Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

482 results about "Fringe pattern" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fringe pattern definition, fringe pattern meaning | English dictionary. fringe. 1 an edging consisting of hanging threads, tassels, etc. n an incidental or additional advantage, esp. a benefit provided by an employer to supplement an employee's regular pay, such as a pension, company car, luncheon vouchers, etc.

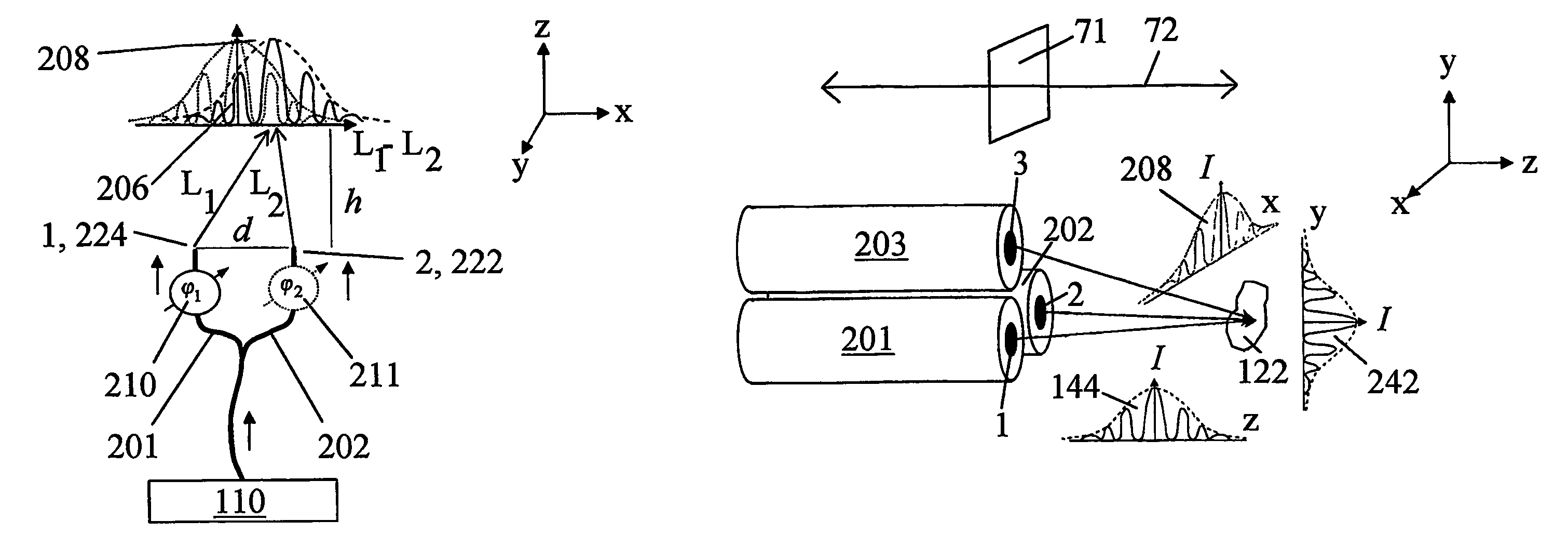

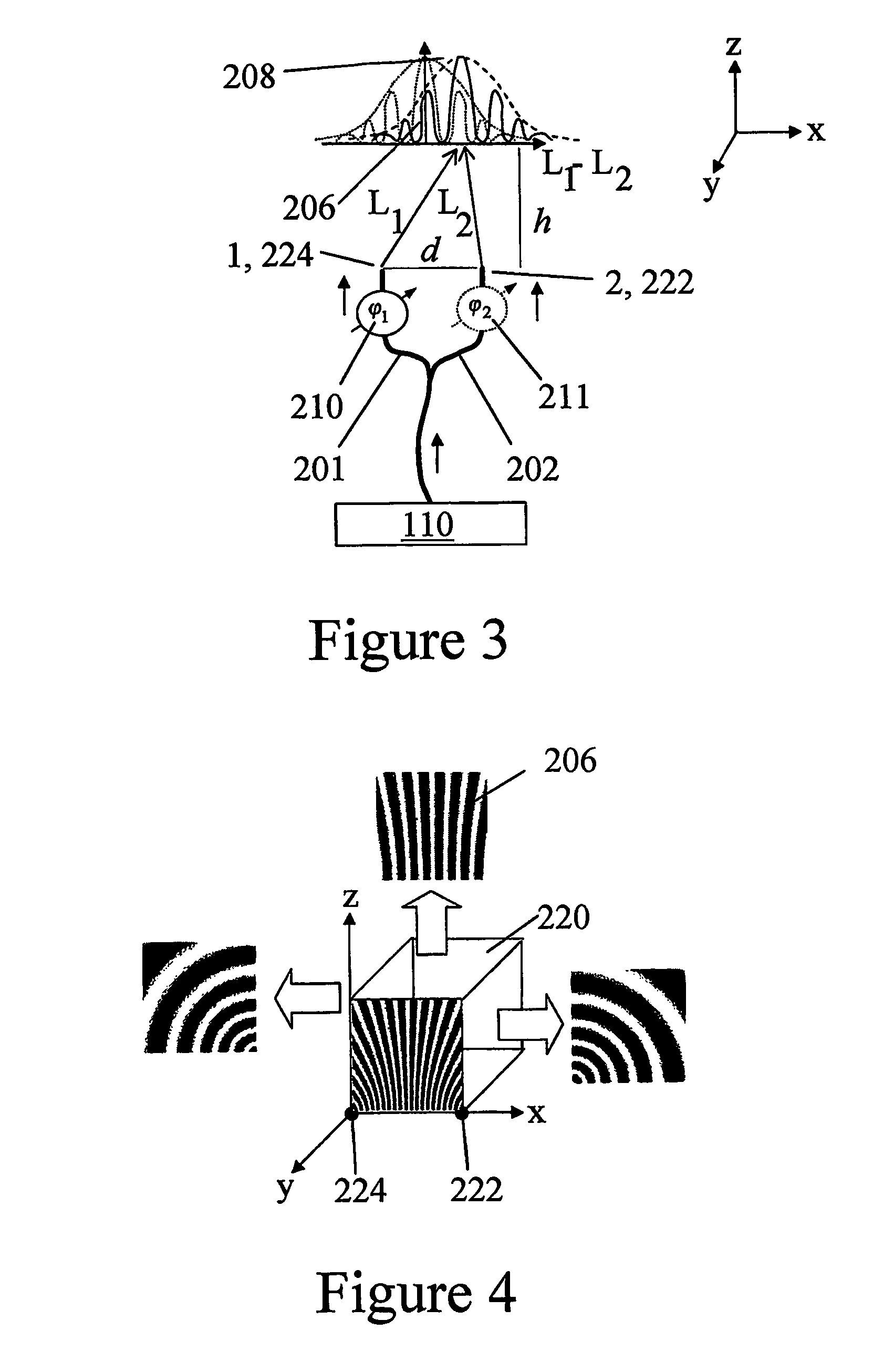

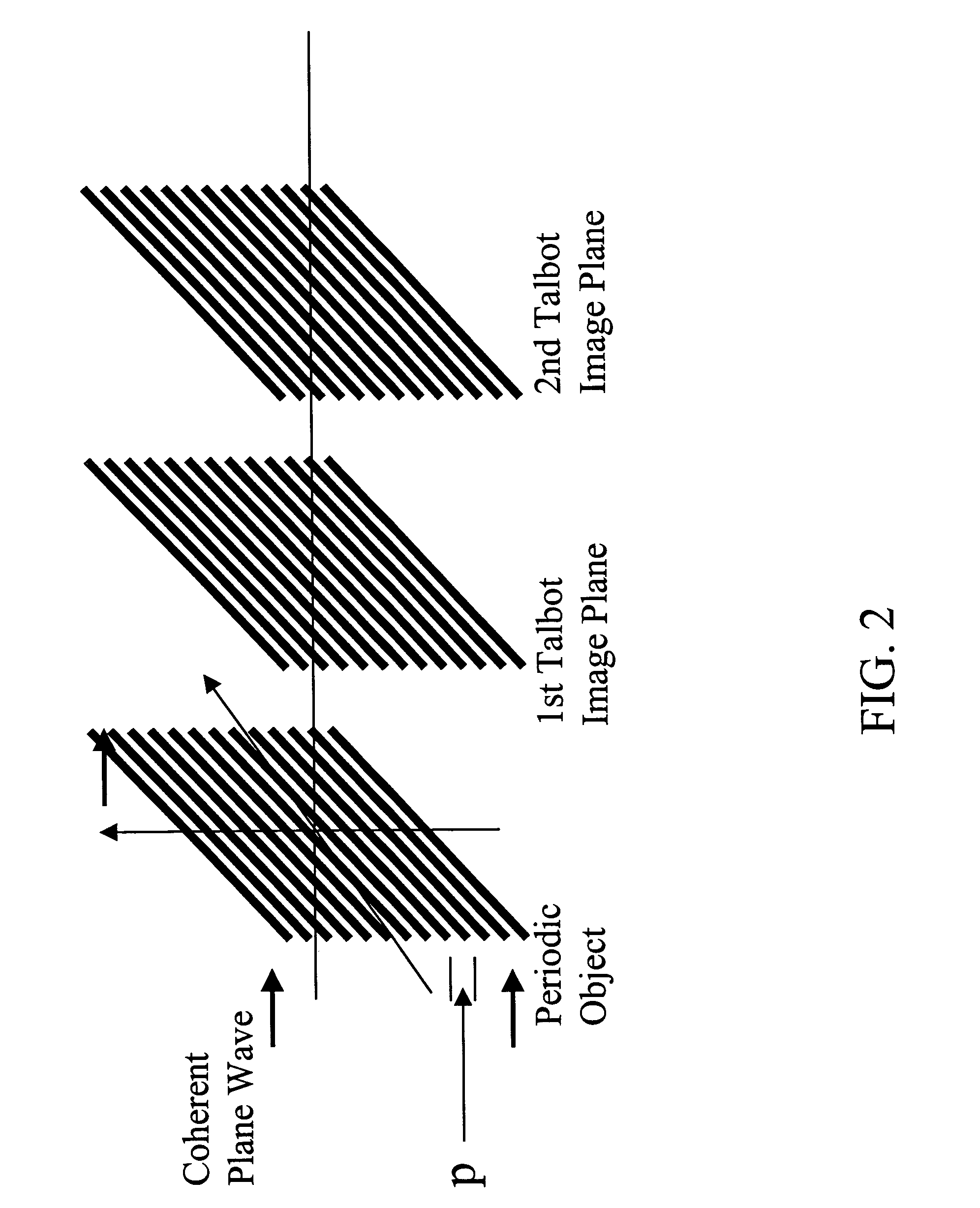

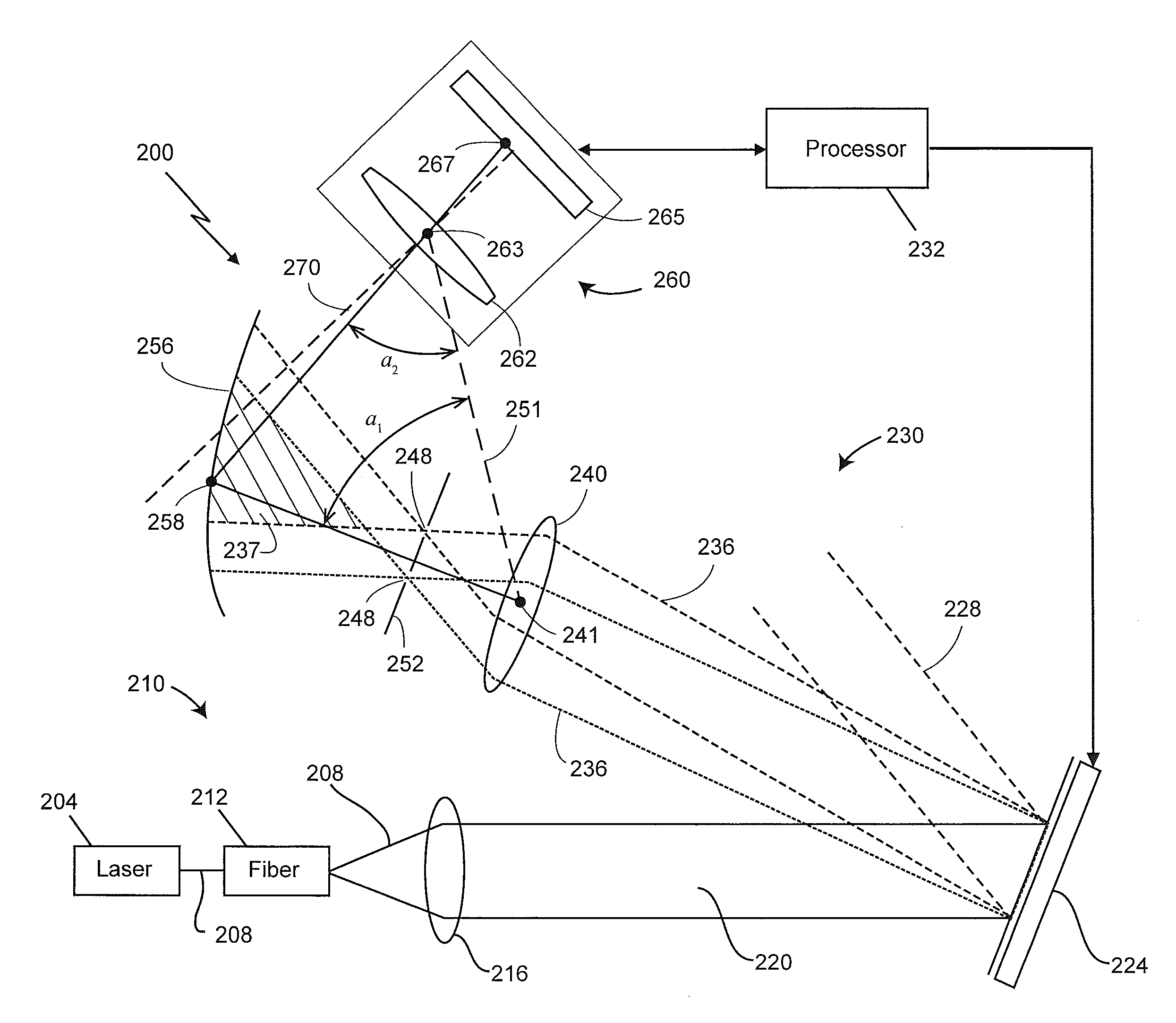

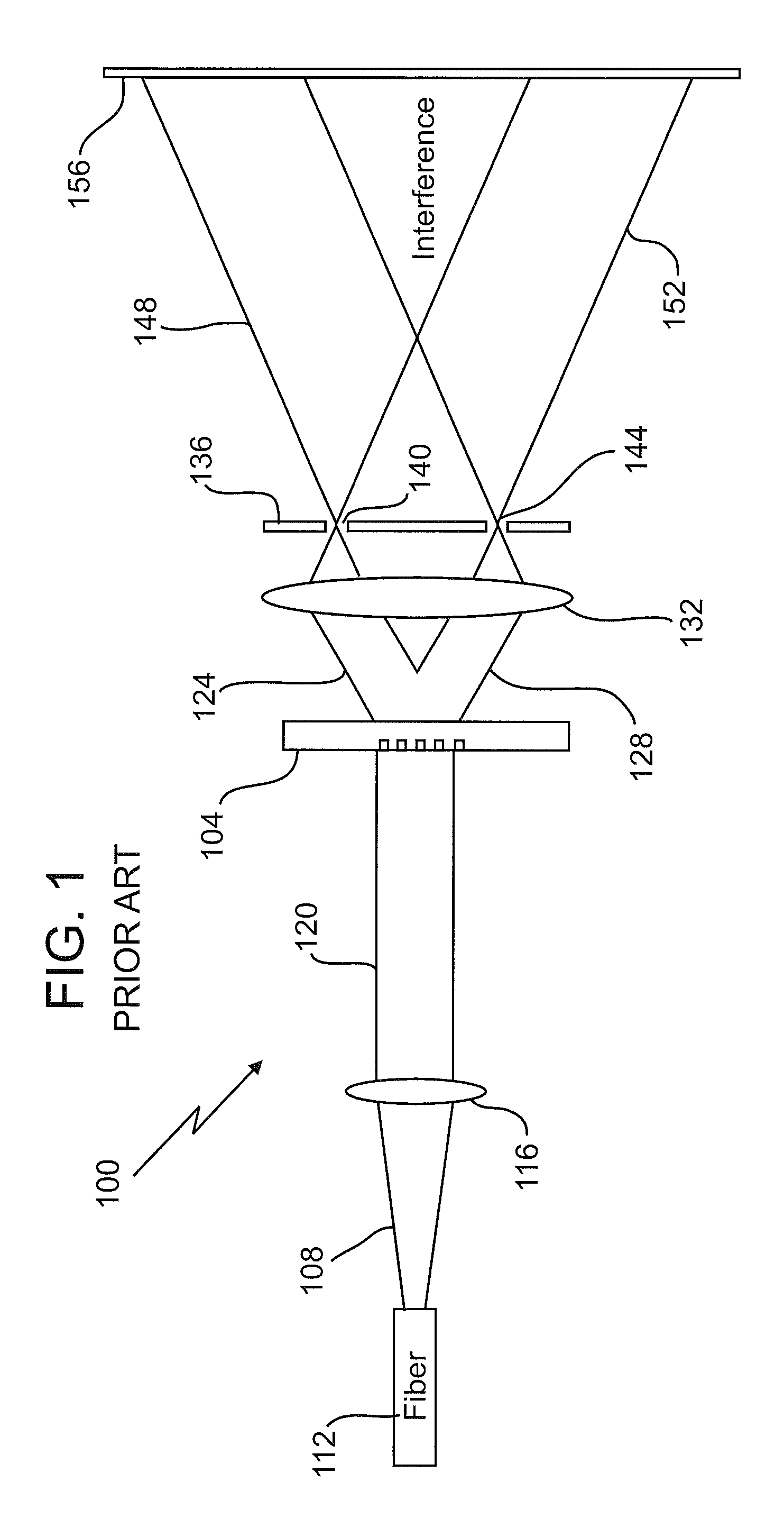

Optical coherence tomography with 3d coherence scanning

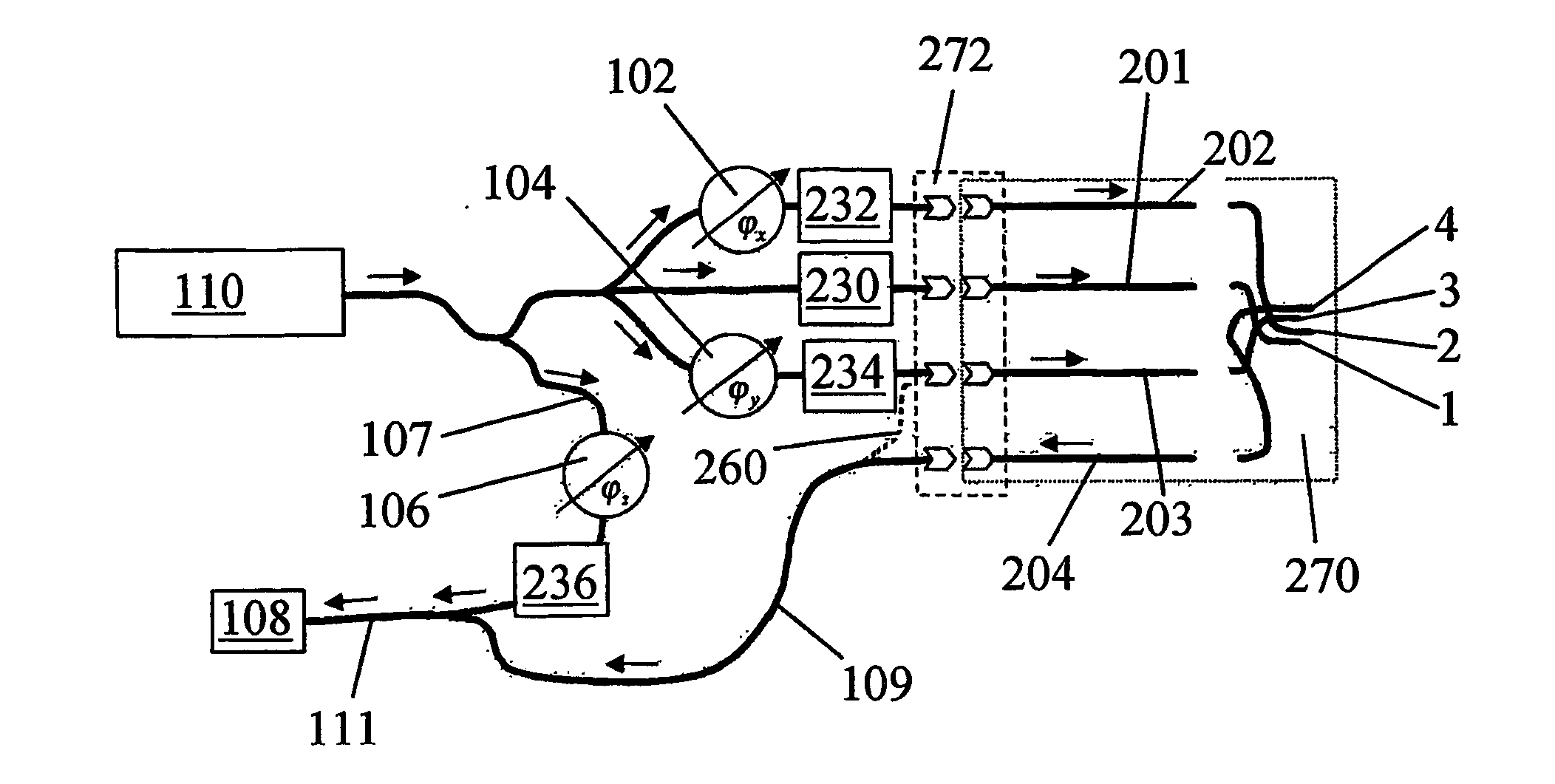

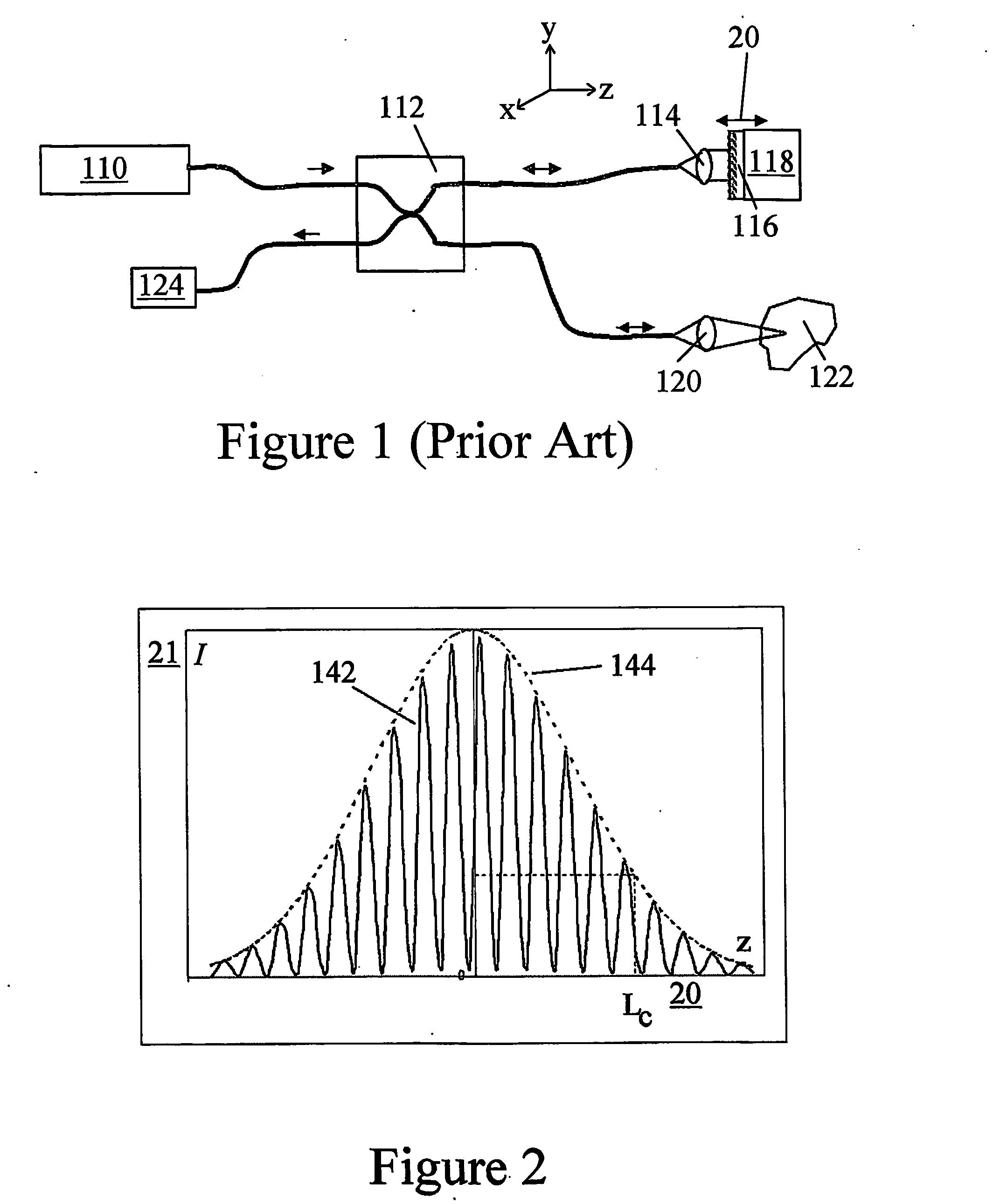

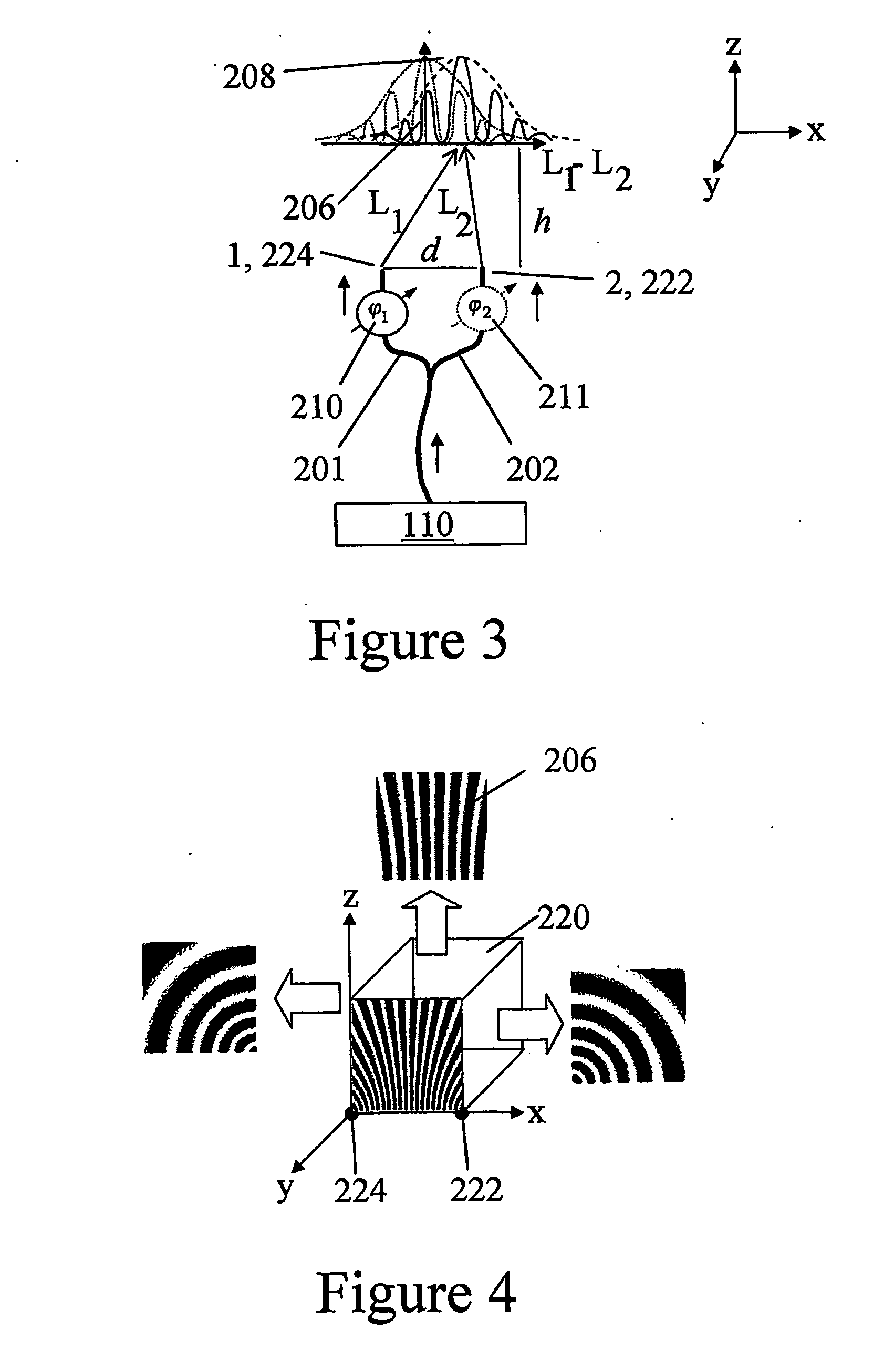

Optical coherence tomography with 3D coherence scanning is disclosed, using at least three fibers (201, 202, 203) for object illumination and collection of backscattered light. Fiber tips (1, 2, 3) are located in a fiber tip plane (71) normal to the optical axis (72). Light beams emerging from the fibers overlap at an object (122) plane, a subset of intersections of the beams with the plane defining field of view (266) of the optical coherence tomography apparatus. Interference of light emitted and collected by the fibers creates a 3D fringe pattern. The 3D fringe pattern is scanned dynamically over the object by phase shift delays (102, 104) controlled remotely, near ends of the fibers opposite the tips of the fibers, and combined with light modulation. The dynamic fringe pattern is backscattered by the object, transmitted to a light processing system (108) such as a photo detector, and produces an AC signal on the output of the light processing system (108). Phase demodulation of the AC signal at selected frequencies and signal processing produce a measurement of a 3D profile of the object.

Owner:APPLIED SCI INNOVATIONS +1

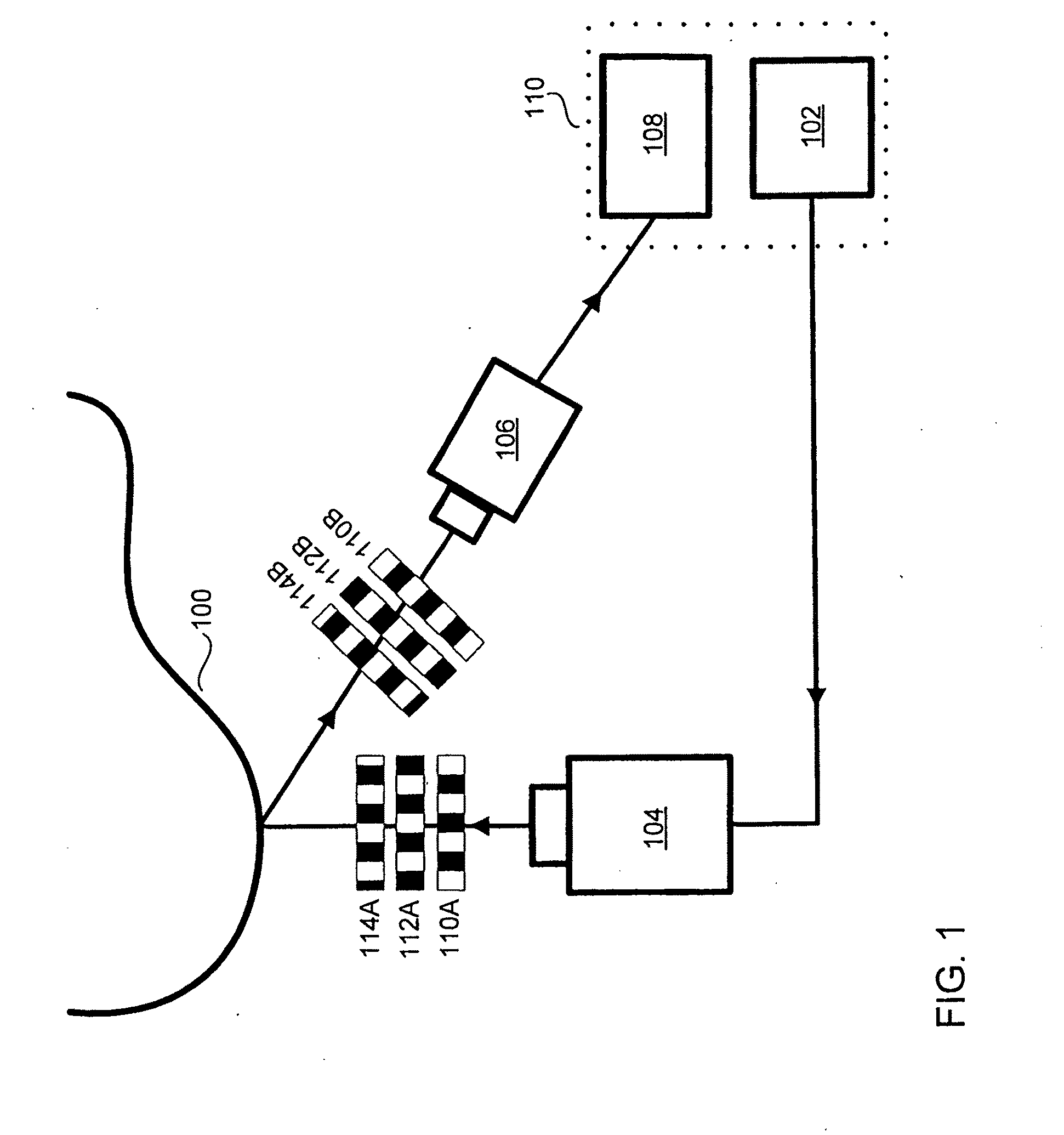

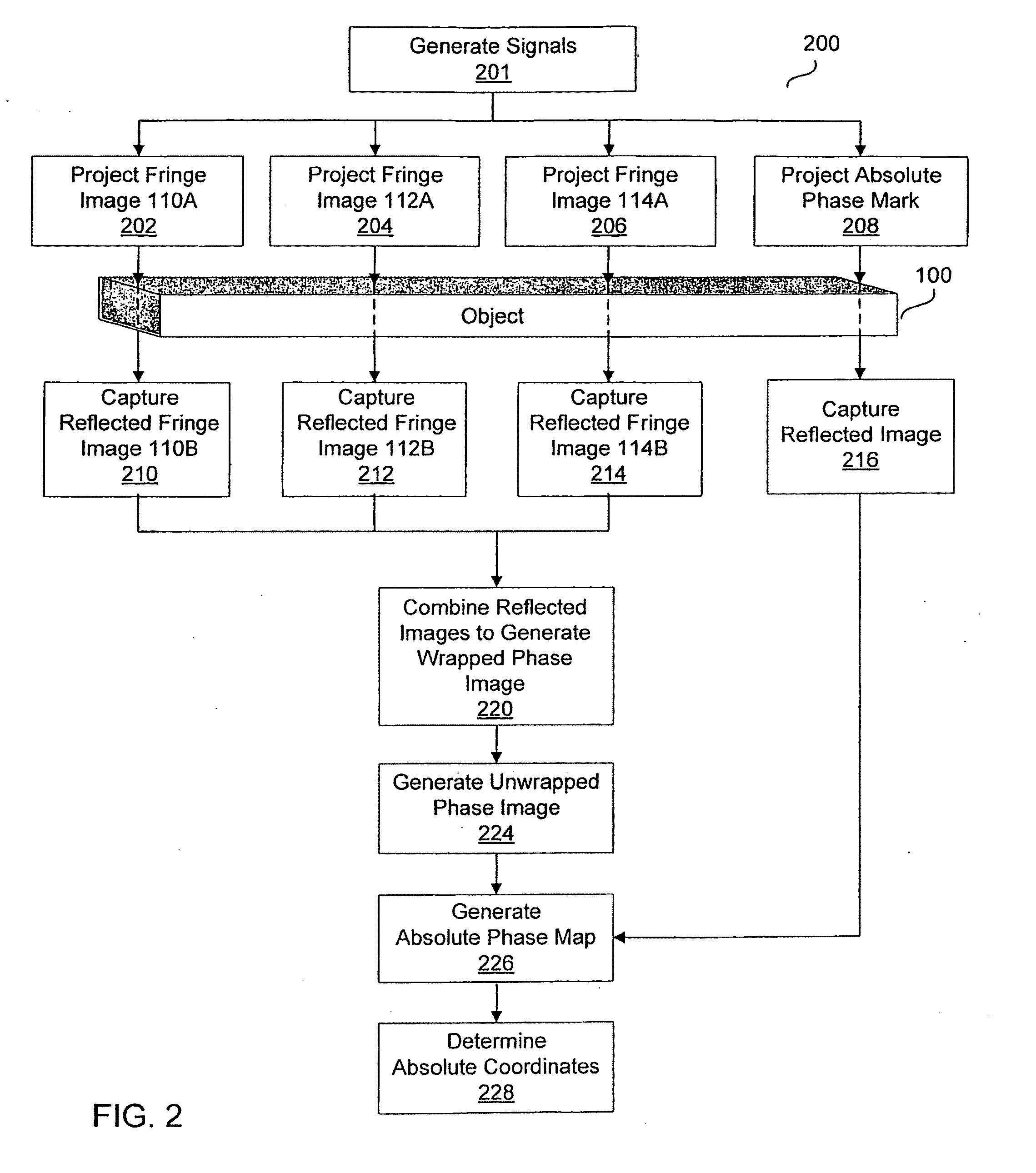

Method and Apparatus for Absolute-Coordinate Three-Dimensional Surface Imaging

InactiveUS20090238449A1Readily displayed and manipulatedSimple structureImage analysisCharacter and pattern recognitionComputer graphics (images)Surface geometry

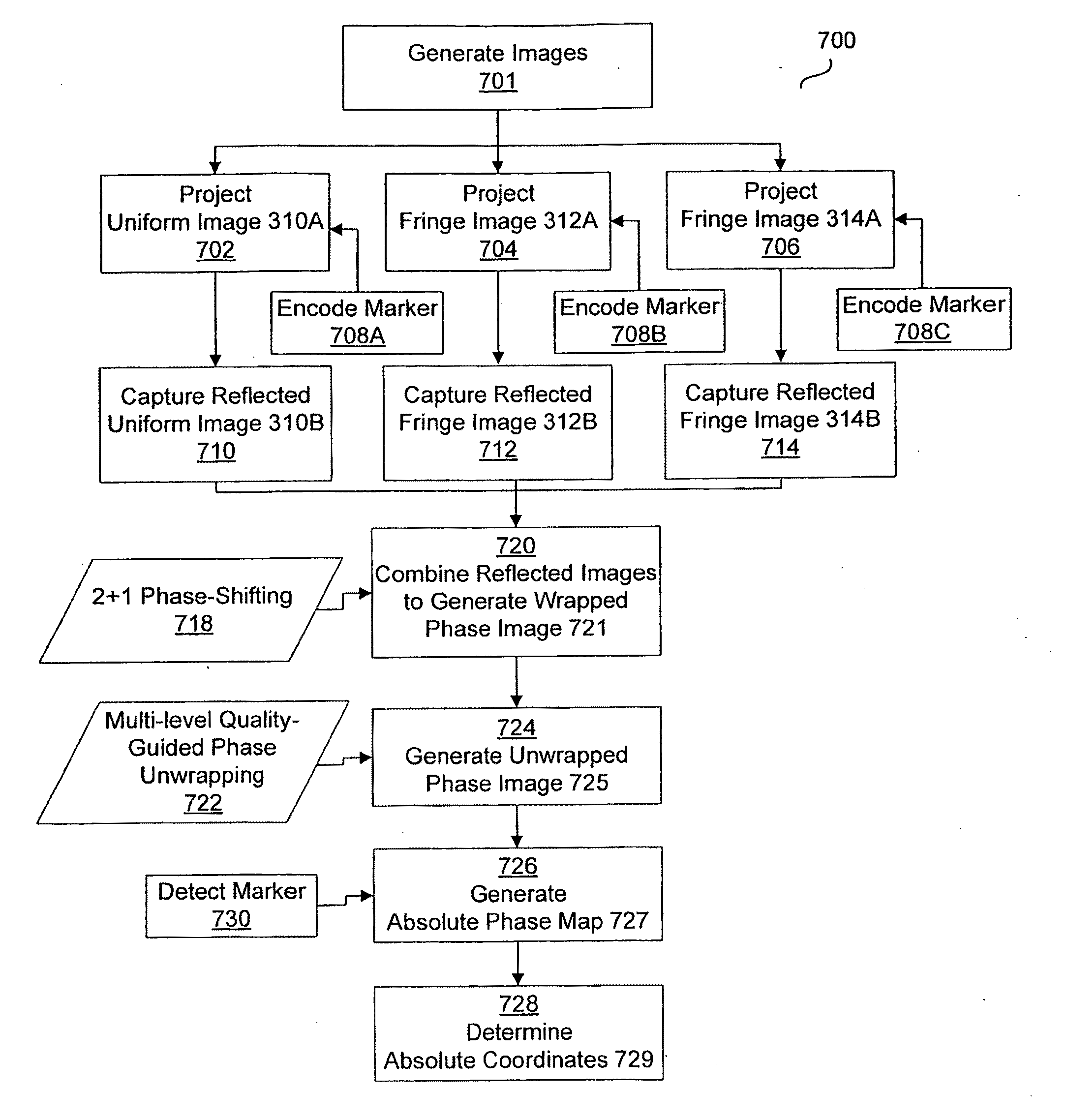

A method and associated apparatus for capturing an image of a 3D object (100) which encodes the surface geometry of at least a portion of the object, comprising: 1. projecting (304) a plurality of fringe patterns (312A, 314A) onto the object; 2. capturing (306) phase alterations in reflections of the fringe patterns (312B, 314B) from the object; 3. projecting a uniform image (310A) onto the object; 4. capturing a reflection of the uniform image (310B) from the object; and 5. combining (310) captured phase alterations and captured uniform image reflection on a pixel-by-pixel basis, thereby forming a holoimage representation of the object.

