Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

20167results about "Cleaning using gases" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

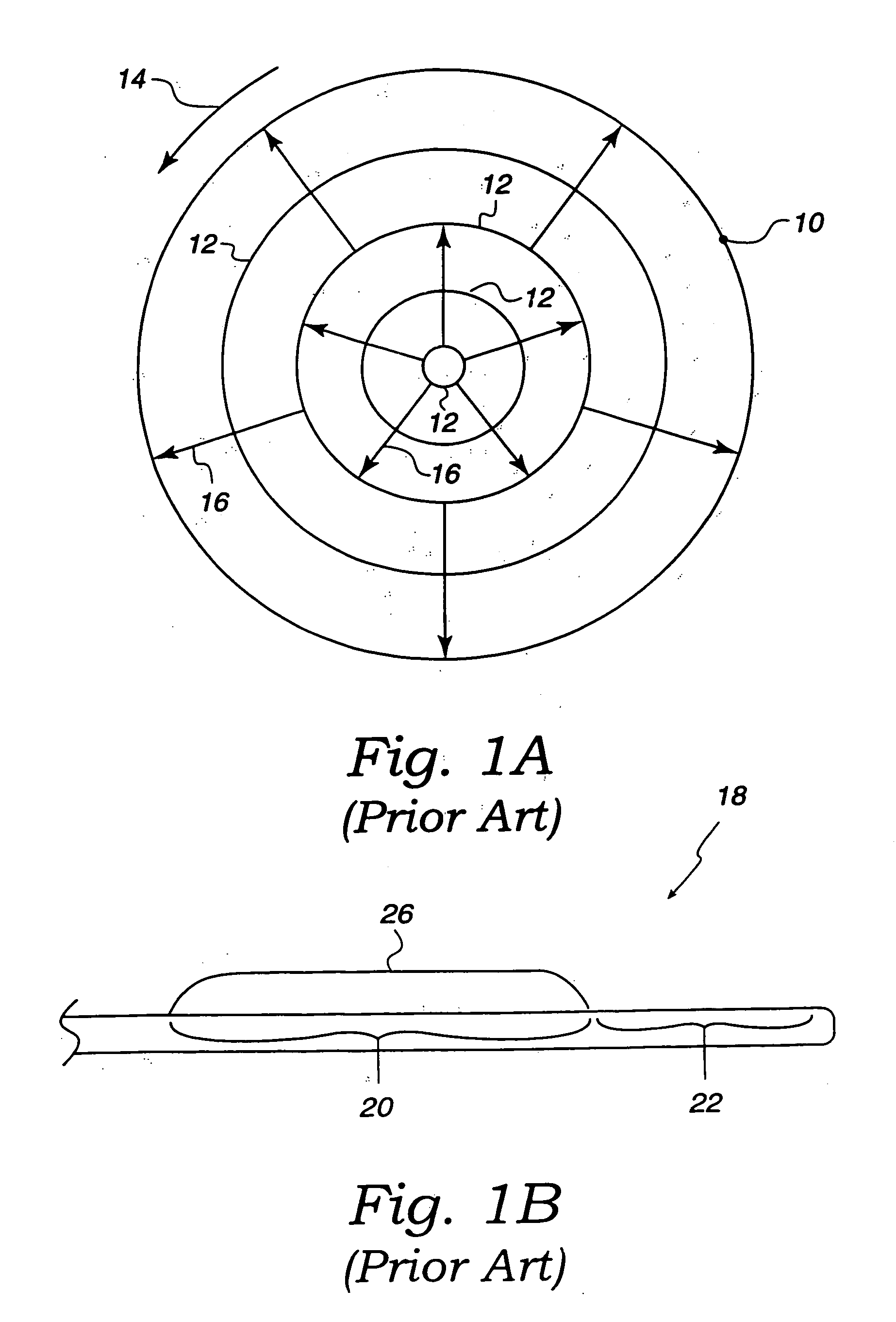

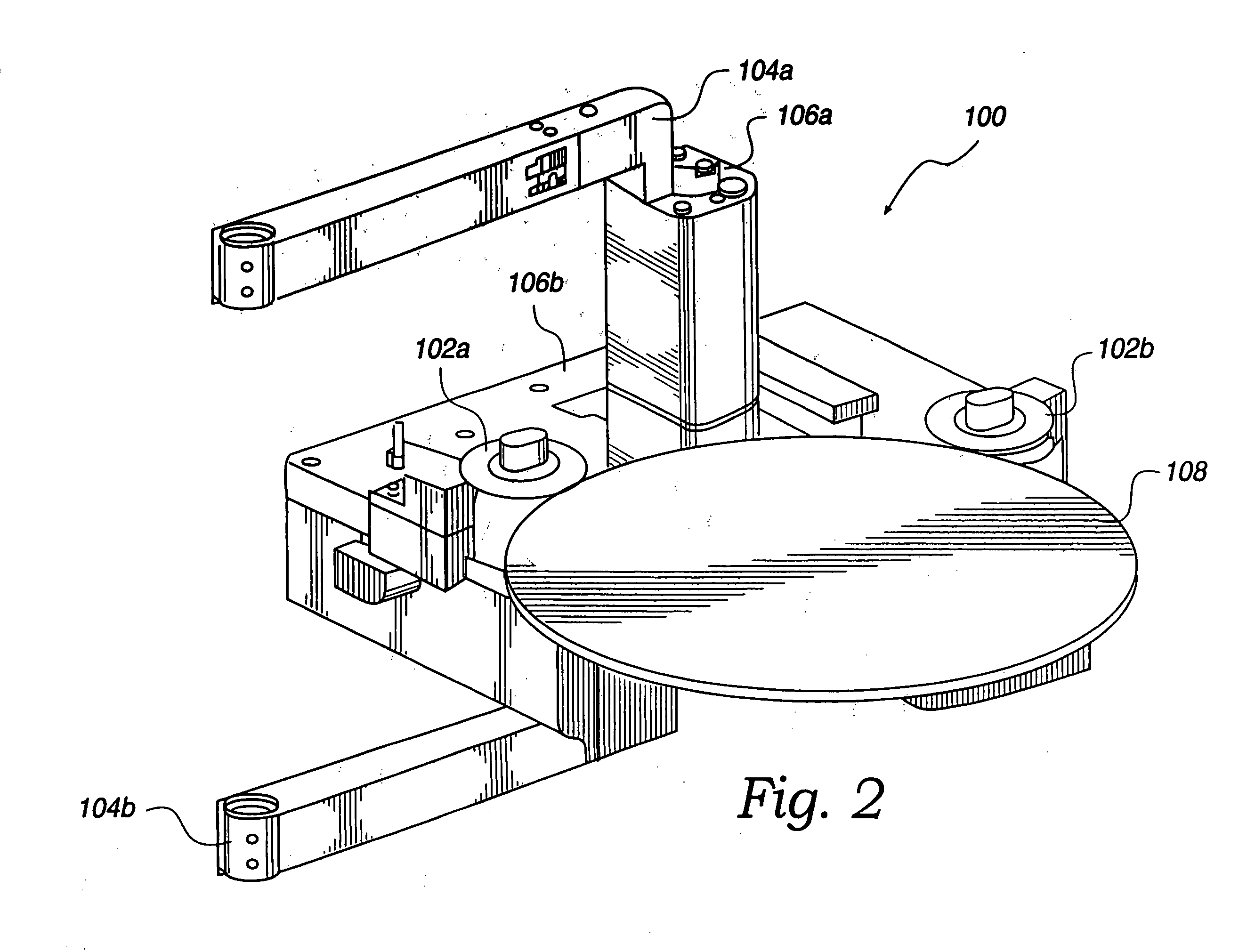

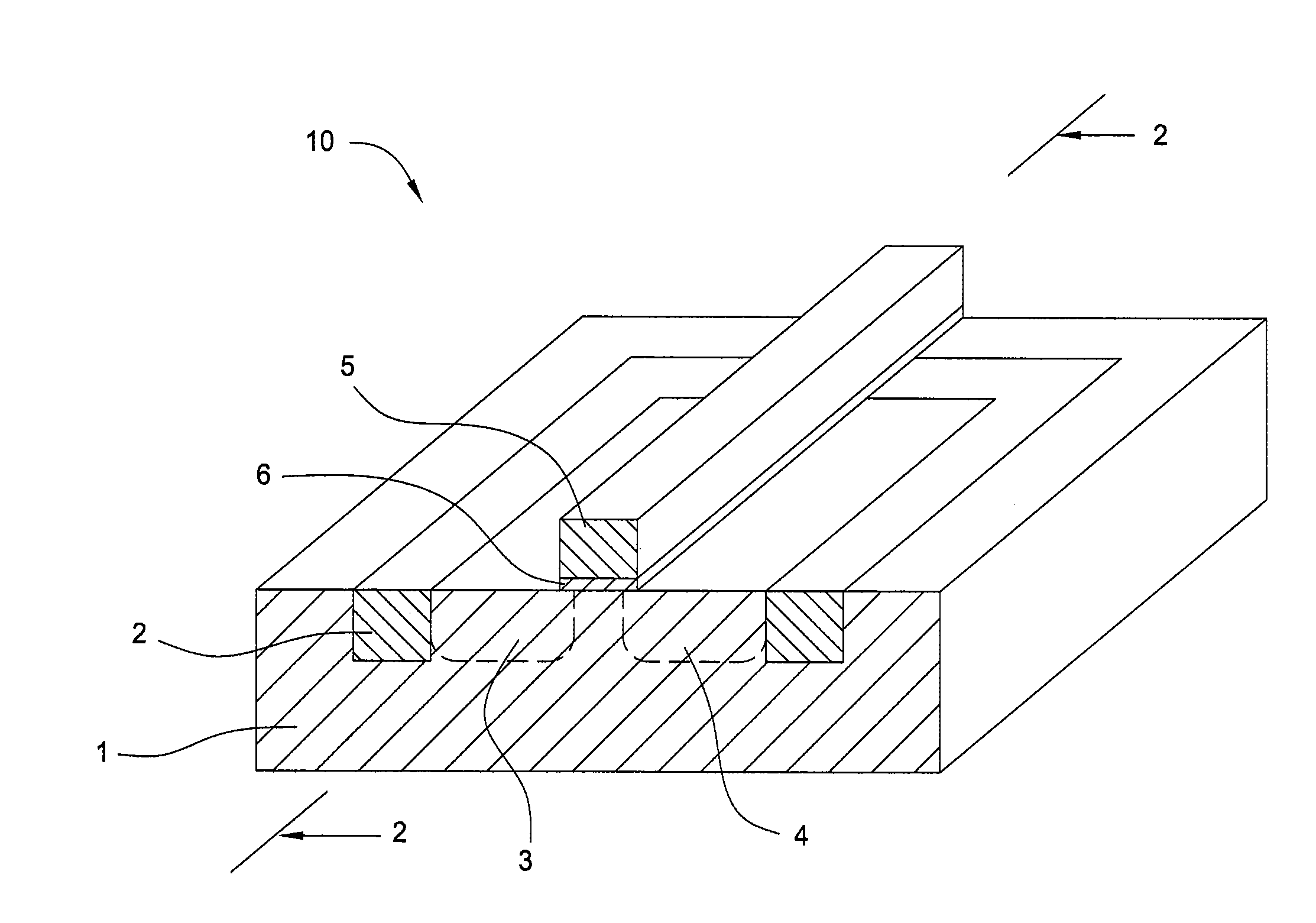

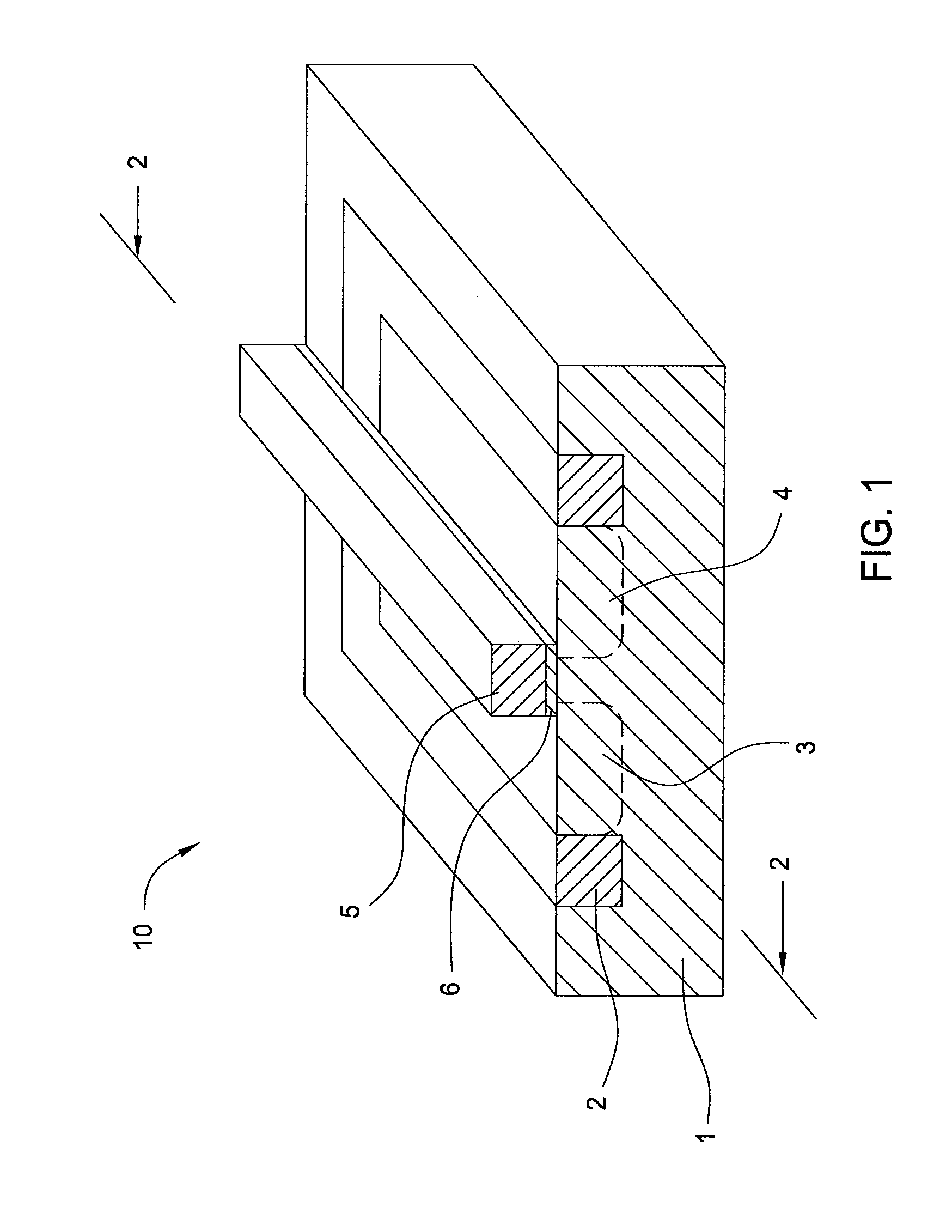

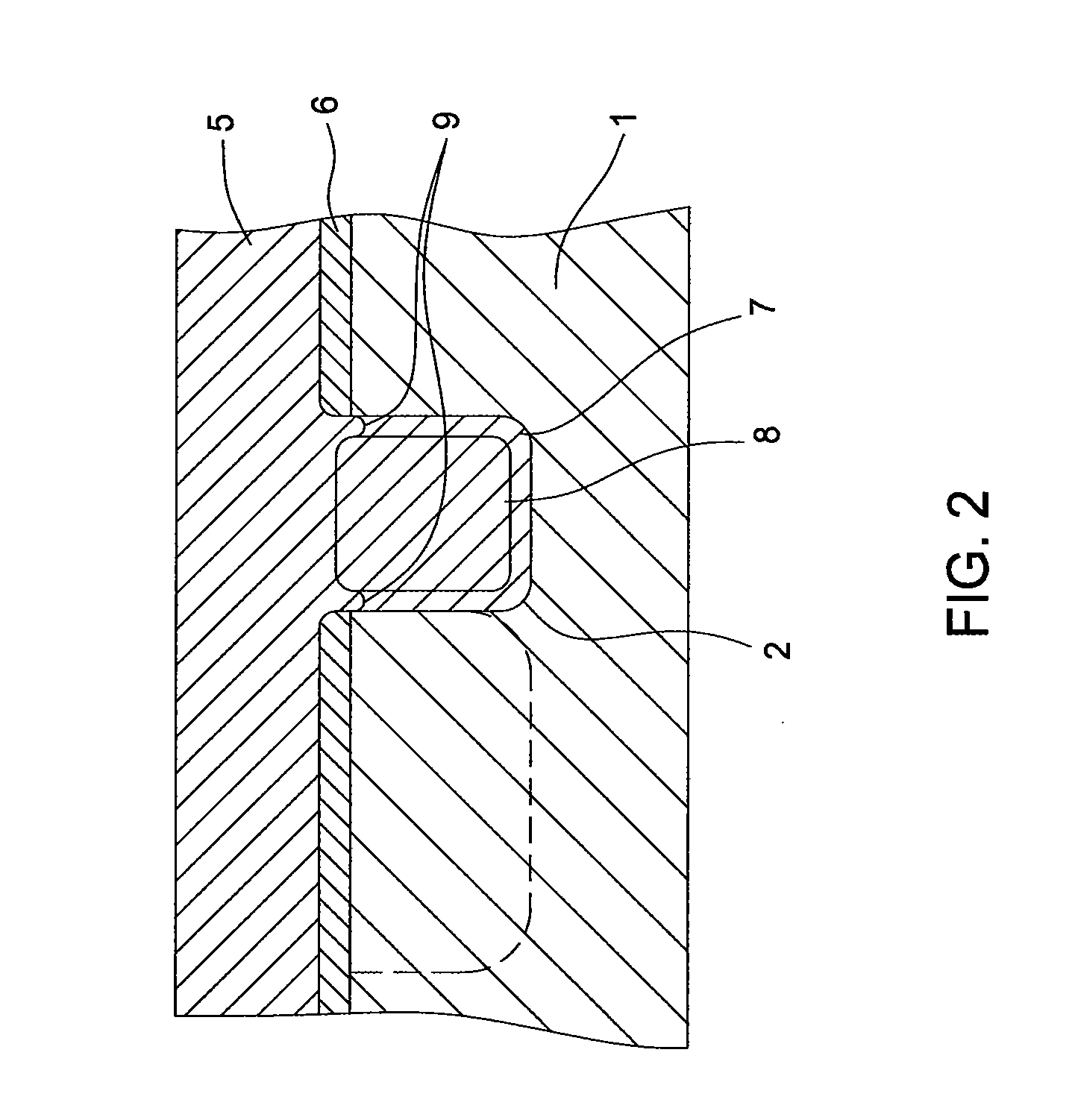

Apparatus and method for utilizing a meniscus in substrate processing

InactiveUS20050217703A1Process environment can be powerfully controlled and managedMore processedLiquid surface applicatorsSemiconductor/solid-state device manufacturingActive agentEngineering

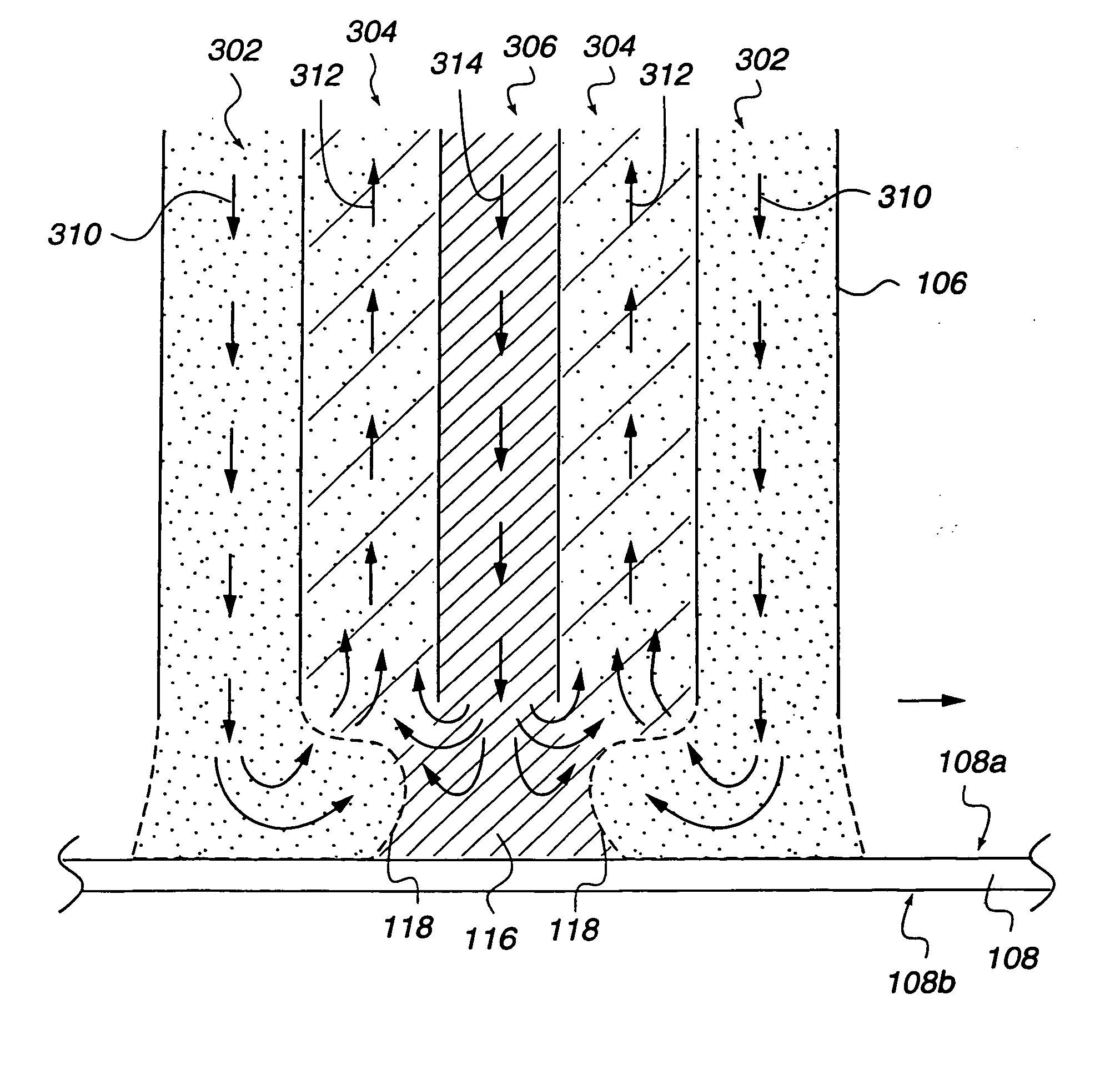

An apparatus for processing a substrate is provided which includes a proximity head proximate to a surface of the substrate when in operation. The apparatus also includes an opening on a surface of the proximity head to a cavity defined in the proximity head where the cavity delivers an active agent to the surface of the substrate through the opening. The apparatus further includes a plurality of conduits on the surface of the proximity head that generates a fluid meniscus on the surface of the substrate surrounding the opening.

Owner:LAM RES CORP

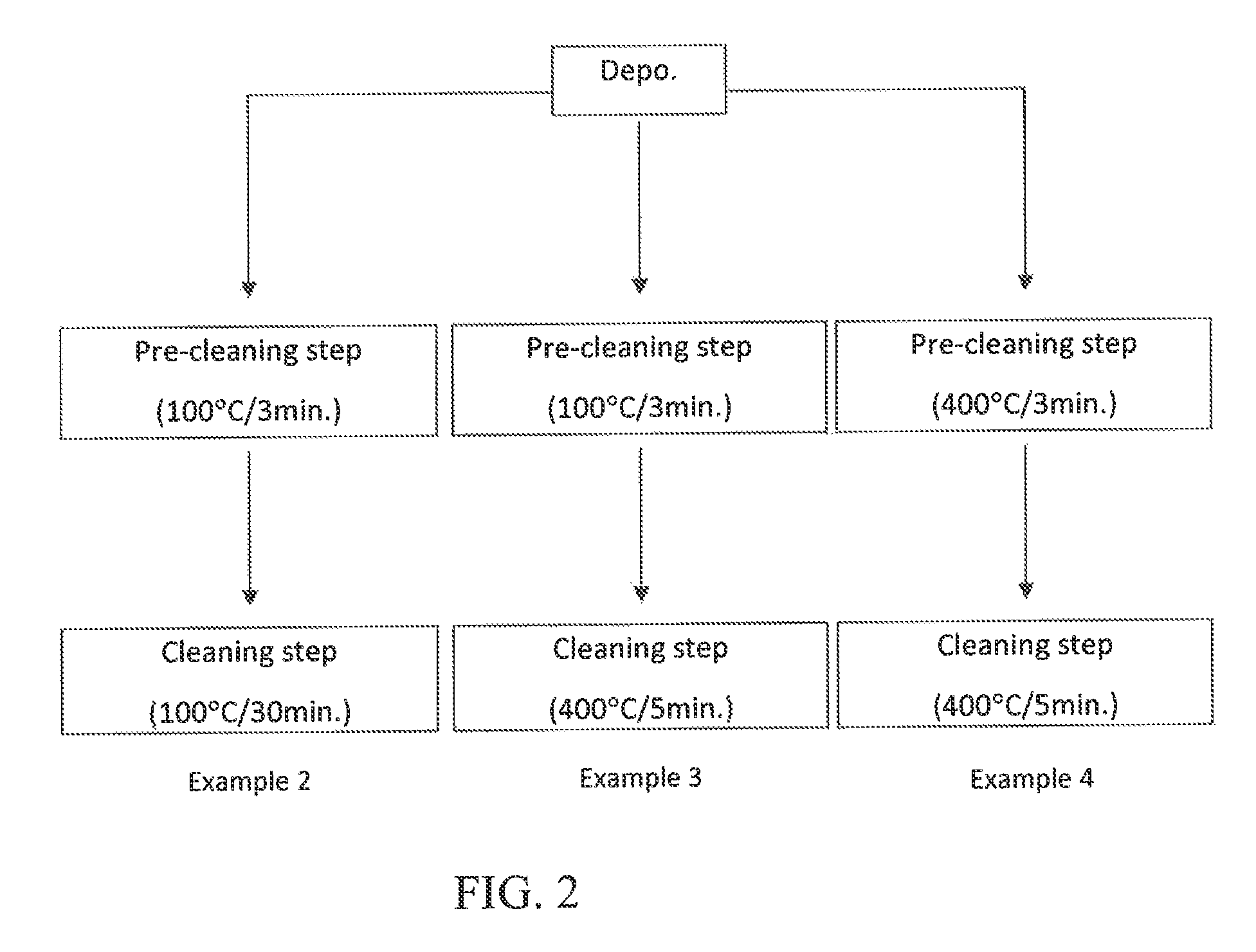

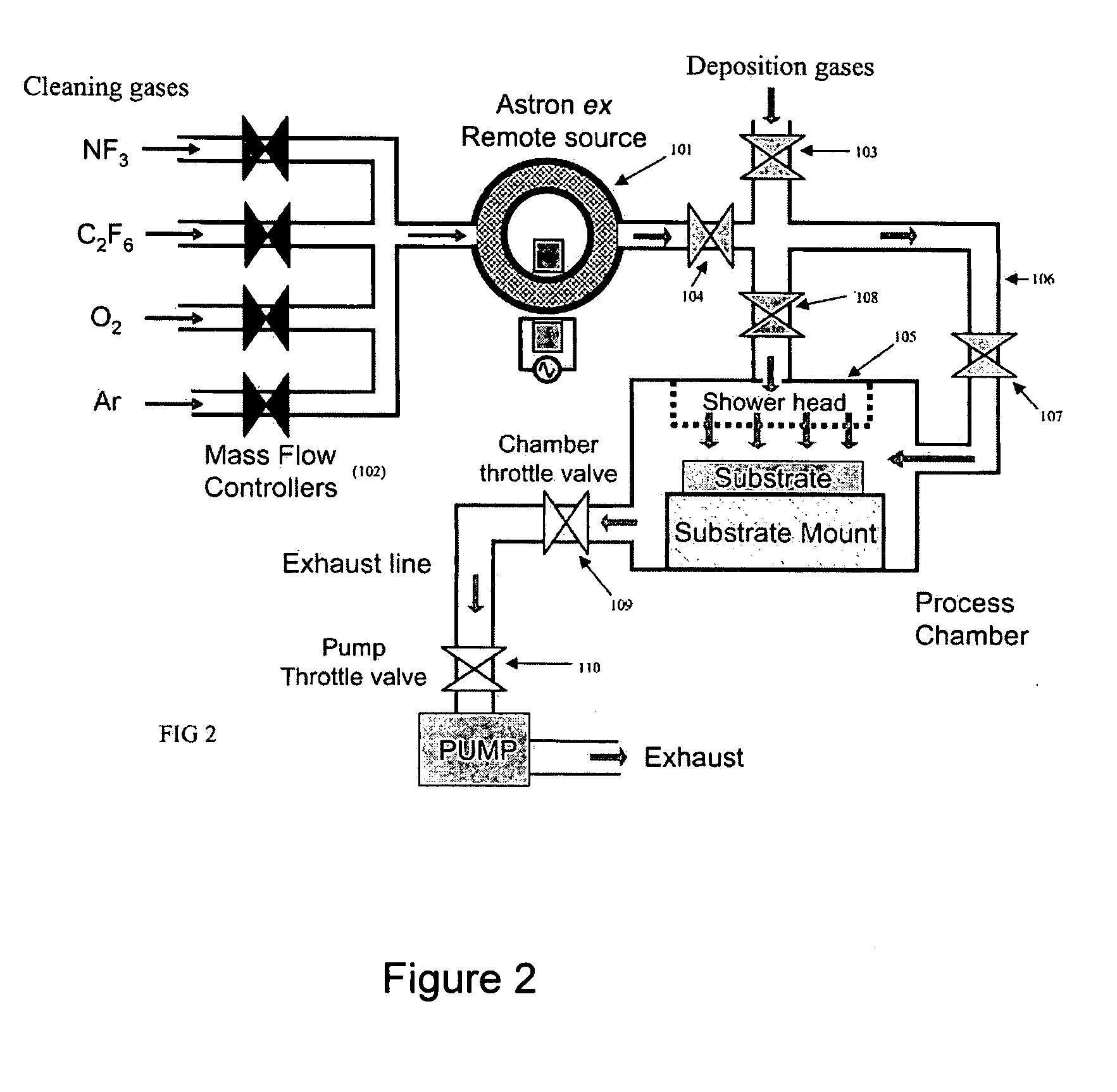

Method for cleaning reaction chamber using pre-cleaning process

ActiveUS9142393B2Improve efficiencyElectric discharge tubesHollow article cleaningNitrogenSilicon oxide

