Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

138 results about "Thickness shear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Strain localization into shear bands in metallic glasses is typically described as a mechanism that occurs at the nano-scale, leaving behind a shear defect with a thickness of 10–20 nm.

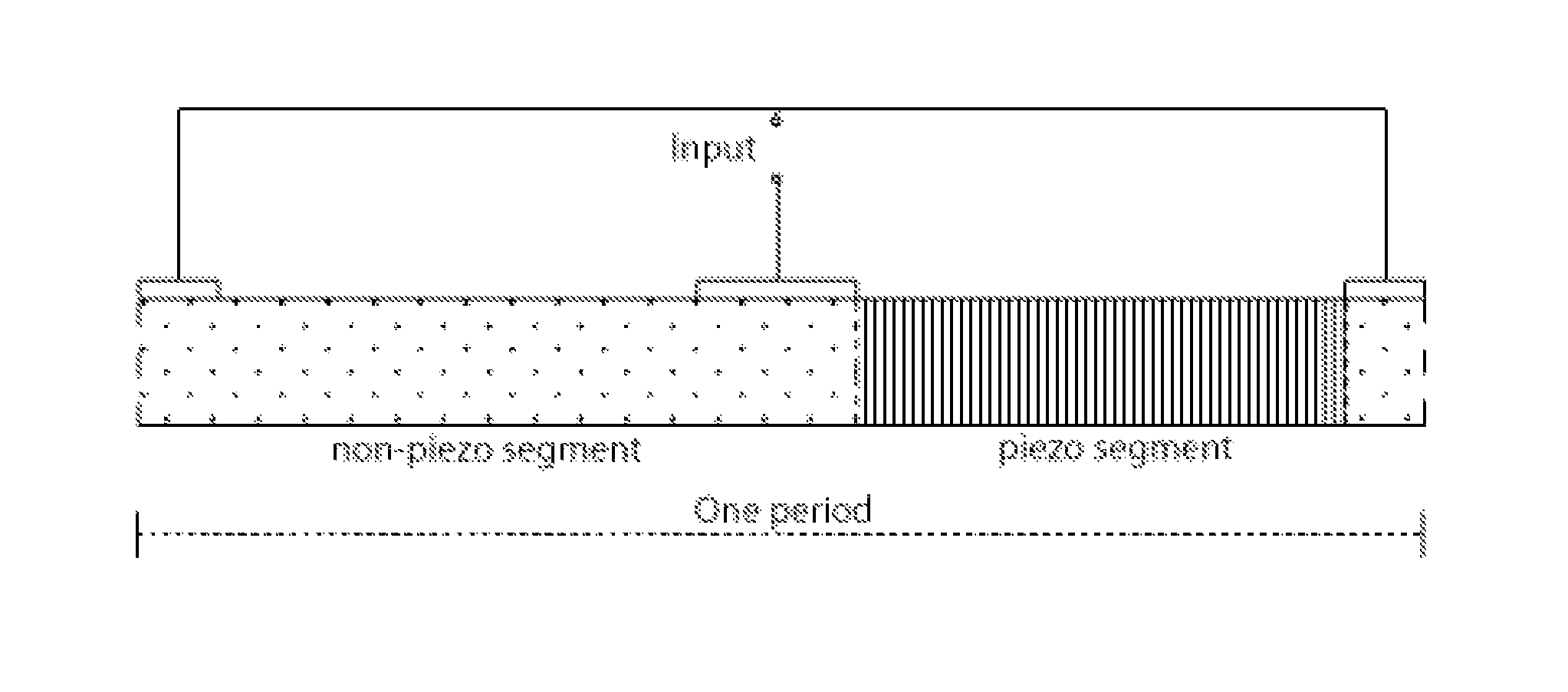

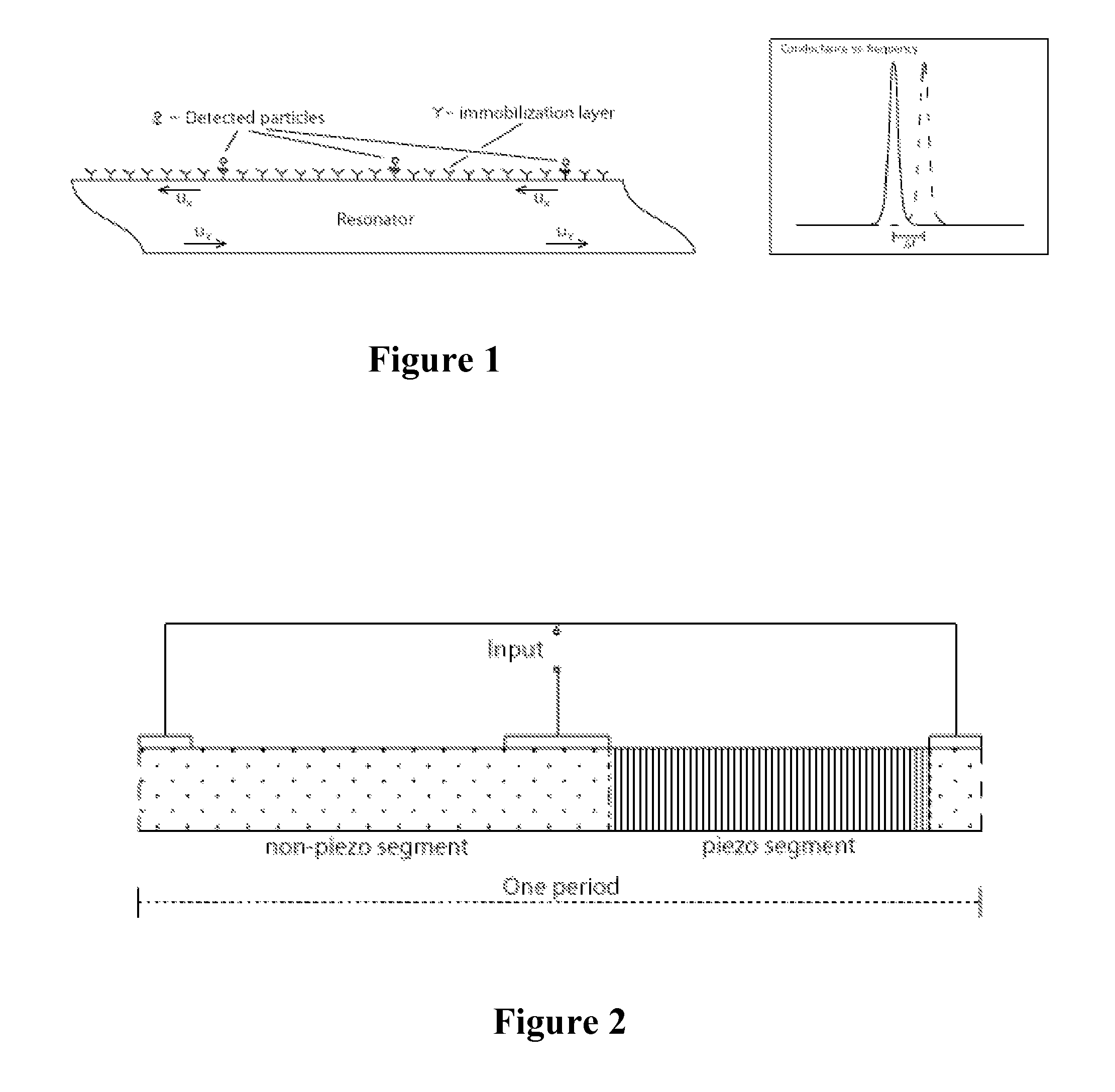

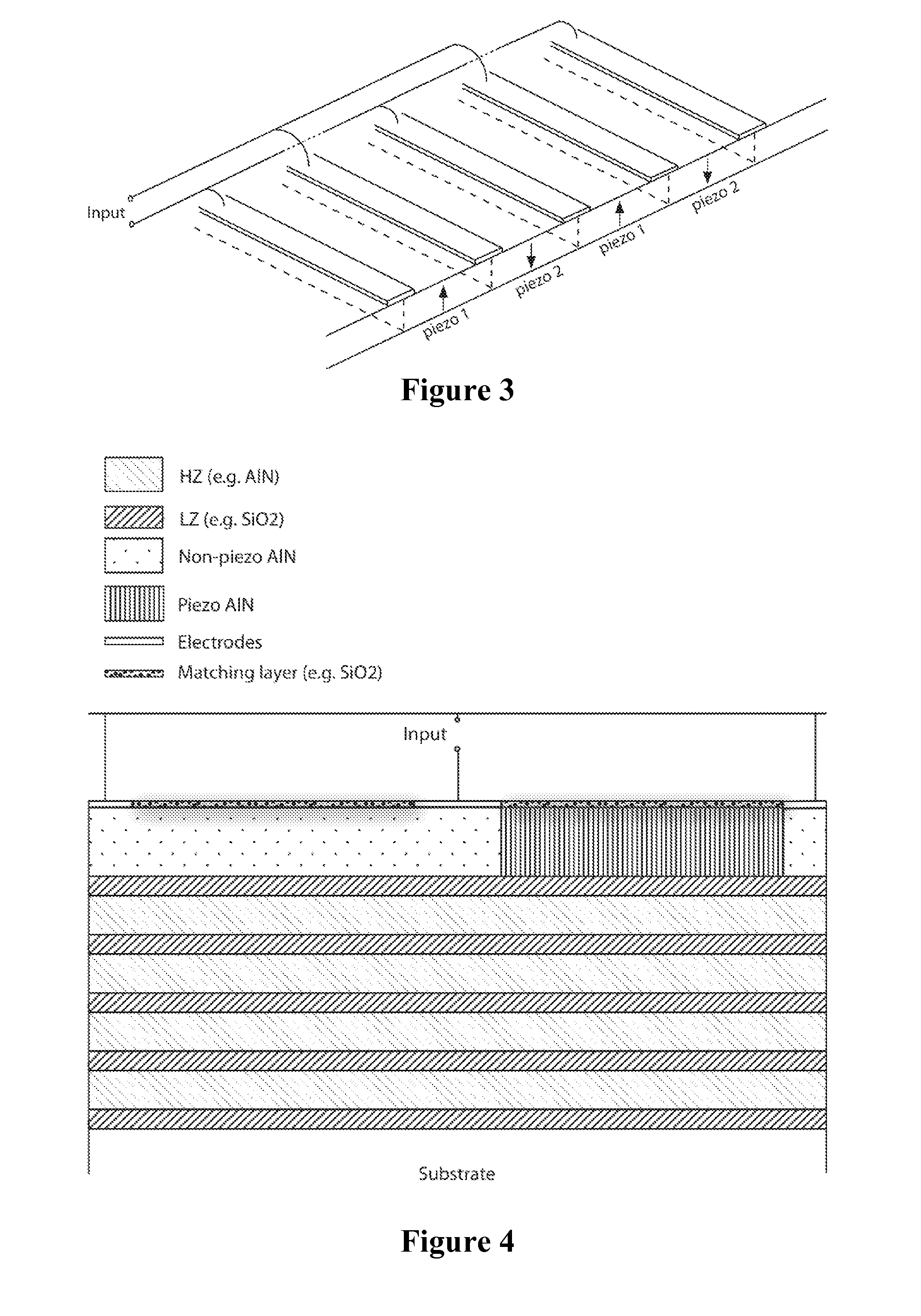

Piezoelectric resonator operating in thickness shear mode

InactiveUS8829766B2Piezoelectric/electrostriction/magnetostriction machinesImpedence networksElectrical polarityAcoustic wave

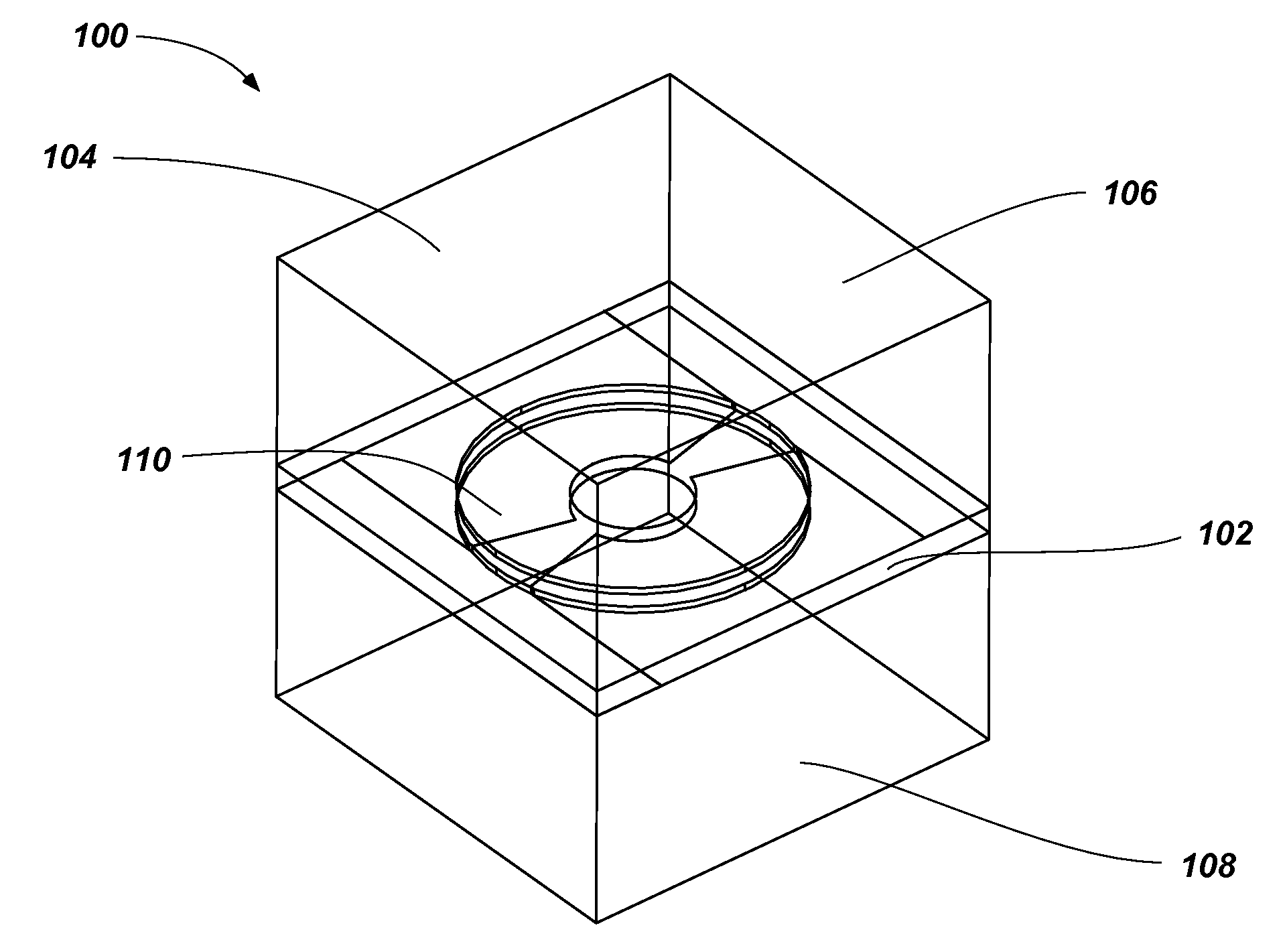

An acoustic wave resonator device comprising a resonant layer that comprises a series of side-by-side areas of first and second dielectric materials. In one embodiment the first dielectric material is a piezoelectric, in particular the first dielectric material can be a piezoelectric and the second dielectric material can be non-piezoelectric. In another embodiment, the first dielectric material is a piezoelectric of first polarity and the second dielectric material is a piezoelectric of opposite polarity or different polarity. Where needed, the resonant layer is supported on a reflector composed of series of layers of high acoustic impedance material(s) alternating with layers of low acoustic impedance material(s). For example, the reflector comprises AlN, Al2O3, Ta2O5, HfO2 or W as high impedance material and SiO2 as low impedance material.

