Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

780results about How to "Quick calibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

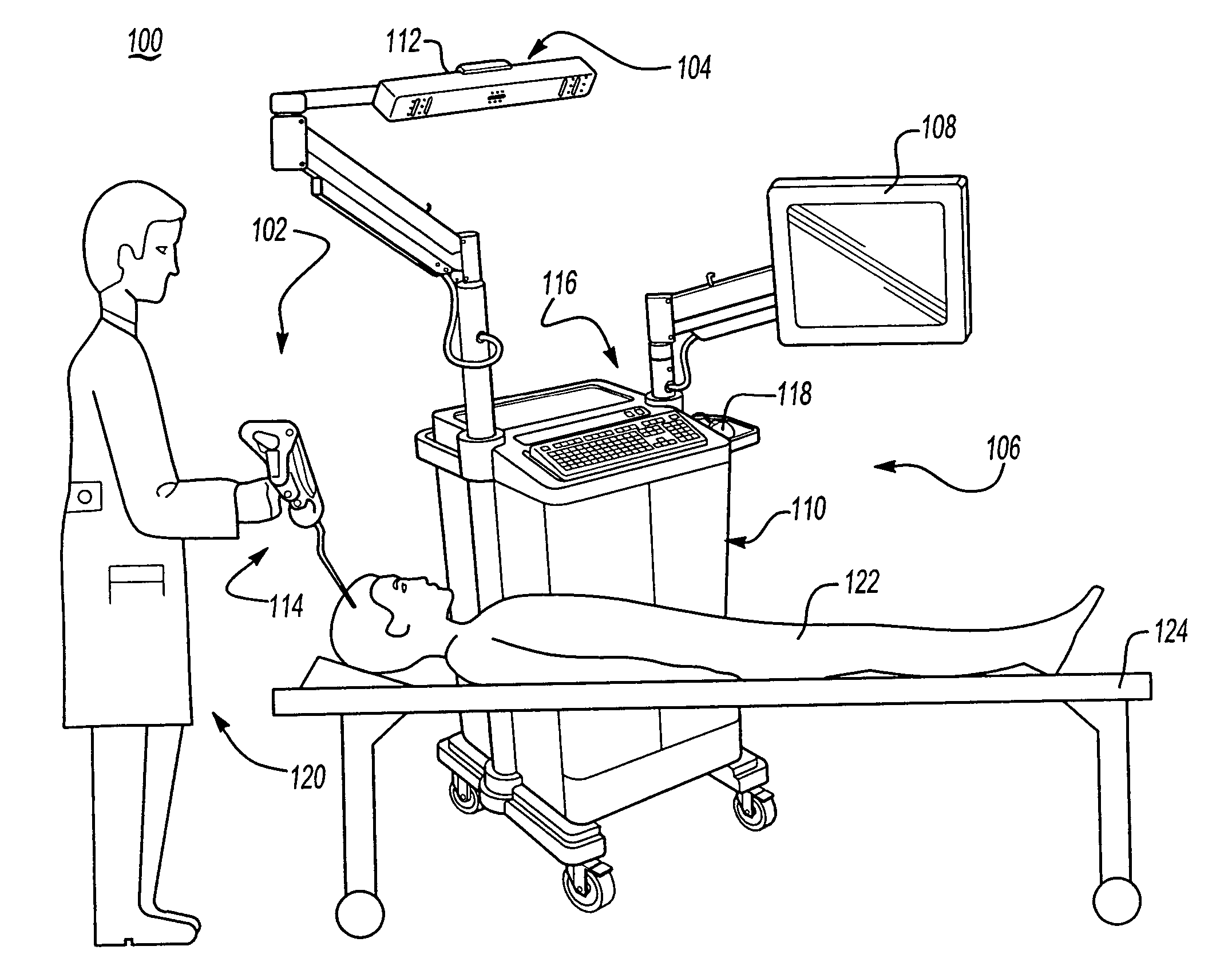

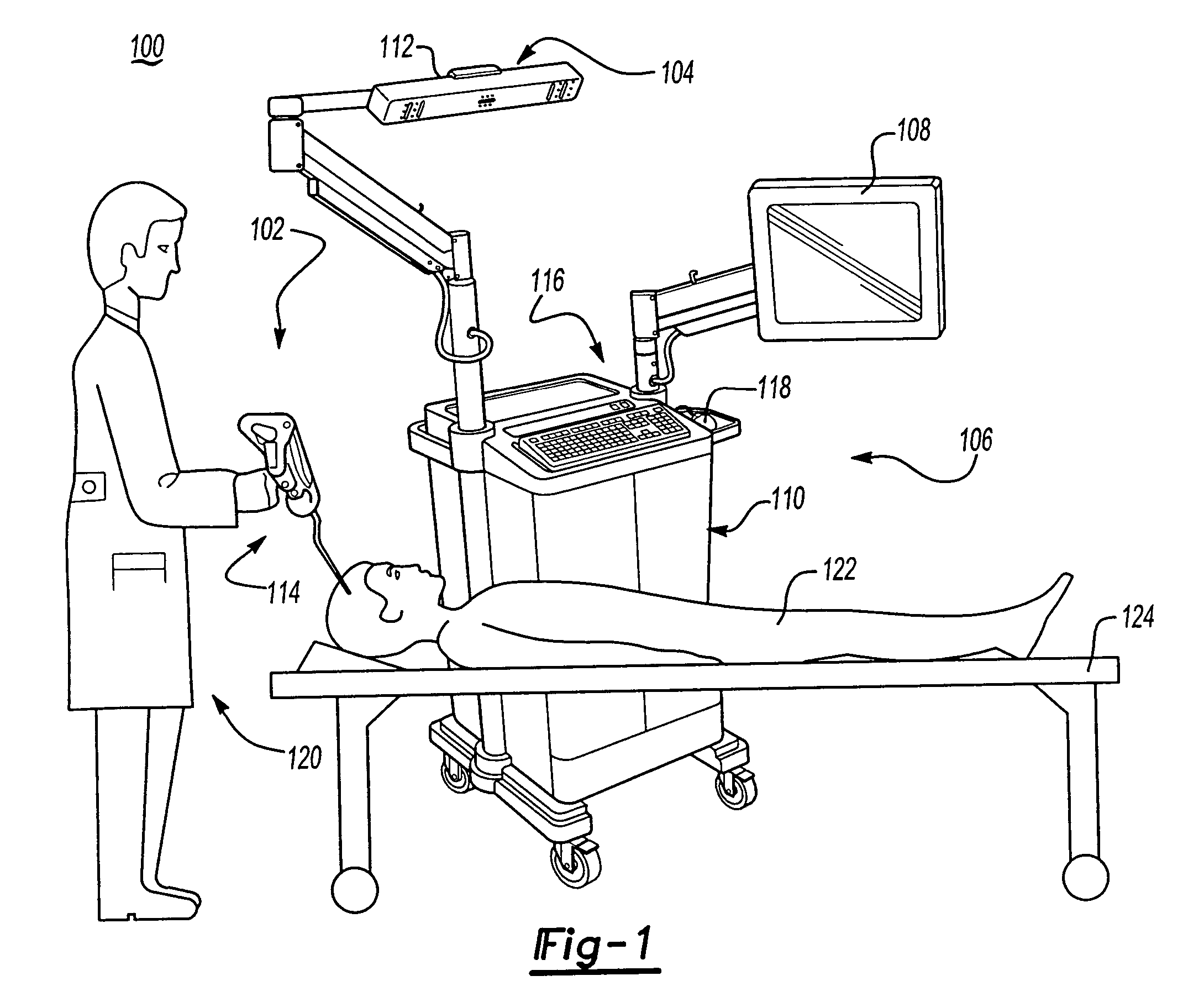

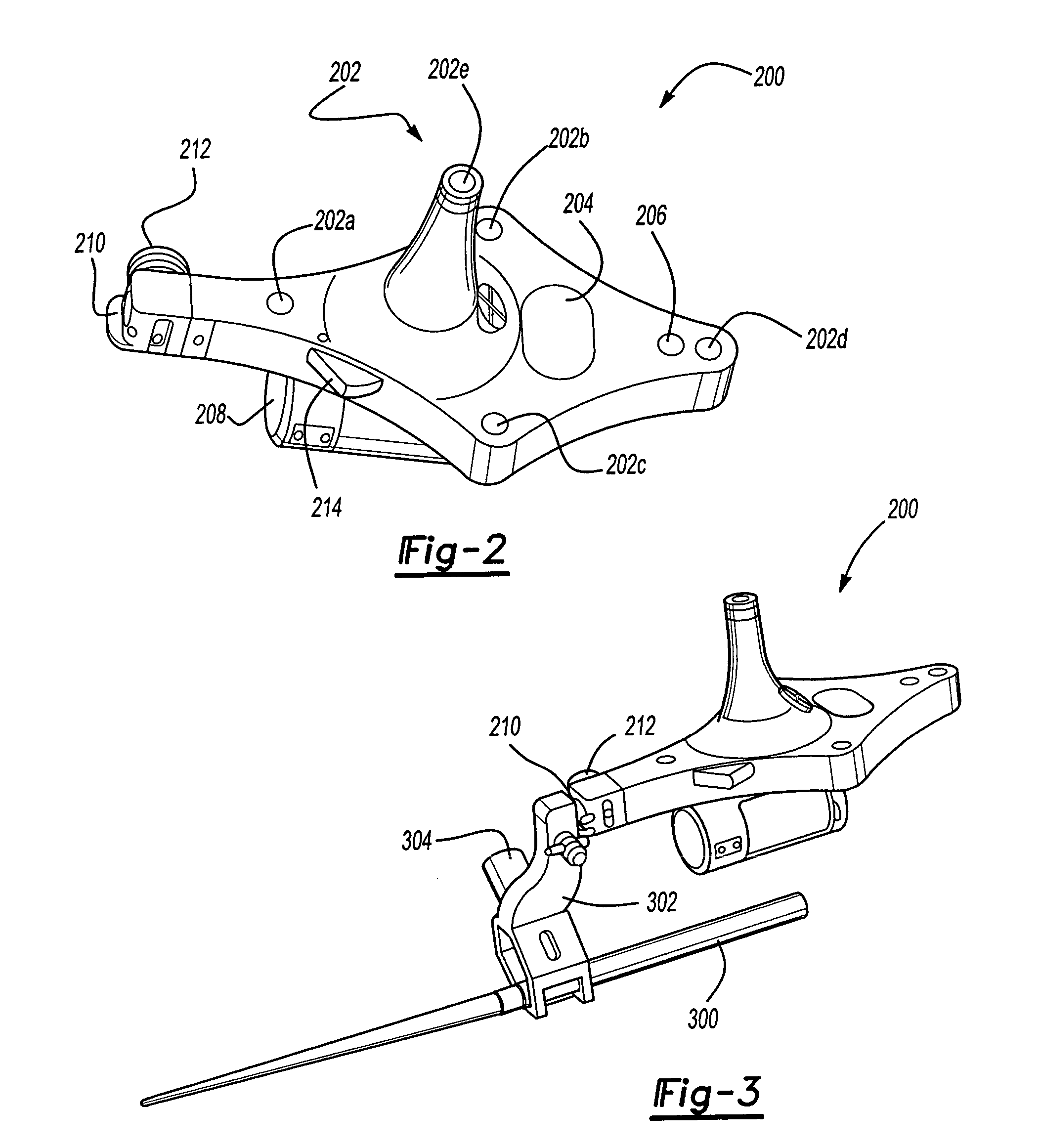

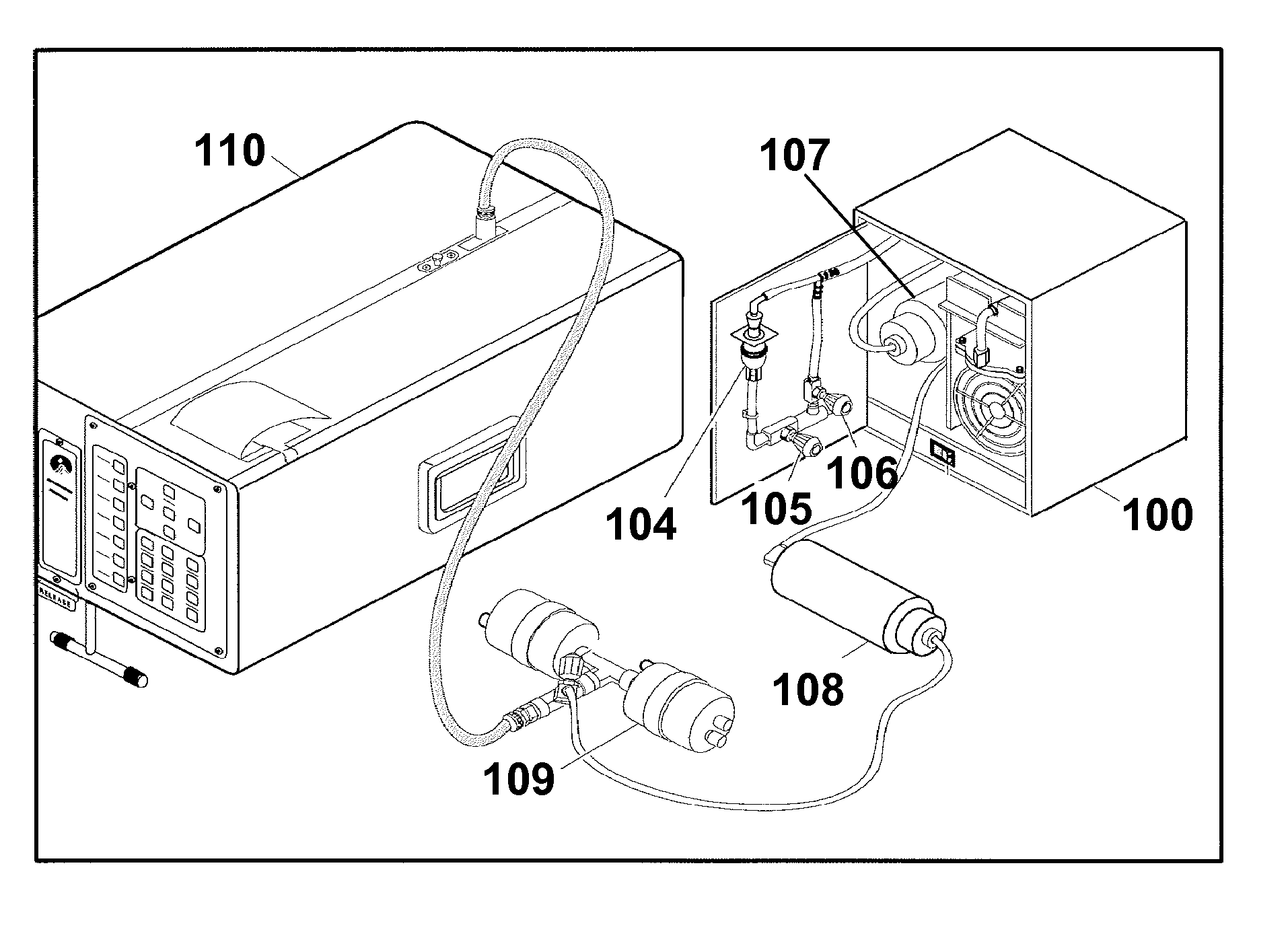

Surgery system

ActiveUS7725162B2Prolong lifeLower life cycle costsNon-electrical signal transmission systemsSurgical navigation systemsSensor arrayTransceiver

A surgery system comprising at least one smart instrument, a computer system, and a sensor system adapted to wirelessly sense the position of the at least one smart instrument and to transmit position information to the computer system, wherein the sensor system includes a sensor array and the sensor array includes at least three linear CCD cameras and at least one infrared transceiver.

