Method for design piezoelectric resonator electrode shapes

A design method and electrode shape technology, applied in electrical components, impedance networks, etc., can solve the problems of rectangular electrode stress concentration, adverse effects on the overall performance of the resonator, and the inability to meet the miniaturization of the electrode trapped resonator.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

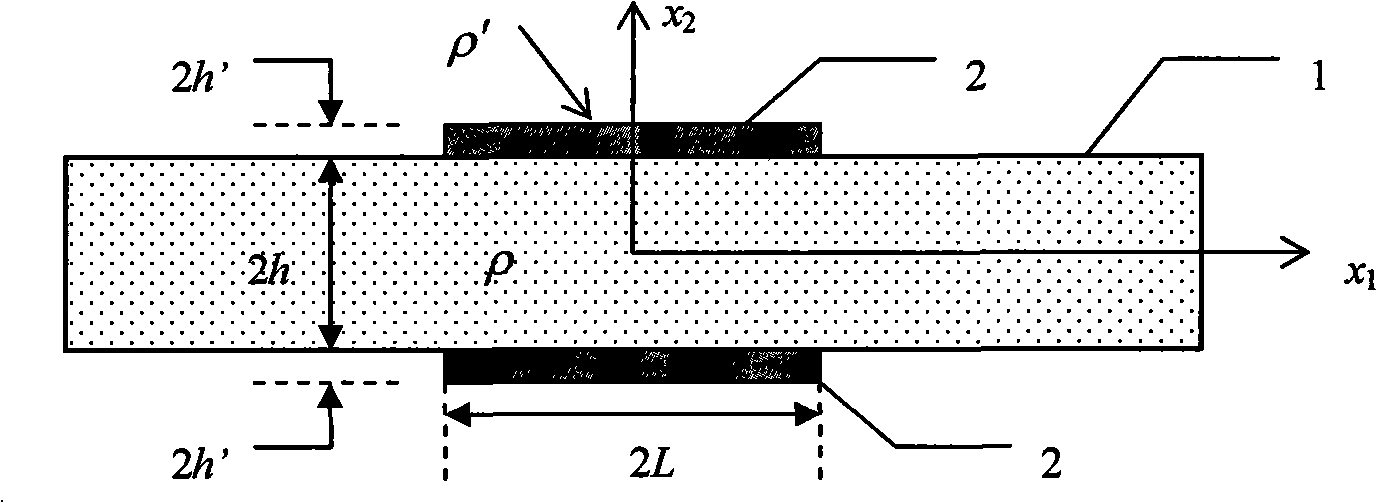

[0028] Such as figure 1 As shown, the piezoelectric crystal resonator is composed of a piezoelectric plate 1 in the middle layer and two upper and lower electrode plates 2. x 1 Axis and x 3 The axis is the coordinate axis in the plane, x 2 It is the normal coordinate axis of the plate: the thickness of the piezoelectric plate 1 is 2h, and the density is ρ; the thickness of each electrode plate 2 is 2h', the density is ρ', and the length of the section is 2L.

