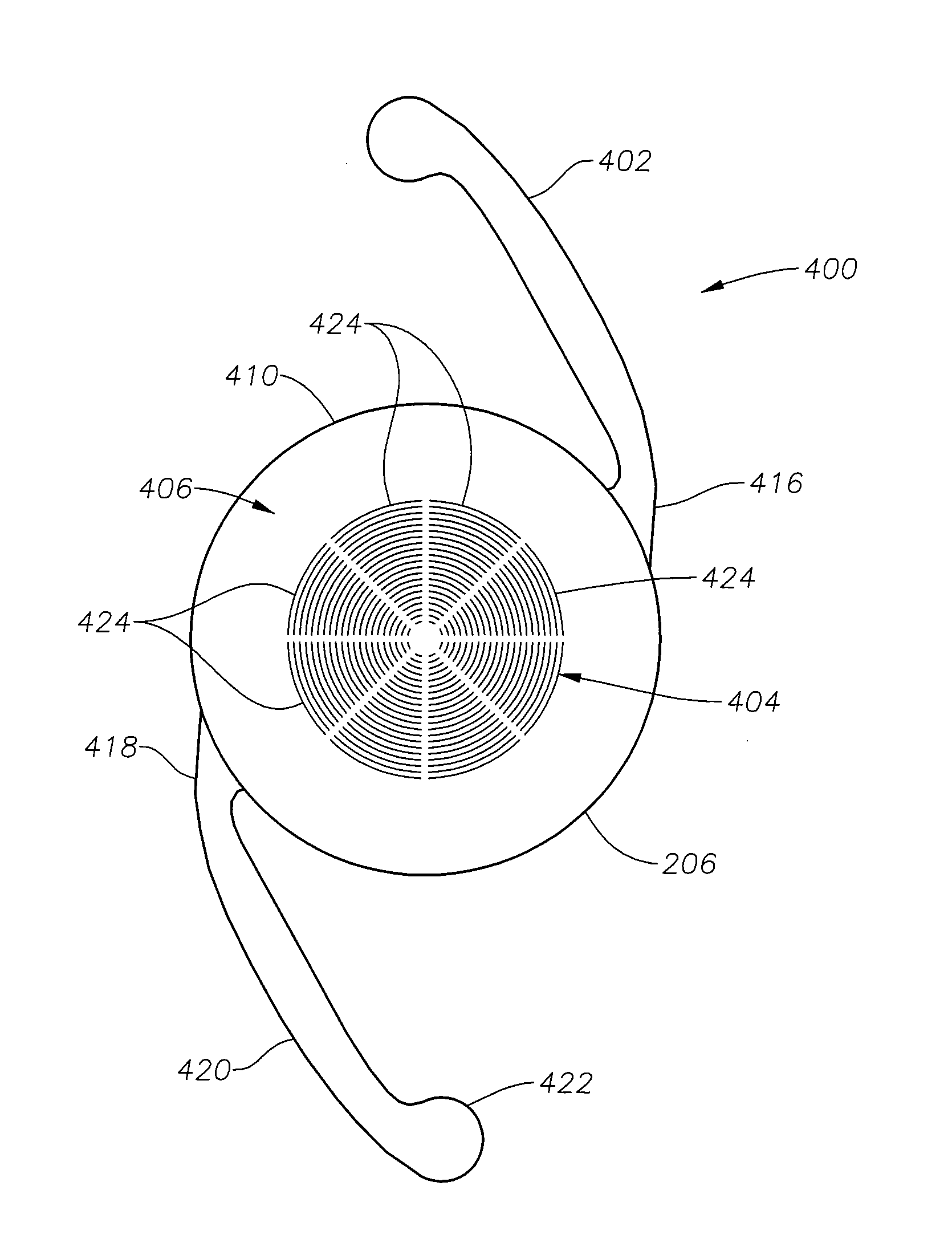

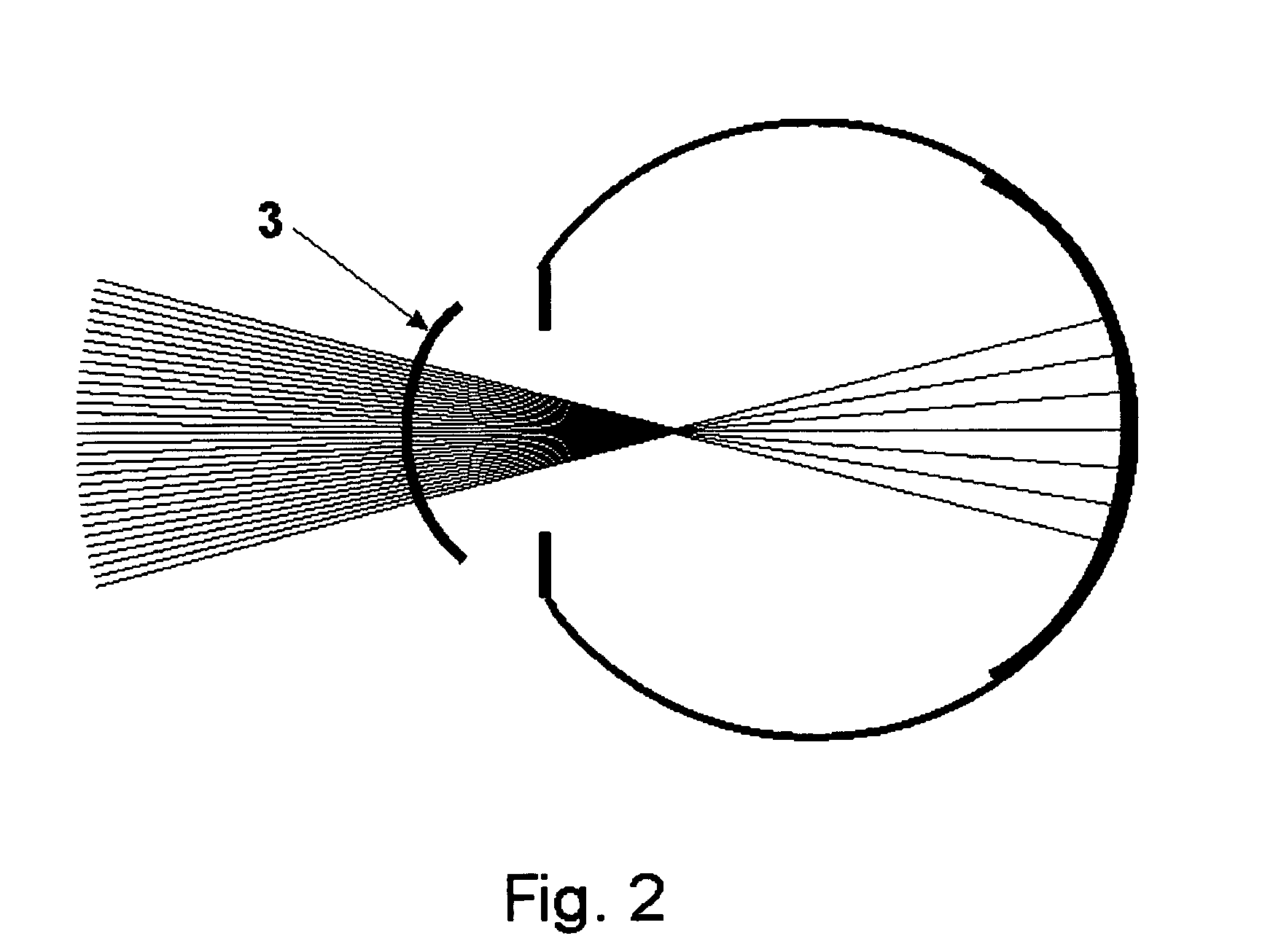

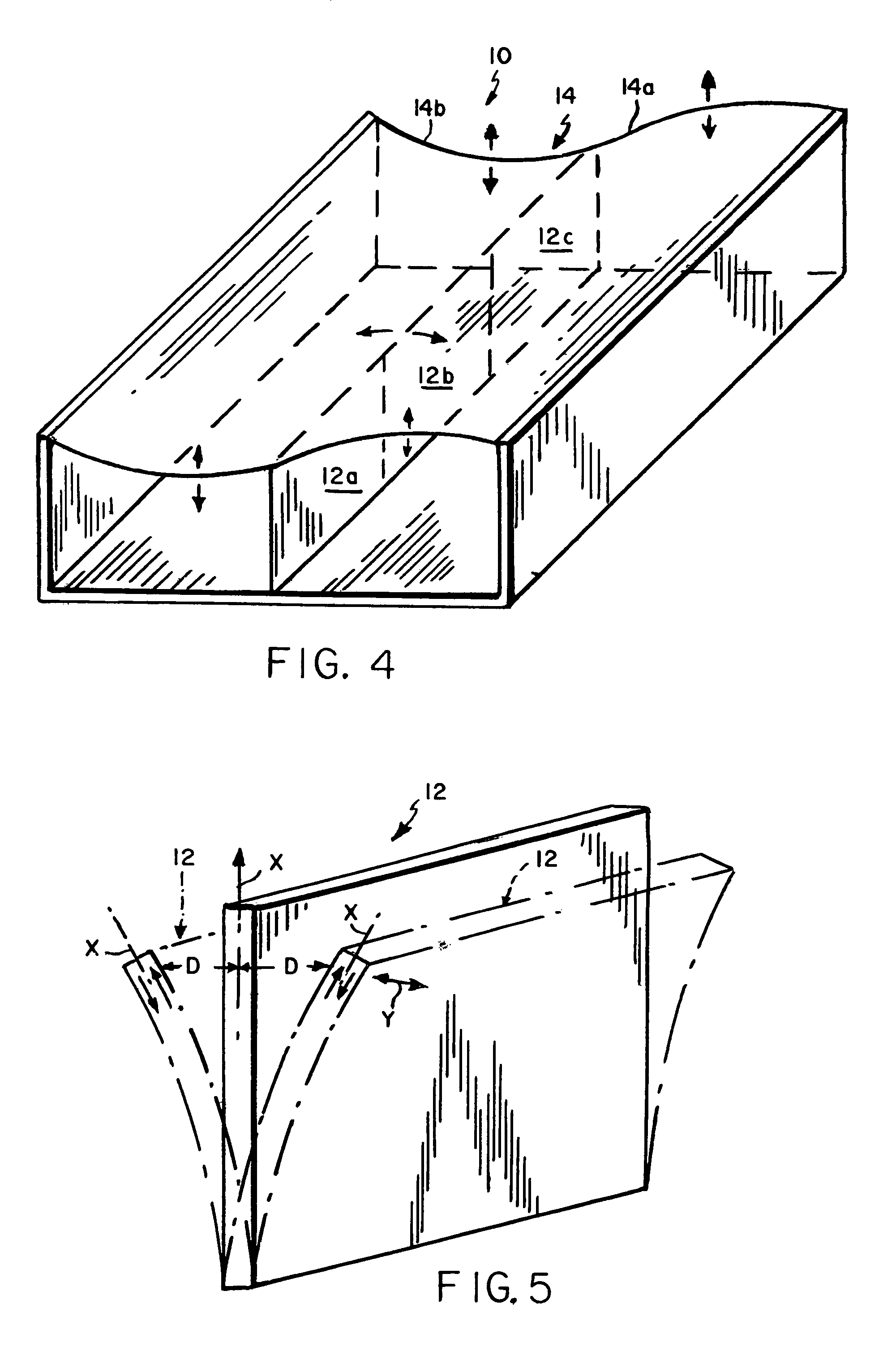

Radially segmented apodized diffractive multifocal design for ocular implant

ActiveUS20100161048A1Reduce step heightIncrease depth of focusIntraocular lensMedicineOptical energy

A radially segmented apodized diffractive multifocal IOL for ocular implant is provided. The ocular implant can comprise a radially segmented apodized diffractive multifocal intraocular lens optic and a number of haptics. The radially segmented apodized diffractive multifocal IOL may pass optical energy in both photopic and mesopic conditions. The radially segmented apodized diffractive multifocal IOL includes a number of radially segmented apodization zones, each radially segmented apodization zones having a unique focal length. The haptics mechanically couple to the apodized diffractive multifocal IOL optic in order to position and secure the apodized diffractive multifocal IOL within the eye. The radially segmented apodized diffractive multifocal IOL may include both a diffractive region and a refractive region.

