Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Equal performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrically optimized hybird "last mile" telecommunications cable system

InactiveUS6091025AEqual performanceEquivalent signal performanceCoaxial cables/analogue cablesQuad constructionsElectrical conductorTelecommunications cable

A cable system is provided which can accomodate electrical and optical cabling. The conductors of the system employ a layer which is impedance-matched to space, decreasing their cross-section to electromagnetic interference. The conductors of the system also employ a layer which symmetrizes electromagnetic interference signals, reducing the effect of interference and crosstalk on the signals carried by the conductors. The system also includes a node interface device for connection to a global electrical and fiber network. The node interface device connects to a user interface device through the cable.

Owner:KHAMSIN TECH LLC

Polymeric reference electrode

InactiveUS20060065527A1High mechanical strengthEqual performanceMaterial electrochemical variablesVitrificationPlasticizer

The invention is a polymeric reference electrode having properties equal to or superior to prior art electrodes without the presence of a plasticizer and in which such properties are achieved by incorporation in the membrane of a polymer with a sufficiently low glass transition temperature (Tg) to mimic the characteristics of a highly plasticized thermoplastic membrane. Preferred polymers are the polyacrylates, preferably with a linear backbone and pendant substituent groups. The membrane may further include lipophilic polymers and lipophilic additives, such as salts. In the reference electrode the membrane is overlaid on an internal electrode comprised of an internal contact optionally coated with an electrolyte and entrapped in a hydrophilic polymer. The polymeric reference electrode is preferably for use in the context of an ion selective electrode assembly.

Owner:SENDX MEDICAL

Detergent compositions

InactiveUS6274538B1Enhanced builder performanceImproves stain removalInorganic/elemental detergent compounding agentsDetergent bleaching agentsChemistry

Owner:THE PROCTER & GAMBLE COMPANY

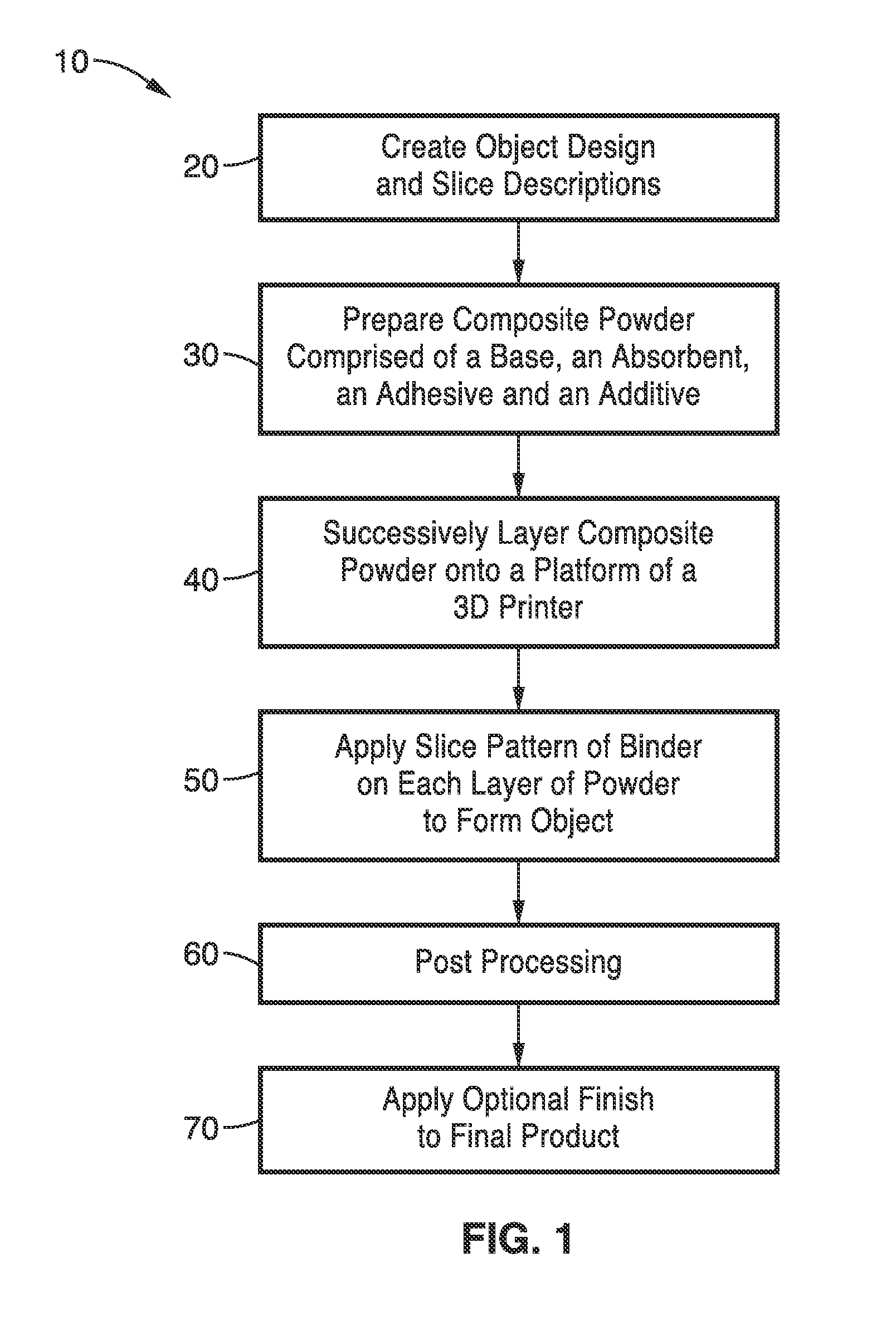

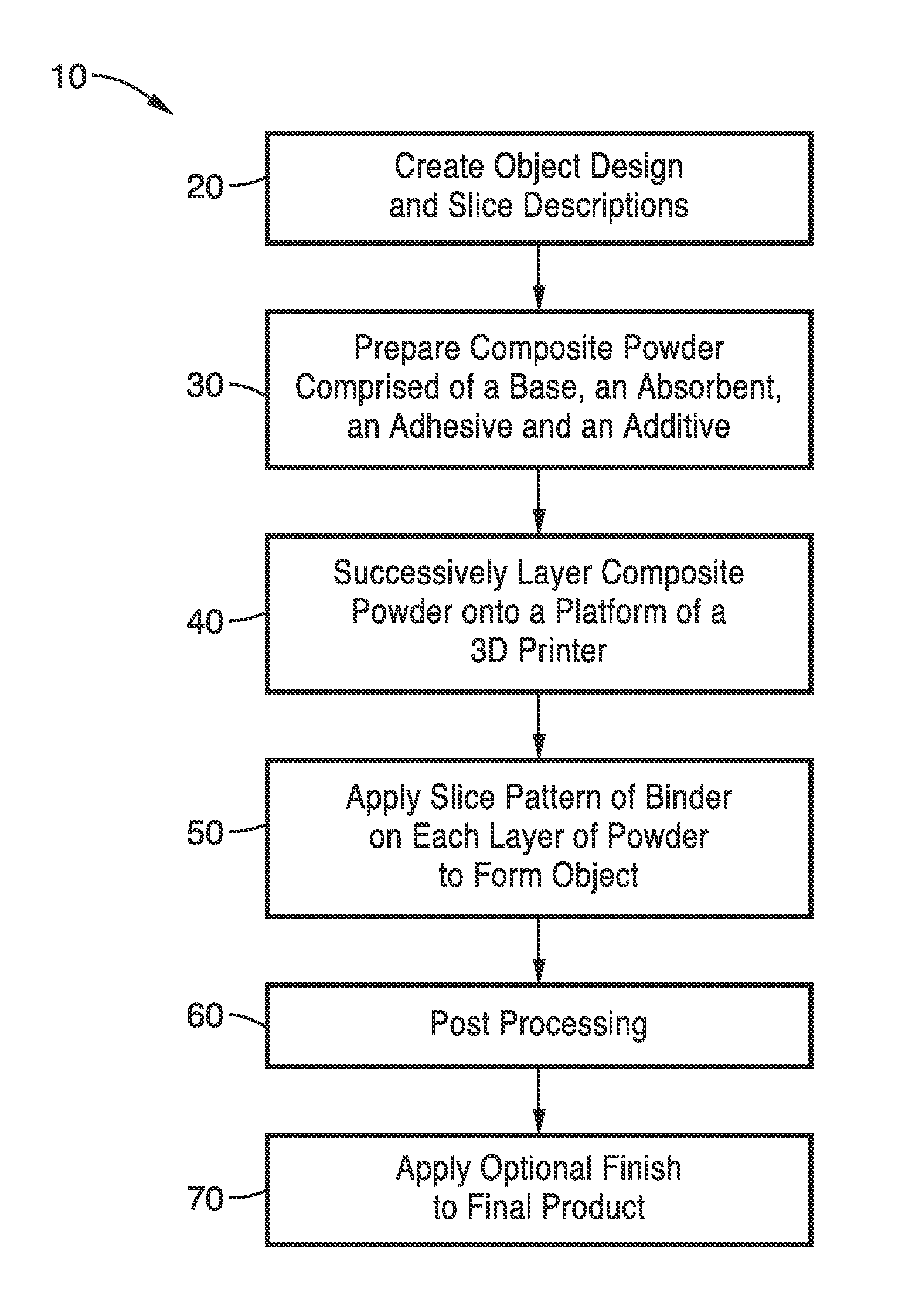

3D printing powder compositions and methods of use

ActiveUS20140252672A1Low costWide scaleSolid waste managementCeramic shaping apparatusCompressive strengthUltimate tensile strength

Powder compositions that can be used with traditional 3D printing technology and methods for producing 3D printed building materials that have comparable compressive strength to standard concrete and tensile strength up to 70% greater than standard concrete.

Owner:RGT UNIV OF CALIFORNIA

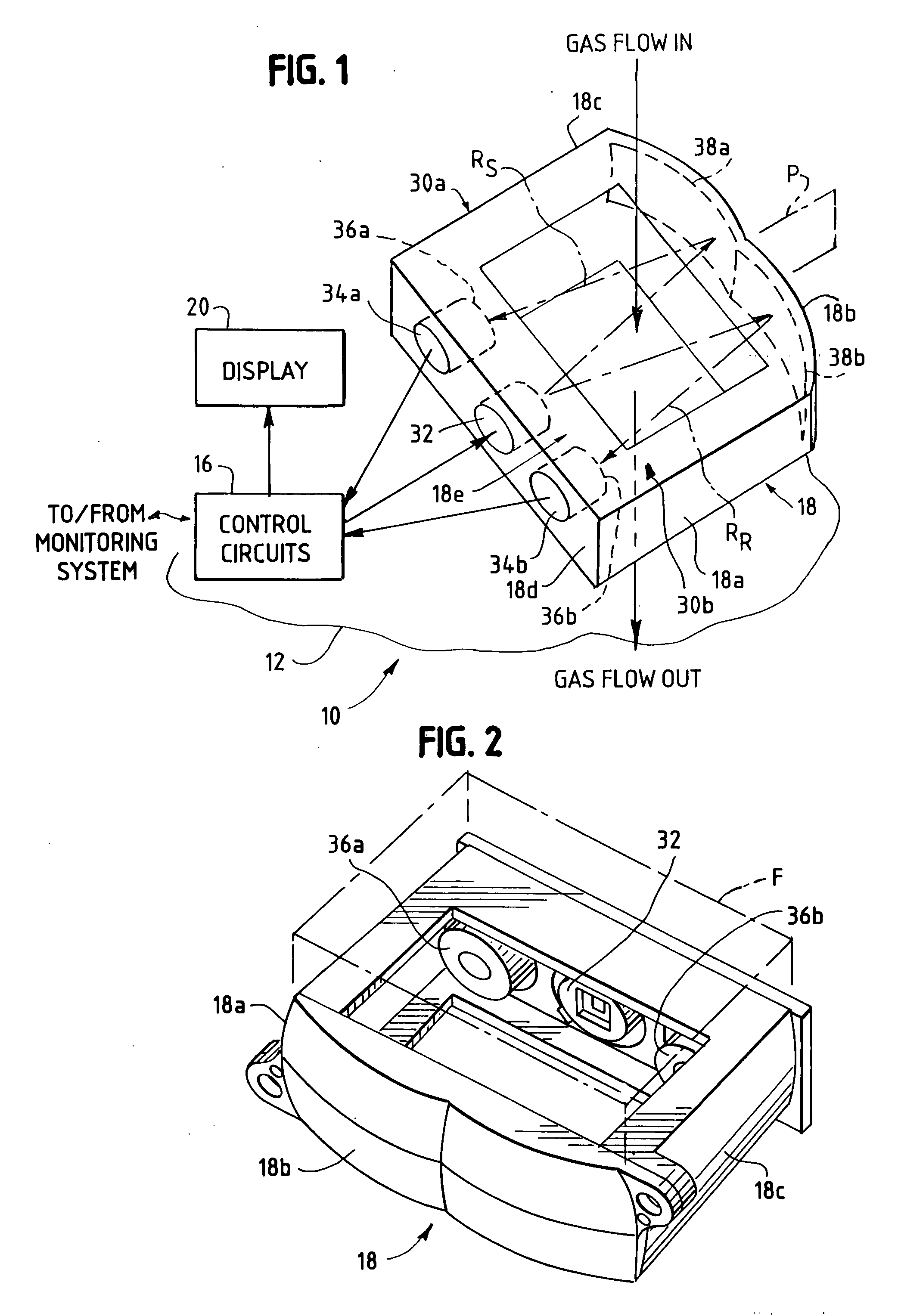

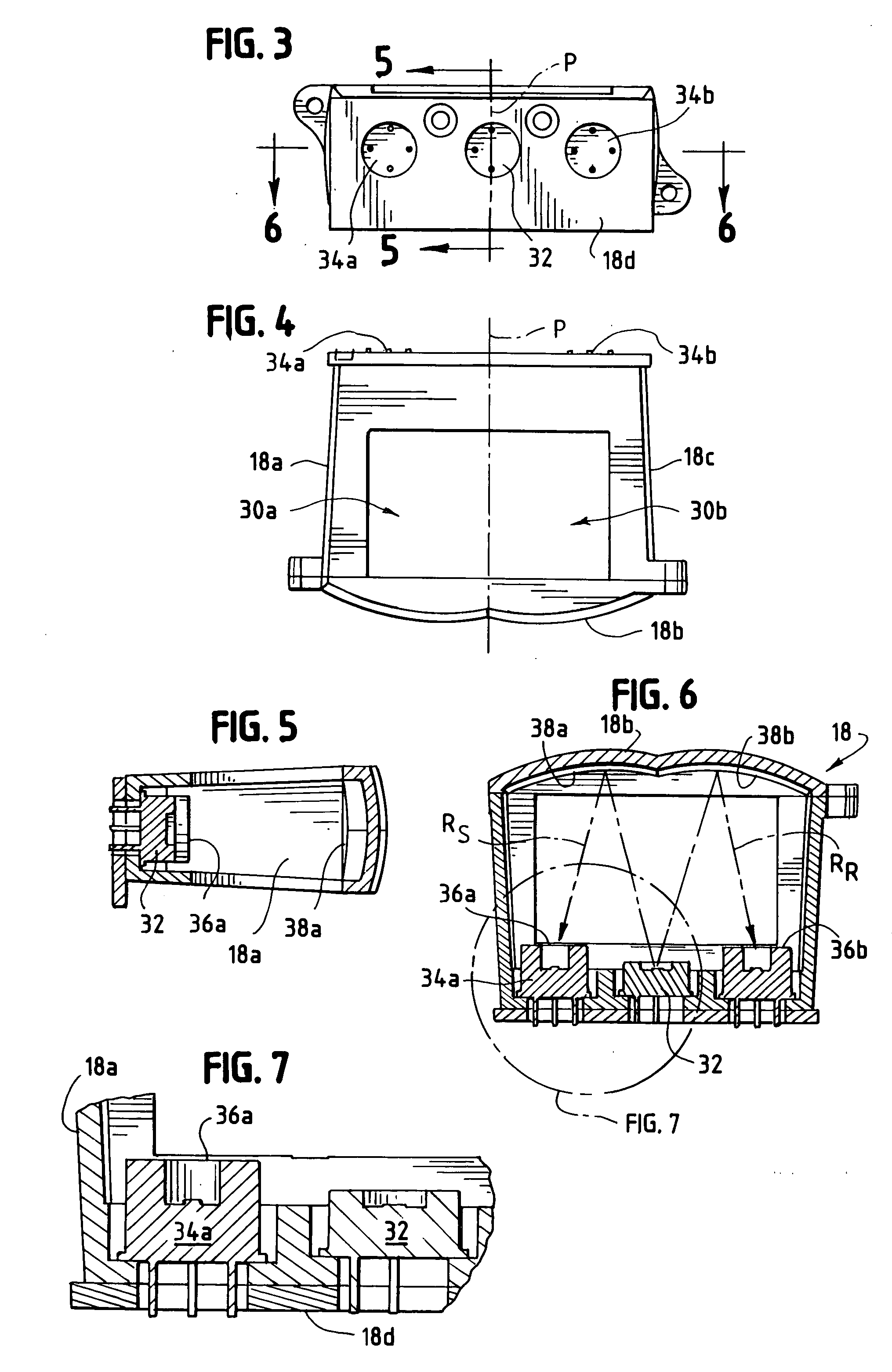

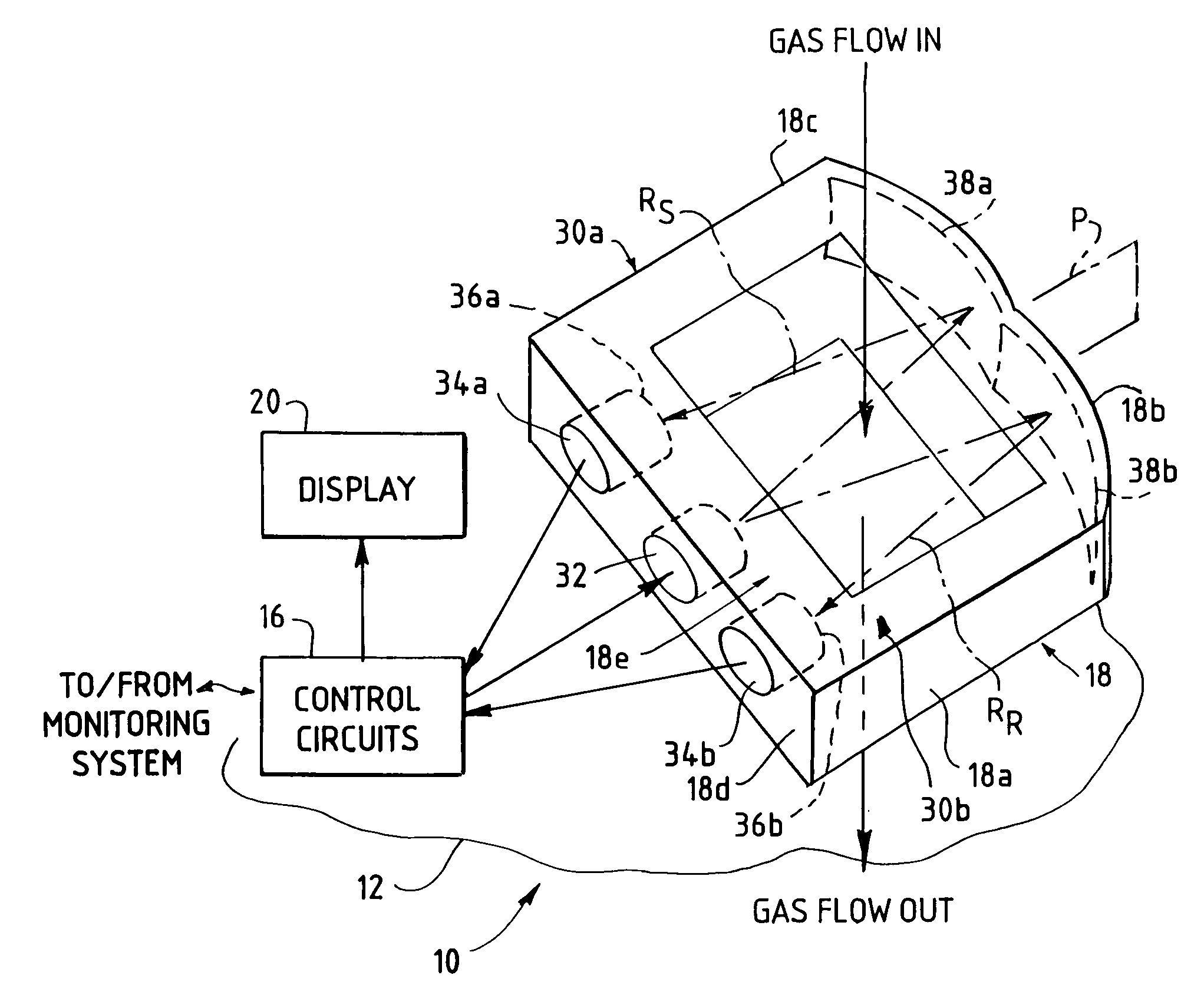

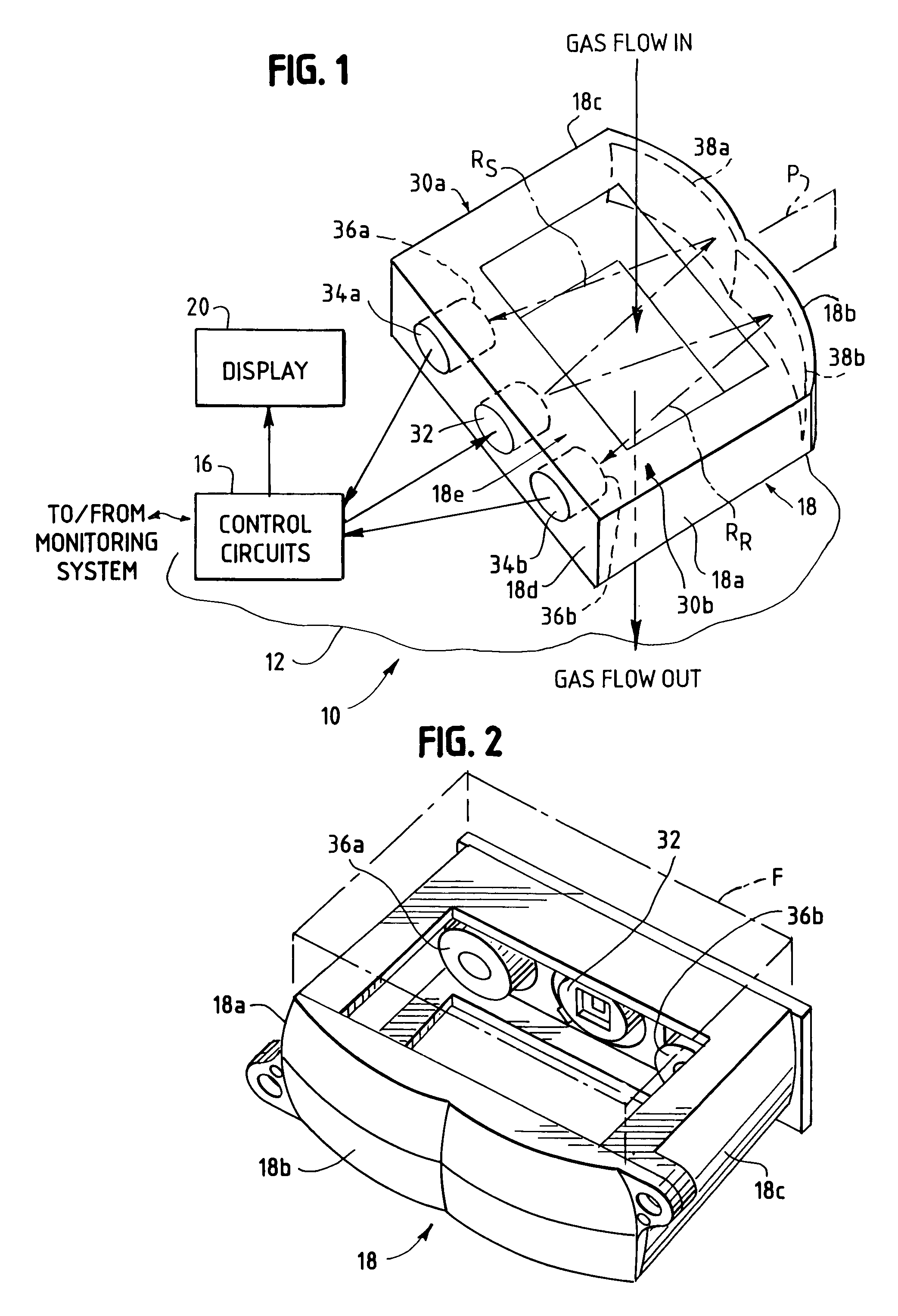

Chamber for gas detector

InactiveUS20050017206A1Affect performanceEqual performanceRadiation pyrometryInvestigating moving fluids/granular solidsPhase detectorGas detector

A gas sensor, which could be a sensor of combustible gases, incorporates a diffusion chamber having symmetrical sensing and reference portions. A common source emits infrared-type radiant energy symmetrically into the two portions. Each portion incorporates a curved reflective surface which reflects incident infrared onto a respective sensor. Each sensor has a filter which passes a different selected band of energy. A fluid, such as gas being sensed, passes laterally through the chamber.

Owner:HONEYWELL INT INC

3D printing powder compositions and methods of use

ActiveUS9388078B2Low costWide scaleSolid waste managementCeramic shaping apparatusCompressive strengthUltimate tensile strength

Powder compositions that can be used with traditional 3D printing technology and methods for producing 3D printed building materials that have comparable compressive strength to standard concrete and tensile strength up to 70% greater than standard concrete.

