Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

904 results about "Dielectric thin films" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

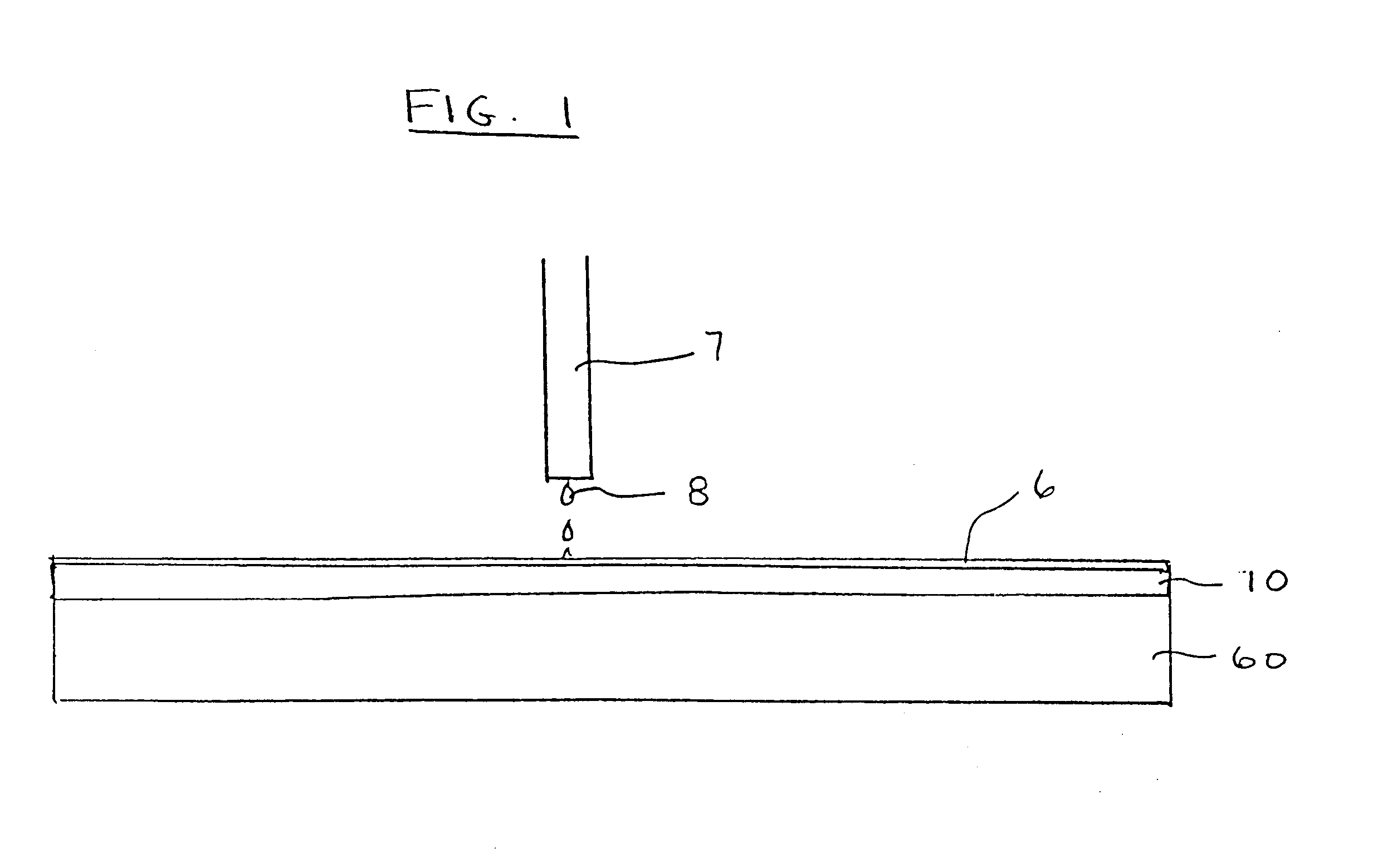

Thin dielectric films are versatile tools for controlling the propagation of light. They can be used, for example, as anti-reflective coatings to reduce the amount of stray light in a system. They can also be used as low-loss reflectors or as filters to selectively transmit certain frequencies of radiation.

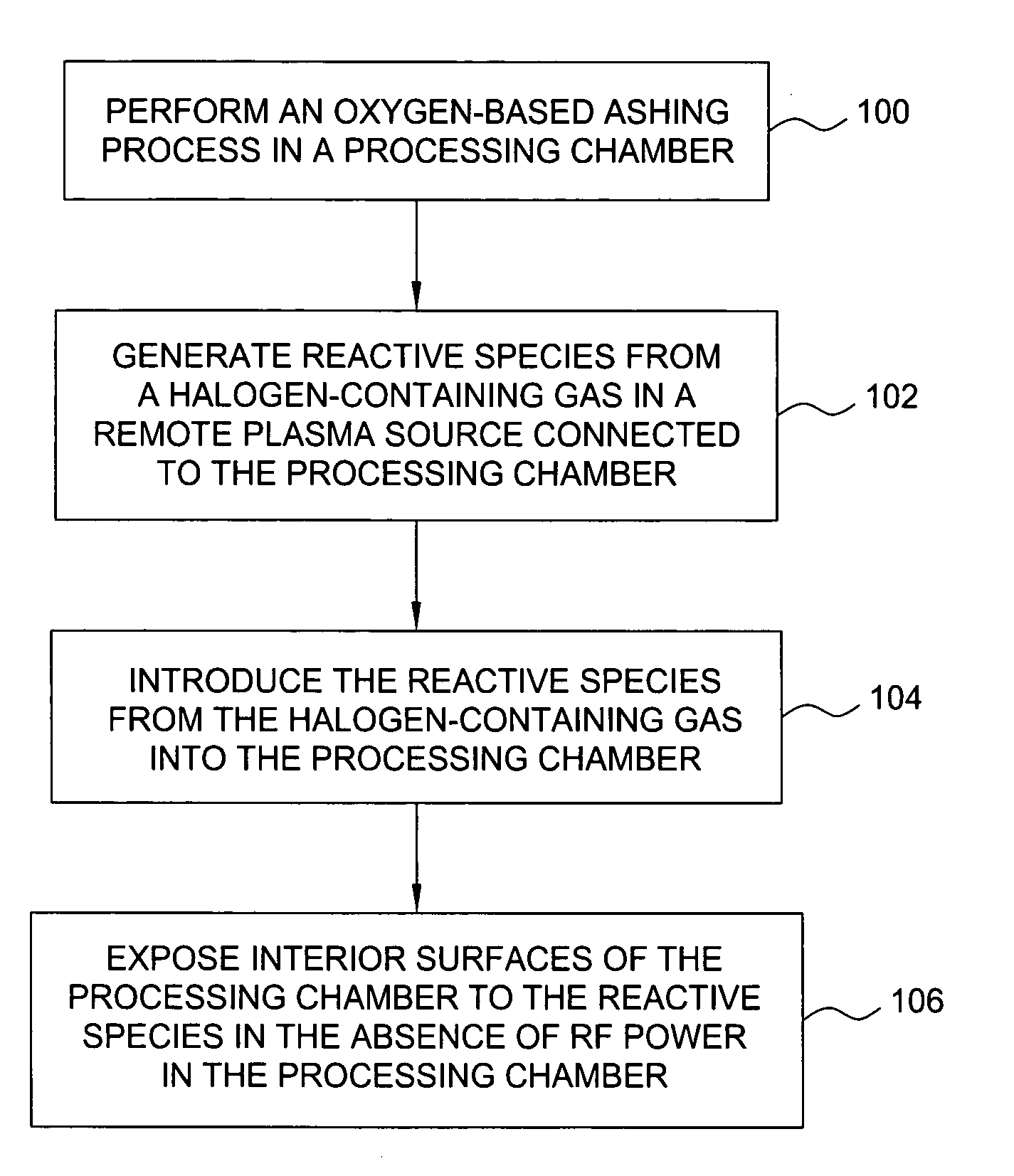

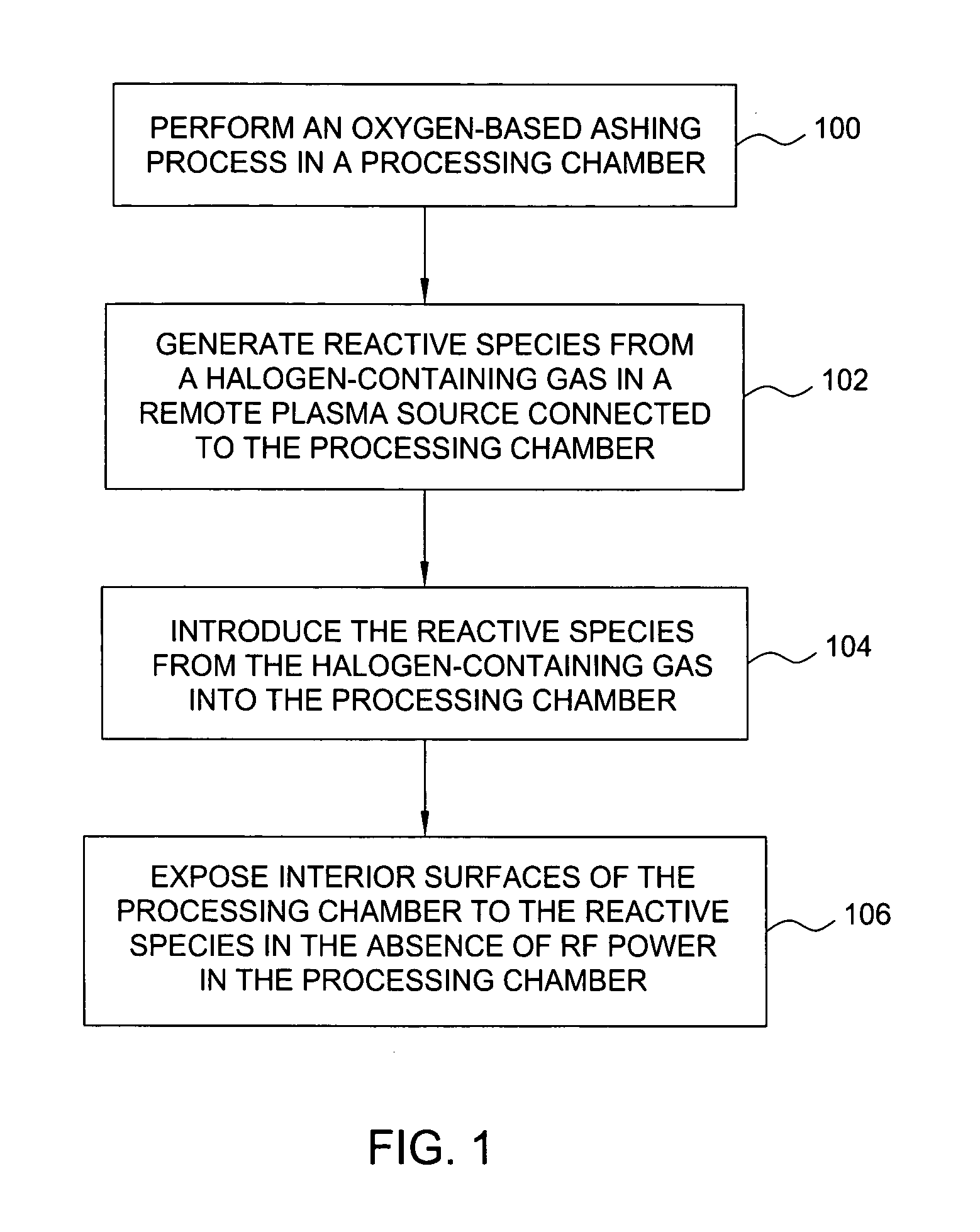

Enhancement of remote plasma source clean for dielectric films

Methods for cleaning semiconductor processing chambers used to process carbon-containing films, such as amorphous carbon films, barrier films comprising silicon and carbon, and low dielectric constant films including silicon, oxygen, and carbon are provided. The methods include using a remote plasma source to generate reactive species that clean interior surfaces of a processing chamber in the absence of RF power in the chamber. The reactive species are generated from an oxygen-containing gas, such as O2, and / or a halogen-containing gas, such as NF3. An oxygen-based ashing process may also be used to remove carbon deposits from the interior surfaces of the chamber before the chamber is exposed to the reactive species from the remote plasma source.

Owner:APPLIED MATERIALS INC

Method for depositing dielectric films

ActiveUS20130344248A1Reduces and substantially eliminates amountGood control over concentrationChemical vapor deposition coatingHydrogen halideDecomposition

A method is provided for depositing a dielectric film on a substrate. According to one embodiment, the method includes providing the substrate in a process chamber, exposing the substrate to a gaseous precursor to form an adsorbed layer on the substrate, exposing the adsorbed layer to an oxygen-containing gas, a nitrogen-containing gas, or an oxygen- and nitrogen-containing gas, or a combination thereof, to form the dielectric film on the substrate, generating a hydrogen halide gas in the process chamber by a decomposition reaction of a hydrogen halide precursor gas, and exposing the dielectric film to the hydrogen halide gas to remove contaminants from the dielectric film.

Owner:TOKYO ELECTRON LTD

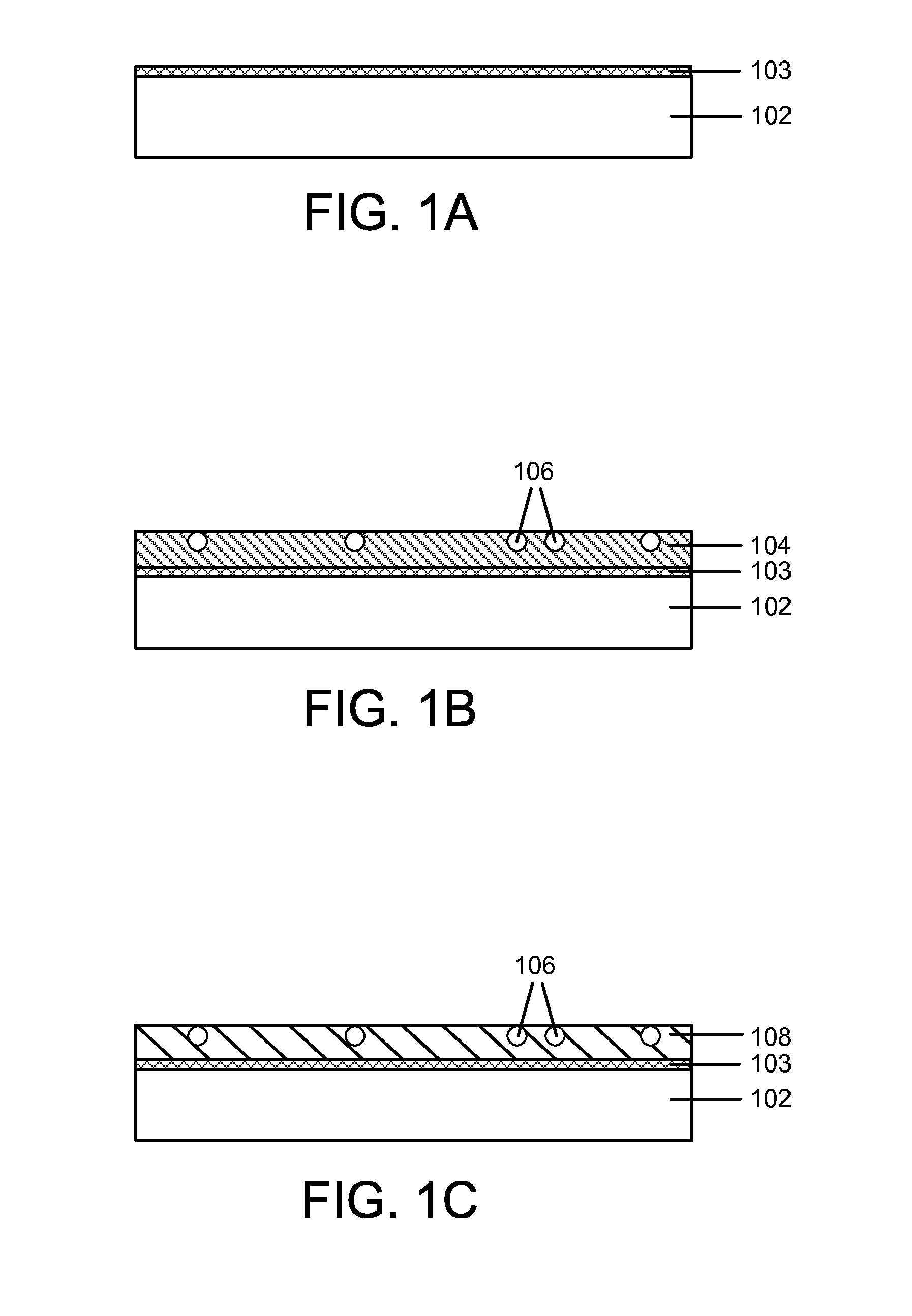

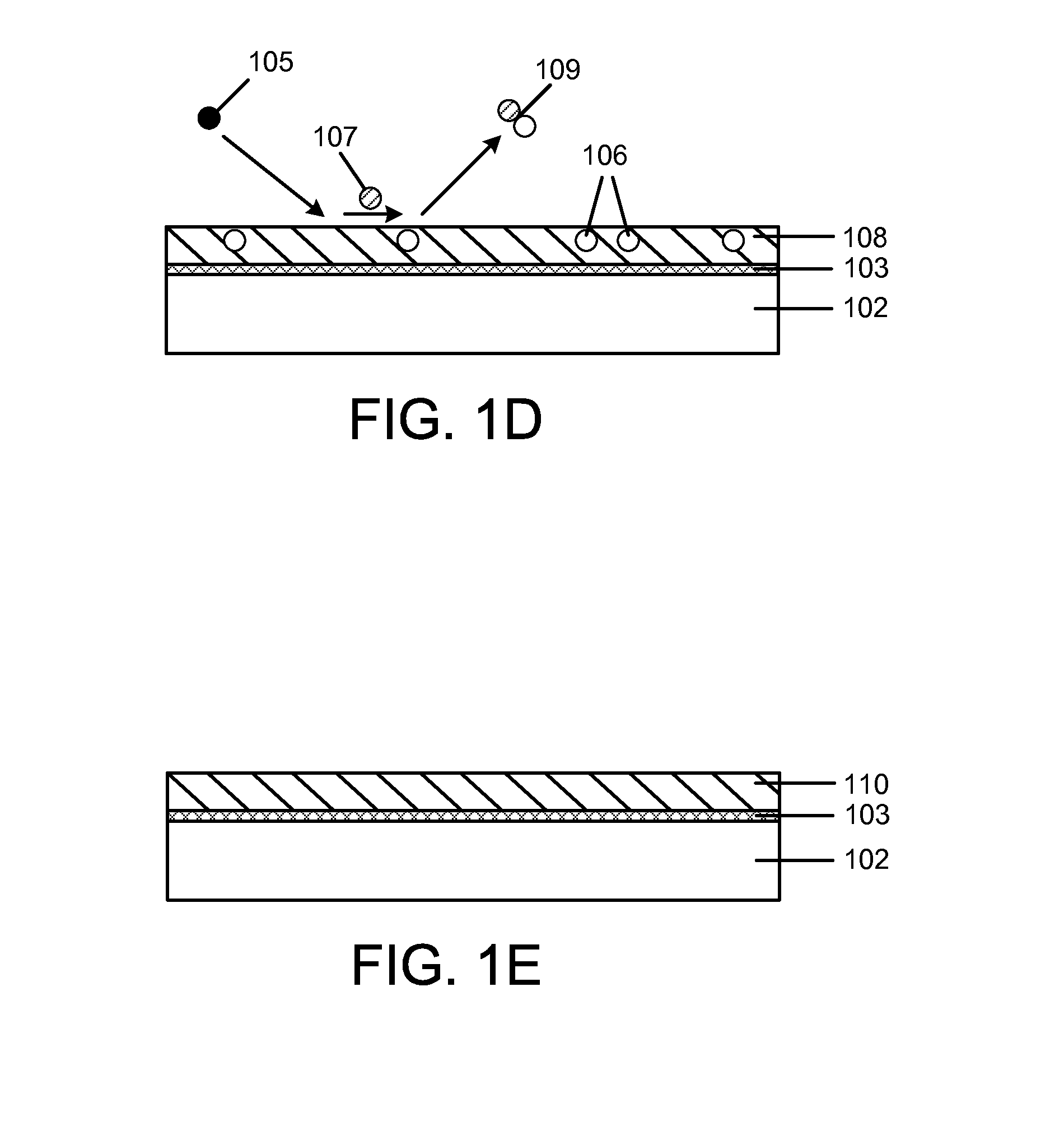

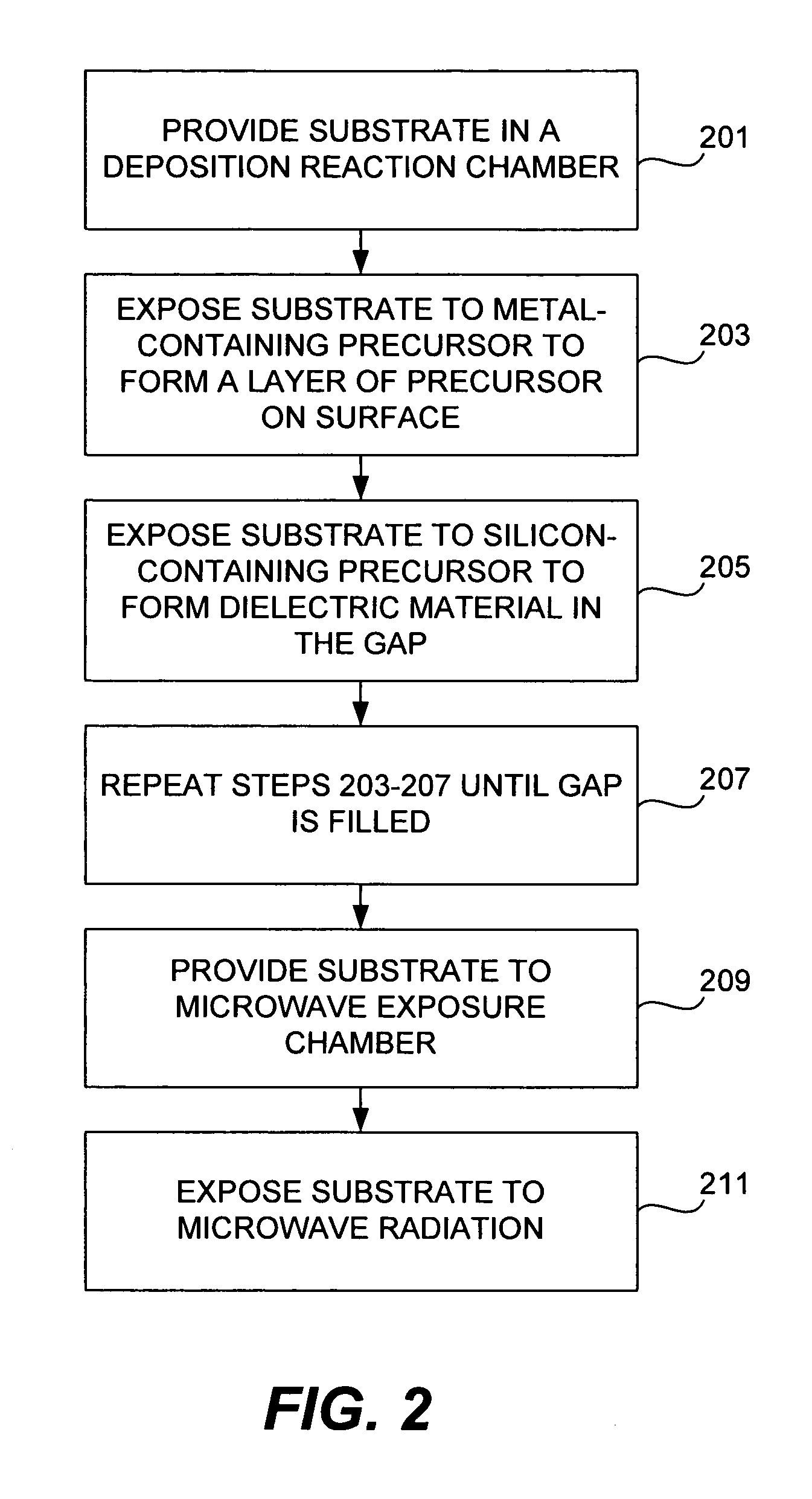

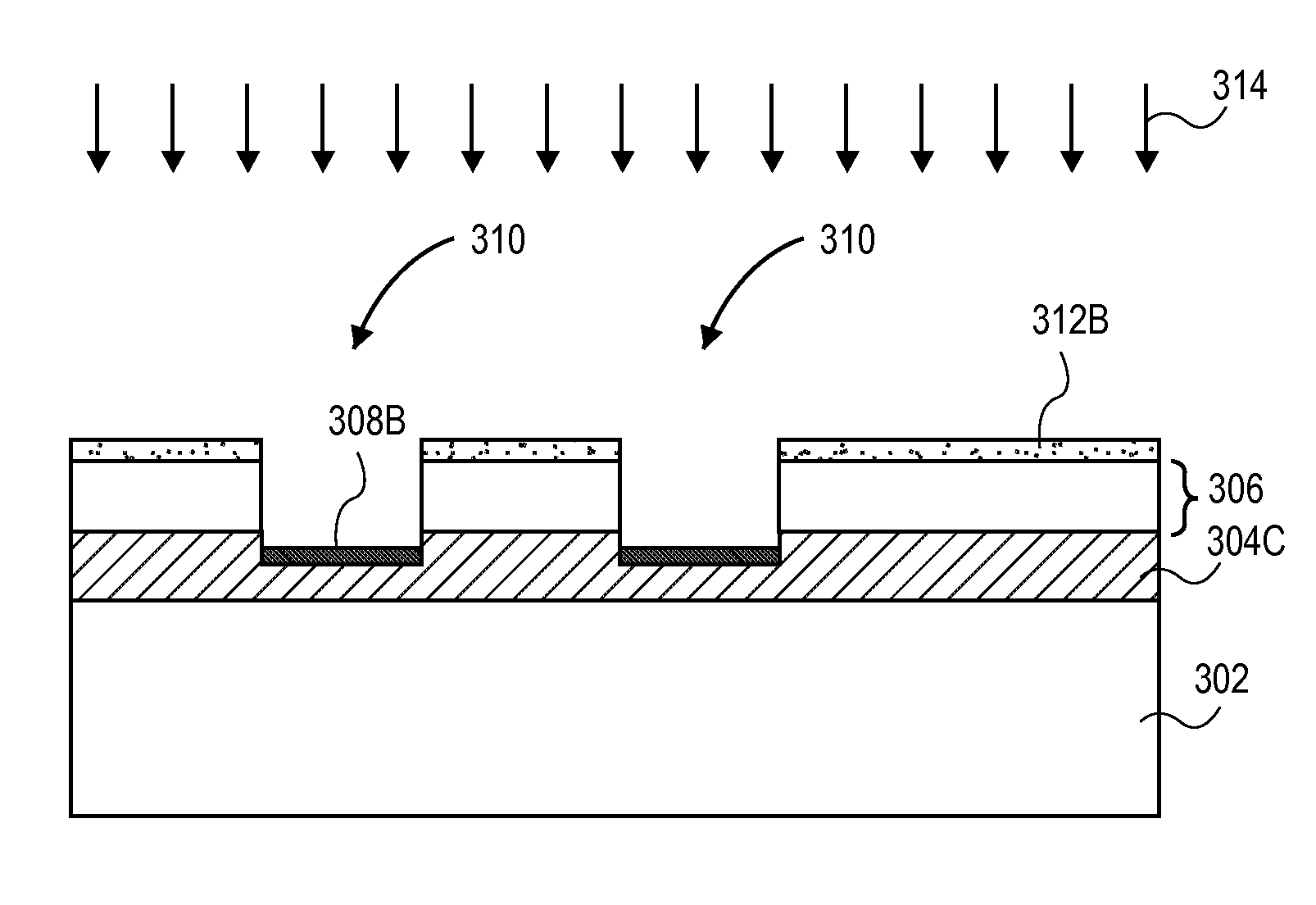

Hydroxyl bond removal and film densification method for oxide films using microwave post treatment

ActiveUS7589028B1High densityImprove film propertiesRadiation applicationsSemiconductor/solid-state device manufacturingDielectricMicrowave

Methods of forming dielectric films with increased density and improved film properties are provided. The methods involve exposing dielectric films to microwave radiation. According to various embodiments, the methods may be used to remove hydroxyl bonds, increase film density, reduce or eliminate seams and voids, and optimize film properties such as dielectric constant, refractive index and stress for particular applications. In certain embodiments, the methods are used to form conformal films deposited by a technique such as PDL. The methods may be used in applications requiring low thermal budgets.

Owner:NOVELLUS SYSTEMS

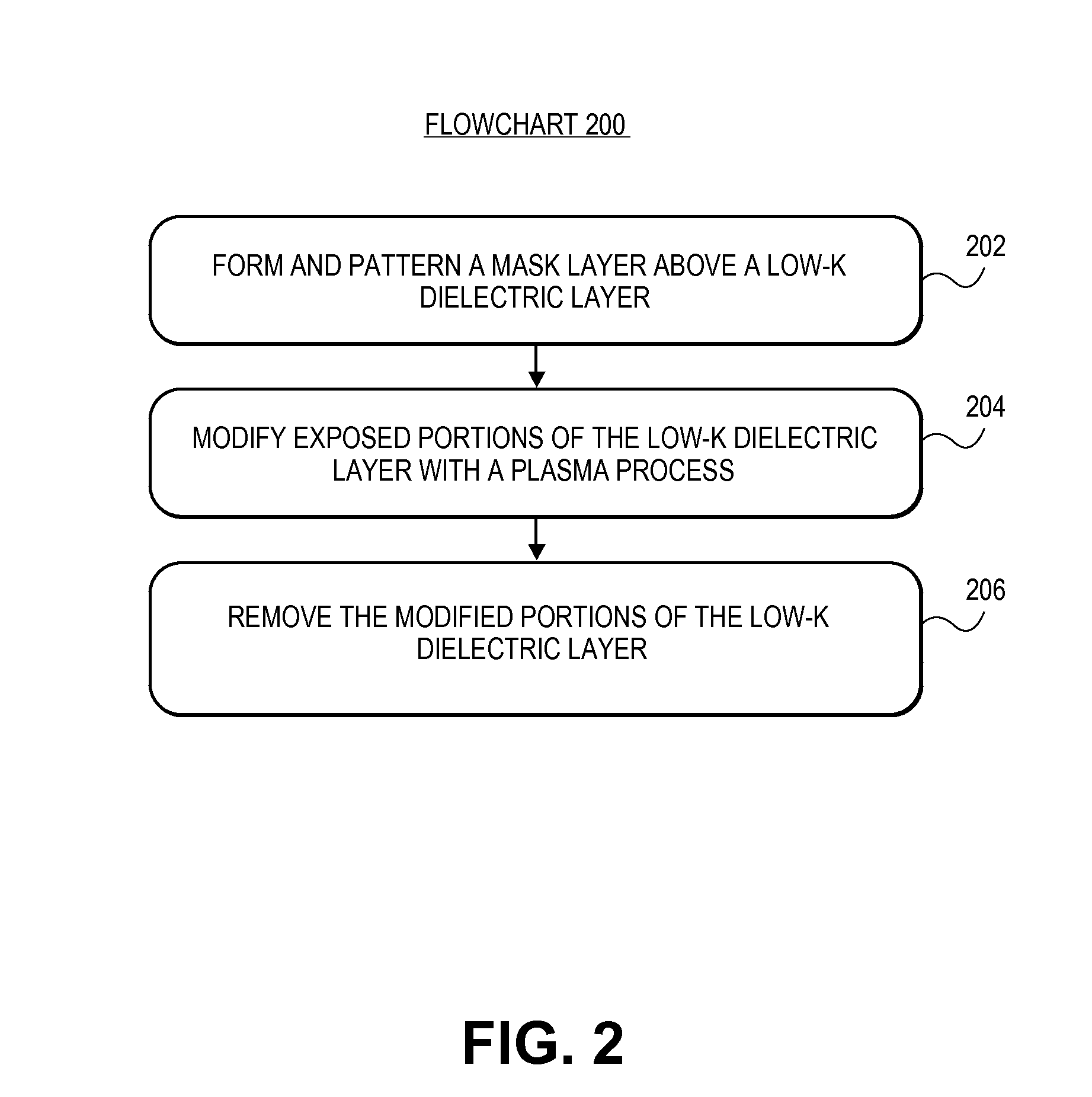

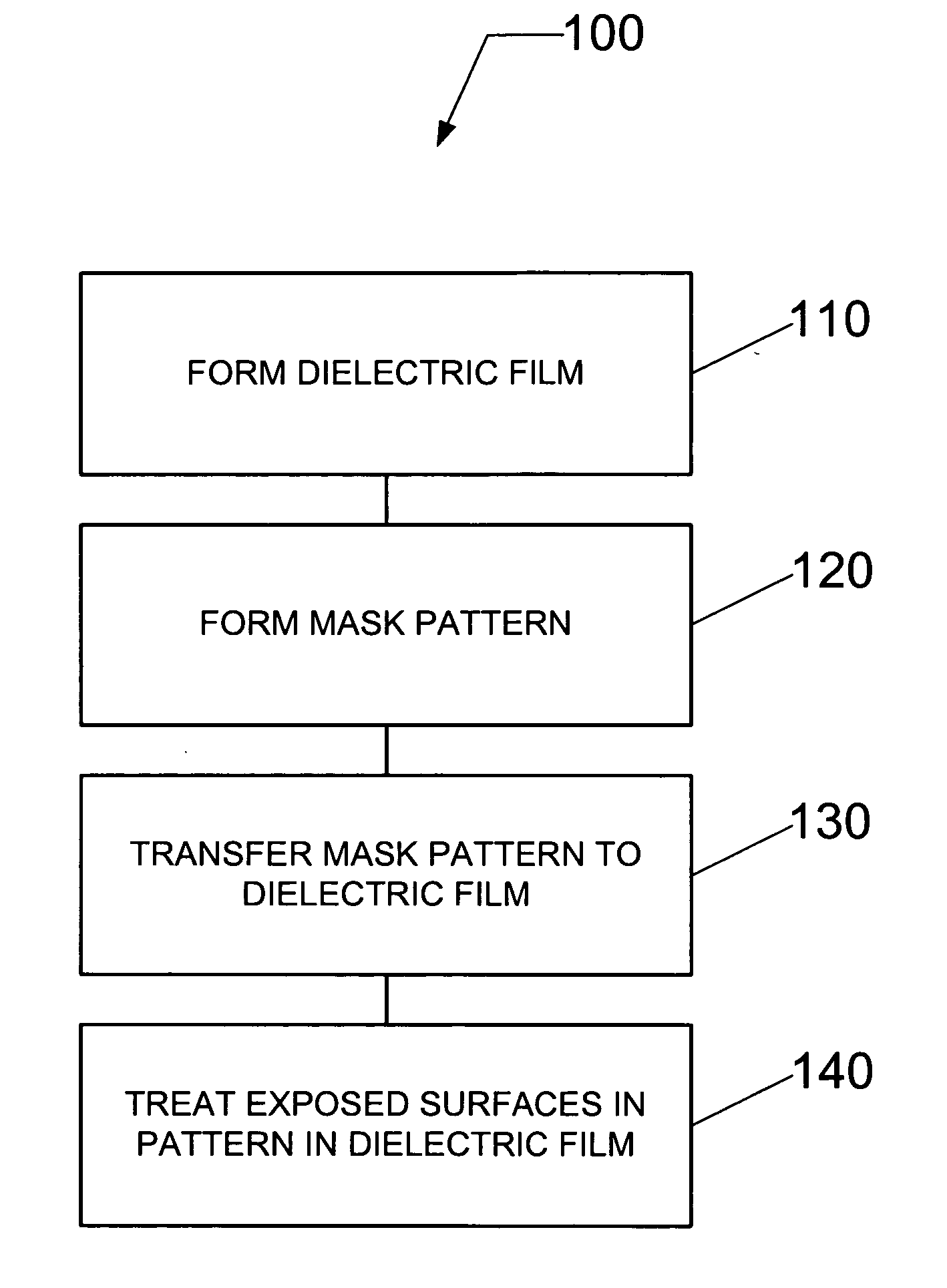

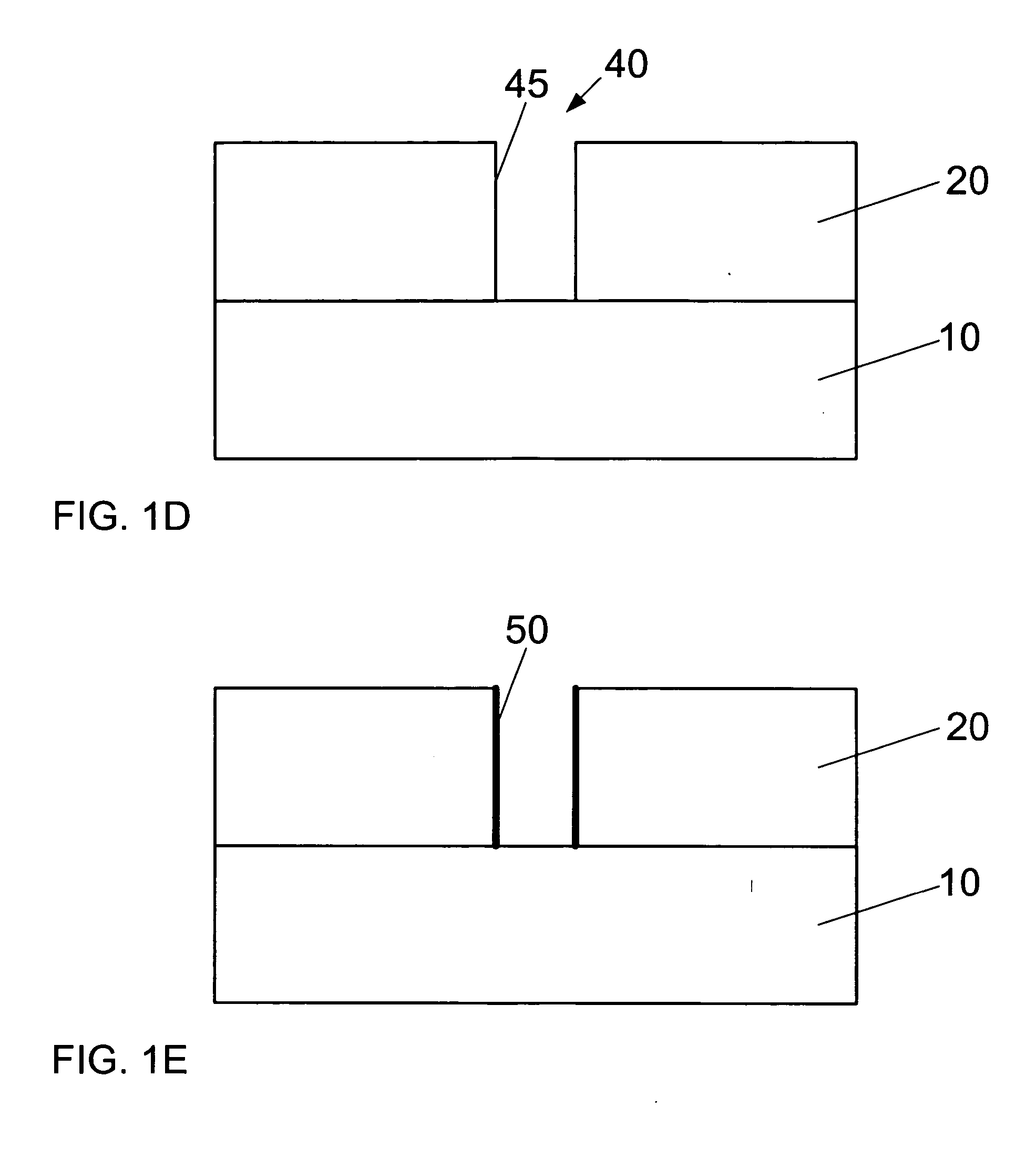

Method of patterning a low-k dielectric film

Methods of patterning low-k dielectric films are described. For example, a method includes forming and patterning a mask layer above a low-k dielectric layer, the low-k dielectric layer disposed above a substrate. Exposed portions of the low-k dielectric layer are modified with a plasma process. The modified portions of the low-k dielectric layer are removed selective to the mask layer and unmodified portions of the low-k dielectric layer.