Owner:STRYKER CORP

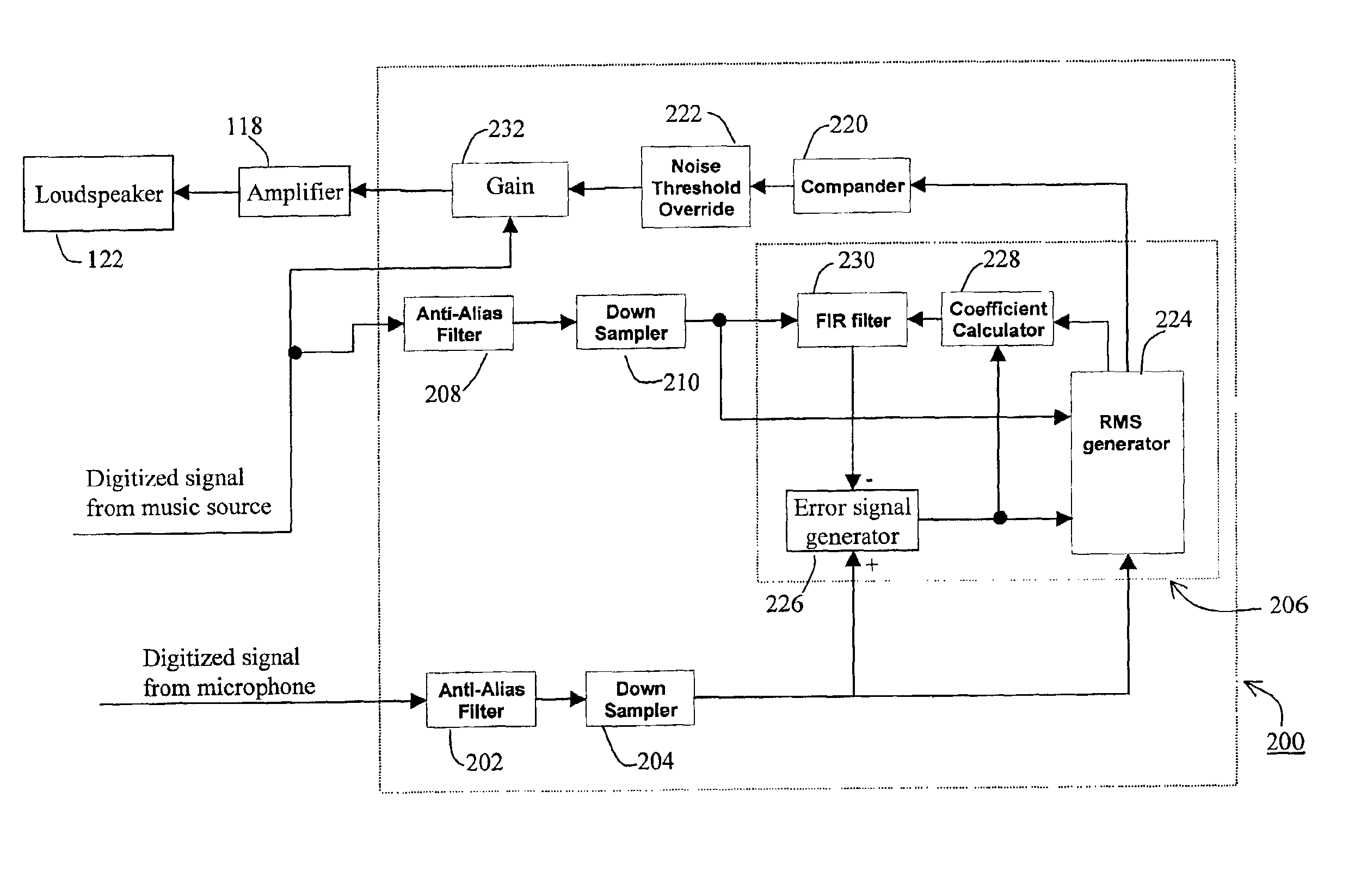

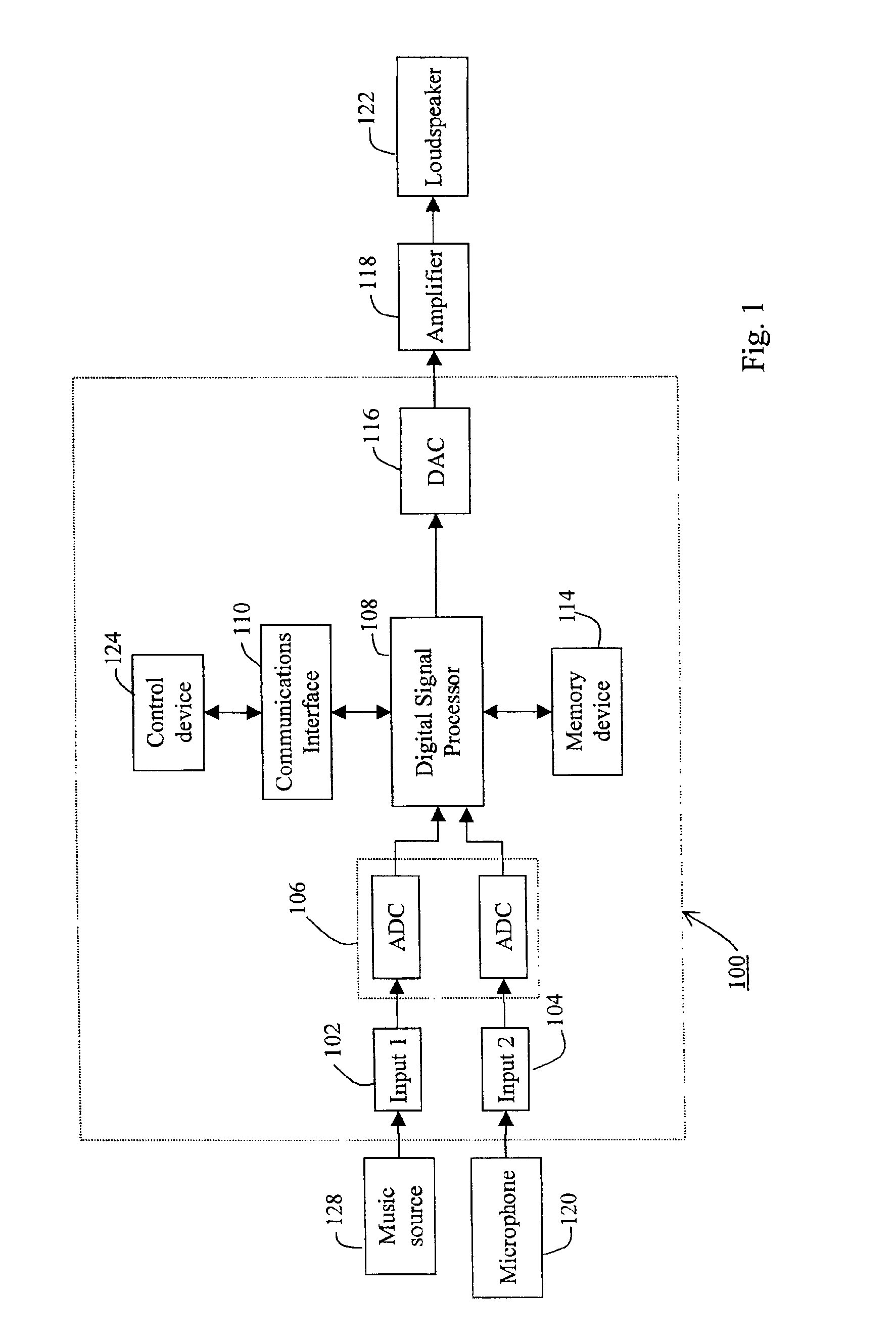

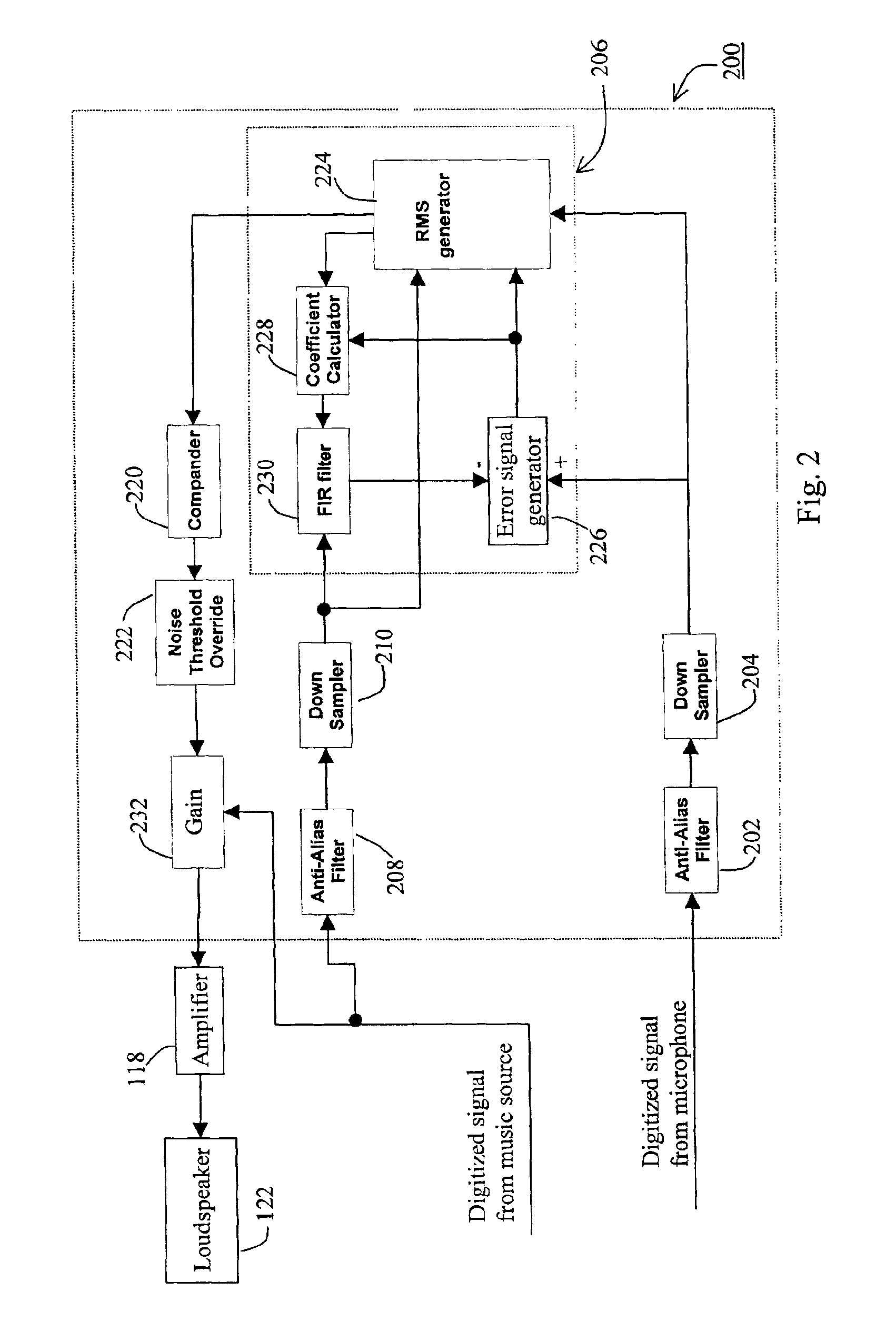

Method and apparatus for automatic volume control in an audio system

InactiveUS6868162B1Quick calibrationSet become largeGain controlAutomatic tone/bandwidth controlAdaptive filterAutomatic control

An audio system (100) is provided with improved adaptive filter (206) to automatically adjust signal gain depending on the ambient noise level. The original music signal passes through a normalized adaptive filter (206), and is subtracted from the ambient room signal detected by a microphone (120), resulting in an error signal that is an estimate of the ambient noise. The error signal is used to update a set of adaptation coefficients so that the normalized adaptive filter more accurately simulates the room transfer function, resulting in an better estimate of the ambient noise. The audio system (100) is calibrated automatically upon initial use to determine adaptation coefficients and noise threshold level to prevent runaway gain. System parameters are adjusted using a controller (124) with a user-friendly interface (400).

Owner:MACKIE DESIGNS

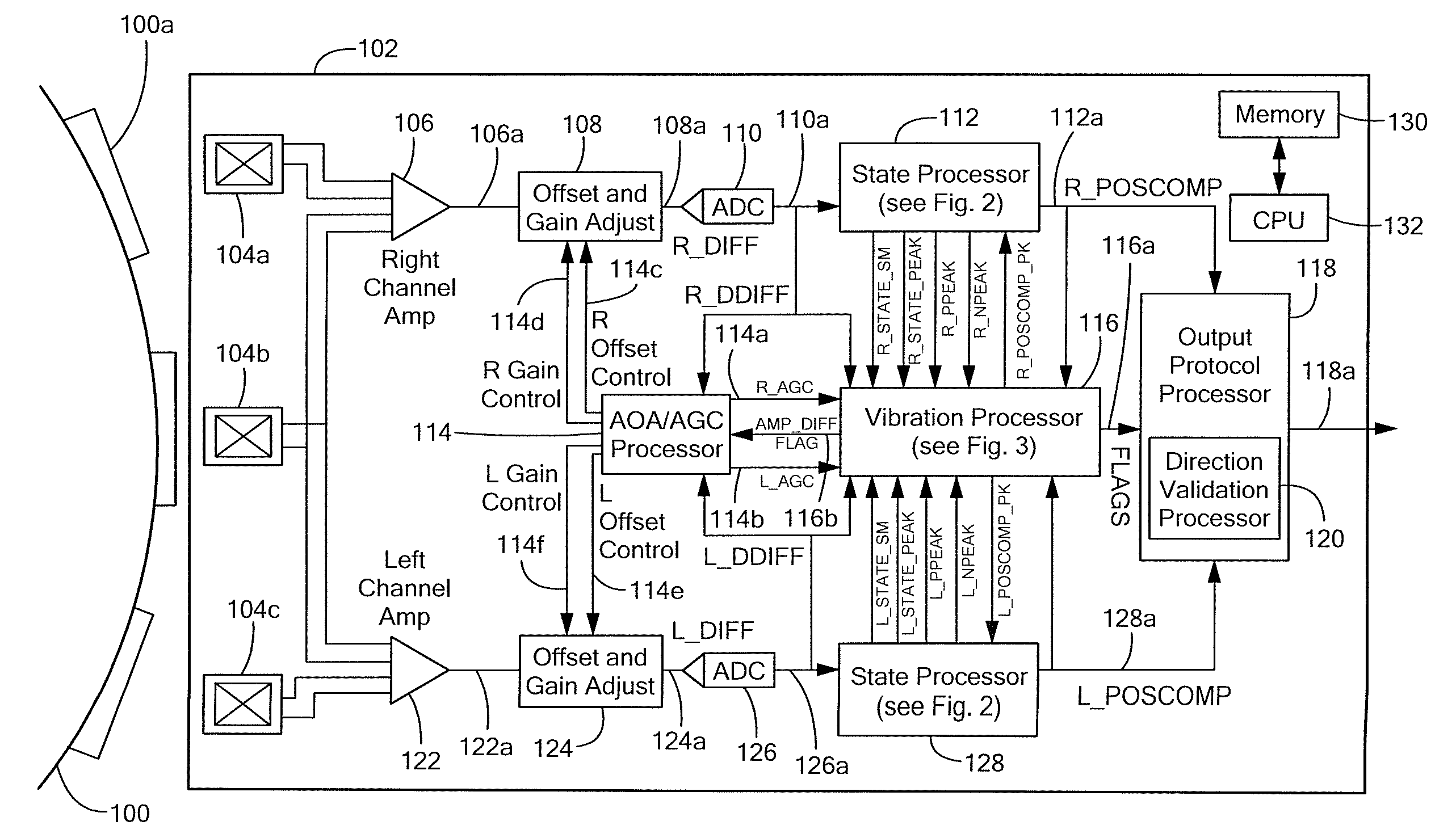

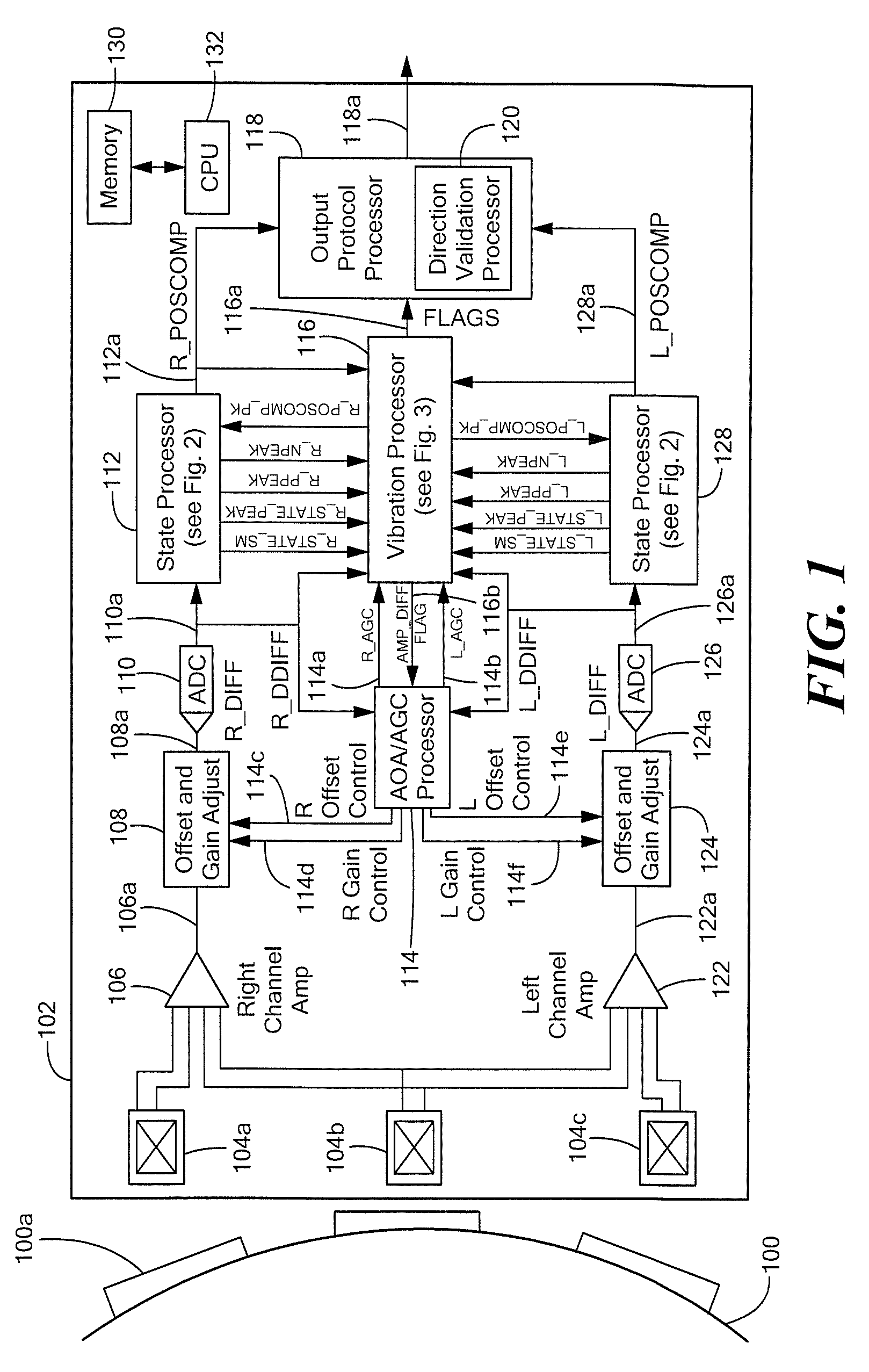

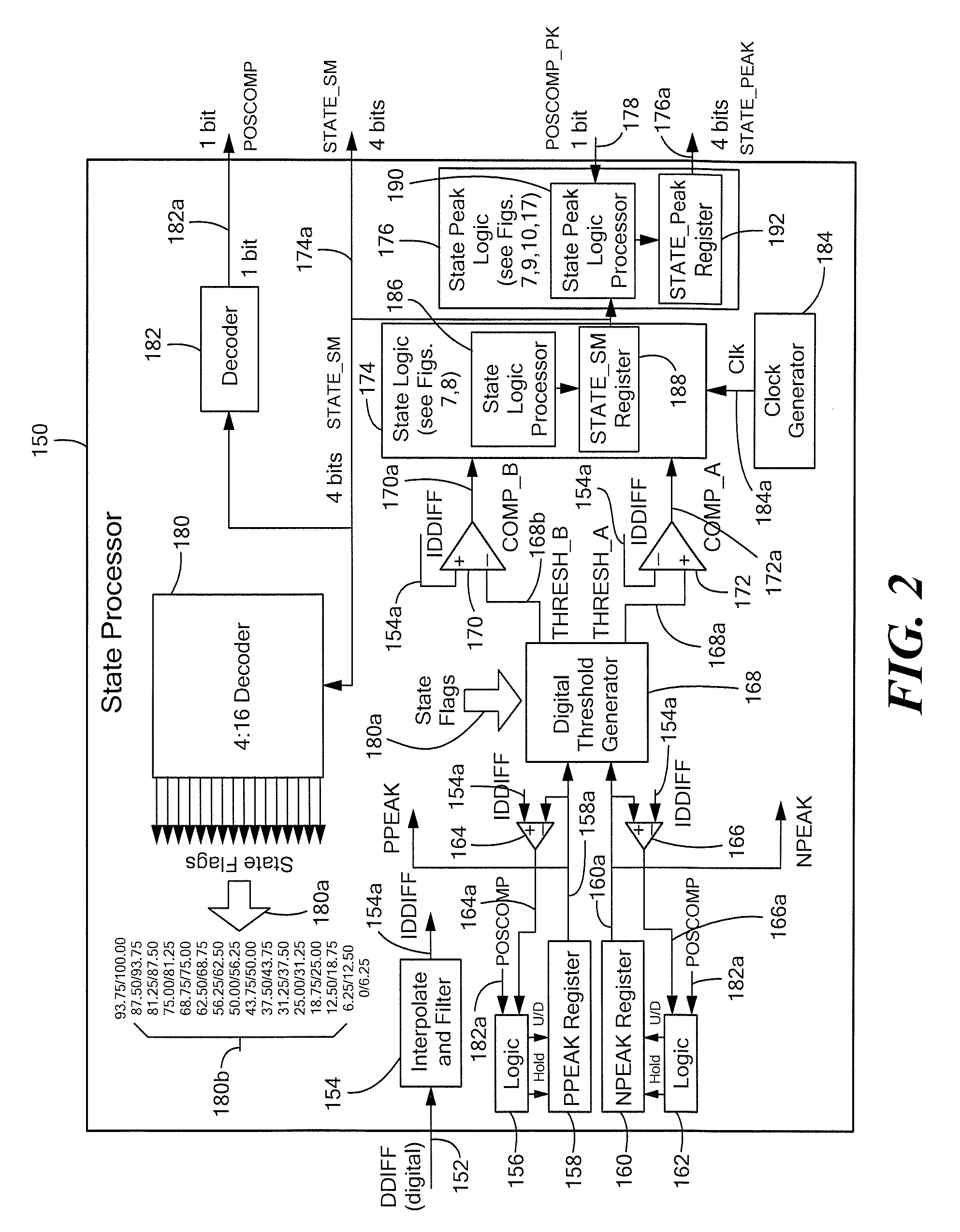

Motion Sensor, Method, and Computer-Readable Storage Medium Providing a Motion Sensor That Can Rapidly Calibrate Gains

ActiveUS20110298448A1Accurate gain calibrationRapid gain calibrationUsing electrical meansLinear/angular speed measurementEngineeringMotion sensors

Owner:ALLEGRO MICROSYSTEMS INC

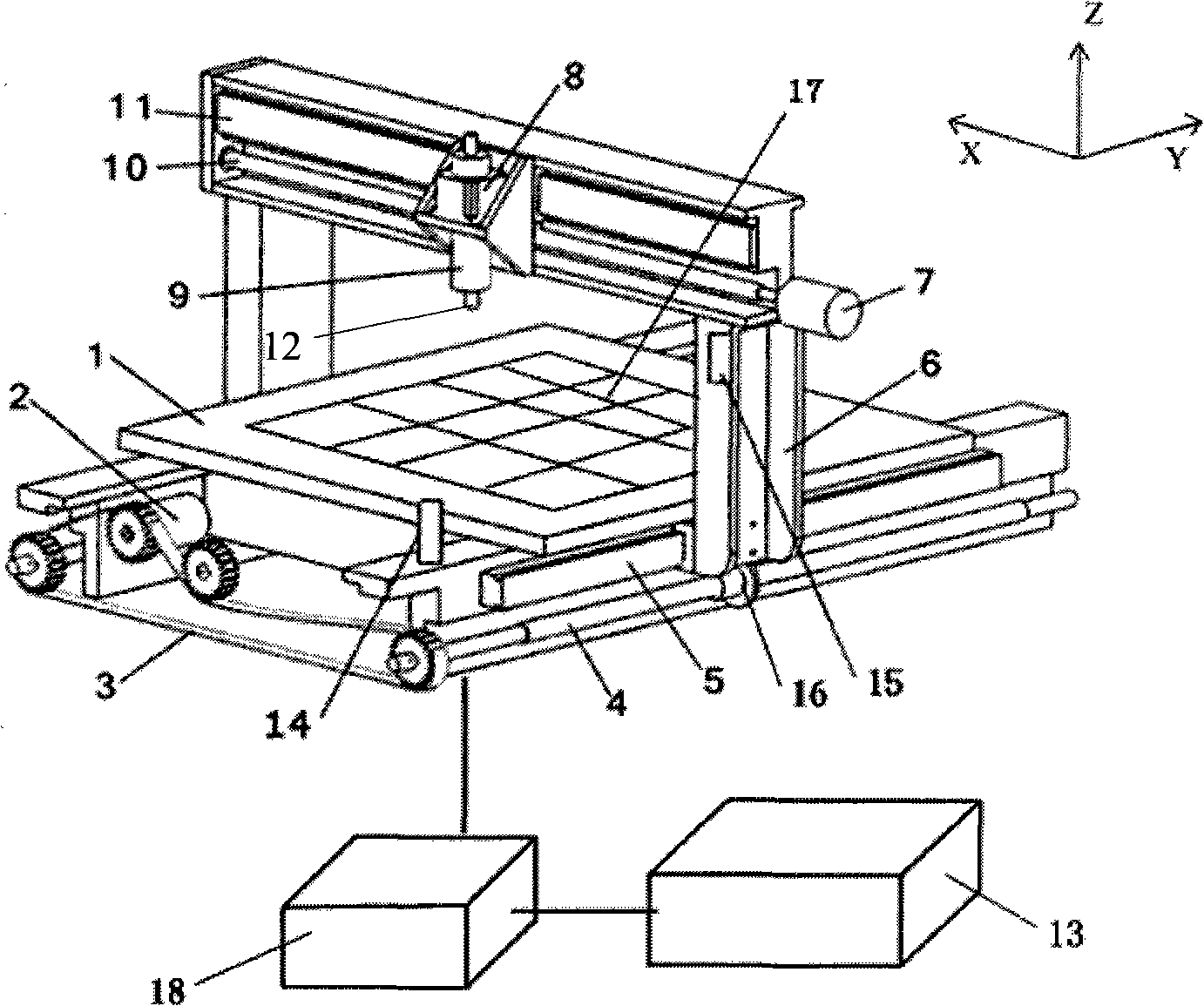

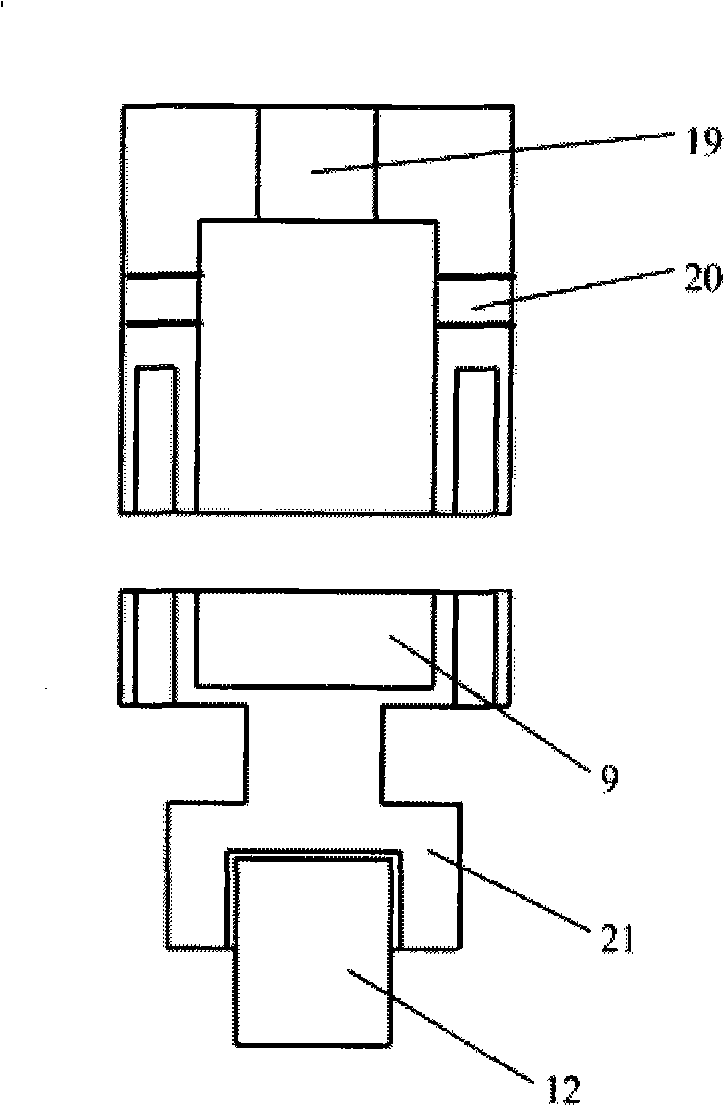

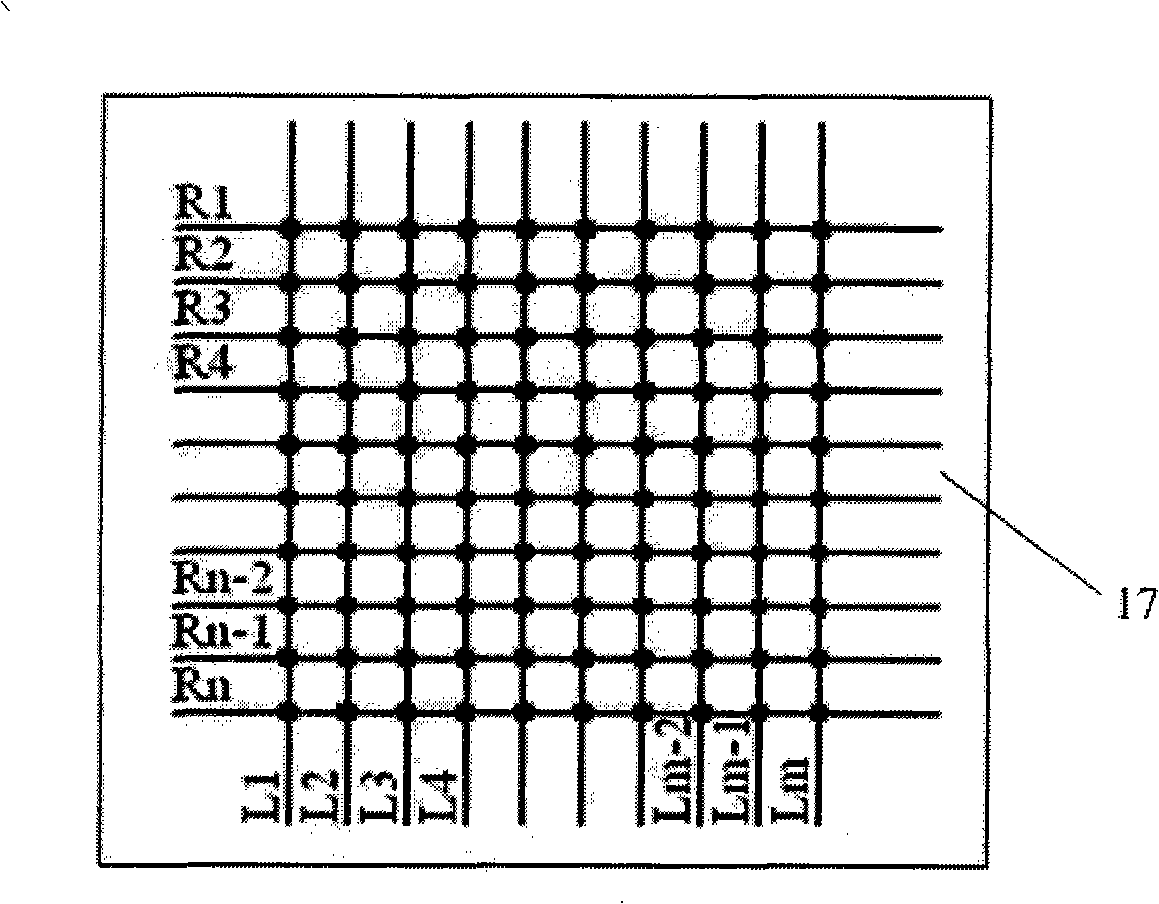

Mechanics sensor array calibrating apparatus and working method thereof

ActiveCN101281073APrecision mechanical designQuick start and stopForce/torque/work measurement apparatus calibration/testingSensor arrayElectricity

The present invention discloses a mechanical sensor array calibration device and the working method thereof. The device comprises locating transmission part and control part which is electrically connected with the locating transmission part; wherein, the locating transmission part comprises calibrated working platform and pressure head testing part; the pressure head testing part is connected with a force sensor through an extension head of a Z-directional linear stepper motor. Using the working method of the device adopts three stepper motors as the driving source; two stepper motors drive the coordinate motion of the slides on the guide rail to finish the location of coordinate point on the working platform; an extension of a linear stepper motor drives the pressure head to exert force on the tested sensor; when the force exerted by the pressure head achieves the set pressure valve, the singlechip collects the output of the tested sensor and the force sensor and the position coordinate of the tested sensor. The present invention is able to execute the choose and configuration of the calibrating mode and process according to the specific sensor array and the specific calibrating demand so as to enlarge the using range of the device.

