Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1661 results about "Piezoelectric thin films" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

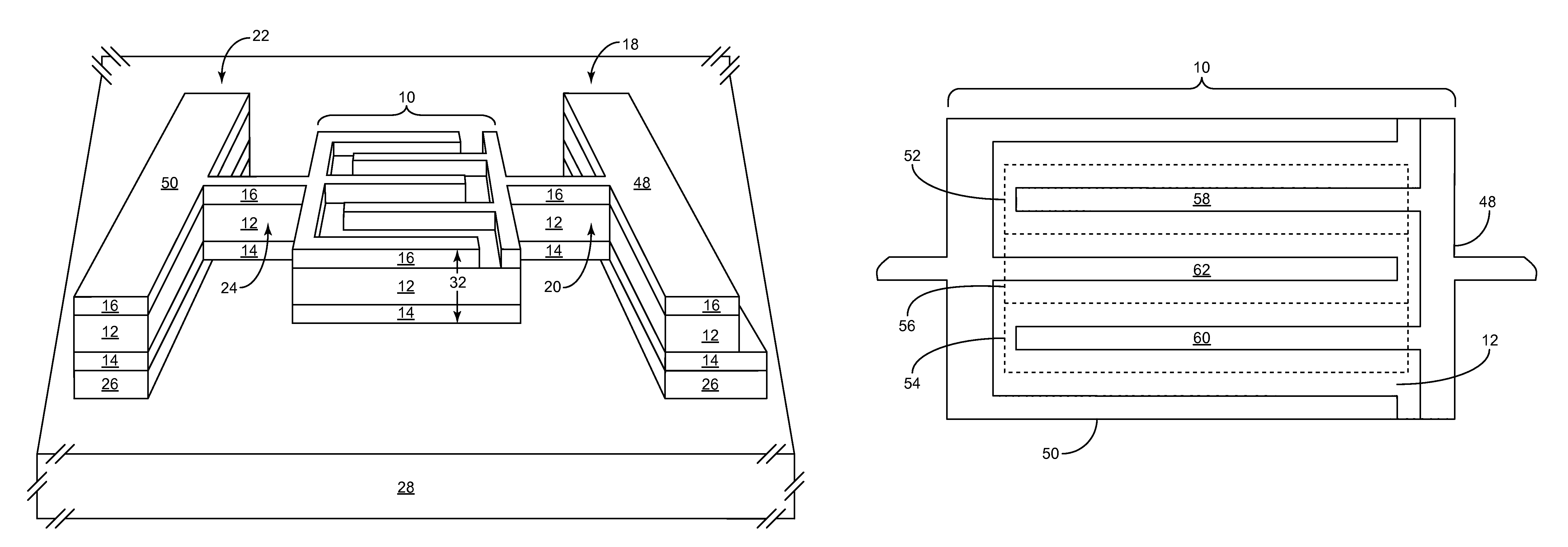

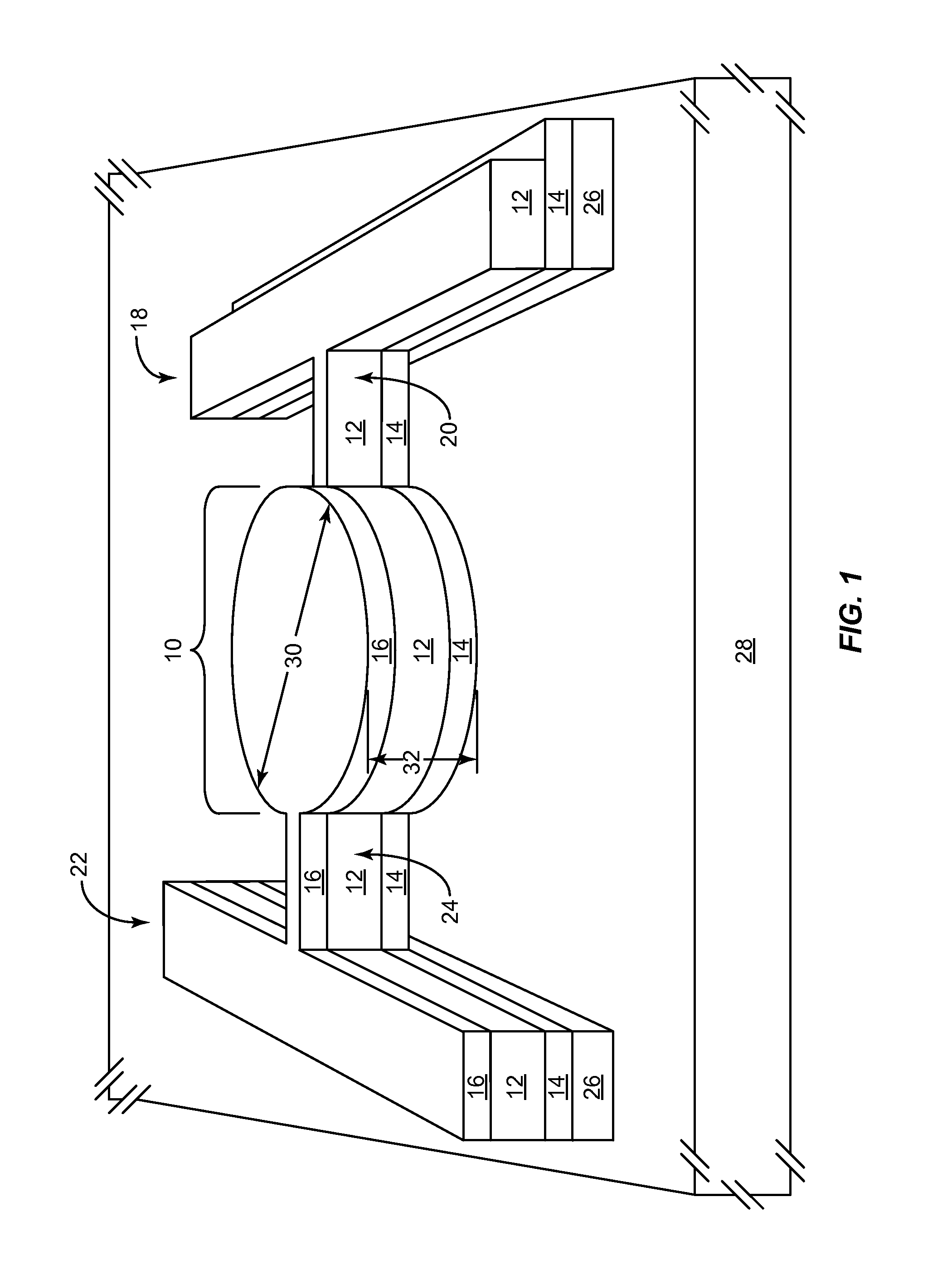

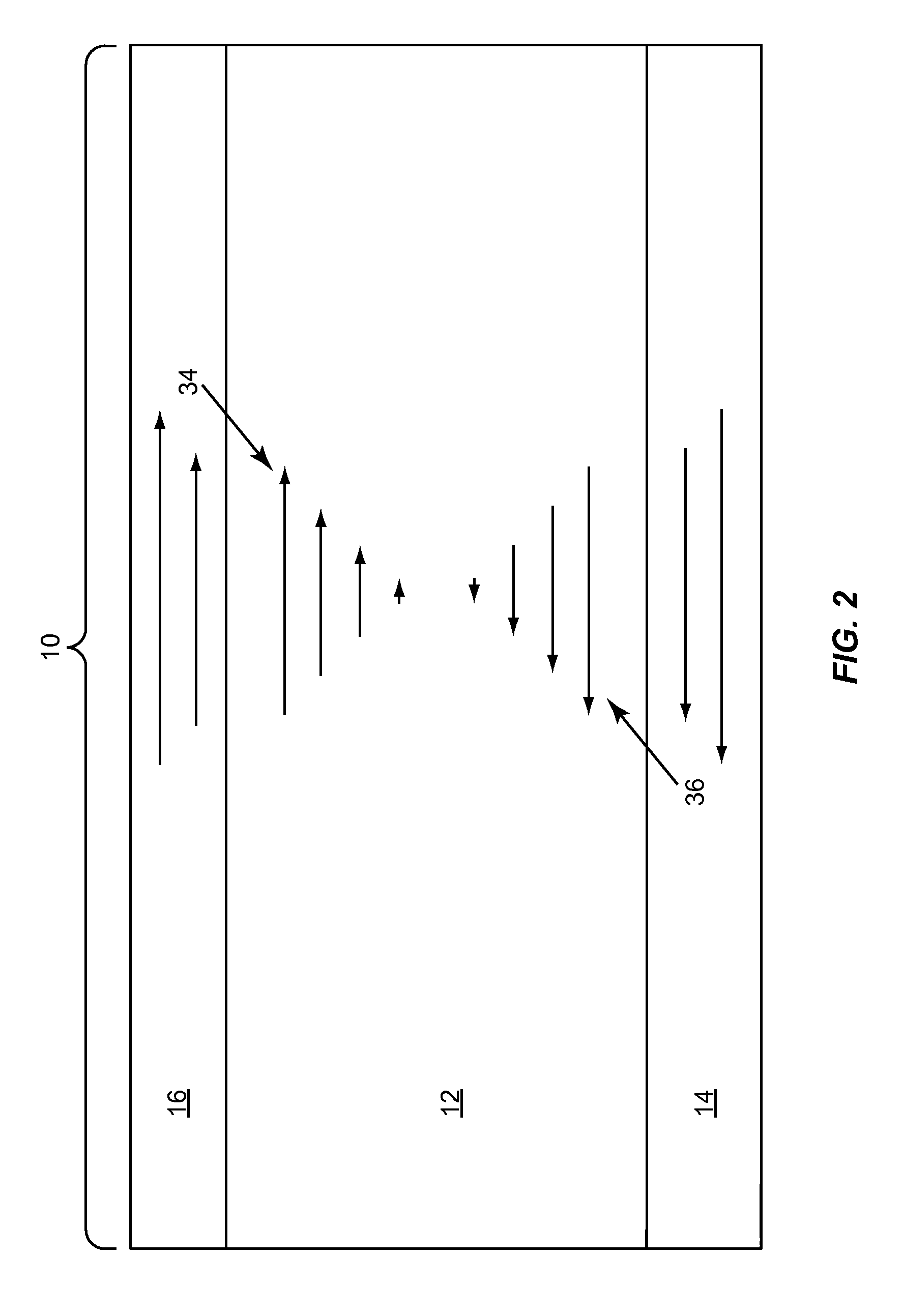

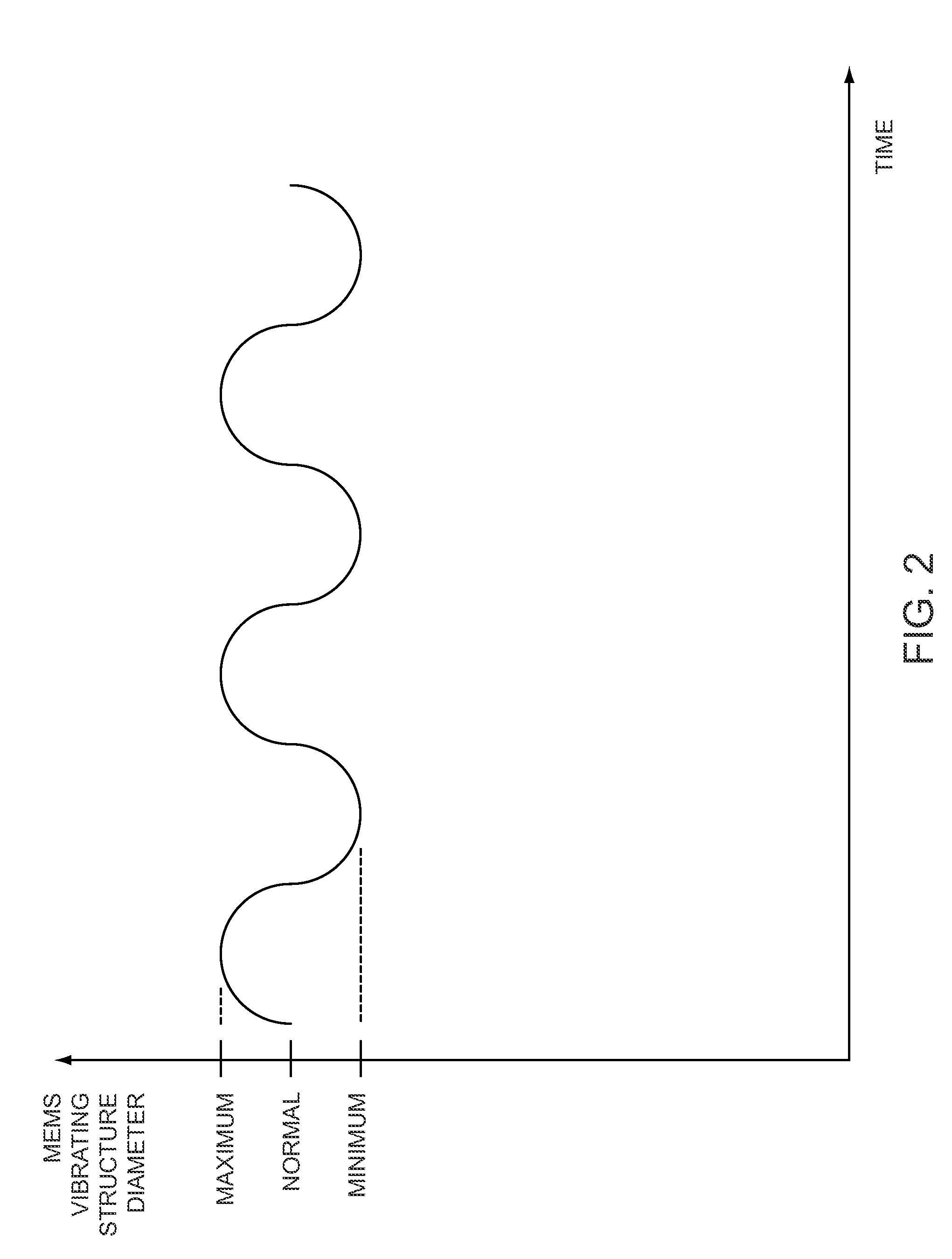

MEMS vibrating structure using an orientation dependent single-crystal piezoelectric thin film layer

ActiveUS20140210314A1Impedence networksPiezoelectric/electrostriction/magnetostriction machinesSingle crystalPiezoelectric thin films

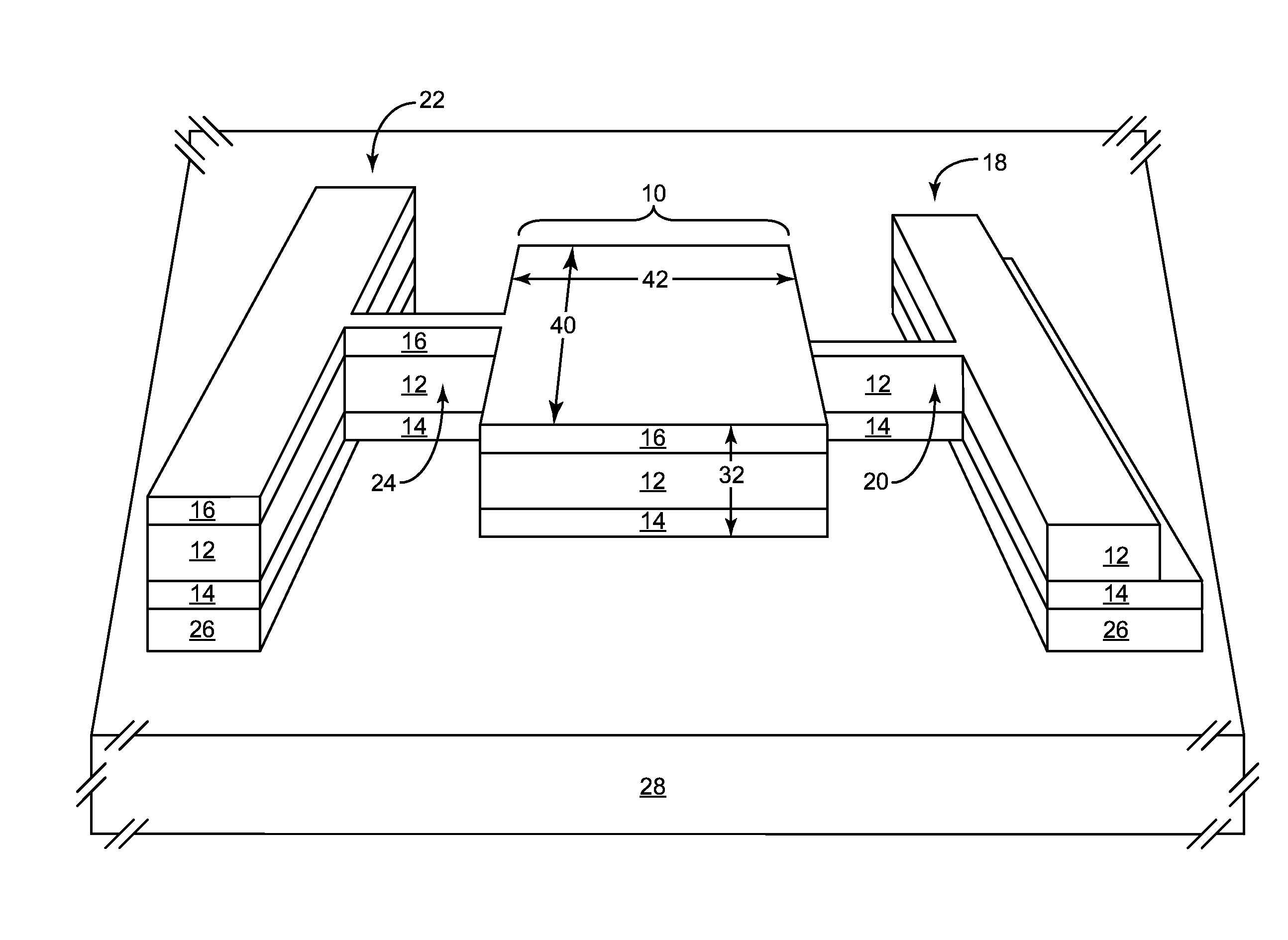

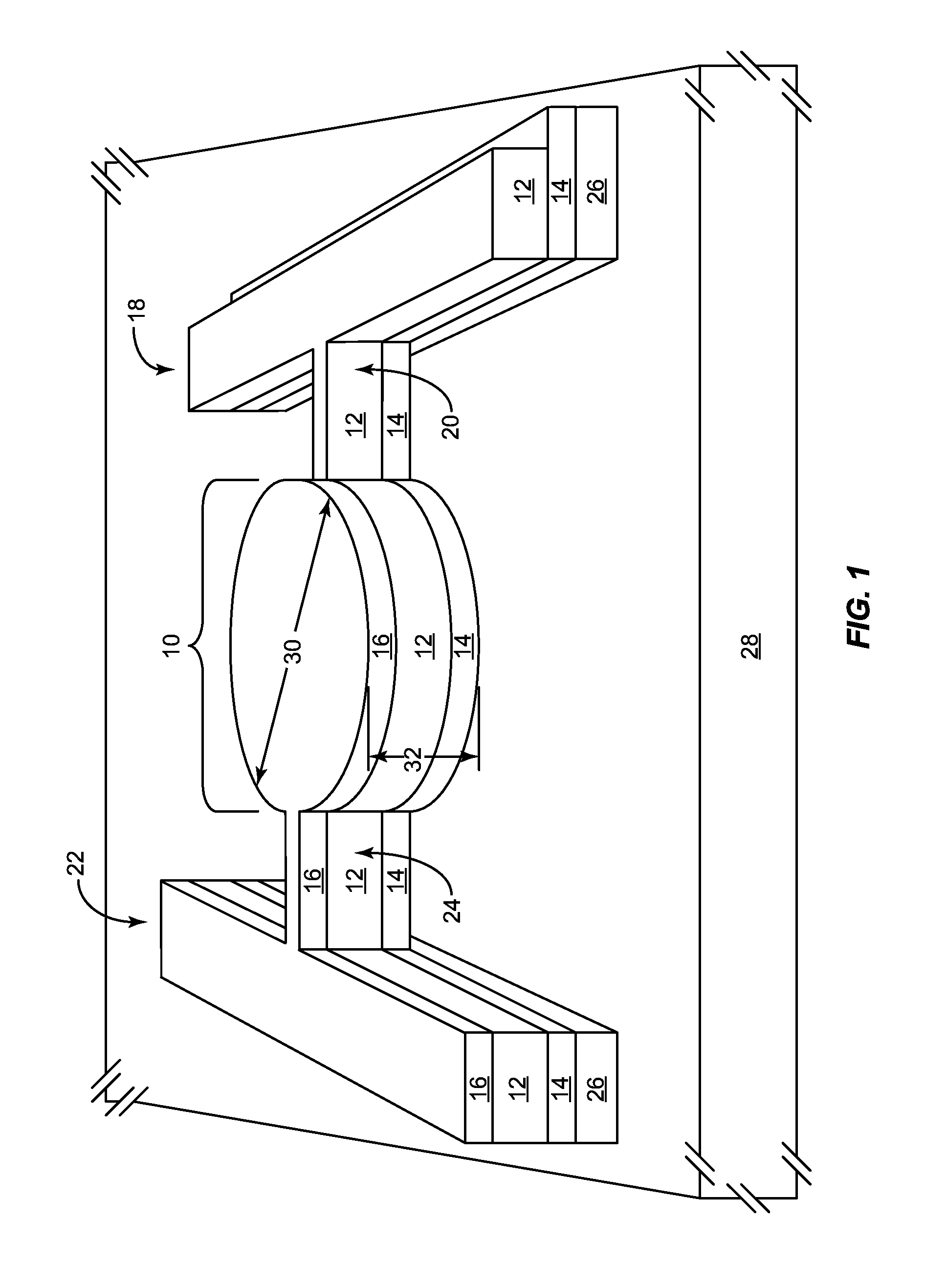

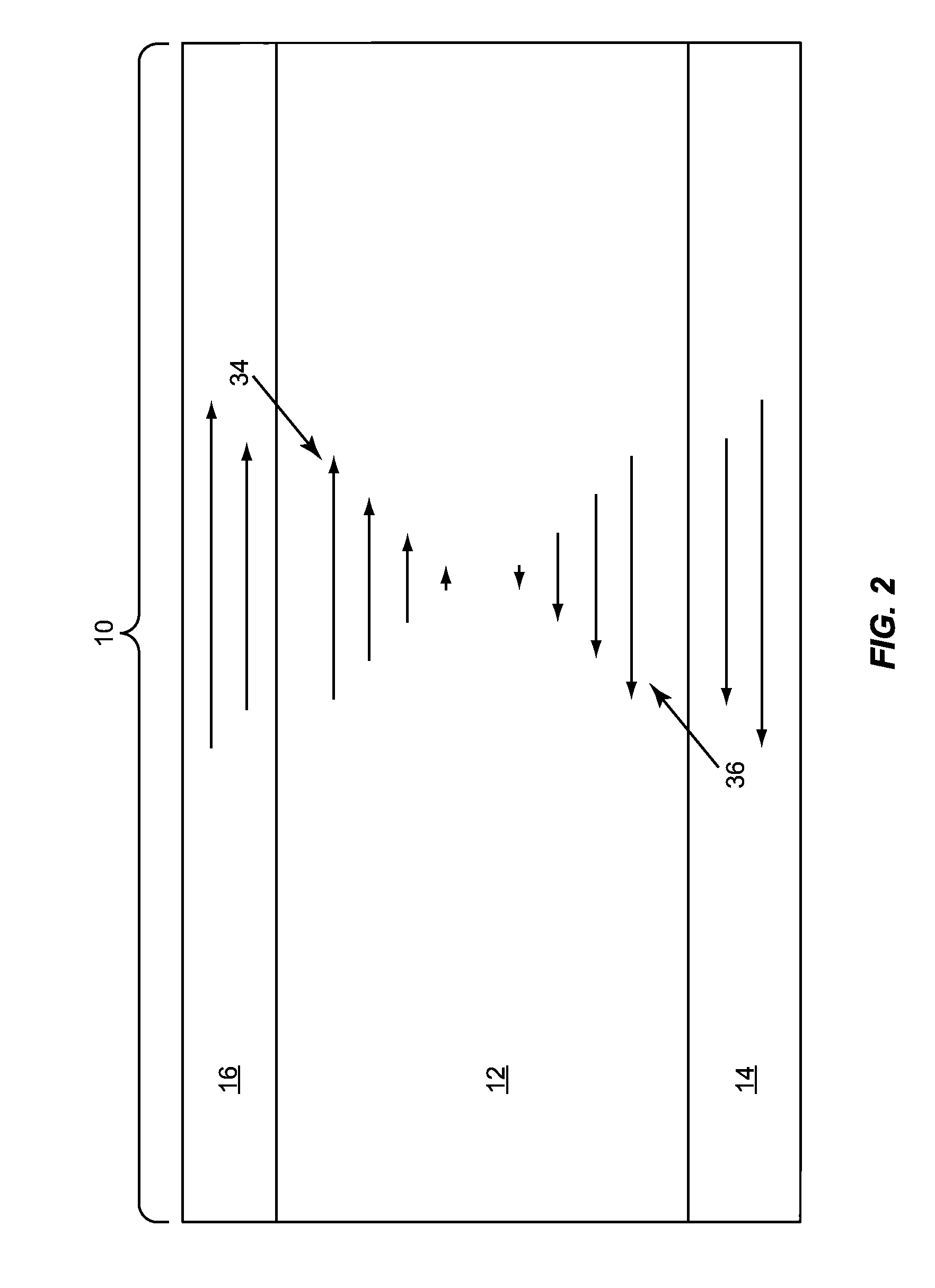

A micro-electrical-mechanical system (MEMS) vibrating structure includes a carrier substrate, a first anchor, a second anchor, a single crystal piezoelectric body, and a conducting layer. The first anchor and the second anchor are provided on the surface of the carrier substrate. The single-crystal piezoelectric body is suspended between the first anchor and the second anchor, and includes a uniform crystalline orientation defined by a set of Euler angles. The single-crystal piezoelectric body includes a first surface parallel to and facing the surface of the carrier substrate on which the first anchor and the second anchor are formed and a second surface opposite the first surface. The conducting layer is inter-digitally dispersed, and is formed on the second surface of the single-crystal piezoelectric body. The first surface of the single-crystal piezoelectric body is left exposed.

Owner:QORVO US INC

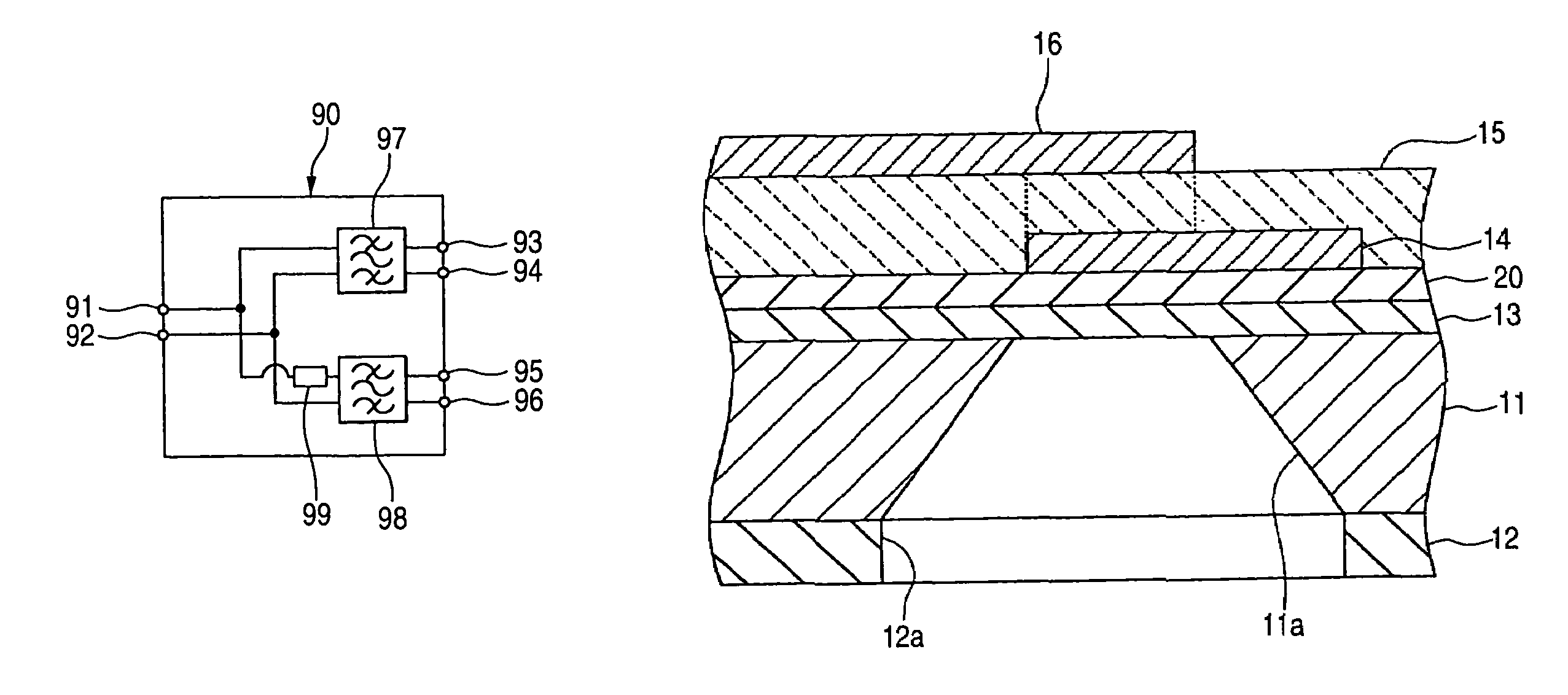

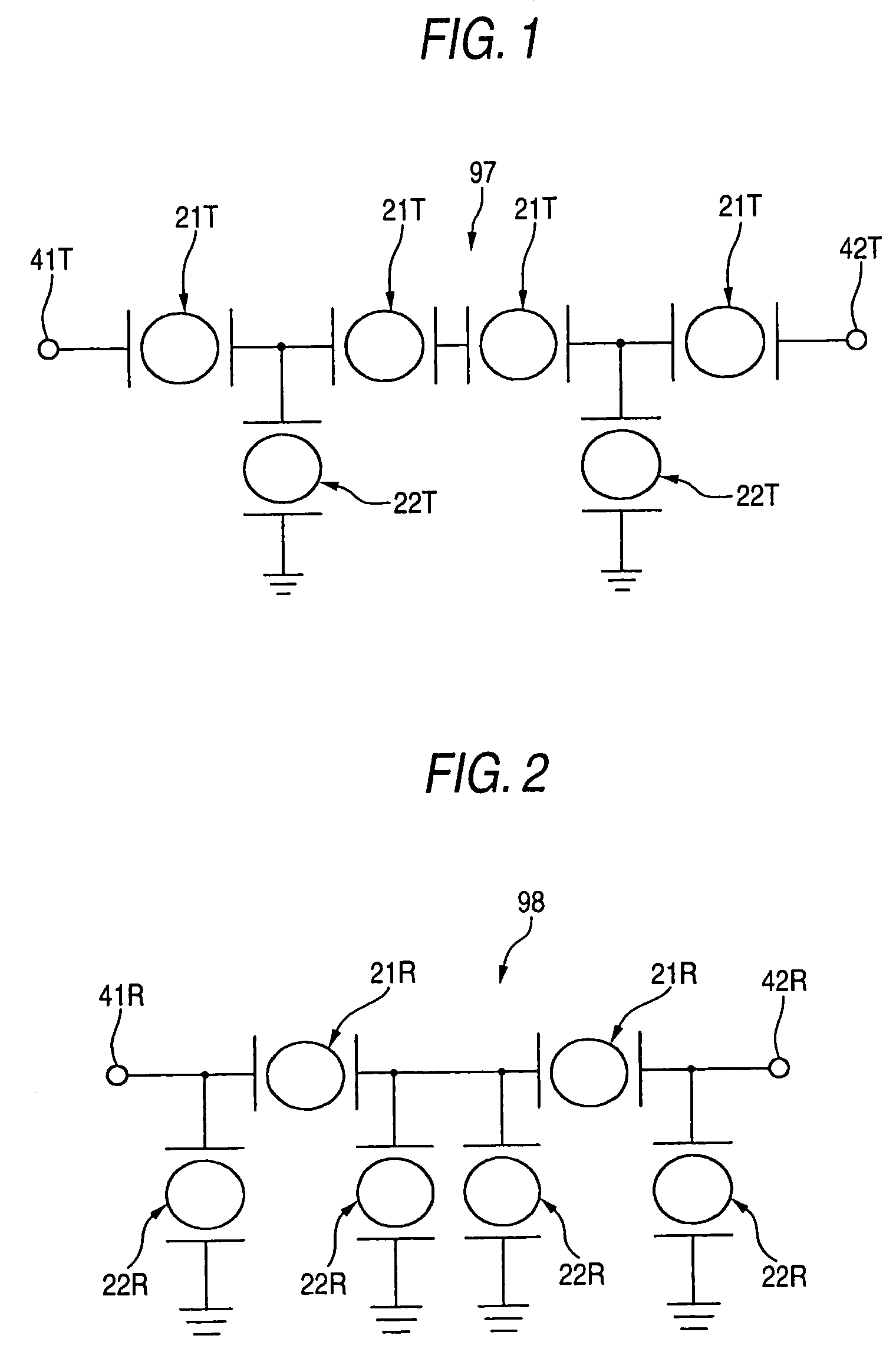

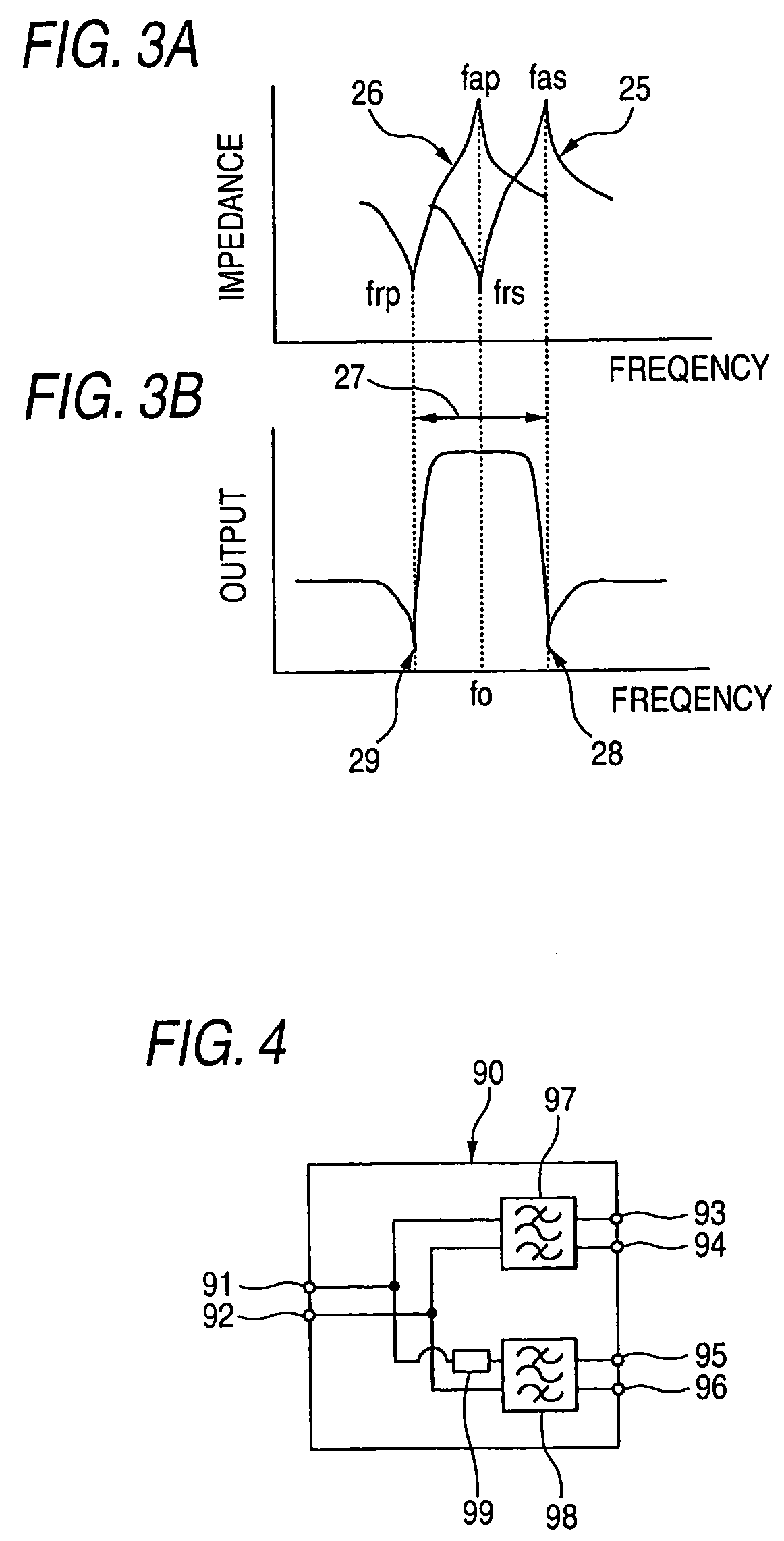

Piezoelectric resonant filter and duplexer

ActiveUS6989723B2Reduction in width can be suppressedAvoid disadvantagesImpedence networksPiezoelectric/electrostrictive/magnetostrictive devicesResonant filterTemperature coefficient

A piezoelectric resonant filter includes a group of series resonators and a group of parallel resonators for forming a ladder-type filter circuit. Each of the resonators has a piezoelectric thin film having piezoelectric characteristic, and lower and upper electrodes disposed on opposite surfaces of the piezoelectric thin film for applying an excitation voltage to the piezoelectric thin film. The group of the parallel resonators exhibits a low frequency side attenuation extremum in the filter whereas the group of the series resonators exhibits a high frequency side attenuation extremum in the filter. At least one of the group of the series resonators and the group of the parallel resonators has a temperature compensating layer for bringing the temperature coefficient of the resonant frequency close to zero.

