Self-propelling cleaner

a cleaner and self-propelling technology, applied in the direction of cleaning equipment, cleaning action control, electric equipment installation, etc., can solve the problems of difficult to determine the full dust state, difficult to accurately detect the amount of dust within the dust chamber, and difficult to determine whether the operation is stopped

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

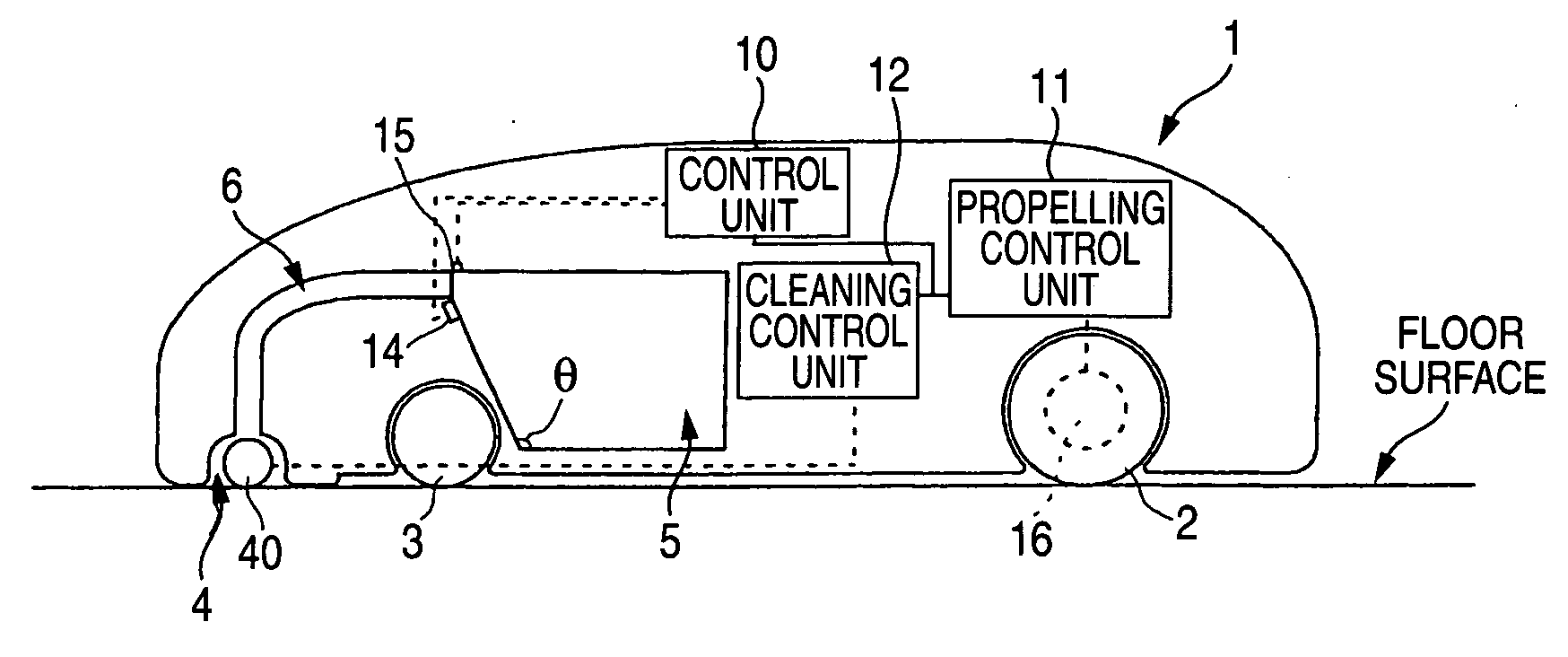

[0023] A self-propelling cleaner according to the invention will be explained with reference to drawings. In the embodiment, the explanation will be made as to a self-propelling cleaner of a strike-up type which strikes dust up by a brush within a nozzle and accommodates the dust thus struck-up within a dust chamber.

