Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1050results about How to "Accurate shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

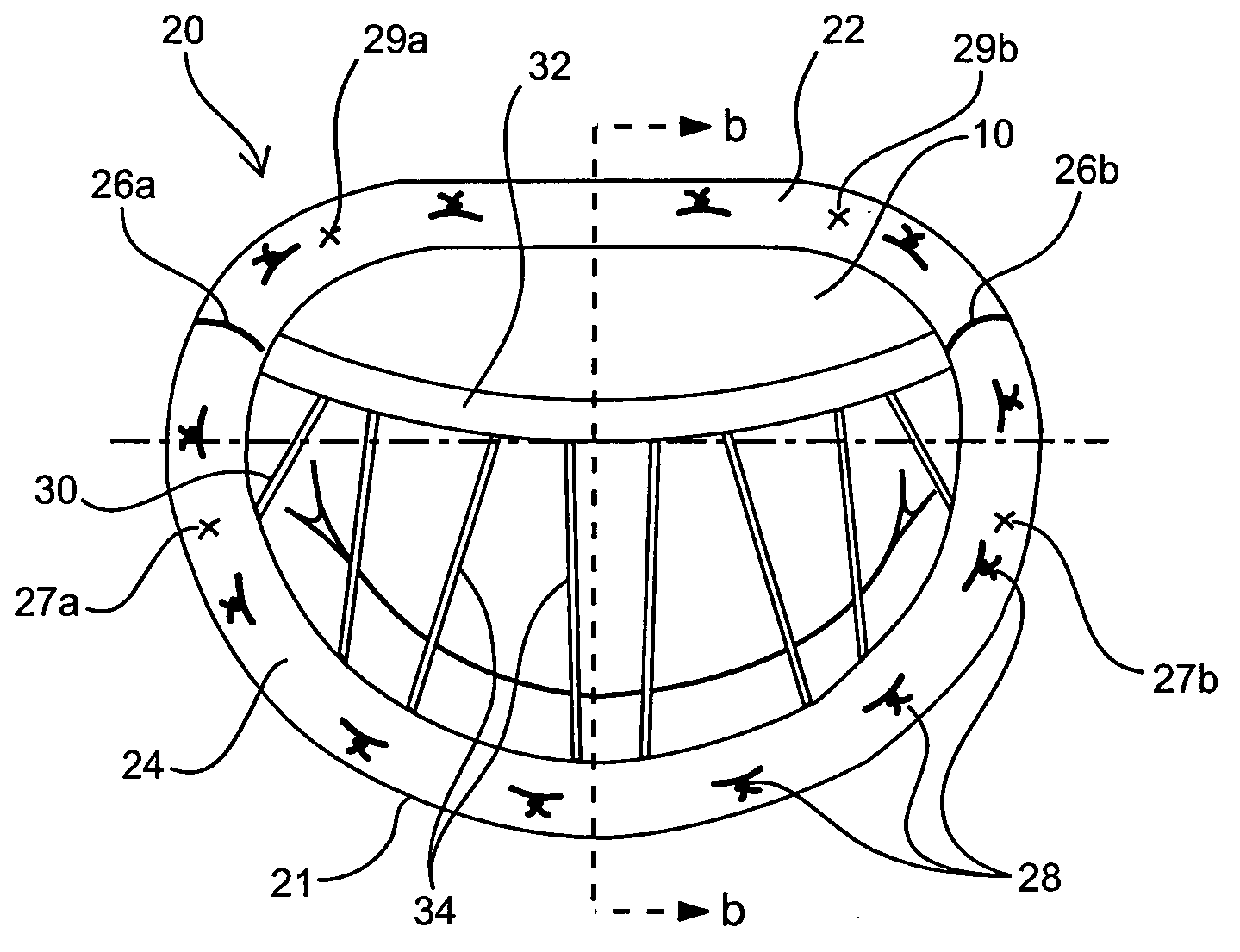

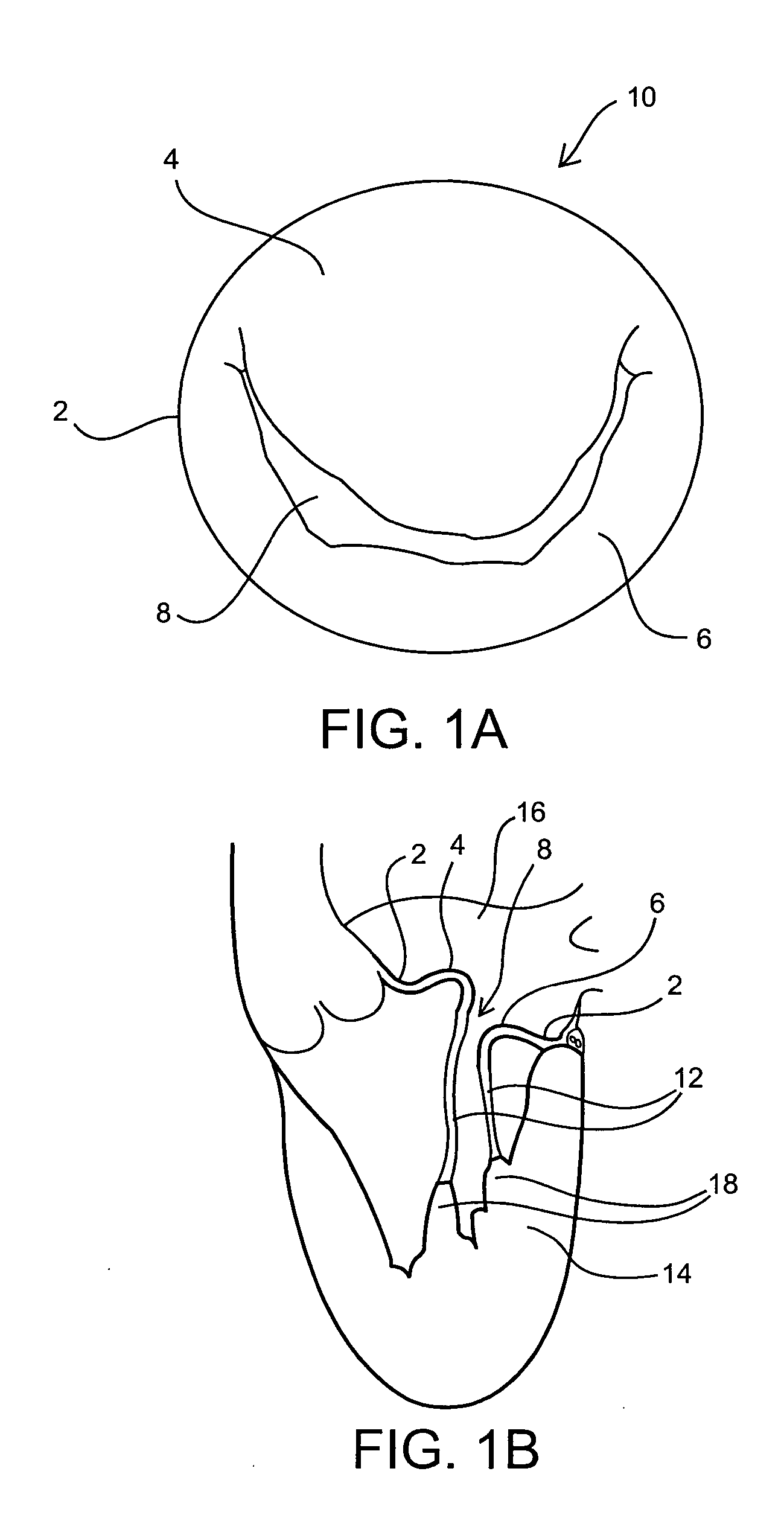

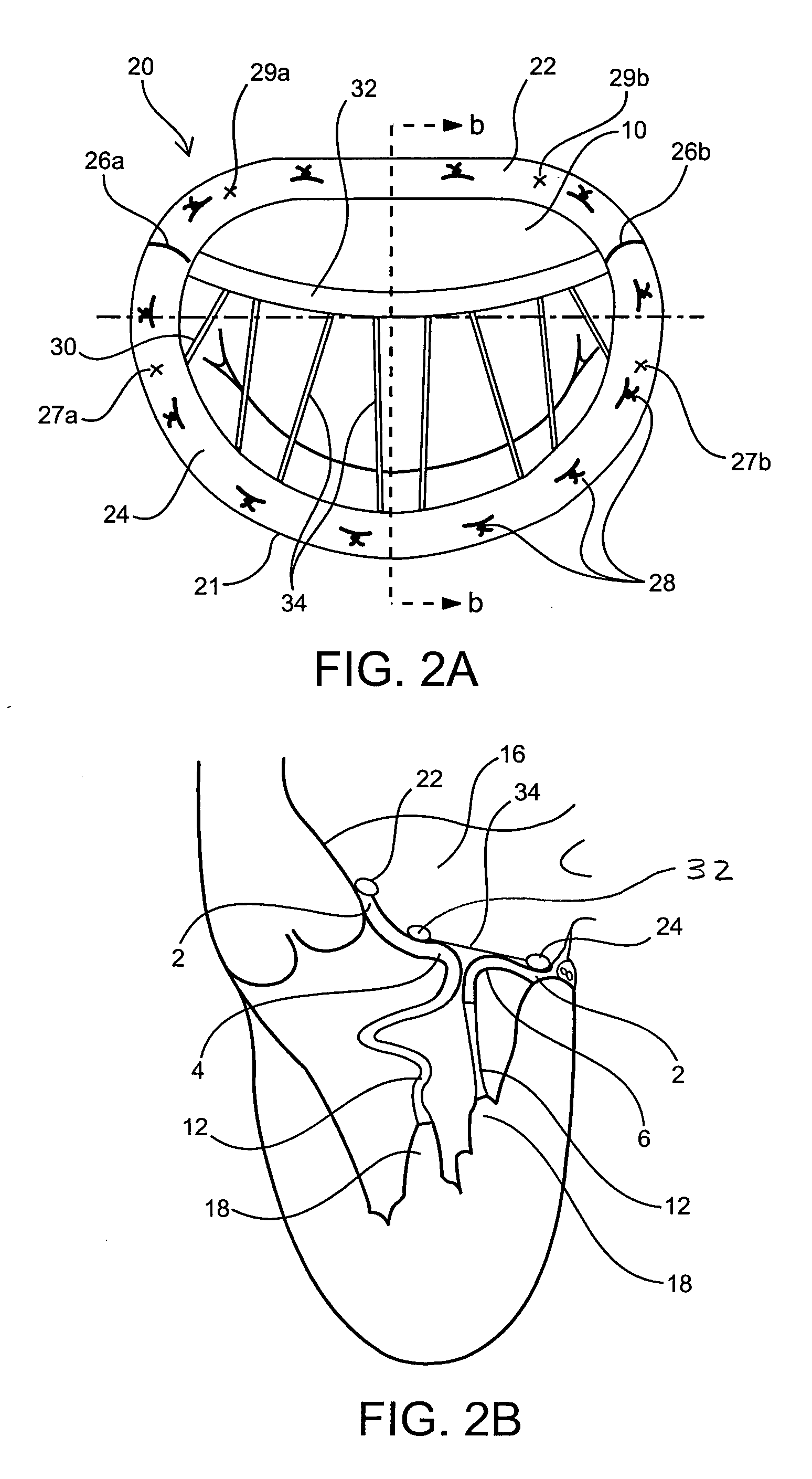

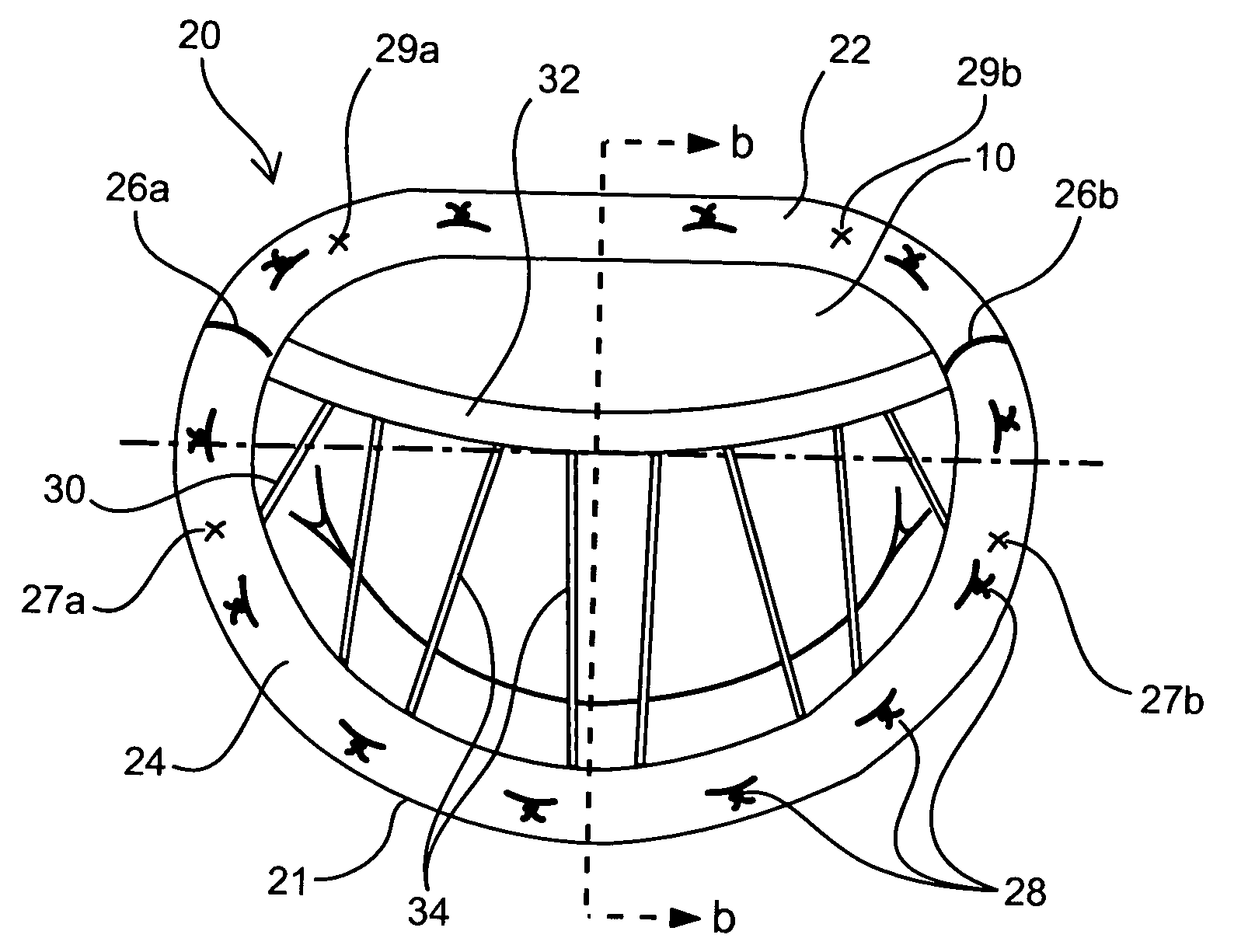

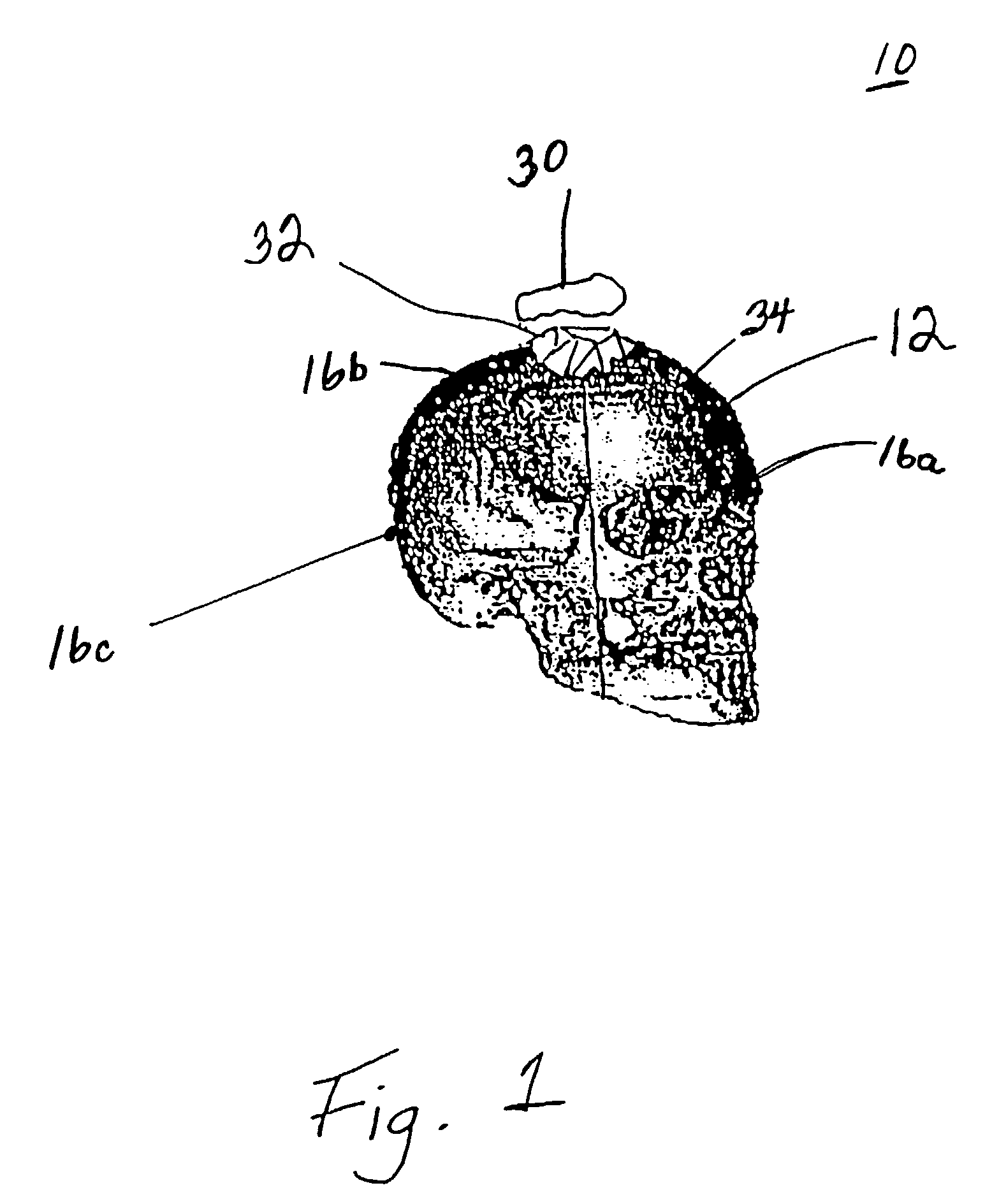

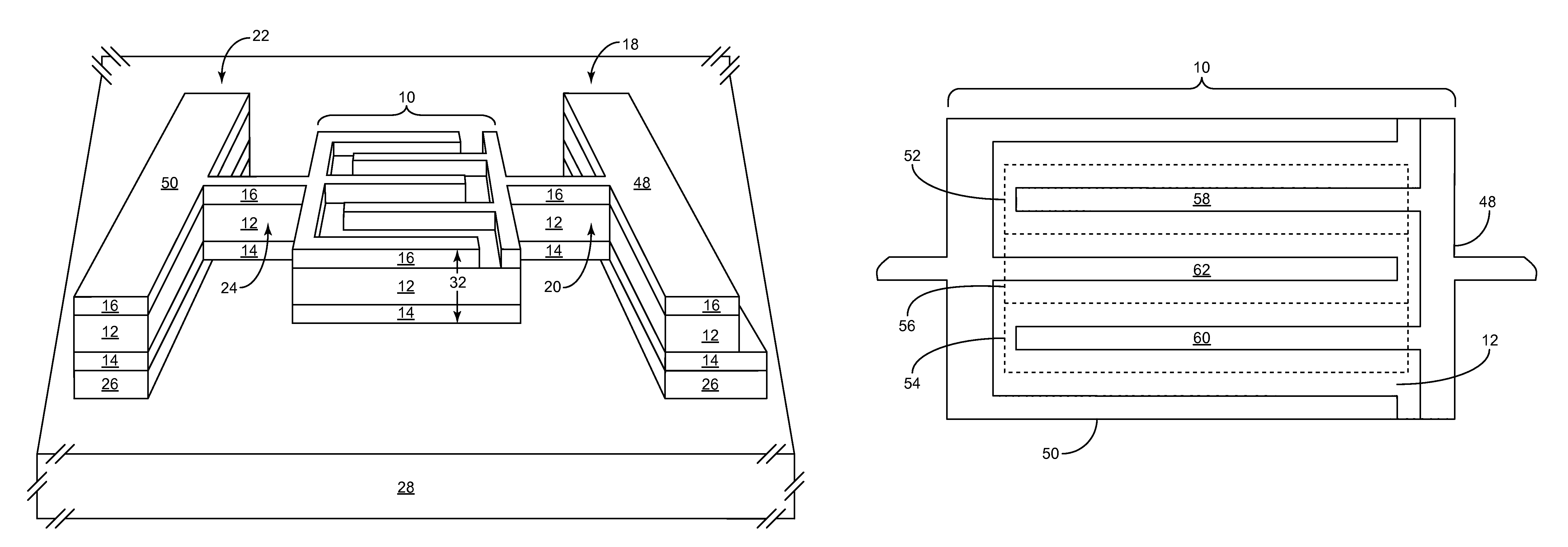

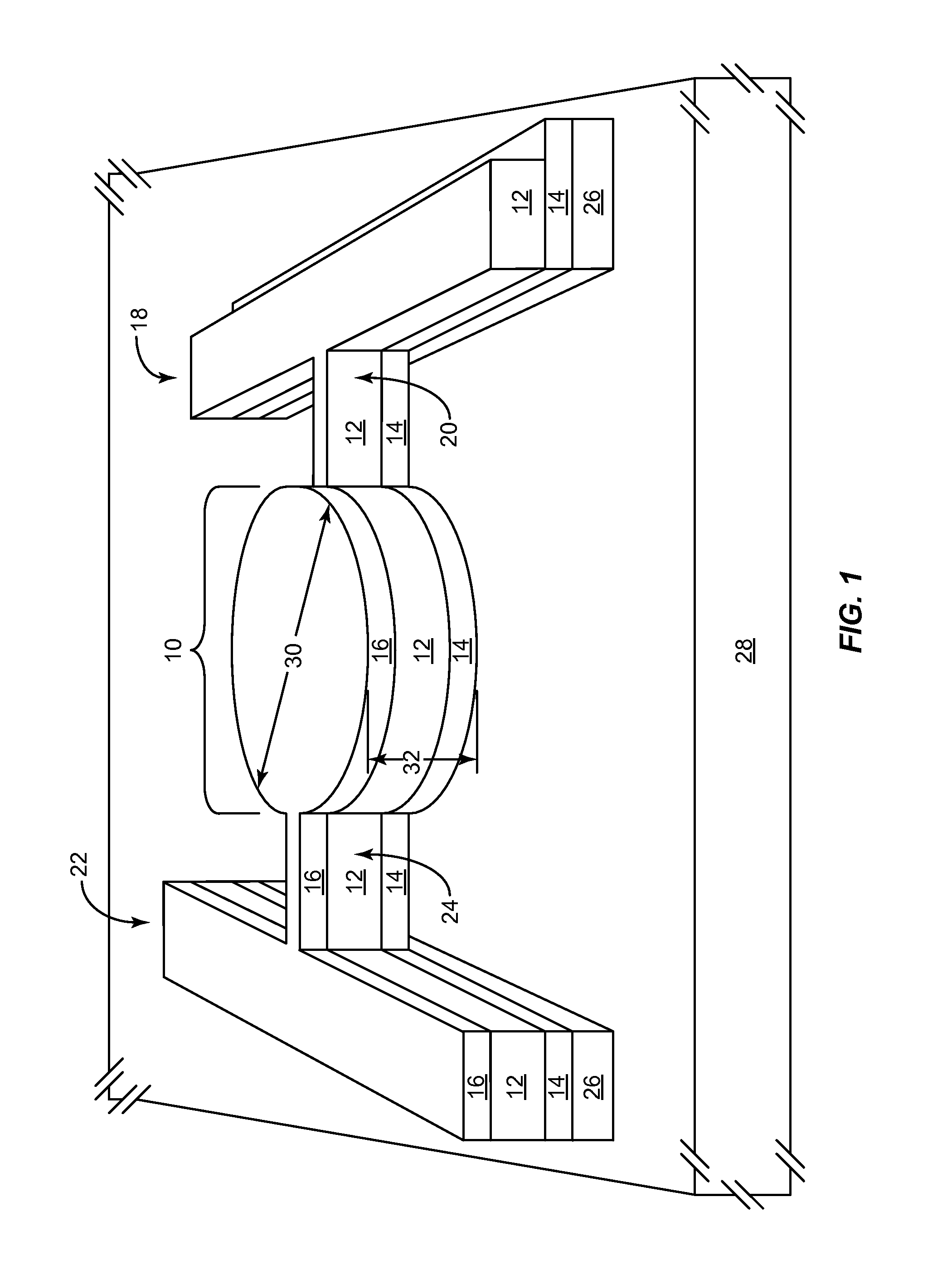

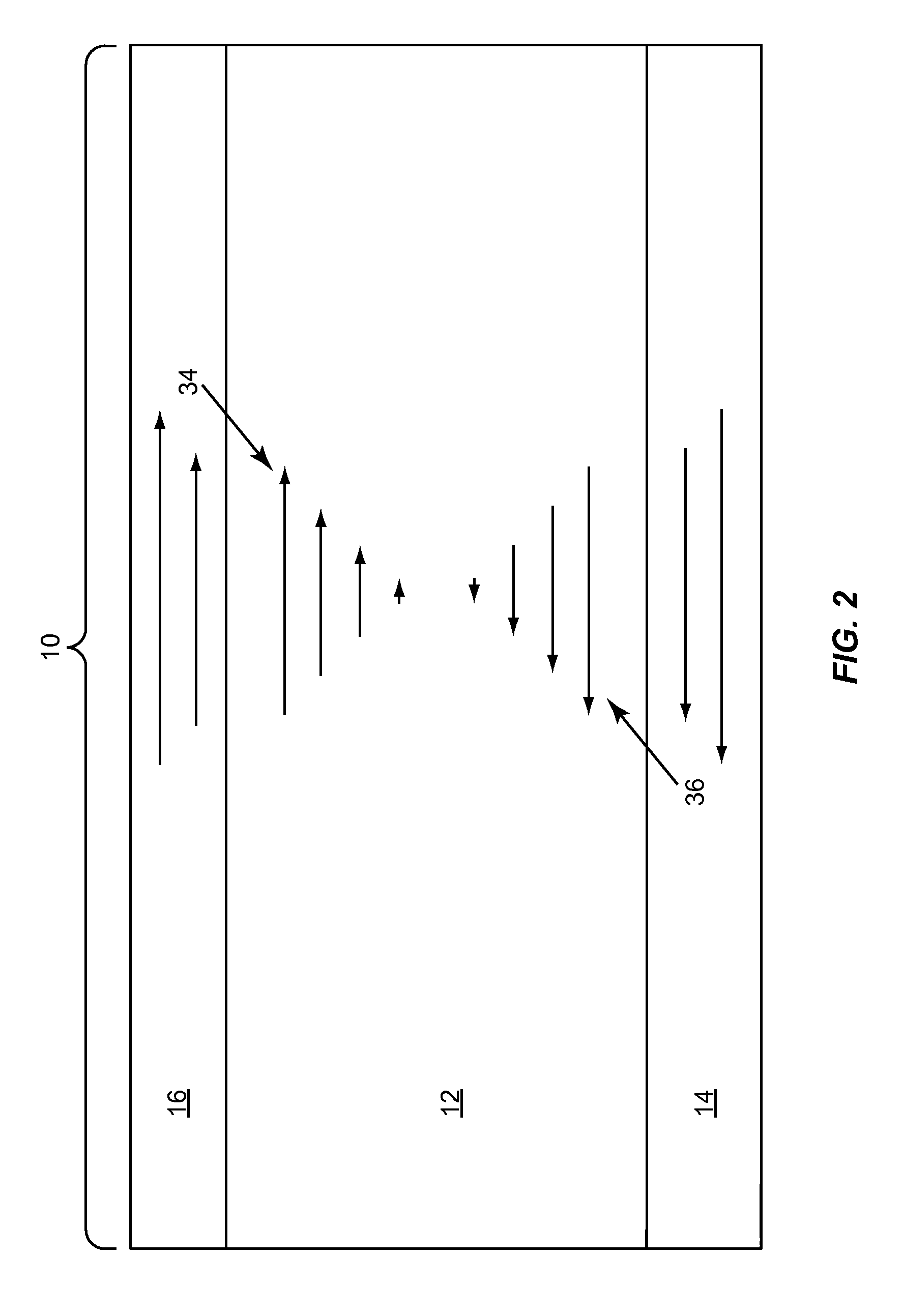

Annuloplasty rings and methods for repairing cardiac valves

InactiveUS20050004668A1Facilitate customized remodelingAccurate shapeBone implantAnnuloplasty ringsStructure functionImplanted device