Owner:APPLIED MATERIALS INC

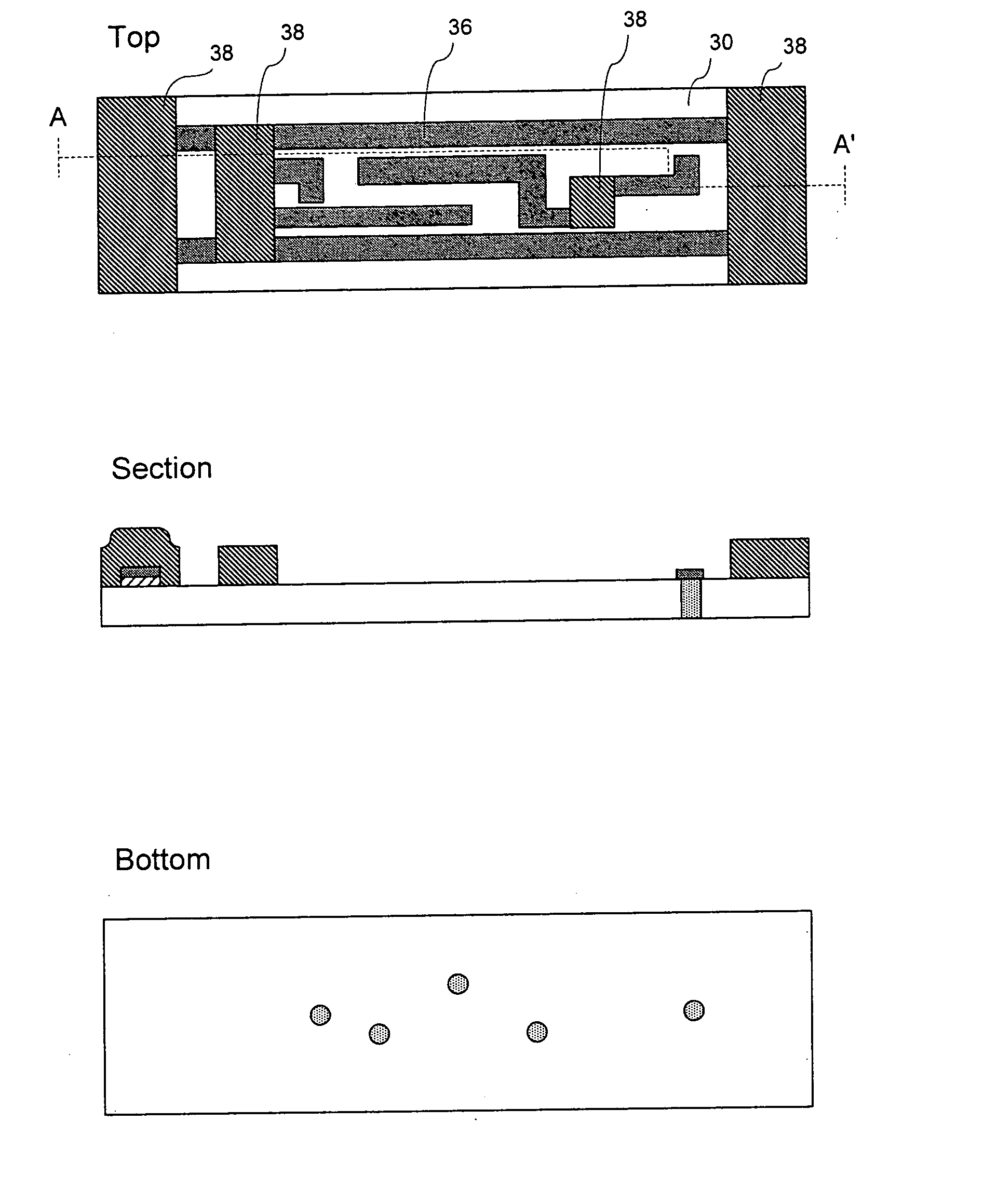

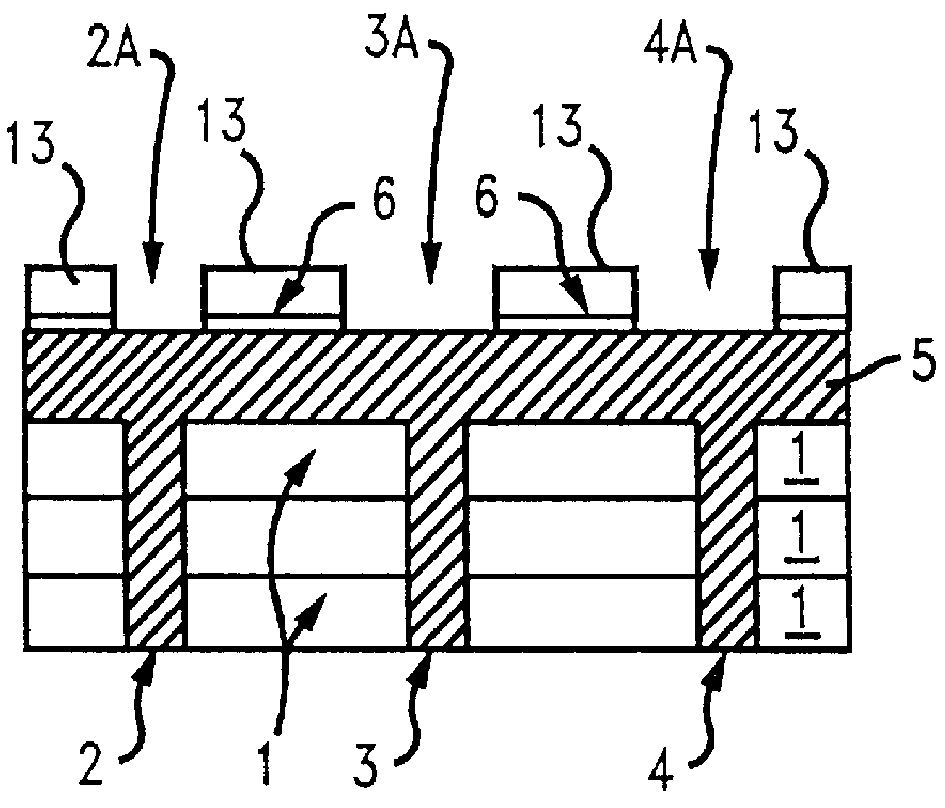

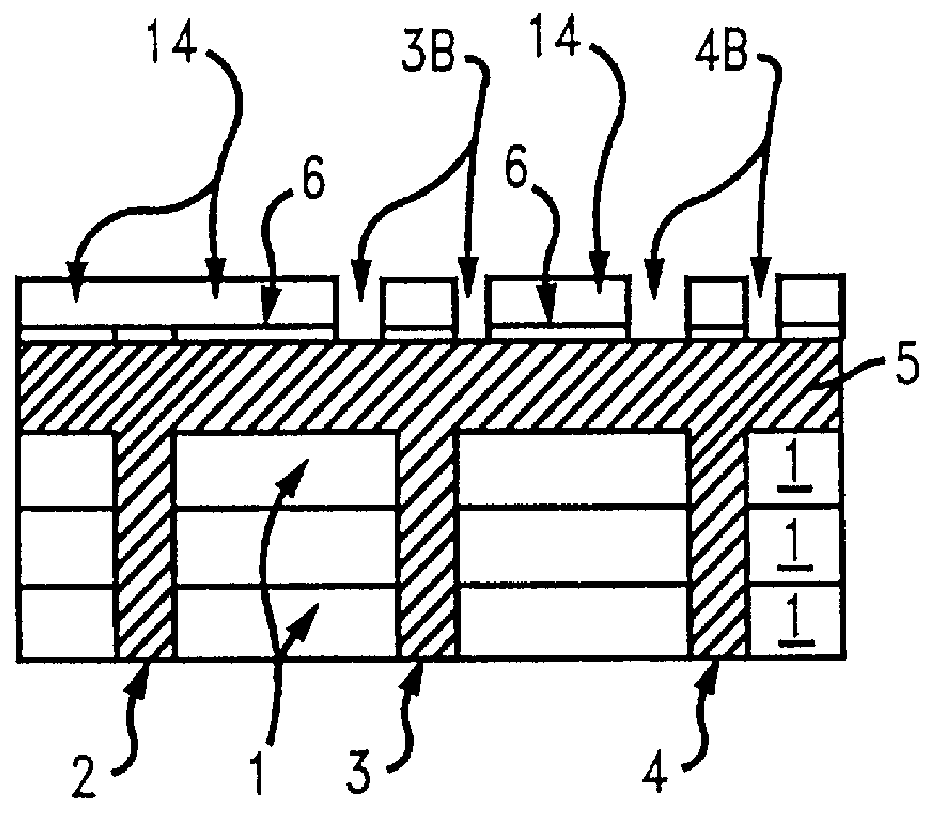

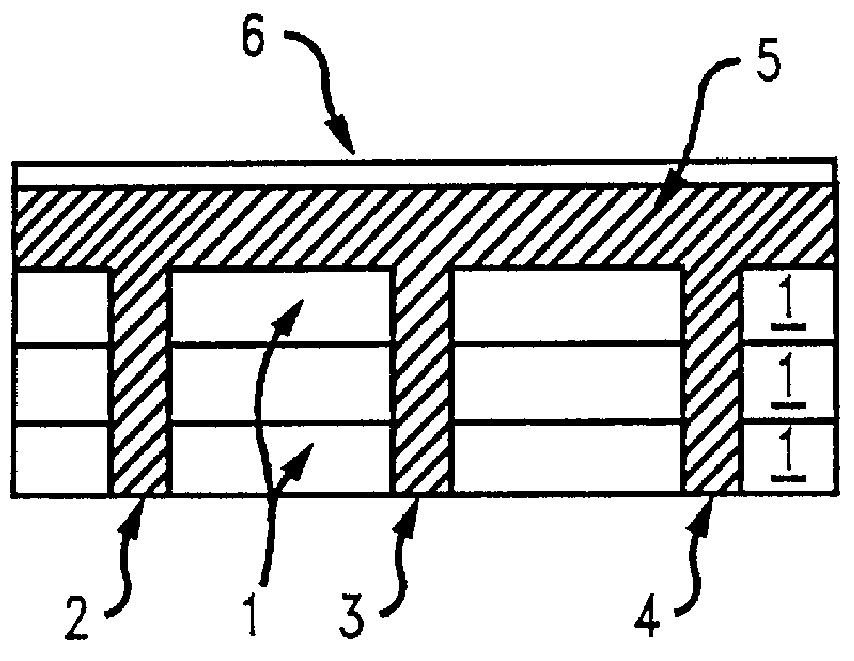

High reliability multlayer circuit substrates and methods for their formation

InactiveUS20040061234A1Semiconductor/solid-state device detailsPrinted circuit aspectsElectrical conductorOptoelectronics

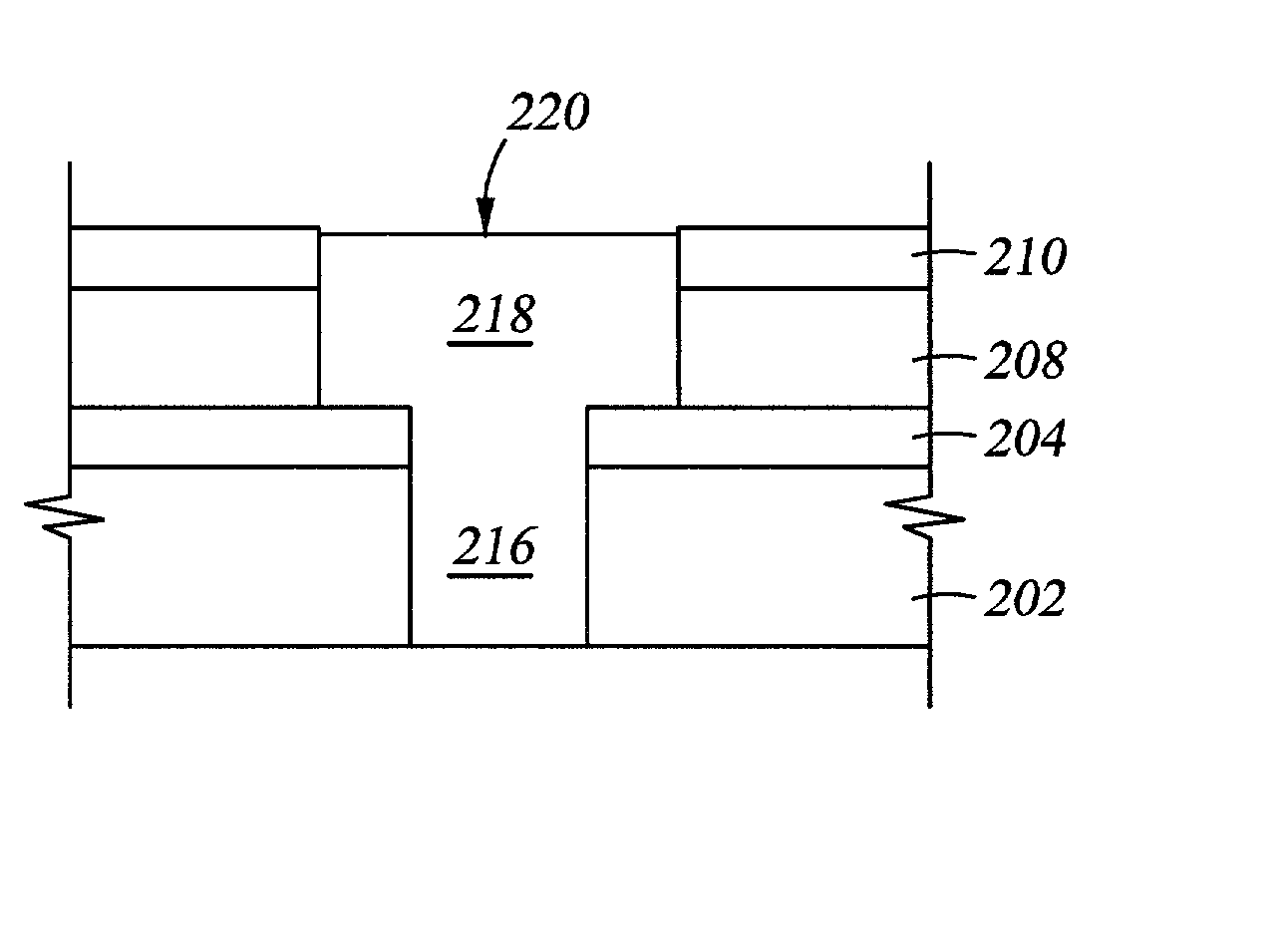

A multilayer circuit substrate for multi-chip modules or hybrid circuits includes a dielectric base substrate, conductors formed on the base substrate and a vacuum deposited dielectric thin film formed over the conductors and the base substrate. The vacuum deposited dielectric thin film is patterned using sacrificial structures formed by shadow mask techniques. Substrates formed in this manner enable significant increases in interconnect density and significant reduction of over-all substrate thickness.

Owner:MEDTRONIC MIMIMED INC

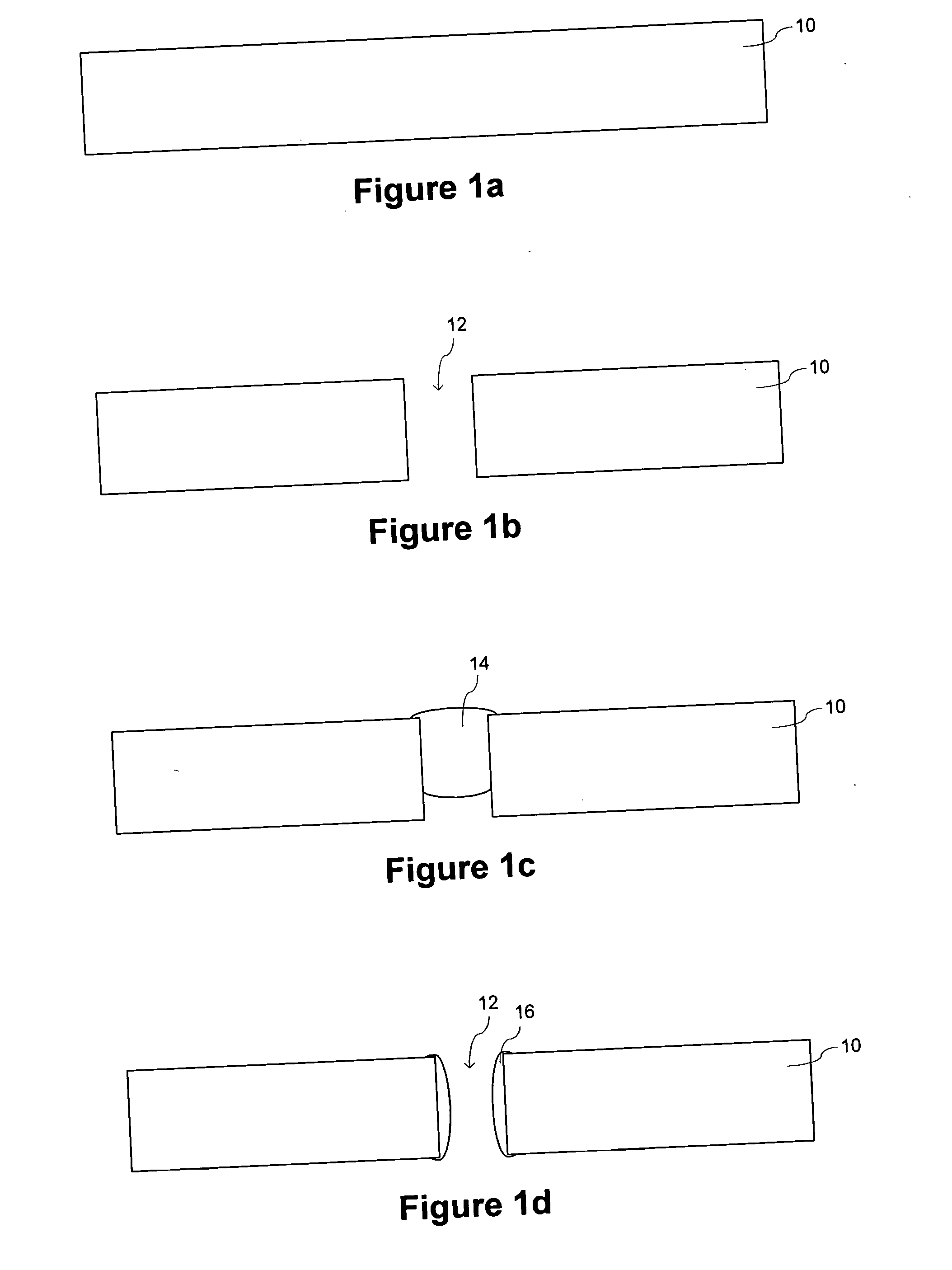

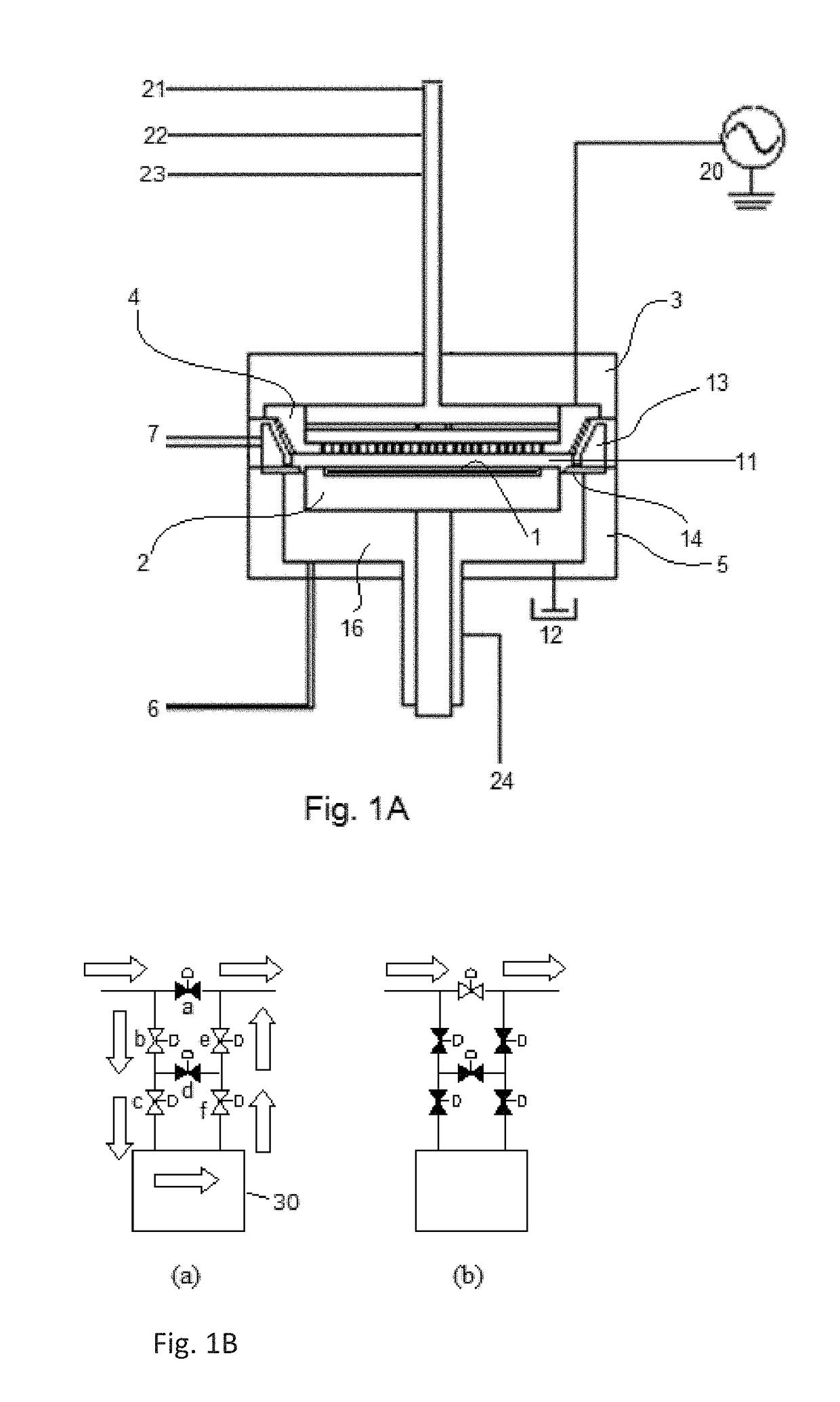

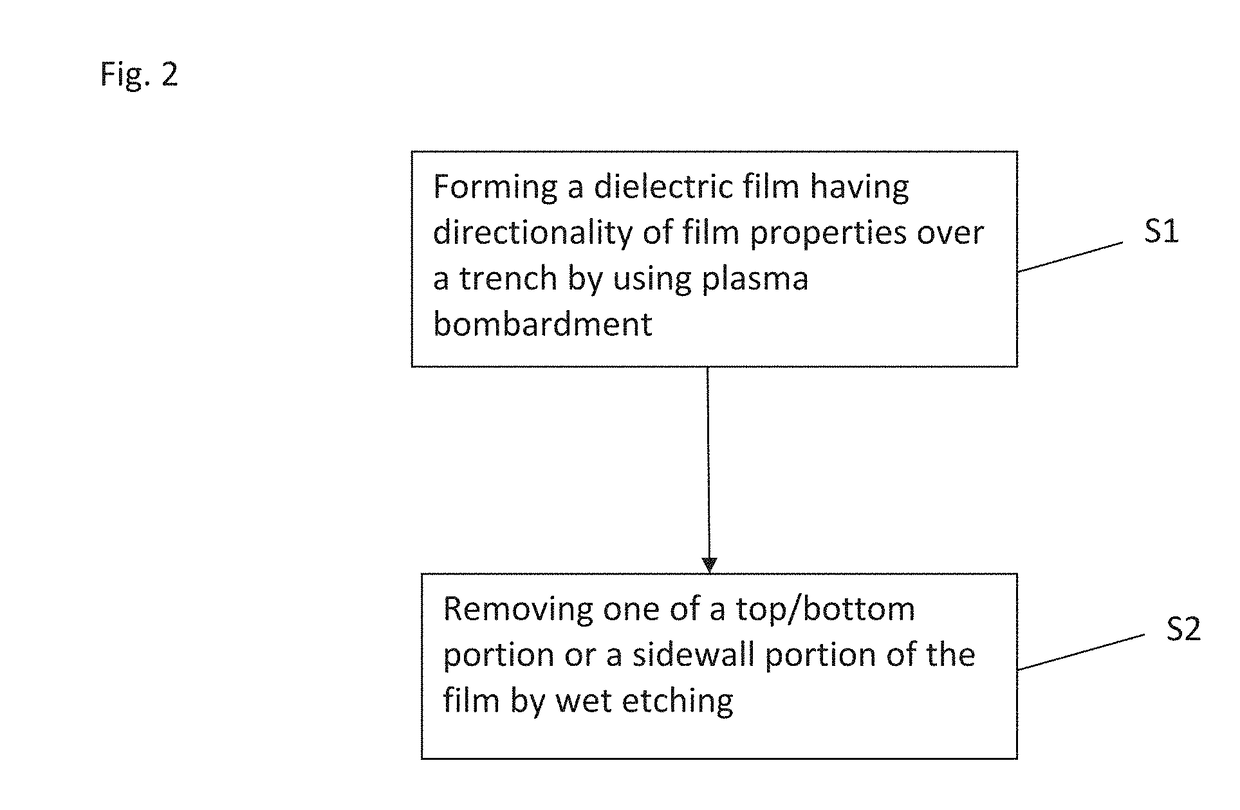

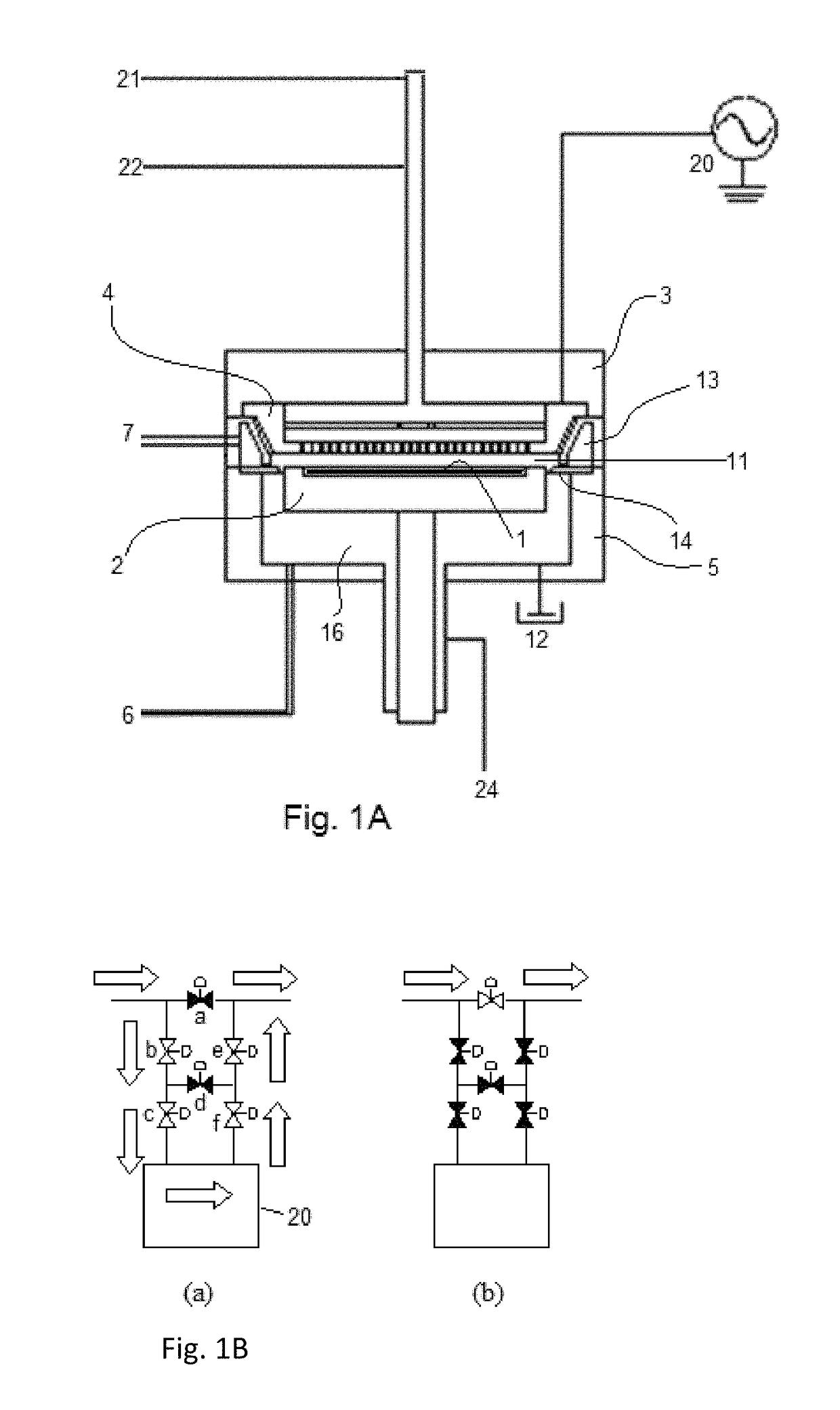

Method for forming silicon nitride film selectively on sidewalls or flat surfaces of trenches

ActiveUS20170250068A1Improve film qualityDecreasing density of filmElectric discharge tubesSemiconductor/solid-state device manufacturingSilicon nitrideEtching

A method for fabricating a layer structure in a trench includes: simultaneously forming a dielectric film containing a Si—N bond on an upper surface, and a bottom surface and sidewalls of the trench, wherein a top / bottom portion of the film formed on the upper surface and the bottom surface and a sidewall portion of the film formed on the sidewalls are given different chemical resistance properties by bombardment of a plasma excited by applying voltage between two electrodes between which the substrate is place in parallel to the two electrodes; and substantially removing either one of but not both of the top / bottom portion and the sidewall portion of the film by wet etching which removes the one of the top / bottom portion and the sidewall portion of the film more predominantly than the other according to the different chemical resistance properties.

