Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

346results about "Arm with actuators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

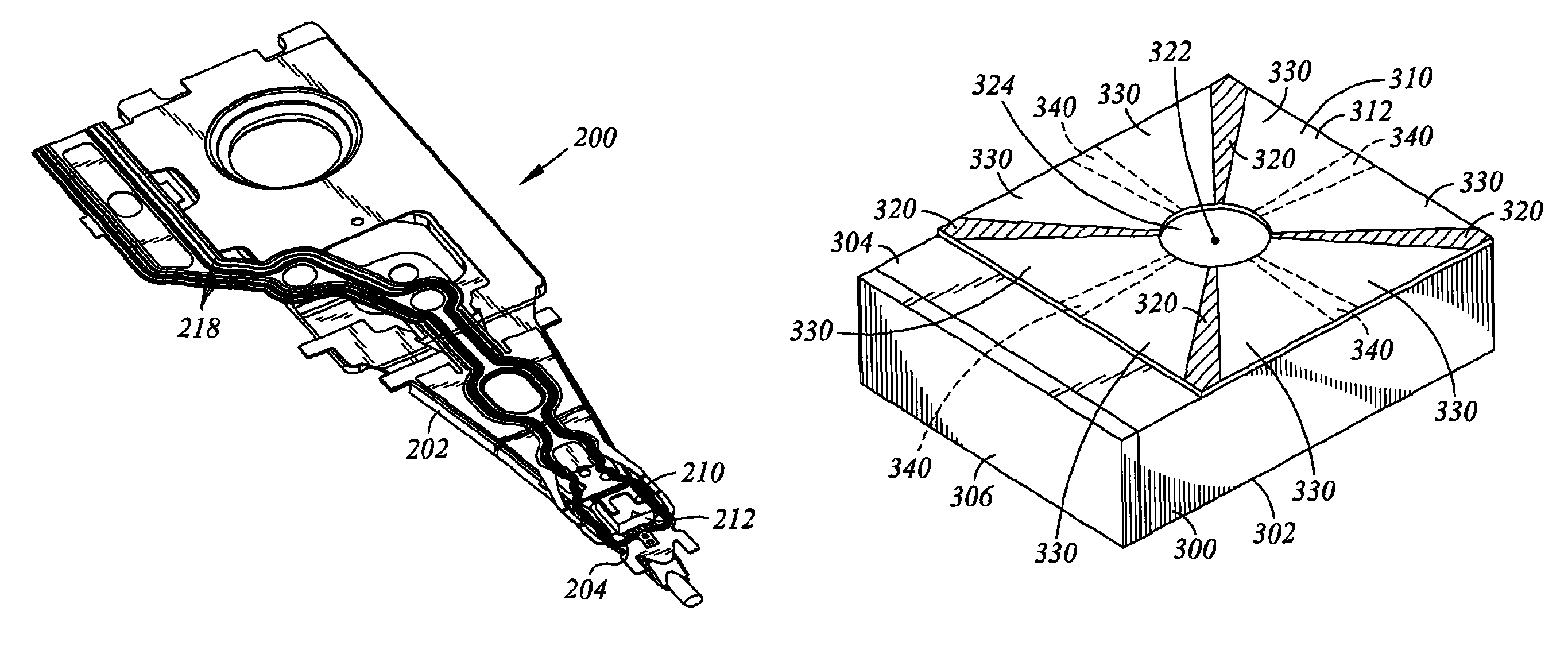

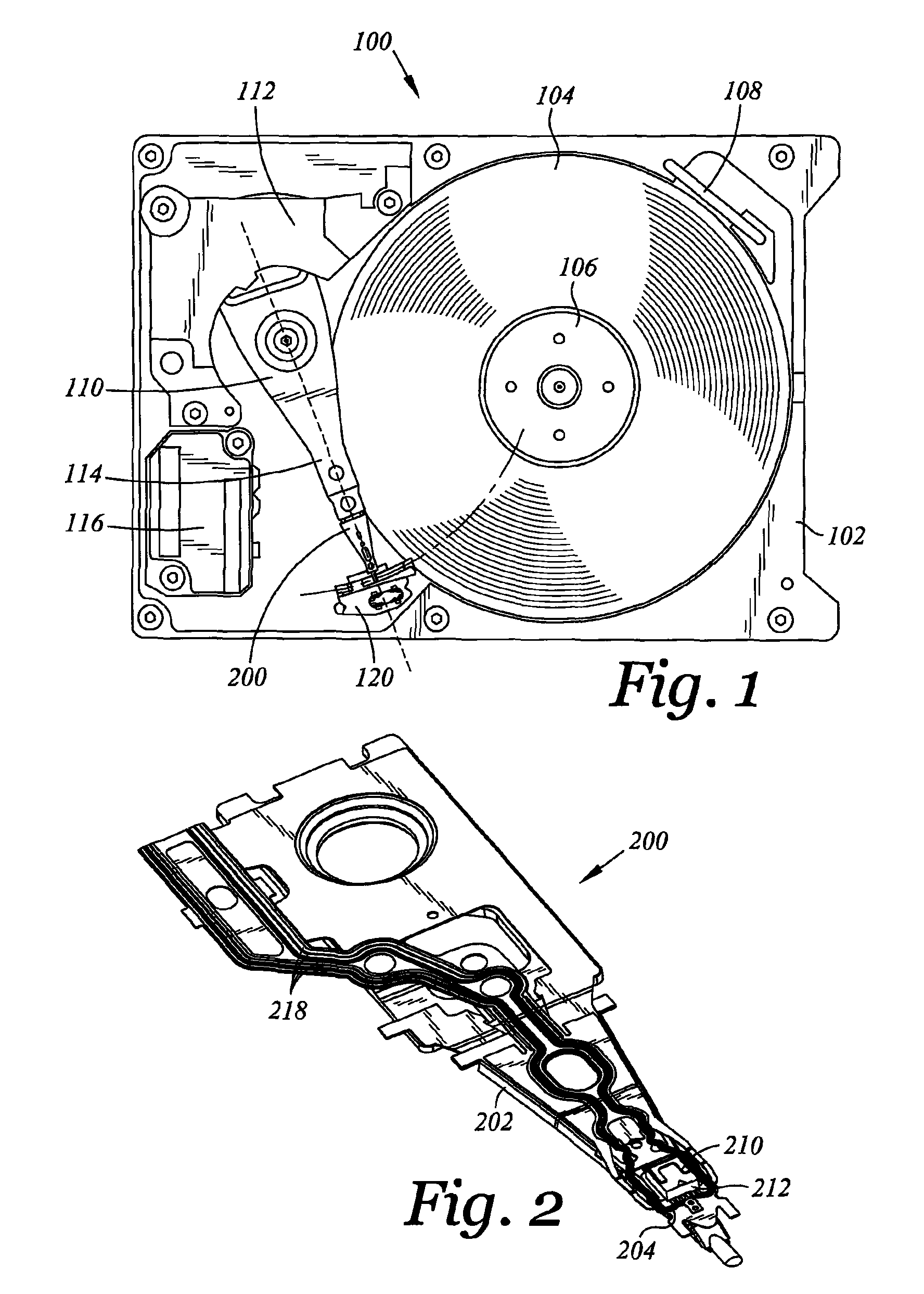

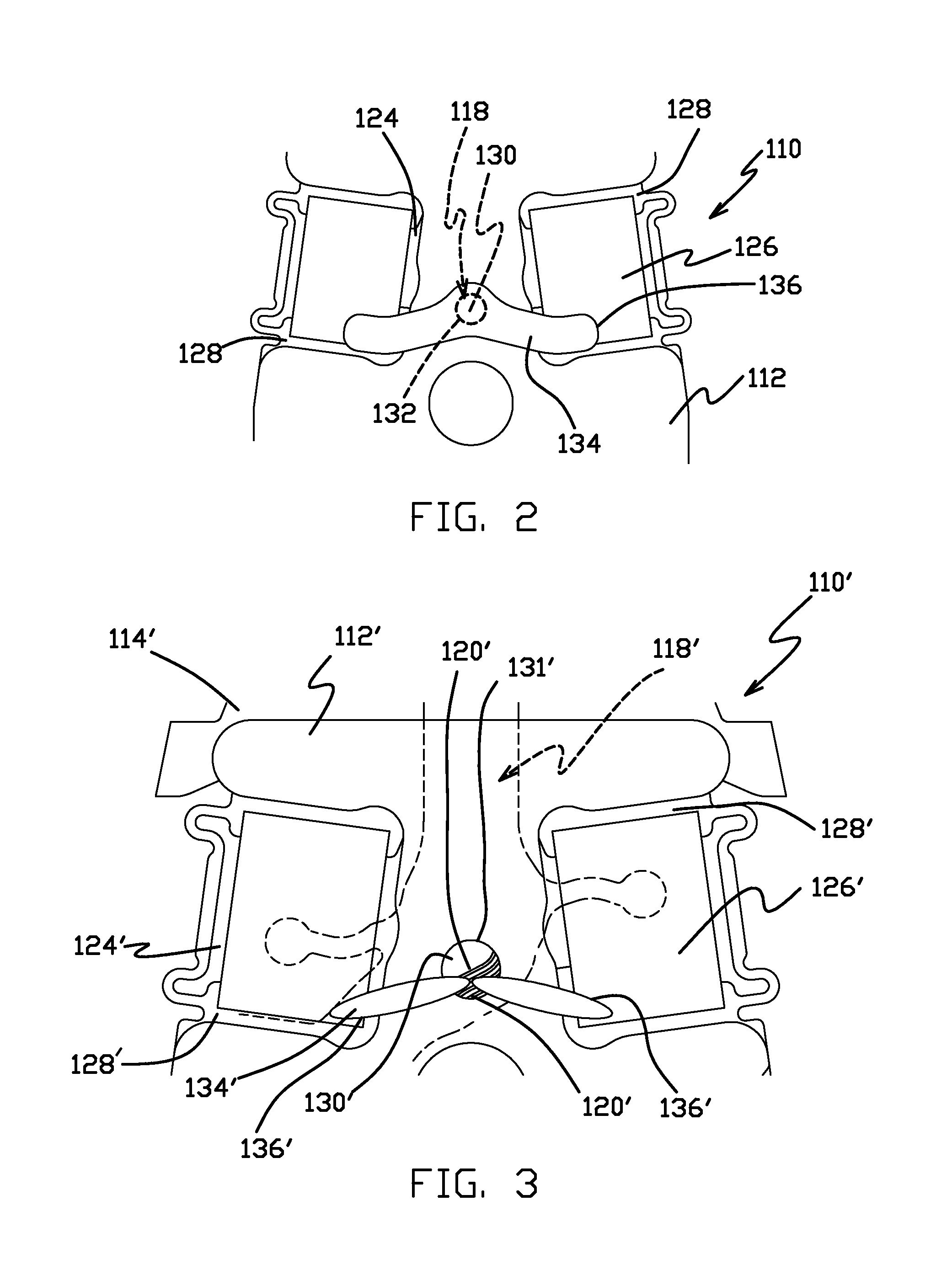

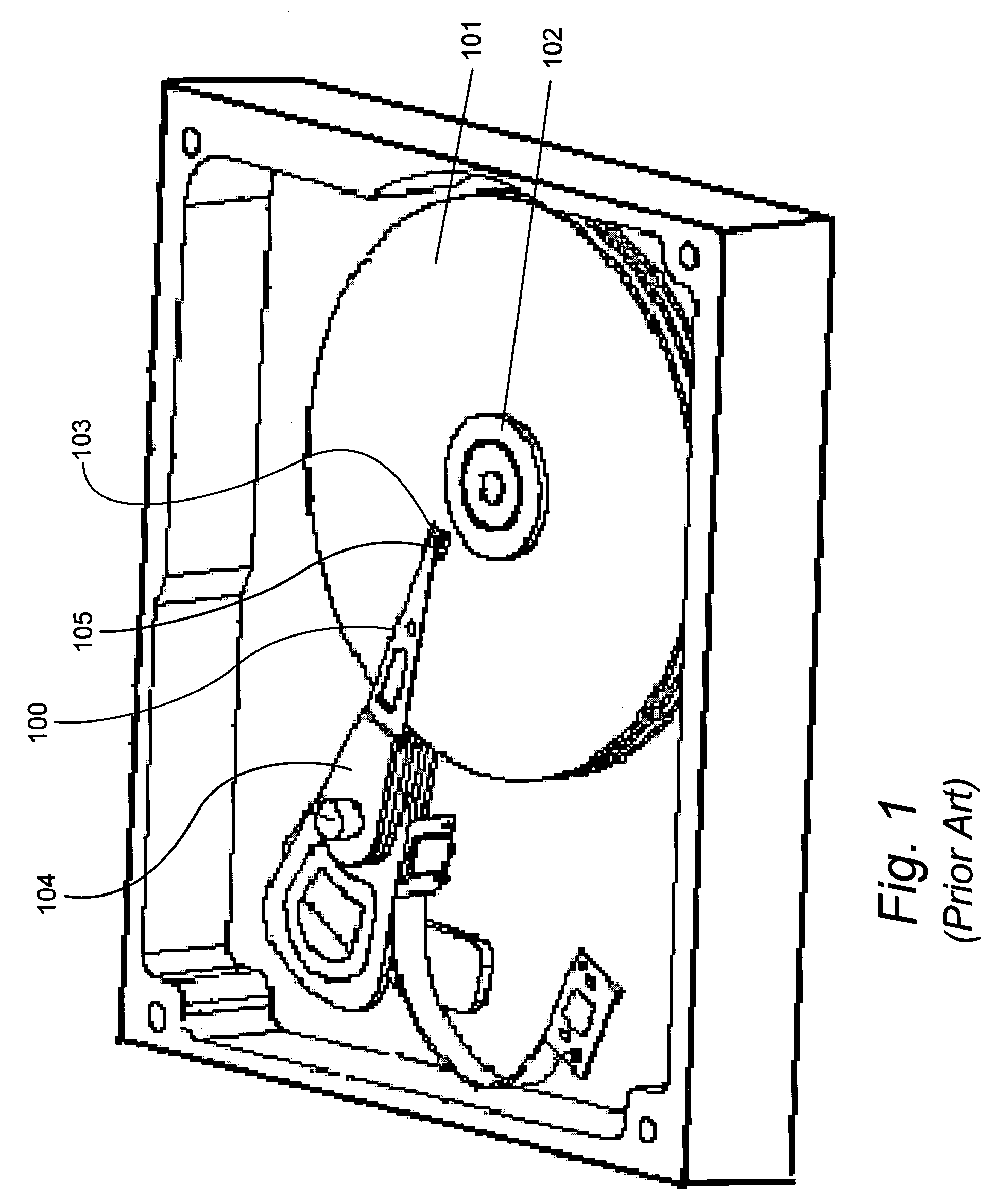

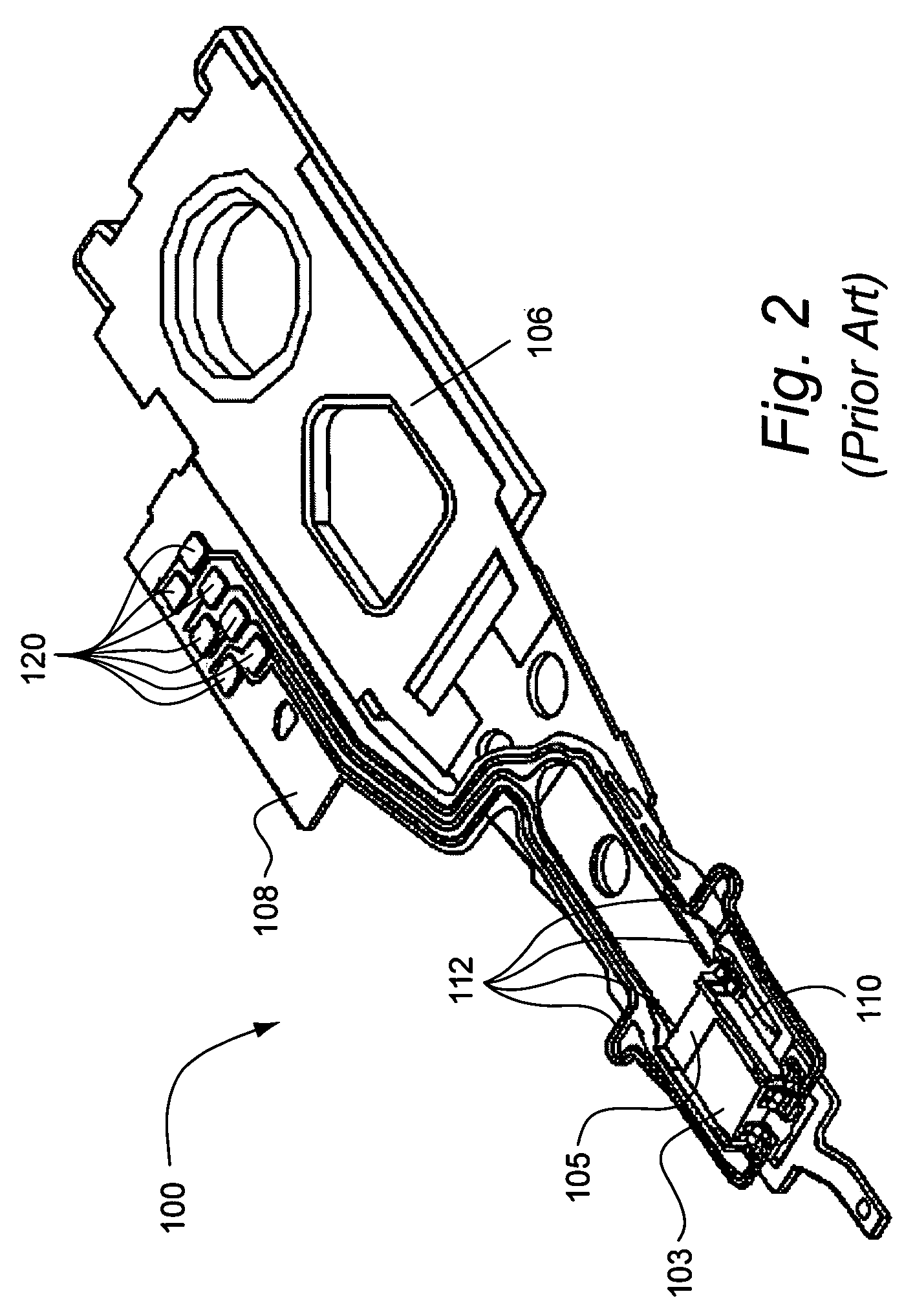

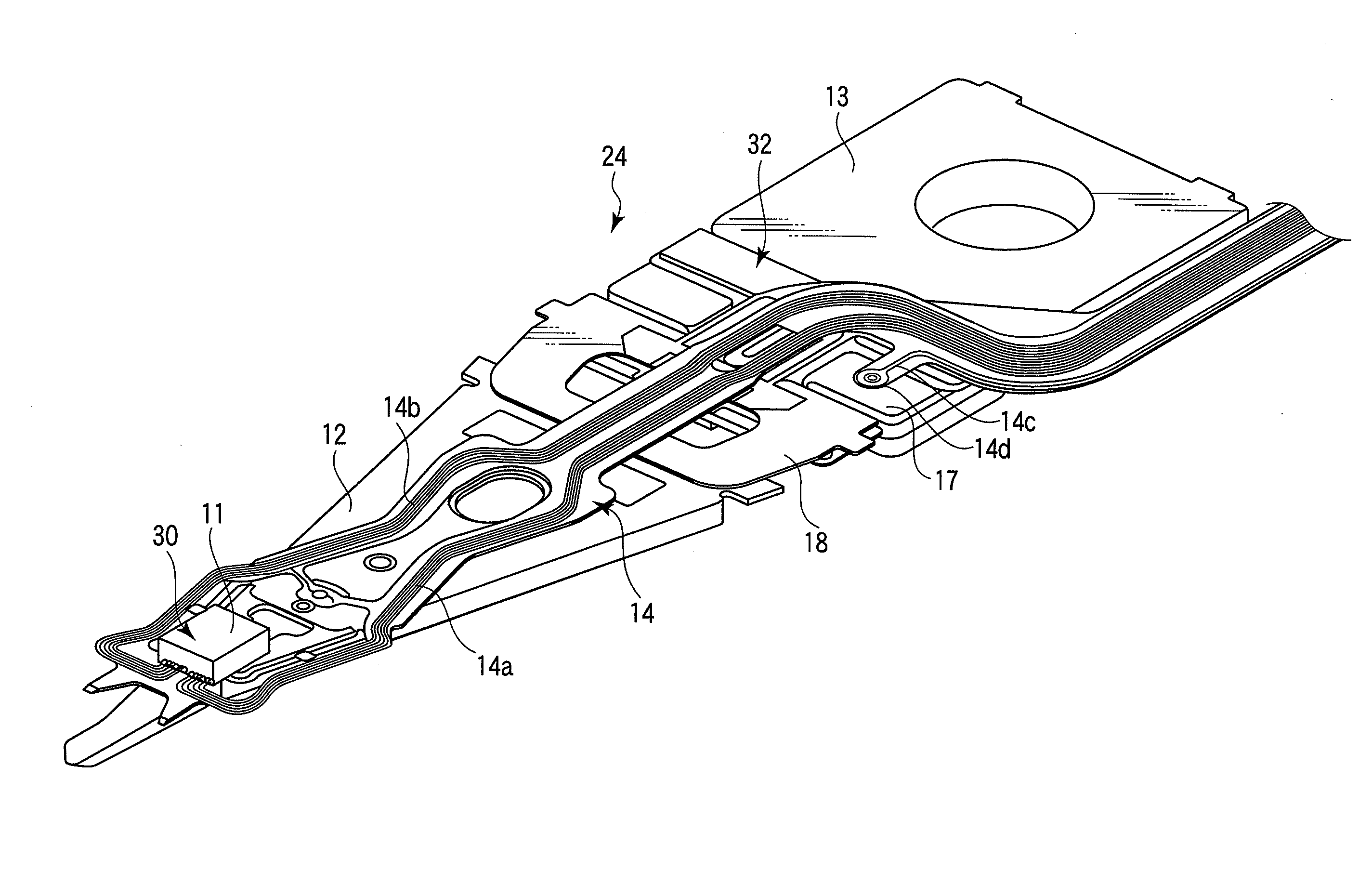

Head gimbal assembly having a radial rotary piezoelectric microactuator between a read head and a flexure tongue

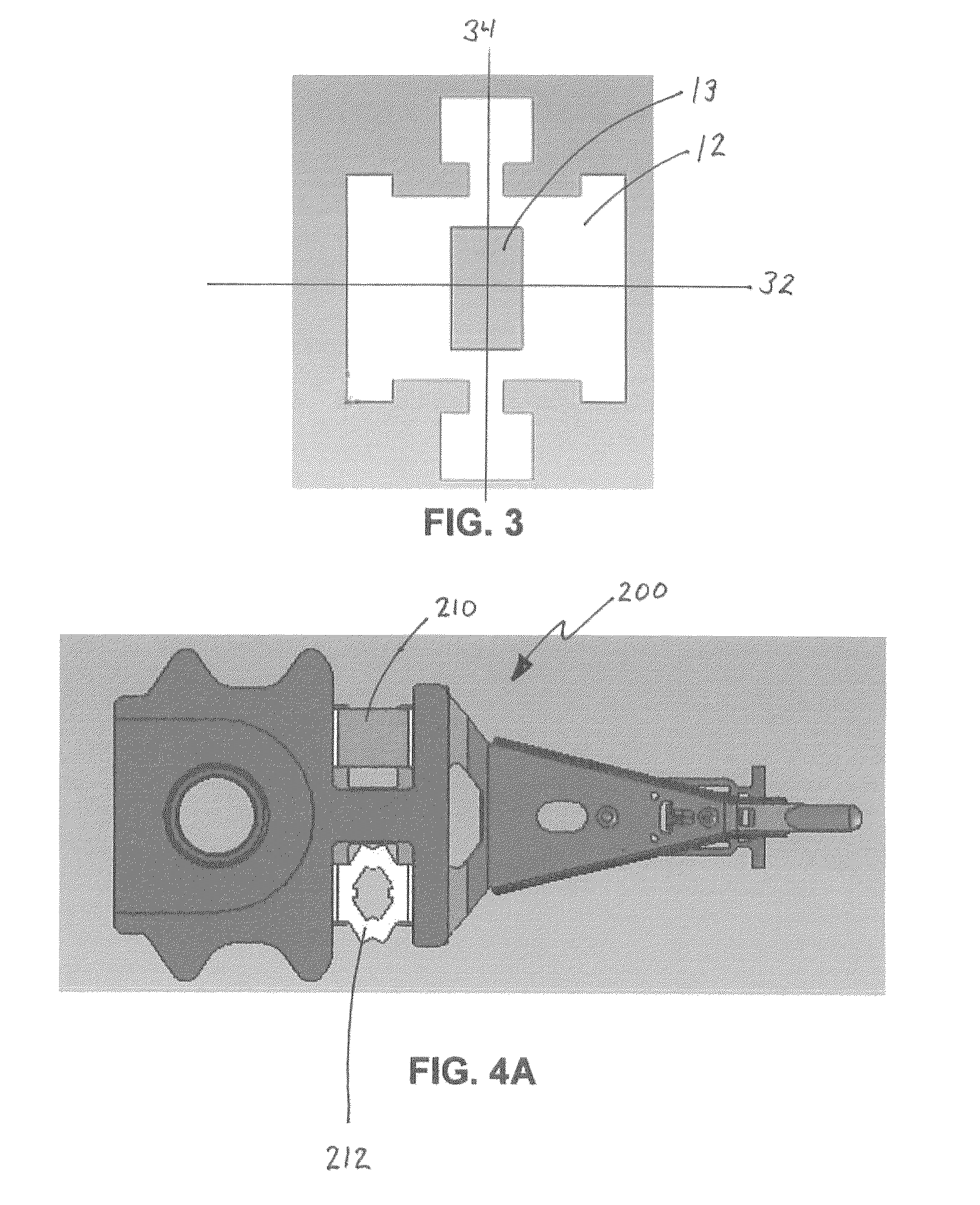

A novel head gimbal assembly (HGA) includes a piezoelectric microactuator having a first side and an opposing second side. The first side includes a plurality of anchor regions that extend radially from a center point and are bonded to the gimbal tongue. The first side also includes a first plurality of non-bonded regions lying between the anchor regions. The second side includes a plurality of link regions that extend radially from the center point and are bonded to a top surface of the read head. The second side also includes a second plurality of non-bonded regions lying between the link regions. Each of the plurality of link regions is angularly spaced between two of the plurality of anchor regions.