Owner:ASM IP HLDG BV

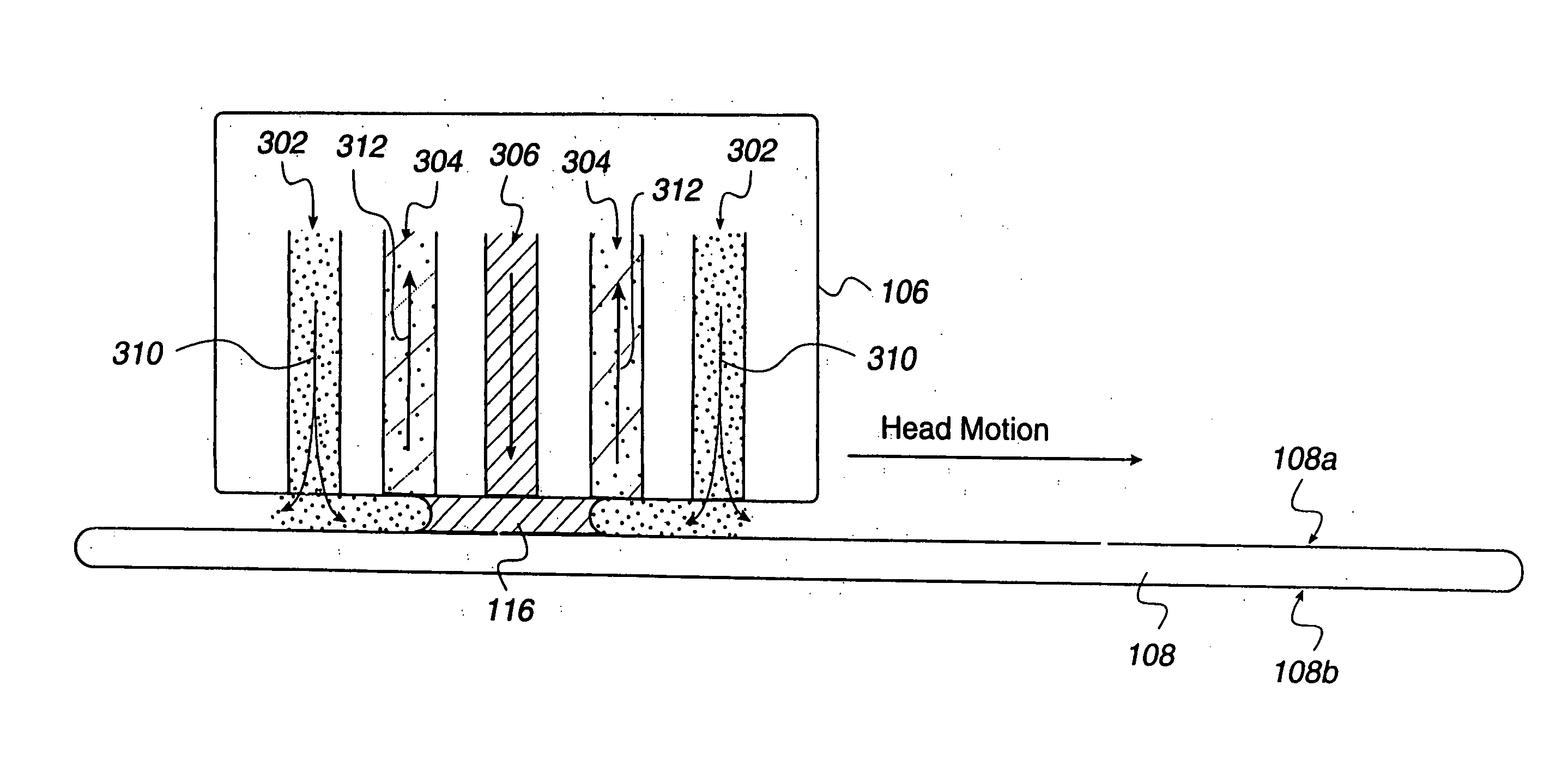

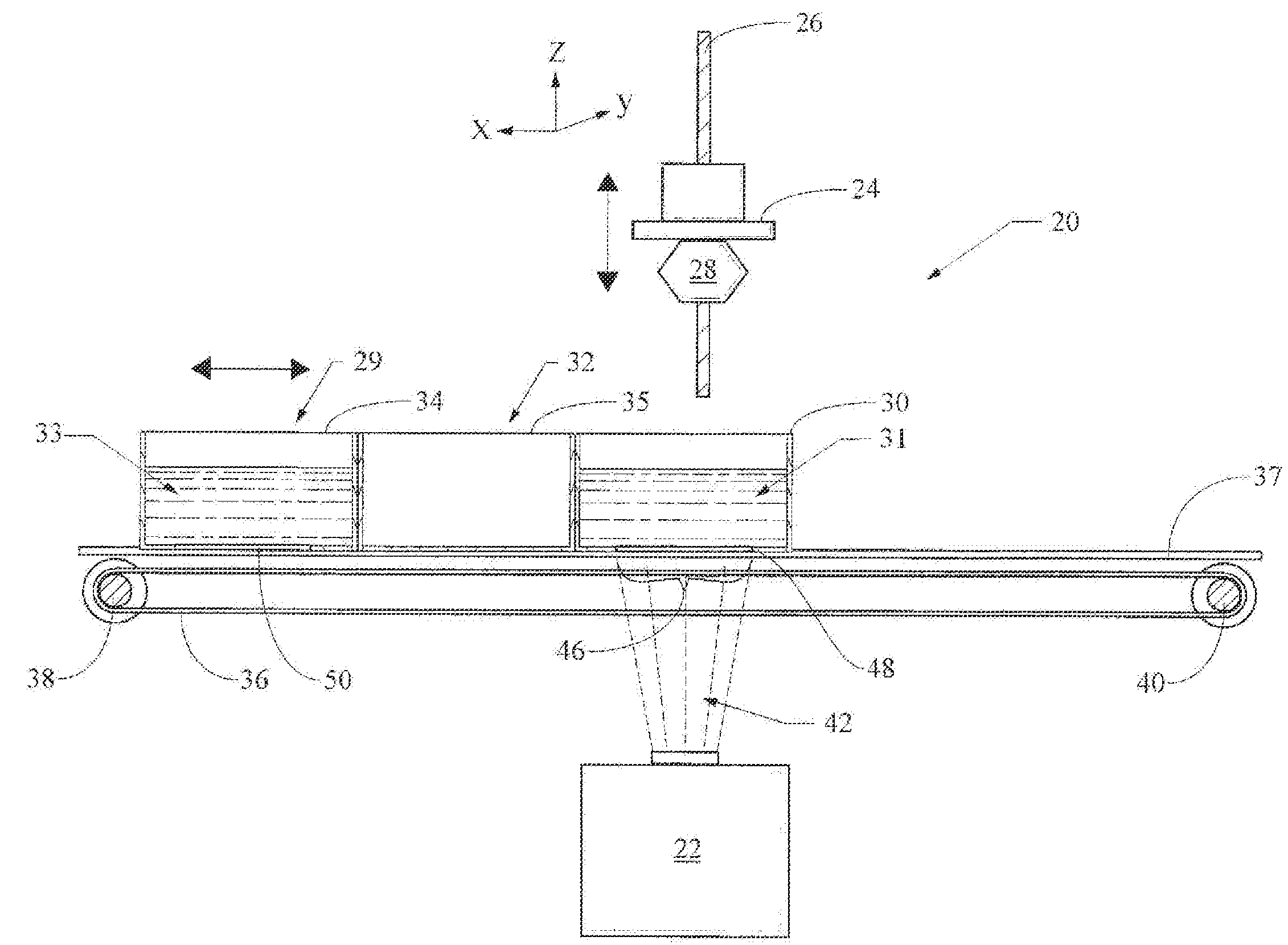

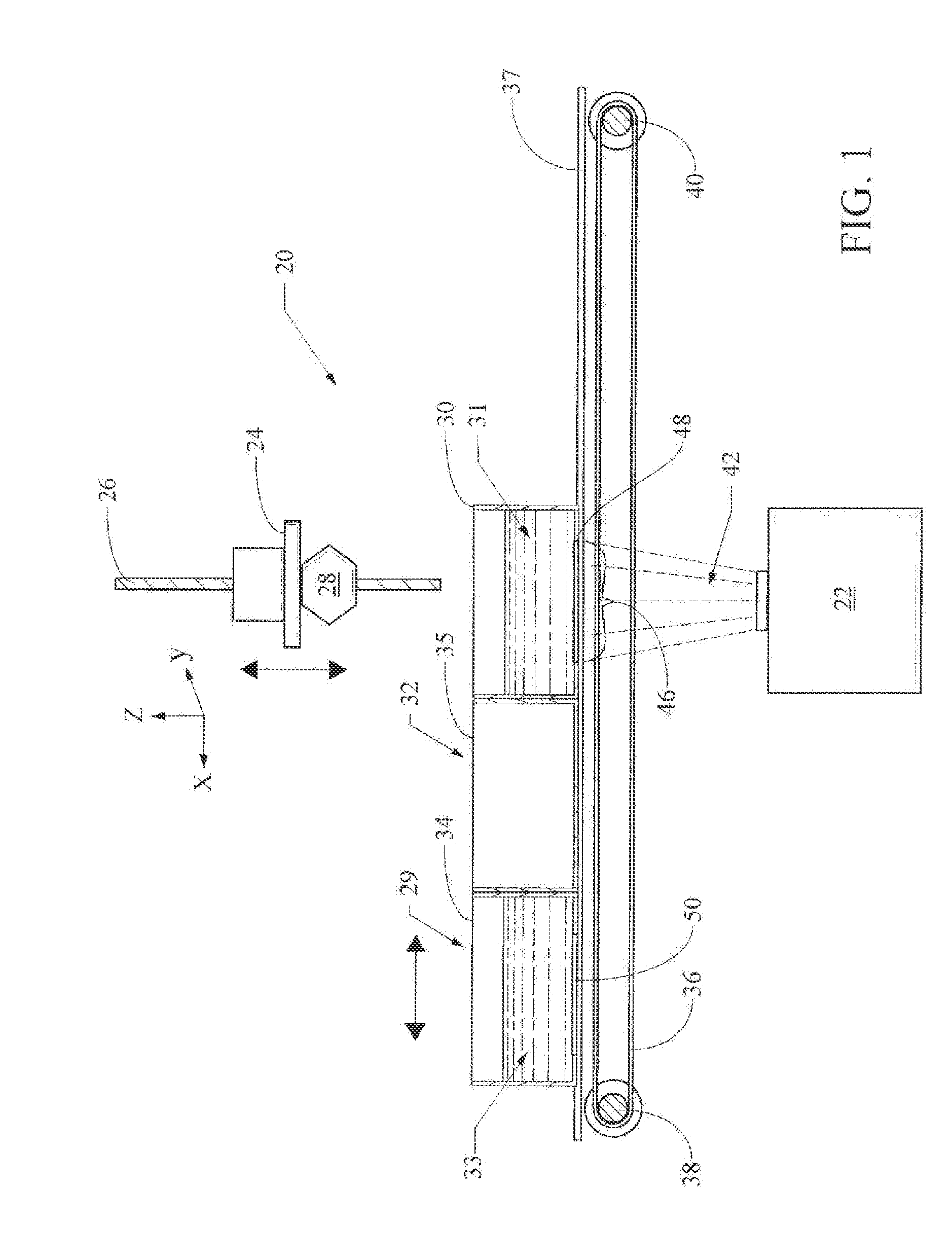

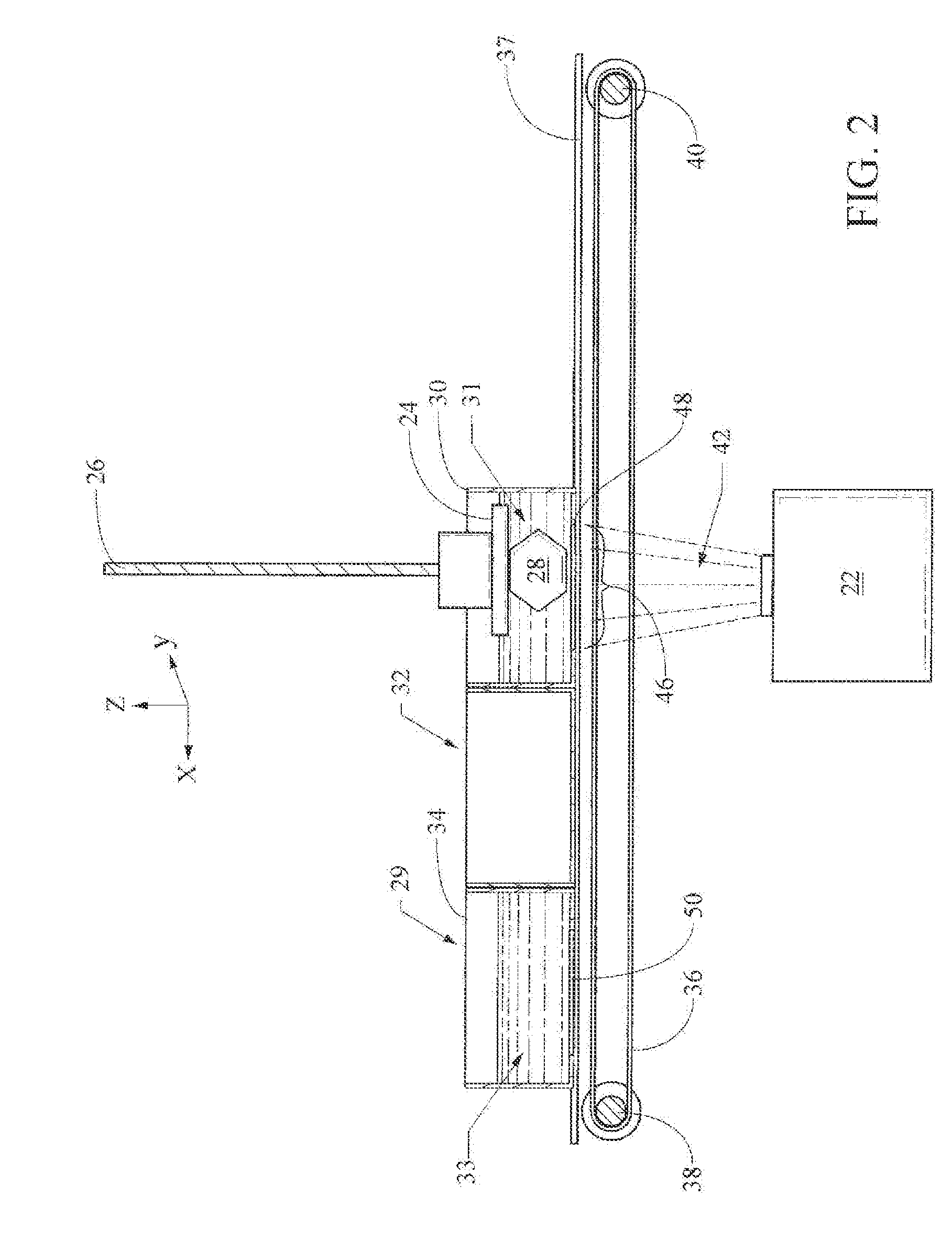

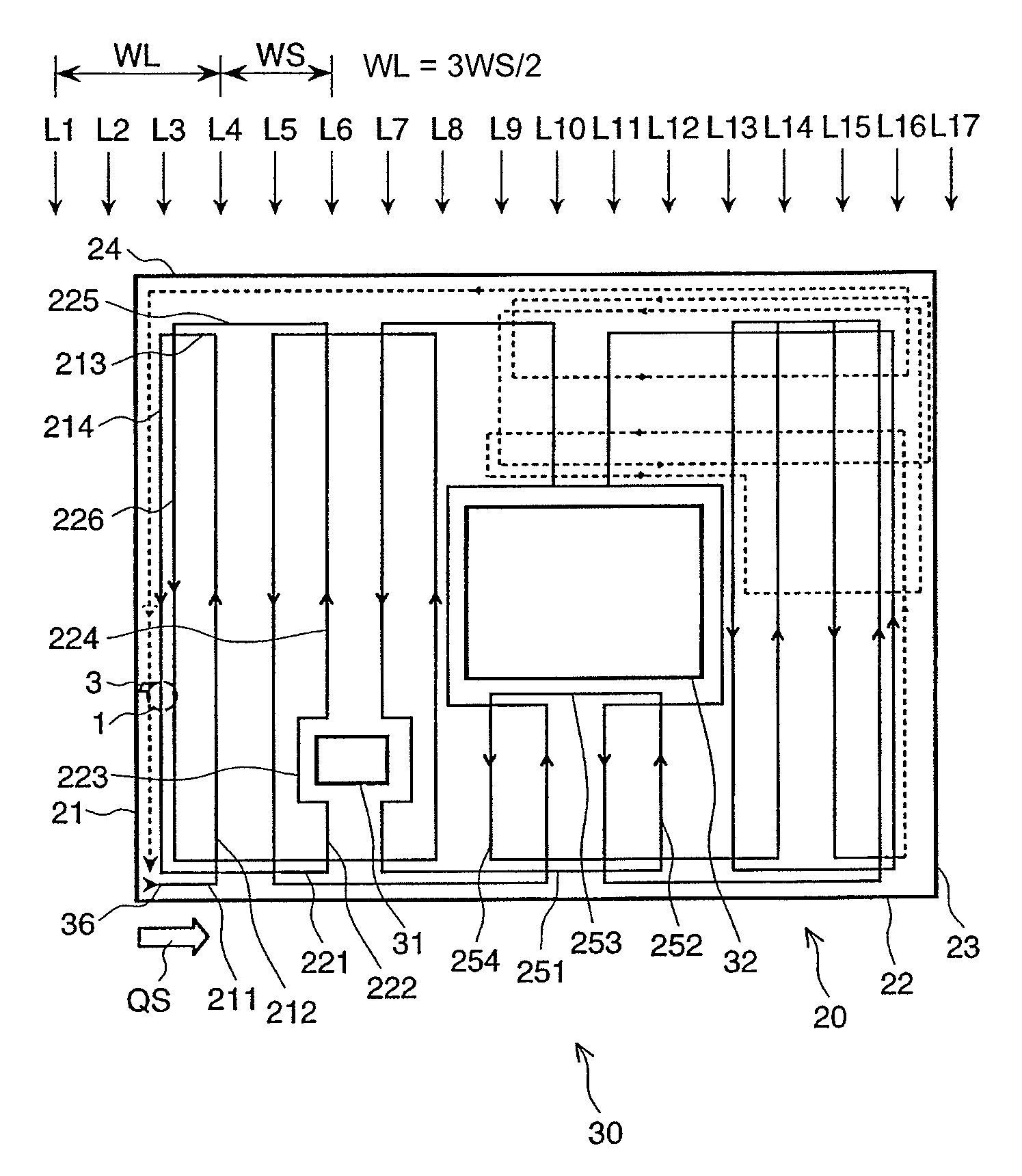

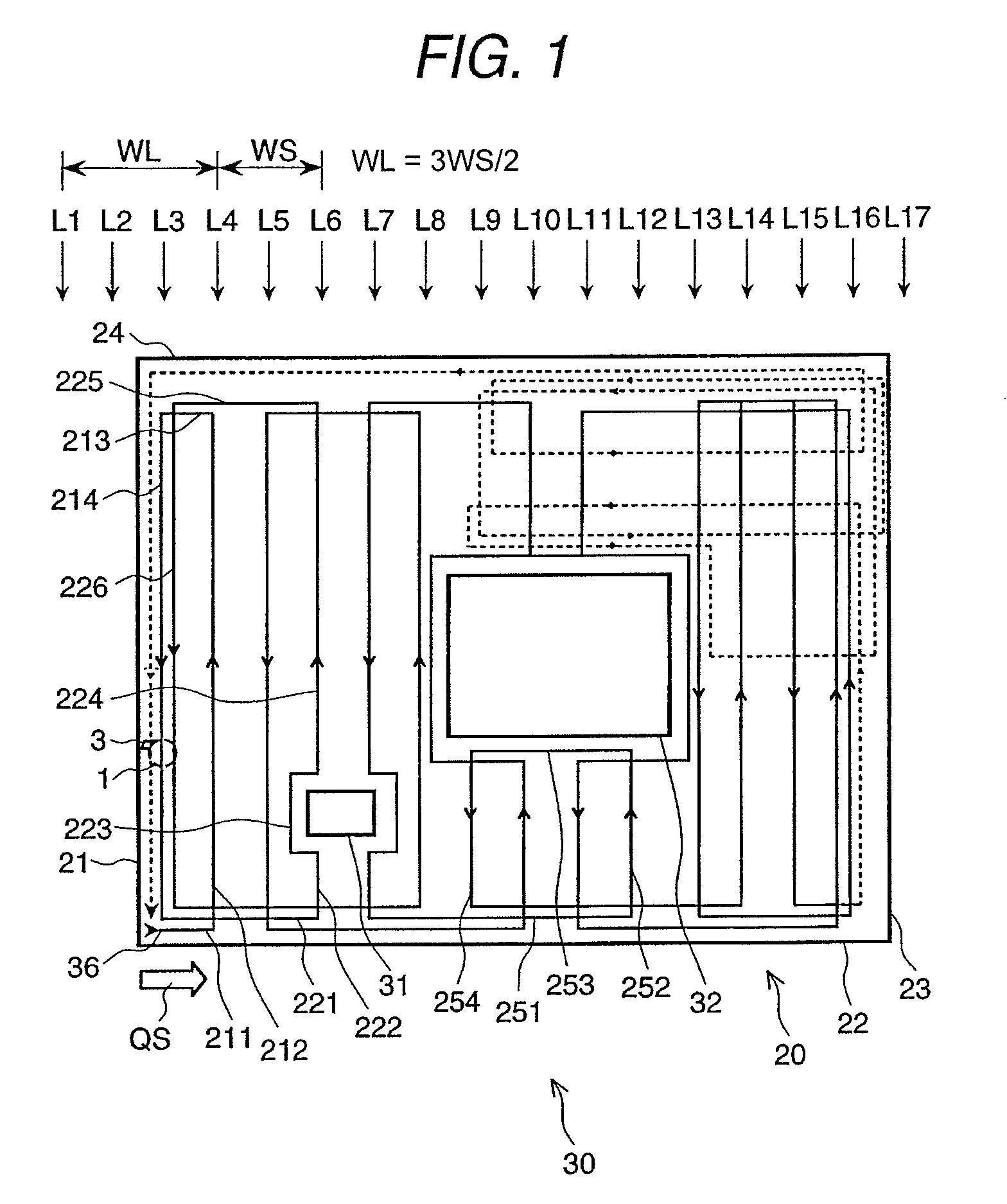

Method and apparatus for processing wafer surfaces using thin, high velocity fluid layer

InactiveUS20050145265A1Efficient processingReducing unwanted fluidElectrolysis componentsDrying solid materials without heatHigh velocityBiomedical engineering

Among the many embodiment, in one embodiment, a method for processing a substrate is disclosed which includes generating a fluid layer on a surface of the substrate, the fluid layer defining a fluid meniscus. The generating includes moving a head in proximity to the surface, applying a fluid from the head to the surface while the head is in proximity to the surface of the substrate to define the fluid layer, and removing the fluid from the surface through the proximity head by a vacuum. The fluid travels along the fluid layer between the head and the substrate at a velocity that increases as the head is in closer proximity to the surface.

Owner:LAM RES CORP

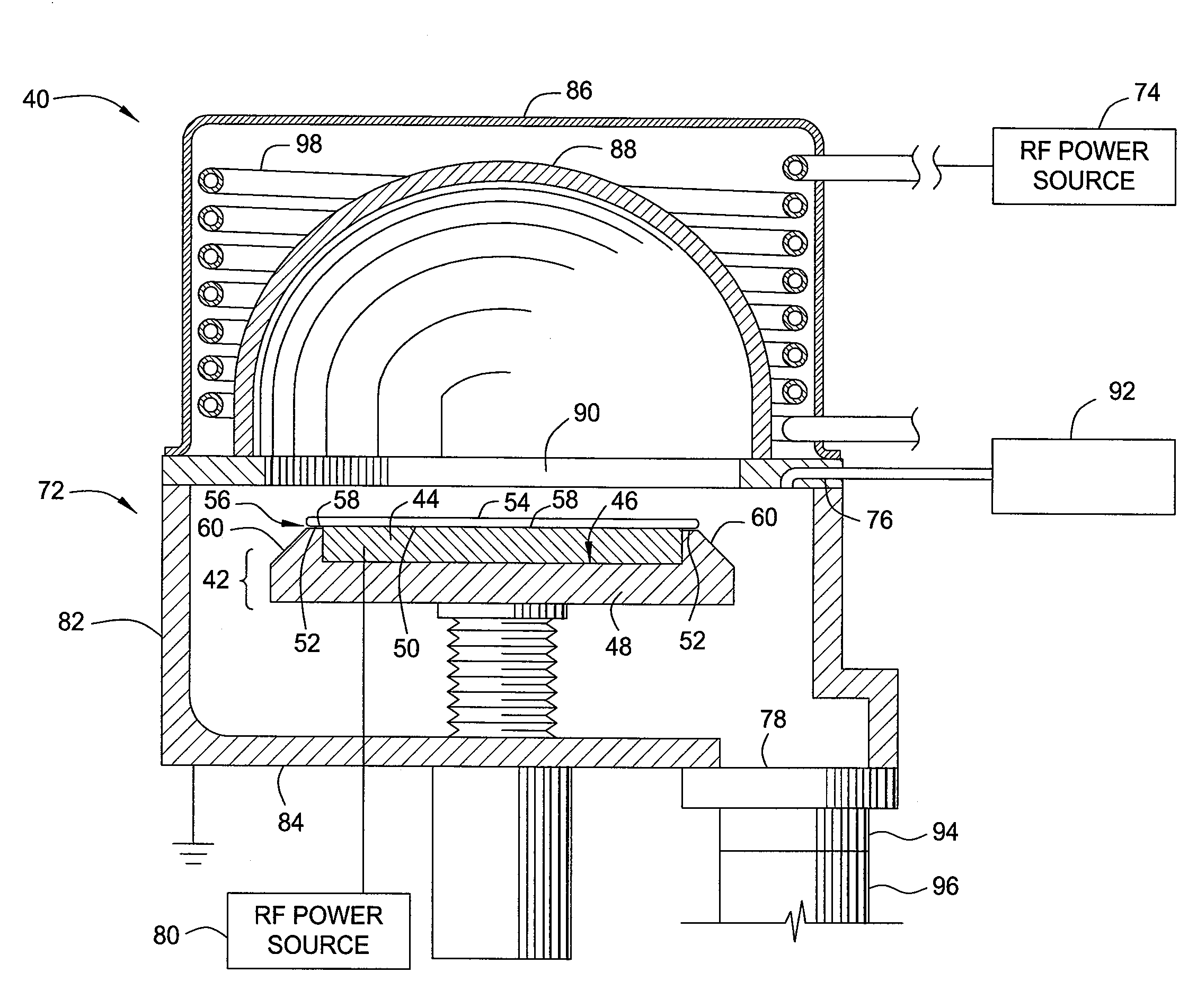

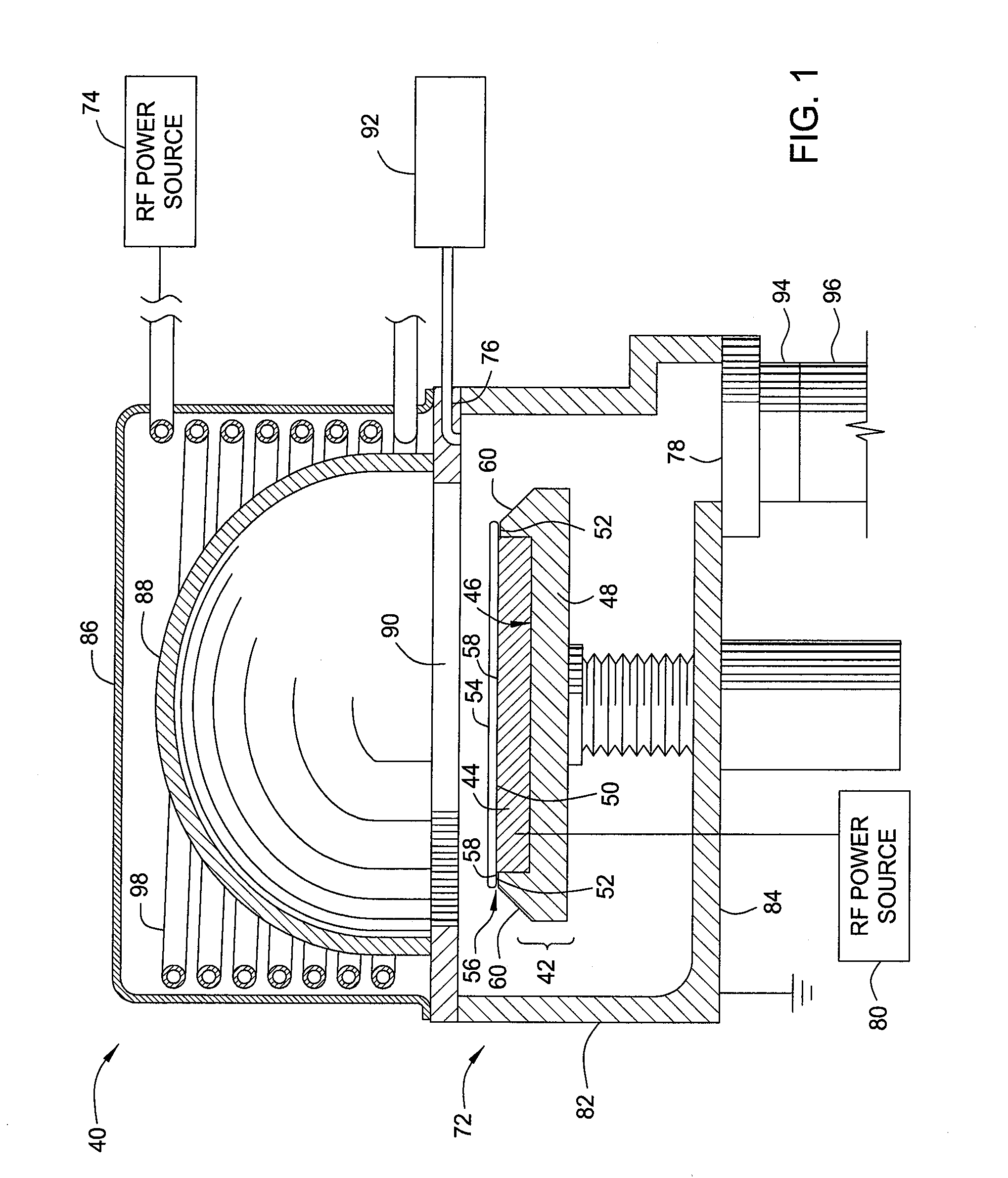

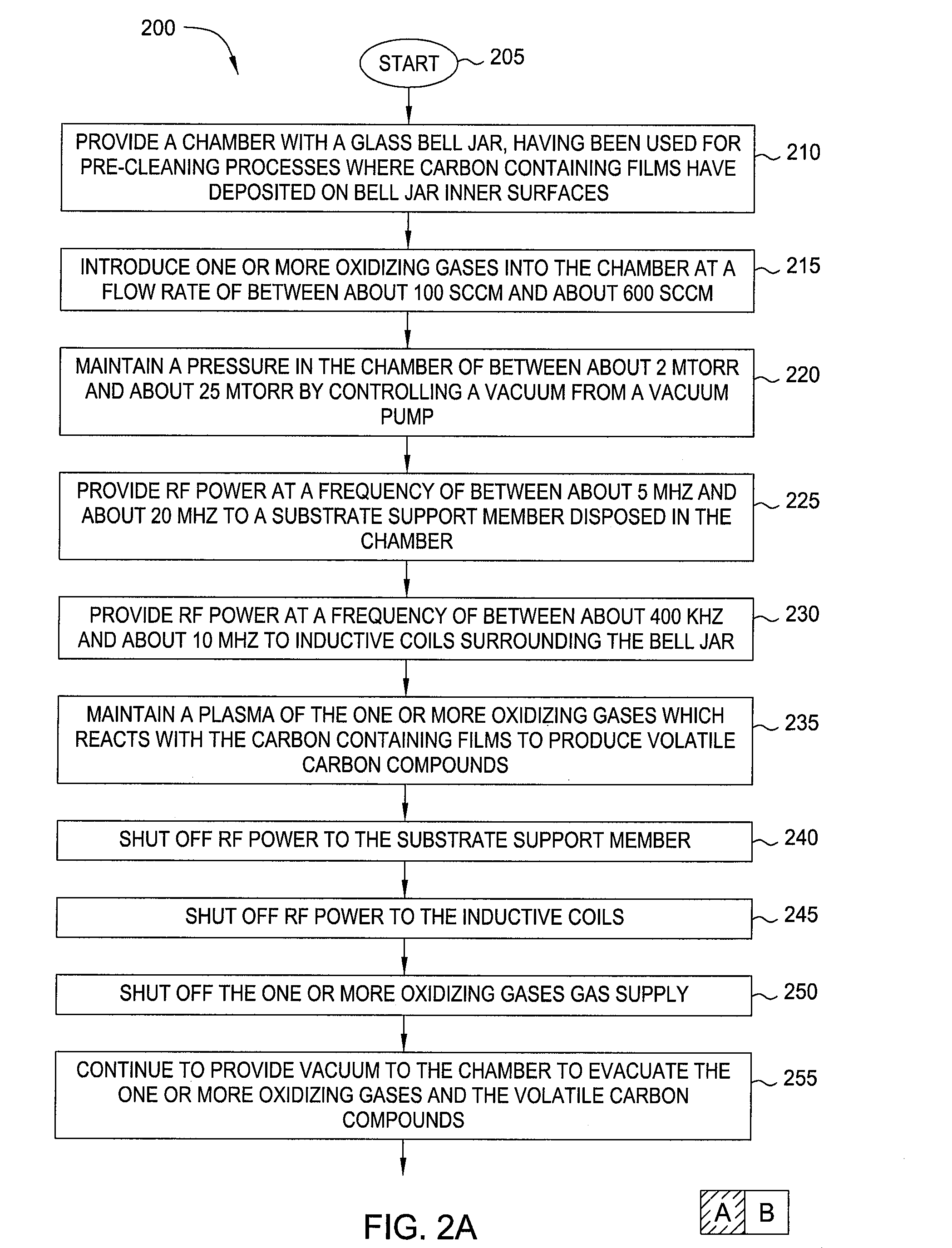

Oxygen plasma clean to remove carbon species deposited on a glass dome surface

InactiveUS20080173326A1Decorative surface effectsHollow article cleaningChemical compoundOxygen plasma

A method for in-situ cleaning of a dielectric dome surface having been used in pre-clean processes is provided. Carbon containing deposits are removed by providing a plasma of one or more oxidizing gases which react with the carbon containing films to form volatile carbon containing compounds.

Owner:APPLIED MATERIALS INC

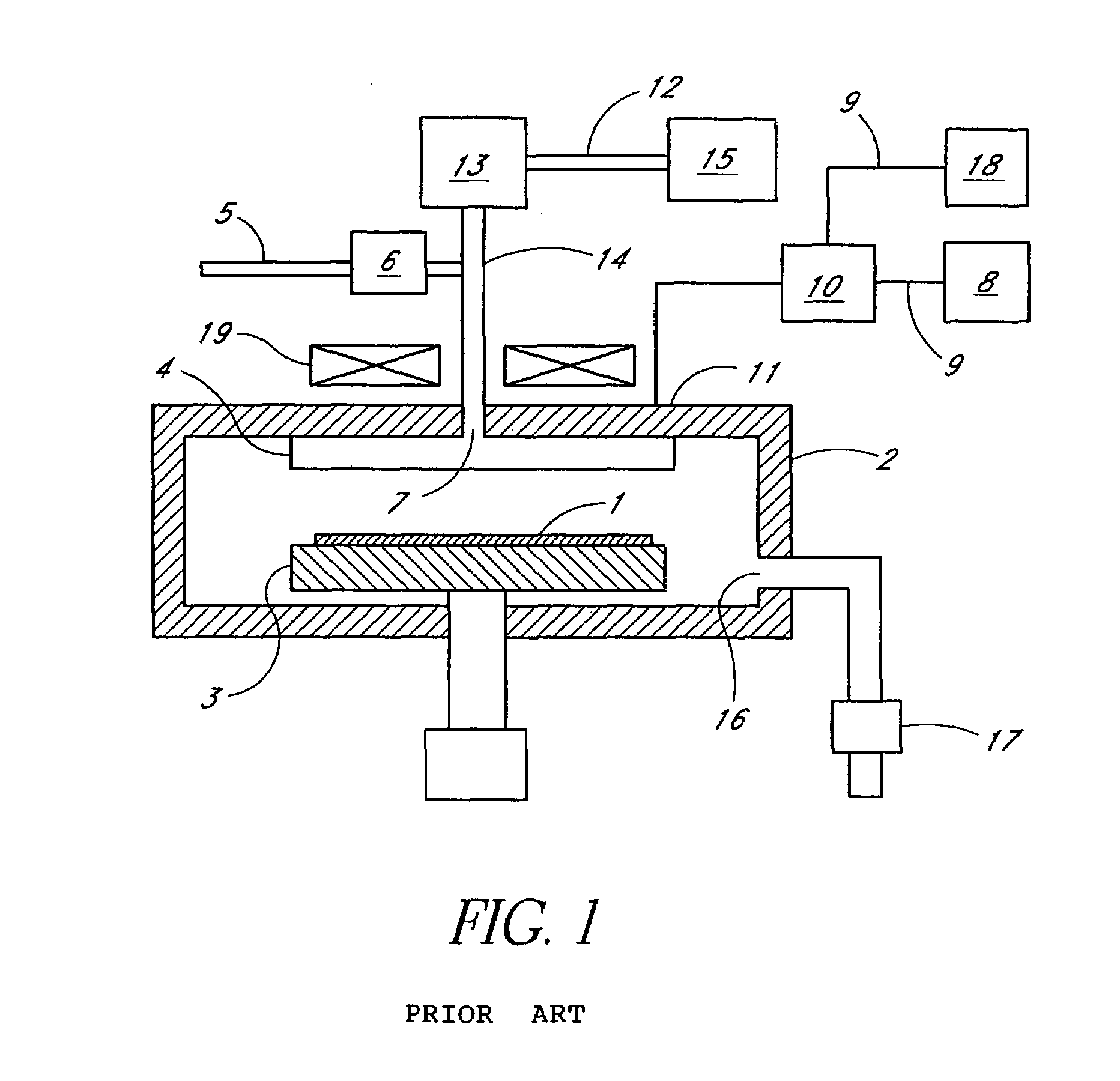

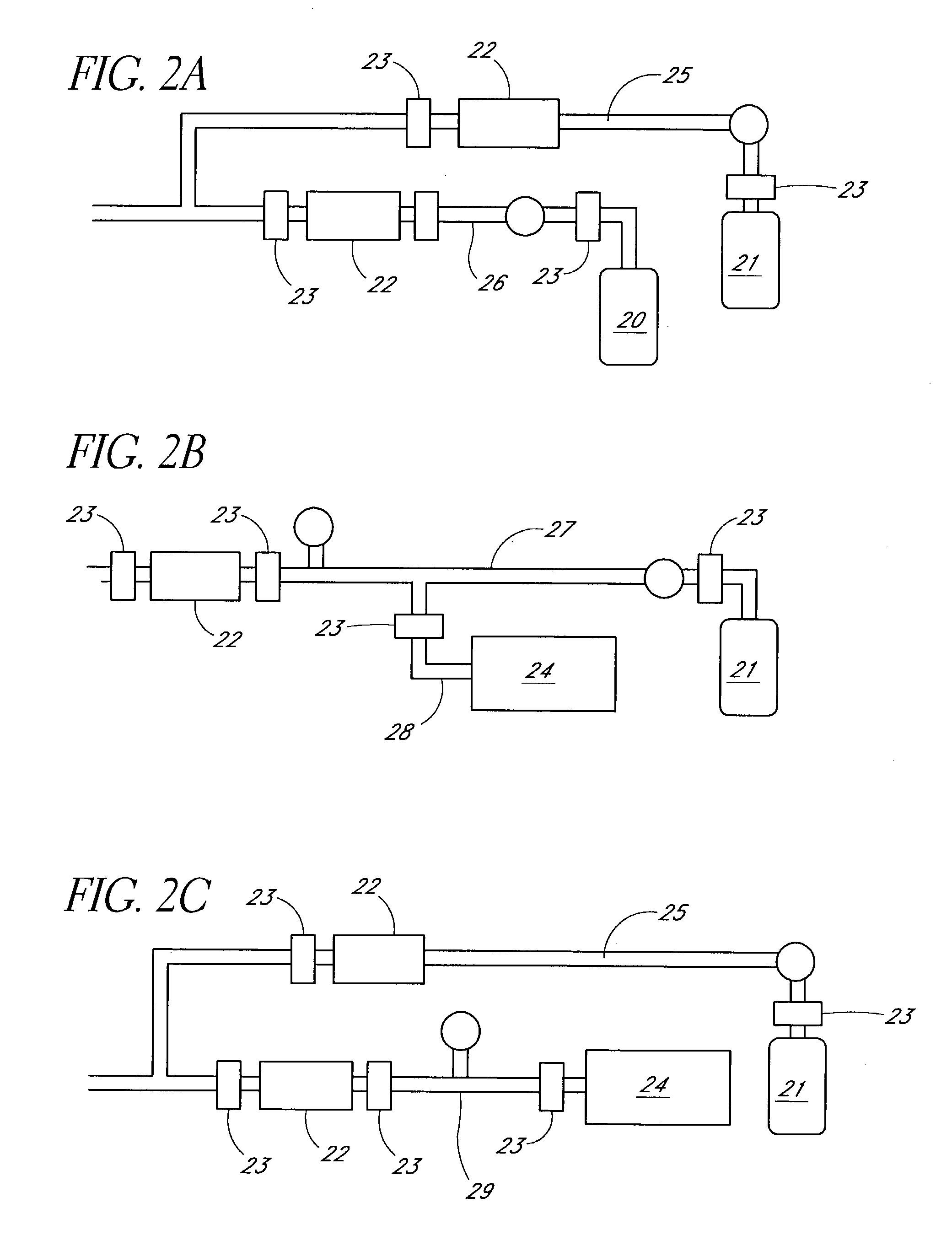

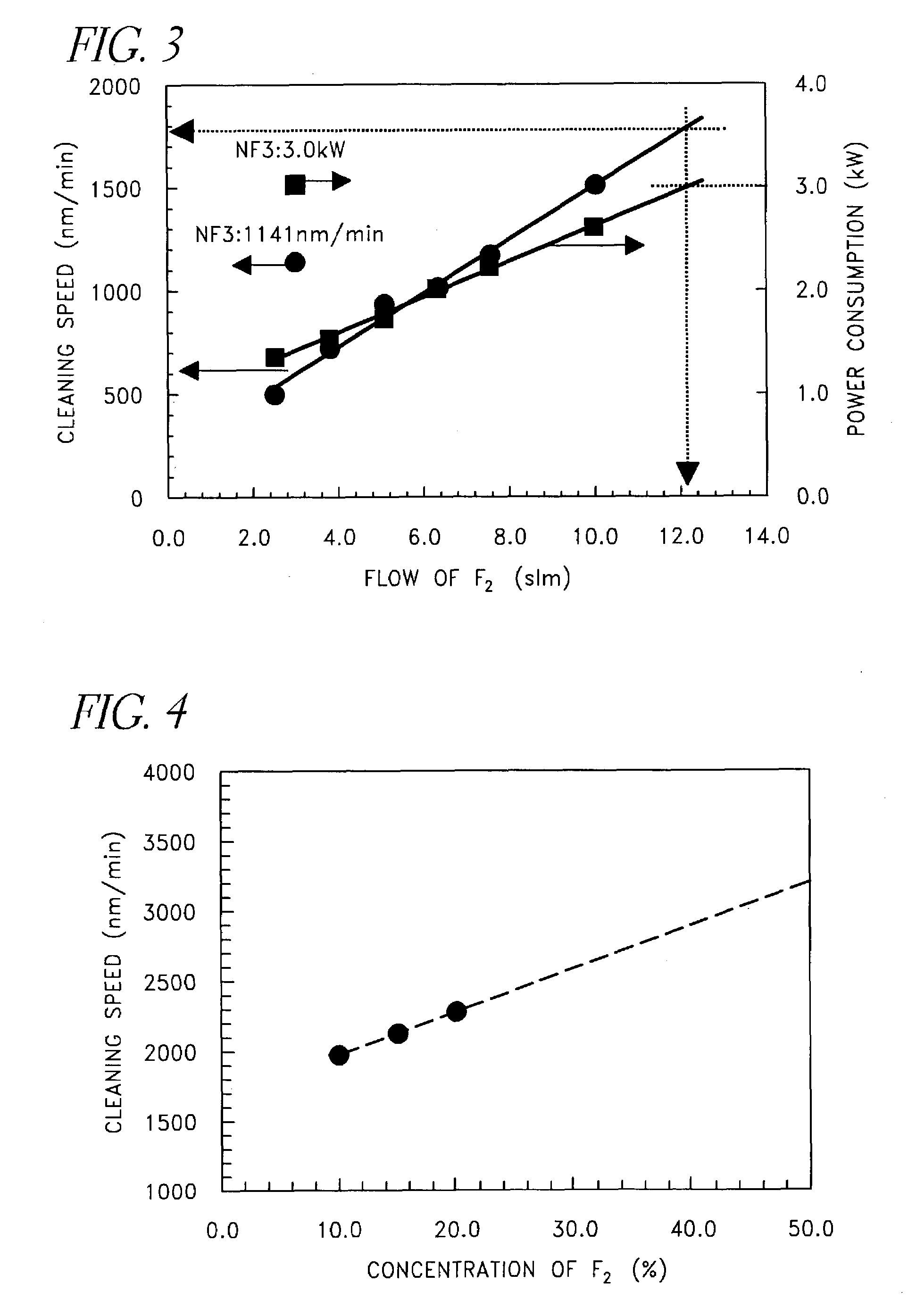

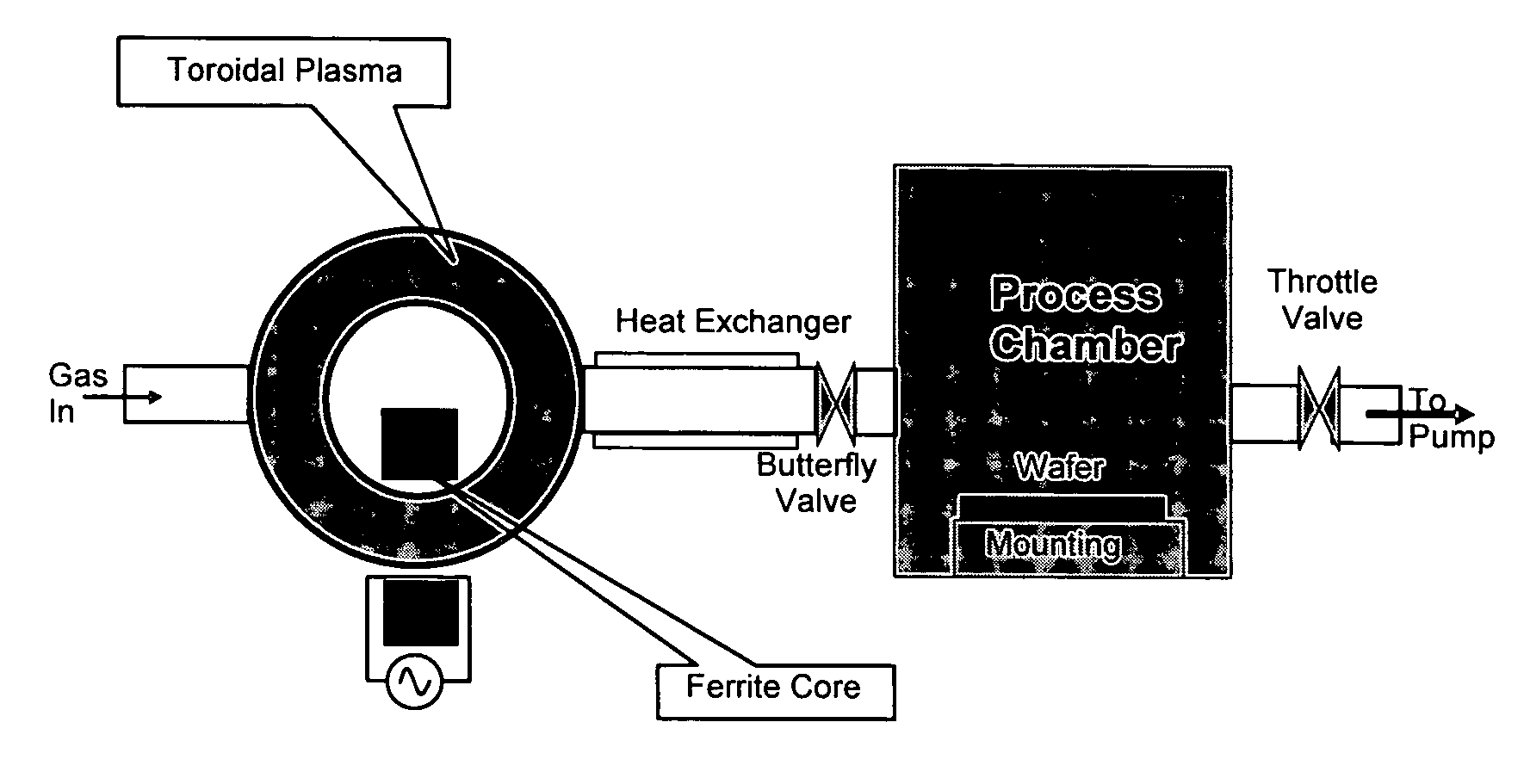

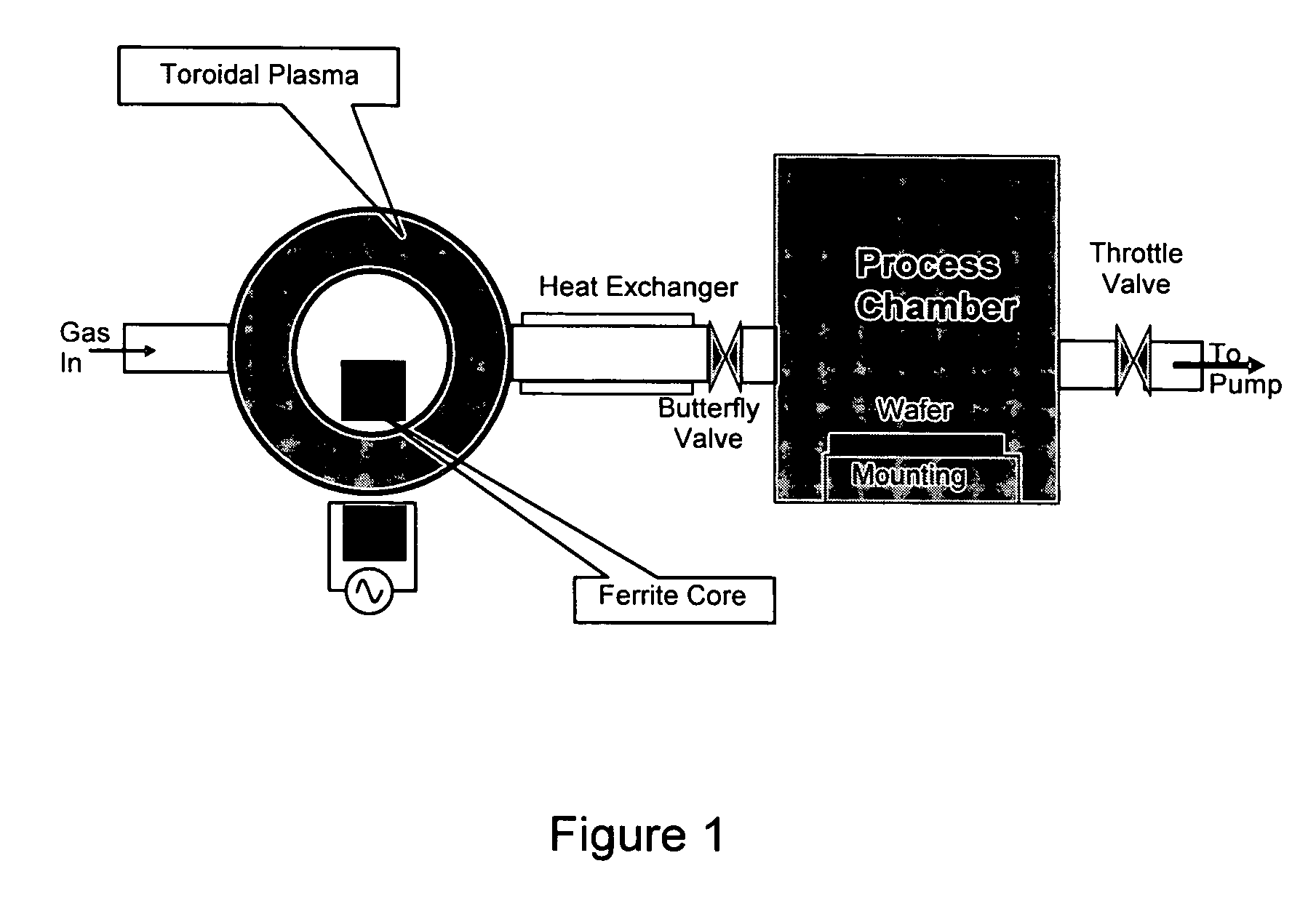

Method of cleaning CVD equipment processing chamber

ActiveUS7234476B2Reduce operating costsImprove efficiencyElectric discharge tubesHollow article cleaningRemote plasmaOperational costs

A method of remote plasma cleaning a processing chamber of CVD equipment, which has high cleaning rates, low cleaning operational cost and high efficiency, is provided. The method comprises supplying cleaning gas to the remote plasma-discharge device; activating the cleaning gas inside the remote plasma-discharge device; and bringing the activated cleaning gas into the processing chamber and which is characterized in that a mixed gas of F2 gas and an inert gas are used as the cleaning gas. A concentration of the F2 gas is 10% or higher. The F2 gas, which is a cleaning gas, is supplied to the remote plasma-discharge device from an F2 gas cylinder by diluting F2 gas at a given concentration by an inert gas.