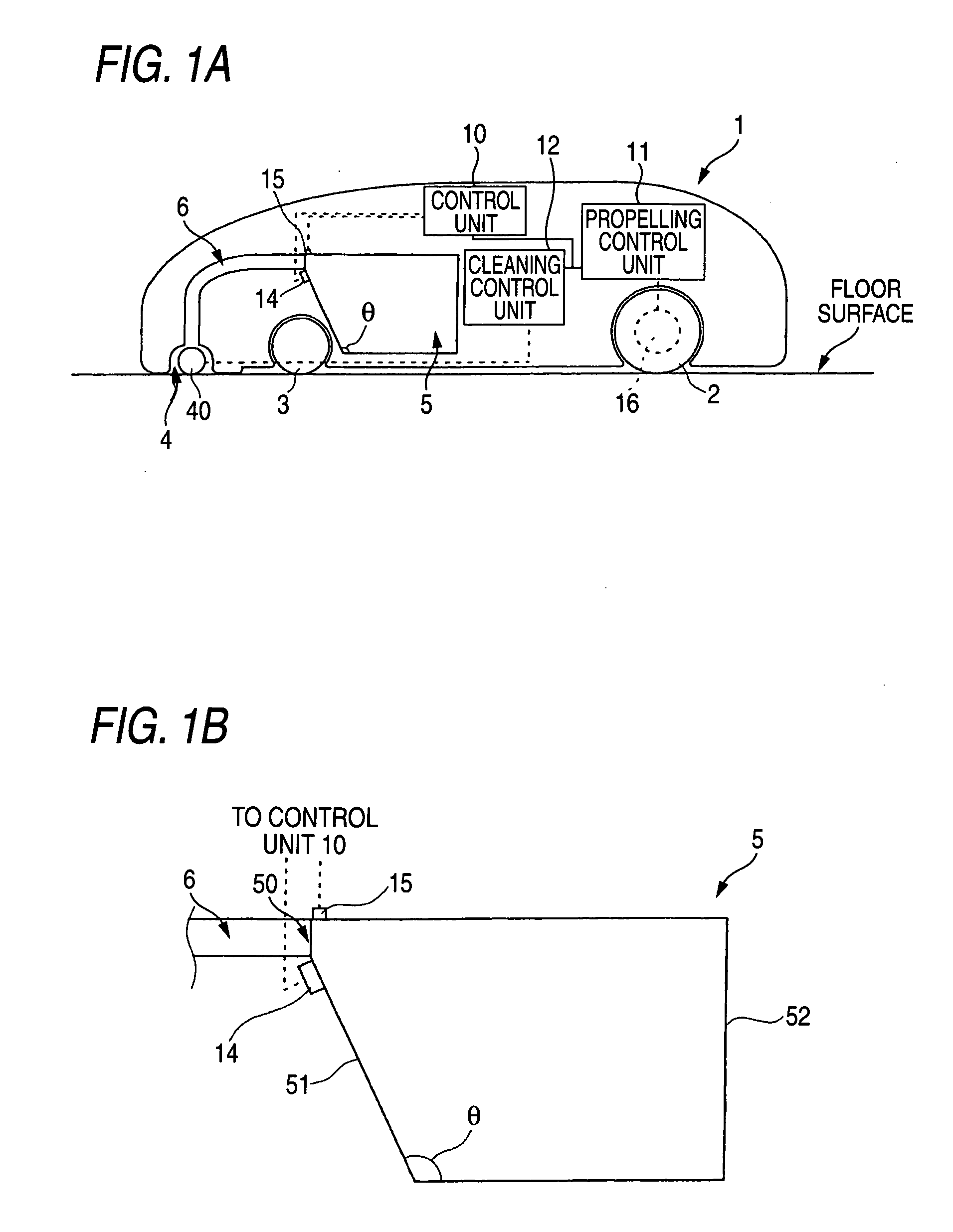

[0024]FIG. 1A is a block diagram showing the schematic configuration of the self-propelling cleaner according to this embodiment, and FIG. 1B is an enlarged sectional diagram showing a dust chamber 5.

[0025] The self-propelling cleaner is configured by a propelling control unit and a propelling unit for propelling a main body 1 along a route within a cleaning region set in advance, and a cleaning unit for removing dust on the floor surface within the cleaning region and accommodating the dust therein.

[0026] Driving wheels 2 and driving motors 16 coupled to the driving wheels 2 to rote the driving wheels 2 are provided at the left and right portions of the lower portion ...