Owner:SNAPTRACK

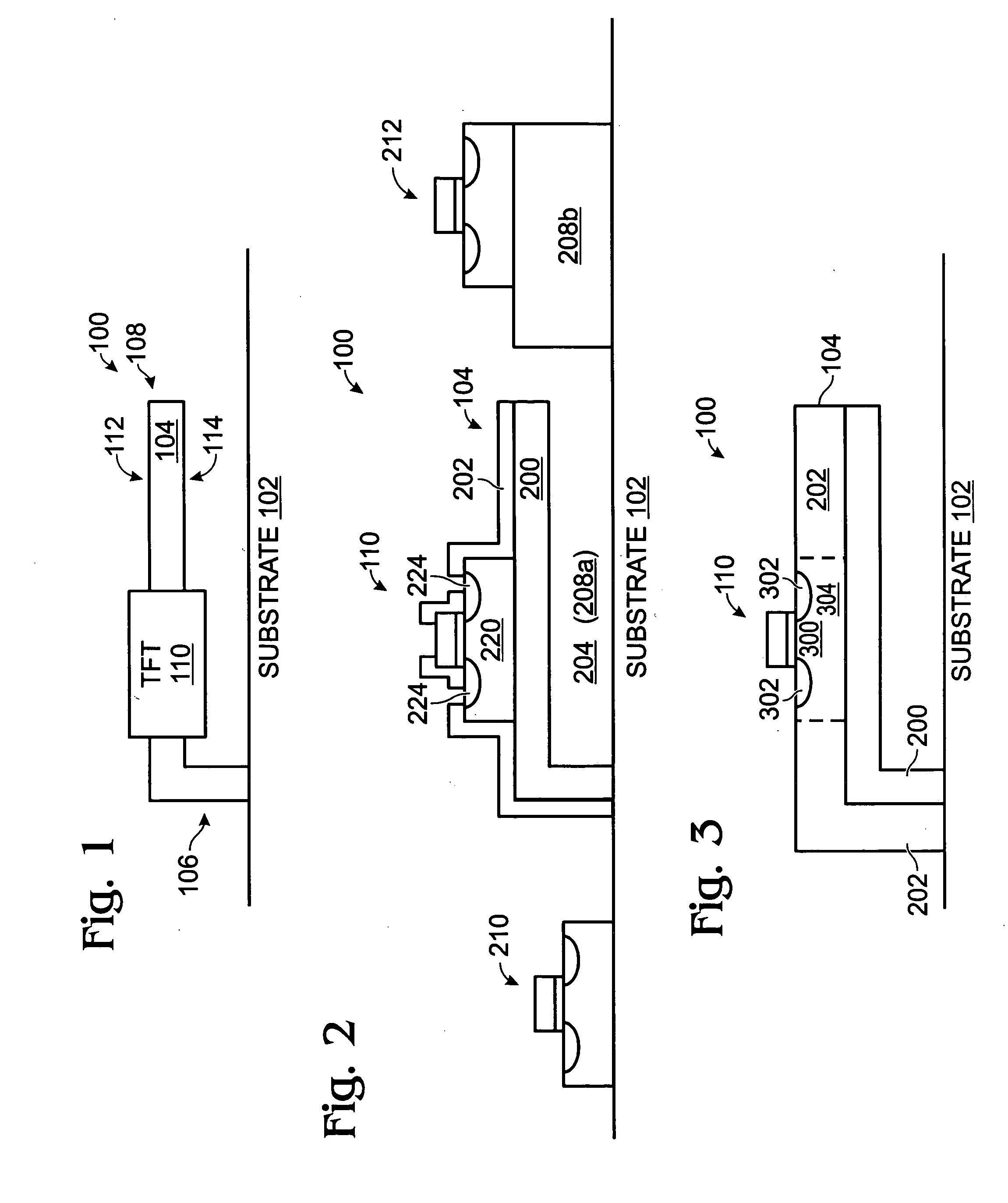

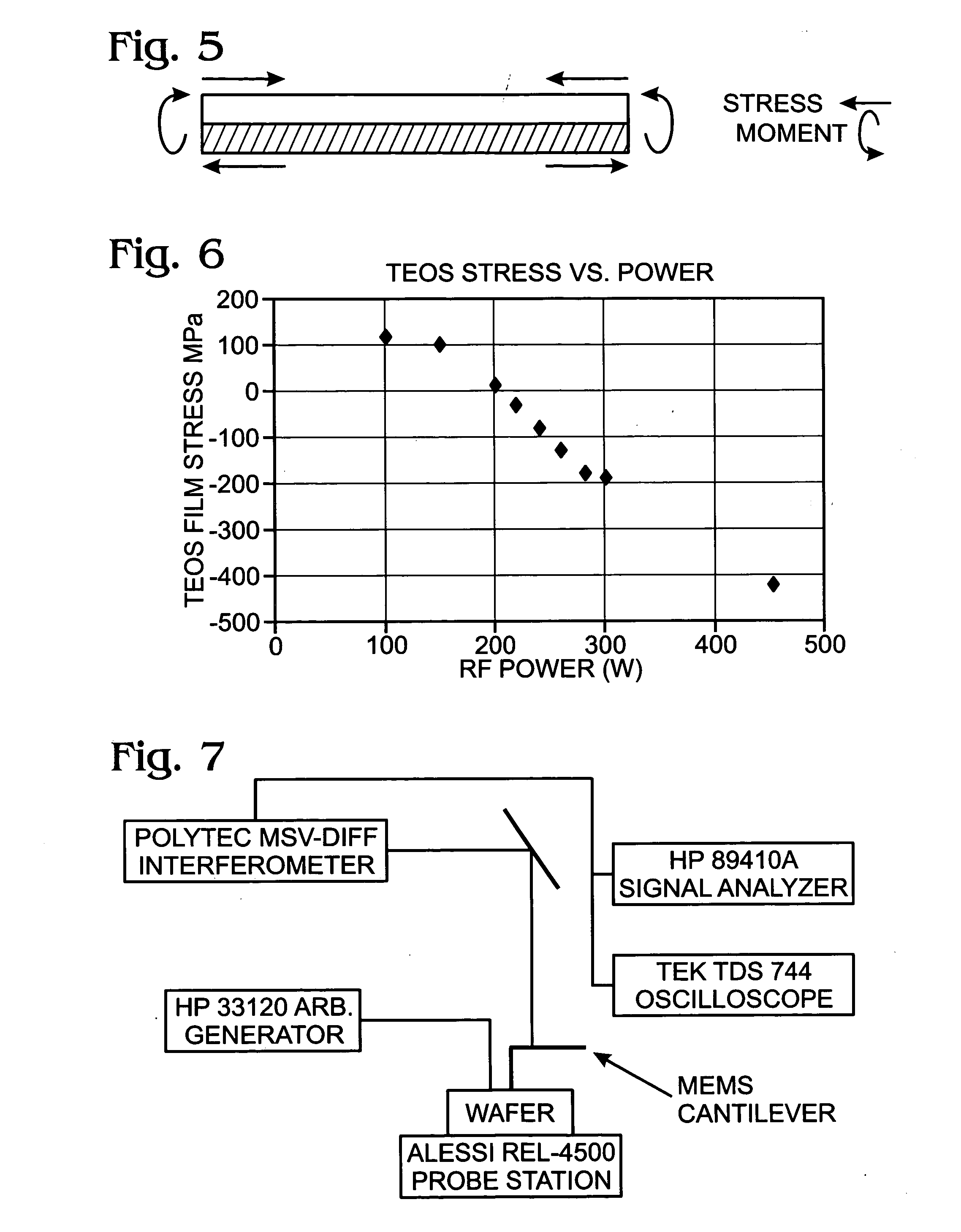

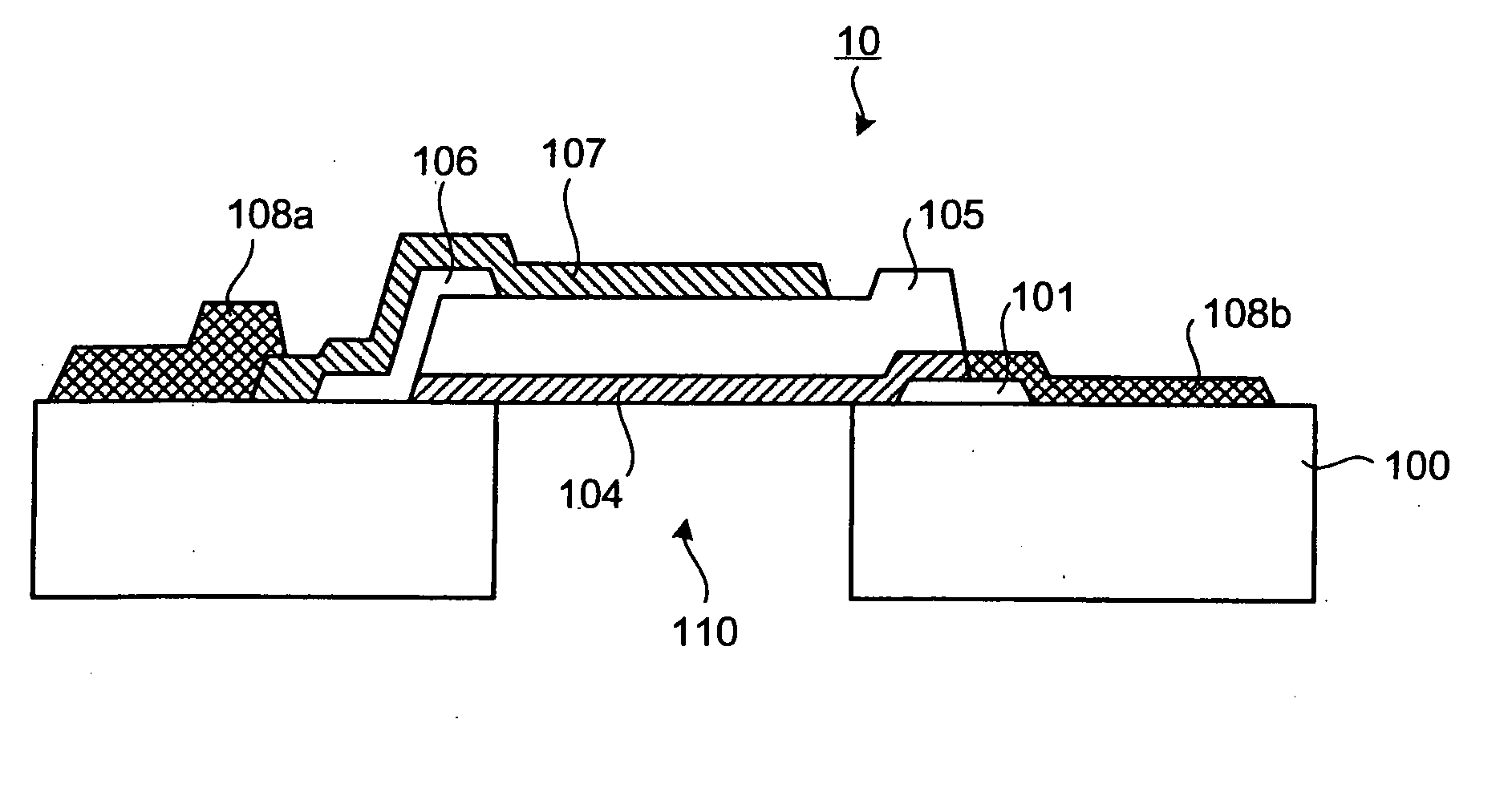

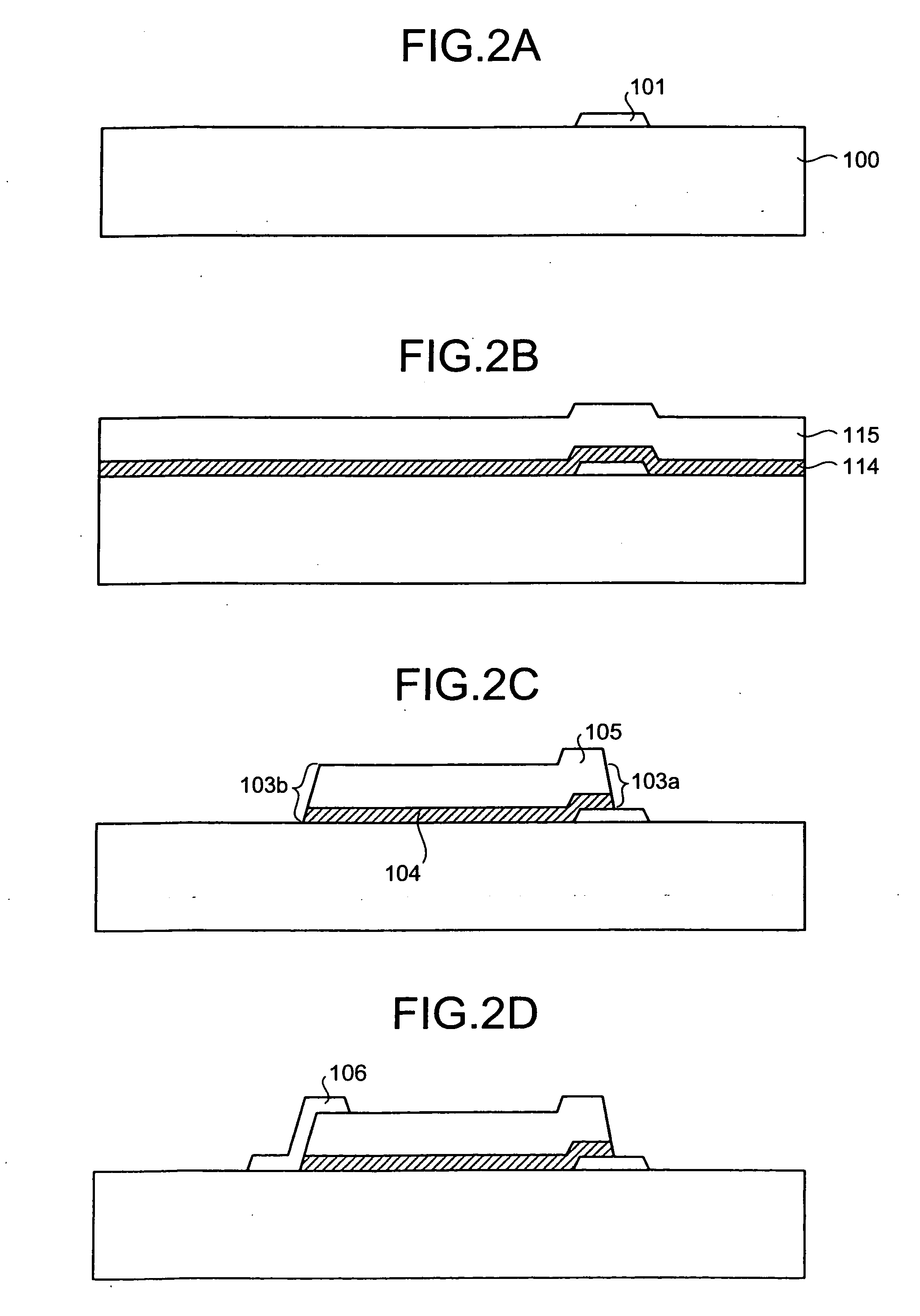

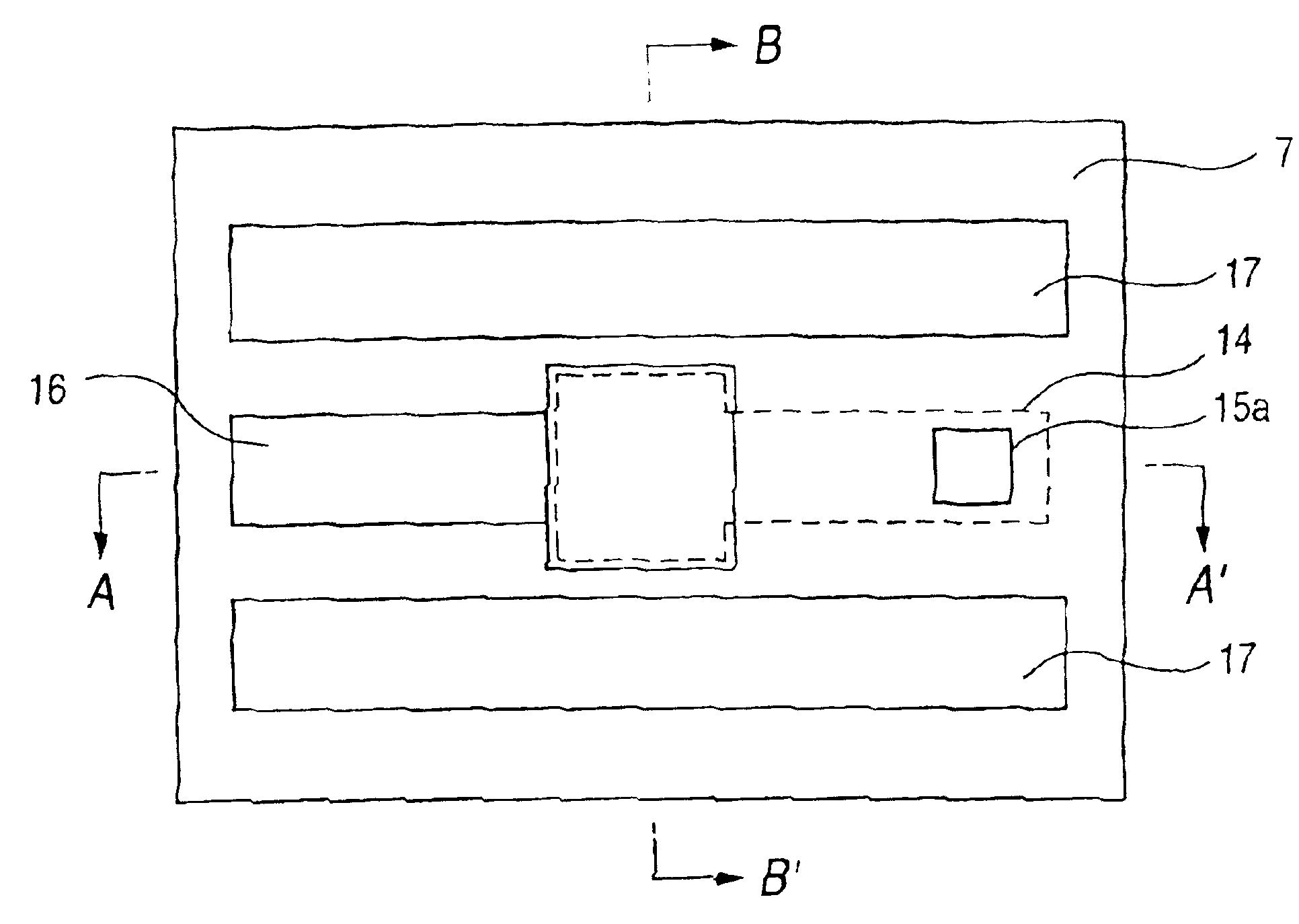

Piezo-TFT cantilever MEMS

InactiveUS20050130360A1Piezoelectric/electrostrictive microphonesAcceleration measurement using interia forcesSecondary layerStress level

A piezo-TFT cantilever microelectromechanical system (MEMS) and associated fabrication processes are provided. The method comprises: providing a substrate, such as glass for example; forming thin-films overlying the substrate; forming a thin-film cantilever beam; and simultaneously forming a TFT within the cantilever beam. The TFT is can be formed least partially overlying a cantilever beam top surface, at least partially overlying a cantilever beam bottom surface, or embedded within the cantilever beam. In one example, forming thin-films on the substrate includes: selectively forming a first layer with a first stress level; selectively forming a first active Si region overlying the first layer; and selectively forming a second layer overlying the first layer with a second stress level. The thin-film cantilever beam is formed from the first and second layers, while the TFT source / drain (S / D) and channel regions are formed from the first active Si region.

