Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43724results about "Total factory control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

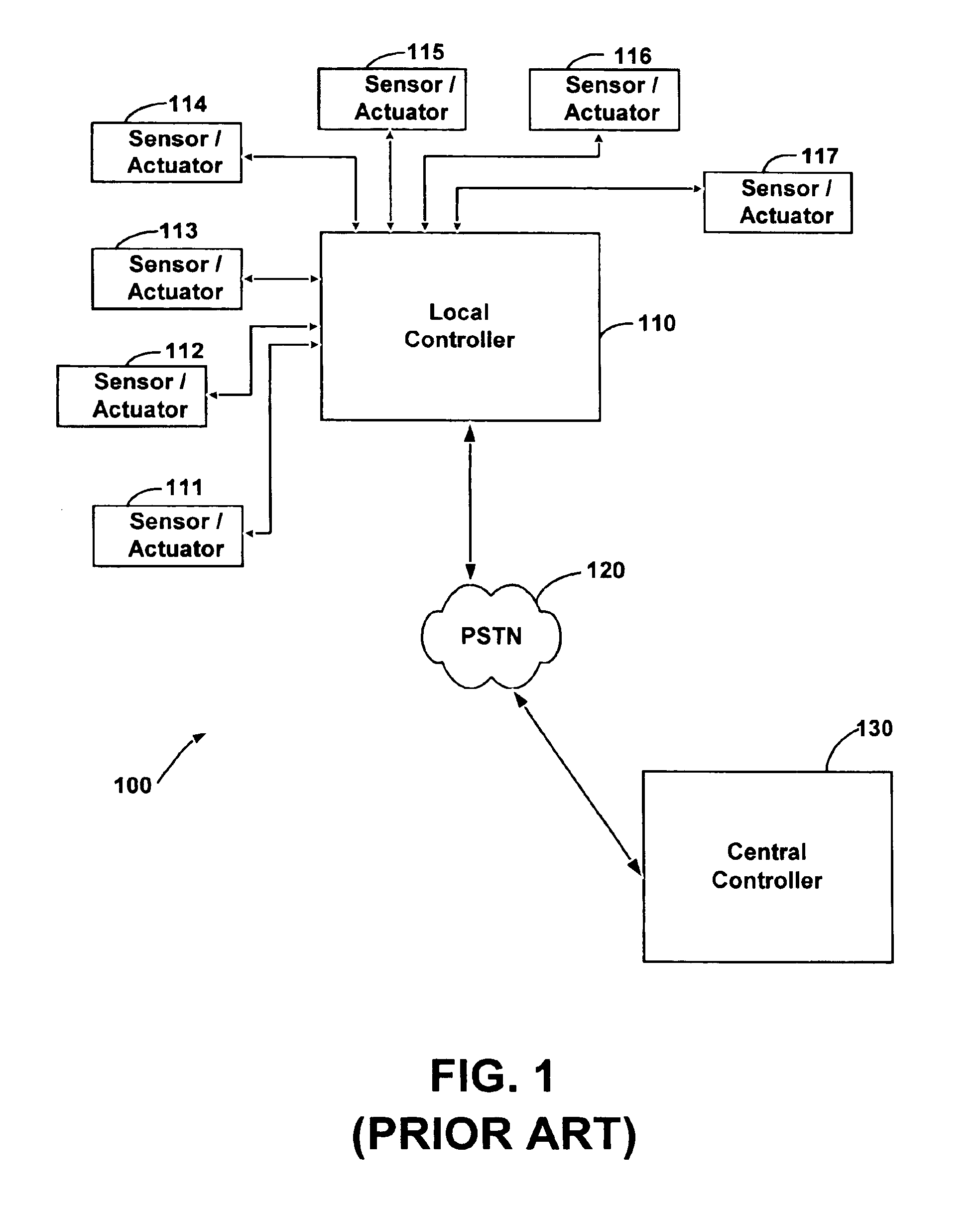

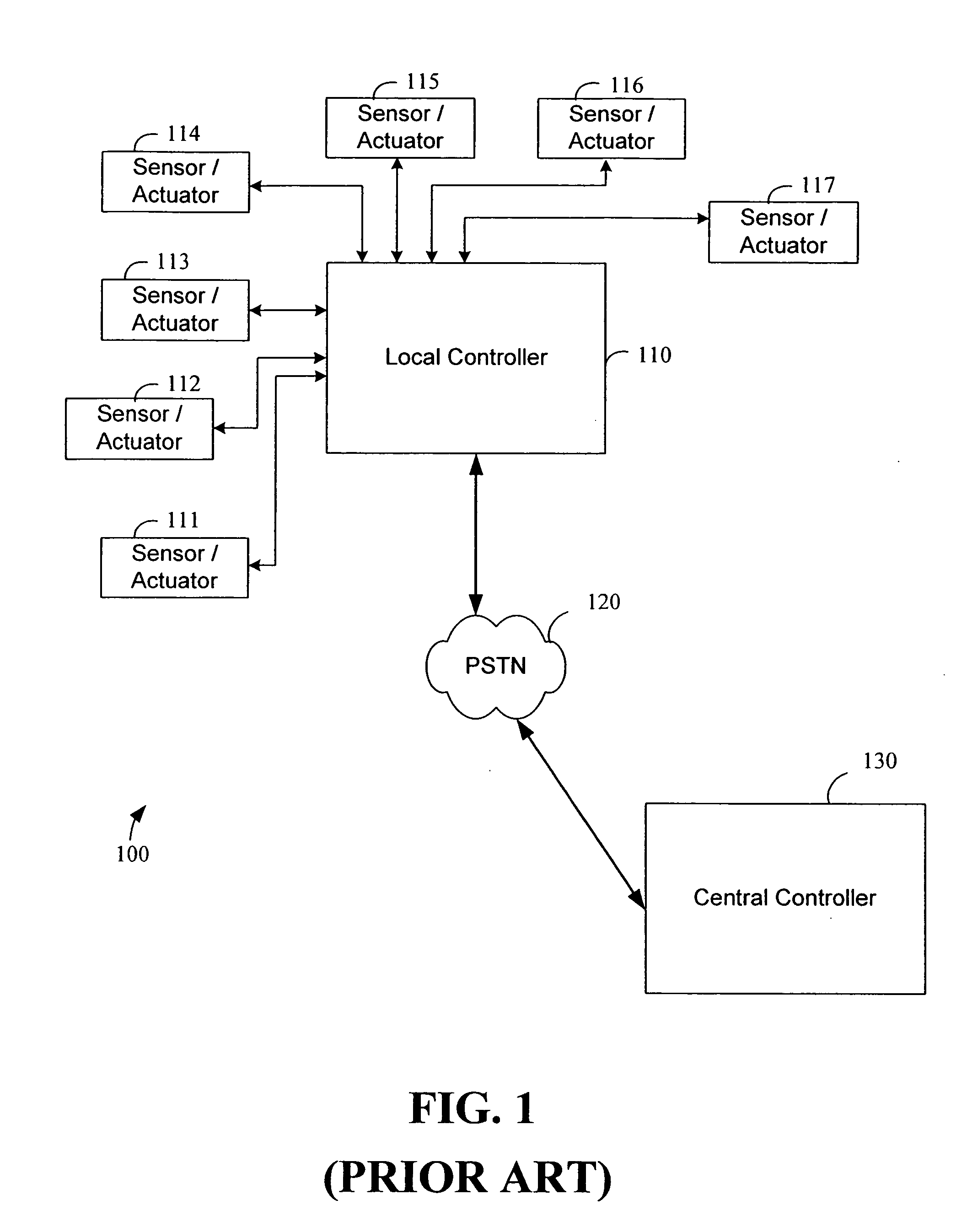

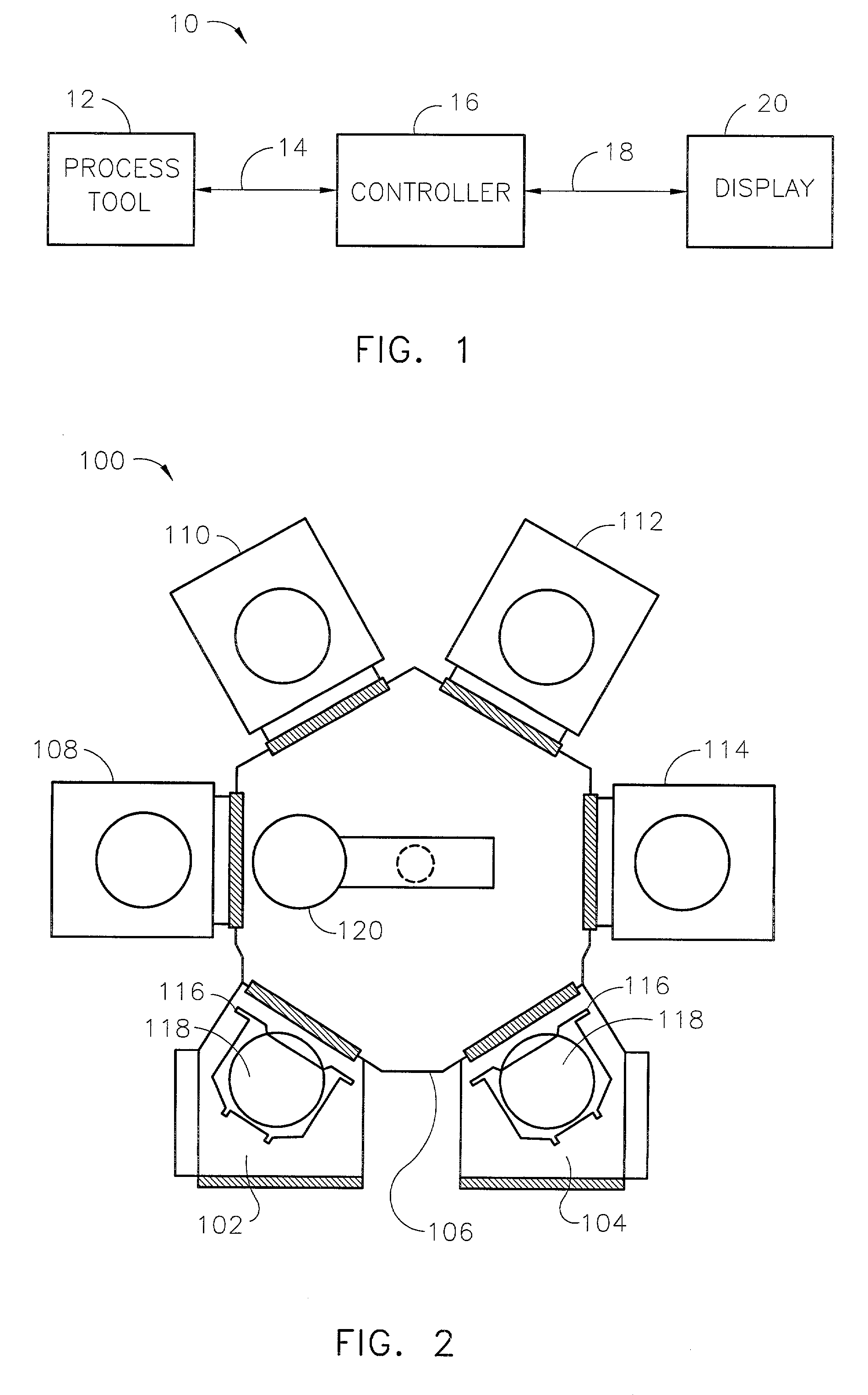

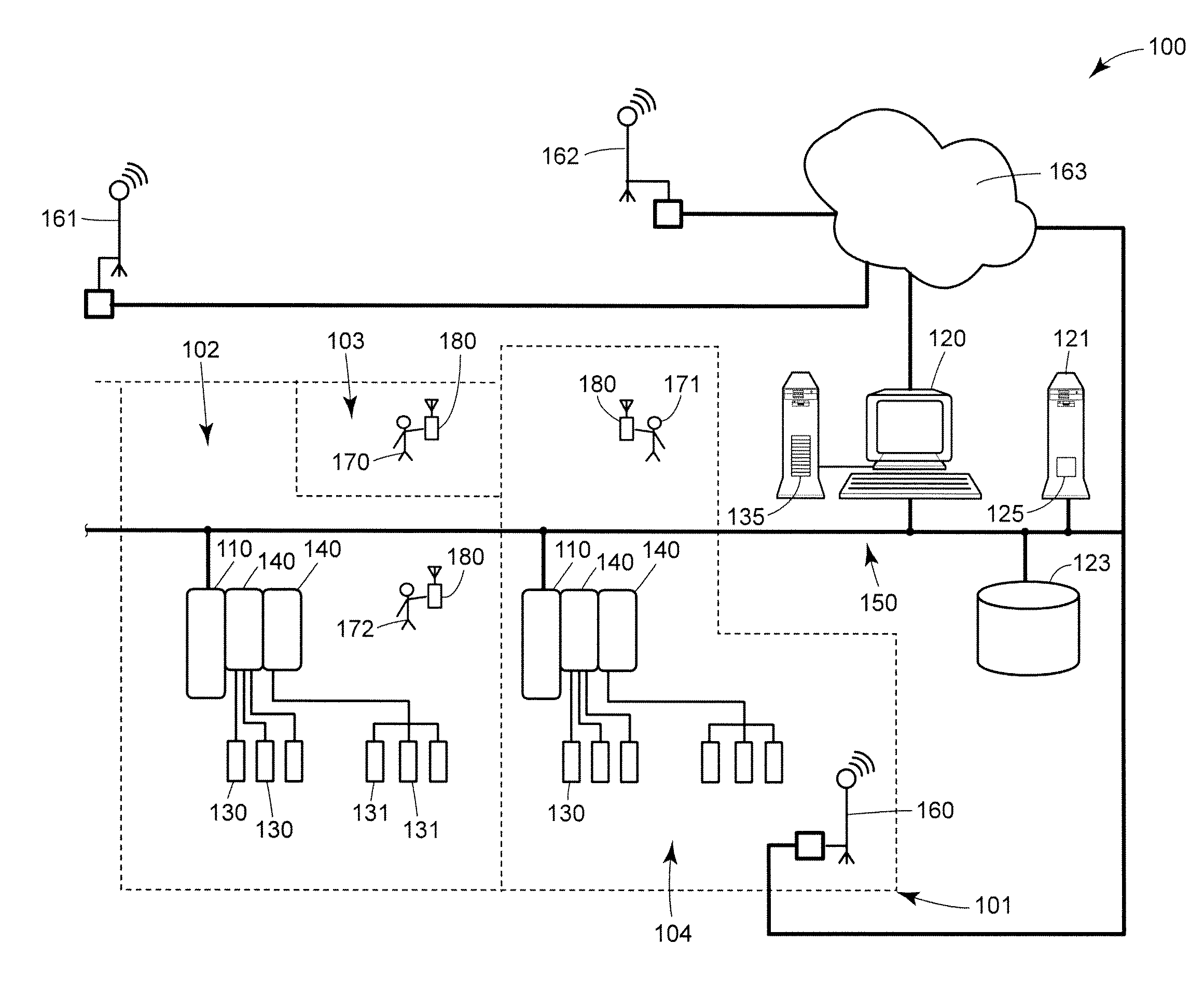