Owner:SNAPTRACK

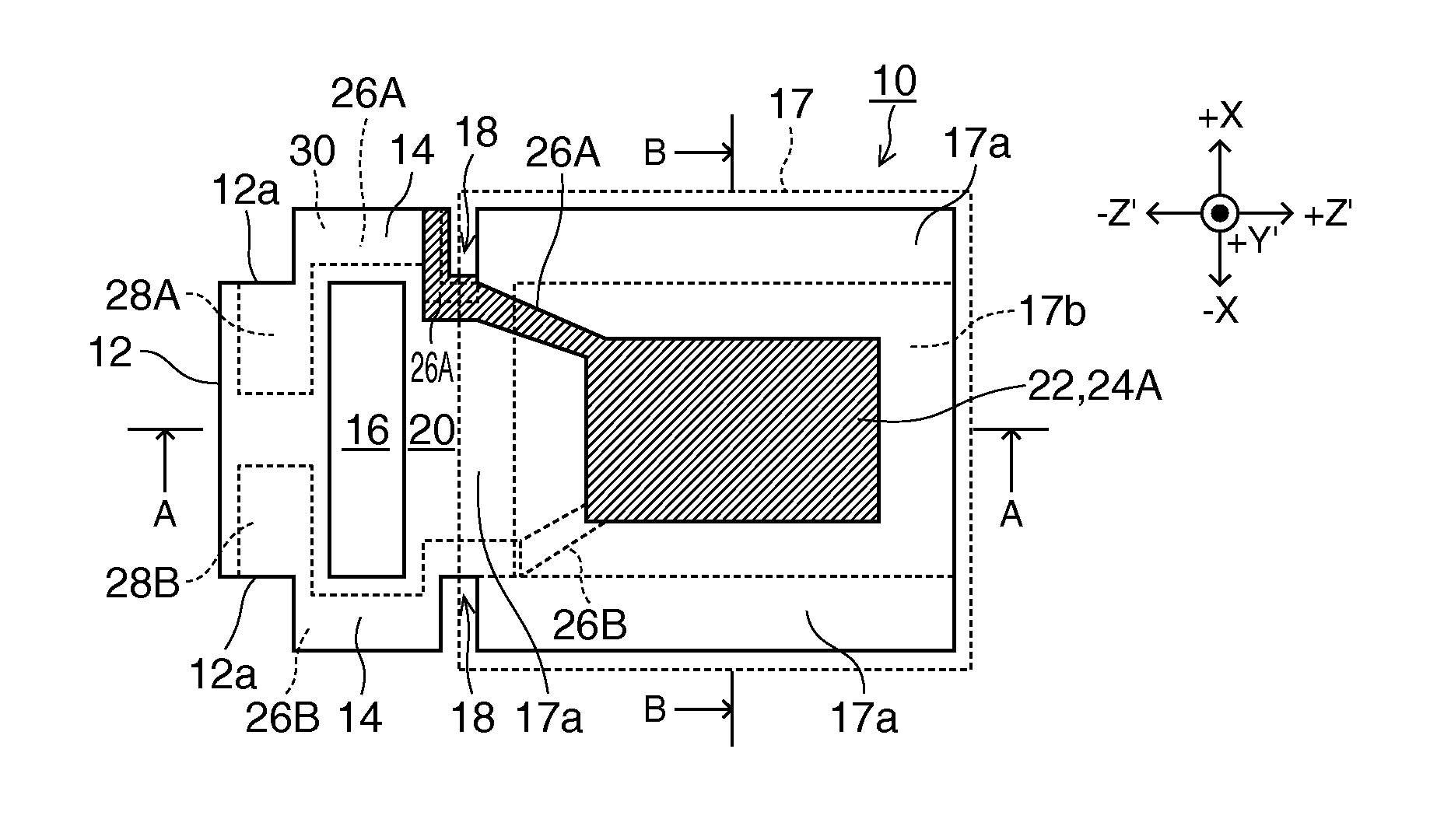

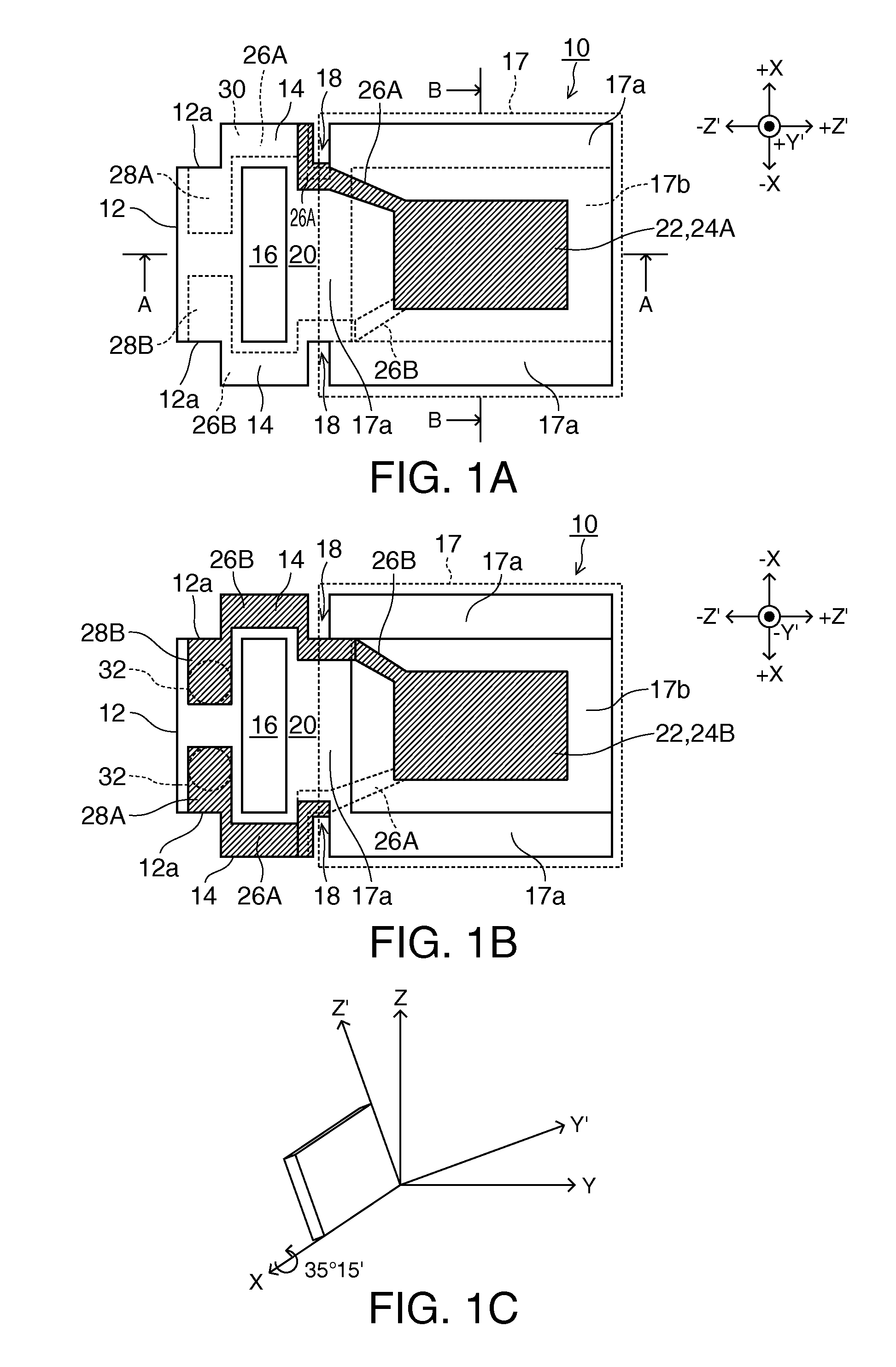

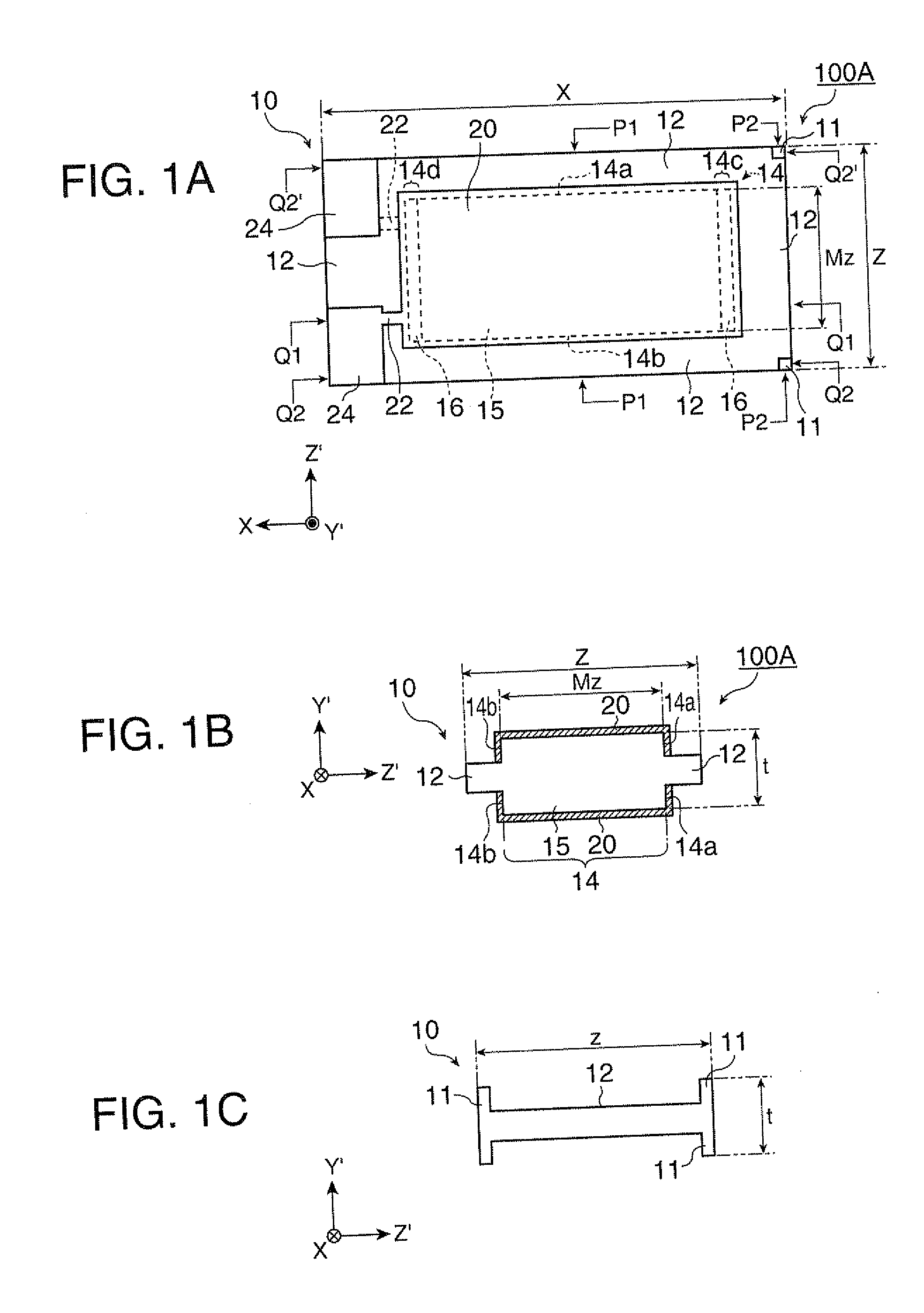

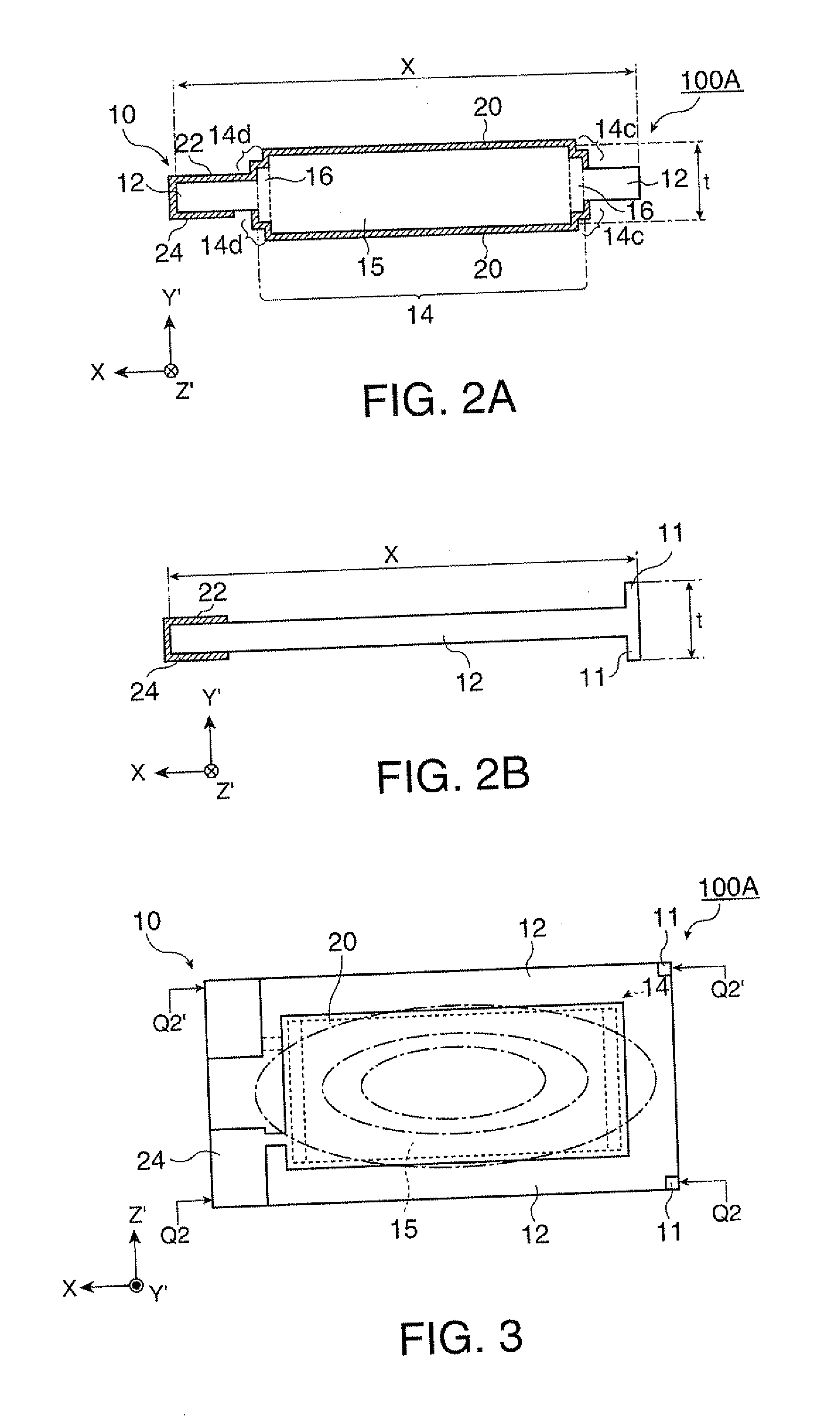

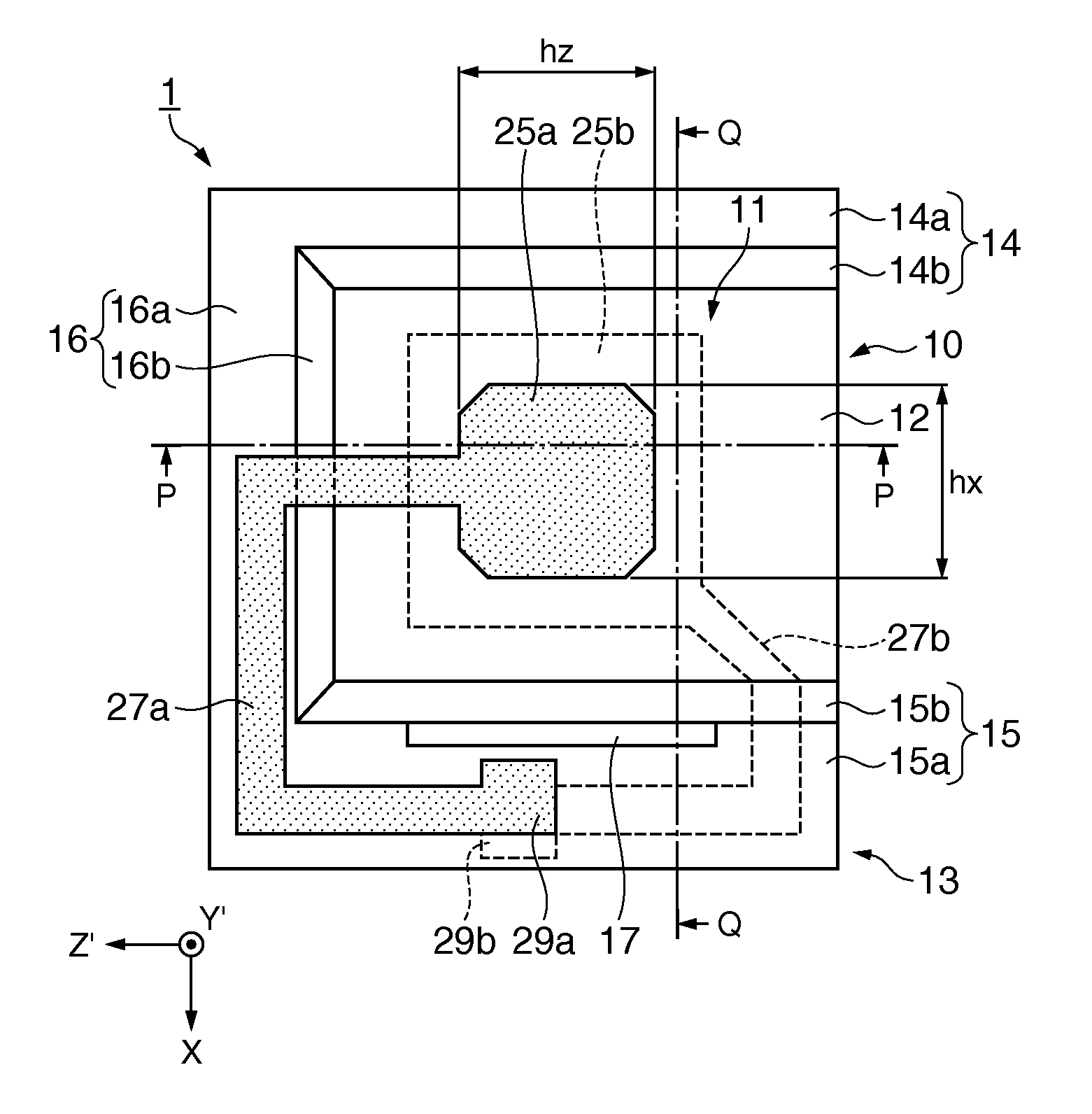

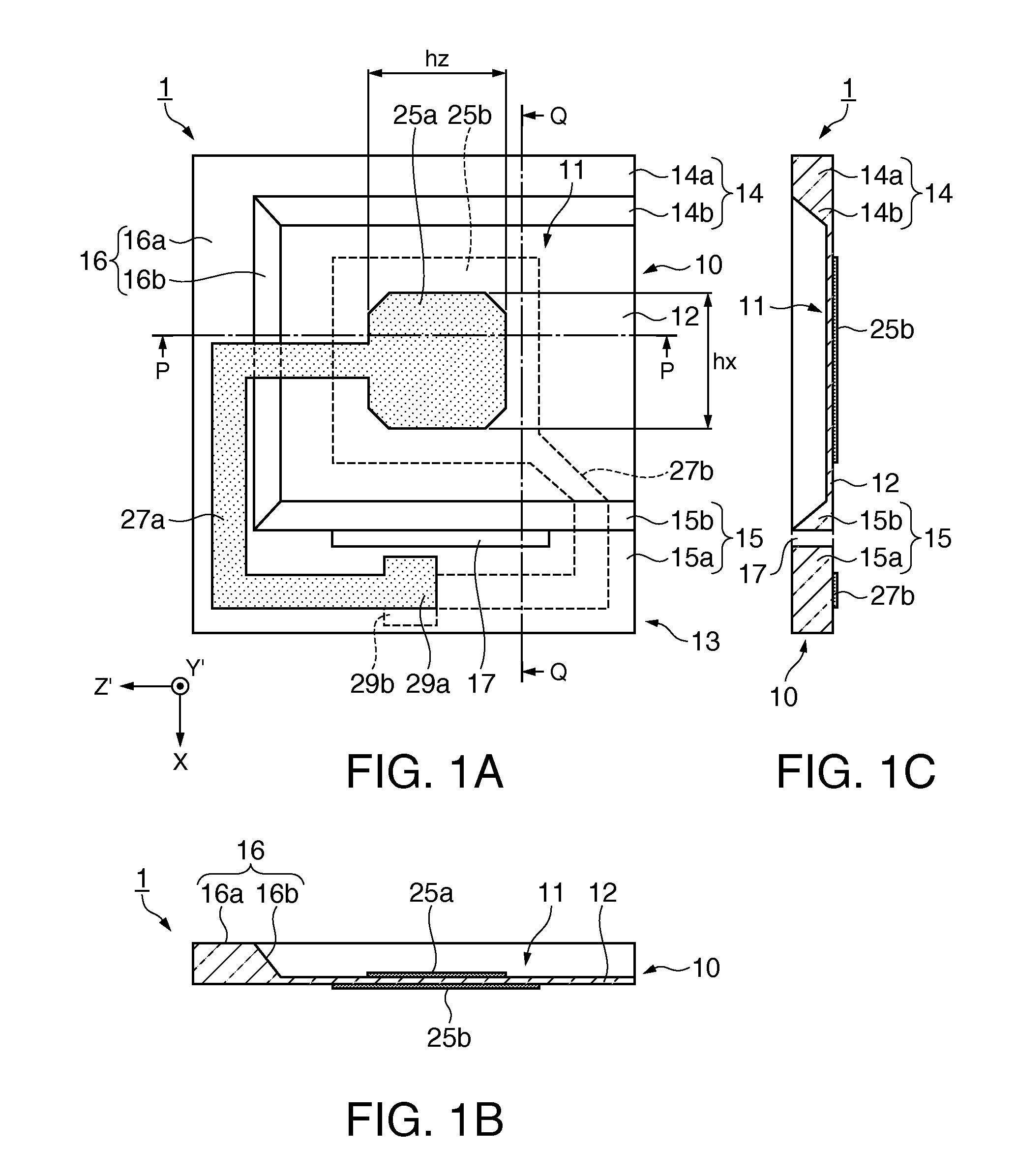

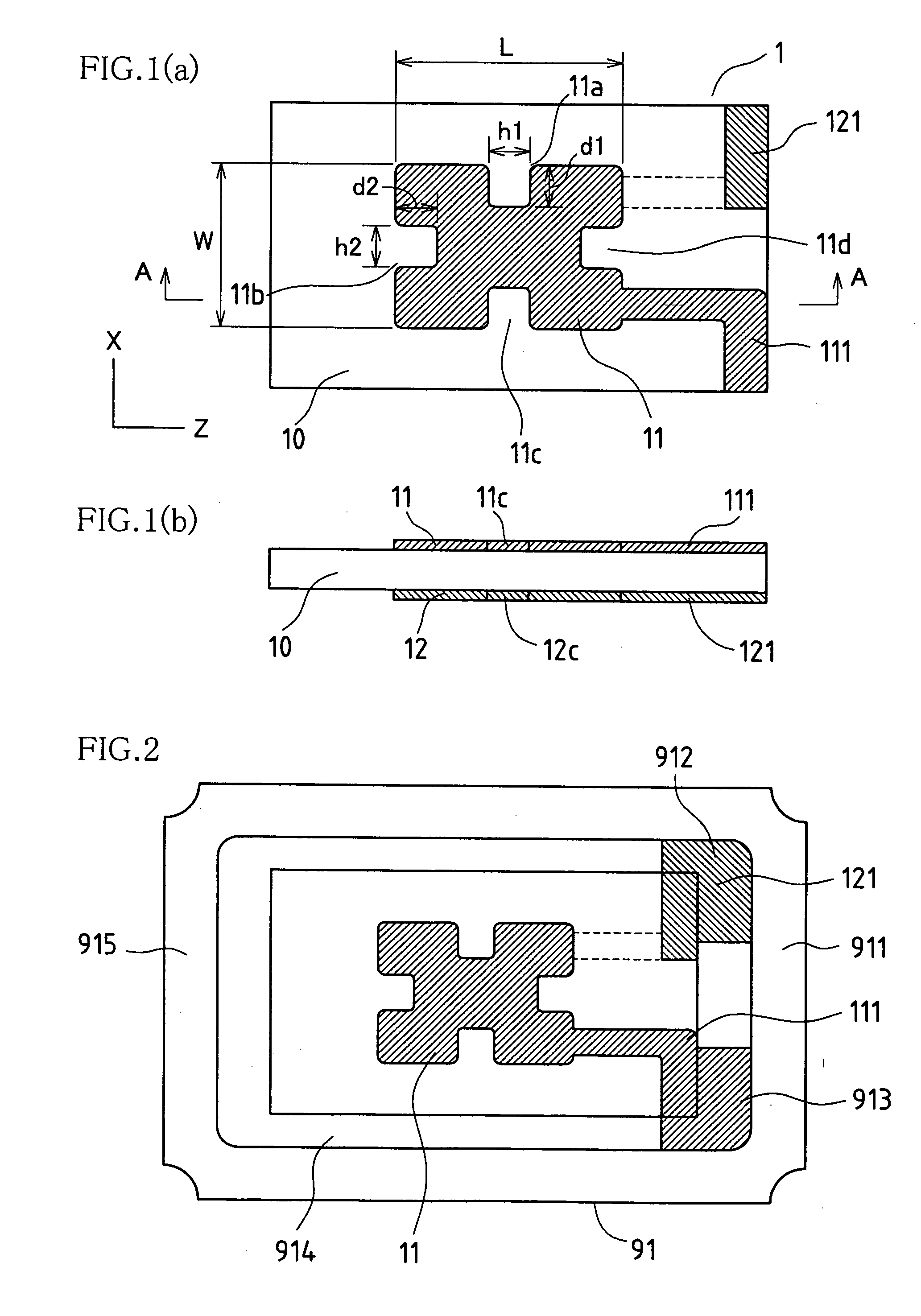

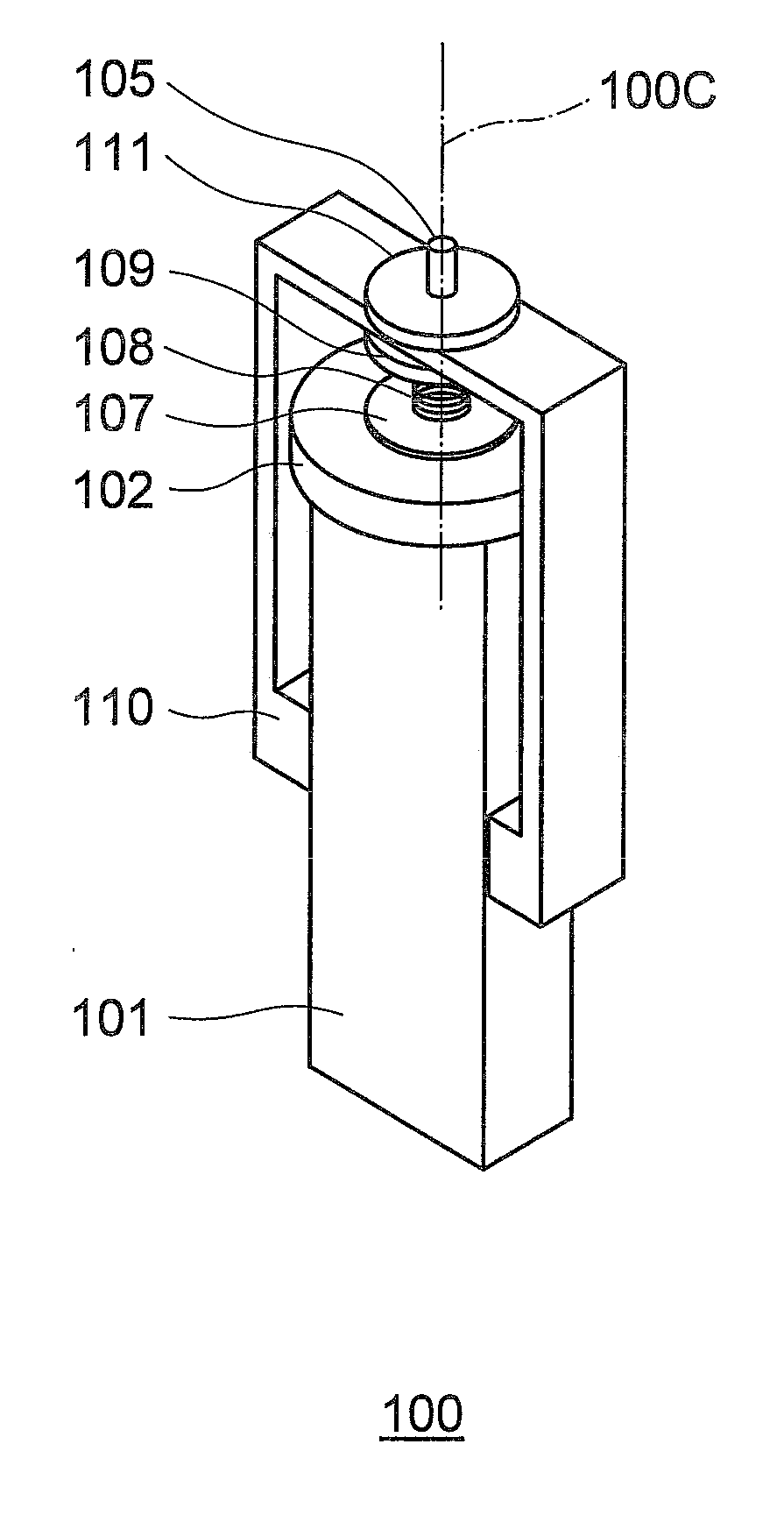

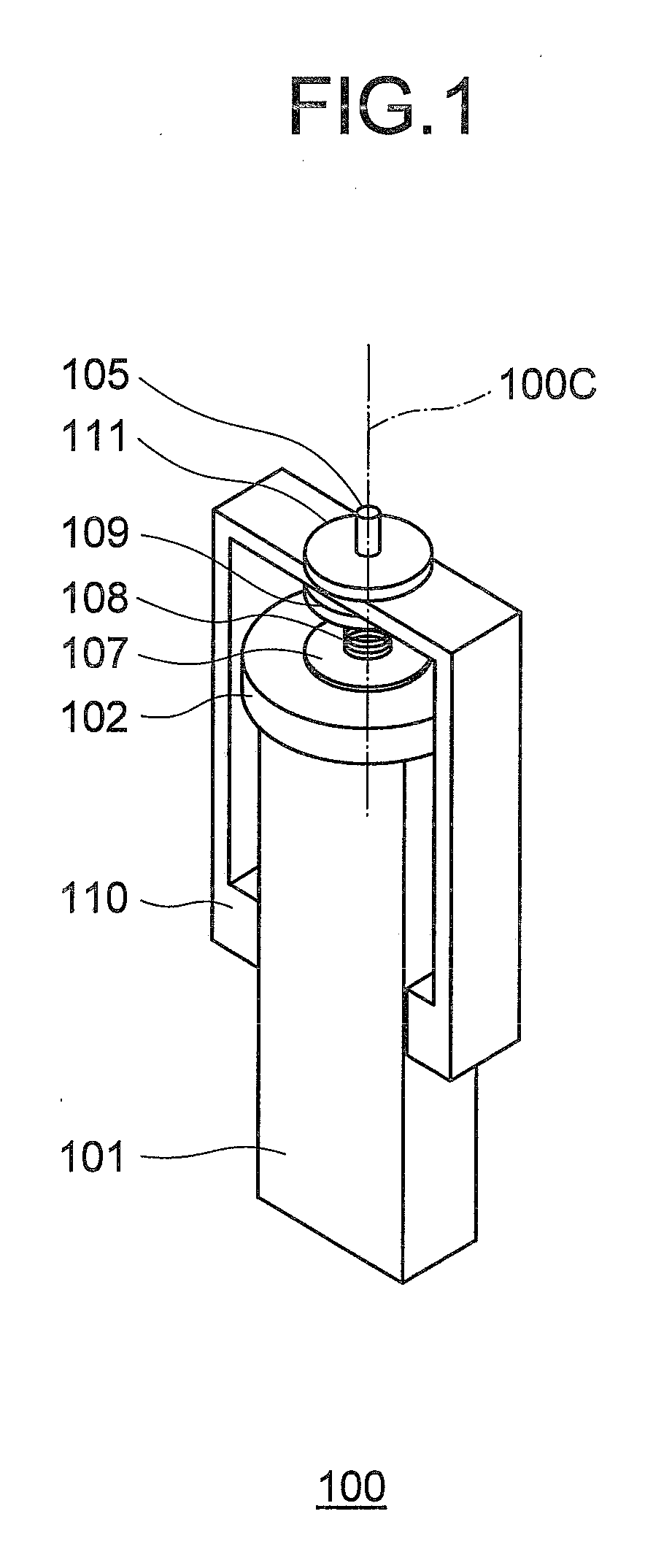

Piezoelectric resonator element, piezoelectric, resonator, and piezoelectric oscillator

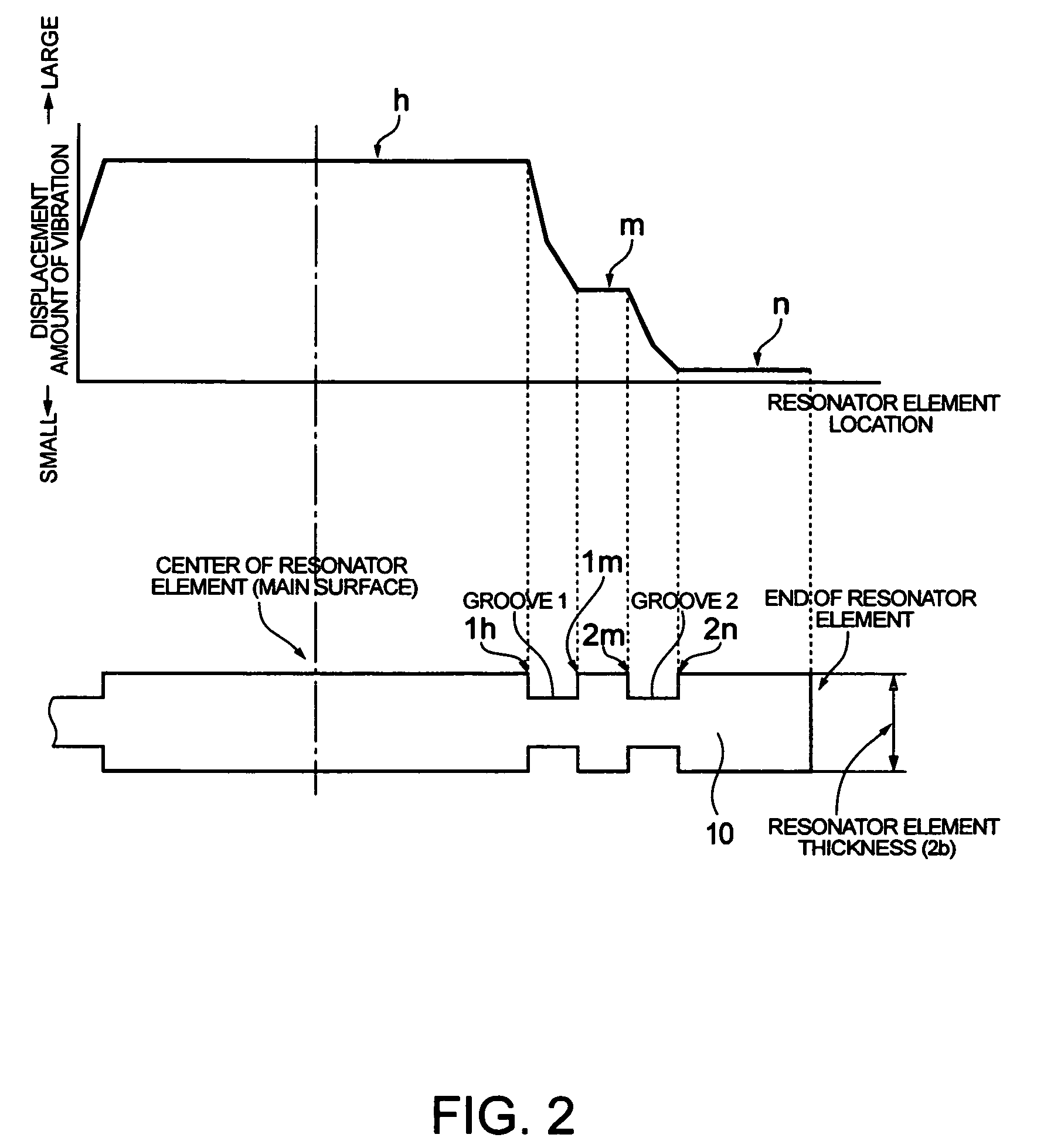

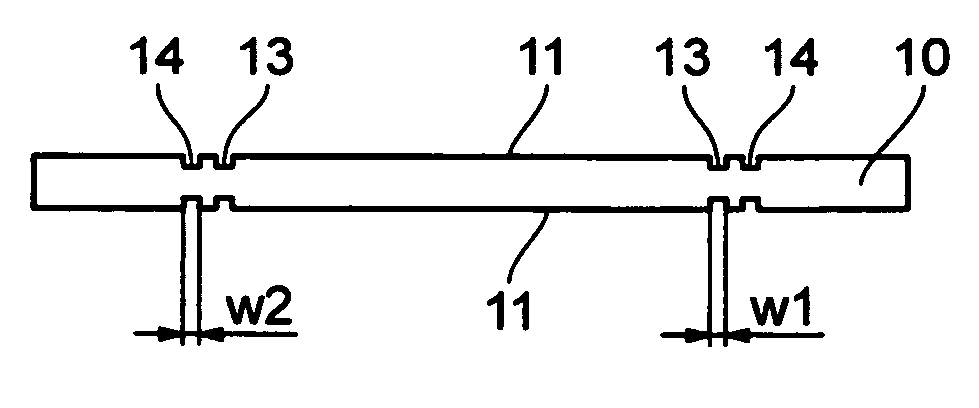

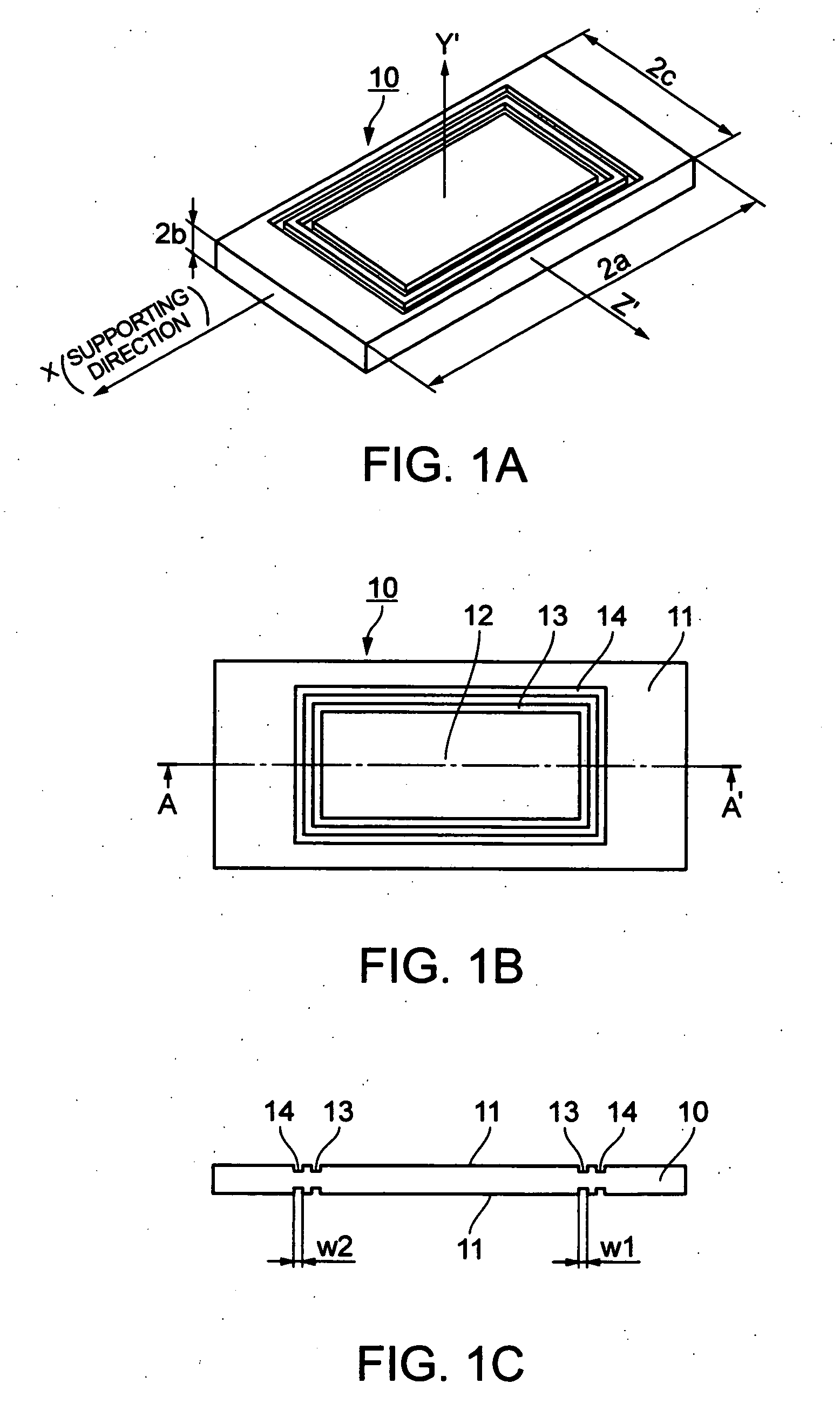

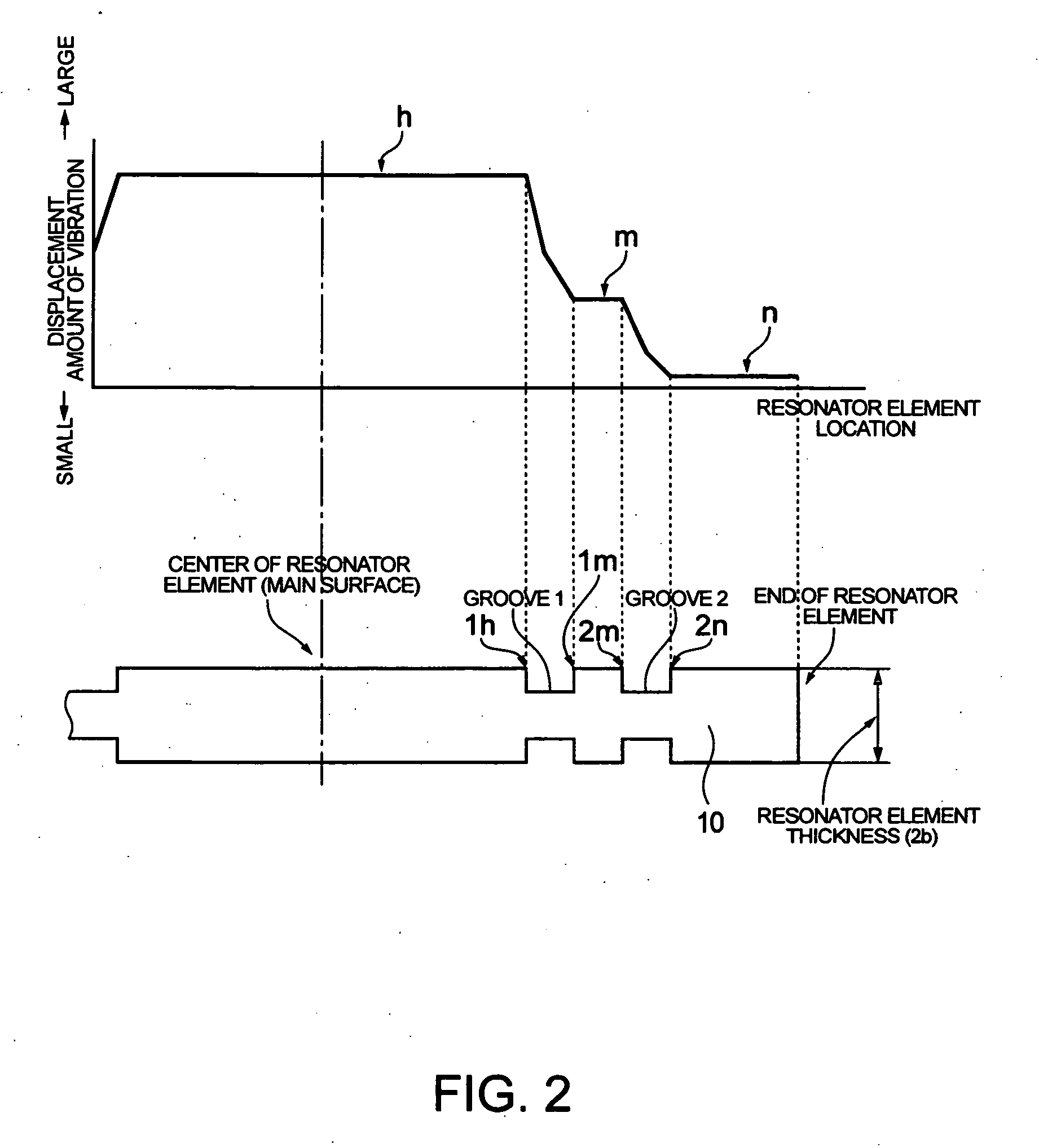

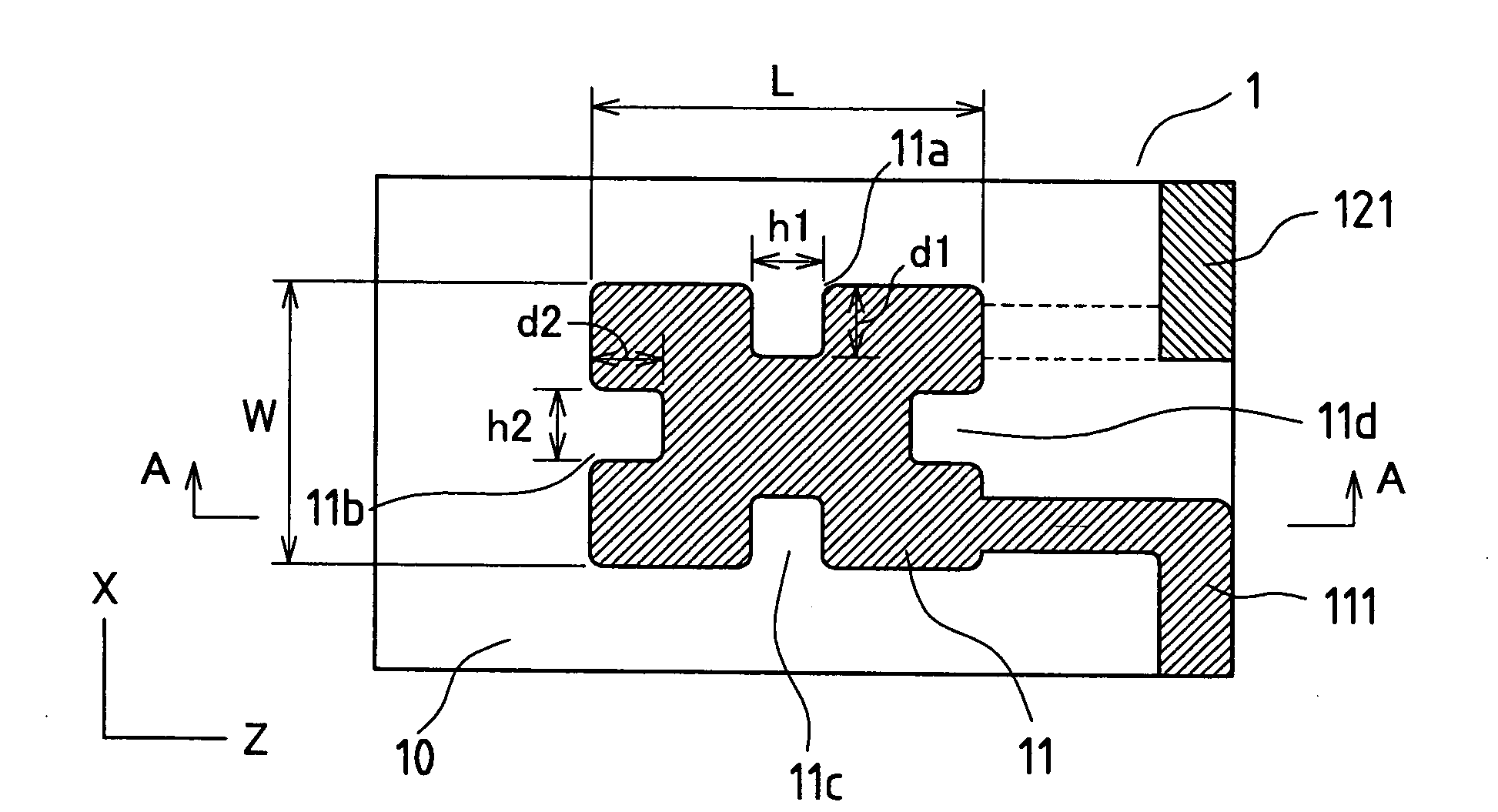

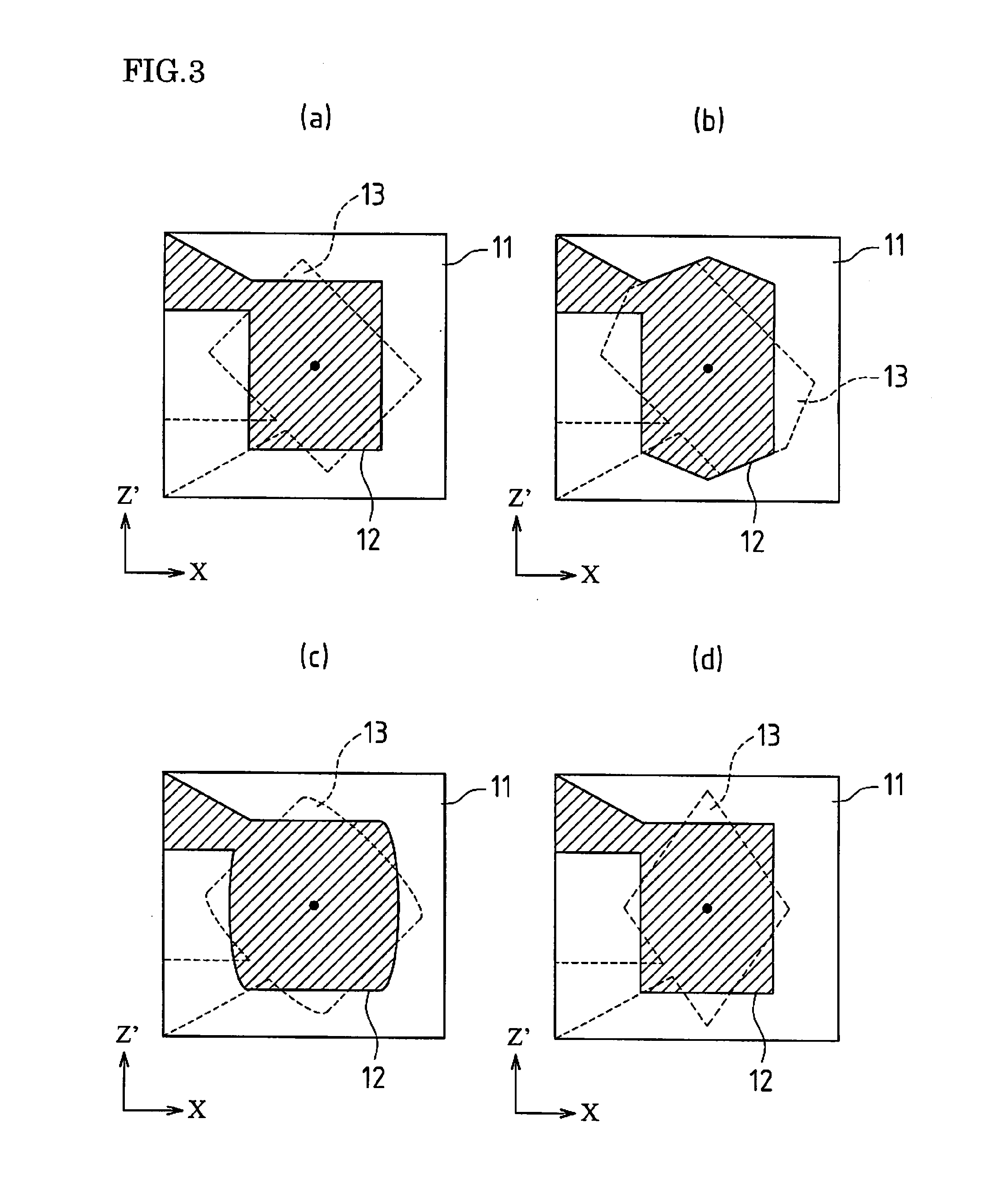

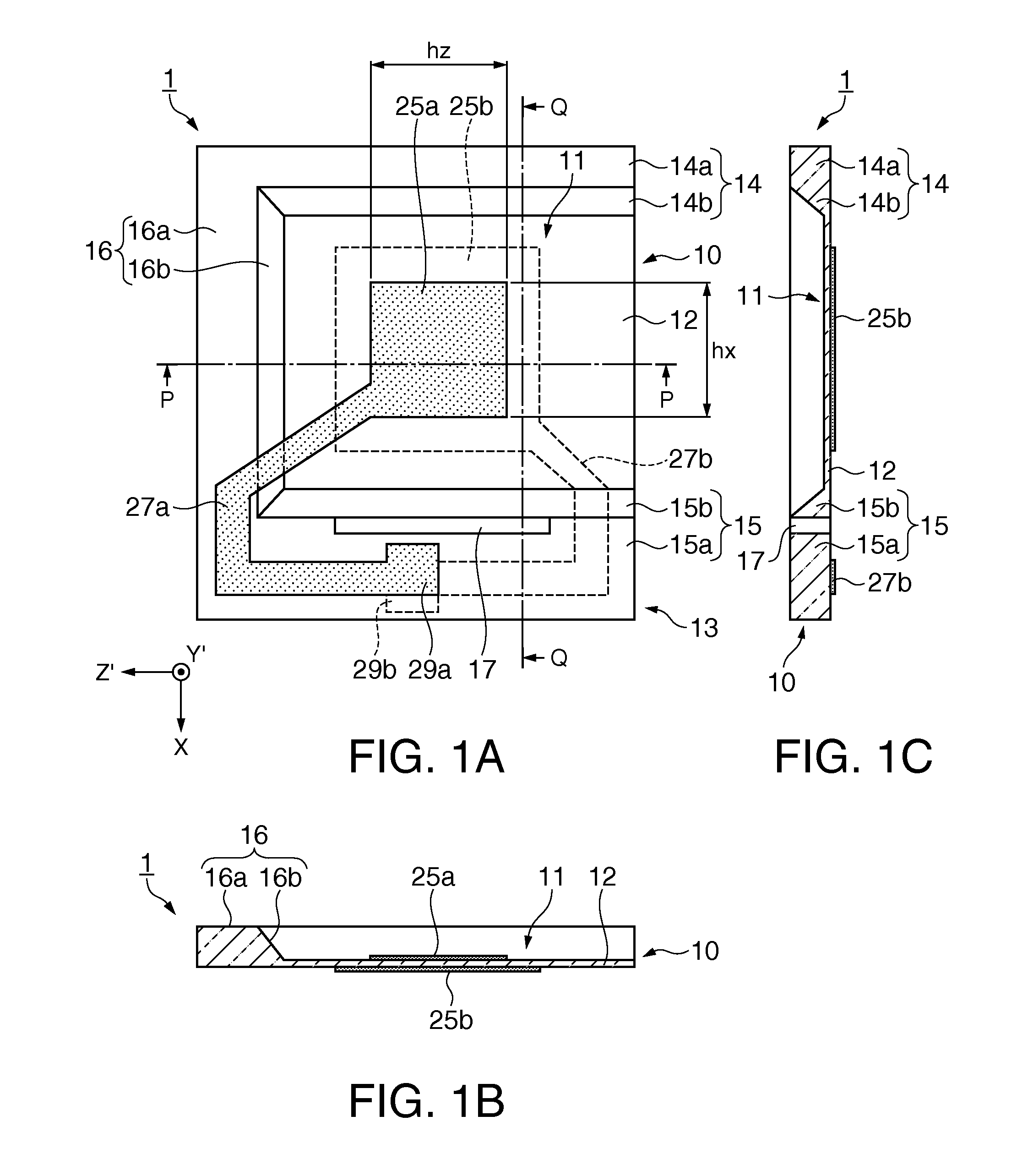

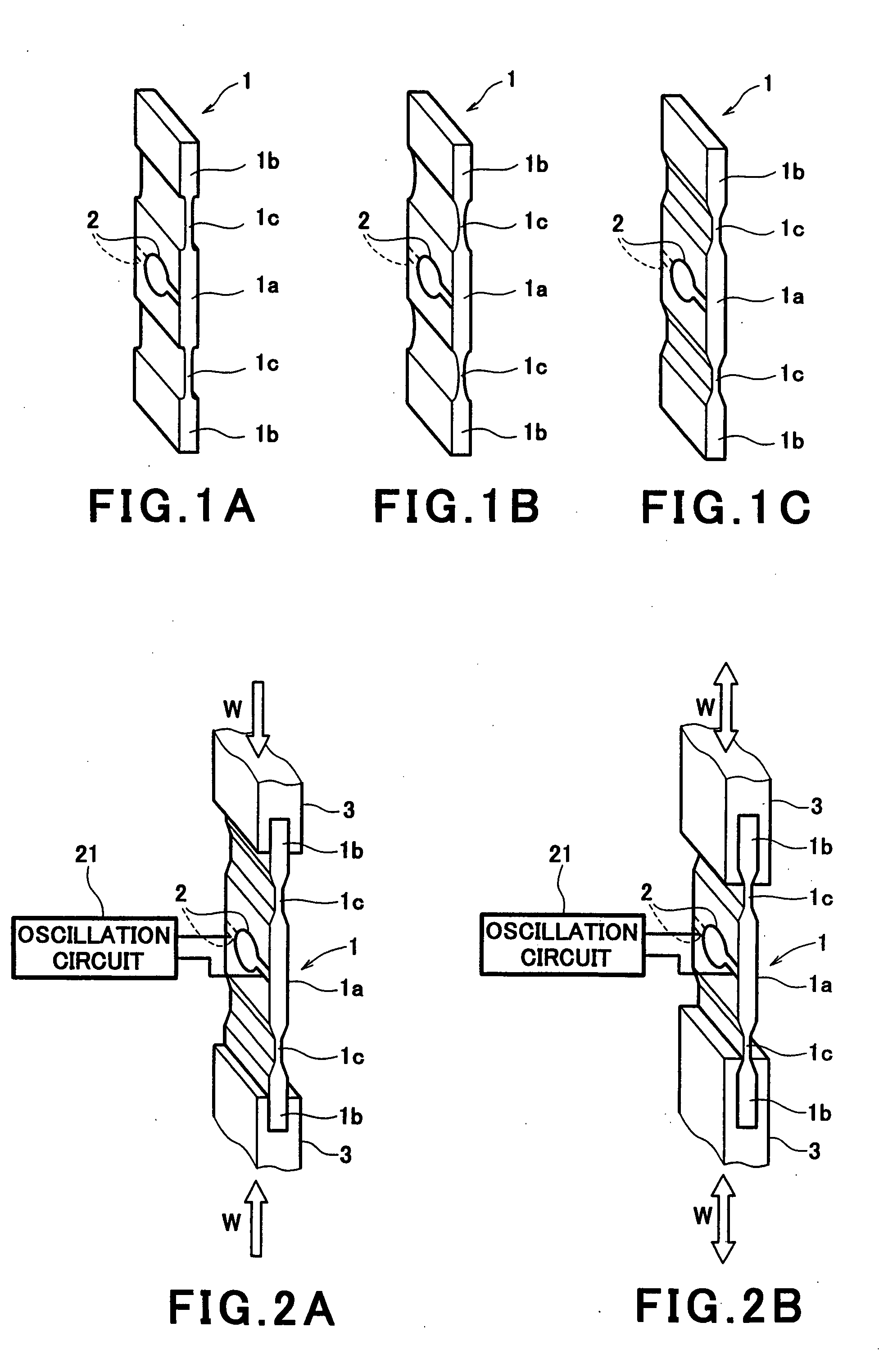

InactiveUS7368857B2Good effectEffective attenuationPiezoelectric/electrostriction/magnetostriction machinesImpedence networksAcousticsThickness shear