Owner:SHARP KK

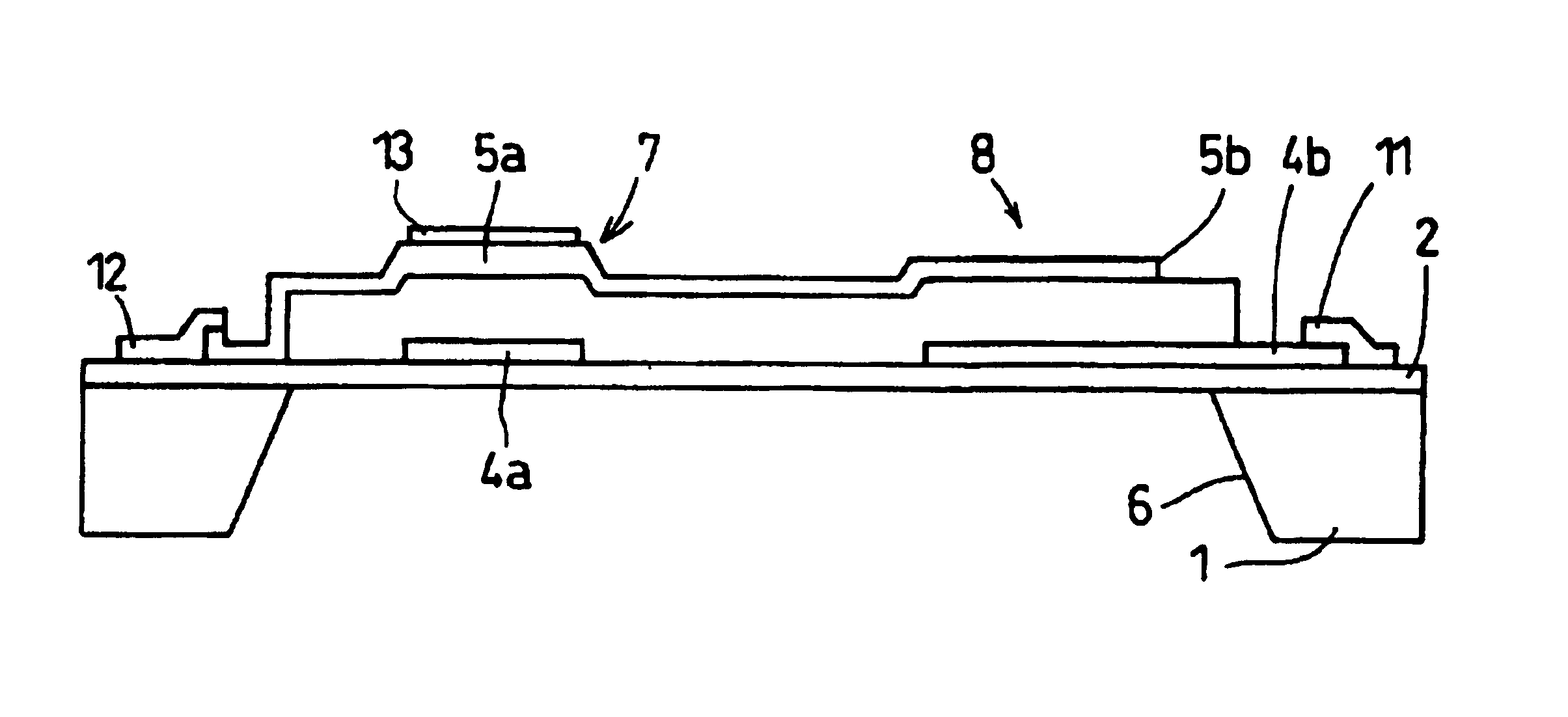

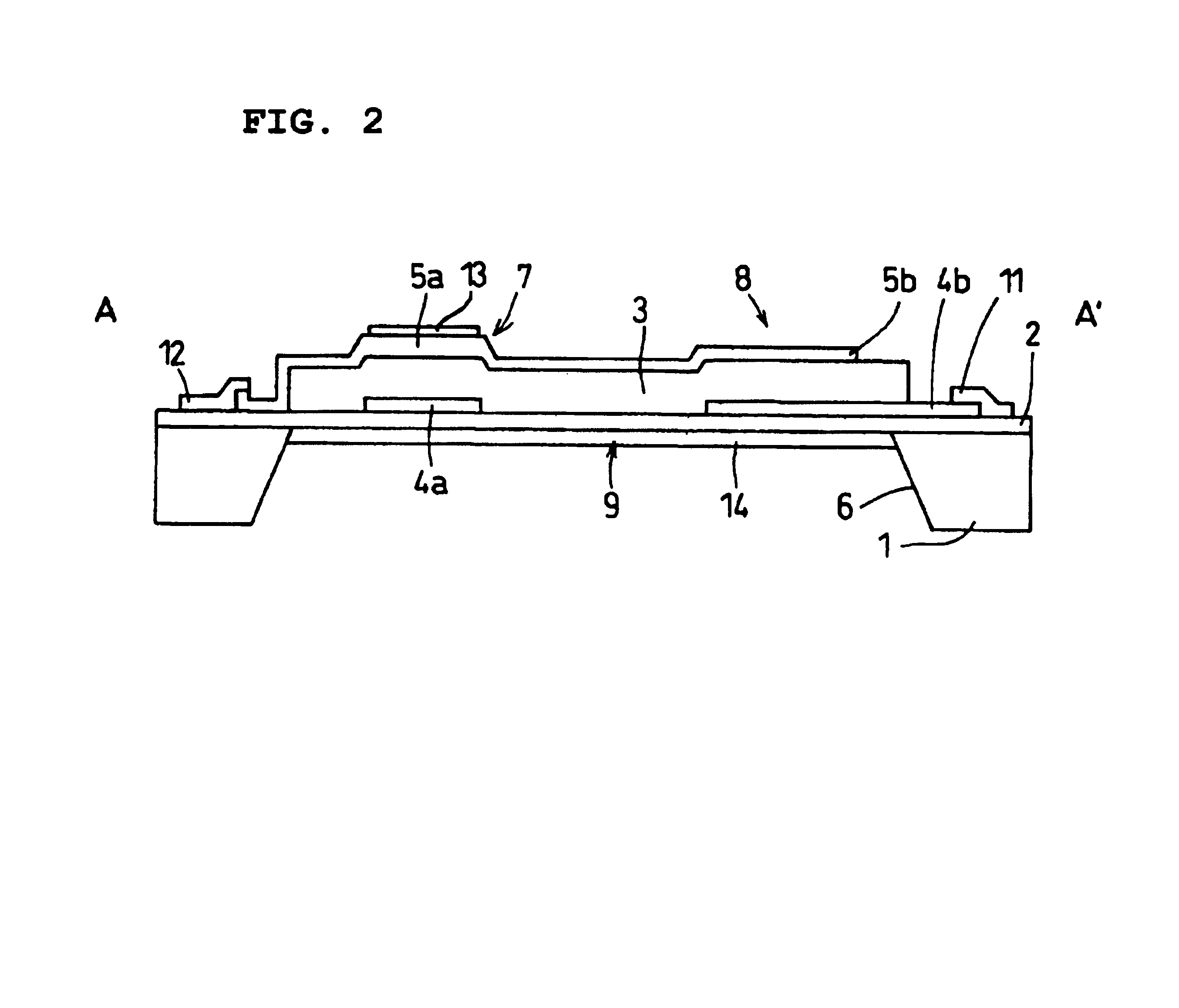

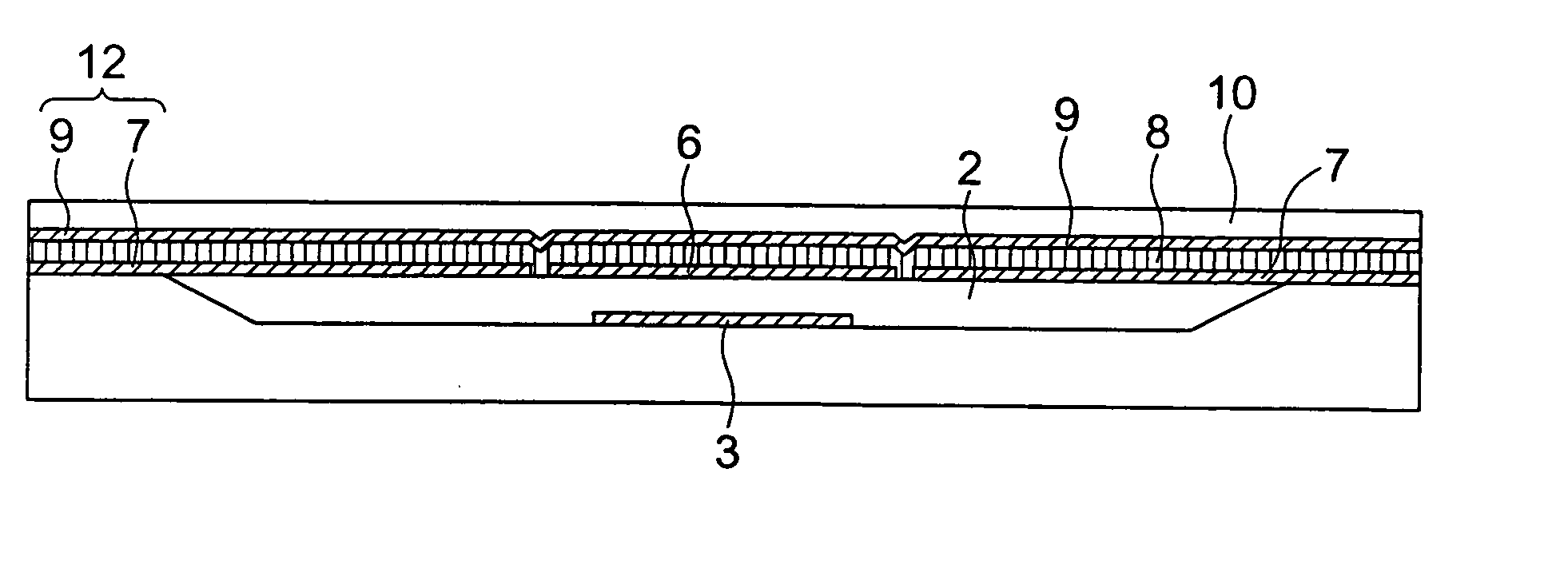

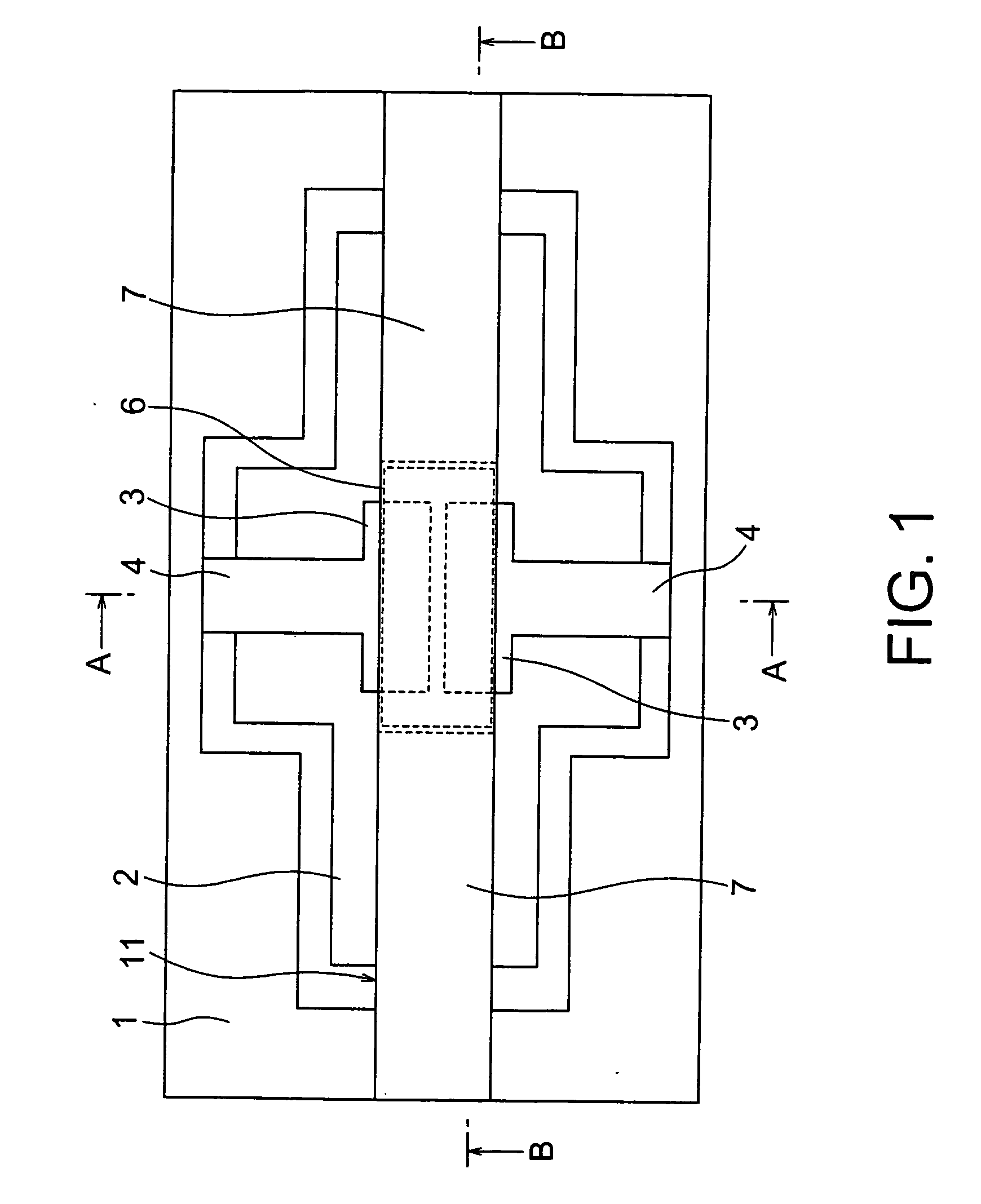

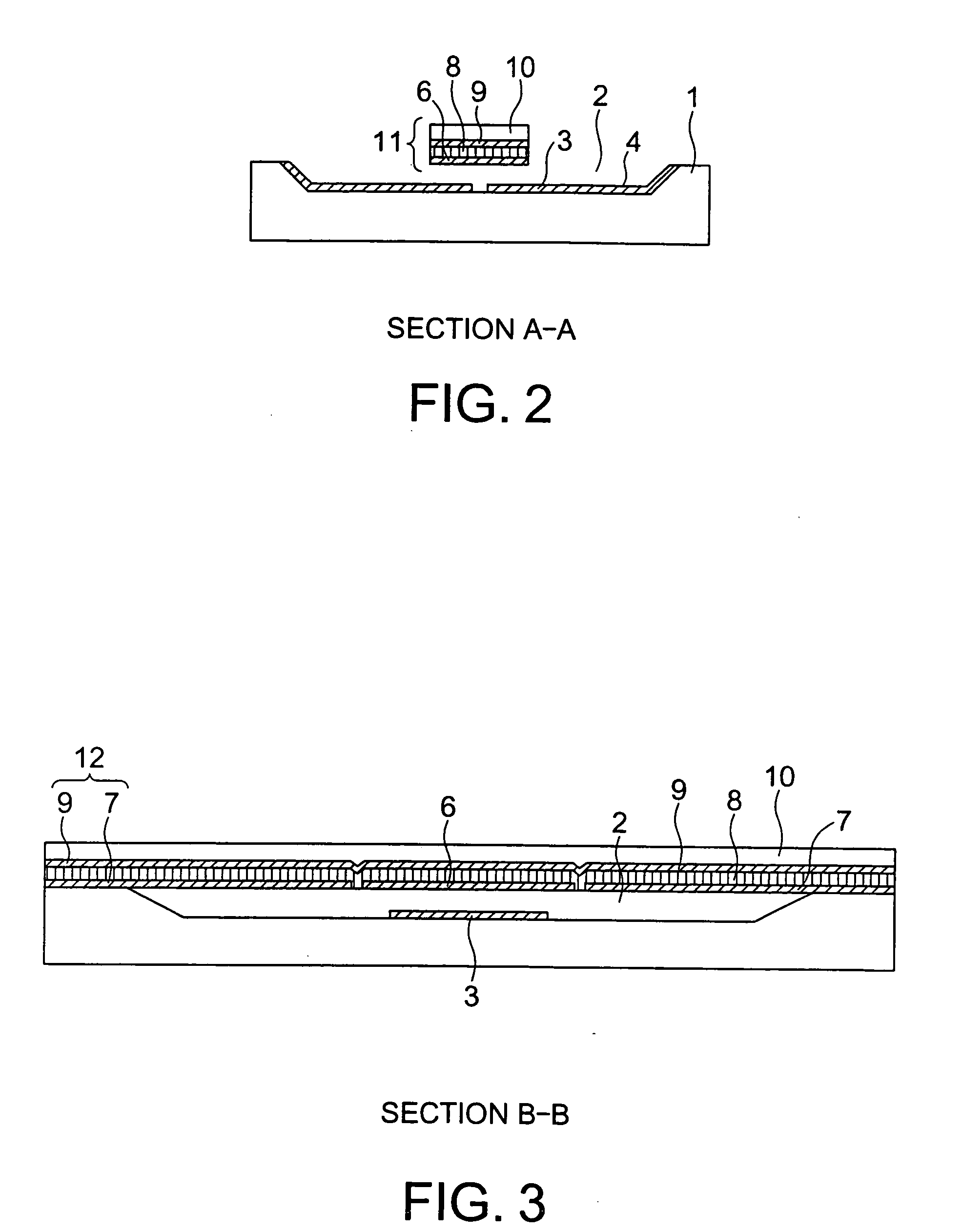

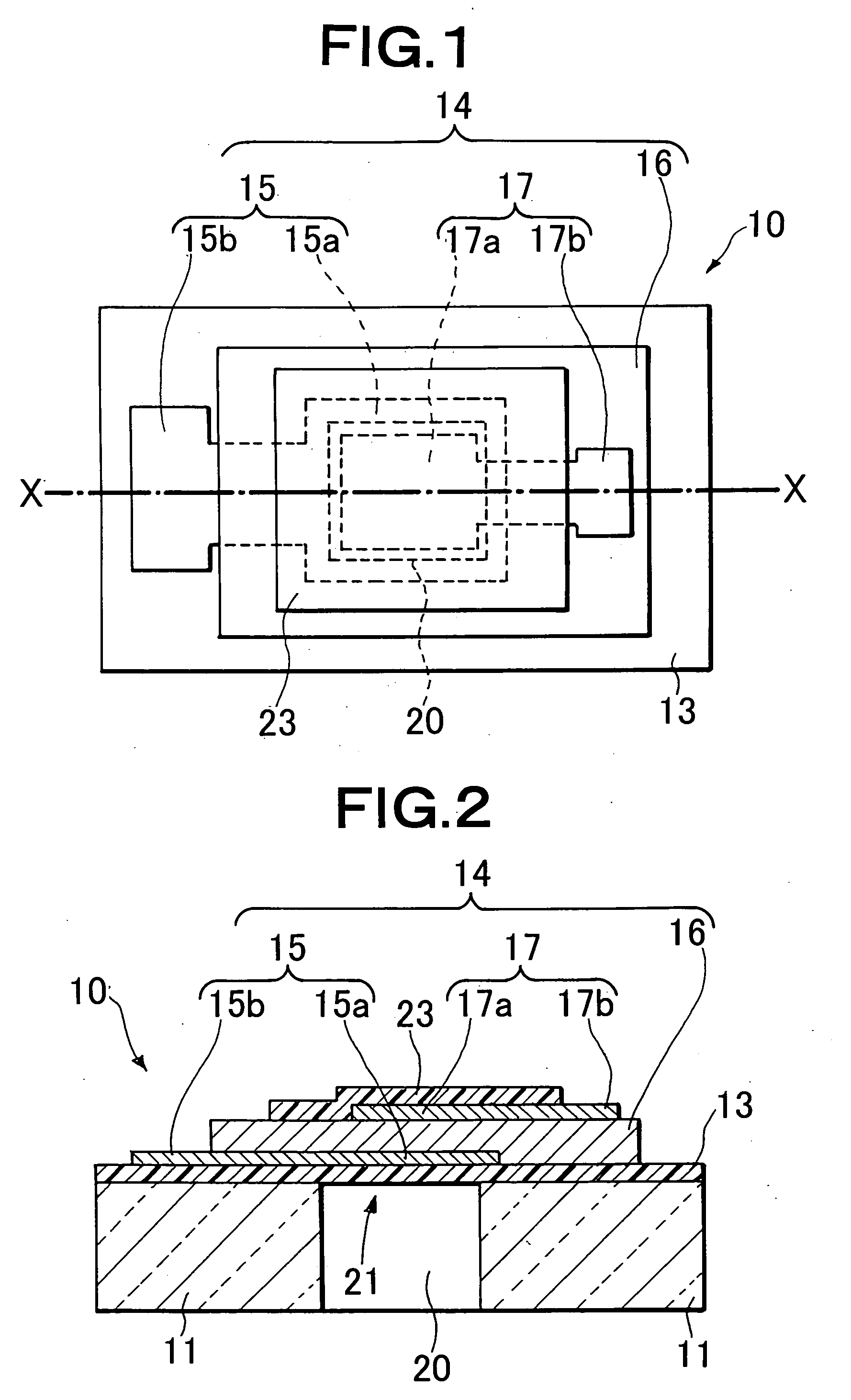

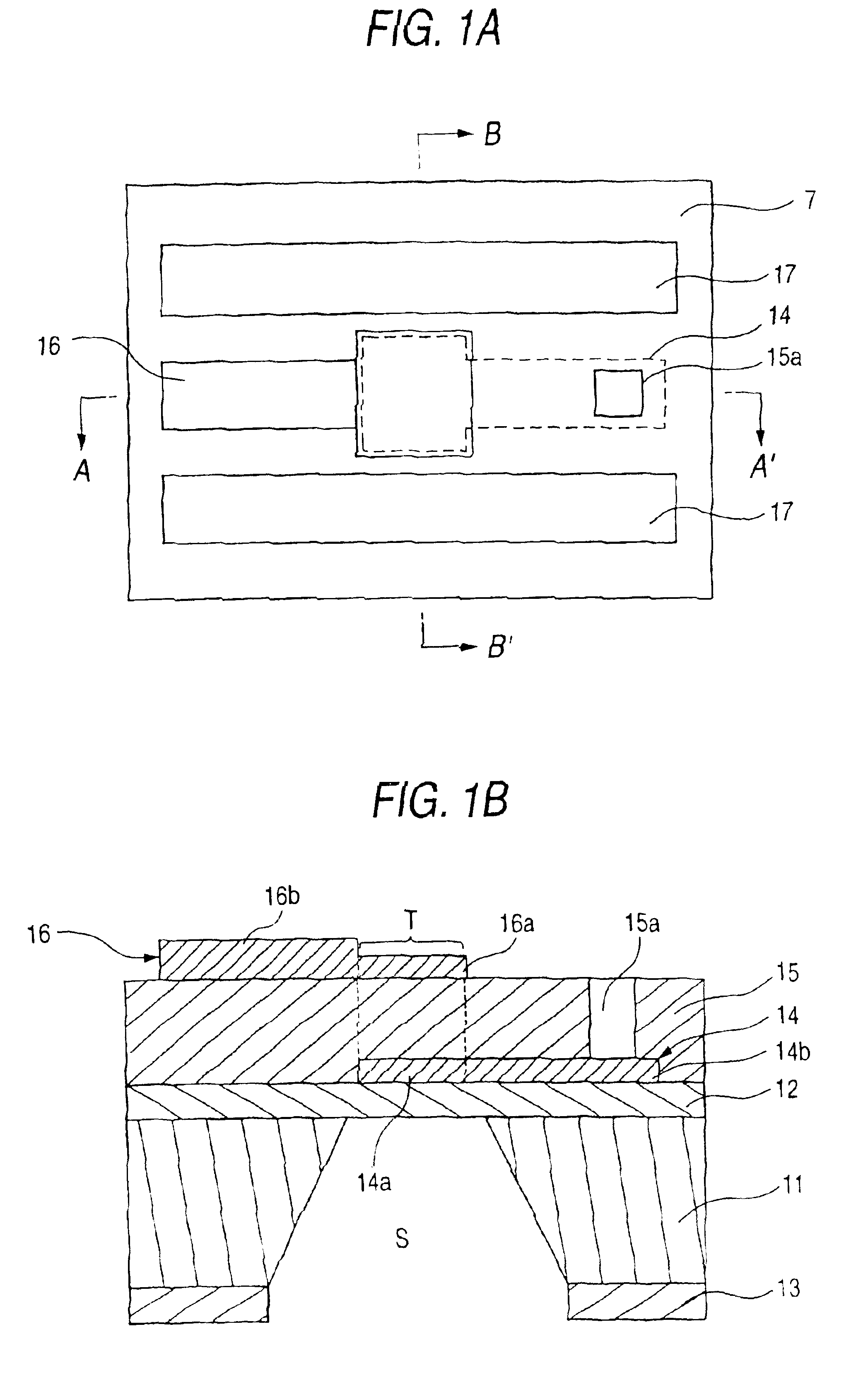

Piezoelectric filter, duplexer, composite piezoelectric resonator, communication device and method for adjusting frequency of piezoelectric filter

ActiveUS7019604B2Improve efficiencyHigh frequency accuracyPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksElectronic componentCommunication device

A piezoelectric filter and other electronic components are constructed such that the accuracy of frequency adjustment can be increased and an improvement in efficiency of the adjustment operation can be achieved. The piezoelectric filter includes a plurality of piezoelectric resonators including a substrate and a vibration portion provided on the substrate, the vibration portion having a structure in which the top and bottom surfaces of a thin film portion including at least one piezoelectric thin film are sandwiched between at least a pair of an upper electrode and a lower electrode facing each other, wherein the upper electrode of a predetermined piezoelectric resonator is made of a material having susceptibility to etching that is different from that of the upper electrode of the other piezoelectric resonator.

Owner:MURATA MFG CO LTD

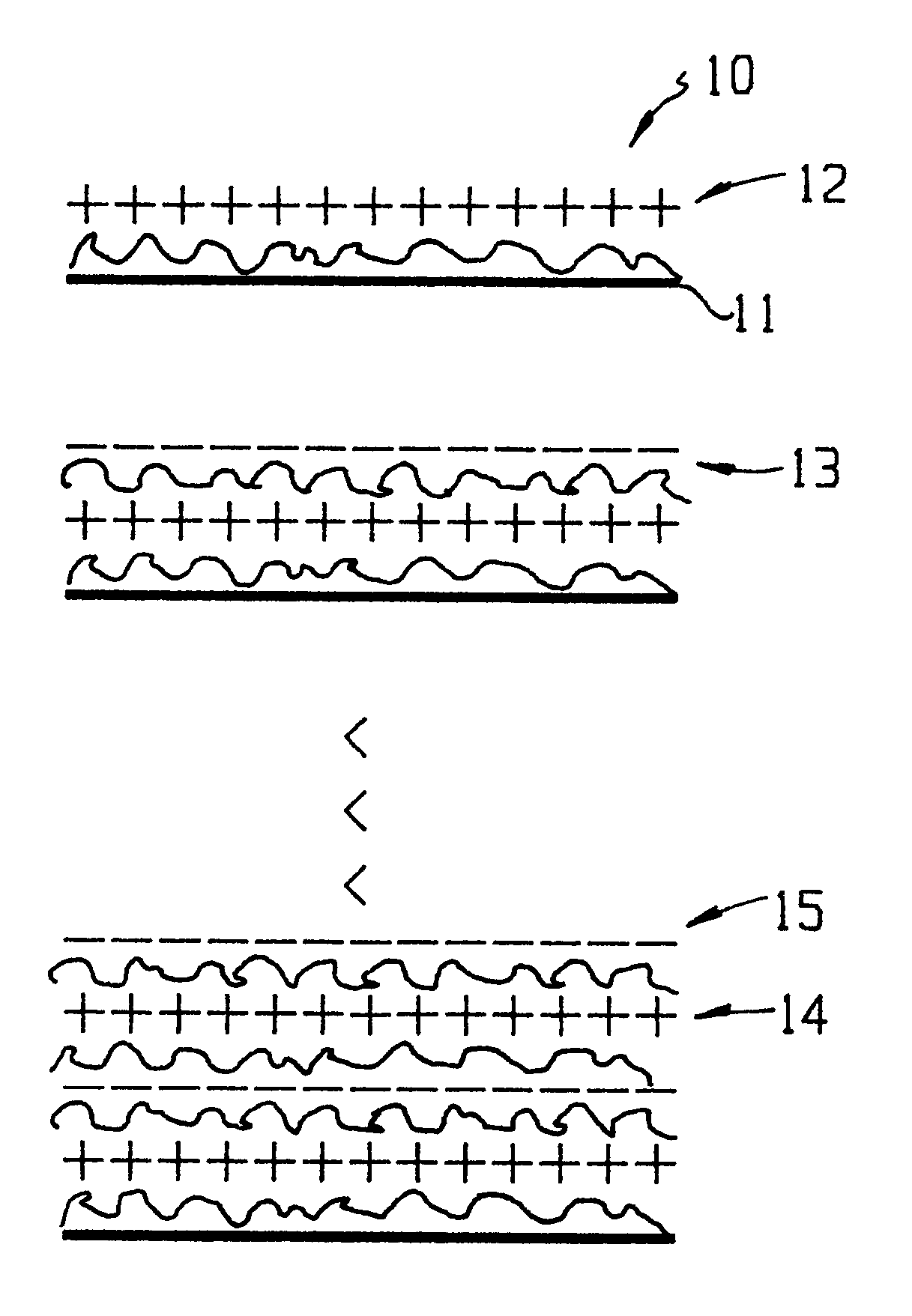

Electrostrictive and piezoelectric thin film assemblies and method of fabrication therefor

InactiveUS6447887B1Avoid misalignmentUniform propertyAnodisationMaterial nanotechnologyMolecular levelEngineering

An electrostatic self-assembly method of fabricating electrostrictive and piezoelectric thin film assemblies not only provides a thinner film than is attainable by conventional methods, but provides excellent molecular-level uniformity and precise structural control, and thus large, effective piezoelectric coefficients. The method produces a thin film assembly including (a) a substrate, and (b) a film having one or a plurality of layers disposed upon the substrate, wherein at least one of the layers includes a dipolar material, and this layer of dipolar material has a uniform thickness of at most 500 nm.

Owner:VIRGINIA TECH INTPROP INC

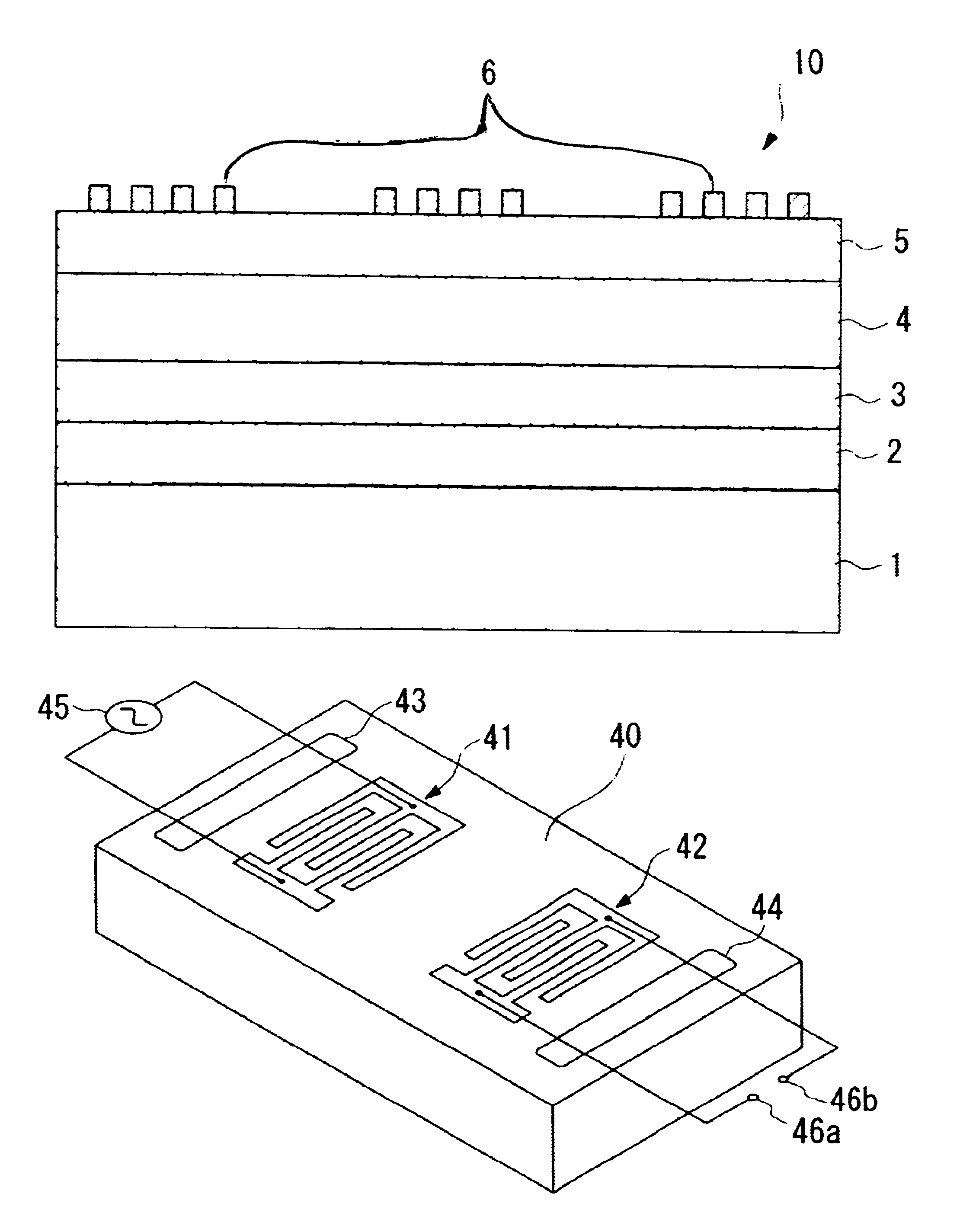

Surface acoustic wave device with KNb03 piezoelectric thin film, frequency filter, oscillator, electronic circuit, and electronic apparatus

InactiveUS6720846B2Polycrystalline material growthPiezoelectric/electrostriction/magnetostriction machinesTectorial membraneFrequency filtering

Surface acoustic wave device having a high k<2>, and a frequency filter, oscillator, electronic circuit and electronic device employing this surface acoustic wave device is provided, wherein a first oxide thin film layer comprising SrO or MgO and a second oxide thin film layer comprising SrTiO3 are sequentially formed on top of a (110) Si substrate, or a first oxide thin film layer comprising CeO2, ZrO2 or yttrium-stabilized zirconia and a second oxide thin film layer comprising SrTiO3 are sequentially formed on top of a (100) Si substrate, a KNbO3 piezoelectric thin film being then formed on top of either of these second oxide thin film layers, and then, a protective film comprising oxide or nitride is formed on top of the KNbO3 piezoelectric thin film, finally, at least one electrode is formed on top of this protective film, to form a surface acoustic wave device, which surface acoustic wave device is employed to form a frequency filter, oscillator, electronic circuit, or electronic device.

