Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3258results about "Power cables" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

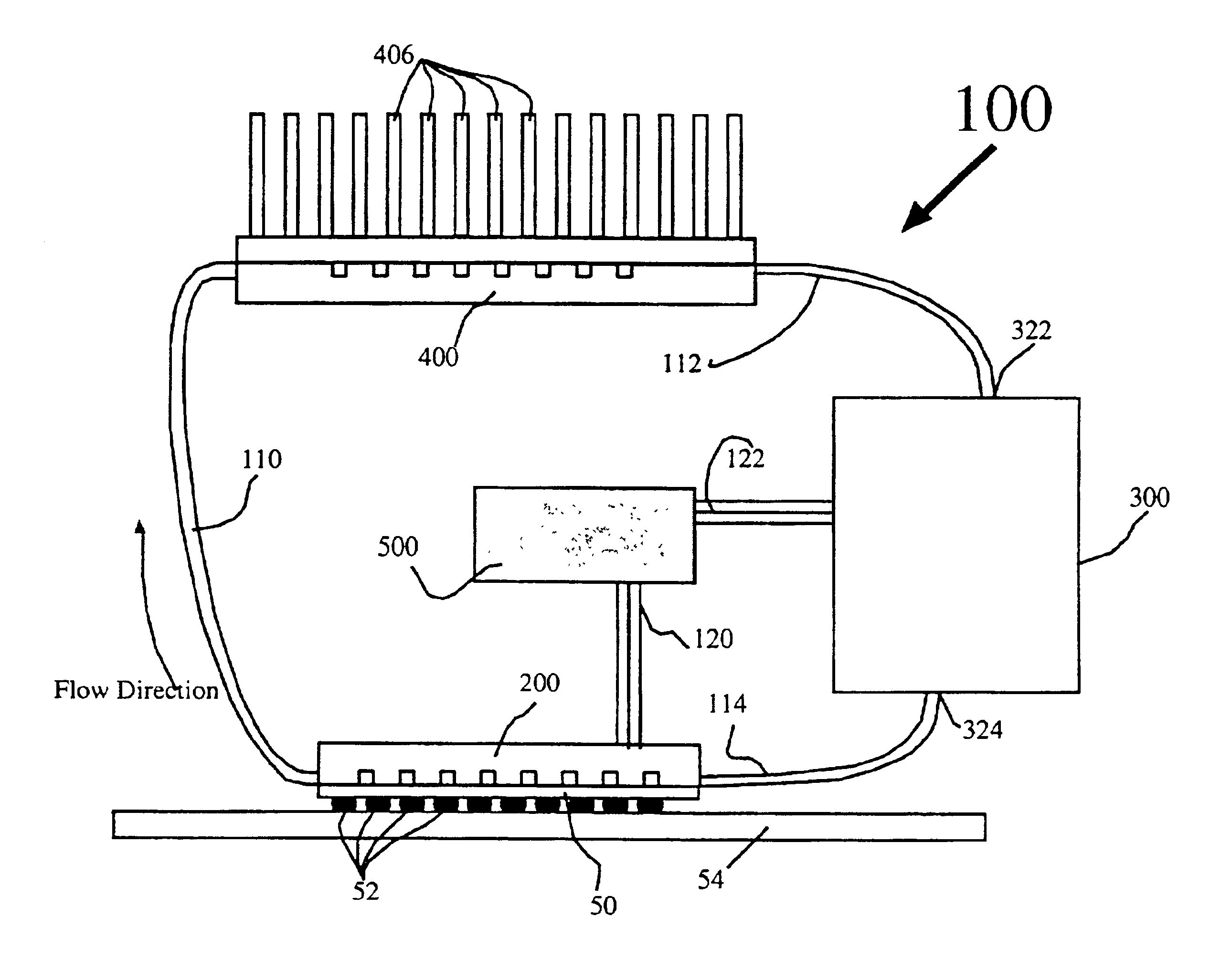

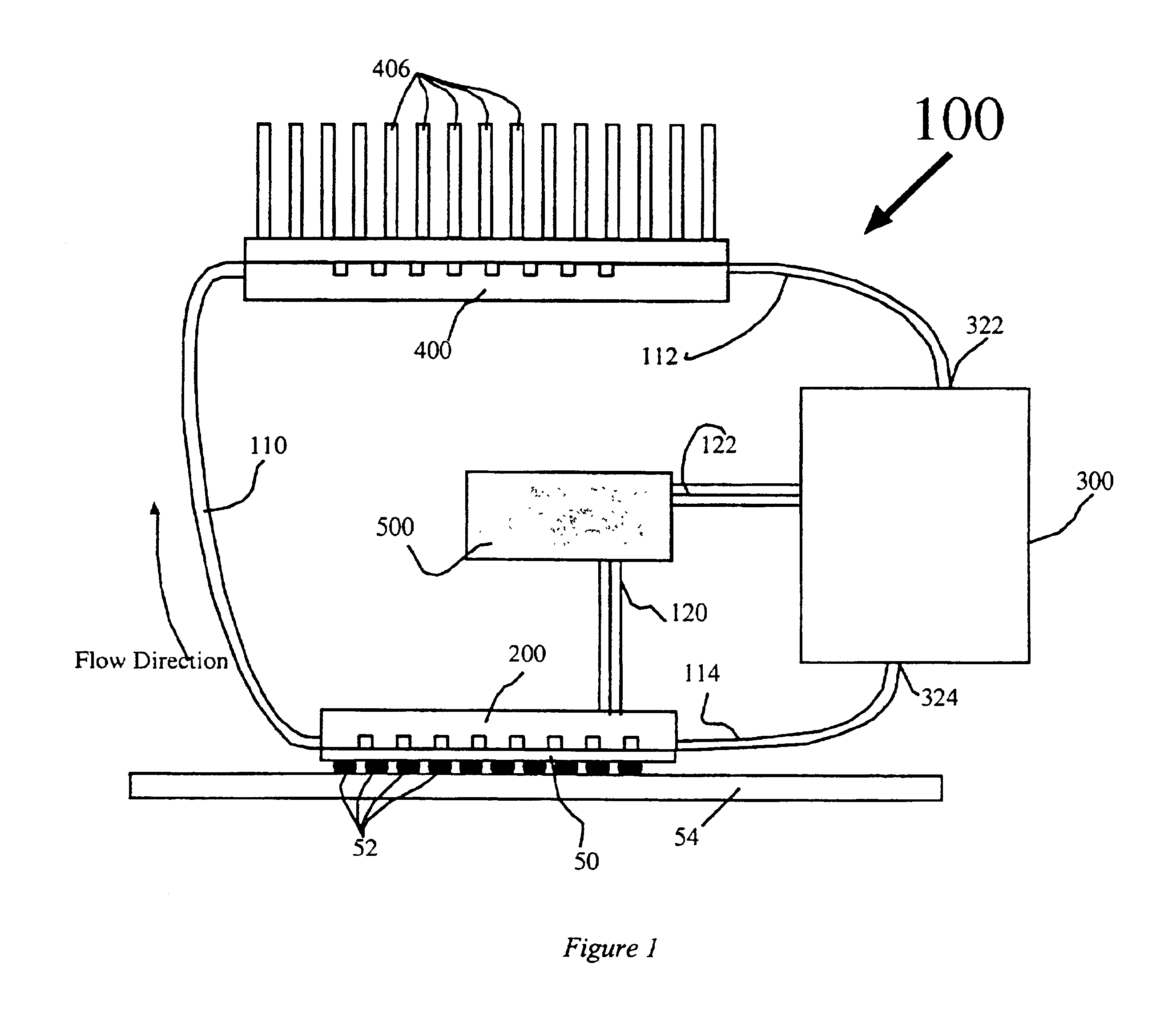

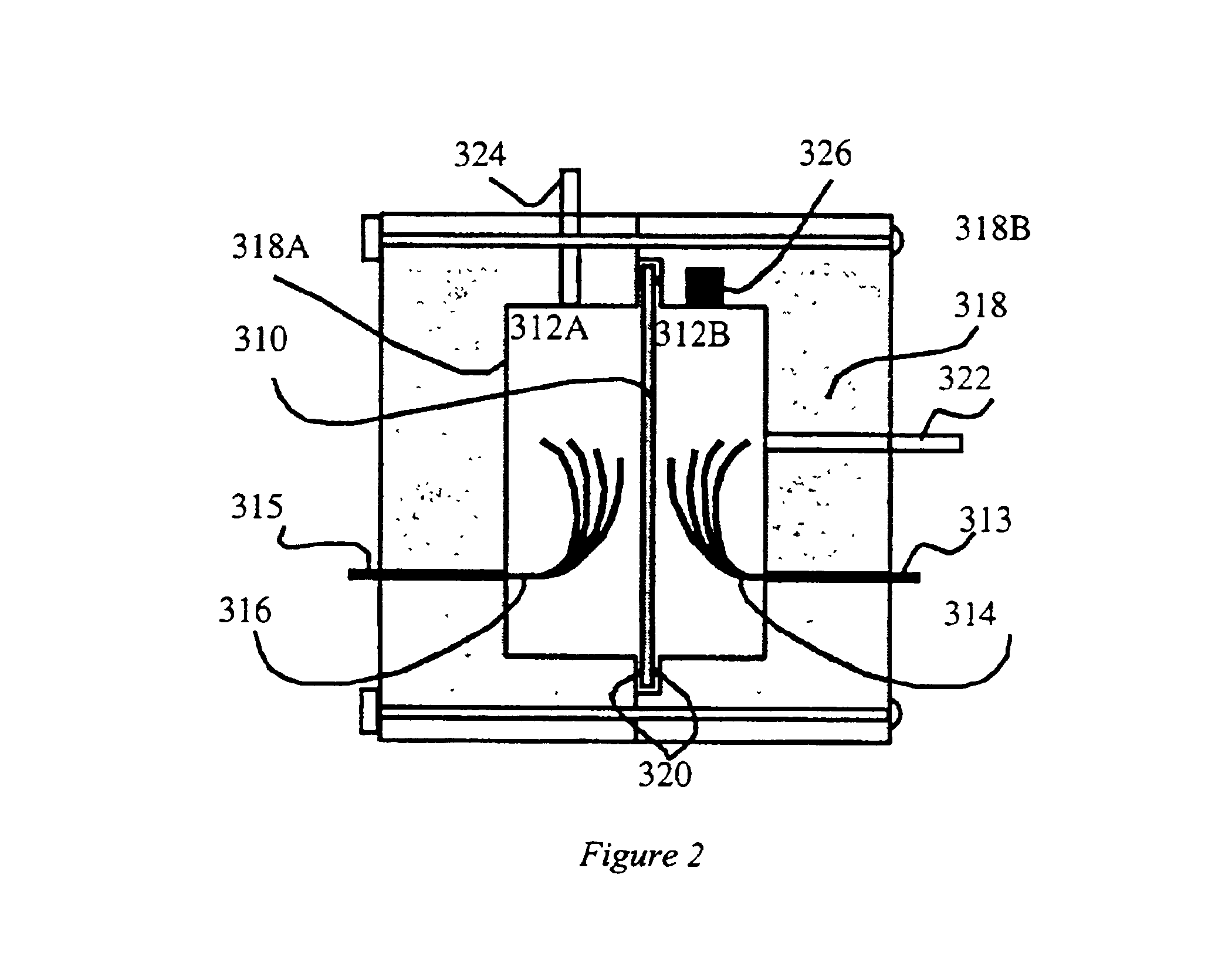

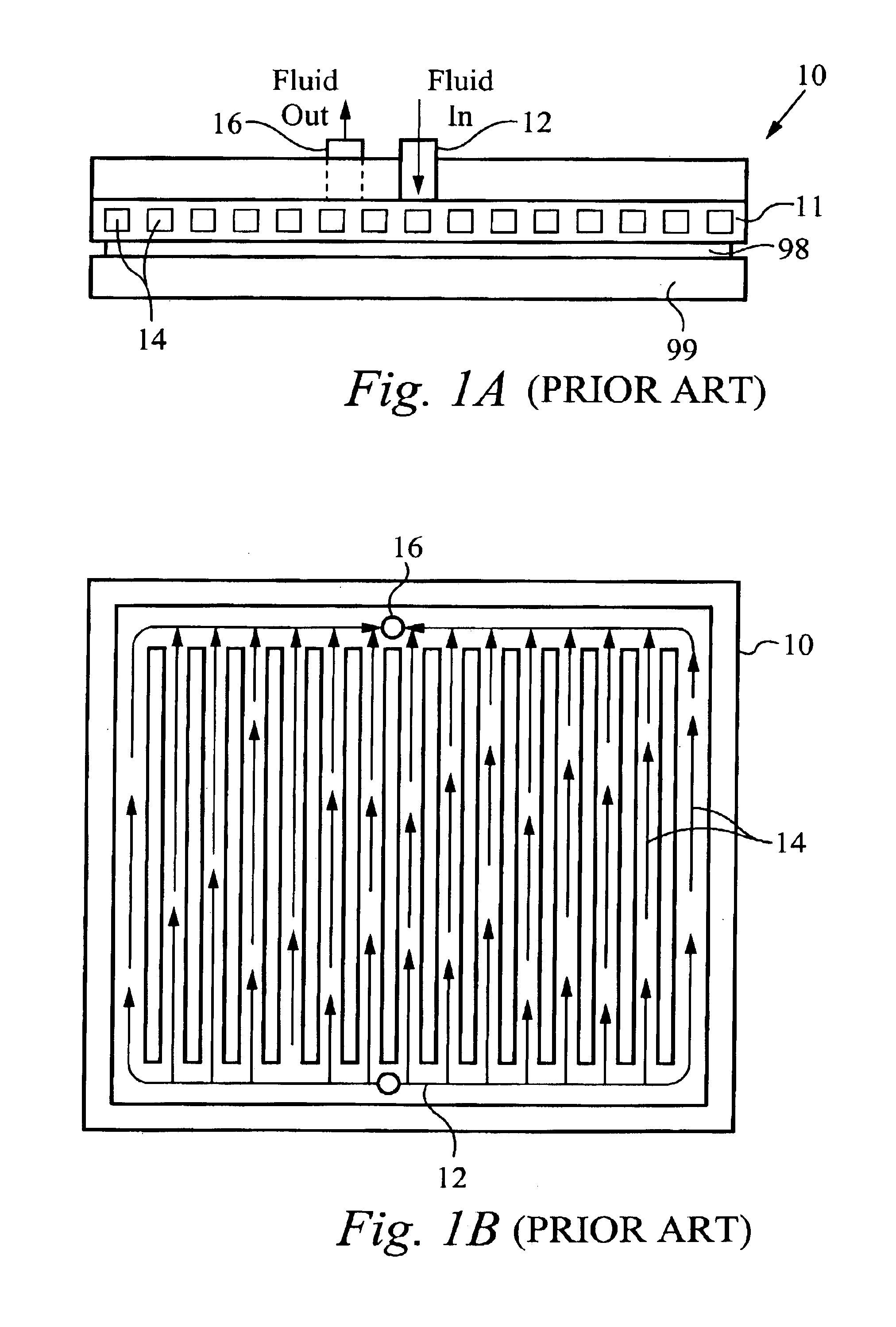

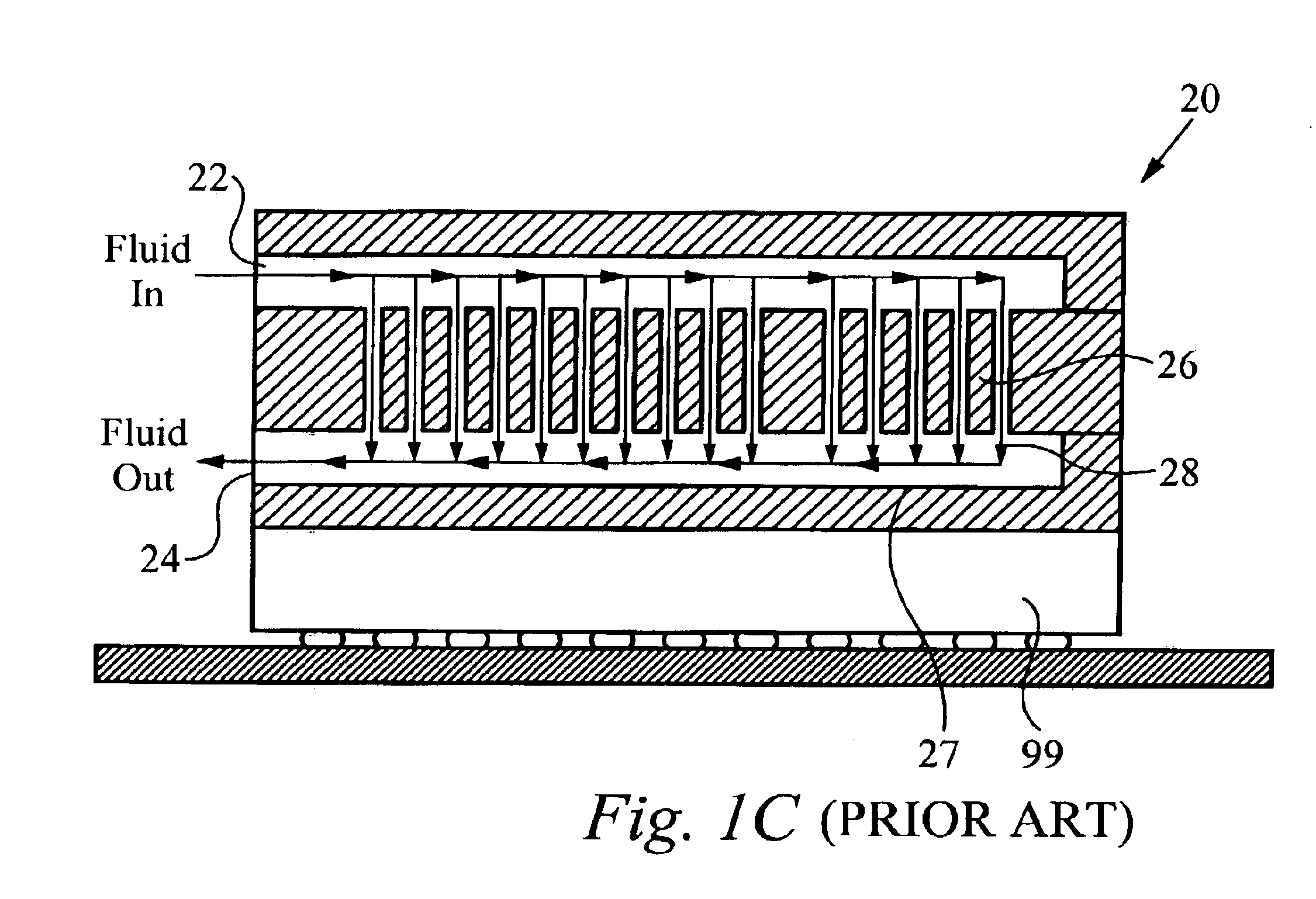

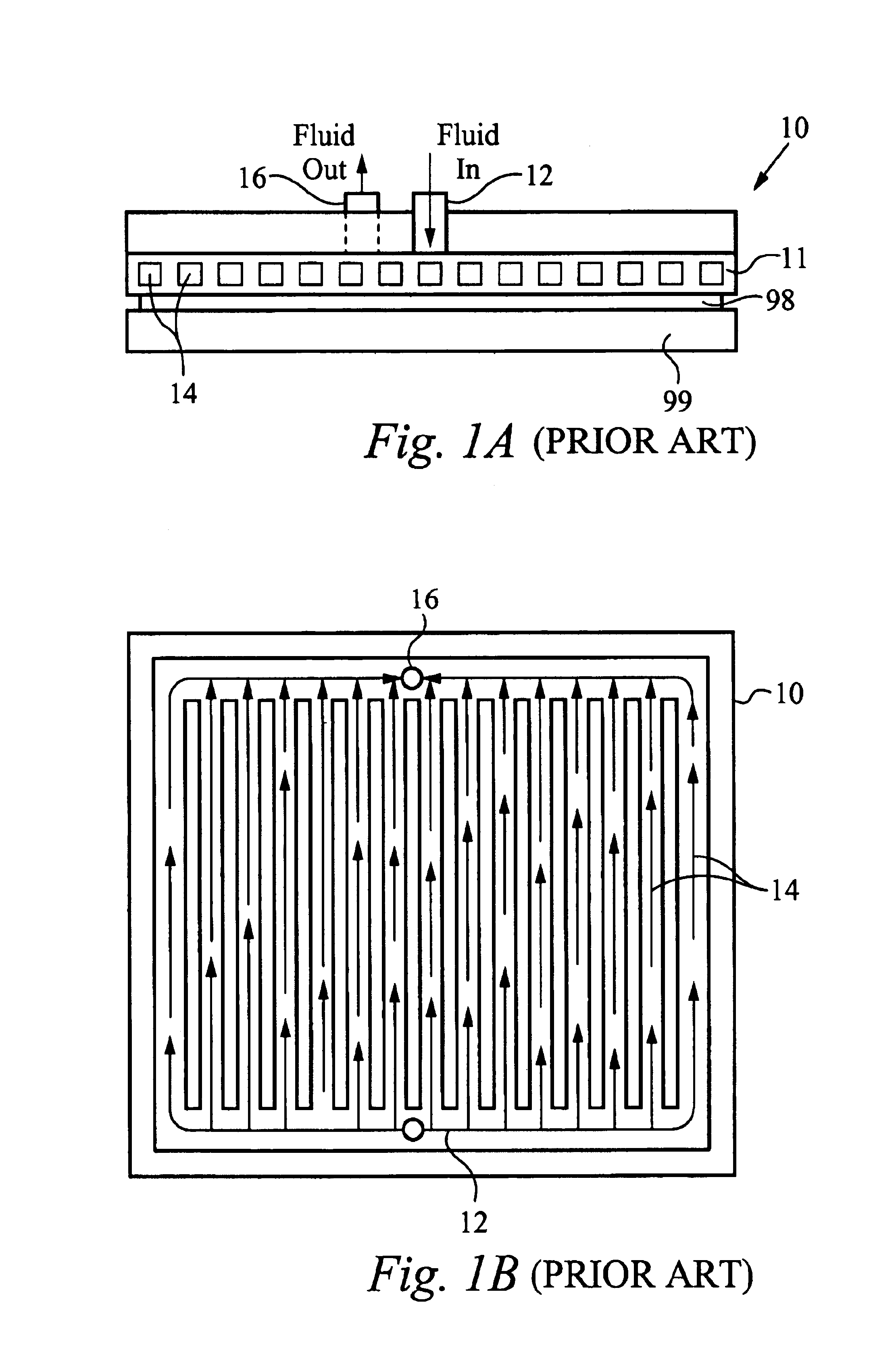

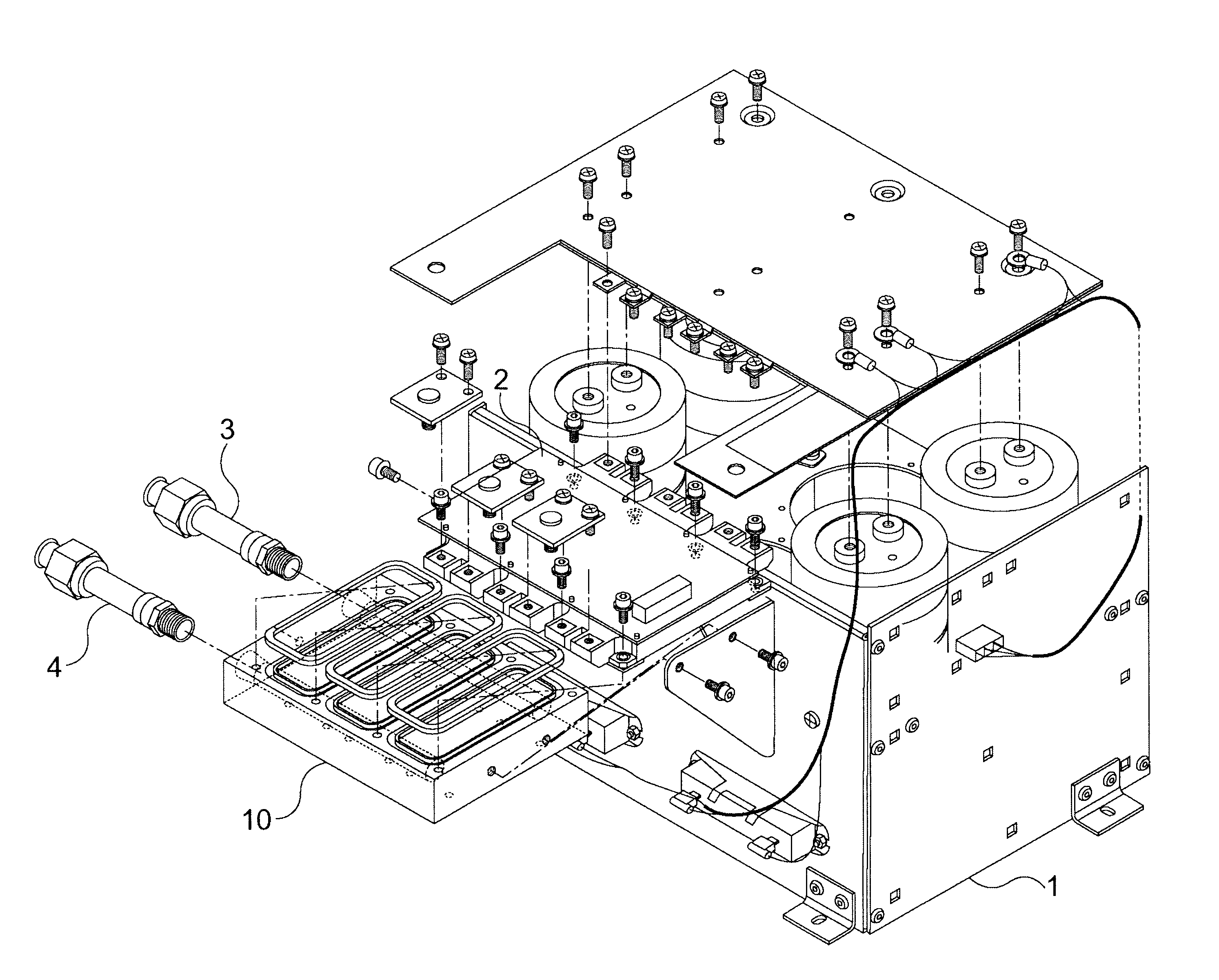

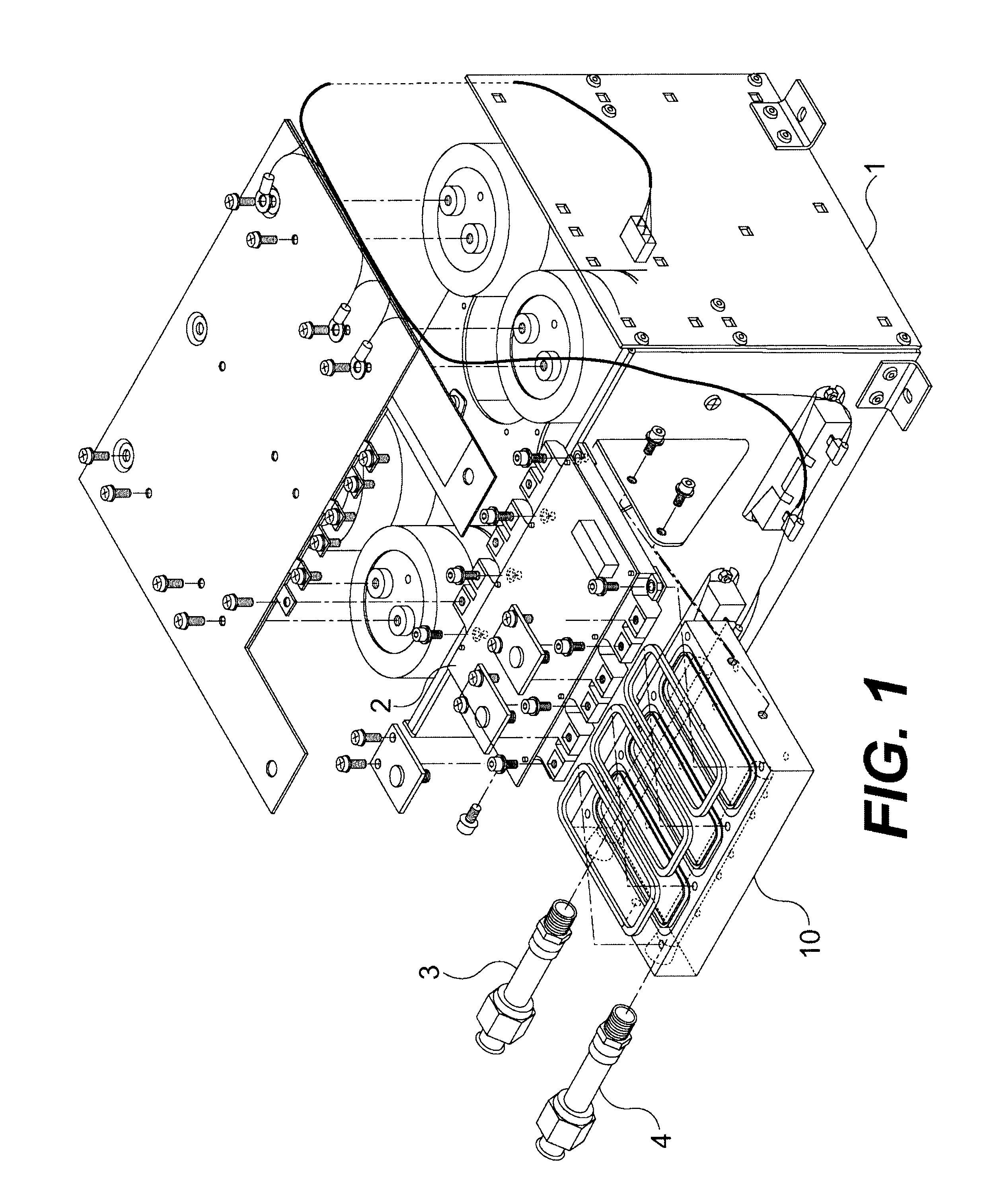

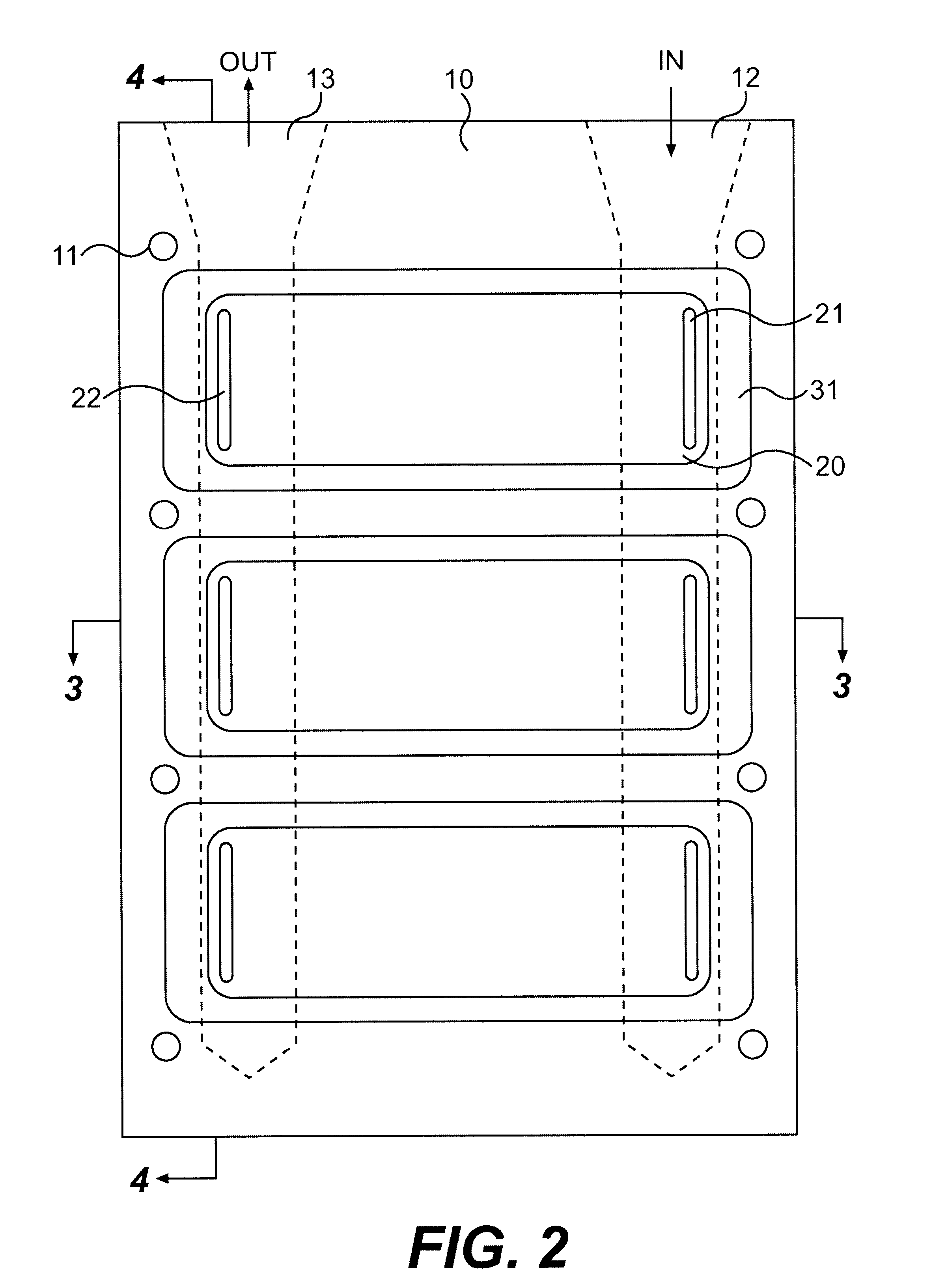

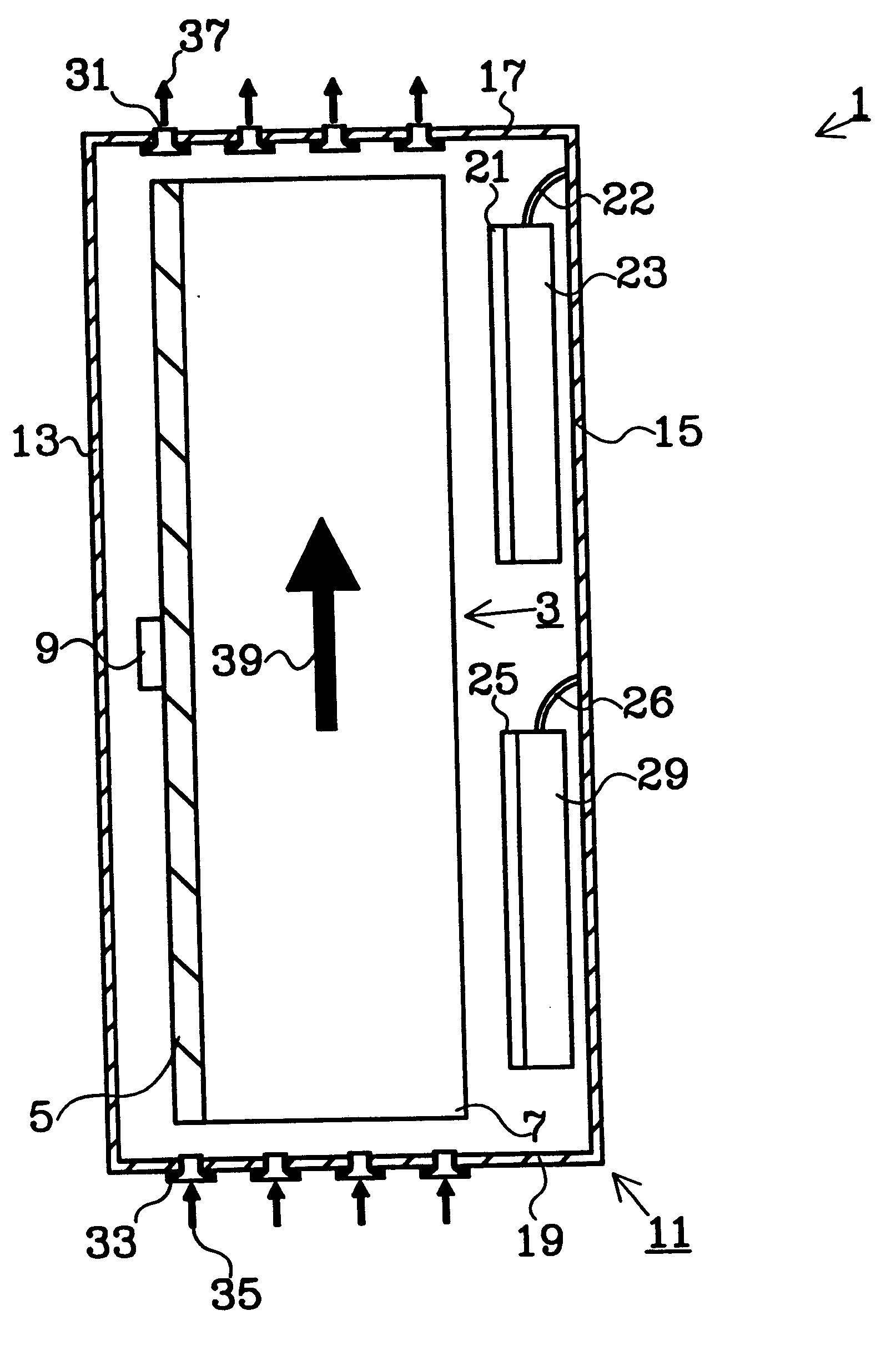

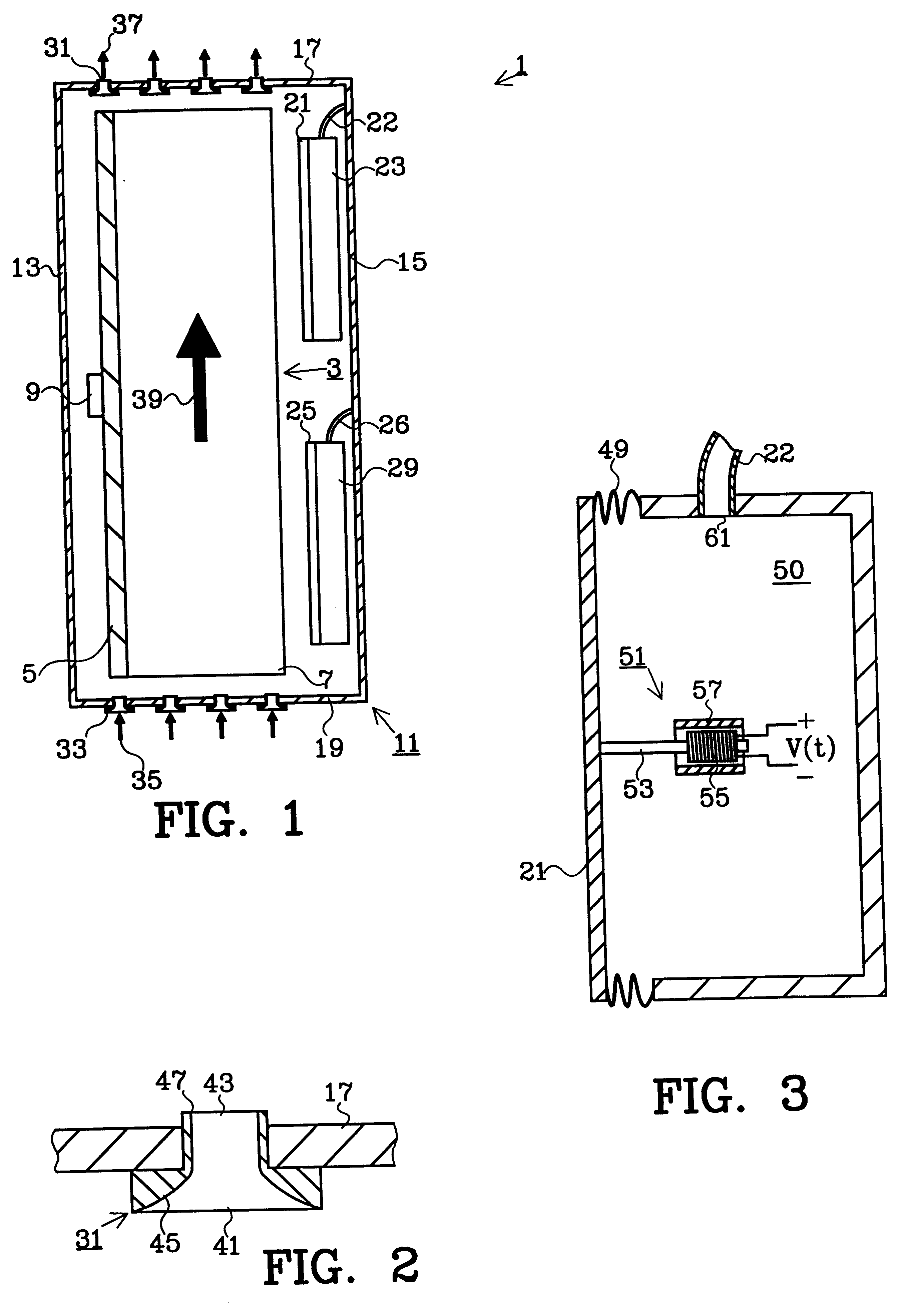

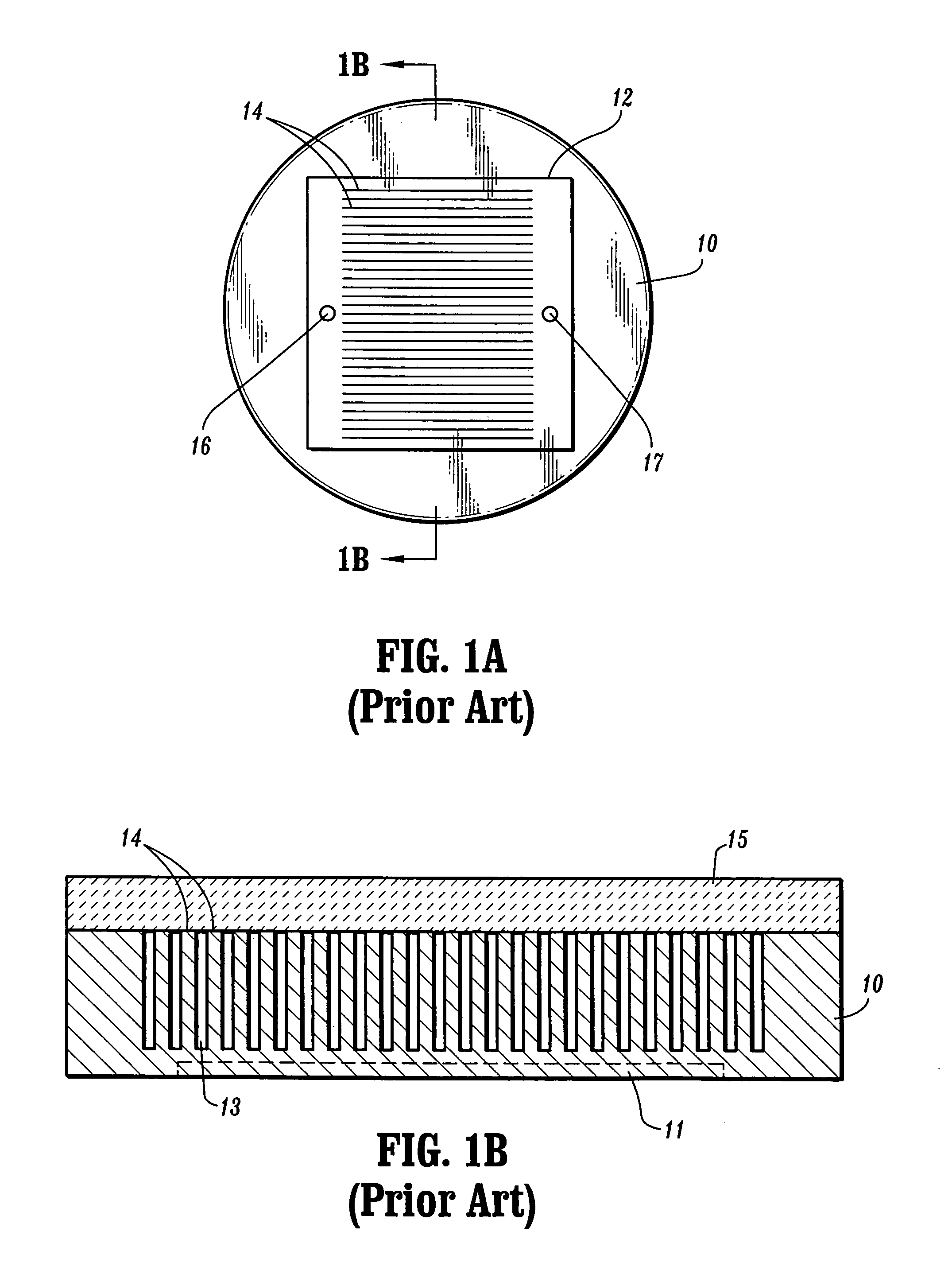

Electroosmotic microchannel cooling system

InactiveUS6942018B2High heat fluxIncrease powerFixed microstructural devicesSemiconductor/solid-state device detailsElectricityClosed loop