Owner:ASM IP HLDG BV

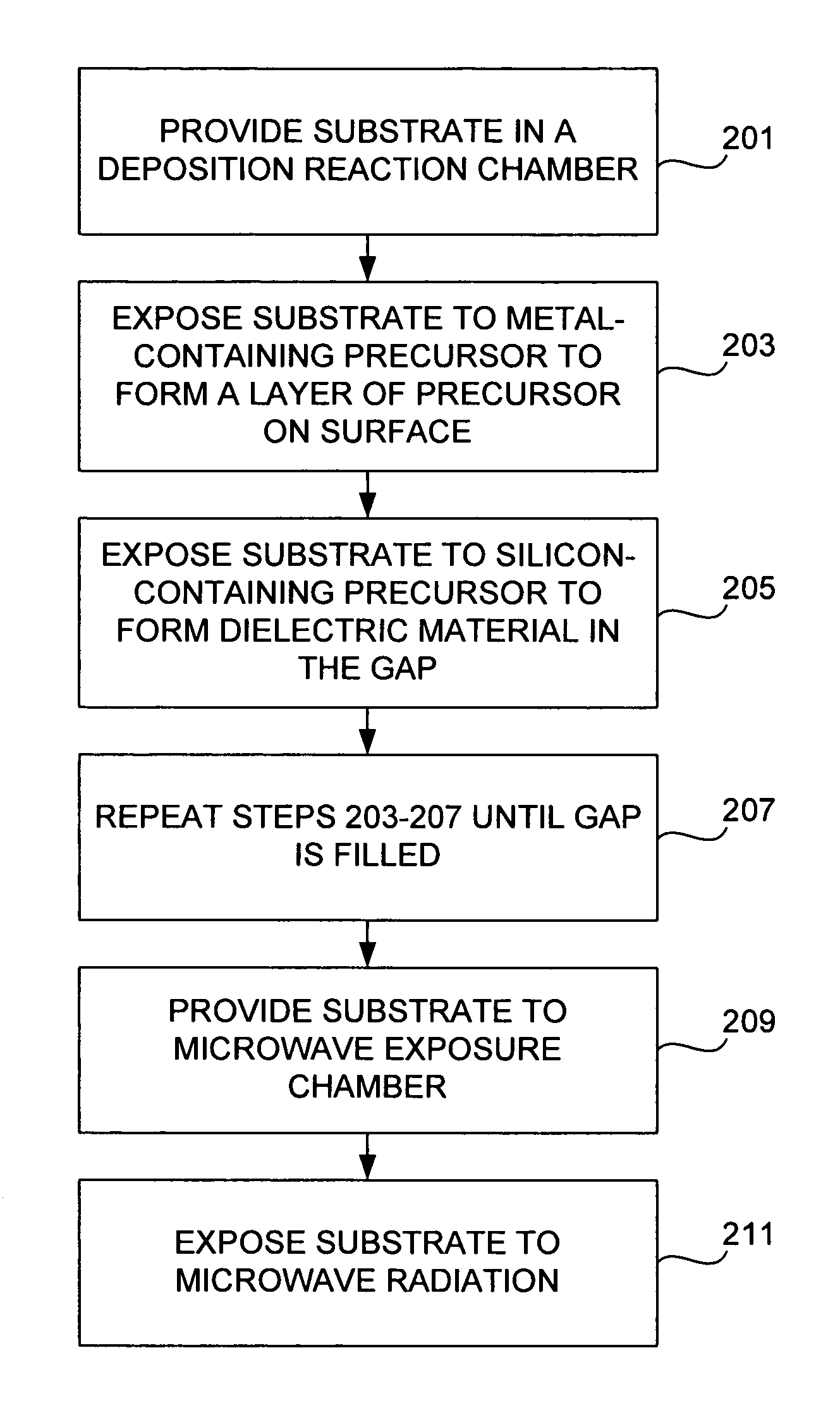

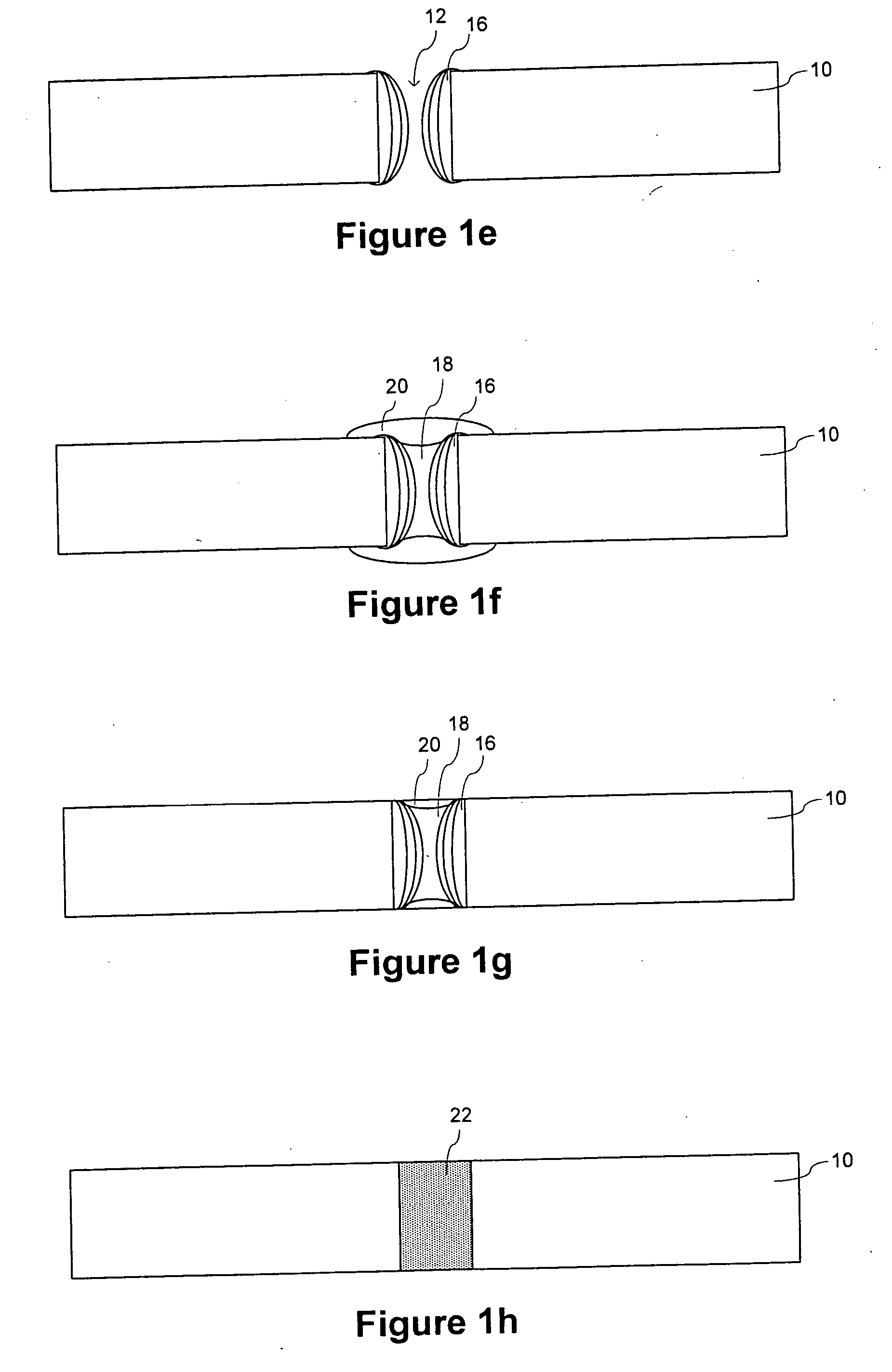

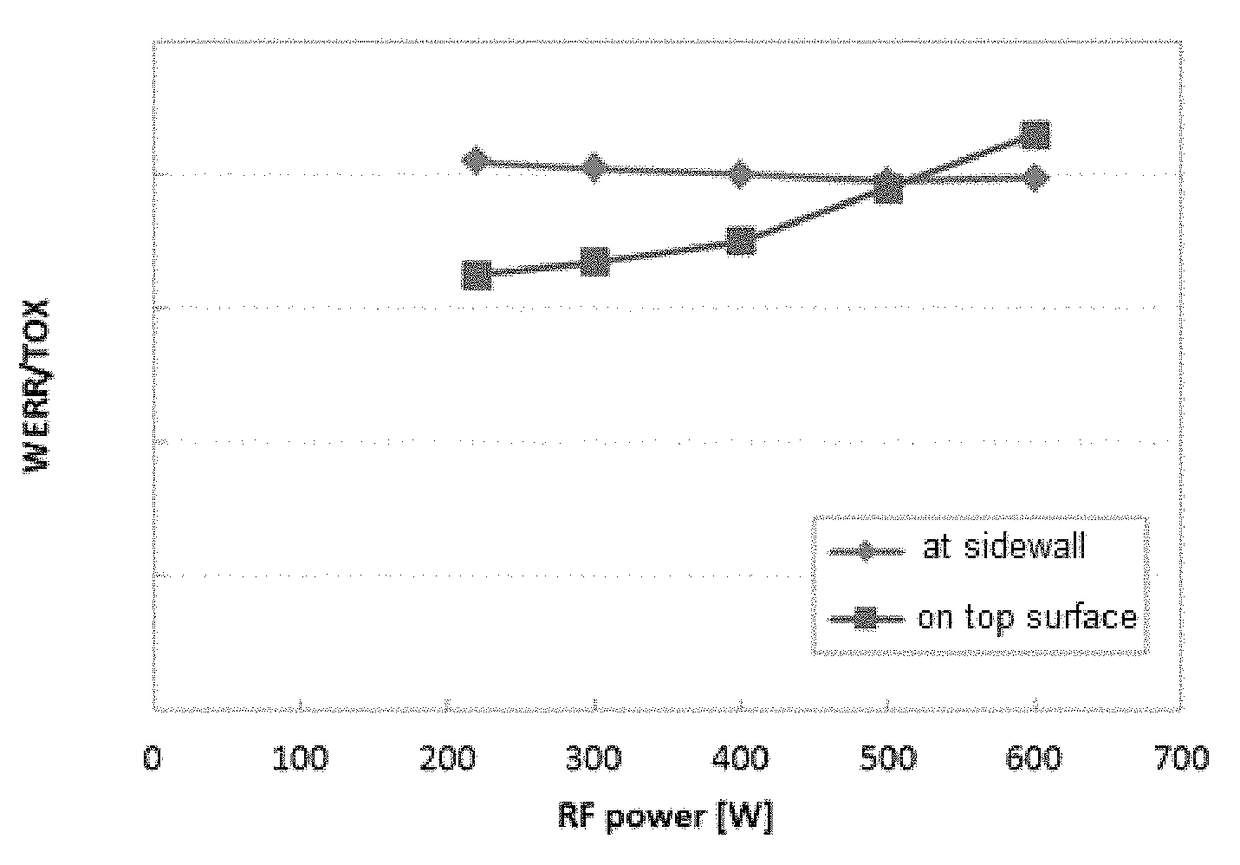

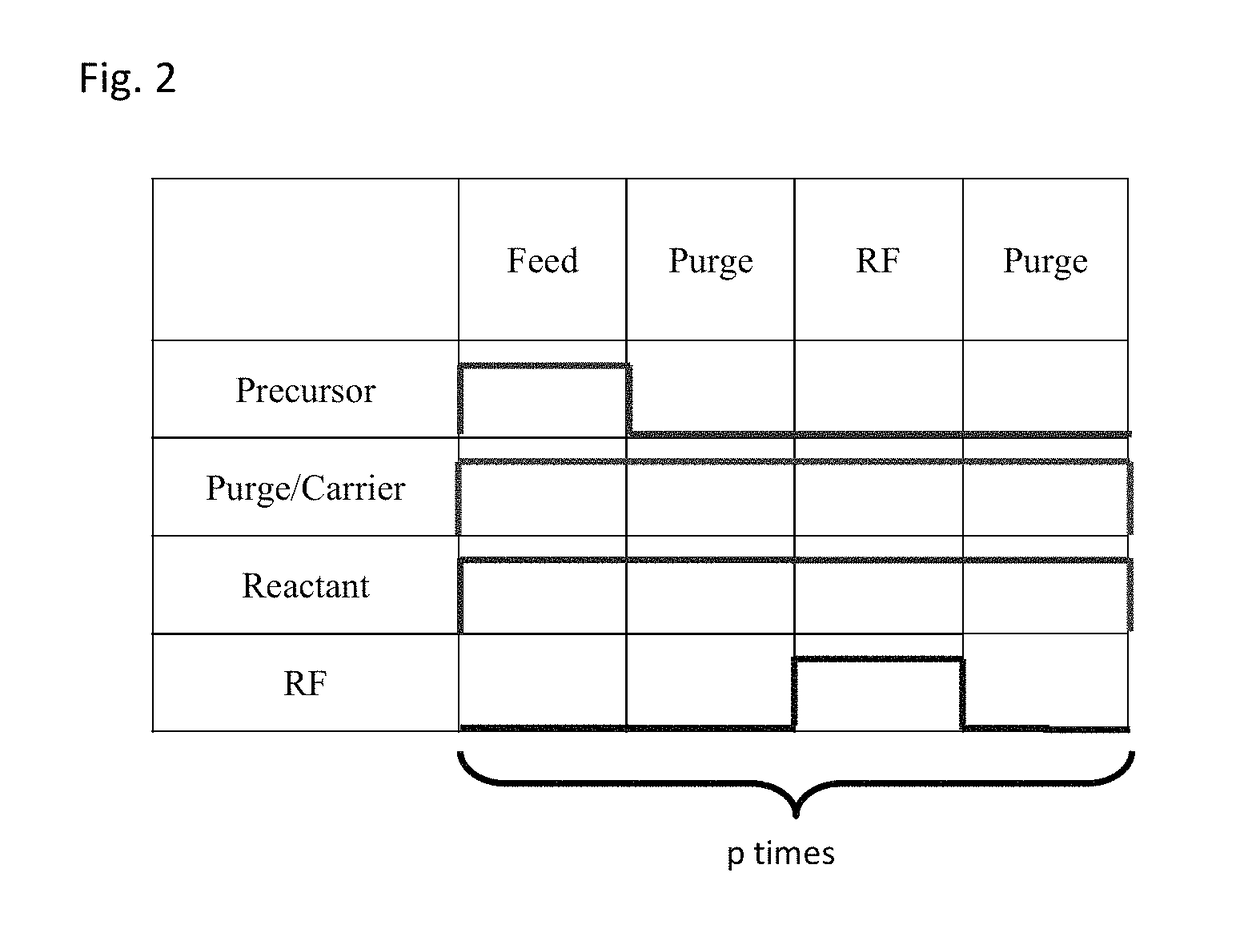

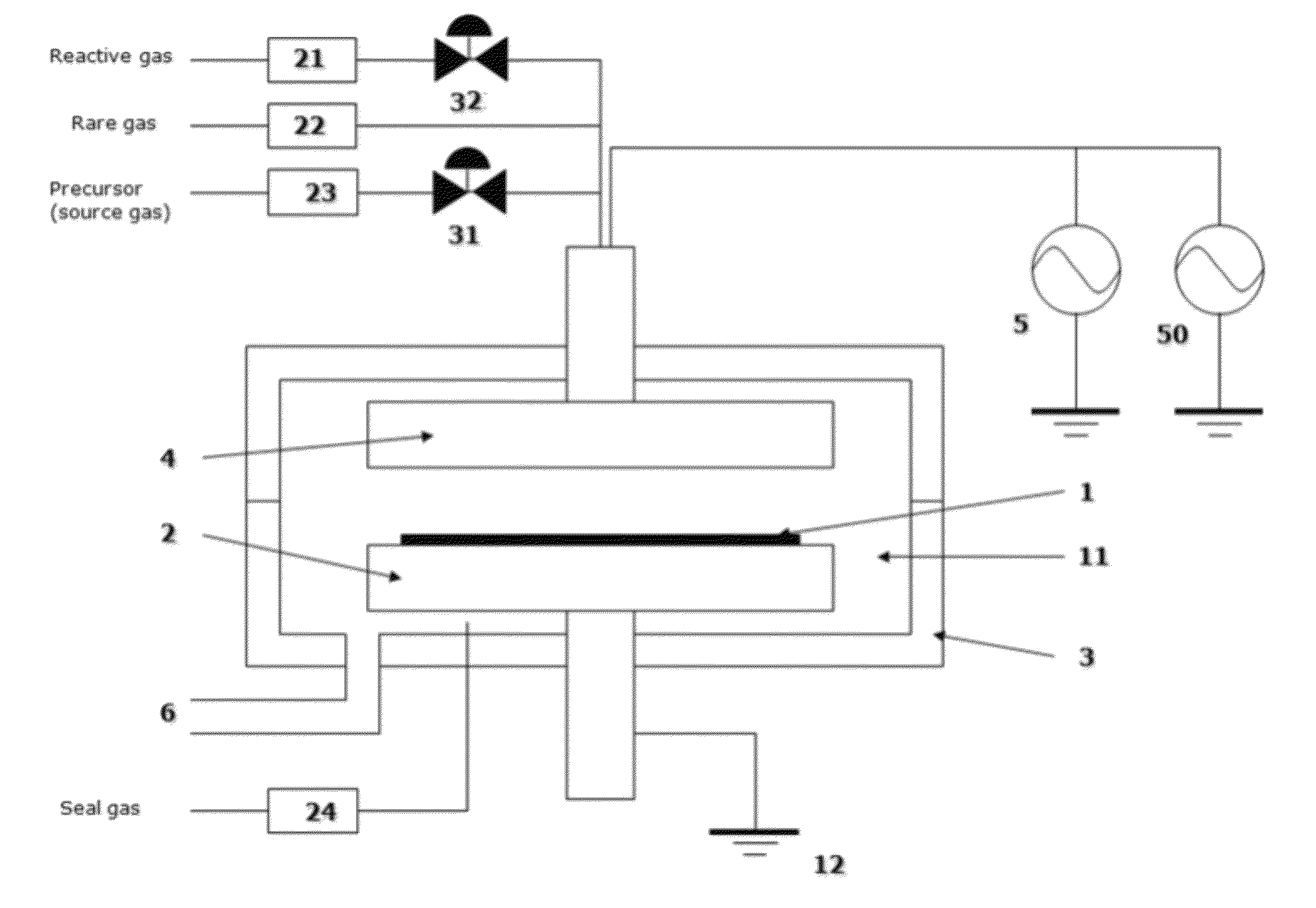

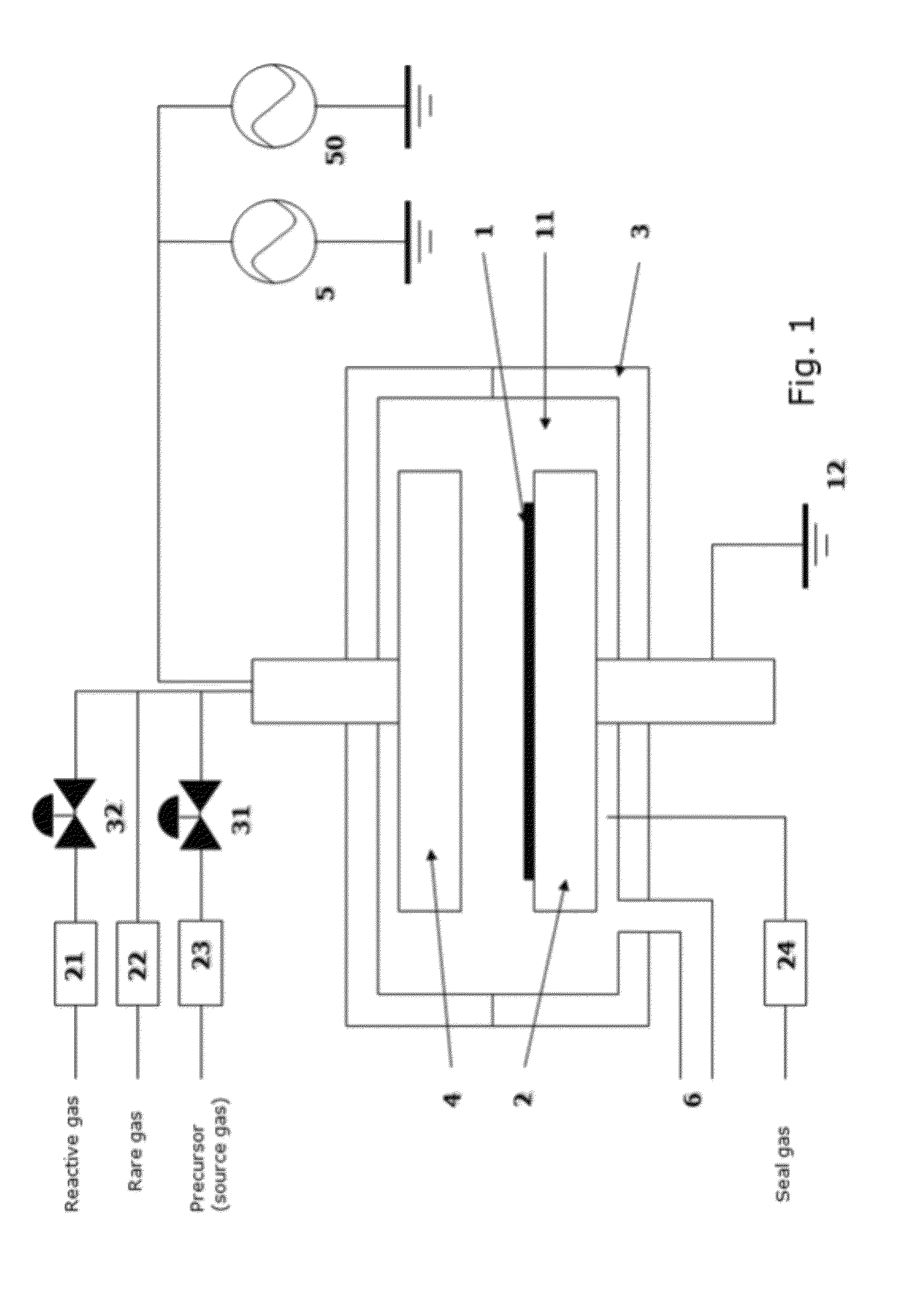

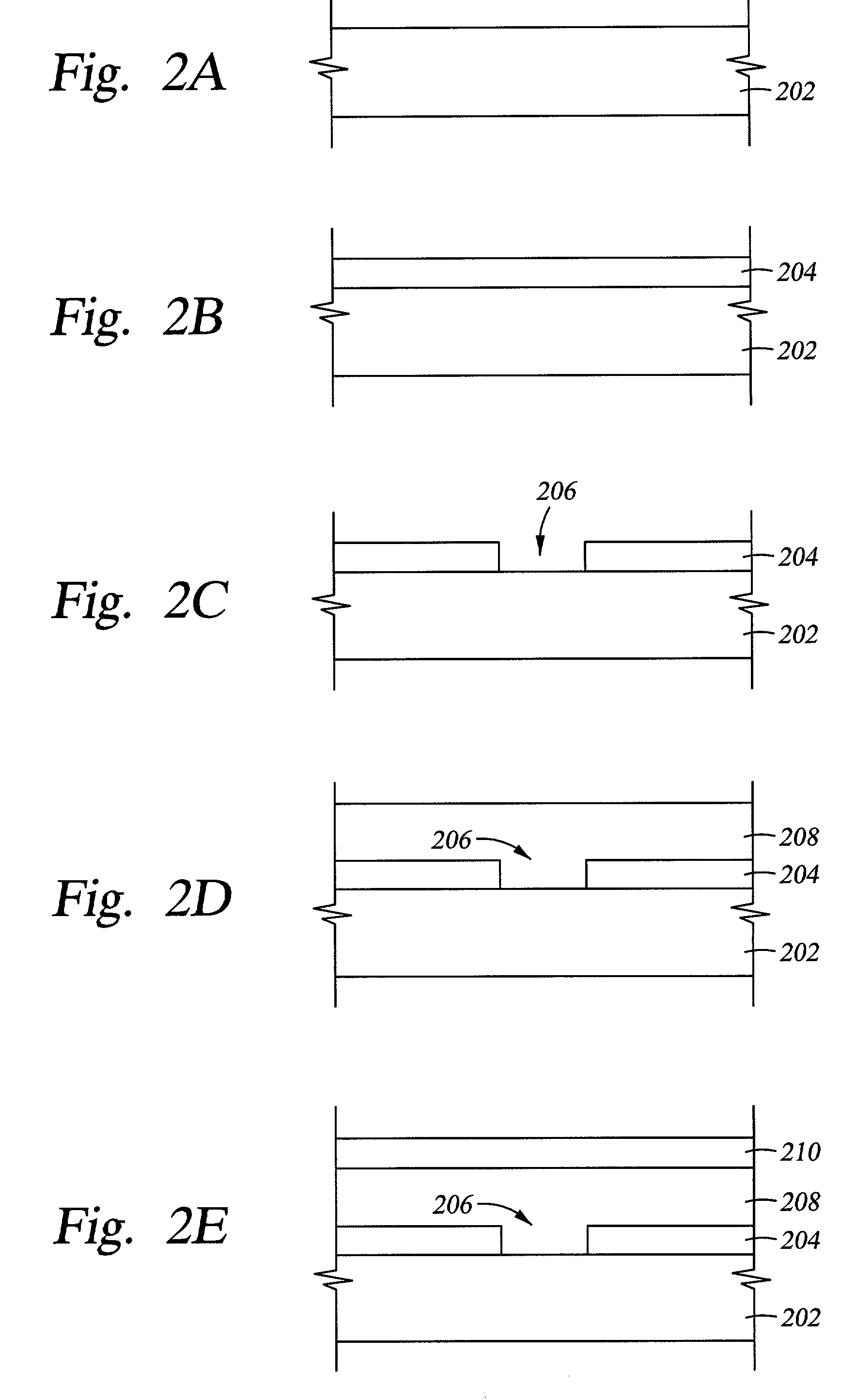

Method for depositing dielectric film in trenches by PEALD

ActiveUS9909214B2Quality improvementReduce the differenceElectric discharge tubesDecorative surface effectsDielectric membraneThin membrane

A method for depositing a dielectric film in a trench by plasma-enhanced atomic layer deposition (PEALD) includes depositing a dielectric film in a trench of a substrate by PEALD under conditions wherein the wet etch rate of the depositing film on a top surface of the substrate is substantially equivalent to or higher than the wet etch rate of the depositing film at a sidewall of the trench, wherein a precursor fed into the reaction space has —N(CH3)2 as a functional group.

Owner:ASM IP HLDG BV

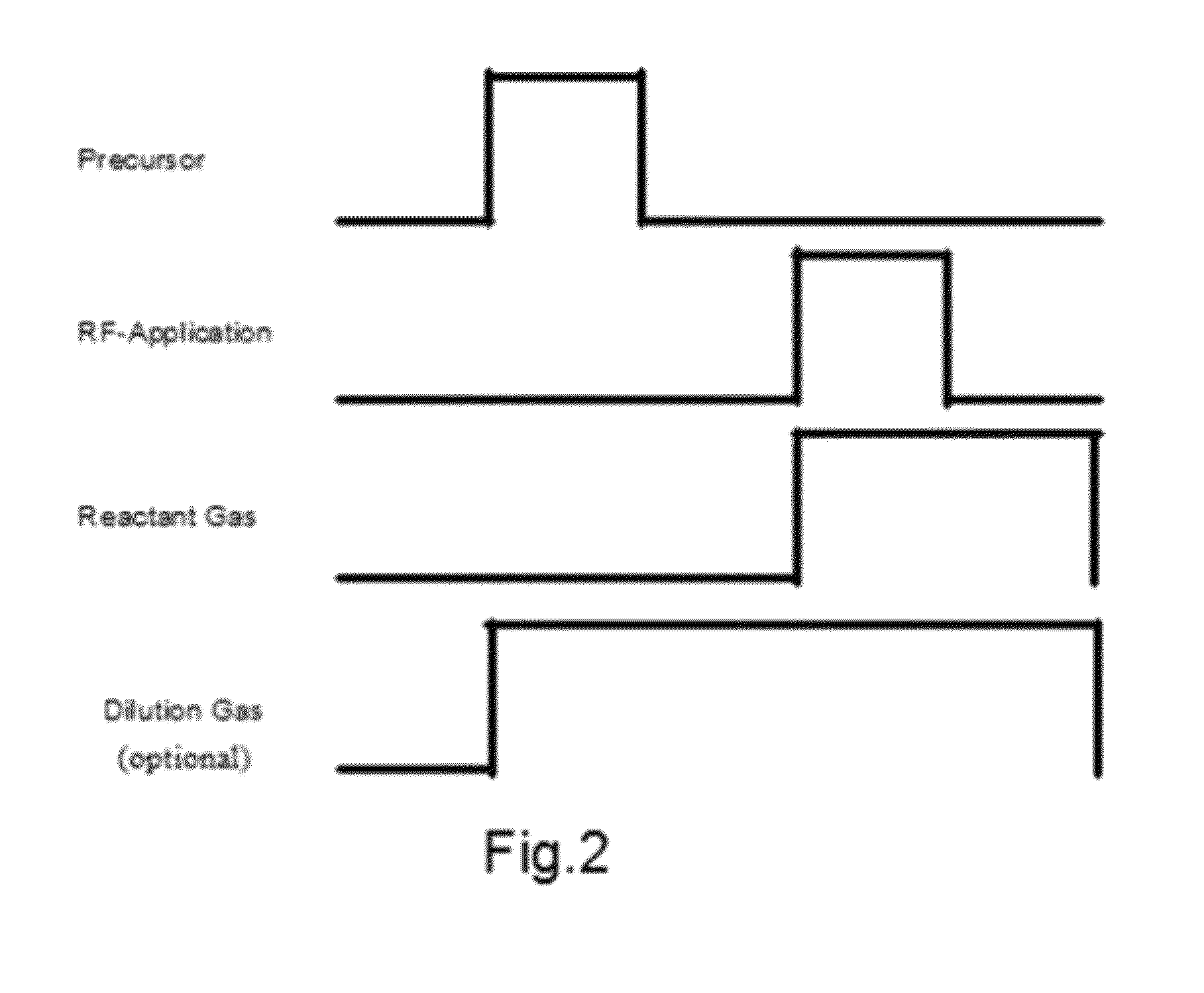

Method of Depositing Dielectric Film by ALD Using Precursor Containing Silicon, Hydrocarbon, and Halogen

ActiveUS20120295449A1Accelerates the carbonization processHigh conformalitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricHalogen

A method of forming a dielectric film having at least Si—N, Si—C, or Si—B bonds on a semiconductor substrate by atomic layer deposition (ALD), includes: supplying a precursor in a pulse to adsorb the precursor on a surface of a substrate; supplying a reactant gas in a pulse over the surface without overlapping the supply of the precursor; reacting the precursor and the reactant gas on the surface; and repeating the above steps to form a dielectric film having at least Si—N, Si—C, or Si—B bonds on the substrate. The precursor has at least one Si—C or Si—N bond, at least one hydrocarbon, and at least two halogens attached to silicon in its molecule.

Owner:ASM JAPAN

Method for depositing a low k dielectric film (k<3.5) for hard mask application

InactiveUS20030113995A1Semiconductor/solid-state device detailsSolid-state devicesOptoelectronicsDielectric thin films

A method for depositing a silicon oxycarbide hard mask on a low k dielectric layer is provided. Substrates containing a silicon oxycarbide hard mask on a low k dielectric layer are also disclosed. The silicon oxycarbide hard mask may be formed by a processing gas comprising a siloxane.

Owner:APPLIED MATERIALS INC

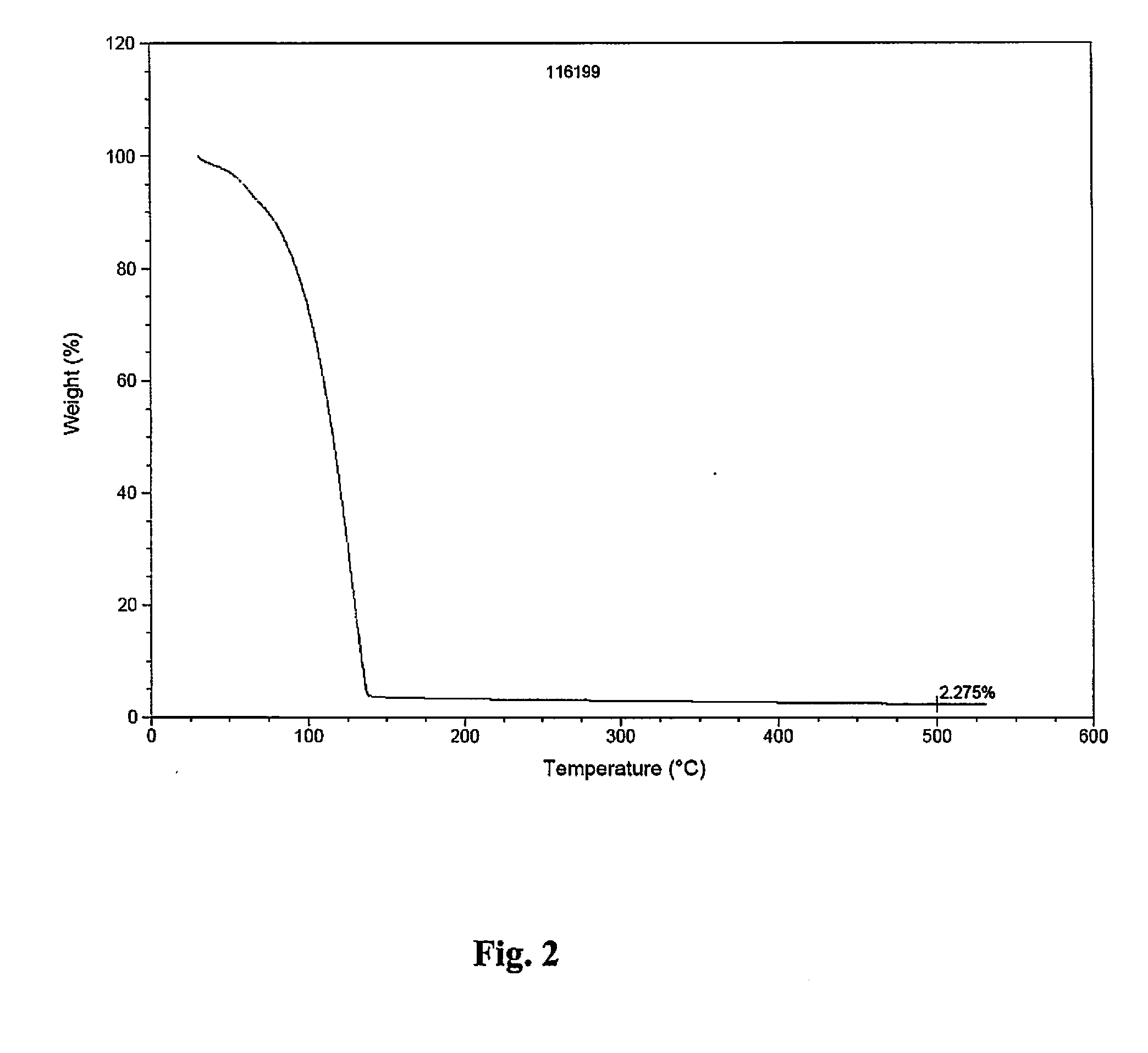

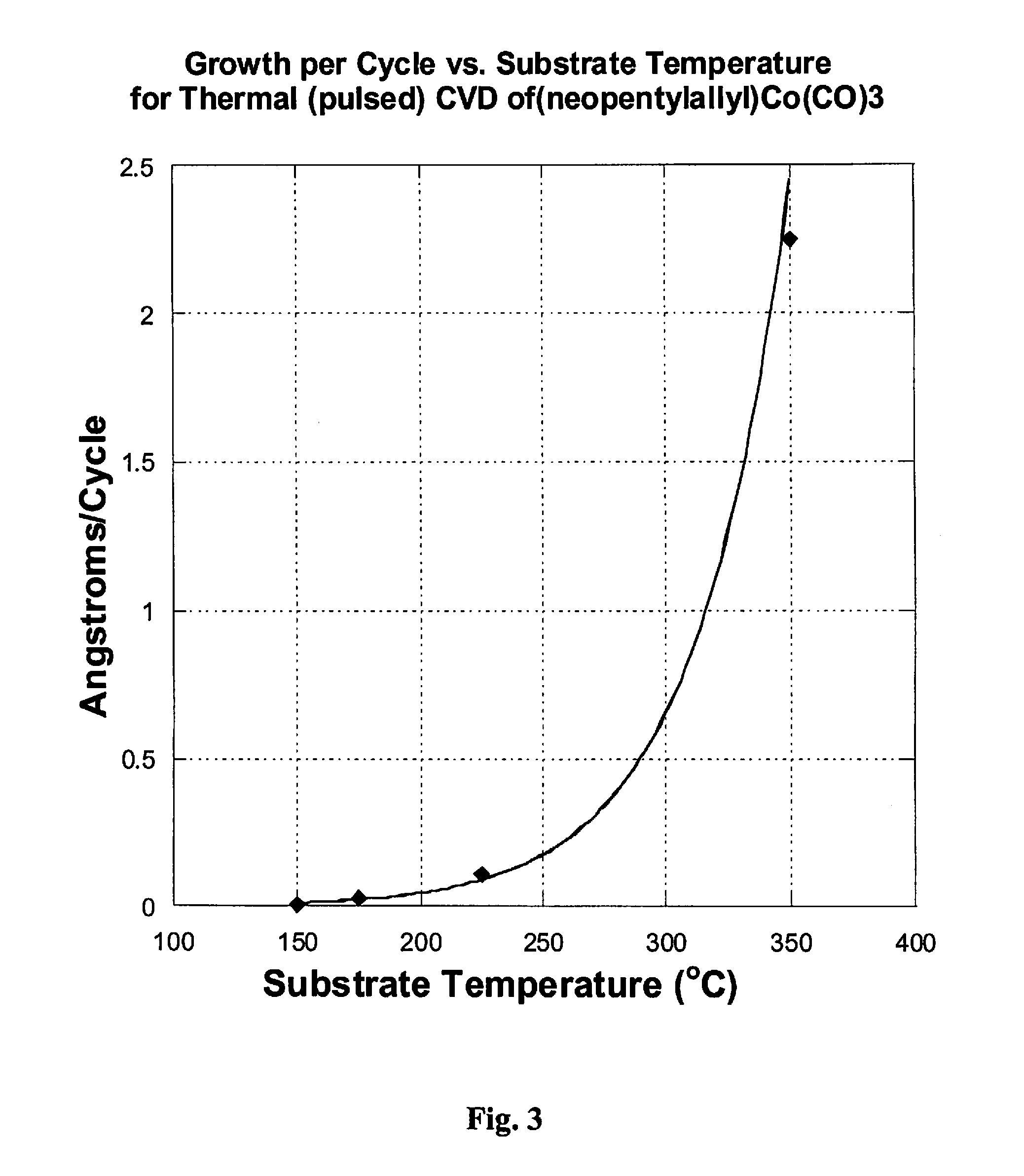

High molecular weight alkyl-allyl cobalttricarbonyl complexes and use thereof for preparing dielectric thin films

ActiveUS20120177845A1Easy to handleCobalt organic compoundsChemical vapor deposition coatingPolymer scienceThin membrane

A method for forming a cobalt-containing thin film by a vapor deposition process is provided. The method comprises using at least one precursor corresponding in structure to Formula (I); wherein R1 and R2 are independently C2-C8-alkyl; x is zero, 1 or 2; and y is zero or 1; wherein both x and y can not be zero simultaneously.

