Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

242 results about "Shear mode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

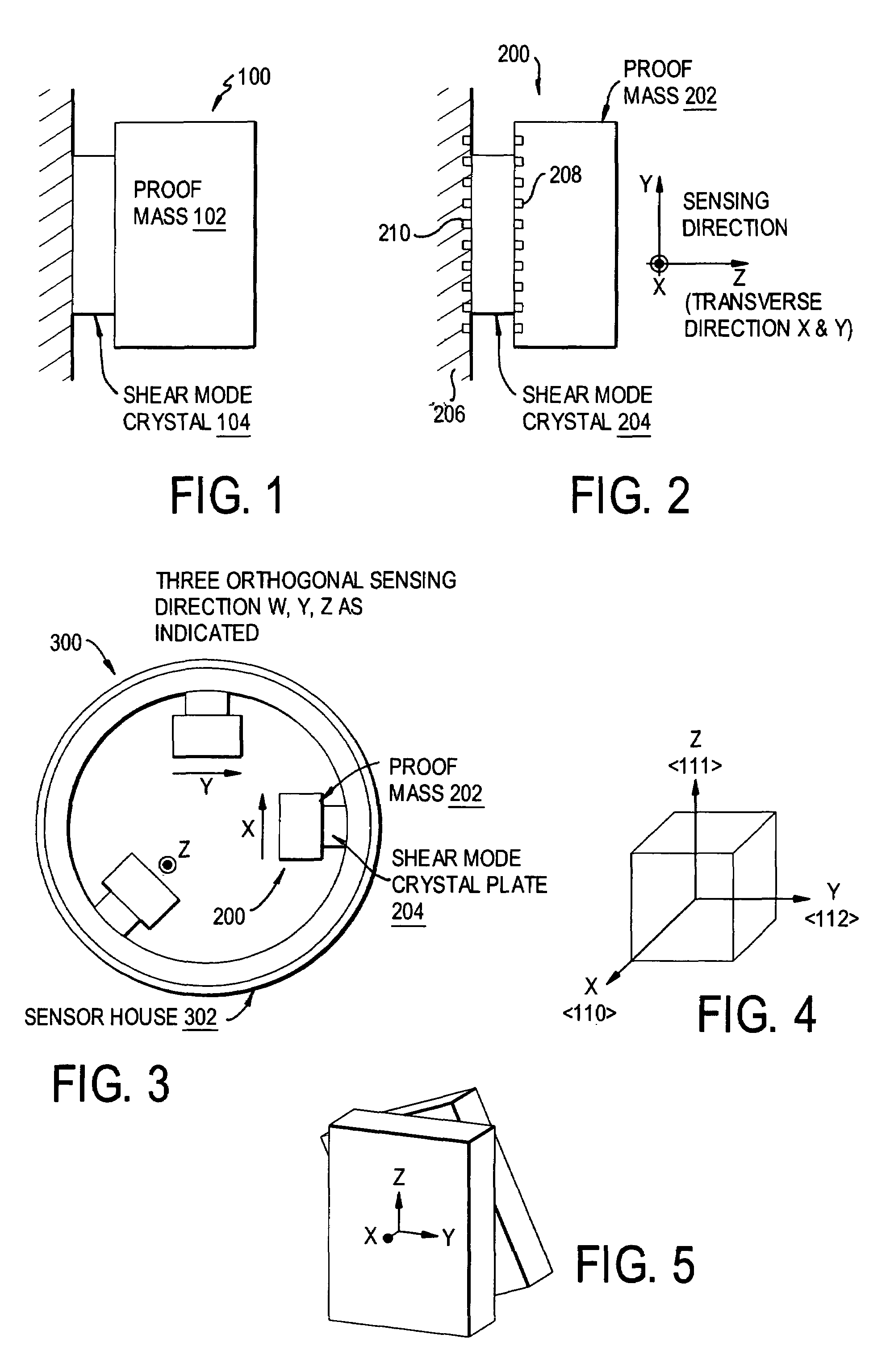

Shear mode accelerometer (vibration sensor) designs feature sensing crystals attached between a center post and a seismic mass. A compression ring or stud applies a pre-load force to the element assembly to insure a rigid structure and linear behavior.

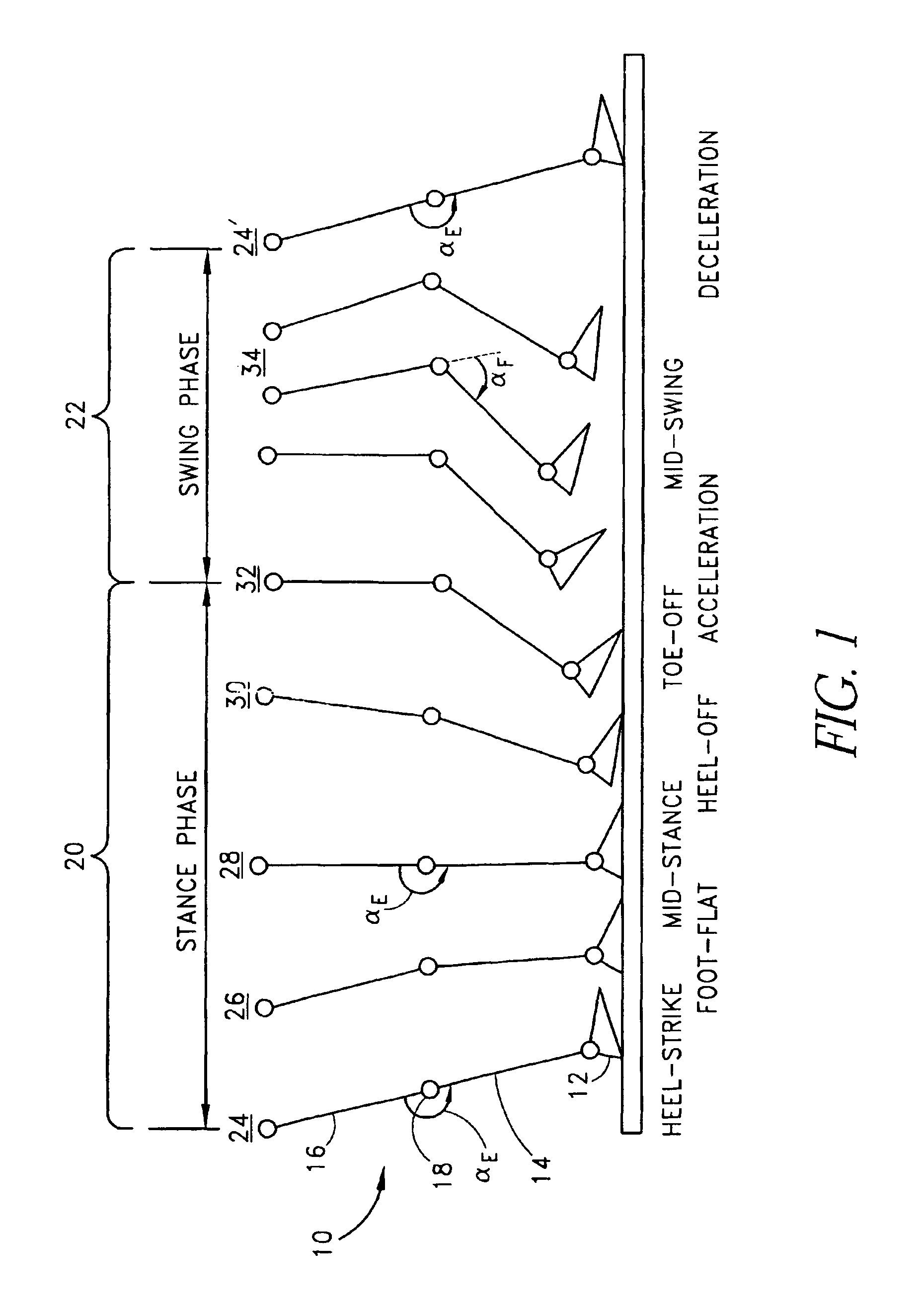

Electronically controlled prosthetic knee

InactiveUS6764520B2Improve efficiencyImprove practicalitySpringsNon-rotating vibration suppressionLow speedMagnetorheological fluid

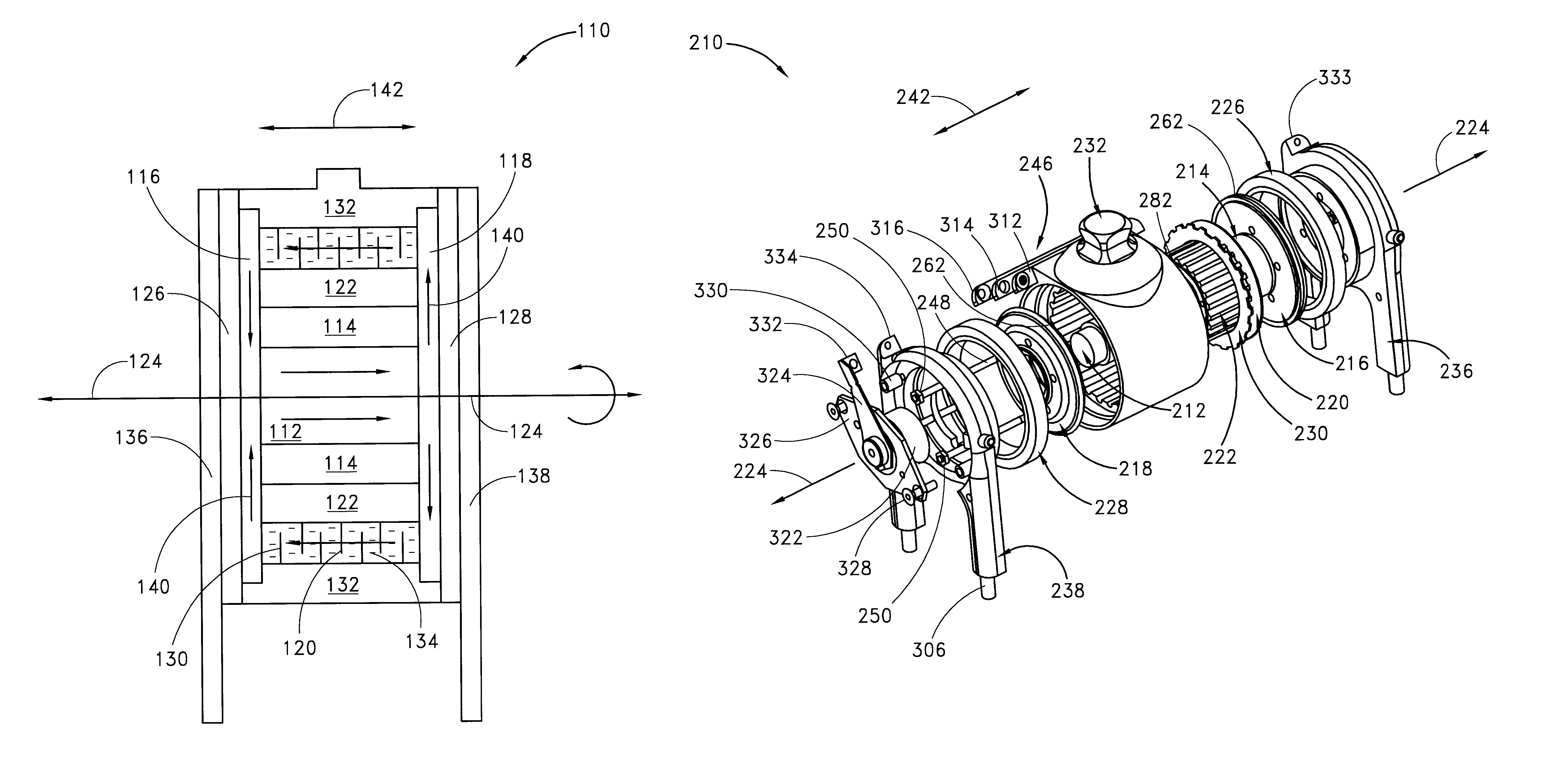

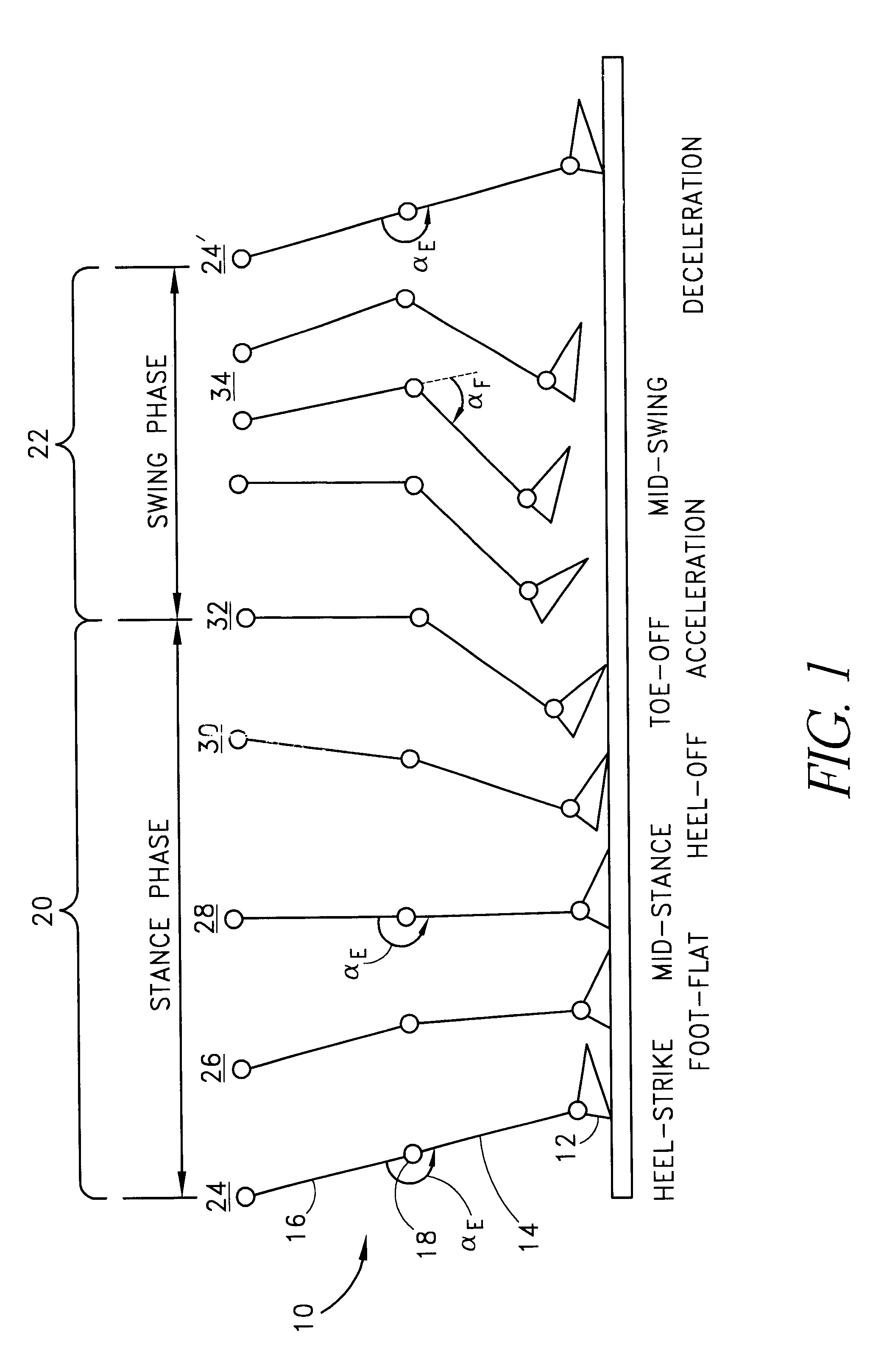

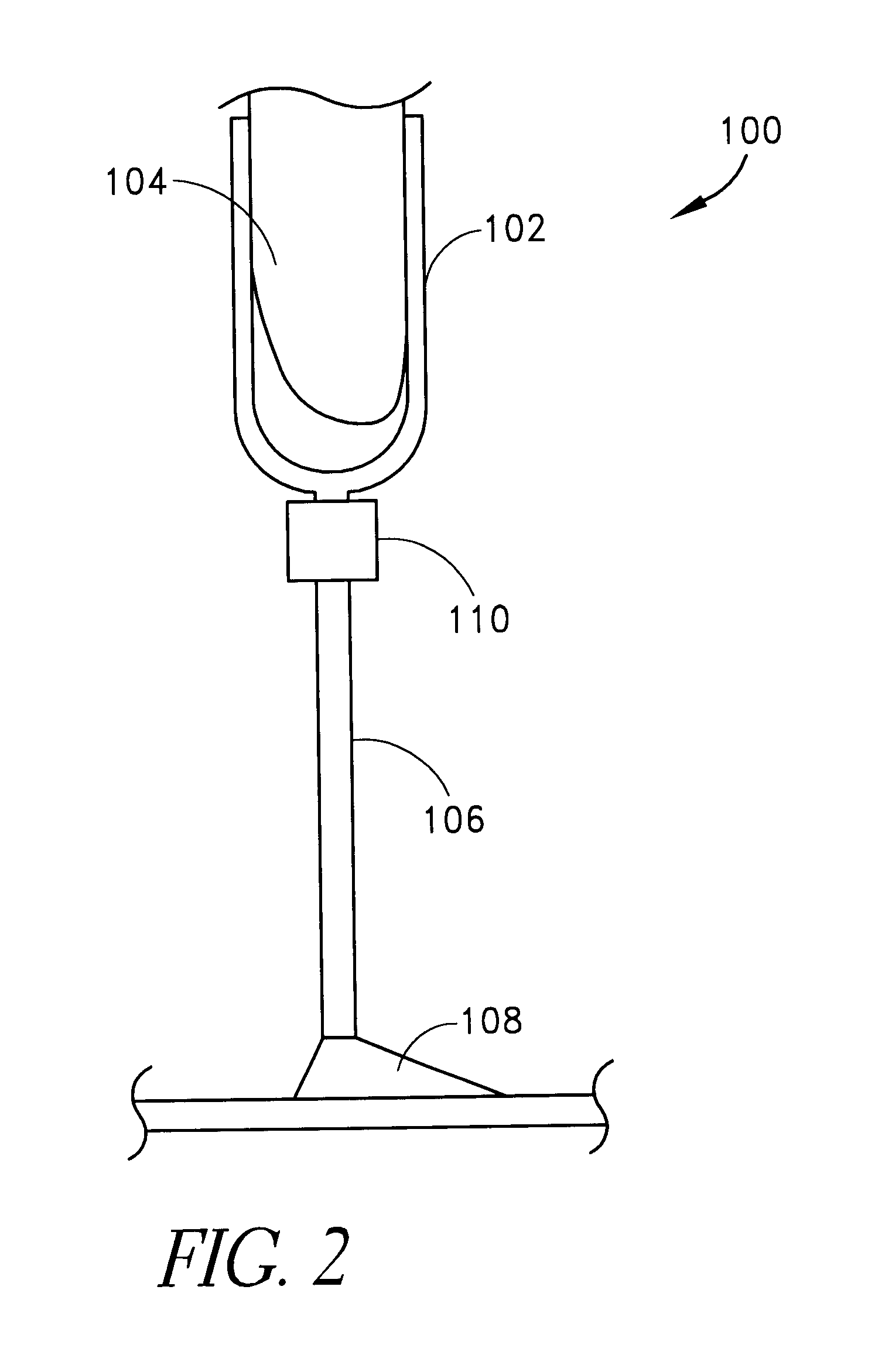

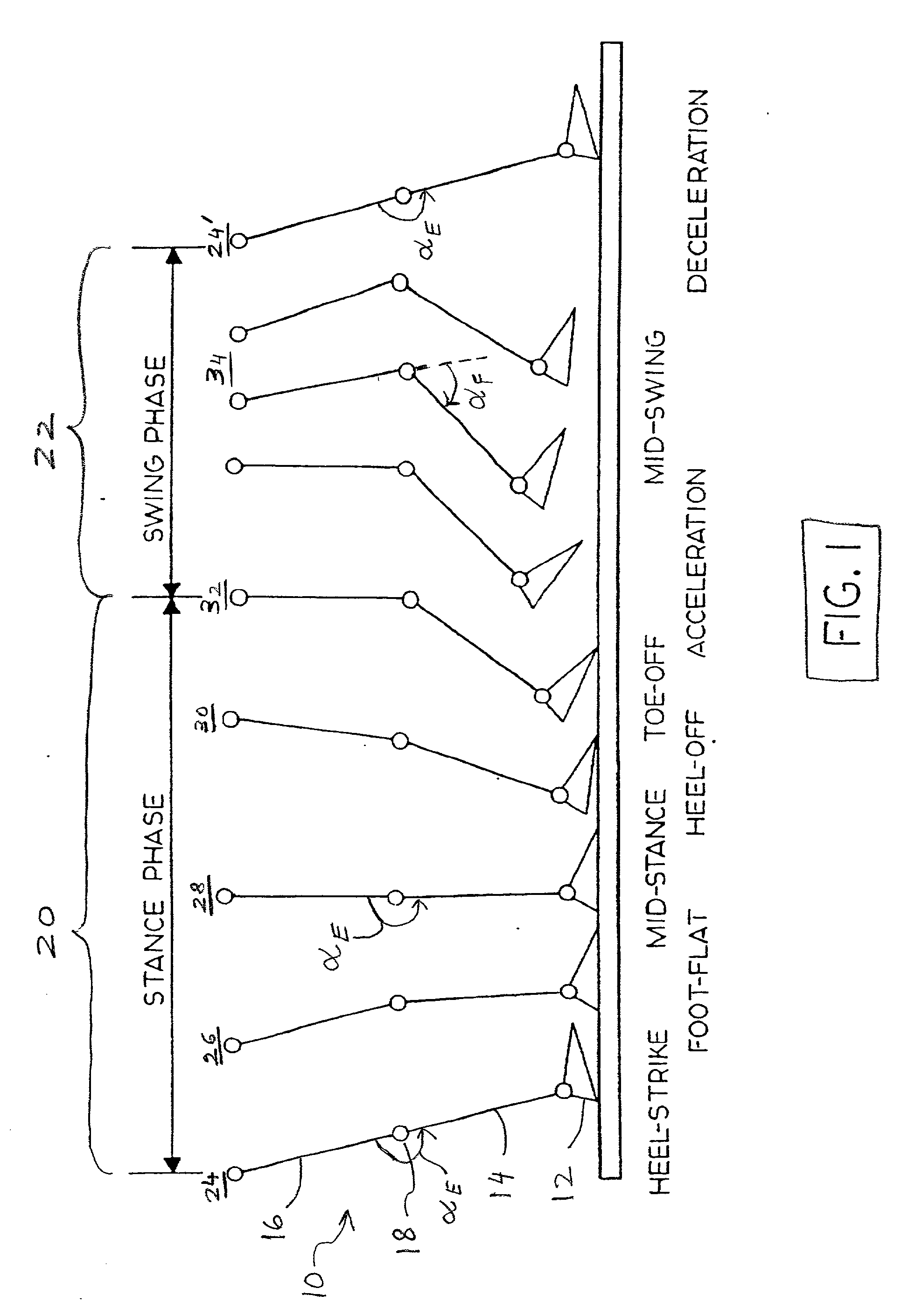

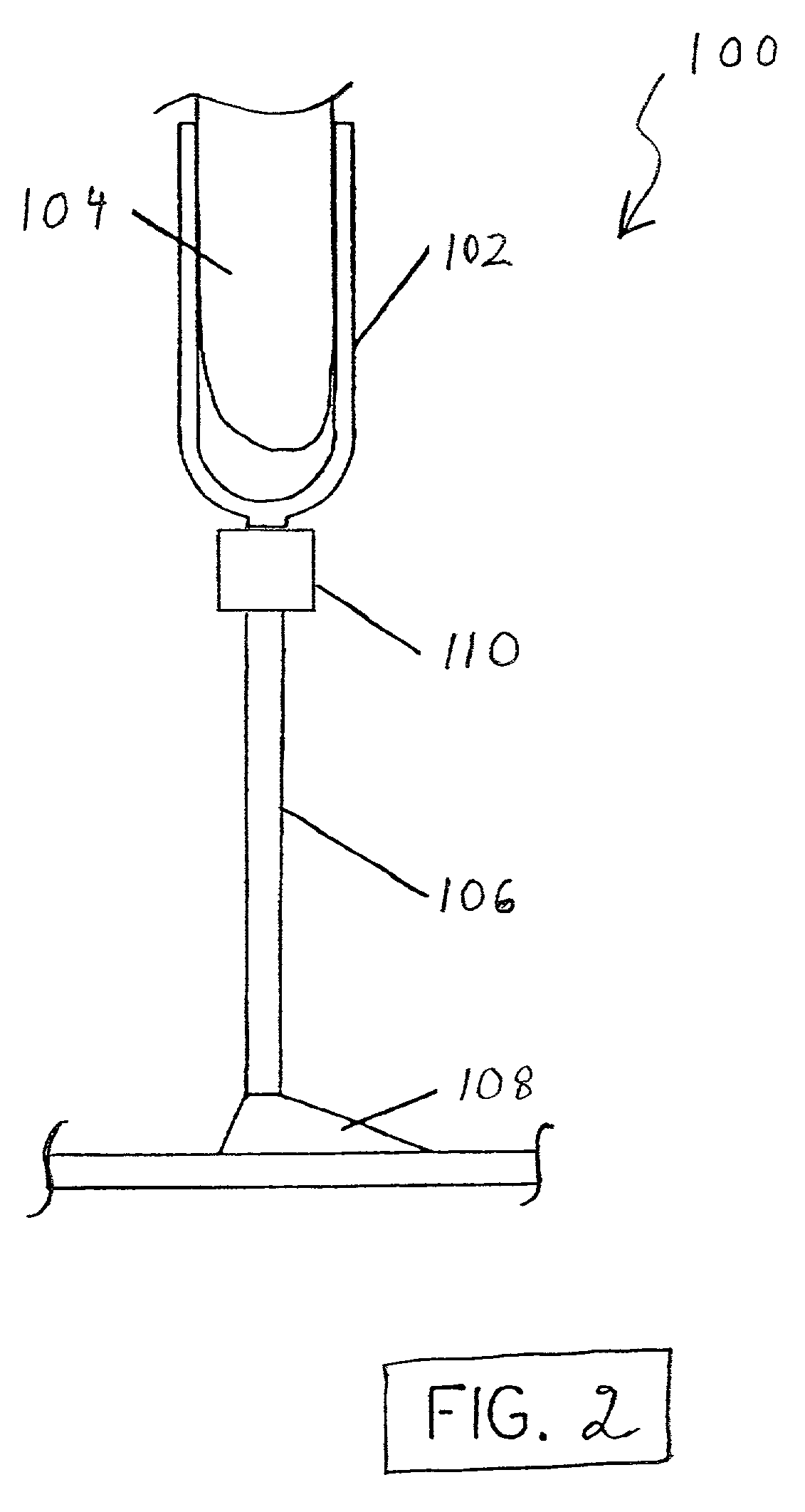

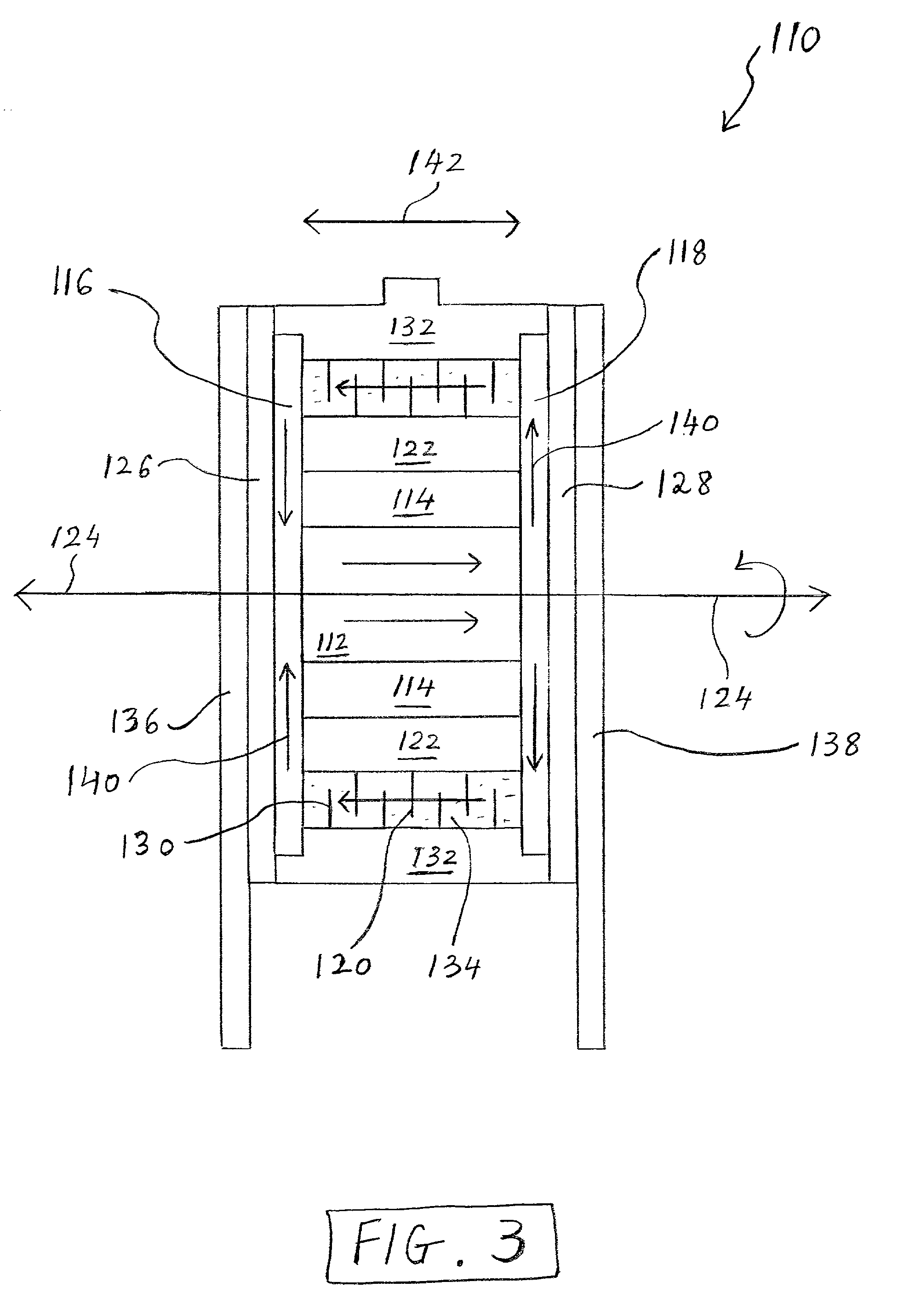

The present invention relates to a variable-torque magnetorheologically actuated prosthetic knee which utilizes a plurality of interspersed and alternating rotors and stators to shear magnetorheological fluid in gaps formed therebetween. Advantageously, by operating in the "shear mode" there is substantially no or negligible fluid pressure buildup or change. Moreover, the multiple MR fluid gaps or flux interfaces desirably allow for the production of a large torque at low speed-eliminating the need for a transmission-and also for a wide dynamic torque range. One embodiment of the invention allows the rotors and / or stators to close the gaps therebetween to create a frictional torque component, thereby forming a "hybrid" braking system which provides a total torque or damping which is a combination of viscous torque and frictional torque.

Owner:MASSACHUSETTS INST OF TECH

Electronically controlled prosthetic knee

InactiveUS20010029400A1Move and/or adapt comfortably and safelyImprove efficiencySpringsNon-rotating vibration suppressionFriction torqueMagnetorheological fluid

The present invention relates to a variable-torque magnetorheologically actuated prosthetic knee which utilizes a plurality of interspersed and alternating rotors and stators to shear magnetorheological fluid in gaps formed therebetween. Advantageously, by operating in the "shear mode" there is substantially no or negligible fluid pressure buildup or change. Moreover, the multiple MR fluid gaps or flux interfaces desirably allow for the production of a large torque at low speed-eliminating the need for a transmission-and also for a wide dynamic torque range. One embodiment of the invention allows the rotors and / or stators to close the gaps therebetween to create a frictional torque component, thereby forming a "hybrid" braking system which provides a total torque or damping which is a combination of viscous torque and frictional torque.