Owner:ASM JAPAN

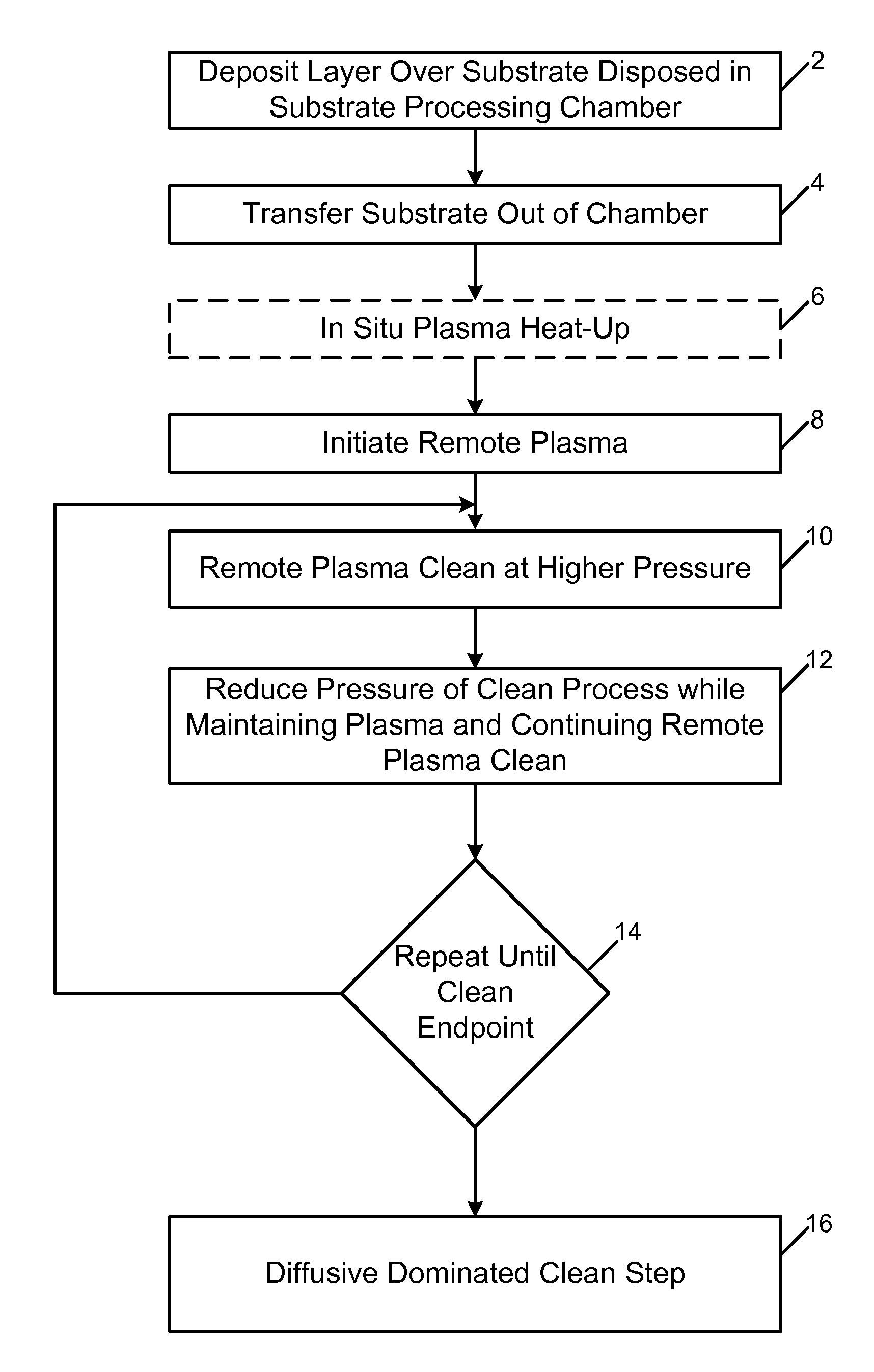

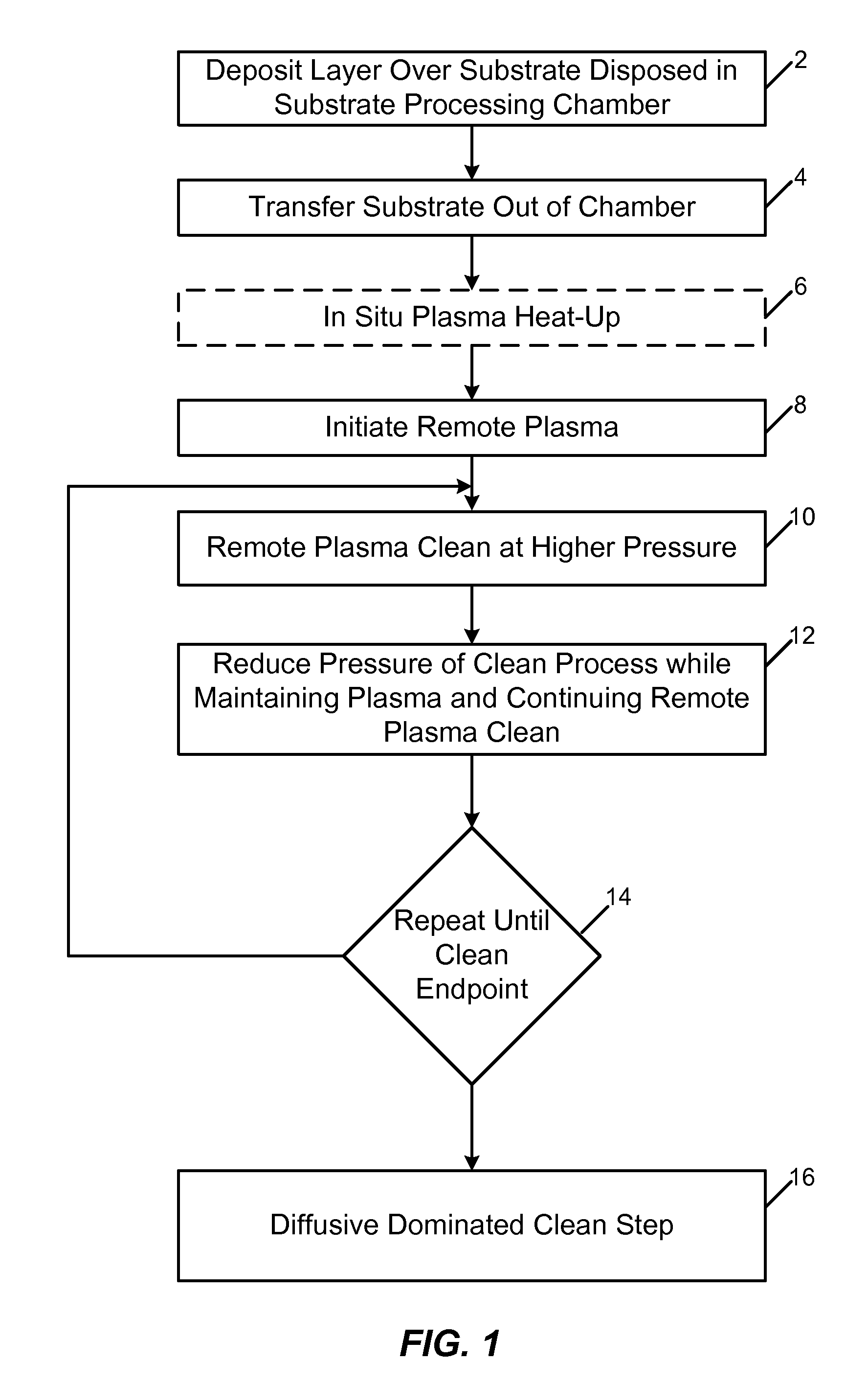

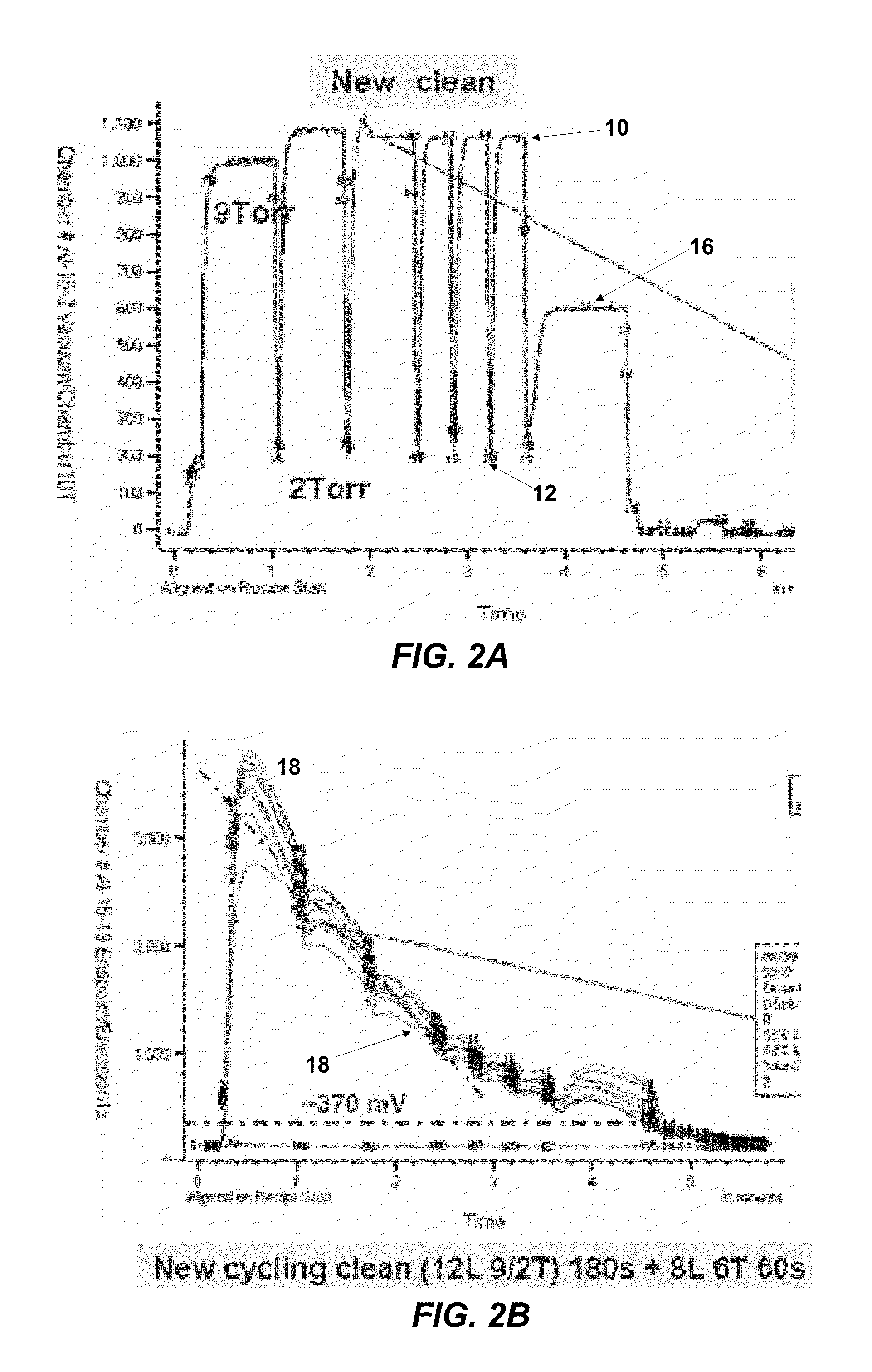

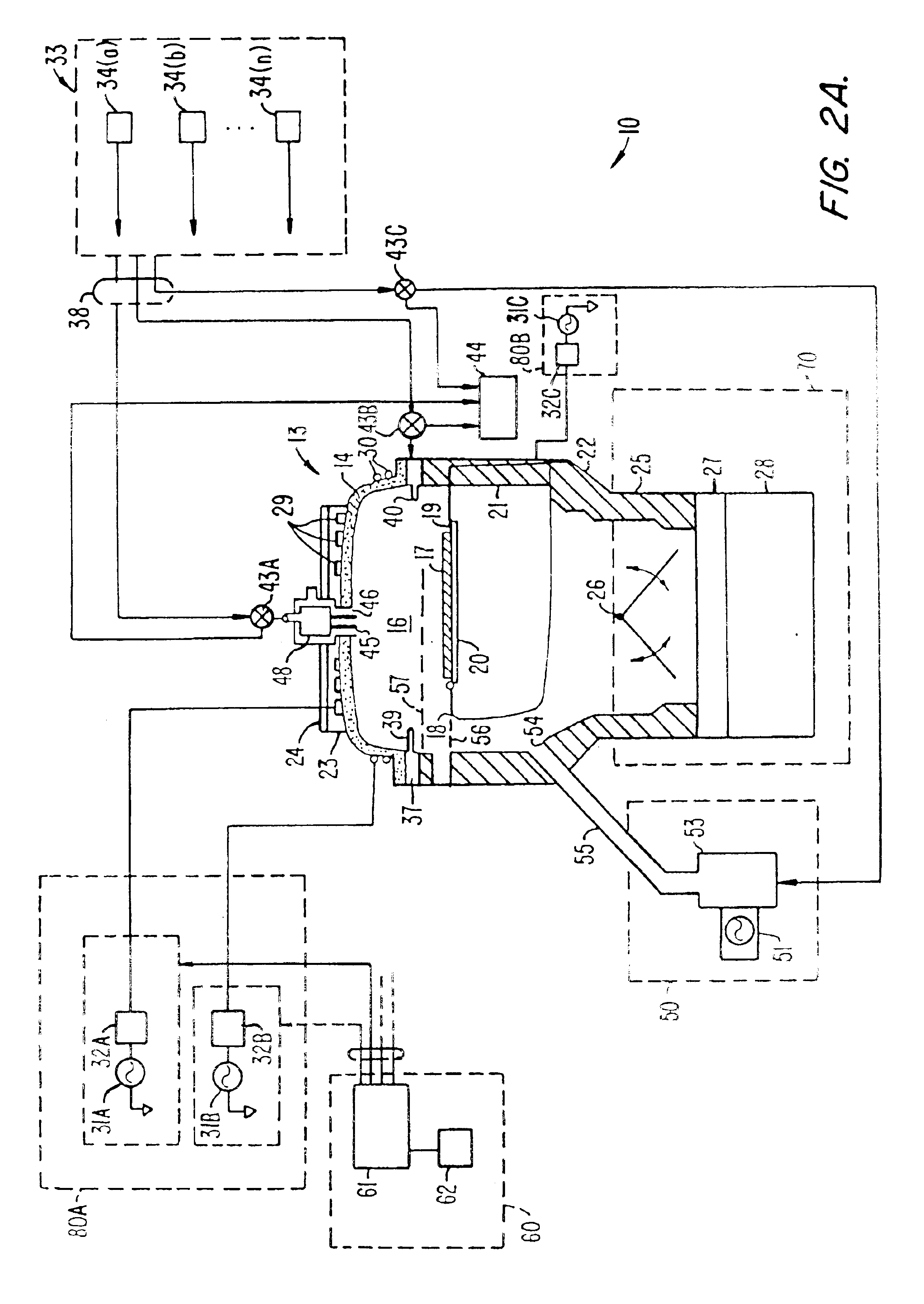

Remote plasma clean process with cycled high and low pressure clean steps

InactiveUS7967913B2Hollow article cleaningSemiconductor/solid-state device manufacturingRemote plasmaContinuous flow

A remote plasma process for removing unwanted deposition build-up from one or more interior surfaces of a substrate processing chamber after processing a substrate disposed in the substrate processing chamber. In one embodiment, the substrate is transferred out of the substrate processing chamber and a flow of a fluorine-containing etchant gas is introduced into a remote plasma source where reactive species are formed. A continuous flow of the reactive species from the remote plasmas source to the substrate processing chamber is generated while a cycle of high and low pressure clean steps is repeated. During the high pressure clean step, reactive species are flown into the substrate processing chamber while pressure within the substrate processing chamber is maintained between 4-15 Torr. During the low pressure clean step, reactive species are flown into the substrate processing chamber while reducing the pressure of the substrate processing chamber by at least 50 percent of a high pressure reached in the high pressure clean step.

Owner:APPLIED MATERIALS INC

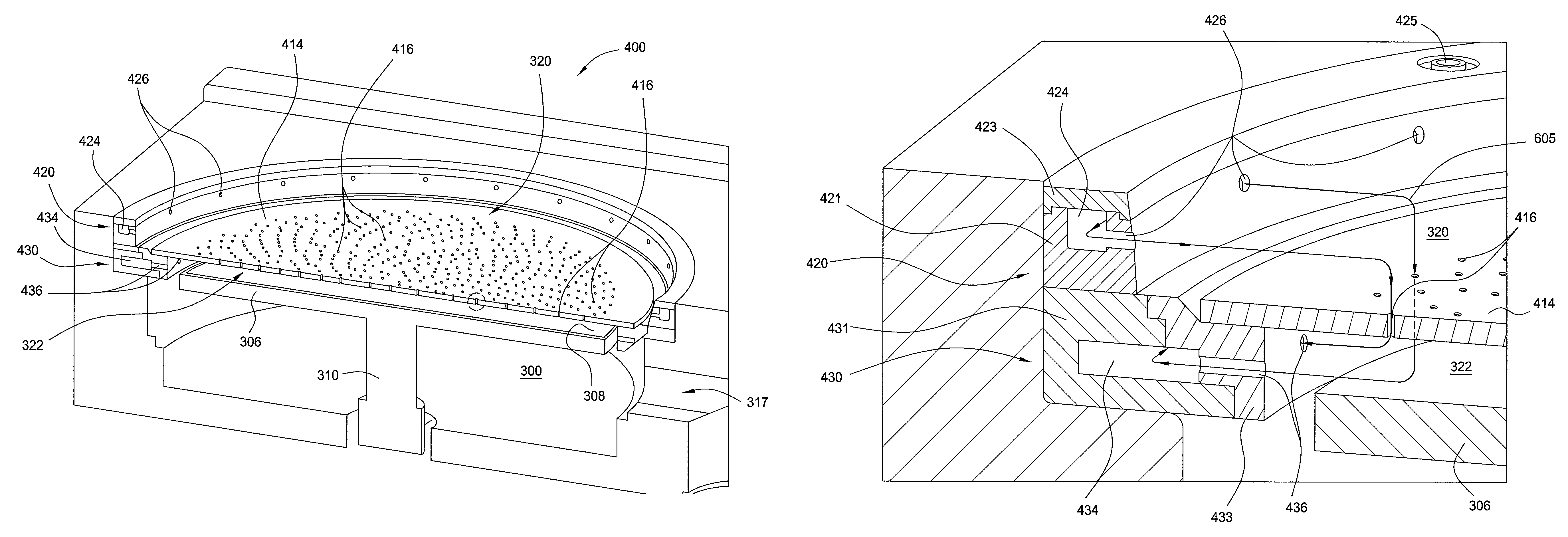

Quartz showerhead for nanocure UV chamber

Embodiments of the invention generally provide apparatuses and methods for controlling the gas flow profile within a processing chamber. In one embodiment, a processing tool includes an ultraviolet processing chamber defining a processing region, a substrate support, a window disposed between a UV radiation source and the substrate support, and a transparent showerhead disposed within the processing region between the window and the substrate support and having one or more transparent showerhead passages between upper and lower processing regions. The processing tool also includes a gas distribution ring having one or more gas distribution ring passages between a gas distribution ring inner channel and the upper processing region and a gas outlet ring positioned below the gas distribution ring, the gas outlet ring having one or more gas outlet passages between a gas outlet ring inner channel within the gas outlet ring and the lower processing region.

Owner:APPLIED MATERIALS INC

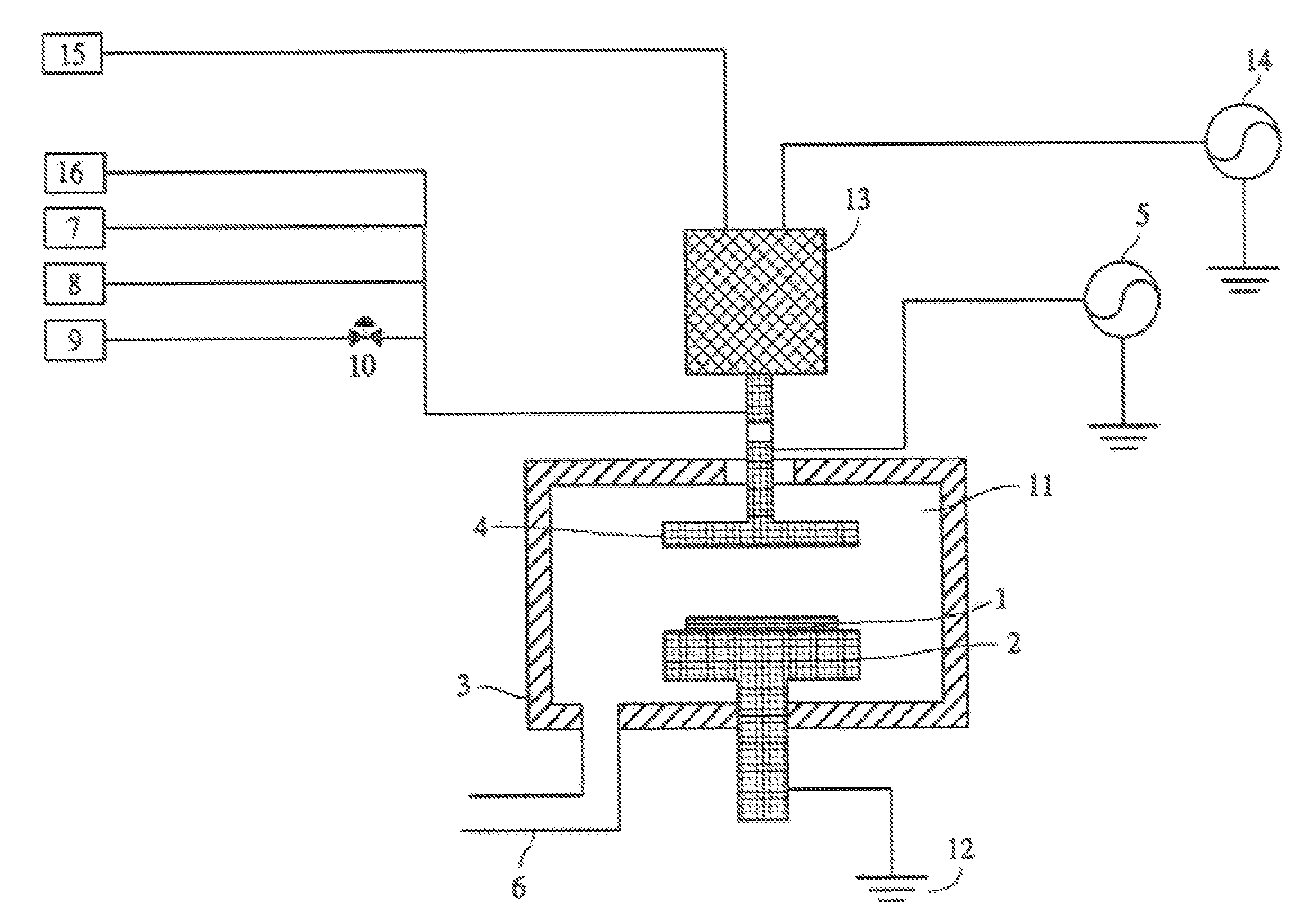

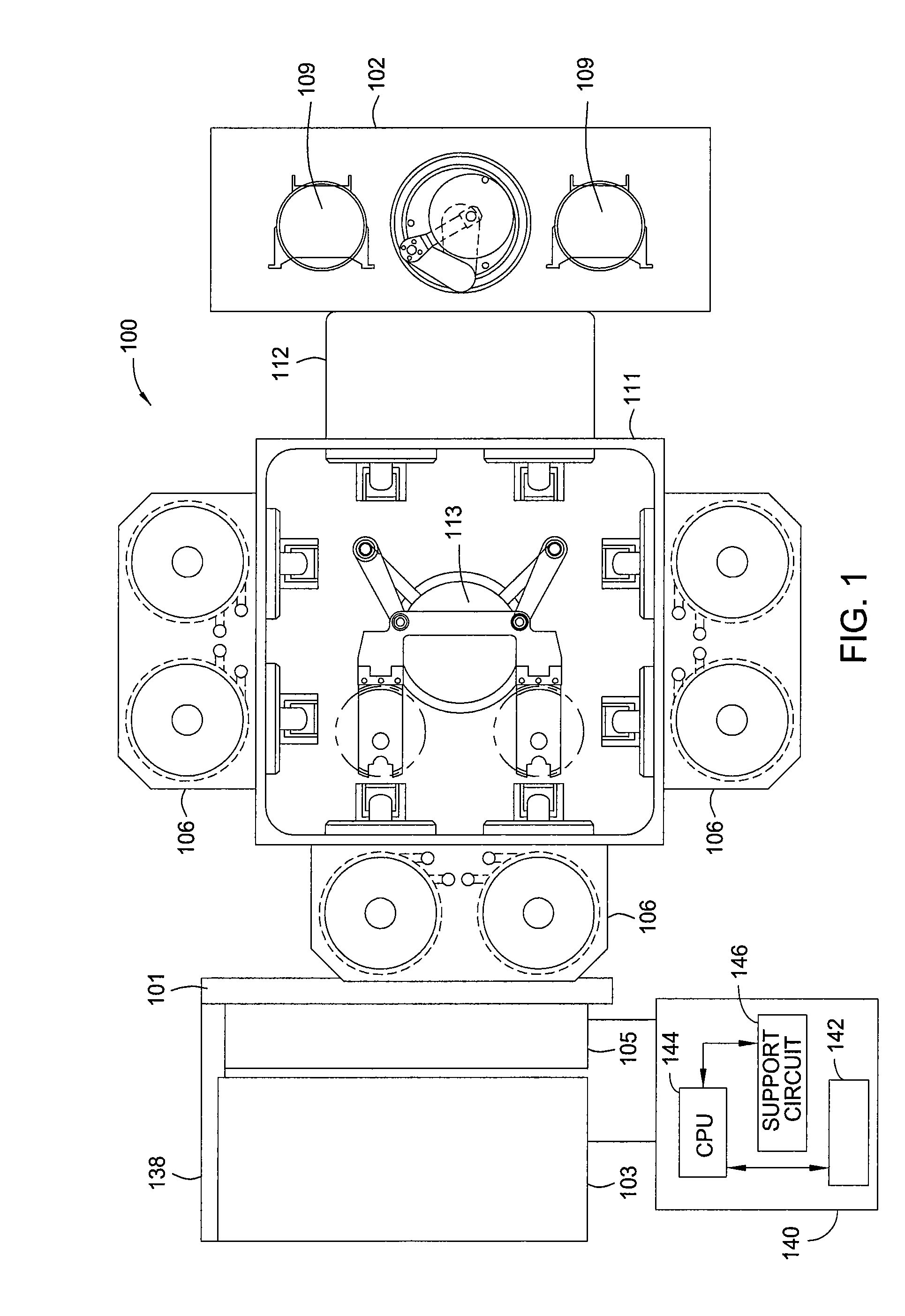

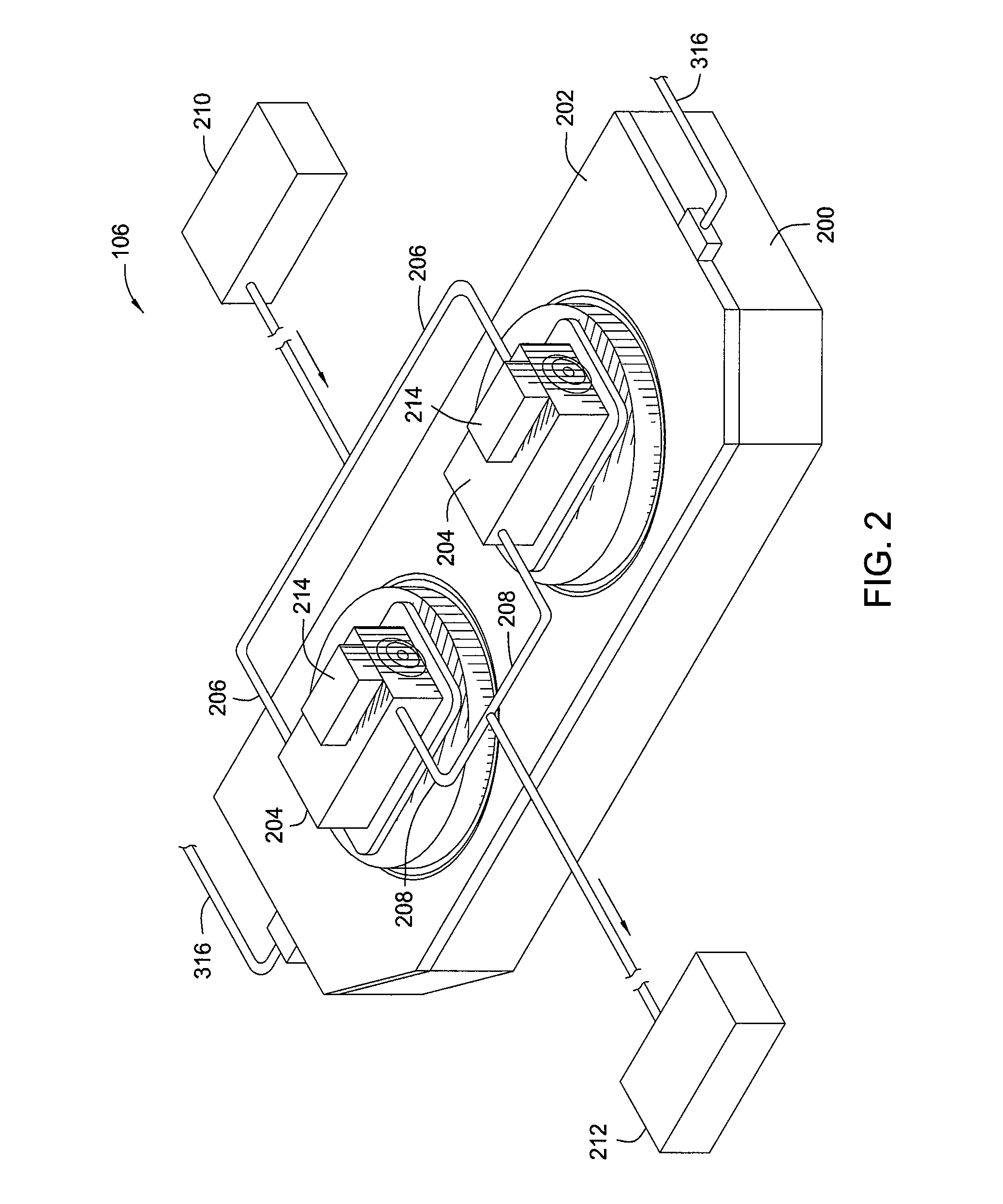

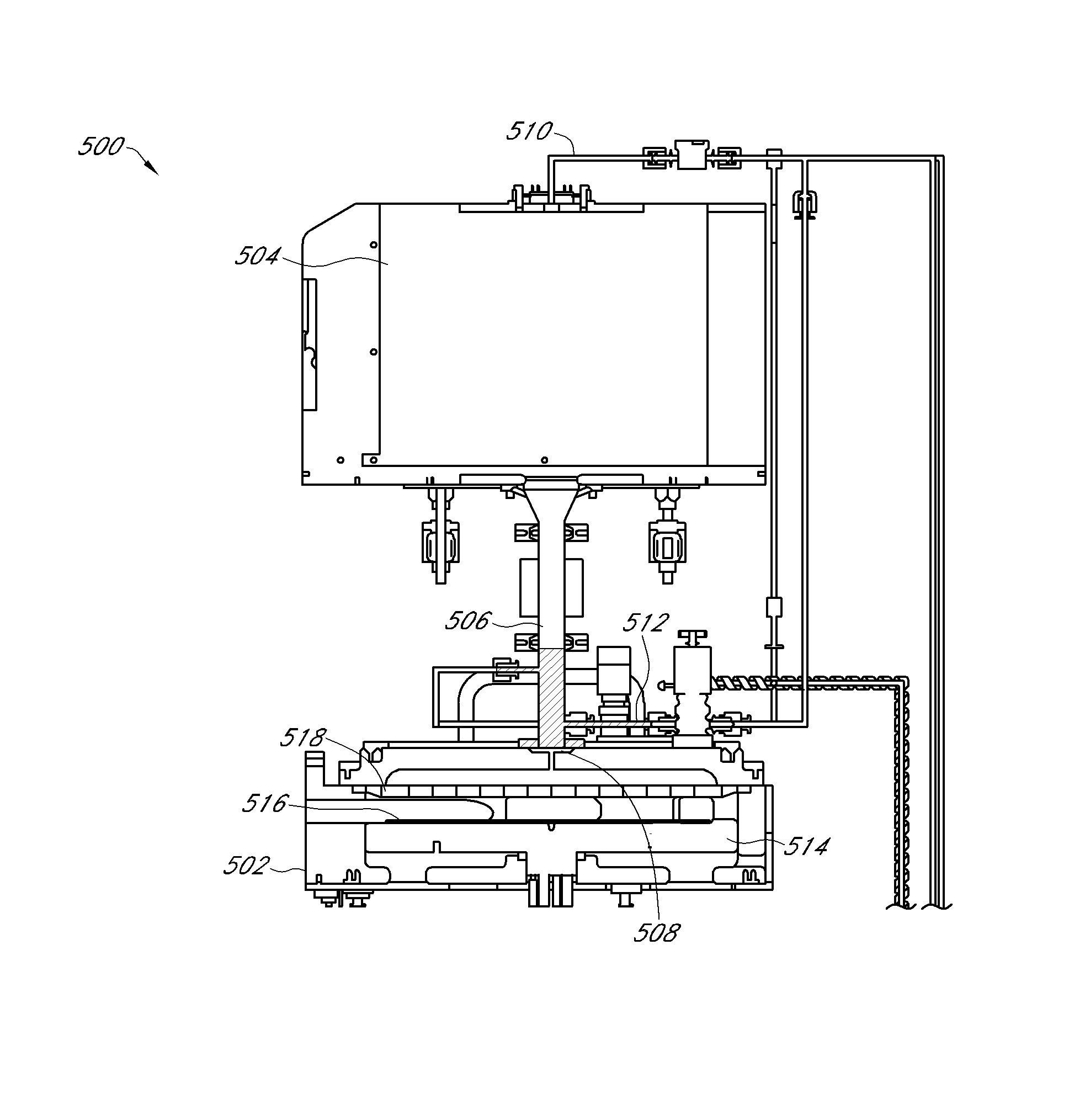

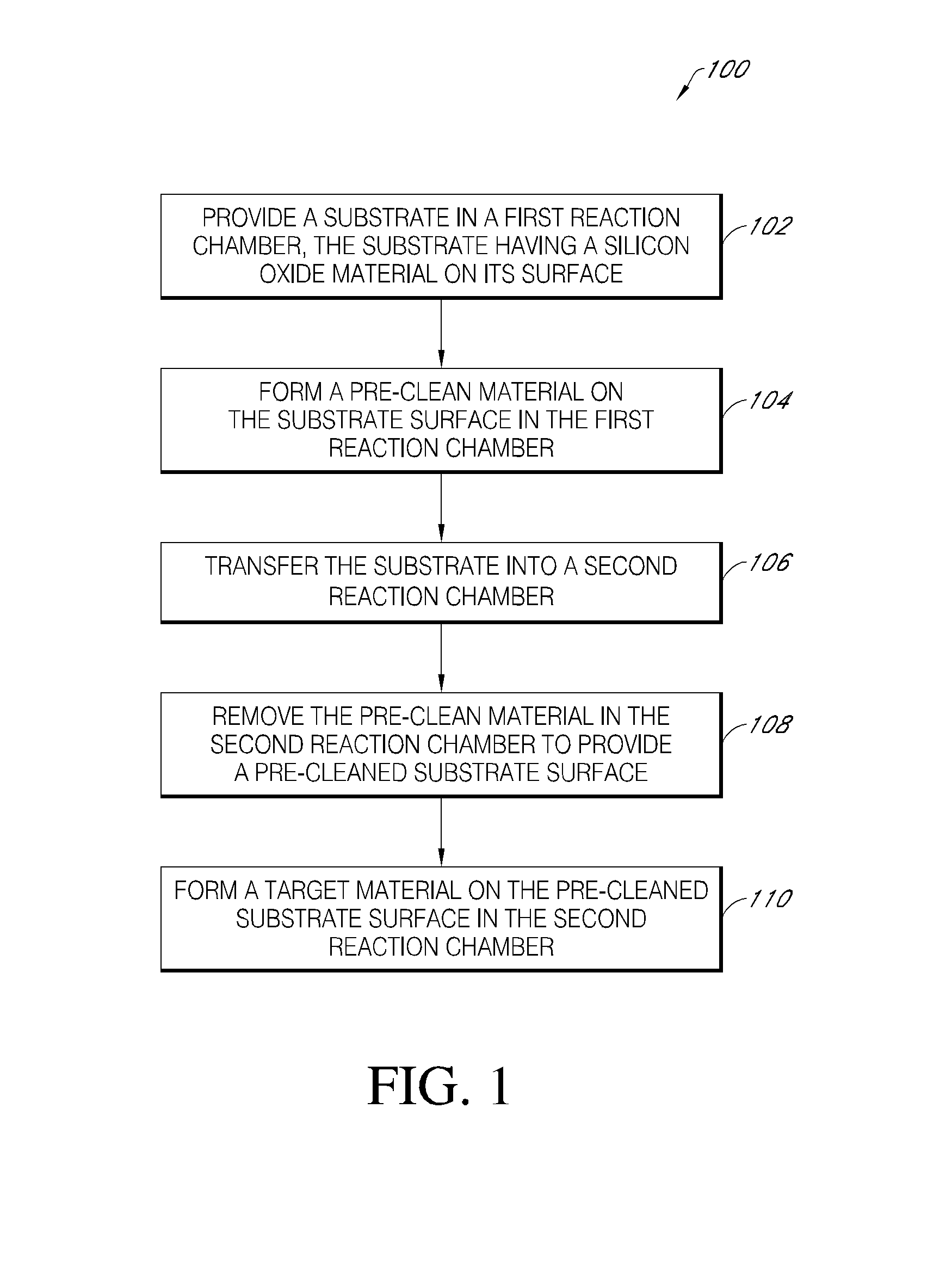

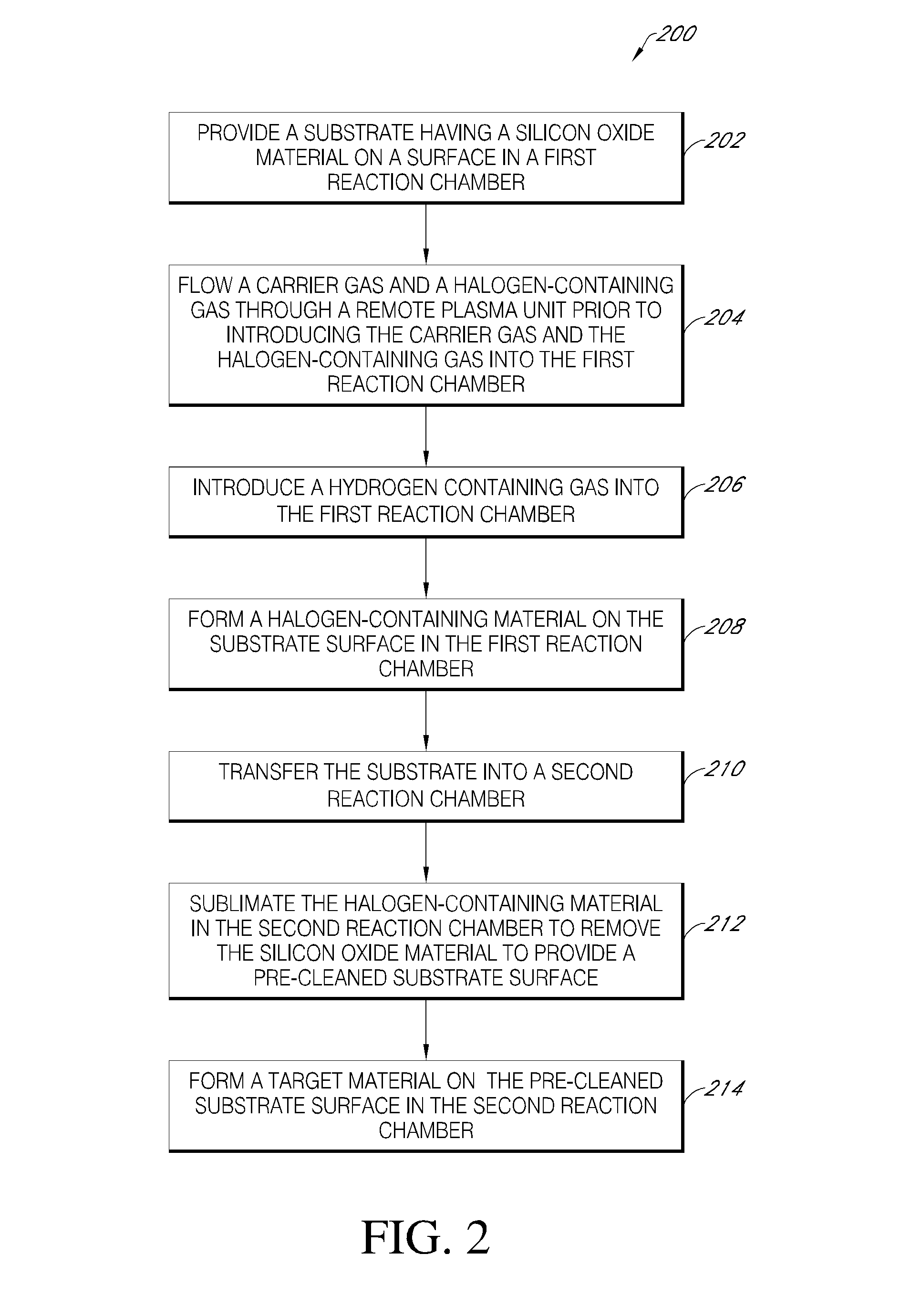

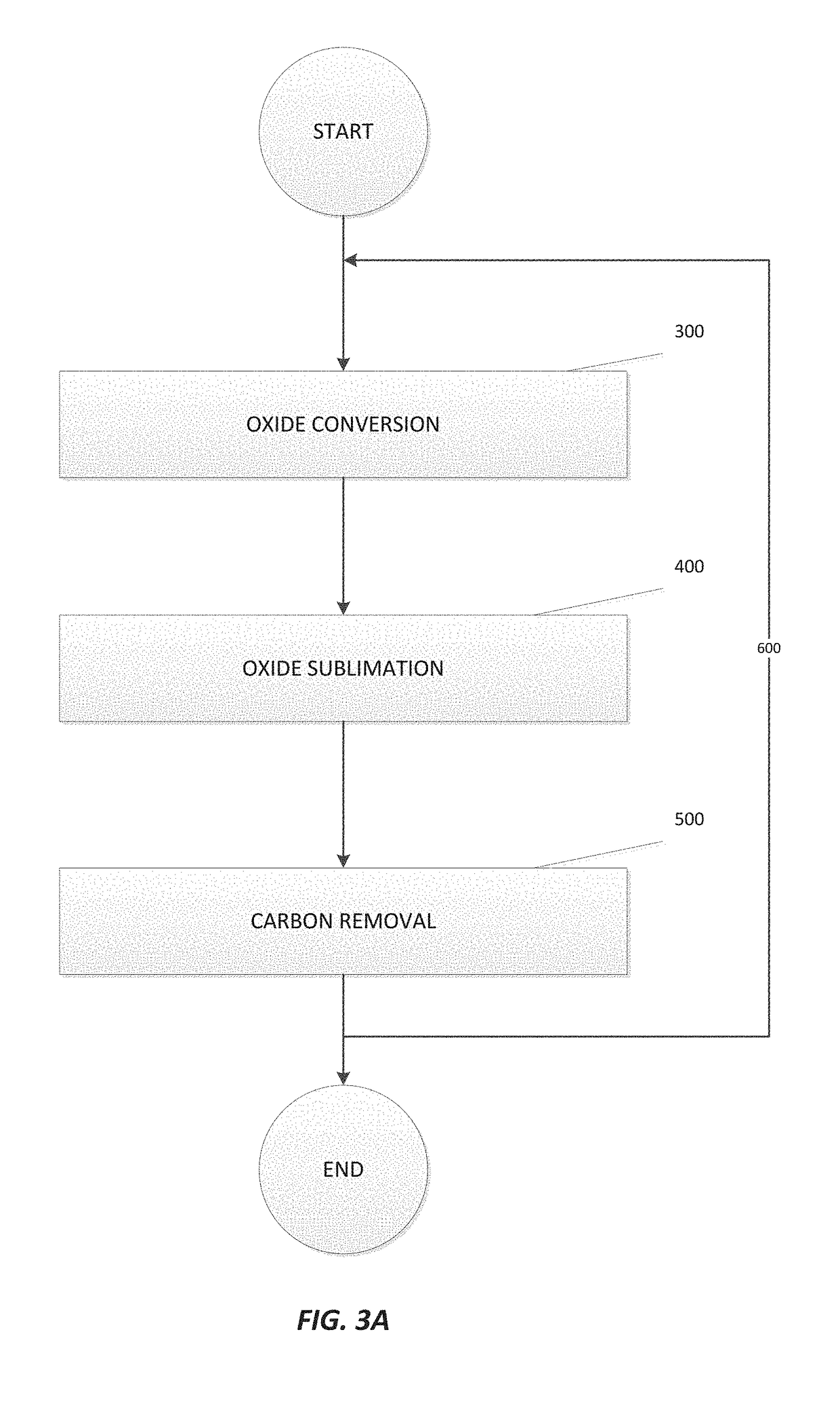

Plasma pre-clean module and process

ActiveUS9299557B2Polycrystalline material growthSemiconductor/solid-state device manufacturingConductive materialsSilicon oxide

A method for integrated circuit fabrication can include removing silicon oxide by a pre-clean process. The pre-clean process can include depositing a halogen-containing material on the surface of a substrate in a first reaction chamber, and transferring the substrate having the halogen-containing material to a second reaction chamber. Silicon oxide material can be removed from a surface of the substrate by sublimating the halogen-containing material in the second reaction chamber. A target material, such as a conductive material, may subsequently be deposited on the substrate surface in the second reaction chamber.