Owner:ANHUI ZHONGKE BENYUAN INFORMATION TECH CO LTD

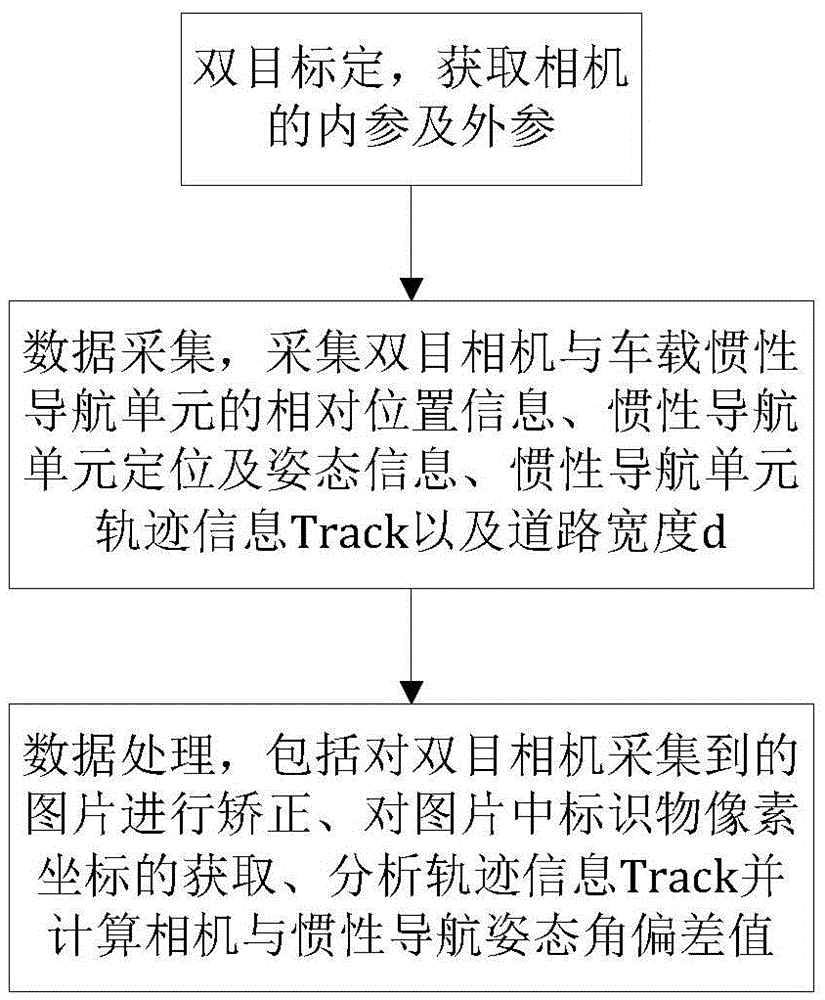

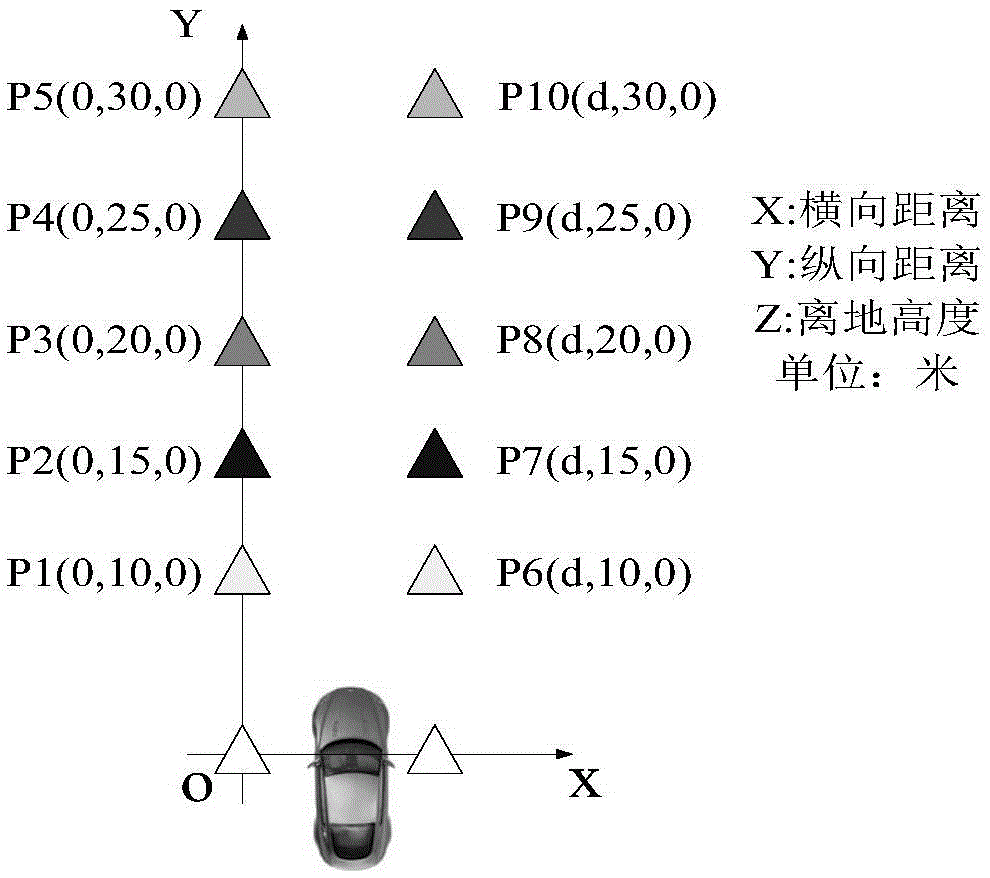

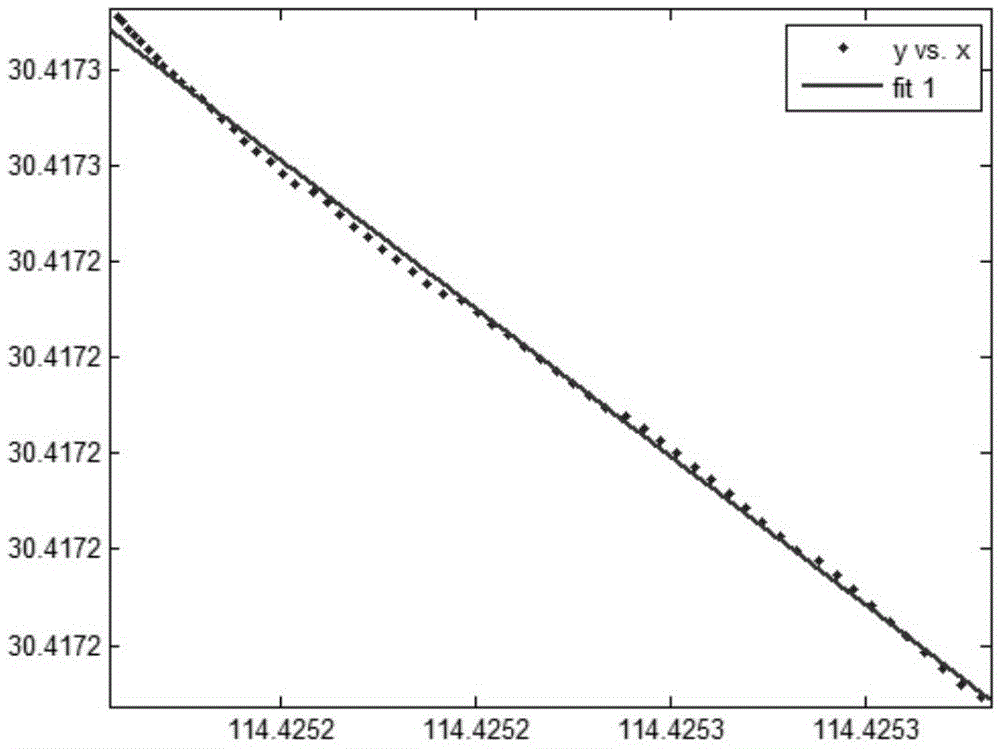

Joint calibration method of binocular camera and inertial navigation unit in automatic driving

ActiveCN105588563AEase of useSimple processImage analysisNavigation by speed/acceleration measurementsData acquisitionMarine navigation

The invention provides a joint calibration method of a binocular camera and an inertial navigation unit in automatic driving. The joint calibration method comprises steps as follows: acquisition of internal parameters and external parameters of the binocular camera; data acquisition: relative position information of the binocular camera and the vehicle-mounted inertial navigation unit, positioning and altitude information of the inertial navigation unit, track information Track of an inertial navigation module and the road width d are acquired; data processing: pictures acquired by the binocular camera are corrected, pixel coordinates of markers in the pictures are acquired, the track information Track is analyzed, the deviation value of the camera and an inertial navigation altitude angle is calculated, the spatial position relation of the binocular camera relative to the inertial navigation unit is acquired in a calibration manner, and influence of the altitude of the camera on road image data acquisition can be effectively compensated.

Owner:WUHAN KOTEI TECH CORP

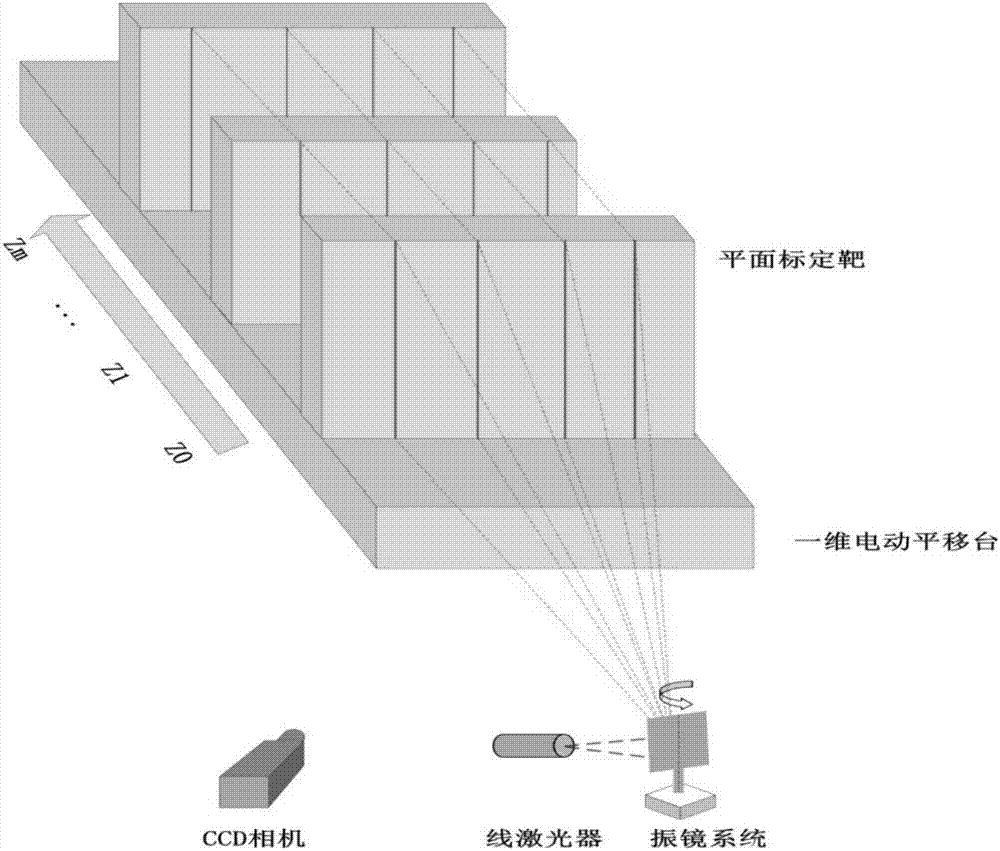

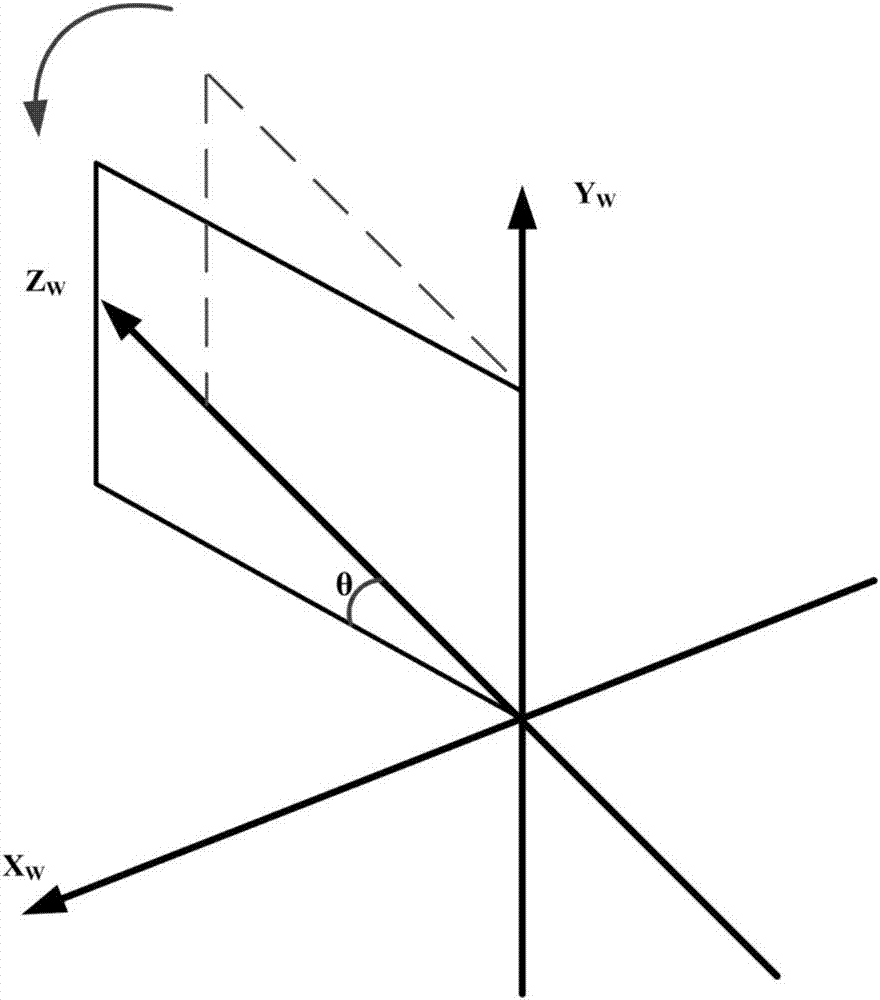

Method for overall calibration of galvanometer type line laser scanning three-dimensional measuring system

ActiveCN107014312AReduce the impactFlexible calibration schemeUsing optical meansLaser scanningGalvanometer

The invention discloses a method for overall calibration of a galvanometer type line laser scanning three-dimensional measuring system. First two lenses whose effective focal lengths are f1 and f2 are selected, and a camera is utilized to shoot a plane target and feature point coordinates are extracted, and main point coordinates of an image are calculated according to a varifocal method; then the lens whose focal length is f1 is used as a lens of the system, and for the feature point coordinates on the plane target which are obtained by the lens, intrinsic parameters and extrinsic parameters of the camera are calibrated; next, by changing galvanometer control voltage and driving a one-dimensional translation table to move, line laser stripes in different depth directions and different optical planes are obtained, and through operation of plane fitting and intersecting line obtaining, a transformation relation between a target coordinate system and a world coordinate system is obtained; and finally, coordinates under a system model are all unified to an image pixel coordinate system and the world coordinate system, thereby completing calibration of the whole system. The method has the advantages of simple calibration process, high calibration precision, fast calibration speed and the like.

Owner:XI AN JIAOTONG UNIV

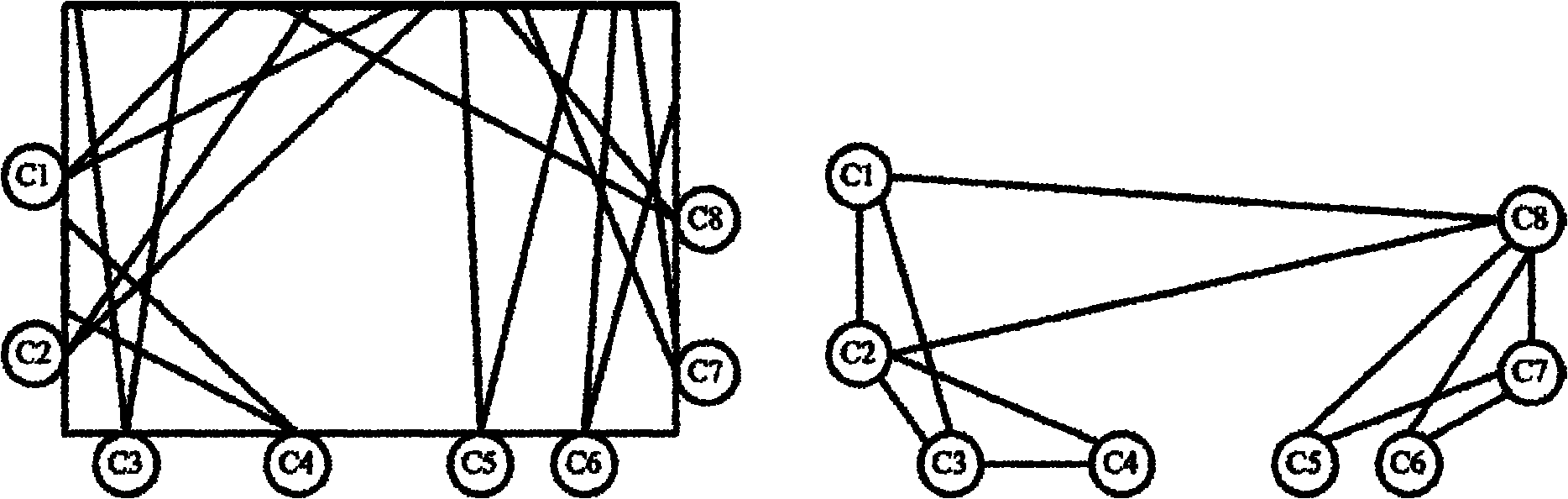

Multi-camera system calibrating method based on optical imaging test head and visual graph structure

ActiveCN102034238AHigh precisionImprove robustnessImage analysisStereoscopic photographyEssential matrixMulti camera

The invention provides a multi-camera system calibrating method based on an optical imaging test head and a visual graph structure. The method comprises the following steps: independently calibrating each camera by the optical imaging test head to obtain the initial values of the internal parameter and aberration parameter of each camera; calibrating the multiple cameras two by two, and obtaining the fundamental matrix, polar constraint, rotation matrix and translation vector between every two cameras with a plurality of overlapped regions at a view field by means of linear estimation; building the connection relationship among the multiple cameras according to the graph theory and the visual graph structure, and estimating the rotation vector quantity initial value and translation vector quantity initial value of each camera relative to the referred cameras by a shortest path method; and optimally estimating all the internal parameters and external parameters of the all cameras and the acquired three-dimensional sign point set of the optical imaging test head by a sparse bundling and adjusting algorithm to obtain a high-precision calibrating result. The multi-camera system calibrating method is simple in a calibrating process from the partial situation to the overall situation and from the robust to the precise, ensures high-precise and robust calibration, and is applied to calibrating multi-camera systems with different measurement ranges and different distribution structures.