Owner:MASSACHUSETTS INST OF TECH

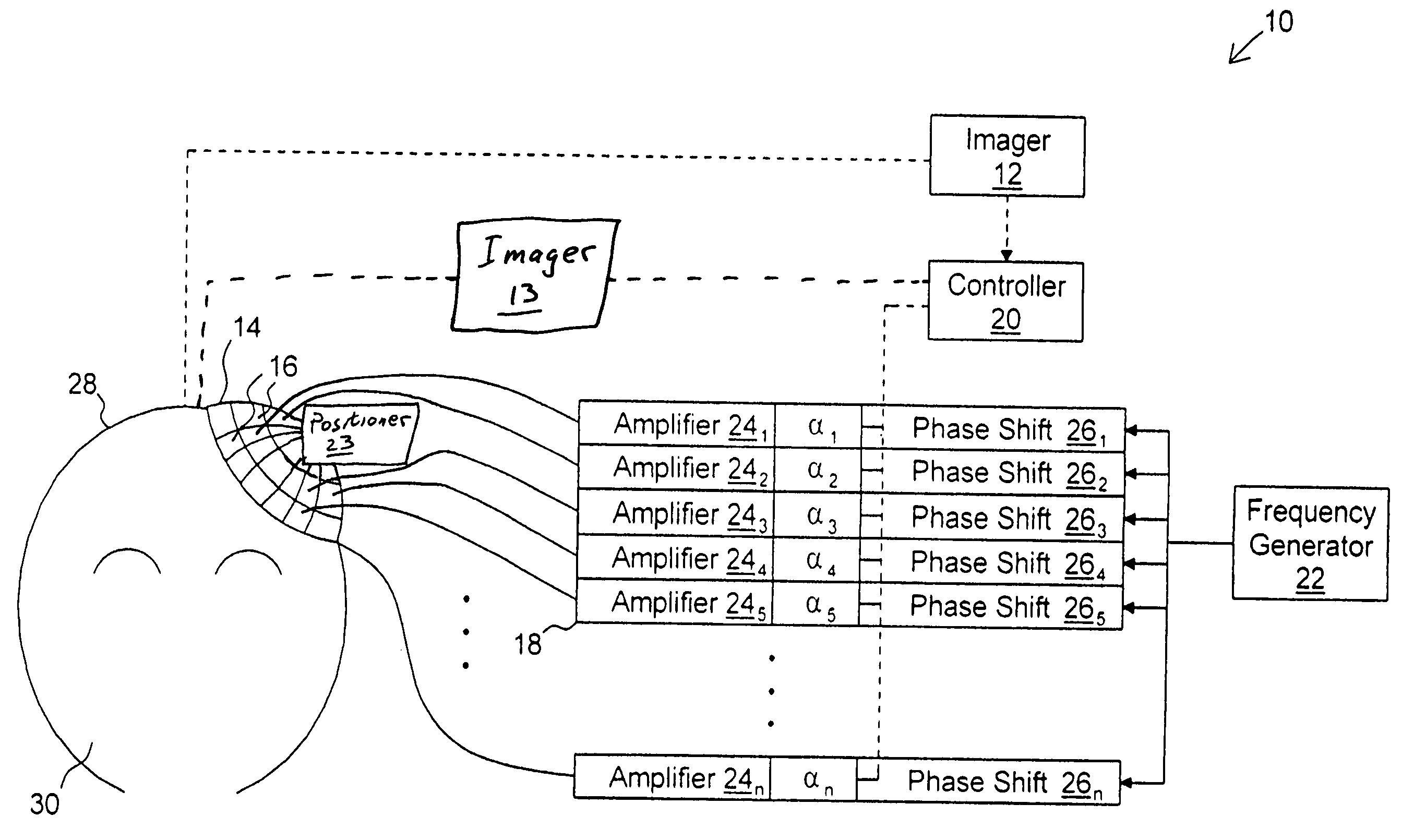

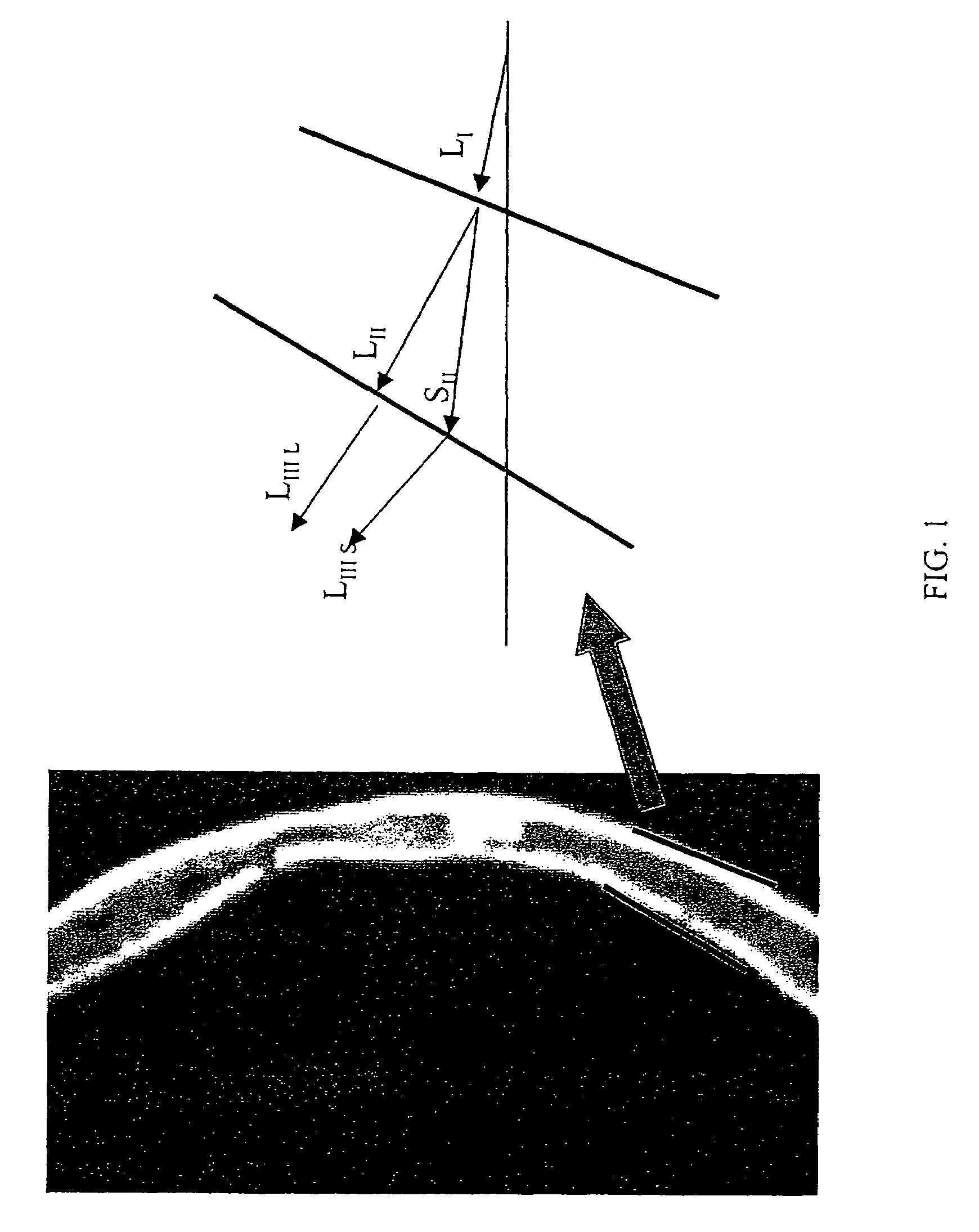

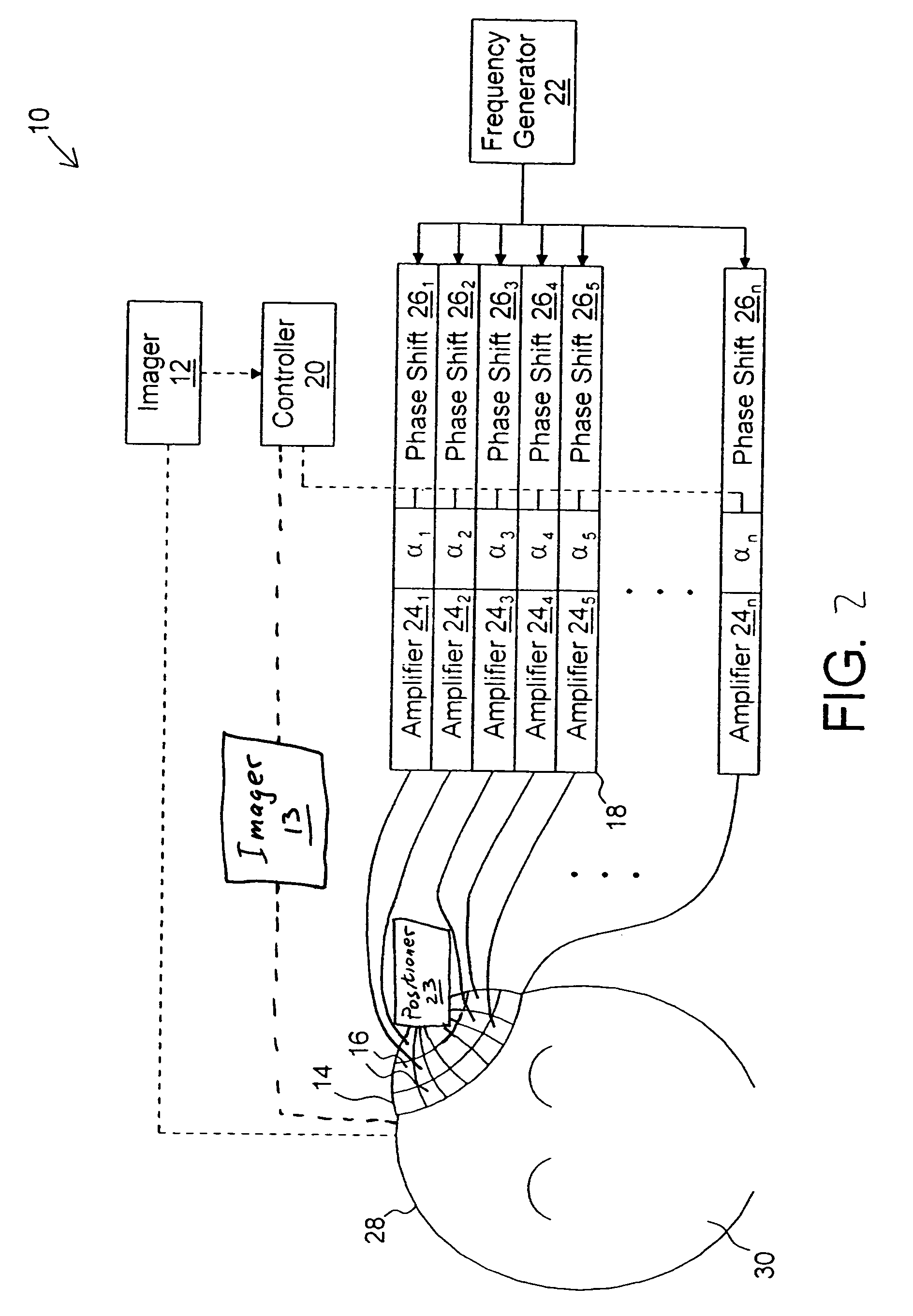

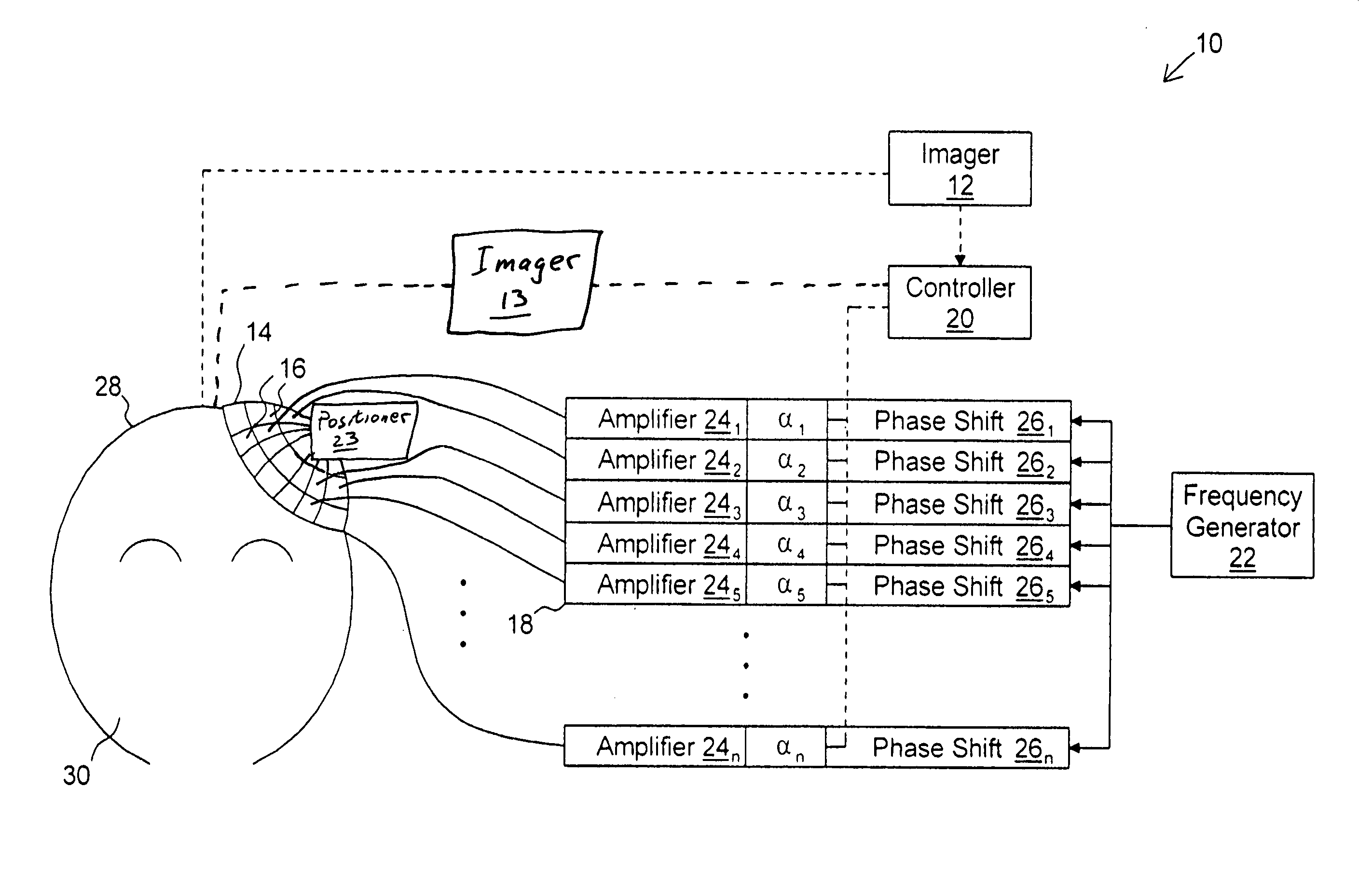

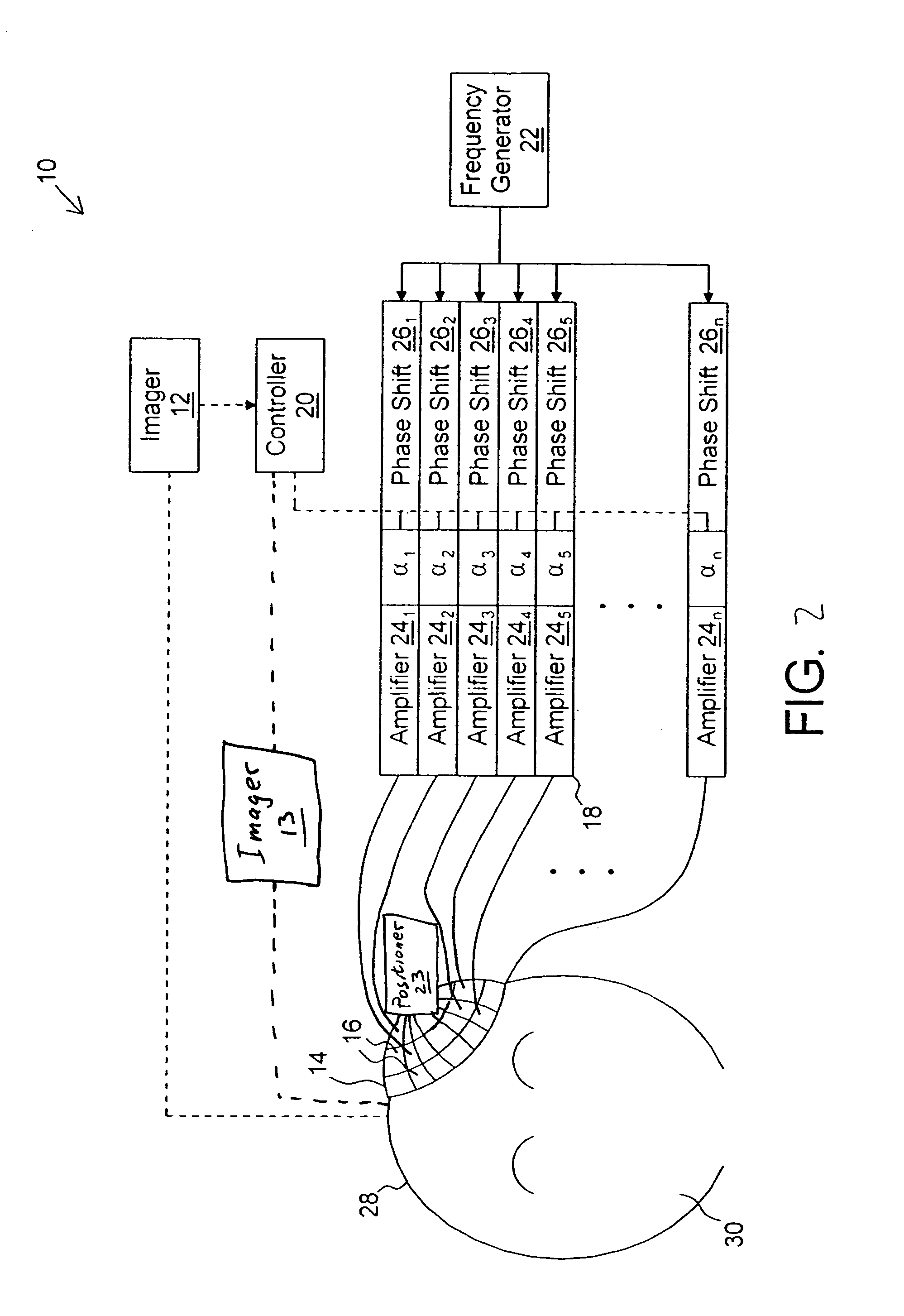

Shear mode therapeutic ultrasound

A method of delivering ultrasound signals using shear waves includes applying a portion of at least a first ultrasound beam to a subject at at least a first incident angle relative to the surface of the subject to induce shear waves in the subject, energy in the shear waves forming a substantial part of energy of first ultrasound waves at a desired region in the subject at a therapeutic level.

Owner:HYNYNEN KULLERVO +1

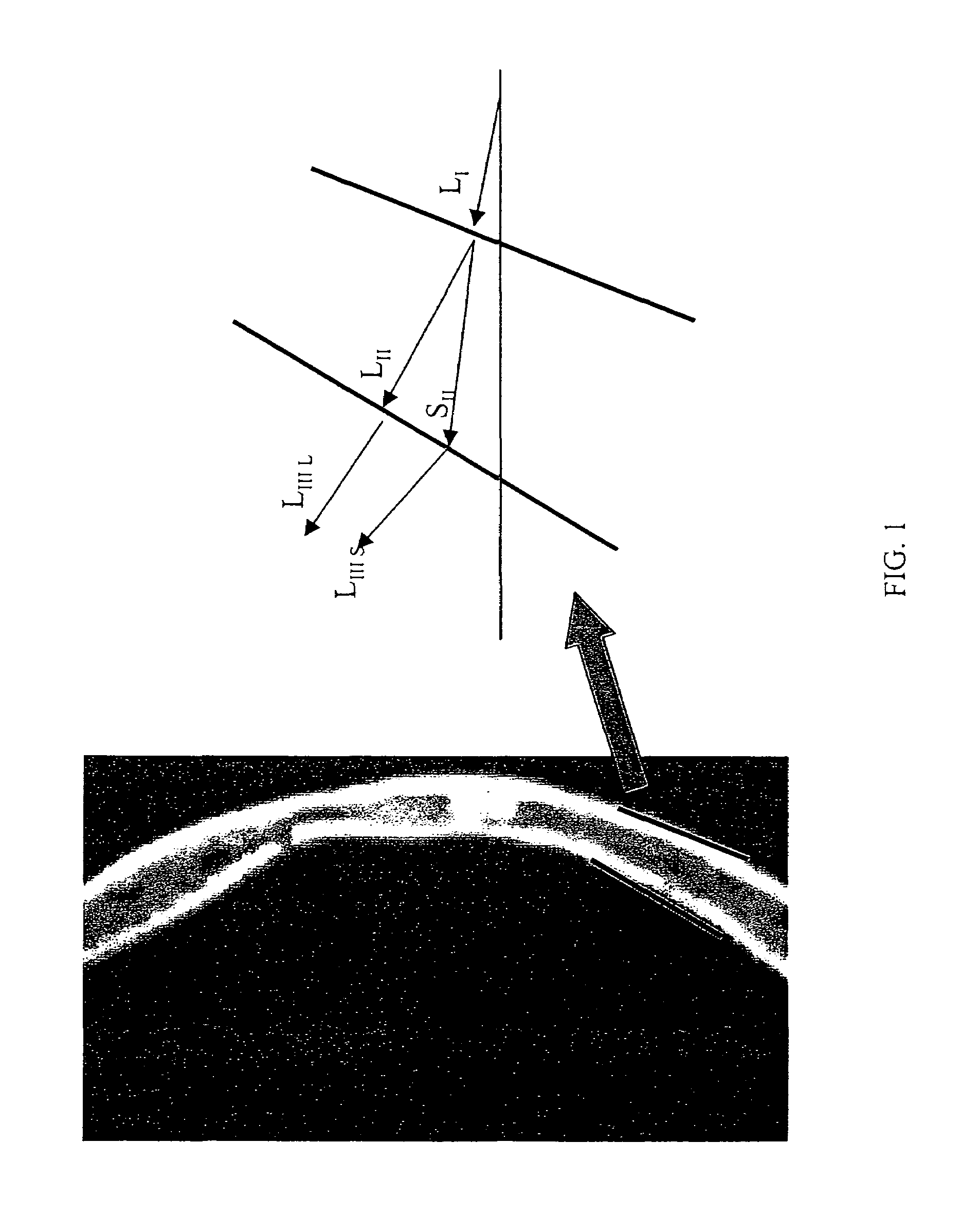

Shear mode diagnostic ultrasound

ActiveUS7175599B2Simple equipmentHigh gainUltrasound therapyBlood flow measurement devicesSonificationDiagnostic ultrasound

A method of diagnosing a subject by delivering ultrasound signals using shear waves includes applying a portion of an ultrasound mainbeam to a bone surface at an incident angle relative to the surface of the bone to induce shear waves in the bone, energy in the shear waves forming a substantial part of energy of first ultrasound waves at a desired region in the subject through the bone, detecting at least one of reflected and scattered energy of the applied ultrasound mainbeam, and analyzing the detected energy for a diagnostic purpose.