Owner:RGT UNIV OF CALIFORNIA

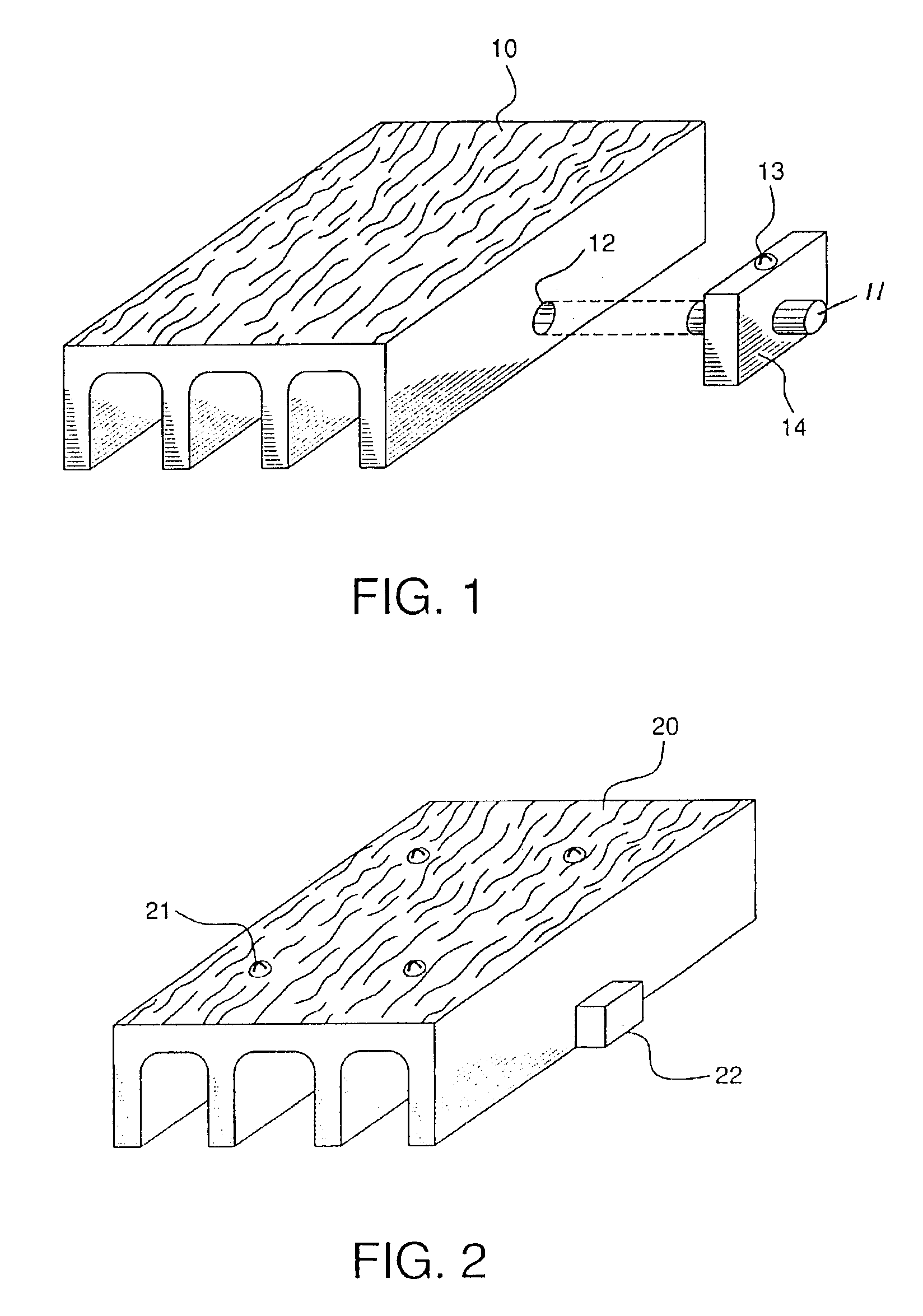

Plastic fencing system reinforced with fiberglass reinforced thermoplastic composites