Owner:FLEXCOR

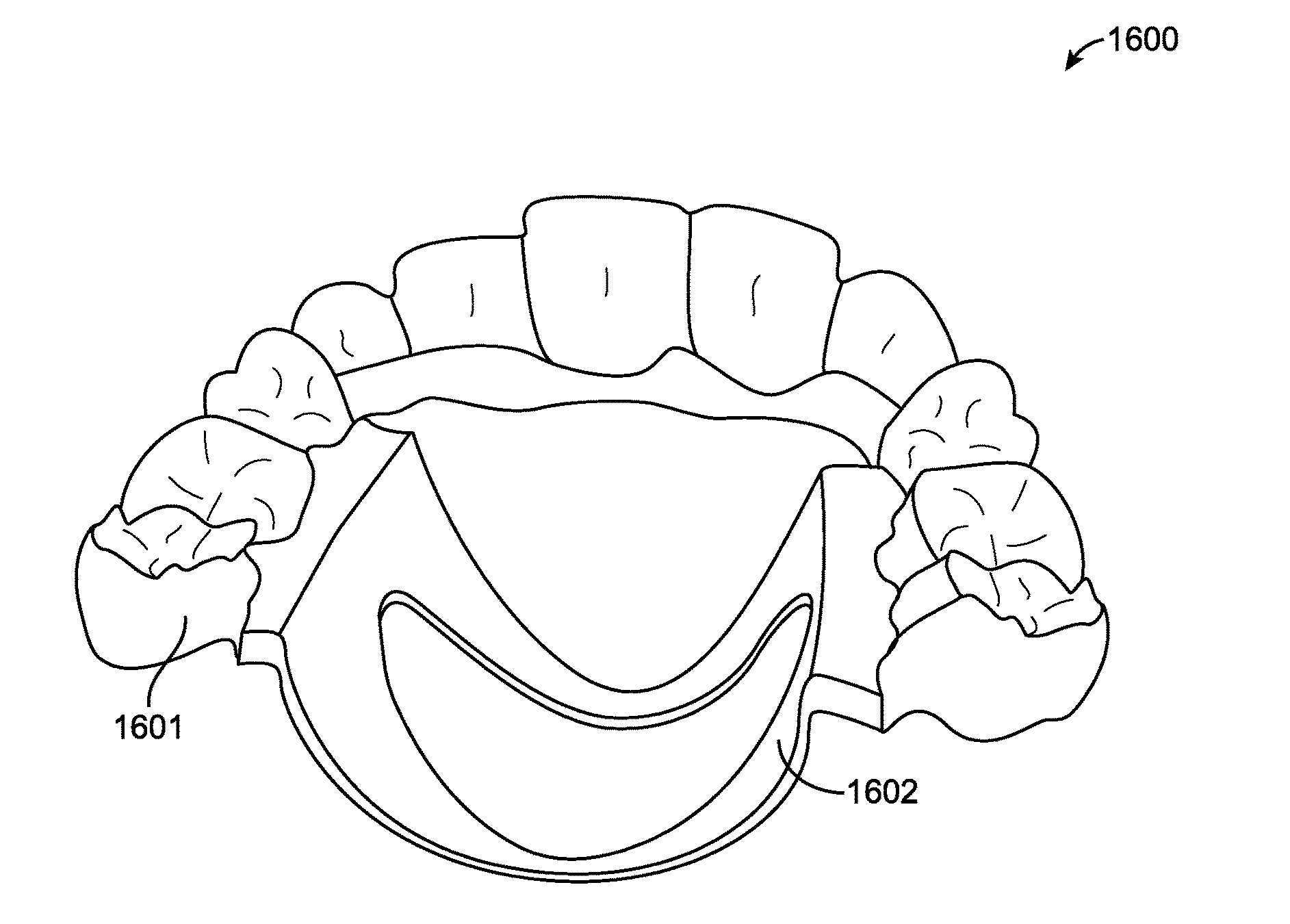

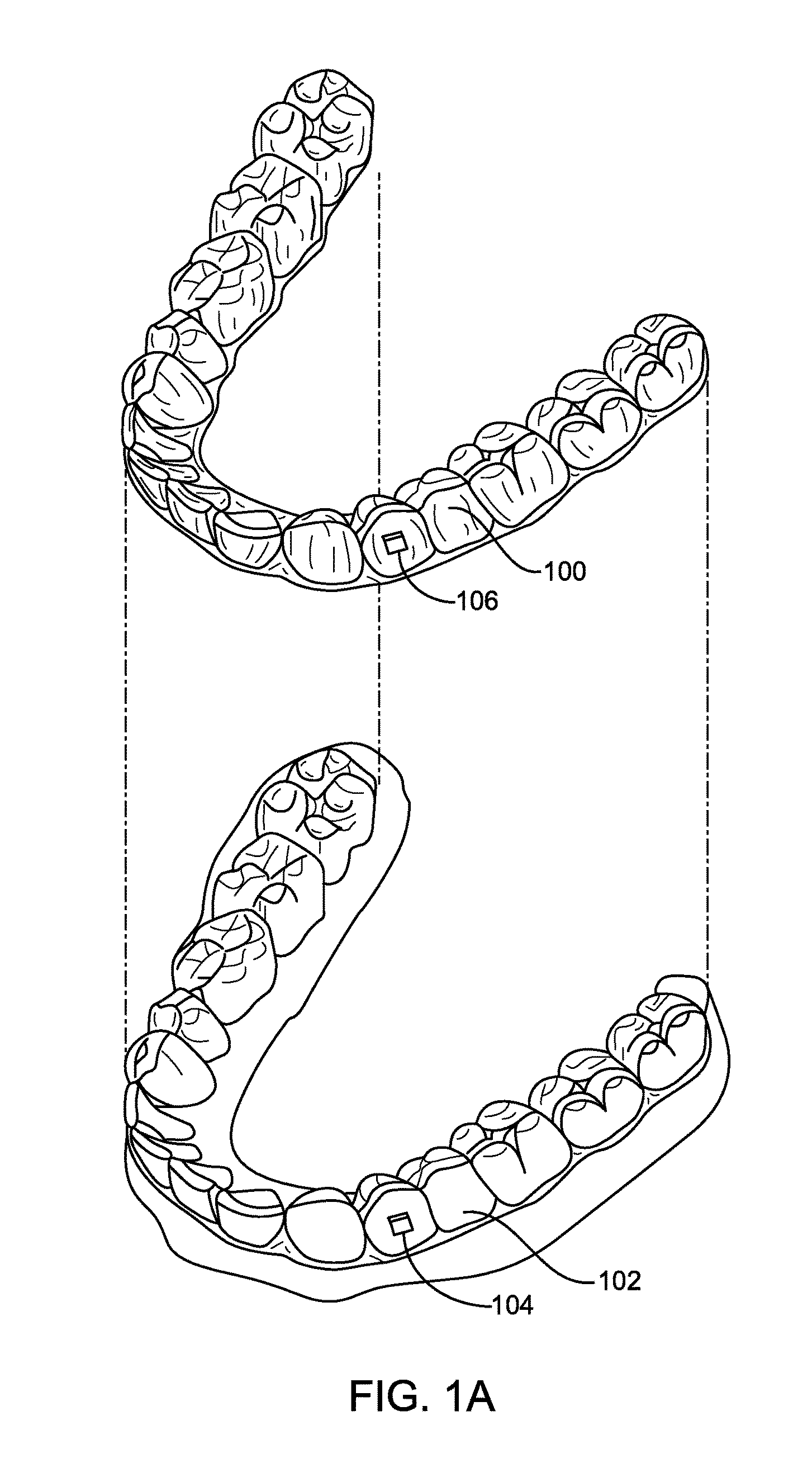

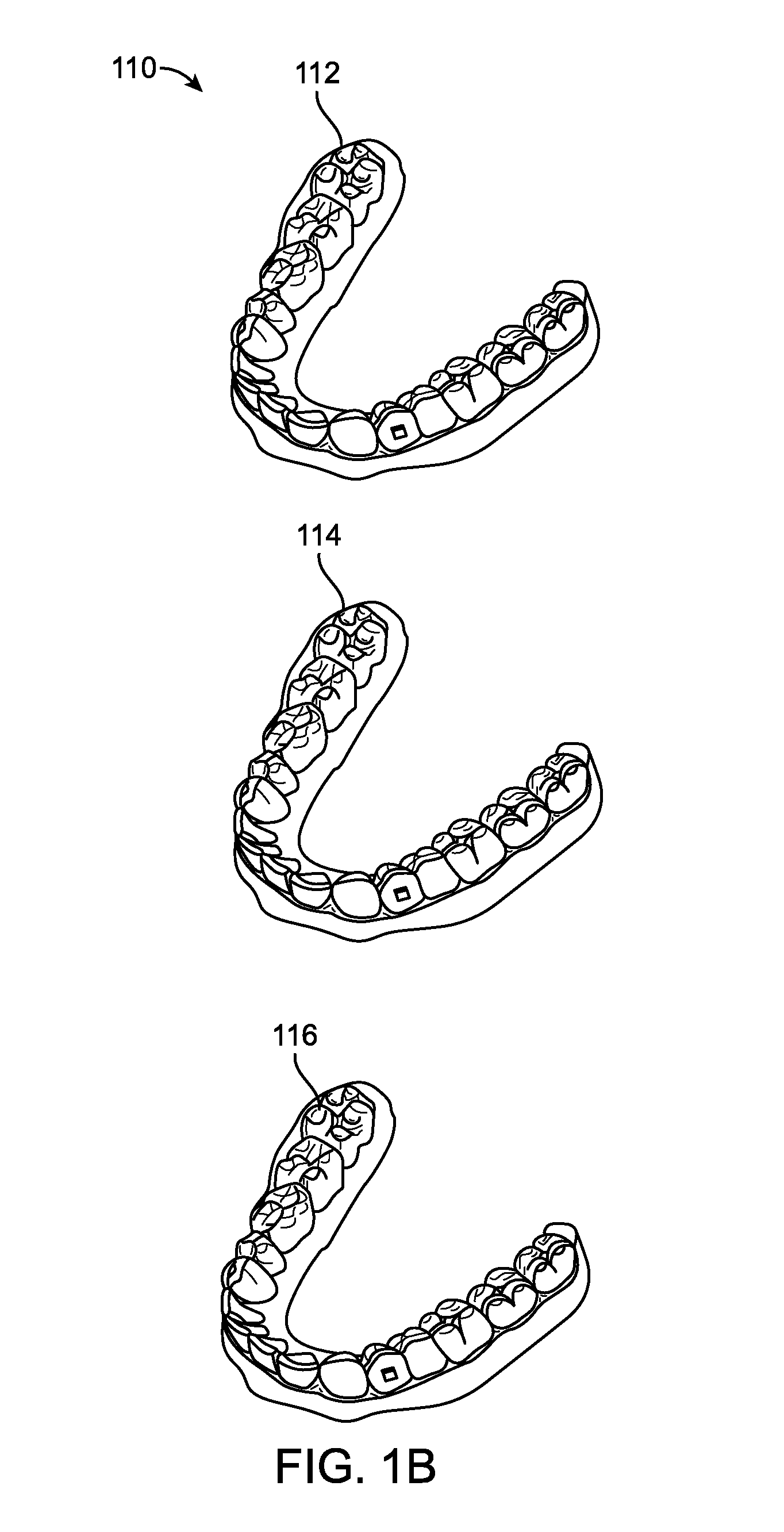

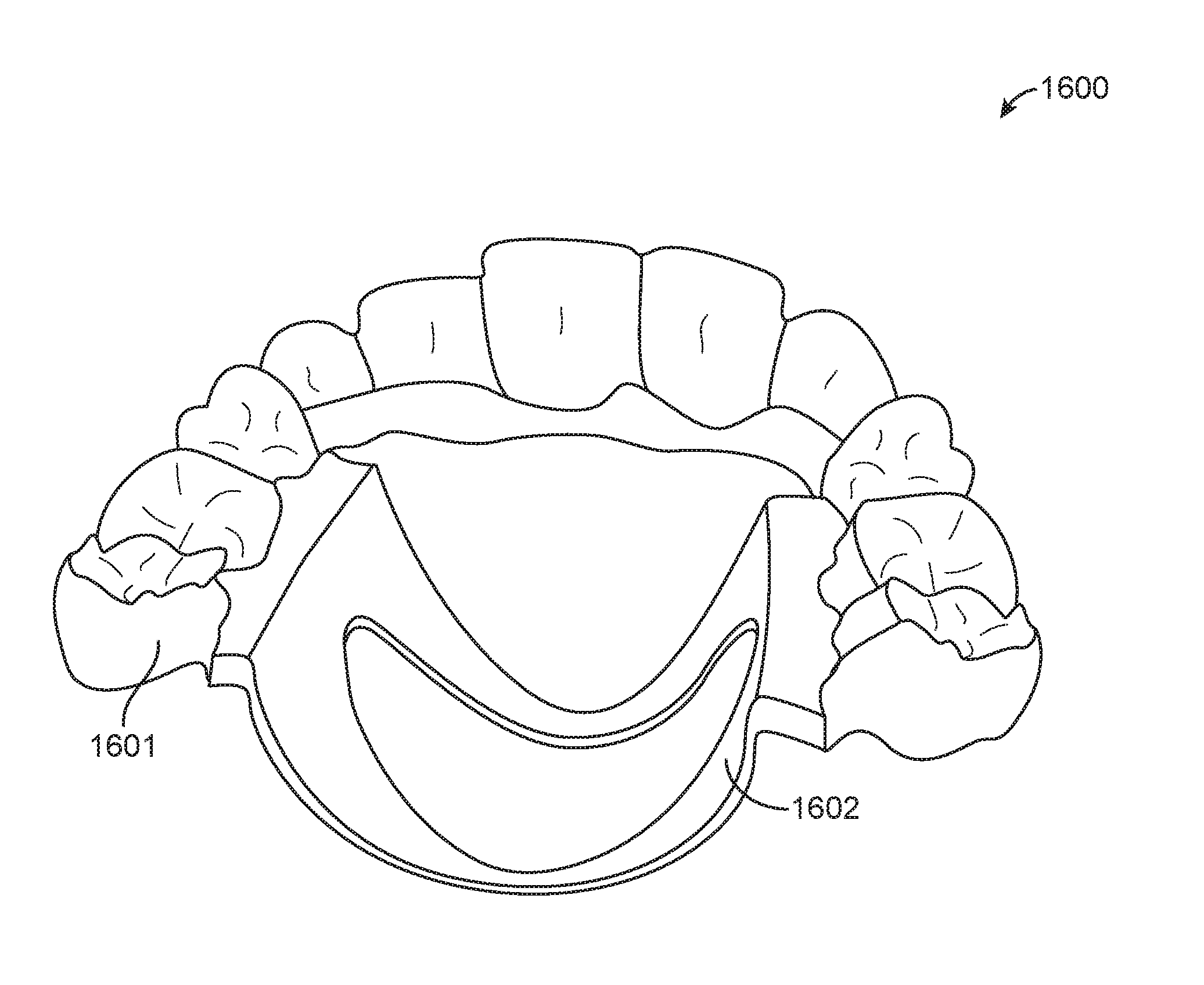

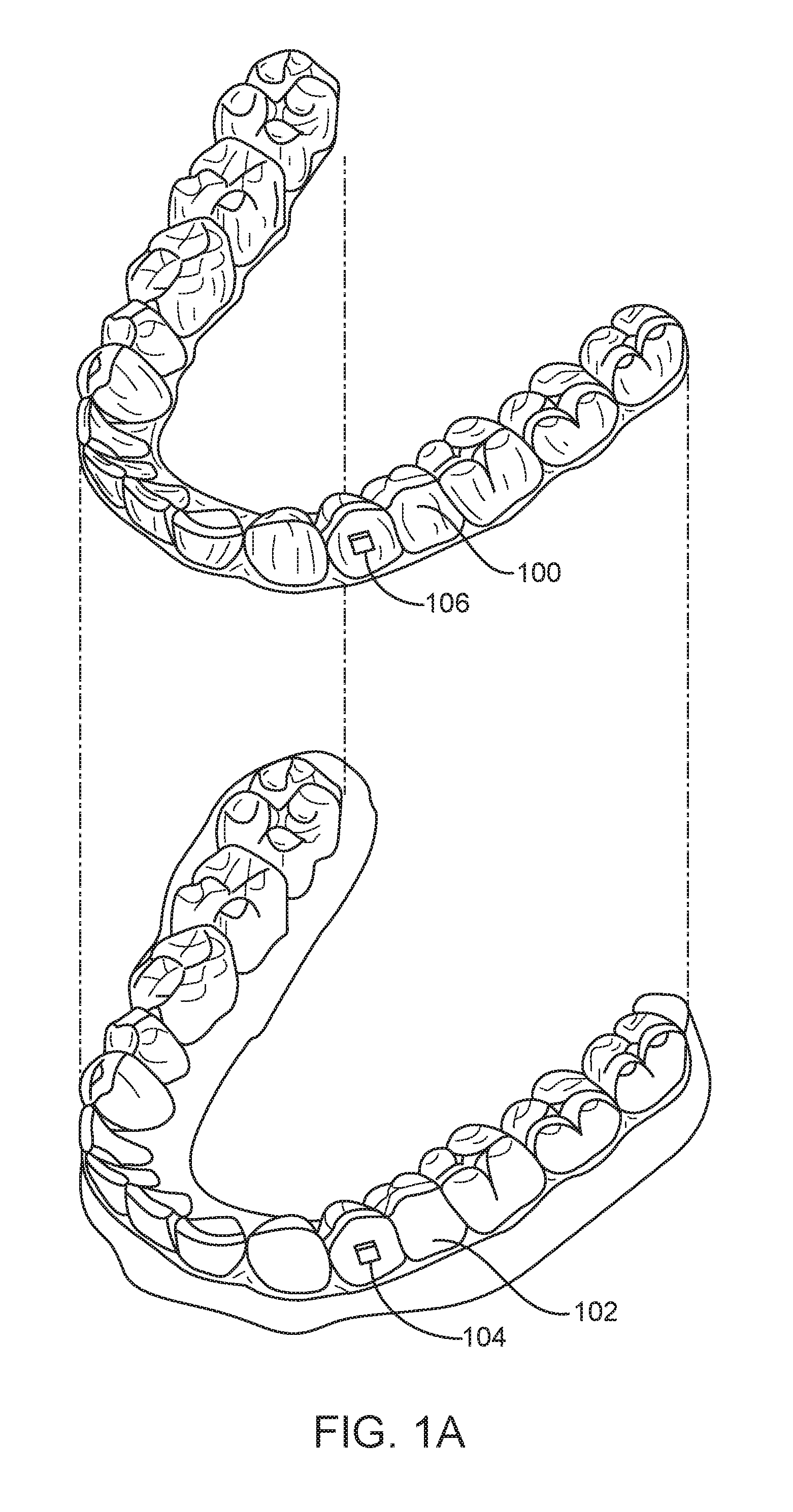

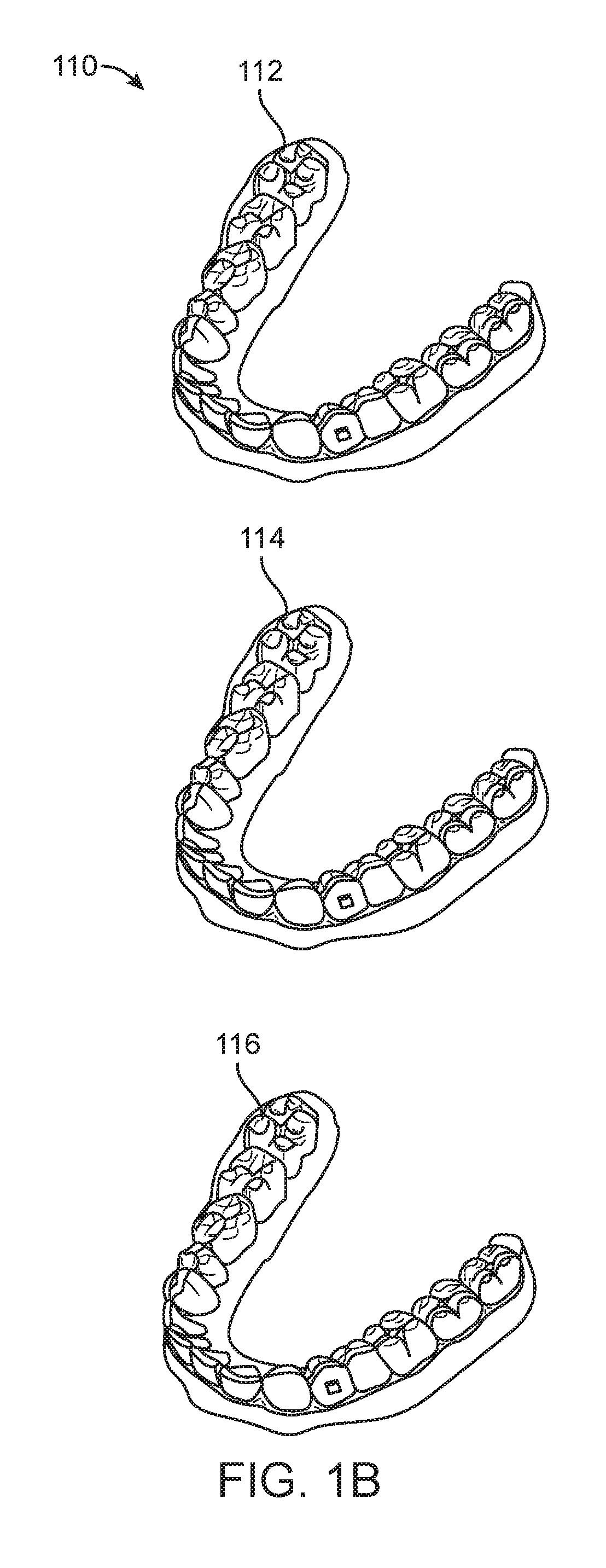

Direct fabrication of aligners for palate expansion and other applications

ActiveUS20170007367A1Improve accuracyImproved strength , accuracyAdditive manufacturing apparatusMechanical/radiation/invasive therapiesOrthodontics

Owner:ALIGN TECH

Direct fabrication of aligners for arch expansion

ActiveUS20170007366A1Improve accuracyImproved strength , accuracyAdditive manufacturing apparatusMechanical/radiation/invasive therapiesEngineering

Owner:ALIGN TECH

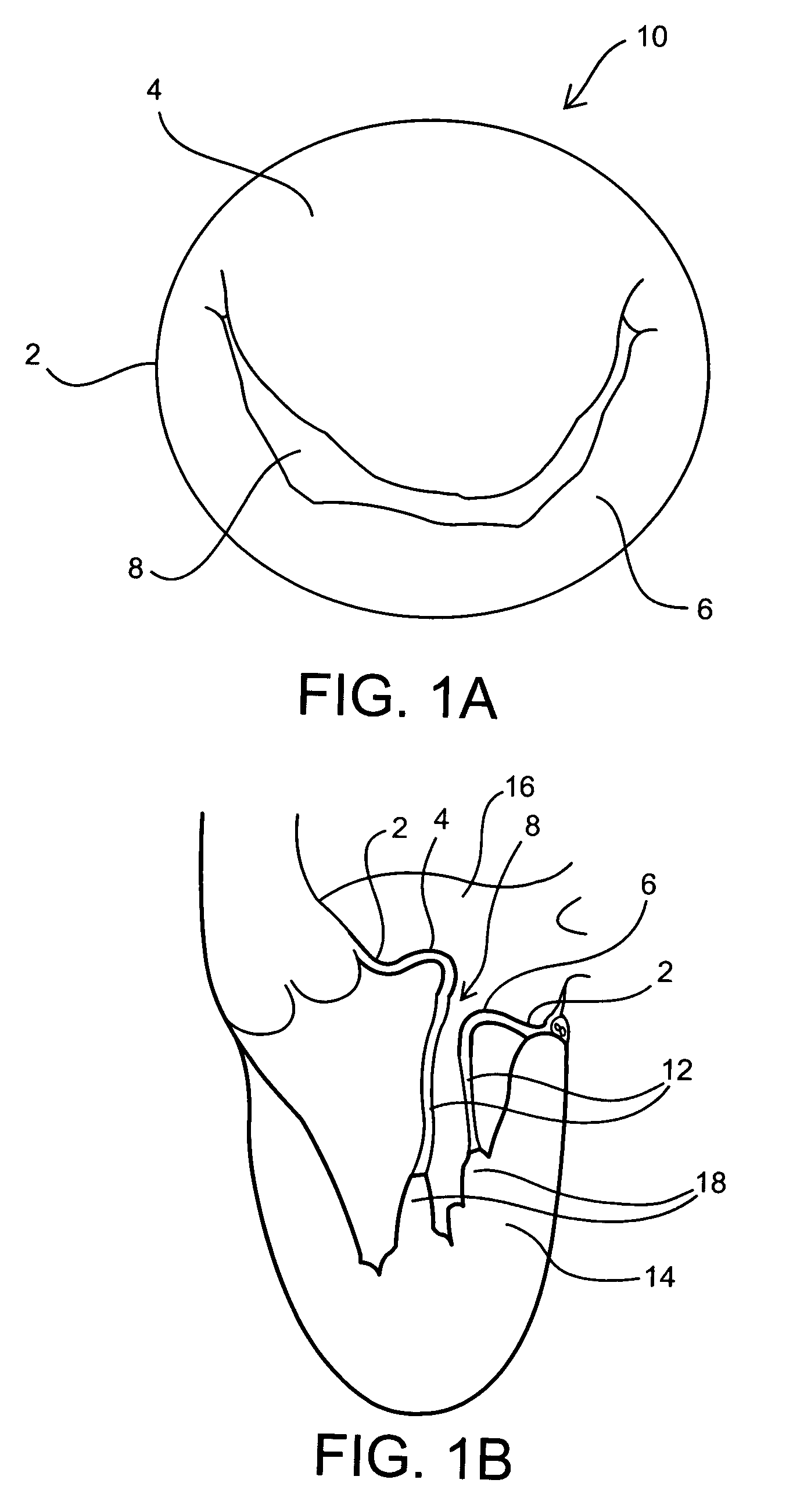

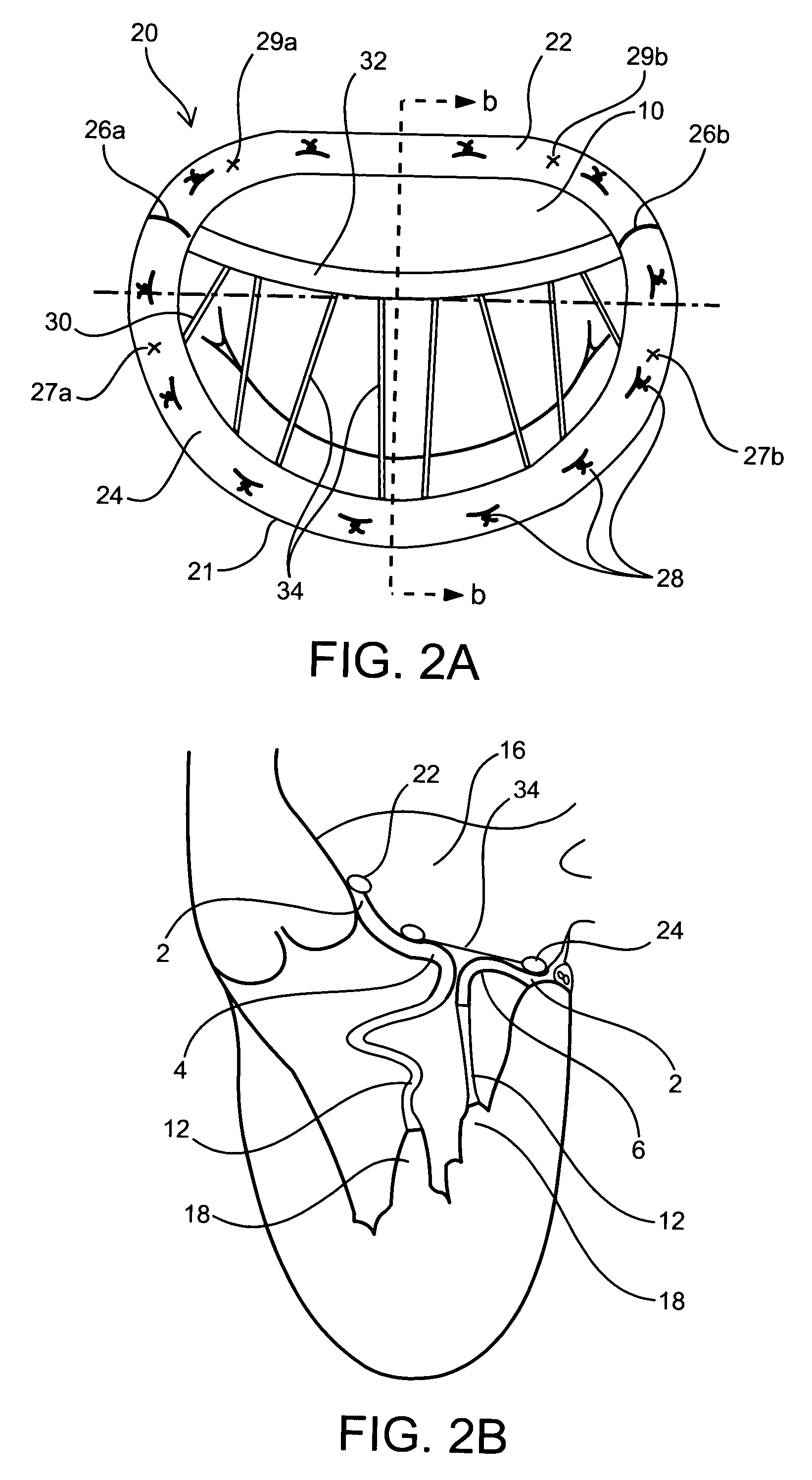

Annuloplasty rings and methods for repairing cardiac valves

InactiveUS20050004665A1Simple procedureCorrect dysfunctionBone implantAnnuloplasty ringsStructure functionAnnuloplasty rings

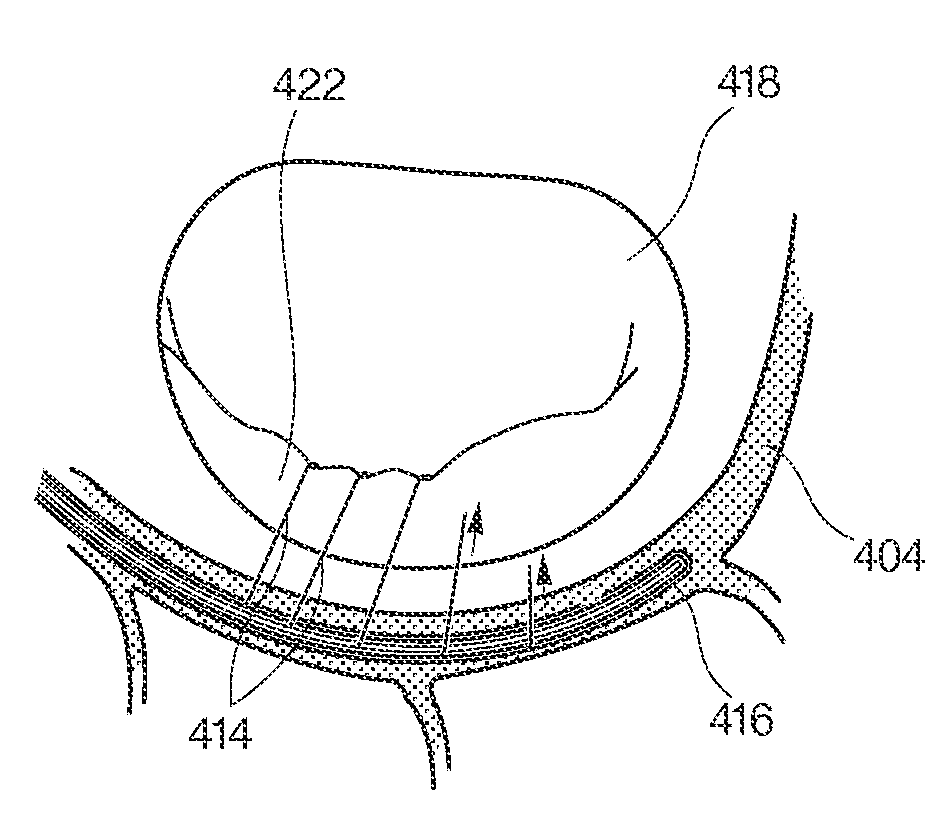

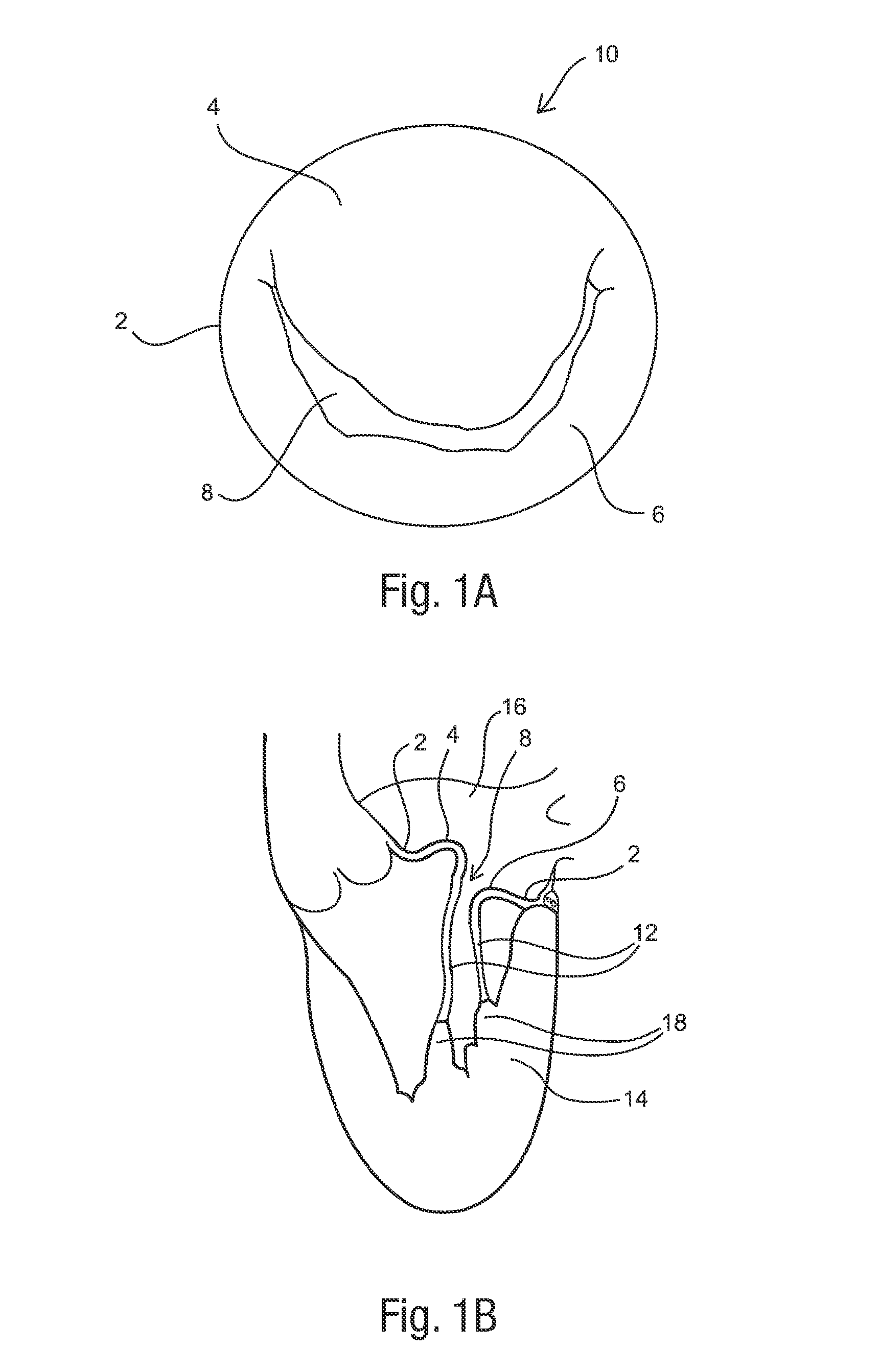

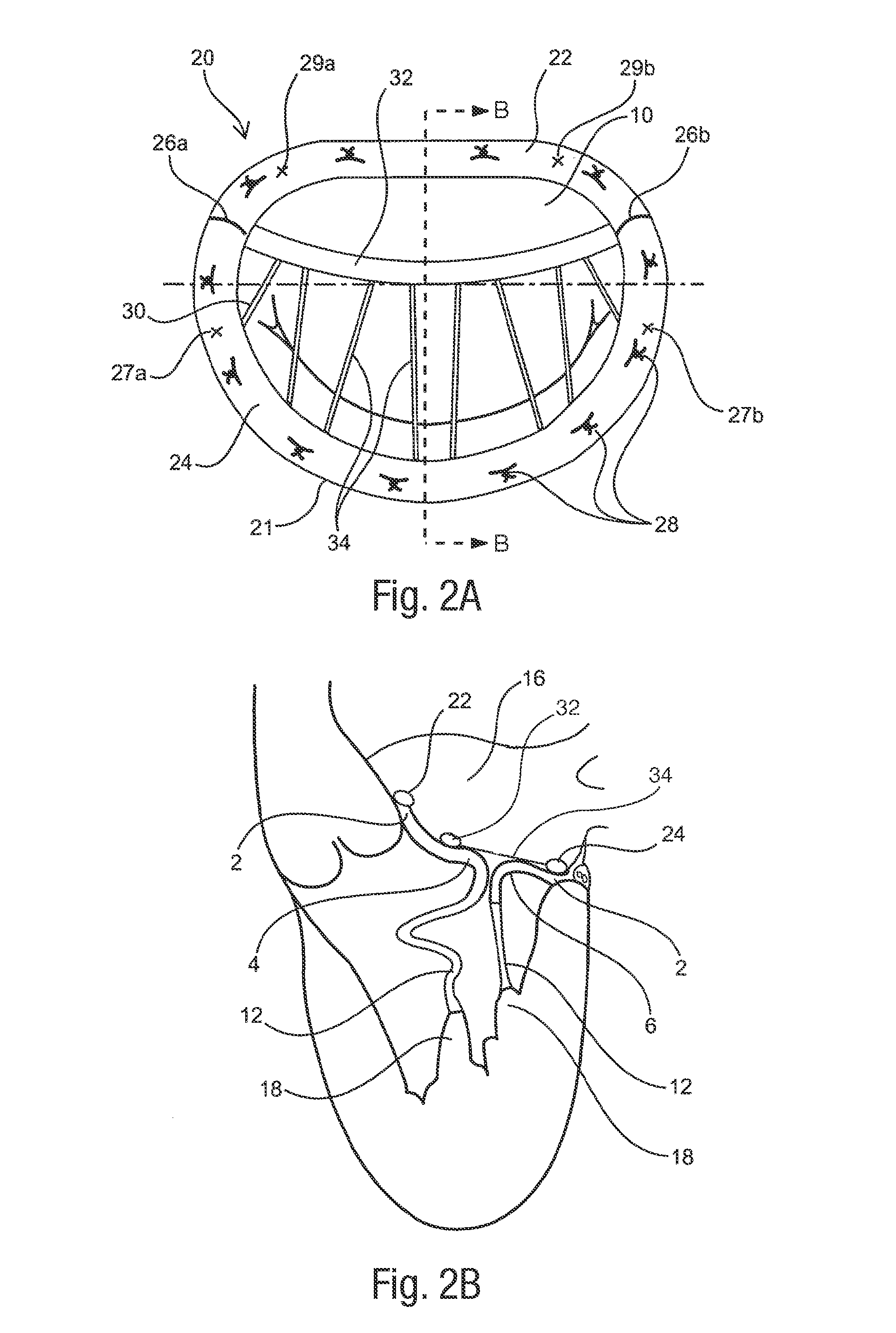

Implantable devices and methods for the repair of a defective cardiac valve are provided. The implantable devices include an annuloplasty ring and a restraining or support structure or mechanism. The annuloplasty ring functions to reestablish the normal size and shape of the annulus bringing the leaflet in proximity to each other. The restraining structure functions to restrain the abnormal motion of at least a portion of the valve being repaired. The restraining structure may include at least one restraining member across the interior of the circumference of the ring in a configuration consisting of a primary member to which secondary members are attached or one where all members traverse the ring. Kits for using the devices and practicing the methods of the invention are also provided.

Owner:FLEXCOR

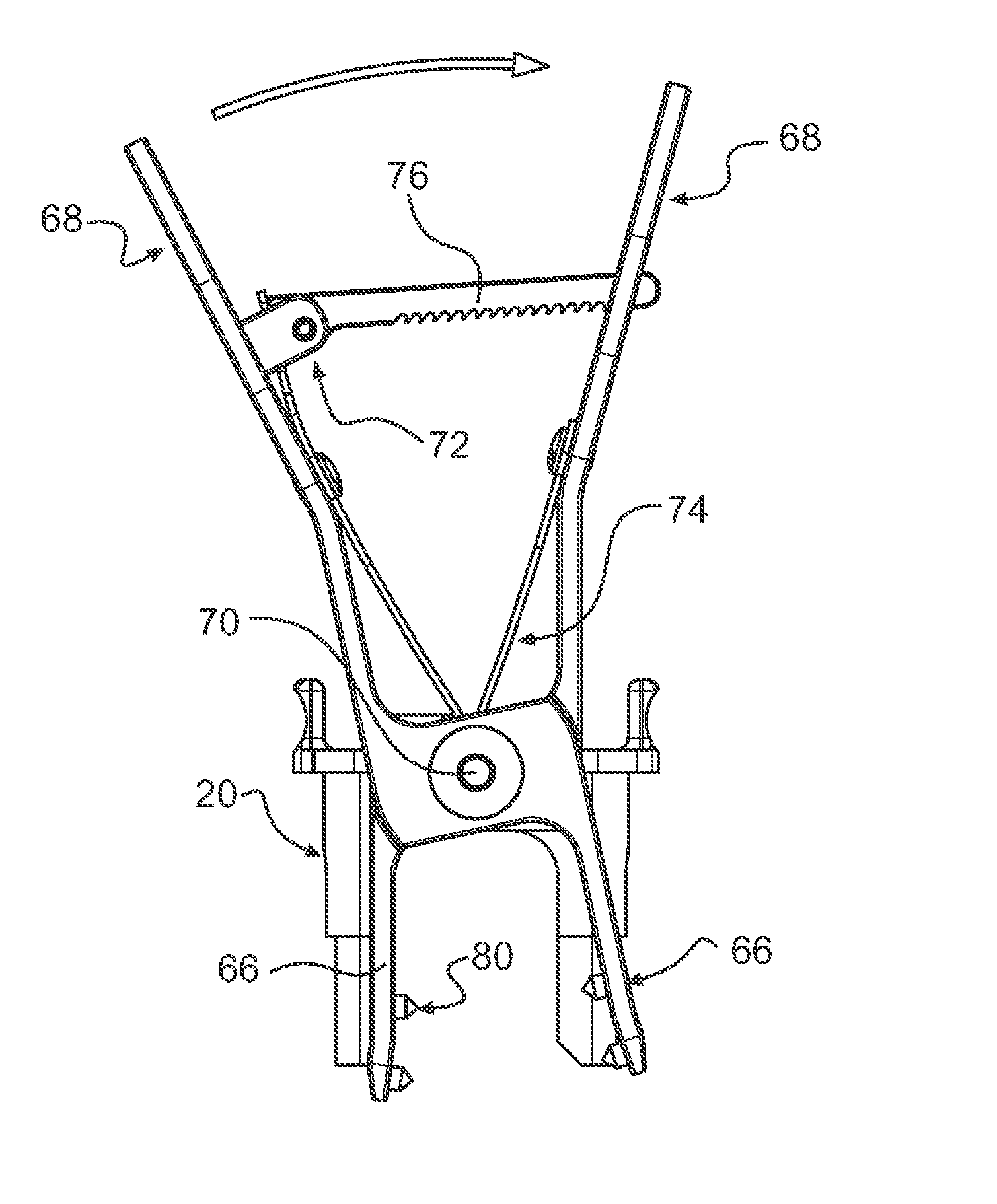

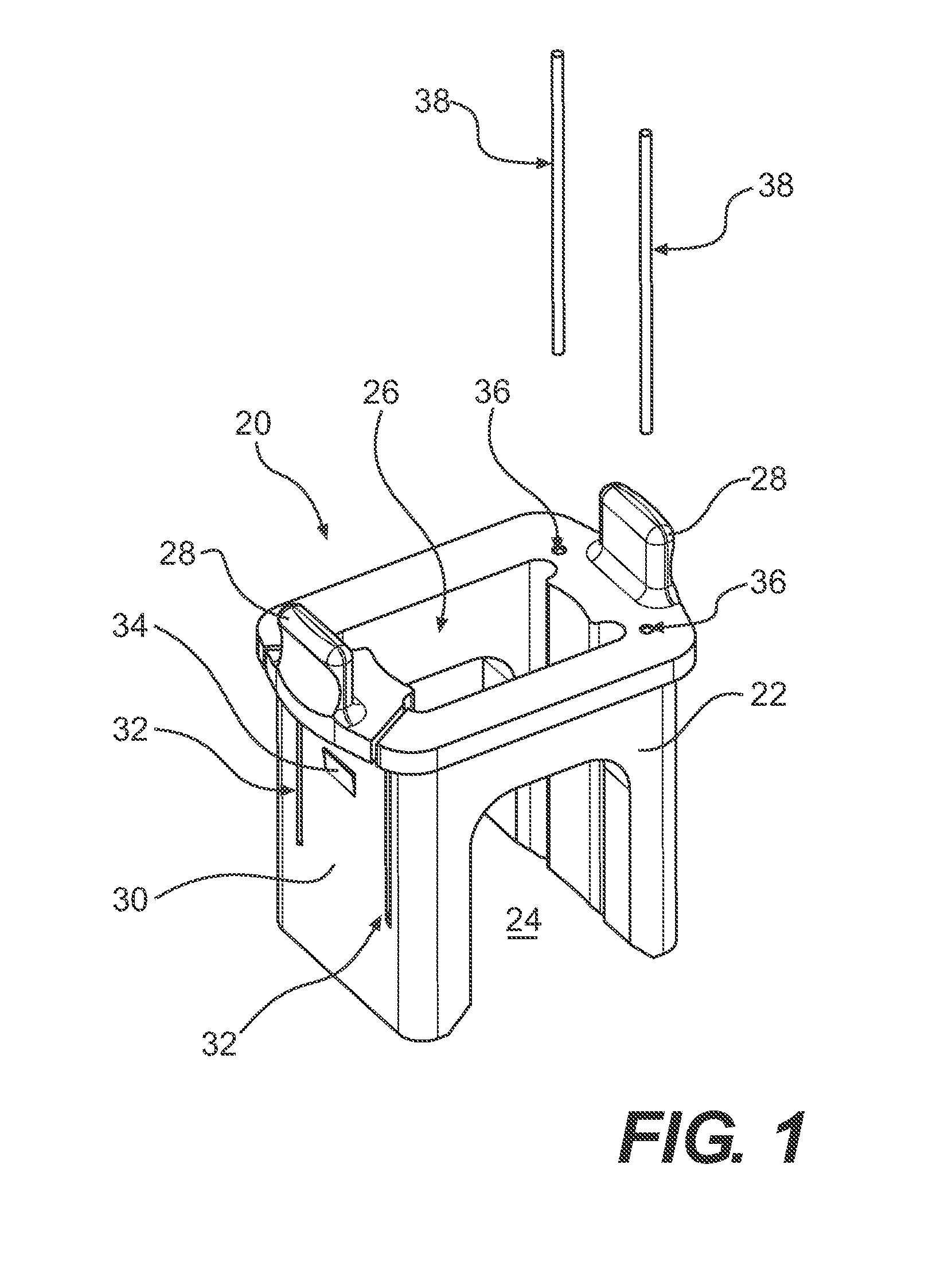

Cutting guide apparatus and surgical method for use in knee arthroplasty

InactiveUS20070073305A1Avoiding minimizing errorPrecise alignmentNon-surgical orthopedic devicesSurgical sawsKnee JointProsthesis

Novel cutting guides and surgical methods for use in knee arthroplasty are described. Embodiments of the inventive cutting guide apparatus include fixed and adjustable cutting guide blocks having a series of slots designed to accommodate a cutting saw. The cutting guides and surgical method are designed to allow for the provision of all desired surgical cuts upon the distal end of the femur, for subsequent implantation of a prosthesis thereto, without having to remove the cutting guide block.