Owner:ALCON INC

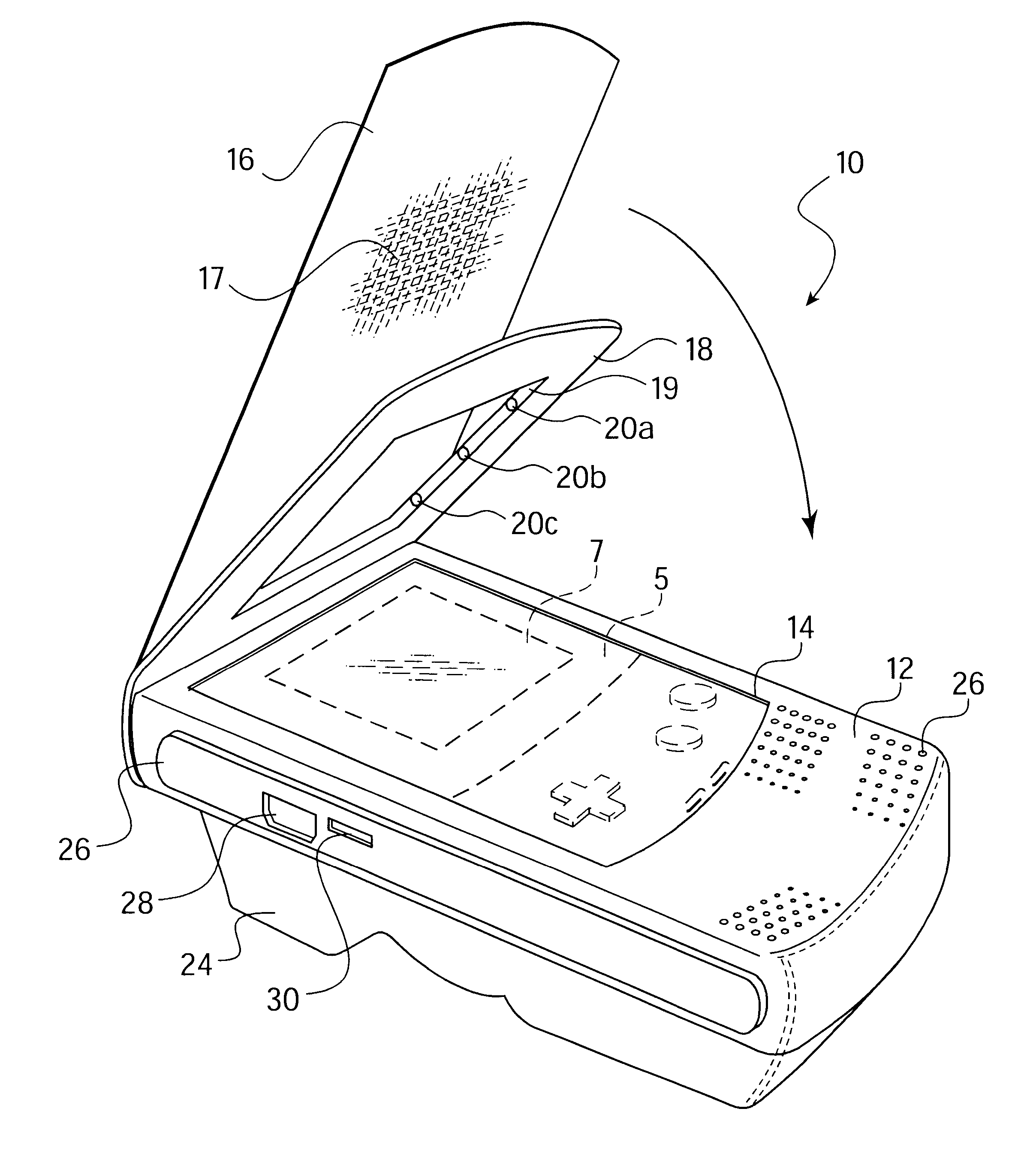

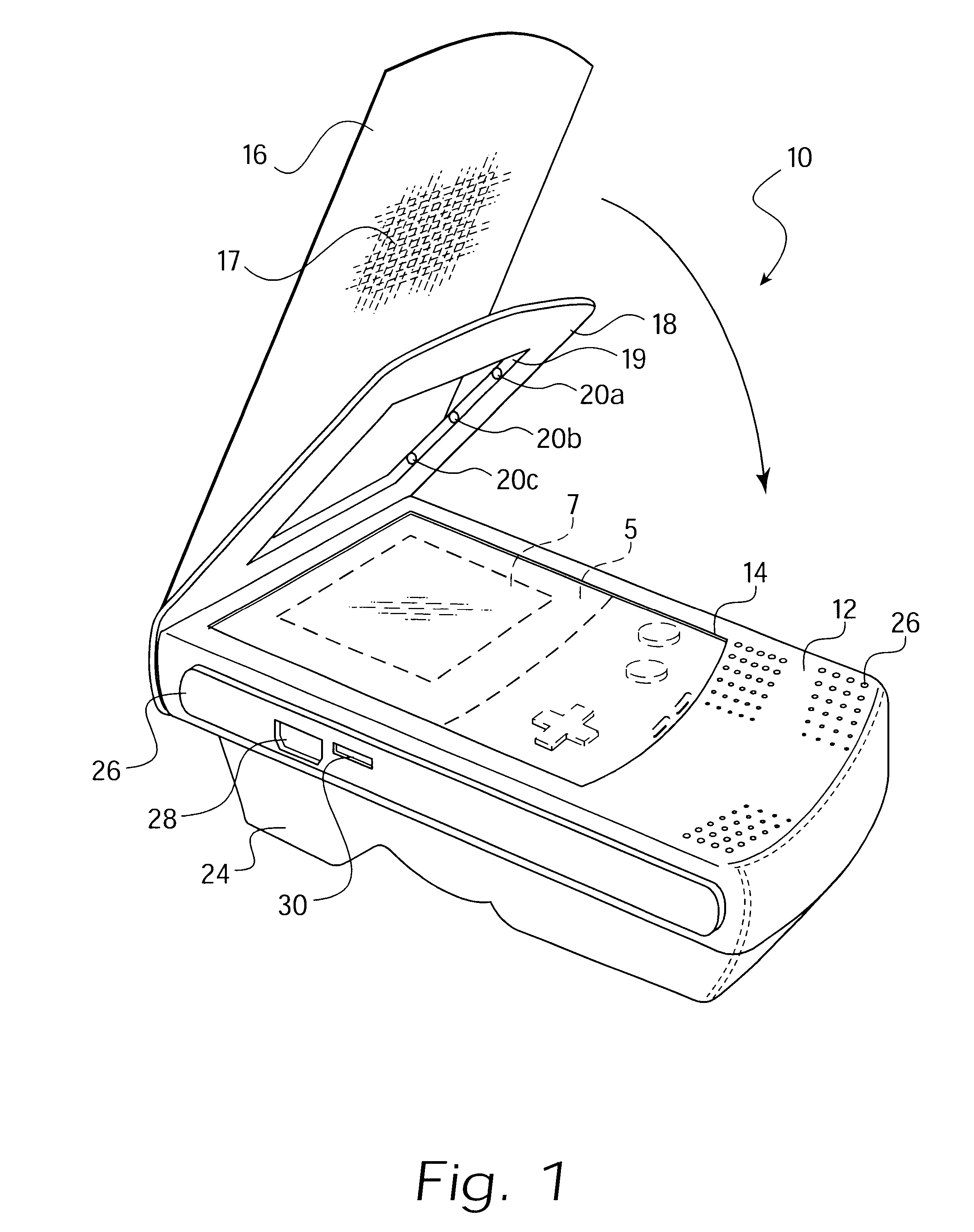

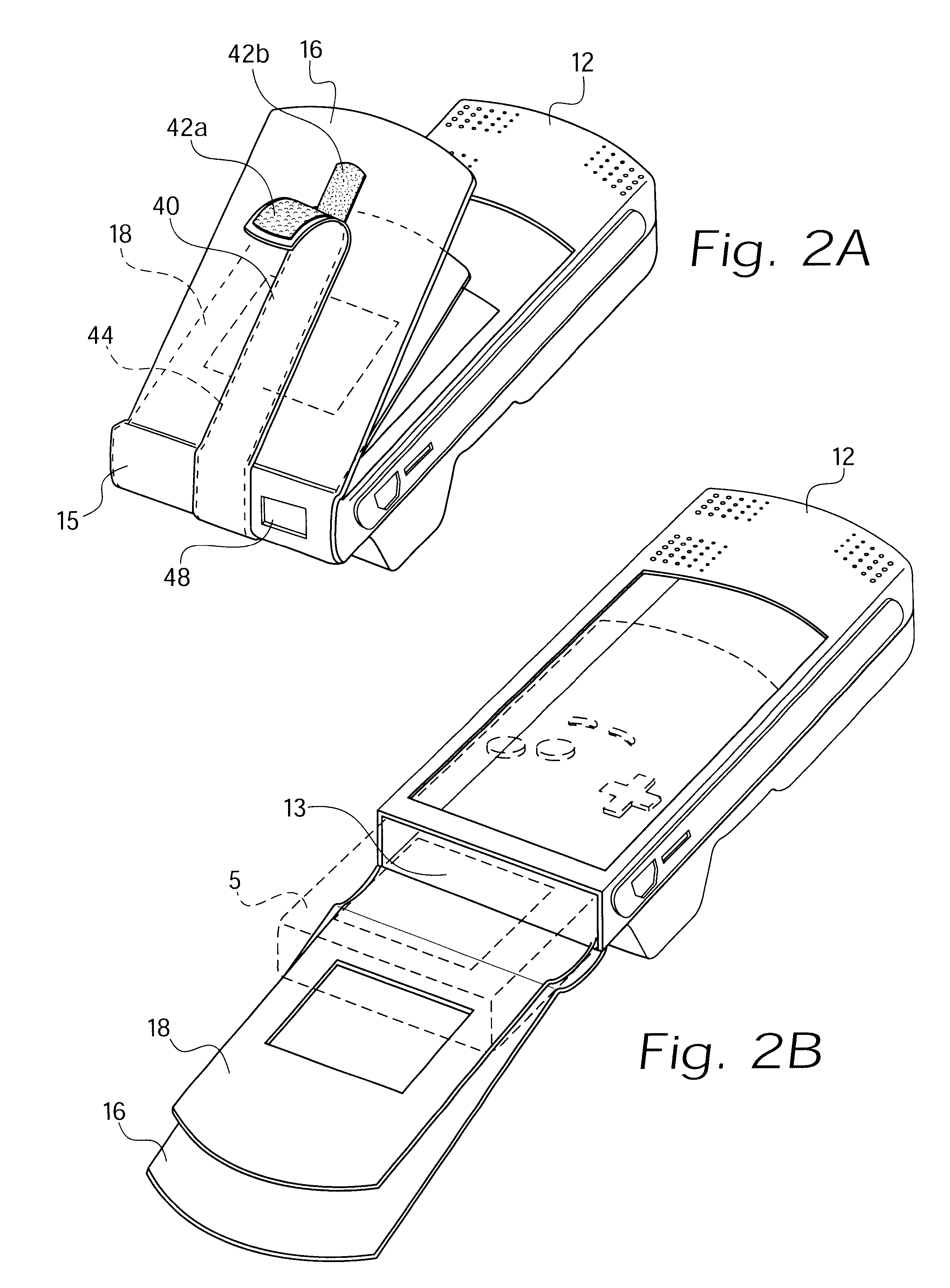

Hand held video game case with universal power pack

InactiveUS6347796B1Safe storageReduce glareOther accessoriesContainer/bottle contructionHand heldEngineering

A case and universal power pack for a hand held video game device includes a power pack with integrated plug engaging the external power supply jack on the hand held game device, and thereby provides power to the game device. A cover flap may be selectively adjusted by the user to provide optimum playing conditions and includes a glare reducing surface to further aid in providing the optimum playing environment. The case includes grip strips on opposing sides thereof, and includes access points for accessing the various external controls and jacks of the game device. The power pack is accessible from inside the case when the game device is removed therefrom.

Owner:ARISTA ENTERPRISES

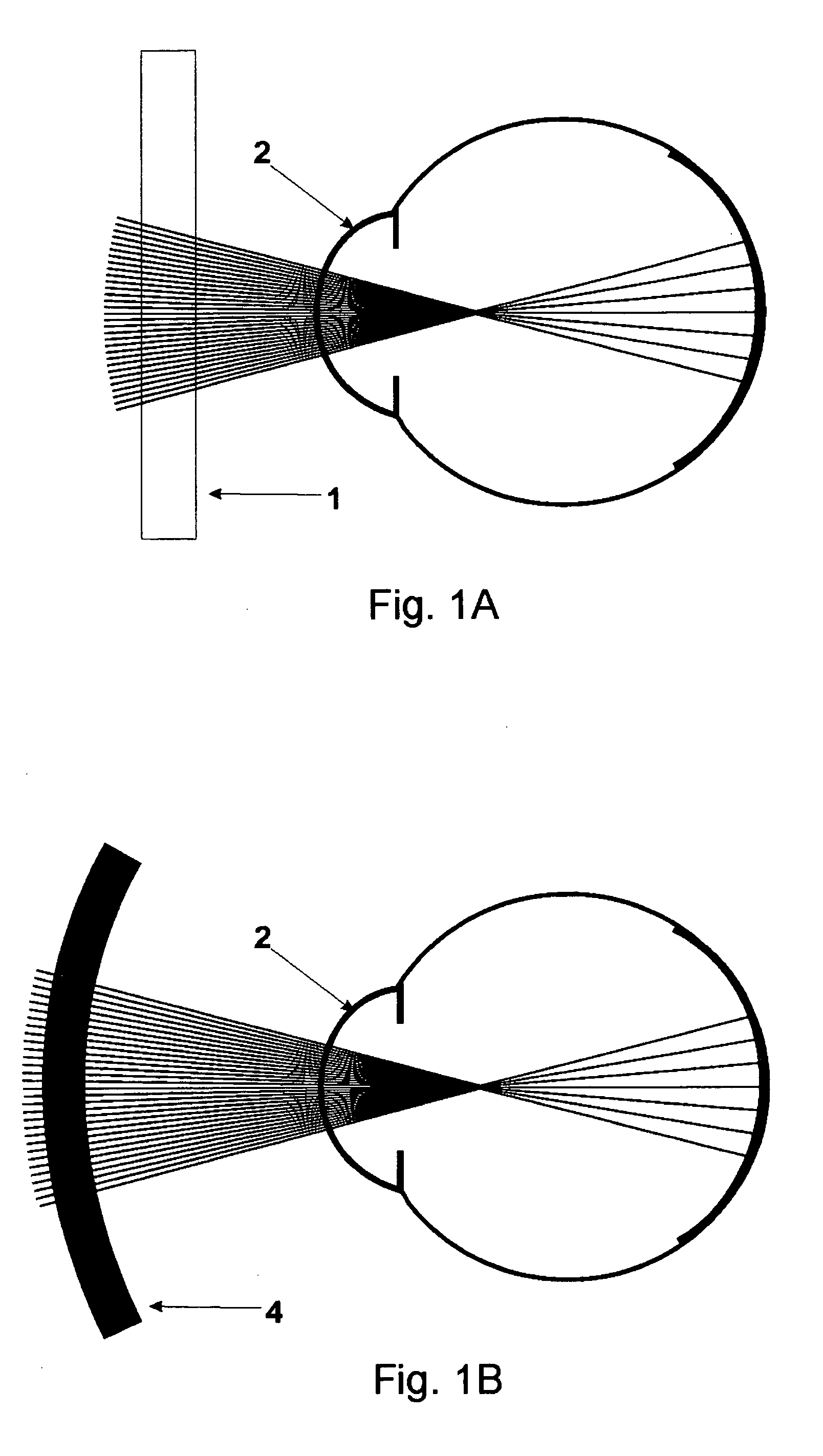

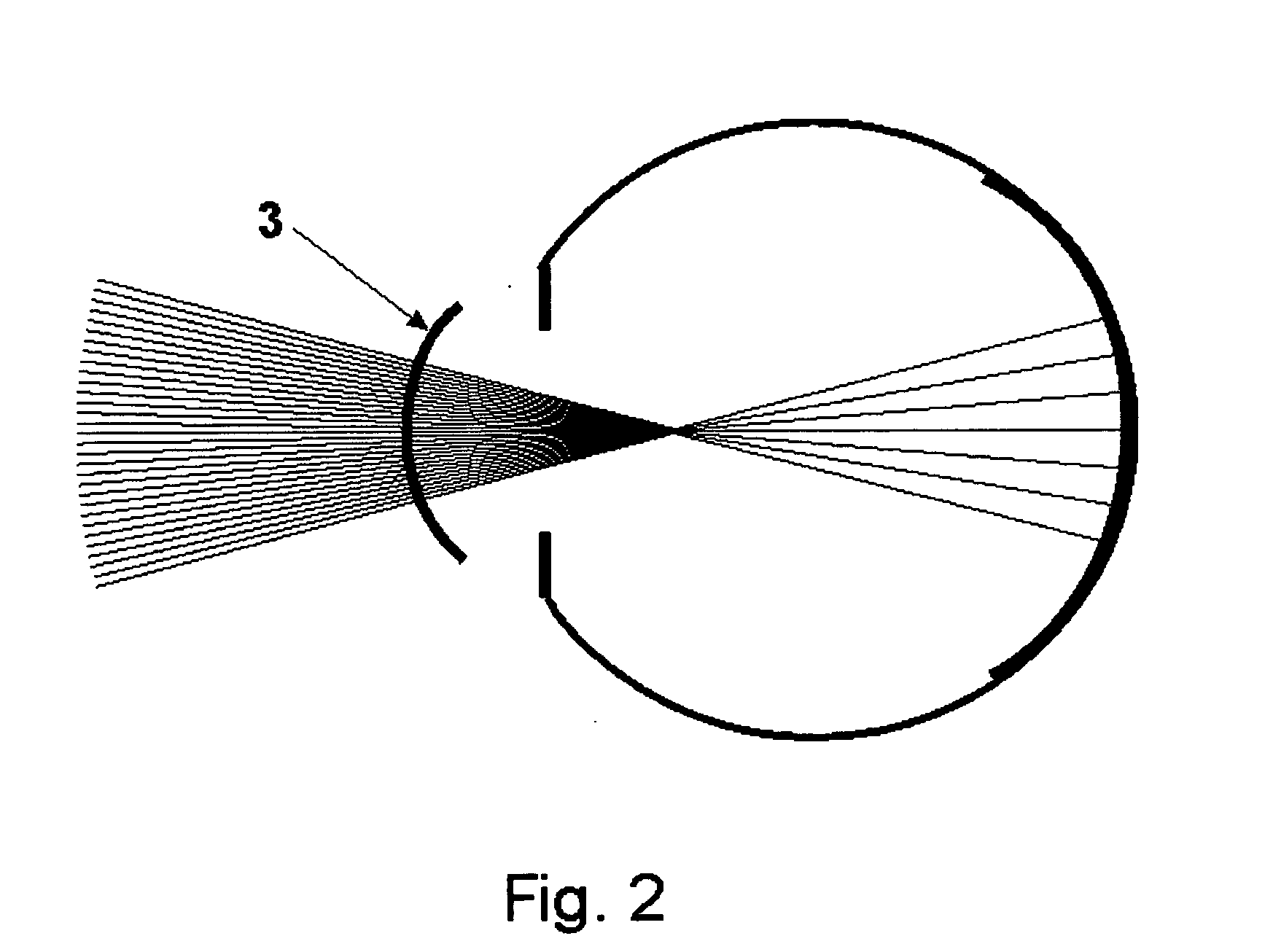

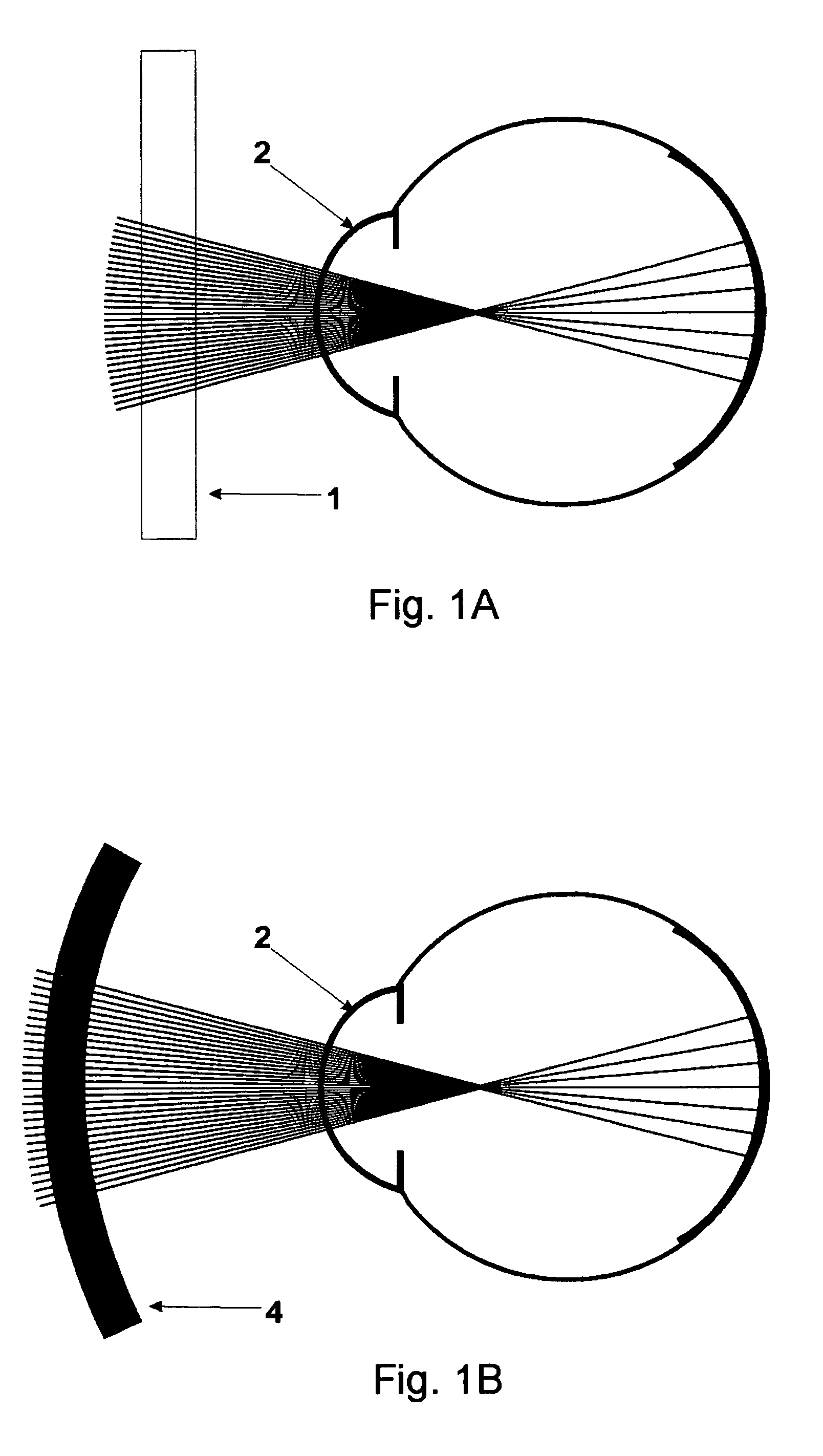

Specially coherent optics

ActiveUS20060244907A1Improve accuracyLow costCharacter and pattern recognitionOptical partsComputer graphics (images)Depth of field

A refinement in optics providing images with improved sharpness, better control of depth of field, vision-improvement applications, and 3-D capture and display.