Owner:ASM IP HLDG BV

Method and apparatus for making three-dimensional objects from multiple solidifiable materials

Owner:GLOBAL FILTRATION SYST

Passivation layer formation by plasma clean process to reduce native oxide growth

ActiveUS20080160210A1Format be limitLighting and heating apparatusVacuum evaporation coatingAmmoniaSubstrate surface

Embodiments described herein provide methods for removing native oxide surfaces on substrates while simultaneously passivating the underlying substrate surface. In one embodiment, a method is provided which includes positioning a substrate containing an oxide layer within a processing chamber, adjusting a first temperature of the substrate to about 80° C. or less, generating a cleaning plasma from a gas mixture within the processing chamber, such that the gas mixture contains ammonia and nitrogen trifluoride having an NH3 / NF3 molar ratio of about 10 or greater, and condensing the cleaning plasma onto the substrate. A thin film, containing ammonium hexafluorosilicate, is formed in part, from the native oxide during a plasma clean process. The method further includes heating the substrate to a second temperature of about 100° C. or greater within the processing chamber while removing the thin film from the substrate and forming a passivation surface thereon.

Owner:APPLIED MATERIALS INC

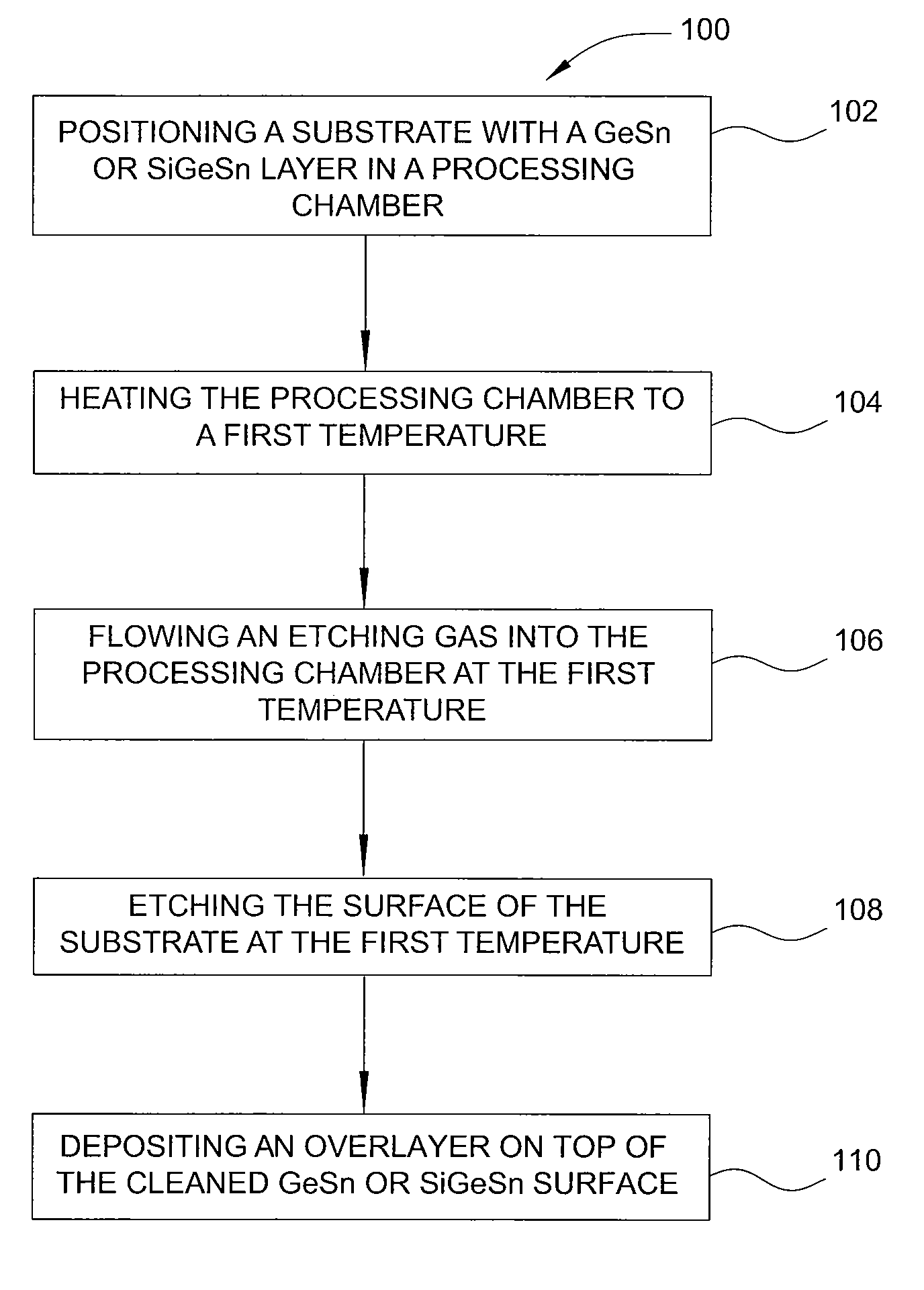

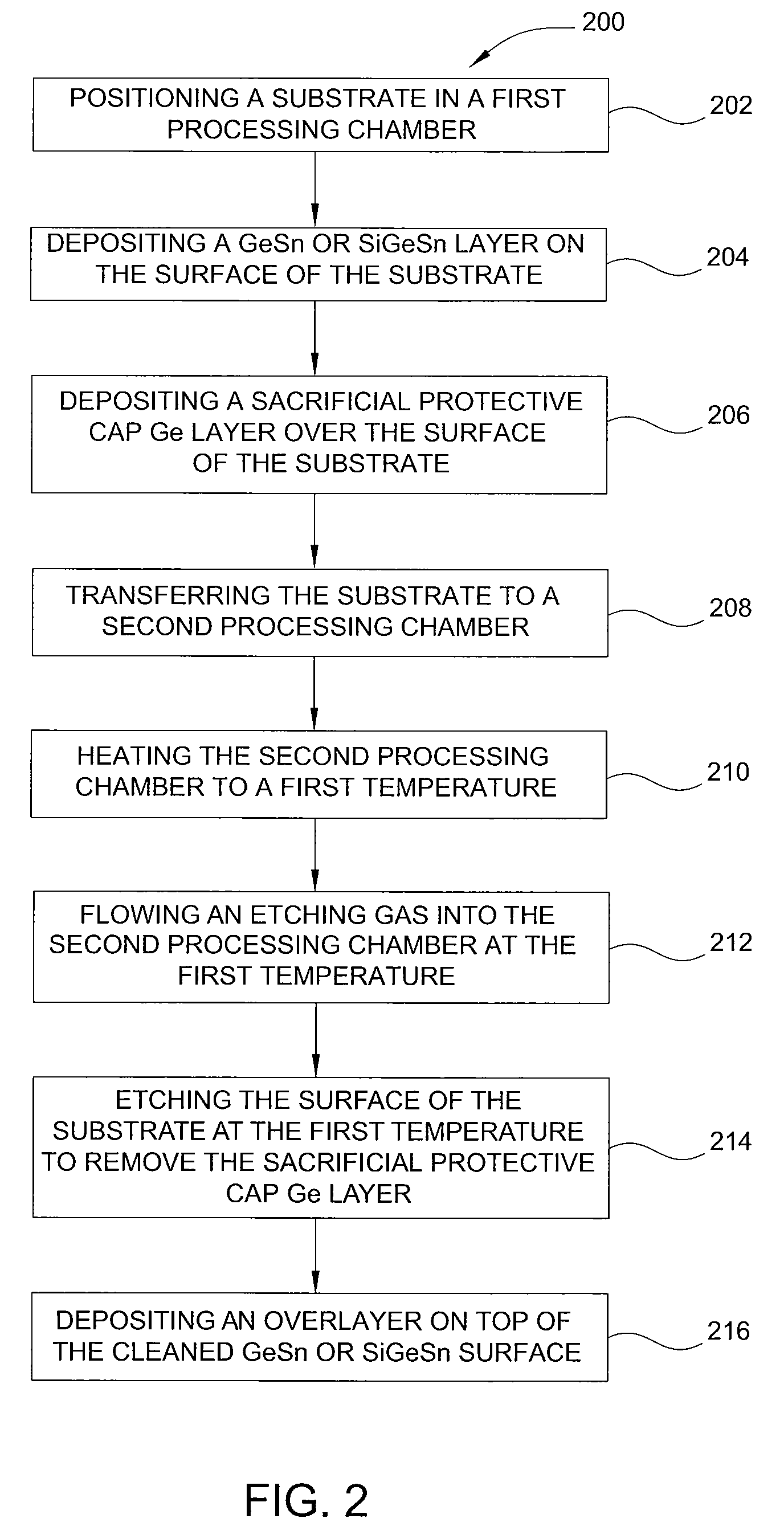

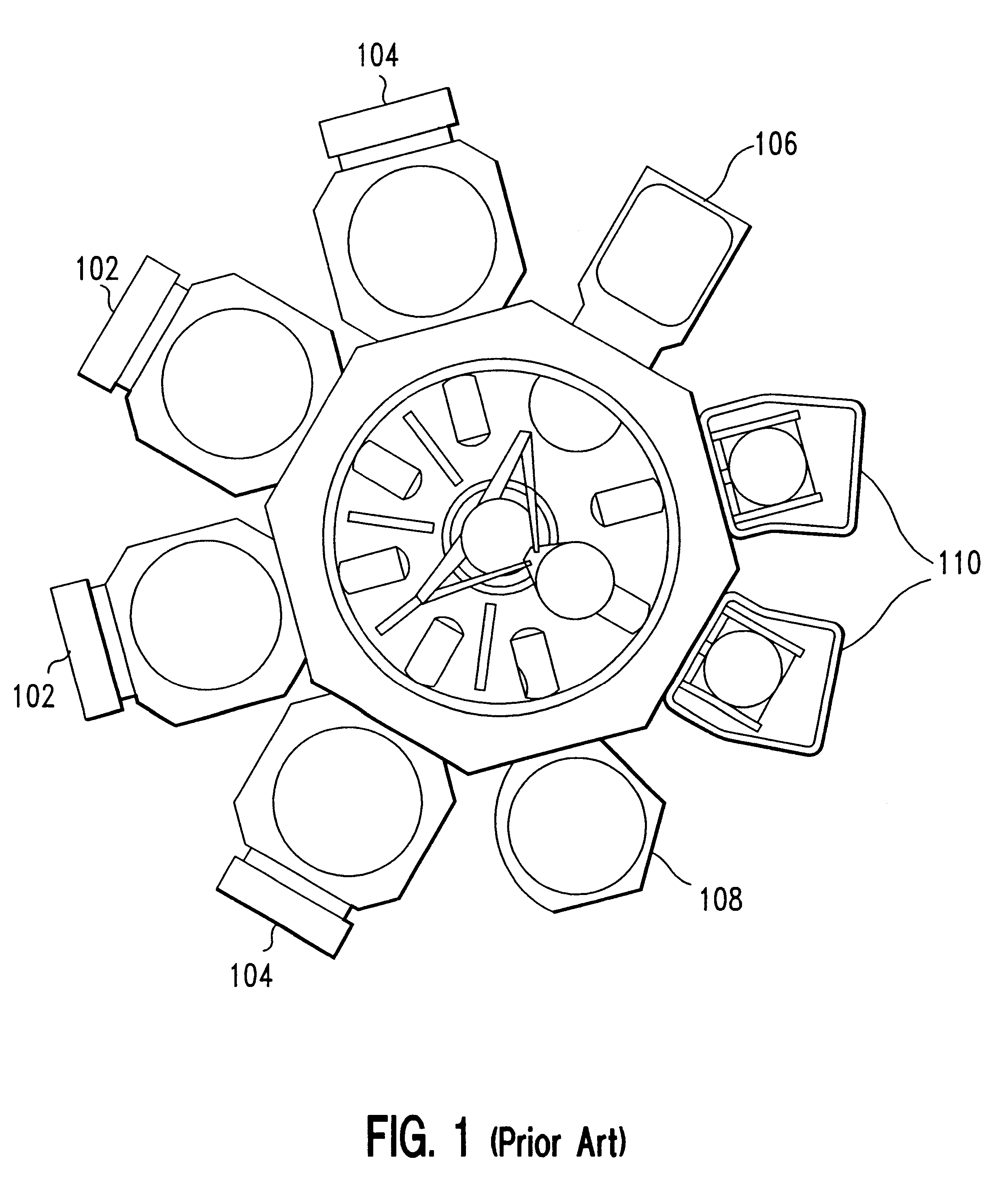

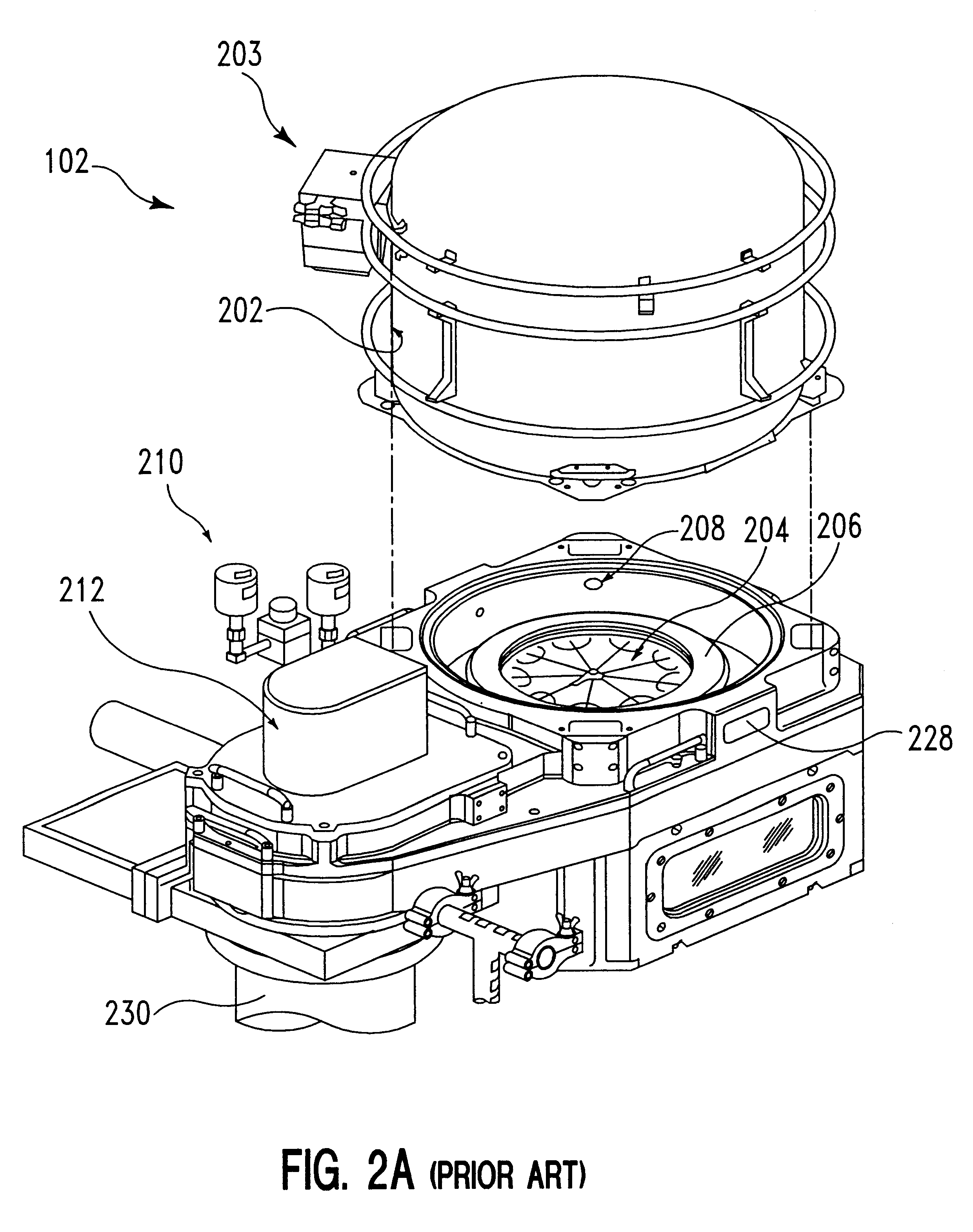

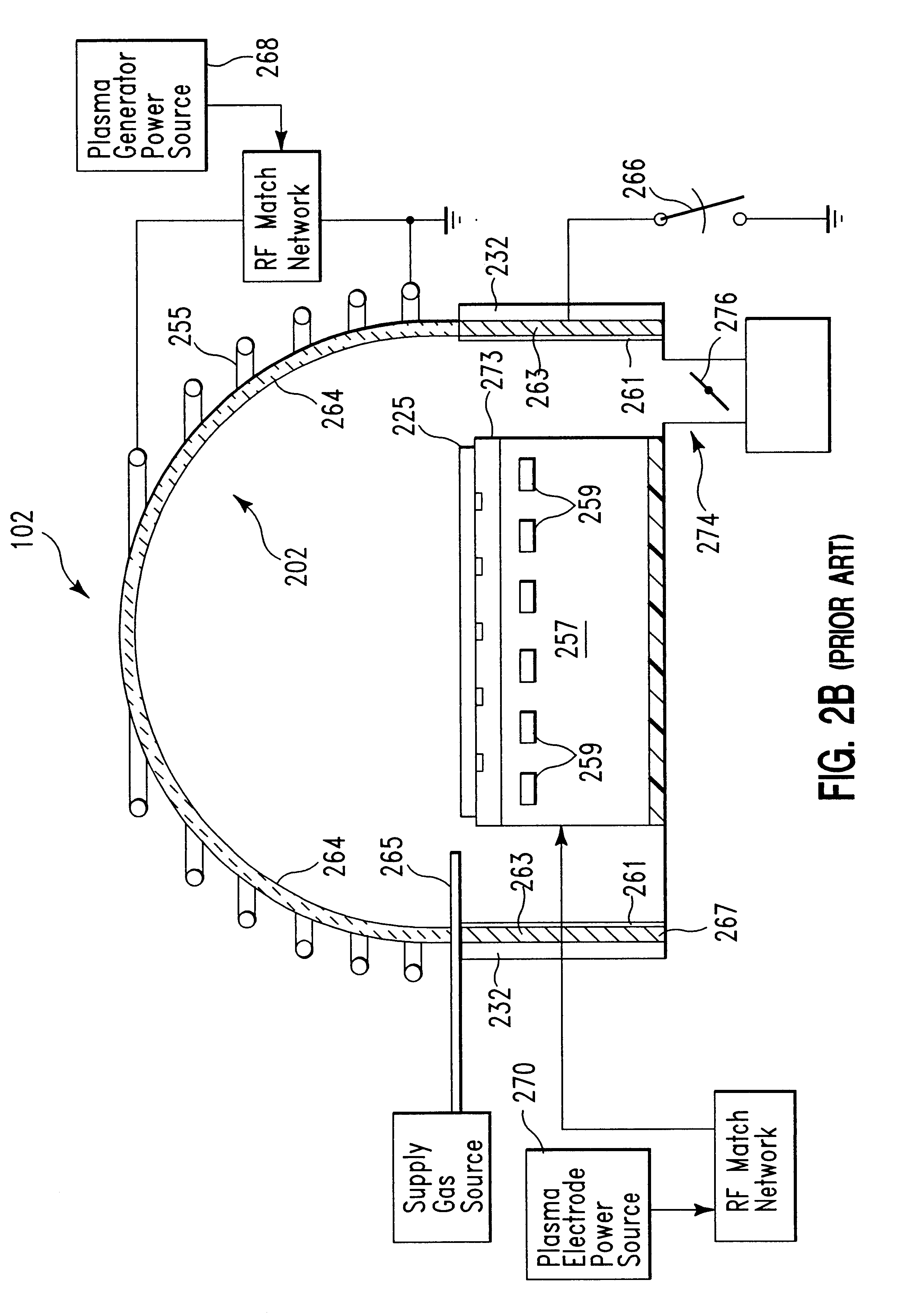

Method of epitaxial germanium tin alloy surface preparation

Methods of preparing a clean surface of germanium tin or silicon germanium tin layers for subsequent deposition are provided. An overlayer of Ge, doped Ge, another GeSn or SiGeSn layer, a doped GeSn or SiGeSn layer, an insulator, or a metal can be deposited on a prepared GeSn or SiGeSn layer by positioning a substrate with an exposed germanium tin or silicon germanium tin layer in a processing chamber, heating the processing chamber and flowing a halide gas into the processing chamber to etch the surface of the substrate using either thermal or plasma assisted etching followed by depositing an overlayer on the substantially oxide free and contaminant free surface. Methods can also include the placement and etching of a sacrificial layer, a thermal clean using rapid thermal annealing, or a process in a plasma of nitrogen trifluoride and ammonia gas.

Owner:APPLIED MATERIALS INC

Method of cleaning a semiconductor device processing chamber after a copper etch process

The present invention is a method for removing deposited etch byproducts from surfaces of a semiconductor processing chamber after a copper etch process. The method of the invention comprises the following general steps: (a) an oxidation step, in which interior surfaces of the processing chamber are contacted with an oxidizing plasma; (b) a first non-plasma cleaning step, in which interior surfaces of the processing chamber are contacted with an H+hfac-comprising gas; and (c) a second cleaning step, in which interior surfaces of the processing chamber are contacted with a plasma containing reactive fluorine species, whereby at least a portion of the copper etch byproducts remaining after step (b) are volatilized into gaseous species, which are removed from the processing chamber. The method of the invention is preferably performed at a chamber wall temperature of at least 150° C. in order to achieve optimum cleaning of the chamber at the chamber operating pressures typically used during the cleaning process. The dry cleaning method of the invention can be performed between wafer processing runs without opening the processing chamber, thereby minimizing potential contamination to the chamber as well as chamber downtime.

Owner:APPLIED MATERIALS INC

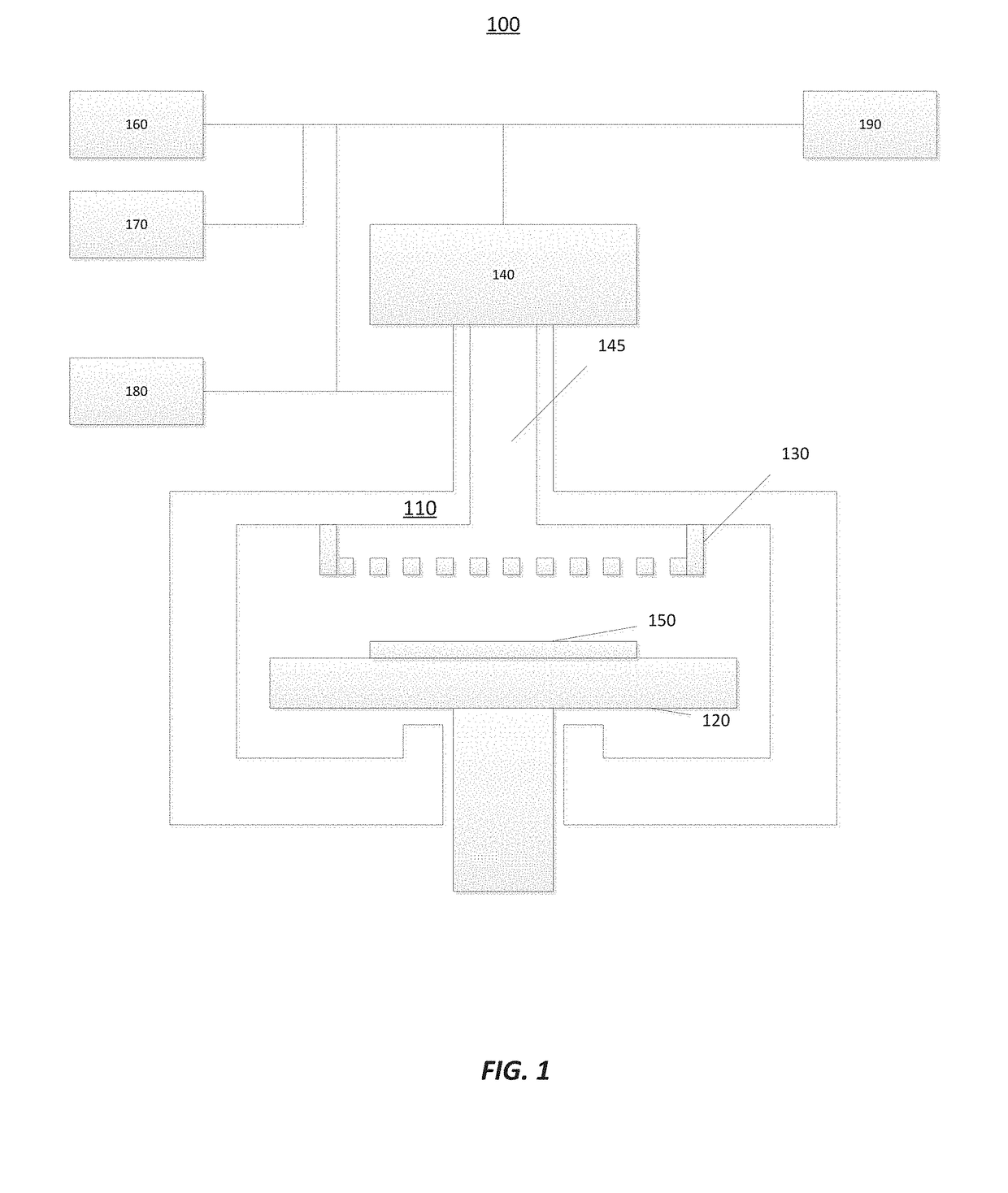

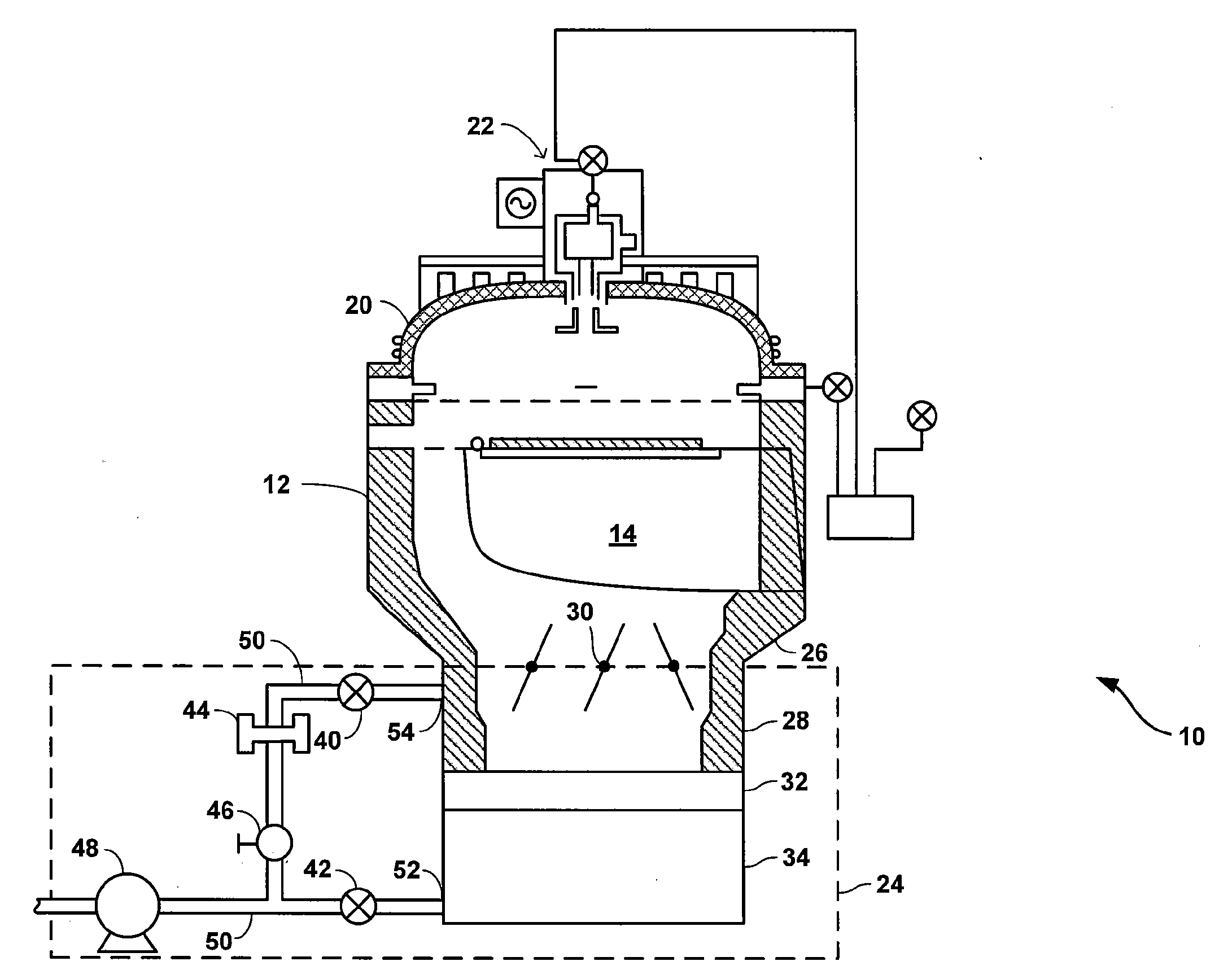

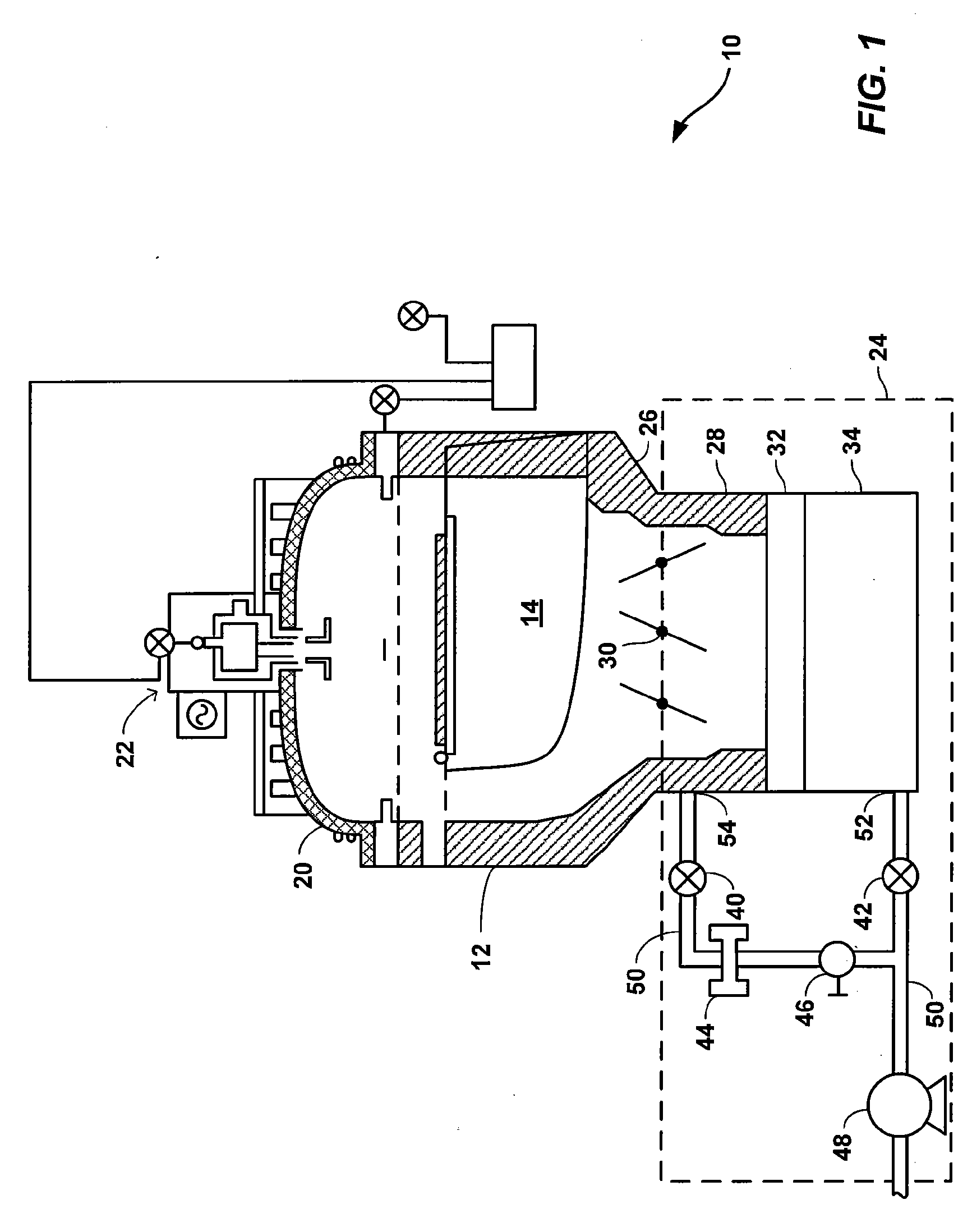

Apparatus for use with hydrogen radicals and method of using same

PendingUS20190348261A1To offer comfortExtend your lifeFouling preventionElectric discharge tubesEnvironmental engineeringChemical engineering

A system and method suitable for removing both carbon-based contaminants and oxygen-based contaminants from a substrate within a single process chamber are disclosed.