Owner:SEIKO EPSON CORP

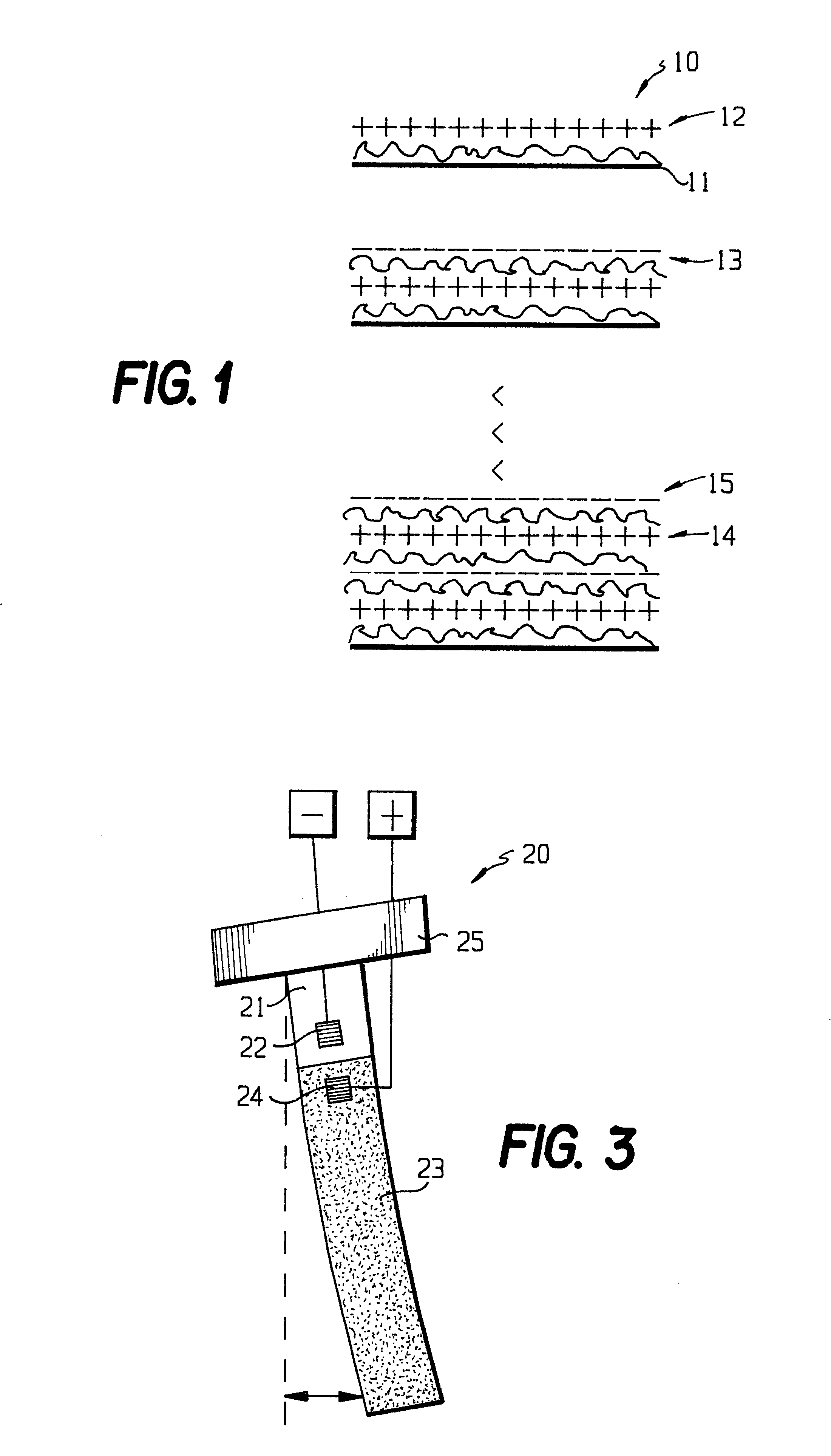

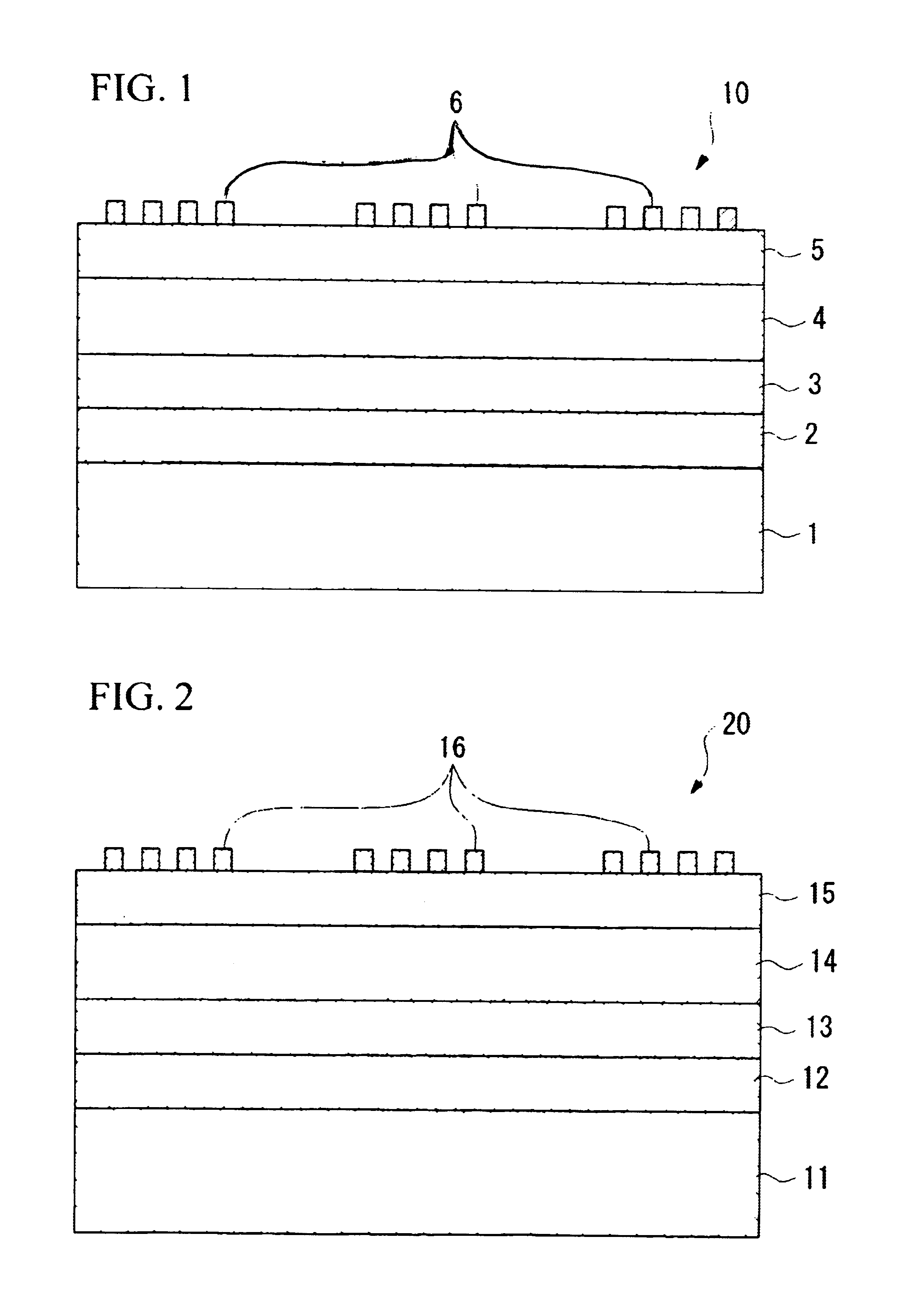

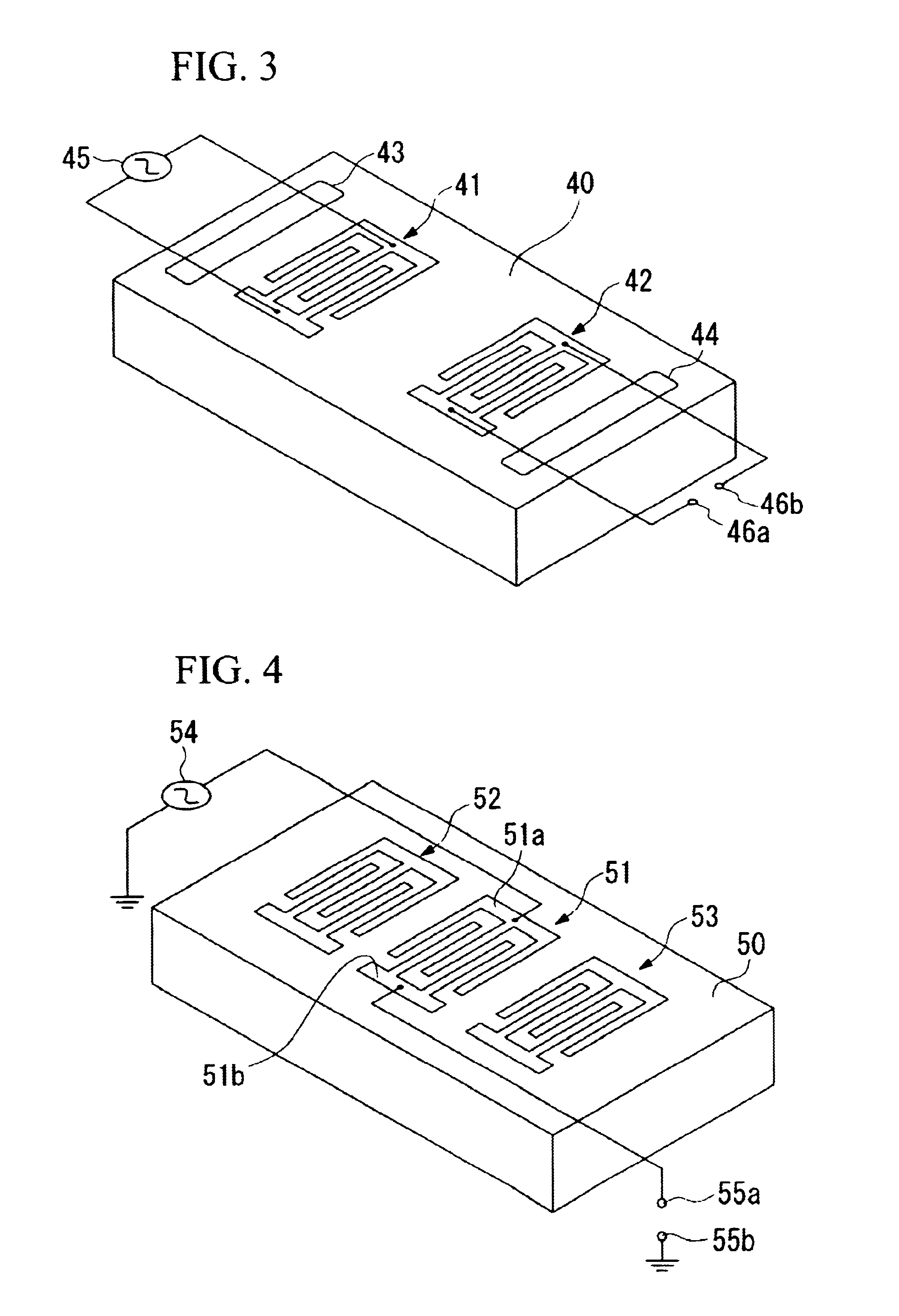

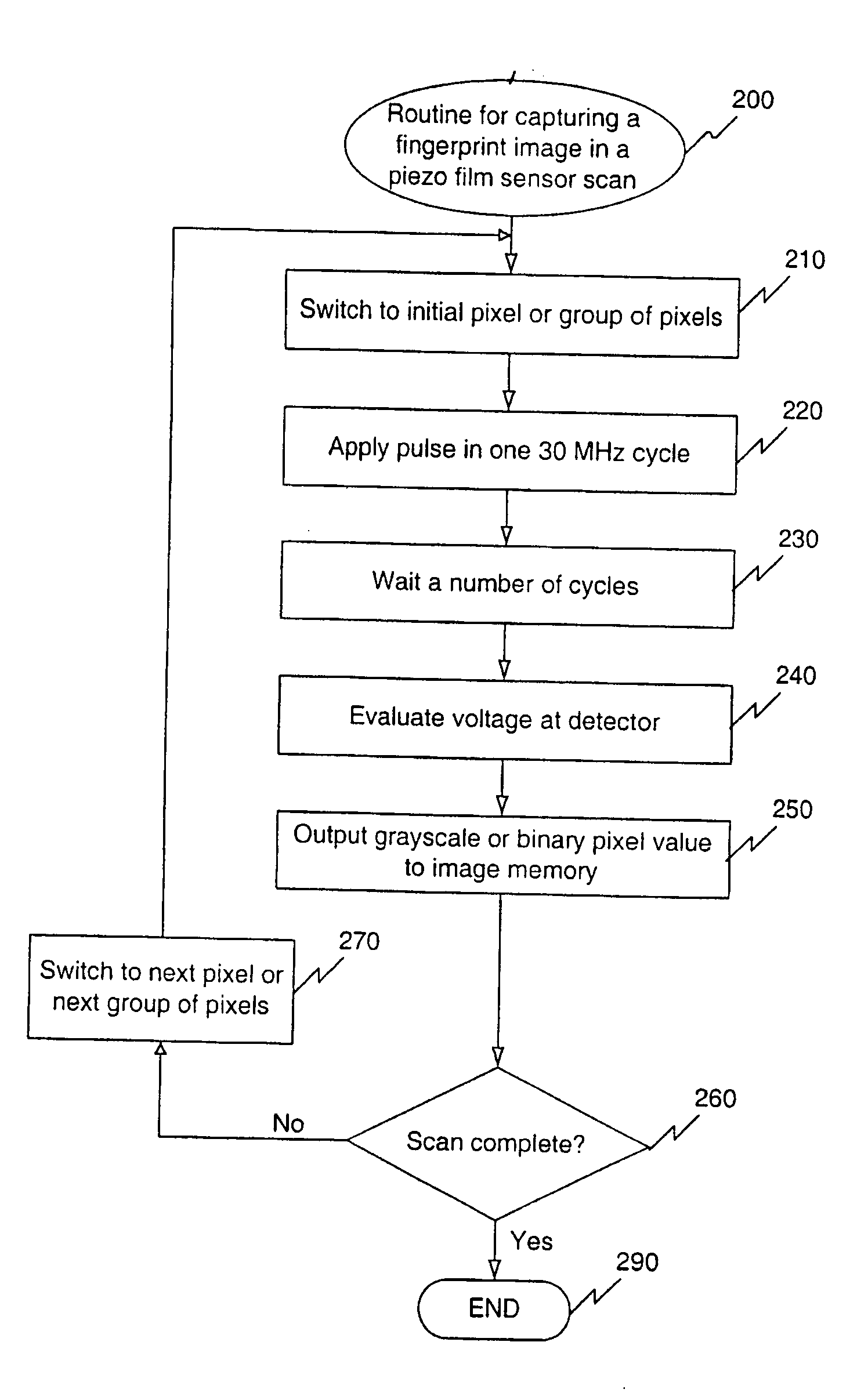

Biometric piezo scanner

InactiveUS20080175450A1Provide informationBlood flow measurement devicesPerson identificationSensor arrayElectrical conductor

A piezoelectric thin film sensor array is used to scan and capture biometric data, for example, a fingerprint image. In one embodiment, a multi-layer structure includes a PVDF layer in between two conductor grids arranged orthogonally to one another. Urethane can be added to one side where a finger is placed. A foam substrate can be used as a support. In one feature, the PVDF, and grids can be peeled off like a label for easy replacement. Multiplexers are switched to scan the sensor. A single pixel or a group of pixels can be detected and output to an image memory. The presence of a fingerprint ridge is detected by virtue of a ring-down oscillation that arises from reflection when an electric field is applied to the piezoelectric thin film sensor array at a pixel in contact with the fingerprint ridge. For example, such a ring-down value associated with a fingerprint ridge can be detected at about 150 ns. (or 5 cycles at 30 MHZ). Other reflections indicative of additional biometrics (e.g. from tissue, blood, bone, fingernail, etc.) can also be detected. A Doppler effect due to reflections from circulating blood can also be detected. Such a Doppler effect can provide further information about direction and speed of blood circulation. An instantaneous pyroelectric effect can also be detected to indicate a live finger presence.

Owner:SONAVATION INC

Piezoelectric-driven MEMS device and method for manufacturing the same

InactiveUS20050242687A1Fabricated reliably and consistentlyPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesThin membraneEngineering

A piezoelectric-driven MEMS device can be fabricated reliably and consistently. The piezoelectric-driven MEMS device includes: a movable flat beam having a piezoelectric film disposed above a substrate with a recessed portion such that the piezoelectric film is bridged over the recessed portion, piezoelectric drive mechanisms disposed at both ends of the piezoelectric film and configured to drive the piezoelectric film, and a first electrode disposed at the center of the substrate-side of the piezoelectric film, and a second electrode disposed on a flat part of the recessed portion of the substrate and facing the first electrode of the movable flat beam.

Owner:KK TOSHIBA

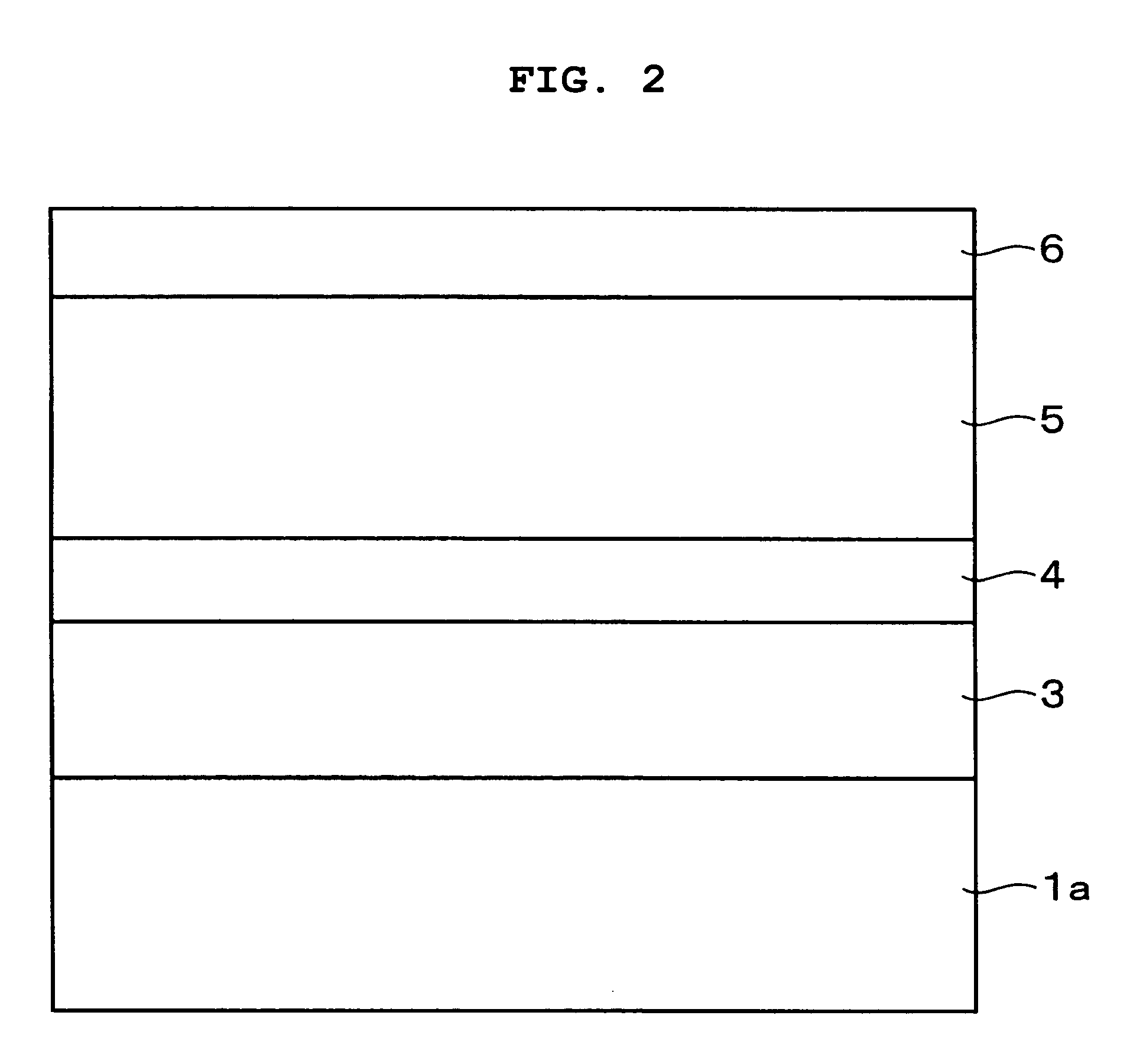

Aluminum nitride thin film, composite film containing the same and piezoelectric thin film resonator using the same

ActiveUS20070080611A1Improve featuresHigh crystallinityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesRocking curveComposite film

A piezoelectric thin film resonator has a substrate and a piezoelectric layered structure including a lower electrode, piezoelectric aluminum nitride thin film with c-axis orientation and upper electrode formed on the substrate in this order. The lower electrode are made of a metal thin film including a layer containing ruthenium as a major component having a full-width half maximum (FWHM) of a rocking curve of a (0002) diffraction peak of ruthenium of 3.0° or less. The piezoelectric aluminum nitride thin film formed on the lower electrode has a full-width half maximum (FWHM) of a rocking curve of a (0002) diffraction peak of 2.0° or less.

Owner:MEMS SOLUTIONS INC

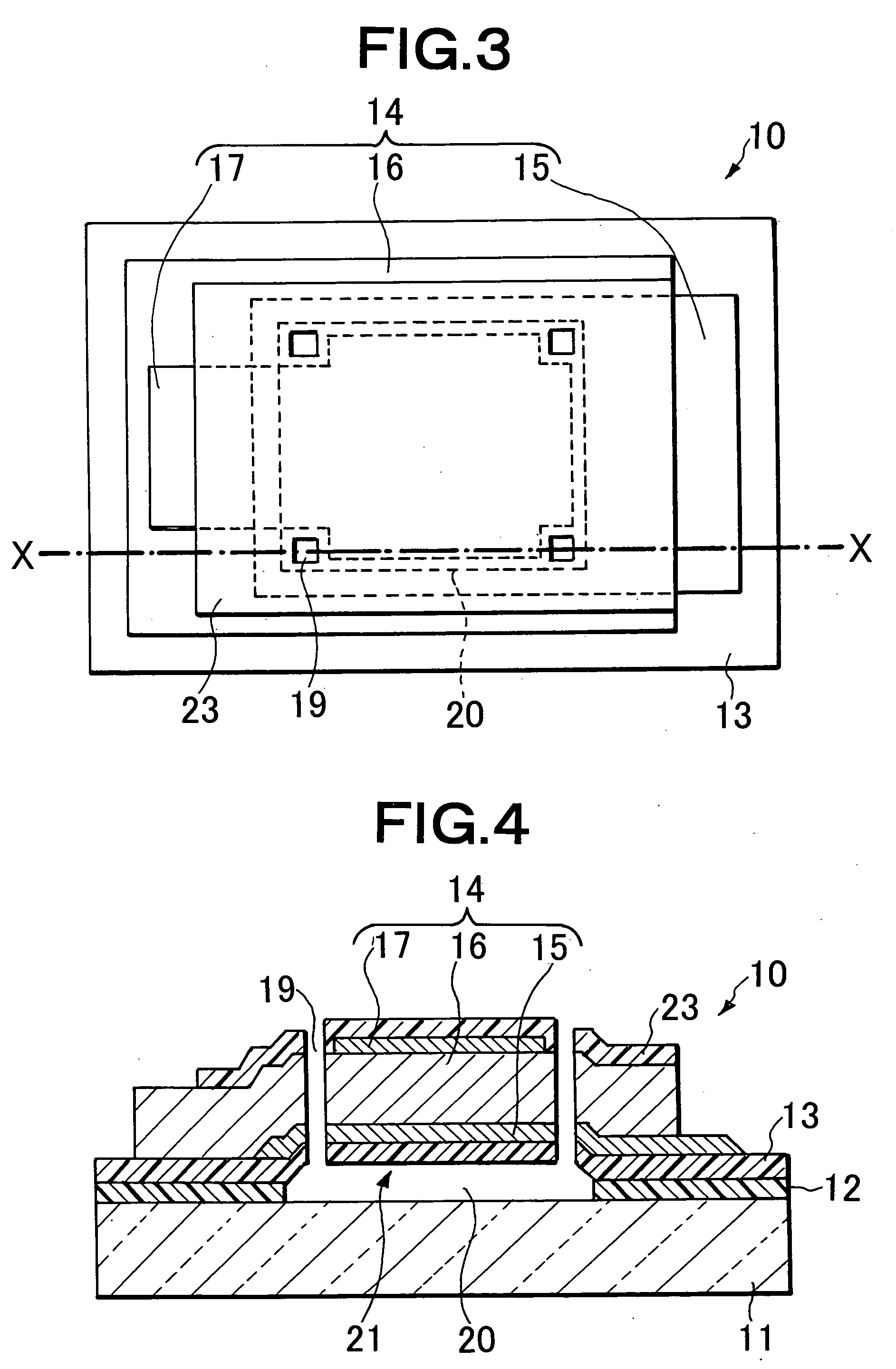

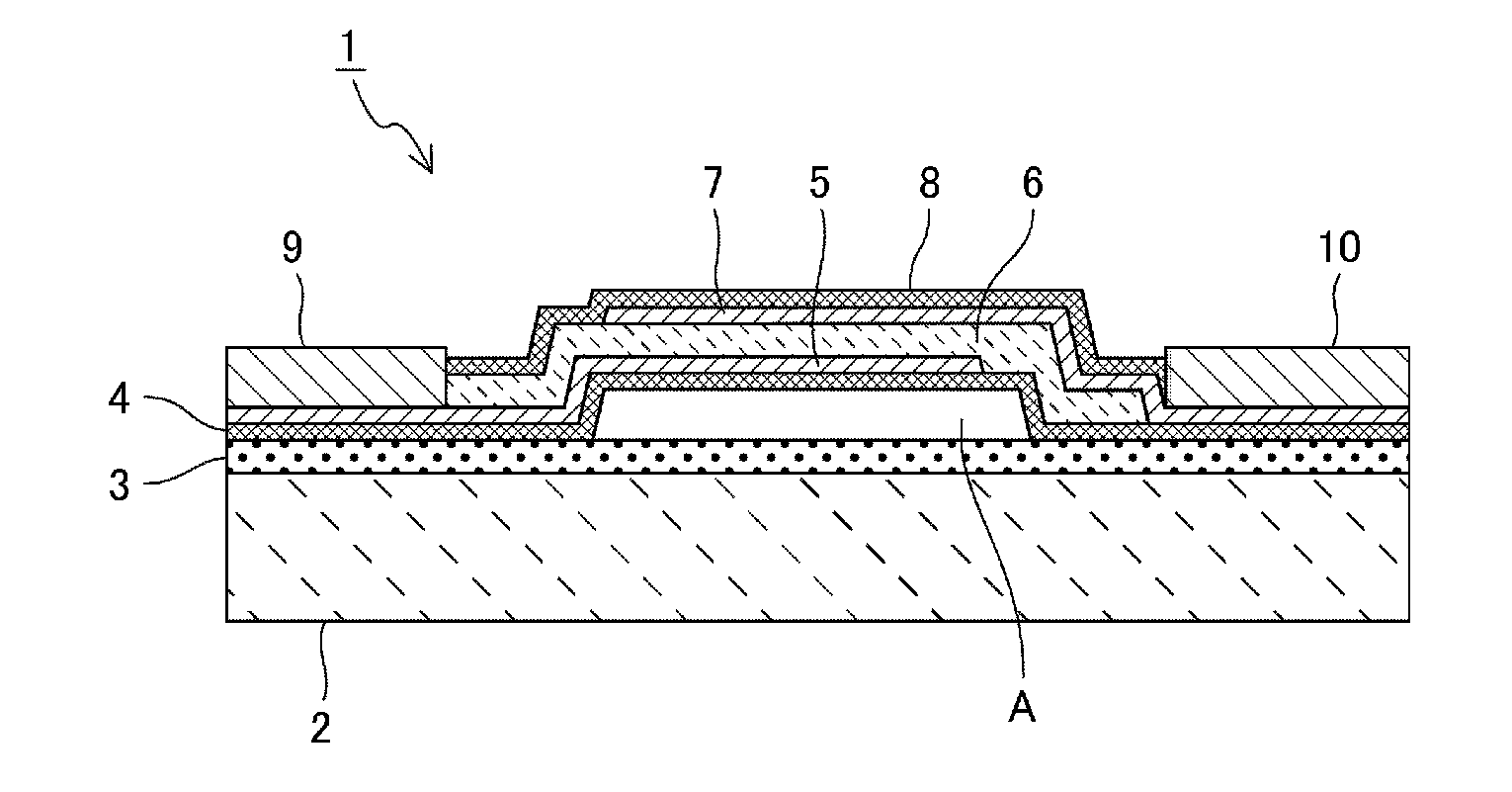

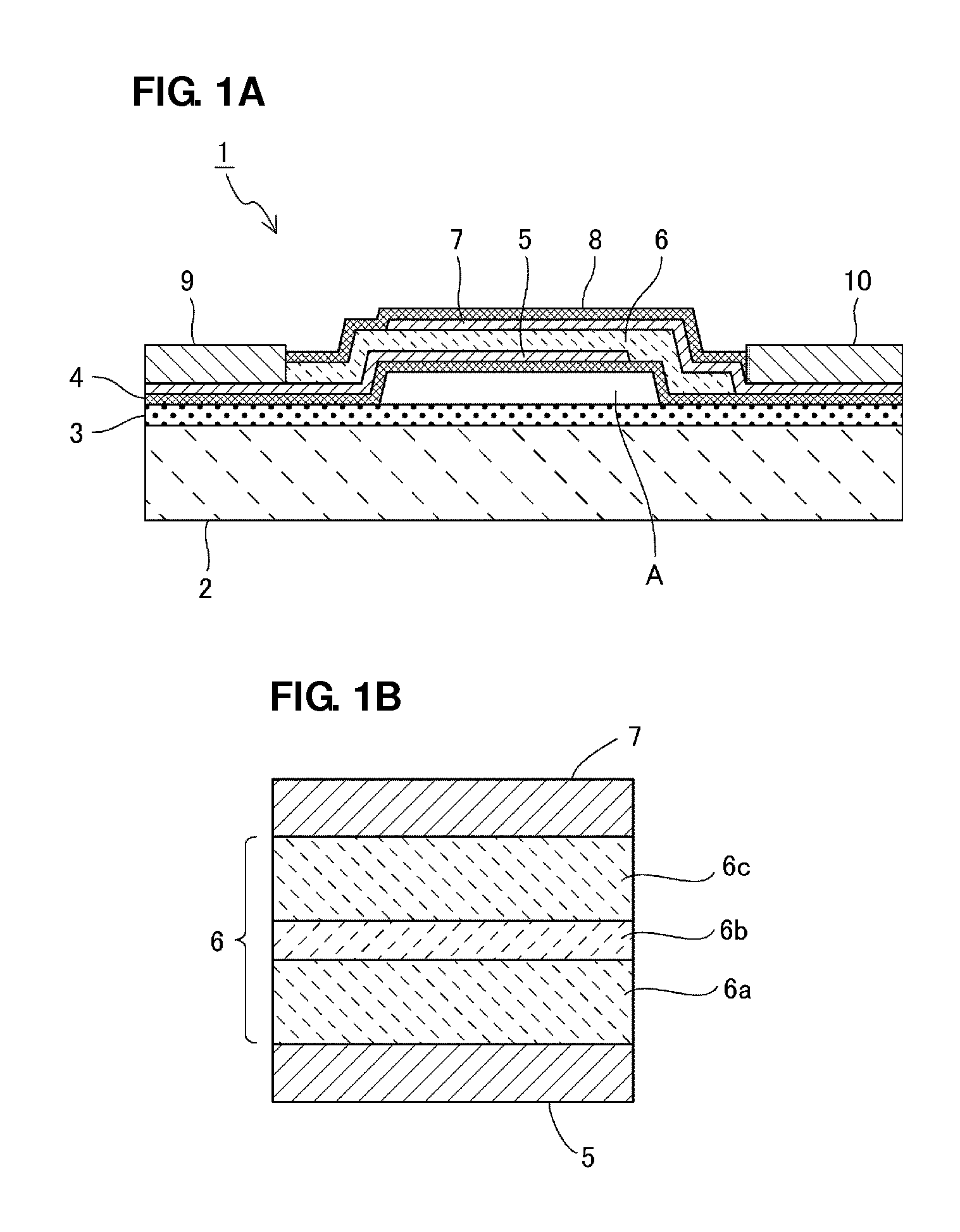

Thin film piezoelectric resonator and method of manufacturing the same

ActiveUS20090033177A1Good vibesOvercome problemsPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksOptoelectronicsPiezoelectric thin films

A thin film piezoelectric resonator includes a substrate having a cavity; a first electrode extending over the cavity; a piezoelectric film placed on the first electrode; and a second electrode placed on the piezoelectric film, the second electrode having a periphery partially overlapping on the cavity and tapered to have an inner angle of 30 degrees or smaller defined by a part of the periphery thereof and a bottom thereof.

Owner:KK TOSHIBA

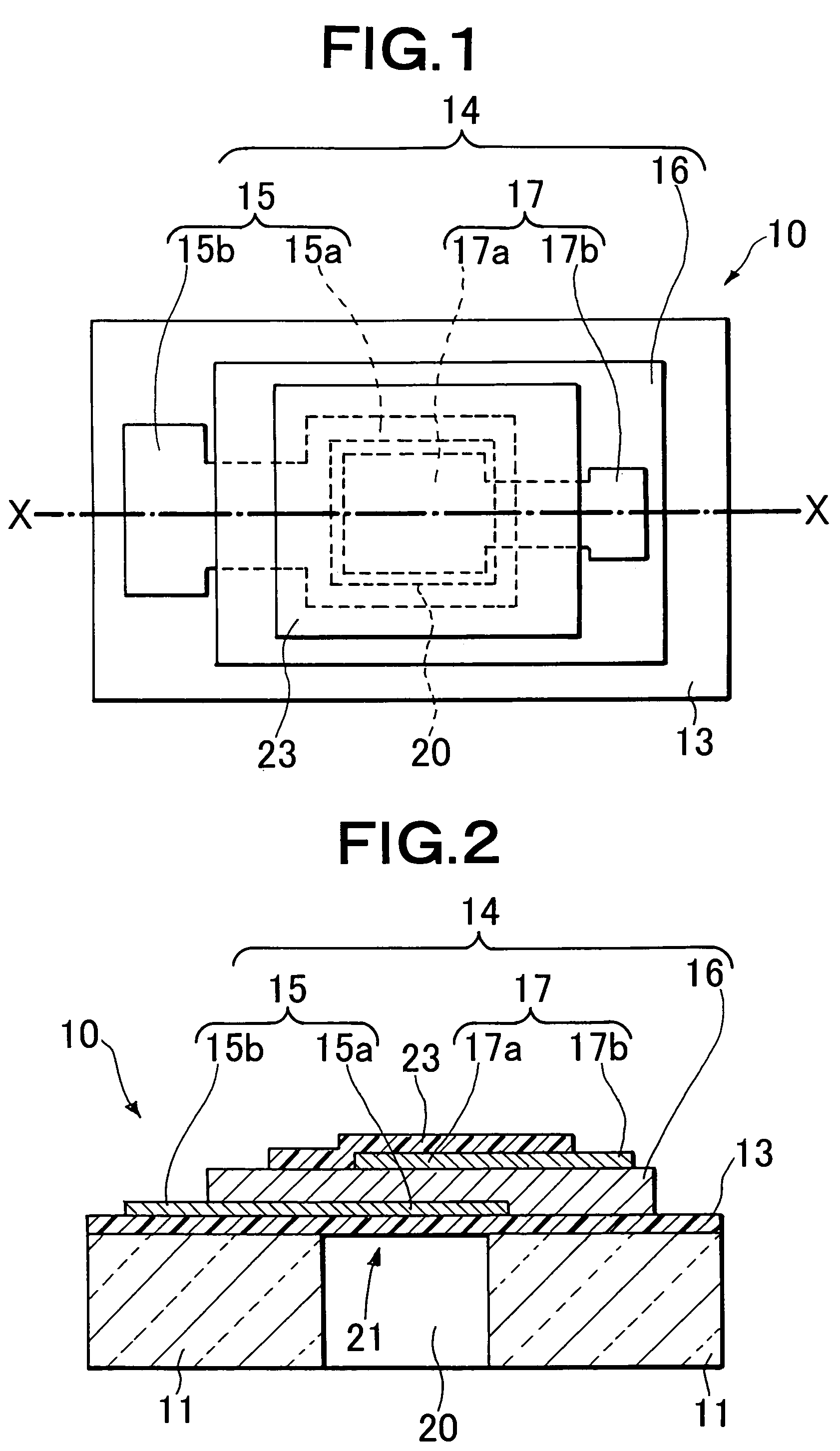

Piezoelectric resonator, piezoelectric filter, duplexer, communication apparatus, and method for manufacturing piezoelectric resonator

InactiveUS6906451B2Improve flatnessOutstanding crystallinityPiezoelectric/electrostriction/magnetostriction machinesImpedence networksOxygenPiezoelectric thin films

A piezoelectric thin film resonator having a stabilized temperature characteristic of resonant frequency, a method for manufacturing the same, and a communication apparatus using the piezoelectric thin film resonator are provided. The piezoelectric thin film resonator is provided with a substrate having an opening, first and second insulation films which are provided on one surface of the substrate while covering the opening and which primarily include SiO2 and Al2O3, respectively, Al2O3 having oxygen defect and being in an amorphous state, and a piezoelectric thin film which is provided on the second insulation film and is sandwiched between electrodes and which primarily includes ZnO.

Owner:MURATA MFG CO LTD

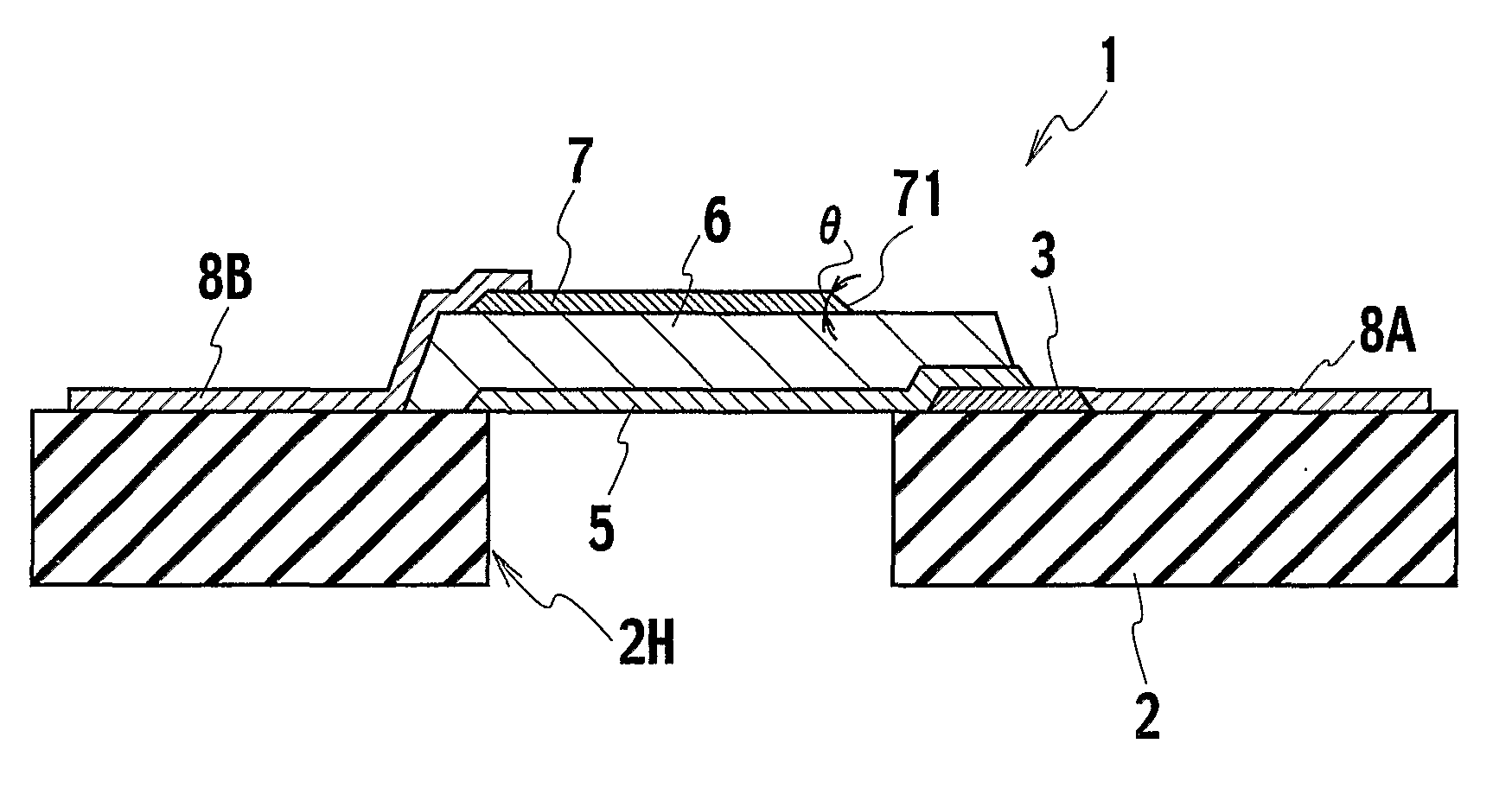

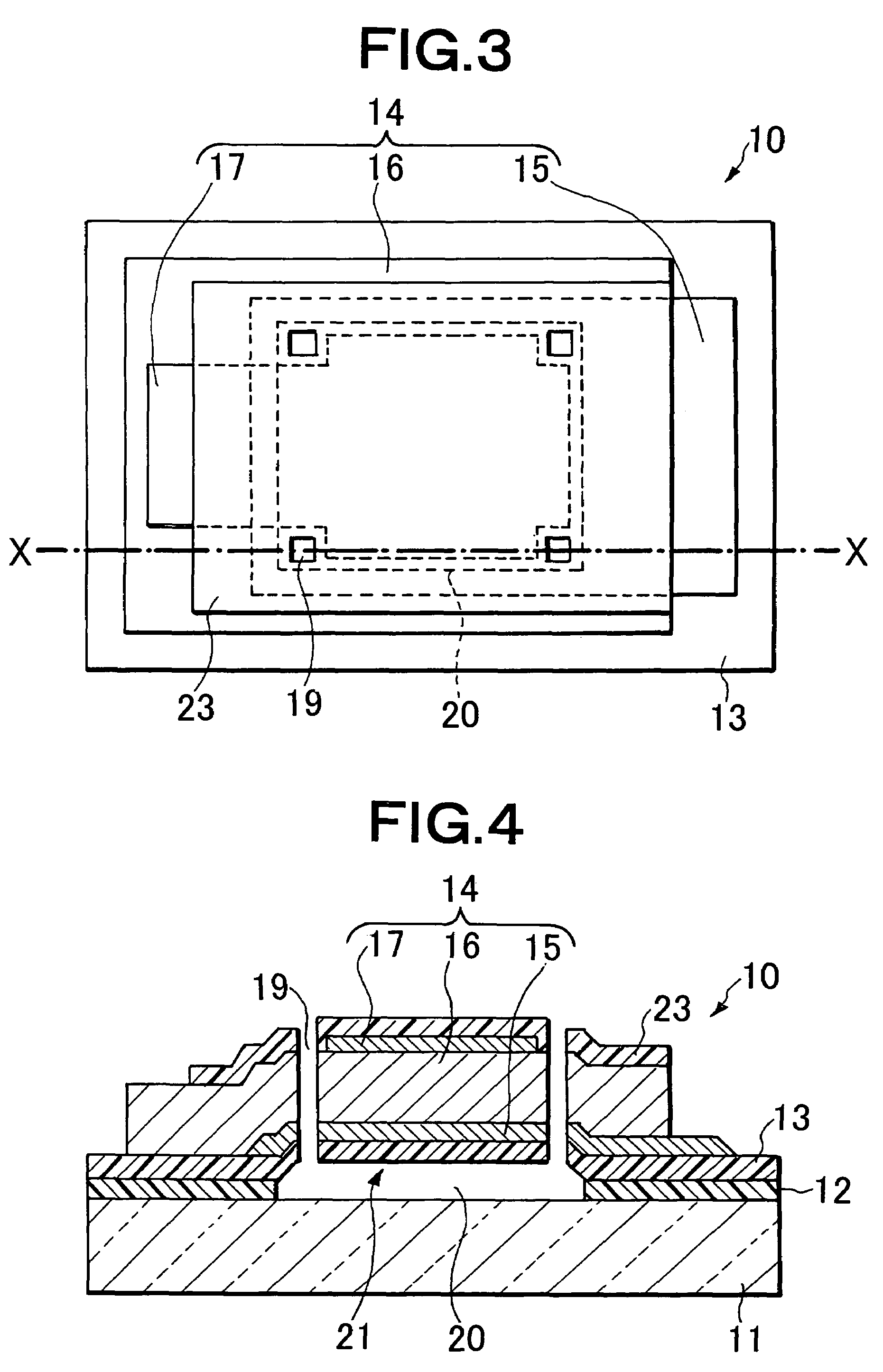

Thin film piezoelectric resonator and manufacturing process thereof

ActiveUS20050248232A1Piezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesResonanceOptoelectronics

a thin film piezoelectric resonator includes a substrate having a cavity, and a resonance portion located on the substrate and right above the cavity. The resonance portion includes a lower electrode layer located at a side of the cavity, an upper electrode layer opposite to the lower electrode layer, and a piezoelectric thin film located between the upper electrode layer and the lower electrode layer. A side of the piezoelectric thin film and a side of the lower electrode layer are located in a common plane.