Owner:WESTERN DIGITAL TECH INC

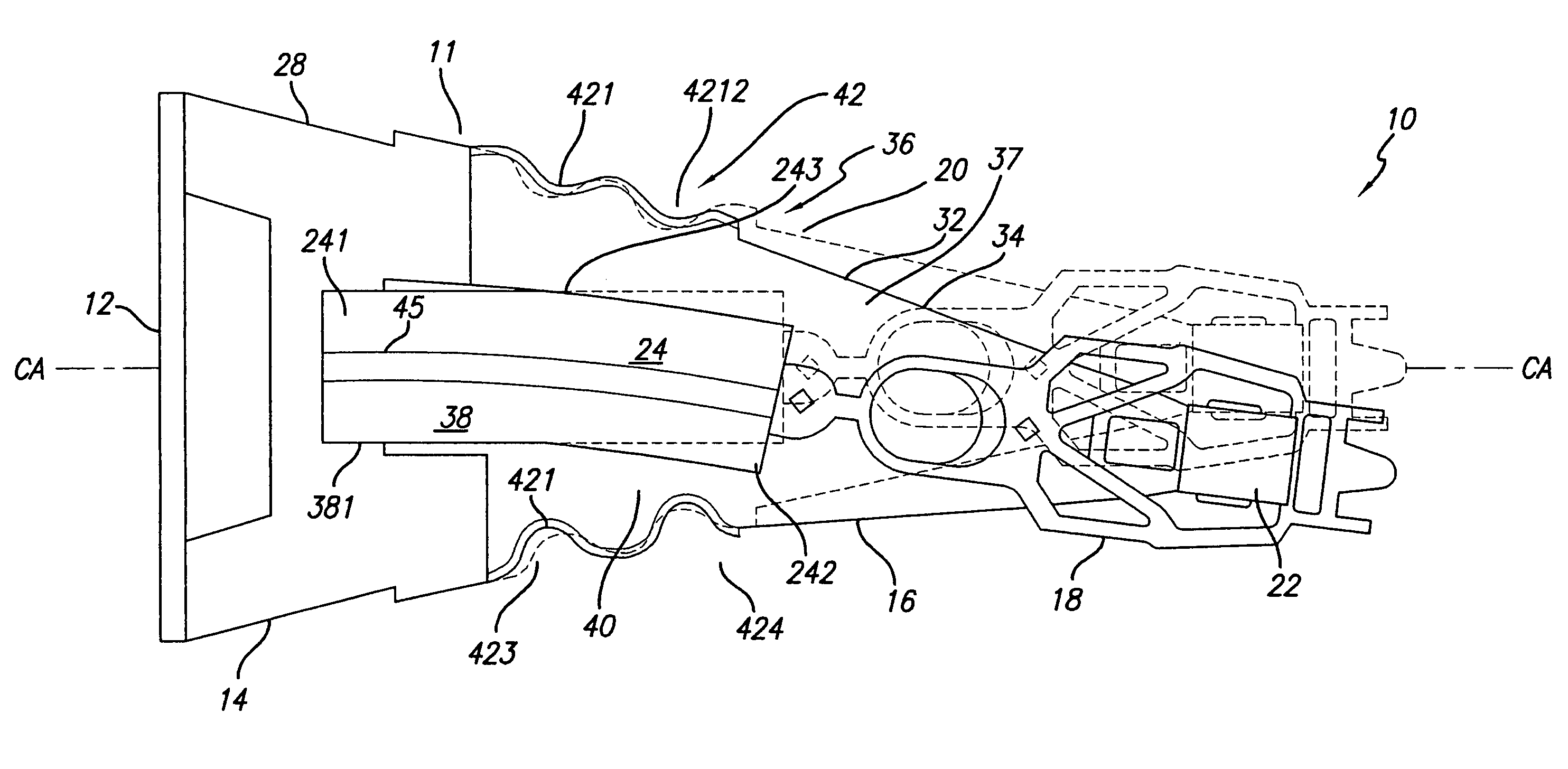

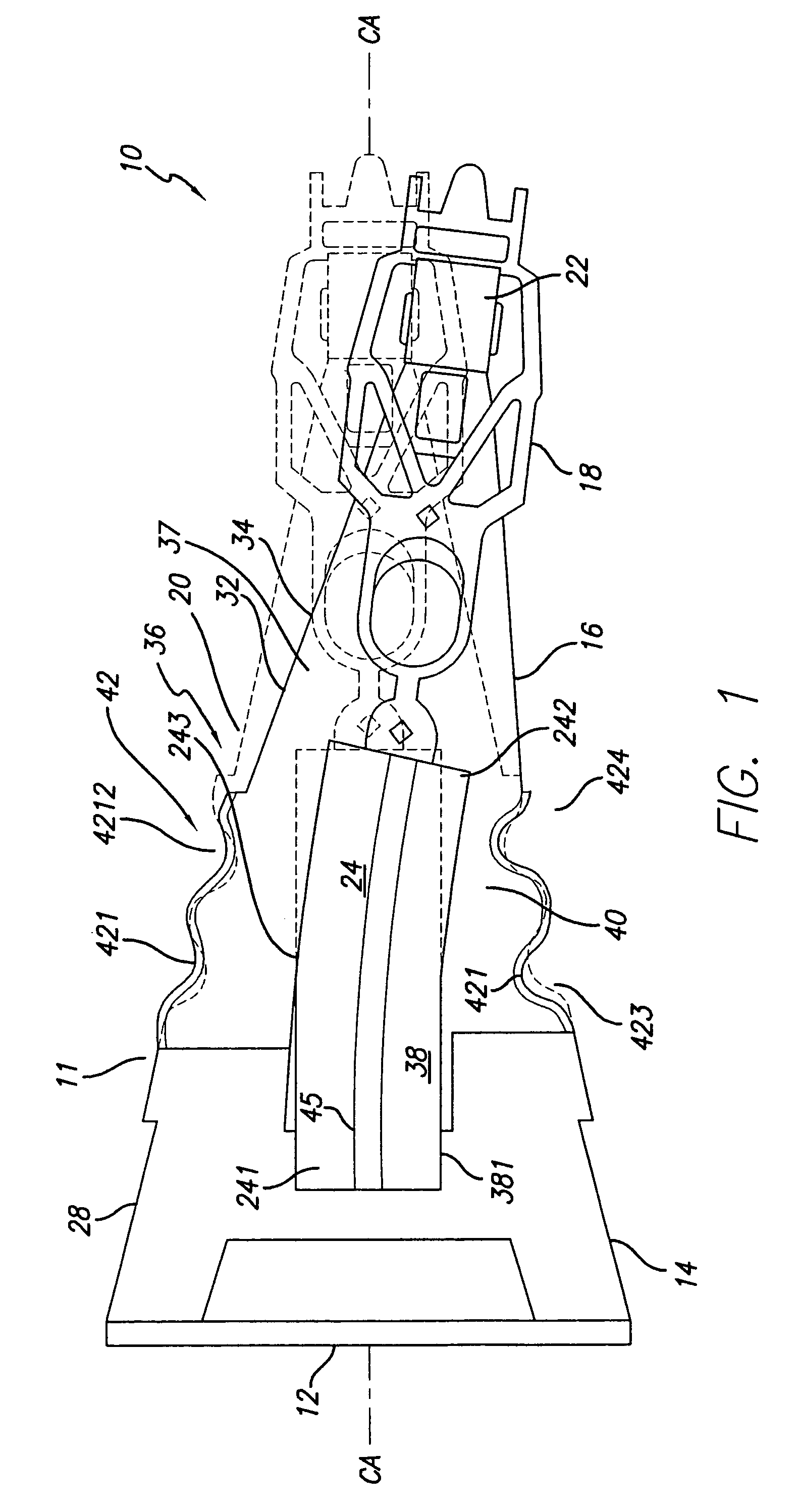

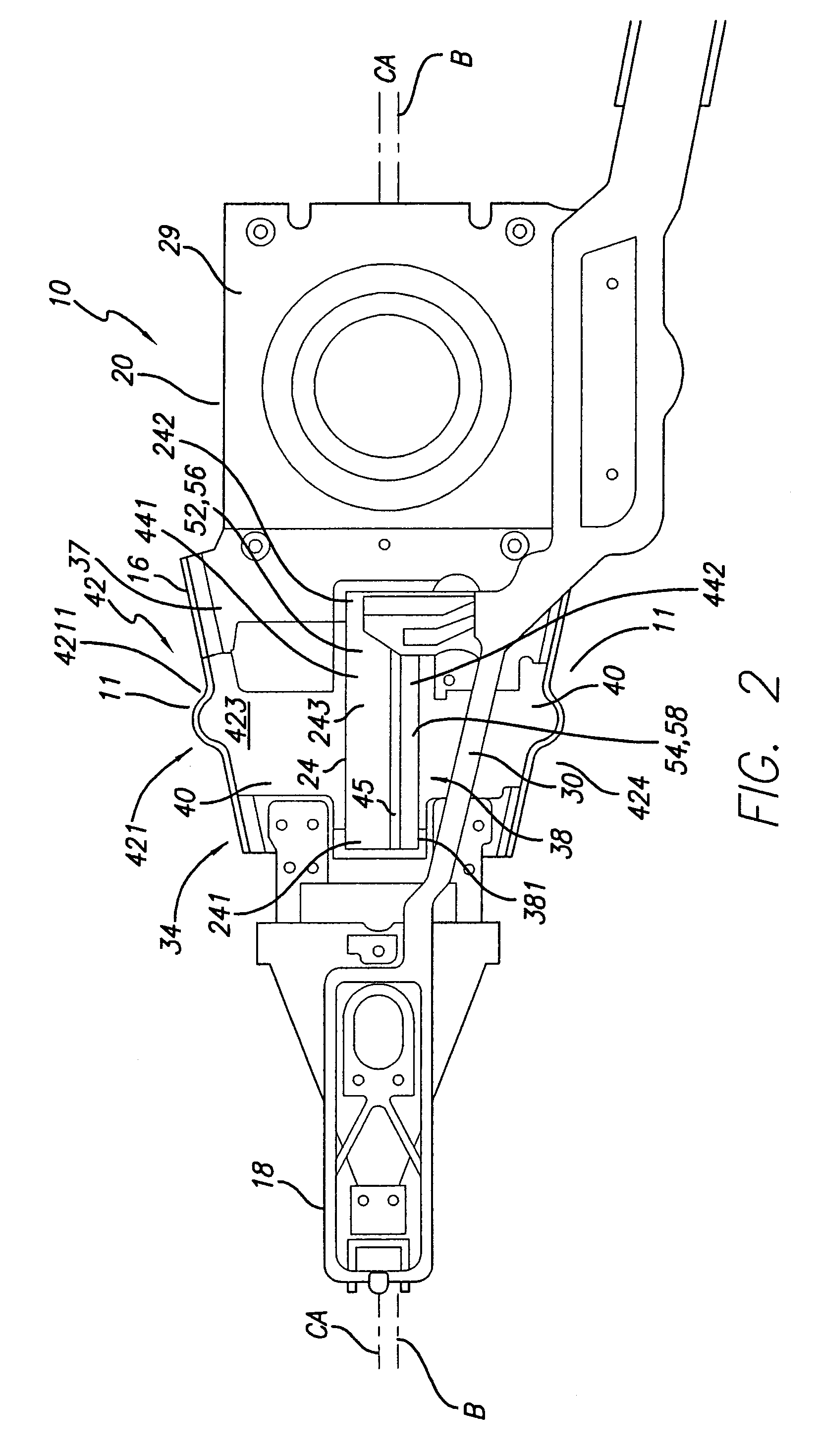

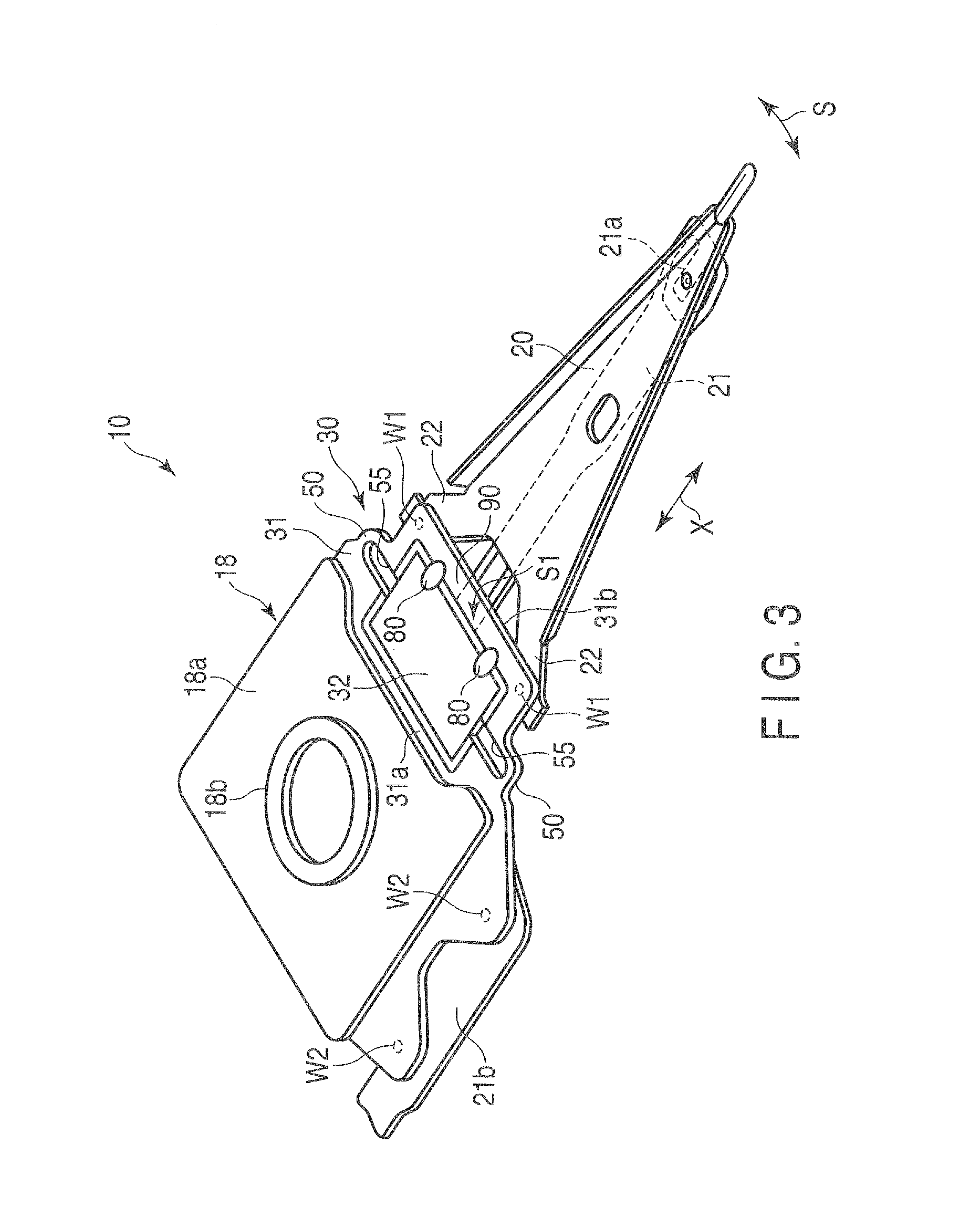

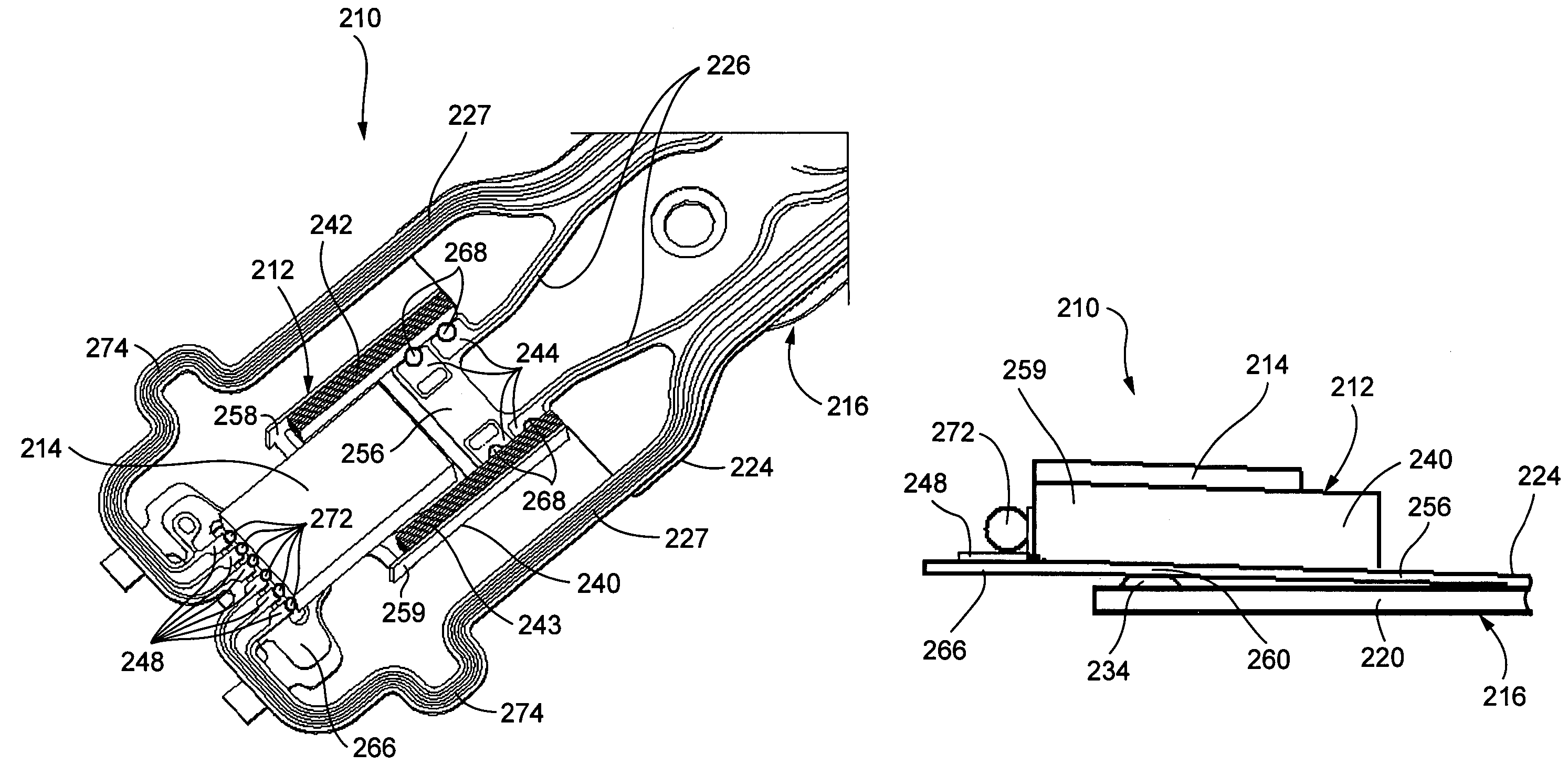

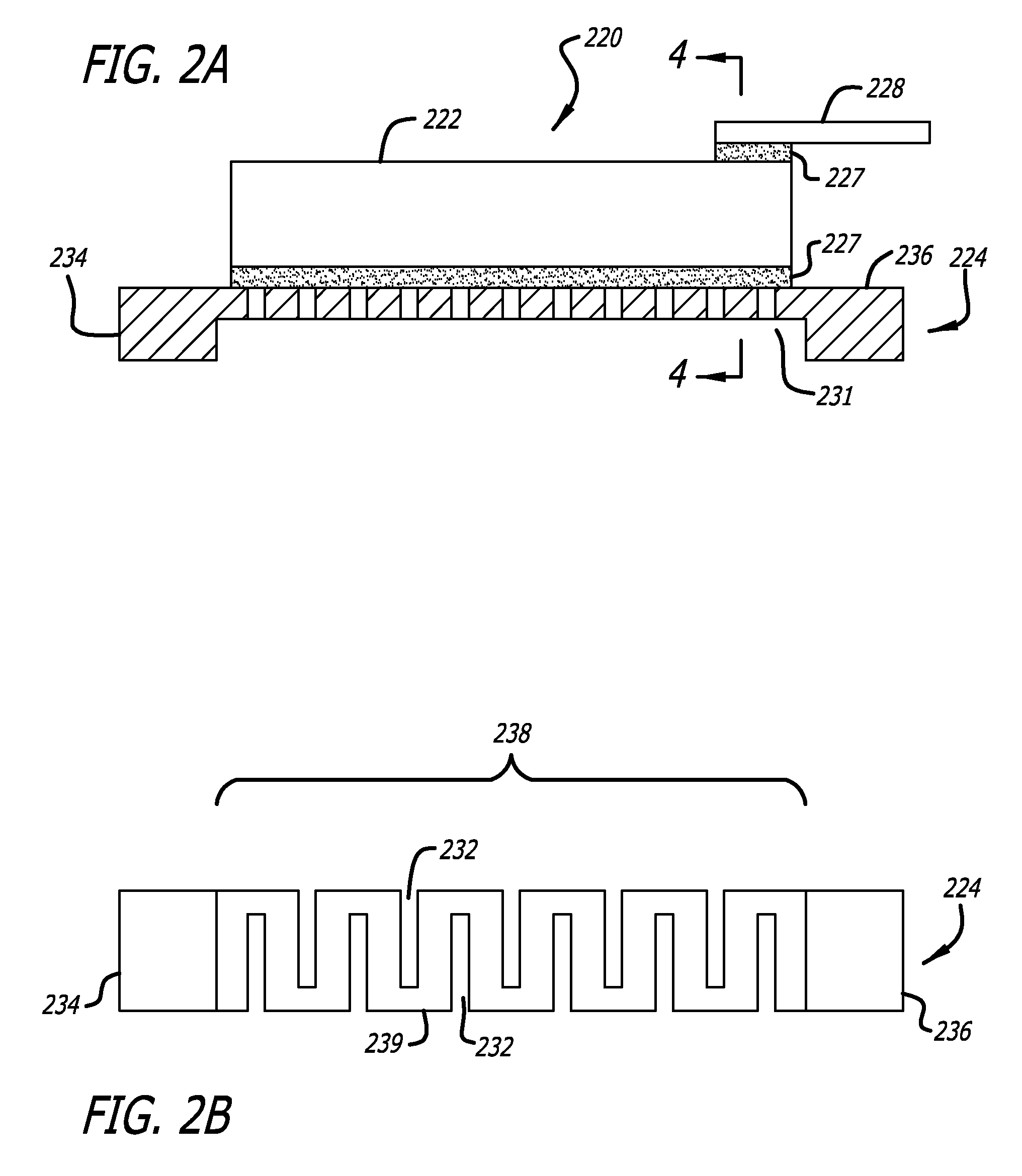

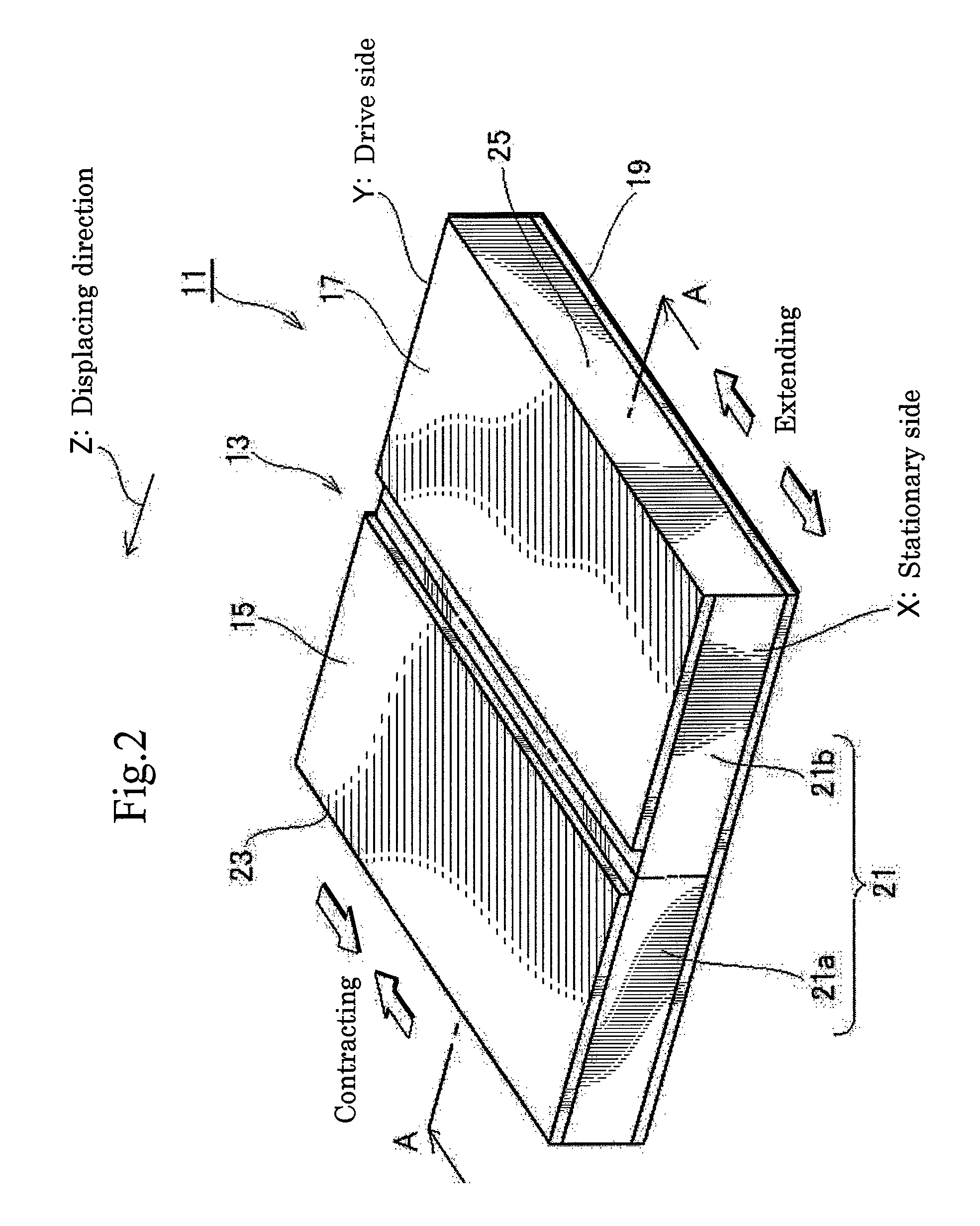

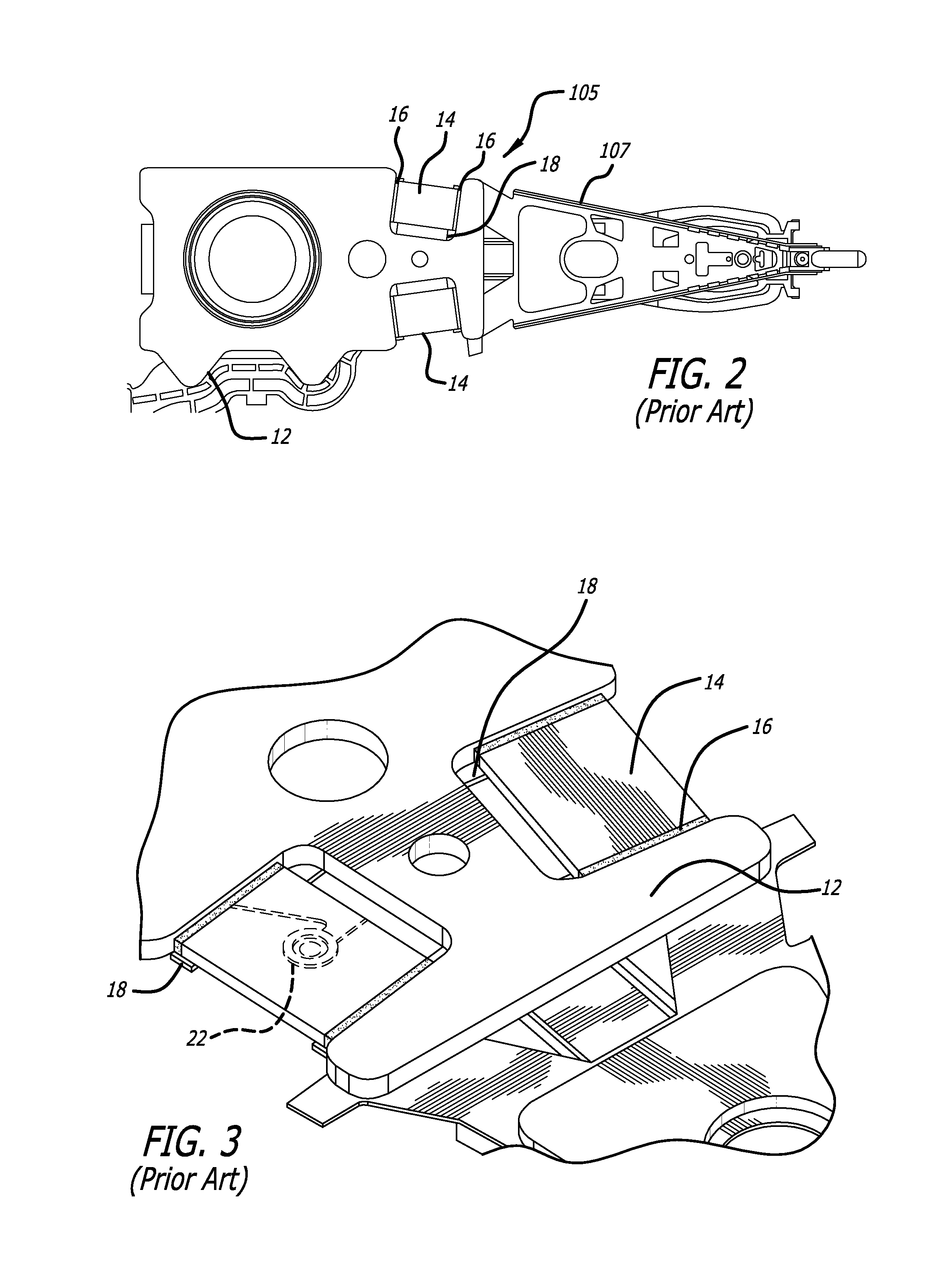

Loading-protected bending microactuator in additive suspensions

ActiveUS7459835B1Improved disk drive suspensionLow costPiezoelectric/electrostriction/magnetostriction machinesArm with actuatorsDistal portionEngineering

A microactuated disk drive suspension for supporting a slider at a disk includes a load beam extending in a plane and having on a common axis a base section adapted for mounting to an actuator, a spring section and a beam section carrying a flexure and the slider thereon. The suspension has relatively movable proximate and distal portions on the common axis that are joined by a bending system cantilevered from the proximate portion and including a cantilevered bending motor opposed to the common axis and having a laterally bendable unsupported region. A cantilevered laterally bendable load assist structure defined by the suspension edges is provided arranged to block undue loading of the bending motor unsupported region.

Owner:MAGNECOMP

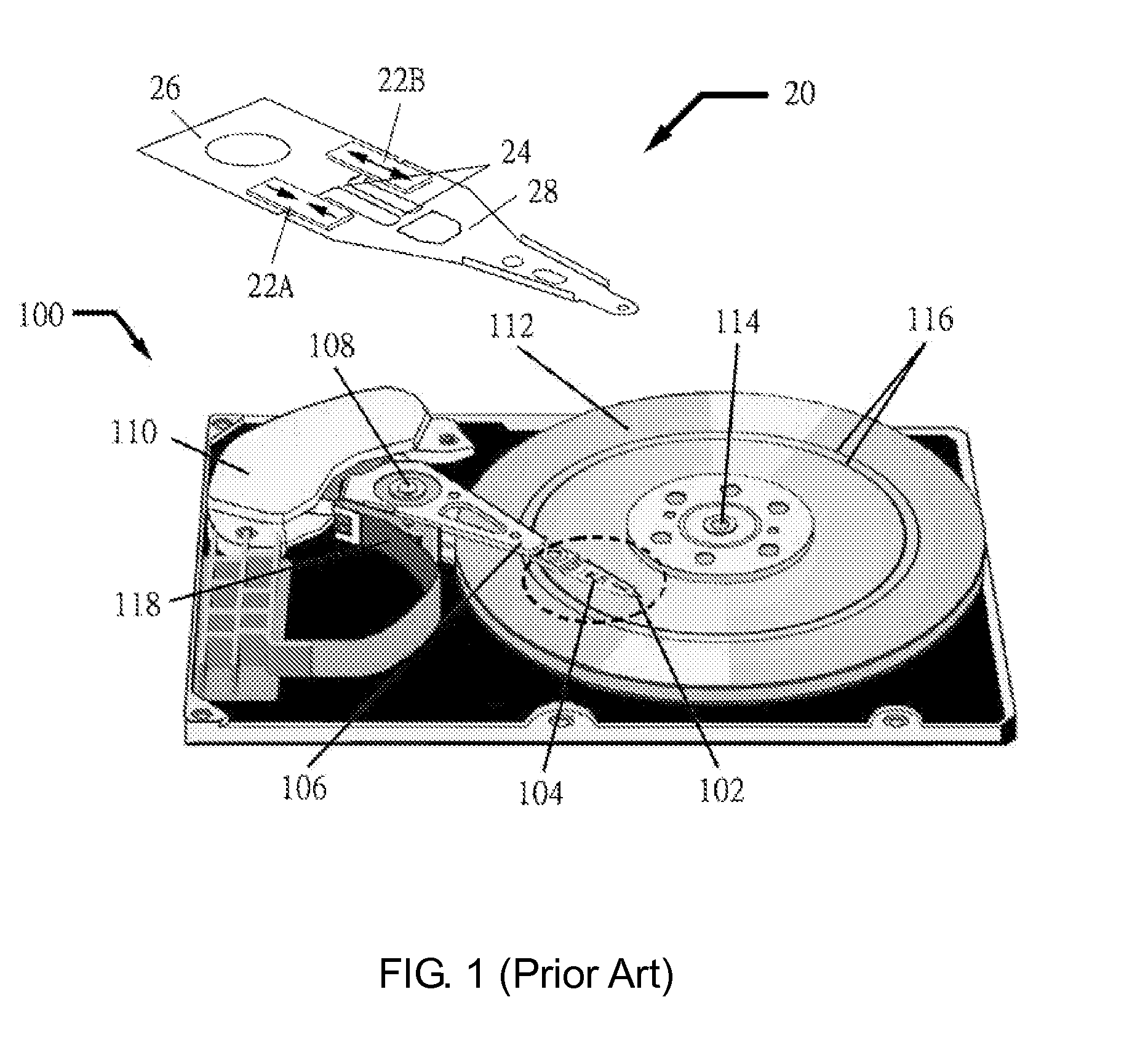

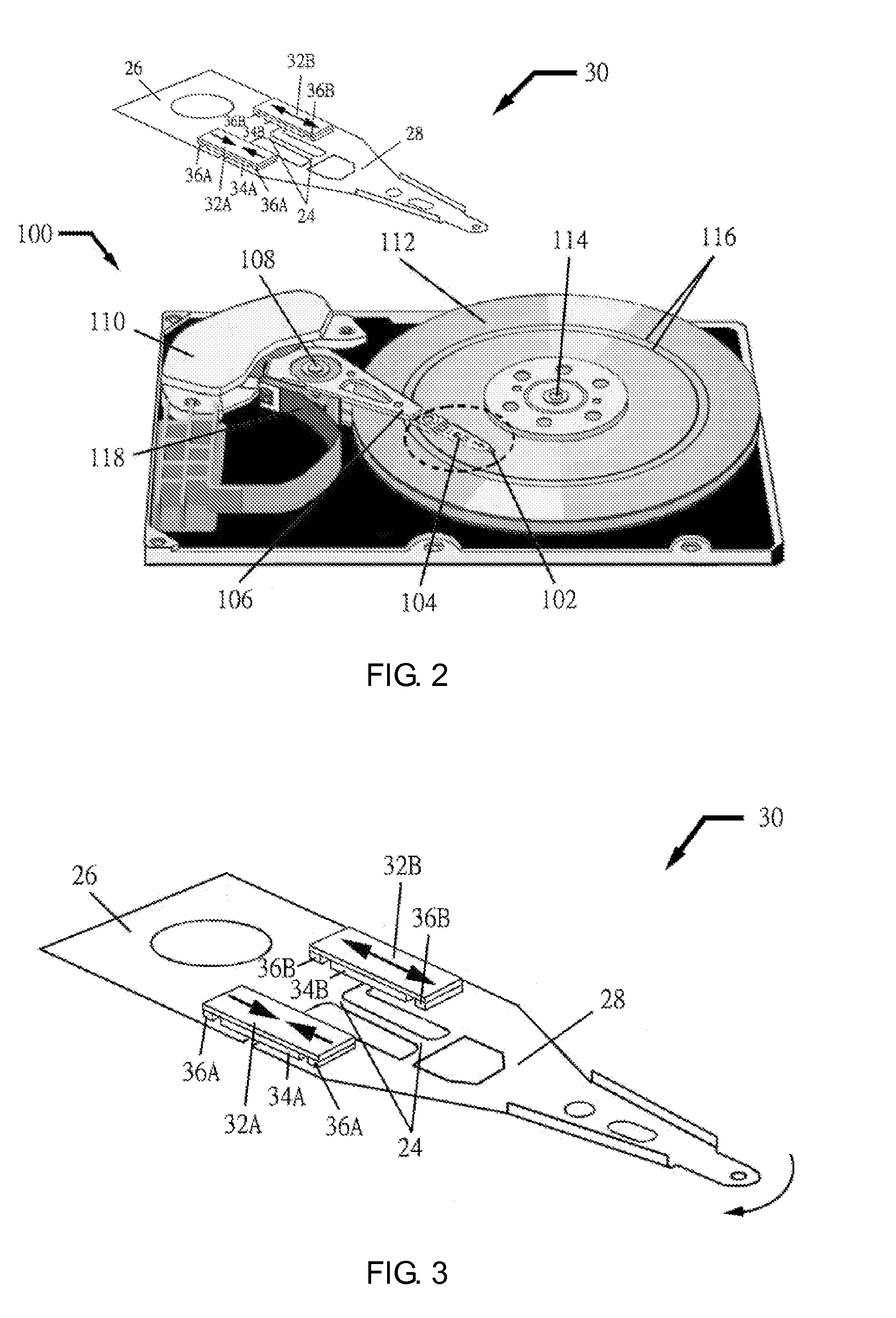

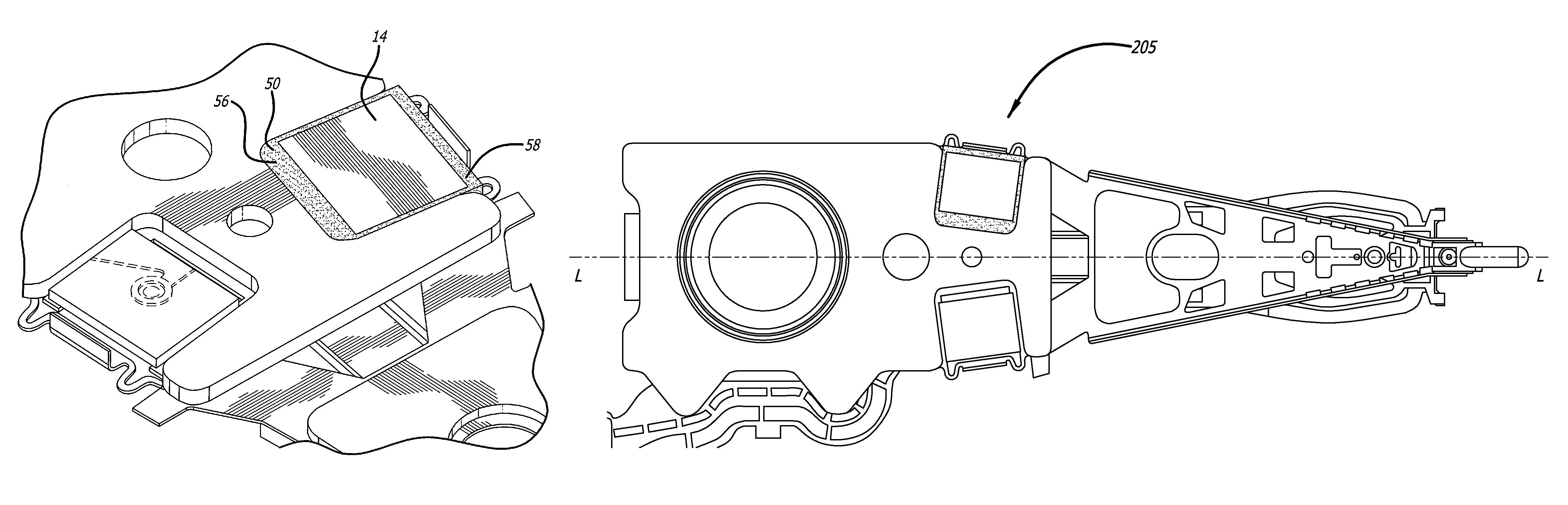

Suspension assembly having a microactuator electrically connected to a gold coating on a stainless steel surface

ActiveUS8542465B2Electrical connection between head and armArm with actuatorsPiezoelectric microactuatorEngineering