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

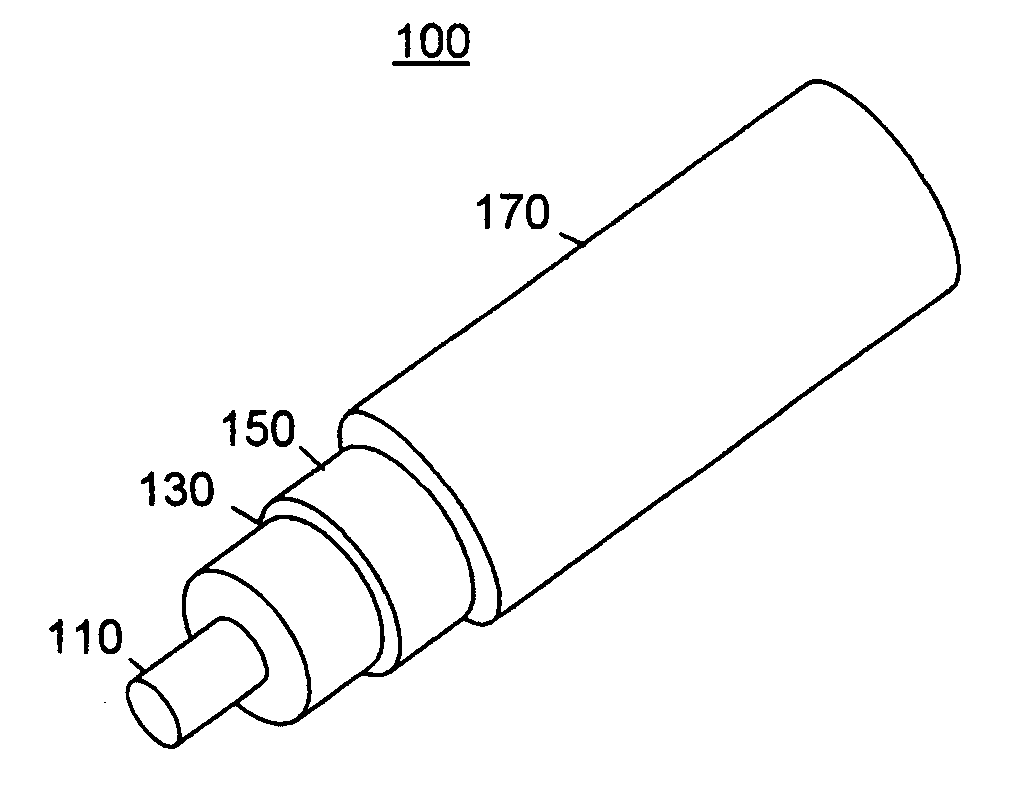

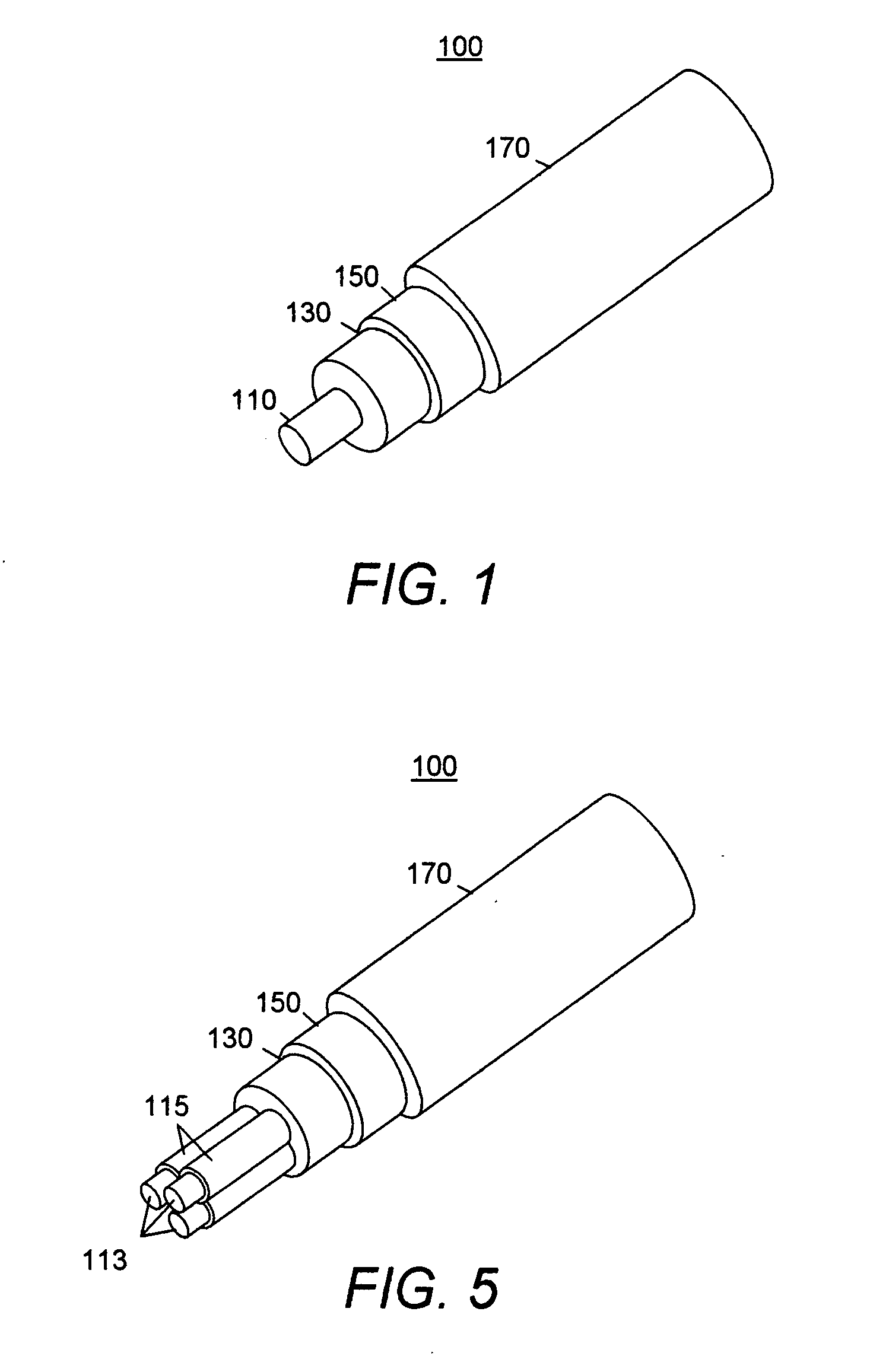

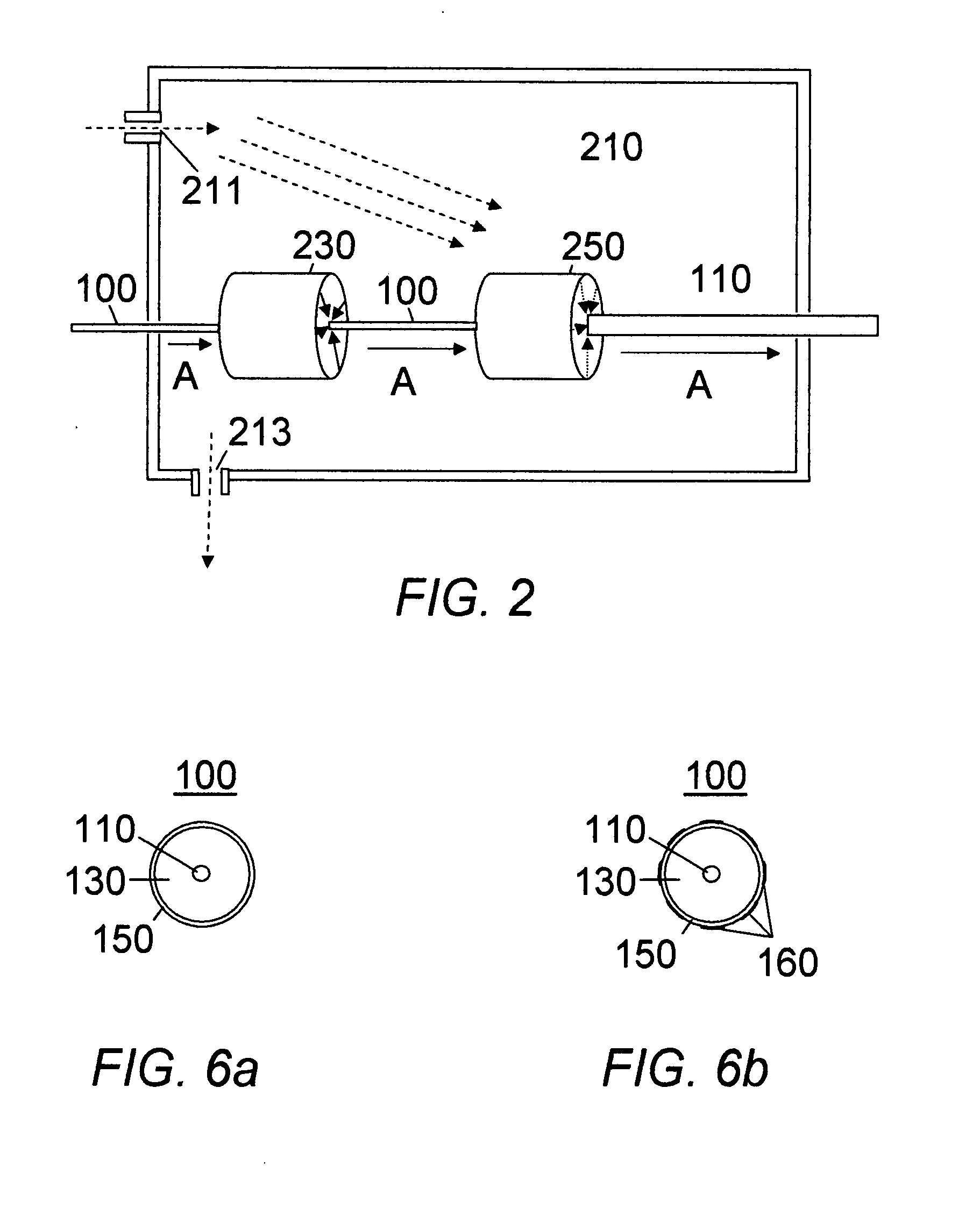

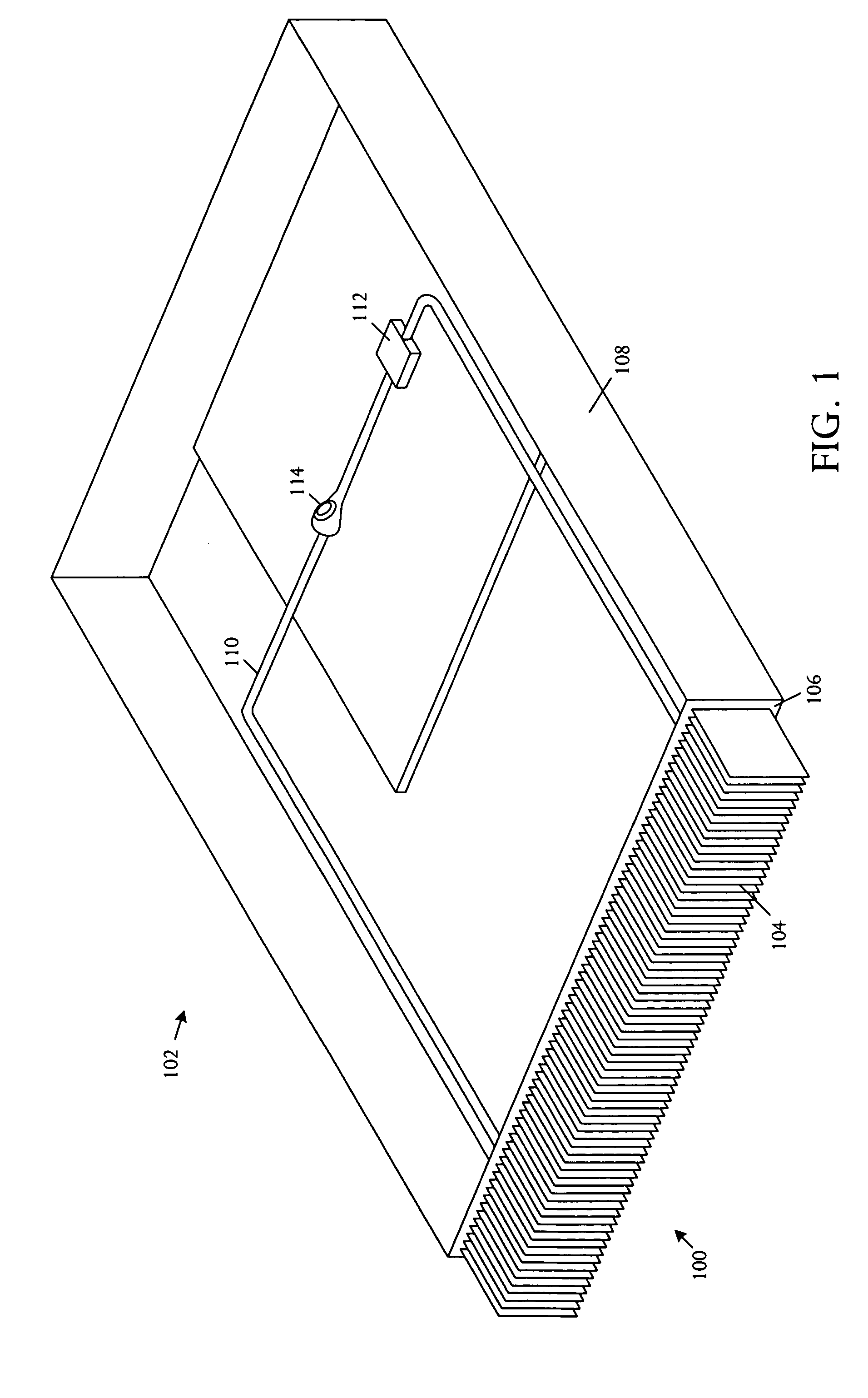

Multi-layer cable design and method of manufacture

InactiveUS20080060832A1Economically manufacturedVolume/mass flow measurementFluid pressure measurement by electric/magnetic elementsCathodic arc depositionFiber

A novel method of designing and fabricating flexible and lightweight cable [100] having a central conductor [110], a dielectric layer [130], an outer conductor [150] and an insulation coating [170] using thin film technology is disclosed. The dielectric layer [130] is ‘grown’ on dielectric layer [130] using electrophoretic deposition to a specified thickness, based upon its intended use. It may include nano-diamonds. Ion beam assisted deposition is used to metalize the cable dielectric layer [130]. This may be ion beam assisted sputtering, ion beam assisted evaporative deposition or ion beam assisted cathodic arc deposition. In an alternative embodiment, the outer conductor may be etched to provide greater flexibility, or to add a piezoelectric layer. The central conductor [110] may be created from dielectric fibers [113] which are metalized as described above. The piezoelectric layer added to create ultrasonic transducer cables.

Owner:RAZAVI ALI

Electrically optimized hybird "last mile" telecommunications cable system

InactiveUS6091025AEqual performanceEquivalent signal performanceCoaxial cables/analogue cablesQuad constructionsElectrical conductorTelecommunications cable

A cable system is provided which can accomodate electrical and optical cabling. The conductors of the system employ a layer which is impedance-matched to space, decreasing their cross-section to electromagnetic interference. The conductors of the system also employ a layer which symmetrizes electromagnetic interference signals, reducing the effect of interference and crosstalk on the signals carried by the conductors. The system also includes a node interface device for connection to a global electrical and fiber network. The node interface device connects to a user interface device through the cable.

Owner:KHAMSIN TECH LLC

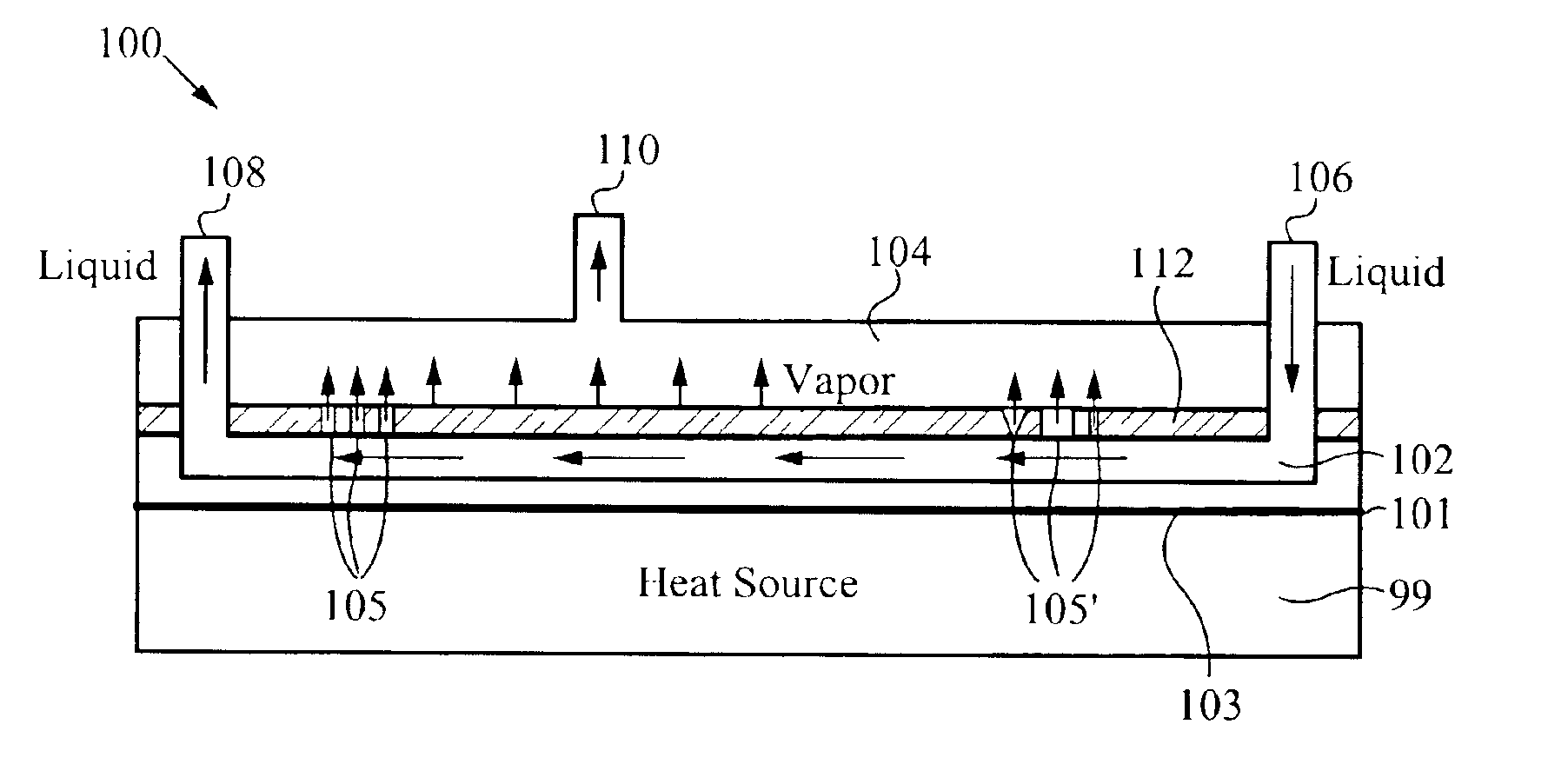

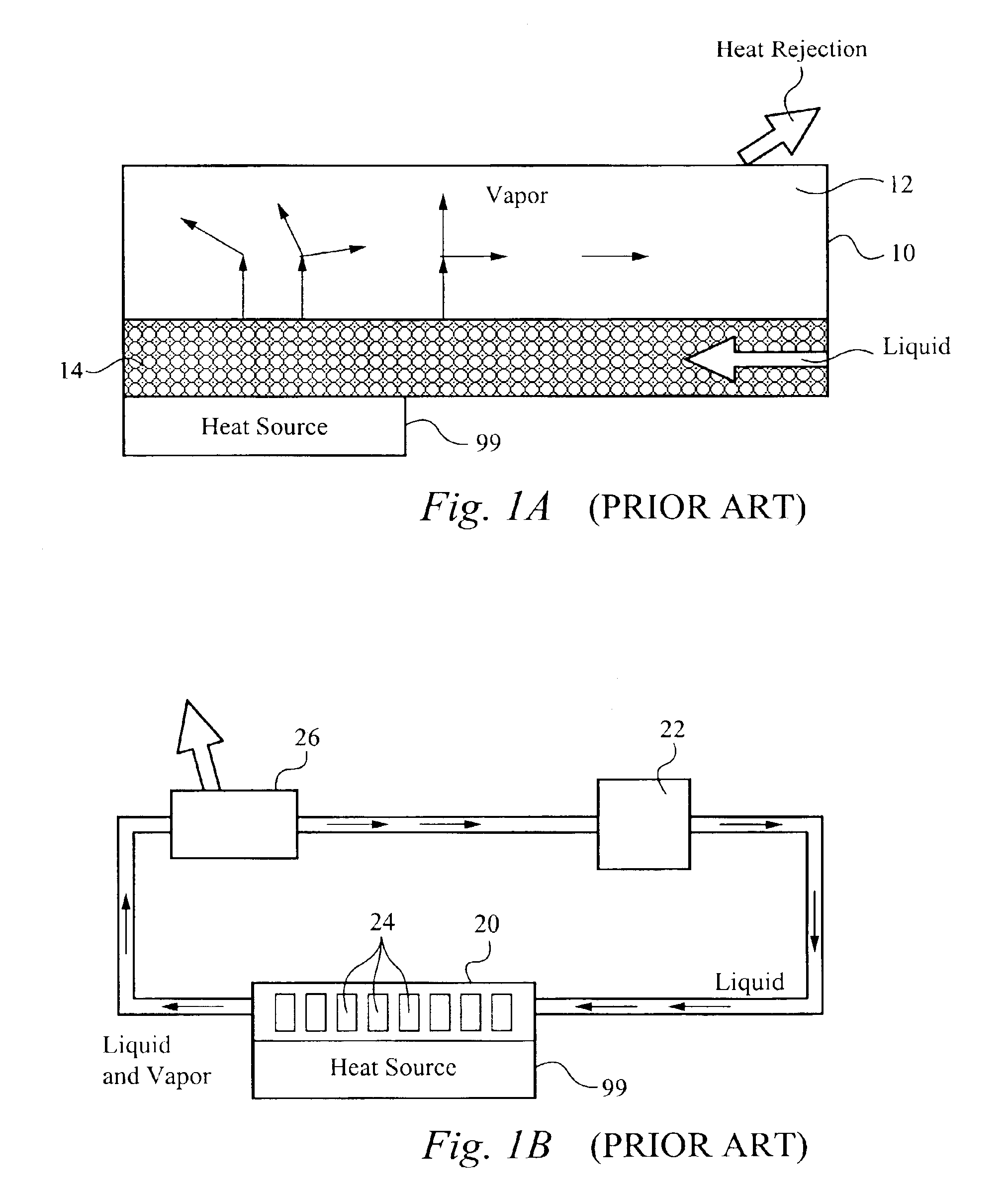

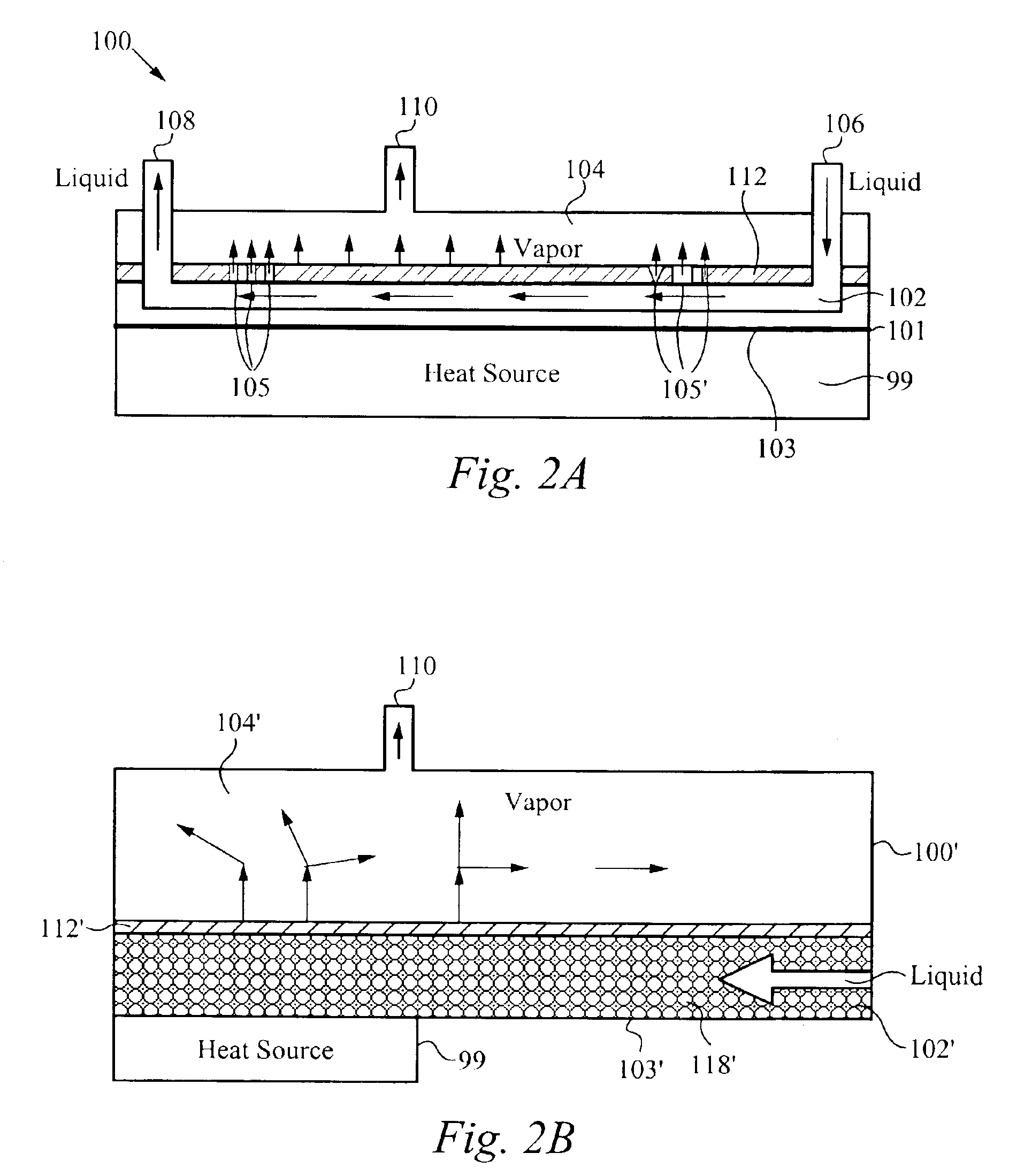

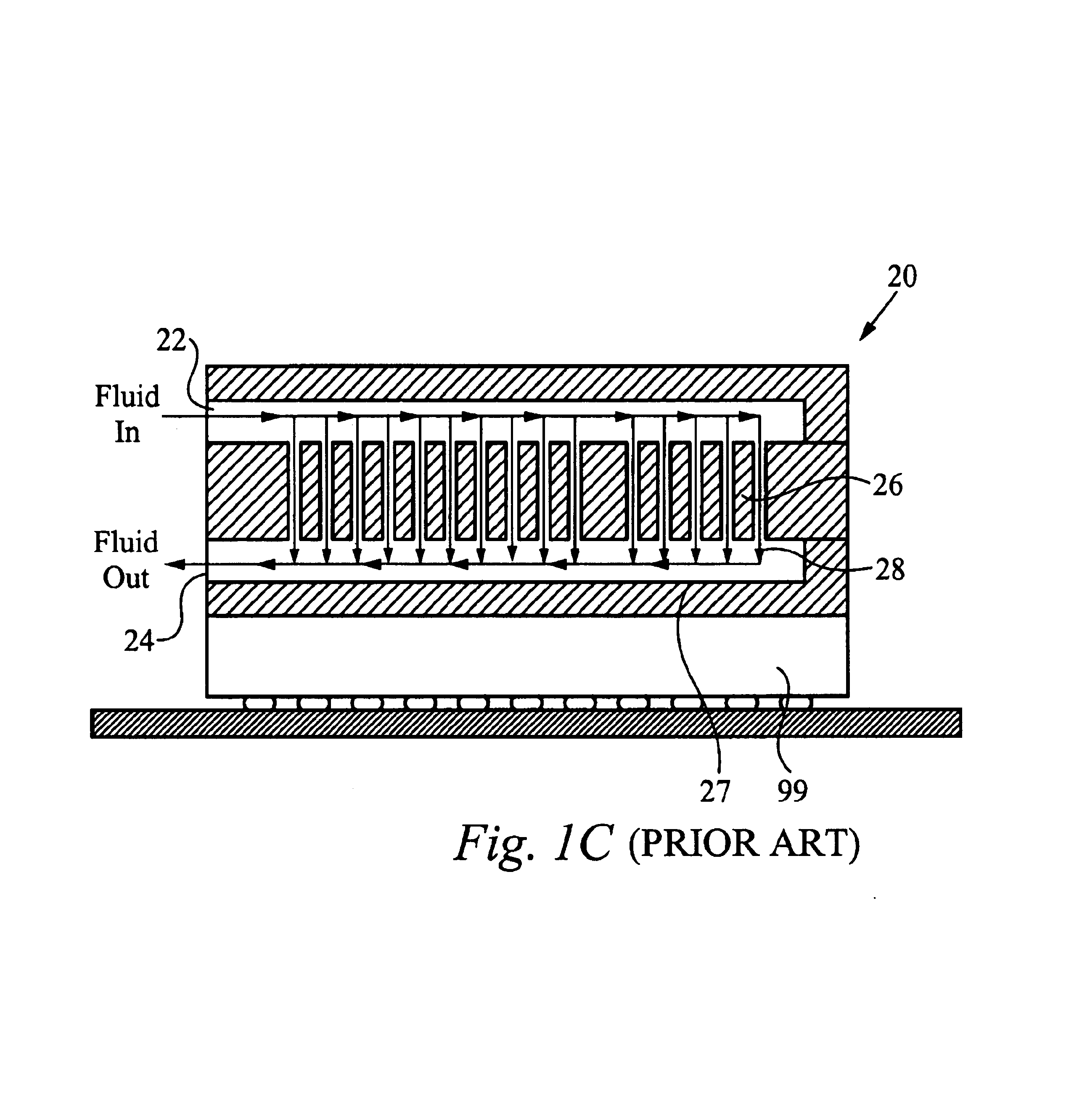

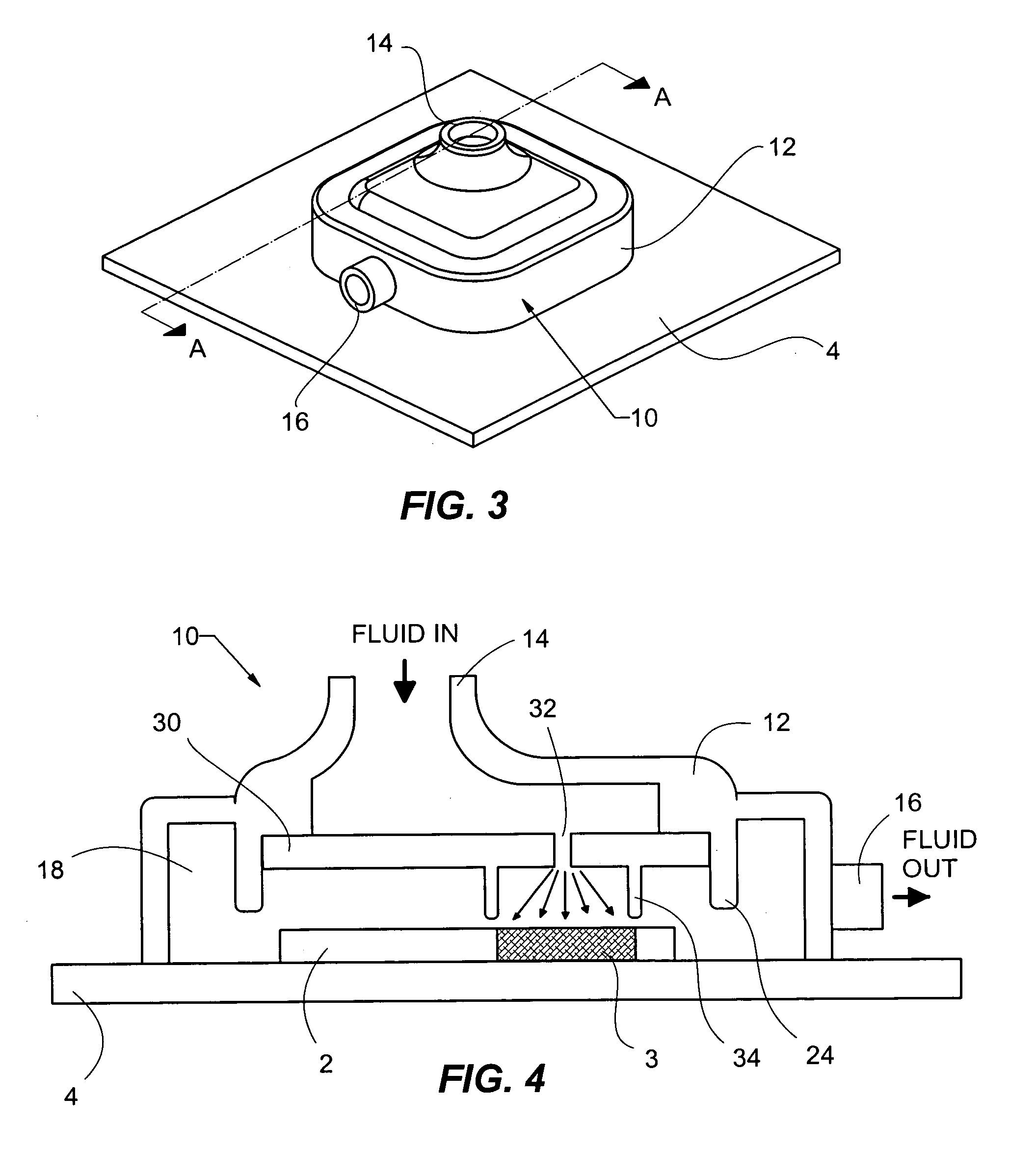

Vapor escape microchannel heat exchanger

InactiveUS6994151B2Semiconductor/solid-state device detailsSolid-state devicesHeat pipeHydrophobic surfaces

A vapor escape membrane for use in a heat exchanging device, including a heat pipe or heat sink that runs liquid into a cooling region positioned adjacent to the heat producing device, the vapor escape membrane comprising: a porous surface for removing vapor produced from the liquid in the cooling region, the membrane configured to confine the liquid only within the cooling region. The vapor escape membrane transfers vapor to a vapor region within the heat exchanging device, wherein the membrane is configured to prevent liquid in the cooling region from entering the vapor region. The membrane is configured to include a hydrophobic surface between the membrane and the cooling region, wherein the liquid in the cooling region does not flow through the porous surface. The vapor escape membrane includes a plurality of apertures for allowing vapor to transfer therethrough, each of the apertures having a predetermined dimension.