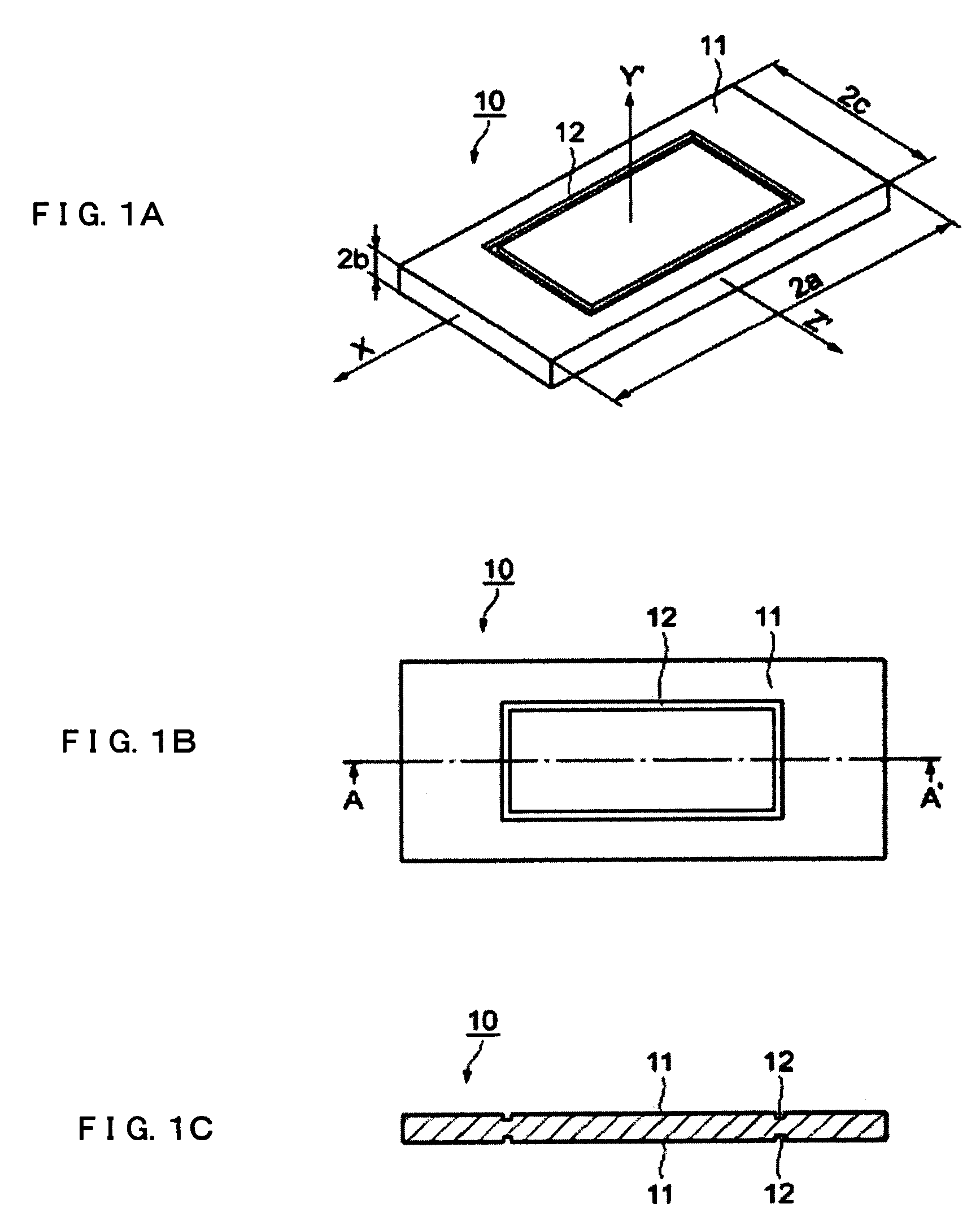

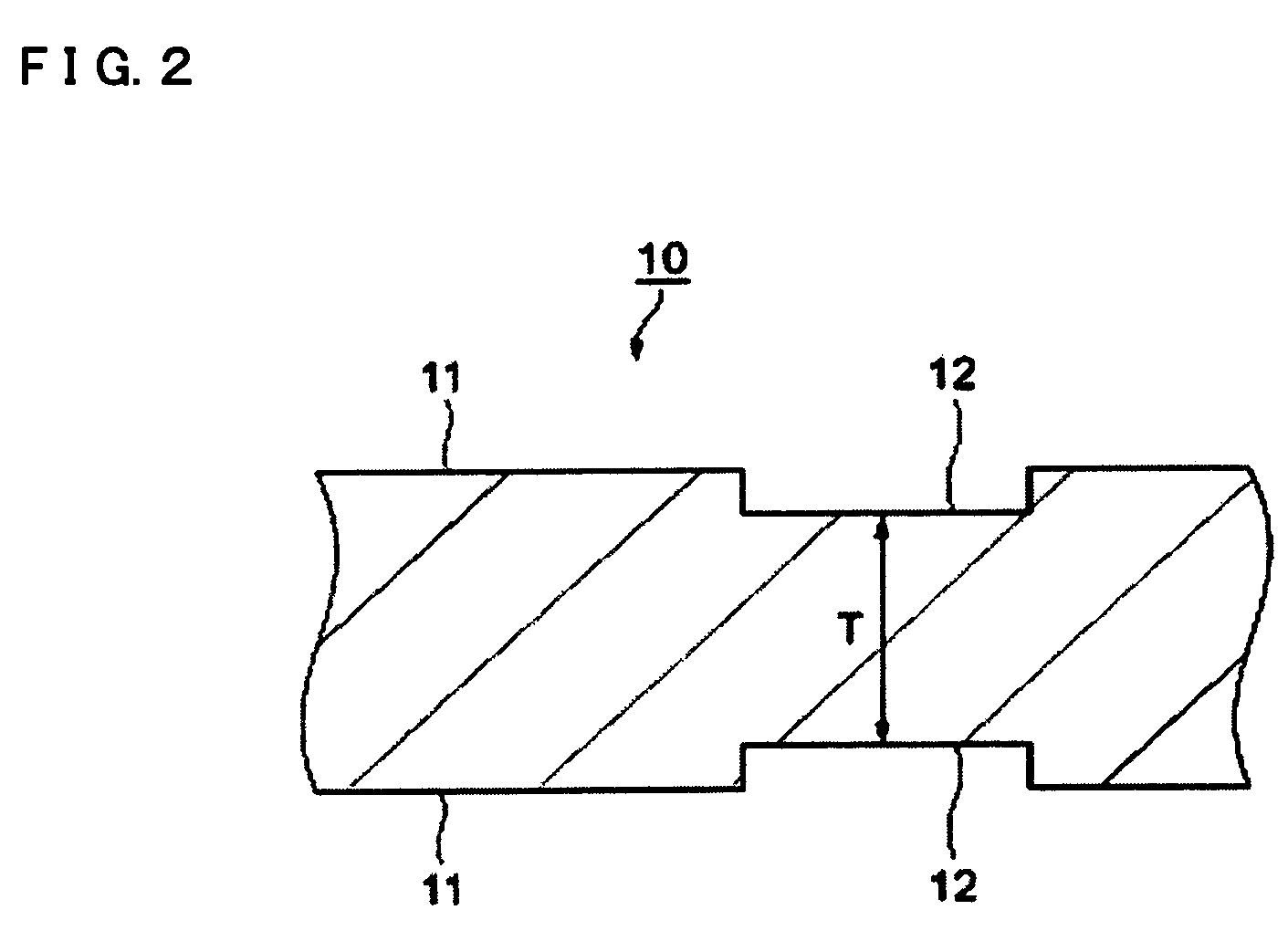

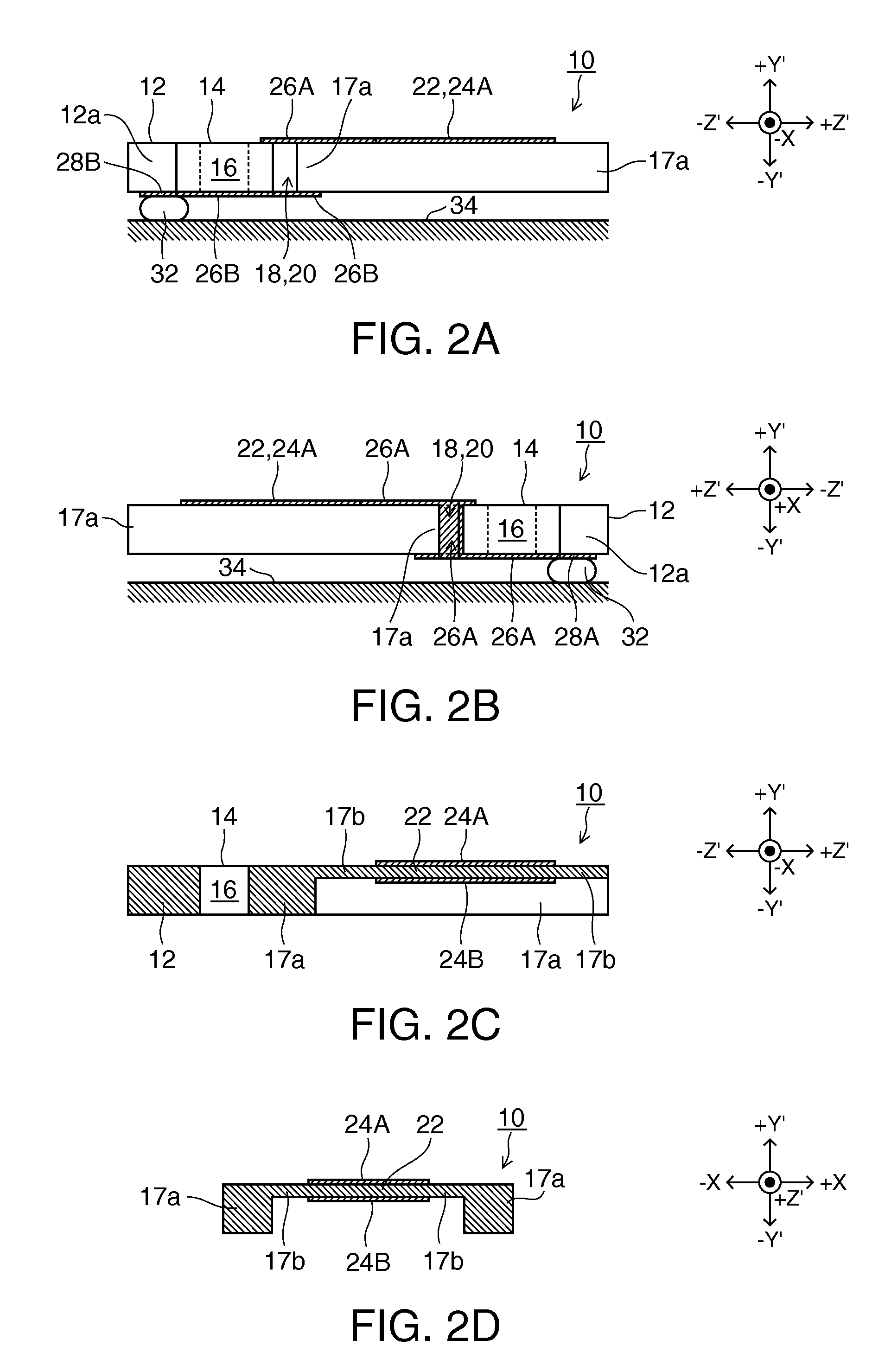

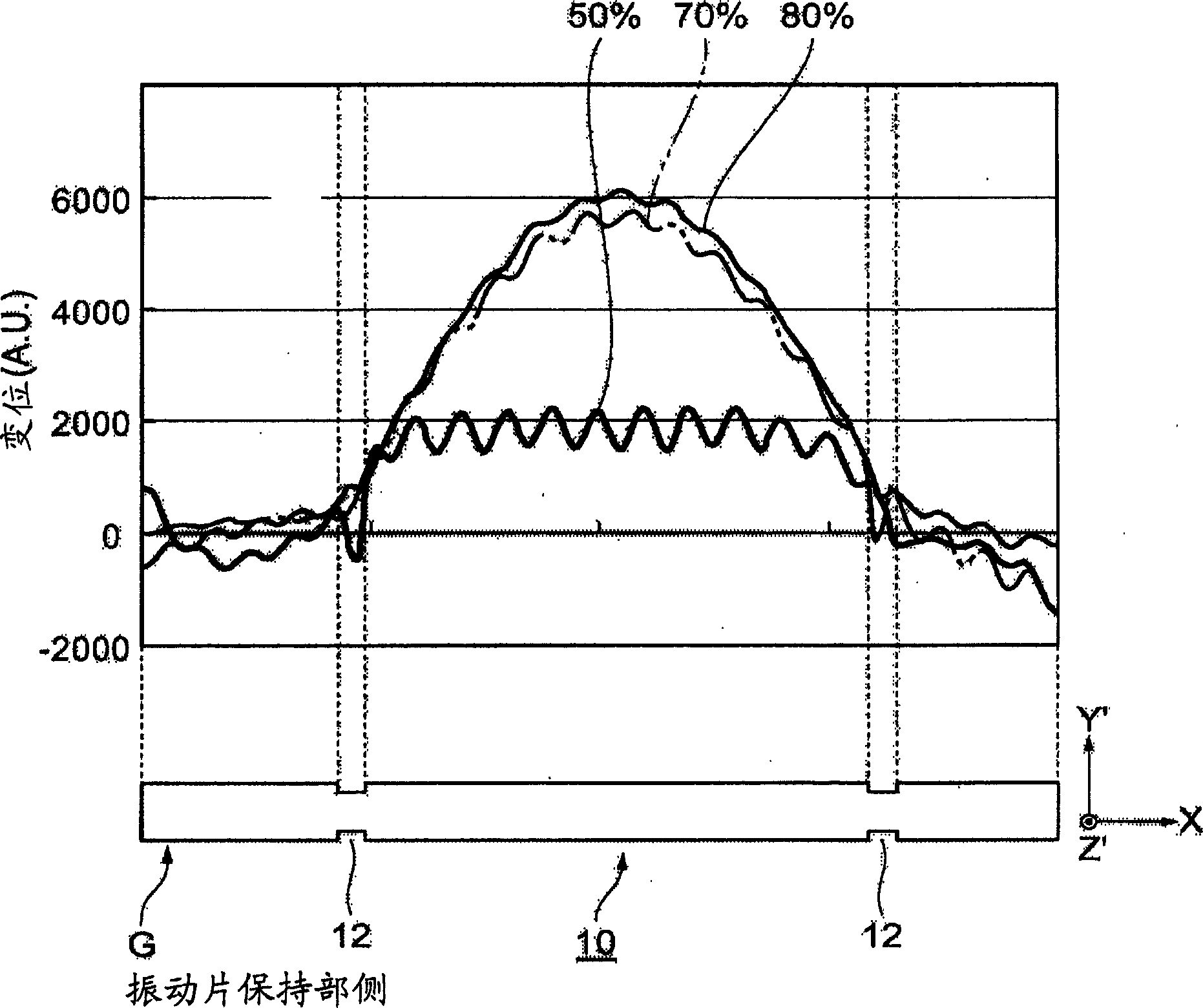

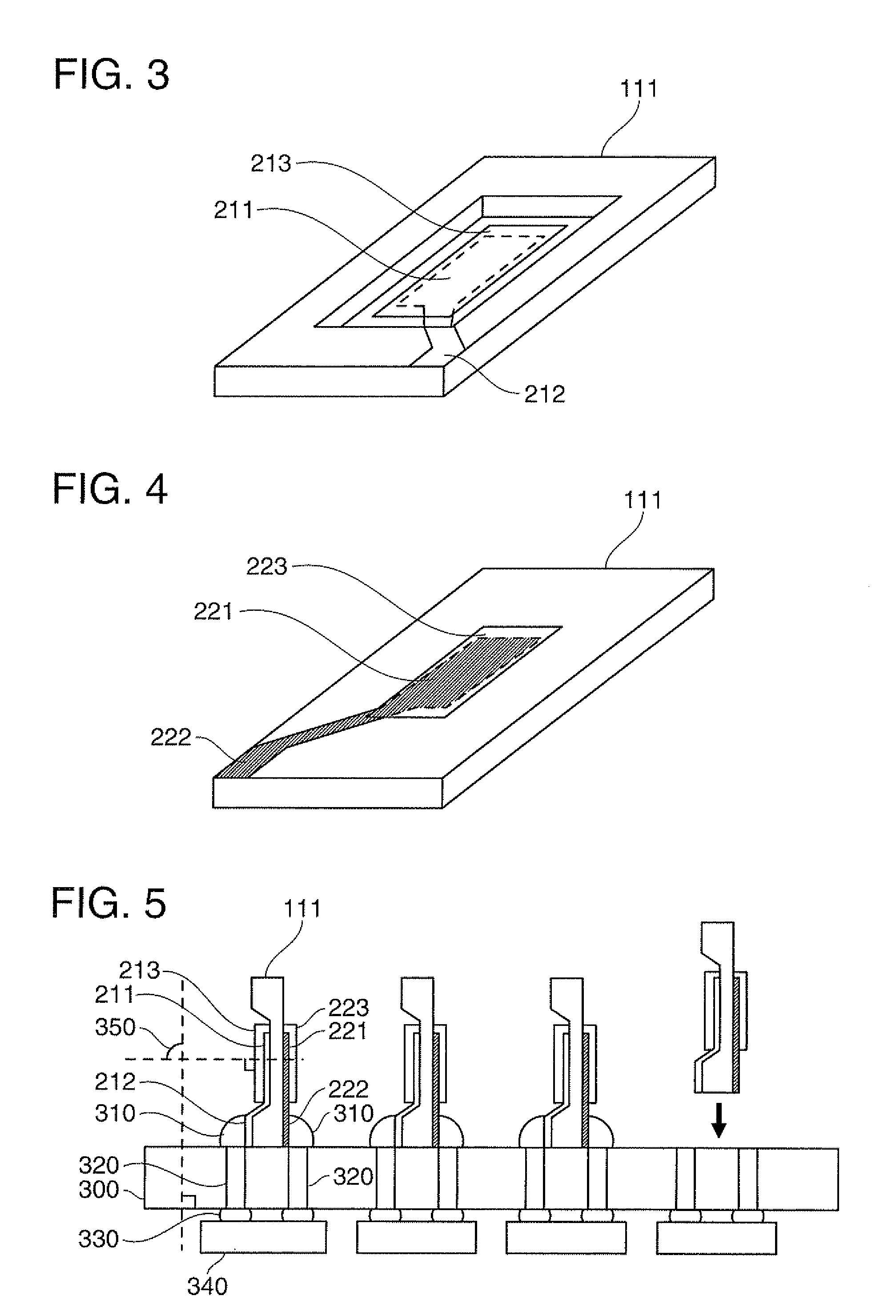

Exemplary embodiments provide a piezoelectric resonator element, to reduce the reaching of an attenuating vibration of a main vibration to a marginal edge of the piezoelectric resonator element, as well as to stabilize an oscillating-frequency without worsening the CI value, nor inducing another vibration mode. The piezoelectric resonator element having a thickness shear vibration as a main vibration, a first groove and a second groove formed so as to surround the center part of a main surface, and the thickness at the first groove and the second groove structured to be between 70% to 96%, inclusive, of the thickness of the center part of the resonator element.

Owner:SEIKO EPSON CORP

Piezoelectric resonator element, piezoelectric resonator, and piezoelectric oscillator

InactiveUS7301258B2Gradual dampeningPrevent electrical characteristicImpedence networksPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric actuatorsAcoustics

Owner:SEIKO EPSON CORP

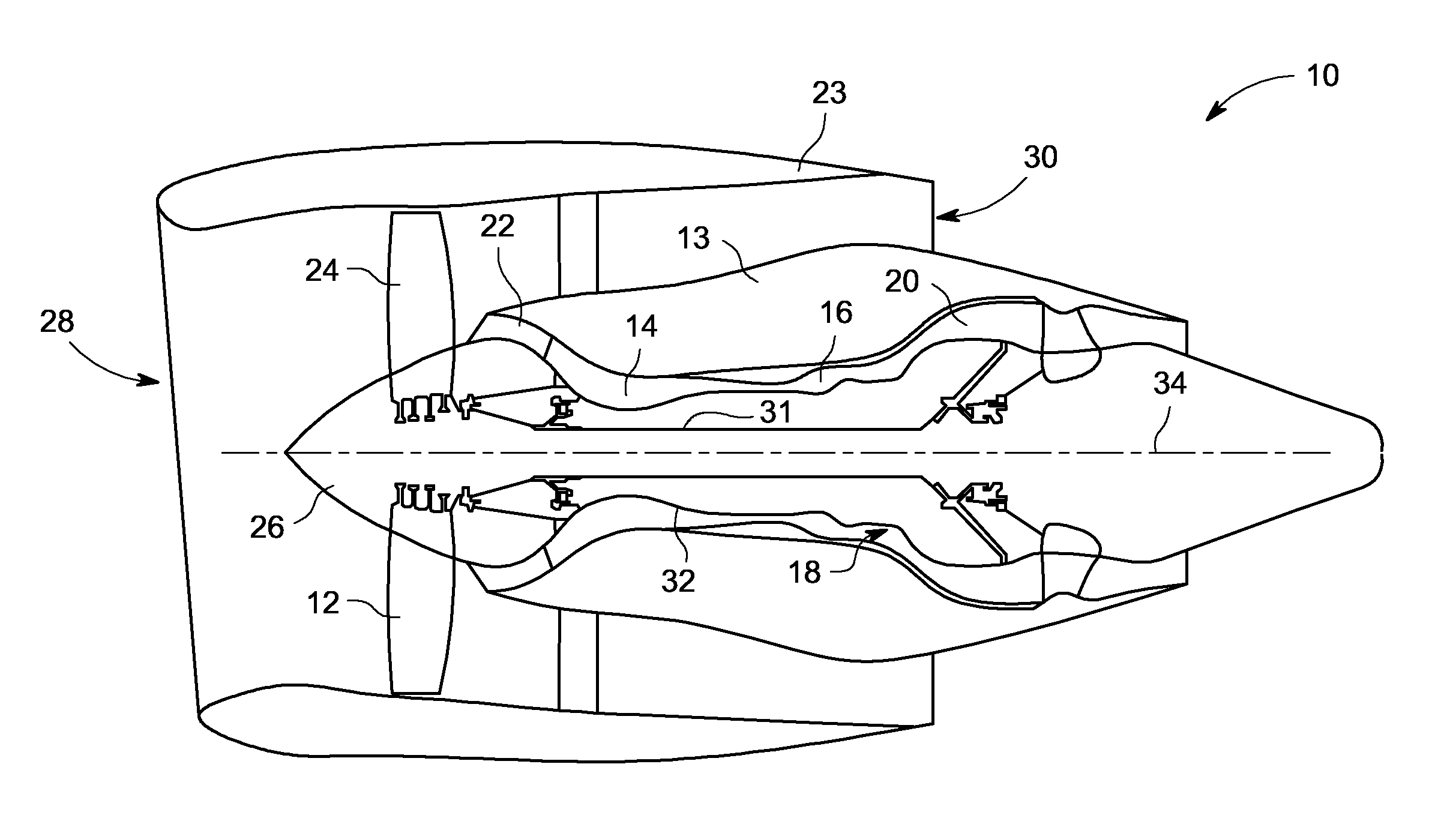

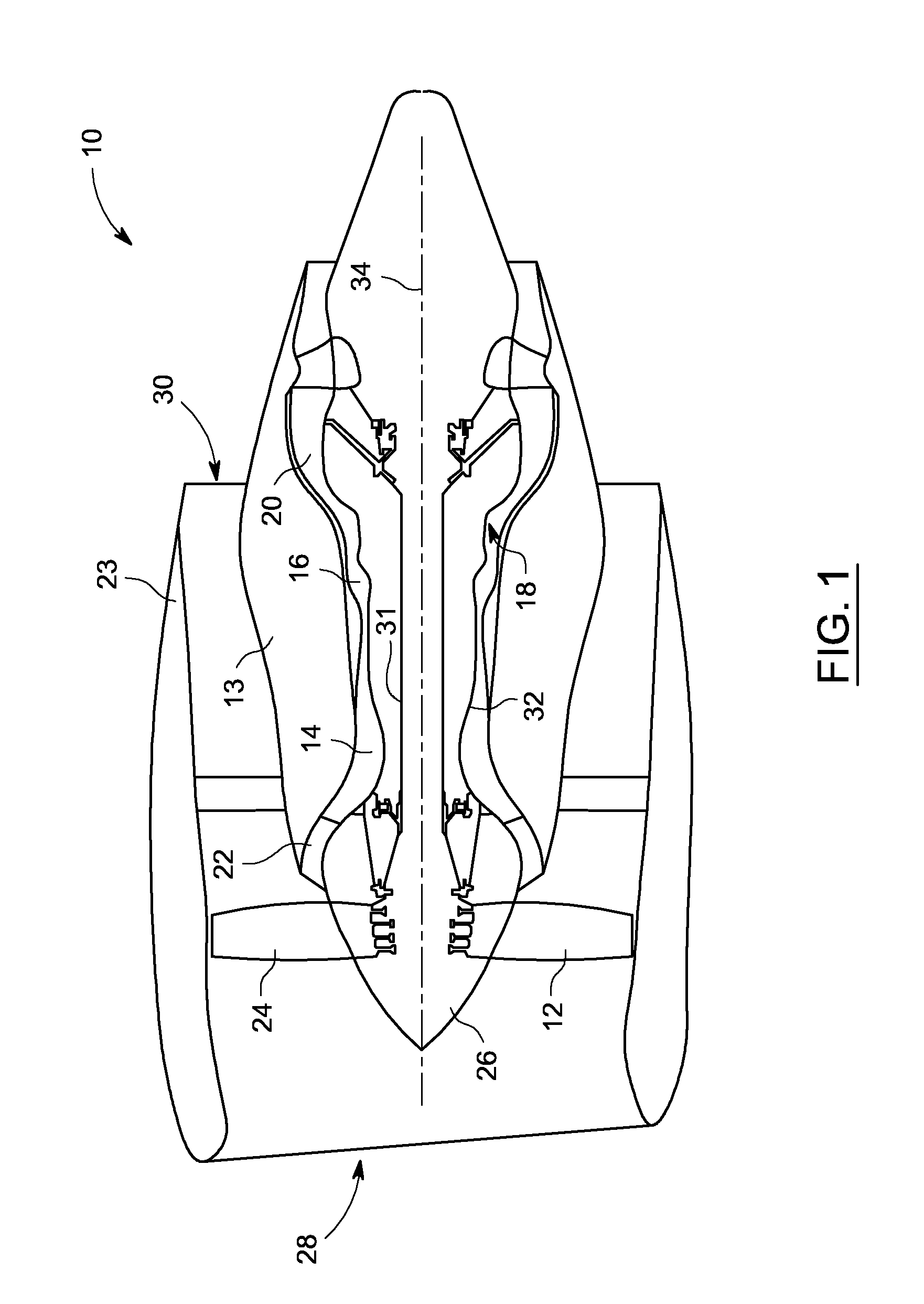

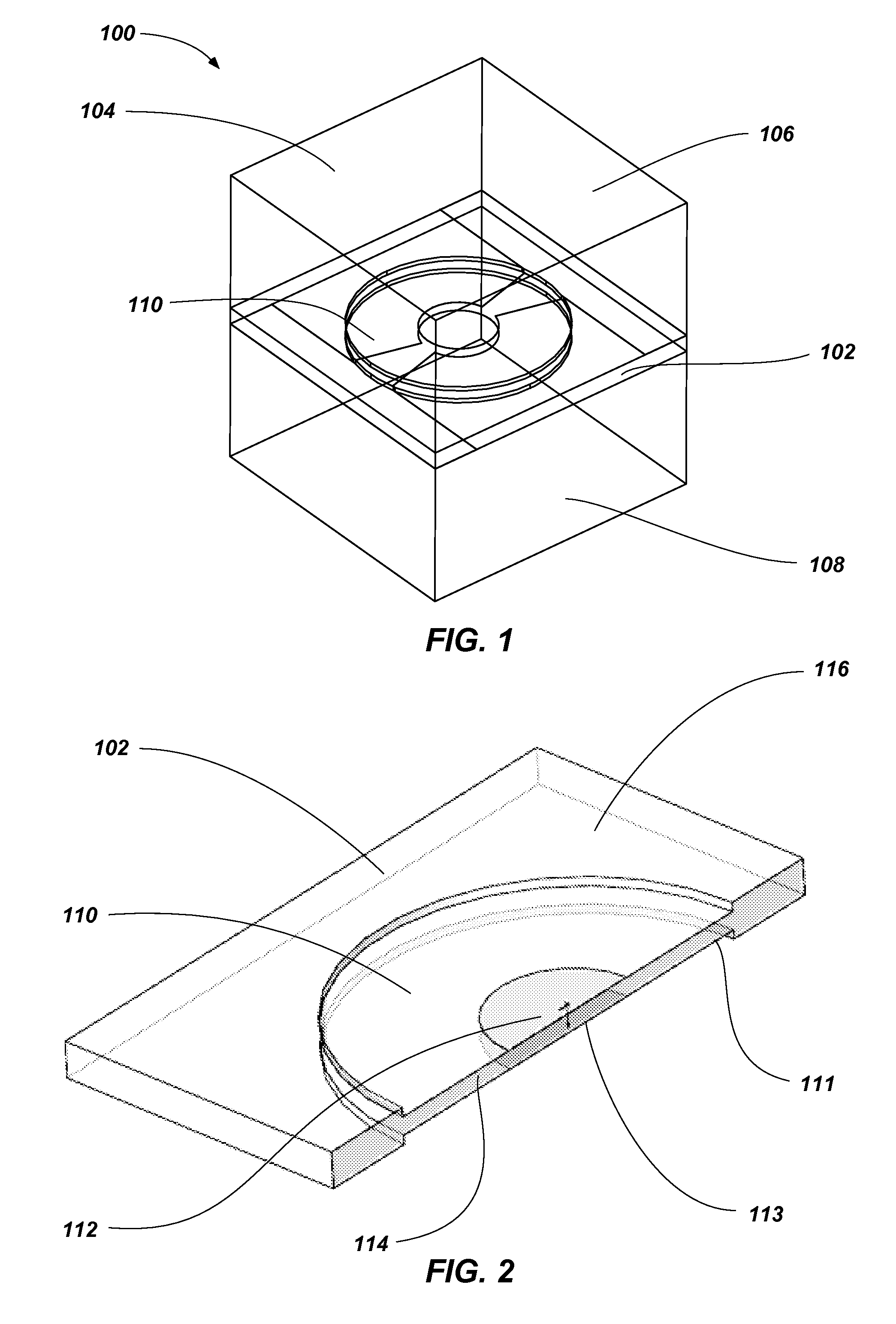

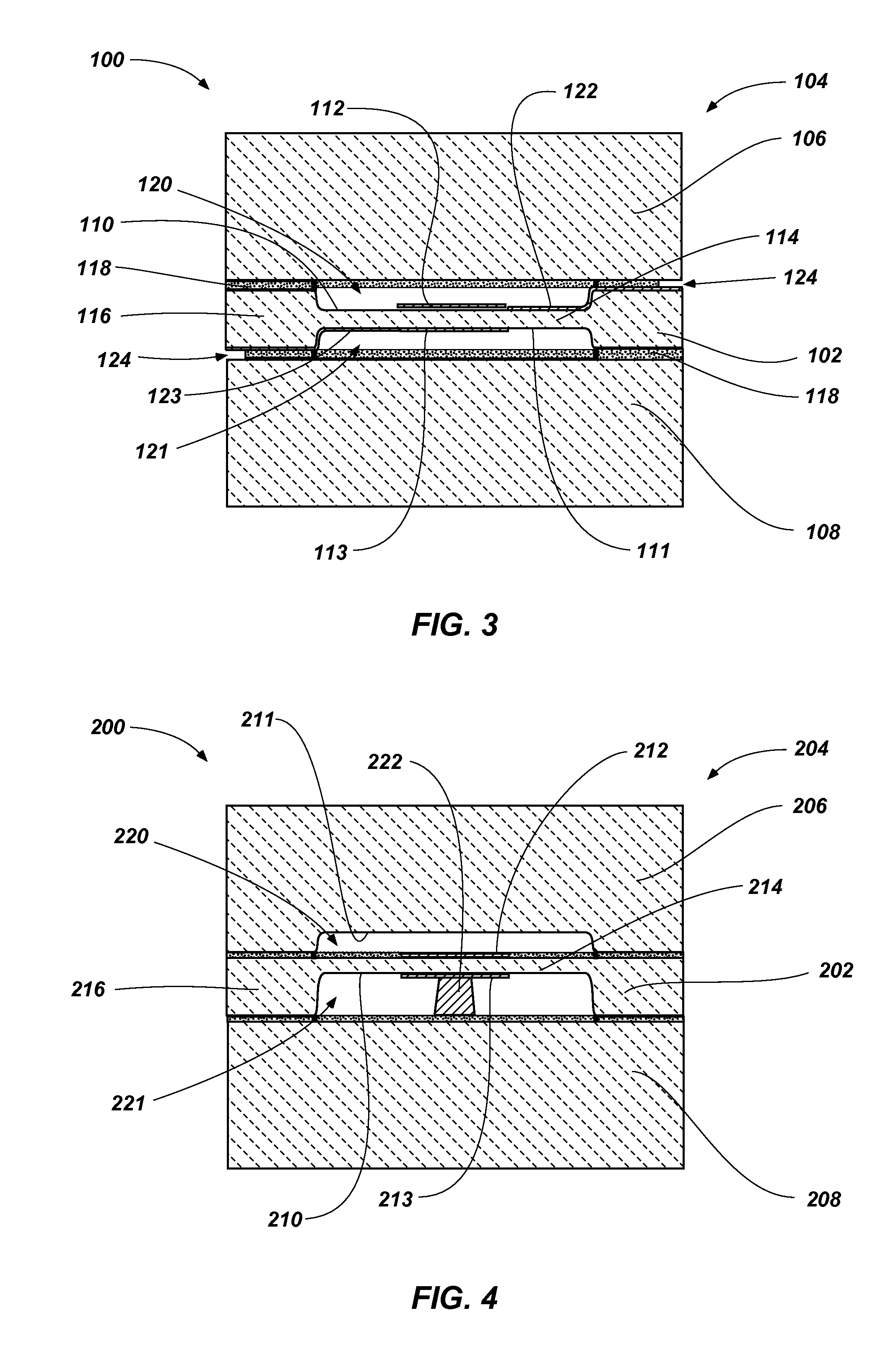

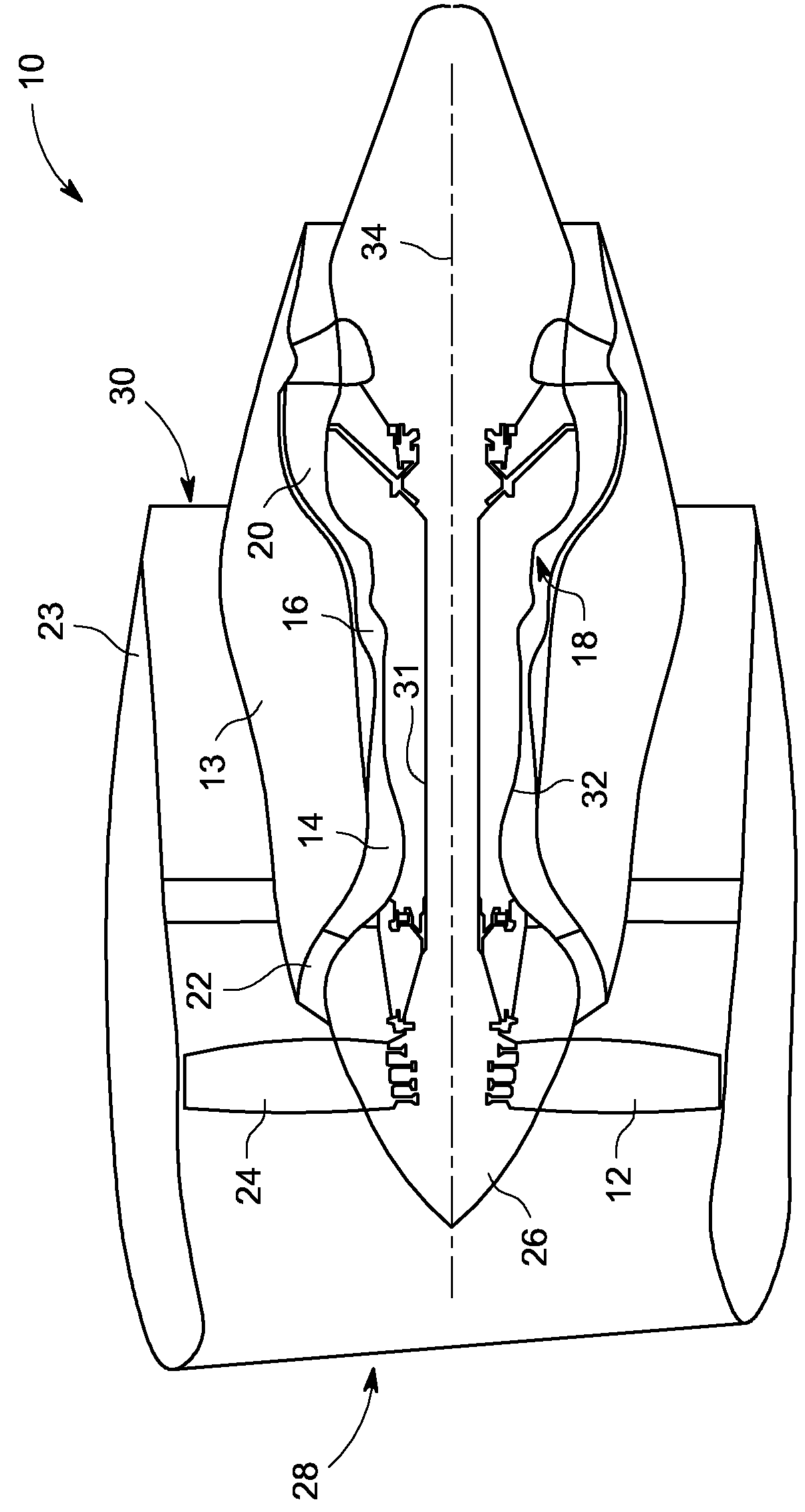

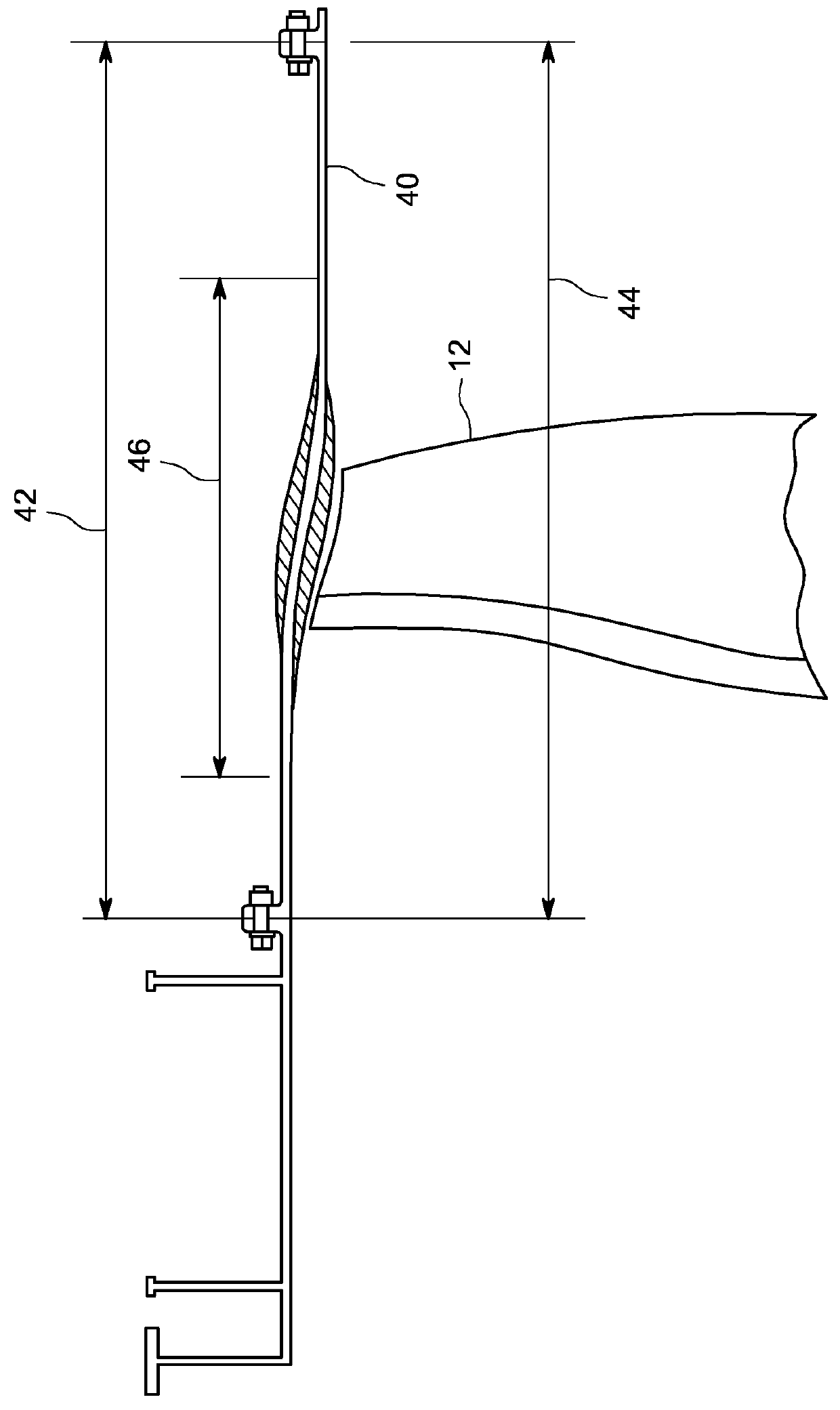

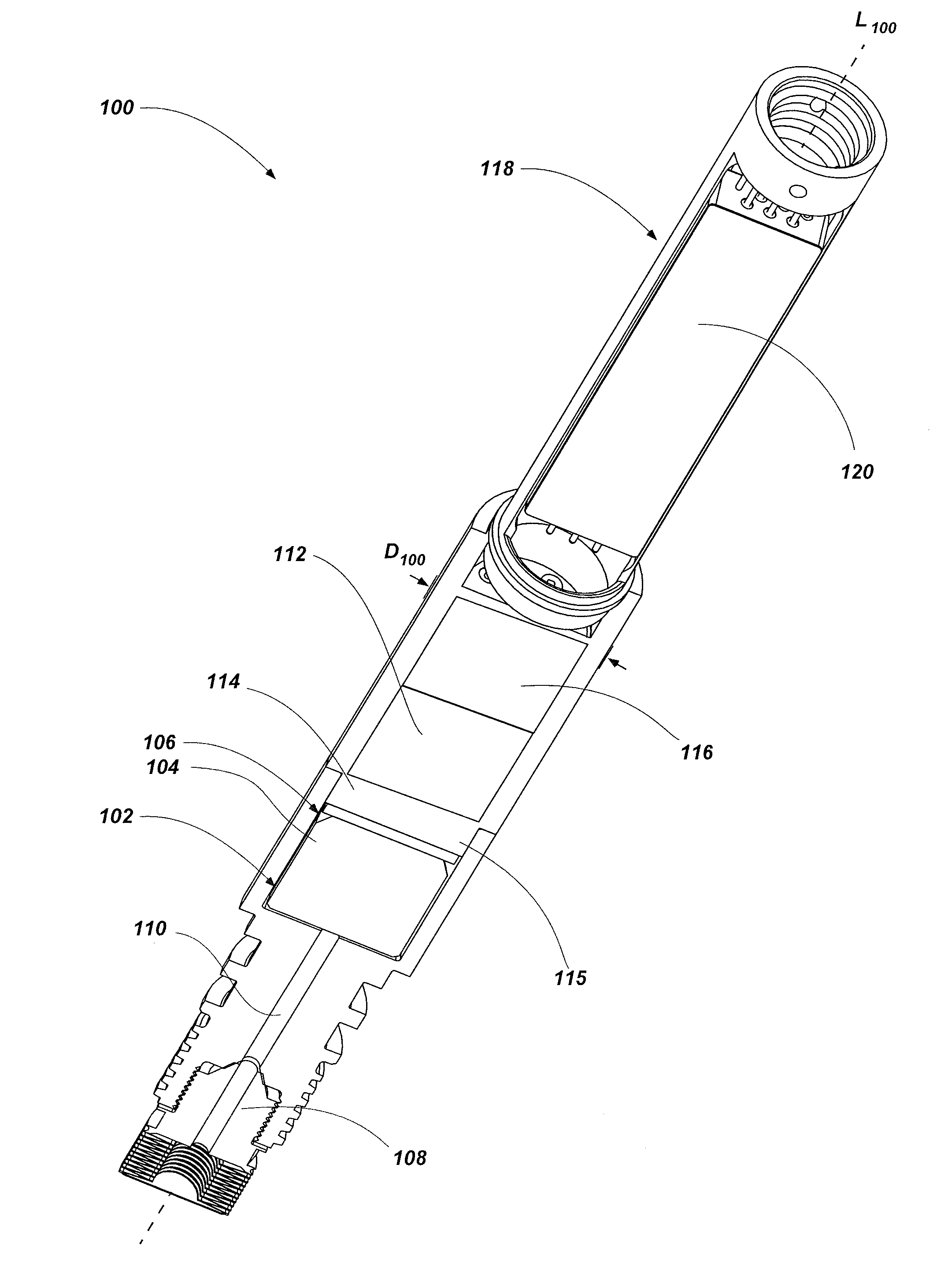

Containment case and method of manufacture

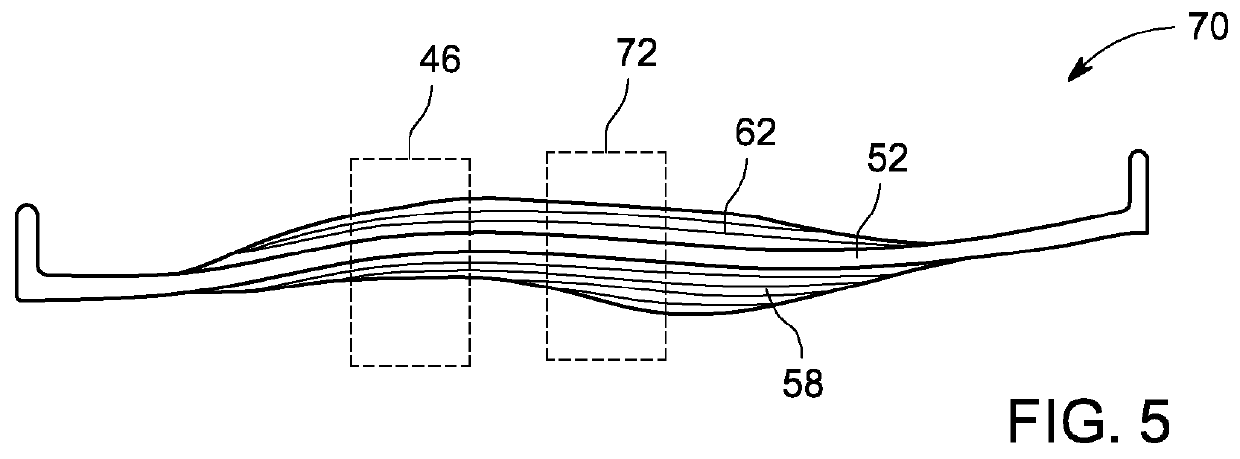

ActiveUS20130153456A1Increased shear strengthLower resistanceBlade accessoriesEfficient propulsion technologiesIn planeUltimate tensile strength

A containment case comprises a composite core, with an inner and outer surface, at least one puncture resistant layer bonded to the inner surface of the composite core and at least one energy capture layer bonded to the outer surface of the composite core. The puncture resistant layer having a high through-thickness shear strength and high interlaminar toughness at impact. The energy capture layer having a high in-plane tensile strength and low resistance to delamination and fiber-matrix debonding at impact. A method of fabricating a containment case includes the steps of disposing one or more layers of a puncture resistant material on a layup mandrel, disposing one more layers of a structural composite material on an exterior surface of the puncture resistant material, disposing one or more layers of an energy capture material on an exterior surface of the structural material and curing a resin in the plurality of layers.