Owner:SIMMONS JOHN CASTLE

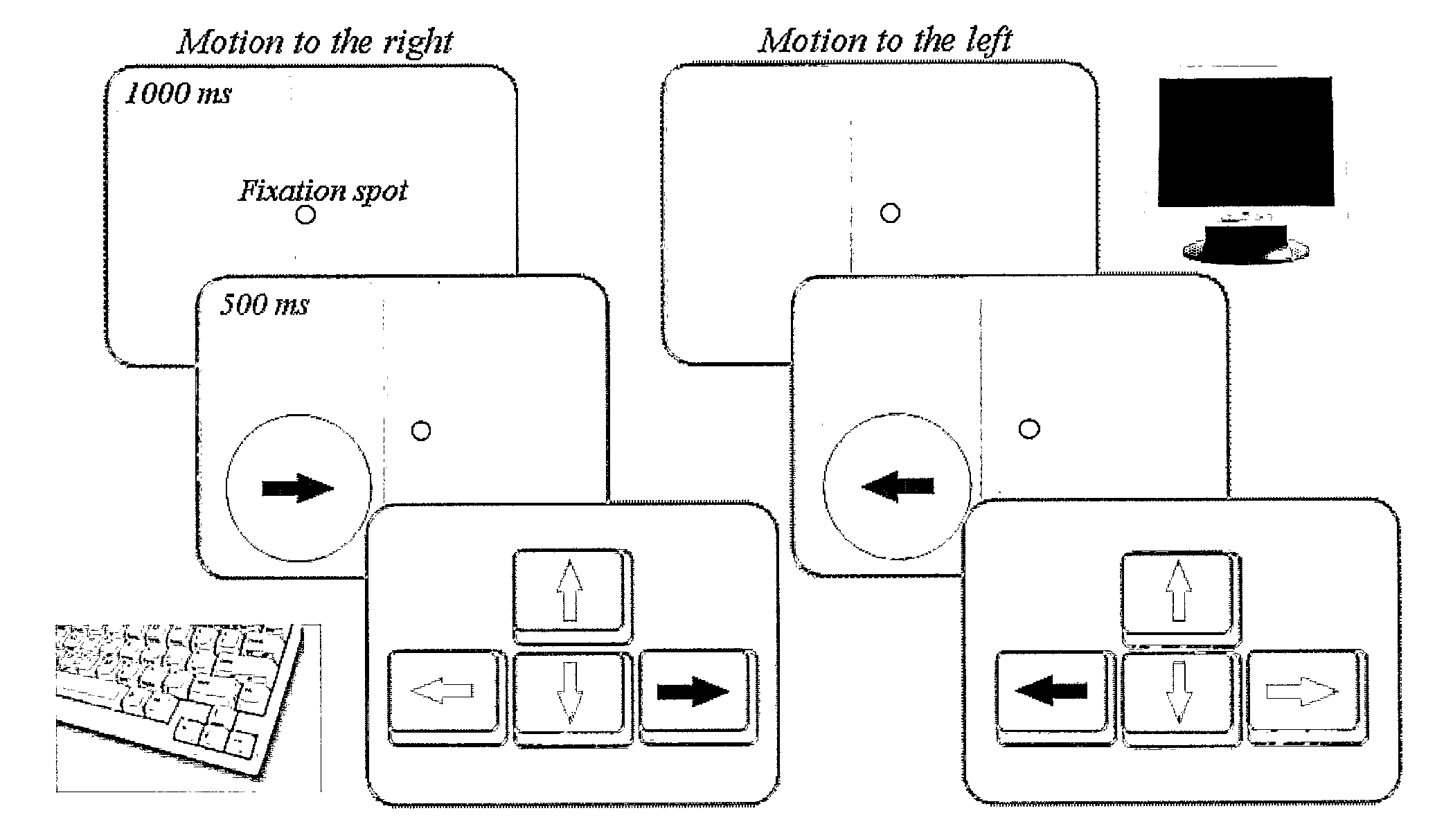

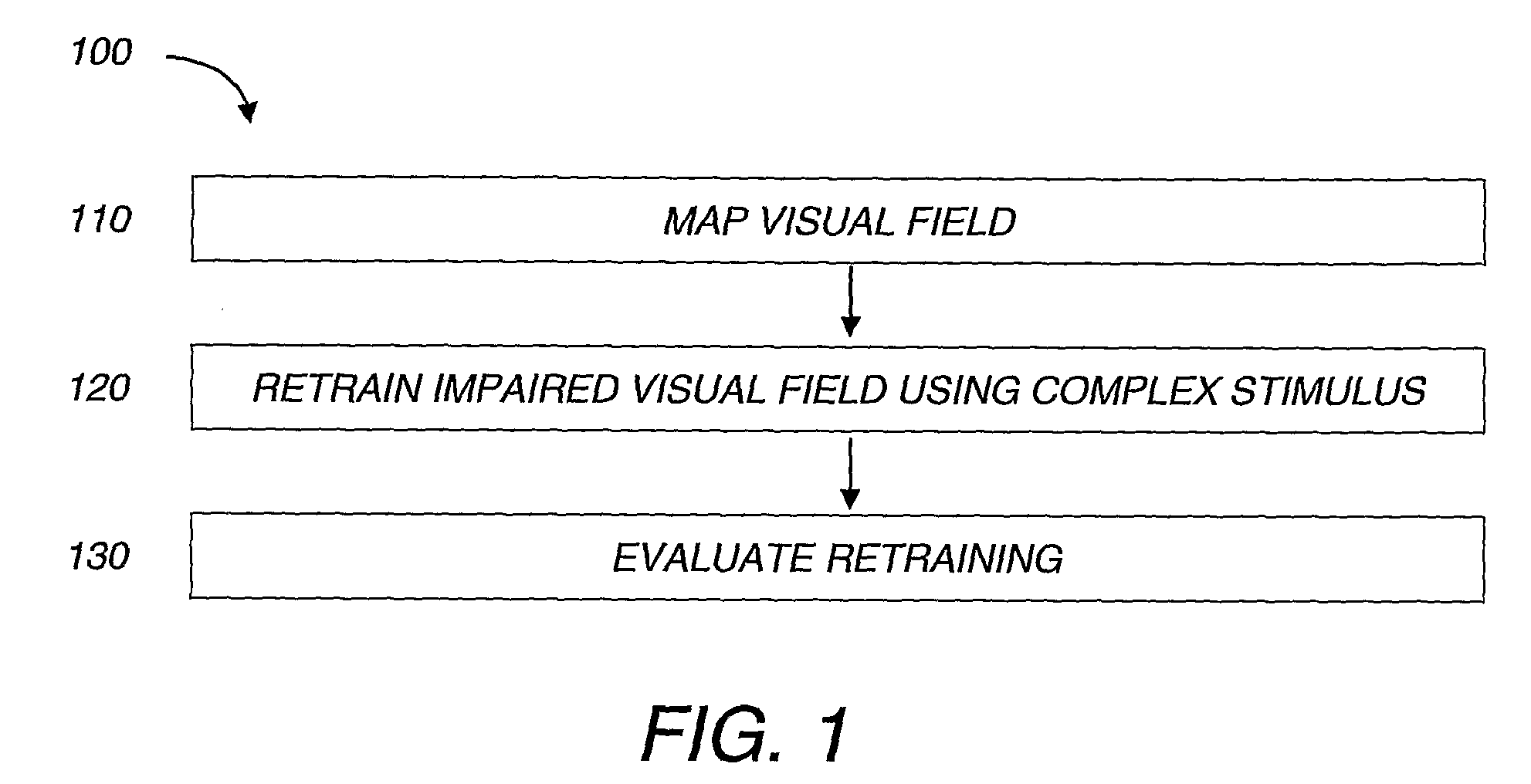

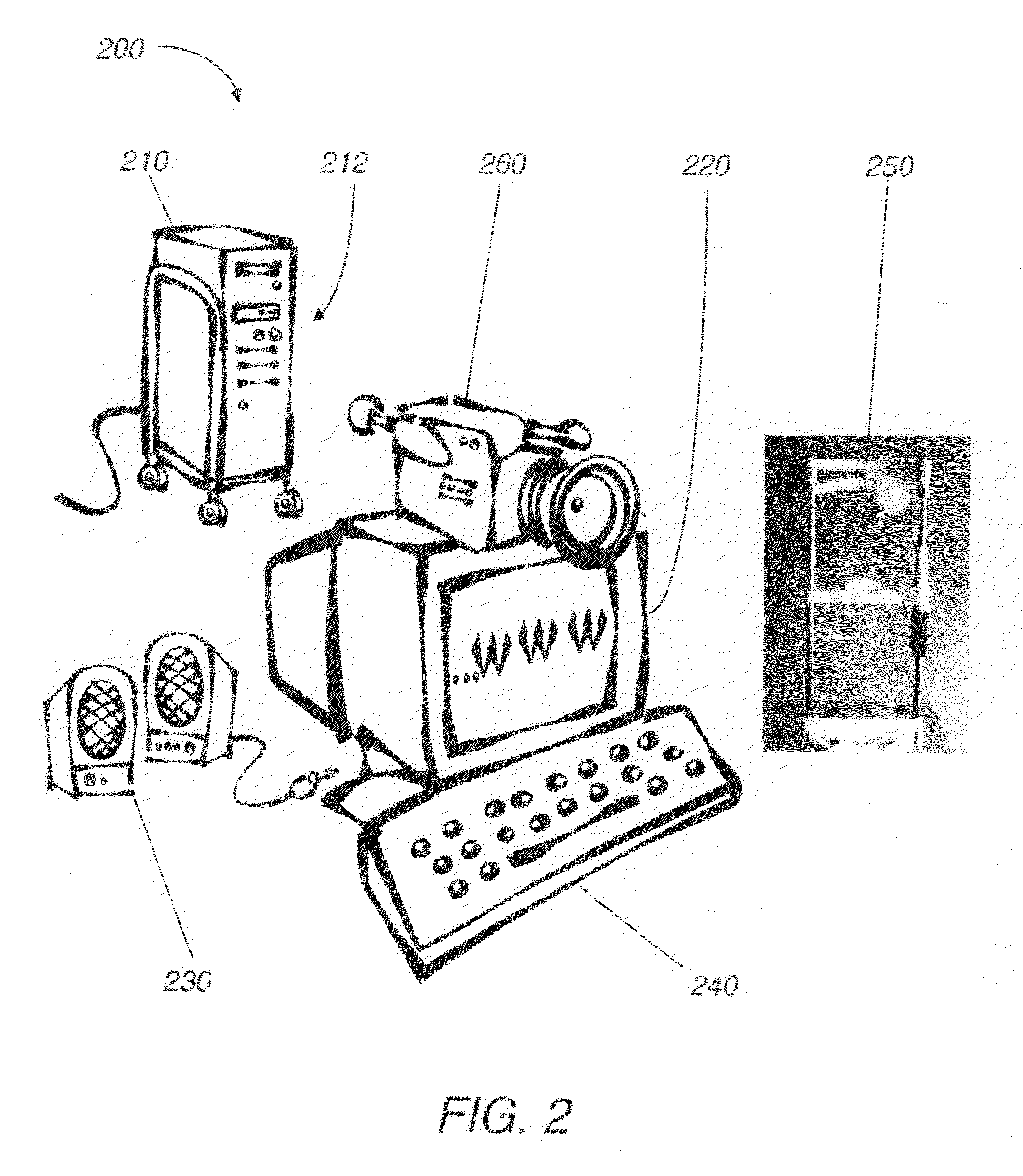

Systems and methods For Improving Visual Discrimination

ActiveUS20080278682A1Reduce glareEasy to testEye exercisersEye diagnosticsPattern perceptionVisual discrimination

A system and method for retraining the visual system of a subject with damage to the striate and / or extrastriate visual cortex includes displaying a visual stimulus within a first location of an impaired visual field of the subject; and detecting the subject's perception of an attribute of the visual stimulus. The system and method are believed to effectively recruit undamaged higher level structures in the visual system to assume the functions of the damaged structures.

Owner:UNIVERSITY OF ROCHESTER +1

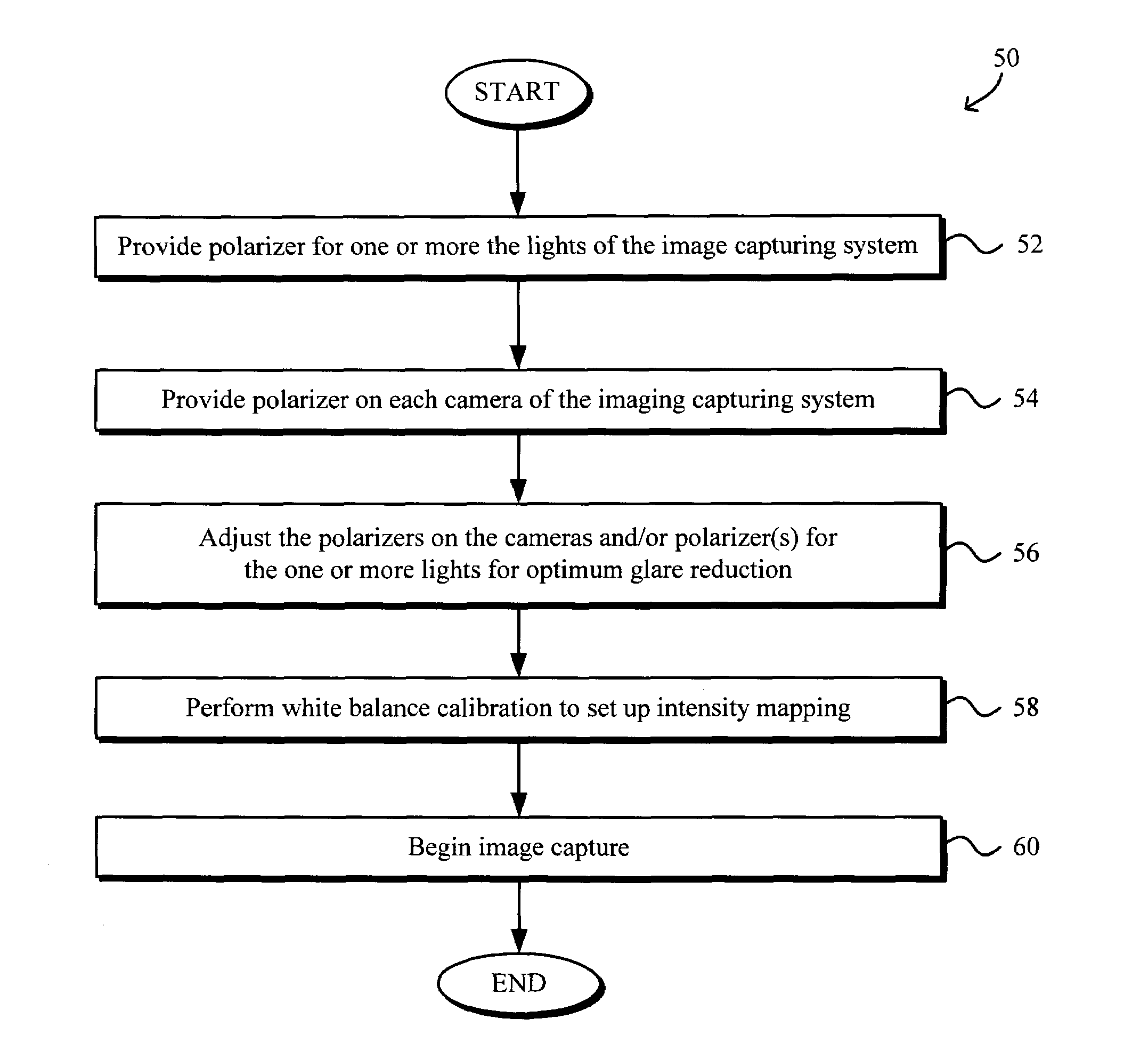

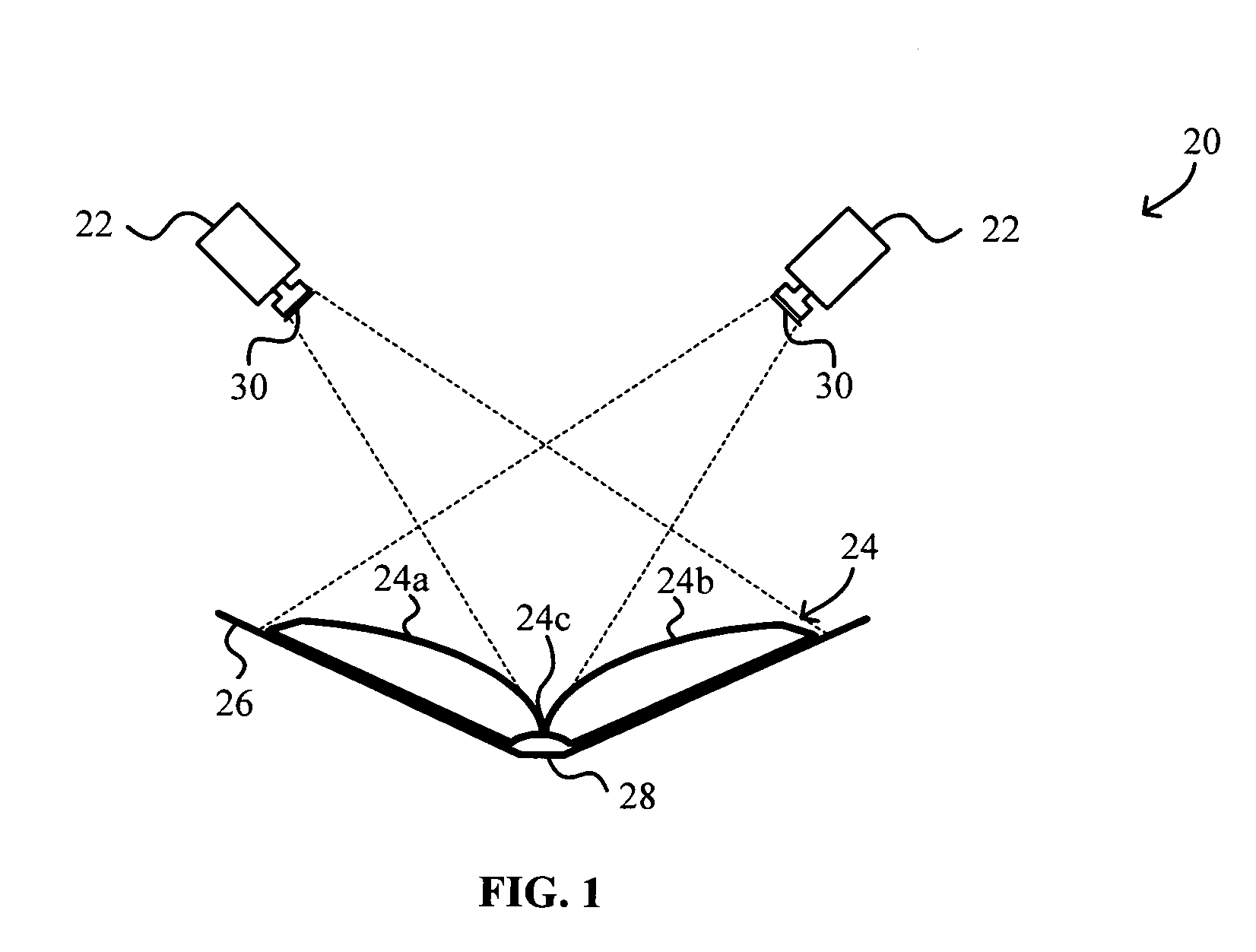

Systems and methods for glare removal using polarized filtering in document scanning

InactiveUS7561312B1Facilitate blocking light reflectionEnhance light reflectionTelevision system detailsColor television detailsComputer graphics (images)Light reflection

Systems and methods using polarized filtering for glare removal to improve the process of scanning documents, particularly bound documents with glossy content, are disclosed. The system may generally include a lighting source for illuminating a document, a lighting source polarizer attached to the lighting source to polarize light therefrom, a camera for capturing images of the document, and a camera polarizer attached to the camera. The camera polarizer and the lighting source polarizer may be positioned relative to each other so as to facilitate blocking light reflections causing glare off of the document resulting from the lighting source and arriving at the camera. The system may include multiple lighting sources, some or all of which may have a lighting source polarizer attached thereto.