Owner:CERTAINTEED CORP

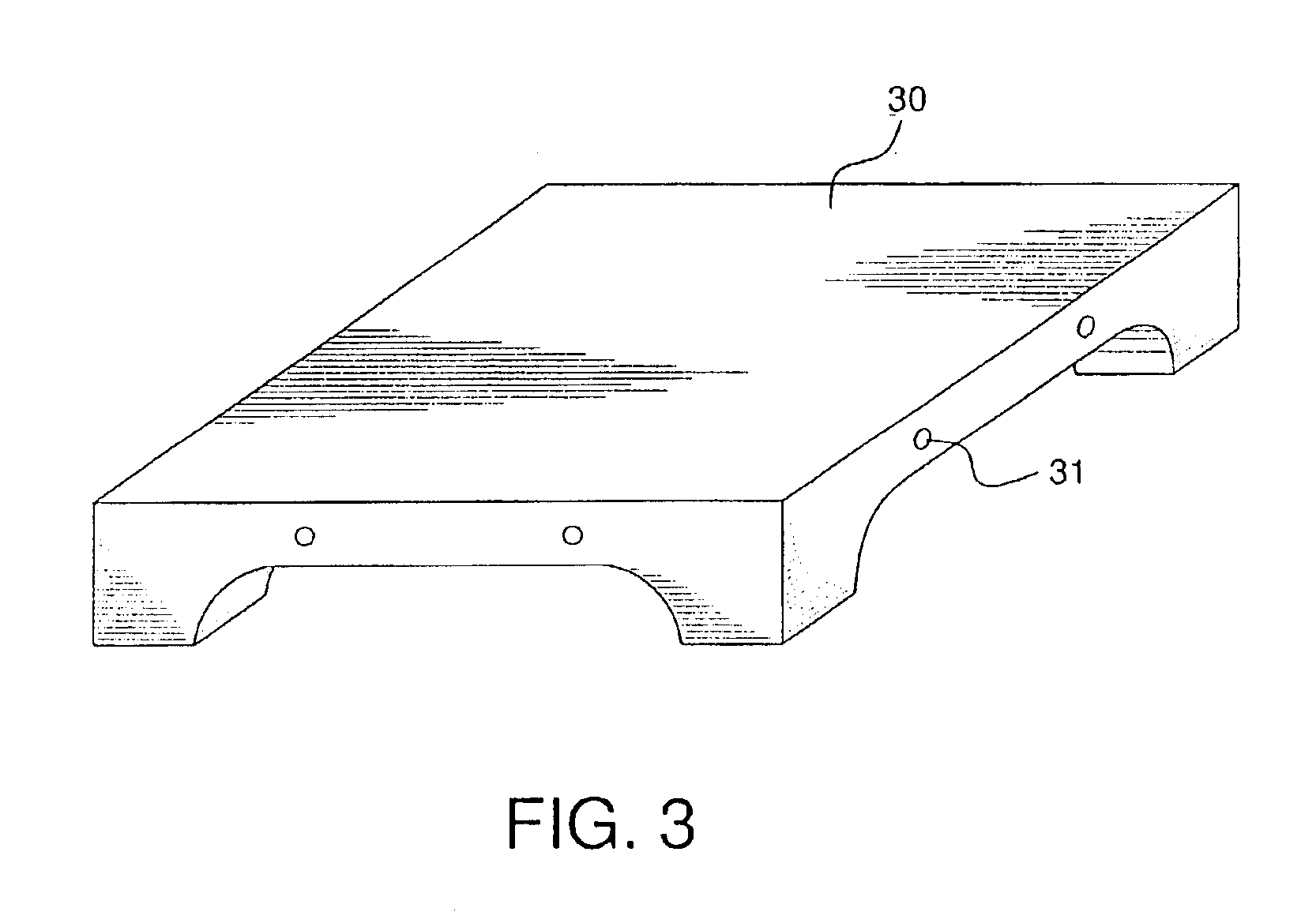

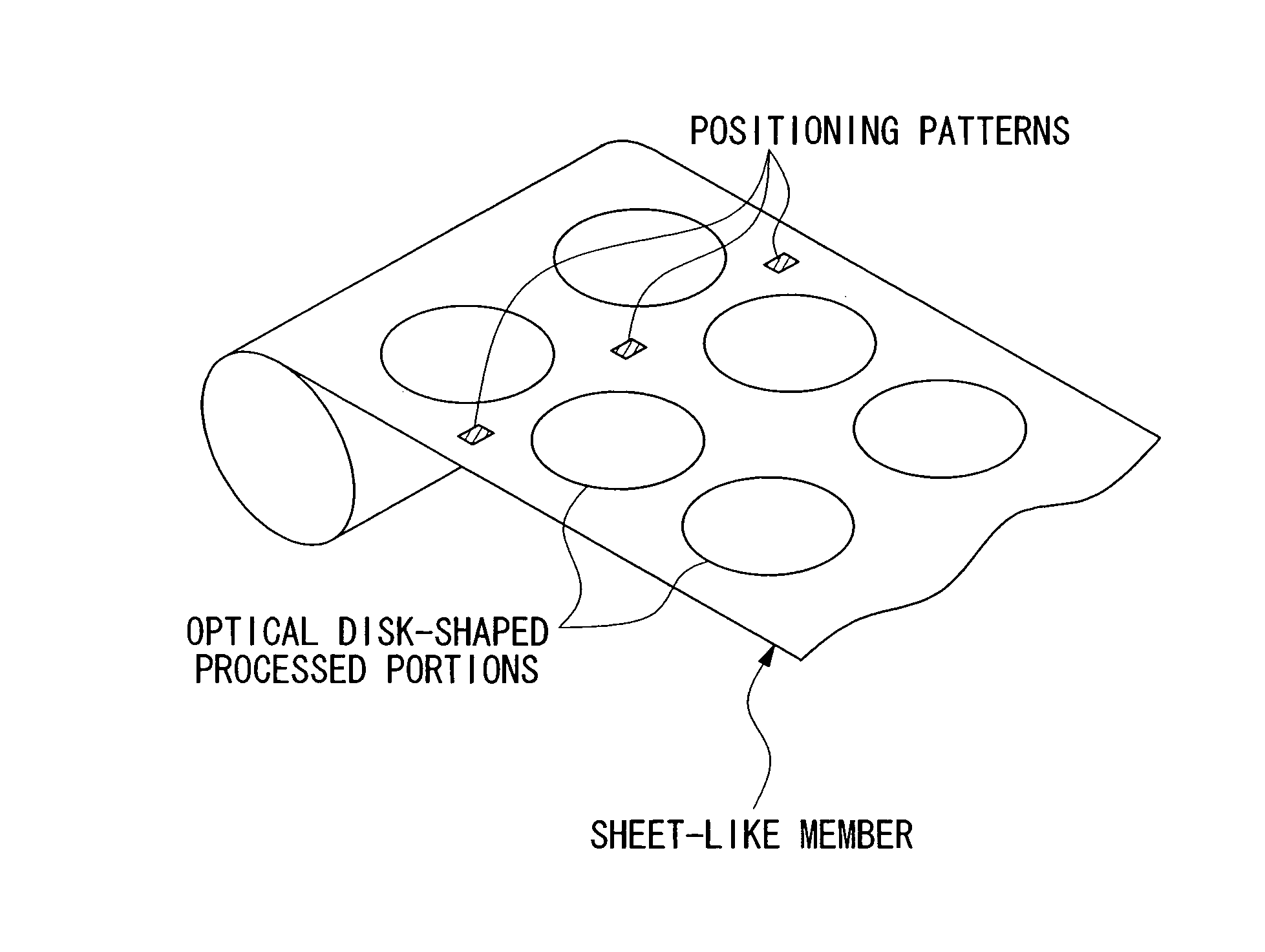

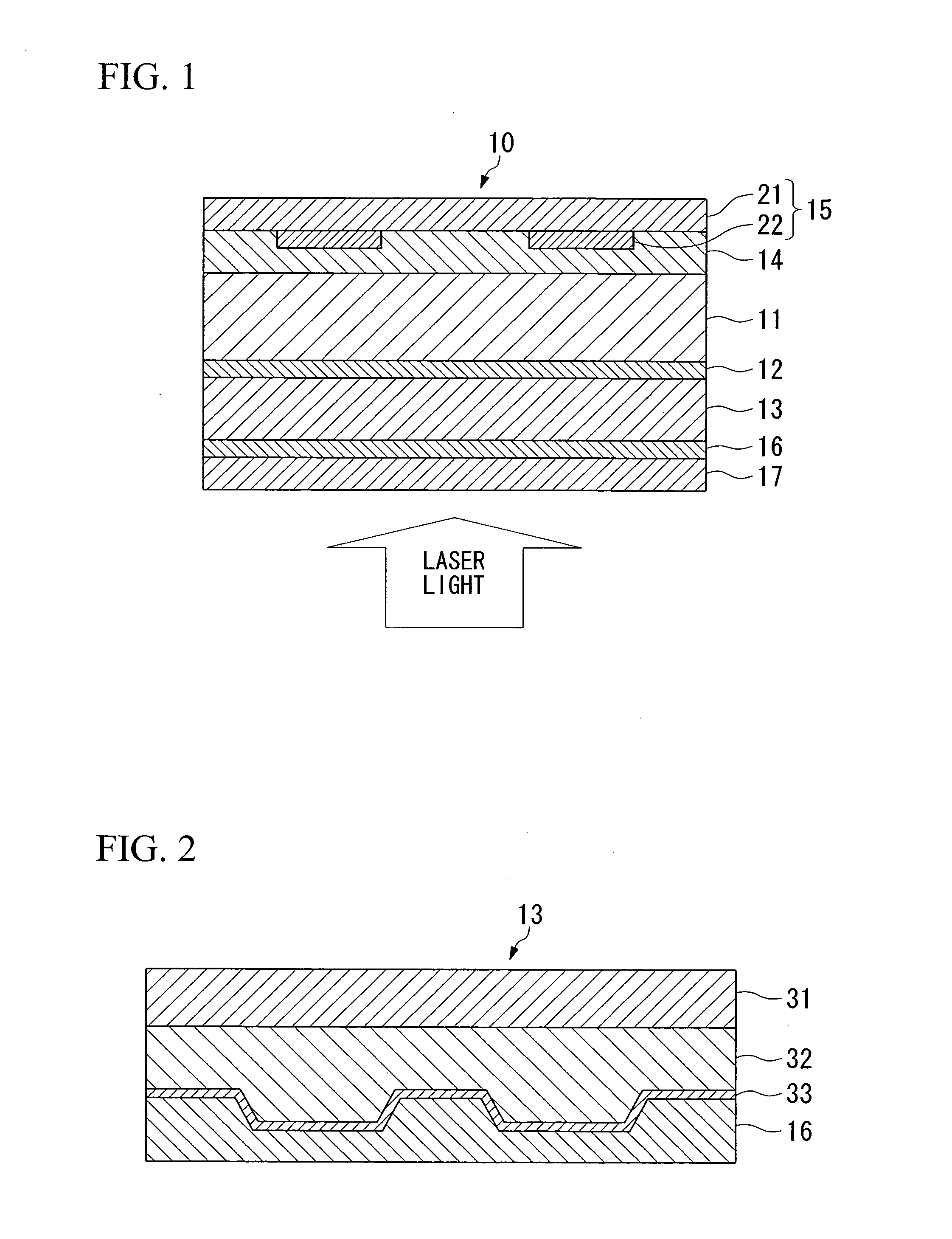

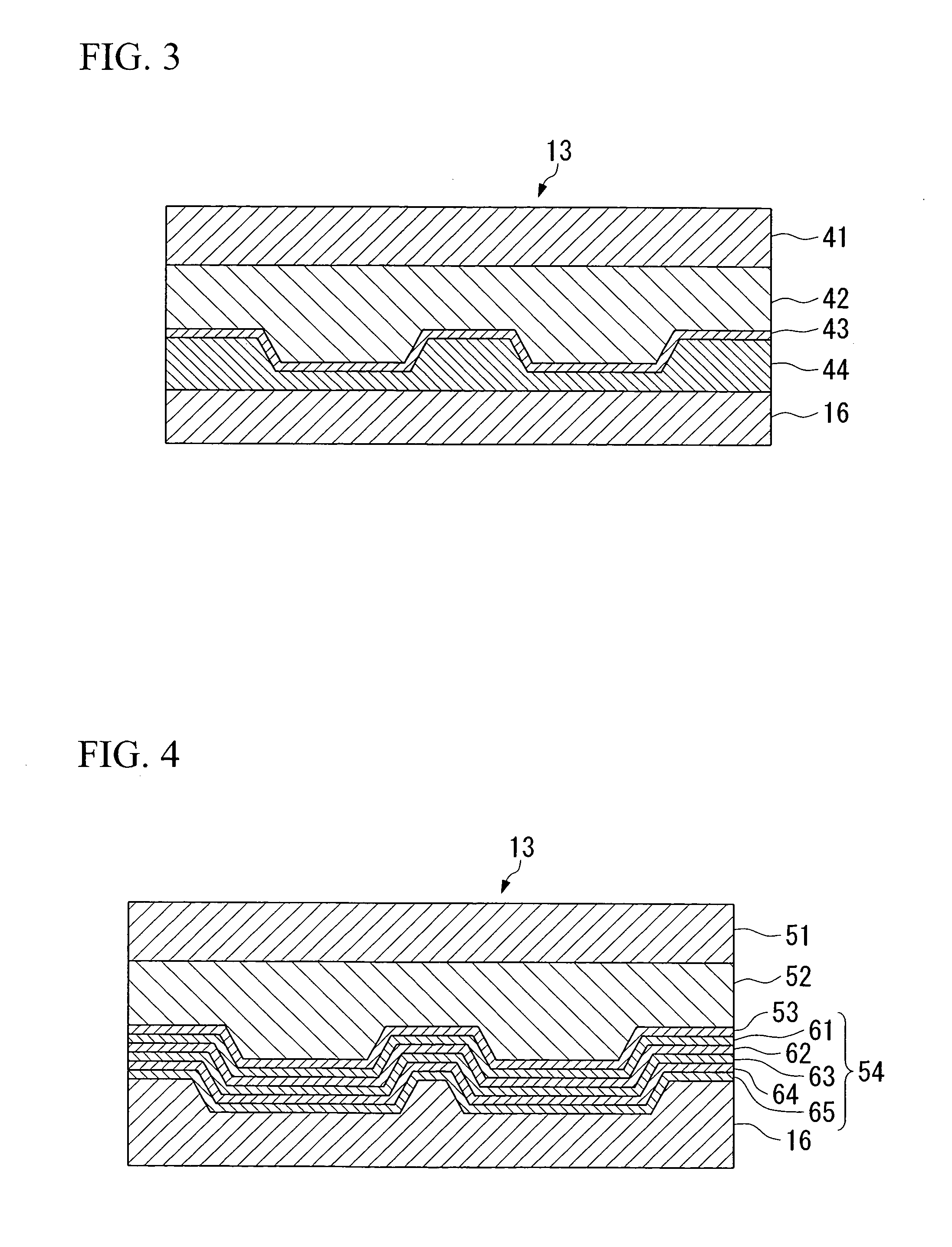

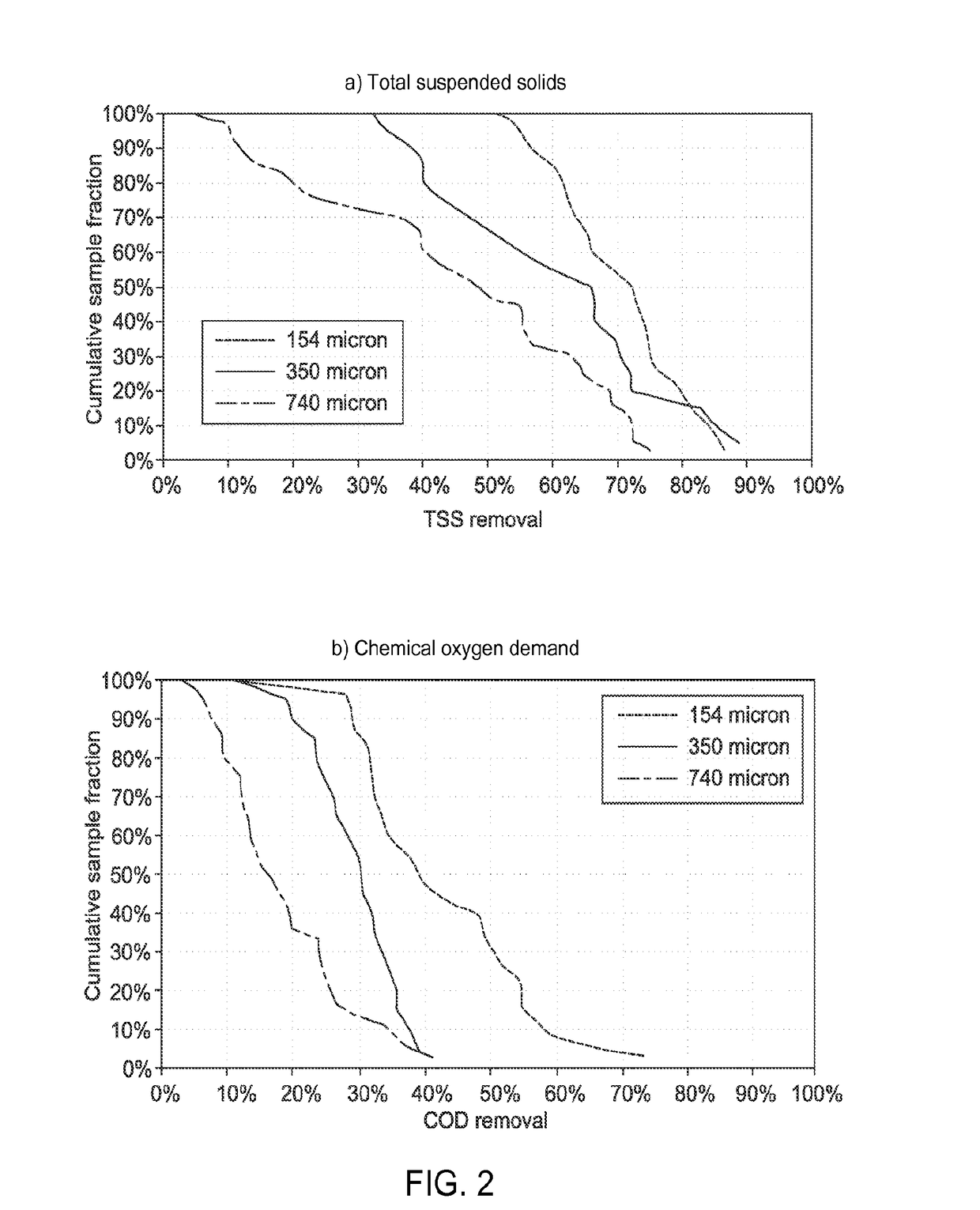

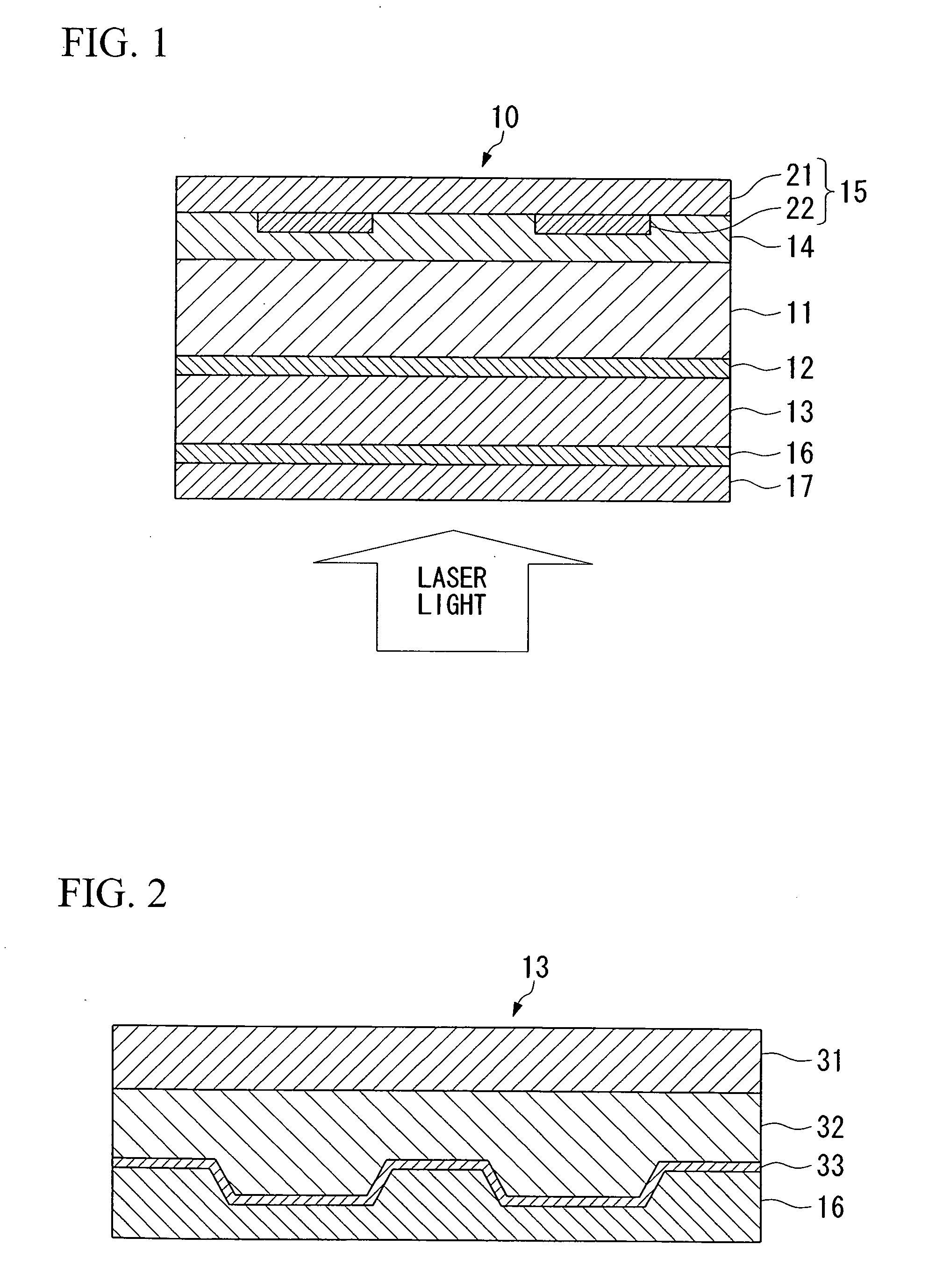

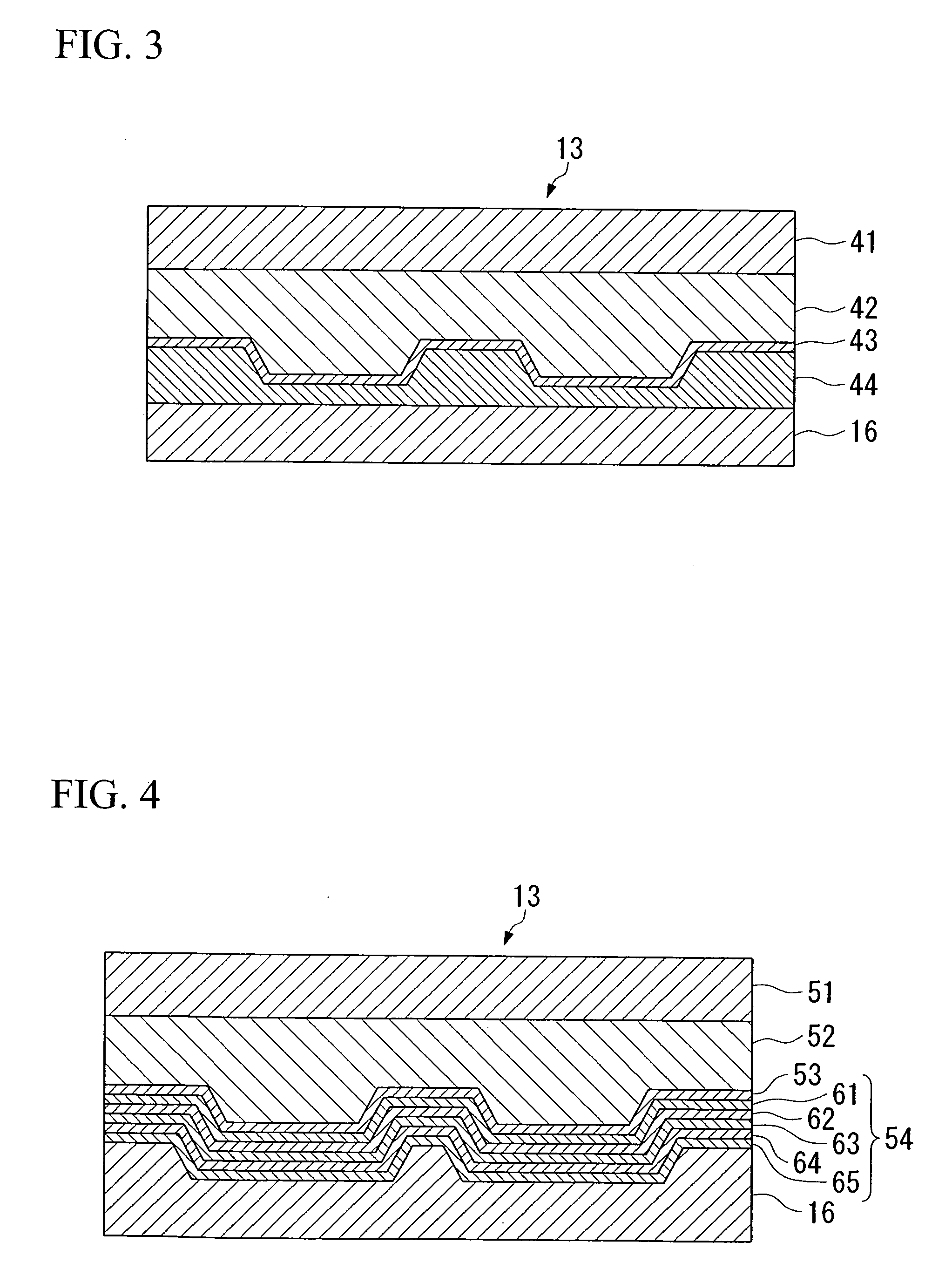

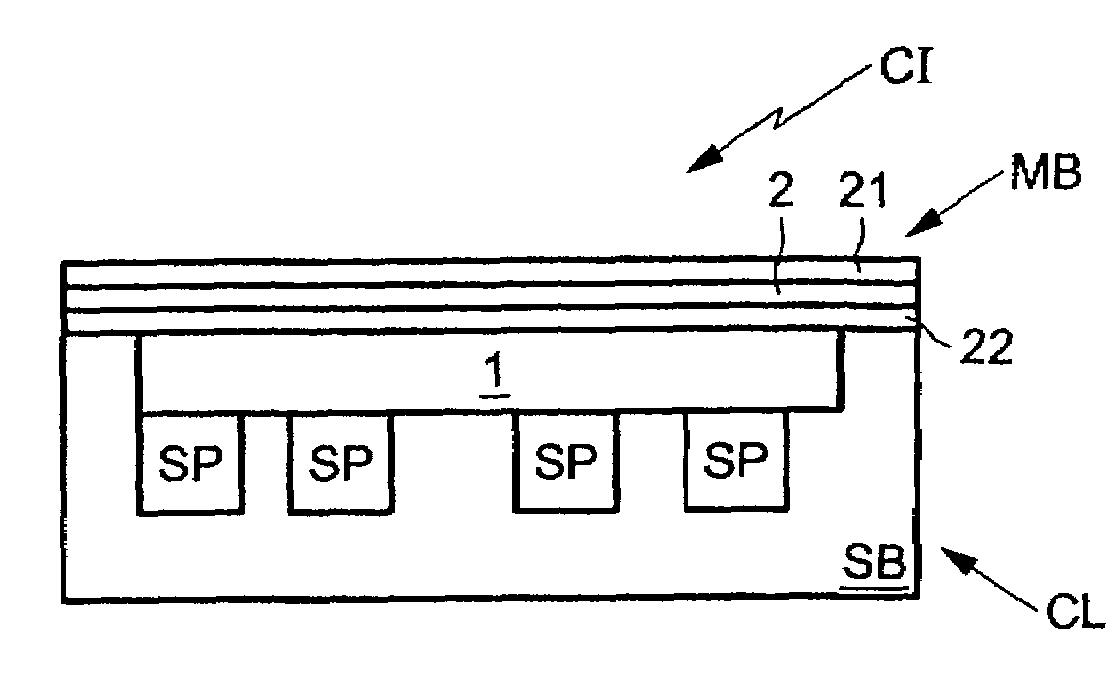

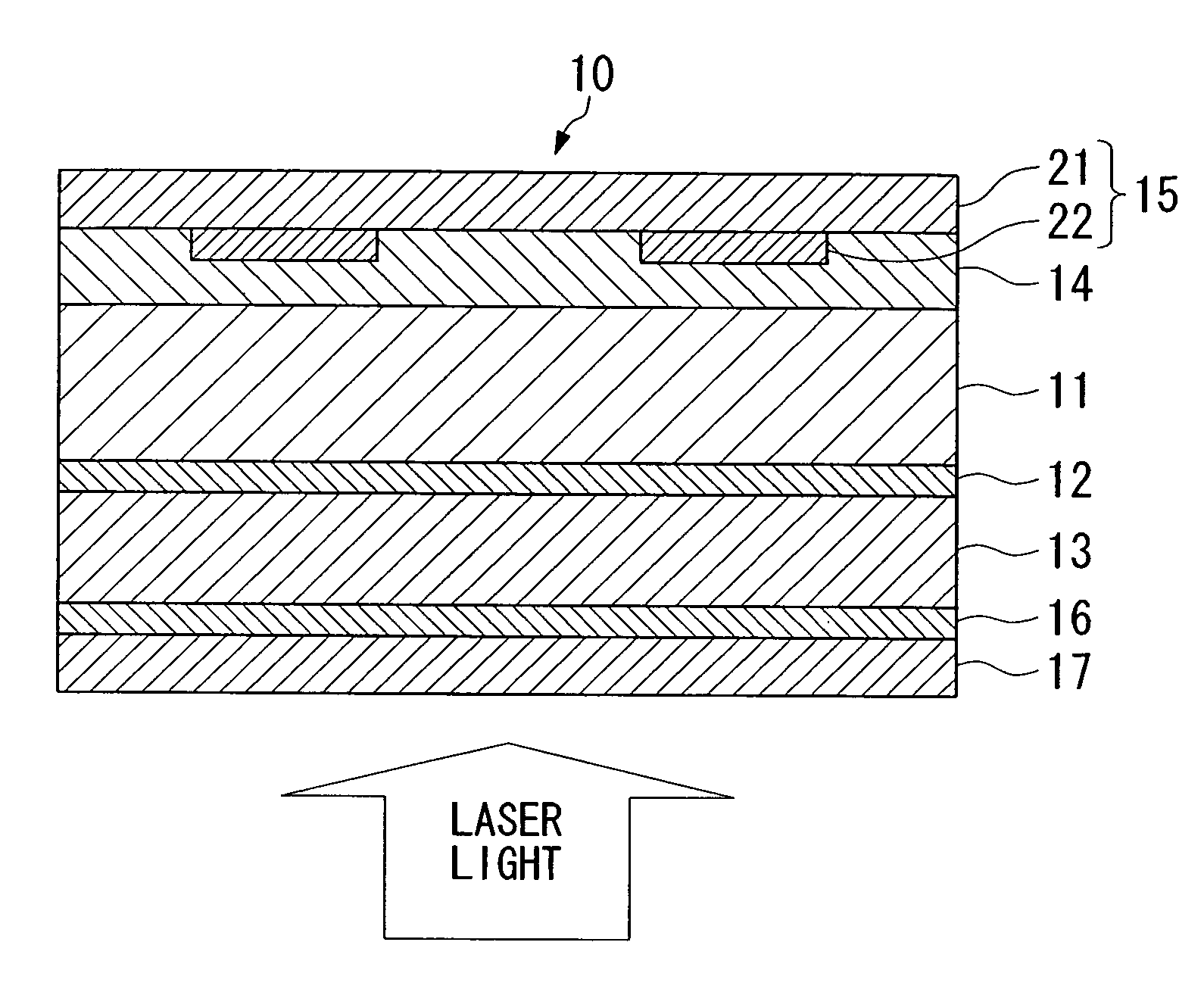

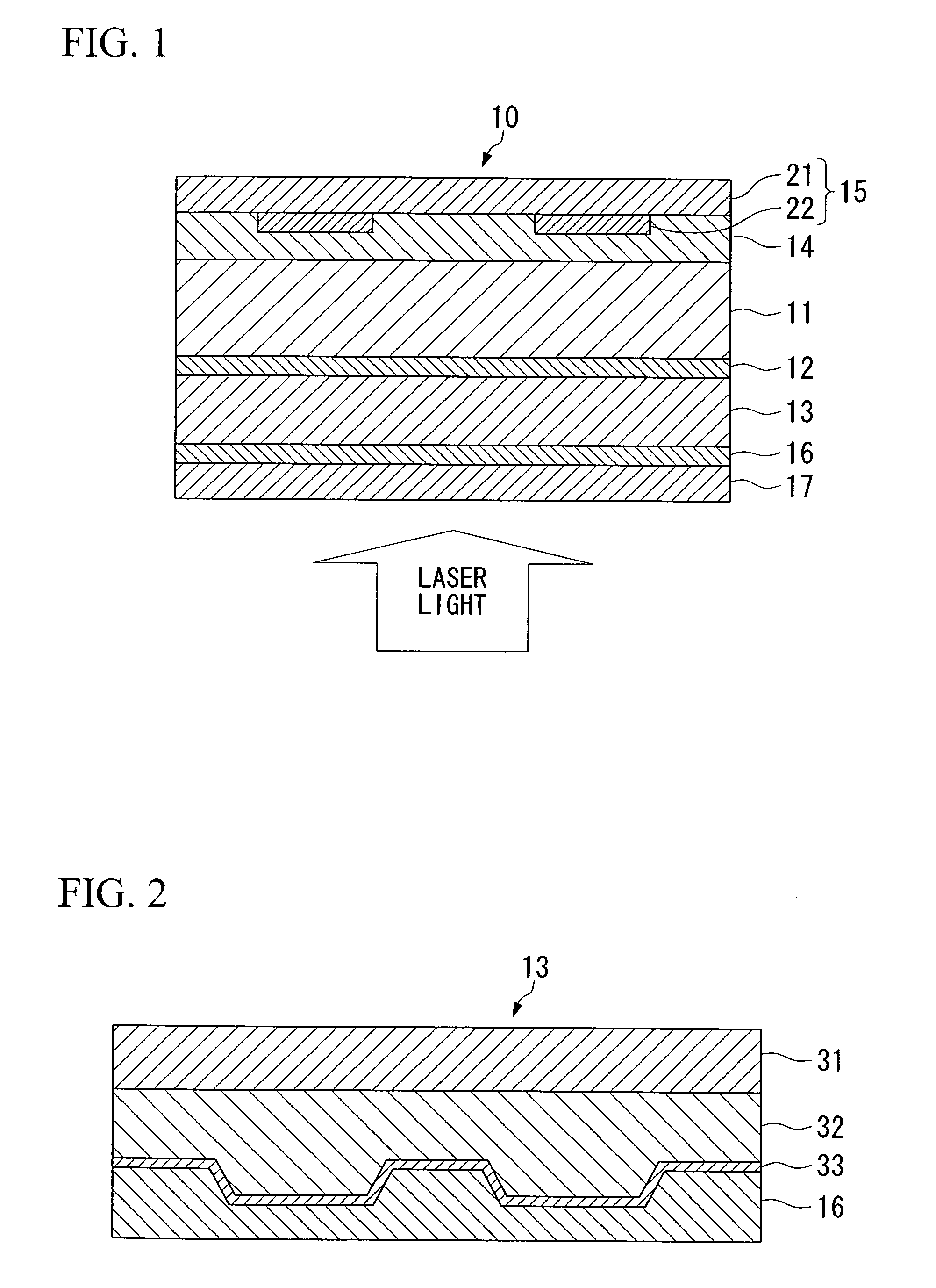

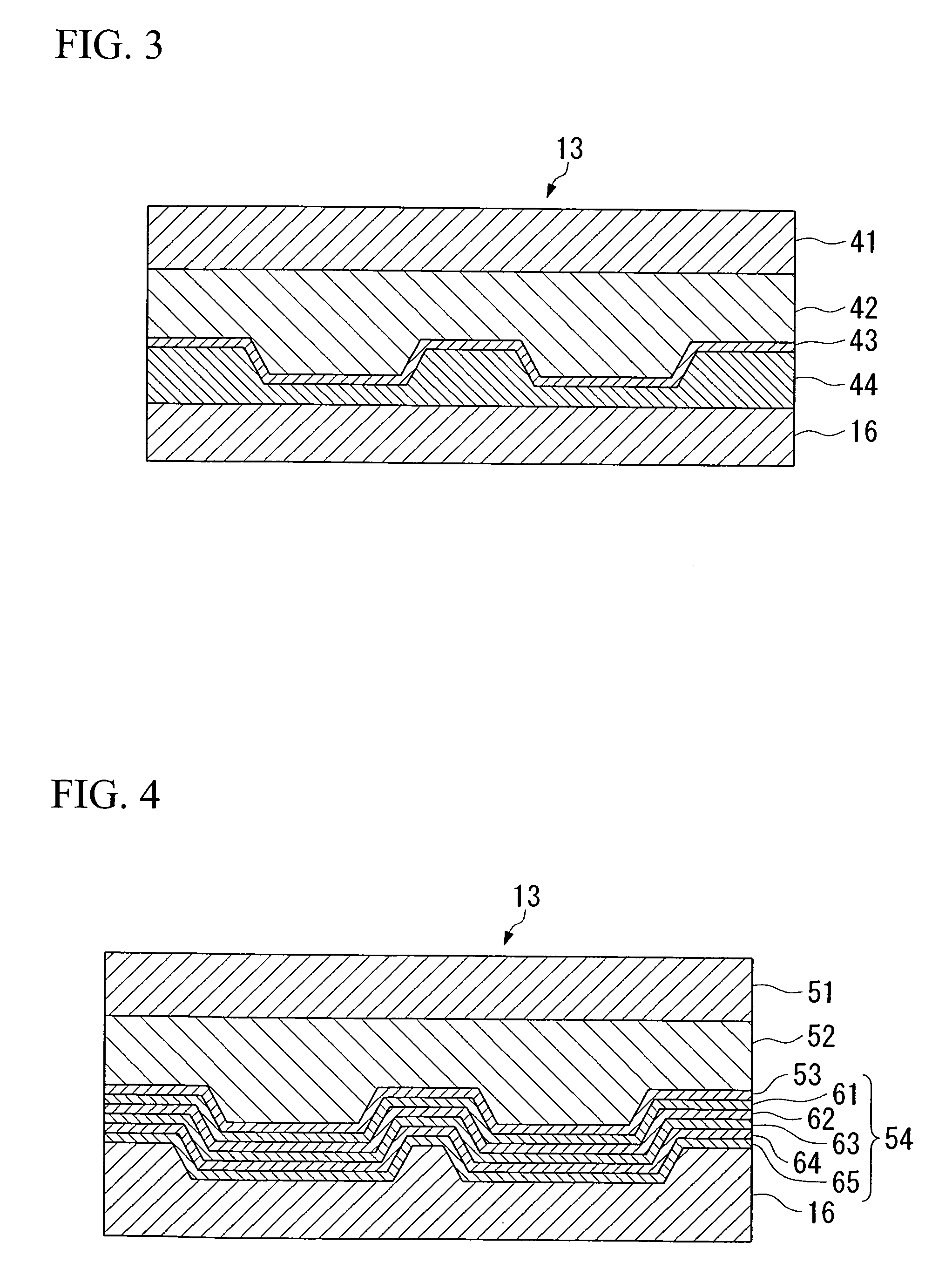

Optical disk and production method therefor

InactiveUS20060083151A1Easy and inexpensive to produceWater absorption and moisture absorption of the substrate can be suppressedRecord carriersLamination ancillary operationsPolyolefinEngineering

An optical disk (10) of the present invention comprises a substrate (11) included a biodegradable resin or polyolefin resin, a recording layer (13) provided on at least one side of the substrate (11), and a printing layer (15) provided on the other side of substrate (11), wherein recording layer (13) and printing layer (15) have a base material layer (recording layer base material, printing base material (21)) included a non-hydrophilic film. This type of optical disk (10) has performance equal to that of conventional optical disks, has a minimal effect on the environment during disposal and is able to suppress warping of the substrate. In addition, a manufacturing method of an optical disk of the present invention comprises a recording layer sheet fabrication step in which a recording layer sheet is fabricated by forming tracks on a recording layer base material, a printing sheet fabrication step in which a printing sheet is fabricated by carrying out printing on a printing base material, and respective lamination steps in which the substrate sheet, recording layer sheet and printing sheet are laminated.

Owner:TOPPAN PRINTING CO LTD +1

Cleaning composition and method of forming the same

InactiveUS20180265808A1Low viscosityEasy to cleanNon-ionic surface-active compoundsOrganic detergent compounding agentsBetaineActive component

A cleaning composition for dishwashing including an alkoxylated polyethylenimine and a surfactant actives component. The surfactant actives component includes an anionic surfactant, an additional surfactant, a betaine, and an amine oxide. A method of forming the cleaning composition is also disclosed. The method includes the step of combining the alkoxylated polyethylenimine and the surfactant actives component to form the cleaning composition.

Owner:BASF CORP

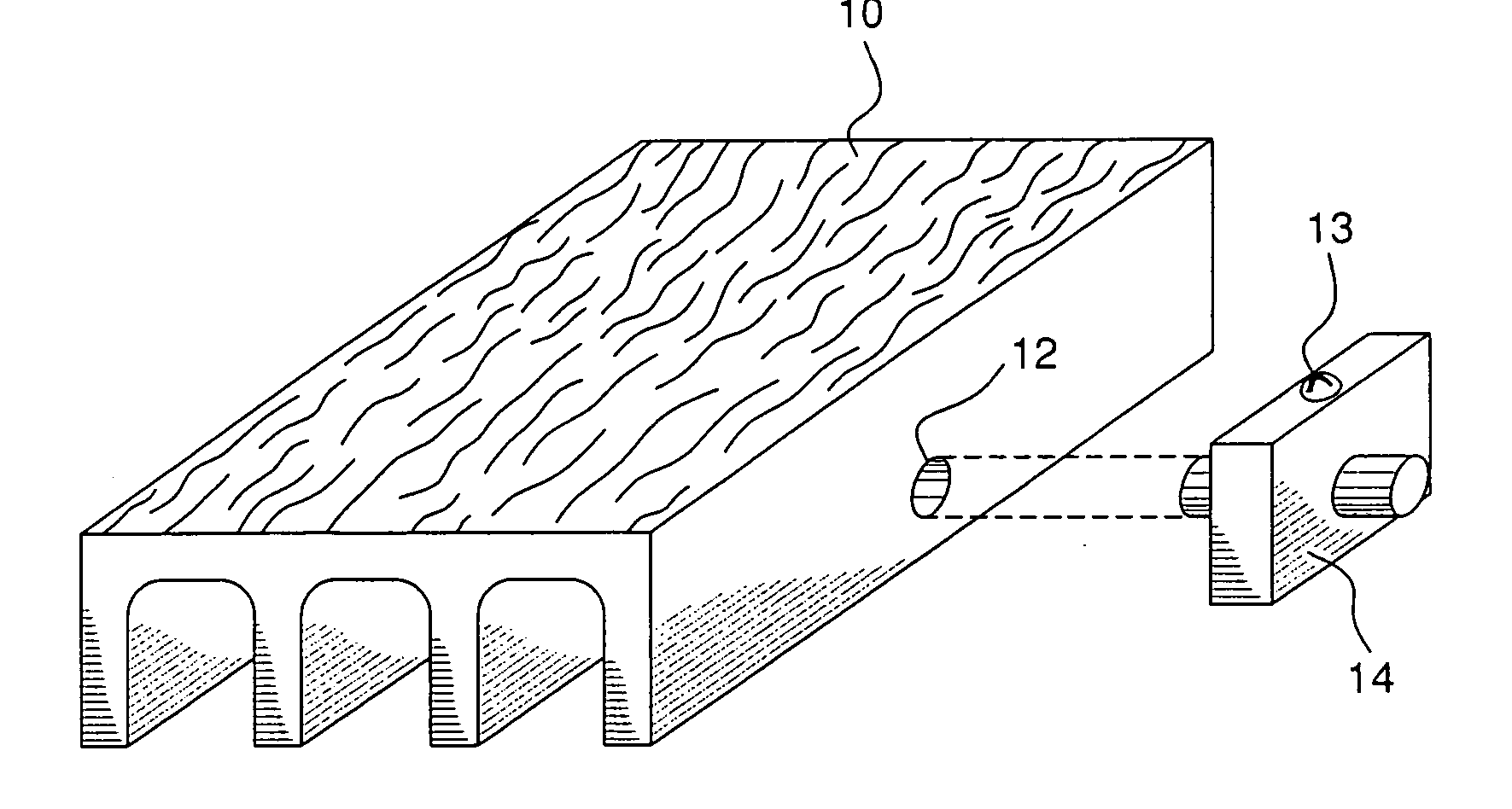

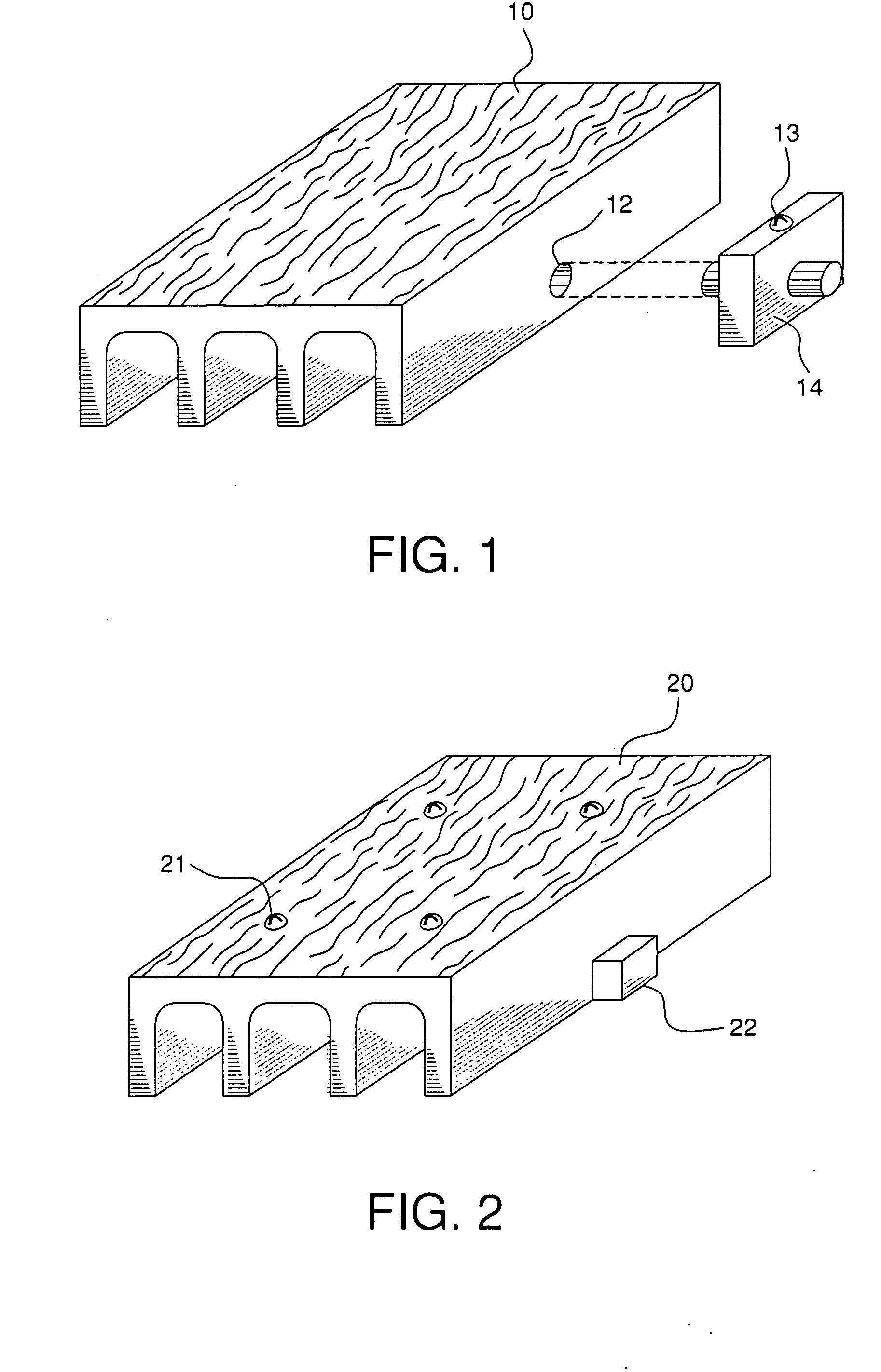

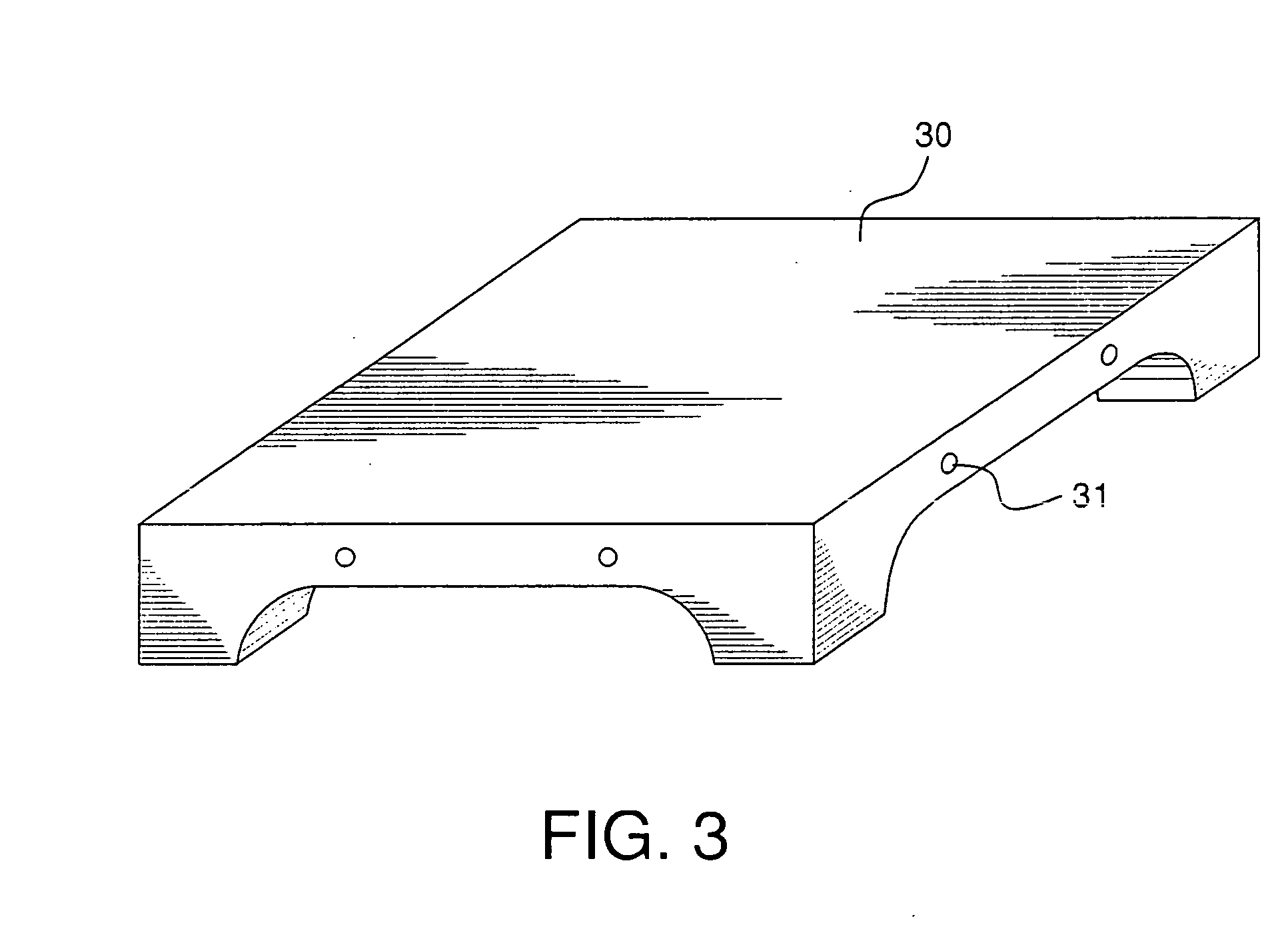

Thermoplastic composite building material and method of making same

InactiveUS20050029709A1Improve the immunityWell-defined wood grain surfaceWood working apparatusCeramic shaping apparatusMohs scale of mineral hardnessHardness

Polymer composite building materials are provided which contain about 30-80 weight percent resin, 20-70 weight percent fillers and additives, in which the fillers contain at least one bulk filler for reducing the amount of resin needed to make the building material, and at least one aesthetically functional filler for providing the building material with an aesthetic appearance. The bulk filler and the aesthetically functional filler are non toxic, resistant to bacterial attack, and have a Mohs hardness of less than about 5.