Owner:GENERAL ELECTRIC CO

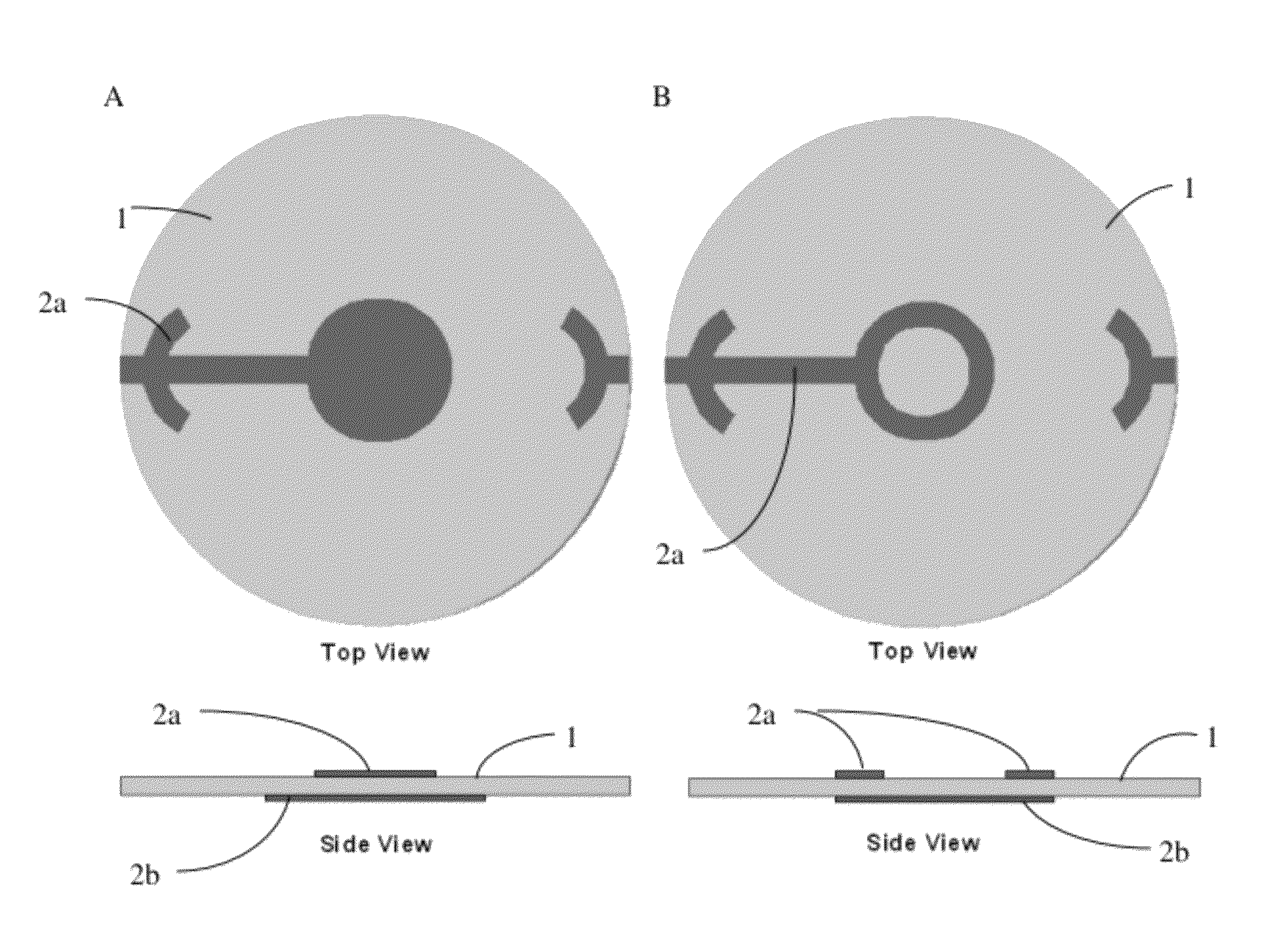

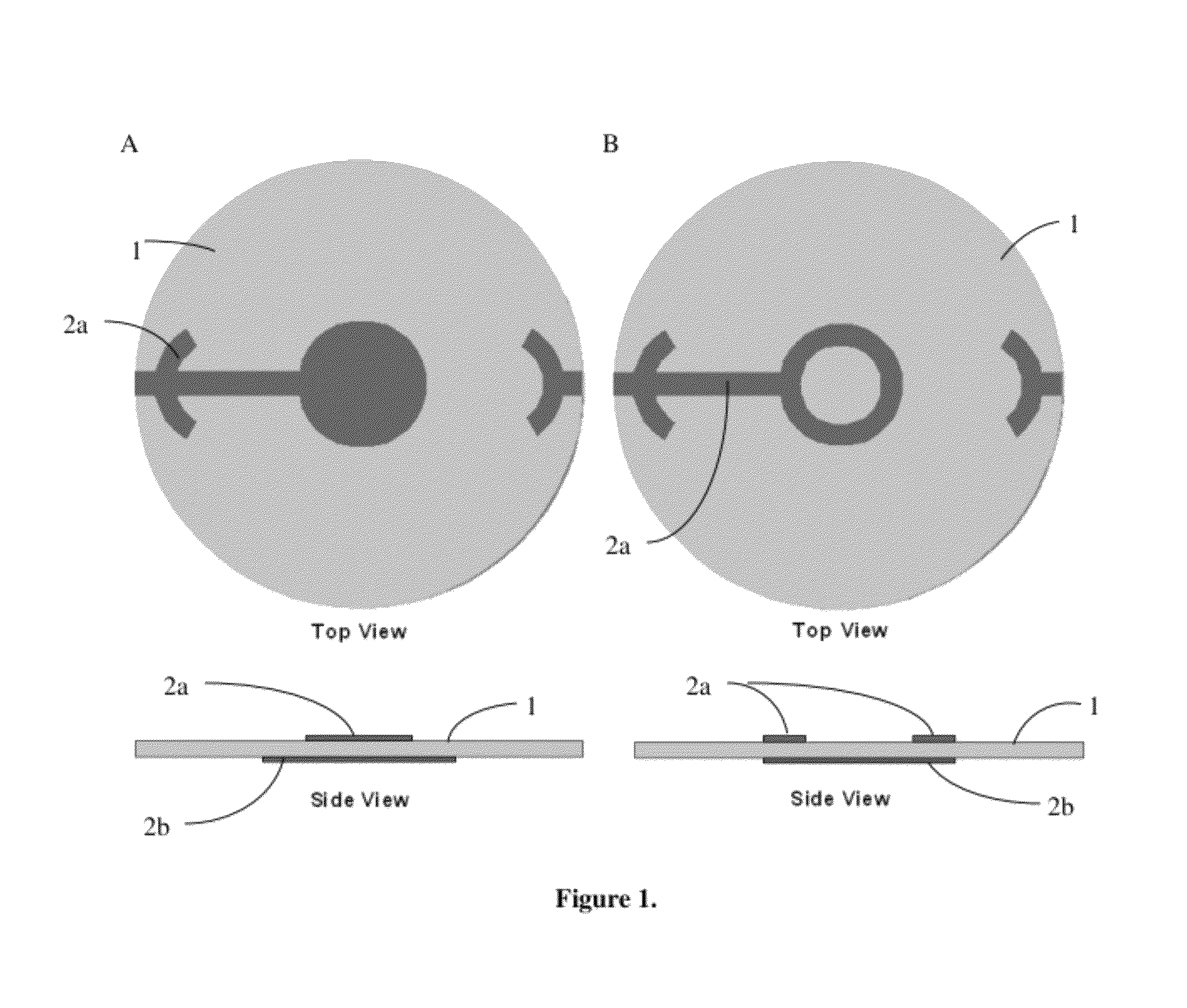

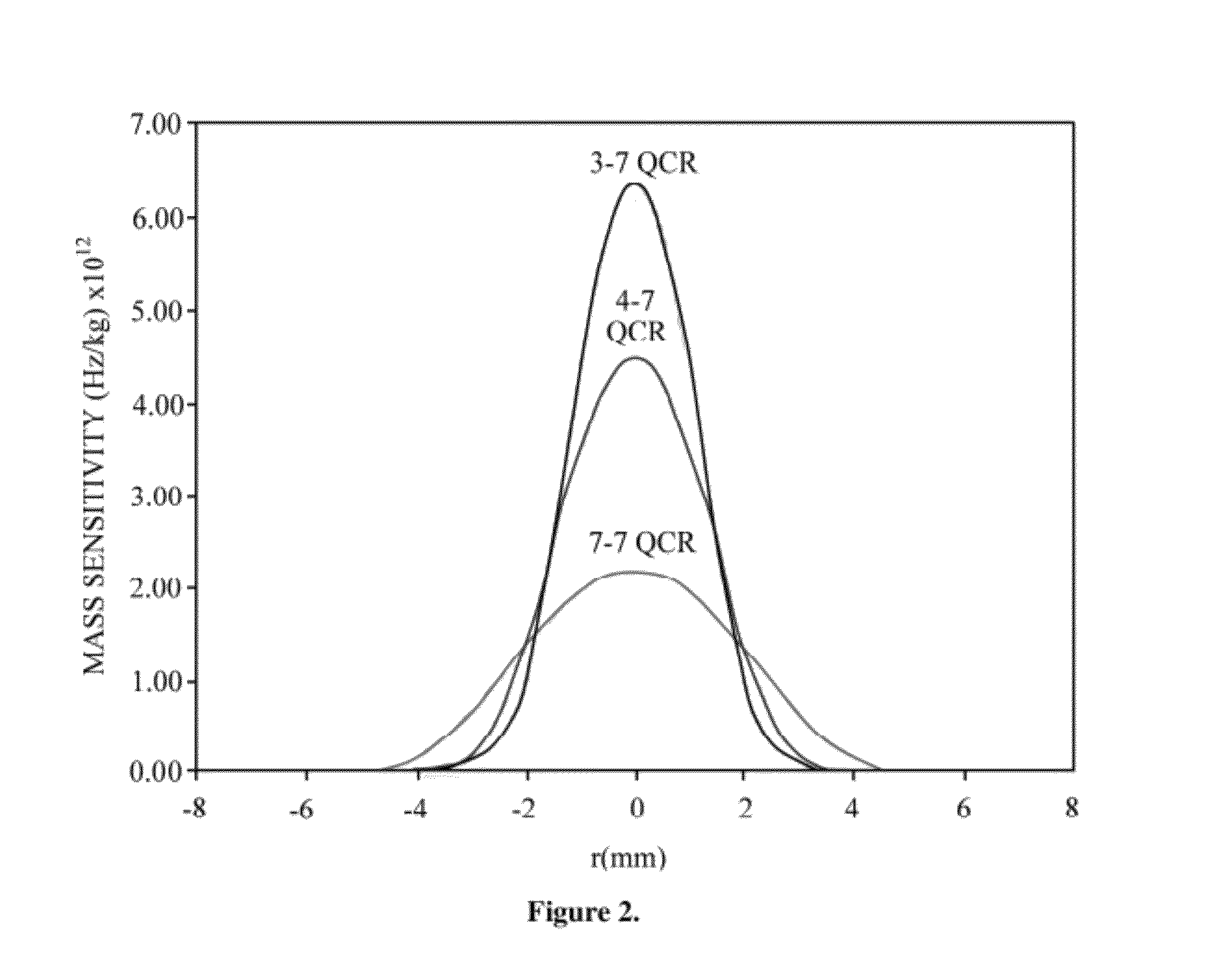

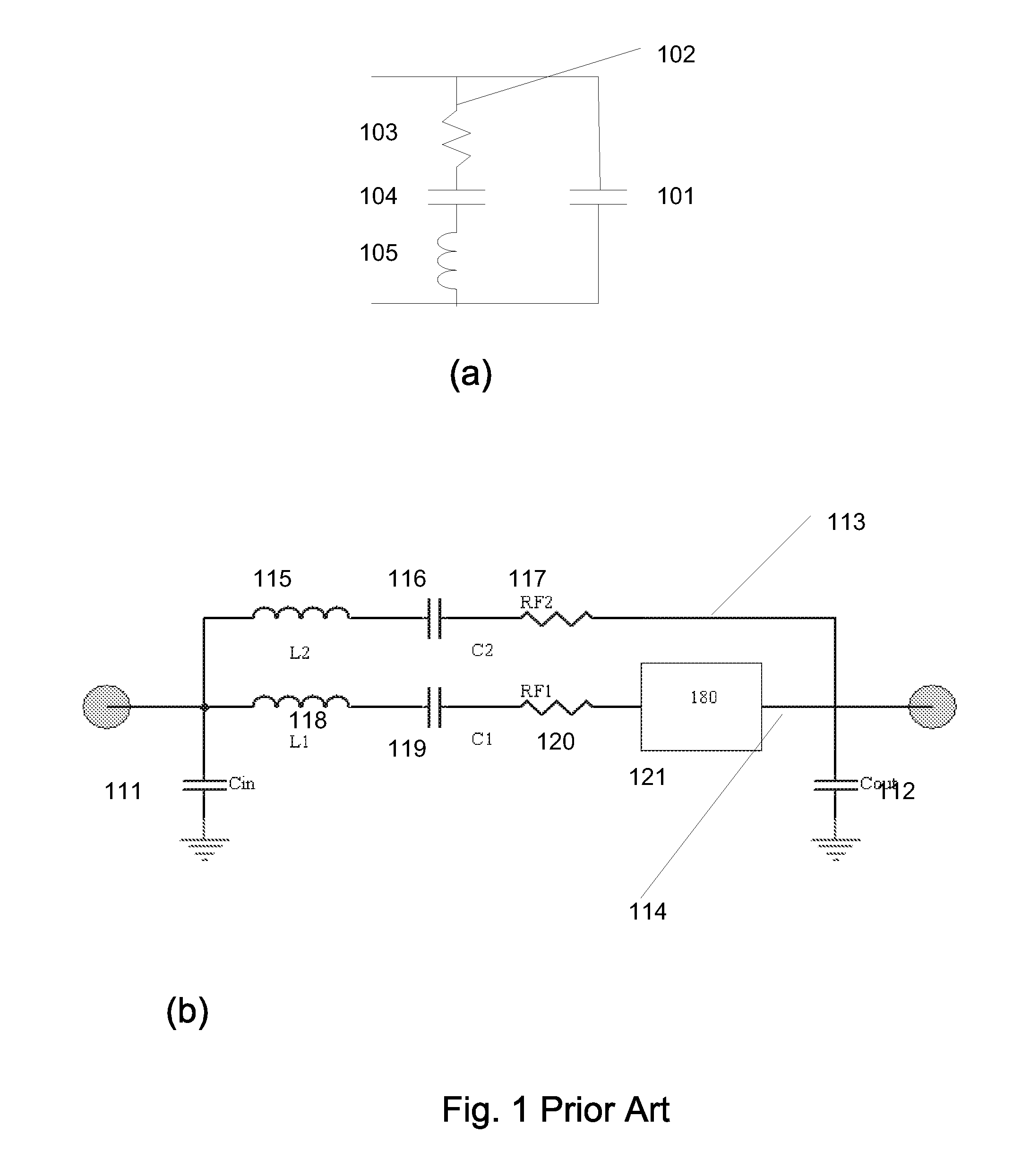

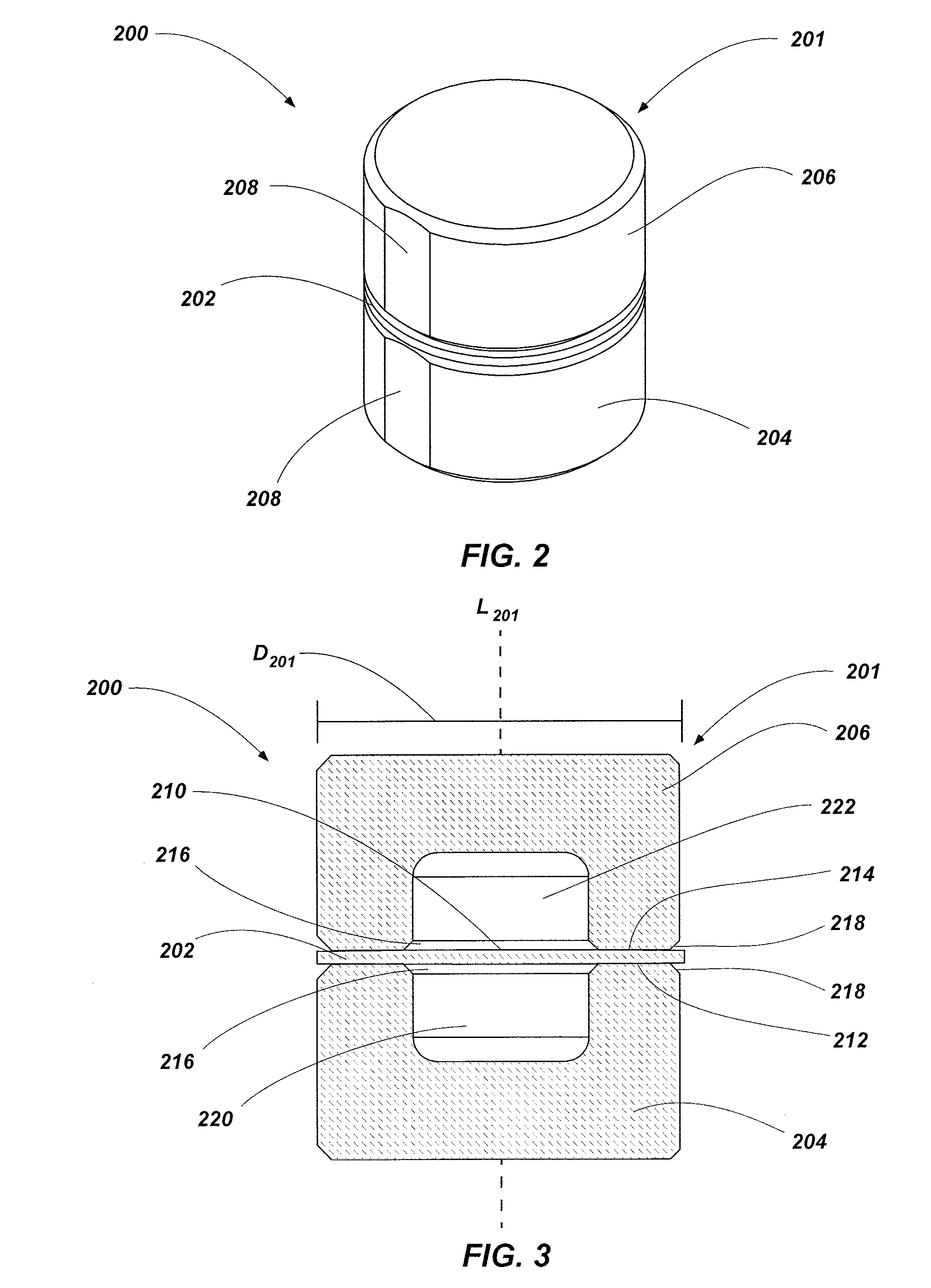

Uniform mass sensitivity thickness shear mode quartz resonator

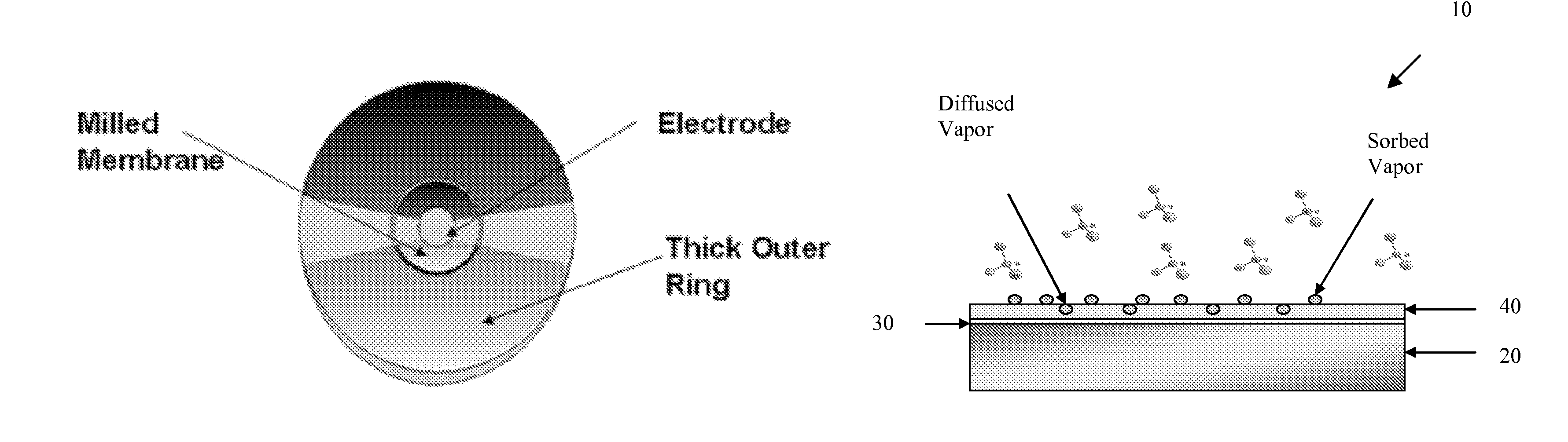

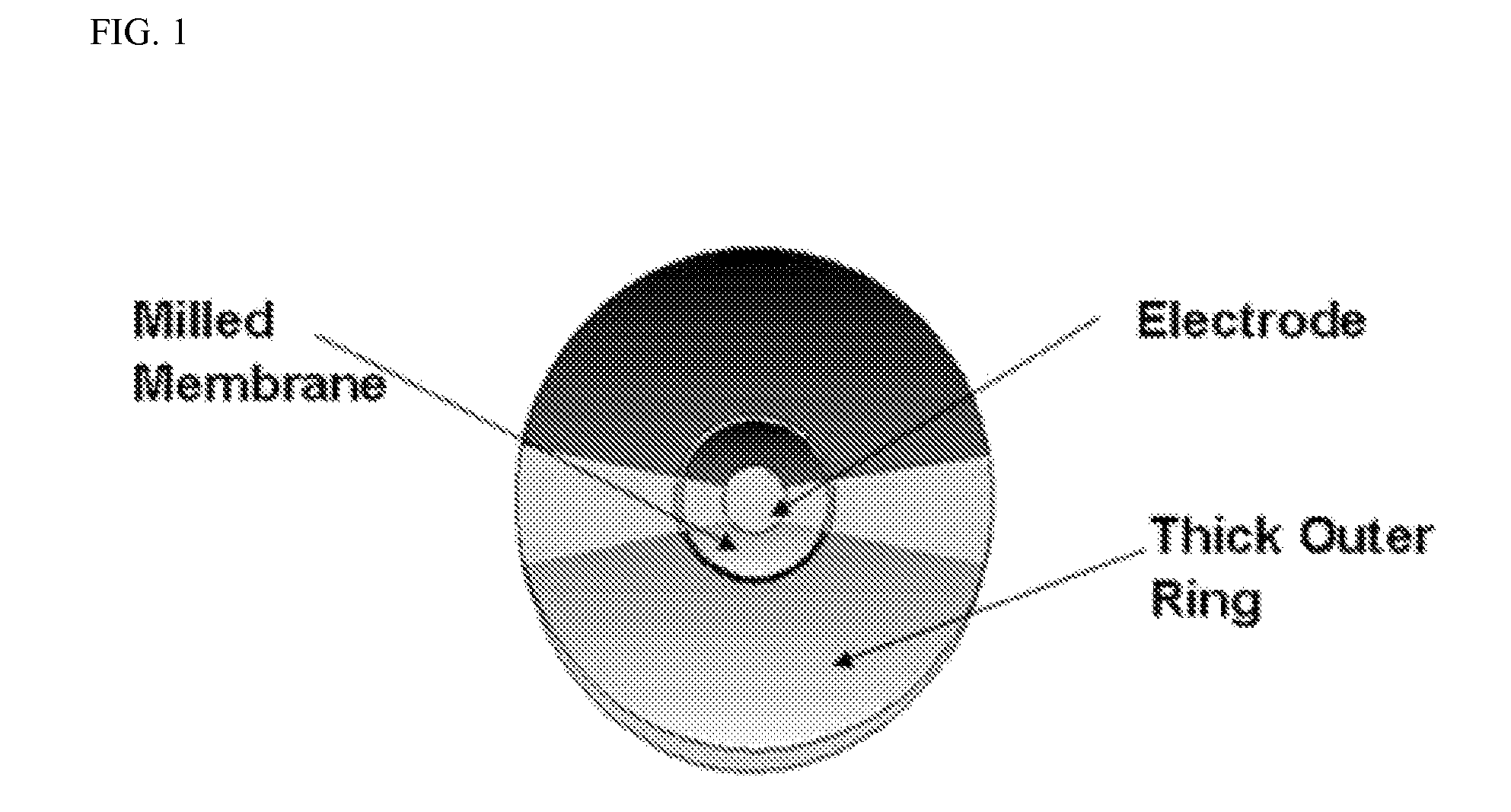

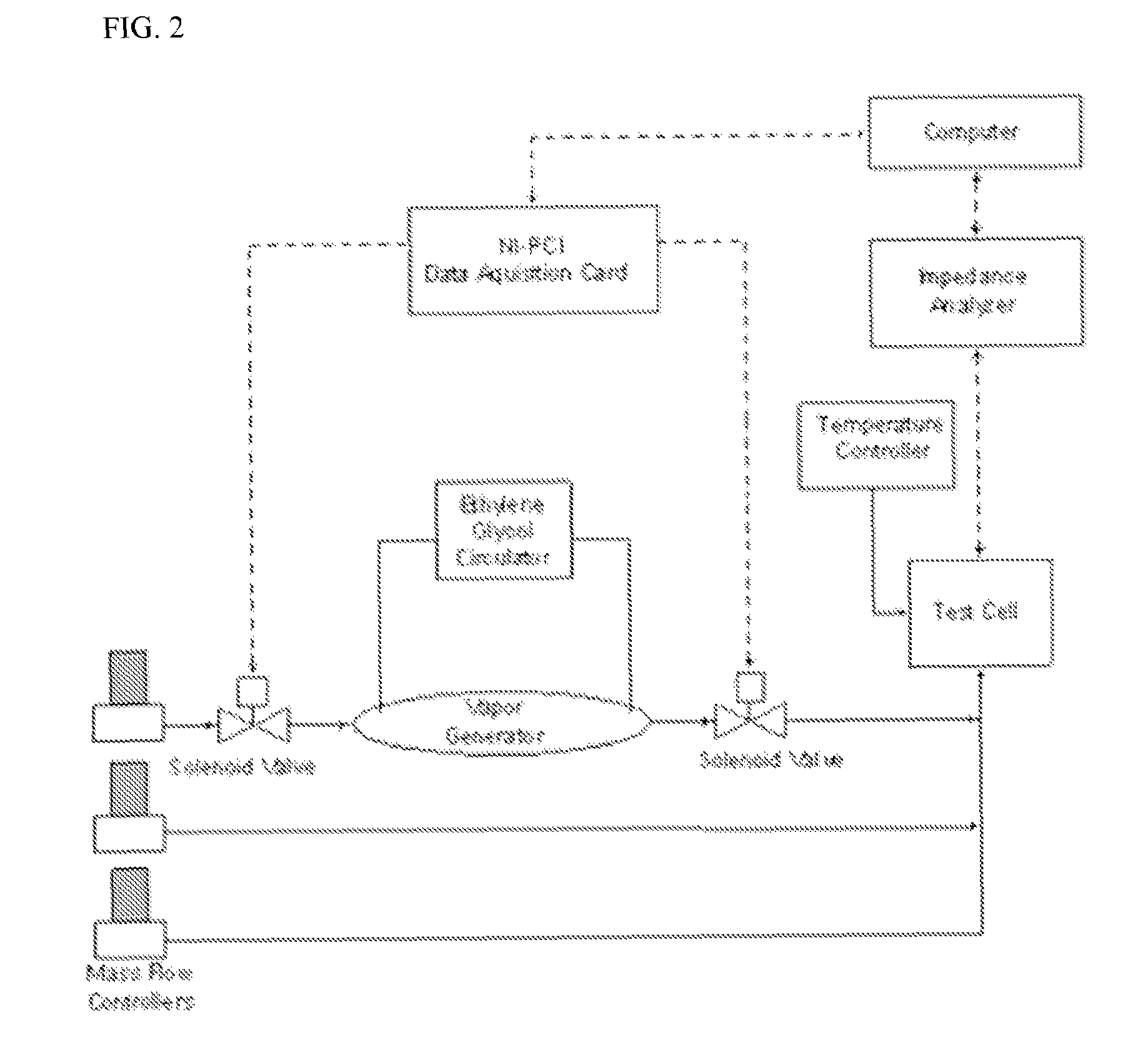

ActiveUS8215171B1Accurate and inexpensive characterizationUniform sensitivityAnalysing fluids using sonic/ultrasonic/infrasonic wavesWeighing apparatus using elastically-deformable membersMass loadingSensitivity distribution

A ring electrode design that produces a uniform mass sensitivity distribution across a TSM device is presented. A new technique and apparatus to measure this mass sensitivity distribution is also presented. Novel electrode geometries on thickness shear mode (TSM) quartz resonators achieve radial uniformity of mass sensitivity, how receptive the device is to mass loadings, and high frequency stability across the active sensing area of the sensor device. The device allows for absolute mass measurement down to the nanogram level. Fabricated devices utilizing model predictions were tested using this apparatus, and good agreement between theory and experiment is found.

Owner:BANK OF AMERICA CORP +1

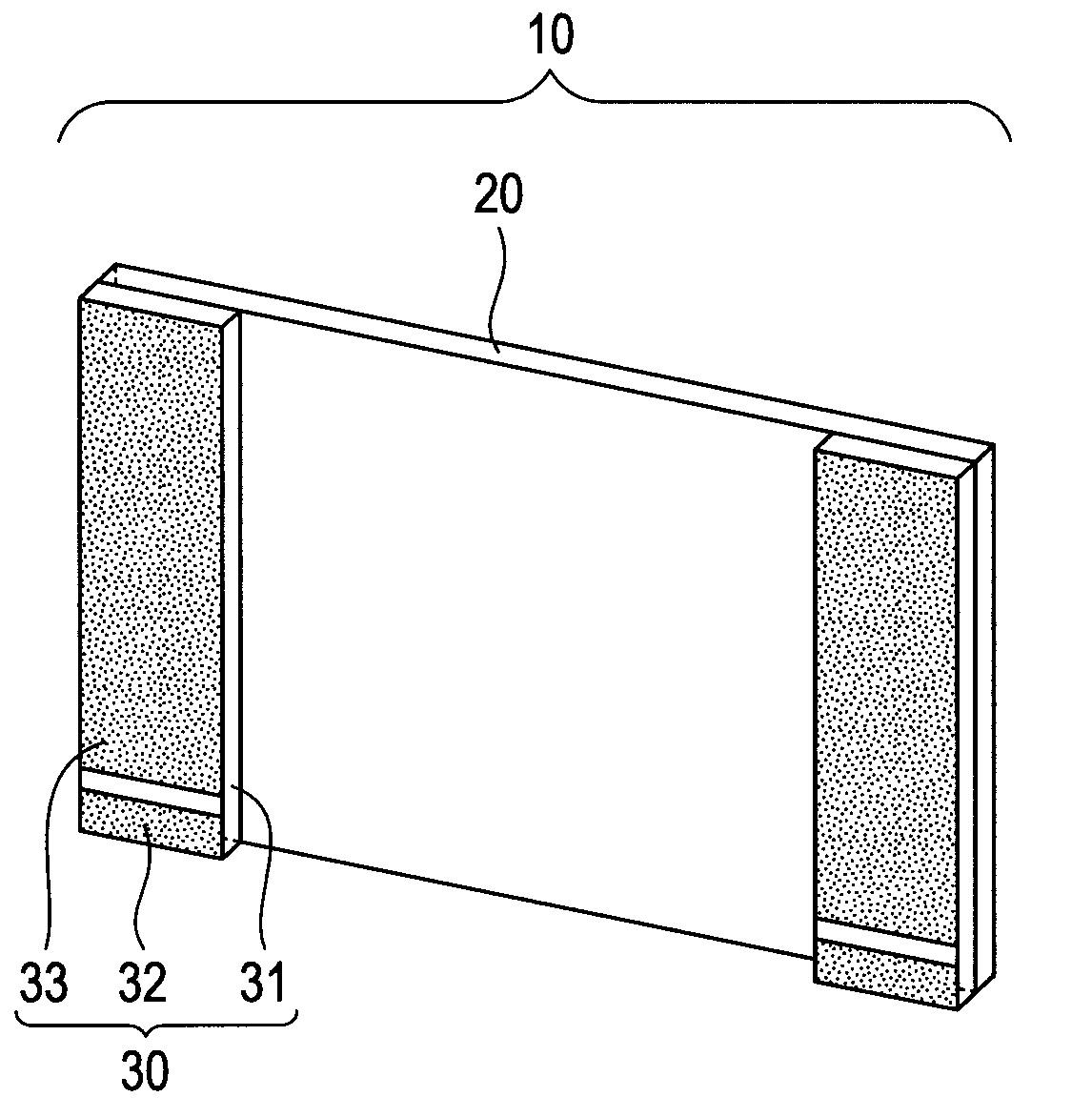

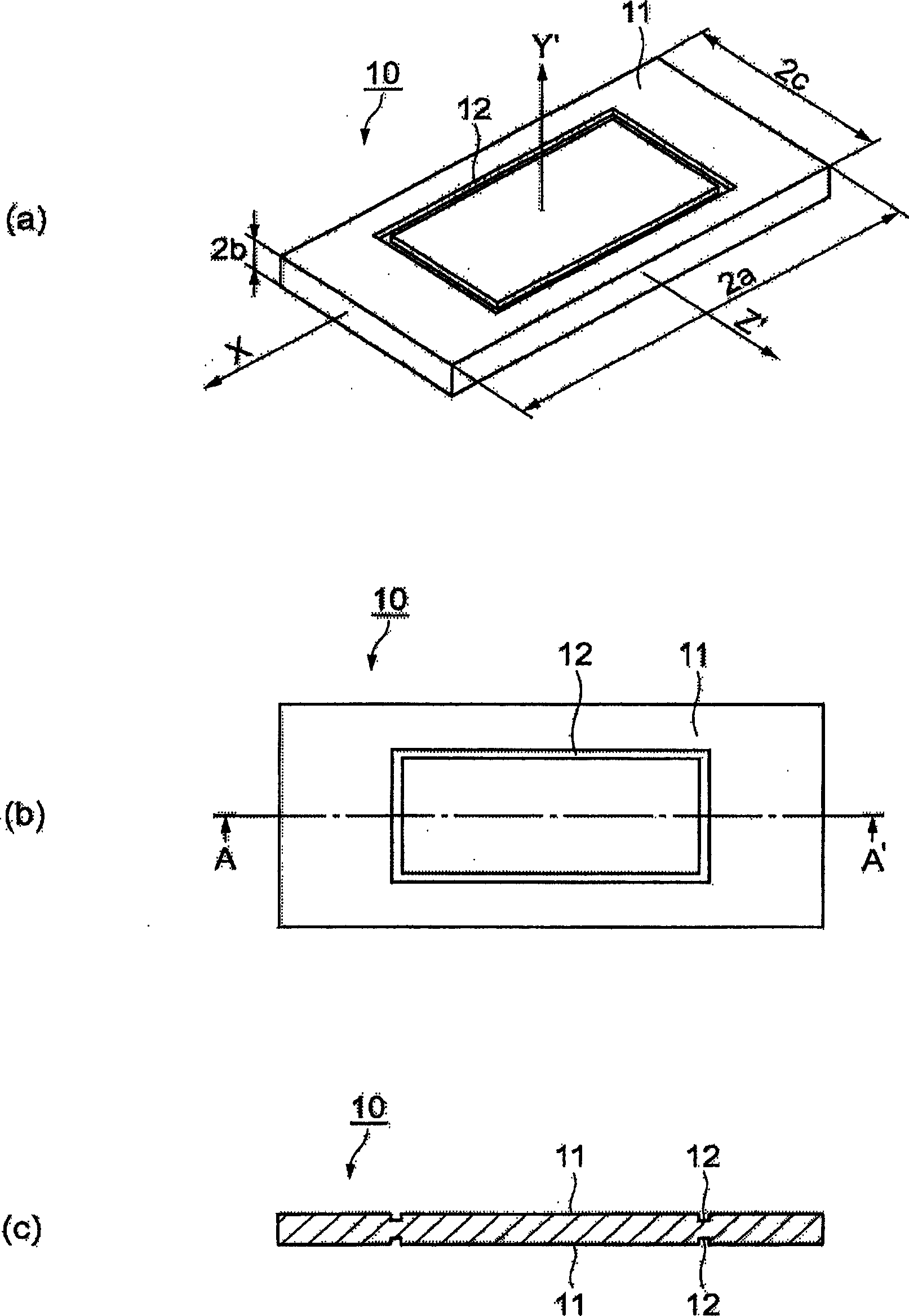

Piezoelectric vibrator element, piezoelectric module, and electronic device

ActiveUS20120133248A1Relieve stressReduce stress propagationImpedence networksPiezoelectric/electrostriction/magnetostriction machinesEngineeringMechanical engineering

A piezoelectric vibrator element includes a vibrating portion that excites thickness-shear vibration, and a peripheral portion that is disposed on the periphery of the vibrating portion and has a thickness thinner than the vibrating portion, the vibrating portion and the peripheral portion being formed in a piezoelectric substrate. A buffering portion and a mount portion are sequentially connected to the peripheral portion. The buffering portion includes a slit formed between the mount portion and the peripheral portion. The mount portion has notches which are formed at both end portions in a direction orthogonal to an arrangement direction of the mount portion, the buffering portion, and the peripheral portion.

Owner:SEIKO EPSON CORP

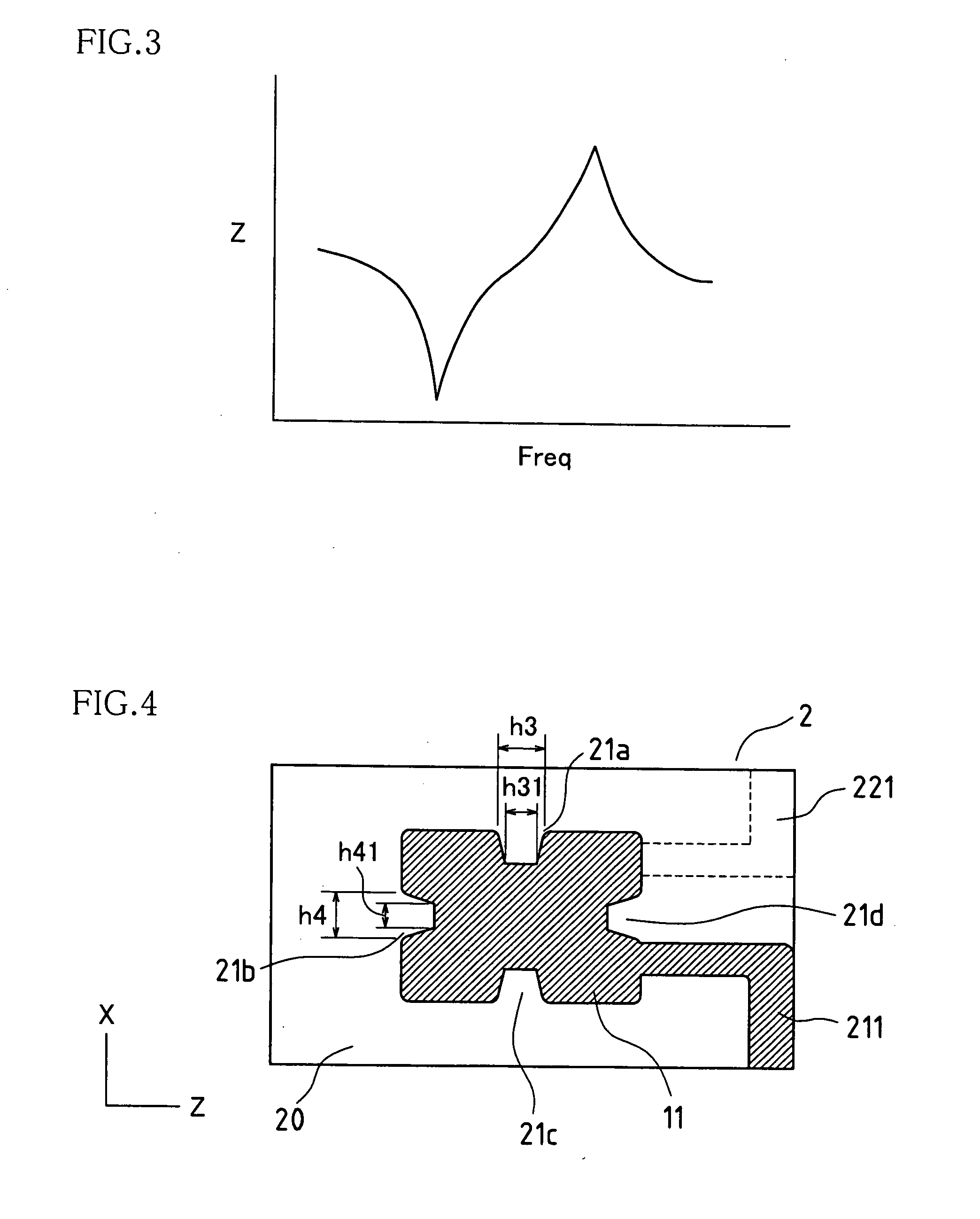

Vibrating element, vibrator, oscillator, and electronic device

ActiveUS20120229223A1Reduce the valueEliminate contactImpedence networksPiezoelectric/electrostriction/magnetostriction machinesElectronThickness shear

A vibrating element includes a piezoelectric substrate having an excitation section adapted to excite a thickness-shear vibration, and provided with a step section in each of side surfaces on both ends, and a peripheral section having a thickness smaller than a thickness of the excitation section, and the peripheral section has at least one projection section disposed on both principal surfaces in an area where a vibratory displacement when the excitation section excites a vibration is sufficiently attenuated.