Owner:ASM IP HLDG BV

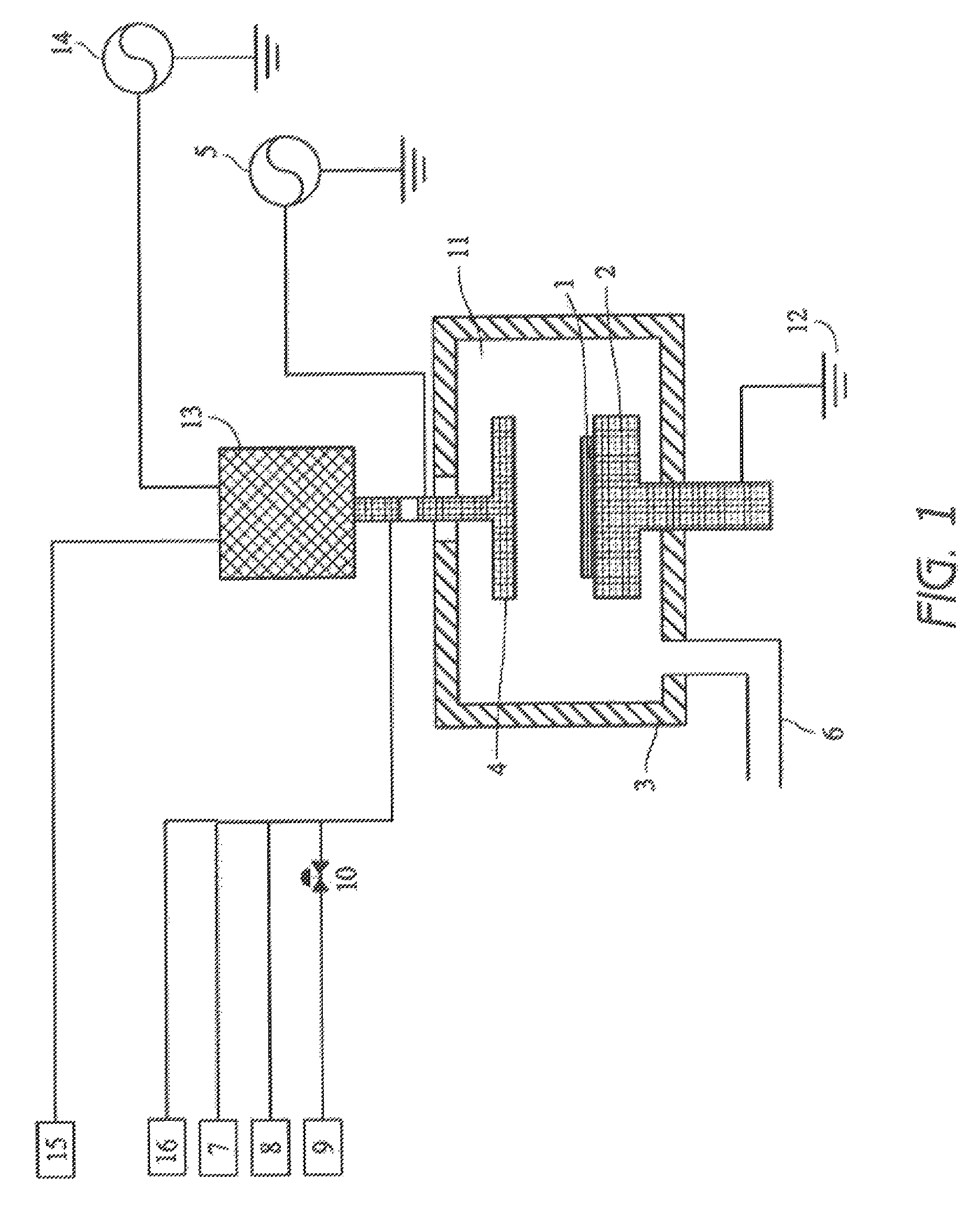

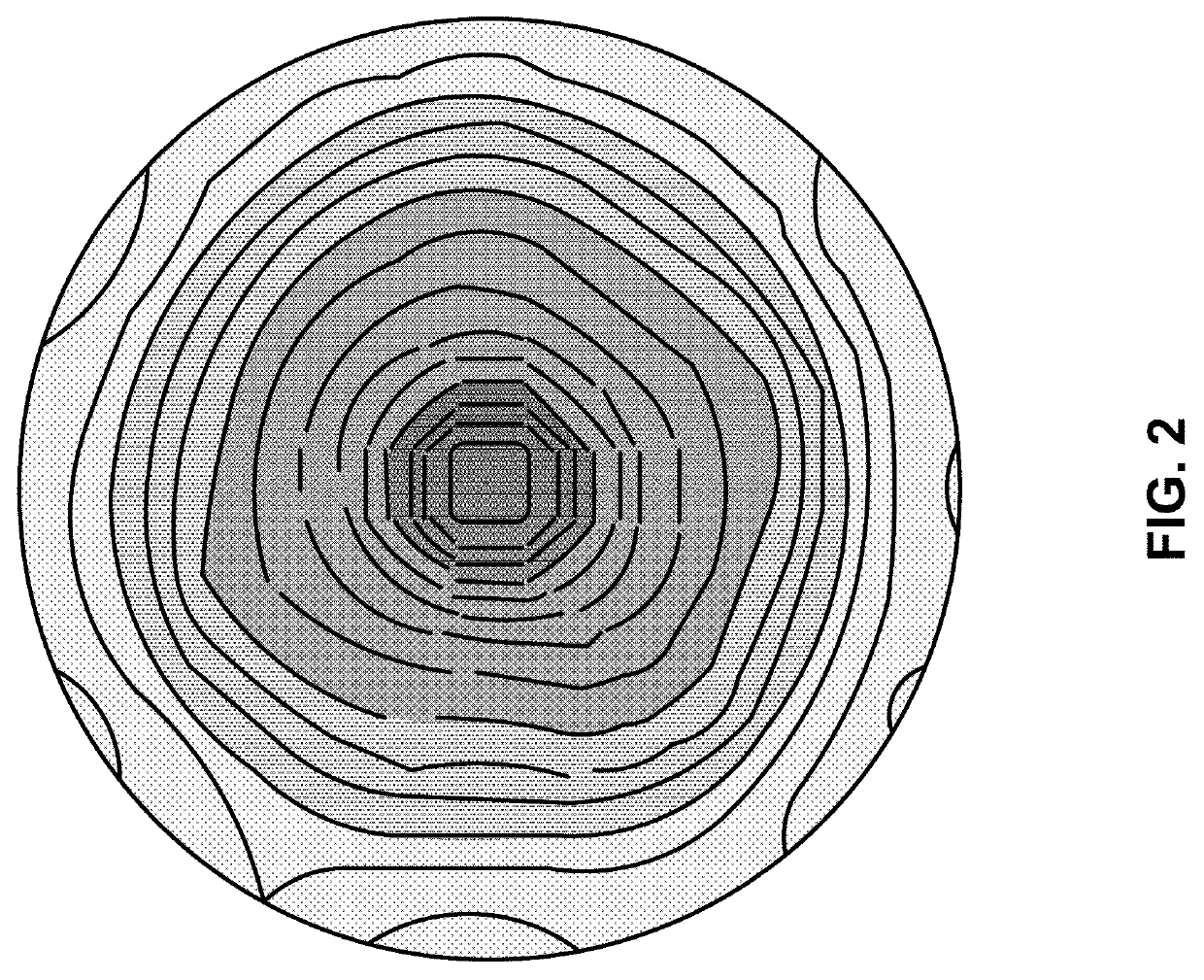

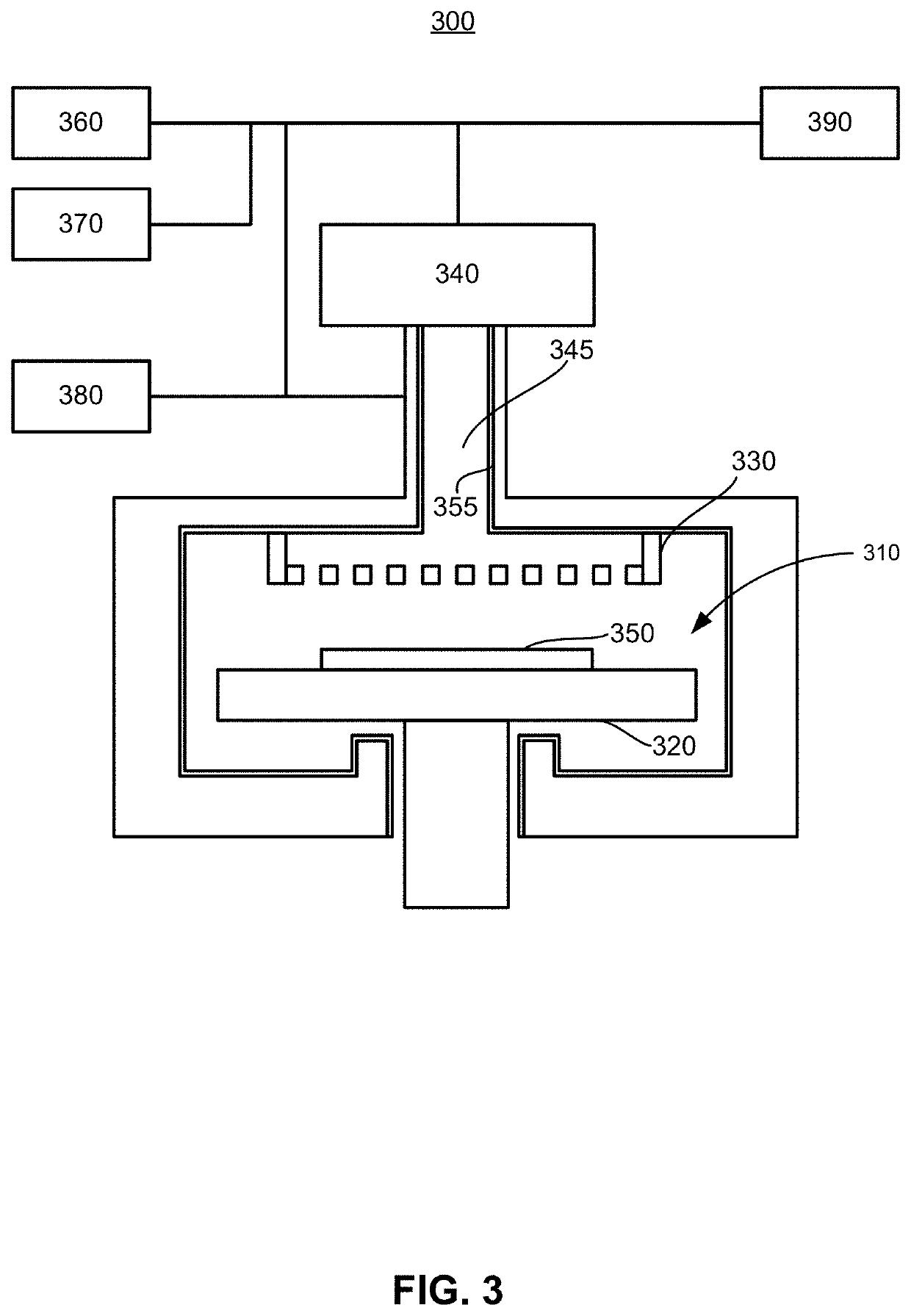

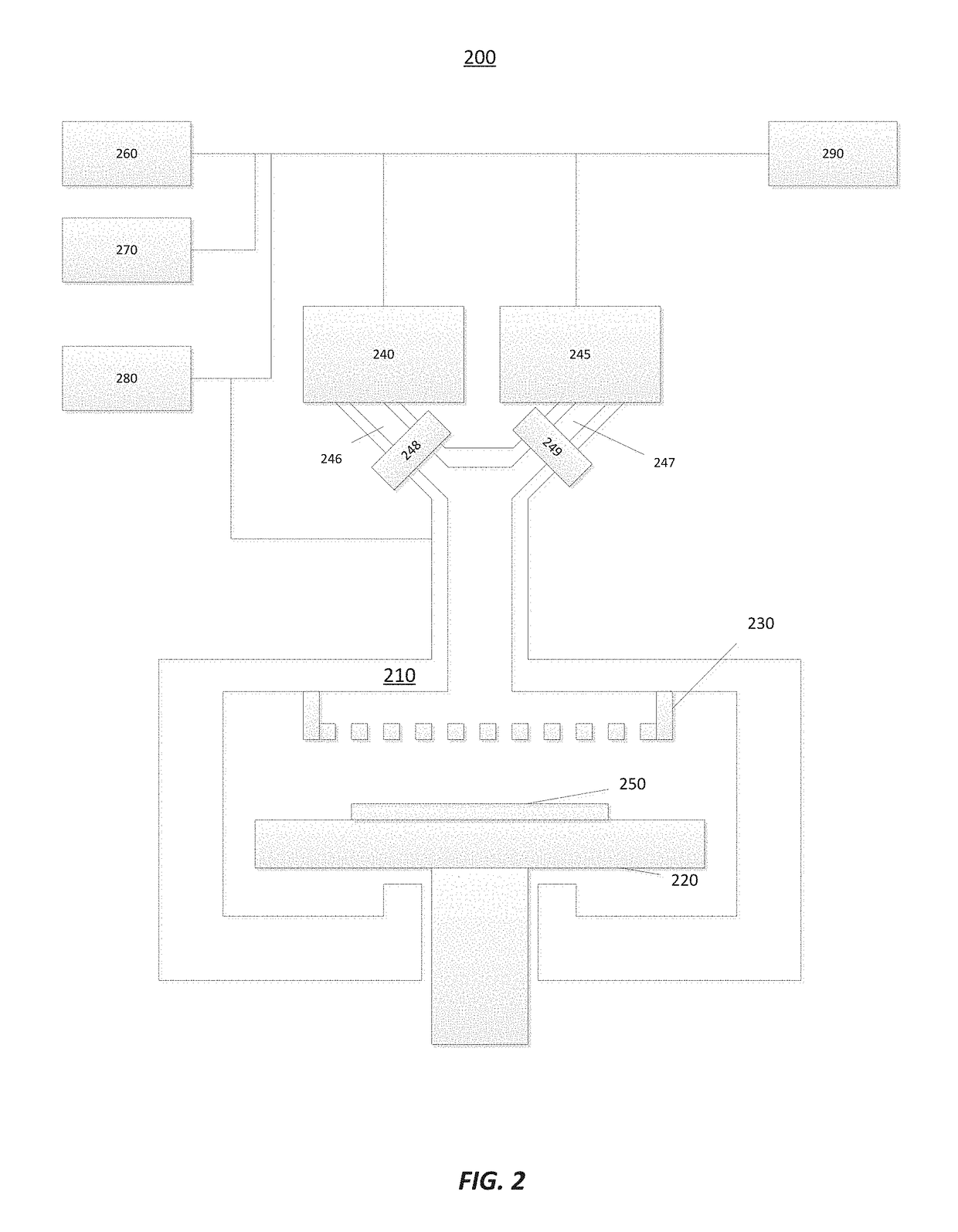

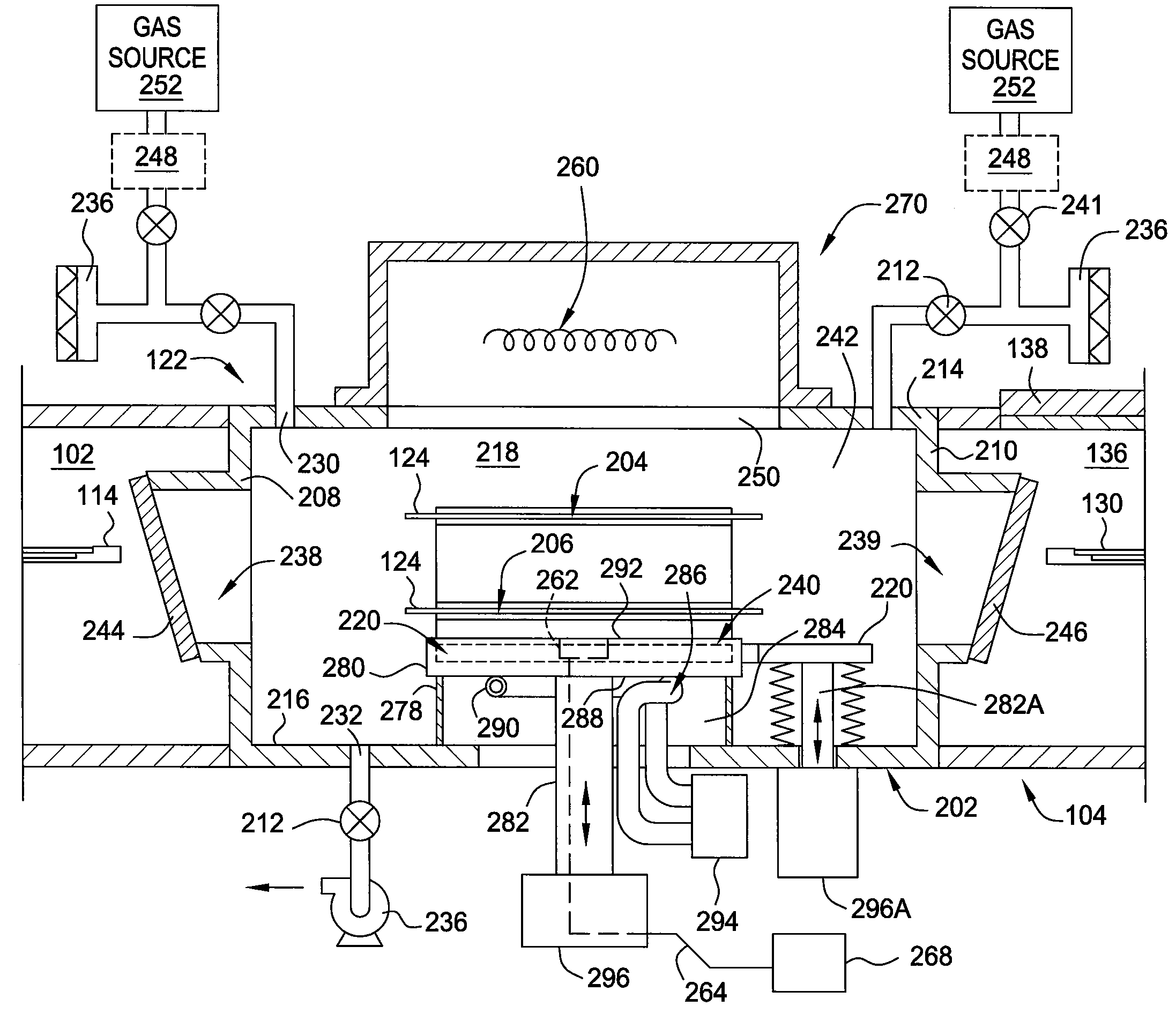

Apparatus and method for removal of oxide and carbon from semiconductor films in a single processing chamber

InactiveUS20190019670A1Electric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaSingle process

A system and method for removing both carbon-based contaminants and oxygen-based contaminants from a semiconductor substrate within a single process chamber is disclosed. The invention may comprise utilization of remote plasma units and multiple gas sources to perform the process within the single process chamber.

Owner:ASM IP HLDG BV

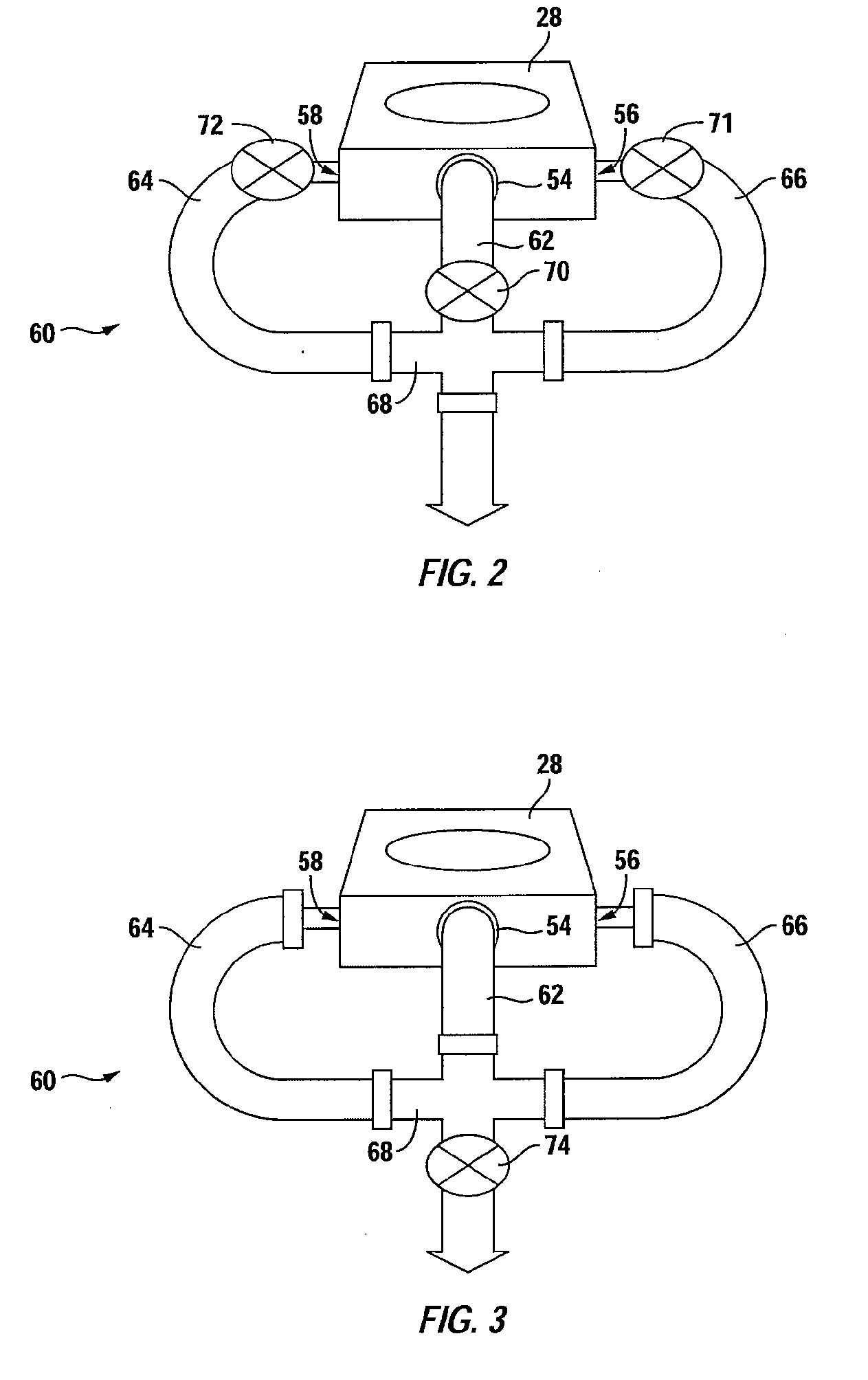

Multi-port pumping system for substrate processing chambers

InactiveUS20090120464A1Improve pumping capacityImprove rendering capabilitiesFrozen sweetsSemiconductor/solid-state device manufacturingEngineeringMulti port

An exhaust foreline for purging fluids from a semiconductor fabrication chamber is described. The foreline may include a first, second and third ports independently coupled to the chamber. A semiconductor fabrication system is also described that includes a substrate chamber that has a first, second and third interface port. The system may also include a multi-port foreline that has a first, second and third port, where the first foreline port is coupled to the first interface port, the second foreline port is coupled to the second interface port, and the third foreline port is coupled to the third interface port. The system may further include an exhaust vacuum coupled to the multi-port foreline.

Owner:APPLIED MATERIALS INC

Method for removing surface deposits and passivating interior surfaces of the interior of a chemical vapor deposition reactor

InactiveUS20090047447A1Efficient removalInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsGas phaseSulfur

The present invention relates to plasma cleaning methods for removing surface deposits from a surface, such as the interior of a depositions chamber that is used in fabricating electronic devices. The present invention also provides gas mixtures and activated gas mixtures which provide superior performance in removing deposits from a surface. The methods involve activating a gas mixture comprising a carbon or sulfur source, NF3, and optionally, an oxygen source to form an activated gas, and contacting the activated gas mixture with surface deposits to remove the surface deposits wherein the activated gas mixture acts to passivate the interior surfaces of the apparatus to reduce the rate of surface recombination of gas phase species.

Owner:MASSACHUSETTS INST OF TECH

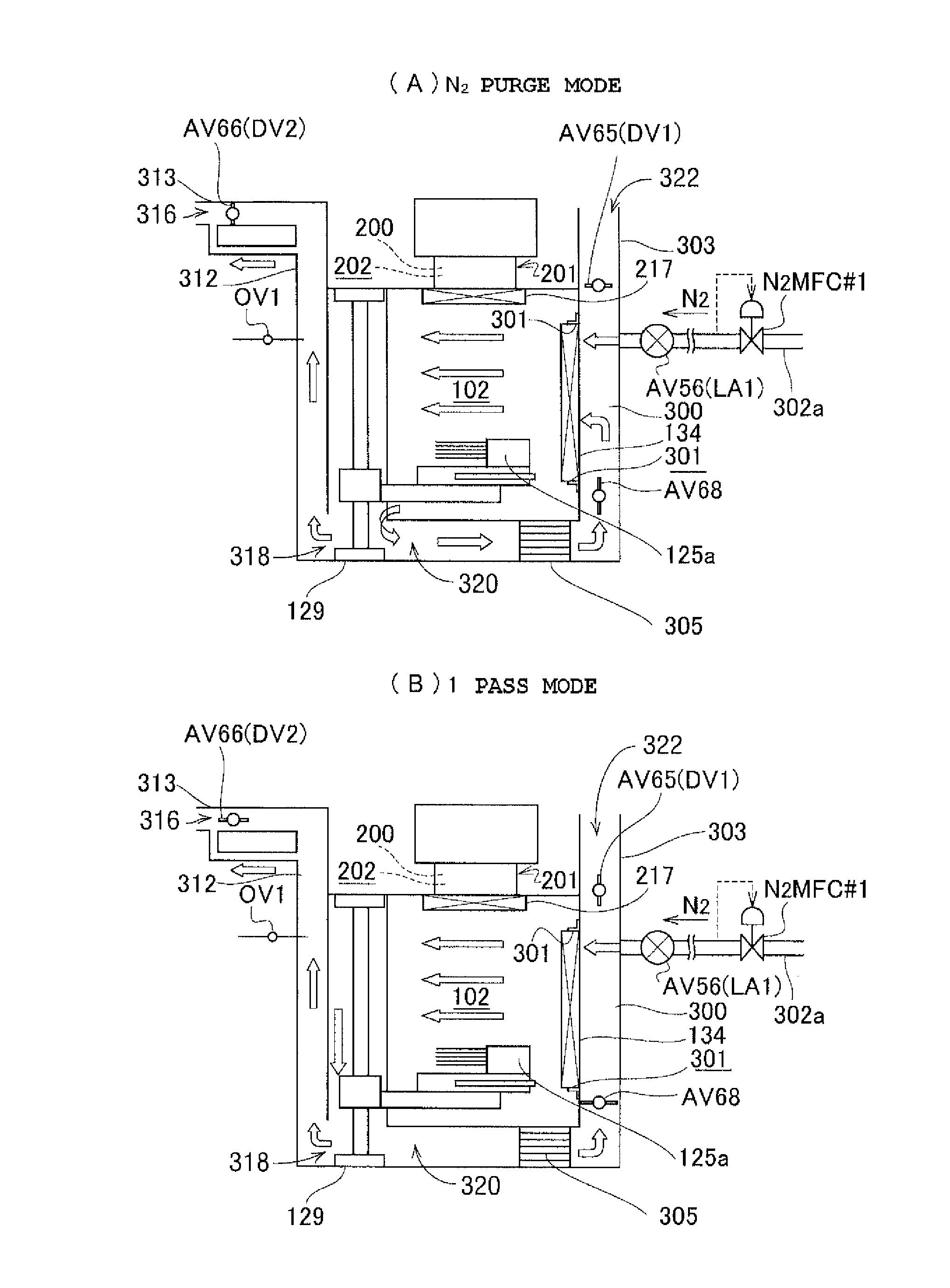

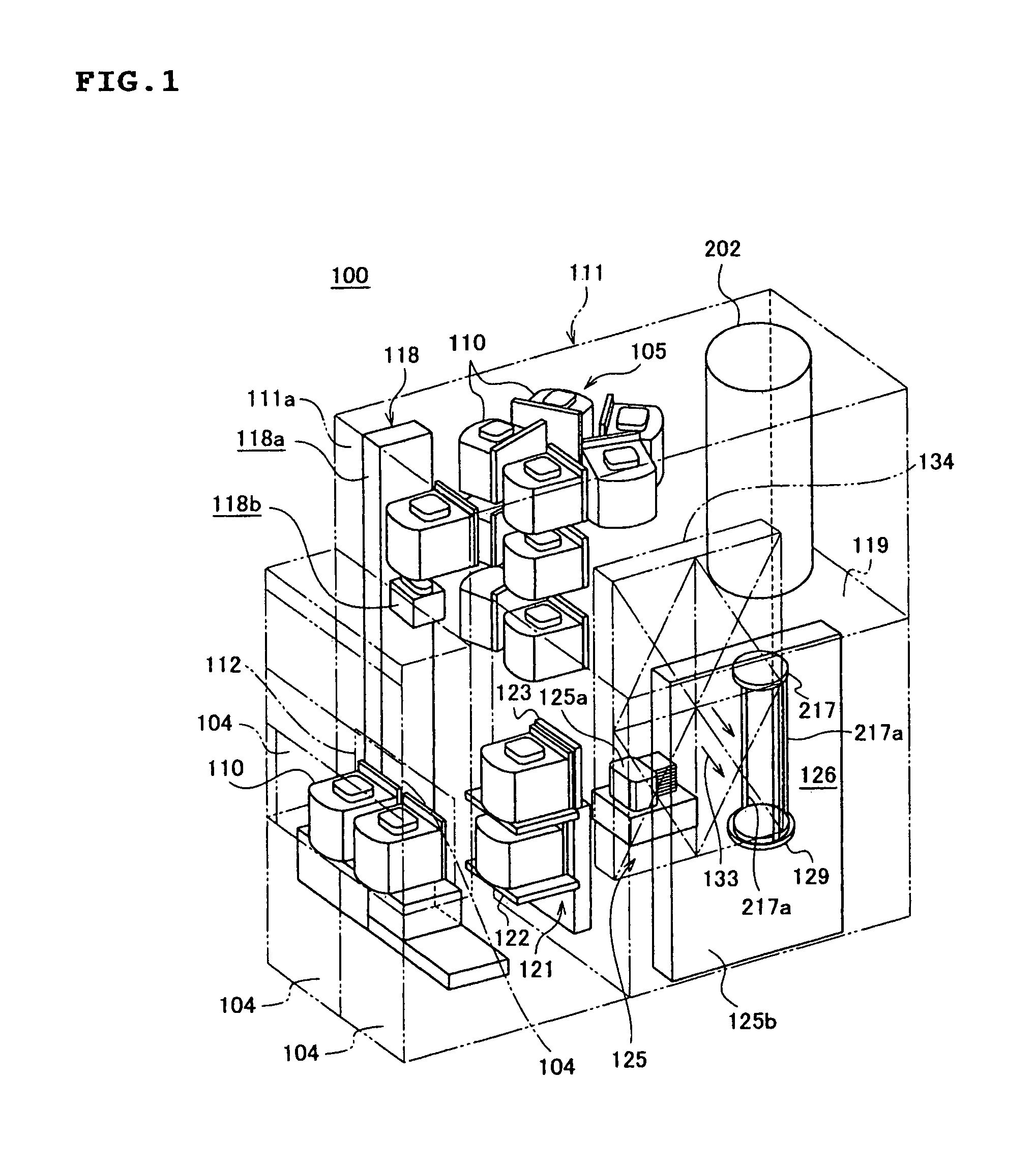

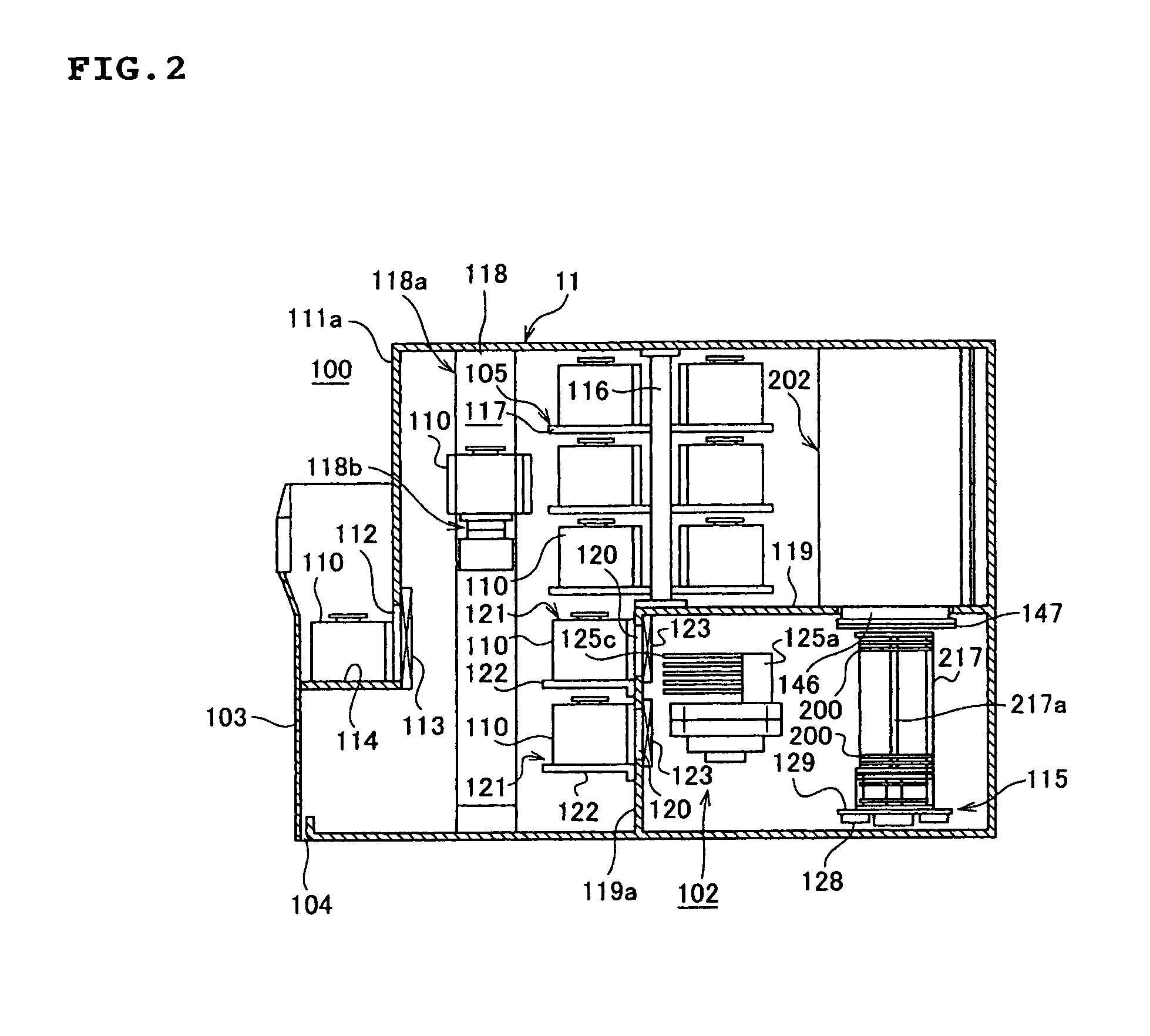

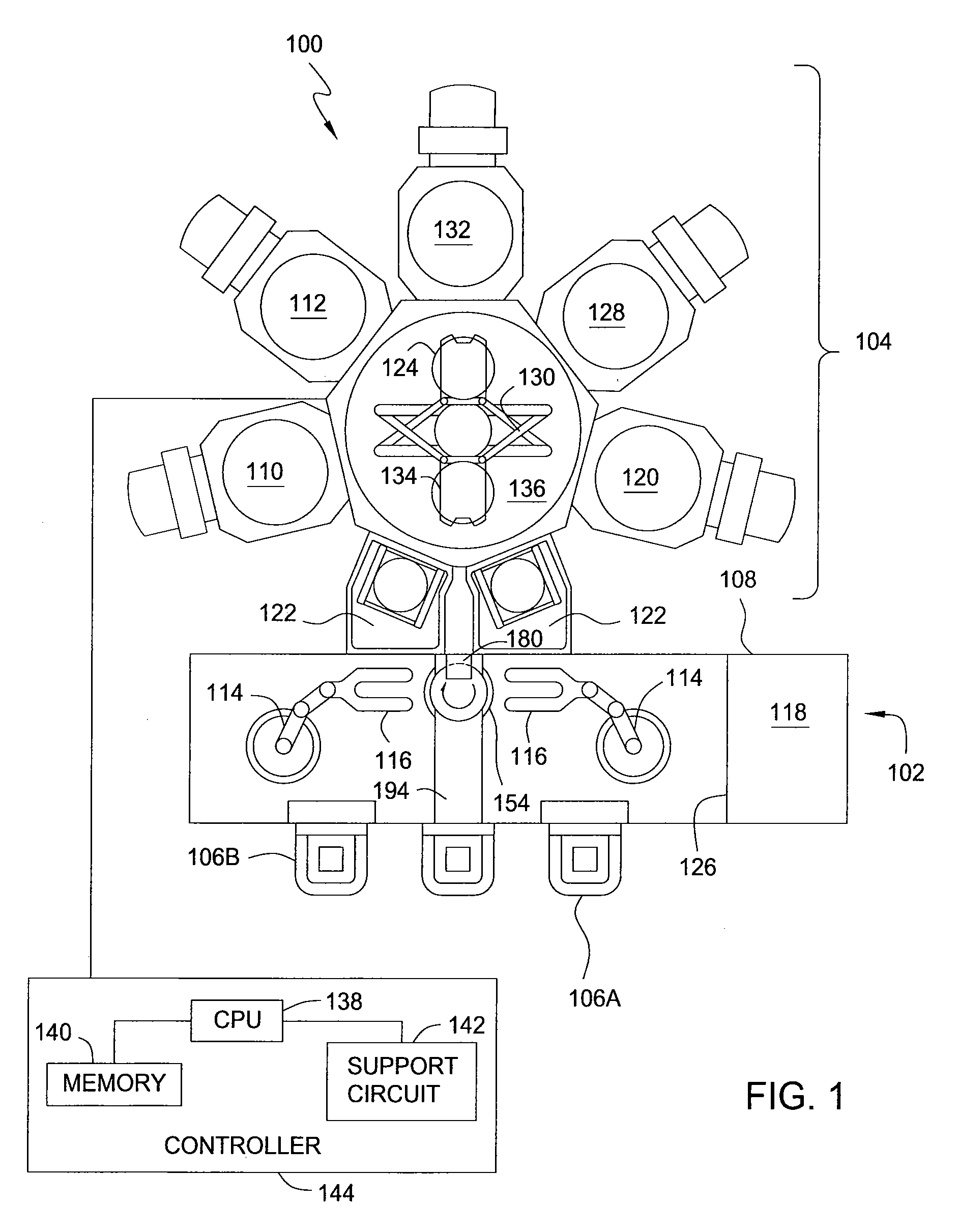

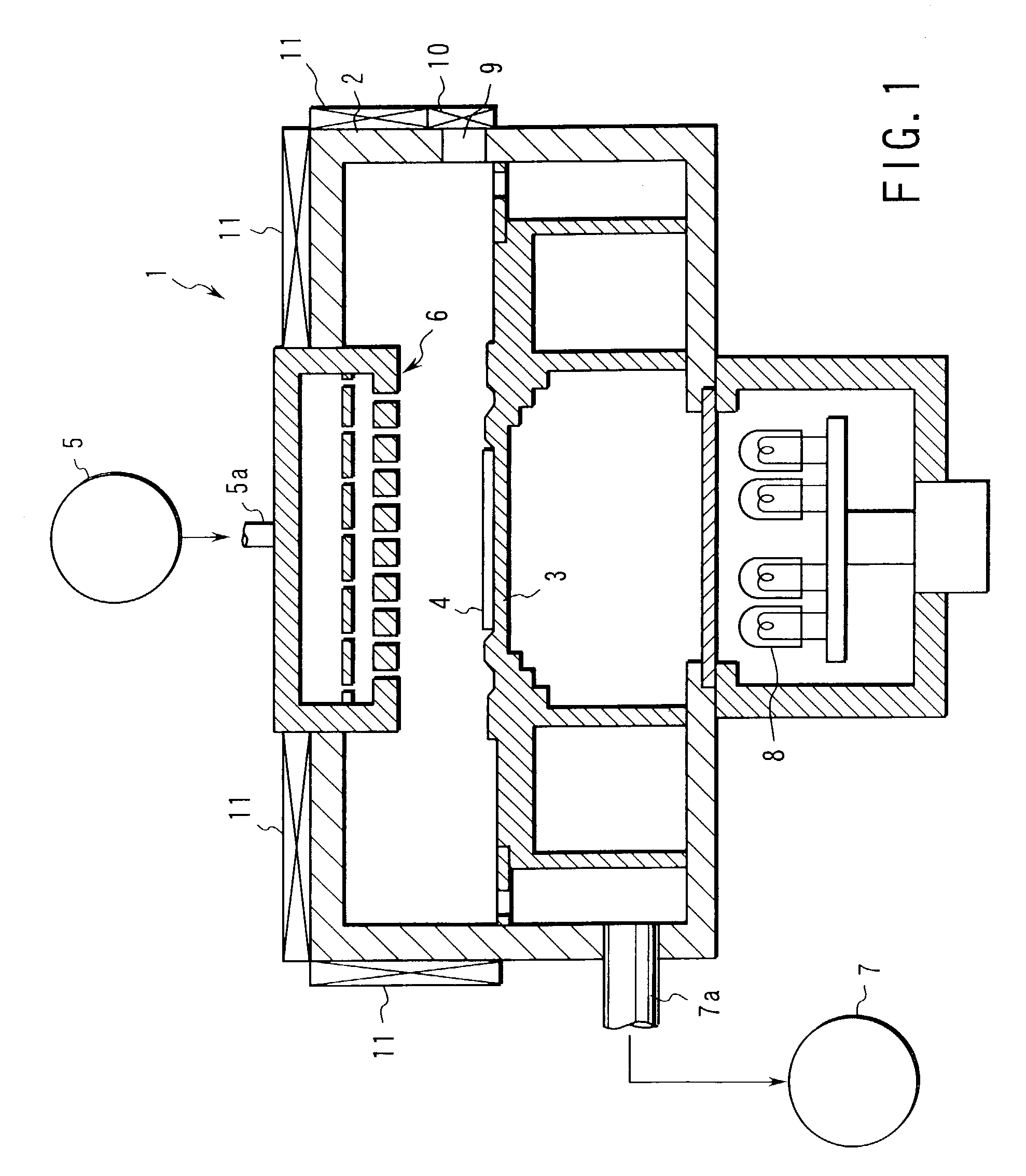

Substrate processing apparatus

ActiveUS8443484B2Avoid stickingPrevent surfaceMechanical cleaningPressure cleaningProcess engineeringIndustrial engineering

To automatically purge a transfer chamber by means of inert gas. There is provided a substrate processing apparatus including a controller that performs control so that a transfer chamber 102 connected to a processing chamber 202 for processing a substrate is purged by gas, the controller having a switching unit that switches a function of exhausting the gas in the transfer chamber 102 in a set direction, and a function of circulating the gas through the transfer chamber 102 in an inert gas atmosphere.