Owner:LIONBERGER DAVID R +1

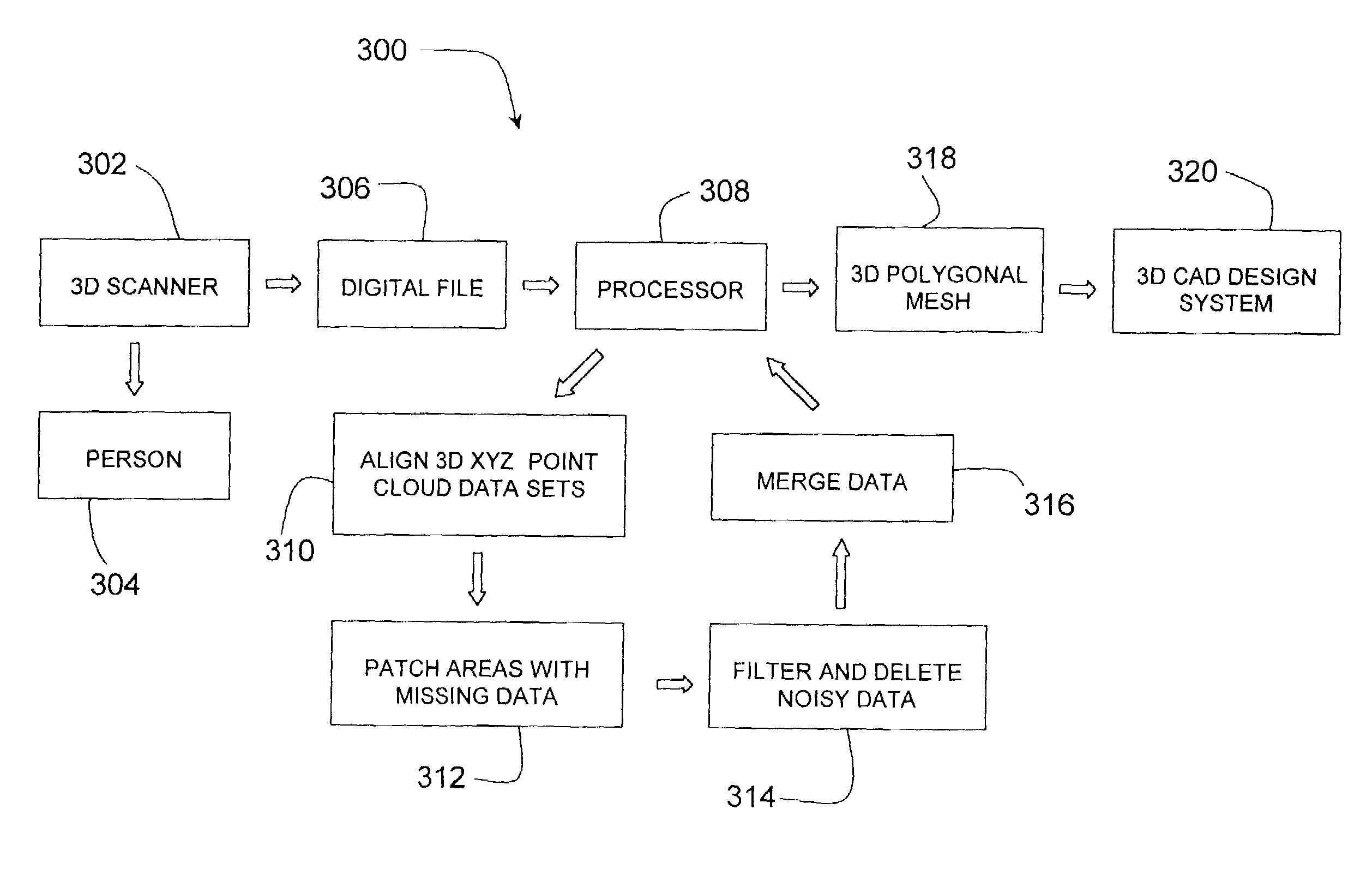

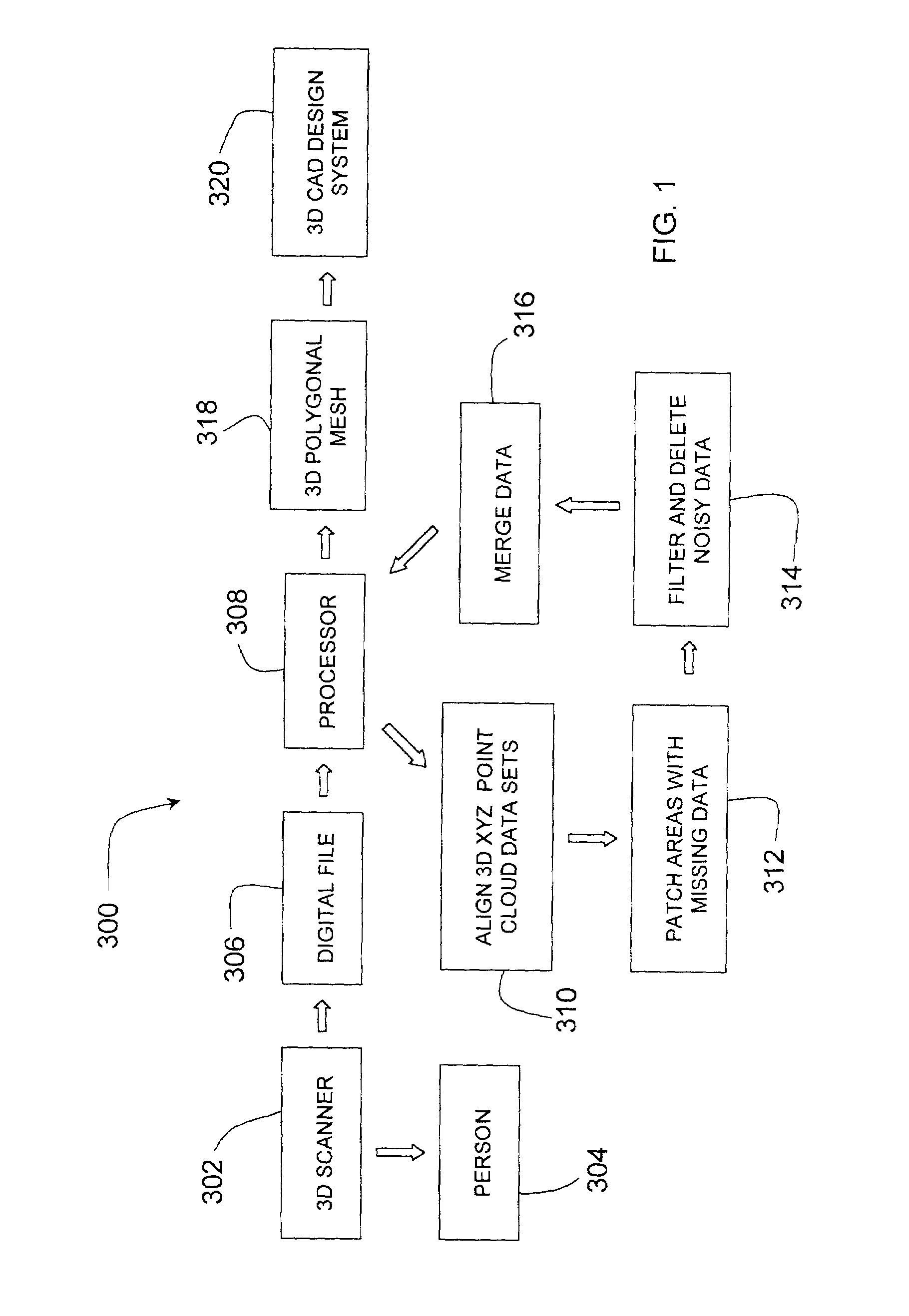

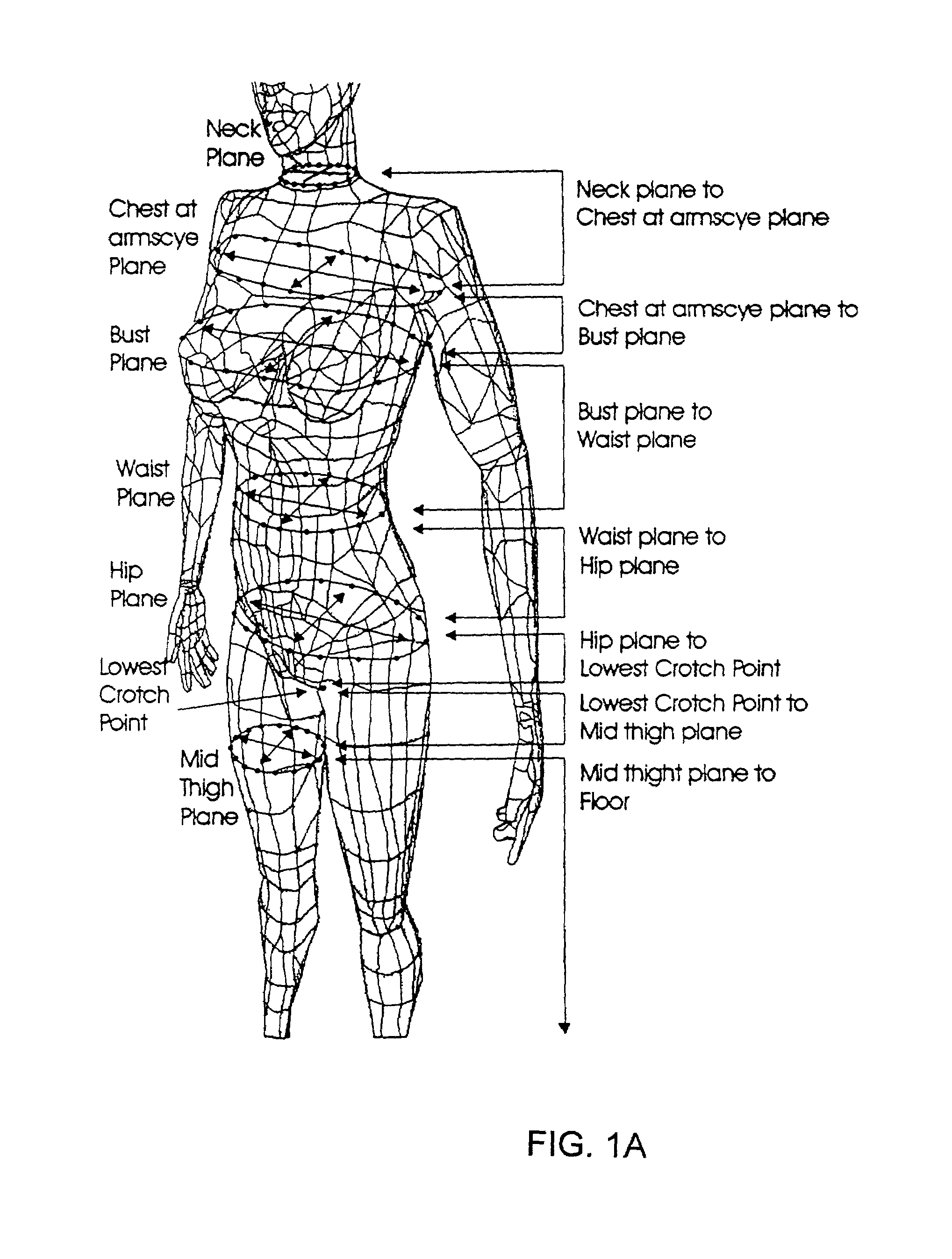

System and method for three-dimensional shape and size measurement

InactiveUS6968075B1Accurate measurementData augmentationData processing applicationsSpecial data processing applicationsComputer Aided DesignSize measurement

A method for three-dimensional shape and size measurement of a three-dimensional body surface comprising providing a three-dimensional scanner, providing a processor, providing a three-dimensional Computer Aided Design system, scanning in three dimensions with the three-dimensional scanner at least a portion of the three-dimensional body surface, creating a data file representative of the three-dimensional body surface, processing the data file with the processor, importing the data file into the three-dimensional Computer Aided Design System, employing the three-dimensional Computer Aided Design System relative to the data file to define and record three-dimensional measuring data relative to at least a portion of the three-dimensional body surface, A and employing the three-dimensional Computer Aided Design System to exploit the three-dimensional measuring data.

Owner:CHANG KURT C

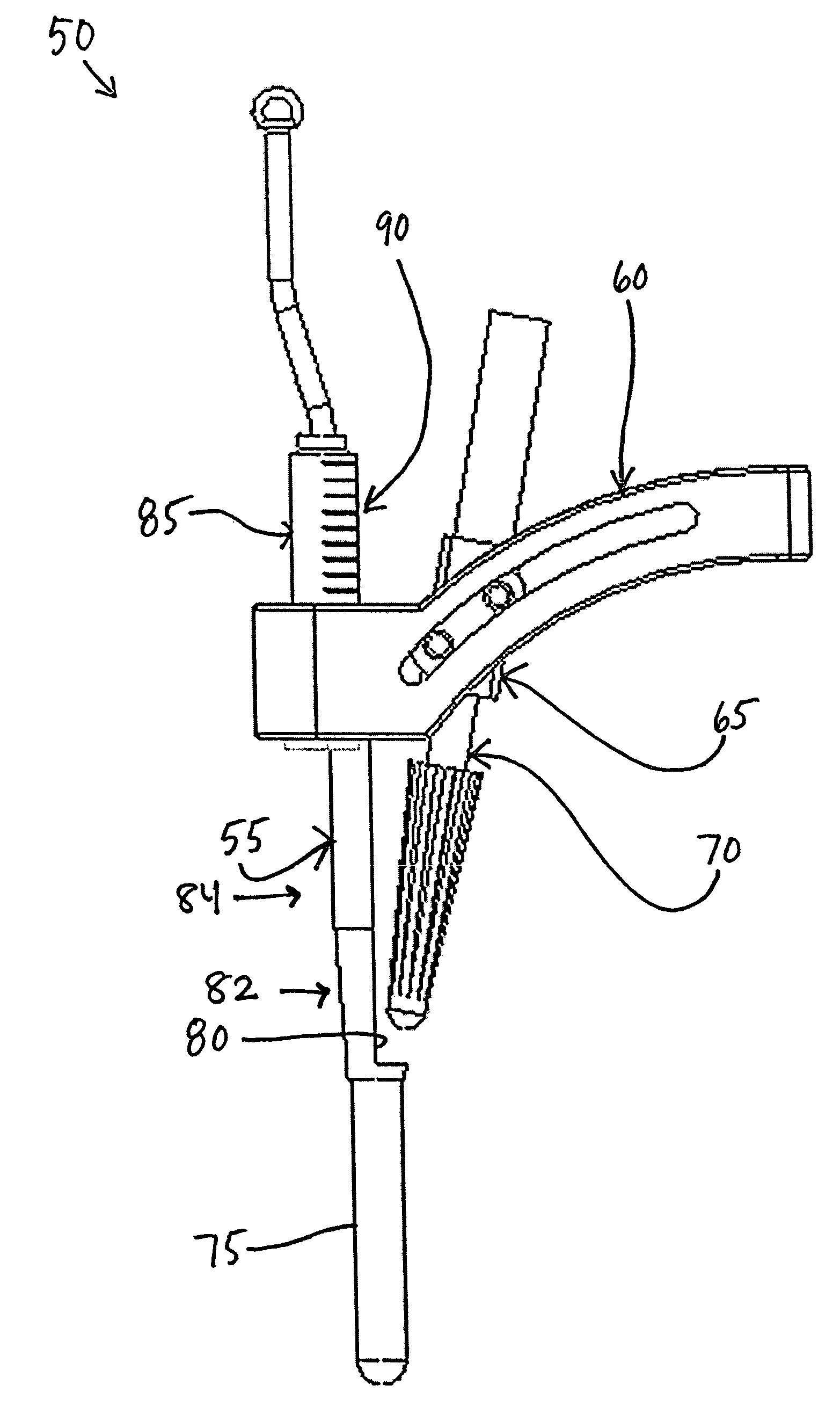

Bone milling instrument

InactiveUS7255702B2Complex and anatomically correct implant shapeAccurate shapeProsthesisOsteosynthesis devicesAttachment siteBiomedical engineering

A bone milling instrument is disclosed for creating a shaped cavity from an initial cavity in a bone, the bone milling instrument comprising a reference frame, a centering member at the distal end of the reference frame, a registration surface for engaging a portion of the initial cavity, and an attachment site provided proximally of the registration surface, a guidance support member, an attachment mechanism at the first end of the guidance support member, and a constrained pathway extending between the ends of the guidance support member; a shuttle having a first connection element configured for positionably attaching the shuttle to the guidance support member, and a second connection element configured to provide a rotational coupler; and a cutting device having a cutting portion configured at a distal end thereof, and an attachment portion provided at a proximal end.

Owner:SHALBY ADVANCED TECH INC

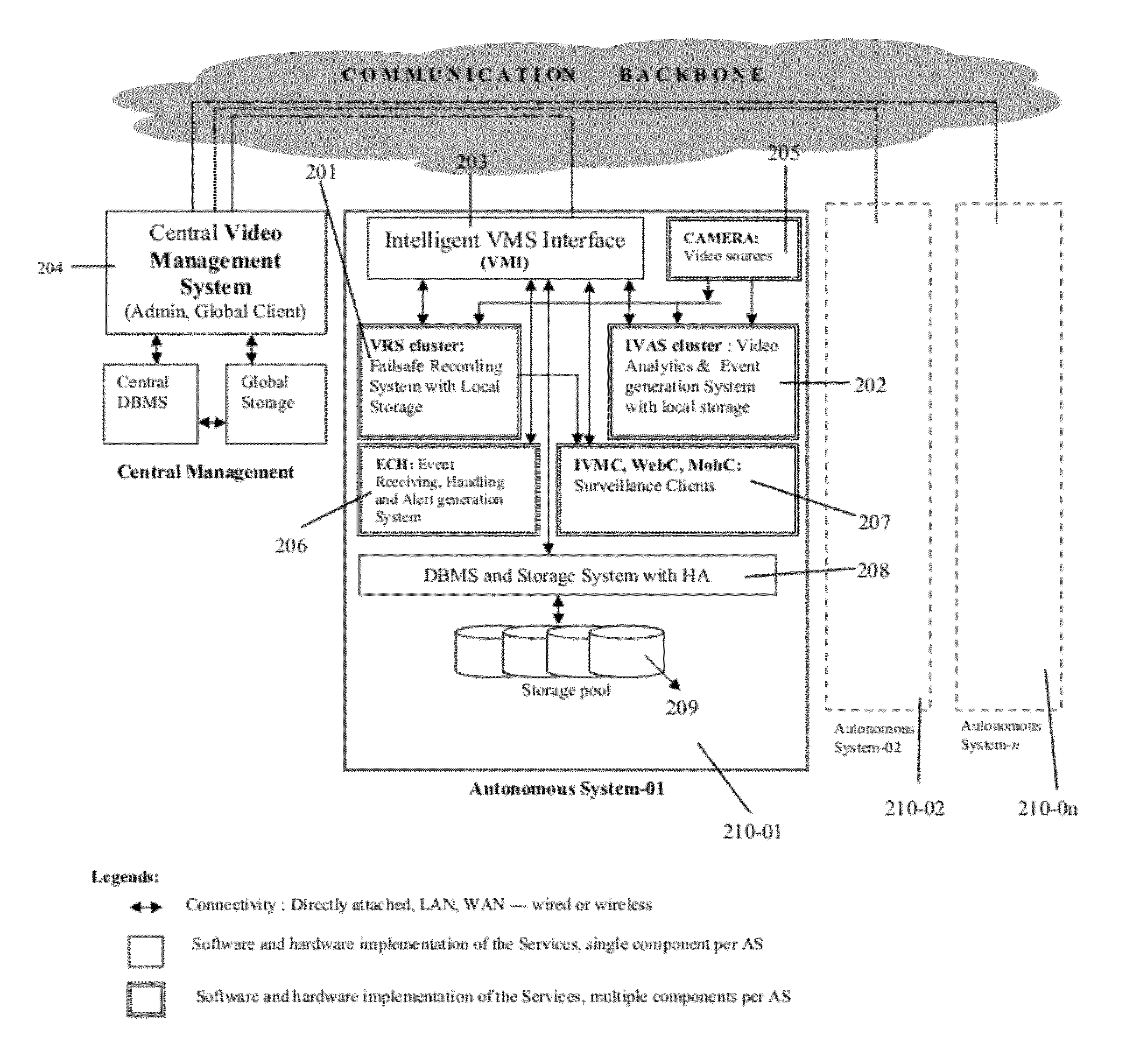

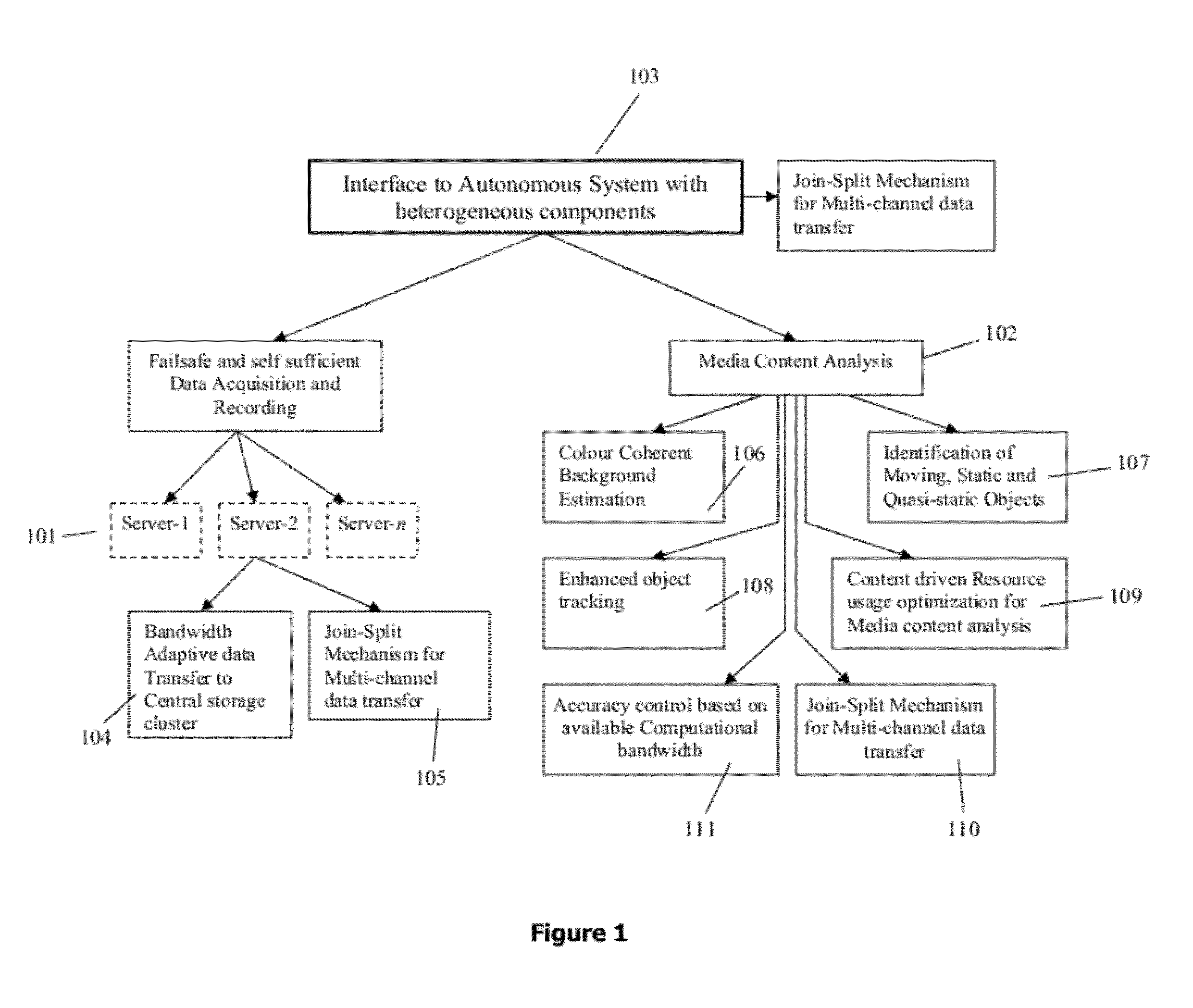

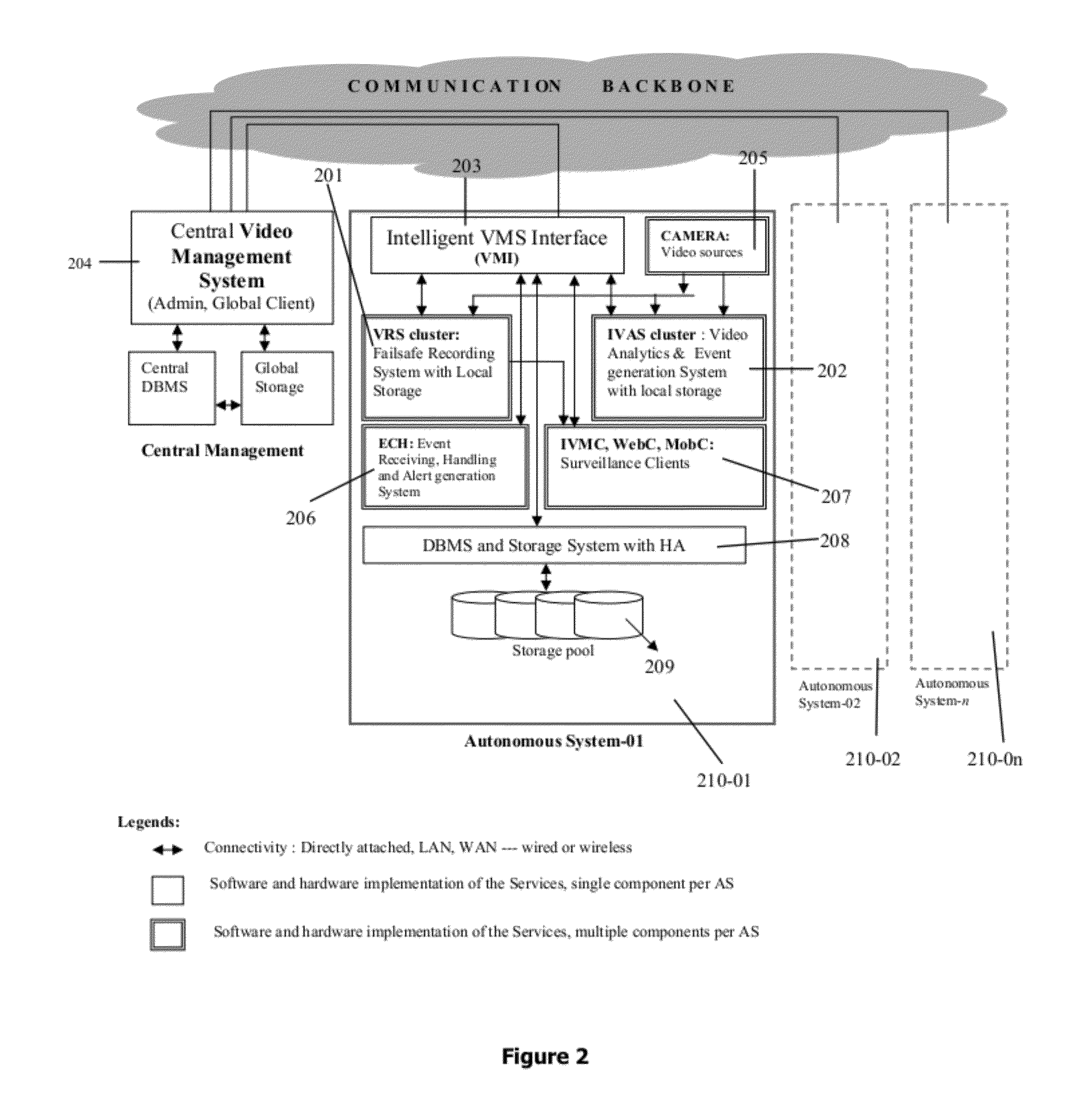

Integrated intelligent server based system and method/systems adapted to facilitate fail-safe integration and/or optimized utilization of various sensory inputs

ActiveUS20120179742A1Accurate predictive colour background estimationPrecise positioningTelevision system detailsRoad vehicles traffic controlFace detectionOperational system

Integrated intelligent system adapted for any operating system and / or multi-OS computing environment seamlessly having sensory input / data acquisition cum recording server group and / or analytics server group enabling fail-safe integration and / or optimized utilization of various sensory inputs for various utility applications. Also disclosed as added advancements include intelligent method / system for cost-effective and efficient band adaptive transferring / recording sensory data from single or multiple data sources to network accessible storage devices, fail safe and self sufficient server group based method for sensory input recording and live streaming in a multi-server environment, intelligent and unified method of colour coherent object analysis, face detection in video images and the like, resource allocation for analytical processing involving multi channel environment, multi channel join-split mechanism adapted for low and / or variable bandwidth network link, enhanced multi-colour and / or mono-colour object tracking and also an intelligent automated traffic enforcement system.

Owner:VIDEONETICS TECH PRIVATE

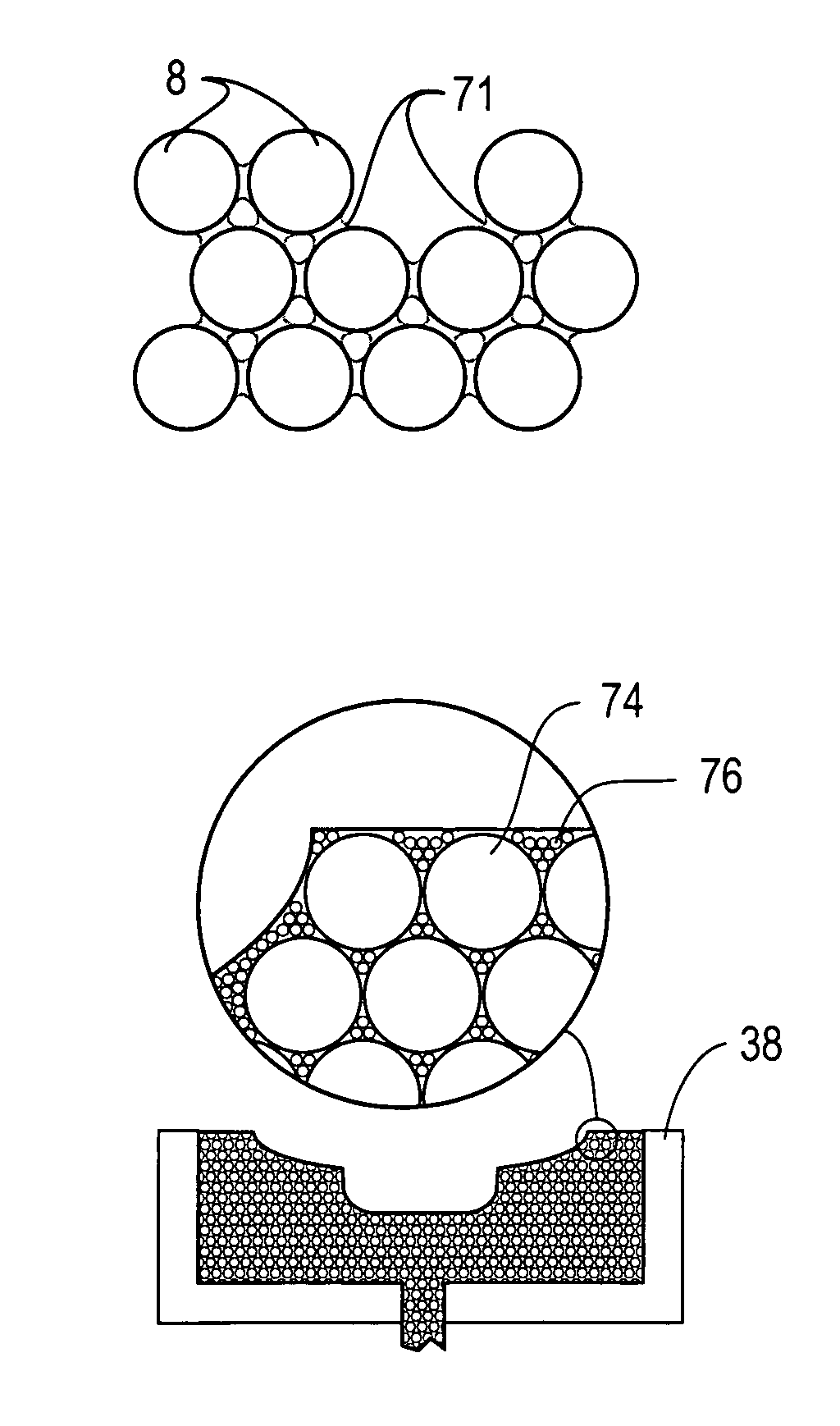

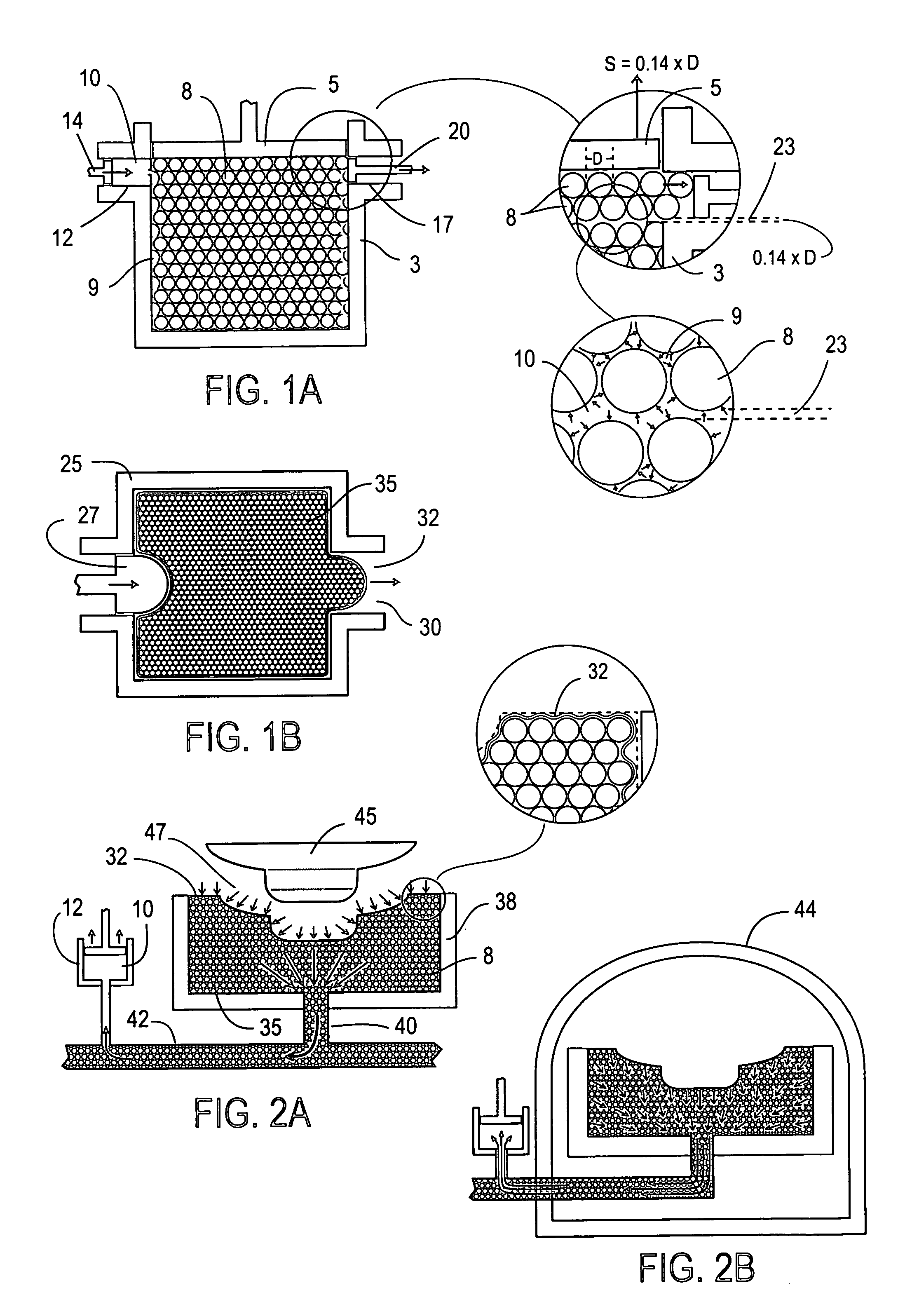

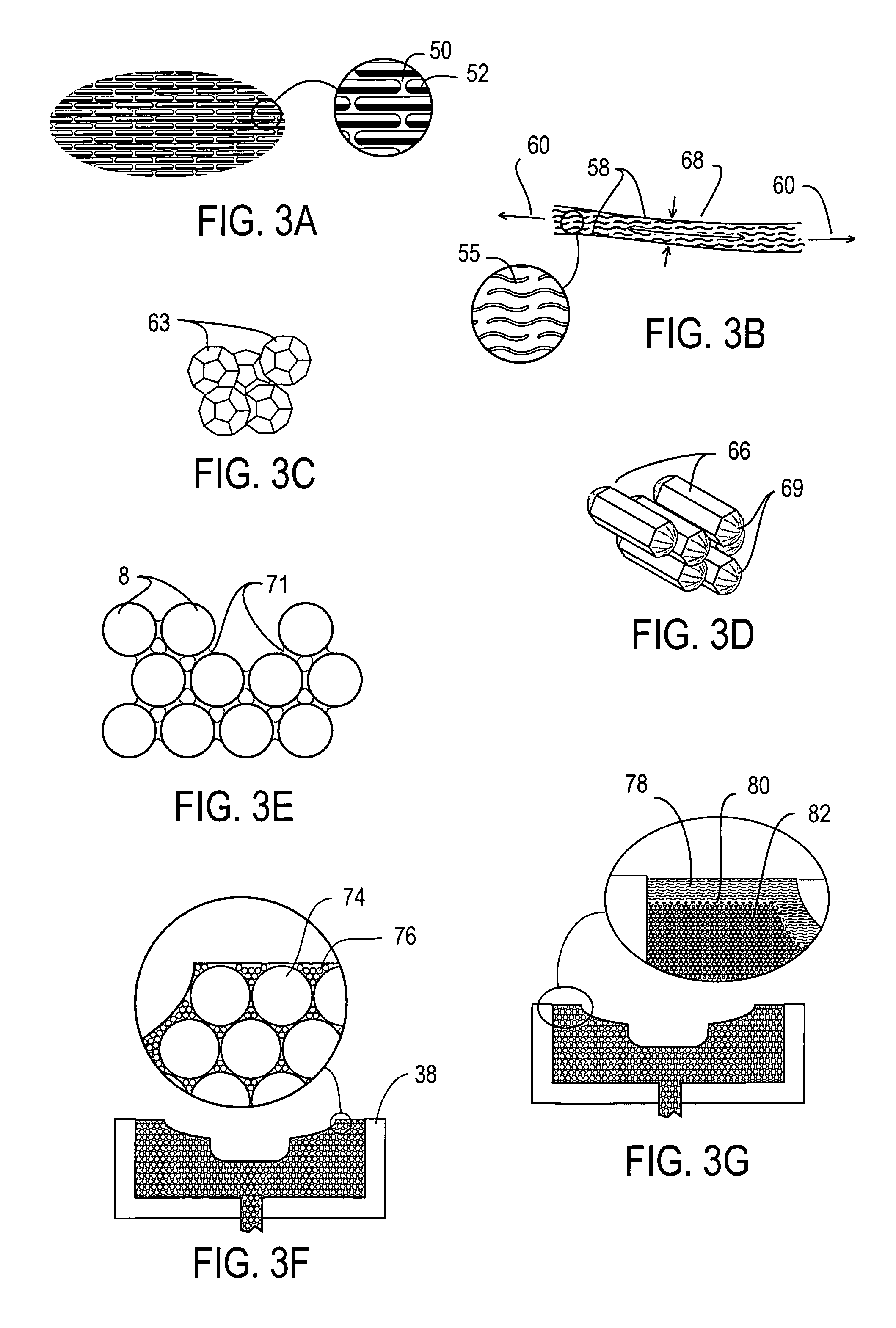

Use of state-change materials in reformable shapes, templates or tooling

Techniques for generating a stable, force-resisting positive or negative representation of a shape. A state-changeable mixture includes uniform, generally ordered, closely-spaced solid bodies and a liquid carrier medium, with the liquid filling any voids or interstices between the bodies and excluding air or gas bubbles from the mixture. Within the mixture, the solid bodies can be caused to transition from a near-liquid or fluent condition of mobility to a stable, force-resisting condition. To create mobility, a small excess quantity or transition liquid is introduced to create a fluent condition by providing a slight clearance between the bodies which permits the gently-forced introduction of at least two simultaneous slip planes between ordered bulk masses of the bodies at any point in the mixture. Transition to the stable condition is caused by extraction of the transition liquid, removing the clearance between bodies and causing them to make stable, consolidated contact.

Owner:TRAN BAO

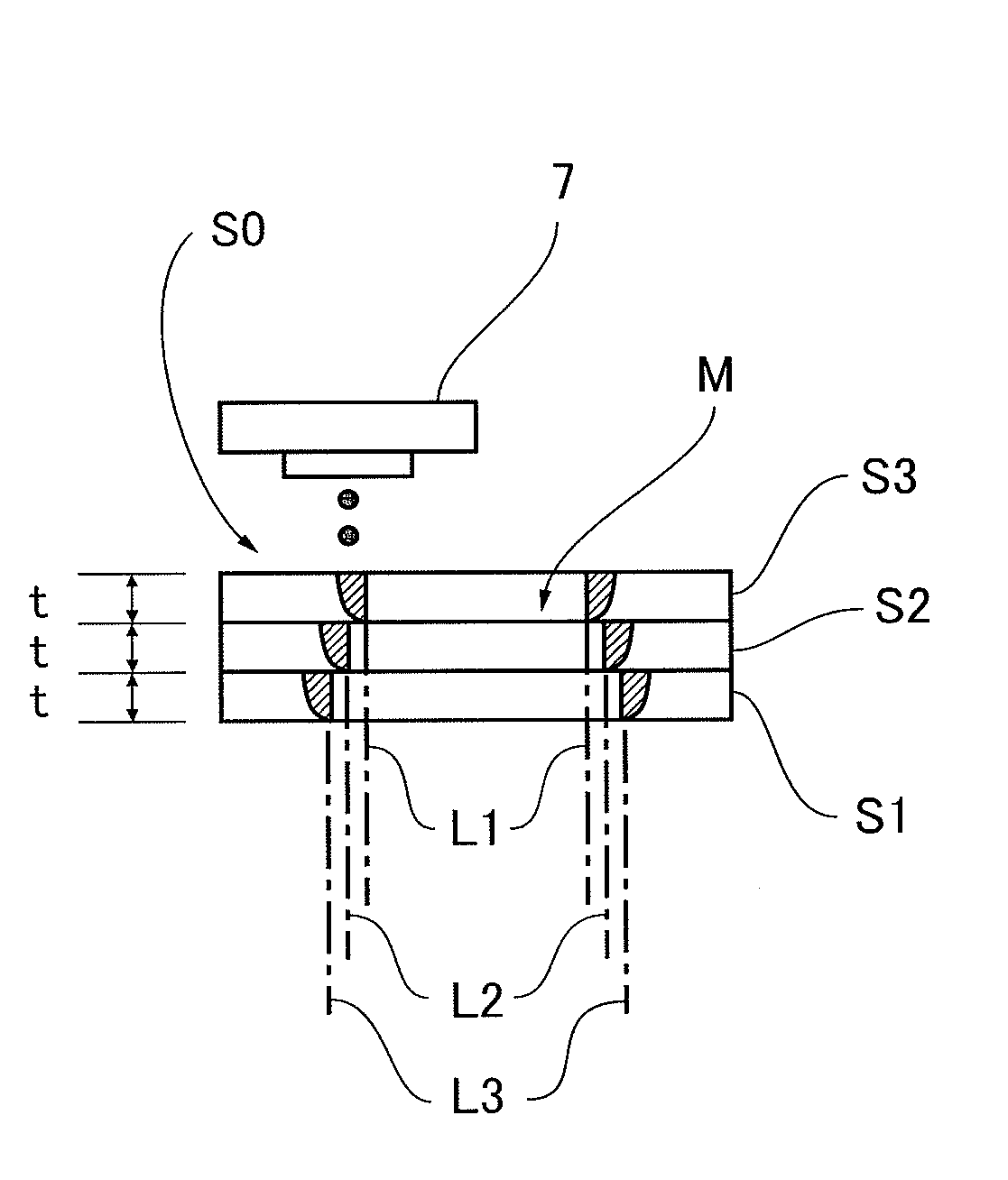

System and method for producing a three-dimensional model

InactiveUS7702380B1Accurate shapeSmall sizeAdditive manufacturing apparatusMaterial analysis using wave/particle radiationMedical deviceImaging data

A shape of a medical device to be implanted into a subject is verified by acquiring a plurality of inter-fiduciary marker dimensions from the subject. Three-dimensional image data of the markers and a tissue of interest, included in the subject, is obtained. Respective measurements between the fiduciary markers around the subject and in the image data are confirmed. The tissue of interest and the fiduciary markers are identified in the image data. Points of the tissue of interest and the fiduciary markers are rendered as a 3-dimensional surface representation. A 3-dimensional model of the tissue of interest and the fiduciary markers is generated as a function of the surface representation. A shape of the medical device to be implanted into the subject is determined as a function of the 3-dimensional model.