Owner:VERTIV CORP

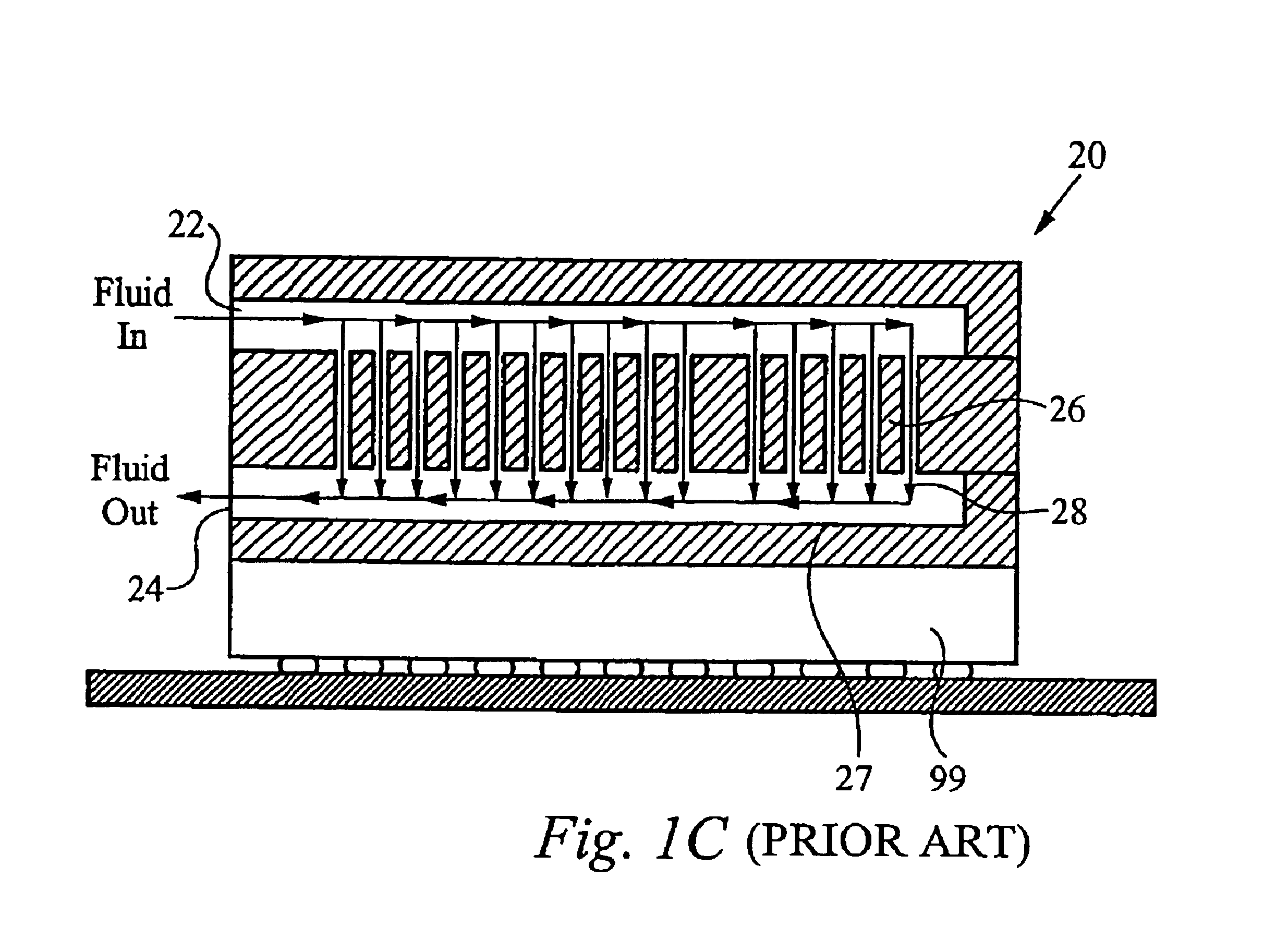

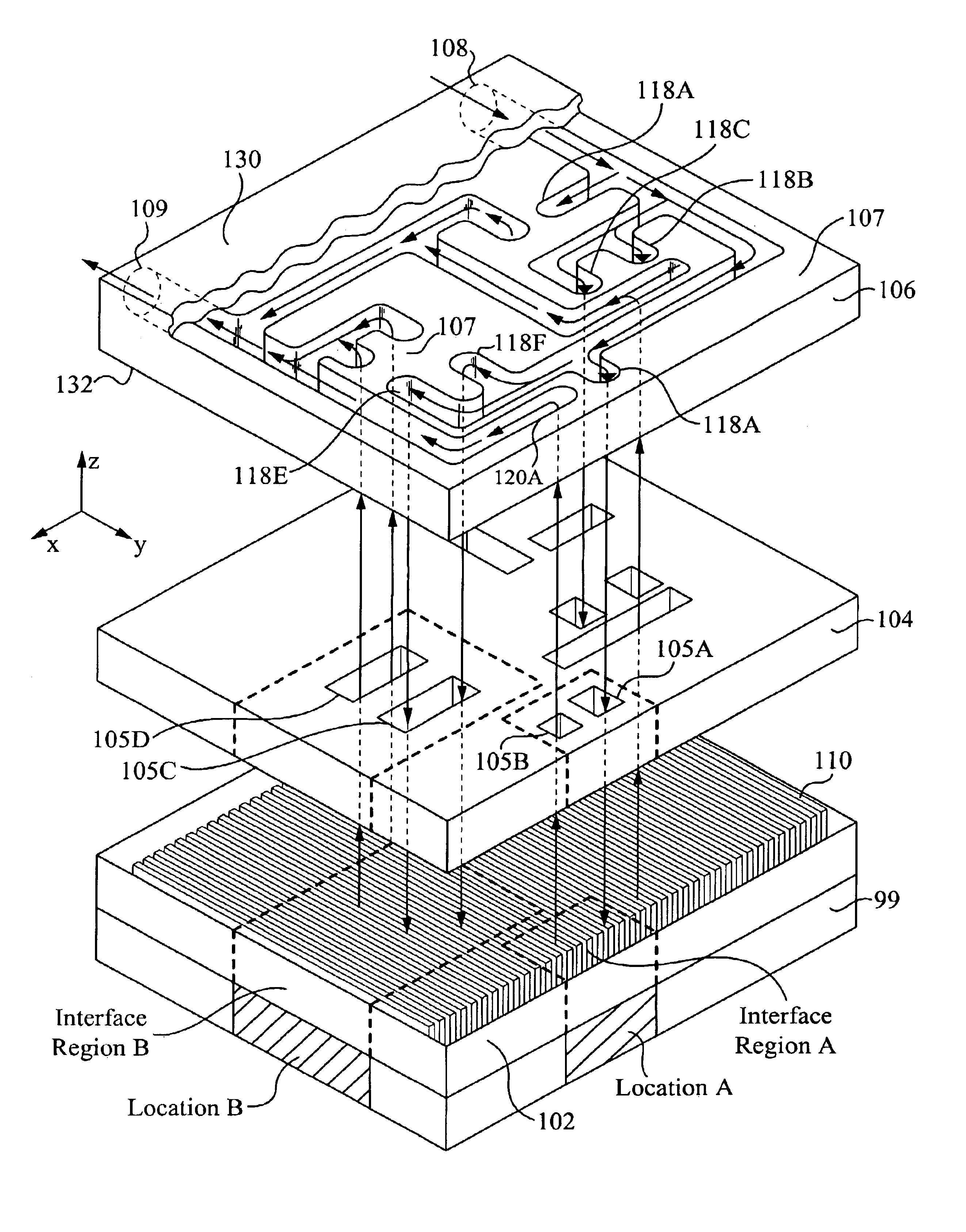

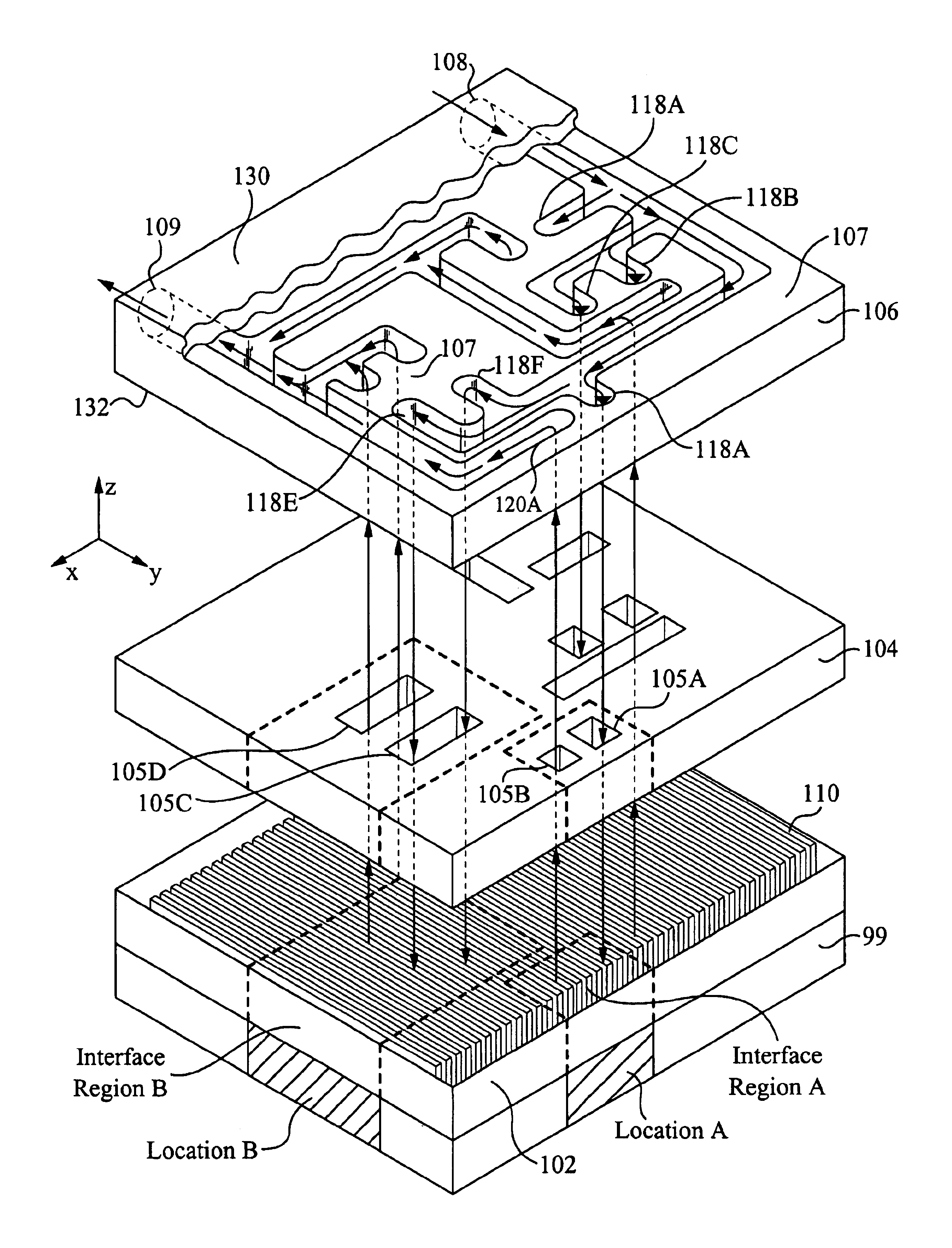

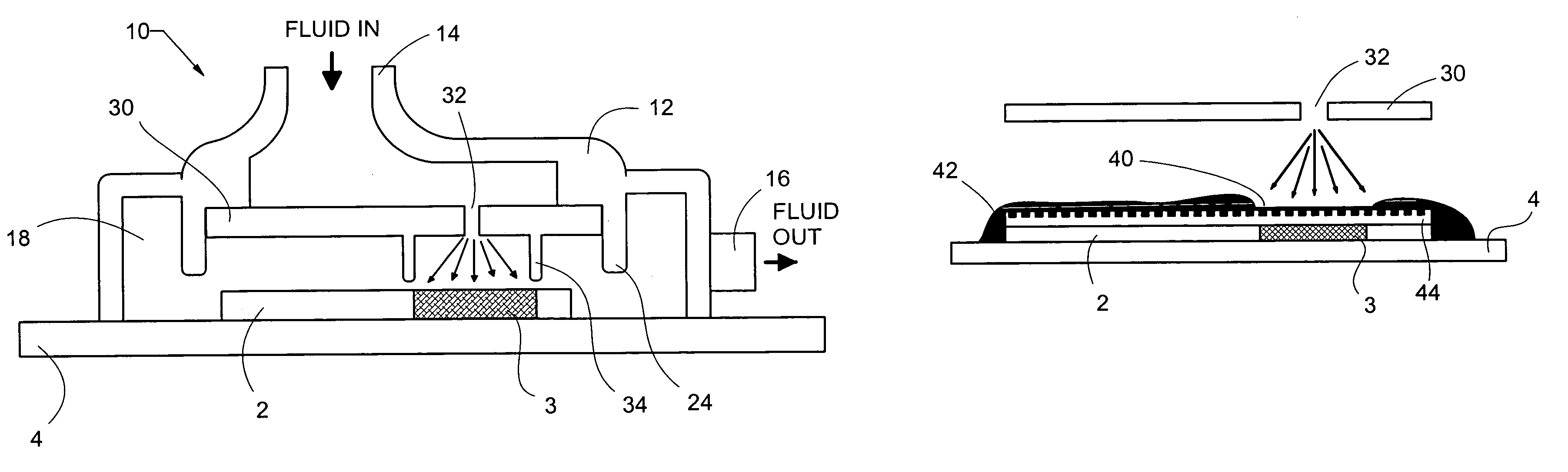

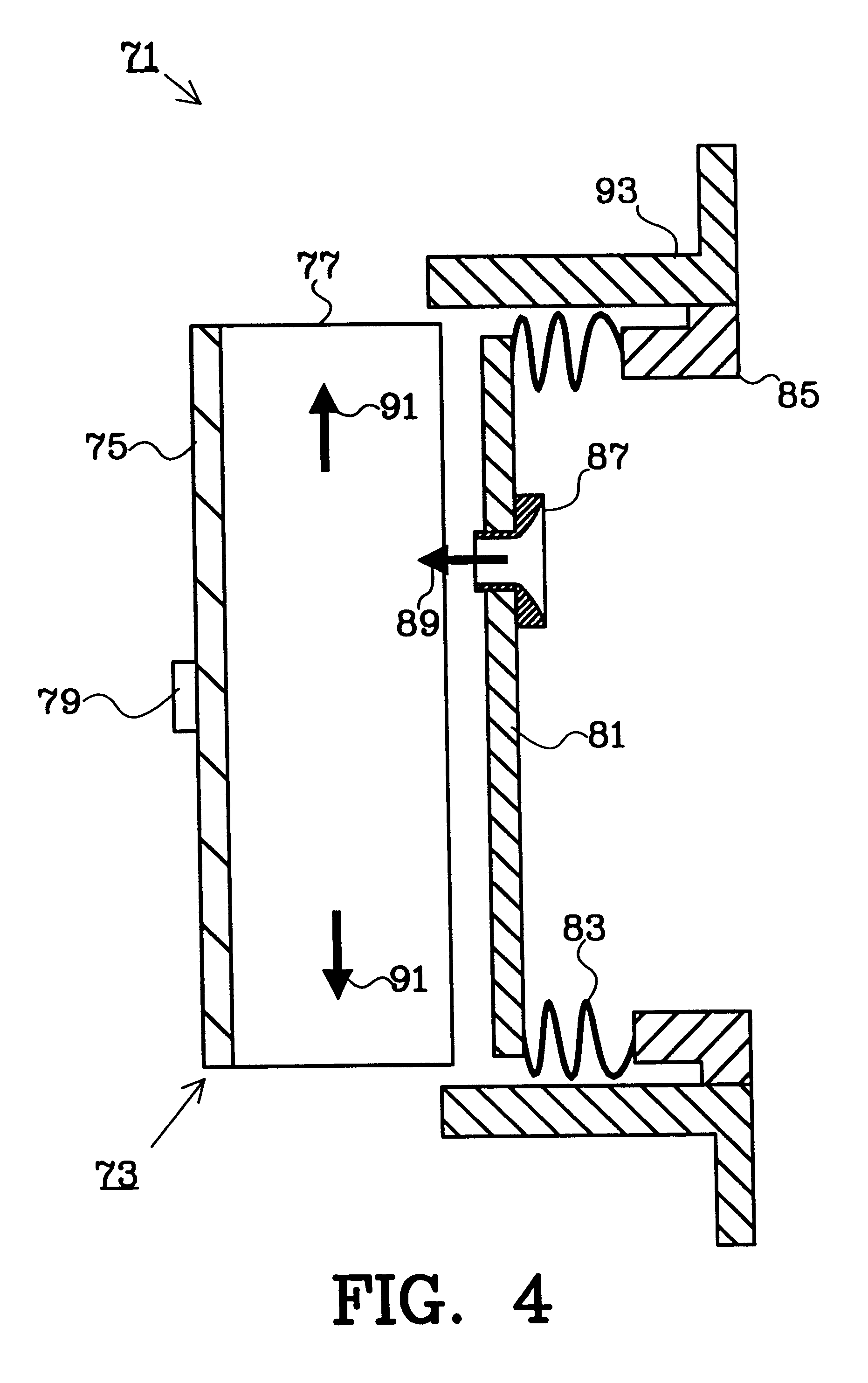

Method and apparatus for efficient vertical fluid delivery for cooling a heat producing device

InactiveUS7000684B2Minimized fluid path distanceImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesInterface layerPath distance

A heat exchanger and method of manufacturing thereof comprises an interface layer for cooling a heat source. The interface layer is coupled to the heat source and is configured to pass fluid therethrough. The heat exchanger further comprises a manifold layer that is coupled to the interface layer. The manifold layer includes at least one first port that is coupled to a first set of individualized holes which channel fluid through the first set. The manifold layer includes at least one second port coupled to a second set of individualized holes which channel fluid through the second set. The first set of holes and second set of holes are arranged to provide a minimized fluid path distance between the first and second ports to adequately cool the heat source. Preferably, each hole in the first set is positioned a closest optimal distance to an adjacent hole the second set.

Owner:VERTIV CORP

Method and apparatus for achieving temperature uniformity and hot spot cooling in a heat producing device

ActiveUS7104312B2Minimize temperature differenceTemperatue controlSemiconductor/solid-state device detailsTemperature differenceEngineering

A method of controlling temperature of a heat source in contact with a heat exchanging surface of a heat exchanger, wherein the heat exchanging surface is substantially aligned along a plane. The method comprises channeling a first temperature fluid to the heat exchanging surface, wherein the first temperature fluid undergoes thermal exchange with the heat source along the heat exchanging surface. The method comprises channeling a second temperature fluid from the heat exchange surface, wherein fluid is channeled to minimize temperature differences along the heat source. The temperature differences are minimized by optimizing and controlling the fluidic and thermal resistances in the heat exchanger. The resistances to the fluid are influenced by size, volume and surface area of heat transferring features, multiple pumps, fixed and variable valves and flow impedance elements in the fluid path, pressure and flow rate control of the fluid, and other factors.

Owner:VERTIV CORP

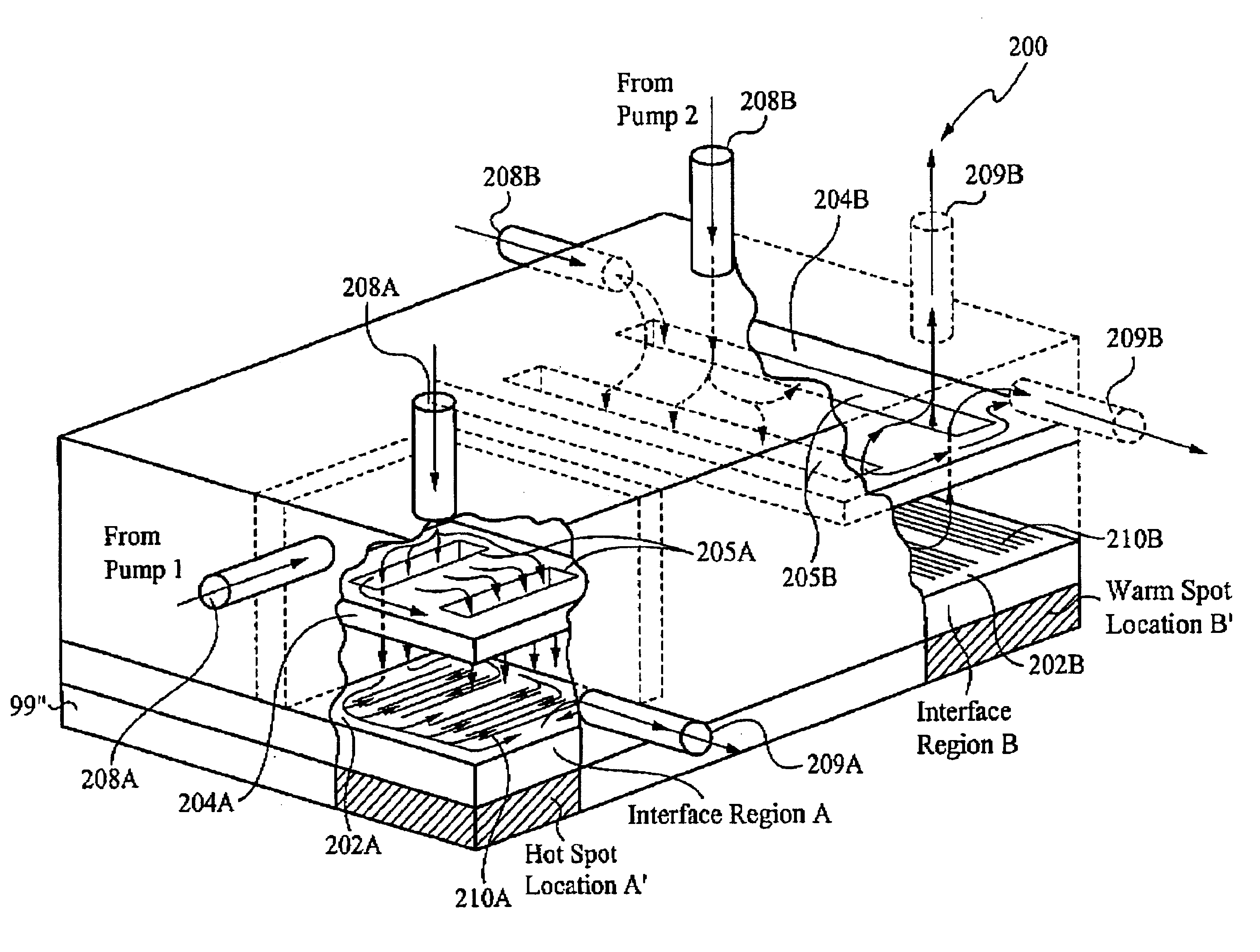

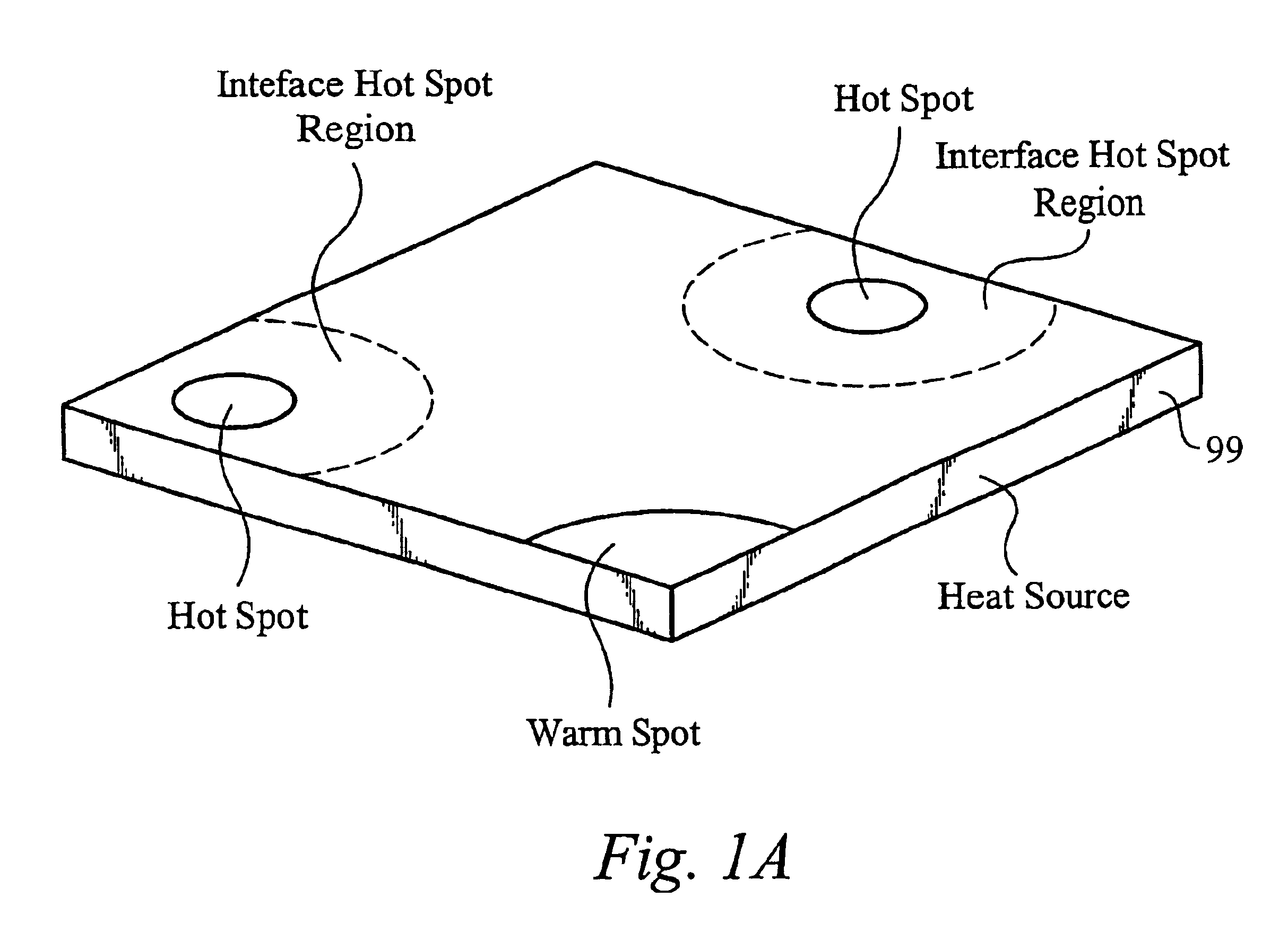

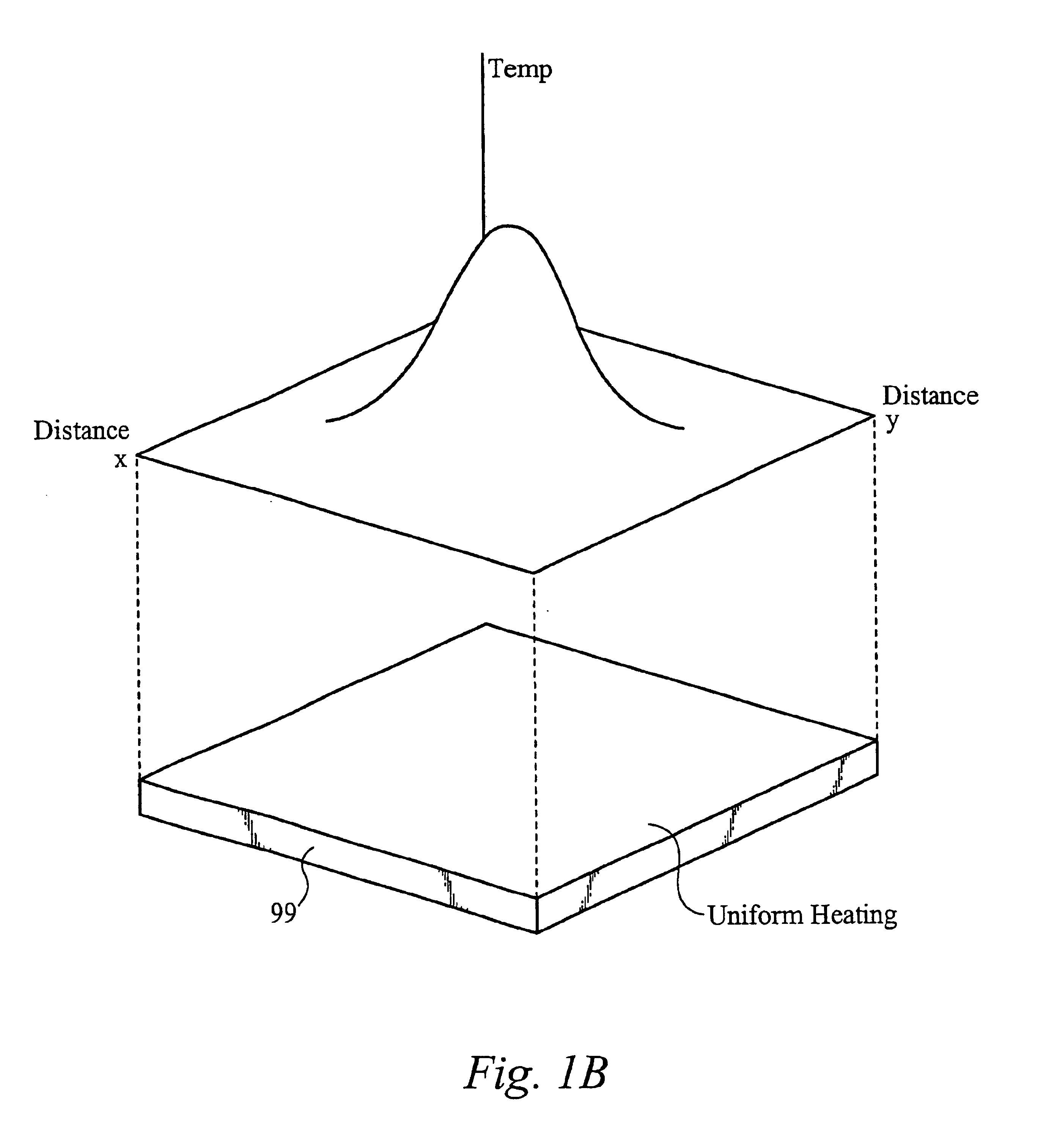

Method and apparatus for flexible fluid delivery for cooling desired hot spots in a heat producing device

InactiveUS6988534B2Temperatue controlSemiconductor/solid-state device detailsInter layerInterface layer

A heat exchanger apparatus and method of manufacturing comprising: an interface layer for cooling a heat source and configured to pass fluid therethrough, the interface layer having an appropriate thermal conductivity and a manifold layer for providing fluid to the interface layer, wherein the manifold layer is configured to achieve temperature uniformity in the heat source preferably by cooling interface hot spot regions. A plurality of fluid ports are configured to the heat exchanger such as an inlet port and outlet port, whereby the fluid ports are configured vertically and horizontally. The manifold layer circulates fluid to a predetermined interface hot spot region in the interface layer, wherein the interface hot spot region is associated with the hot spot. The heat exchanger preferably includes an intermediate layer positioned between the interface and manifold layers and optimally channels fluid to the interface hot spot region.

Owner:VERTIV CORP

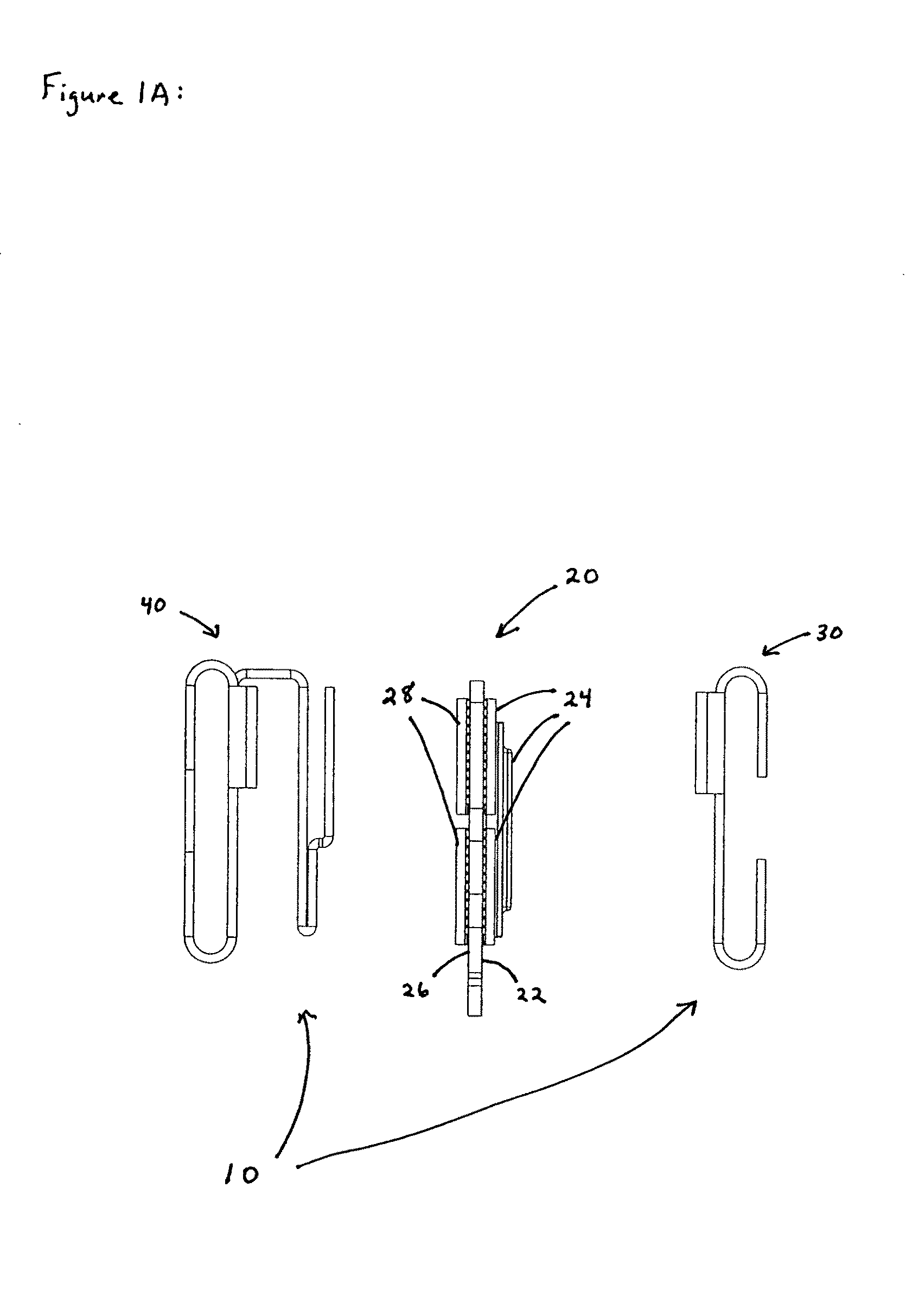

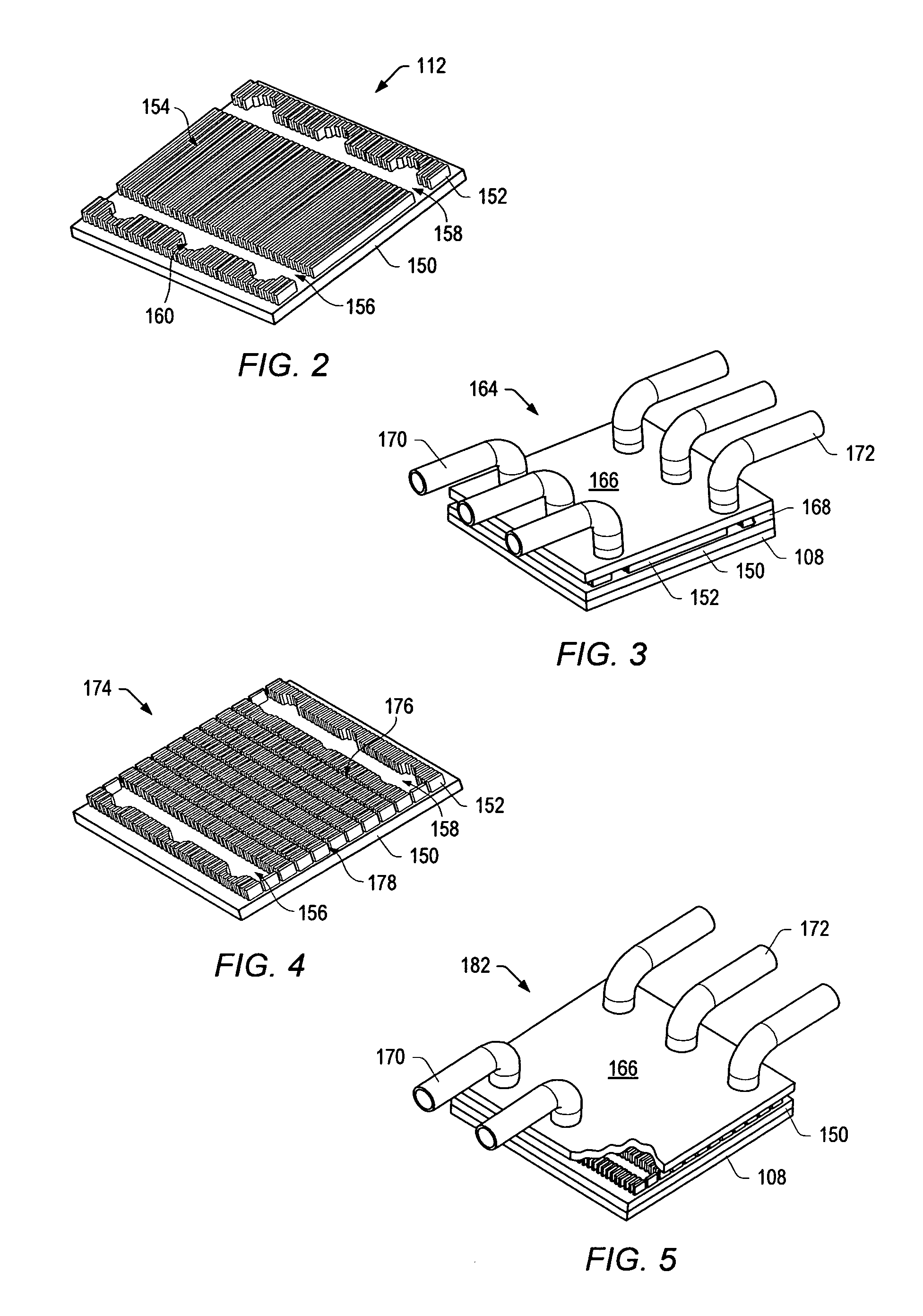

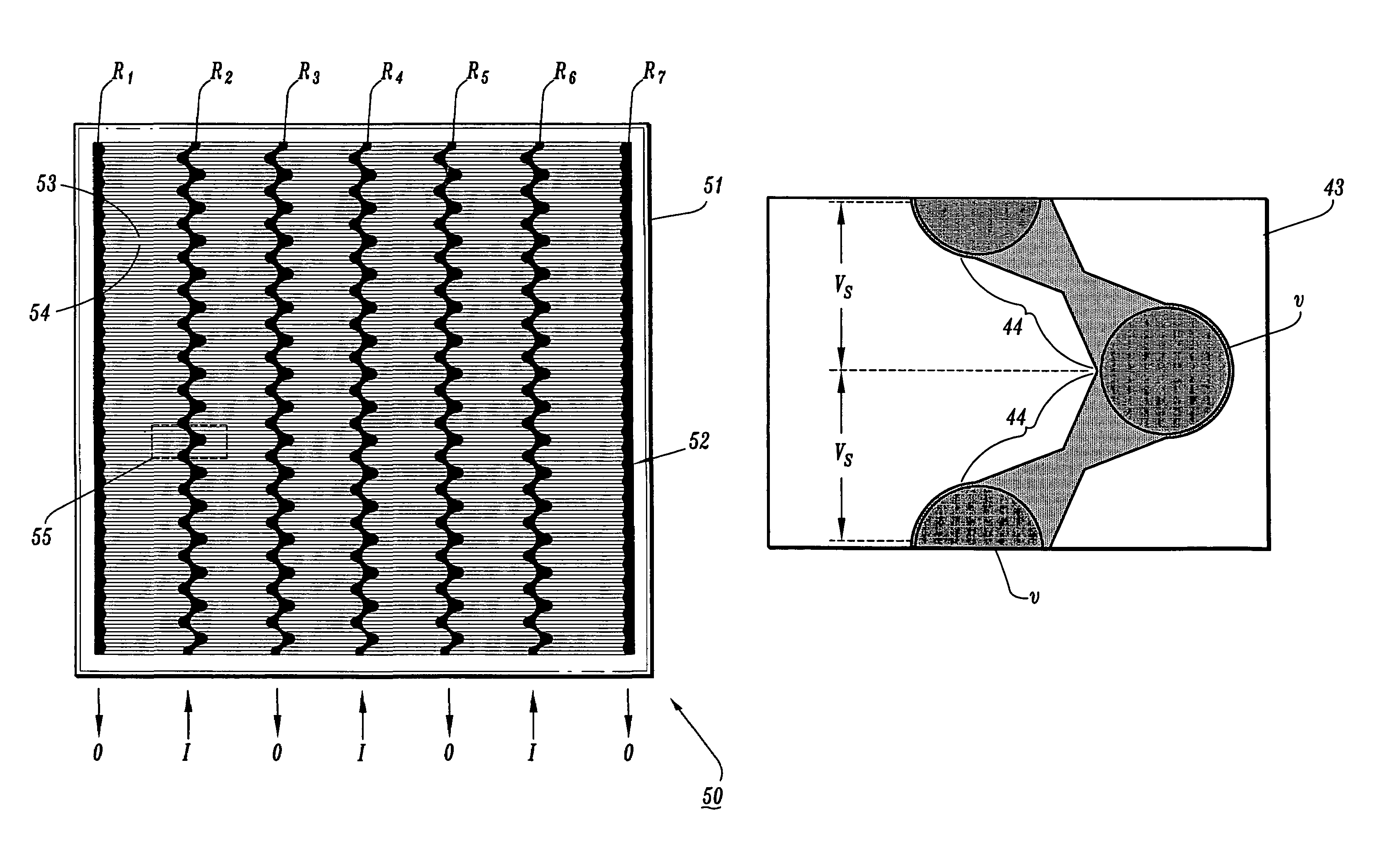

Interwoven manifolds for pressure drop reduction in microchannel heat exchangers

InactiveUS6986382B2Semiconductor/solid-state device detailsSolid-state devicesInterface layerEngineering

A microchannel heat exchanger coupled to a heat source and configured for cooling the heat source comprising a first set of fingers for providing fluid at a first temperature to a heat exchange region, wherein fluid in the heat exchange region flows toward a second set of fingers and exits the heat exchanger at a second temperature, wherein each finger is spaced apart from an adjacent finger by an appropriate dimension to minimize pressure drop in the heat exchanger and arranged in parallel. The microchannel heat exchanger includes an interface layer having the heat exchange region. Preferably, a manifold layer includes the first set of fingers and the second set of fingers configured within to cool hot spots in the heat source. Alternatively, the interface layer includes the first set and second set of fingers configured along the heat exchange region.

