Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5901results about How to "Avoid generating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

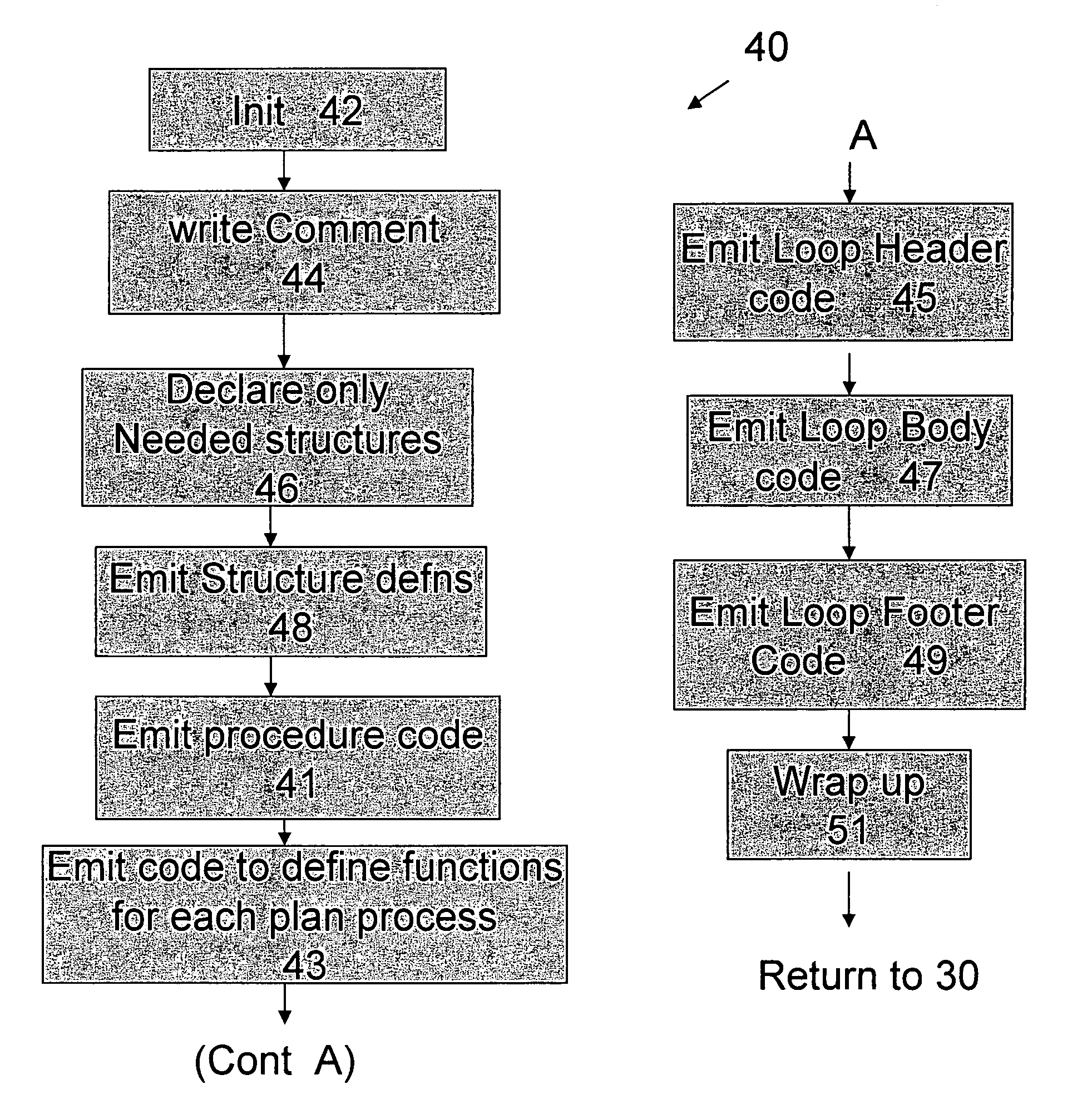

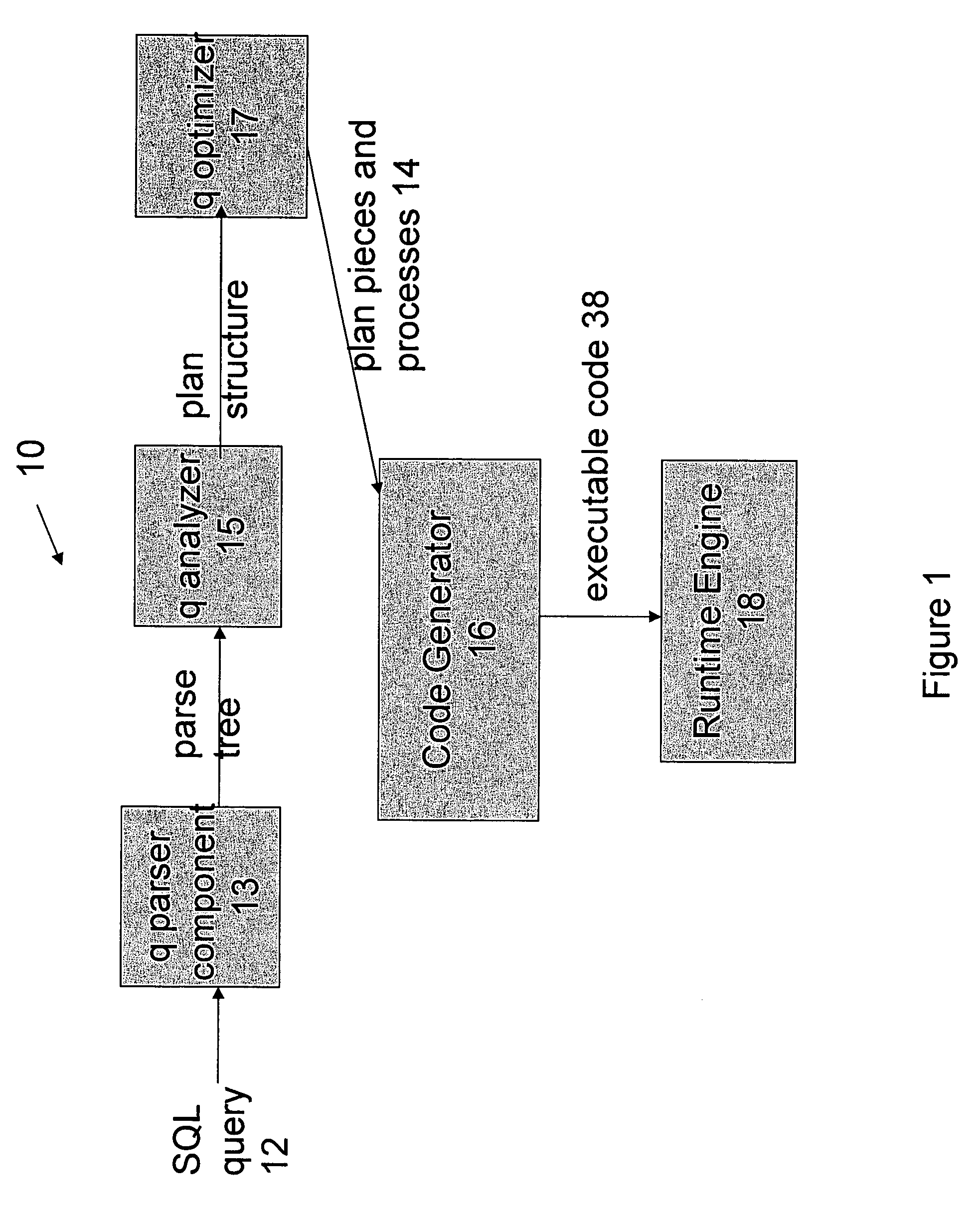

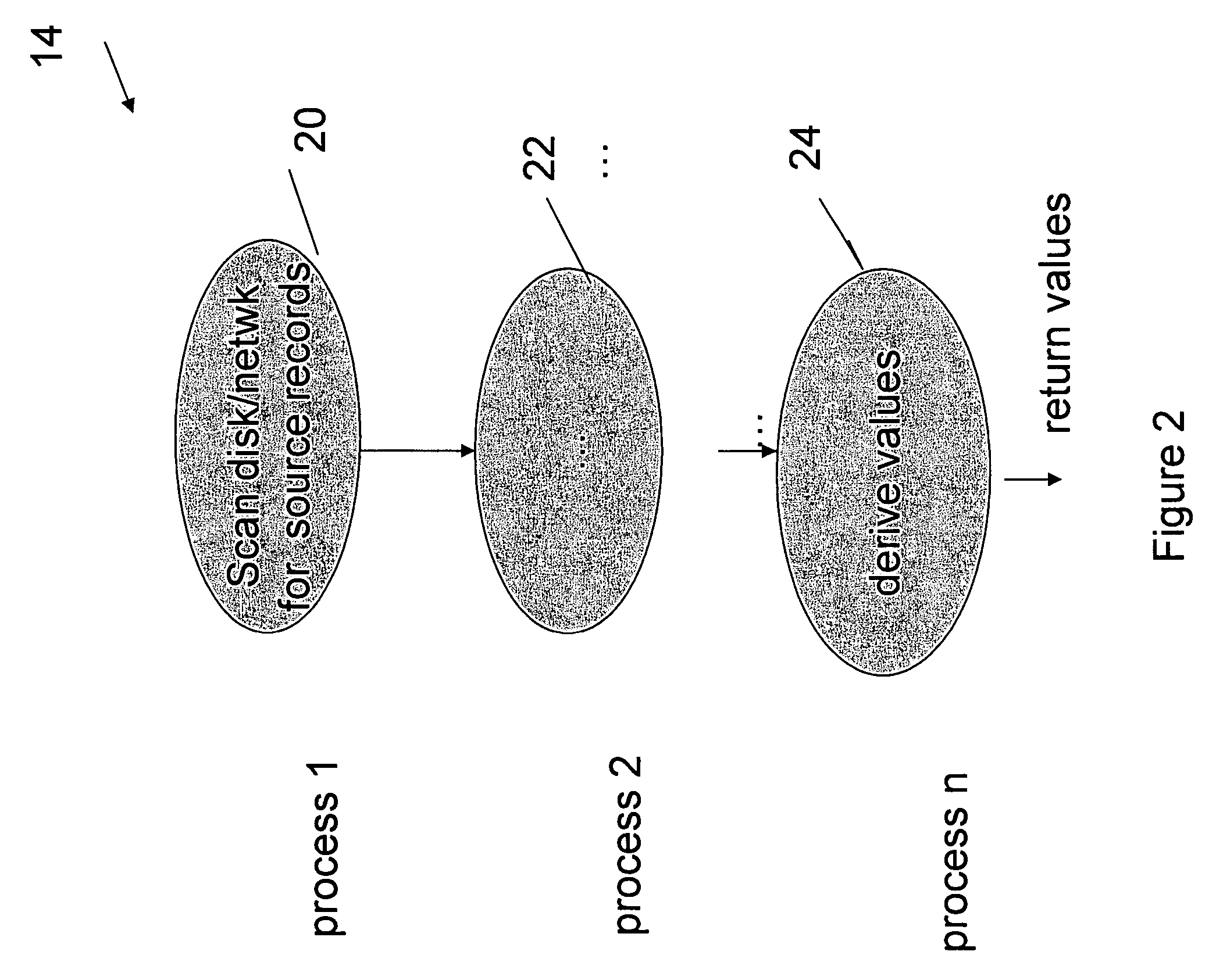

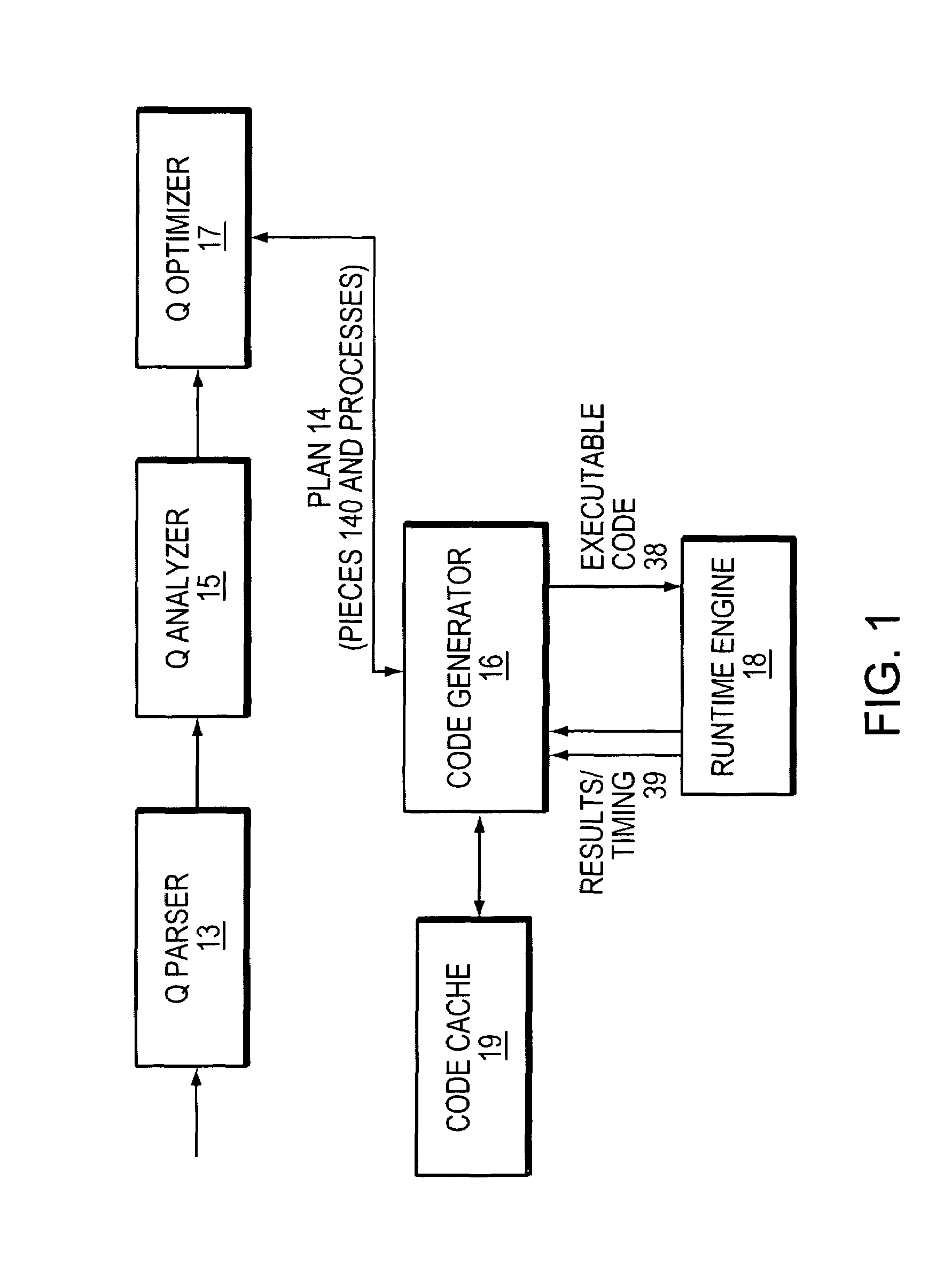

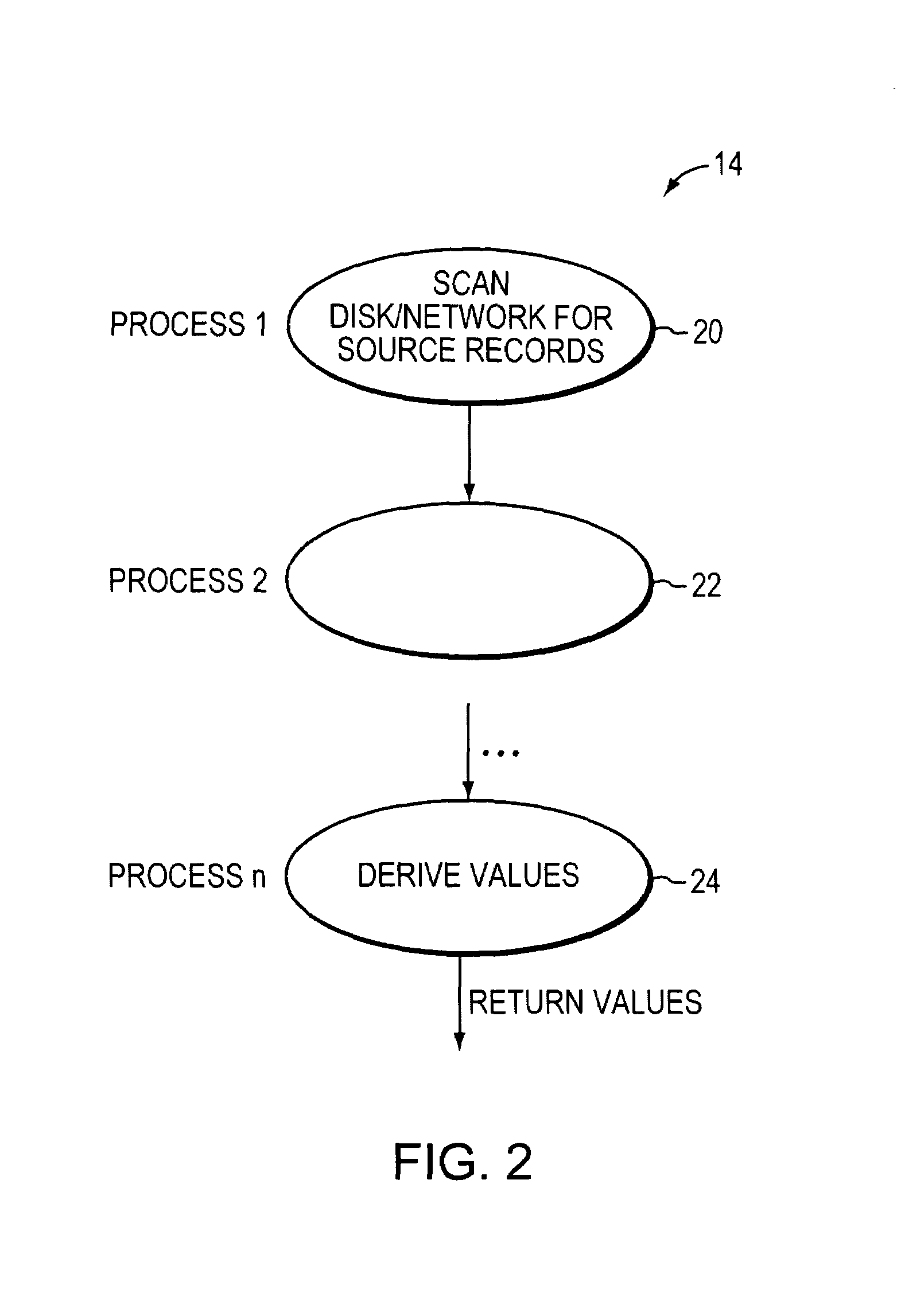

Optimized SQL code generation

ActiveUS7430549B2Reduce and minimize compilation timeReduce and minimize execution timeDigital data information retrievalData processing applicationsExecution planCode generation

This invention relates generally to a system for processing database queries, and more particularly to a method for generating high level language or machine code to implement query execution plans. The present invention provides a method for generating executable machine code for query execution plans, that is adaptive to dynamic runtime conditions, that is compiled just in time for execution and most importantly, that avoids the bounds checking, pointer indirection, materialization and other similar kinds of overhead that are typical in interpretive runtime execution engines.

Owner:INT BUSINESS MASCH CORP

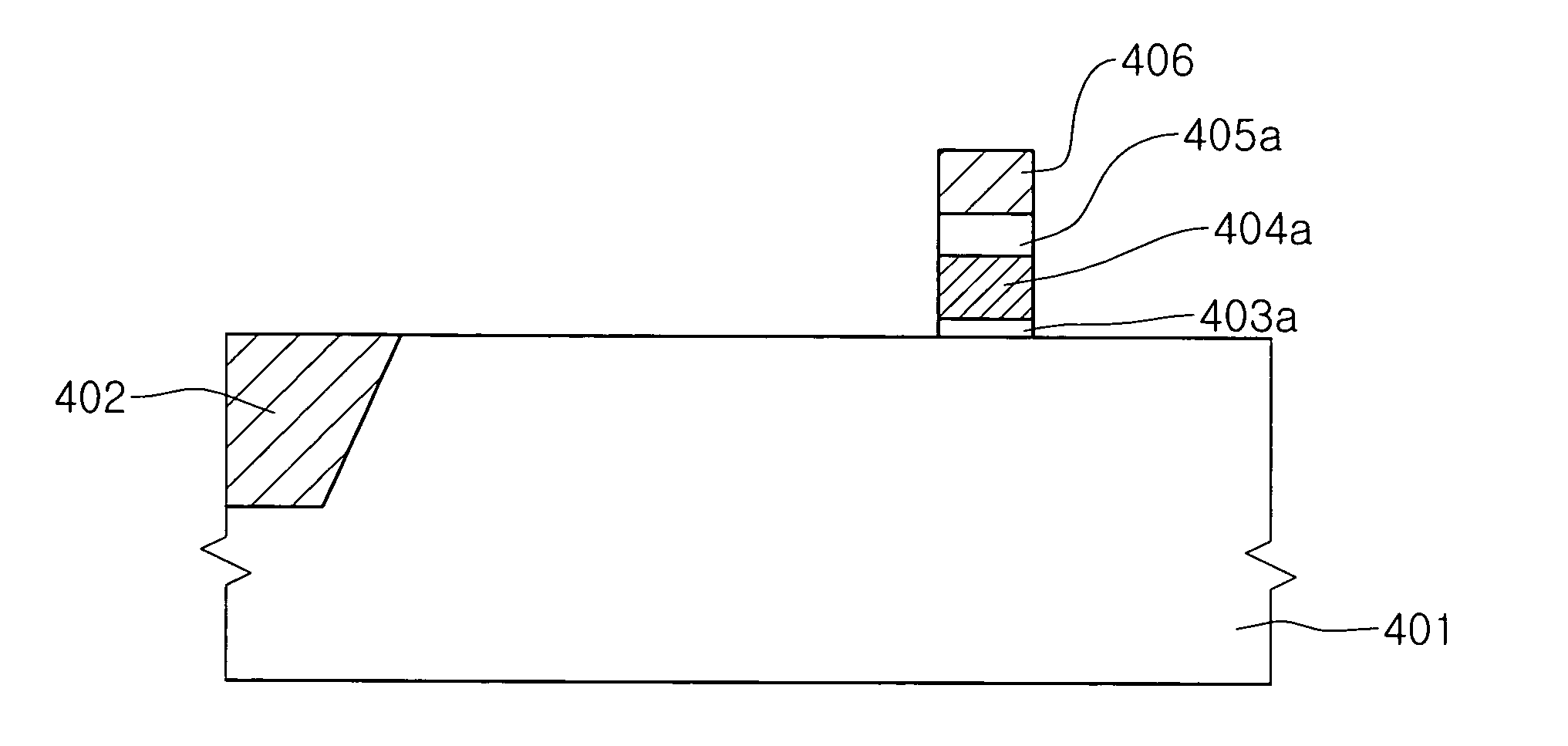

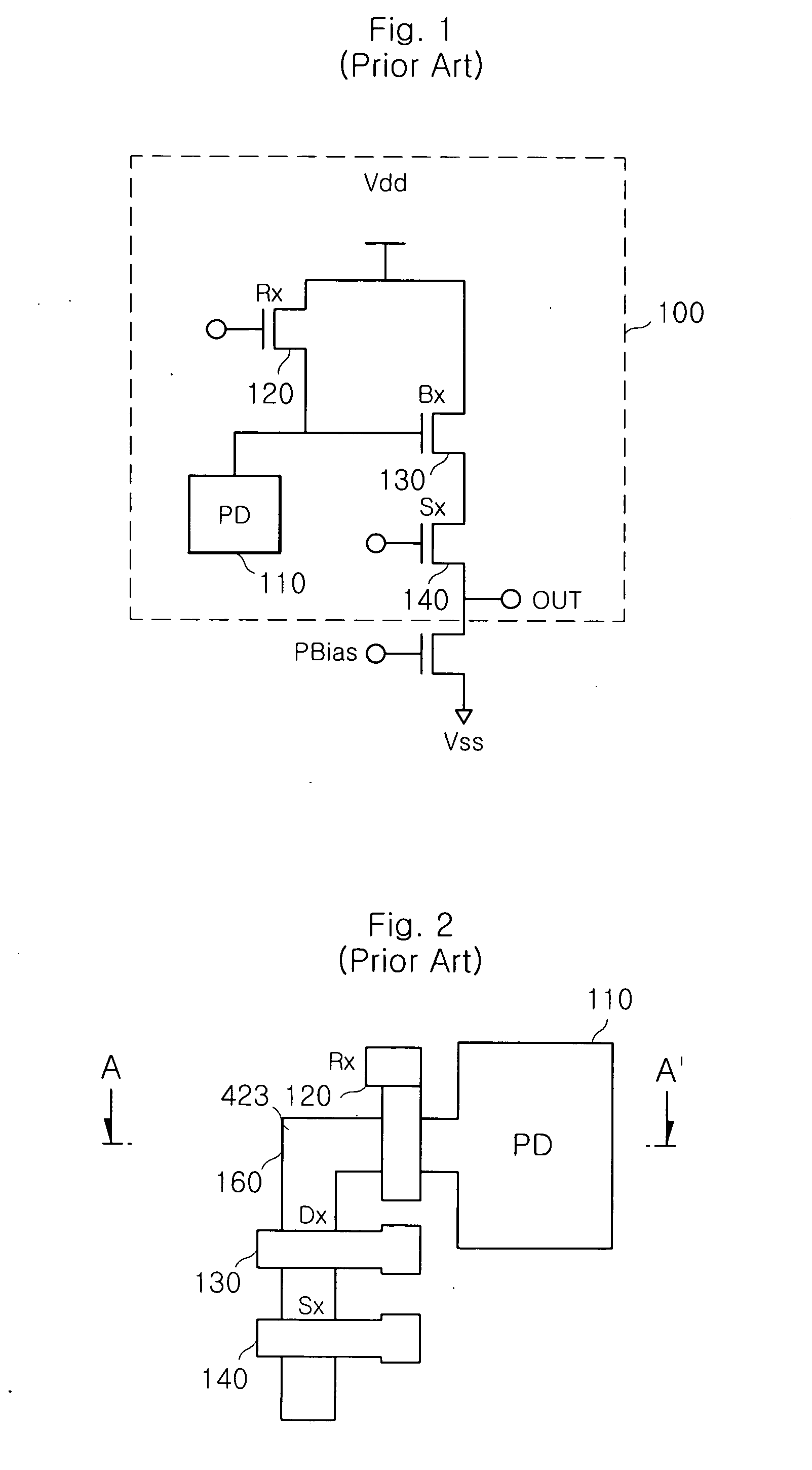

Method for manufacturing a CMOS image sensor

ActiveUS20050064665A1Avoid generatingAvoid it happening againSolid-state devicesSemiconductor/solid-state device manufacturingDopantCMOS

A method for manufacturing structures of a CMOS image sensor. The method comprises the steps of depositing a gate insulating layer and a conductive layer on a semiconductor substrate; depositing an ion implantation barrier layer on the conductive layer; patterning the deposited gate insulating layer, conductive layer and ion implantation barrier layer to form a patterned, composite gate insulating layer, gate electrode and ion implantation barrier structure; forming a second photosensitive layer pattern to define a photodiode region; and implanting low-concentration dopant ions into the substrate using the second photosensitive layer pattern as an ion implantation mask to form a low-concentration dopant region within the photodiode region.