Owner:OSTEOPLASTICS

Annuloplasty rings for repairing cardiac valves

InactiveUS8052751B2Simple procedureCorrect dysfunctionBone implantAnnuloplasty ringsStructure functionAnnuloplasty rings

Owner:FLEXCOR

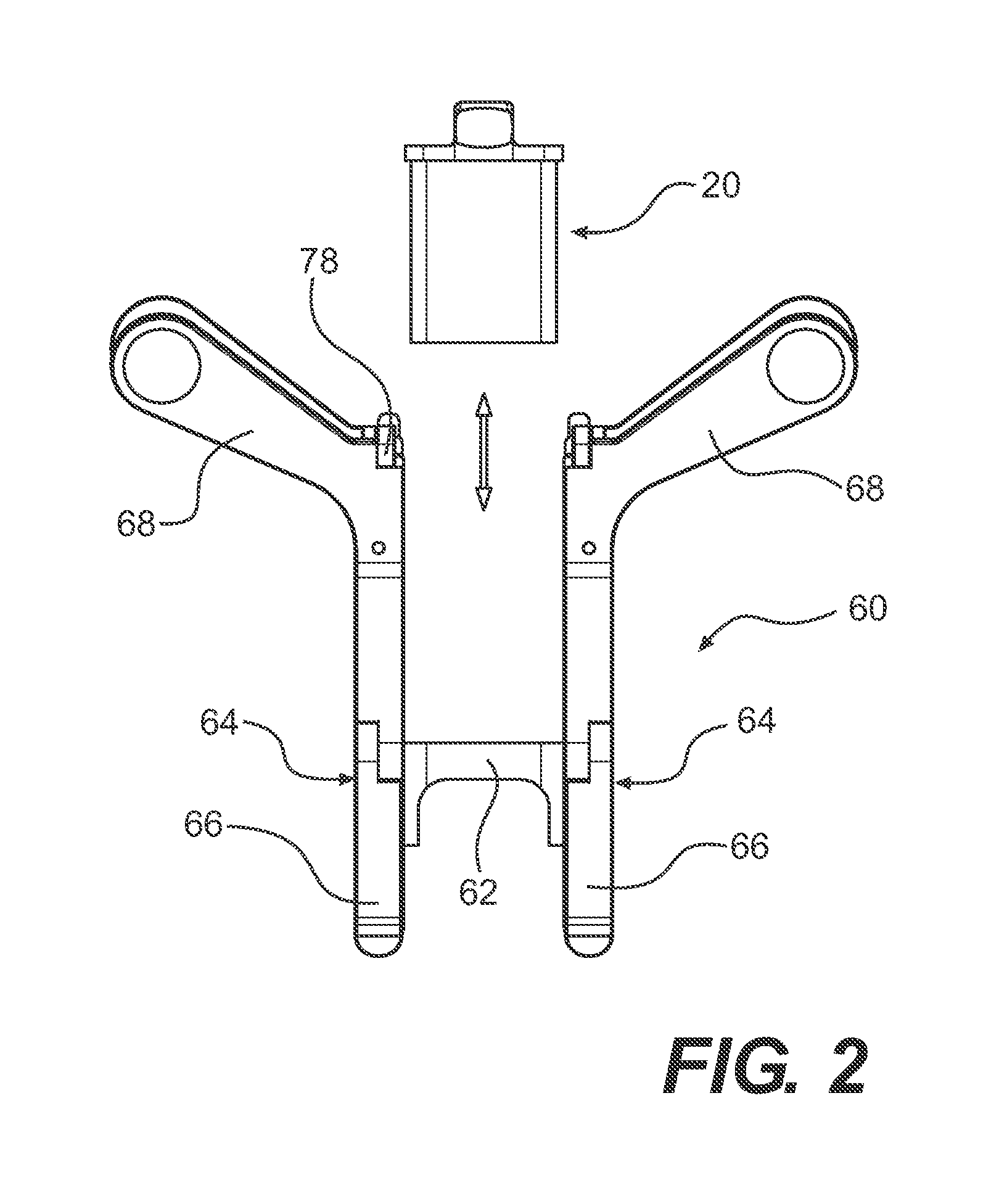

Method and system for performing interspinous space preparation for receiving an implant

A method and system are provided for preparing an interspinous space to receive an implantable device. The system may comprise a cutting tool guide having a guiding surface for directing a cutting tool therethrough and a holder for positioning the cutting tool guide relative to the interspinous space. The holder may be configured to adjustably attach to at least one of a pair of spinous processes defining the interspinous space.

Owner:XTANT MEDICAL INC

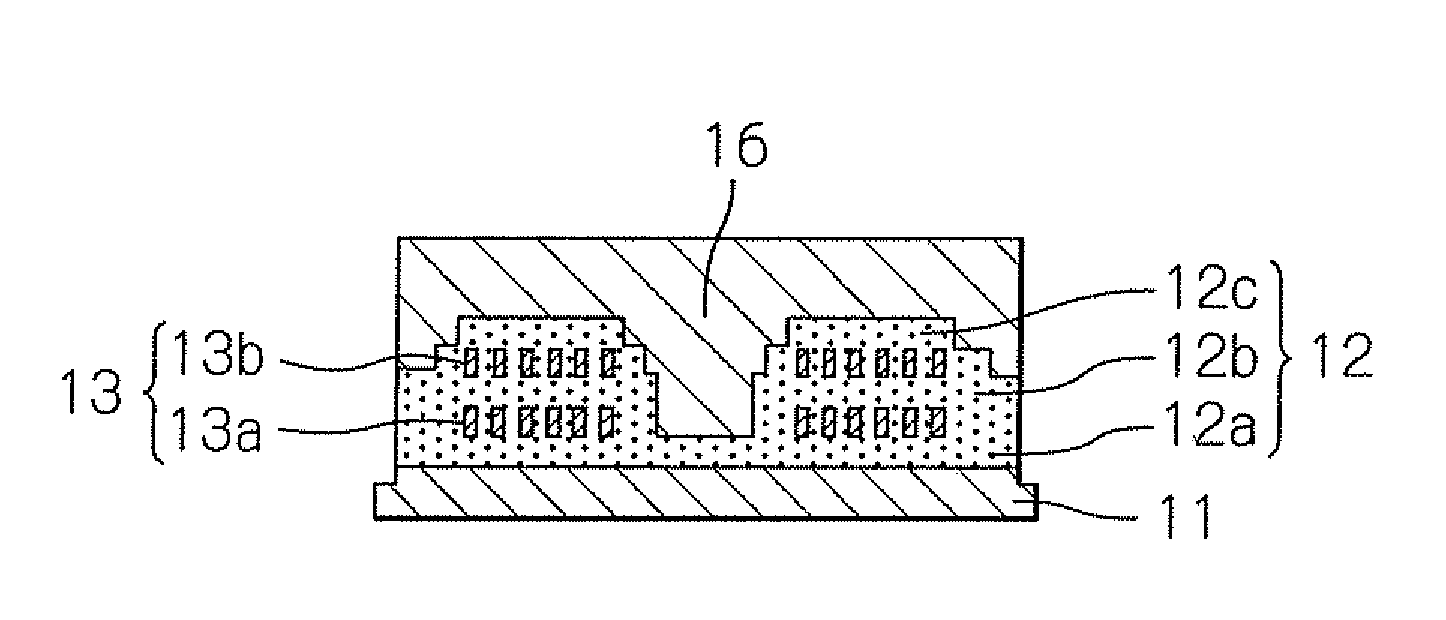

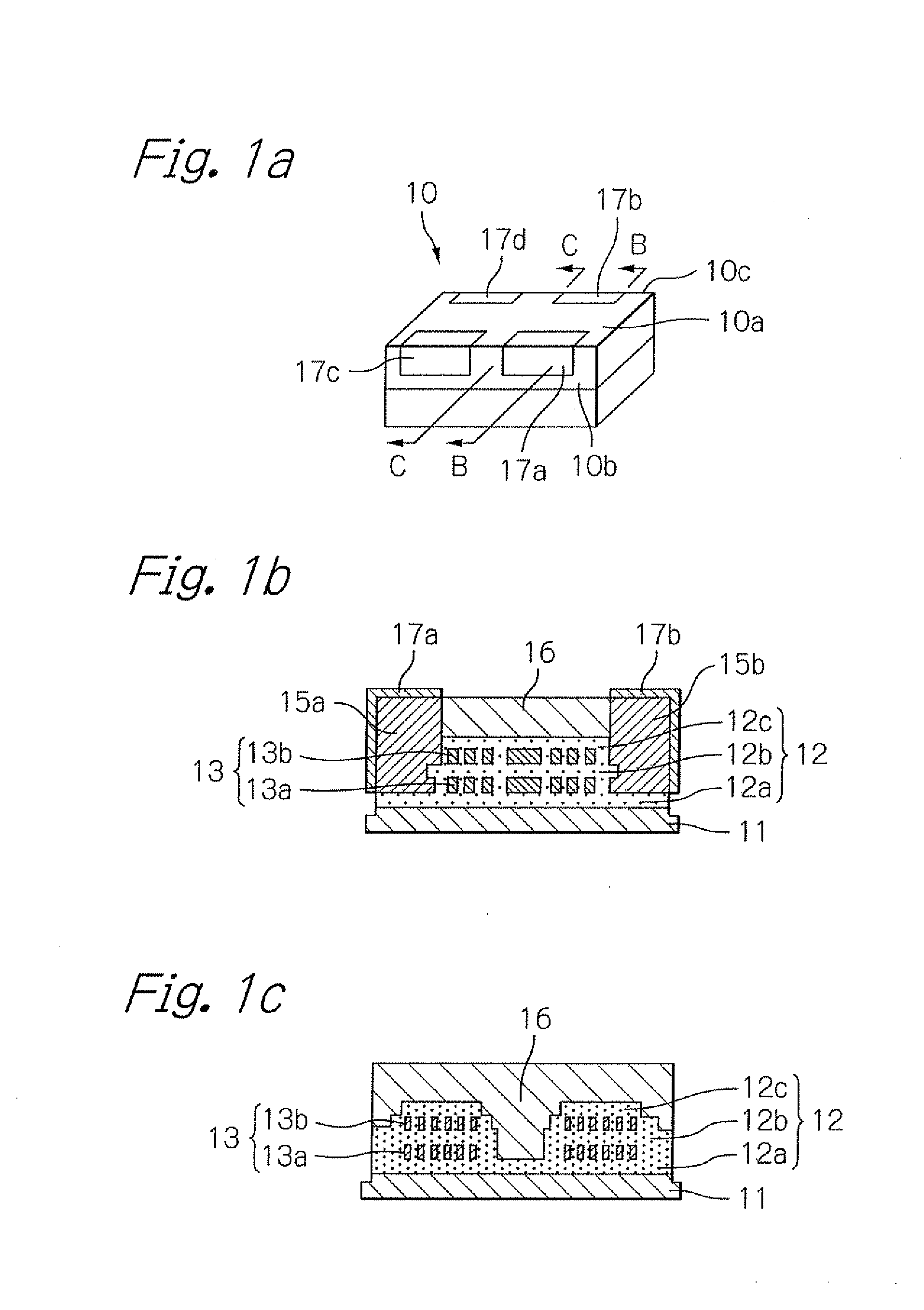

Electronic component and manufacturing method of electronic component

ActiveUS20100157565A1Sufficient soldering strengthIncrease electrode areaSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsInsulation layerElectrical conductor

A manufacturing method of electronic components includes forming a first insulation layer on a substrate, forming a plurality of passive elements on the first insulation layer, forming a second insulation layer on the passive elements, forming a plurality of conductor layers electrically connected to the respective passive elements, on the outer side of the second insulation layer to be exposed to an upper surface of each electronic component, and forming grooves between the electronic components including the respective passive elements to expose side surfaces of each electronic component and parts of the conductor layers from the side surfaces of each electronic component. The manufacturing method further including plating a plurality of external electrodes on the respective conductor layers exposed to the upper surface and the side surfaces of each electronic component, and cutting the substrate to completely separate into individual electronic components.

Owner:TDK CORPARATION

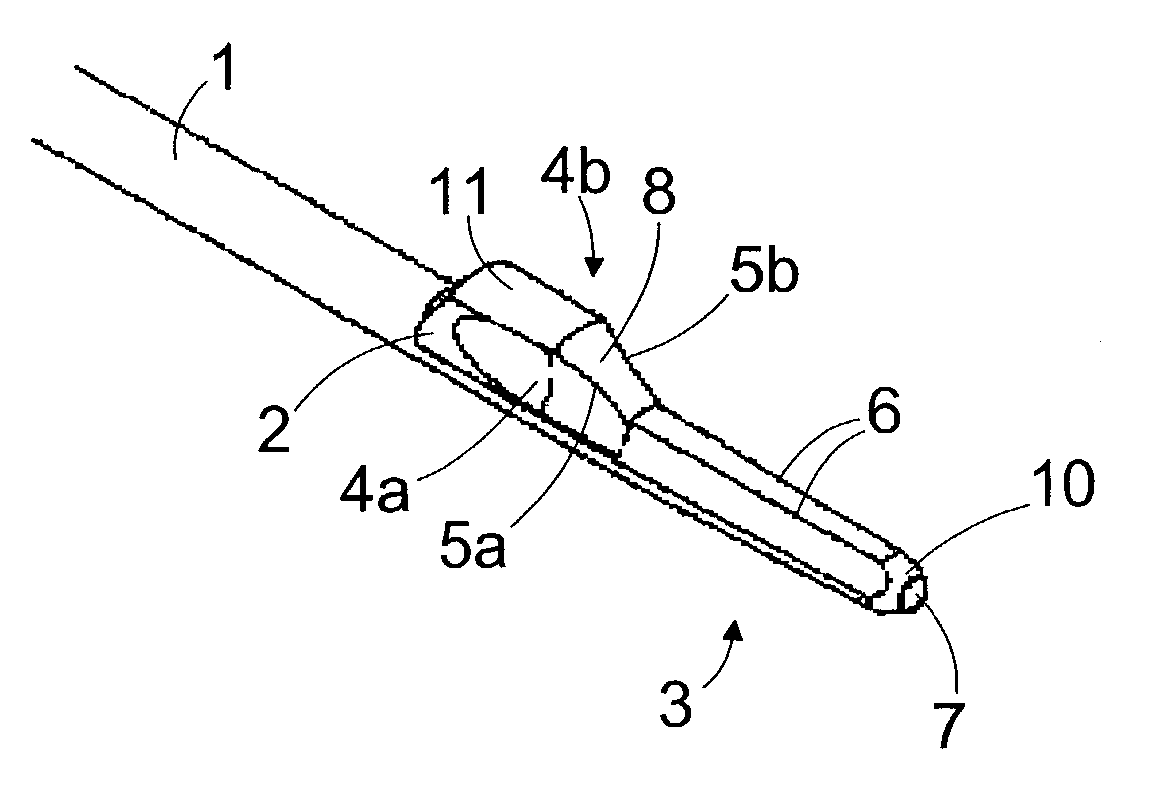

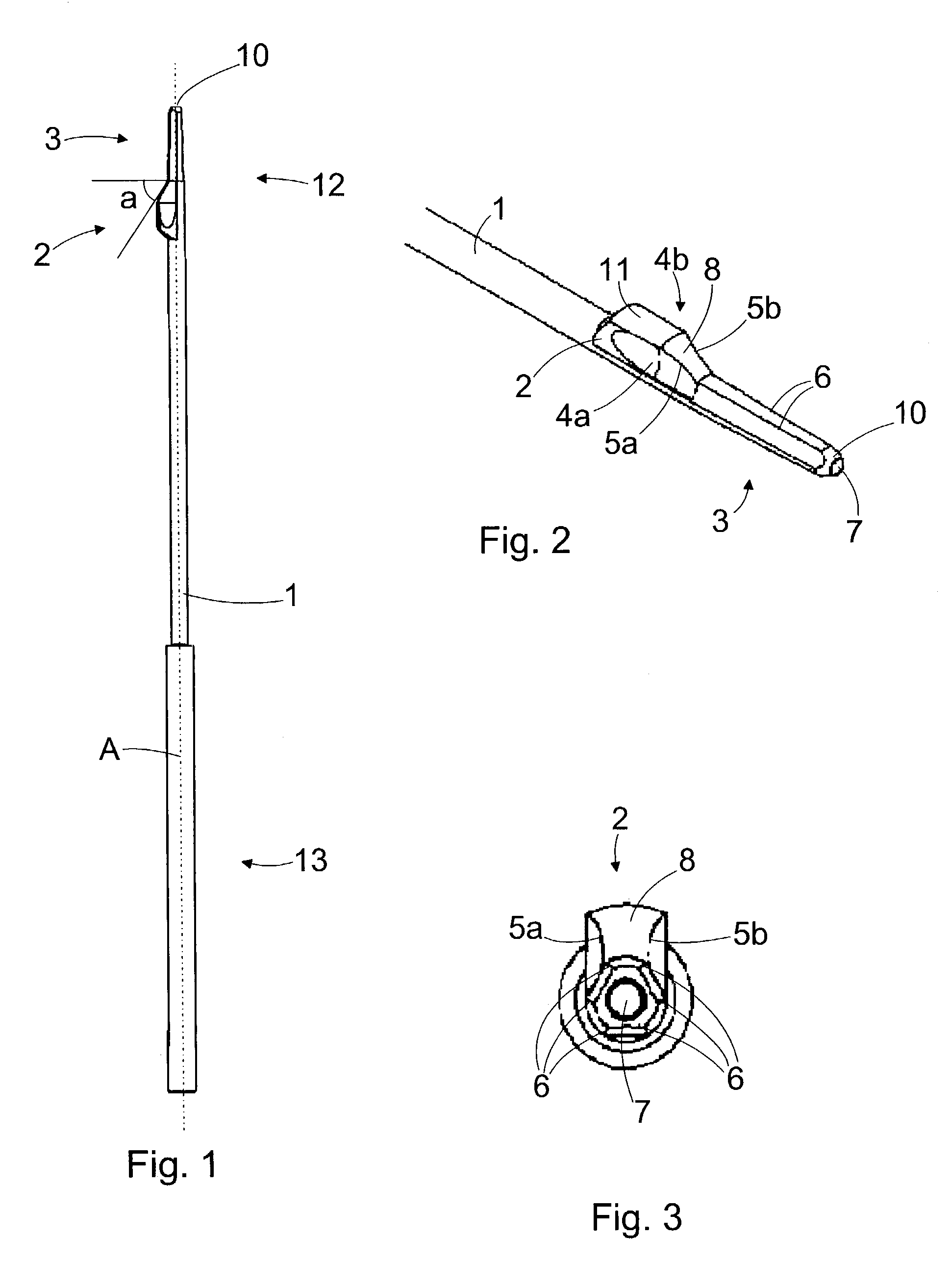

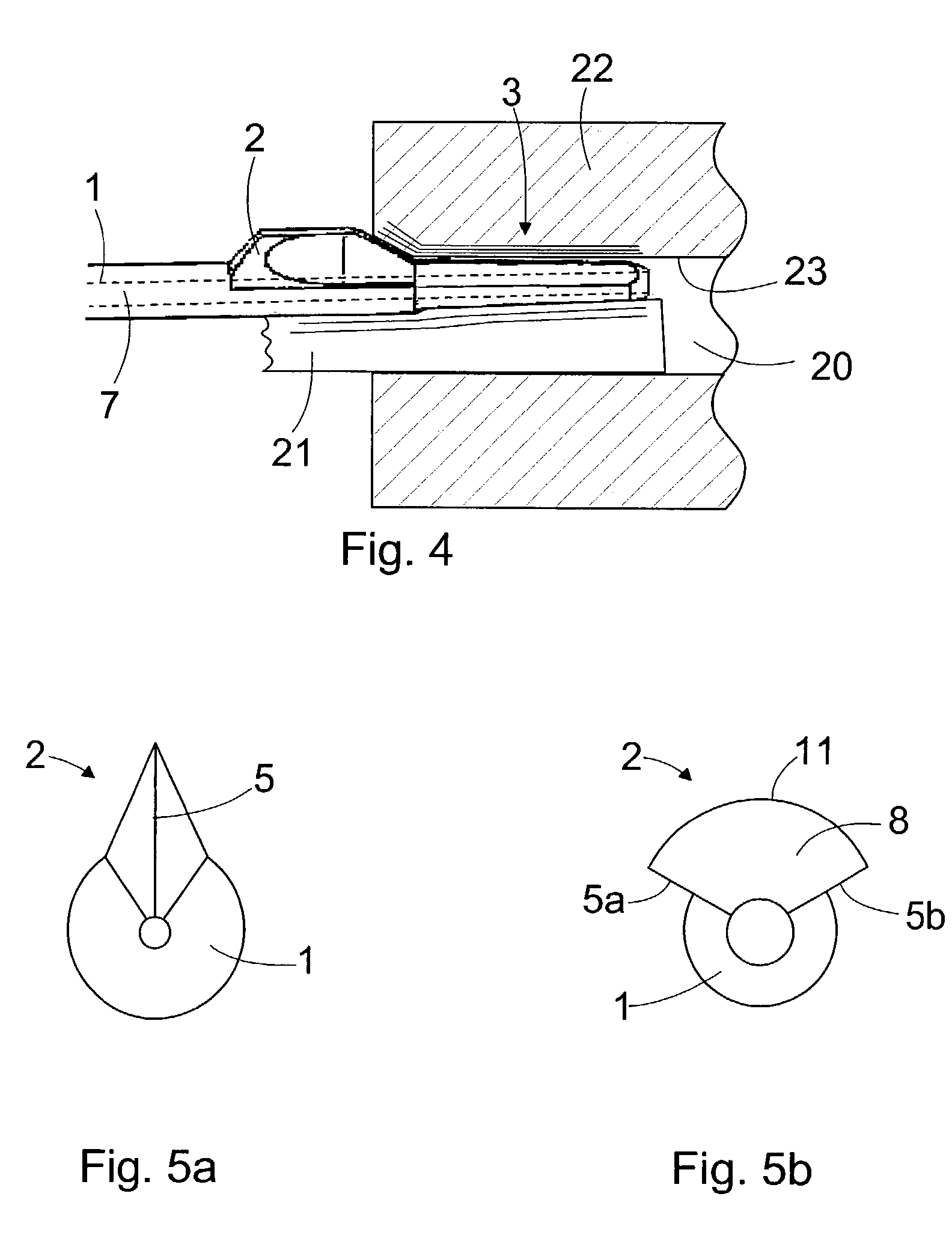

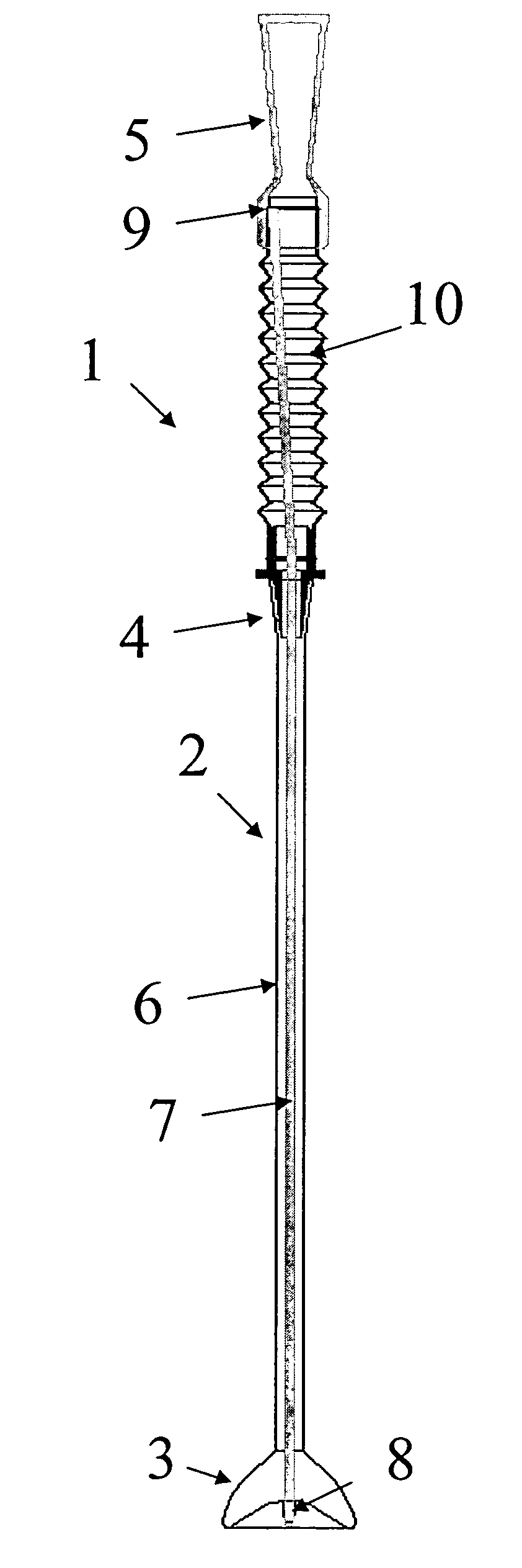

Instrument

InactiveUS7041107B2Reduce risk of damageReduce in quantityProsthesisOsteosynthesis devicesTurn angleEngineering

An instrument for shaping a mouth part of a drilled tunnel provided in a bone. The instrument includes a shaft having a longitudinal axis and a first and a second end. The first end of the shaft is provided with a projection, which includes a blade for shaping the mouth part of the drilled tunnel when the instrument is turned around the longitudinal axis of the shaft. The instrument is asymmetric at an intersecting surface perpendicular to the longitudinal axis and intersecting with the blade, the instrument thus shaping the surfaces surrounding the first end only substantially within an area corresponding with a turning angle of such a turning movement.

Owner:INION

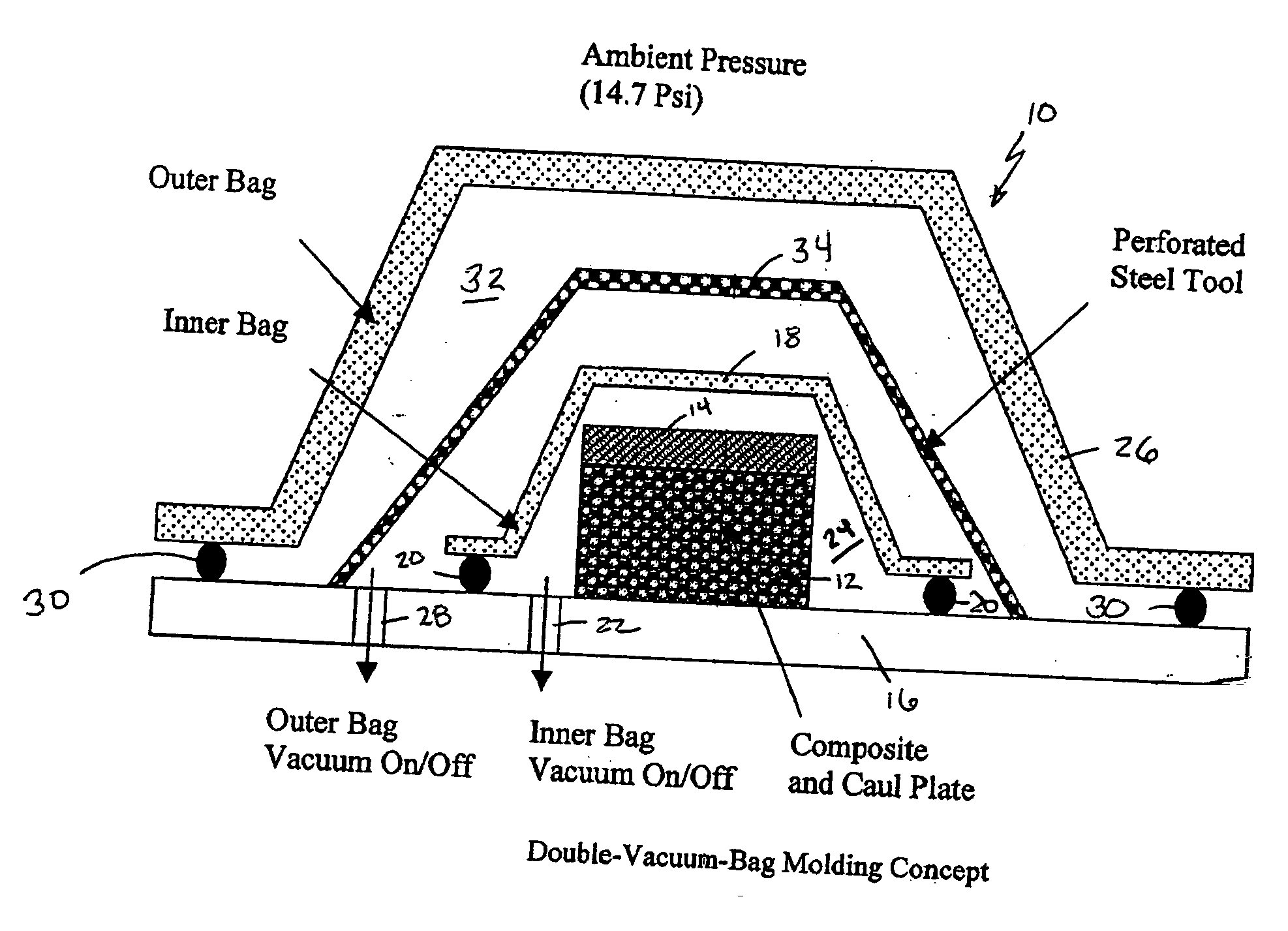

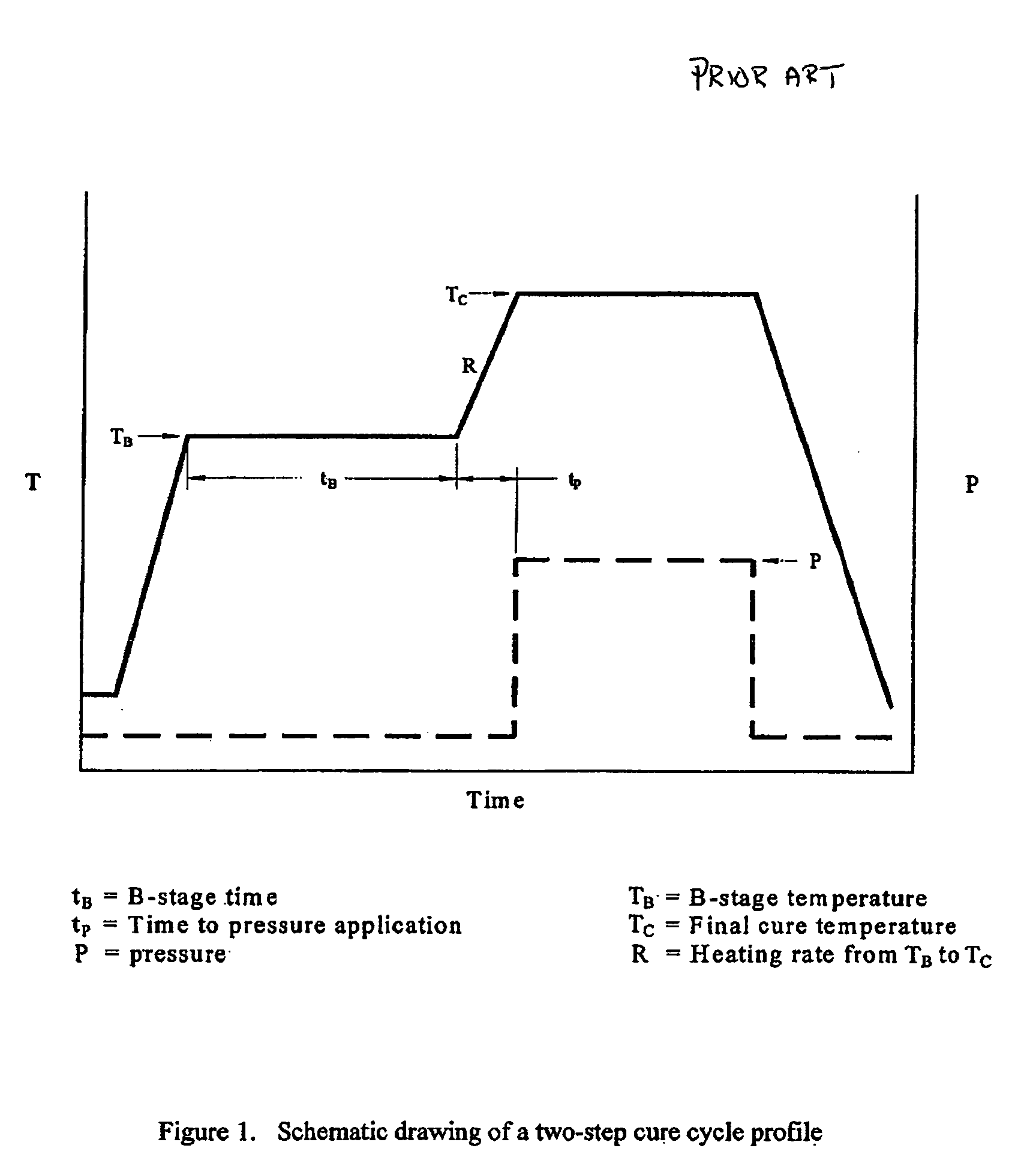

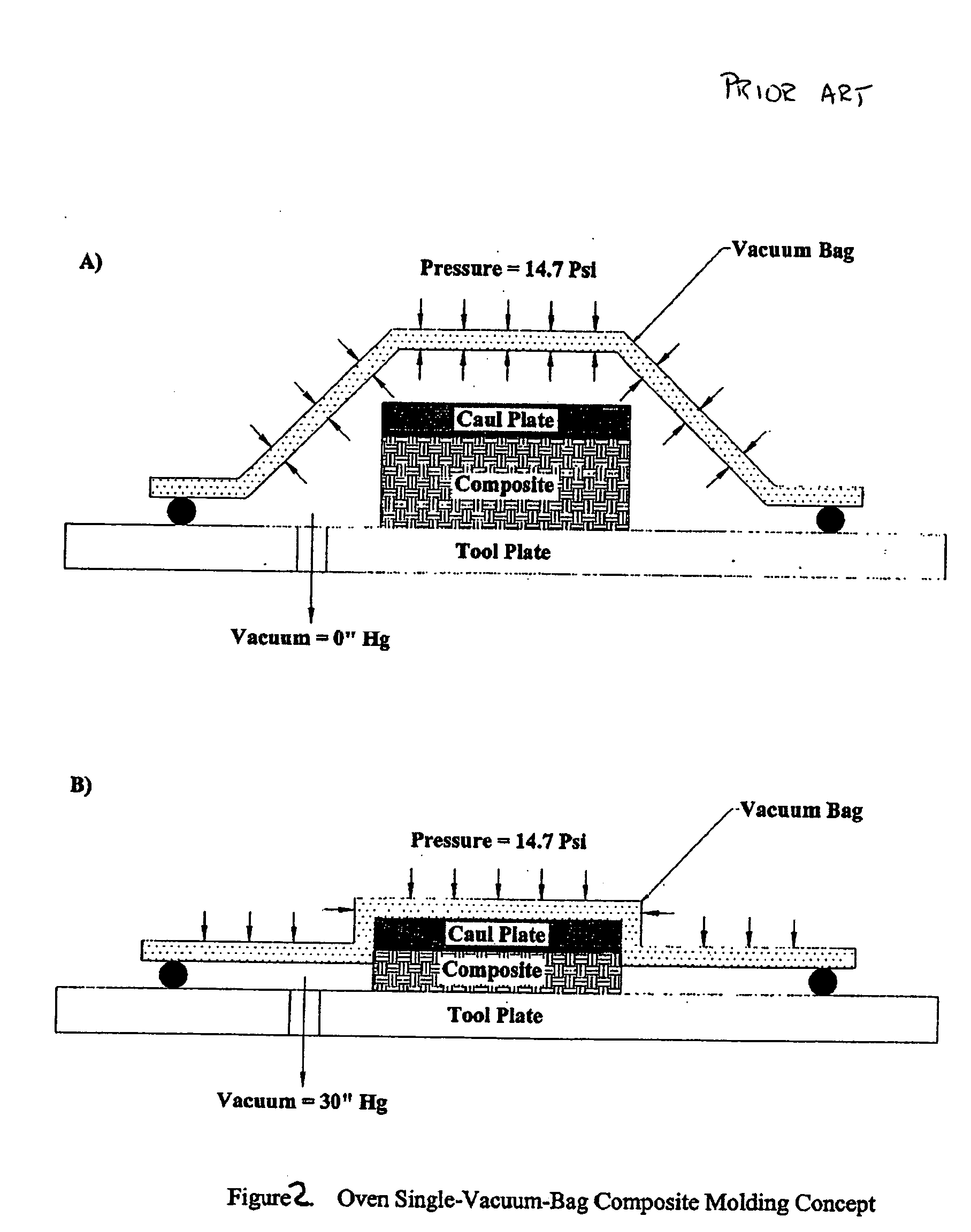

Double vacuum bag process for resin matrix composite manufacturing

InactiveUS20050253309A1Improve performanceImprove propertiesLaminationLamination apparatusRelative pressureResin matrix

A double vacuum bag molding assembly with improved void management and laminate net shape control which provides a double vacuum environment for use in fabricating composites from prepregs containing air and / or volatiles such as reactive resin matrix composites or composites from solvent containing prepregs with non-reactive resins matrices. By using two vacuum environments during the curing process, a vacuum can be drawn during a B-stage of a two-step cycle without placing the composite under significant relative pressure. During the final cure stage, a significant pressure can be applied by releasing the vacuum in one of the two environments. Inner and outer bags are useful for creating the two vacuum environments with a perforated tool intermediate the two. The composite is placed intermediate a tool plate and a caul plate in the first environment with the inner bag and tool plate defining the first environment. The second environment is characterized by the outer bag which is placed over the inner bag and the tool plate.