Owner:GOOGLE LLC

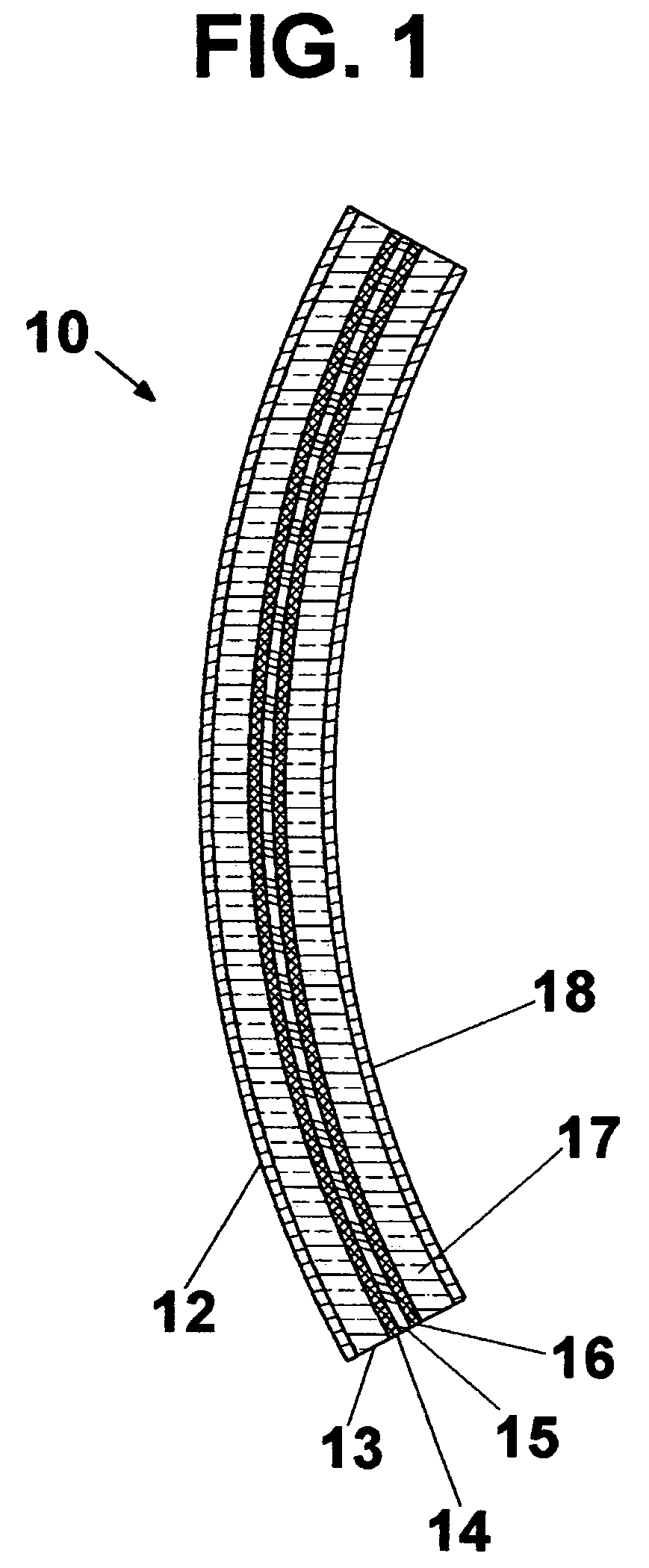

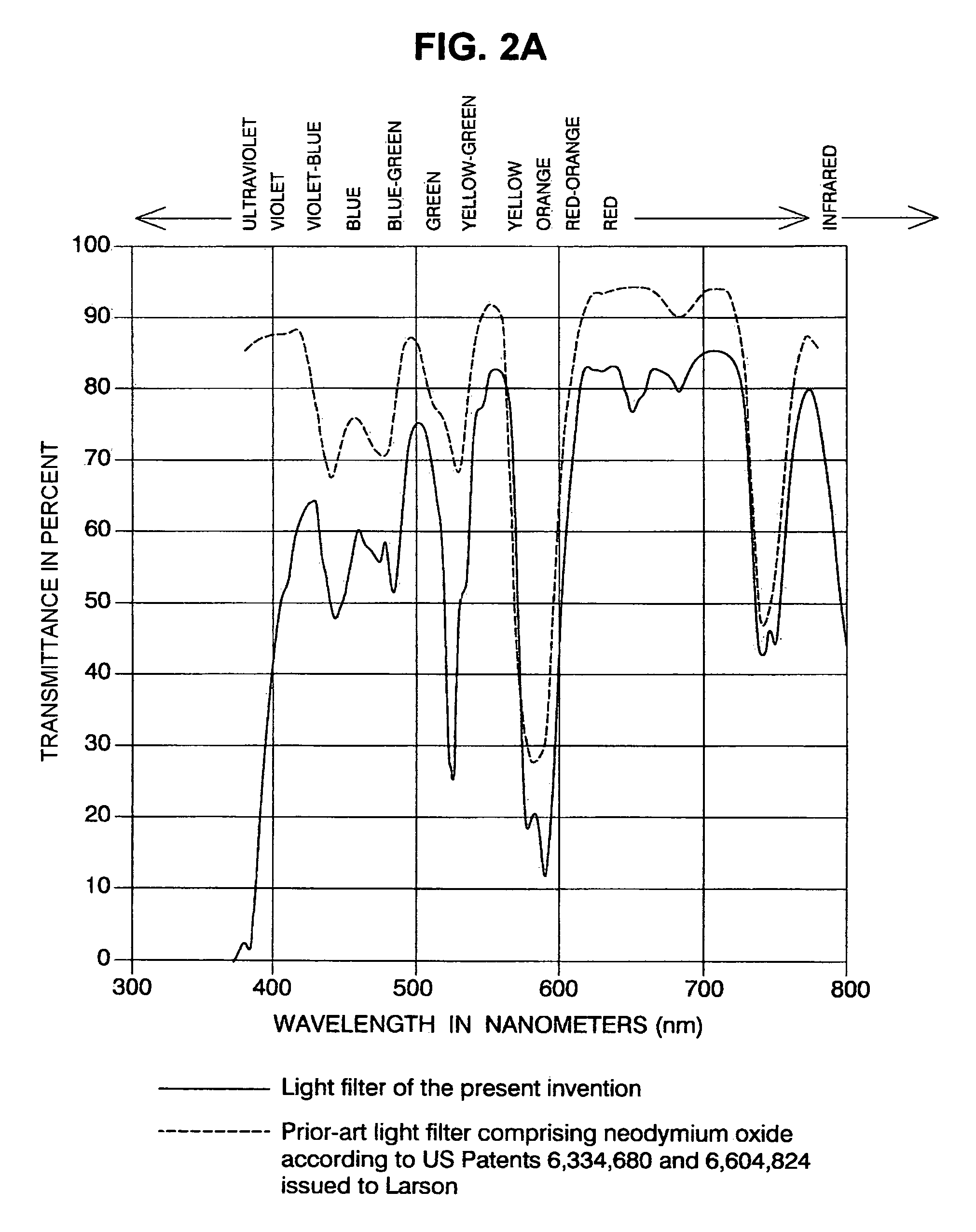

Polarized contrast enhancing sunglass lens

InactiveUS7597441B1Promotes accurate color perceptionHigh light transmittanceSpectales/gogglesOptical partsUv spectrumUltraviolet

The invention is a polarized sunglass lens that utilizes a multiband contrast enhancer comprised of three rare-earth oxides to provide relatively high peak transmittance in portions of the red and green spectrum, relatively lower transmittance for the blue spectrum, and very low transmittance for the UV spectrum. The lens provides enhanced perception of colors, heightened contrast, and improved visual acuity. The inclusion of vanadium pentoxide in the lens provides attenuation of the UV spectrum, thus protecting the user's eyes and the internal layers and colorants from UV-induced damage. The front lens element can be either the multiband contrast enhancer or a photochromic lens element.

Owner:FARWIG MICHAEL J

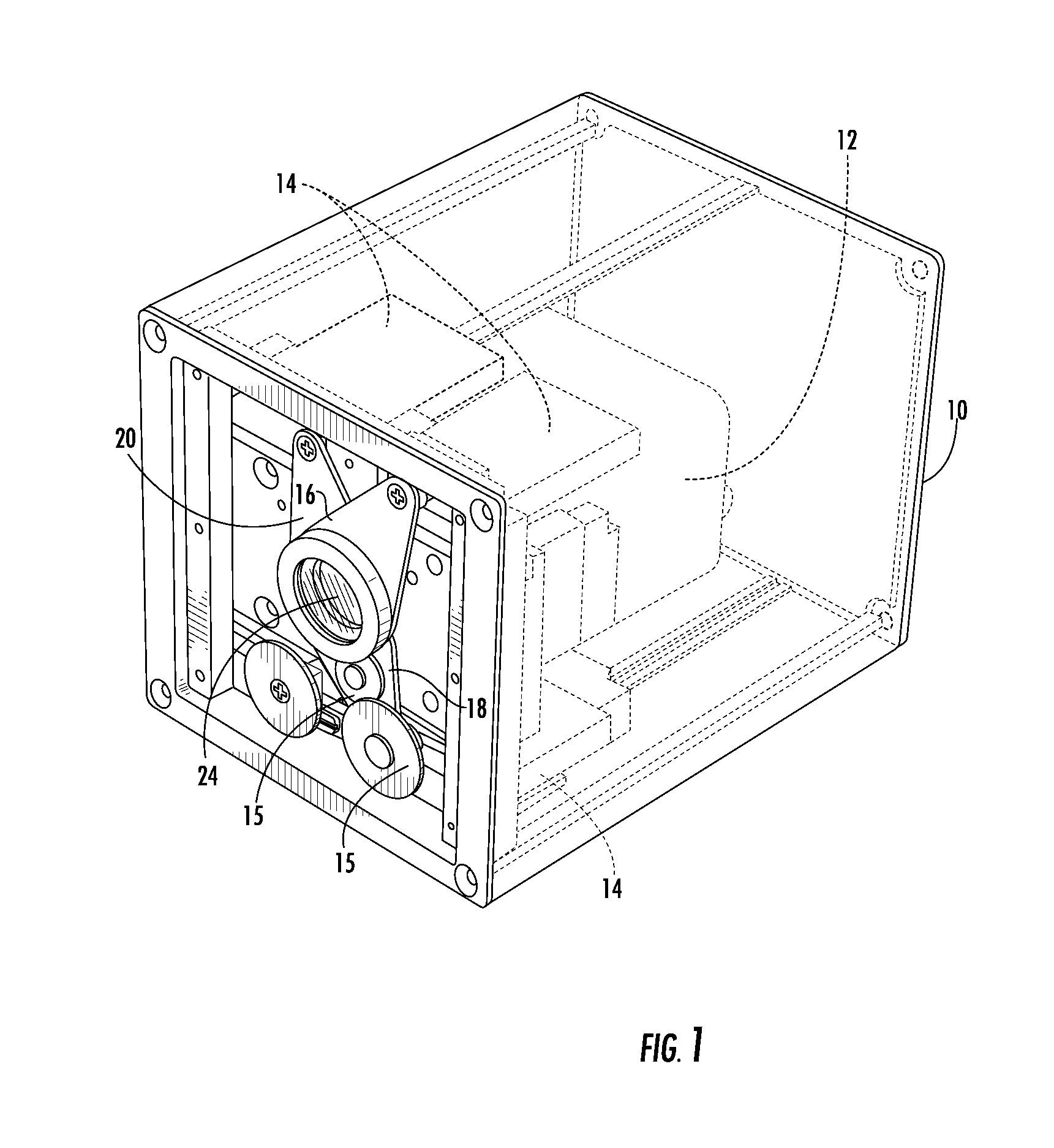

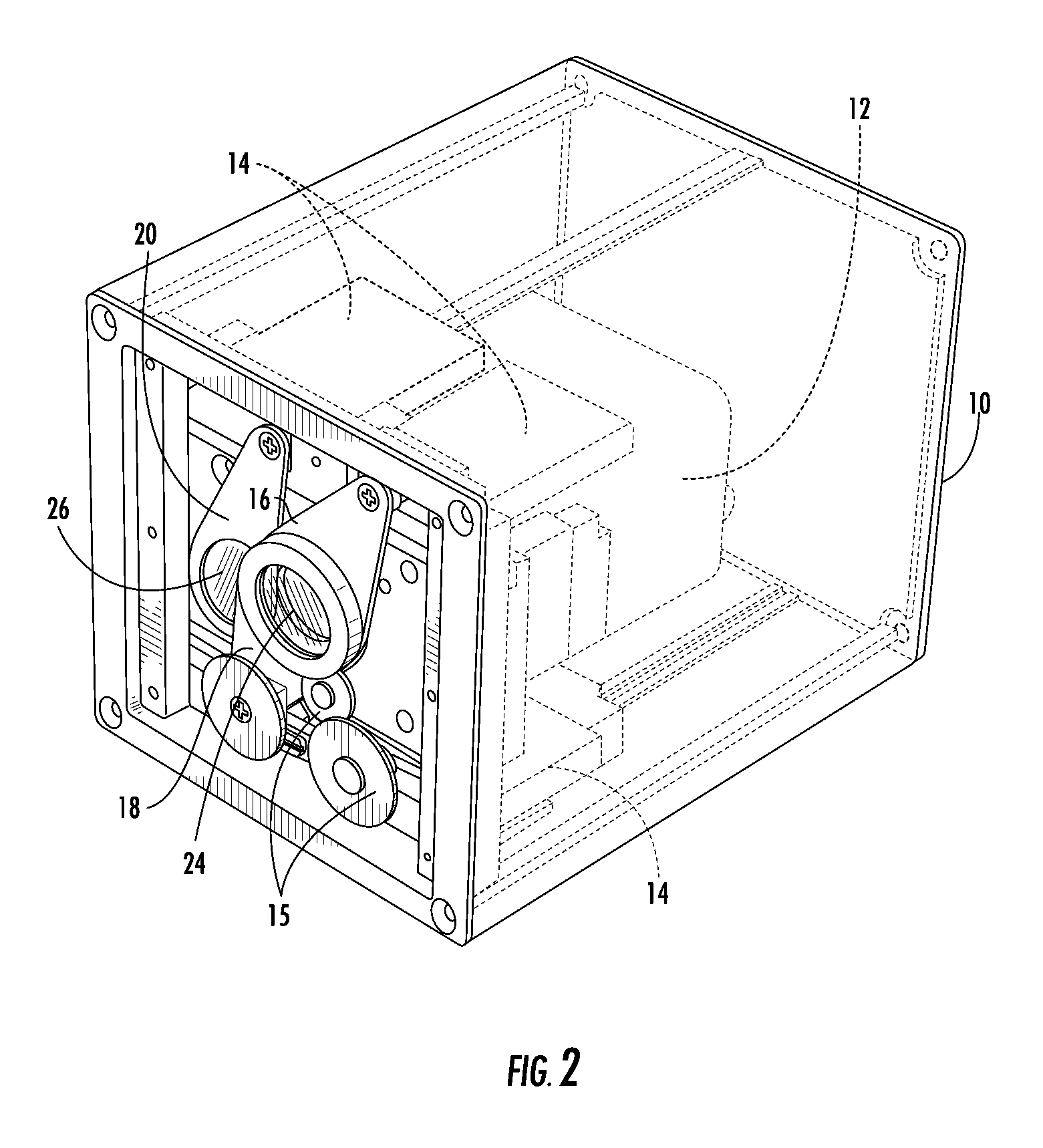

Filter assembly and image enhancement system for a surveillance camera and method of using the same

InactiveUS20080252882A1Reduce glareReduce the amount requiredTelevision system detailsRadiation pyrometrySurveillance cameraDeconvolution

A filter assembly adapted to be used with a camera for selectively controlling the light that reaches the camera's aperture. In one embodiment, the filter assembly comprises three filters adapted to be independently moved between a first position wherein they are not in front of the camera's aperture and a second position wherein they are in front of the camera's aperture. The first and second filters are polarizing filters adapted to block portions of visible light. The third filter is an infrared filter adapted to block infrared light. In addition to moving between its first position and its second position, the second filter is also adapted to rotate up to 360 degrees. The image captured by the camera may be improved using a computer implemented image enhancement system that uses one or more of multi-spectral imaging, deconvolution, edge enhancement, and dynamic range translation.