Owner:SIGMA ALDRICH CO LLC

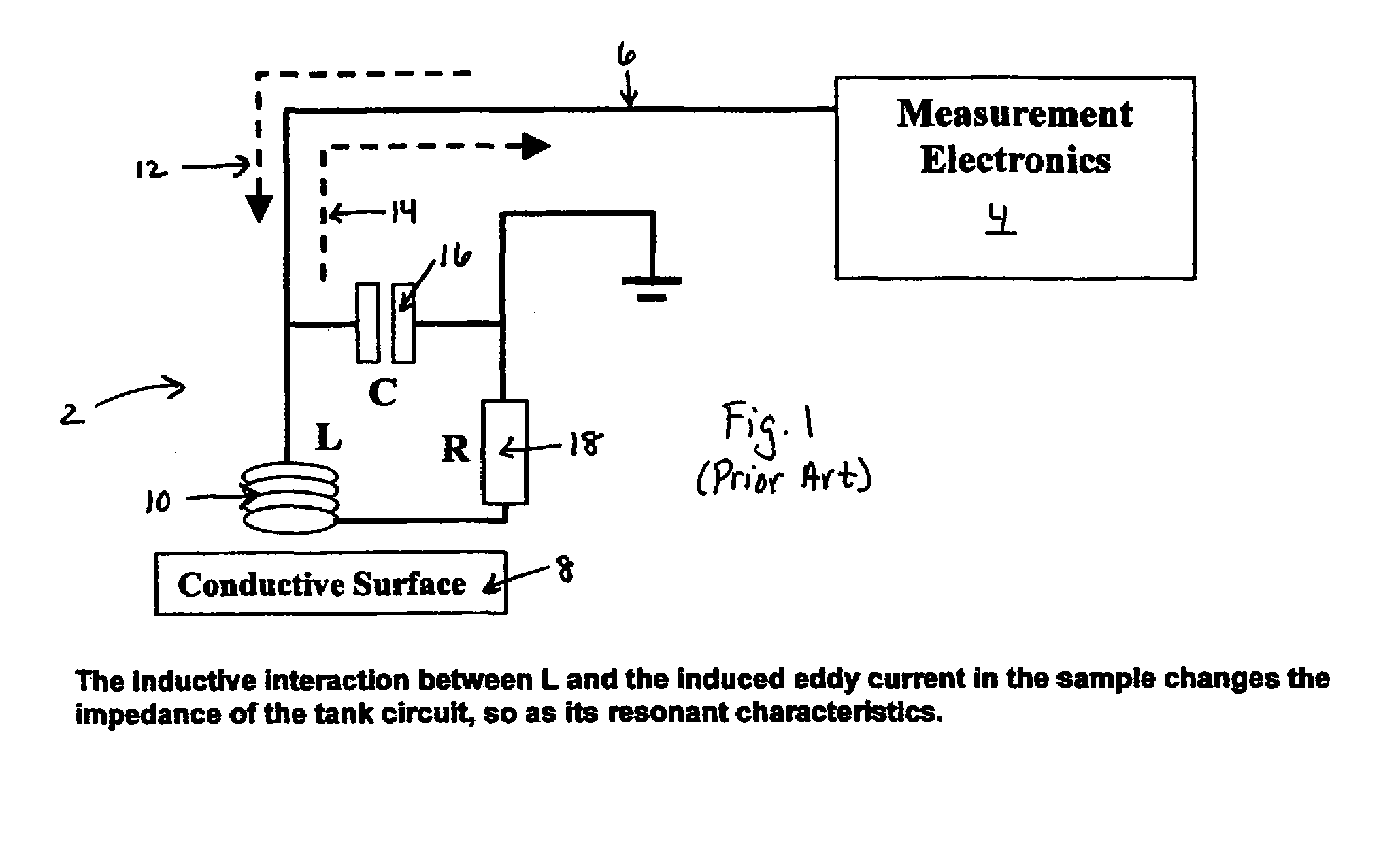

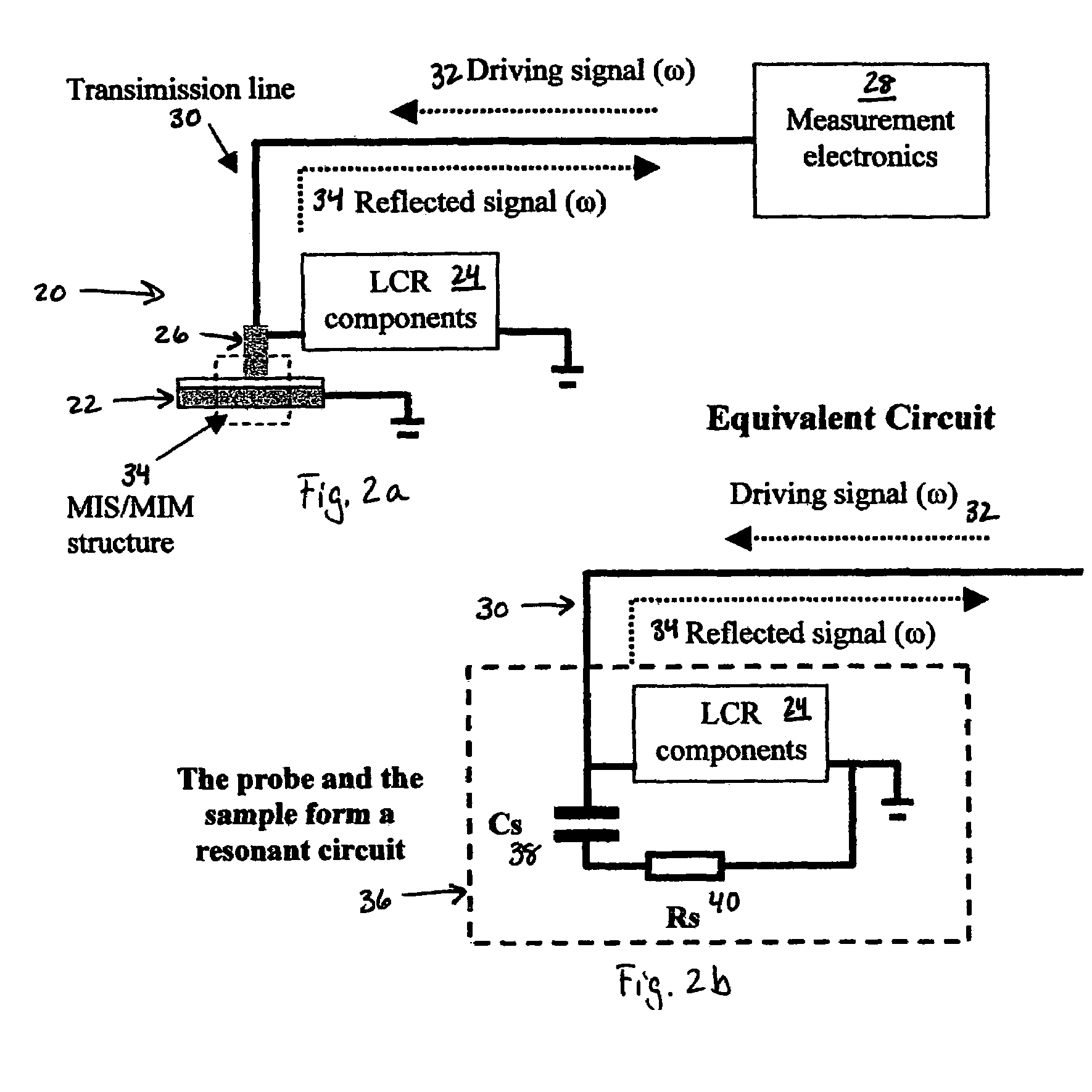

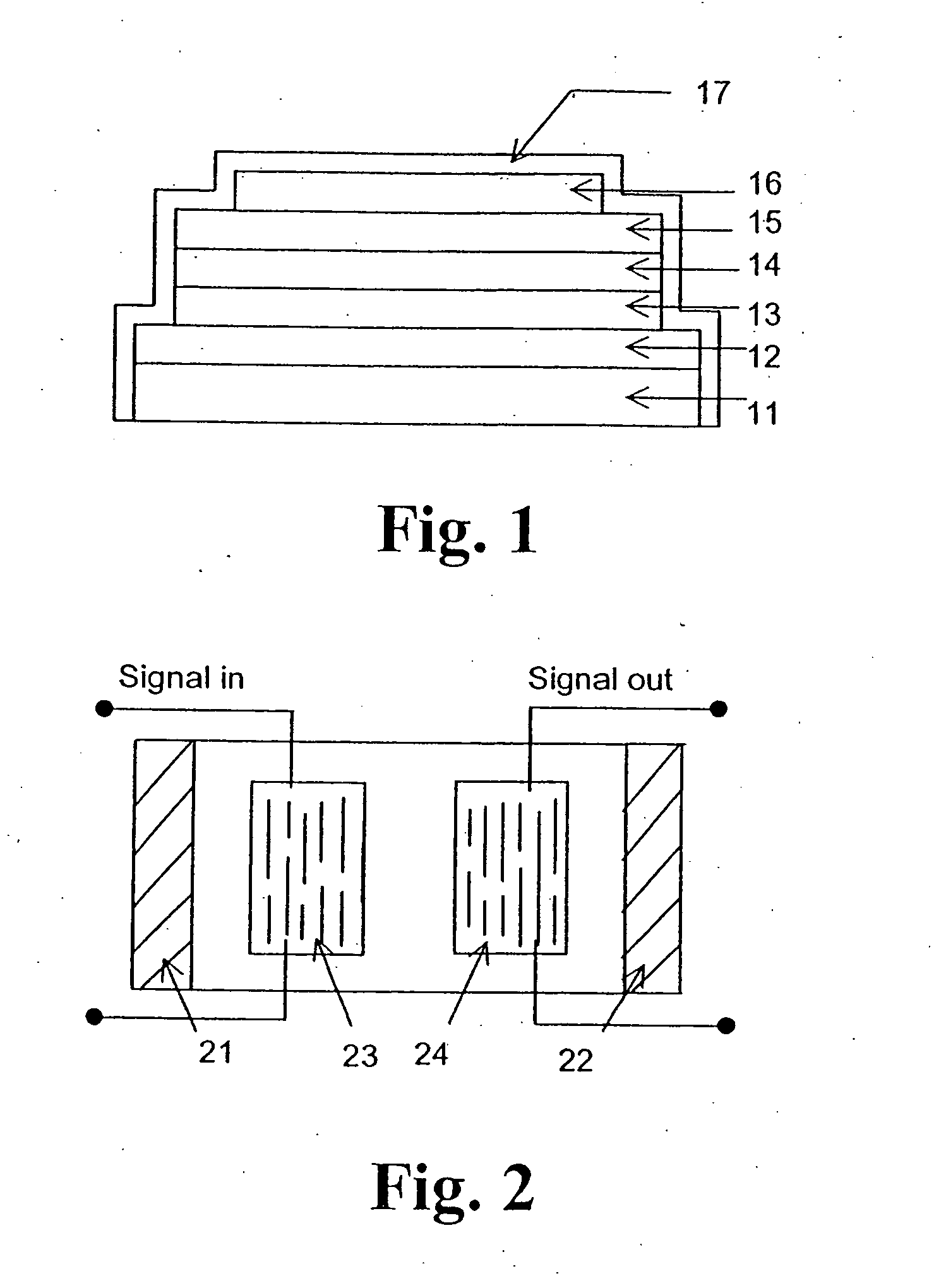

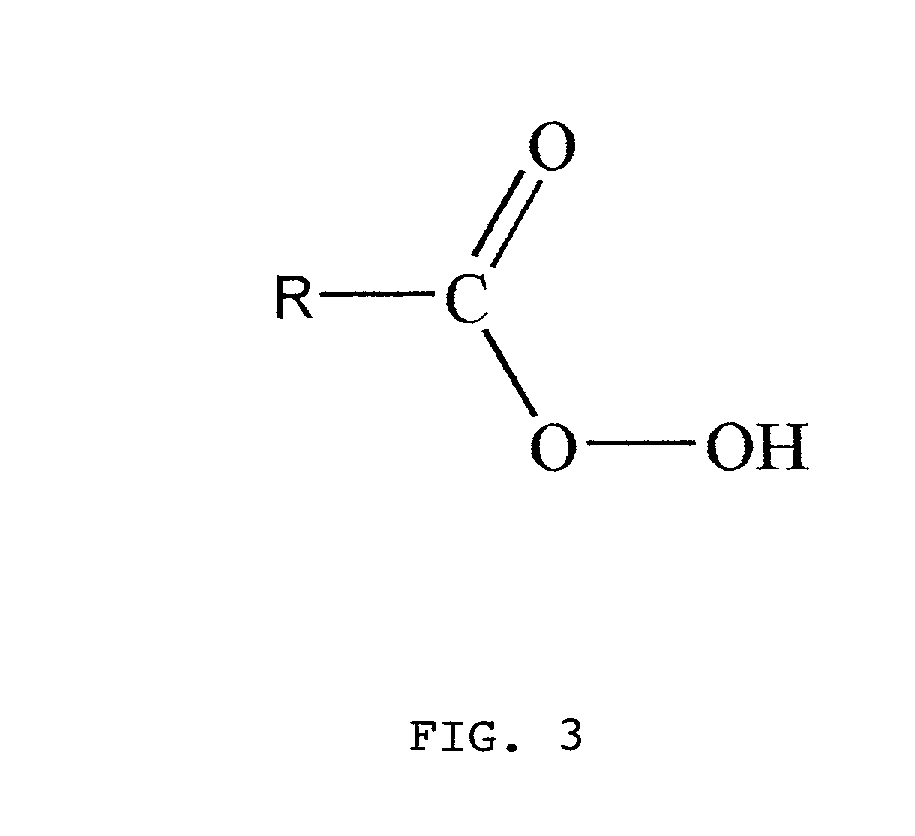

Capacitance probe for thin dielectric film characterization

ActiveUS7001785B1Semiconductor/solid-state device testing/measurementResistance/reactance/impedenceElectrical conductorCapacitive measurement

A capacitance probe for thin dielectric film characterization provides a highly sensitive capacitance measurement method and reduces the contact area needed to obtain such a measurement. Preferably, the capacitance probe is connected to a measurement system by a transmission line and comprises a center conductive tip and RLC components between the center conductor and the ground of the transmission line. When the probe tip is in contact with a sample, an MIS or MIM structure is formed, with the RLC components and the capacitance of the MIS or MIM structure forming a resonant circuit. By sending a driving signal to the probe and measuring the reflected signal from the probe through the transmission line, the resonant characteristic of the resonant circuit can be obtained. The capacitance of the MIS or MIM structure is obtainable from the resonant characteristics and the dielectric film thickness or other dielectric properties are also extractable.

Owner:VEECO METROLOGY

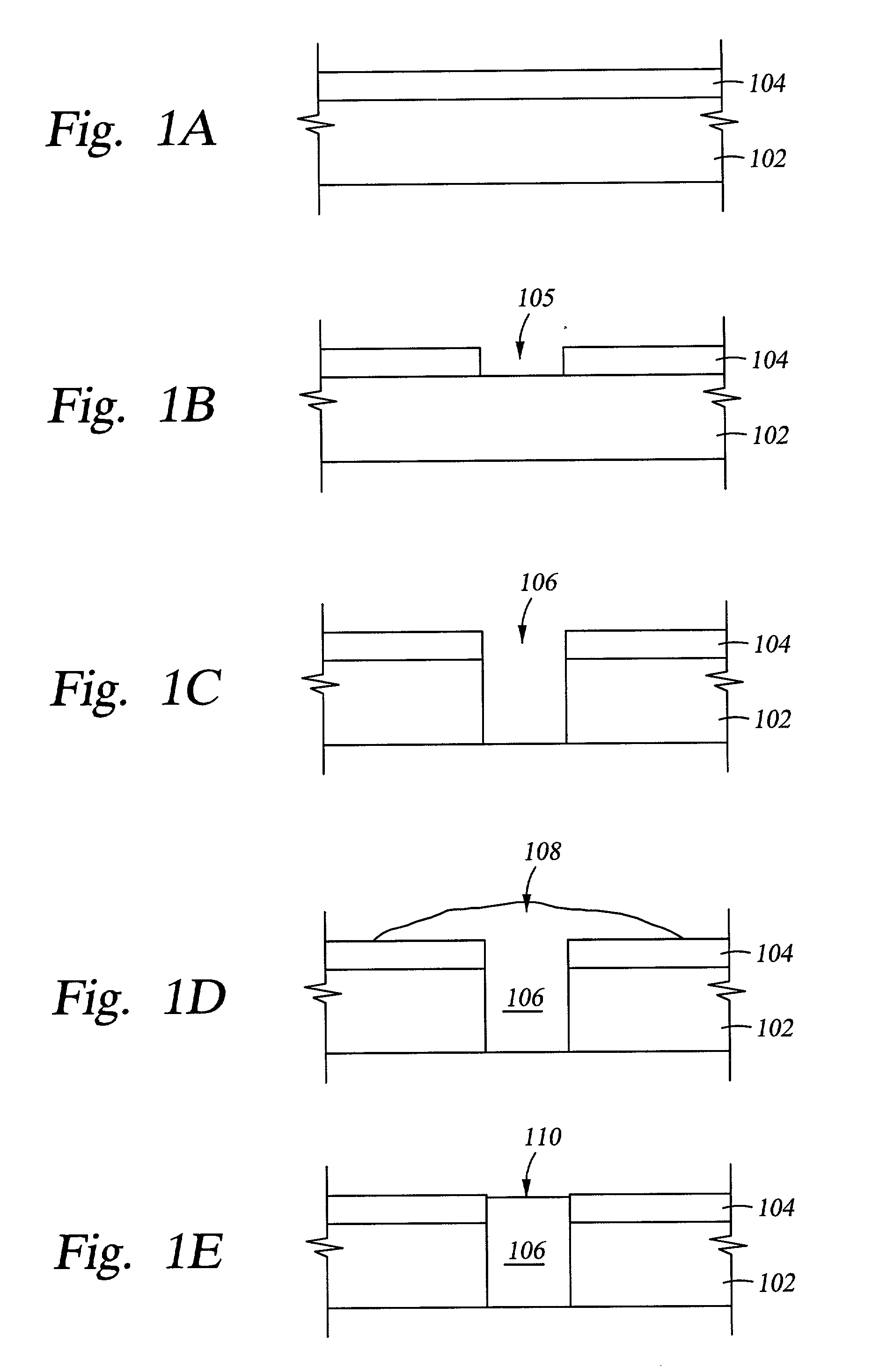

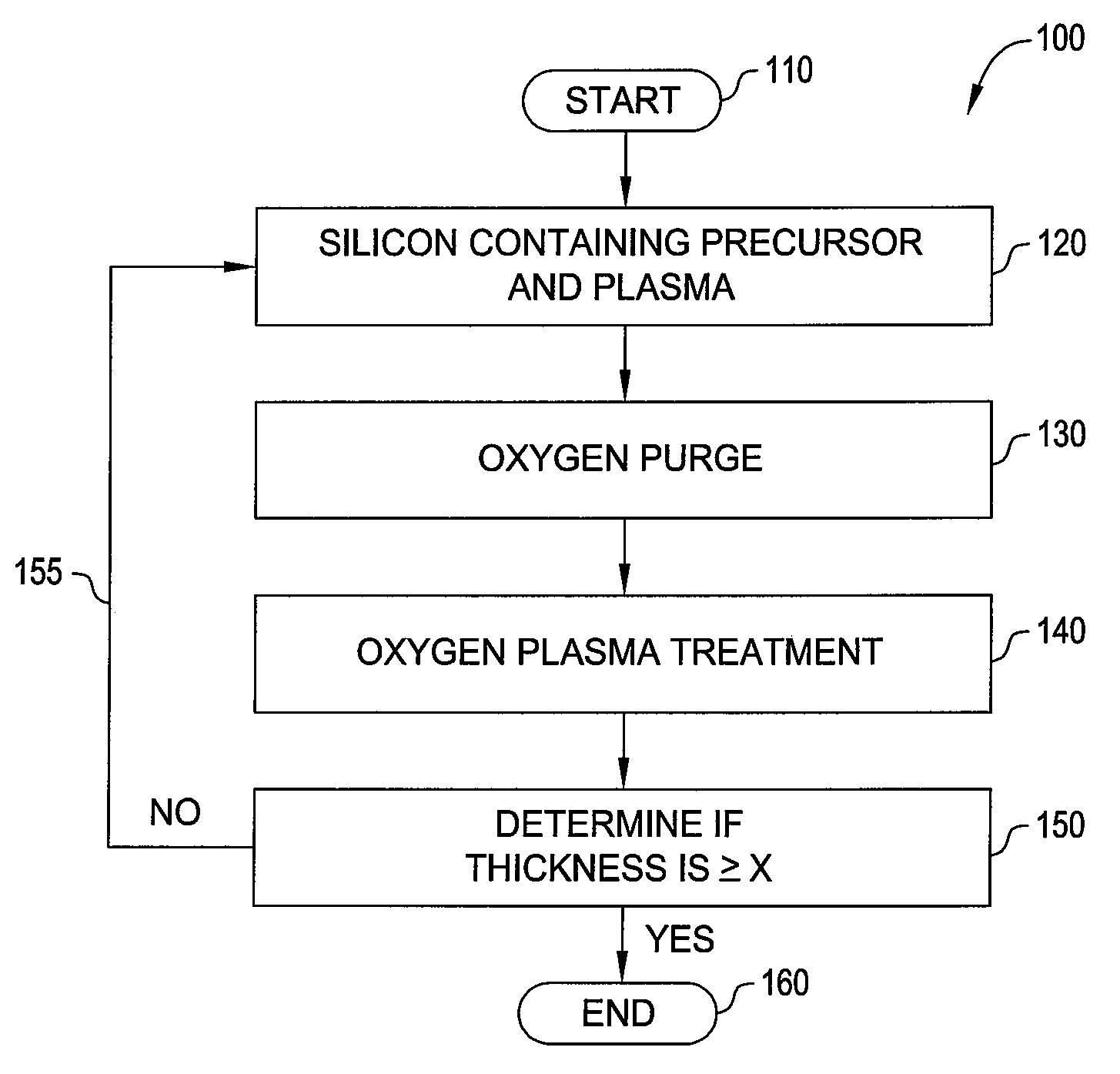

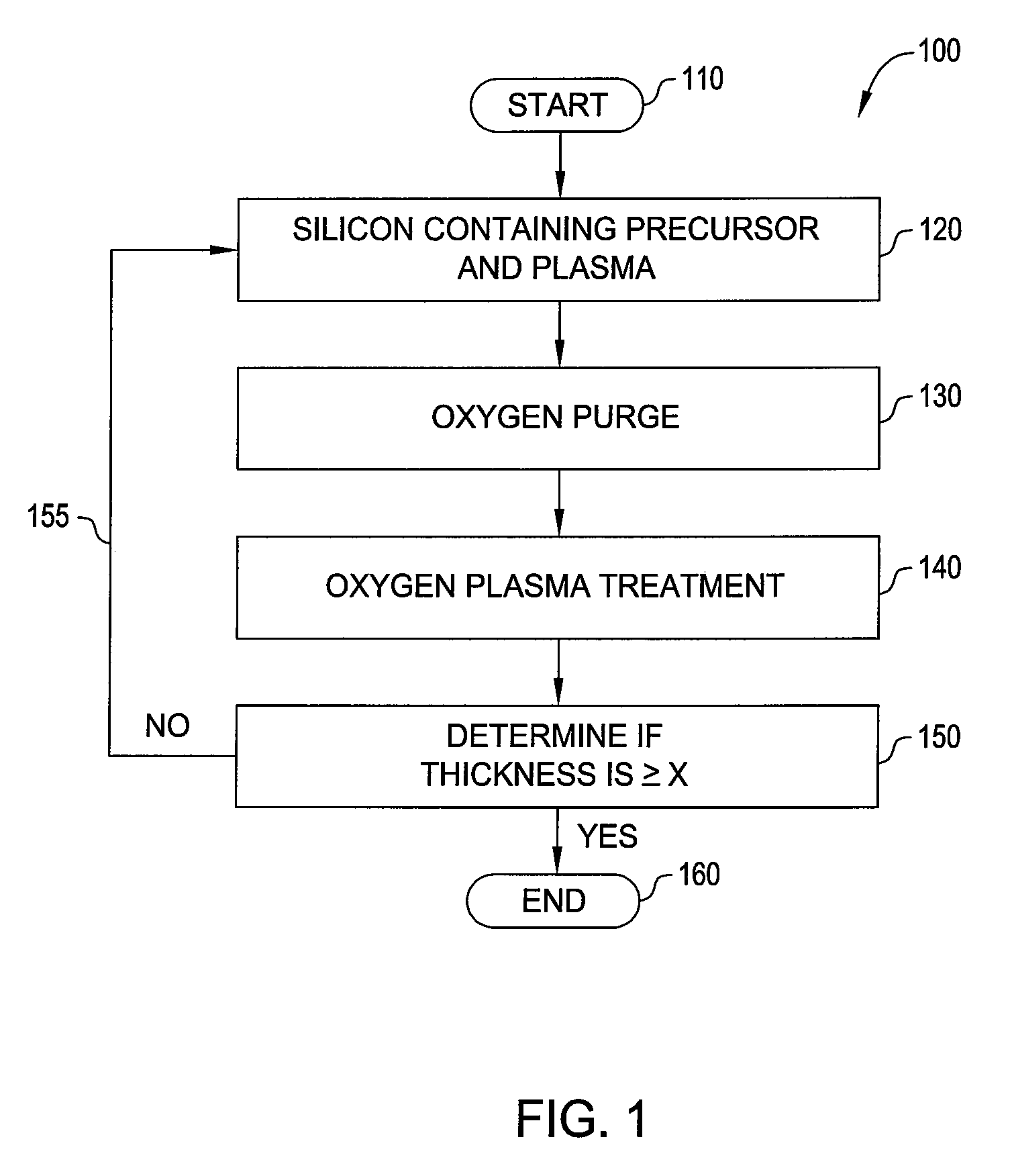

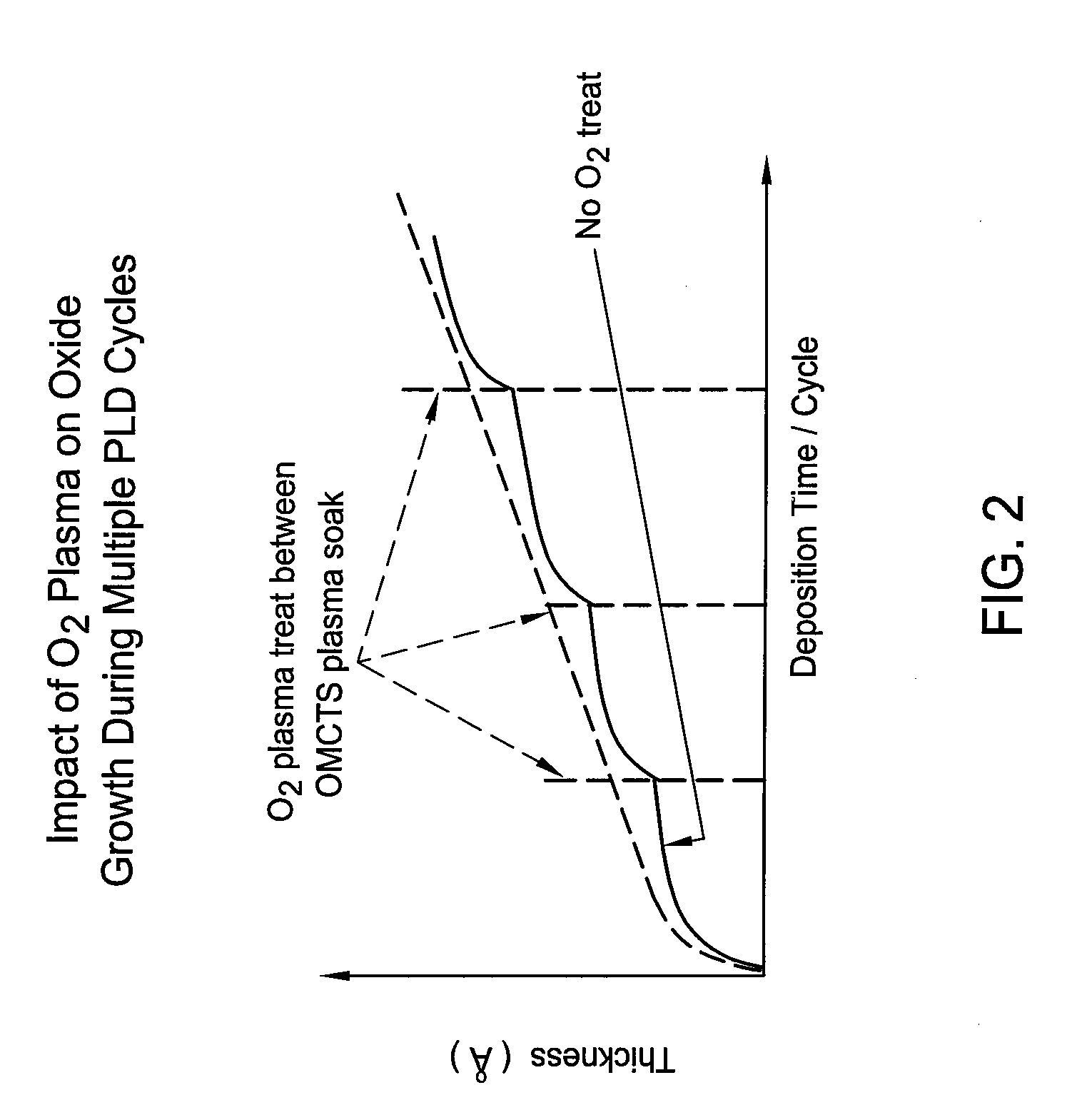

Method to improve the step coverage and pattern loading for dielectric films

A method of forming a layer on a substrate in a chamber, wherein the substrate has at least one formed feature across its surface, is provided. The method includes exposing the substrate to a silicon-containing precursor in the presence of a plasma to deposit a layer, treating the deposited layer with a plasma, and repeating the exposing and treating until a desired thickness of the layer is obtained. The plasma may be generated from an oxygen-containing gas.