Owner:NASA

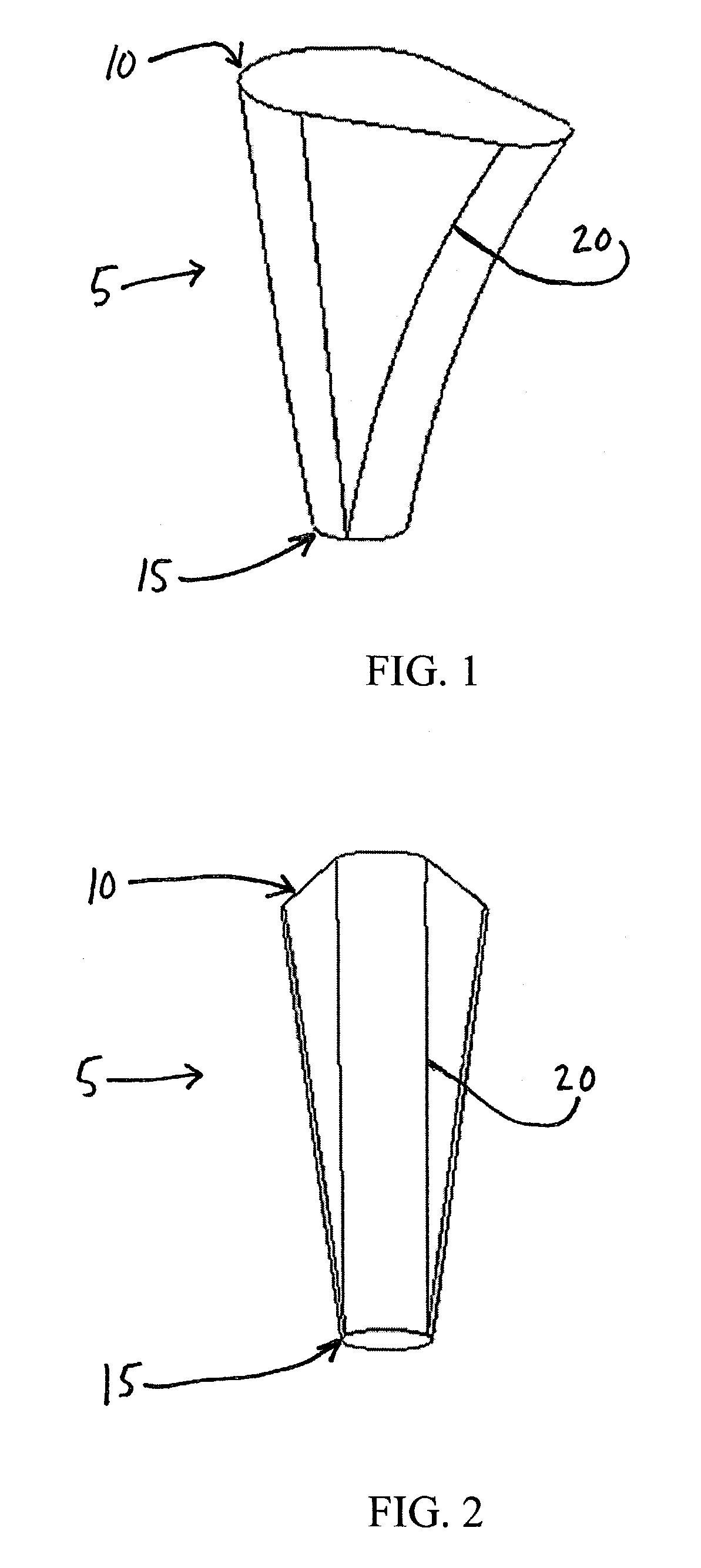

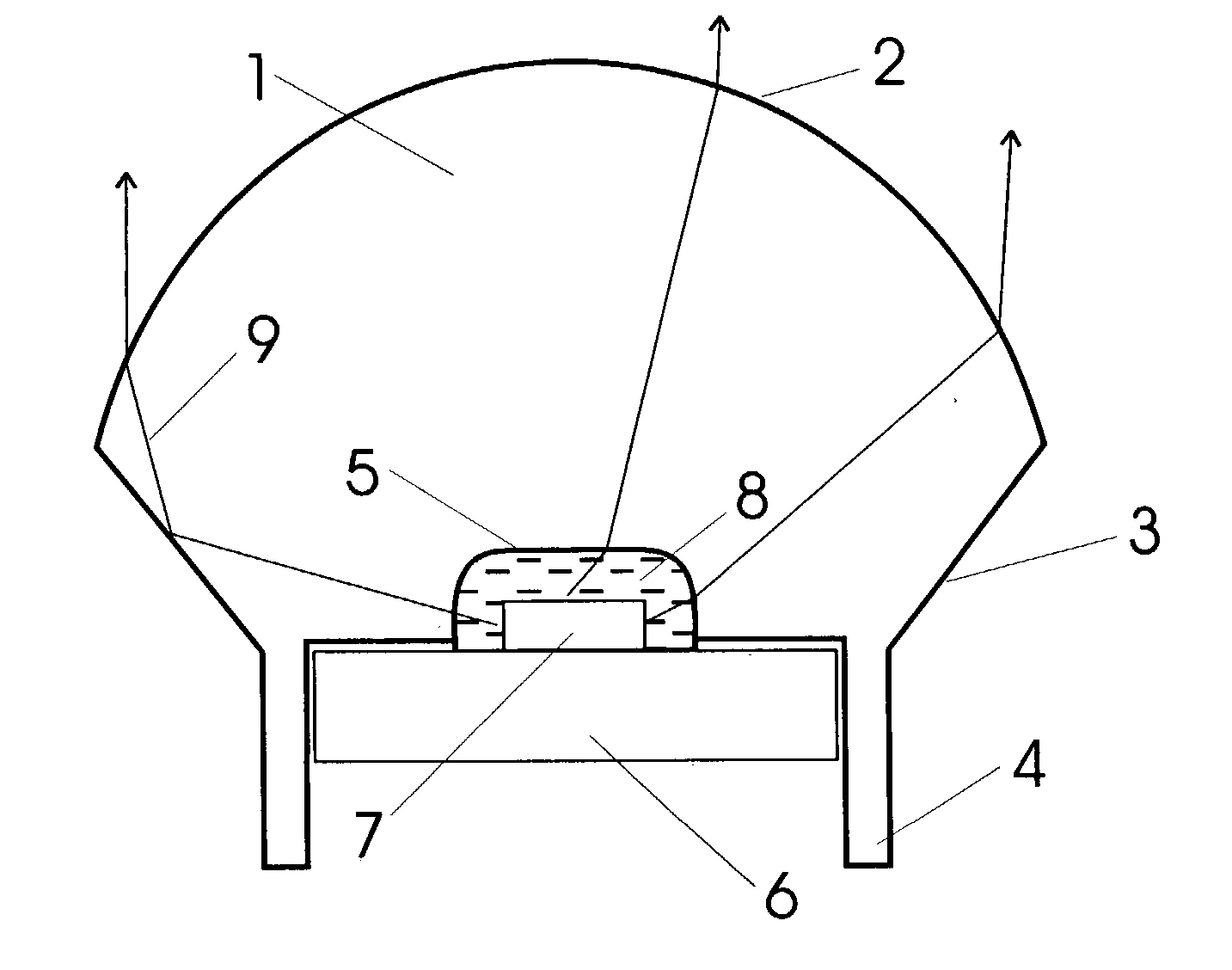

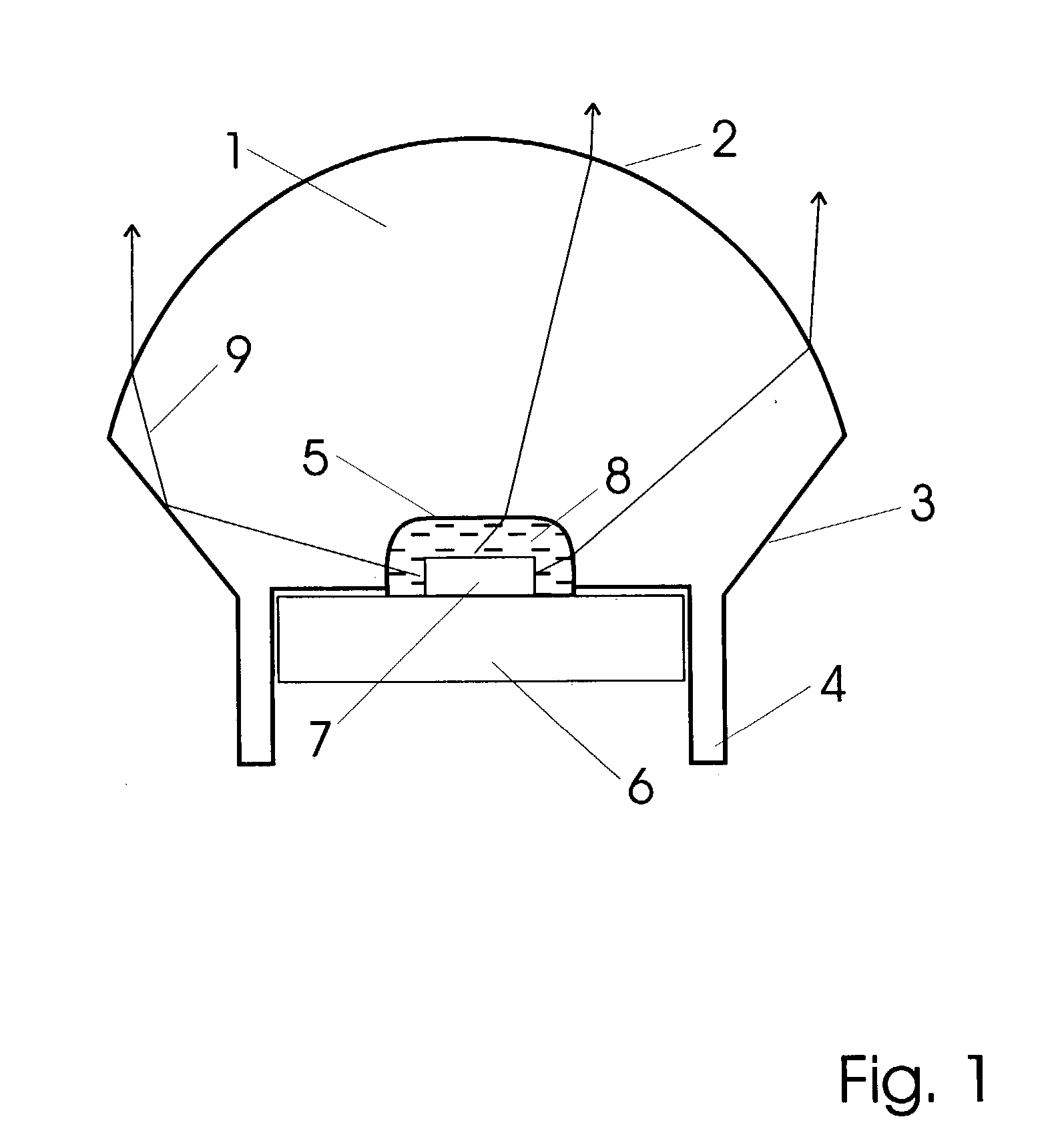

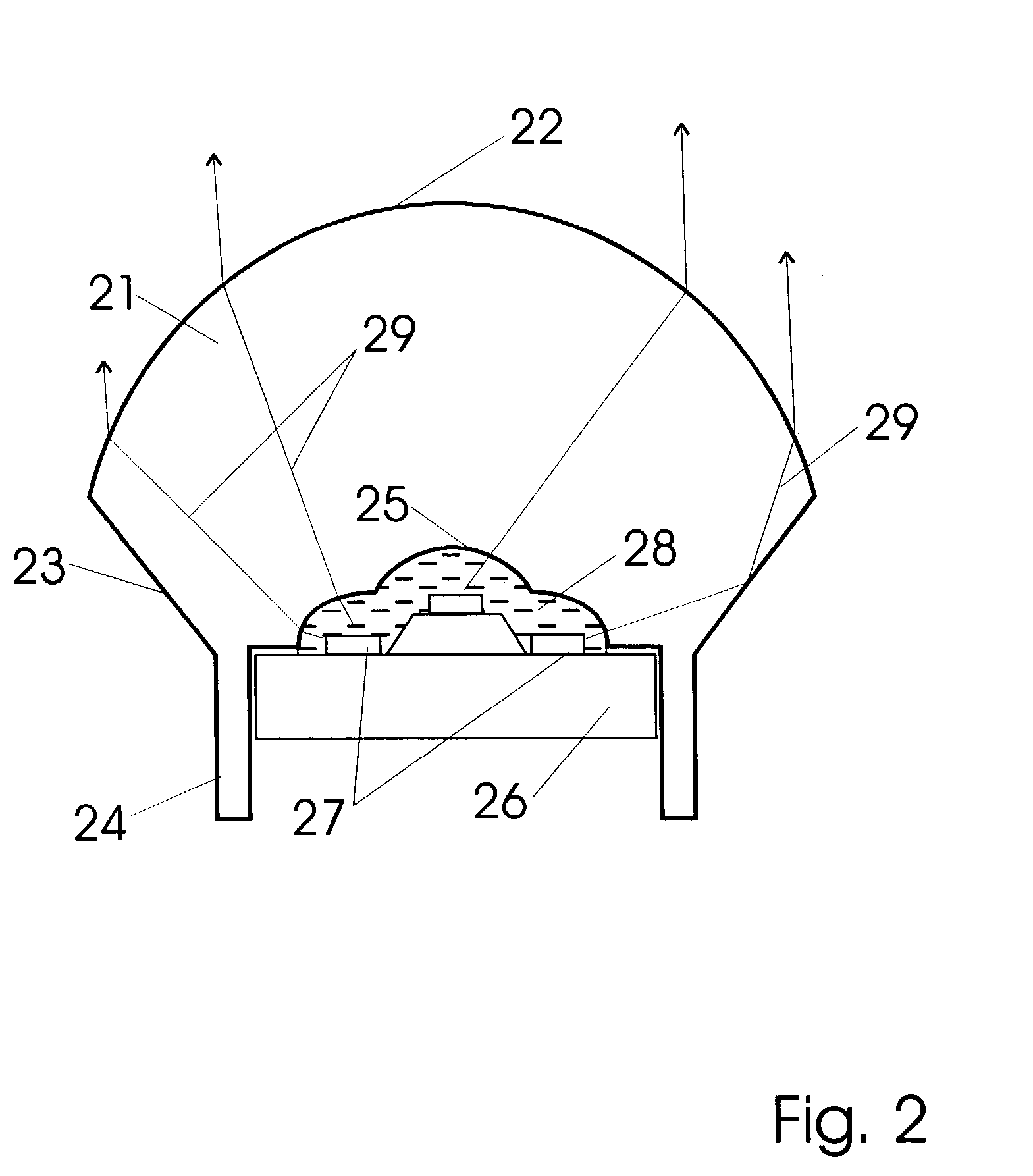

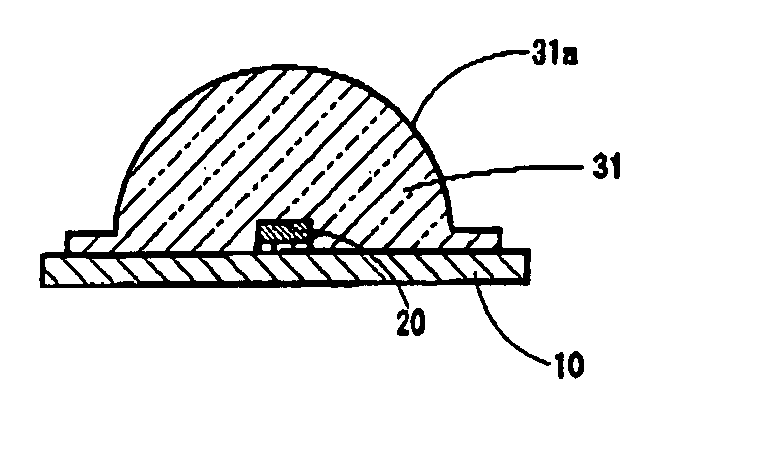

Light emitting diode package with self dosing feature and methods of forming same

InactiveUS20040183081A1Low color temperatureAccurate shapeSolid-state devicesSemiconductor devicesLength waveSemiconductor

Light emitting diodes are prepared with specialized packages which provide a dosing feature with respect to a phosphor wavelength converting medium. Elements of the device package form a specially shaped cavity when coupled together. The shape and size of the cavity operates to control the dosing of phosphor spiked medium of soft gel. The gel fills the cavity such that light emitted from a semiconductor die is exposed to a similar cross section independent of the exact direction of light propagation. In this way, 'white' LED systems are formed from blue emitting diodes as highly controlled phosphor dosing permits precise amounts of blue light to be converted to yellow light without problems with angular uniformity observed in competing technologies.

Owner:ACOL TECH

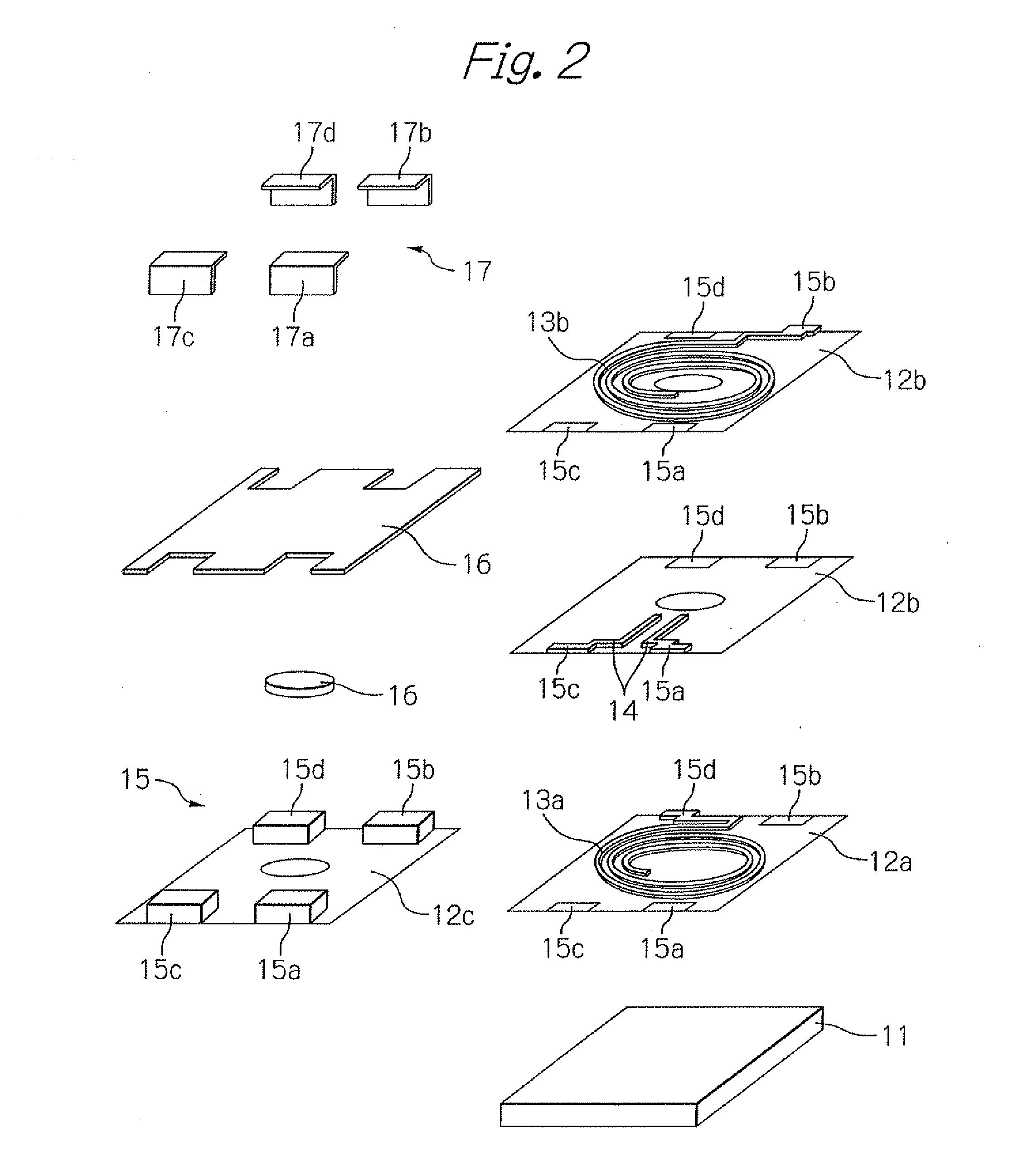

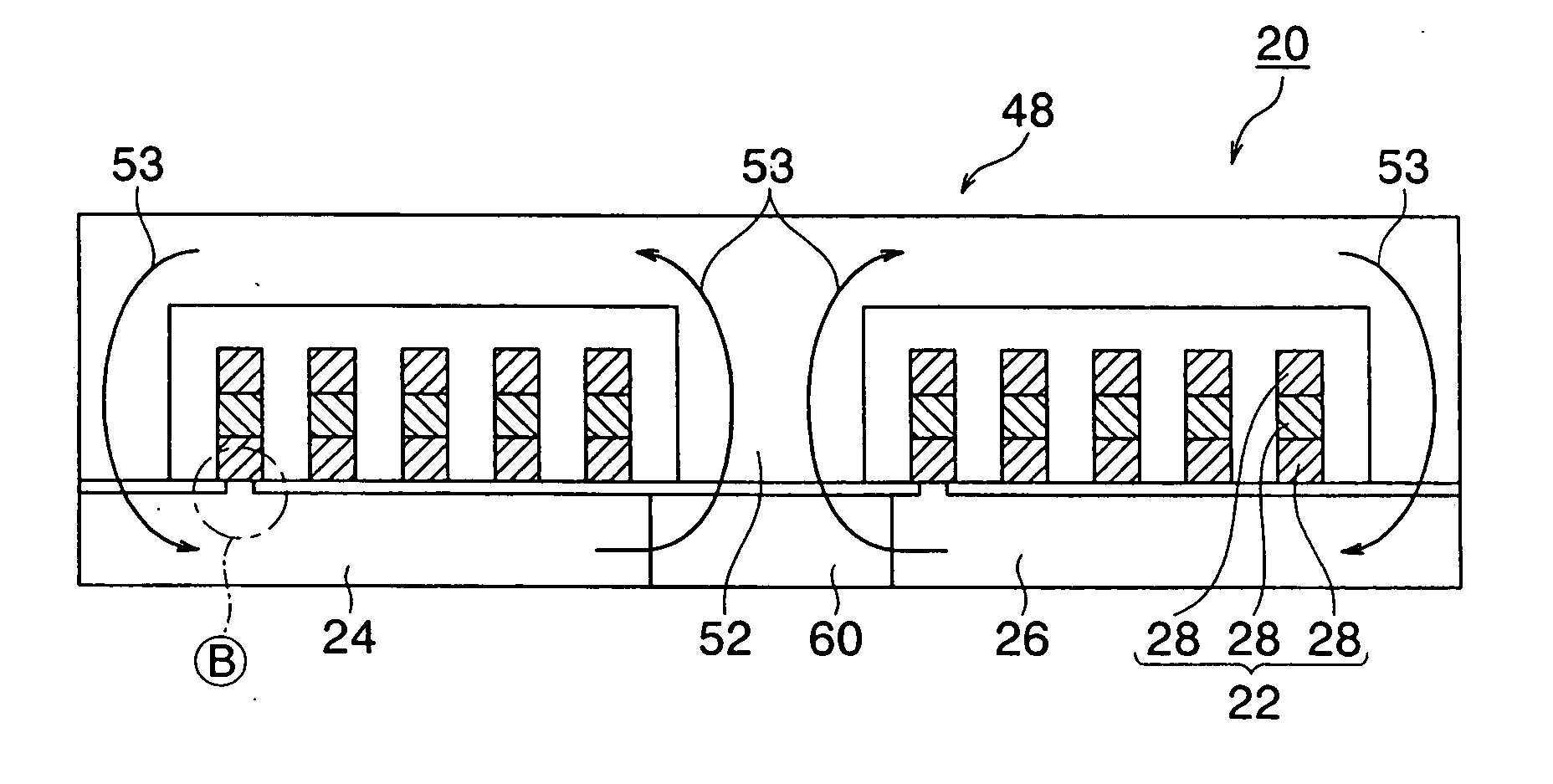

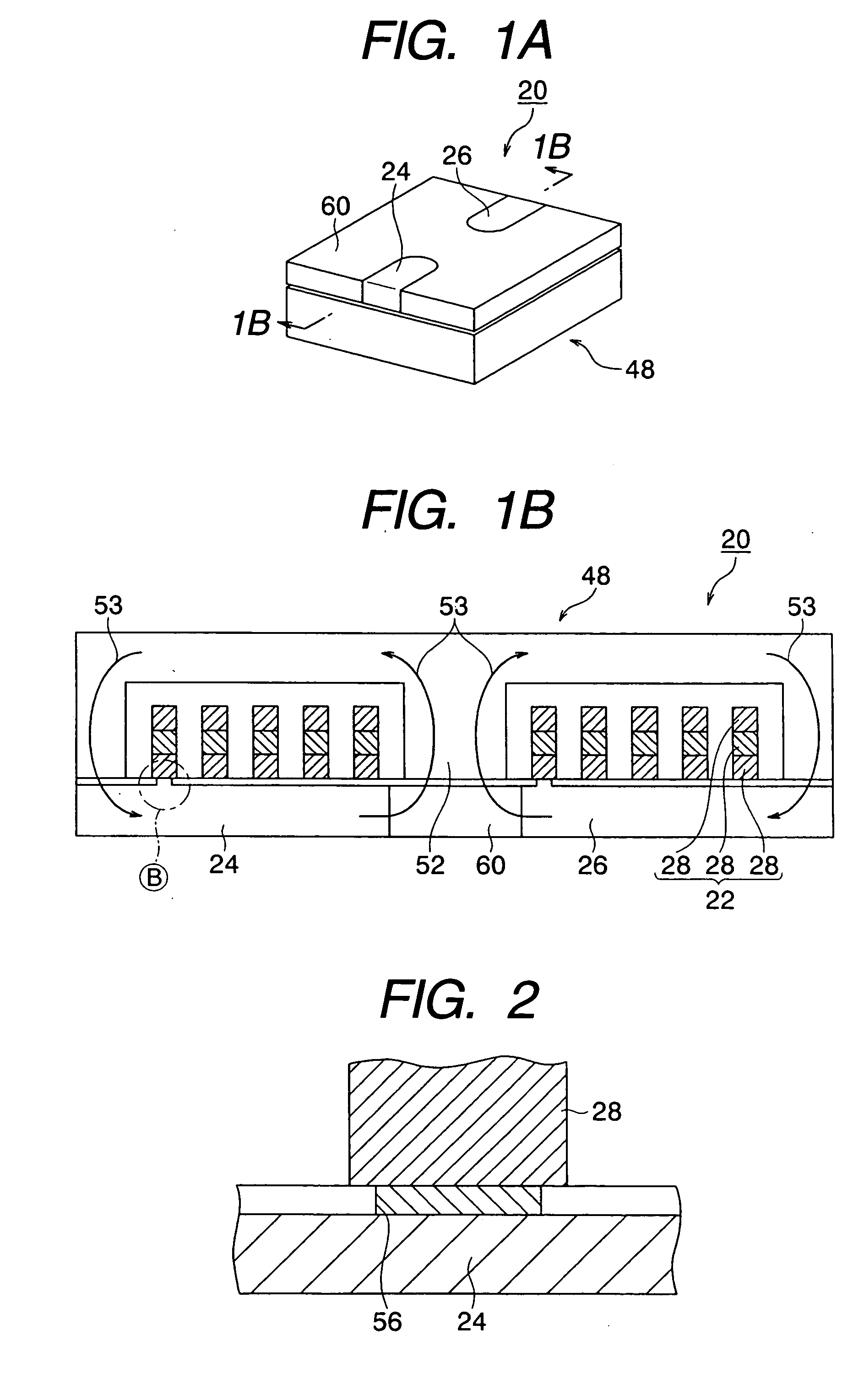

High density inductor and method for producing same

InactiveUS20040164835A1Reduce core sizeAccurate shapeTransformers/inductances coils/windings/connectionsSolid-state devicesHigh densityInductor

A method for producing a high density inductor includes the steps of forming a coil having a spiral shape, sealing the coil in the interior of a core member, and forming a terminal electrode for allowing electric conduction to said coil on the outside of said core member. In this method, the coil is formed by repeating a process of forming a wire layer by means of a thin film forming process and a process of forming an additional wire layer on top of the wire layer by means of the thin film forming process to pile up the wire layers. With this production method, it is possible to form a coil with a high aspect ratio. In addition, the inductor is designed in such a way that the core member envelopes only the coil. With that design, it is possible to make the inductor compact.

Owner:TDK CORPARATION

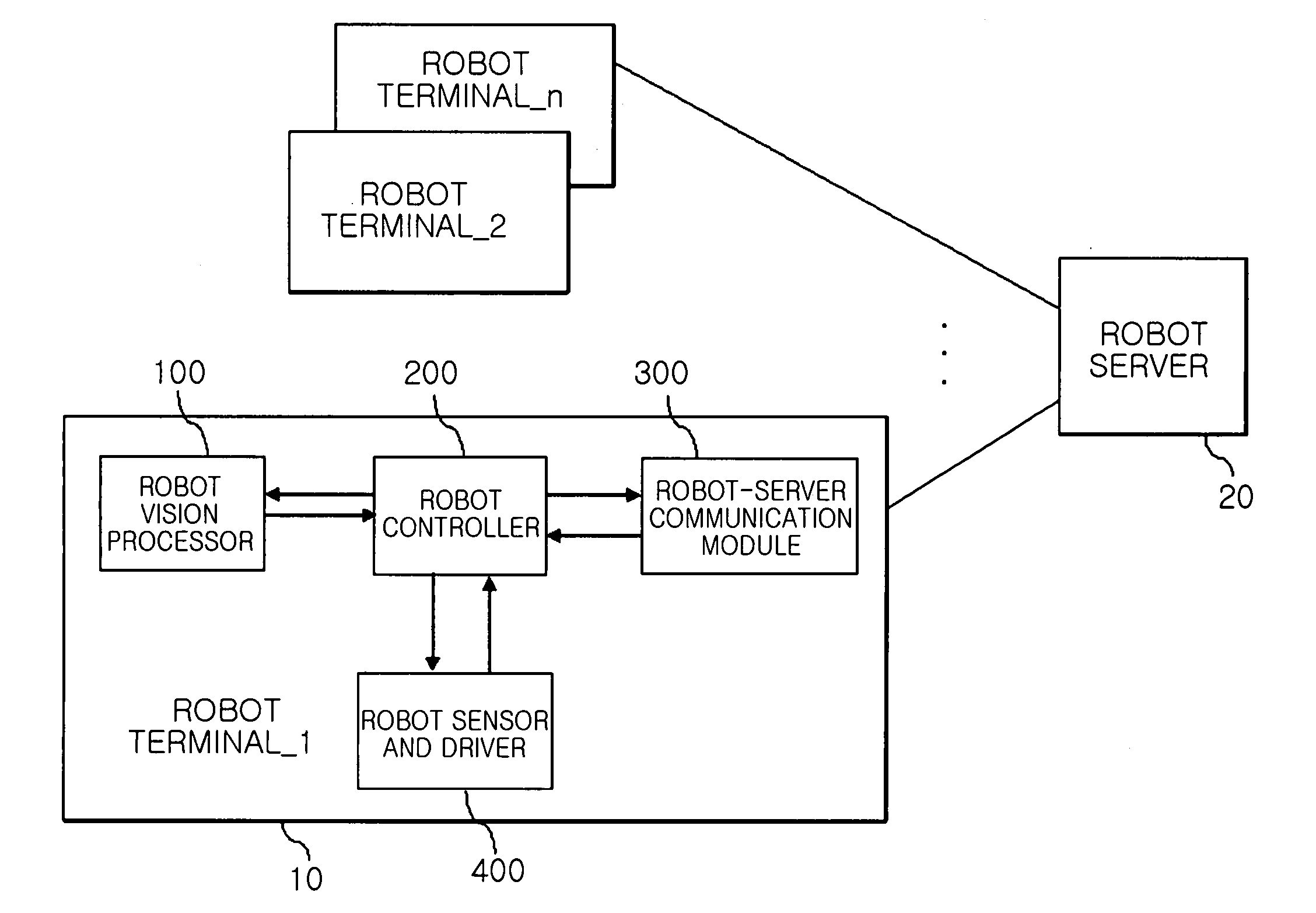

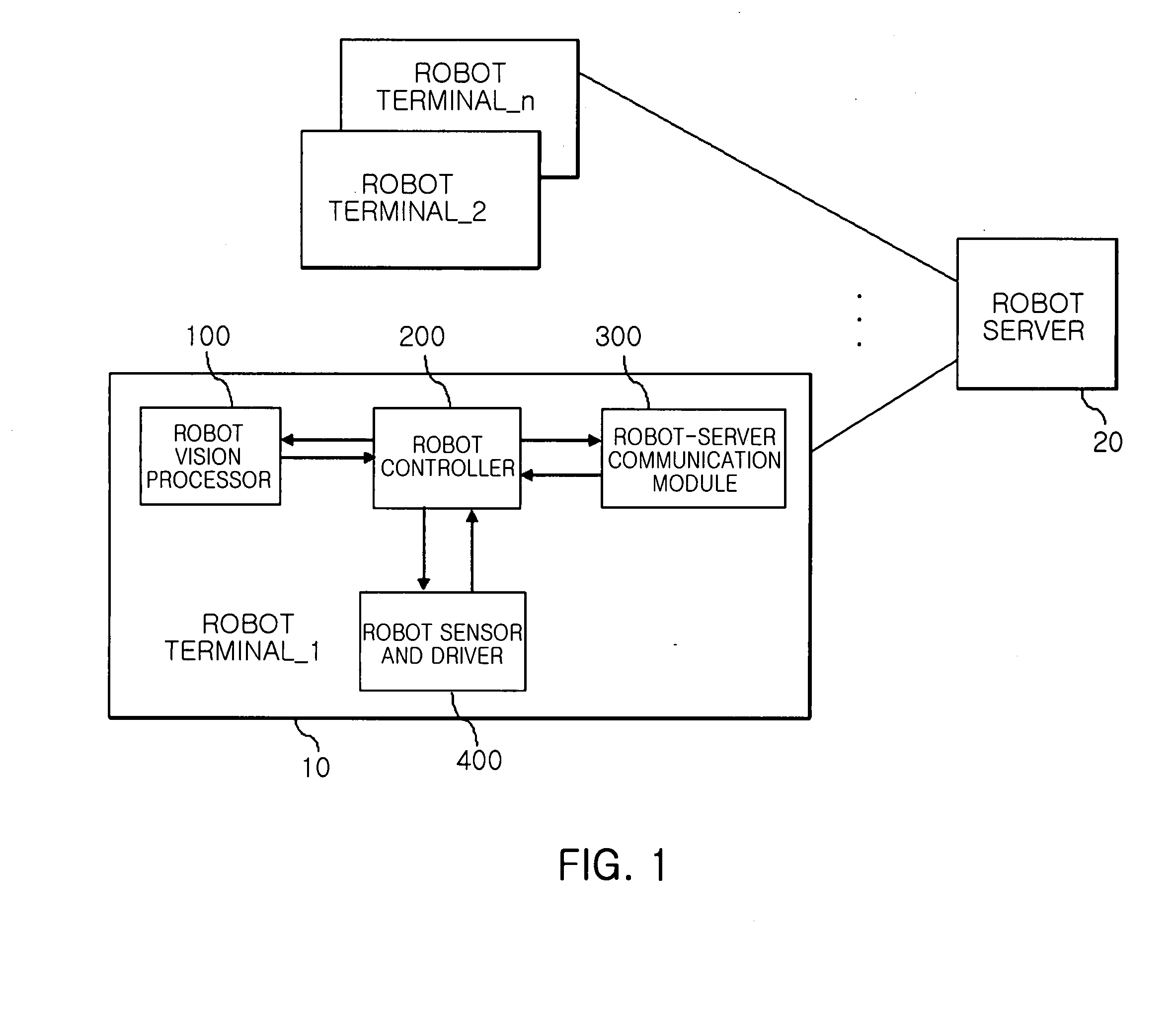

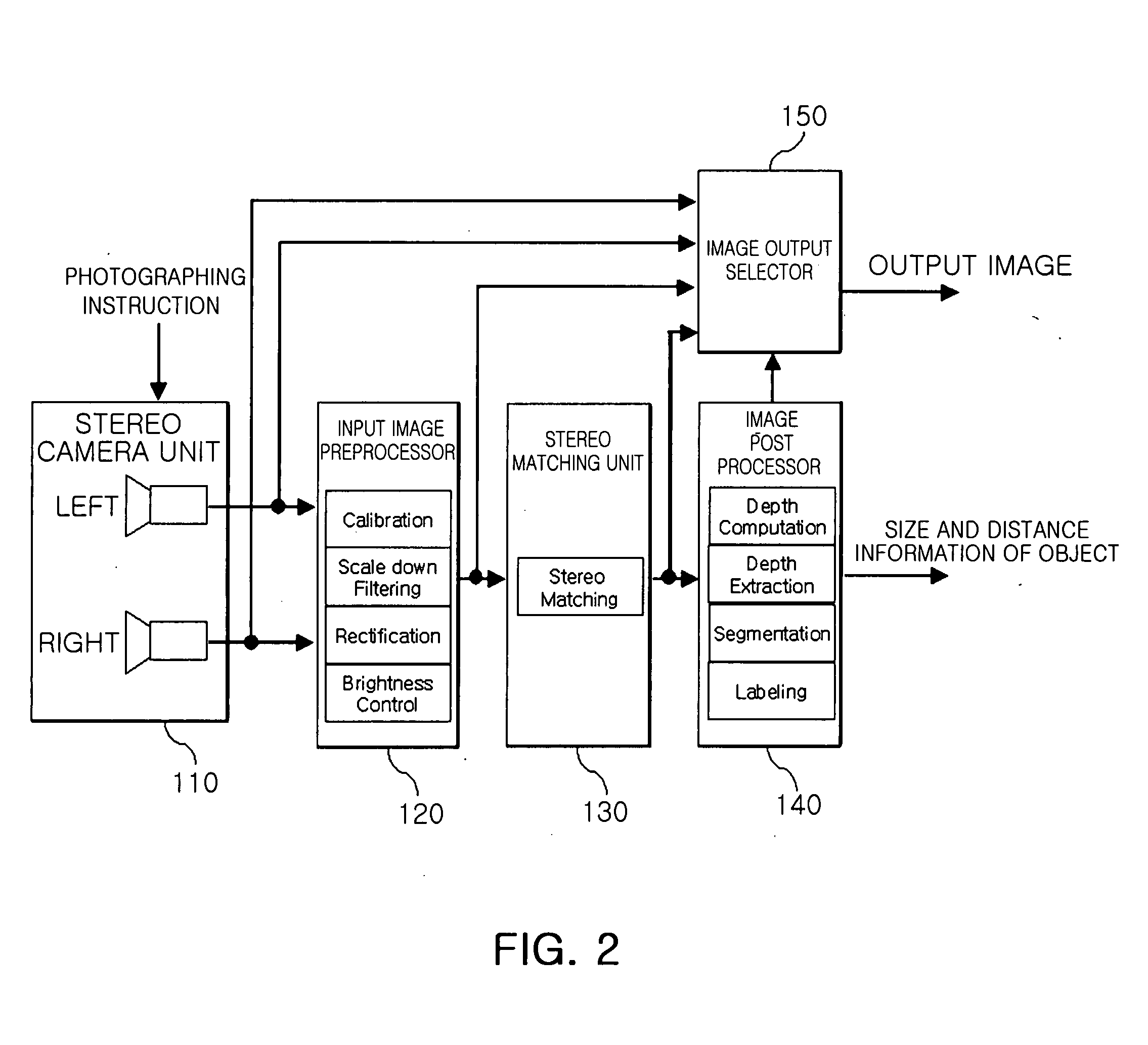

Method for searching target object and following motion thereof through stereo vision processing and home intelligent service robot using the same

InactiveUS20080215184A1Reduce computing loadReduce network trafficProgramme-controlled manipulatorComputer controlVision processingDriver/operator

A home intelligent service robot for recognizing a user and following the motion of a user and a method thereof are provided. The home intelligent service robot includes a driver, a vision processor, and a robot controller. The driver moves an intelligent service robot according to an input moving instruction. The vision processor captures images through at least two or more cameras in response to a capturing instruction for following a target object, minimizes the information amount of the captured image, and discriminates objects in the image into the target object and obstacles. The robot controller provides the capturing instruction for following the target object in a direction of collecting instruction information to the vision processor when the instruction information is collected from outside, and controls the intelligent service robot to follow and move the target object while avoiding obstacles based on the discriminating information from the vision processor.