Owner:THE BRIGHAM & WOMEN S HOSPITAL INC

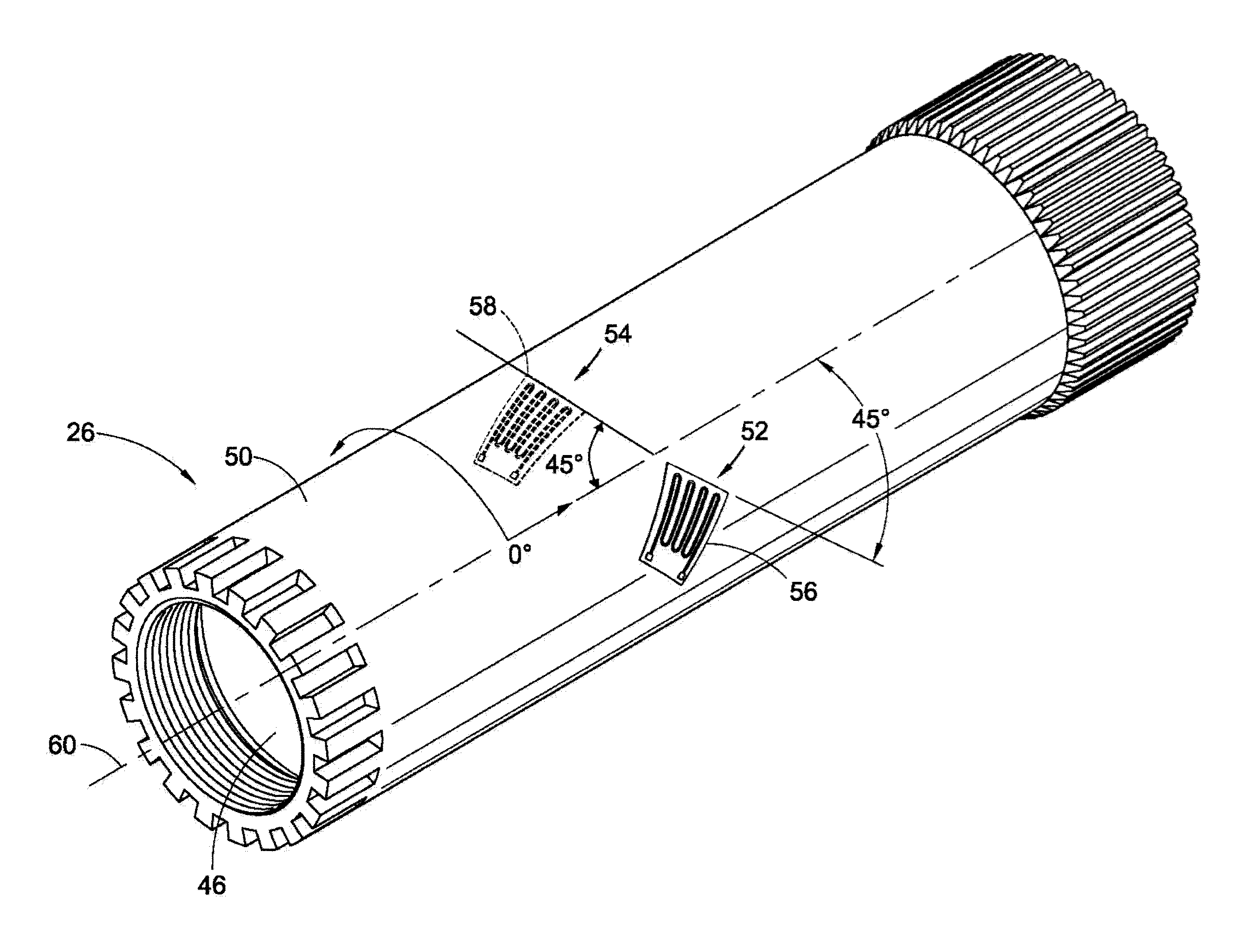

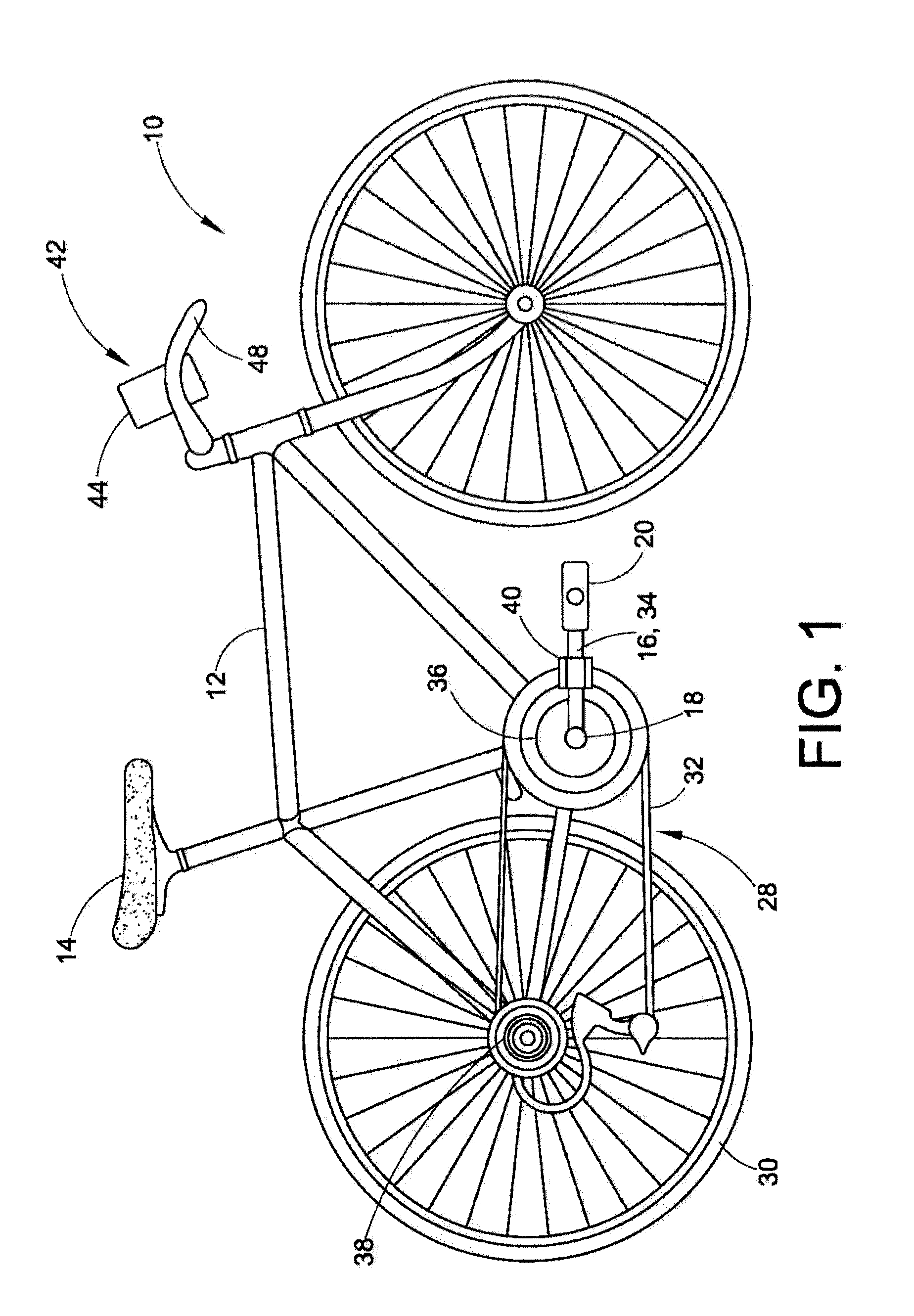

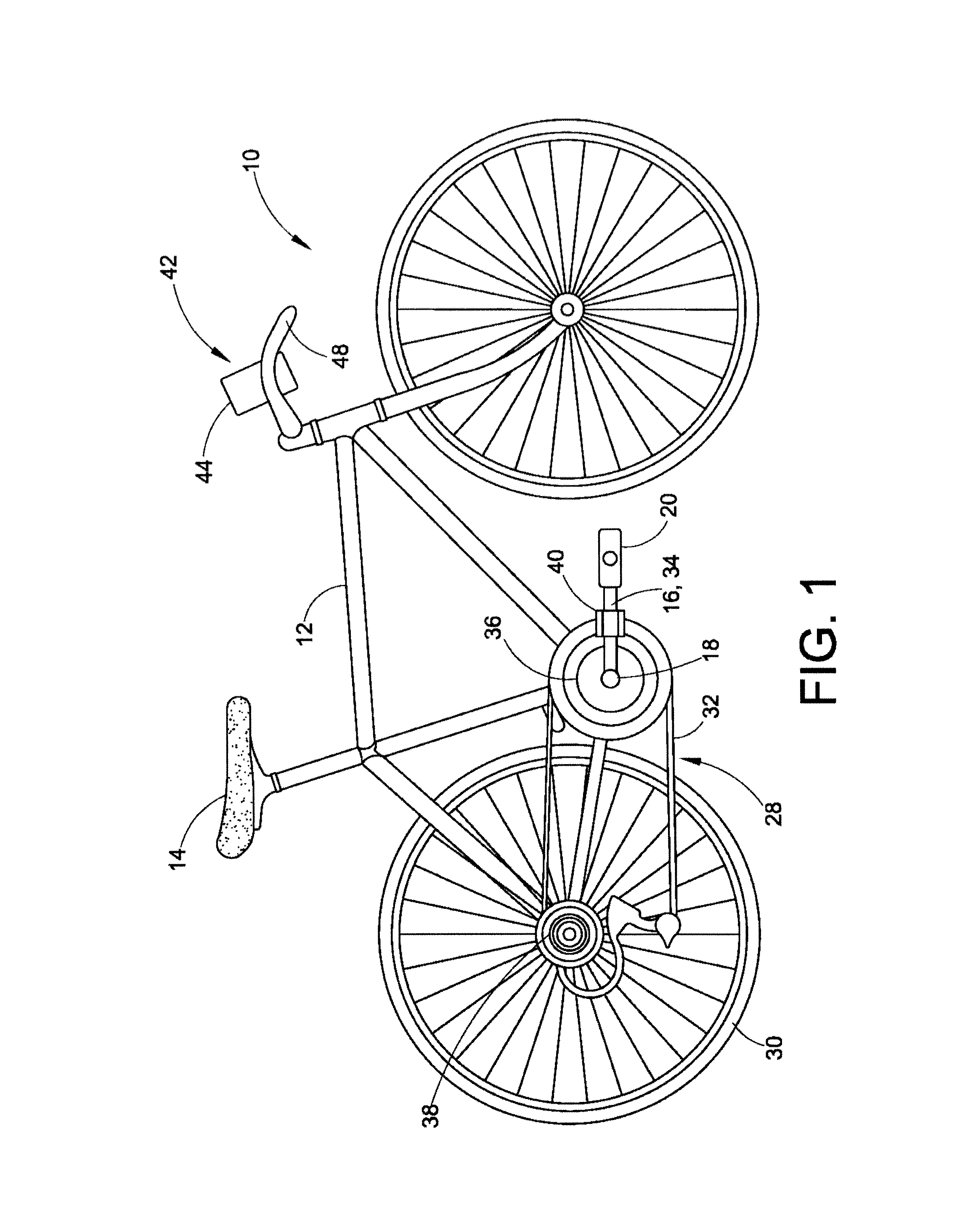

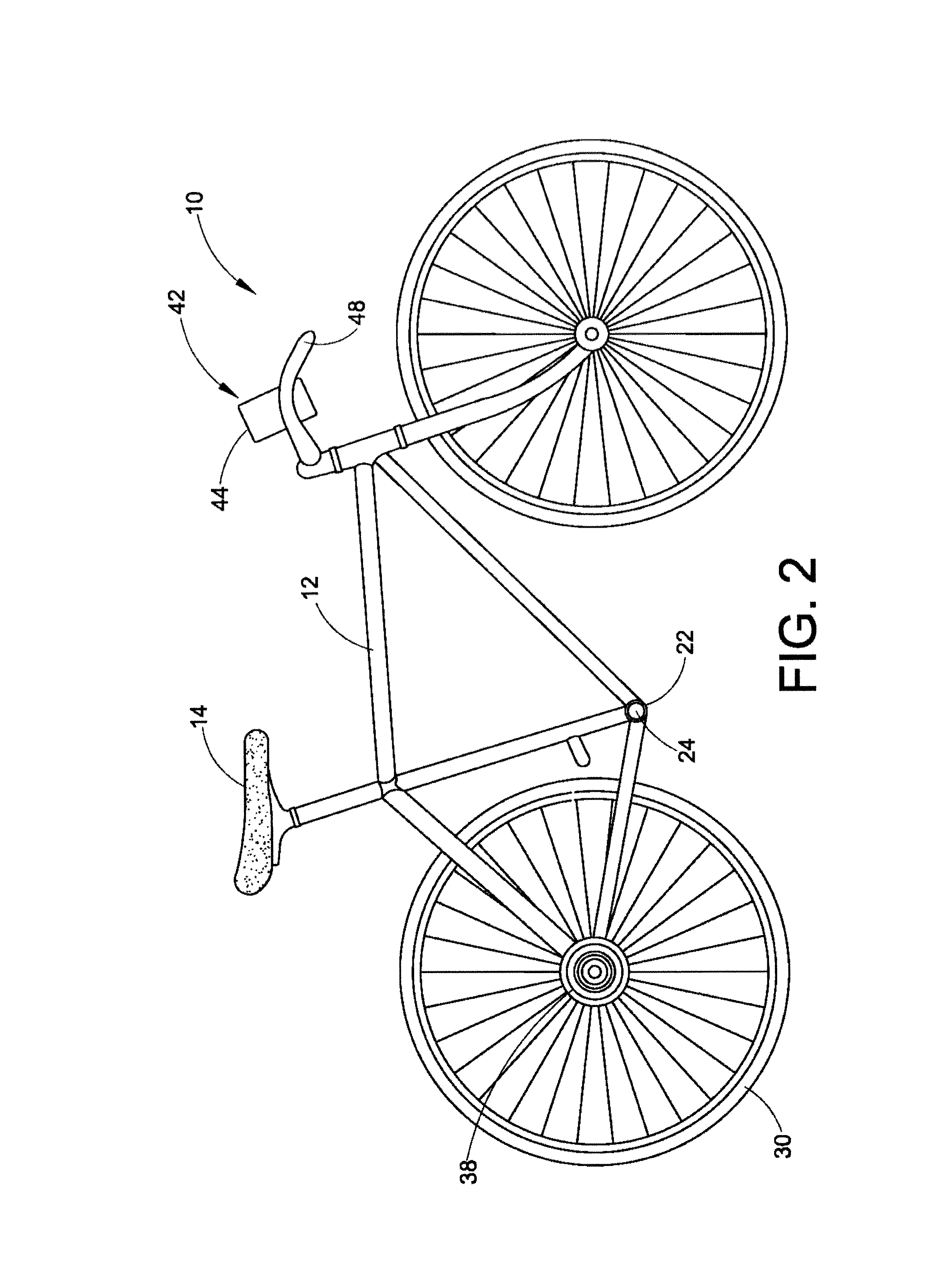

Torque sensor

A torque sensor for a human-powered object includes a spindle connecting crank arms of the object. In one embodiment, the object can be a bicycle. The torque sensor further includes at least one strain gauge mounted to the spindle in a shear pattern to measure shear strain perpendicular to a radius of the spindle. In some embodiments, the torque sensor further includes a carrier fixed to a hollow interior of the spindle, where at least one strain gauge is mounted to the spindle via the carrier. Advantageously, the torque sensor provides a low cost method to measure power.

Owner:GRASSI MICHAEL J

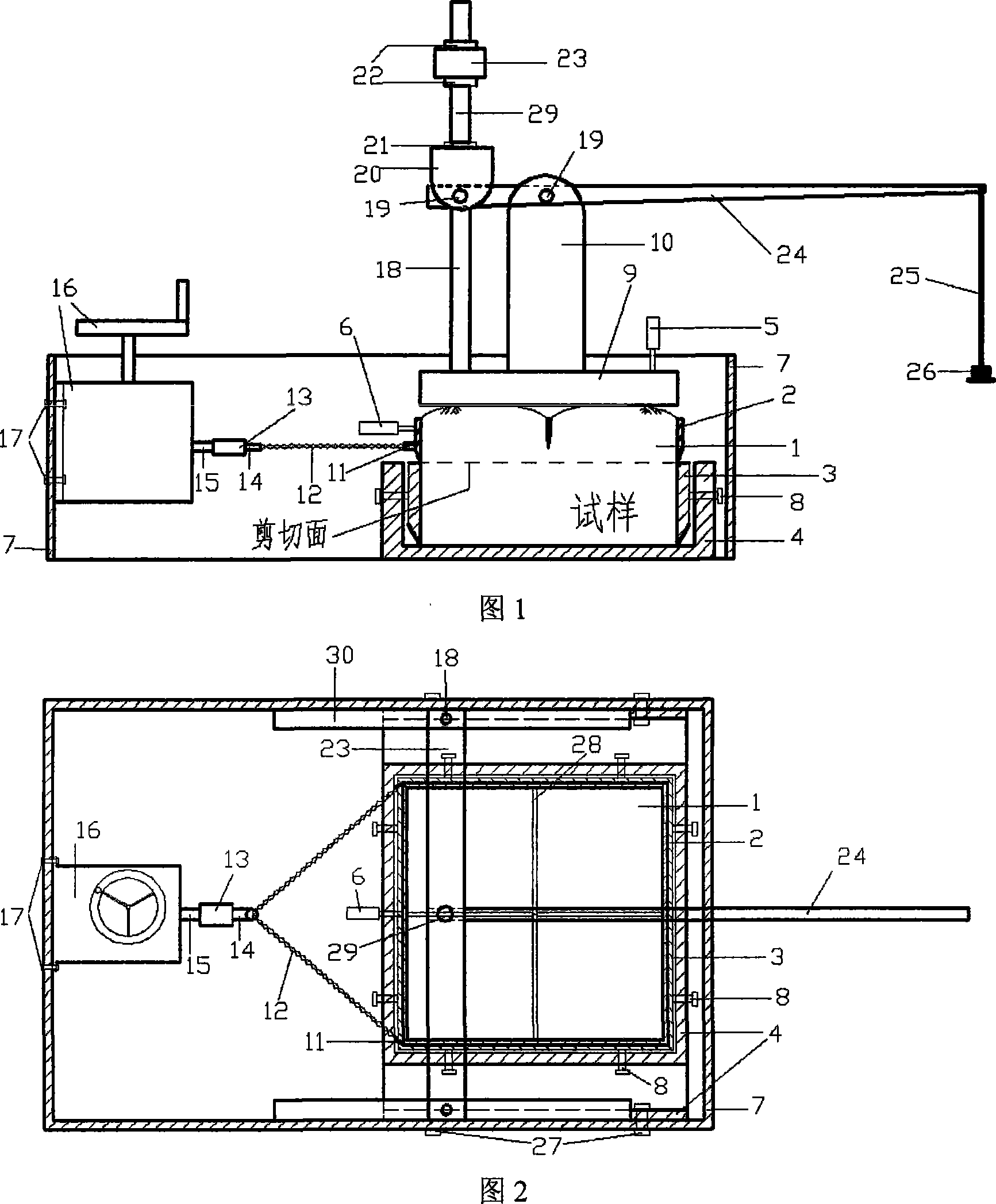

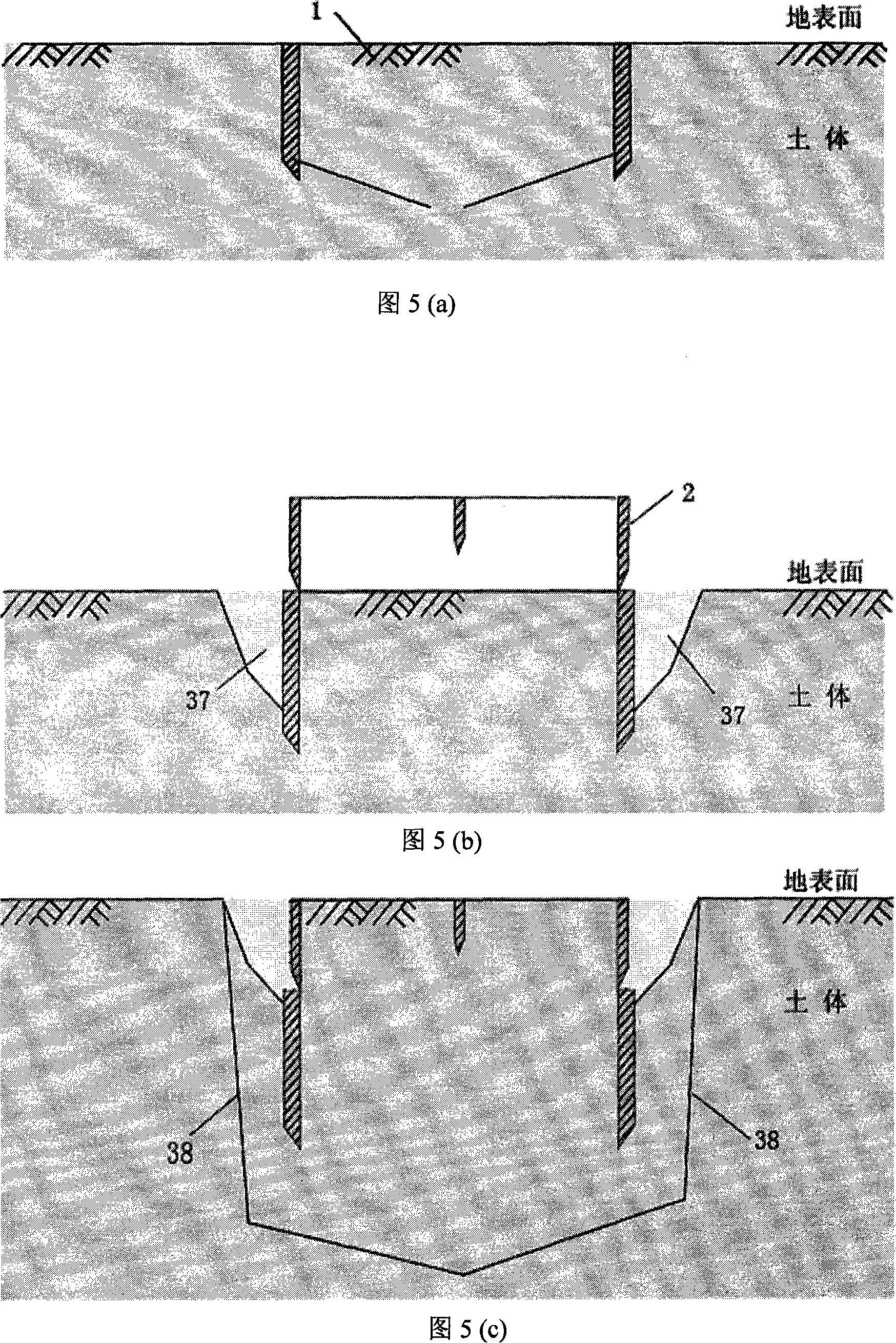

Portable on-spot and indoor dual-purpose direct-cutting experiment instrument and its sampling method

InactiveCN101105433AEasy detectionTruly reflect the volume changeWithdrawing sample devicesMaterial strength using steady shearing forcesField testsEngineering

A direct shear tester for both portable field test and indoor test and a sampling and testing method are provided. The tester comprises a sampling device, a portable vertical load system and a horizontal shear system. The testing method comprises burying a rigid frame together with a cruciform shear frame in the soil of a place to be test, digging out the whole soil containing the rigid frame and the cruciform shear frame to obtain an integrated sample with less interference, placing and fixing the integrated sample in a rigid frame base on a box-shaped frame, applying a vertical force by using the portable vertical load system on the box-shaped frame, and measuring the strength of the sample by using the shear frame. During the test process, the volume change of the sample in the vertical direction is not limited. The tester has simple structure, easy operation and good portability. The testing method employs flexible tension shear mode instead of the rigid top-bunt shear mode, overcomes the friction and sampling problems, and avoids the vertical pressure offset during the test process by using the portable vertical loading system, thereby increasing the test accuracy.