Owner:DONGBU HITEK CO LTD

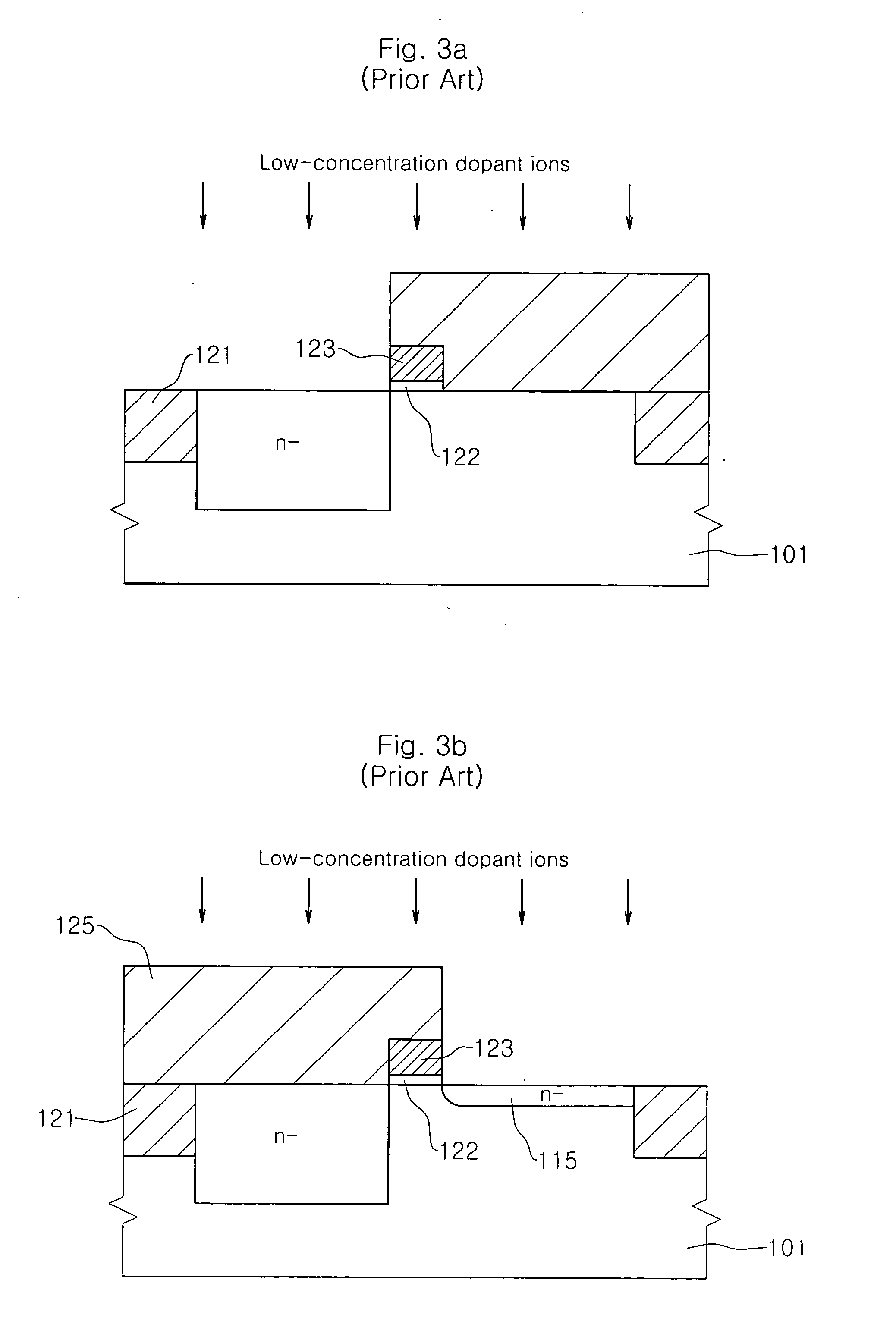

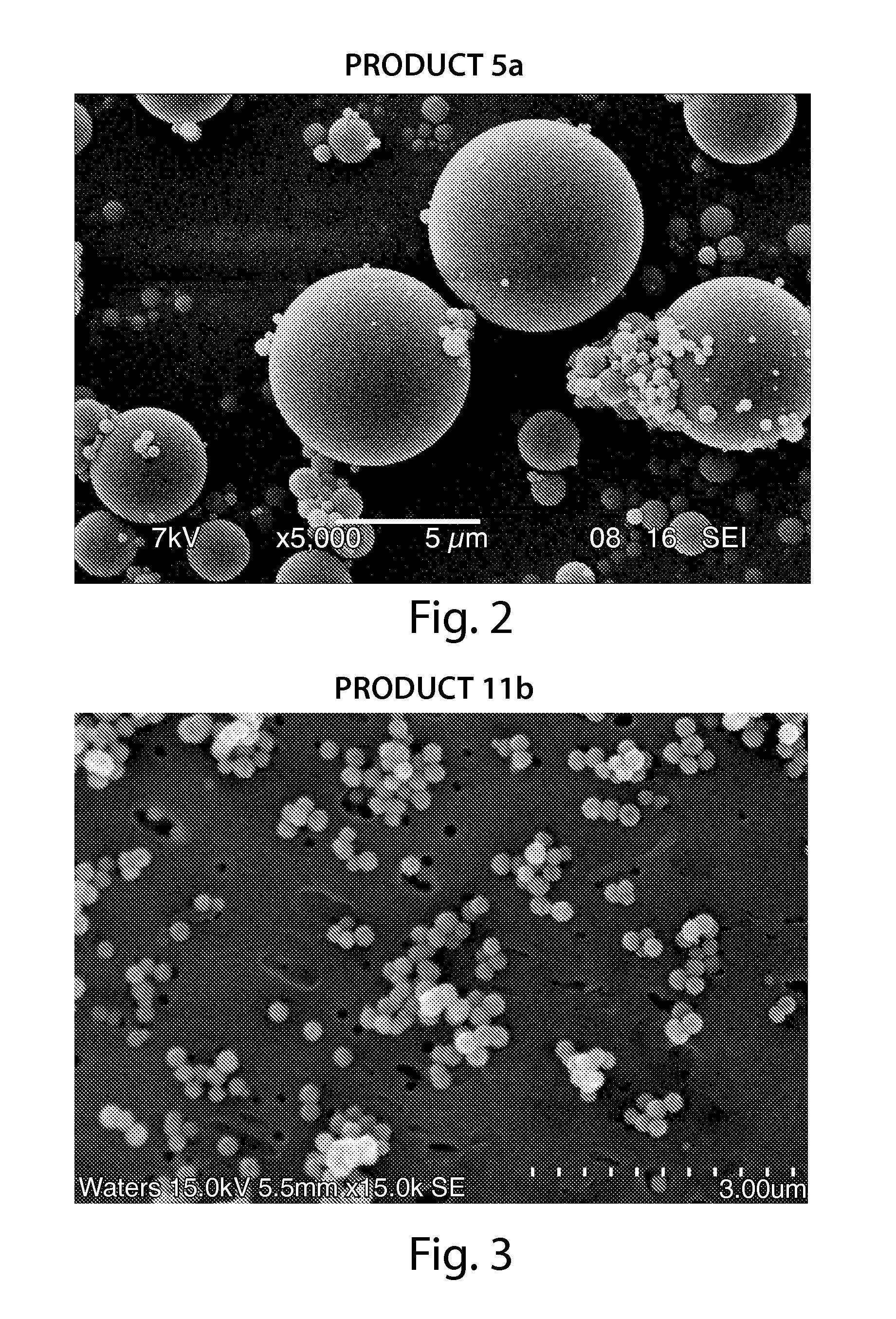

Superficially porous materials comprising a substantially nonporous core having narrow particle size distribution; process for the preparation thereof; and use thereof for chromatographic separations

InactiveUS20130112605A1Prevent fine generationInhibit aggregationIon-exchanger regenerationPretreated surfacesChromatographic separationHybrid material

Novel chromatographic materials for chromatographic separations, columns, kits, and methods for preparation and separations with a superficially porous material comprising a substantially nonporous core and one or more layers of a porous shell material surrounding the core. The material of the invention is comprised of superficially porous particles and a narrow particle size distrution. The material of the invention is comprised of a superficially porous monolith, the substantially nonporous core material is silica; silica coated with an inorganic / organic hybrid surrounding material; a magnetic core material; a magnetic core material coated with silica; a high thermal conductivity core material; a high thermal conductivity core material coated with silica; a composite material; an inorganic / organic hybrid surrounding material; a composite material coated with silica; a magnetic core material coated with an inorganic / organic hybrid surrounding material; or a high thermal conductivity core material coated with an inorganic / organic hybrid surrounding material.

Owner:WATERS TECH CORP

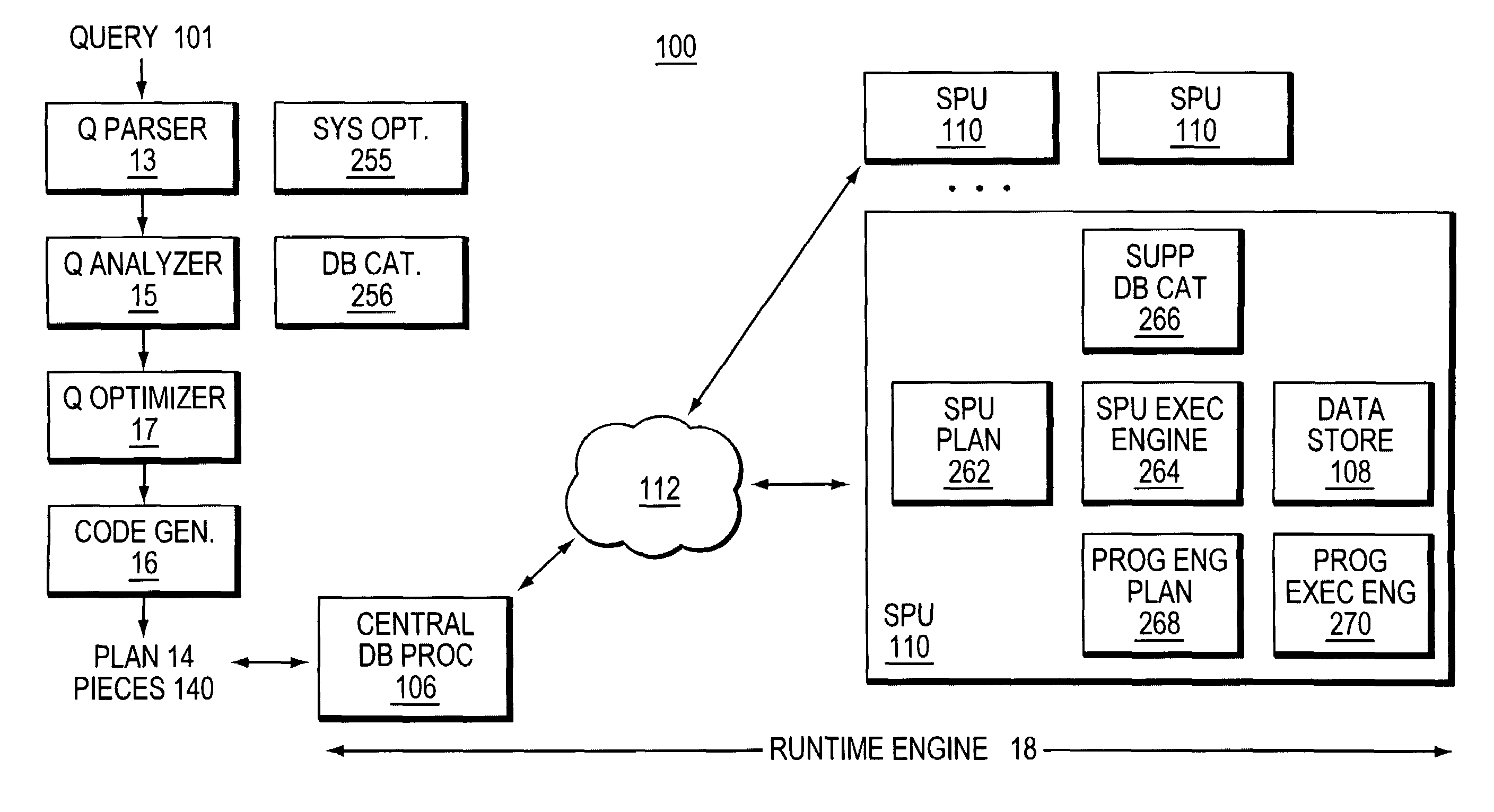

SQL code generation for heterogeneous environment

ActiveUS7433863B2Avoid generatingDigital data information retrievalData processing applicationsDatabase queryExecution plan

This invention relates generally to a system for processing database queries, and more particularly to a method for generating high level language or machine code to implement query execution plans. in one preferred embodiment, the method begins by receiving a subject query, and then forming an execution plan corresponding to the subject query. The execution plan will typically have a sequence of component snippets or pieces and corresponding processes for implementing the pieces. For at least one piece in the plan, the process then (a) generates source code using different code generation techniques as a function of expected runtime processing machine types; and then (b) compiles the generated source code to form machine executable code for implementing the subject query. As a result, the query executed directly as machine executable code thereby avoiding runtime interpretation of the pieces in the execution plan.

Owner:INT BUSINESS MASCH CORP

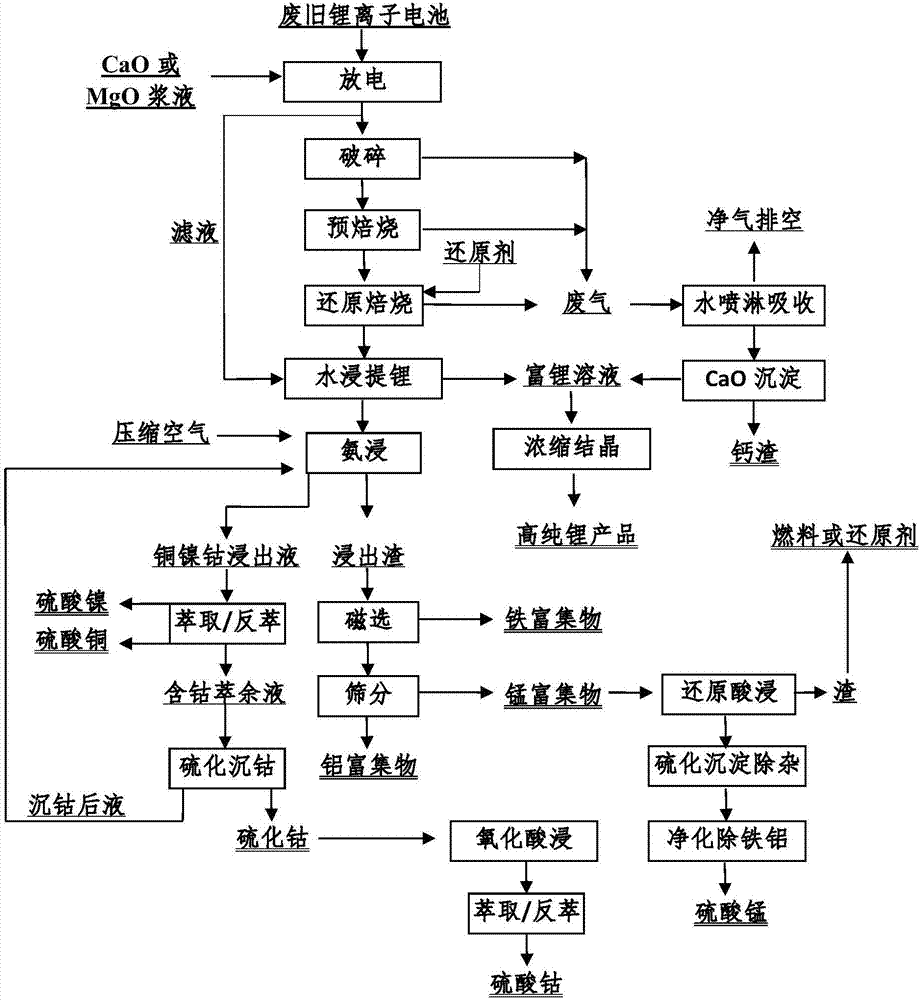

Method for comprehensively recycling valuable metals from spent lithium ion battery

ActiveCN107017443AThe pre-processing process is simpleHigh recovery rateWaste accumulators reclaimingProcess efficiency improvementVulcanizationSlag

The invention discloses a method for comprehensively recycling valuable metals from a spent lithium ion battery. The method comprises the following steps: carrying out electric discharge treatment on a spent battery, crushing, pre-roasting at 300-400 DEG C, adding a reducing agent, and carrying out reduction roasting at 450-700 DEG C; carrying out water extraction and evaporative crystallization on fine aggregates obtained through the reduction roasting, so as to obtain a high-purity lithium product, leaching copper, nickel and cobalt from leached slag and roasted lump materials by virtue of ammonia oxide, carrying out magnetic separation and sieving on ammonia leaching slag so as to obtain iron and aluminum enriched products, and carrying out reduction acid leaching, purification and edulcoration on sieved products, so as to obtain a high-purity manganese sulfate solution; and carrying out extraction and selective reverse extraction on ammonia leaching liquid, so as to obtain a high-purity nickel sulfate solution and a high-purity copper sulfate solution, and carrying out vulcanization cobalt precipitation, oxidation acid leaching and extraction purification on raffinate, so as to obtain a high-purity cobalt sulfate solution. The method is high in extraction rate of valuable metals and applicable to the treatment of multiple waste lithium ion battery raw materials and efficient utilization of multiple elements, and sorting is not required.

Owner:GUANGDONG GUANGHUA SCI TECH

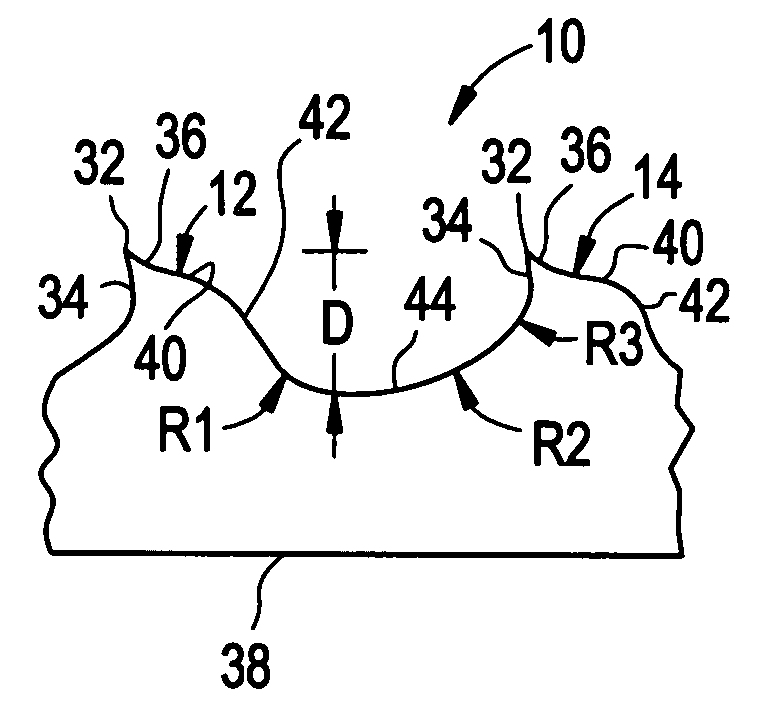

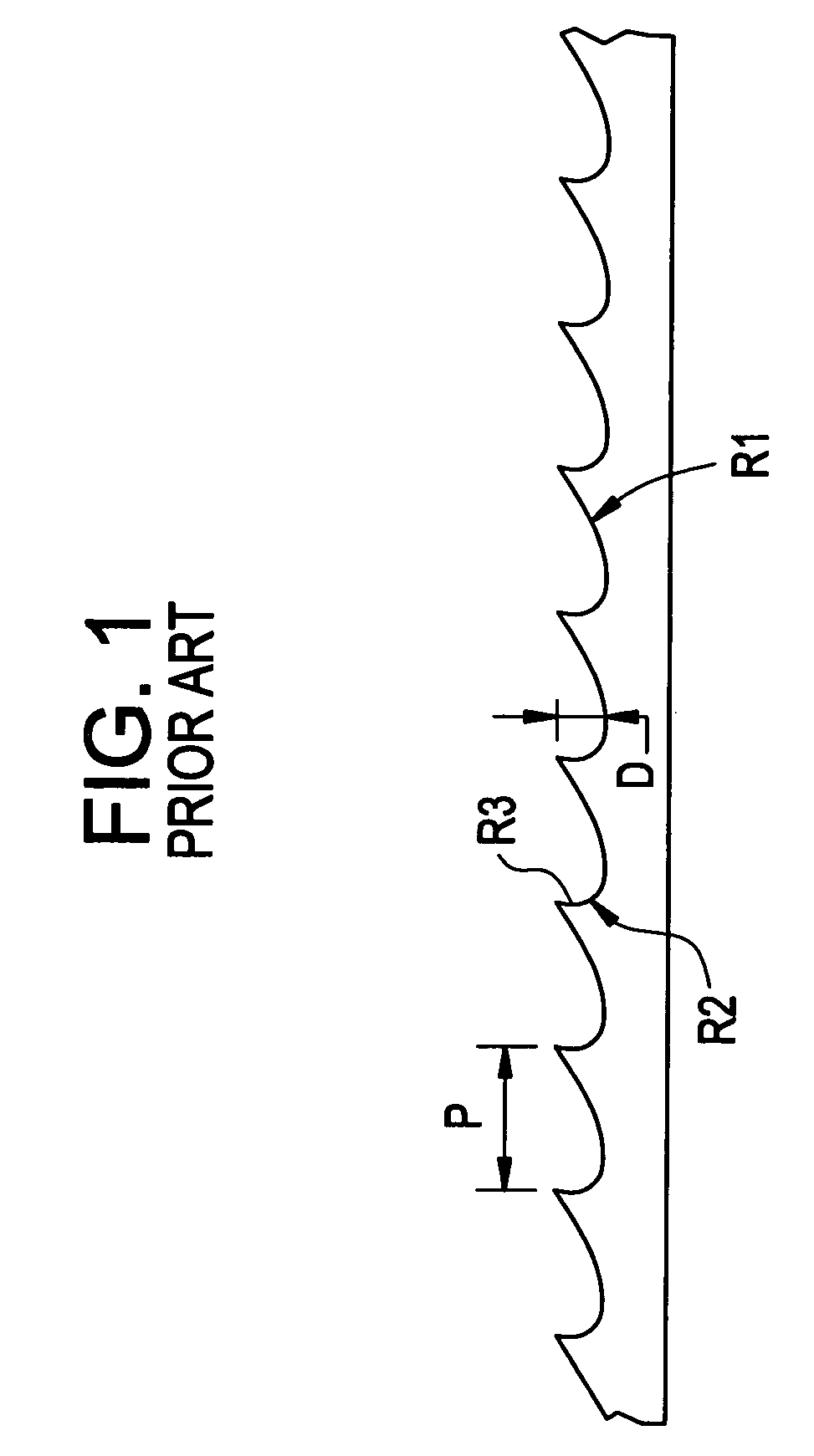

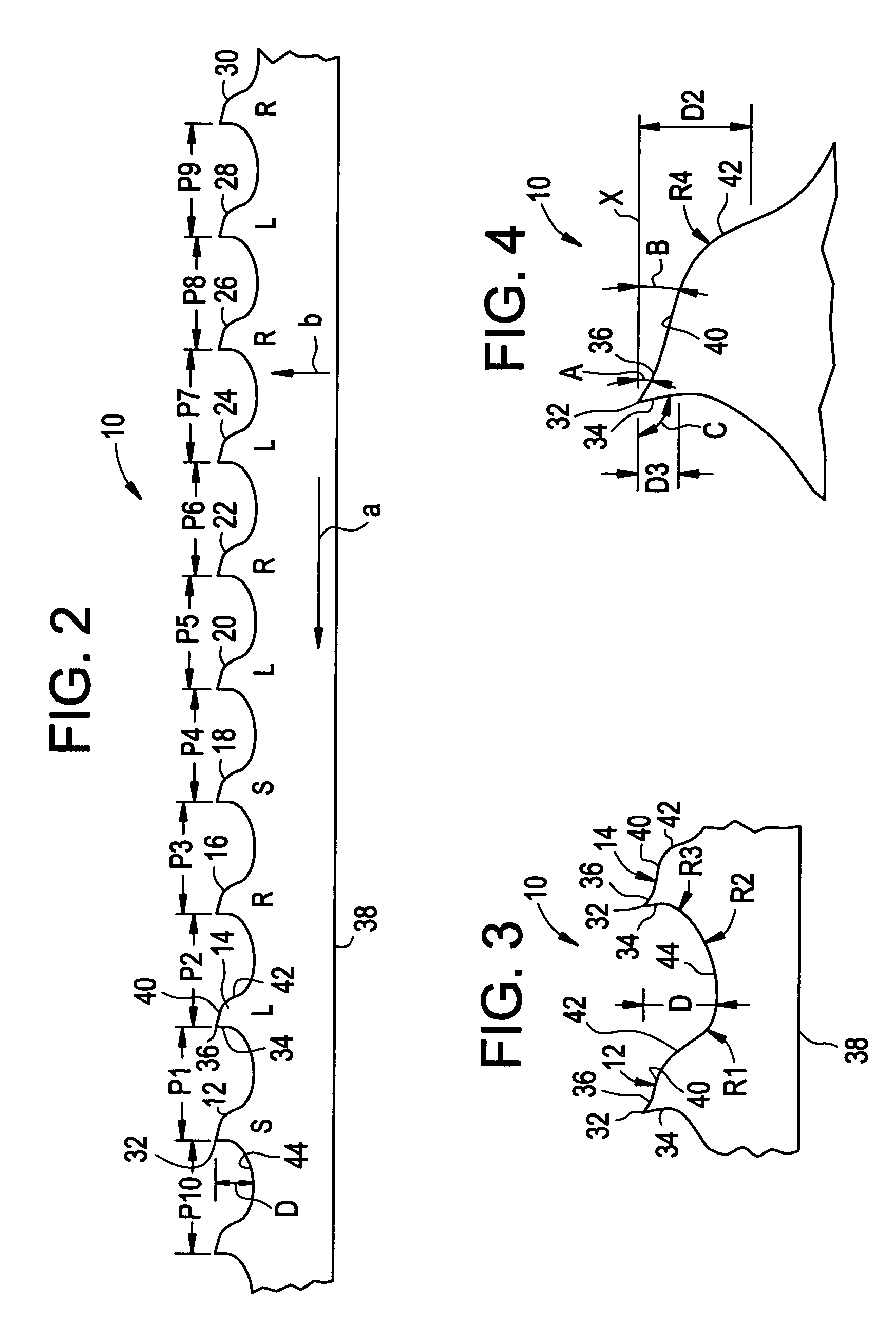

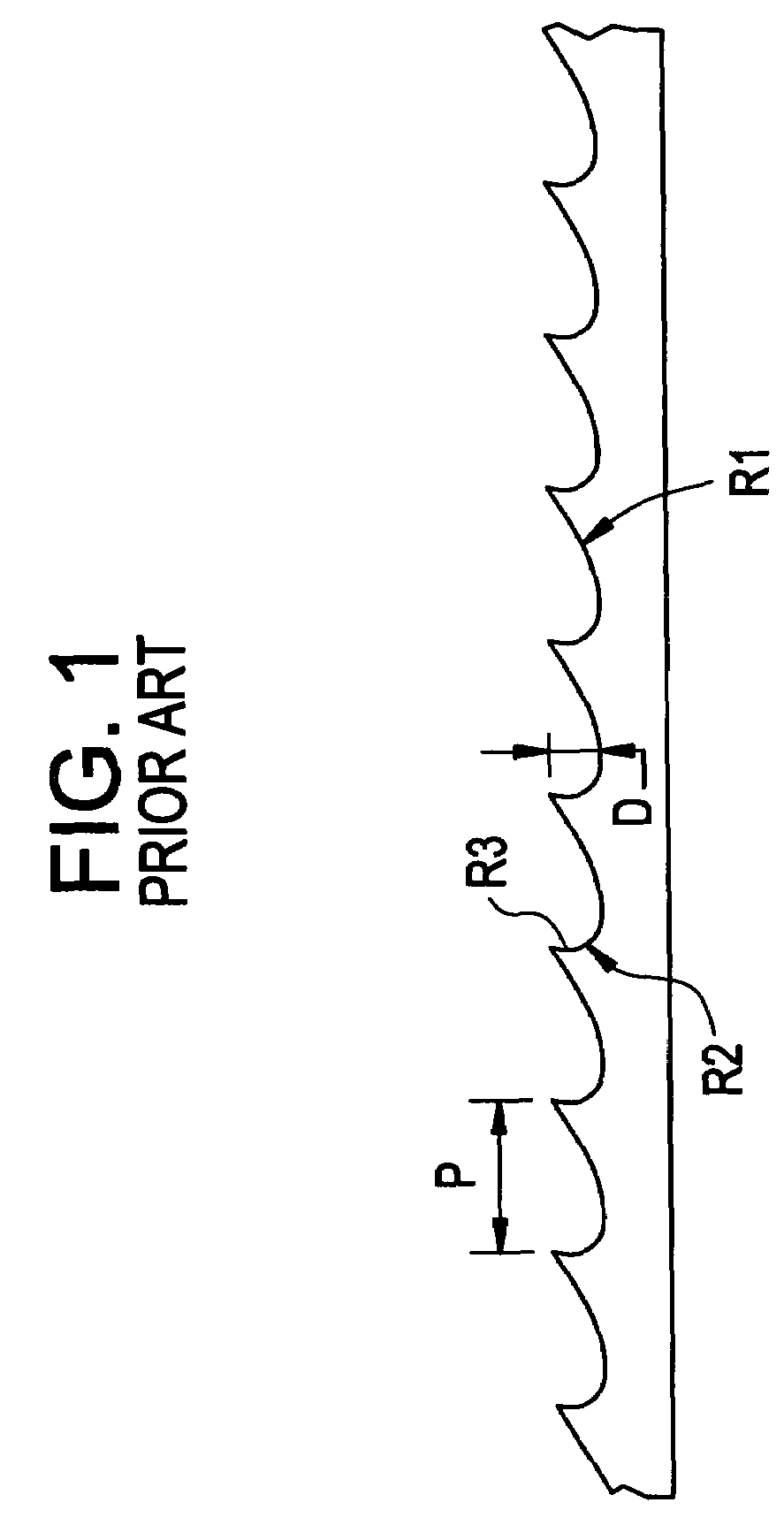

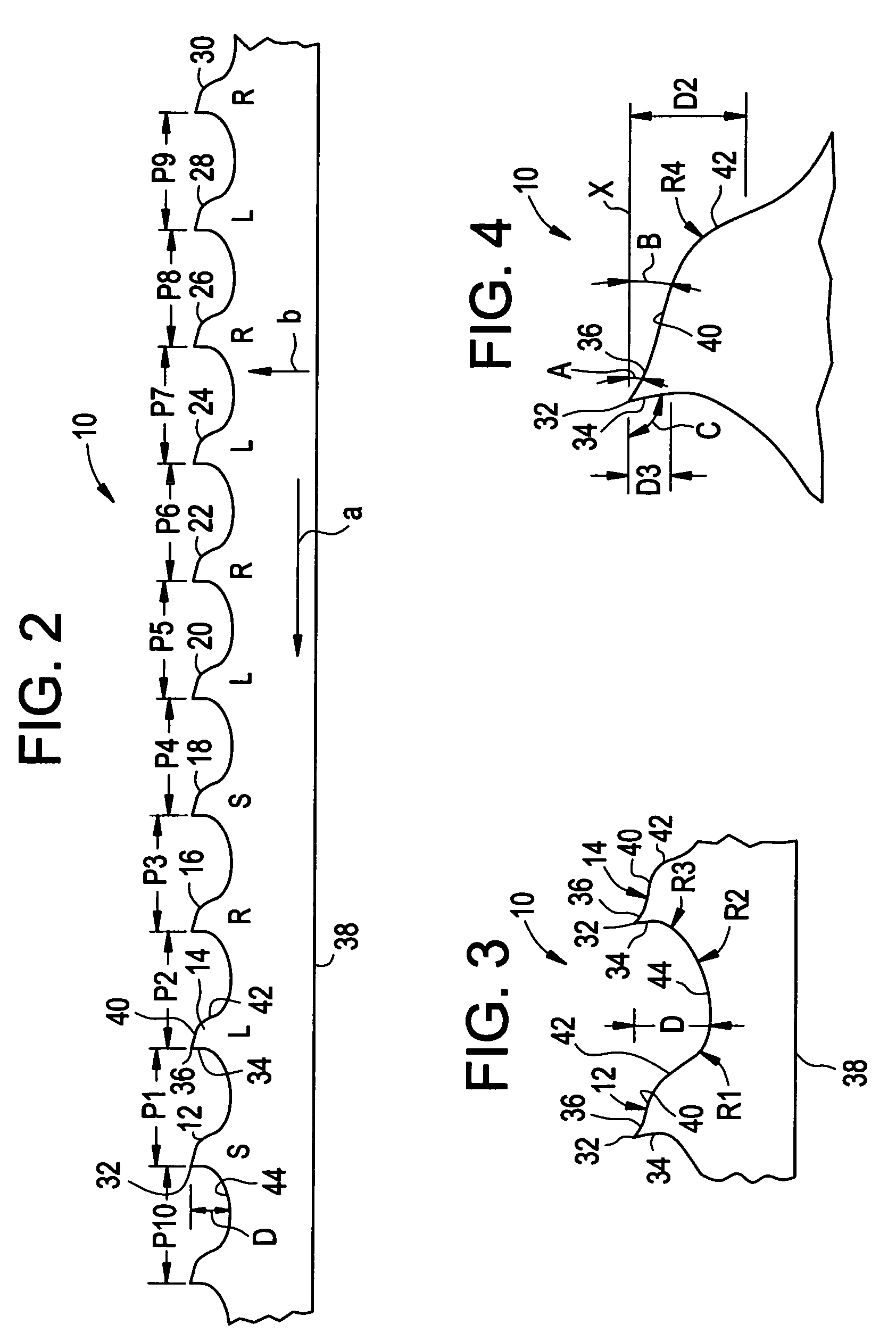

Saw blade having increased tooth stiffness and resistance to fatigue failure

InactiveUS20060065098A1Increase Section WidthPrevent set collapseMetal sawing devicesMetal sawing toolsEngineeringWood cutting

A wood-cutting band saw blade includes a cutting edge defined by a plurality of teeth spaced relative to each other, wherein each tooth includes a tip; a rake face formed on one side of the tip; a primary clearance surface formed on an opposite side of the tip relative to the rake face; a secondary clearance surface formed on an opposite side of the primary clearance surface relative to the tip; a tertiary clearance surface formed on an opposite side of the secondary clearance surface relative to the primary clearance surface; and a gullet located on an opposite side of the rake face relative to the tip and defining a depth (D) between a base surface of the gullet and the tip. Each tooth further defines a first gullet radius (R1) located between the gullet and tertiary clearance surface; a second gullet radius (R2) extending between a base surface of the gullet and the rake face; and a pitch (P) between the respective tooth and a preceding tooth in a cutting direction of the saw blade. In each tooth, R2>D>R1, D / P is within the range of about 25% to about 35% and R2 / R1≧about 1.4. R1 defines a minimum radius (Rmin) at a base of the gullet and Rmin / D>about 20%.