Owner:KK TOSHIBA

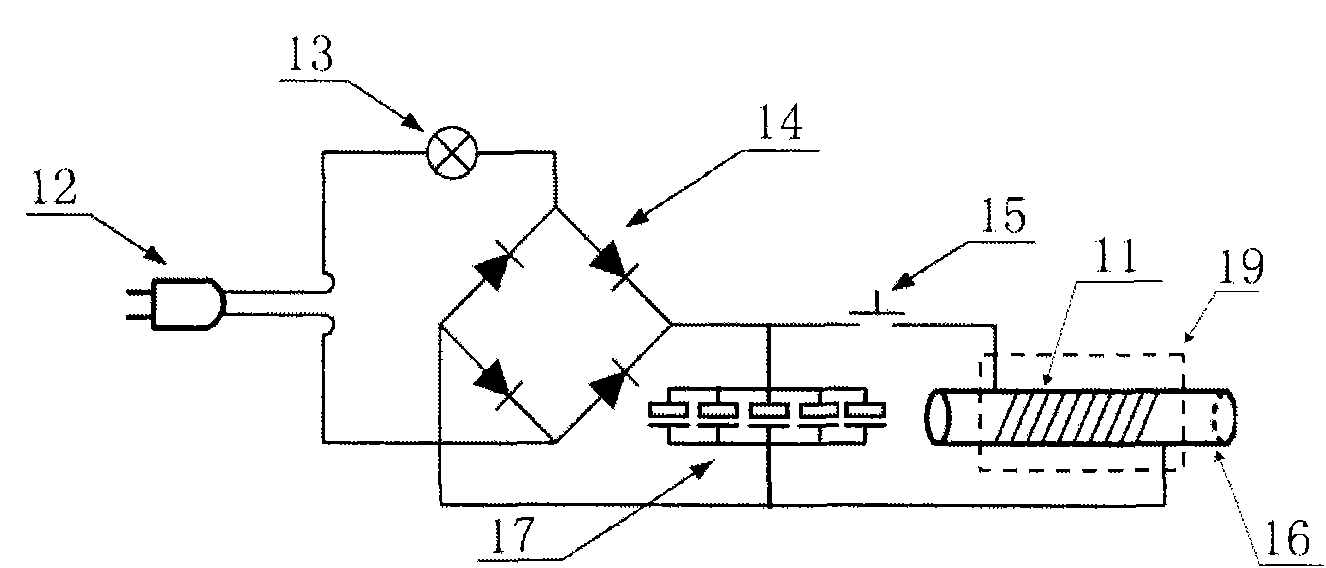

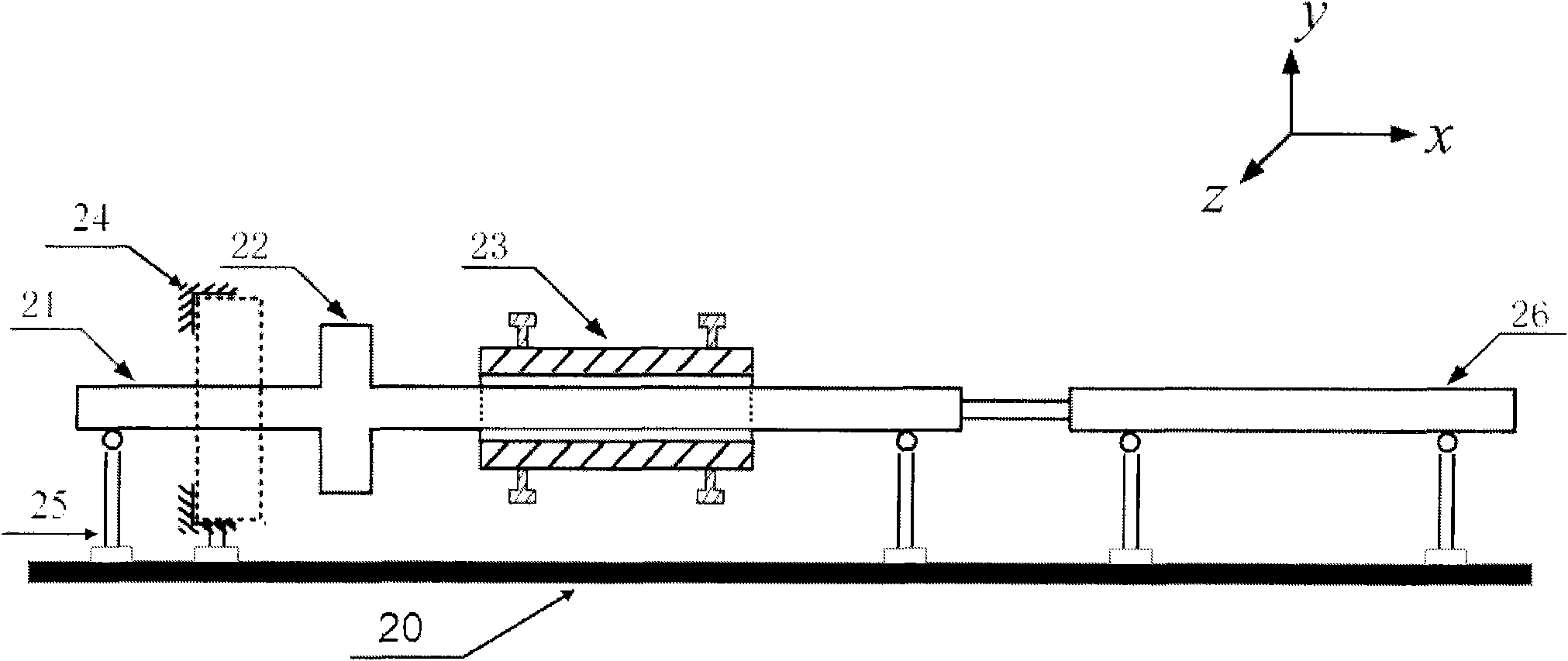

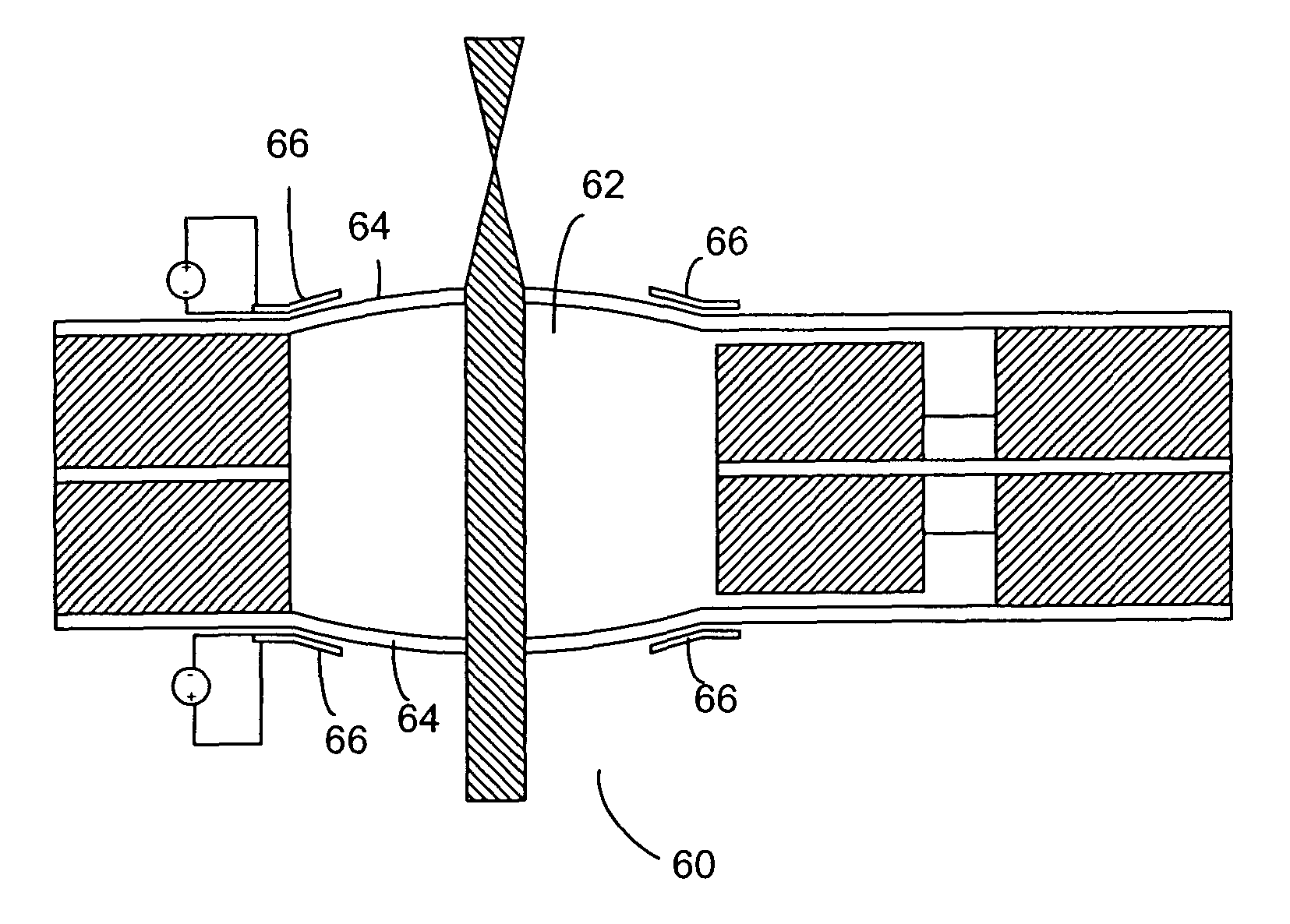

System and method for performing impact loading on micro test piece and measuring dynamic mechanical property

InactiveCN102135480ASolve the study of dynamic mechanical properties at high strain ratesLaunch fastStrength propertiesFerroelectric thin filmsStress–strain curve

The invention relates to a system and a method for performing impact loading on a micro test piece and measuring dynamic mechanical property. The method comprises the following steps of: instantly accelerating a bullet by using an electromagnetic pulse launch technology and launching the bullet at high speed; transmitting a stretching stress wave generated by collision of the bullet to the micro test piece by using a separated Hopkinson bar technology so as to generate the impact loading on the micro test piece; recording strain data of an input bar and an output bar, and acquiring an enlarged surface dynamic deformation image of the micro test piece; analyzing and obtaining a stress strain curve of the micro test piece subjected to the impact loading having different strain rates; and analyzing the surface dynamic deformation image of the micro test piece and obtaining a distribution of a bidimensional displacement field and a strain field during dynamic impact loading of the micro test piece. By the system and the method, the problem of research on the dynamic mechanical property of a micro electro mechanical system (MEMS), and membrane materials such as piezoelectric thin films, ferroelectric thin films and the like is solved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Piezoelectric resonator including an acoustic reflector portion

ActiveUS7868519B2Quality improvementImprove resonance characteristicsPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesResonanceAcoustics

Owner:MURATA MFG CO LTD

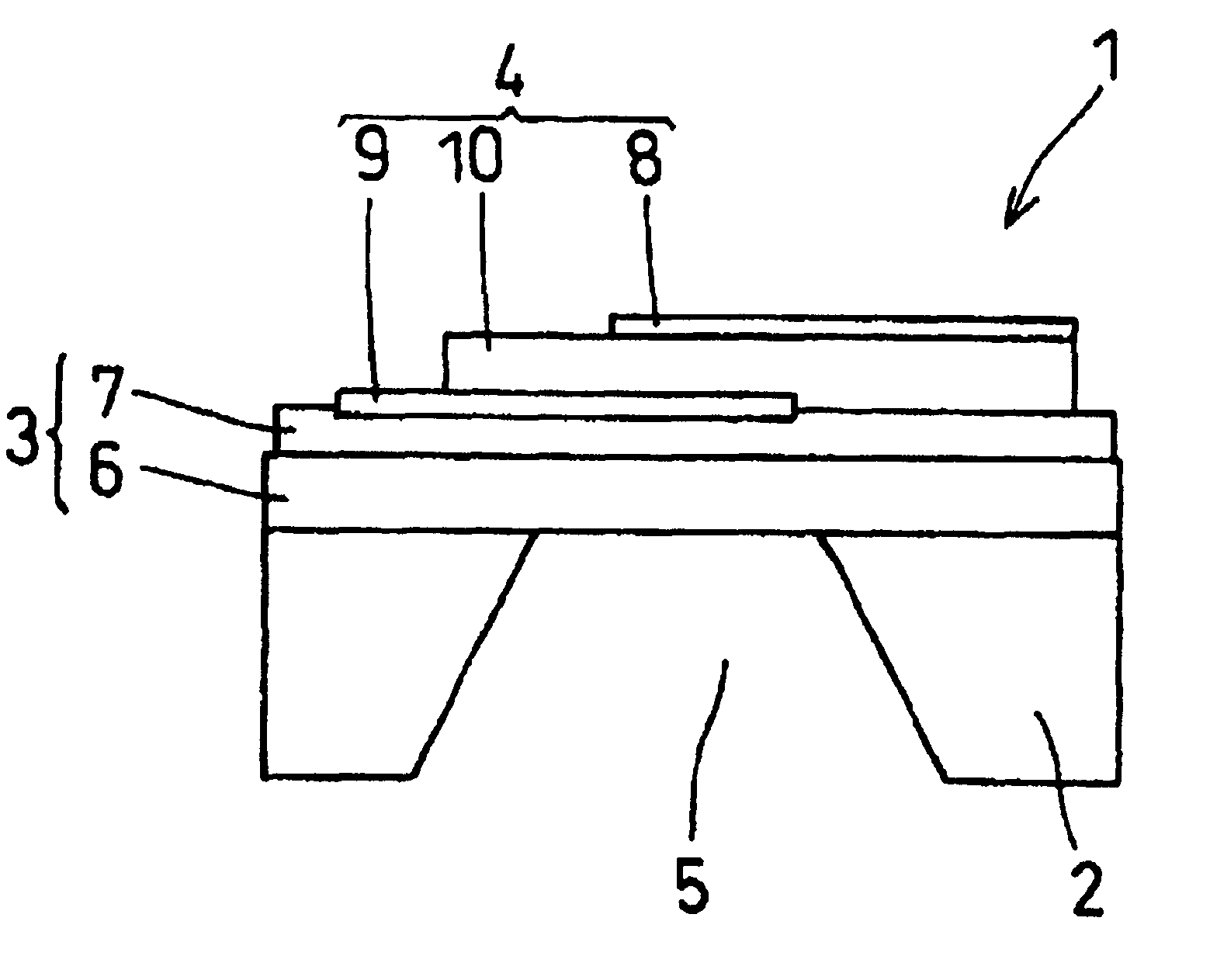

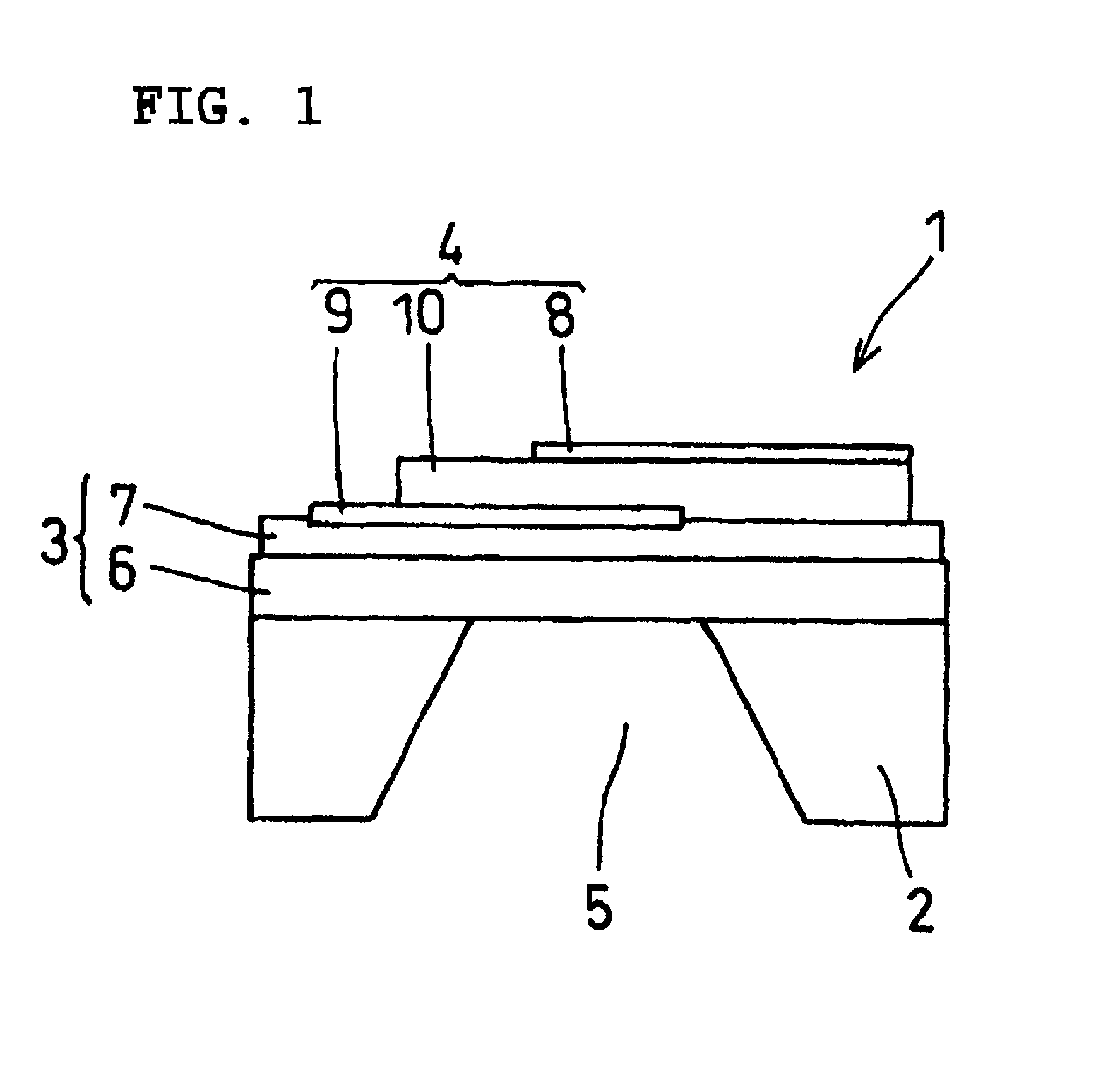

Piezoelectric thin-film resonator, piezoelectric filter, and electronic component including the piezoelectric filter

InactiveUS7002437B2Improve featuresHigh resolutionPiezoelectric/electrostriction/magnetostriction machinesImpedence networksElectronic componentResonator

A piezoelectric thin-film resonator includes a supporting substrate. A piezoelectric thin-film is formed on the supporting substrate. A lower electrode and an upper electrode are formed with the piezoelectric thin-film therebetween. The stiffness of at least one of the lower and upper electrodes is higher than that of the piezoelectric thin-film.

Owner:MURATA MFG CO LTD

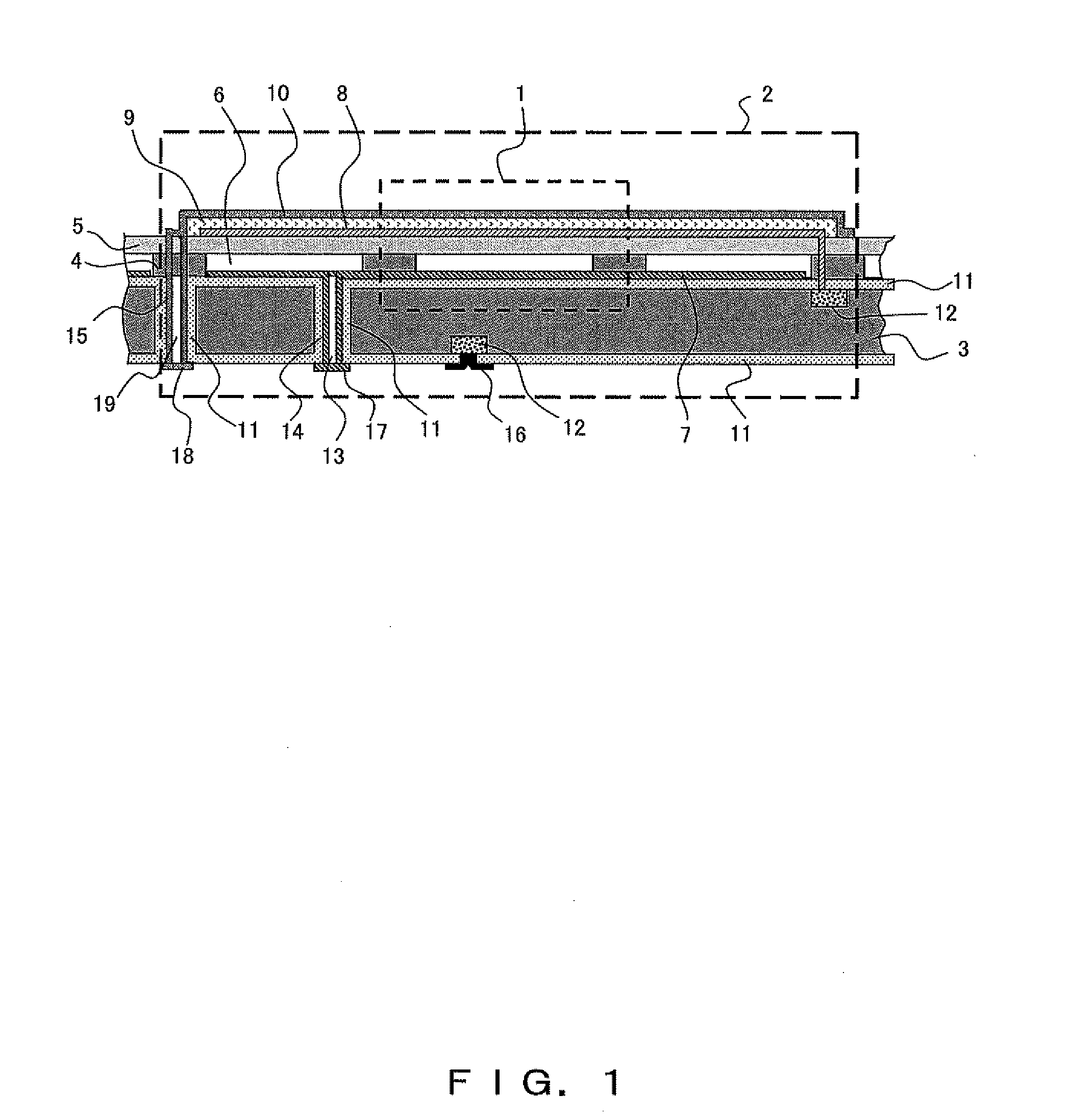

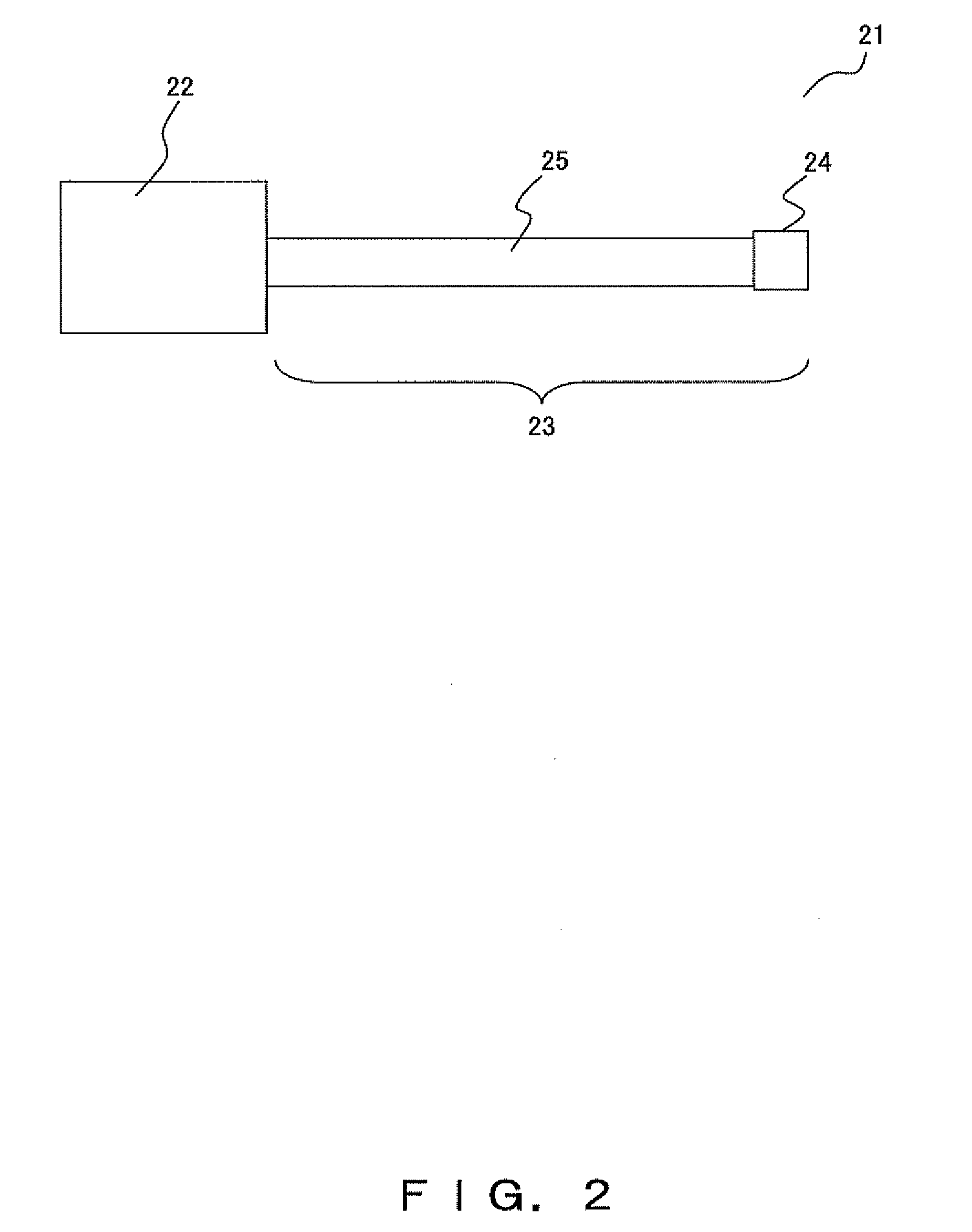

Ultrasound transducer manufactured by using micromachining process, its device, endoscopic ultrasound diagnosis system thereof, and method for controlling the same

ActiveUS20090001853A1Ultrasonic/sonic/infrasonic diagnosticsPiezoelectric/electrostriction/magnetostriction machinesUltrasonic sensorControl signal

An ultrasound transducer manufactured by using a micromachining process comprises: a first electrode into which a control signal for transmitting ultrasound is input; a substrate on which the first electrode is formed; a second electrode that is a ground electrode facing the first electrode with a prescribed space between the first and second electrodes; a membrane on which the second electrode is formed and which vibrates and generates the ultrasound when a voltage is applied between the first and second electrodes; a piezoelectric film contacting the membrane; and a third electrode electrically continuous to the piezoelectric film.

Owner:OLYMPUS CORP

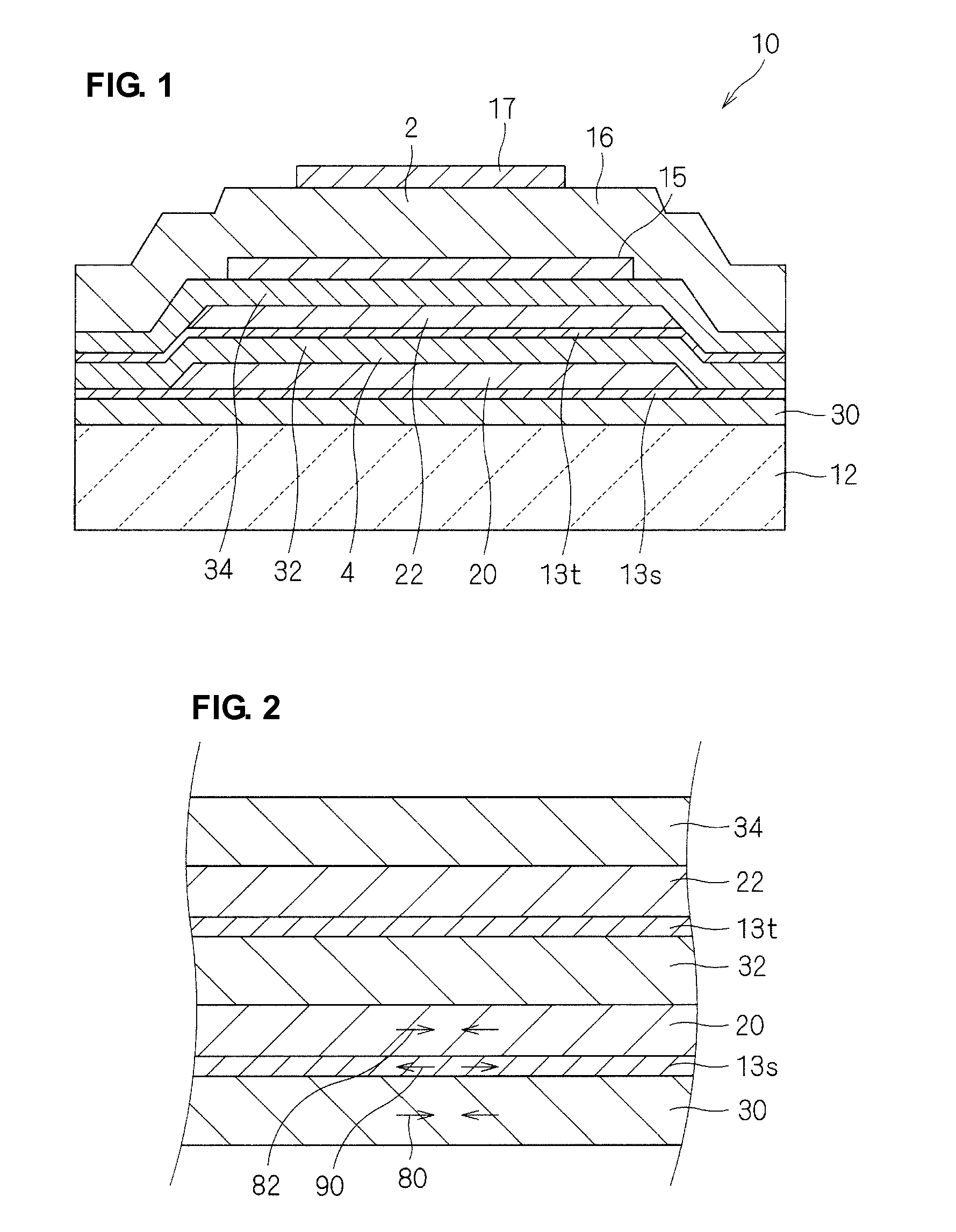

Piezoelectric thin-film resonator and method for producing piezoelectric thin film

ActiveUS20130127300A1Increase freedomExpand the scope ofImpedence networksPiezoelectric/electrostriction/magnetostriction machinesThin membranePiezoelectric thin films

A piezoelectric thin-film resonator includes a piezoelectric thin film which includes aluminum nitride containing Sc and which has a concentration distribution such that the concentration of Sc is non-uniform in a thickness direction of the piezoelectric thin film; a first electrode; a second electrode facing the first electrode across the piezoelectric thin film; and a substrate supporting a piezoelectric vibrating section defined by the piezoelectric thin film and the first and second electrodes.