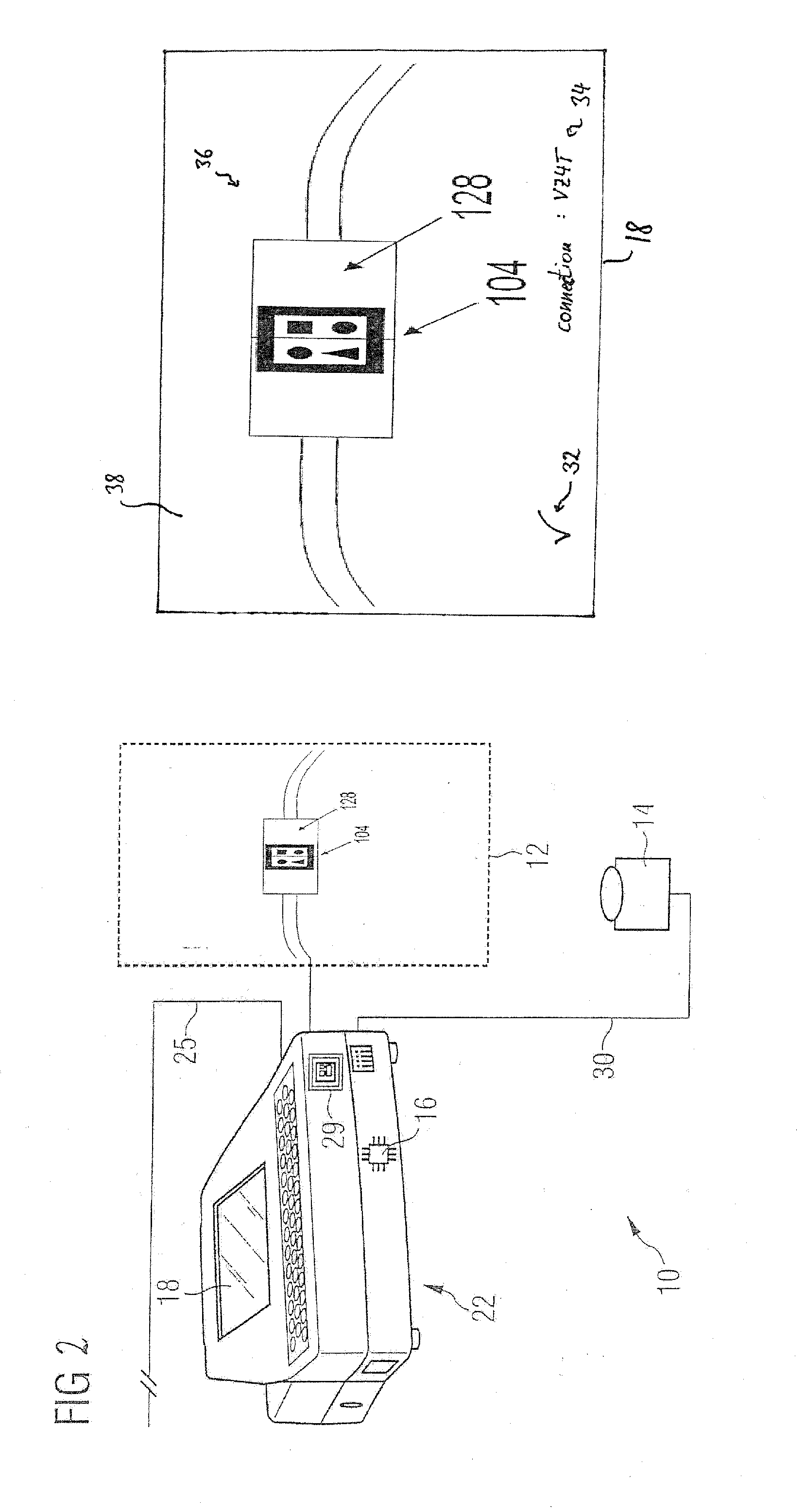

System and method for monitoring and controlling remote devices

InactiveUS6914893B2Easy to integrateEasily mapped into the packet protocolActive radio relay systemsElectric testing/monitoringTransceiverTelecommunications link

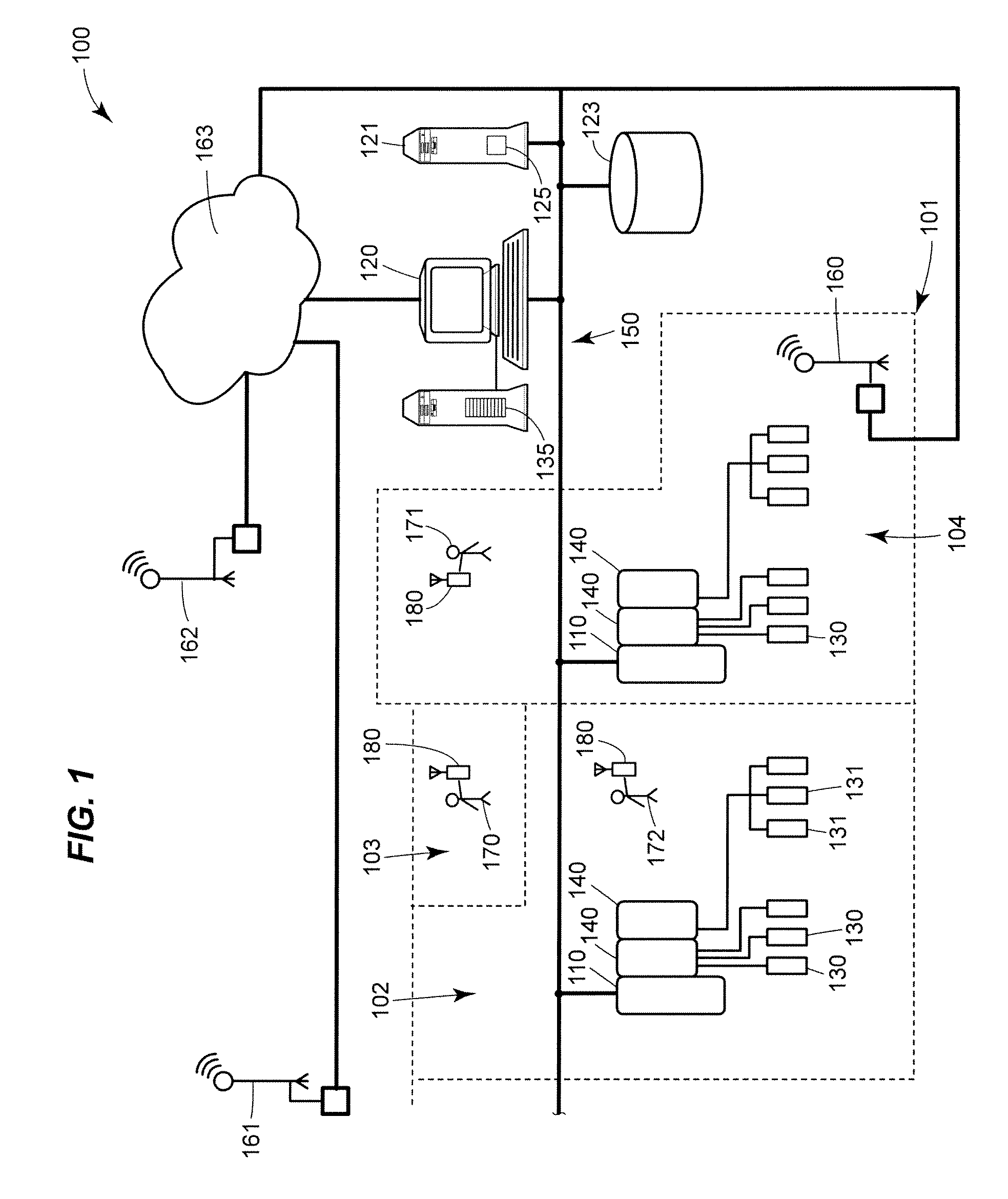

The present system is directed to a computerized system for monitoring and controlling remote devices by transmitting data between the remote systems and a gateway interface via a packet message protocol system. The system comprises one or more remote sensors to be read and possibly one or more actuators to be remotely controlled. The remote sensor(s) / actuator(s) then interface with uniquely identified remote transceivers that transmit and / or receive data. If necessary in individual applications, signal repeaters may relay information between the transceiver(s) and the gateway interface. Communication links between the remote transceivers and the gateway interface are preferably wireless but may also be implemented via a mixture of wireless and wired communication links. To successfully communicate between the transceiver(s) and the gateway interface, the present invention receives a plurality of RF signal transmissions containing a packet protocol via RF signals that includes sender and receiver identifiers, a description of the packet itself, a message number, any commands, the data, and an error detector. In addition, the packet protocol can be easily integrated with alternate data communication protocols for use with systems other than the Internet.