Owner:IRWIN IND TOOL CO

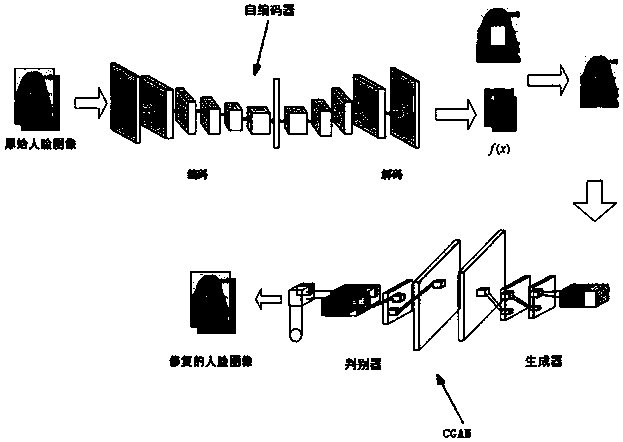

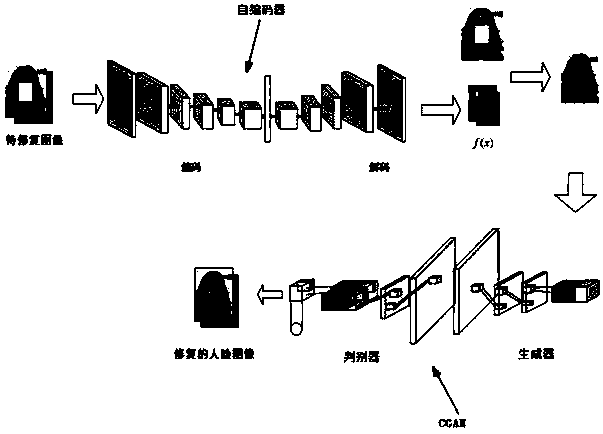

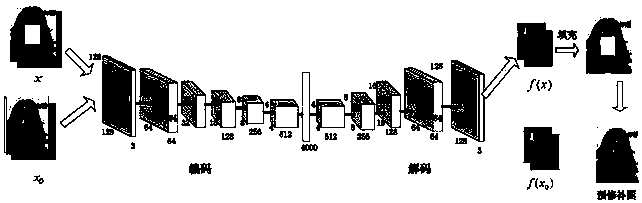

Method for repairing face defect images based on auto-encoder and generative adversarial networks

ActiveCN108520503AImprove clarityAvoid generatingImage enhancementCharacter and pattern recognitionPattern recognitionData set

The present invention provides a method for repairing face defect images based on an auto-encoder and generative adversarial networks. Through combination of the auto-encoder and the generative adversarial networks, the method comprises the following steps of: (1) performing face data set defect preprocessing; (2) employing the data set after processing to train the auto-encoder to allow the auto-encoder to reach the optimal state; (3) employing the data set after processing to train the condition generative adversarial networks to allow the condition generative adversarial networks to reach the optimal state; (4) inputting a defect image to be repaired into the trained encoder to generate a face image to be repaired; and (5) inputting the image to be repaired to the condition generative adversarial networks to generate much clearer and more natural restored face image. The method improves the restoring definition of the defect face area and the fidelity of the defect content, avoids the pseudomorphism of the defect area edges to the maximum extent, restricts the generation direction of the defect area and generates much clearer and more natural restoring effect.

Owner:XIANGTAN UNIV

Catalyst for dehydrogenation of propane for preparing propylene and preparation method thereof

ActiveCN101972664BHigh propane conversionExcellent anti-coke performanceMolecular sieve catalystsHydrocarbonsChemistryMolecular sieve

The invention discloses a catalyst, which is carried by an AlSn-SBA-15 molecular sieve with SnAl double metal-containing framework, for dehydrogenation of propane for preparing propylene. In the catalyst, the AlSn-SBA-15 molecular sieve with SnAl double metal-containing framework is used as a carrier, platinum-group element metal is used as a main catalyst, IVA-group, IA-group or IIA-group element metal is used as an auxiliary agent, and high-temperature-resistant inorganic oxide is used for forming an adhesive. A multi-step dipping method is used in the preparation of the catalyst, namely the alkaline metal auxiliary agent is dipped, so that the acidity and alkalinity of the catalyst and the types of cations in pores of the molecular sieve are effectively modulated by cation exchange technology, and the platinum-group element metal is dipped. The catalyst has superior anti-carbon deposit performance, high propane conversion rate under the reaction conditions of high temperature and low pressure, propylene selectivity and reaction stability.

Owner:CHINA PETROLEUM & CHEM CORP

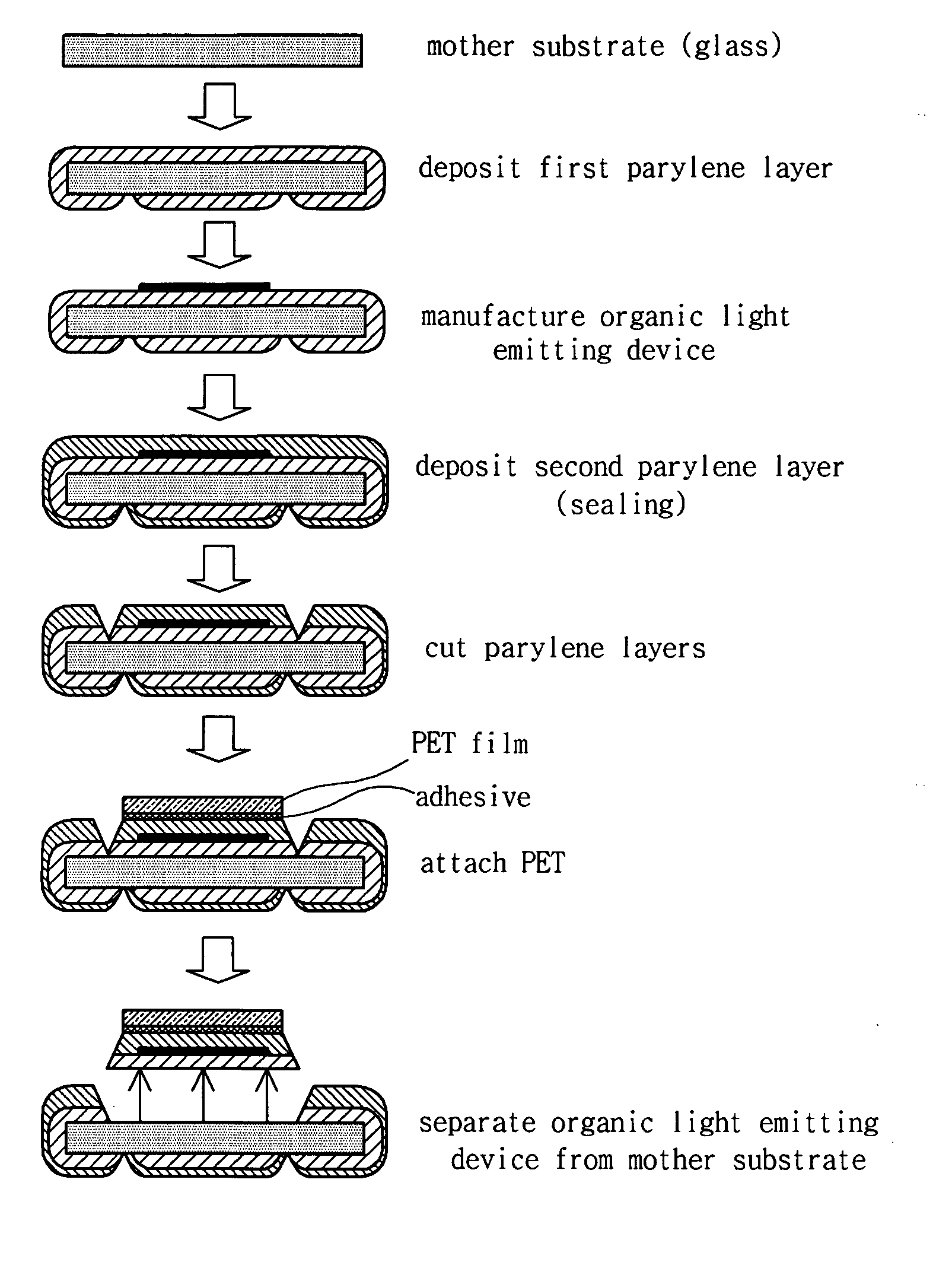

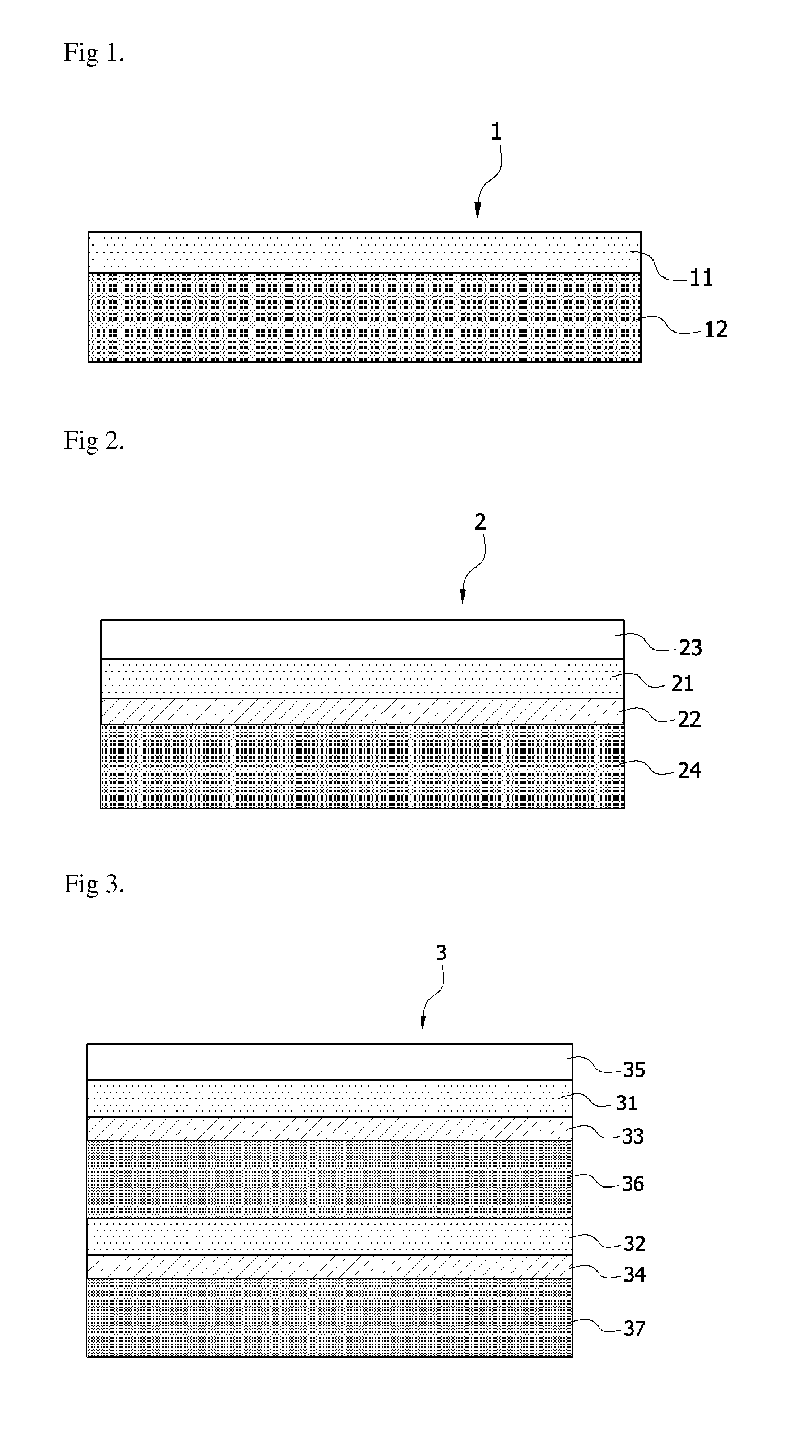

Method of manufacturing device having flexible substrate and device having flexible substrate manufactured using the same

ActiveUS20070105252A1Avoid generatingRelieve stressElectroluminescent light sourcesSolid-state devicesEngineeringVacuum evaporation

The present invention relates to a method of manufacturing a device having a flexible substrate and a device having a flexible substrate manufactured using the method. According to the method of manufacturing a device having a flexible substrate of the invention, glass is used as a mother substrate, a polymer layer, which is used as a substrate, is formed on the mother substrate using a chemical vapor deposition method or a vacuum evaporation method, a device is formed, and finally, the substrate where the device is formed is separated from the mother substrate, such that a large-scale device having a flexible substrate can be manufactured. Further, as a substrate forming an organic light emitting device and a sealant are formed of the same material, the device is not bent due to stress generated from the device itself after the device is manufactured.

Owner:LG DISPLAY CO LTD

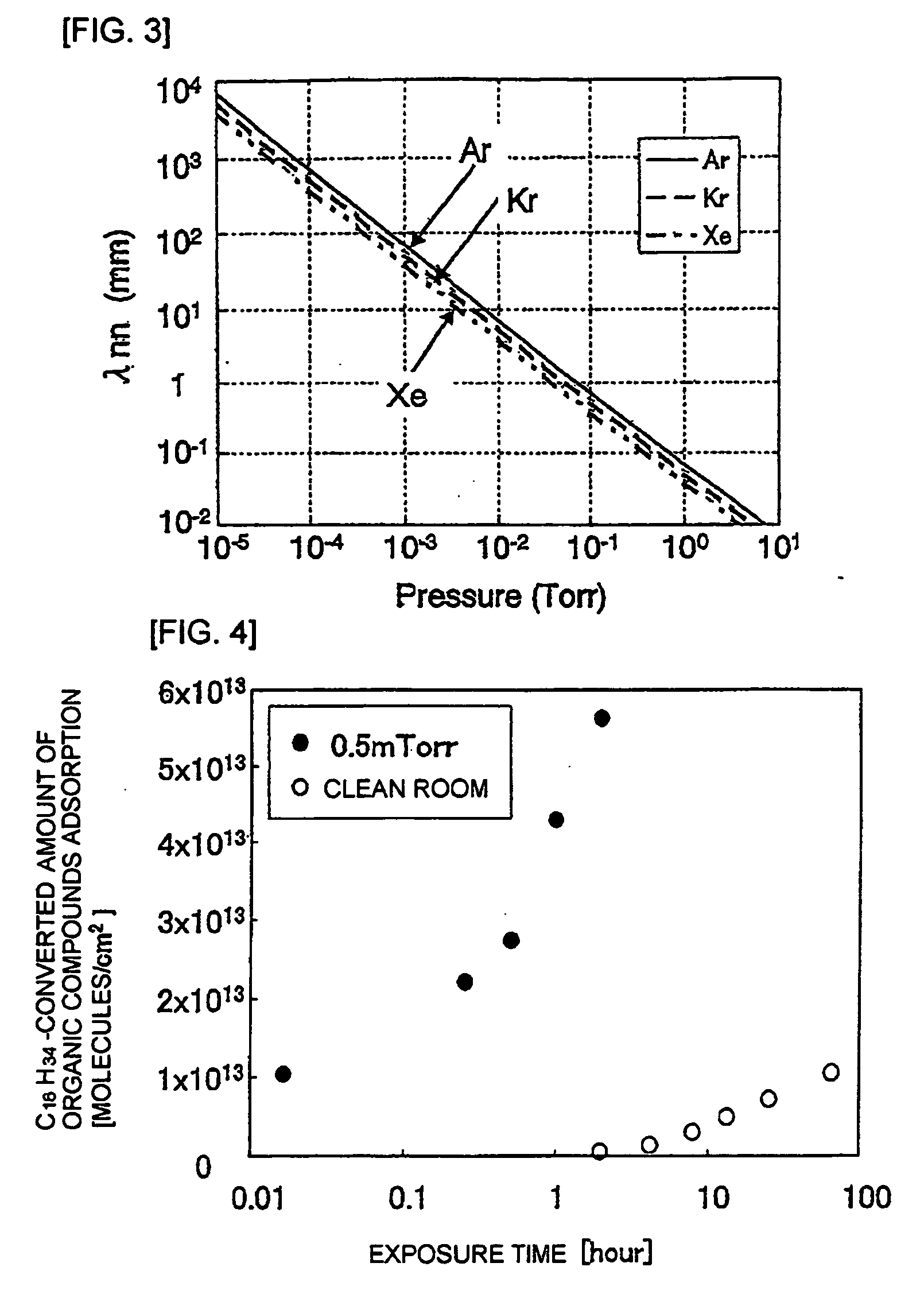

Device and method for producing single crystals by vapor deposition

ActiveUS20050000406A1Down and eliminate formationPreventing structural defect generationFrom gel statePolycrystalline material growthGas phaseSingle crystal

A method and a device to grow from the vapor phase, a single crystal of either SiC, a group III-nitride, or alloys thereof, at a growth rate and for a period of time sufficient to produce a crystal of preferably several centimeters length. The diameter of the growing crystal may be controlled. To prevent the formation of undesirable polycrystalline deposits on surfaces in the downstream vicinity of the single crystal growth area, the local supersaturation of at least one component of the material grown is lowered by introducing a separate gas flow comprising at least one halogen element or a combination of said halogen and hydrogen species.

Owner:NORSTEL

Electric wire coated with polyvinyl chloride resin composition and cable

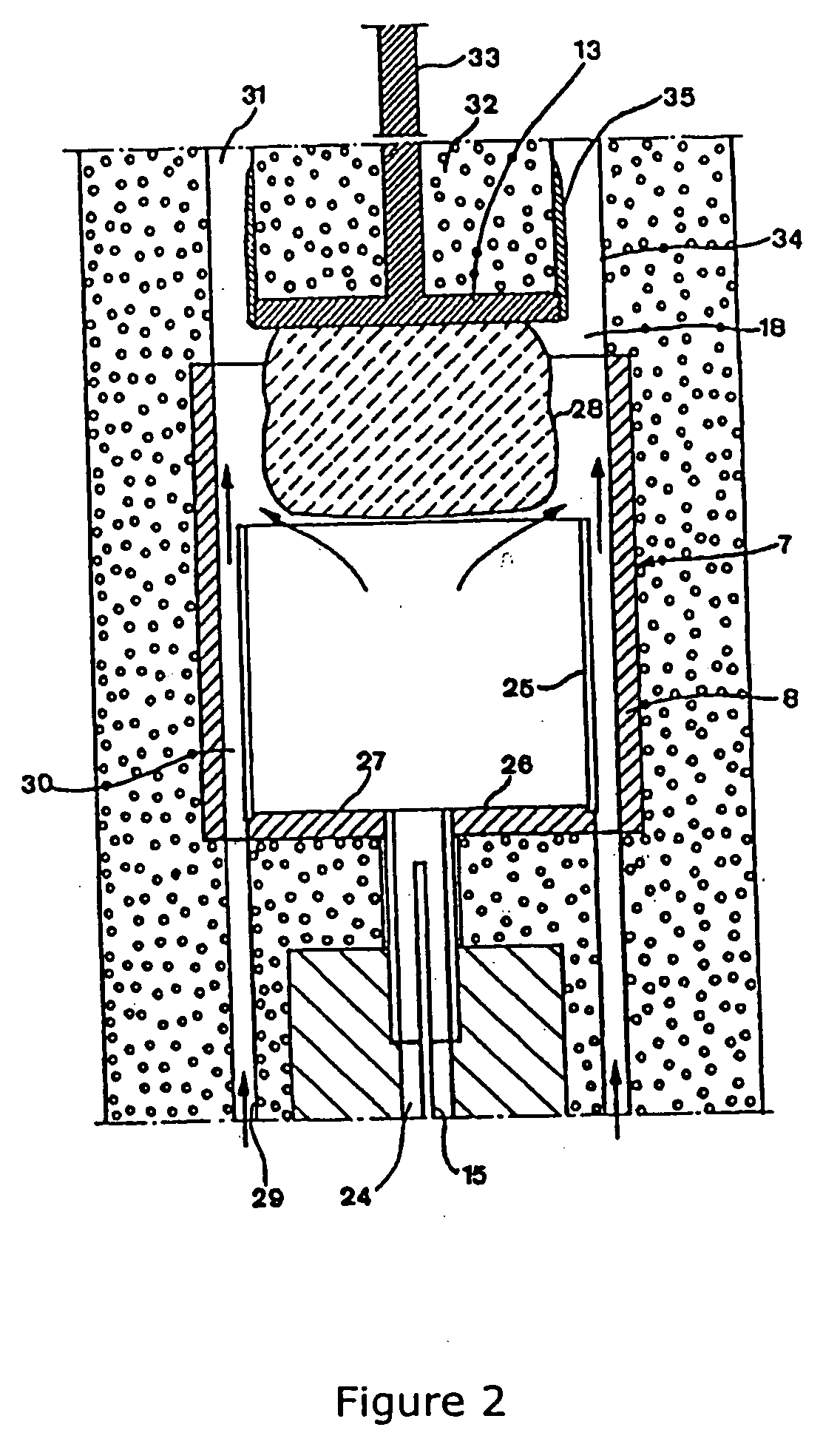

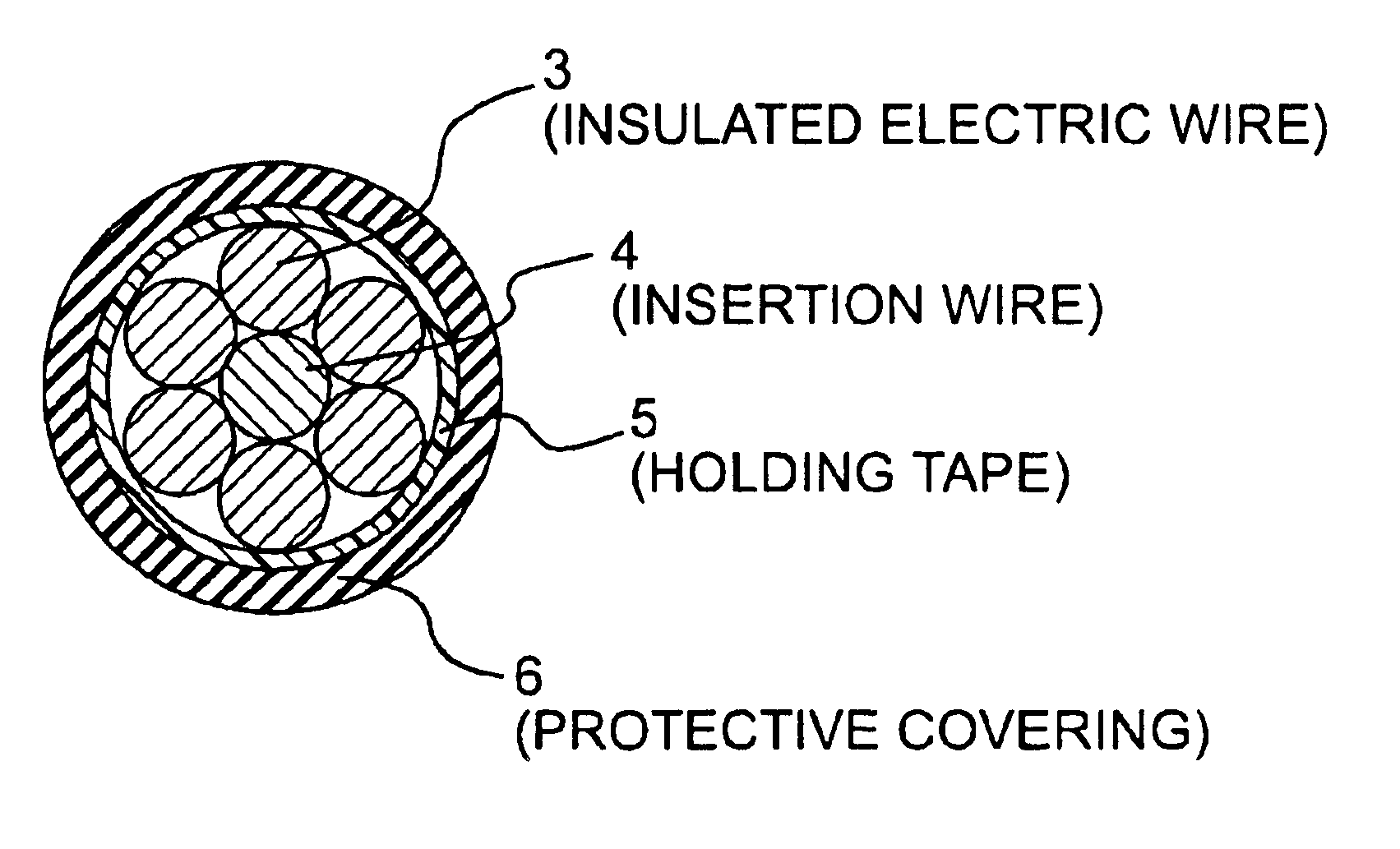

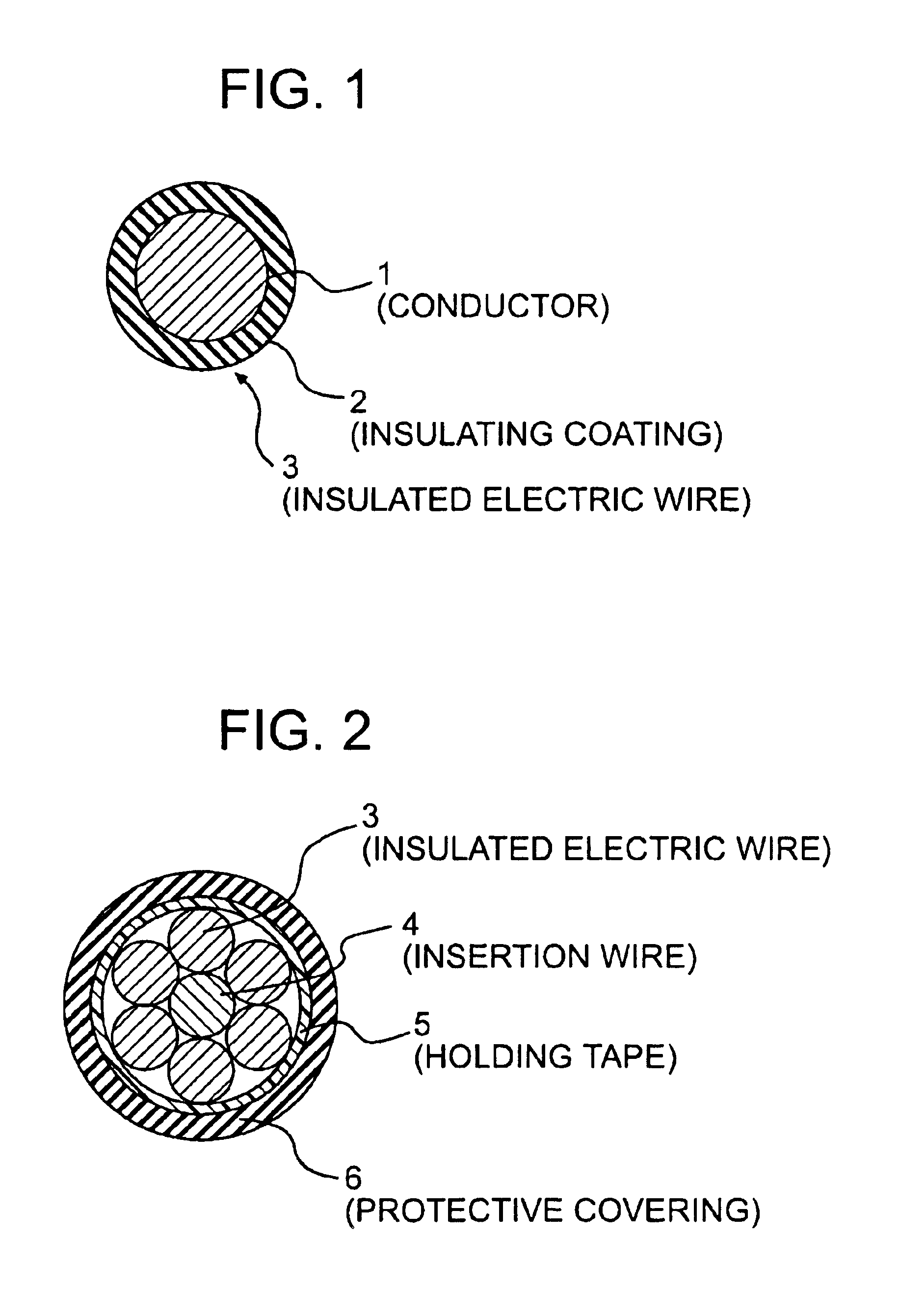

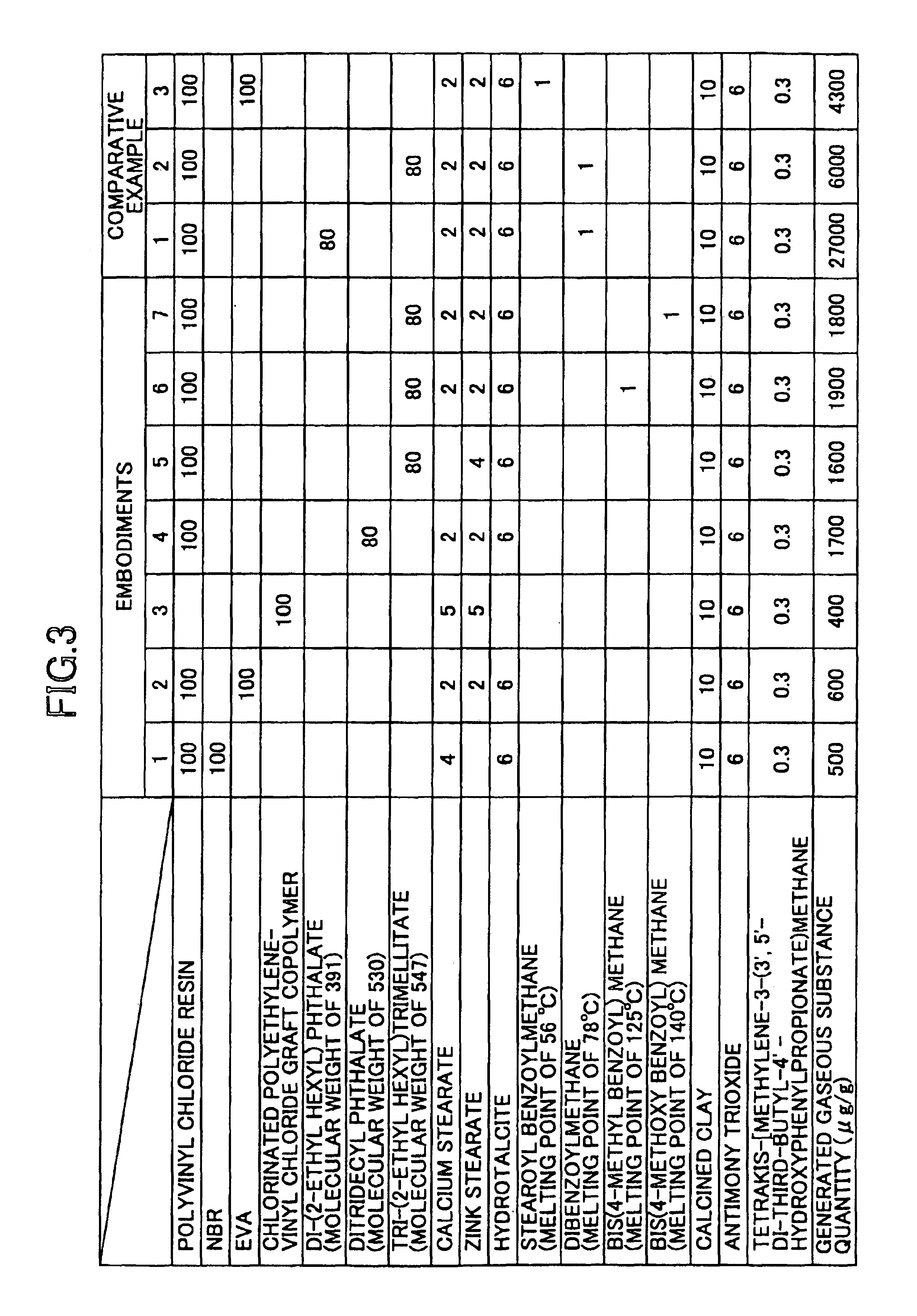

InactiveUS6903264B2Avoid generatingInhibit coloringPlastic/resin/waxes insulatorsInsulated cablesPlasticizerHydrotalcite

An electric wire with coating of polyvinyl chloride family resin composition is characterized by having a coating layer including polyvinyl chloride family composition obtained from adding more than one of any calcium soap, zinc soap and hydrotalcite to resin including polyvinyl chloride resin as a main constituent, and further adding thereto plasticizer so as to obtain a heat-stable vinyl chloride composition, and further adding thereto as stabilization auxiliaries high-melting-point β-diketone compound having a melting point more than 100° C. out of β-diketone compounds expressed by a general formula of R.CO.CH2.CO.R′.