Owner:KESTERSON JOHN

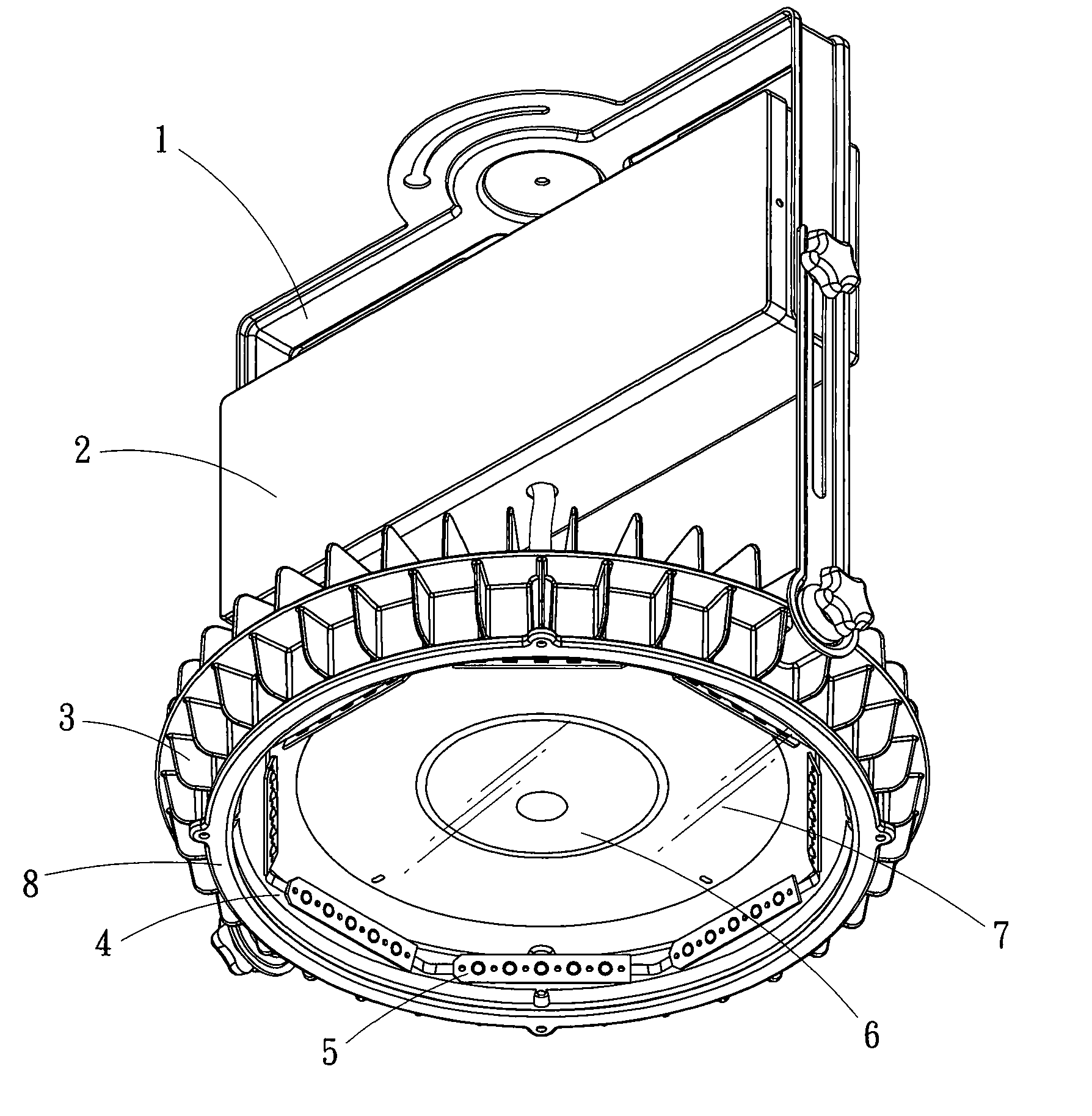

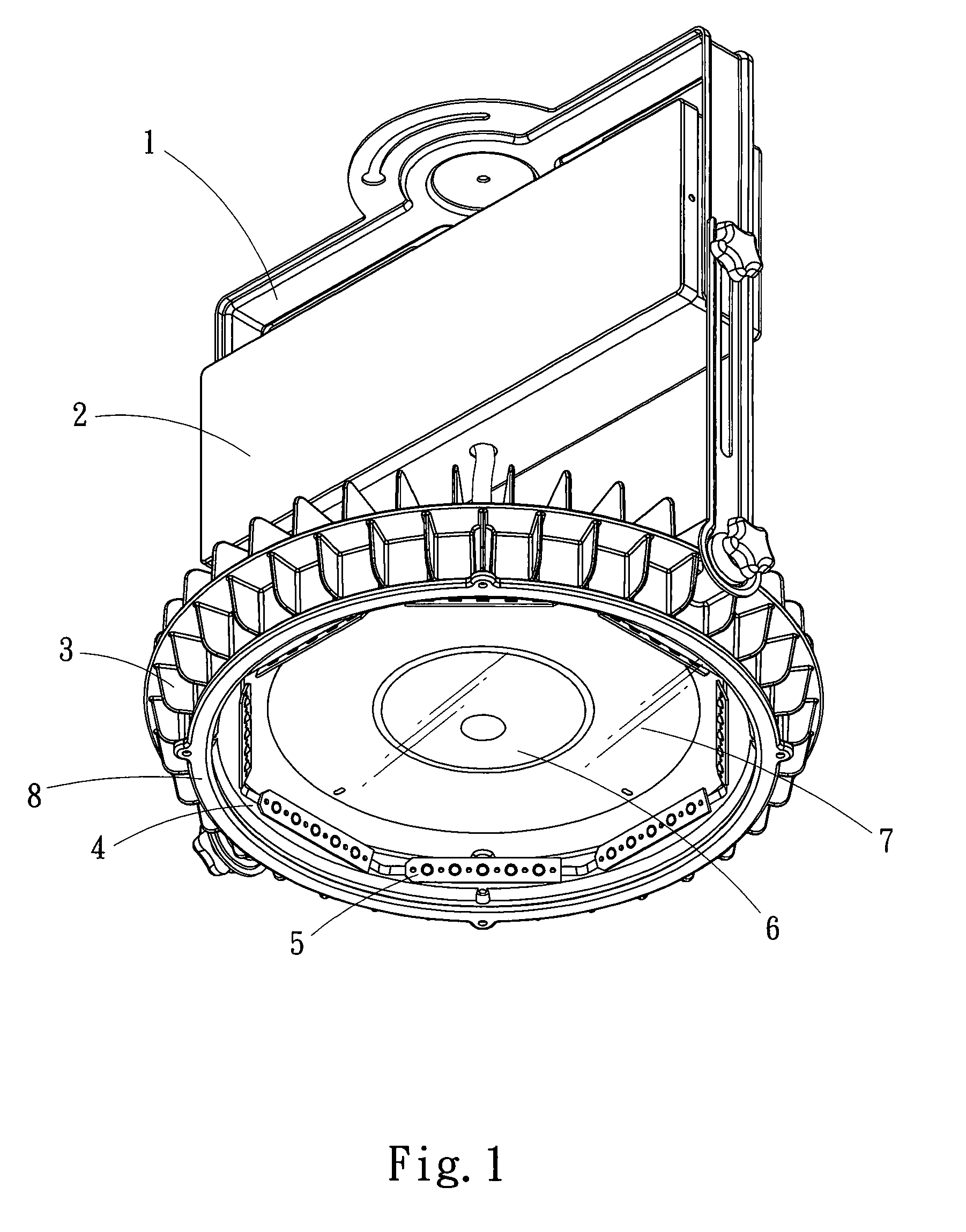

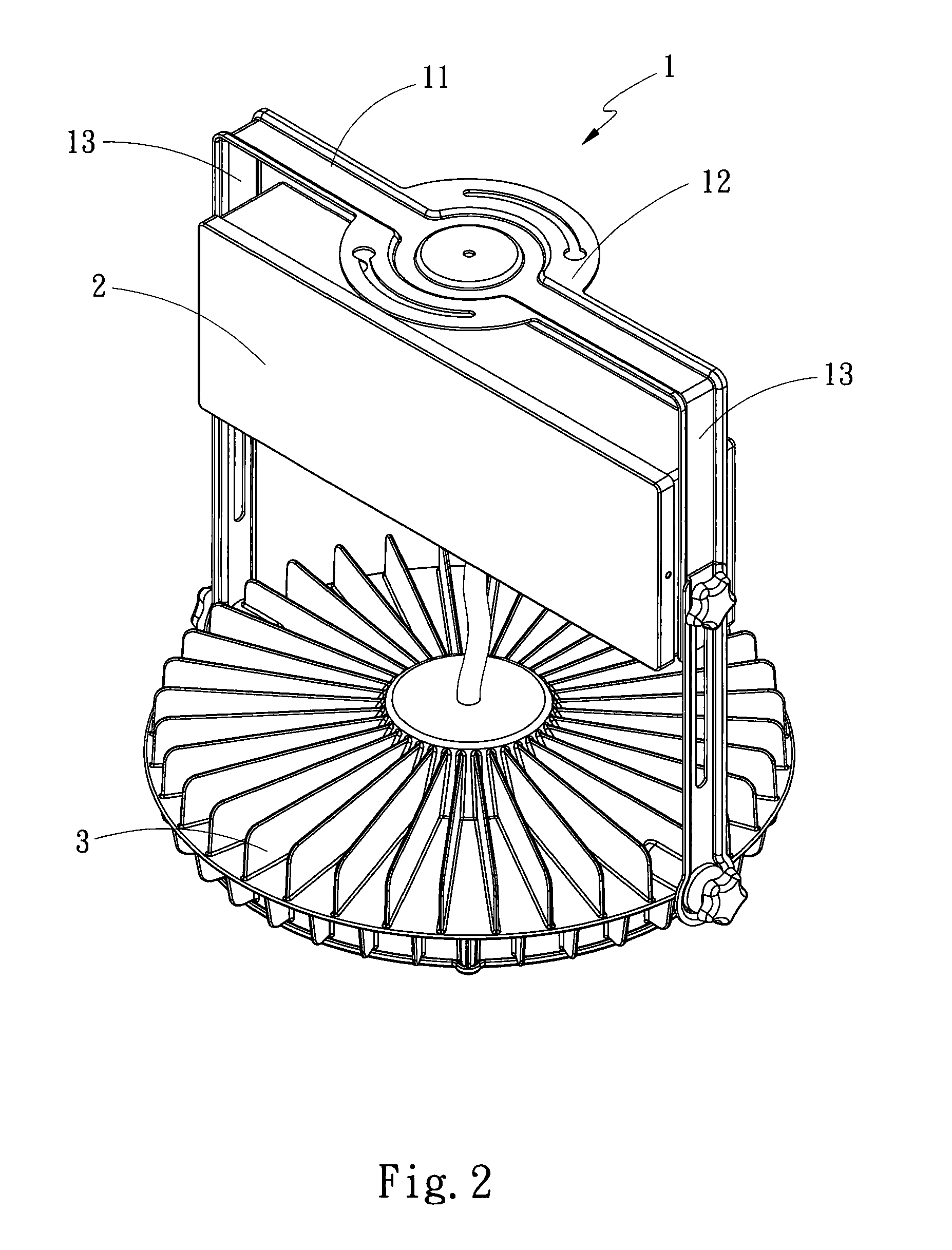

Wide angle LED lamp structure

InactiveUS20110002124A1Reduce glareSave energyLighting support devicesPoint-like light sourceLight reflectionEngineering

A wide angle LED lamp structure provides a LED holder, which can be adjusted to have wide angle illumination range, embedded in a LED room of a heat dissipation base, cooperating with lamp cover and light reflection board, so that the illumination range becomes wider while maintaining the brightness even, and also the dazzle from LED lamp can be reduced. Besides, the LED holder can be replaced according to the different needs of illumination range, and the number of LED bulbs on the inclined plane of LED holder also can be varied in accordance with a user's demands, thereby enhancing the efficiency of each lamp.

Owner:LI HONG TECHNOLOGICAL

Specially coherent optics

ActiveUS7697750B2Expand potential and precisionImprove eyesightCharacter and pattern recognitionOptical partsComputer graphics (images)Depth of field

A refinement in optics providing images with improved sharpness, better control of depth of field, vision-improvement applications, and 3-D capture and display.