Owner:CERTAINTEED CORP

Chamber for gas detector

InactiveUS7034304B2Affect performanceEqual performanceRadiation pyrometryInvestigating moving fluids/granular solidsPhase detectorGas detector

Owner:HONEYWELL INT INC

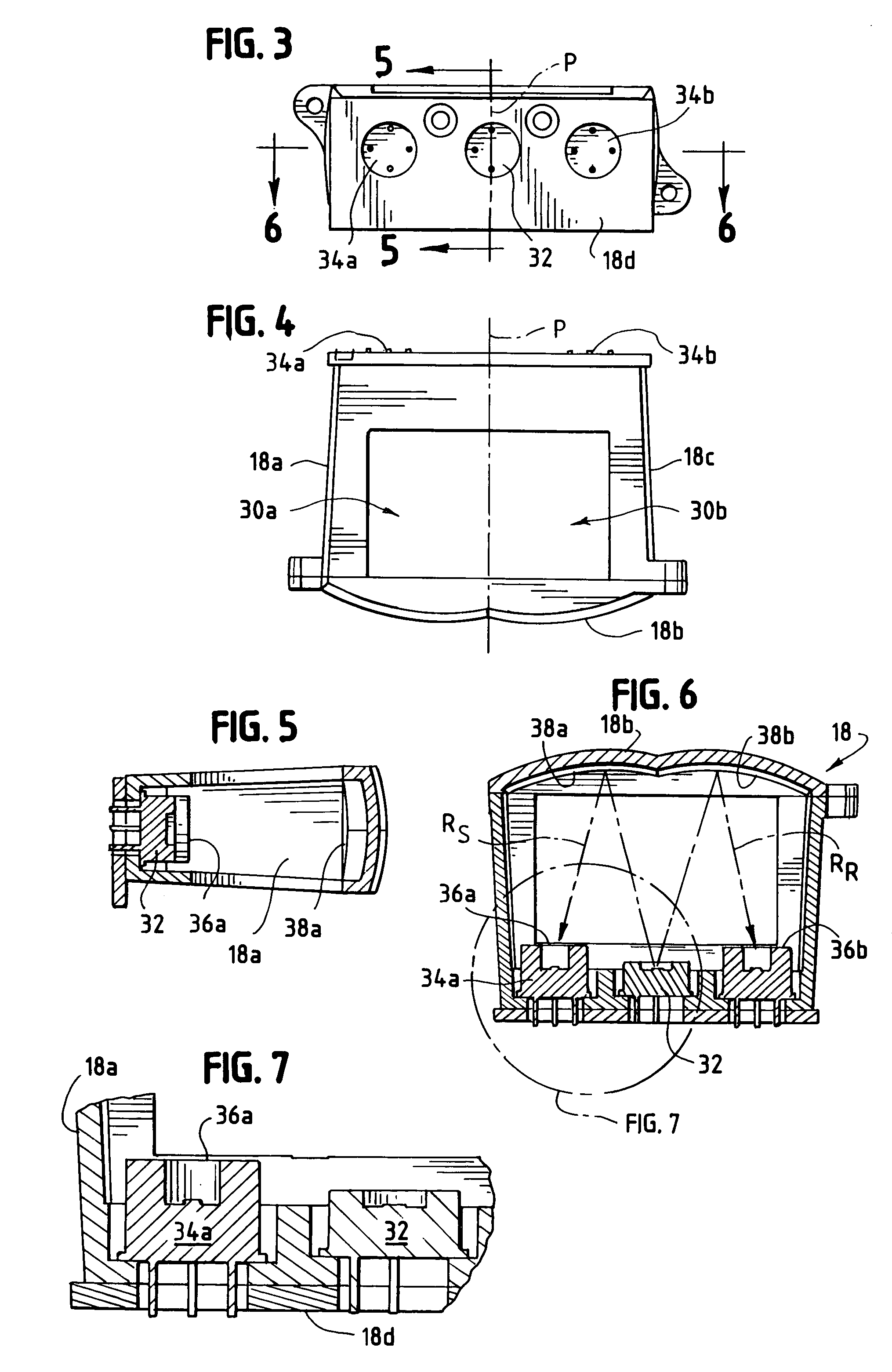

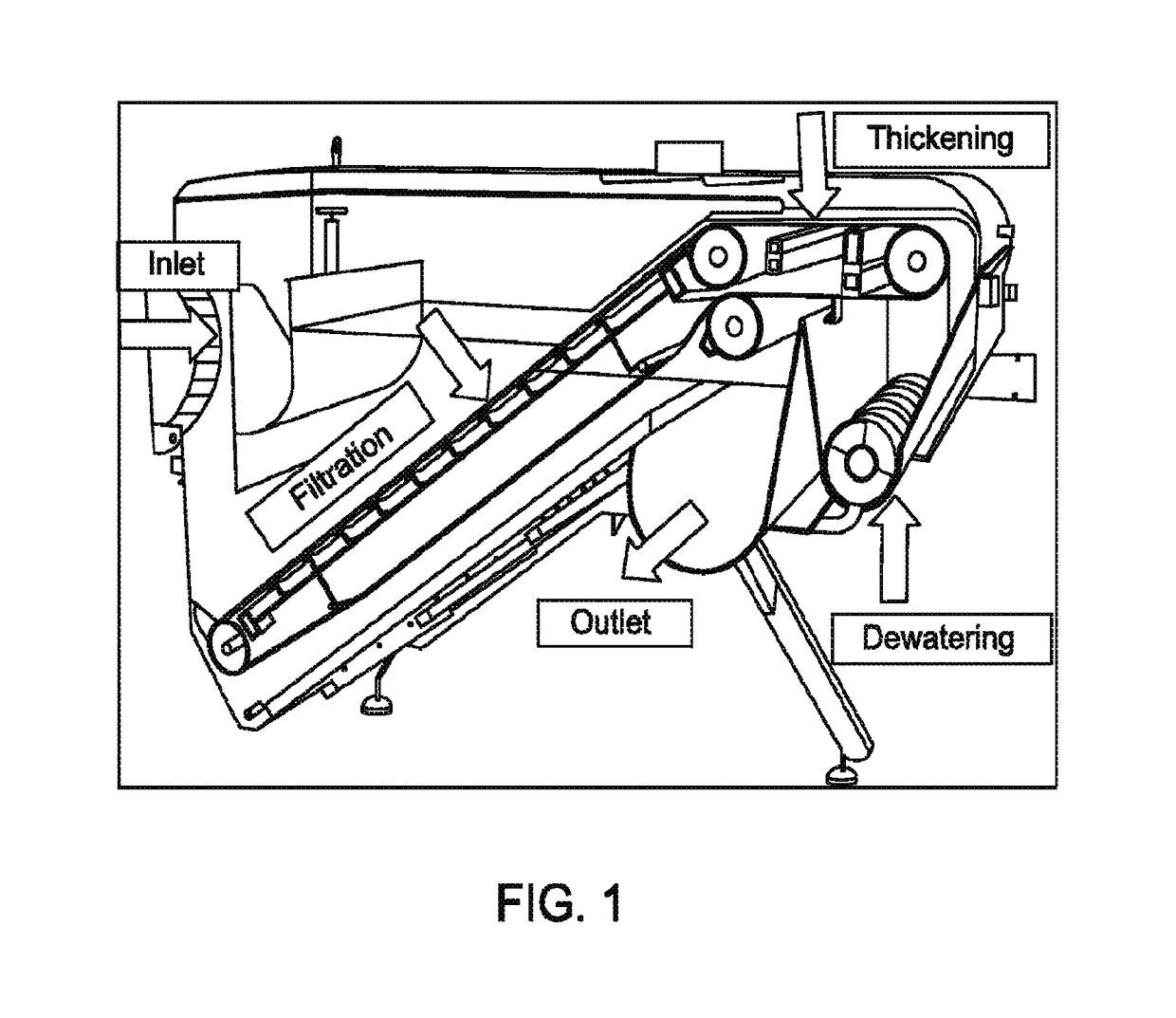

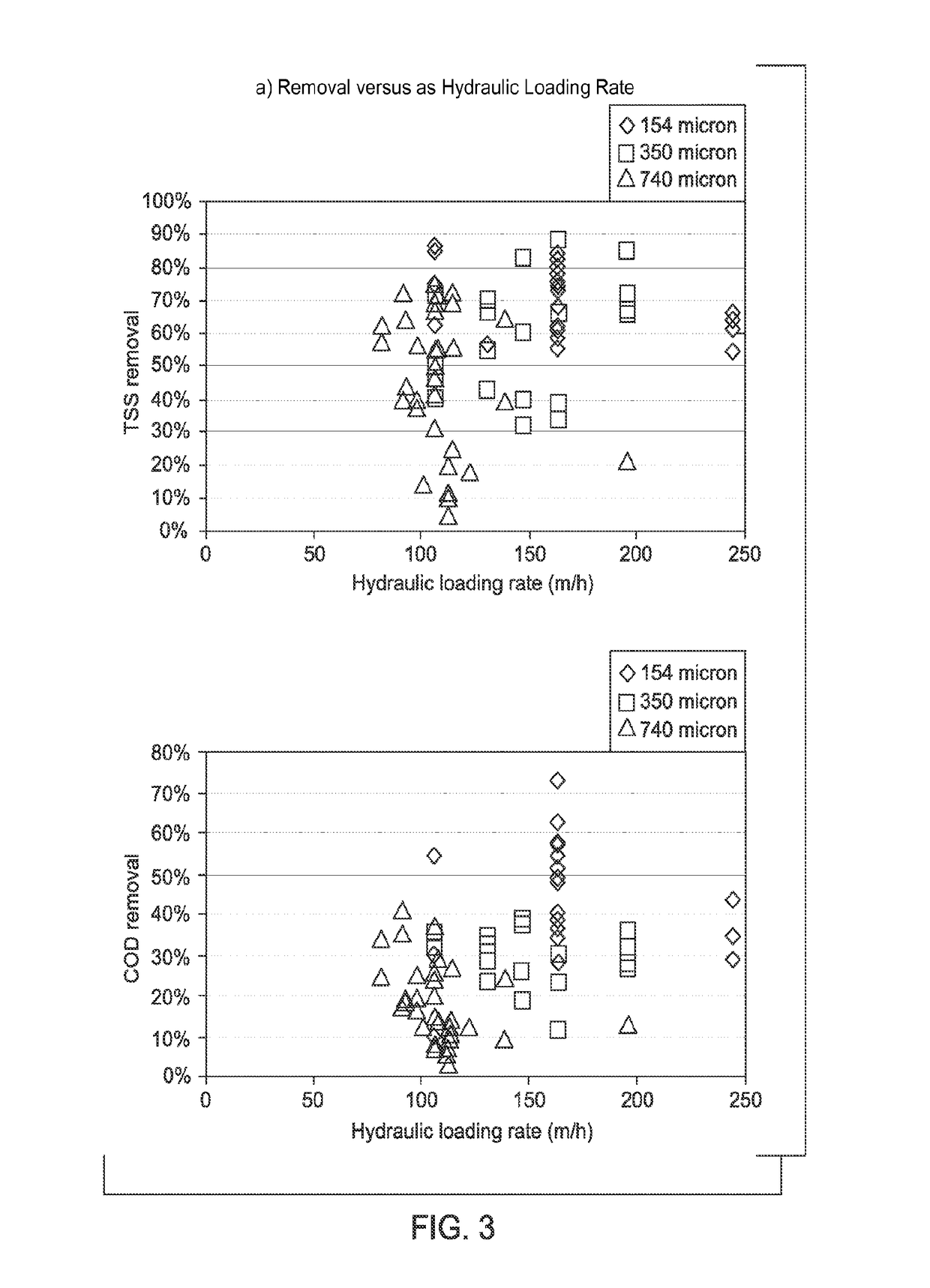

Wastewater treatment with primary treatment and mbr or mabr-ifas reactor

ActiveUS20170088449A1Small plant footprintElimination of fine screeningMembranesSludge treatment by de-watering/drying/thickeningActivated sludgeMembrane bioreactor

Wastewater is treated though primary treatment of the water by way of a micro-sieve to produce a primary effluent and primary sludge. There is secondary treatment of the primary effluent by way of a membrane bioreactor (MBR) or an integrated fixed film activated sludge (IFAS) reactor to produce a secondary effluent and a waste activated sludge. The micro-sieve may have openings of 250 microns or less, for example about 150 microns. In a process, a gas transfer membrane is immersed in water. Pressurized air flows into the gas transfer membrane. An exhaust gas is withdrawn from the gas transfer membrane and used to produce bubbles from an aerator immersed in the water.