Owner:TAISEI CORP +1

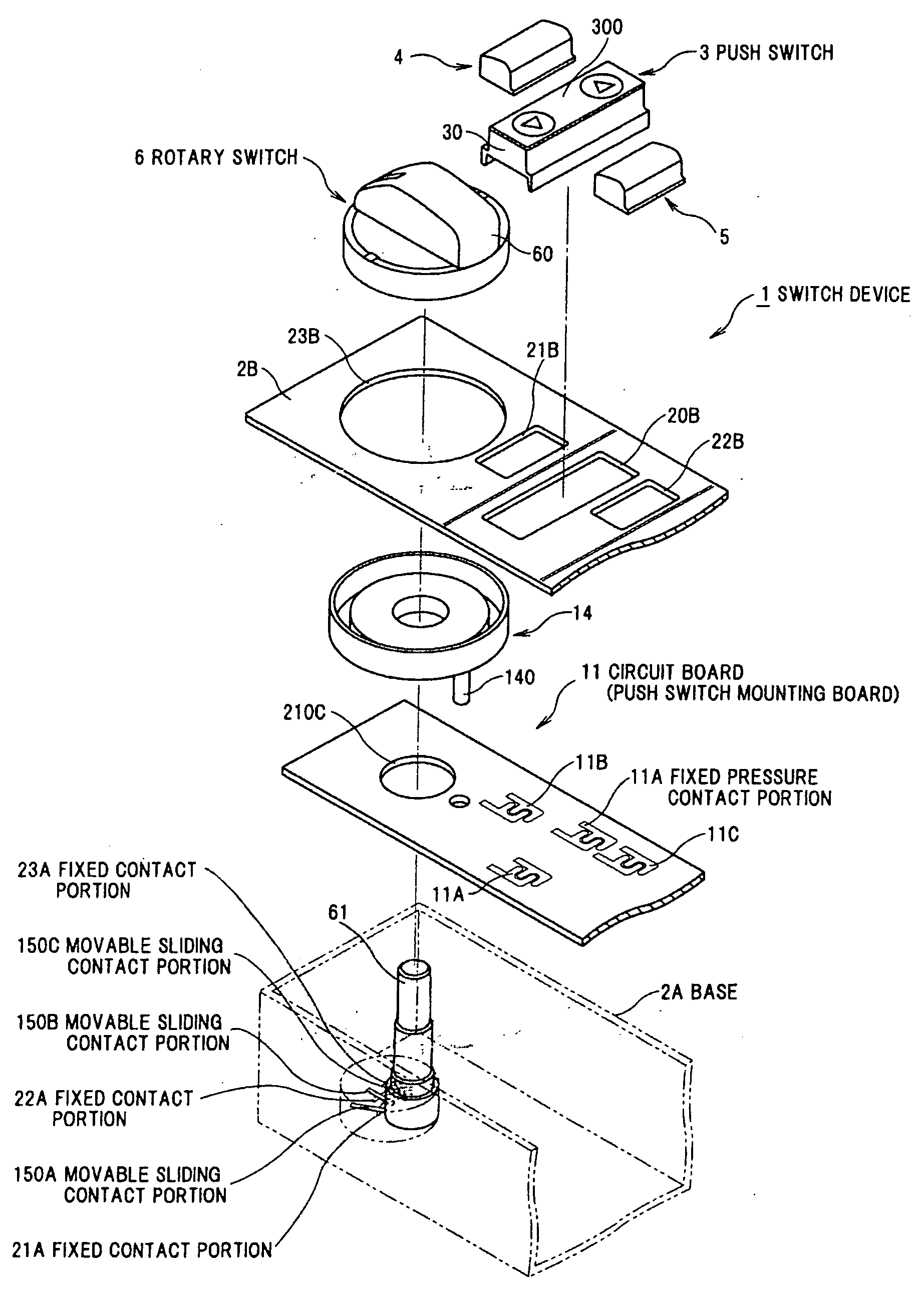

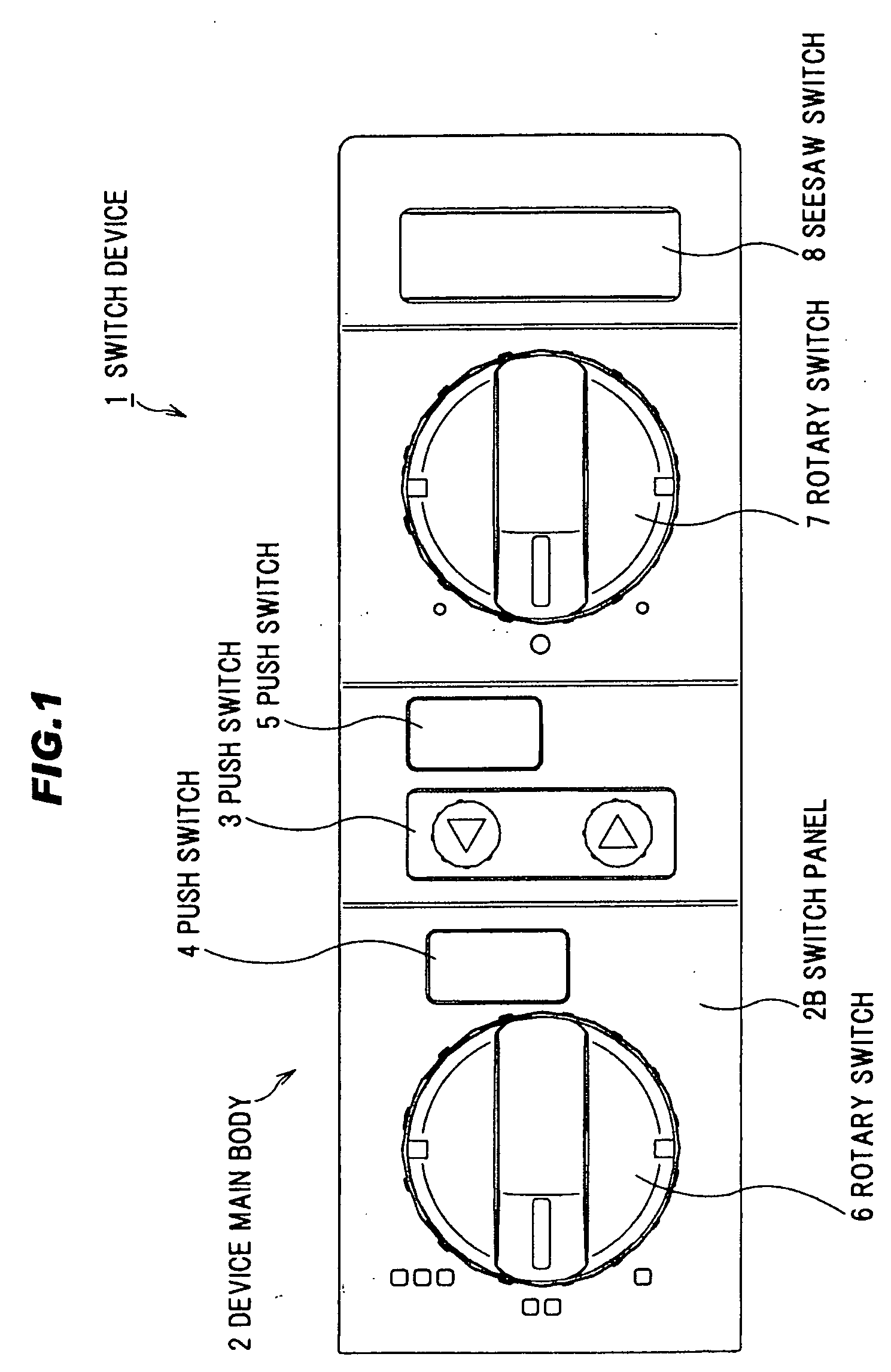

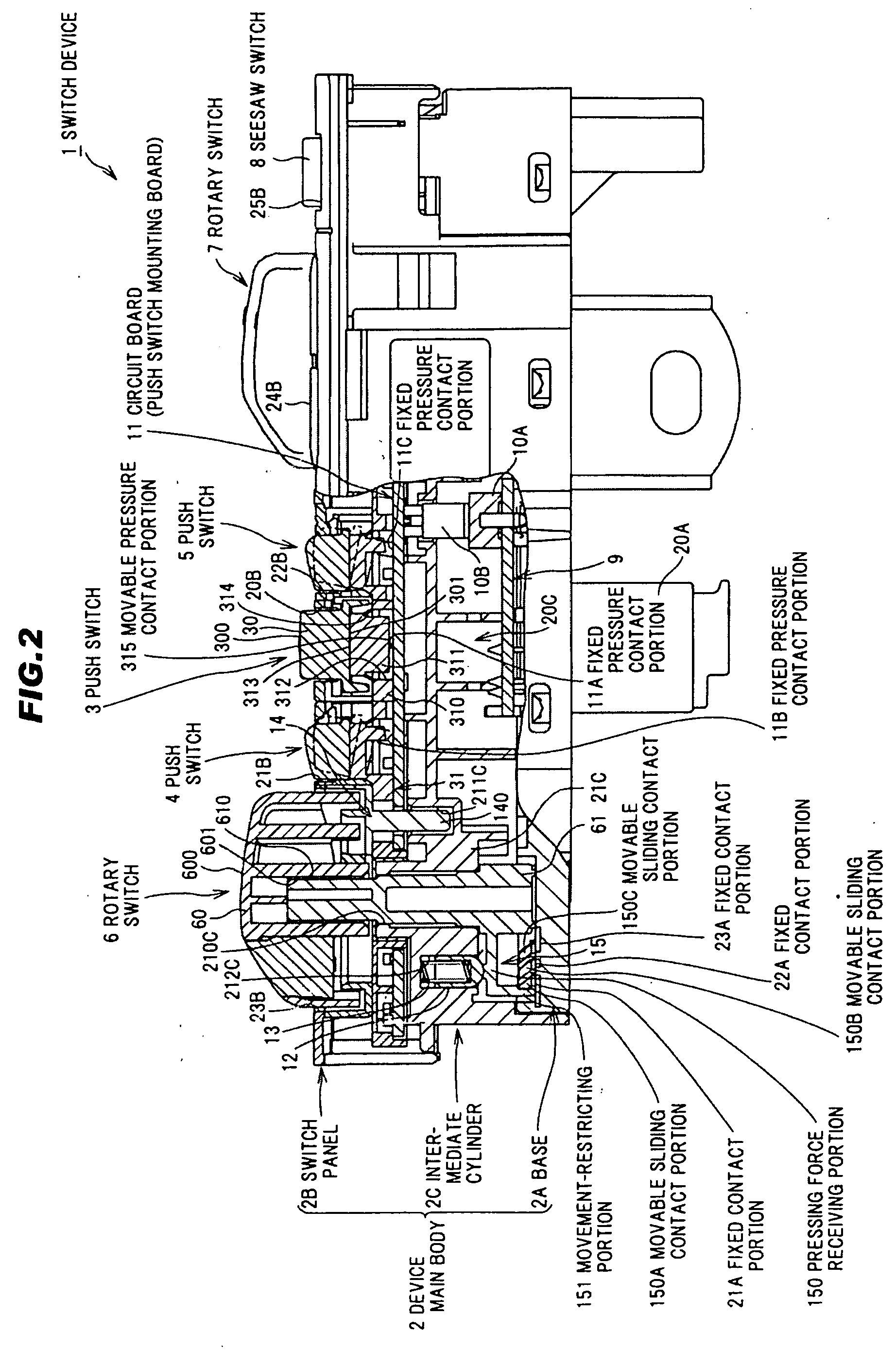

Switch device

InactiveUS20090188780A1Avoid generatingPrevent greaseEmergency actuatorsSwitch side locationEngineeringSliding contact

A switch device, includes a device main body incorporating a fixed pressure contact portion and includes a fixed sliding contact portion that forms a circuit together with the fixed pressure contact portion, and at least one pair of switches supported on the device main body, each switch comprising an operating knob. One switch of the at least one pair of switches includes a pressure-operated switch includes a movable pressure contact portion corresponding to the fixed pressure contact portion, and another switch includes a slide-operated switch includes a movable sliding contact portion corresponding to the fixed sliding contact portion.

Owner:KK TOKAI RIKA DENKI SEISAKUSHO

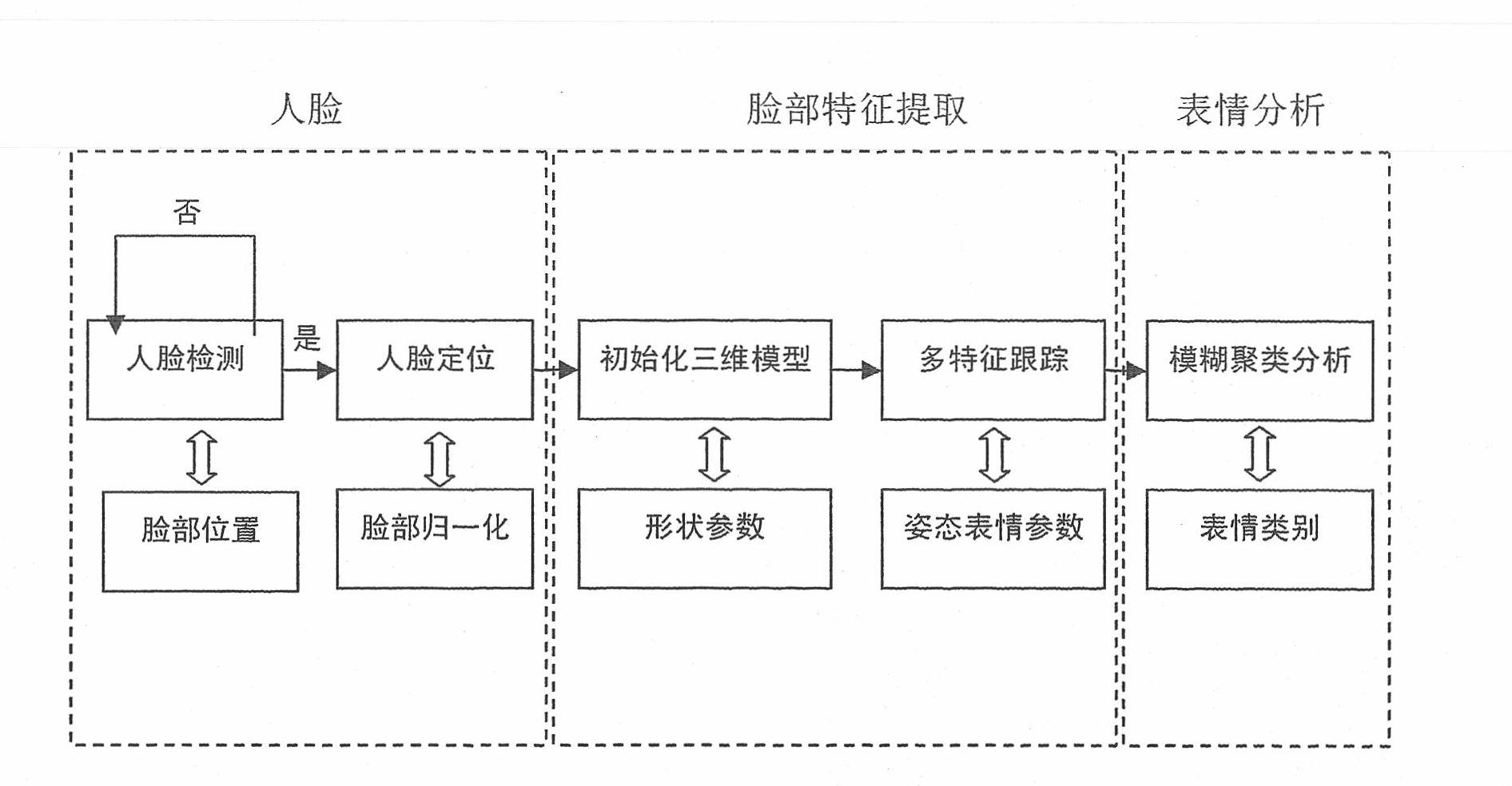

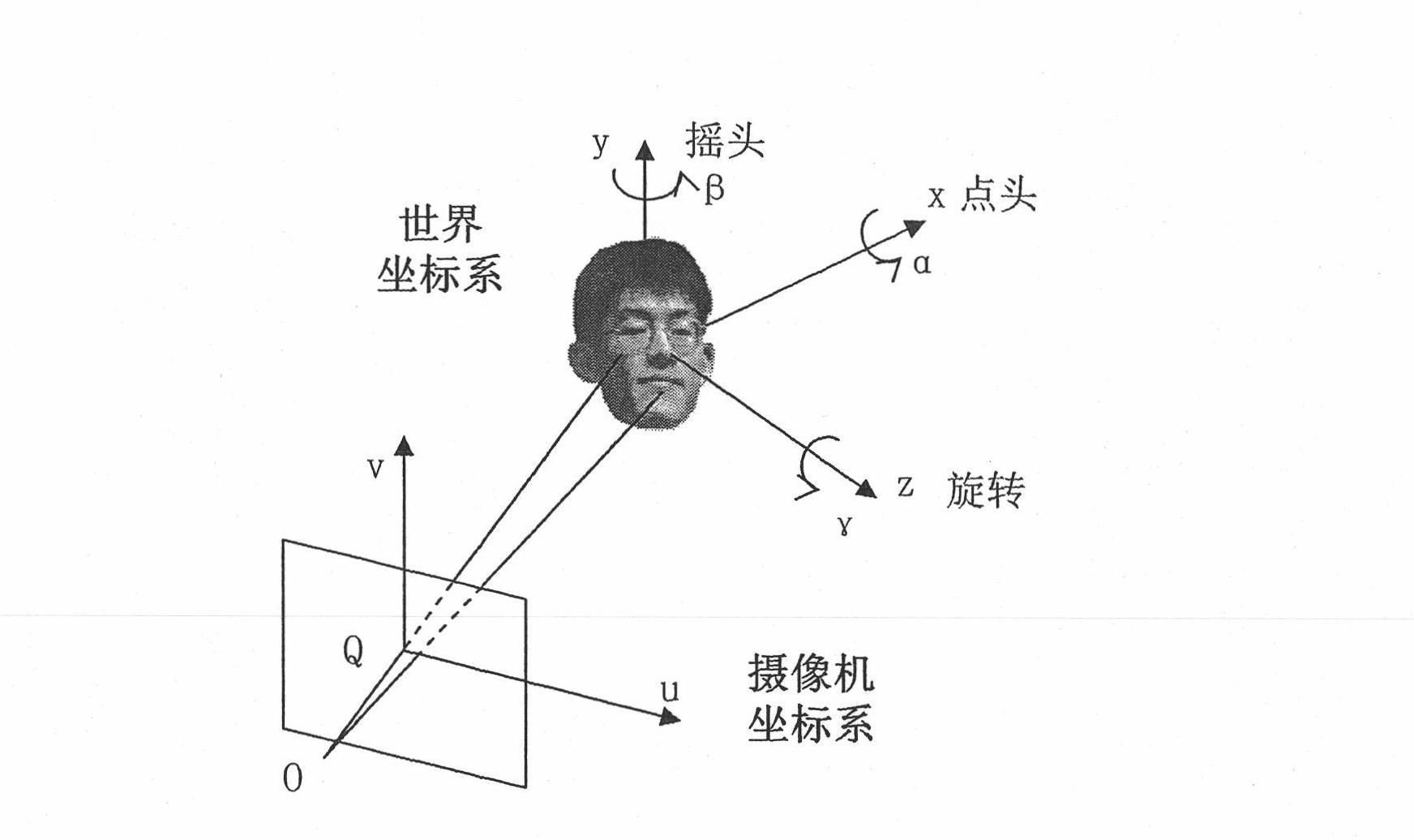

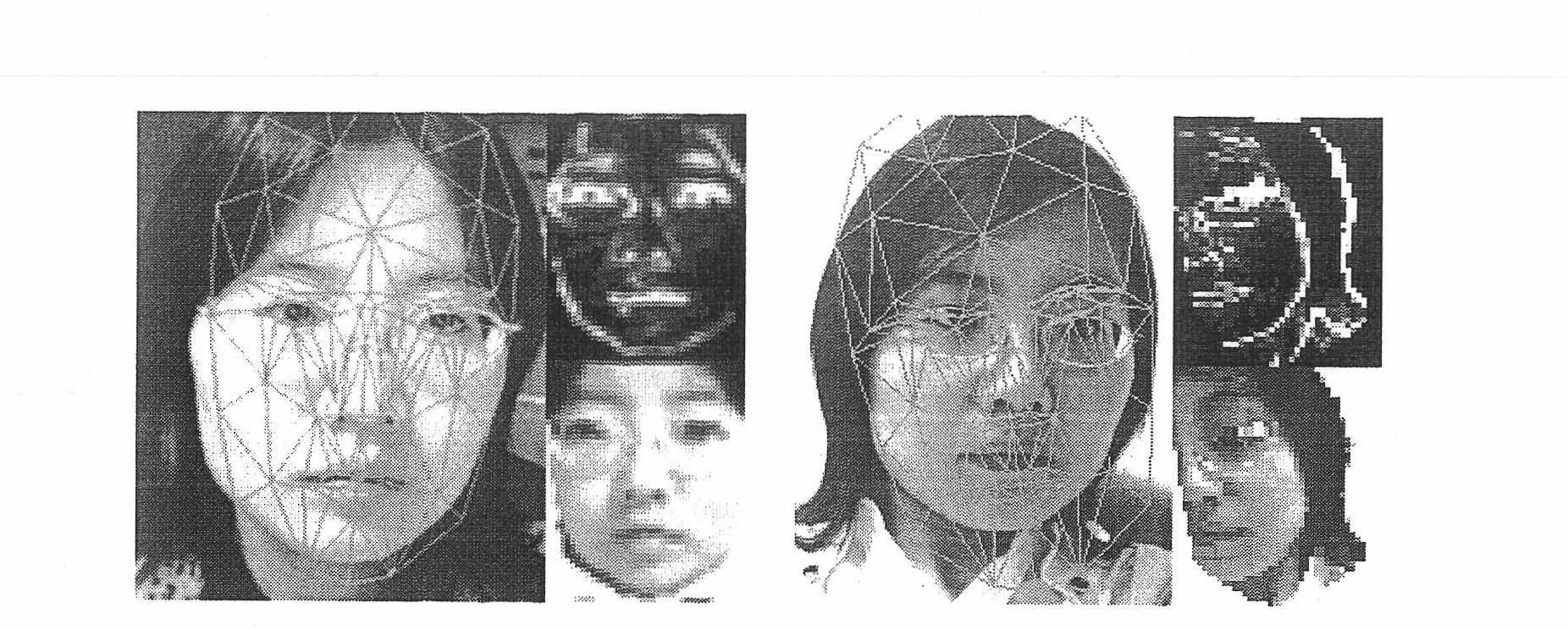

Method for analyzing facial expressions on basis of motion tracking

InactiveCN101777116ARealize automatic detection and positioningImprove performanceImage analysisCharacter and pattern recognitionFace detectionStudy methods

The invention relates to a method for analyzing facial expressions on the basis of motion tracking, in particular to a technique for face multi-feature tracking and expression recognition. The method comprises the following steps: pre-processing an inputted video image, and carrying out the face detection and face principle point location to determine and normalize the position of the face; modeling the face and expressions by using a three-dimensional parametric face mesh model, extracting the robust features and tracking the positions, gestures and expressions of the face in the inputted video image by combining the online learning method, so as to achieve the rapid and effective face multi-feature tracking; and taking the tracked expression parameters as the features for expression analysis; and carrying out the expression analysis by using an improved fuzzy clustering algorithm based on Gaussian distance measurement, so as to provide the fuzzy description of the expression.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

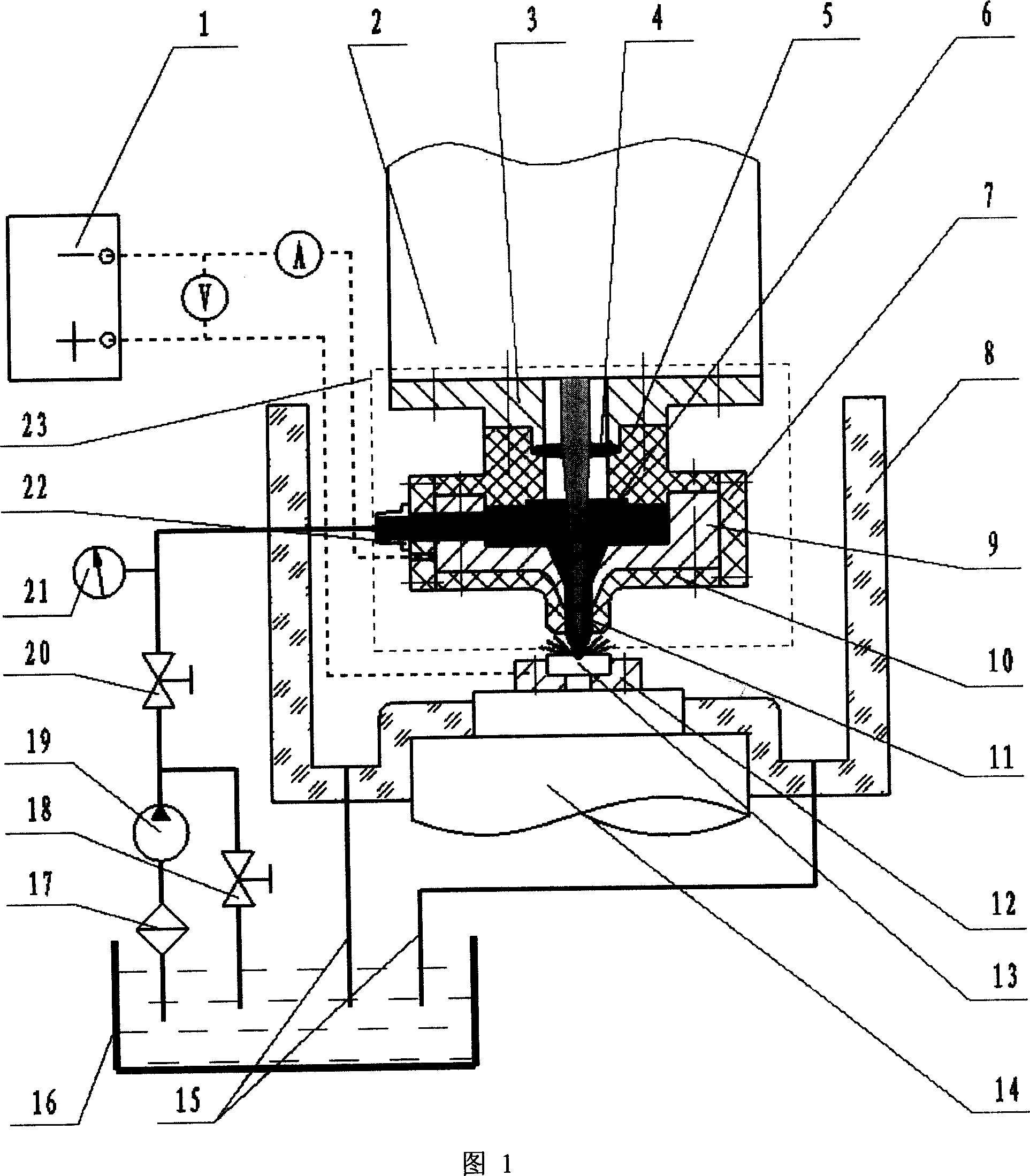

Spraying liquid bunch electrolysis-laser composite processing method and apparatus thereof

InactiveCN1919514ASolve processing problemsEfficient removalLaser beam welding apparatusElectrolysisLaser processing

The invention discloses a spraying liquid beam electrolytic-laser compound manufacturing method and device, which comprises the following steps: utilizing layer generating device to produce laser beam on the working piece, manufacturing hole, seam and groove, generating high-speed spraying liquid removing material with the same shaft of laser beam through spraying liquid beam device. The device contains layer, working piece assembling chuck, power and spraying liquid beam device, wherein the spraying liquid beam device concludes assembling seat of spraying device, insulating switching seat, cathode, focal lens, protective lens, insulating sleeve and sprayer.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Touch panel

ActiveUS20140134434A1Improve cohesionIncrease elasticityFilm/foil adhesivesLayered productsElectrical conductorSide chain

Provided is a touch panel. The touch panel includes a base and a pressure-sensitive adhesive layer attached to the base and having a peel strength with respect to a polycarbonate sheet of 1,900 g / 25 mm or more. The pressure-sensitive adhesive layer includes an acryl polymer compound containing an acryl polymer and a thiol polymer derived by binding a thiol compound into a chain, or a side chain or terminal end of a chain of the acryl polymer. Accordingly, penetration of oxygen, moisture or other impurities at an interface between the base film and the pressure-sensitive adhesive layer, or at an interface between a conductor thin film and a pressure-sensitive adhesive layer may be effectively inhibited, and degradation in optical properties such as visibility due to bubbles generated at a pressure-sensitive adhesive interface may be prevented. In addition, when the pressure-sensitive adhesive layer is directly attached to the conductor thin film and even exposed to severe conditions such as high temperature or high temperature and high humidity, the change in the resistance of the conductor thin film may be effectively inhibited, and thus the touch panel may be stably driven for a long time.