Owner:HANGZHOU CONFORMAL & DIGITAL TECH CORP

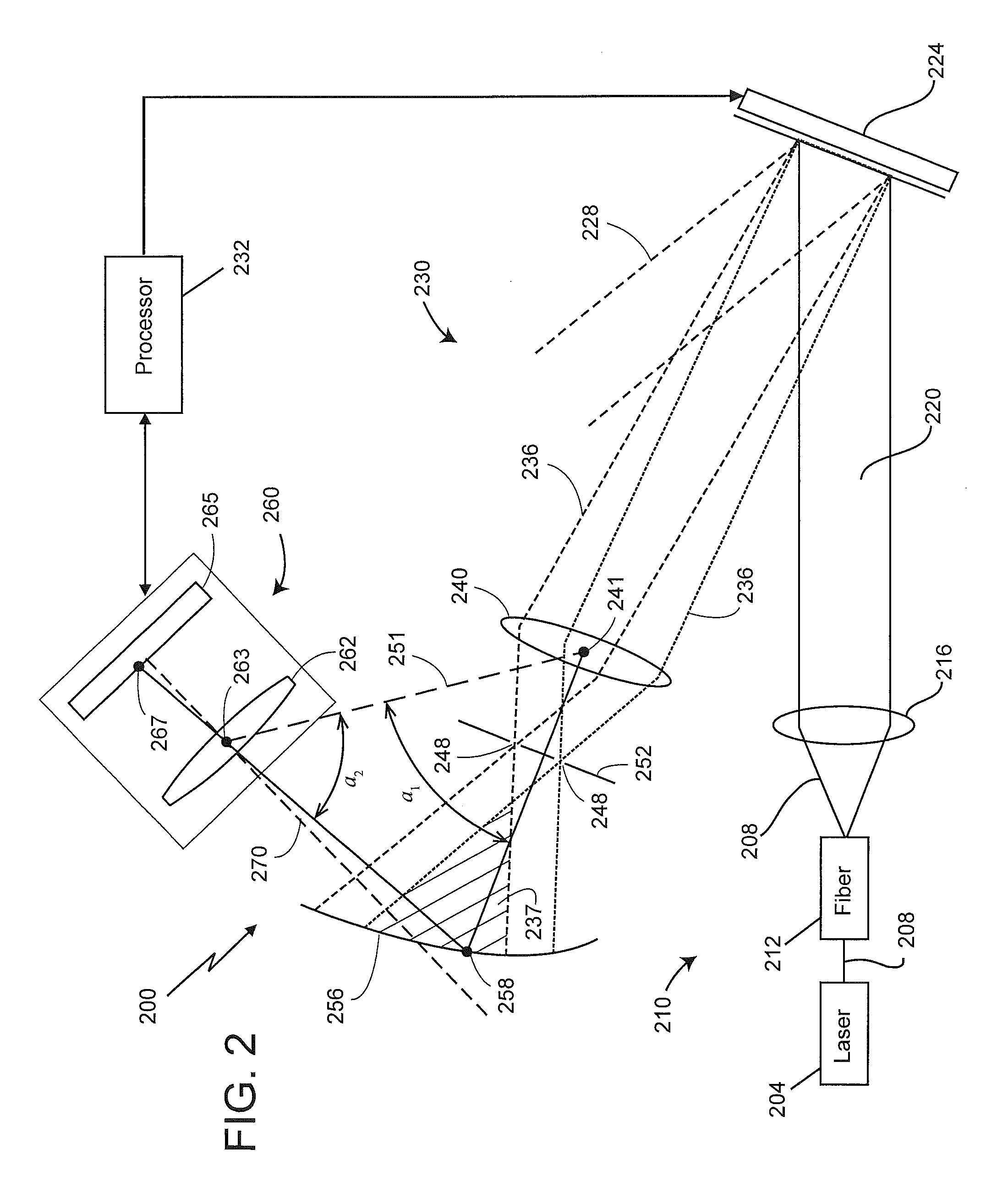

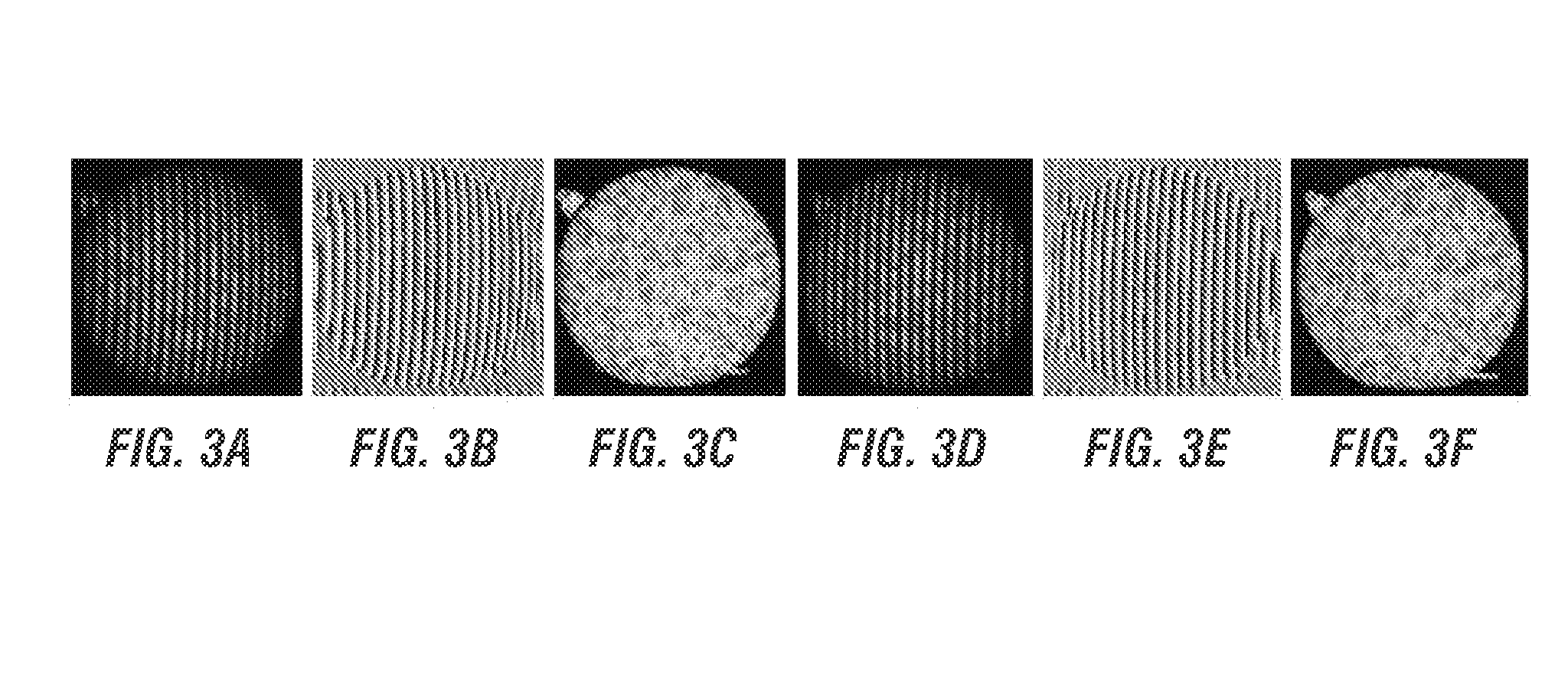

3D shape measurement system and method including fast three-step phase shifting, error compensation and calibration

InactiveUS20070115484A1Improve system speedFacilitates establishment of coordinate relationshipUsing optical means3d shapesPhase shifted

A structured light system for object ranging / measurement is disclosed that implements a trapezoidal-based phase-shifting function with intensity ratio modeling using sinusoidal intensity-varied fringe patterns to accommodate for defocus error. The structured light system includes a light projector constructed to project at least three sinusoidal intensity-varied fringe patterns onto an object that are each phase shifted with respect to the others, a camera for capturing the at least three intensity-varied phase-shifted fringe patterns as they are reflected from the object and a system processor in electrical communication with the light projector and camera for generating the at least three fringe patterns, shifting the patterns in phase and providing the patterns to the projector, wherein the projector projects the at least three phase-shifted fringe patterns sequentially, wherein the camera captures the patterns as reflected from the object and wherein the system processor processes the captured patterns to generate object coordinates.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Optical coherence tomography with 3d coherence scanning

Optical coherence tomography with 3D coherence scanning is disclosed, using at least three fibers (201, 202, 203) for object illumination and collection of backscattered light. Fiber tips (1, 2, 3) are located in a fiber tip plane (71) normal to the optical axis (72). Light beams emerging from the fibers overlap at an object (122) plane, a subset of intersections of the beams with the plane defining field of view (266) of the optical coherence tomography apparatus. Interference of light emitted and collected by the fibers creates a 3D fringe pattern. The 3D fringe pattern is scanned dynamically over the object by phase shift delays (102, 104) controlled remotely, near ends of the fibers opposite the tips of the fibers, and combined with light modulation. The dynamic fringe pattern is backscattered by the object, transmitted to a light processing system (108) such as a photo detector, and produces an AC signal on the output of the light processing system (108). Phase demodulation of the AC signal at selected frequencies and signal processing produce a measurement of a 3D profile of the object.