Owner:HOHAI UNIV

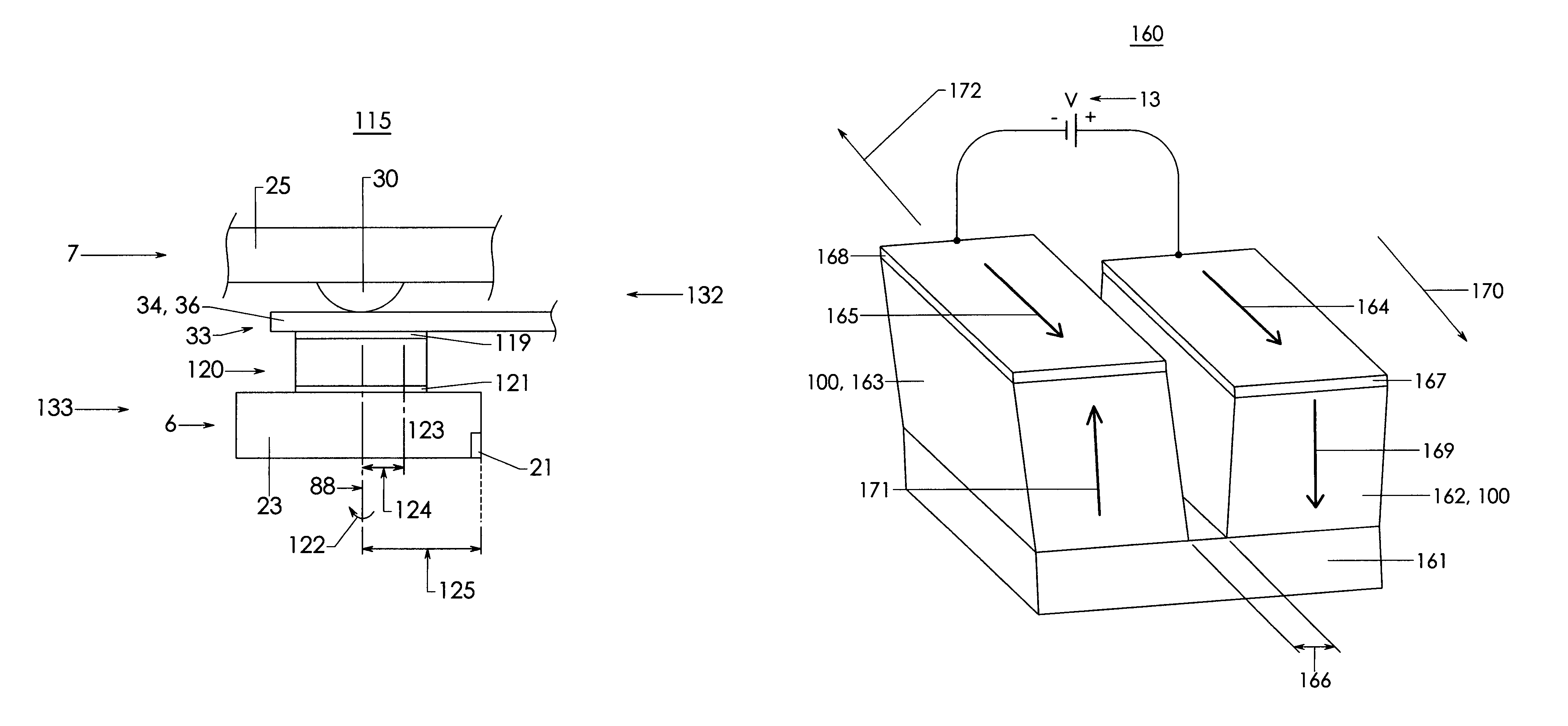

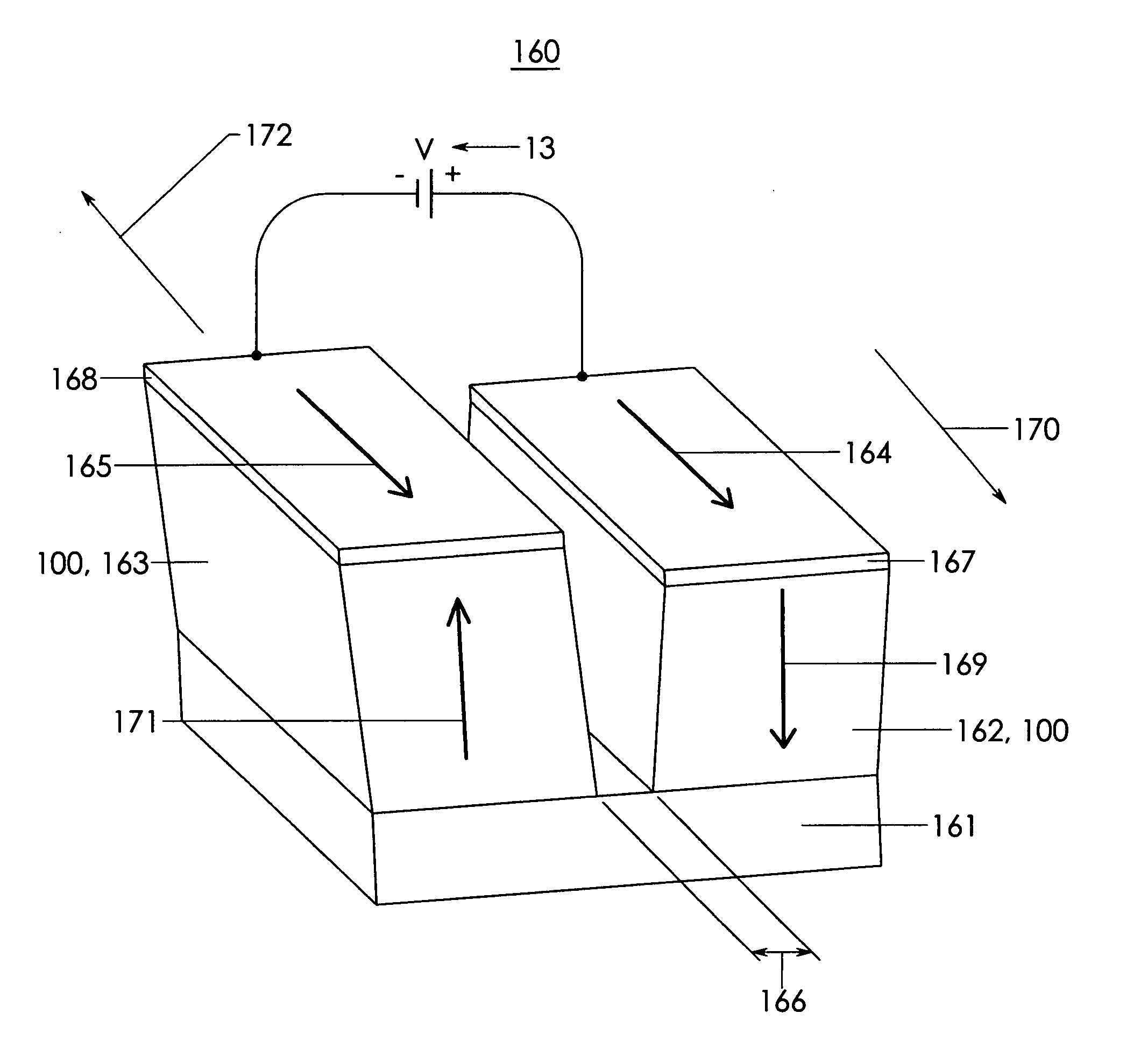

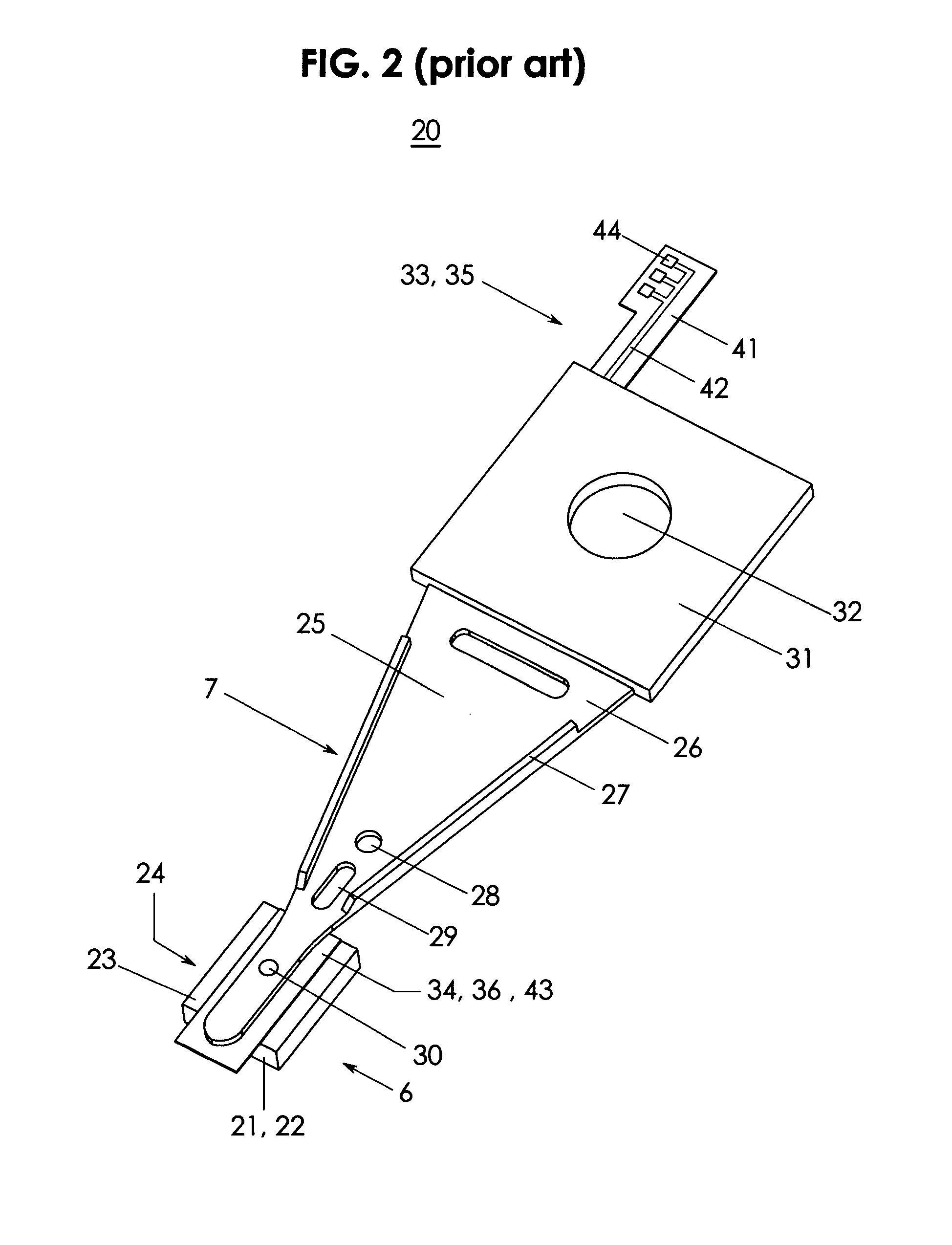

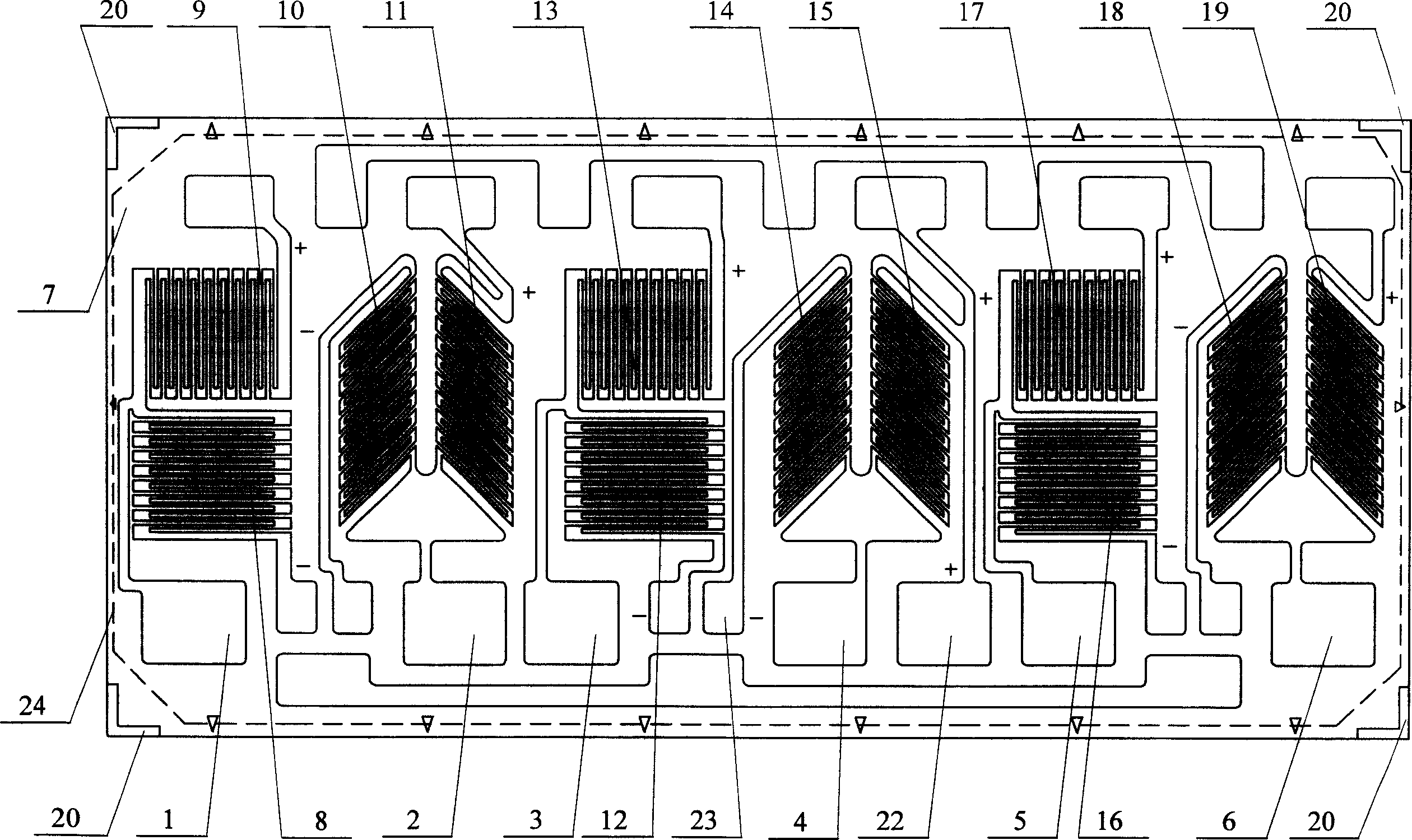

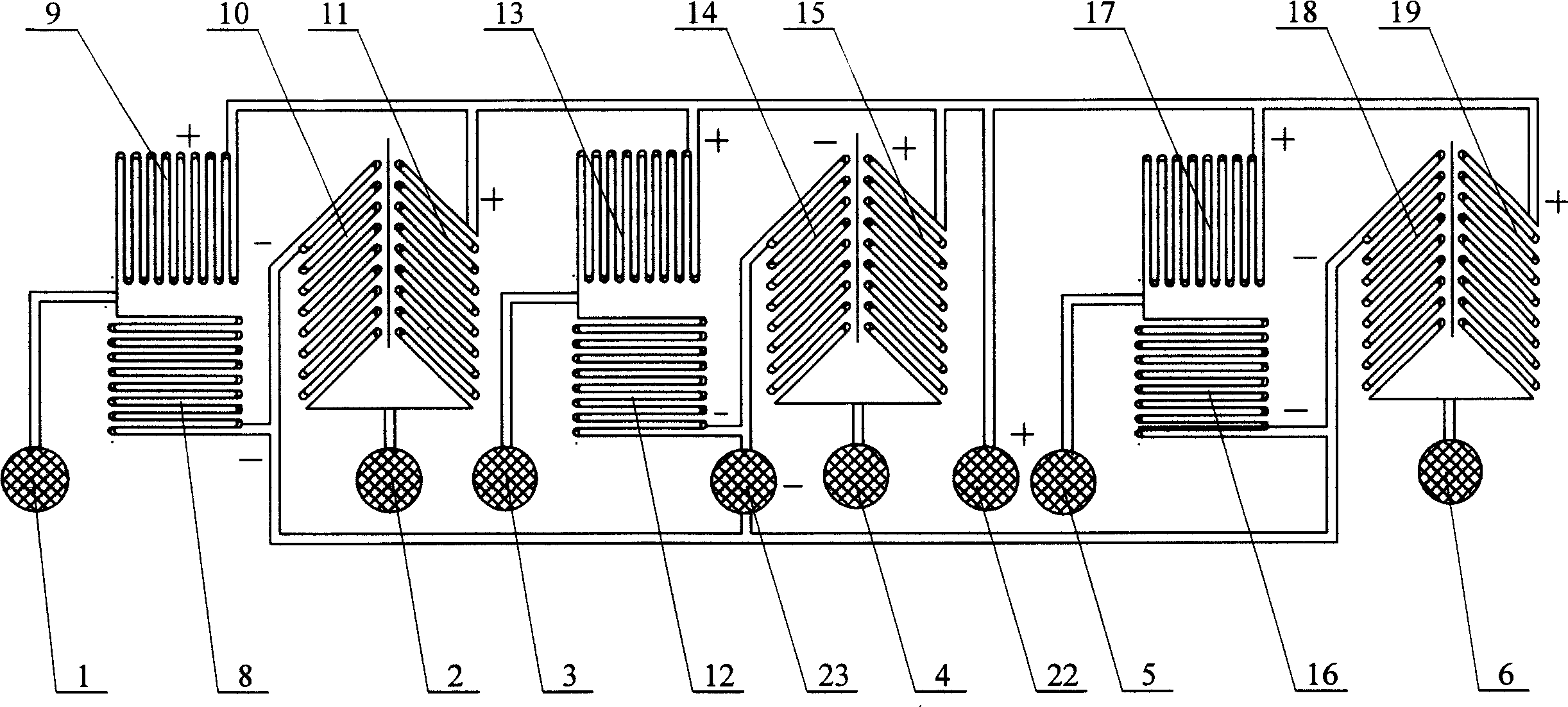

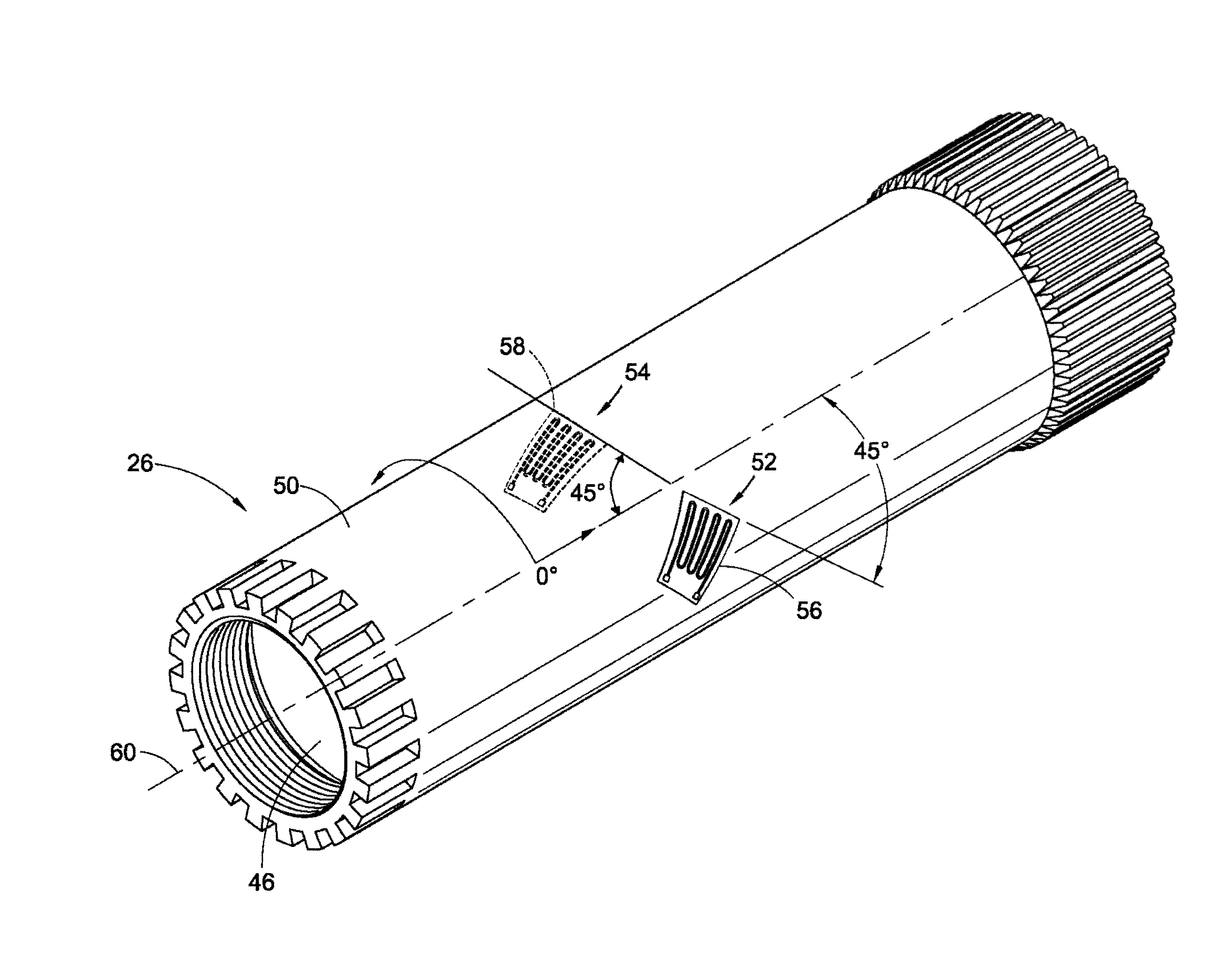

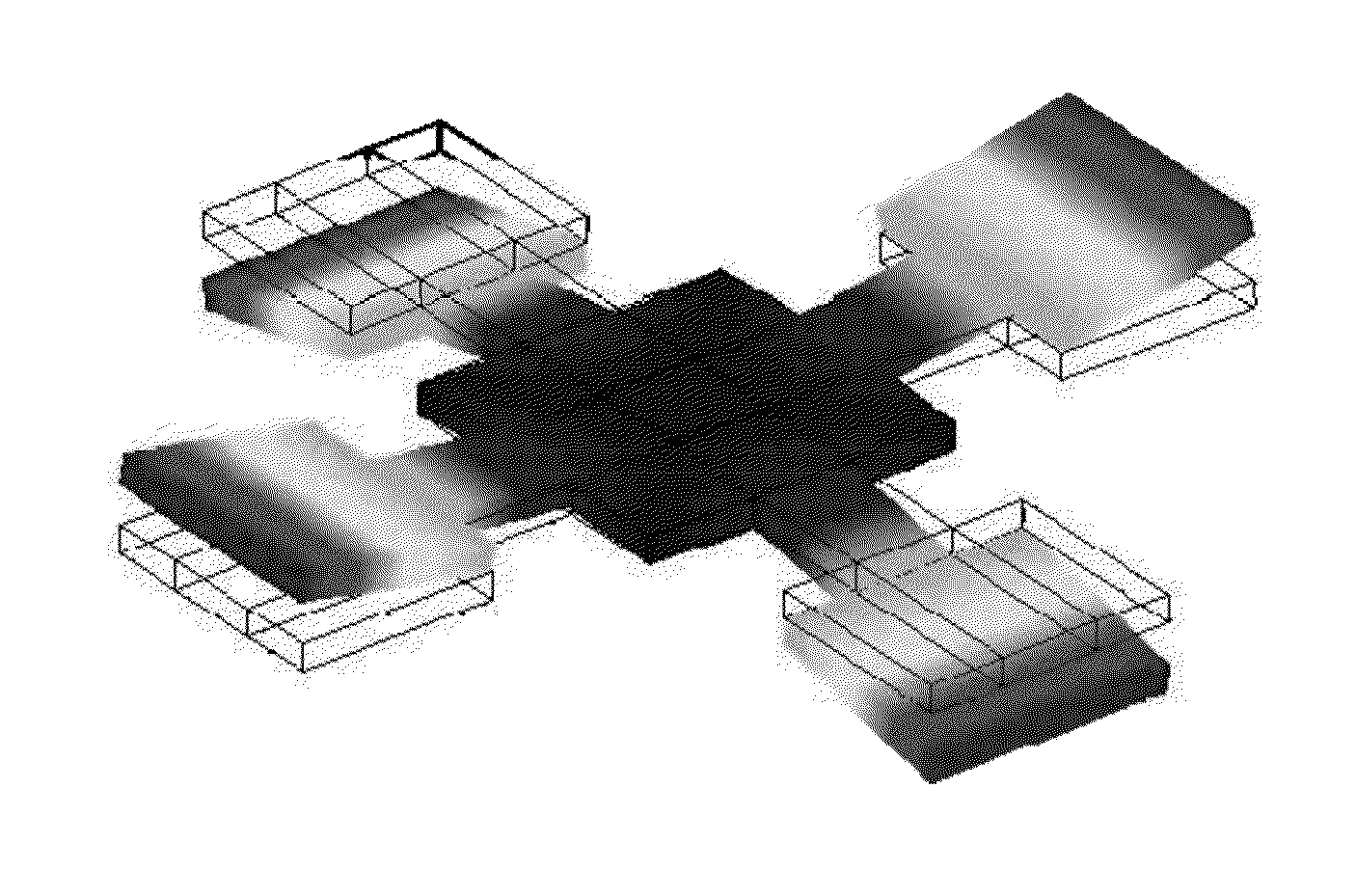

Rotational, shear mode, piezoelectric motor integrated into a collocated, rotational, shear mode, piezoelectric micro-actuated suspension, head or head/gimbal assembly for improved tracking in disk drives and disk drive equipment

ActiveUS8125741B2High track densityImprove data storage capacityDriving/moving recording headsArm with actuatorsShock resistanceControl theory

A rotational, shear mode, piezoelectric motor is integrated with a suspension, head or head gimbal assembly (HGA) into a collocated, rotational, shear mode, piezoelectric micro-actuated suspension, head or head gimbal assembly (HGA) for use in disk drives and disk drive manufacturing equipment. When excited by a control voltage, the collocated, shear mode, piezoelectric micro-actuated HGA rotates the head enabling high frequency, high resolution track positioning of the read / write element. The motor is integrated with the head and flexure (collocation). The head rotates about a rotation axis that is ideally located at the center of mass of the head. A shear mode piezoelectric motor rotates the head. A collocated, rotational, shear mode, piezoelectric micro-actuated HGA has high stiffness, high frequency response, high positioning resolution, low mass and low internal vibration for improved tracking, increased track density and greater disk drive storage capacity. Furthermore, its solid integration improves shock resistance and reduces micro-contamination.

Owner:MAGNECOMP +1

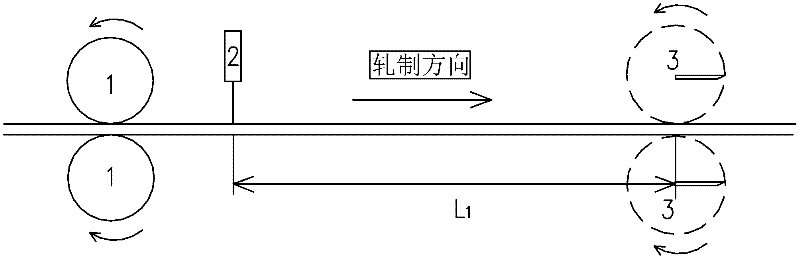

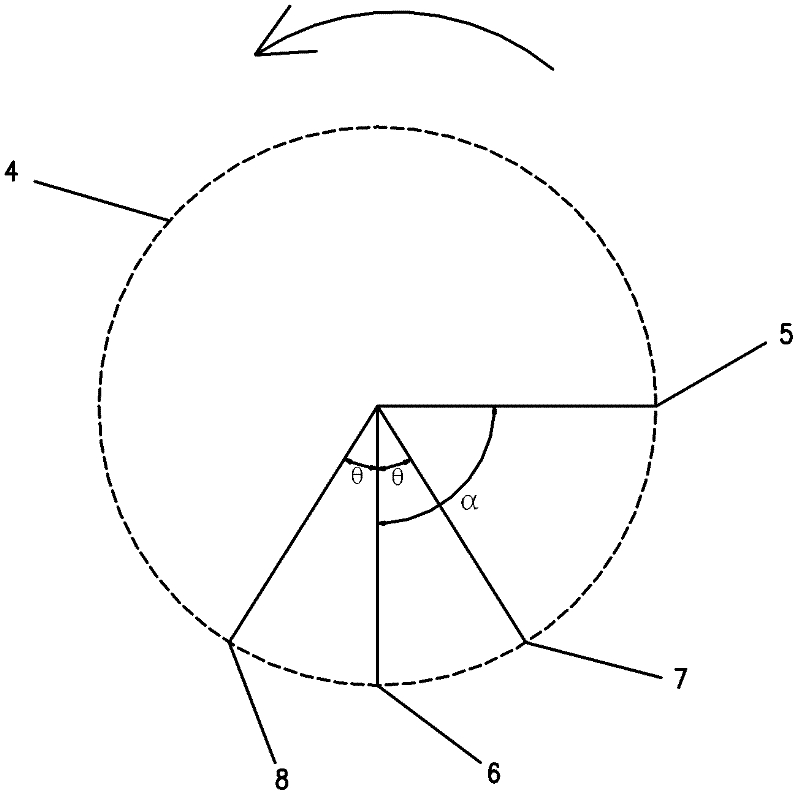

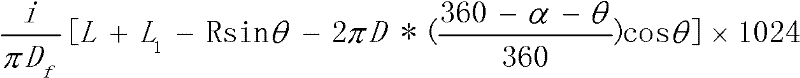

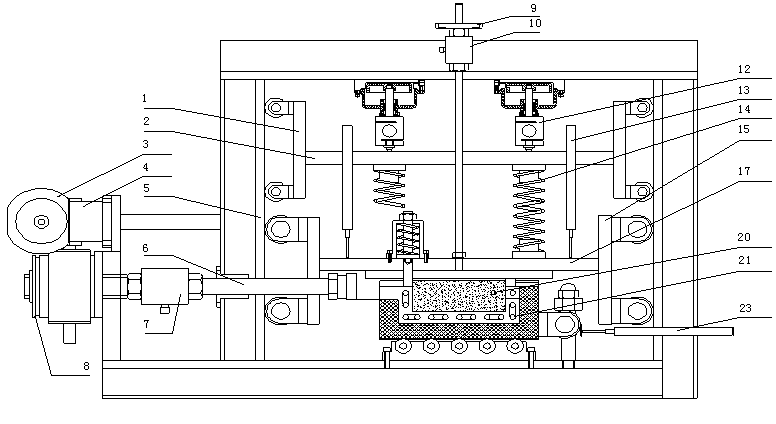

New method for controlling flying shears for bars and wires based on T400

InactiveCN102441569ASimple control structureImprove cut qualityRoll mill control devicesMetal rolling arrangementsWire rodStart stop

The invention provides a new method for controlling flying shears for bars and wires based on T400, which is an advanced electrical control method for start-stop type flying shears for bars and wires. The method comprises the steps of accurate shearing-blade position control, shearing length control and automatic shearing optimization, and the like; in the process of production, when an upstream rolling mill has an accident, or the quality of a section of a rolled piece is poor, a fragmentation function can be started on line so as to carry out partial fragmentation or complete fragmentation on the rolled piece, and the fragmentation and shearing speed is in step with the running speed of the rolled piece automatically; and when the fragmentation operation is stopped, a flying shear is automatically positioned to a start position and enters into a standby state of the normal shear mode. In the invention, the powerful computation function of the T400 is fully used, core control parts of the flying shear are completely integrated into the T400, and high-speed counters, shaft positioning modules and touch screens are not required, therefore, the cost is reduced, and high accuracy is obtained; and when the flying shear carries out double-length shearing at a speed of 21 m / s, the double-length error is basically within 75 mm, and partial double-length error can be within 30 mm.

Owner:WISDRI WUHAN AUTOMATION

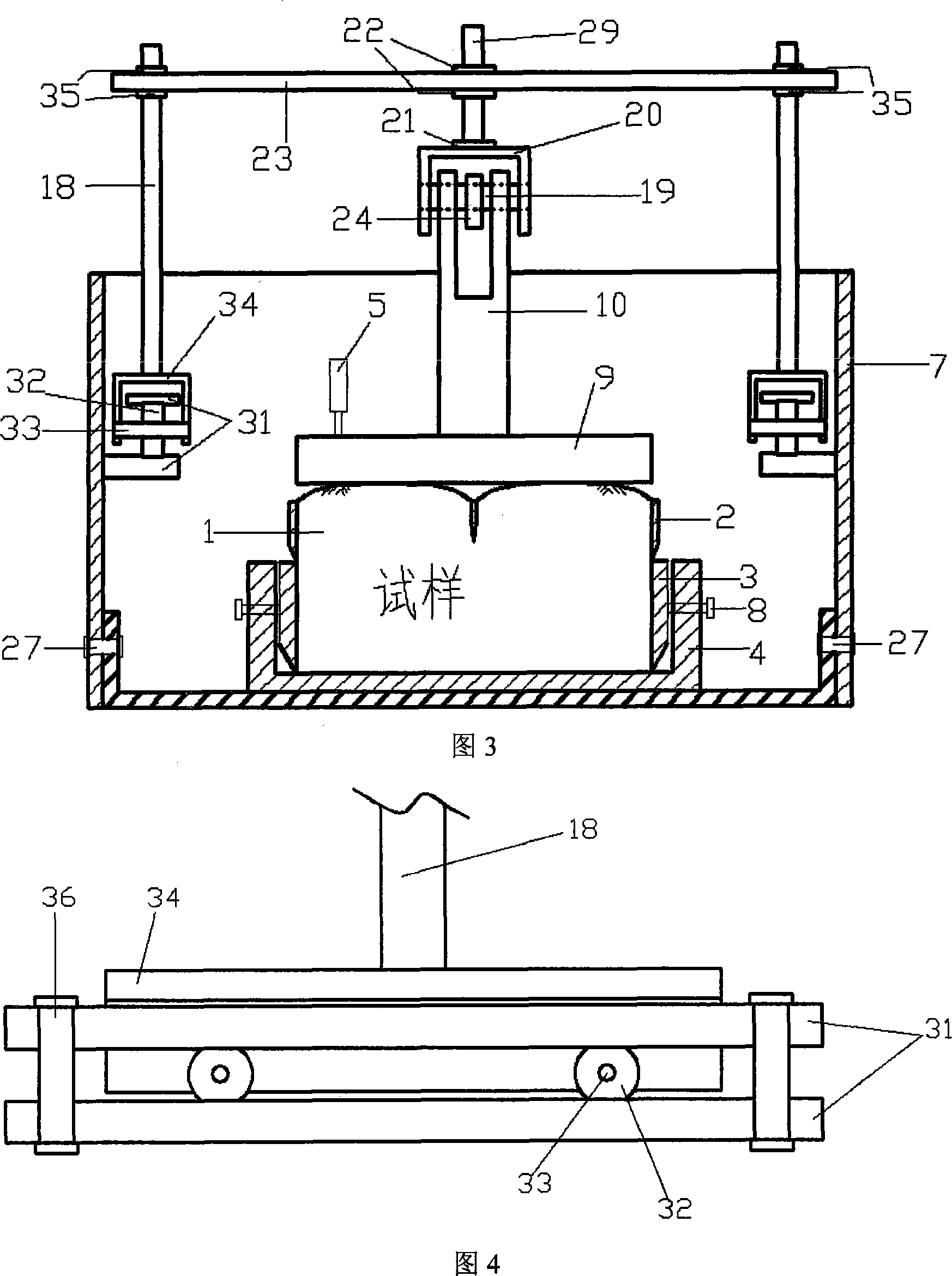

Large-scale multifunctional frozen soil-composition contact surface cycle direct shear apparatus and test operation method

ActiveCN102798575AEasy to controlPrecision stressMaterial strength using steady shearing forcesTemperature controlConstant stress

The invention is a large multifunctional frozen soil-structure interface cyclic direct shear apparatus and a test operation method. The structure of the apparatus comprises a horizontal and vertical loading system, a horizontal and vertical displacement and a load sensor, a temperature control and refrigeration system, a temperature sensor, a data collecting and self-stabilizing system, a guide rail system, and a soil sample box and supports. The test operation method comprises the steps of: 1. Installing the interface steel of required roughness; 2. Applying normal boundary conditions to a soil sample; 3. Cooling the soil sample; and 4. When the temperature cools to a target temperature, performing a shearing to the frozen soil interface in a selected shearing speed, at the same time the date collecting system beginning to record the stress-strain relation of the frozen soil interface. The apparatus and the method are the advantageous in that: 1) accurate control of the interface temperature in the temperature range between 0 DEG C and -20 DGE C can be achieved; 2) three normal boundary conditions of constant stiffness, constant displacement and constant stress can be accurately applied; 3) interfaces of various roughness can be simulated; 4) two shear modes of cyclic shear and monotonic shear can be realized; and 5) the stress applying and displacement control are accurate.

Owner:NANJING FORESTRY UNIV

Electronically controlled prosthetic knee

InactiveUSRE42903E1Negligible changeNegligible pressureSpringsNon-rotating vibration suppressionMagnetorheological fluidControl theory

The present invention relates to a variable-torque magnetorheologically actuated prosthetic knee which utilizes a plurality of interspersed and alternating rotors and stators to shear magnetorheological fluid in gaps formed therebetween. Advantageously, by operating in the “shear mode” there is substantially no or negligible fluid pressure buildup or change. Moreover, the multiple MR fluid gaps or flux interfaces desirably allow for the production of a large torque at low speed—eliminating the need for a transmission—and also for a wide dynamic torque range. One embodiment of the invention allows the rotors and / or stators to close the gaps therebetween to create a frictional torque component, thereby forming a “hybrid” braking system which provides a total torque or damping which is a combination of viscous torque and frictional torque.

Owner:MASSACHUSETTS INST OF TECH

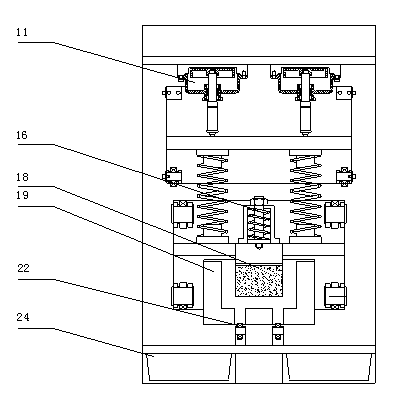

Controllable vibration isolator based on magnetic current change elastic element and damping element coupled action

InactiveCN101324257AMeet the requirements of the suspension parametersImproves sealing reliabilityNon-rotating vibration suppressionElastomerMagnetic current

The invention relates to an engine vibration isolation device of a magneto-rheological fluid damper in extrusion mode and a magneto-rheological elastomer in shearing mode for supporting static loads. The vibration isolation device comprises two pars of a damping adjusting unit and a rigidity adjusting unit; the damping adjusting unit is connected with the rigidity adjusting unit through a rigid connecting rod; the vibration of an engine causes the connecting rod to move upwards and downwards, so that the magneto-rheological fluid in the damping adjusting unit flows in radial direction and shearing occurs to the magneto-rheological elastomer in the rigid adjusting unit; a magnetic field generated by two exciting coils can be respectively adjust damping parameters and rigidity parameters of a vibration isolator. The magneto-rheological vibration isolator can meet the independent adjustment of the damping parameters and the elastic parameters of the vibration isolator under different vibrational excitation conditions, and achieve the coupling control of the transmission of engine vibration energy, and has great realistic significance in improving the technical level and market competence of special vehicles.