Owner:LG CHEM LTD

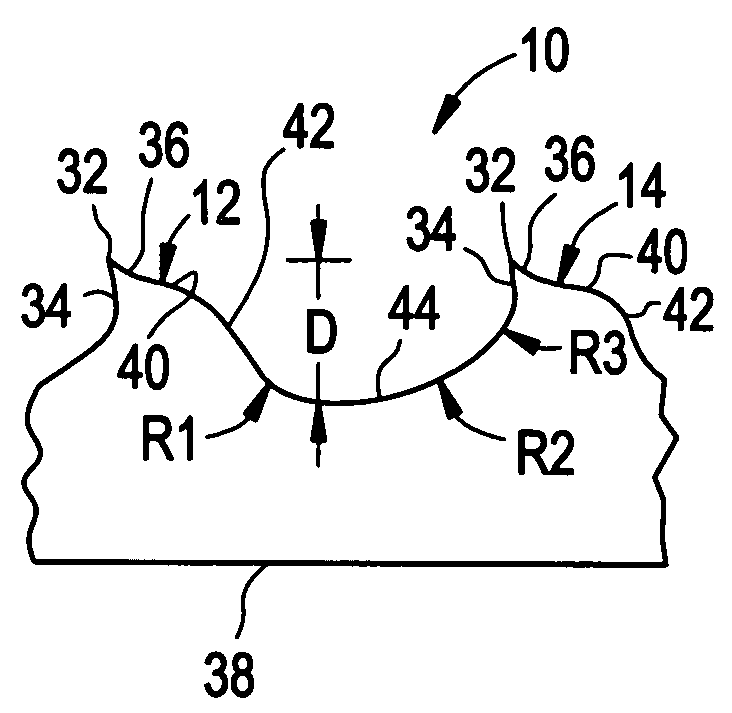

Saw blade having increased tooth stiffness and resistance to fatigue failure

InactiveUS7174823B2Increase Section WidthIncrease stiffnessMetal sawing devicesMetal sawing toolsEngineering

A band saw blade comprising a plurality of teeth, wherein each tooth comprises a tip; a rake face formed on one side of the tip; a primary clearance surface formed on an opposite side of the tip relative to the rake face; a secondary clearance surface formed on an opposite side of the primary clearance surface relative to the tip; and a gullet located on an opposite side of the rake face relative to the tip and defining a depth (D) between a base surface of the gullet and the tip. Each tooth further defines a first gullet radius (R1) located between the gullet and the secondary clearance surface; a second gullet radius (R2) extending between a base surface of the gullet and the rake face; and a pitch (P) between the respective tooth and a preceding tooth. In each tooth, R2>D>RQ, and D / P is between about 25% and 35%.

Owner:IRWIN IND TOOL CO

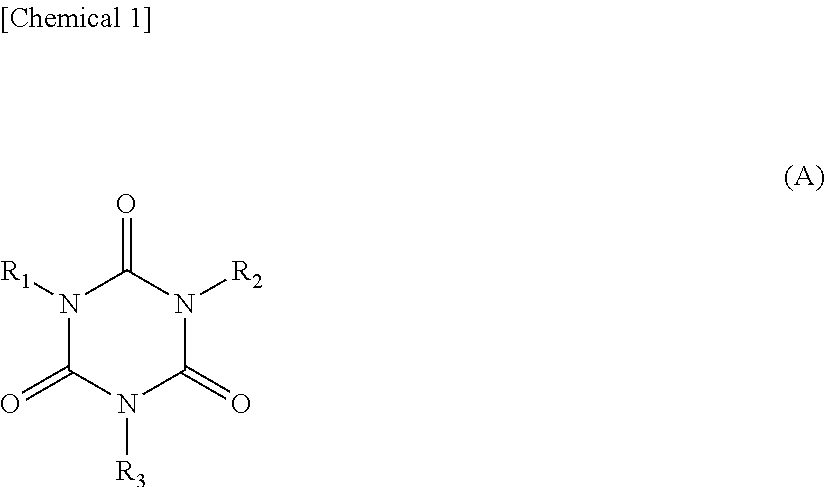

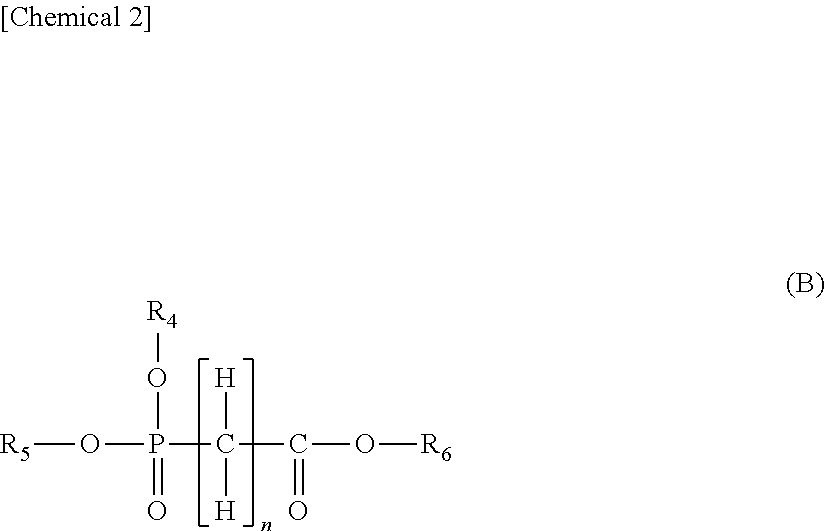

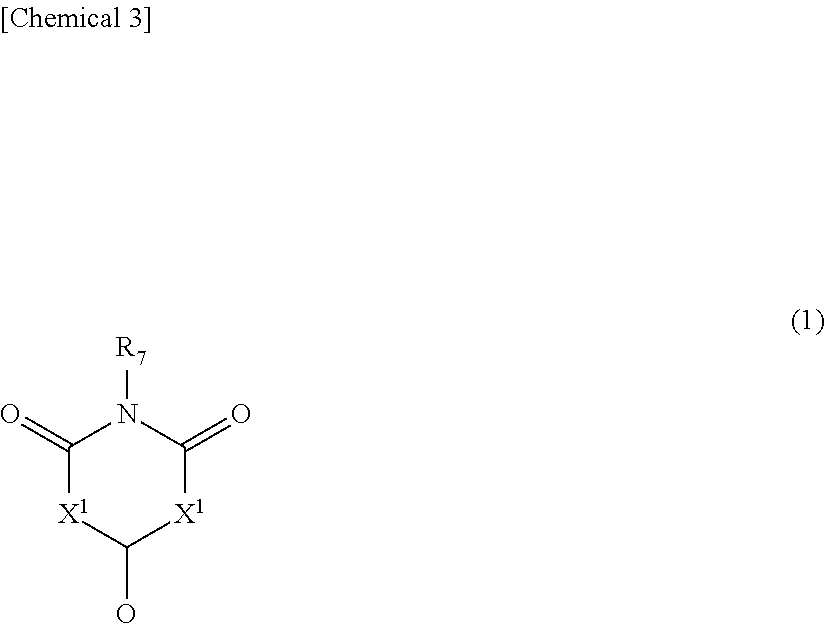

Nonaqueous electrolyte solution and nonaqueous electrolyte battery using same

InactiveUS20150364794A1Improve balanceImprove featuresCell electrodesLi-accumulatorsPhysical chemistryBattery cell

A nonaqueous electrolyte solution for a secondary battery that inhibits increases in resistance during high-temperature storage in a charged state and decreases in capacity, as well as a secondary battery that uses this lithium nonaqueous electrolyte solution. A lithium nonaqueous electrolyte secondary battery that incorporates this non-aqeuous electrolyte solution and that demonstrates a favorable overall balance of battery performance with respect to performance such as durability, capacity, resistance and output characteristics.

Owner:MITSUBISHI CHEM CORP

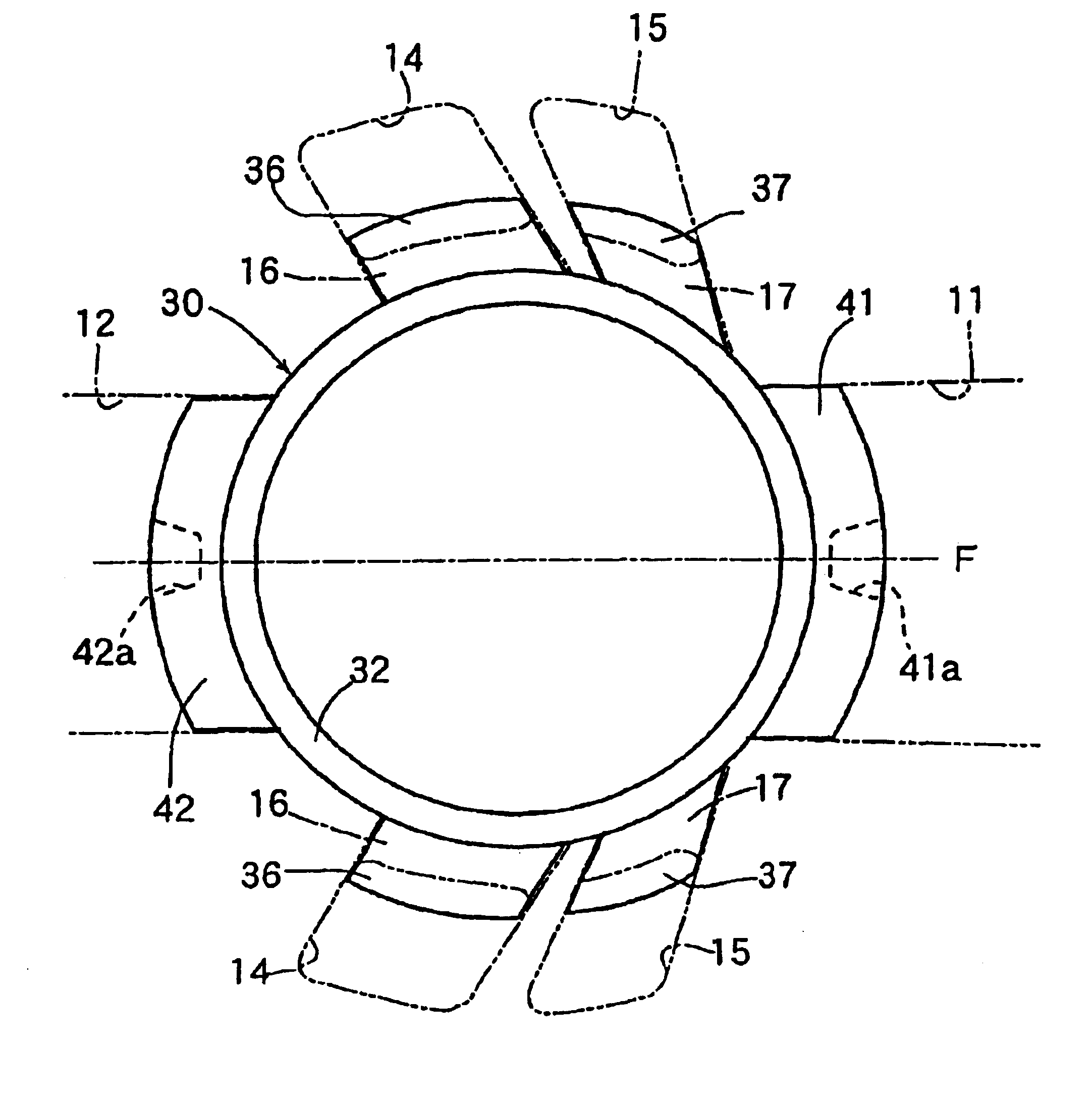

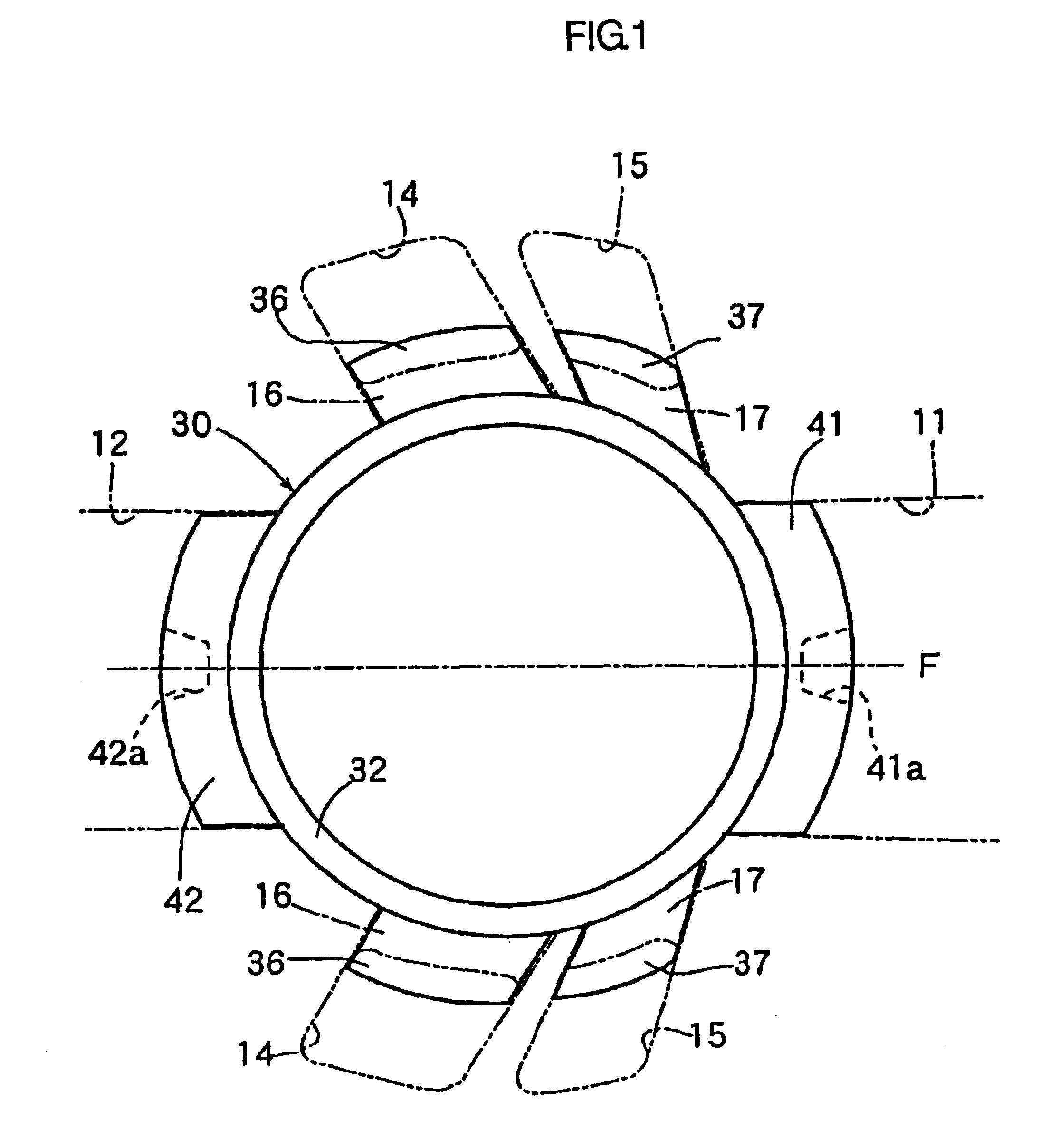

Insert core and method for manufacturing a cylinder for internal combustion engine by making use of the insert core

There is provided a method for manufacturing a cylinder for an internal combustion engine by making use of an insert core, which makes it possible to manufacture the cylinder by a die casting method such as a high-pressure die casting method at low cost and in high accuracy. The insert core to be employed herein includes: a cylindrical body having substantially the same outer diameter as the diameter of bore of the cylinder to be obtained; a scavenging port-forming portion projecting radially outward from the cylindrical body and having substantially the same cross-sectional configuration as that of the scavenging port; a suction port-forming portion projecting radially outward from the cylindrical body and having substantially the same cross-sectional configuration as that of at least the cylinder bore-side end portion of a suction port; and an exhaust port-forming portion projecting radially outward from the cylindrical body and having substantially the same cross-sectional configuration as that of at least the cylinder bore-side end portion of an exhaust port.

Owner:KIORITZ

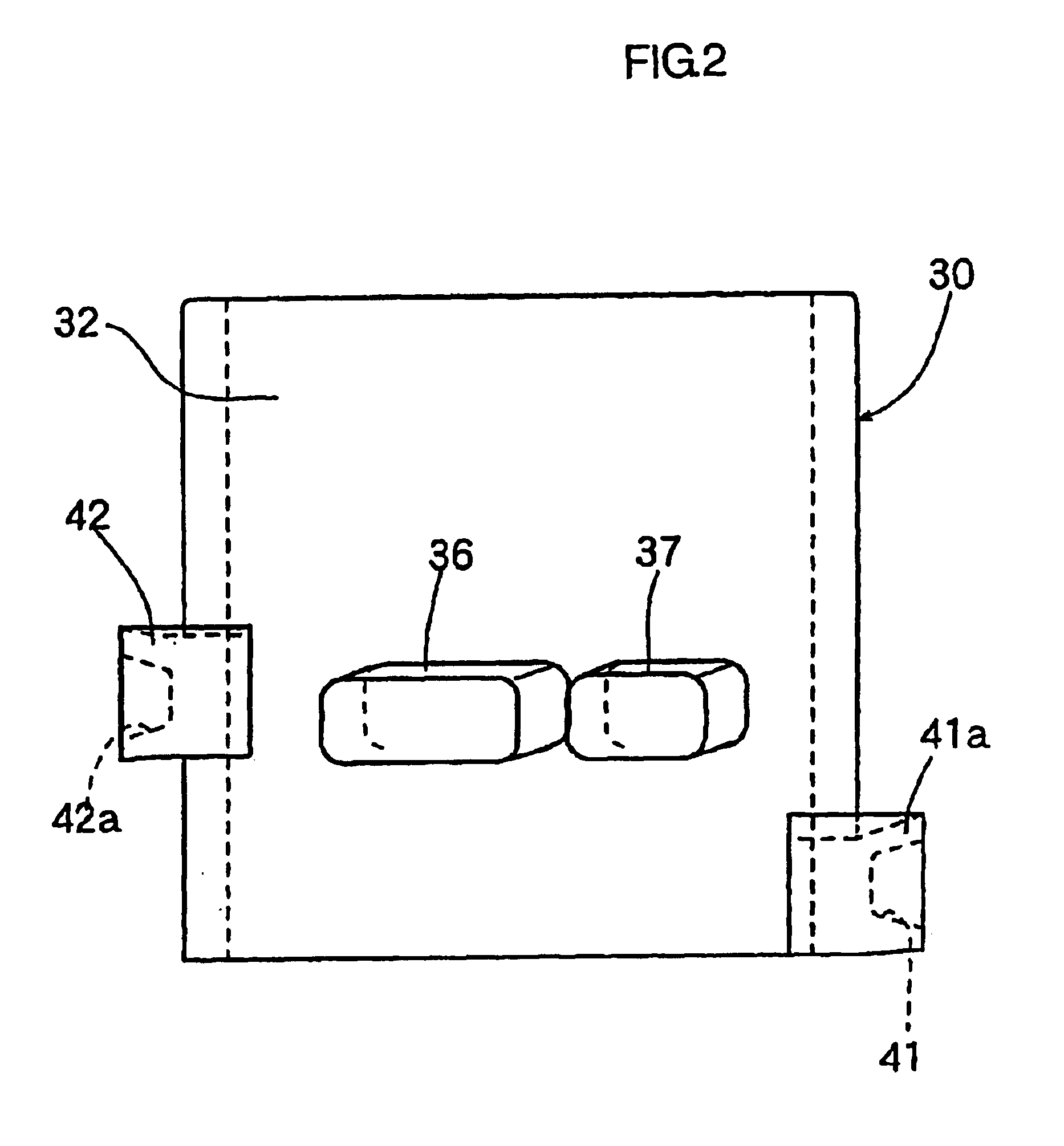

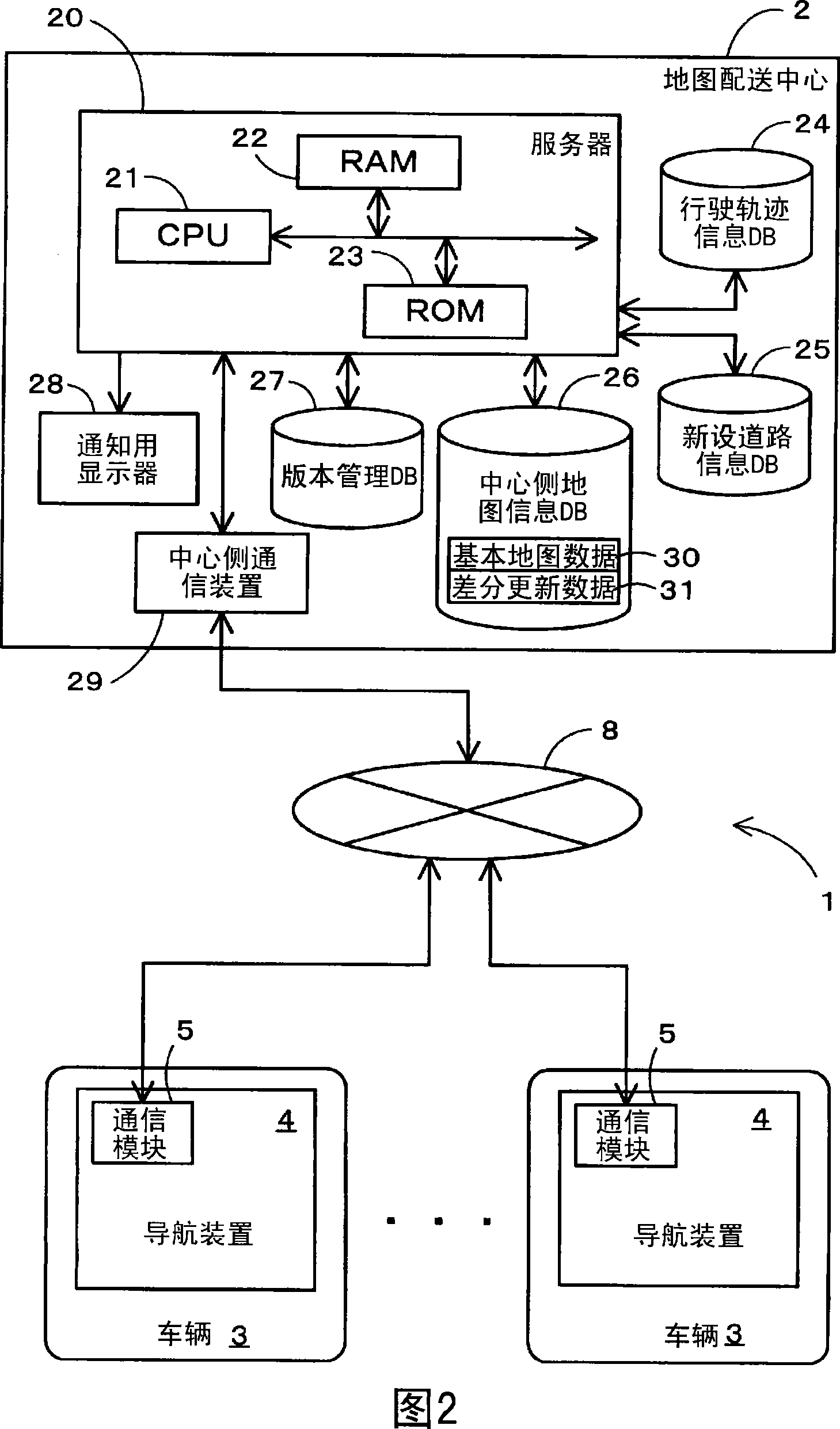

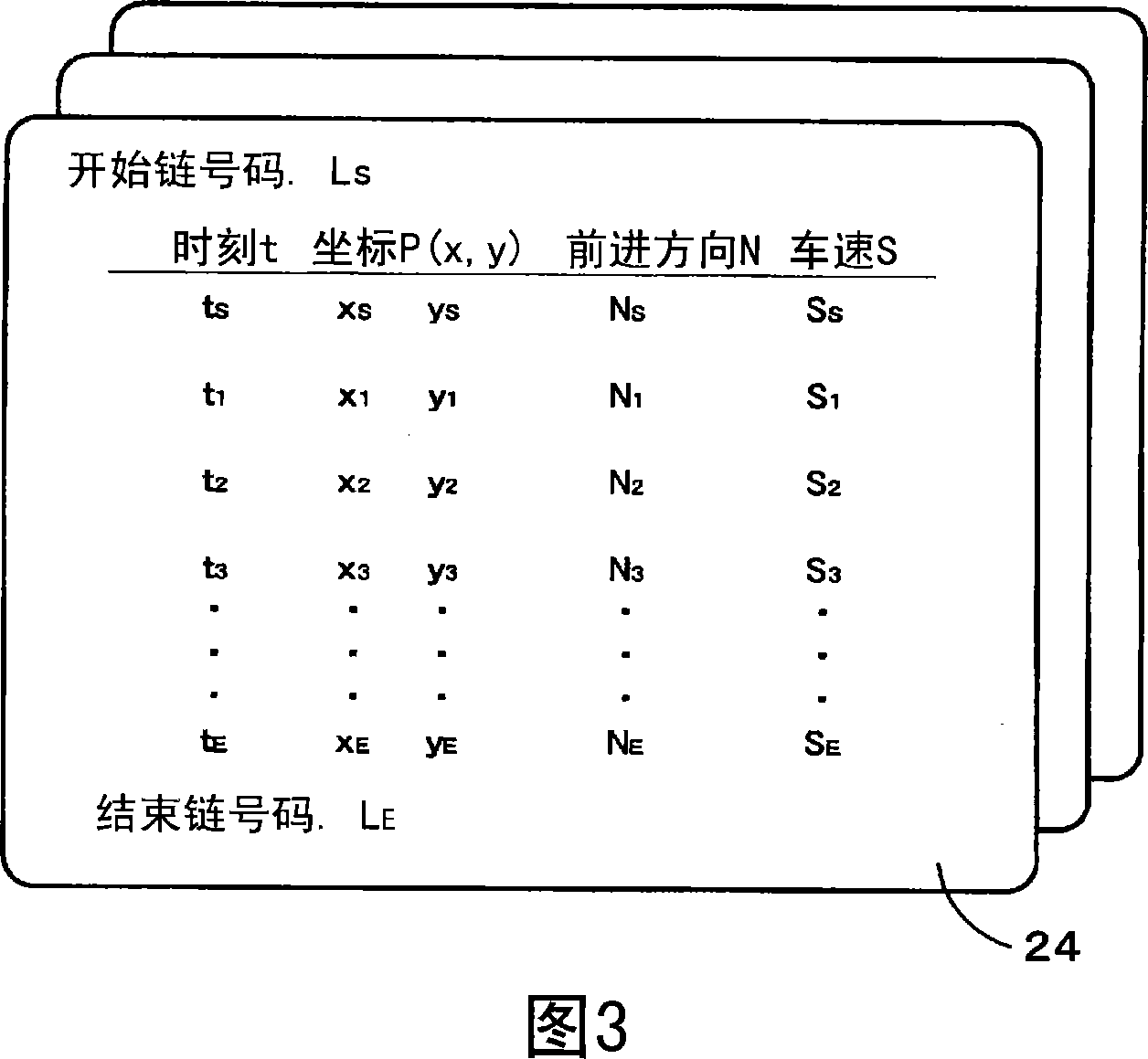

Map information generating systems

InactiveCN101210825AGenerate quickly and correctlyExclude correctInstruments for road network navigationRoad vehicles traffic controlComputer scienceDistribution centre

The invention provides a cartographic information generating system which is used for generating information about the new added roads to the cartographic information stored in a navigation device and etc.. The traveling locus information generated when vehicles (3) serving as probe cars travel along paths that are not included in navigation map data (53) provided in the navigation device (4) is transmitted to a map distribution center (2) as probe data. After receiving the traveling locus information from the navigation device (4) of each vehicle (3), the map distribution center (2) gathers together the received data, groups together traveling locus information relating to the same path, and then generates new road information relating to a single new road in each group.