Owner:KOKUSA ELECTRIC CO LTD

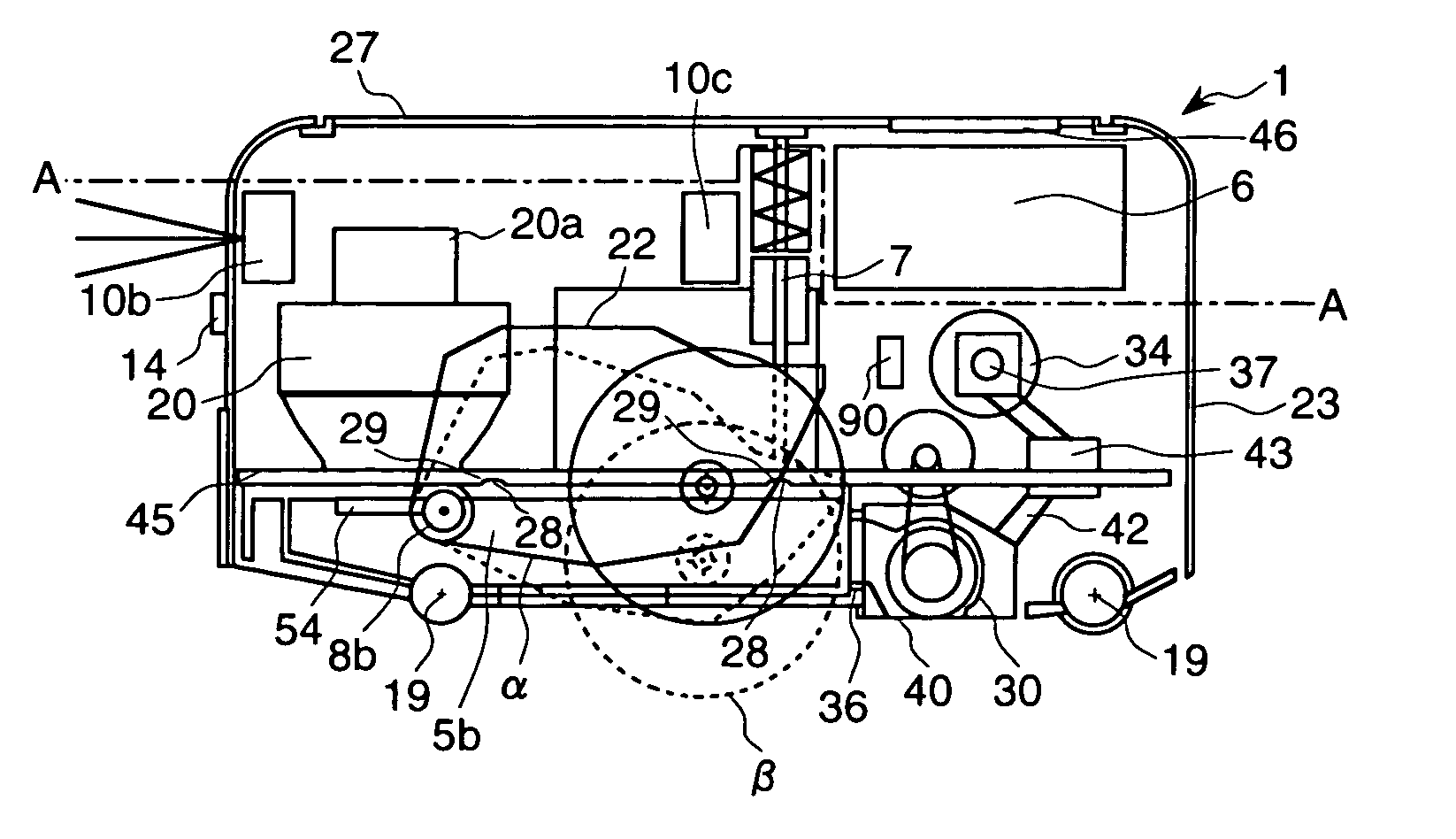

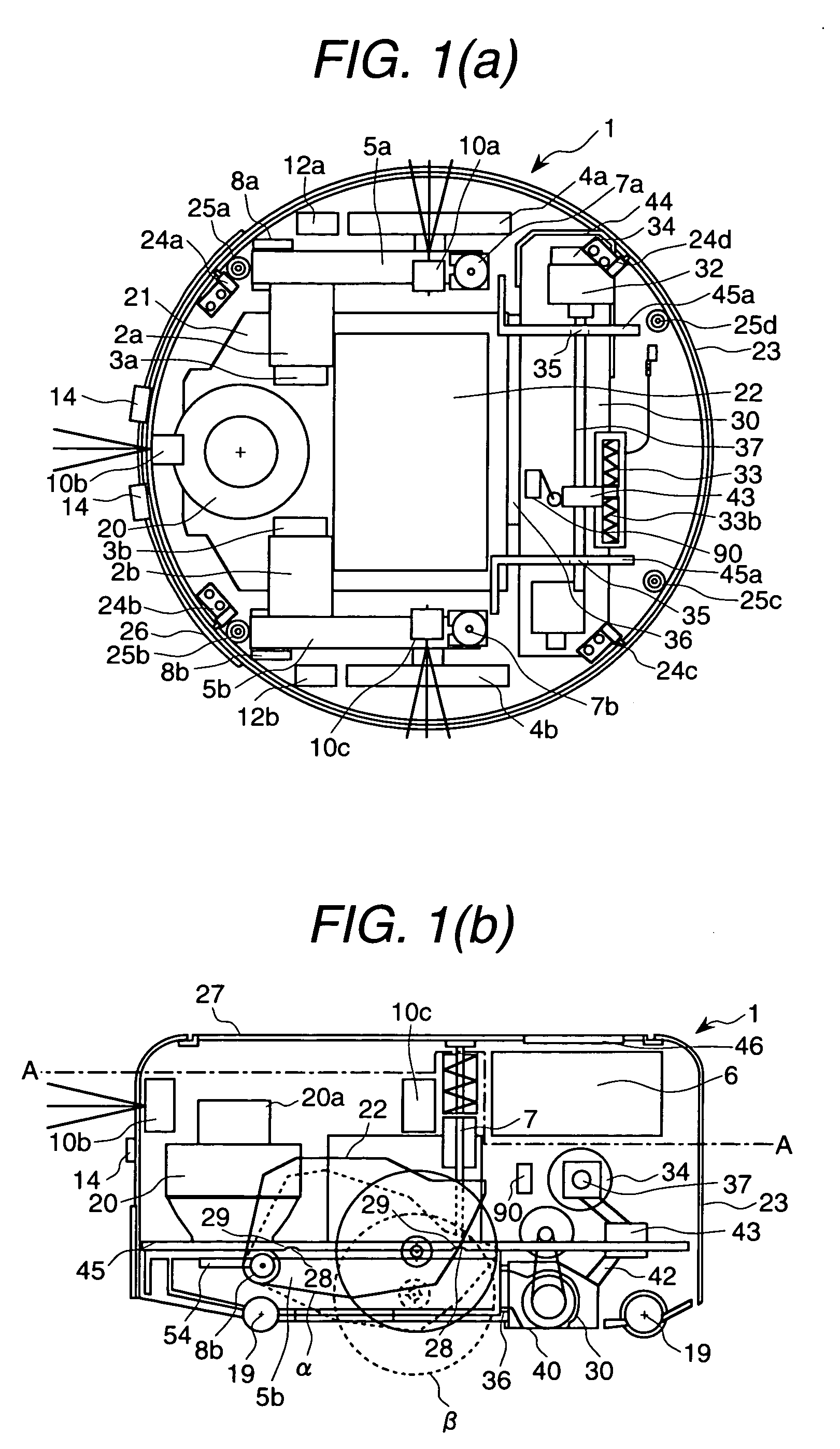

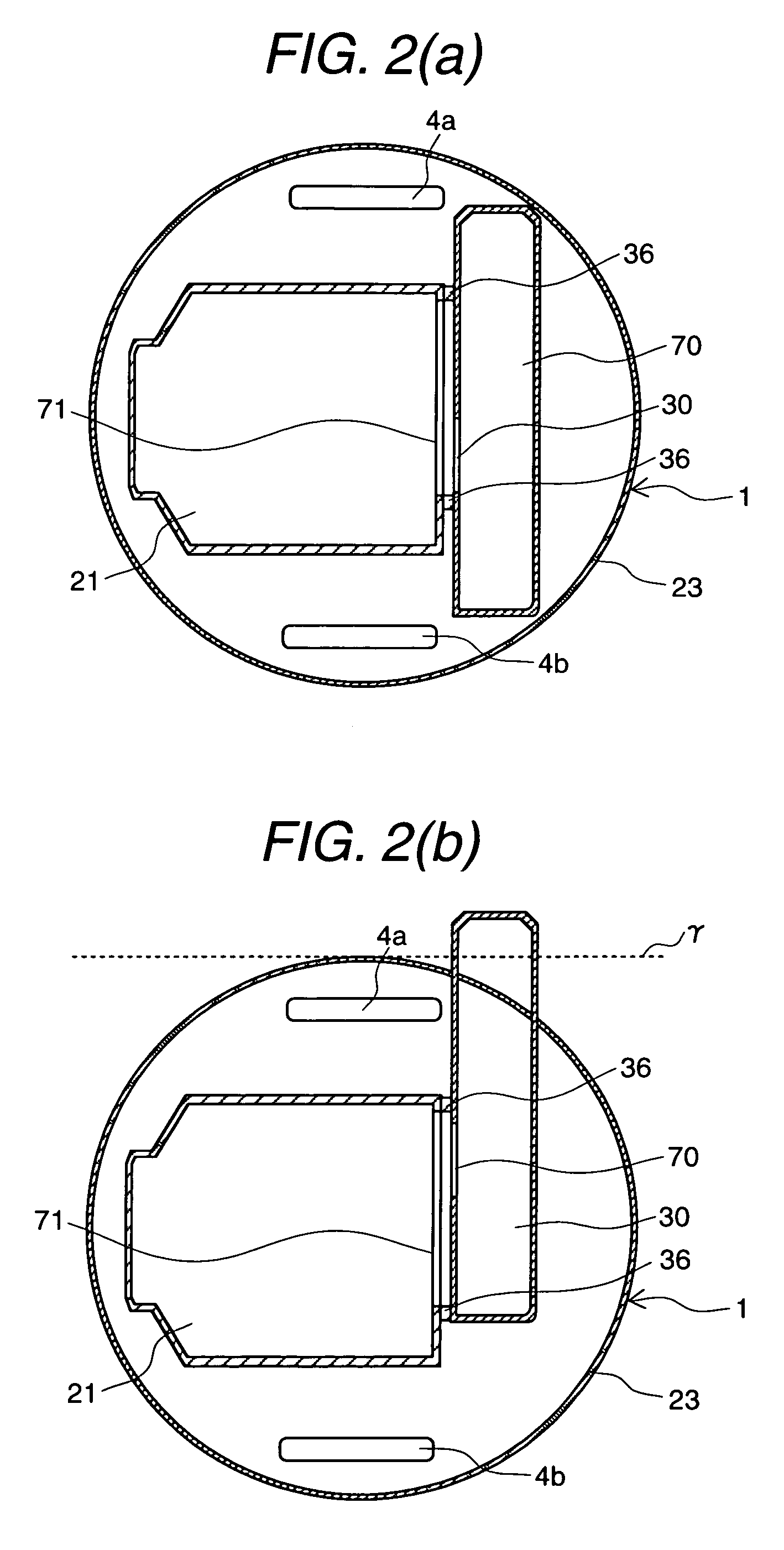

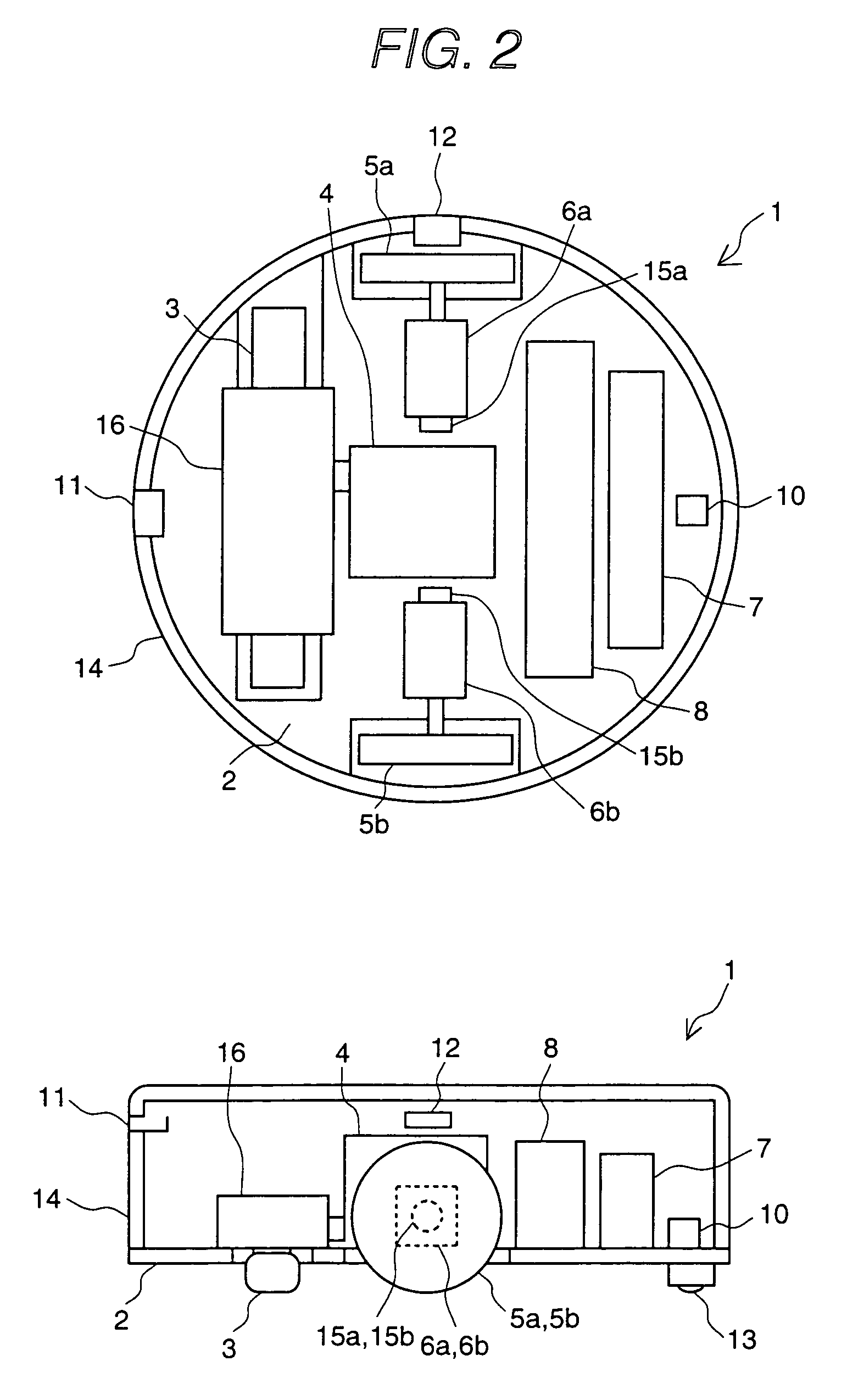

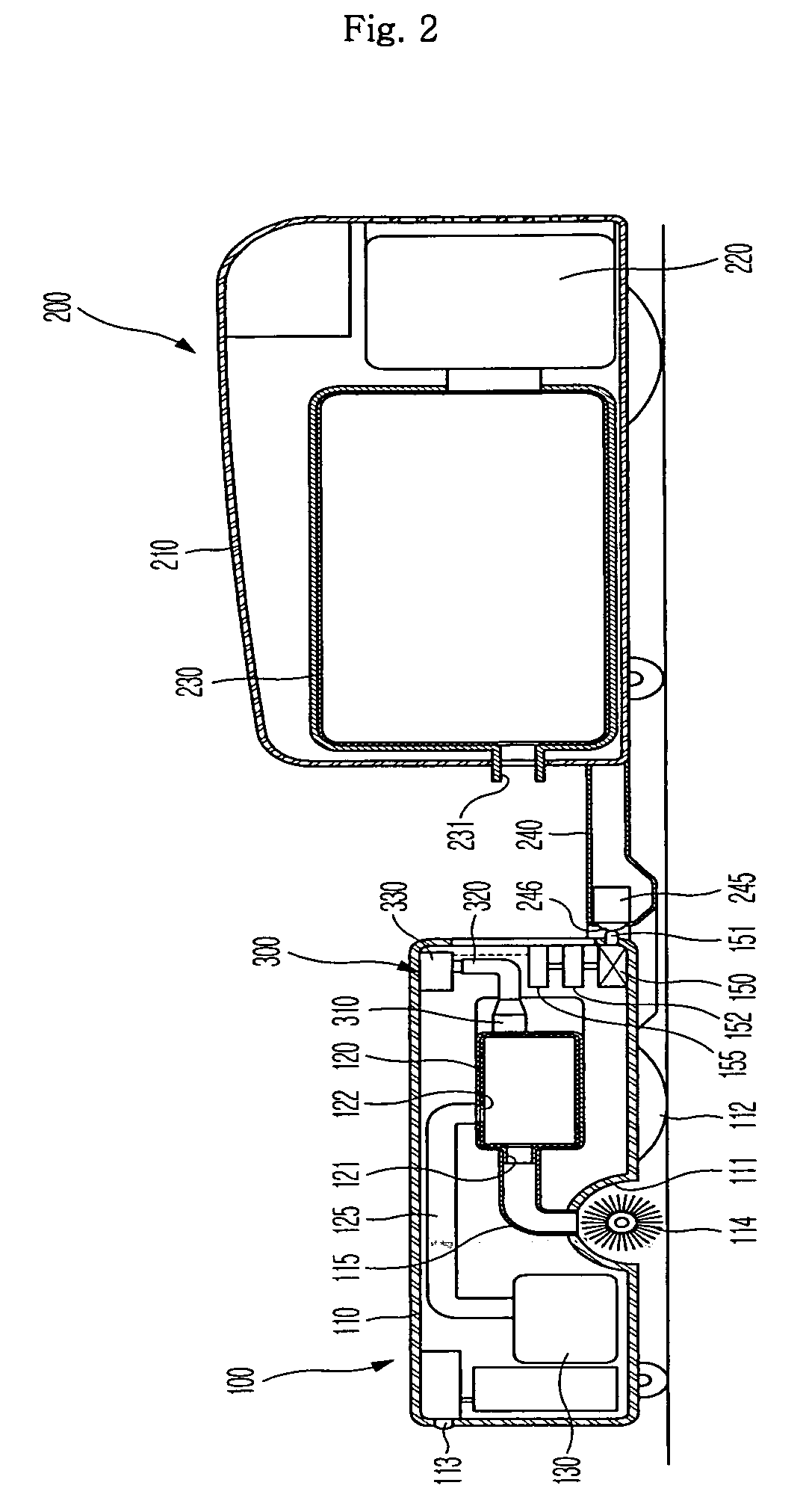

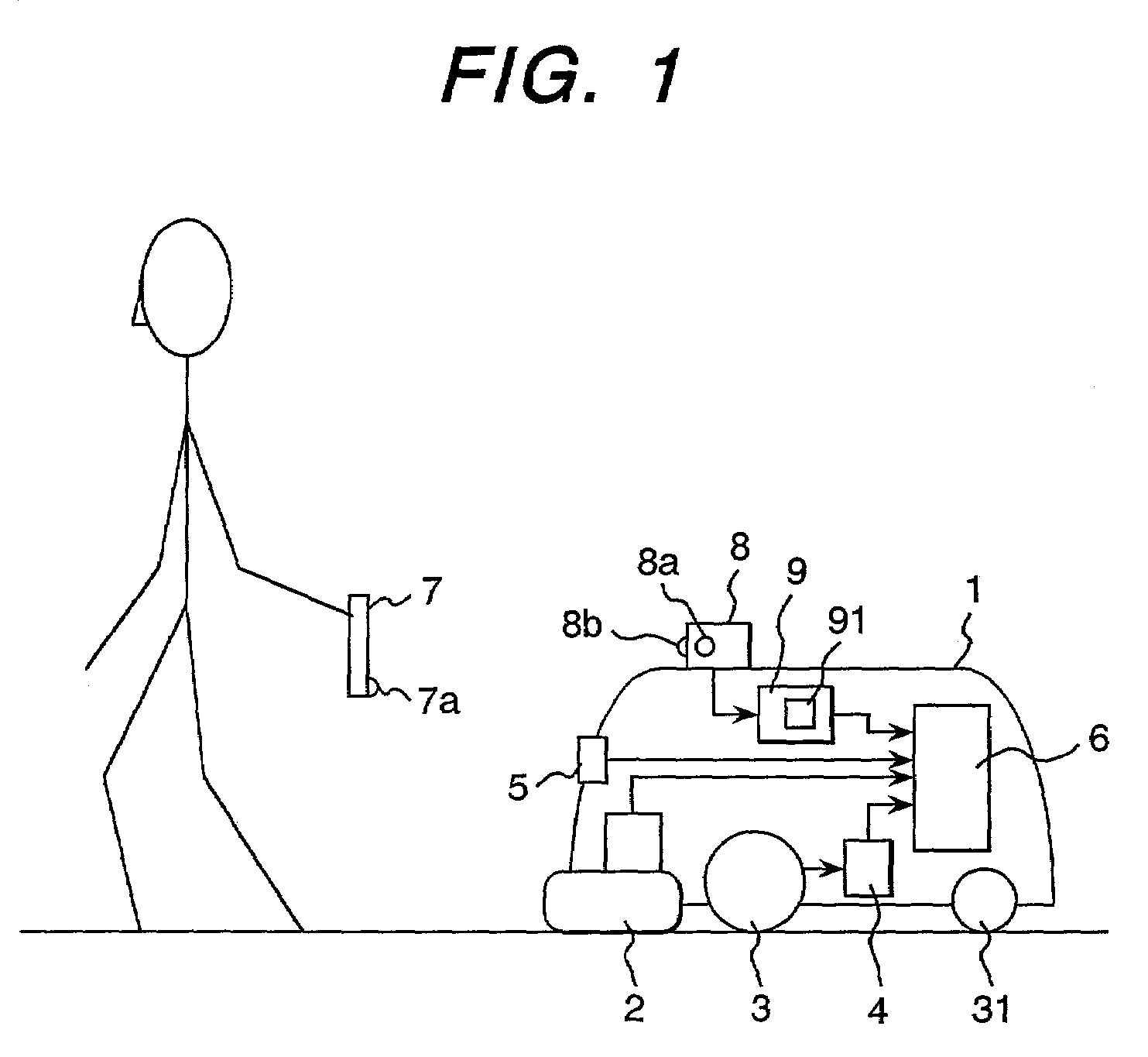

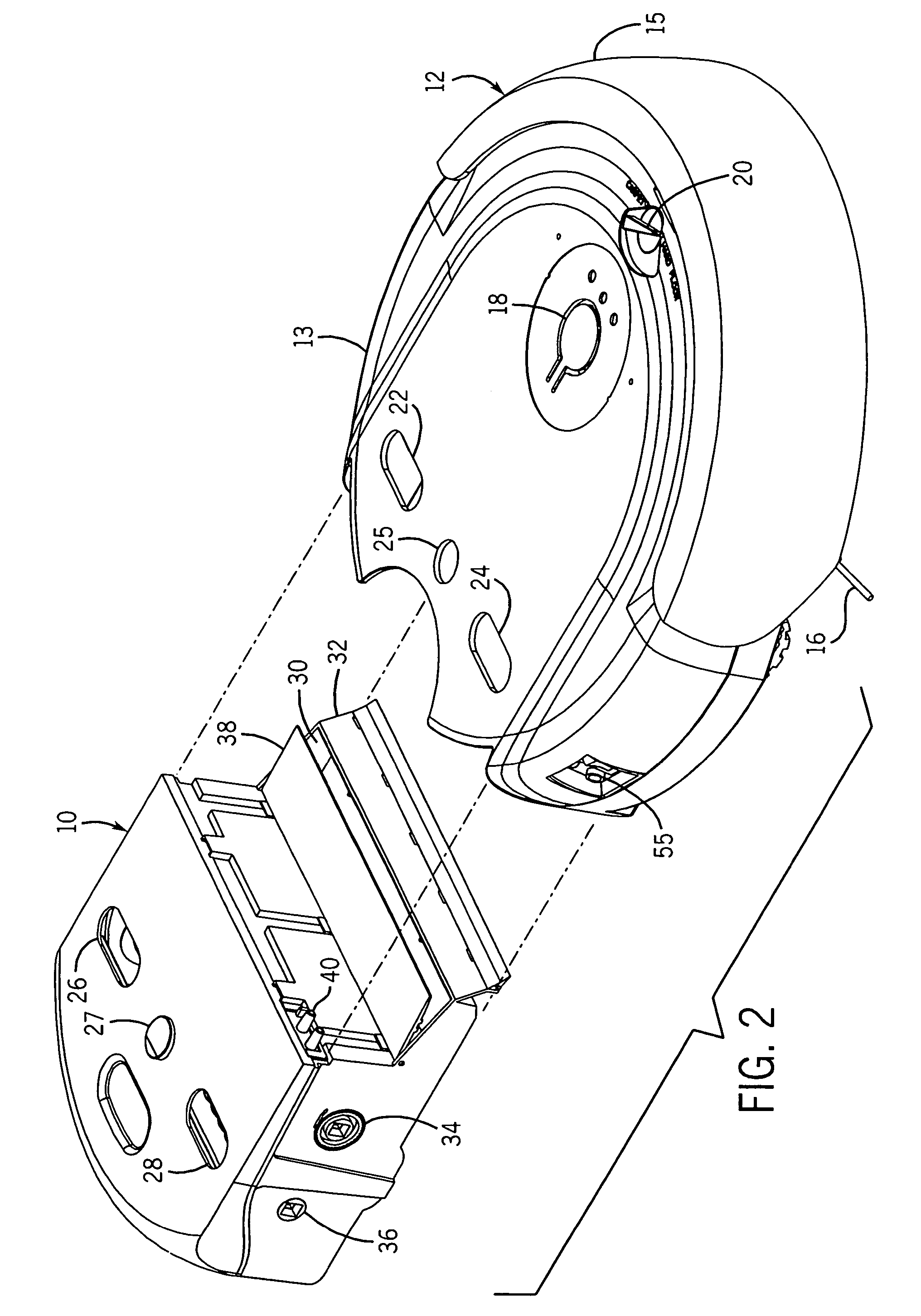

Self-propelled cleaning device and charger using the same

InactiveUS20040255425A1Automatic obstacle detectionMechanical cleaningEngineeringMechanical engineering

Owner:HITACHI LTD +1

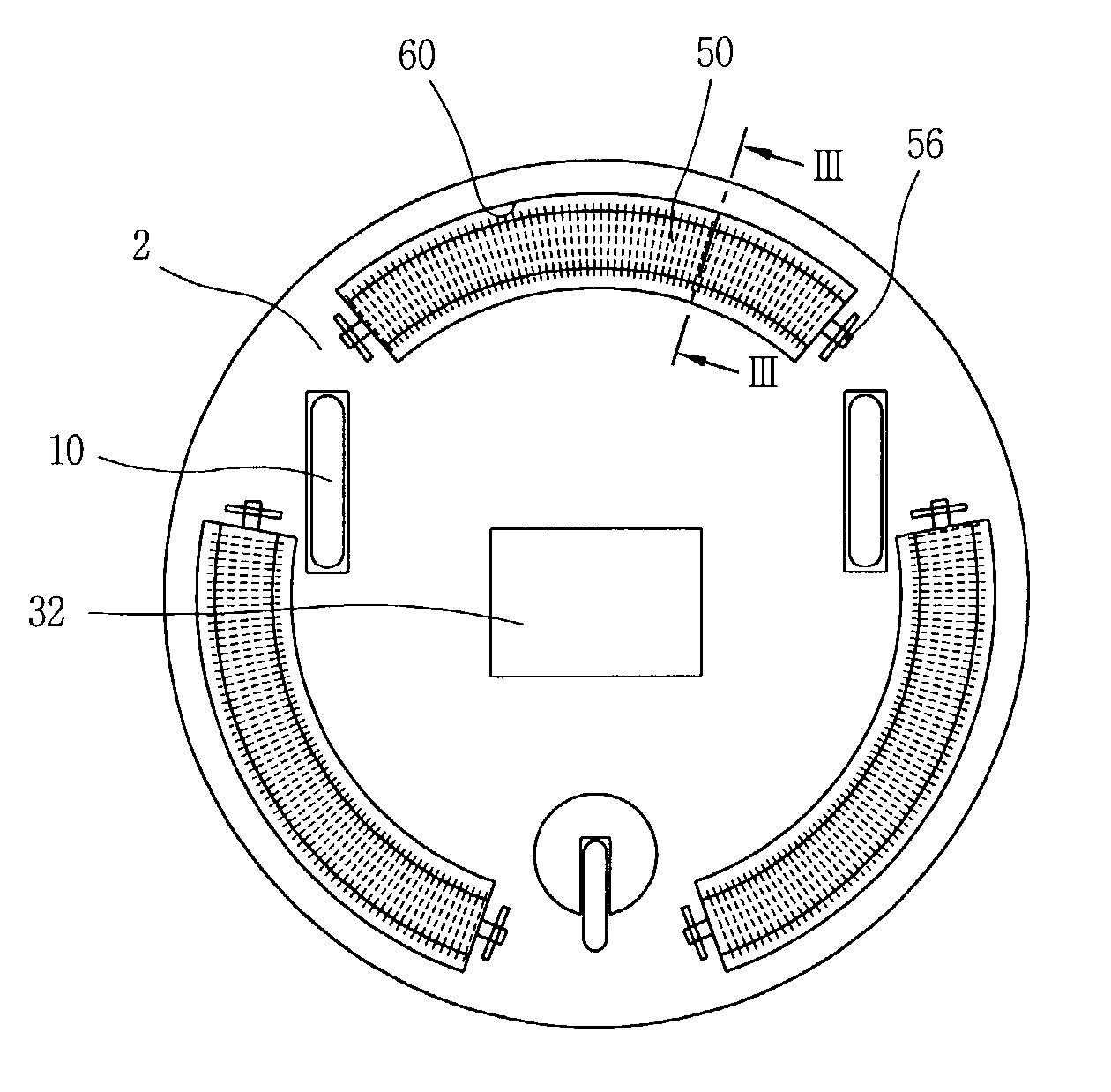

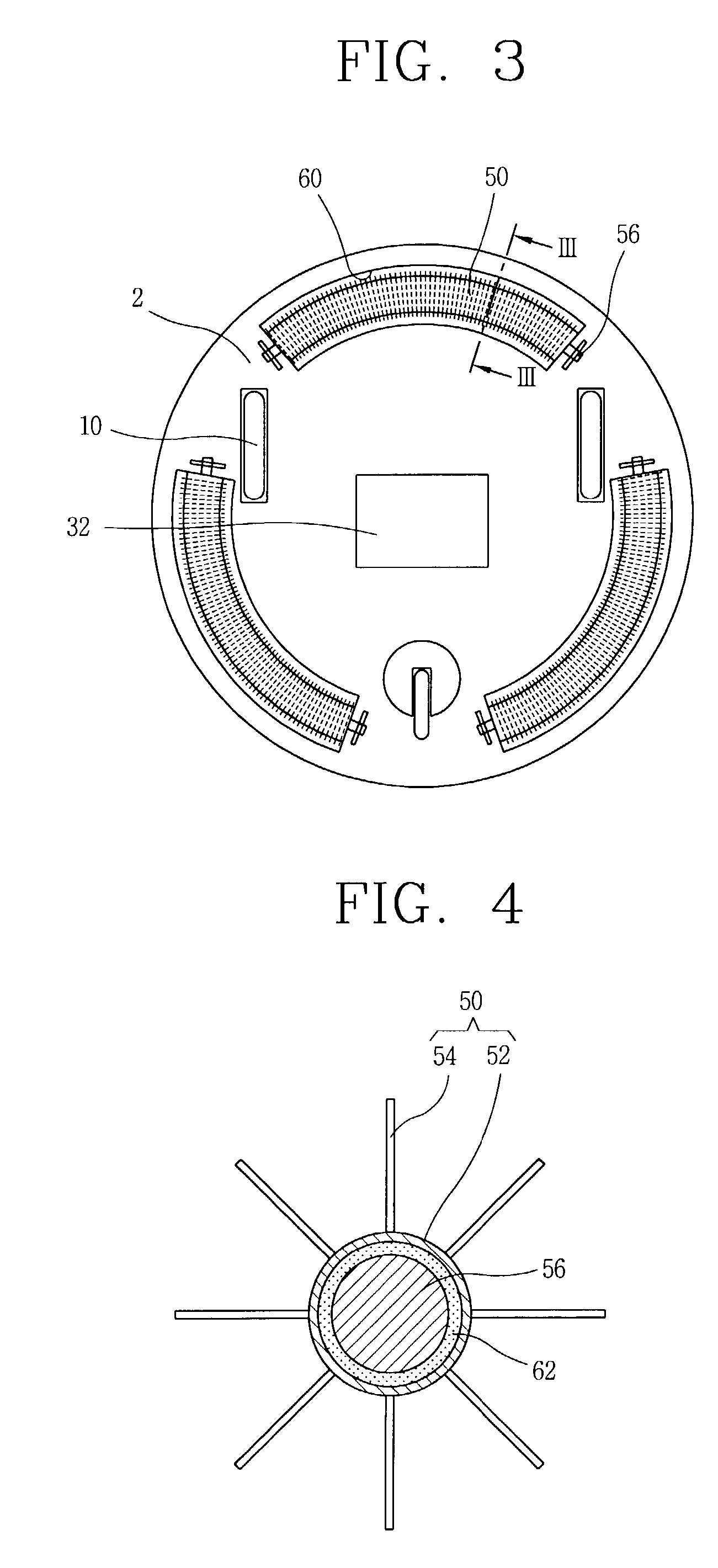

Brush assembly of cleaner

InactiveUS6971140B2Easy to cleanSmall sizeMechanical cleaningPressure cleaningEngineeringMechanical engineering

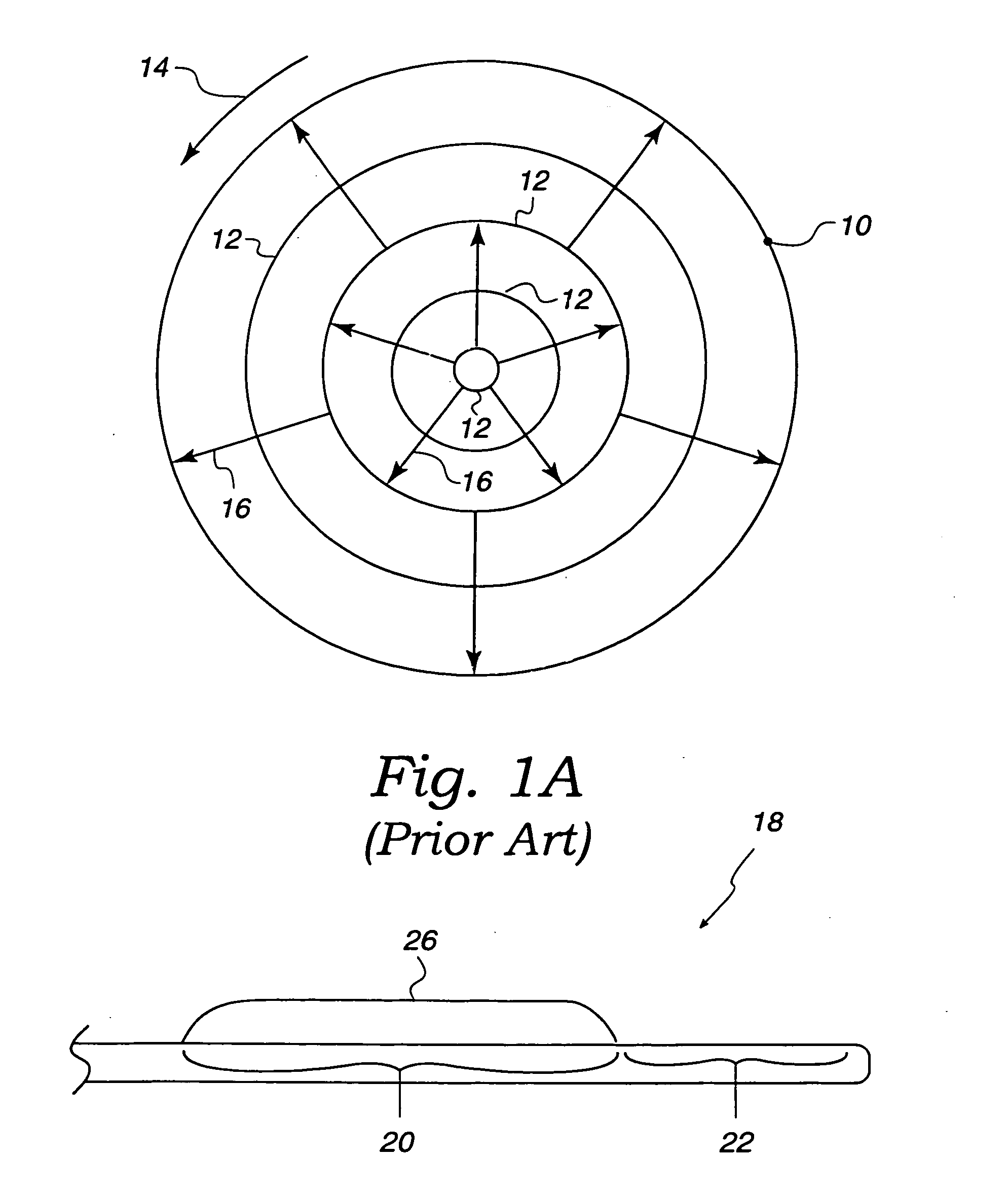

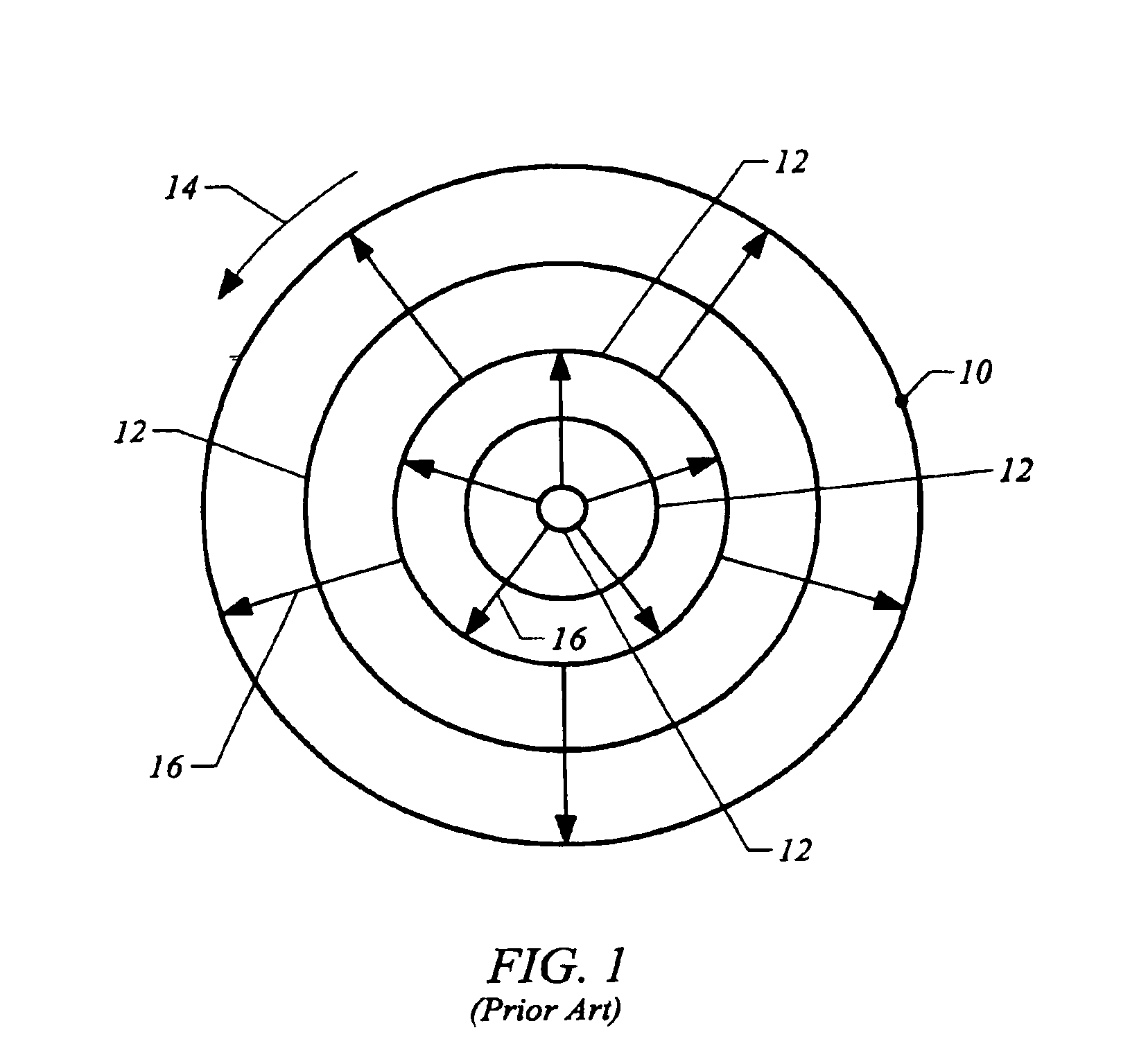

In a brush assembly of a cleaner including plural brushes arranged at the bottom surface of a cleaner body radially at regular intervals; plural supporting shafts for rotatively supporting the brushes; and a driving unit connected to the brushes in order to rotate the brushes, by arranging the plural brushes radially, dust and filth can be collected in a wider region, and accordingly a cleaning performance can be improved. In addition, by forming the brushes as a curved shape, it is possible to compact a size of the cleaner.

Owner:LG ELECTRONICS INC

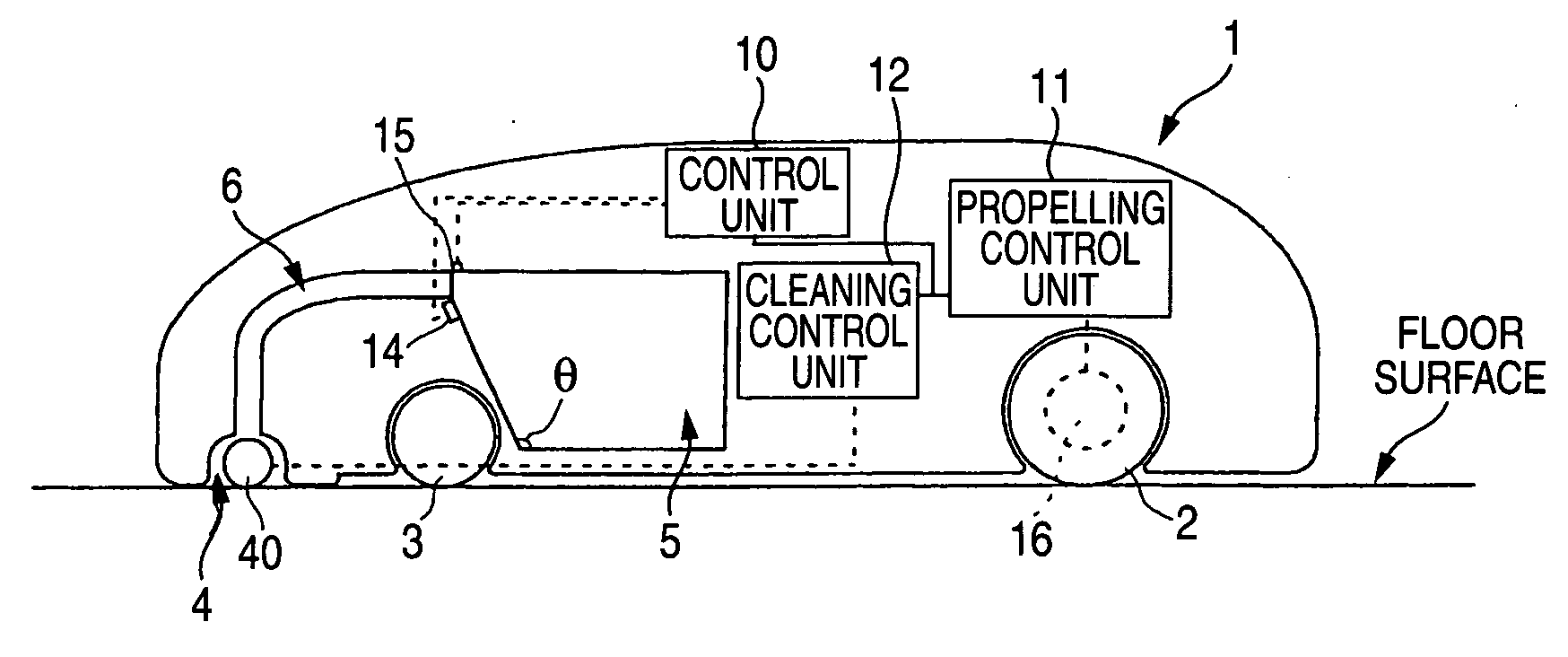

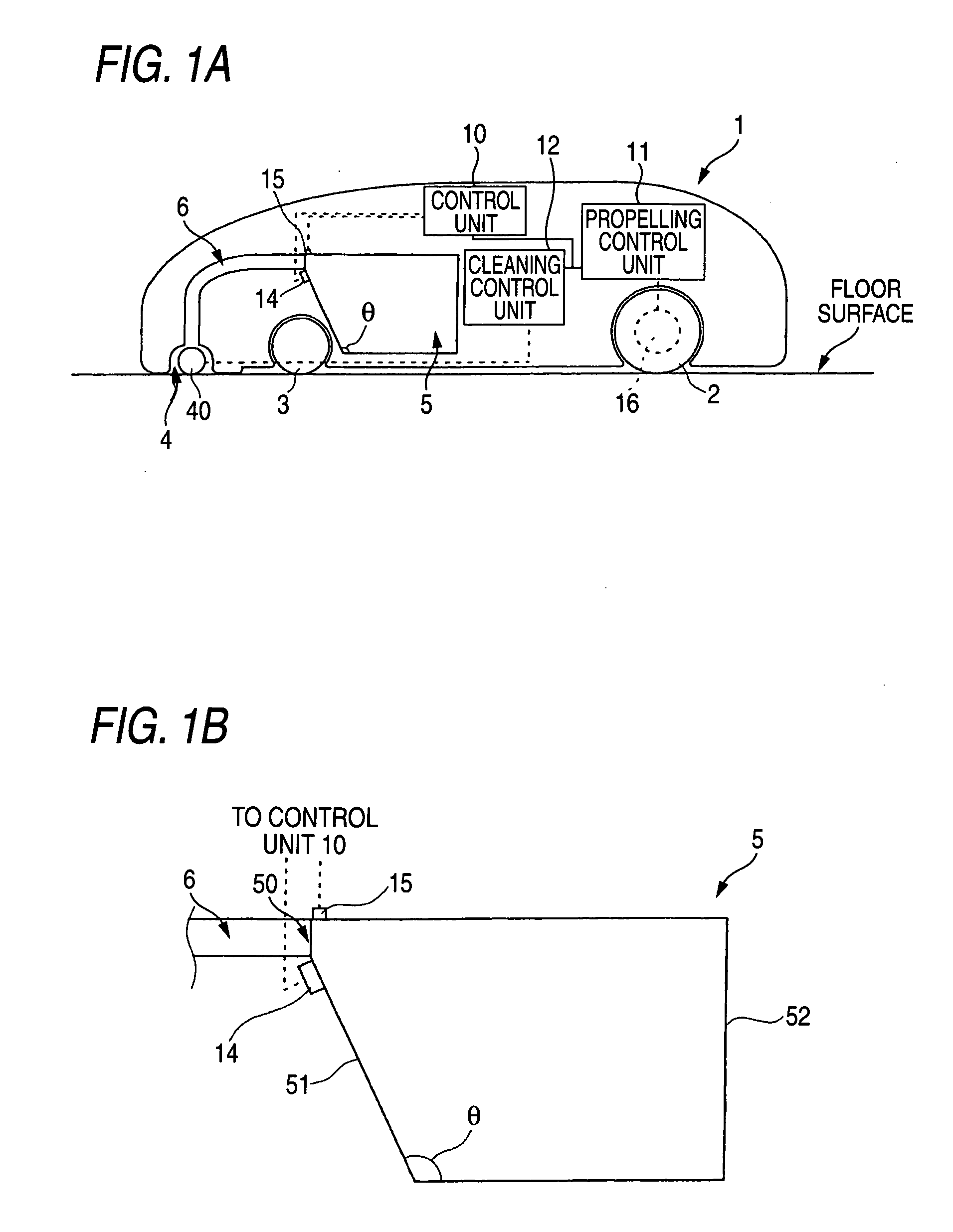

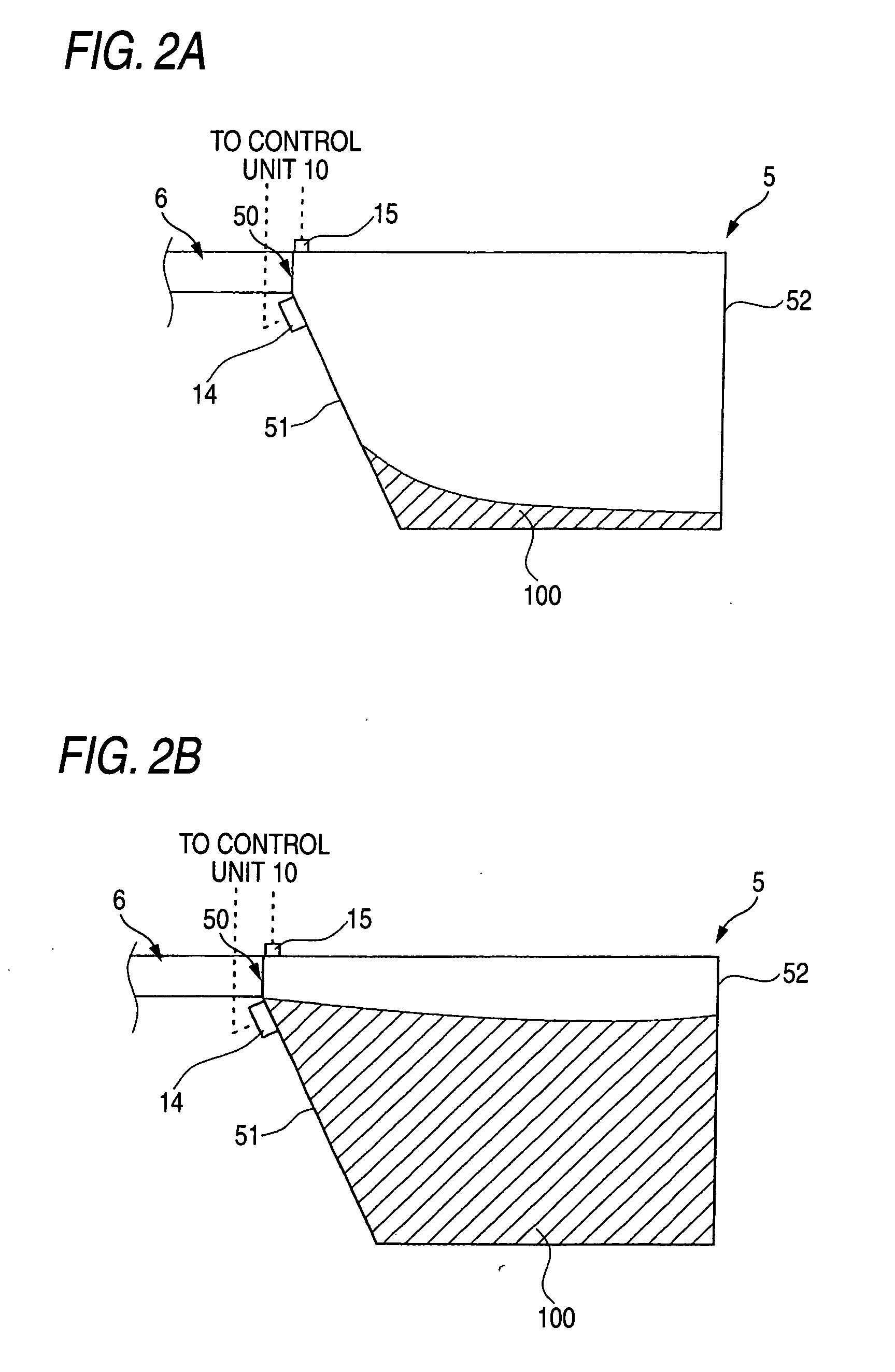

Self-propelling cleaner

A side wall 51 provided with a coupling hole 50 coupled to the dust transporting pipe 6 of a dust chamber 5 is configured in a sloped shape so as to have a predetermined angle θ with respect to the bottom surface of the dust chamber. A photo detector 14 having a light receiving surface along the surface 51 is disposed near the coupling hole 50 of the side wall 51. A photo diode 15 for irradiating light toward the photo detector 14 is disposed on the upper surface of the dust chamber 5. When dust is filled within the dust chamber 5, since dust is accumulated on the photo detector 14, the photo detector 14 does not outputs a light detection signal.