Owner:VERTIV CORP

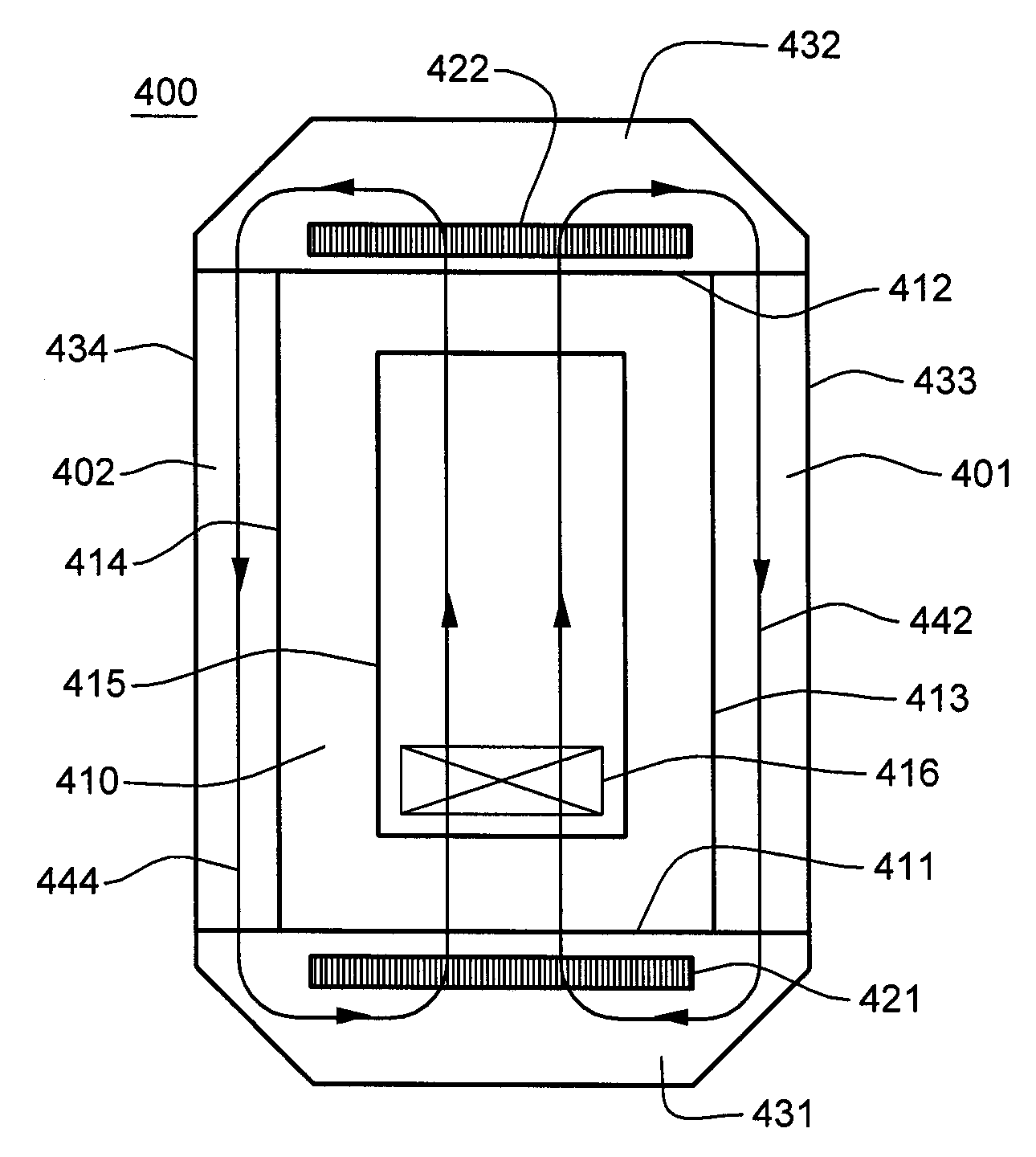

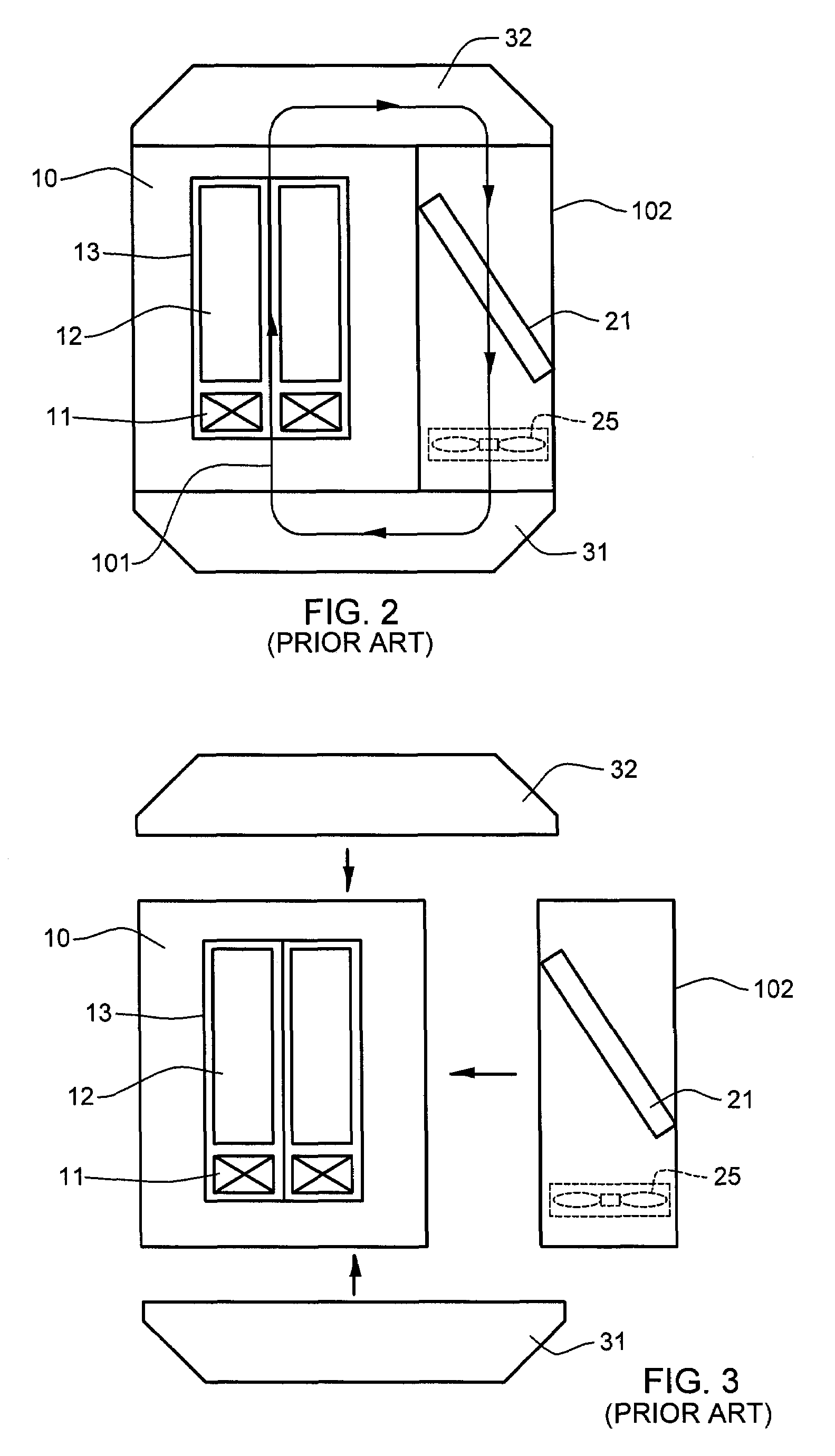

Cooling apparatus and method for an electronics module employing an integrated heat exchange assembly

A cooling apparatus for an electronics assembly having a substrate and one or more electronics devices includes an enclosure sealably engaging the substrate to form a cavity, with the electronics devices and a heat exchange assembly being disposed within the cavity. The heat exchange assembly defines a primary coolant flow path and a separate, secondary coolant flow path. The primary coolant flow path includes first and second chambers in fluid communication, and the secondary flow path includes a third chamber disposed between the first and second chambers. The heat exchange assembly provides a first thermal conduction path between primary coolant in the first chamber and secondary coolant in the third chamber, and a second thermal conduction path between primary coolant in the second chamber and secondary coolant in the third chamber. The heat exchange assembly further includes coolant nozzles to direct primary coolant towards the electronics devices.

Owner:IBM CORP

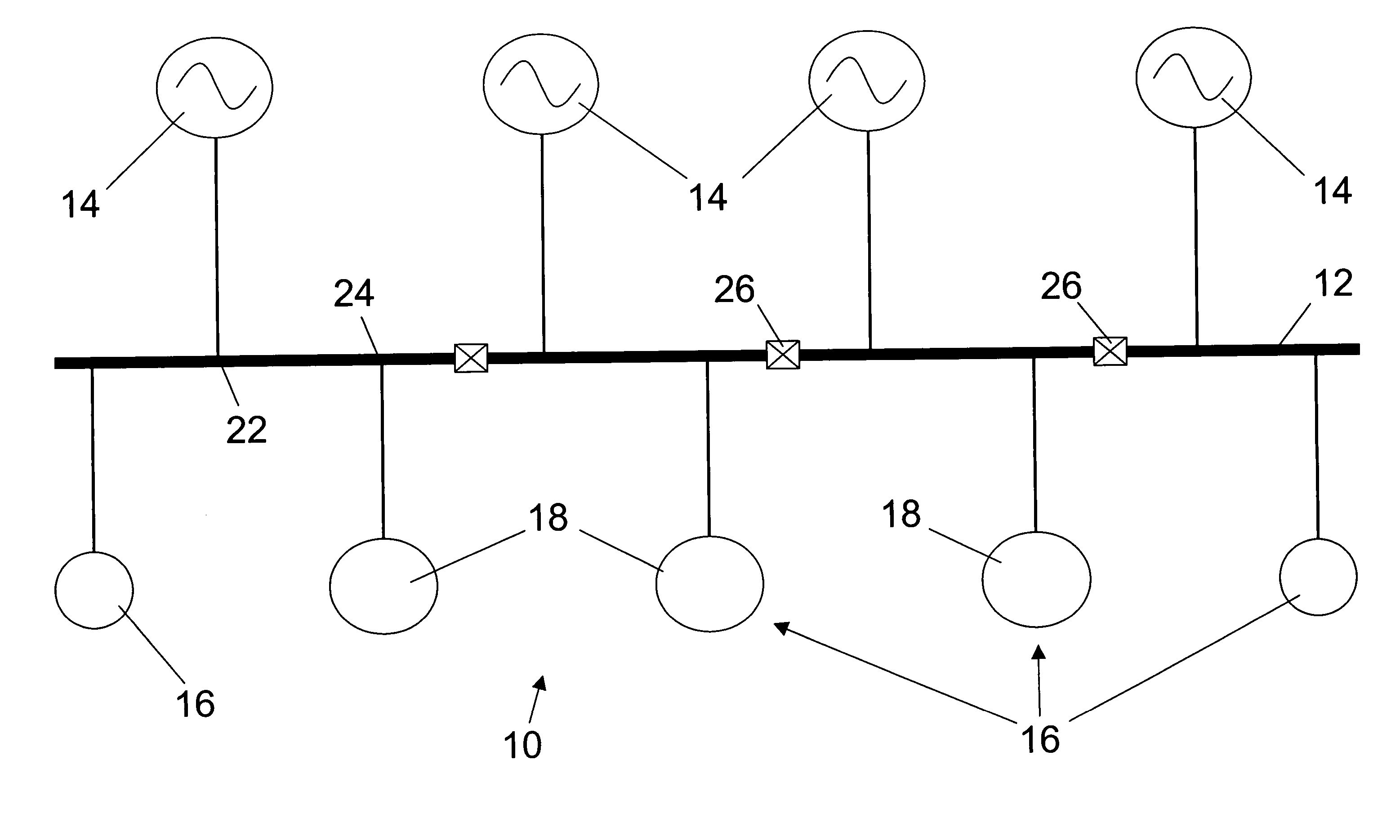

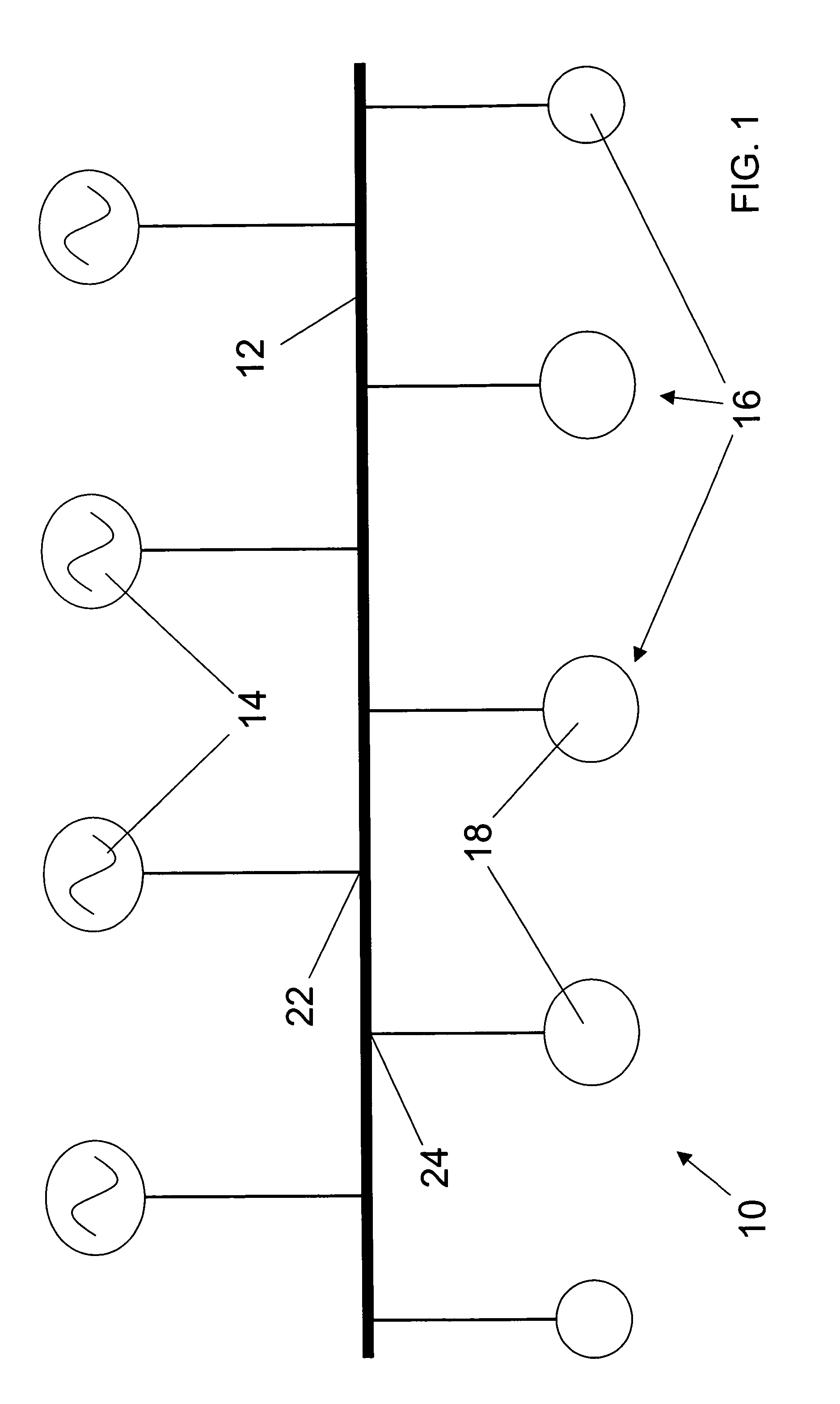

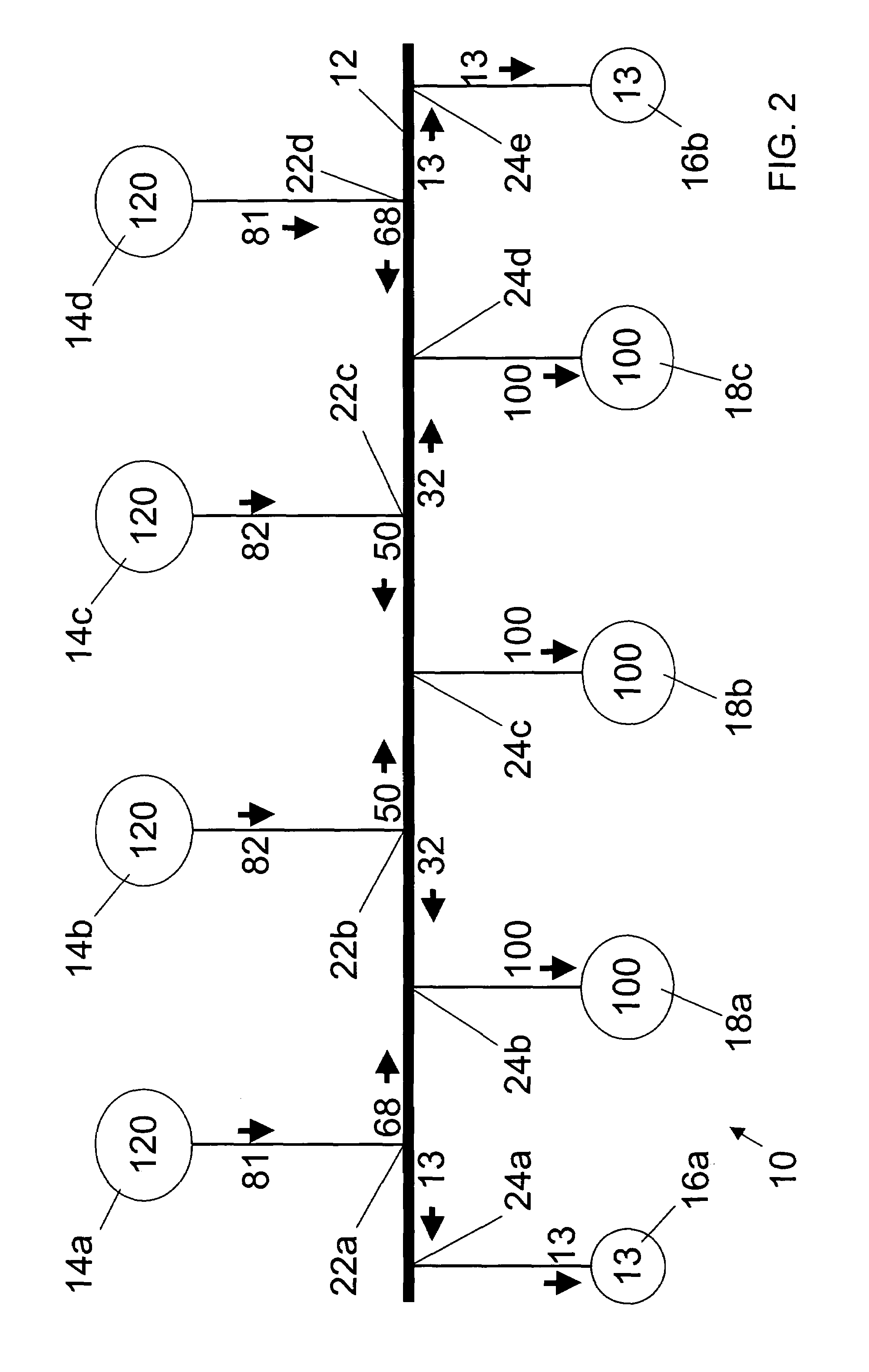

Stand-alone electrical system for large motor loads

ActiveUS7388303B2Sufficient rateMinimal impactSolidificationLiquefactionElectric power systemDistributed power

An electrical power system that can be used to interconnect a plurality of generators to a plurality to loads while being rated at less than a total power consumed. The system is preferably used to distribute power for a Liquefied Natural Gas (LNG) facility. The system broadly comprises a primary bus connected between the generators and the loads, such as electrical compressor motors used in the LNG facility. The generators and the loads are arranged along the primary bus in order to distribute the power from the generators to the loads, without overloading the primary bus.

Owner:CONOCOPHILLIPS CO

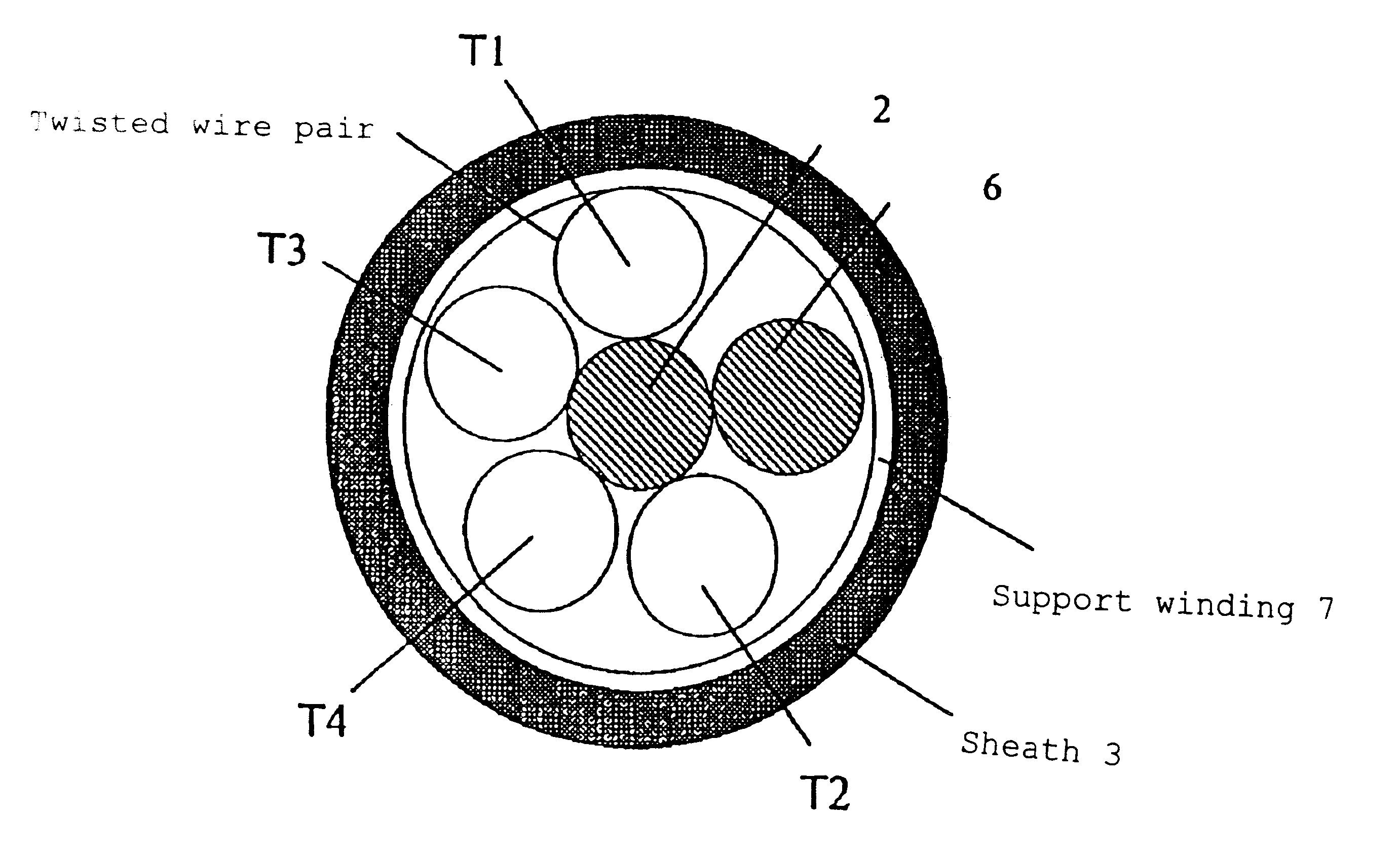

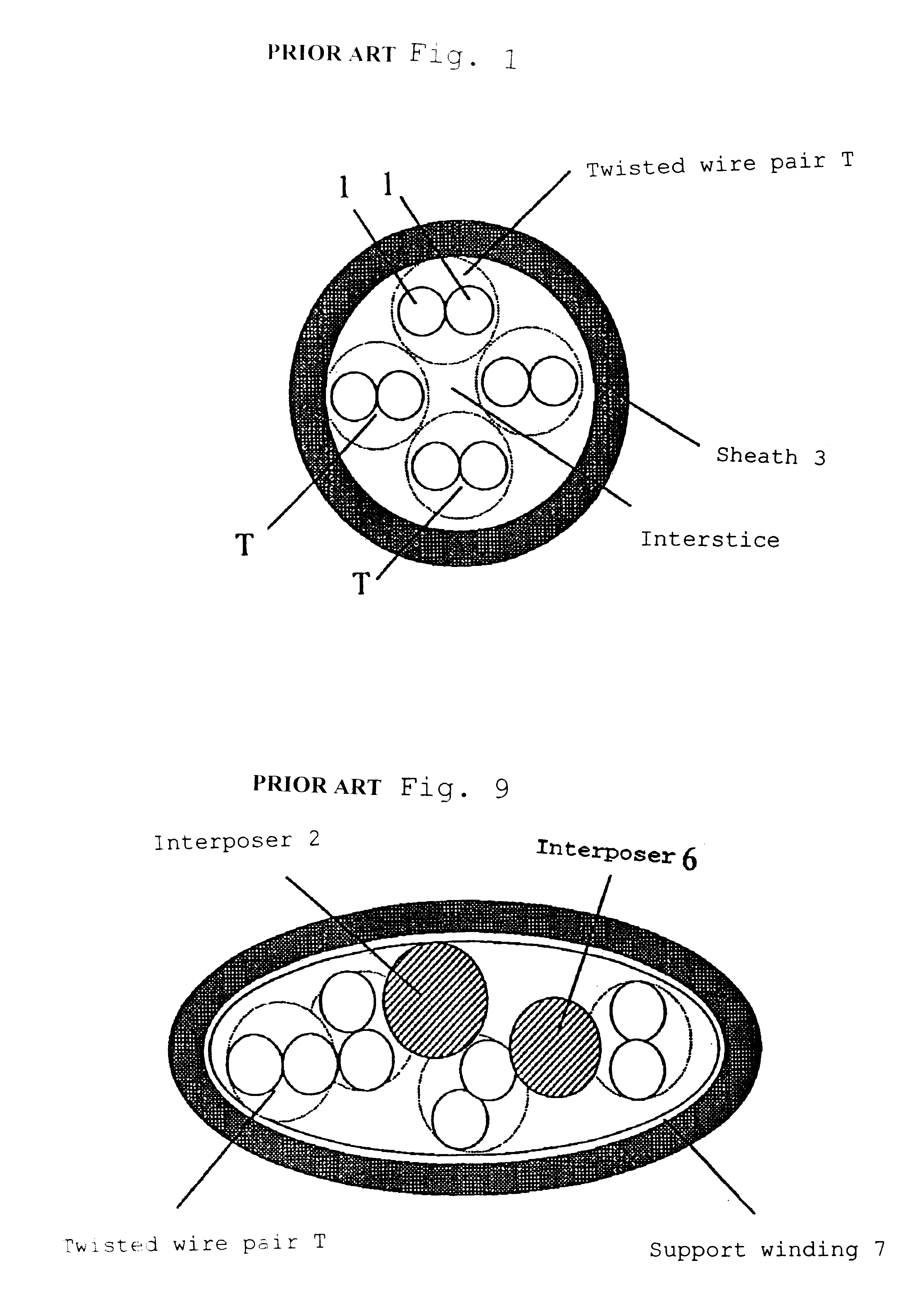

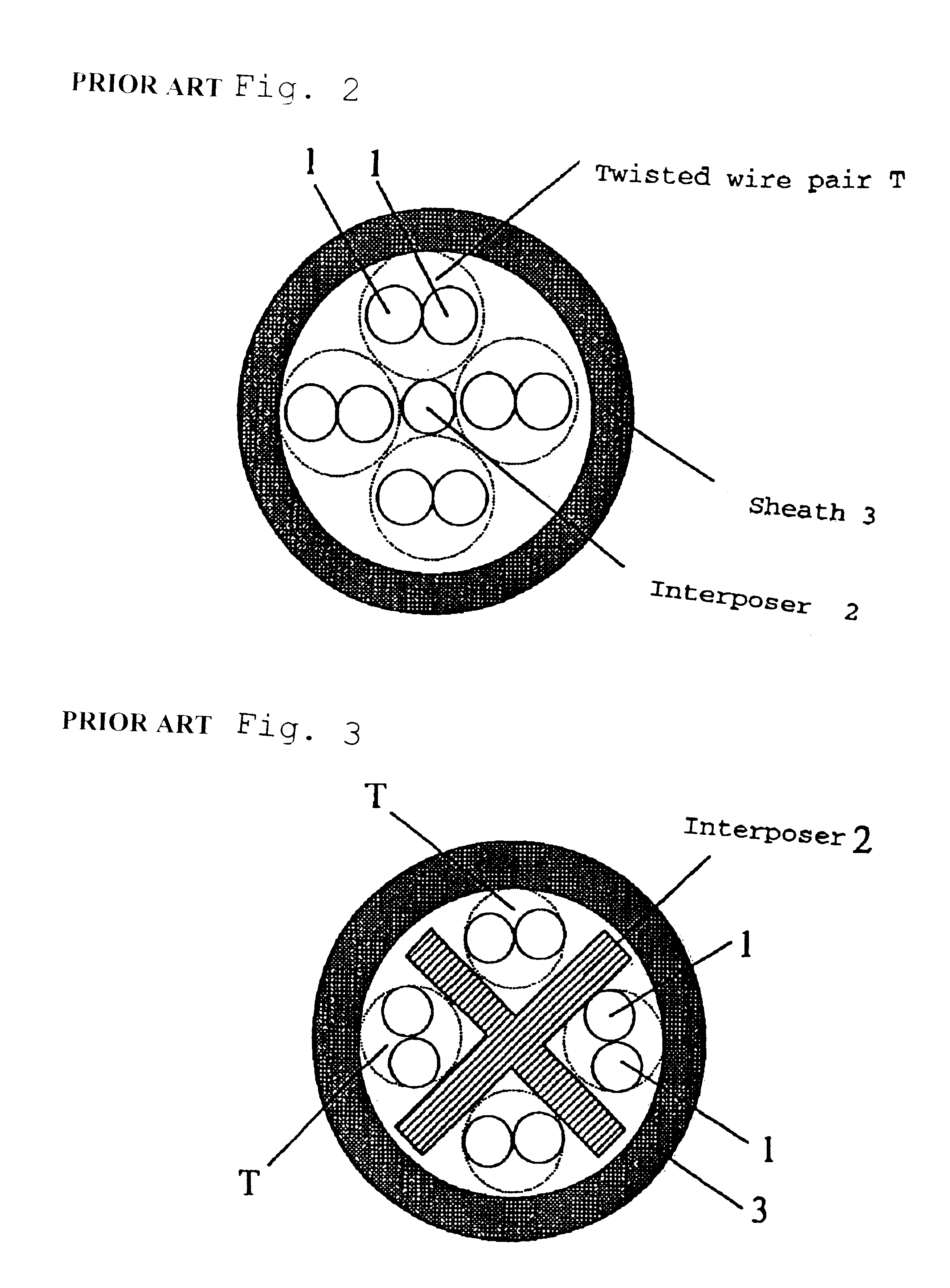

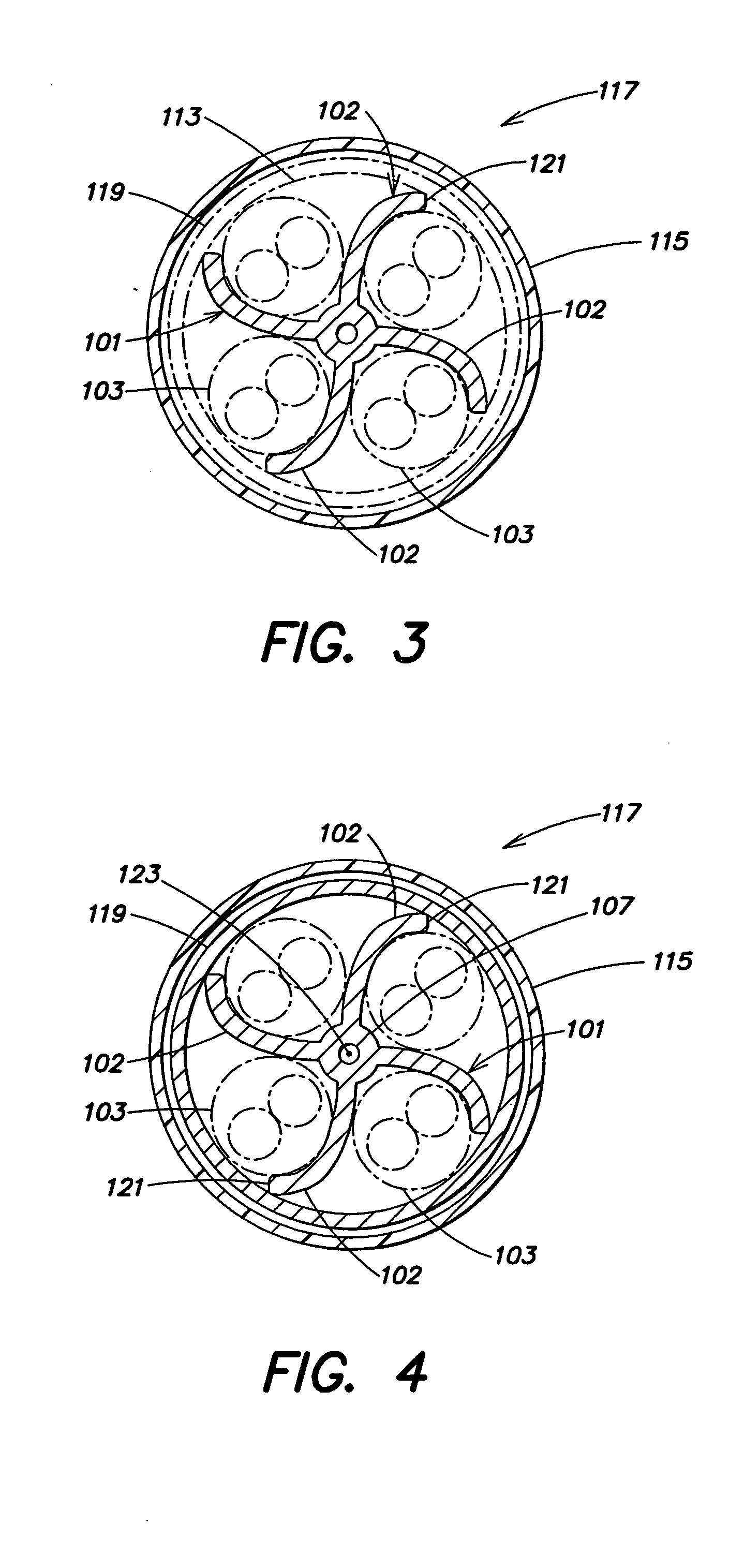

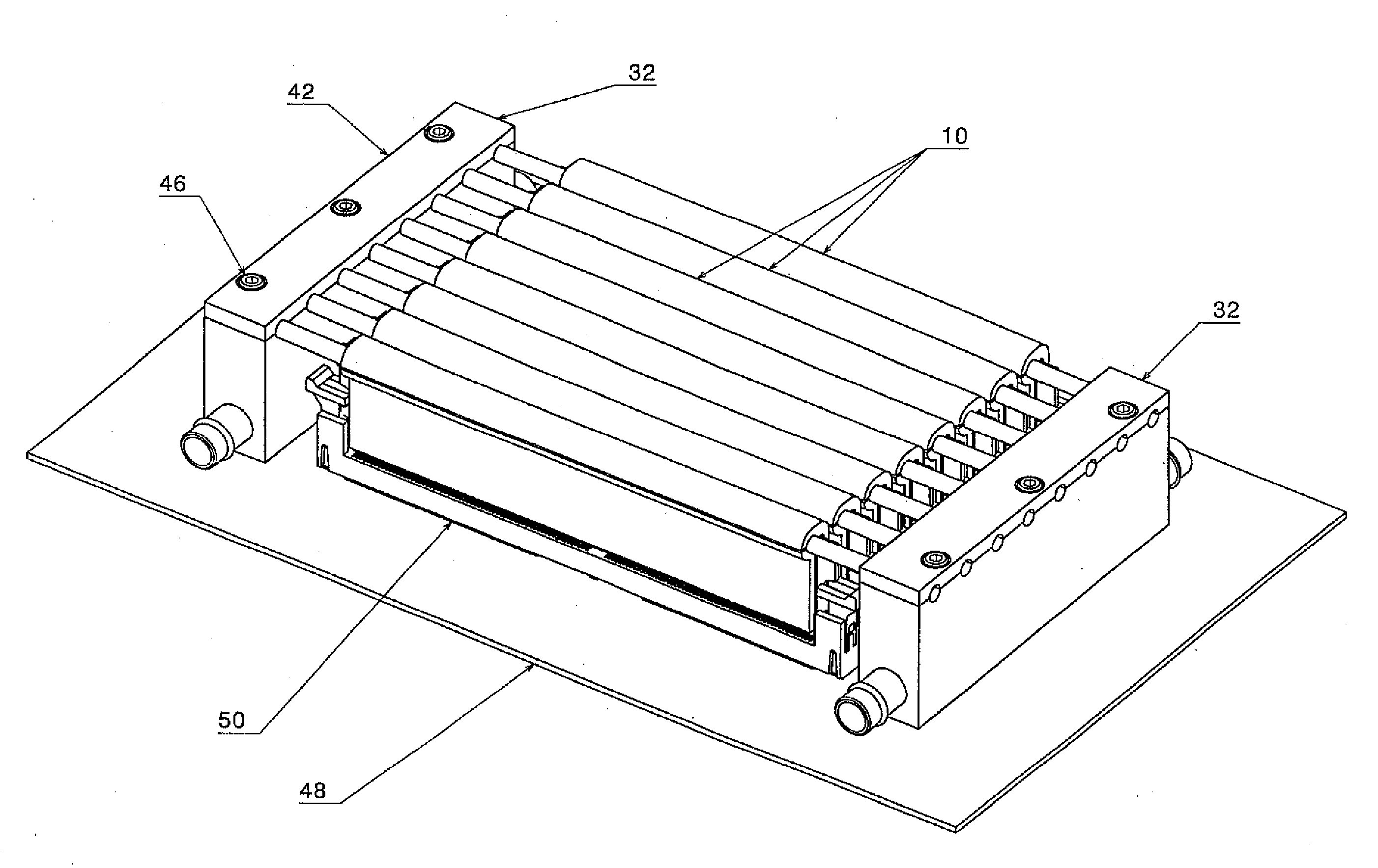

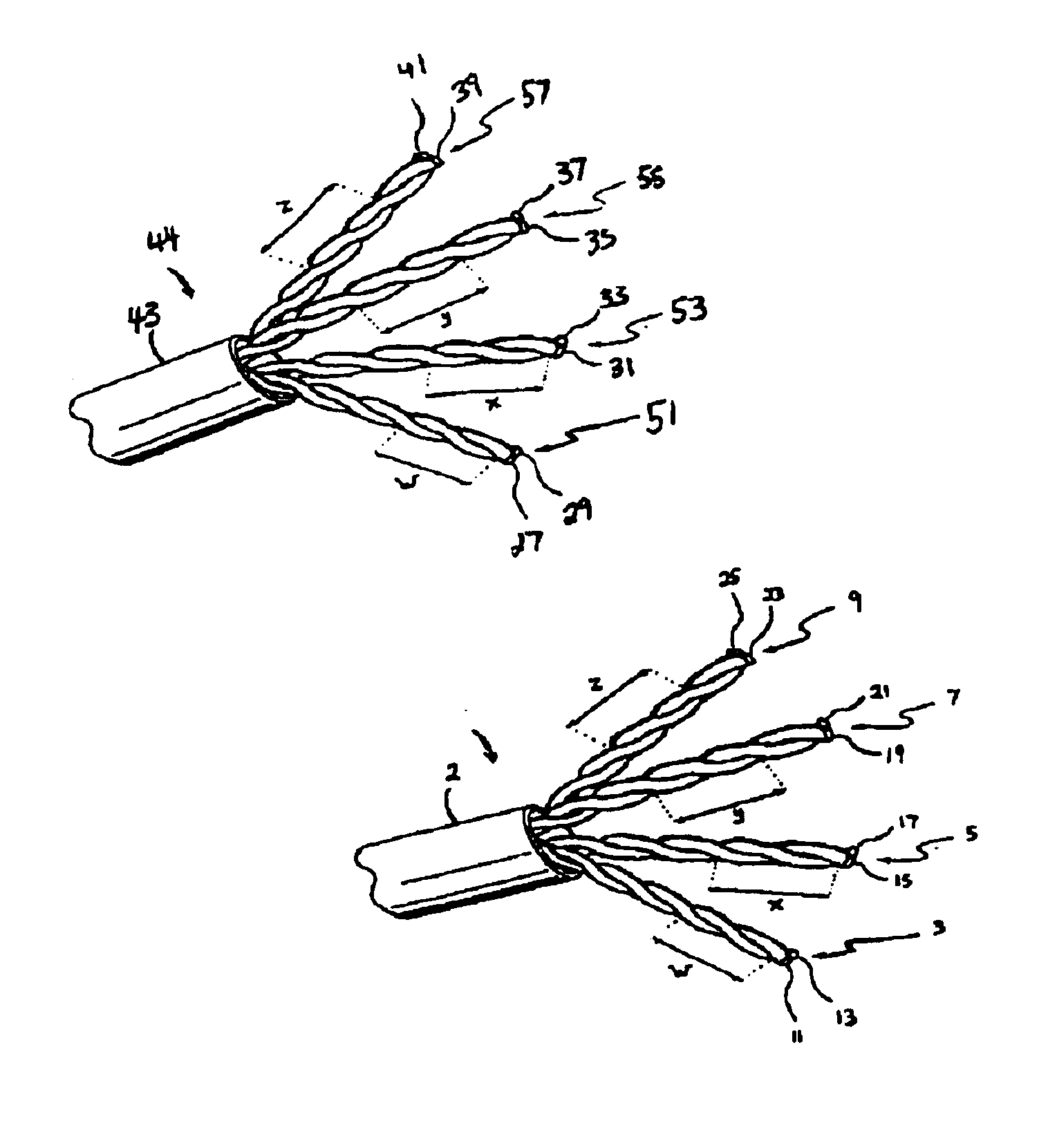

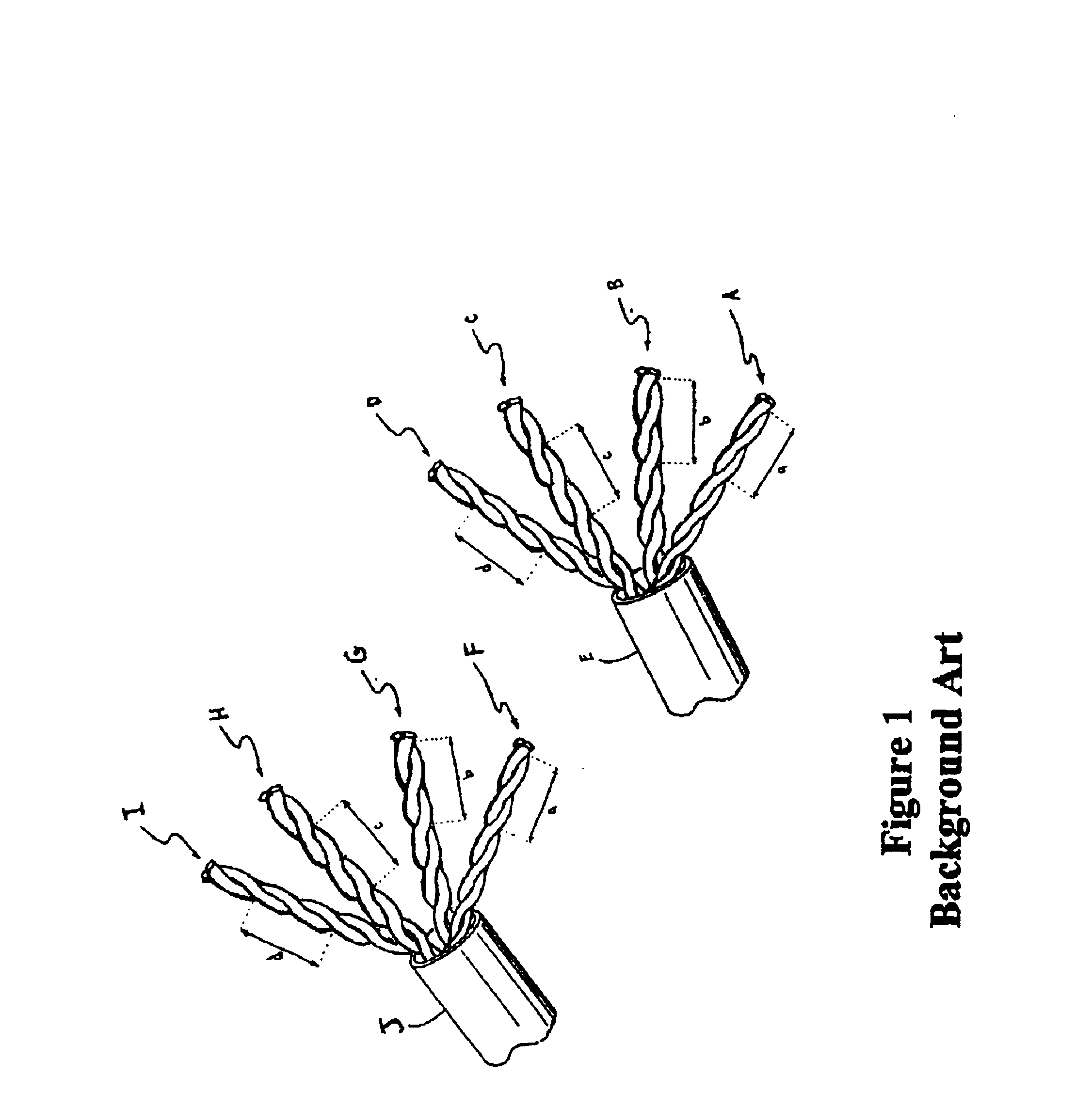

Communication cable

InactiveUS6300573B1Reduce the differenceIncrease spacingInsulated cablesPower cablesPolyolefinProximal point

A communication cable is provided that satisfies the requirement of Cat.6 for near-end cross talk wherein the difference between the maximum and minimum values of delay time among the four twisted wire pairs constituting the cable is within 25 ns / 100 m. The communication cable is made by entwining four twisted wire pairs (T1), (T2), (T3), (T4) made by twisting pairs of insulated wires made by covering electrically conductive wires by polyolefin thermoplastic resin with each pair being twisted with a twist pitch different from the others (pitch: P1<P2<P3<P4) and the inter-pair interposer (6) made of polyolefin thermoplastic resin, while being entwined with each wire pair, around a central interposer (2) made of polyolefin thermoplastic resin having cross sectional area of S1. Cross sectional area S1 of the central interposer (2) satisfies the relationship of inequality S1>=[{4.1 d / (1+{square root over (2)})}.0.35]2xpi, while the inter-pair interposer (6) that is entwined with the twisted wire pairs is located at such a position as adjoins the twisted wire pair (T1) having the least pitch P1 and does not adjoin the twisted wire pair (T4) having the largest pitch P4.