Owner:AISIN AW CO LTD

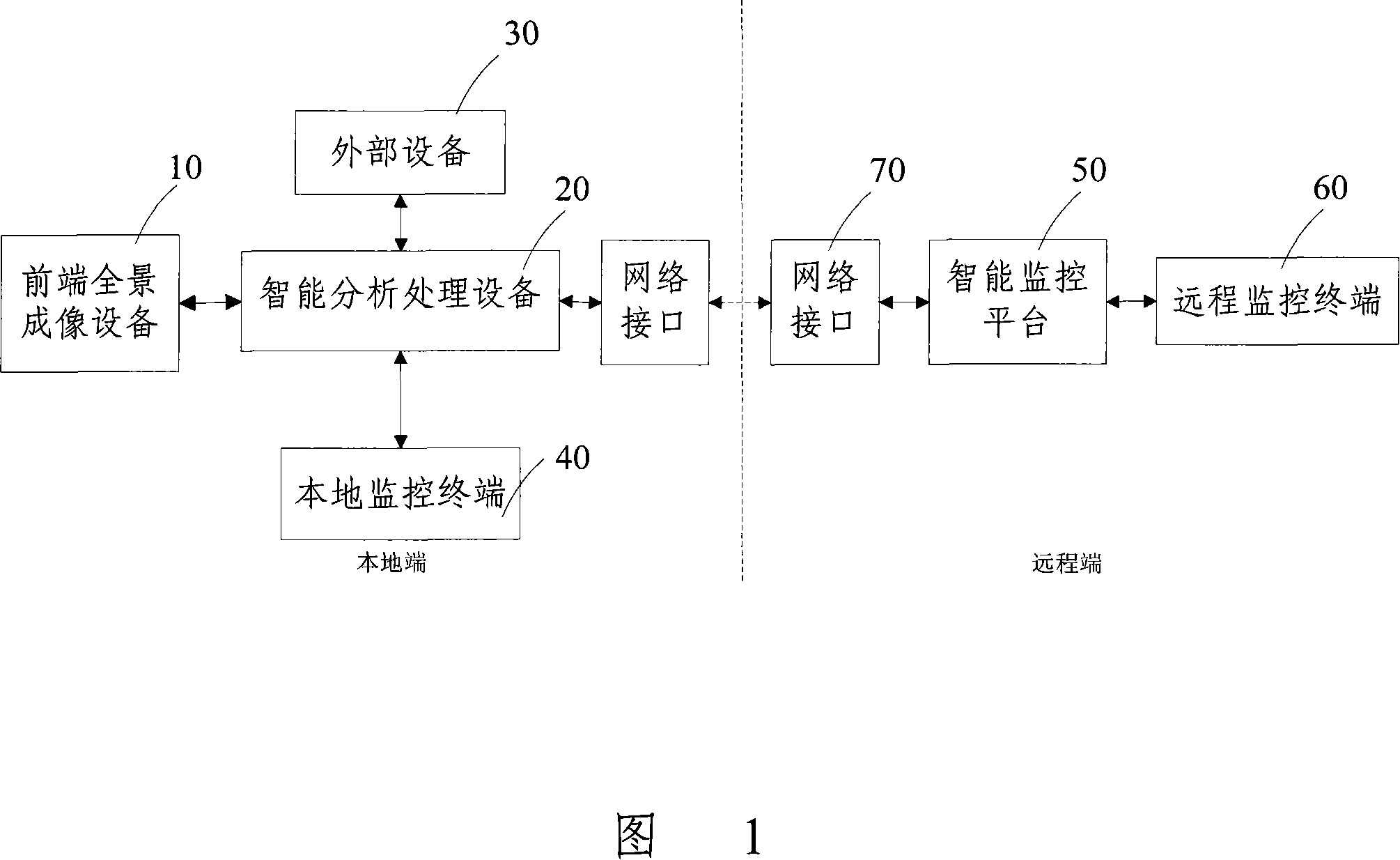

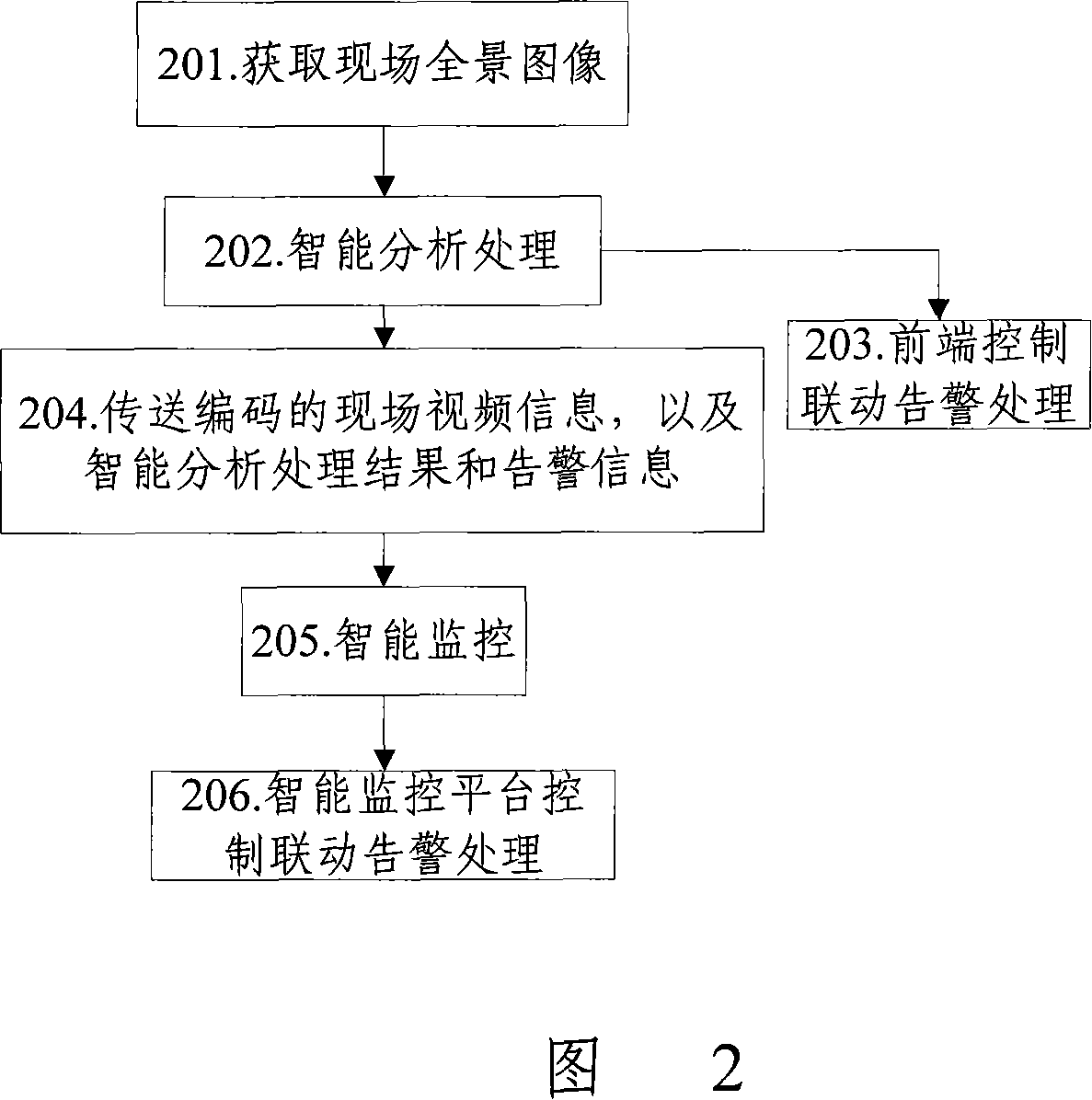

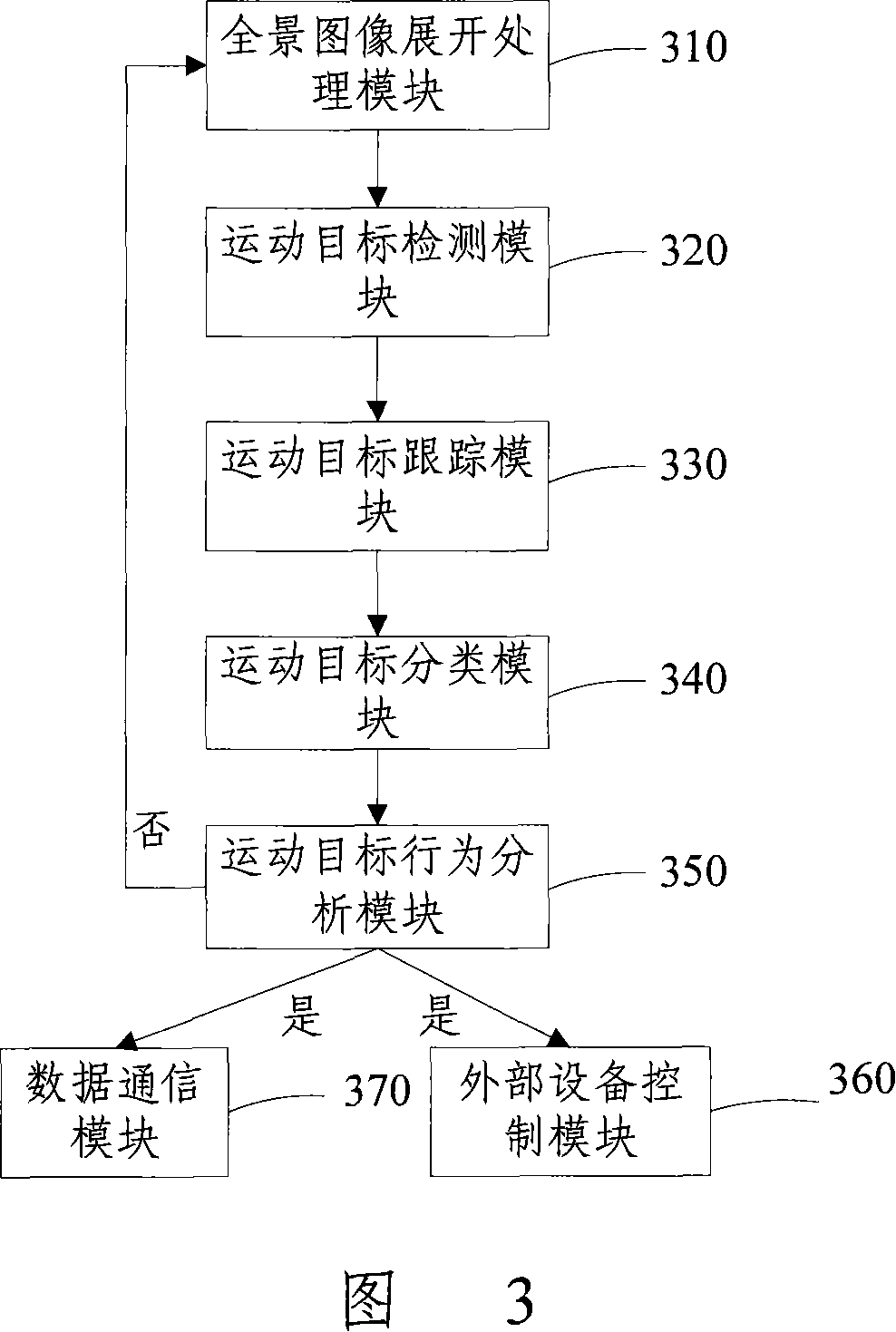

Panorama video intelligent monitoring method and system

InactiveCN101123722ALess investmentLower requirementImage analysisClosed circuit television systemsVideo monitoringImaging processing

The invention discloses a panorama video intelligent monitoring method, comprising: A. acquiring a scene panorama image and unfolding it; B. performing intelligent analysis on a moving target in the panorama unfolded image. The invention also discloses a panoramic video intelligent monitoring system, a device for intelligent analysis and processing of panoramic images, and a method and device for unfolding panoramic images. By using these methods, systems, devices and devices, it is possible to reduce Installation cost, automatically distinguish "abnormalities" in the screen, and implement moving target detection, tracking, classification and behavior analysis, realize intelligent alarm, effectively prevent incidents from happening, and save manpower and material resources.

Owner:无锡安科兴业科技有限公司

Process for welding 800MPa high-strength steel without preheating

ActiveCN1962151AStrong resistance to crack generation and propagationImprove crack resistanceArc welding apparatusFurnace typesWeld seamEngineering

The invention relates to a non-preheat welding method of high-strength steel whose tensile strength 800MPa, wherein it comprises (1), the connector has V-shape slope cut; (2), cleaning the slope before welding; (3), using impulse welding power source to weld in Ar+CO2 mixed gas or CO2 gas, while the welding voltage is 30-34V, the welding current is 200-240A, the welding speed is 0.4cm / s-0.6cm / s, the welding heat input is 10kJ / cm-20kJ / cm, and the protect gas flux is 15L / min-25L / min;(4), using 600MPa or 700MPa drug welding or solid welding wire to weld bottom, while other welding channels use 800MPa drug welding wire to multilayer weld, without intermission; (5), using alumina silicate plate to cover the welding head, to cool. The invention can avoid preheat and following thermal treatment, with low cost, while the welding seam has high flexibility.

Owner:BEIJING CHONGLEE MACHINERY ENG

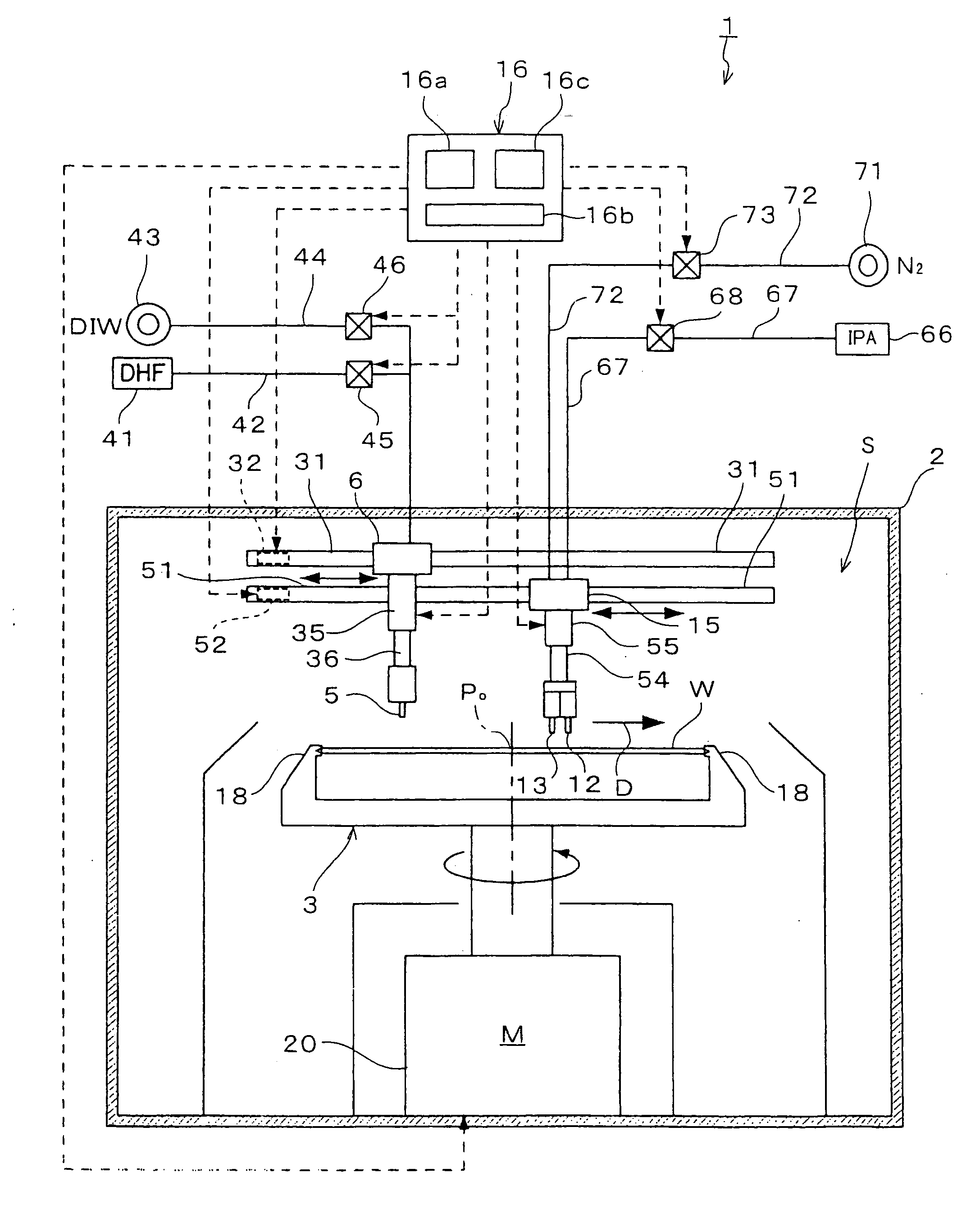

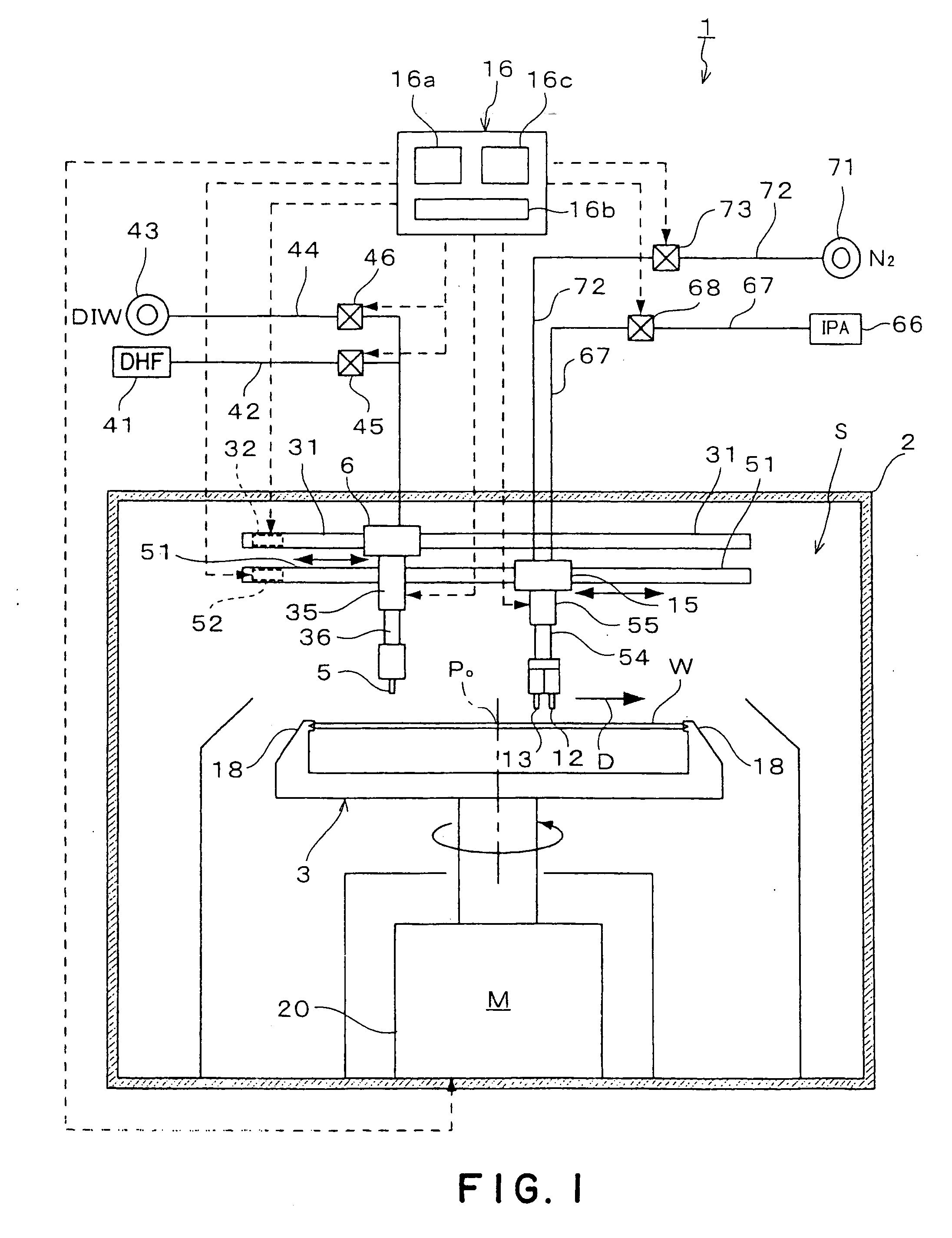

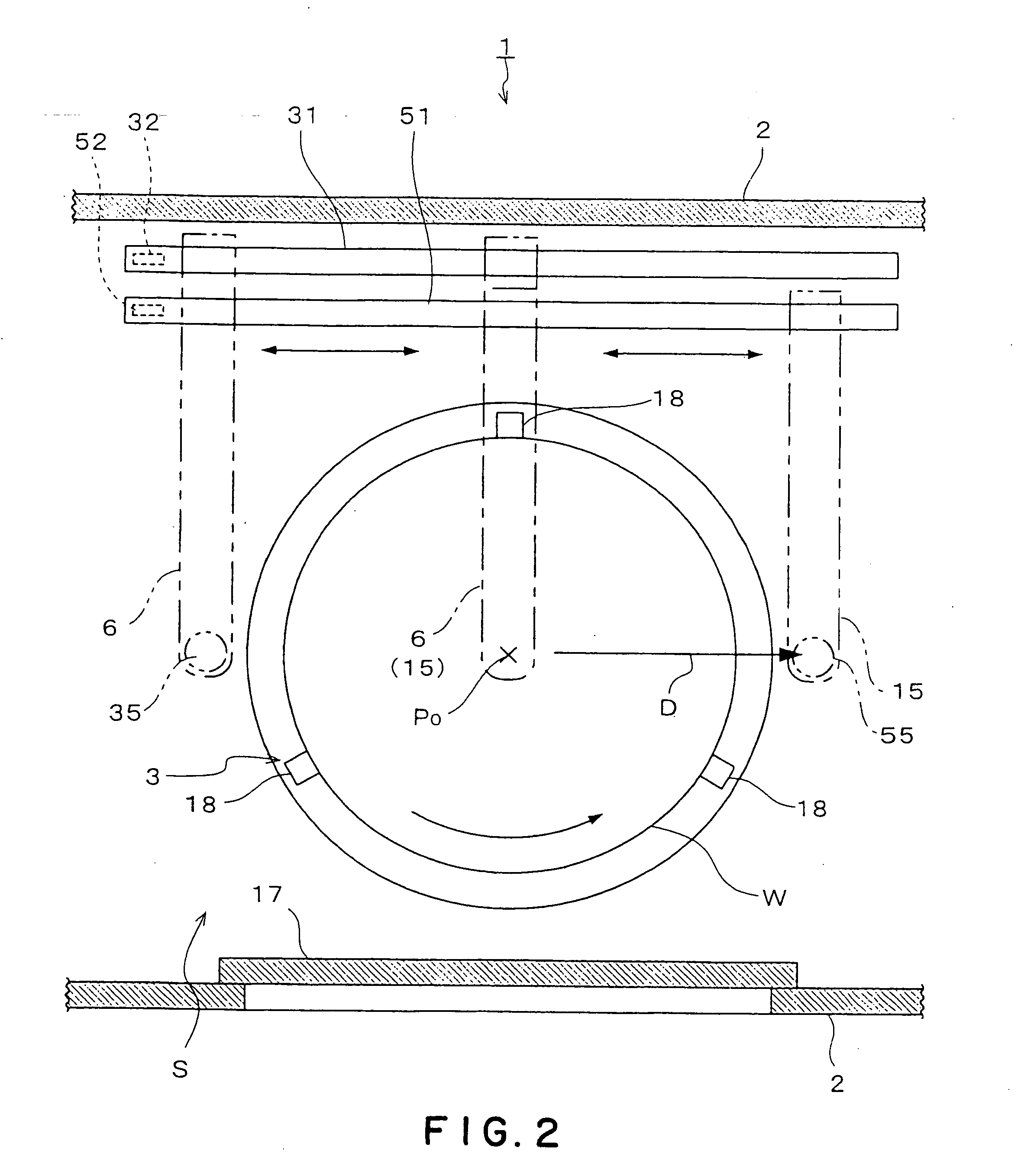

Substrate Processing method and substrate processing apparatus

ActiveUS20070017555A1Decreasing amount of usedAvoid it happening againSemiconductor/solid-state device manufacturingCleaning using gasesEngineeringIon

A substrate (W) is processed with the use of a process liquid such as a deionized water. Then, a first fluid which is more volatile than the process liquid is supplied to an upper surface of the substrate (W) from a fluid nozzle (12) to form a liquid film. Next, a second fluid which is more volatile than the process liquid is supplied to the upper surface of the substrate (W) from the fluid nozzle (12), while the wafer (W) is being rotated. During this supply operation, a supply position (Sf) of the second fluid to the substrate (W) is moved radially outward from a rotational center (Po) of the substrate (W). As a result, it is possible to prevent the generation of particles on the substrate (W) after it is dried by using the first and second fluids.

Owner:TOKYO ELECTRON LTD

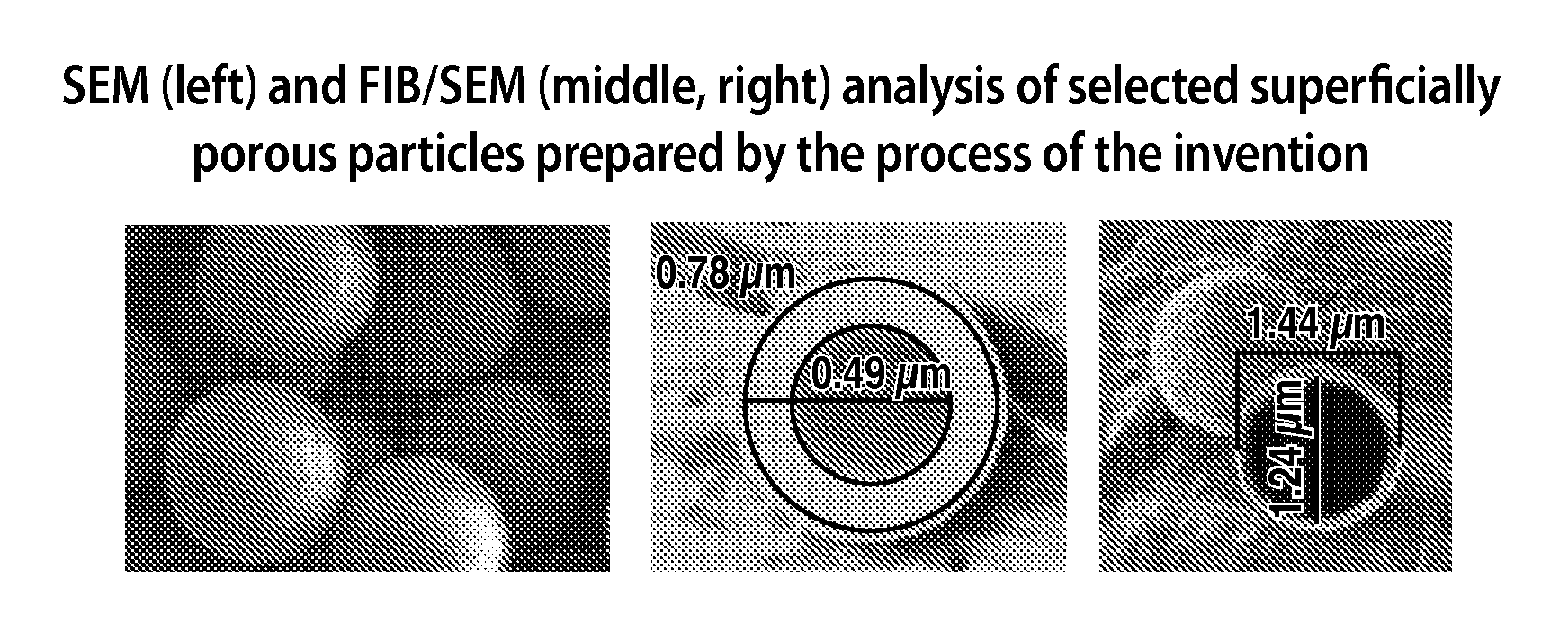

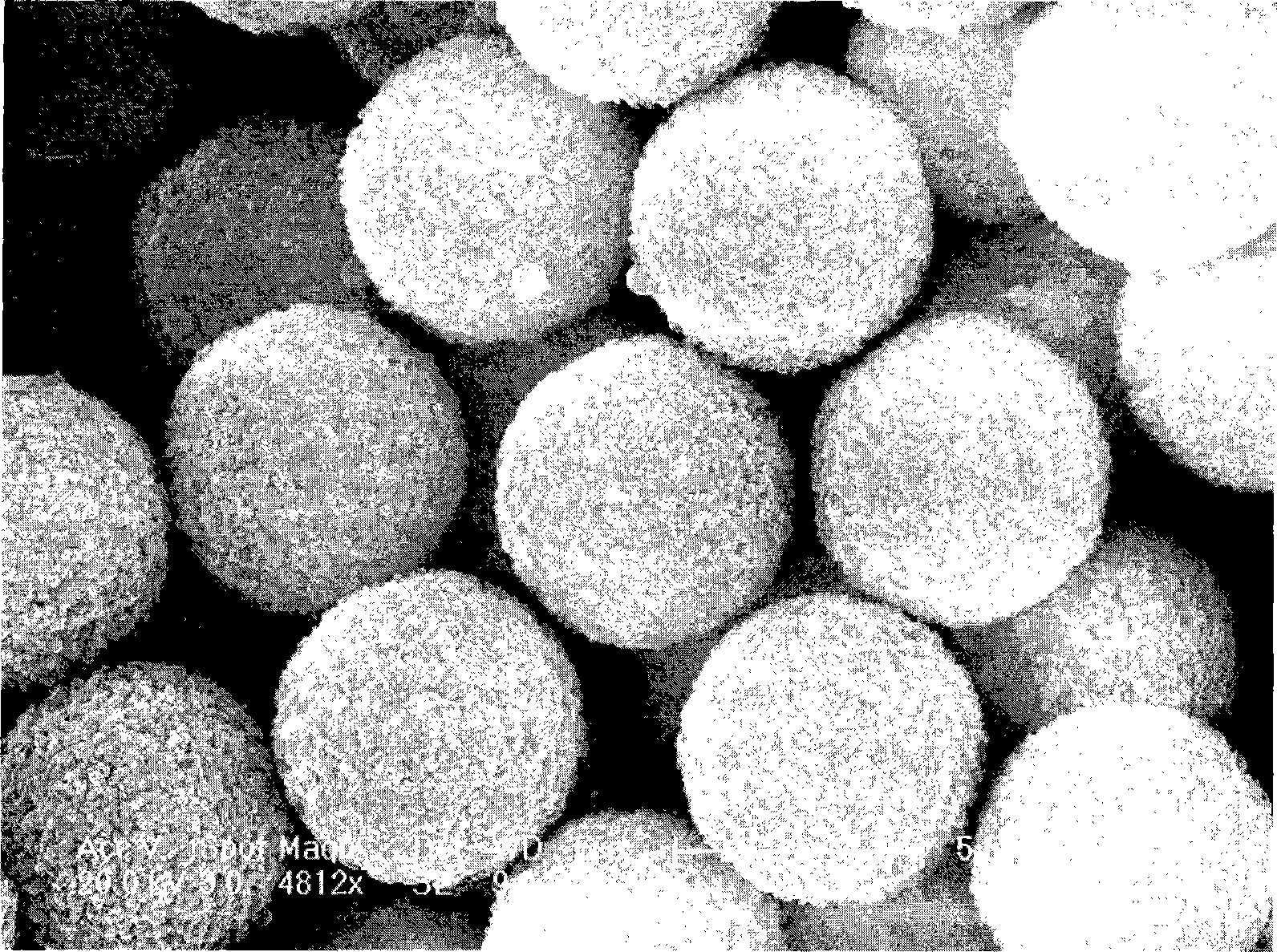

Preparation of monodisperse porous polymer microsphere

The invention provides a preparation method of a monodisperse porous polymer microsphere. After a second stage of swelling of two-stage seed swelling polymerization, remnant monomer separation technology is adopted to avoid the aggregation of the microspheres and the generation of secondary particles, thereby greatly improving the stability of preparing monodisperse porous polymer microsphere through the two-stage seed swelling polymerization. The two-stage seed swelling polymerization can stably prepare the following monodisperse porous polymer microspheres: P(St-co-DVB) (PSD for short) and P(St-co-DVB-co-MMA) (PSDA for short), wherein, St is referred to as styrene, DVB as divinybenzene, MMA as methyl methacrylate, AN as acrylonitrile and co as copolymerization. The monodisperse porous polymer microsphere PSDA prepared by the method can be seen in an attached drawing.

Owner:芜湖万隆新材料有限公司

Preparation method of high-performance anti-corrosion repairing mortar

A preparation method of high-performance anti-corrosion repairing mortar including following components, by weight: 150-250 parts of cement, 280-725 parts of quartz sand, 50-200 parts of mineral powder, 50-150 parts of fly ash, 0-50 parts of silicon ash, 5-10 parts of barium nitrate, 0.1-1 part of an early strength agent, 1-4 parts of PP fibers, 0.5-20 parts of latex powder, 0.5-5 parts of cellulose ether, 0.5-2 parts of a water repellent agent, 0.001-0.1 parts of an air entraining agent, 0.1-2 parts of a water reducing agent, 0-1 part of a defoaming agent, and 100-250 parts of water. The invention, aiming to the characteristic of sulphate attack and the performance requirement of repairing mortar, discloses the repairing mortar which can repair the surface of damaged concrete with a protective film formed thereon to prevent the concrete form being corroded again. The repairing mortar is good in construction performance, can be used for coating the surface of the damaged concrete or filling damaged positions of the concrete. The repairing mortar is high in bonding strength and strength, is good in anti-permeability and flexibility, is simple in preparation process, is especially suitable for repairing the concrete subjected to sulphate attack, is great in market prospect and is good in practicability.