Owner:FUNAI ELECTRIC CO LTD

Self-propelled cleaning device and method of operation thereof

InactiveUS7515991B2Quick cleanAutomatic obstacle detectionTravelling automatic controlGyroscopeEngineering

Owner:HITACHI LTD +1

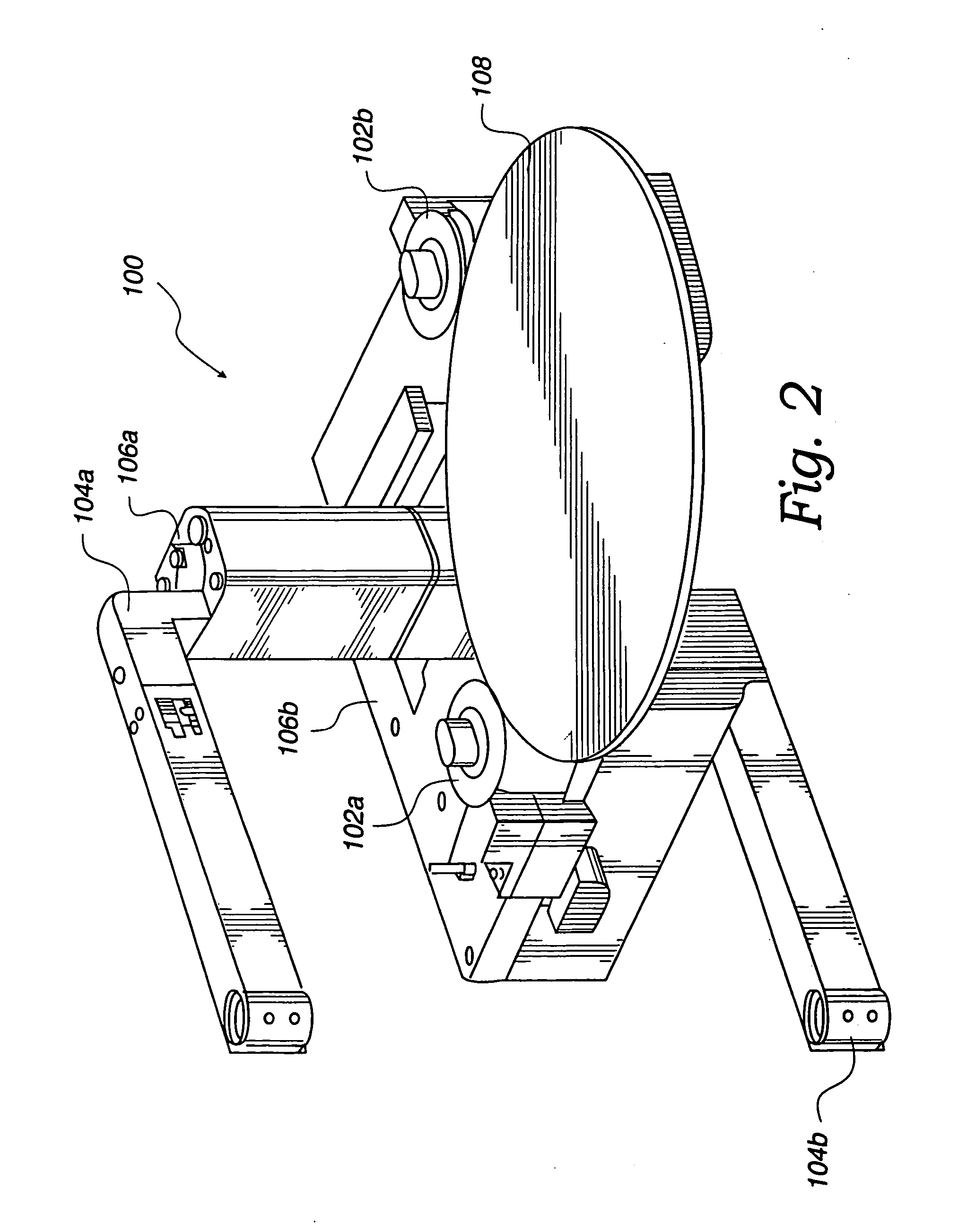

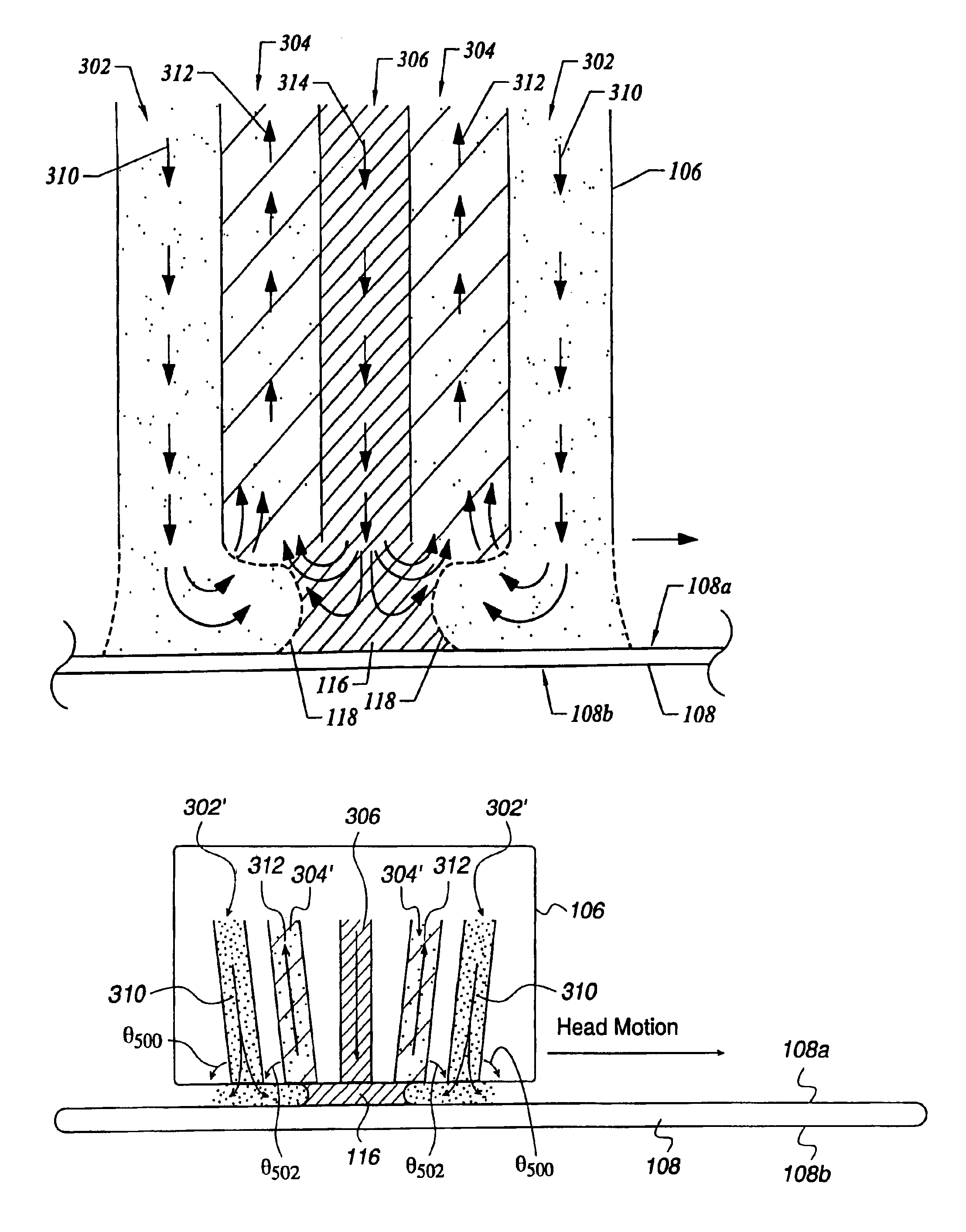

Methods and systems for processing a substrate using a dynamic liquid meniscus

InactiveUS6988327B2Increase in sizeHigh gradientDrying solid materials with heatDrying solid materials without heatEngineeringLiquid meniscus

A system and method of moving a meniscus from a first surface to a second surface includes forming a meniscus between a head and a first surface. The meniscus can be moved from the first surface to an adjacent second surface, the adjacent second surface being parallel to the first surface. The system and method of moving the meniscus can also be used to move the meniscus along an edge of a substrate.

Owner:LAM RES CORP

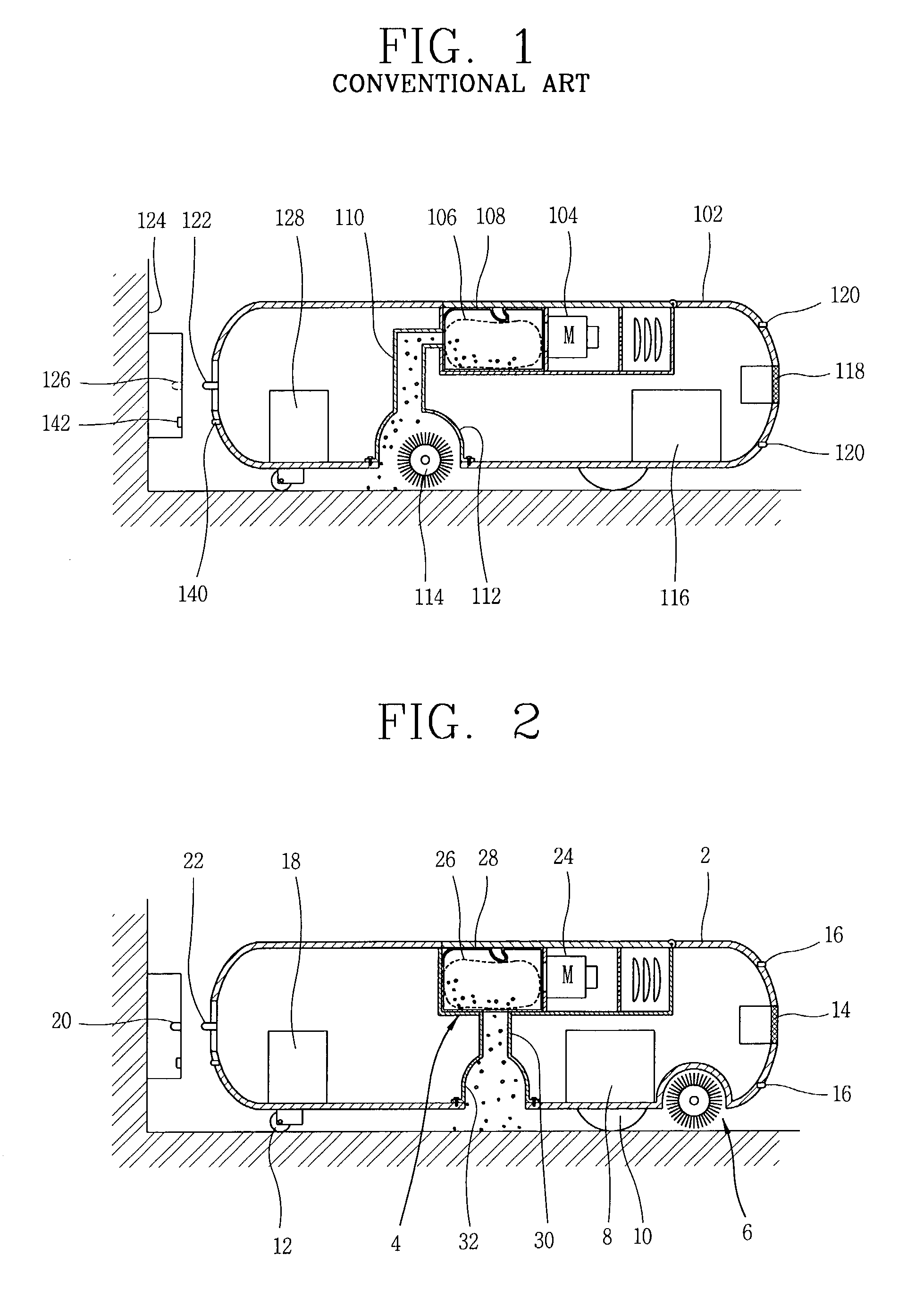

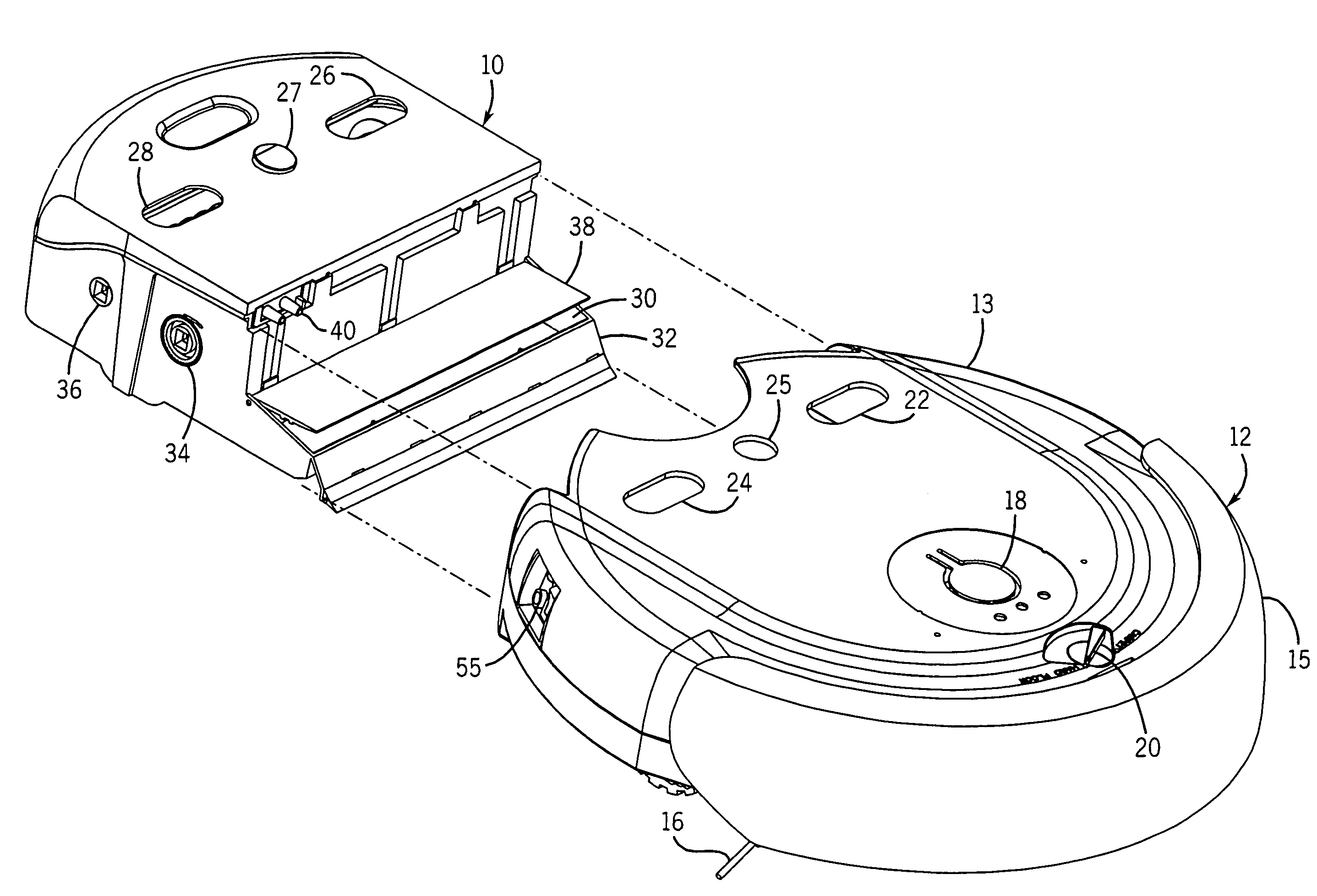

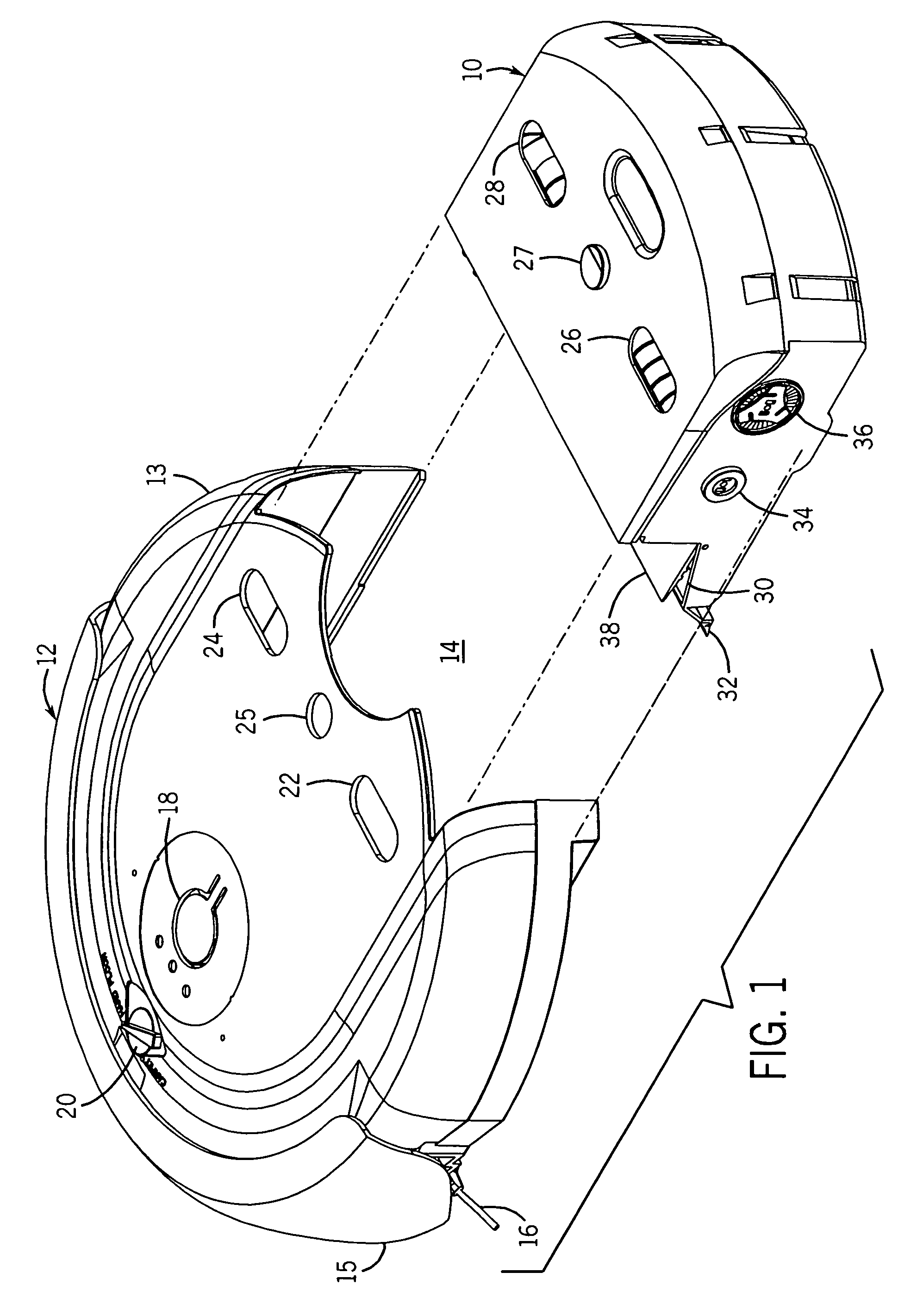

Robot cleaning system and dust removing method of the same

InactiveUS7849555B2Shorten the lengthSmall sizeCleaning filter meansMechanical cleaningDocking stationControl theory

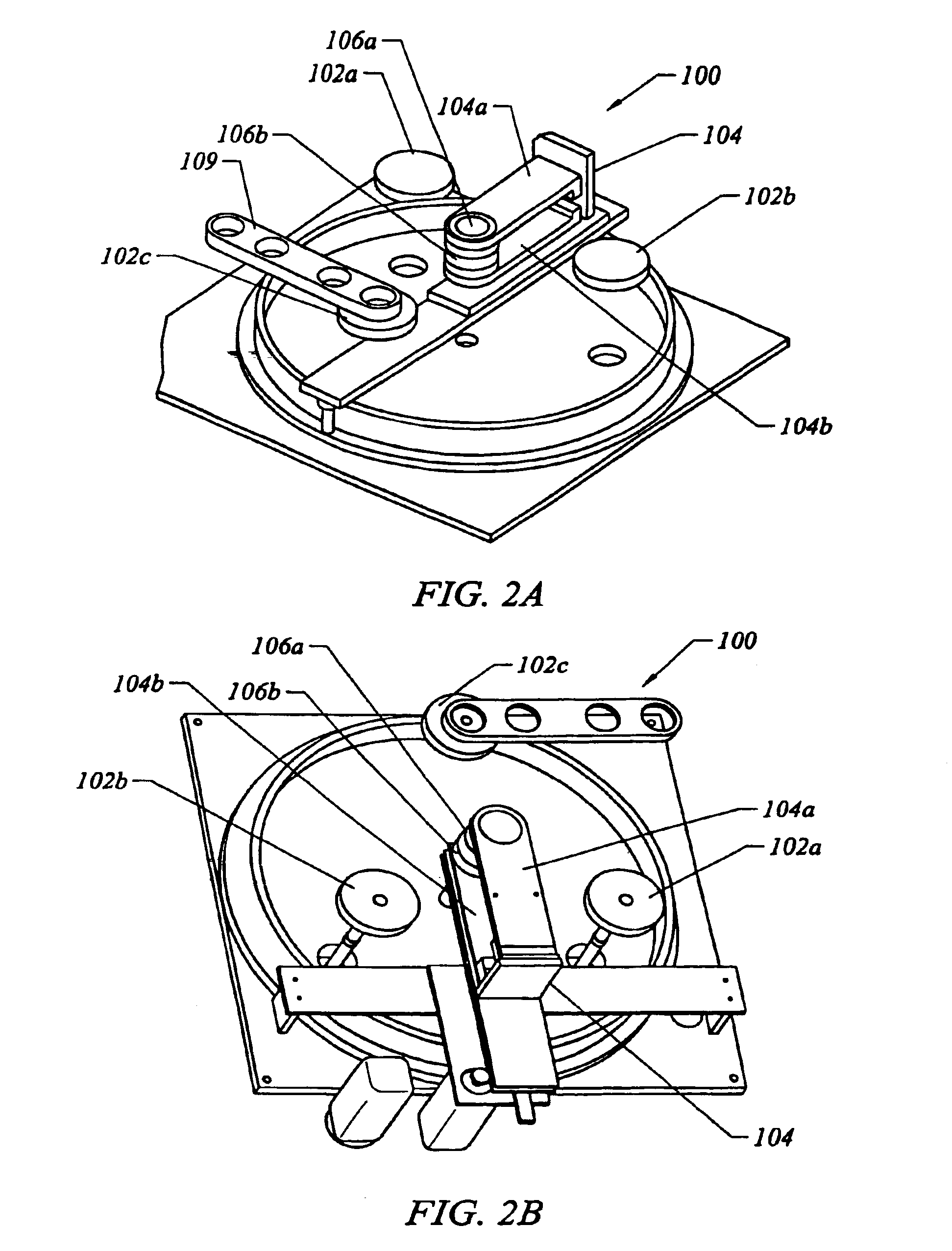

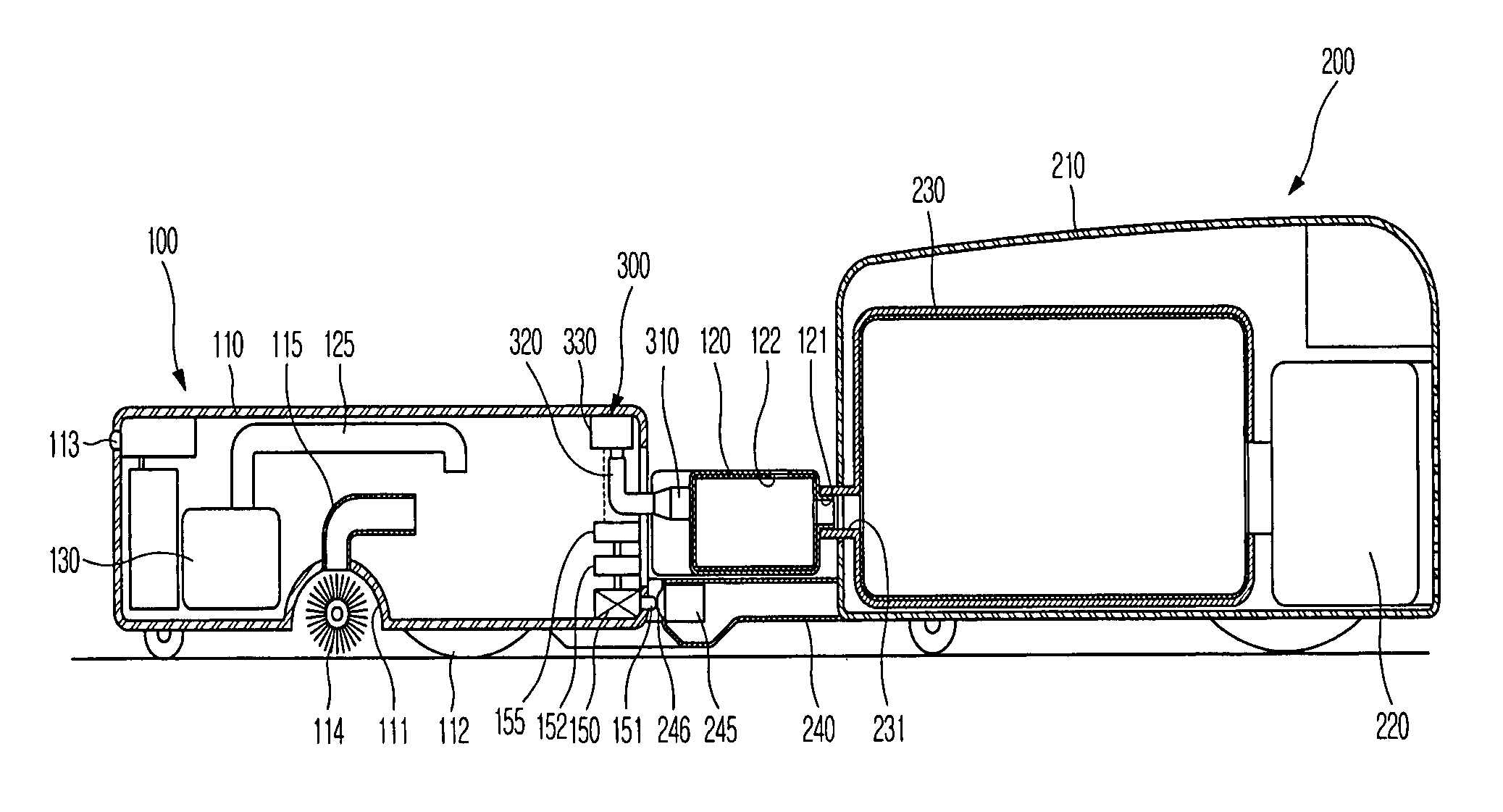

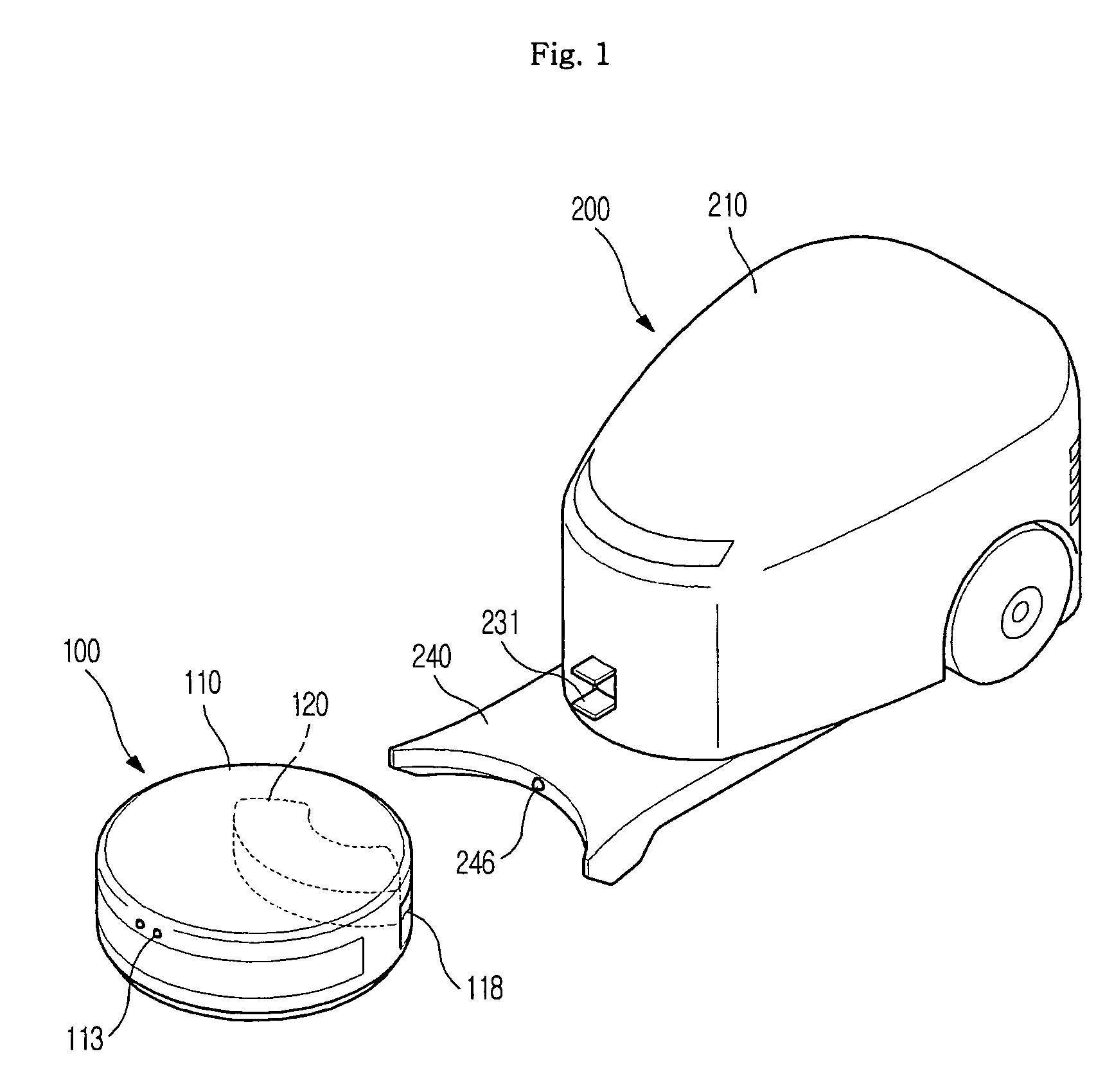

A robot cleaning system and a dust removing method of the same that are capable of moving a first dust collector mounted in a robot cleaner to a docking station to remove dust collected in the first dust collector. The robot cleaning system includes a robot cleaner having an opening, though which a first dust collector to collect suctioned dust is carried in and out of the robot cleaner, a docking station, to which the robot cleaner is docked to remove the dust collected in the first dust collector, and a collector moving unit to move the first dust collector to the docking station.