Owner:CHONGQING UNIV

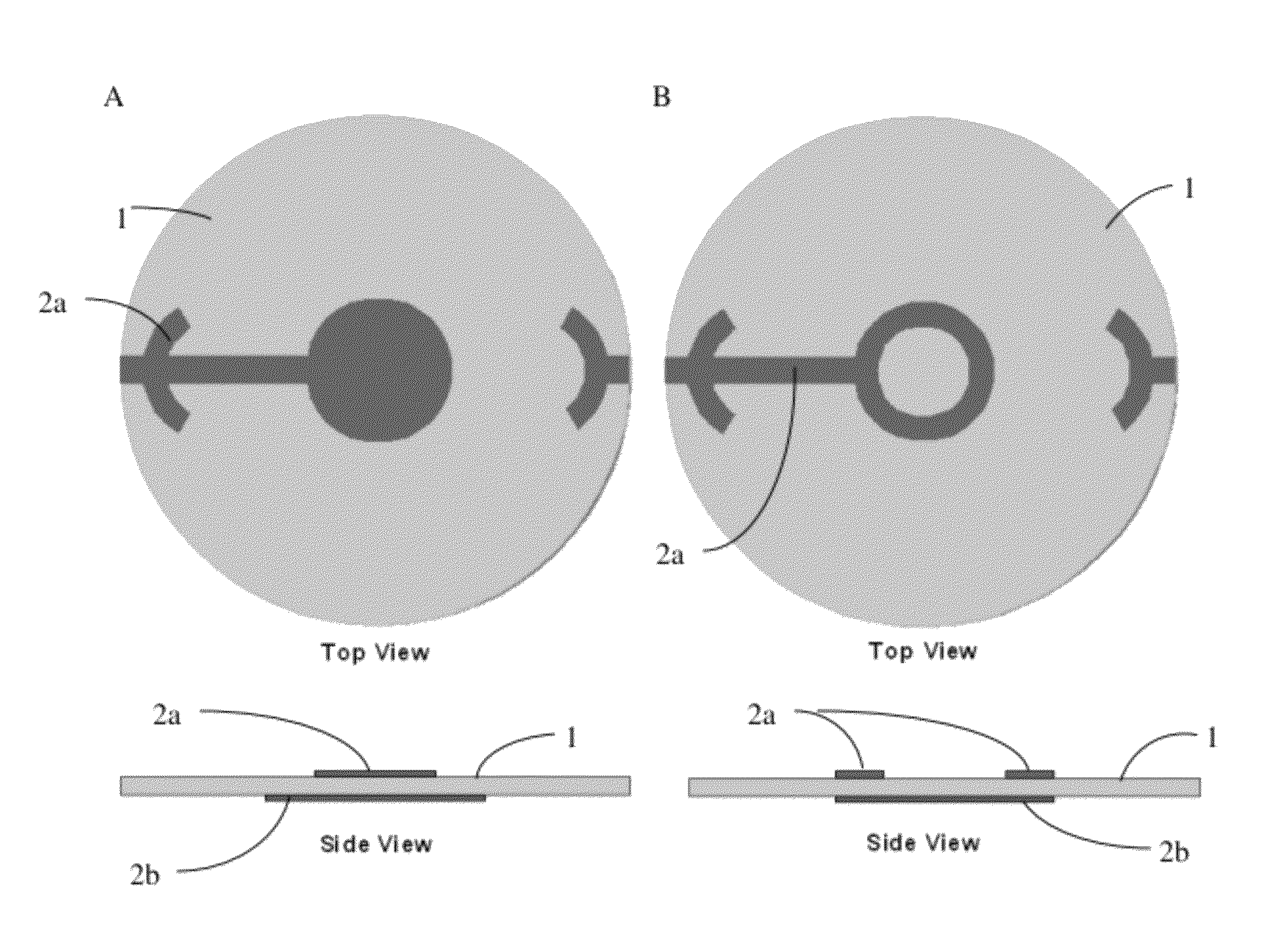

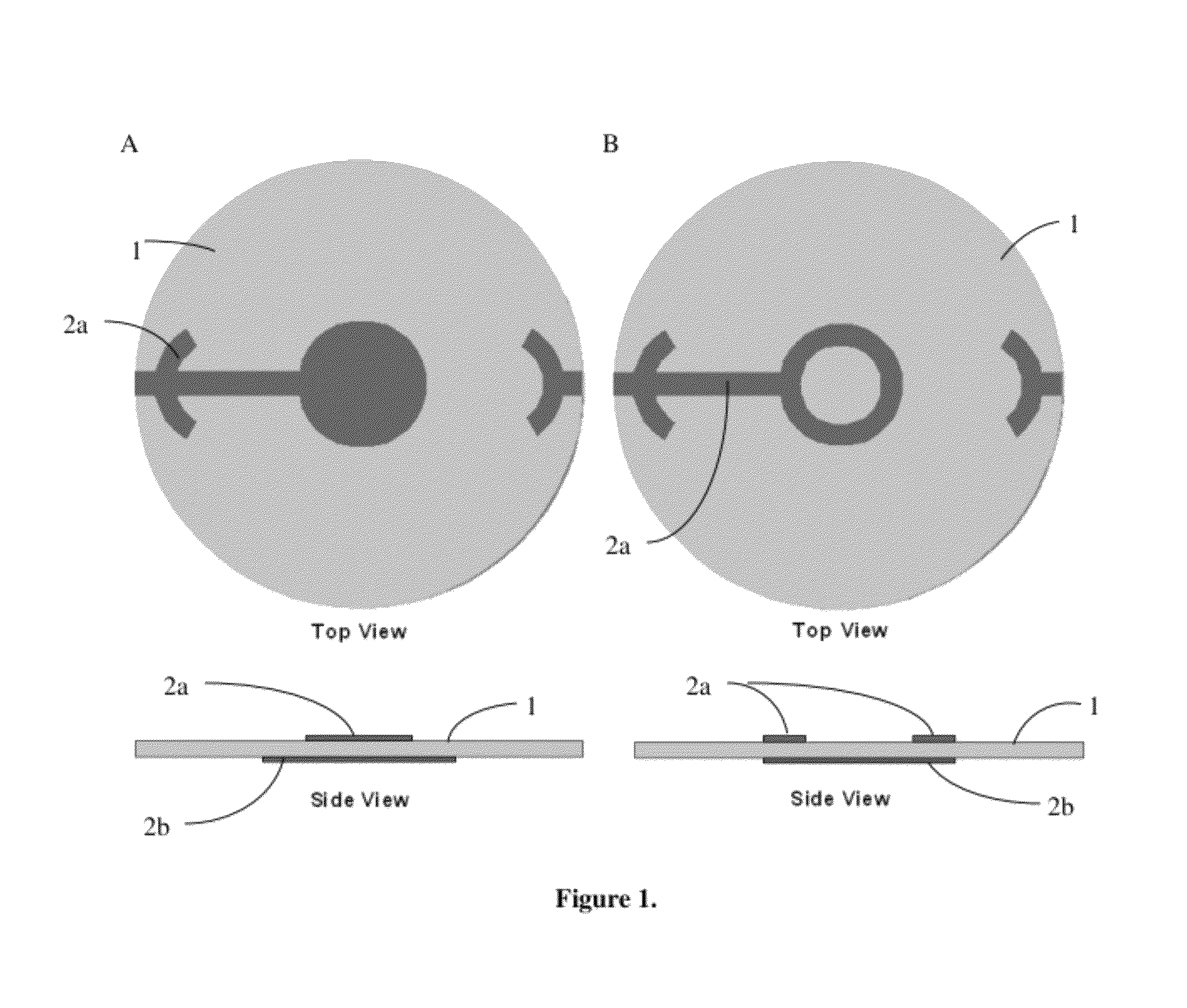

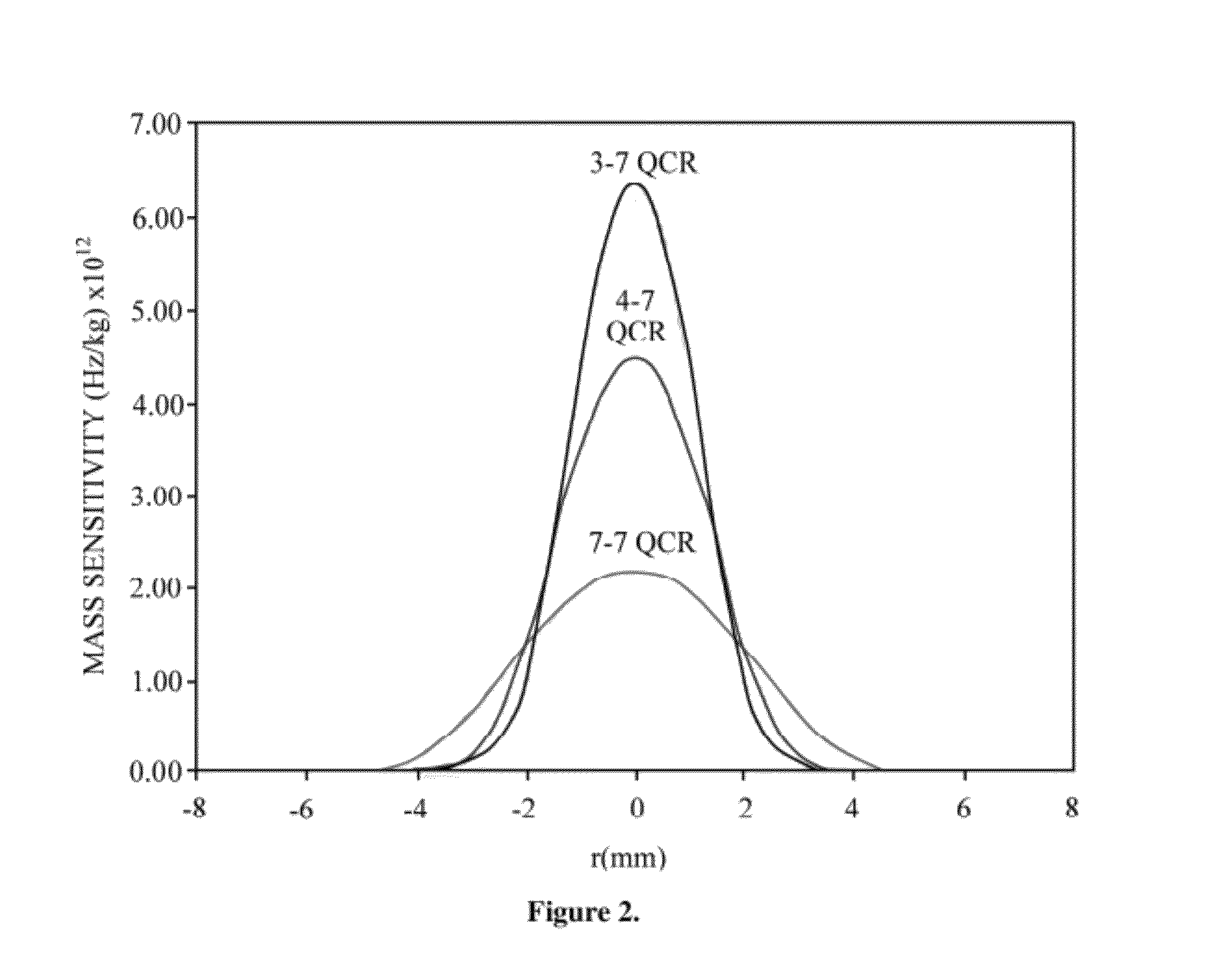

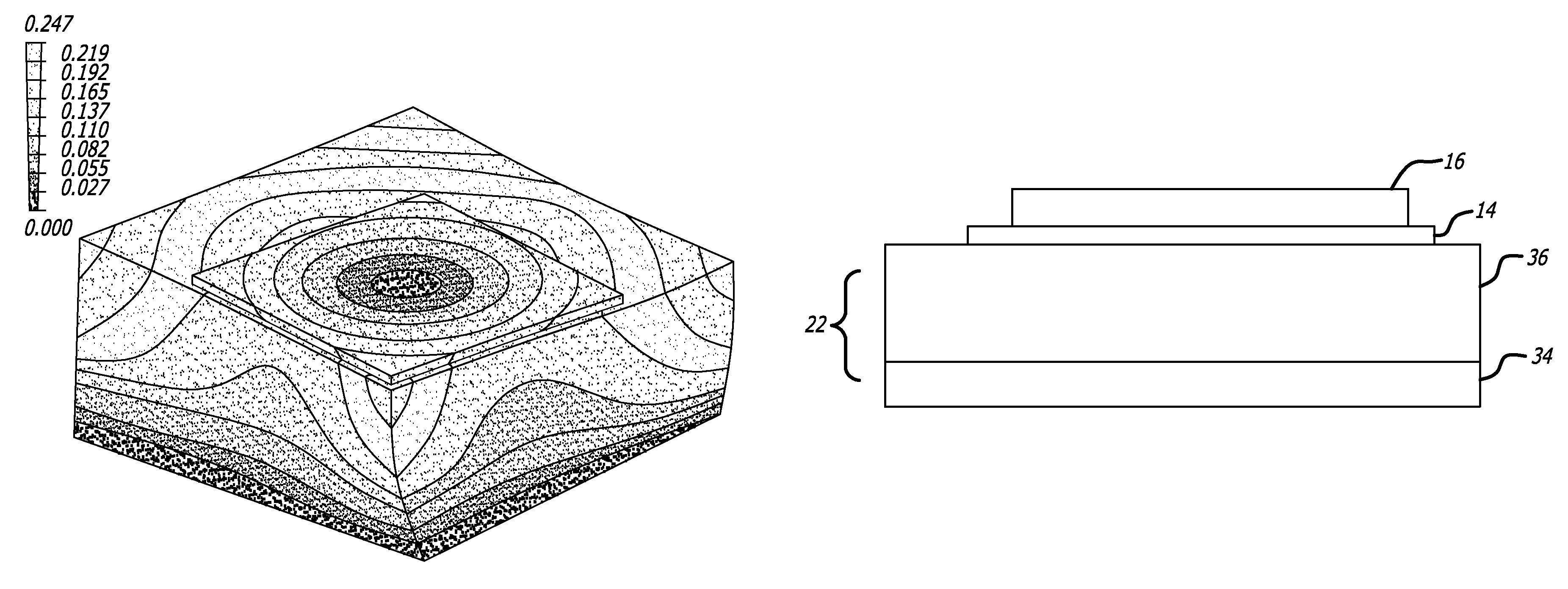

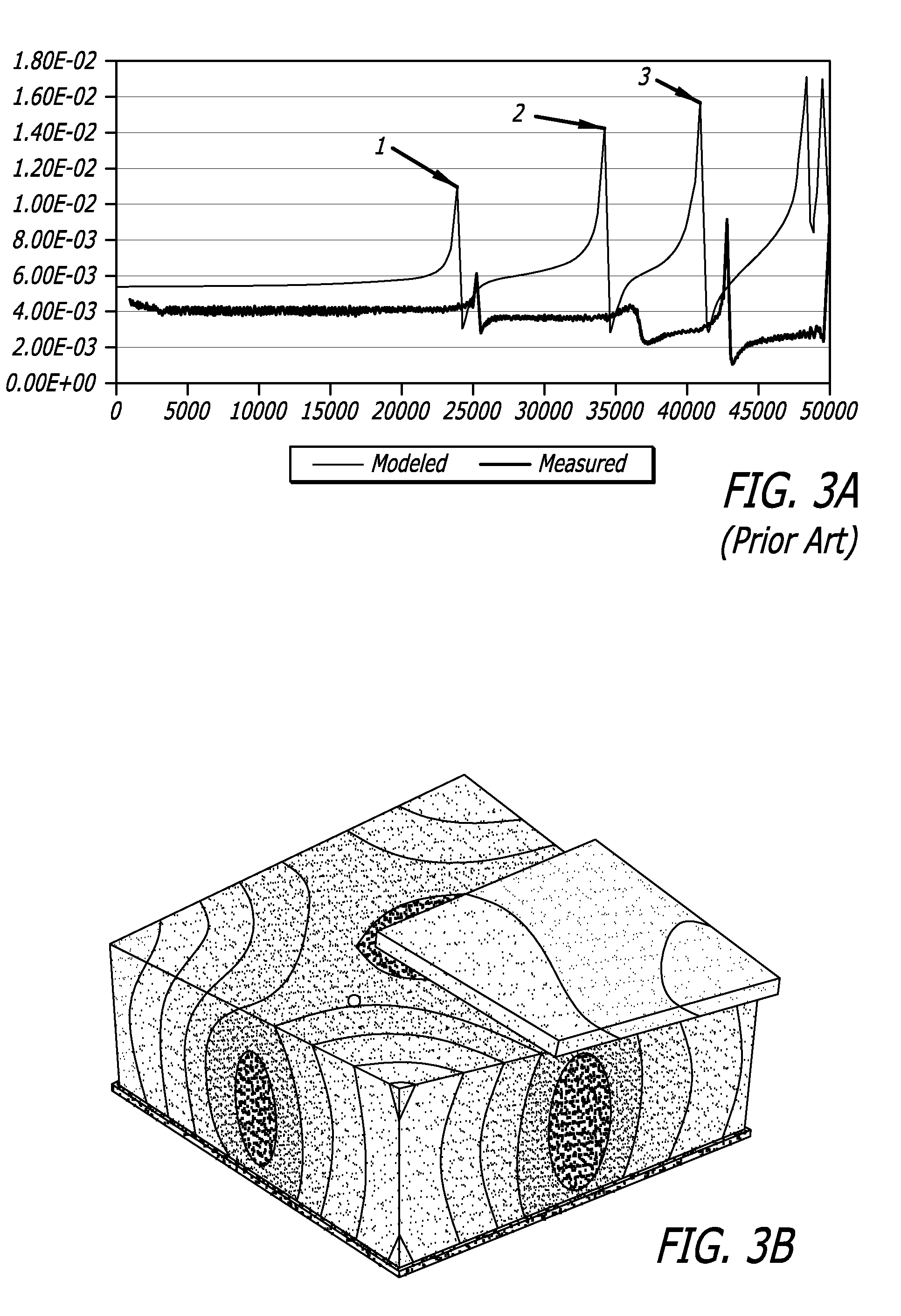

Uniform mass sensitivity thickness shear mode quartz resonator

ActiveUS8215171B1Accurate and inexpensive characterizationUniform sensitivityAnalysing fluids using sonic/ultrasonic/infrasonic wavesWeighing apparatus using elastically-deformable membersMass loadingSensitivity distribution

A ring electrode design that produces a uniform mass sensitivity distribution across a TSM device is presented. A new technique and apparatus to measure this mass sensitivity distribution is also presented. Novel electrode geometries on thickness shear mode (TSM) quartz resonators achieve radial uniformity of mass sensitivity, how receptive the device is to mass loadings, and high frequency stability across the active sensing area of the sensor device. The device allows for absolute mass measurement down to the nanogram level. Fabricated devices utilizing model predictions were tested using this apparatus, and good agreement between theory and experiment is found.

Owner:BANK OF AMERICA CORP +1

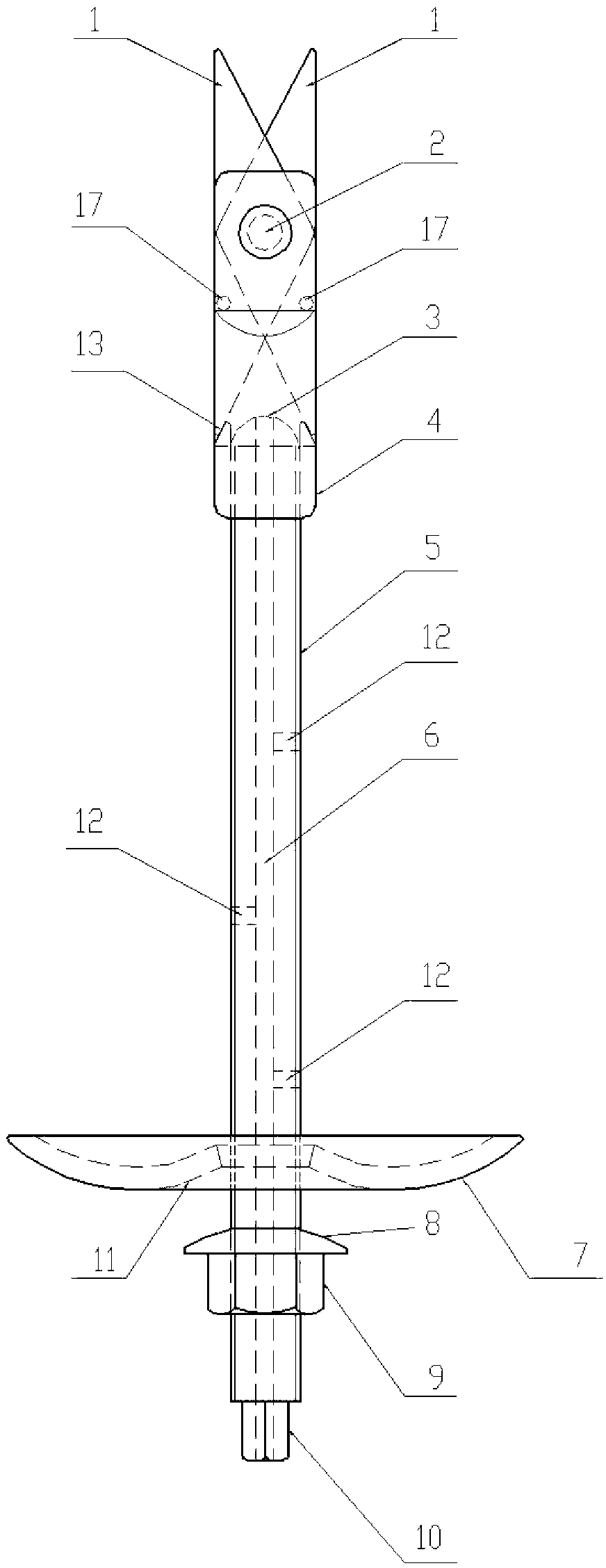

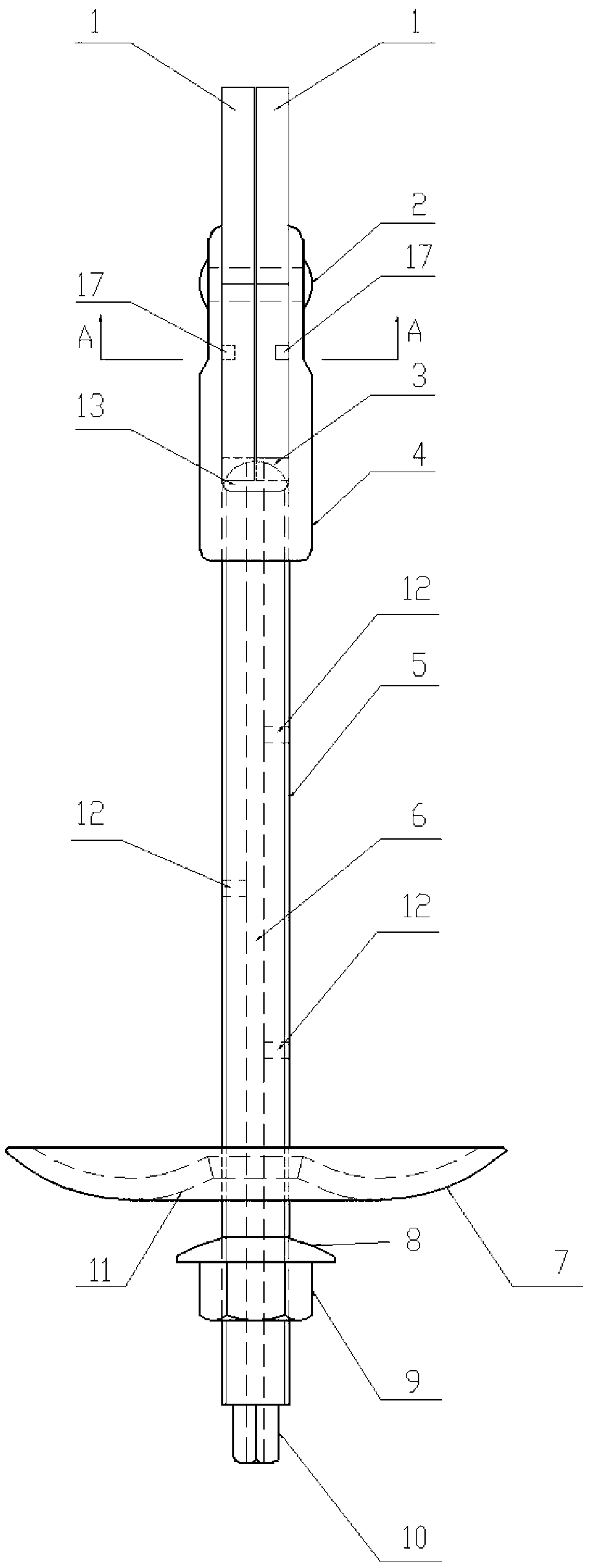

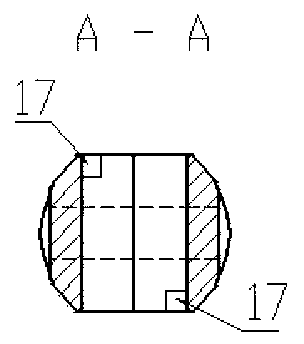

Shear type expansion anchor rod and extension application thereof

InactiveCN103104270AEasy precision requirementsReduced precision requirementsBulkheads/pilesDowelsEngineeringStructural engineering

The invention provides a shear type expansion anchor rod which comprises a fixing part, a pushing part and a tightening part, wherein the fixing part is provided with an expansion part. The shear type expansion anchor rod is characterized in that the pushing part is matched with the fixing part, the pushing part and the fixing part can move along the coaxial direction of the axis of the fixing part, the expansion part is hinged with the top end portion of the fixing part, the lower end portion of the expansion part is provided with an inclined surface facing the pushing part, the top end portion of the pushing part can contact with the inclined surface of the lower end portion of the expansion part and pushes the expansion part along the inclined surface, the expansion part is stretched in a shear mode towards the outer side of the pushing part, and the tightening part is arranged at the lower end of the pushing part and can move in the coaxial direction of the axis of the pushing part. The shear type expansion anchor rod is simple and ingenious in structure, the expansion part is stretched in the shear mode, the stretched range is large, anchoring force is strong, and the shear type expansion anchor rod not only is used for surrounding rock support and protection, but also is widely suitable for anchoring or fixation of mines, tunnels, protection slops, foundation trenches, buildings and other engineering. Extension application comprises underpinnings for constructing the buildings, stand columns for highway sides, and the like, and safety, reliability and universal values of the shear type expansion anchor rod are achieved really.