Owner:SEIKO EPSON CORP

Piezoelectric resonator element, piezoelectric resonator, and piezoelectric oscillator

InactiveUS20050200240A1Gradual dampeningPrevent electrical characteristicPiezoelectric/electrostriction/magnetostriction machinesImpedence networksAcousticsThickness shear

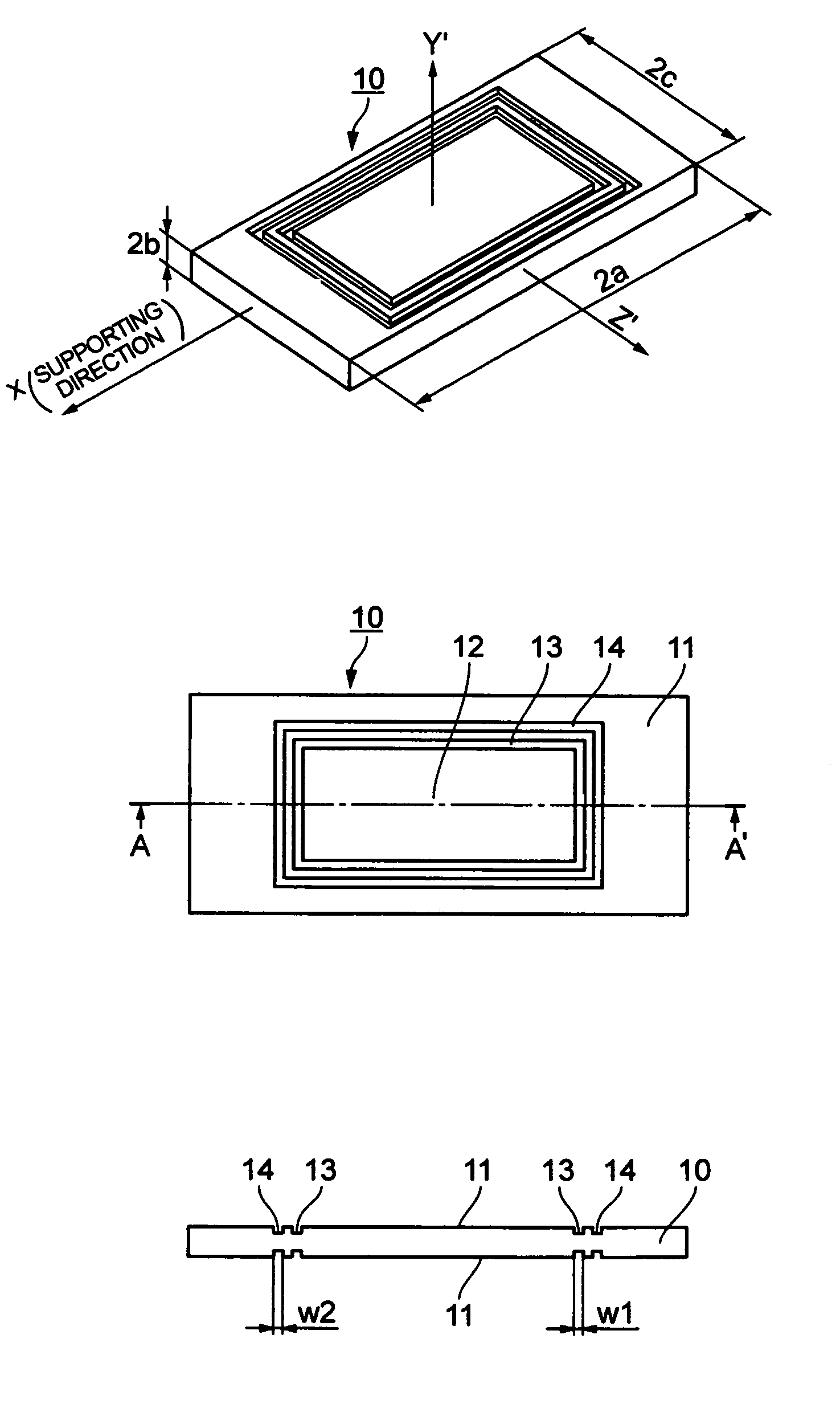

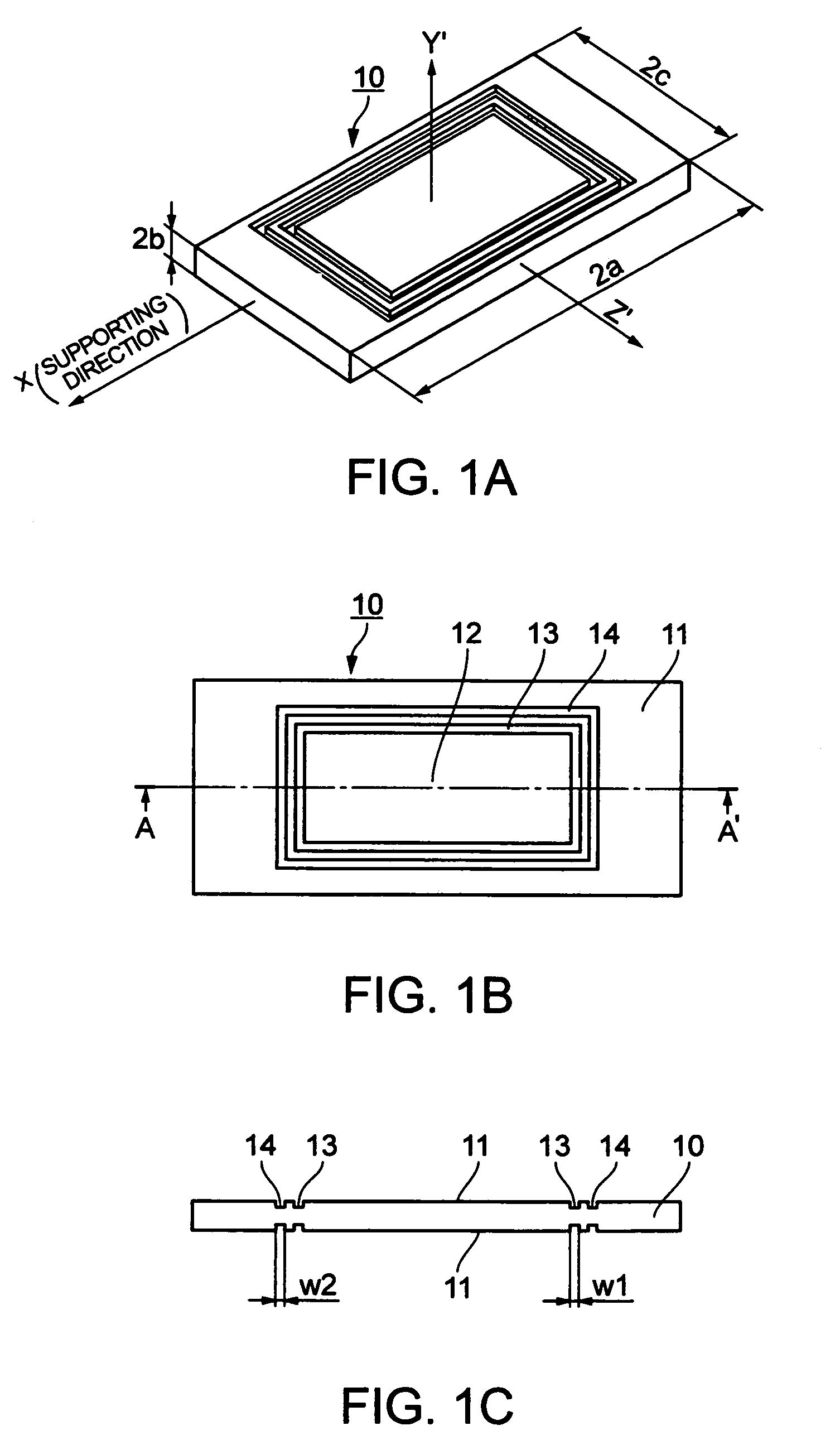

Aspects of the invention provide piezoelectric resonator element having a plurality of grooves for suppressing propagation of the thickness shear vibration from the center portion to the outer peripheral portion of the main surface being placed in enclosure-like shapes surrounding the center portion of at least one of the main surfaces.

Owner:SEIKO EPSON CORP

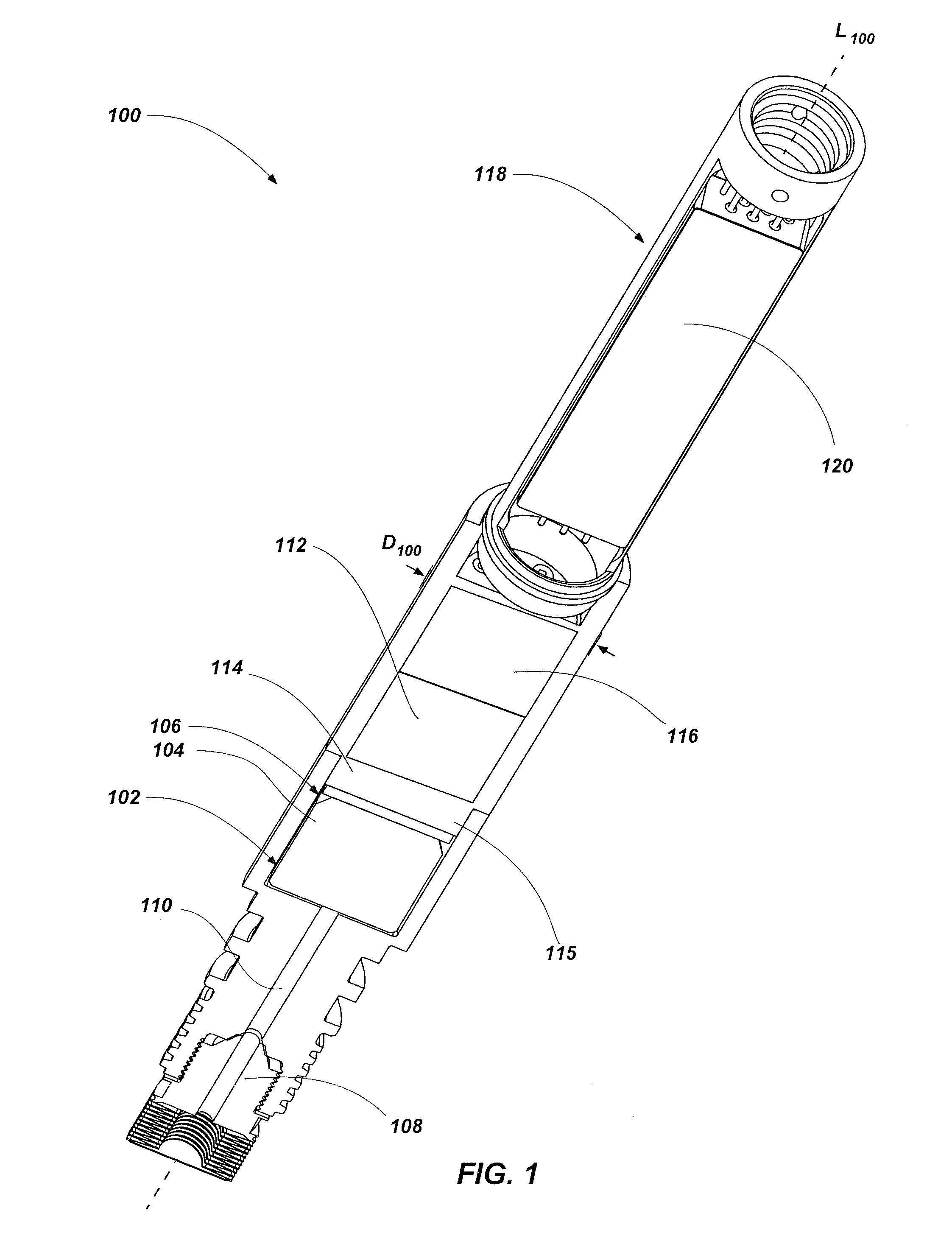

Sensors for measuring at least one of pressure and temperature, sensor arrays and related methods

ActiveUS20120181900A1Piezoelectric/electrostrictive device manufacture/assemblySurveySensor arrayWafering

Arrays of resonator sensors include an active wafer array comprising a plurality of active wafers, a first end cap array coupled to a first side of the active wafer array, and a second end cap array coupled to a second side of the active wafer array. Thickness shear mode resonator sensors may include an active wafer coupled to a first end cap and a second end cap. Methods of forming a plurality of resonator sensors include forming a plurality of active wafer locations and separating the active wafer locations to form a plurality of discrete resonator sensors. Thickness shear mode resonator sensors may be produced by such methods.

Owner:QUARTZDYNE

Resonator element, resonator, electronic device, electronic apparatus, and mobile object

ActiveUS20130257554A1Improve reliabilityDeteriorating valueImpedence networksPiezoelectric/electrostriction/magnetostriction machinesElectronThickness shear

A resonator element includes a substrate vibrating in a thickness-shear vibration mode, a first excitation electrode disposed on one principal surface of the substrate, and has a shape obtained by cutting out four corners of a quadrangle, and a second excitation electrode disposed on the other principal surface of the substrate, and a ratio (S2 / S1) between the area S1 of the quadrangle and the area S2 of the first excitation electrode fulfills 87.7%≦(S2 / S1)<95.0%.

Owner:SEIKO EPSON CORP

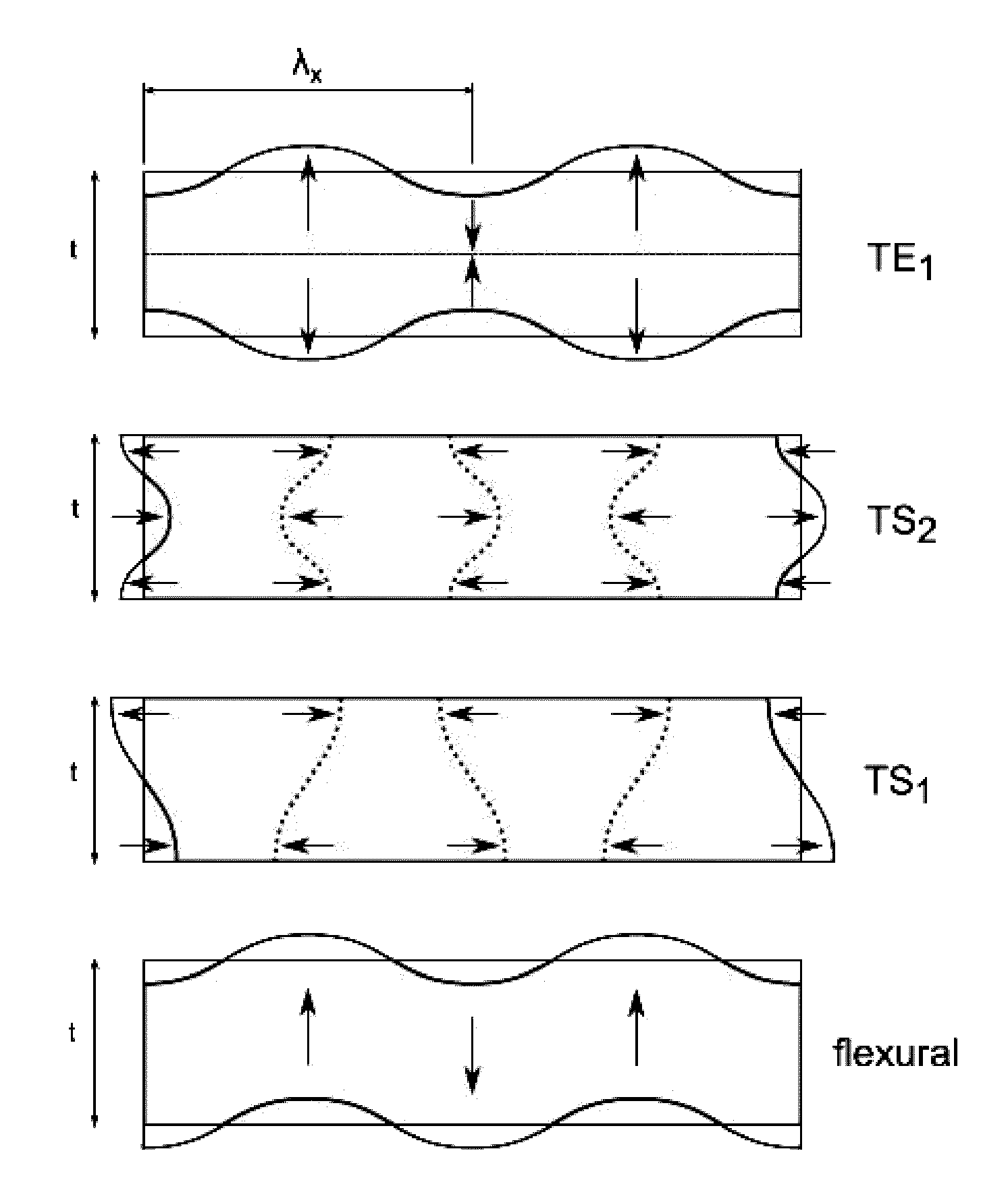

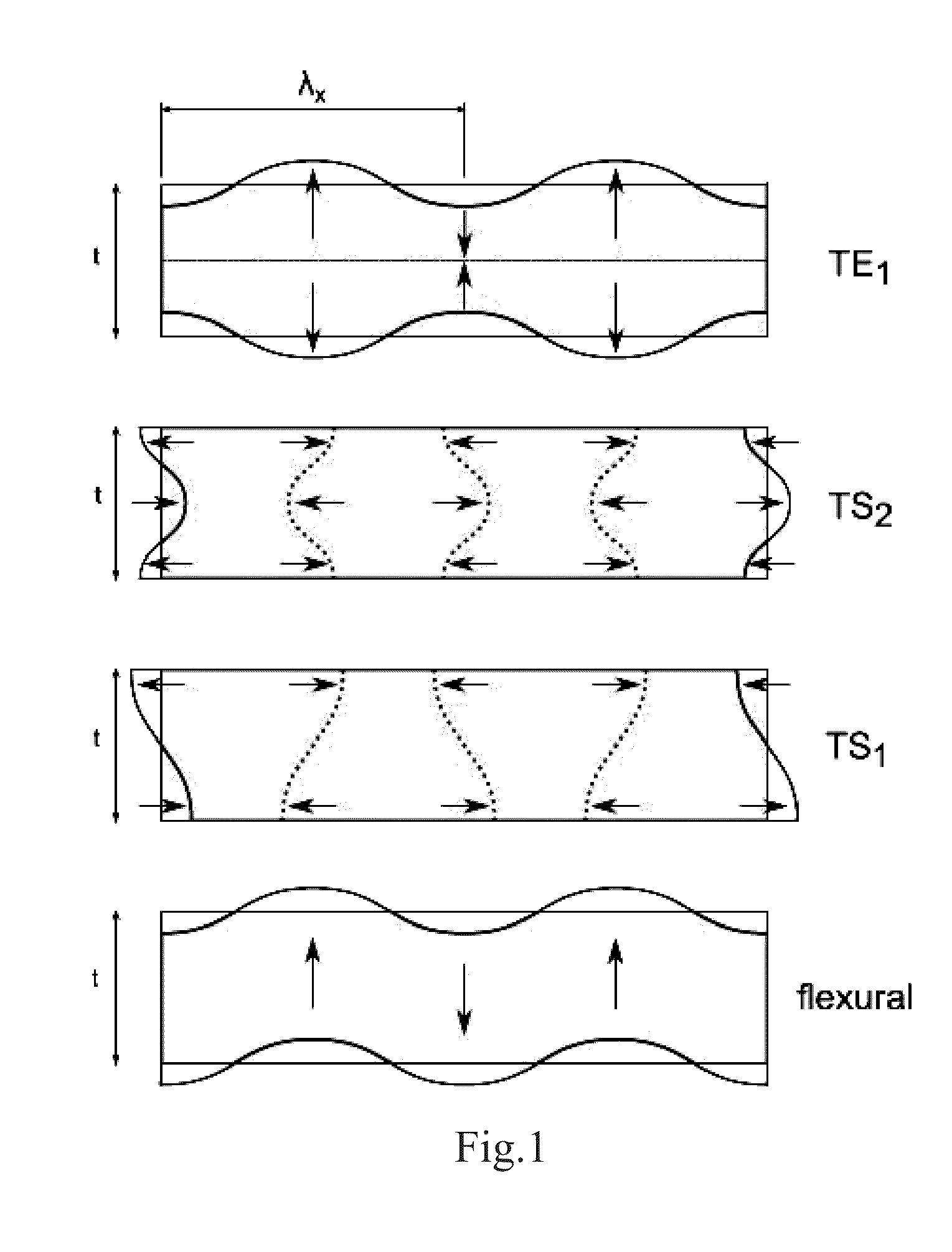

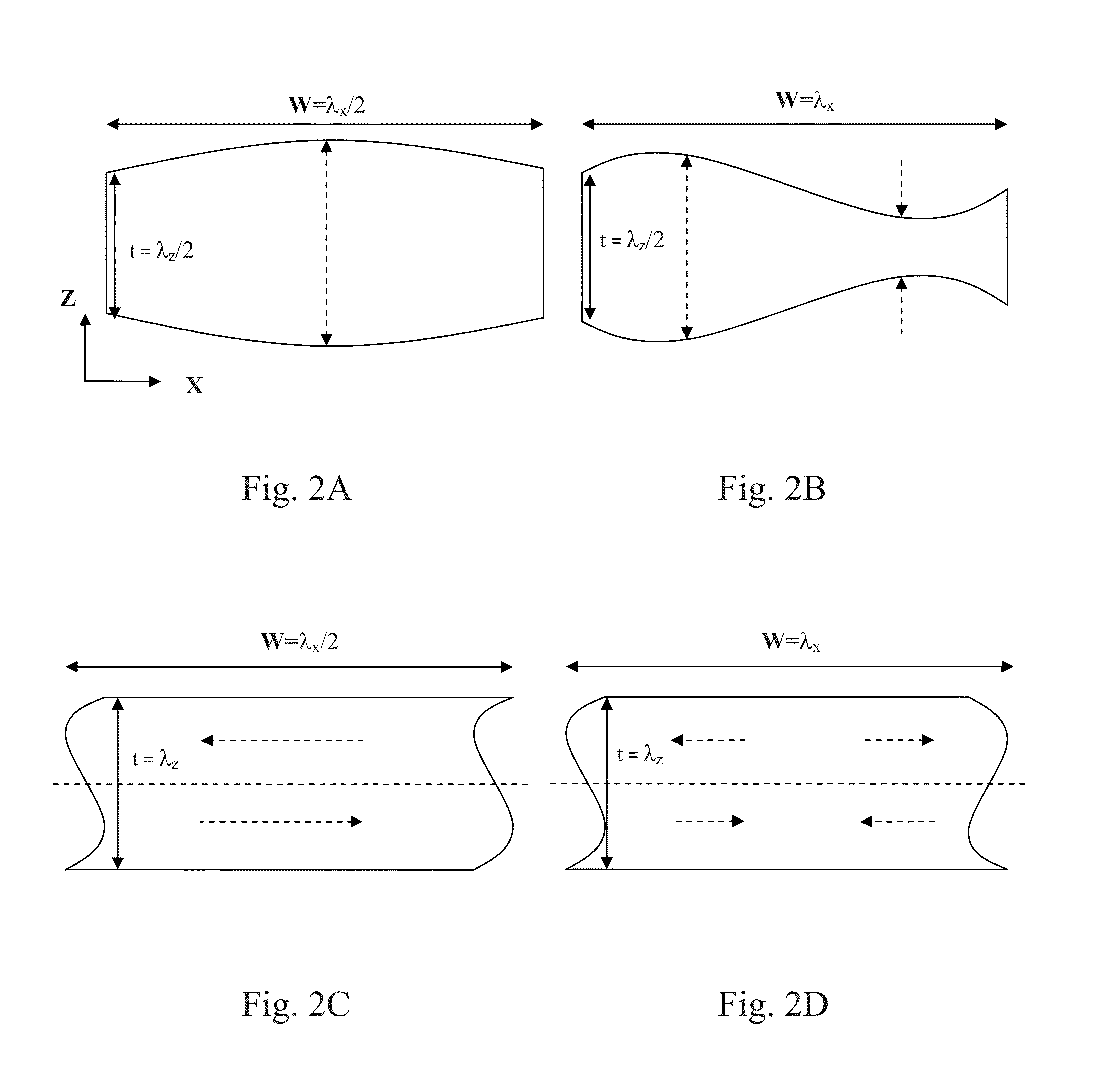

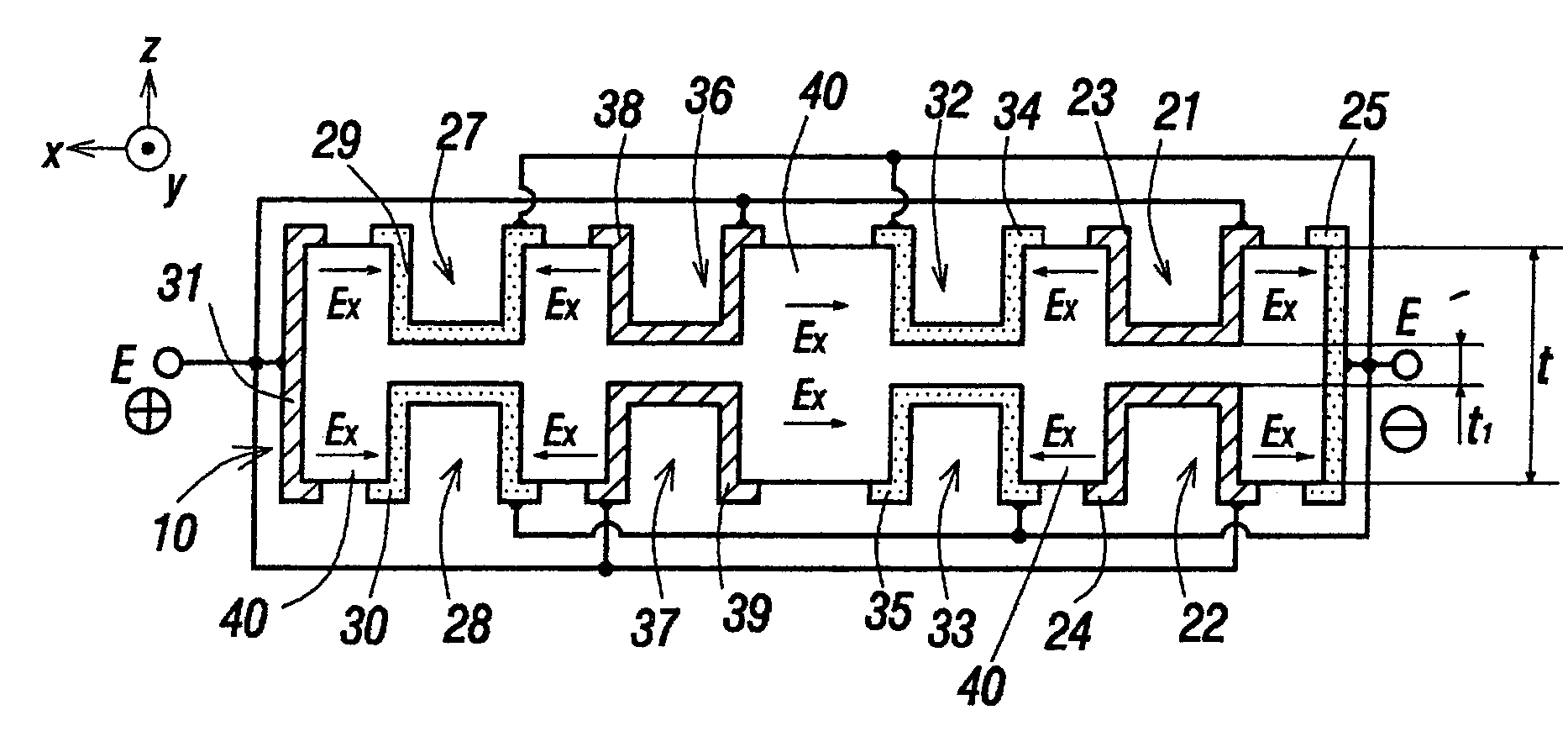

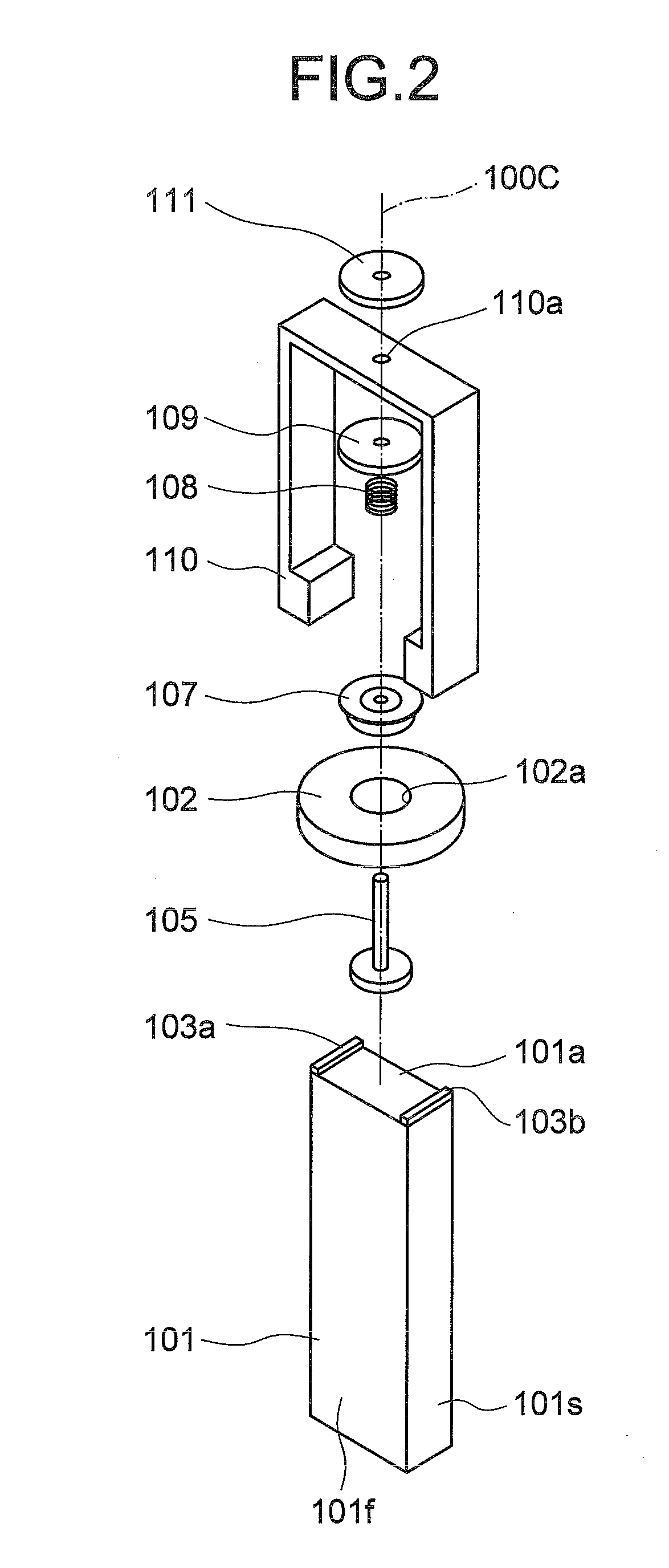

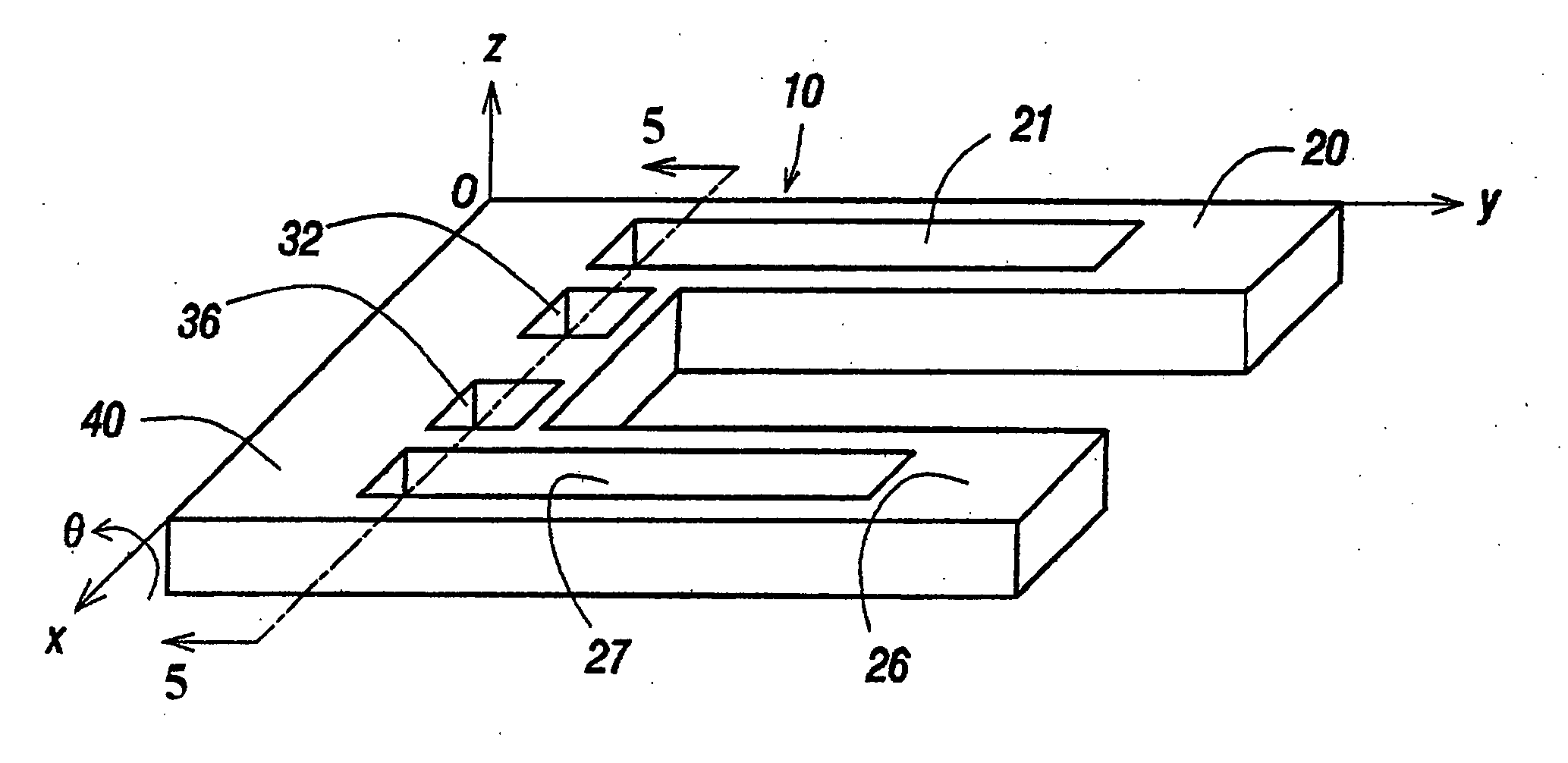

Wide-band acoustically coupled thin-film baw filter

ActiveUS20130057360A1Wide frequency bandwidthTolerance costPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksThickness shearPhysics

In a bulk acoustic wave (BAW) filter based on laterally acoustically coupled resonators on piezoelectric thin films, one can utilize two distinct acoustic plate wave modes of different nature, for example the thickness extensional (longitudinal) TE1 and the second harmonic thickness shear (TS2) mode to form a bandpass response. The invention is based on the excitation of at least two lateral standing wave resonances belonging to different plate wave modes that facilitate the transmission of signal. The passband is designed by tailoring the wave propagation characteristics in the device such that the resonances are excited at suitable frequencies to form a passband of a desired shape. The bandwidth of the filter described herein may therefore be more than twice that of the existing state-of-the-art microacoustic filters. Consequently, it has significant commercial and technological value.

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT

Crystal Resonator

ActiveUS20090085428A1Satisfactory characteristicReduce vibrationImpedence networksPiezoelectric/electrostriction/magnetostriction machinesThickness shearPhysics

A crystal resonator comprises an AT-cut crystal vibrating element that is driven by a thickness-shear mode and is in the shape of a rectangular plate. A pair of excitation electrodes is formed, facing front and rear surfaces of the crystal vibrating element. Each of the excitation electrodes is formed in the shape of a quadrangle as viewed from the top, and mass adjustment portions are formed at least two opposite sides of each of the excitation electrodes formed on the front and rear surfaces.

Owner:DAISHINKU CORP

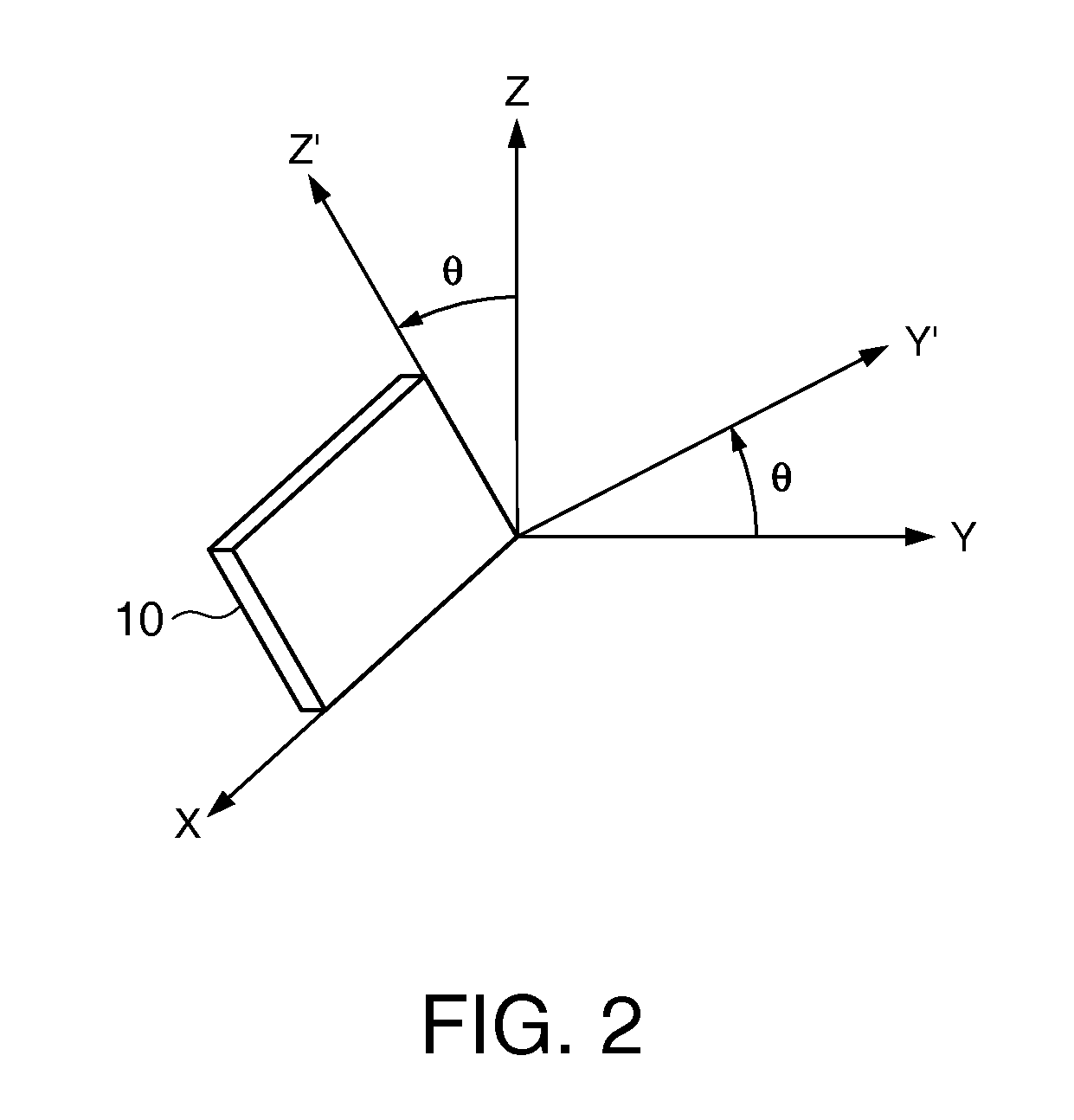

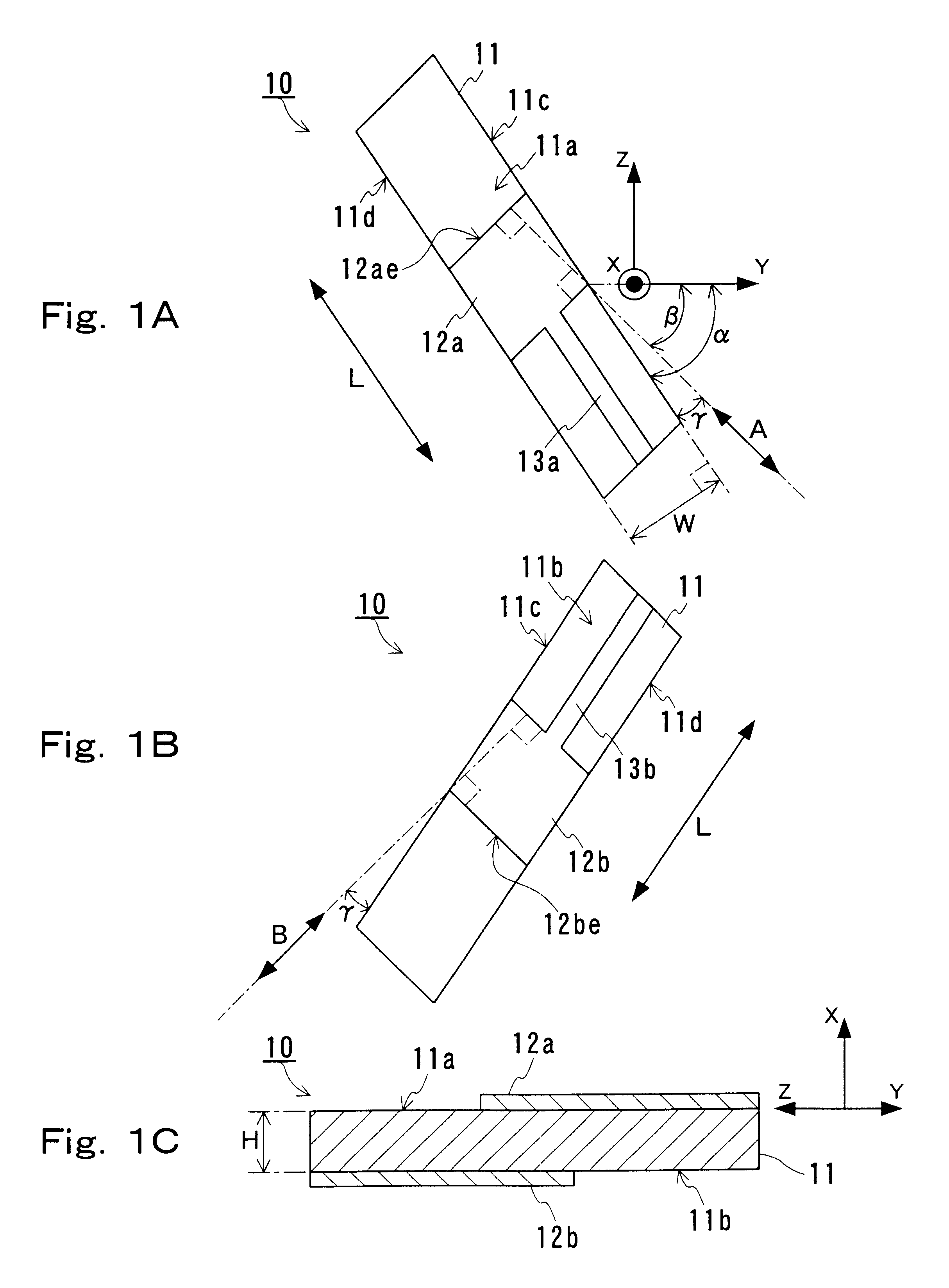

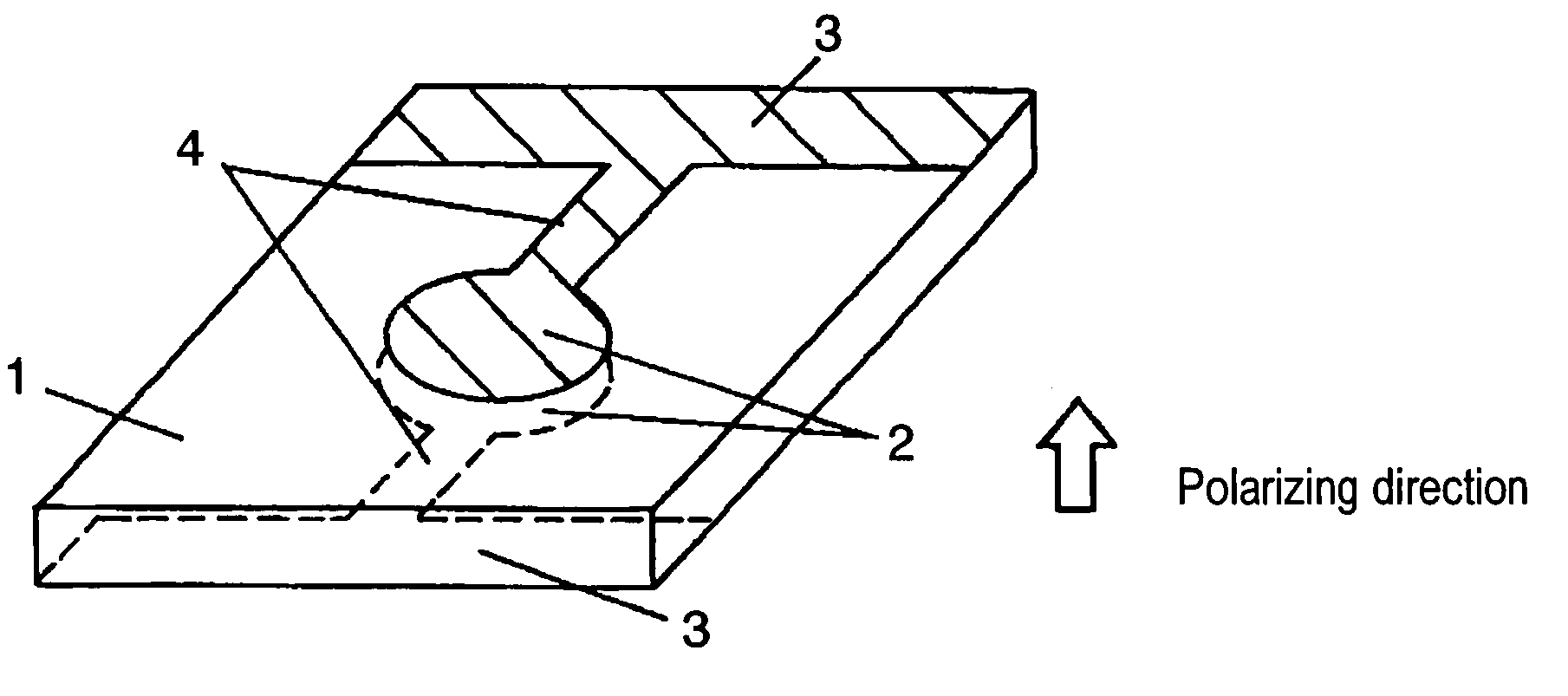

Piezoelectric element having thickness shear vibration and mobile communication device using the same