Owner:SUZHOU DEKA TESTING TECH CO LTD

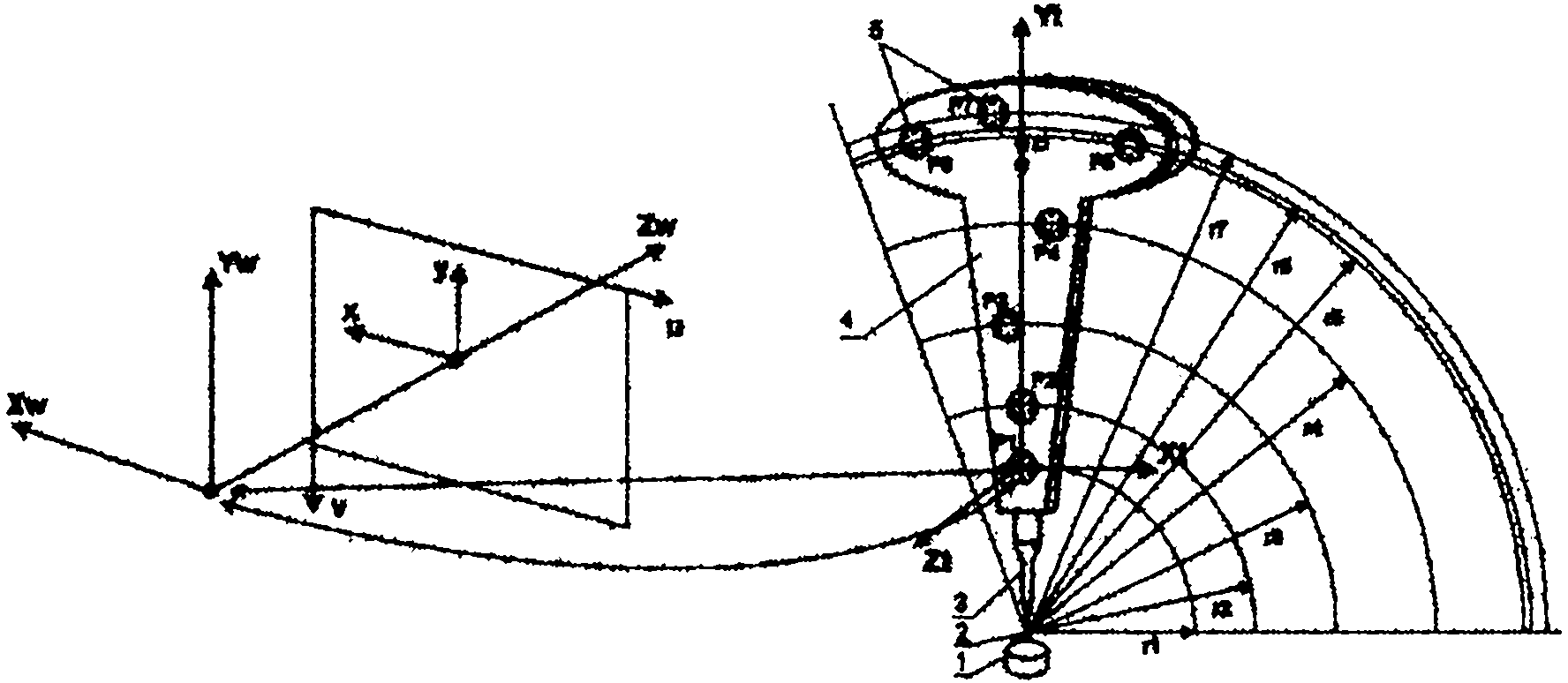

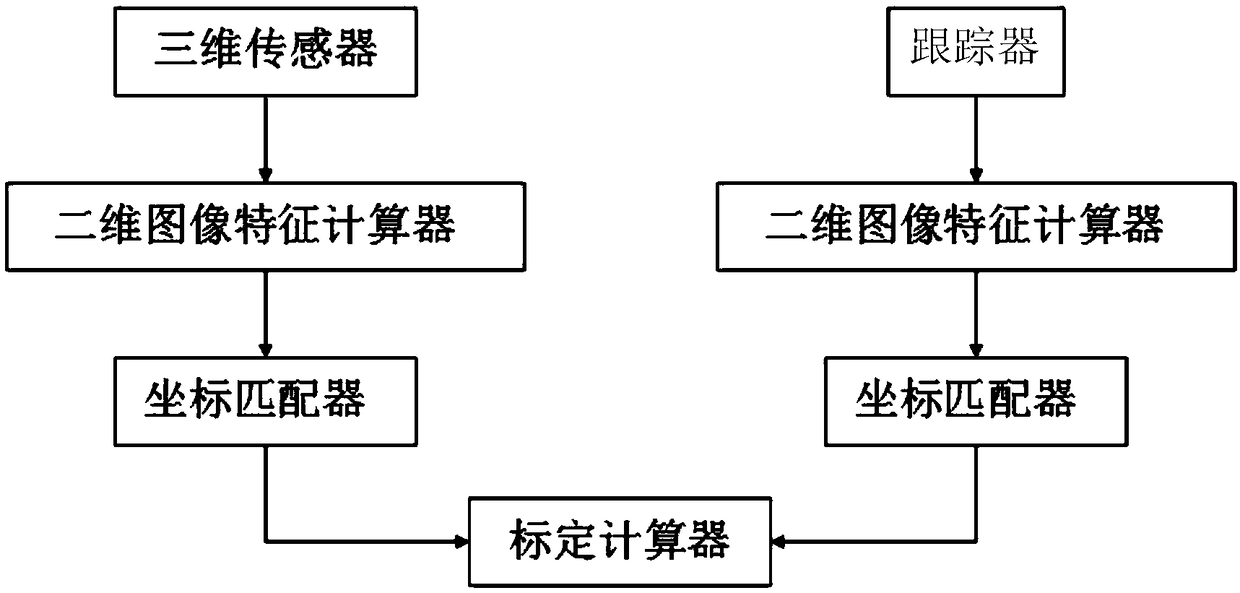

Scanning method and system of tracking type three-dimensional scanning device, storage medium and equipment

ActiveCN109000582AQuick calibrationHigh positioning accuracyUsing optical meansImaging Feature3d scanning

The invention provides a scanning method of a tracking type three-dimensional scanning device. The scanning method comprises feature capturing, coordinates matching, conversion matrix calculating anddemarcation. The invention further relates to a scanning system of the tracking type three-dimensional scanning device. The scanning system comprises a three-dimensional sensor which comprises a firstimage acquisition device and a first target feature which can be captured of a tag point, a calibration reference machine which comprises a second target feature which can be captured of a tag point,a tracker and a computing element which comprises a two-dimensional image feature calculator, a coordinate matcher and a calibration calculator. The invention further relates to a storage medium andequipment. A tracking type capture mode is adopted, the calibration process is quick, positioning accuracy is high, stability is excellent, calibration is convenient and quick, and application range is wide. The scanning range is enlarged, scanning application flexibility is improved, and blind area scanning is achieved. Technical bases are provided for three-dimensional scanning and measuring operation of large and complex objects to be scanned based on the tracking type three-dimensional scanning device.

Owner:SCANTECH (HANGZHOU) CO LTD

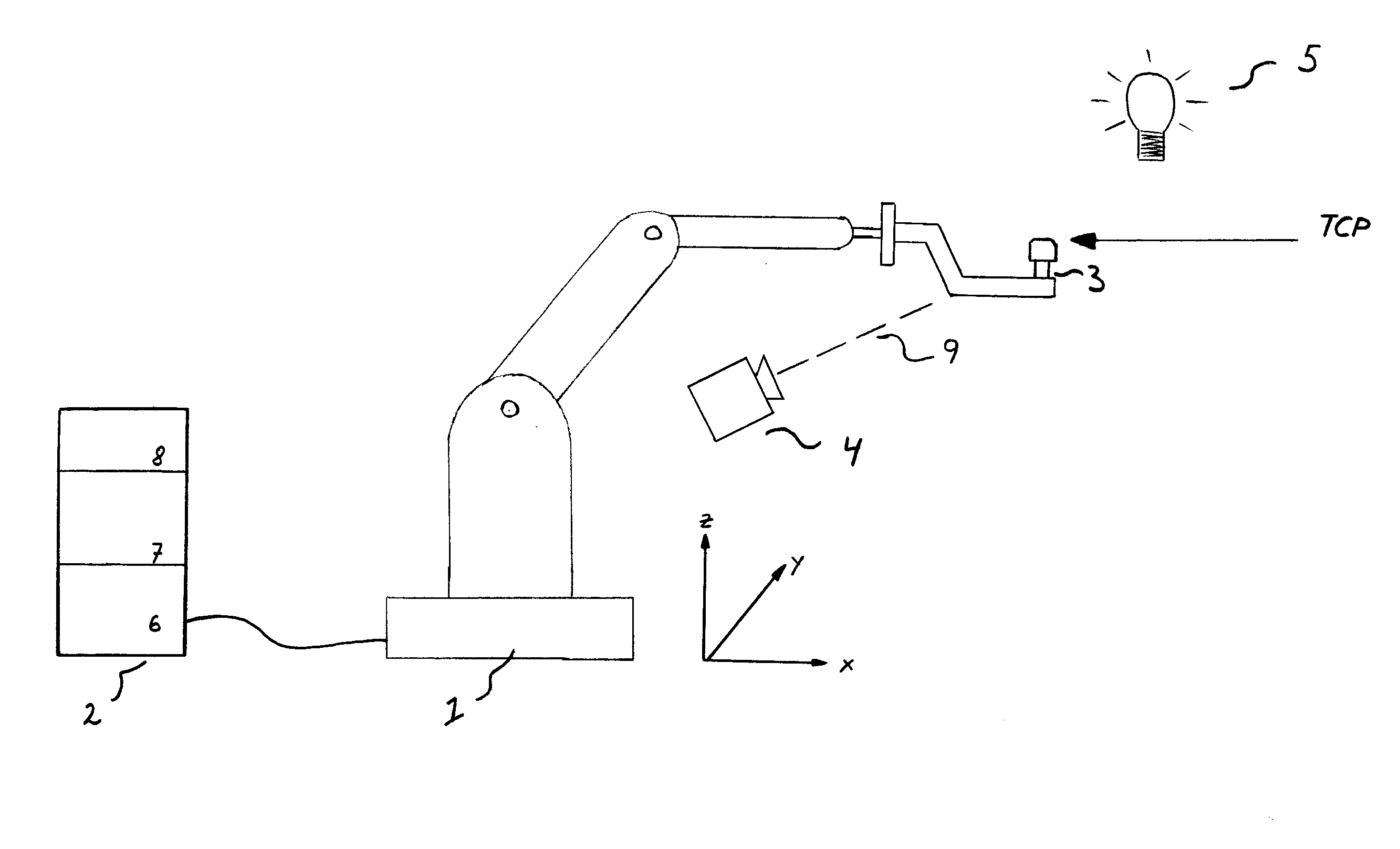

Device and Method for Calibrating the Center Point of a Tool Mounted on a Robot by Means of a Camera

InactiveUS20080252248A1High repeat accuracyHigh operate availabilityProgramme-controlled manipulatorComputer controlImage basedSituated computing

A device and a method for tool center point calibration of an industrial robot. The device is intended to calibrate an industrial robot with respect to a tool mounted on the robot. The device includes a camera designed to take a plurality of images of at least part of the robot tool for a plurality of different tool orientations, an image-processing unit designed to determine the positions of the robot tool in the orientations based on the images, a calculation module adapted to calculate the position of the center point of the robot tool, based on the determined positions, and a control module adapted to calculate the corrective movements of the robot.

Owner:ABB (SCHWEIZ) AG

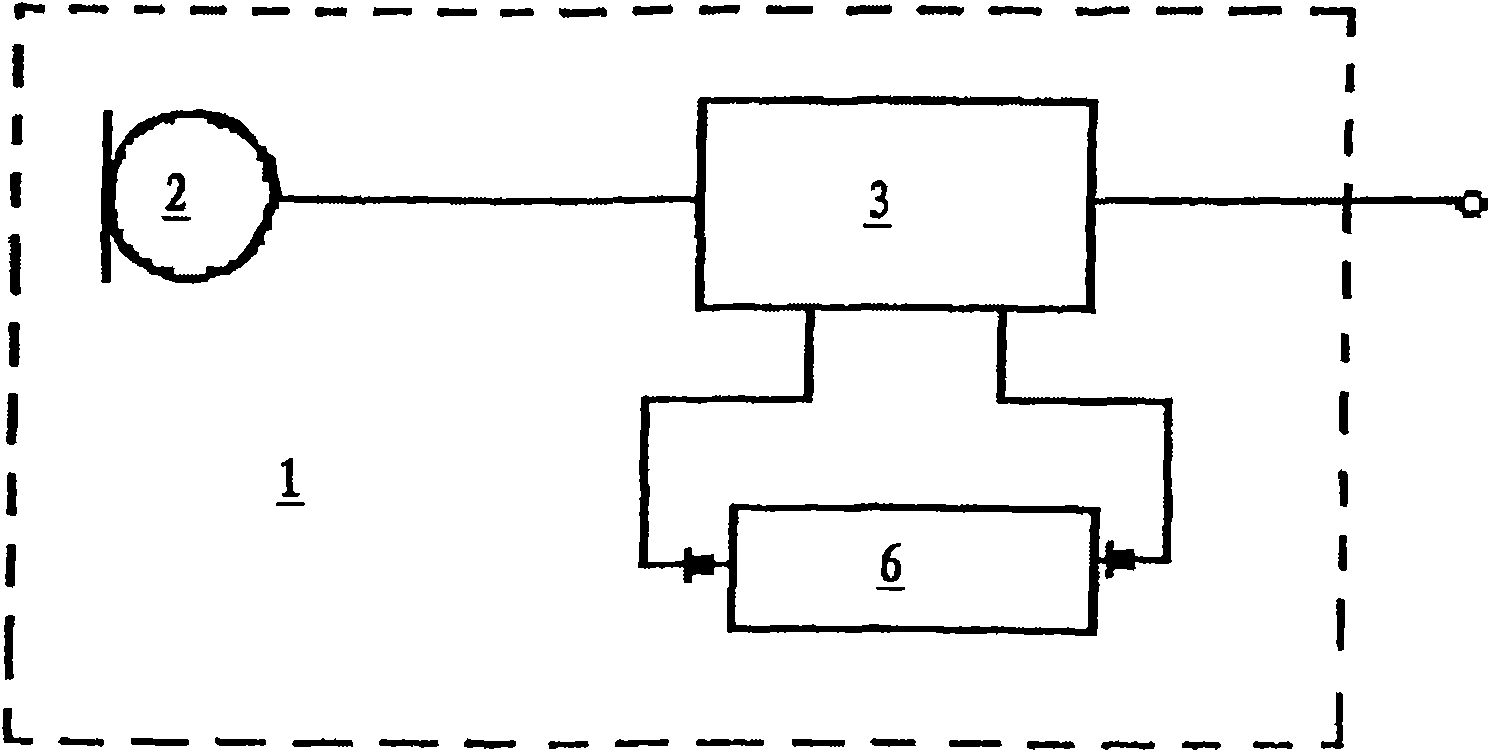

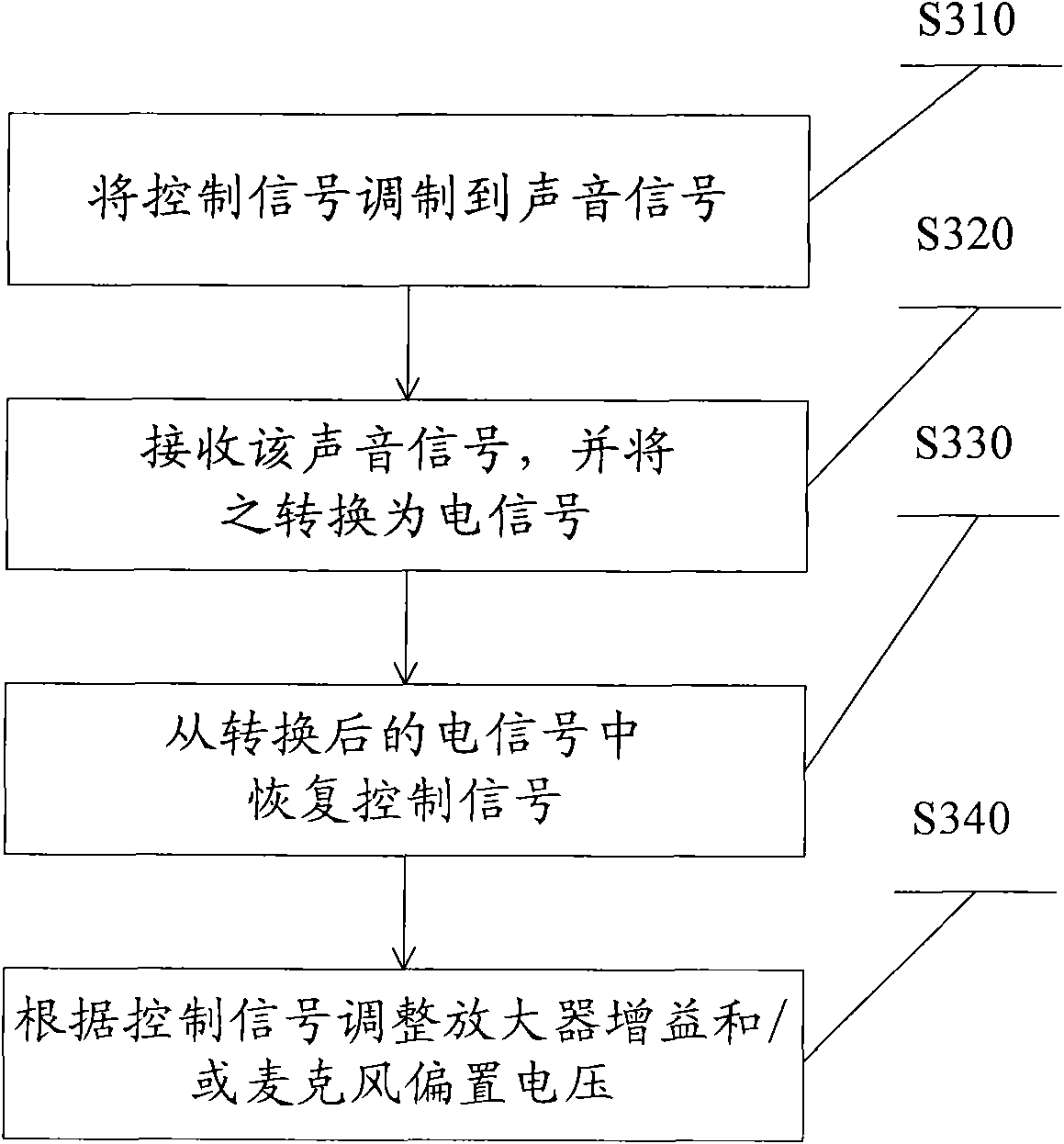

Method and device for calibrating sensitivity of microphone

ActiveCN101621728AFree pin connectionQuick calibrationElectrical apparatusElectricityAudio power amplifier

The invention relates to a method for calibrating sensitivity of a microphone, comprising the following steps: receiving a power supply voltage signal and a sound input signal; judging whether the power supply voltage signal meets a preset condition or not, if so, entering a calibrating mode to continue, and otherwise, stopping; restoring a clock signal from a sound signal; restoring a data signal from the power supply voltage signal; and regulating the amplifier gain and / or microphone bias voltage according to the clock signal and the data signal. A microphone calibrating circuit applying the method comprises a clock restoring module, a data signal restoring module, a gain regulating and controlling and register interface module and a storage, wherein the clock restoring module is used for restoring the clock signal from an output signal of a sound / electricity switching assembly; the data signal restoring module is used for restoring the data signal from the power supply voltage signal, the gain regulating and controlling and register interface module is used for writing amplifier gain regulating data into the storage according to the output of the clock restoring module and the data signal restoring module, and the storage is used for receiving the amplifier gain regulating data from the gain regulating and controlling and register interface module and is used as the grain arrangement when an amplifier normally operates.