Owner:APPLIED MATERIALS INC

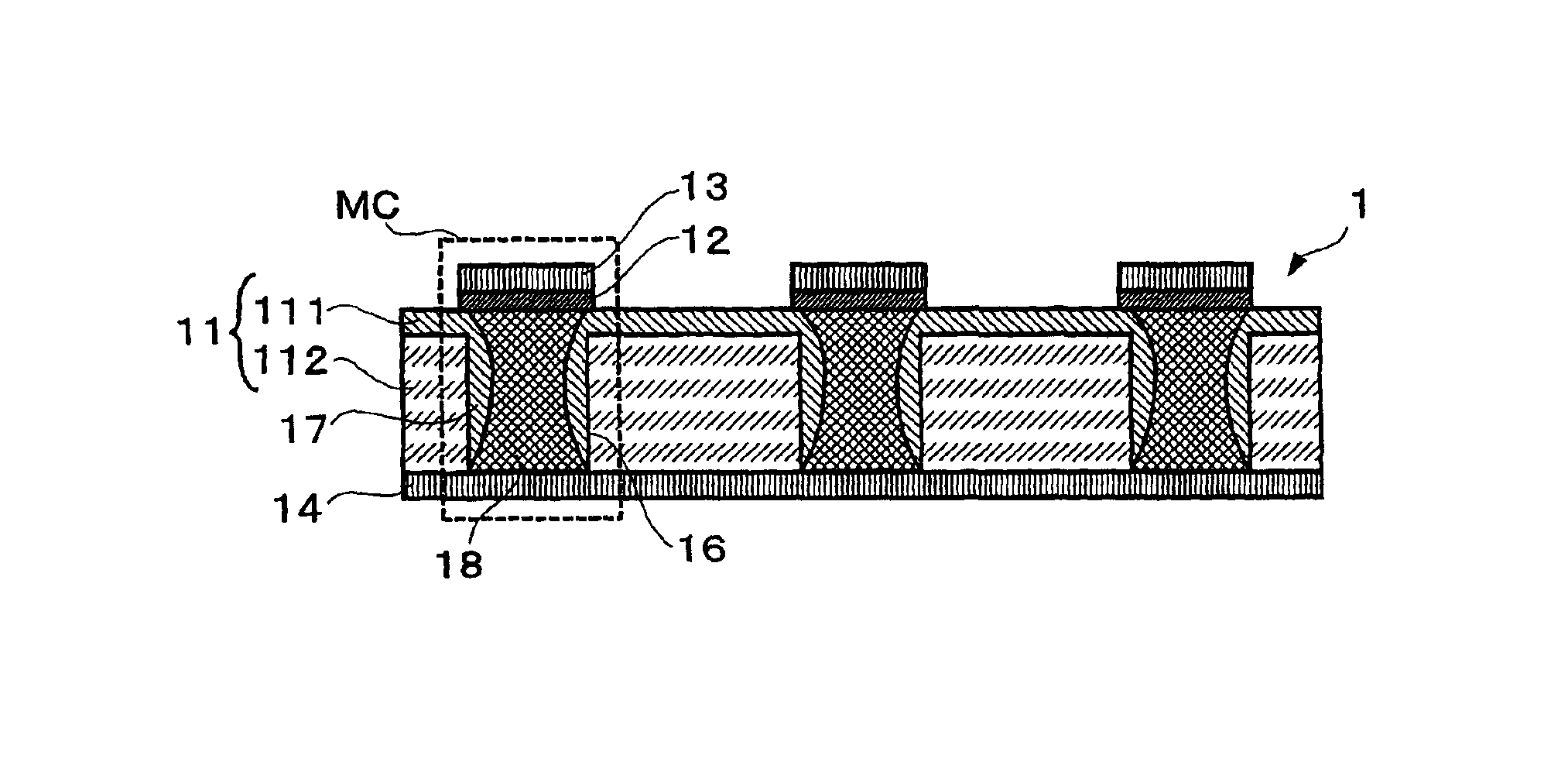

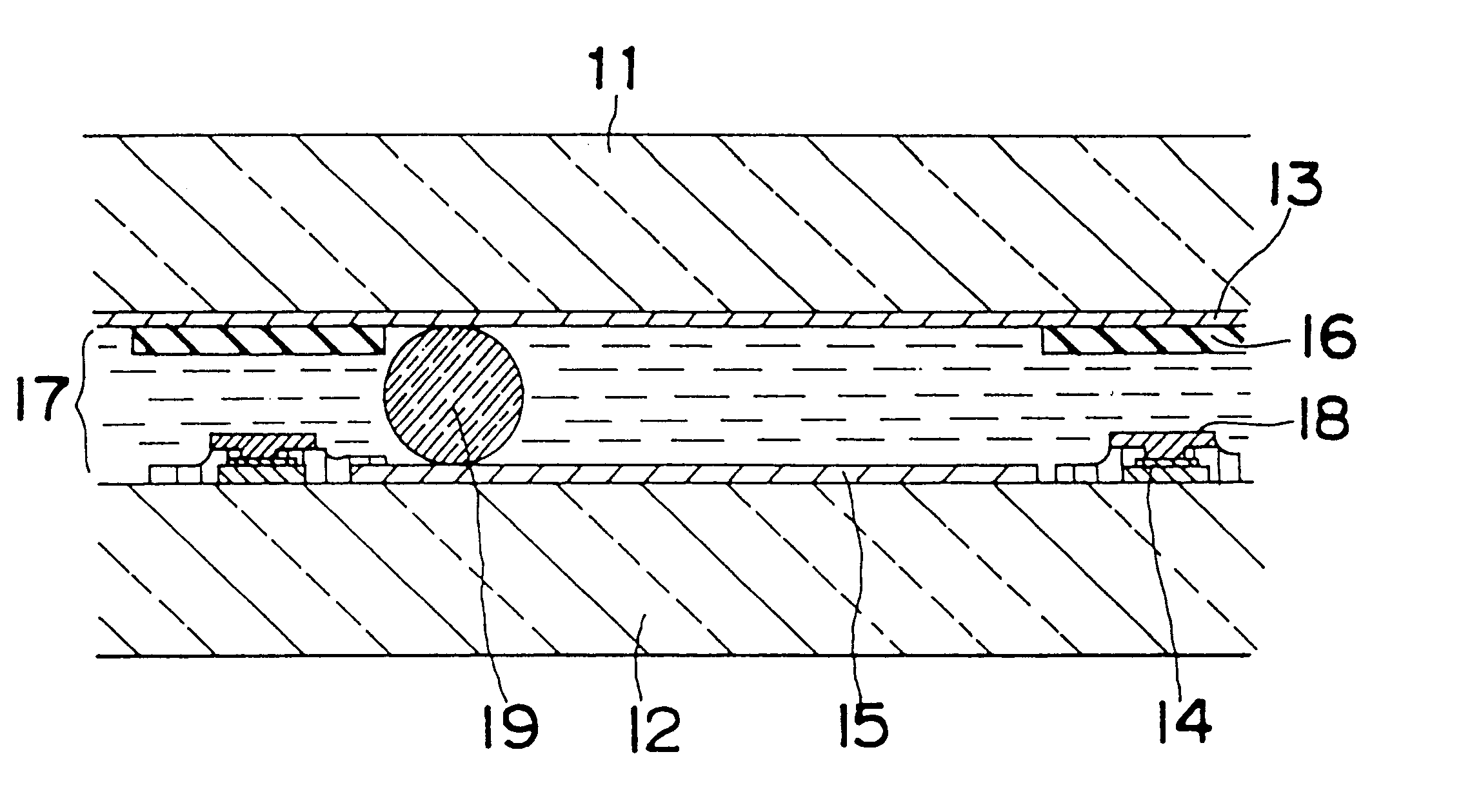

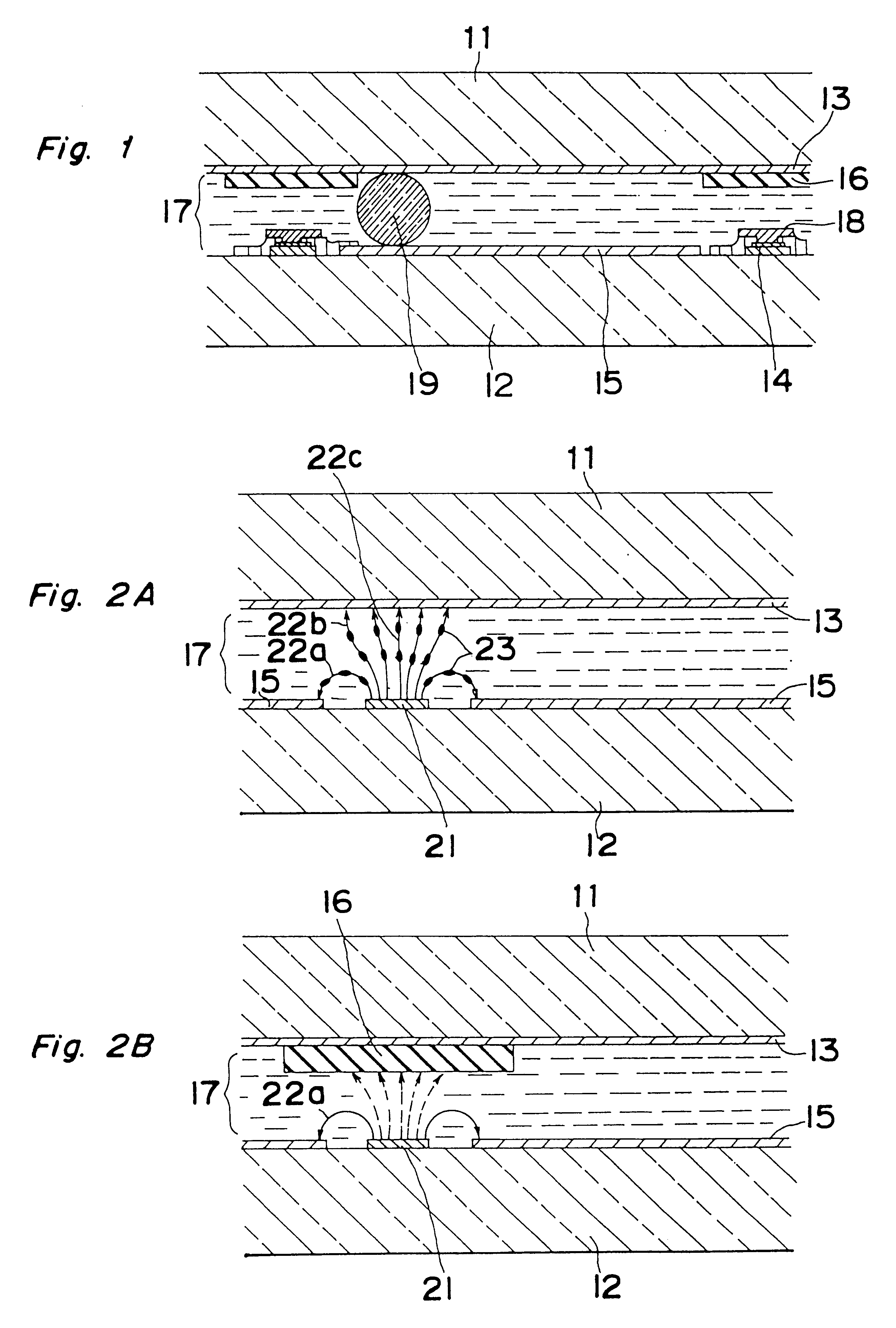

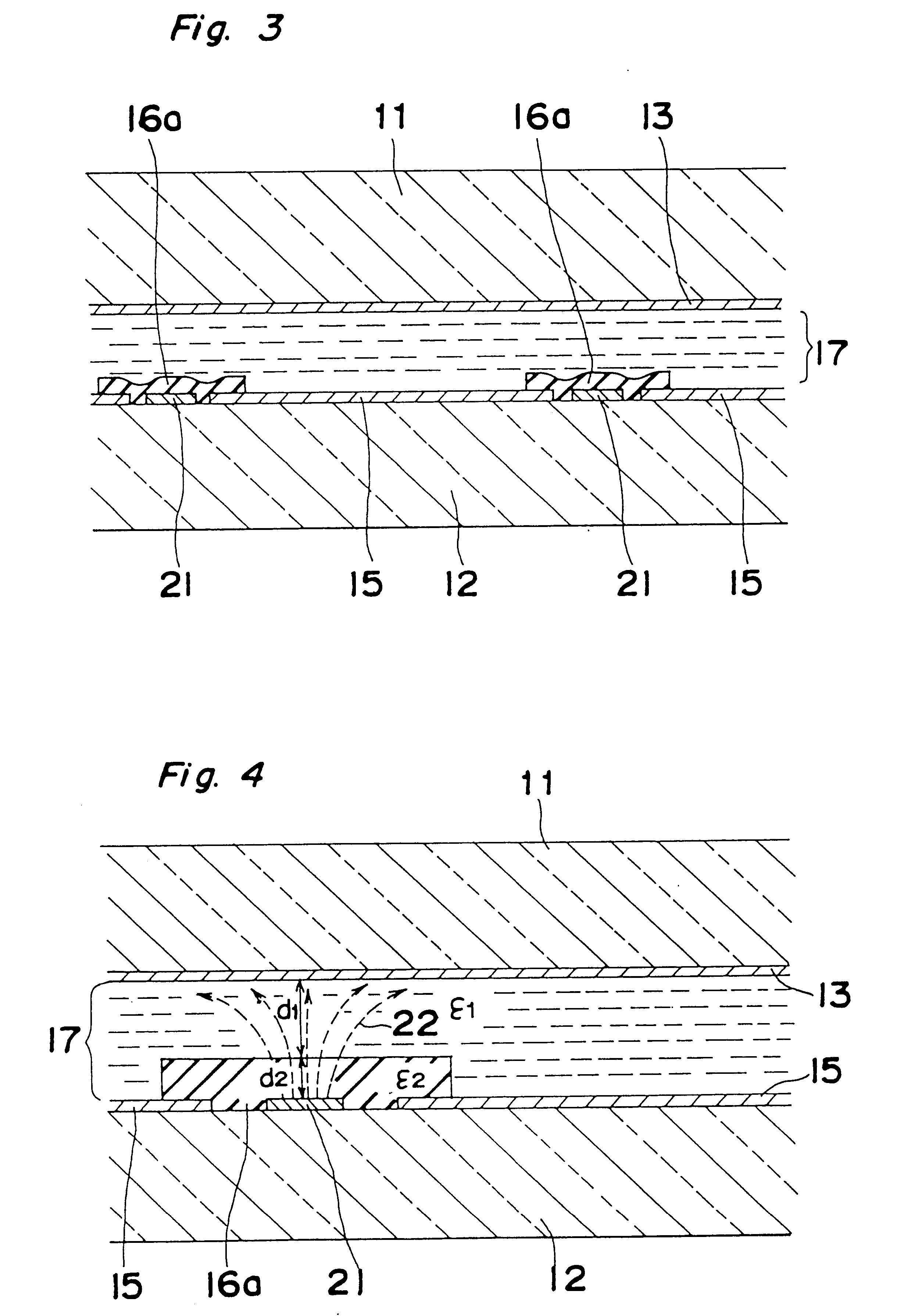

Non-volatile memory with phase-change recording layer

InactiveUS6900517B2Increase possible numberReduce power consumptionTransistorVariable resistance carrier recordingElectrical impulseEngineering

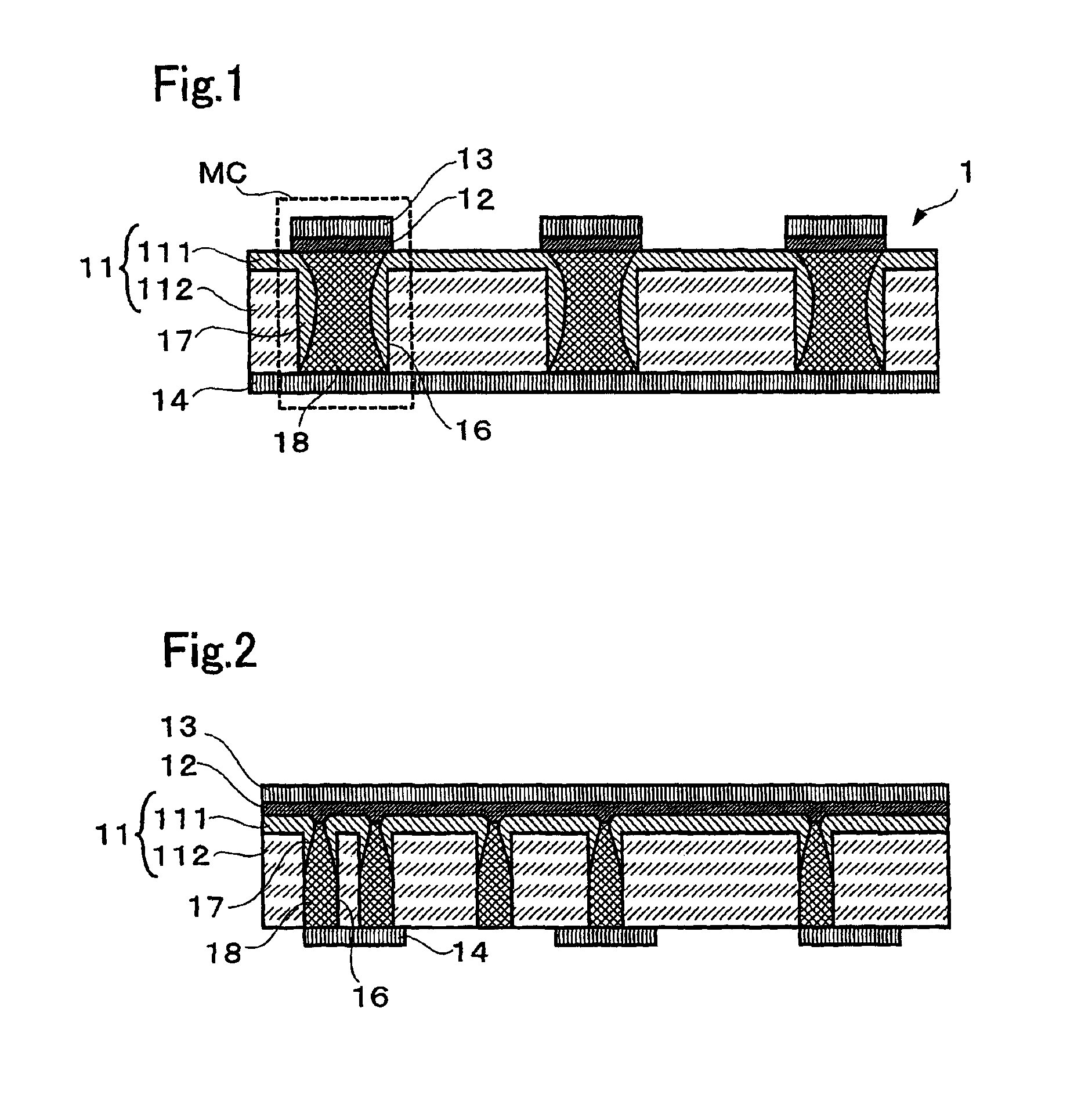

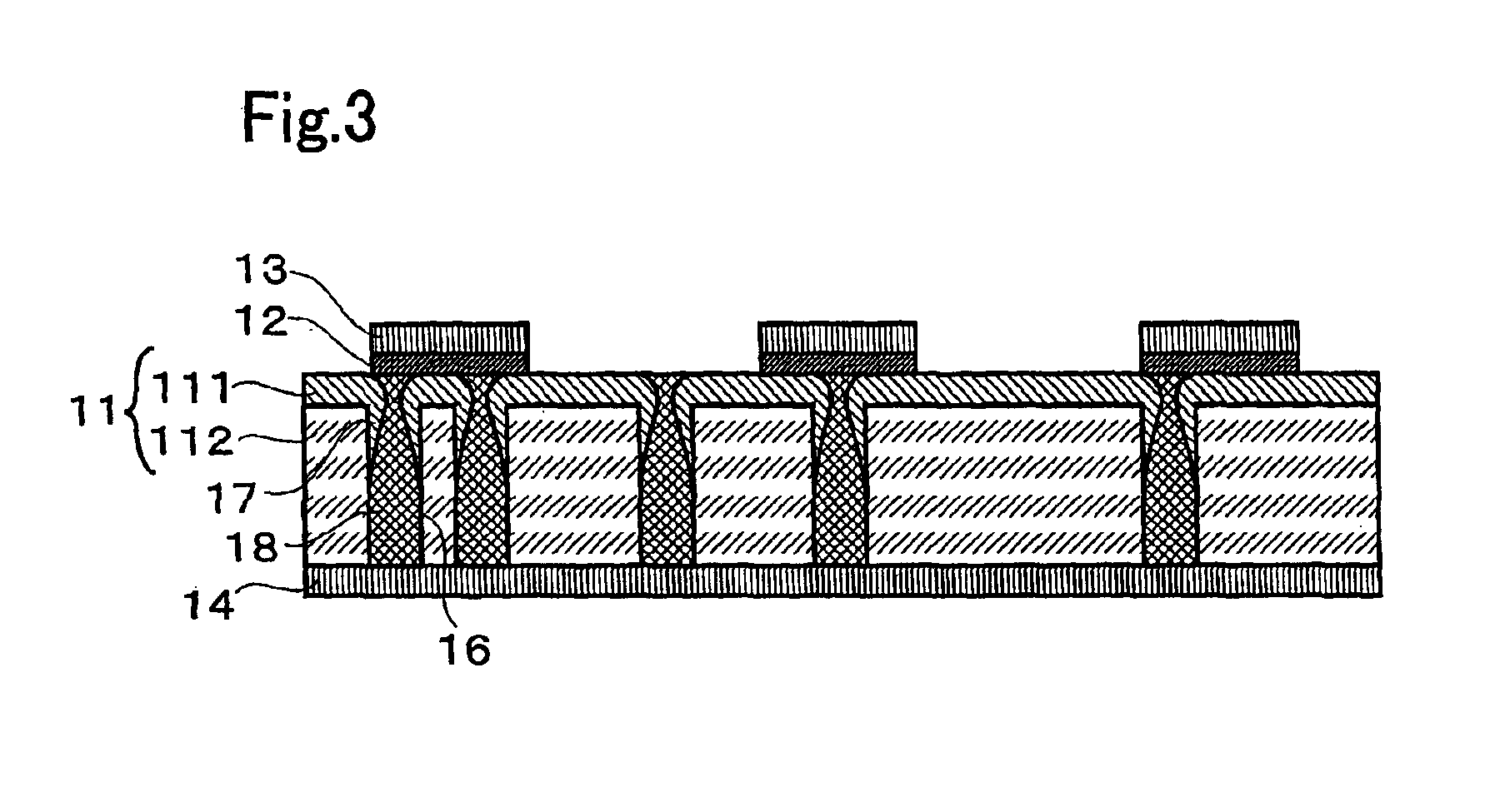

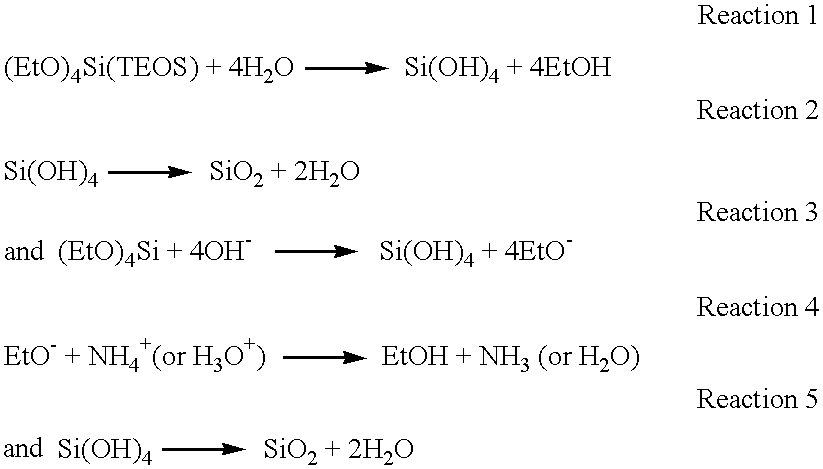

A non-volatile memory, which comprises an insulating substrate (11) that has a first electrode (18) that extends through the substrate from the front surface to the rear surface thereof; a second electrode (13) that is formed on one side of the insulating substrate (11); and a recording layer (12) that is clamped between the first electrode (18) and the second electrode (13) and whose resistance value varies when an electric pulse is applied across the first electrode (18) and the second electrode (13); wherein the insulating substrate (11) has a layered structure composed of an organic dielectric thin film (112) and an inorganic dielectric layer (111) that is thinner than the organic dielectric thin film (112); with the recording layer (12) being formed on the side on which the inorganic dielectric layer is formed. Use of this non-volatile memory increases the possible number of data writing cycles while saving power.

Owner:PANASONIC CORP

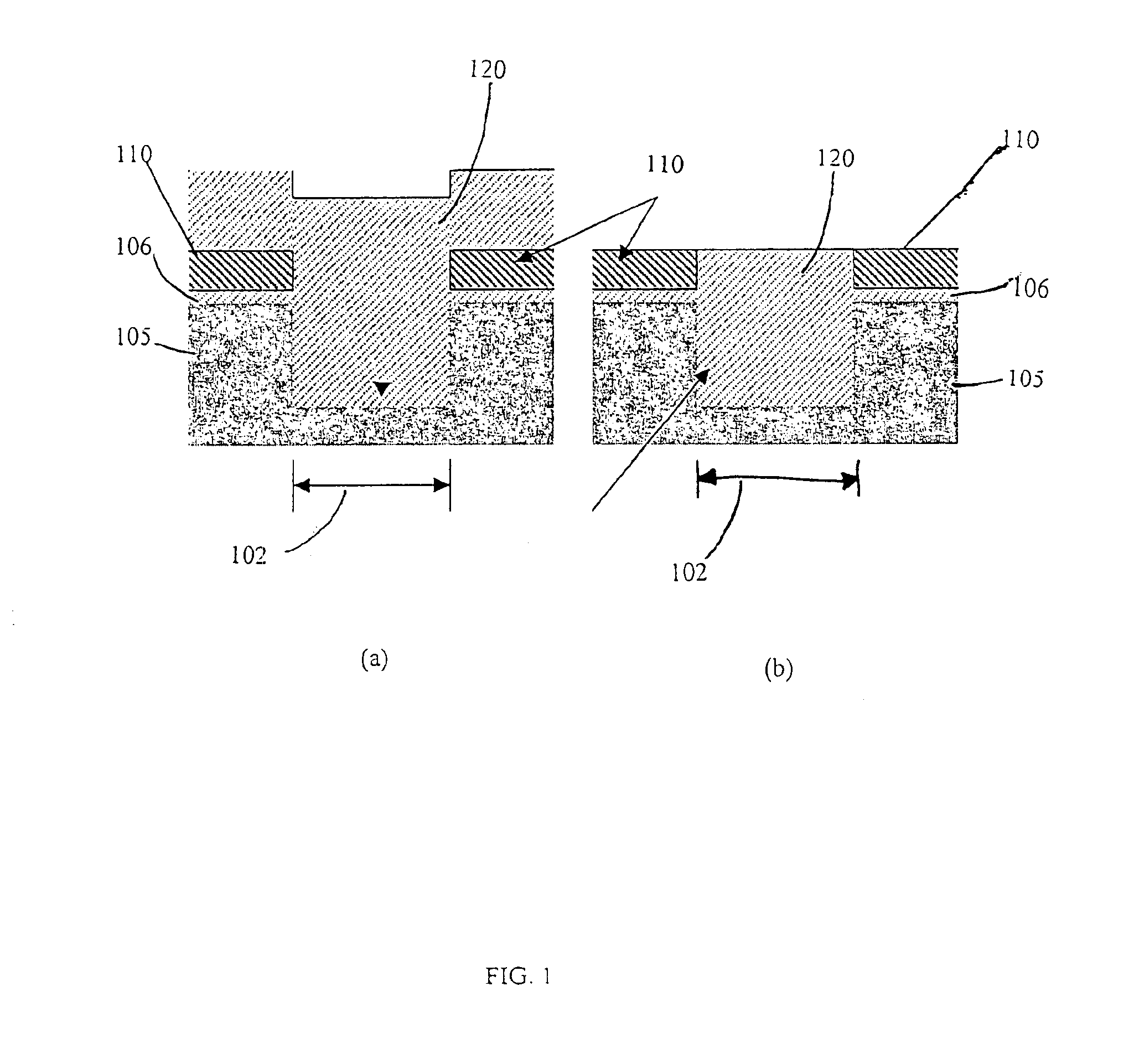

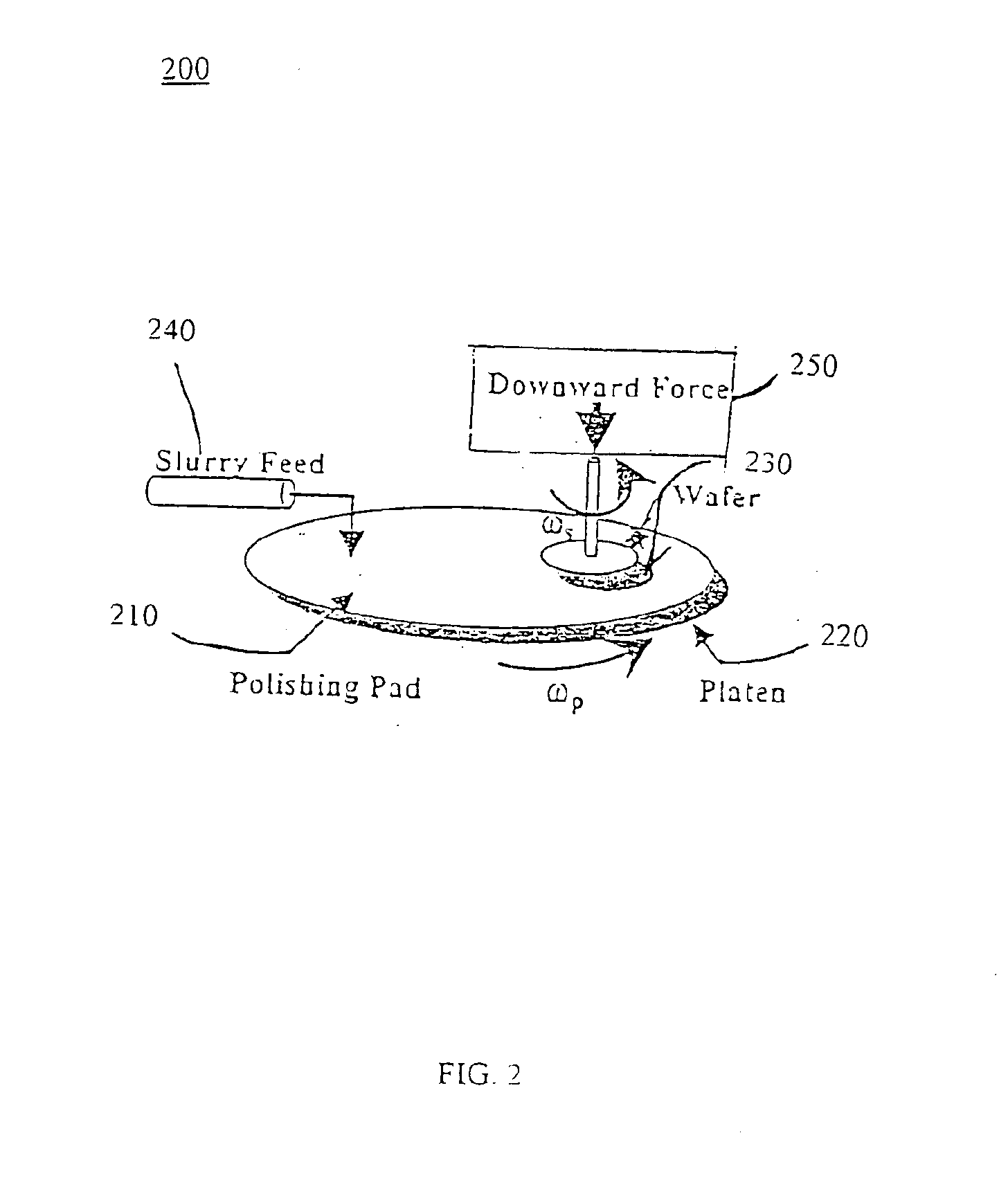

Planarization compositions and methods for removing interlayer dielectric films

InactiveUS6322600B1Improve planarization qualityQuality improvementPigmenting treatmentOther chemical processesThinningDielectric thin films

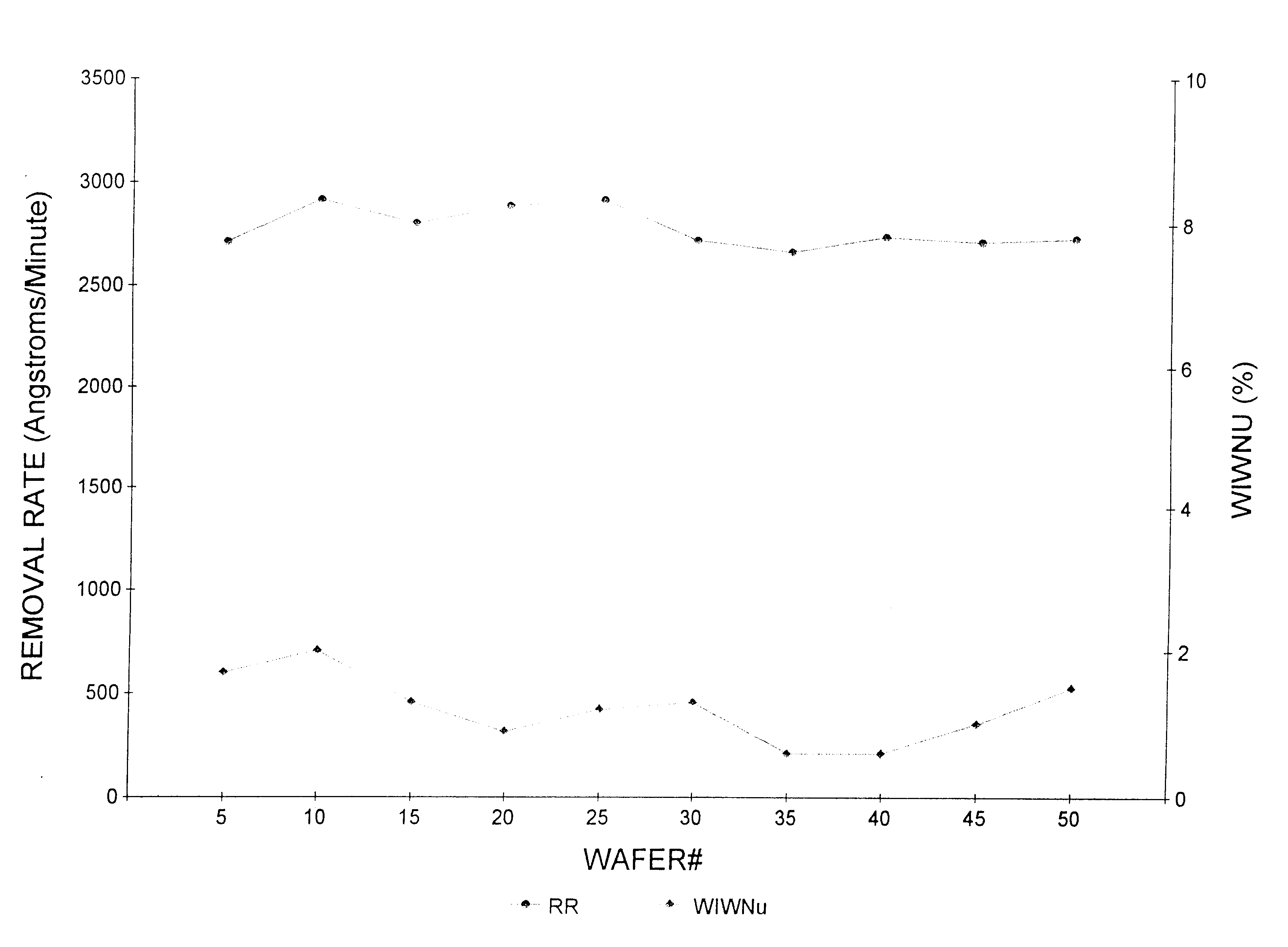

A planarization composition is set forth for chemical mechanical planarization of dielectric layers for semiconductor manufacture. The composition comprises spherical silica particles having an average diameter of from 30 nm to about 400 nm, and a narrow range of particle sizes, wherein about 90% of the particles is within 20% of the average particle diameter. The composition includes a liquid carrier comprising up to about 9% alcohol and an amine hydroxide in the amount of about 0.2 to about 9% by weight. The pH of the composition is in the range of about 9 to about 11.5, and the remainder of the solution is water. The composition has low amounts of metal ions, and the composition is used for thinning, polishing and planarizing interlayer dielectric thin films, shallow trench isolation structures, and isolation of gate structures. The invention also comprises methods for using the planarization composition in the manufacture of semiconductor devices.