Owner:BL TECH INC

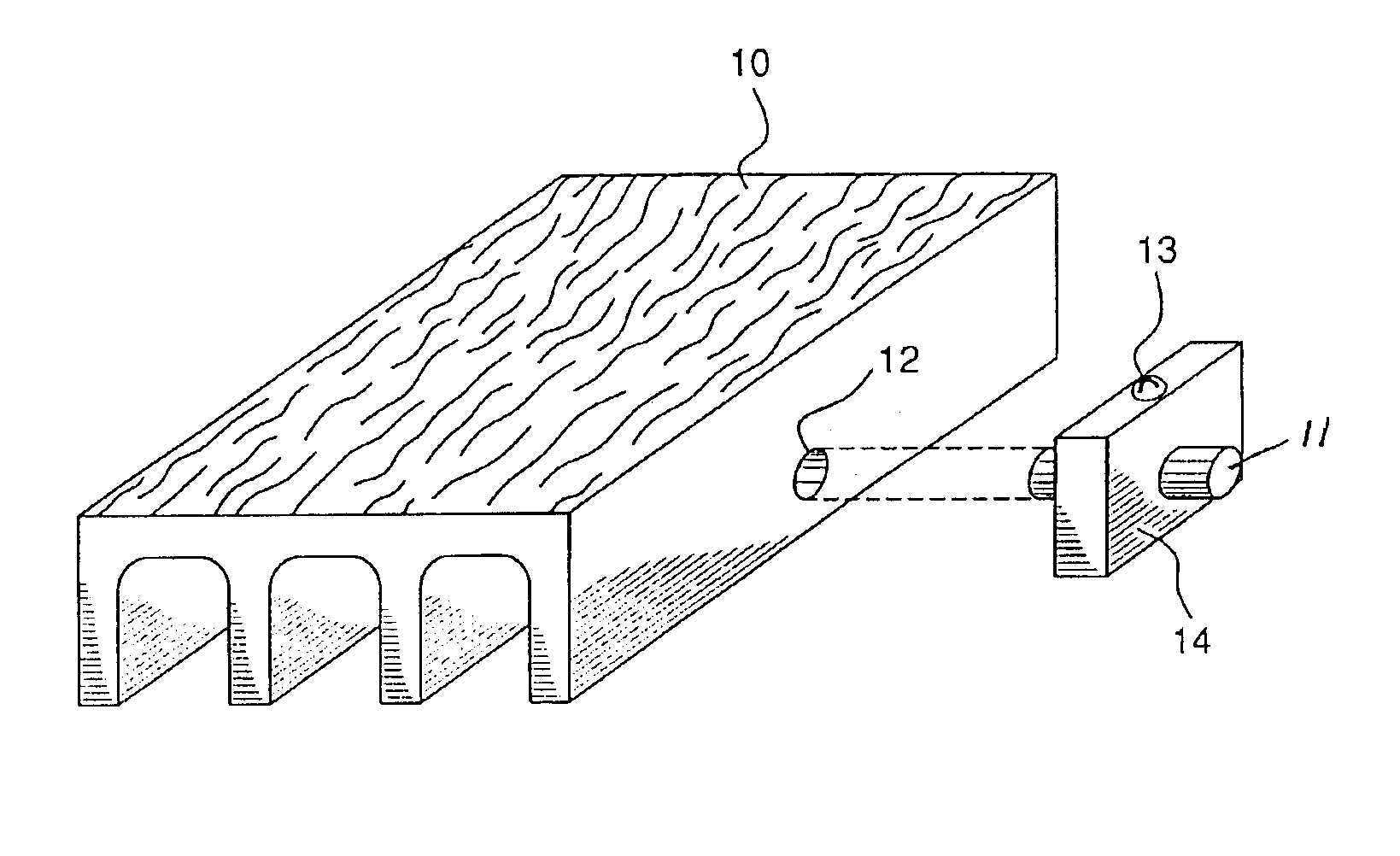

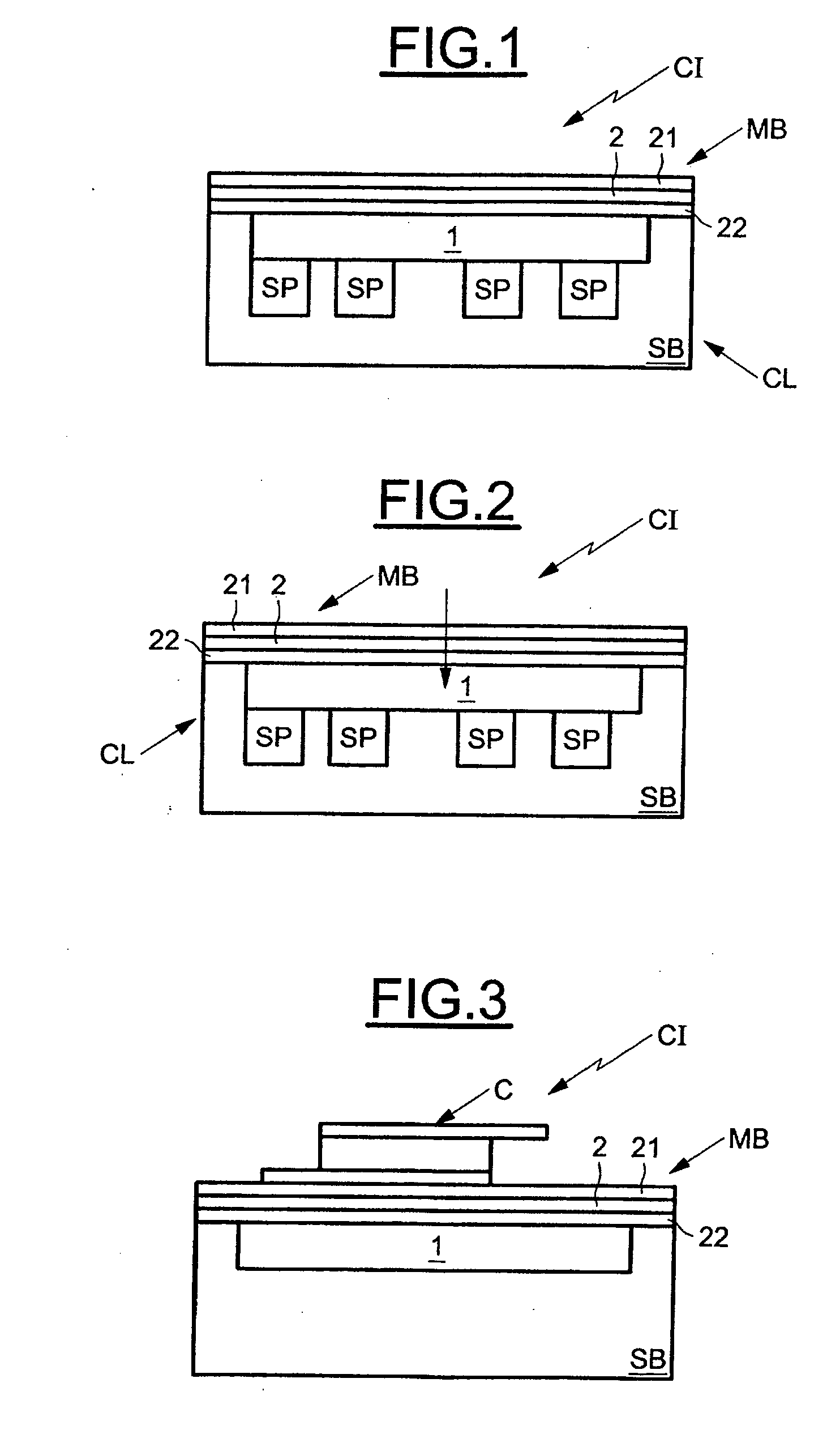

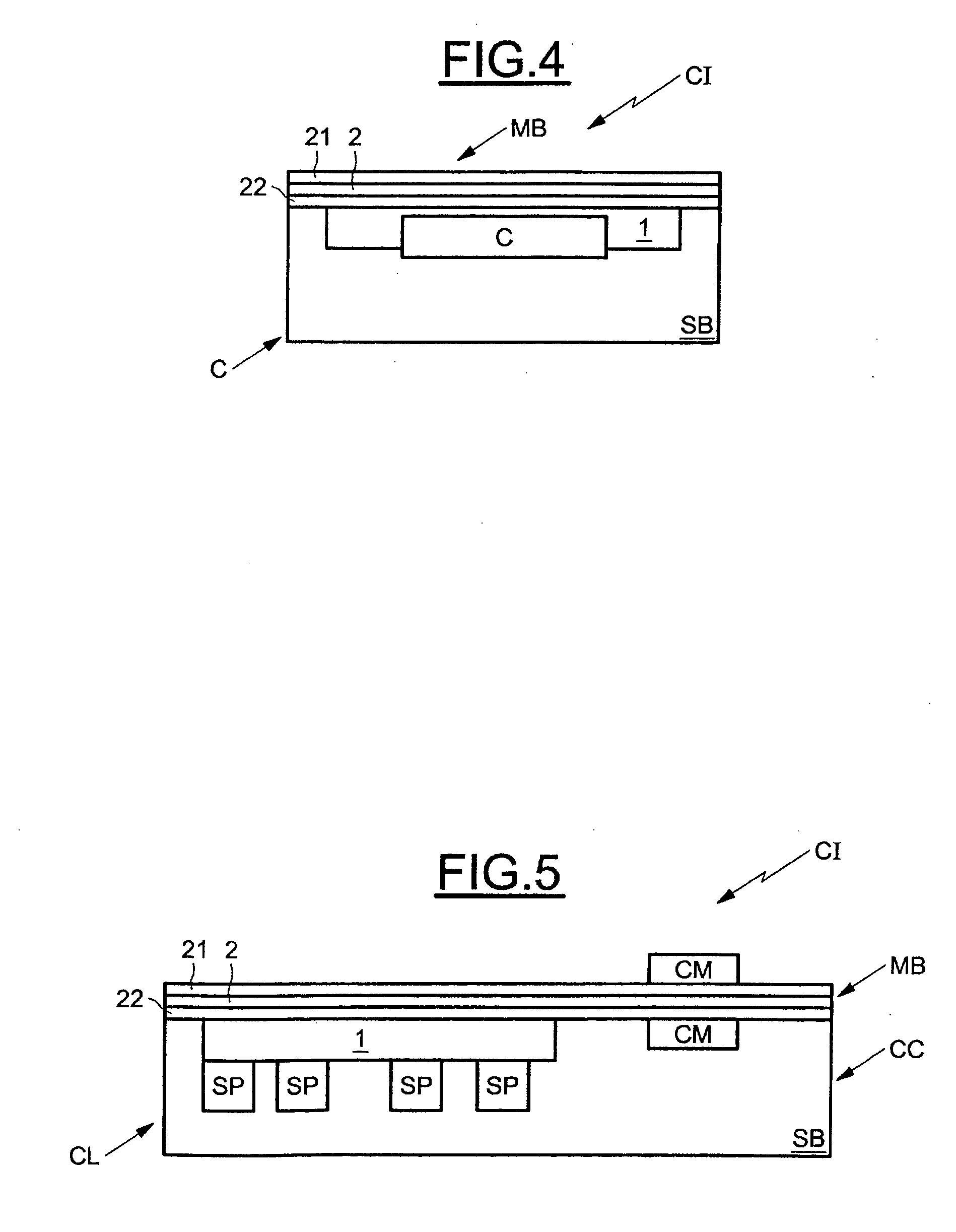

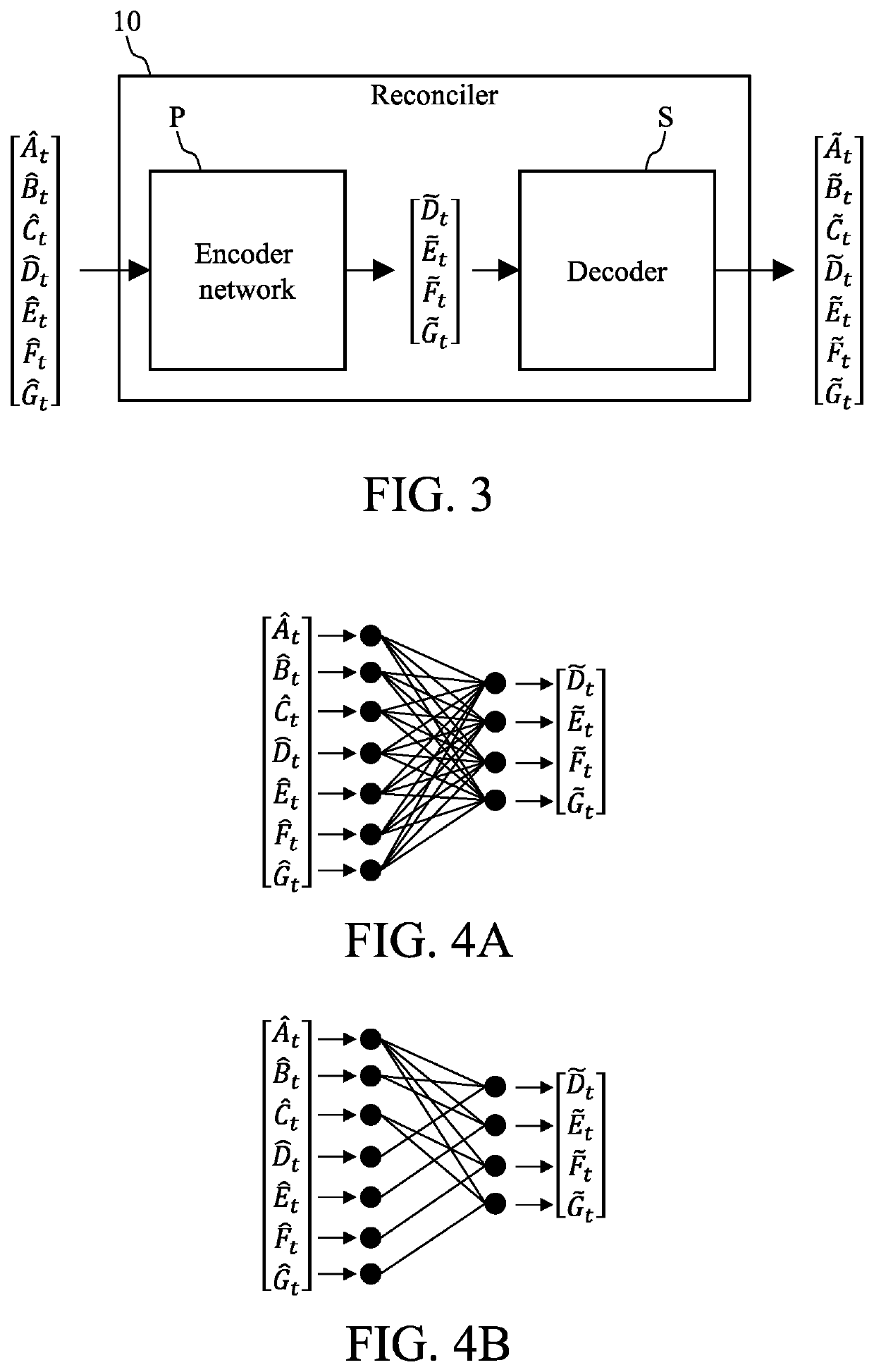

Optical disk and its manufacturing method

InactiveUS20060133256A1Little substrate warpingLow production costRecord information storageRecord carrier materialsCompact Disc manufacturingEngineering

An optical disk (10) of the present invention has a substrate (11) included a resin-impregnated paper, in which resin is impregnated into paper, or resin-coated paper, in which the paper surface is coated with a resin, and a recording layer (13) formed on at least one side of the substrate (11). This type of optical disk (10) has performance equal to that of conventional optical disks and has a minimal effect on the environment during disposal. In addition, a manufacturing method of an optical disk of the present invention has a recording layer sheet fabrication step in which a recording layer sheet is fabricated by forming tracks on a recording layer base material, and a recording layer sheet lamination step in which a recording layer (13) included the recording layer sheet is provided on a substrate (11) included resin-impregnated paper or resin-coated paper by laminating the recording layer sheet with the resin-impregnated paper in which a resin is impregnated into paper or the resin-coated paper in which the surface of the paper is coated with a resin. This type of manufacturing method of an optical disk allows optical disk (10) to be produced inexpensively.

Owner:SONY CORP +1

Process for obtaining a thin, insulating, soft magnetic film of high magnetization

ActiveUS20060082390A1Improve permeabilityLow magnetic lossNanostructure applicationNanomagnetismMagnetizationAmorphous matrix

A thin soft magnetic film combines a high magnetization with an insulating character. The film is formed by nitriding Fe-rich ferromagnetic nanograins immersed in an amorphous substrate. A selective oxidation of the amorphous substrate is then performed. The result is a thin, insulating, soft magnetic film of high magnetization. Many types of integrated circuits can be made which include a component using a membrane incorporating the above-mentioned thin film.

Owner:STMICROELECTRONICS SRL +1

Thermoplastic Resin Composition with Excellent Heat Resistance and Molded Article Manufactured Using the Same

A heat resistant thermoplastic resin composition and a molded article manufactured using the same. The heat resistant thermoplastic resin composition includes about 100 parts by weight of an aromatic vinyl compound; about 20 parts by weight to about 60 parts by weight of a polycarbonate resin; and about 30 parts by weight to about 60 parts by weight of an impact modifier. The heat resistant thermoplastic resin composition and a molded article manufactured using the same can have excellent properties in terms of impact resistance, heat resistance, and / or chemical resistance and can be eco-friendly due to low level of VOC emissions.

Owner:LOTTE ADVANCED MATERIALS CO LTD

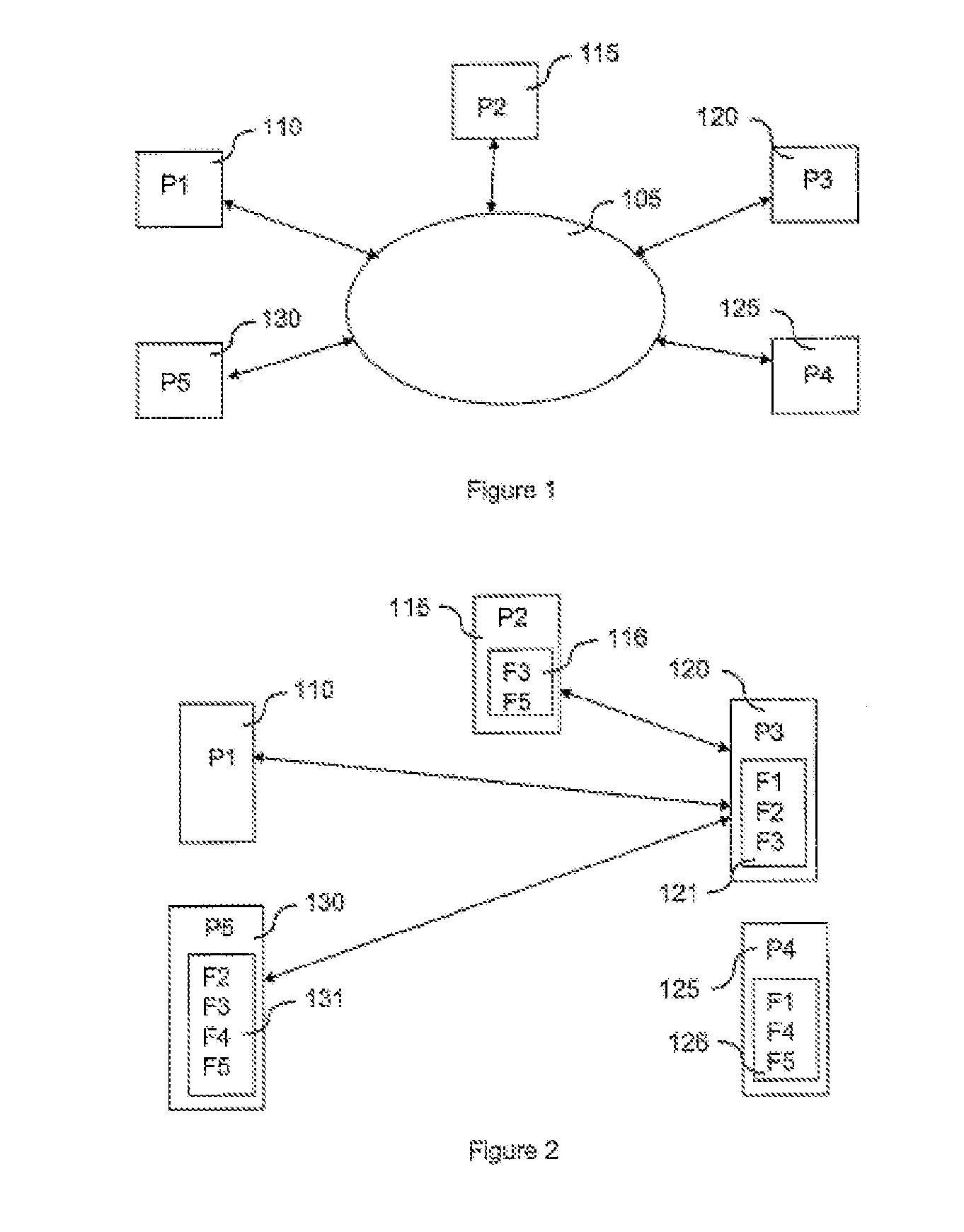

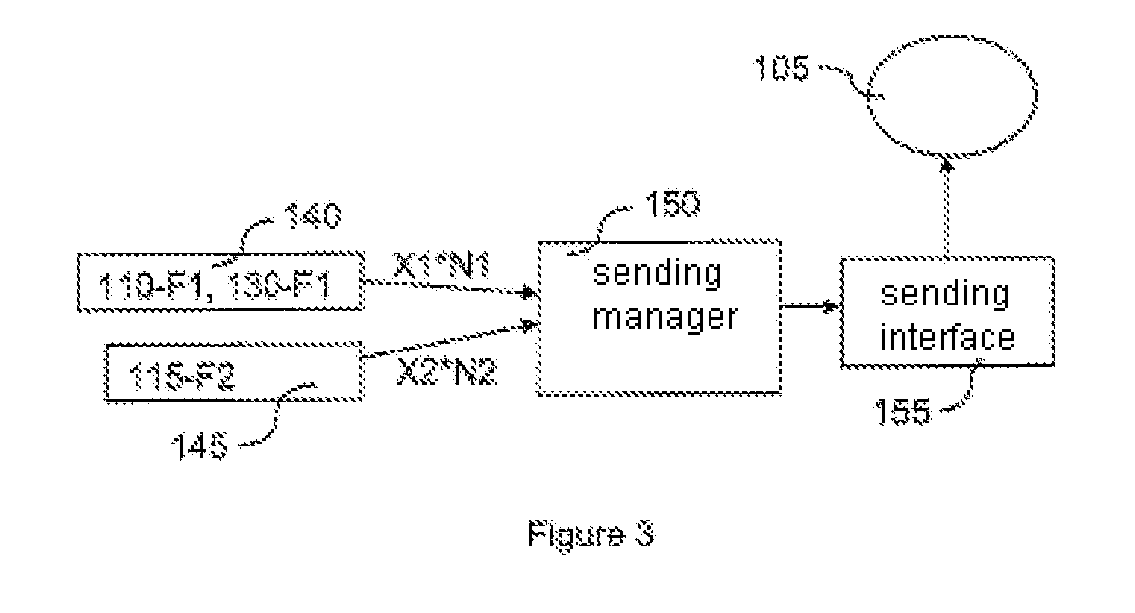

Method and device for transmitting content

InactiveUS20120284363A1Increase and decrease distortionTimely responseMultiple digital computer combinationsTransmissionComputer networkOperations research

A process and device are provided for transmitting content i by a supplier of this content. The process includes: a step of receiving by the supplier a transmission request of the content i originating from a requester, a step of obtaining by the supplier an estimation Ni of a number of suppliers of the content, and a step of transmitting the content i, during which the supplier sends the requester at least part of the content i by allocating to the requester an average proportion of the bandwidth allocated by this supplier to distribution of content calculated in the form of a coefficient, which is function of the number Ni of suppliers of the content i and of a real value A, common to all the content to be transmitted, serving to adjust the impact on the coefficient of the number Ni of suppliers of the content i.

Owner:FRANCE TELECOM SA

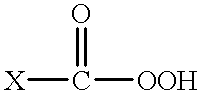

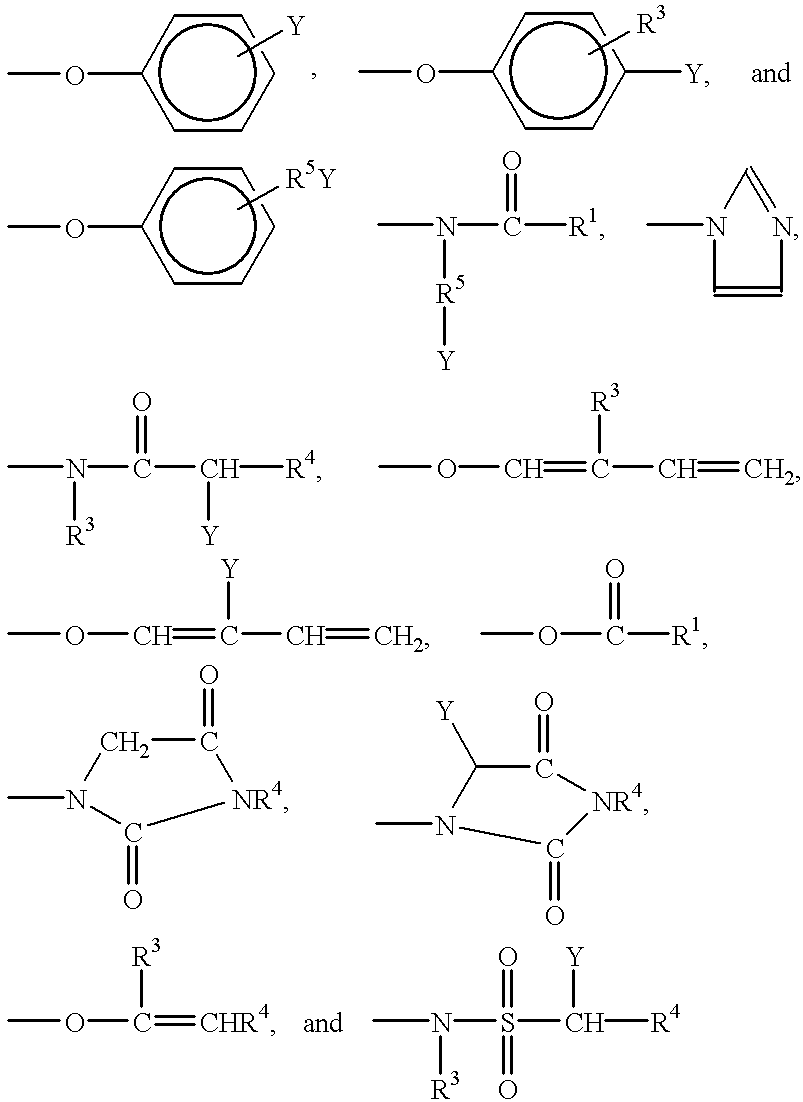

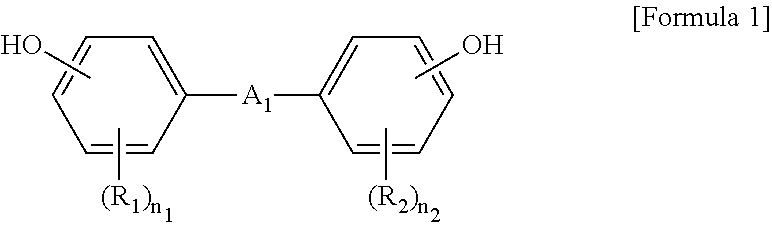

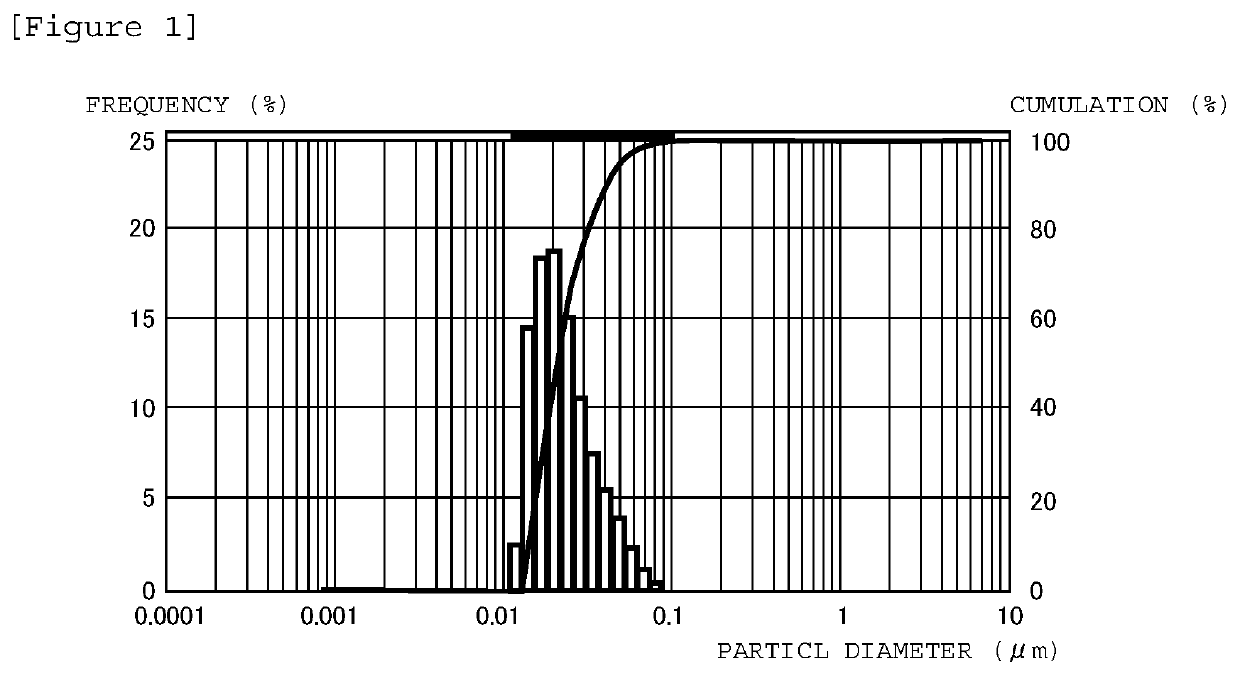

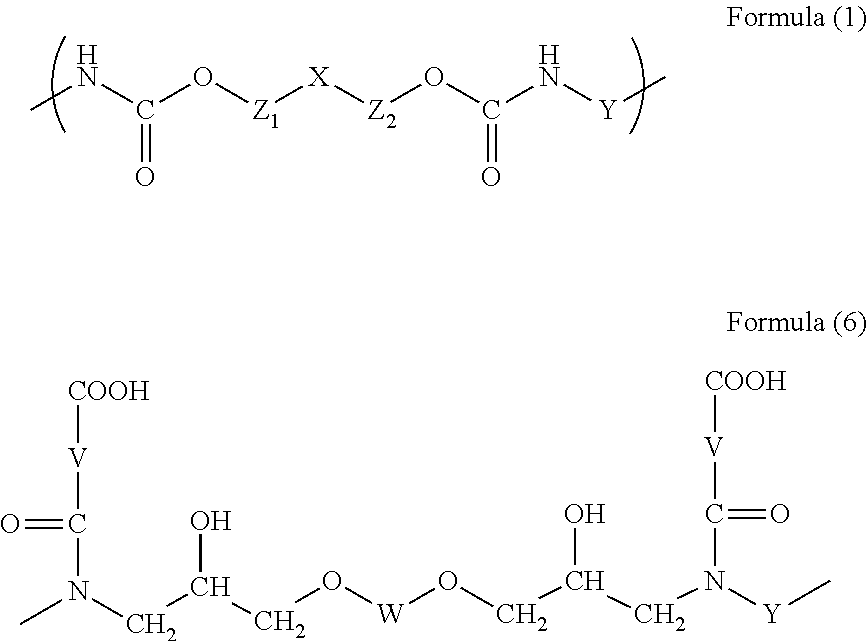

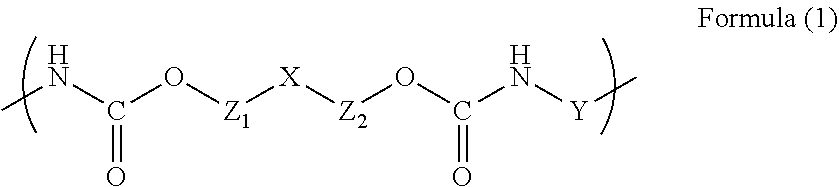

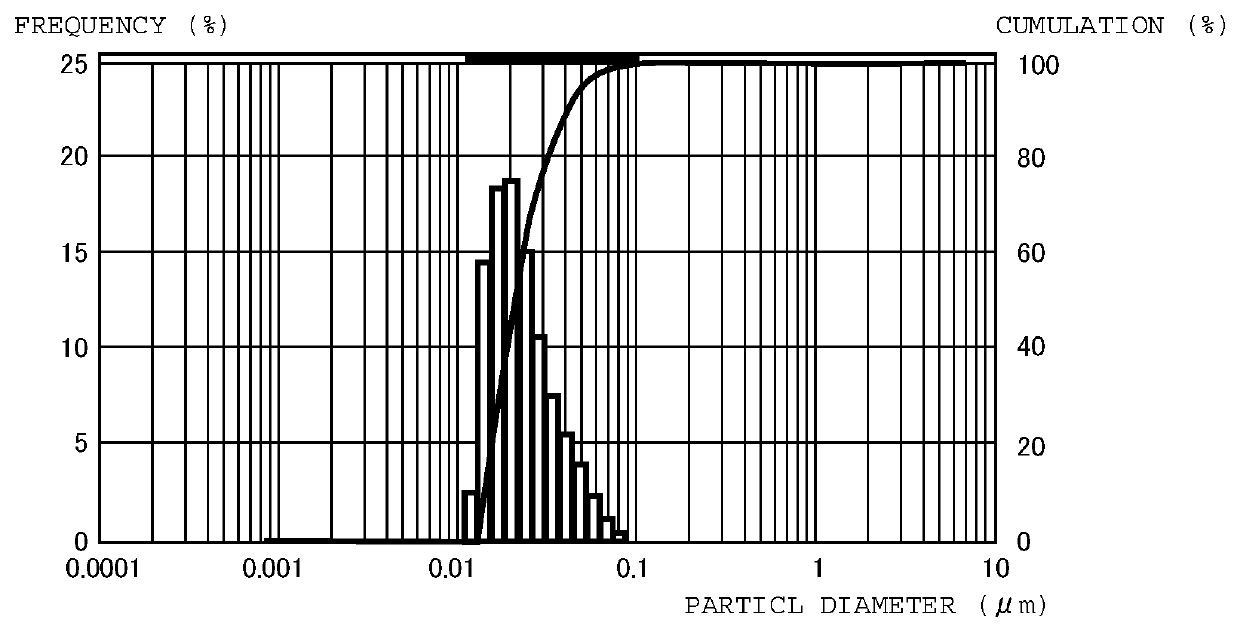

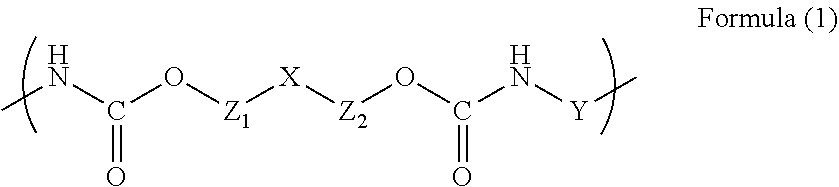

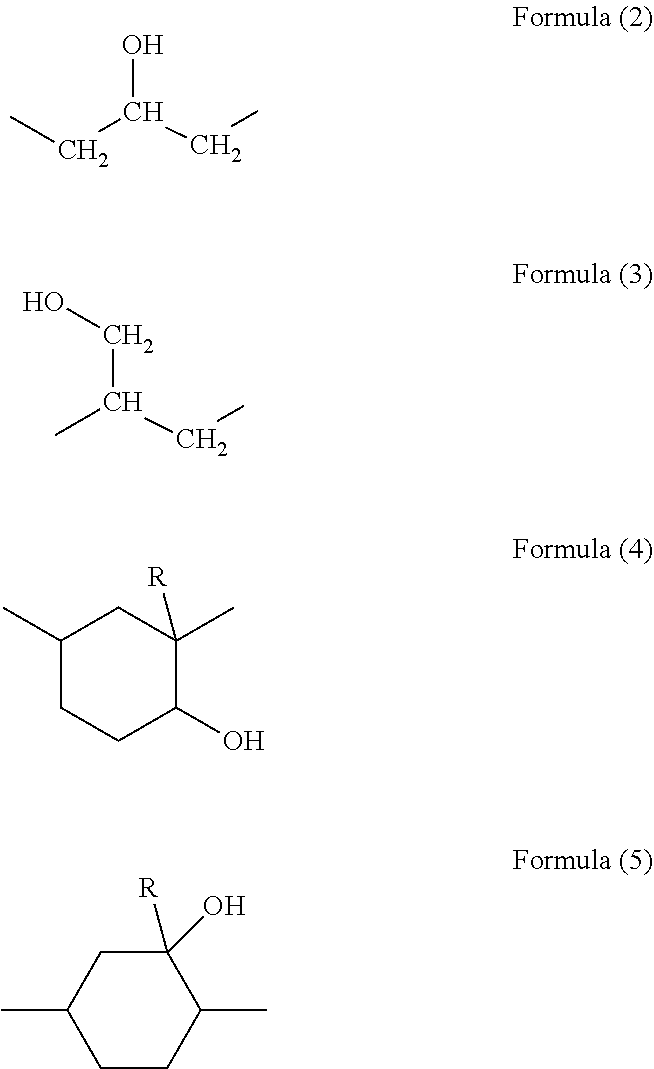

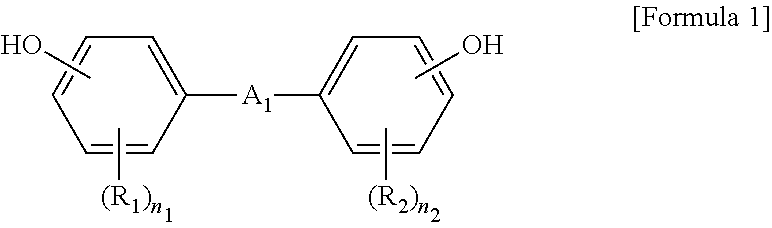

Aqueous polyhydroxyurethane resin dispersion, method for producing said aqueous dispersion, gas-barrier resin film produced using said aqueous dispersion, aqueous polyhydroxyurethane resin dispersion composition containing clay mineral, gas-barrier coating agent comprising said composition, and gas-barrier resin film

ActiveUS20190338160A1Improve stabilityExcellent gas barrier performancePolyurea/polyurethane coatingsChemical structureClay minerals

There are provided: an aqueous polyhydroxyurethane resin dispersion which can achieve long-term storage that is a requirement for industrial applications, and with which a coating film having an excellent gas-barrier property can be formed; an aqueous dispersion composition containing a complex of the resin and a clay mineral; and a film having an excellent gas-barrier property, which is produced using the aqueous polyhydroxyurethane resin dispersion or the aqueous dispersion composition. Specifically, there are provided: an aqueous polyhydroxyurethane resin dispersion containing a polyhydroxyurethane resin finely dispersed in water, wherein the polyhydroxyurethane resin contains a repeating unit represented by formula (1) as a basic structure and has a carboxyl group-containing chemical structure moiety represented by formula (6) in the structure; an aqueous dispersion composition containing this polyhydroxyurethane resin component and a layered clay mineral favorably made into a composite; and a gas-barrier resin film which is produced using the aqueous polyhydroxyurethane resin dispersion or the aqueous dispersion composition.