Owner:WESTERN DIGITAL TECH INC

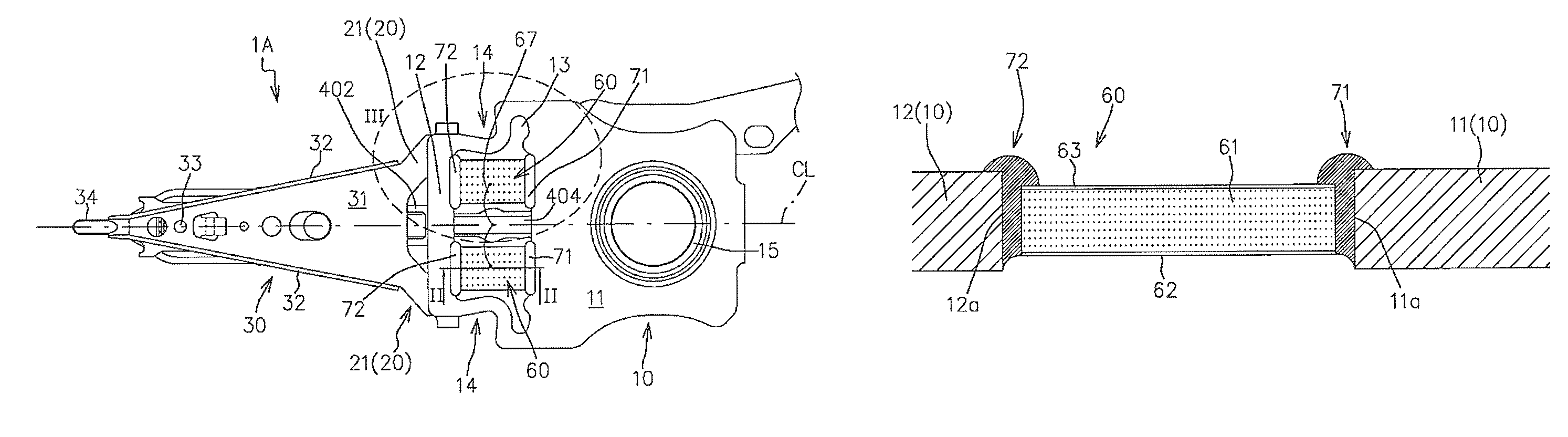

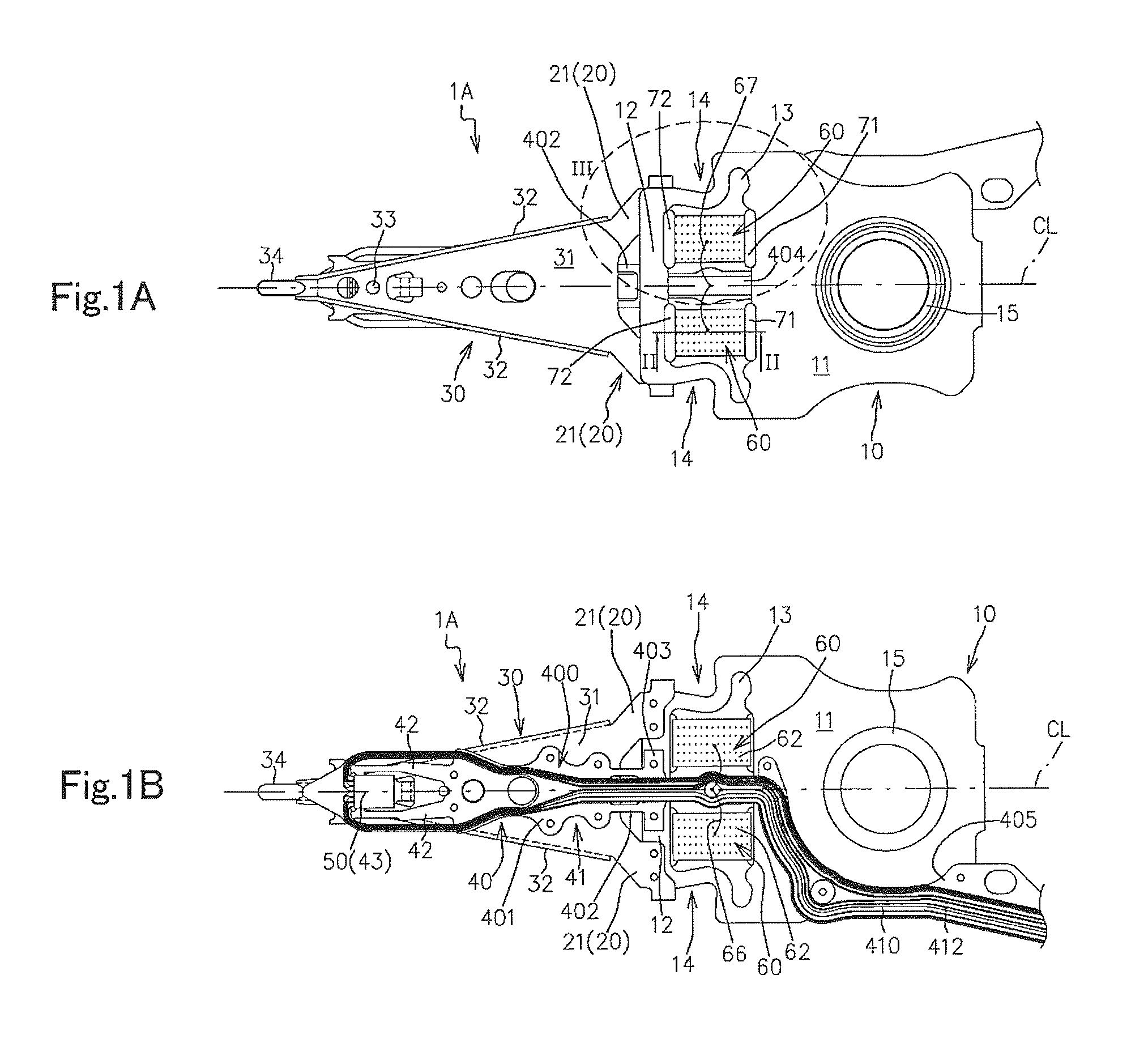

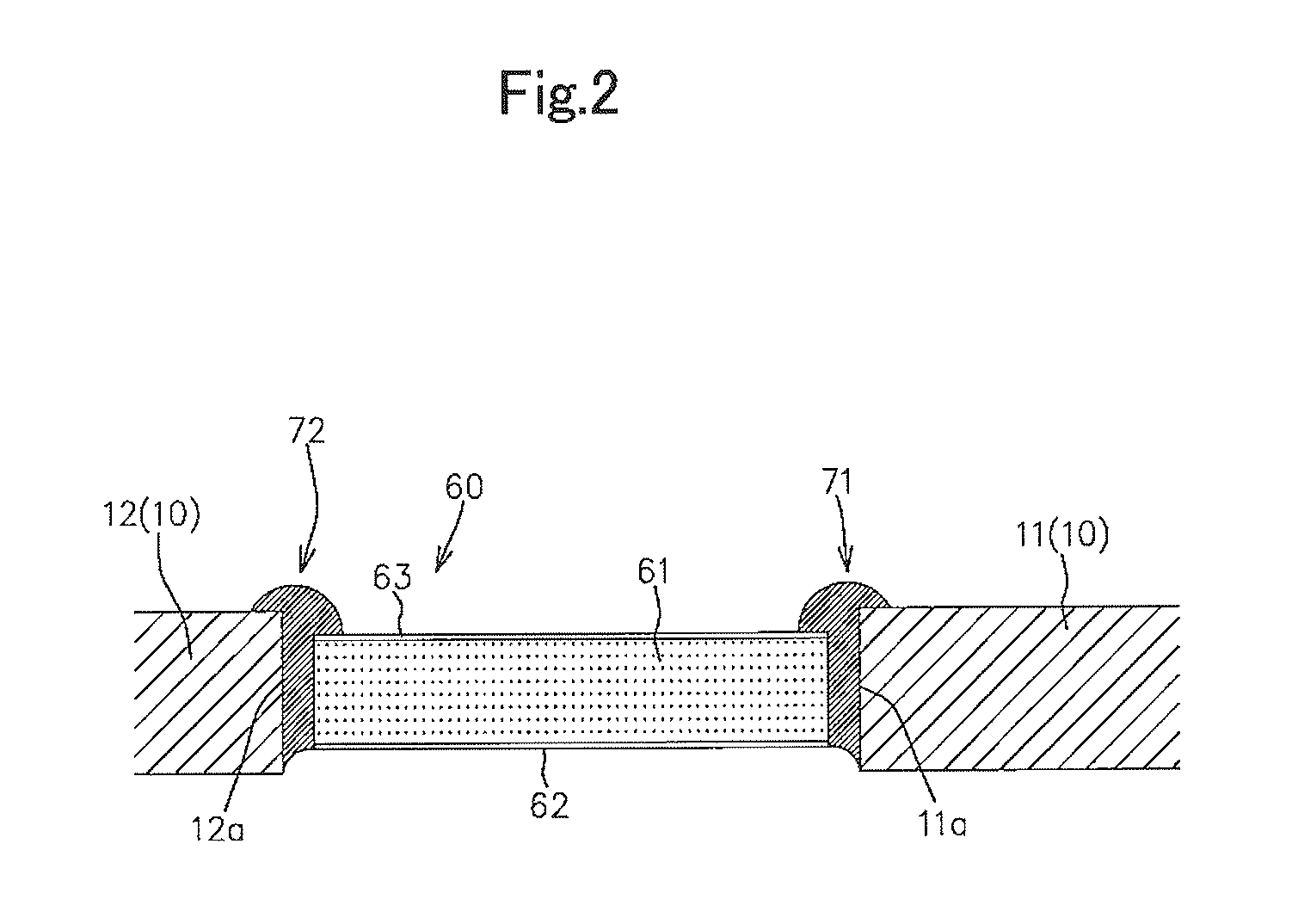

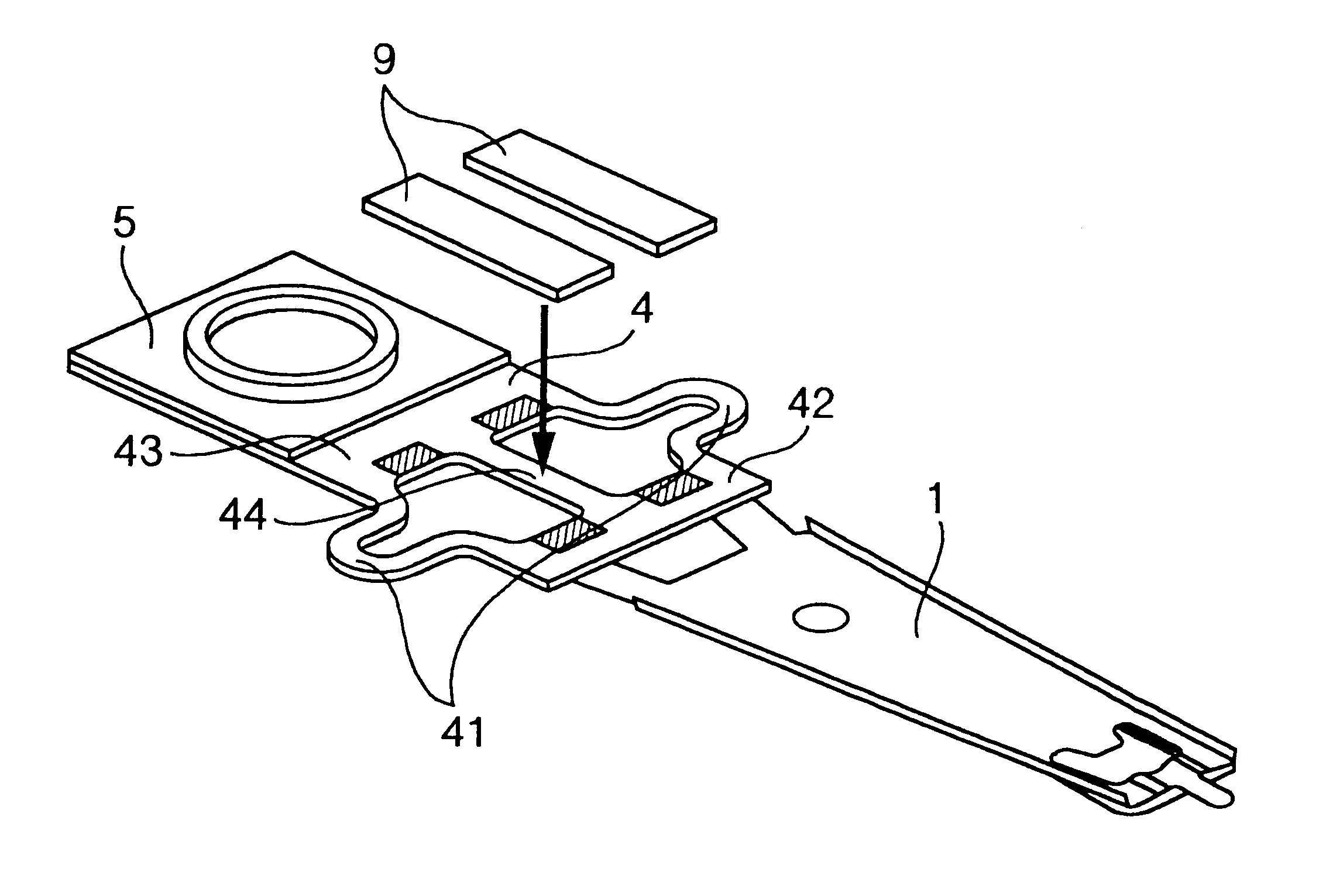

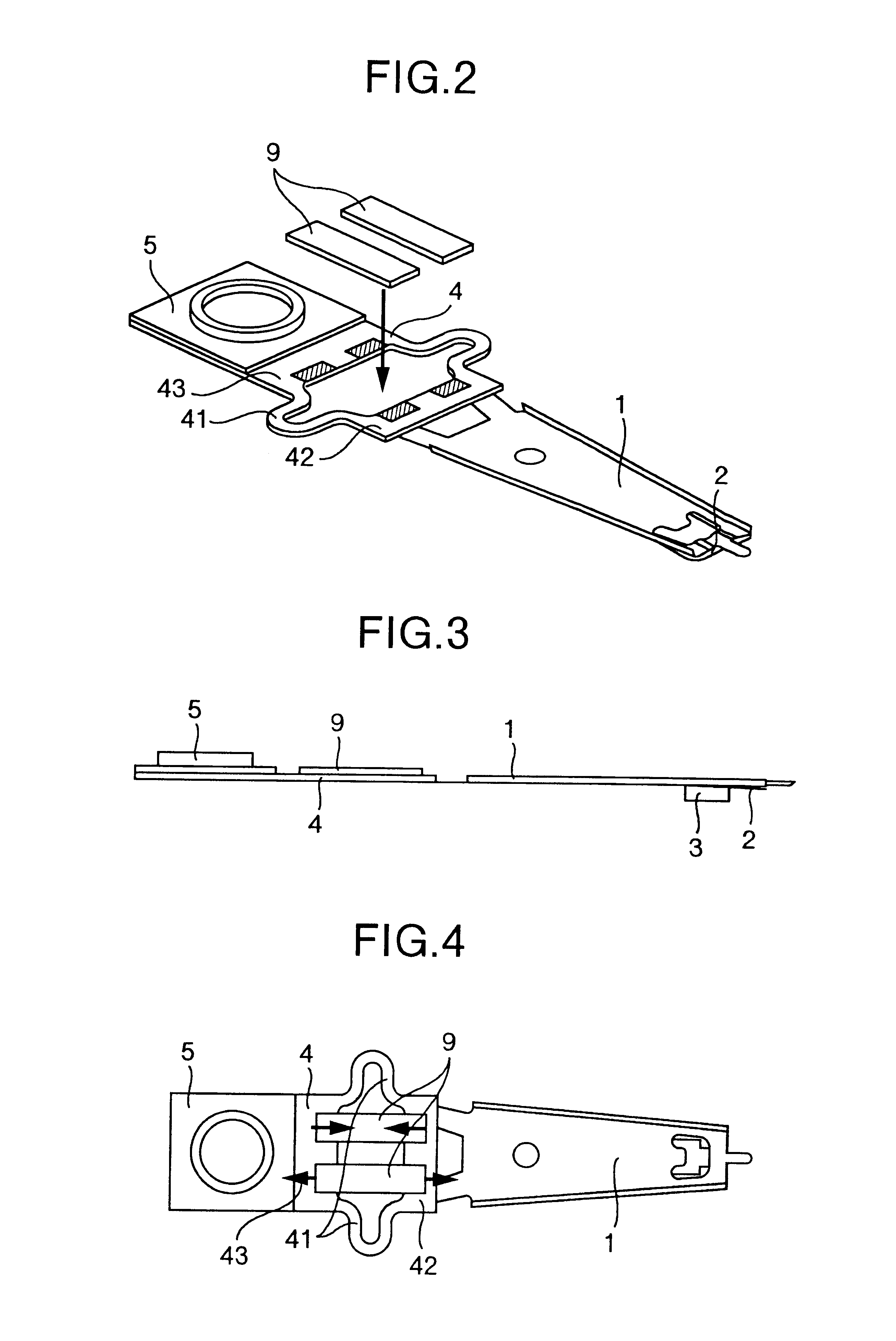

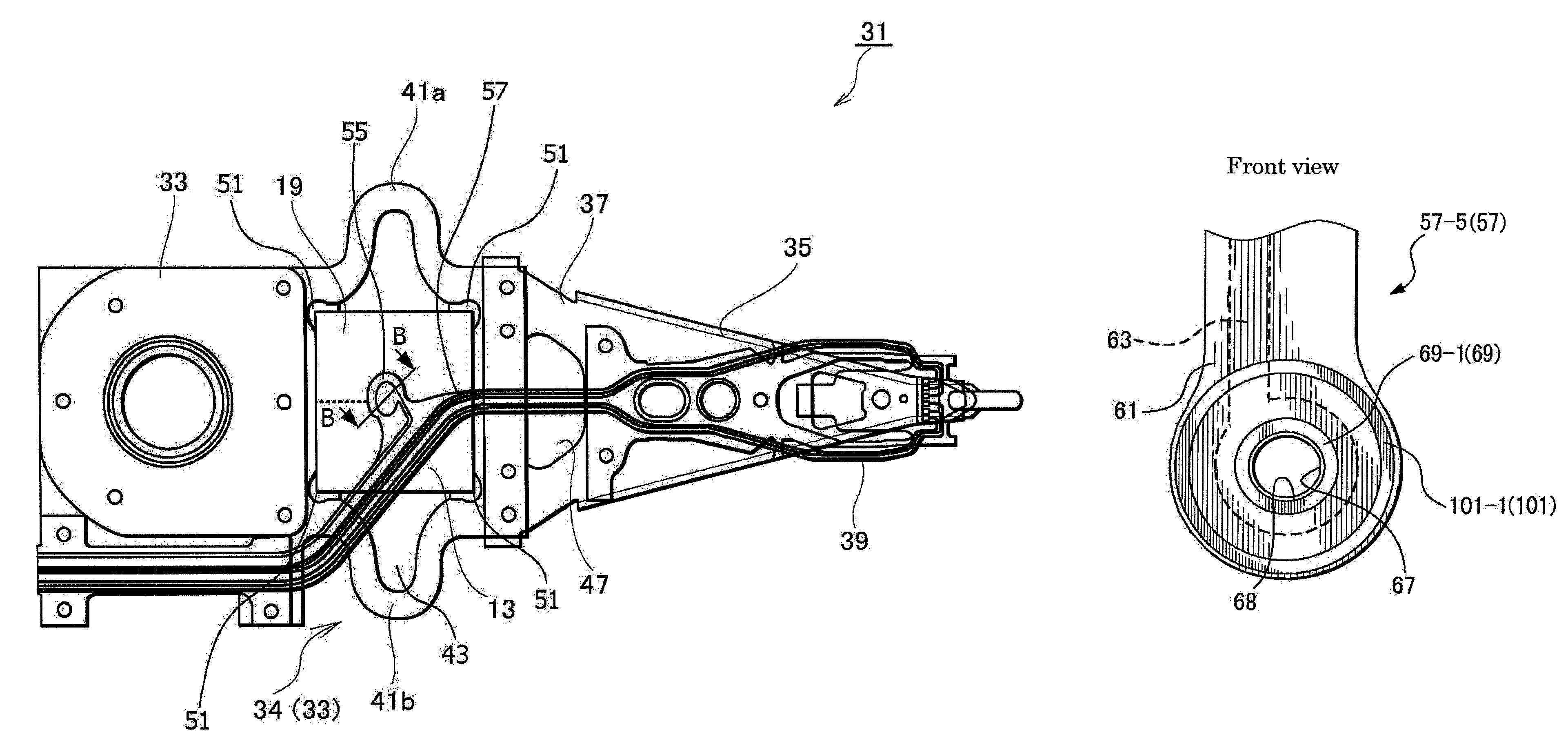

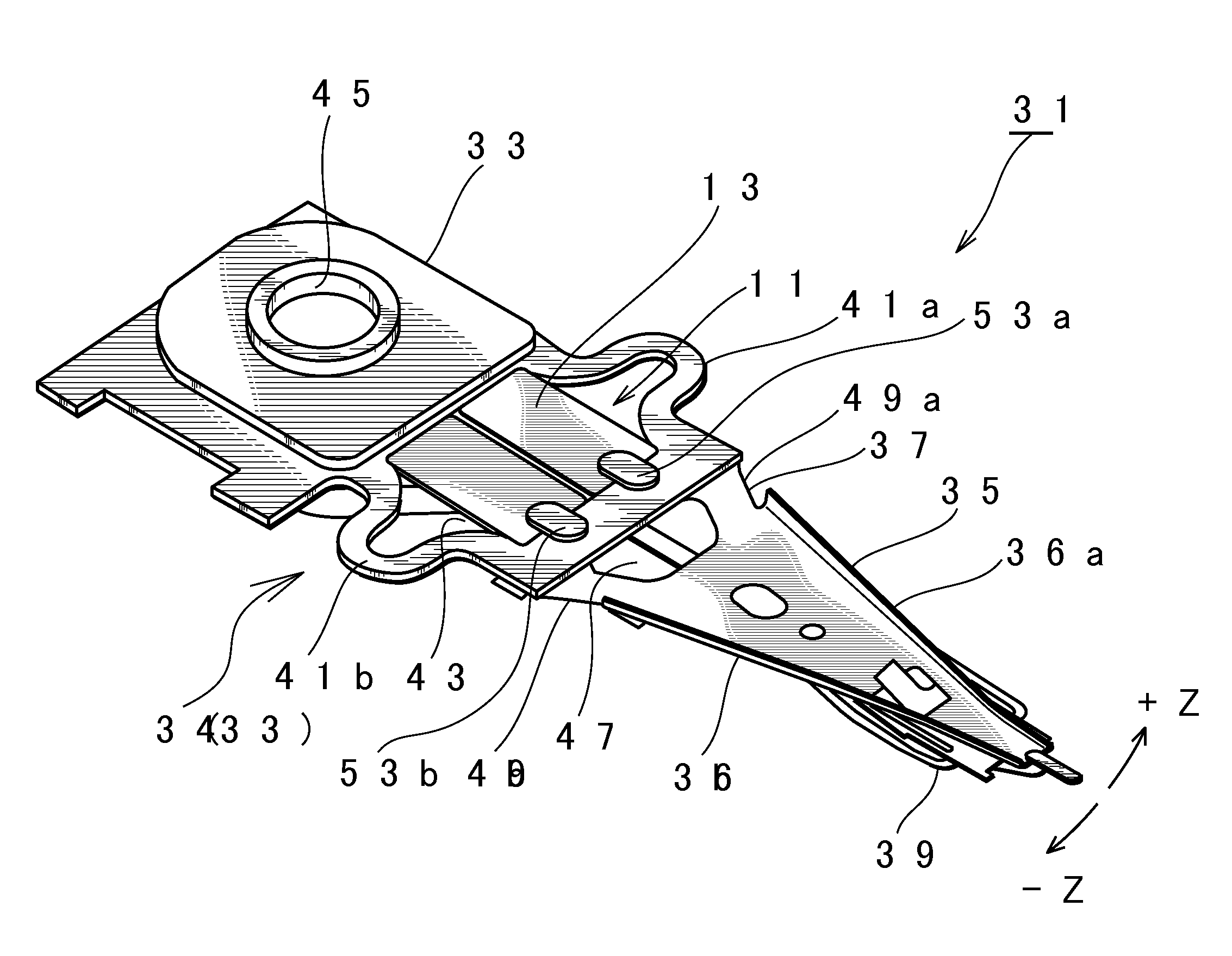

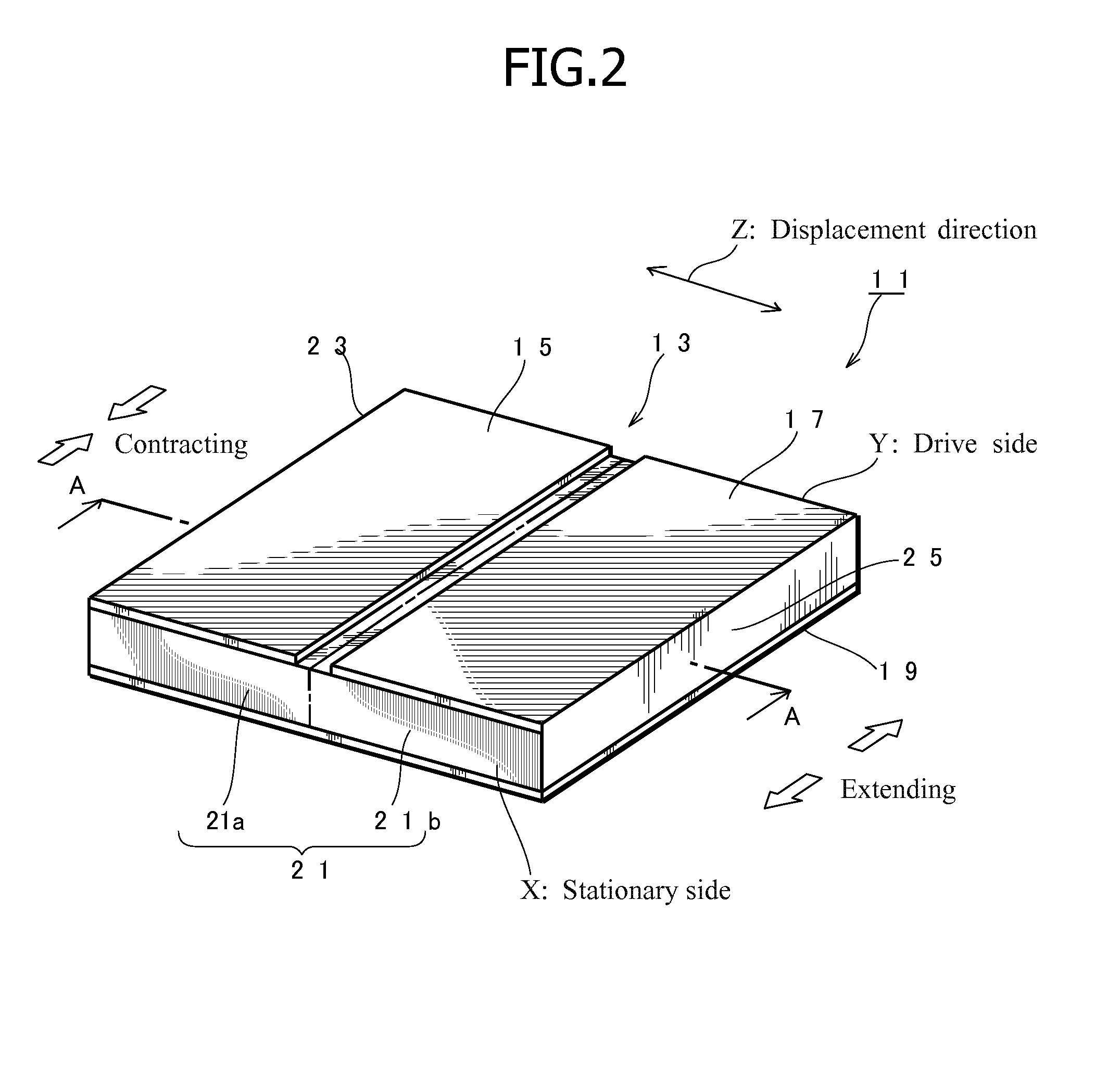

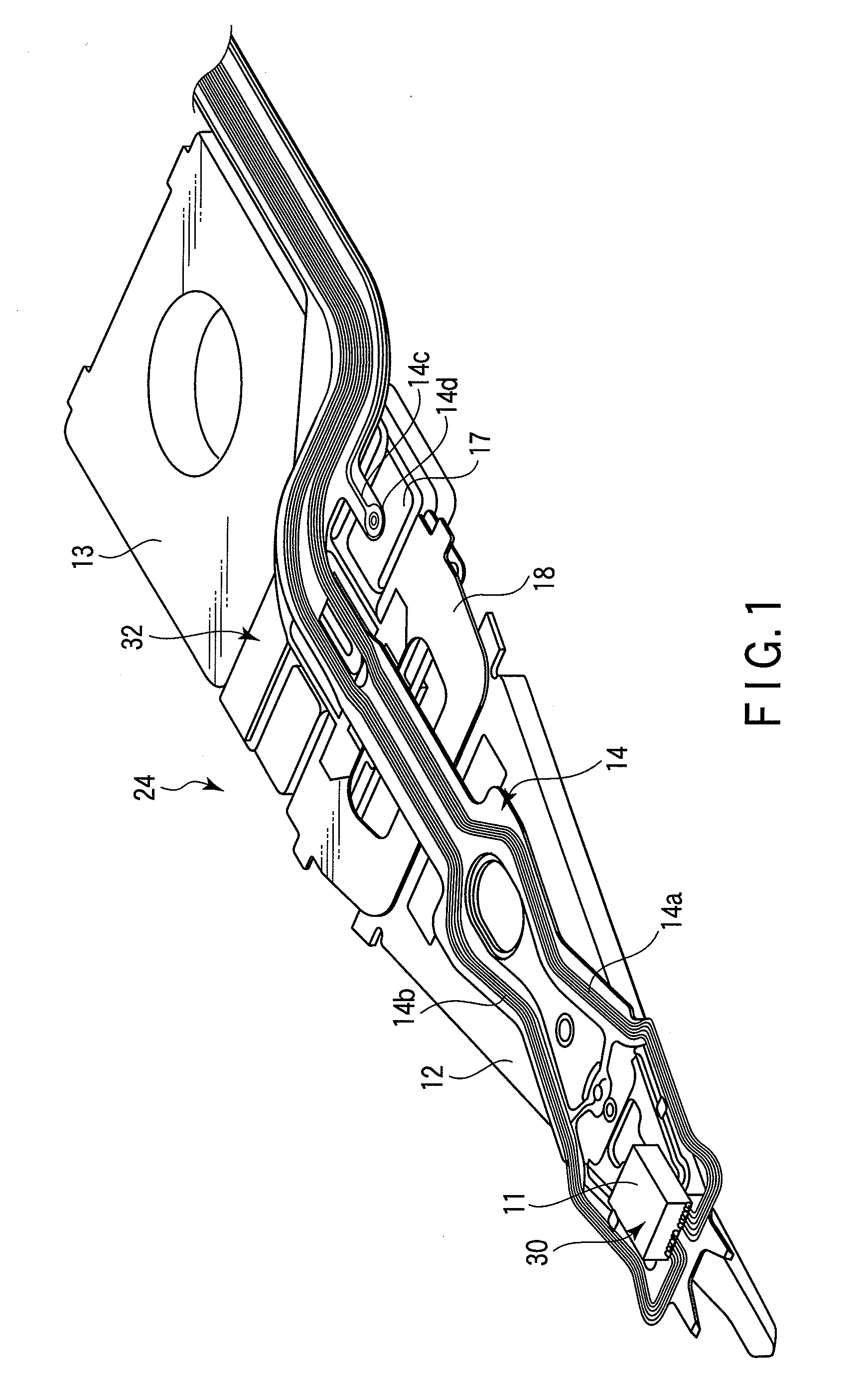

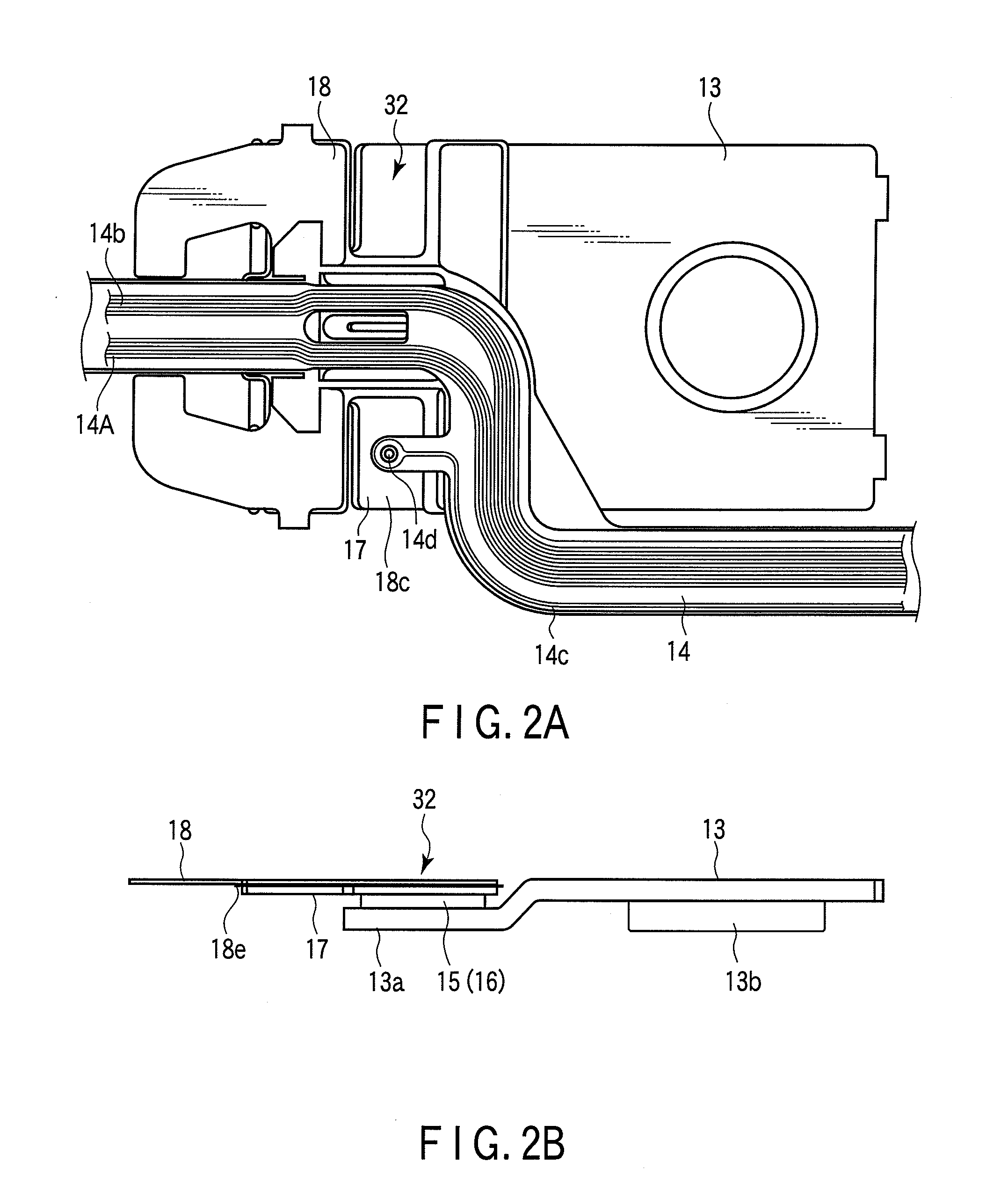

Electrical connecting structure for piezoelectric element, piezoelectric actuator, head suspension, and electrical connecting structure for conductive part

ActiveUS20100067151A1Accurate wiringReliability is deterioratedArm with actuatorsPiezoelectric/electrostriction/magnetostriction machinesAdhesivePiezoelectric actuators

A piezoelectric element 13 has a common electrode 19 that receives electricity from a terminal 57. The terminal 57 has a through hole 67 and an electric insulating layer 61. The piezoelectric element 13 is arranged so that the common electrode 19 faces the electric insulating layer 61 of the terminal 57. A liquid stopper 69 is formed around the through hole 67 so as to come between the common electrode 19 and the terminal 57 when the common electrode 19 and terminal 57 are set to face each other. A liquid conductive adhesive 71 is injected into the through hole 67 to fill a gap defined by the liquid stopper 69 between the terminal 57 and the common electrode 19 and secure electric connection between the terminal 57 and the common electrode 19. This configuration improves the reliability of wiring to the piezoelectric element and prevents the piezoelectric element from being damaged.

Owner:NHK SPRING CO LTD

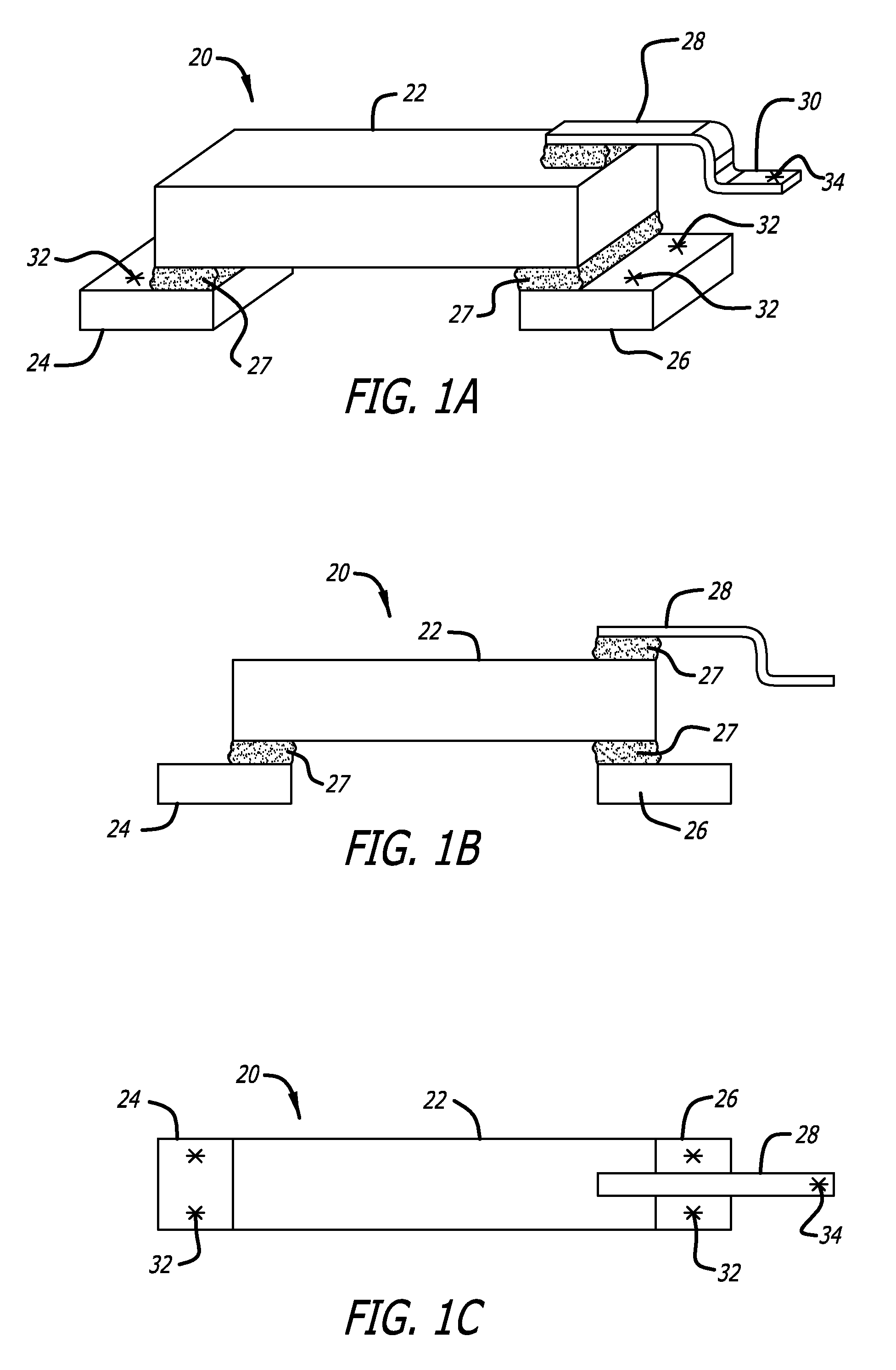

Low resistance ground joints for dual stage actuation disk drive suspensions

ActiveUS8885299B1Resistance conductiveConductive adhesiveElectrical connection between head and armArm with actuatorsDual stageEngineering

Stable, low resistance conductive adhesive ground connections between motor contacts and a gold-plated contact area on a stainless steel component of a dual stage actuated suspension. The stainless steel component can be a baseplate, load beam, hinge, motor plate, add-on feature or flexure.