Owner:SIMMONS JOHN CASTLE

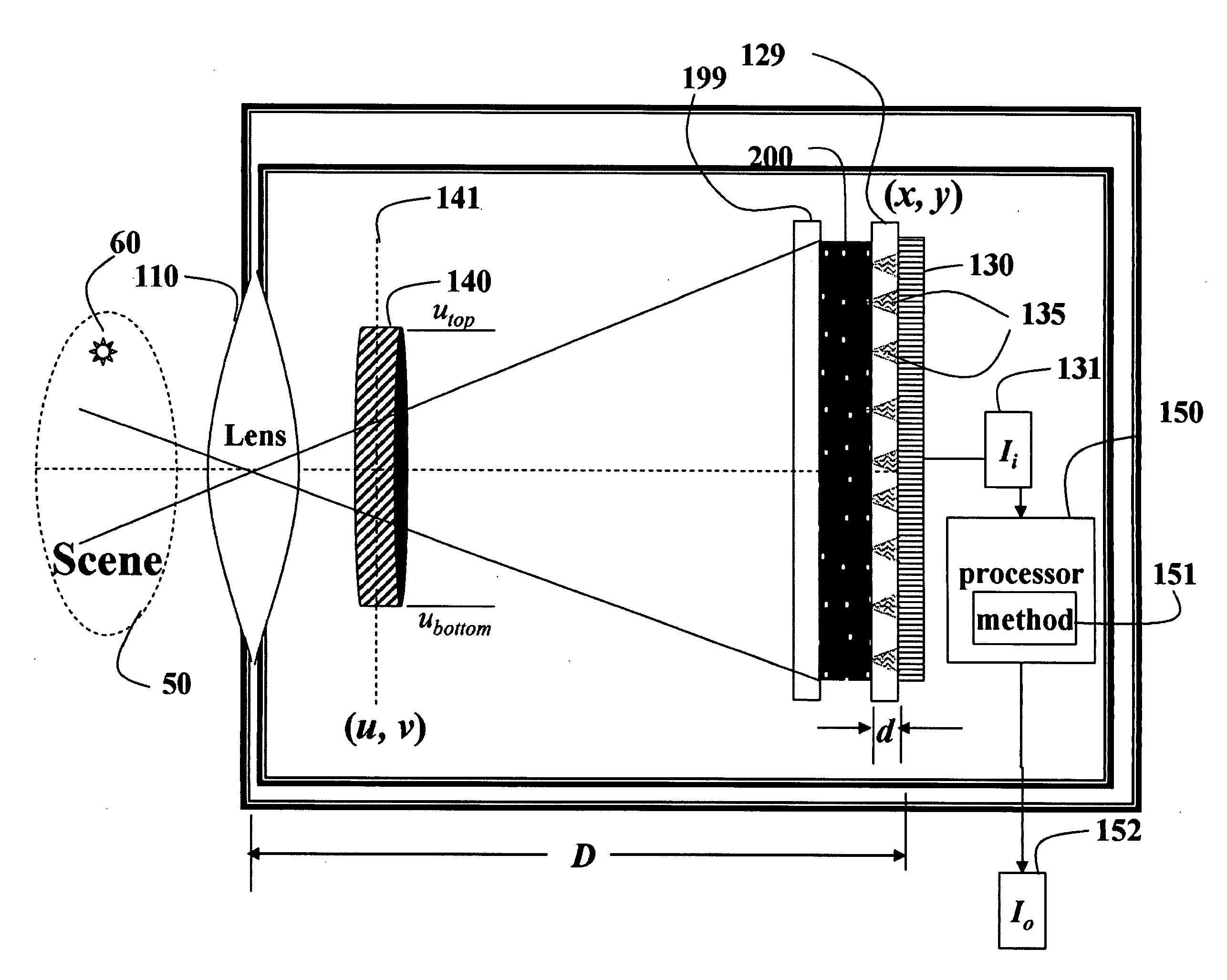

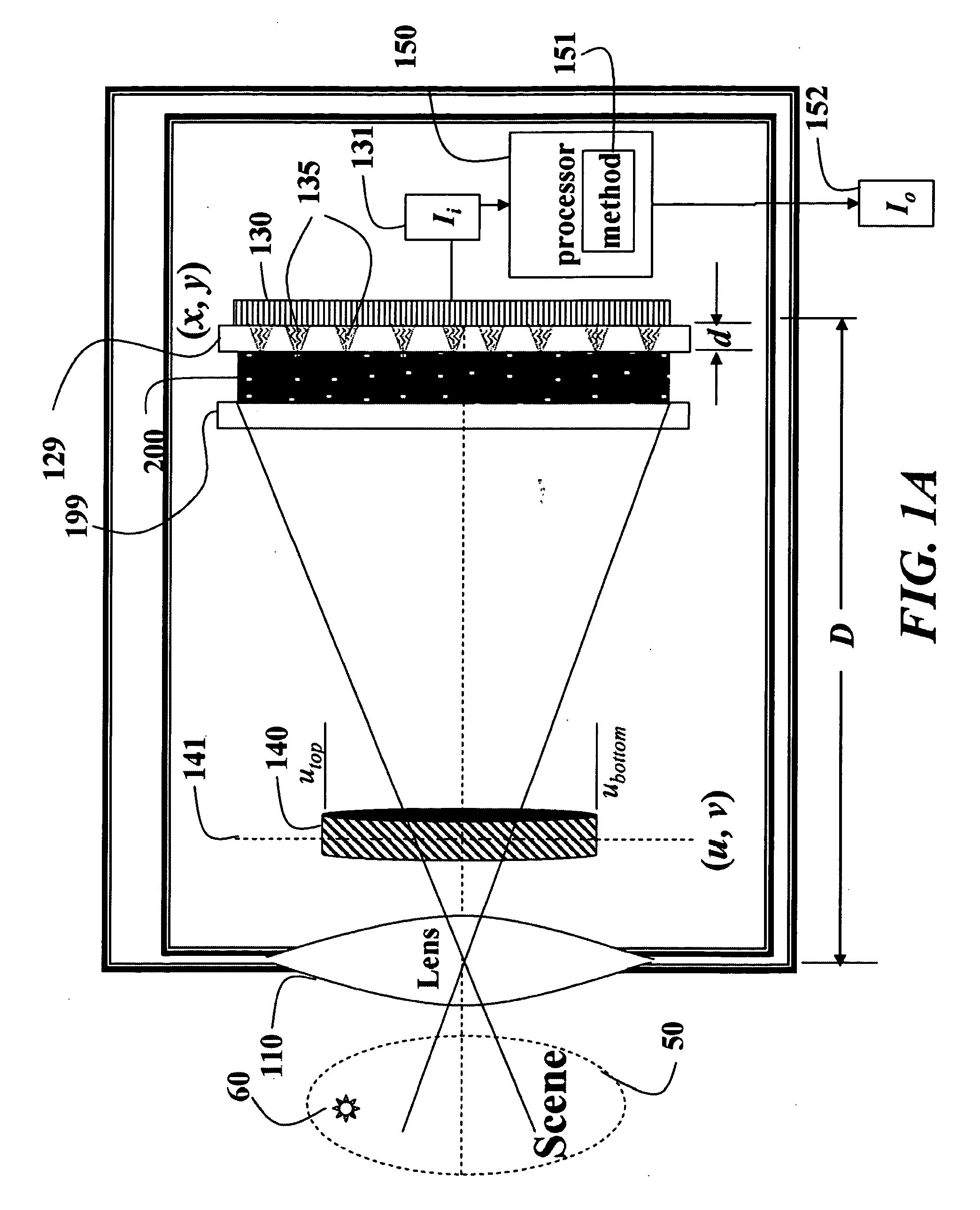

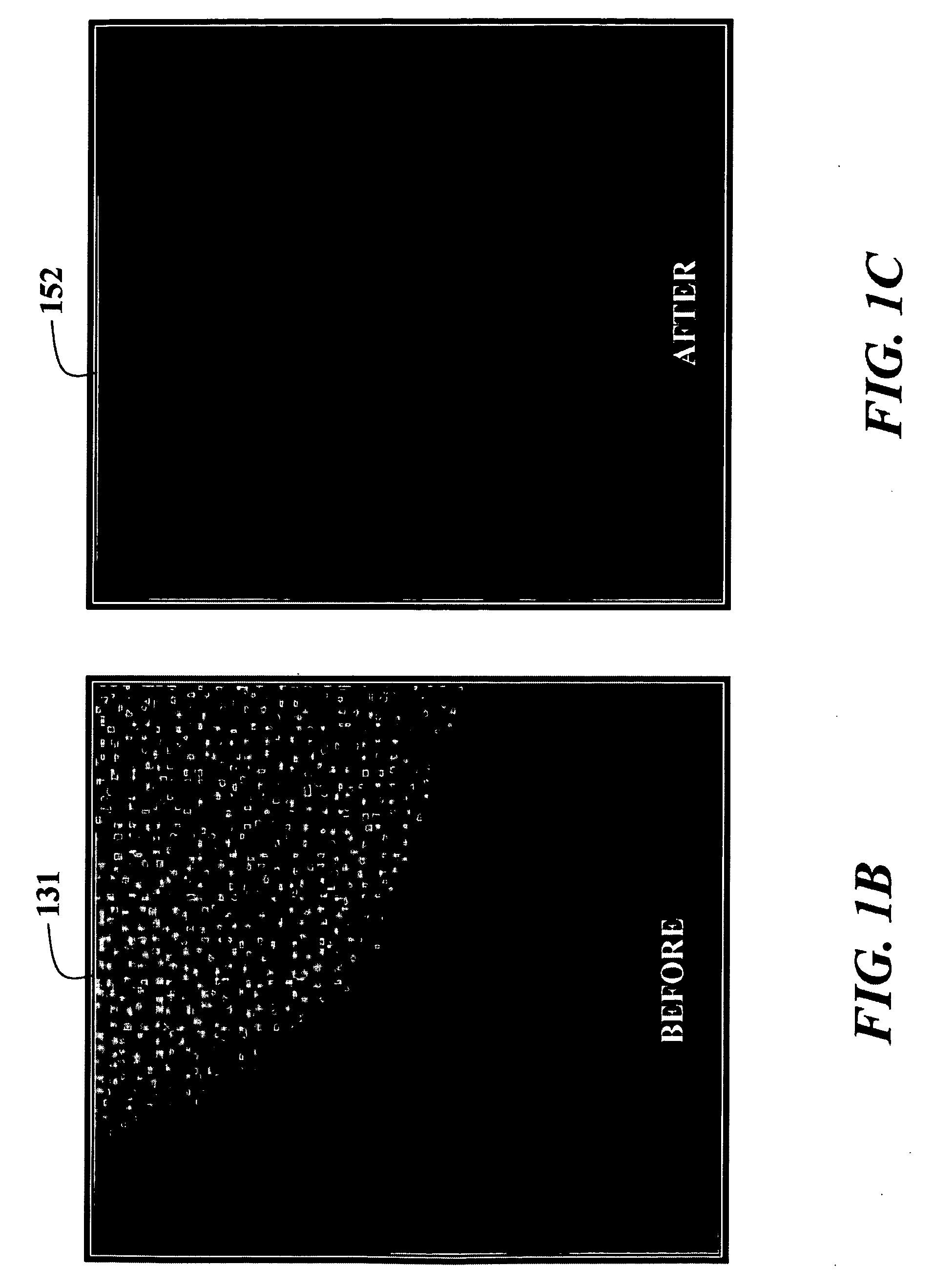

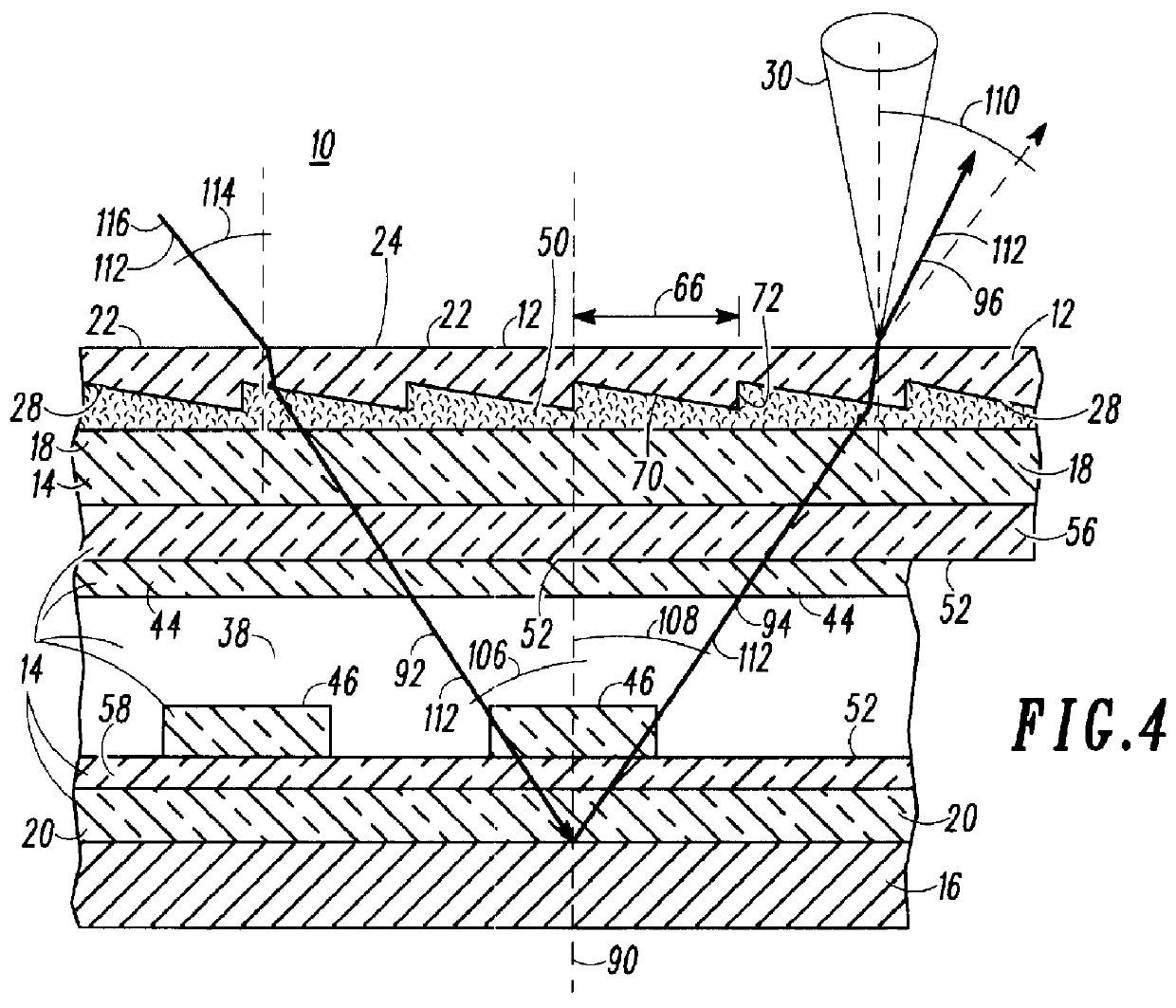

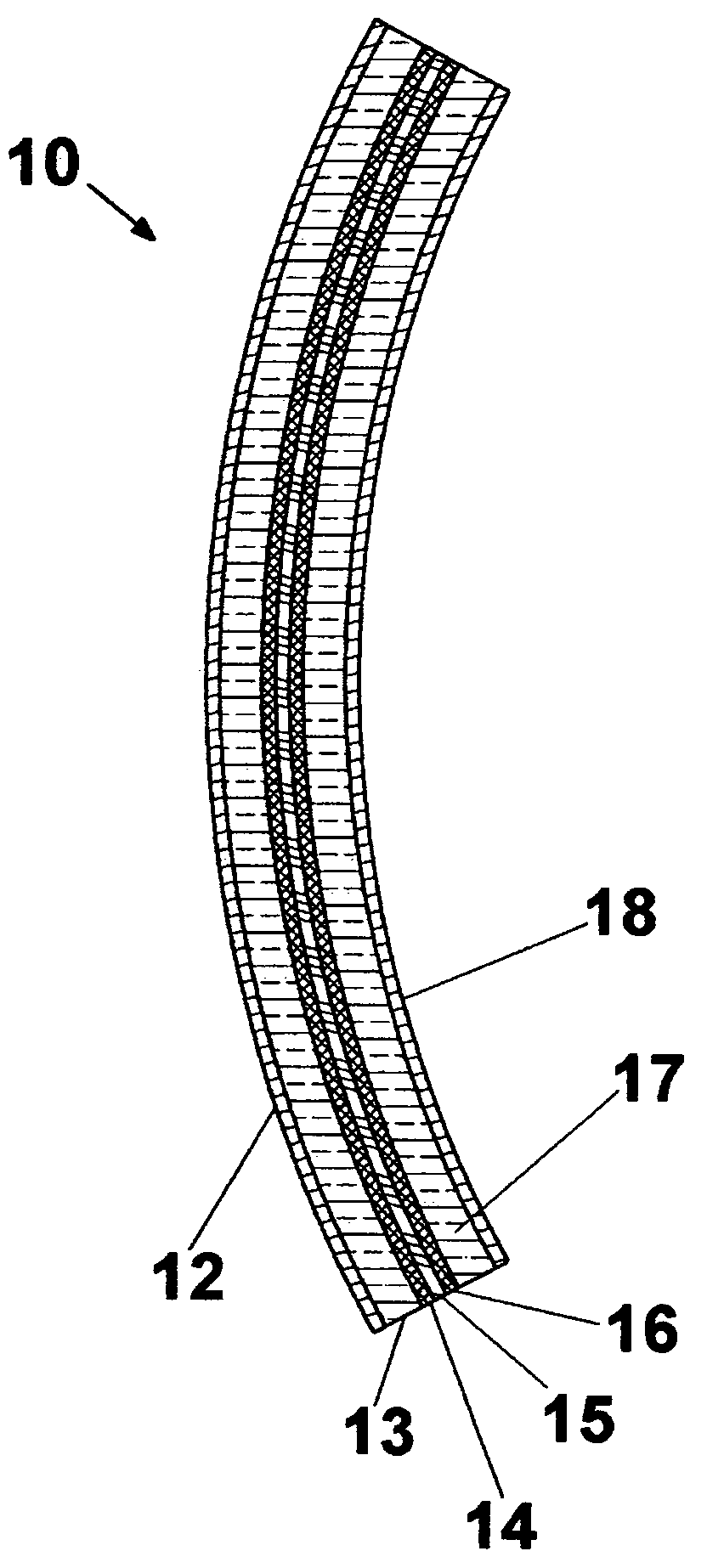

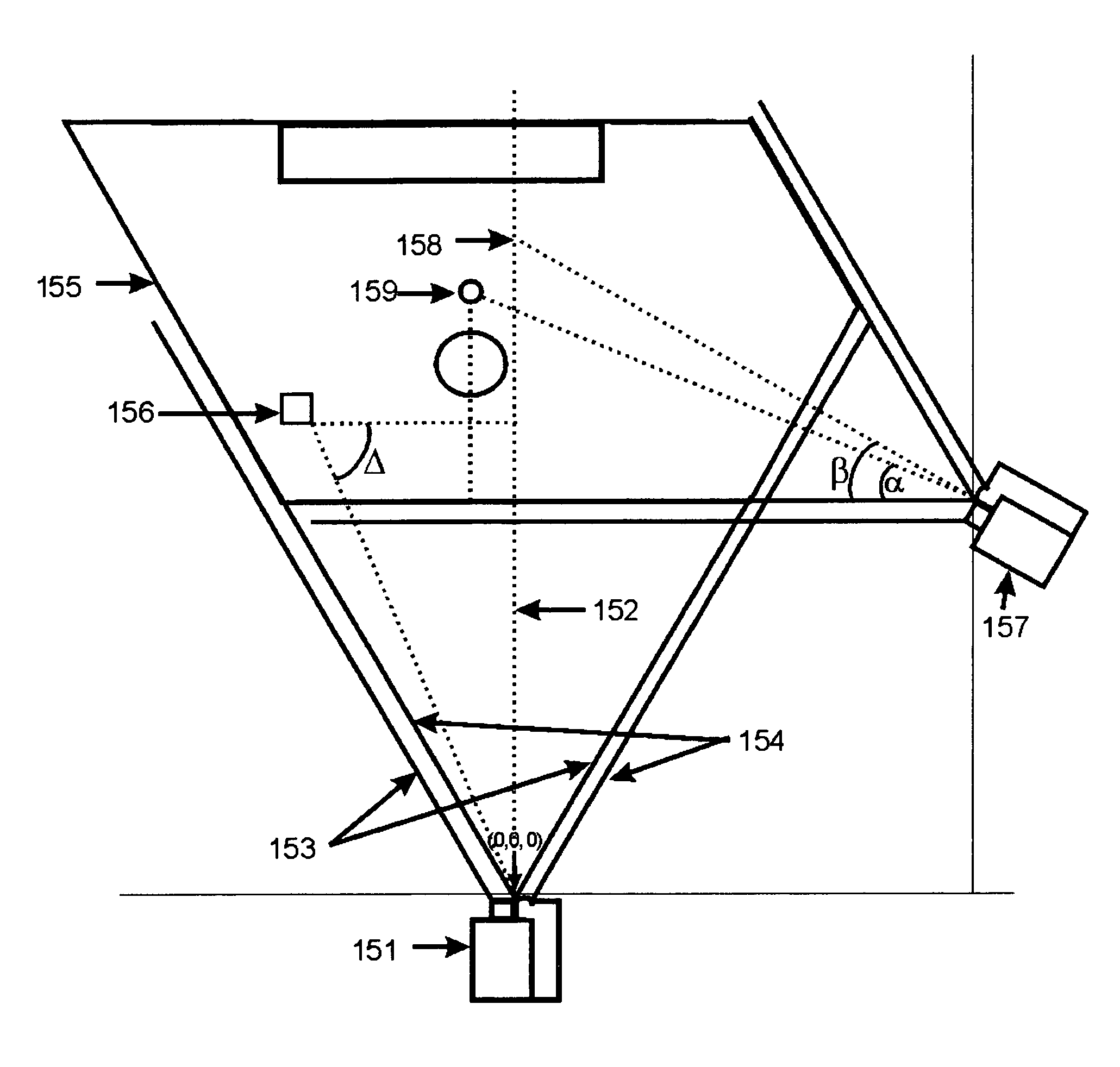

Illumination and imaging system with glare reduction and method therefor

ActiveUS20080084499A1Reduce glareImprove image processing capabilitiesImage enhancementTelevision system detailsDriver/operatorExternal energy

A system and method are provided for actively illuminating and capturing images of an object, such as a driver of a vehicle to reduce glare. The system includes a video imaging camera orientated to generate images of the subject object (e.g., eye(s)) in successive video frames. The system also includes first and second light sources operable to illuminate the object one at a time. The system further includes a processor for processing the image by performing pixel-wise min operation to combine multiple frames into a single frame to reduce glare in the image. The system may remove glare caused by the illuminators and caused by external energy sources.