Owner:DAINICHISEIKA COLOR & CHEM MFG CO LTD

Aqueous polyhydroxyurethane resin dispersion, method for producing said aqueous dispersion, gas-barrier resin film produced using said aqueous dispersion, aqueous polyhydroxyurethane resin dispersion composition containing clay mineral, gas-barrier coating agent comprising said composition, and gas-barrier resin film

ActiveUS10689543B2Improve stabilityExcellent gas barrier performancePolyurea/polyurethane coatingsMaterials scienceCarboxylic group

An aqueous polyhydroxyurethane resin dispersion, which can be stored for a long time, and with which a coating film having a high gas-barrier property can be formed; an aqueous dispersion composition containing a complex of the resin and a clay mineral; and a film having a high gas-barrier property produced using the aqueous polyhydroxyurethane resin dispersion or the aqueous dispersion composition are provided. The aqueous polyhydroxyurethane resin dispersion comprises a polyhydroxyurethane resin finely dispersed in water, where the polyhydroxyurethane resin has in its structure, a repeating unit represented by formula (1) as a basic structure and a carboxyl group-containing chemical structure moiety represented by formula (6), described in this specification. The aqueous dispersion composition comprising the polyhydroxyurethane resin and a layered clay mineral form composite. The film having a high gas-barrier is produced using the aqueous dispersion or the aqueous dispersion composition.

Owner:DAINICHISEIKA COLOR & CHEM MFG CO LTD

Process for obtaining a thin, insulating, soft magnetic film of high magnetization

ActiveUS7504007B2Reduce saturationAvoid problemsNanostructure applicationNanomagnetismMagnetizationNanometre

Owner:STMICROELECTRONICS SRL +1

Coating additive and preparation method and using method thereof

The invention relates to a coating additive. The coating additive is prepared from the following components in percentage by weight: 12-18% of aluminium-magnesium silicate, 2-5% of white carbon black,0.5-0.8% of PVB, 4-7% of phenolic resin powder, 3-5% of maleated rosin powder, 4-8% of attapulgite, 1-2% of sodium hexametaphosphate, 4-8% of organobentonite, 10-15% of spodumene, 15-20% of mica powder, 15-20% of anhydrous sodium sulphate and 6-10% of a dispersing agent. A preparation method of the coating additive comprises the following steps that all the components are mixed according to the weight percentage, stirring is conducted for 10-15 minutes by a spiral rod stirrer, and after even stirring, the powdery coating additive is obtained; and during using, aggregate and a solvent only need to be added into the coating additive, stirring is conducted for at least 20 min by a high-speed dispersion machine, and thus the coating additive can be applied. Compared with the prior art, the coating additive is easy to produce and convenient to package and transport, and all aspects of performance of casting coating made of the coating additive is superior.

Owner:SHANGHAI ZONGHUA IND

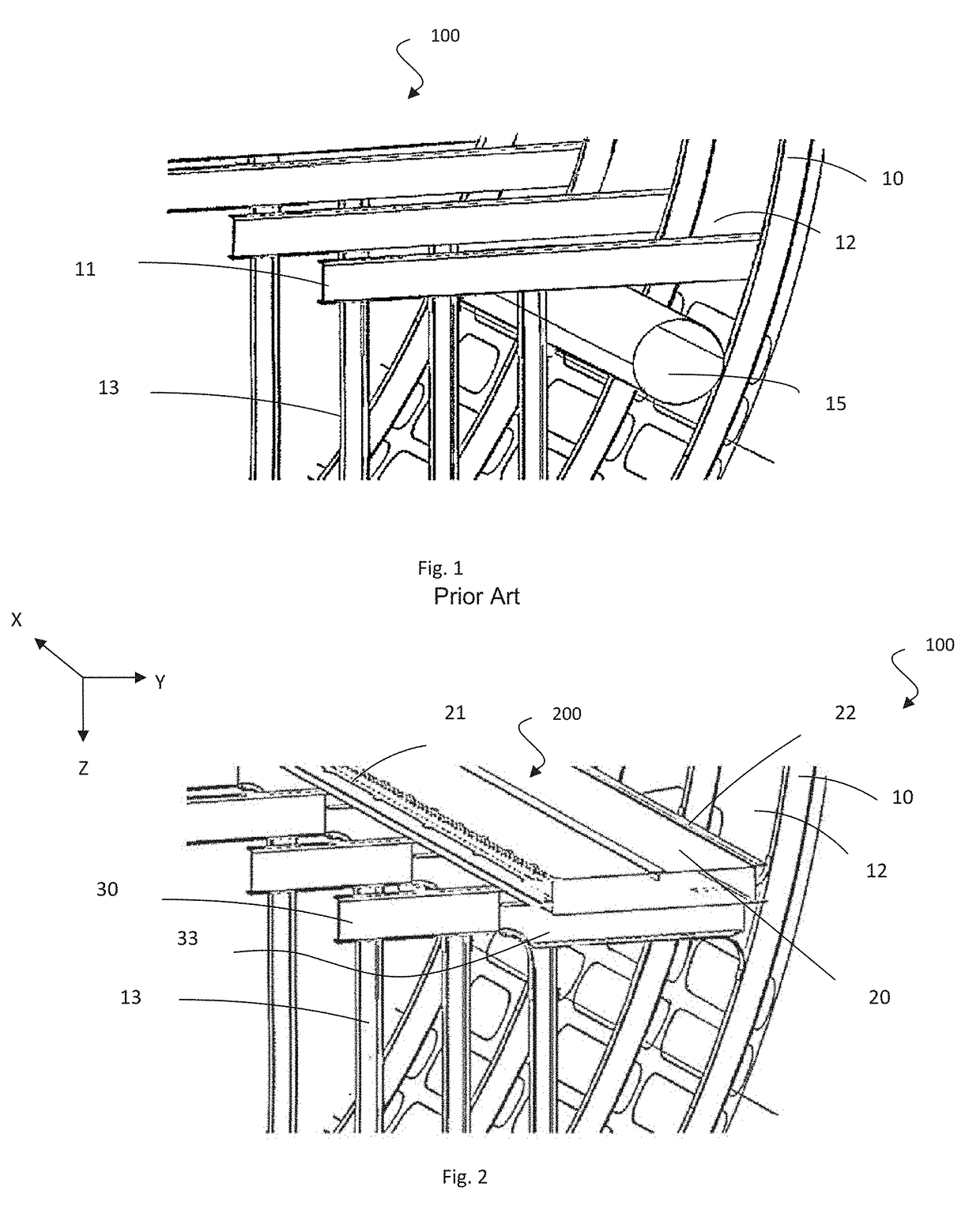

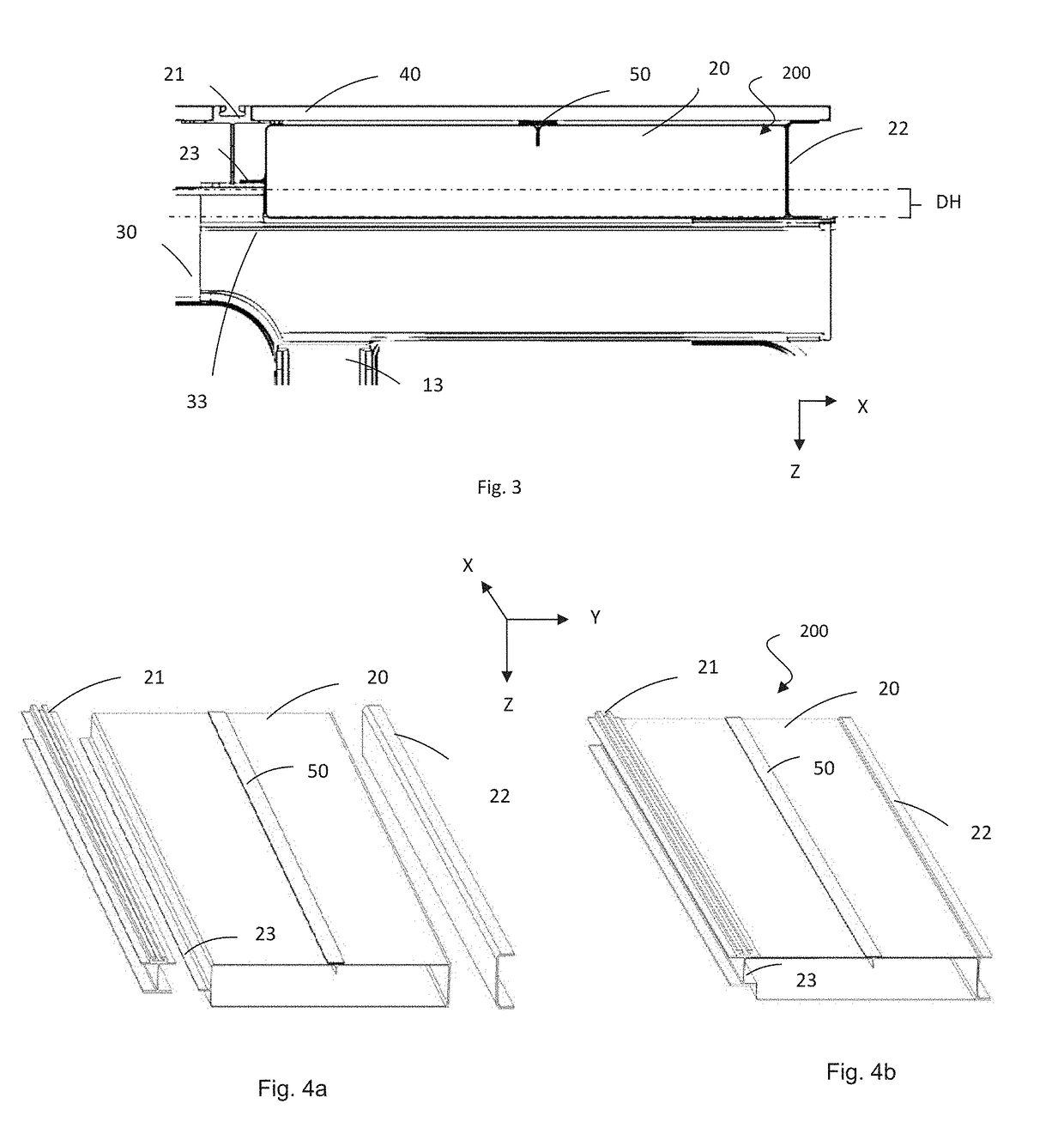

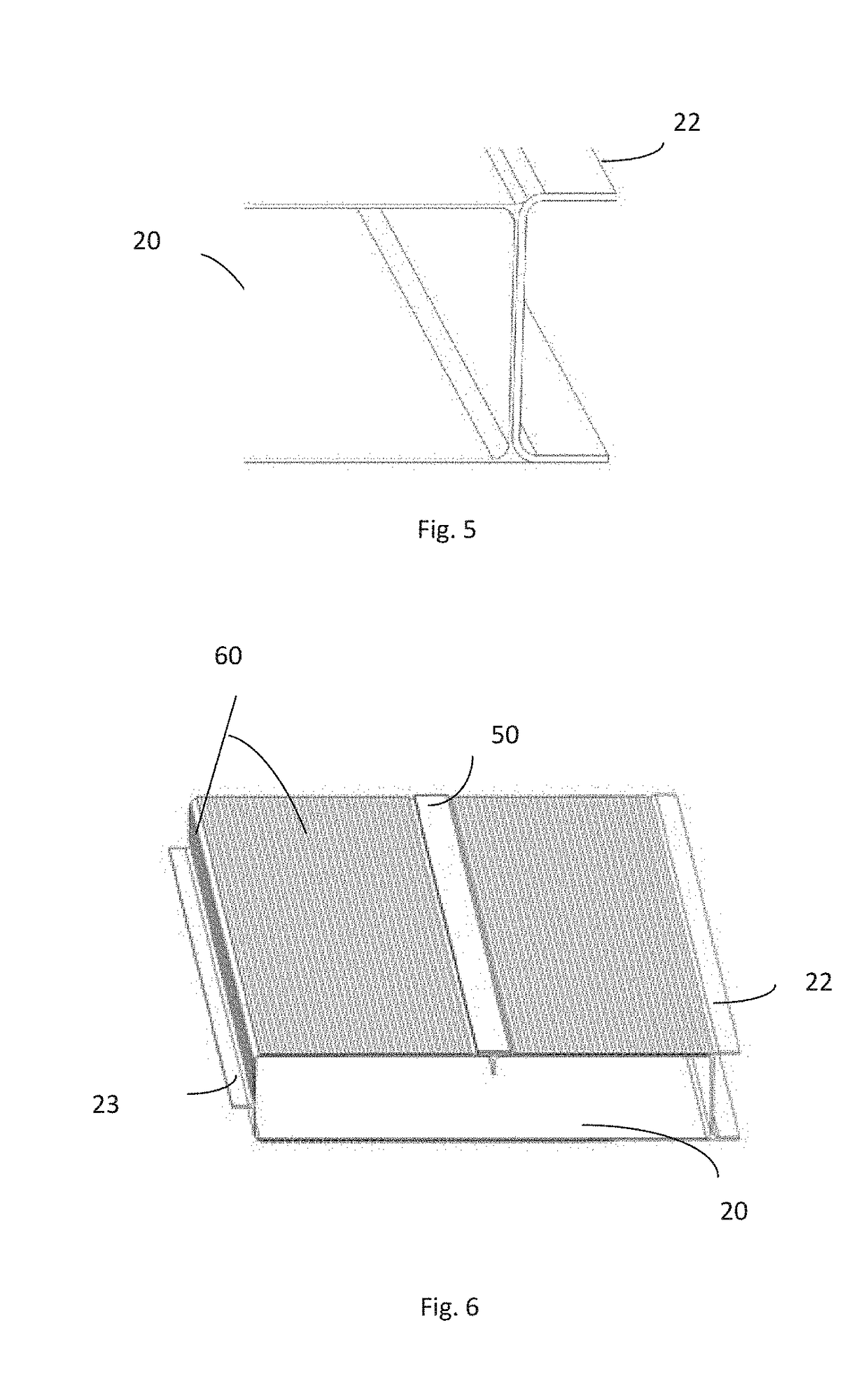

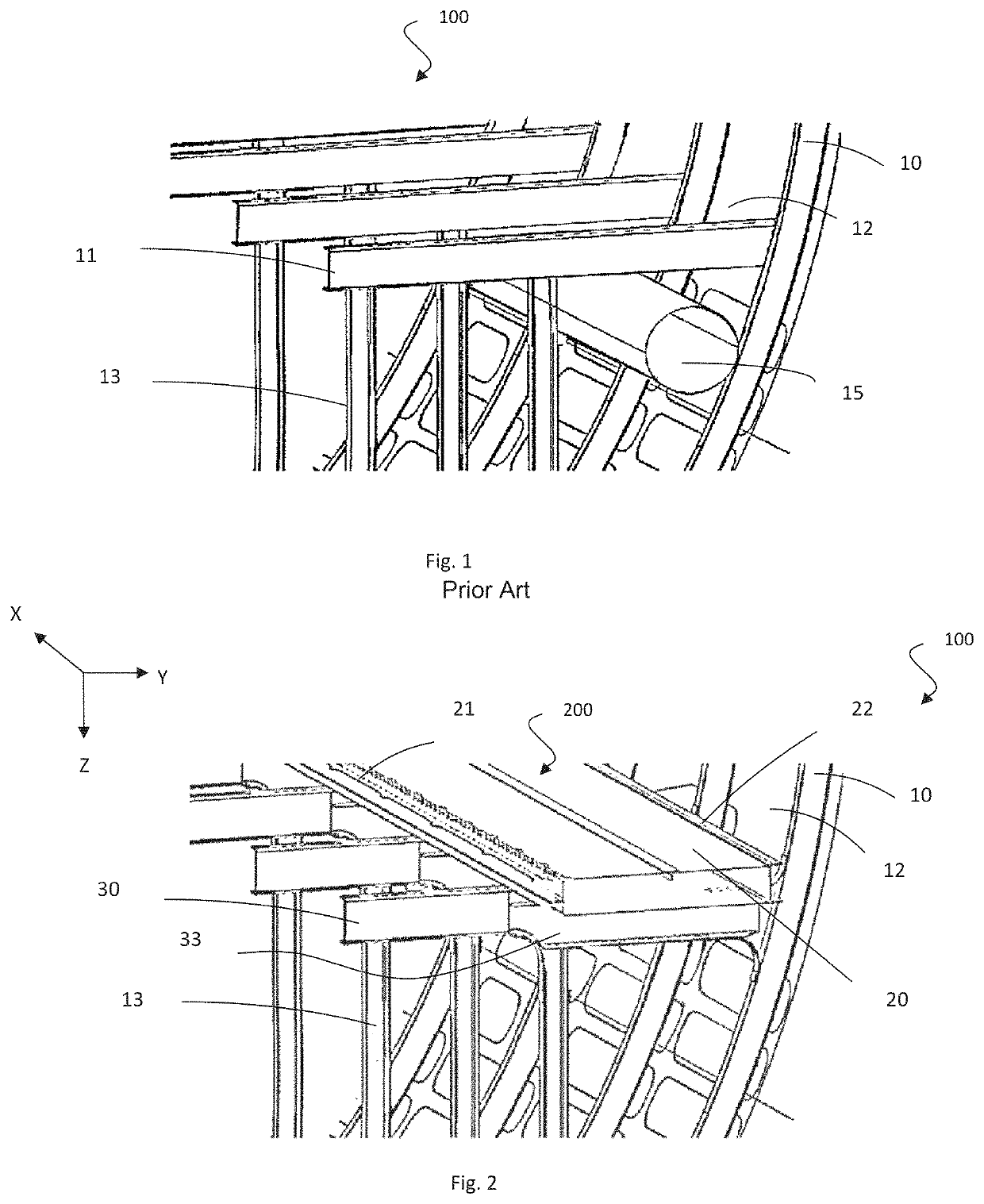

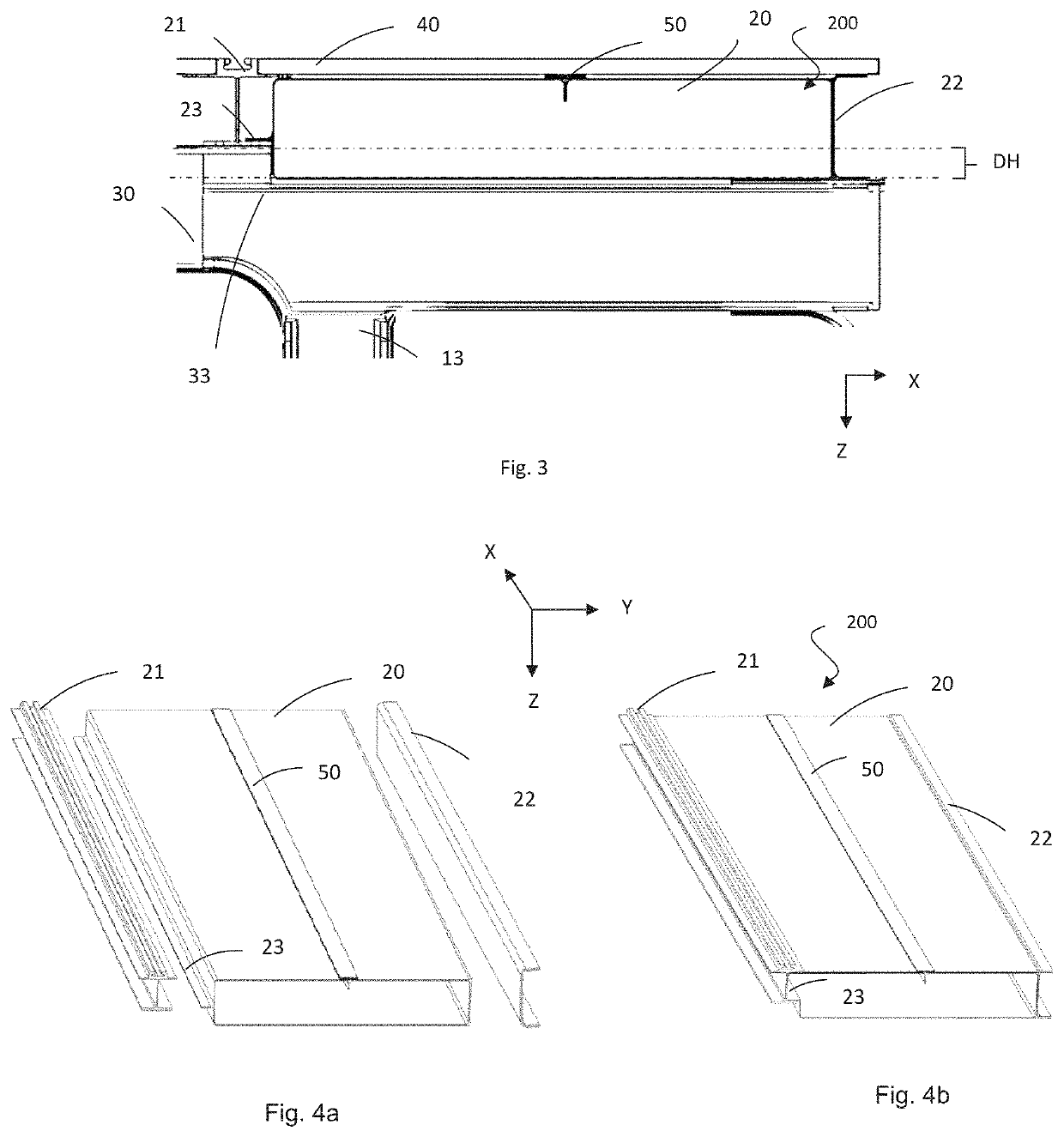

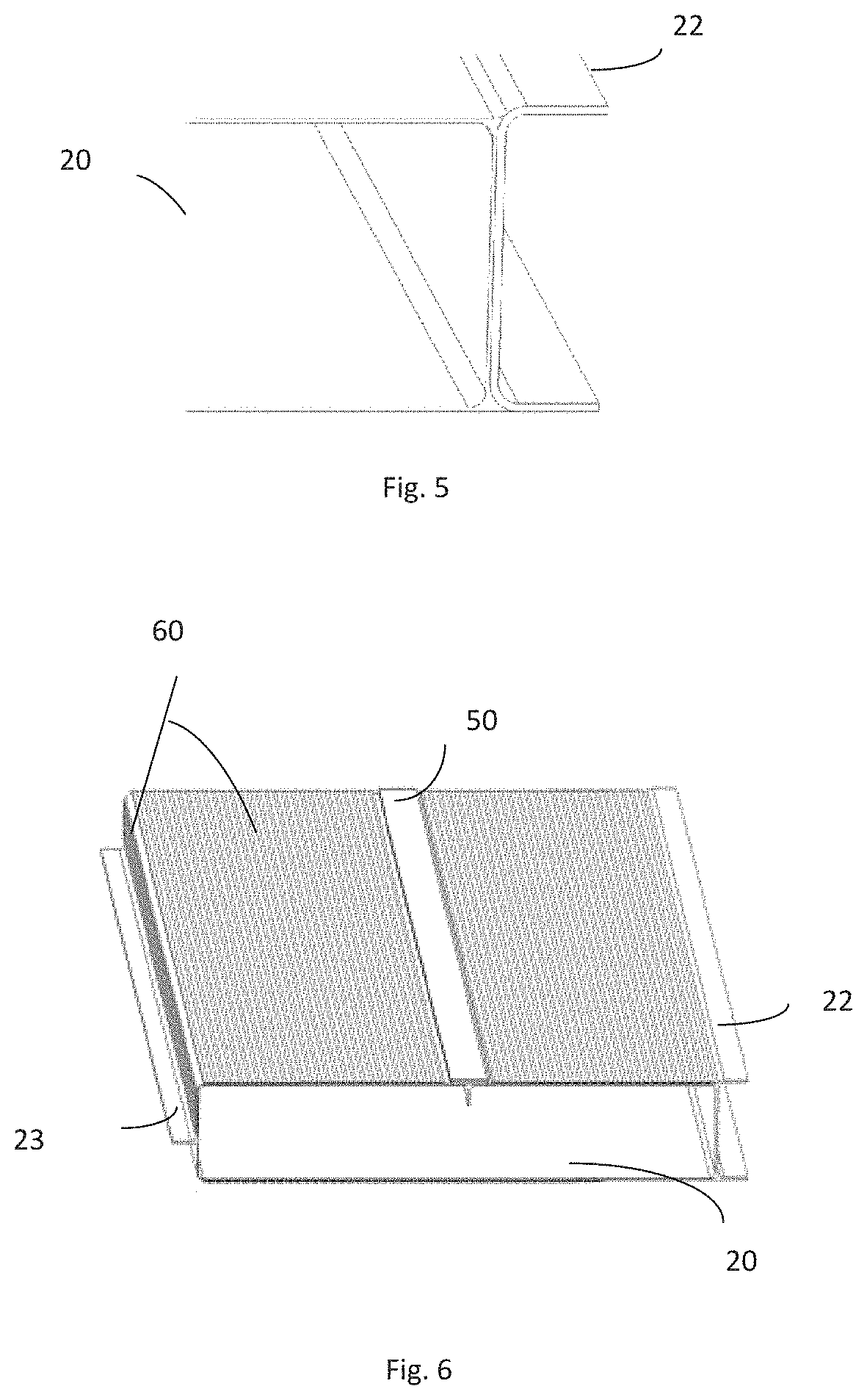

Fuselage and aircraft including an air distribution multifunctional substructure and assembly method

ActiveUS20190016464A1Simplify and reduce timeEasy maintenanceFuselage framesElectric power distributionDistribution systemSubstructure

An aircraft fuselage including a fuselage skin, cross-members supporting a floor of the aircraft, wherein the fuselage includes a multifunctional substructure fixed to at least one of the cross-members in a lowered part of the cross-member. The multifunctional substructure comprises: at least one duct of an air distribution system having a substantially rectangular section at the location of the at least one cross-member and having lateral walls of the duct that are substantially vertical; a seat fixing track or a stiffener fixed on a first lateral wall of the duct of the multifunctional substructure, and; a seat fixing track or a stiffener fixed on a second lateral wall, opposite the first lateral wall, of the duct of the multifunctional substructure.