Owner:HUTCHINSON TECH

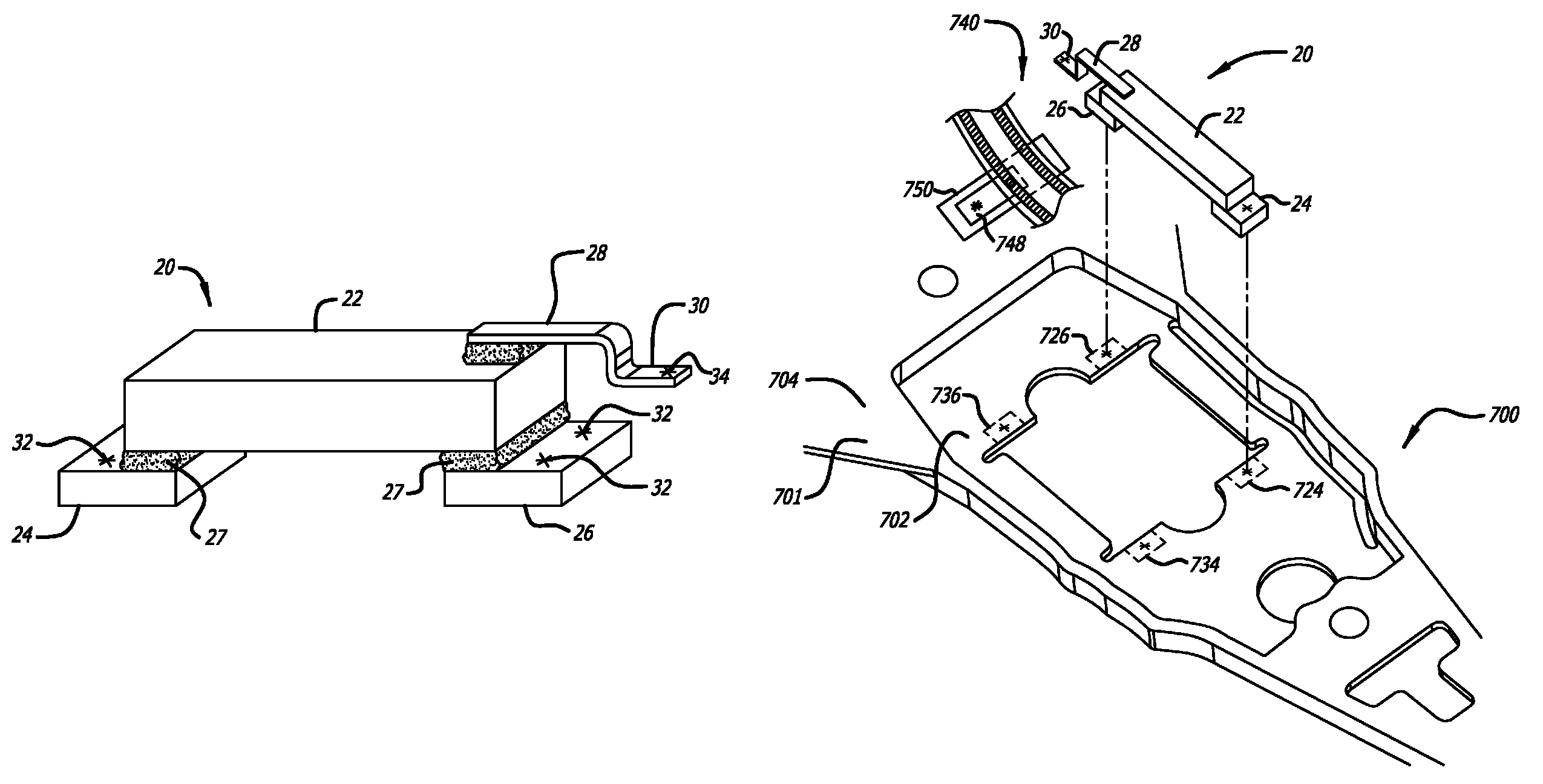

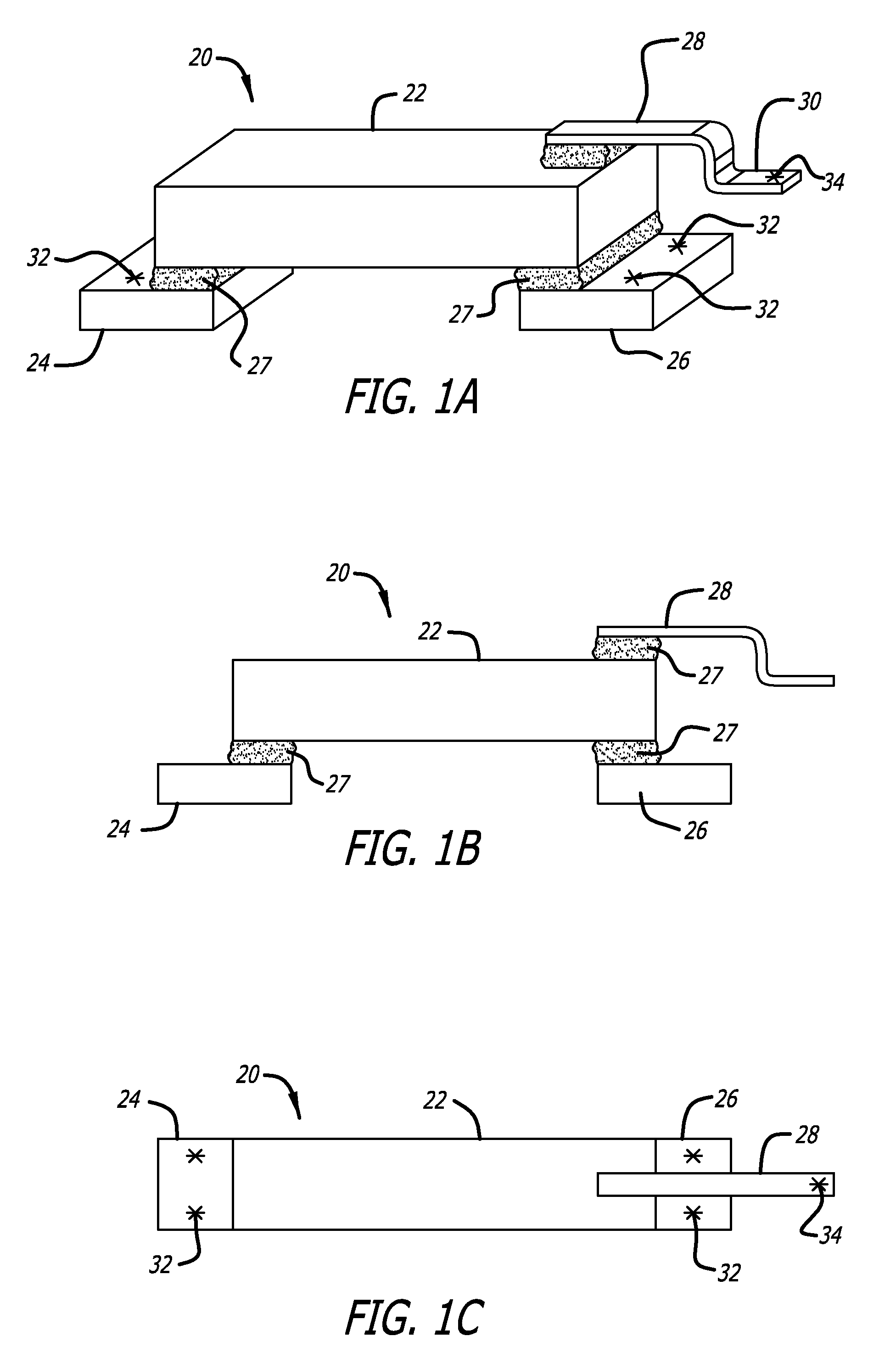

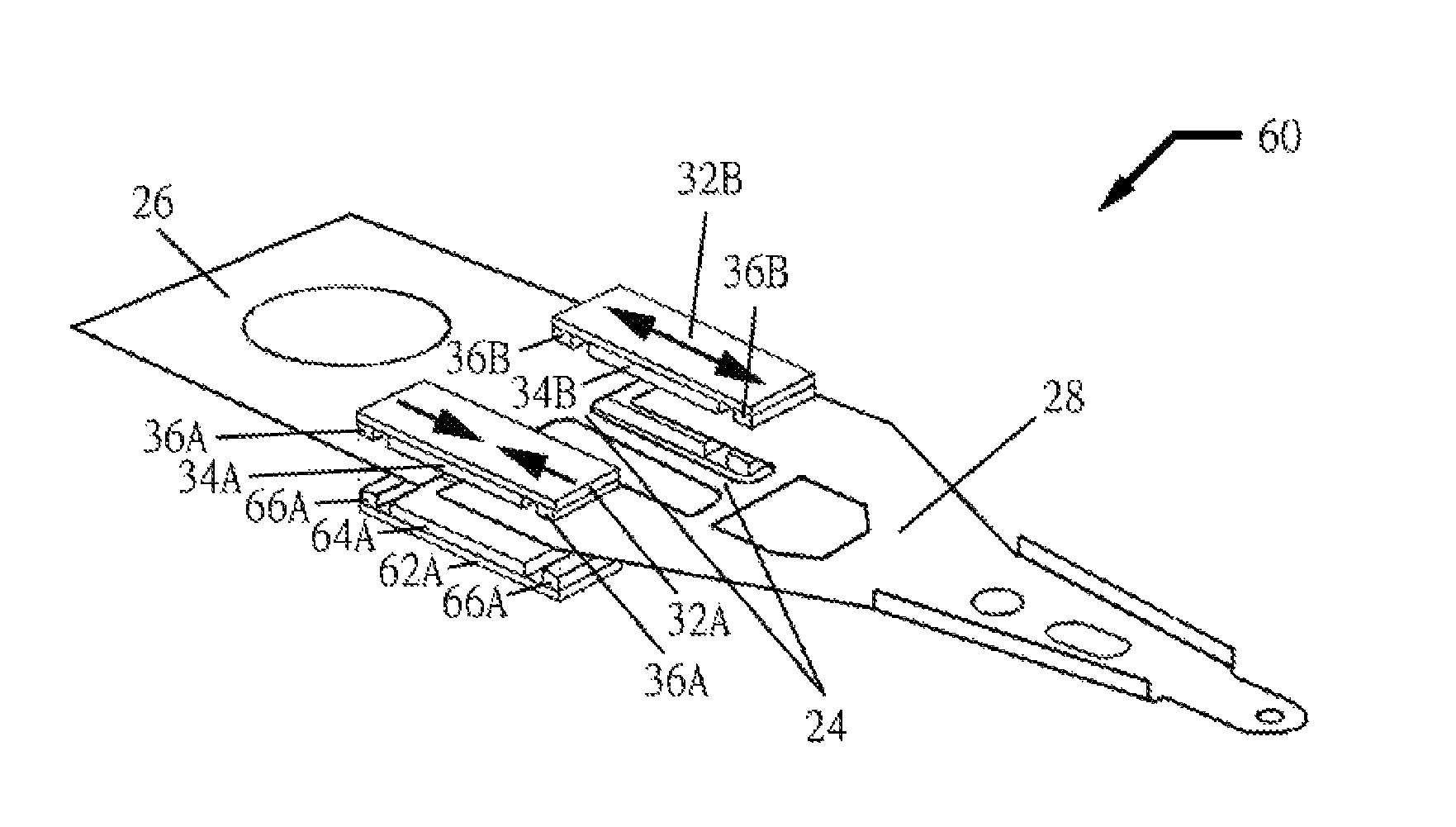

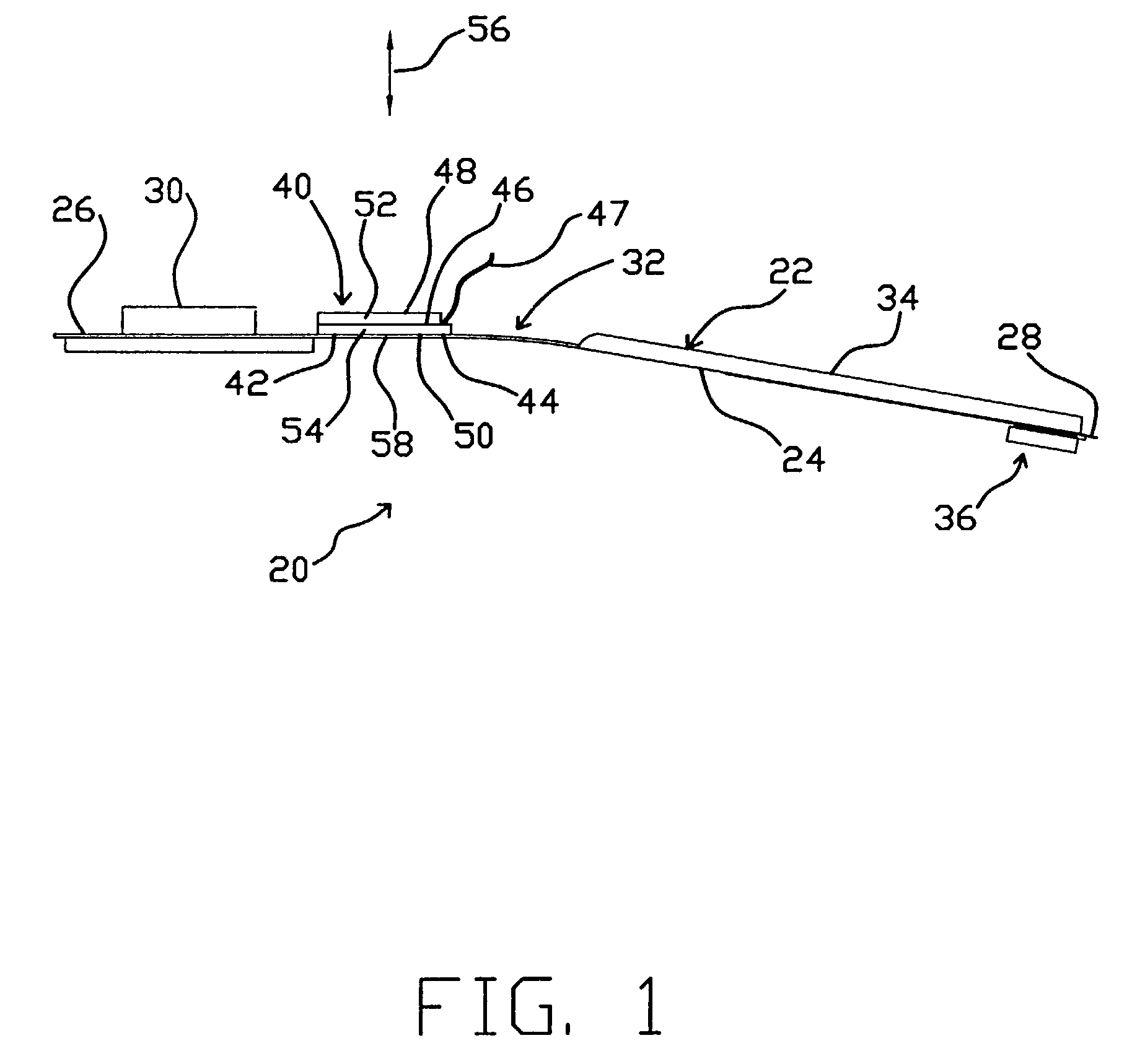

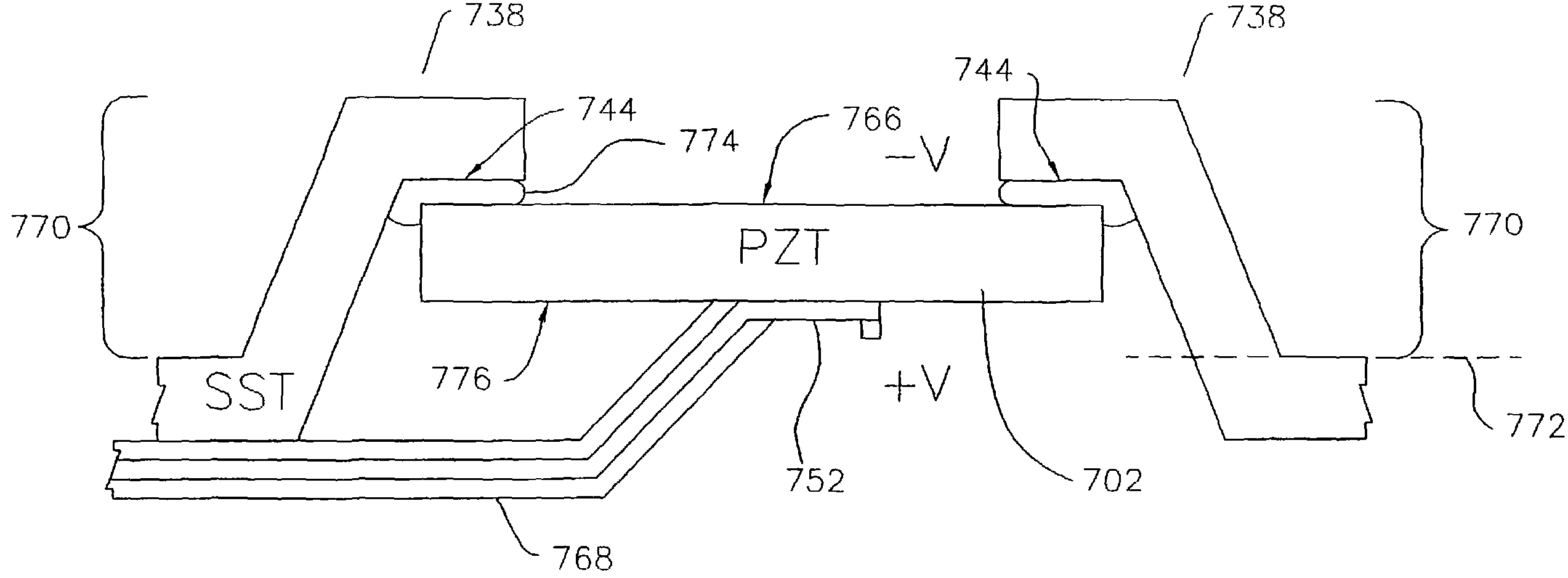

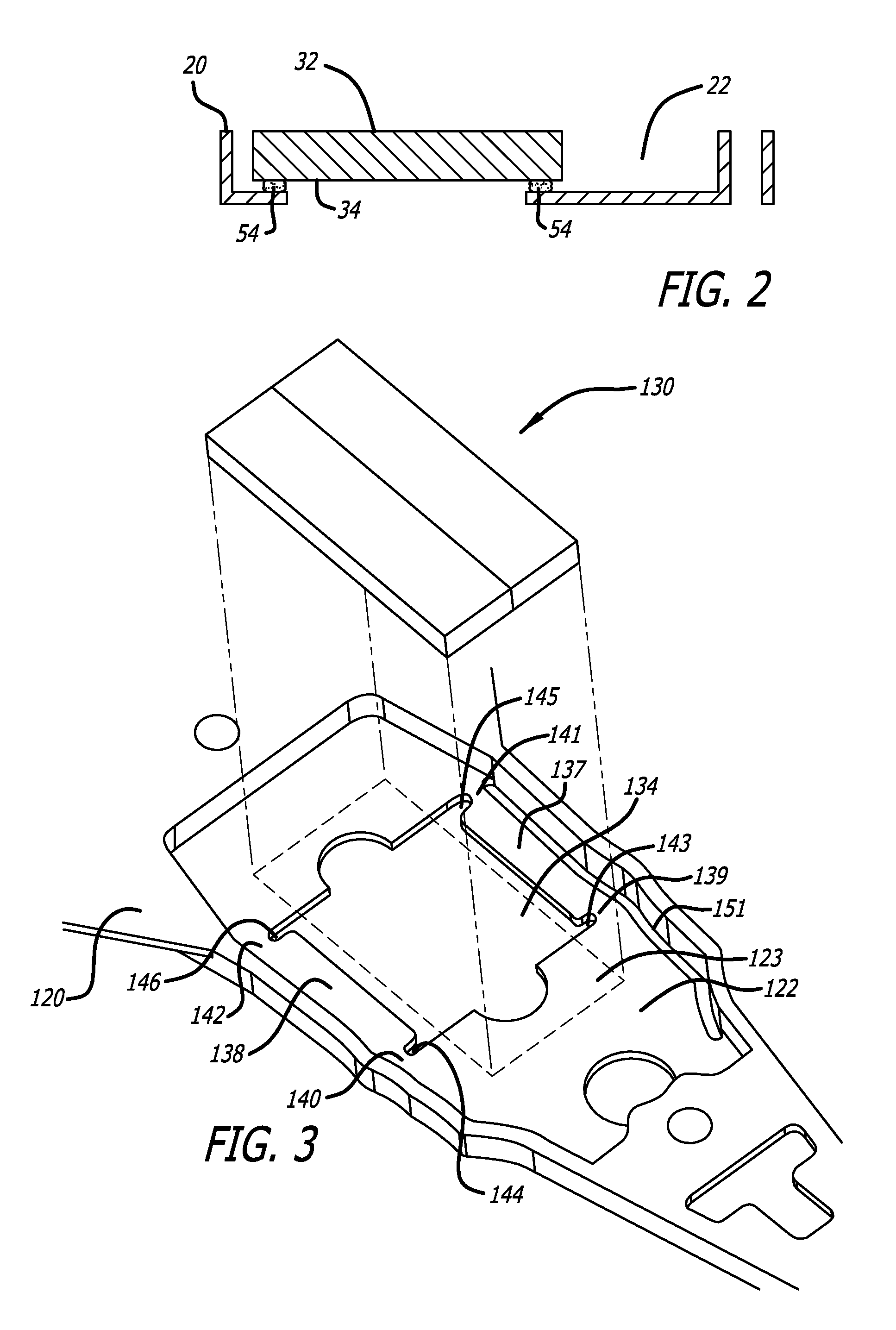

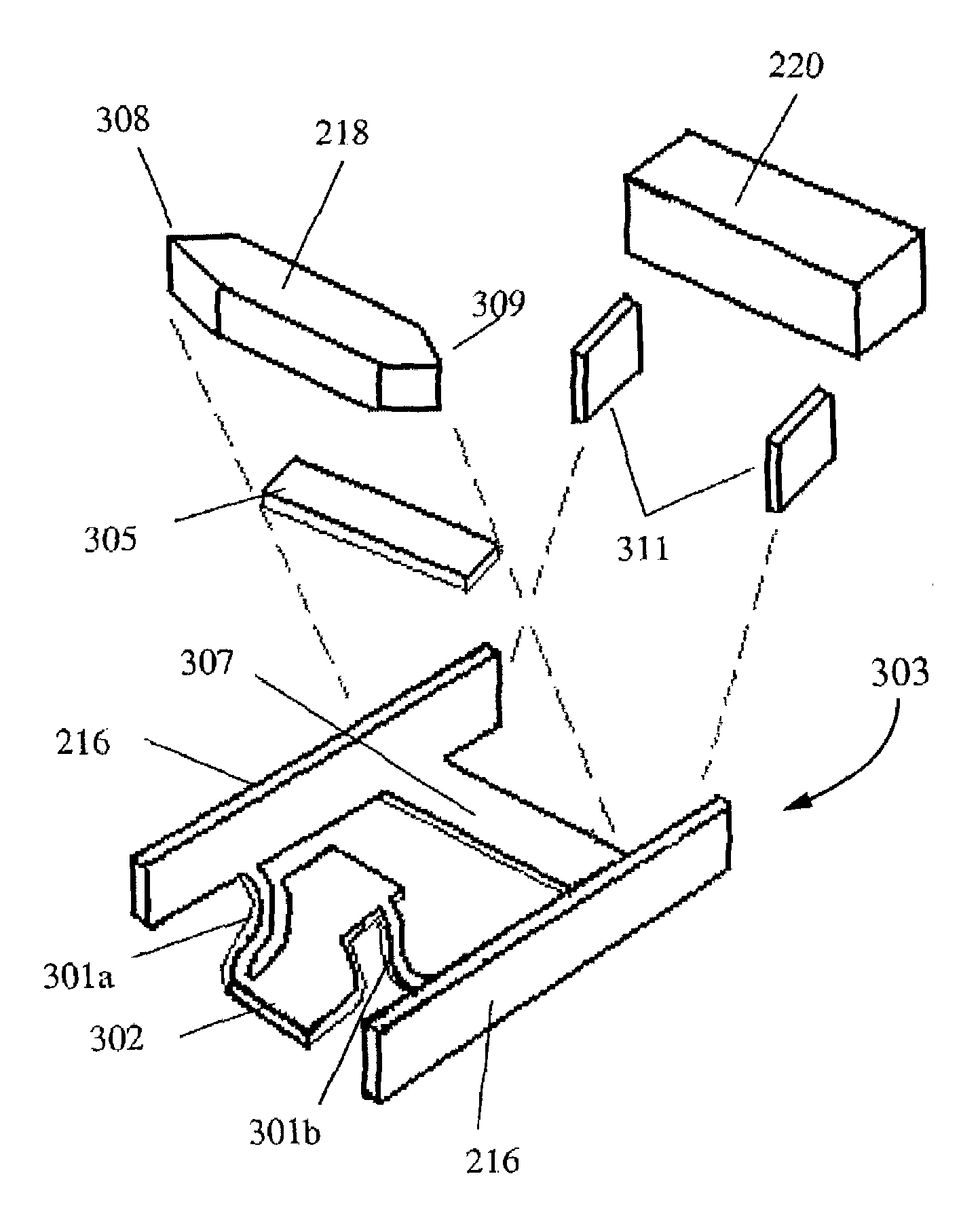

Wireless Microactuator Motor Assembly for Use in a Hard Disk Drive Suspension, and Mechanical and Electrical Connections Thereto

ActiveUS20100271735A1Sufficient resiliencyOvercome lack of conductivityPiezoelectric/electrostrictive device manufacture/assemblyArm with actuatorsHard disc driveElectrical conductor

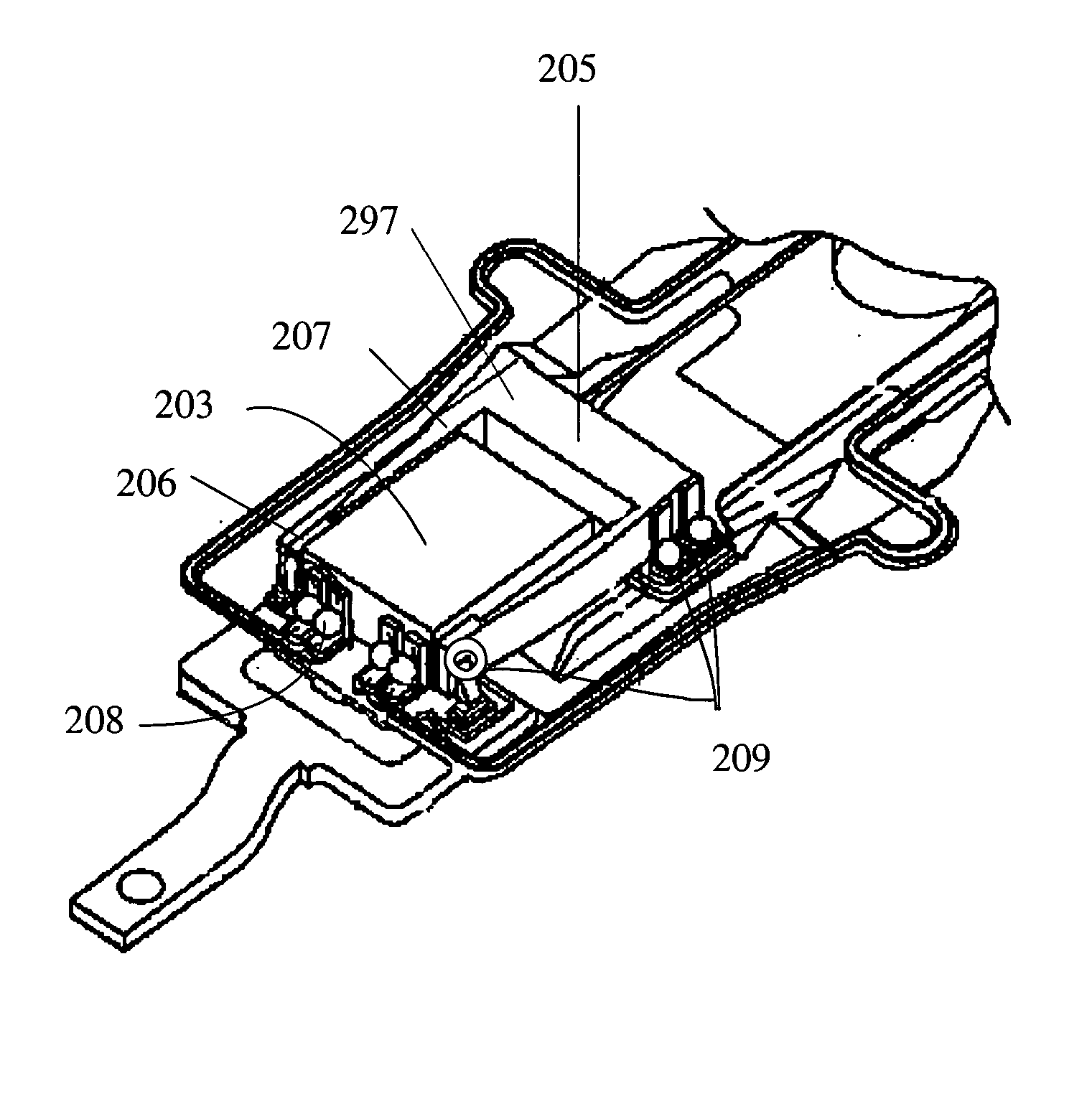

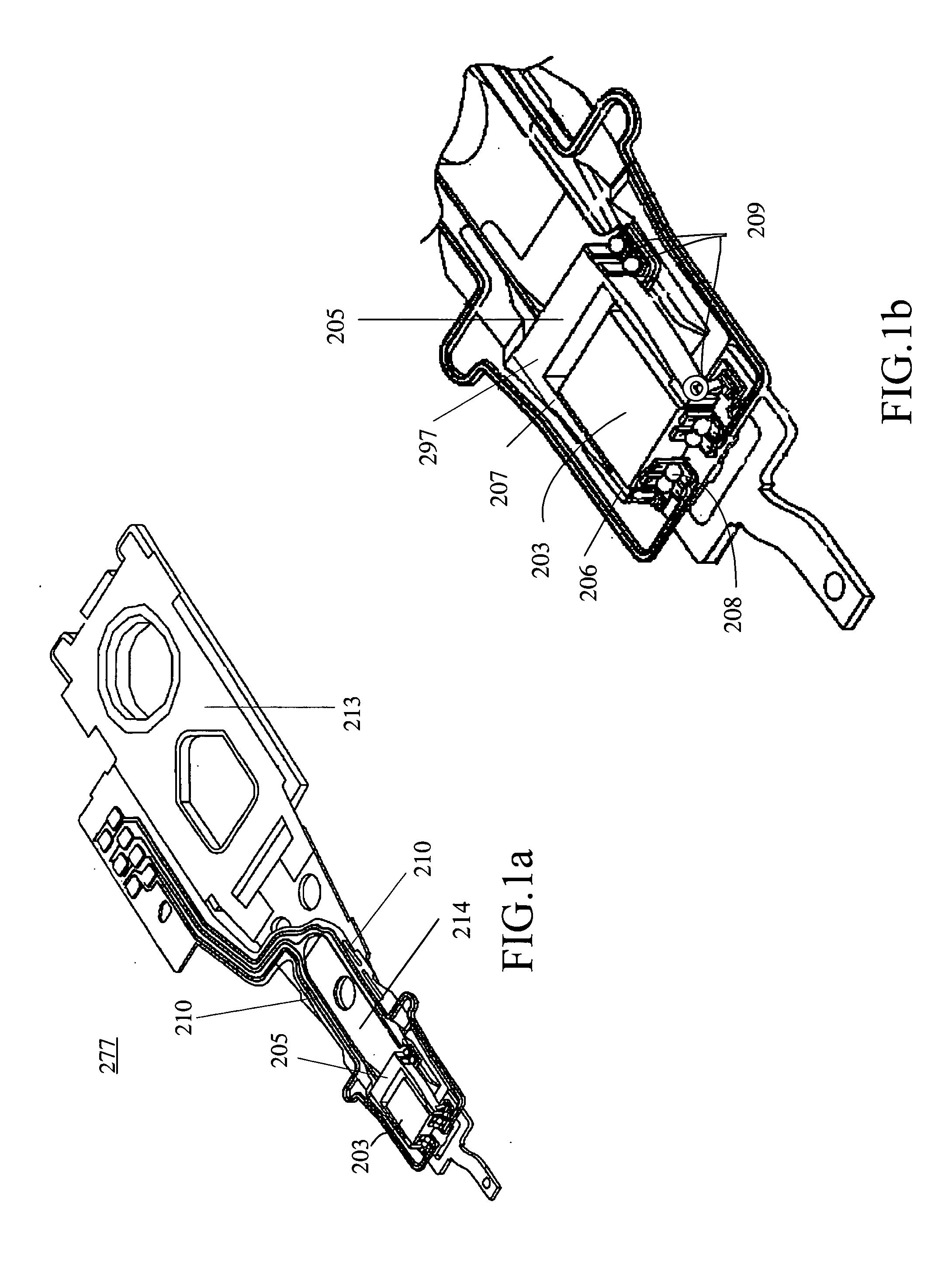

A microactuator assembly for a hard disk drive head suspension has an expandable base of stainless steel sheet material defining a negative lead affixed to the negative electrode on the bottom surface of a piezoelectric element, and a piece of stainless steel sheet material defining a positive lead attached to the positive electrode on the top surface of the piezoelectric element. The leads may be affixed directly to the piezoelectric element via conductive adhesive. The microactuator assembly can be assembled separately, and then laser welded into place on a suspension. A bond pad made of stainless steel sheet material extends from the flexible circuit, is electrically connected to the microactuator driving voltage conductor within the flexible circuit through a via, and is electrically isolated from the suspension substrate by an insulating film. The microactuator unit positive lead is mechanically and electrically connected to the bond pad via laser welding.

Owner:MAGNECOMP

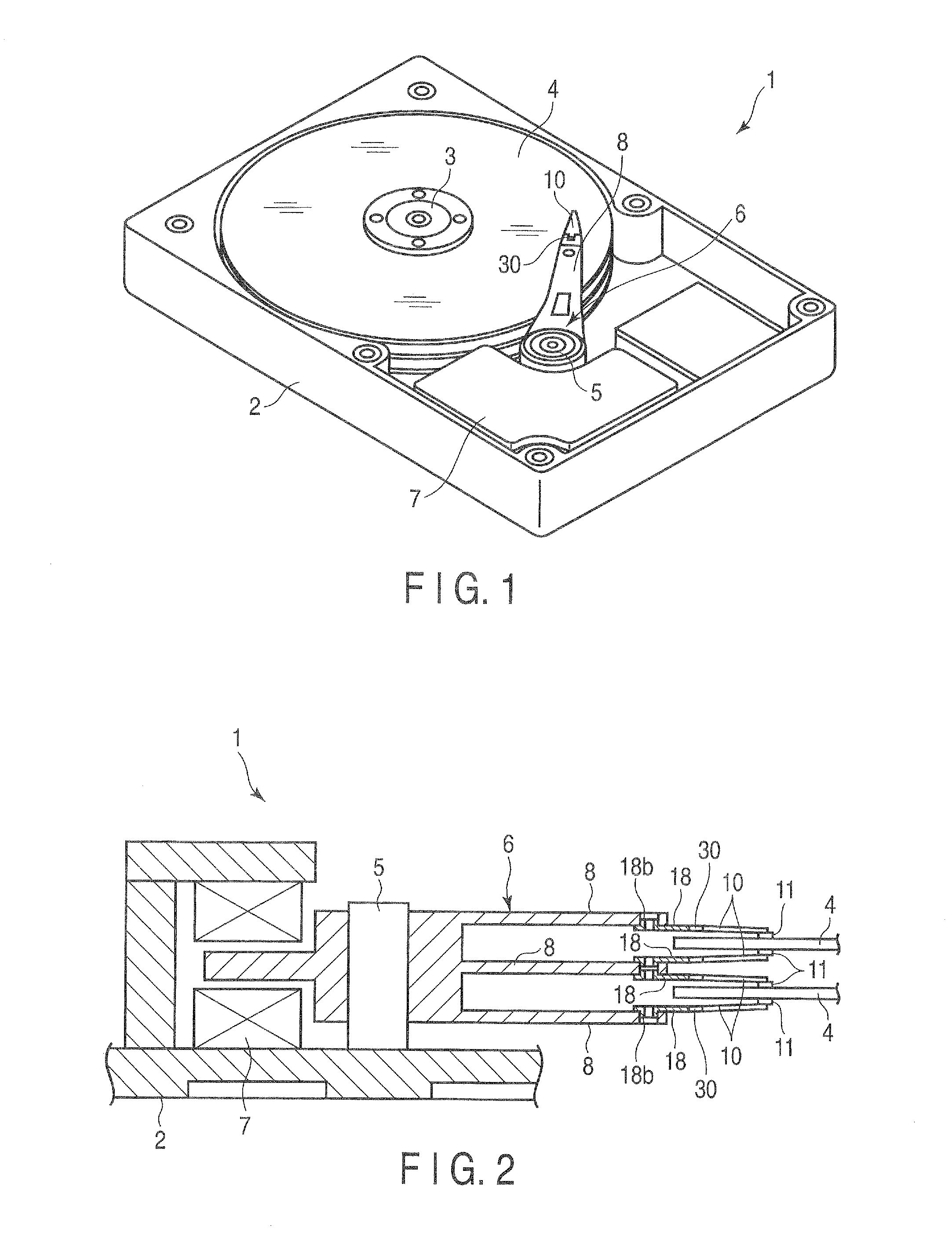

Electronic apparatus and disk drive suspension

ActiveUS20110242708A1Conductive and reliableReliable conductionArm with actuatorsRecord information storageGold particlesMicroactuator

A microactuator element as an example of an electrical component is disposed on a metallic, electrically conductive plate member. A conductive resin member is disposed on a current-carrying part of the conductive plate member and a conduction part of the microactuator element. A thin porous plating layer of thickness 100 nm or less includes a large number of gold particles is formed in a region of a surface of the conductive plate member which covers the current-carrying part. The conductive resin member is secured to the conductive plate member through the thin porous gold plating layer and electrically connected to the conductive plate member.

Owner:NHK SPRING CO LTD

Magnetic head suspension for supporting piezoelectric elements in a non-facing manner relative to suspension structure

ActiveUS8248735B2Prevent and reduce deformationArm with actuatorsRecord information storageEngineeringElectrode