Owner:APTIV TECH LTD

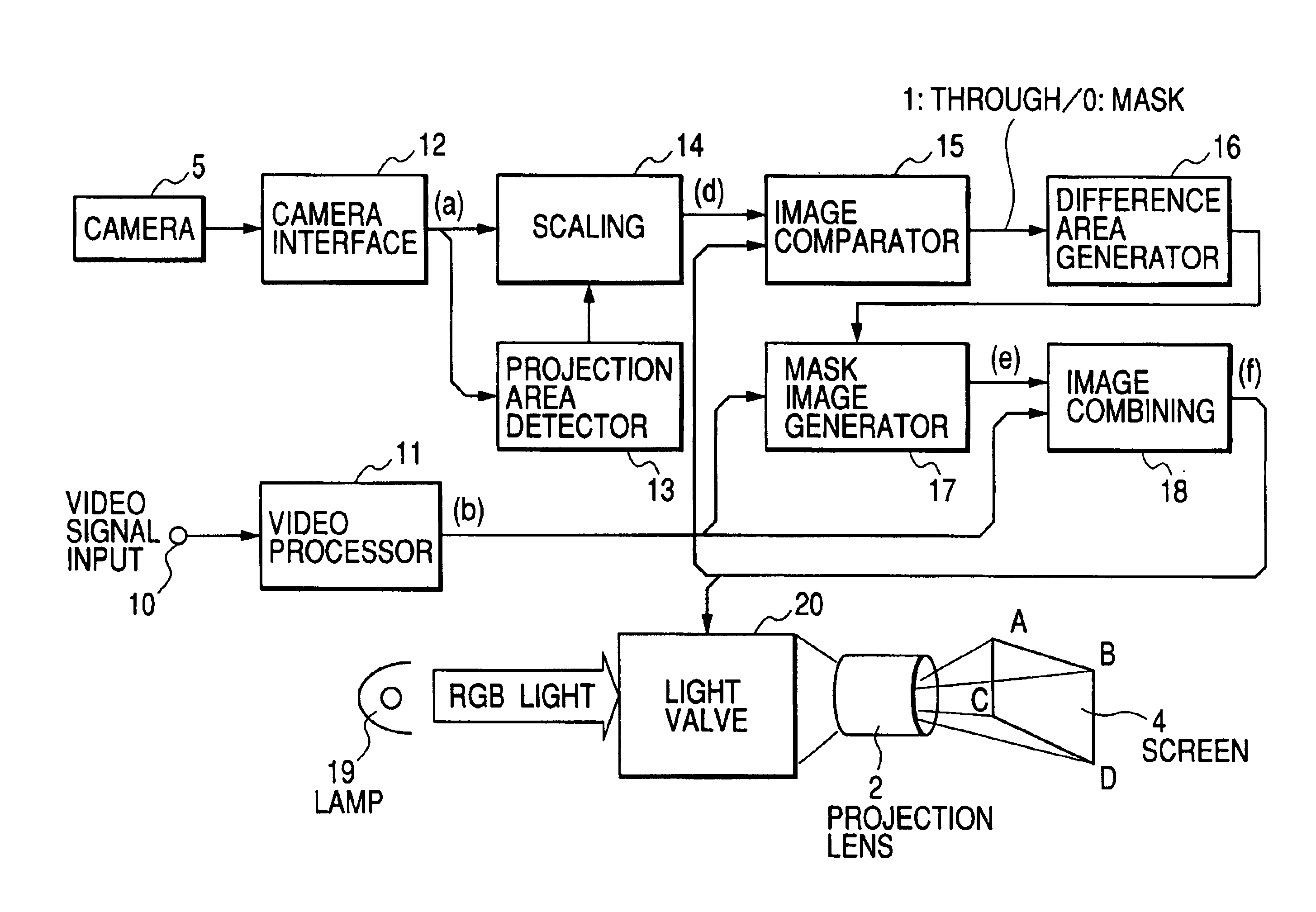

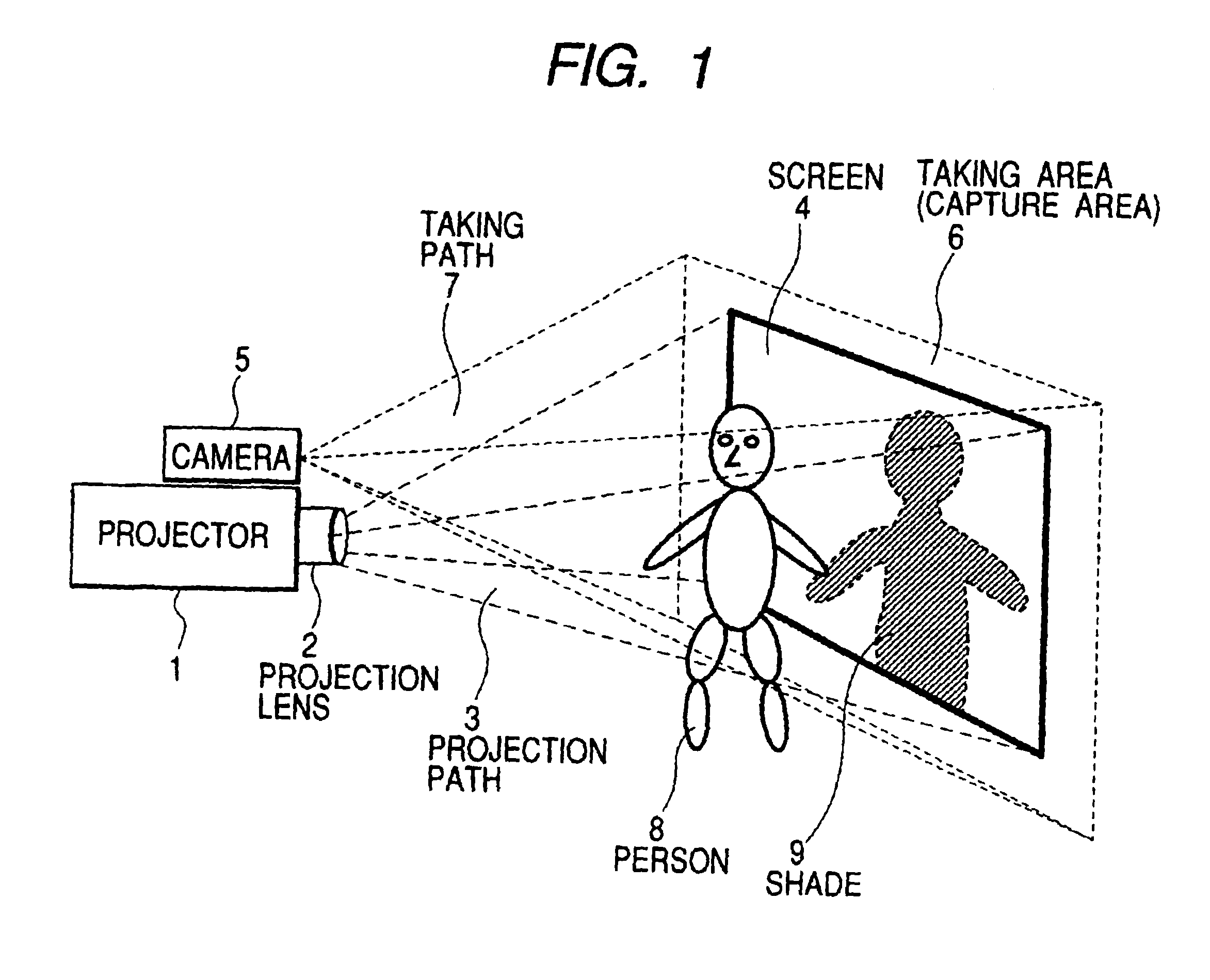

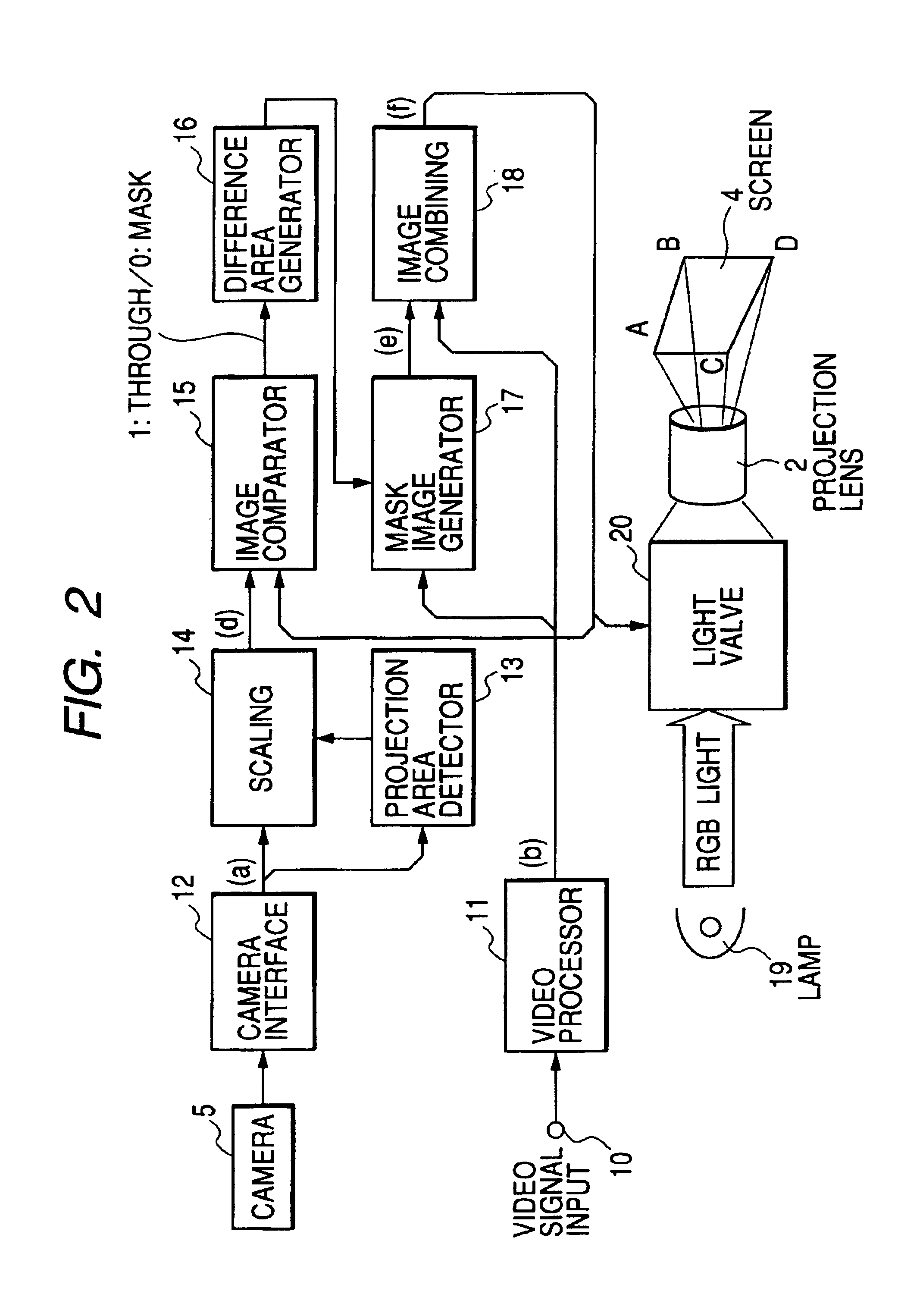

Anti-glare device for projector

InactiveUS6945653B2Reduce glareReduce lightTelevision system detailsPicture changing apparatusComputer graphics (images)Image signal

There is provided a safe image display apparatus for projecting an image on a screen that can minimize a stimulus to eyes, retinae and optic nerves from projected light entering into the eyes directly. By comparing a displayed image captured by a camera with an input image signal, a changed area is detected as a difference area and, then, a projected image signal is generated wherein a picture area image signal in the input image signal that corresponds to this difference area is masked by a black signal. The obtained projected image signal is projected onto the screen.

Owner:MAXELL HLDG LTD

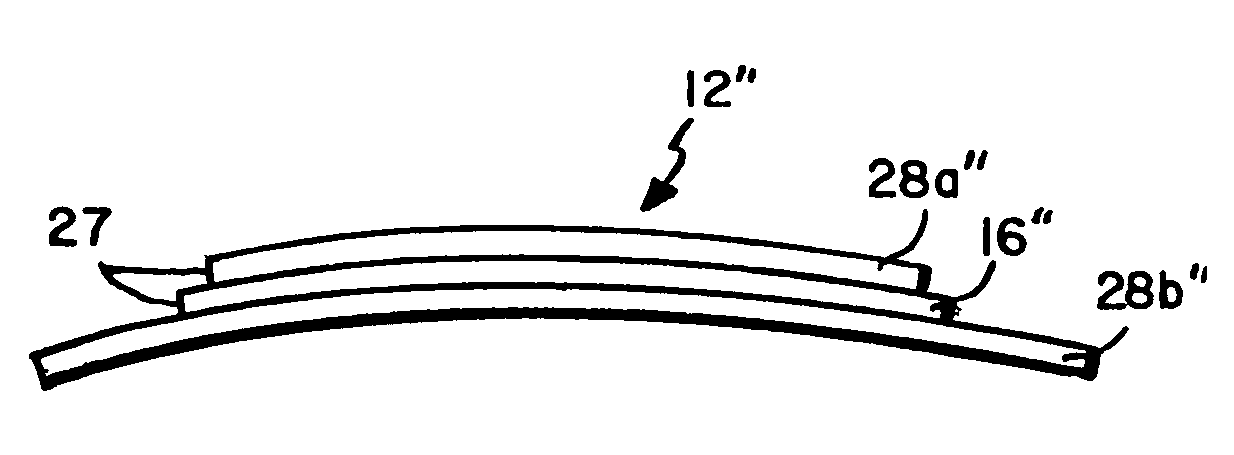

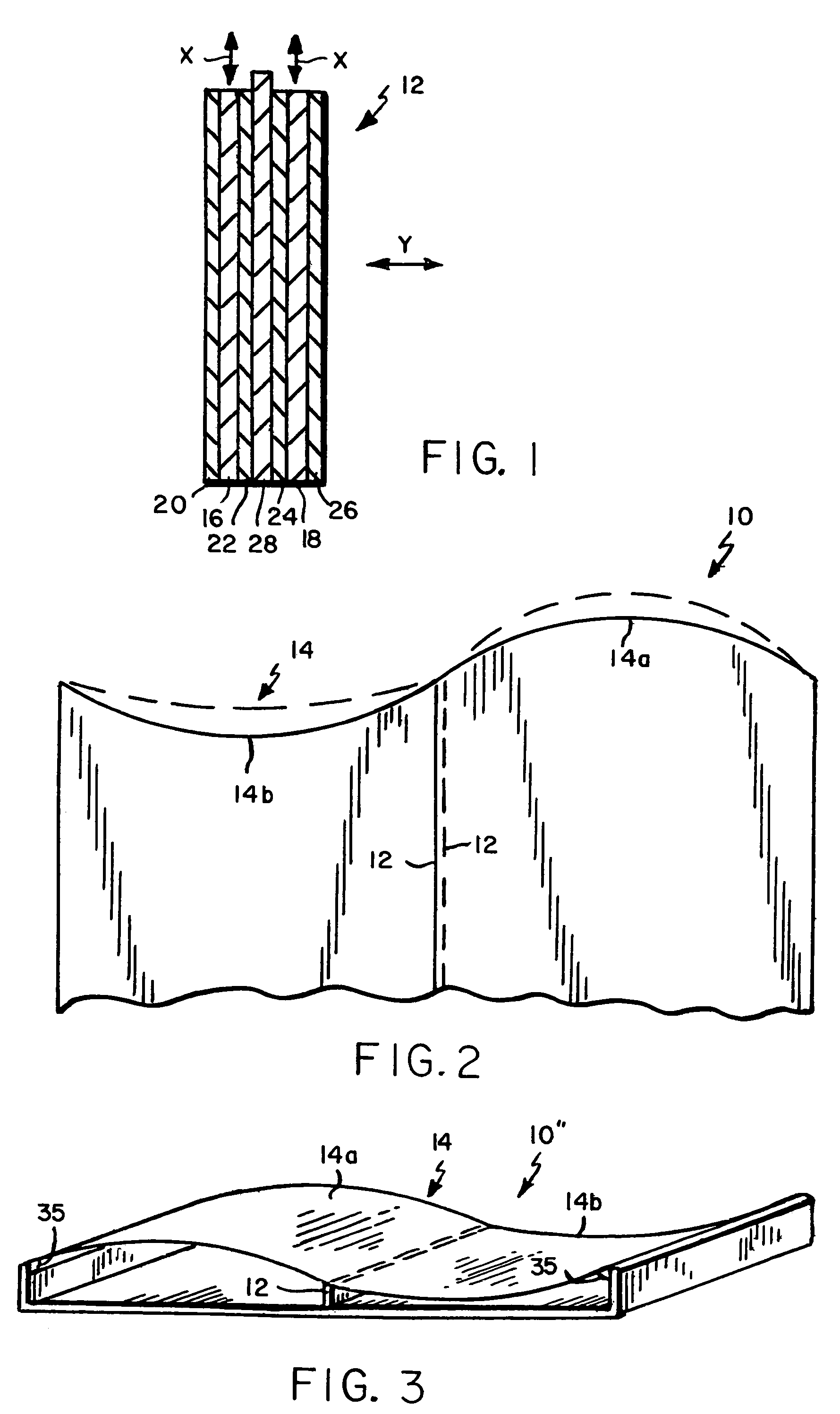

Mechanical-to-acoustical transformer and multi-media flat film speaker

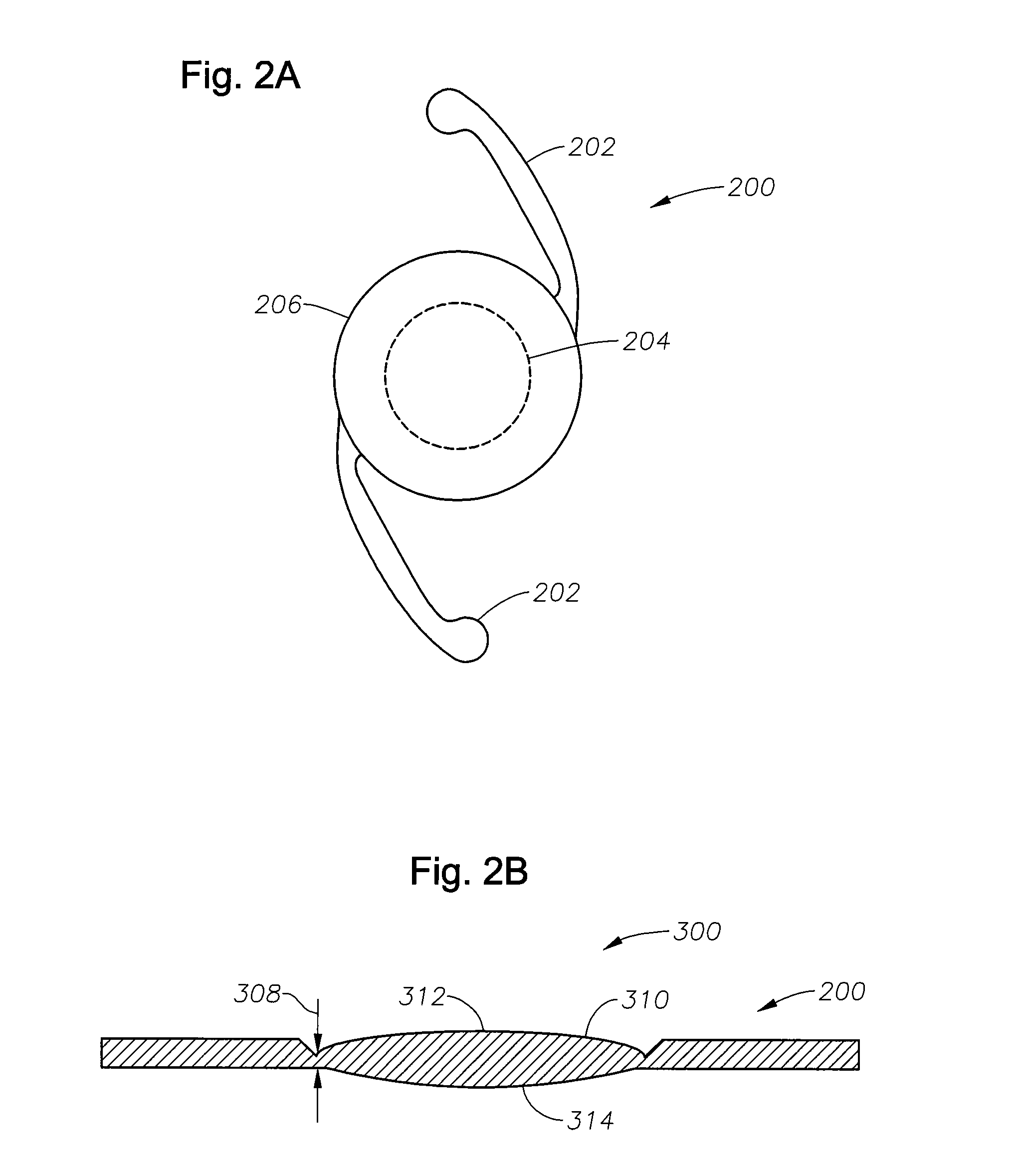

InactiveUS7038356B2Reduce glareMinimize hysteresisPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive transducersLoudspeakerEngineering

A mechanical-to-acoustical transducer has at least one actuator, preferably a piezo motor, that is coupled, generally perpendicularly, to one edge of a diaphragm formed from a thin, flexible sheet material. The diaphragm is fixed at a point spaced from the actuator in the direction of its motion so that excursion of the actuator is translated into a corresponding, mechanically-amplified, excursion of the diaphragm—typically amplified five to seven times. The diaphragm is curved, preferably parabolically, and to a small degree. The diaphragm, if optically clear, can be mounted on a frame over a video display screen to provide a screen speaker. Preferably, such a screen speaker is pinned or adhered at upper and lower edges at or near its vertical centerline and is supported by and driven at both lateral edges by one or more single layer piezo actuators. The actuators are secured at one end to the frame or other stationary member, and at a free, movable end, to an edge of the diaphragm, generally at right angles. A gasket seals the edges of the diaphragm to maintain an acoustic pressure gradient across the diaphragm.