Owner:ADVANCED TECH MATERIALS INC

Display panel and display device using the same

InactiveUS6218679B1Liquid crystal compositionsBuilt-on/built-in screen projectorsDisplay deviceUltraviolet

Owner:GK BRIDGE 1

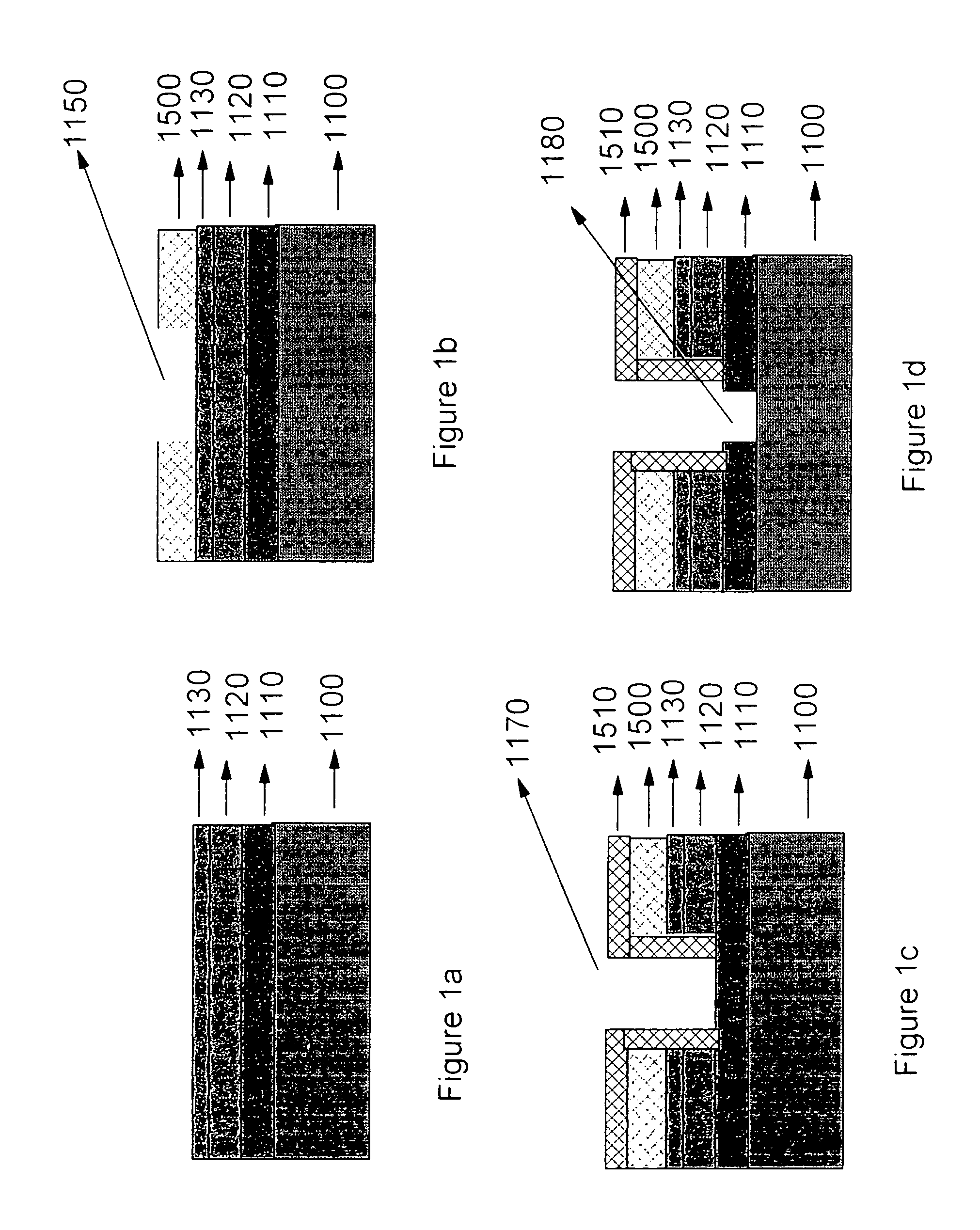

Structure for a thin film multilayer capacitor

An electronic component structure is proposed, wherein an interposer thin film capacitor structure is employed between an active electronic component and a multilayer circuit card. A method for making the interposer thin film capacitor is also proposed. In order to eliminate fatal electrical shorts in the overlying thin film regions that arise from pits, voids, or undulations on the substrate surface, a thick first metal layer, on the order of 0.5-10 mu m thick, is deposited on the substrate upon which the remaining thin films, including a dielectric film and second metal layer, are then applied. The first metal layer includes of Pt or other electrode metal, or a combination of Pt, Cr, and Cu metals, and a diffusion barrier layer. Additional Ti layers may be employed for adhesion enhancement. The thickness of the first metal layers are approximately: 200 A for the Cr layer; 0.5-10 mu m for the Cu layer; 1000 A-5000 A for the diffusion barrier; and 100 A-2500 A for a Pt layer.

Owner:IBM CORP

Treatment of low dielectric constant films using a batch processing system

ActiveUS20070077782A1Reduce diffuseImprove adhesionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingBatch processingOptoelectronics

A method and system for treating a dielectric film in a batch processing system includes exposing at least one surface of the dielectric film to a treating compound including a CxHy containing compound, where x and y represent integers greater than or equal to unity. The plurality of wafers are heated when the treating compound is introduced. The dielectric film can include a low dielectric constant film with or without pores having an etch feature formed therein following dry etch processing.

Owner:TOKYO ELECTRON LTD

Process for producing metal oxide films at low temperatures

InactiveUS20050112874A1Rapid productionQuality improvementSolid-state devicesSemiconductor/solid-state device manufacturingOrganic filmOrganic solar cell

A process for producing metal oxide thin films on a substrate by the ALD method comprises the steps of bonding no more than about a molecular monolayer of a gaseous metal compound to a growth substrate, and converting the bonded metal compound to metal oxide. The bonded metal compound is converted to metal oxide by contacting it with a reactive vapour source of oxygen other than water, and the substrate is kept at a temperature of less than 190° C. during the growth process. By means of the invention it is possible to produce films of good quality at low temperatures. The dielectric thin films having a dense structure can be used for passivating surfaces that do not endure high temperatures. Such surfaces include, for example, organic films in integrated circuits and polymer films such as in organic electroluminescent displays and organic solar cells. Further, when a water-free oxygen source is used, surfaces that are sensitive to water can be passivated.

Owner:ASM INTERNATIONAL

Vapor phase treatment of dielectric materials

InactiveUS20060216952A1Reduce gapSemiconductor/solid-state device manufacturingChemical vapor deposition coatingVapor phaseDielectric thin films

The invention concerns a method for applying a surface modification agent composition for organosilicate glass dielectric films. More particularly, the invention pertains to a method for treating a silicate or organosilicate dielectric film on a substrate, which film either comprises silanol moieties or has had at least some previously present carbon containing moieties removed therefrom. The treatment adds carbon containing moieties to the film and / or seals surface pores of the film, when the film is porous.

Owner:HONEYWELL INT INC

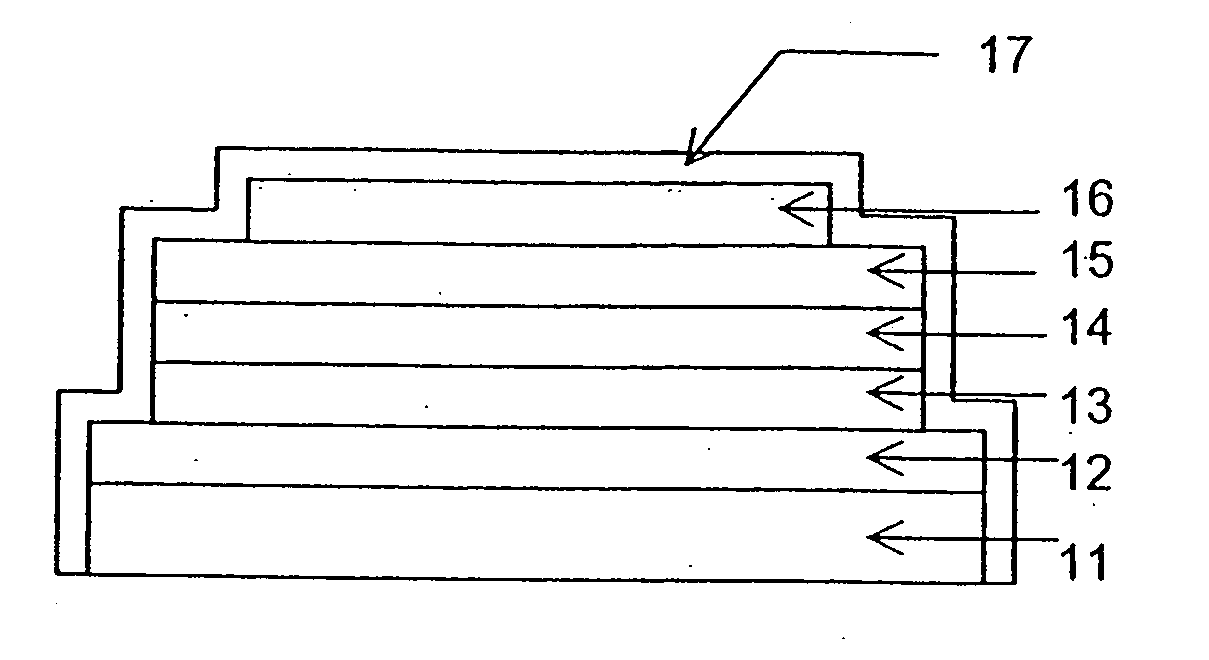

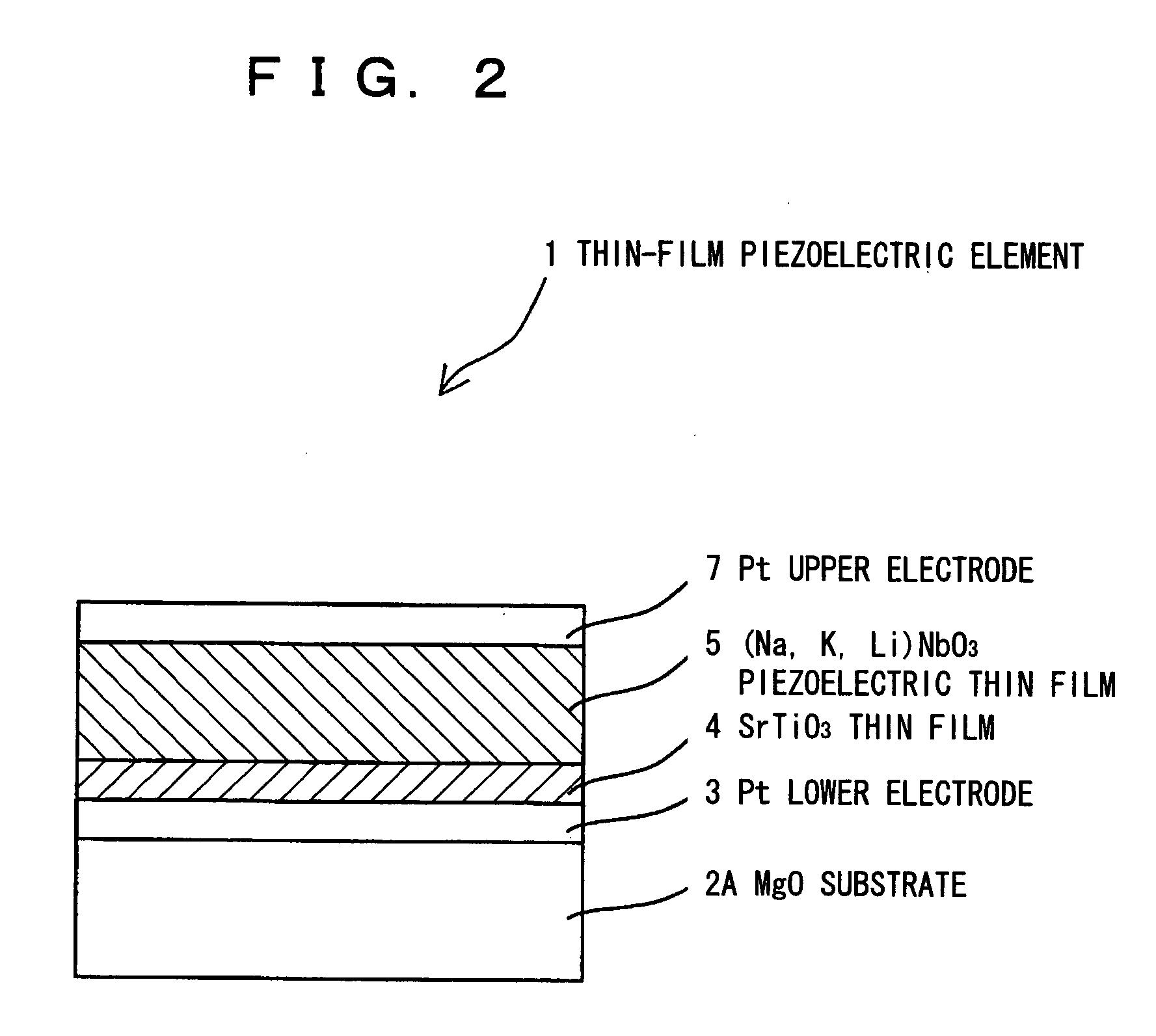

Piezoelectric thin film element

InactiveUS20070024162A1Excellent dielectric strength voltageExcellent piezoelectric propertiesPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesDielectric strengthDielectric thin films

A thin-film piezoelectric element has a substrate, a lower electrode, a piezoelectric portion, and an upper electrode that are sequentially formed on the substrate. The piezoelectric portion has a dielectric thin film that has an alkali niobium oxide-based perovskite structure expressed by general formula (NaxKyLiz)NbO3 (0<x<1, 0<y<1, 0≦z<1, x+y+z=1), and a high voltage-withstand dielectric that has a dielectric strength voltage greater than that of the dielectric thin film.

Owner:SUMITOMO CHEM CO LTD

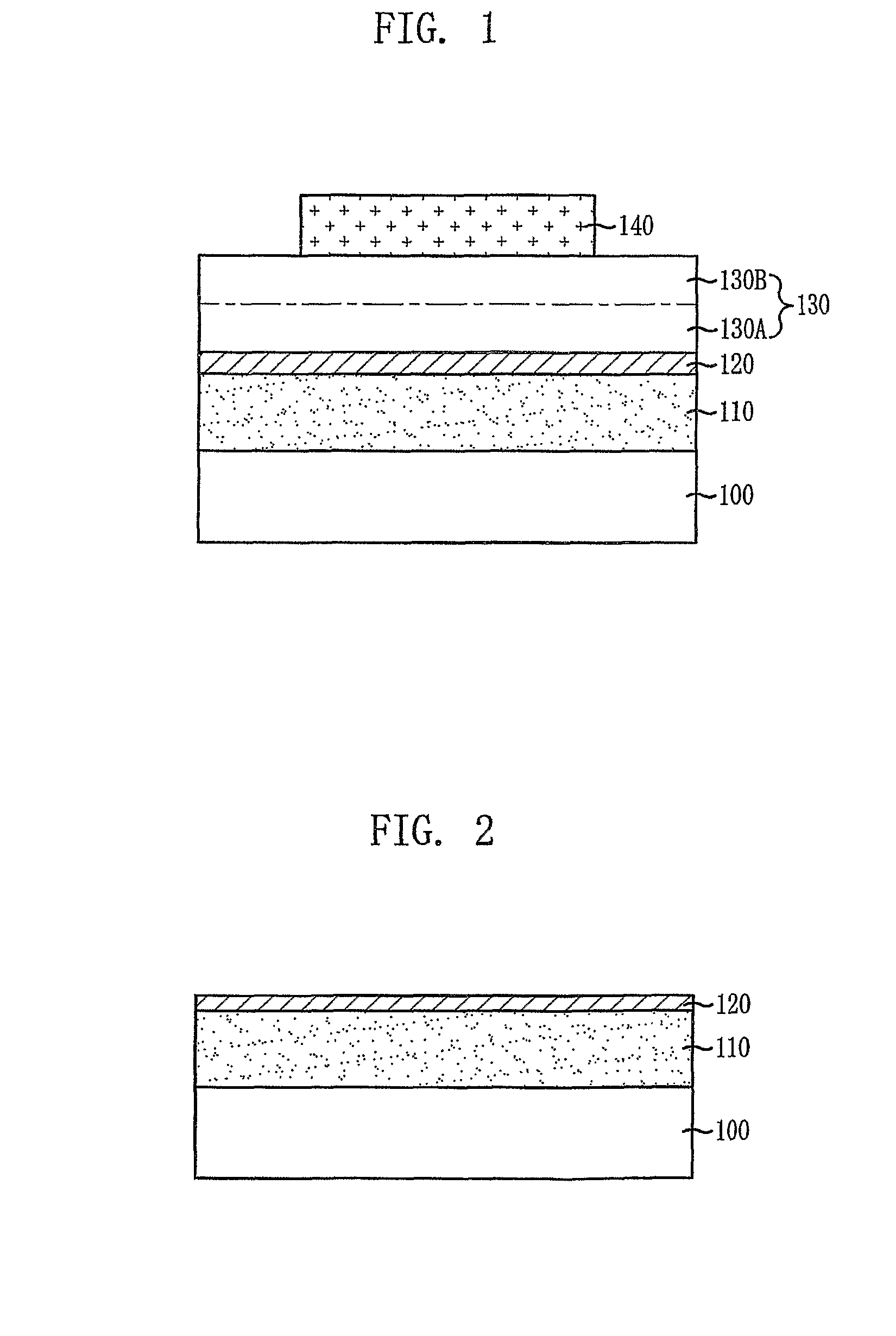

Memory device and manufacturing method thereof

InactiveUS20100065803A1Effective controlInhibit migrationSemiconductor/solid-state device manufacturingDigital storageEngineeringVolumetric Mass Density

Provided is a resistance variable non-volatile memory device using a trap-controlled Space Charge Limited Current (SCLC), and a manufacturing method thereof. The memory device includes a bottom electrode; an inter-electrode dielectric thin film diffusion prevention film formed on the bottom electrode; a dielectric thin film formed on the inter-electrode dielectric thin film diffusion prevention film and having a plurality of layers with different charge trap densities; and a top electrode formed on the dielectric thin film.

Owner:ELECTRONICS & TELECOMM RES INST

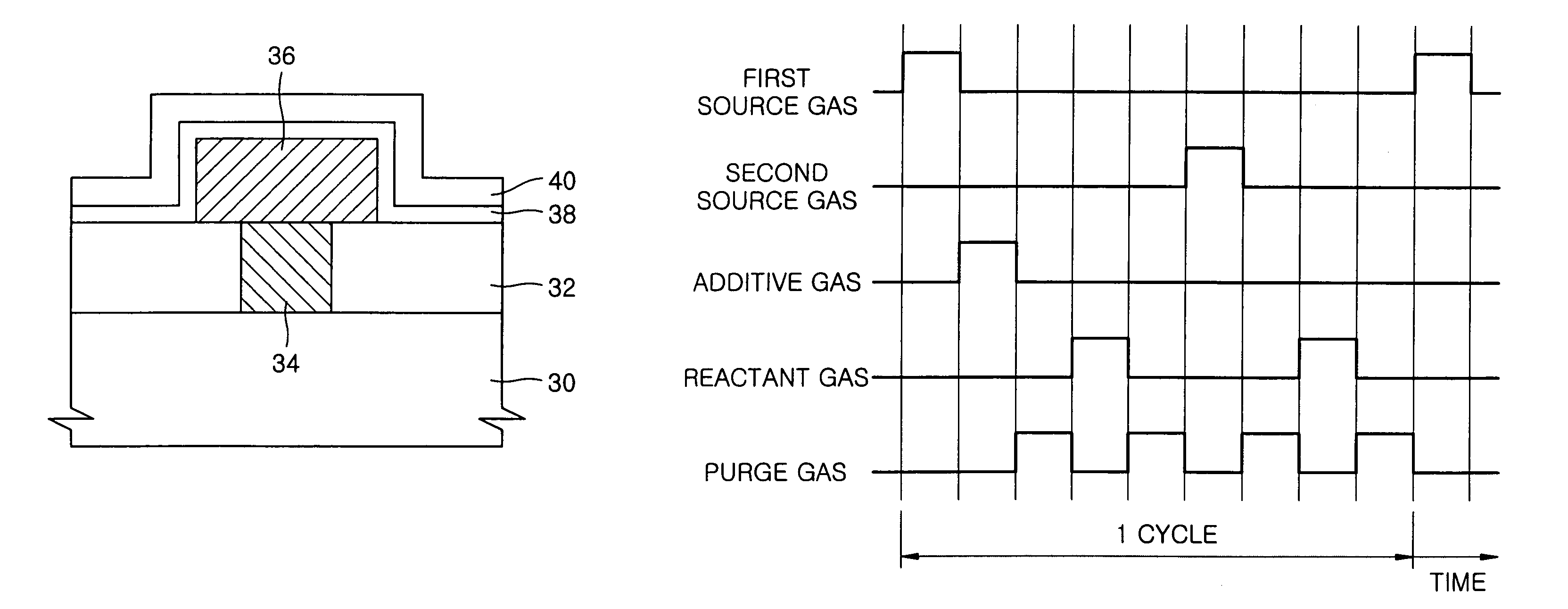

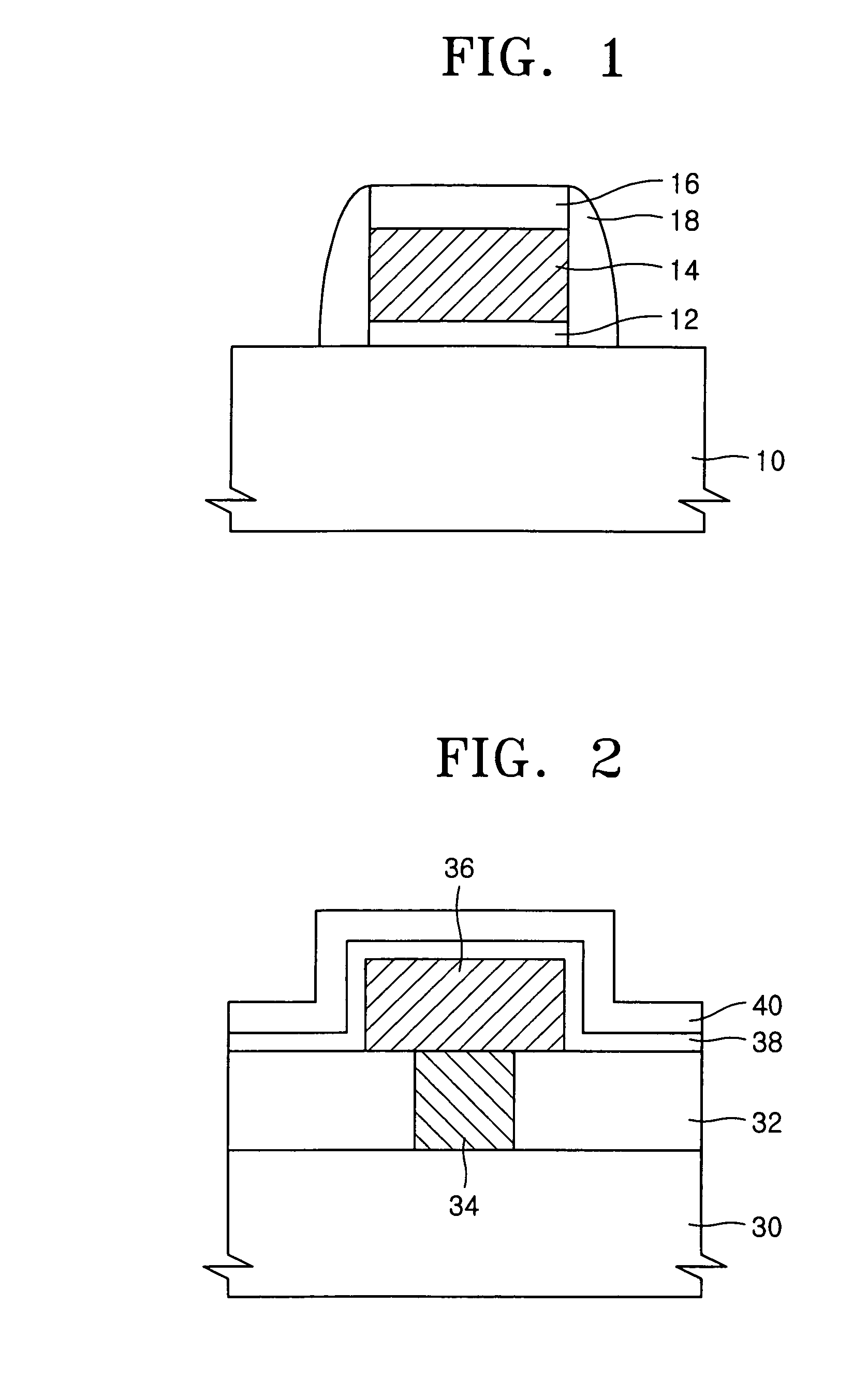

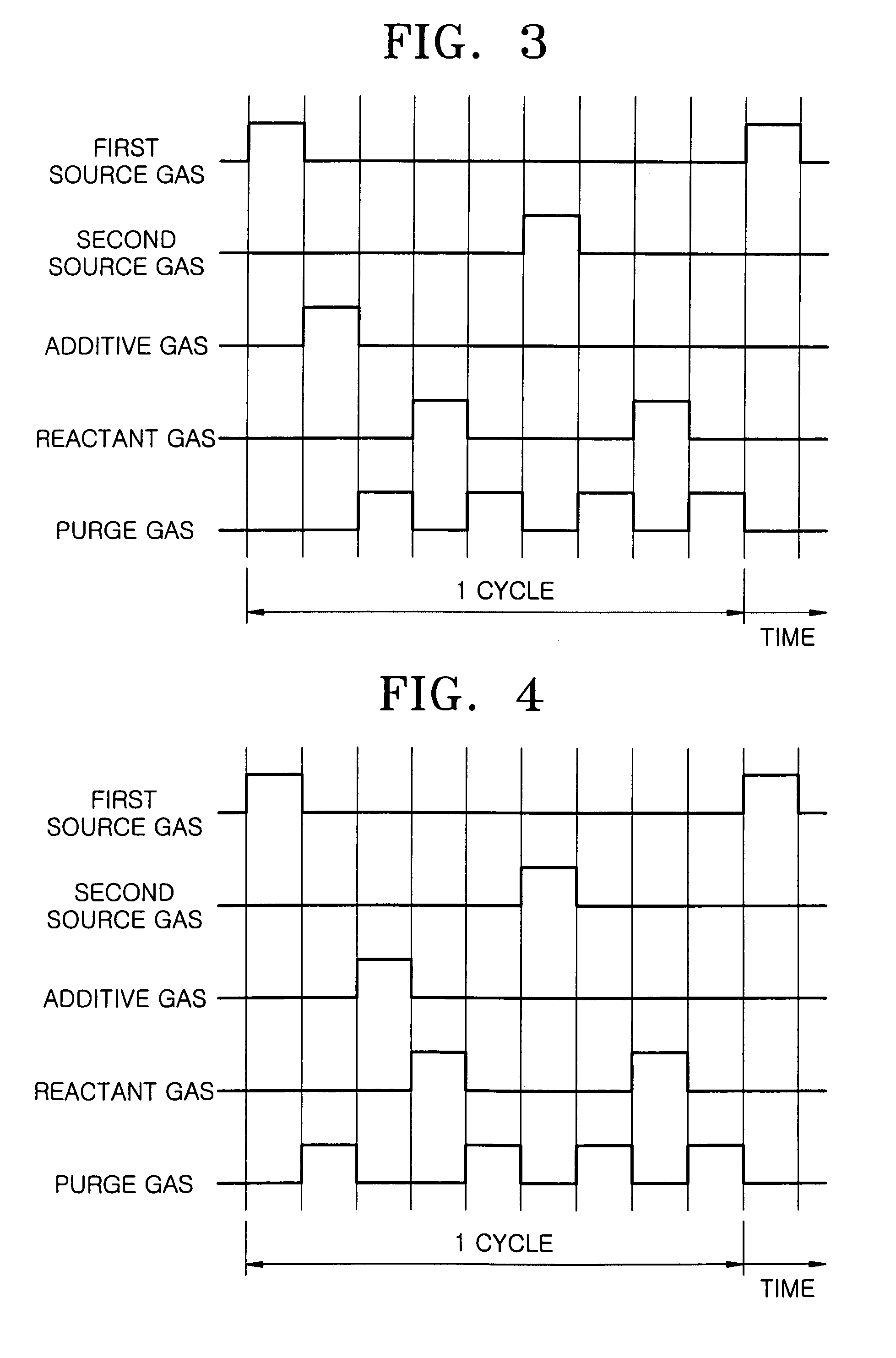

High dielectric film and related method of manufacture

ActiveUS7521331B2Increase currentSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDevice materialNitrogen

A method of forming a high dielectric film for a semiconductor device comprises supplying a first source gas to a reaction chamber during a first time interval, supplying a first reactant gas to the reaction chamber during a second time interval after the first time interval, supplying a second source gas to the reaction chamber for a third time interval after the second time interval, supplying a second reactant gas to the reaction chamber for a fourth time interval after the third time interval, and supplying an additive gas including nitrogen to the reaction chamber during a fifth time interval.