Owner:MURATA MFG CO LTD

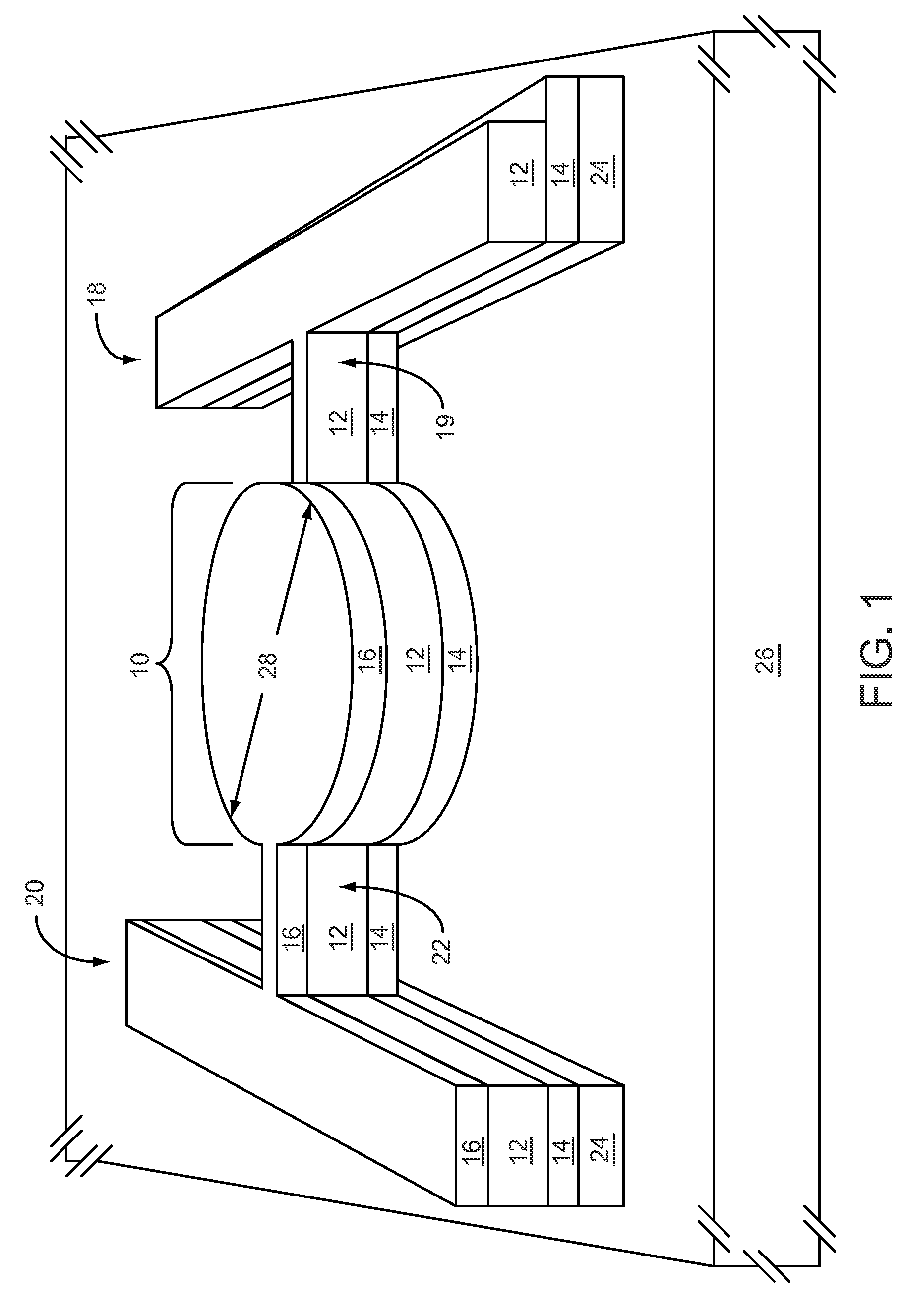

Method for manufacturing a vibrating MEMS circuit

ActiveUS9369105B1Low temperature coefficientAccurate shapePiezoelectric/electrostrictive device manufacture/assemblyImpedence networksElectromechanical coupling coefficientCrystal orientation

A method for making a micro-electro-mechanical systems (MEMS) vibrating structure is disclosed. The MEMS is supported by a MEMS anchor system and includes a single-crystal piezoelectric thin-film layer that has a specific non-standard crystal orientation, which may be selected to increase an electromechanical coupling coefficient, decrease a temperature coefficient of frequency, or both. The MEMS vibrating structure may have dominant lateral vibrations or dominant thickness vibrations. The single-crystal piezoelectric thin-film layer may include Lithium Tantalate or Lithium Niobate, and may provide MEMS vibrating structures with precise sizes and shapes, which may provide high accuracy and enable fabrication of multiple resonators having different resonant frequencies on a single substrate.

Owner:QORVO US INC

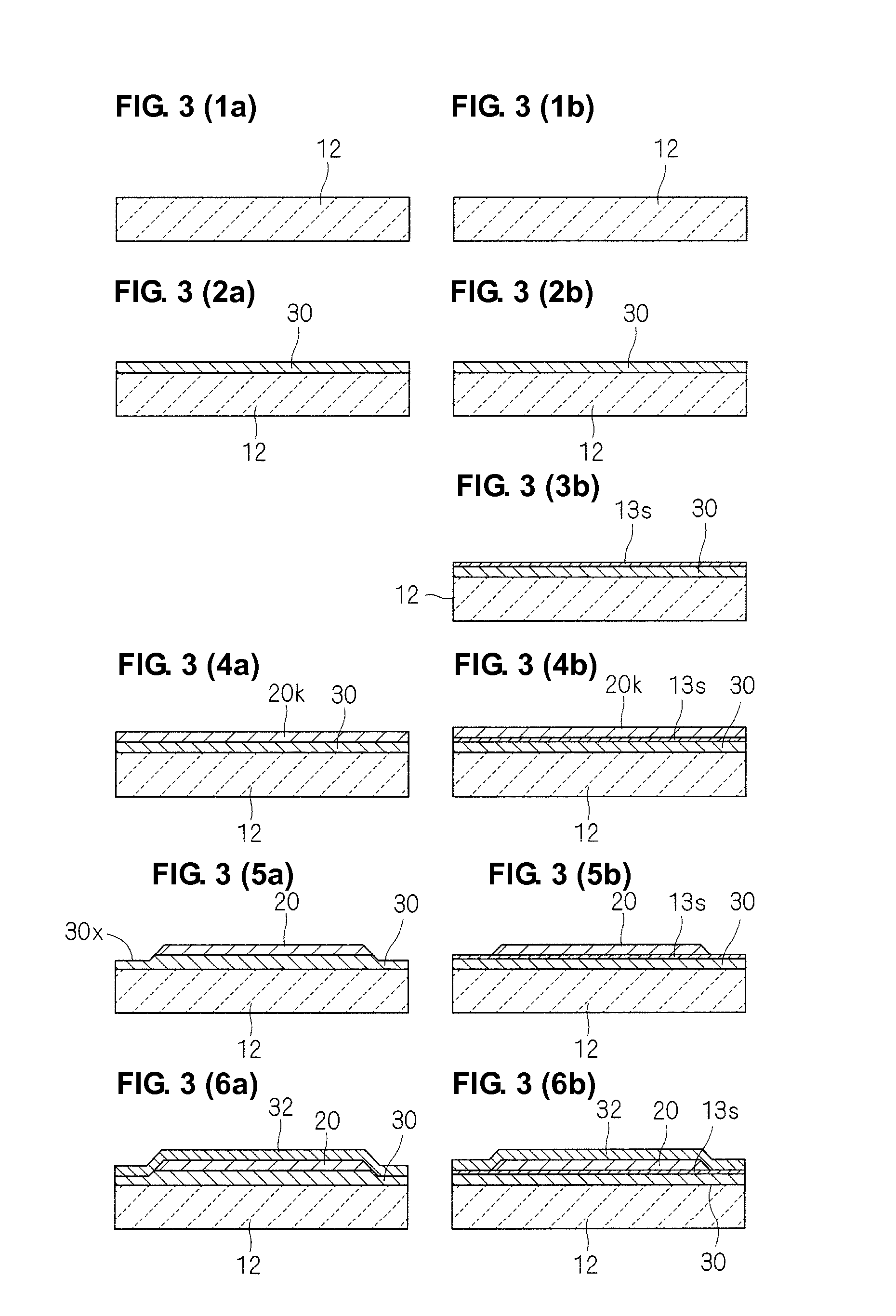

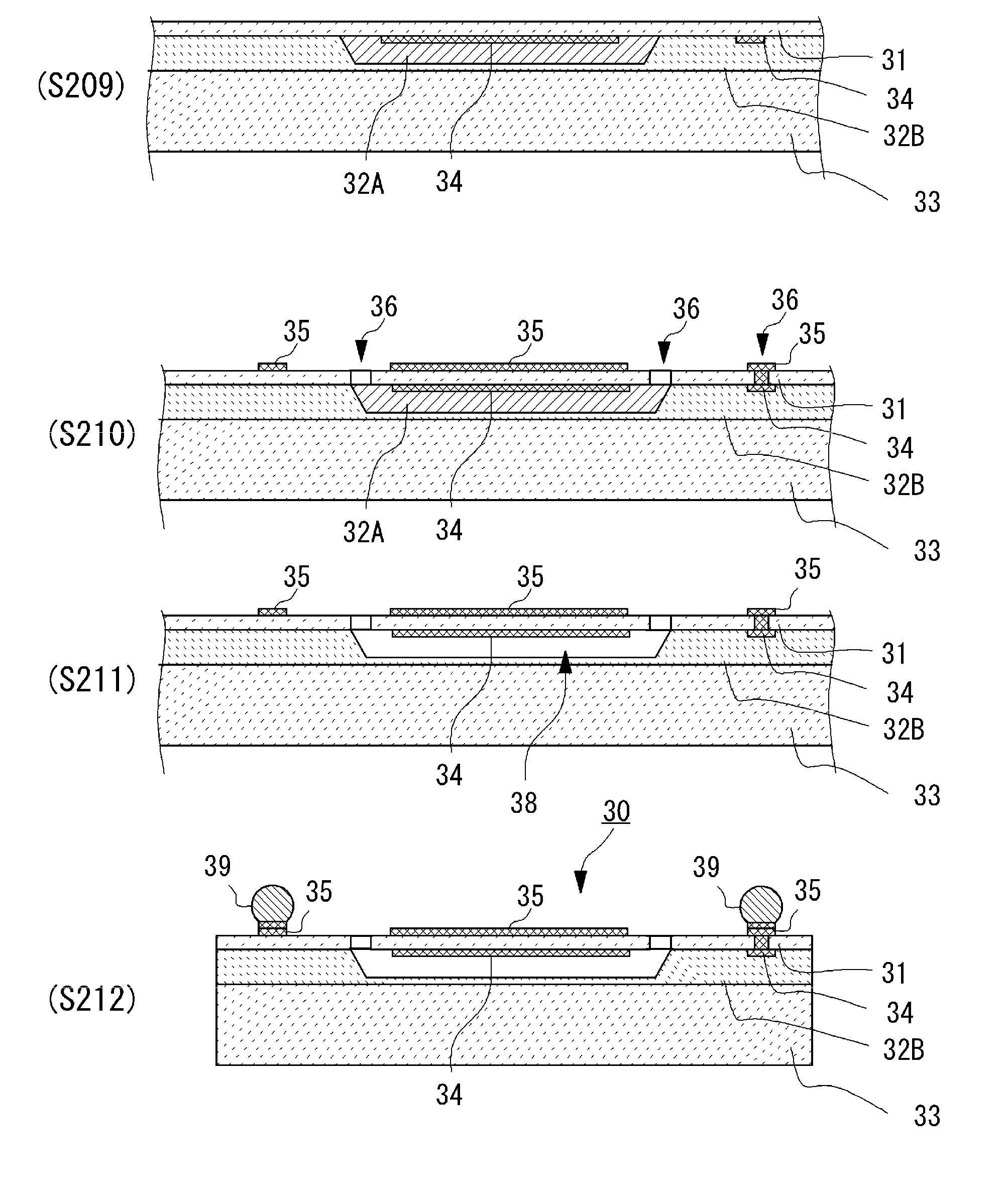

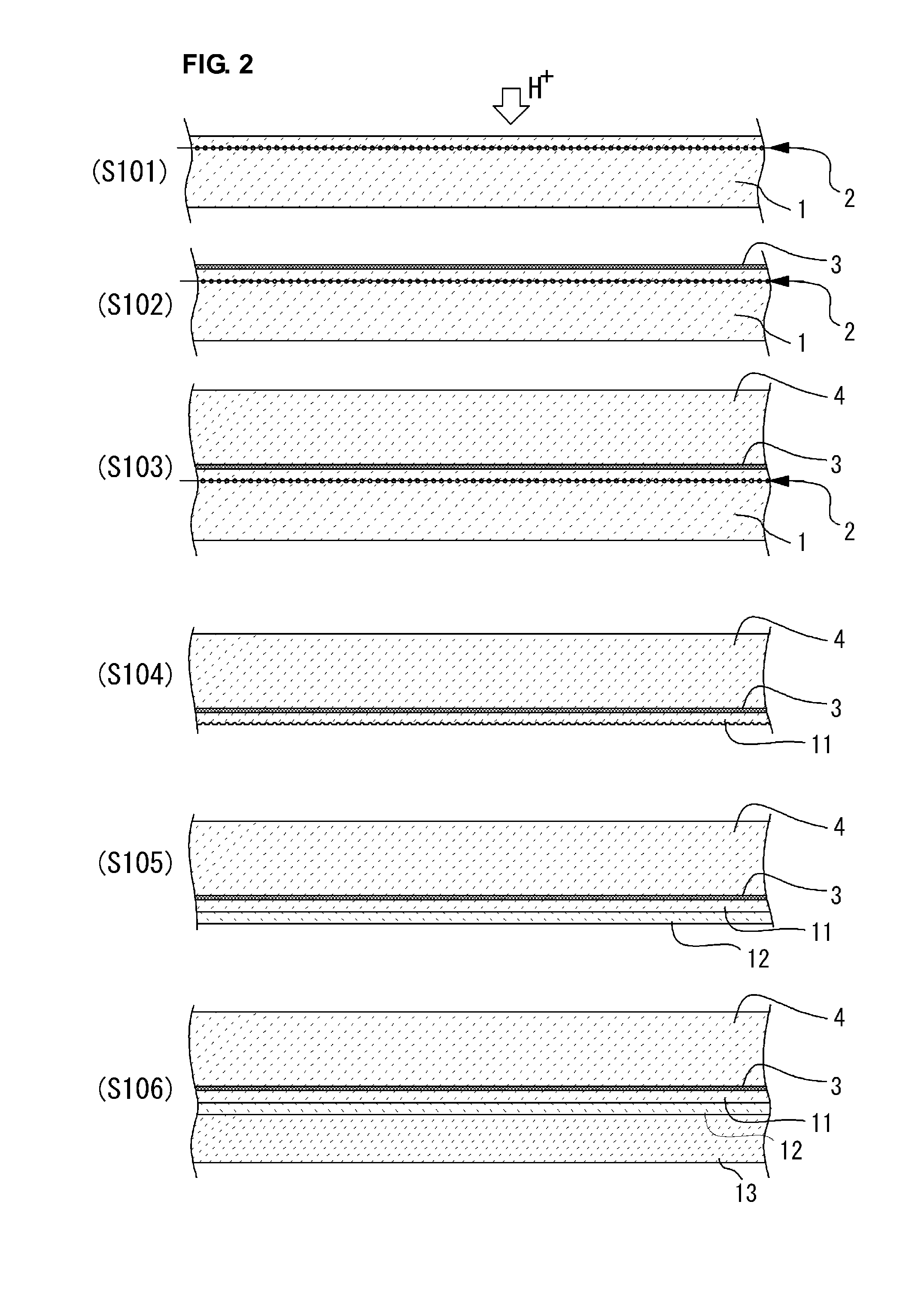

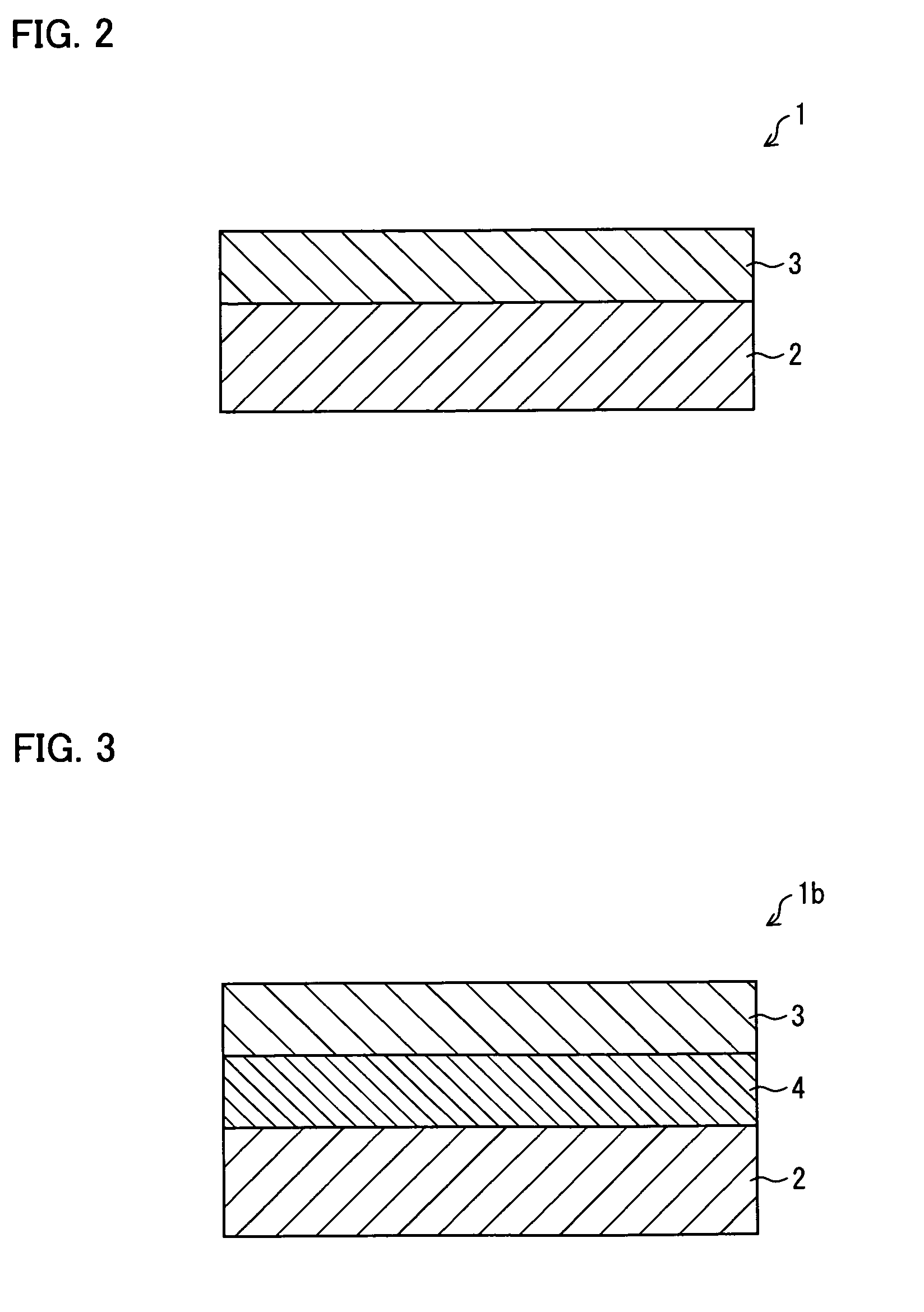

Method for manufacturing composite piezoelectric substrate and piezoelectric device

ActiveUS20110278993A1Improve featuresLess piezoelectric degradationPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesMetallurgyIon implantation

A piezoelectric device is manufactured in which the material of a supporting substrate can be selected from various alternative materials. Ions are implanted into a piezoelectric substrate to form an ion-implanted portion. A temporary supporting substrate is formed on the ion-implanted surface of the piezoelectric substrate. The temporary supporting substrate includes a layer to be etched and a temporary substrate. The piezoelectric substrate is then heated to be divided at the ion-implanted portion to form a piezoelectric thin film. A supporting substrate is then formed on the piezoelectric thin film. The supporting substrate includes a dielectric film and a base substrate. The temporary supporting substrate is made of a material that produces a thermal stress at the interface between the temporary supporting substrate and the piezoelectric thin film less than the thermal stress at the interface between the supporting substrate and the piezoelectric thin film.

Owner:MURATA MFG CO LTD

Piezoelectric thin-film resonator, piezoelectric filter, and electronic component including the piezoelectric filter

InactiveUS7276994B2Impedence networksPiezoelectric/electrostriction/magnetostriction machinesElectronic componentPiezoelectric thin films

A piezoelectric thin-film resonator includes a supporting substrate. A piezoelectric thin-film is formed on the supporting substrate. A lower electrode and an upper electrode are formed with the piezoelectric thin-film therebetween. The stiffness of at least one of the lower and upper electrodes is higher than that of the piezoelectric thin-film.

Owner:MURATA MFG CO LTD

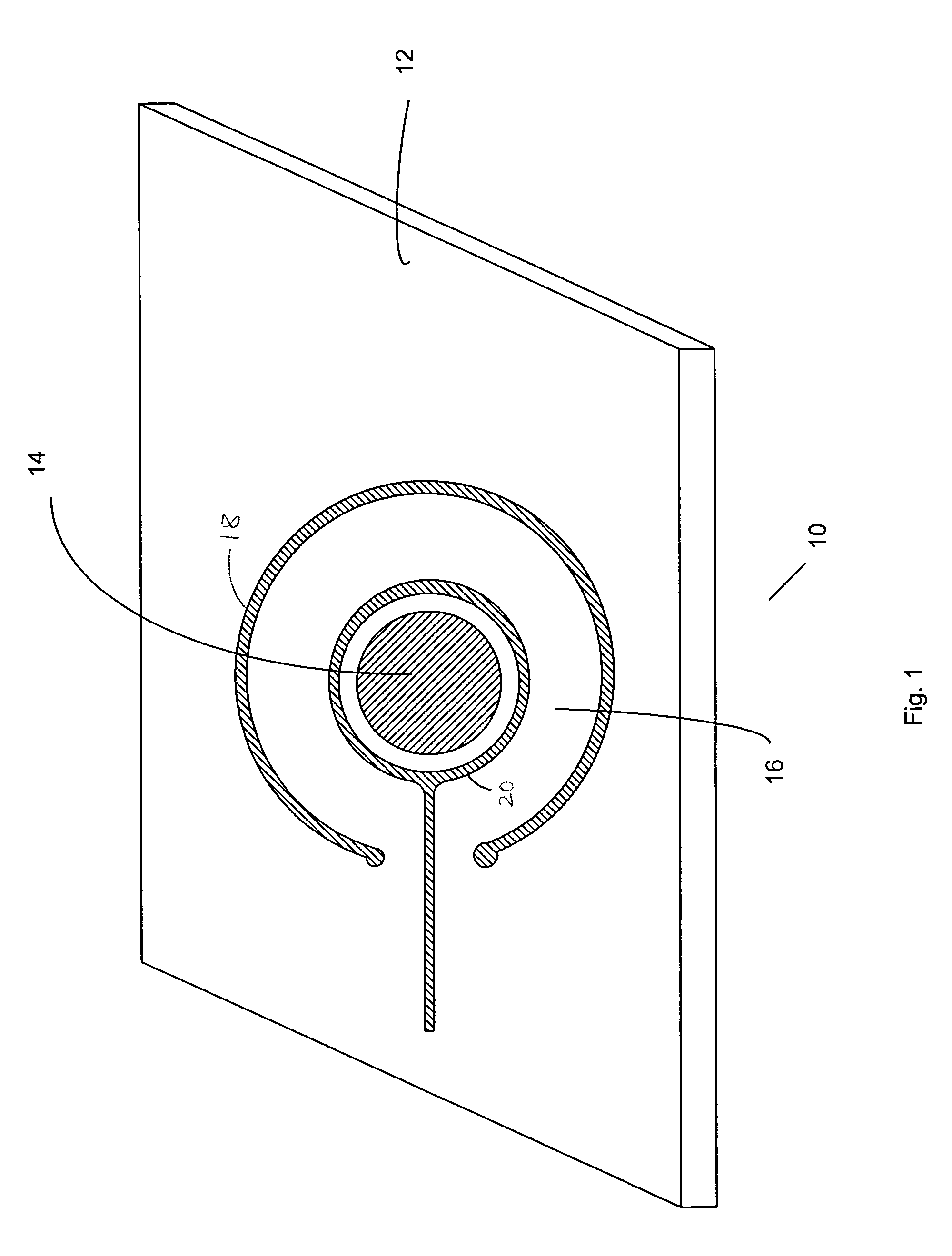

High speed piezoelectric optical system with tunable focal length

ActiveUS7369723B1Curvature can be modifiedAltering focal length of lensCoupling light guidesLensOptical storageLens plate

A varifocal optical system includes a substantially circular membrane deposited on a substrate, and a ring-shaped PZT thin film deposited on the outer portion of the circular membrane. The membrane may be a MEMS-micromachined membrane, made of thermal oxide, polysilicon, ZrO2 and SiO2. The membrane is initially in a buckled state, and may function as a mirror or a lens. Application of an electric voltage between an inner and outer electrode on the piezoelectric thin film induces a lateral strain on the PZT thin film, thereby altering the curvature of the membrane, and thus its focal length. Focal length tuning speeds as high as 1 MHz have been demonstrated. Tuning ranges of several hundred microns have been attained. The varifocal optical system can be used in many applications that require rapid focal length tuning, such as optical switching, scanning confocal microscopy, and vibration compensation in optical storage disks.