Owner:EMO LABS

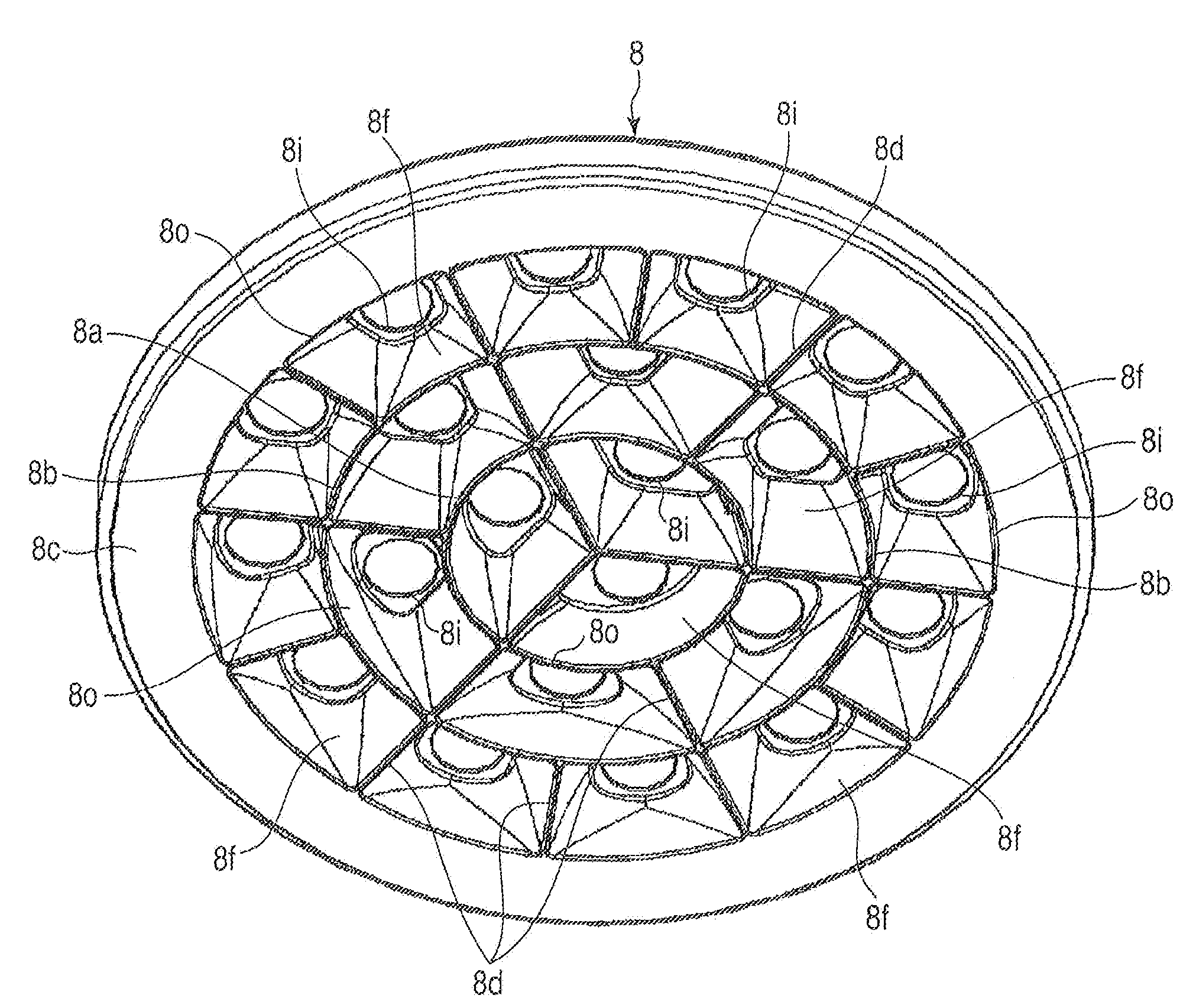

Lighting apparatus

InactiveUS20100038657A1Improve propertiesReduce glarePoint-like light sourceLighting support devicesLight equipmentEffect light

A lighting apparatus is provided with a plurality of light-emitting devices, a substrate, a blind member, and a reflector. The reflector is formed with a plurality of reflective surfaces corresponding to the light-emitting devices, individually. The shielding angle at which light emitted from that one of the light-emitting devices which is located on the outermost periphery is intercepted by the reflective surface corresponding to the outermost light-emitting device is greater than shielding angles at which light emitted from the light-emitting devices located inside the outermost light-emitting device is intercepted by the reflective surfaces corresponding to the inside light-emitting devices.

Owner:TOSHIBA LIGHTING & TECH CORP +1

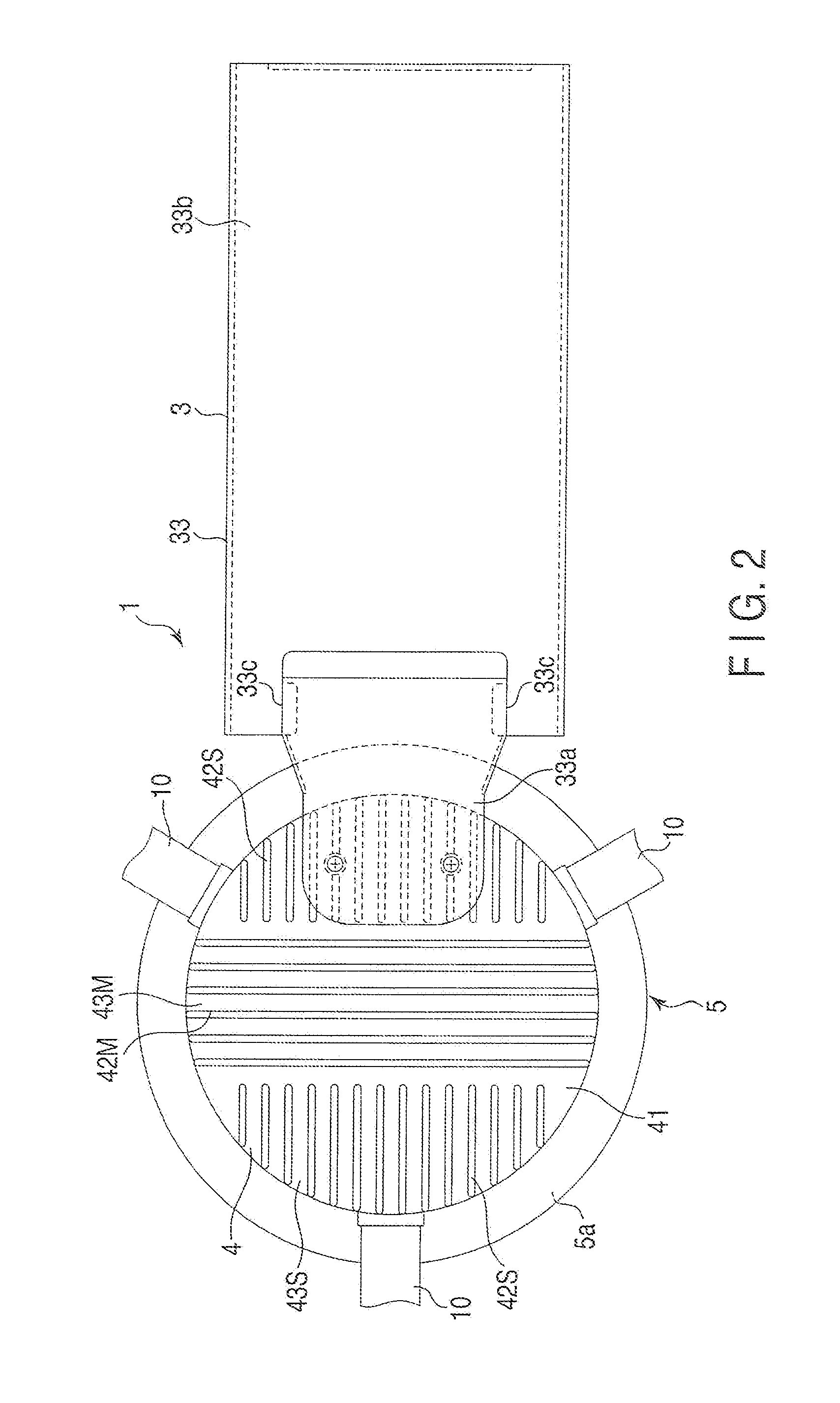

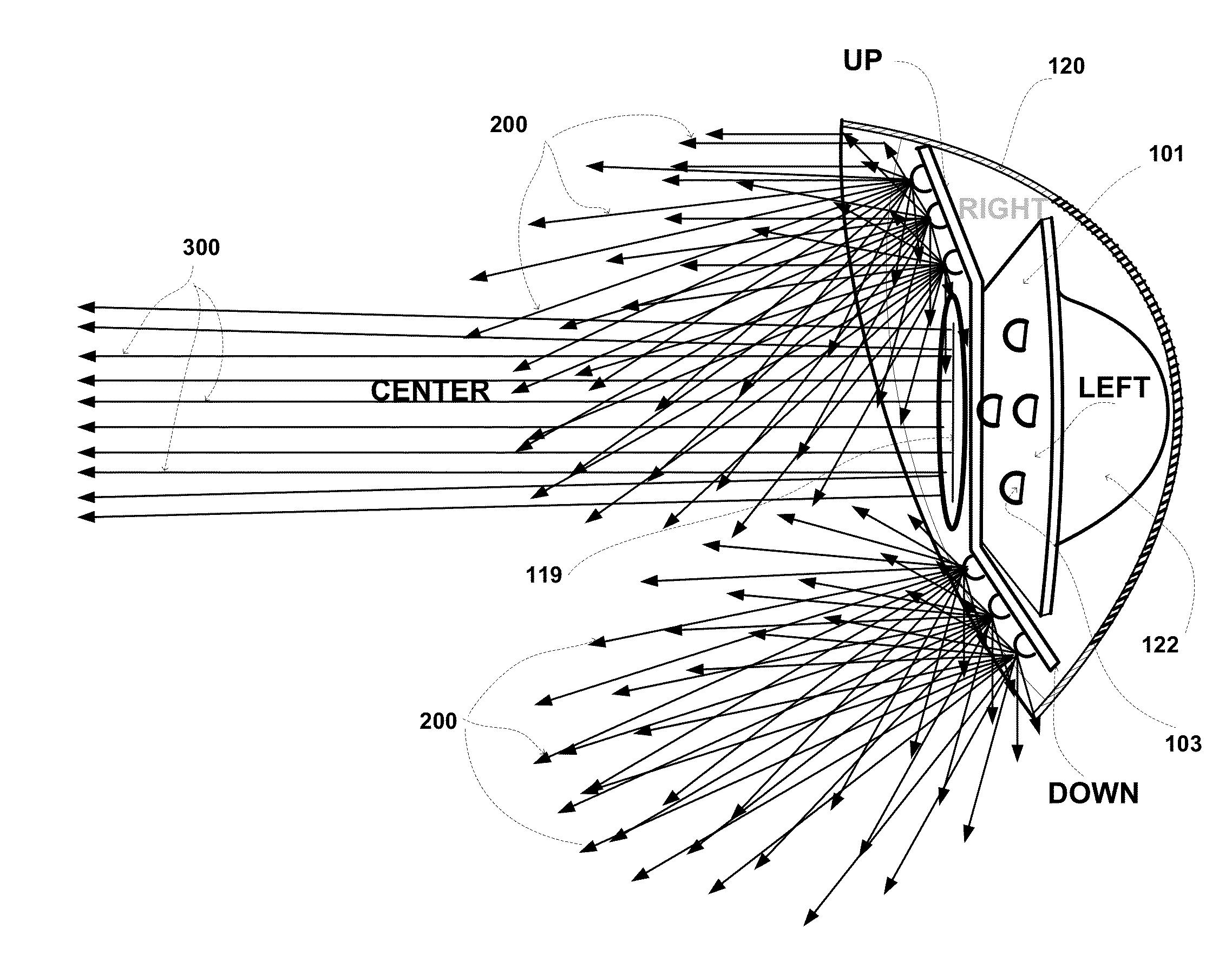

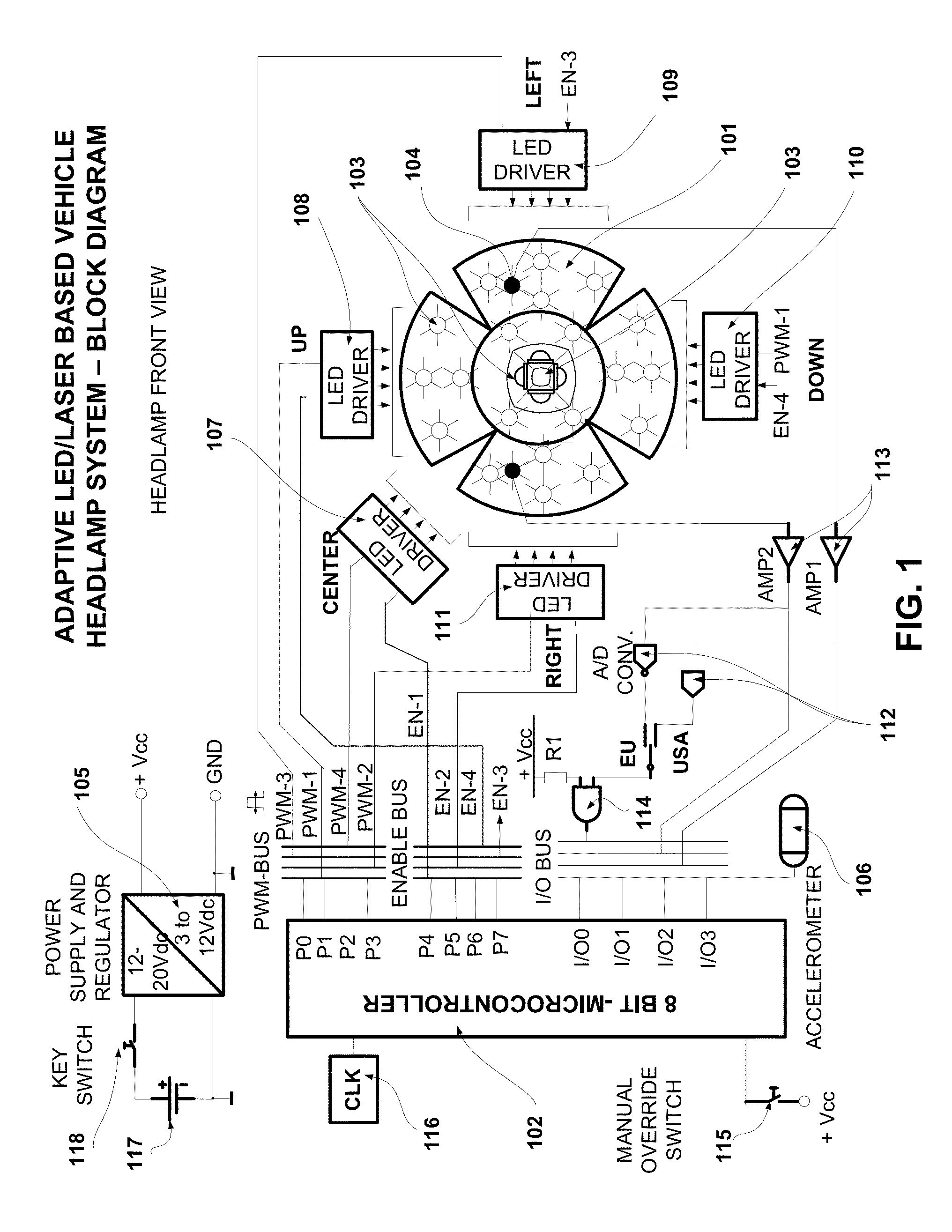

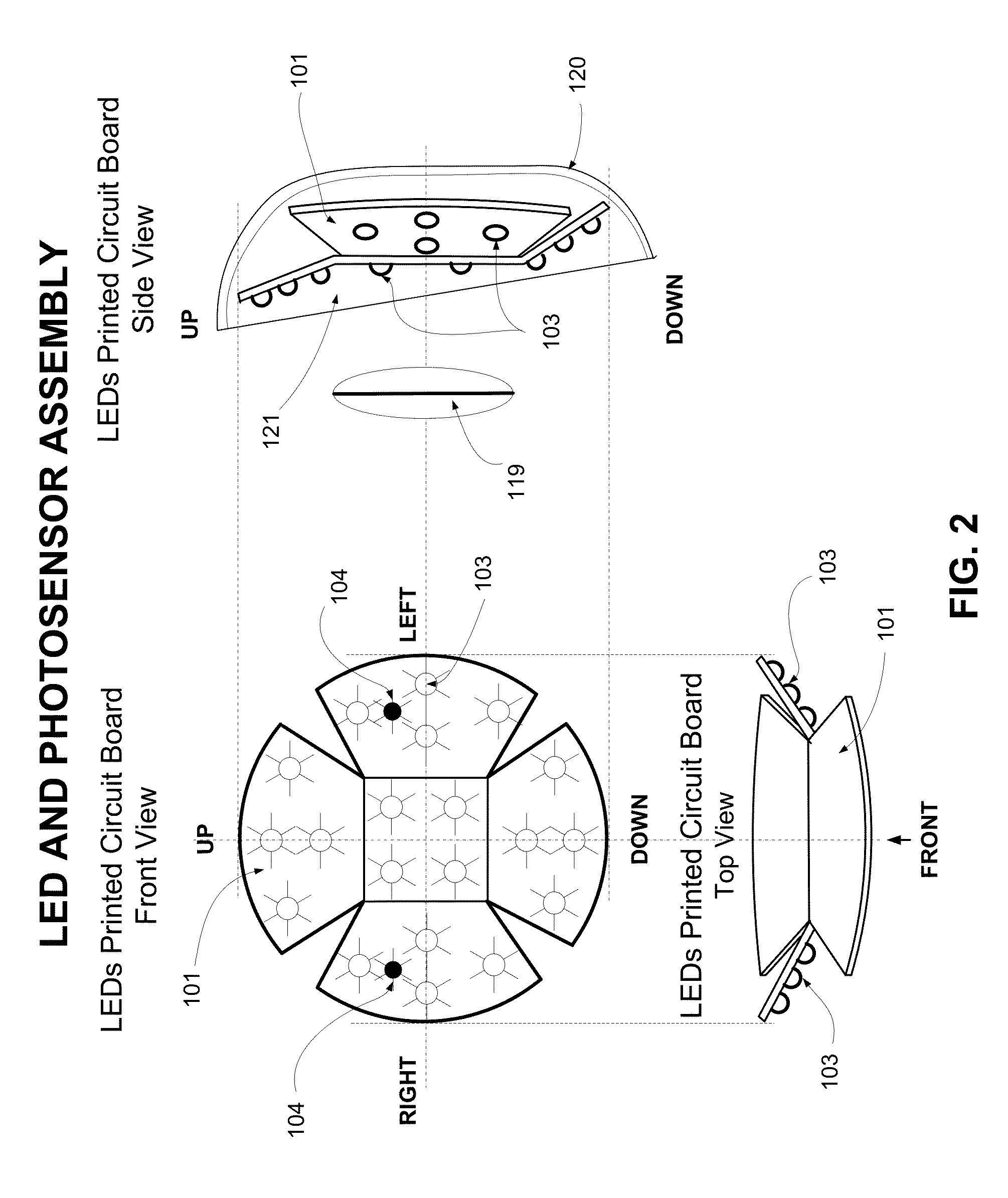

Adaptive external vehicle illumination system

ActiveUS20130258688A1Reduce glareQuality improvementVehicle headlampsLighting support devicesLaser transmitterAccelerometer

An asymmetric geometry headlamp for vehicular use is built as a multifaceted three dimensional body which has multiple light emitting devices (LEDs and / or laser emitters) installed on its angled facets, hence forming a multipurpose illumination apparatus within a single assembly which is designed to provide; a low beam with a wide illuminated area covering 2PiSteradians, a high beam all position and signaling lights. A microprocessor based system runs real time, continuously adaptive control routines for day and night conditions and provides the electric signals necessary for the independent control of the luminous intensity, direction and color spectrum to each facet of the headlamp's LEDs (light emitting diodes) and for the high beam. Multiple photo-sensors, CCD or CMOS video cameras, position encoders and accelerometers provide the feedback signals used in the automation of all lighting functions in a system designed to completely replace the manual actuation of lights on vehicles.

Owner:IP CONSULTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com