Owner:SAMSUNG ELECTRONICS CO LTD

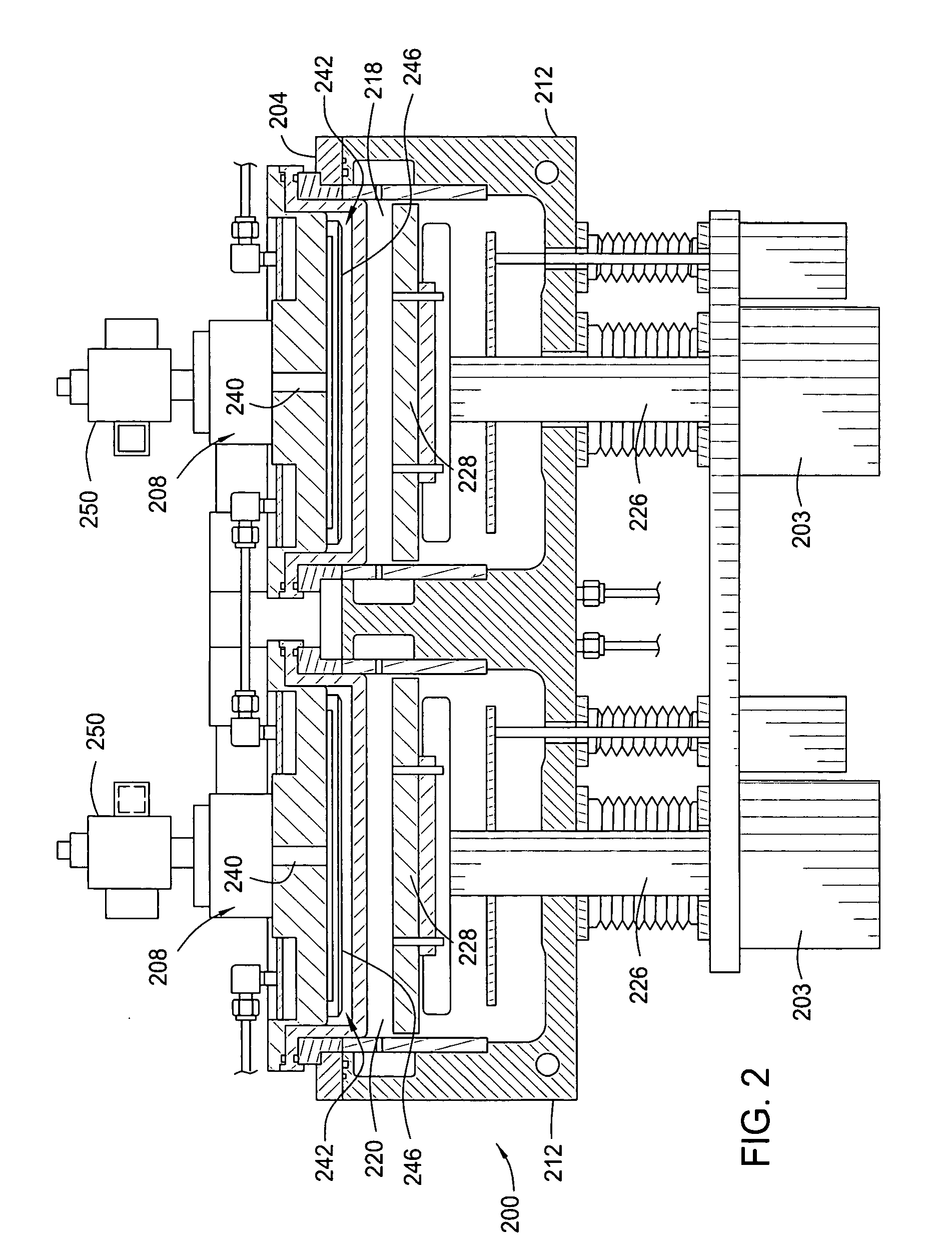

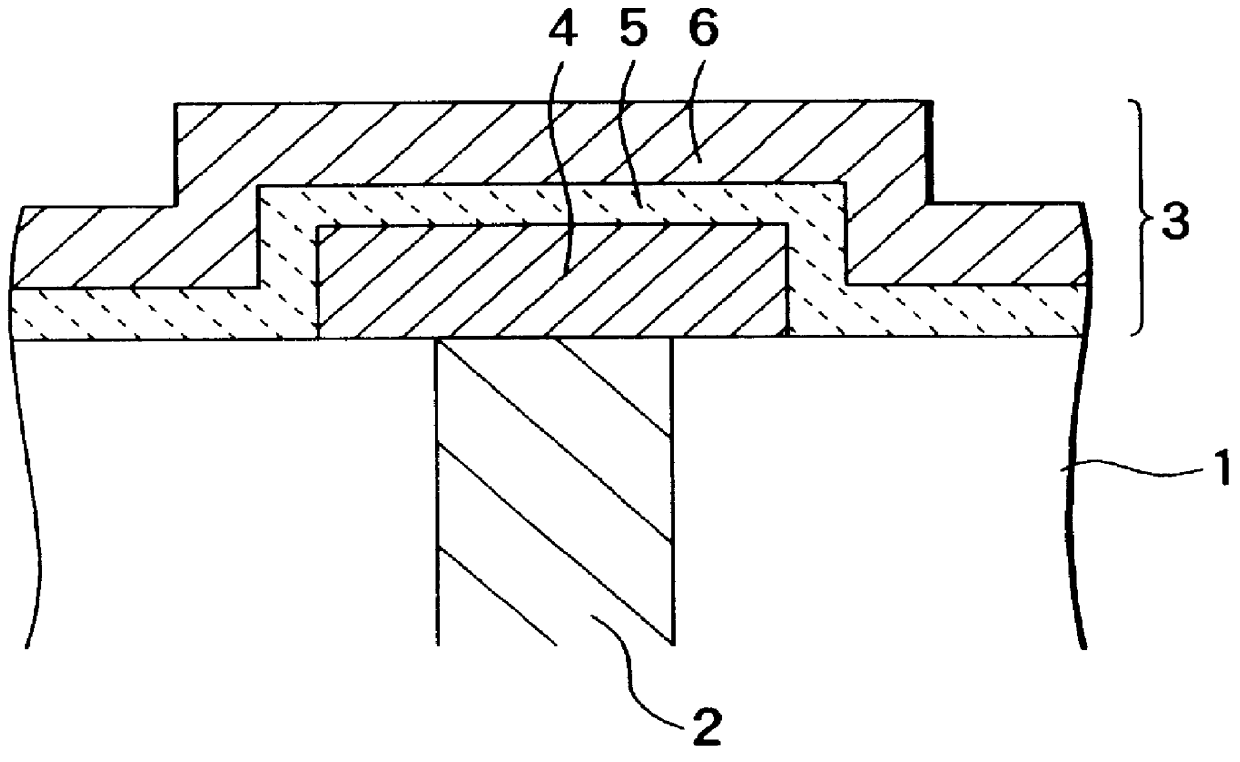

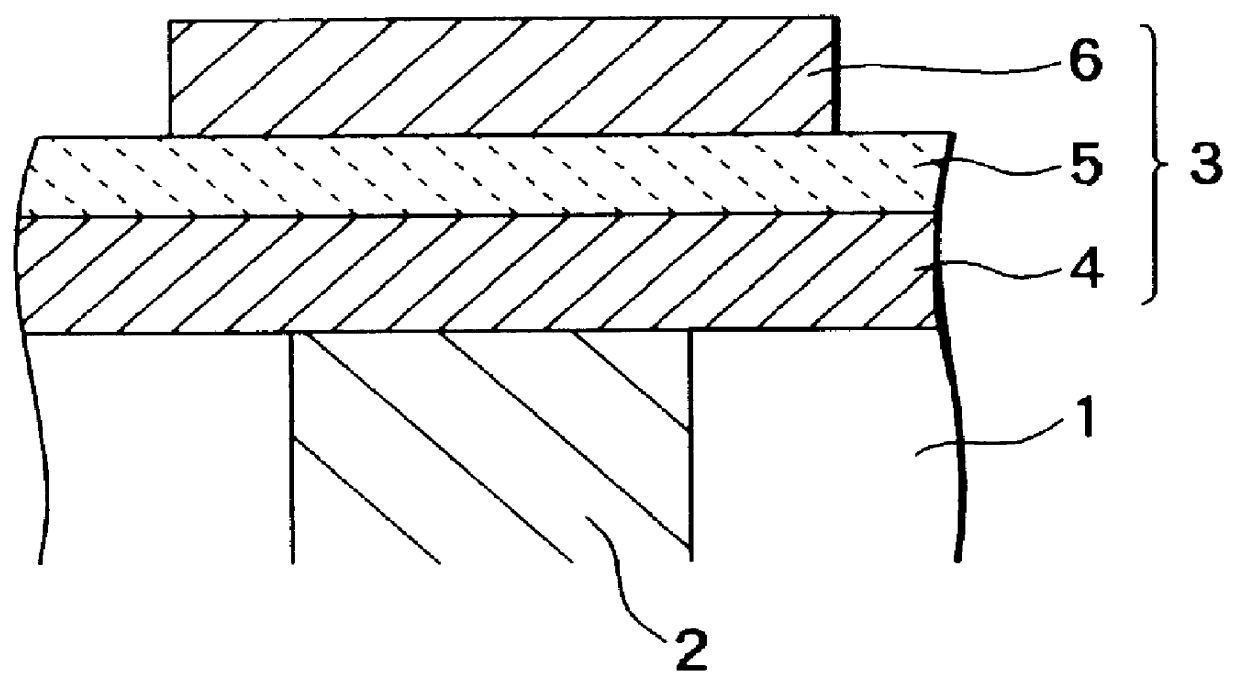

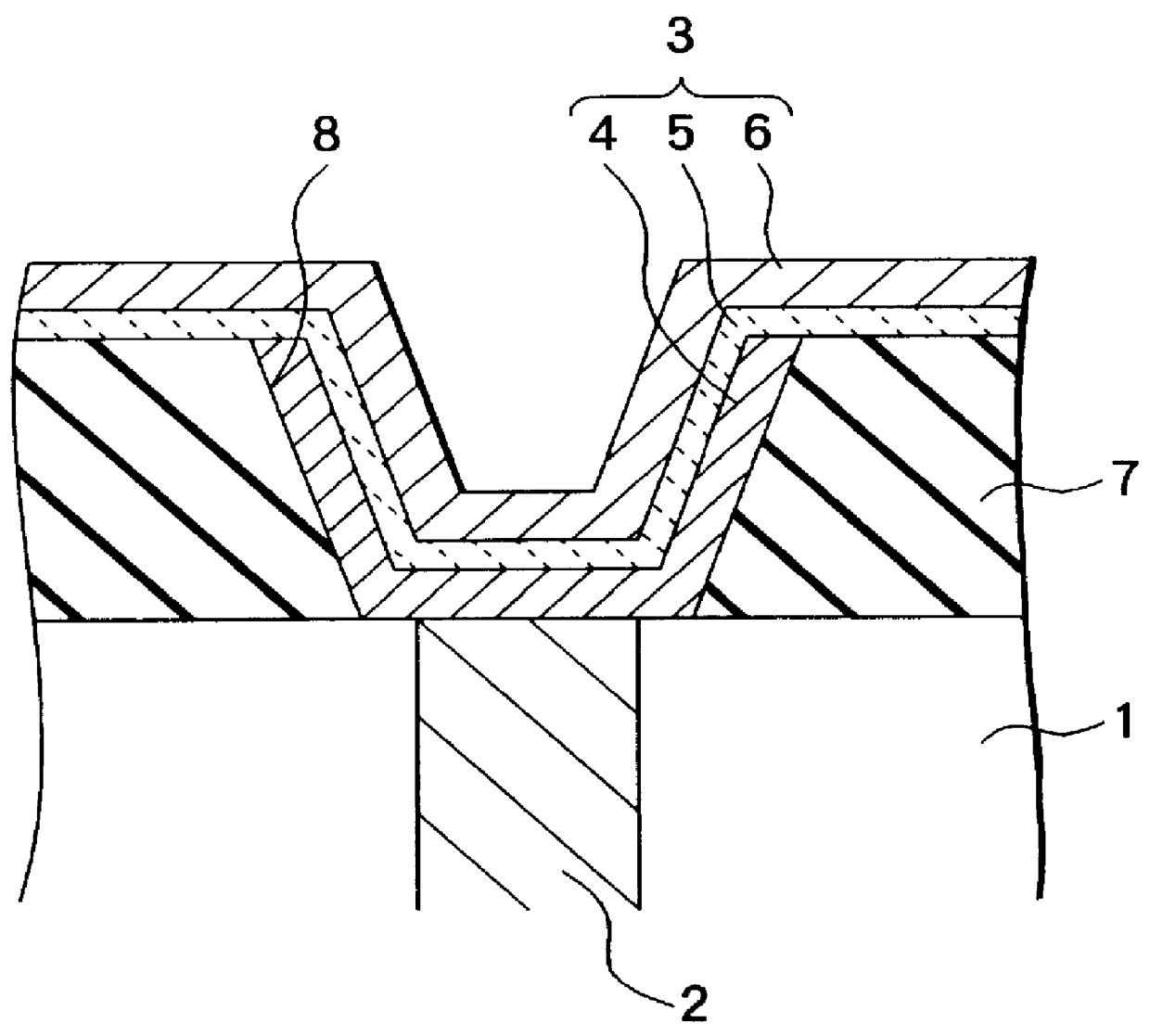

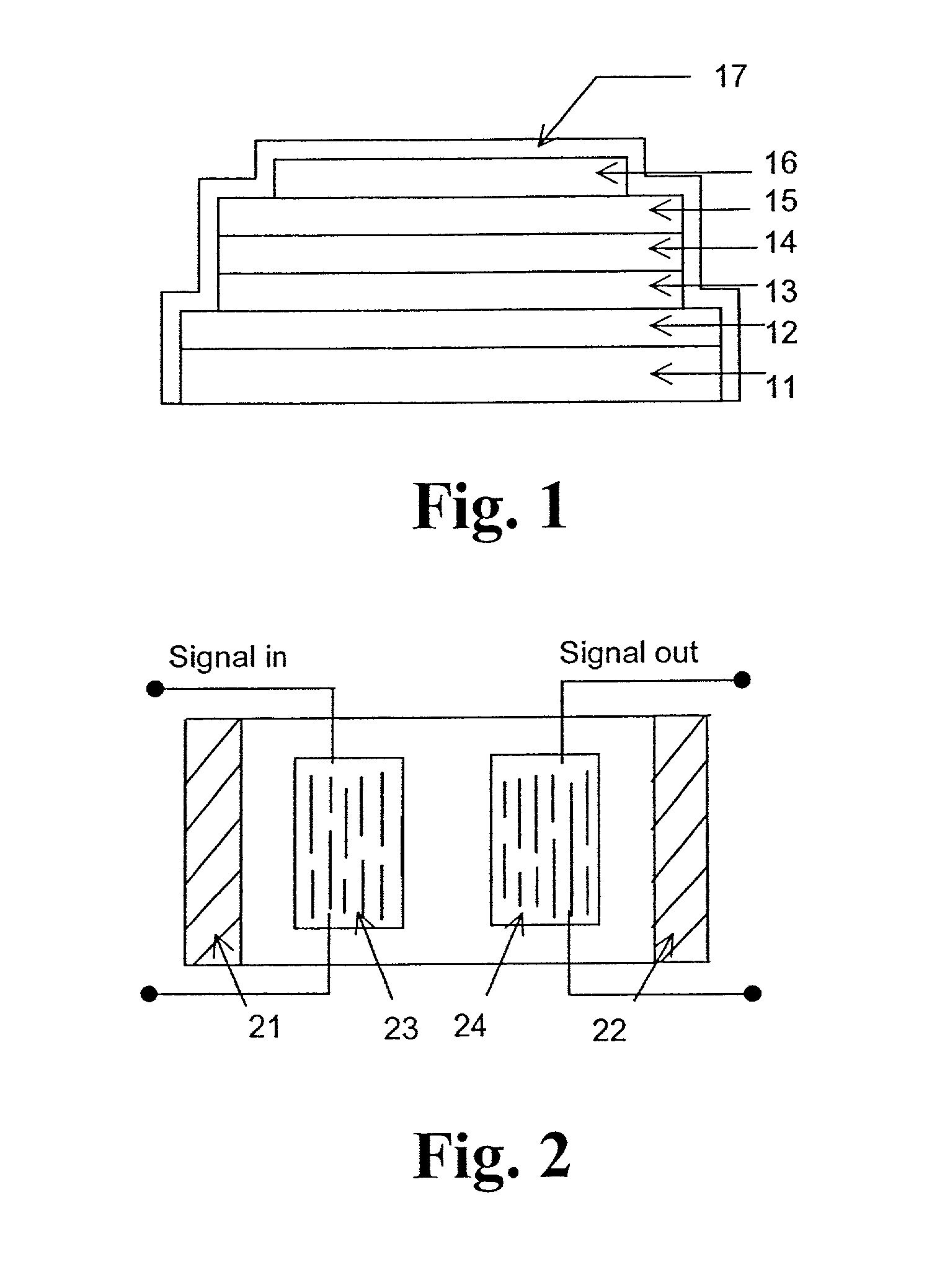

Thin film dielectric device

A thin film dielectric device is disclosed, that comprises a substrate, a lower electrode formed on the substrate and composed of a laminate film having columnar grains that have grown in a vertical to a surface of the substrate, a dielectric thin film formed on the lower electrode and composed of a perovskite oxide, the dielectric thin film being a polycrystalline film having columnar grains that have successively grown from the columnar grains of the lower electrode and that takes over a crystal orientation of the lower electrode, the lattice constant of the lower electrode being matched with the lattice constant of the dielectric thin film at the interface therebetween with the columnar grains, and an upper electrode formed on the dielectric thin film. The lattice matching of the columnar grains solves problems of the increase of the leak current of the thin film dielectric device and the degradation of the dielectric breakdown resistance. In addition, the polycrystalline film having the columnar grains that succeed at the interface of the electrode / dielectric thin film can be properly formed on the semiconductor substrate such as Si substrate. Thus, the thin film dielectric device according to the present invention can be applied to a real LSI circuit and so forth.

Owner:KK TOSHIBA

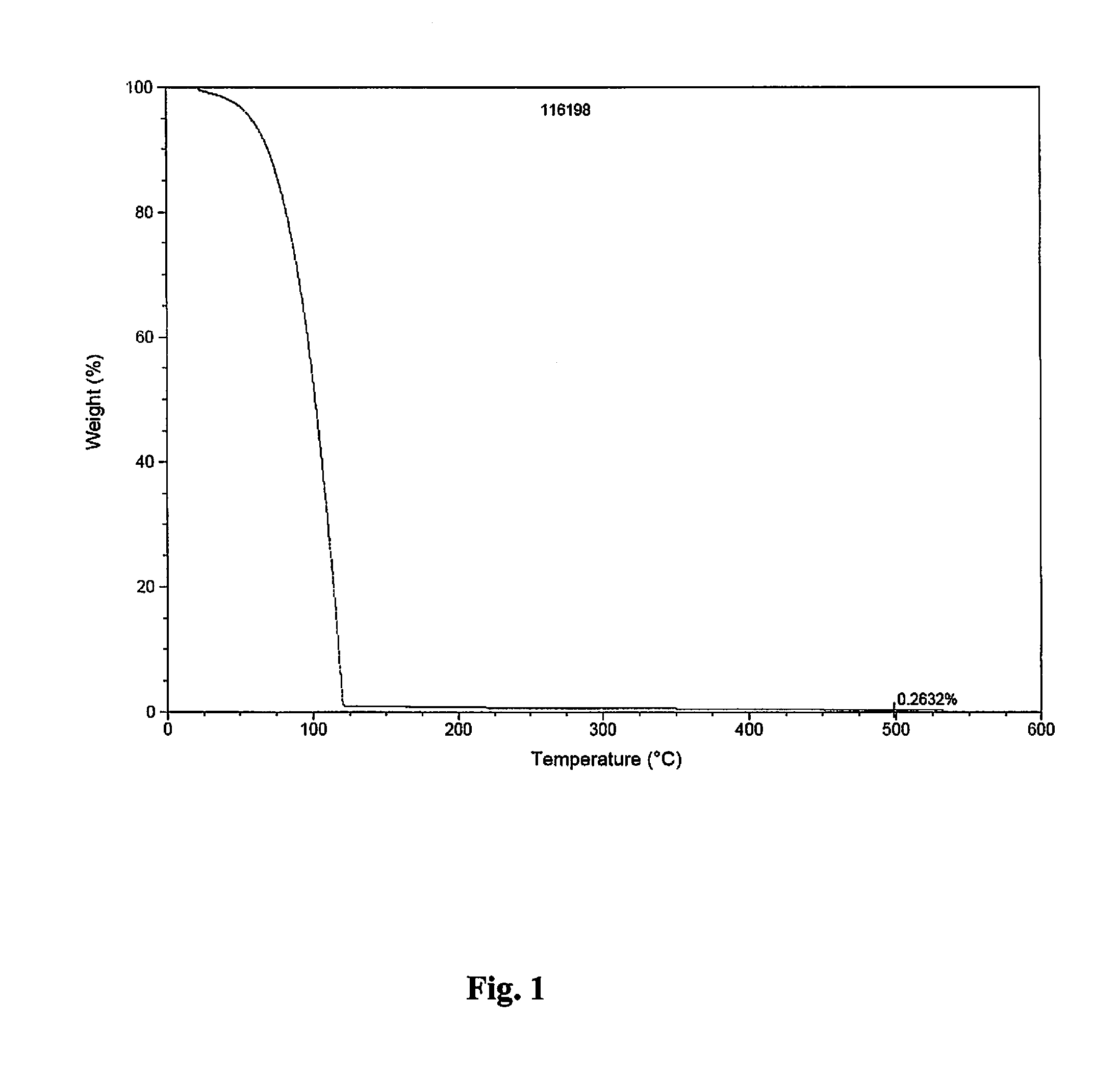

Process for producing aluminum oxide films at low temperatures

InactiveUS20020106451A1Solid-state devicesVacuum evaporation coatingOxygenOrganic electroluminescence

A process for producing aluminum oxide thin films on a substrate by the ALD method comprises the steps of bonding a vaporizable aluminum compound to a growth substrate, and converting the bonded organoaluminum compound to aluminum oxide. The bonded aluminum compound is converted to aluminum oxide by contacting it with a reactive vapor source of oxygen other than water, and the substrate is kept at a temperature of less than 190° C. during the growth process. By means of the invention it is possible to produce films of good quality at low temperatures. The dielectric thin films having a dense structure can be used for passivating surfaces that do not endure high temperatures. Such surfaces include, for example, polymer films such as organic electroluminescent displays. Further, when a water-free oxygen source is used, surfaces that are sensitive to water can be passivated.

Owner:ASM INTERNATIONAL

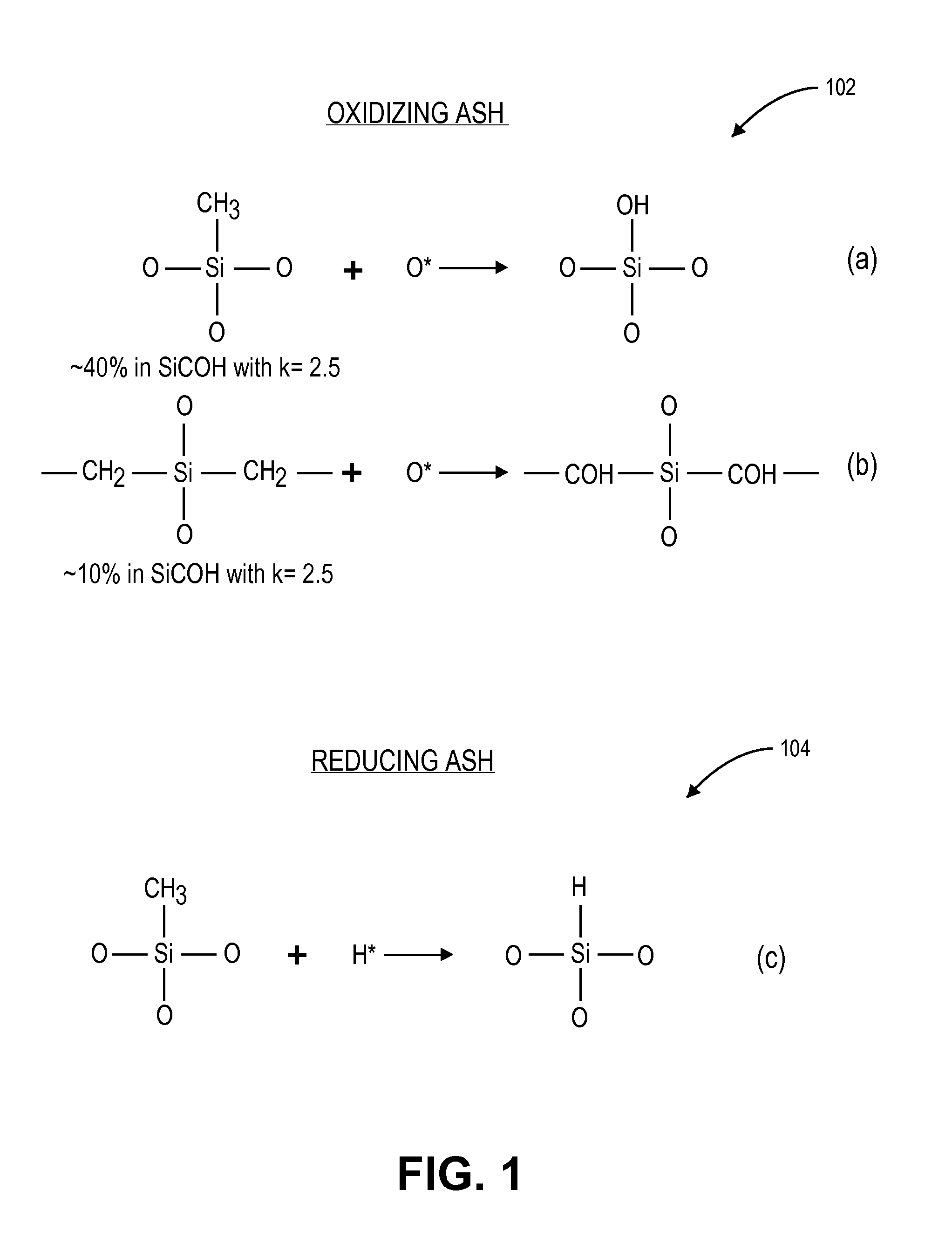

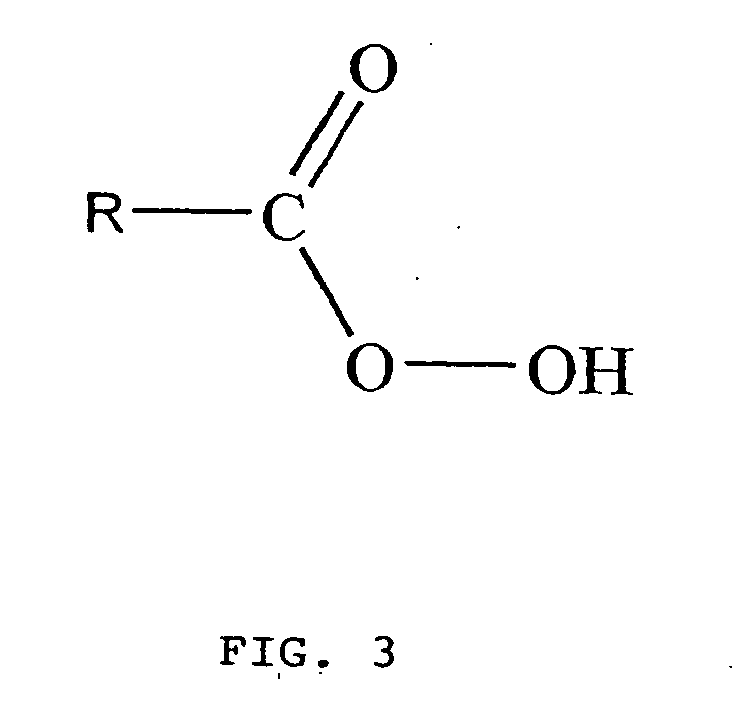

Recovery of hydrophobicity of low-k and ultra low-k organosilicate films used as inter metal dielectrics

InactiveUS7179758B2Low costHigh mechanical strengthSolid-state devicesSemiconductor/solid-state device manufacturingChemical treatmentPolymer science

Often used to reduce the RC delay in integrated circuits are dielectric films of porous organosilicates which have a silica like backbone with alkyl or aryl groups (to add hydrophobicity to the materials and create free volume) attached directly to the Si atoms in the network. Si—R bonds rarely survive an exposure to plasmas or chemical treatments commonly used in processing; this is especially the case in materials with an open cell pore structure. When Si—R bonds are broken, the materials lose hydrophobicity, due to formation of hydrophilic silanols and low dielectric constant is compromised. A method by which the hydrophobicity of the materials is recovered using a novel class of silylation agents which may have the general formula (R2N)XSiR′Y where X and Y are integers from 1 to 3 and 3 to 1 respectively, and where R and R′ are selected from the group of hydrogen, alkyl, aryl, allyl and a vinyl moiety. Mechanical strength of porous organosilicates is also improved as a result of the silylation treatment.

Owner:GLOBALFOUNDRIES INC

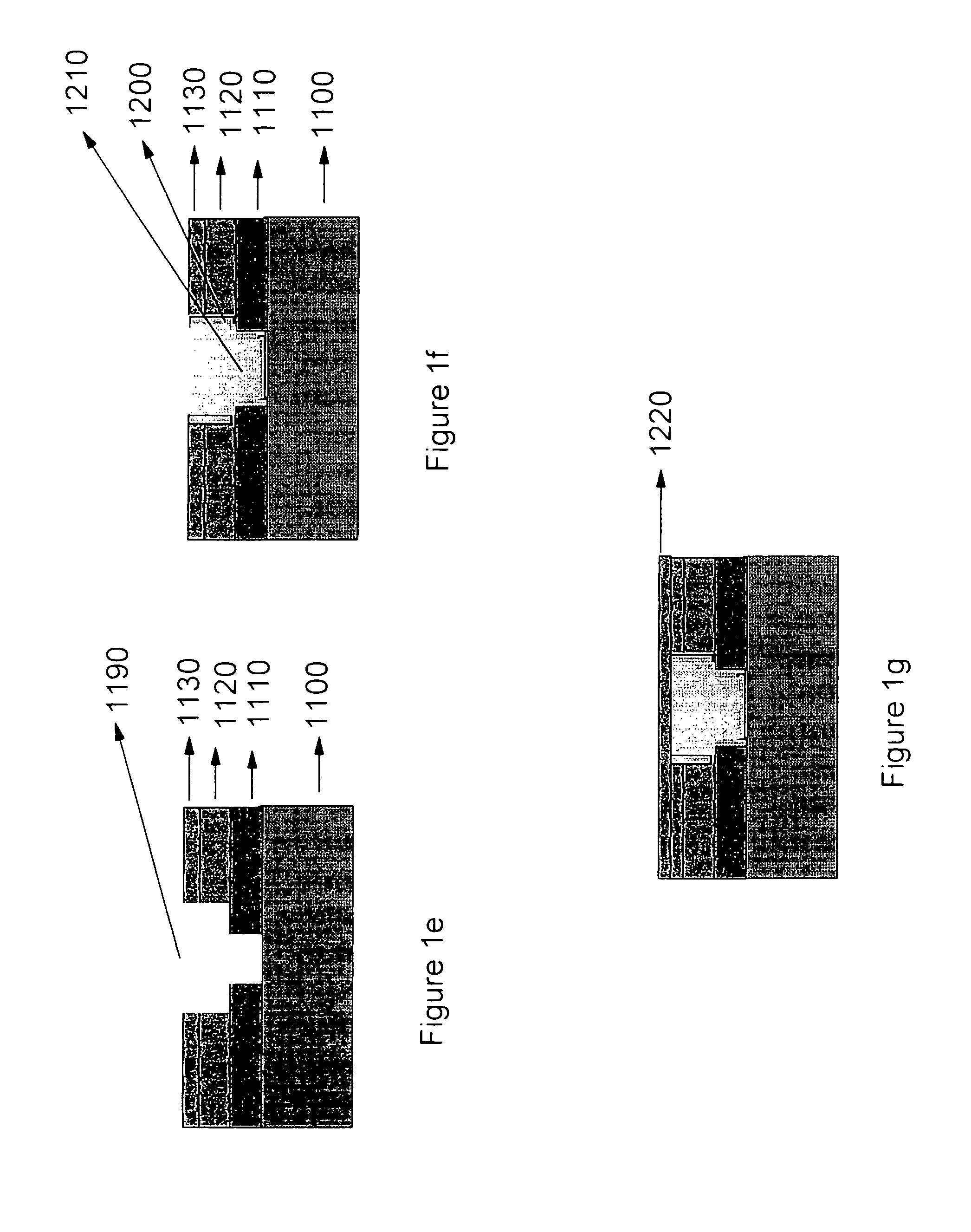

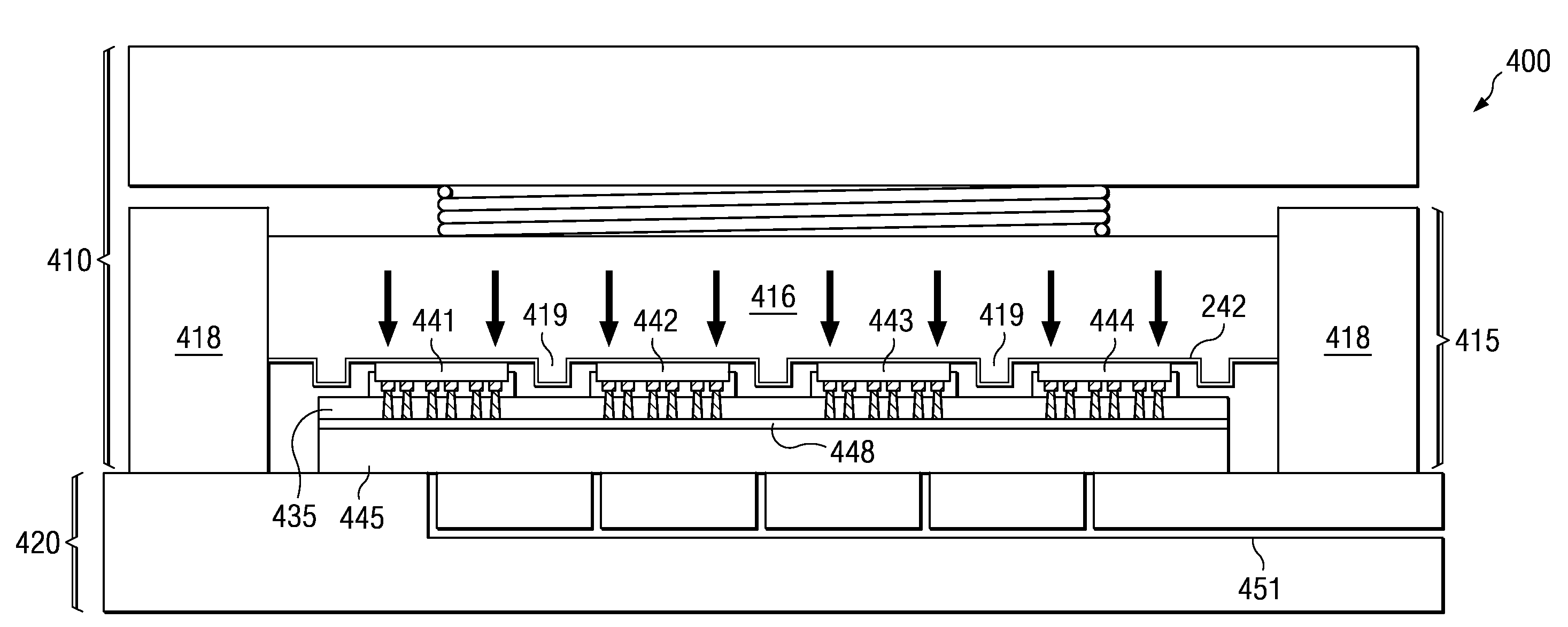

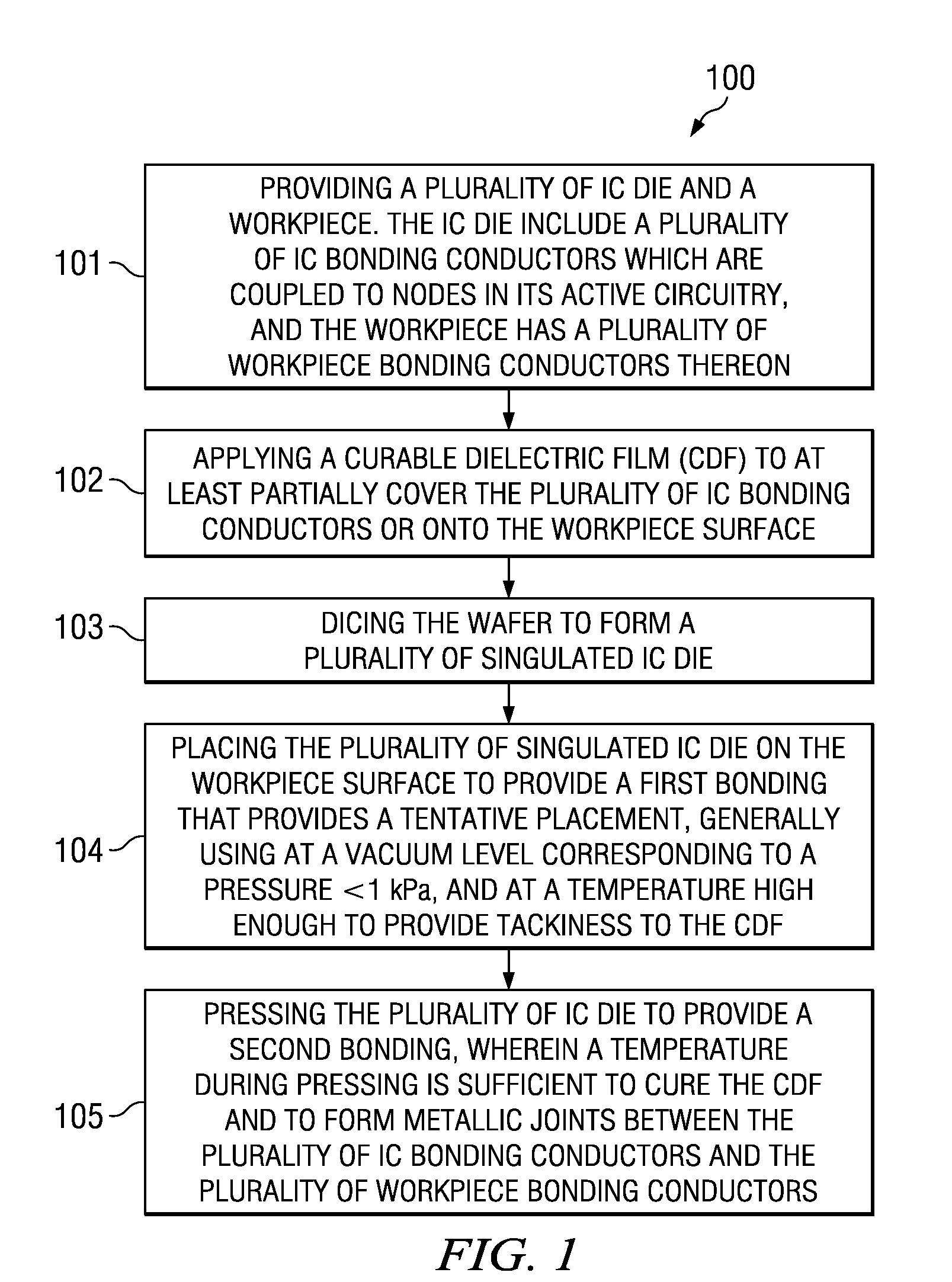

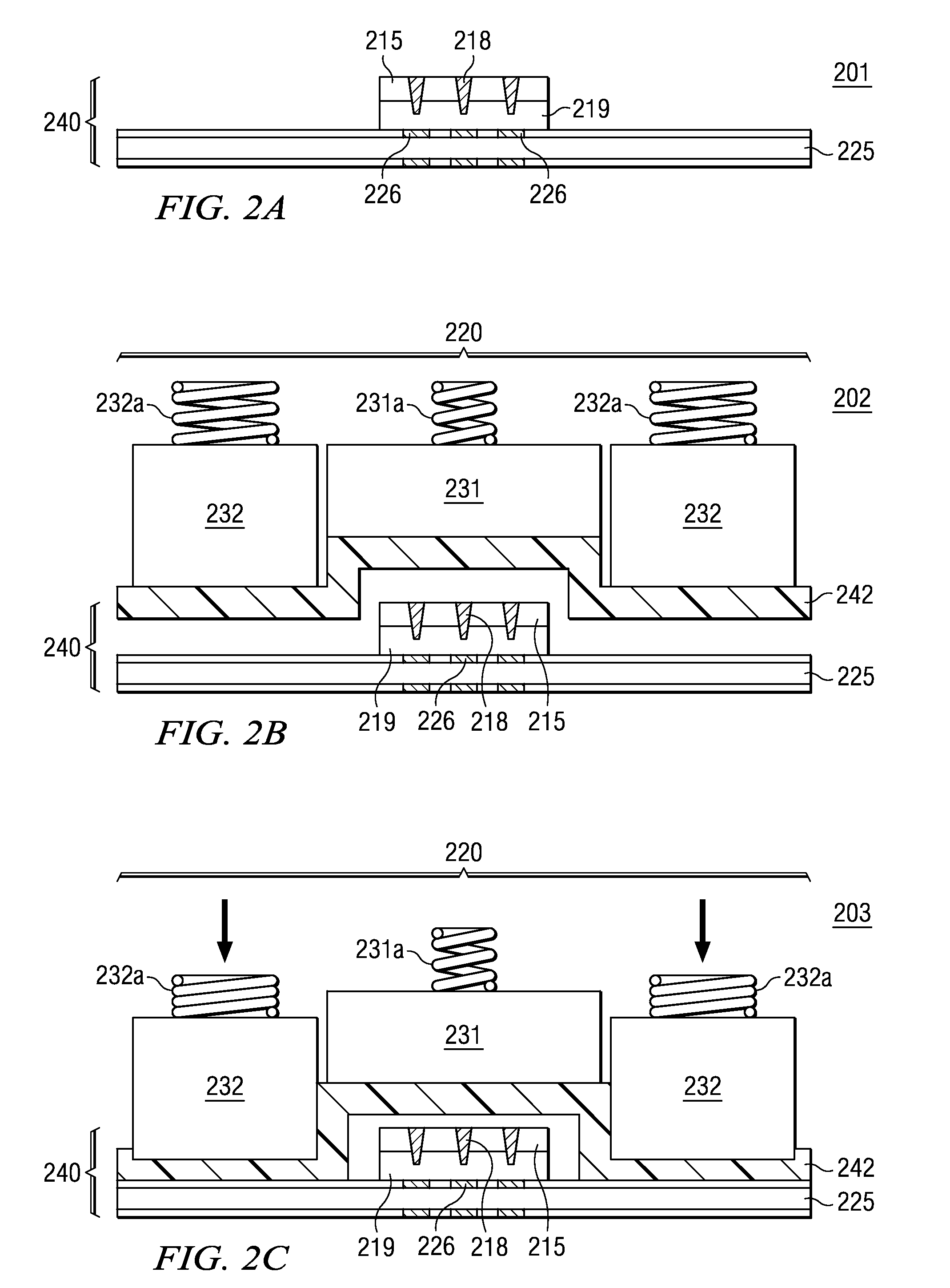

Combined metallic bonding and molding for electronic assemblies including void-reduced underfill

ActiveUS20090291524A1Small sizeReducing joint misalignmentCasting safety devicesSolid-state devicesElectrical conductorDielectric membrane

A method for forming electronic assemblies includes providing a plurality of IC die each having IC bonding conductors and a workpiece having workpiece bonding conductors. A curable dielectric film is applied to the IC bonding conductors or the workpiece surface. The plurality of IC die are placed on the workpiece surface so that the plurality of IC bonding conductors are aligned to and face the plurality of workpiece bonding conductors to provide a first bonding. The placing is performed at a vacuum level corresponding to a pressure <1 kPa, and at a temperature sufficient to provide tackiness to the curable dielectric film. The plurality of IC die are then pressed to provide a second bonding. A temperature during pressing cures the curable dielectric film to provide an underfill and forms metallic joints between the plurality of IC bonding conductors and the plurality of workpiece bonding conductors.