Owner:SANCALL CORP

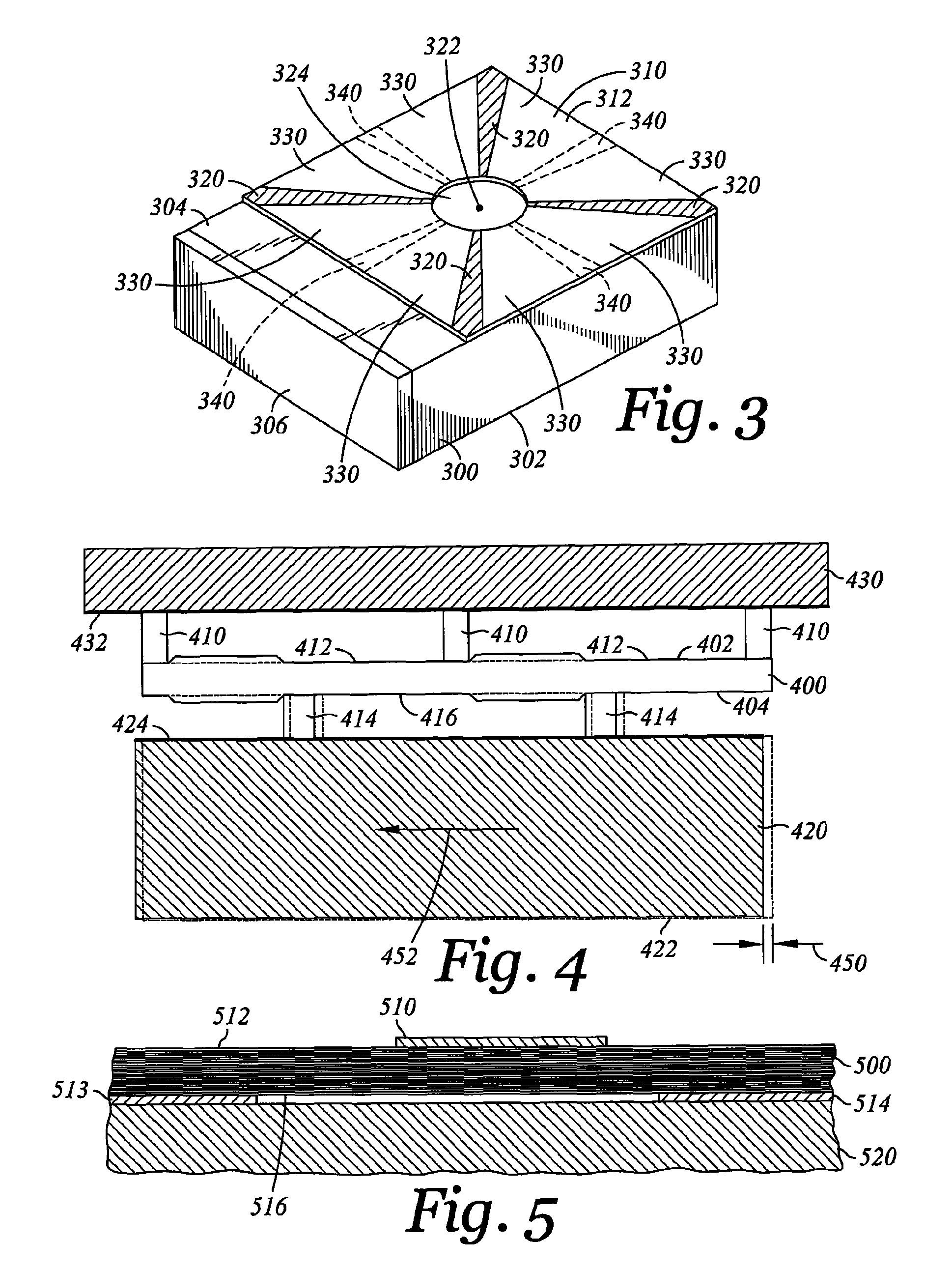

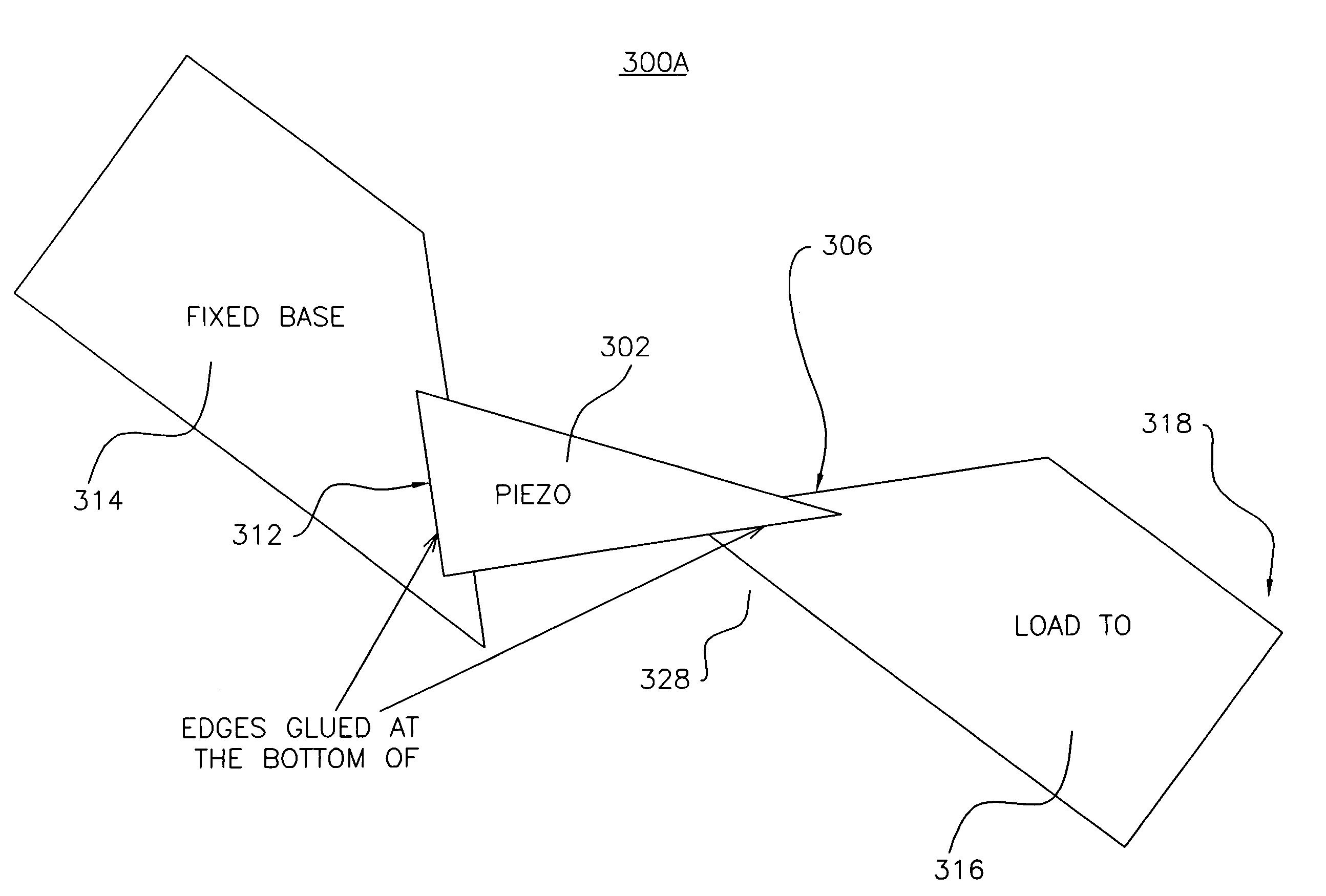

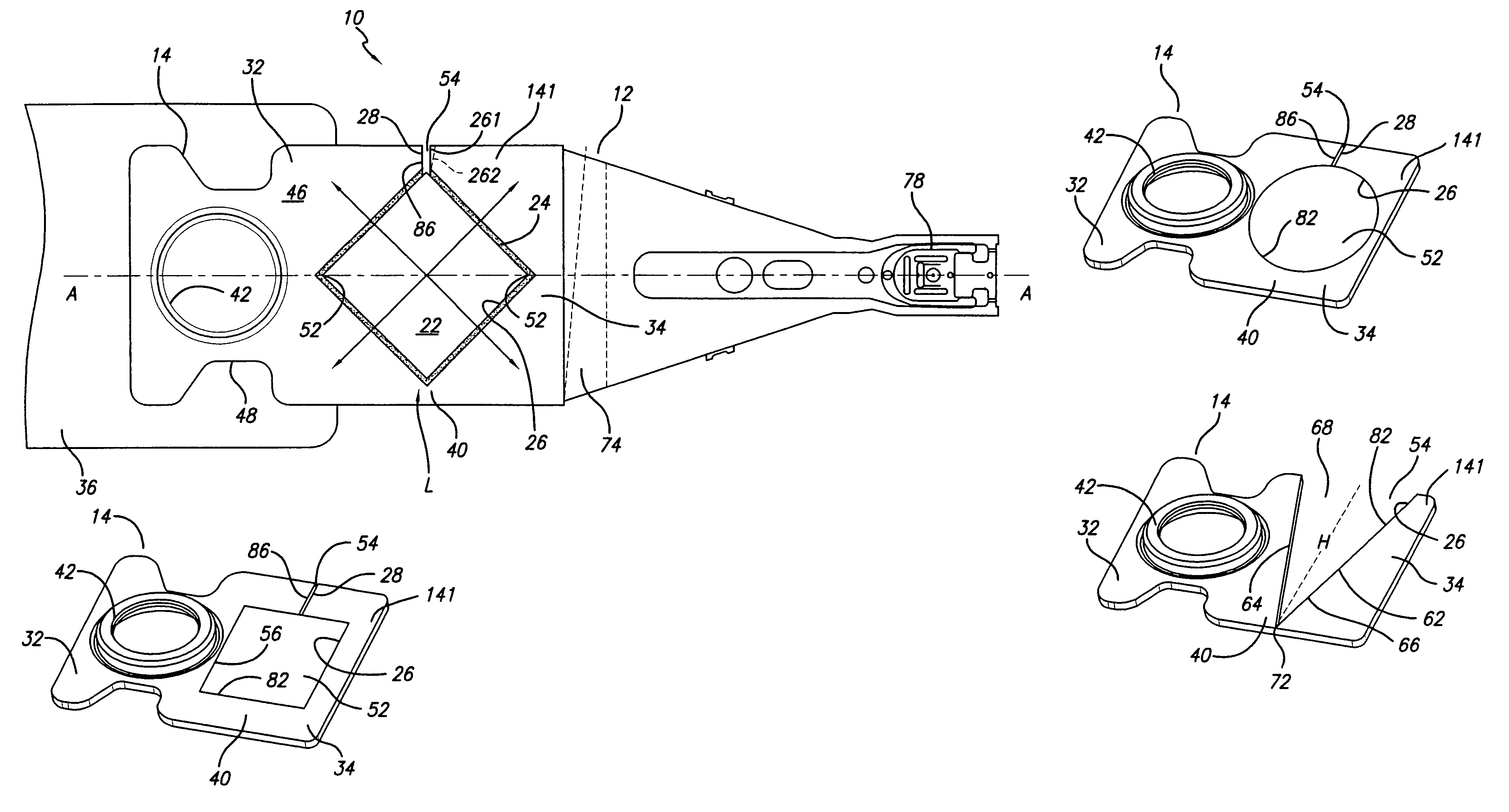

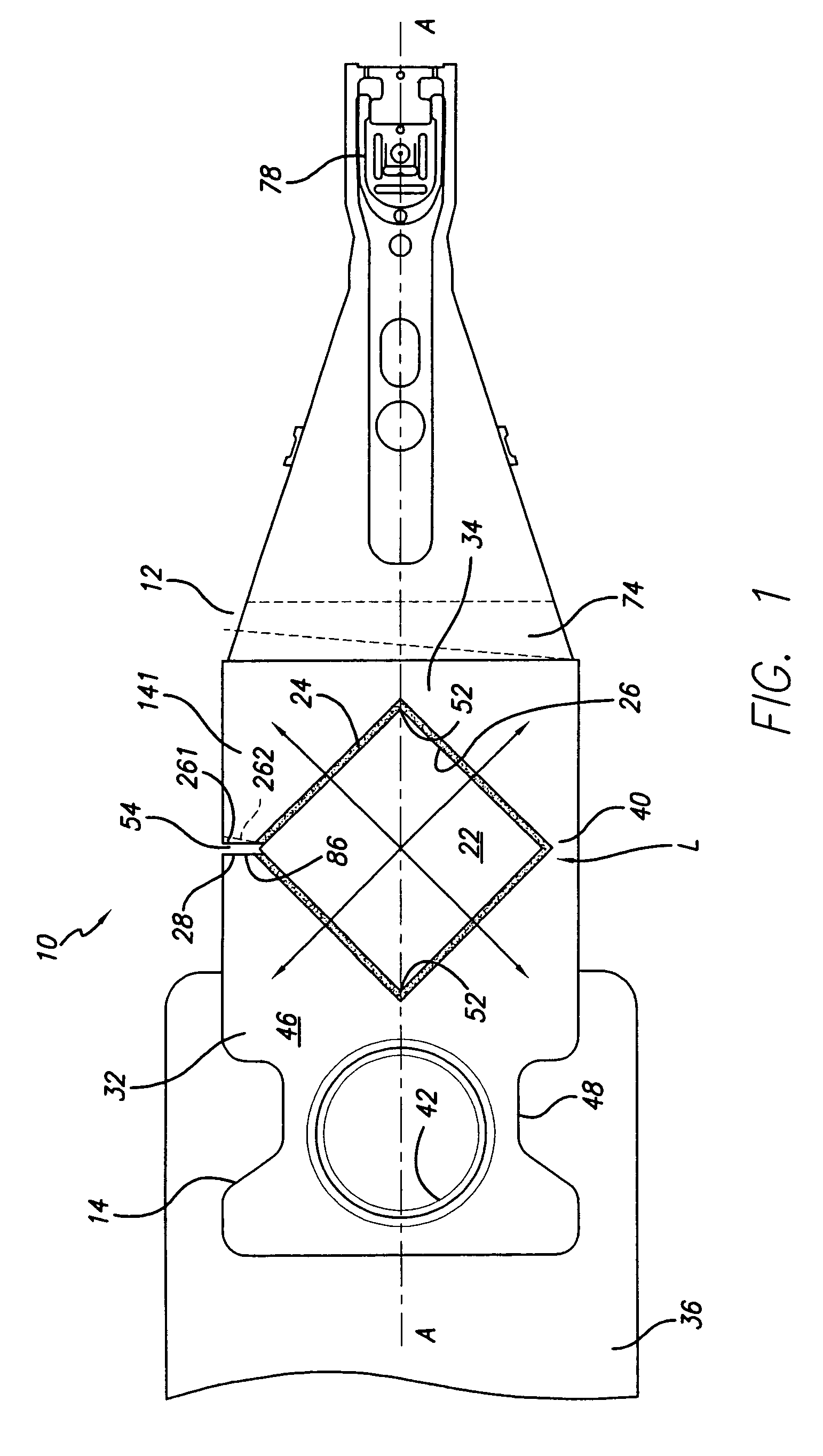

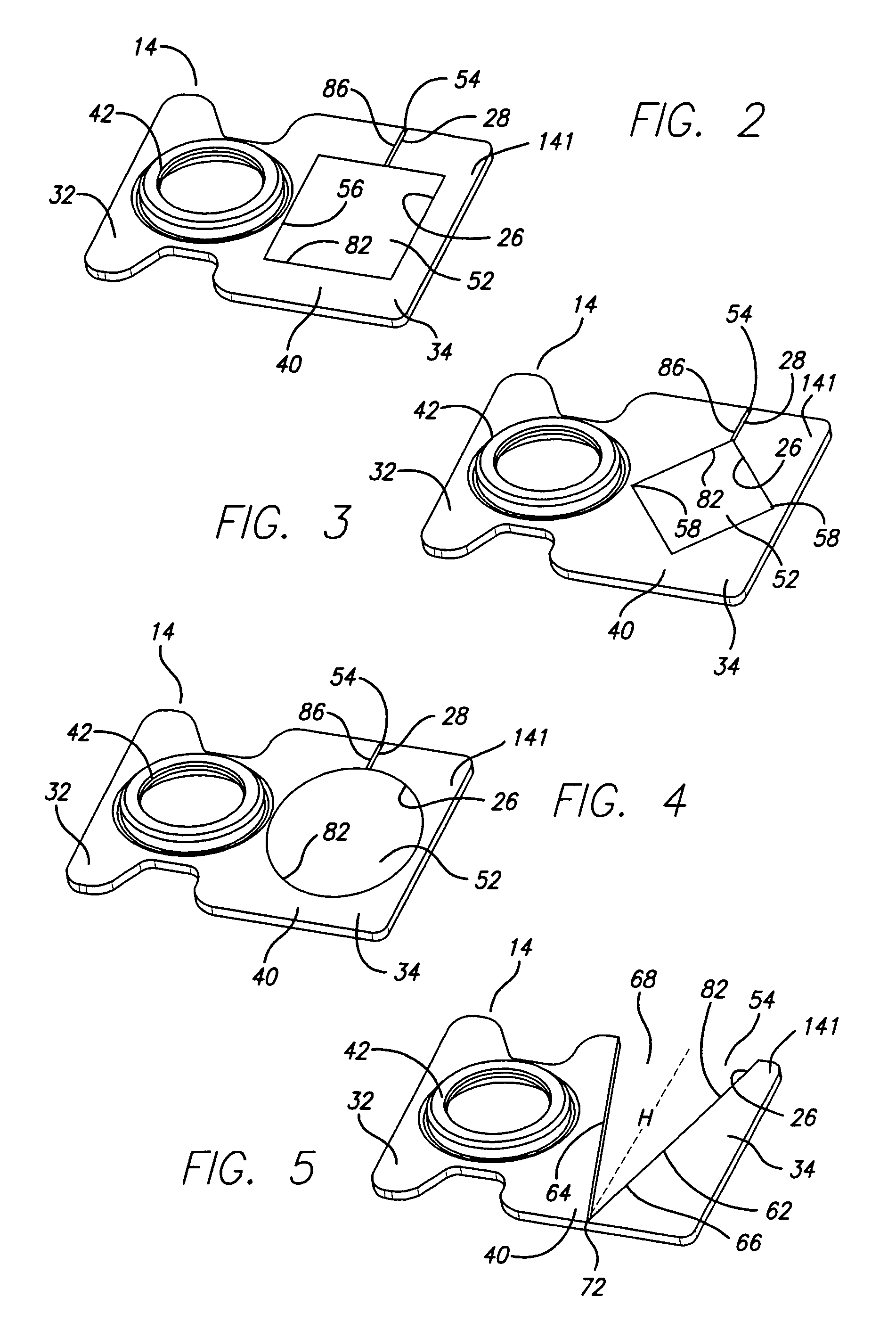

Single PZT actuator for effecting rotation of head suspension loads

ActiveUS7595965B1Easy to routeImprove reliabilityArm with actuatorsRecord information storagePiezoelectric microactuatorEngineering

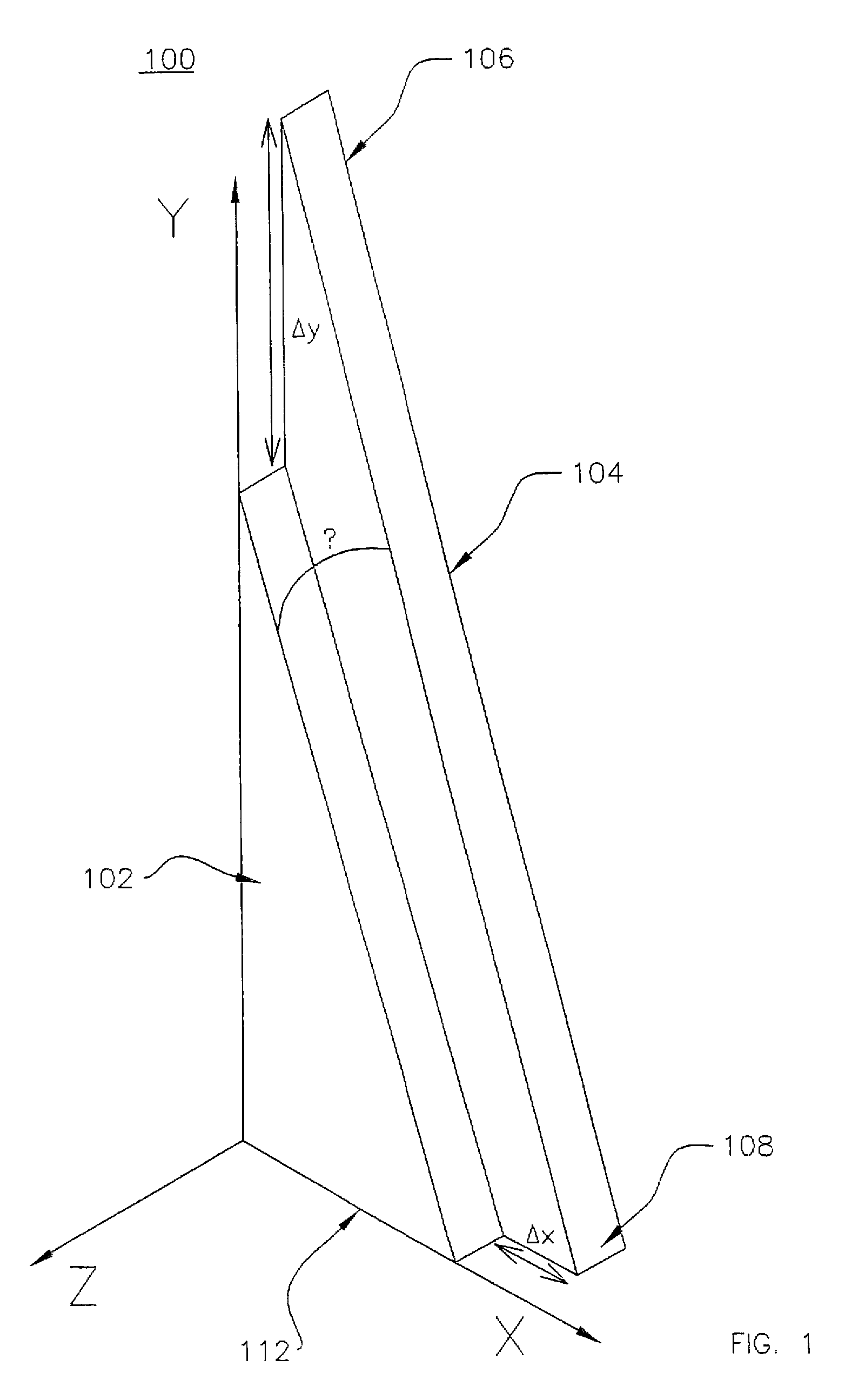

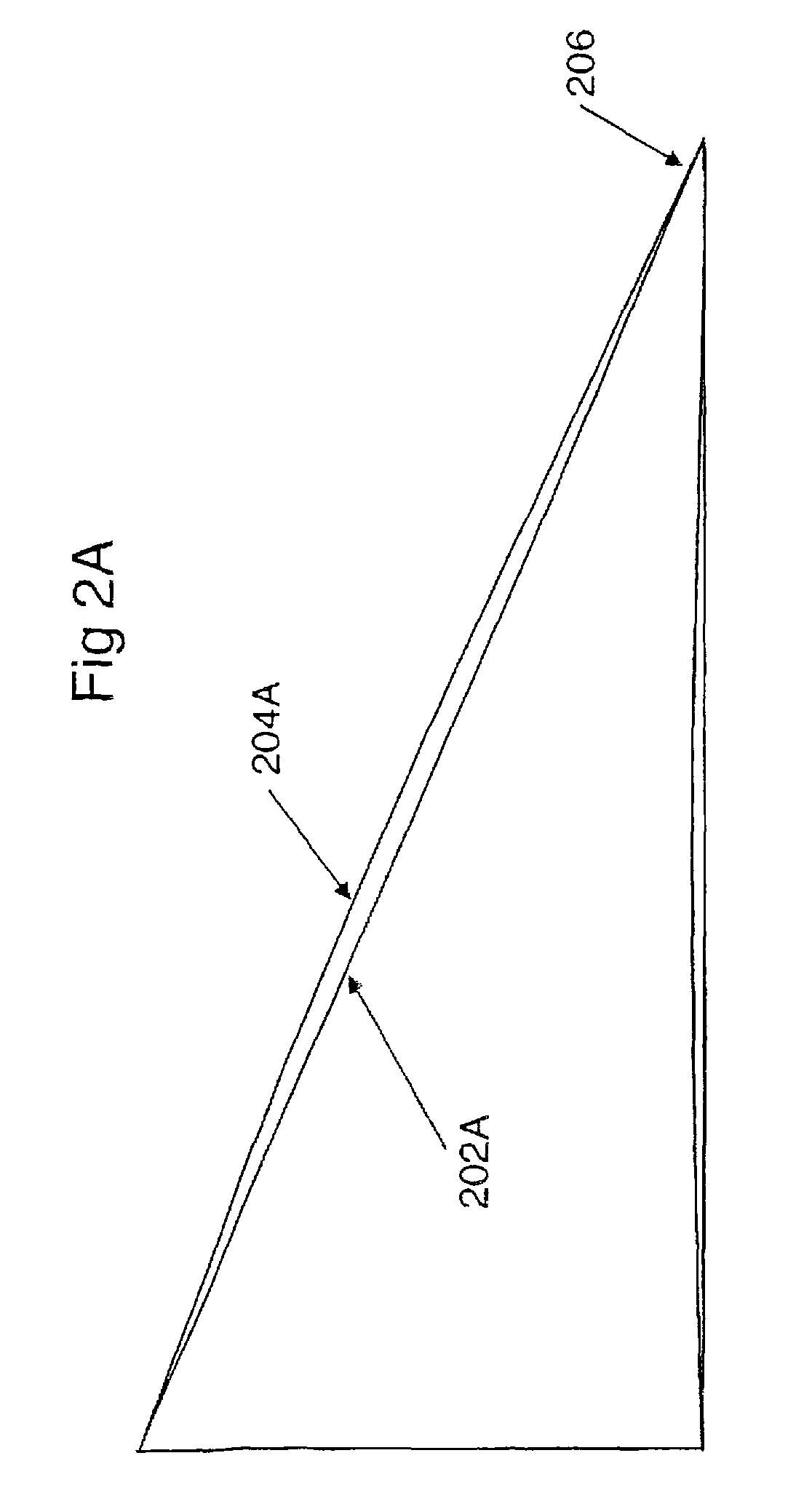

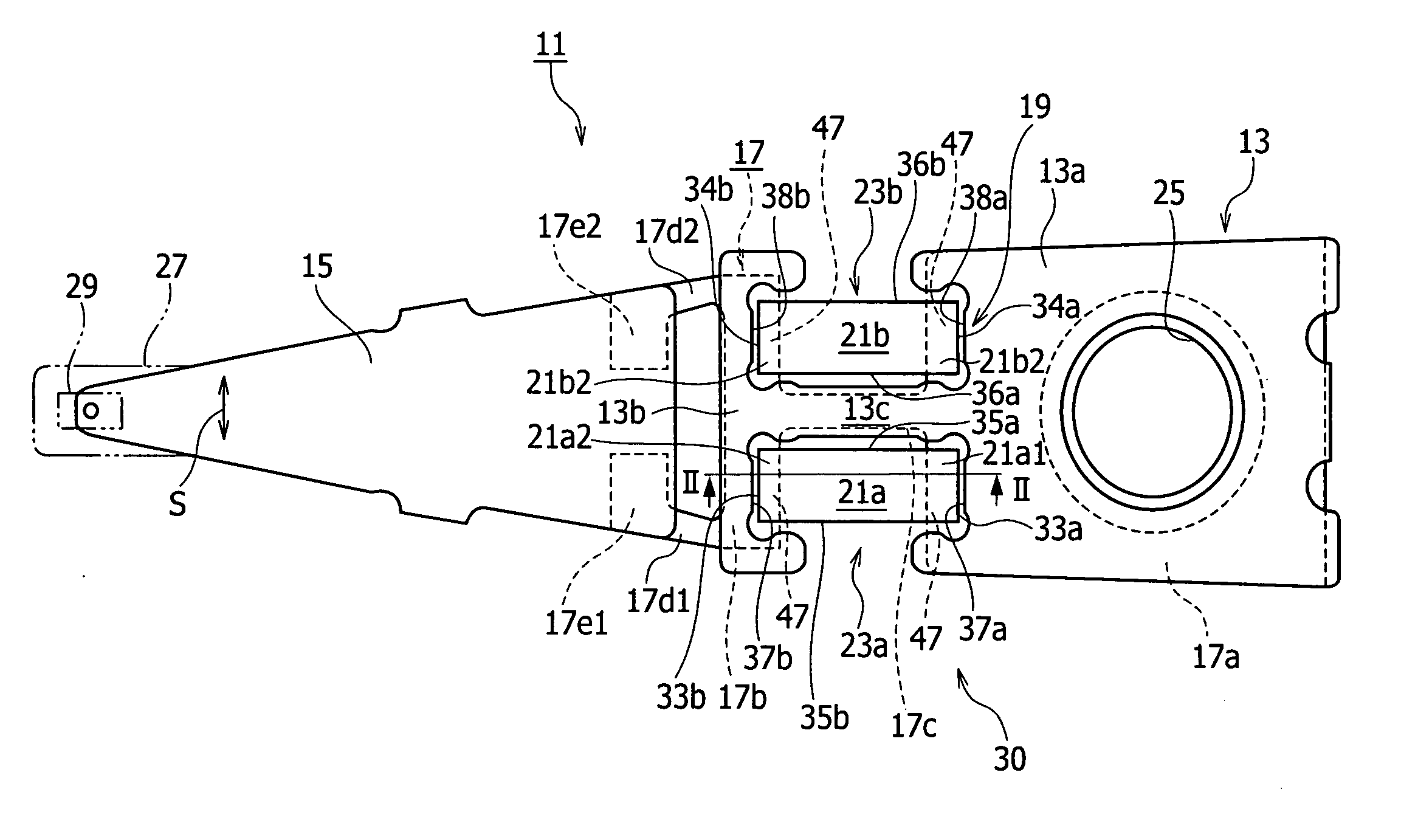

A head suspension assembly couples a baseplate to a rotatable load through a planar triangular piezo microactuator for effecting hingeless rotation of the load. The microactuator expands, responsive to an excitation voltage, with greater magnitude in one direction than in another direction normal to the first direction, resulting in an angular movement of the hypotenuse thereby rotating the load. The upper surface of the microactuator is grounded to a bottom surface of the baseplate or load beam to position the microactuator lead connection surface closest to the load to facilitate trace routing. A load beam grounding surface may be raised to accommodate the microactuator and fix the lead connection surface on a common plane with the unraised surface to further minimize trace routing and provide access for bonding the trace to the load beam.

Owner:MAGNECOMP

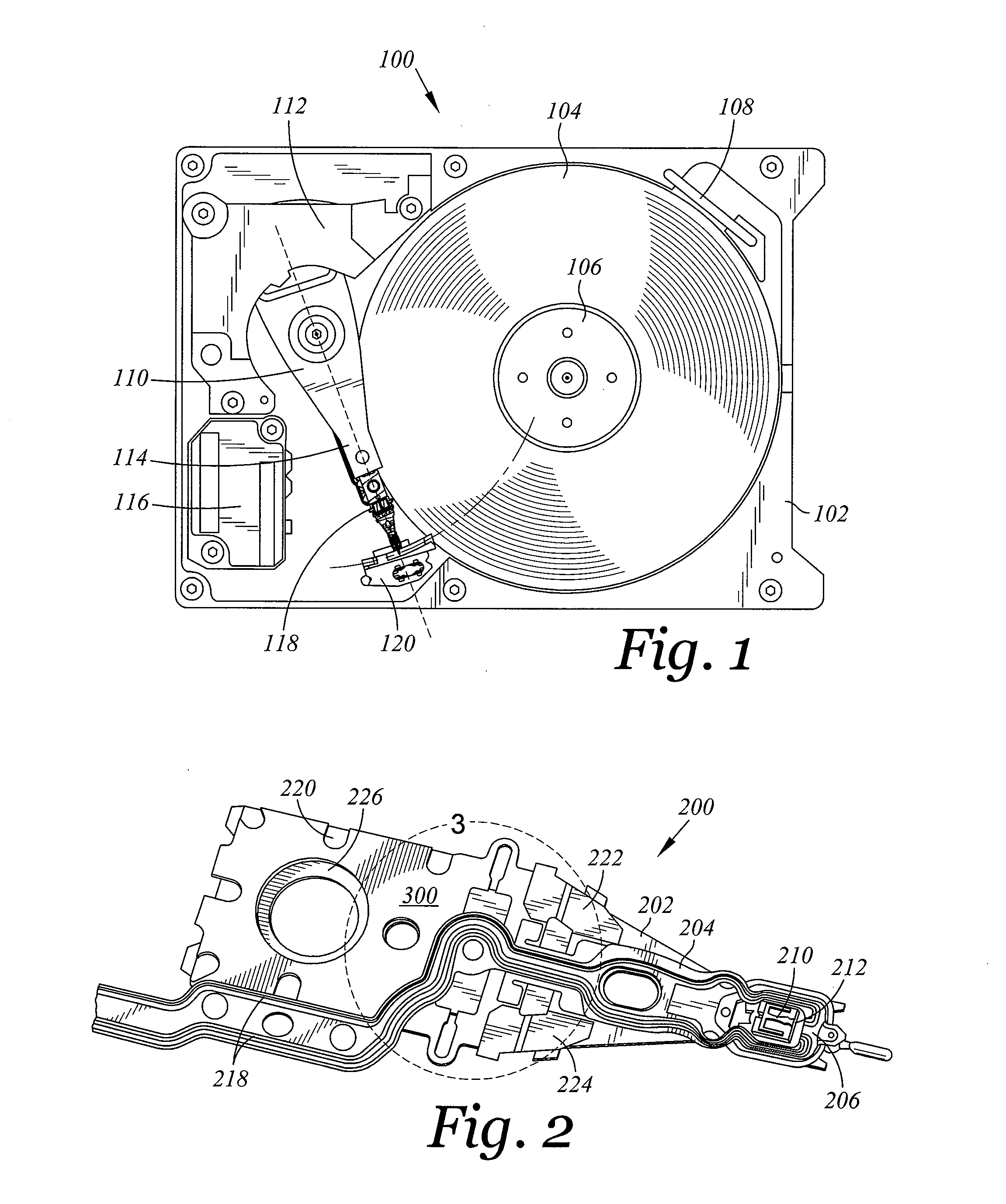

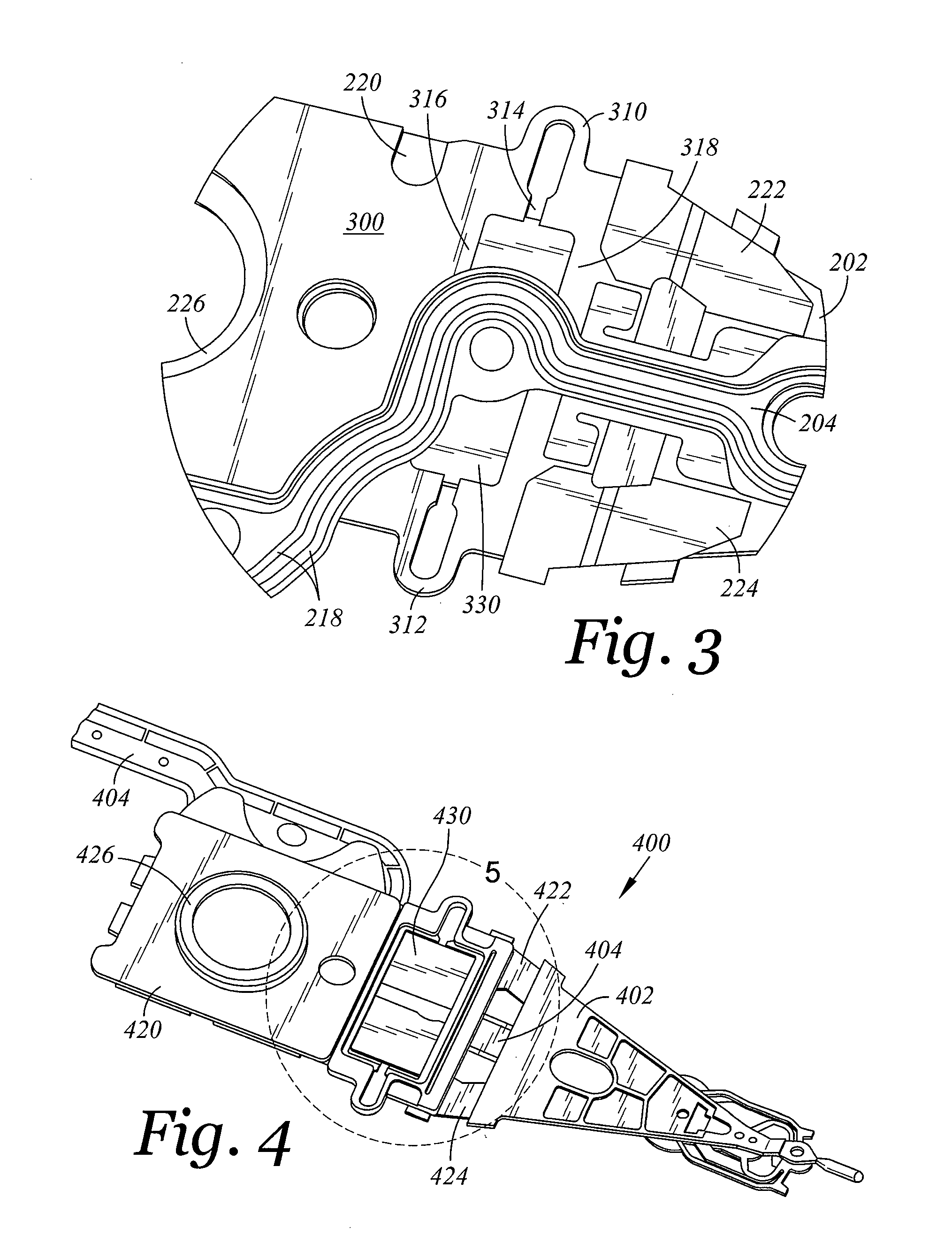

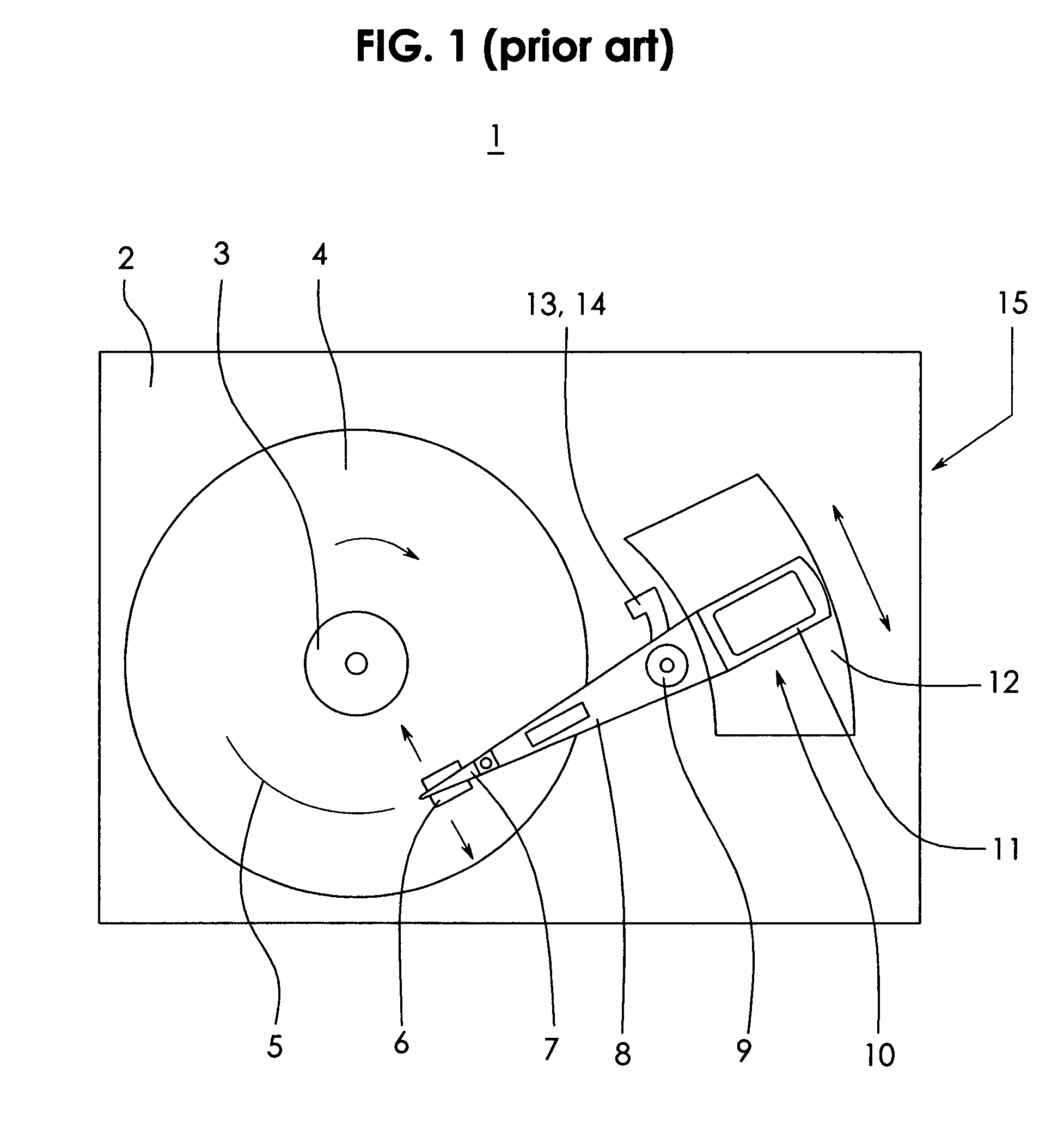

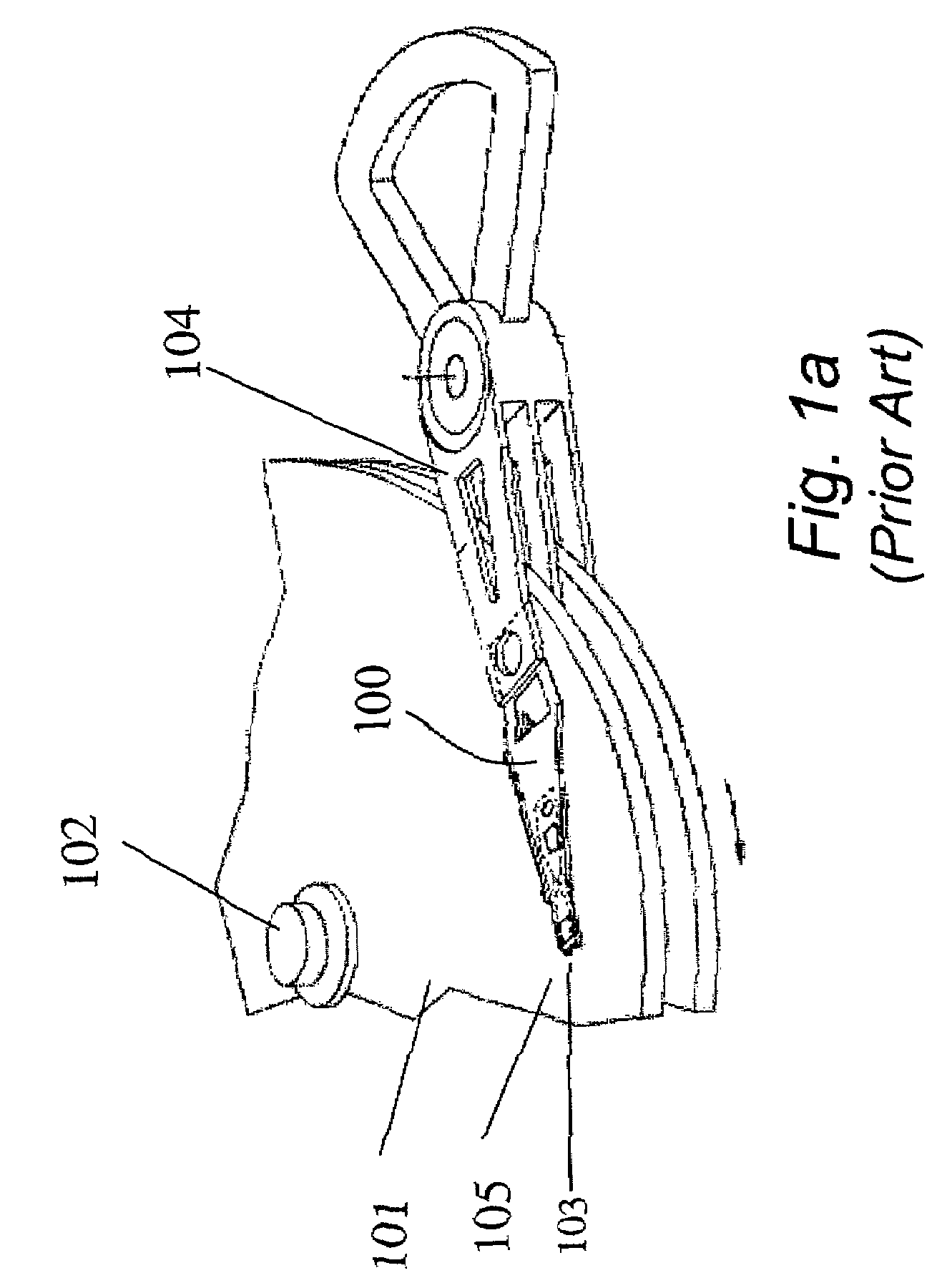

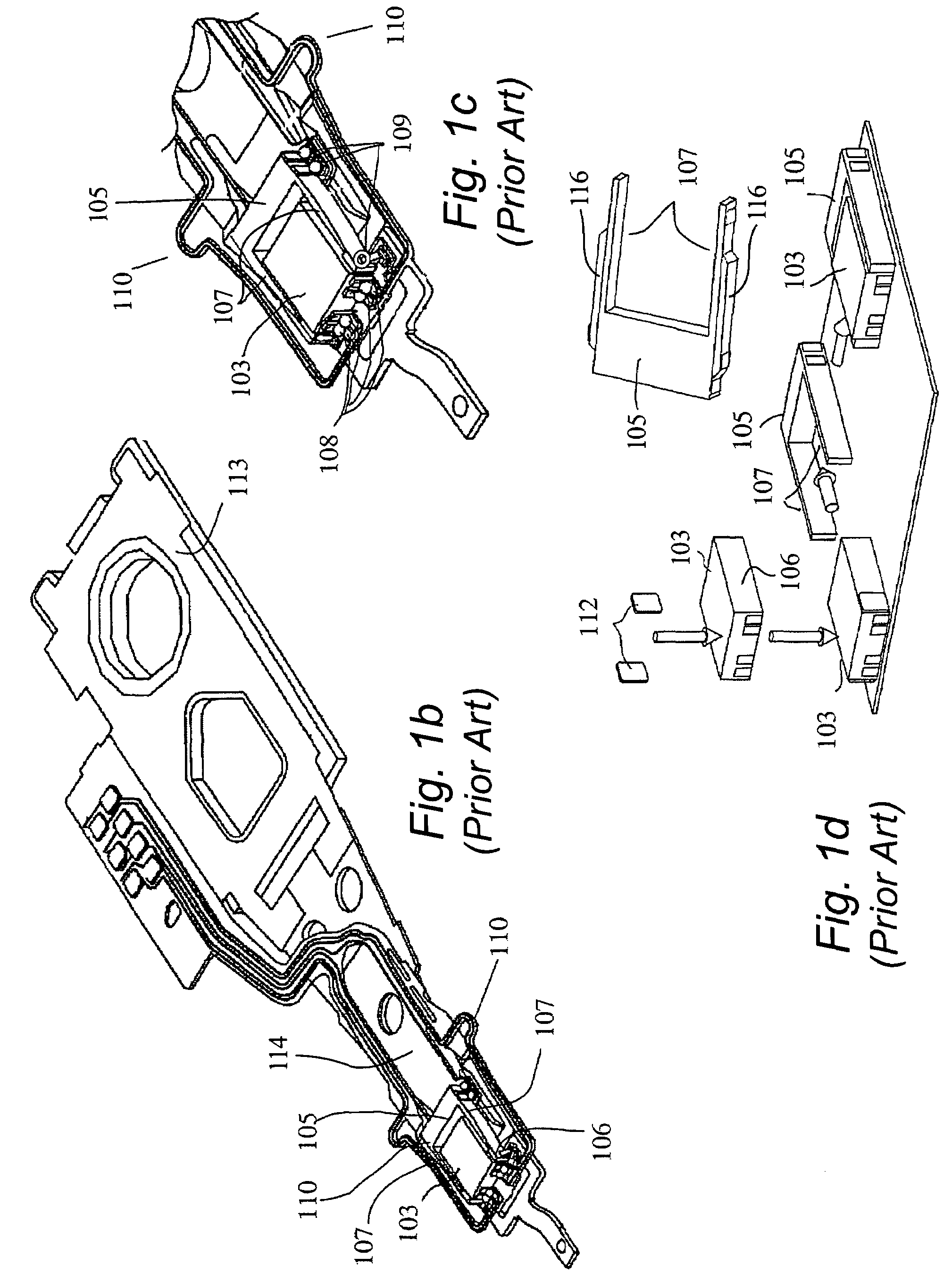

Rotational micro-actuator integrated with suspension of head gimbal assembly, and disk drive unit with the same

InactiveUS7719798B2Improve resonance performanceArm with actuatorsRecord information storageMicro actuatorEngineering

A micro-actuator for a head gimbal assembly includes a metal frame including a bottom support integrated with a suspension flexure of the head gimbal assembly, a top support adapted to support a slider of the head gimbal assembly, and a pair of side arms that interconnect the top support and the bottom support. The top support includes a rotatable plate, connection arms that couple the rotatable plate to respective side arms, and an electrical pad support plate that supports bonding pads. A PZT element is mounted to each of the side arms. Each PZT element is excitable to cause selective movement of the side arms.