Owner:裴志胜

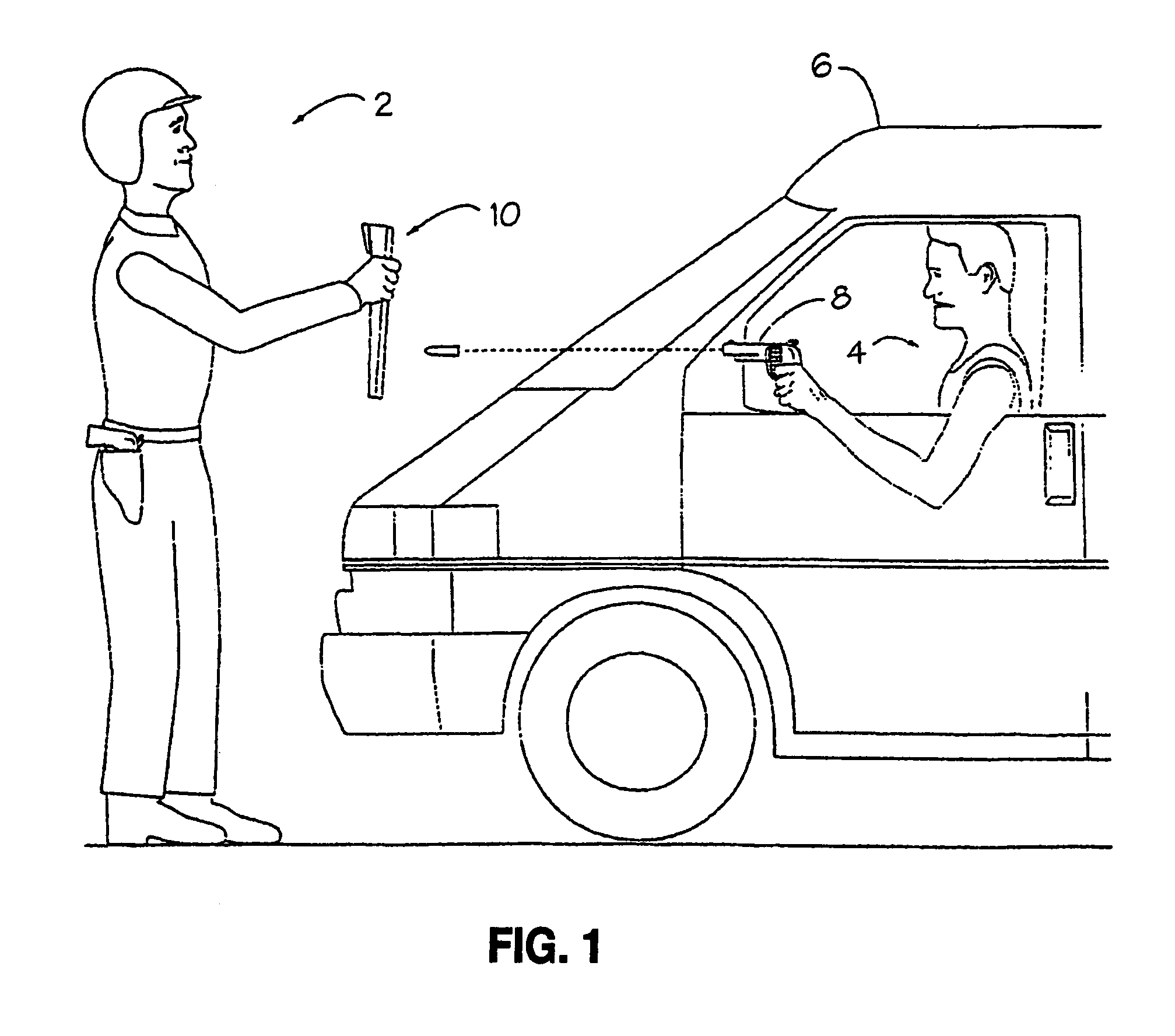

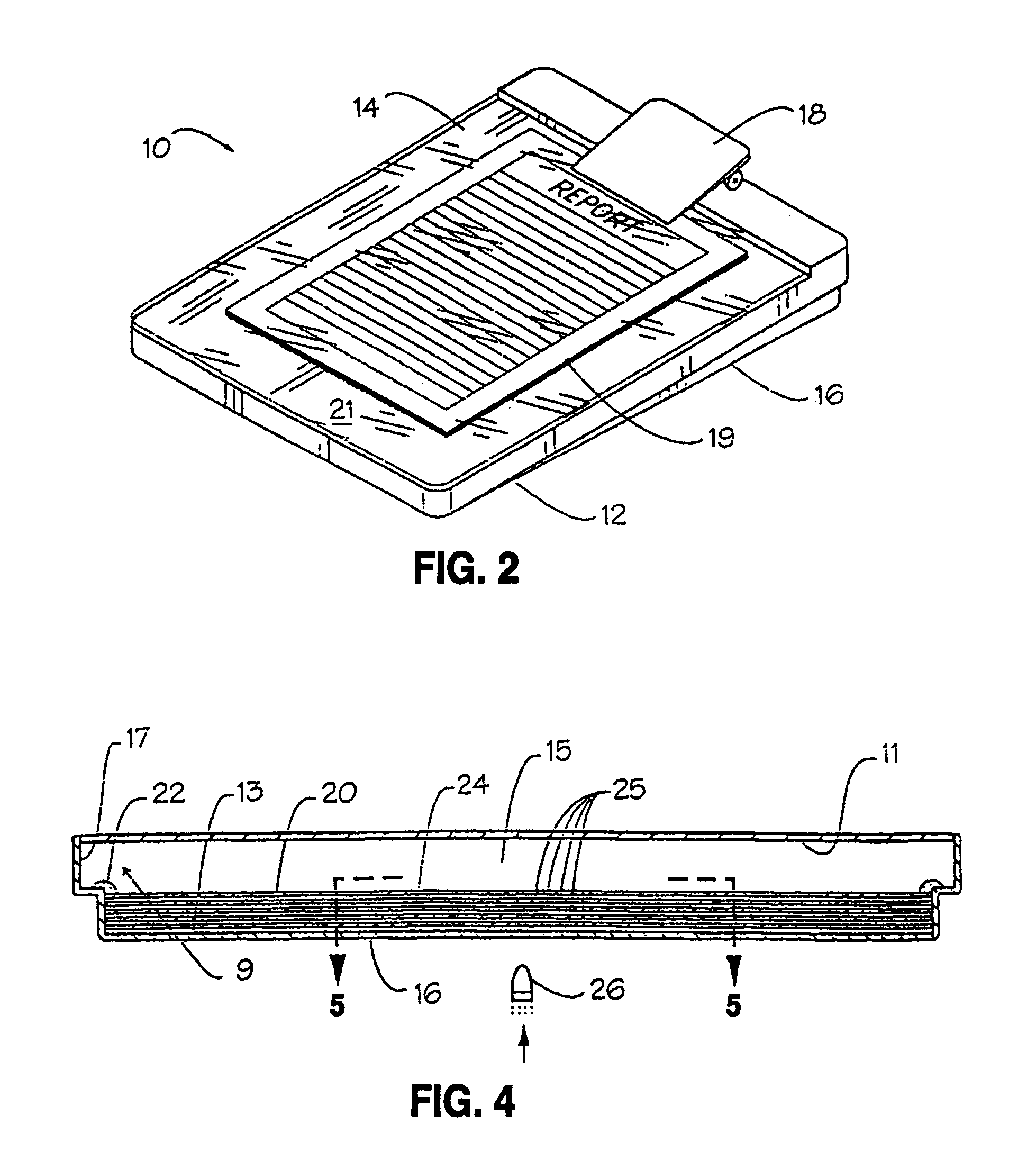

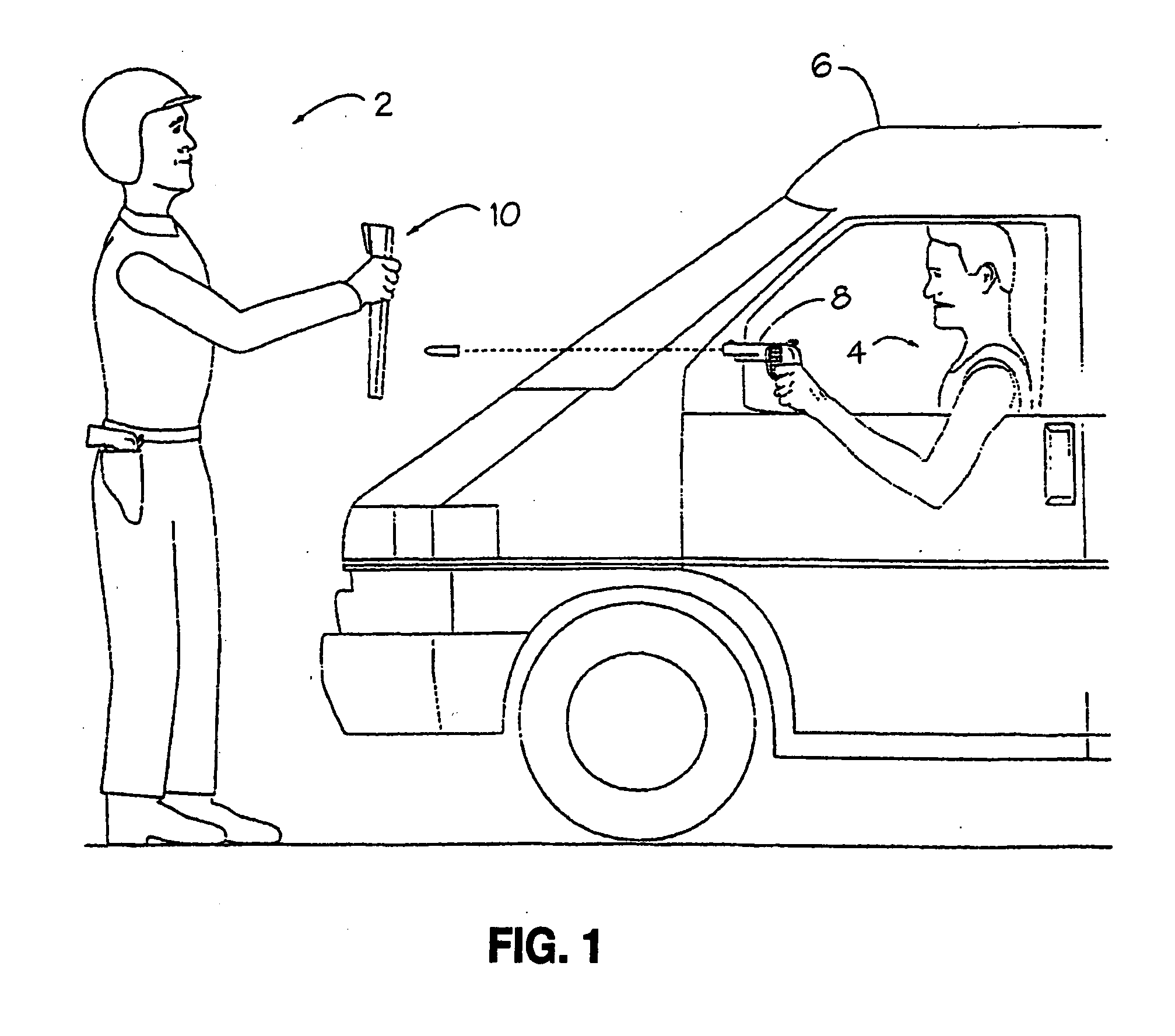

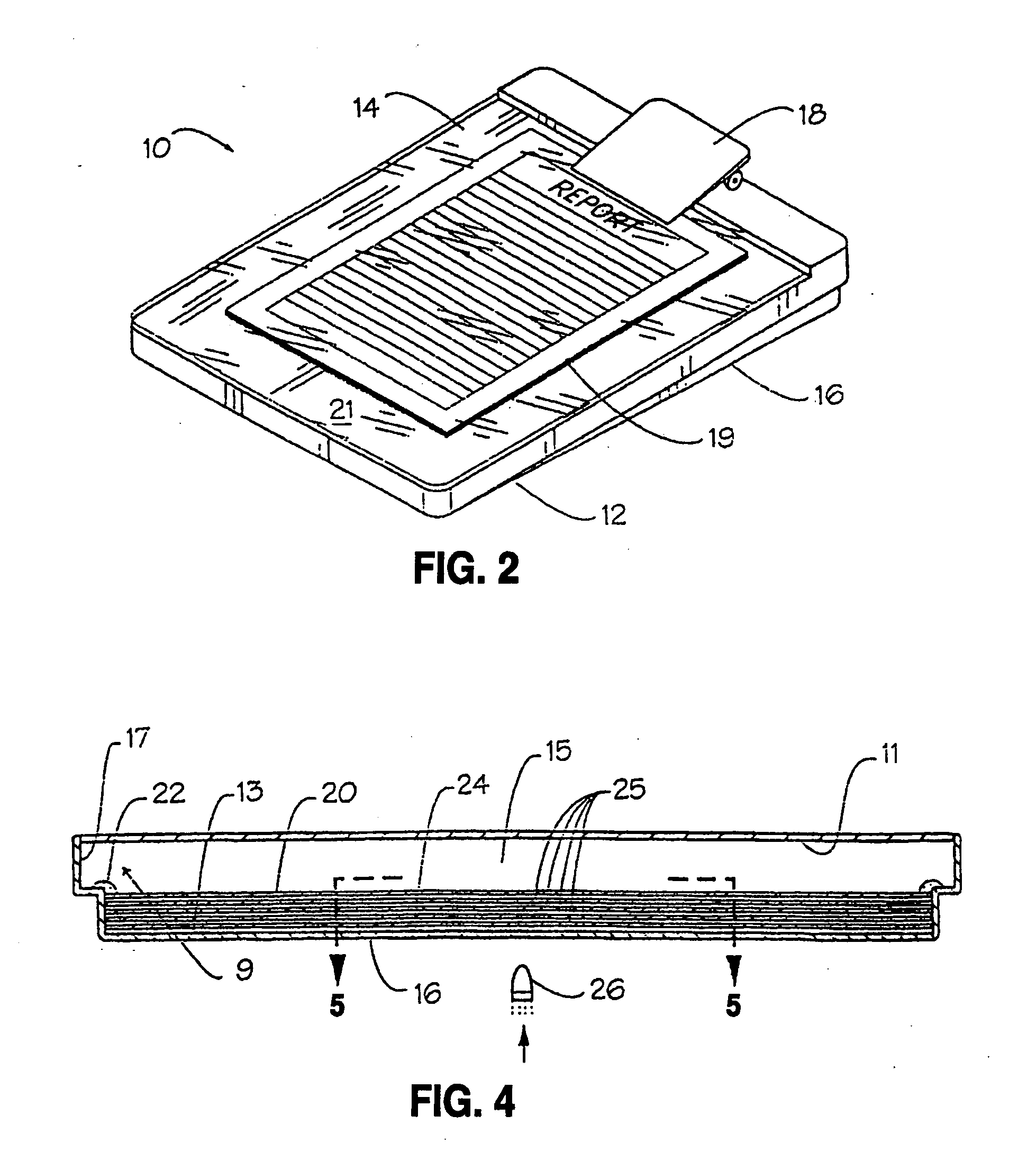

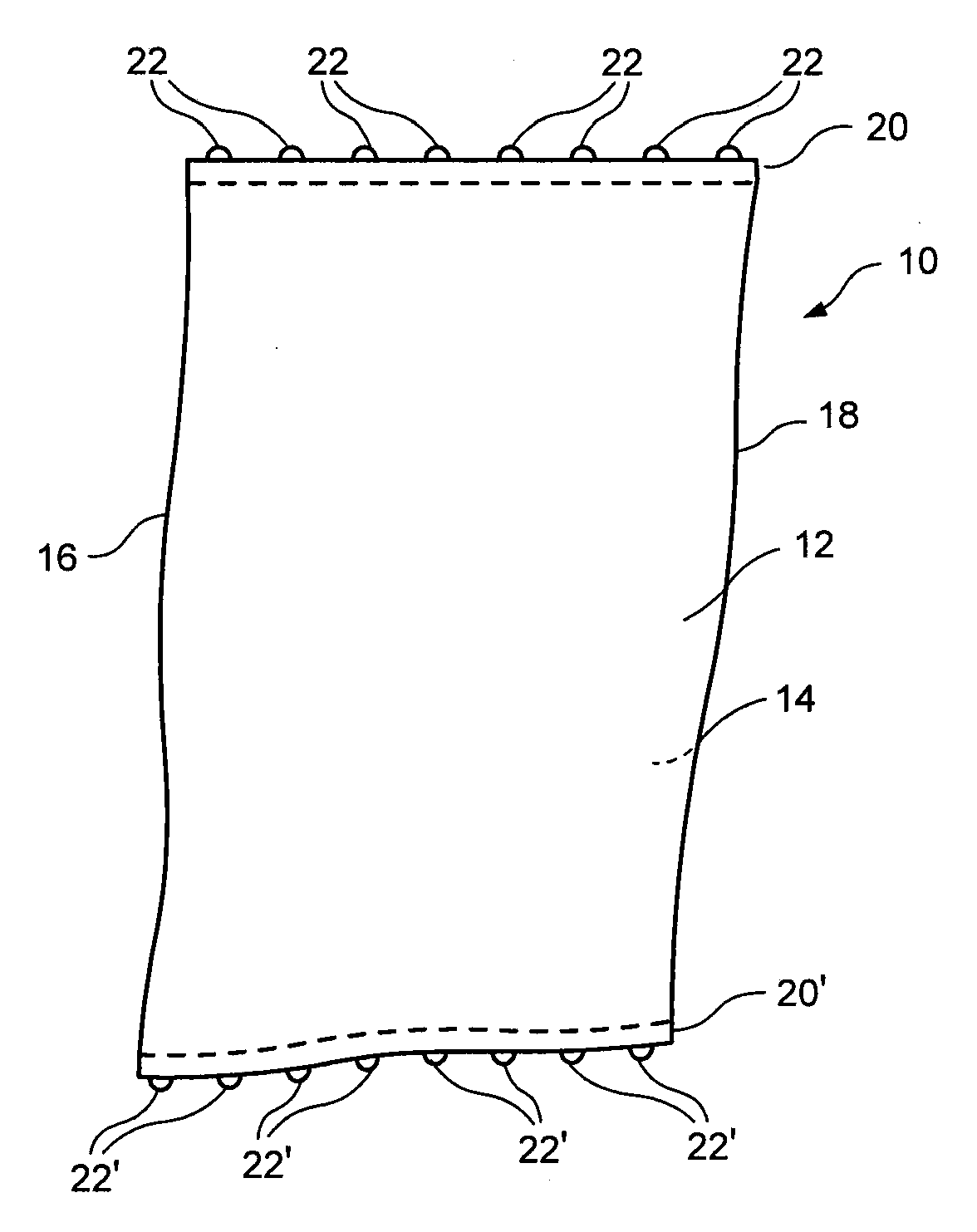

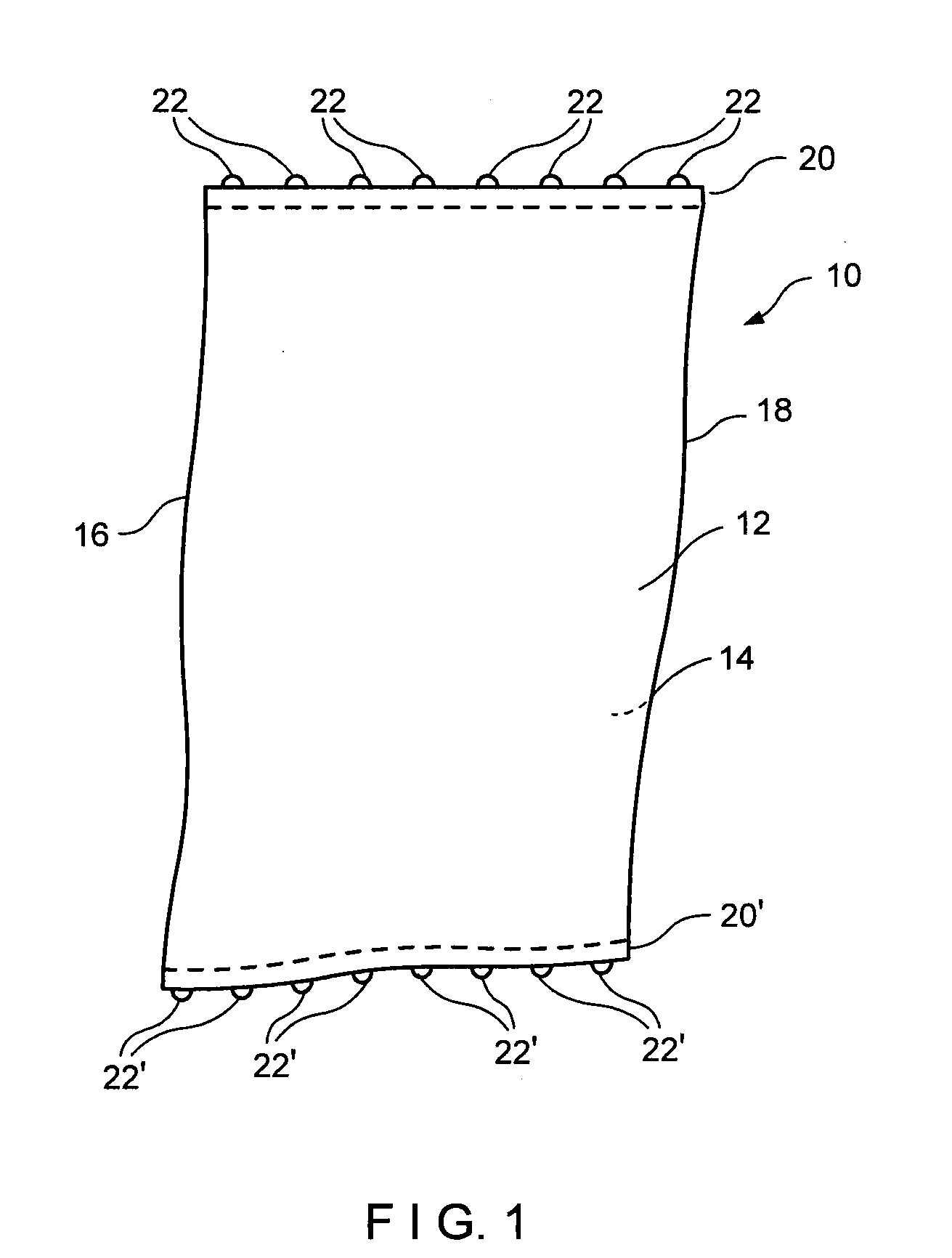

Bullet-resistant hand-held defensive object

A bullet-resistant defensive device is disclosed made up of layers of bullet resistant material layered together and connected along their peripheral edge on a frame to form a planar shield. The shield so formed works such that a bullet striking the shield causes the layered bullet resistant material to flex thereby dissipating the force of the bullet, the material when it stretches transfers the force of the bullet from a shear mode to a tensile mode. One preferred embodiment incorporates the invention into a clipboard box for use by police officers for protecting against head, neck and hand wounds from handguns fired at close range from vehicles. The hand-held, bullet resistant clipboard box holds documents and writing implements, and the bullet-resistant material is located within the clipboard box interior cavity and configured for catching a fired bullet before it can pass through the entire clipboard.

Owner:MAGSHIELD TECH

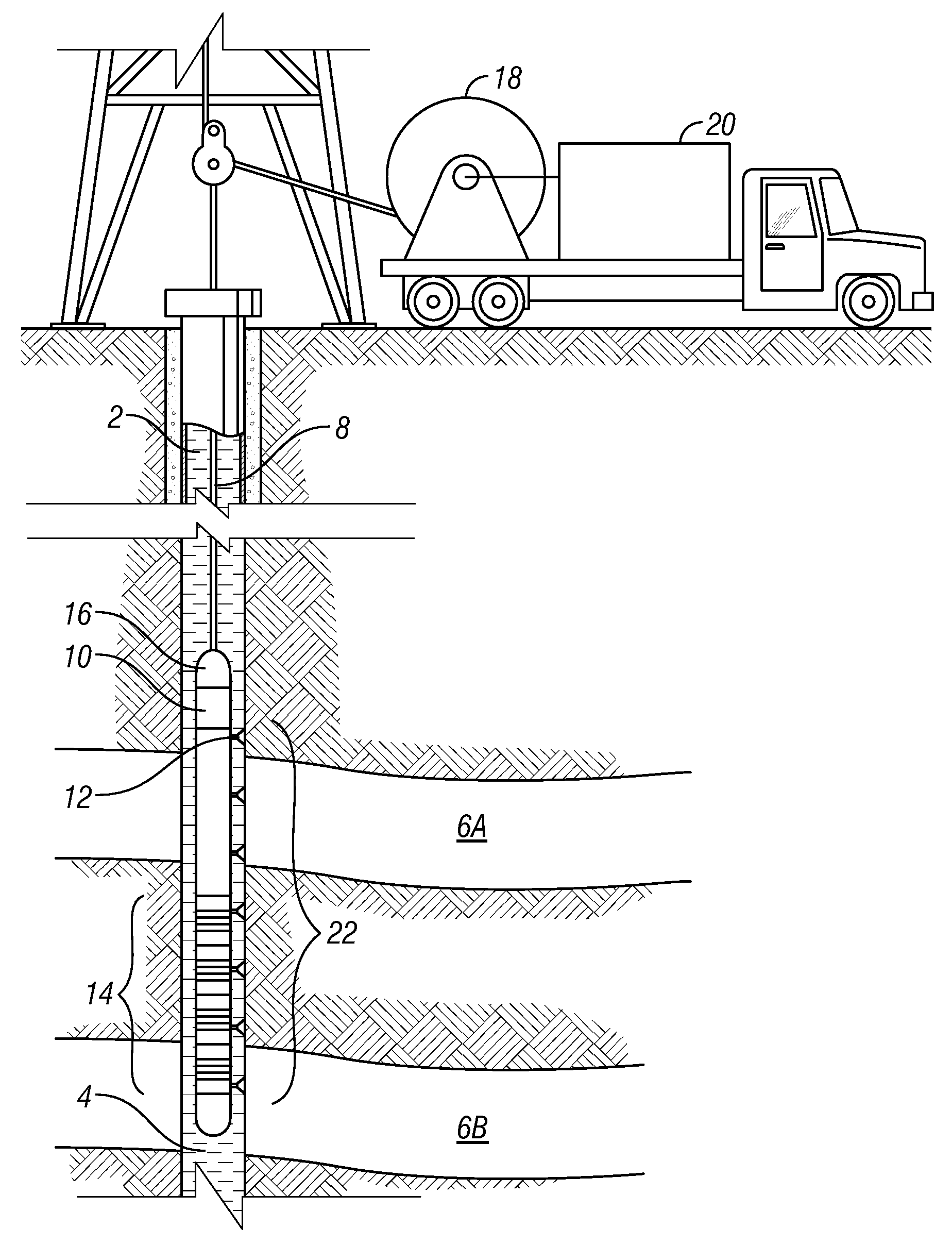

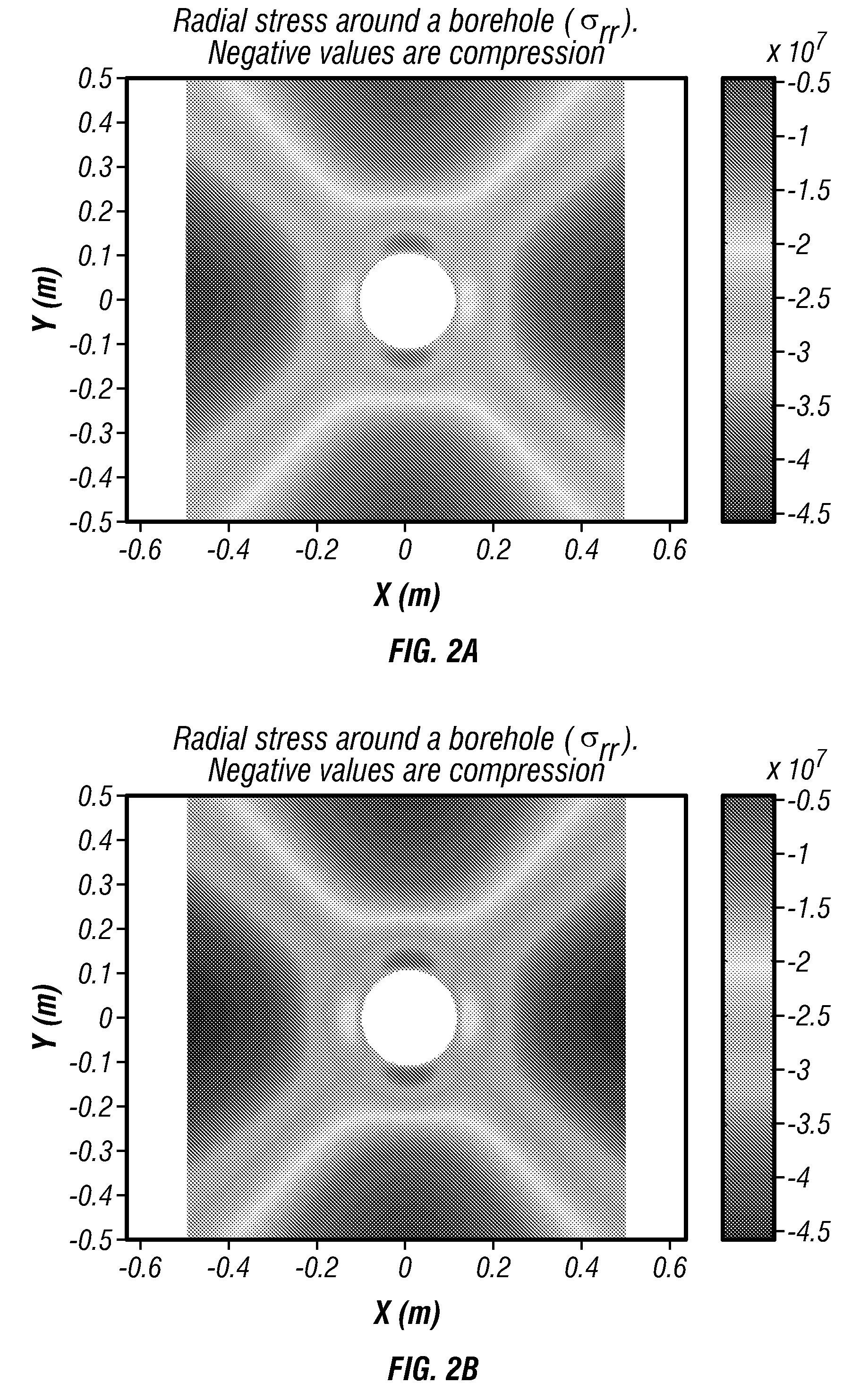

Identification of Stress in Formations Using Angles of Fast and Slow Dipole Waves in Borehole Acoustic Logging

InactiveUS20090185446A1Electric/magnetic detection for well-loggingSeismology for water-loggingAcousticsShear mode

Cross-dipole measurements are obtained in a borehole. By estimating a direction of polarization of the fast shear mode at low and high frequencies and comparing the estimated distances, a cause of anisotropy is established. Formation stresses and directions may be estimated.

Owner:BAKER HUGHES INC

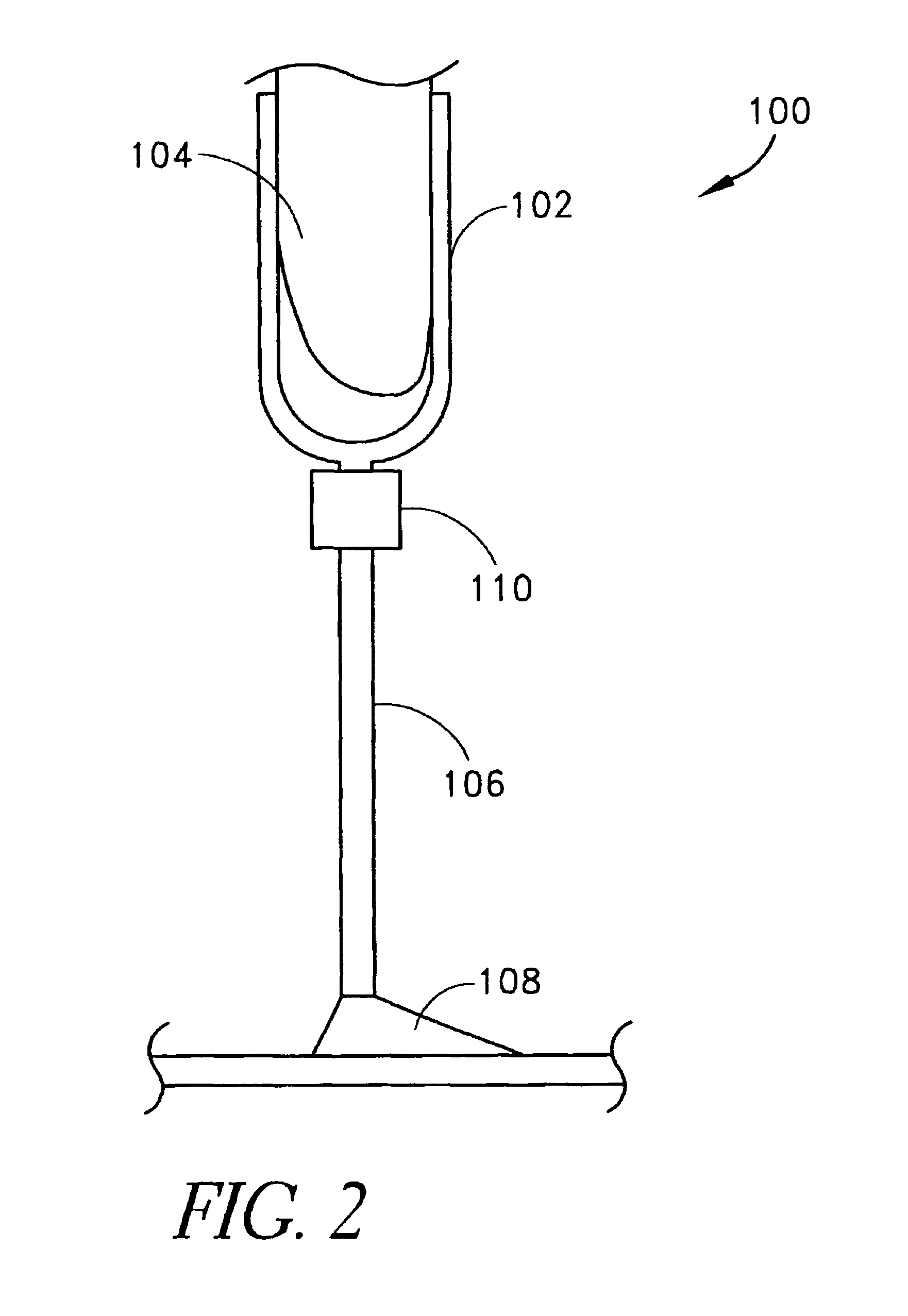

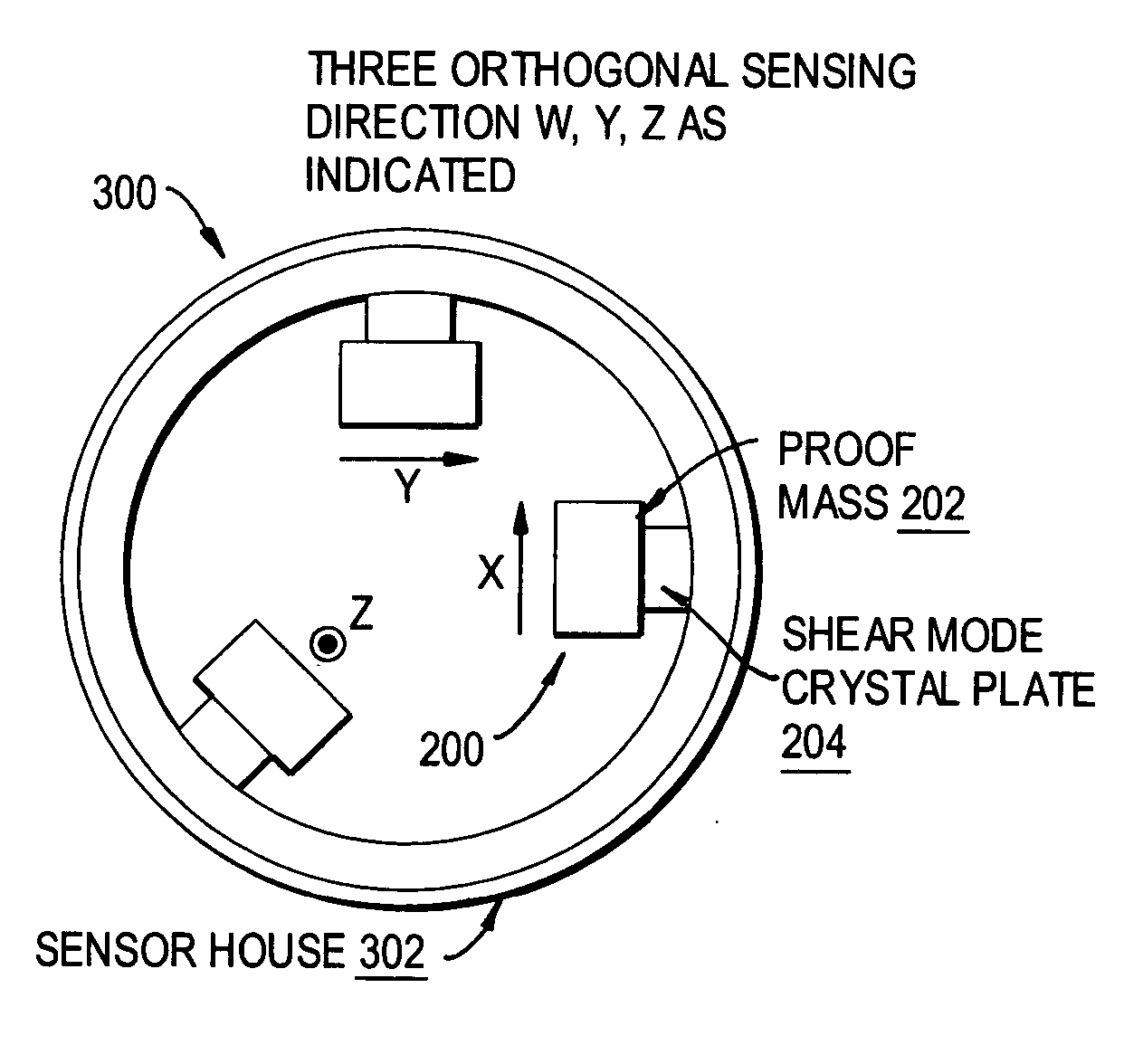

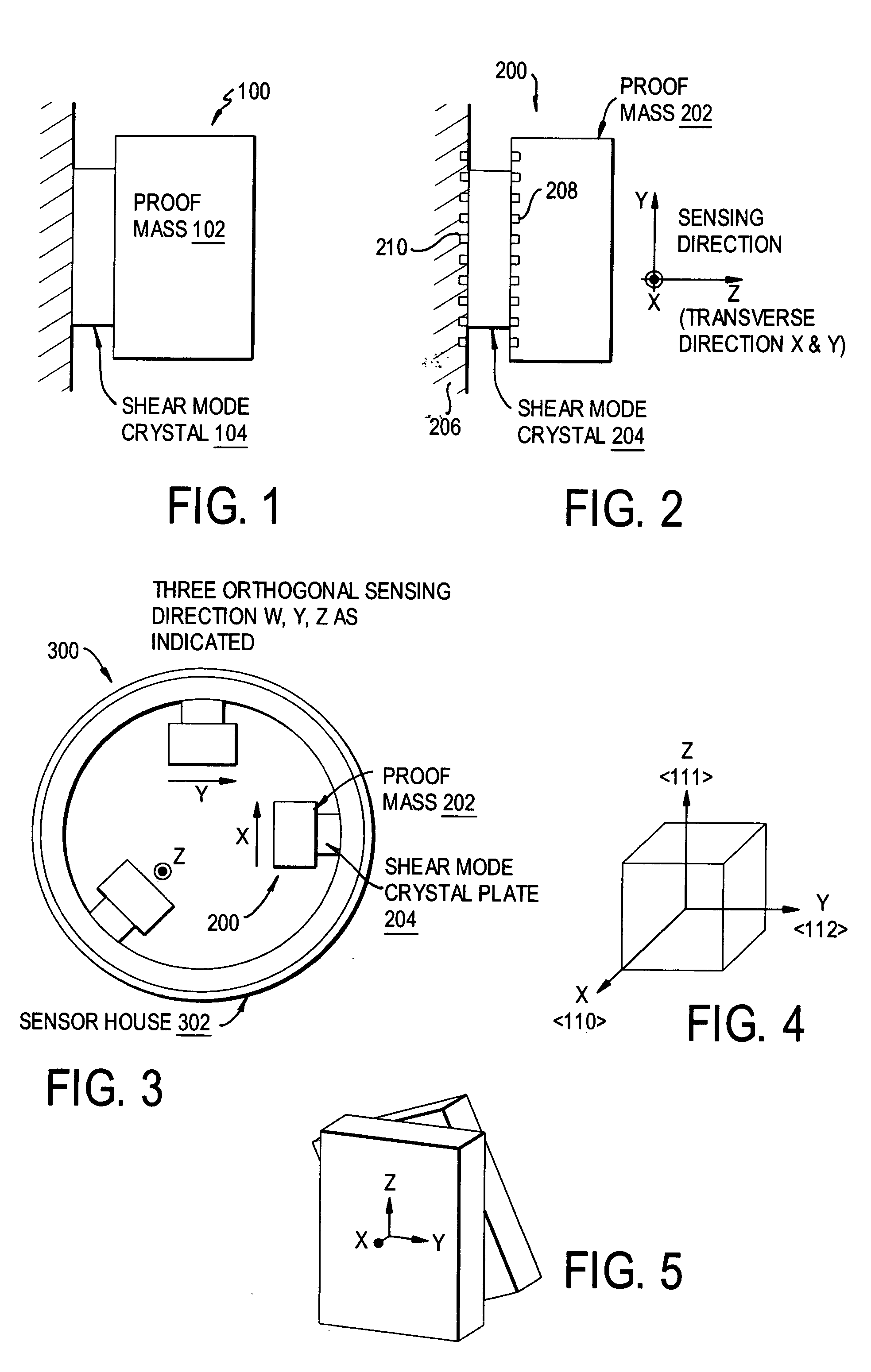

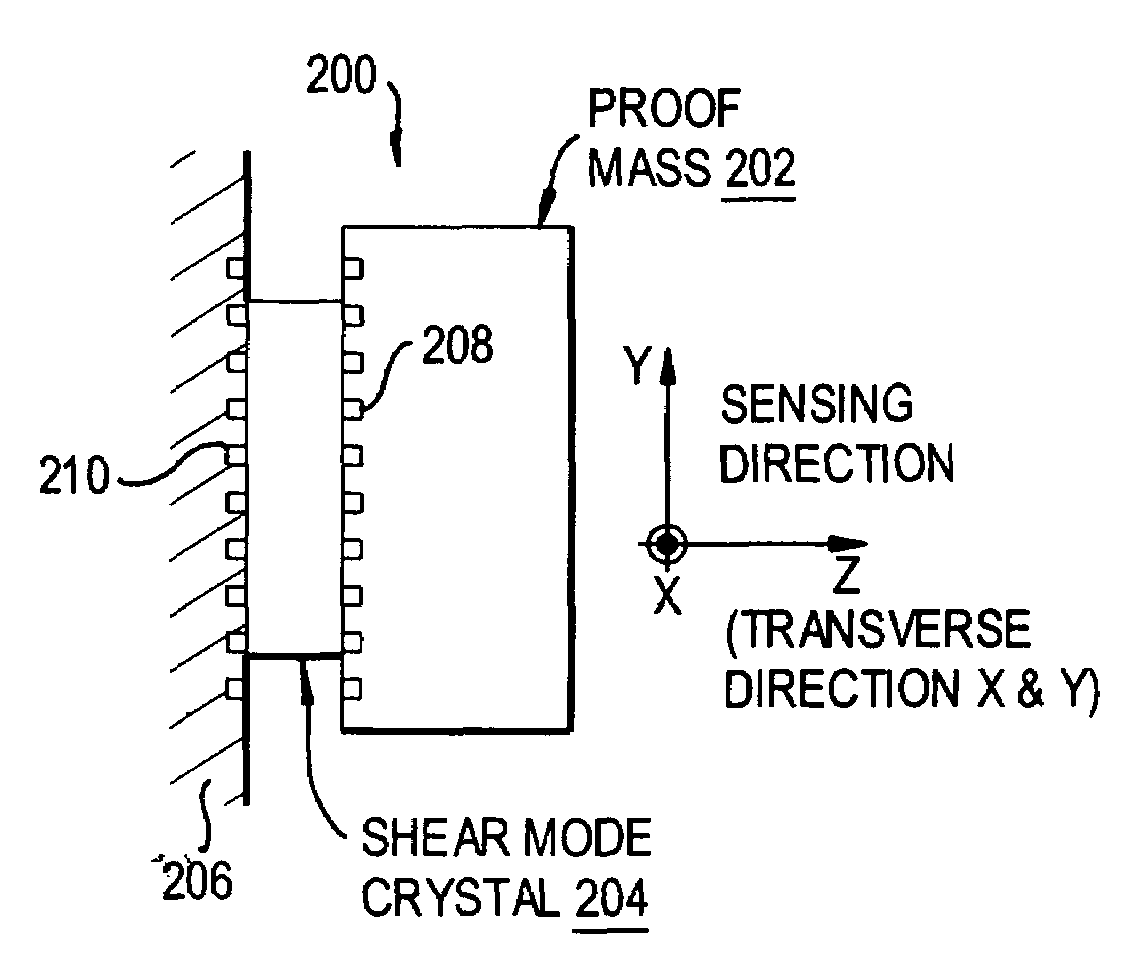

Acoustic vector sensor

InactiveUS20050034519A1Improve noise levelNarrow bandwidthAnalysing fluids using sonic/ultrasonic/infrasonic wavesAcceleration measurement using interia forcesElectricityAcoustic energy

The present invention is directed to an acoustic vector sensor, specifically an underwater acoustic vector sensor. The acoustic vector sensor contains three piezoelectric sensors orthogonally mounted inside a rigid housing, where each of the piezoelectric sensors measures acoustic energy from one of the three different, orthogonal, axial directions (X, Y, and Z). The piezoelectric sensor contains a proof mass, a base, and a piezoelectric crystal sandwiched therebetween. The bonding surfaces of the proof mass and the base are preferably castellated; and the piezoelectric crystal is preferably a shear mode (d15) relaxor single crystal.