Owner:SIPCO

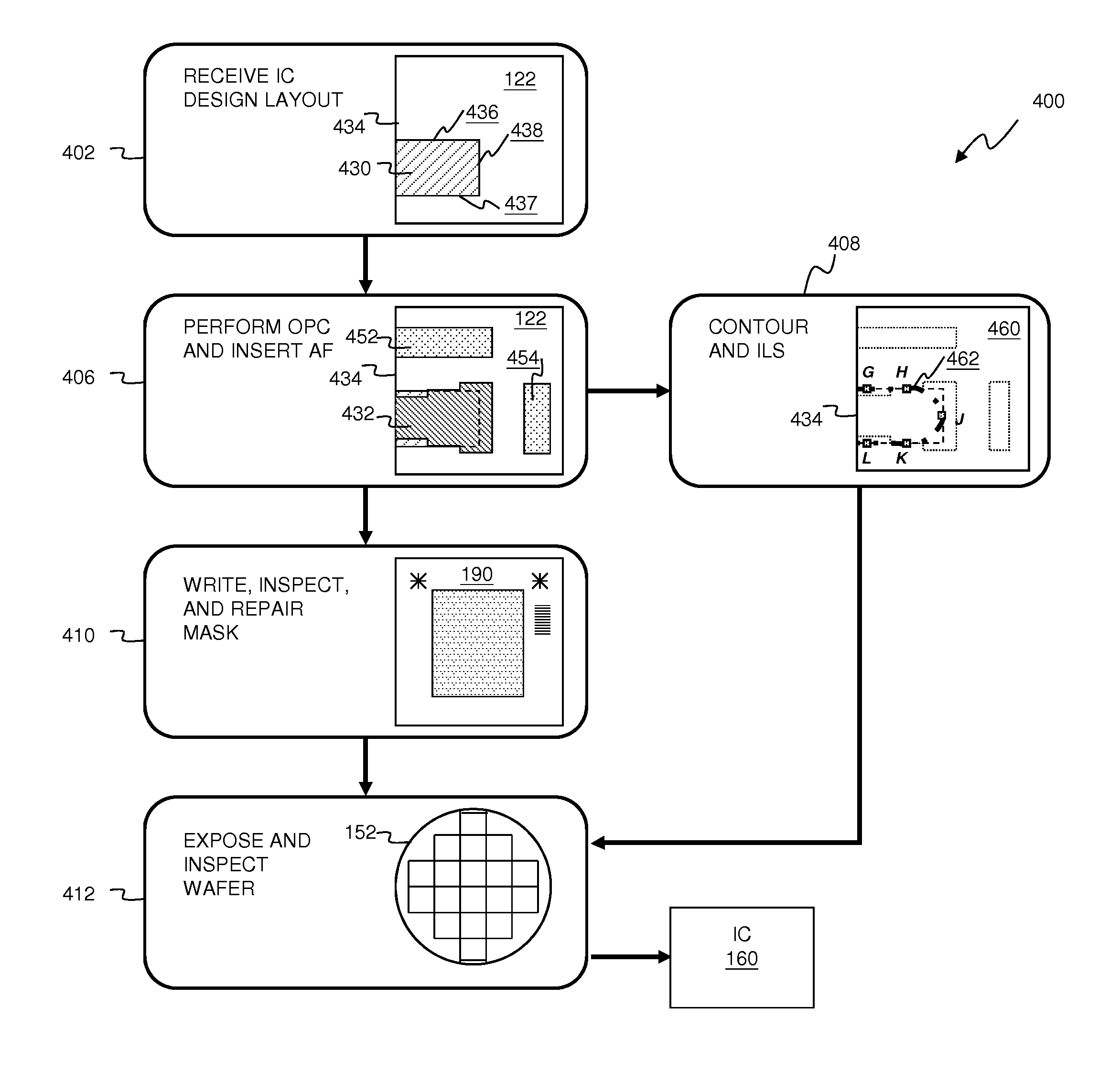