Owner:TEXAS INSTR INC

Holographic displays with high resolution

InactiveUS20120019883A1Holographic light sources/light beam propertiesActive addressable light modulatorElectricityHigh density

Provided is a holographic display that realizes a high-resolution three-dimensional (3D) image as a spatial light modulation panel system having a fast response time and enabling the formation of high-density pixels is developed. The holographic display includes, a spatial light modulator using a polymer thin film or a dielectric thin film that enable the formation of high-density pixels and has a fast response time, a fine displacement panel system sequentially moving the spatial light modulator in synchronization with a hologram fringe signal, and an optical system including a coherent light source, a spatial light modulation panel system, and an optical element that are efficiently disposed. The holographic display has a feature that realizes a high-resolution 3D image in a scheme that integrates and displays an image while sequentially moving a spatial light modulator simply or overlaps a hologram fringe pattern.

Owner:ELECTRONICS & TELECOMM RES INST

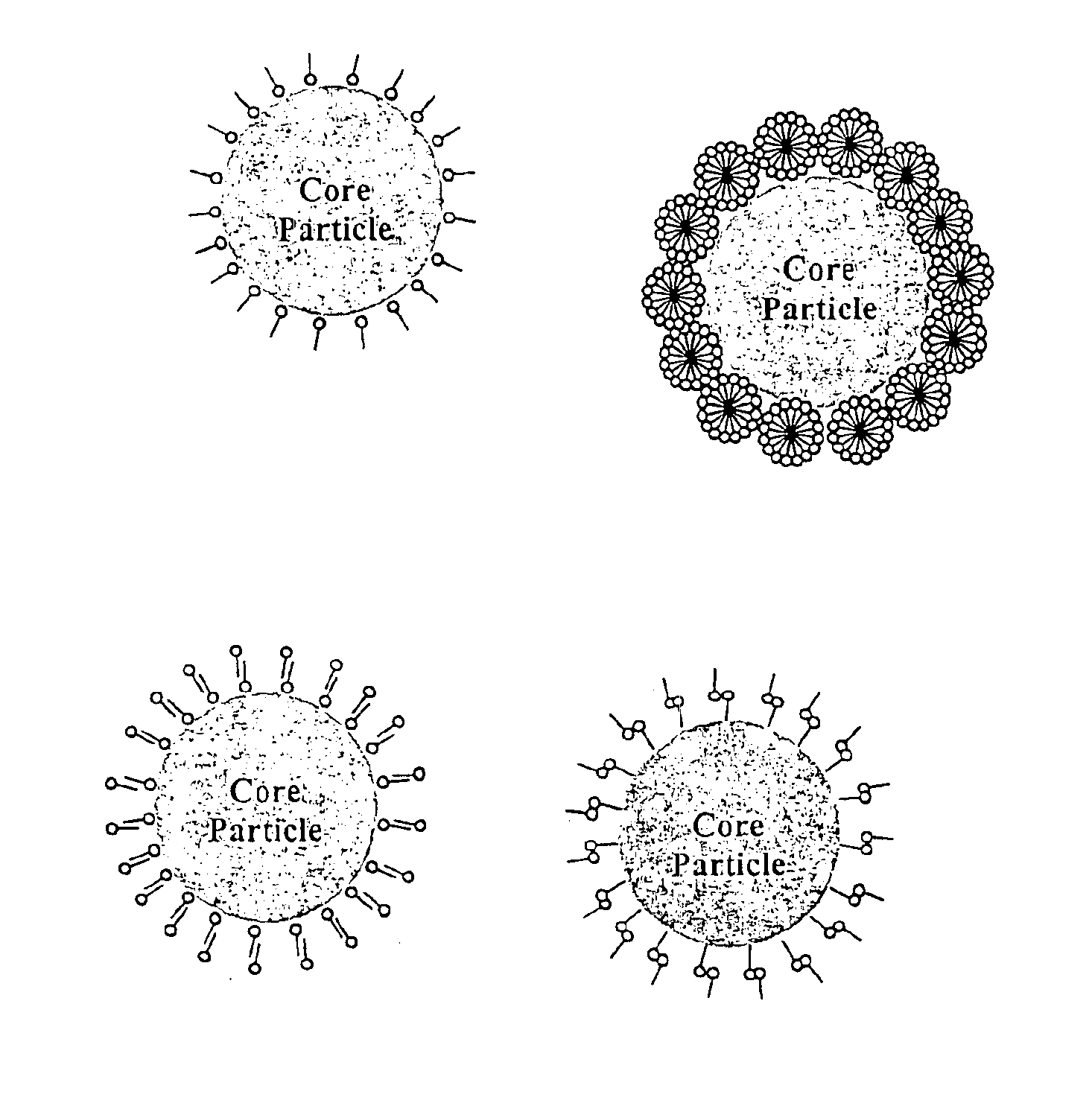

High selectivity and high planarity dielectric polishing

InactiveUS6866793B2Efficiently planarizedImprove planarization efficiencyPolycrystalline material growthFrom normal temperature solutionsSlurryDielectric structure

A slurry includes a plurality of particles and at least one selective adsorption additive. The particles are preferably composite particles including a core surrounded by a shell provided by the selective adsorption additive. The slurry can be used to polish a structure including silicon dioxide or a low K dielectric film and a silicon nitride containing film, such as to form a shallow trench isolation (STI) structure or a metal-dielectric structure. The silicon nitride containing film surface substantially adsorbs the selective adsorption additive, whereas the silicon dioxide or low K dielectric film shows non-substantial adsorption characteristics to the adsorption additive. In another embodiment of the invention, silicon dioxide or low K dielectric film shows non-substantial adsorption of the selective adsorption additive at a pressure above a predetermined first pressure, and substantial adsorption of the selective adsorption additive for pressures below a predetermined second pressure, where the first pressure is greater than the second pressure.

Owner:UNIV OF FLORIDA

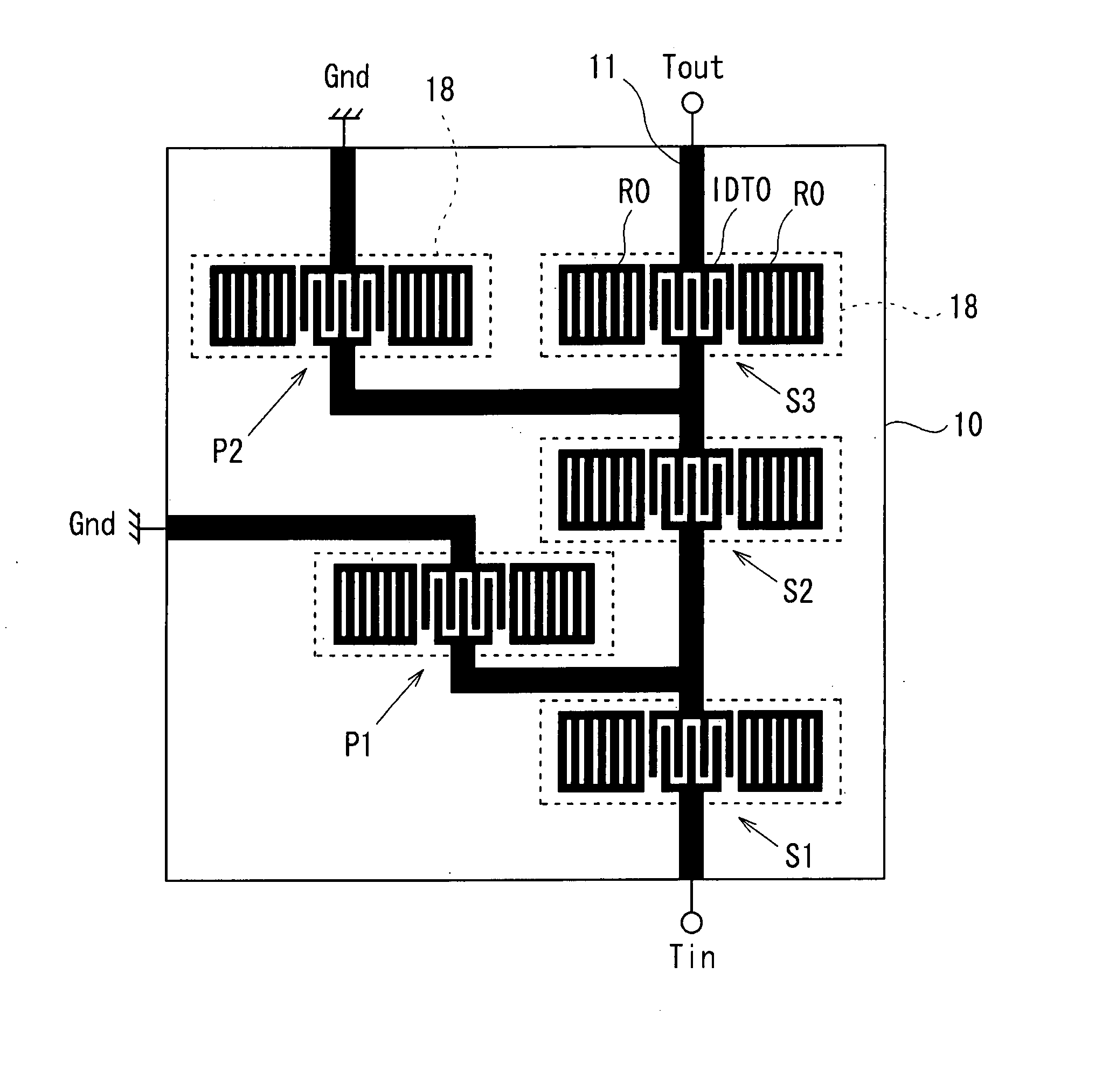

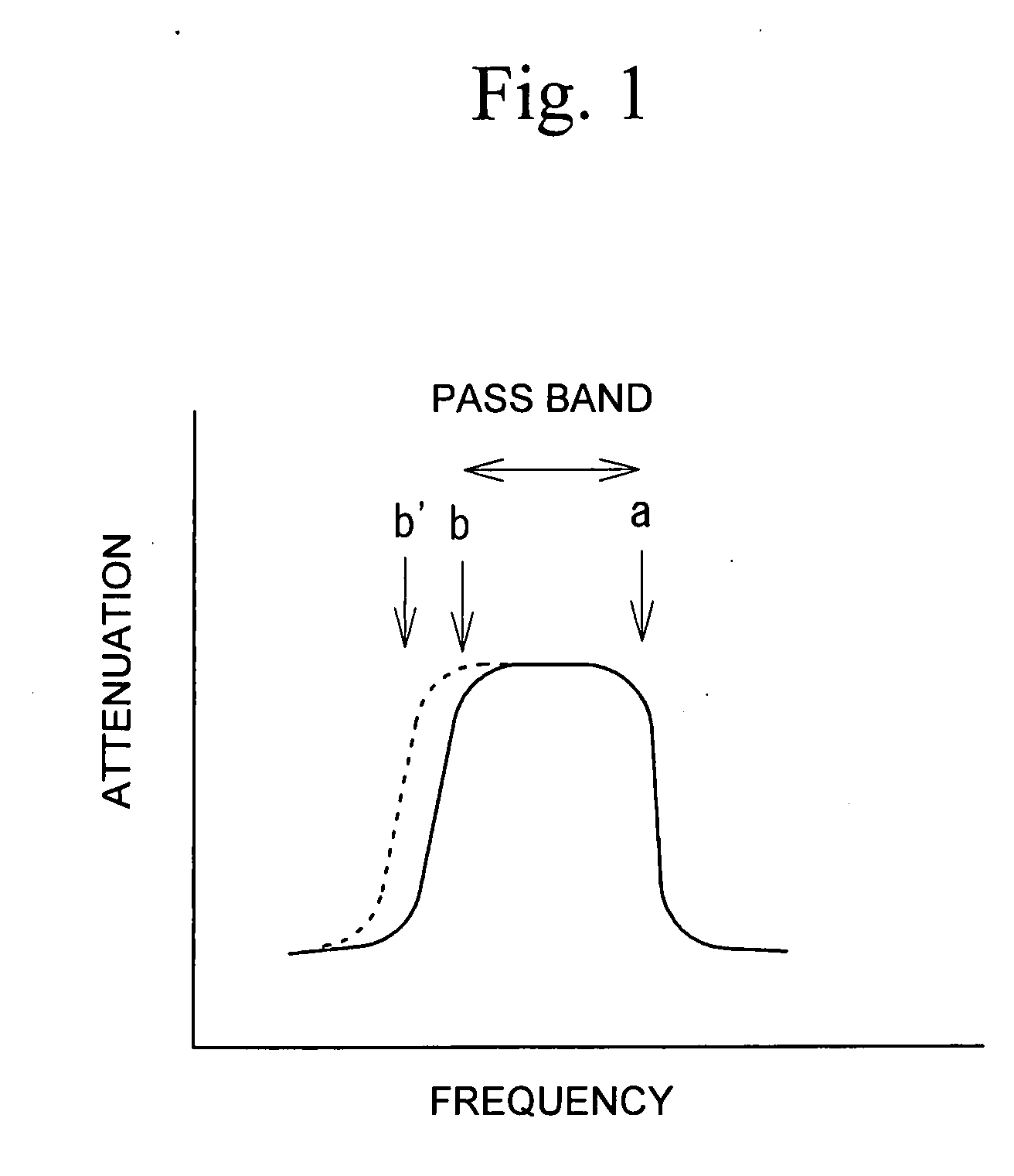

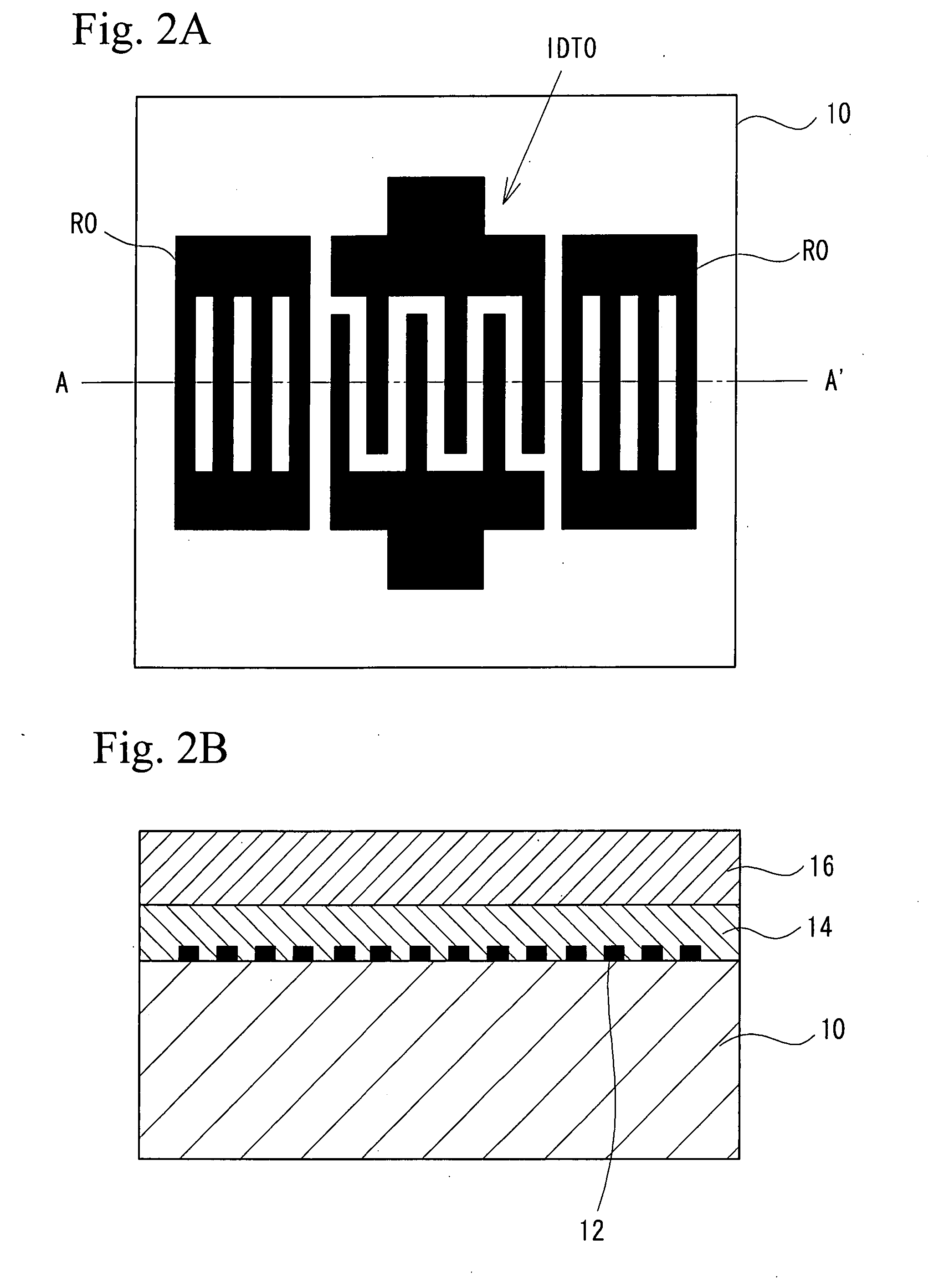

Acoustic wave device, resonator and filter

ActiveUS20080074212A1Reduction in TCFImpedence networksPiezoelectric/electrostriction/magnetostriction machinesAcoustic waveDielectric thin films

A filter includes a parallel resonator having first comb electrodes provided on a piezoelectric substrate and a first dielectric film that covers the first comb electrodes, and a series resonator having second comb electrodes provided on the piezoelectric substrate and a second dielectric film covers the second comb electrodes and is made of a material identical to that of the first dielectric film. The first dielectric film has a different thickness from that of the second dielectric film.

Owner:TAIYO YUDEN KK

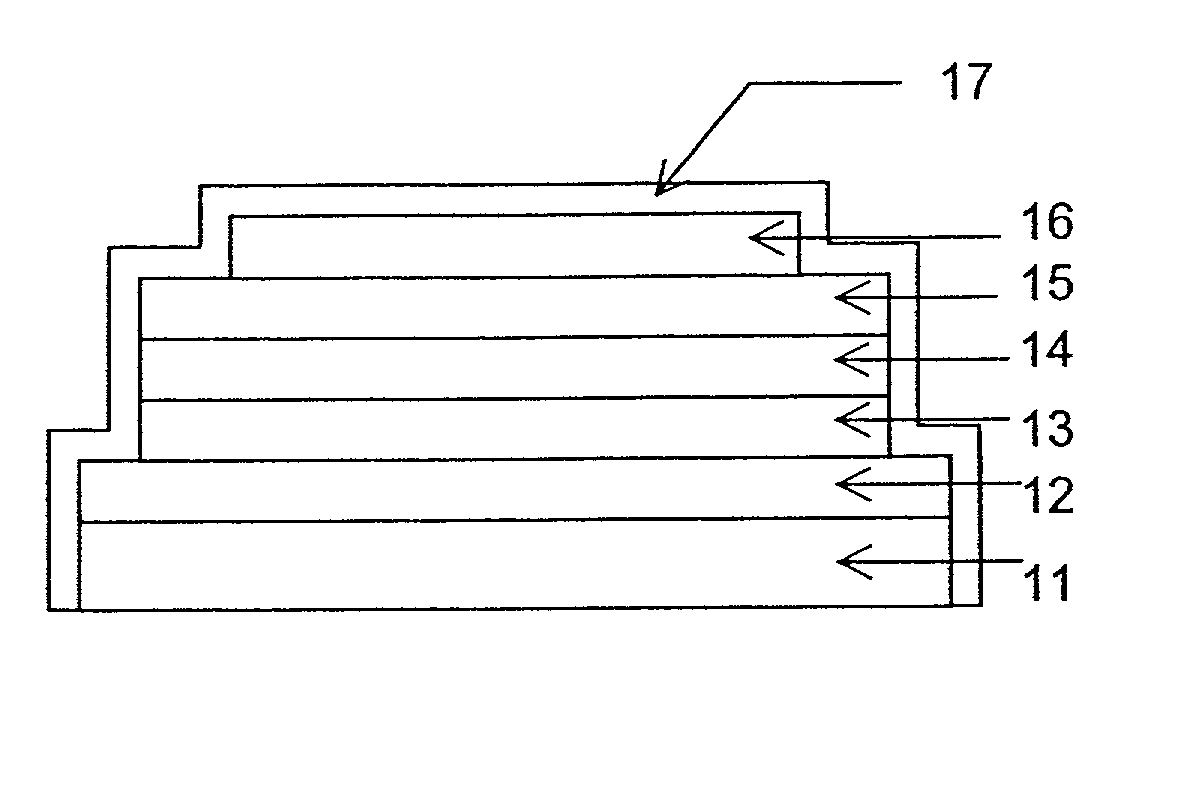

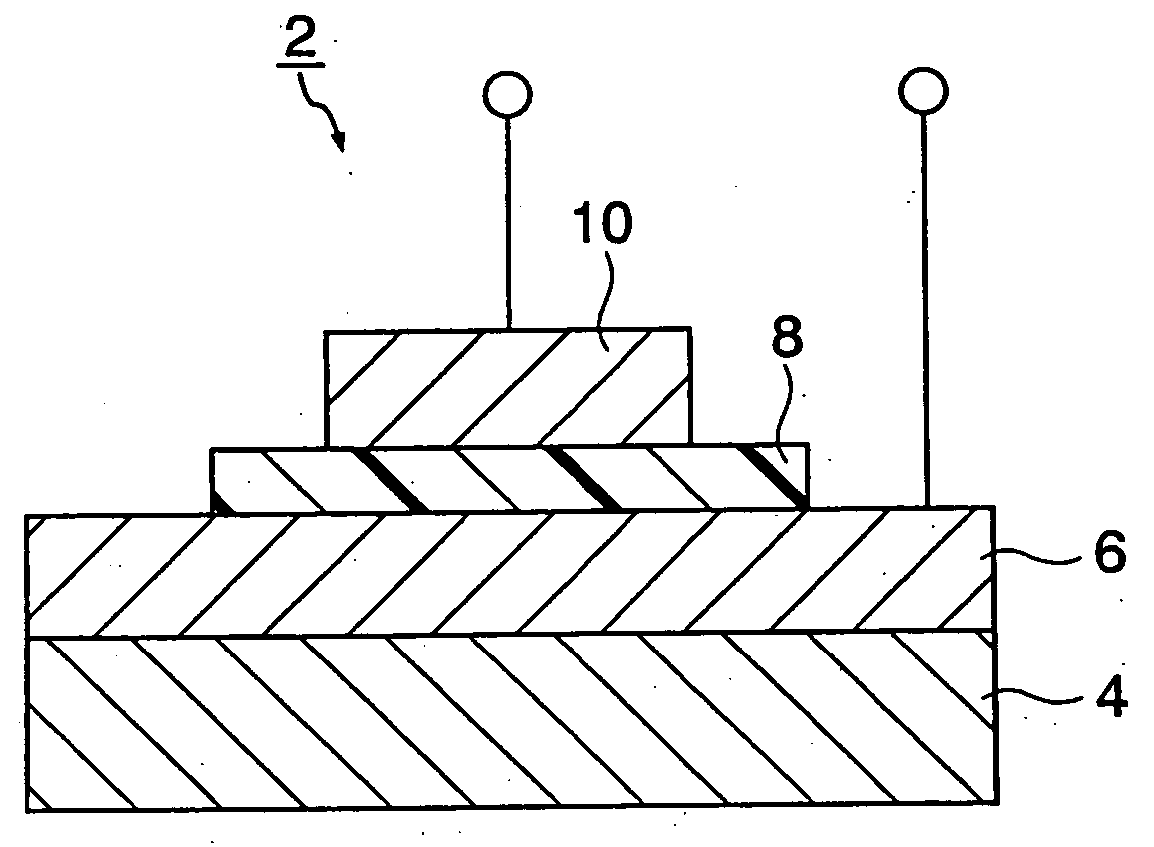

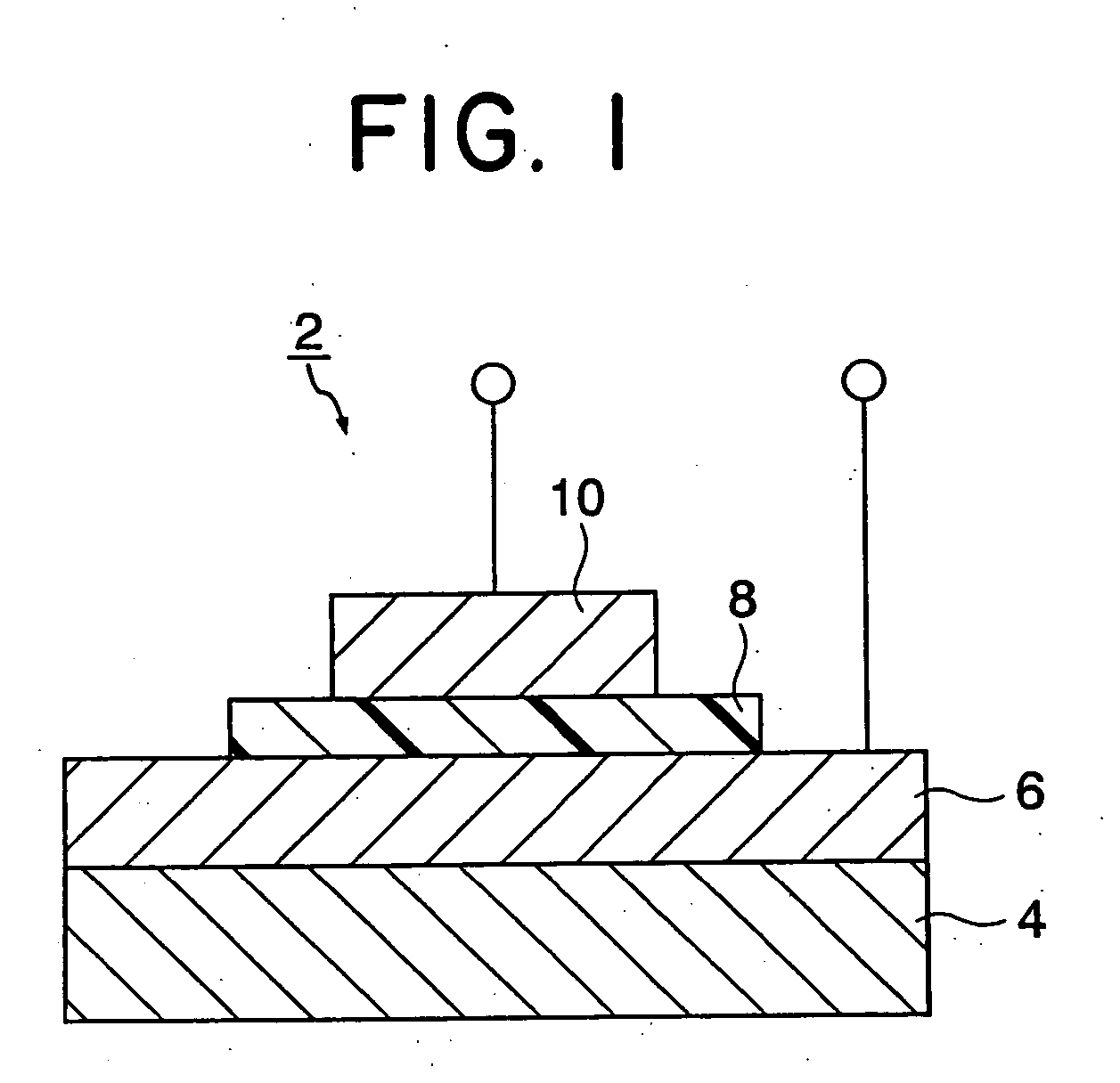

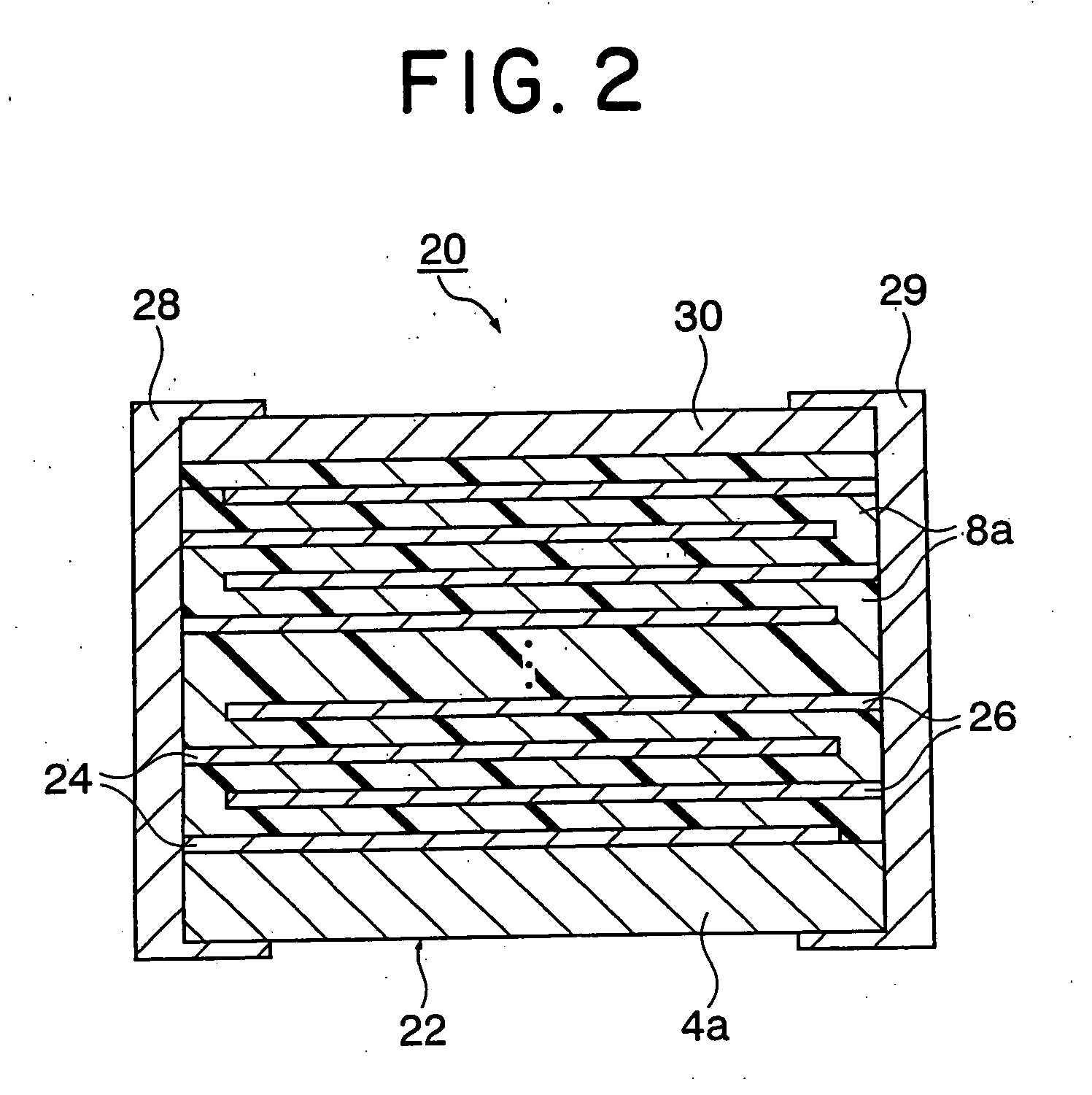

Compositions for thin-film capacitive device, high-dielectric constant insulating film, thin-film capacitance device, and thin-film multilayer ceramic capacitor

InactiveUS20040245561A1Good temperature characteristicsHigh dielectric constantTransistorThin/thick film capacitorCapacitanceCeramic capacitor

A thin-film capacitor (2) in which a lower electrode (6), a dielectric thin-film (8), and an upper electrode (10) are formed in order on a substrate (4). The dielectric thin-film (8) is made of a composition for thin-film capacitance devices. The composition includes a bismuth layer-structured compound whose c-axis is oriented vertically to the substrate and which is expressed by a formula: (Bi2O2)<2+>(Am-1BmO3m+1)<2->, or Bi2Am-1BmO3m+3 wherein "m" is an even number, "A" is at least one element selected from Na, K, Pb, Ba, Sr, Ca and Bi, and "B" is at least one element selected from Fe, Co, Cr, Ga, Ti, Nb, Ta Sb, V, Mo and W. The temperature characteristics of the dielectric constant are excellent. Even if the dielectric thin-film is made more thinner, the dielectric constant is relatively high, and the loss is small. The leak characteristics are excellent, the break-down voltage is improved and the surface smoothness is excellent.

Owner:TDK CORPARATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com