Owner:CHARLES STARK DRAPER LABORATORY

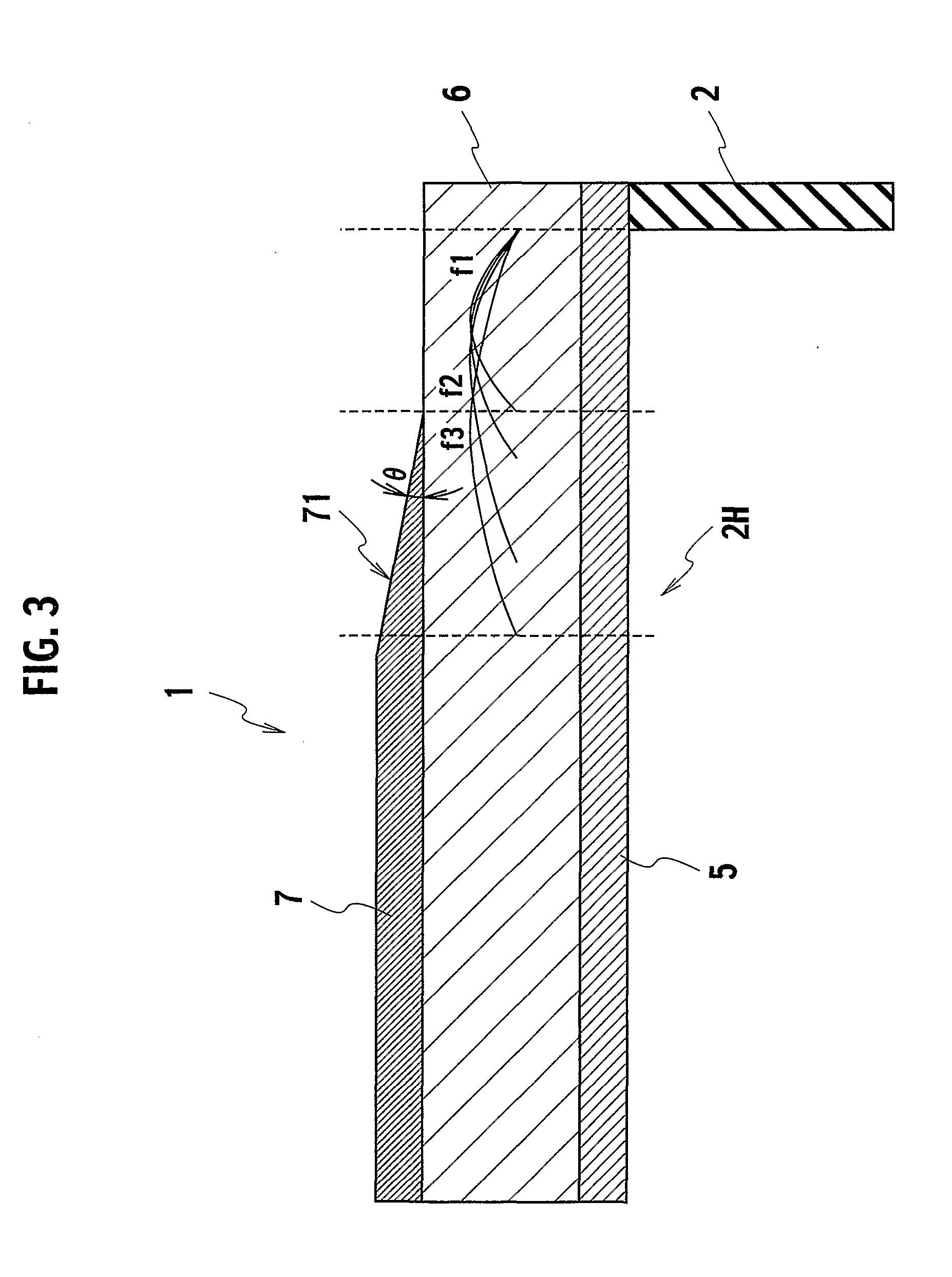

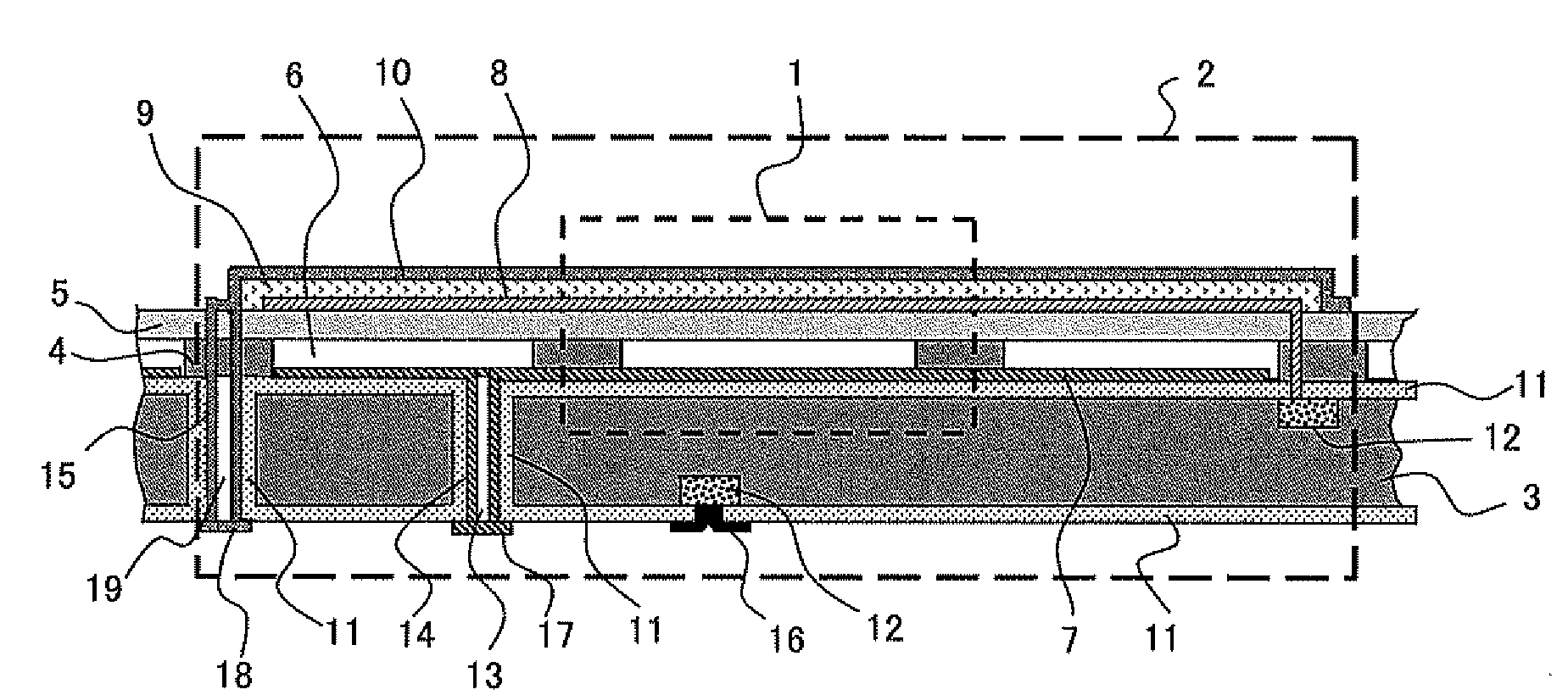

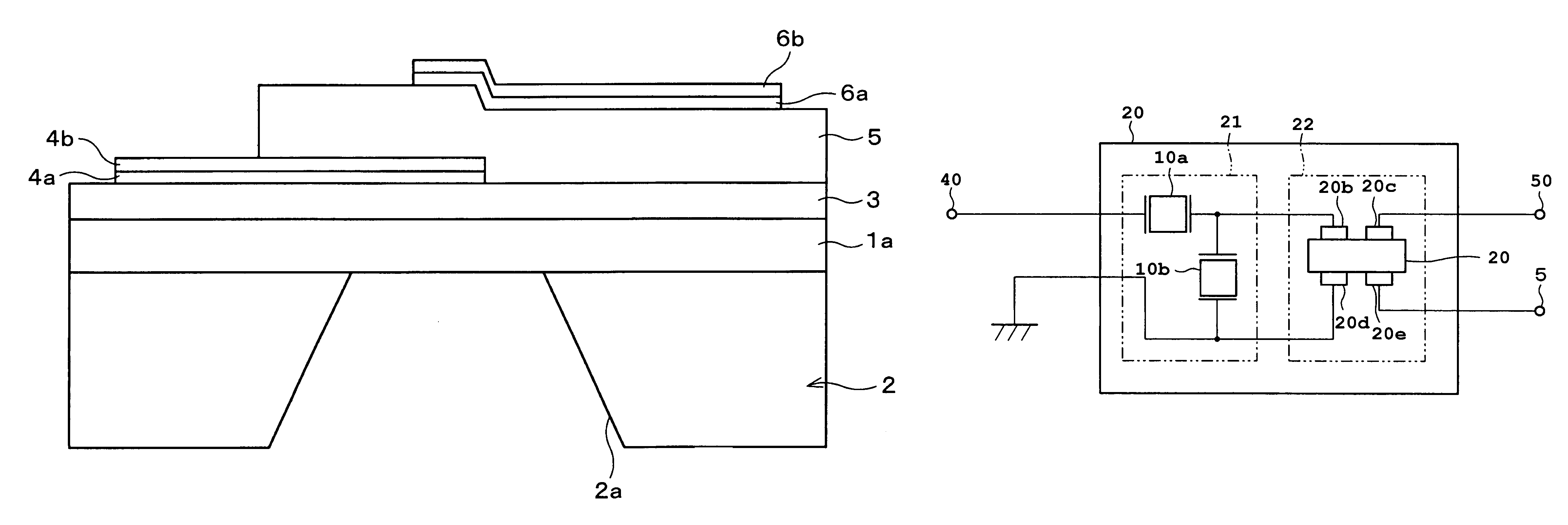

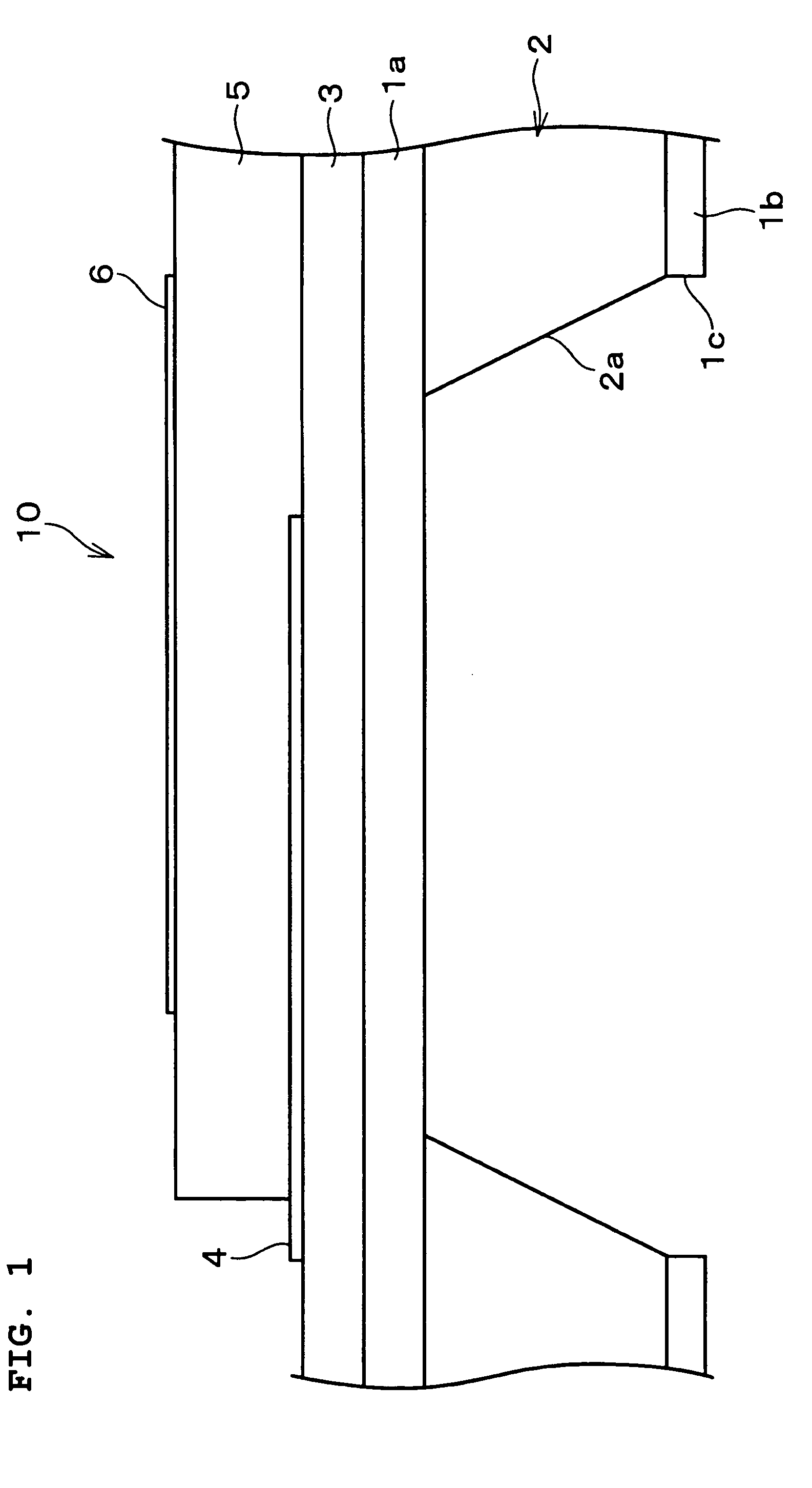

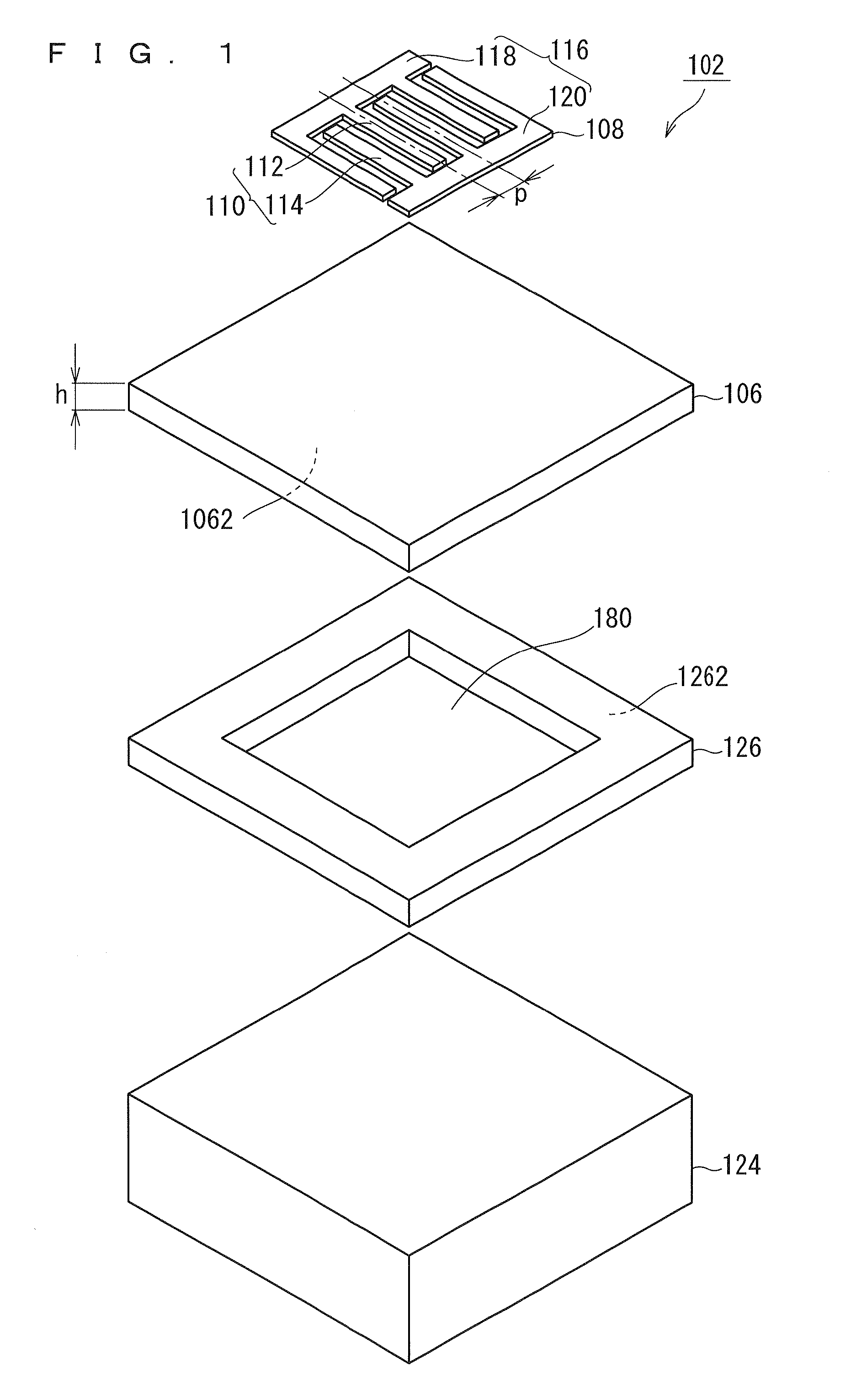

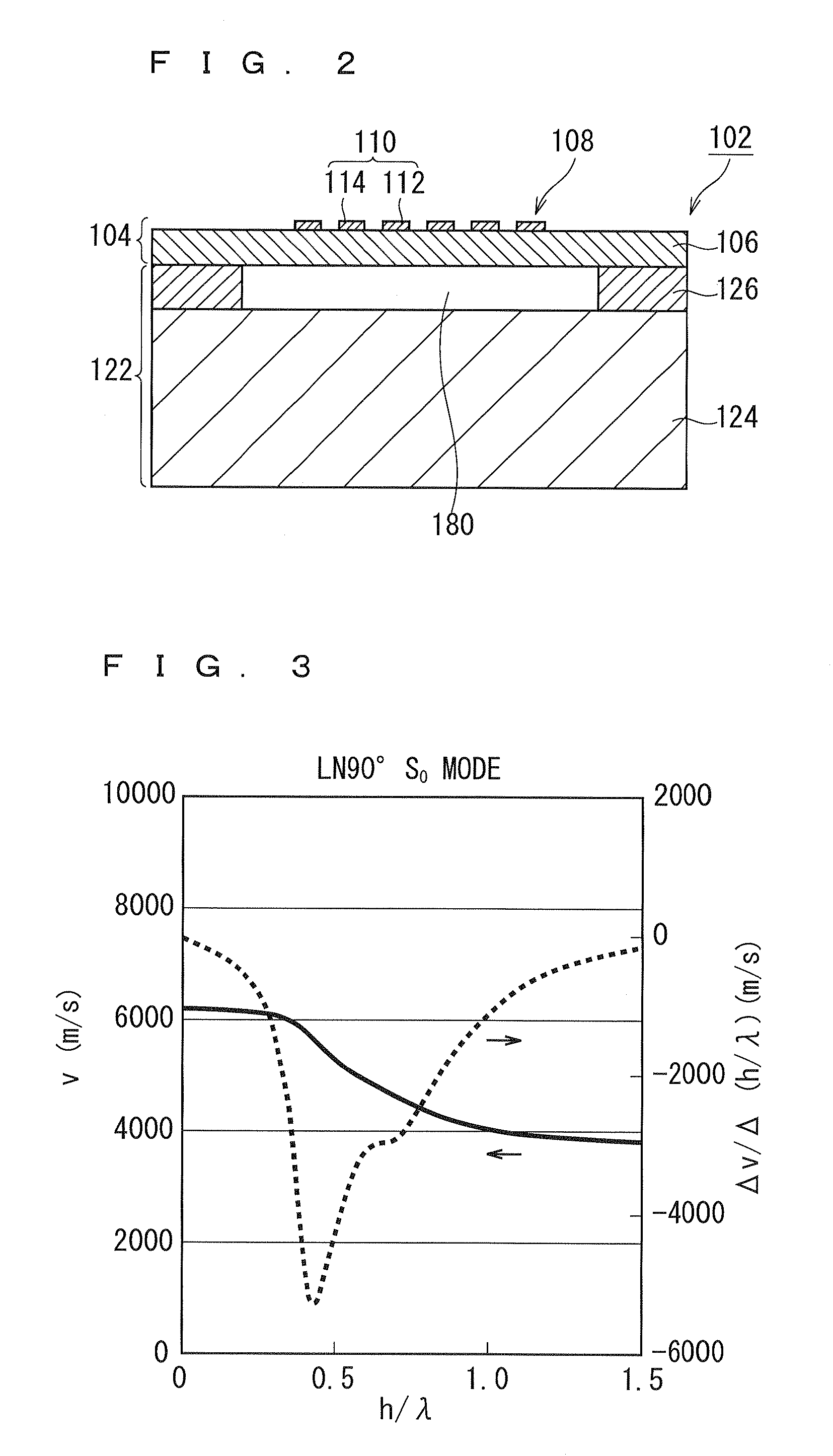

Elastic wave device and manufacturing method for same

ActiveUS9748923B2Lower electrode resistanceImprove featuresImpedence networksEngineeringPiezoelectric thin films

An elastic wave device includes a support layer with a through-hole or a recess opened at an upper surface thereof, a piezoelectric thin film arranged on the support layer to extend above the recess or the through-hole of the support layer, and an IDT electrode defined on at least one of upper and lower surfaces of the piezoelectric thin film in a region of the piezoelectric thin film, the region extending above the recess, or the through-hole. A secondary mode of a plate wave, which contains a U1 component as a main component, is utilized. The piezoelectric thin film is made of LiTaO3, and Euler angles (φ, θ, ψ) of the LiTaO3 fall within specific ranges.

Owner:MURATA MFG CO LTD

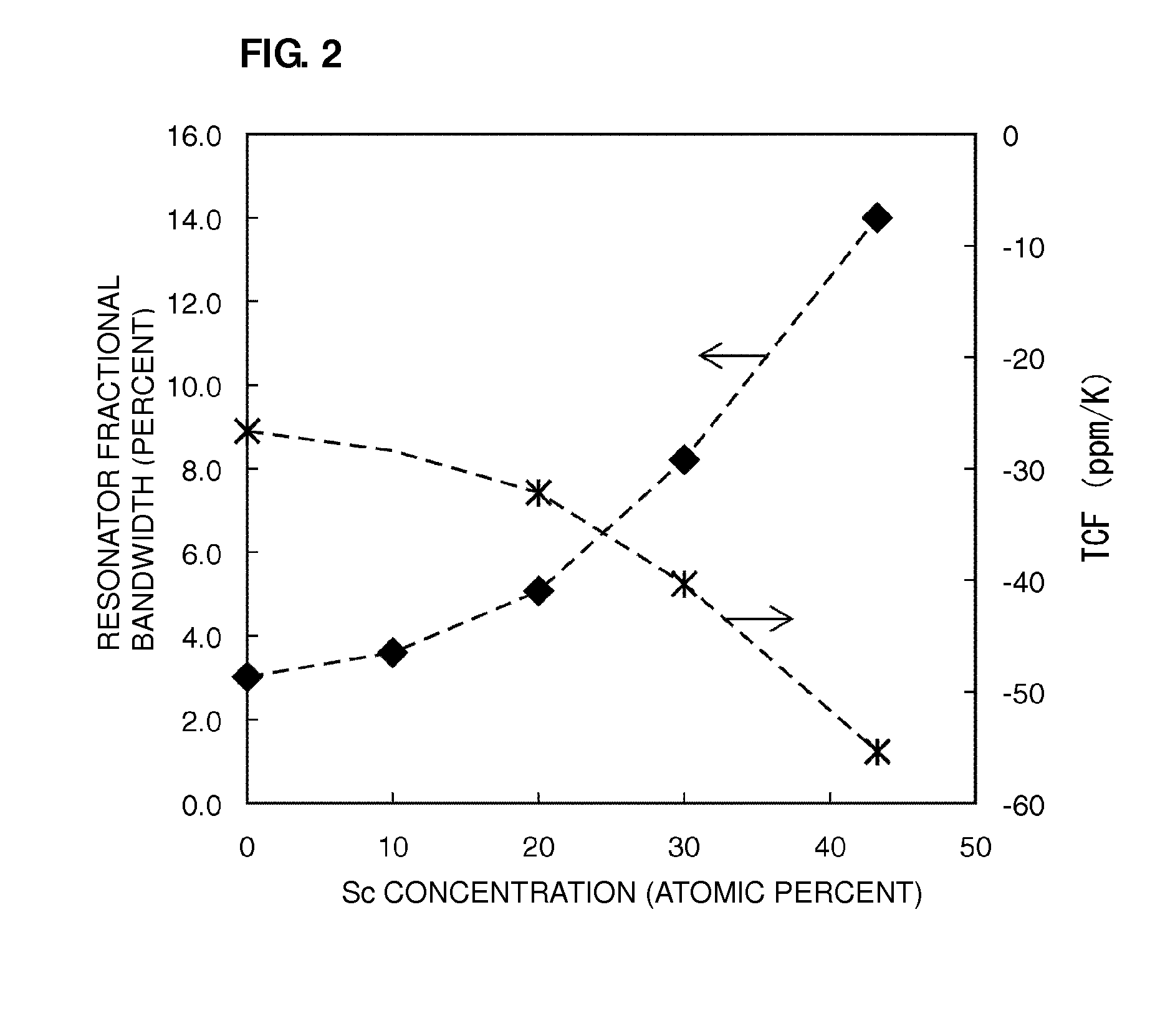

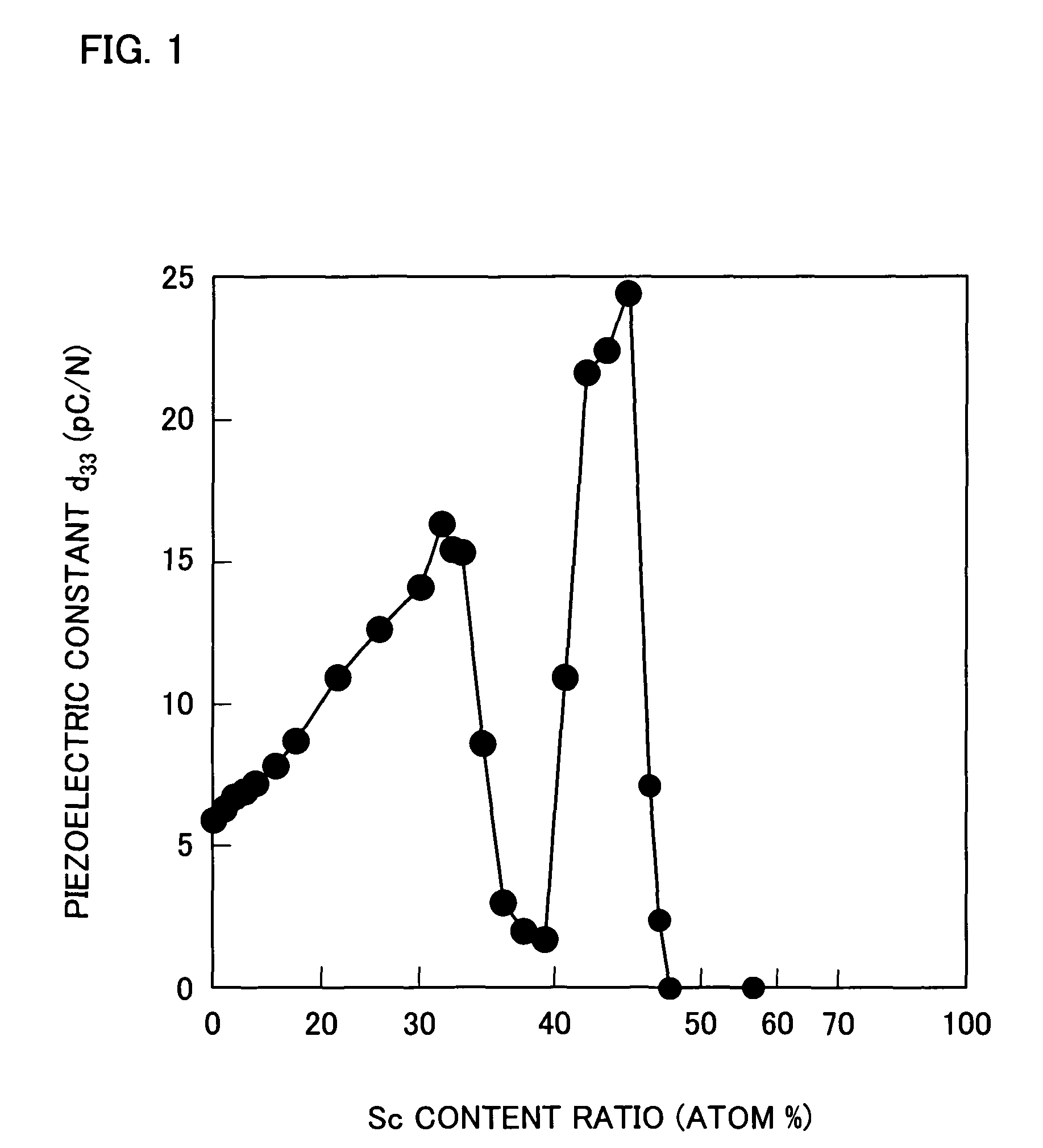

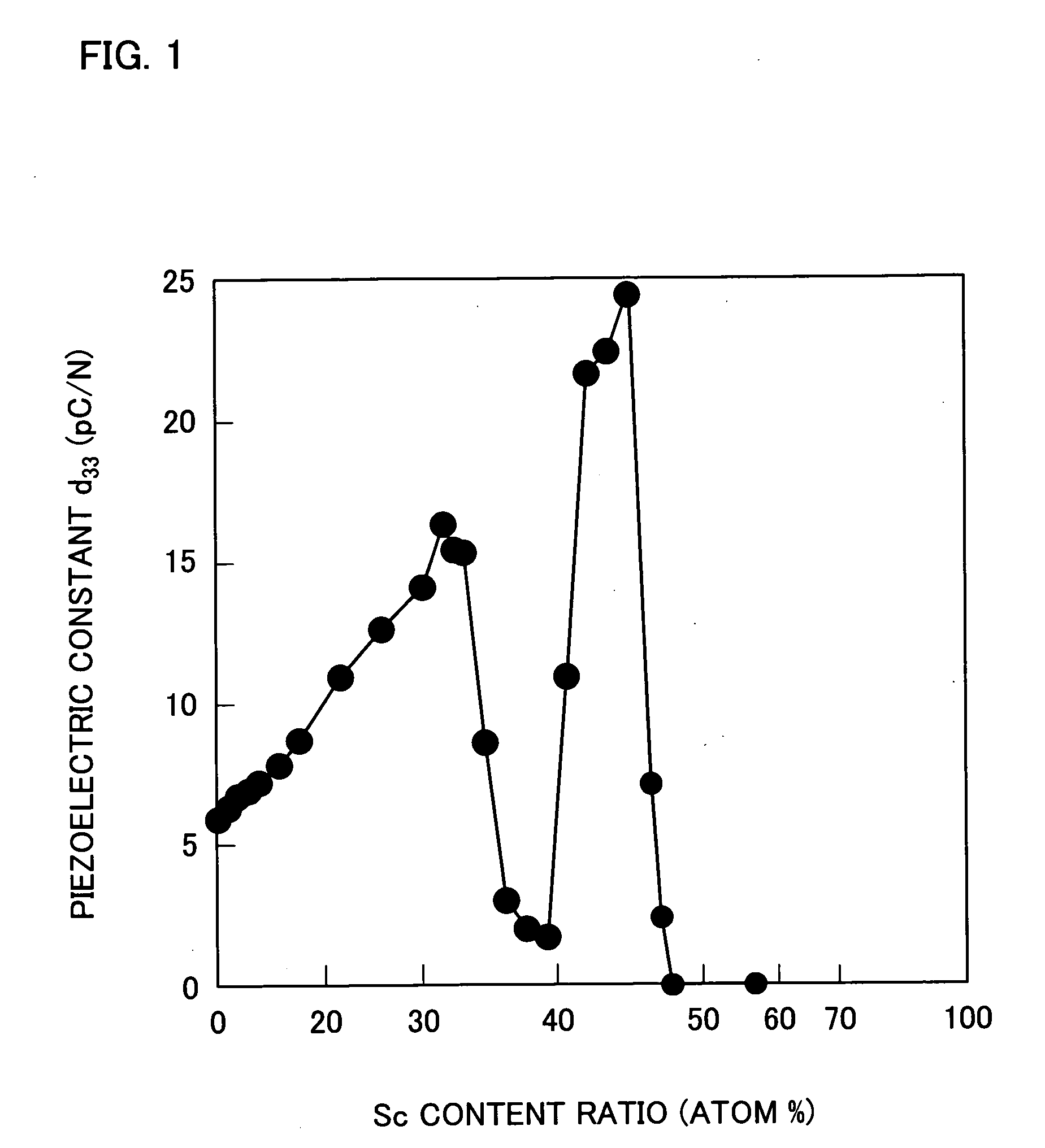

Piezoelectric thin film, piezoelectric material, and fabrication method of piezoelectric thin film and piezoelectric material, and piezoelectric resonator, actuator element, and physical sensor using piezoelectric thin film

ActiveUS7758979B2Improved piezoelectric responsePiezoelectric response of the aluminum nitride thin film that contains scandium can be further improvedImpedence networksNatural mineral layered productsActuatorTemperature coefficient

A piezoelectric thin film of the present invention includes an aluminum nitride thin film that contains scandium. A content ratio of scandium in the aluminum nitride thin film is 0.5 atom % to 50 atom % on the assumption that a total amount of the number of scandium atoms and the number of aluminum atoms is 100 atom %. According to this arrangement, the piezoelectric thin film of the present invention can improve a piezoelectric response while keeping characteristics of elastic wave propagation speed, Q value, and frequency-temperature coefficient that the aluminum nitride thin film has.

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

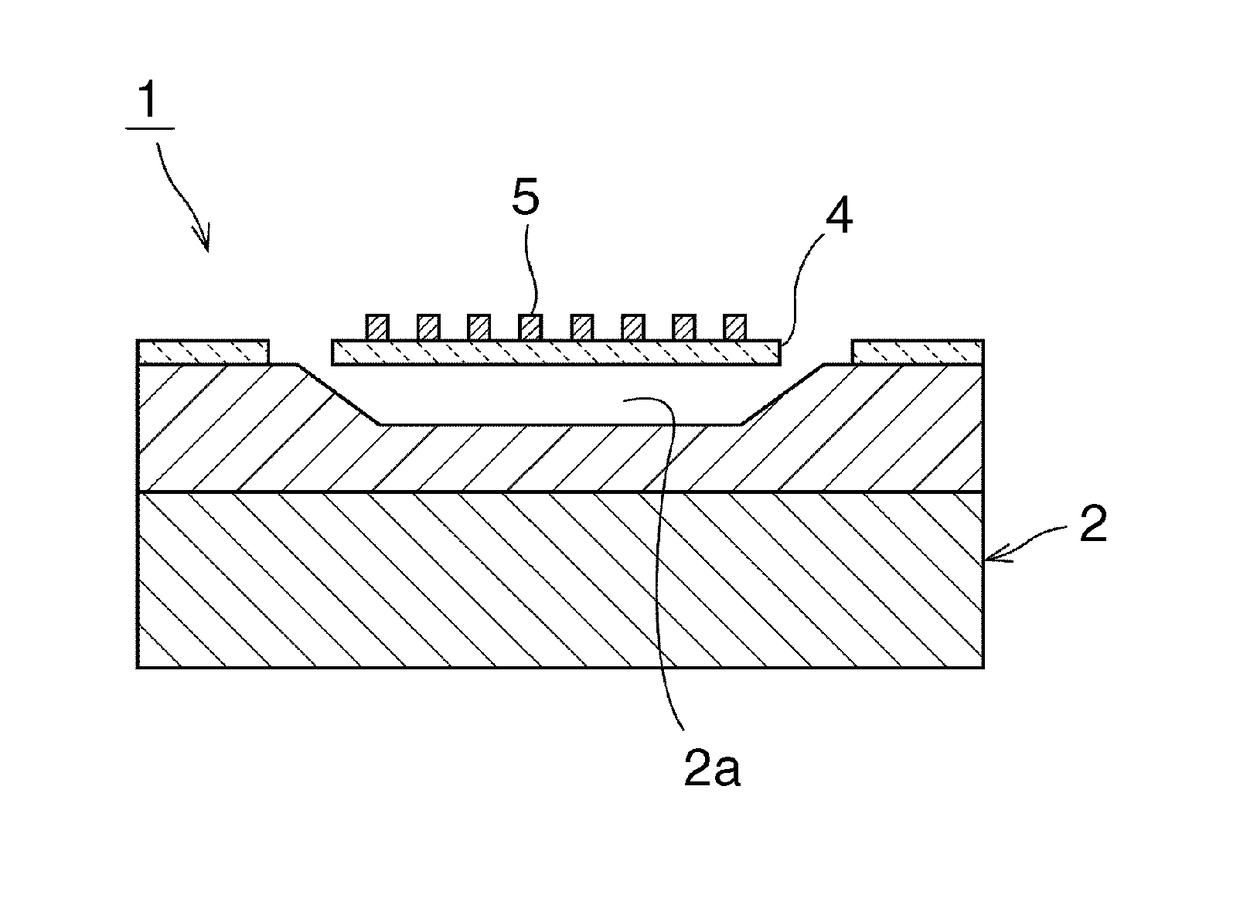

Lamb wave device

ActiveUS20100123367A1Little changeImpedence networksPiezoelectric/electrostriction/magnetostriction machinesAcousticsPiezoelectric thin films

There is provided a lamb wave device with small variations in frequency, the device including: a piezoelectric thin film; an IDT electrode which is provided on a main surface of the piezoelectric thin film; and a support structure which supports a laminate of the IDT electrode and the piezoelectric thin film, and is formed with a cavity that isolates the laminate, wherein a film thickness h of the piezoelectric thin film and a pitch p of a finger of the IDT electrode are selected such that a lamb wave is excited at a target frequency, the lamb wave making dispersibility of a sonic velocity v with respect to the film thickness h of the piezoelectric thin film small.