Owner:SHANDONG GETTOP ACOUSTIC

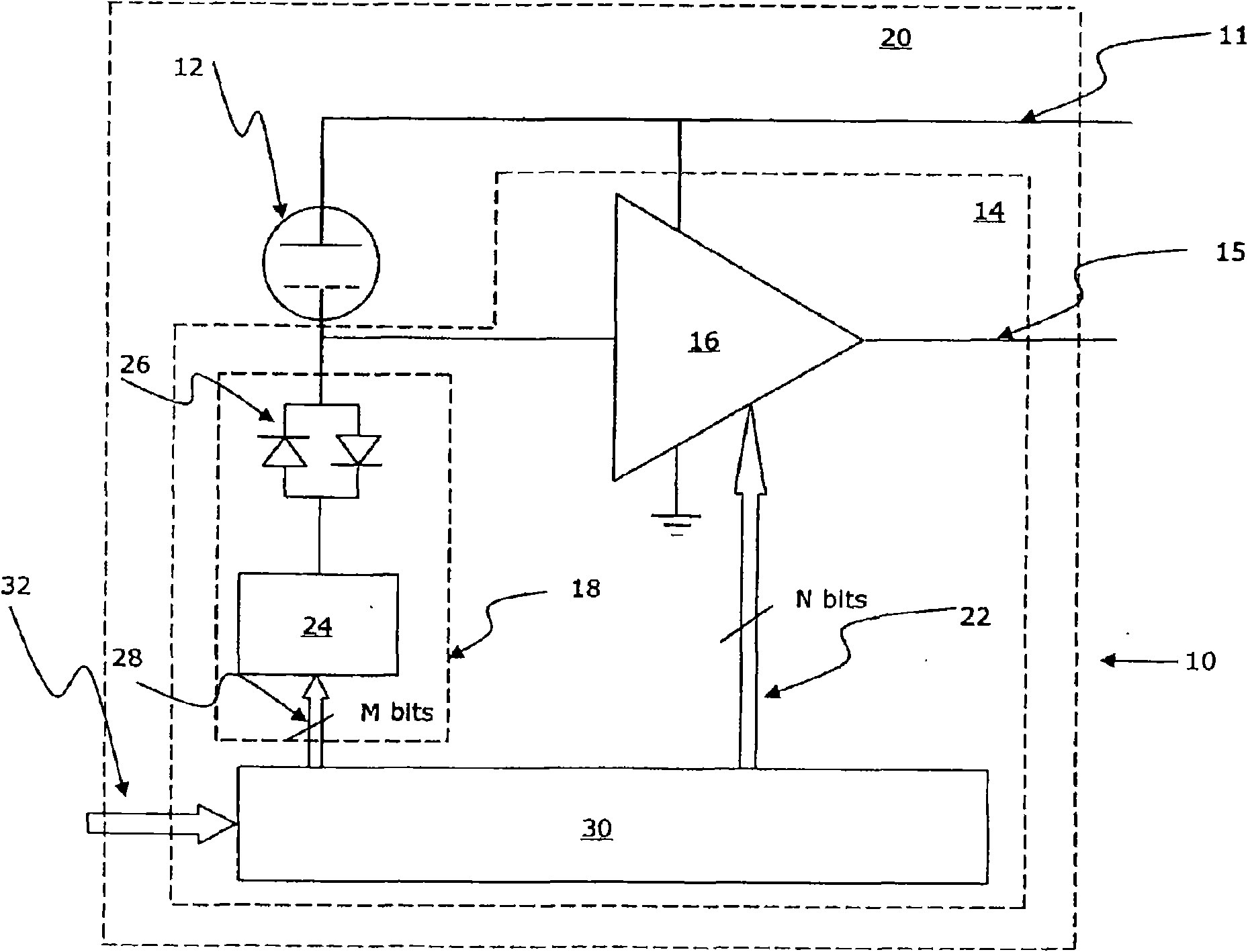

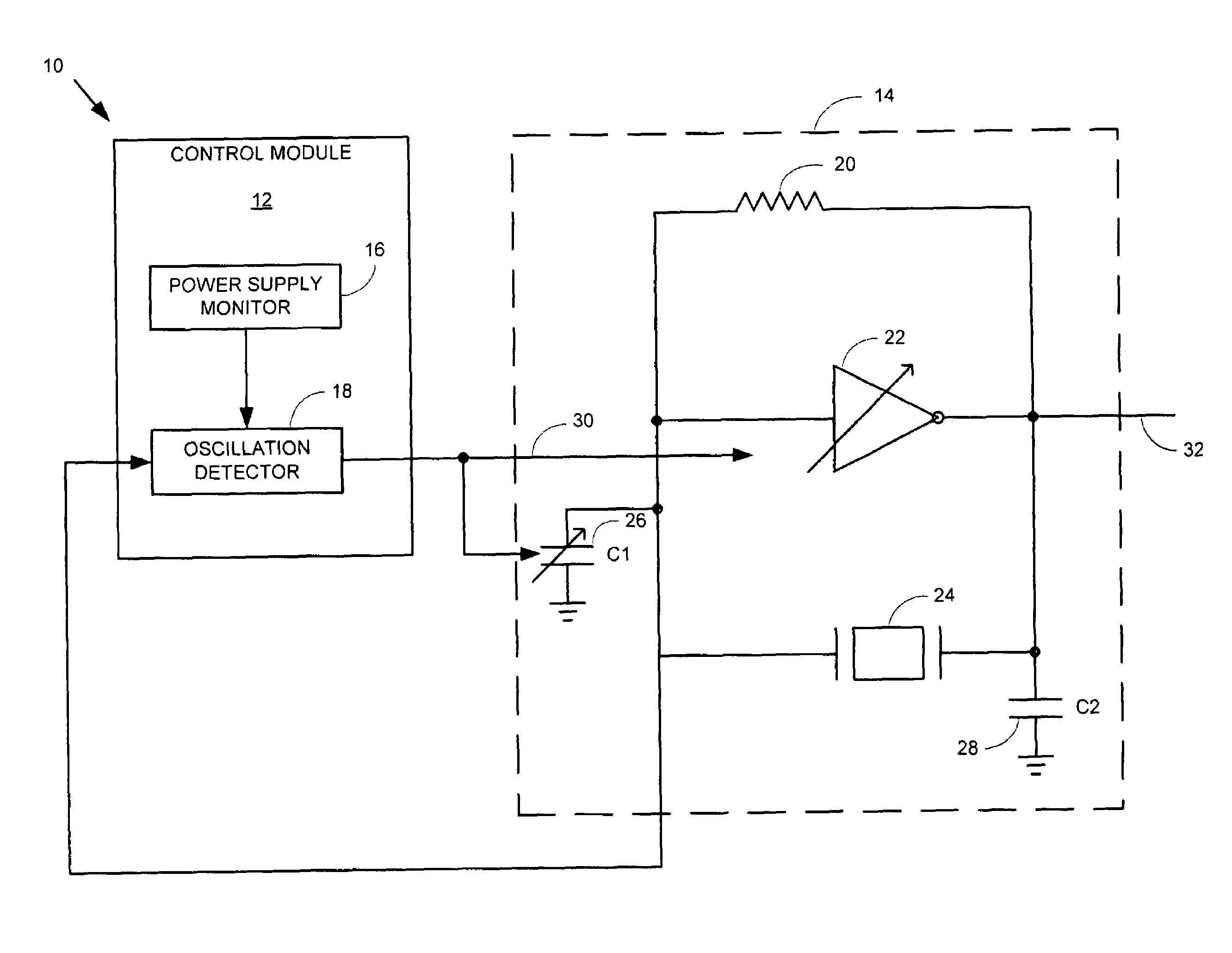

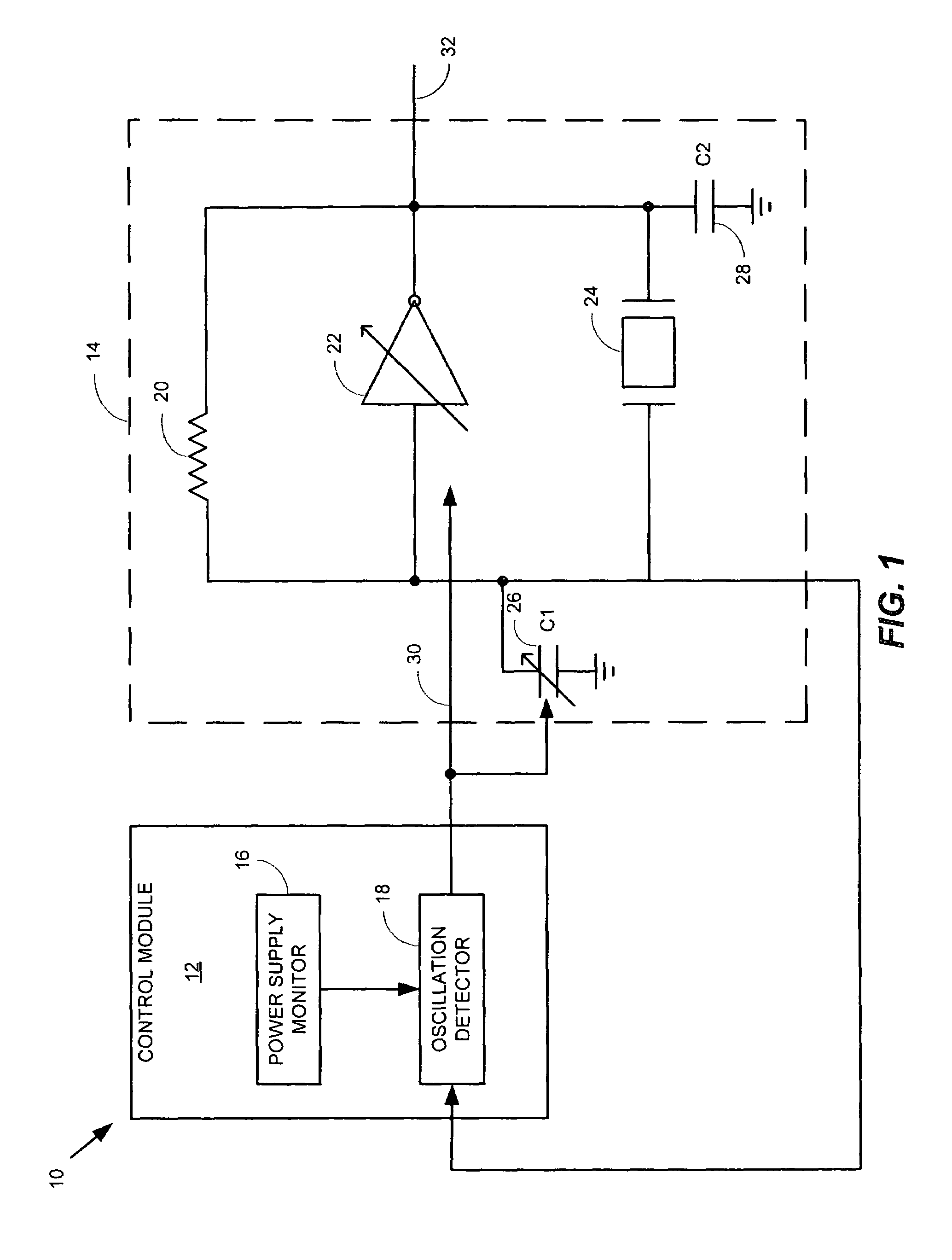

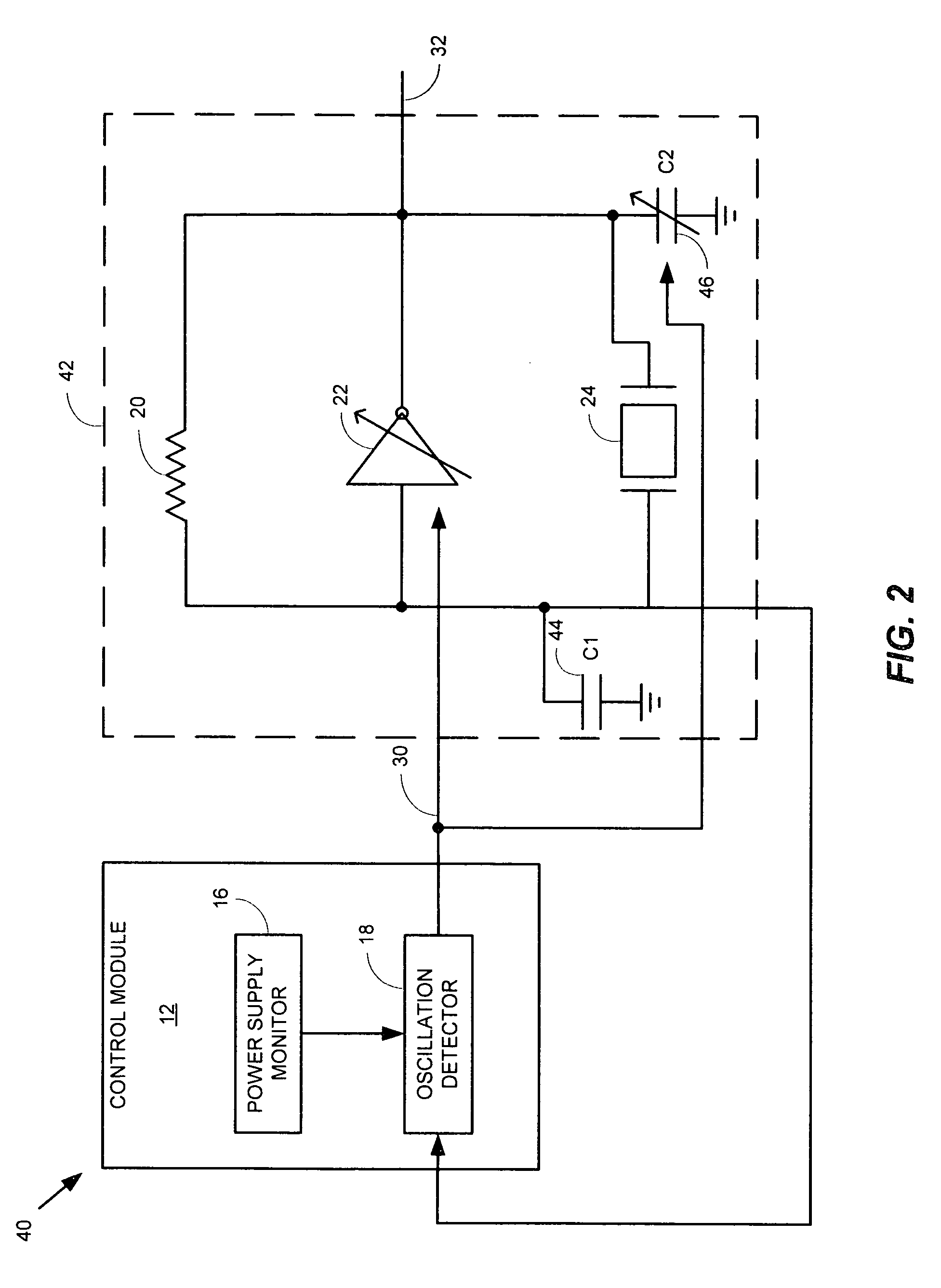

Method and apparatus for a crystal oscillator to achieve fast start-up time, low power and frequency calibration

InactiveUS7348861B1Fast frequency calibrationFast startup timePulse automatic controlAngle modulation detailsCapacitanceAudio power amplifier

One embodiment of the present invention includes a frequency generation circuit including a control module, an oscillator circuit coupled to the control module, the oscillator circuit having a start-up time defined by the time required to reach a desired frequency. The oscillator circuit includes an amplifier having an input and an output and being programmably-alterable by the control module, a first capacitor coupled to the input of the amplifier and being programmably-alterable, in capacitance, by the control module, a second capacitor coupled to the output of the amplifier, a crystal resonator coupled to the first and second capacitors for generating an output signal having a desired frequency, wherein fast start-up time is achieved.

Owner:MEDIATEK INC

Automobile instrument automatic pointer pressing system

ActiveCN104786036AHigh precisionIncrease productivityMetal working apparatusMetal-working hand toolsHuman–machine interfaceControl system

The invention discloses an automobile instrument automatic pointer pressing system which comprises a main control system, a pointer pressing device controlled by the main control system and a clamping device used for clamping an instrument panel. The main control system comprises a main controller, a control module, a man-machine interface and a vision analyzing and positioning system; the pointer pressing device comprises a three-shaft servo moving platform on a rack, a pointer pressing machine head arranged on the moving platform and a material supply device arranged on the moving platform; the control module controls a picking and pressing mechanism in the pointer pressing device to take pointers according to instrument pointer position and state data, obtained by the vision analyzing and positioning system, in the material supply device, and the pointer pressing angle and the pointer pressing depth of the pointer pressing device are controlled according to the motor shaft coordinate position, obtained by the vision analyzing and positioning system, of an instrument panel with pointers to be pressed and angle and position data input from the man-machine interface and required by placemen of the pointers. By means of the vision analyzing and positioning system, zero-scale individual difference positions are corrected, pointing directions of instruments are kept consistent. Pointer pressing precision and production efficiency are greatly improved through the automatic pointer pressing system.

Owner:NINGBO DAZHENG IND ROBOT TECH CORP

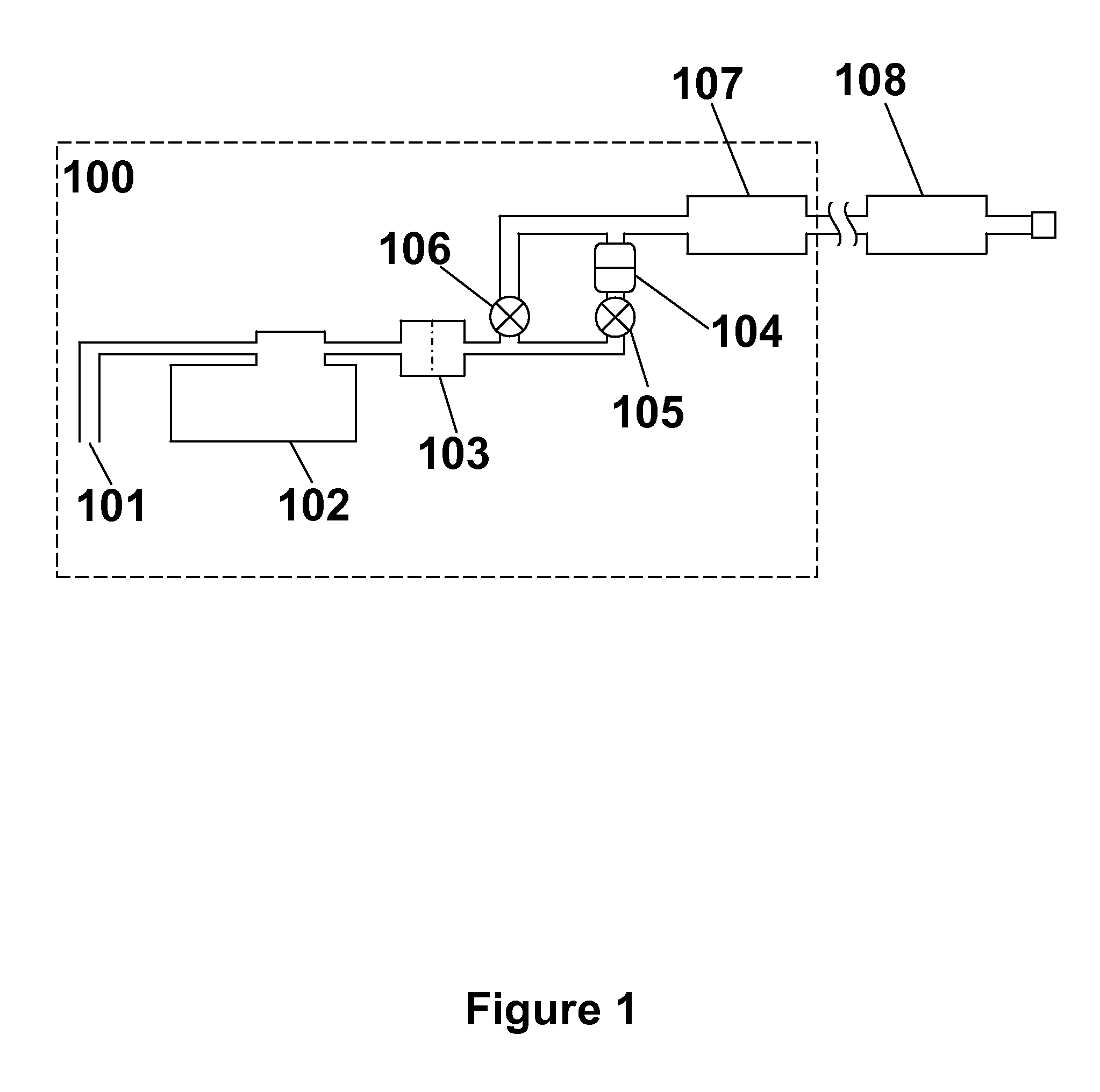

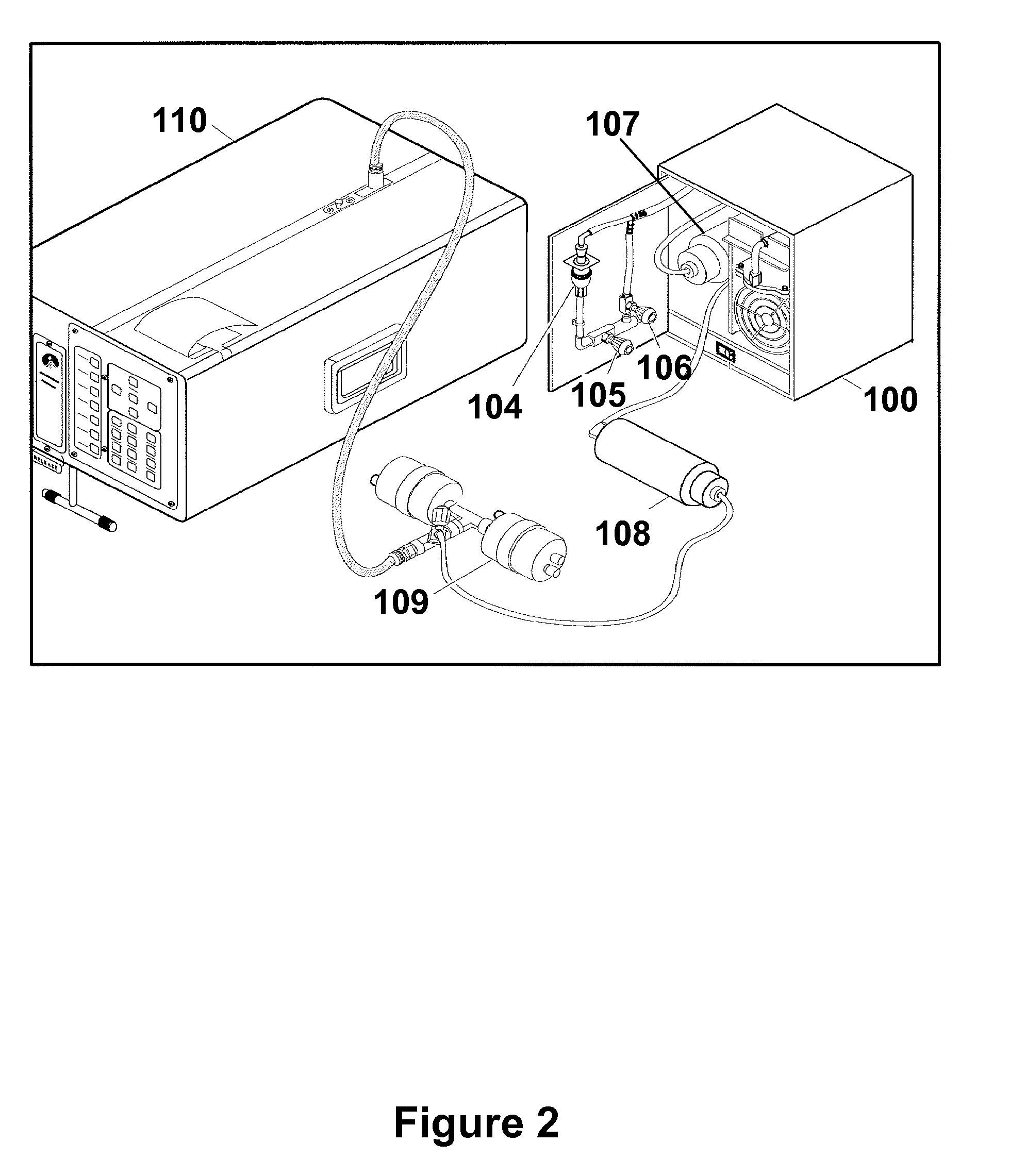

System and method for calibration verification of an optical particle counter

ActiveUS20090128810A1Quick calibrationReduce power consumptionMaterial analysis by optical meansParticle size analysisVerification systemOptics

Described herein is a portable, low power consuming optical particle counter calibration verification system and reliable and sensitive methods for verifying the calibration status of a gas or liquid particle counter. The calibration verification systems described herein are useful for quickly determining the calibration status of an optical particle counter at its point of use, as well as for allowing the end user to determine if an optical particle counter is in need of a recalibration before the recommended calibration schedule suggests.