Owner:FURUKAWA ELECTRIC CO LTD

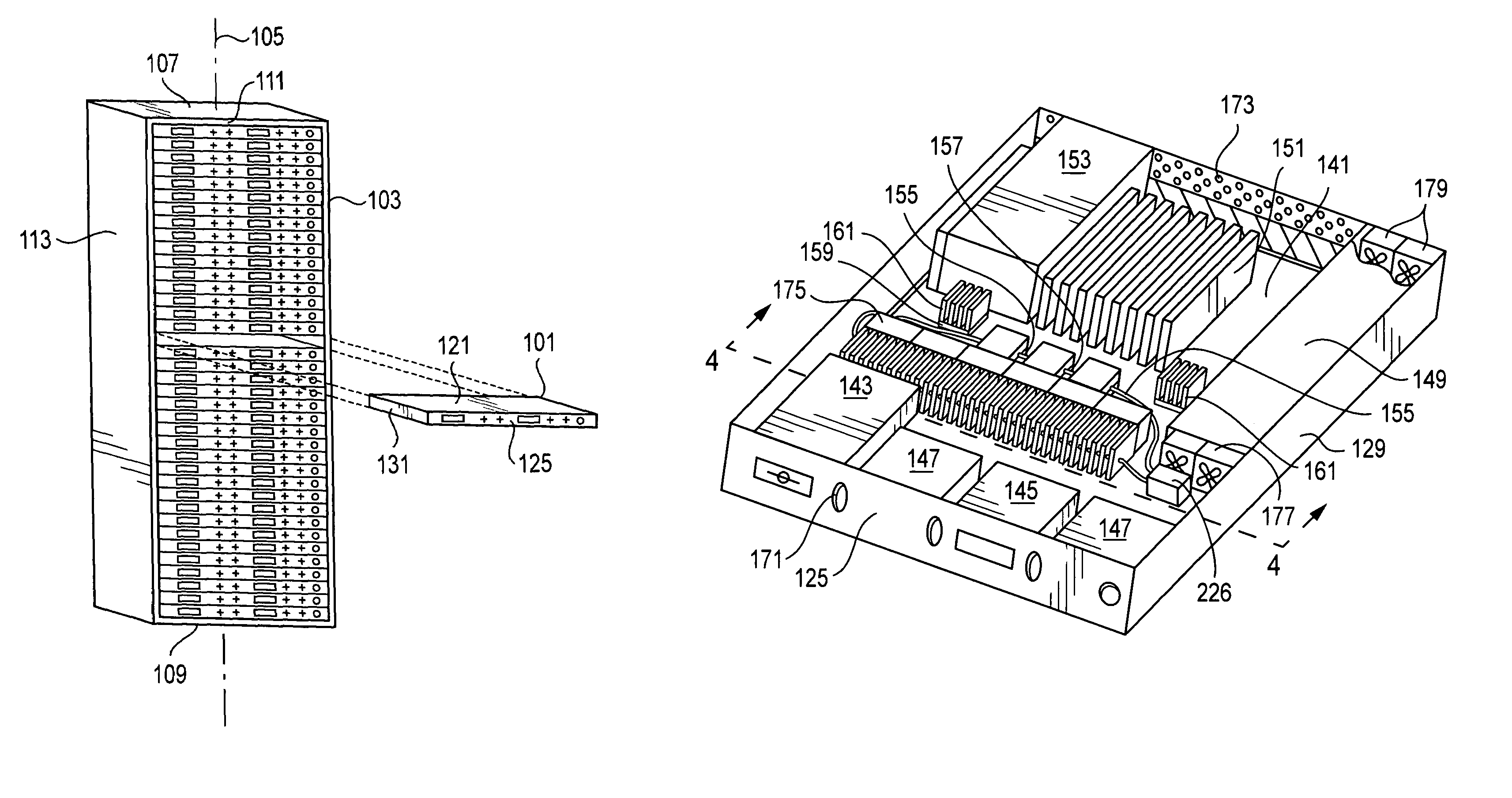

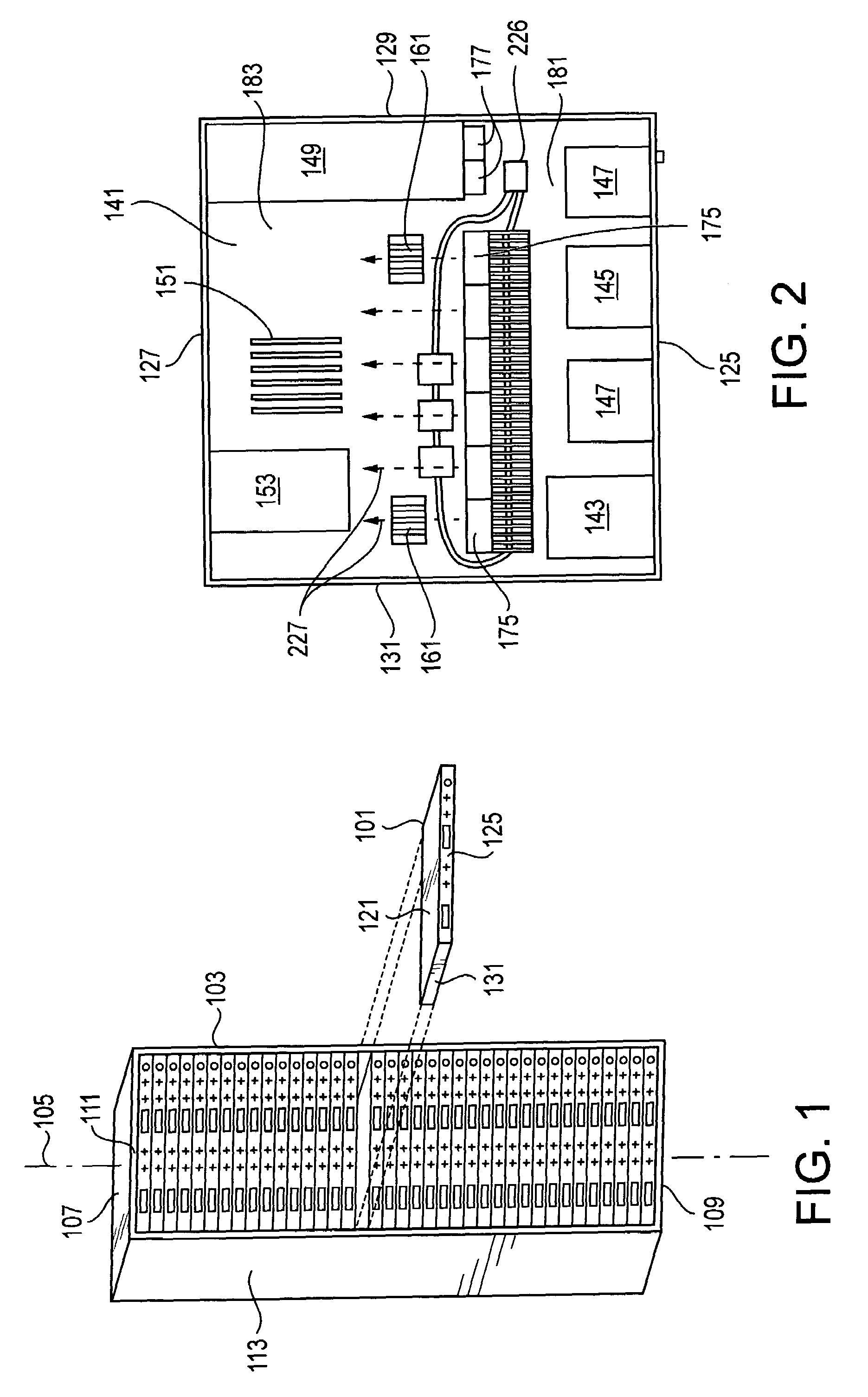

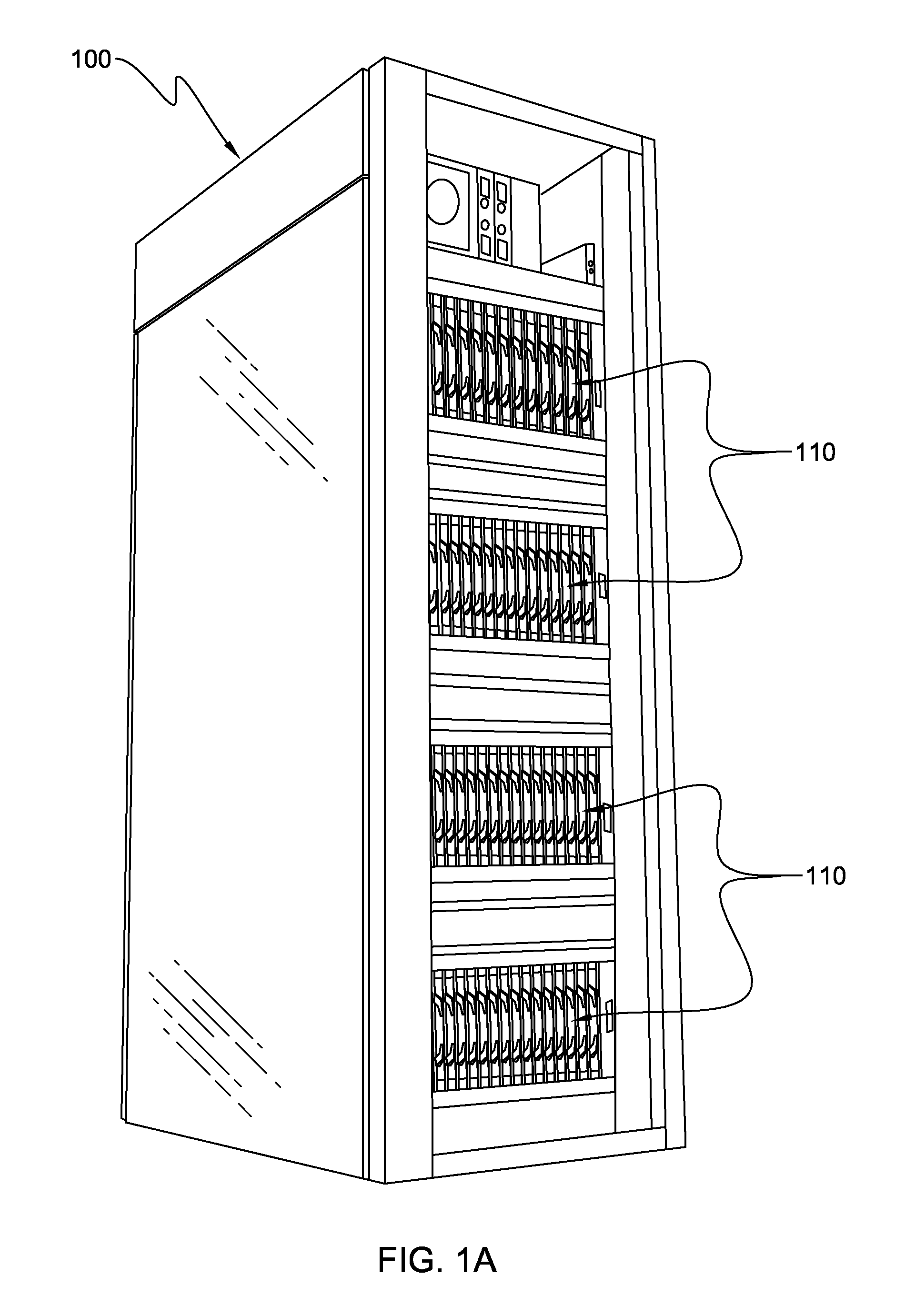

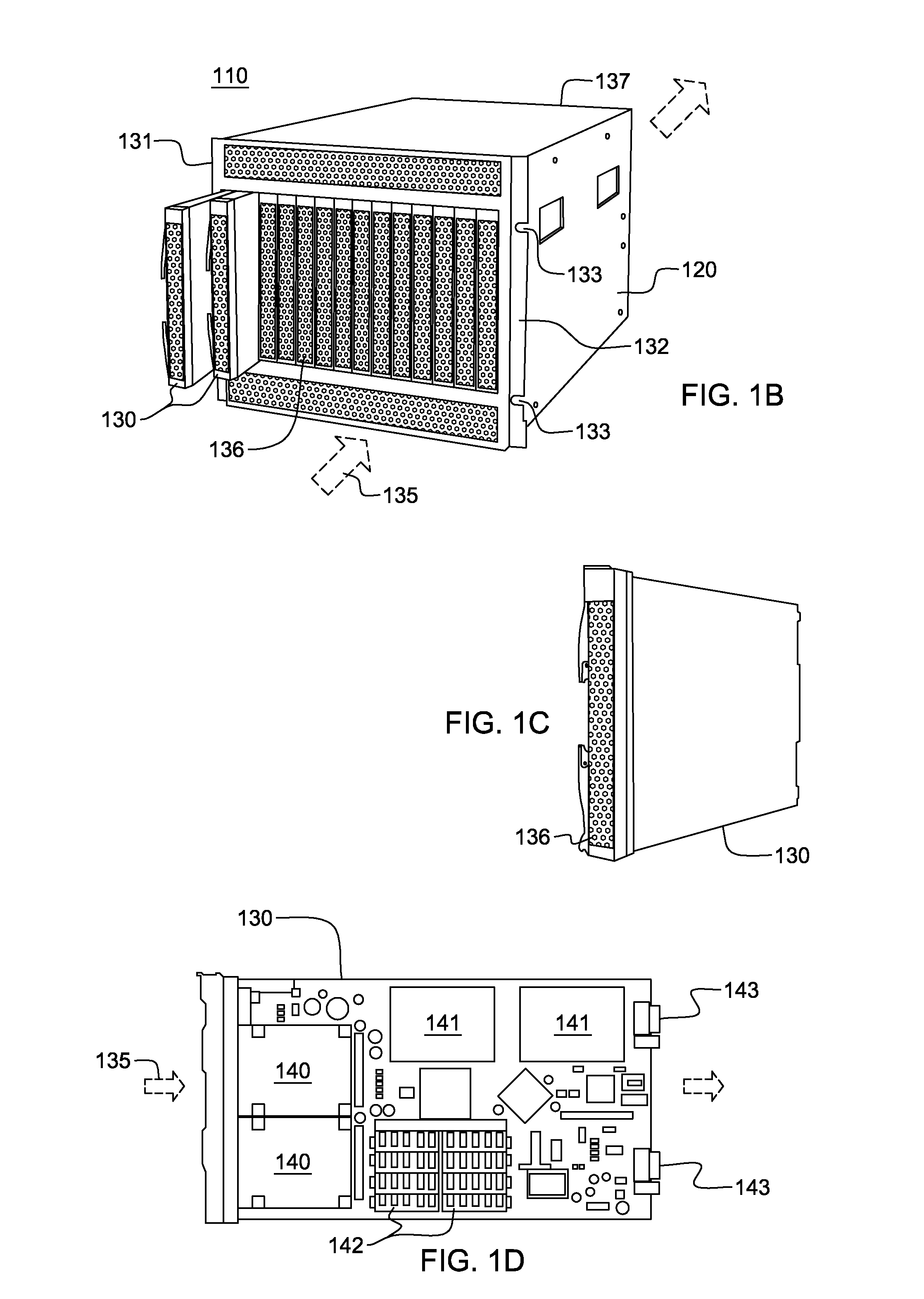

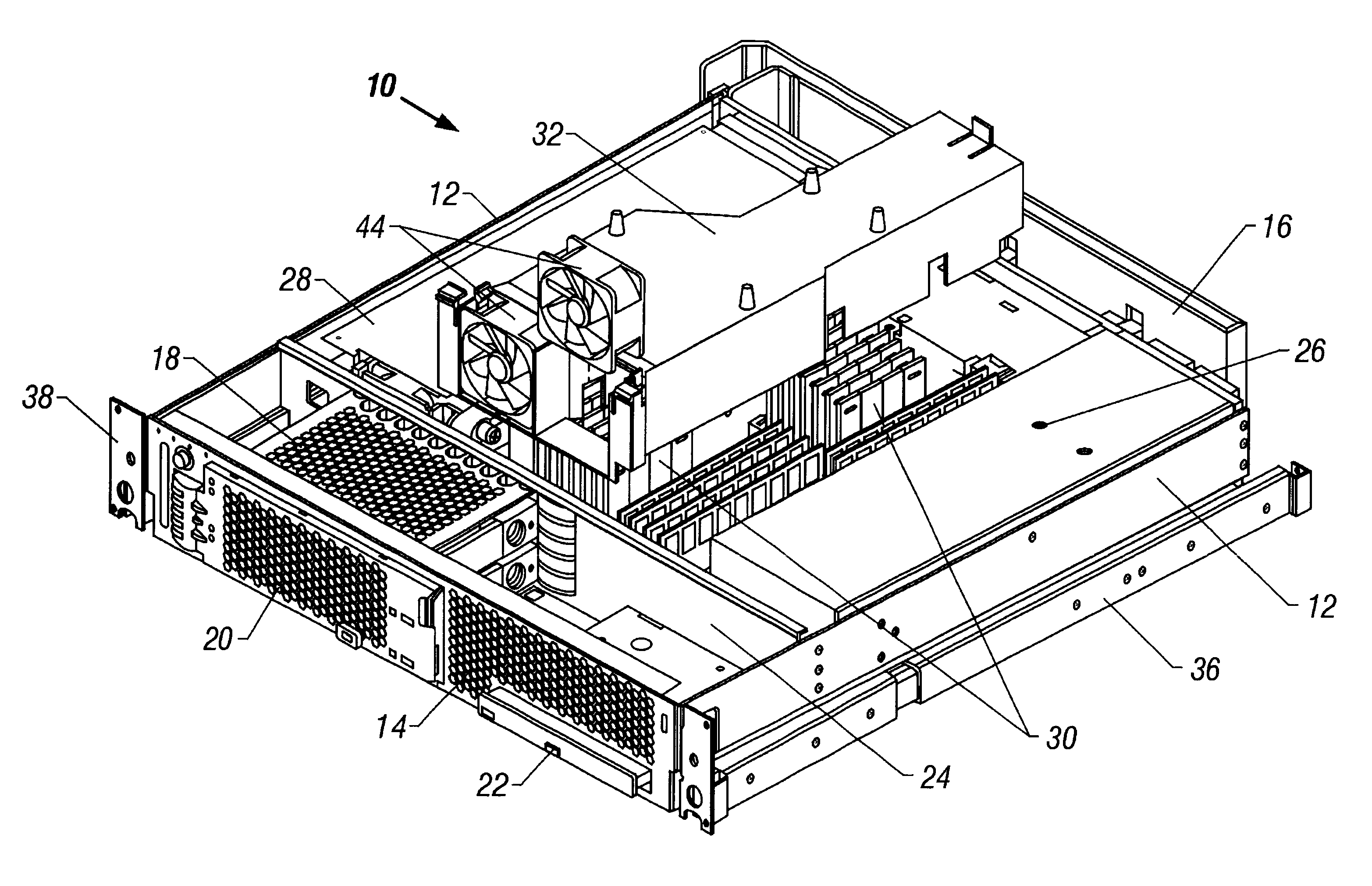

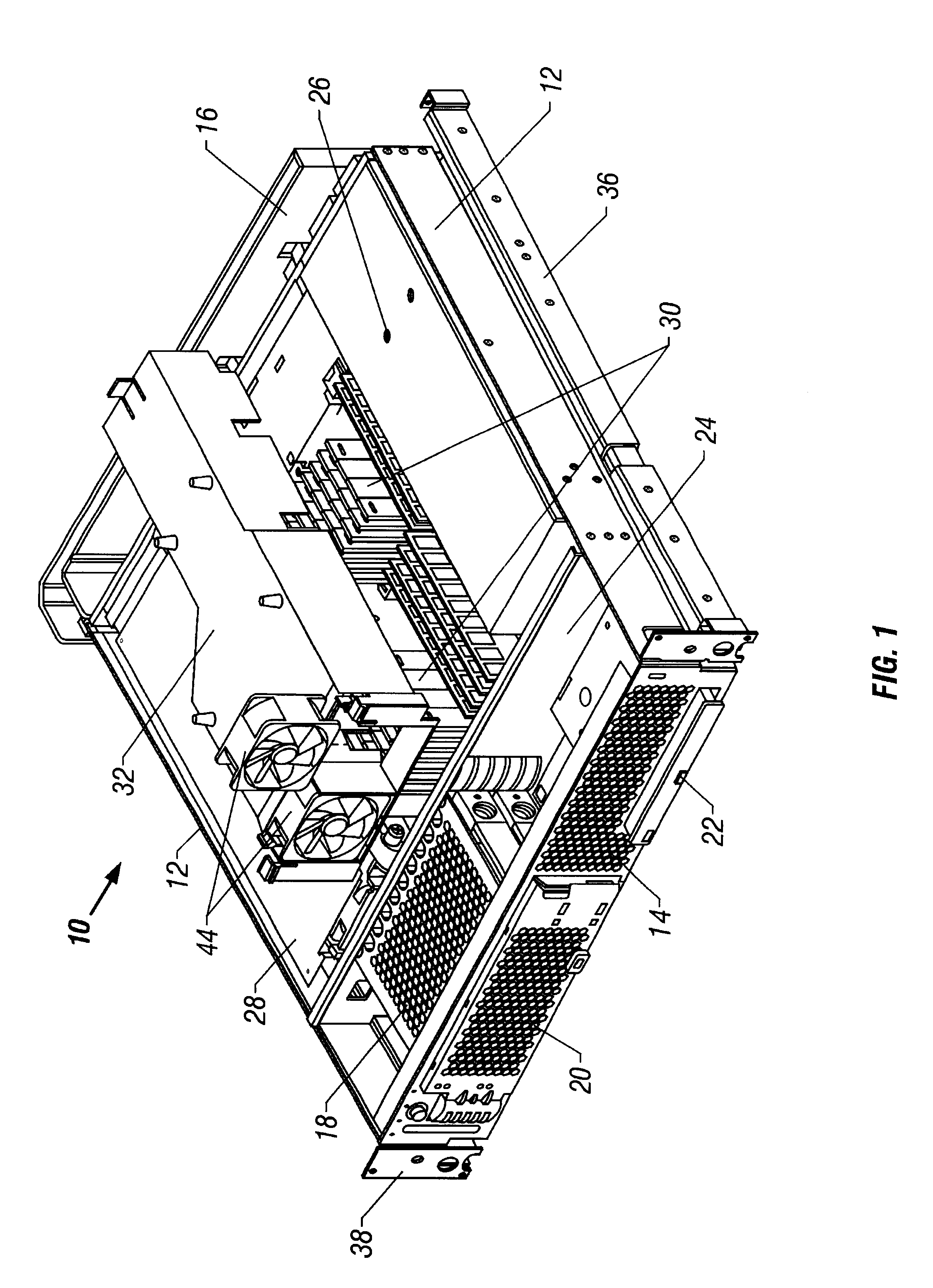

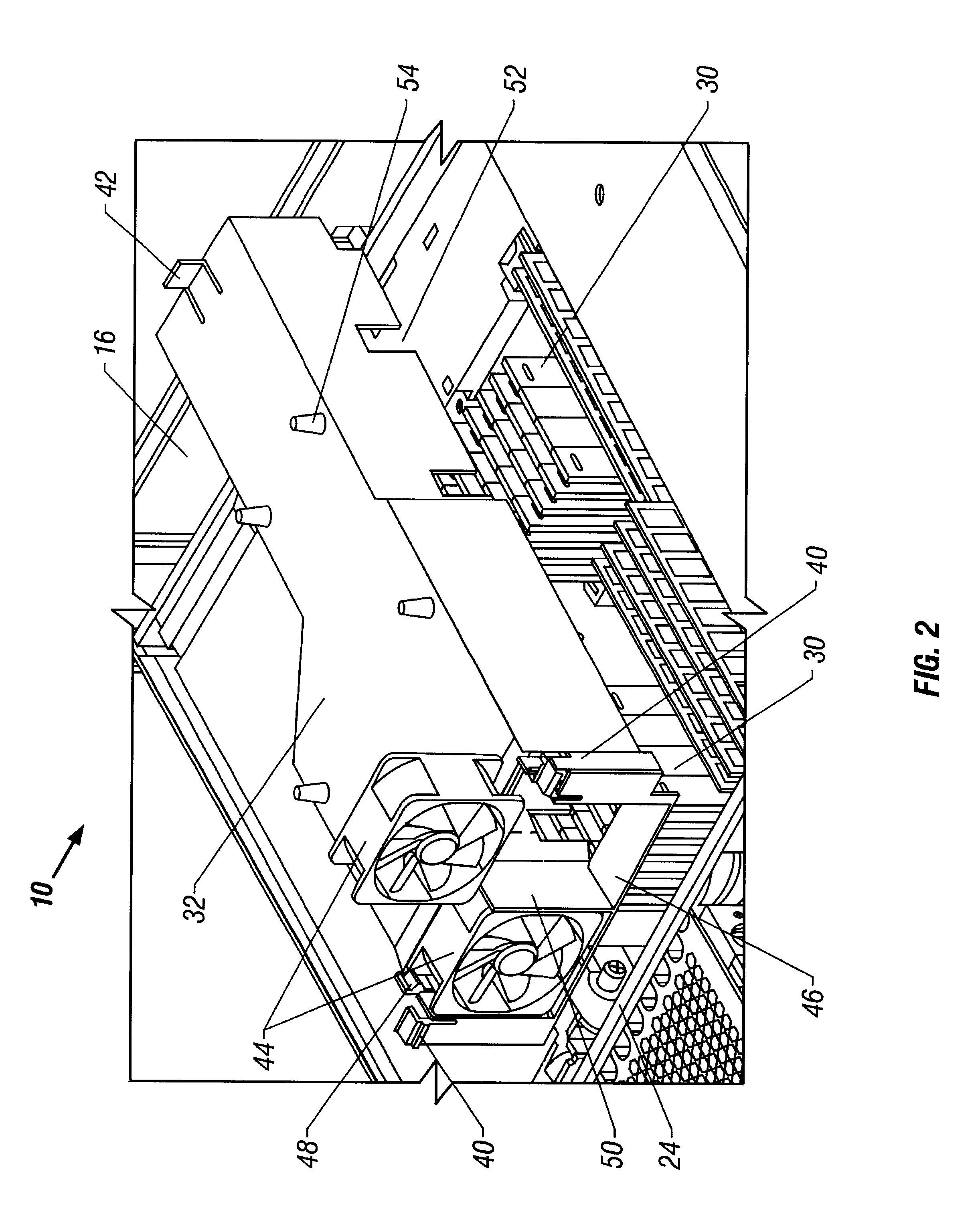

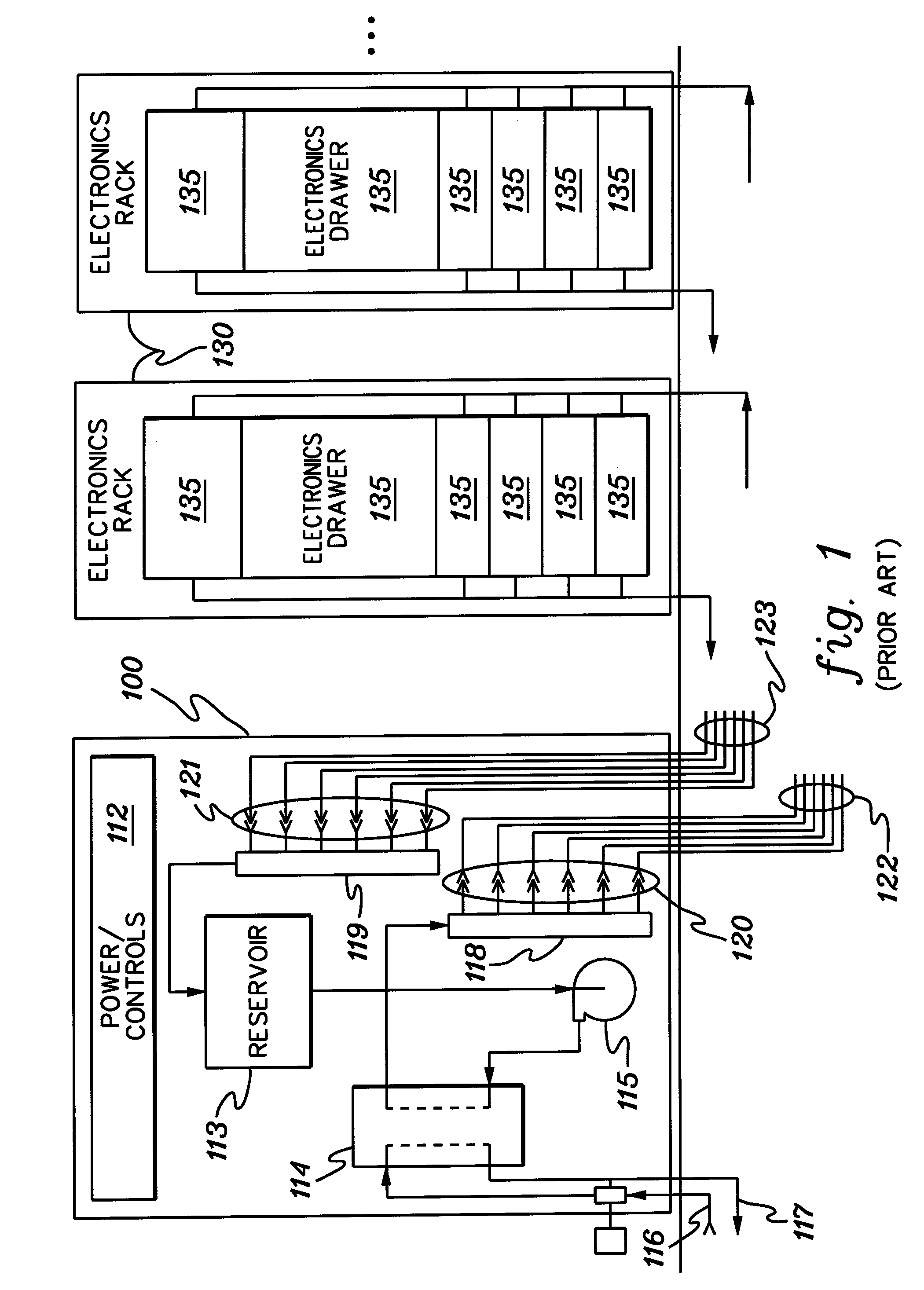

Small form factor liquid loop cooling system

ActiveUS7203063B2Easy to useDigital data processing detailsIndirect heat exchangersSmall form factorComputerized system

An enclosure forms a plurality of tiers vertically stacked in a longitudinal dimension. Each tier is a 1U modular computer system having a computer chassis configured for mounting in the multi-tiered support, and computer components that need cooling within the computer chassis. A cold plate is in thermal communication with at least one of the computer components, and convectively removes heat from that component using a liquid coolant. A heat exchanger dissipates heat from the liquid coolant, and provides liquid coolant back to the cold plate. An air mover within the chassis cools the heat exchanger, blows air across other components needing cooling, and removes heated air from the chassis. The air mover may extend substantially across the chassis, or it may blow crosswise from an outlet-ventilating direction.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

Apparatus and method for facilitating pumped immersion-cooling of an electronic subsystem

ActiveUS20100103618A1Facilitate egressOvercomes shortcomingDomestic cooling apparatusSemiconductor/solid-state device detailsEngineeringCoolant pump

Apparatus and method are provided for facilitating pumped, immersion-cooling of an electronic subsystem having multiple different types of components to be immersion-cooled. The apparatus includes a container sized to receive the electronic subsystem, and a coolant inlet port and a coolant outlet port for facilitating ingress and egress of coolant through the container. The apparatus further includes a coolant pump assembly coupled in fluid communication with the coolant inlet and outlet ports of the container for facilitating active pumping of coolant through the container. When the electronic subsystem is operatively inserted into the container and coolant is pumped through the container, the multiple different types of components of the electronic subsystem are immersion-cooled by the coolant. In one embodiment, a filler element is disposed within the container, and is sized to reduce the amount of coolant within the container, while still maintaining the components of the electronic subsystem immersion-cooled.

Owner:LENOVO GLOBAL TECH INT LTD

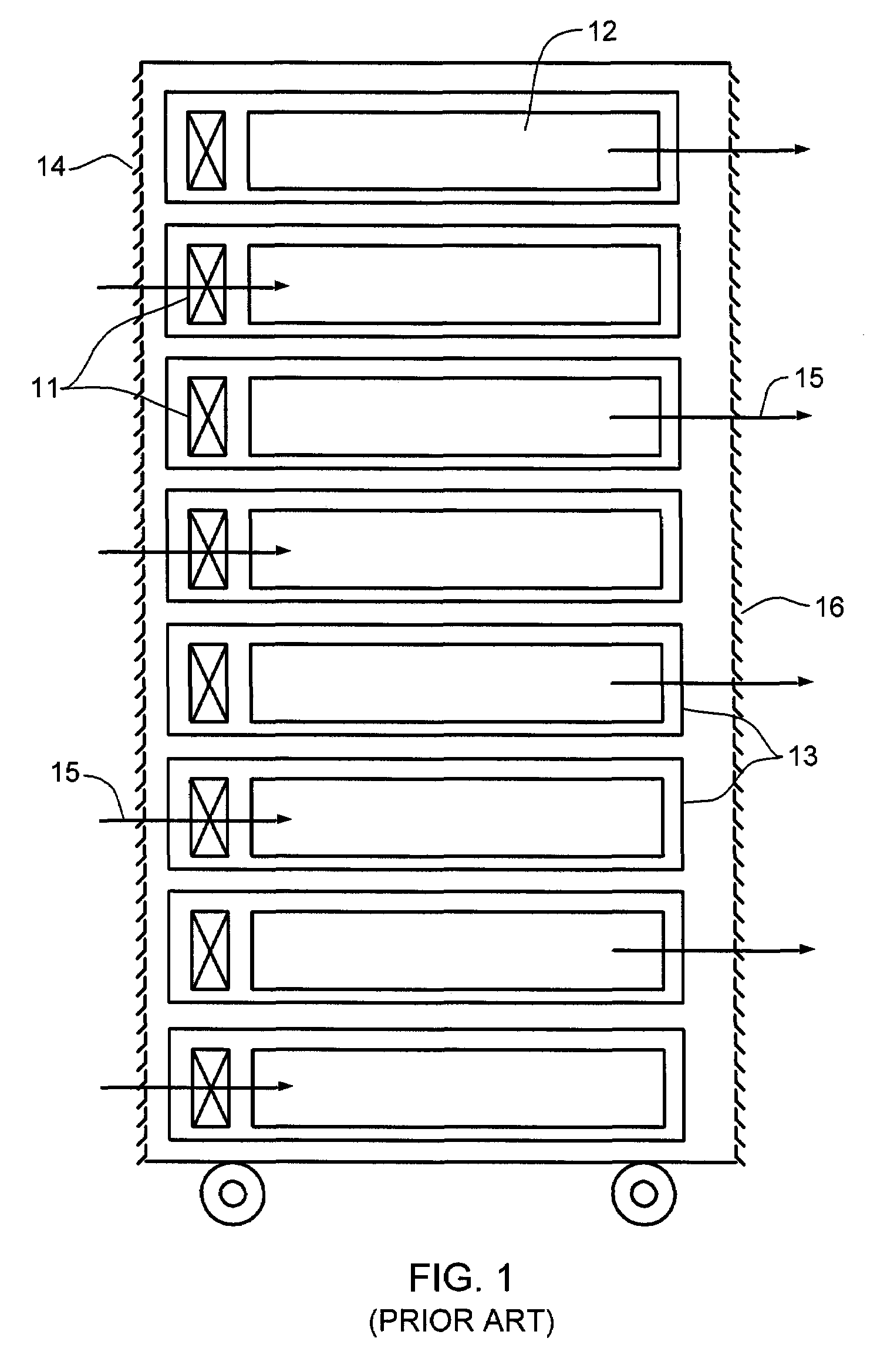

Method and apparatus for cooling electronic components

InactiveUS6400568B1Digital data processing detailsSemiconductor/solid-state device detailsProcess engineeringElectronic component

The present invention discloses improved cooling designs and methods for the cooling of heat sources. One embodiment of the present invention is a cooling system comprising a housing and at least one divider disposed within the housing. The at least one divider creates a plurality of airflow channels through the housing. Another embodiment of the invention is a method for dissipating heat from heat sources within an electrical assembly comprising at least partially separating the heat sources with a divider. Separate airflow channels are created whereby the separated heat sources are disposed within the separated airflow channels. Forced airflow streams are generated through the separated airflow channels, thereby dissipating heat from the heat sources into the forced airflow streams.