Owner:NGK INSULATORS LTD

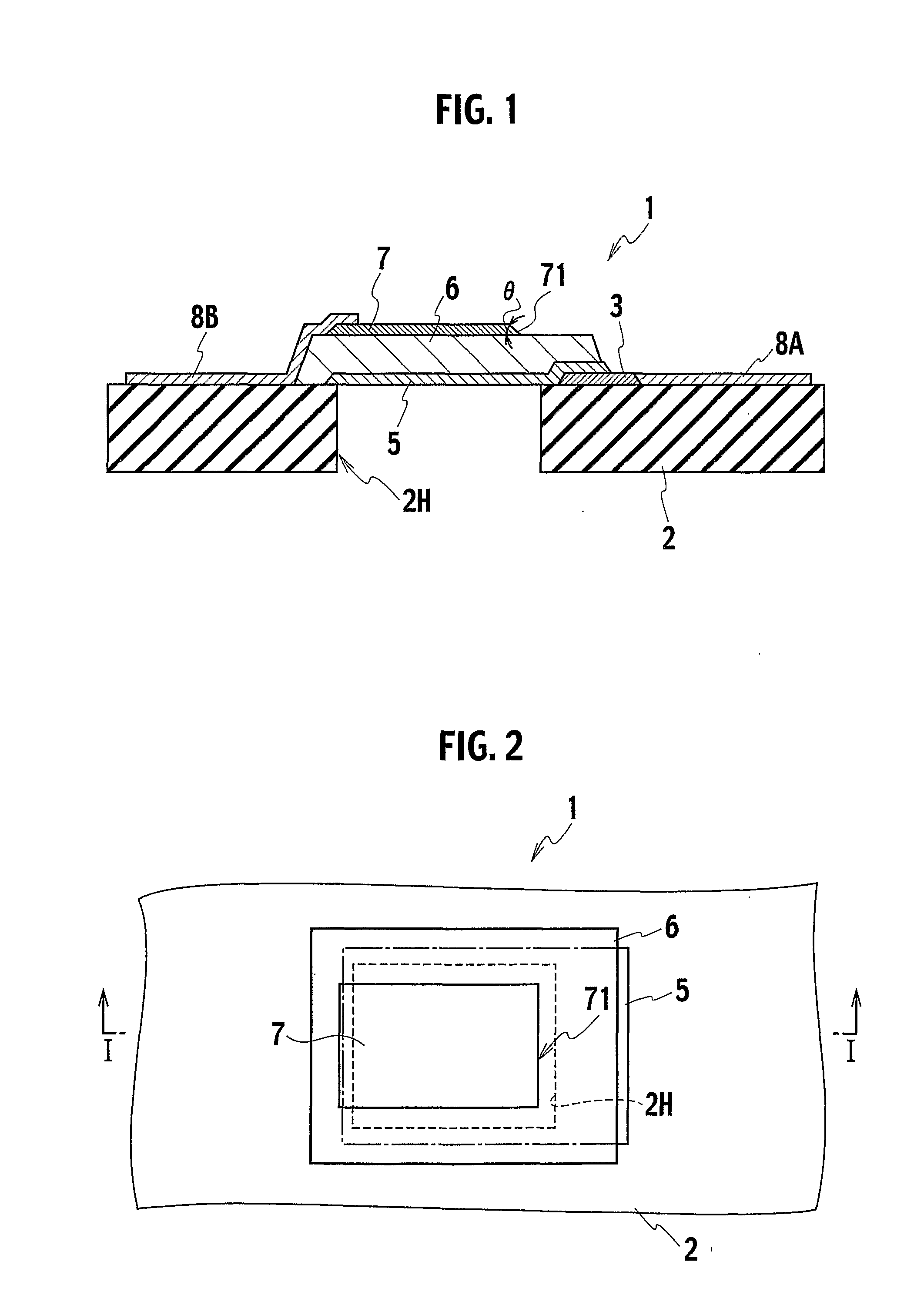

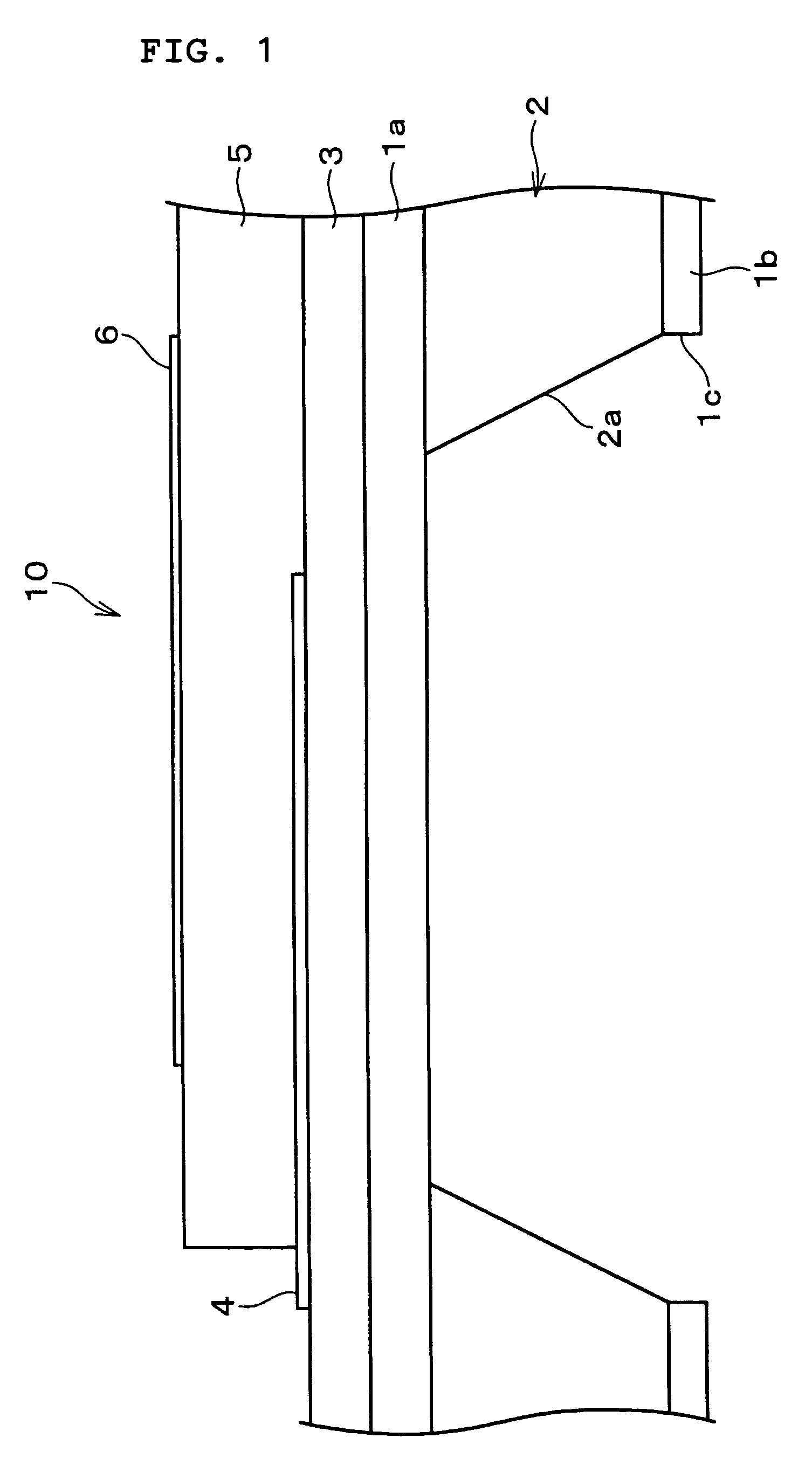

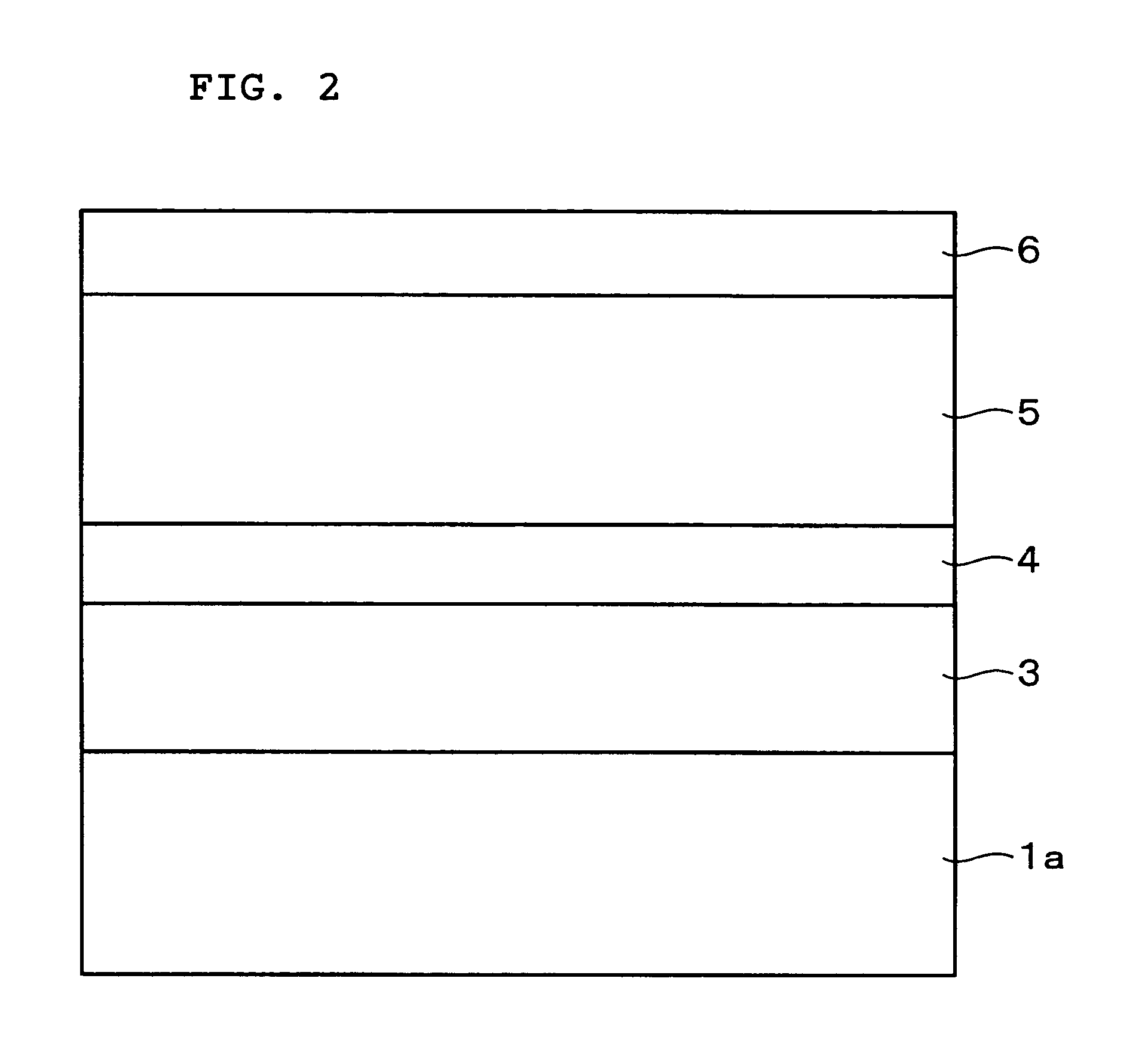

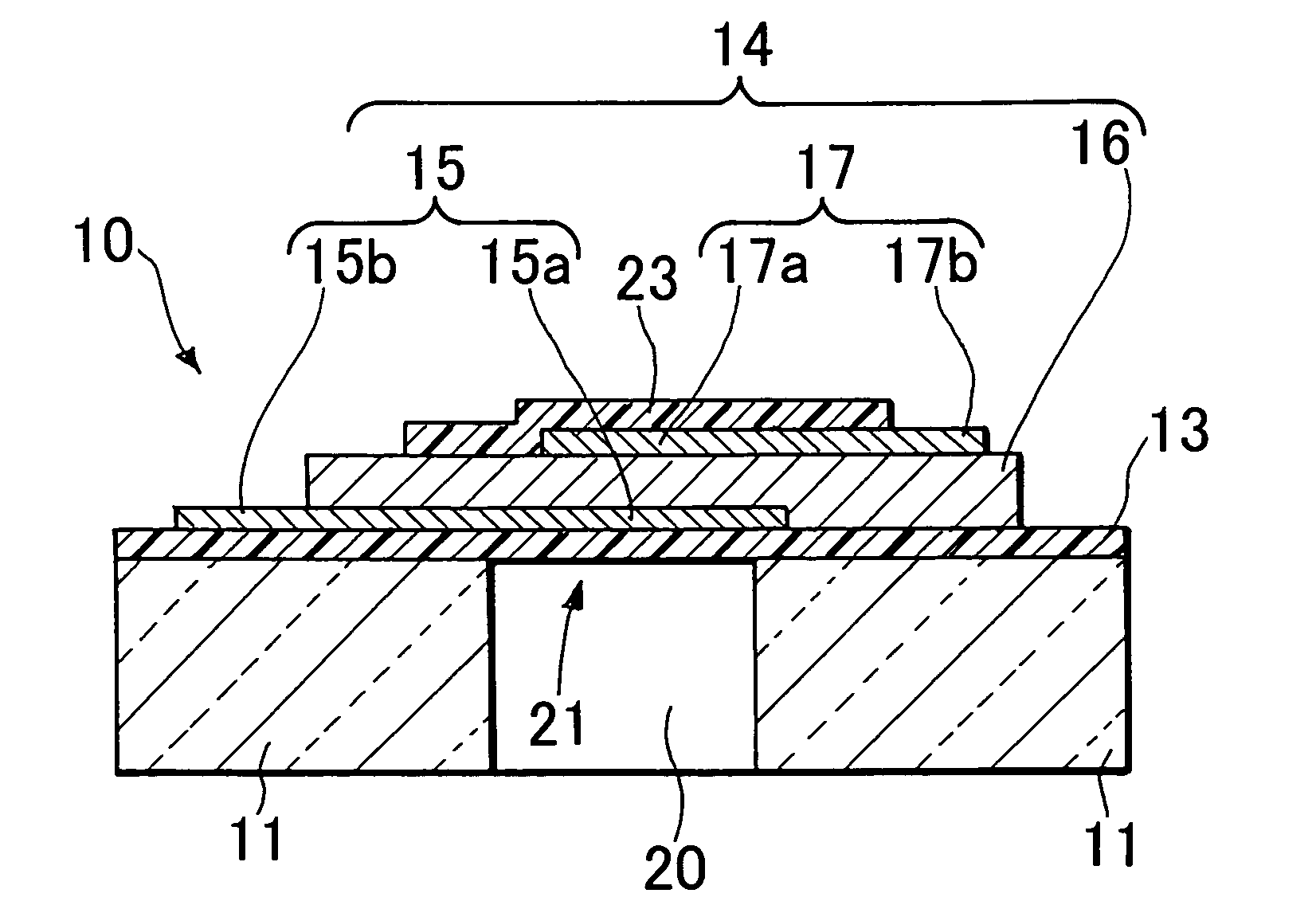

MEMS vibrating structure using a single-crystal piezoelectric thin film layer

ActiveUS7586239B1Improve accuracyReduce lossImpedence networksPiezoelectric/electrostriction/magnetostriction machinesCrystal orientationSingle crystal

The present invention relates to a micro-electro-mechanical systems (MEMS) vibrating structure having dominant lateral vibrations supported by a MEMS anchor system, and includes a single-crystal piezoelectric thin-film layer that has been grown with a specific crystal orientation. Since the MEMS vibrating structure has dominant lateral vibrations, its resonant frequency may be controlled by its size and shape, rather than layer thickness, which provides high accuracy and enables multiple resonators having different resonant frequencies on a single substrate.

Owner:QORVO US INC

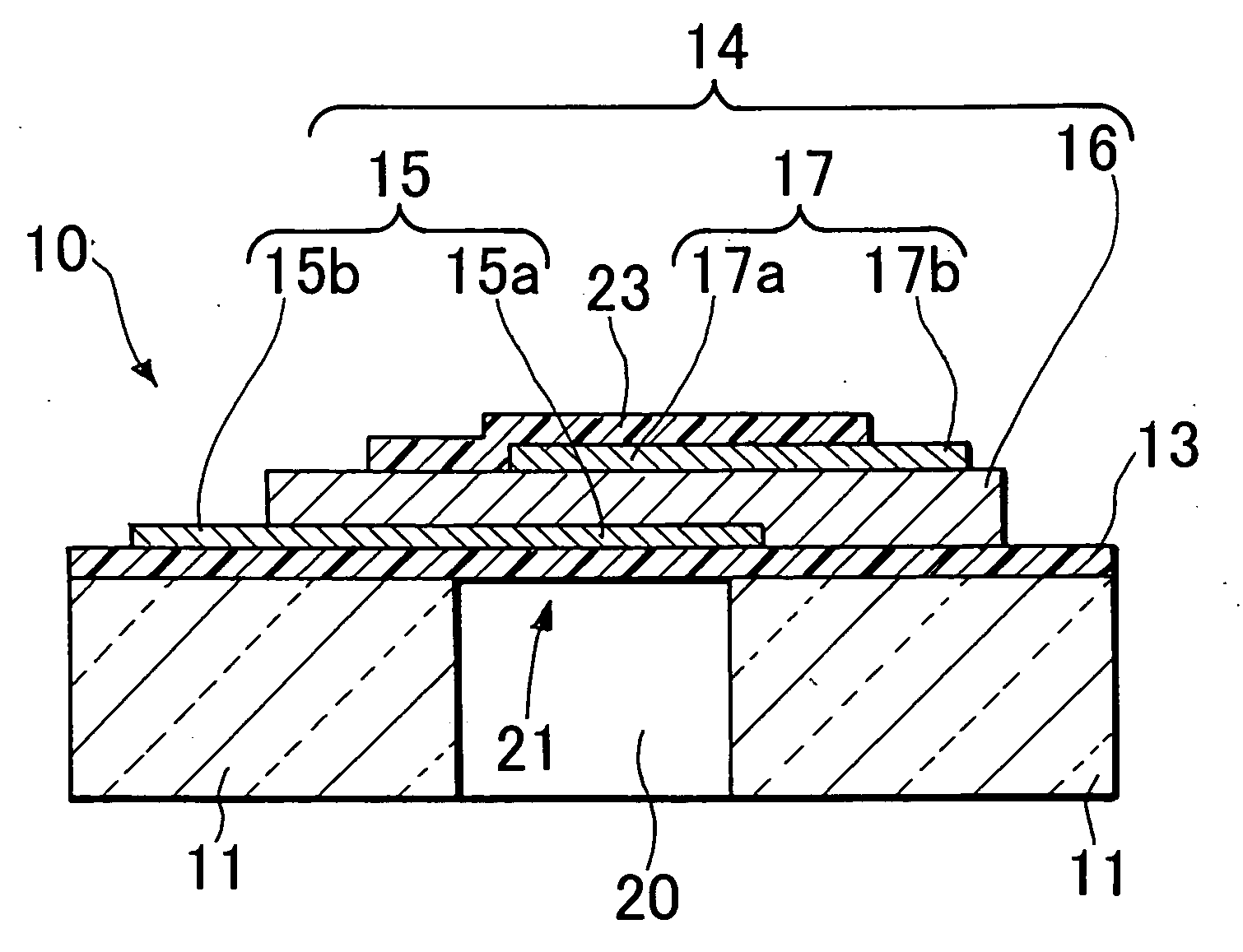

Thin-film piezoelectric resonator and method for fabricating the same

ActiveUS6977563B2Impedence networksPiezoelectric/electrostrictive/magnetostrictive devicesOptoelectronicsPiezoelectric thin films

A thin-film piezoelectric resonator including a piezoelectric thin film having piezoelectric characteristic, and an upper electrode and a lower electrode arranged on opposite surfaces of the piezoelectric thin film for applying an excitation voltage to the piezoelectric thin film, wherein: each of the upper electrode and the lower electrode includes a resonant portion, and a lead-out portion; and the electrode thickness of at least one part of the lead-out portion in at least one of the upper electrode and the lower electrode is larger than the electrode thickness of the resonant portion formed to be continued from the lead-out portion.

Owner:SNAPTRACK

Aluminum nitride thin film, composite film containing the same and piezoelectric thin film resonator using the same

ActiveUS7482737B2Improvement factorImprove sound qualityPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksRocking curveComposite film

A piezoelectric thin film resonator has a substrate and a piezoelectric layered structure including a lower electrode, piezoelectric aluminum nitride thin film with c-axis orientation and upper electrode formed on the substrate in this order. The lower electrode are made of a metal thin film including a layer containing ruthenium as a major component having a full-width half maximum (FWHM) of a rocking curve of a (0002) diffraction peak of ruthenium of 3.0° or less. The piezoelectric aluminum nitride thin film formed on the lower electrode has a full-width half maximum (FWHM) of a rocking curve of a (0002) diffraction peak of 2.0° or less.

Owner:MEMS SOLUTIONS INC

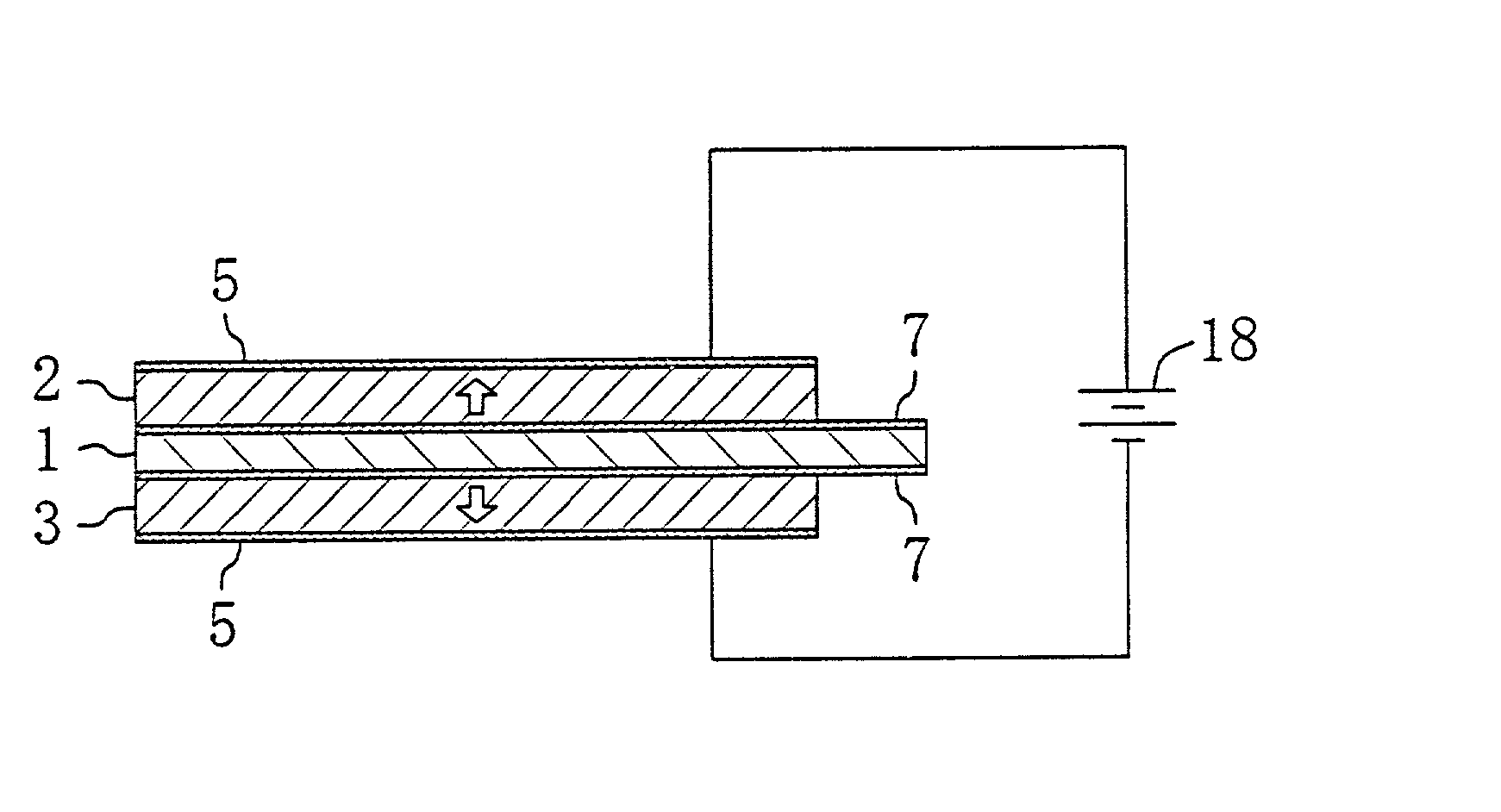

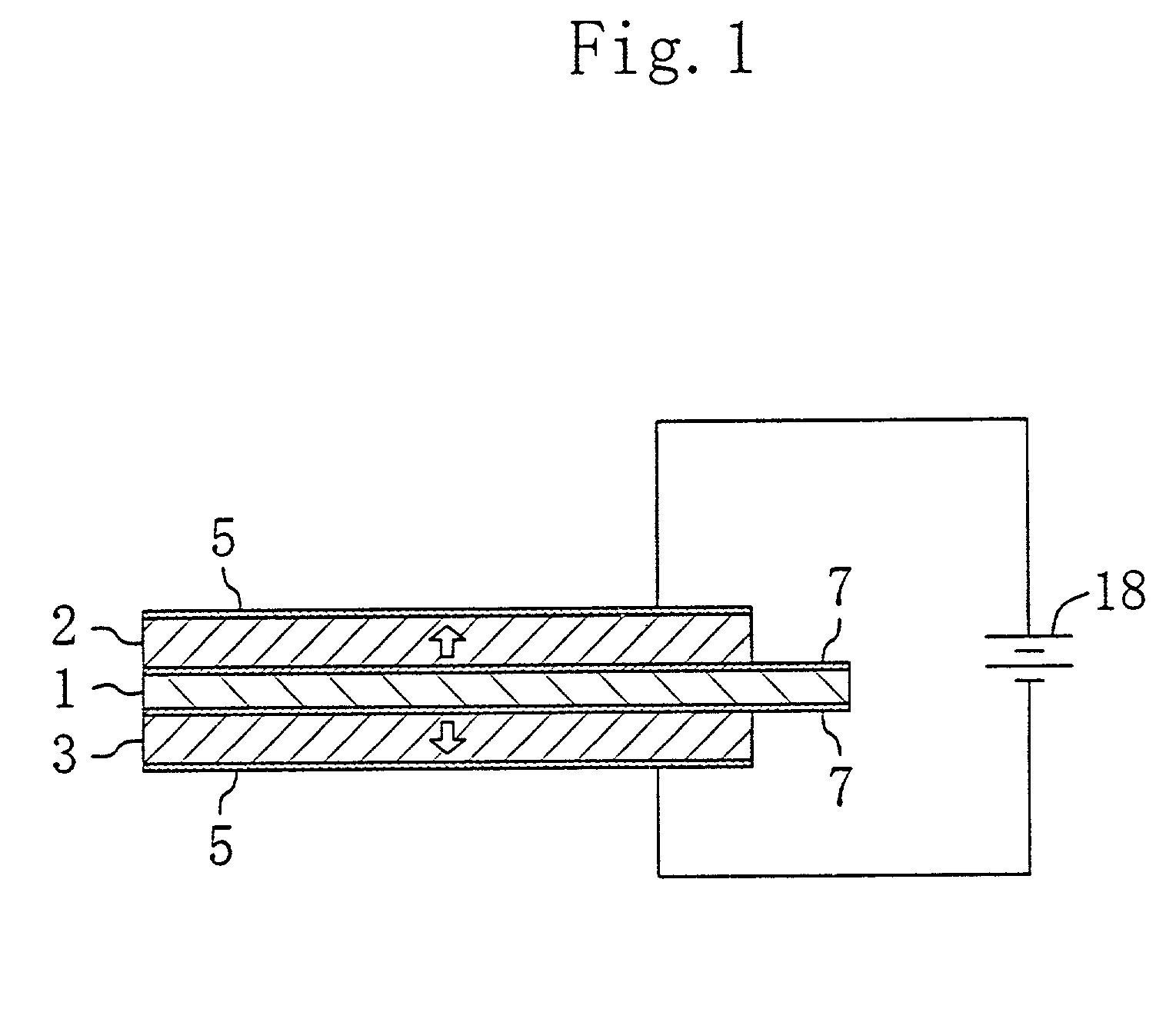

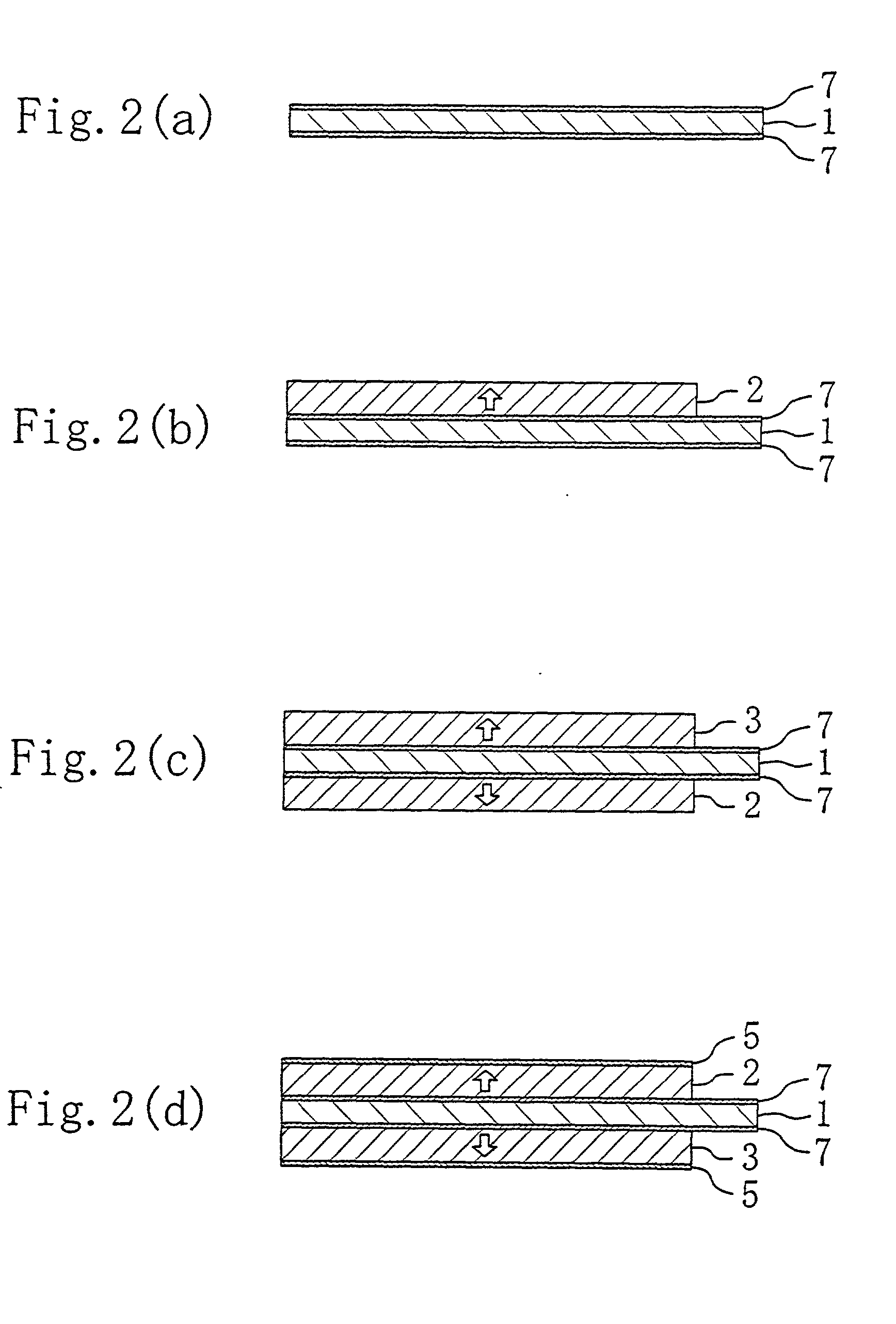

Thin-film piezoelectric bimorph element, mechanical detector and inkjet head using the same, and methods of manufacturing the same

InactiveUS20020149296A1Low costEasy and low-cost formationAcceleration measurement using interia forcesPiezoelectric/electrostriction/magnetostriction machinesSputteringMetal sheet

To manufacture a compact and high-performance thin-film piezoelectric bimorph element at low cost, first and second piezoelectric thin films (2, 3) are formed by sputtering on the both surfaces of a metal thin plate (1) which are opposing relation to each other along the thickness thereof, while the respective states of polarizations of the first and second piezoelectric thin films (2, 3) are controlled. A pair of electrode films (5) are formed on the respective surfaces of the first and second piezoelectric thin films (2, 3) opposite to the metal thin plate (1).

Owner:PANASONIC CORP

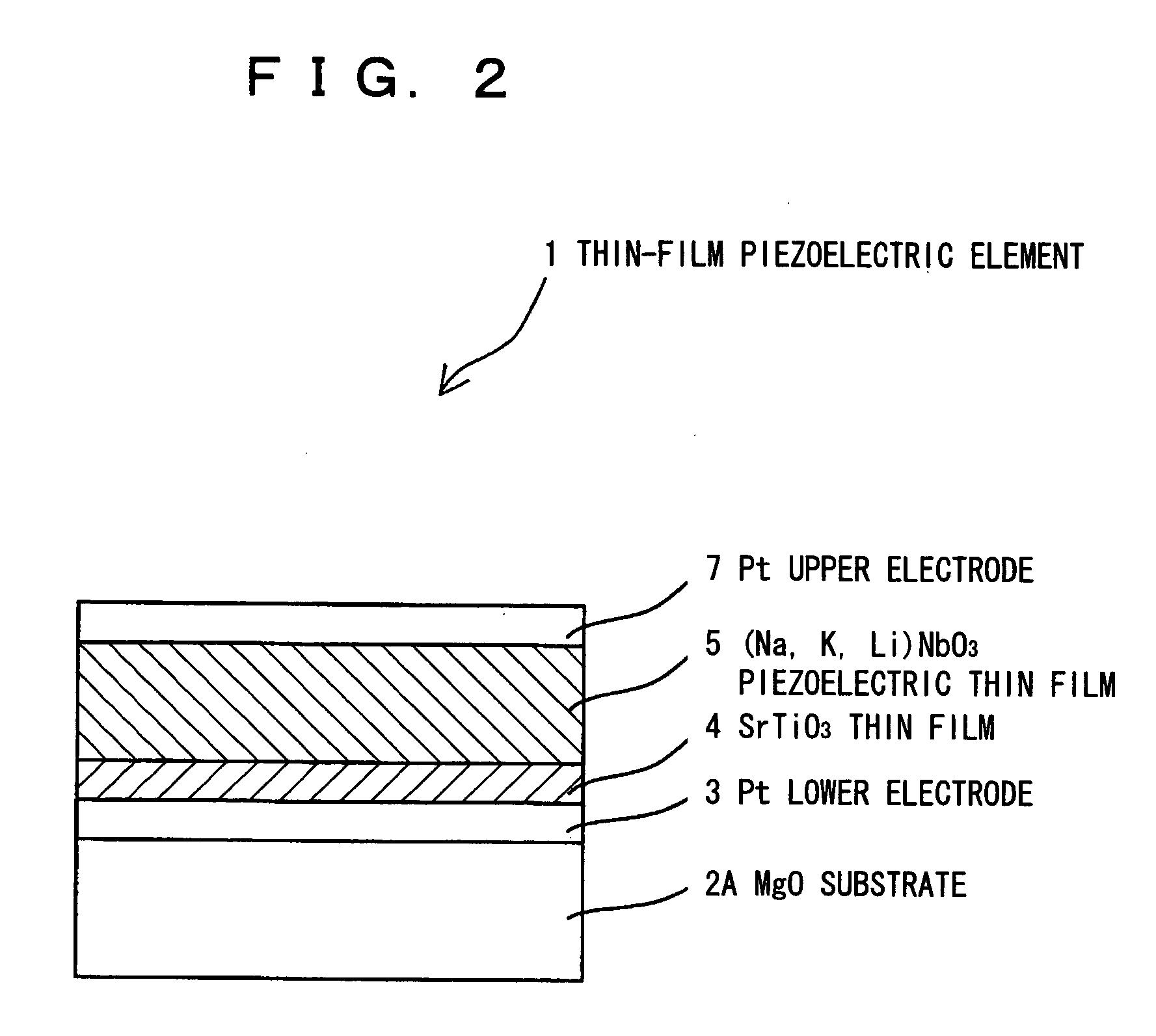

Piezoelectric thin film element

InactiveUS20070024162A1Excellent dielectric strength voltageExcellent piezoelectric propertiesPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesDielectric strengthDielectric thin films

A thin-film piezoelectric element has a substrate, a lower electrode, a piezoelectric portion, and an upper electrode that are sequentially formed on the substrate. The piezoelectric portion has a dielectric thin film that has an alkali niobium oxide-based perovskite structure expressed by general formula (NaxKyLiz)NbO3 (0<x<1, 0<y<1, 0≦z<1, x+y+z=1), and a high voltage-withstand dielectric that has a dielectric strength voltage greater than that of the dielectric thin film.

Owner:SUMITOMO CHEM CO LTD

Piezoelectric thin film, piezoelectric material, and fabrication method of piezoelectric thin film and piezoelectric material, and piezoelectric resonator, actuator element, and physical sensor using piezoelectric thin film

ActiveUS20080296529A1Improved piezoelectric responsePiezoelectric response of the aluminum nitride thin film that contains scandium can be further improvedImpedence networksPiezoelectric/electrostrictive device material selectionActuatorTemperature coefficient

A piezoelectric thin film of the present invention includes an aluminum nitride thin film that contains scandium. A content ratio of scandium in the aluminum nitride thin film is 0.5 atom % to 50 atom % on the assumption that a total amount of the number of scandium atoms and the number of aluminum atoms is 100 atom %. According to this arrangement, the piezoelectric thin film of the present invention can improve a piezoelectric response while keeping characteristics of elastic wave propagation speed, Q value, and frequency-temperature coefficient that the aluminum nitride thin film has.

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com