Owner:ELECTRONICS & TELECOMM RES INST

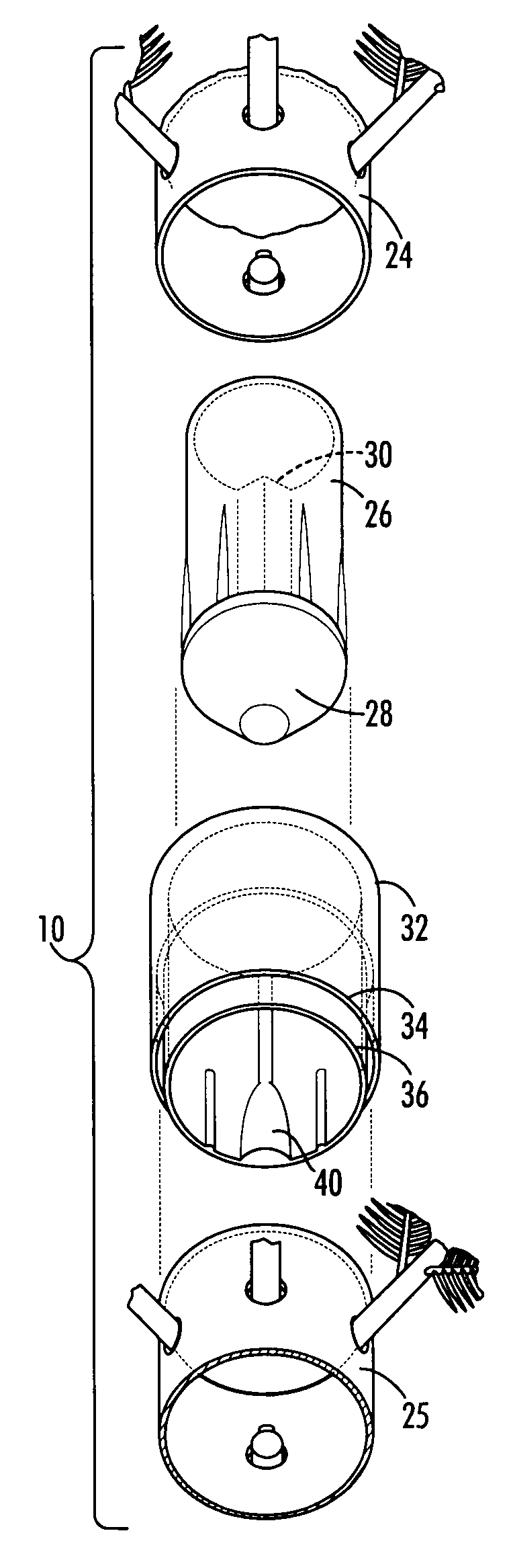

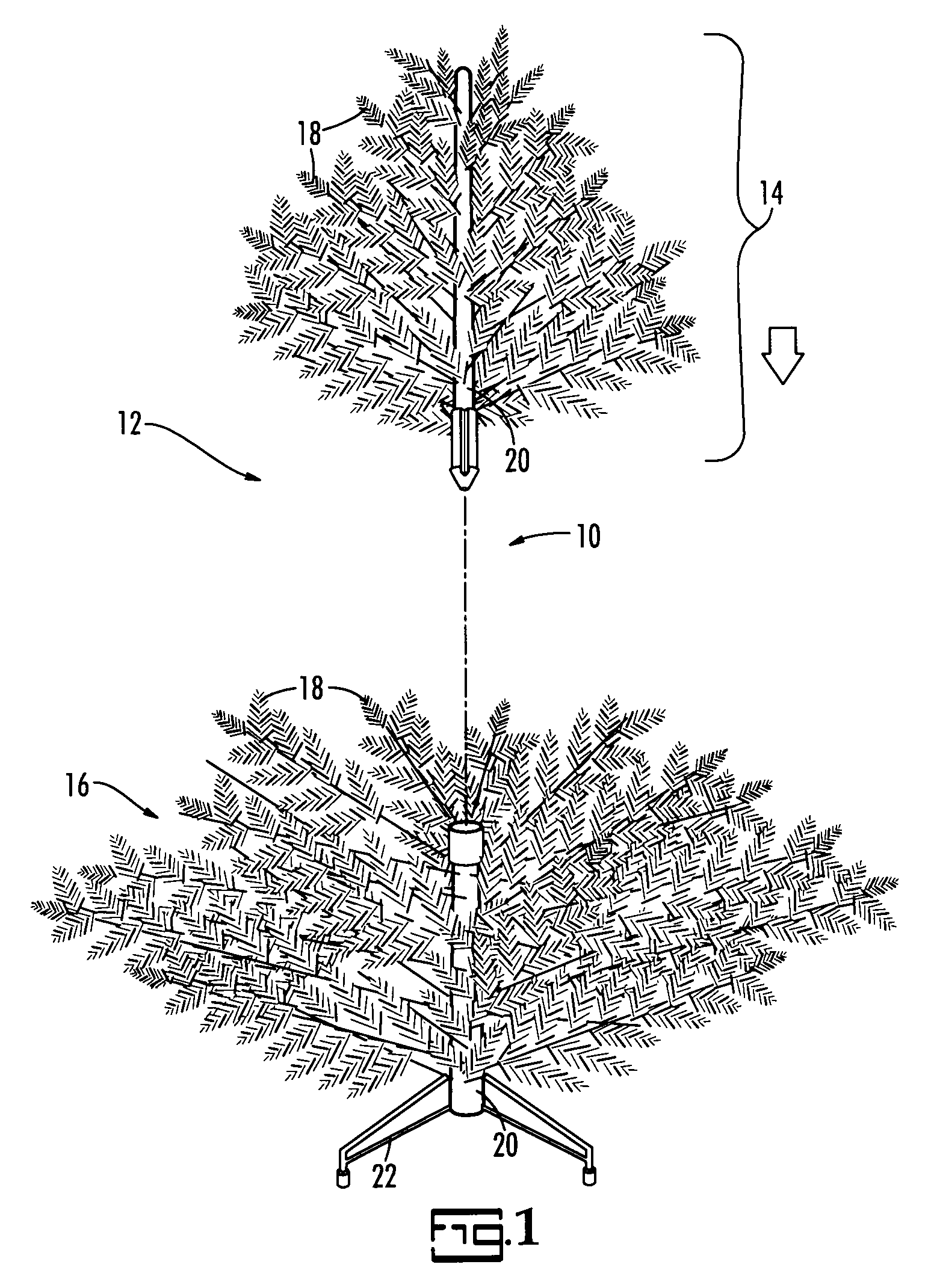

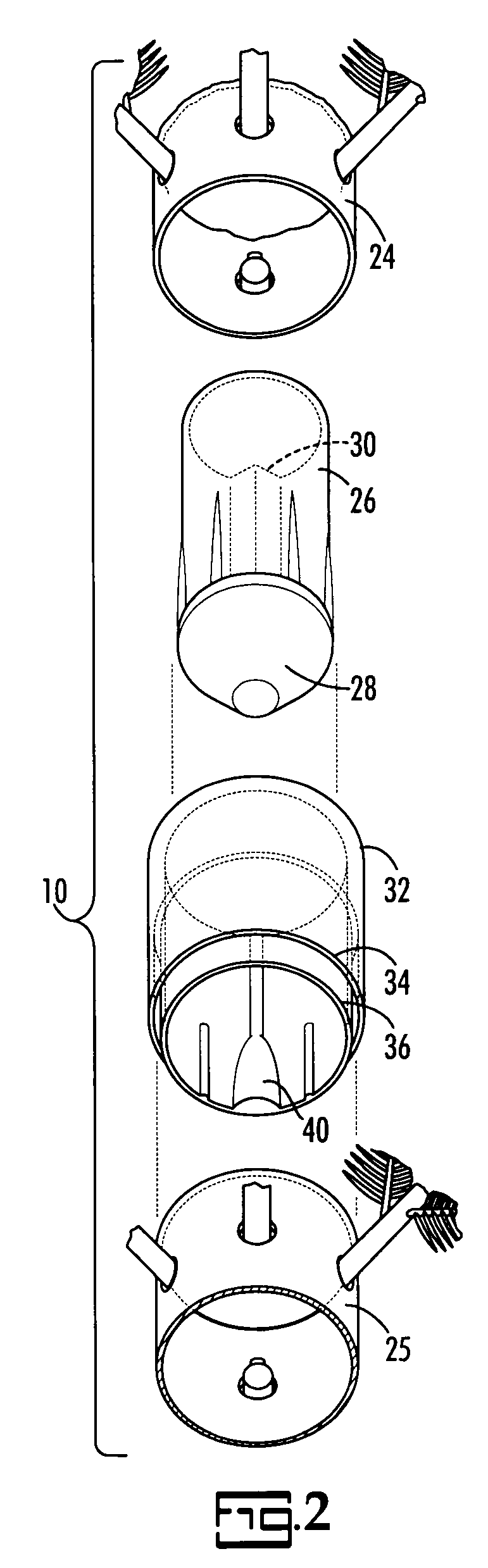

Tree pole coupler system

InactiveUS20100072747A1Easily insertAvoid corrosionSleeve/socket jointsArtificial flowers and garlandsConcentric cylinderTree trunk

A coupler system for use in assembling artificial tree trunks or poles. In particular, the coupler system includes a first part having a cone-shaped end and carrying a wedge-shaped groove parallel to its axis, which is insertable into a second part that is formed as a pair of concentric cylinders. The inner of these cylinders receives the first part of the coupler system and includes a bulge parallel to its axis that aligns with the wedge-shaped groove of the first part when the two are fitted together. Preferably, the end of the first part opposite the cone-shaped end is dimensioned to fit into a first tubular segment that stands as a surrogate for a tree trunk. Additionally, the outer of the concentric cylinders is dimensioned to receive a second tubular segment.

Owner:THE PRE LIT TREE CONCEPT

Medical device

InactiveUS20050049577A1Facilitate comfortable insertionReduce adhesionWound drainsCatheterDevices fixationMedical treatment

The invention provides a medical device such as a catheter for draining fluids from the body of a living being. The device has a braided portion with crossed filaments which form a braiding angle with a centre axis of the device. The braided portion can be expanded in a direction transverse to the centre axis e.g. in order to anchor the device in the body, e.g. to retain a urinary catheter in the bladder of a patient. The filaments form at least two different braiding angles which thereby facilitate an increased expansion or expansion into a specific shape of the expanded portion and thereby facilitates an improved anchoring of the device in the body.

Owner:RANIER LIMITED

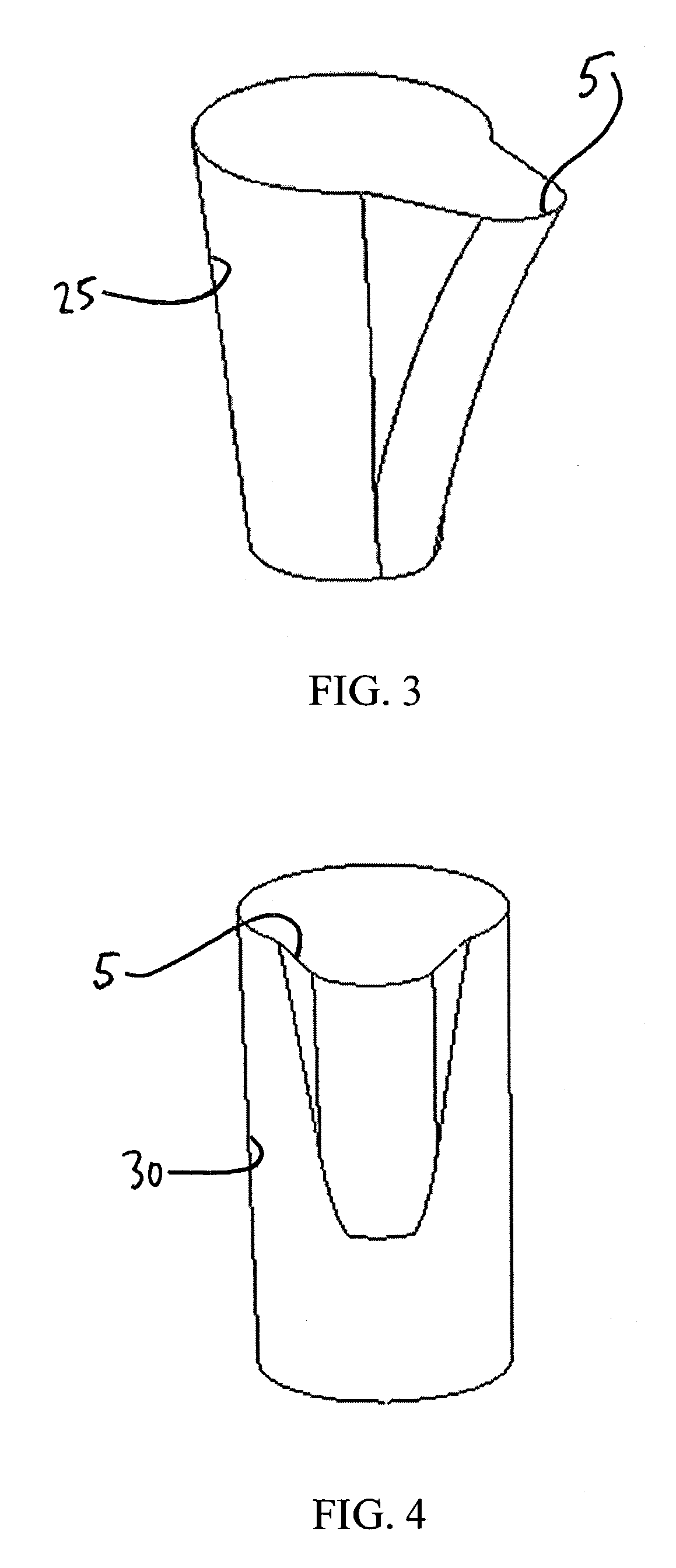

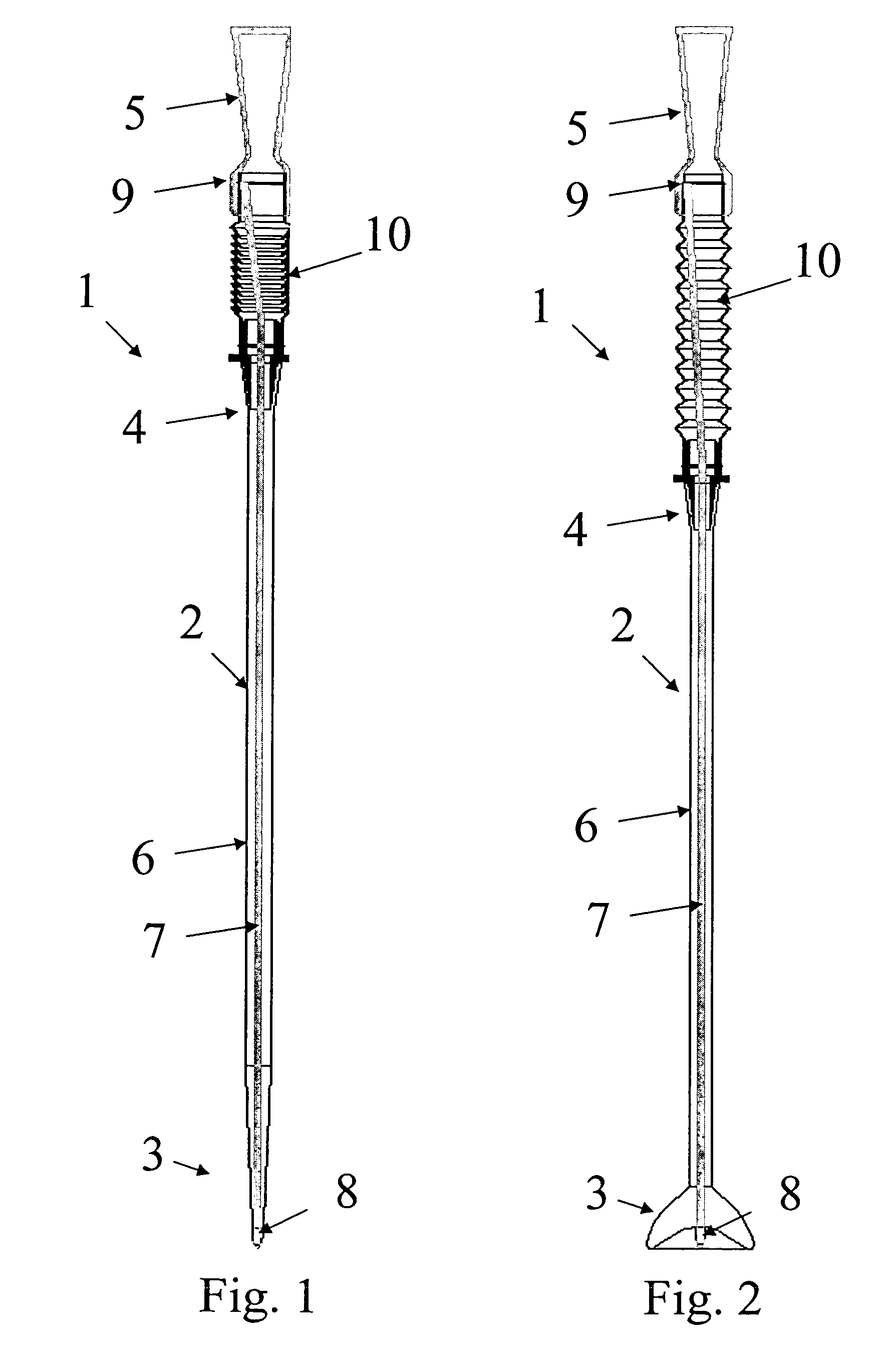

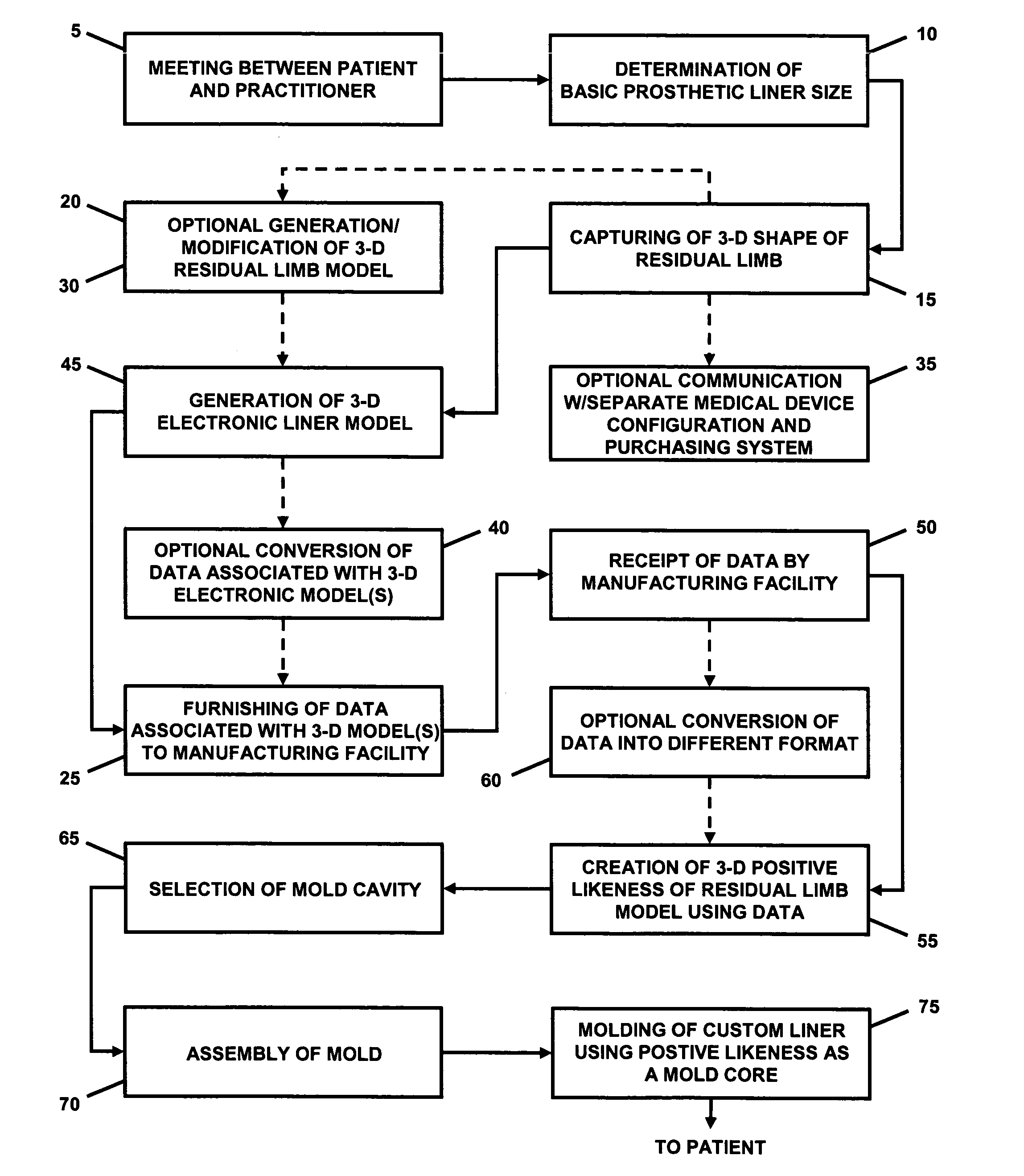

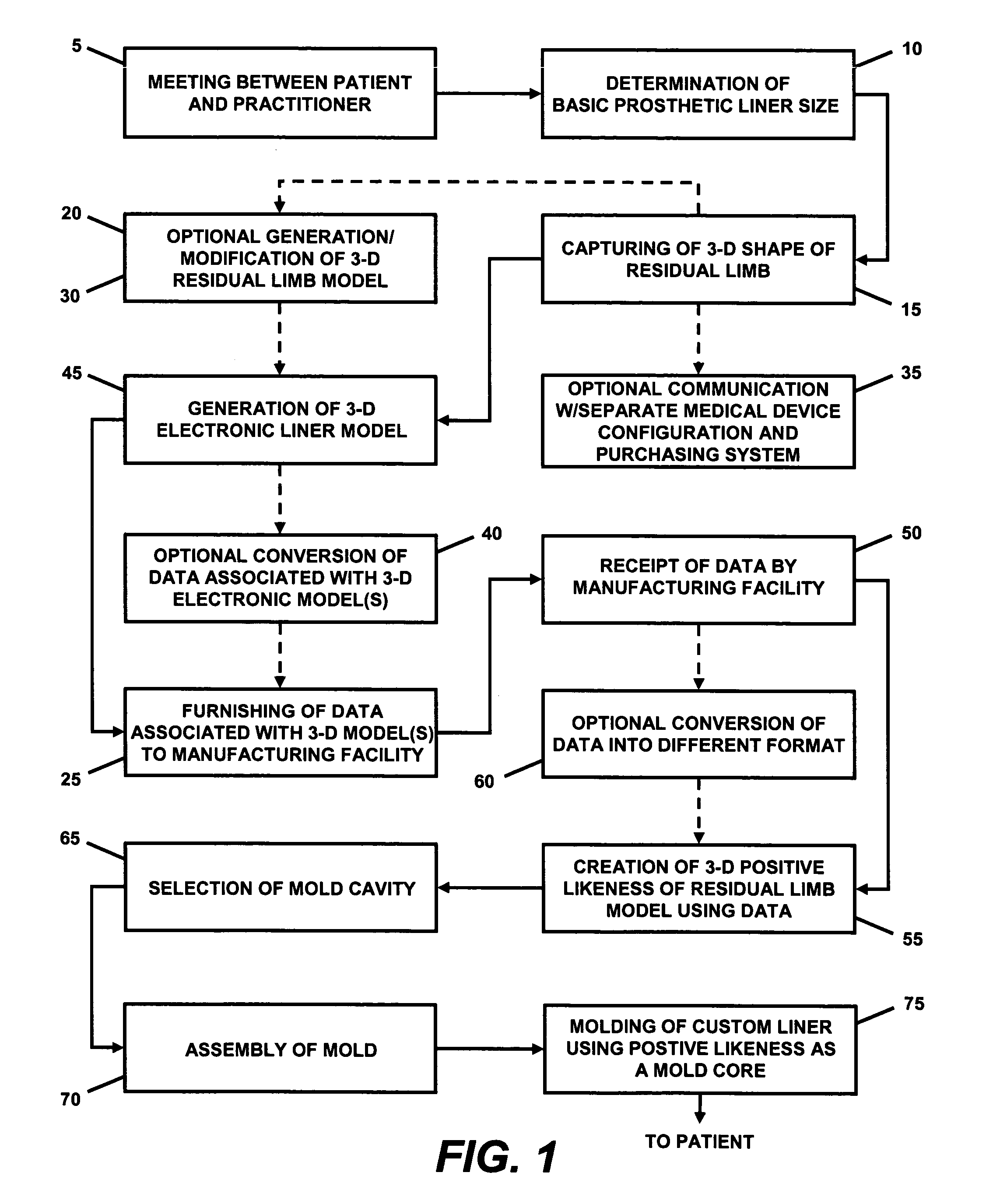

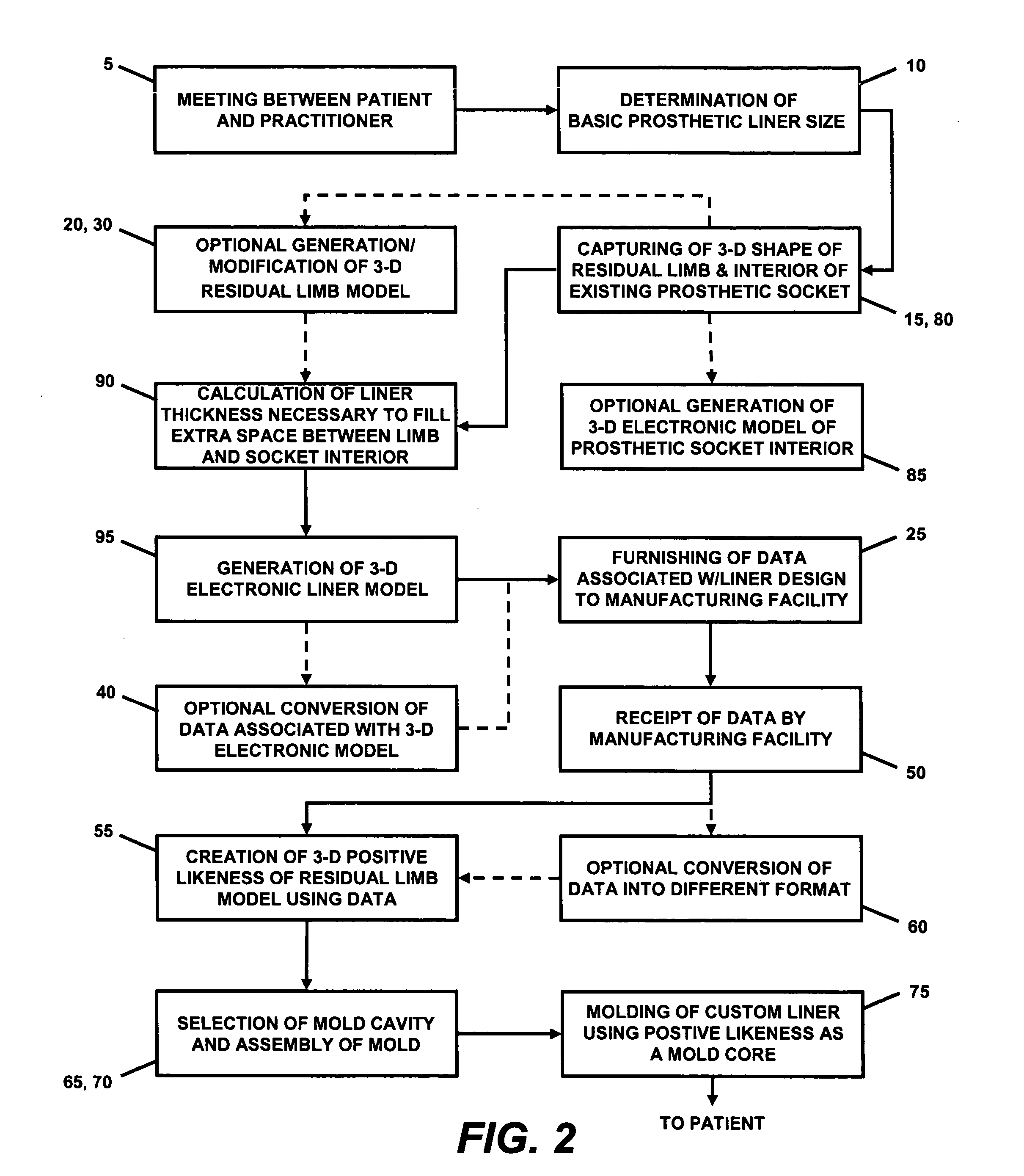

Custom prosthetic liner manufacturing system and method

ActiveUS20050119777A1Good for scrollingEasy doffingProgramme controlDigital data processing detailsResidual limbDevice prosthetic

A system and method for manufacturing a custom prosthetic liner. The system may include a shape capture device for capturing the shape of a residual limb. The captured shape may be used to generate a 3-dimensional electronic liner model using a processor and specialized software. A 3-dimensional electronic model of the residual limb may also be produced. Preferably, an interface is provided that allows a user of the system to alter the shape and / or size of the 3-dimensional model(s) to allow the subsequently-produced liner to accommodate particular features of the residual limb. Data associated with at least the resulting 3-dimensional liner model is provided to a manufacturing facility equipped to produce a custom liner therefrom. The data may be remotely transmitted to the manufacturing facility. A positive likeness of the residual limb is created from the data associated with the 3-dimensional model(s), and is subsequently used as a mold core in the liner molding process.

Owner:WILLOWWOOD GLOBAL LLC

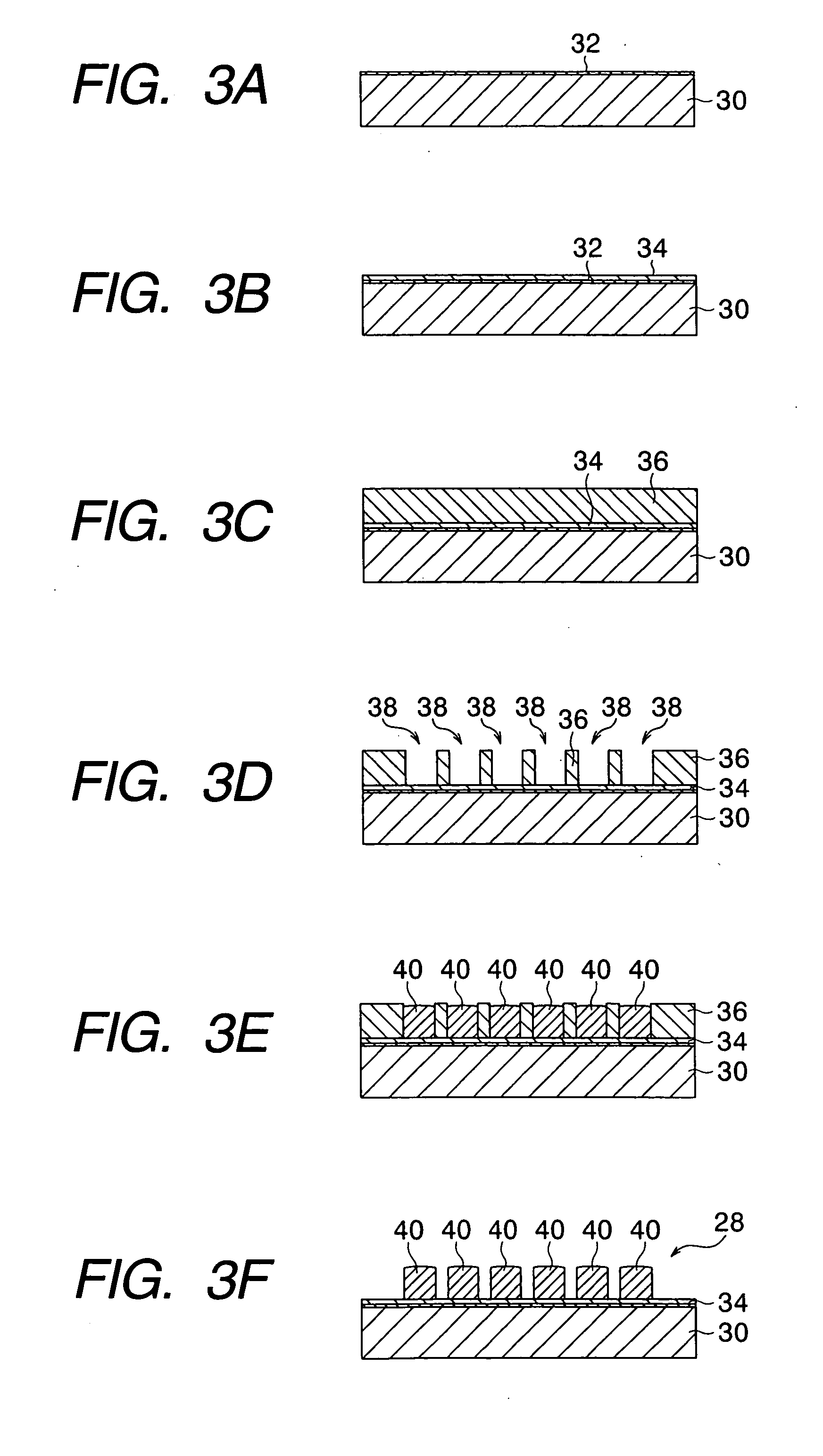

Method for manufacturing a vibrating MEMS circuit

ActiveUS9369105B1Low temperature coefficientAccurate shapePiezoelectric/electrostrictive device manufacture/assemblyImpedence networksElectromechanical coupling coefficientCrystal orientation

A method for making a micro-electro-mechanical systems (MEMS) vibrating structure is disclosed. The MEMS is supported by a MEMS anchor system and includes a single-crystal piezoelectric thin-film layer that has a specific non-standard crystal orientation, which may be selected to increase an electromechanical coupling coefficient, decrease a temperature coefficient of frequency, or both. The MEMS vibrating structure may have dominant lateral vibrations or dominant thickness vibrations. The single-crystal piezoelectric thin-film layer may include Lithium Tantalate or Lithium Niobate, and may provide MEMS vibrating structures with precise sizes and shapes, which may provide high accuracy and enable fabrication of multiple resonators having different resonant frequencies on a single substrate.

Owner:QORVO US INC

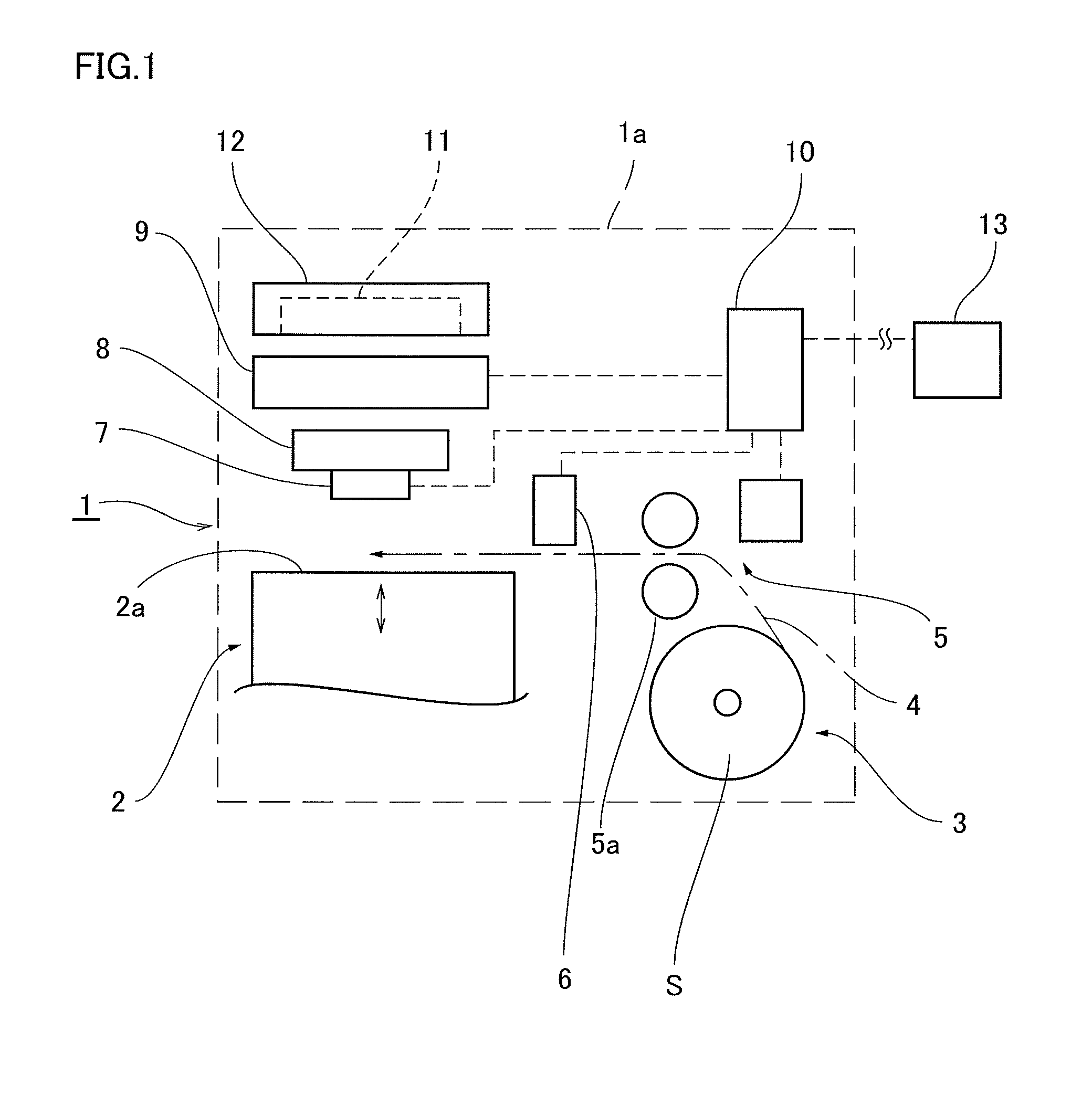

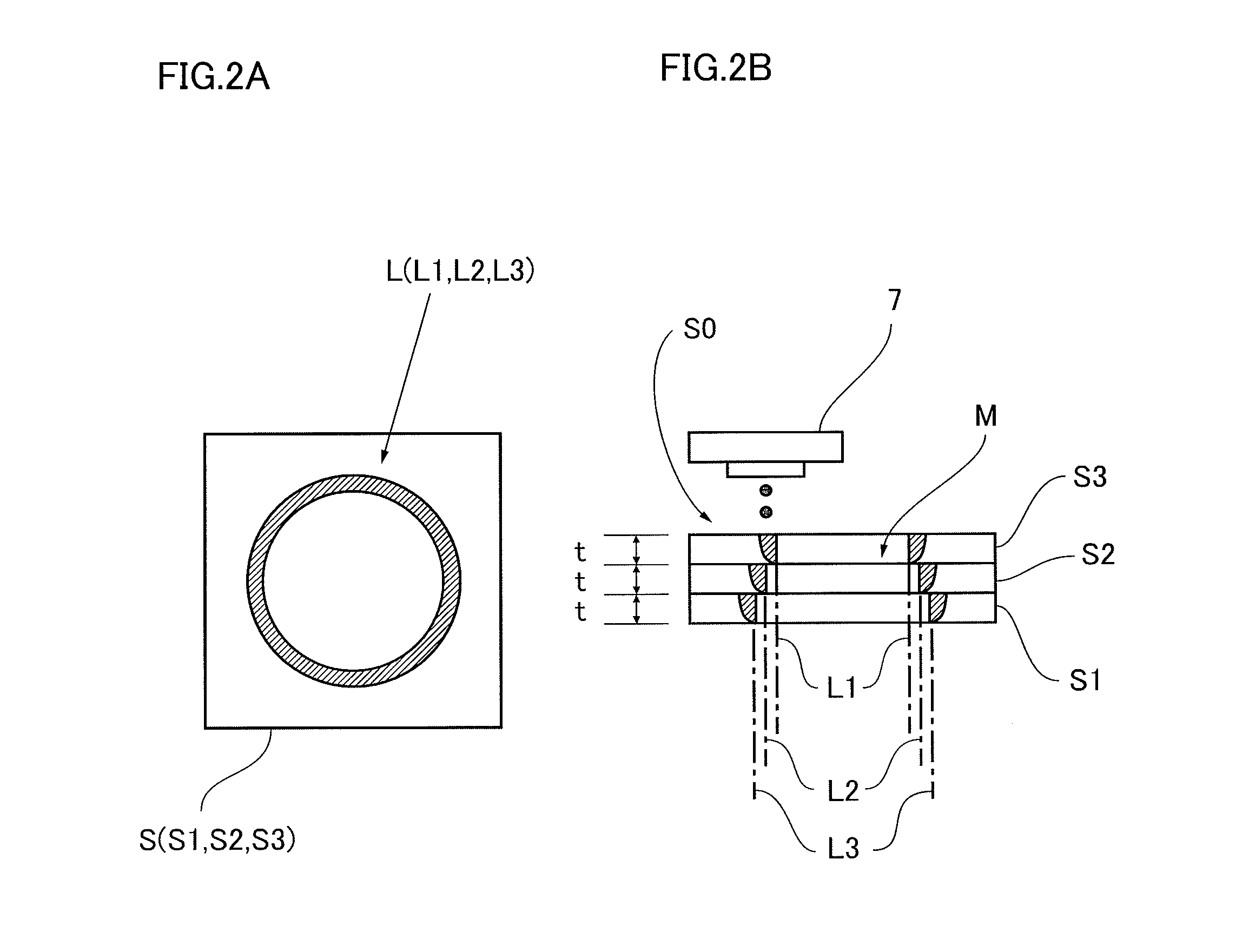

Method and device for forming three-dimensional model, sheet material processing method, and sheet material processing device

ActiveUS20090321979A1Short useSimple configurationWood working apparatusDough shapingThree dimensional modelPaper sheet

Three-dimensional models can be produced by a sheet deposition method using a sheet material made of water-soluble paper as the depositing material. Each layer of the sheet material is made severable along the contour lines of the three-dimensional model by discharging water using the nozzle of a fluid discharge head onto each layer of the sheet material. A coloring solution is discharged from the fluid discharge head when each layer is deposited to color the sheet material. After the deposition is completed, the unnecessary parts of the sheet material can be pulled away to complete the three-dimensional model. Alternatively, by discharging a setting solution using a nozzle of the fluid discharge head onto each layer of the sheet material, each layer of the sheet material in the section area of the three-dimensional model can be insolubilized, and a color setting solution can be discharged to color and set the colored parts. After the deposition is completed, the deposition can be immersed in water to remove the sheet material that was not insolubilized and complete the three-dimensional model.