InactiveUS6621194B1Impedence networksPiezoelectric/electrostriction/magnetostriction machinesAcousticsCommunication device

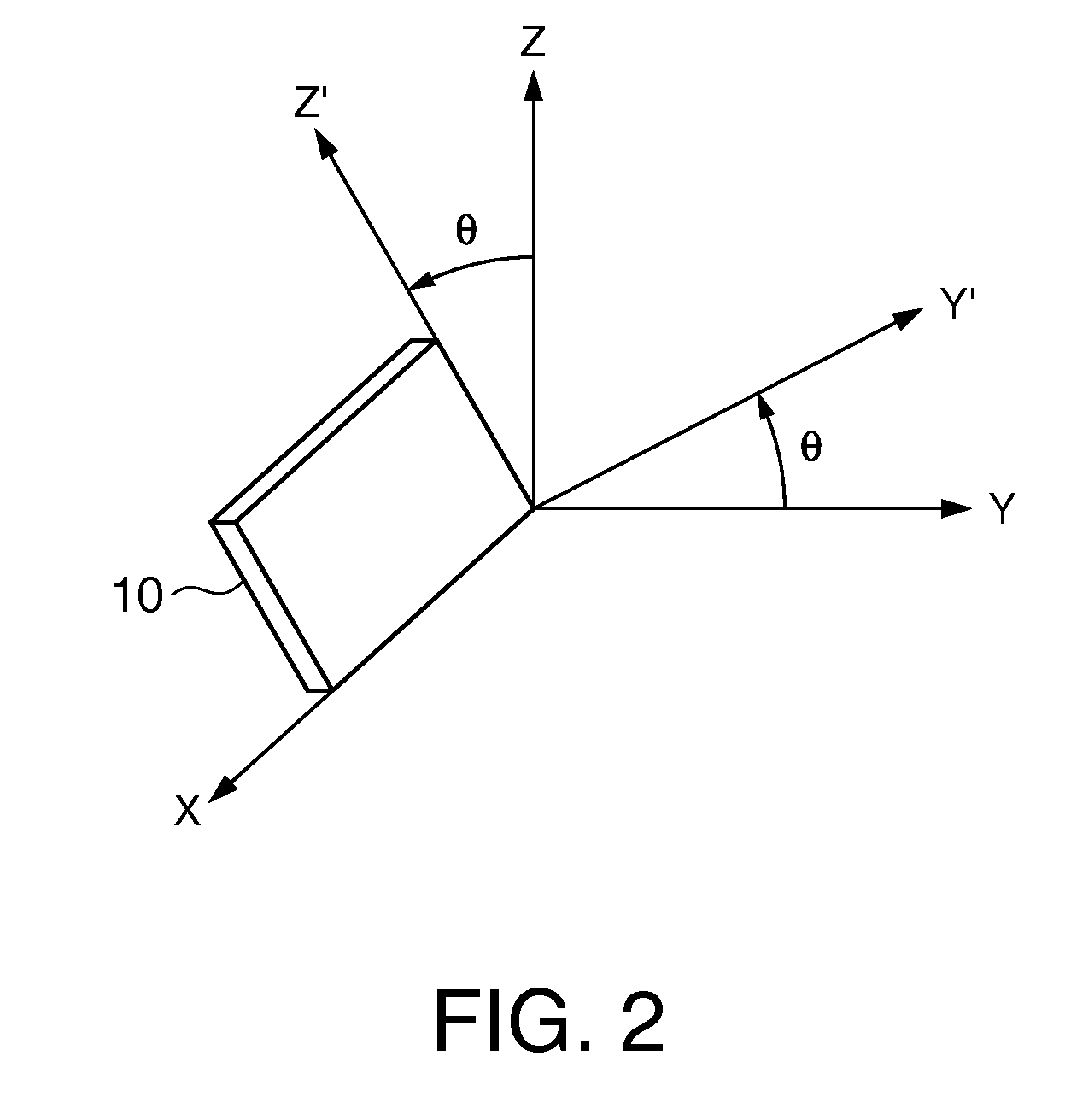

A piezoelectric element includes a piezoelectric substrate formed of a piezoelectric material and a pair of electrodes formed on a first principal plane and a second principal plane of the piezoelectric substrate, wherein thickness shear vibration occurs, and the vibration direction of the thickness shear vibration is nonparallel to the side walls of the piezoelectric substrate.

Owner:PANASONIC CORP

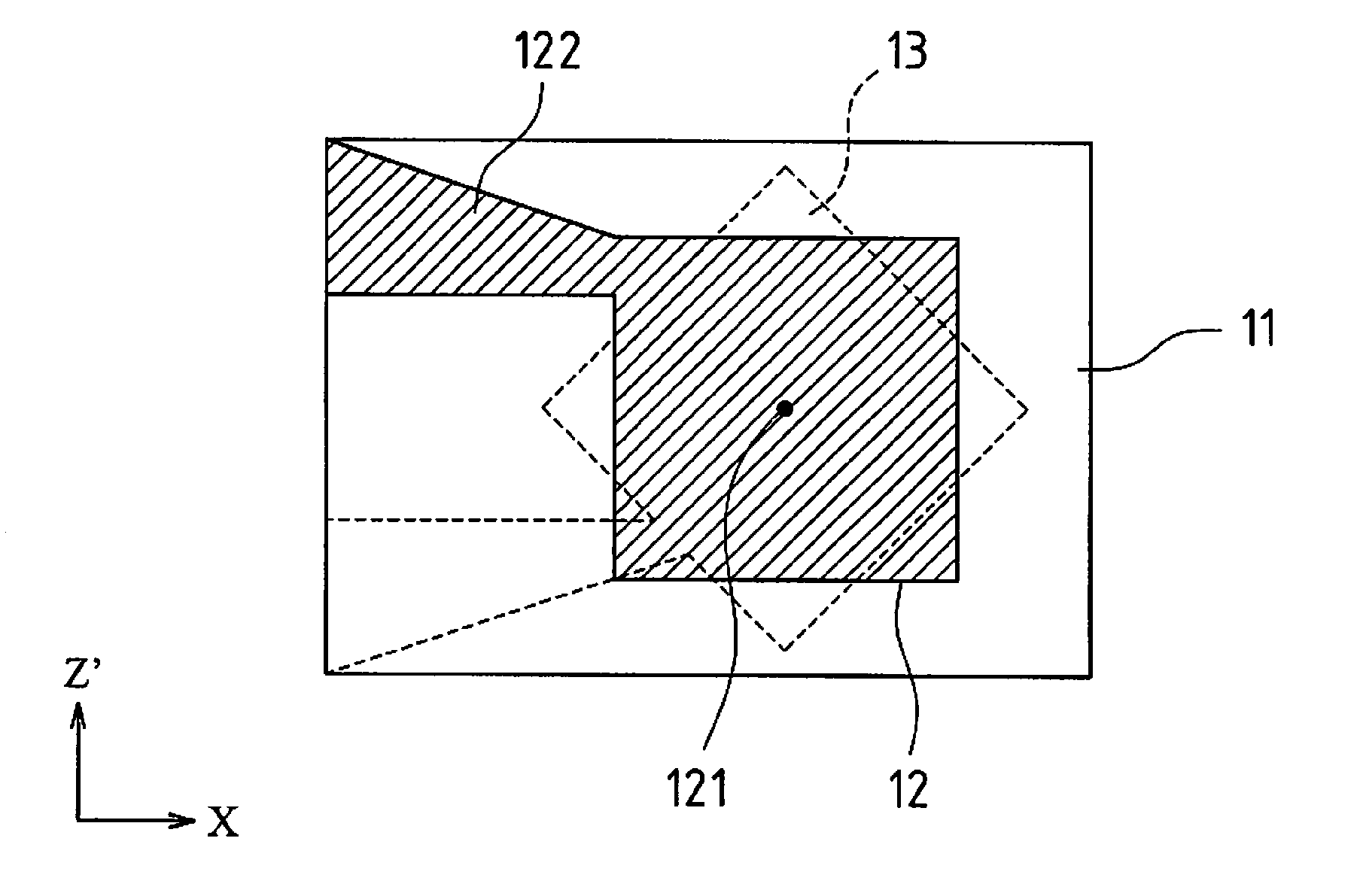

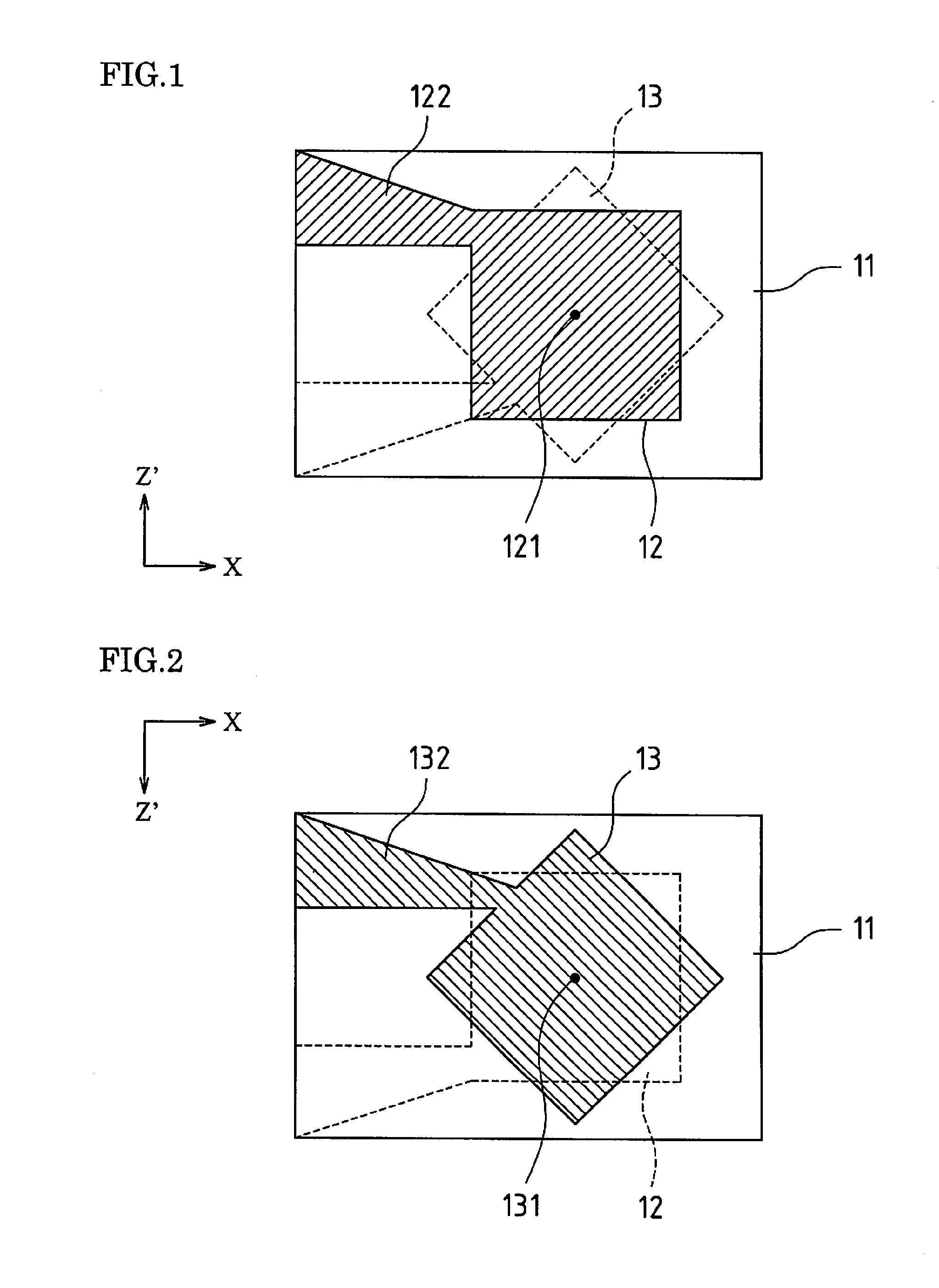

Piezoelectric resonator

ActiveUS20100327705A1Improve featuresReduce vibrationImpedence networksPiezoelectric/electrostriction/magnetostriction machinesForming faceEngineering

A piezoelectric resonator includes a pair of driving electrodes and a pair of lead electrodes that are formed facing each other on the frontside and backside of a piezoelectric plate that operates in a thickness-shear vibration mode. The front and back driving electrodes are formed such that they each have one or more pairs of parallel sides and have the same shape, and their centers face each other. The parallel sides of one of the front and back driving electrodes are formed parallel with either the X-axis or the Z′-axis of the piezoelectric plate, but the parallel sides of the other driving electrodes are formed without being parallel with the X-axis and Z′-axis thereof.

Owner:DAISHINKU CORP

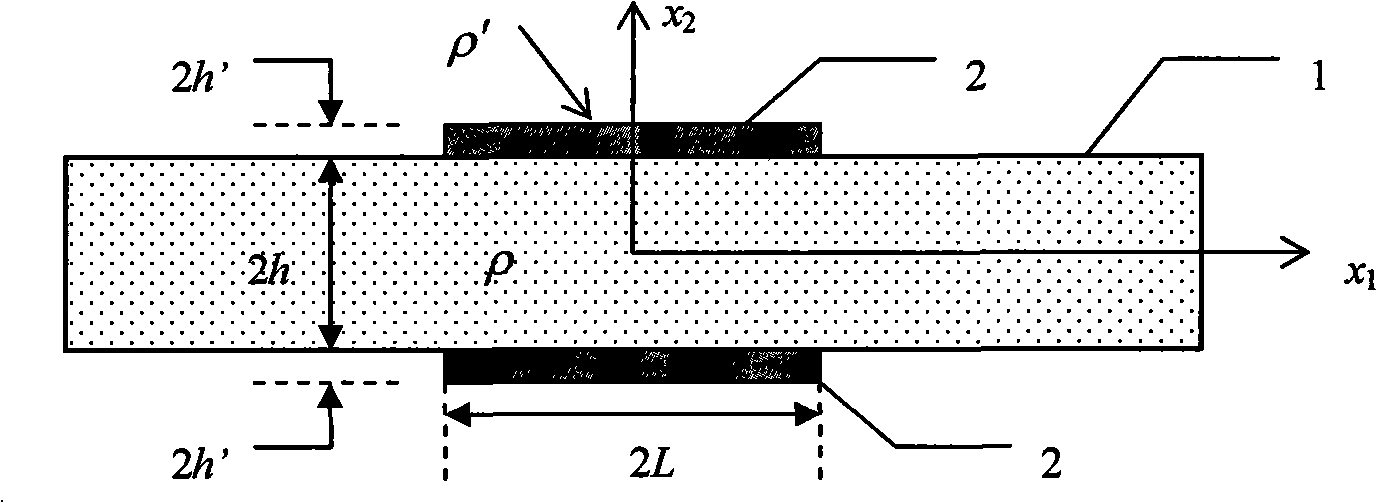

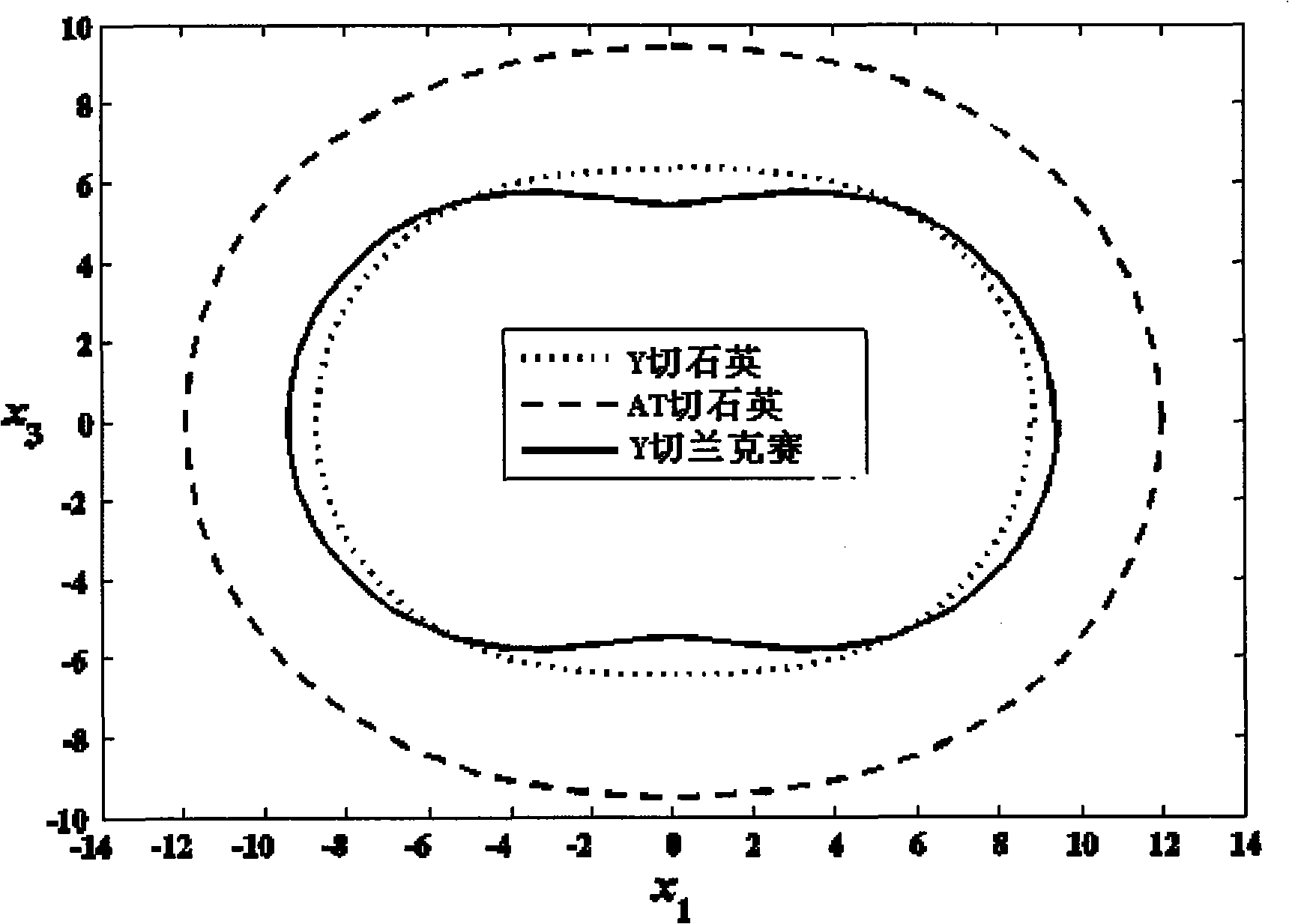

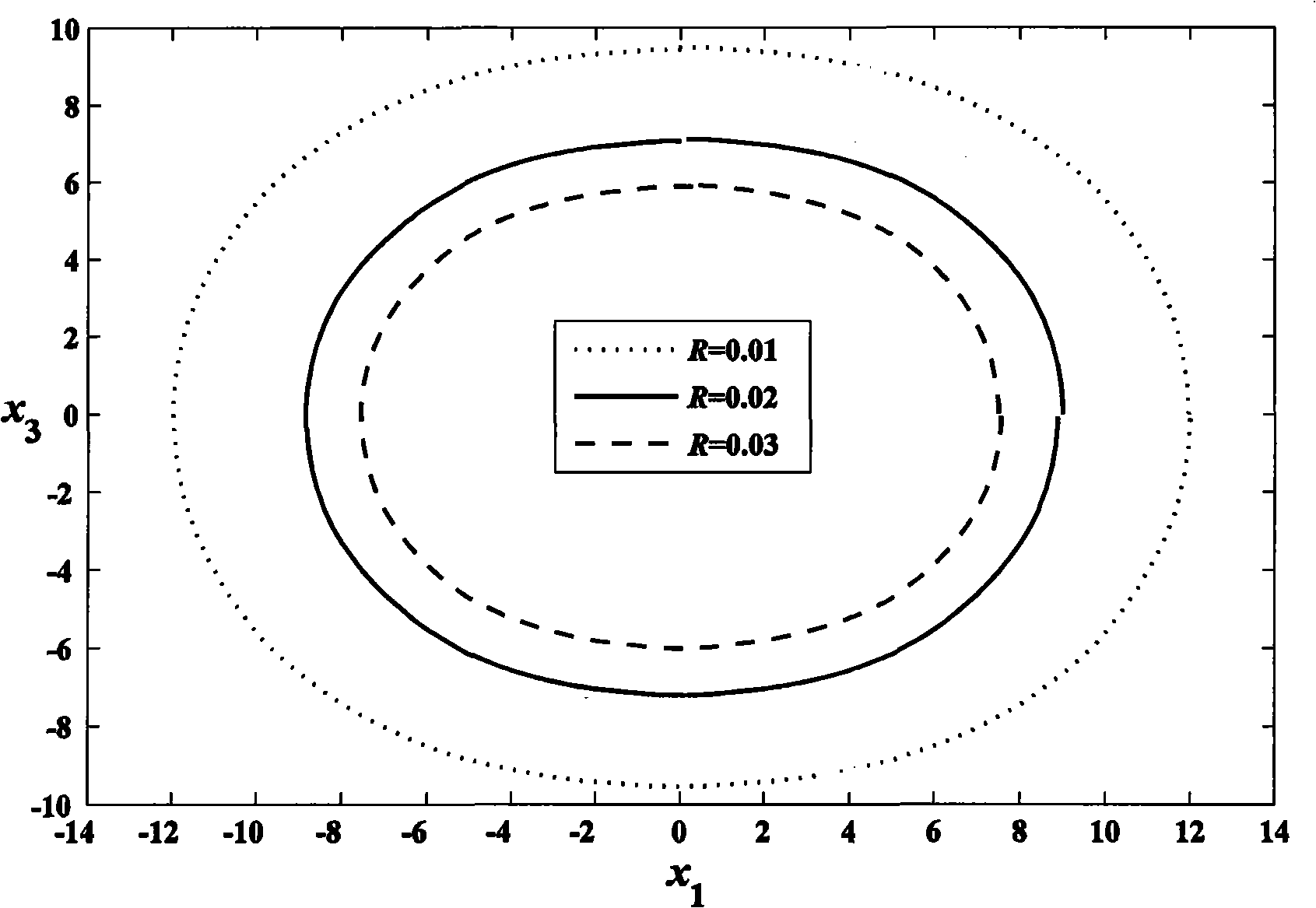

Method for design piezoelectric resonator electrode shapes

InactiveCN101257287AMiniaturizationLight structureImpedence networksMiniaturizationCondensed matter physics

A piezoelectric resonator electrode shape design method is disclosed. The electrode shape at each direction can satisfy Bechmann number, thereby all the particle vibration covered by a same electrode are in the same phase. According to Y cutting quartz plate, At cutting quartz plate and Y cutting crystal plate thickness shearing resonator, the shaft x1 and the shaft x3 are coordinate axis in a place, x2 is a normal coordinate axis of the plate, Phi is a rotation angle from the shaft x1 to the shaft x3 in the plane, the electrode length L follows the expression (the above formula) of the angle Phi. The resonator structure of electrode after optimum design is portable, with good performance and high precision, which is propitious to miniaturization of device; meanwhile design method is simple and easy of bulk production.

Owner:CENT SOUTH UNIV

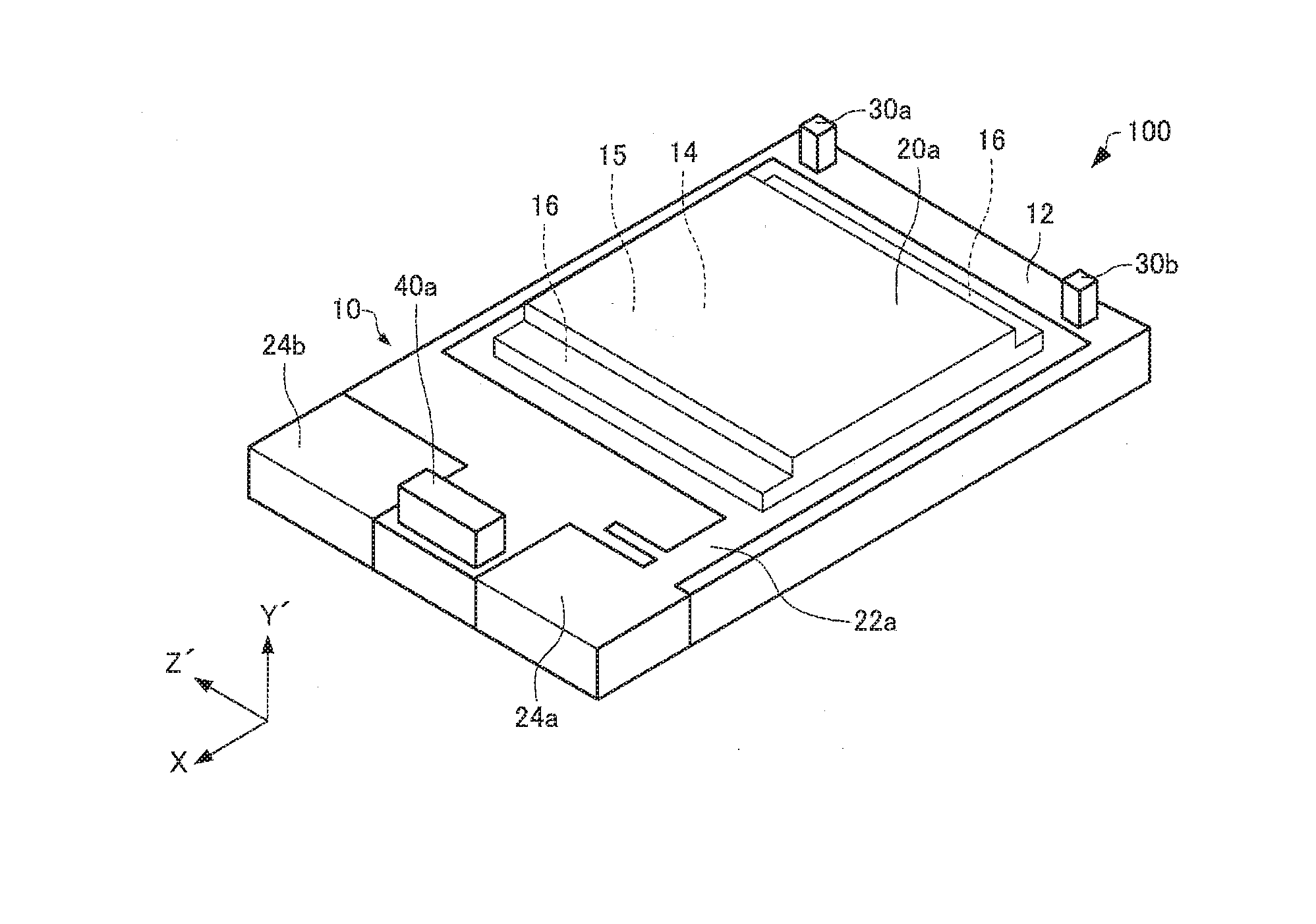

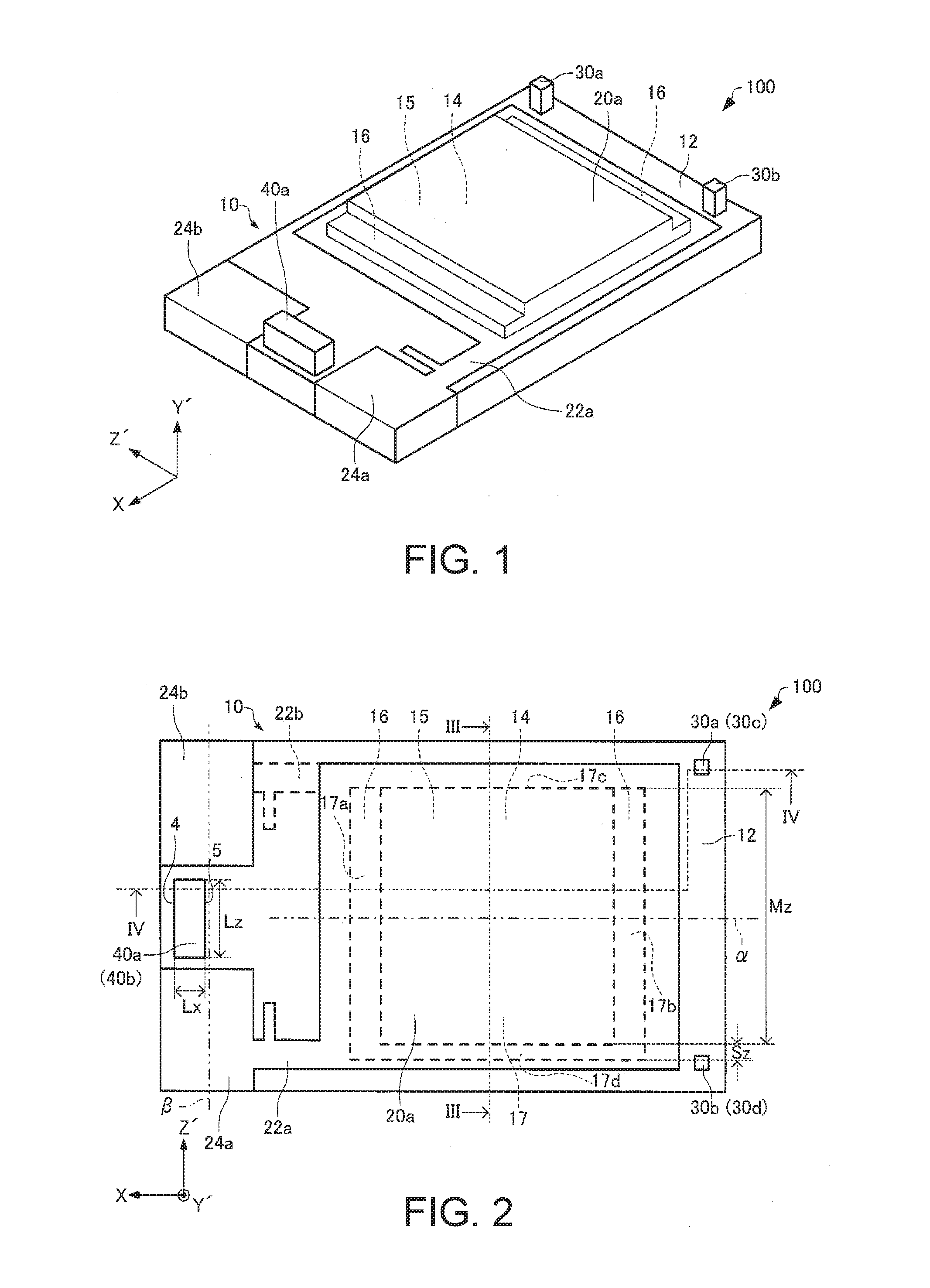

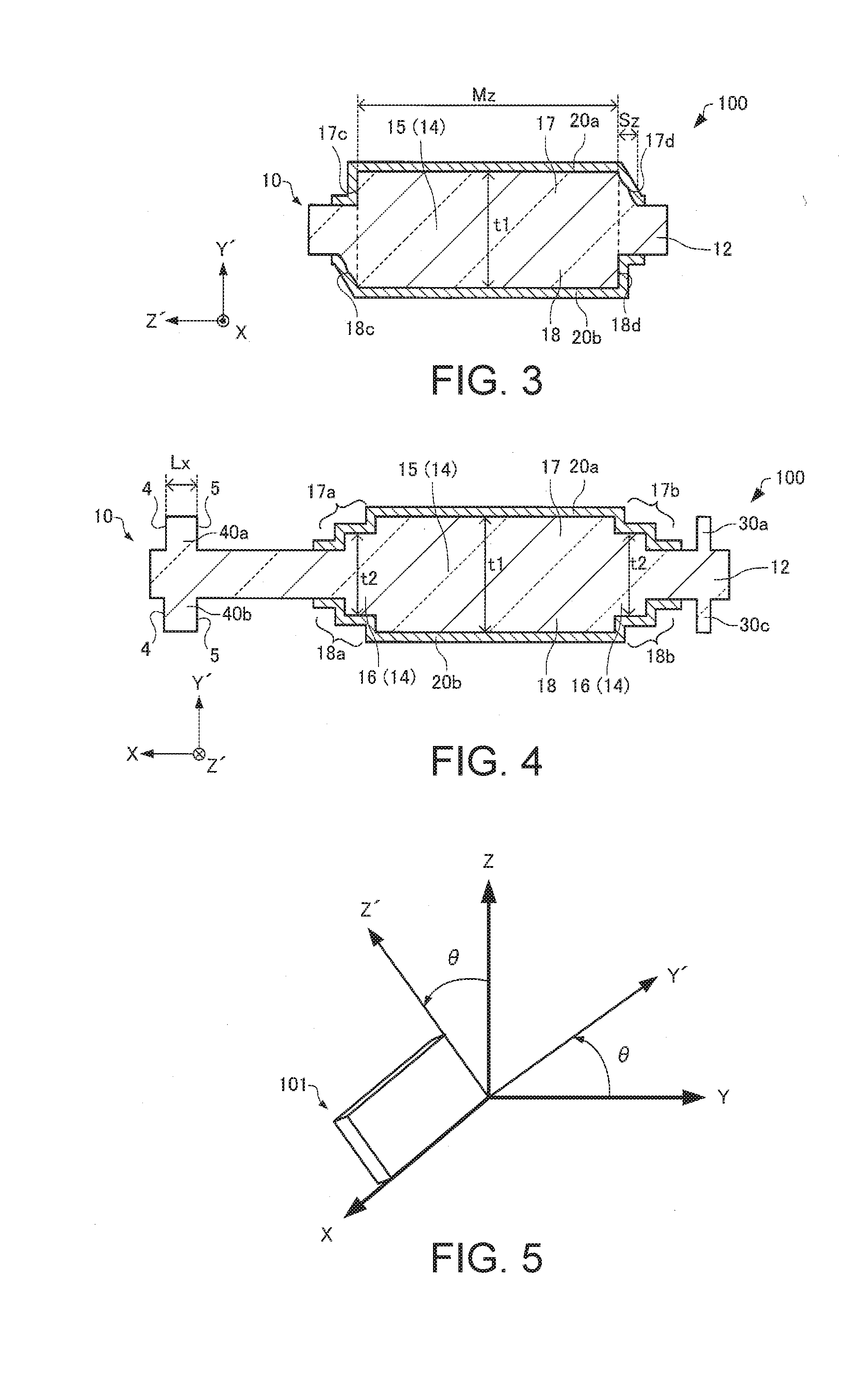

Resonator element, resonator, resonator device, oscillator, electronic apparatus, and moving object

ActiveUS20160226465A1Reduce deteriorationImpedence networksOscillations generatorsLength waveElectron

A resonator element includes a quartz crystal substrate in which a plane including X and Z′ axes is set as a main plane and a direction oriented along a Y′ axis is a thickness direction. The quartz crystal substrate includes a first region in which thickness shear vibration is generated, a second region that has a thickness thinner than the first region, and first protrusions that are disposed between one pair of electrode pads disposed to be lined in a direction oriented along a Z′ axis on a mounted side of the second region. When Lx is a length of the first protrusions along the X axis and X is a wavelength of flexural vibration of the quartz crystal substrate, a relation of “λ / 2×(2n+1)−0.1λ≦Lxλ / 2×(2n+1)+0.1 λ” (where n is a positive integer) is satisfied.

Owner:SEIKO EPSON CORP

Resonator element, resonator, electronic device, electronic apparatus, and mobile object

ActiveUS20130257553A1Improve reliabilityReduce the valuePiezoelectric/electrostriction/magnetostriction machinesImpedence networksElectronThickness shear

A resonator element includes a substrate including a first principal surface and a second principal surface respectively forming an obverse surface and a reverse surface of the substrate, and vibrating in a thickness-shear vibration mode, a first excitation electrode disposed on the first principal surface, and a second excitation electrode disposed on the second principal surface, and being larger than the first excitation electrode in a plan view, the first excitation electrode is disposed so as to fit into an outer edge of the second excitation electrode in the plan view, and the energy trap confficient M fulfills 15.5≦M≦36.7.

Owner:SEIKO EPSON CORP

Containment case and method of manufacture

ActiveUS9248612B2Increased shear strengthLower resistanceBlade accessoriesEfficient propulsion technologiesIn planeUltimate tensile strength

A containment case comprises a composite core, with an inner and outer surface, at least one puncture resistant layer bonded to the inner surface of the composite core and at least one energy capture layer bonded to the outer surface of the composite core. The puncture resistant layer having a high through-thickness shear strength and high interlaminar toughness at impact. The energy capture layer having a high in-plane tensile strength and low resistance to delamination and fiber-matrix debonding at impact. A method of fabricating a containment case includes the steps of disposing one or more layers of a puncture resistant material on a layup mandrel, disposing one more layers of a structural composite material on an exterior surface of the puncture resistant material, disposing one or more layers of an energy capture material on an exterior surface of the structural material and curing a resin in the plurality of layers.