Owner:AMPHENOL MARYLAND INC

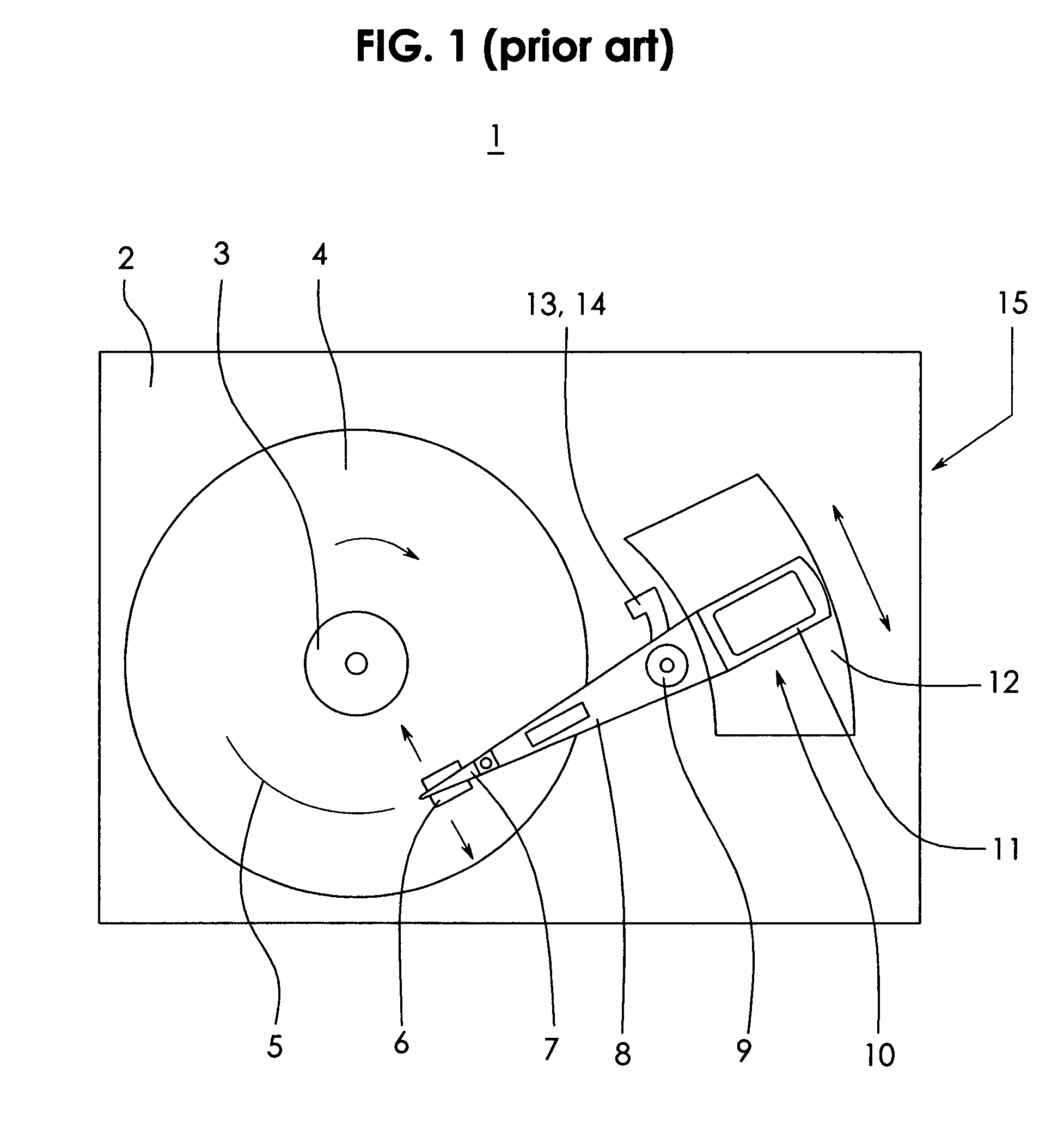

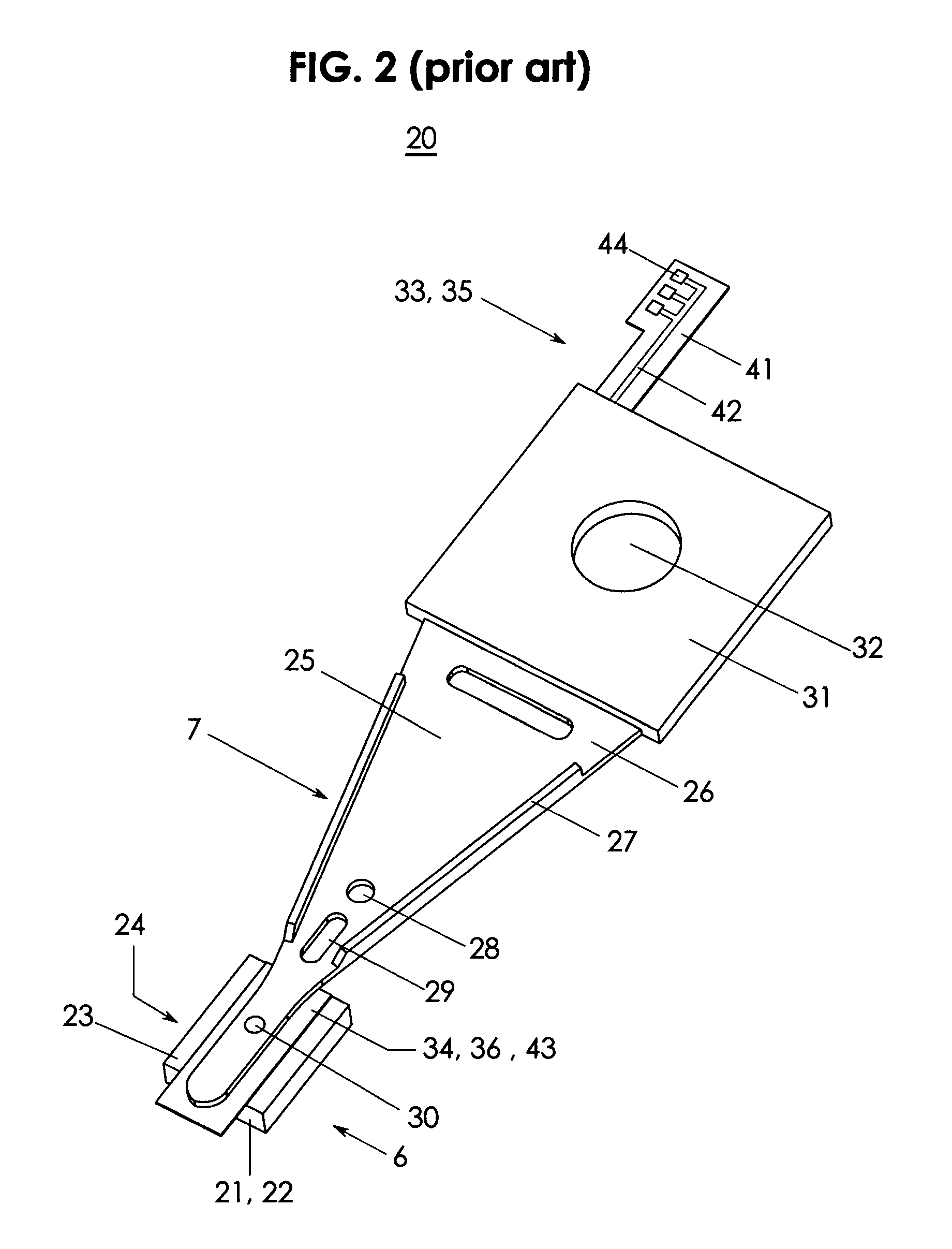

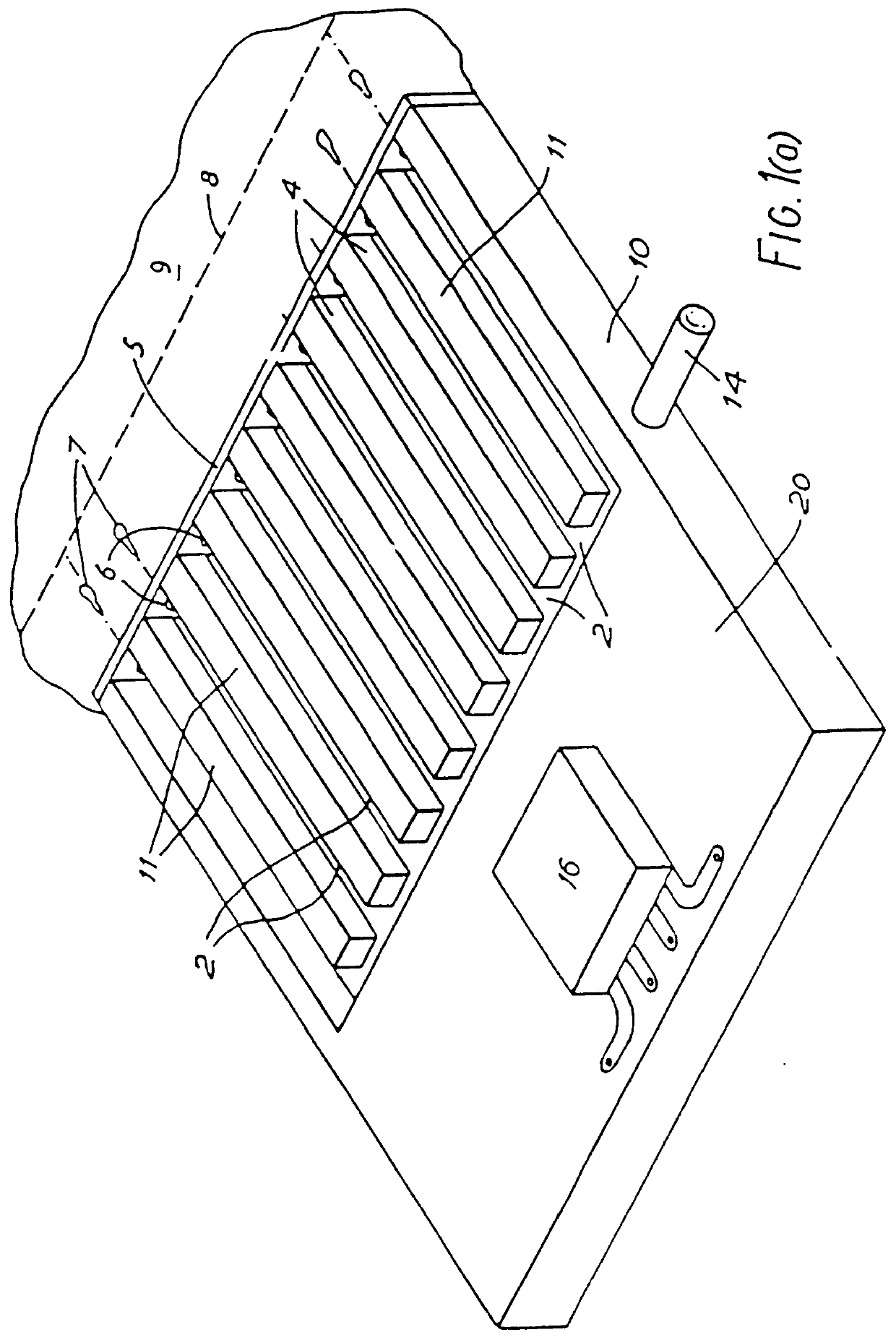

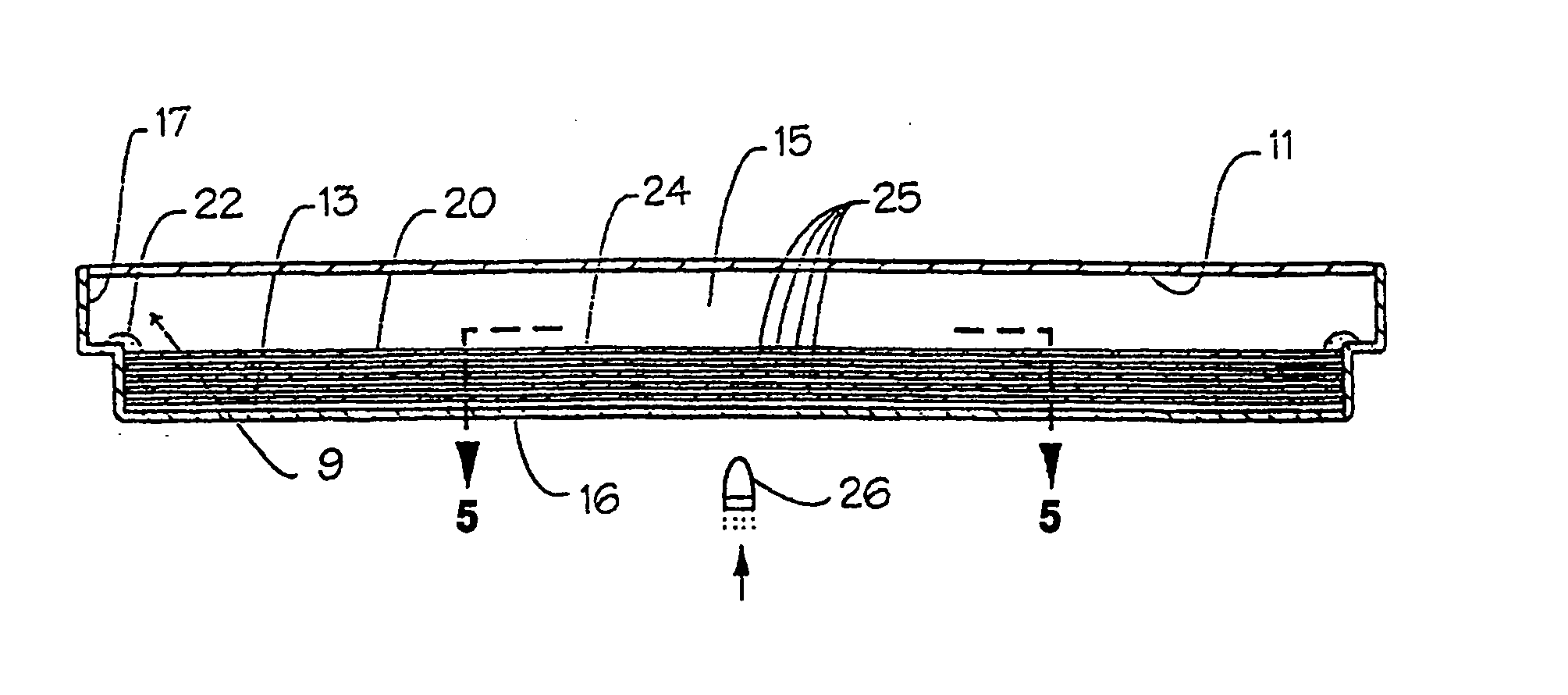

Droplet deposition apparatus

InactiveUSRE36667E1Reduce manufacturing costInking apparatusPiezoelectric/electrostrictive devicesAcoustic wavePiezo electric

A pulsed droplet ink jet printer has relatively long thin ink channels extending in parallel between an ink manifold 13, and a nozzle plate 5 providing a nozzle 6 for each channel. Side walls 11 may be formed substantially entirely of piezo-electric material so as to be displaceable transversely into a selected channel on the application of an electric field. This transverse displacement produces an acoustic wave in the channel which results in the ejection of an ink droplet. The side walls may deflect in shear mode to a cross-section of chevron formation. Usefully, it is arranged that both side walls adjoining the selected channel are displaced inwardly of the channel to cooperate in droplet ejection. Under this arrangement, the channels are assigned alternately to first and second groups of channels, only one group of channels being capable of actuation at any one instant. The nozzles associated with the respective groups of channels may be offset so as to compensate for the time delay in actuation of channels in the first and second groups.

Owner:XAAR TECH LTD

Rotational, shear mode, piezoelectric motor integrated into a collocated, rotational, shear mode, piezoelectric micro-actuated suspension, head or head/gimbal assembly for improved tracking in disk drives and disk drive equipment

ActiveUS20090021857A1High track densityImproved fine track positioningDriving/moving recording headsArm with actuatorsShock resistanceControl theory

A rotational, shear mode, piezoelectric motor is integrated with a suspension, head or head gimbal assembly (HGA) into a collocated, rotational, shear mode, piezoelectric micro-actuated suspension, head or head gimbal assembly (HGA) for use in disk drives and disk drive manufacturing equipment. When excited by a control voltage, the collocated, shear mode, piezoelectric micro-actuated HGA rotates the head enabling high frequency, high resolution track positioning of the read / write element. The motor is integrated with the head and flexure (collocation). The head rotates about a rotation axis that is ideally located at the center of mass of the head. A shear mode piezoelectric motor rotates the head. A collocated, rotational, shear mode, piezoelectric micro-actuated HGA has high stiffness, high frequency response, high positioning resolution, low mass and low internal vibration for improved tracking, increased track density and greater disk drive storage capacity. Furthermore, its solid integration improves shock resistance and reduces micro-contamination.

Owner:MAGNECOMP +1

Piezoelectric crystal elements of shear mode and process for the preparation thereof

InactiveUS20060012270A1Optimize shear mode piezoelectric propertySuper-high piezoelectric performanceUltrasonic/sonic/infrasonic diagnosticsPiezoelectric/electrostrictive device manufacture/assemblyTransducerRoom temperature

Piezoelectric crystal elements are provided having preferred cut directions that optimize the shear mode piezoelectric properties. In the discovered cut directions, the crystal elements have super-high piezoelectric performance with d15, d24 and d36 shear modes at room temperature. The d15 shear mode crystal gives a maximum d value and is free from the cross-talk of d11 and d16. The d36 mode is extremely reliable compared to other shear elements due to its ready re-poling capability. The crystal elements may be beneficially used for high-sensitive acoustic transducers.

Owner:H C MATERIALS CORP

Six-dimensional force sensor integrated strain gauge

The disclosed integrated strainmeter includes substrate and strain gauges fixed on the substrate. Strain gauges are composed of three sets of dual-gate in 90 degree mode and three sets of dual-gate in shear mode alternant arranged in parallel. Each set of dual-gate in 90 degree mode and each set of dual-gate in shear mode constitute a half bridge measuring circuit. Each half bridge measuring circuit possesses a signal output end. Being connected to each other, positive pole end of each half bridge measuring circuit is connected to power source. Being connected to each other, negative pole end of each half bridge measuring circuit is connected to ground. Comparing with prior art, the invention solves issues of fussy sticking procedure, difficult to guarantee consistency of strain and too many leads, and possessing advantages of high precision, less number of leads and one time of procedure for sticking strain gauges on columniform elastic body.

Owner:HARBIN INST OF TECH

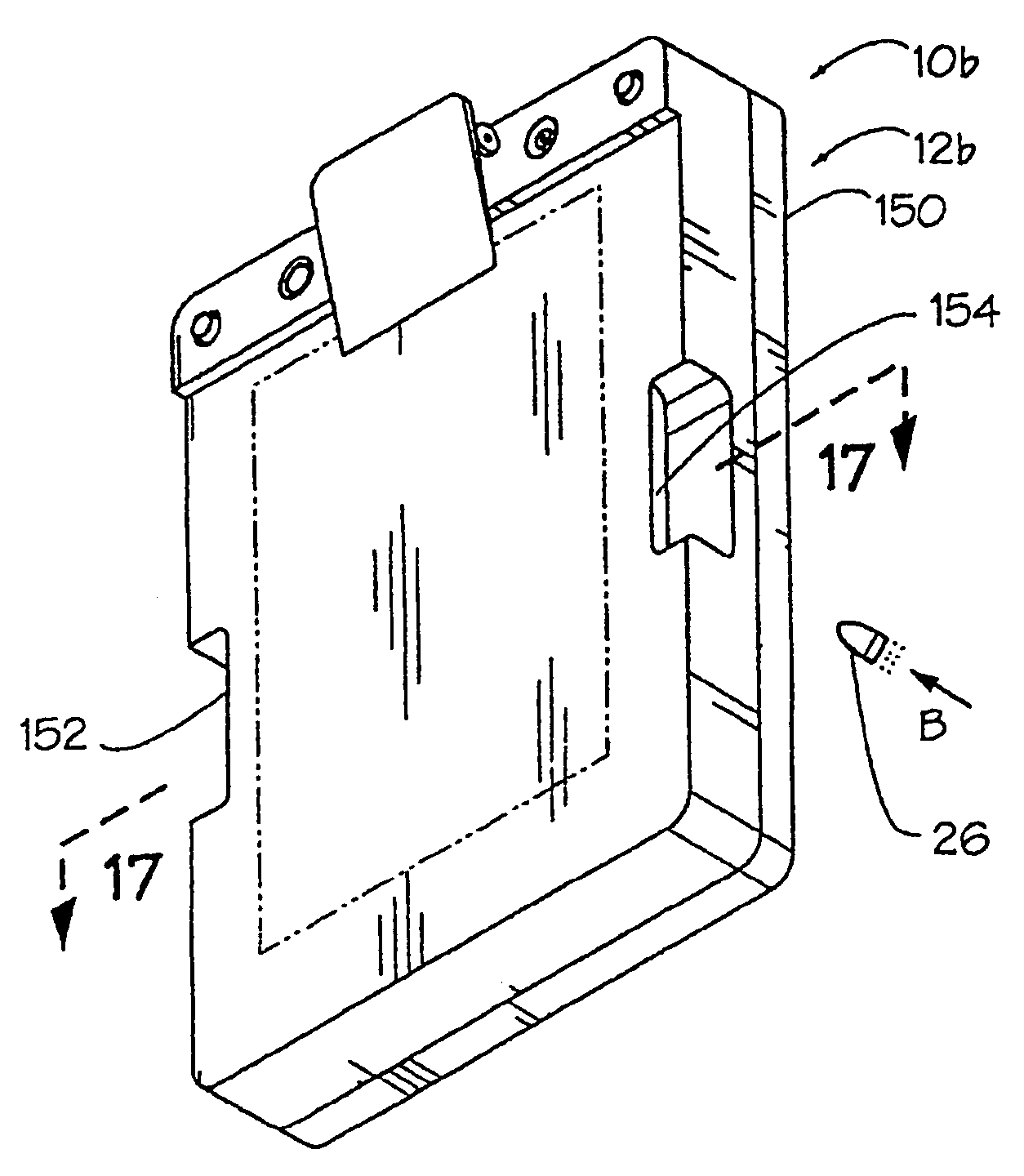

Bullet-resistant hand-held defensive object

InactiveUS20050053769A1Protect from harmEasy to placeLayered productsWeapons typesHand heldEngineering

A bullet-resistant defensive device is disclosed made up of layers of bullet resistant material layered together and connected along their peripheral edge on a frame to form a planar shield. The shield so formed works such that a bullet striking the shield causes the layered bullet resistant material to flex thereby dissipating the force of the bullet, the material when it stretches transfers the force of the bullet from a shear mode to a tensile mode. One preferred embodiment incorporates the invention into a clipboard box for use by police officers for protecting against head, neck and hand wounds from handguns fired at close range from vehicles. The hand-held, bullet resistant clipboard box holds documents and writing implements, and the bullet-resistant material is located within the clipboard box interior cavity and configured for catching a fired bullet before it can pass through the entire clipboard.

Owner:MAGSHIELD TECH

Torque sensor

A torque sensor for a human-powered object includes a spindle connecting crank arms of the object. In one embodiment, the object can be a bicycle. The torque sensor further includes at least one strain gauge mounted to the spindle in a shear pattern to measure shear strain perpendicular to a radius of the spindle. In some embodiments, the torque sensor further includes a carrier fixed to a hollow interior of the spindle, where at least one strain gauge is mounted to the spindle via the carrier. Advantageously, the torque sensor provides a low cost method to measure power.

Owner:GRASSI MICHAEL J

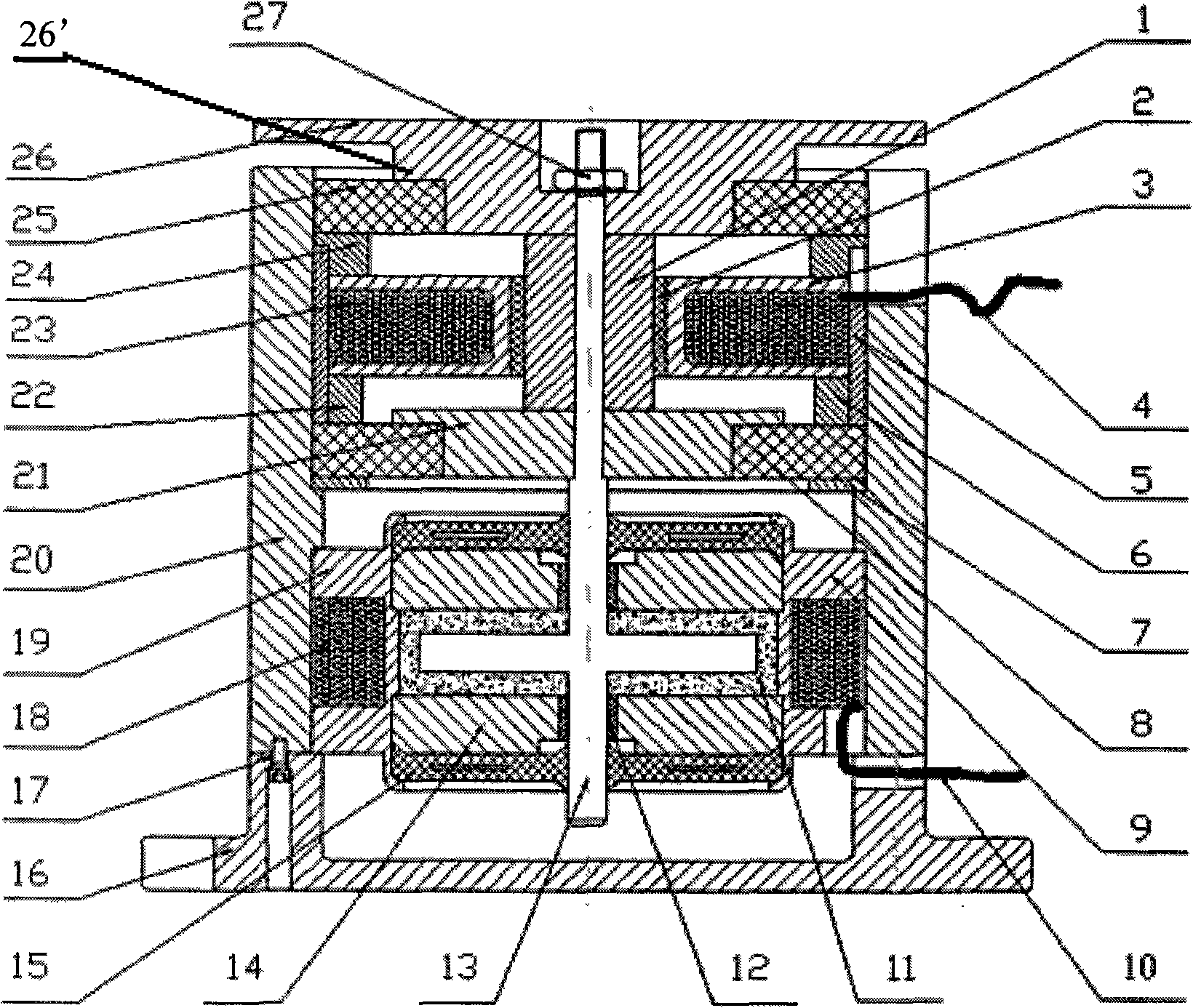

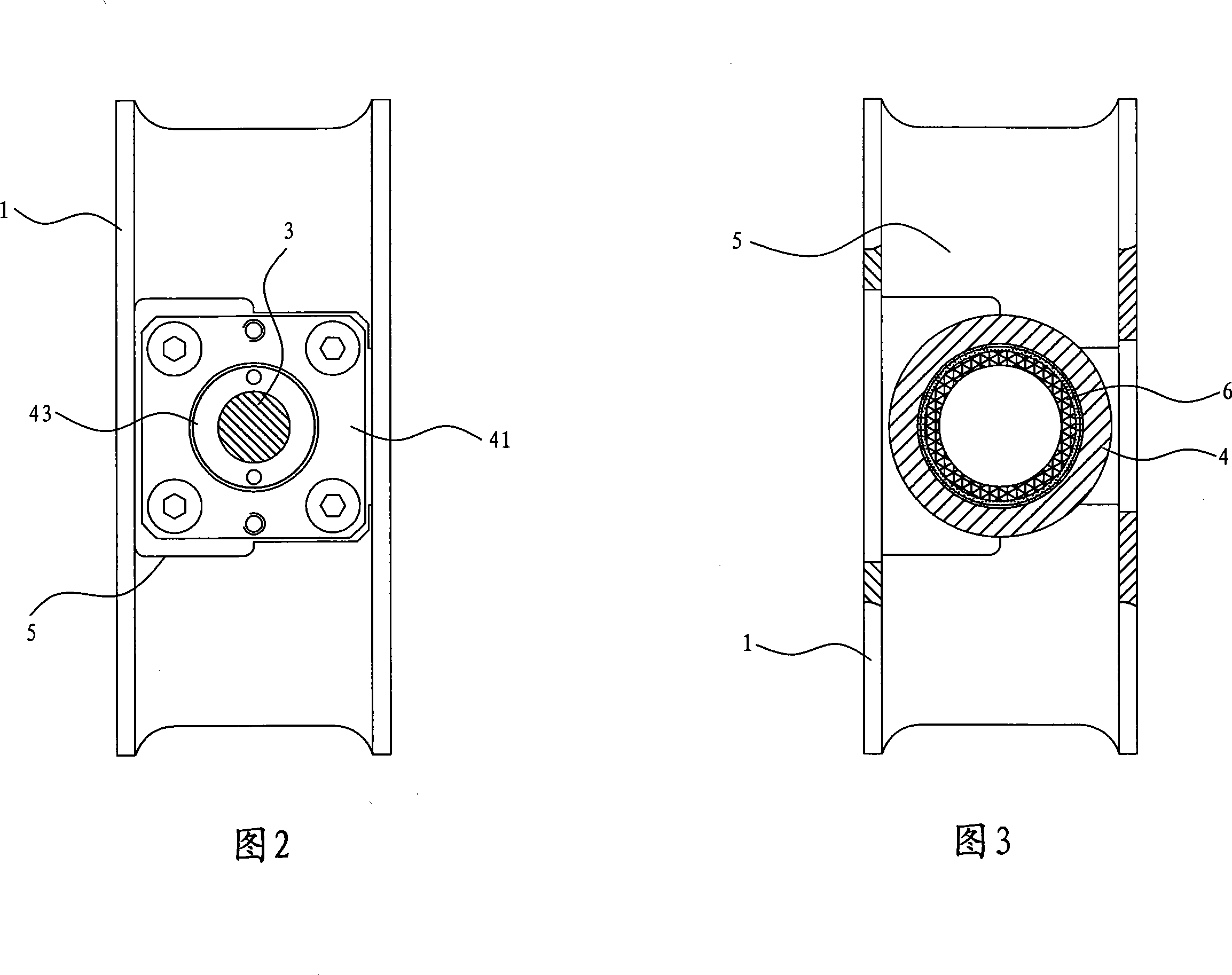

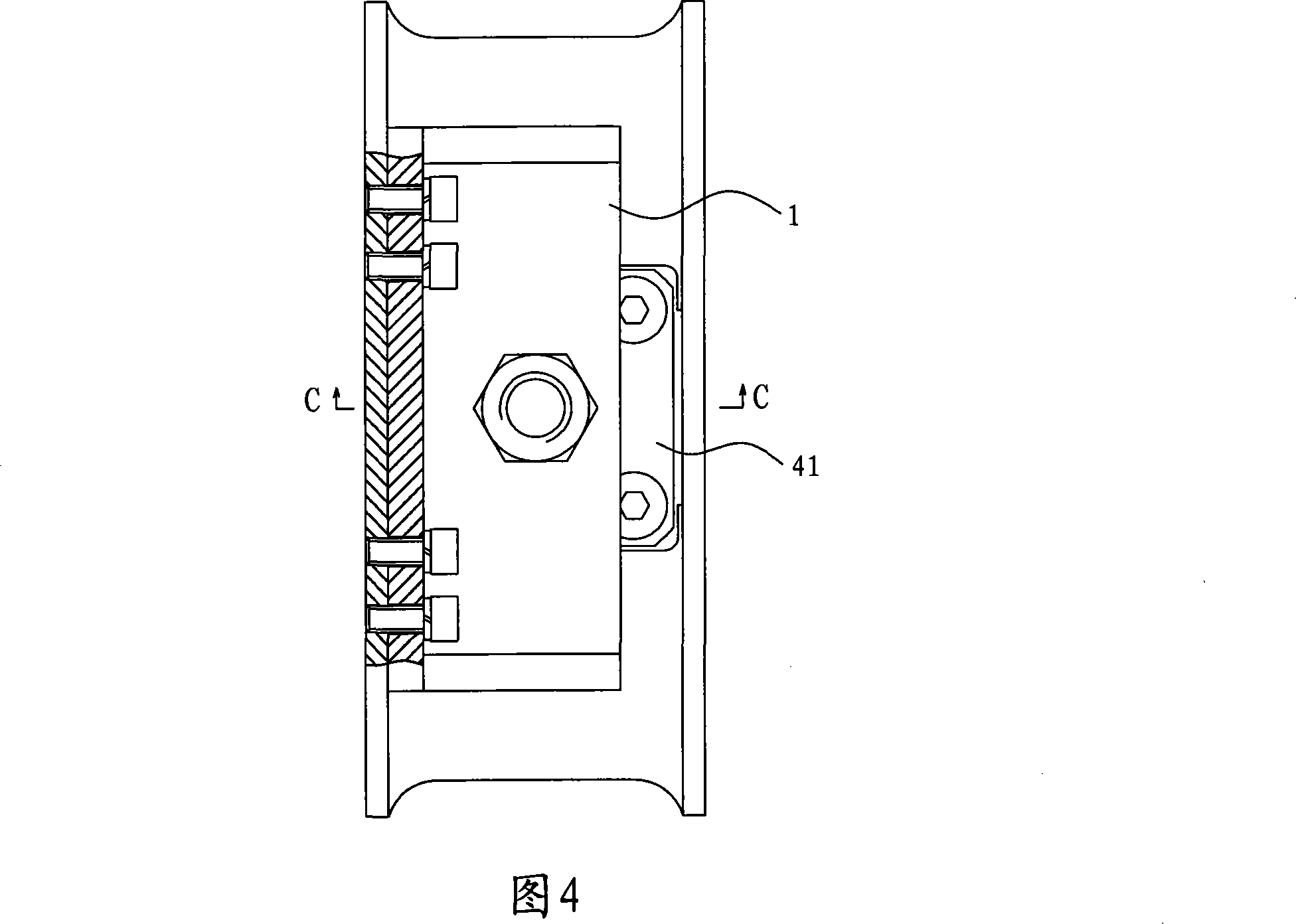

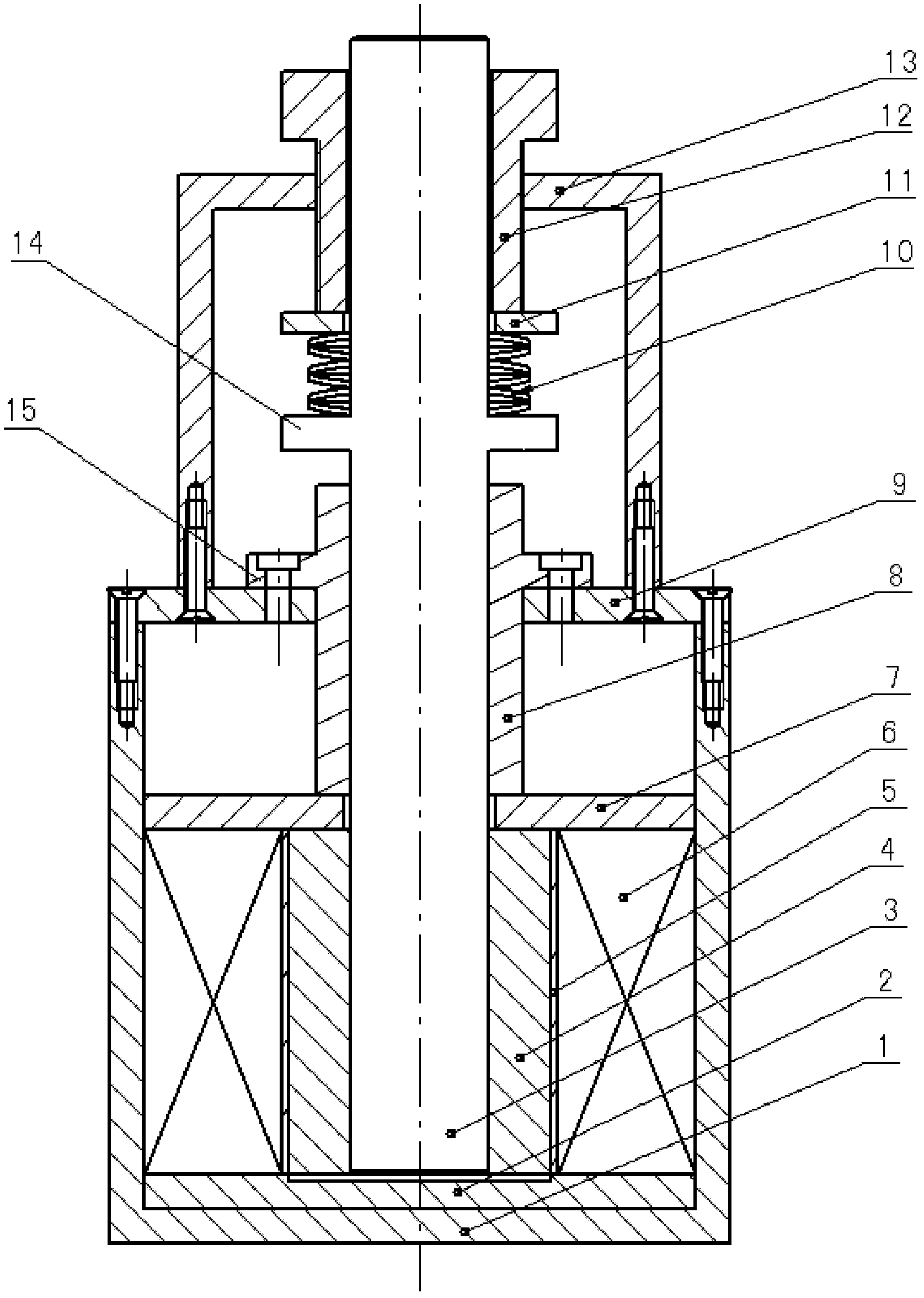

Shearing type MR fluid shock absorber

InactiveCN101235864AImprove working conditionThe damping coefficient can be adjusted in real timeNon-rotating vibration suppressionDamping factorEngineering

The invention provides a shear mode magneto-rheological fluid damper which is capable of achieving automatic reset, and comprises a seat board 1, a seat board 2 and a magneto-rheological fluid damper, wherein the magneto-rheological fluid damper is arranged between the seat board 1and the seat board 2, a rubber damping device is arranged between the board plate 1 and the seat board 2, thereby when the seat board 1 and the seat board 2 are arranged on a damping object, the magneto-rheological fluid damper provides a damping effect of real-time adjustable damping coefficient and accurate control for the damping object, the rubber damping device besides provides an additional non-main damping action, the more important is that the magneto-rheological fluid damper is recovered to an initial state, and the whole shear mode magneto-rheological fluid damper is maintained in an ideal working state.