Owner:SAE MAGNETICS (HK) LTD

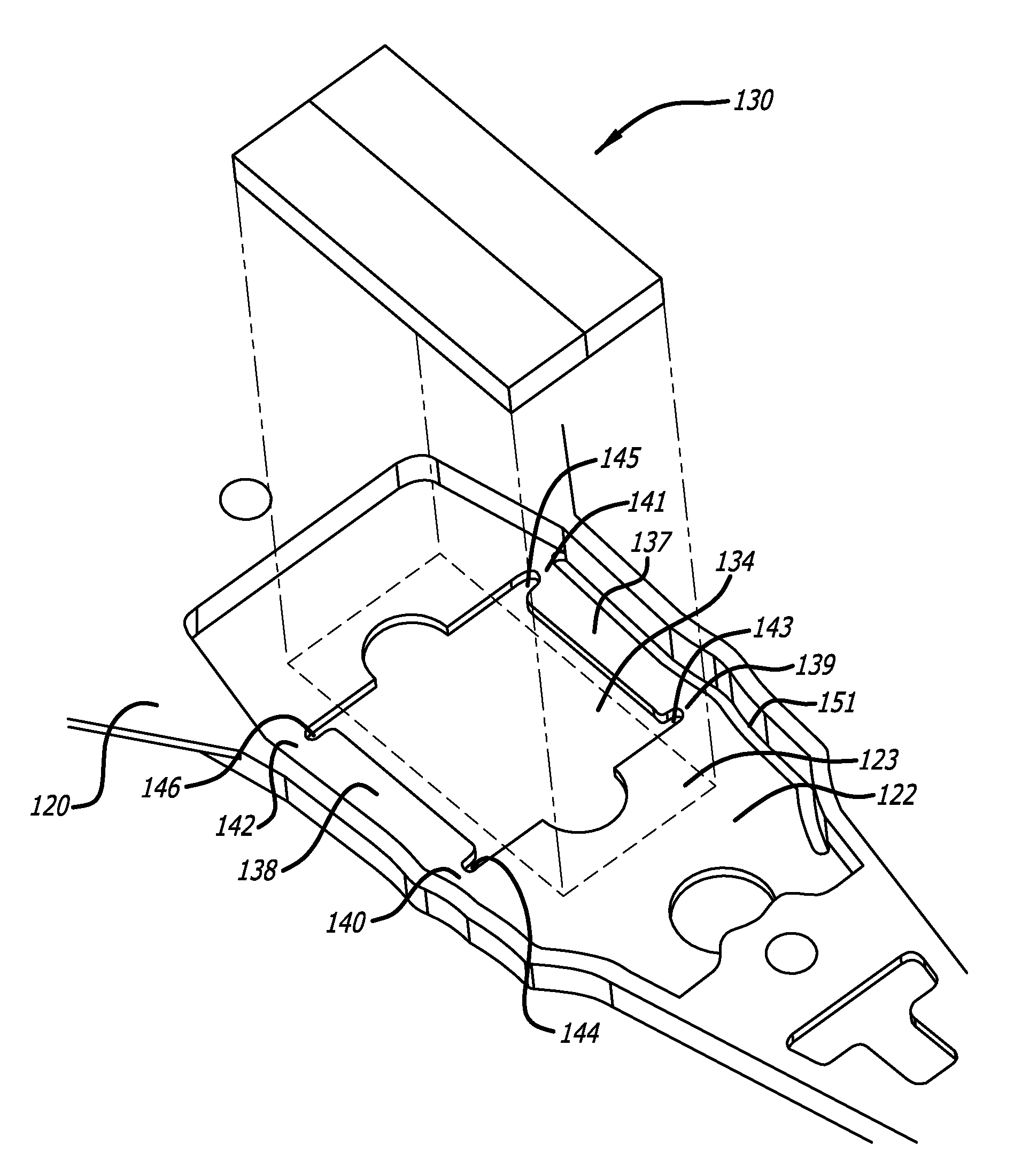

Wireless microactuator motor assembly for use in a hard disk drive suspension, and mechanical and electrical connections thereto

ActiveUS8189301B2Sufficient resiliencyOvercome lack of conductivityArm with actuatorsSolid-state devicesHard disc driveElectricity

A microactuator assembly for a hard disk drive head suspension has an expandable base of stainless steel sheet material defining a negative lead affixed to the negative electrode on the bottom surface of a piezoelectric element, and a piece of stainless steel sheet material defining a positive lead attached to the positive electrode on the top surface of the piezoelectric element. The leads may be affixed directly to the piezoelectric element via conductive adhesive. The microactuator assembly can be assembled separately, and then laser welded into place on a suspension. A bond pad made of stainless steel sheet material extends from the flexible circuit, is electrically connected to the microactuator driving voltage conductor within the flexible circuit through a via, and is electrically isolated from the suspension substrate by an insulating film. The microactuator unit positive lead is mechanically and electrically connected to the bond pad via laser welding.

Owner:MAGNECOMP

Head gimbal assembly with dual-mode piezo microactuator

ActiveUS7417830B1Reduce vibrationAdversely affect shock absorptionArm with actuatorsRecord information storagePiezoelectric microactuatorEngineering

A disk drive suspension has a load beam having a base, a flexure for carrying a slider, and a mount plate. The suspension mount plate has a first portion attachable to an actuator and movable by the actuator as the primary shifting force on the load beam, suitable for larger positioning movements. A second portion of the mount plate is attached to the load beam base and is movable relative to the mount plate first portion. A microactuator moves the second mount plate portion relative to the first mount plate portion as a secondary shifting force on the load beam, suitable for very small positioning movements.

Owner:MAGNECOMP

Piezoelectric actuated suspension with passive damping in hard disk drives

ActiveUS7983008B2Precise positioningSufficient shock resistanceArm with actuatorsRecord information storageViscoelastic dampingHard disc drive

A piezoelectric actuated suspension with passive damping is disclosed for precision positioning of hard disk drive while reducing undesired shock vibrations. Along the longitudinal axis of an etched suspension, two piezoelectric actuators dispose near the base plate to provide a push-pull motion. The actuators have two main portions. The first portion is piezoelectric elements to provide active positioning. The second portion is viscoelastic damping layers underneath the piezoelectric elements for passive damping. The complementary parts such as stiff edge elements and optional soft boundary covers are used to enhance the actuating abilities of the actuators and prevent any contaminants of the viscoelastic layers from going into the clean sealed chamber of the hard disk drive, respectively. The present invention further relates to a dual-stage servo system in a hard disk drive for fine positioning of the read / write head and better shock resistance via the piezoelectric actuated suspension with passive damping.

Owner:THE CHINESE UNIVERSITY OF HONG KONG

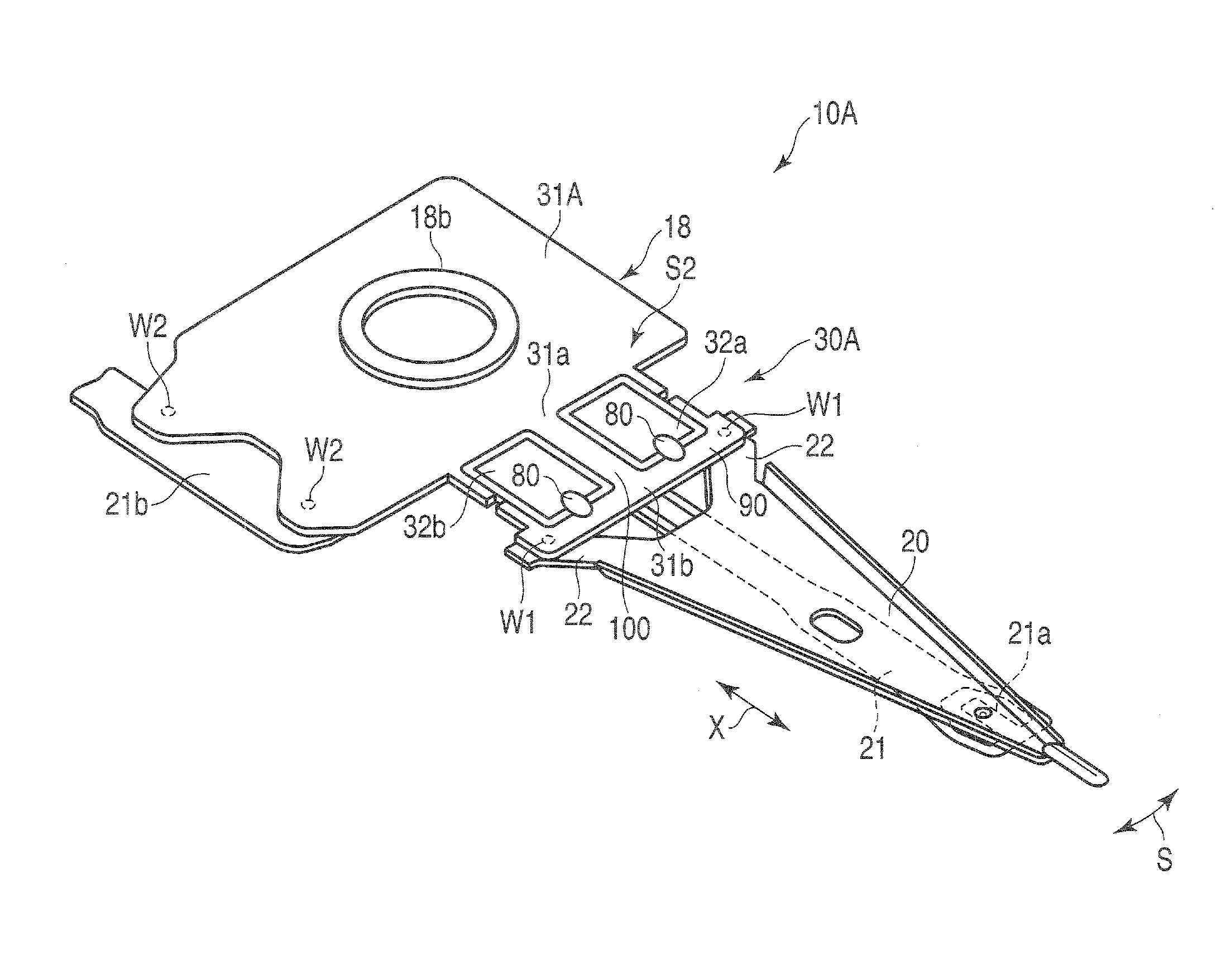

Suspension assembly having a microactuator electrically connected to a gold coating on a stainless steel surface

ActiveUS20110228425A1Electrical connection between head and armArm with actuatorsPiezoelectric microactuatorMetallurgy

A novel suspension assembly includes a suspension assembly mounting plate, a microactuator mounting structure extending from the suspension assembly mounting plate, a load beam extending from the microactuator mounting structure, and a laminated flexure attached to the load beam. The laminated flexure includes a tongue that has a read head bonding surface. The suspension assembly includes a stainless steel surface having a gold coating, and a piezoelectric microactuator attached to the microactuator mounting structure and electrically connected to the gold coating.

Owner:WESTERN DIGITAL TECH INC

Wiring connecting structure for piezoelectric actuator, piezoelectric actuator, and head suspension

ActiveUS20100177445A1Reliability is deterioratedHigh bonding strengthPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric actuatorsEngineering

A wiring connecting structure for a piezoelectric actuator includes a terminal 57-1, a through hole 67 formed through the terminal 57-1, a first liquid stopper 69-1 arranged around the through hole 67 in a gap between the terminal 57-1 and a common electrode 19 of a piezoelectric element 13 of the piezoelectric actuator, and a liquid trap 73 arranged adjacent to the first liquid stopper 69-1. The terminal 57-1 faces the common electrode 19 with an electric insulating layer 61 being on the piezoelectric element 13 side and the first liquid stopper 69-1 being in the gap between the common electrode 19 and the terminal 57-1. A liquid conductive adhesive 79 is filled in the through hole 67. If there is an excess of the liquid adhesive 79, the excess is guided into a trapping space 77 of the liquid trap 73, to prevent the excess from oozing out.

Owner:NHK SPRING CO LTD

Wiring connecting structure for piezoelectric actuator, piezoelectric actuator, and head suspension

ActiveUS8248734B2Reliability is deterioratedHigh bonding strengthPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric actuatorsEngineering

A wiring connecting structure for a piezoelectric actuator includes a terminal 57-1, a through hole 67 formed through the terminal 57-1, a first liquid stopper 69-1 arranged around the through hole 67 in a gap between the terminal 57-1 and a common electrode 19 of a piezoelectric element 13 of the piezoelectric actuator, and a liquid trap 73 arranged adjacent to the first liquid stopper 69-1. The terminal 57-1 faces the common electrode 19 with an electric insulating layer 61 being on the piezoelectric element 13 side and the first liquid stopper 69-1 being in the gap between the common electrode 19 and the terminal 57-1. A liquid conductive adhesive 79 is filled in the through hole 67. If there is an excess of the liquid adhesive 79, the excess is guided into a trapping space 77 of the liquid trap 73, to prevent the excess from oozing out.

Owner:NHK SPRING CO LTD

Method for actively controlling the gram load on a disk drive suspension assembly

InactiveUS7082670B2Large range of motionOptimization rangePrinted circuit assemblingPiezoelectric/electrostrictive device manufacture/assemblyElectricityControl system

A method and apparatus for actively controlling the gram load on a disk drive suspension assembly and to a disk drive using the present disk drive suspension assembly. The gram load can be actively changed by changing the applied voltage to one or more multi-layer piezoelectric actuators attached to the head suspension. The active gram control system allows the gram load to be changed on a non-permanent basis and to control the gram load to a much finer scale than can be accomplished using conventional techniques. By attaching the first and second ends of the piezoelectric actuator to discrete locations on the load beam, while the portion of the piezoelectric actuator between the first and second ends remains unattached to the load beam, a force non-parallel to the load beam can be applied to the head suspension.

Owner:HUTCHINSON TECH

Wiring connecting structure for piezoelectric element, wiring connecting method, piezoelectric actuator, and head suspension

ActiveUS20100165515A1Without breaking the piezoelectric element or deteriorating the reliability thereofReliability is deterioratedPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric actuatorsEngineering

A wiring connecting structure for a piezoelectric element is capable of performing wiring to the piezoelectric element without deteriorating the quality and reliability of the piezoelectric element. The piezoelectric element is arranged between a base and head of an object, to minutely move the head in a sway direction according to deformation that occurs on the piezoelectric element in response to a voltage applied from a terminal to an electrode of the piezoelectric element. The wiring connecting structure includes first and second liquid stoppers arranged between the terminal and the electrode, the second liquid stopper being arranged outside the first liquid stopper. The wiring connecting structure also includes an adhesive part to connect the electrode to the terminal. The adhesive part has a conductive adhesive part defined by the first liquid stopper and a sealing adhesive part defined by the second liquid stopper. The sealing adhesive part seals the first liquid stopper and conductive adhesive part.

Owner:NHK SPRING CO LTD

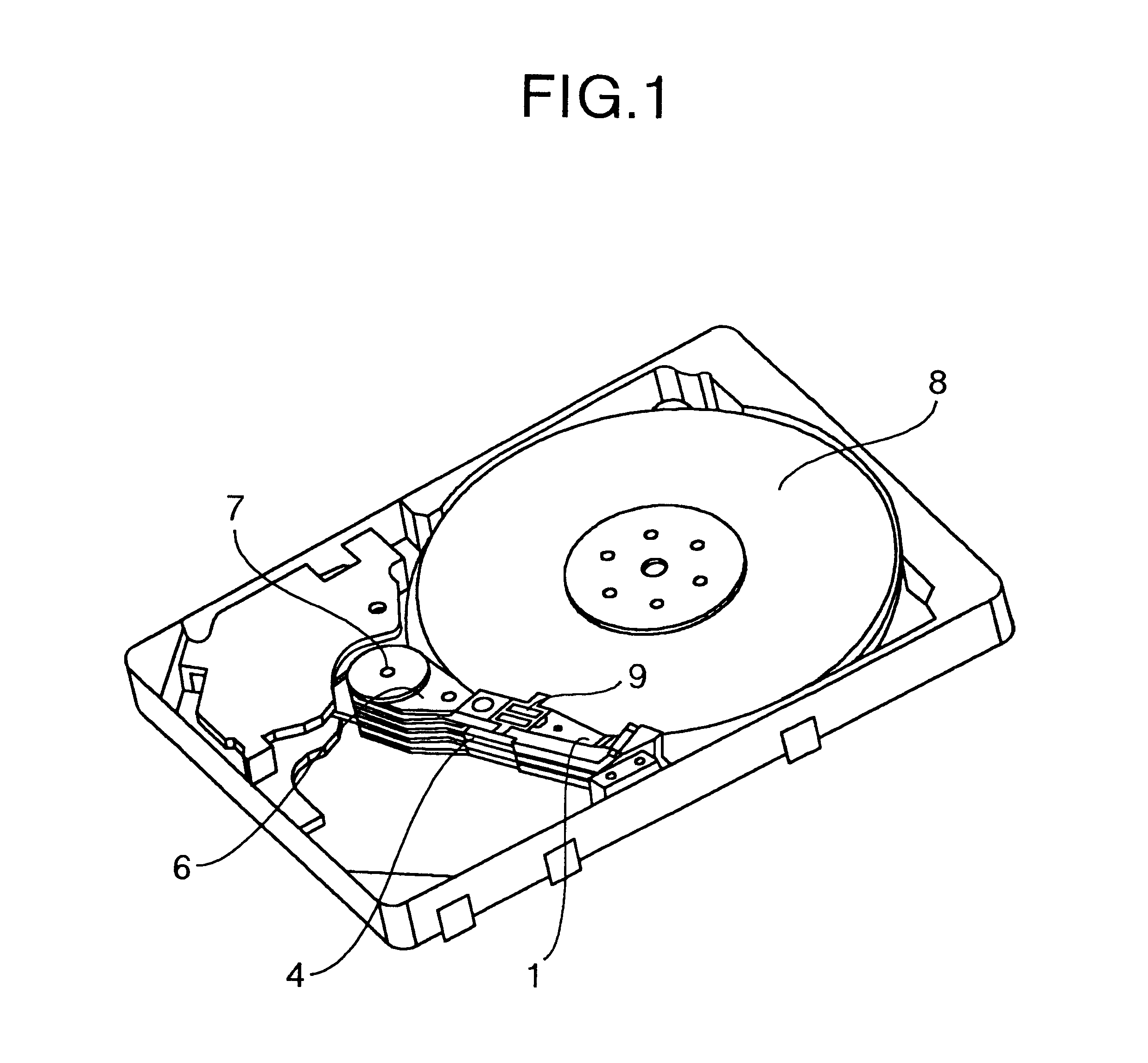

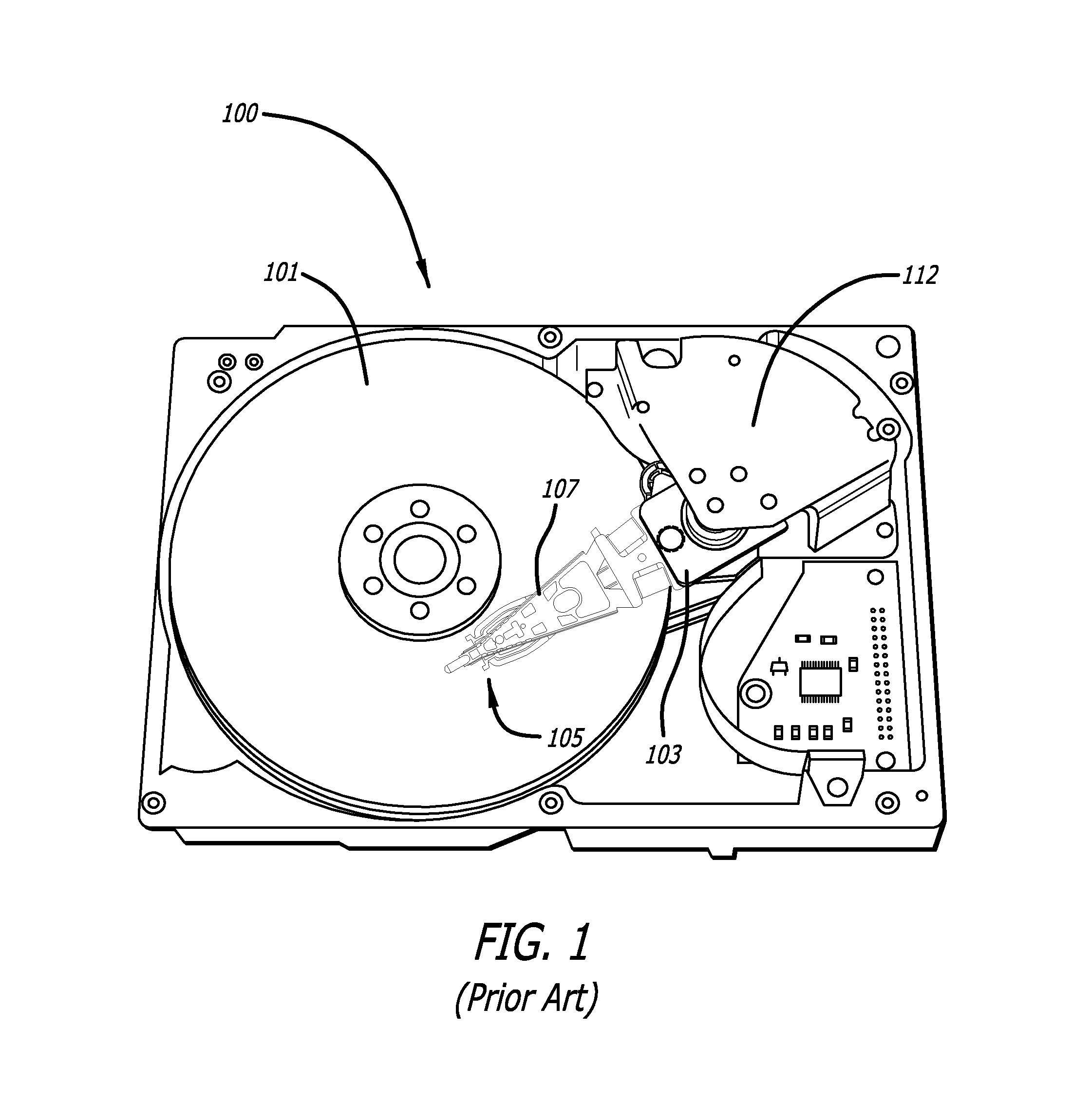

Magnetic disk apparatus

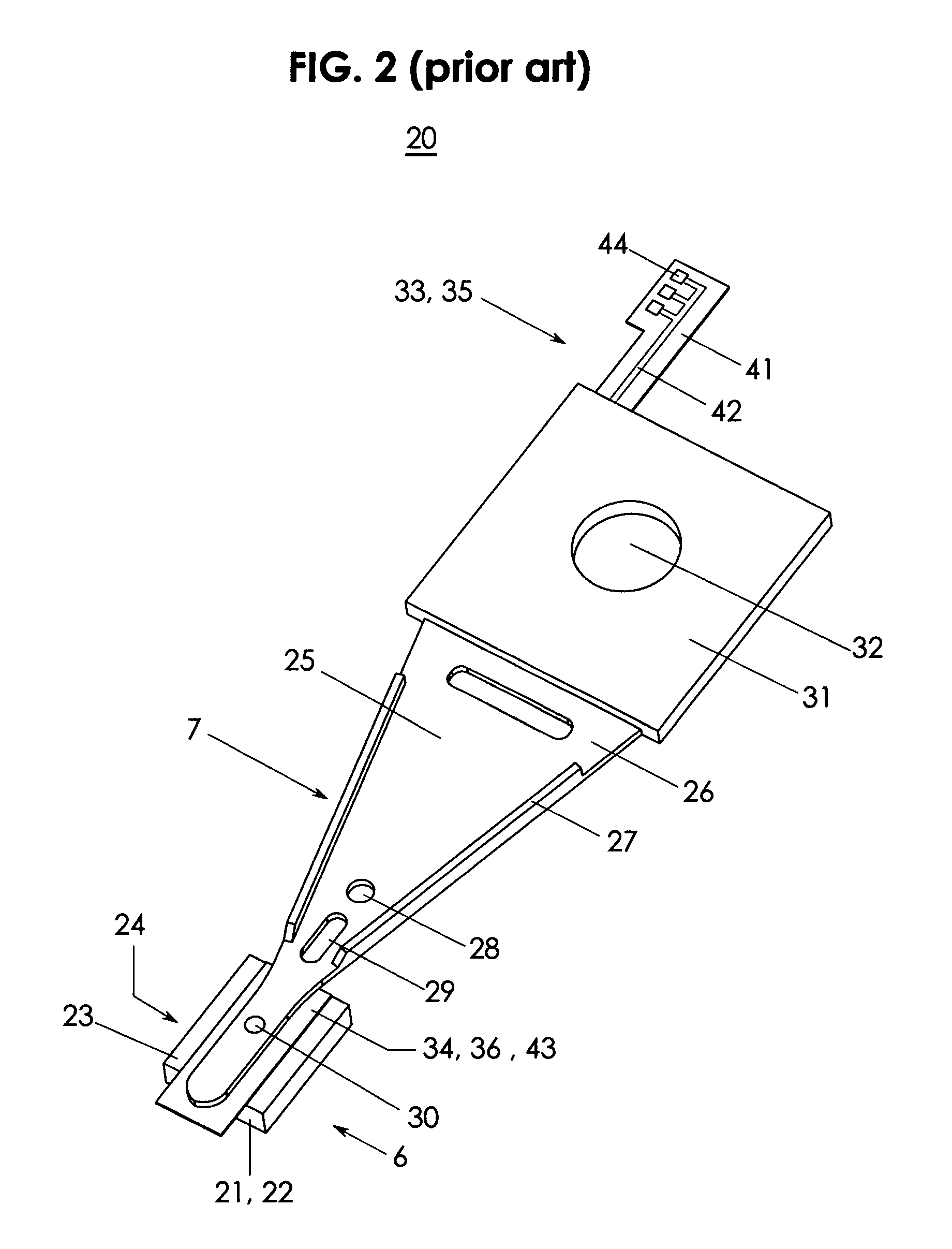

InactiveUS6614627B1Precise positioningSimple structureArm with actuatorsRecord information storageCouplingEngineering

A magnetic disk apparatus of the present invention is equipped with a microactuator for micro motion using piezoelectric elements in addition to a coarse adjustment actuator such as a voice coil motor or the like, eliminates parts that slide between the microactuator and surrounding members, and alleviates stress on the piezoelectric elements even if an impact is given to the magnetic disk apparatus. Thus, a first actuator fixing portion on a carriage side and a second actuator fixing portion on a magnetic head side of a microactuator mounting portion are coupled with a plurality of flexible coupling portions and coupling portions are placed outside the microactuator in substantially symmetric with respect to a centerline in a longitudinal direction of a suspension.