Owner:SEIKO EPSON CORP

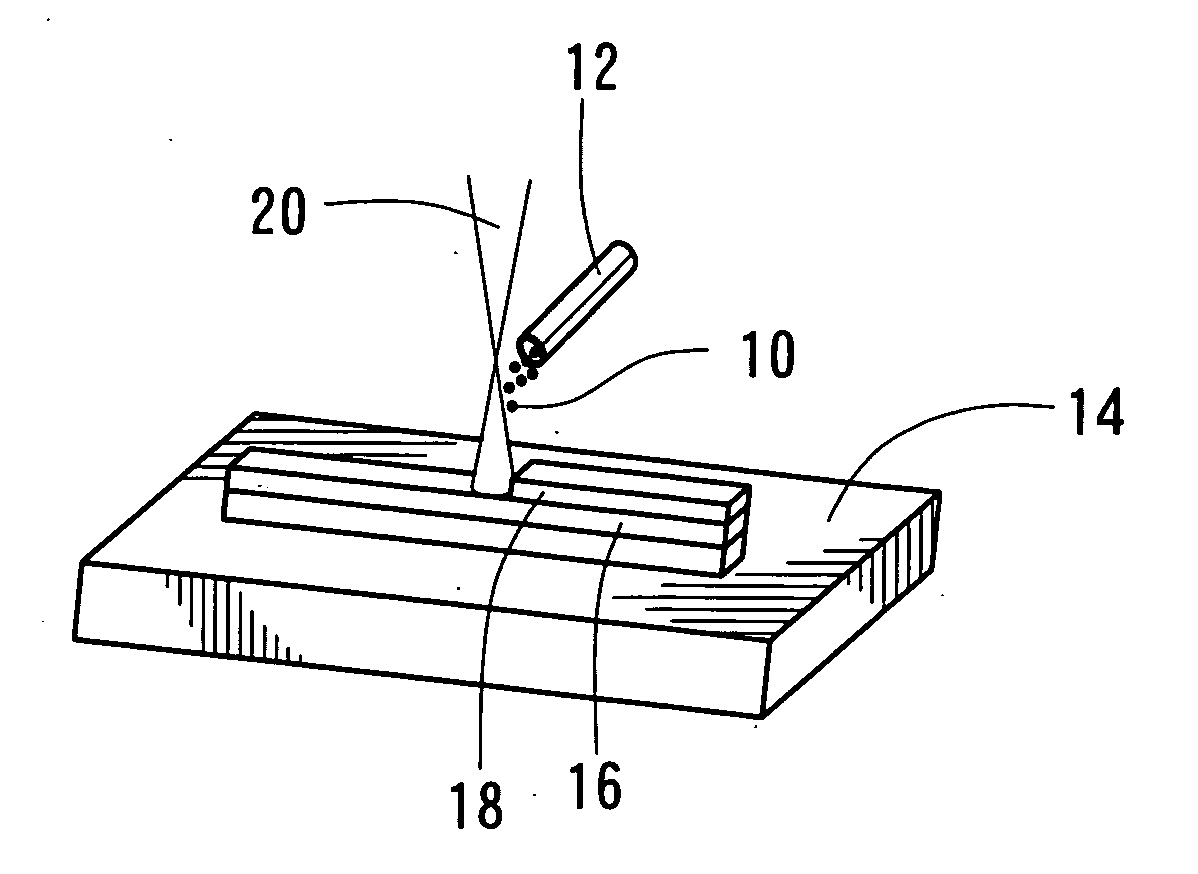

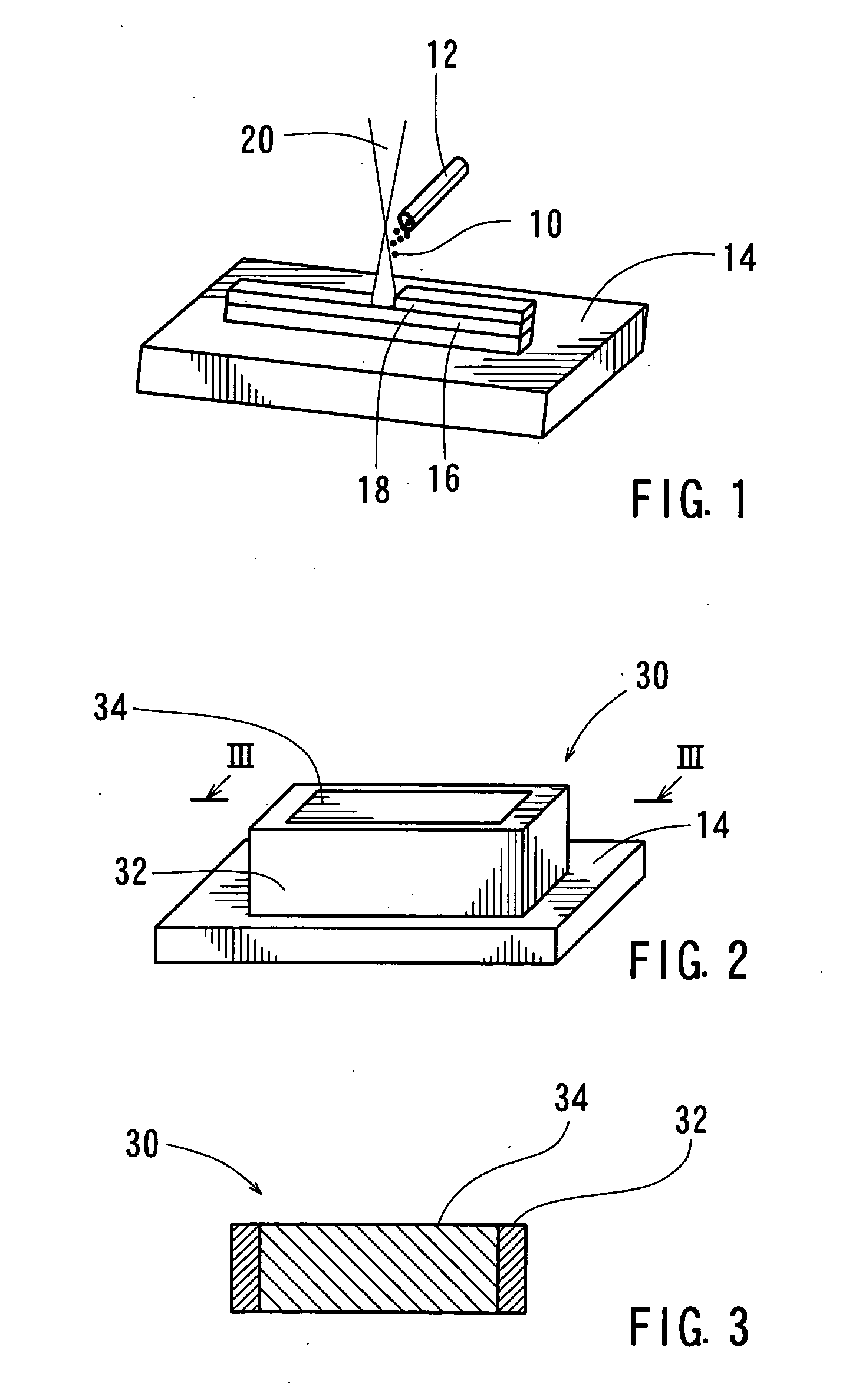

Method and apparatus for manufacturing three-dimensional objects

InactiveUS20060165546A1Low molding precisionPrevent unnecessary powder particle depositionAdditive manufacturing apparatusIncreasing energy efficiencyHigh densitySurface layer

The present invention teaches a method and an apparatus for manufacturing a three-dimensional object having a smooth outer surface, without any step of removing a surface layer each time a sintered layer is formed so as to manufacture a three-dimensional object consisting of integrally built-up sintered layers. The method may include the steps of: (i) supplying powder particles (10) onto a moving area while heating the powder particles (10) with heat (20) from a high-density energy heat source so as to form a sintered layer (16); and (ii) supplying powder particles 10 onto a moving area on the sintered layer while heating the powder particles (10) with heat (20) from the high-density energy heat source so as to form another sintered layer (18) integrally on the sintered layer (16), wherein the step (ii) is repeated a predetermined number of times.

Owner:AISAN IND CO LTD

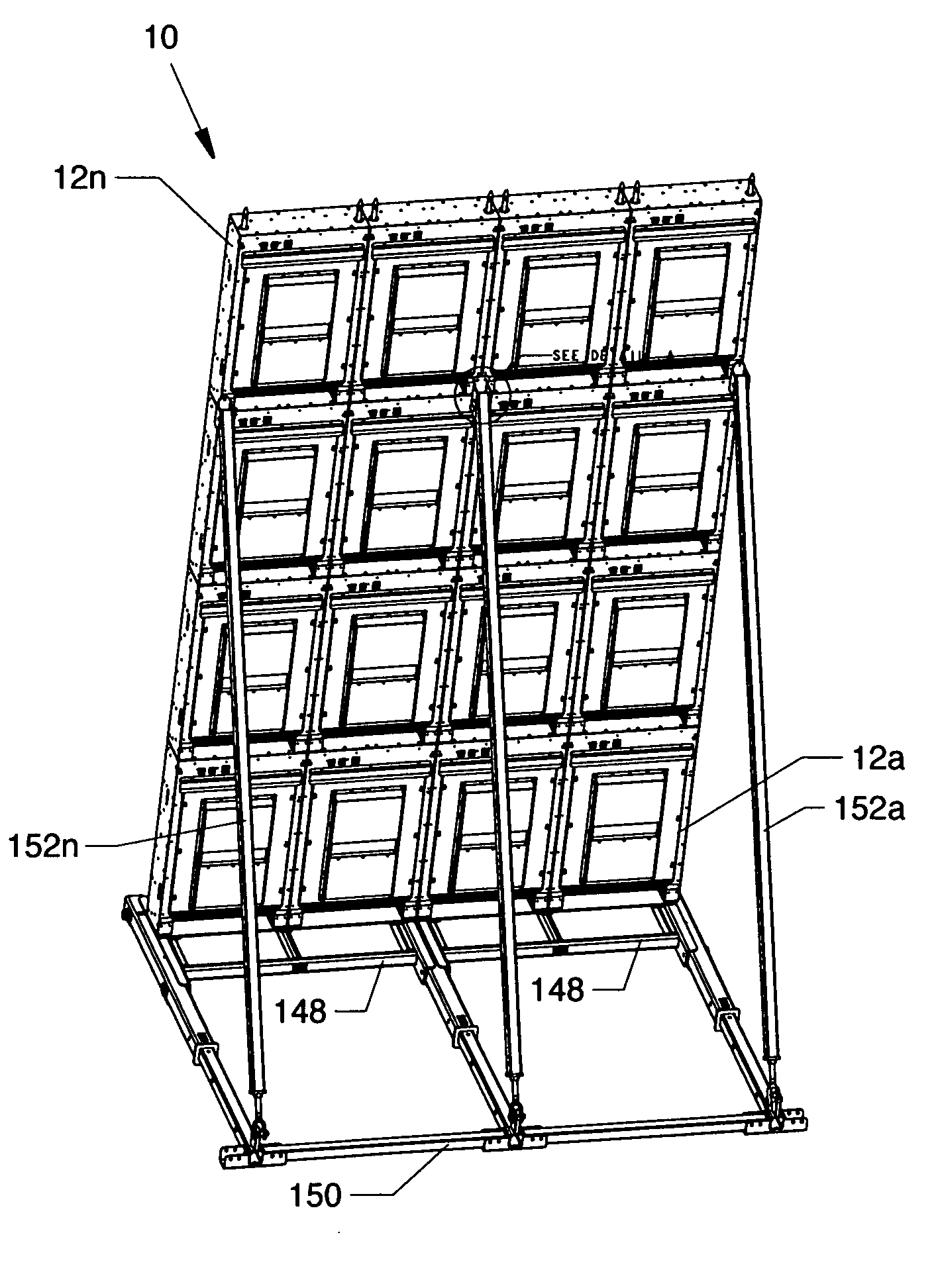

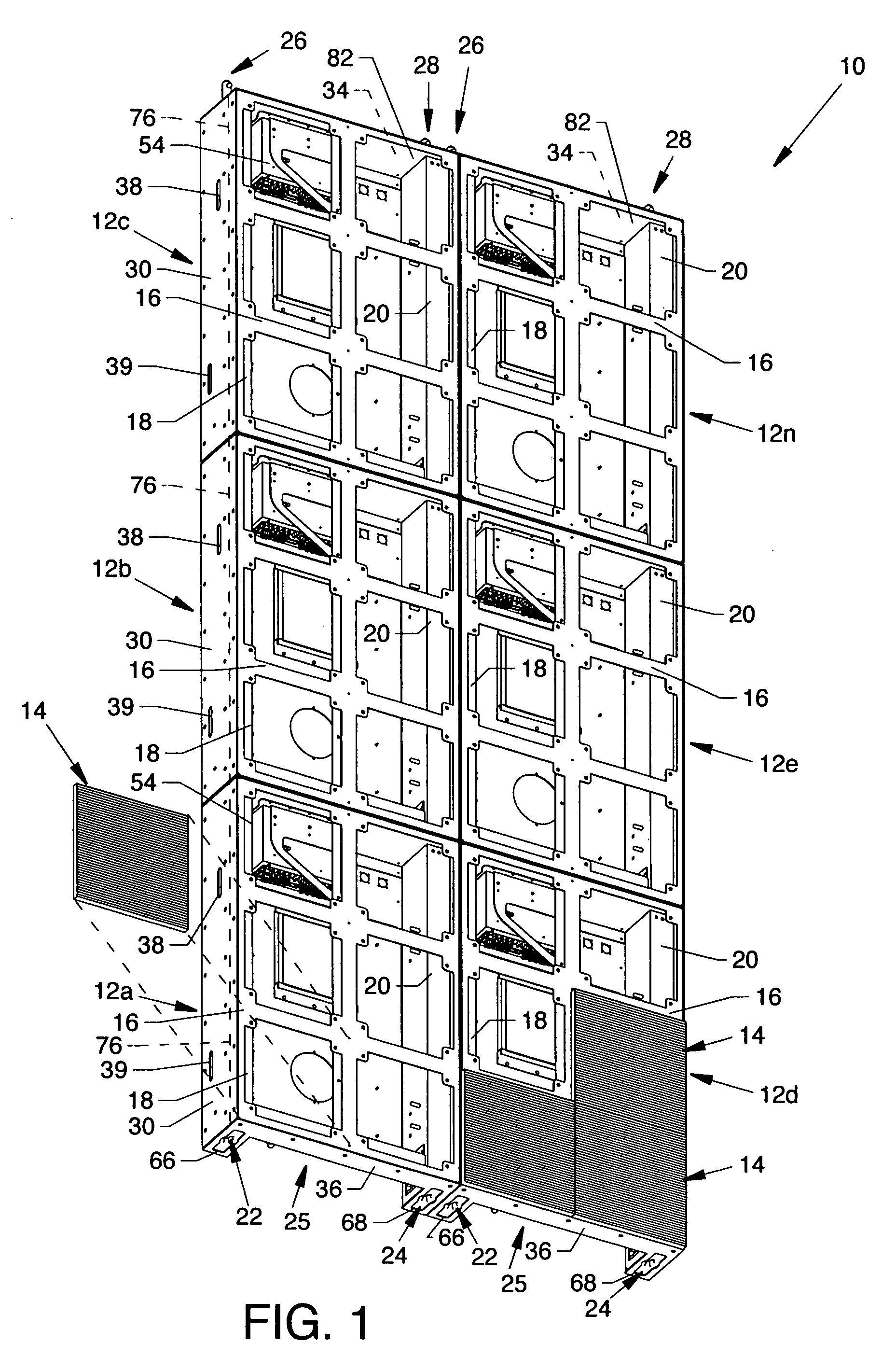

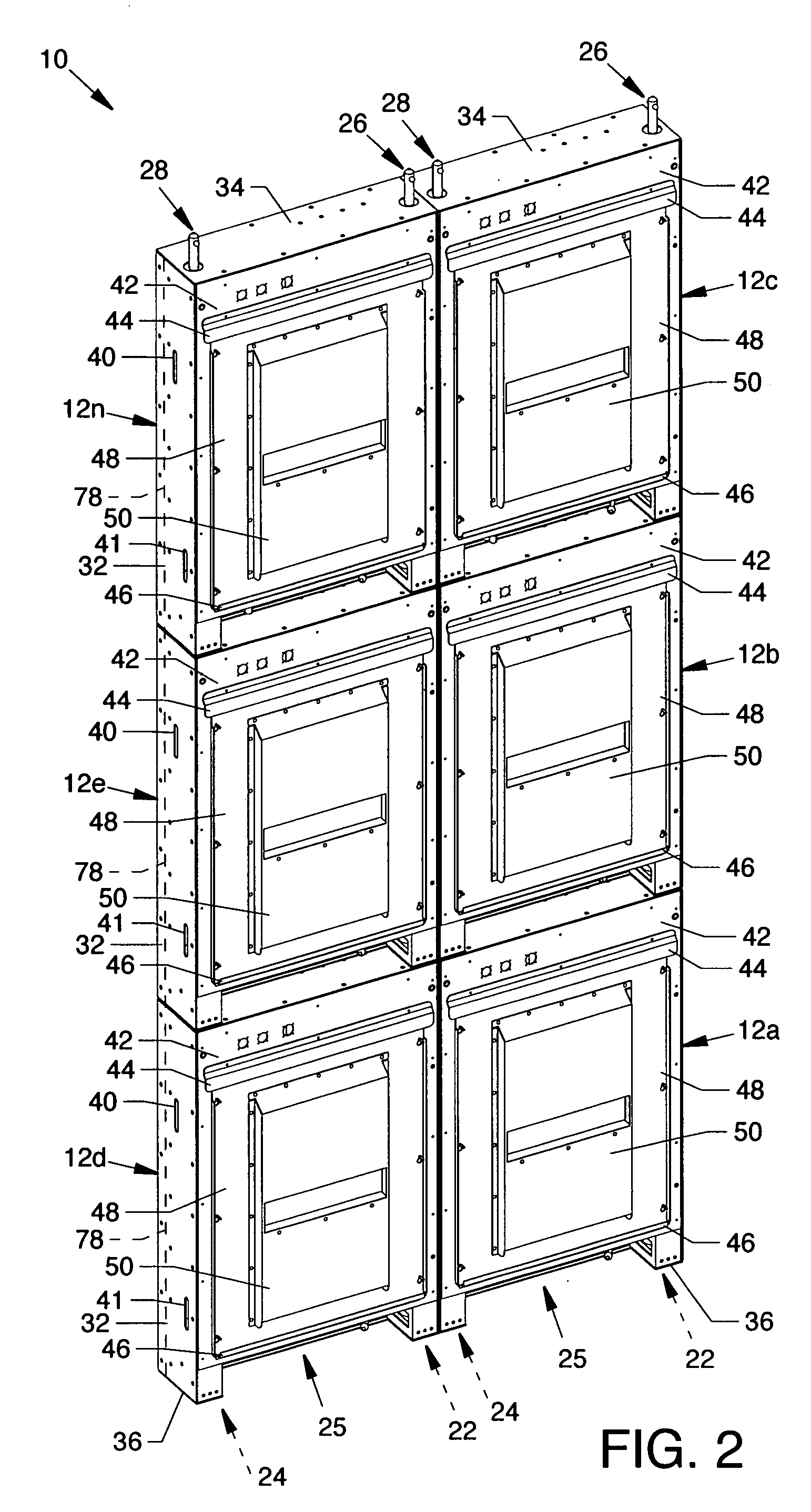

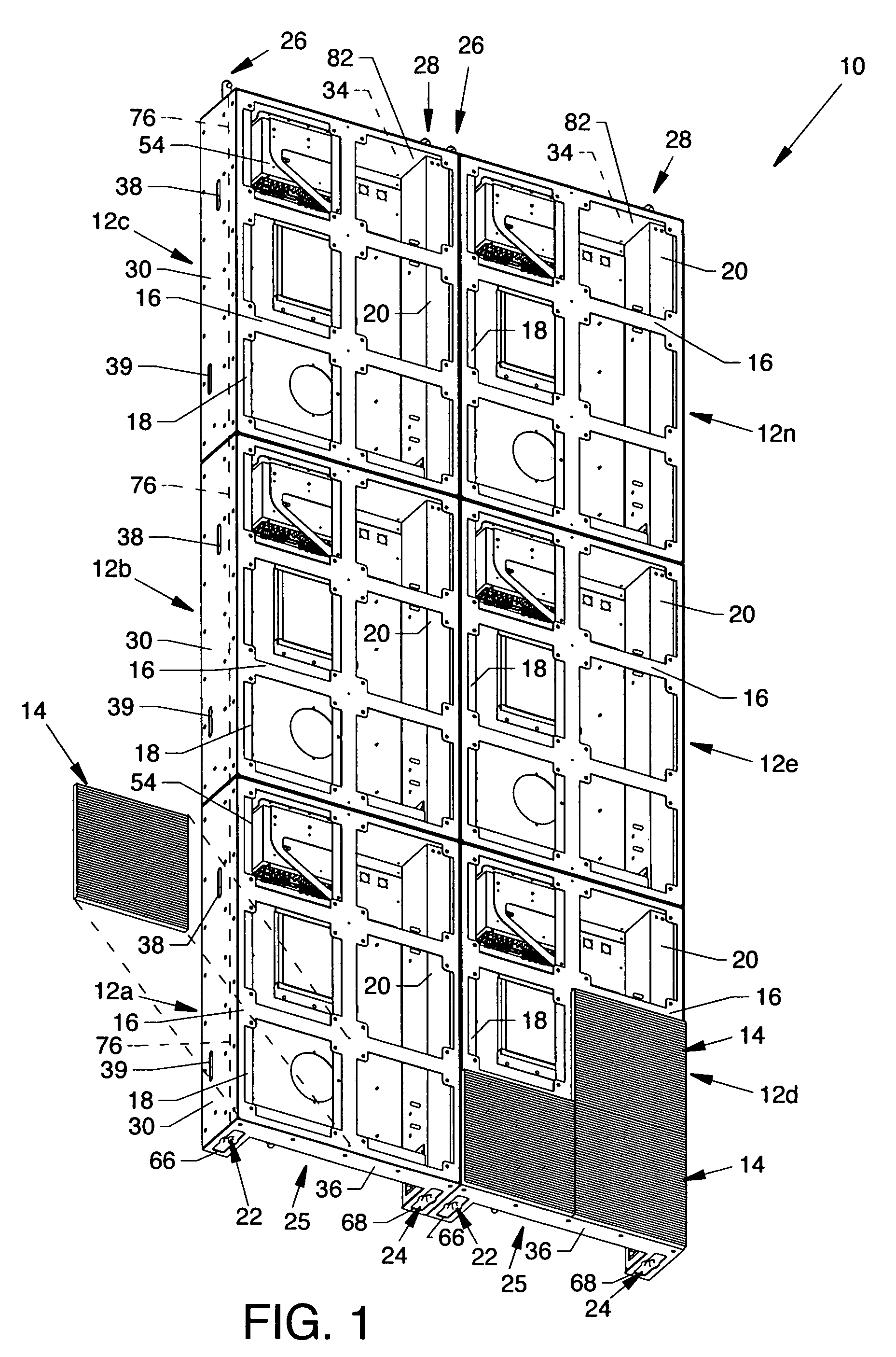

Transportable electronic sign display system

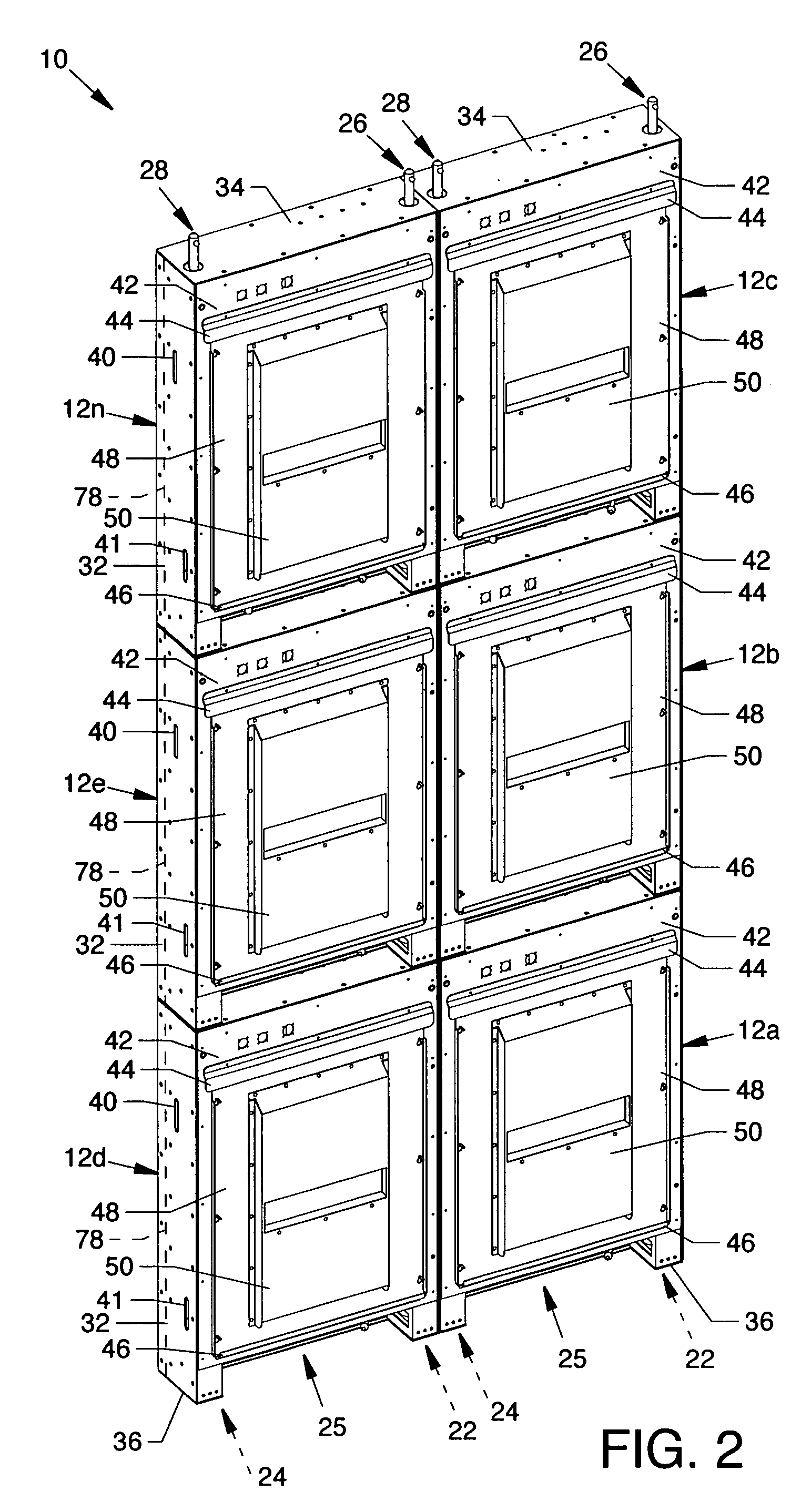

ActiveUS20080263924A1Lengthy set-up timeDown time minimizedRod connectionsCouplings for rigid shaftsModularityComputer module

A transportable electronic sign display system having modular cabinets which support electronic display modules and electronics having male and female latching assemblies connecting adjacent electronic display modules. Robust male and female latching assemblies at the top and bottom of electronic display modules provide for forcible positive action latching between vertically situated electronic display modules to provide a minimally visible horizontally oriented seam therebetween. Side latches between horizontally situated electronic display modules assemblies provide for latching to provide a minimally visible vertically oriented seam therebetween.

Owner:DAKTRONICS

Transportable electronic sign display system

ActiveUS7774968B2Lengthy set-up timeLarge tolerance of initial cabinet placementRod connectionsCouplings for rigid shaftsMobile electronicsElectronics

A transportable electronic sign display system having modular cabinets which support electronic display modules and electronics having male and female latching assemblies connecting adjacent electronic display modules. Robust male and female latching assemblies at the top and bottom of electronic display modules provide for forcible positive action latching between vertically situated electronic display modules to provide a minimally visible horizontally oriented seam therebetween. Side latches between horizontally situated electronic display modules assemblies provide for latching to provide a minimally visible vertically oriented seam therebetween.

Owner:DAKTRONICS

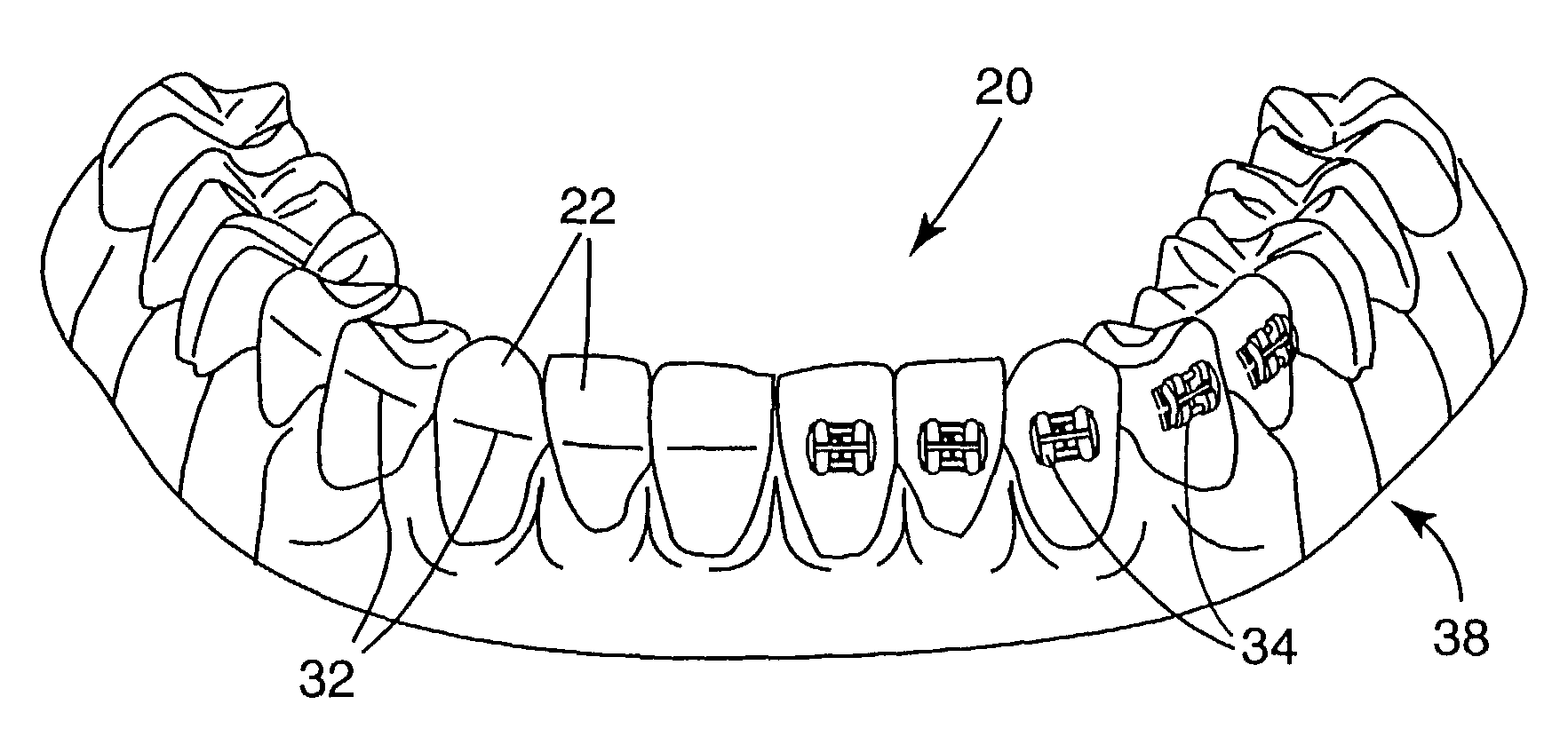

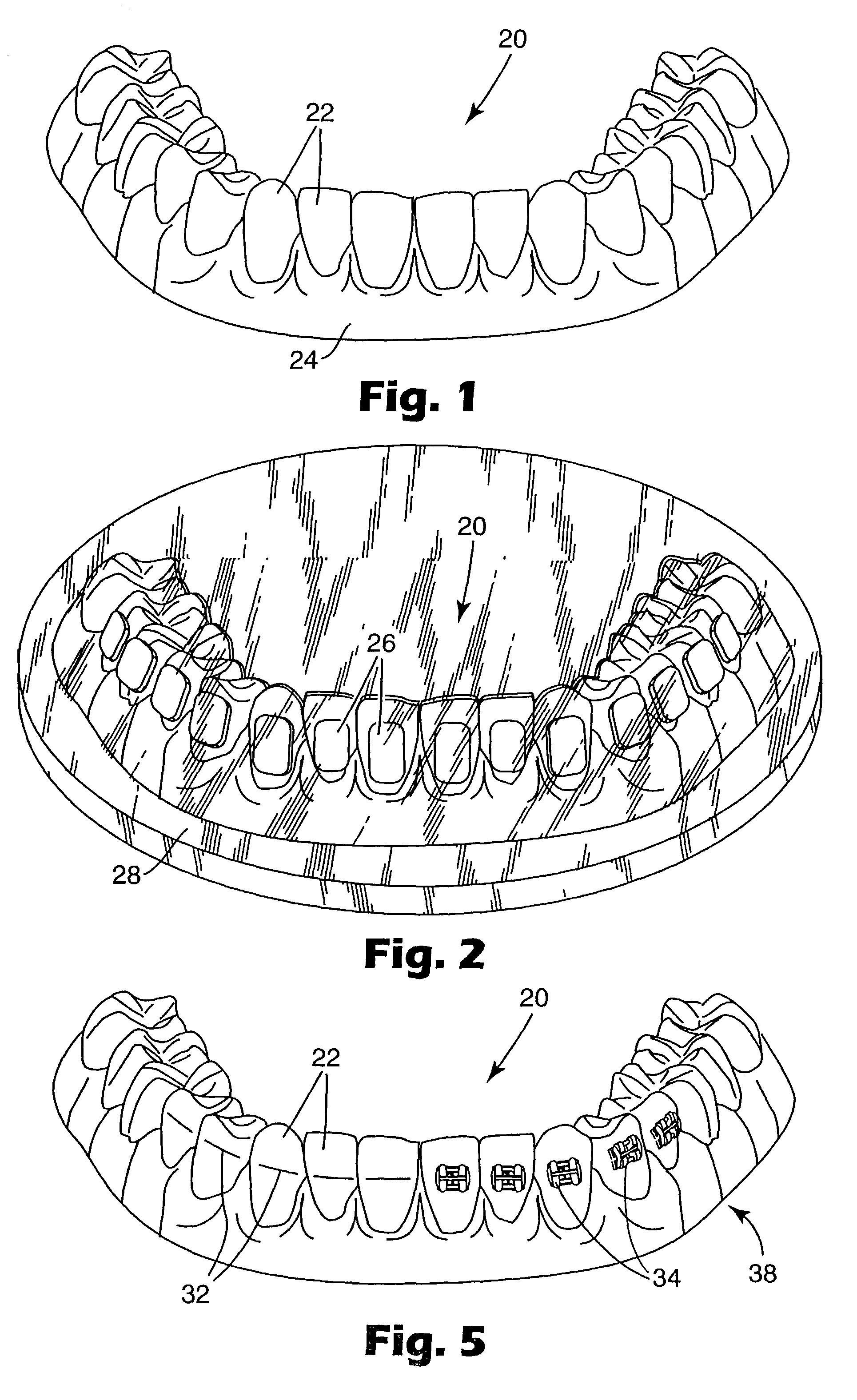

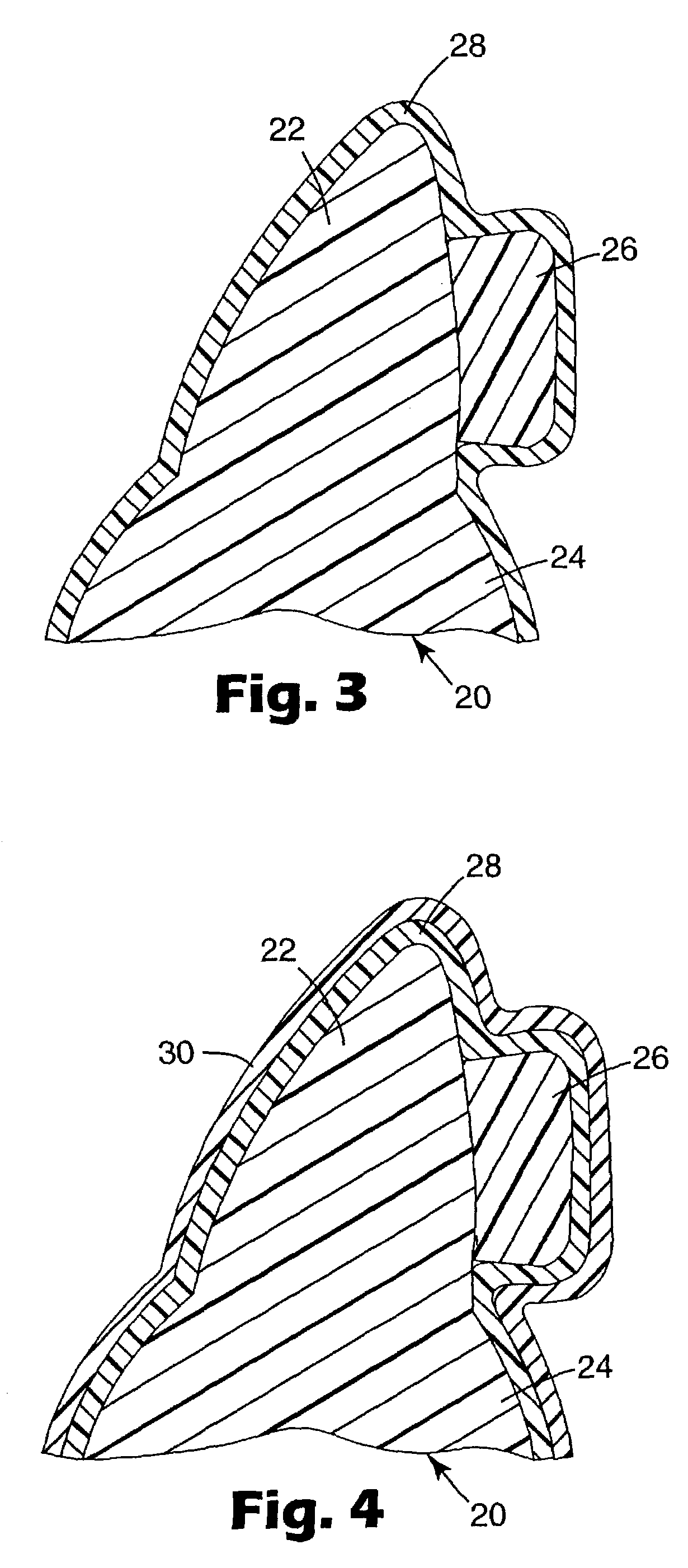

Orthodontic appliances having a contoured bonding surface

ActiveUS7188421B2Increase the joint surfaceAccurate shapeBracketsAdditive manufacturing apparatusOrthodontic AdhesivesPhotoinitiator

A quantity of a photocurable composition, such as an orthodontic adhesive containing a photoinitiator, is placed between the base of an orthodontic appliance and a replica of a patient's tooth structure. The replica is made using a material that transmits actinic radiation. As the appliance is pressed into firm contact with the replica tooth structure, an outer surface of the photocurable composition assumes the configuration of the underlying portion of the replica tooth structure. Actinic radiation is then directed to the photocurable composition, and at least part of the actinic radiation is directed through the replica tooth model in order to harden the photocurable composition. The hardened composition provides a contoured bonding surface having a shape that matches corresponding regions of the patient's tooth structure. Methods are also disclosed for making an orthodontic indirect bonding transfer apparatus for use with appliances having a contoured bonding surface.