Owner:APPLIED SCI INNOVATIONS +1

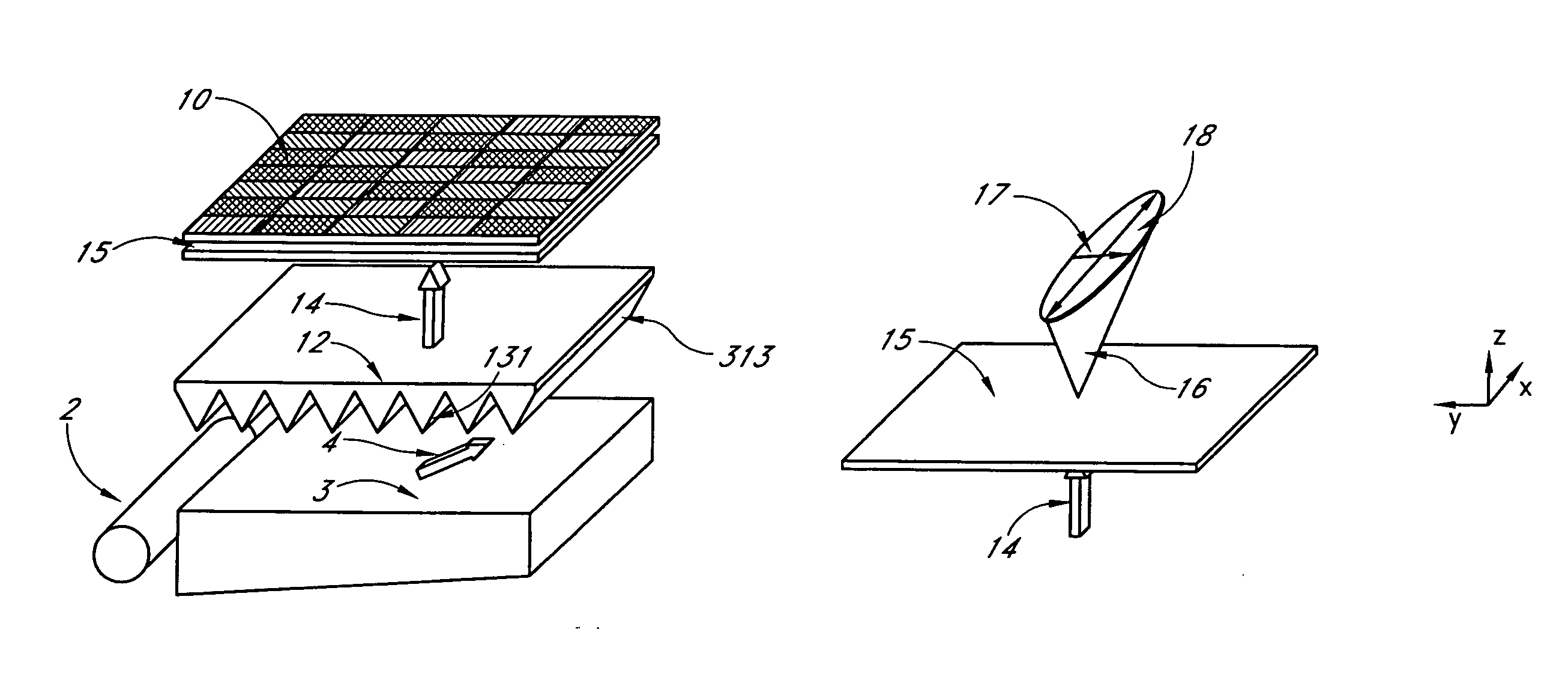

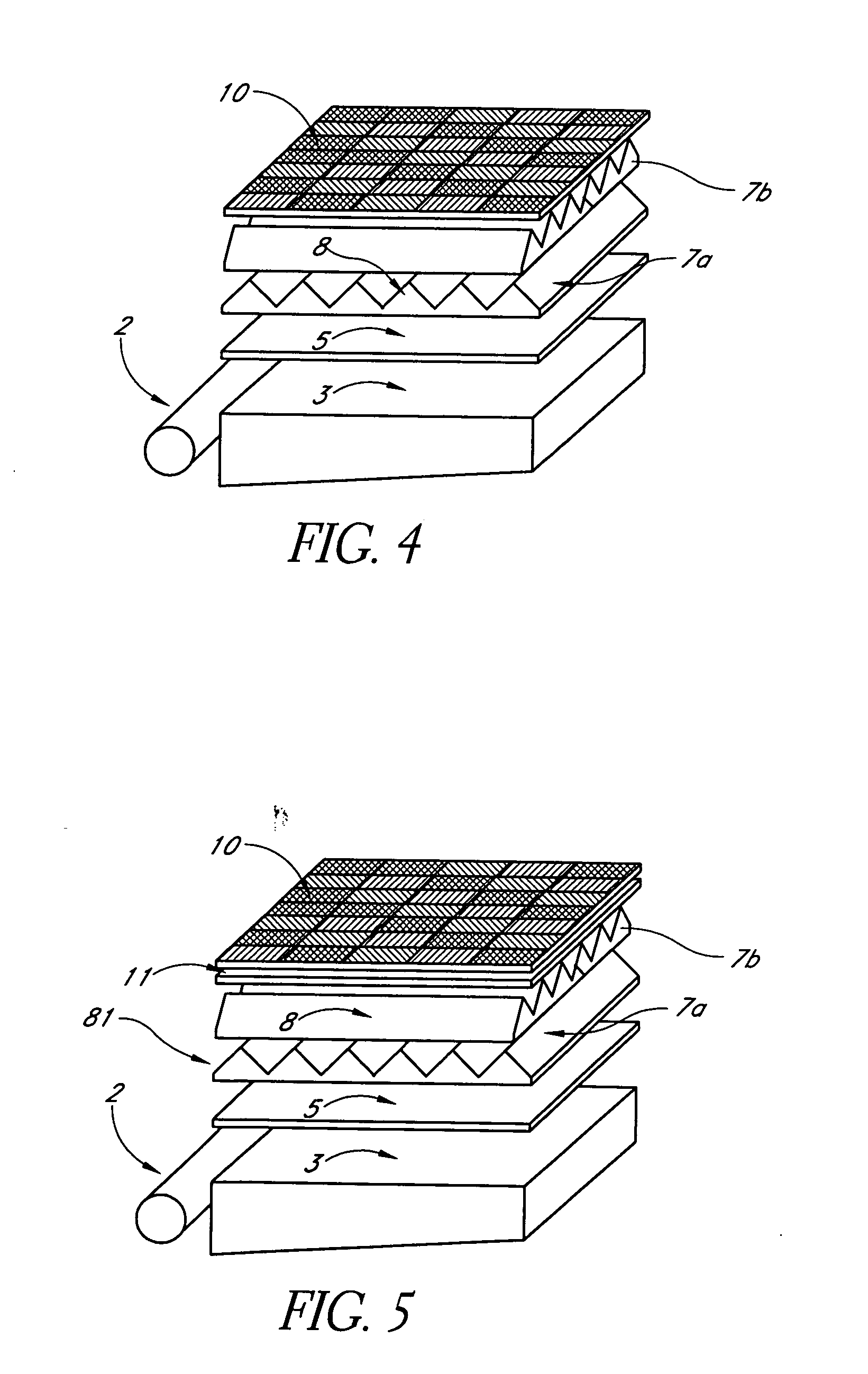

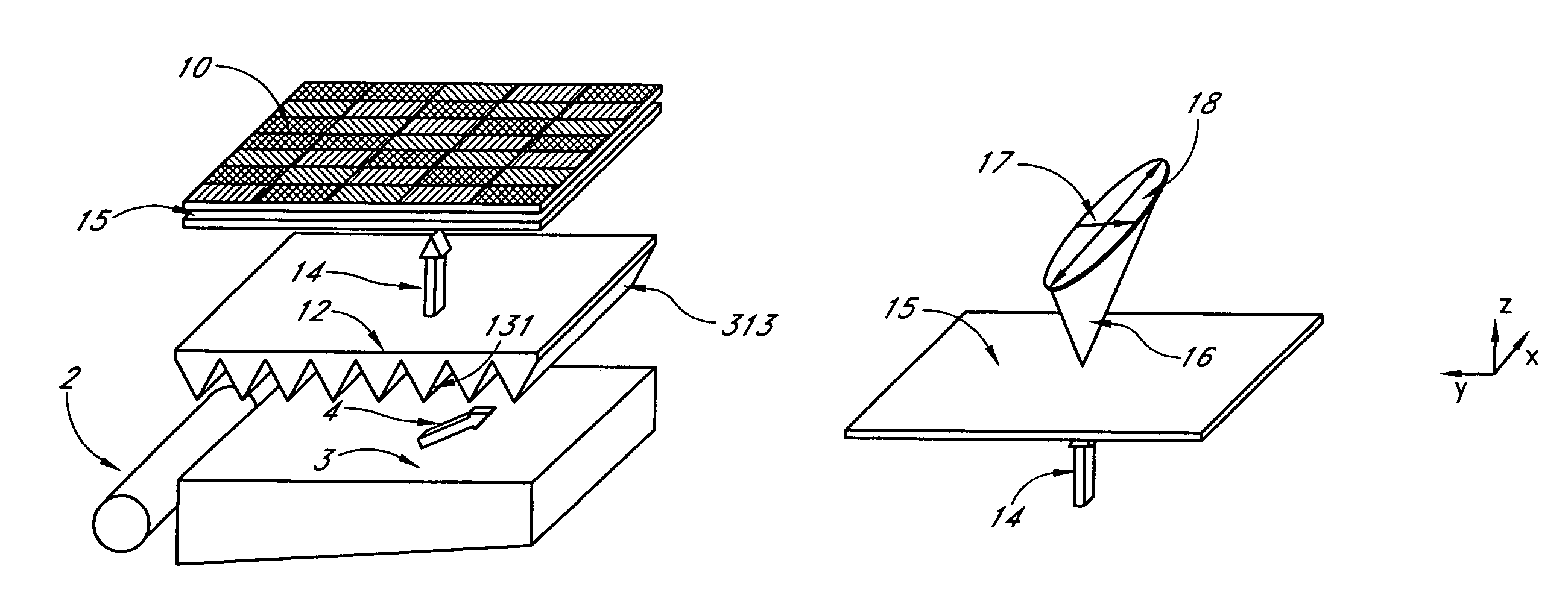

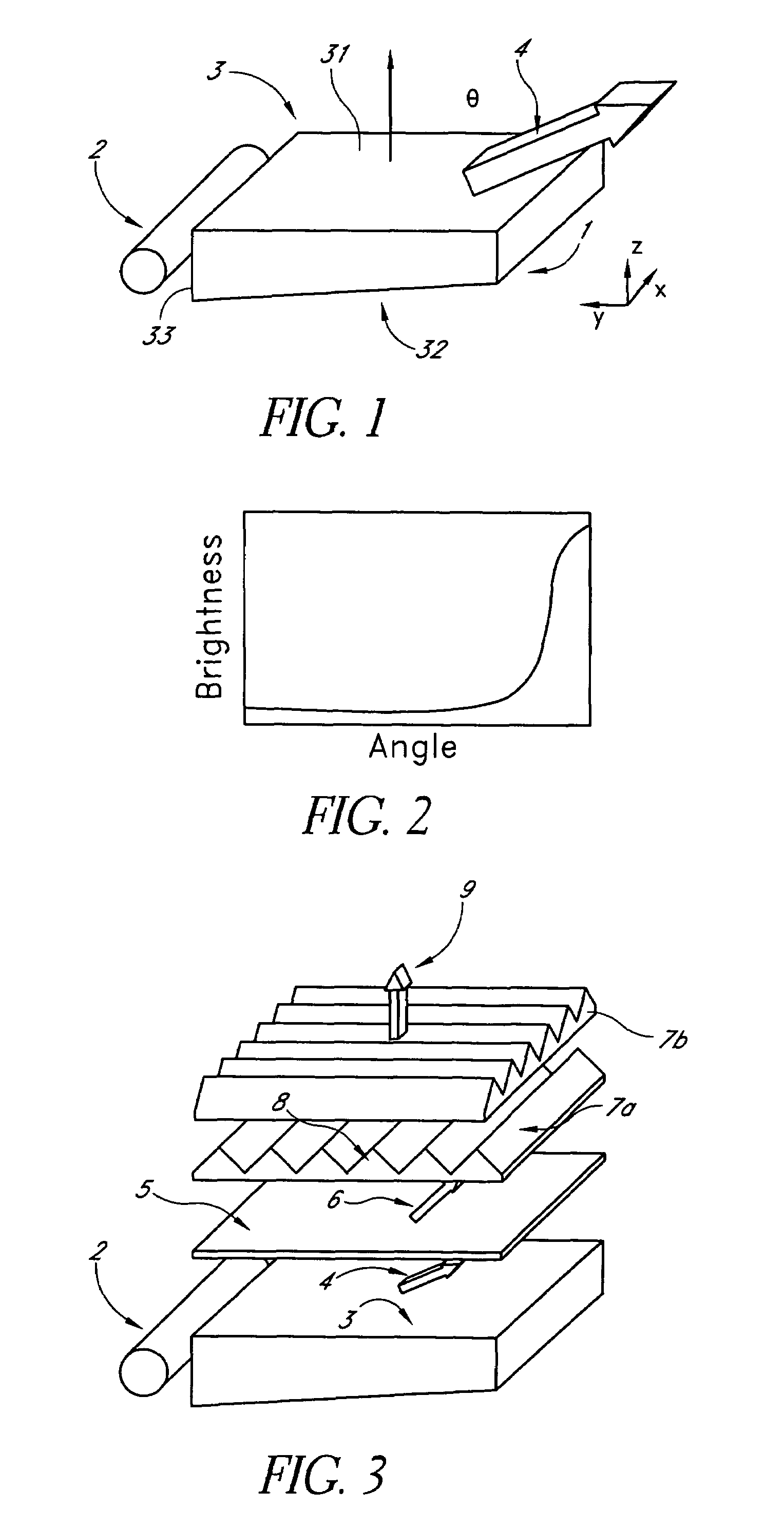

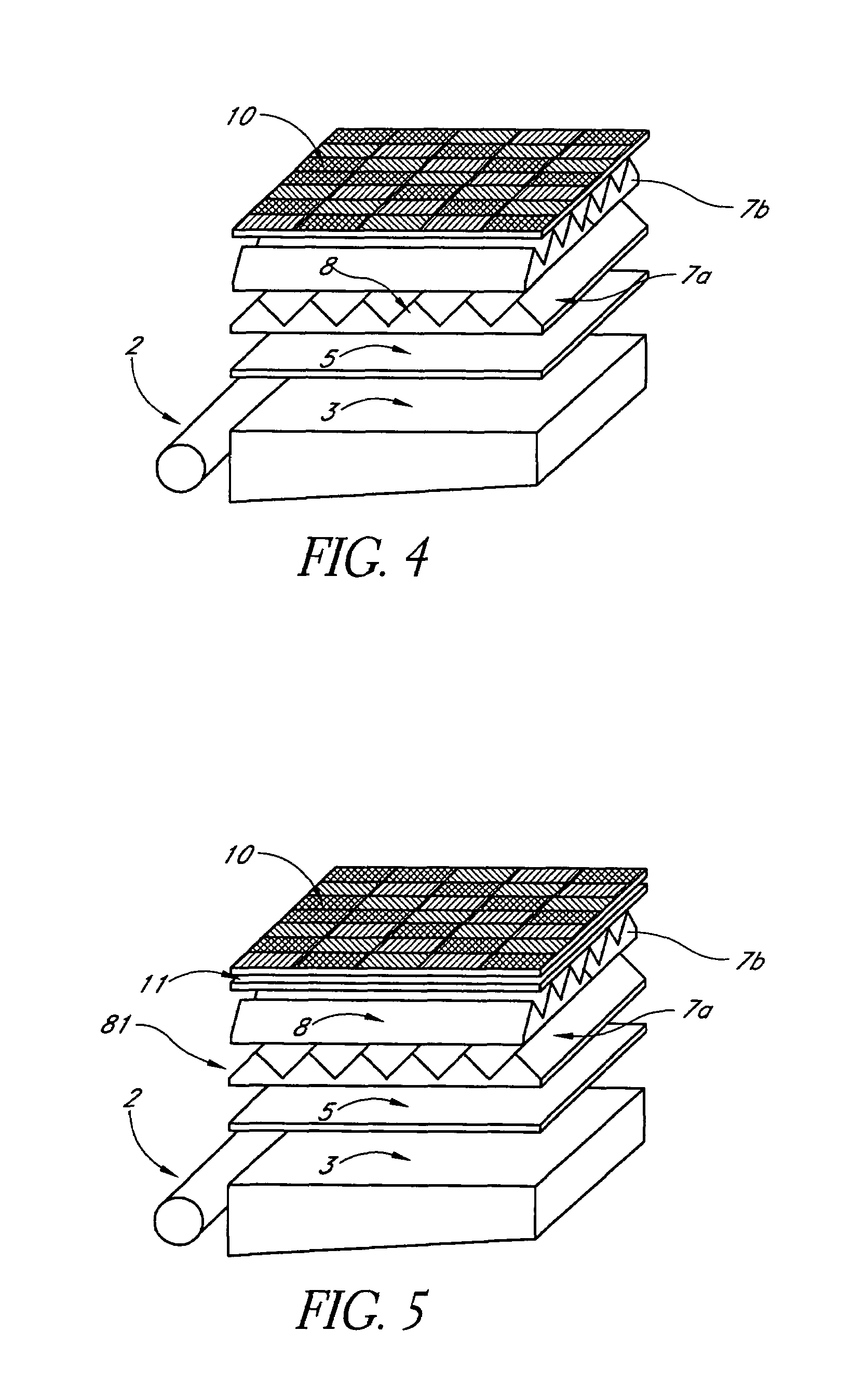

Elliptical diffusers used in displays

A backlit light display comprises a light guide panel, a prismatic film, an asymmetric top diffuser and an LCD. A linear light source is disposed along a side face of the light guide panel. Light from the linear light source is transmitted though the light guide panel where it is spread and uniformly output through a front face to the prismatic film. Light incident on the prismatic film is redirected more along a first direction than along a second direction. This light is directed more normal to the LCD. An asymmetric diffuser is applied between the prismatic film and the LCD panel to smear the periodic information from the prismatic film and eliminate the Moiré fringe pattern resulting from interference between the periodic structure of the prismatic film and the periodic arrangement of pixels in the LCD. The asymmetric diffuser is aligned with respect to the prismatic film such that it scatters and spreads light more in a second direction than the first direction.