Owner:AIRBUS SAS

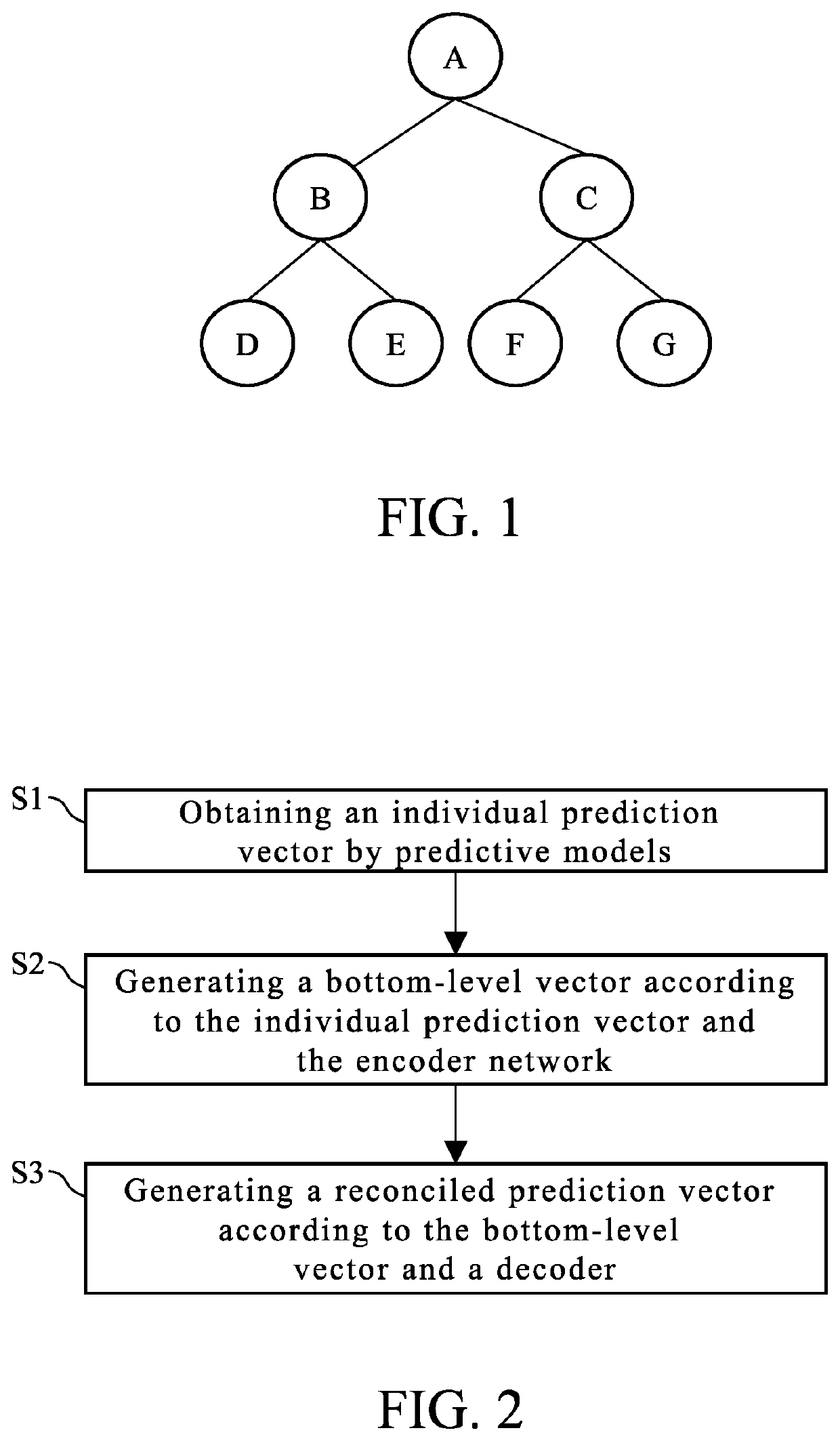

Hierarchical time-series prediction method

PendingUS20220156555A1Equal performanceEasy to implementForecastingNeural architecturesAlgorithmEngineering

A hierarchical time-series prediction method is adapted to a plurality of reconciled predictions of a plurality of nodes of a hierarchical structure. The plurality of nodes have a plurality of time-series respectively, the plurality of reconciled predictions correspond to the plurality of time-series, the plurality of nodes comprises a plurality of bottom nodes, and the hierarchical time-series prediction method comprises: generating a plurality of individual predictions corresponding to the plurality of time-series respectively by a plurality of predictive models; generating a plurality of bottom-level predictions corresponding to the plurality of bottom nodes according to the plurality of individual predictions and an encoder network; and generating the plurality of reconciled predictions according to the plurality of bottom-level predictions and a decoder associated with the hierarchical structure.

Owner:INVENTEC PUDONG TECH CORPOARTION +1

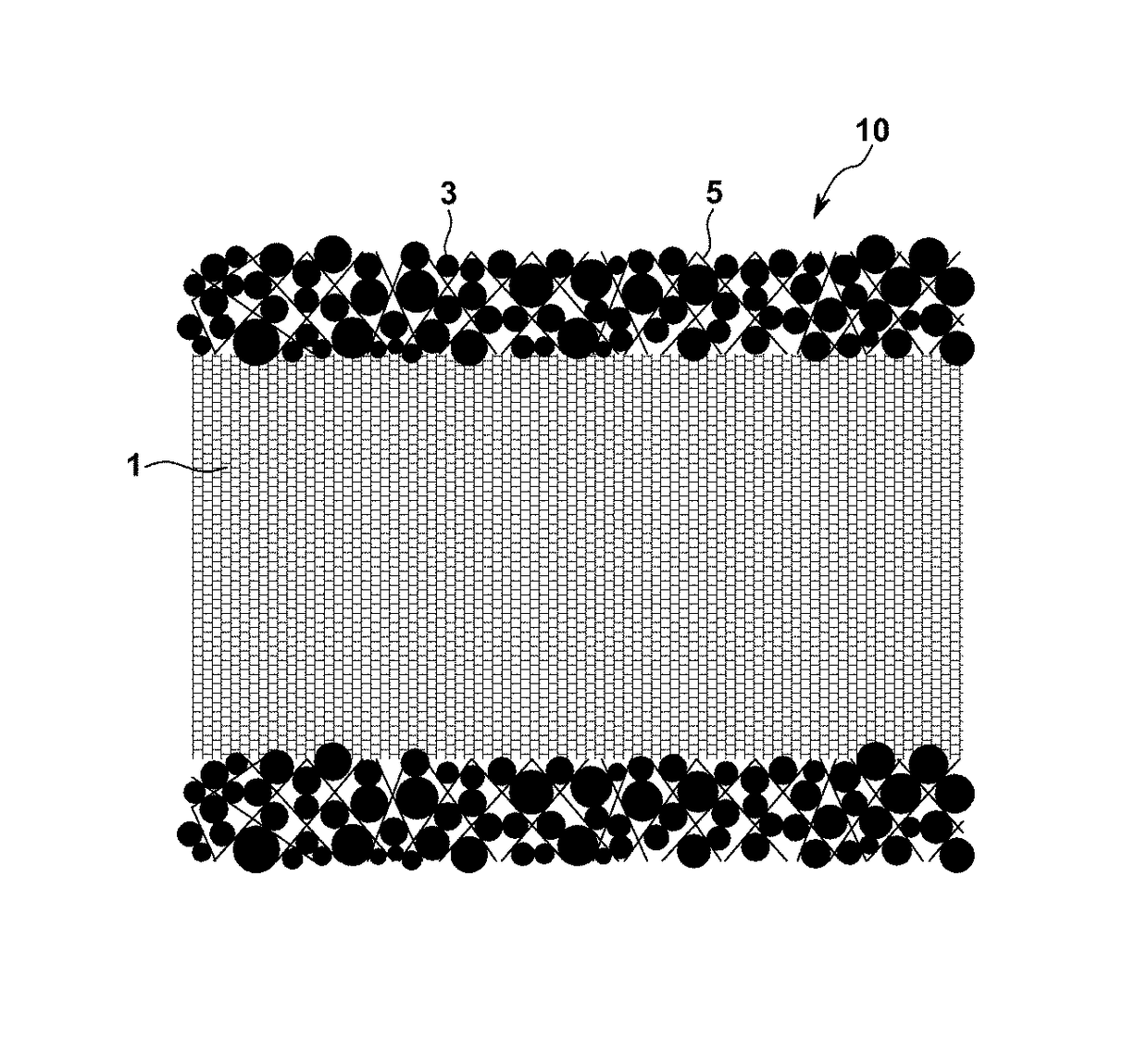

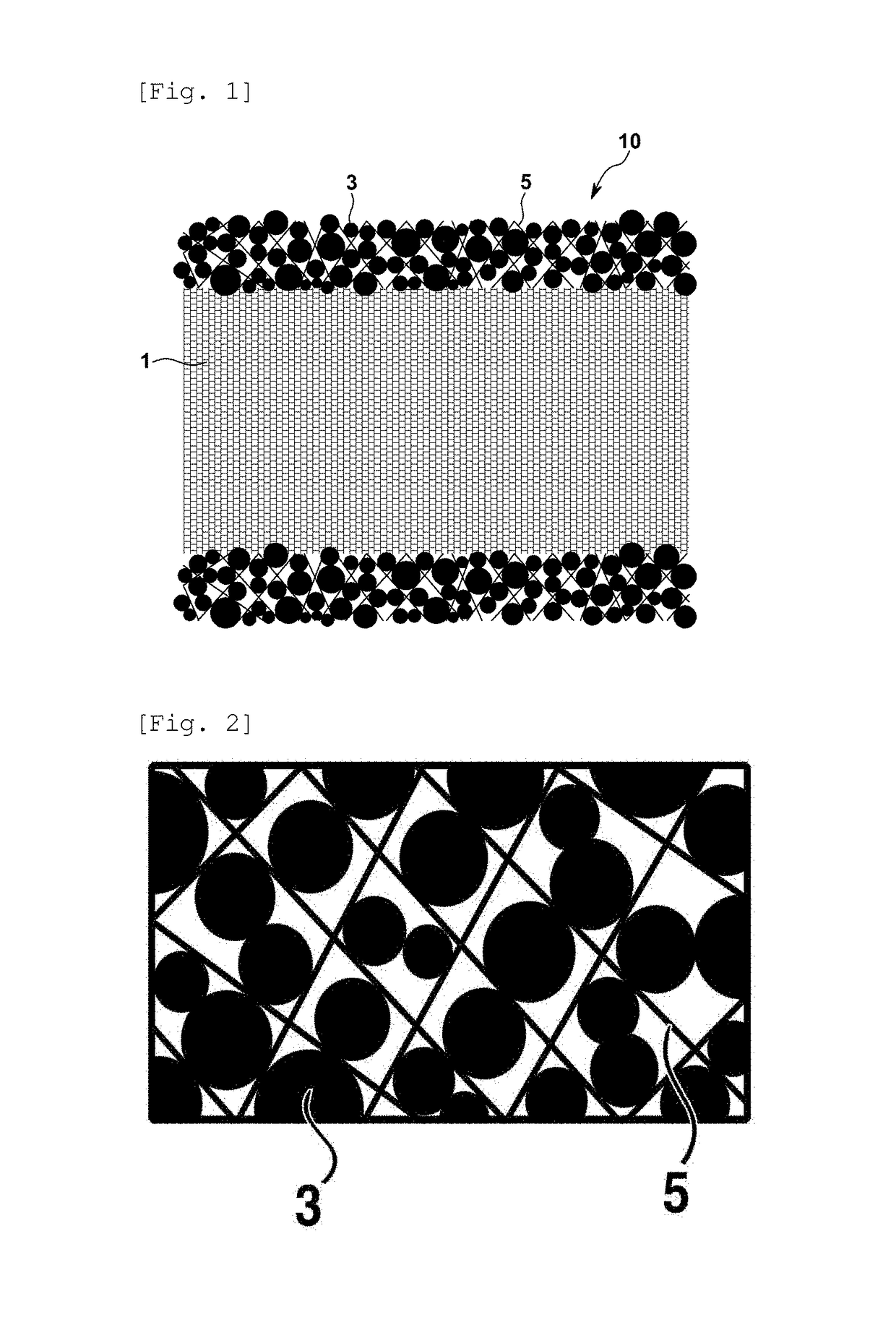

Separator with enhanced heat resistance and electrochemical device containing the same

ActiveUS9911958B2Increased insolubilityGood dimensional stabilityLi-accumulatorsCell component detailsLithiumInorganic particle

Disclosed is a separator containing a porous polymer substrate and an inorganic particle layer formed on at least one surface of the porous polymer substrate, and the separator has increased insolubility for an electrolyte and enhanced dimensional stability at high temperatures, therefore, short circuit between a cathode and an anode may be suppressed even when an electrochemical device is overheated, and high temperature cycle characteristics of the electrochemical device are enhanced. In addition, discharge characteristics are improved due to an ion conductance enhancement, since the impregnation of the separator for the electrolyte increases. Therefore, the separator according to the present invention is suited for electrochemical devices that require heat resistance, in particular, for lithium secondary batteries for electric vehicles, since, while the separator according to the present invention has excellent heat resistance, an electrochemical device that includes the separator gives equal performance in electrochemical properties when compared to existing separators.