Owner:3M INNOVATIVE PROPERTIES CO

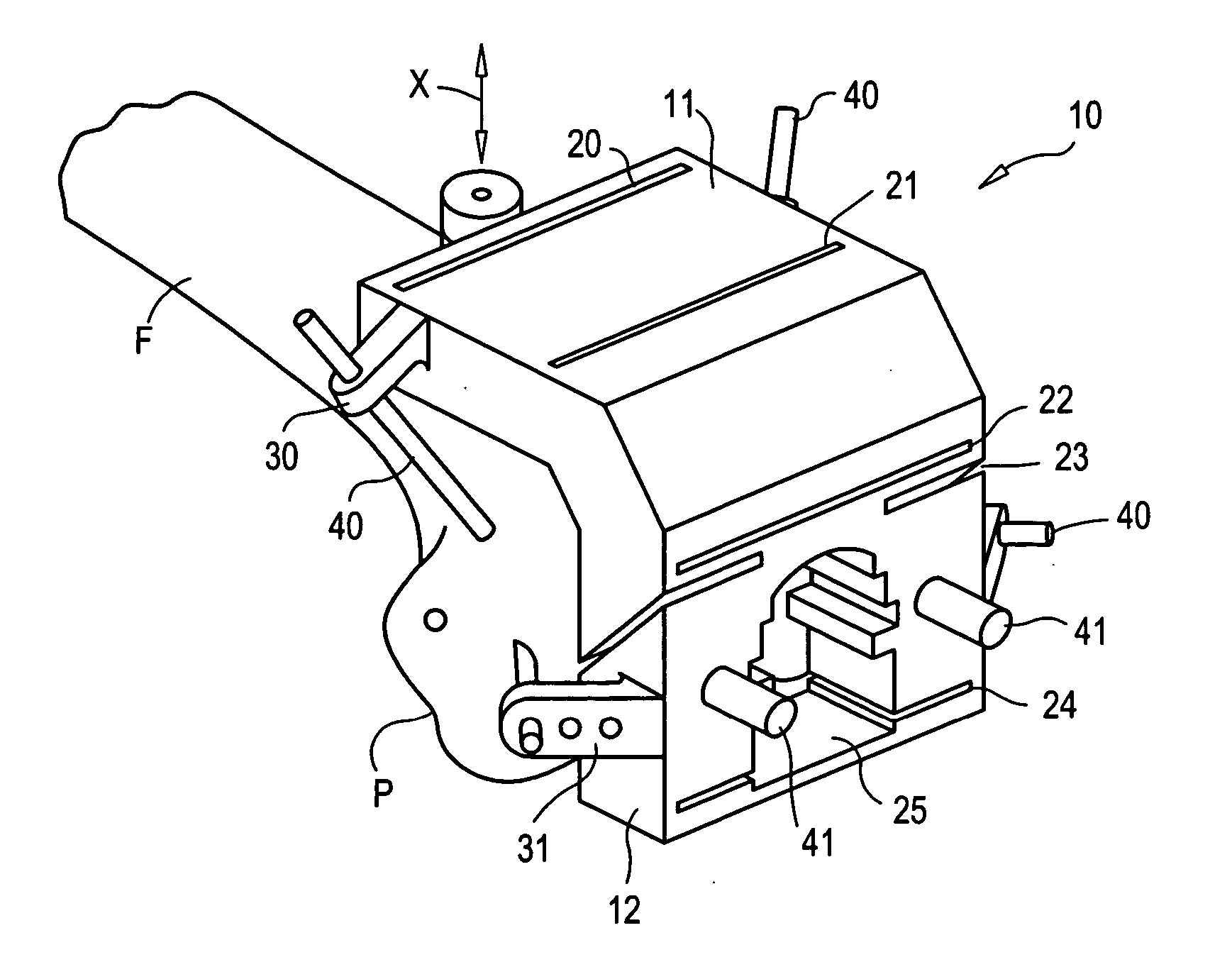

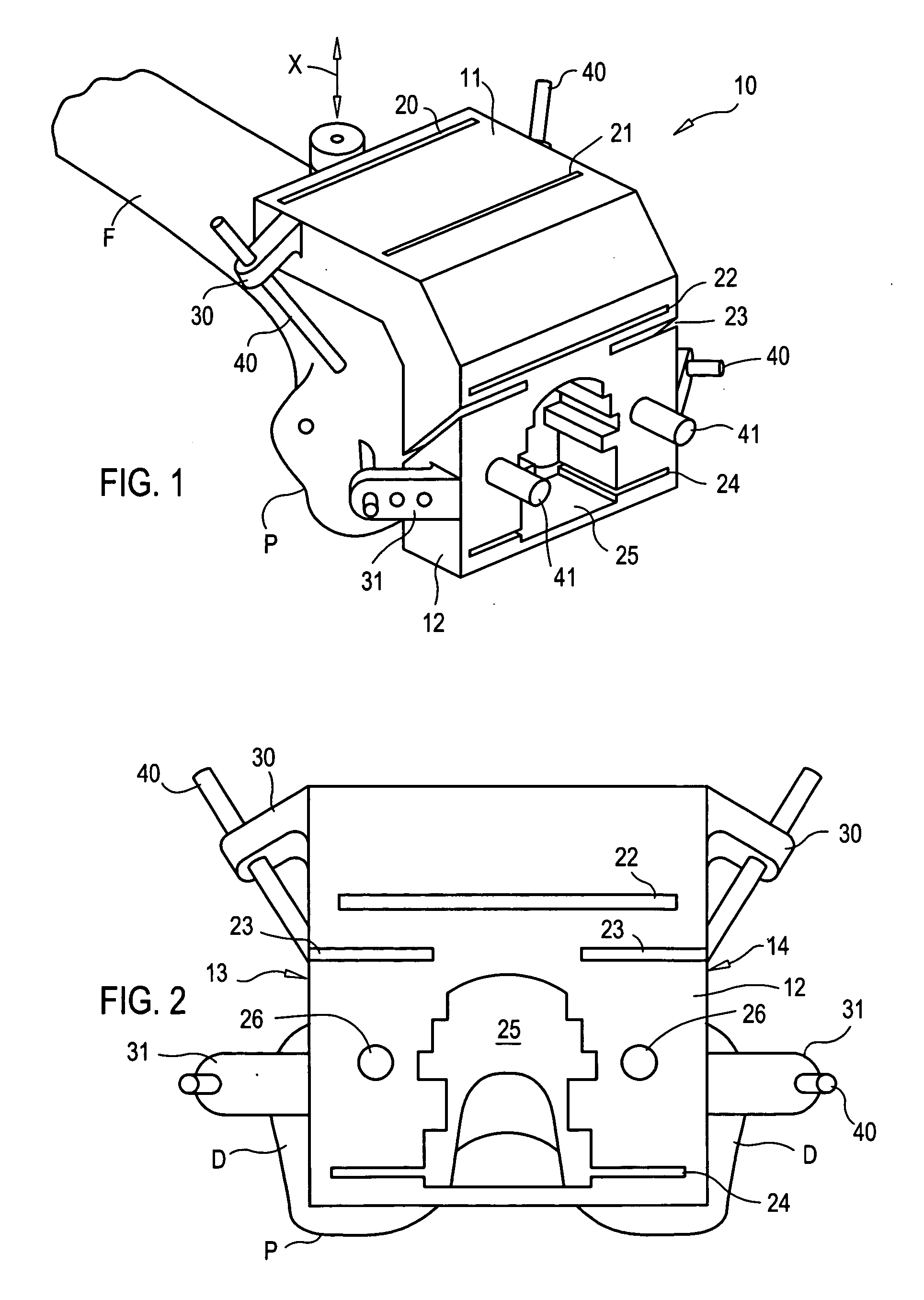

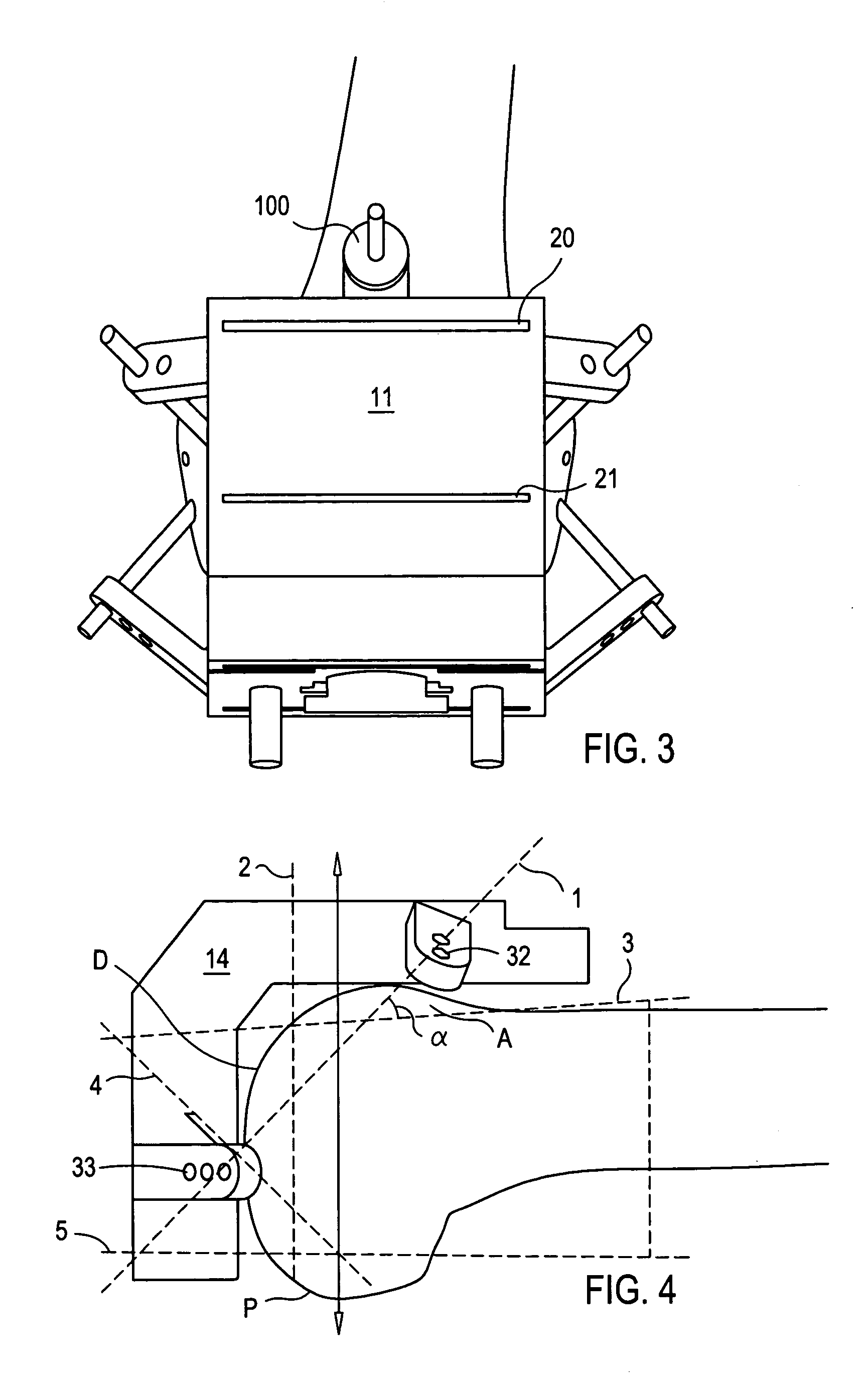

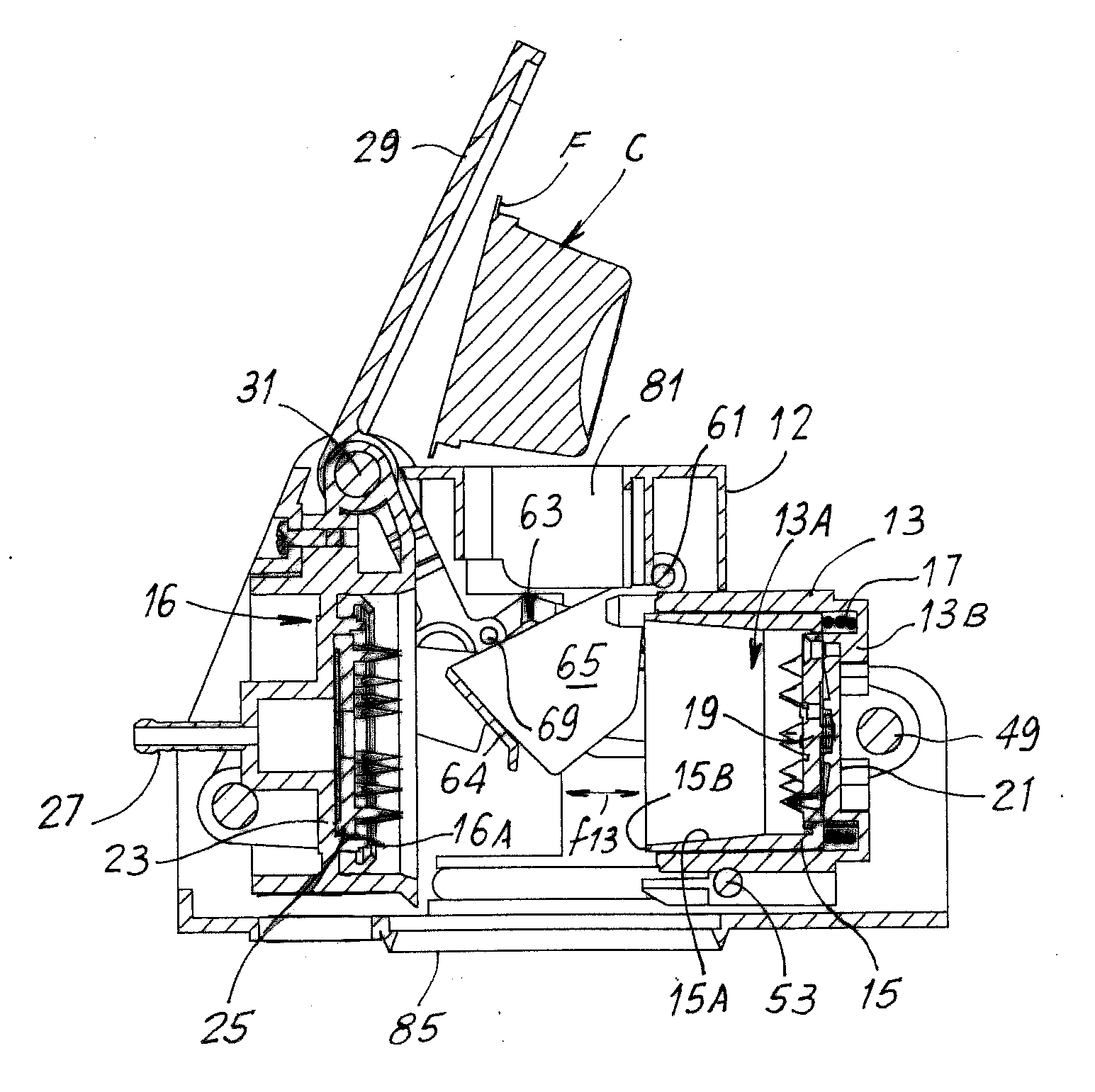

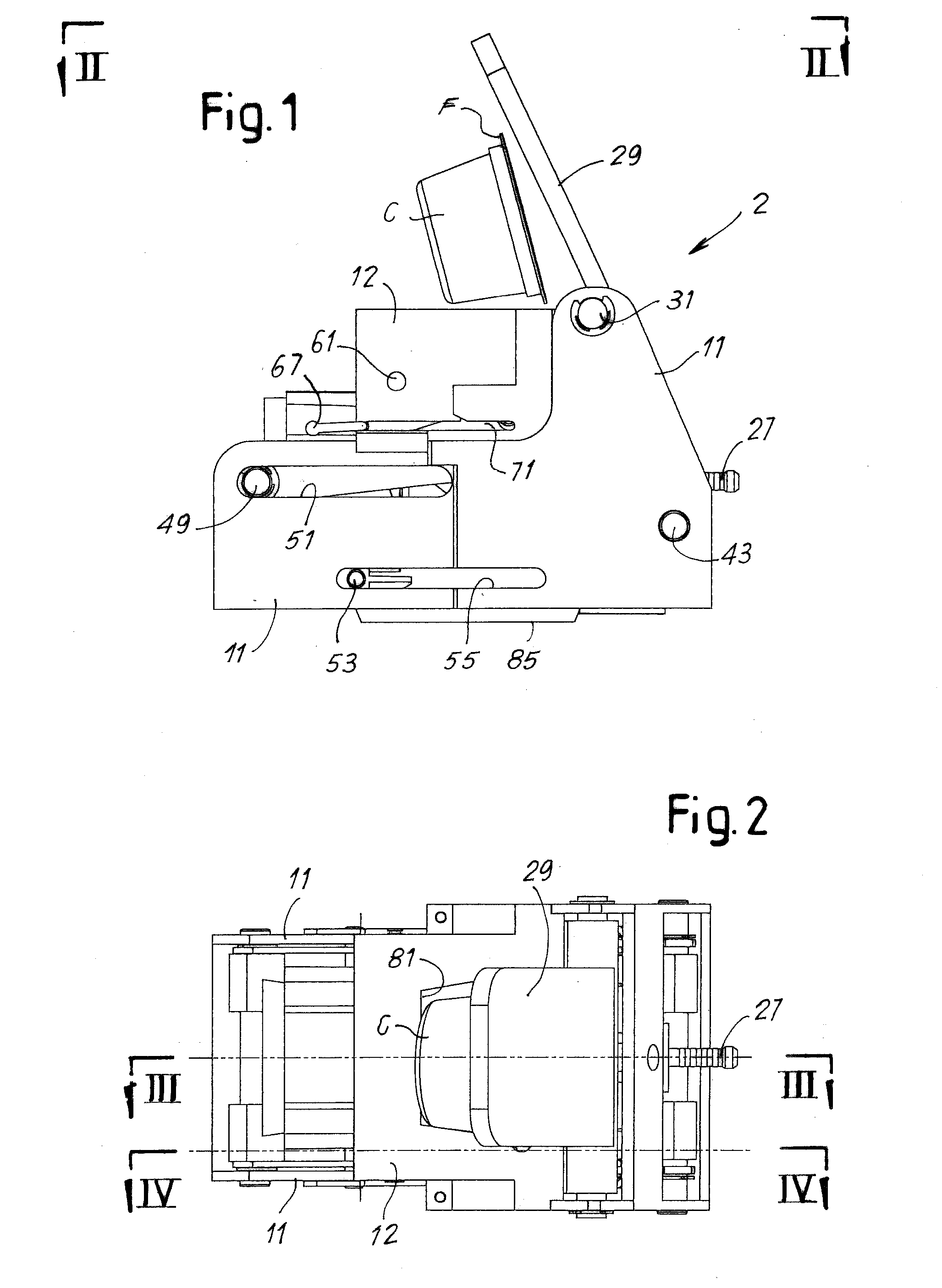

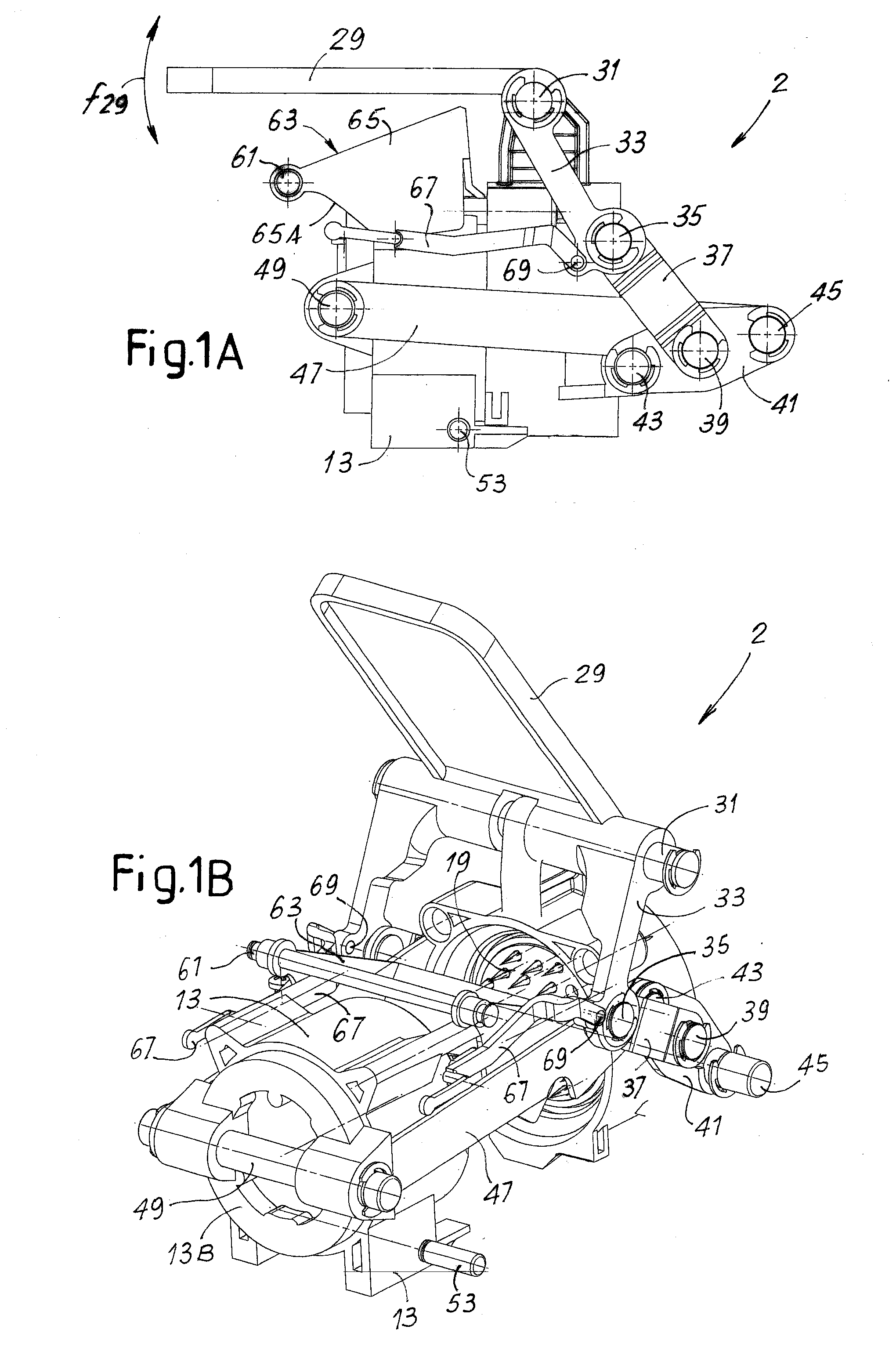

Brewing unit with horizontal motion

ActiveUS20130239820A1Compact and simple to manufactureEasy to useBeverage vesselsEngineeringMechanical engineering

The brewing unit comprises: a brewing chamber (13,16) with a first brewing chamber portion (13) and a second brewing chamber portion (16), mobile one with respect to the other to open and close the brewing chamber; a channel (81) for inserting said capsules (C) towards said brewing chamber; a mobile deviator (63) interposing between said first brewing chamber portion (13) and said second brewing chamber portion (16) to deviate said capsules (C) towards the inside of one of said first and second brewing chamber portions (13, 16) of.

Owner:VERSUNI HLDG BV

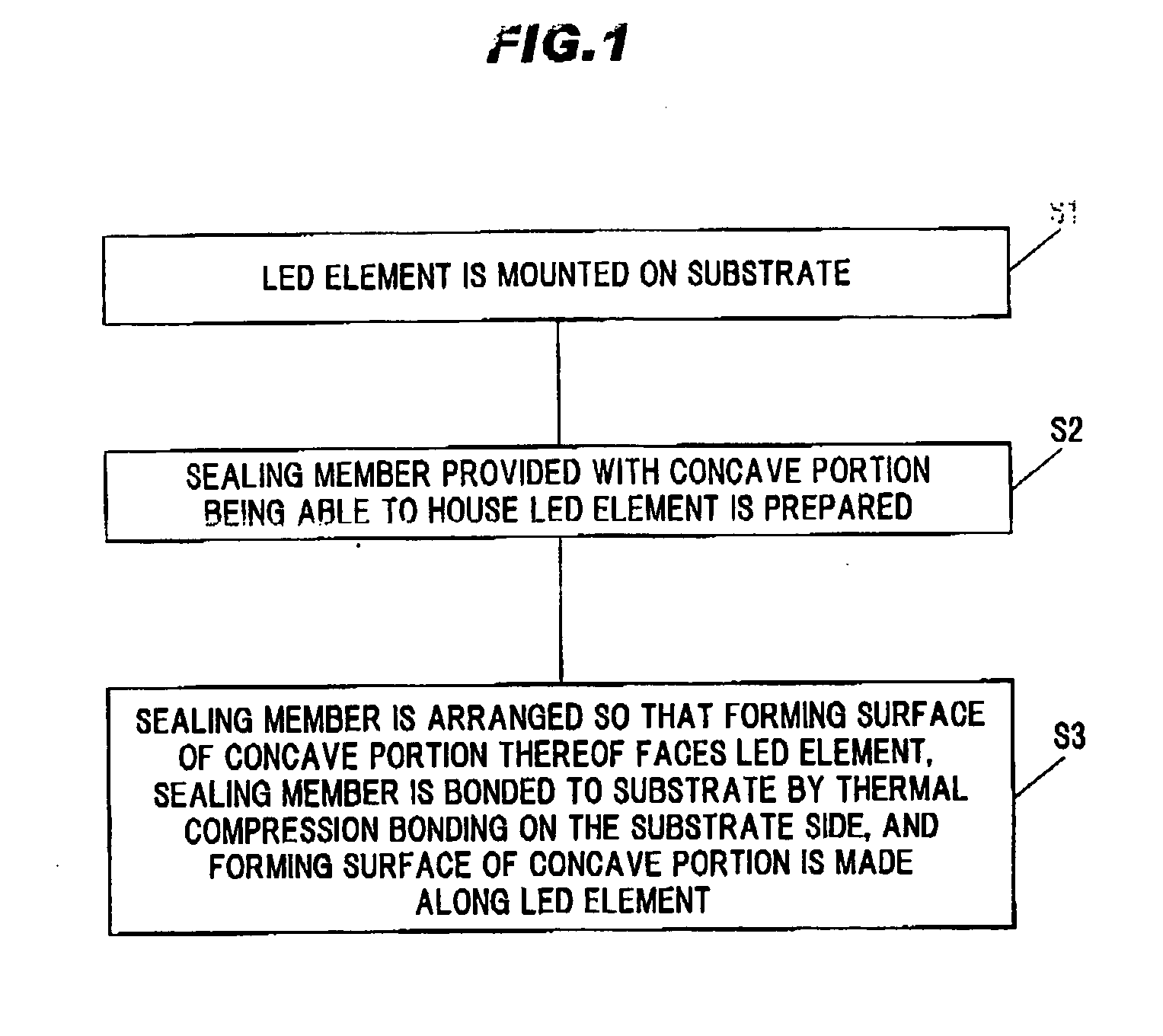

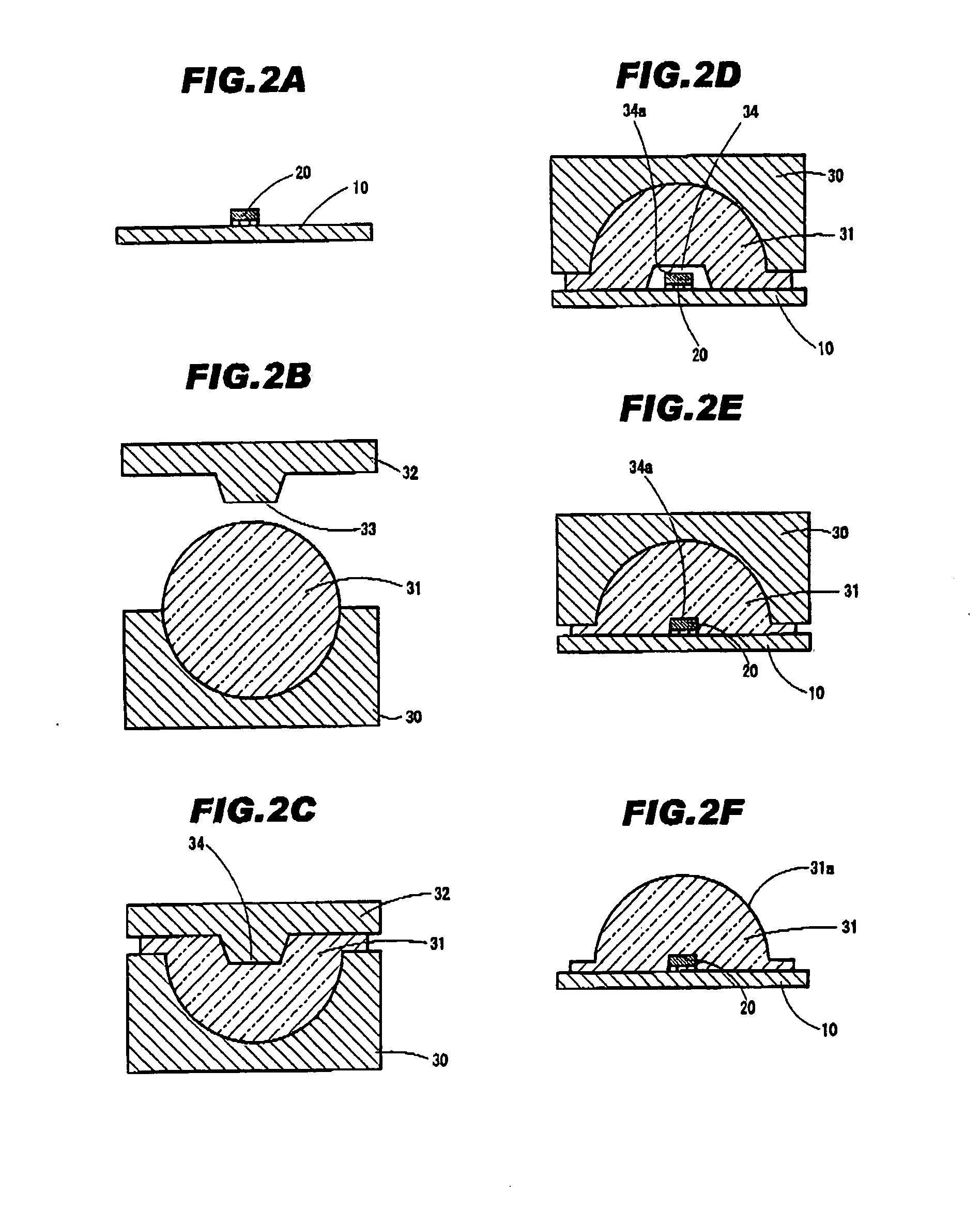

Method of manufacturing led lamp

ActiveUS20100244071A1Prevented from being directly pressedFlat surfaceSolid-state devicesSemiconductor/solid-state device manufacturingThermal compressionEngineering

A method of manufacturing a LED lamp that is formed by sealing a LED element mounted on a substrate with glass, includes a mounting process for mounting the LED element on the substrate, a sealing member preparation process for preparing a glass sealing member that includes a concave portion being capable of housing the LED element, and a sealing process wherein the sealing member is arranged so that a forming surface of the concave portion faces the LED element, the sealing member is bonded to the substrate by thermal compression bonding, and the forming surface of the concave portion is made along the LED element.

Owner:TOYODA GOSEI CO LTD

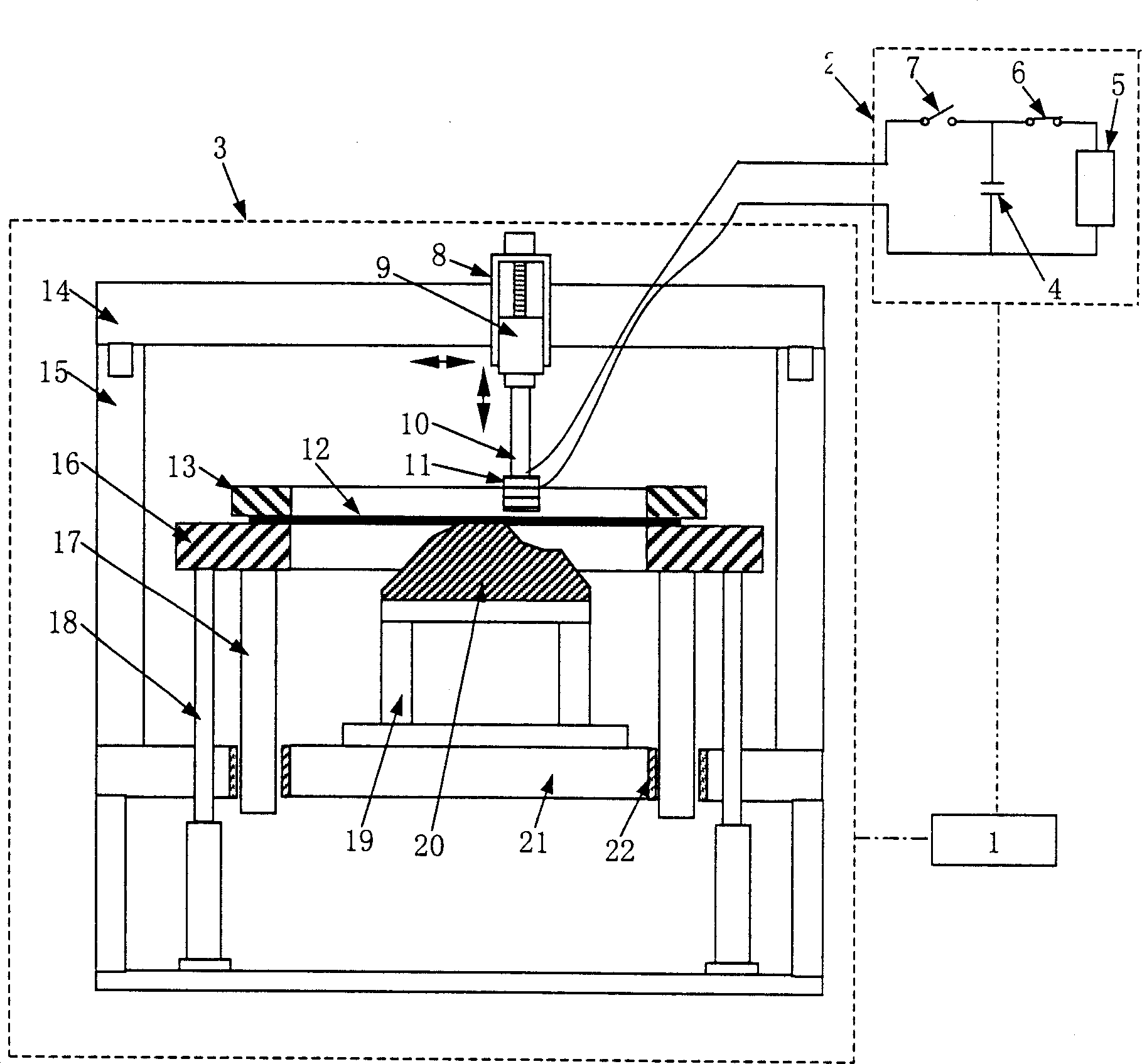

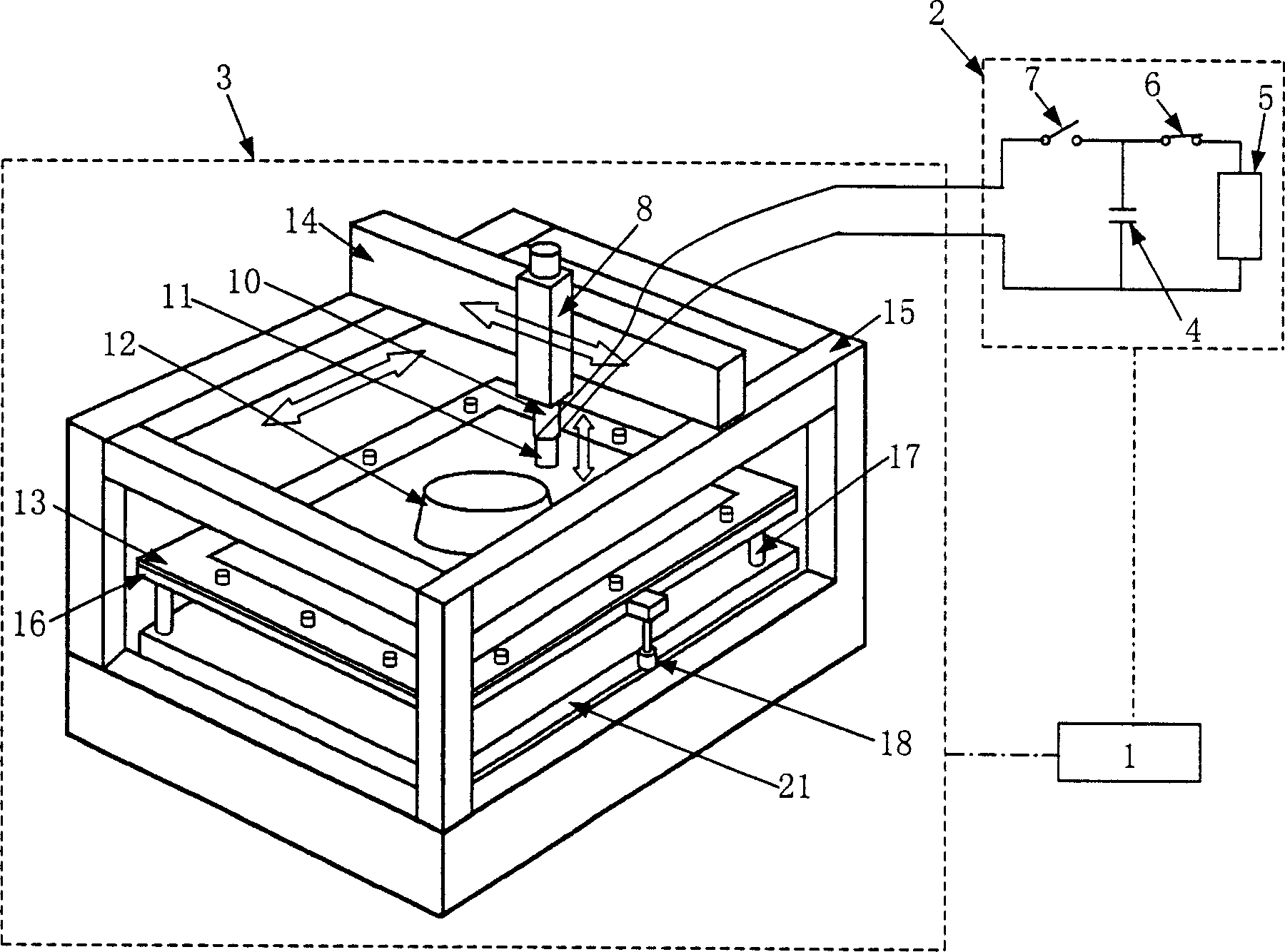

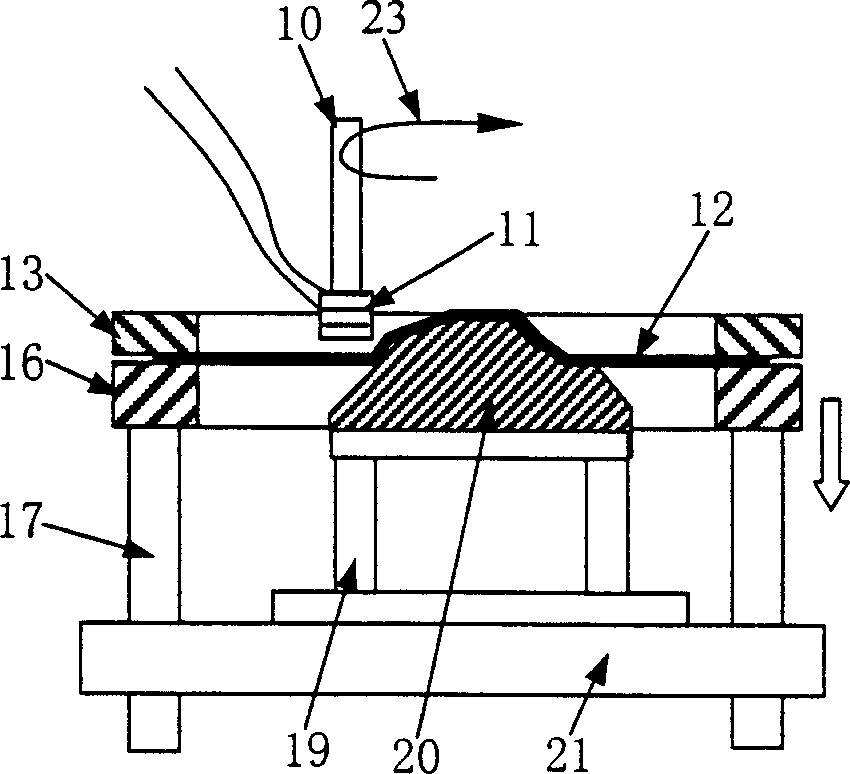

Electromagnetic inching forming method and its device for plate moving coil

InactiveCN1821910AGood repeatabilityEasy energy control and automated productionProgramme controlComputer controlEngineeringElectromagnetic pulse

This invention relates to an electromagnetic progressive shaping method for plate moving coils and a device, in which, said device includes a computer control system, an electromagnetic force generation system and a three-shaft digital control shaping system including a plate clamping elevating device, a supporting model frame and an electromagnetic shaping clamping rod, in which, the computer controls the coil to move downward along the contour of a model profile from the top according to the contour data of the model profile and the plate is formed partly relying on the magnetic force of coil till to the bottom of the model and finish the entire process.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com