Owner:PARTICLE MEASURING SYST

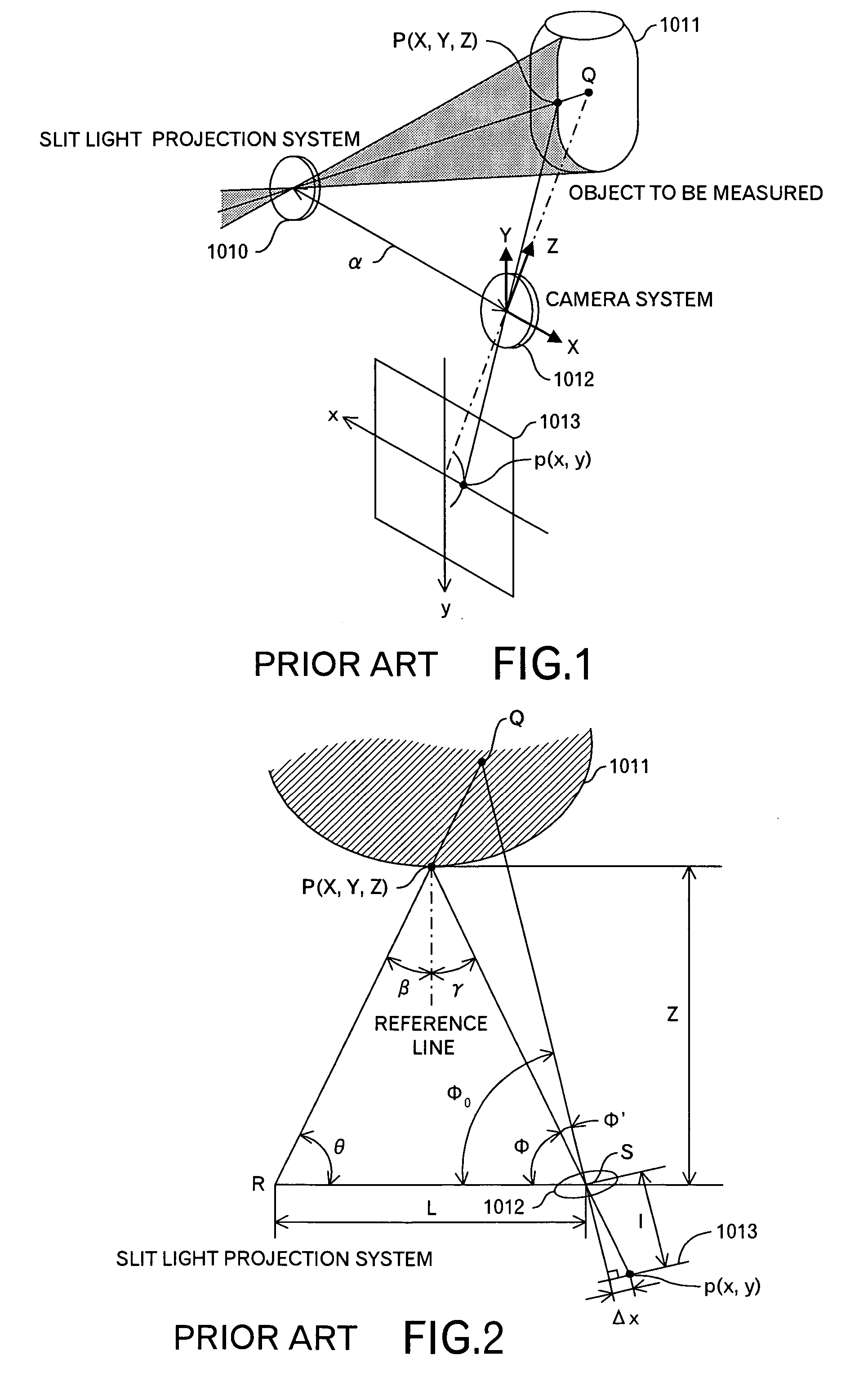

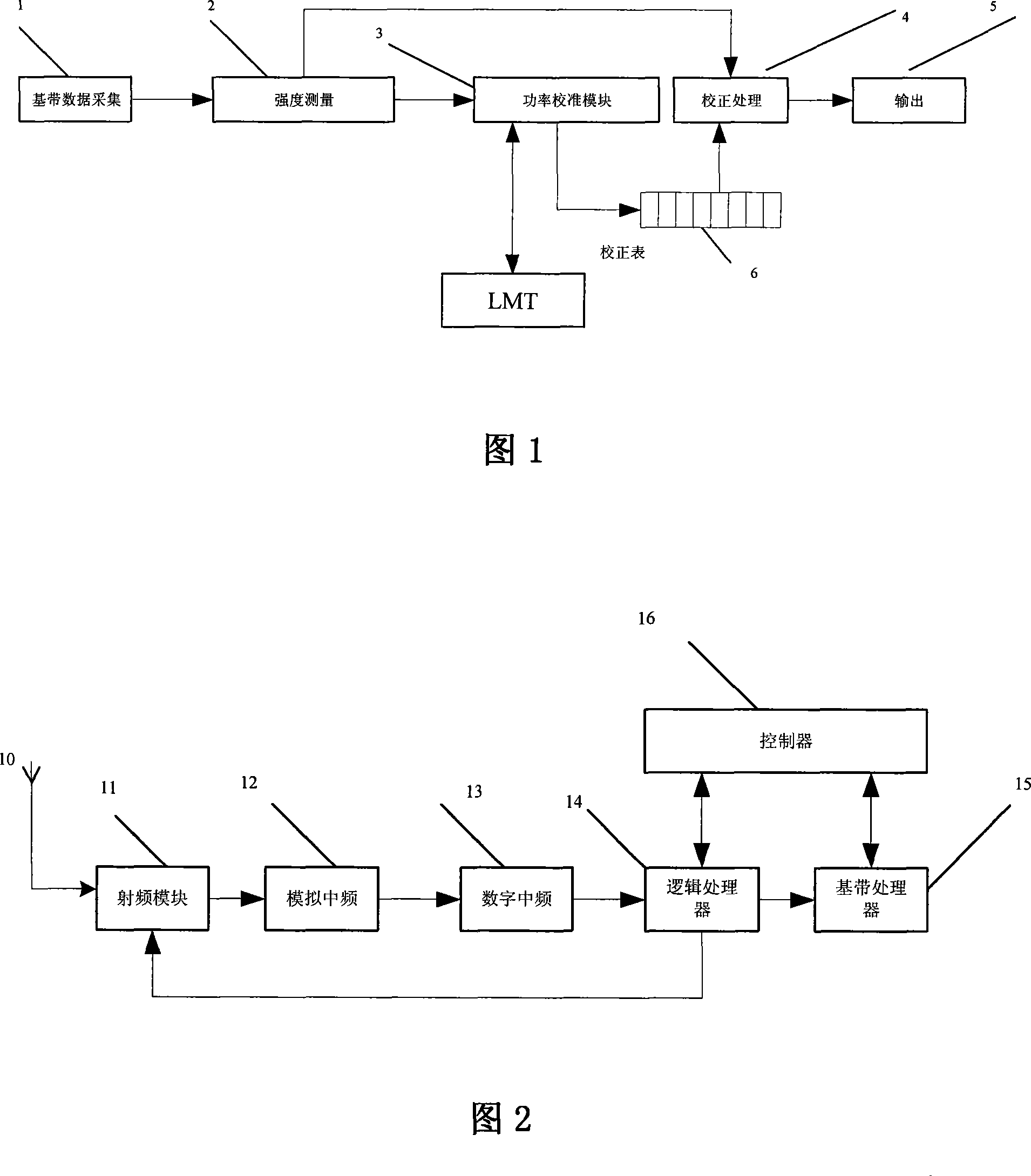

Method for measuring three-dimensional contour based on phase method

InactiveCN101074869AEasy to buildShorten the timePhotogrammetry/videogrammetryUsing optical meansField of viewSystem parameters

A 3-D outline measuring method based on phase includes calibrating internal parameter of video camera by applying nonlinear means, forming measurement system to cover required region of measured object by both projector and video camera simultaneously, setting up measurement relational expression (MRE) of formed measurement system, collecting sample points by placing calibration plate at 3-4 different positions in measurement scope, substituting obtained sample points into MRE to obtain system parameter, placing measured object in said measurement scope to obtain phase value being substituted in MRE and video camera model to obtain 3-D outline of object.

Owner:HAIAN COUNTY SHENLING ELECTRICAL APPLIANCE MFG +1

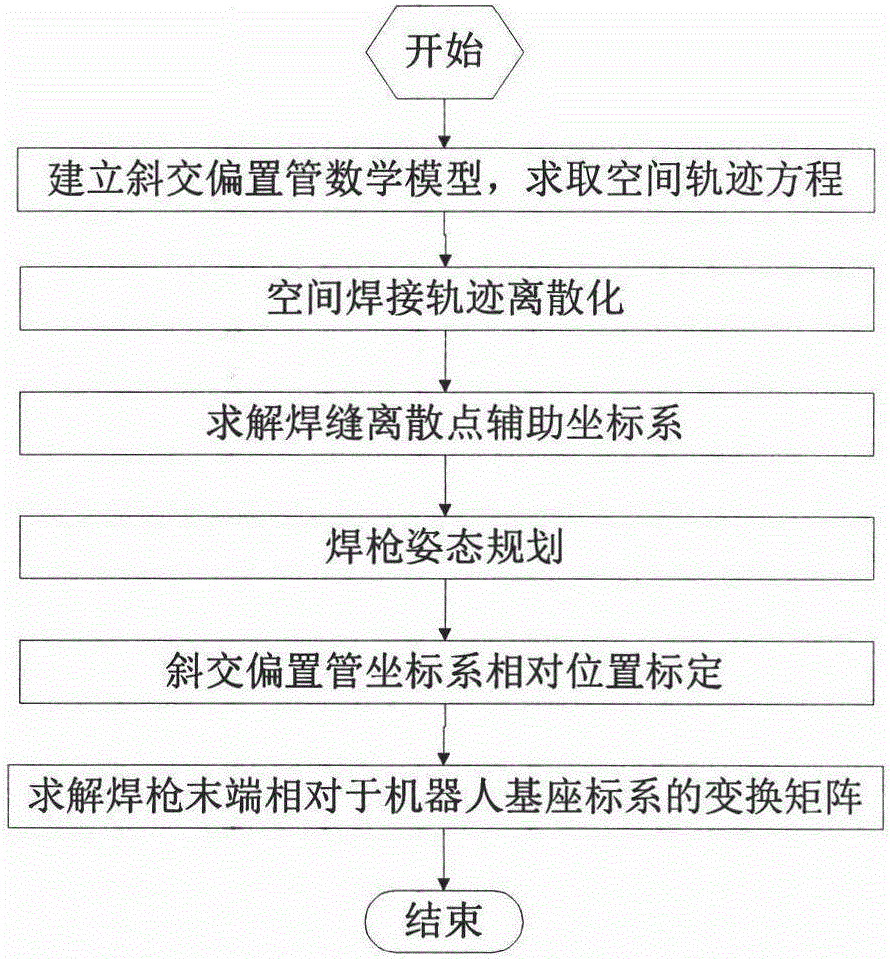

Skew offset pipe trajectory planning method based on arc welding robot system

InactiveCN105772905AImprove welding stabilityQuick calibrationProgramme-controlled manipulatorArc welding apparatusRobotic systemsMathematical model

The invention discloses a skew offset pipe trajectory planning method based on an arc welding robot system. According to the method, a corresponding skew offset pipe mathematical model is established and an equation of a space welding curve is worked out; in combination with a Frenet-Serret ternary space vector principle in a curve theory, a pose array of all discrete points on a space weld joint path is worked out, and welding postures of a welding gun are planned; and finally, a relation between a skew pipe coordinate system and a robot base coordinate system during actual welding is calibrated through a special teaching mode. By means of the skew offset pipe trajectory planning method based on the arc welding robot system, the positions and postures of the welding gun can be effectively controlled when an arc welding robot welds intersecting pipes. Compared with traditional intersection line trajectory planning, through the trajectory planning method provided by the invention, the fluctuation range of each joint angle can be reduced, occurrence of singular points of joints can be reduced, and accordingly the welding stability is effectively improved.

Owner:NANJING UNIV OF TECH

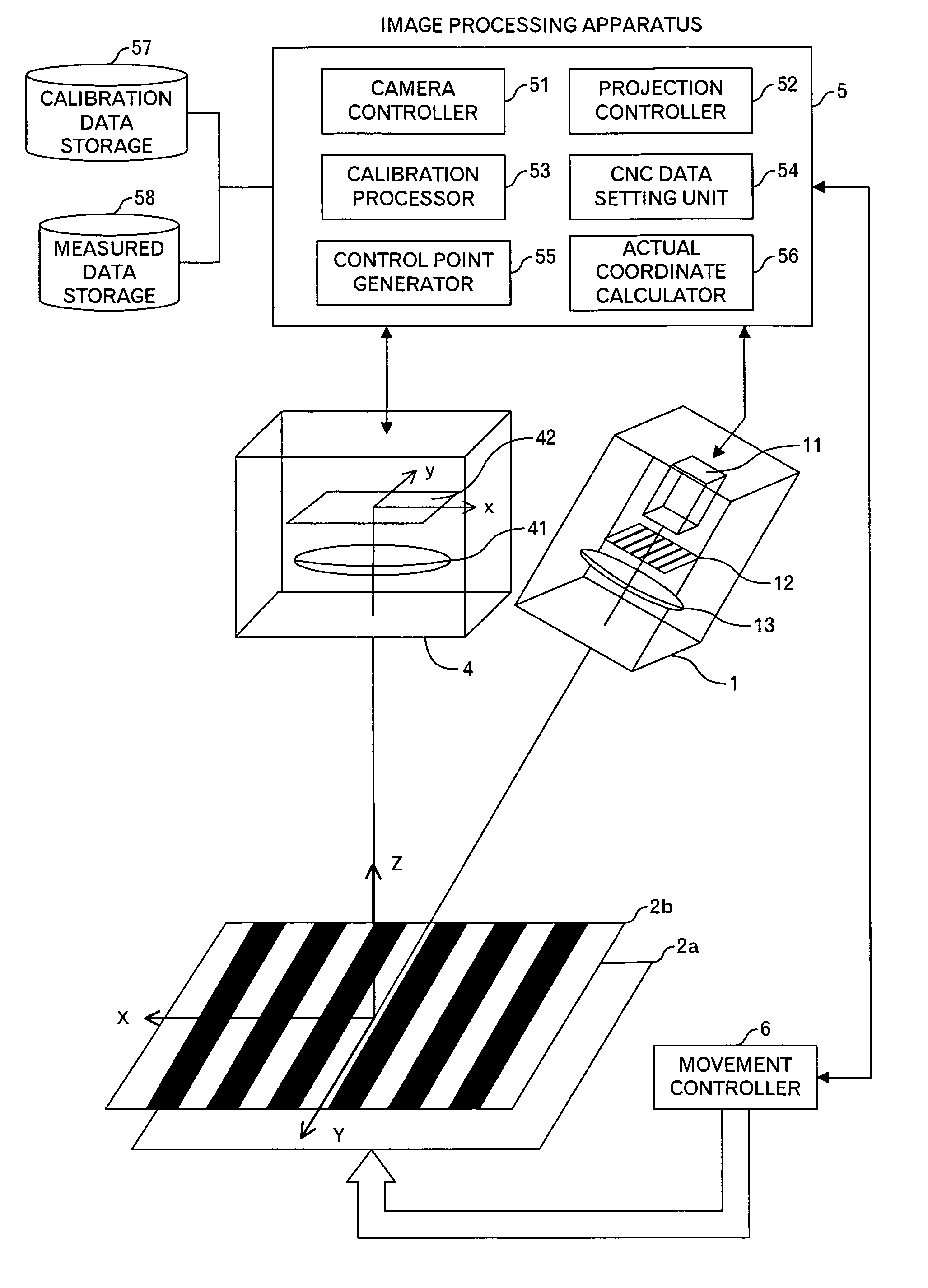

Measuring technology and computer numerical control technology

ActiveUS20050046873A1Eliminate errorsQuick calibrationImage analysisInterferometric spectrometryProduct typeNumerical control

A measuring apparatus of this invention comprises: a projector; a camera; a generator that generates, from a photographed image of a fringe pattern projected by the projector at a time of calibration onto each of surfaces, first tuples, each including coordinates of a point on a light receiving plane (LRP) of the camera, light intensity of the point and the height of the surface; a converter that converts the light intensity to a phase angle of the projected fringe pattern (PFP), and generates second tuples, each including the coordinates of the point on the LRP, the phase angle and the height of the surface; a hypersurface generator that generates data representing a tensor product type composite hypersurface (TPTCH) from data of the second tuples; an extractor that extracts data of third tuples, each including coordinates of a point on the LRP and light intensity from a photographed image of a fringe pattern projected by the projector at a time of measurement onto an object to be measured; a second converter that converts the light intensity to a phase angle of the PFP to generate data of fourth tuples, each including the coordinates of the point on the LRP and the phase angle; and an interpolator that carries out interpolation by using the data representing the TPTCH to generate height data corresponding to the data of the fourth tuple.

Owner:FUJITSU LTD

Calibration method for automotive radar using phased array

InactiveUS20130088382A1Easy to operateImprove long-term accuracyAntennasRadio wave reradiation/reflectionEngineeringPhased array

Examples of the present invention include calibration methods for phased array radar apparatus. The calibration methods include an electronic calibration of phase shifters, and compensation for mechanical misalignment. Approaches are particularly useful for automotive radar, and may be used for initial calibration after installation on a factory line, or at later times such as at a service station whenever recalibration becomes necessary.

Owner:TOYOTA JIDOSHA KK

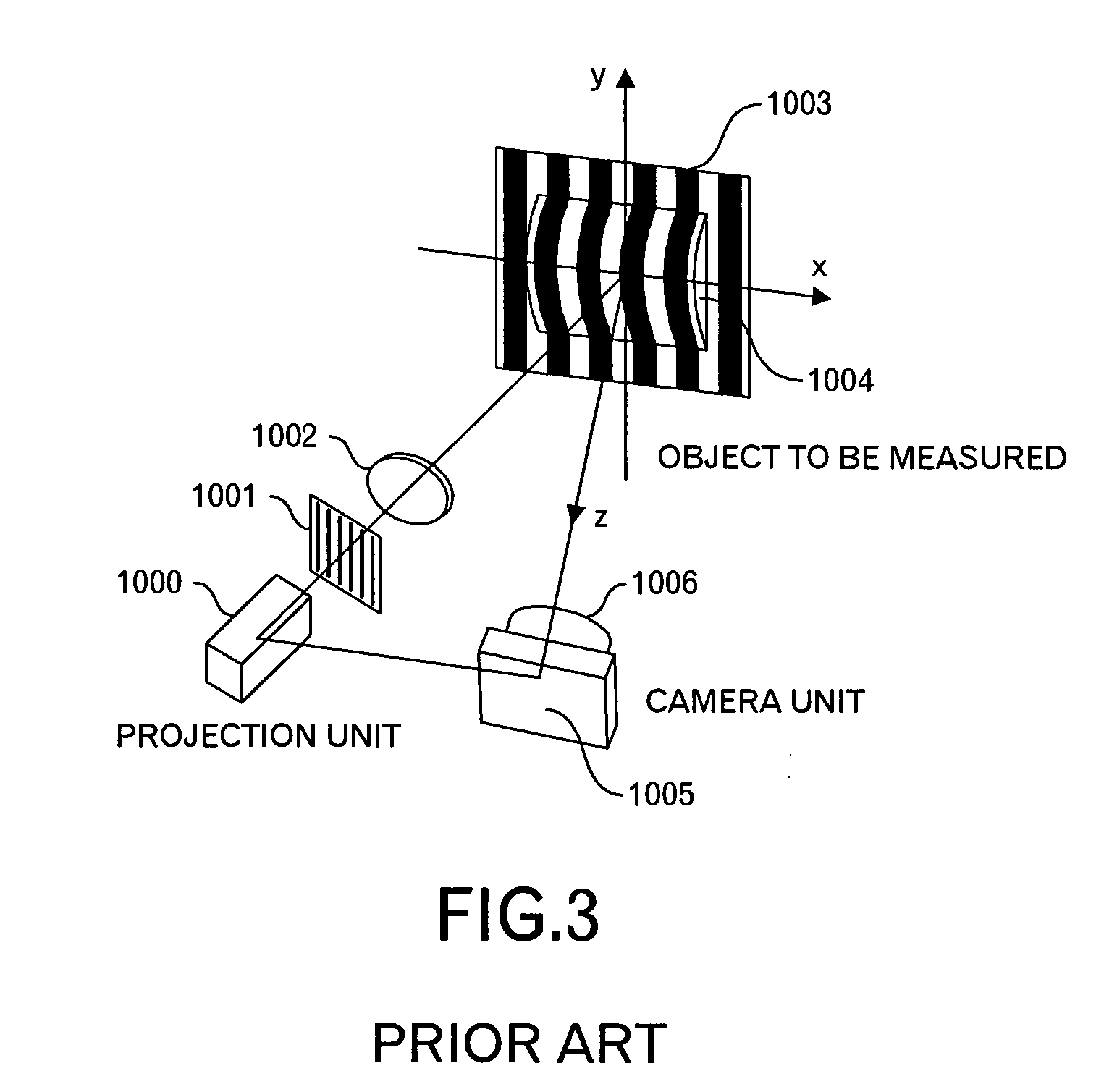

Apparatus and method to correct image

ActiveUS20110310376A1Improve accuracyImprove reliabilityOptical rangefindersHeight/levelling measurementComputer science

An apparatus and method of correcting an image are provided. The apparatus includes a receiver to receive a depth value and a luminous intensity, the depth value and the luminous intensity being measured by at least one depth sensor, and a correction unit to read a correction depth value of a plurality of correction depth values mapped to different depth values and different luminous intensities from a first storage unit and to correct the measured depth value using the read correction depth value, the correction depth value being mapped to the measured depth value and the measured luminous intensity.