Owner:WESTERN DIGITAL TECH INC +1

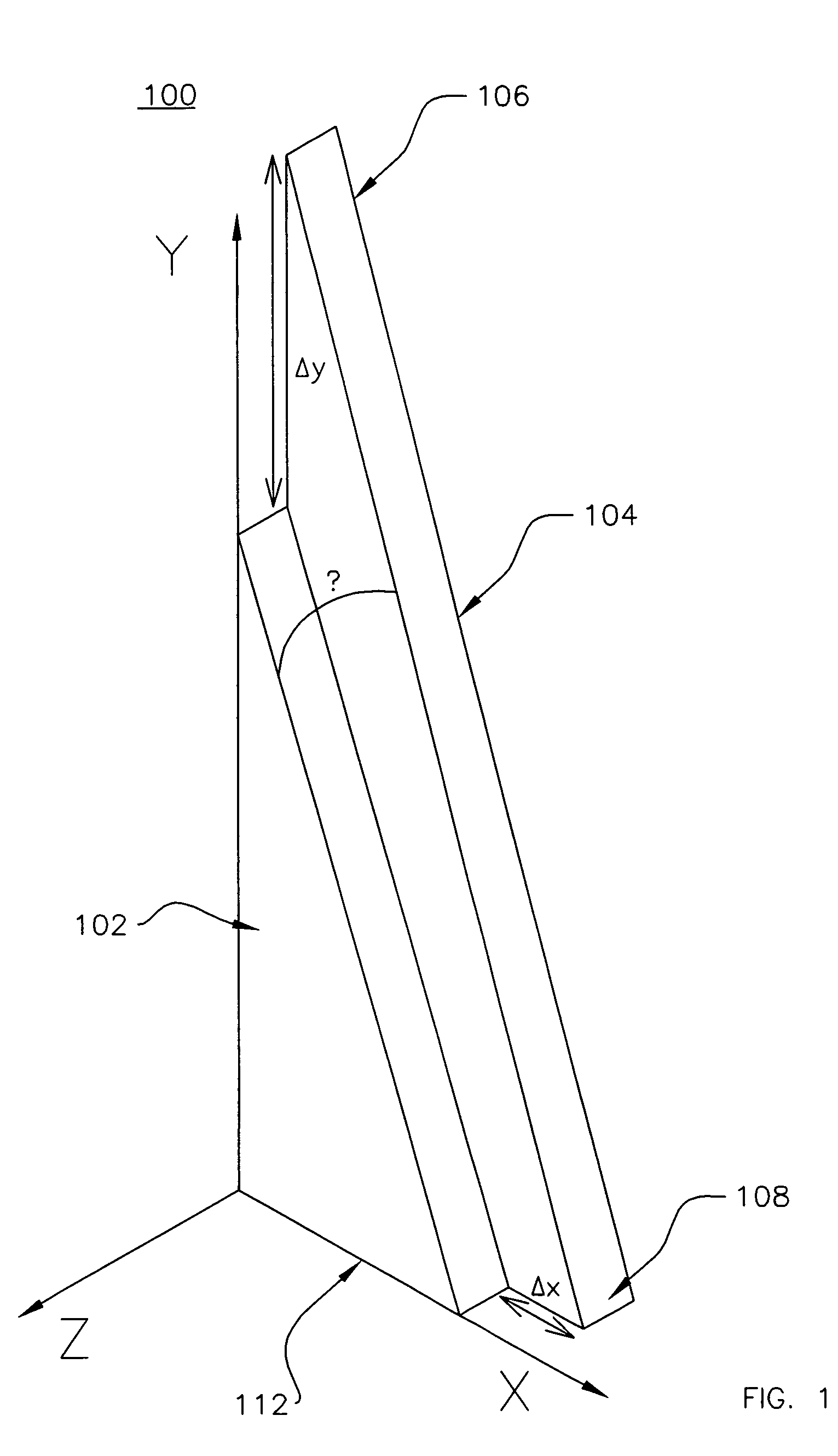

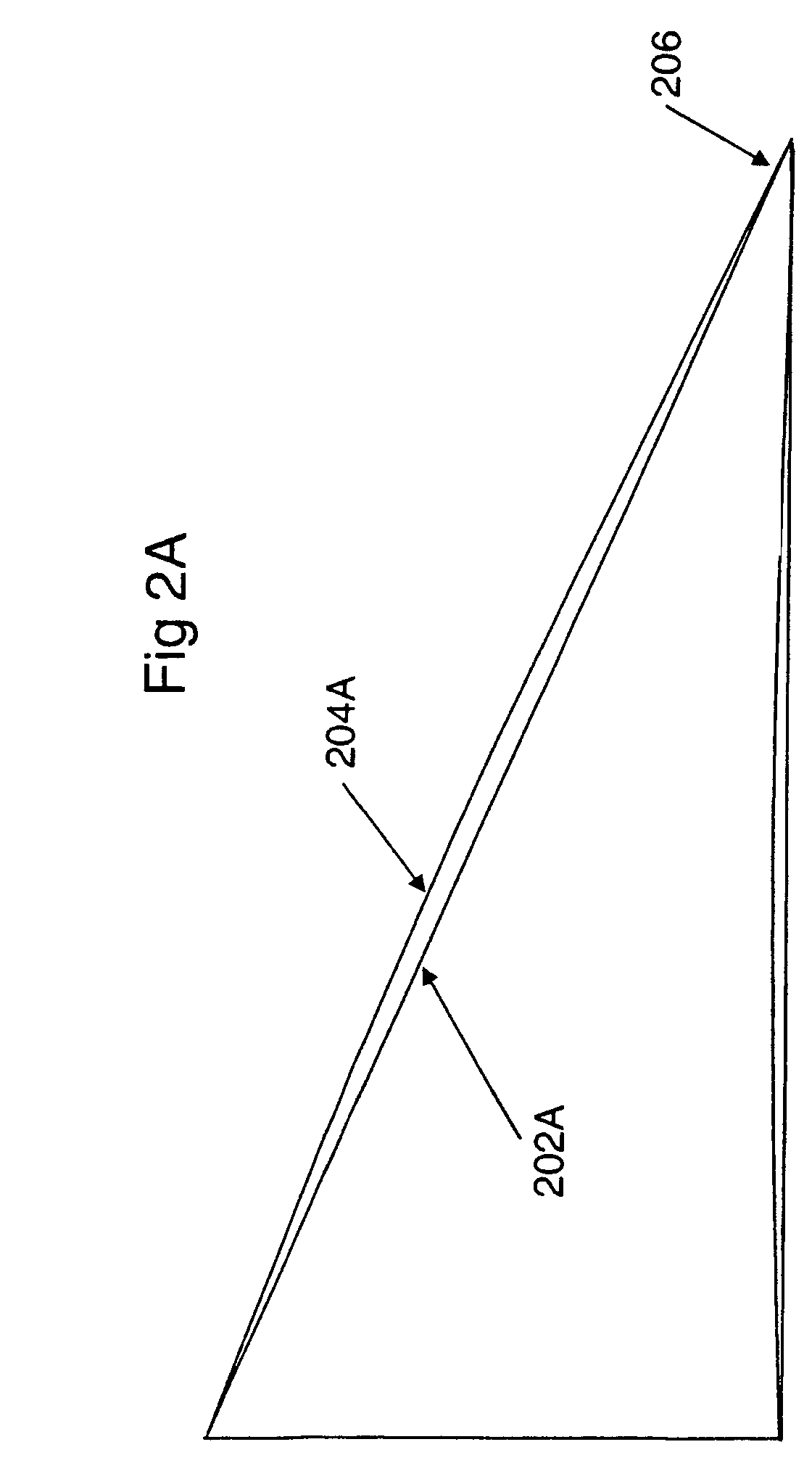

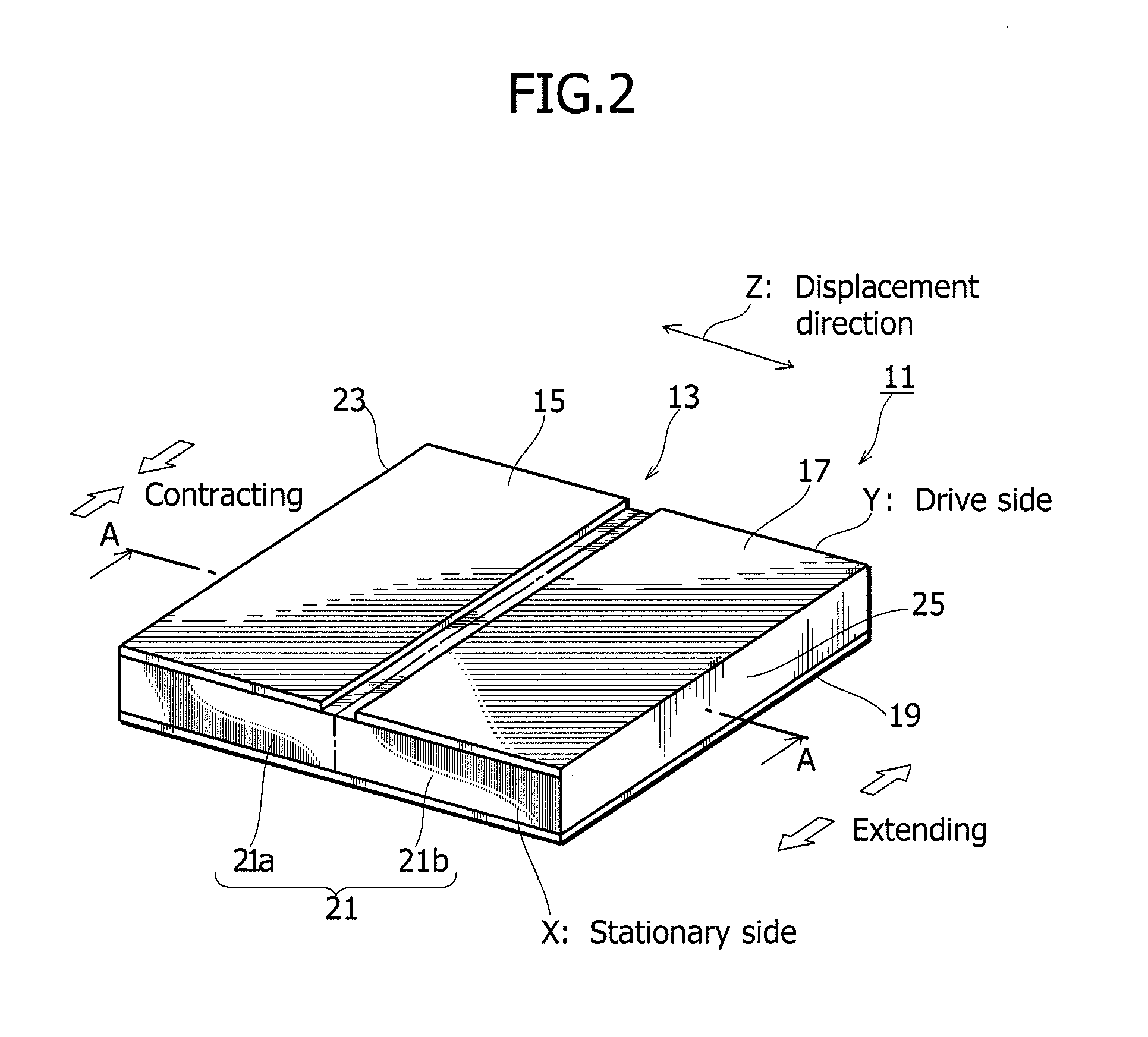

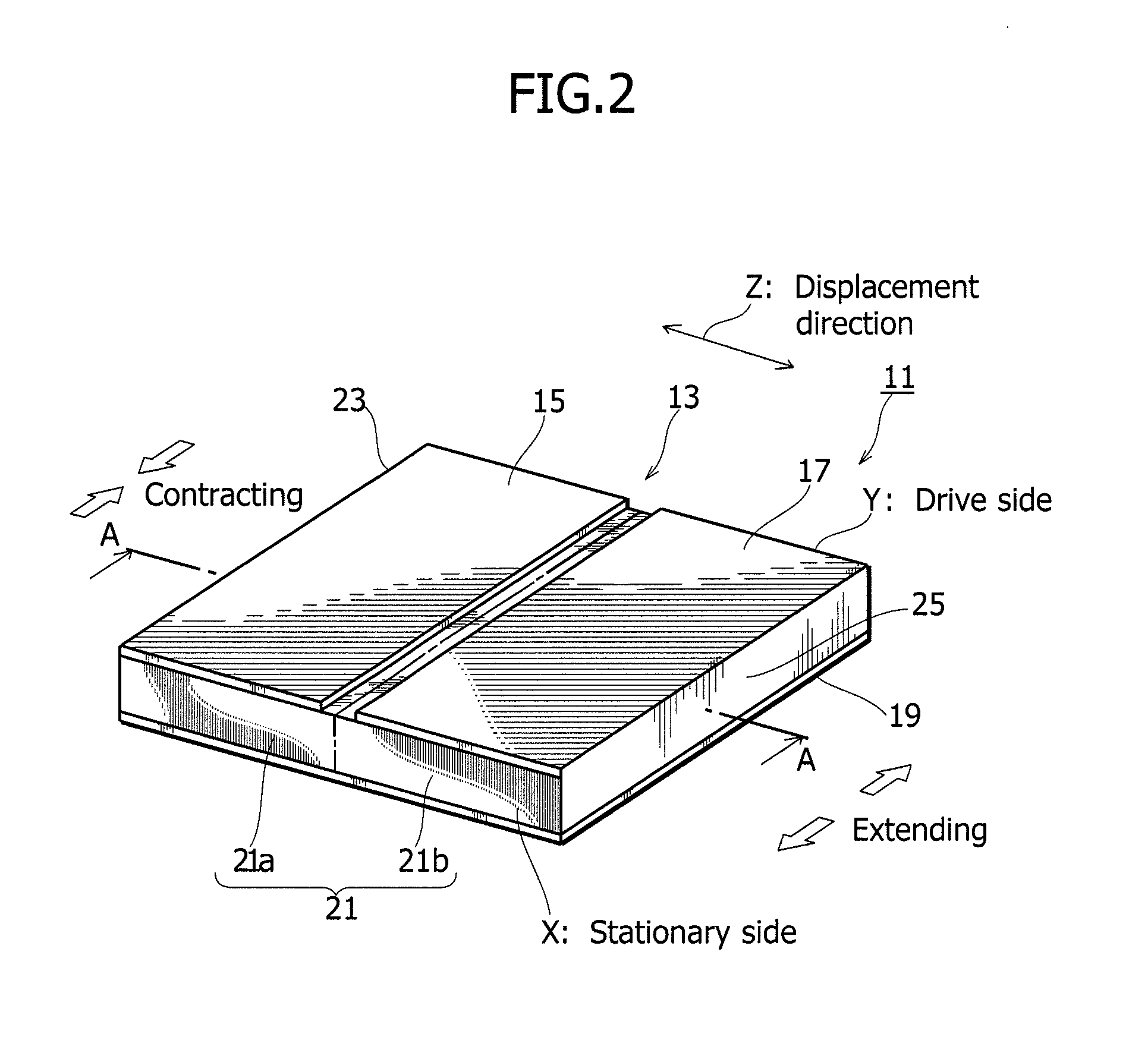

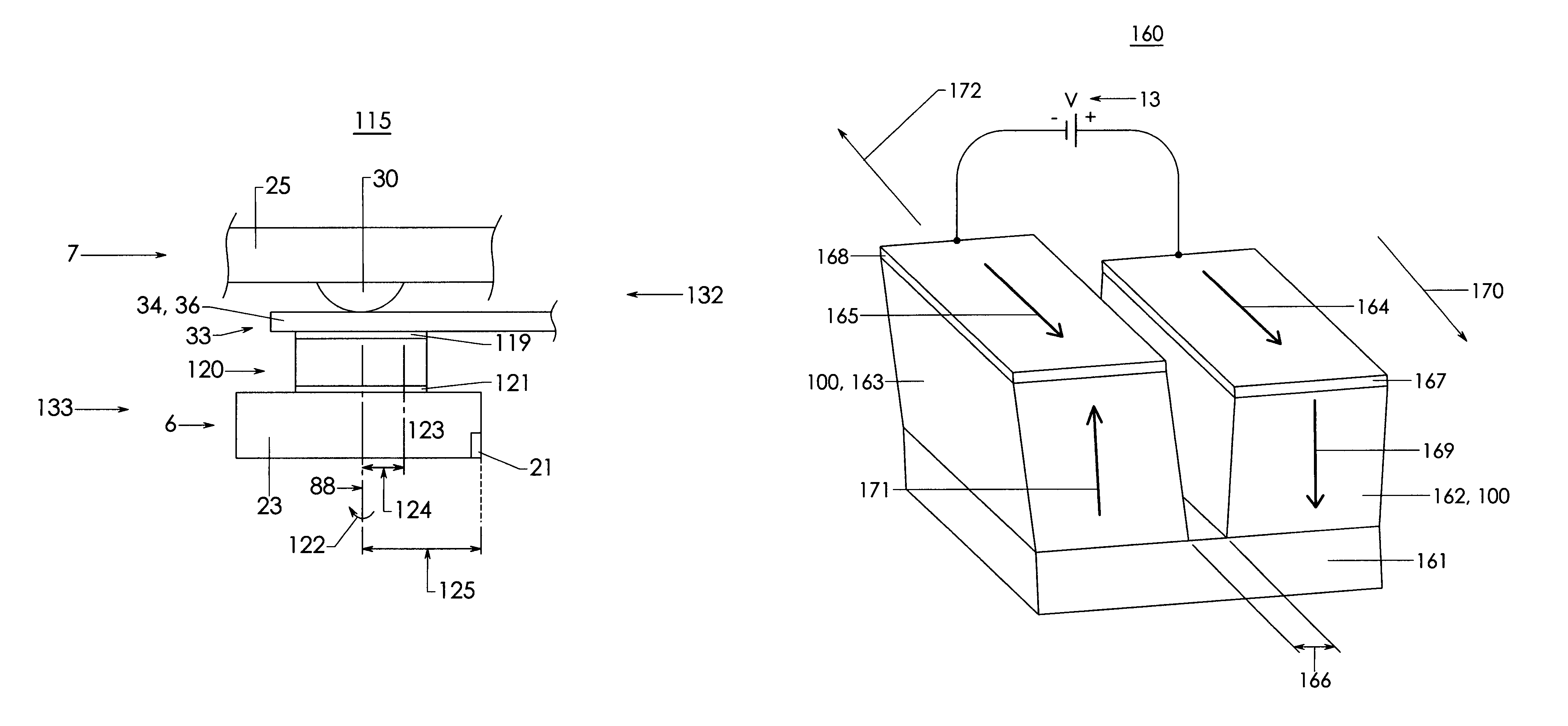

Rotational, shear mode, piezoelectric motor integrated into a collocated, rotational, shear mode, piezoelectric micro-actuated suspension, head or head/gimbal assembly for improved tracking in disk drives and disk drive equipment

ActiveUS8125741B2High track densityImprove data storage capacityDriving/moving recording headsArm with actuatorsShock resistanceControl theory

A rotational, shear mode, piezoelectric motor is integrated with a suspension, head or head gimbal assembly (HGA) into a collocated, rotational, shear mode, piezoelectric micro-actuated suspension, head or head gimbal assembly (HGA) for use in disk drives and disk drive manufacturing equipment. When excited by a control voltage, the collocated, shear mode, piezoelectric micro-actuated HGA rotates the head enabling high frequency, high resolution track positioning of the read / write element. The motor is integrated with the head and flexure (collocation). The head rotates about a rotation axis that is ideally located at the center of mass of the head. A shear mode piezoelectric motor rotates the head. A collocated, rotational, shear mode, piezoelectric micro-actuated HGA has high stiffness, high frequency response, high positioning resolution, low mass and low internal vibration for improved tracking, increased track density and greater disk drive storage capacity. Furthermore, its solid integration improves shock resistance and reduces micro-contamination.

Owner:MAGNECOMP +1

Wiring connecting structure for piezoelectric element, wiring connecting method, piezoelectric actuator, and head suspension

ActiveUS8149542B2Without breaking the piezoelectric element or deteriorating the reliability thereofReliability is deterioratedArm with actuatorsPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric actuatorsVoltage

A wiring connecting structure for a piezoelectric element is capable of performing wiring to the piezoelectric element without deteriorating the quality and reliability of the piezoelectric element. The piezoelectric element is arranged between a base and head of an object, to minutely move the head in a sway direction according to deformation that occurs on the piezoelectric element in response to a voltage applied from a terminal to an electrode of the piezoelectric element. The wiring connecting structure includes first and second liquid stoppers arranged between the terminal and the electrode, the second liquid stopper being arranged outside the first liquid stopper. The wiring connecting structure also includes an adhesive part to connect the electrode to the terminal. The adhesive part has a conductive adhesive part defined by the first liquid stopper and a sealing adhesive part defined by the second liquid stopper. The sealing adhesive part seals the first liquid stopper and conductive adhesive part.

Owner:NHK SPRING CO LTD

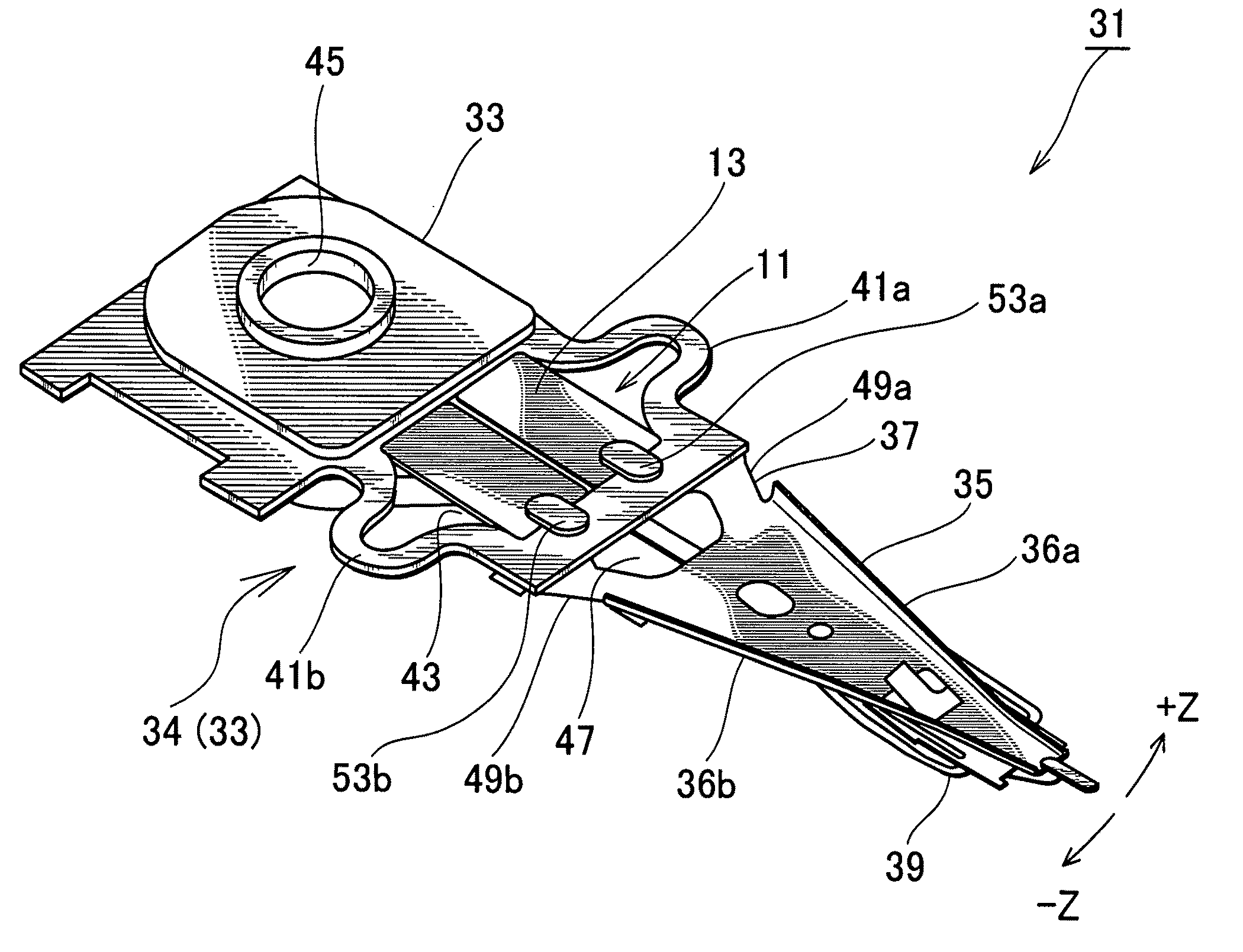

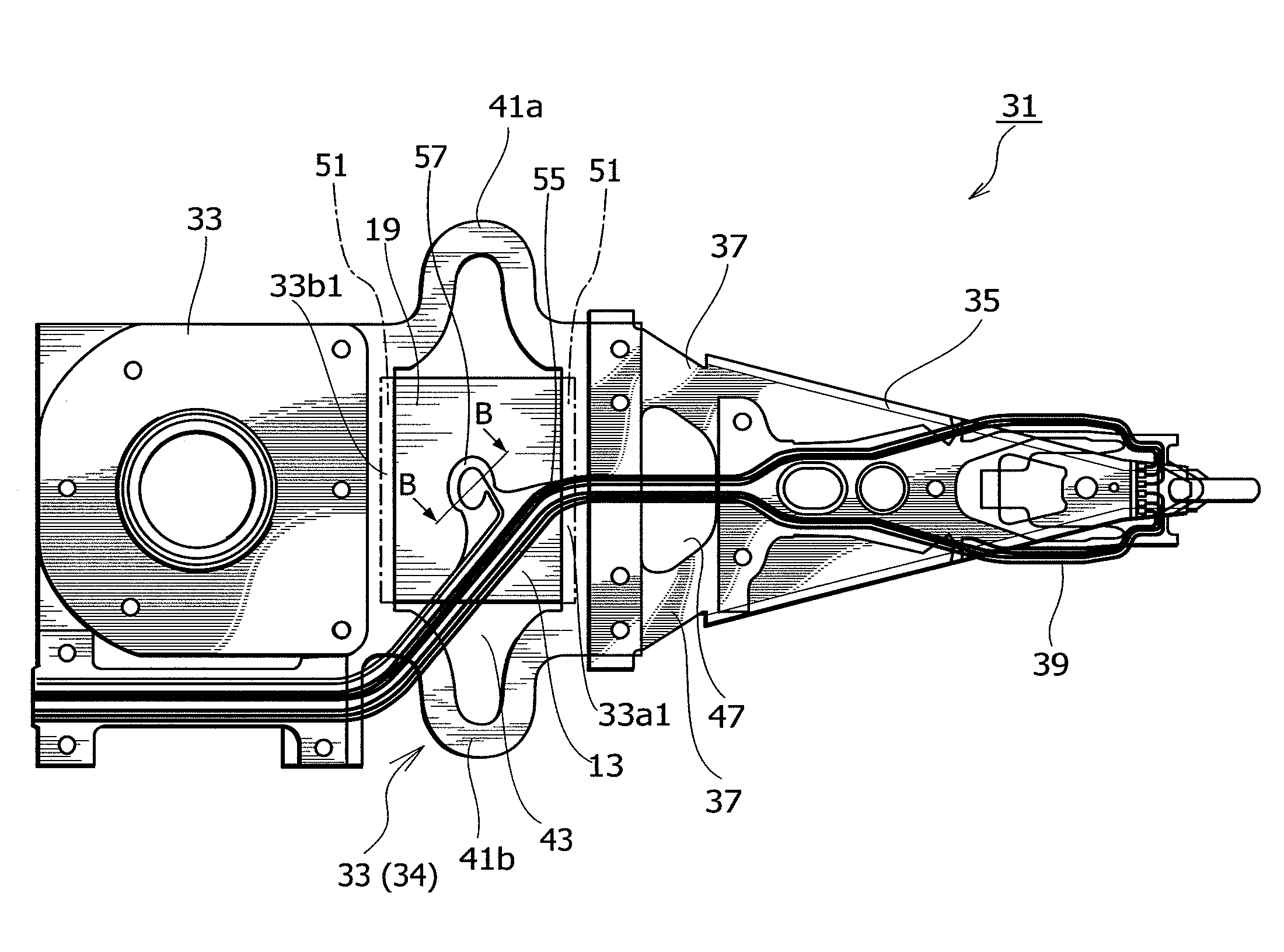

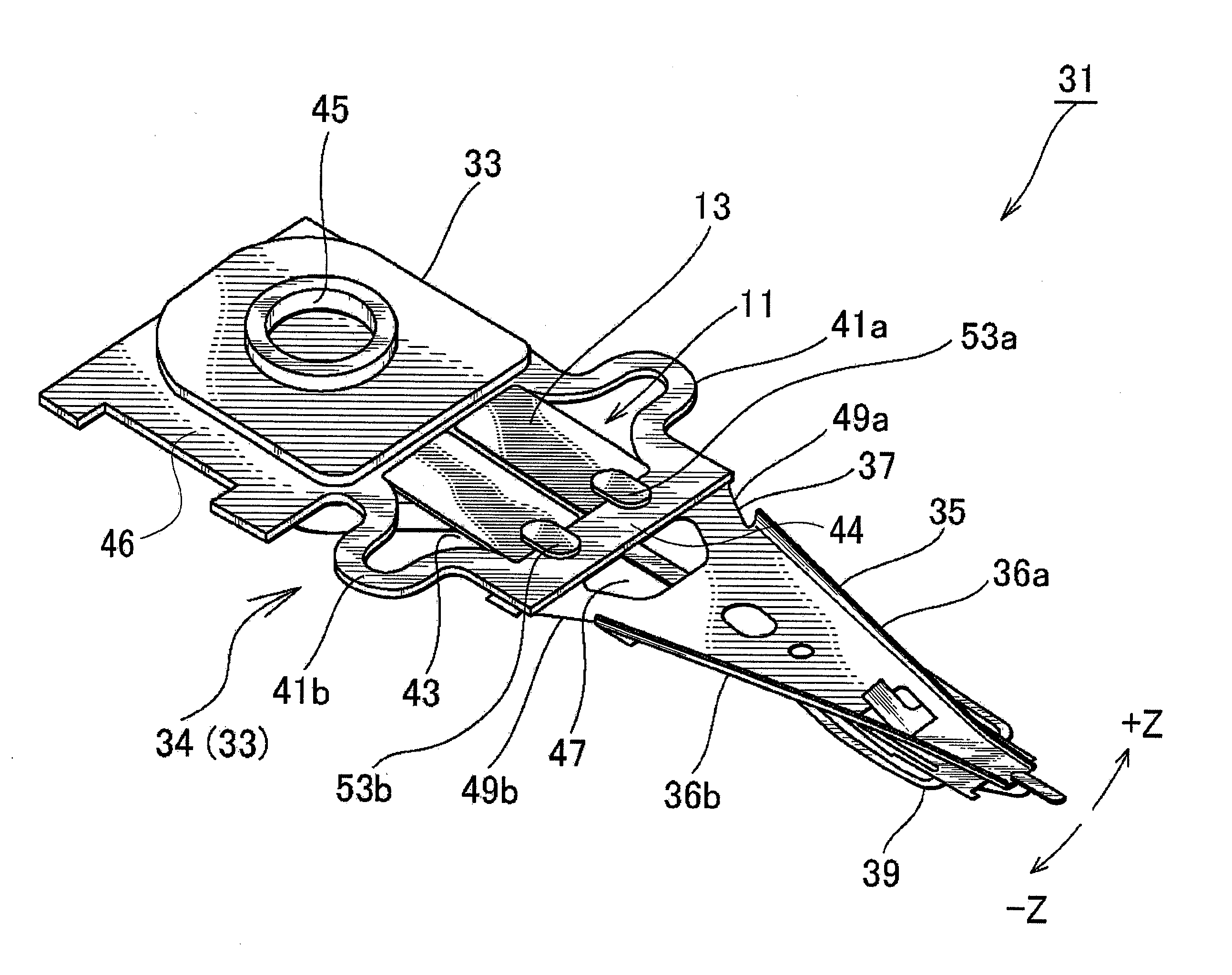

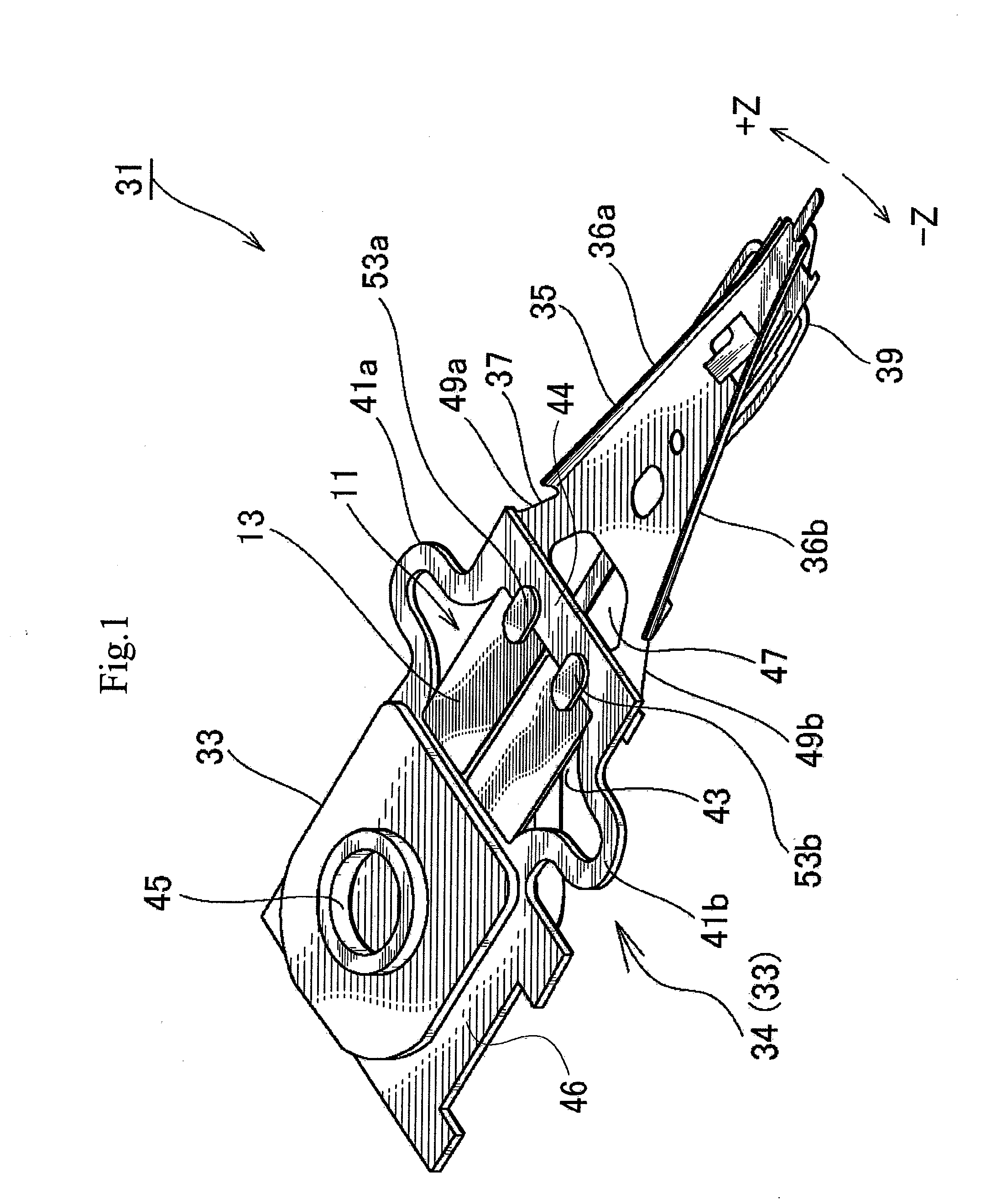

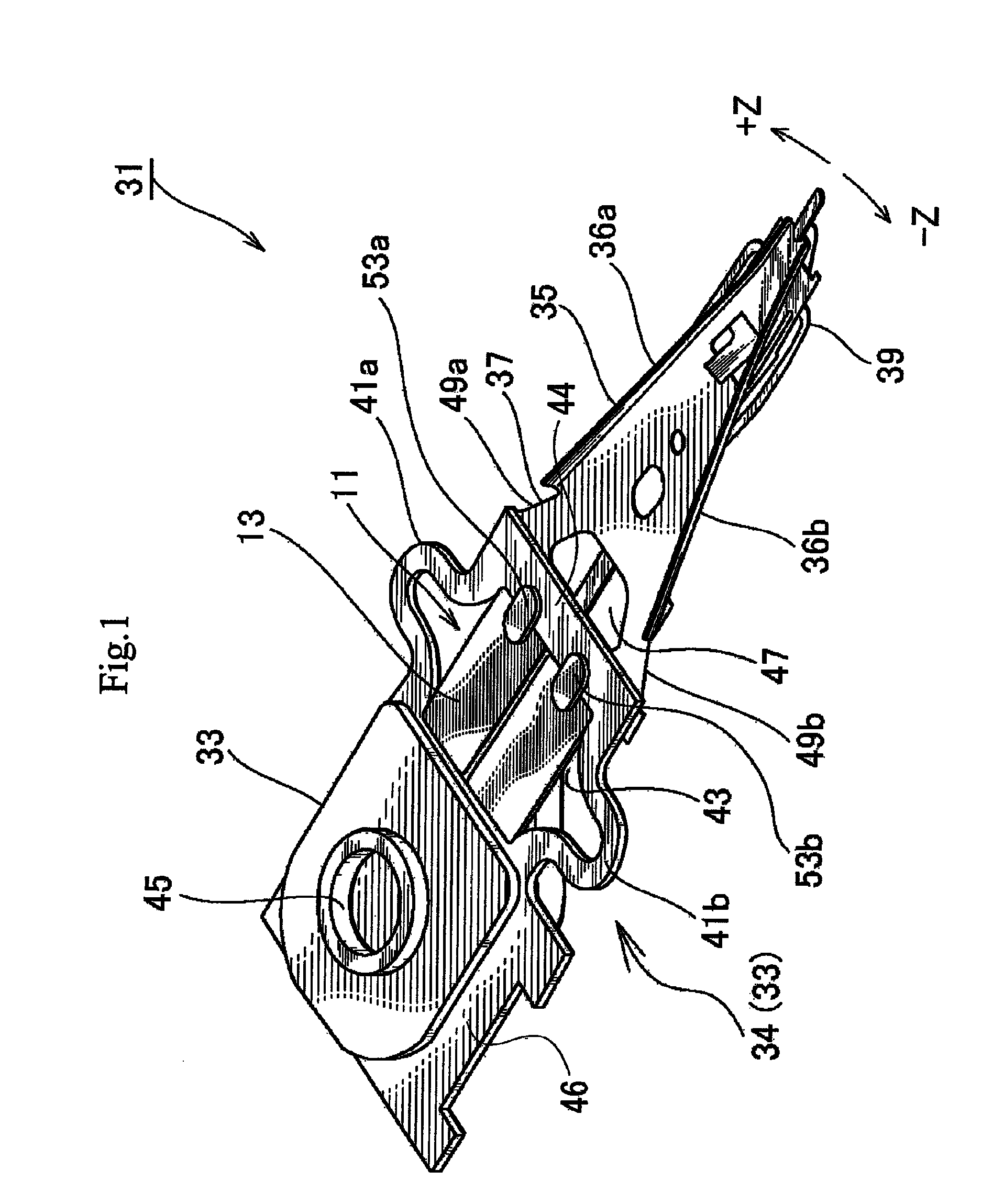

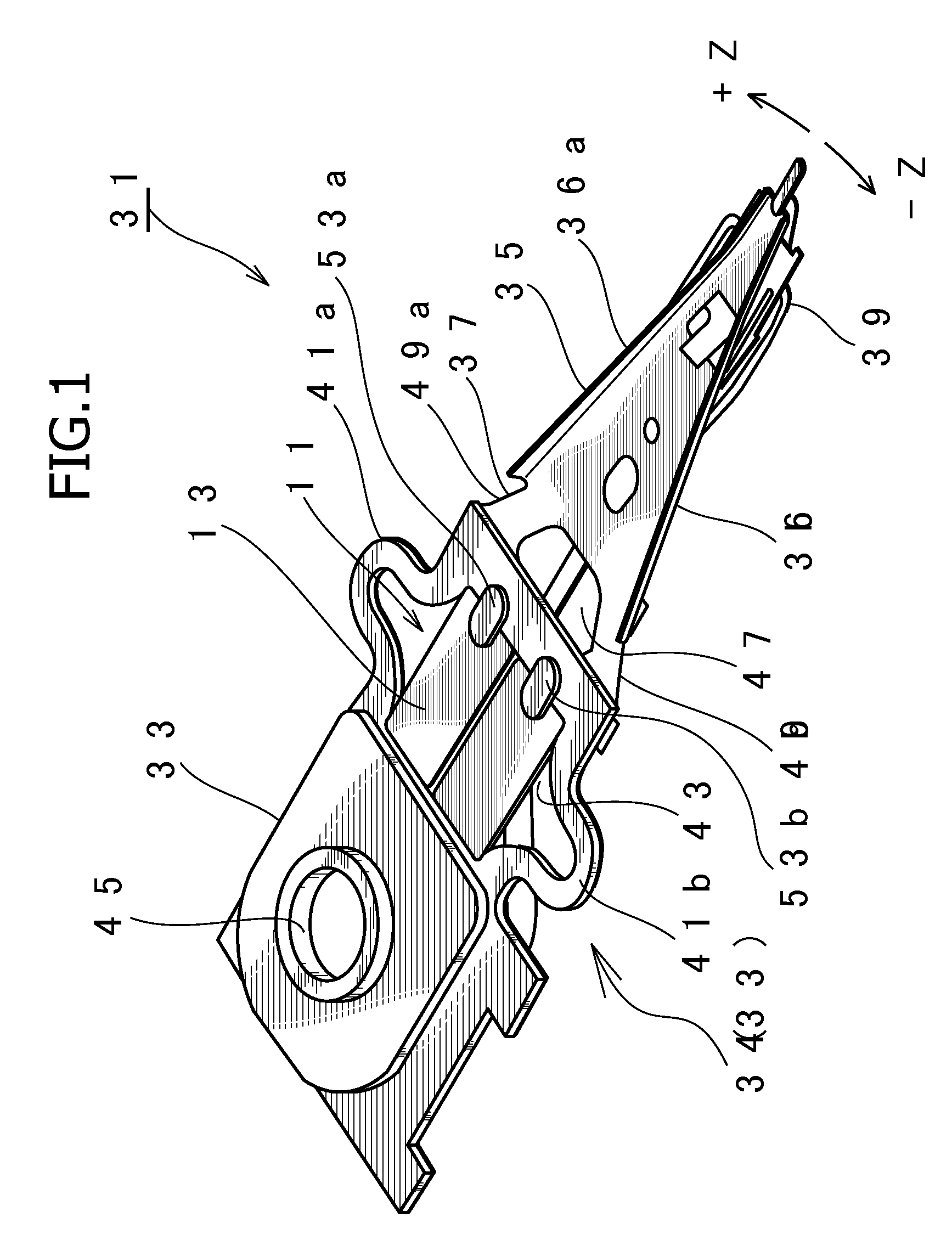

Head suspension

ActiveUS20100073825A1Properly keeping rigidity balanceProperly vibration characteristicArm with actuatorsRecord information storageAdhesiveMechanical engineering

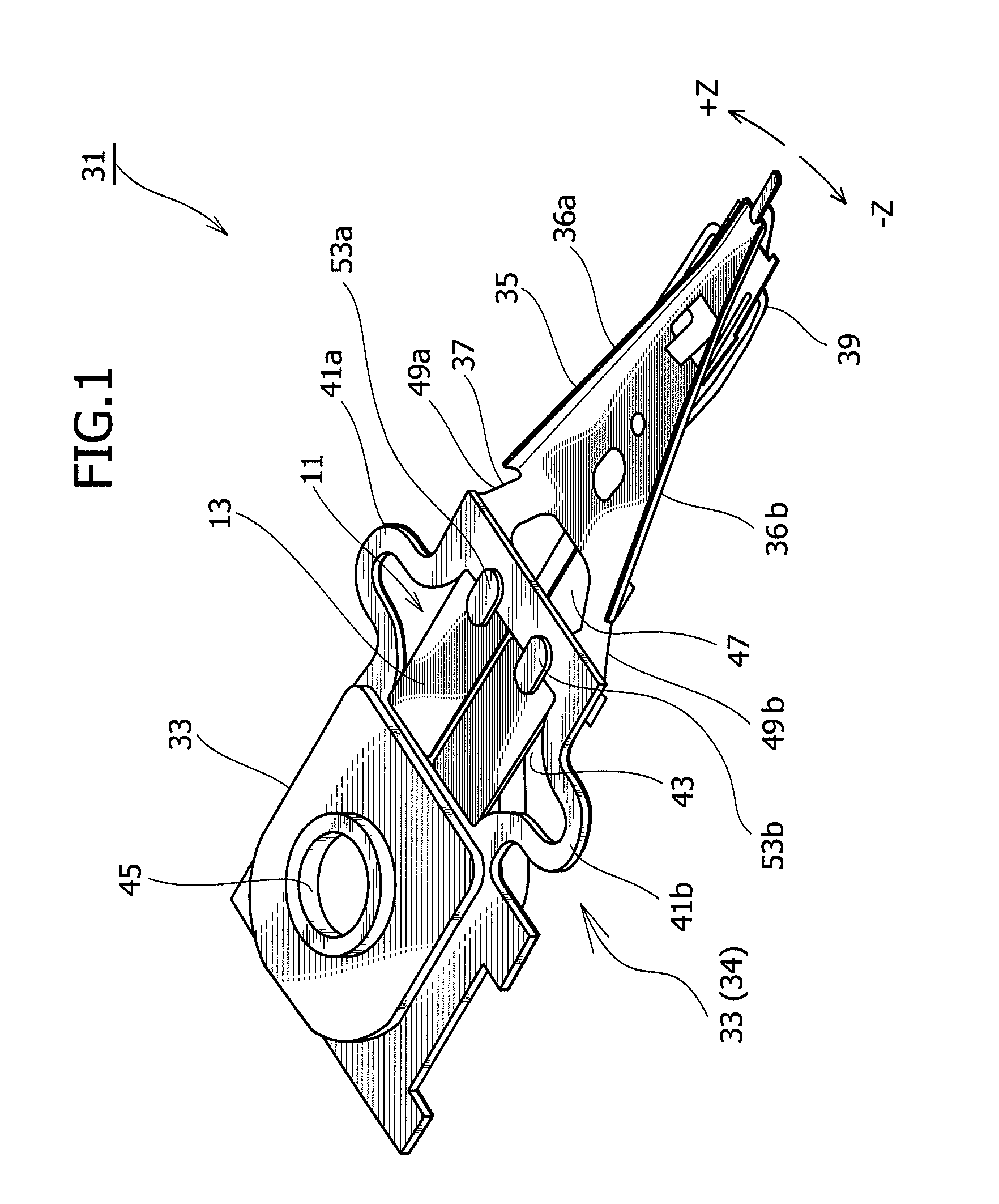

A head suspension has a piezoelectric element 13 that deforms in response to a voltage applied thereto, a base plate 33 provided with an opening 43 to which the piezoelectric element is attached, and a load beam 35 that is fixed to the base plate 33 so that a front end of the load beam 35 moves in a sway direction according to the deformation of the piezoelectric element 13. The head suspension includes an adhesive 51 applied to a gap 50 between the piezoelectric element 13 and the opening 43, to attach the piezoelectric element 13 to the opening 43. The adhesive 51 has a thixotropic characteristic and is sol when applied to the gap 50. A displacement of the piezoelectric element is correctly transmitted to the load beam. The head suspension properly keeps a rigidity balance and vibration characteristic.