Owner:WAVEFRONT TECH INC

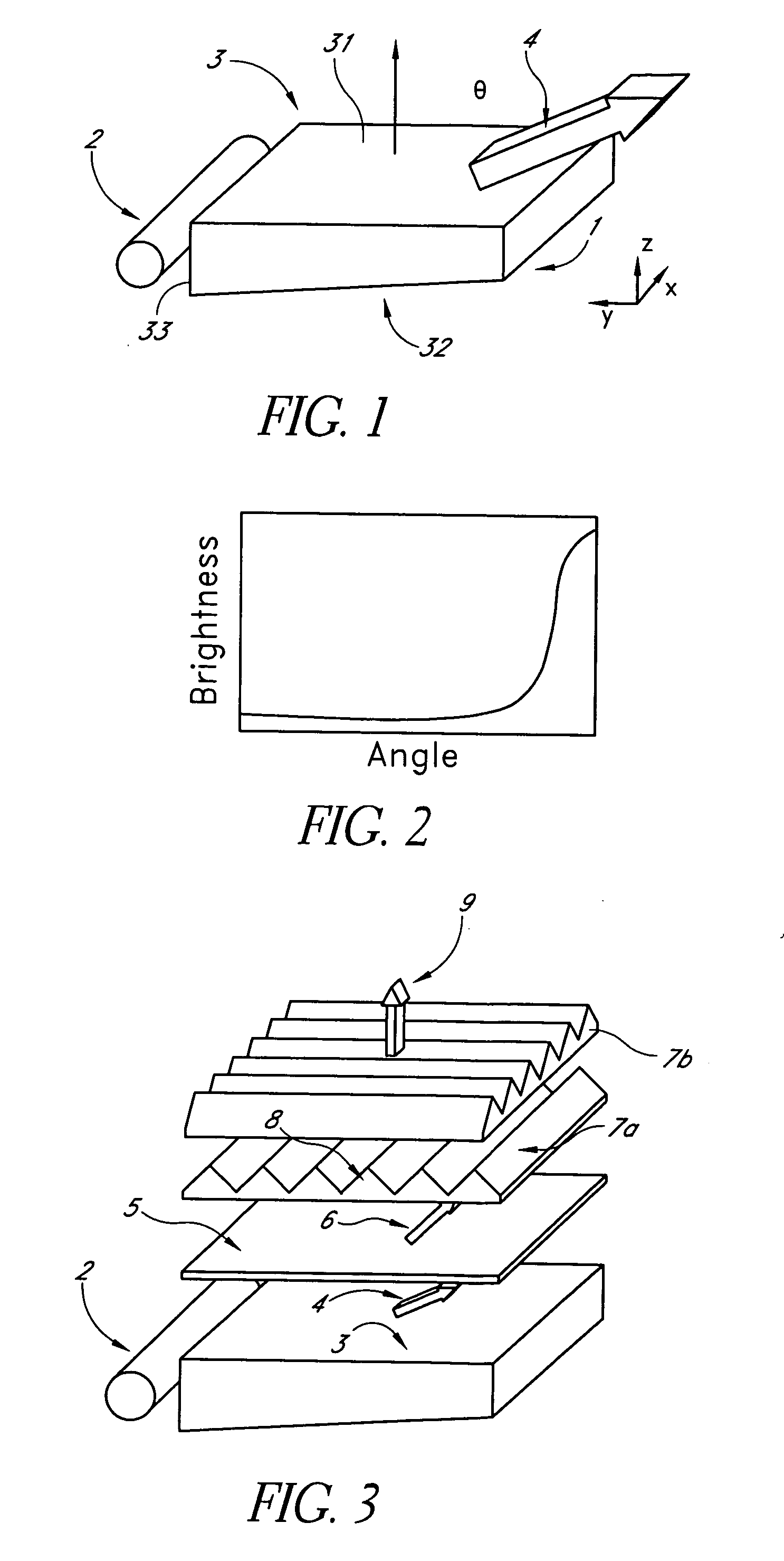

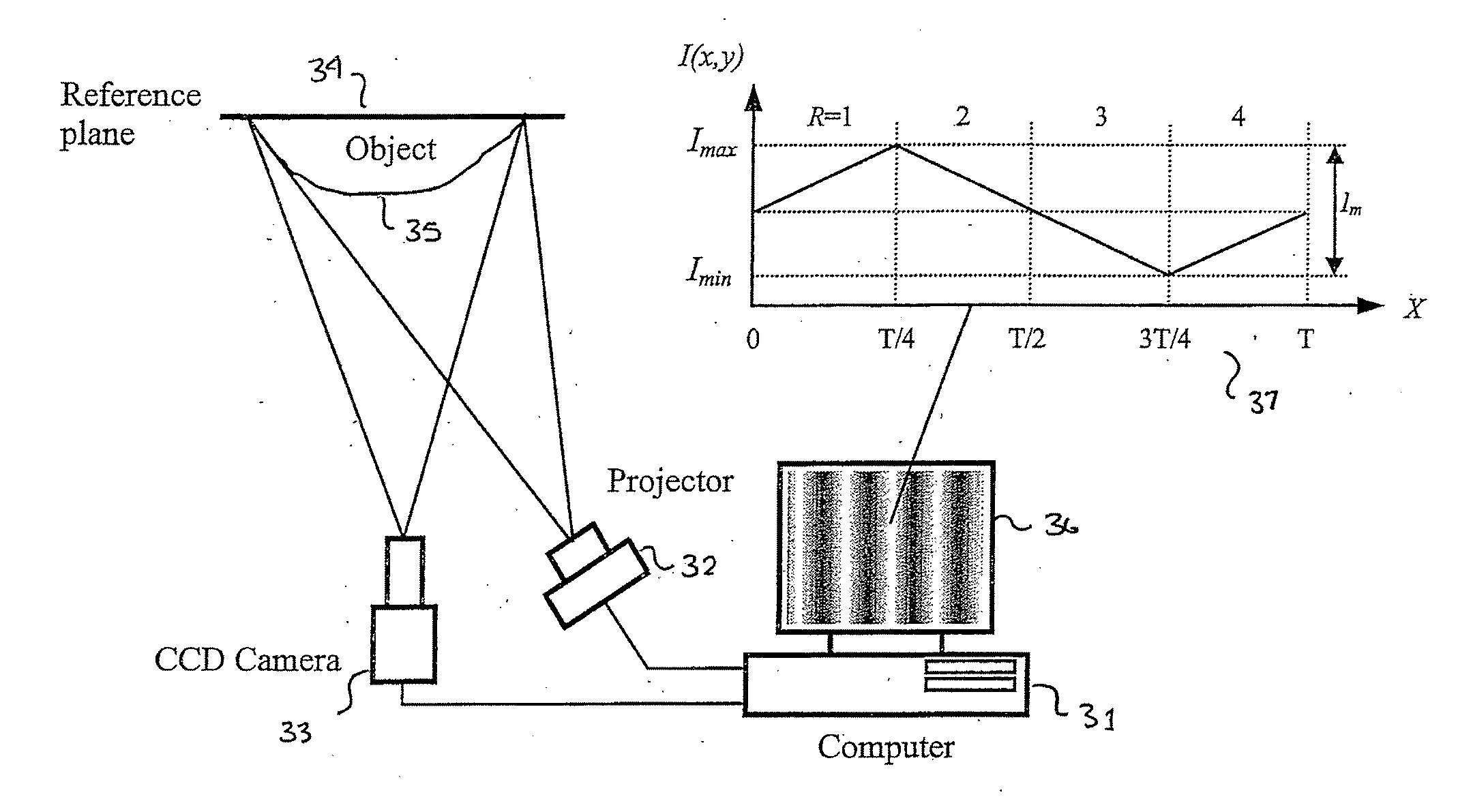

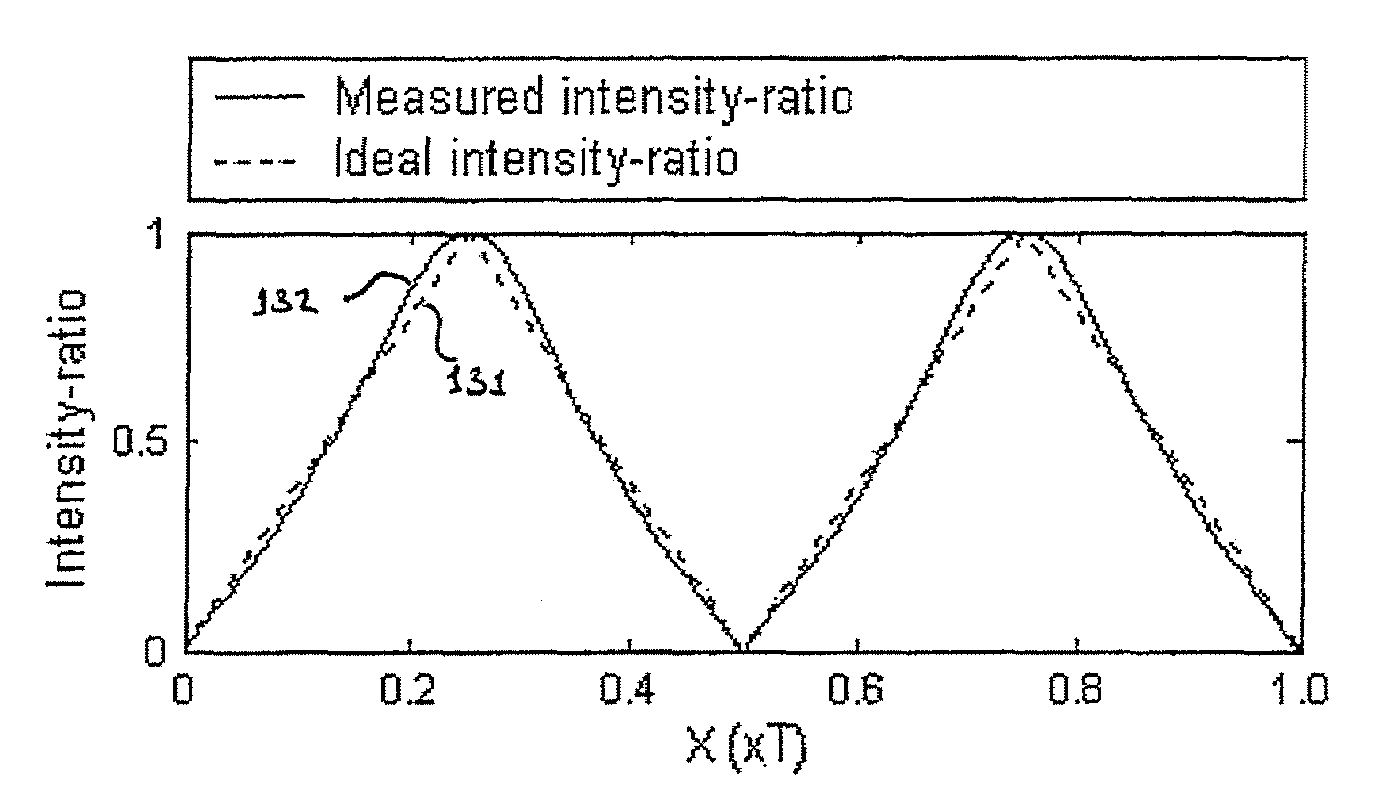

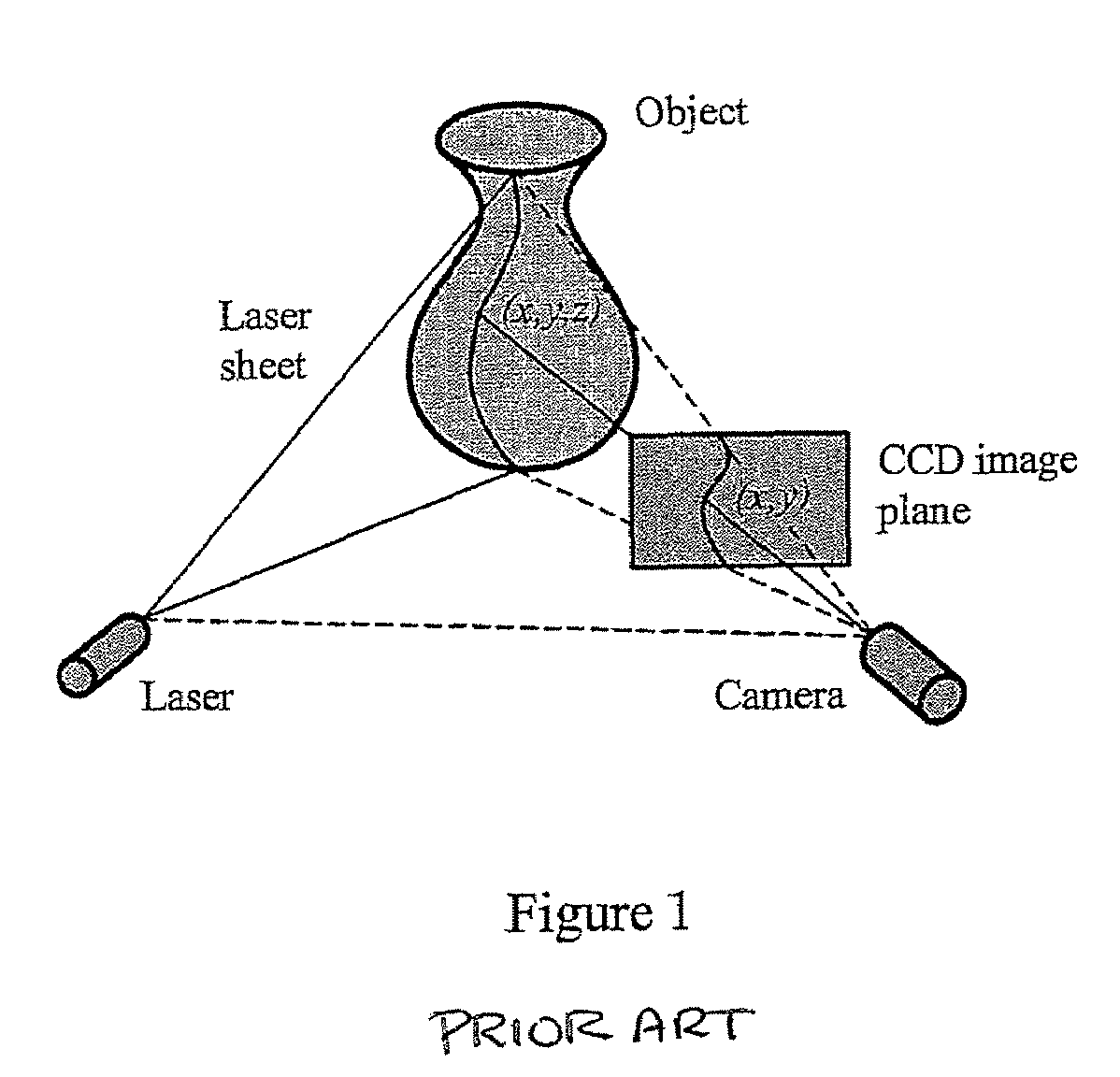

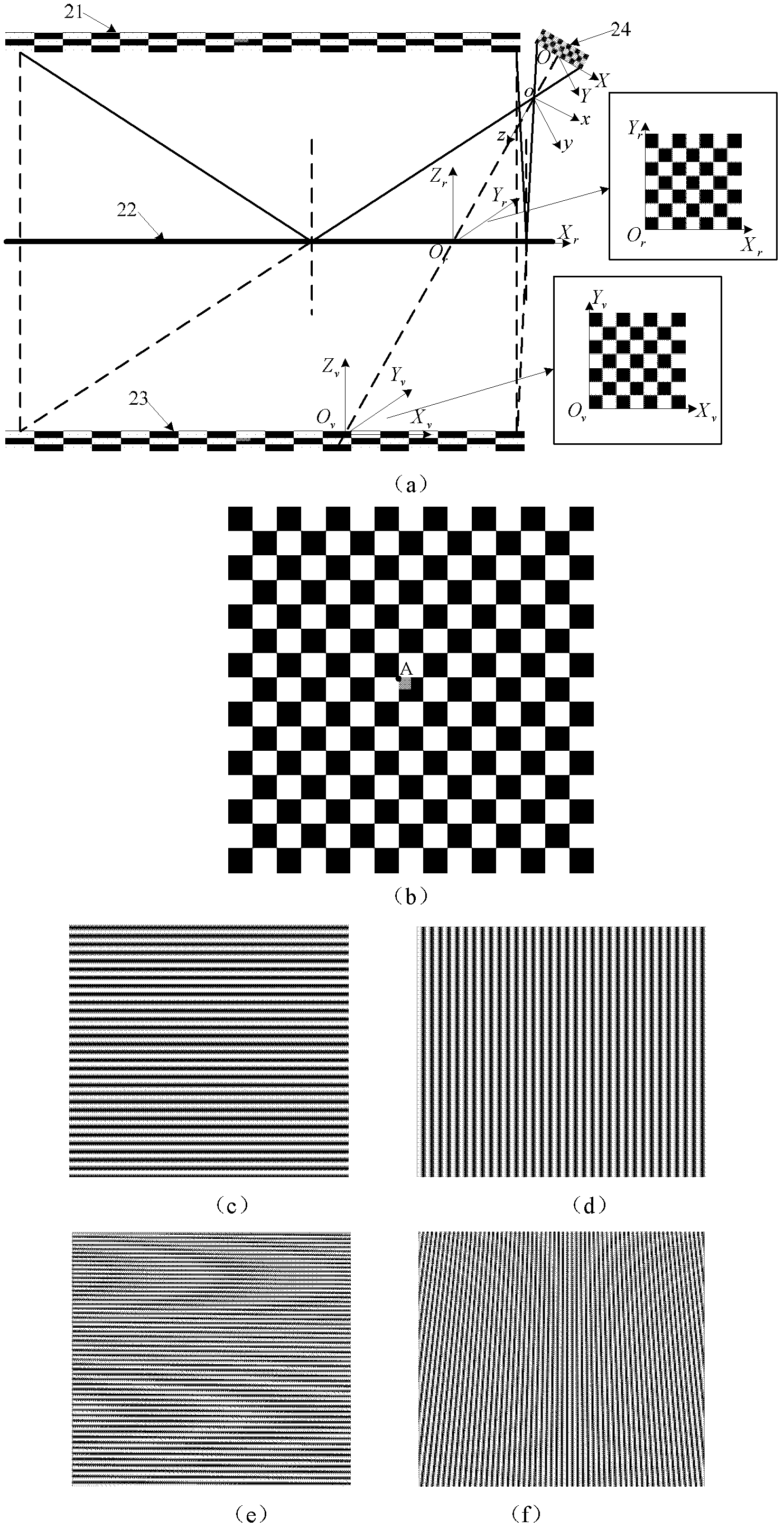

Full-field three-dimensional measurement method

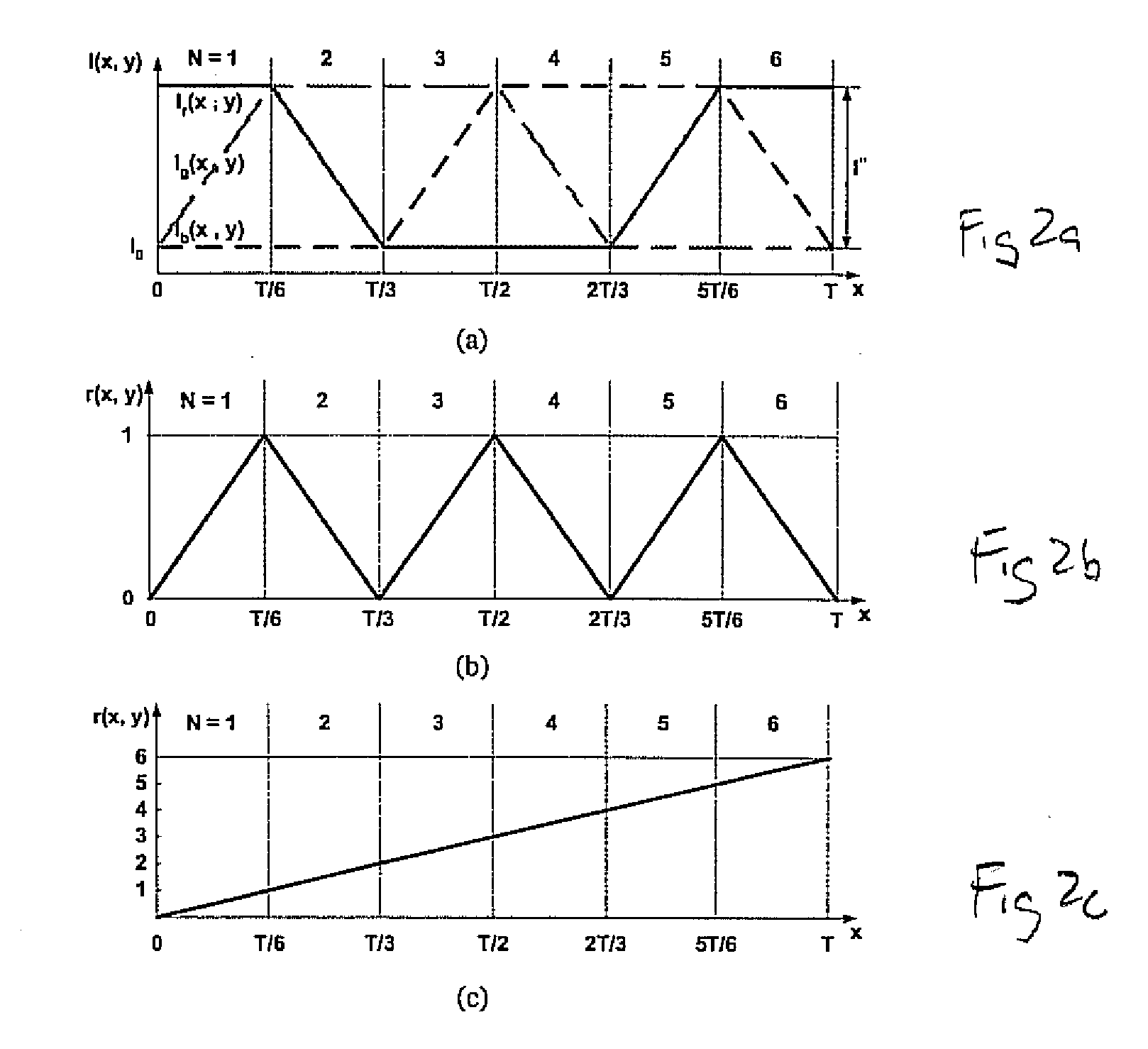

InactiveUS20070206204A1Improve processing speedSimple calculationUsing optical meansTriangulationFull field

A method and system for full-field fringe-projection for 3-D surface-geometry measurement, referred to as “triangular-pattern phase-shifting” is disclosed. A triangular grey-scale-level-coded fringe pattern is computer generated, projected along a first direction onto an object or scene surface and distorted according to the surface geometry. The 3-D coordinates of points on the surface are calculated by triangulation from distorted triangular fringe-pattern images acquired by a CCD camera along a second direction and a triangular-shape intensity-ratio distribution is obtained from calculation of the captured distorted triangular fringe-pattern images. Removal of the triangular shape of the intensity ratio over each pattern pitch generates a wrapped intensity-ratio distribution obtained by removing the discontinuity of the wrapped image with a modified unwrapping method. Intensity ratio-to-height conversion is used to reconstruct the 3-D surface coordinates of the object. Intensity-ratio error compensation involves estimating intensity-ratio error in a simulation of the measurement process with both real and ideal captured triangular-pattern images obtained from real and ideal gamma non-linearity functions. A look-up table relating the measure intensity-ratio to the corresponding intensity-ratio error is constructed and used for intensity-ratio error compensation. The inventive system is based on two-step phase-shifting but can be extended for multiple-step phase-shifting.

Owner:UNIVERSITY OF WATERLOO

Elliptical diffusers used in displays

A backlit light display comprises a light guide panel, a prismatic film, an asymmetric top diffuser and an LCD. A linear light source is disposed along a side face of the light guide panel. Light from the linear light source is transmitted though the light guide panel where it is spread and uniformly output through a front face to the prismatic film. Light incident on the prismatic film is redirected more along a first direction than along a second direction. This light is directed more normal to the LCD. An asymmetric diffuser is applied between the prismatic film and the LCD panel to smear the periodic information from the prismatic film and eliminate the Moiré fringe pattern resulting from interference between the periodic structure of the prismatic film and the periodic arrangement of pixels in the LCD. The asymmetric diffuser is aligned with respect to the prismatic film such that it scatters and spreads light more in a second direction than the first direction.

Owner:WAVEFRONT TECH INC

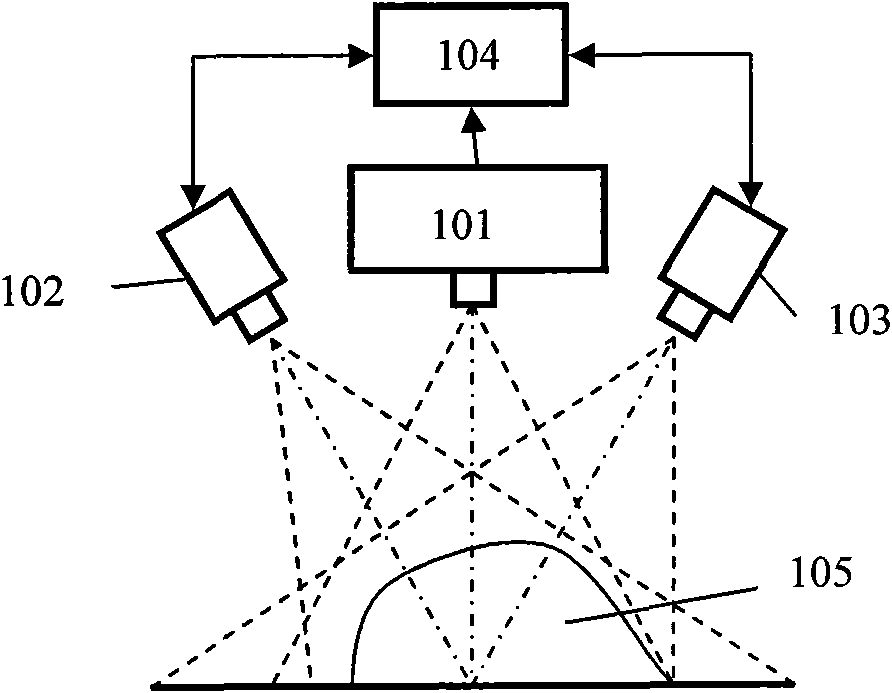

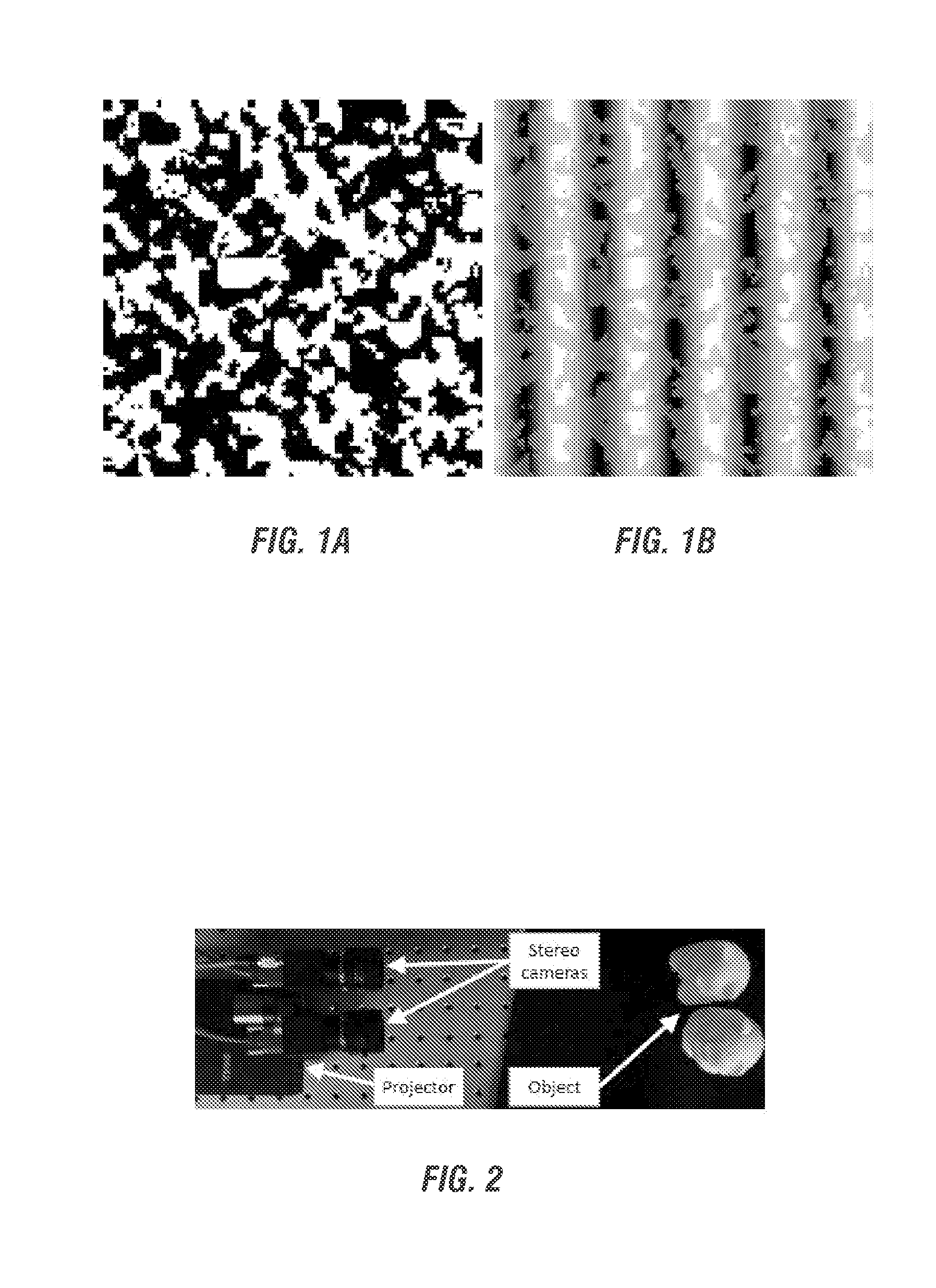

Combined three-dimensional digital imaging method of digital speckle projection and phase measuring profilometry

ActiveCN101608908AAcquisition speed is fastHigh precisionUsing optical meansPoint cloudDigital imaging

The invention relates to a combined three-dimensional digital imaging method of digital speckle projection and phase measuring profilometry. The method comprises the following steps: (1), a random digital speckle pattern is projected onto an object and acquired through two cameras on left and right sides; (2), a sinusoidal fringe pattern is projected onto the object, and a corresponding sinusoidal fringe pattern is acquired; (3), the folded phase value of a coding fringe pattern is calculated; (4), a series of points (Pr1 to Prn) on the right camera corresponding to a point P1 on the left camera are searched according to the folded phase value; (5), the point Pr on the right camera corresponding to the point P1 is fixed in the position of P1 according to the acquired digital speckle pattern; (6), processes of the step (4) and (5) are performed to all points on the left and right cameras, to find all the corresponding point pairs; (7), the corresponding point pairs are re-established into three-dimensional point cloud data. The method has the advantages that the imaging speed is fast, small calculated amount, accurate result, and the method is suitable for the fields of on-line three-dimensional detection and dynamic three-dimensional data acquisition with higher accuracy and speed requirements.