Owner:SAMSUNG ELECTRONICS CO LTD

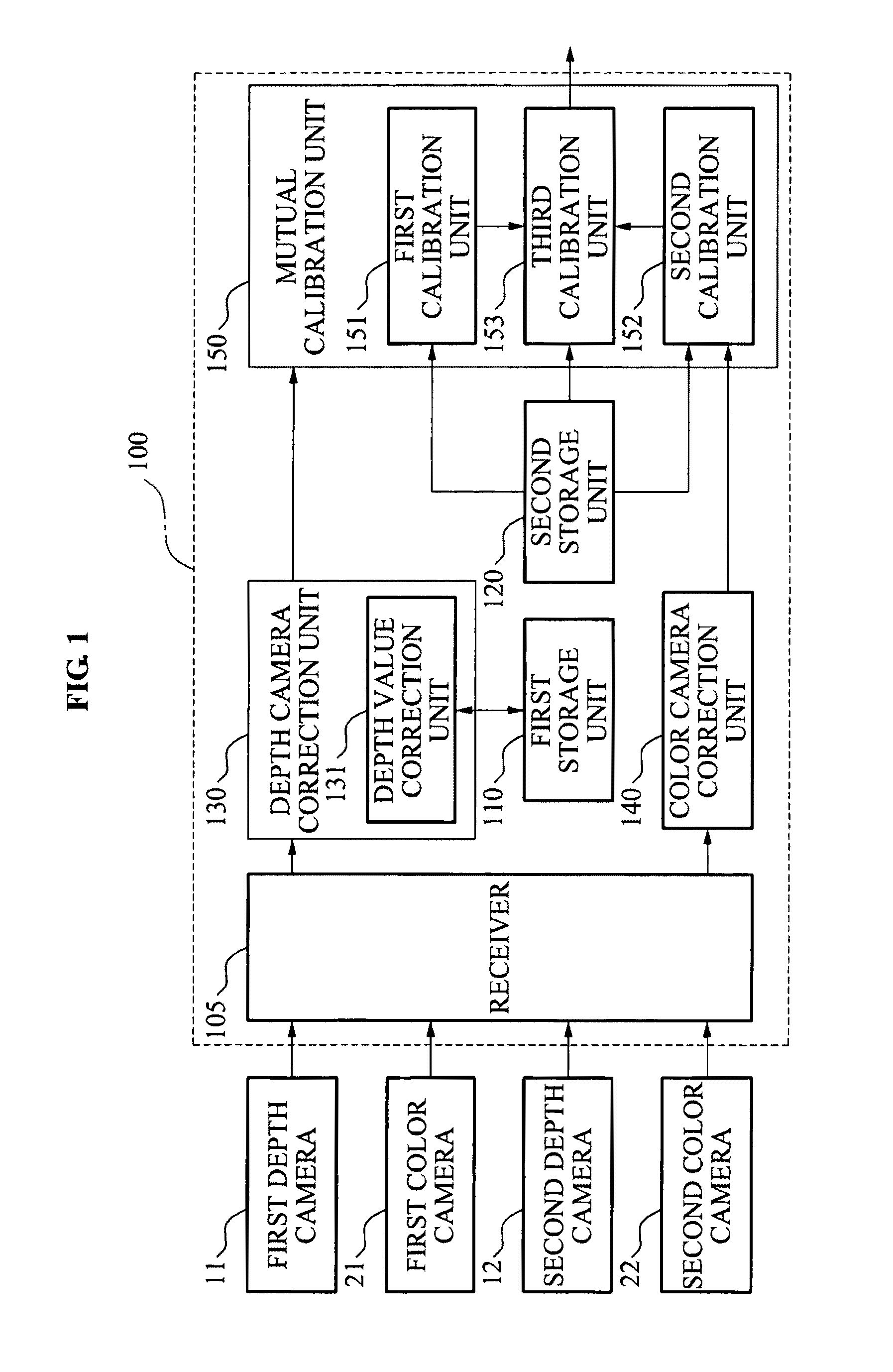

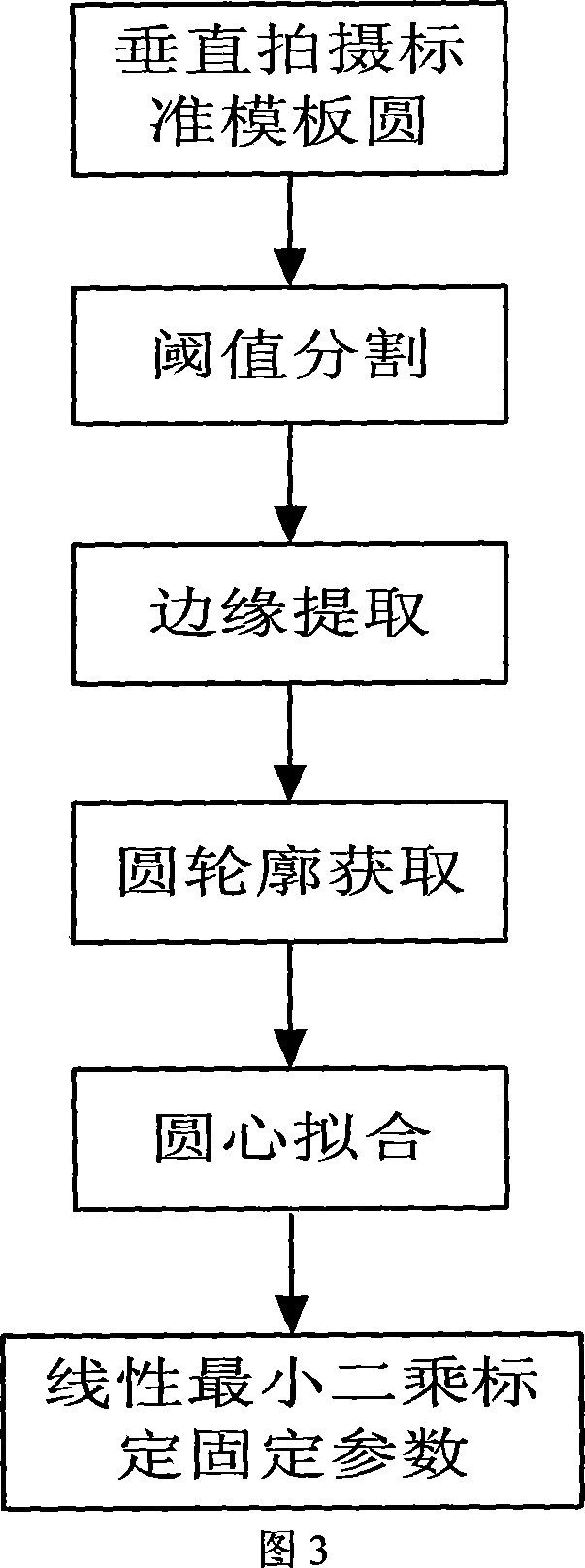

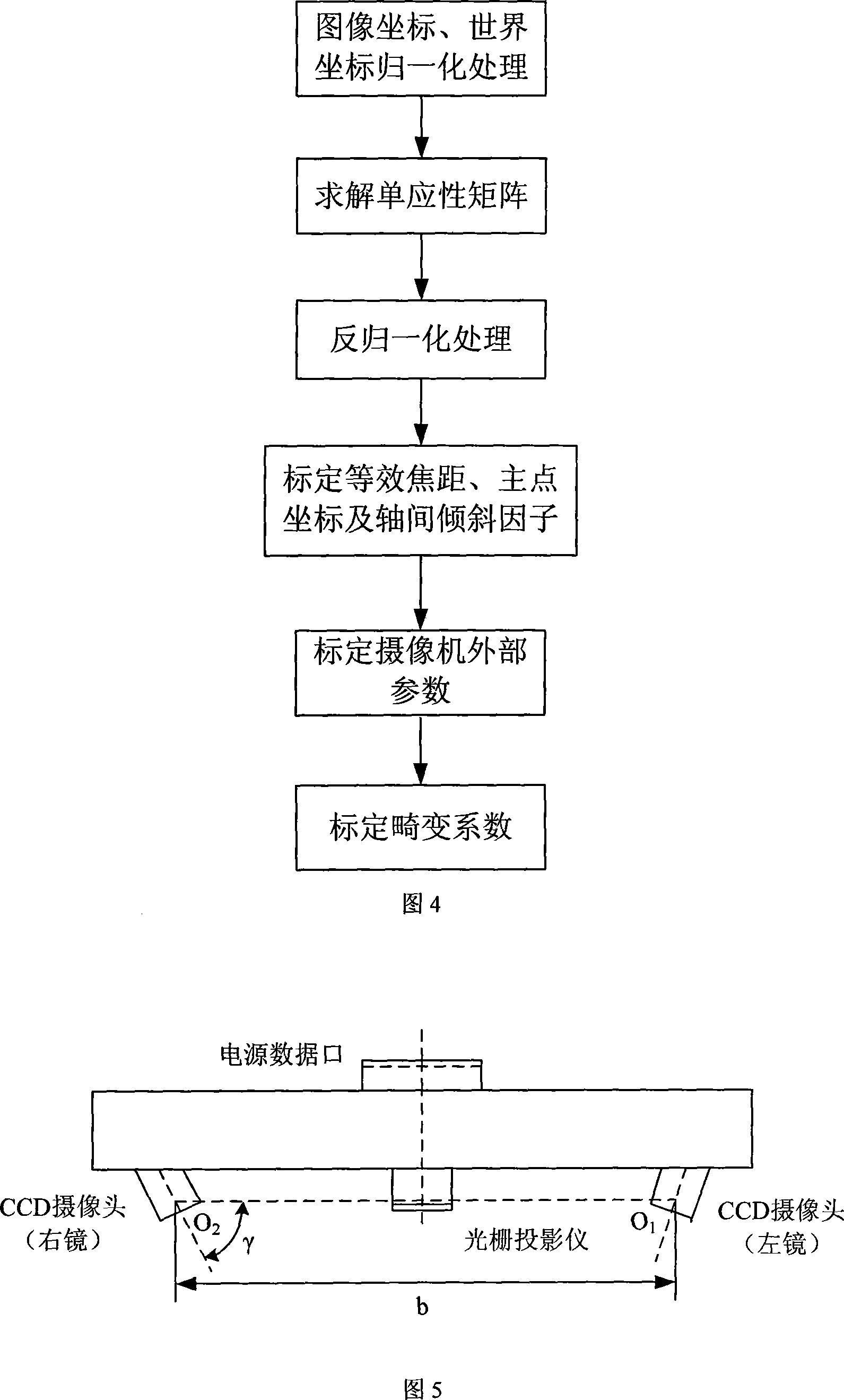

Calibrating method based on fixed parameters and variable parameters for three-dimensional scanning system

InactiveCN101025824ACompatible with practical engineering applicationsCalibration Distortion CoefficientImage analysisImaging processingModel parameters

A calibration method based on fixed and variable parameters in three-dimensional scanning system relates to the camera model parameter calibration in the visual system including the following steps: (1) fixed parameters calibration is primarily to acquire coordinates of sampling points on circular contour and heart in image coordinates through image processing techniques, and then use n sampling points to get aspect ratio through least squares method, (2) after obtaining the fixed parameters, it uses the image coordinates of image midpoint and the corresponding space coordinates of world midpoint to demarcate the initial value of variable parameters for the camera, including the equivalent focal length, main point coordinates, axis tilt factor, distortion factor and external parameters, (3) after demarcation, it takes fixed parameters as a constraint for nonlinear optimization objective function to establish a binding target function and get the optimal solution of variable parameters through the nonlinear optimization method.

Owner:南通鑫唐纺织印染有限公司 +1

Method for determining the relative position of a first and a second imaging device and devices therefore

InactiveUS20120007943A1Reduce necessary processing powerSimple processImage enhancementImage analysisComputer visionRadiology

Owner:ALCATEL LUCENT SAS

Calibration device, method, and program for on-board camera

ActiveUS20120007985A1Improve accuracyImprove productivityImage enhancementImage analysisProduction rateComputer graphics (images)

An on-board camera calibration device with high productivity is provided which allows speedy calibration of the on-board camera with high precision with a simple construction. Based on an actual coordinate specified in a projecting plane of a camera coordinate system and a converted coordinate obtained by converting an initial coordinate of a calibration point with using unfixed camera adjustment values, the adjustment values corresponding to angles of rotation about one or two axes from among three axes of the camera coordinate system are calculated and the camera adjustment values are updated. Based on the actual coordinate and the converted coordinate in accordance with the updated camera adjustment values, the adjustment values corresponding to angles of rotation about the remaining axes of the camera coordinate system is calculated and the camera adjustment values are updated. When the predetermined completion condition is satisfied, the updated camera adjustment values are fixed.

Owner:AISIN SEIKI KK

System and method for calibration verification of an optical particle counter

ActiveUS7973929B2Quick calibrationReduce power consumptionMaterial analysis by optical meansParticle size analysisVerification systemParticle counter

Described herein is a portable, low power consuming optical particle counter calibration verification system and reliable and sensitive methods for verifying the calibration status of a gas or liquid particle counter. The calibration verification systems described herein are useful for quickly determining the calibration status of an optical particle counter at its point of use, as well as for allowing the end user to determine if an optical particle counter is in need of a recalibration before the recommended calibration schedule suggests.

Owner:PARTICLE MEASURING SYST

Motion sensor, method, and computer-readable storage medium providing a motion sensor that adjusts gains of two circuit channels to bring the gains close to each other

ActiveUS8680848B2Easy to placeRapidly and accurately calibrateLinear/angular speed measurementUsing electrical meansControl signalEngineering

Owner:ALLEGRO MICROSYSTEMS INC

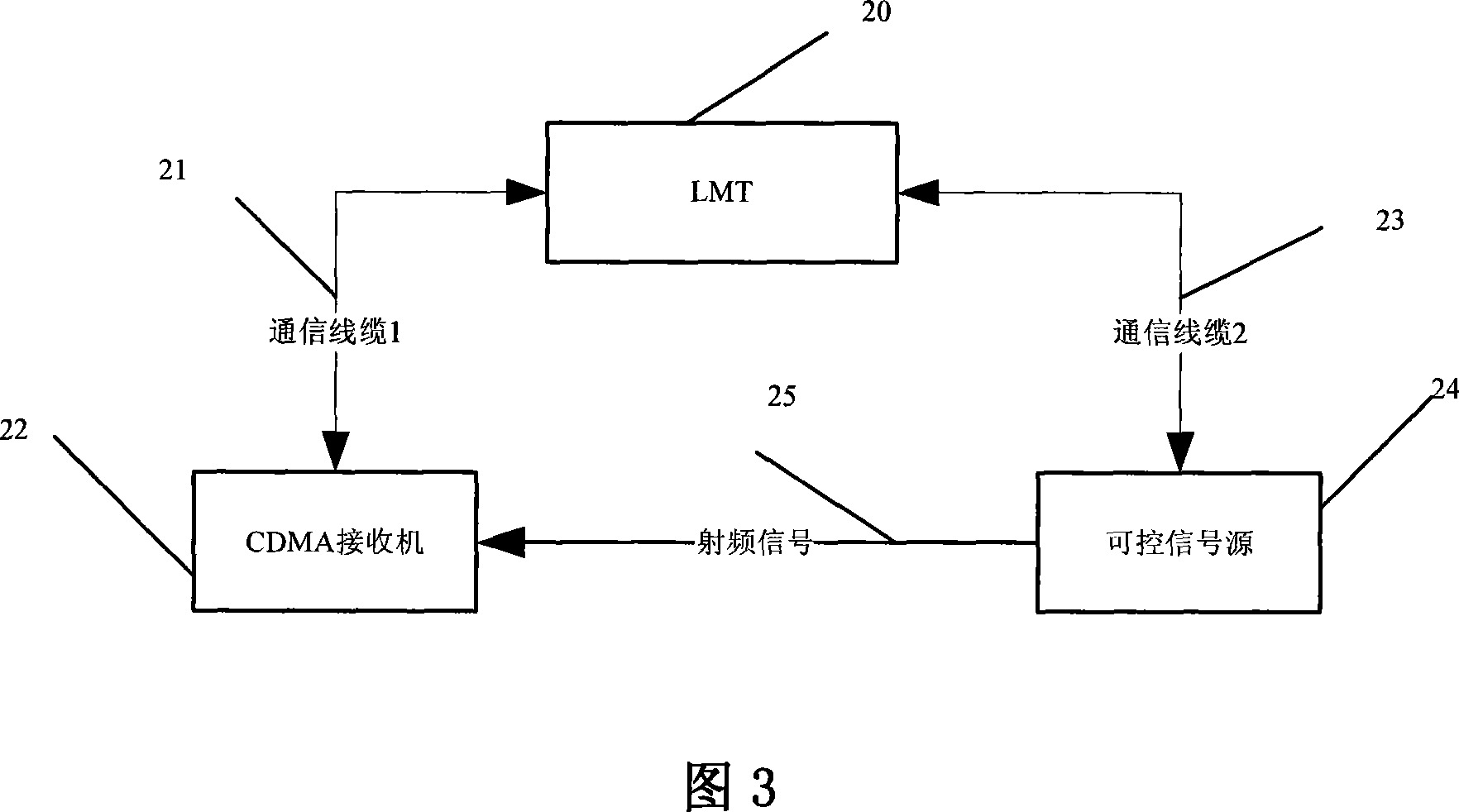

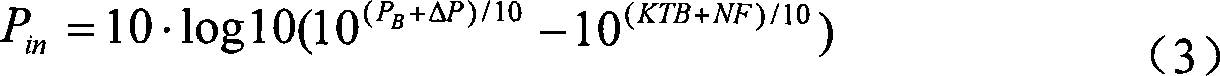

A power calibration and real time correction device for CDMA receiver and its implementation method

ActiveCN101188463AReduce consumptionHigh speedReceivers monitoringRadio/inductive link selection arrangementsCdma systemsNonlinear gain

The invention relates to a CDMA receiver power calibration and real-time correction device and the realization method thereof, and the method can be used for the power calibration and the real-time correction of terminal equipment such as the CDMA system, the base station facilities, and the road measurement meter. The method adopts a segment look-up table approach, and not only uses the fastness and simplicity of the look-up table approach but also combines segment treatment, thereby reducing the consumption of the storage room as much as possible. For linear gain section of a receiving link, i.e. the so-called big signal calibration, the look-up table approach is used directly; for non-linear gain section, i.e. small signal calibration, a noise compensation calibration method is adopted. The invention is used especially for the power calibration and the real-time correction of the massive equipment, and the power calibration method can meet the demand of automation and have the advantages of low cost, fast speed and high calibration precision.

Owner:WUHAN HONGXIN TELECOMM TECH CO LTD

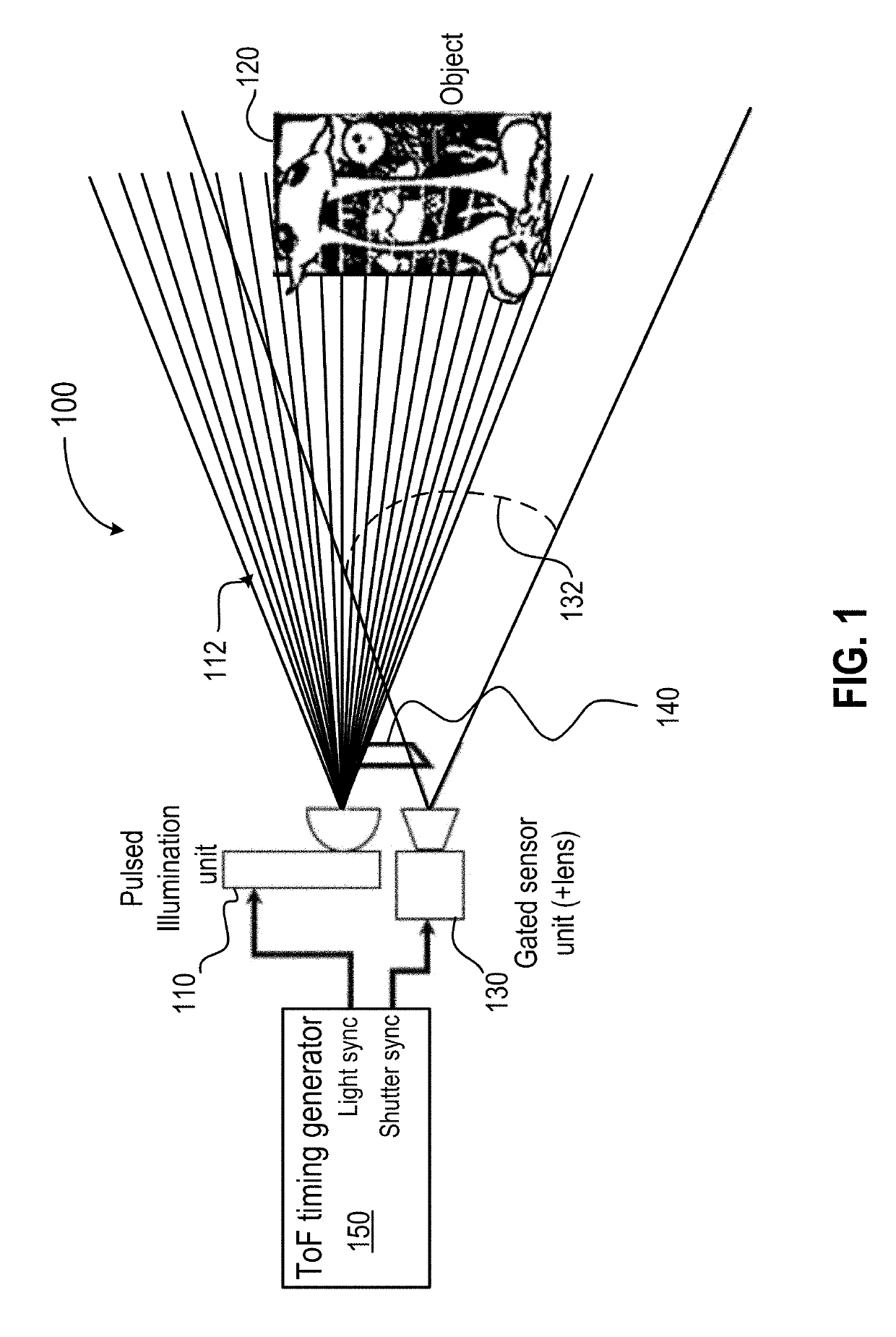

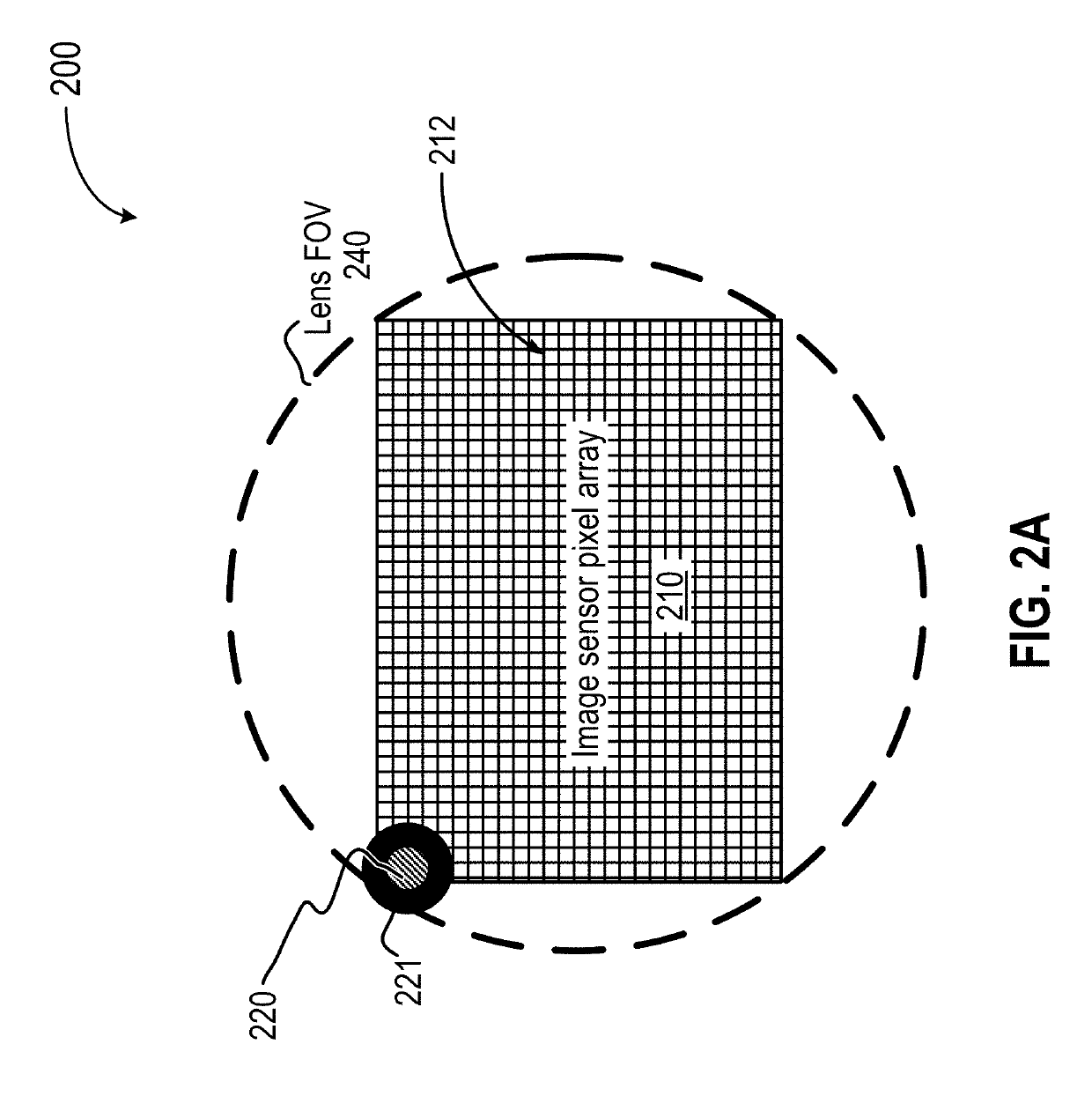

Global shutter pixel circuit and method for computer vision applications

ActiveUS20190181171A1Fast time-of-flight gatingFast signal transmissionTelevision system detailsSolid-state devicesVoltage pulseFloating diffusion

An image sensor device includes a plurality of pixel cells arranged in a pixel array, a control circuit for controlling an exposure phase and a sampling phase of the image sensor device. Each of the plurality of pixel cells includes a photodiode, a storage diode, and a floating diffusion region. The control circuit is configured to activate the photodiode in a plurality of time windows to sense light reflected from a target as a result of a corresponding plurality of emitted light pulses, with a pre-determined delay time between each time window and a corresponding emitted light pulse. The photodiode can be activated using a plurality of bias voltage pulses or a plurality of global shutter signal pulses.