Owner:潍坊德霖建材科技有限公司

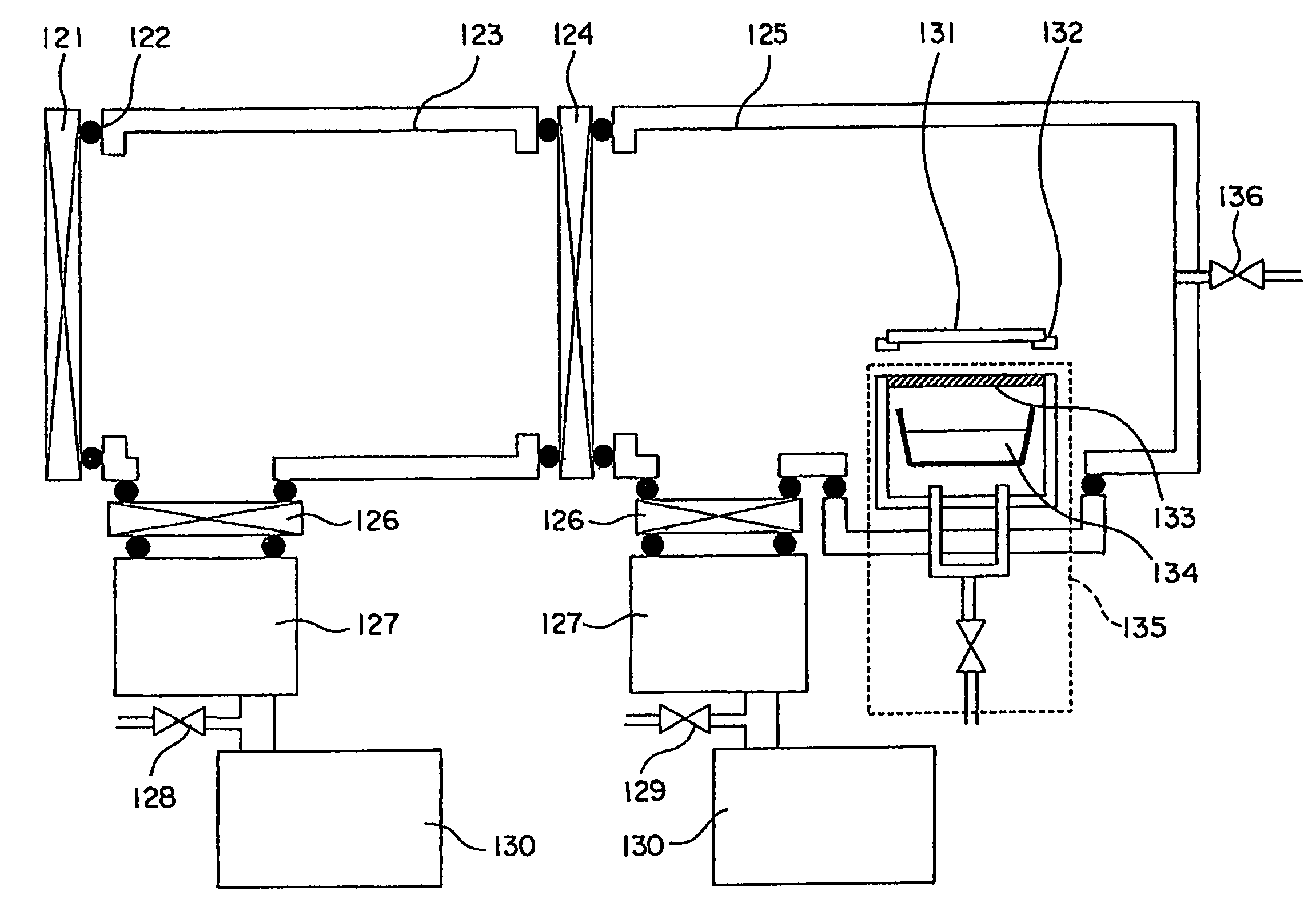

Film-Forming Apparatus And Film-Forming Method

InactiveUS20080241587A1High film forming rateUniform film formationDischarge tube luminescnet screensElectroluminescent light sourcesEngineeringRaw material

For increasing the film-forming rate and enabling uniform film formation and waste elimination of raw material, a film-forming method and a film-forming apparatus can reach an evaporated film-forming material to a surface of a substrate by the flow of a transport gas so as to control the film-forming conditions by the flow of the gas. Thereby a uniform thin film can be deposited on the large-area substrate. That is, by directing the evaporated raw material toward the substrate, it is possible to increase the film-forming rate and achieve uniform film formation.

Owner:OHMI +1

Electrical connecting structure and electrical connecting method for piezoelectric element, piezoelectric actuator, and head suspension

ActiveUS20100165516A1Without deteriorating productivity and reliabilityImprove automationArm with actuatorsPiezoelectric/electrostriction/magnetostriction machinesElectricityProduction rate

An electrical connecting structure for a piezoelectric element enables wiring to the piezoelectric element to be carried out without deteriorating the productivity and reliability of the piezoelectric element. The electrical connecting structure is formed by facing a common electrode of the piezoelectric element to a terminal that supplies power to the common electrode and by injecting a conductive adhesive into a through hole, which is formed substantially at the center of the piezoelectric element, from an opening of the through hole that is on the opposite side of the common electrode, thereby securing electrical connection between the terminal and the common electrode of the piezoelectric element.

Owner:NHK SPRING CO LTD

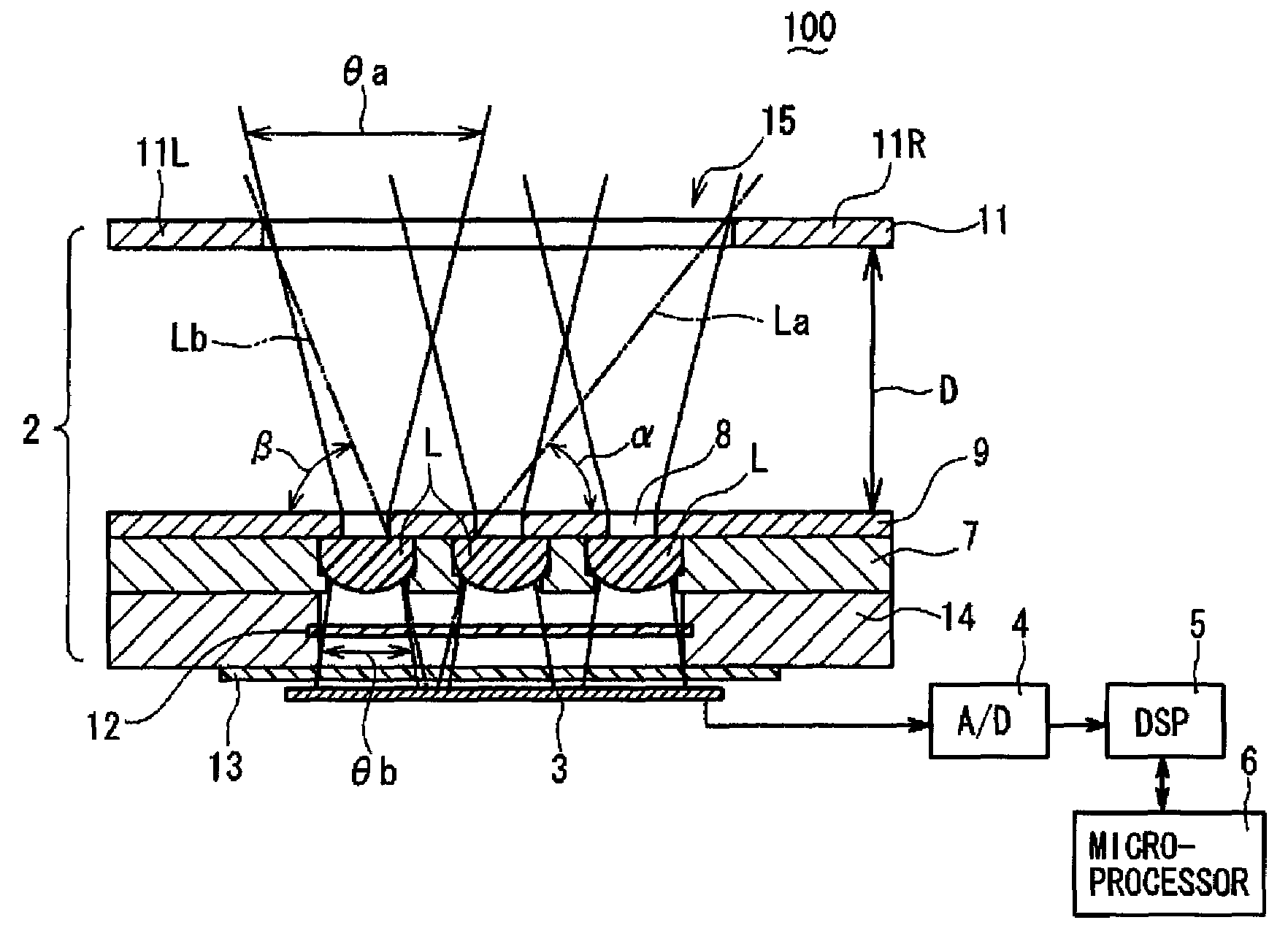

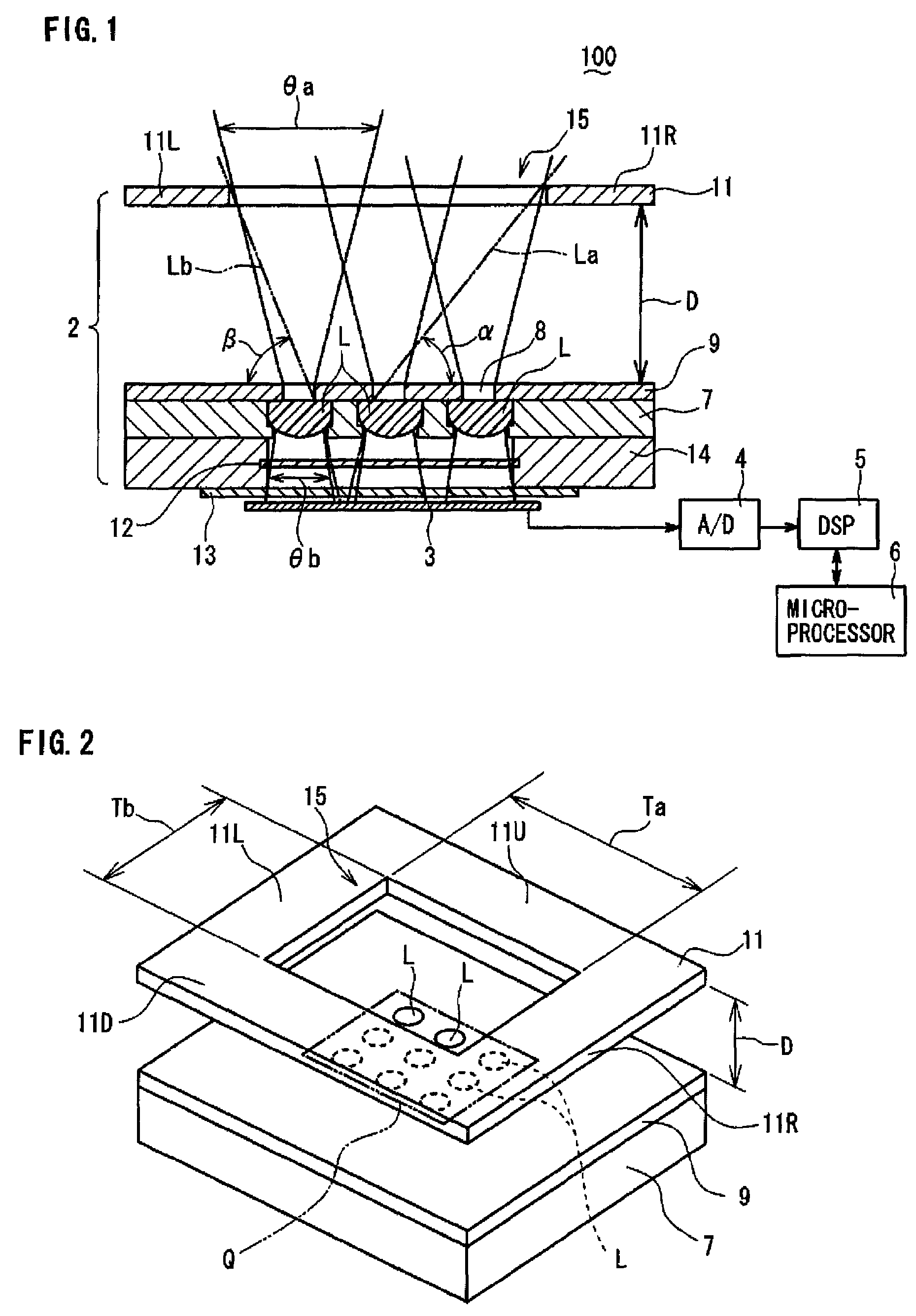

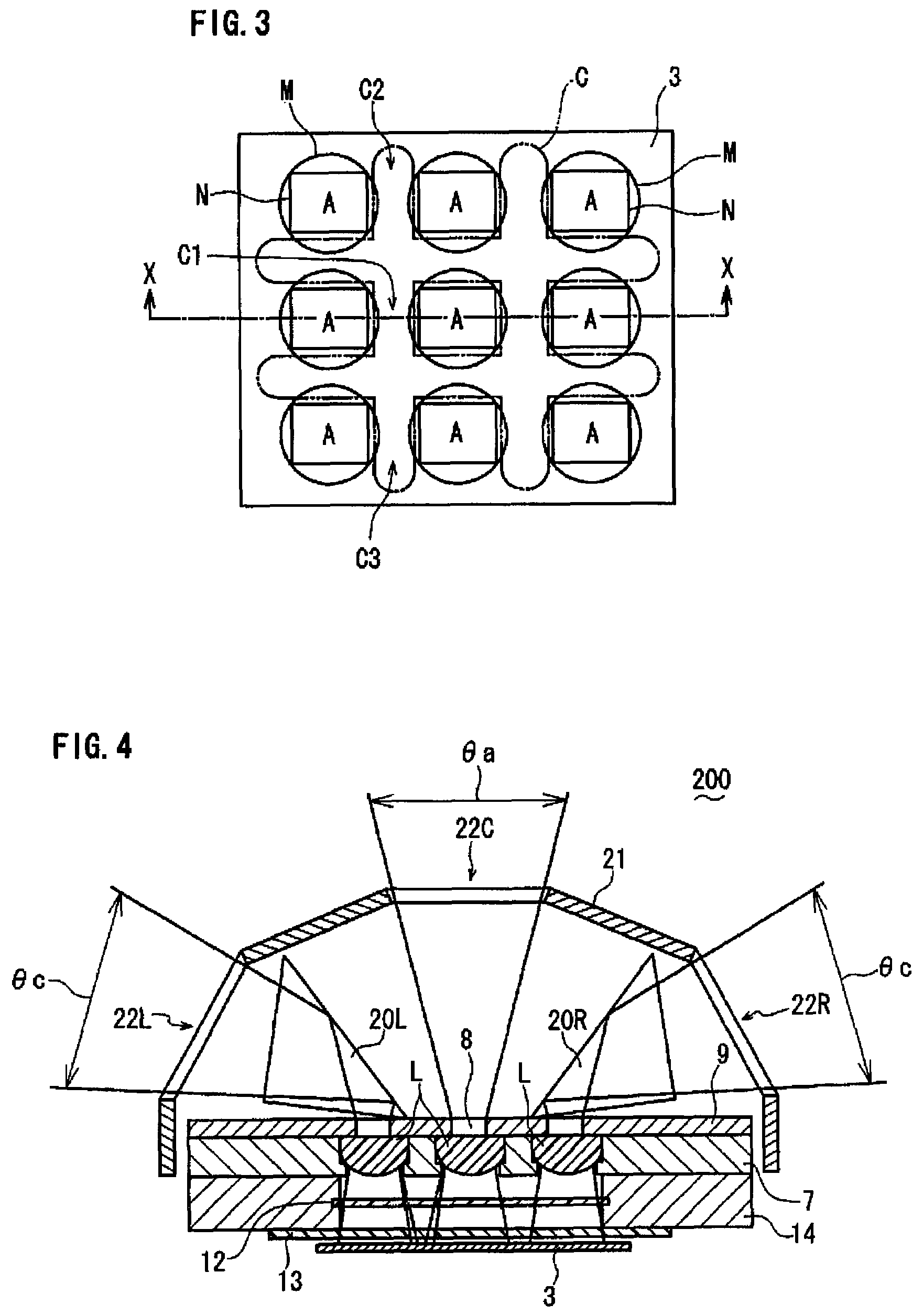

Compound-eye imaging device

InactiveUS7700904B2Avoid generatingEnhance the imageTelevision system detailsSolid-state devicesLight propagationStray light

A compound-eye imaging device comprises nine optical lenses arranged in a matrix array of three rows and three columns, and a solid-state imaging element for capturing unit images formed by the optical lenses. A stray light blocking member having a rectangular-shaped window is provided on the capture zone side of the optical lenses, eliminating the need to provide, between the solid-state imaging element and the optical lenses, walls by which light propagation paths of lights emitted from the optical lenses are partitioned from each other. The stray light blocking member blocks incident lights in a range outside each effective incident view angle range of each optical lens. This prevents the light entering each optical lens to form a unit image from interfering with other unit images formed by adjacent optical lenses, thereby obtaining a good quality image, without complicating the manufacturing process and increasing the cost thereof.