Owner:SAMSUNG ELECTRONICS CO LTD

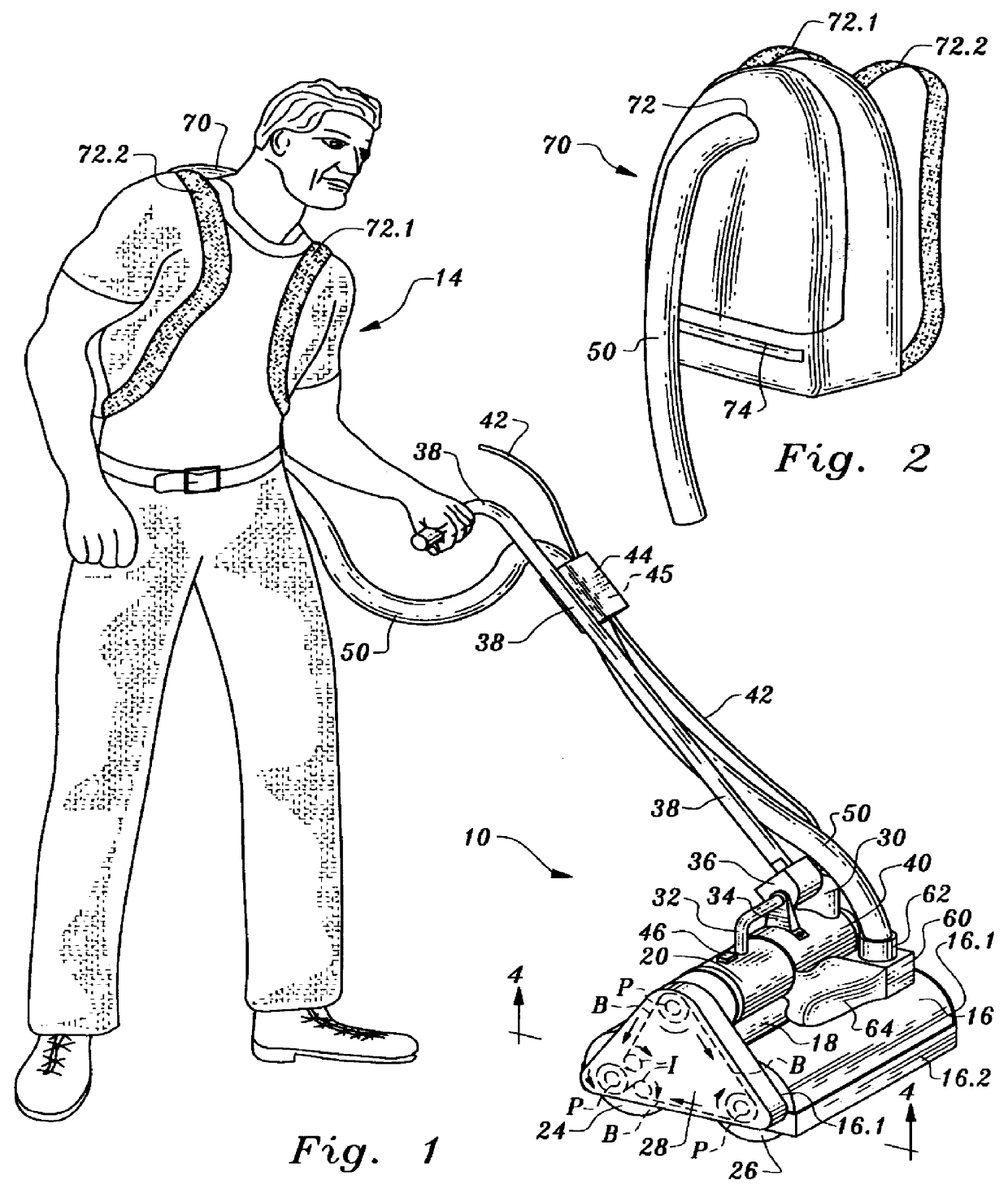

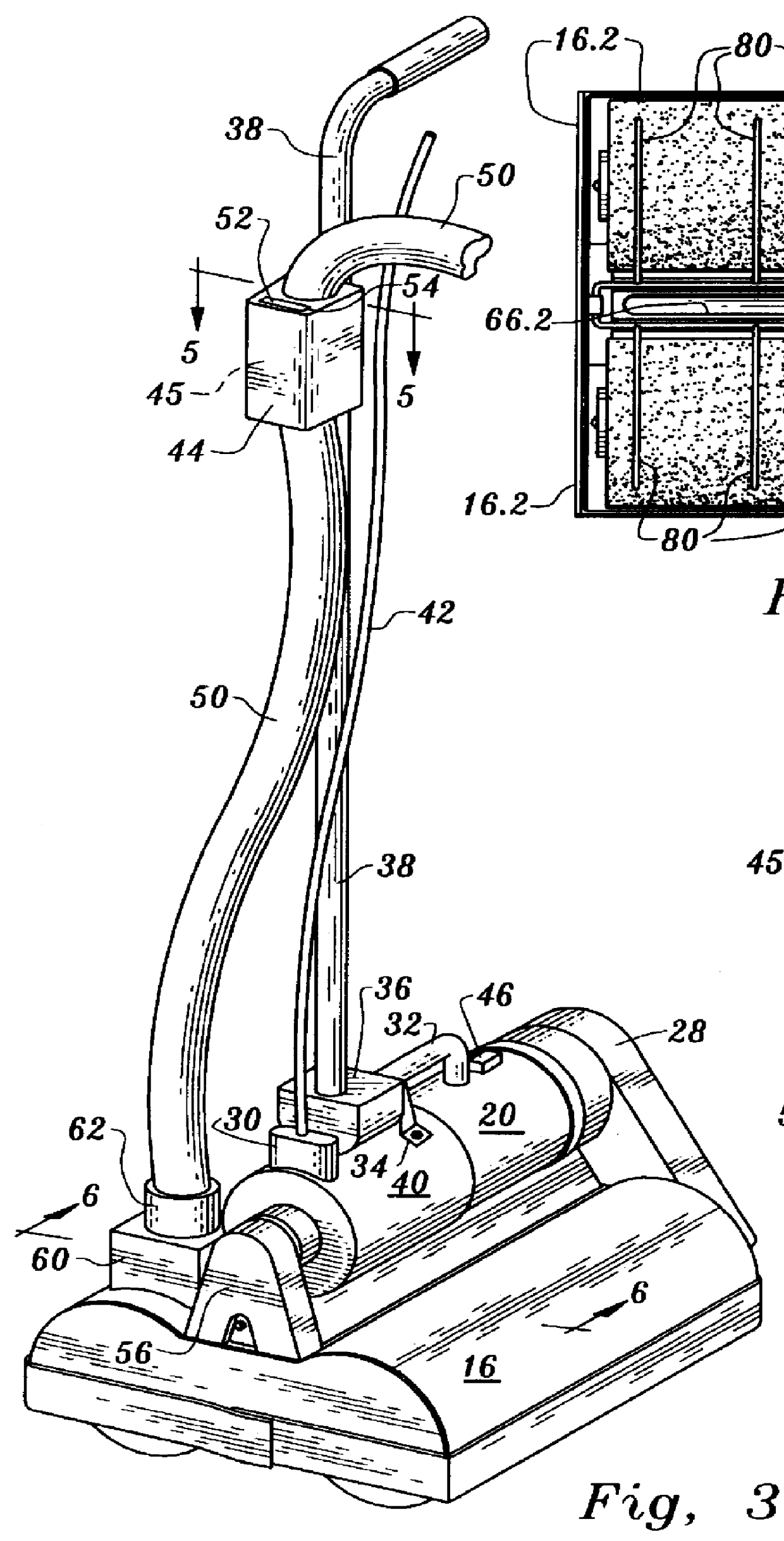

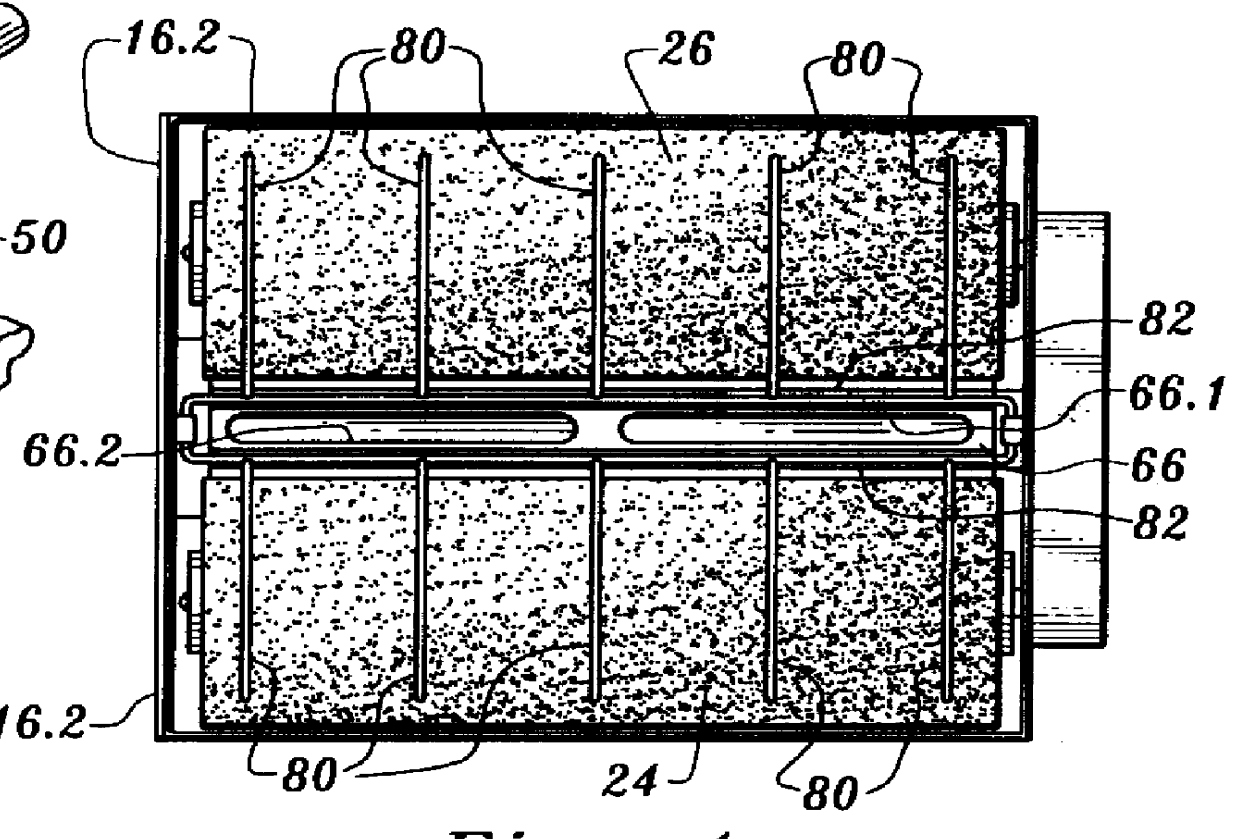

Method for diagnosing, cleaning and preserving carpeting and other fabrics

Owner:PACIFIC SPECIALTY CHEM

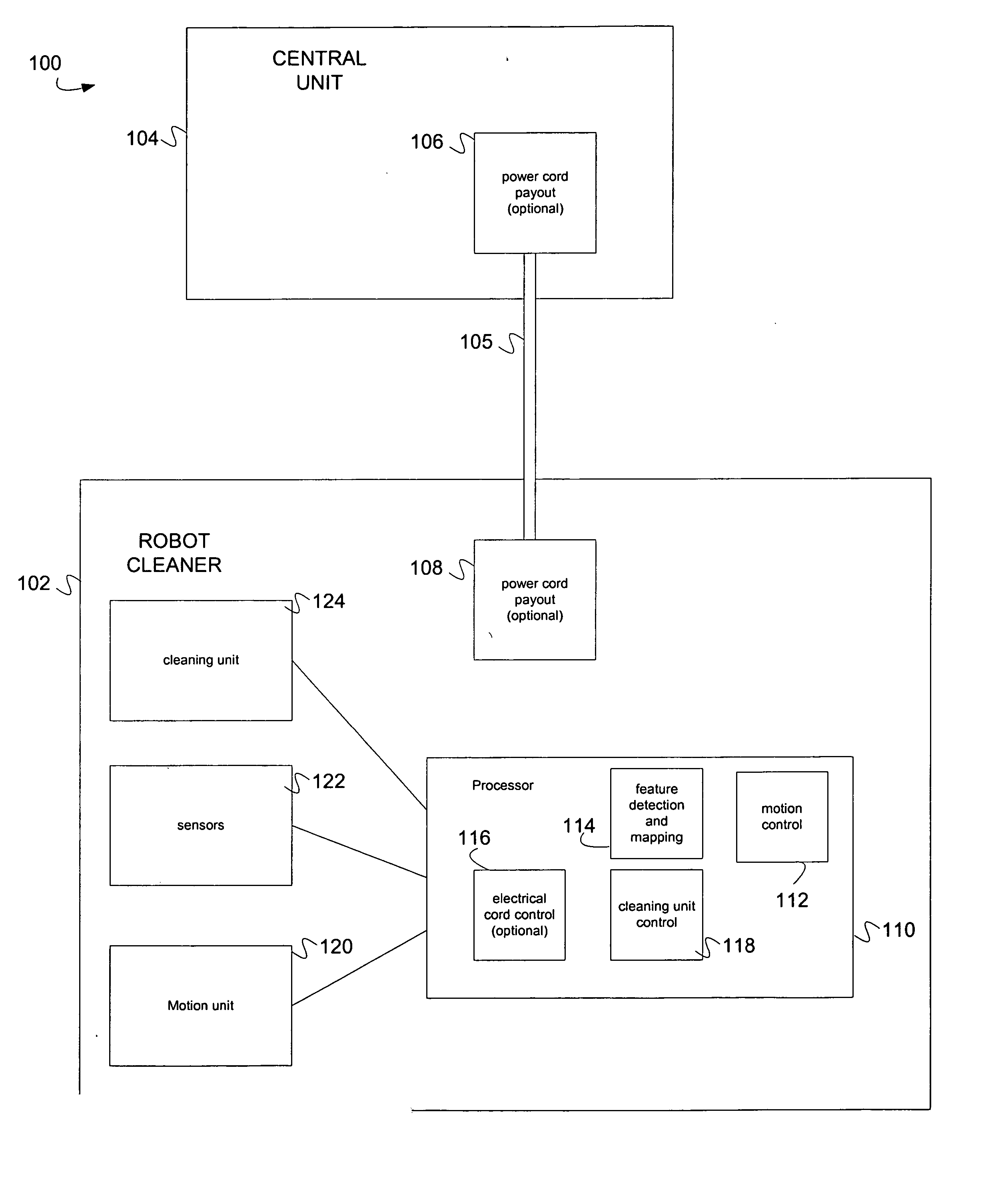

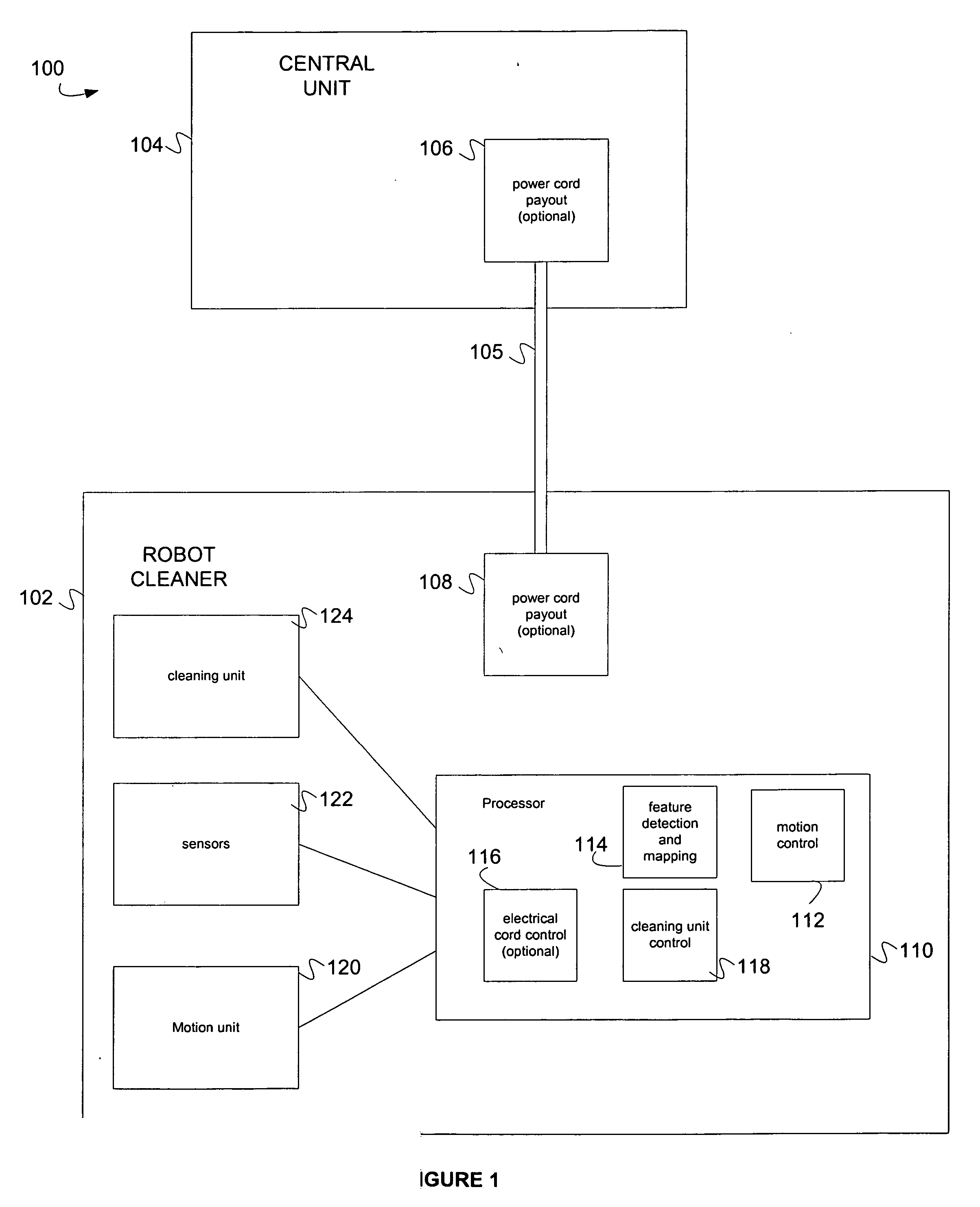

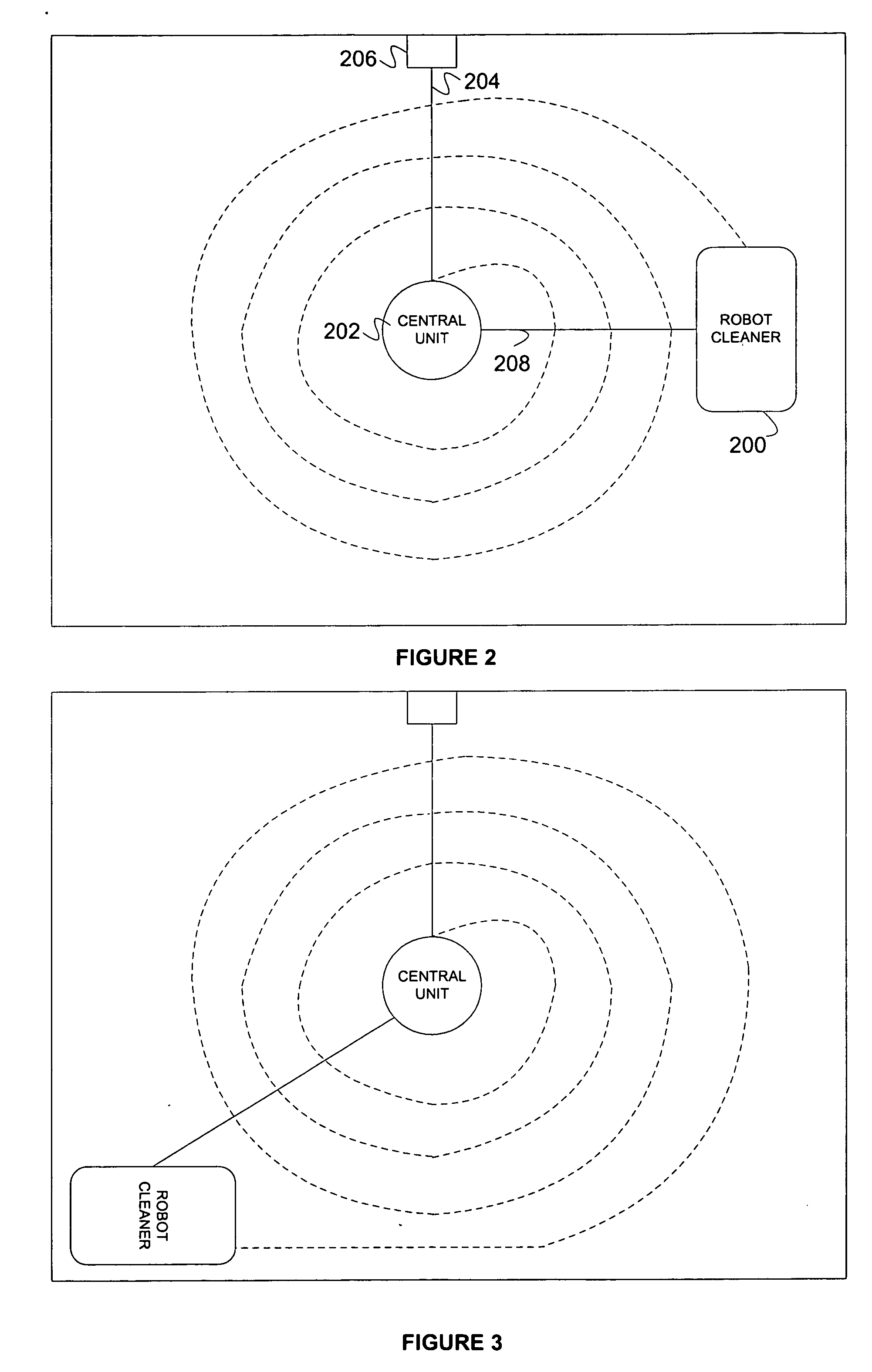

Robot vac with retractable power cord

A robot cleaning system uses a robot cleaner and a unit. The unit is connected to power the robot cleaner by a power cord. The robot cleaner can move around a room while being powered by the unit. In one embodiment, the unit is connected to a power socket by another power cord.

Owner:THE SHARPER IMAGE

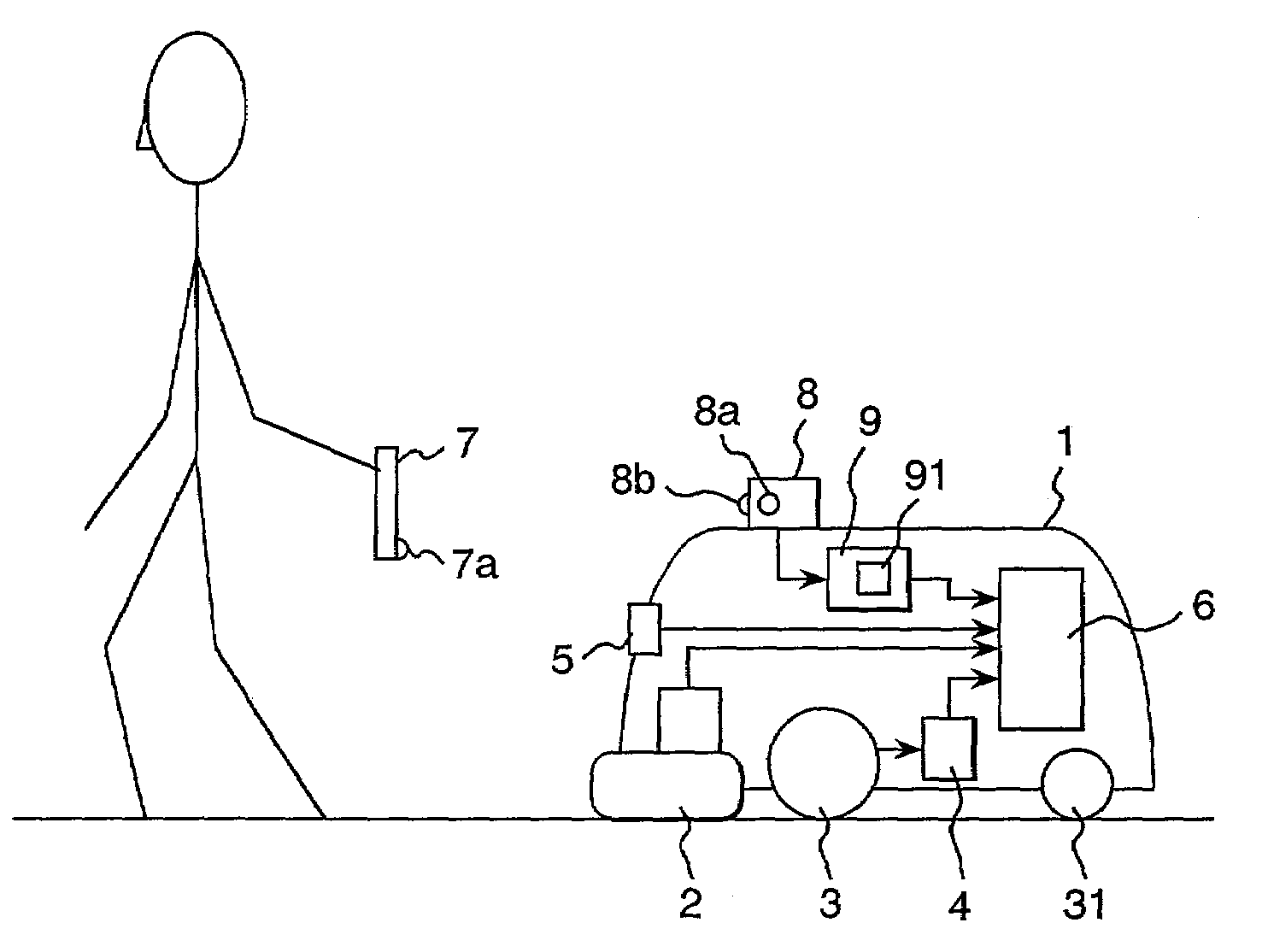

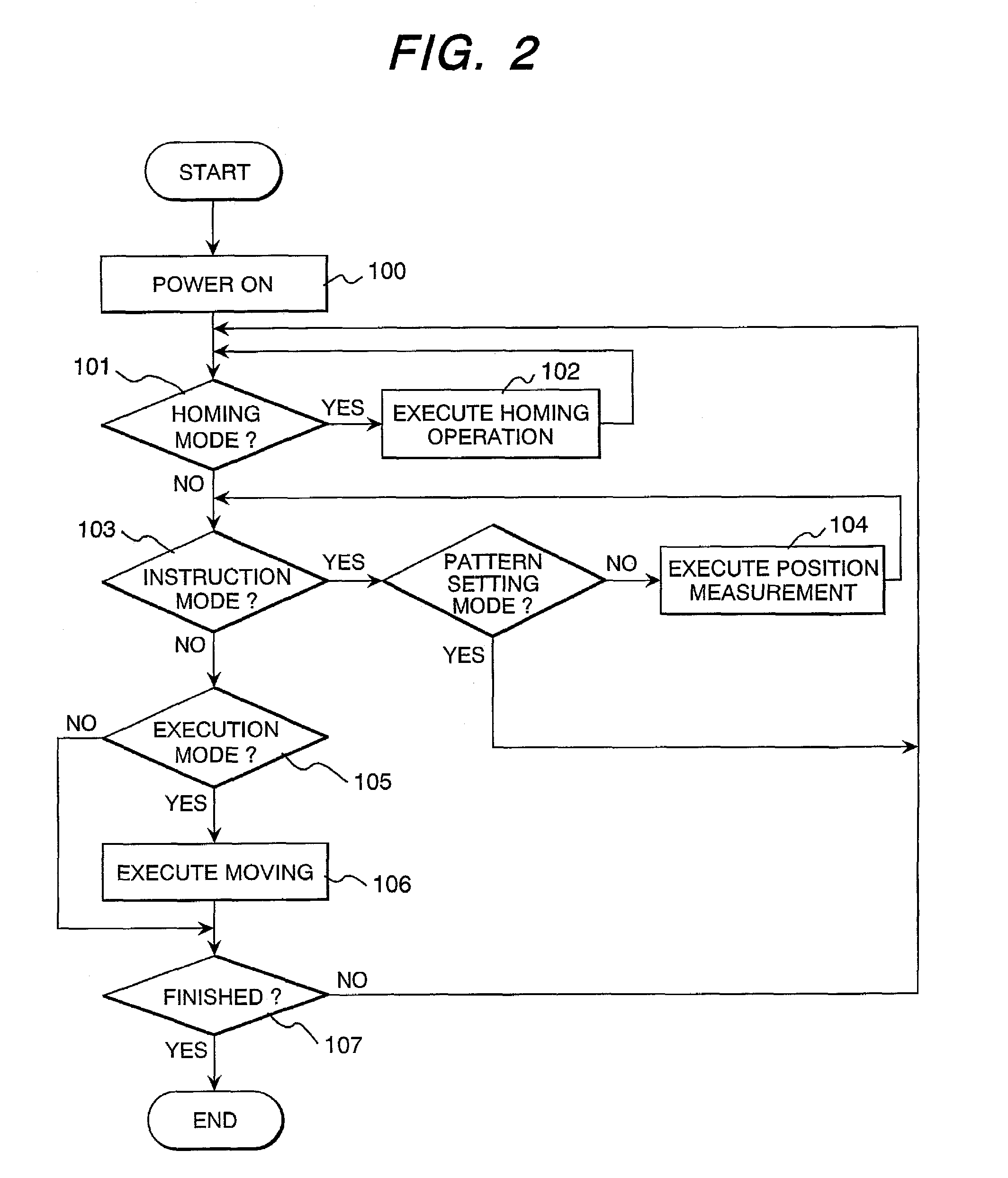

Self-running vacuum cleaner

InactiveUS6968592B2Applied load reductionReduce loadAutomatic obstacle detectionElectric signal transmission systemsOperation modeEngineering

A self-running vacuum cleaner comprises a homing mode of following a back of a user with receiving a signal from a light emitting means or a transmitting means of a position indicator means held by the user, an instruction operation mode, in which the user instructs a cleaning area to the self-running vacuum cleaner, and an execution mode for cleaning up the cleaning area instructed. When the self-running vacuum cleaner operates under the homing mode or the instruction mode, a signal from the light-emitting means or the transmitting means is received by a receiver means attached on a periphery portion of a measuring means, which is provided in an upper portion of the vacuum cleaner. Comparing the signals from the two (2) receiver means in strength thereof determines the distance and the direction from the position indicated by the light-emitting means or the transmitting means up to the vacuum cleaner.

Owner:HITACHI LTD

Methods to prevent wheel slip in an autonomous floor cleaner

ActiveUS7389166B2Weight moreReduce contact areaMechanical cleaningPressure cleaningDrive wheelEngineering

Owner:SC JOHNSON & SON INC

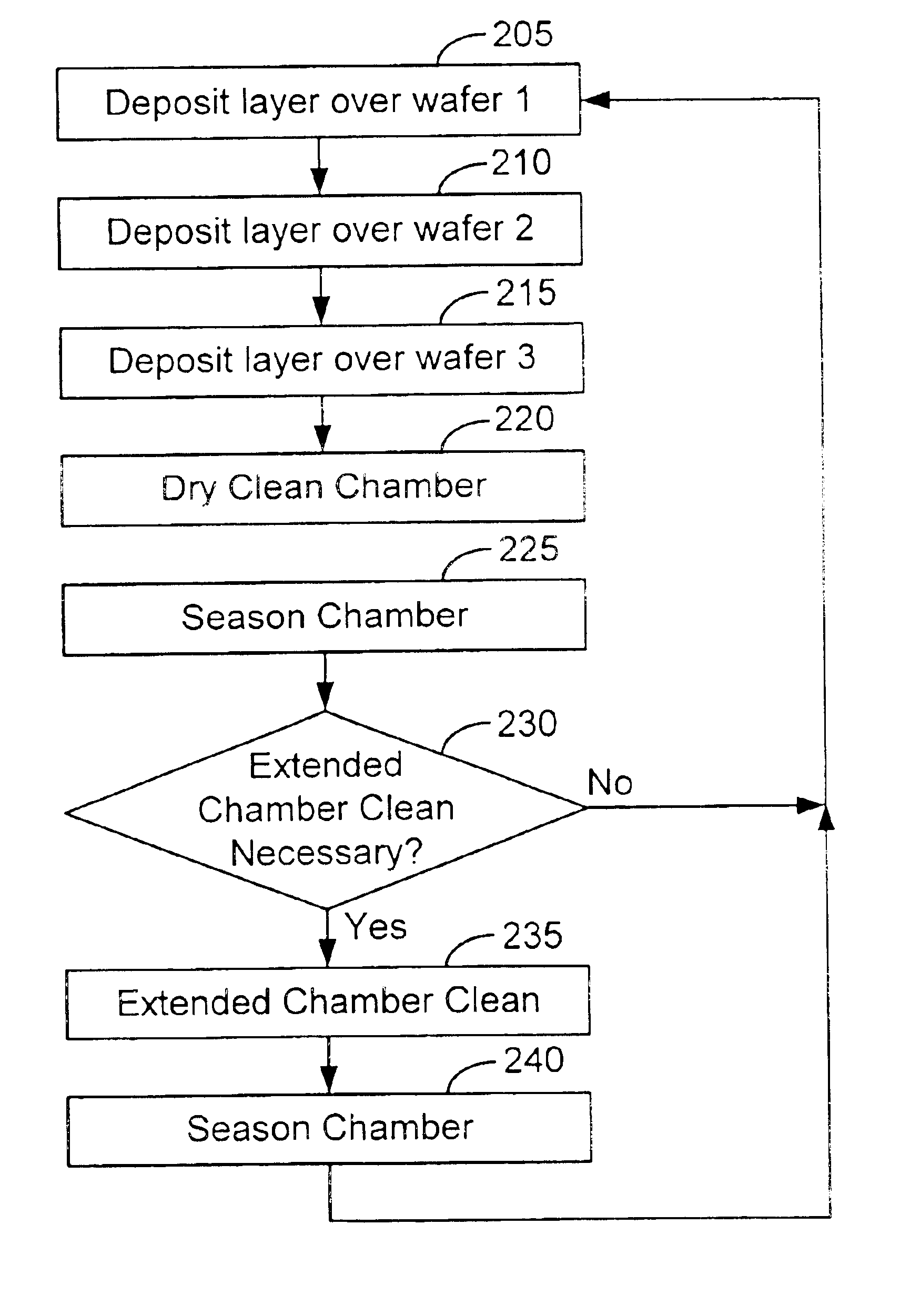

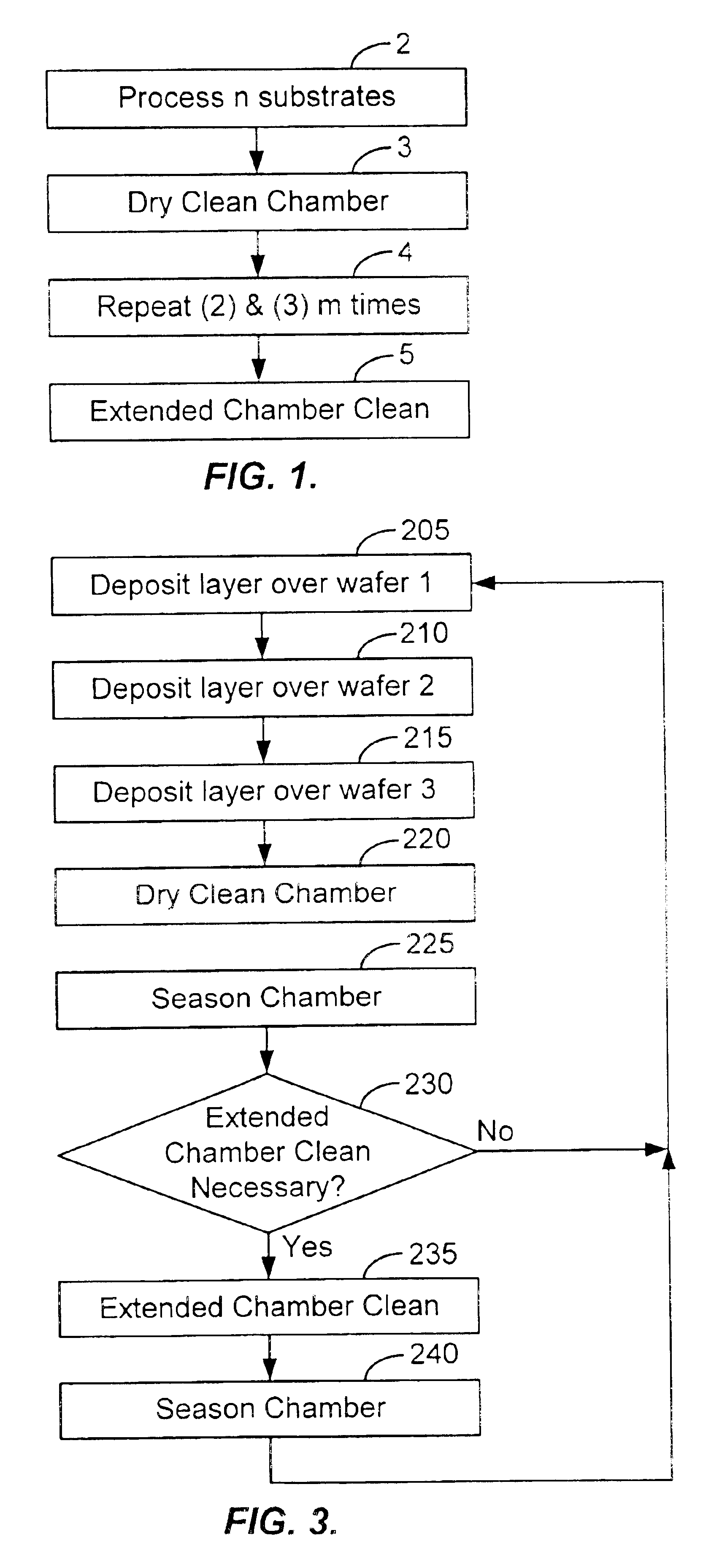

Method of cleaning a semiconductor processing chamber

A method of operating a substrate processing chamber. In one embodiment the method includes processing one or more substrates in the substrate processing chamber and subsequently cleaning the chamber using a dry cleaning process. This substrate processing and dry cleaning sequence is then repeated multiple times before chamber is further cleaned by flowing a cleaning gas into the chamber and forming a plasma within the chamber from the cleaning gas in an extended cleaning process. During the extended cleaning process the plasma is maintained within the chamber for a total of at least 5 minutes before the chamber is reused to process a substrate.

Owner:APPLIED MATERIALS INC

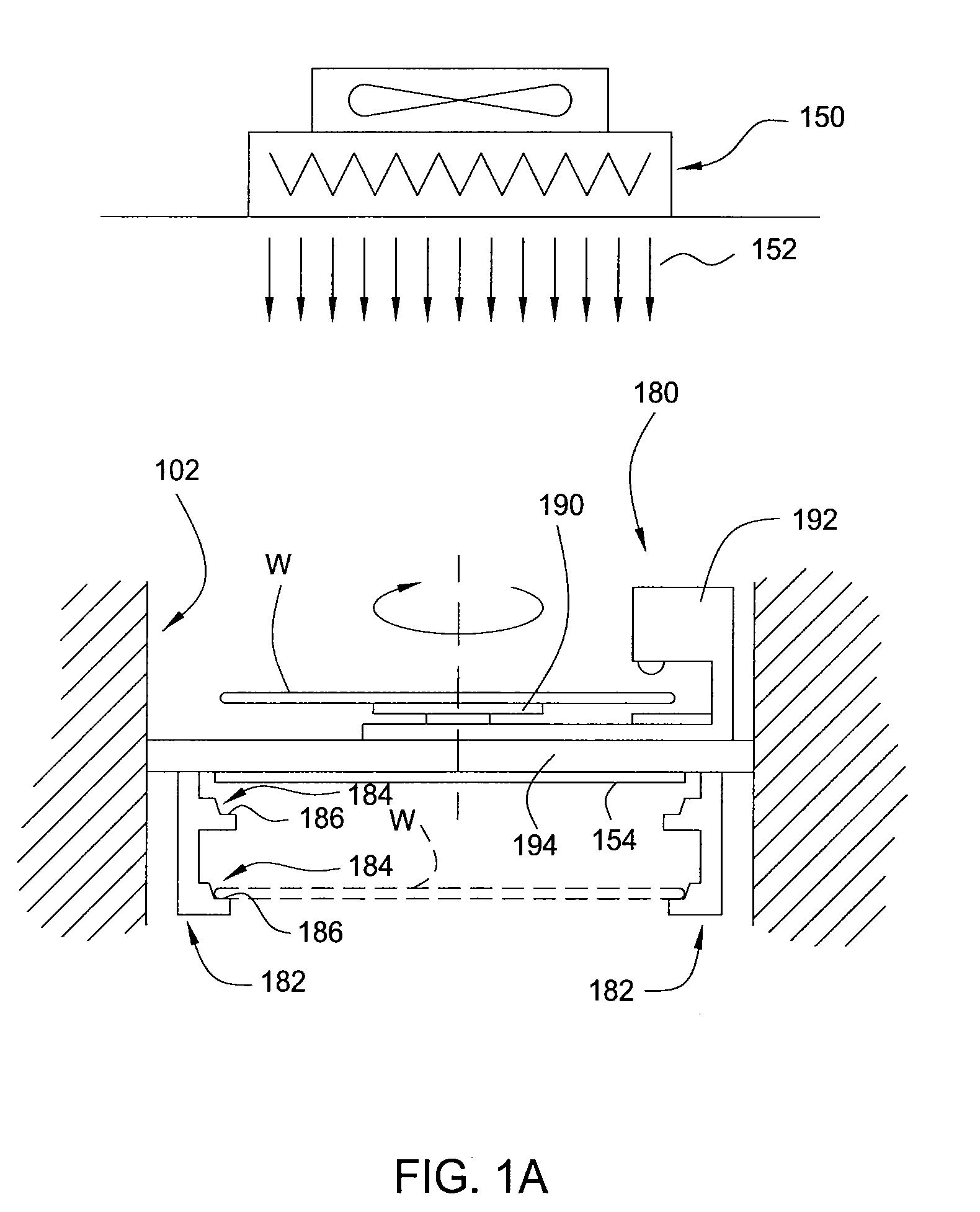

Apparatus for efficient removal of halogen residues from etched substrates

An apparatus for removing volatile residues from a substrate is provided. In one embodiment, an apparatus for removing halogen-containing residues from a substrate includes a chamber suitable for operating maintaining a vacuum therein and a heat module positioned to heat a substrate disposed in the chamber. The apparatus for removing halogen-containing residues from a substrate also includes at least one of A) a temperature controlled pedestal having a projection extending radially therefrom suitable for supporting the temperature control pedestal on a ledge of the chamber body, the projection thermally isolating the base from the chamber body; B) a pair of substrate holders that include two support flanges extending radially inward from an inner edge of an arc-shaped body, each support flange having a substrate support step that includes a sloped landing; or C) a domed window.

Owner:APPLIED MATERIALS INC

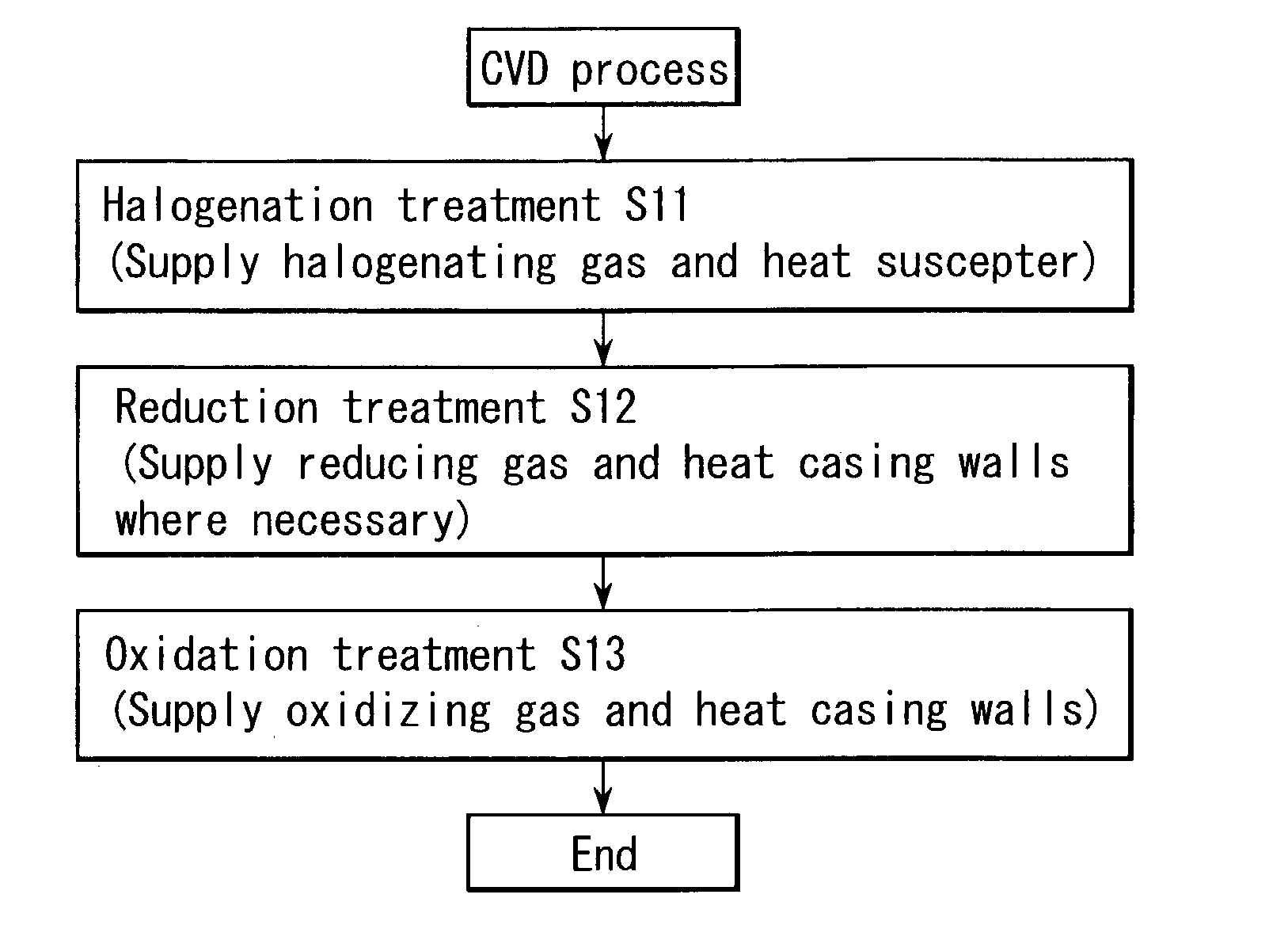

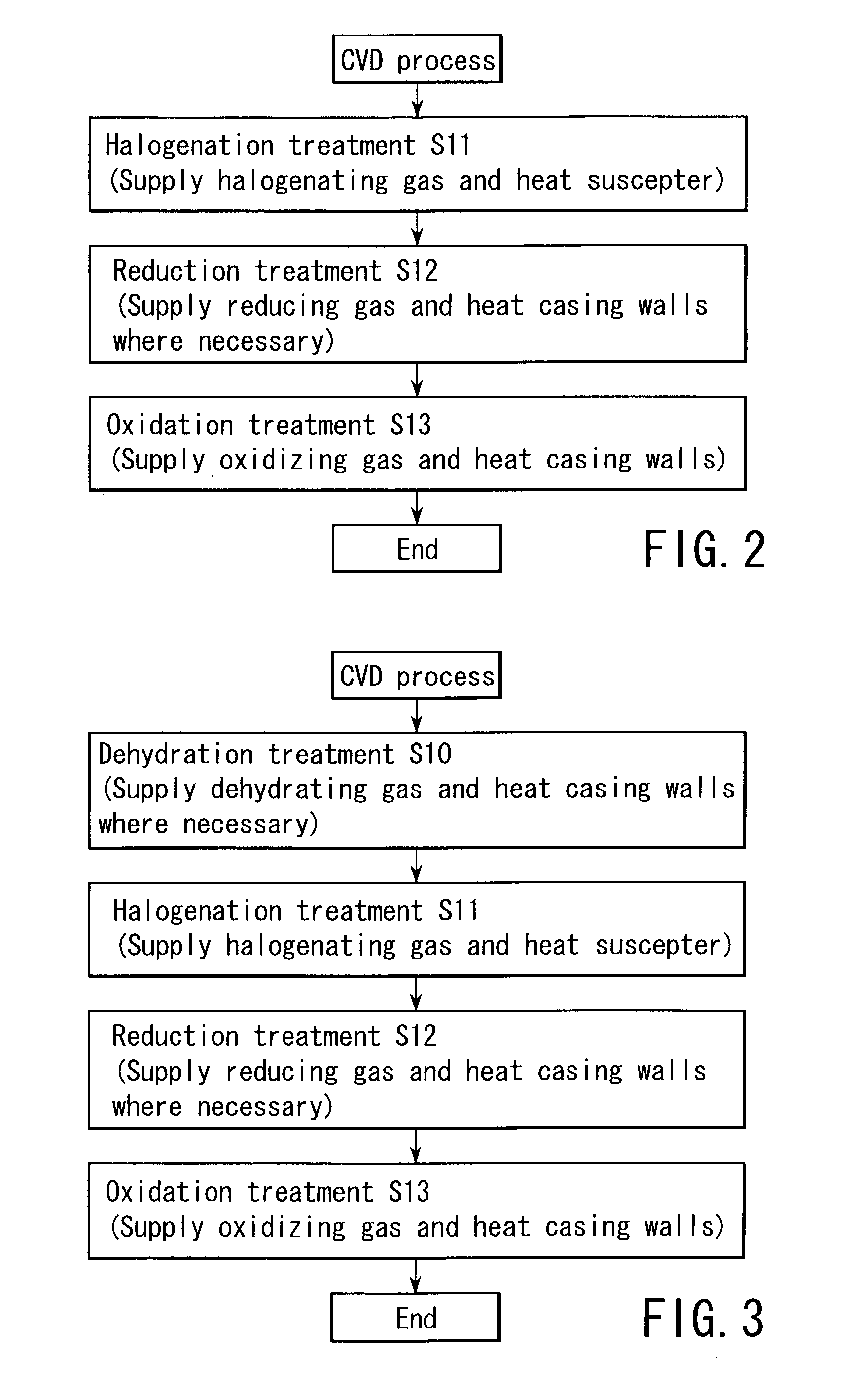

Method of cleaning processing chamber of semiconductor processing apparatus

InactiveUS20030205237A1Hollow article cleaningElectrostatic cleaningReduction treatmentSemiconductor

A method of cleaning the interior of a processing chamber first performs a halogenation treatment by supplying a treatment gas containing a halogenating gas into the processing chamber and heating a support member for a target substrate, thereby halogenating a metal element in a by-product film. A reduction treatment is then performed by supplying a treatment gas containing a reducing gas into the processing chamber, thereby reducing a halide of the metal element and liberating the metal element. An oxidation treatment is then performed by supplying a treatment gas containing an oxidizing gas into the processing chamber and heating the casing walls of the processing chamber, thereby passivating the liberated metal element by oxidation.

Owner:TOKYO ELECTRON LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com