Owner:MAGIC LEAP

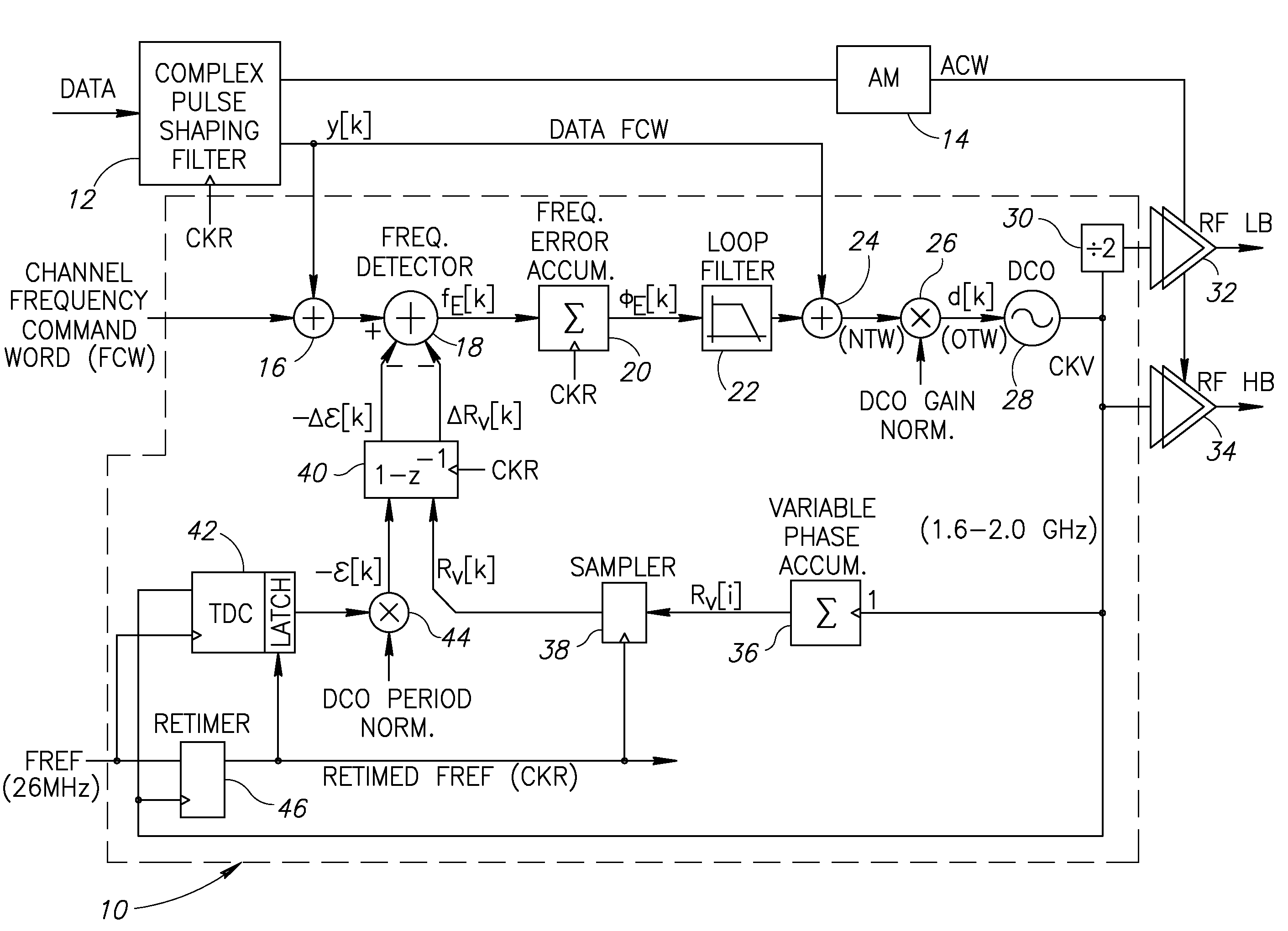

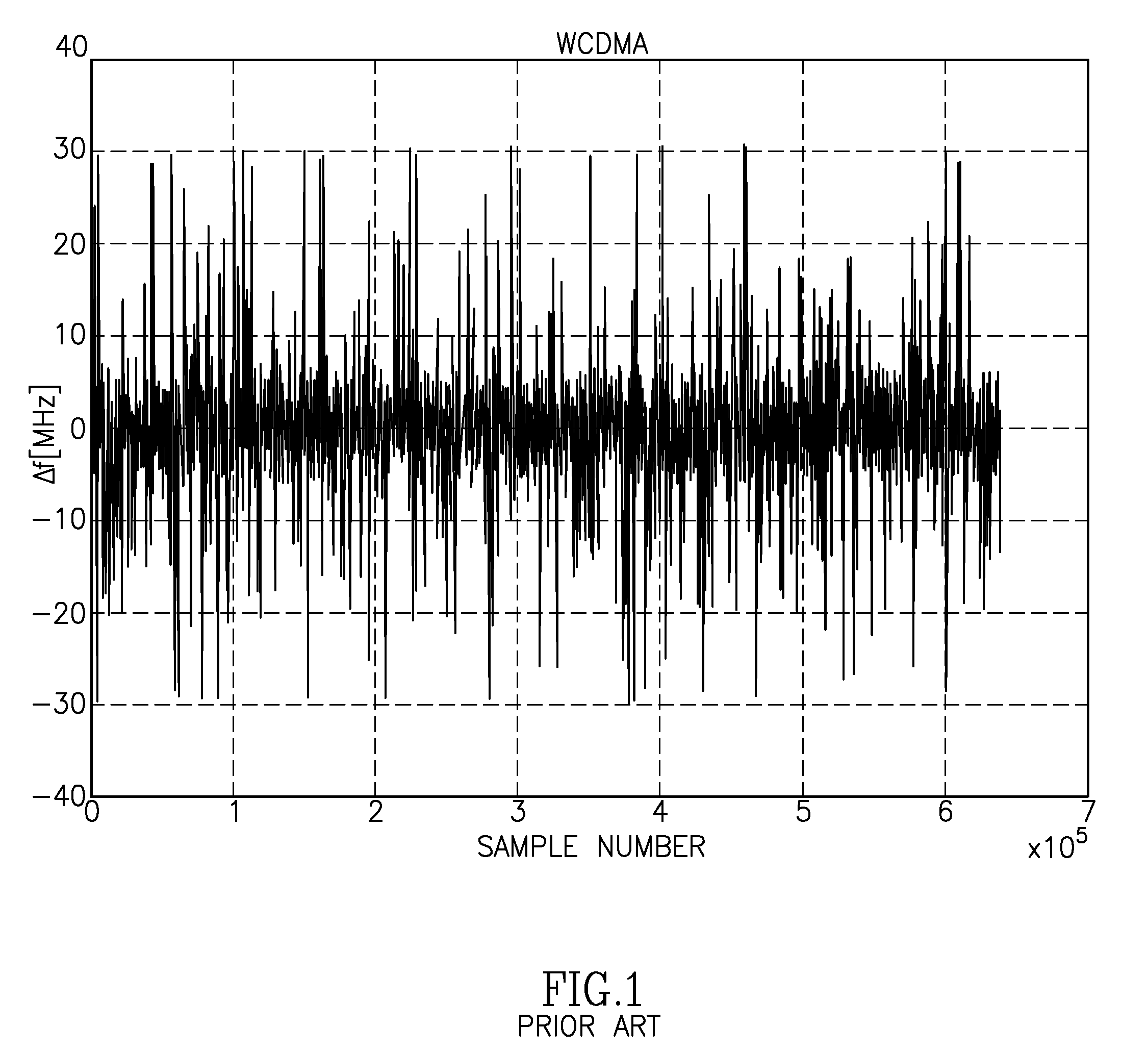

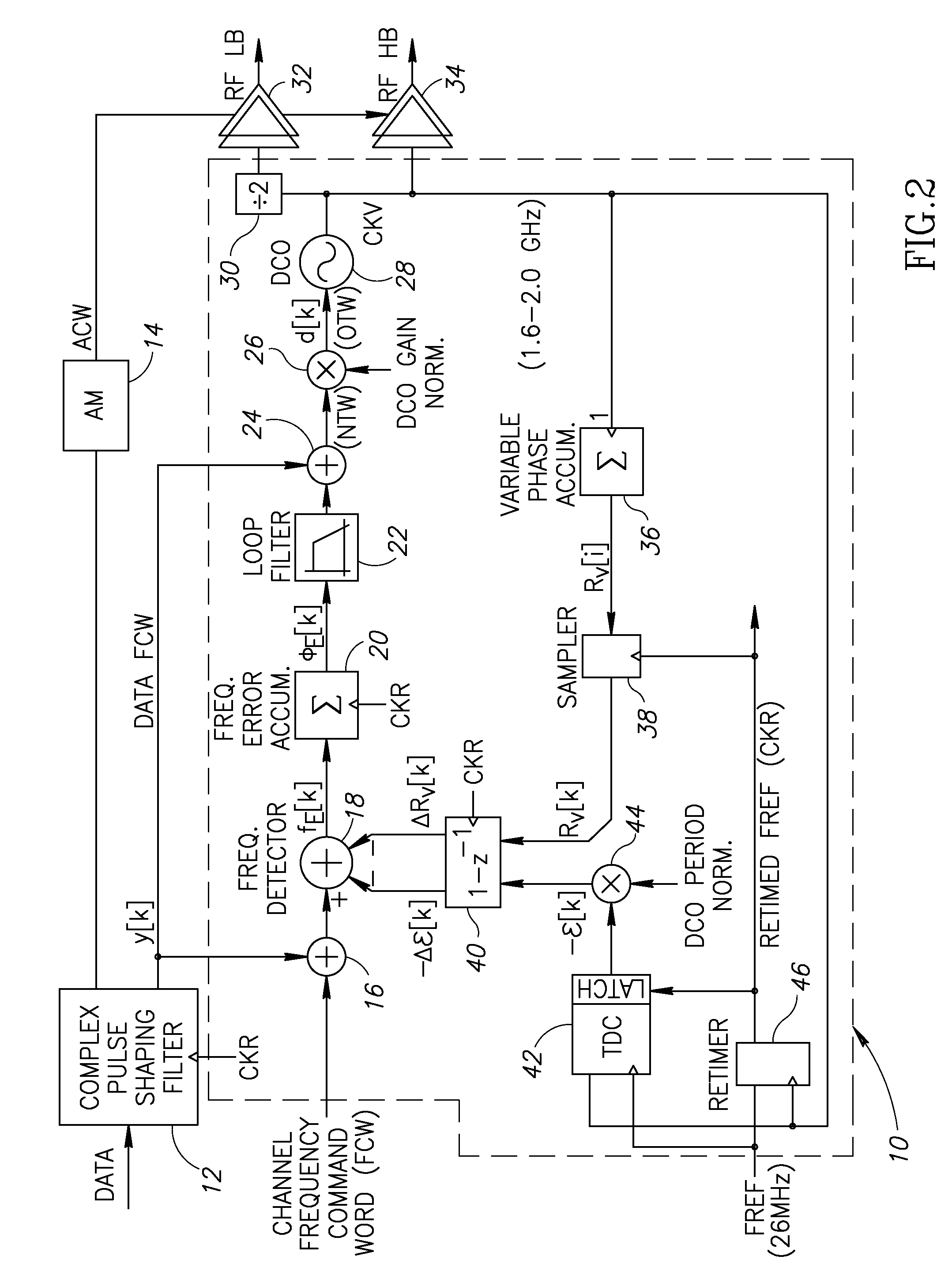

Frequency tuning range extension and modulation resolution enhancement of a digitally controlled oscillator

ActiveUS20070188243A1Easy to adjustIncrease rangeSimultaneous amplitude and angle modulationPulse automatic controlCMOSImage resolution

A novel apparatus and method of extending the frequency tuning range and improving the modulation resolution of an RF digitally controlled oscillator (DCO). In addition to the coarse PVT MIM varactor bank, the DCO uses a single unified bank of varactors that is further subdivided divided into an MSB bank, LSB bank and sigma-delta (SD-LSB) bank. Any ratio mismatches between MSBs and LSBs are digitally calibrated out using a DCO step-size pre-distortion scheme wherein the LSB steps are adjusted to account for the ratio mismatch between the MSB / LSB step sizes. A harmonic characterization technique is used to estimate the mismatches in the minimal size CMOS tuning varactors of a digitally controlled RF oscillator (DCO), wherein the nominal ratio mismatch between the MSB and LSB devices is estimated using hybrid stochastic gradient DCO gain estimation algorithms. The nominal ratio mismatch and the mismatches in the MSB and LSB banks are used to determine the average MSB / LSB mismatch. The average mismatch value is then used to correct the LSB steps.

Owner:TEXAS INSTR INC

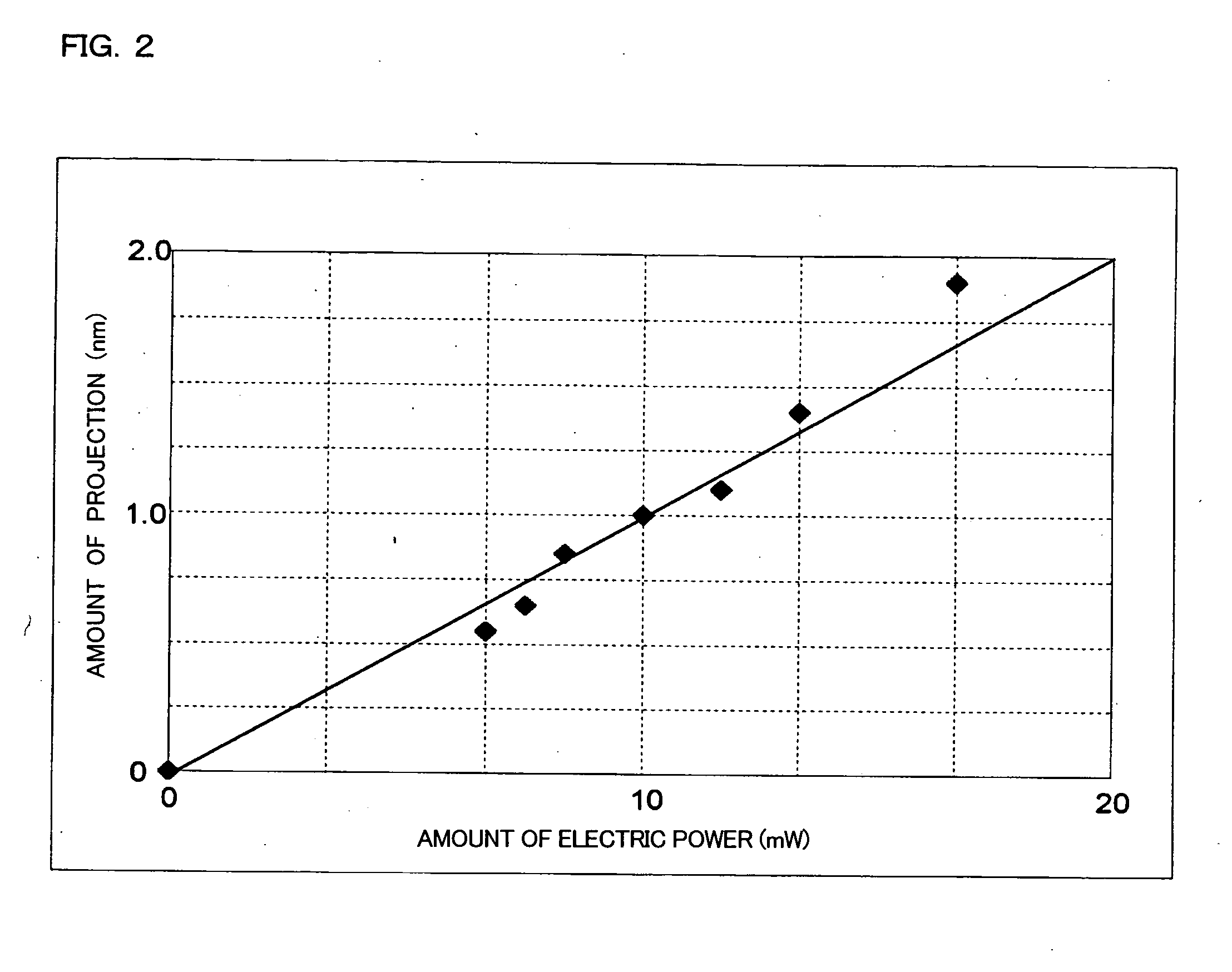

Information storage apparatus

InactiveUS20070133118A1Quick calibrationShort timeDriving/moving recording headsRecord information storageMagnetic polesEngineering

An information storage apparatus includes a magnetic head having a magnetic pole end that is controllable so as to project, a recording medium for recording and / or reproducing data, a protrusion provided on a surface of the recording medium, the protrusion being used for measuring a flying height of the magnetic head, and a flying-height adjustment controller that adjusts the flying height of the magnetic head by controlling the amount of projection of the magnetic pole end of the magnetic head on the basis of the amount of projection obtained when the magnetic pole end of the magnetic head comes into contact with the protrusion.

Owner:FUJITSU LTD

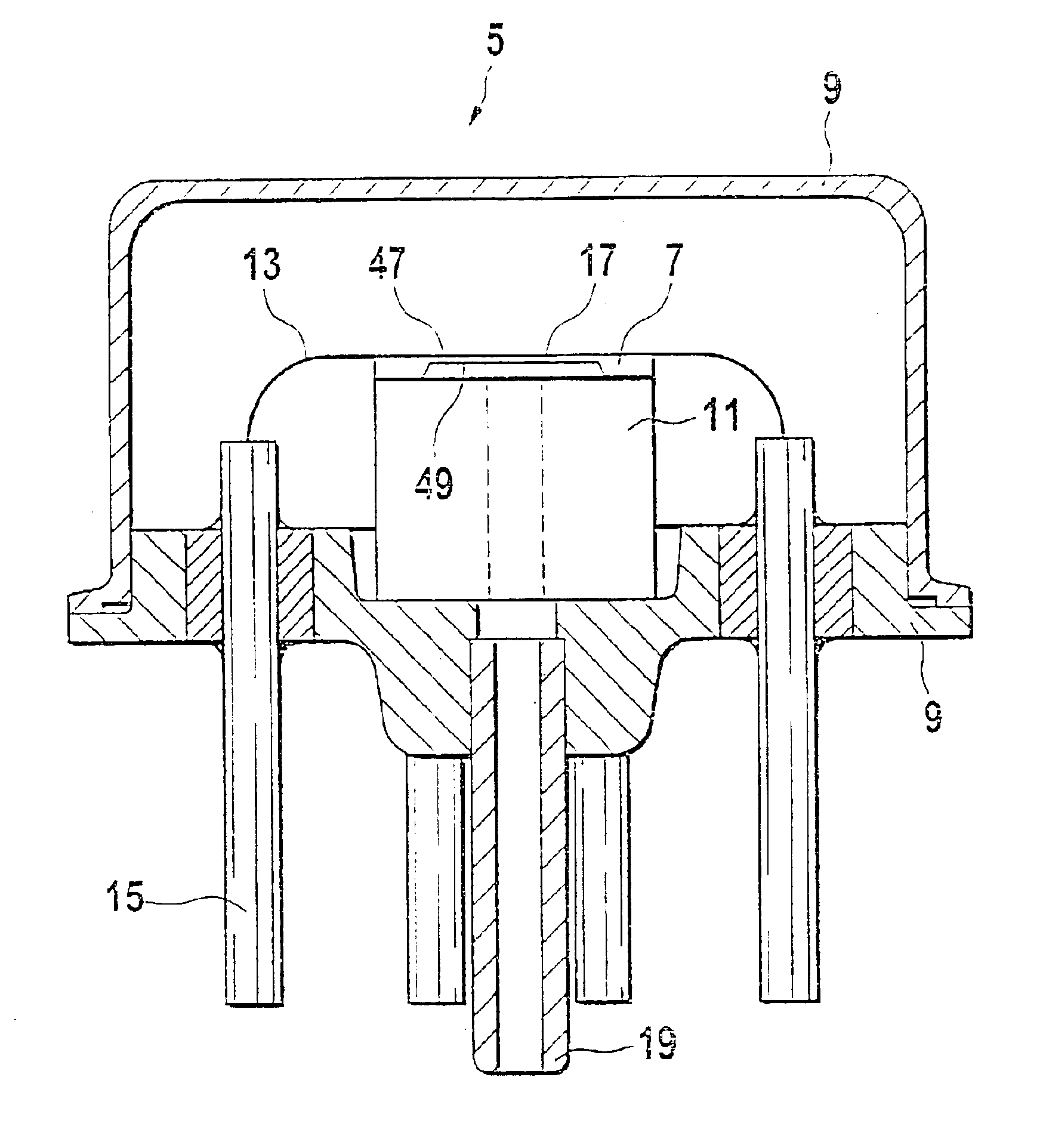

Pressure sensor module with sensor cell and adapter

InactiveUS6871546B2High measurement accuracyQuick calibrationFluid pressure measurement using ohmic-resistance variationSemiconductor/solid-state device detailsPressure transmissionEngineering

In a pressure sensor module according to the prior art, which is intended for detecting the pressure of a corrosive medium, the conventional sensor cell with a pressure sensor chip is modified in order to protect it from corrosion, which results in a large volume for a pressure-transmitting-fluid. This is disadvantageous for the calibration and for a high degree of measurement precision.In a pressure sensor module (1) according to the invention, a convention sensor cell (5) is used that has an adapter (21) connected to it, which has a very small volume for a pressure-transmitting medium.

Owner:ROBERT BOSCH GMBH

Mechanical arm calibration system and calibration method based on four-eye stereo vision

PendingCN110421562ALow costSimple and efficient operationProgramme-controlled manipulatorTotal factory controlCalibration resultLeast squares

The invention discloses a mechanical arm calibration system based on four-eye stereo vision. The system involves a mechanical arm, a control box, a computer, two binocular cameras, a calibration plateand a plurality of marking points, wherein the marking points are fixed at the tail end of the mechanical arm and joints of the mechanical arm, and the two binocular cameras are distributed at the front and the side of the mechanical arm to shoot the plurality of marking points in real time. The invention further discloses a mechanical arm calibration method based on four-eye stereo vision. The method comprises the following steps of solving a conversion matrix of two coordinate systems; acquiring a first batch of data for calculation, and constructing a target function; performing iterativeoptimization on geometric parameters and non-geometric parameters of the mechanical arm by adopting a least squares algorithm; correcting a zero point and the conversion matrix of the mechanical arm,and completing the calibration of the geometric parameters of the mechanical arm by utilizing corrected D-H kinematics parameters; and verifying the calibration result. The system and the method havethe beneficial effects that the calibration of the geometric parameters and the correction of the zero point of the mechanical arm can be rapidly completed.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Multiple Field of View Dual Band Optics with Integrated Calibration Source

ActiveUS20170347037A1Accurate and fast positioningQuick calibrationTelevision system detailsColor television detailsDual frequencyOptical field

A multiple field of view dual band optical device with integrated calibration source is disclosed. Such an optical device is modular, and has a rotating electro-mechanical “tumbler” which houses two orthogonal Galilean afocal optical assemblies as well as at least one uniform temperature source. This modular device is intended to be inserted in front of a camera system which already has an imager optical assembly mated to a detector focal plane array. The disclosed modular device thus serves the purpose of providing to an existing dual-band camera imager up to four new optical fields of view as well as an integral calibration source, all of which can be electro-mechanically selected for viewing by a host camera imager.

Owner:UNTED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE ARMY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com