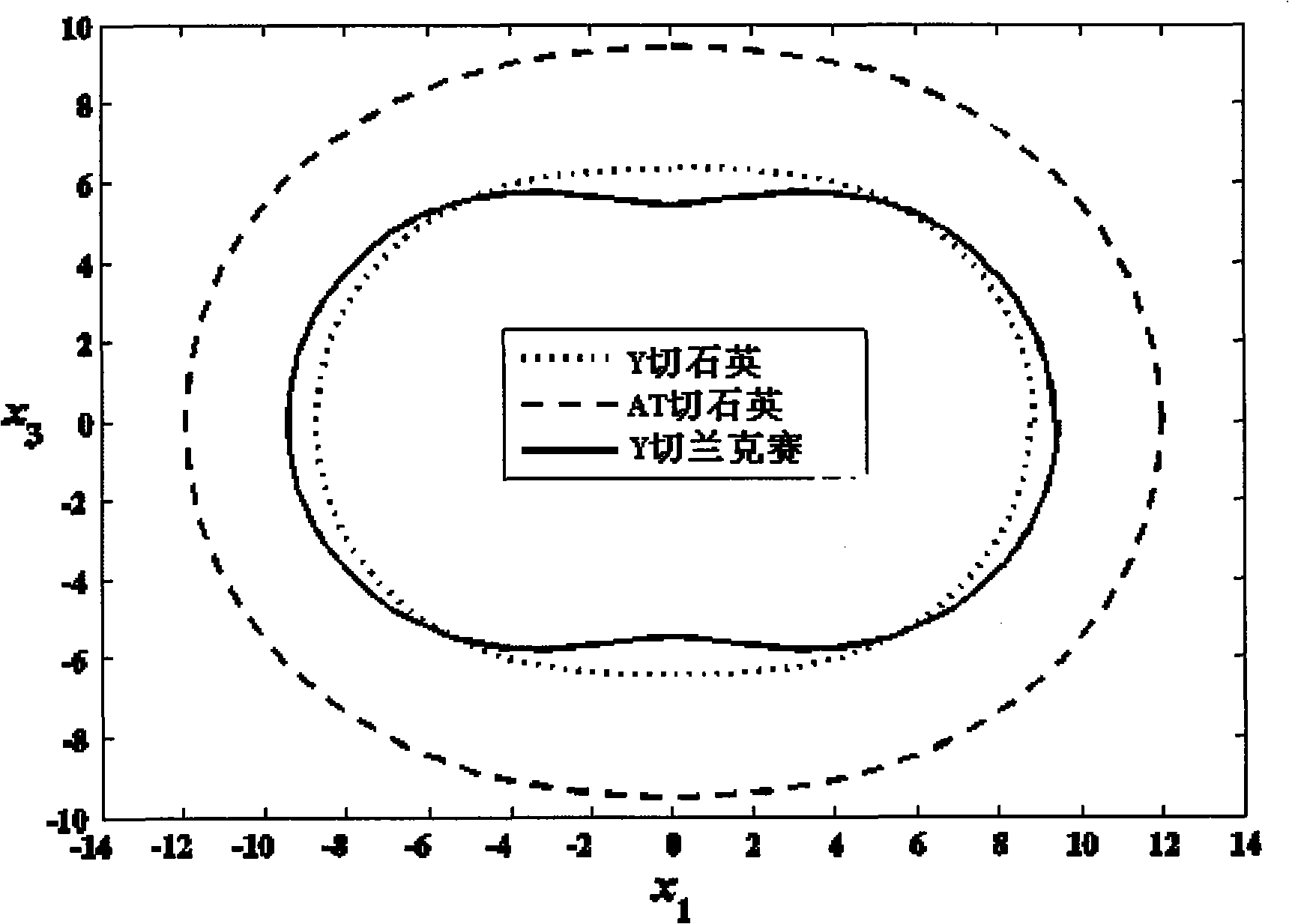

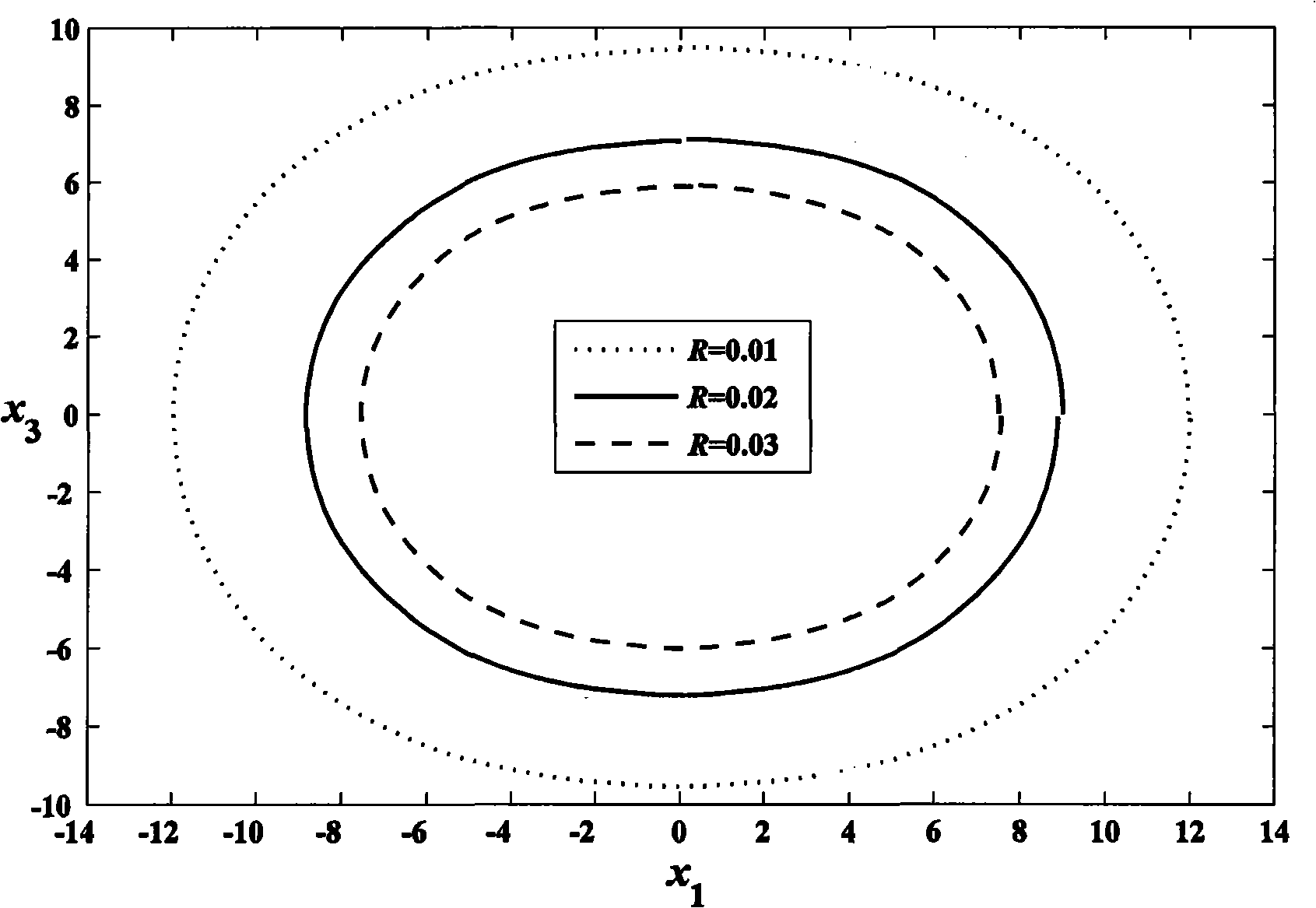

[0029] Select in the calculation: 2h=1mm, Figure 2-Figure 5 It analyzes the dimensionless polar radius r=L / (4h) and the angle expressed by the Cartesian coordinate system. The relationship between the two parameters.

[0030] From figure 2 It can be seen that the optimal electrode shape for At-cut quartz plate and Y-cut quartz plate resonators is close to an ellipse, but it is not a standard ellipse. The long axis is about 25% longer than the short axis; for the Y-cut quartz plate resonator and the elliptical shape The ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com