Owner:ORACLE INT CORP

Cooling apparatus and method for an electronics module employing an integrated heat exchange assembly

A cooling apparatus for an electronics assembly having a substrate and one or more electronics devices includes an enclosure sealably engaging the substrate to form a cavity, with the electronics devices and a heat exchange assembly being disposed within the cavity. The heat exchange assembly defines a primary coolant flow path and a separate, secondary coolant flow path. The primary coolant flow path includes first and second chambers in fluid communication, and the secondary flow path includes a third chamber disposed between the first and second chambers. The heat exchange assembly provides a first thermal conduction path between primary coolant in the first chamber and secondary coolant in the third chamber, and a second thermal conduction path between primary coolant in the second chamber and secondary coolant in the third chamber. The heat exchange assembly further includes coolant nozzles to direct primary coolant towards the electronics devices.

Owner:INT BUSINESS MASCH CORP

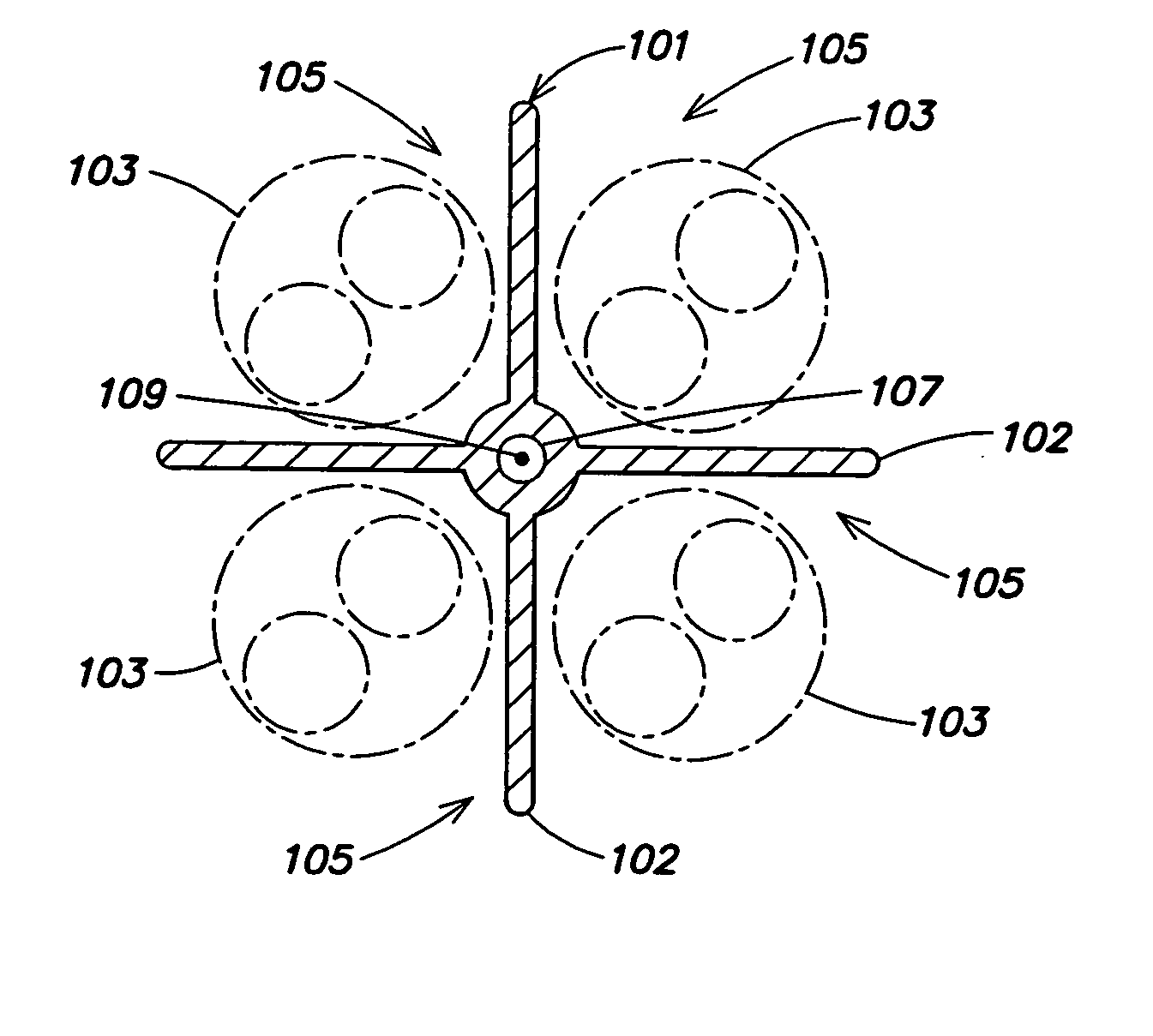

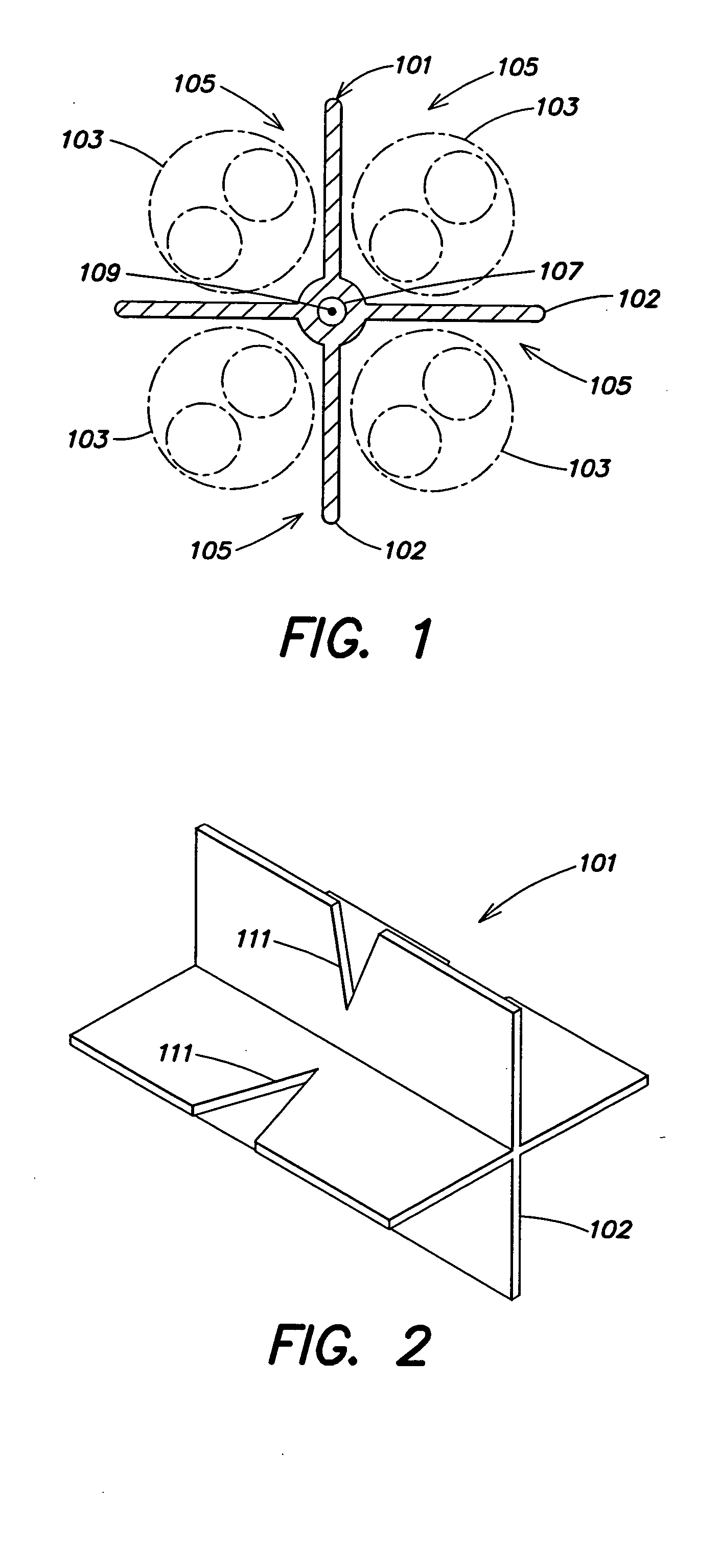

Data cable with cross-twist cabled core profile

Owner:BELDEN TECHNOLOGY INC

Liquid-cooled power semiconductor device heatsink

InactiveUS6434003B1Semiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceEngineering

The present invention relates to a cold plate for cooling electronic components comprising a base having a top surface onto which at least one electronic component is to be placed; a cooling well formed in the top of the base and open at the top; a feed channel formed in the base for carrying fluid into the cooling well; a drain channel formed in the base for carrying cooling fluid away from the cooling well; cooling well inlets and outlets formed in the cooling well and in communication with the feed channel and drain channels, respectively. The feed and drain channels are sufficiently large relative to the size and flow characteristics of the well and cooling well inlets and outlets such that when the cooling fluid flows through the device, the pressure drop across the feed channel is substantially less than the pressure drop across the well.

Owner:YORK INT CORP

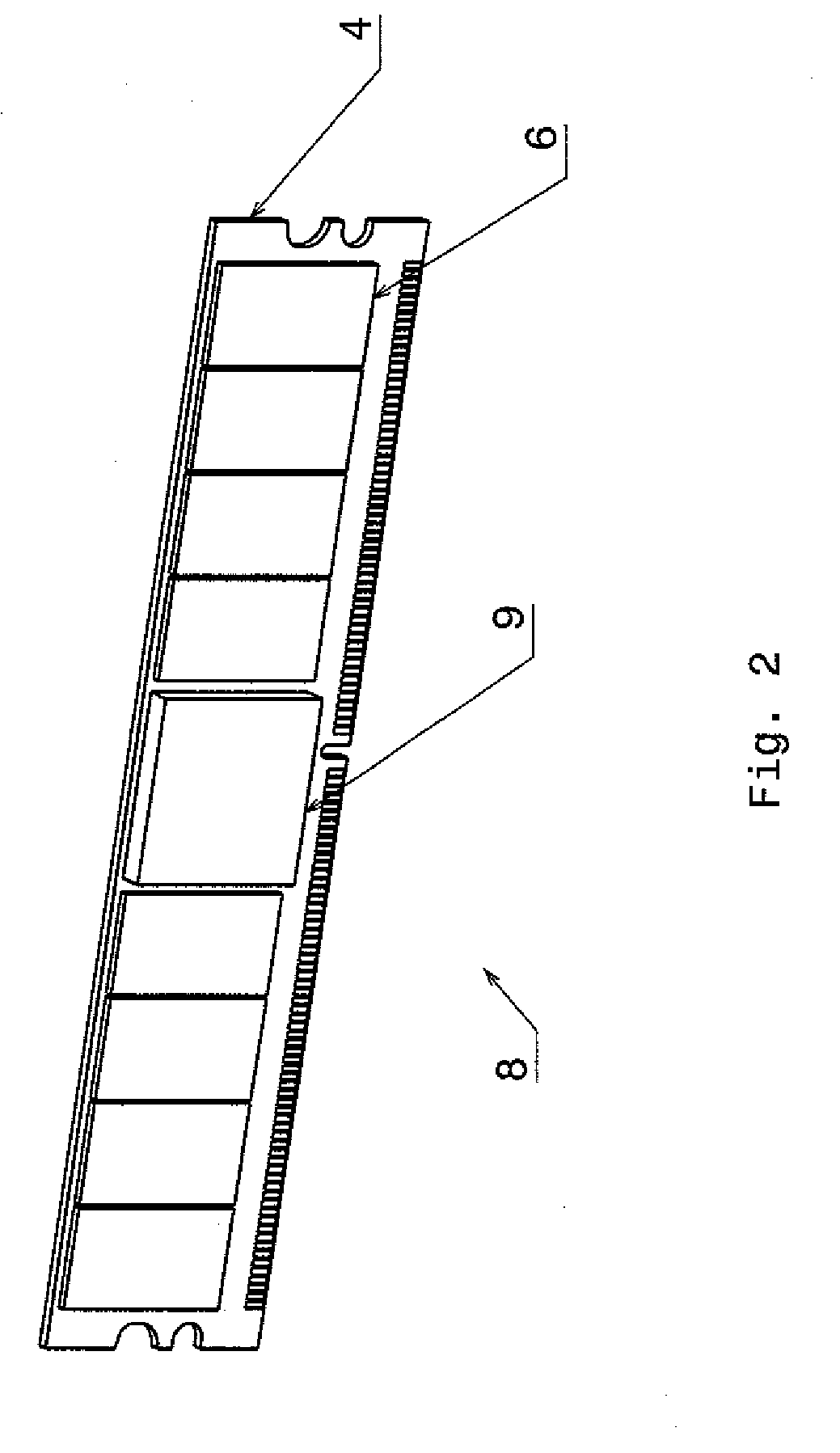

Heat spreader for electronic modules

ActiveUS7619893B1Semiconductor/solid-state device detailsSolid-state devicesElectronic componentHeat spreader

A heat spreader is provided for use with an electronic module. The electronic module has a first side with a first plurality of electronic components mounted thereon and a second side with a second plurality of electronic components mounted thereon. The heat spreader includes a first segment mountable on the module to be in thermal communication with at least one electronic component mounted on the first side, and to be substantially thermally isolated from at least one electronic component mounted on the first side. The heat spreader further includes a second segment mountable on the module to be in thermal communication with the at least one electronic component mounted on the first side that is substantially thermally isolated from the first segment.

Owner:NETLIST INC

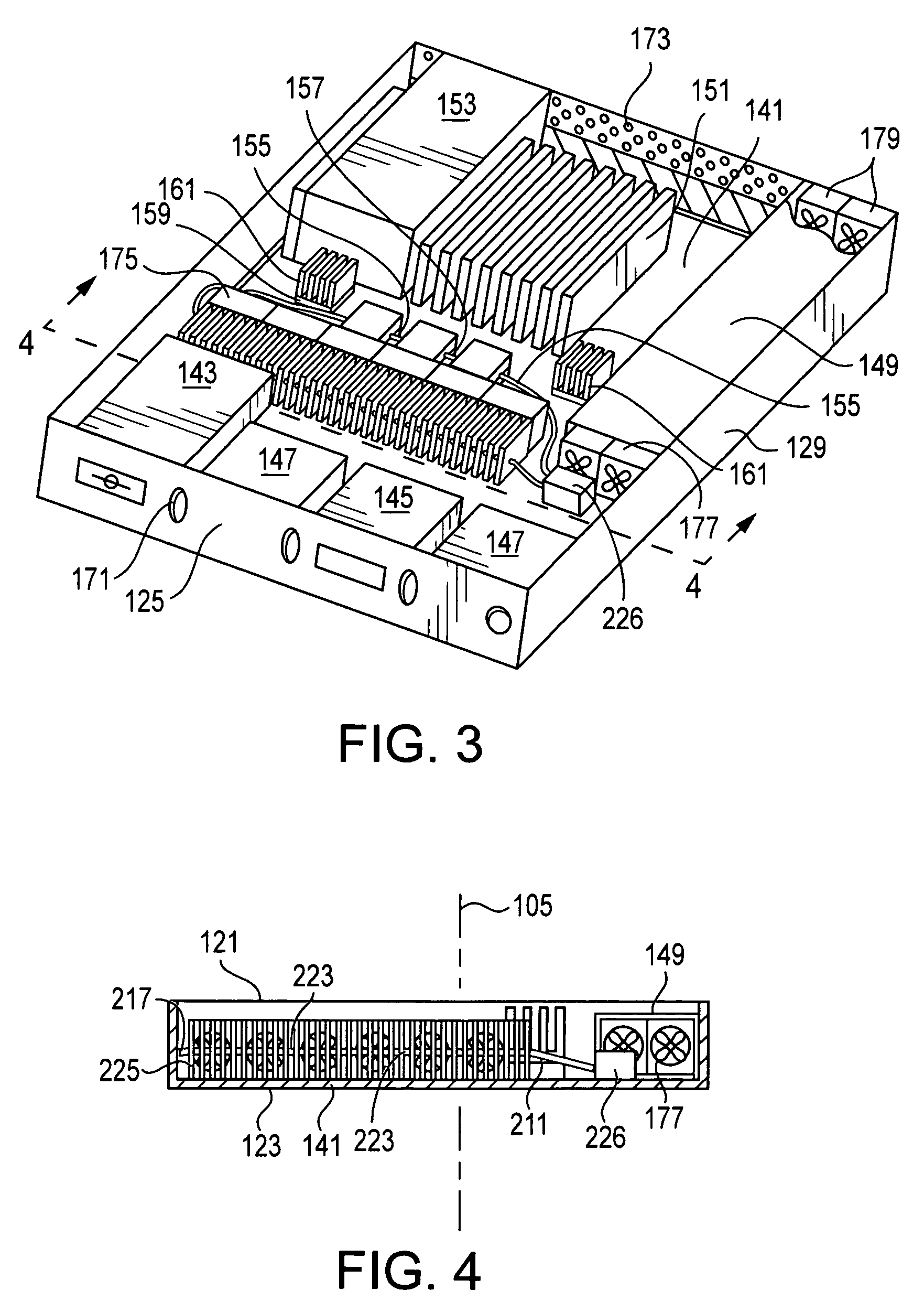

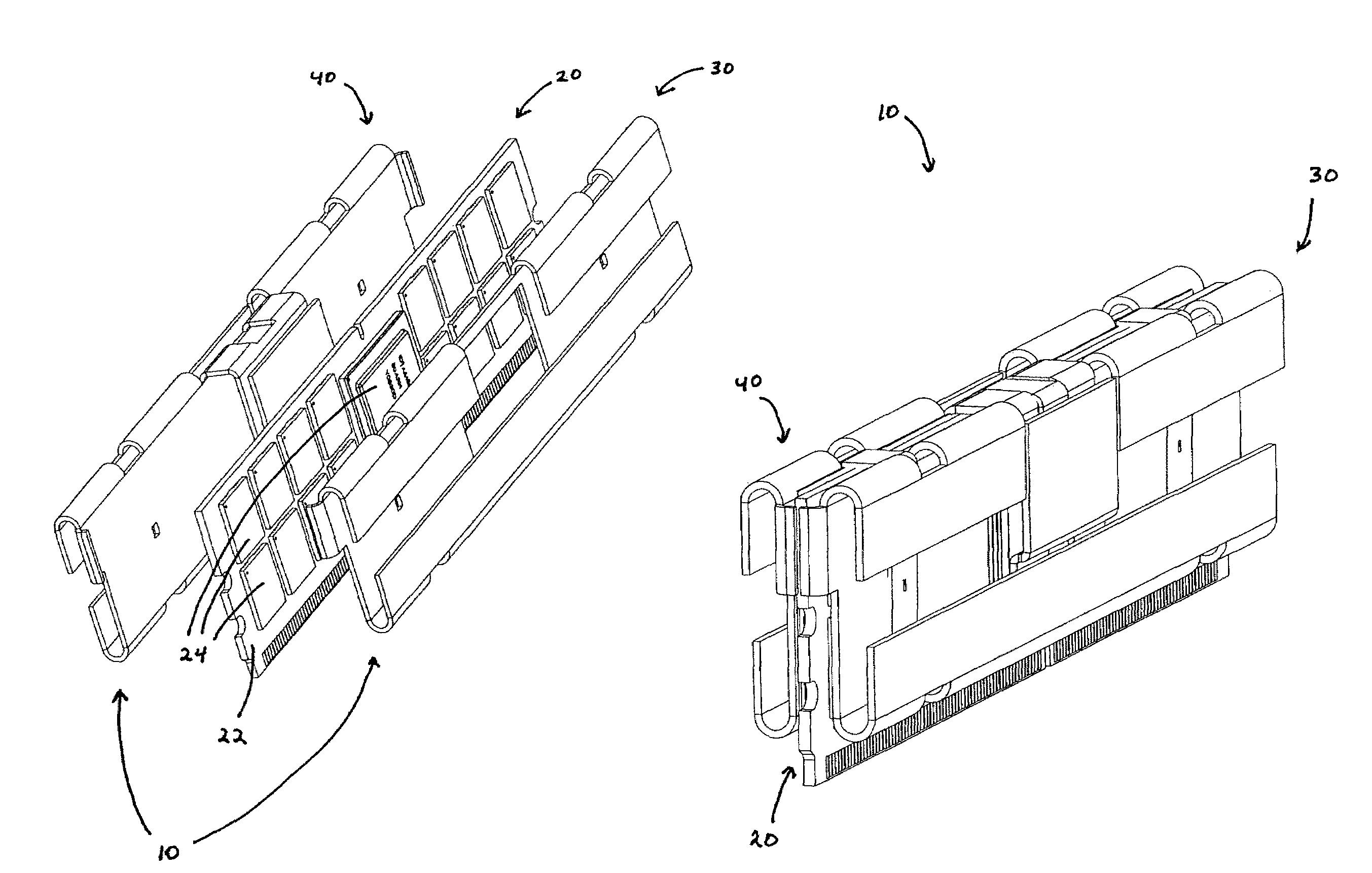

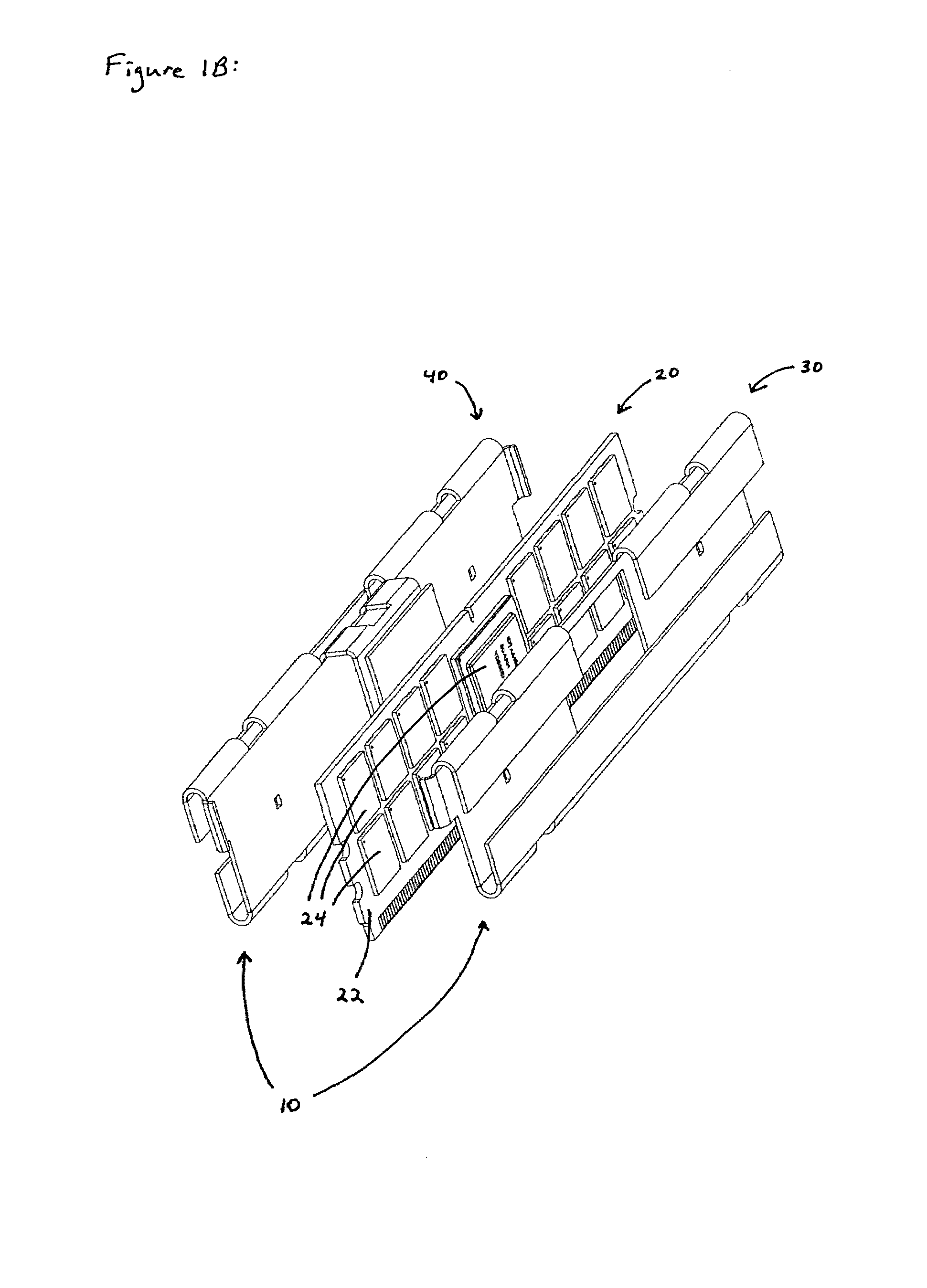

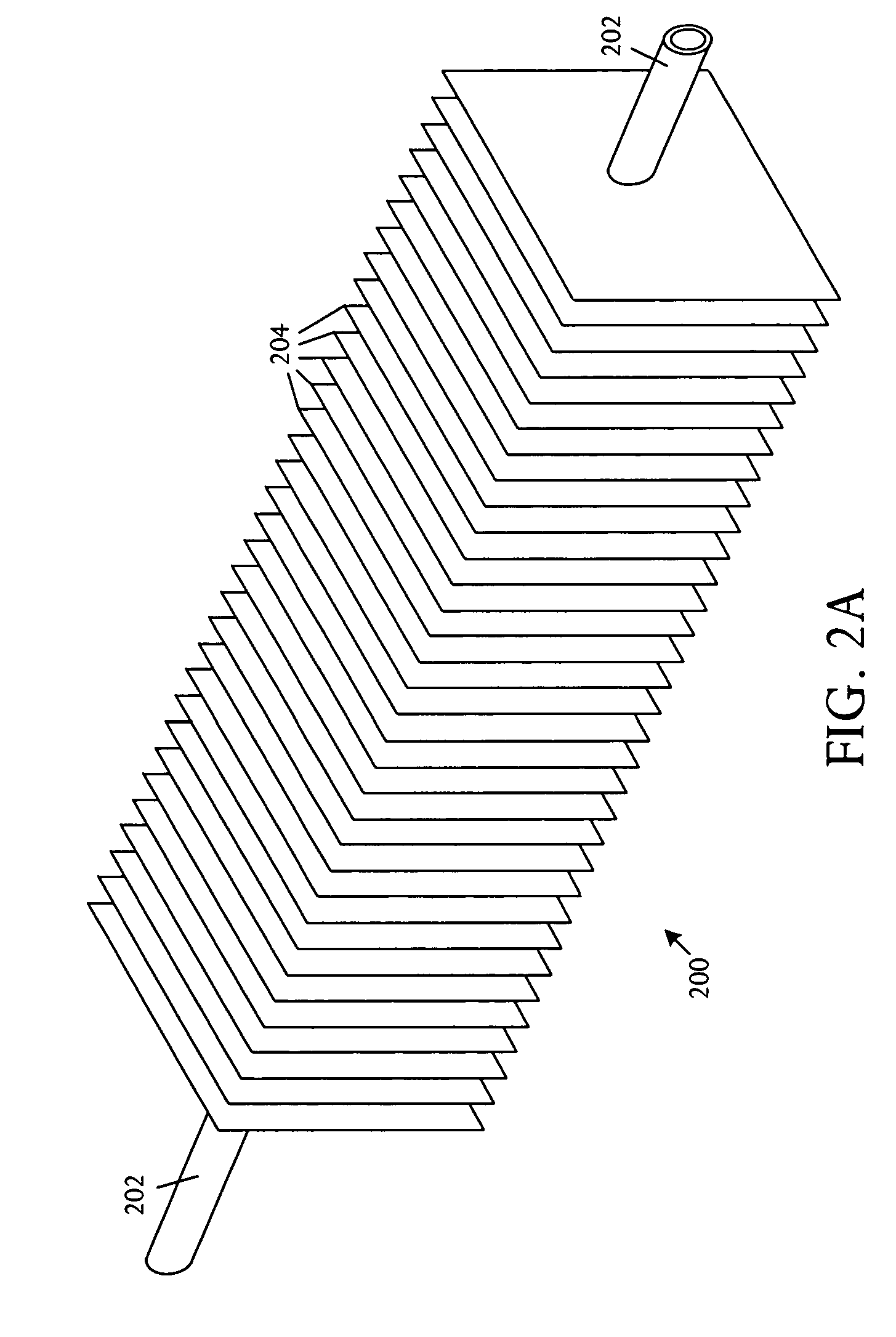

Method and apparatus of water cooling several parallel circuit cards each containing several chip packages

InactiveUS20090277616A1Digital data processing detailsSemiconductor/solid-state device detailsEngineeringChip-scale package

A cooling or heat transfer apparatus and method is disclosed for cooling an electronic device. The apparatus includes a heat producing electronic device which may include an electronic circuit card with many heat sources. A heat transfer device is connected to the heat producing electronic device which is thermally communicating with the heat producing device for transferring heat from the heat producing device to the heat transfer device. A heat conduit is connected to the heat transfer device and thermally communicating with the heat transfer device for transferring heat to the heat conduit from the heat transfer device. A cooling housing is connected to the heat conduit and the cooling housing thermally communicating with the heat conduit for transferring heat to the cooling housing from the heat conduit. The apparatus enables the replacement of circuit cards in the field because it eliminates the need to apply thermal-interface materials.