Owner:HUAQIAO UNIVERSITY

Head gimbal assembly apparatus having an actuator mounted on a mounting plate comprising a ceramic sub-plate formed on a stainless steel mounting plate

ActiveUS8148791B1Accurate resonance testingExtends usable test frequency rangeDriving/moving recording headsArm with actuatorsDensity ratioResonance

A test assembly for a disk drive suspension head gimbal assembly includes a steel mount plate and a mount sub-plate of a material such as silicon carbide having a modulus of elasticity to density ratio that is significantly higher than the ratio for stainless steel. Preferably the mount plate and the mount sub-plate taken together have a first resonant shear frequency of greater than 50 KHz, which is generally greater than the frequency range of interest for testing head gimbal assemblies. The high modulus of elasticity to density ratio helps to ensure that any shear mode resonances of the test assembly occur at frequencies that are higher than the frequencies of interesting for head gimbal assembly shear resonance testing purposes.

Owner:MAGNECOMP

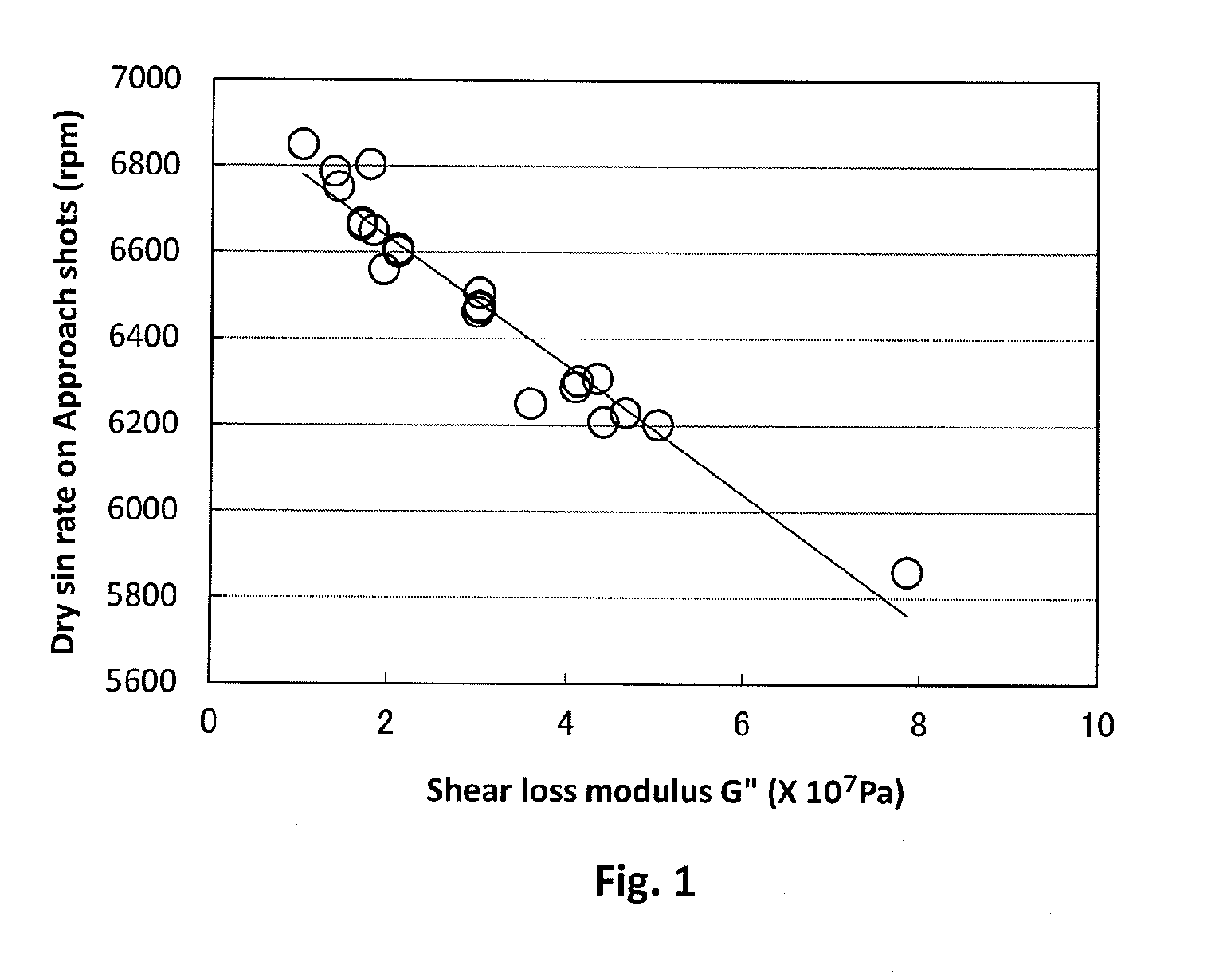

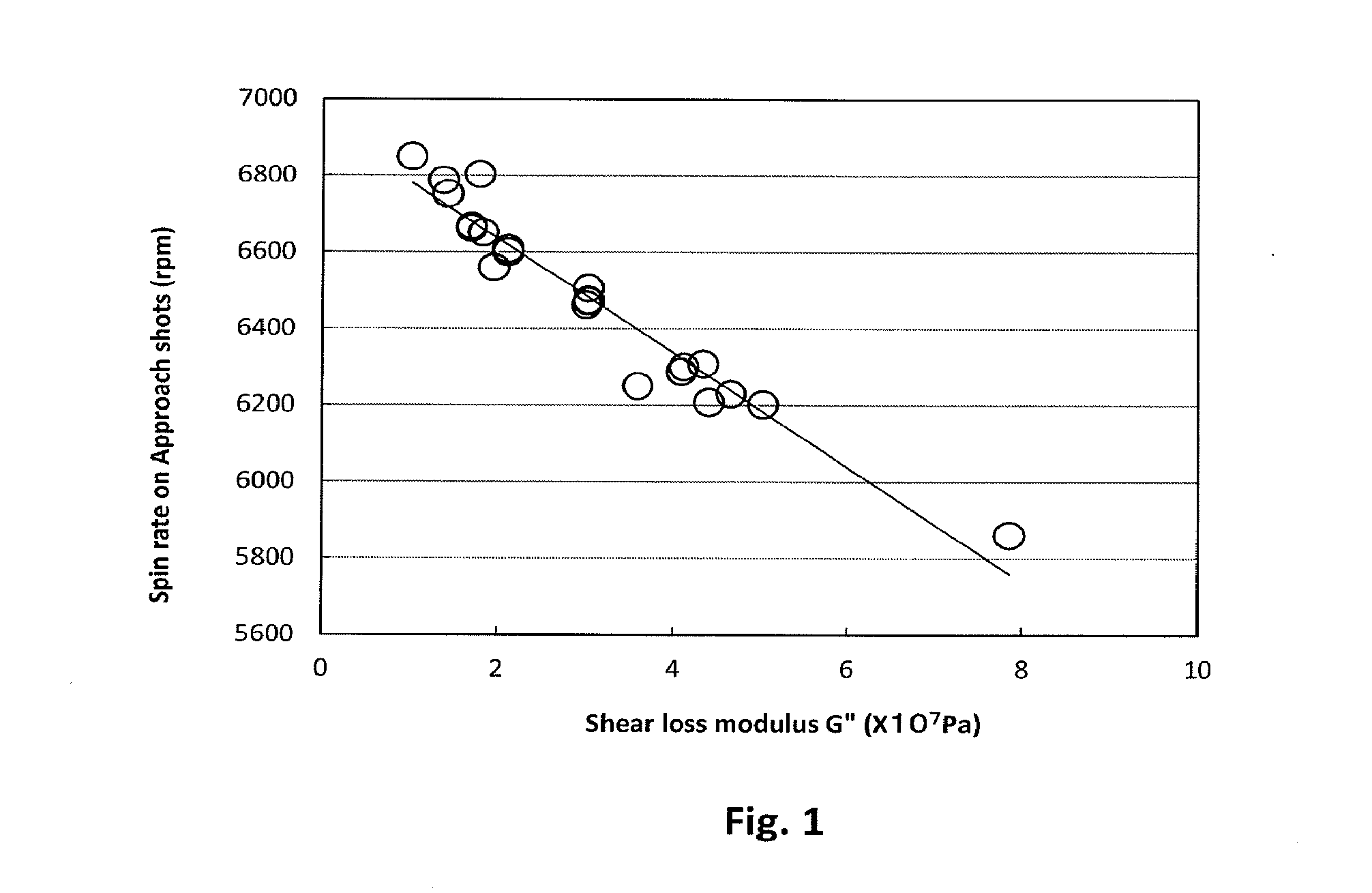

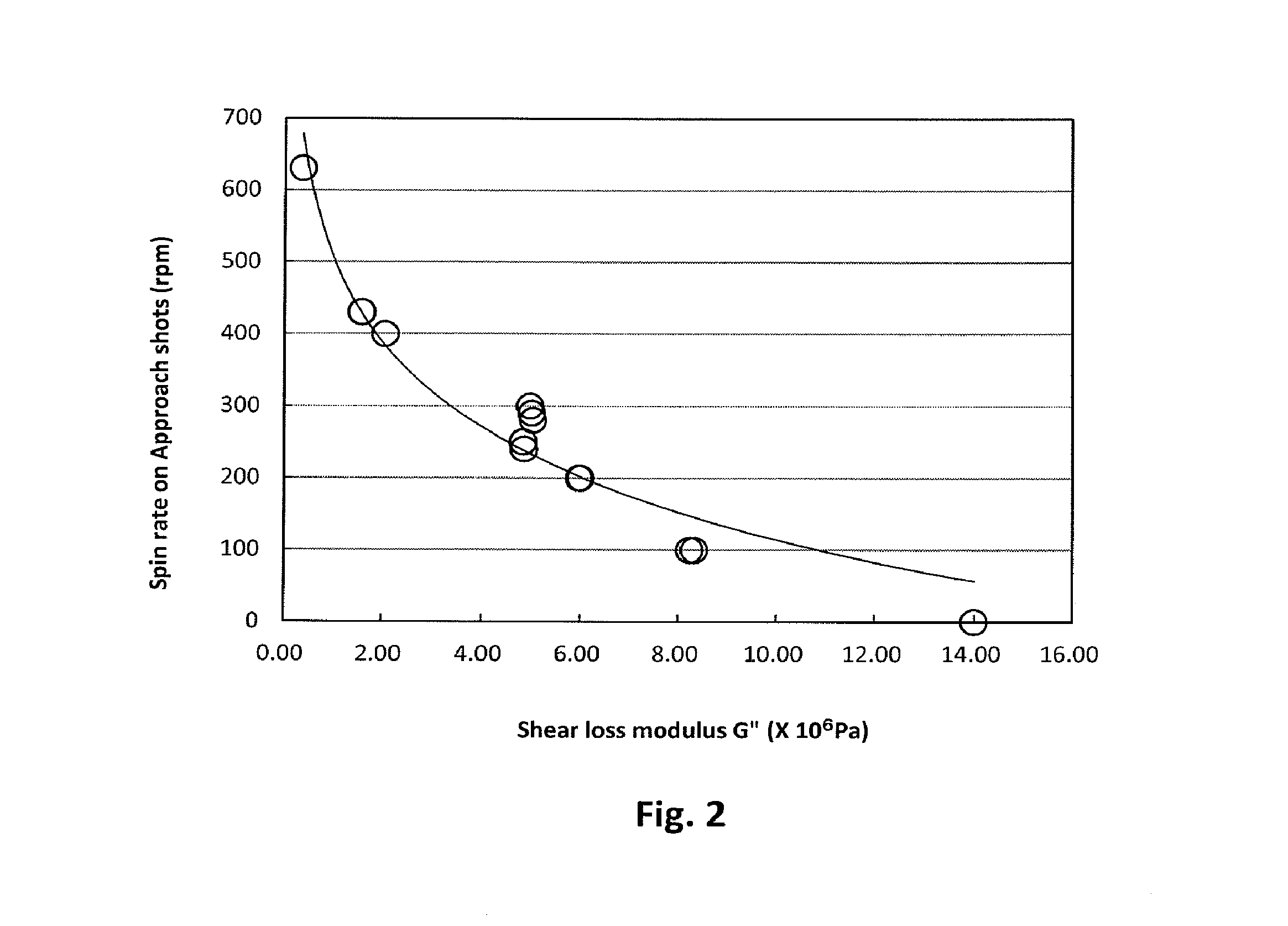

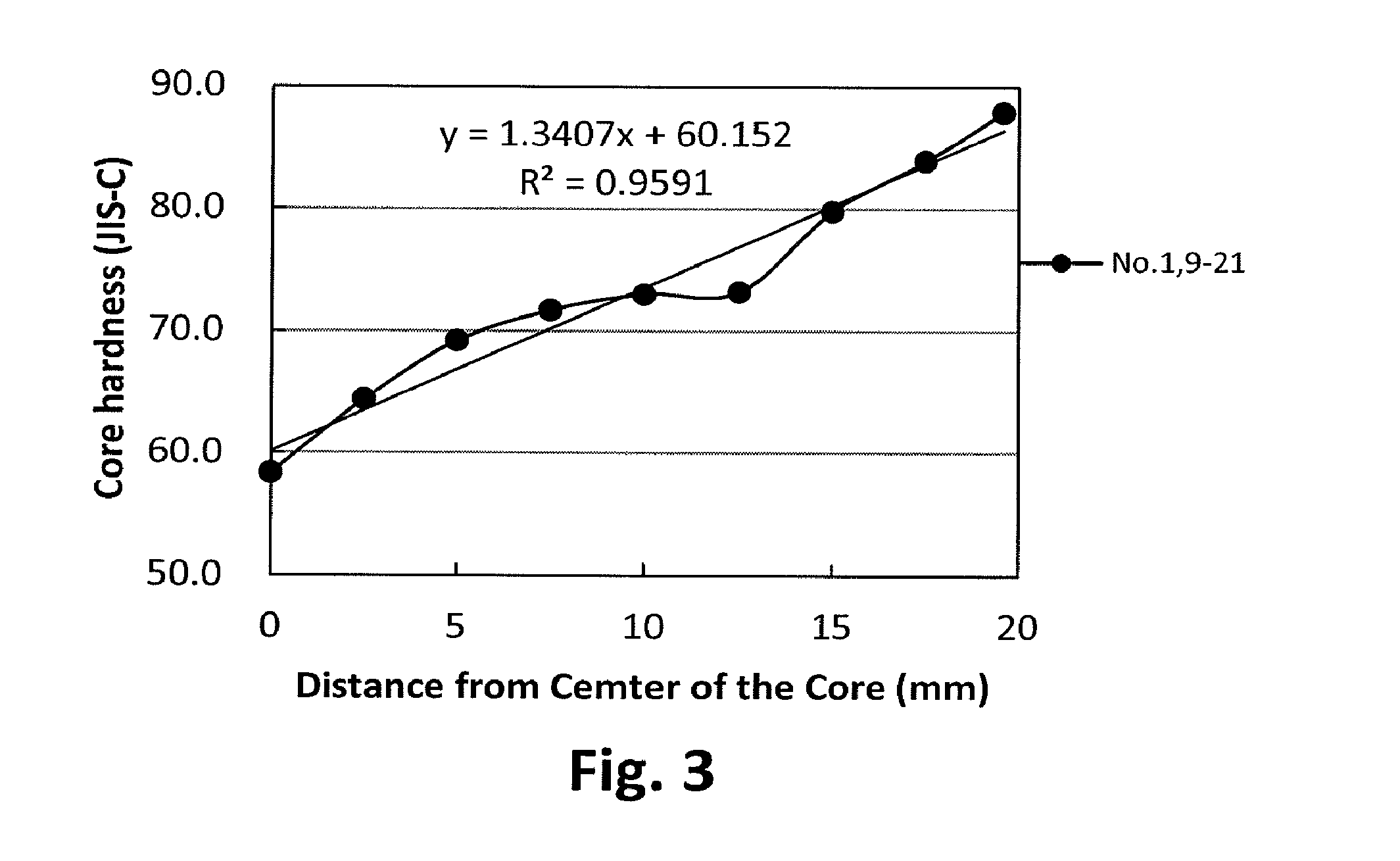

Golf ball

ActiveUS20130053179A1Slow down the spin rateFlying distanceGolf ballsSolid ballsPolyurethane elastomerDynamic viscoelasticity

A golf ball includes a spherical core and a cover covering the spherical core, wherein the cover is formed from a polyurethane composition containing a polyurethane elastomer as a resin component, the polyurethane composition has a shear loss modulus G″ of more than 5.03×106 Pa and 1.17×108 Pa or less when measured in a shear mode using a dynamic viscoelasticity measuring apparatus at the conditions of the temperature of 0° C., and the oscillation frequency of 10 Hz, the golf ball has a hardness distribution that R2 of a linear approximate curve determined by a least-squares method is 0.95 or more, when plotting center hardness (JIS-C) of the spherical core, hardness (JIS-C) measured at intervals of 2.5 mm from the center of the spherical core, surface hardness (JIS-C) of the spherical core, and slab hardness (JIS-C) of the cover versus distances from the center of the spherical core.

Owner:SUMITOMO RUBBER IND LTD

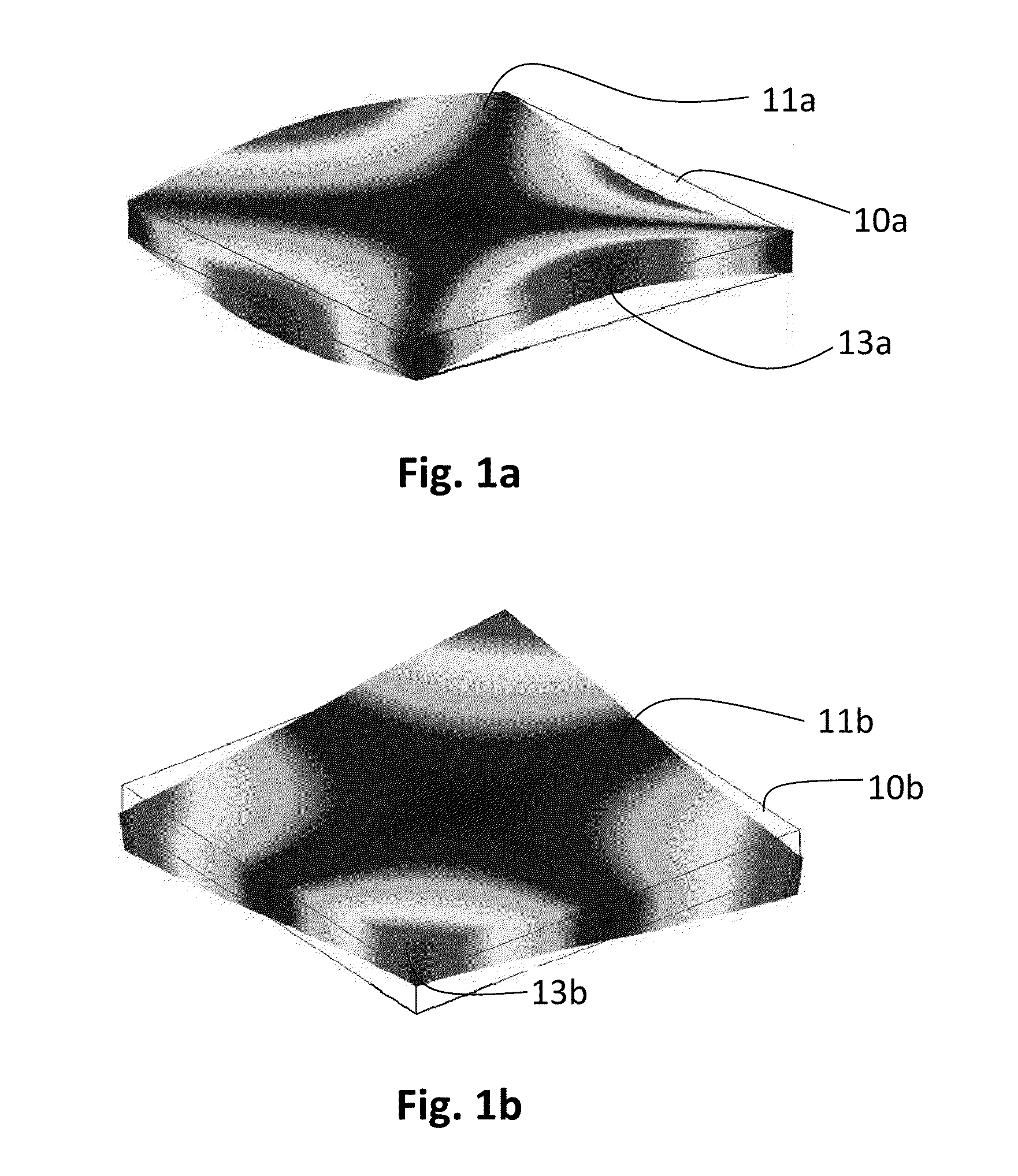

Micromechanical resonator and method for manufacturing thereof

ActiveUS20130187724A1Bias voltage requirementRequirement gapImpedence networksSemiconductor/solid-state device manufacturingCrystal orientationCrystal structure

The invention relates to a temperature compensated micromechanical resonator and method of manufacturing thereof. The resonator comprises a resonator element comprising a semiconductor crystal structure, which is doped so as to reduce its temperature coefficient of frequency, transducer means for exciting to the resonator element a vibrational mode. According to the invention the crystal orientation and shape of the resonator element are chosen to allow for a shear mode having a saddle point to be excited to the resonator element, and said transducer means are adapted to excite said shear mode to the resonator element. Accurate micromechanical resonators with now temperature drift can be achieved by means of the invention.

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT OY

Golf ball

ActiveUS20130053182A1Slow down the spin rateFlying distanceGolf ballsSolid ballsPolyurethane elastomerDynamic viscoelasticity

The present invention provides a golf ball comprising a spherical core and at least one cover layer covering the spherical core, wherein the cover is formed from a polyurethane composition containing a polyurethane elastomer as a resin component, the polyurethane composition satisfying properties of rebound resilience of 54% or more and a shear loss modulus G″ of 5.03×106 Pa or less when measured in a shear mode using a dynamic viscoelasticity measuring apparatus at the conditions of the temperature of 0° C., and the oscillation frequency of 10 Hz, and the spherical core has a hardness distribution that R2 of a linear approximate curve determined by a least-squares method is 0.95 or more, when plotting JIS-C hardness measured at a center, a surface and at intervals of 2.5 mm from the center of the spherical core, versus distances from the center of the spherical core.

Owner:SUMITOMO RUBBER IND LTD

Underwater acoustic vector sensor using transverse-response free, shear mode, PMN-PT crystal

InactiveUS7066026B2Improve noise levelNarrow bandwidthAnalysing fluids using sonic/ultrasonic/infrasonic wavesAcceleration measurement using interia forcesElectricityFree state

The present invention is directed to an acoustic vector sensor, also called particle velocity sensor. <111> direction poled, shear mode, relaxor single crystals are used as the sensing elements. In addition, these crystal plates are cut at a special orientation such that they provide zero or minimum responses in the transverse directions, but have a maximum piezoelectric response in sensing direction. The piezoelectric sensor contains a proof mass, a base, and an aforementioned relaxor crystal. Three of the sensors are mounted orthogonally with a rigid case, and they are designated to sense the acoustic particle velocity in three designated directions, say X, Y, and Z. To solve the adverse lateral constraint problem (also known as clamping effect) associated with the relaxor crystal; reduced bonding area between the proof mass and the relaxor crystal are introduced. This feature greatly reduced the percentage of the bonding area for the crystal; consequently the free-state piezoelectric properties of the relaxor crystals are preserved.

Owner:AMPHENOL MARYLAND INC

Easy open woven polypropylene bag

InactiveUS20100209026A1Easy to openHigh burst resistanceFlexible coversWrappersBursting strengthEngineering

The disclosure relates to a large package, typically with woven polypropylene walls, including an easy-open strip with a pre-activated peel seal. The easy-open strip achieves a high burst strength by configuring the pre-activated peel seal in shear mode in response to internal (product side) forces while achieving a low consumer opening force by configuring the peel seal in response to external (consumer side) forces.

Owner:ILLINOIS TOOL WORKS INC

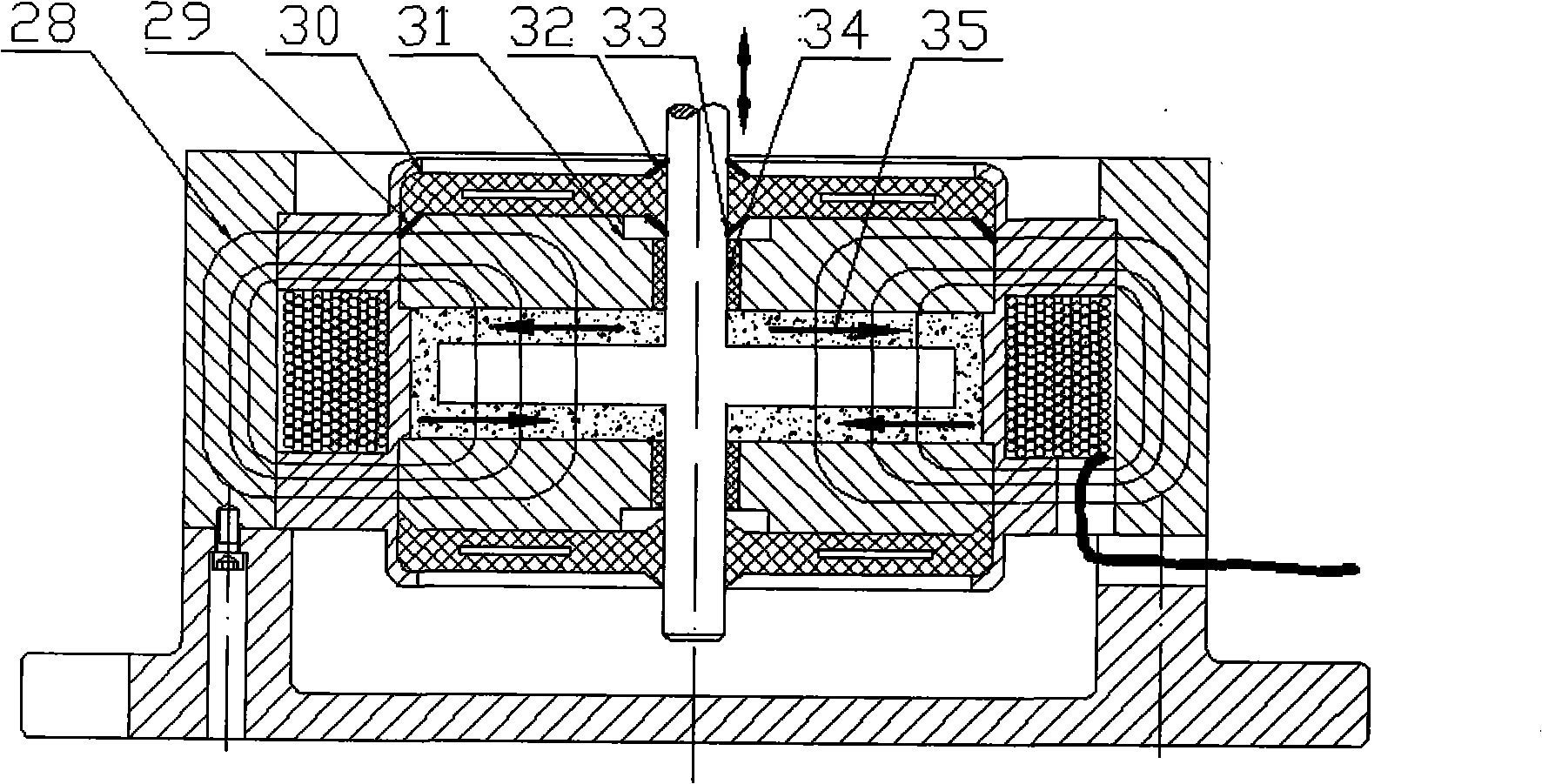

Micro-displacement actuator for shear mode magnetorheological elastomer

InactiveCN102306997AIncrease the itineraryAdjustable strokeDynamo-electric machinesMountingsElastomerMagnetorheological elastomer

The invention discloses a micro-displacement actuator for a shear mode magnetorheological elastomer, and relates to the field of precision mechanical devices. The actuator comprises a lower housing, a lower magnetizer, an output link, the magnetorheological elastomer, a fixed barrel, an excitation coil, an upper magnetizer, a linear bearing, a fixed flange, a pre-tensioning mechanism and an upperhousing. The actuator uses the output line for micro-displacement output, wherein one end of the output link is connected with the inner side of a cylinder of the magnetorheological elastomer, and the other end of the output link is positioned by the linear bearing; and a pressing force is applied to the top end of the output link by the pre-tensioning mechanism. When the actuator works, the pressing force is applied at first to initially deform the cylinder of the magnetorheological elastomer by a shearing function, and the shearing modulus of the magnetorheological elastomer is changed by controlling a magnetic field after power-on to change the deformation of the elastomer, thereby changing the displacement of the end part of the output link to fulfill the aim of micro-displacement output. The actuator provided by the invention has the advantages of long stroke, stroke adjustability and simple structure.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com