Owner:NHK SPRING CO LTD

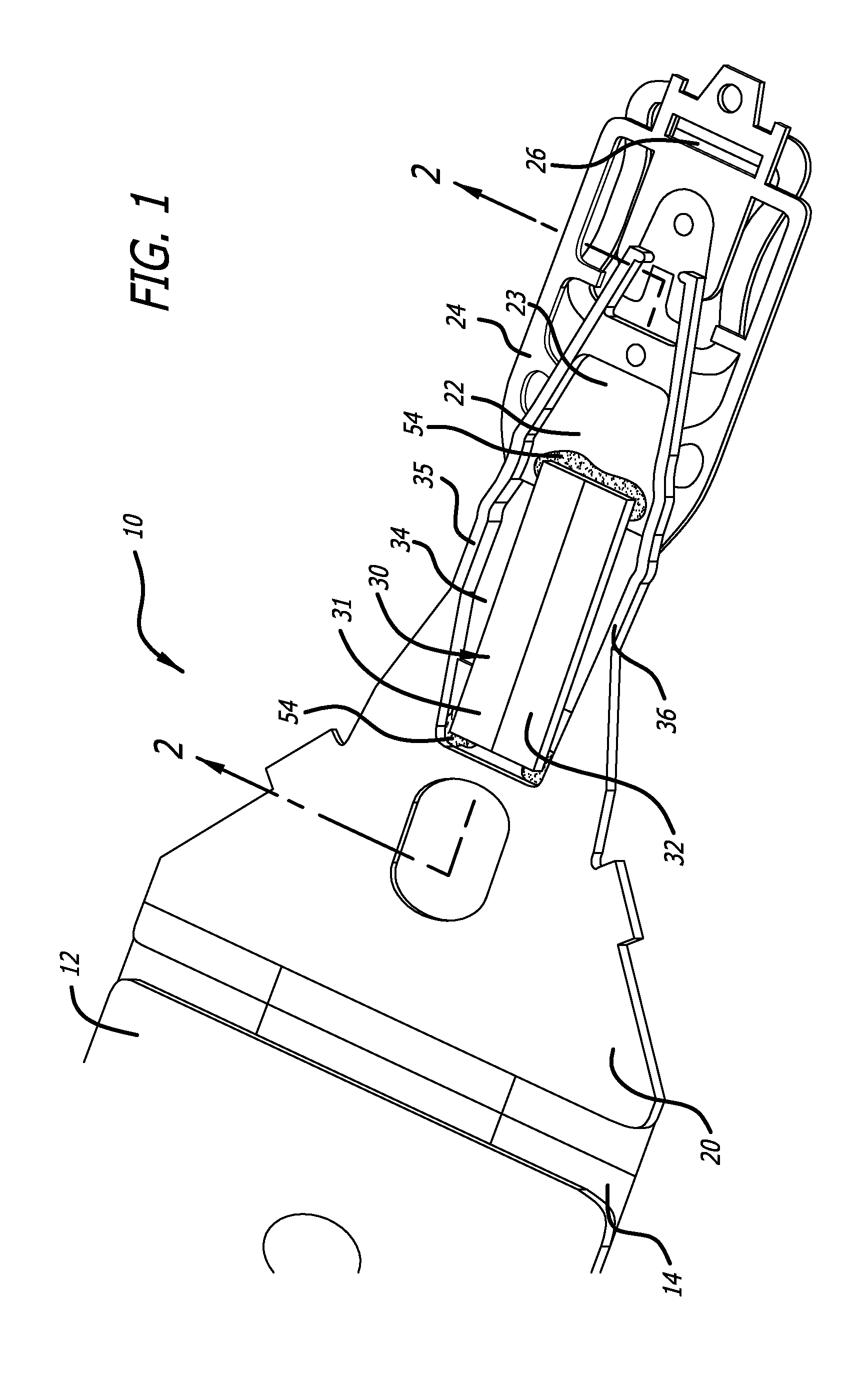

Suspension assembly having recessed actuator with simplified lead connection

ActiveUS7751153B1Easy to routeImprove reliabilityArm with actuatorsRecord information storagePiezoelectric microactuatorEngineering

A head suspension assembly couples a baseplate to a rotatable load through a planar triangular piezo microactuator for effecting hingeless rotation of the load. The microactuator expands, responsive to an excitation voltage, with greater magnitude in one direction than in another direction normal to the first direction, resulting in an angular movement of the hypotenuse thereby rotating the load. The upper surface of the microactuator is grounded to a bottom surface of the baseplate or load beam to position the microactuator lead connection surface closest to the load to facilitate trace routing. A load beam grounding surface may be raised to accommodate the microactuator and fix the lead connection surface on a common plane with the unraised surface to further minimize trace routing and provide access for bonding the trace to the load beam.

Owner:MAGNECOMP

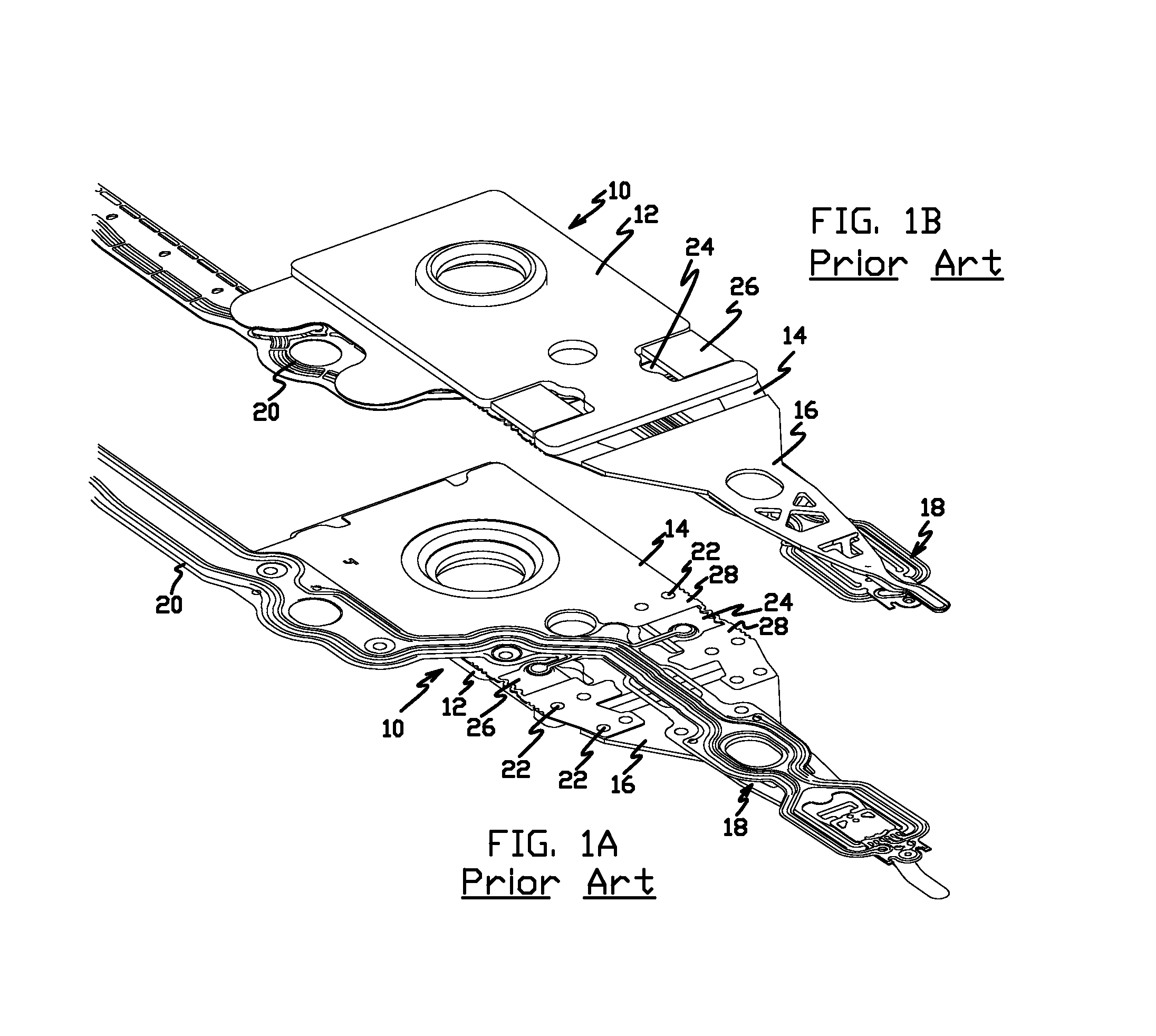

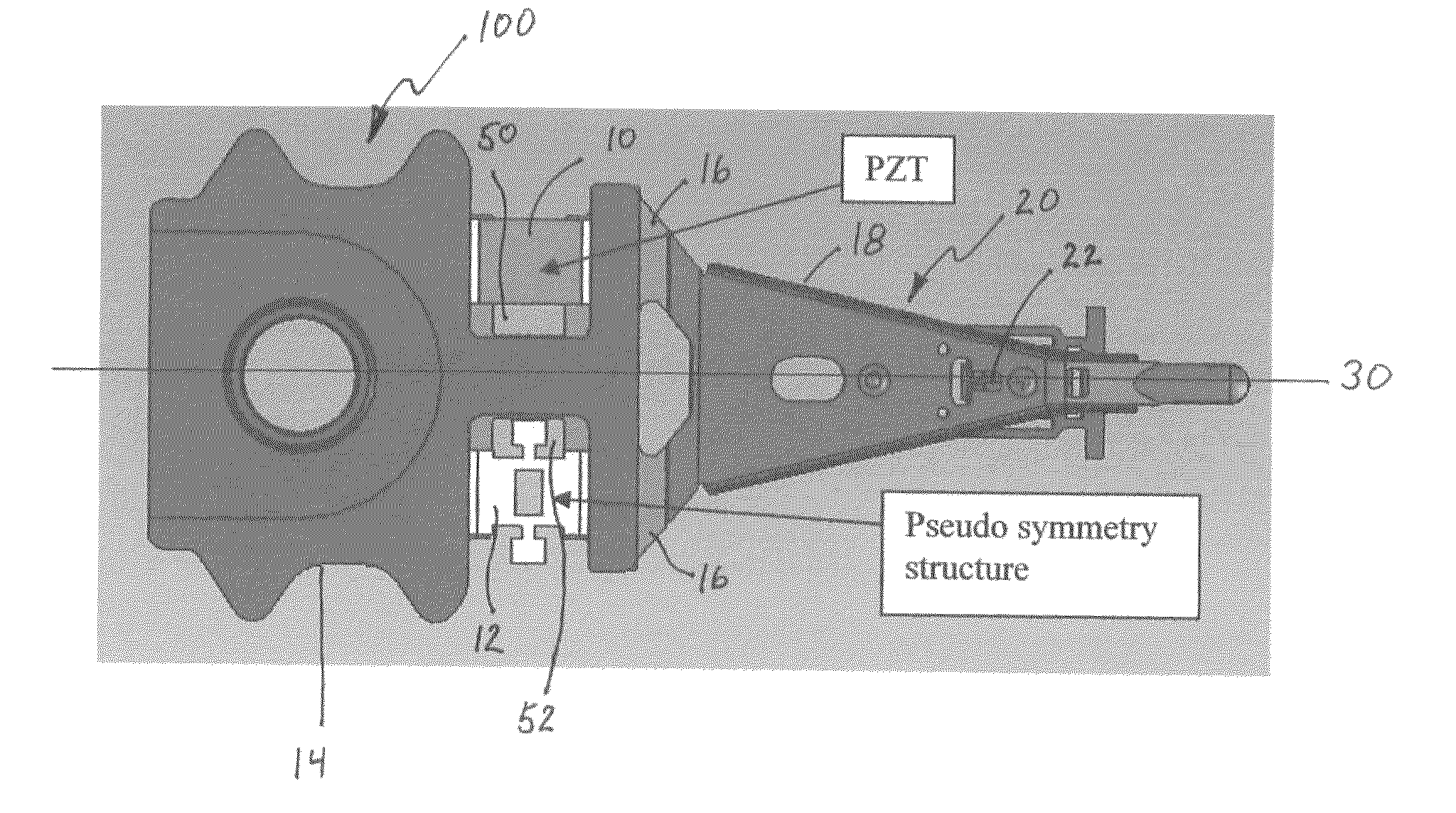

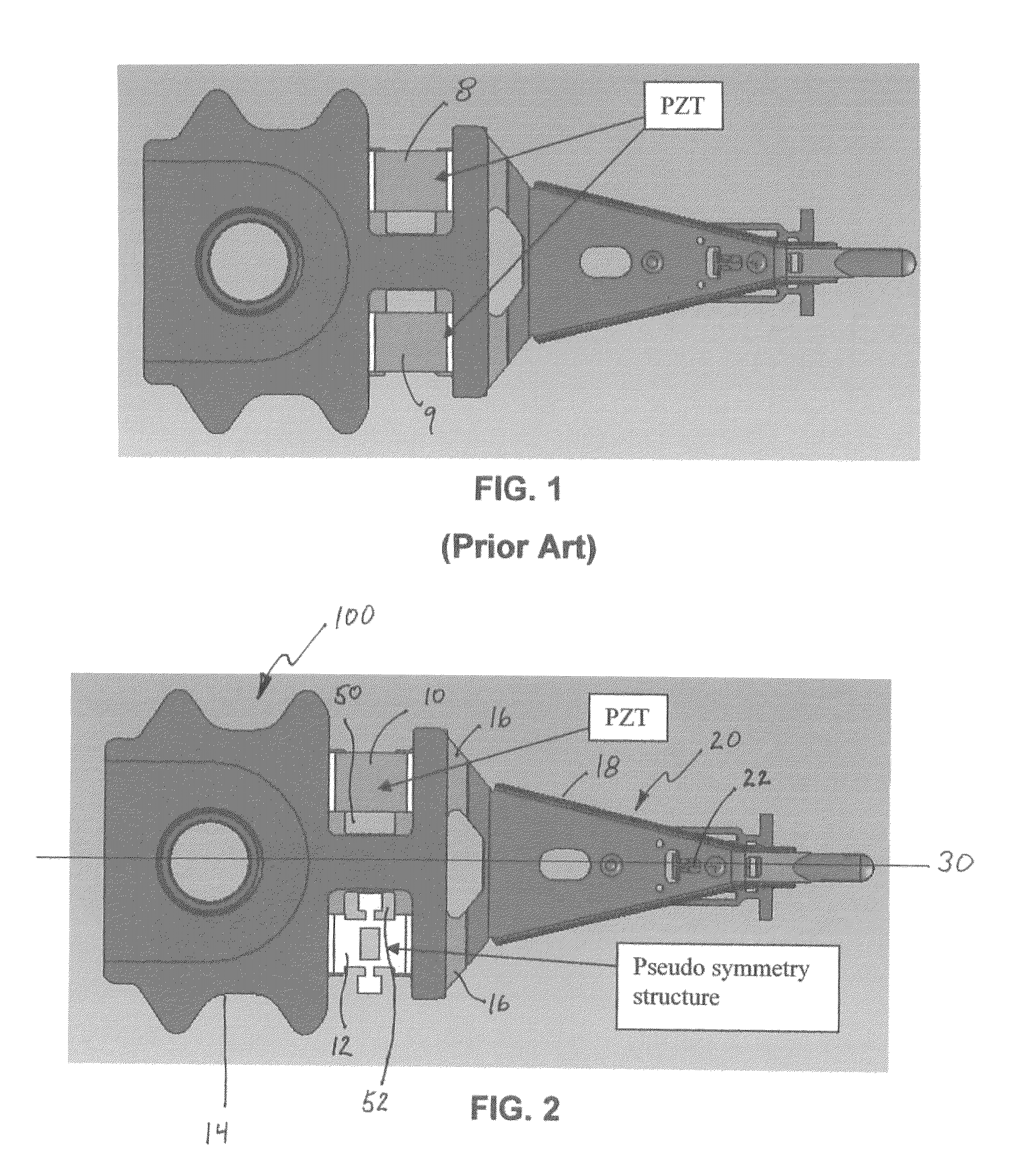

Dual stage actuator suspension having a single microactuator and employing pseudo symmetry to achieve suspension balance

ActiveUS8228642B1Improve performanceSimilar massArm with actuatorsRecord information storageDual stageEngineering

A dual stage actuator (DSA) suspension has a single microactuator such as a PZT element on one side of central longitudinal axis of the suspension, and a pseudo symmetry structure formed or affixed on the other side of the central longitudinal axis opposite the PZT. The pseudo symmetry structure has mass and stiffness that mirrors the PZT, thus keeping the suspension mechanically balanced and symmetric about the longitudinal axis for improved suspension performance especially in a shock environment.

Owner:MAGNECOMP

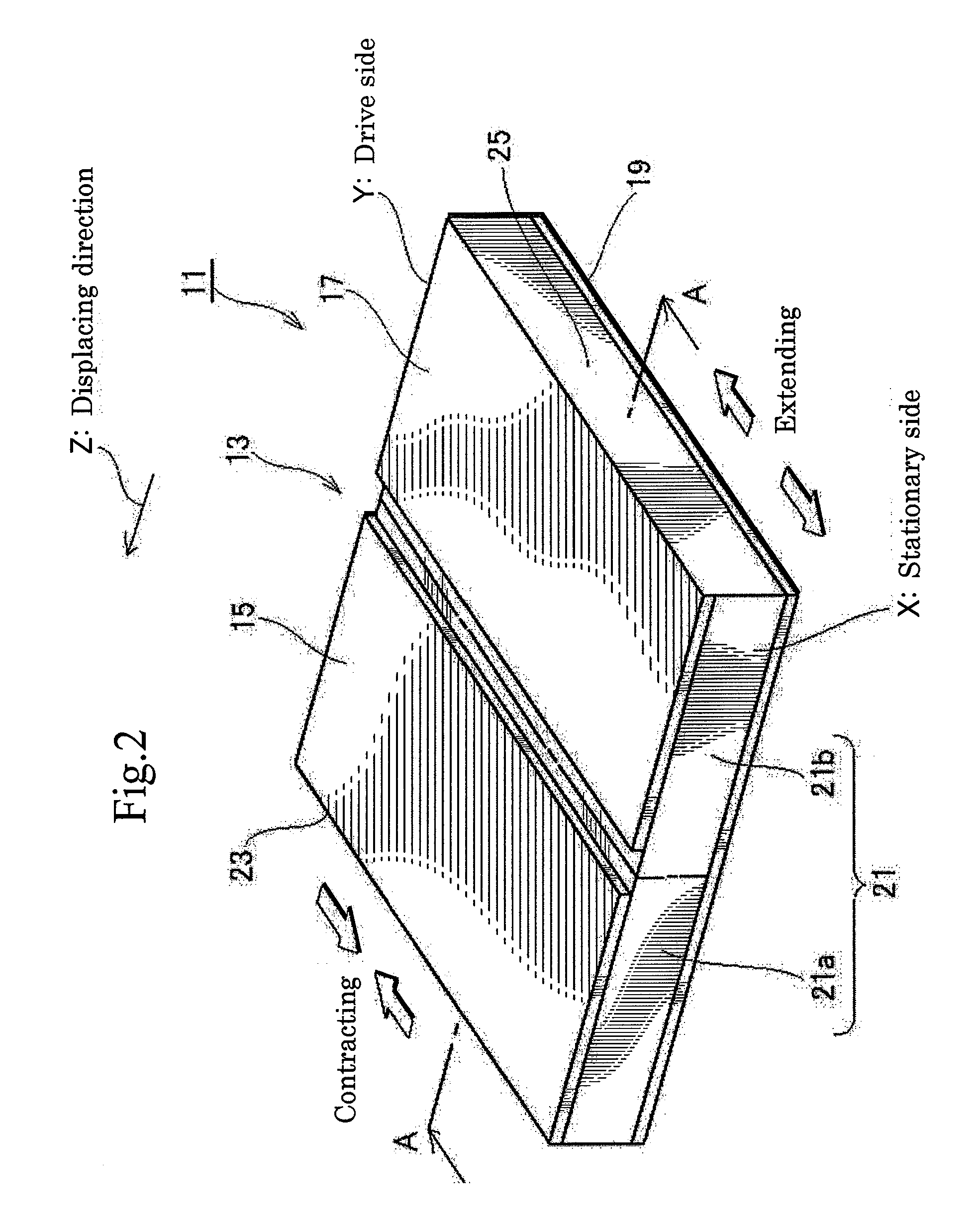

Electrode structure of piezoelectric element, method of forming electrode of piezoelectric element, piezoelectric actuator, and head suspension

ActiveUS20100195252A1Avoid shortingTrack finding/aligningPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric actuatorsMechanical engineering

An electrode structure of a piezoelectric element is provided. The piezoelectric element 23a (23b) constitutes a piezoelectric actuator 19 attached to an attaching part 30 of an object, to minutely move a movable part 15 of the object relative to a base part 13 of the object according to deformation occurring on the piezoelectric element in response to a power applied state of the piezoelectric element. The electrode structure includes an electrode 41a formed on one of a pair of electrode forming faces 31a and 31b of the piezoelectric element on an inner side of a peripheral zone 31a1, the peripheral zone being defined along the periphery of the electrode forming face 31a on which the electrode is formed. The electrode structure also includes a non-electrode part 51 formed in the peripheral zone. Even if the peripheral zone 31a1 of the electrode forming face 31a having a short-circuit causing possibility touches the attaching part 30, no short circuit occurs.

Owner:NHK SPRING CO LTD

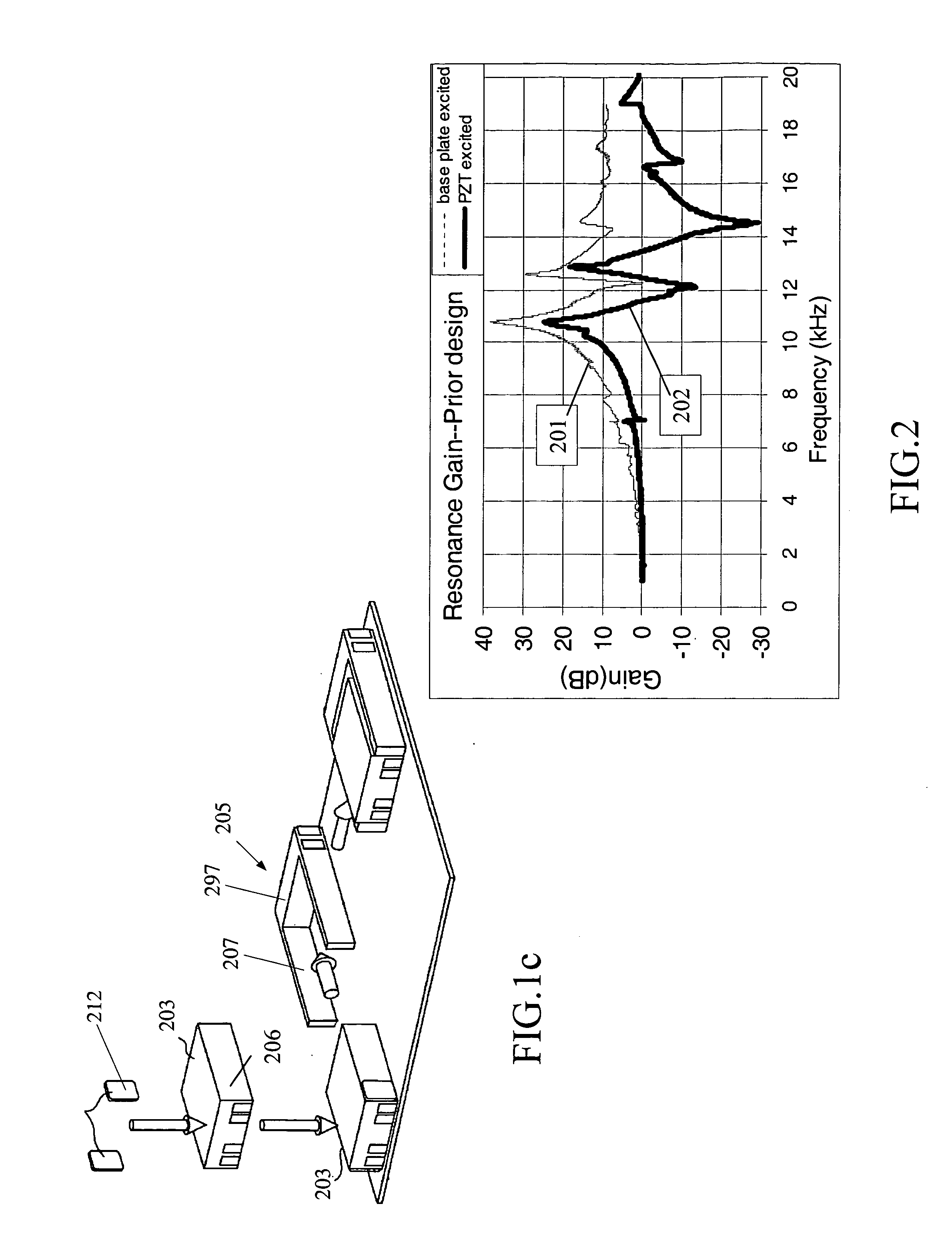

Micro-actuator, vibration canceller, head gimbal assembly, and disk drive unit with the same

InactiveUS20060146449A1Precise positioningImprove featuresArm with actuatorsRecord information storageMicro actuatorResonance

A head gimbal assembly (HGA) for a disk drive unit that includes a micro-actuator, a slider and a suspension to load the slider and the micro-actuator. The micro-actuator is provided with a vibration canceller that counteracts forces generated by activation of the micro-actuator when making fine head position adjustments. The vibration canceller incorporates PZT elements that generate counteracting forces in the bottom plate of the micro-actuator to cancel the vibration generated by the micro-actuator, thereby providing improved resonance performance for a disk drive unit.

Owner:SAE MAGNETICS (HK) LTD

Low profile load beam with etched cavity for PZT microactuator

ActiveUS8149545B1Less windageImproves inertial balancingArm with actuatorsRecord information storageDual stageAtomic physics

A dual-stage actuator disk drive suspension load beam has a recessed cavity formed in it into which the microactuator motor is partially or completely placed. The cavity may be formed by partially etching the load beam during the same etching process that creates the load beam from a sheet of stainless steel material. The partially etched load beam having a cavity for the microactuator motor has the advantages of a lower profile, improved inertial balancing of the suspension, and increased sway resonant frequency.

Owner:MAGNECOMP

Rotational PZT micro-actuator, head gimbal assembly, and disk drive unit with the same

InactiveUS7379274B2Precise positioningImprove featuresArm with actuatorsRecord information storageMicro actuatorControl theory

A head gimbal assembly (HGA) for a disk drive unit that includes a micro-actuator, a slider and a suspension to load the slider and the micro-actuator. The micro-actuator includes a pair of actuator side arms, a PZT element extending between and connecting the actuator side arms; a rotatable plate positioned between the actuator side arms, wherein the slider is mounted on the rotatable plate; and a pair of connection elements that connect the rotatable plate to the actuator side arms, respectively. The rotatable plate rotates in a first direction when the PZT element contracts and a second direction when the PZT element expands.

Owner:SAE MAGNETICS (HK) LTD

Head suspension assembly and magnetic disk drive

According to one embodiment, a head suspension assembly includes a load beam supporting a head, and a microactuator configured to swing the load beam. The microactuator includes two piezoelectric elements configured to undergo shear deformation when supplied with a voltage and juxtaposed in such a manner that respective shear deformations thereof are opposite in direction, a first electrode and a second electrode arranged so as to hold the piezoelectric elements therebetween, and a support plate joined to the first electrode with an insulating layer therebetween and joined to the load beam to support the load beam.

Owner:TOSHIBA STORAGE DEVICE CORP

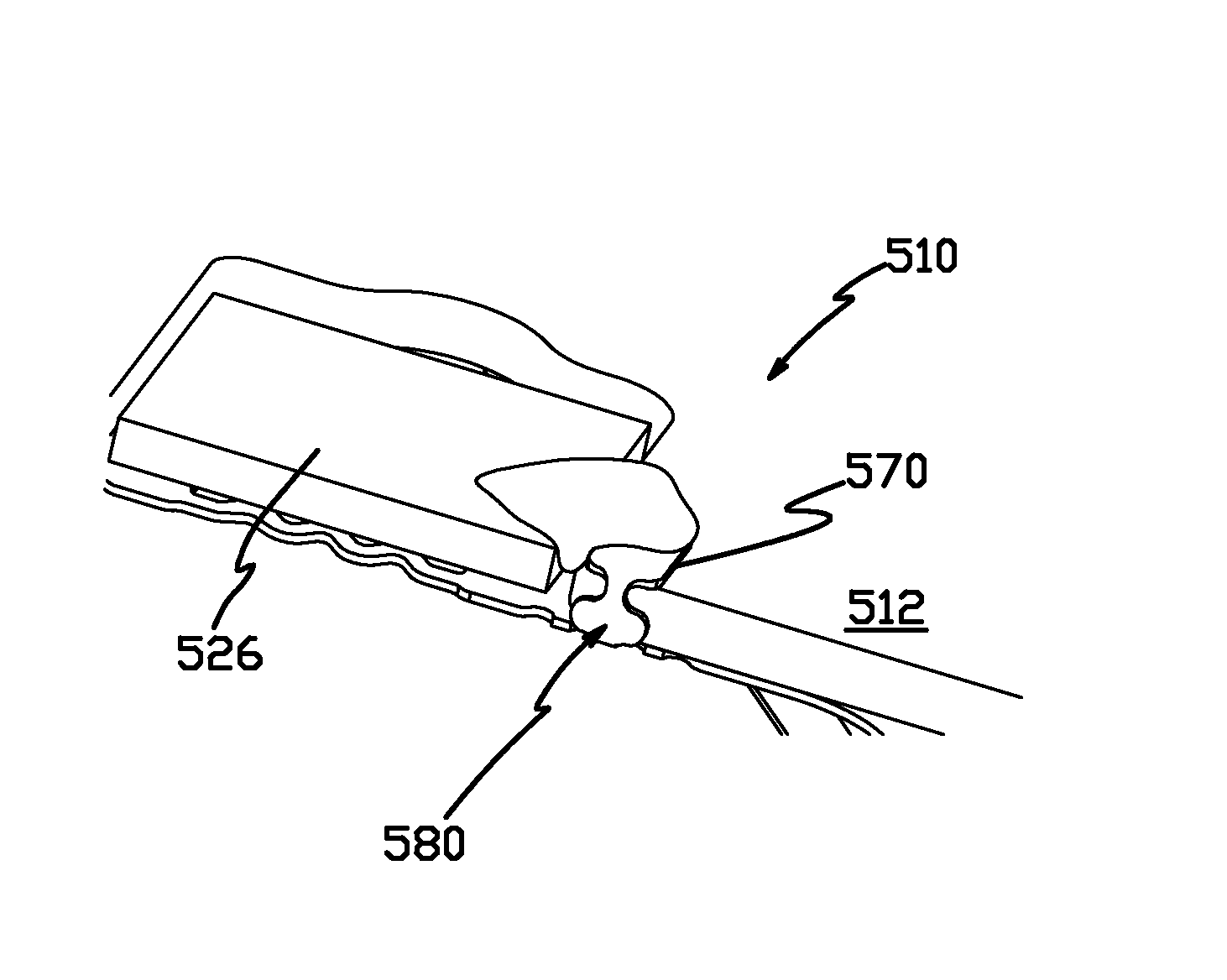

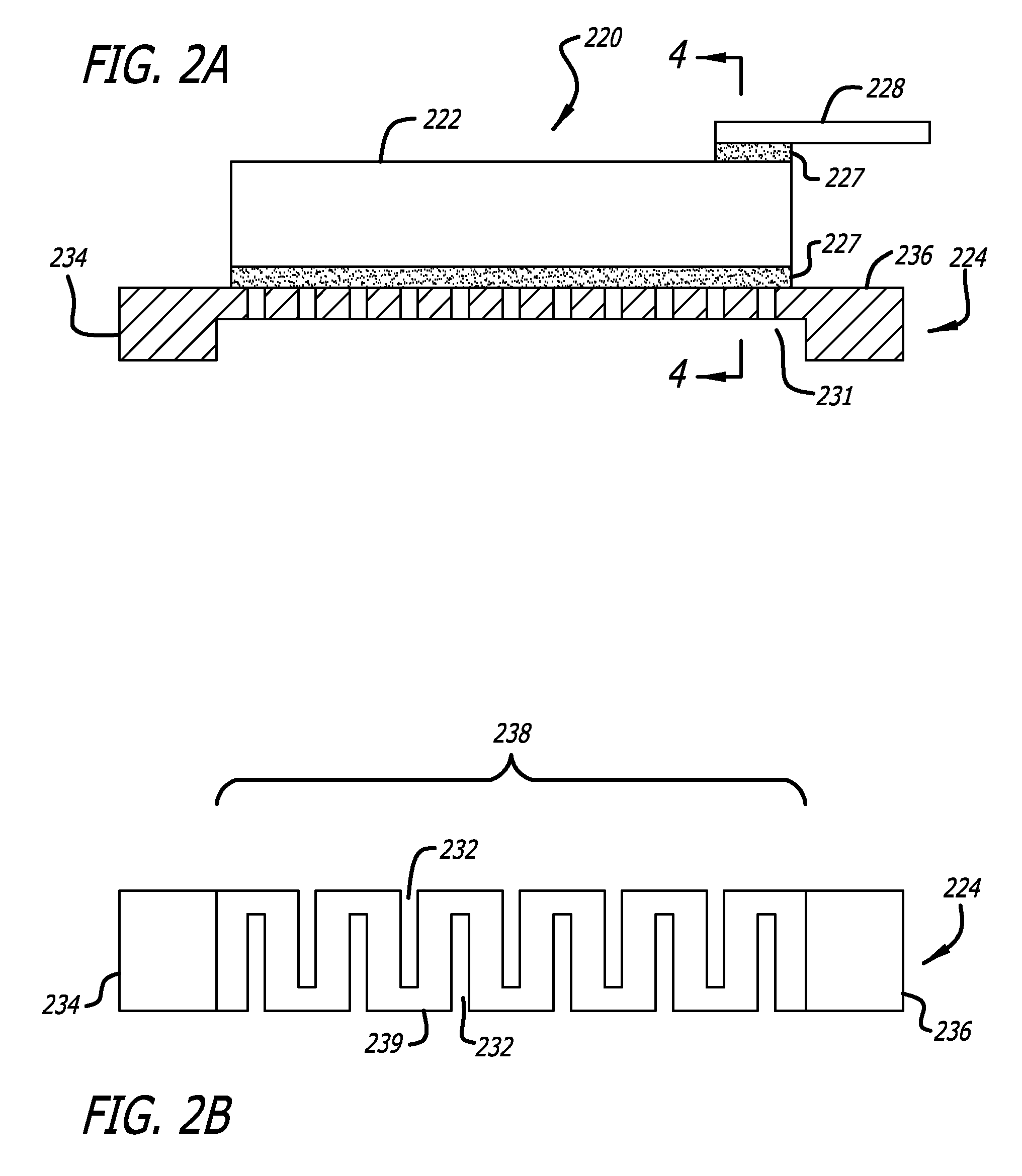

Hard disk drive DSA suspension having PZT encapsulation dam

ActiveUS8526142B1Sufficient flexibilityIncrease stroke lengthArm with actuatorsRecord information storageEpoxyDual stage

A dual stage actuated (DSA) suspension includes a dam-like structure that holds epoxy along the outside lateral side of the PZT microactuators while that epoxy hardens. In the illustrative embodiment, the dam-like structure is in the form of a wing rail that is integrally formed with the suspension base plate, and extends parallel to the outside face of the PZT. The wing rail has an upturned edge to help contain the epoxy while it hardens. The wing rail has springs at its fore and aft ends so that the rail does not unduly limit movement of the PZTs and hence microactuator stroke length. The wing rail does not touch the PZT electrodes. The encapsulation dam allows epoxy to be dispensed after the PZT has been located on the suspension, so as to substantially cover all sides of the PZT and thus prevent the shedding of contaminating particles during operation.

Owner:MAGNECOMP

Popular searches

Mounting/attachment of transducer head Support for heads Piezoelectric/electrostrictive devices Structure of arm assembly Alignment for track following on disks Piezoelectric/electrostrictive/magnetostrictive devices Electrical connection between arm and support Piezoelectric/electrostrictive transducers Semiconductor devices Connection contact member material

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com