Owner:GENERAL ELECTRIC CO

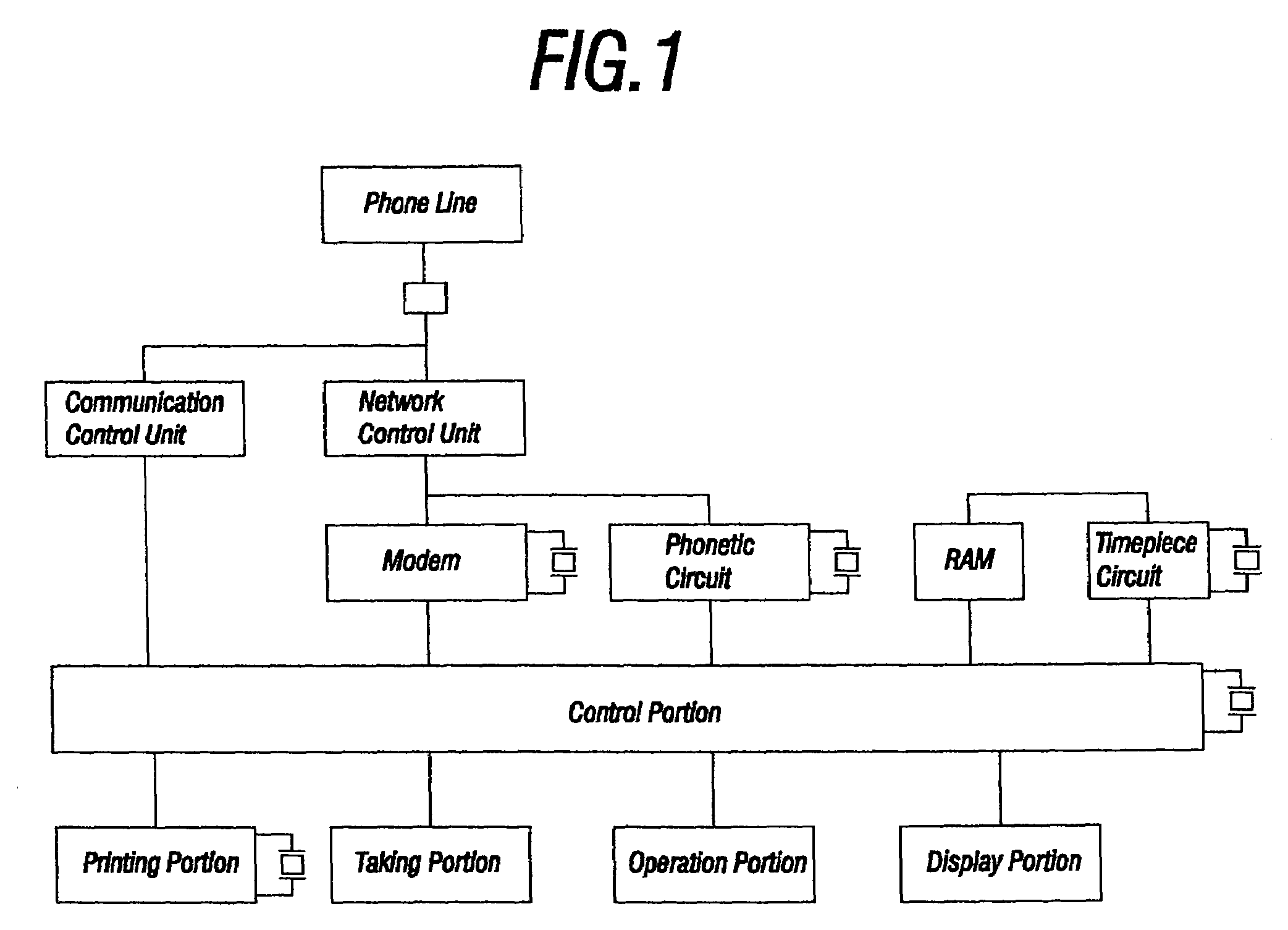

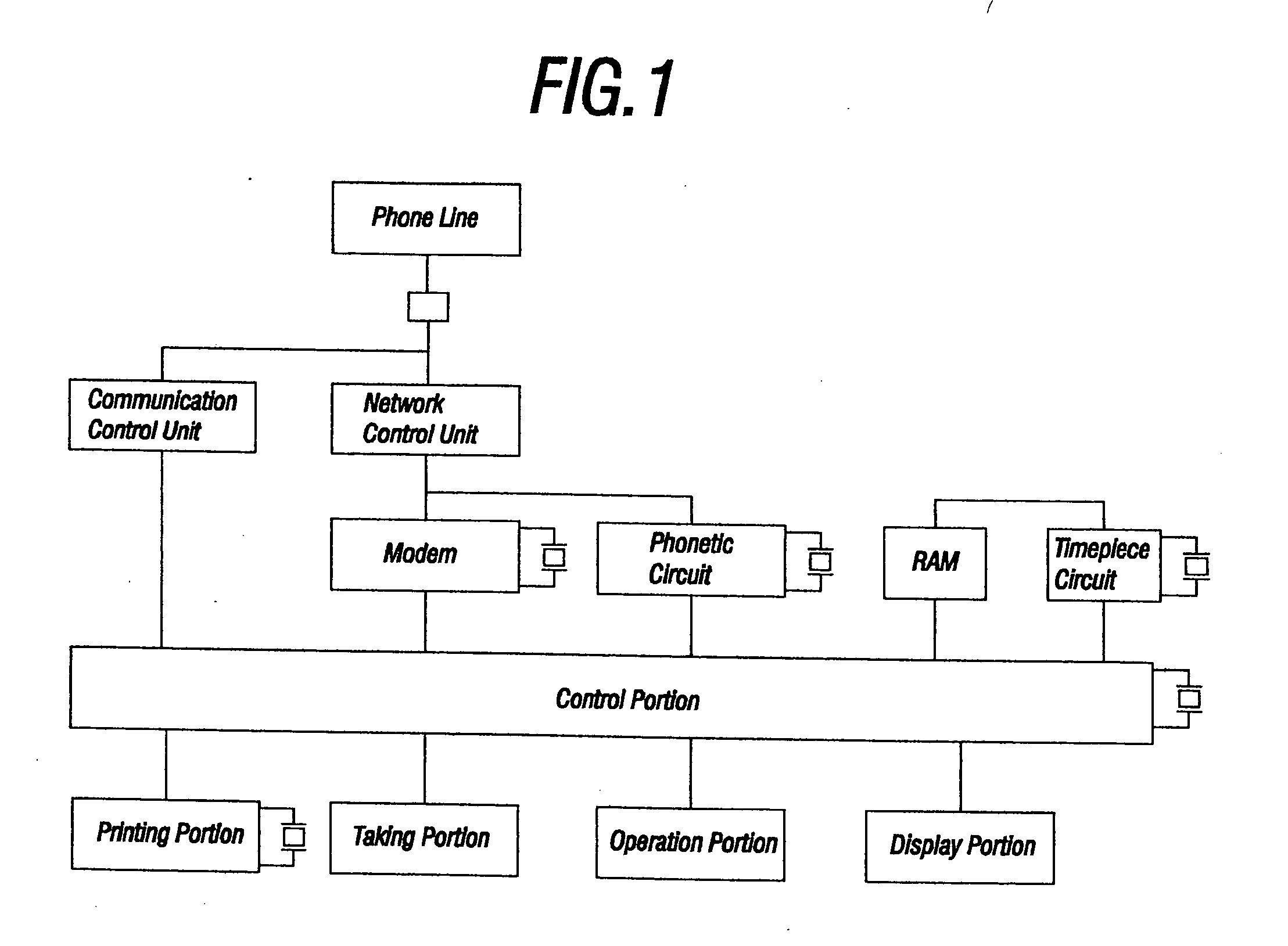

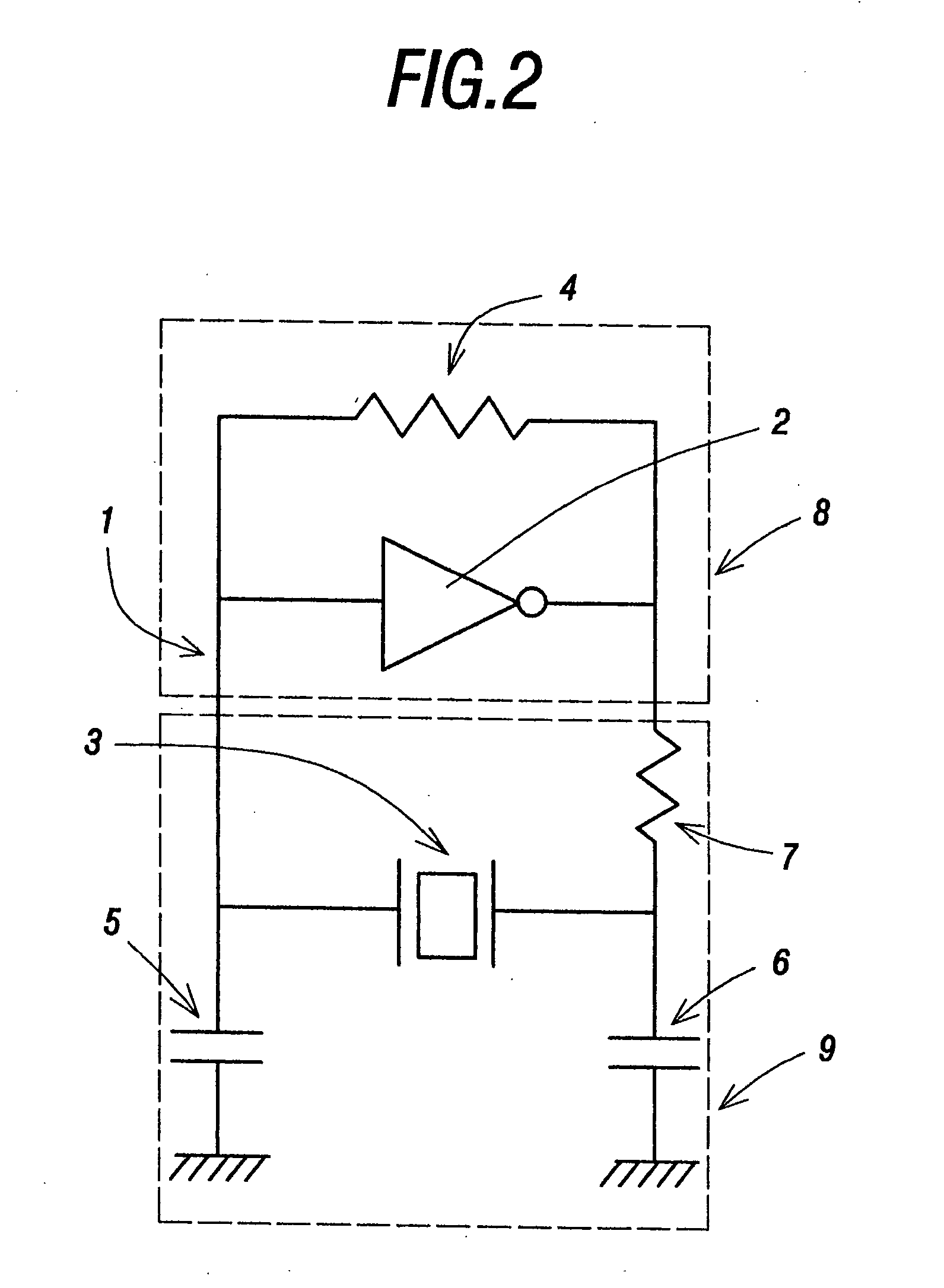

Electronic apparatus with two quartz crystal oscillators utilizing different vibration modes

InactiveUS7170218B2High-frequency stabilitySmall resistanceMultiple-port networksPiezoelectric/electrostriction/magnetostriction machinesQuartz crystal resonatorFeedback circuits

The electronic apparatus comprises a display portion and a quartz crystal oscillator at least, and said electronic apparatus comprises at least two quartz crystal oscillators. Also, each of two quartz crystal oscillators of the at least two oscillators comprises a quartz crystal oscillating circuit having an amplification circuit and a feedback circuit. The feedback circuit is constructed by a flexural mode, quartz crystal tuning fork resonator or a width-extensional mode quartz crystal resonator or a thickness shear mode quartz crystal resonator and for example, the quartz crystal tuning fork resonator comprising tuning fork tines and tuning fork base that are formed integrally, is shown with novel shape and electrode construction. Also, the quartz crystal tuning fork resonator, capable of vibrating in a fundamental mode and having a high frequency stability can be provided with a small series resistance and a high quality factor, even when the tuning fork resonator is miniaturized. This is accomplished by grooves, groove dimensions and electrode construction on the tuning fork tines and / or tuning fork base of the quartz crystal tuning fork resonator. In addition, from a relationship of an amplification rate and a feedback rate, the quartz crystal oscillator having an output signal of a frequency of the fundamental mode vibration for the quartz crystal tuning fork resonator can be provided with the high frequency stability.

Owner:PIEDEK TECHN LAB

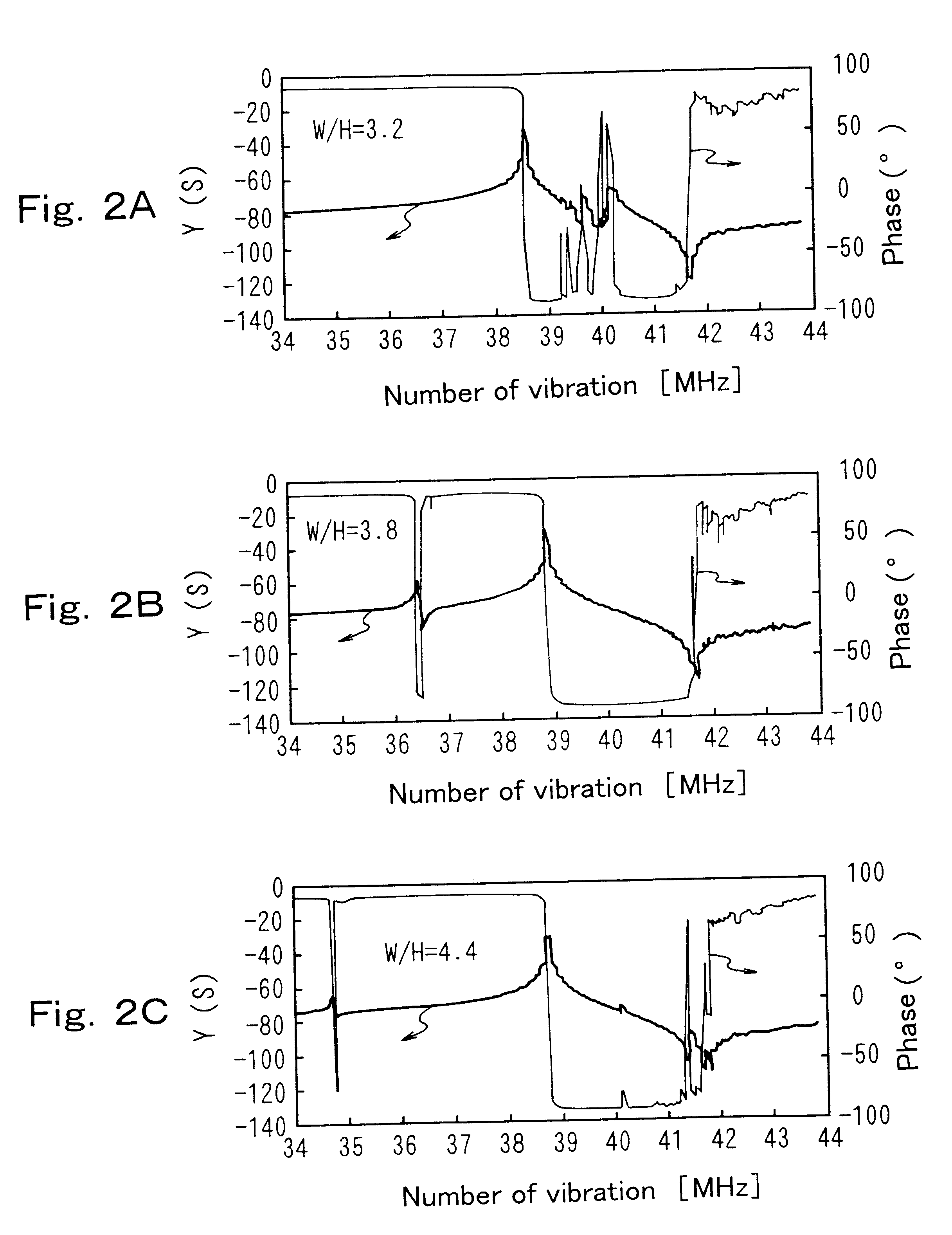

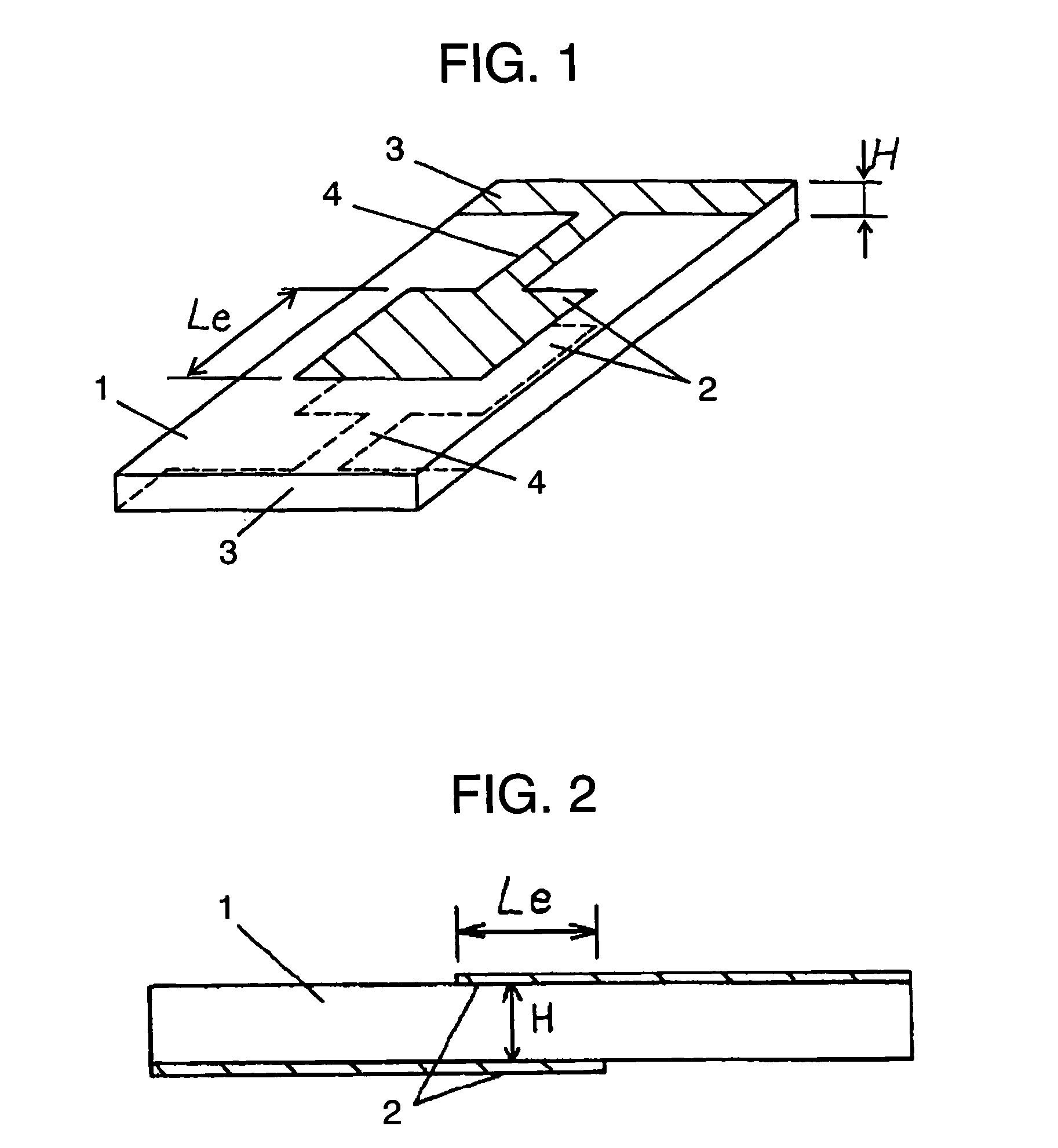

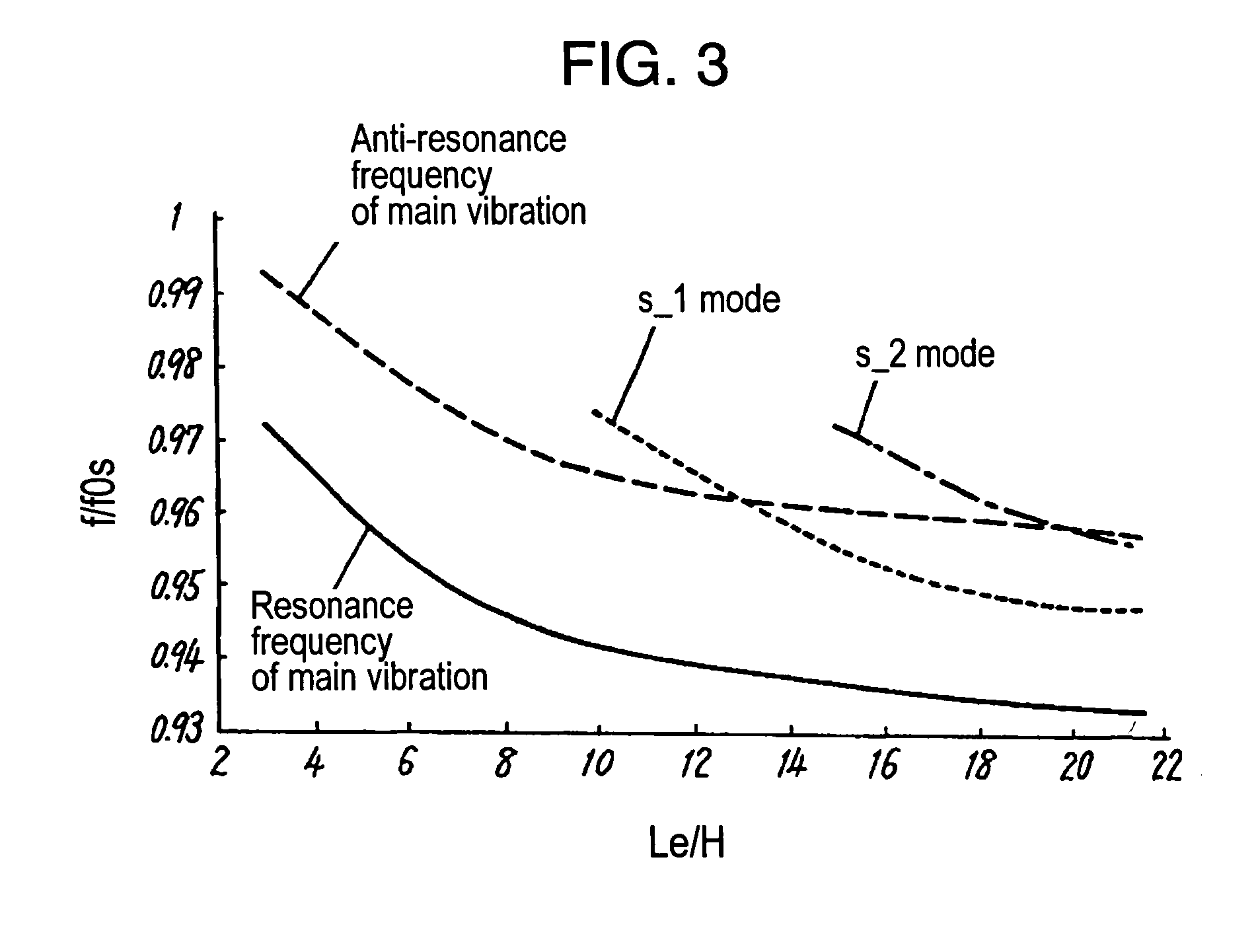

Piezoelectric vibration element and piezoelectric filter

InactiveUS7129799B2Stable filter characteristicStable characteristicsPiezoelectric/electrostriction/magnetostriction machinesImpedence networksResonanceAcoustics

A piezoelectric oscillator using zinc oxide as a piezoelectric plate which eliminates unwanted resonance called inharmonic overtone by optimizing ratio Le / H of driving electrode length Le to oscillator thickness H. Ratio Le / H is set between 4 and 100 in the piezoelectric oscillator polarized in a thickness direction of a piezoelectric plate and using thickness extension vibration as main vibration or the piezoelectric oscillator polarized in a length direction of the piezoelectric plate and using thickness shear vibration as main vibration. This achieves stable characteristic because no unwanted resonance exists between the resonance frequency and anti-resonance frequency of the main vibration.

Owner:PANASONIC CORP

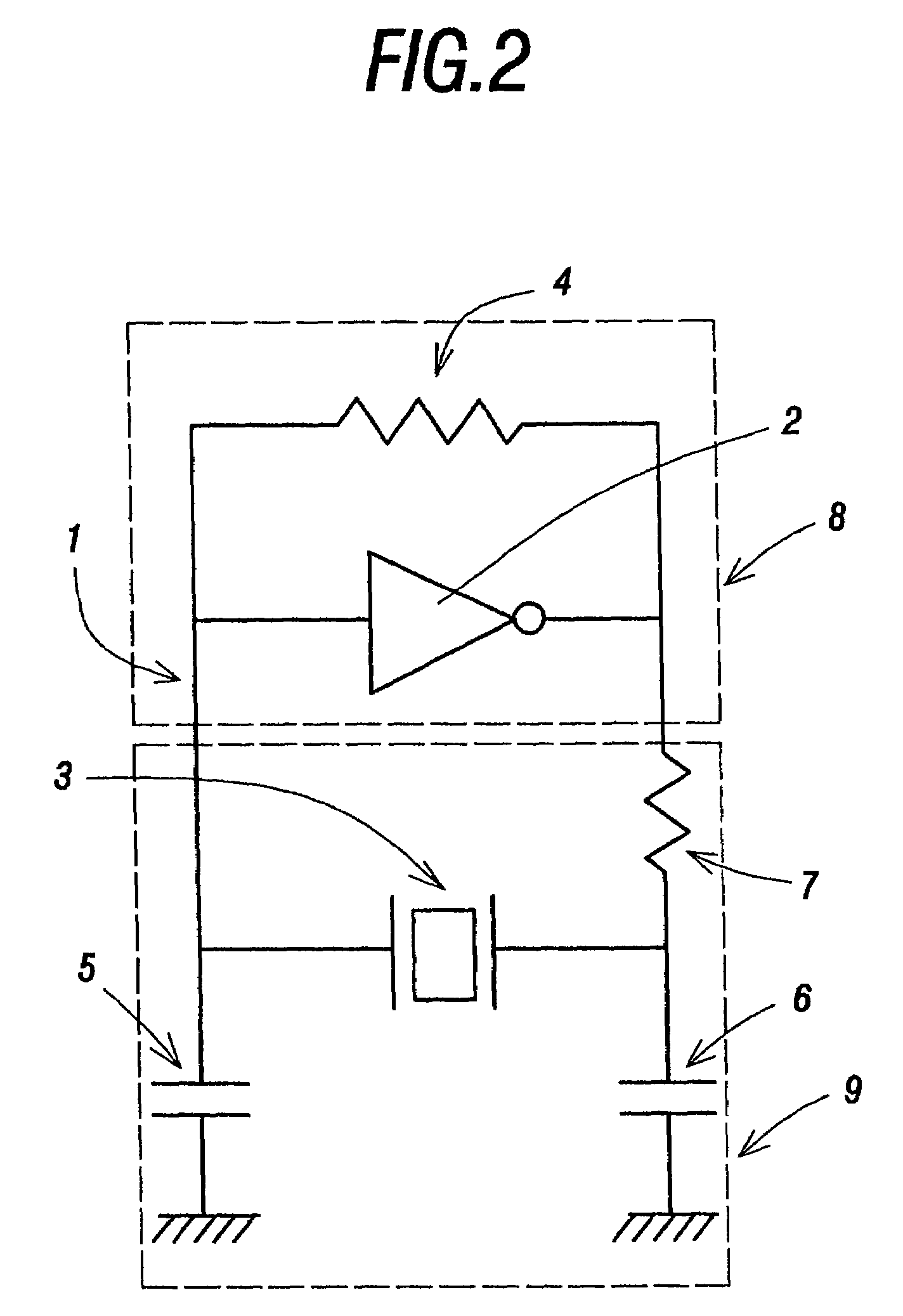

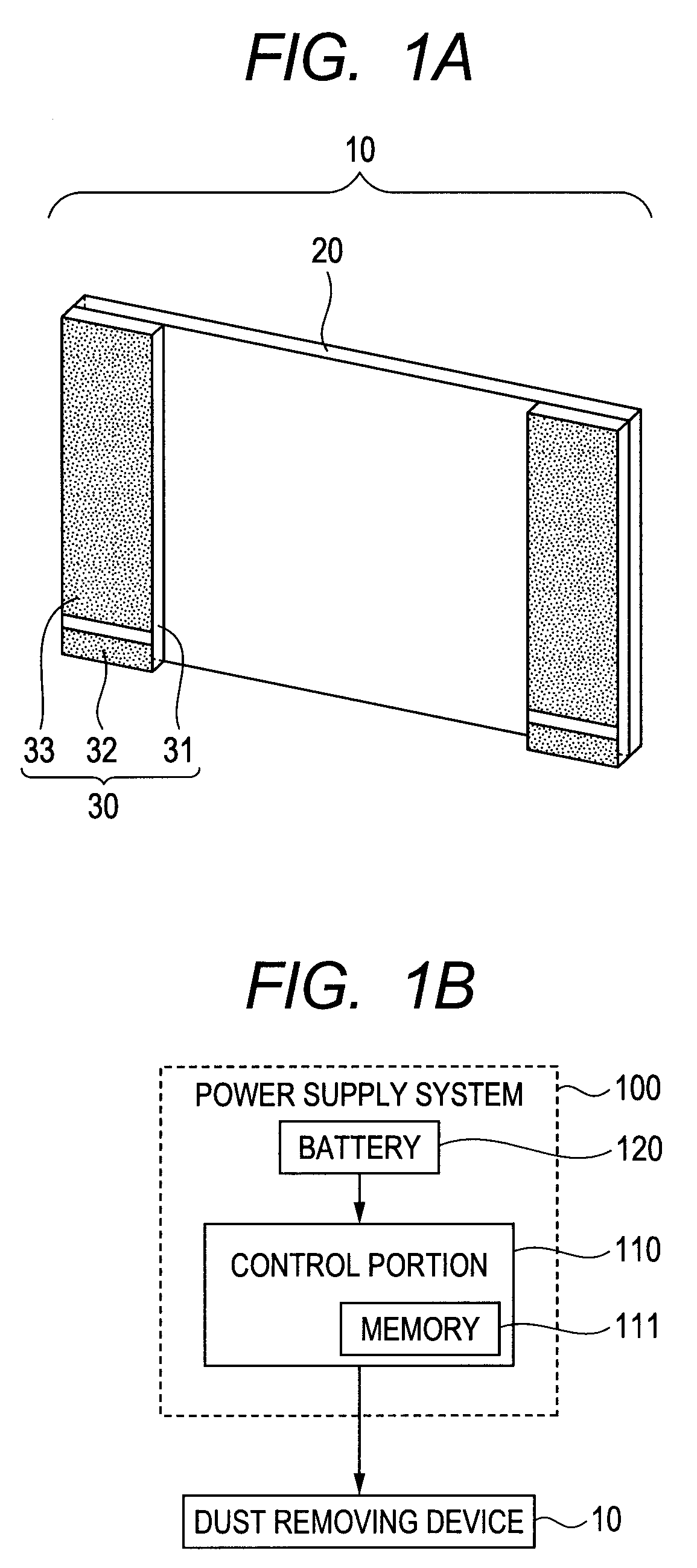

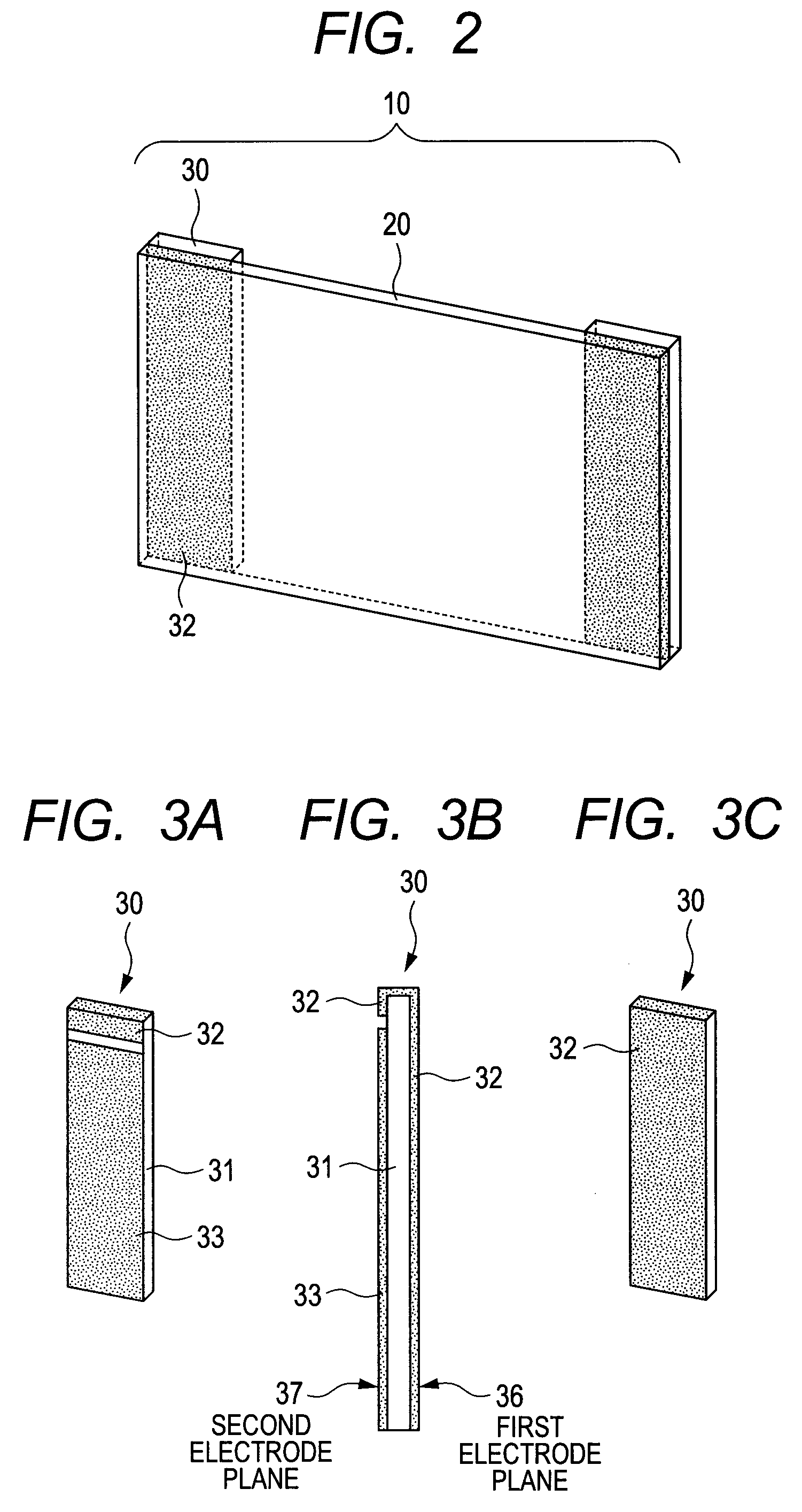

Dust removing device and dust removing method

InactiveUS20110120494A1Promote repairEfficiently utilizing a displacement capability inherent in a piezoelectric deviceTelevision system detailsCarpet cleanersAcousticsPiezoelectric coefficient

In a piezoelectric device, a first electrode and a second electrode are disposed to be opposed to each other on plate surfaces of the piezoelectric device, a first electrode plane of the piezoelectric device is fixedly bonded to a plate surface of a vibrating plate, a piezoelectric material forming the piezoelectric device is polarized in a direction parallel to the first electrode plane, the piezoelectric device is fixed to a base through a second electrode plane of the piezoelectric device, and the piezoelectric device generates a thickness-shear vibration with the fixed second electrode plane being a reference plane. The piezoelectric vibration generated by the piezoelectric device generates a flexural vibration in the vibrating plate, to thereby remove dust adhering to a surface of the vibrating plate.

Owner:CANON KK

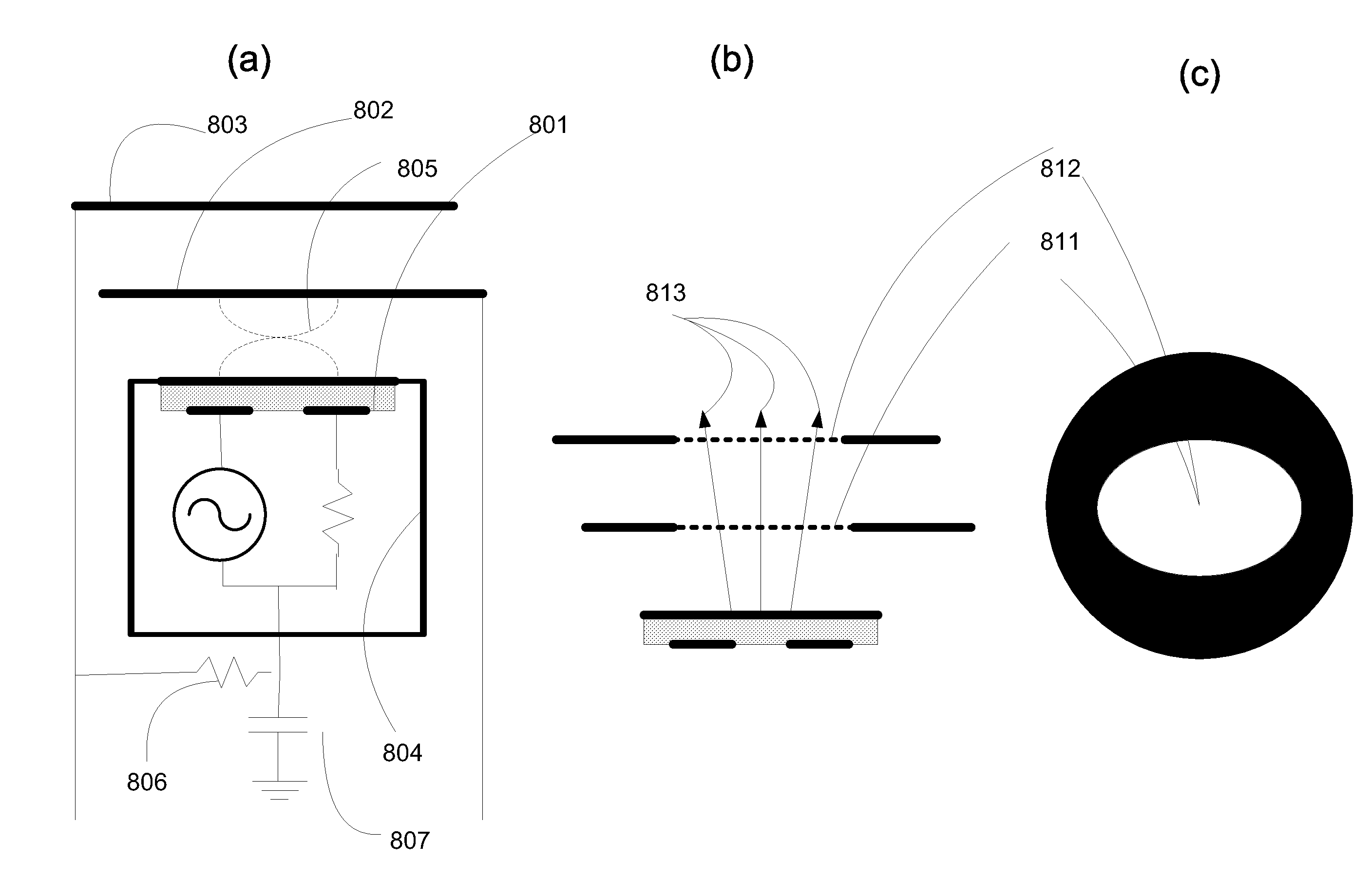

Controlled compressional wave components of thickness shear mode multi-measurand sensors

InactiveUS20110071776A1Altering responseAvoid reflectionsVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesDual modeCompressional wave velocity

The current invention relates to a conductivity-dielectric (CD) electrode design with apertures that allow compressional waves to propagate away from the surface of the acoustic wave device unimpeded. This prevents reflection of compressional waves that would interact with the viscosity sensor surface, thus altering the device response. It allows compressional waves to pass through, and allows the dual mode viscosity sensor responses to be utilized for density / viscosity / elasticity measurement and correlation. The invention further offers methods of instrumentation to detect unwanted reflections, to compensate, and to correct for the distortions caused by reflections. Finally, the invention provides a system and method for utilizing deliberately introduced reflections to obtain additional information, including fluid density.

Owner:MICROSEMI CORP HIGH PERFORMANCE TIMING

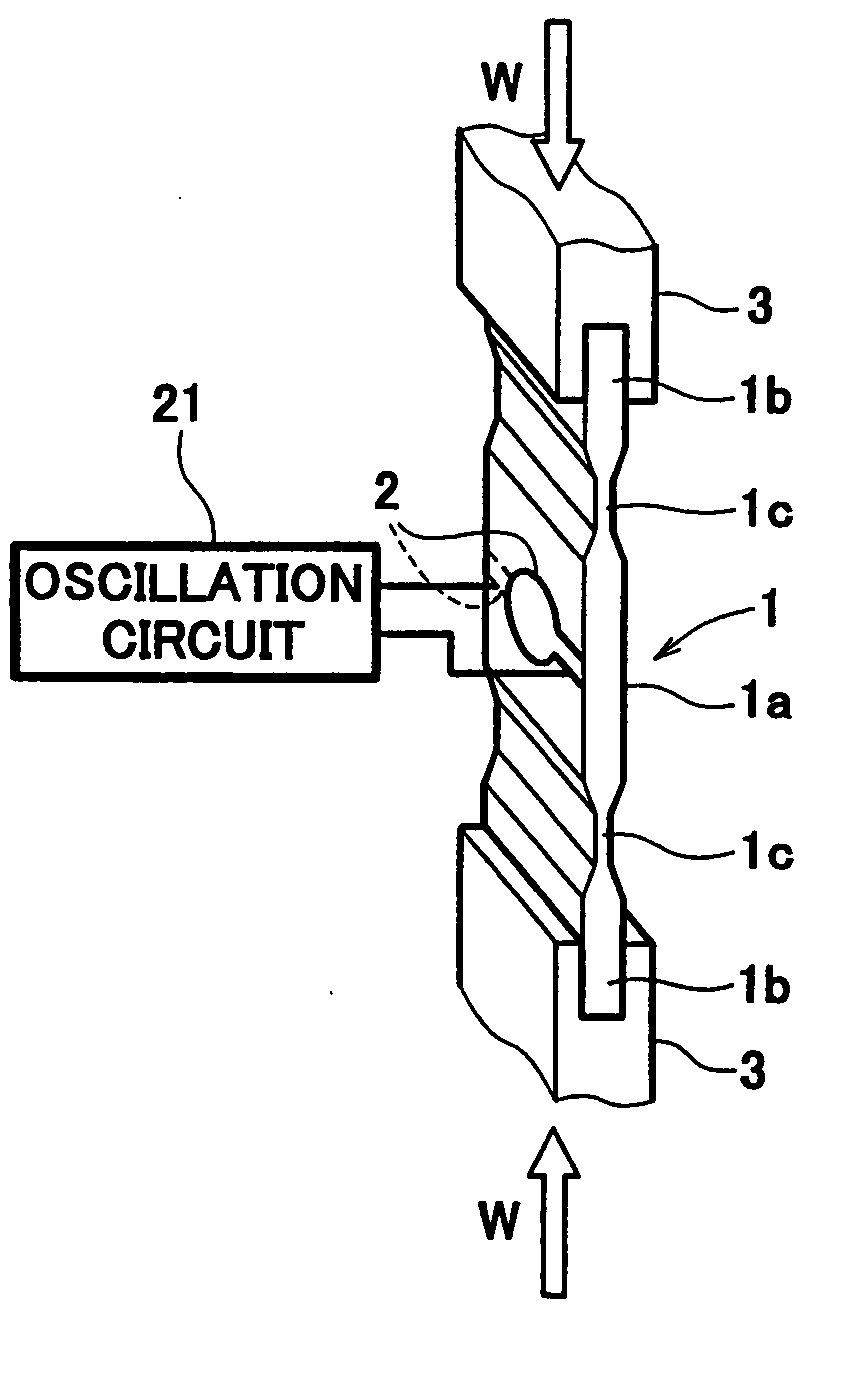

Ultrasonic motor

ActiveUS20110234049A1Simple structureGenerate longitudinal vibrationPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesResonance vibrationThickness shear

In an ultrasonic motor, an elliptical vibration is generated by combining a longitudinal primary resonance vibration resulting from an expansion and a contraction of the vibrator in a direction of the central axis and a torsional secondary resonance vibration or a torsional tertiary resonance vibration resulting from twisting of a rotation axis, and the dimension ratio of the rectangle of the vibrator is chosen such that a resonance frequency of the longitudinal primary resonance vibration, resulting from the expansion and the contraction of the vibrator in the direction of the central axis and a resonance frequency of the torsional secondary resonance vibration or the torsional tertiary resonance vibration resulting from twisting of the rotation axis match. The vibrator includes a torsional piezoelectric body that generates a thickness shear vibration, and that is arranged at an anti-node position of the torsional secondary resonance vibration or the torsional tertiary resonance vibration.