second embodiment

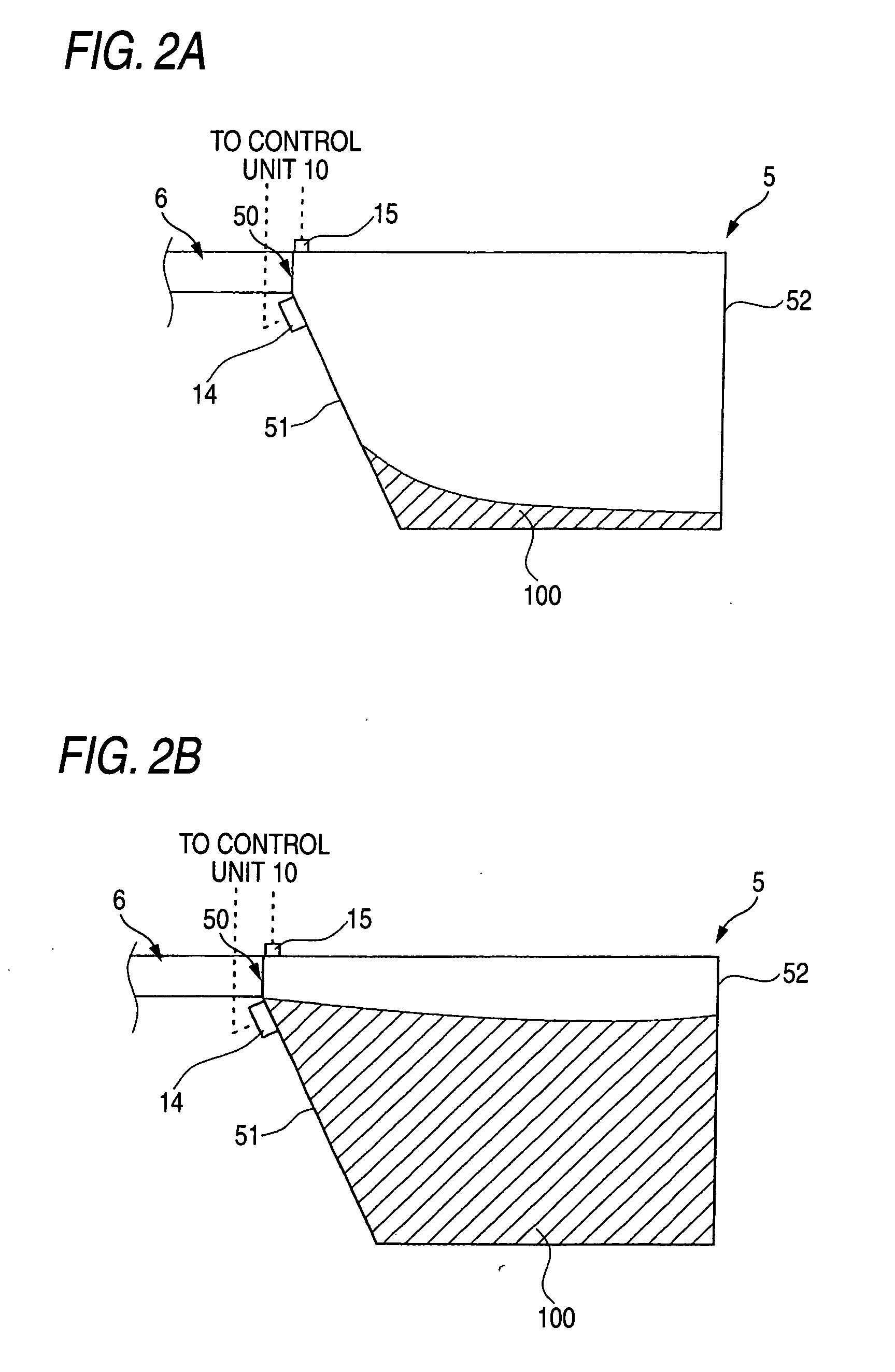

[0041] Next, the self-propelling cleaner will be explained with reference to FIGS. 5A and 5B. In this embodiment, the explanation will be made as to a self-propelling cleaner of a vacuum type which is provided with an evacuation fan at the dust chamber.

[0042]FIGS. 5A and 5B are side views showing the schematic configurations near the dust chamber of the self-propelling cleaner according to this embodiment, wherein FIG. 5A shows a state where an amount of dust accumulated within a dust chamber 5 is small, and FIG. 5B shows a state where the dust chamber 5 is filled with dust.

[0043] The self-propelling cleaner shown in FIGS. 5A and 5B includes an evacuation fan 21 on a side wall 52 opposing to a side wall 51 having a coupling hole 50 coupled to a dust transporting pipe 6 within the dust chamber 5. The evacuation fan 21 is driven by a fanmotor 22. The fan motor 22 is controlled in its operation by a cleaning control unit 12. The remaining configuration of this embodiment is same as t...

third embodiment

[0045] Next, the self-propelling cleaner will be explained with reference to FIGS. 6A-6C.

[0046]FIGS. 6A-6C are side views showing the schematic configurations near the dust chamber of the self-propelling cleaner according to this embodiment, wherein FIG. 6A shows a state where an amount of dust accumulated within a dust chamber 5 is small, FIG. 6B shows a state where an amount of dust accumulated within the dust chamber 5 is close to full, and FIG. 6C shows a state where the dust chamber 5 is filled with dust.

[0047] The self-propelling cleaner shown in FIGS. 6A-6C is configured in a manner that photo detectors 14a, 14b are attached to different vertical positions on the side wall 51 of the dust chamber 5, and photo diodes 15a, 15b for irradiating lights toward the photo detectors 14a, 14b are provided on the upper surface of the dust chamber 5, respectively. The remaining configuration of this embodiment is same as the self-propelling cleaner shown in FIG. 1. The photo detector 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com