Owner:SHINING 3D TECH CO LTD

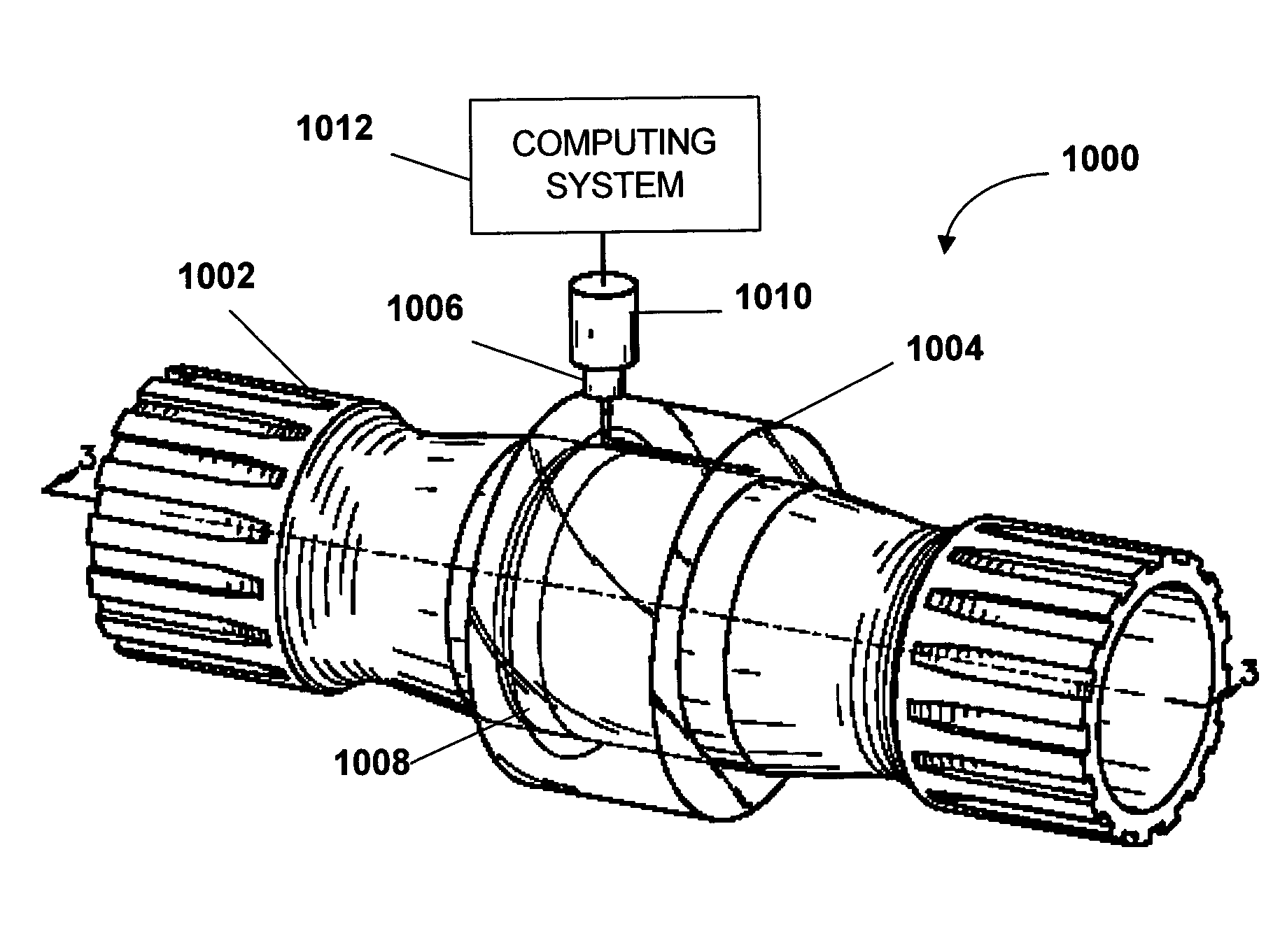

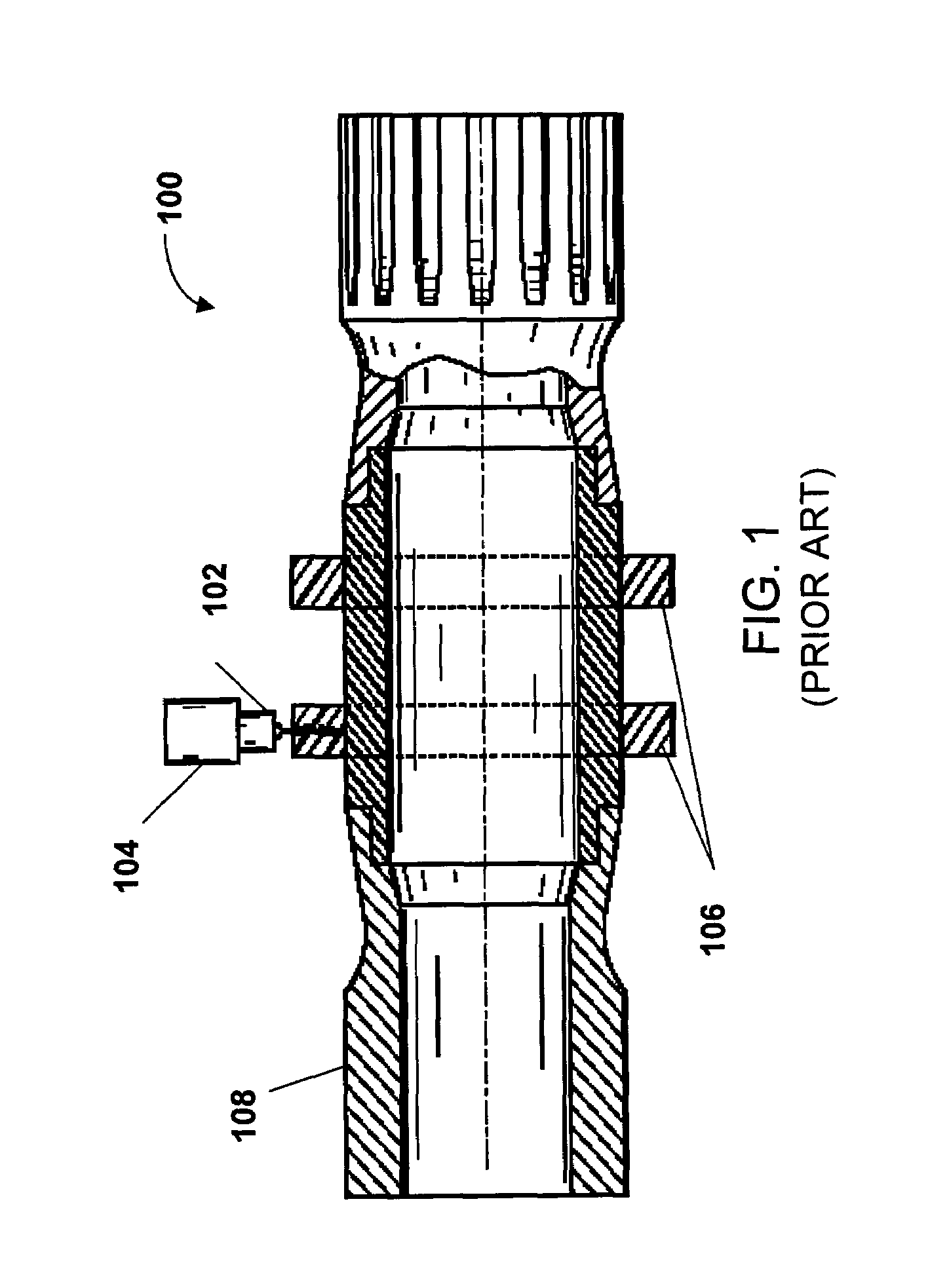

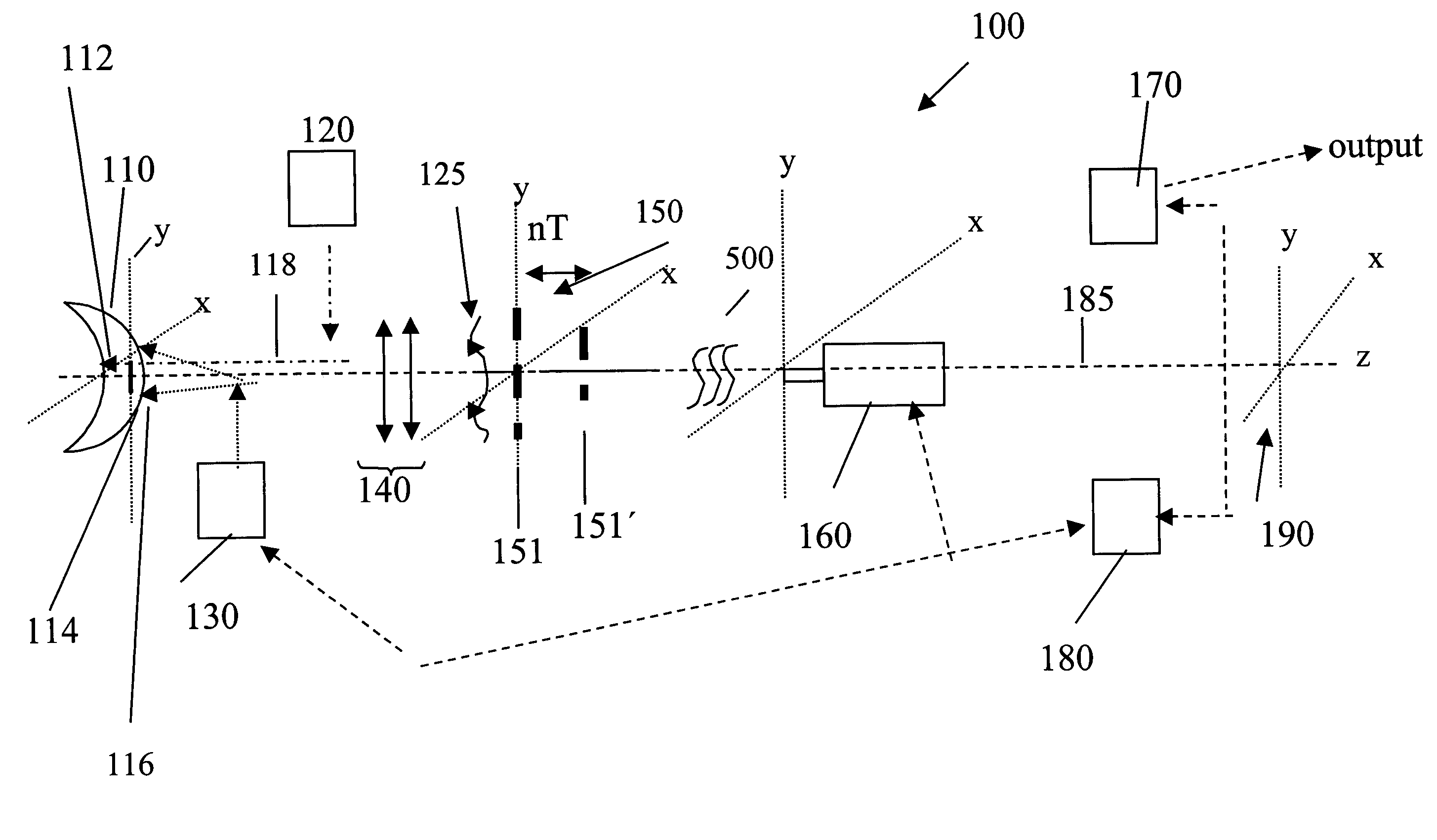

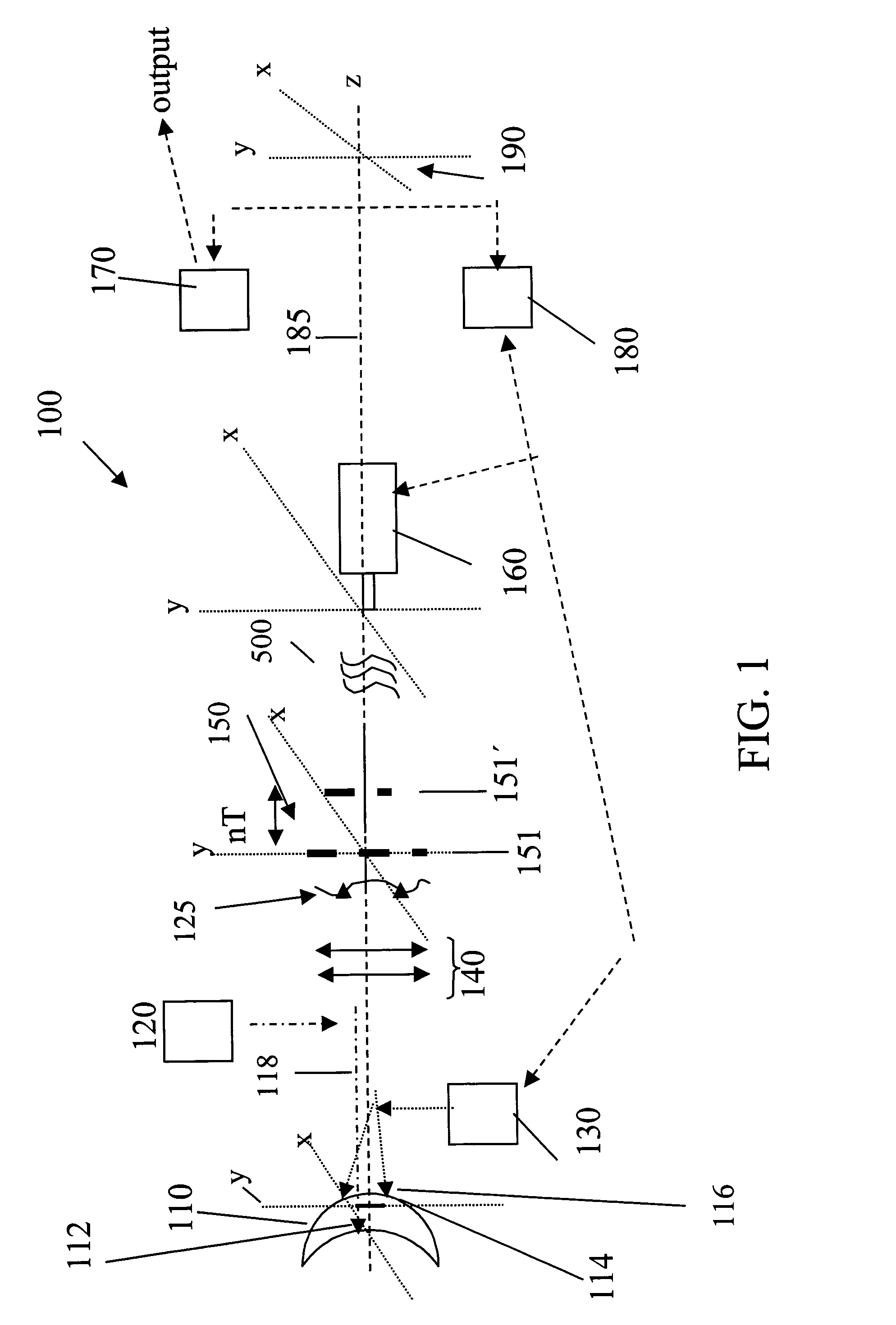

System and method for sensing torque on a rotating shaft

InactiveUS6981423B1Highly responsive, reliable, and safe steeringMinimal light distortionForce measurement by measuring optical property variationWork measurementEngineeringComputing systems

Owner:ROCKWELL AUTOMATION TECH

Dental surface imaging using polarized fringe projection

InactiveUS20100268069A1Enhance the imageLow costImage enhancementImpression capsProgram instructionImaging lens

An intra-oral imaging apparatus having a fringe pattern generator energizable to emit a fringe pattern illumination having a predetermined spatial frequency, with light in the approximate 350-500 nm range. A polarizer in the path of the fringe pattern illumination has a first polarization transmission axis. A projection lens is disposed to direct the polarized fringe pattern illumination as incident illumination toward a tooth surface. An imaging lens is disposed to direct light reflected and scattered at the tooth surface along a detection path. An analyzer is disposed along the detection path, having a second polarization transmission axis. A detector disposed along the detection path obtains image data from the light provided through the analyzer. A control logic processor is responsive to programmed instructions and actuable to adjust the intensity over one or more portions of the fringe pattern illumination according to the image data obtained from the detector.

Owner:CARESTREAM DENTAL LLC

Measurement of the top surface of an object with/without transparent thin films in white light interferometry

White light interferometry is used to obtain the height information of the topmost surface of an object having a transparent thin film on it. N frames of data are acquired from an interferometer while a white light fringe pattern is scanning through a field of view. The modulation fringe envelope R(n) is calculated for every pixel; and the topmost surface position at every pixel is determined as an offset of R(n).

Owner:PHASE SHIFT TECH INC A WHOLLY OWNED SUBSIDIARY OF ADE DBA ADE PHASE SHIFT

Moiré aberrometer

An improved moiré deflectometer device for measuring a wavefront aberration of an optical system includes a light source for illuminating a surface area of the optical system, an optical relay system for directing scattered light to a deflectometer component that converts the wavefront into a moiré fringe pattern, a sensor / camera assembly for imaging and displaying the exit pupil of the optical system and the moiré´ fringe pattern, and a fringe pattern to calculate the wavefront aberration of the optical system, being improved by an illumination source for illuminating the exit pupil of the optical system; and an alignment system cooperating with the illumination source in such a manner to consistently and accurately align a measurement axis of the device to the optical system. An associated method is also disclosed.

Owner:BAUSCH & LOMB INC

Device and method using a spatial light modulator to find 3D coordinates of an object

A method for determining three-dimensional coordinates of an object point on a surface of an object, the method including steps of: providing a source, a projector, and a camera; in each of two instances: spatially modulating source light; sending a modulator pattern of light through the projector lens to form light spots; filtering the spots with a pinhole plate; propagating light from the light spots onto the object to produce a fringe pattern; imaging the object point with a camera lens onto an array point of the photosensitive array to obtain first and second electrical data values from the photosensitive array; and determining the three-dimensional coordinates of the first object point based at least in part on the first electrical data value, the second electrical data value, and a baseline length.

Owner:FARO TECH INC

Full-field three-dimensional measurement method

A method and system for full-field fringe-projection for 3-D surface-geometry measurement, referred to as “triangular-pattern phase-shifting” is disclosed. A triangular grey-scale-level-coded fringe pattern is computer generated, projected along a first direction onto an object or scene surface and distorted according to the surface geometry. The 3-D coordinates of points on the surface are calculated by triangulation from distorted triangular fringe-pattern images acquired by a CCD camera along a second direction and a triangular-shape intensity-ratio distribution is obtained from calculation of the captured distorted triangular fringe-pattern images. Removal of the triangular shape of the intensity ratio over each pattern pitch generates a wrapped intensity-ratio distribution obtained by removing the discontinuity of the wrapped image with a modified unwrapping method. Intensity ratio-to-height conversion is used to reconstruct the 3-D surface coordinates of the object. Intensity-ratio error compensation involves estimating intensity-ratio error in a simulation of the measurement process with both real and ideal captured triangular-pattern images obtained from real and ideal gamma non-linearity functions. A look-up table relating the measure intensity-ratio to the corresponding intensity-ratio error is constructed and used for intensity-ratio error compensation. The inventive system is based on two-step phase-shifting but can be extended for multiple-step phase-shifting.

Owner:UNIVERSITY OF WATERLOO

Absolute three-dimensional shape measurement using coded fringe patterns without phase unwrapping or projector calibration

A stereo-phase-based absolute three-dimensional (3D) shape measurement method is provided that requires neither phase unwrapping nor projector calibration. This proposed method can be divided into two steps: (1) obtain a coarse disparity map from the quality map; and (2) refine the disparity map using local phase information. Experiments demonstrated that the proposed method could achieve high-quality 3D measurement even with extremely low-quality fringe patterns. The method is particular well-suited for a number of different applications including in mobile devices such as phones.

Owner:IOWA STATE UNIV RES FOUND

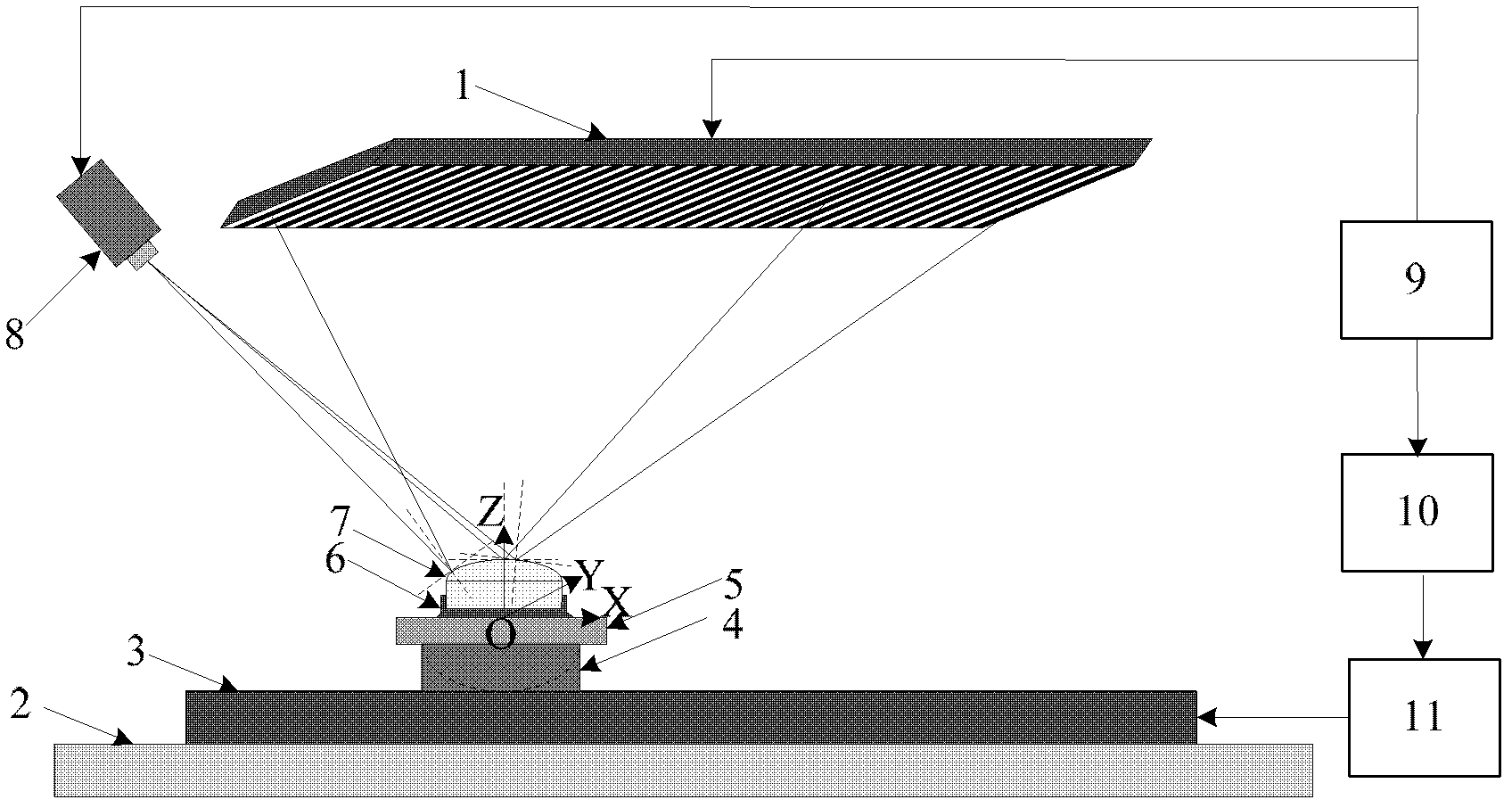

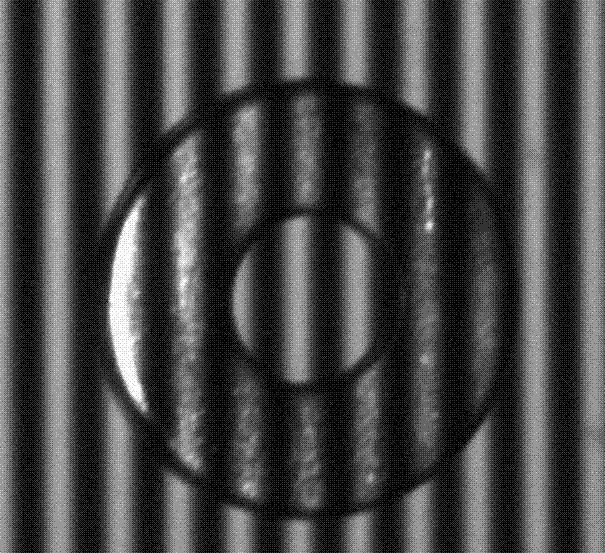

Grating projection rapid non-contact measurement method and device for high-reflectance free-form curved-surface parts

The invention relates to high-precision detection of complex optical curved-surface parts with large-curvature surface shapes, and aims to provide a high-precision detection method for the complex curved-surface parts with large curvature surface shapes, such as optical curved-surface parts, which has the advantages of rapidity, non-contact and no damage to part surfaces and surface layers. The technical scheme adopted by the invention is that the invention provides a grating projection rapid non-contact measurement method and device for high-reflectance free-form curved-surface parts, and the method comprises the following steps that: three degree-of-freedom motion of a measured object is realized with the help of a precision motion control system; coded grating fringes are projected onto the surface of the measured object by using a grating projection device; phase distribution information of the surface of the measured object is obtained from a deformed fringe pattern by using a digital phase shifting technology and a phase unwrapping algorithm; reference phase distribution information is obtained by using a virtual reference surface technology; and three-dimensional morphological information of a measuring area of the surface of the measured object is recovered according to a corresponding relation between phase deviation information and the gradient of the surface of the measured object. The grating projection rapid non-contact measurement method and device are mainly applied to the measurement of the optical curved-surface parts.

Owner:TIANJIN UNIV

Method and apparatus for measuring shape of an object

In accordance with one aspect of the present technique, a system for measuring a shape of an object is provided. The system comprises a projection system operable to project a fringe pattern having a reference mark onto the object. The system further comprises an image-processing system operable to capture an image of the fringe pattern modulated by the object. The image-processing system is further operable to identify the reference mark in the image of the fringe pattern to construct a shape of the object based on the reference mark.