Owner:OLYMPUS CORP

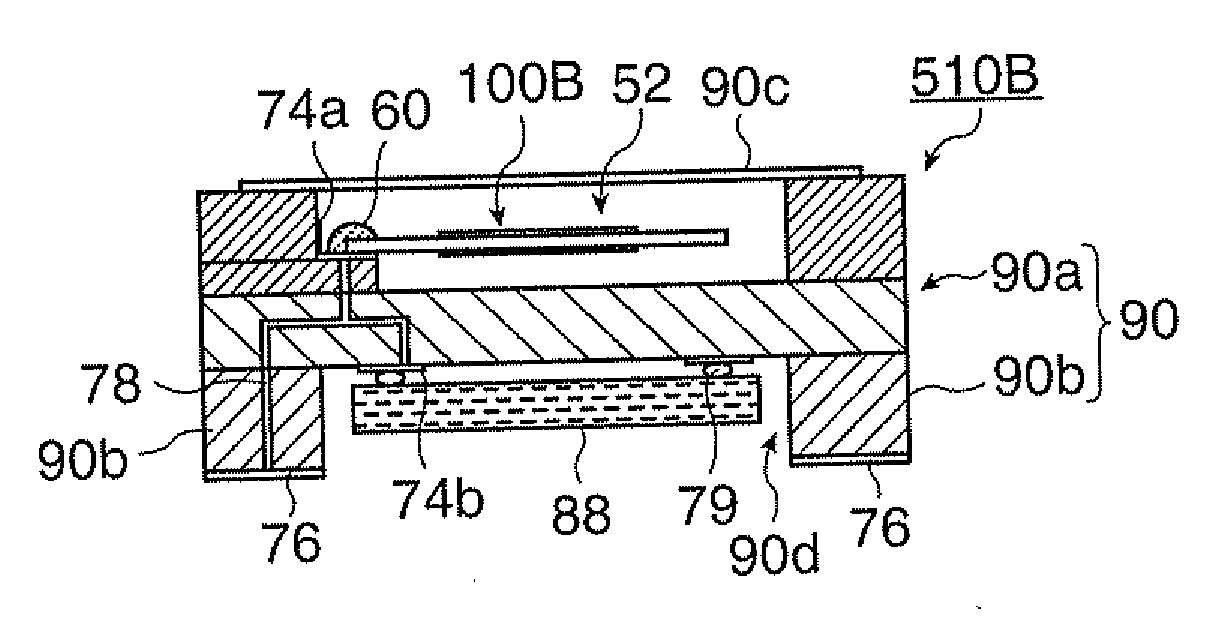

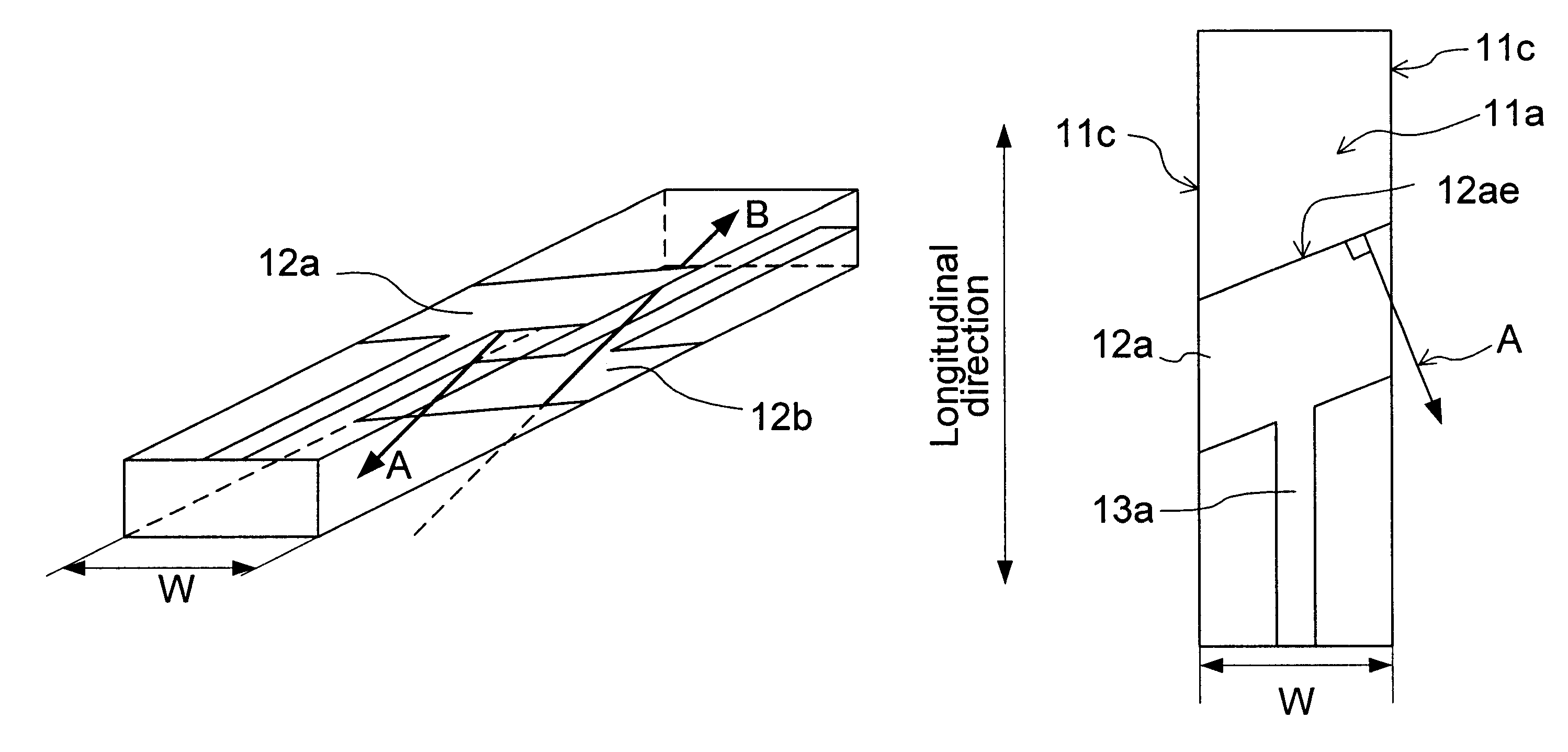

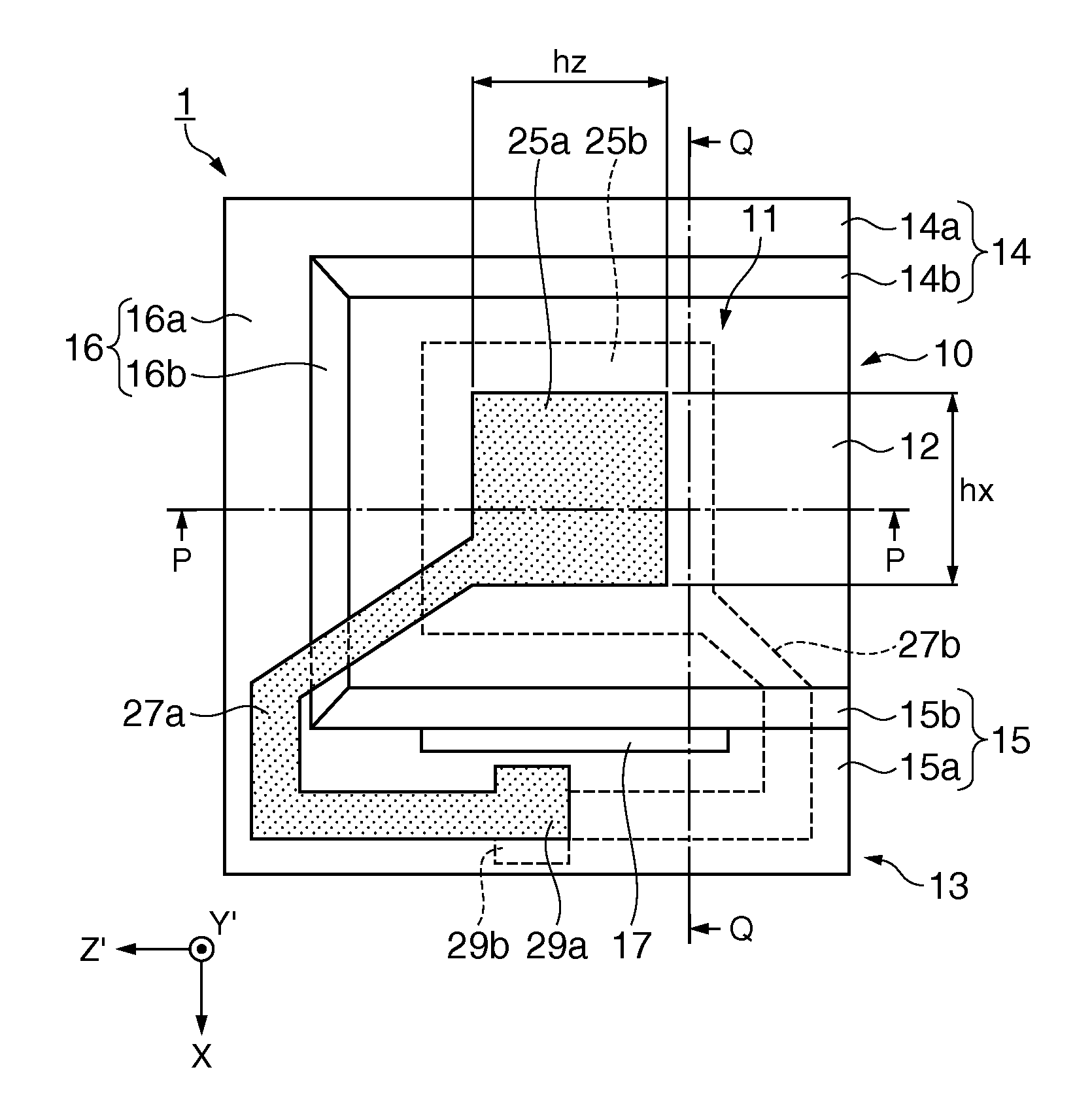

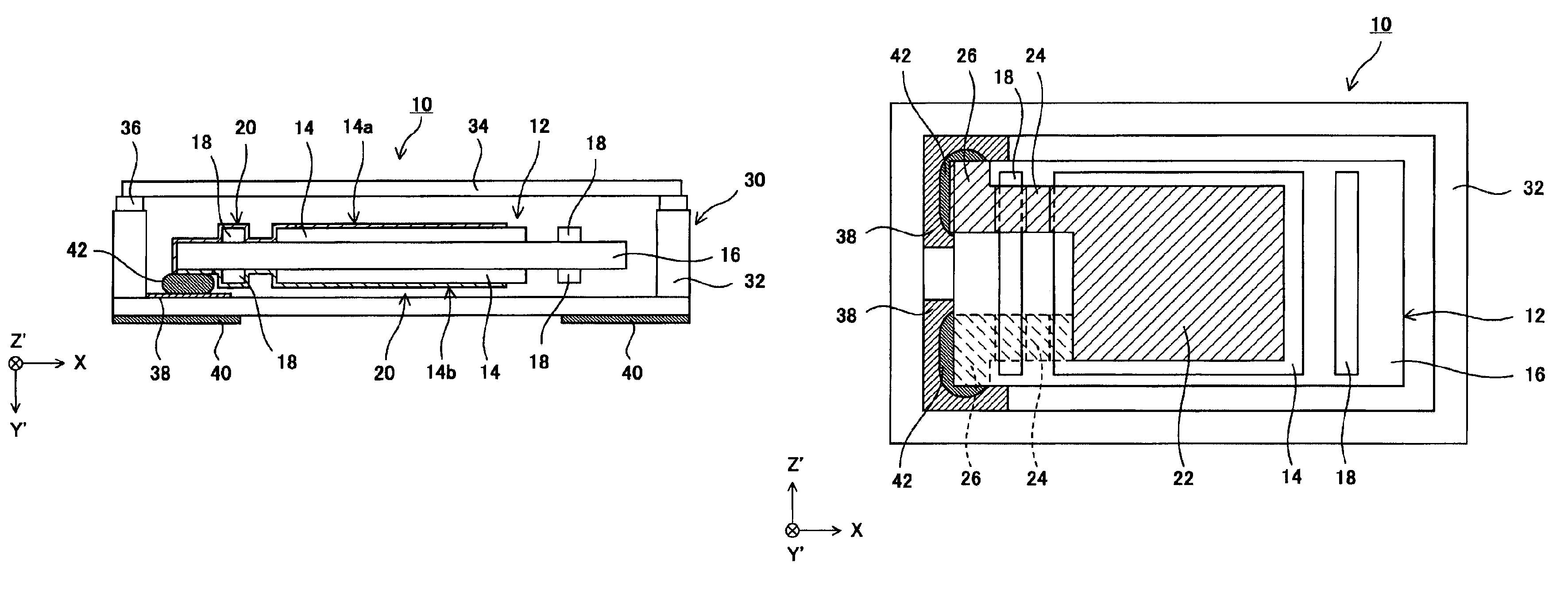

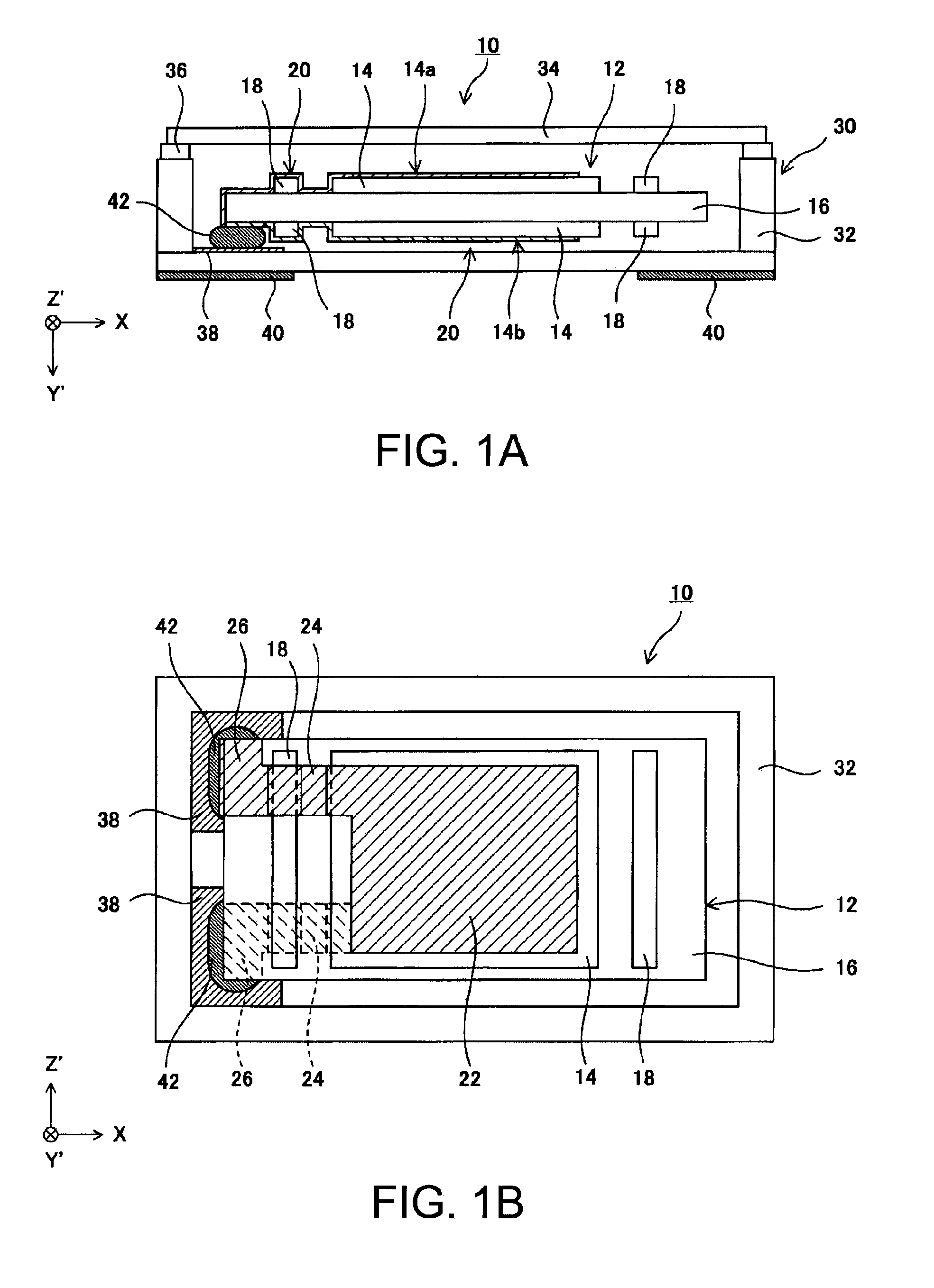

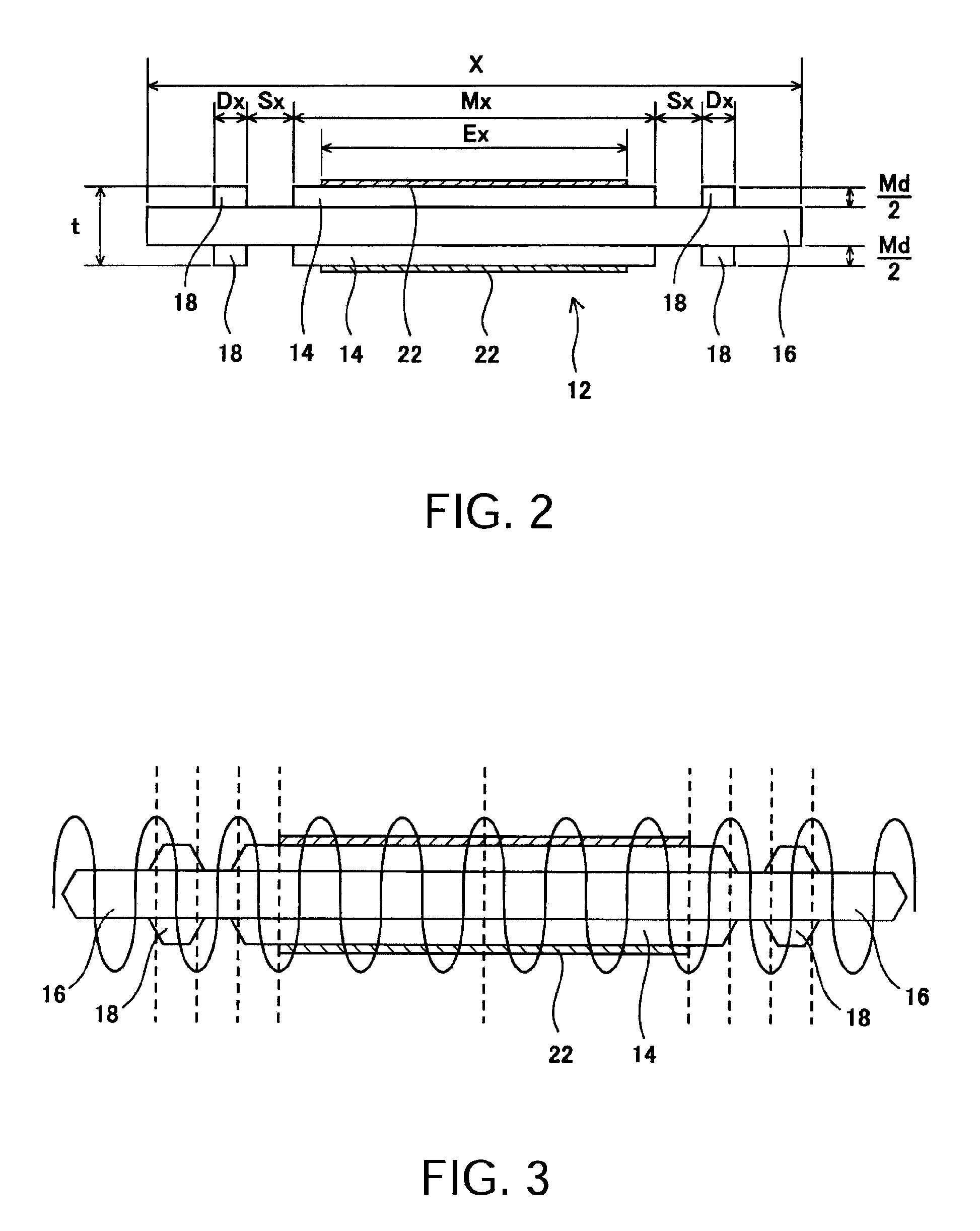

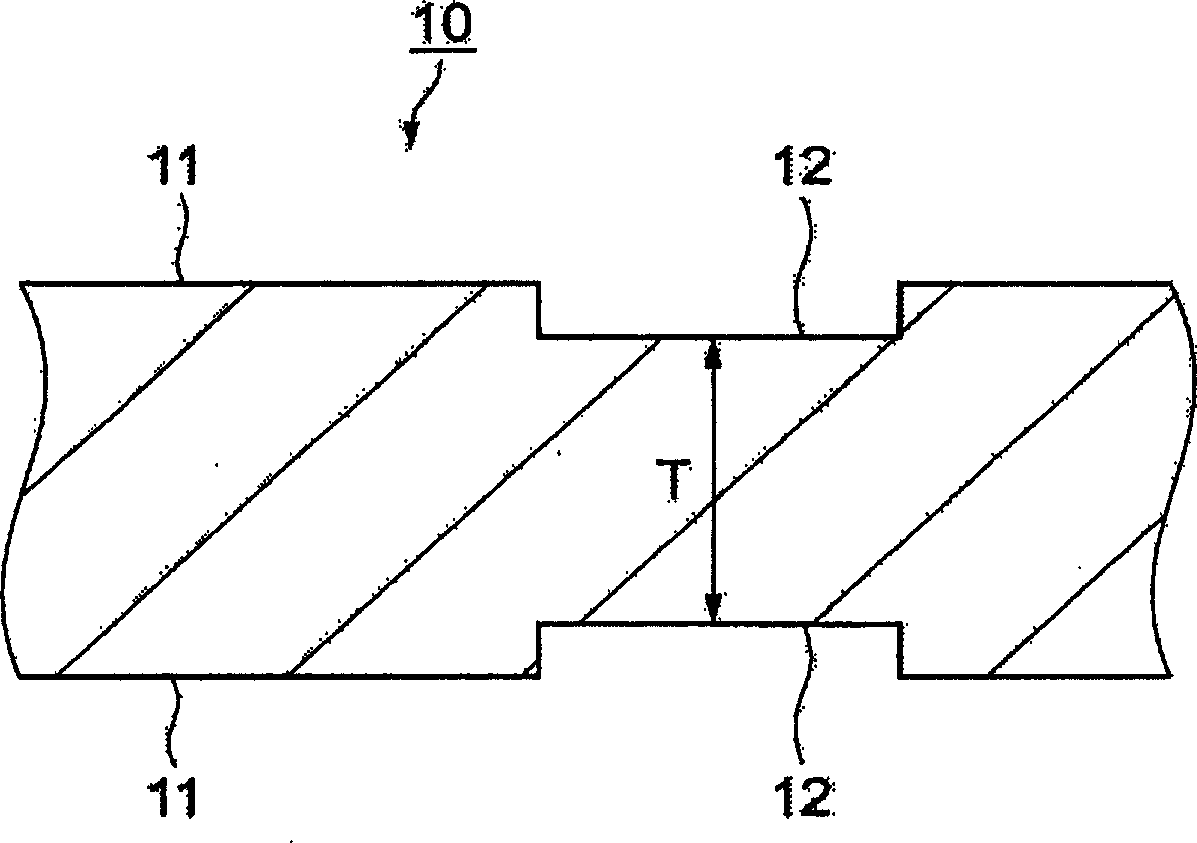

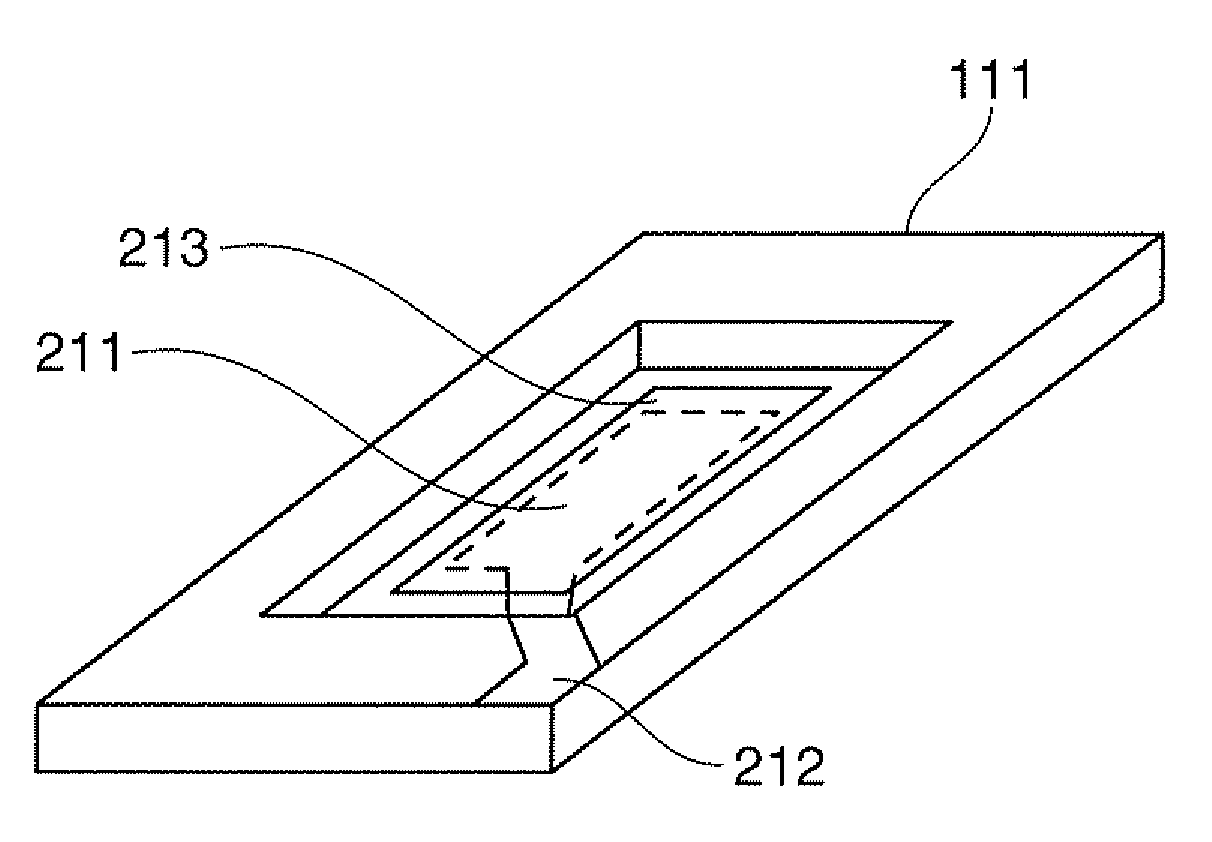

Piezoelectric resonator having mesa type piezoelectric vibrating element

ActiveUS8638022B2Improve productivityPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksLength waveThickness shear

A vibrating element includes: an element plate that has a vibrating portion that performs thickness-shear vibration, a peripheral portion that is integrally formed with the vibrating portion, and a protruding portion that is provided at the peripheral portion; and an excitation electrode that is provided at the vibrating portion. When a side length of the vibrating portion is Mx, when a side length of the excitation electrode is Ex, and when a wavelength of flexure vibrations of the element plate is λ, the relationship of (Mx−Ex) / 2=λ / 2, and Mx / 2={(A / 2)+(¼)}λ (where, A is a positive integer) is satisfied, and when a length of the protruding portion is Dx, and when a distance between the vibrating portion and the protruding portion is Sx, the relationship of Dx=λ / 2)×m, and (λ / 2)×n−0.1λ≦Sx≦(λ / 2)×n+0.1λ (where m and n are positive integers) is satisfied.

Owner:SEIKO EPSON CORP

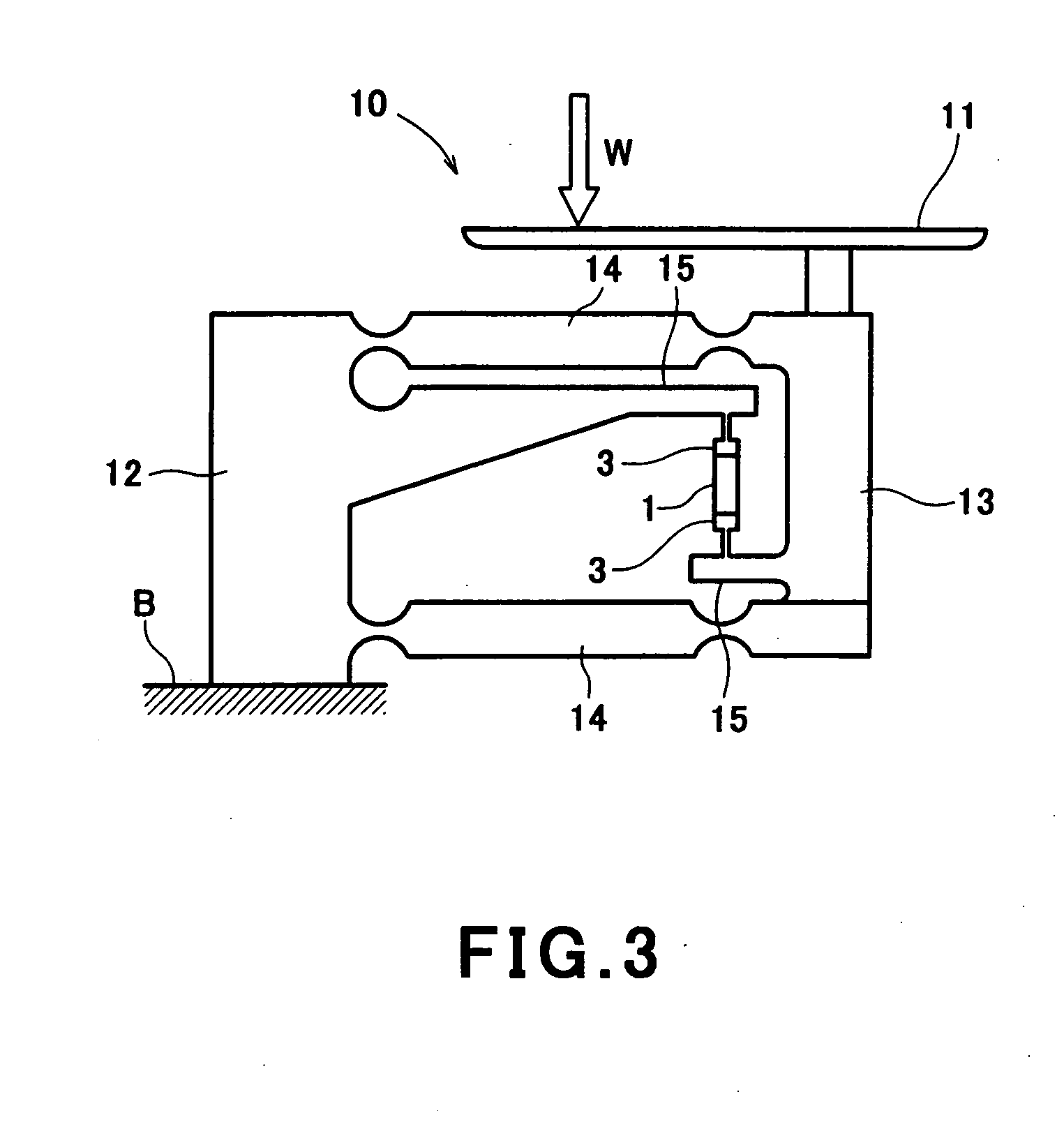

Load sensor with use of crystal resonator

InactiveUS20050139016A1High precisionNotForce measurement by measuring frquency variationsWeighing apparatus using elastically-deformable membersEtchingElectric signal

Excitation electrodes are respectively affixed to central portions of both surfaces of a long plate-shaped AT-cut crystal resonator, the central portion starts a thickness shear oscillation in the length direction of the crystal resonator when an electric signal is applied to the central portion of the crystal resonator through the excitation electrodes. And, channel-shaped, half-circular-shaped, or trapezoid grooves in cross-section are respectively formed in the plate width direction on middle portions between the center portion and end portions of the crystal resonator. These grooves are formed so as to be symmetrical with respect to a thicknesswise central position of the crystal resonator through a well-known etching technique such as photo-etching and the like.

Owner:YAMATO SCALE CO LTD +1

Piezoelectricity libration plate, piezoelectric vibrator and piezoelectric oscillator

InactiveCN1665129APiezoelectric/electrostrictive device manufacture/assemblyImpedence networksEngineeringThickness shear

Exemplary embodiments provide a piezoelectric resonator element, to reduce the reaching of an attenuating vibration of a main vibration to a marginal edge of the piezoelectric resonator element, as well as to stabilize an oscillating-frequency without worsening the CI value, nor inducing another vibration mode. The piezoelectric resonator element having a thickness shear vibration as a main vibration, a first groove and a second groove formed so as to surround the center part of a main surface, and the thickness at the first groove and the second groove structured to be between 70% to 96%, inclusive, of the thickness of the center part of the resonator element.

Owner:SEIKO EPSON CORP

High frequency thickness shear mode acoustic wave sensor for gas and organic vapor detection

InactiveUS7568377B2Electronics SimplifiedSimple designAnalysing fluids using sonic/ultrasonic/infrasonic wavesGas phaseFundamental frequency

A thickness shear mode (TSM) sensor having a visco-elastic polymer coating and a fundamental frequency greater than 20 MHz useful for organic vapor or gas detection. The TSM quartz resonators at a fundamental frequency of 96 MHz were evaluated for their performance in organic vapor sensing applications and results were compared with the performance of 10 and 20 MHz resonators. These devices were produced by chemical milling of AT-cut quartz. Seven test organic vapors were utilized at concentrations ranging from 0.2 volume percent to 13.7 volume percent in the vapor phase. In all cases, the rubbery polymer polyisobutylene was used as a sensing layer. Detailed results for various sensor parameters such as sensitivity, baseline noise and drift, limit of detection, response and recovery times, dynamic range, and repeatability for the 96 MHz device were compared with those for 10 and 20 MHz devices. The test case of benzene / polyisobutylene was chosen to make these detailed comparisons. The 96 MHz device was found to be more sensitive than the lower frequency devices. Device sensitivity was dependent on the benzene concentration. Response and recovery times were smaller for the 96 MHz device. Response times decreased with analyte concentration. Sensor response was in reasonable agreement with the perturbation model of Sauerbrey at lower concentrations and deviated at the higher concentrations for the 96 MHz device. Higher frequency TSM devices can be very useful as organic vapor sensors both in detection and process monitoring applications. These devices have the advantages of simpler electronics, easier design and fabrication, well-developed models and good baseline stability when compared to other acoustic wave devices.

Owner:UNIV OF SOUTH FLORIDA

Sensors for measuring at least one of pressure and temperature, and related assemblies and methods

InactiveUS20150059483A1Fluid pressure measurement by electric/magnetic elementsTransducerEngineering

Thickness shear mode resonator pressure sensors include a housing having an outer dimension that is less than 0.575 inch (14.605 millimeters). Pressure transducers may include a quartz pressure sensor and a quartz reference sensor, wherein an electronics assembly of the pressure transducer is configured to drive at least one of the quartz pressure sensor and the quartz reference sensor at a frequency greater than 10 MHz. Transducer assemblies include an electronics assembly configured to drive at least one quartz sensor of the transducer assembly at a frequency greater than 10 MHz.

Owner:QUARTZDYNE

Electronic apparatus with two quartz crystal oscillators utilizing different vibration modes

InactiveUS20050184628A1High-frequency stabilitySmall resistanceMultiple-port networksPiezoelectric/electrostriction/magnetostriction machinesQuartz crystal resonatorFeedback circuits

The electronic apparatus comprises a display portion and a quartz crystal oscillator at least, and said electronic apparatus comprises at least two quartz crystal oscillators. Also, each of two quartz crystal oscillators of the at least two oscillators comprises a quartz crystal oscillating circuit having an amplification circuit and a feedback circuit. The feedback circuit is constructed by a flexural mode, quartz crystal tuning fork resonator or a width-extensional mode quartz crystal resonator or a thickness shear mode quartz crystal resonator and for example, the quartz crystal tuning fork resonator comprising tuning fork tines and tuning fork base that are formed integrally, is shown with novel shape and electrode construction. Also, the quartz crystal tuning fork resonator, capable of vibrating in a fundamental mode and having a high frequency stability can be provided with a small series resistance and a high quality factor, even when the tuning fork resonator is miniaturized. This is accomplished by grooves, groove dimensions and electrode construction on the tuning fork tines and / or tuning fork base of the quartz crystal tuning fork resonator. In addition, from a relationship of an amplification rate and a feedback rate, the quartz crystal oscillator having an output signal of a frequency of the fundamental mode vibration for the quartz crystal tuning fork resonator can be provided with the high frequency stability.

Owner:PIEDEK TECHN LAB

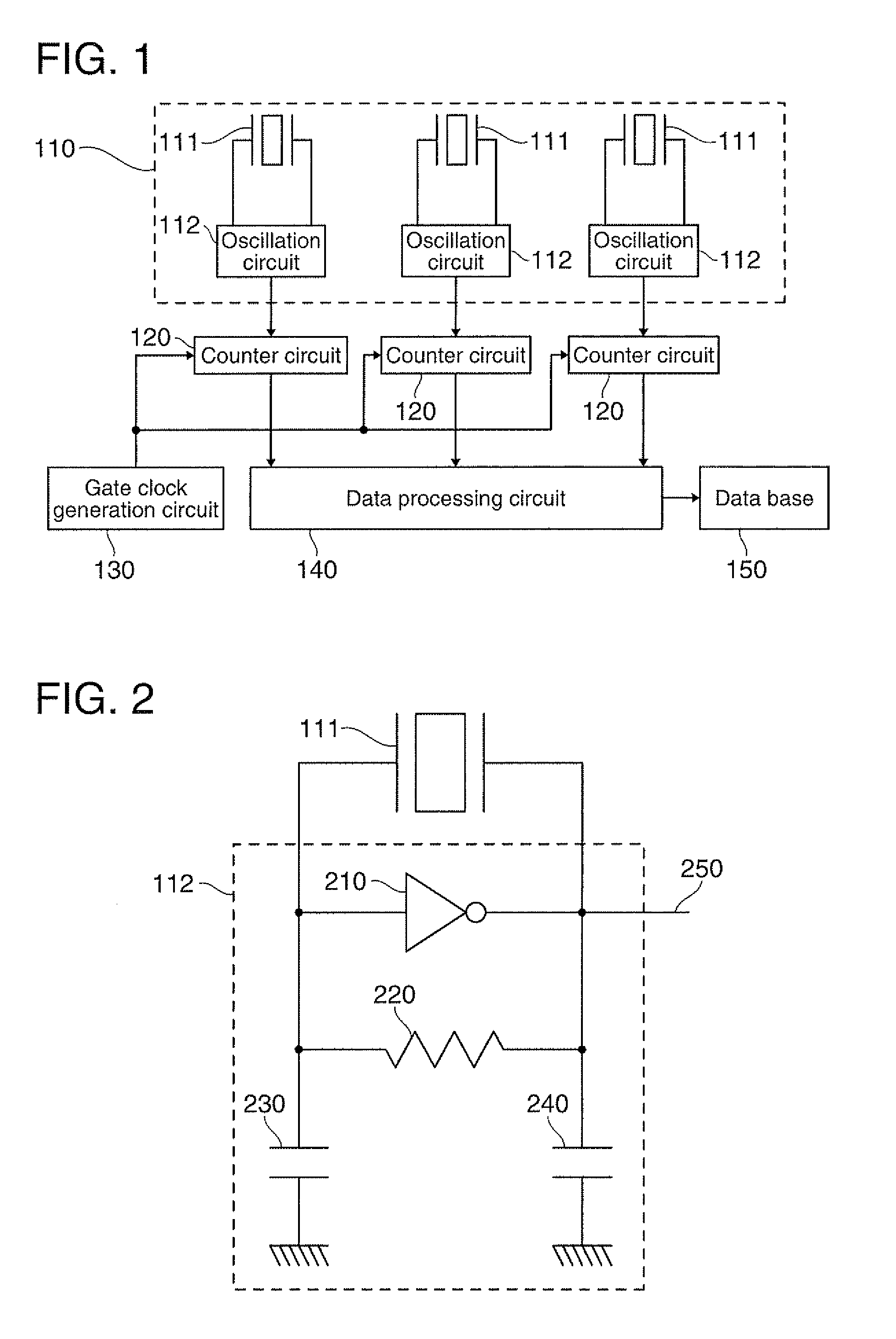

Oscillator, oscillator array and an electronic apparatus

ActiveUS20100277251A1High detection sensitivityPiezoelectric/electrostriction/magnetostriction machinesOscillations generatorsElectronThickness shear

A oscillator include: a vibrator that vibrates in a thickness shear vibration mode; a first adsorption film formed in a first region in a first surface of the vibrator; a second adsorption film formed in a second region in a second surface of the vibrator opposing to the first surface; and a substrate with a surface on which the vibrator is erected, wherein the vibrator contacts the substrate in a third surface that is different from the first surface and the second surface.

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com