Owner:RES & BUSINESS FOUND SUNGKYUNKWAN UNIV

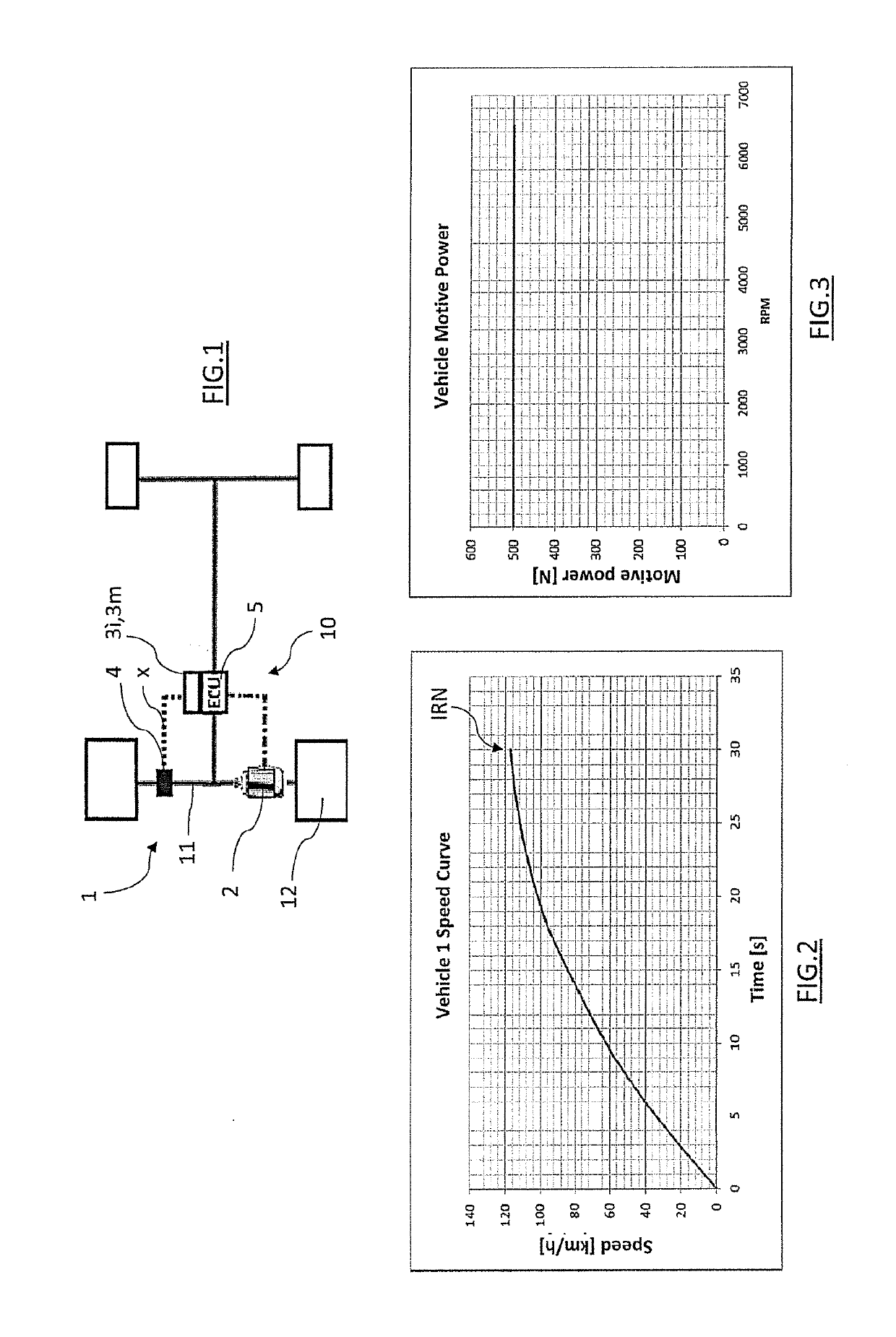

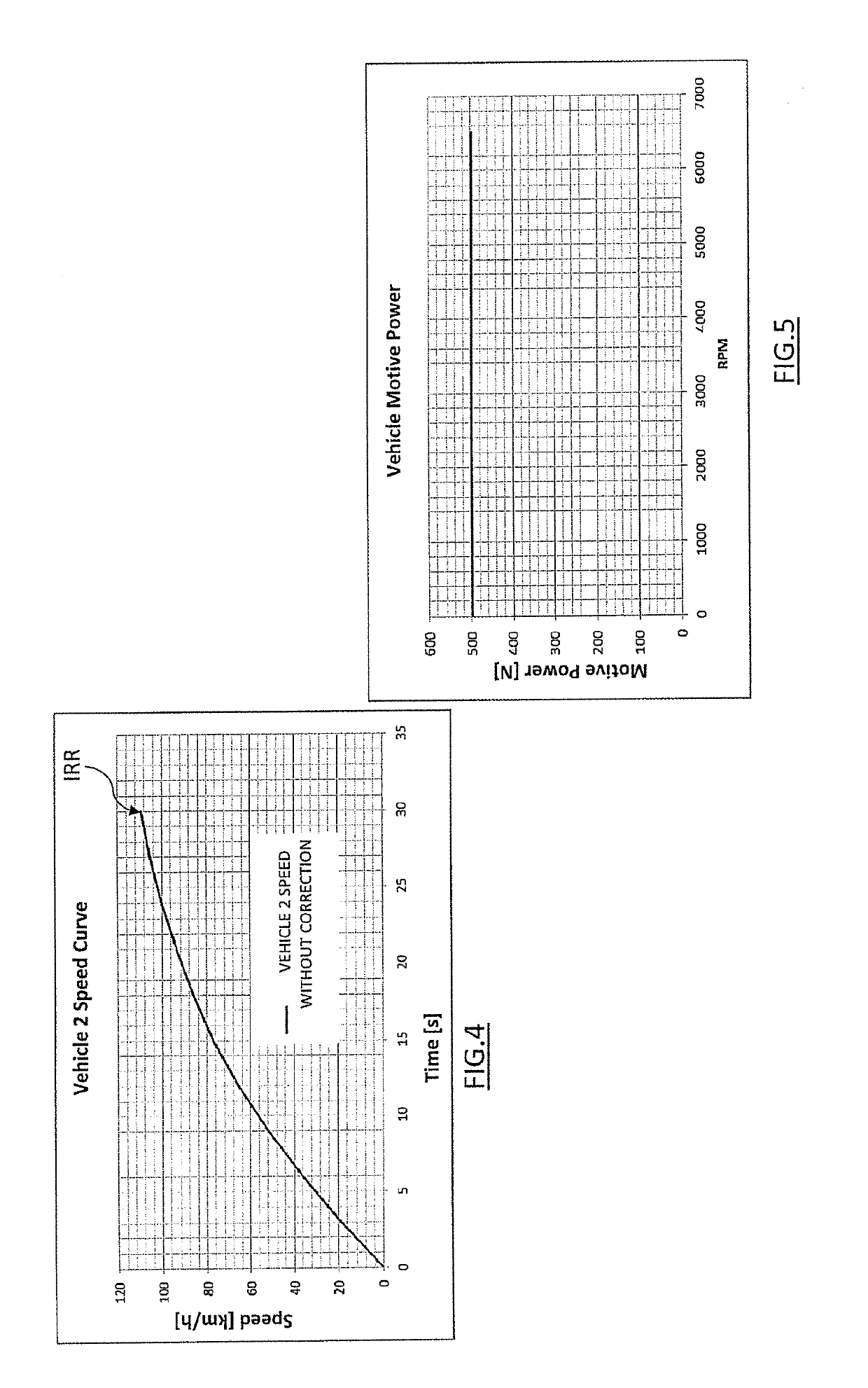

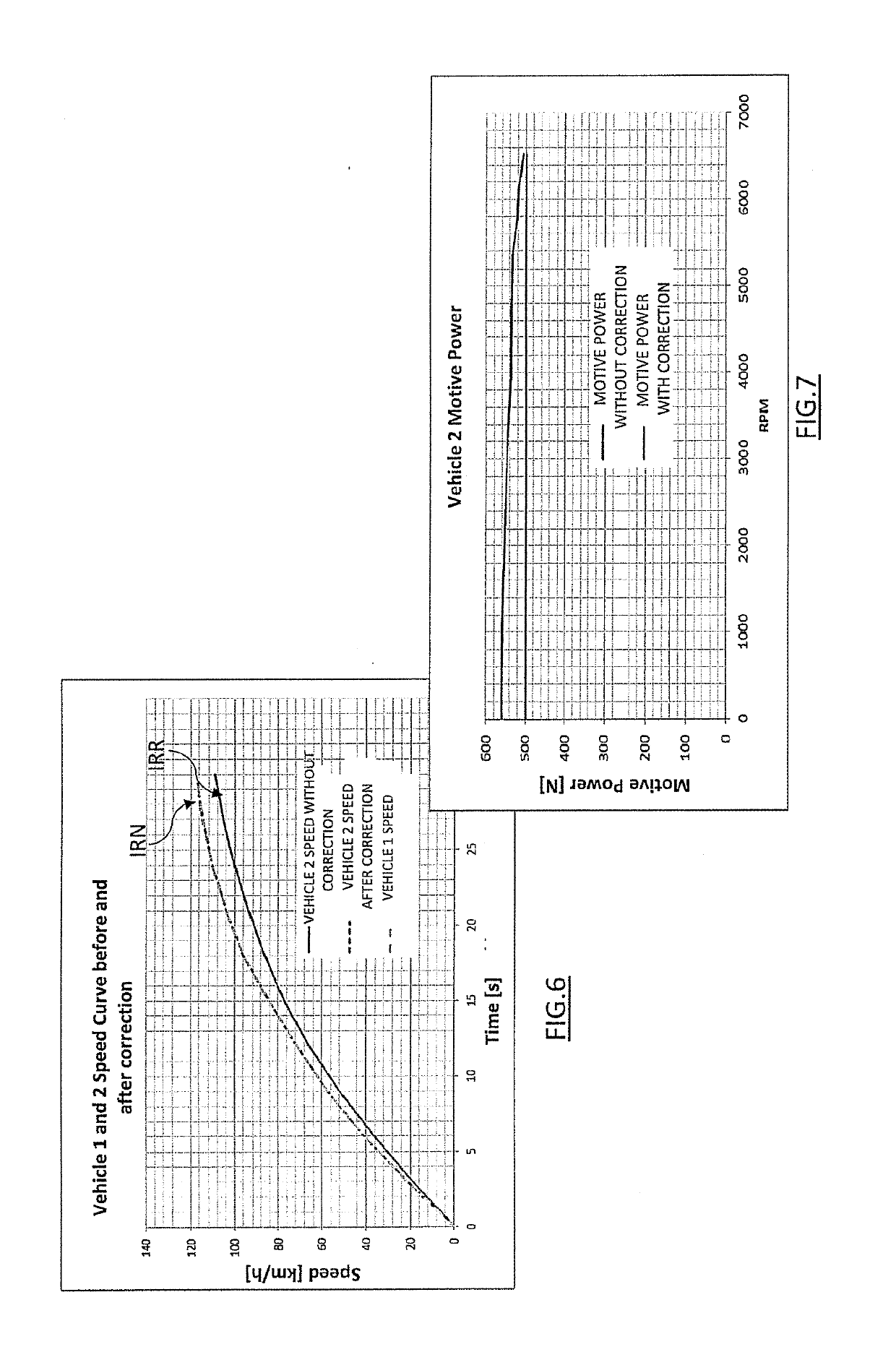

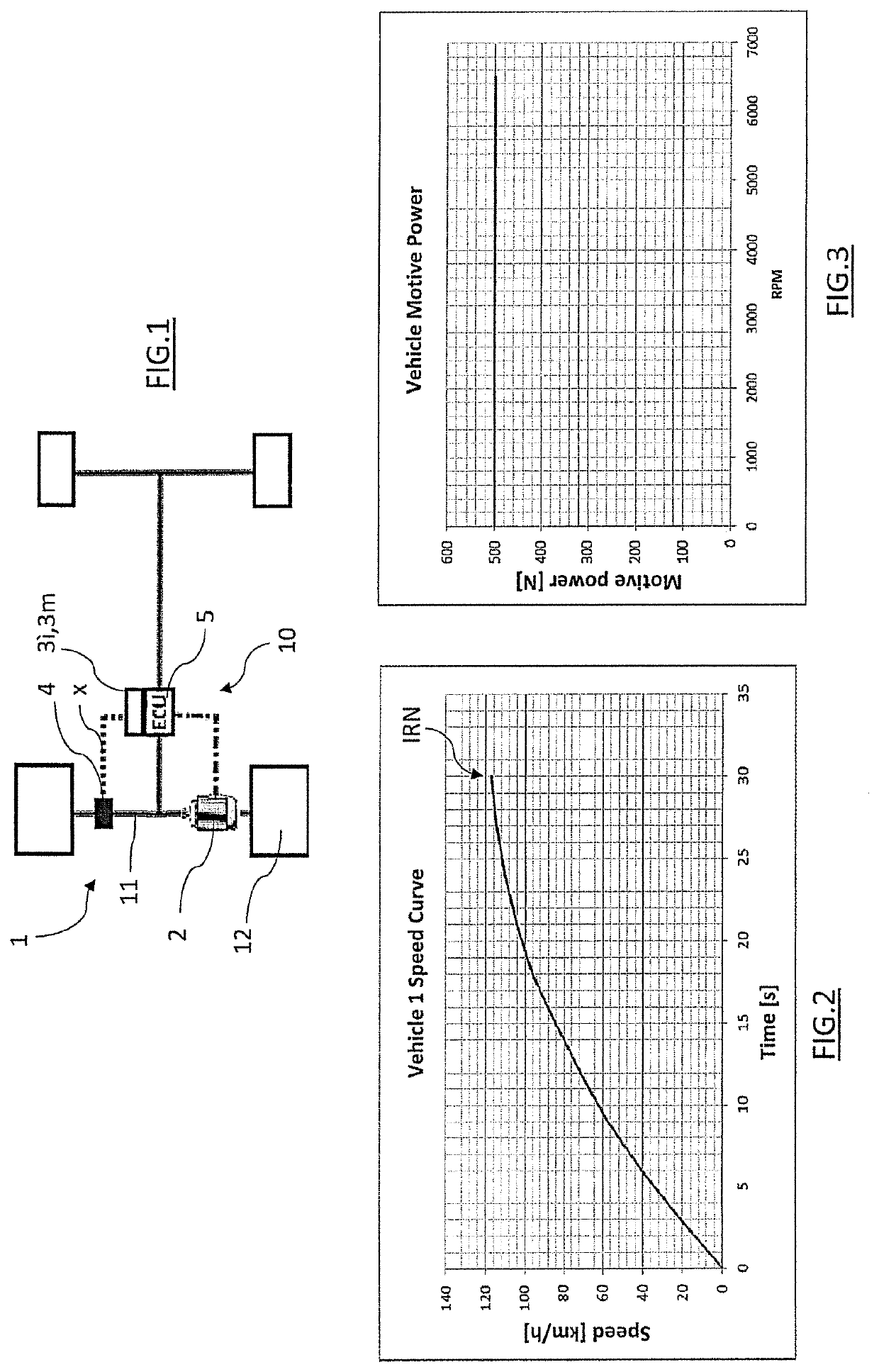

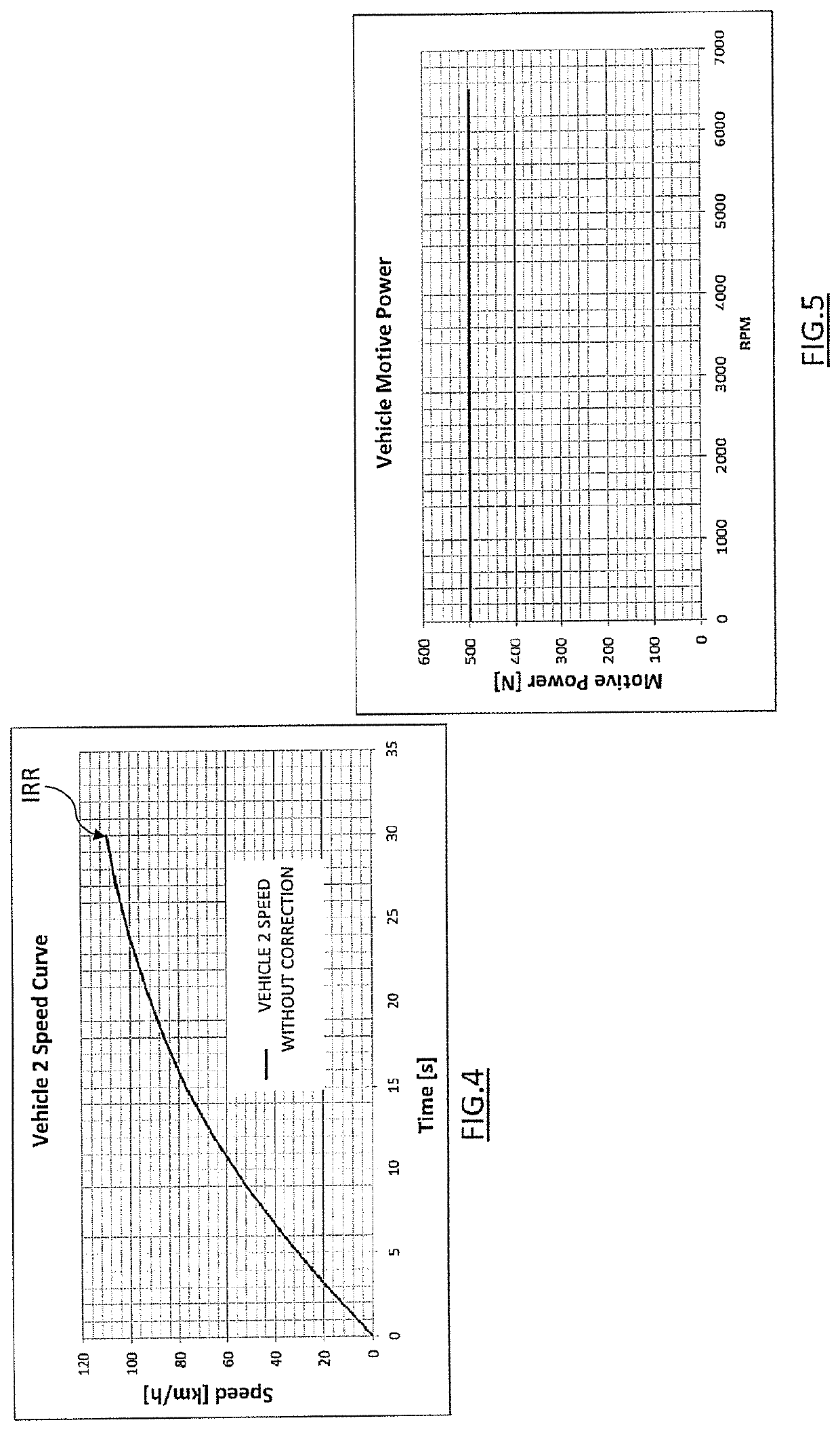

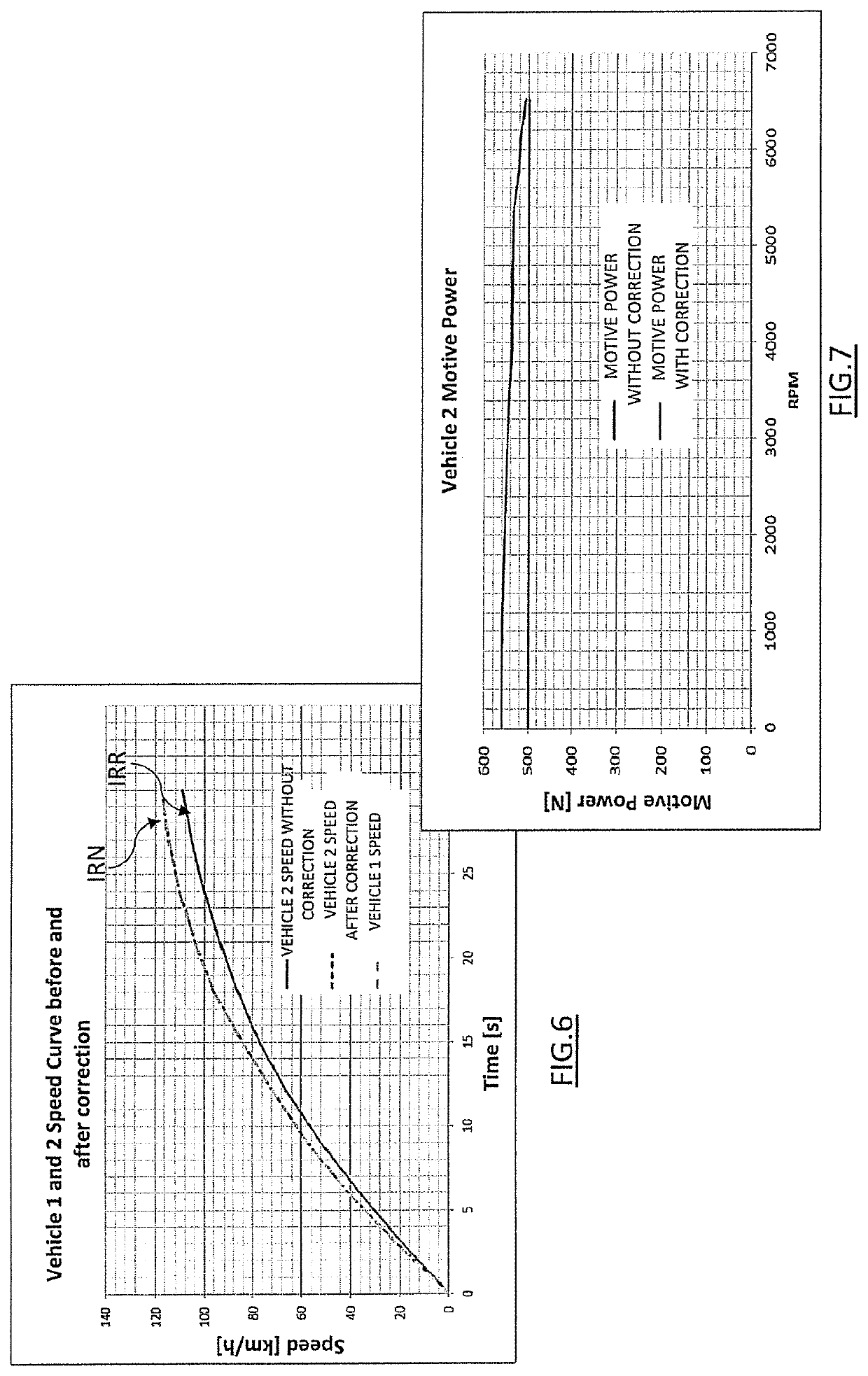

Method and apparatus for automatic adjustment of a vehicle to a predetermined performance condition

A method for automatic adjustment of the performance of a vehicle including the steps of detecting at least one significant physical quantity for checking the performance of the vehicle; defining at least one pair of reference indicators correlated with that physical quantity; saving at least one value of a said reference indicator in a predetermined nominal reference condition; detecting at least one value of a said reference indicator in a real operating condition of the vehicle; comparing said nominal reference indicator and real reference indicator and, if their values are different from each other, and implementing a correction of the driving power of the vehicle to compensate for the difference ascertained.

Owner:SOLAREDGE TECH LTD

Thermoplastic resin composition with excellent heat resistance and molded article manufactured using the same

A heat resistant thermoplastic resin composition and a molded article manufactured using the same. The heat resistant thermoplastic resin composition includes about 100 parts by weight of an aromatic vinyl compound; about 20 parts by weight to about 60 parts by weight of a polycarbonate resin; and about 30 parts by weight to about 60 parts by weight of an impact modifier. The heat resistant thermoplastic resin composition and a molded article manufactured using the same can have excellent properties in terms of impact resistance, heat resistance, and / or chemical resistance and can be eco-friendly due to low level of VOC emissions.

Owner:LOTTE ADVANCED MATERIALS CO LTD

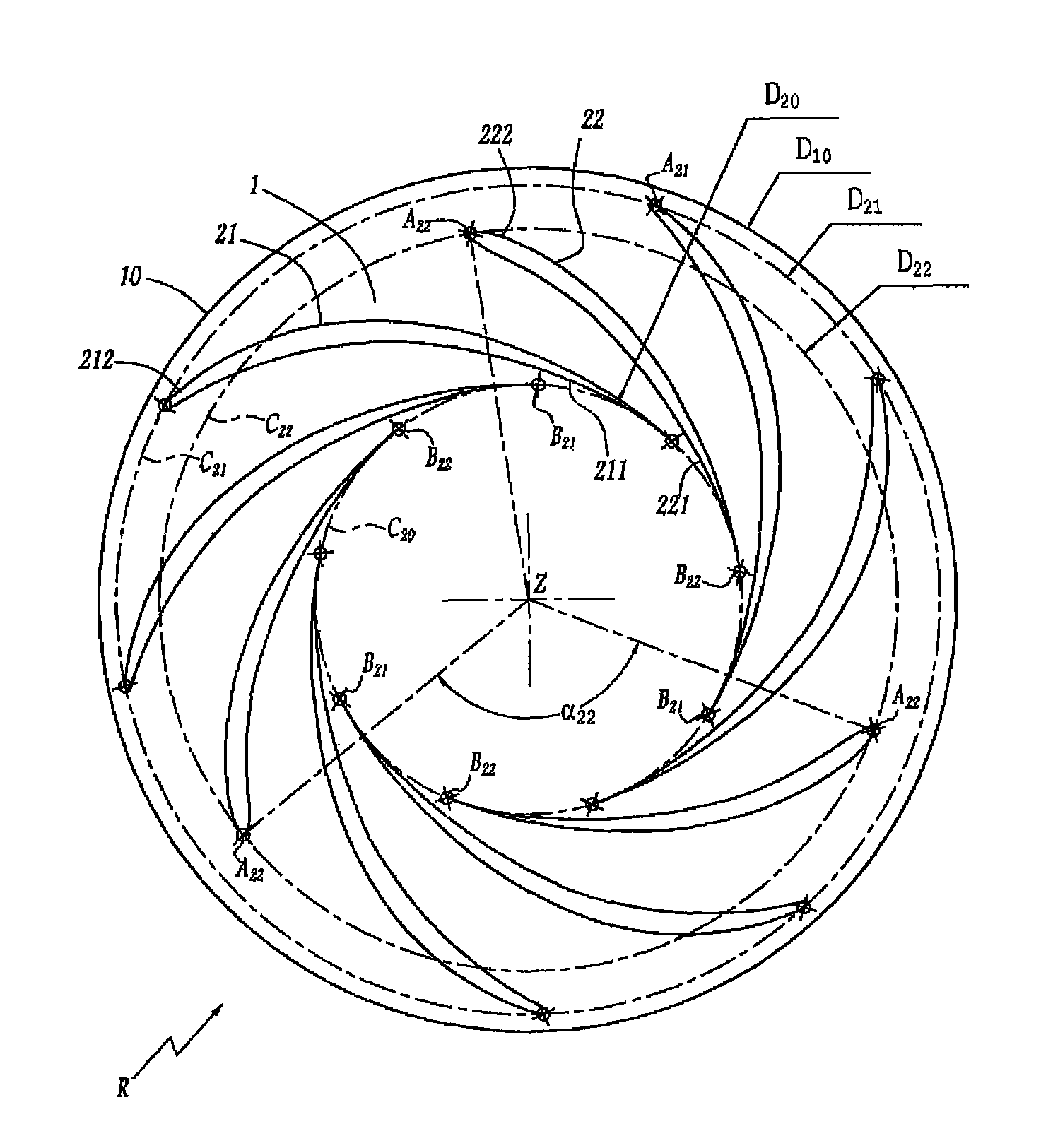

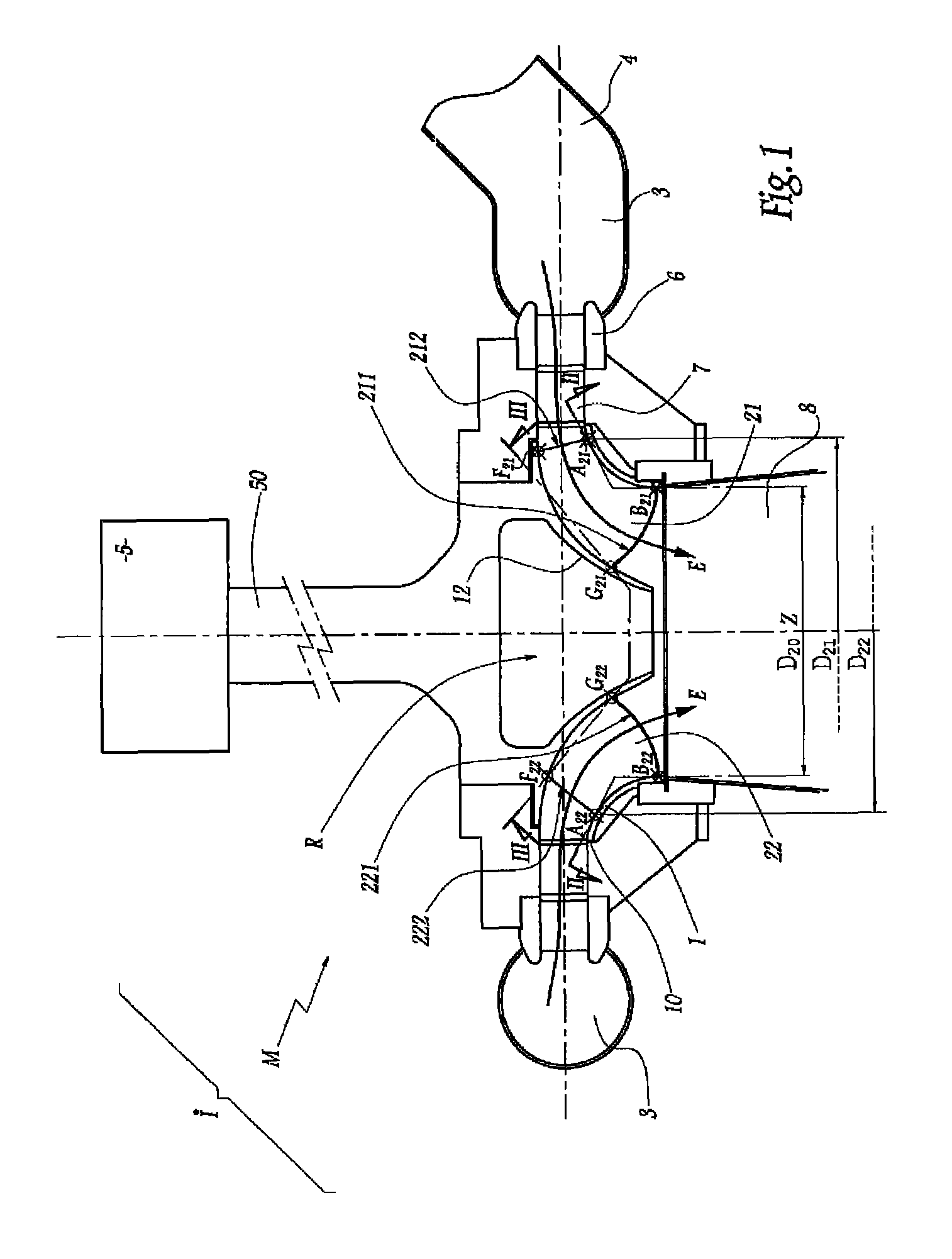

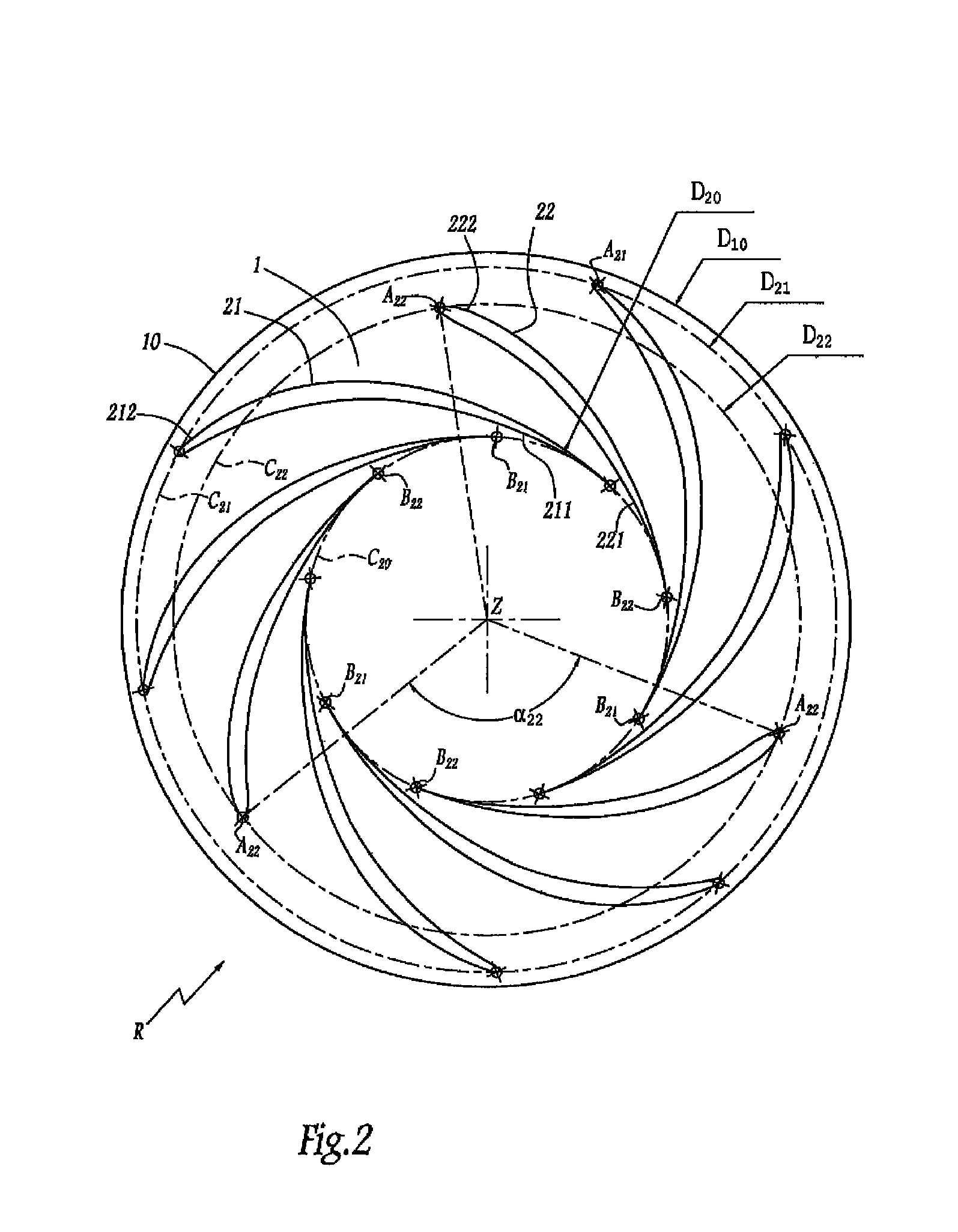

Wheel for a hydraulic machine, a hydraulic machine including such a wheel, and an energy conversion installation equipped with such a hydraulic machine

InactiveUS8684694B2Avoid generatingReduce radial forcePropellersPump componentsEngineeringMechanical engineering

The invention relates to a wheel (R) of the Francis type that comprises a ring (1) with revolution symmetry about the rotation axis (Z) of the wheel (R), and curved blades (21, 22) connected to the ring (1) and each having an outer peripheral edge (212, 222) and an inner central edge (211, 221). The connection points (B21, B22) between the ring (1) and the inner central edges (211, 221) of the blades (21, 22) are located on a same circle (C20) centered on the axis (Z). The connection points (A21, A22) between the ring (1) and the outer peripheral edges (212, 222) of the blades (21, 22) are located on at least two distinct circles (C21, C22) (D21, D22) centered on the axis (Z).

Owner:GE RENEWABLE TECH

Fuselage and aircraft including an air distribution multifunctional substructure and assembly method

ActiveUS11034456B2Simplify and reduce timeFree space volumeFuselage framesDucting arrangementsMechanical engineeringAirframe

An aircraft fuselage including a fuselage skin, cross-members supporting a floor of the aircraft, wherein the fuselage includes a multifunctional substructure fixed to at least one of the cross-members in a lowered part of the cross-member. The multifunctional substructure comprises: at least one duct of an air distribution system having a substantially rectangular section at the location of the at least one cross-member and having lateral walls of the duct that are substantially vertical; a seat fixing track or a stiffener fixed on a first lateral wall of the duct of the multifunctional substructure, and; a seat fixing track or a stiffener fixed on a second lateral wall, opposite the first lateral wall, of the duct of the multifunctional substructure.

Owner:AIRBUS SAS

Optical disk and its manufacturing method

InactiveUS7706240B2Minimal effectEqual performanceRecord information storageRecord carrier materialsEngineeringMinimal effect

An optical disk (10) of the present invention has a substrate (11) included a resin-impregnated paper, in which resin is impregnated into paper, or resin-coated paper, in which the paper surface is coated with a resin, and a recording layer (13) formed on at least one side of the substrate (11). This type of optical disk (10) has performance equal to that of conventional optical disks and has a minimal effect on the environment during disposal. In addition, a manufacturing method of an optical disk of the present invention has a recording layer sheet fabrication step in which a recording layer sheet is fabricated by forming tracks on a recording layer base material, and a recording layer sheet lamination step in which a recording layer (13) included the recording layer sheet is provided on a substrate (11) included resin-impregnated paper or resin-coated paper by laminating the recording layer sheet with the resin-impregnated paper in which a resin is impregnated into paper or the resin-coated paper in which the surface of the paper is coated with a resin. This type of manufacturing method of an optical disk allows optical disk (10) to be produced inexpensively.

Owner:SONY CORP +1

Method and apparatus for automatic adjustment of a vehicle to a predetermined performance condition

ActiveUS11117592B2Equal performanceRace vehiclesTyre measurementsComputer scienceReliability engineering

Owner:SOLAREDGE TECH LTD

Wastewater treatment with primary treatment and MBR or MABR-IFAS reactor

ActiveUS10160679B2Equal performanceLower requirementMembranesSludge treatment by de-watering/drying/thickeningActivated sludgeMembrane bioreactor

Wastewater is treated though primary treatment of the water by way of a micro-sieve to produce a primary effluent and primary sludge. There is secondary treatment of the primary effluent by way of a membrane bioreactor (MBR) or an integrated fixed film activated sludge (IFAS) reactor to produce a secondary effluent and a waste activated sludge. The micro-sieve may have openings of 250 microns or less, for example about 150 microns. In a process, a gas transfer membrane is immersed in water. Pressurized air flows into the gas transfer membrane. An exhaust gas is withdrawn from the gas transfer membrane and used to produce bubbles from an aerator immersed in the water.

Owner:BL TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com