Owner:GENERAL ELECTRIC CO

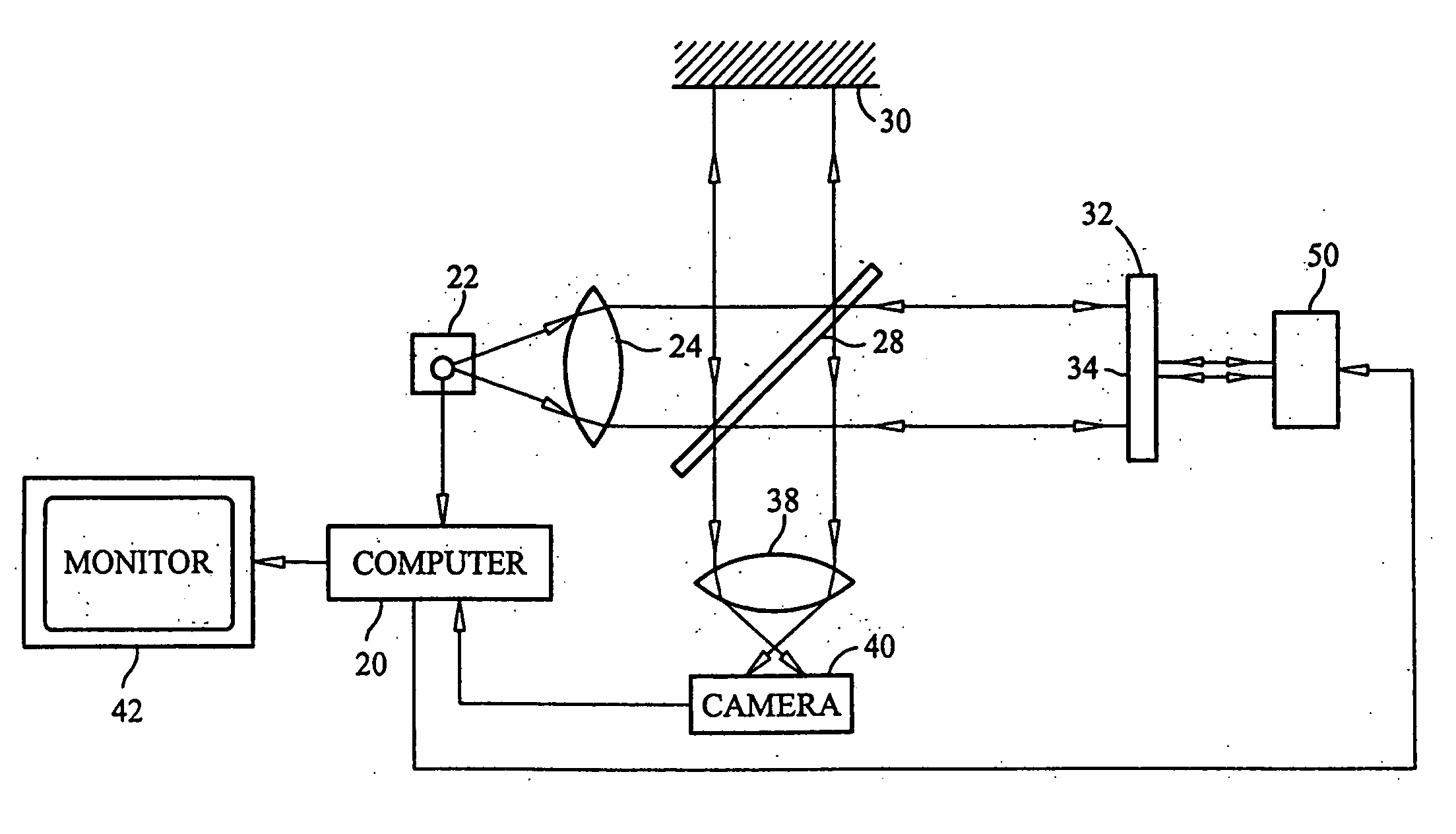

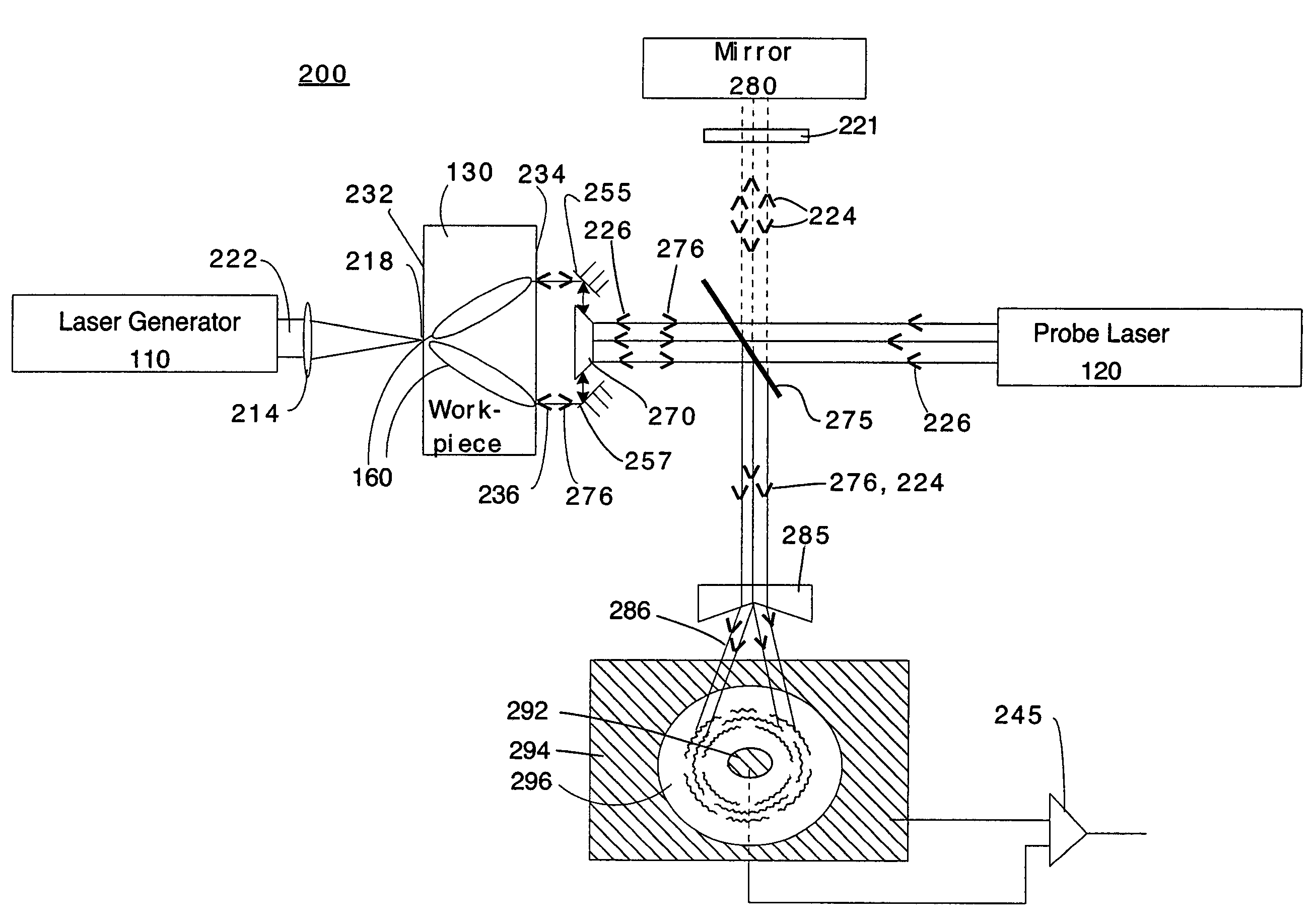

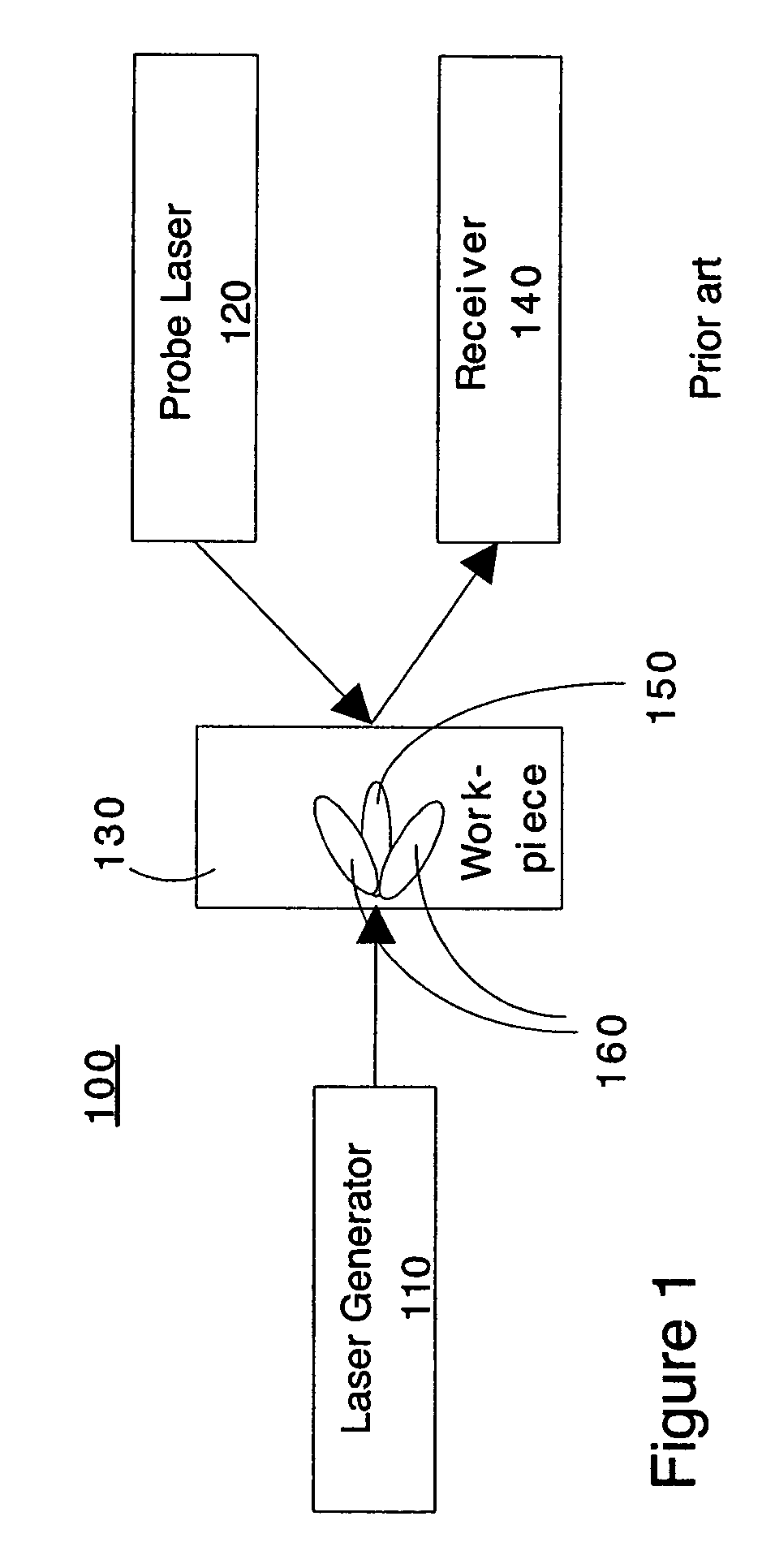

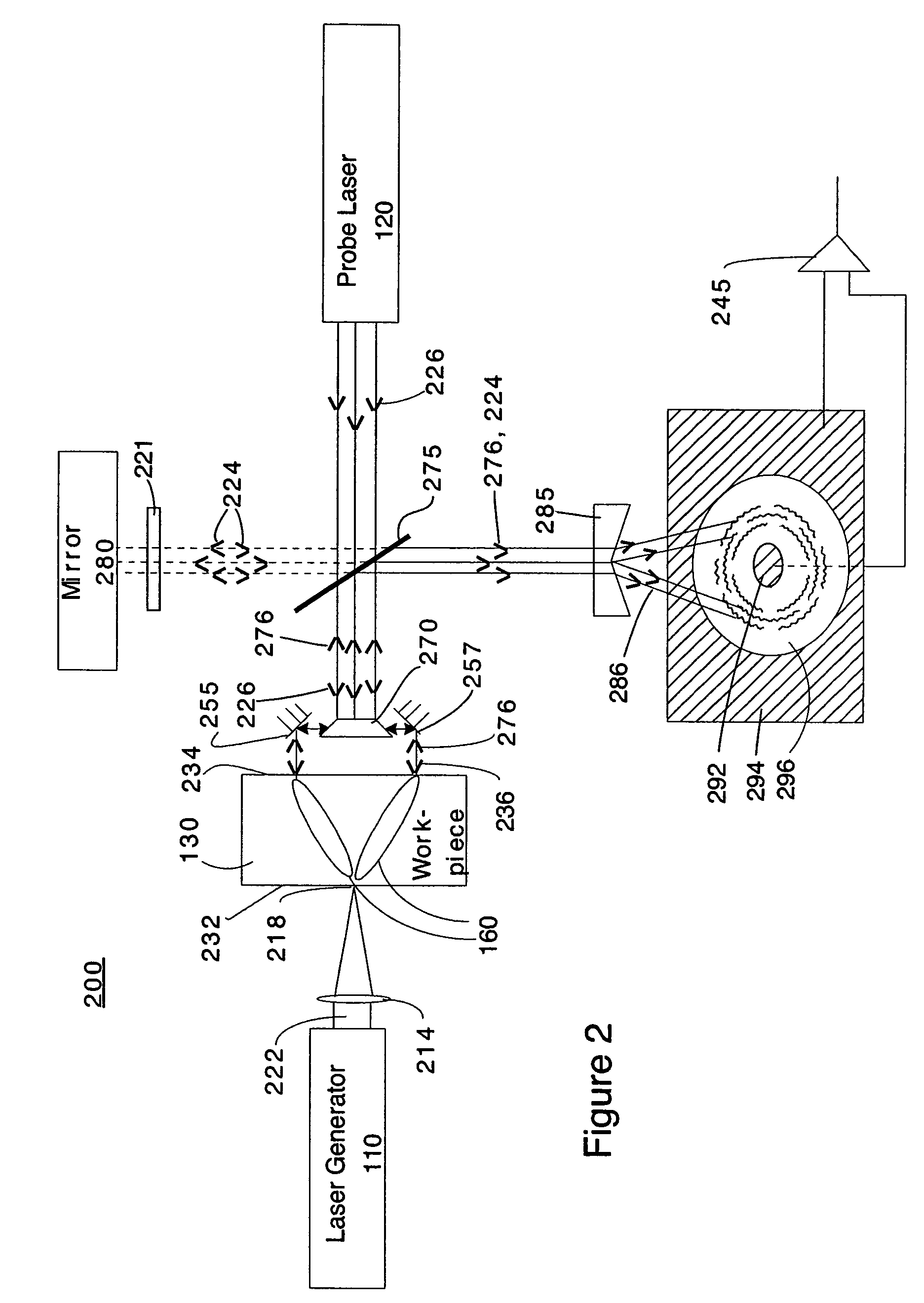

Ultrasound single-element non-contacting inspection system

InactiveUS7262861B1Low costReduce complexityVibration measurement in solidsMaterial analysis using sonic/ultrasonic/infrasonic wavesPhotovoltaic detectorsPhotodetector

A laser ultrasonic inspection apparatus and method which enables remote sensing of thickness, hardness, temperature and / or internal defect detection is disclosed. A laser generator impinges a workpiece with light for generating a thermo-elastic acoustic reaction in a workpiece. A probe laser impinges the workpiece with an annularly-shaped probe light for interaction with the acoustic signal in the workpiece resulting in a modulated return beam. A photodetector having a sensitive region for detecting an annularly-shaped fringe pattern generated by an interaction of a reference signal and with the modulated return beam at said sensitive region.

Owner:HRL LAB

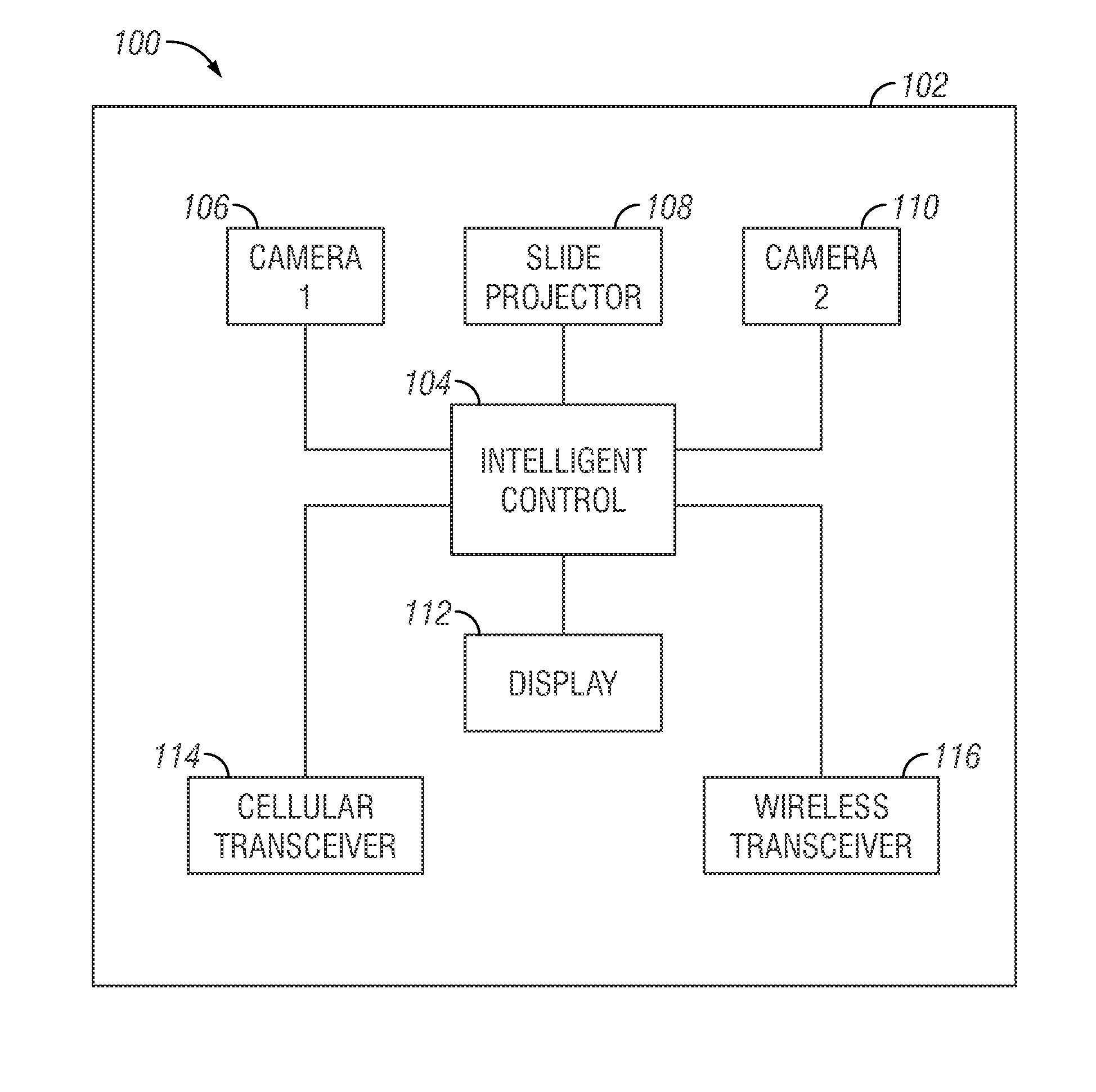

Three dimensional (3D) imaging by a mobile communication device

The disclosure is directed at a method for three-dimensional (3D) imaging for use by a handheld portable device including projecting at least one fringe pattern onto a surface; capturing a two-dimensional (2D) camera image of each deformed light pattern formed by the projected at least one fringe pattern; and determining shape of the surface and an apparatus for performing such method.

Owner:KOFMAN JONATHAN +1

Holographic displays with high resolution

InactiveUS20120019883A1Holographic light sources/light beam propertiesActive addressable light modulatorElectricityHigh density

Provided is a holographic display that realizes a high-resolution three-dimensional (3D) image as a spatial light modulation panel system having a fast response time and enabling the formation of high-density pixels is developed. The holographic display includes, a spatial light modulator using a polymer thin film or a dielectric thin film that enable the formation of high-density pixels and has a fast response time, a fine displacement panel system sequentially moving the spatial light modulator in synchronization with a hologram fringe signal, and an optical system including a coherent light source, a spatial light modulation panel system, and an optical element that are efficiently disposed. The holographic display has a feature that realizes a high-resolution 3D image in a scheme that integrates and displays an image while sequentially moving a spatial light modulator simply or overlaps a hologram fringe pattern.

Owner:ELECTRONICS & TELECOMM RES INST

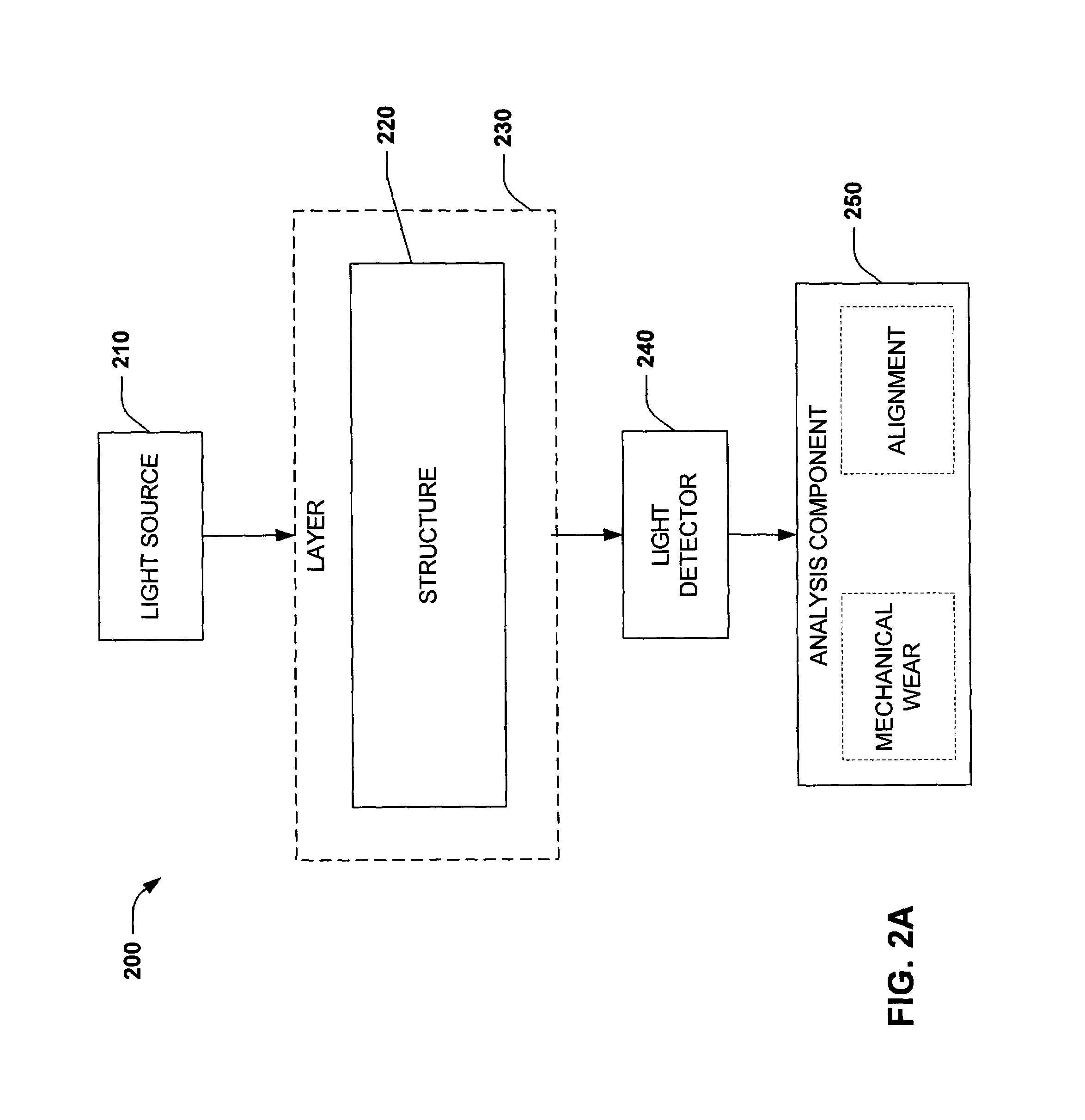

Apparatus and methods for optically monitoring thickness

In one aspect, the invention relates to an apparatus for monitoring thickness variations of an object having first and second opposing surfaces. The apparatus includes a first source positioned to project a first fringe pattern at a first location on the first surface and a second source positioned to project a second fringe pattern at a first location on the second surface. The apparatus further includes a first detector positioned to detect the first fringe pattern at the first location on the first surface, the first detector generating a first signal in response to the first fringe pattern at the first location. The apparatus also includes a second detector positioned to detect the second fringe pattern at the first location on the second surface, the second detector generating a second signal in response to the second fringe pattern at the first location. The apparatus further includes a processor adapted to calculate variations in the thickness of the object in response to the first and the second signals.

Owner:MASSACHUSETTS INST OF TECH

Method for acquiring phase information and system for measuring three dimensional surface profiles

InactiveUS20100189372A1Minimize potential measurement errorCharacter and pattern recognitionUsing optical meansFrequency spectrumBand-pass filter

The present invention provides a band-pass filter, being capable of fitting a frequency spectrum area having phase information in a frequency spectrum image, to obtain a spectrum information corresponding to the phase information during the process of obtaining the phase information from the frequency spectrum image with respect to an object's surface profile. In another embodiment, the present invention further provides a method to optimize the spectrum range of the band-pass filter so as to enhance measuring accuracy and efficiency while restoring the surface of the object. In addition, by employing the foregoing method, the present invention further provides a measurement system for measuring three-dimensional surface shapes in which a deformed fringe pattern with respect to the measured object's surface is acquired and the phase information is obtained from the fringe pattern according to the foregoing method so as to restore the surface profile of the measured object.