Owner:GLOBALFOUNDRIES INC

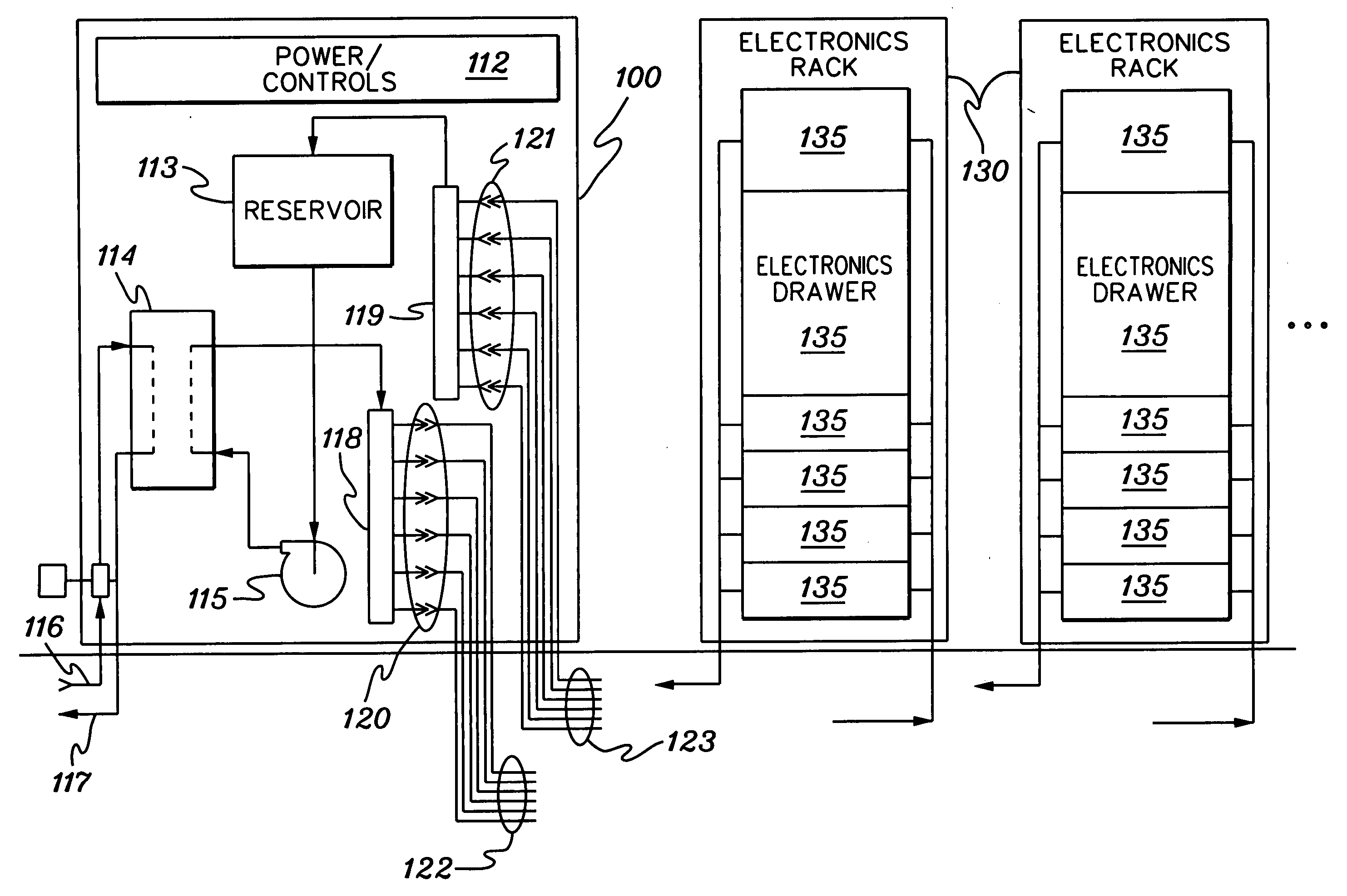

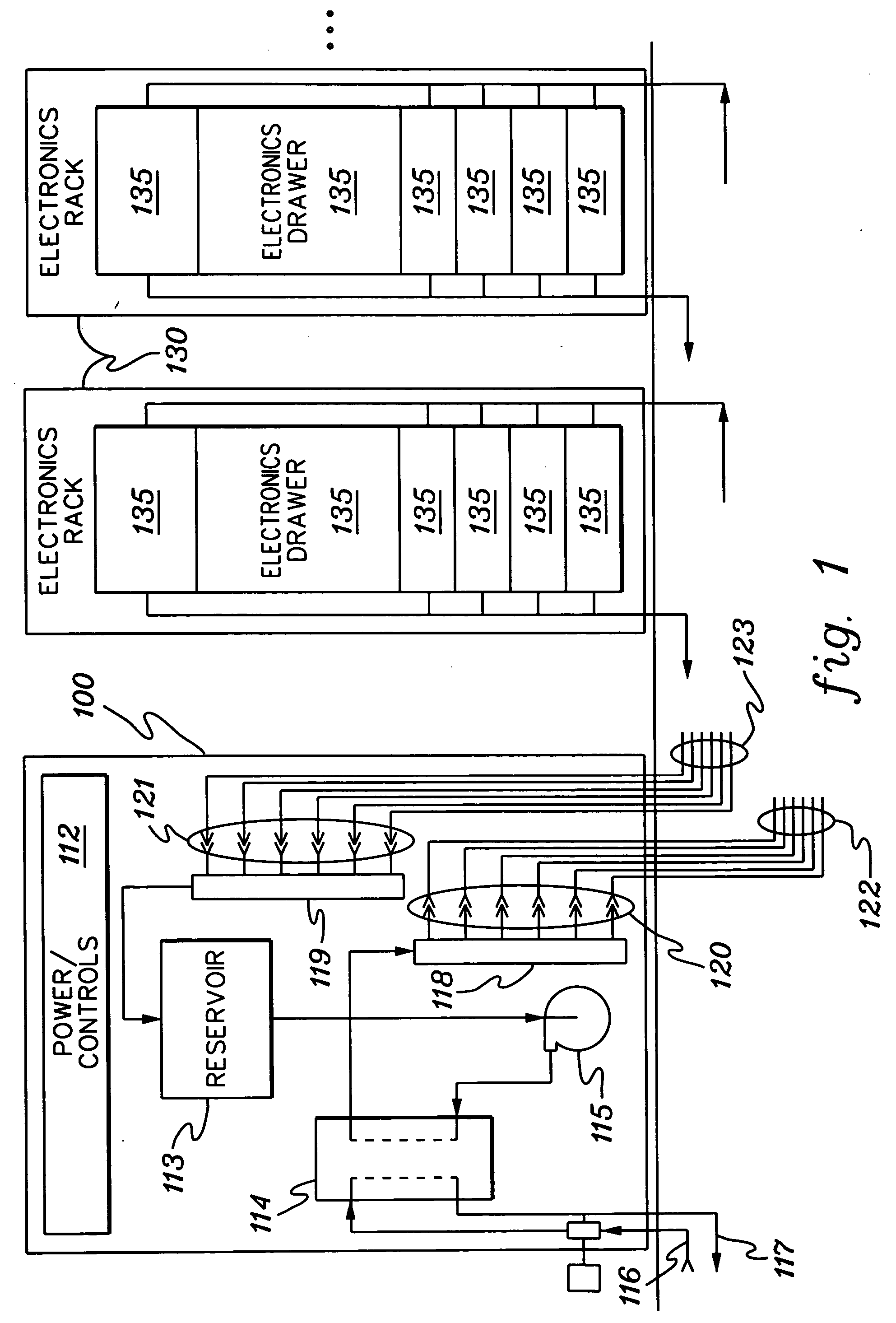

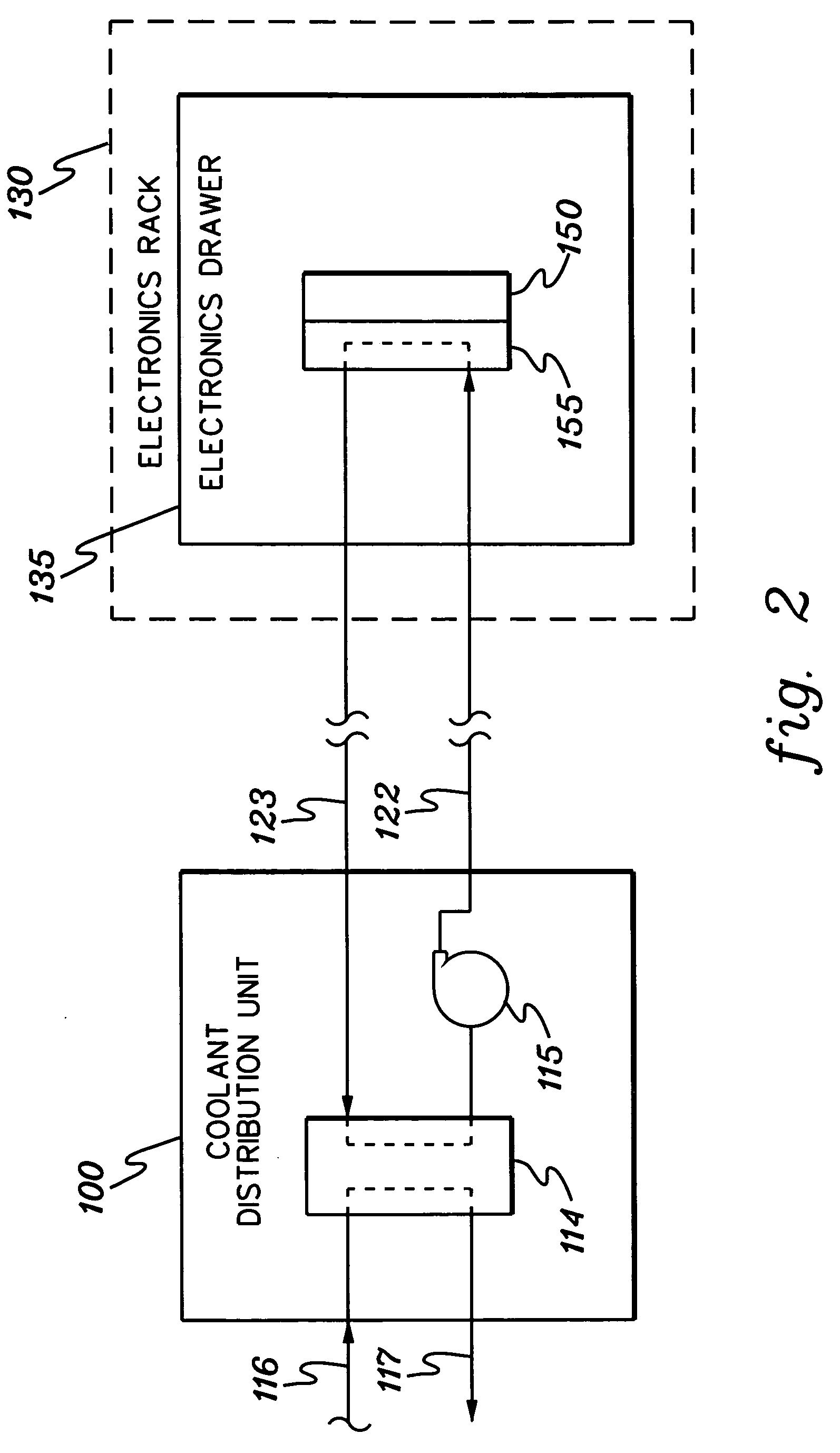

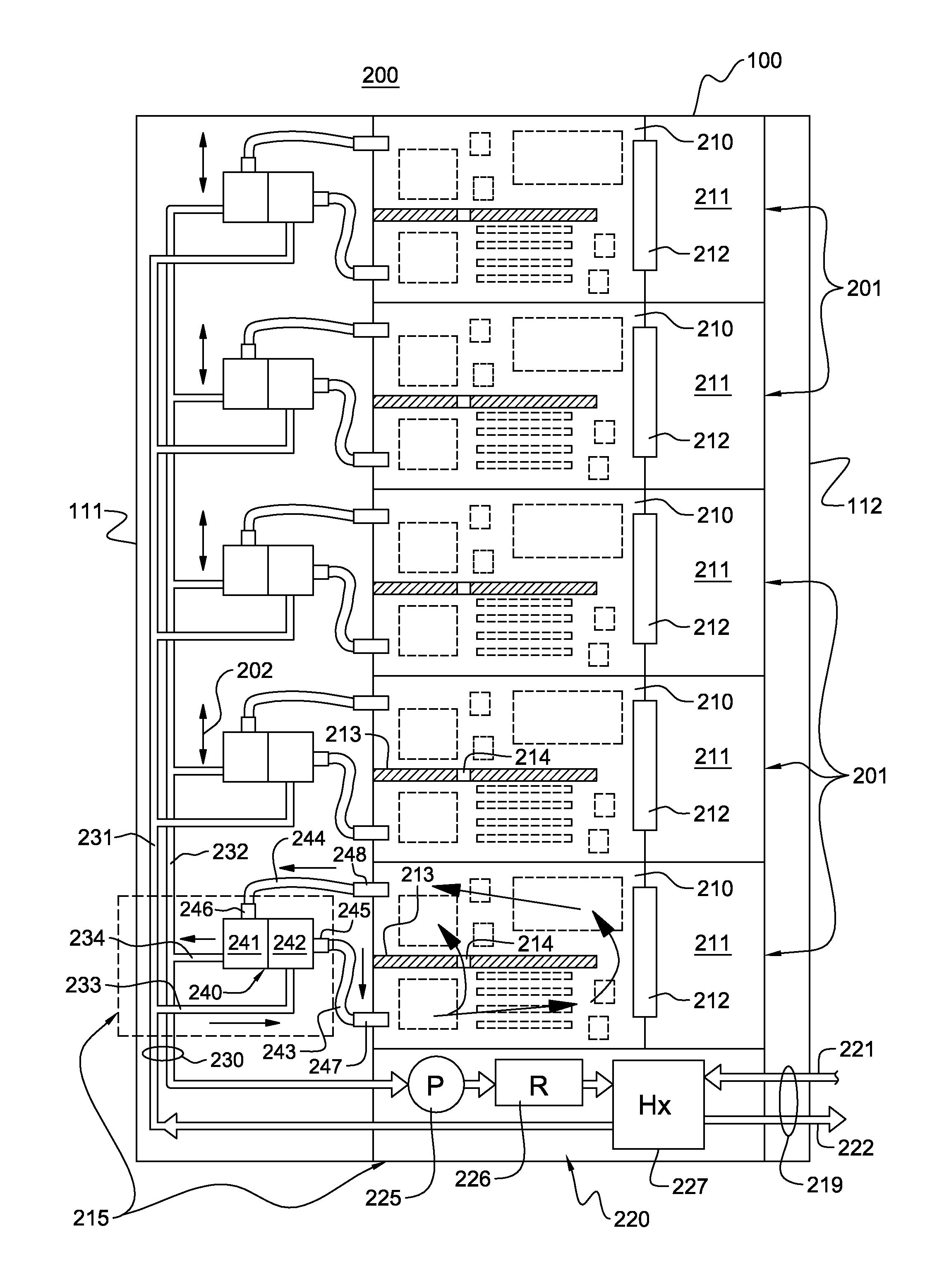

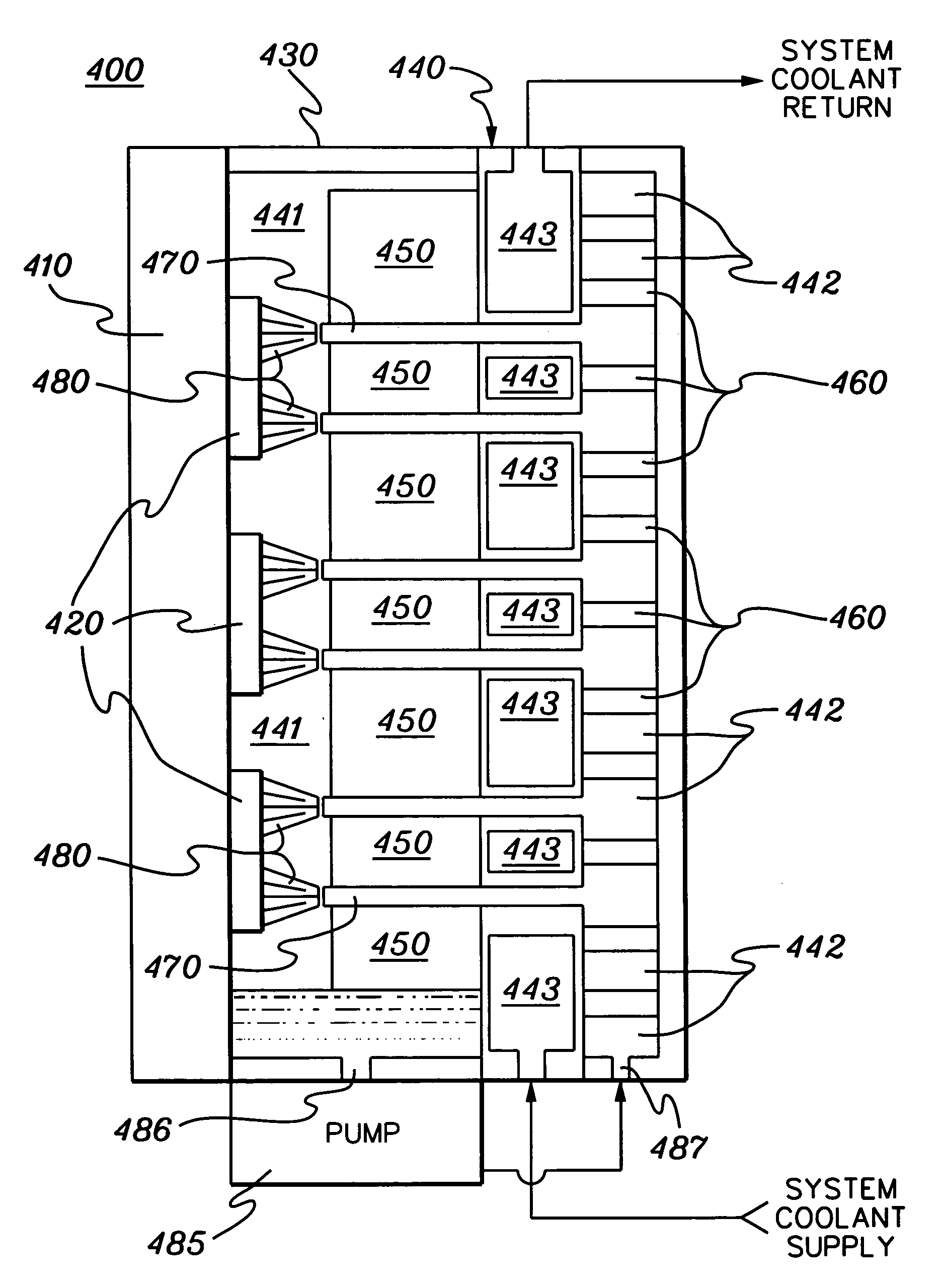

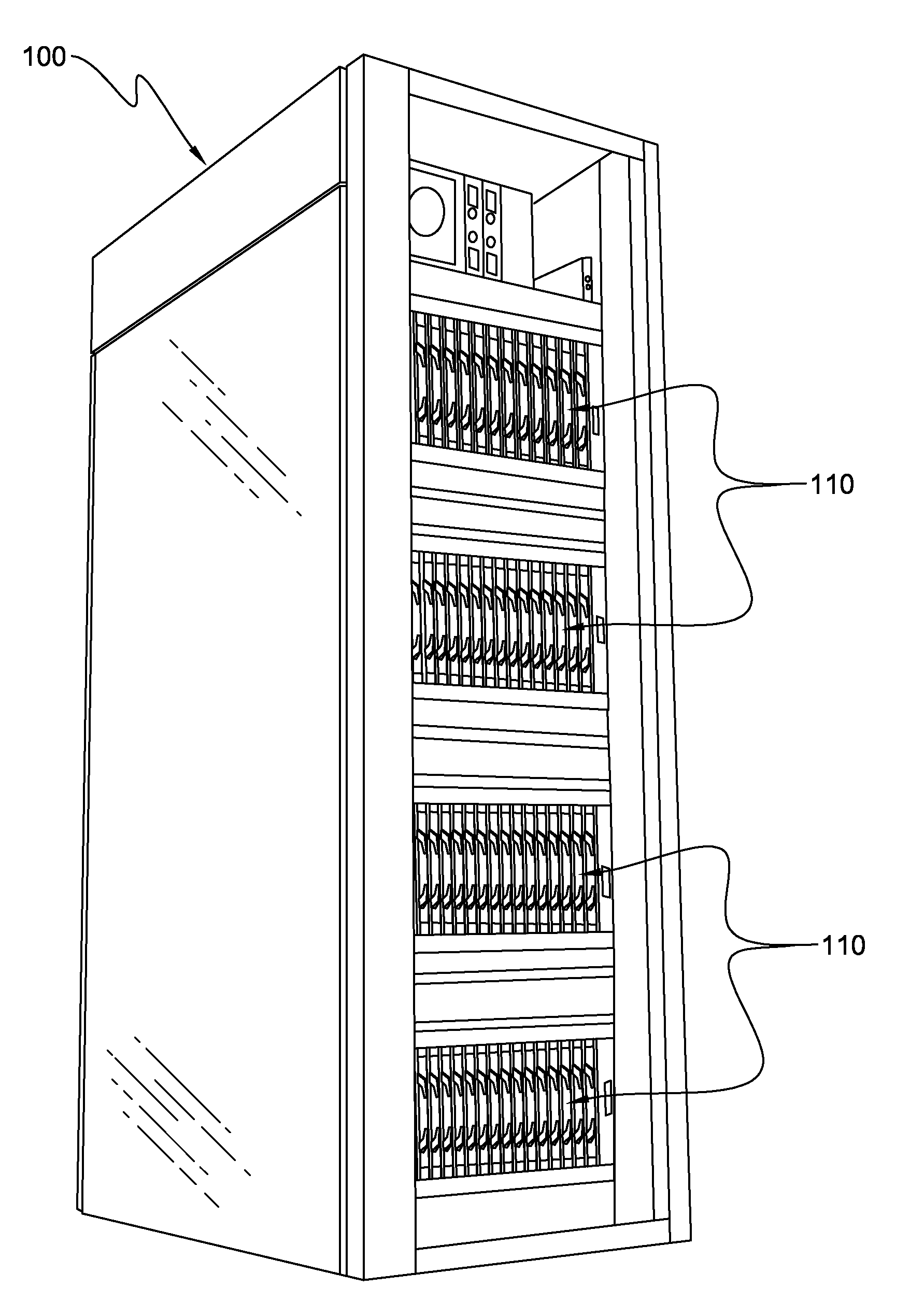

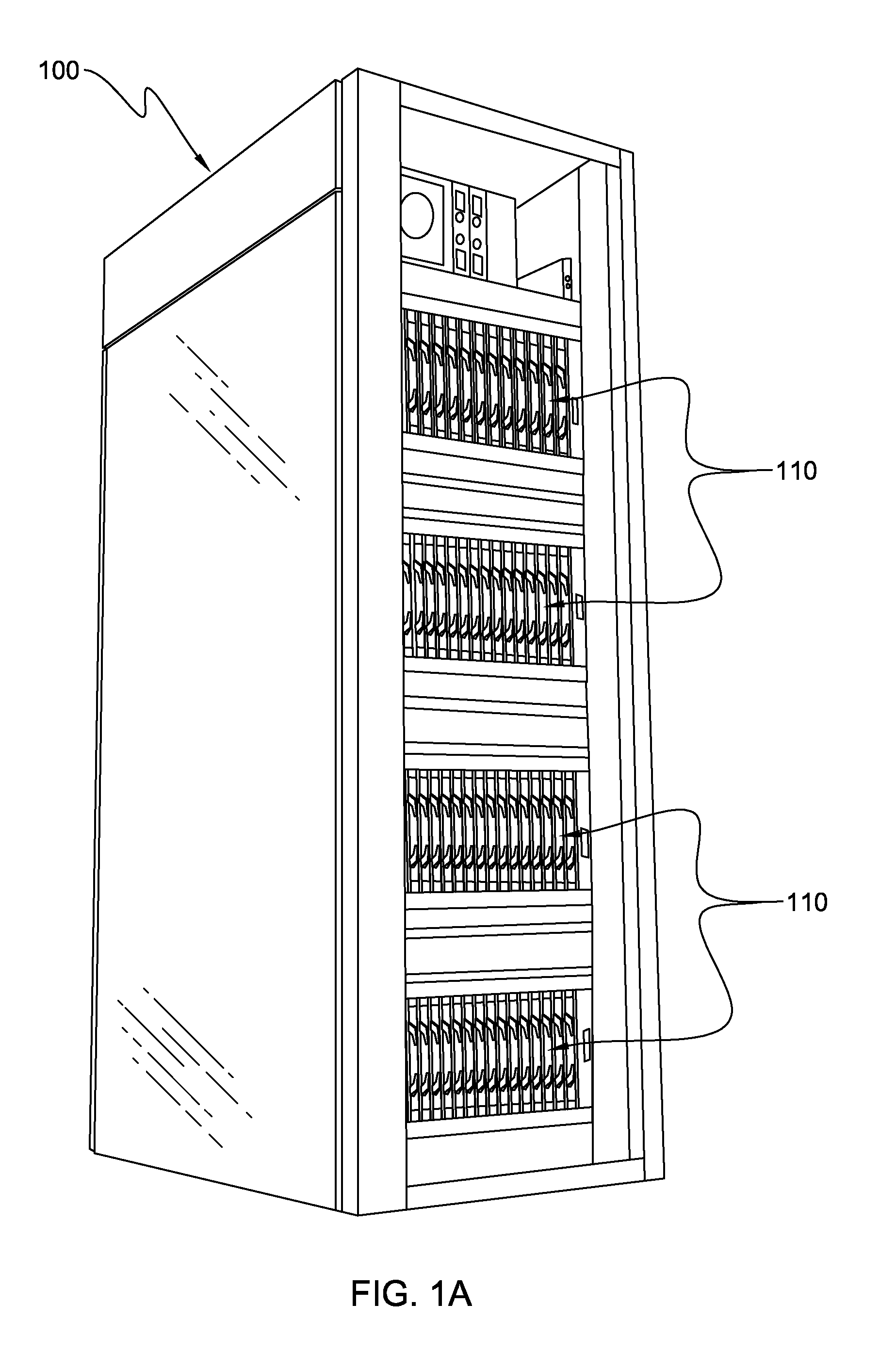

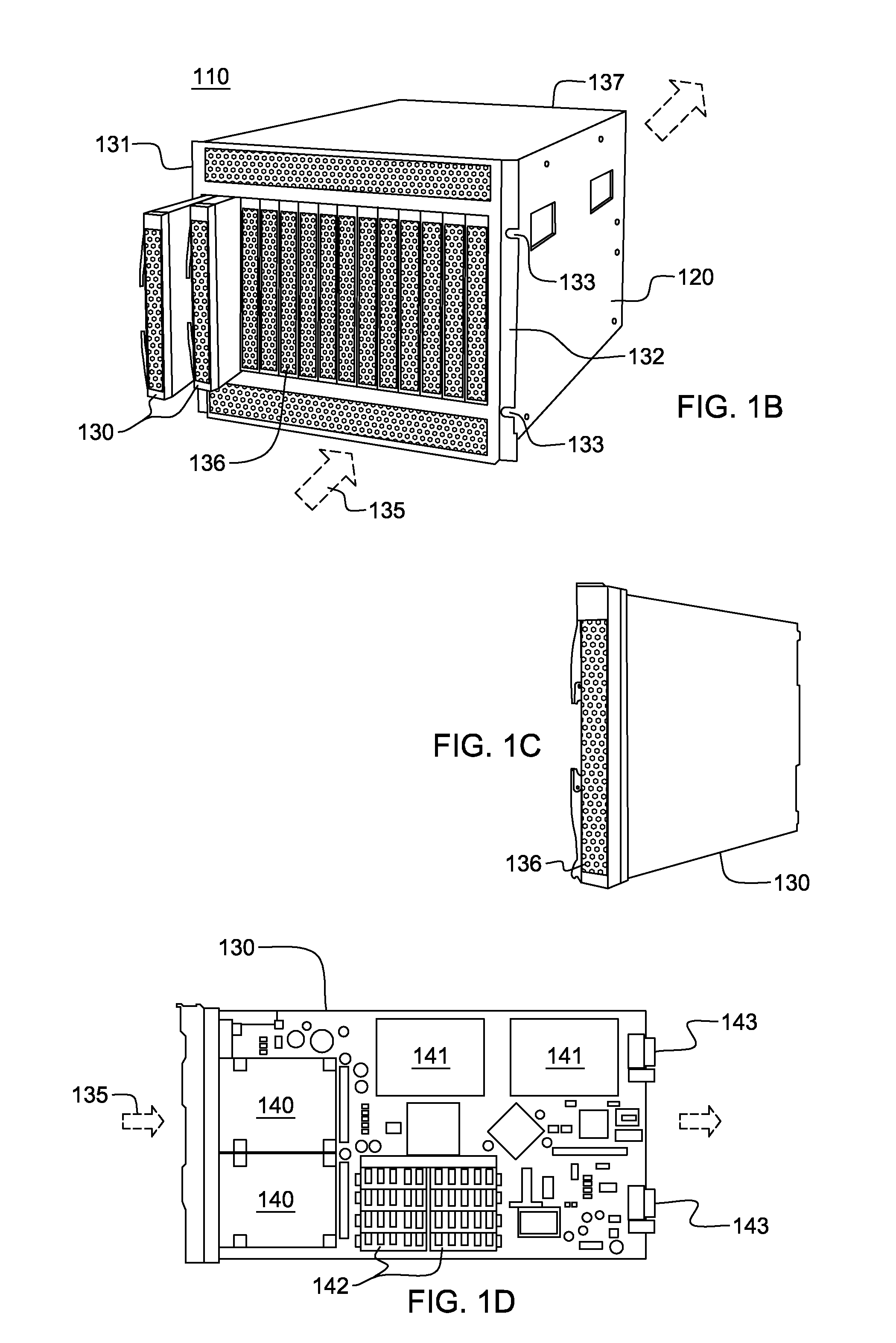

Liquid cooling apparatus and method for cooling blades of an electronic system chassis

InactiveUS20100101765A1Improve heat transfer performanceImprove cooling effectDigital data processing detailsSemiconductor/solid-state device detailsElectronic systemsCoolant flow

Apparatus and method are provided for facilitating liquid cooling of a plurality of blades of an electronic system chassis. The apparatus includes a chassis-level manifold assembly with a first coolant path and a plurality of second coolant paths. The first coolant path is isolated from the plurality of second coolant paths by a heat exchanger. The heat exchanger facilitates transfer of heat from coolant within the second coolant paths to coolant within the first coolant path. Each second coolant path is isolated from the other second coolant paths, and coolant passing therethrough facilitates cooling of a respective blade. When operational, each second coolant path forms a portion of a respective closed loop coolant path extending between the manifold assembly and the electronic system chassis, and in one embodiment, each blade is an immersion-blade, with multiple components thereof immersion-cooled by coolant flowing through the respective second coolant path.

Owner:BRAINSCOPE SPV LLC +1

Etch patterning of nanostructure transparent conductors

Owner:CHAMP GREAT INTL

External liquid loop heat exchanger for an electronic system

A cooling apparatus for usage in an electronic system, a liquid loop heat exchanger body is configured for attachment to an exterior surface of an electronic system chassis.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

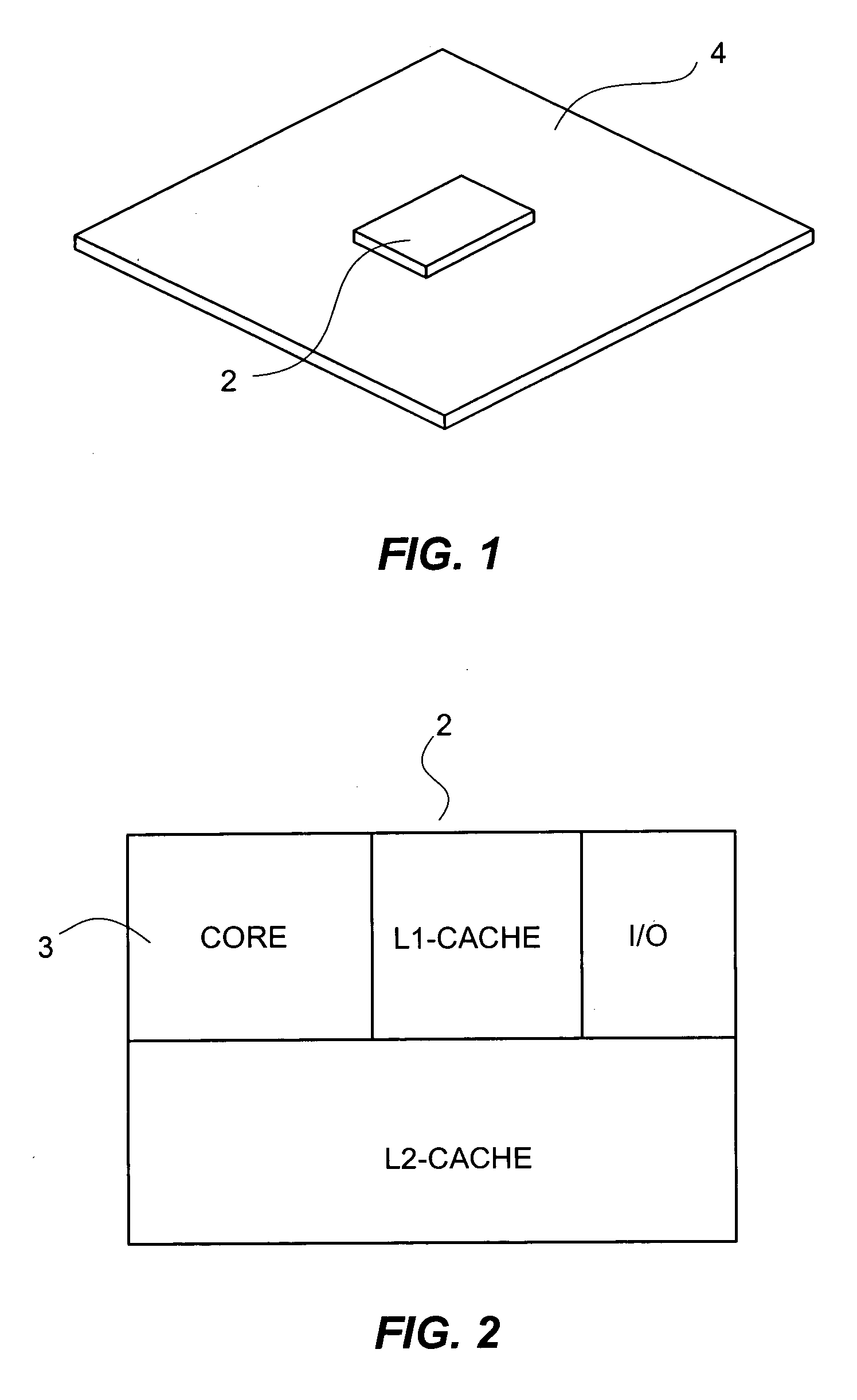

Etched open microchannel spray cooling

ActiveUS6952346B2Simple methodProvide flexibilityDomestic cooling apparatusSemiconductor/solid-state device detailsElectronic componentSpray cooling

The present invention is a spray cooling thermal management device that cools an electronic component. Liquid coolant is dispensed upon a heated surface containing etched open microchannels.

Owner:PARKER INTANGIBLES LLC

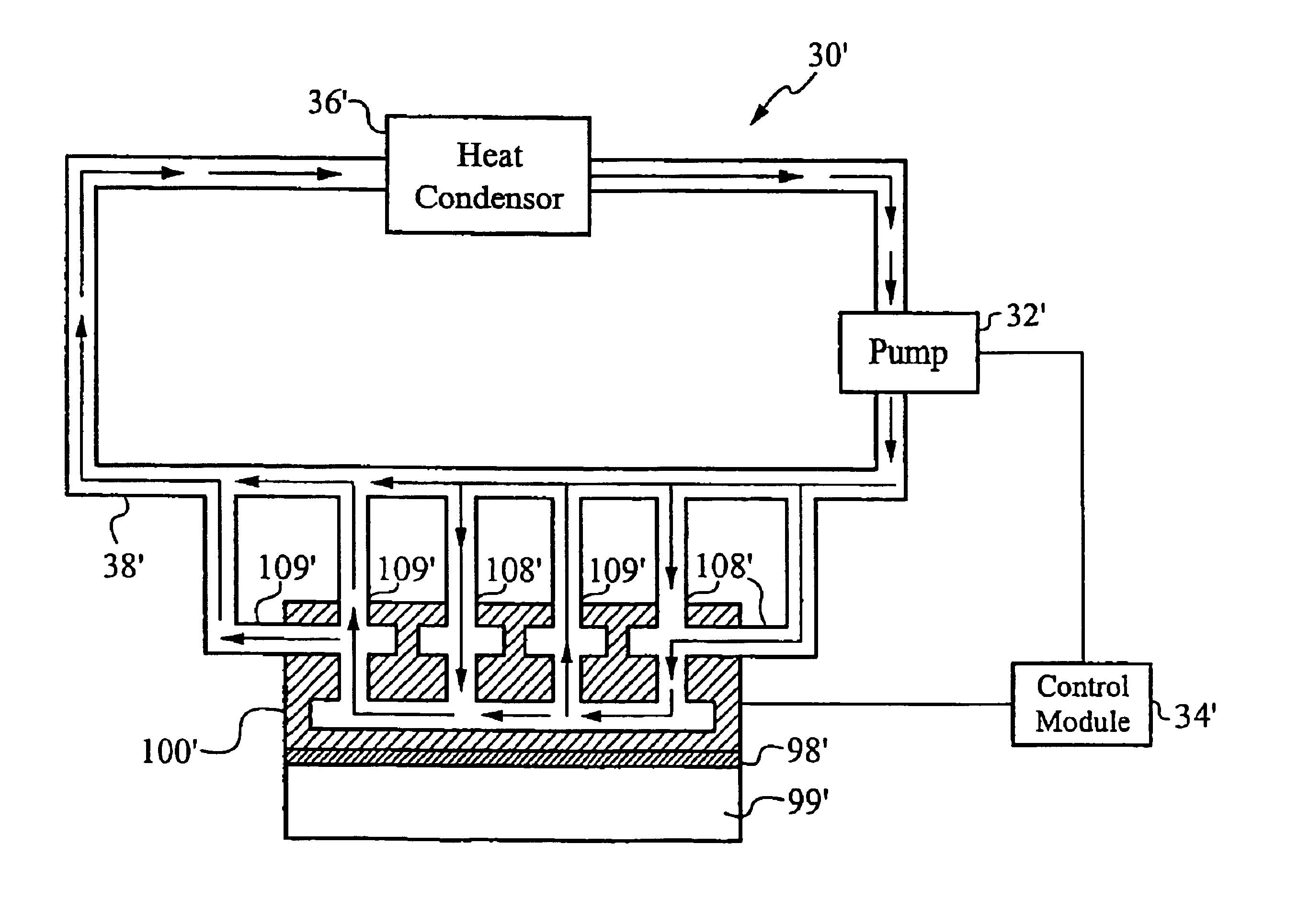

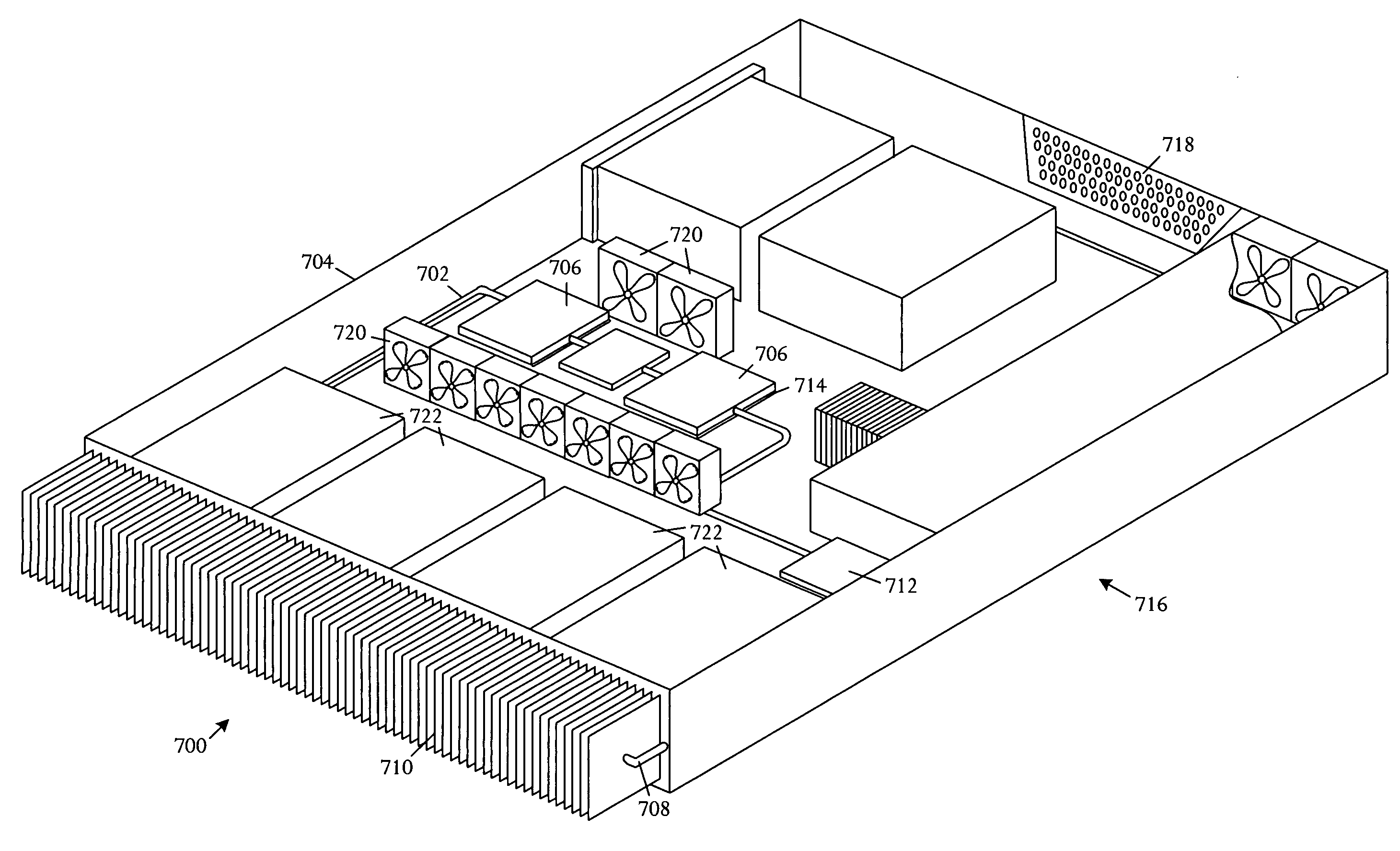

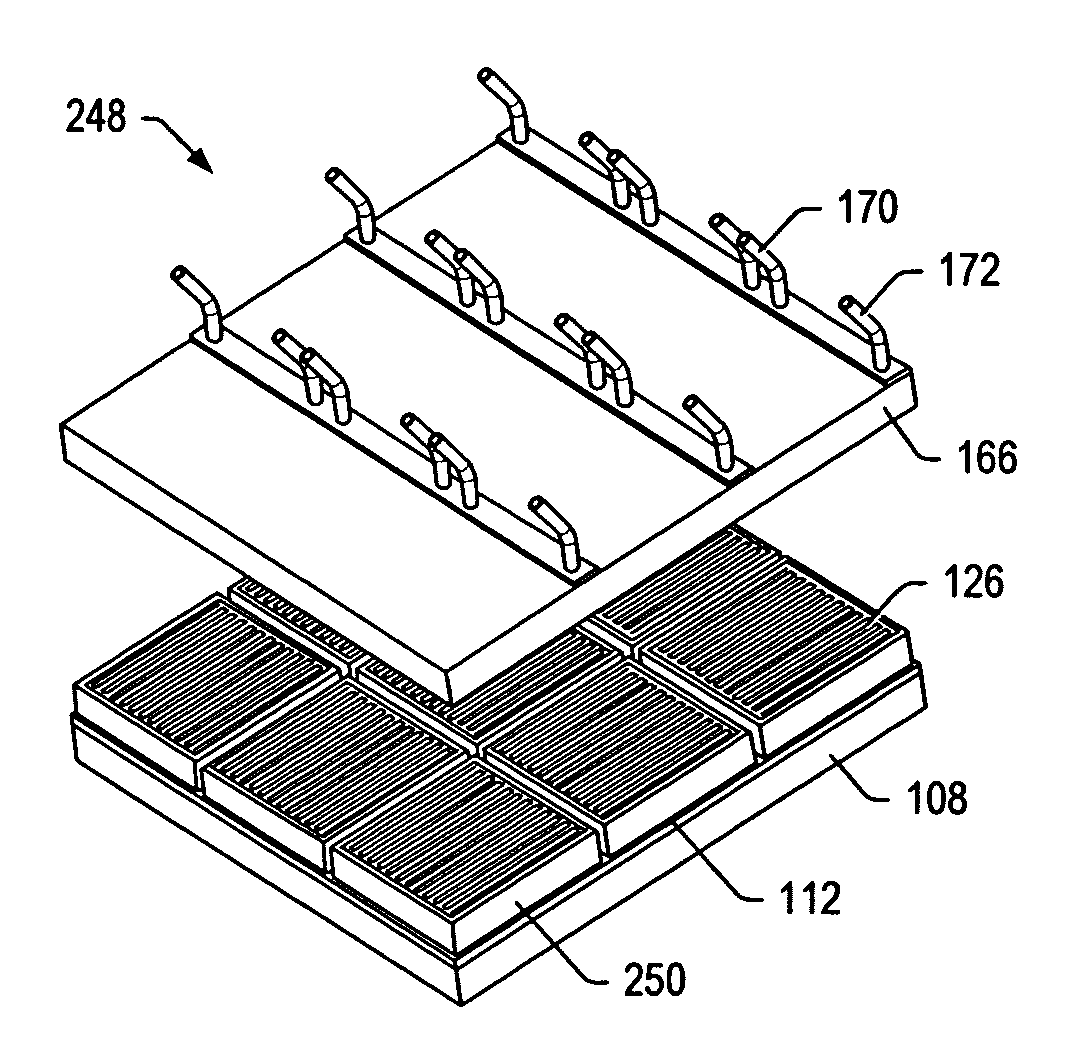

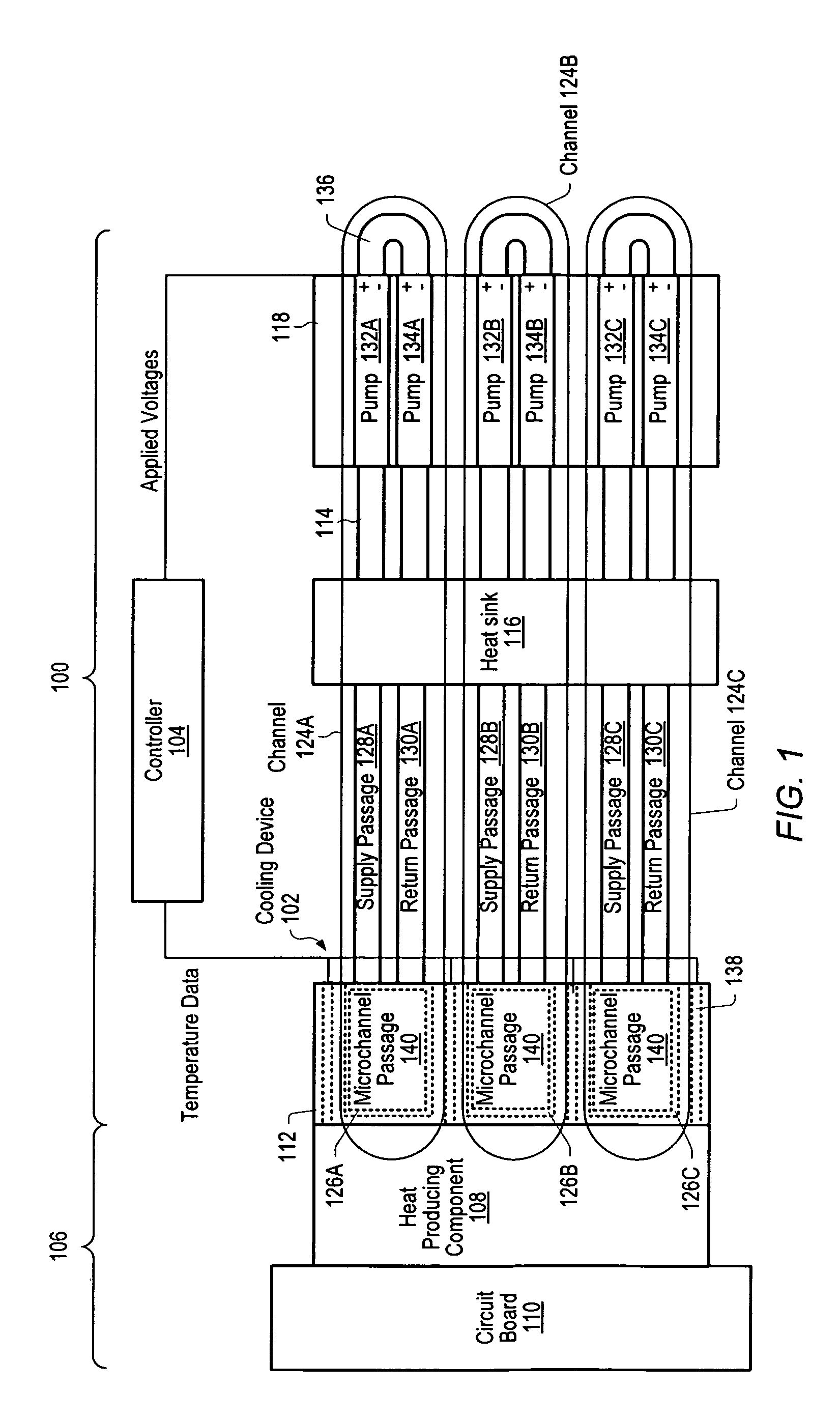

Intelligent microchannel cooling

ActiveUS7672129B1Semiconductor/solid-state device detailsSolid-state devicesMagneto hydrodynamicEngineering

A cooling system for a heat producing component includes a base having two or more cells. The cells may include microchannel passages. A pump system may be coupled to the base. The pump system may circulate fluid independently in each of two or more of the cells. The pump system may include an array of two more magnetohydrodynamic pumps. Each magnetohydrodynamic pump may provide fluid to a different cell. A controller may control a flow rate in each one of cell of the cooling system independently one or more of other cells of the cooling system.