Owner:FUNAI ELECTRIC CO LTD

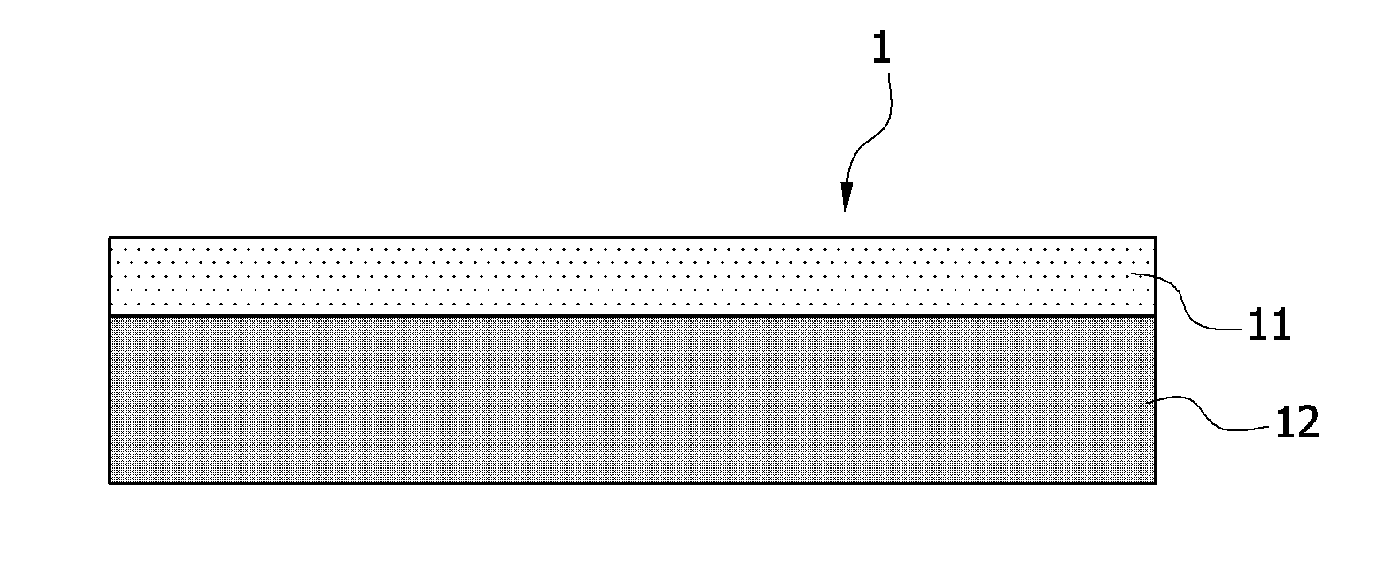

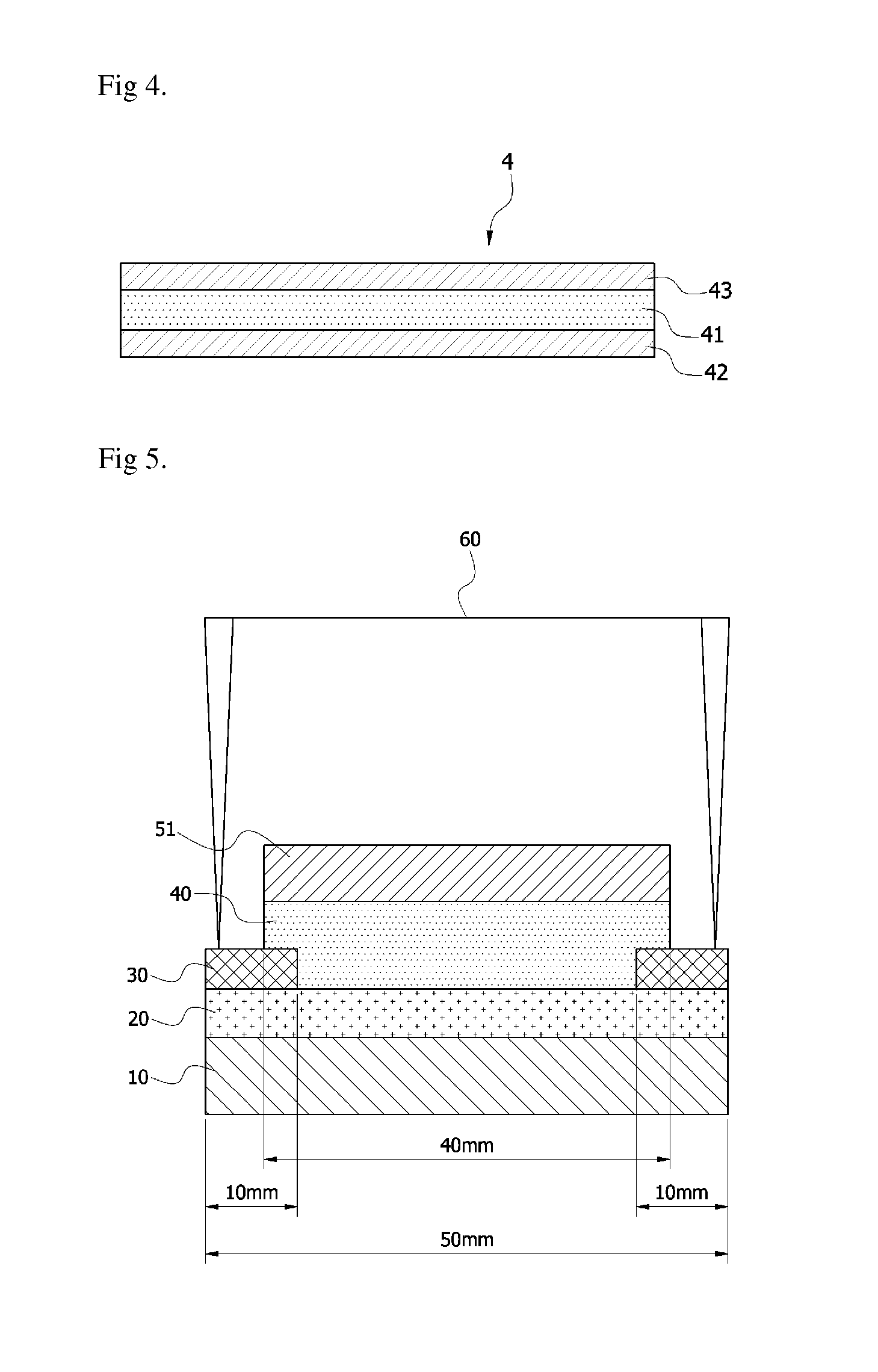

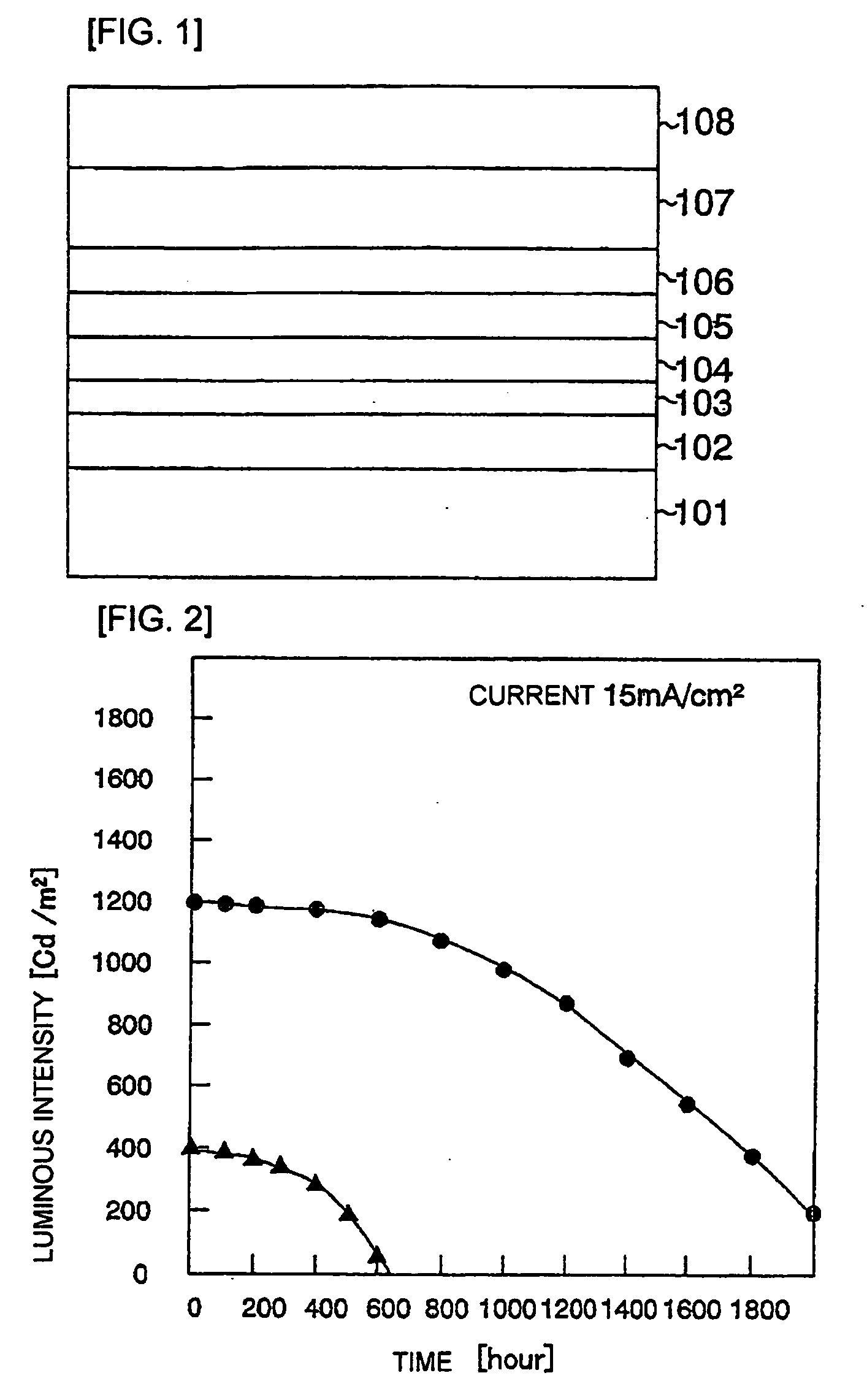

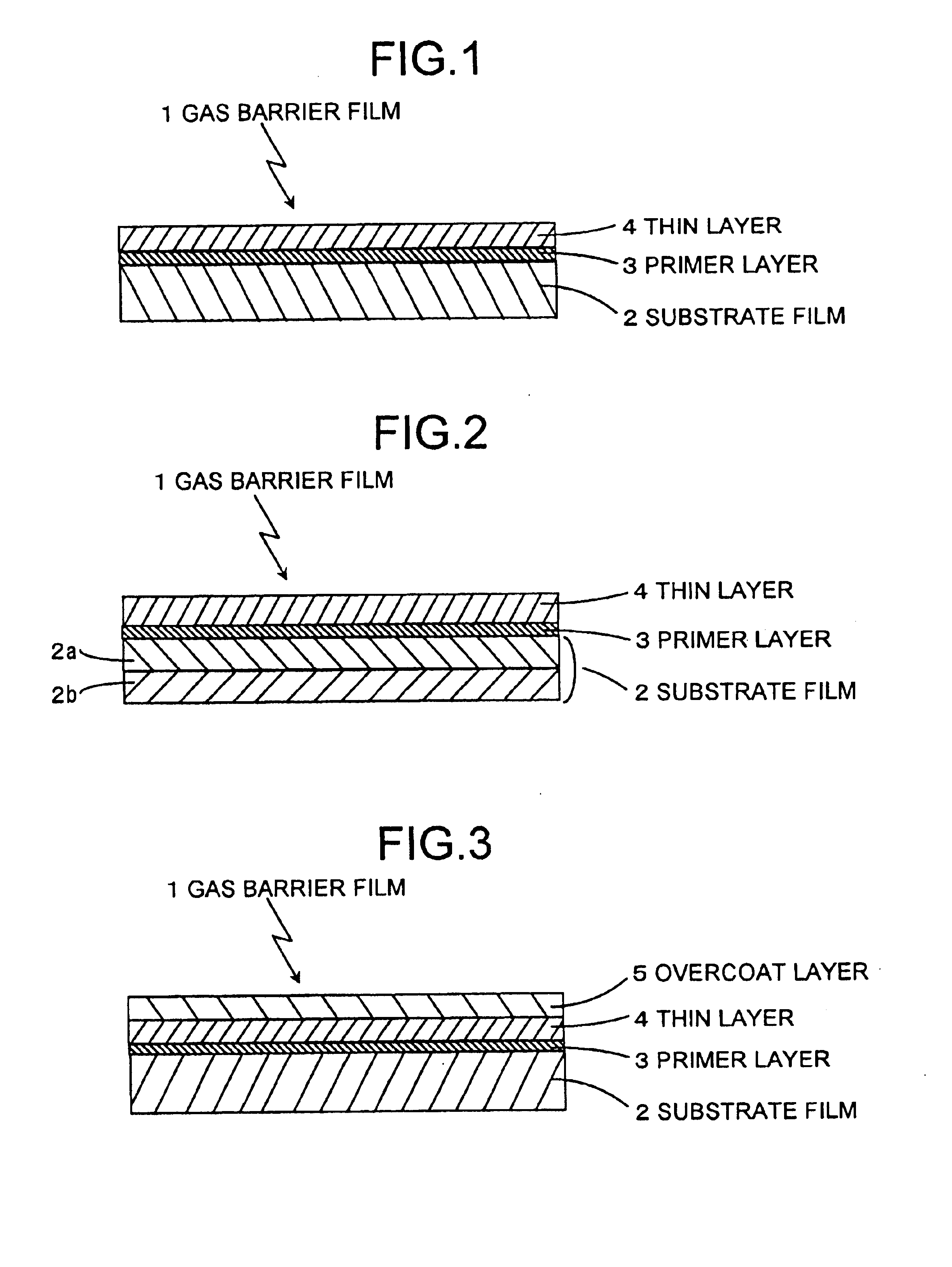

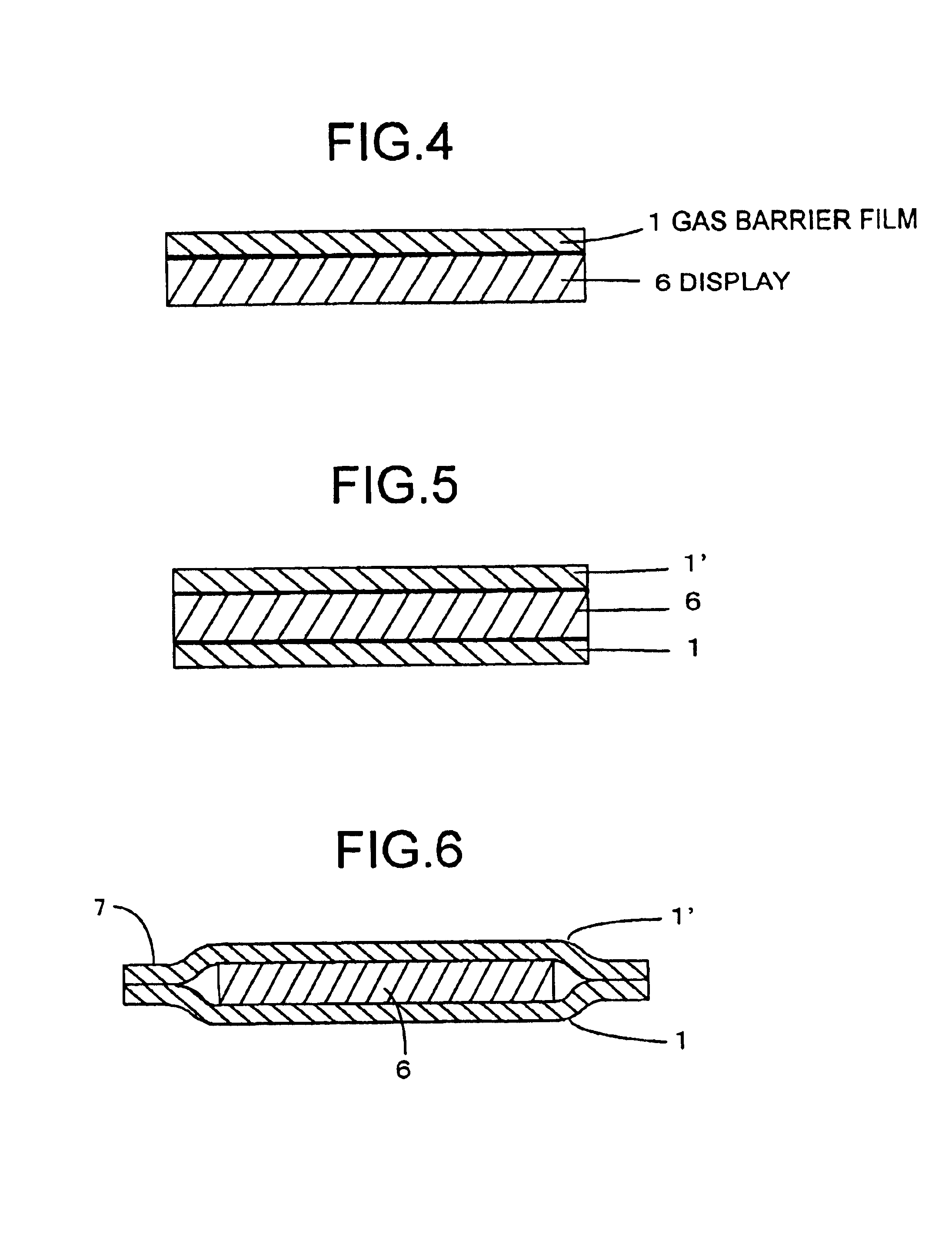

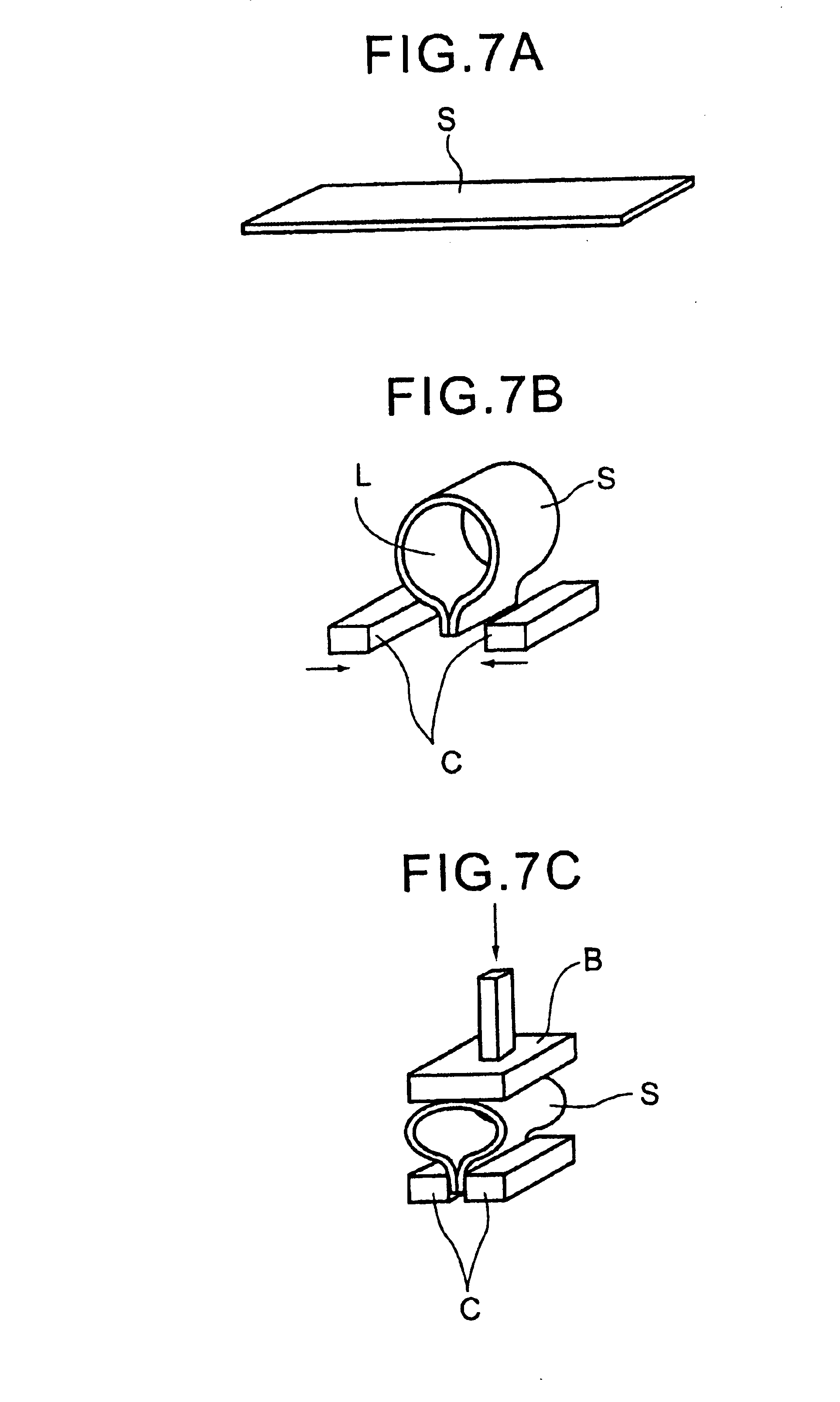

Substrate film, gas barrier film, and display using the same

InactiveUS6866949B2Excellent gas barrier performanceIncreasing the thicknessLiquid crystal compositionsSolid-state devicesVitrificationComposite film

The present invention provides a gas barrier film comprising a composite film provided with a gas barrier layer having a laminated structure including at least a metal oxide thin layer on a substrate film having a (1) 80 ppm / ° C. or less coefficient of thermal expansion at 50° C. to 150° C. and / or a 10 ppm / % RH or less coefficient of humidity expansion at 25° C., and a (2) 150 C. ° or more glass transition temperature, and a display with a display element covered with the same.

Owner:DAI NIPPON PRINTING CO LTD

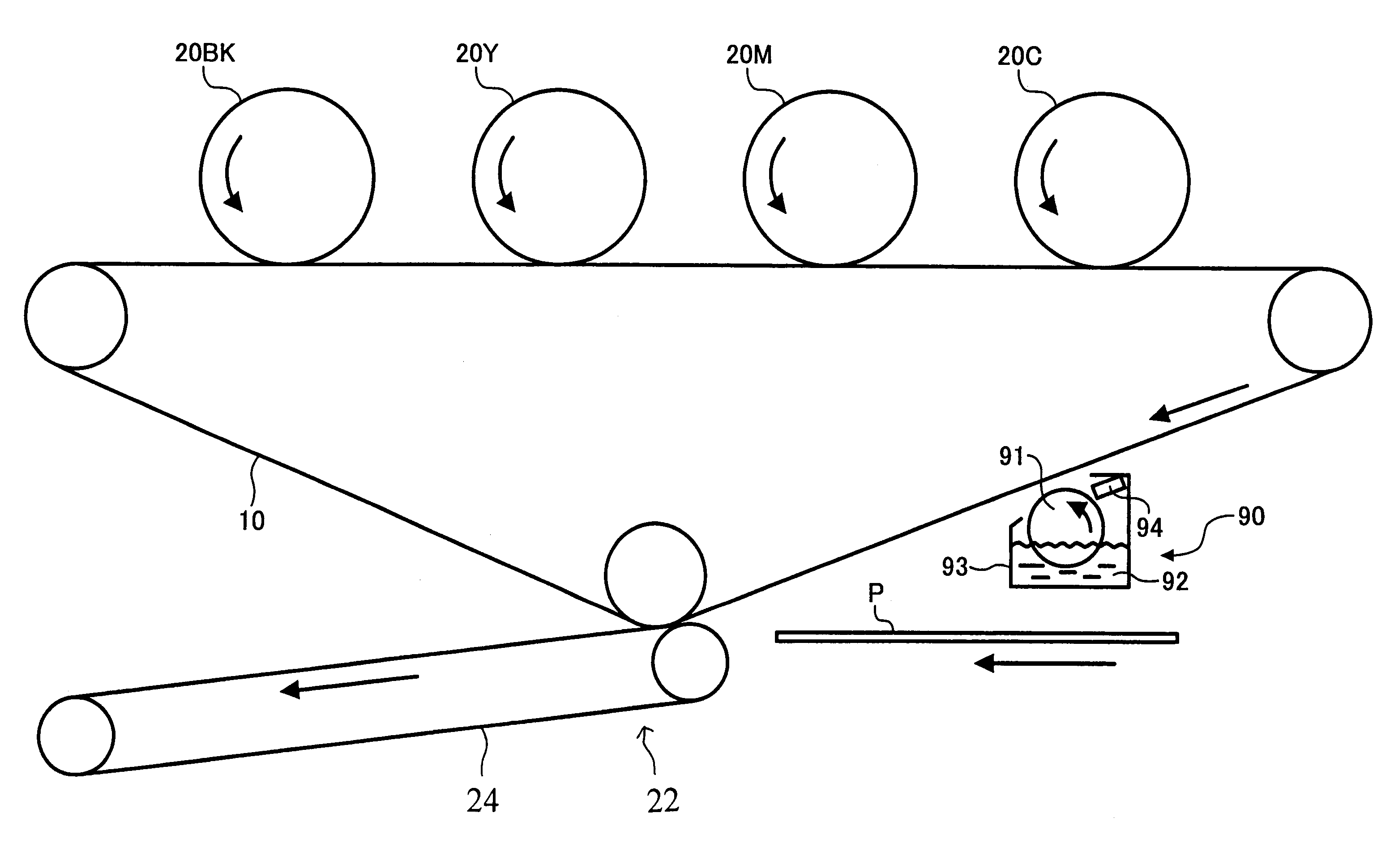

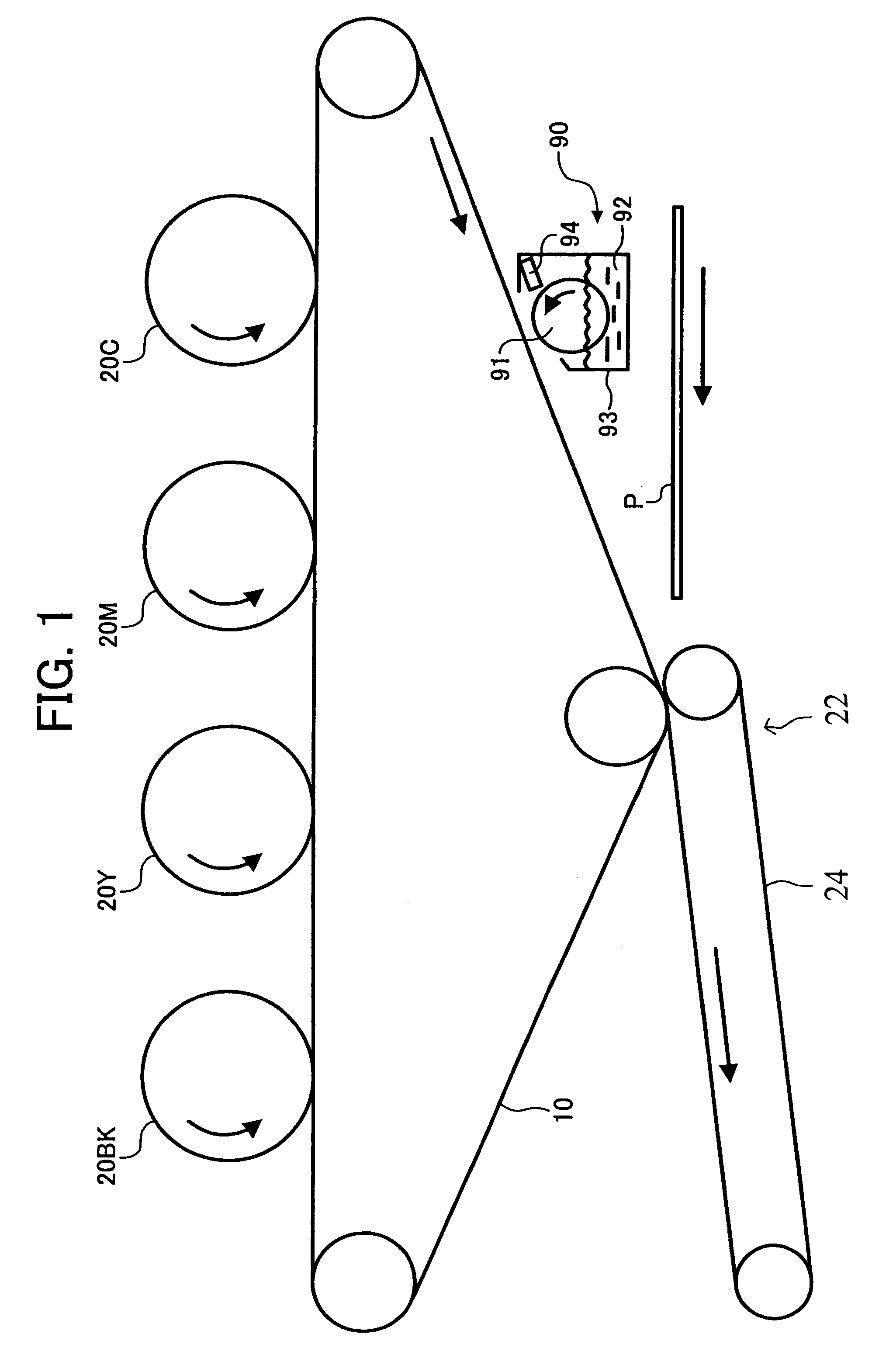

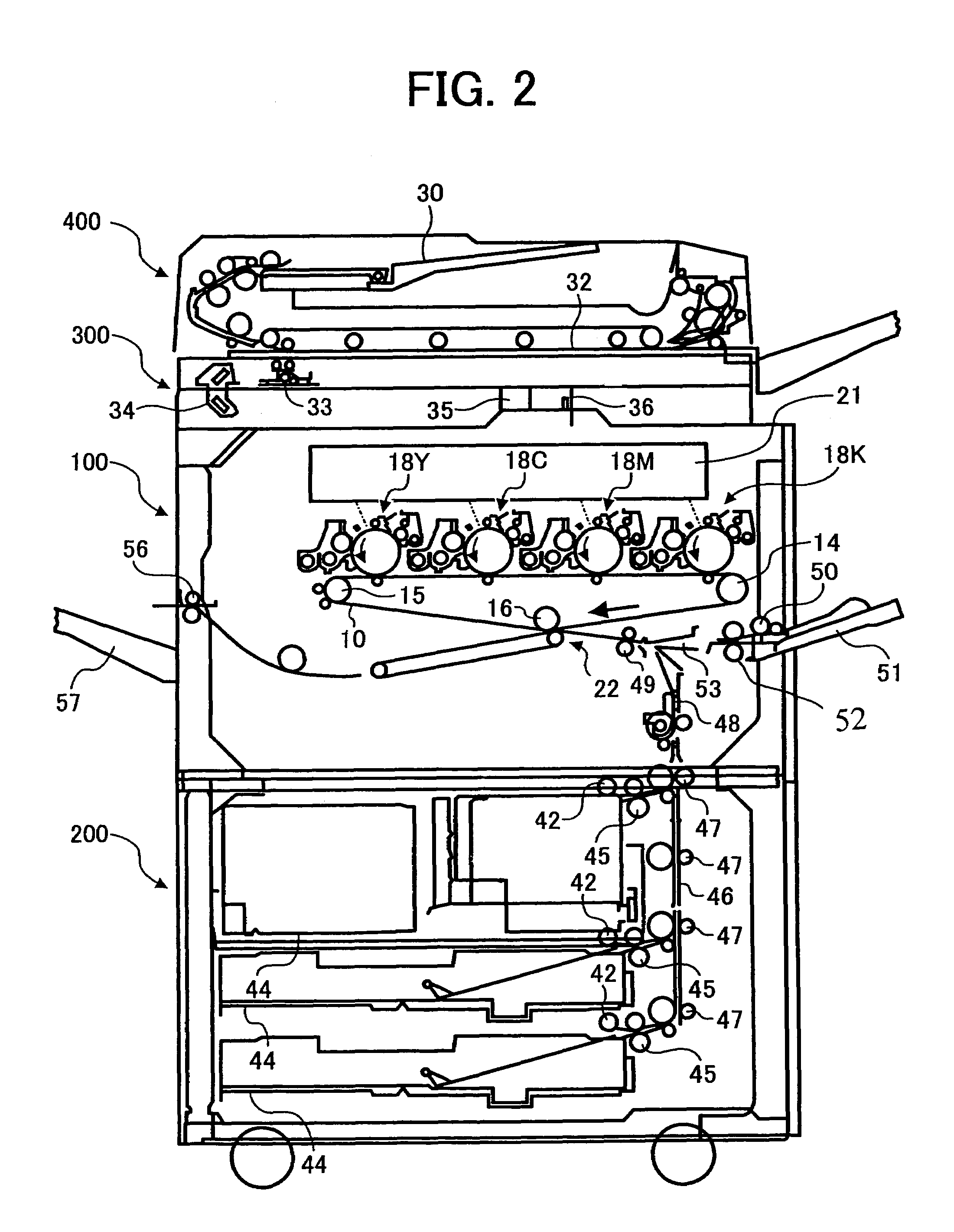

Fixing apparatus and image forming apparatus

InactiveUS7046952B2Avoid generatingPrevent materialOhmic-resistance heatingElectrographic process apparatusElectrical and Electronics engineeringWrinkle

Since a fluorine treatment or the like is applied on a surface of an intermediate transfer belt (10), and thus, the surface bears water repelling property, when fixer (92) is supplied from a fixing apparatus (90) to surface parts of the intermediate transfer belt which are carrying a toner image, the fixer is present only on the toner parts. Namely, the fixer is not attached to surface parts which are not carrying the toner. Consequently, when the surface parts are pressed on transfer paper (P) for transferring and fixing, the fixer attached to the transfer paper is present only on the parts of the toner T. Thus, compared with a conventional case where fixer is imparted to entire transfer paper, a reduced quantity of the fixer is impregnated into the transfer paper, and thus, generation of curls and wrinkles of the transfer paper is restrained.

Owner:RICOH KK

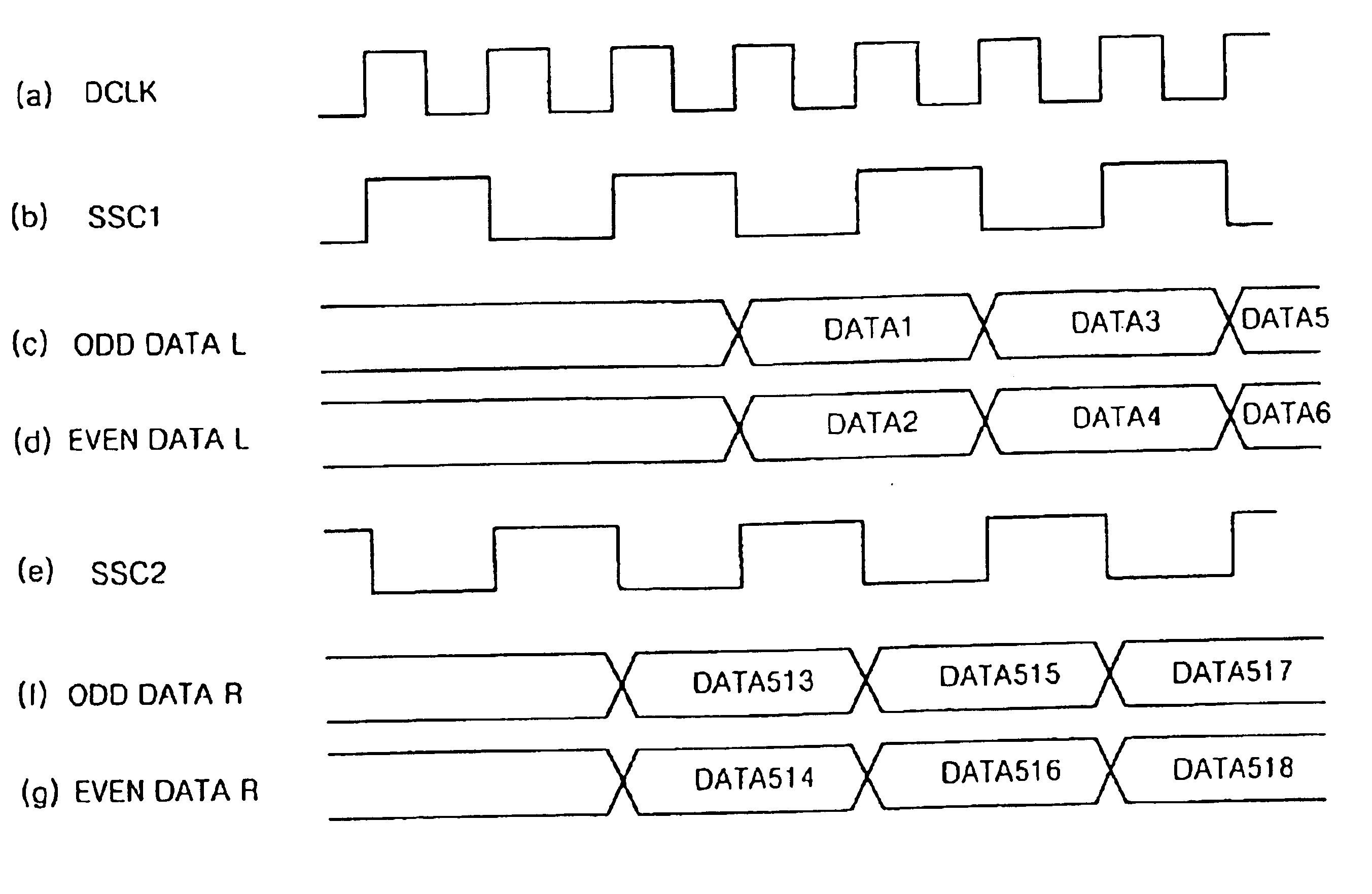

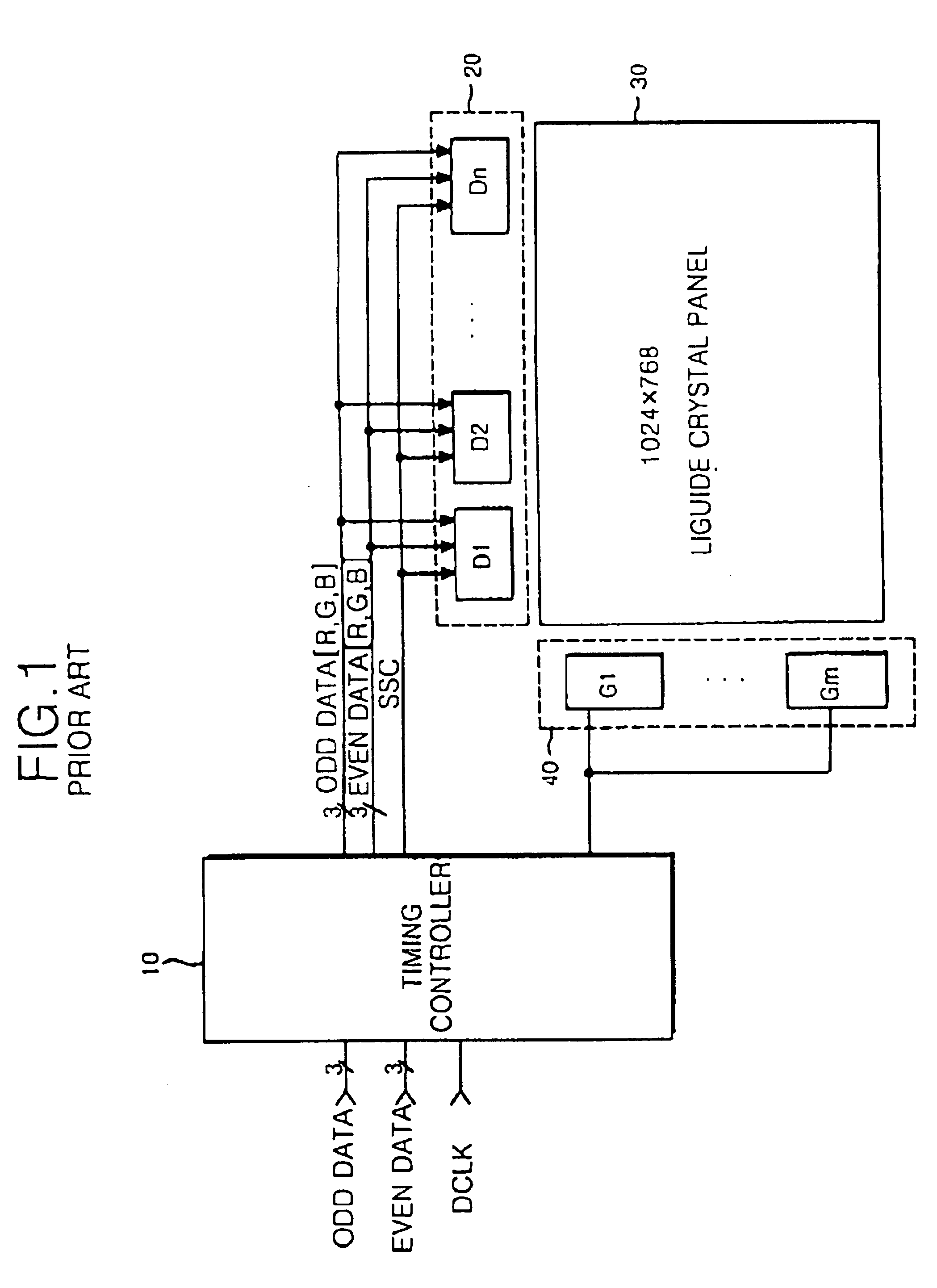

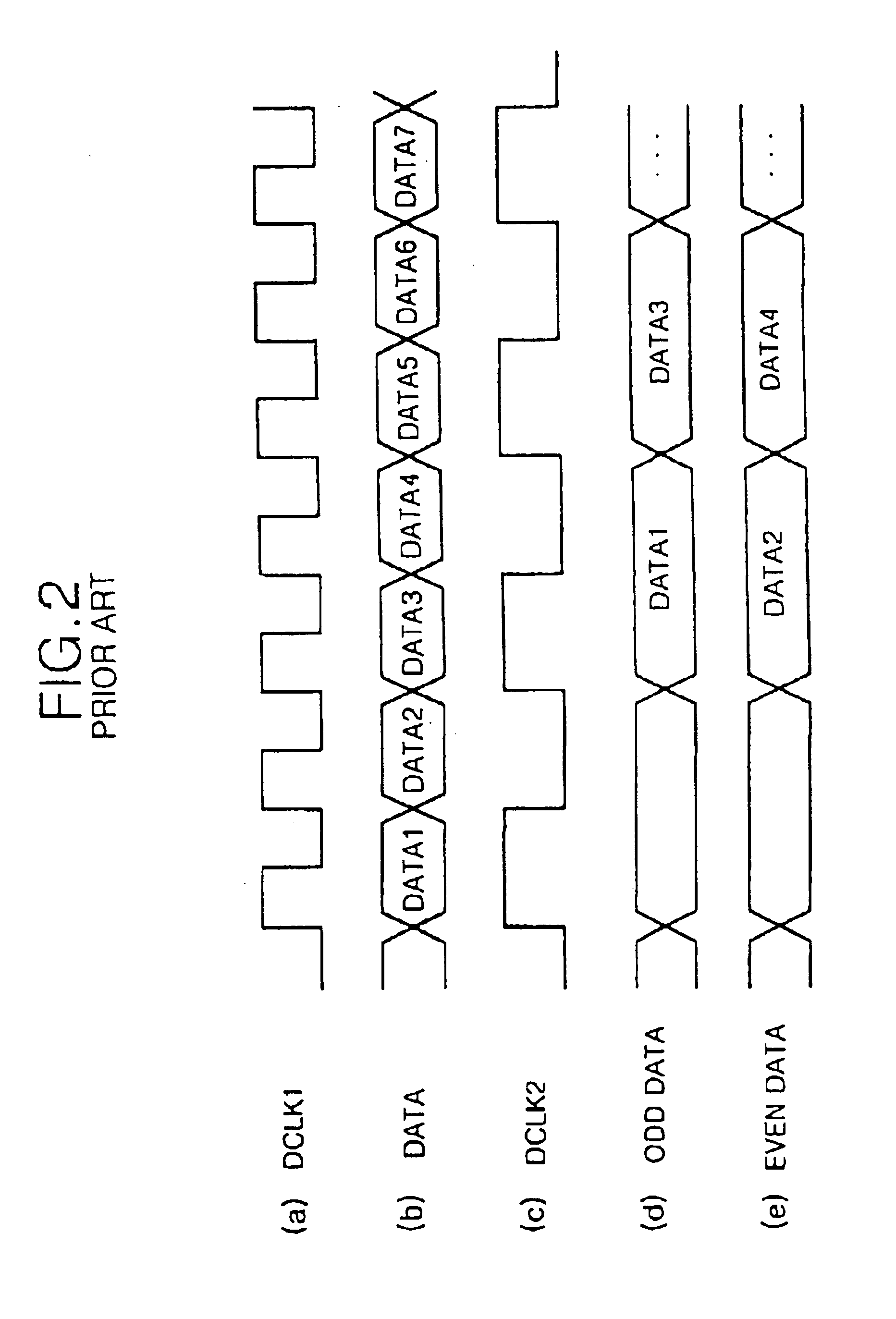

Liquid crystal display and driving method thereof

InactiveUS6867759B1Reduce generationAvoid generatingStatic indicating devicesNon-linear opticsLiquid-crystal displayTransient current

A liquid crystal display device for restraining a generation of transient current is disclosed. In the device, a line memory divides a data for at least one line inputted from the exterior thereof into a plurality of groups to store the divided data therein and outputs the data at a desired unit from each of the groups. A driving circuit includes n driver integrated circuits (wherein n is an integer) that are connected to the line memory and a liquid crystal display panel to drive the liquid crystal display panel in response to the data outputted from the line memory. A timing controller is connected to the line memory and the driving circuit to receive a data clock inputted from the exterior thereof for outputting the data from the plurality of groups of said line memory to the driving circuit every period of the data clock in response to a time corresponding to the number of said groups.

Owner:LG DISPLAY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com