Owner:NAT TAIPEI UNIV OF TECH

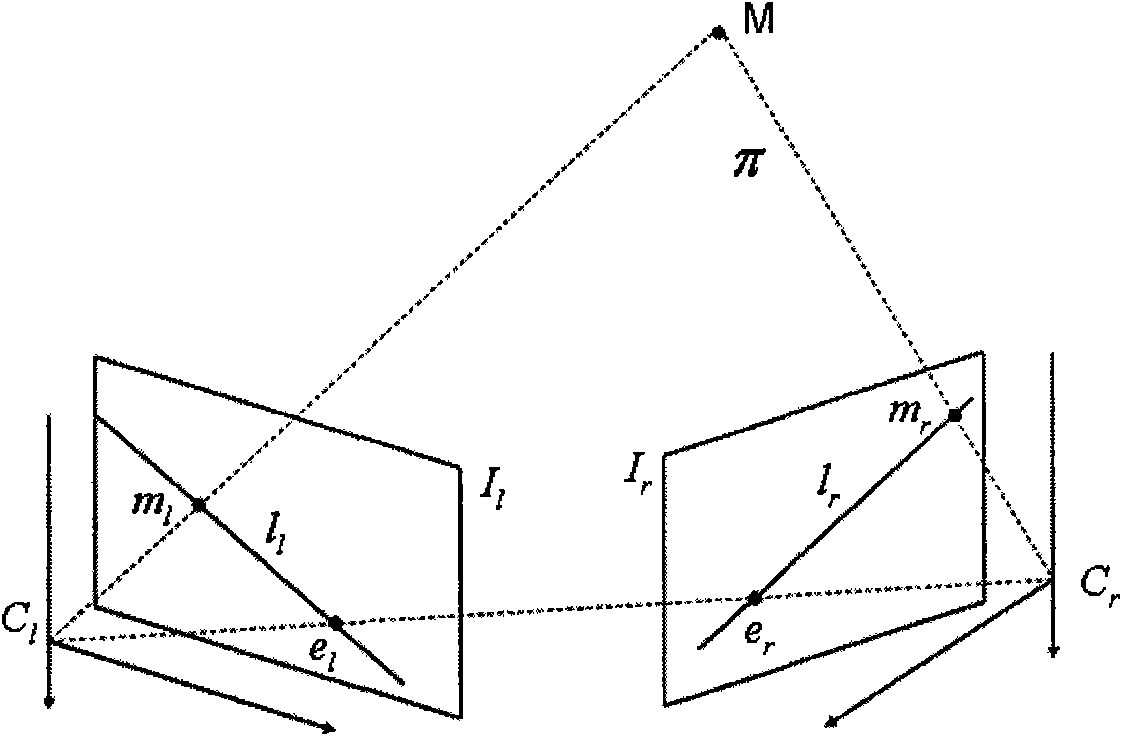

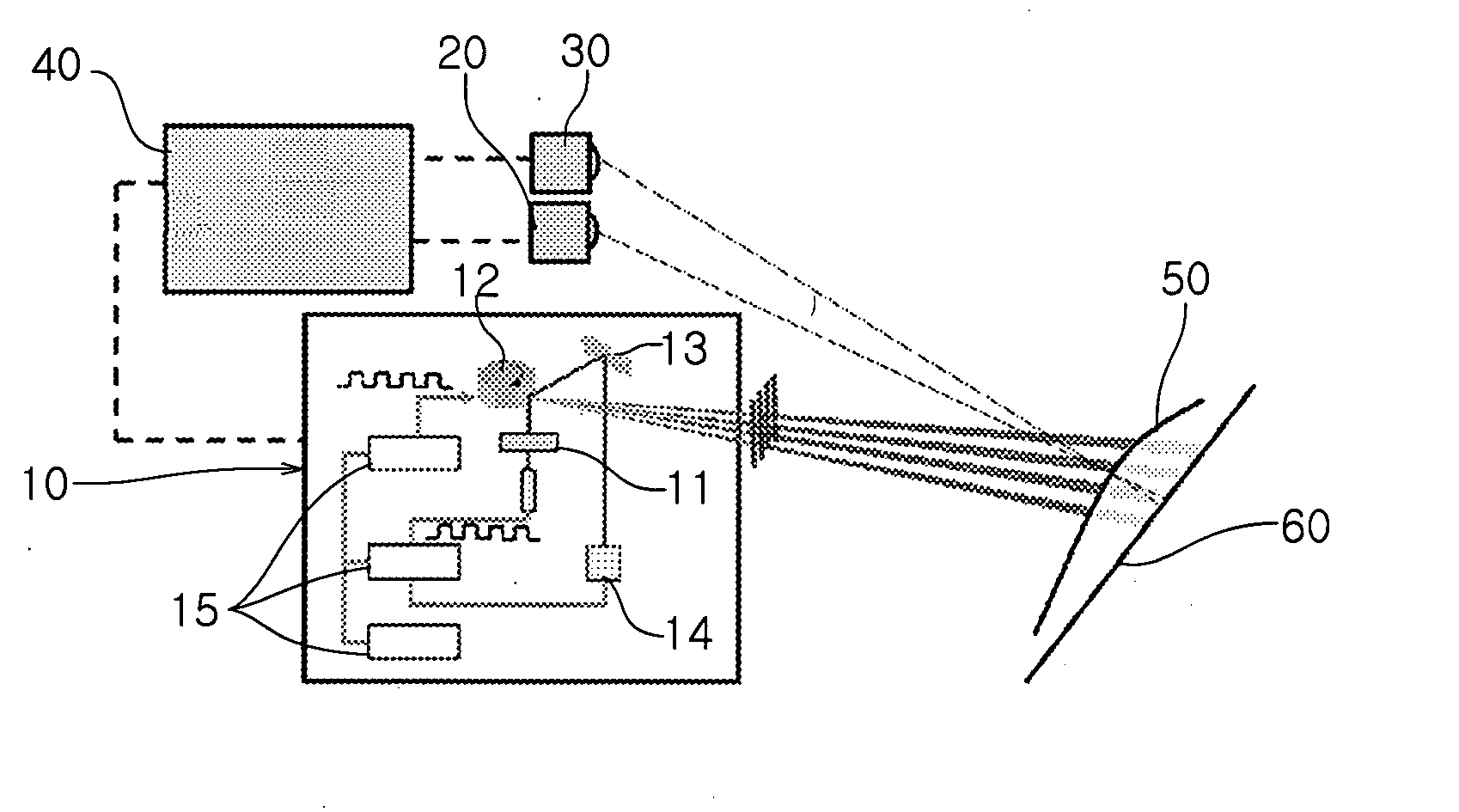

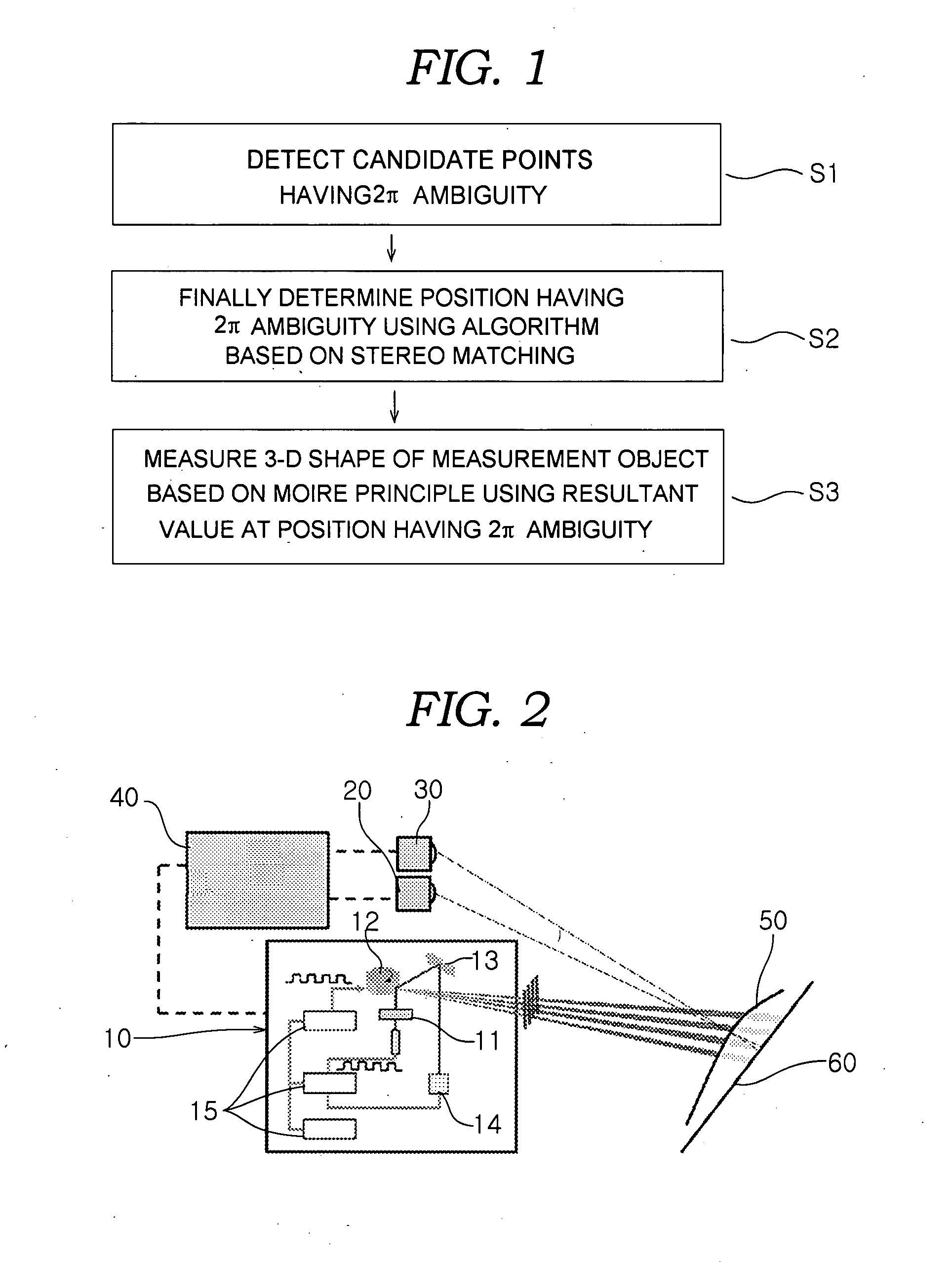

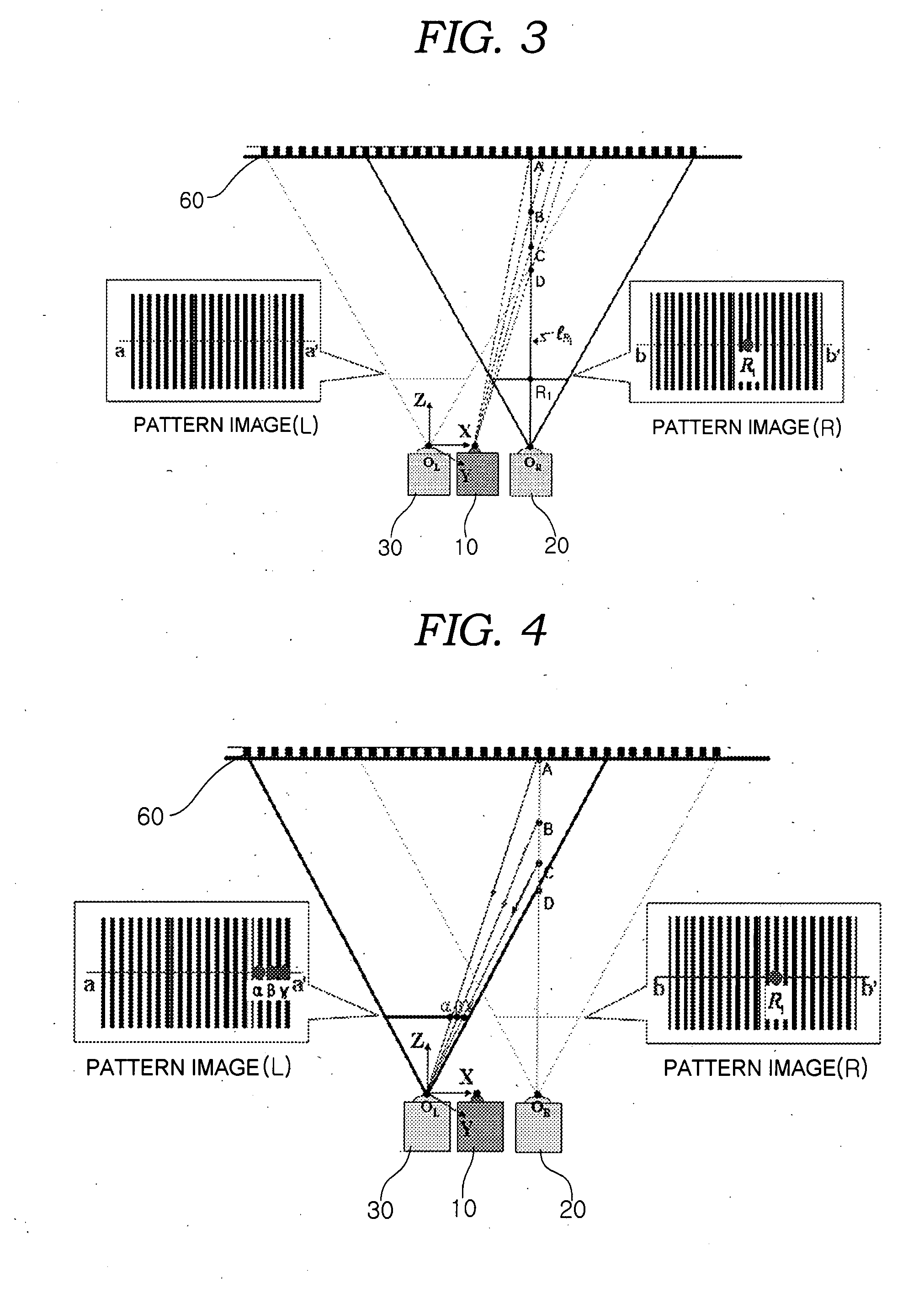

Three-dimensional shape measurement apparatus and method for eliminating2pi ambiguity of moire principle and omitting phase shifting means

InactiveUS20070211258A1Reduce ambiguityAccurate measurementUsing optical meansTextile decorationAmbiguityThree dimensional shape

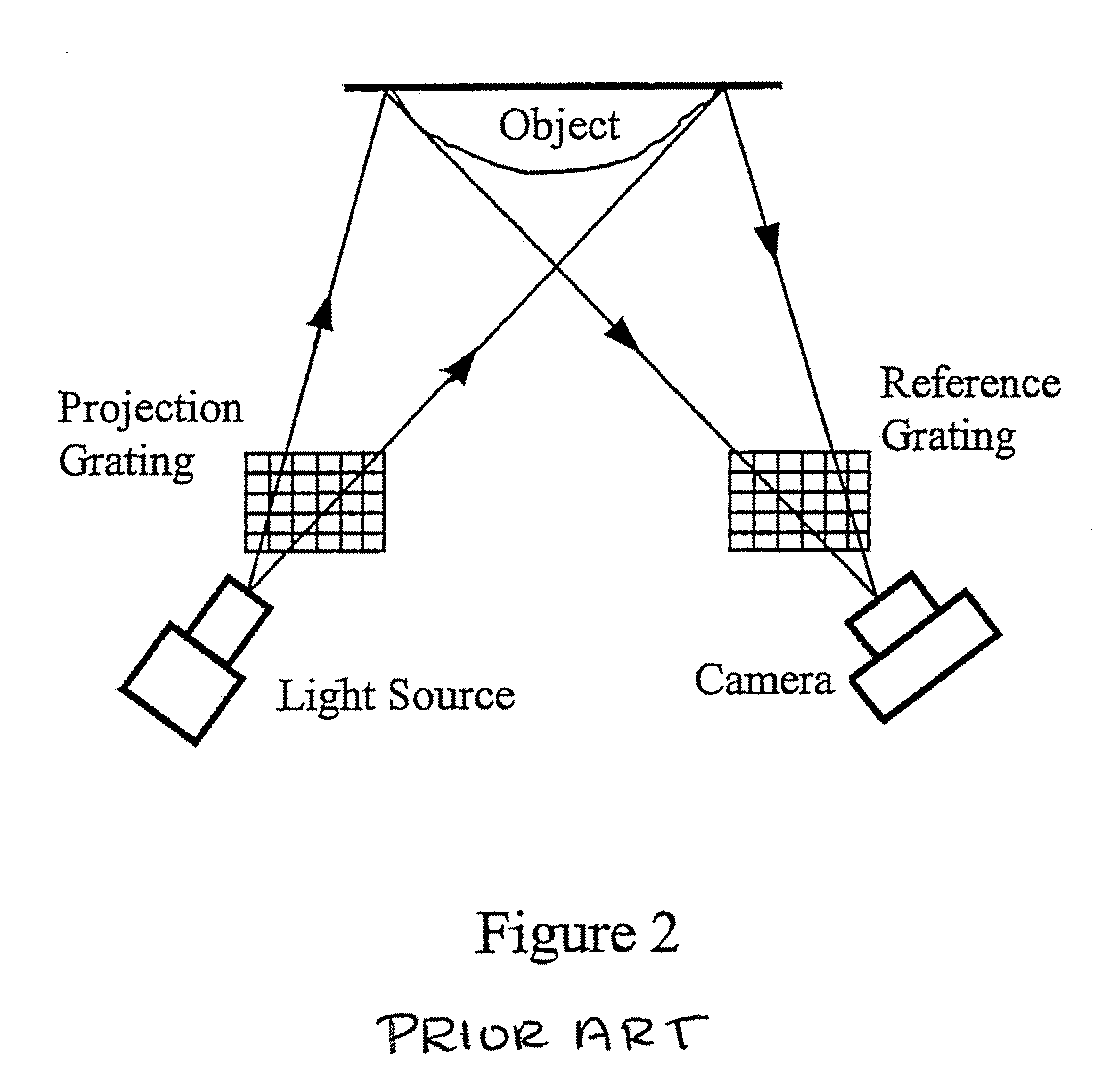

A three-dimensional (3-D) shape measurement method using a Moire measurement principle and a Stereo vision measurement principle is provided. The method comprises; a first step to detect candidate points and 3D positions of the candidate points in world coordinates which are identical results from typical Moiré technique by using a pattern projector, which adjusts a pitch of a fringe pattern and projects the fringe pattern to a measurement object, and a first camera, which detects a modulated fringe pattern caused by shape of shape of the object, by means of obtaining candidate points by comparing a reference fringe pattern to the modulated fringe pattern and calculating 3D positions at an arbitrary point on an image captured from the first camera; a second step to determine a final matching point among the candidate points detected from the first step by using the Stereo vision technique with the first and the second cameras, by means of projecting the 3D positions of the candidate points to an image plane of the second camera based on a camera matrix of the second camera, comparing intensity value of a projected point in the image plane of the second camera to intensity value of given point in the image plane of the first camera, and judging whether the candidate point is matched with an arbitrary point by using the stereo vision criteria; and a third step to measure the depth value of the arbitrary point by using the resultant value of the final matching point, which was determined at the second step. Therefore, the error of 2π ambiguity of the typical Moire principle is eliminated, and thus 3-D shape information can be more rapidly and accurately measured.

Owner:KOREA ADVANCED INST OF SCI & TECH

Method and apparatus for absolute-coordinate three-dimensional surface imaging

InactiveUS7929751B2Readily displayed and manipulatedSimple structureImage analysisCharacter and pattern recognitionComputer graphics (images)Surface geometry

A method and associated apparatus for capturing an image of a 3D object (100) which encodes the surface geometry of at least a portion of the object, comprising: 1. projecting (304) a plurality of fringe patterns (312A, 314A) onto the object; 2. capturing (306) phase alterations in reflections of the fringe patterns (312B, 314B) from the object; 3. projecting a uniform image (310A) onto the object; 4. capturing a reflection of the uniform image (310B) from the object; and 5. combining (310) captured phase alterations and captured uniform image reflection on a pixel-by-pixel basis, thereby forming a holoimage representation of the object.