Owner:ORACLE INT CORP

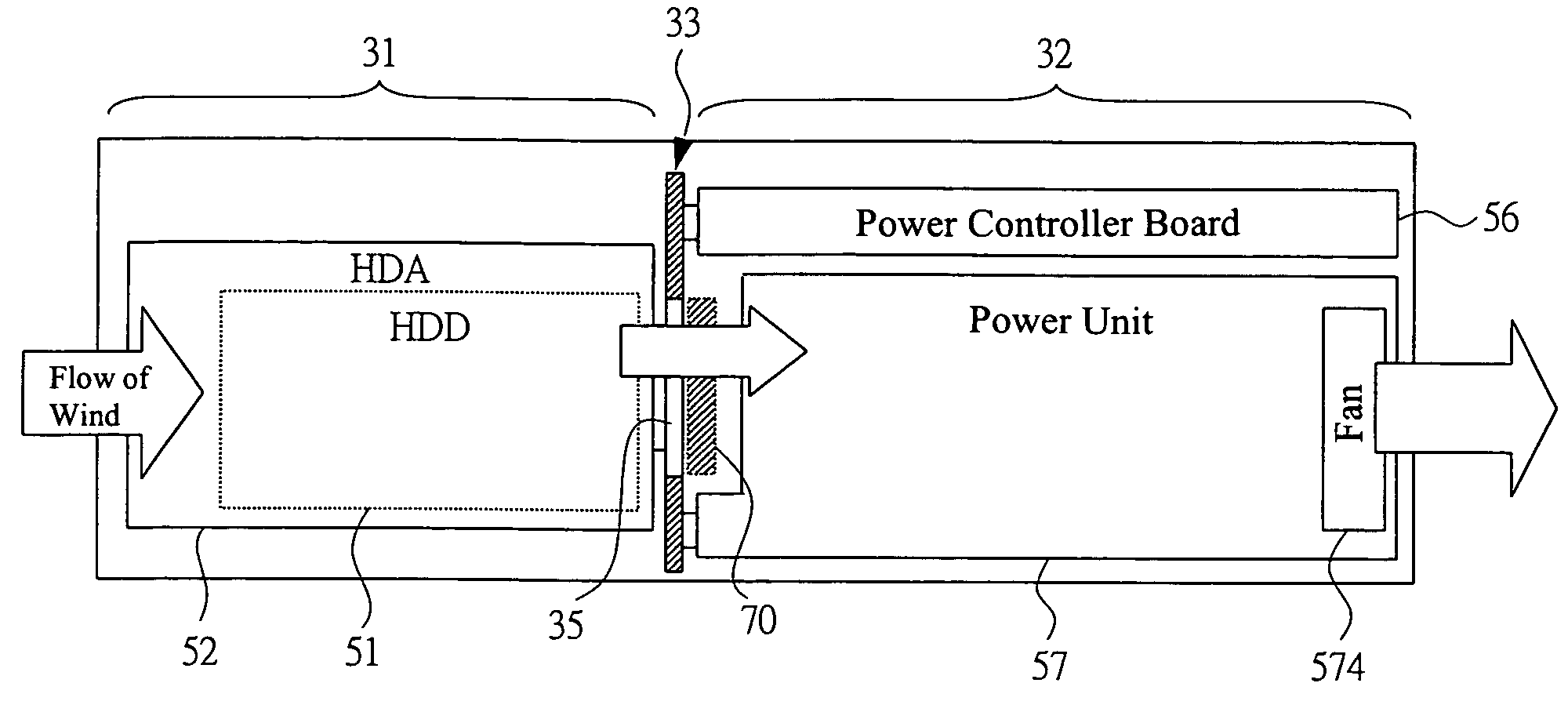

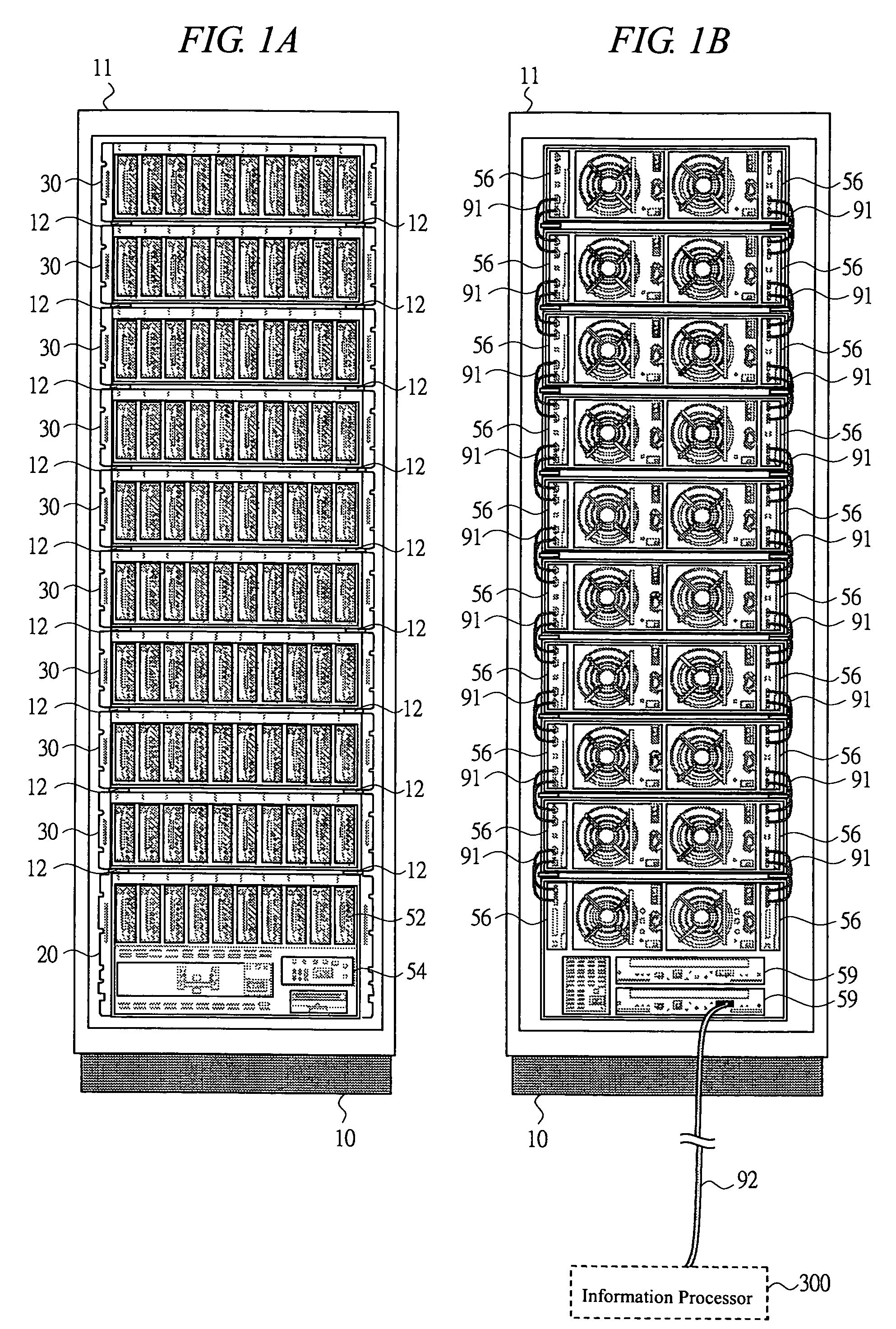

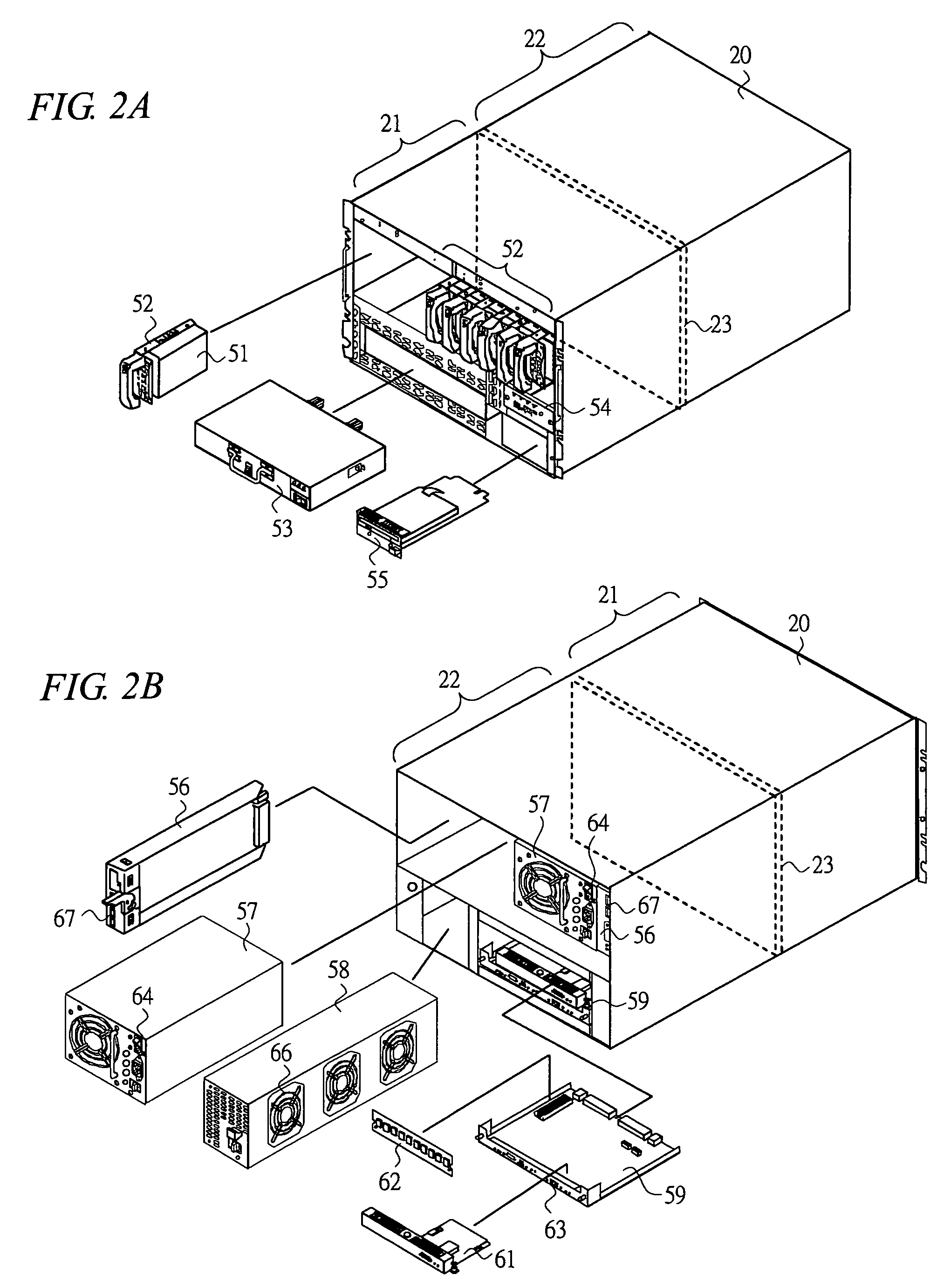

Disk array device

ActiveUS7139170B2Low efficiencyLow flow resistanceDigital data processing detailsAir heatersPower controllerEngineering

In a disk array device for cooling respective sections including a HDD by a fan, drop of cooling efficiency by the difference of conditions of HDD mounted and unmounted sections is prevented and the use of a dummy HDD is deleted / eliminated. A housing contains a HDA mounted on the HDD, a power controller board for performing control to the HDD, a power unit for supplying power to each section, a fan for cooling the housing therein, and a backboard for connecting all the sections. On one backboard surface, the HDA is mounted, which has a cooling function for making cooling air flowing in the housing and exhausting air from the housing via a region on which the HDA are mounted and via a vent hole on the backboard. For the vent hole, a shutter is mounted, which has a mechanism for adjusting an open area rate of the vent hole by opening when the HDA is mounted and closing when removed.

Owner:GOOGLE LLC

Device for increasing heat transfer

InactiveUS6252769B1Not disturbNot disturb surroundingsSemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat transfer

A device for increasing heat transfer from an object includes at least one oscillating membrane for generating air motion in air surrounding the object, and a nozzle for affecting the air motion so that the air motion causes a continuous exchange of the air surrounding the object.

Owner:UNWIRED PLANET

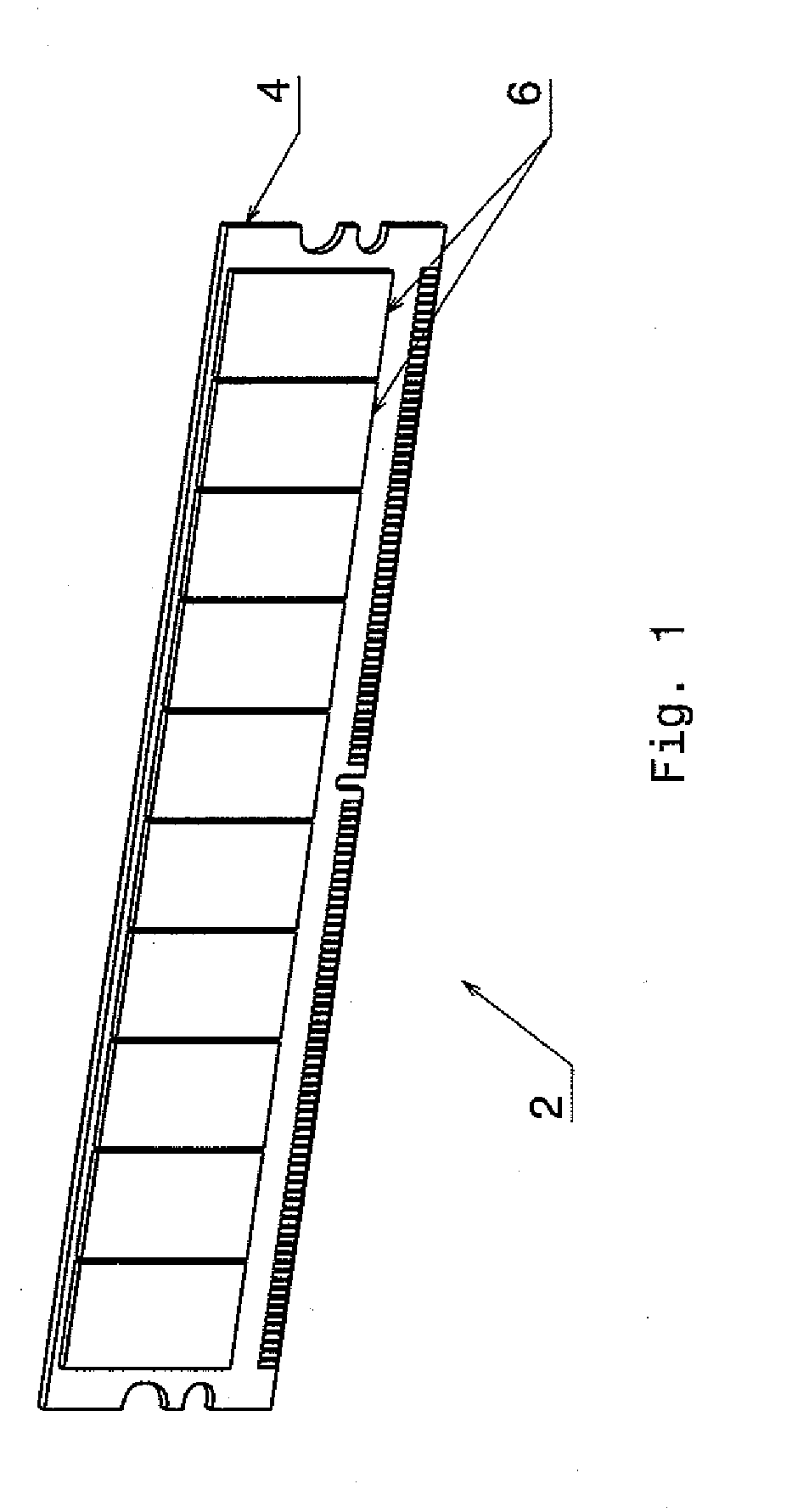

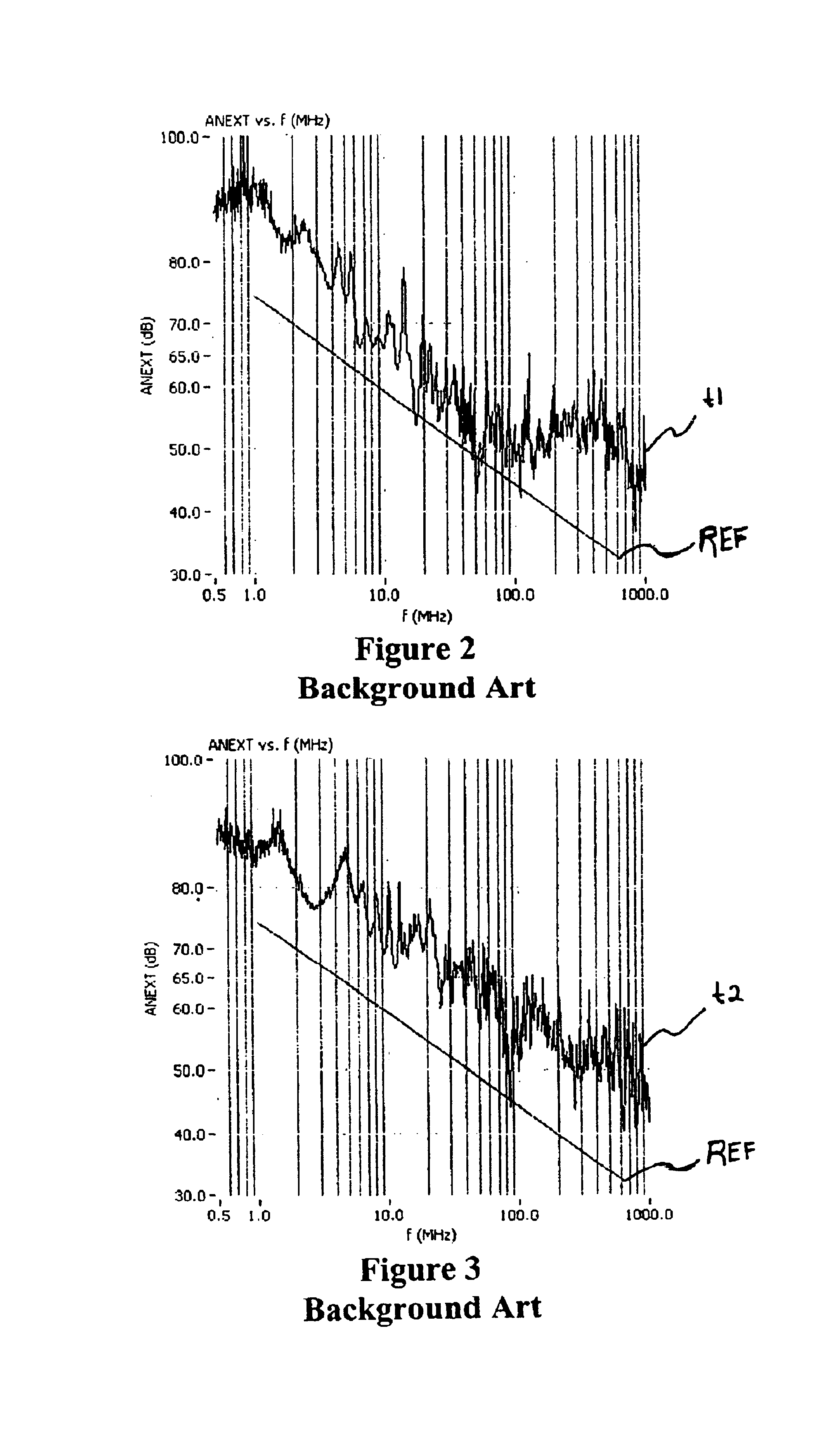

Local area network cabling arrangement with randomized variation

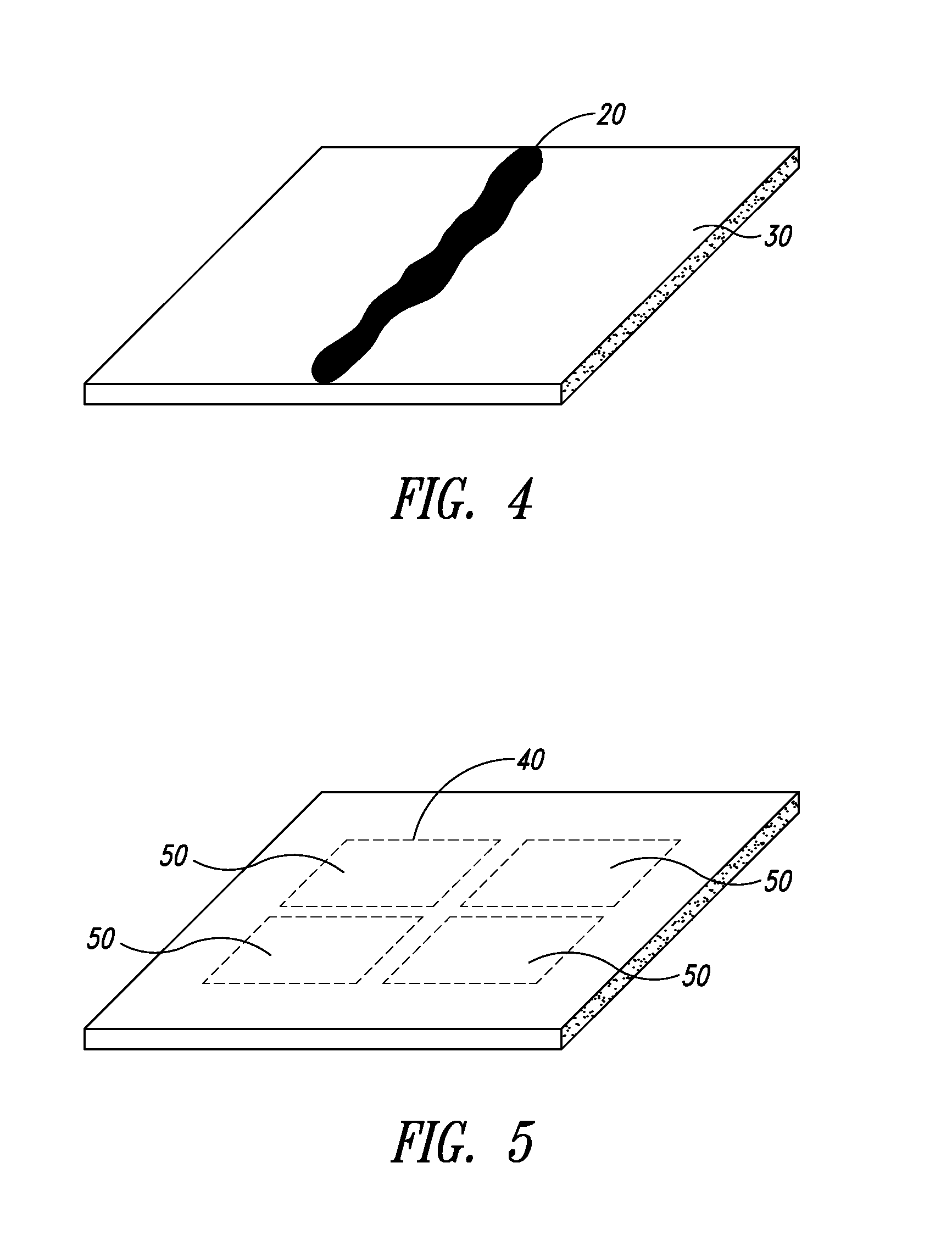

ActiveUS6875928B1Improved internalImproved alien crosstalk performanceInsulated cablesPower cablesArea networkEngineering

A cabling media includes a plurality of twisted wire pairs housed inside a jacket. Each of the twisted wire pairs has a respective twist length, defined as a distance wherein the wires of the twisted wire pair twist about each other one complete revolution. At least one of the respective twist lengths purposefully varies along a length of the cabling media. In one embodiment, the cabling media includes four twisted wire pairs, with each twisted wire pair having its twist length purposefully varying along the length of the cabling media. Further, the twisted wire pairs may have a core strand length, defined as a distance wherein the twisted wire pairs twist about each other one complete revolution. In a further embodiment, the core strand length is purposefully varied along the length of the cabling media. The cabling media can be designed to meet the requirements of CAT 5, CAT 5e or CAT 6 cabling, and demonstrates low alien and internal crosstalk characteristics even at data bit rates of 10 Gbit / sec.

Owner:COMMSCOPE INC

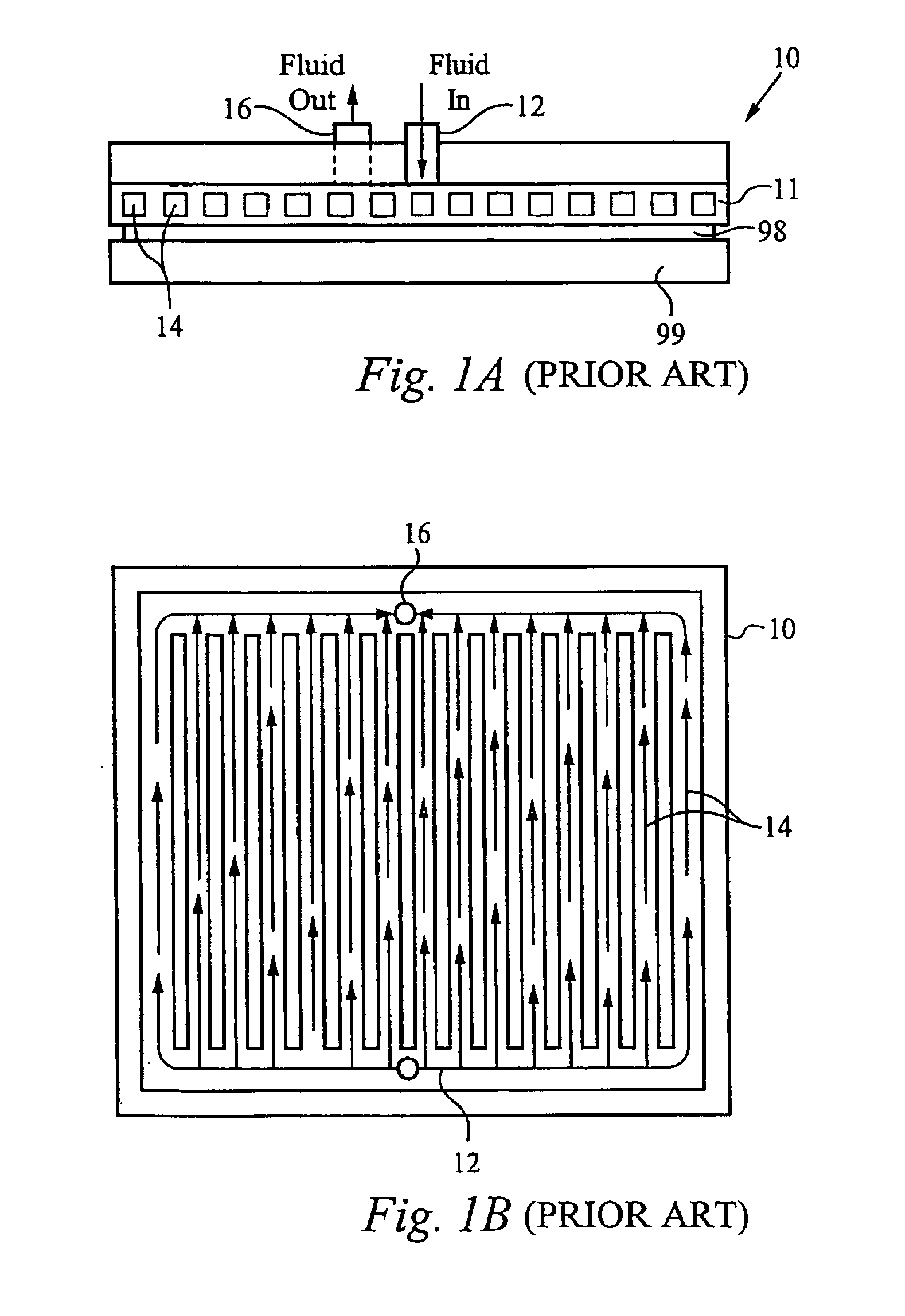

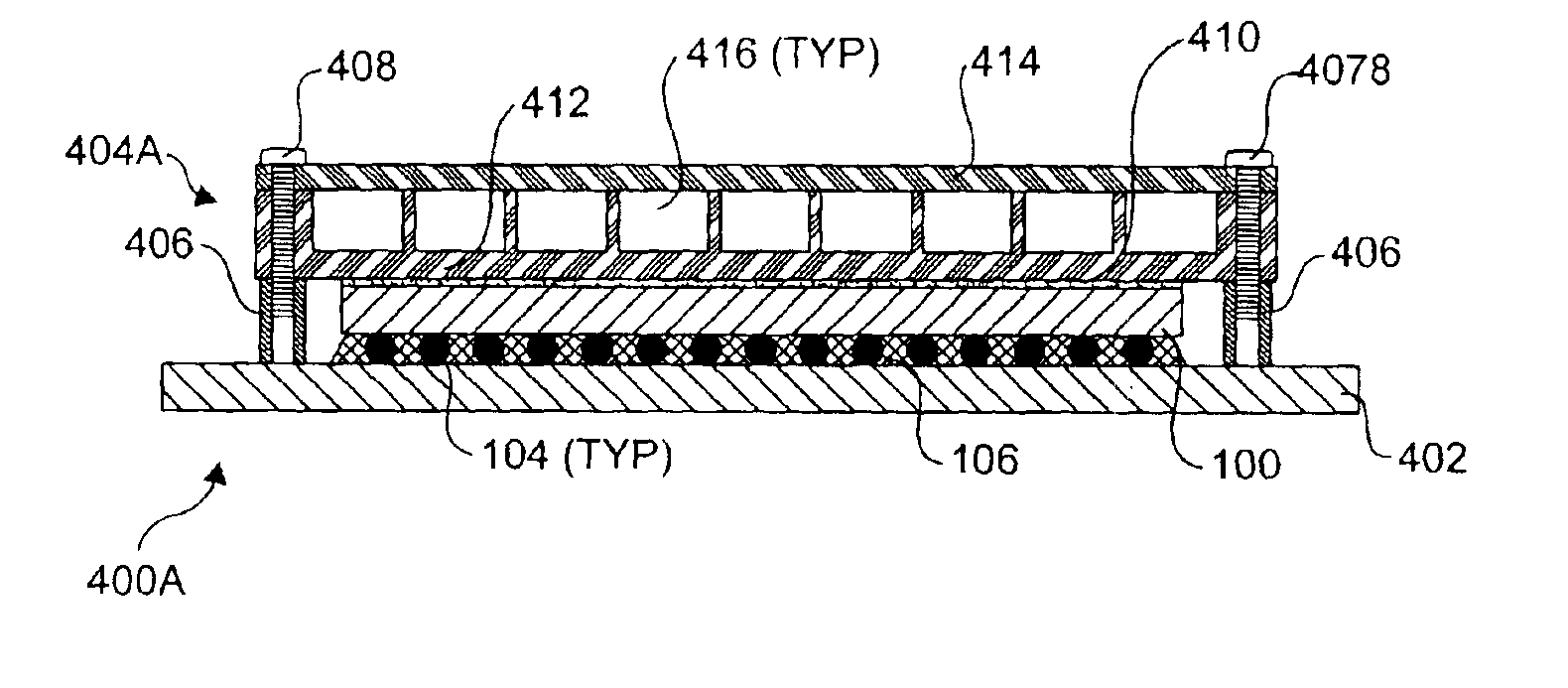

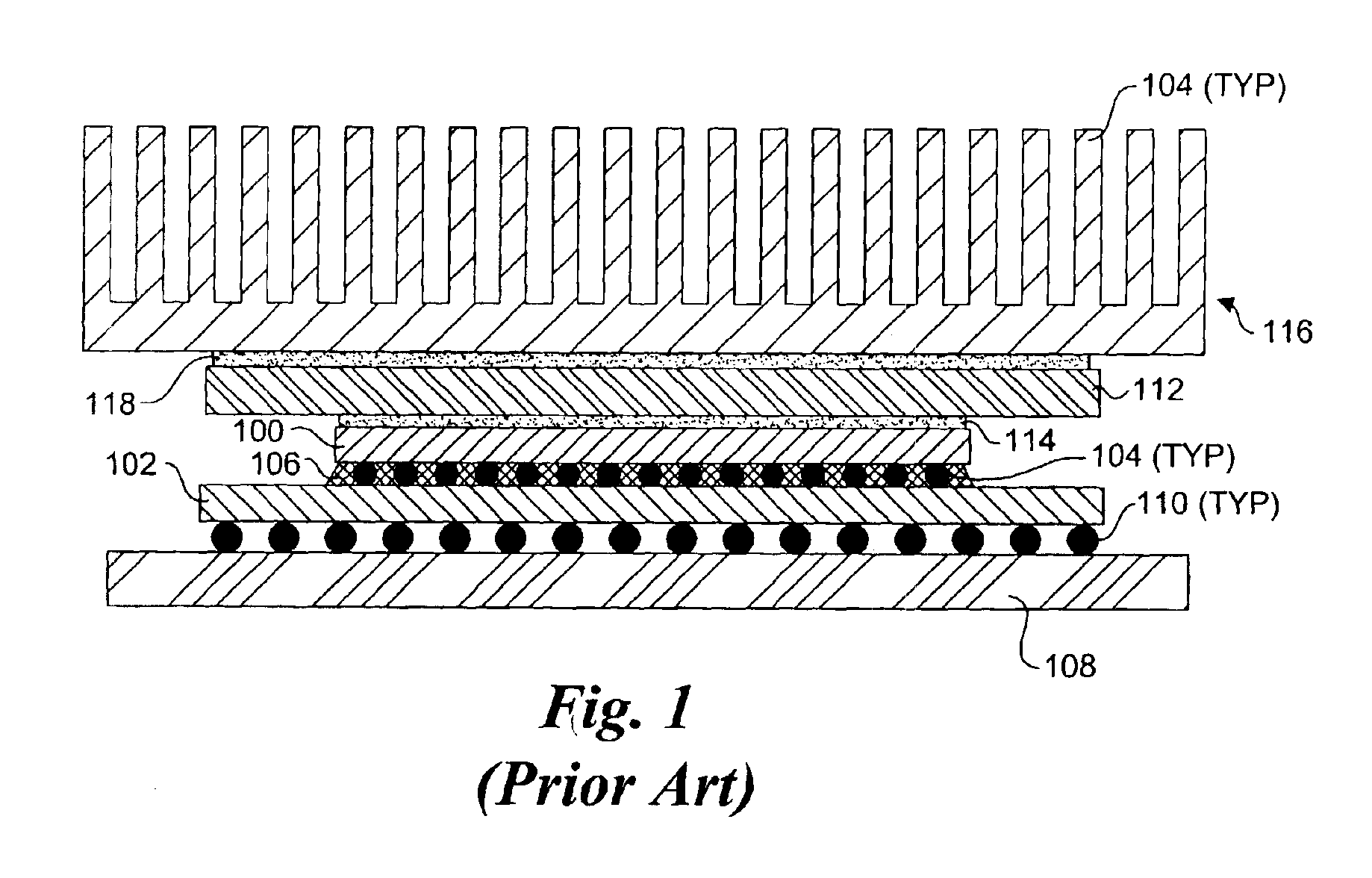

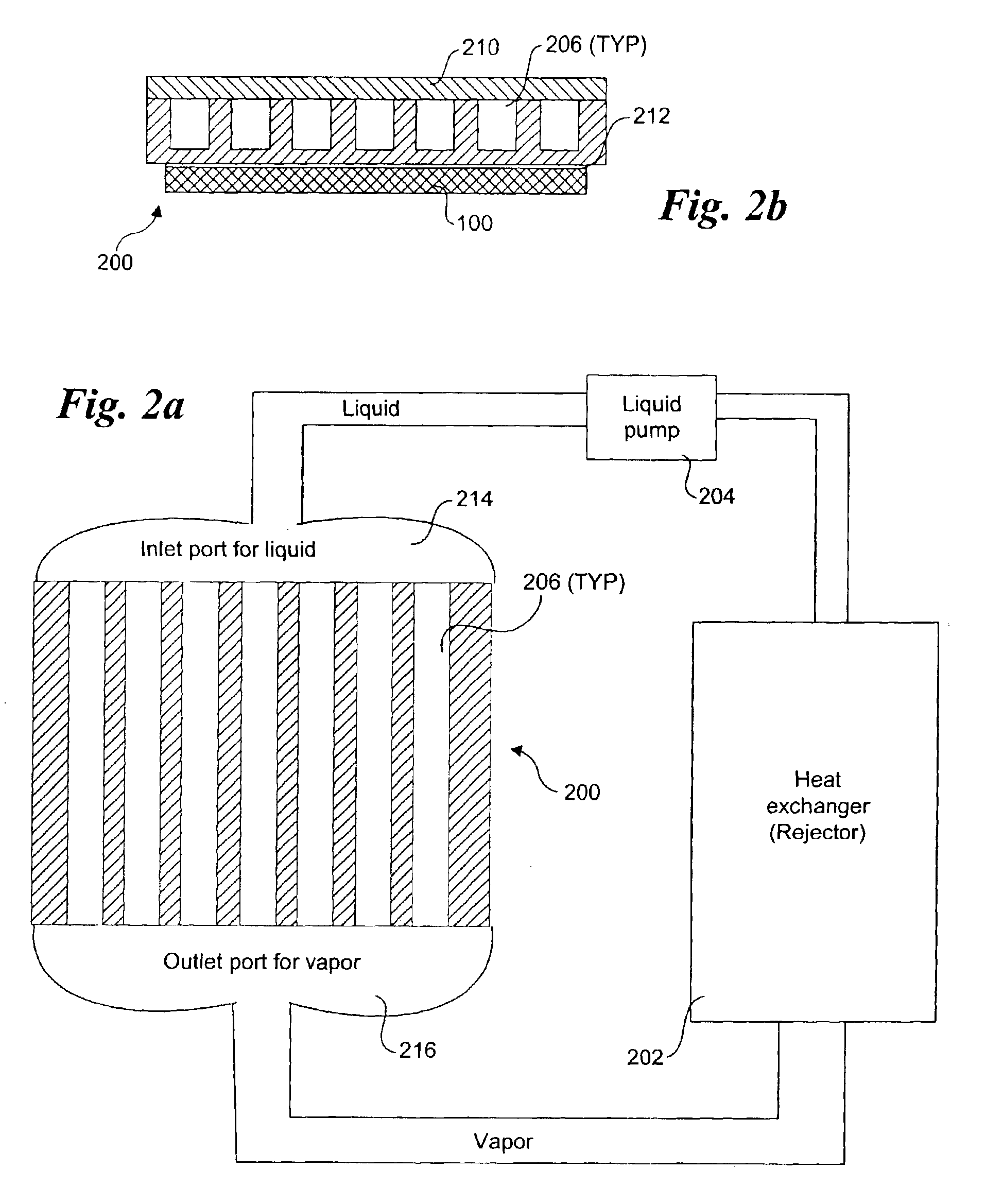

Micro-channel heat exchangers and spreaders

InactiveUS6934154B2Semiconductor/solid-state device detailsSolid-state devicesWorking fluidPlate heat exchanger

Two-phase microchannel heat exchangers for cooling integrated circuit (IC) dies and cooling systems employing the same are disclosed. The heat exchangers include thermal masses having a plurality of microchannels formed therein. In one set of configurations, the IC die is coupled to a thermal mass having a plurality of open microchannels such that a hermetic seal is formed between the die and the bases of the microchannel walls, thus forming a plurality of closed microchannels. In another set of configurations, a separate microchannel heat exchanger is thermally coupled to an IC die and operatively coupled to the IC die via coupling to a substrate on which the IC die is mounted. The microchannel heat exchangers may be employed in a closed loop cooling system includes a pump and a heat rejecter. The microchannels are configured to support two-phase heat transfer using a working fluid such as water.

Owner:TAHOE RES LTD

Cooled electronics system and method employing air-to-liquid heat exchange and bifurcated air flow

Owner:INT BUSINESS MASCH CORP

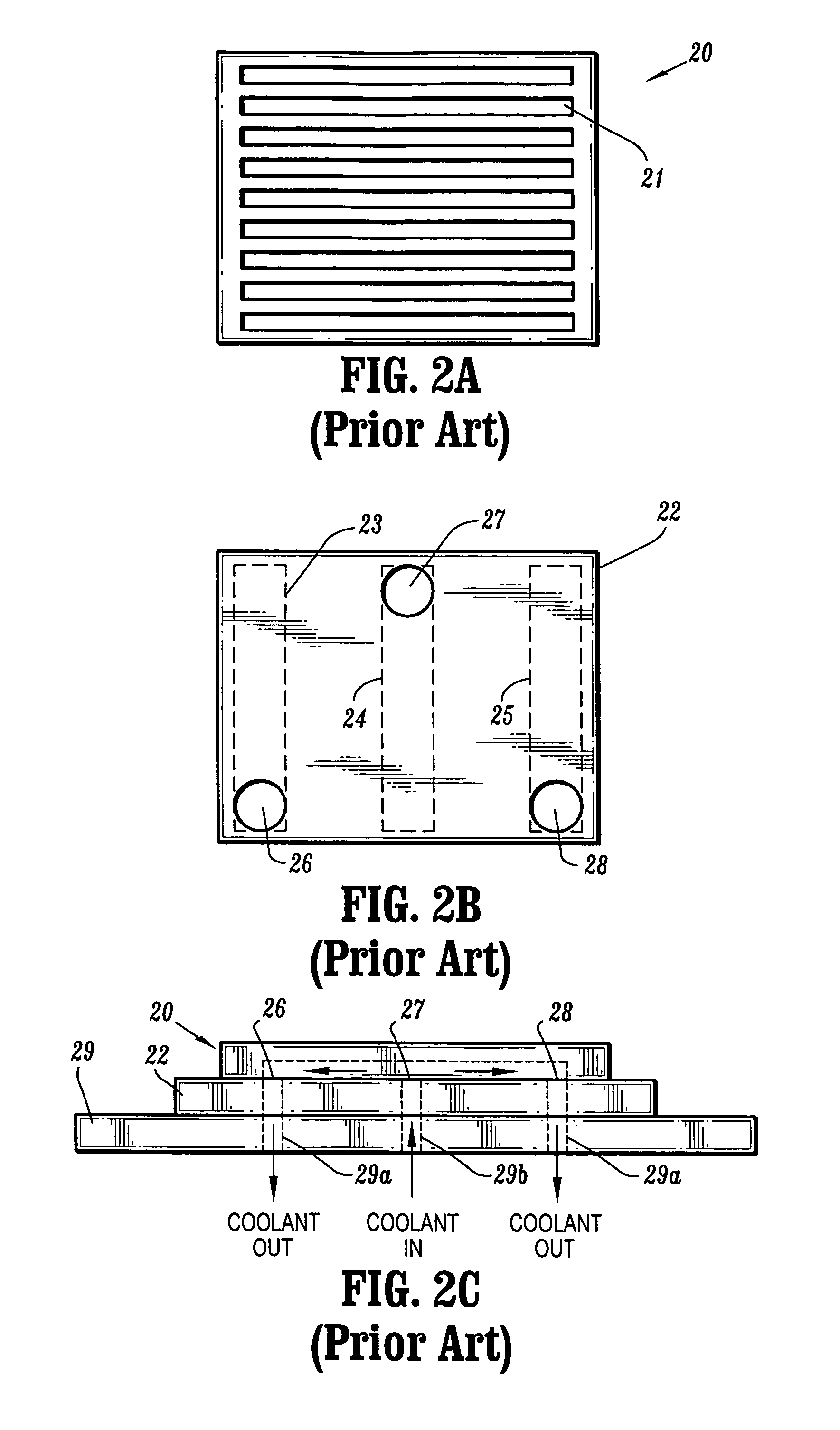

Apparatus and methods for microchannel cooling of semiconductor integrated circuit packages

InactiveUS7190580B2Uniform flow and distributionEfficient and low operating pressure microchannel coolingSemiconductor/solid-state device detailsSolid-state devicesCoolant flowEngineering

Owner:INT BUSINESS MASCH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com