Owner:HANGZHOU CONFORMAL & DIGITAL TECH CORP

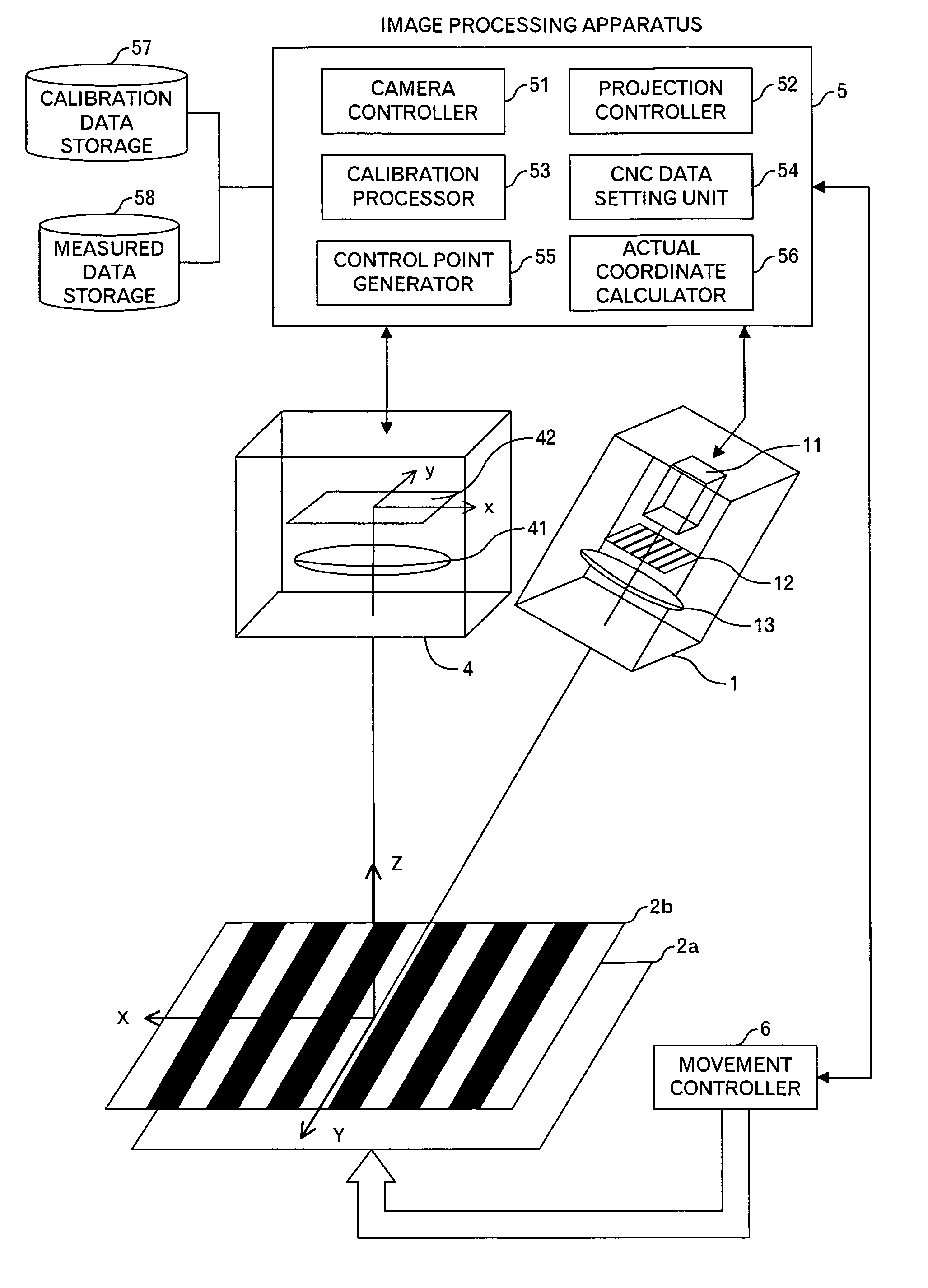

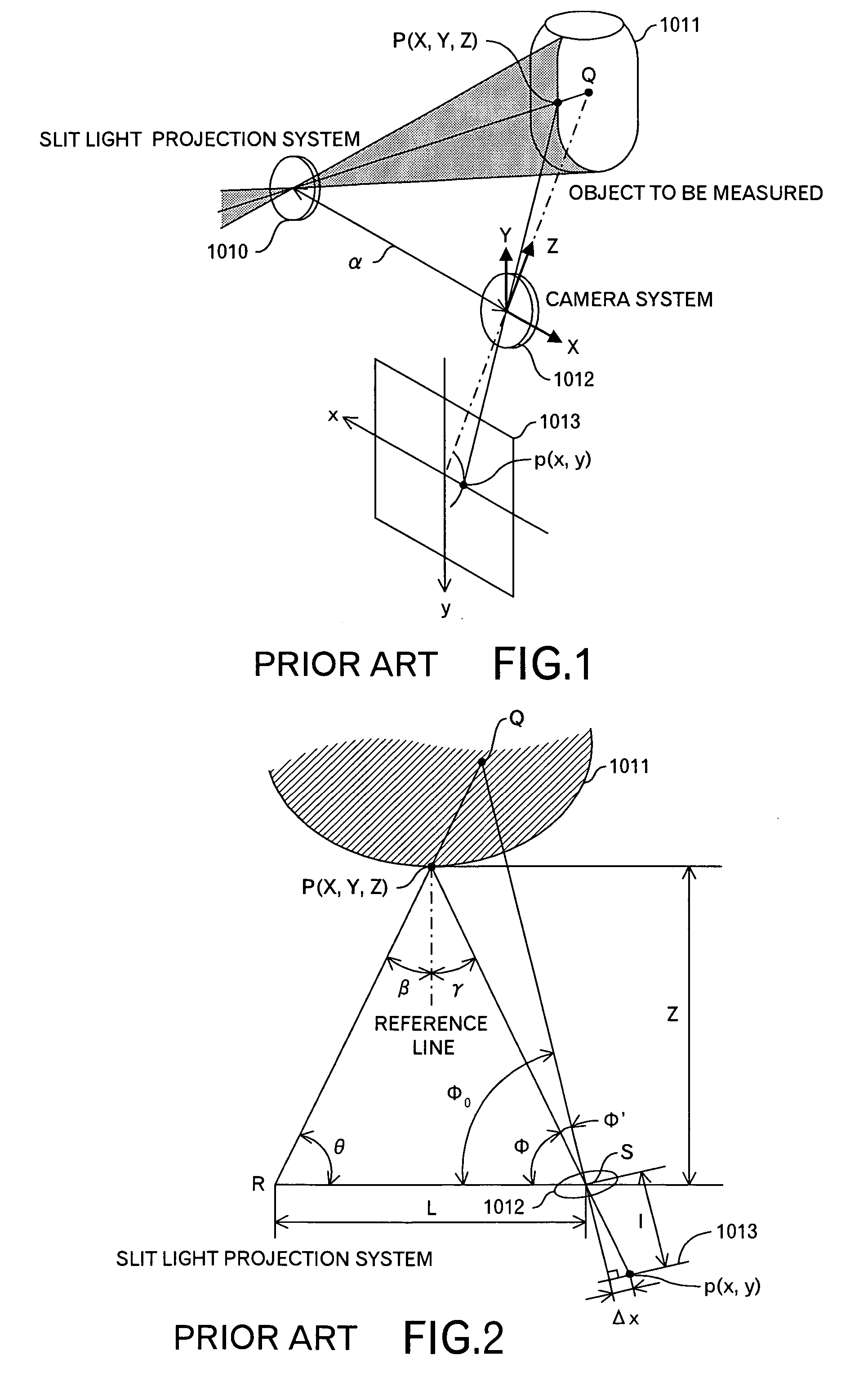

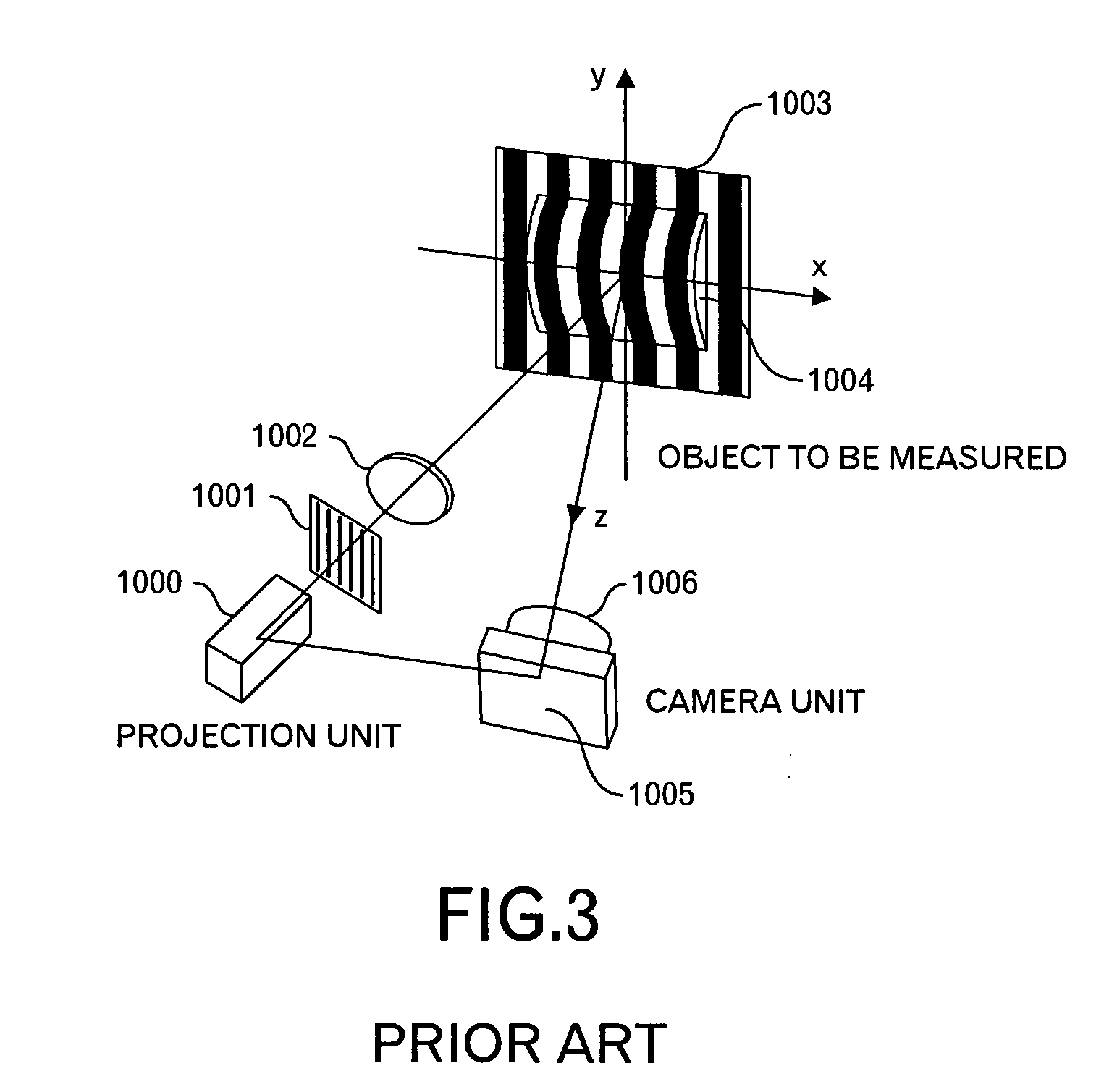

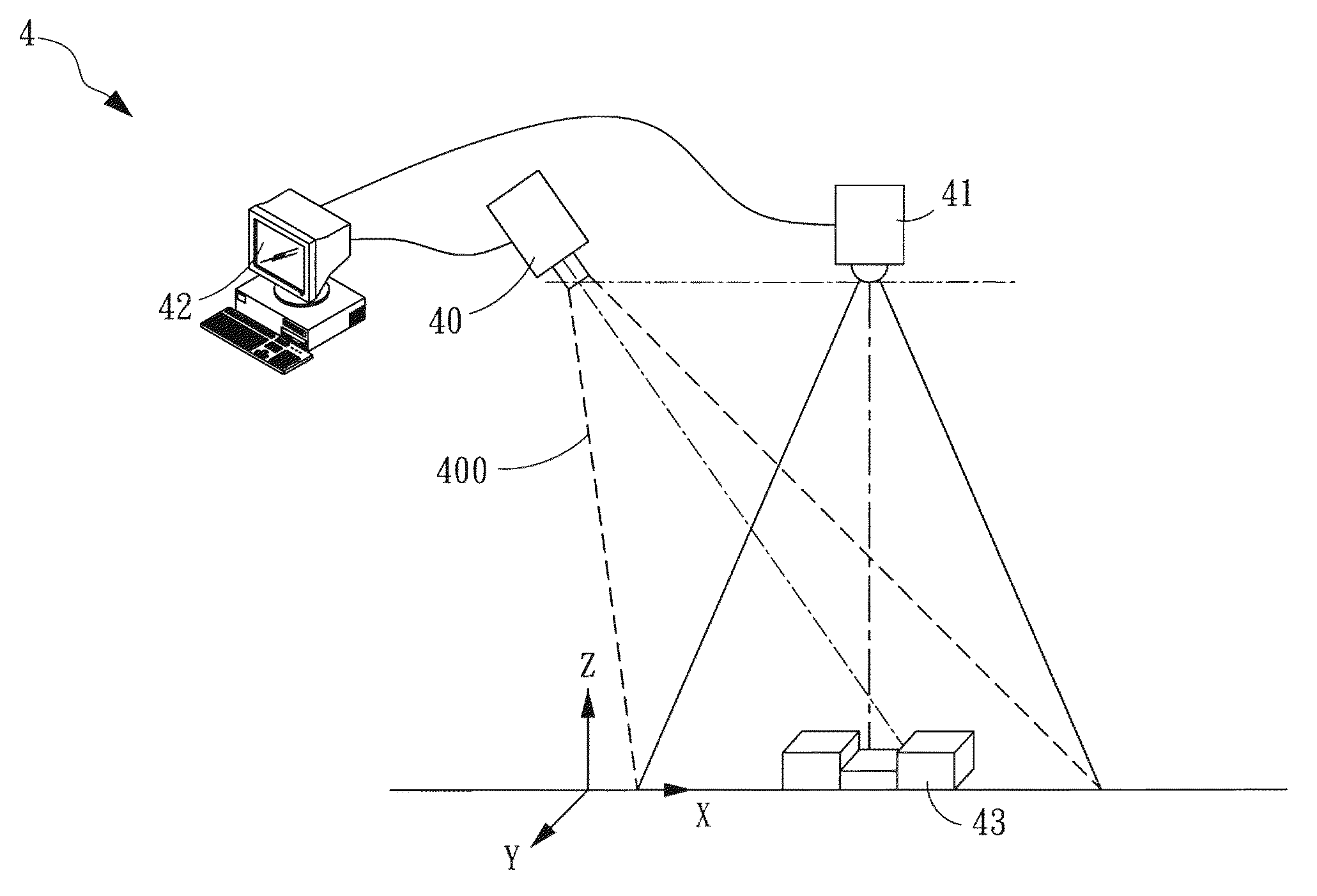

Measuring technology and computer numerical control technology

ActiveUS20050046873A1Eliminate errorsQuick calibrationImage analysisInterferometric spectrometryProduct typeNumerical control

A measuring apparatus of this invention comprises: a projector; a camera; a generator that generates, from a photographed image of a fringe pattern projected by the projector at a time of calibration onto each of surfaces, first tuples, each including coordinates of a point on a light receiving plane (LRP) of the camera, light intensity of the point and the height of the surface; a converter that converts the light intensity to a phase angle of the projected fringe pattern (PFP), and generates second tuples, each including the coordinates of the point on the LRP, the phase angle and the height of the surface; a hypersurface generator that generates data representing a tensor product type composite hypersurface (TPTCH) from data of the second tuples; an extractor that extracts data of third tuples, each including coordinates of a point on the LRP and light intensity from a photographed image of a fringe pattern projected by the projector at a time of measurement onto an object to be measured; a second converter that converts the light intensity to a phase angle of the PFP to generate data of fourth tuples, each including the coordinates of the point on the LRP and the phase angle; and an interpolator that carries out interpolation by using the data representing the TPTCH to generate height data corresponding to the data of the fourth tuple.

Owner:FUJITSU LTD

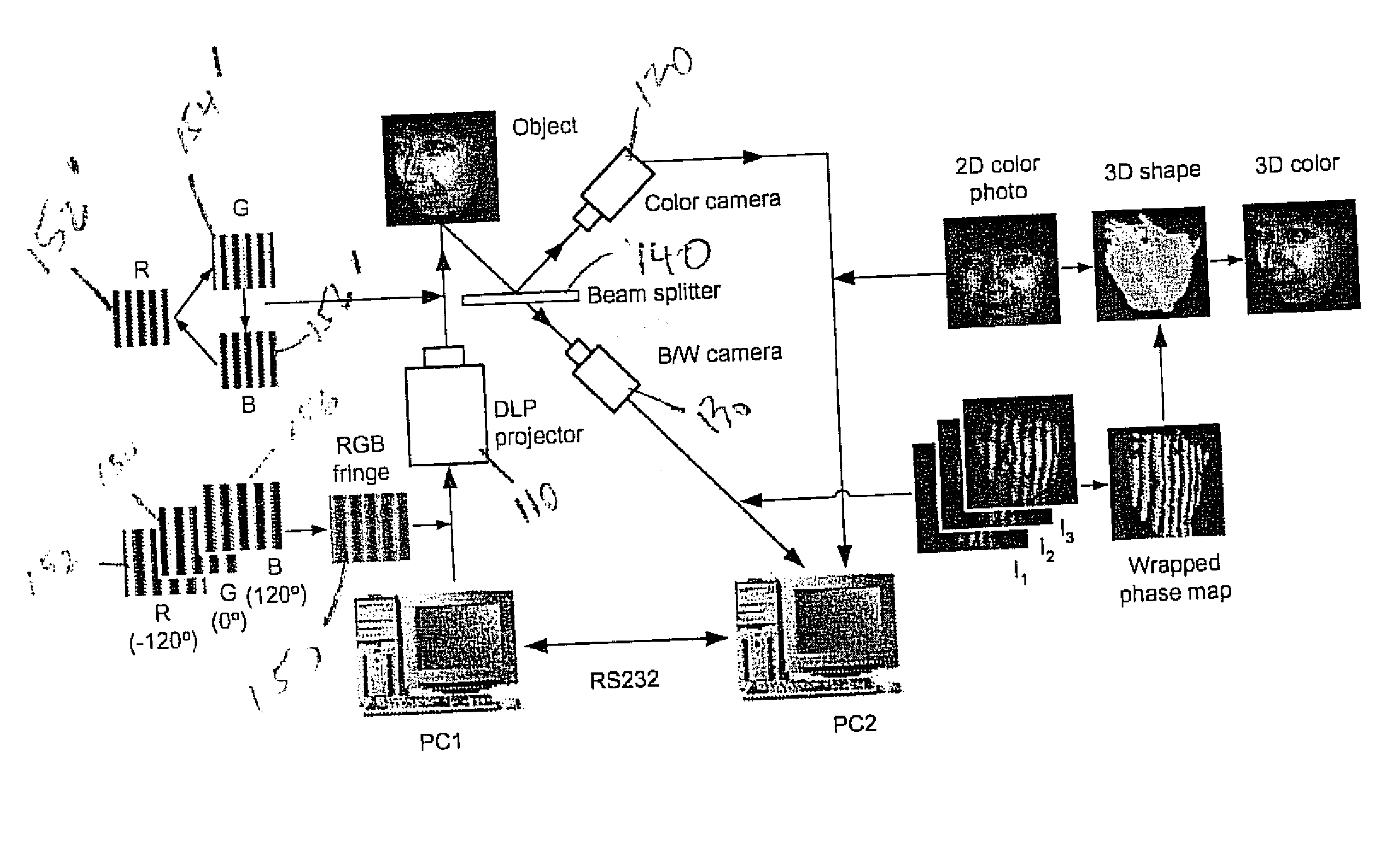

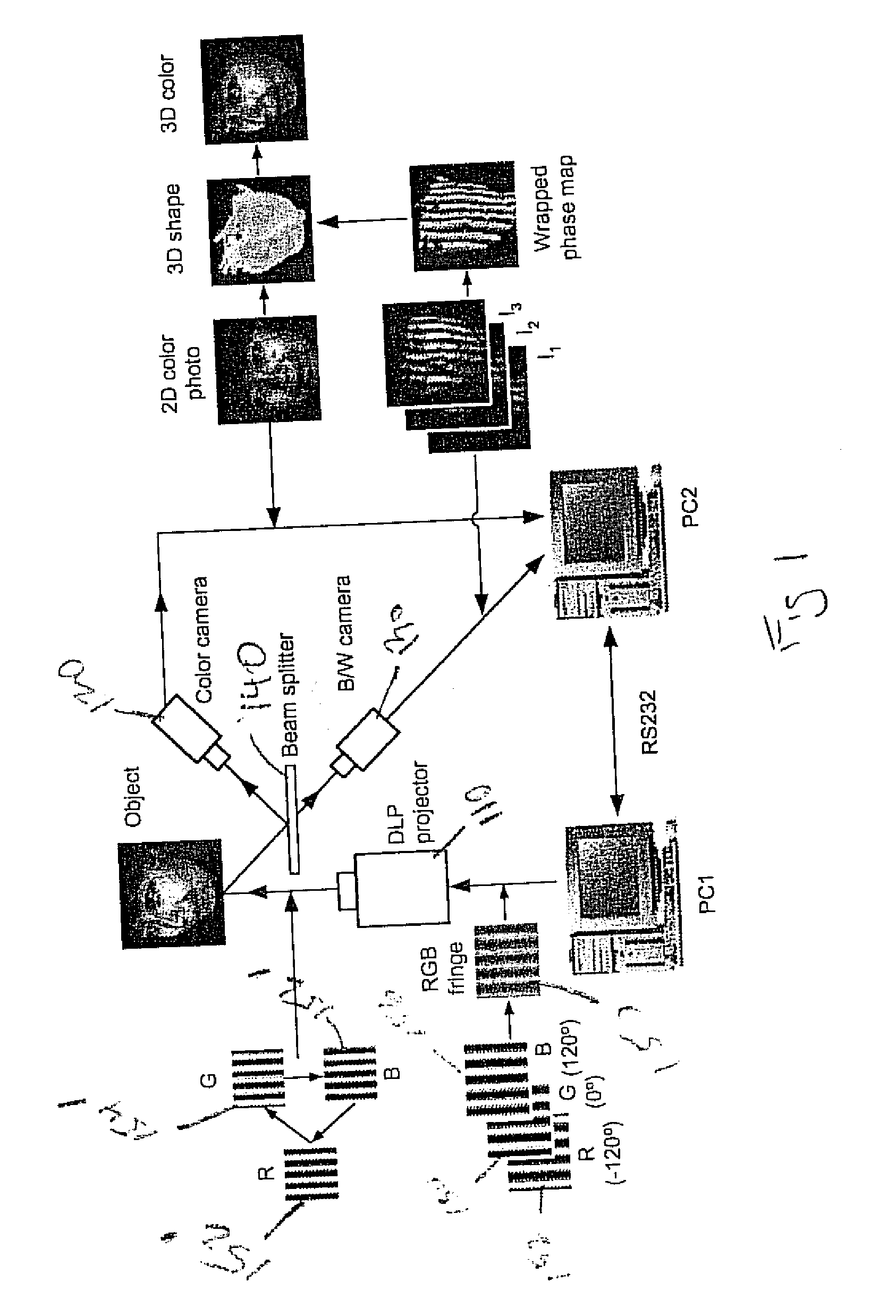

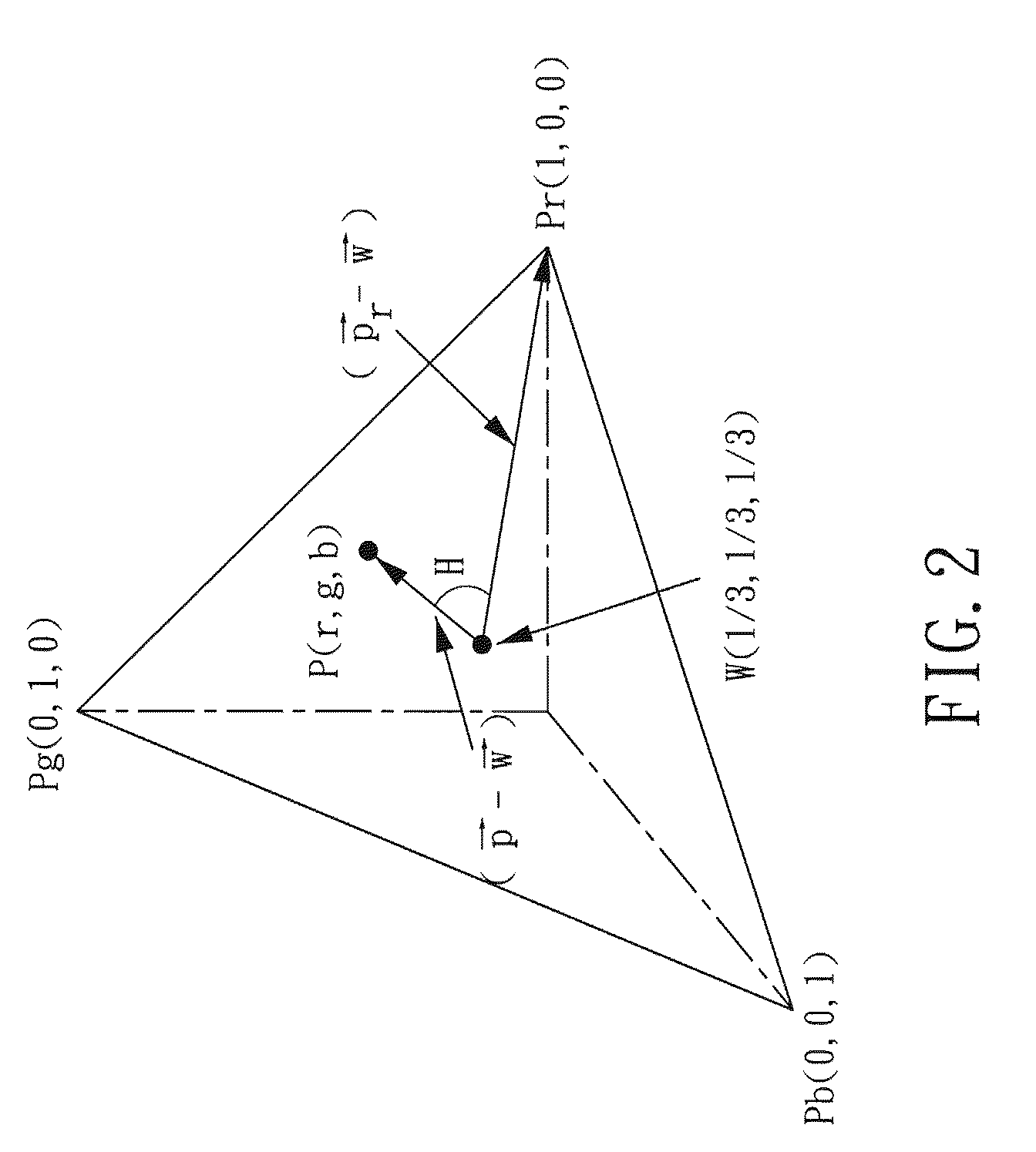

Method for simultaneous hue phase-shifting and system for 3-d surface profilometry using the same

InactiveUS20100188400A1Minimizing undesired effectShorten the timeTelevision system detailsImage analysisColor imagePhase shifted

The present invention provides a method for simultaneous hue phase-shifting and a system for 3-D surface profilometry, wherein a single structured-light fringe pattern with encoded multiple trapezoidal color fringes is projected on an object so as to obtain a color image having deformed fringe patterns and then a hue information extracted from a HSI color model associated with the fringe pattern is transformed into a hue phase-shifting information for restructuring the 3-D surface profile of the object. Since the color structured light is composed of a plurality of colorful light having phase shifts with each other in spatial domain, the single structured-light pattern comprises multiple hue phase-shifting information so that the phase shifting and unwrapping can be performed by one-shot 3-D surface reconstruction process without needs of traditional conventional phase wrapping and Euler's transformation procedures such that the efficiency of phase shifting and 3-D surface measurement can be improved.

Owner:NAT TAIPEI UNIV OF TECH

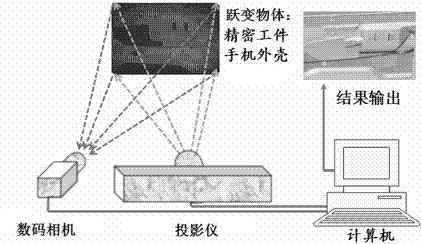

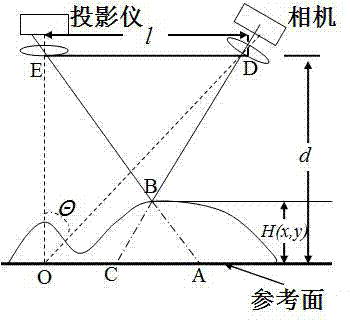

High-precision three-dimensional shape measurement method for jump object

InactiveCN103940371AAccurately getHigh precisionUsing optical meansFull fieldThree dimensional shape

The invention provides a high-precision three-dimensional shape measurement method for a jump object. The method is characterized in that the fringe projection profilometry, in combination with curvelet transform, is applied to three-dimensional shape measurement of the jump object. The fringe profilometry based on structured light projection is a high-precision, quick, noncoherent optical full-field object three-dimensional shape measurement technique, and experimental devices adopted are simple, which mainly include a computer, a projector and a digital camera. The projector is used for projecting a plurality of sets of sine fringe patterns different in frequency to the jump object to be tested; the digital camera is used for recording deformed fringe patterns and transmitting the deformed fringe patterns to the computer, and then the deformed fringe patterns are denoised by virtue of curvelet transform and the phase distribution of the deformed fringes is demodulated in combination with a phase shifting method, and unwrapped phase distribution is obtained by using a phase unwrapping method. At last, three-dimensional data of the jump object is obtained according to a phase-height relation. The high-precision three-dimensional shape measurement method has the major gain that a high-precision fast full-field measurement technique for the three-dimensional shape measurement of the jump object.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

System and method for sensing torque on a rotating shaft

InactiveUS20080041141A1Highly responsive, reliable, and safe steeringMinimal light distortionForce measurement by measuring optical property variationWork measurementEngineeringComputing systems

A system and method relating to the measuring of torque in a rotating shaft is provided. An optical torque sensing system comprises a rotating shaft, wherein a sleeve of photo-elastic material overlays a portion of the shaft. A light emitting component delivers light into the photo-elastic material, wherein the light delivered by the light emitting component is directed through the photo-elastic material along an axis of the rotating shaft. A capturing component captures the light that exits the photo-elastic material. The exiting light comprises fringe pattern data, and a computing system computes torsion strain of the shaft based at least in part on the fringe pattern information

Owner:ROCKWELL AUTOMATION TECH

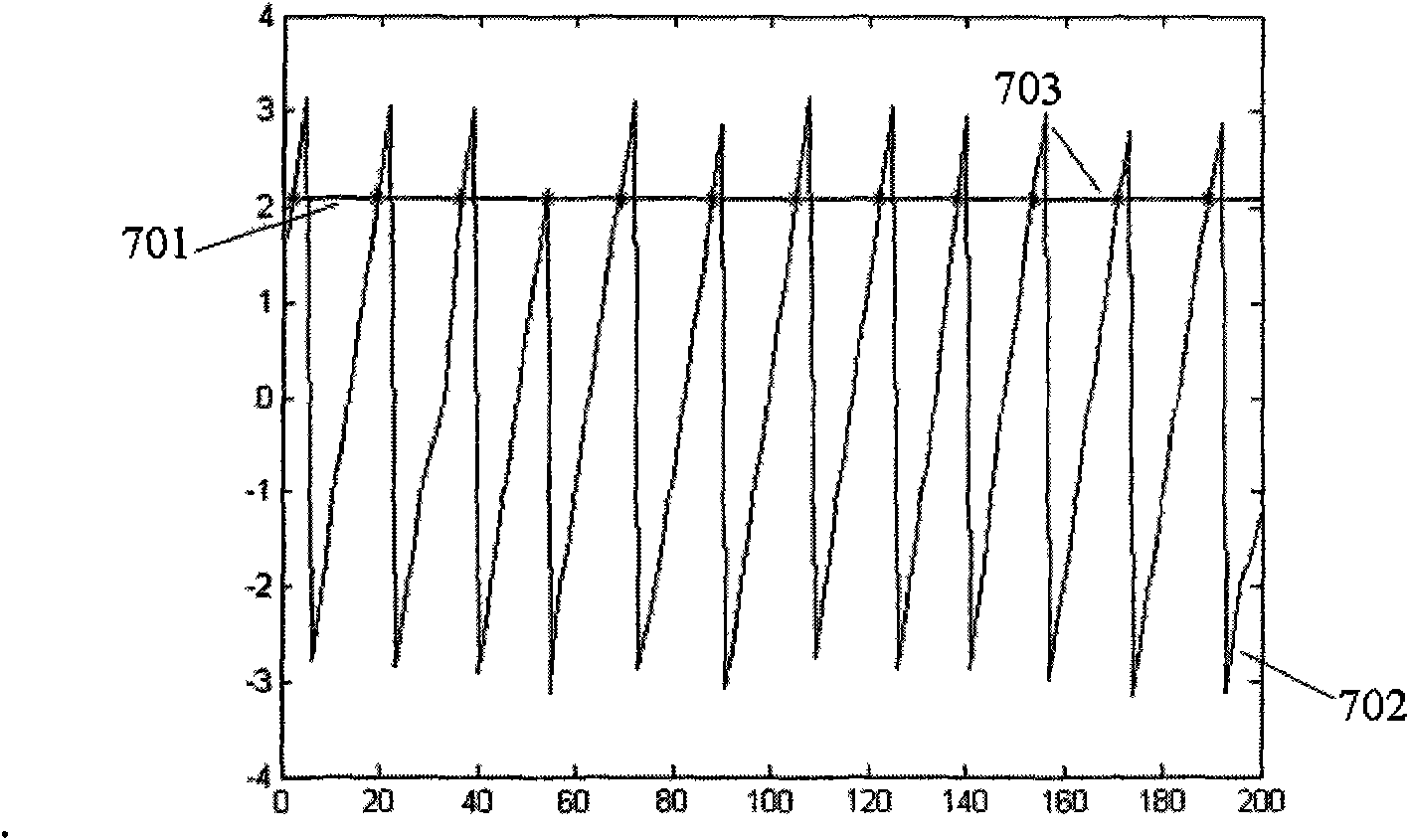

16-step dual-frequency grating phase shift profilometry capable of absolute phase unwrapping

InactiveCN101655360AGuaranteed measurement accuracyGuaranteed Measurement RequirementsUsing optical meansMeasurement studyThree dimensional shape

The invention provides 16-step dual-frequency grating phase shift profilometry capable of absolute phase unwrapping in the three-dimensional sensor technology. The invention is characterized by usingcomputers to design codes to generate 16 dual-frequency grating patterns, using a digital light projector to image the grating patterns on the surface of an object instantaneously in sequence, using apick-up device to record the deforming fringe pattern of the object, subsequently using the functional relationship between the gratings with two frequencies, using the absolute phase unwrapping method to directly realize phase unwrapping of point to point in the whole field range and having no relation with the path for phase unwrapping, effectively inhibiting accumulative error diffusion, usingphase measuring profilometry to process the deforming fringes, accurately restoring the three-dimensional shape of the object and obtaining such digital information as deformation of the object and the like by further analyzing the data processing results. The method can be used for measurement study of the characteristics of the object surface with the characteristic of diffuse reflection. The method has the advantages of high measurement precision and strong adaptability to the surface topography of the object, etc.

Owner:SICHUAN UNIV

Method and an apparatus for the determination of the 3D coordinates of an object

ActiveUS20080130016A1High lamp powerShort measurement timeUsing optical means3d coordinatesY-Coordinate

A method serves for the determination of the 3D coordinates of an object (2). A fringe pattern is projected onto the object (2) in the method. The light reflected by the object (2) is recorded and evaluated. To improve such a method, the fringe pattern is projected onto the object (2) by an imaging element (only FIGURE).

Owner:CARL ZEISS OPTOTECHN GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com