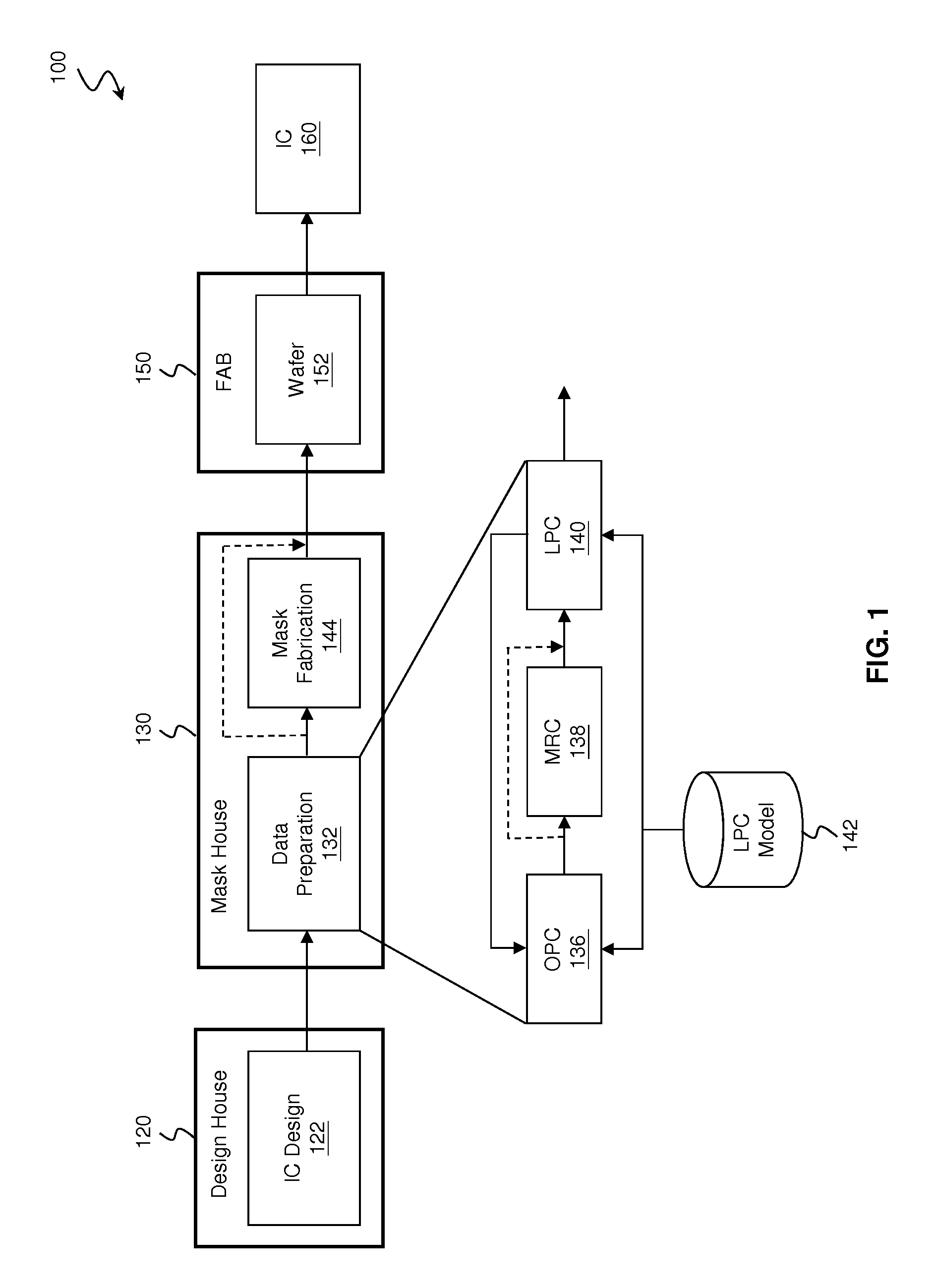

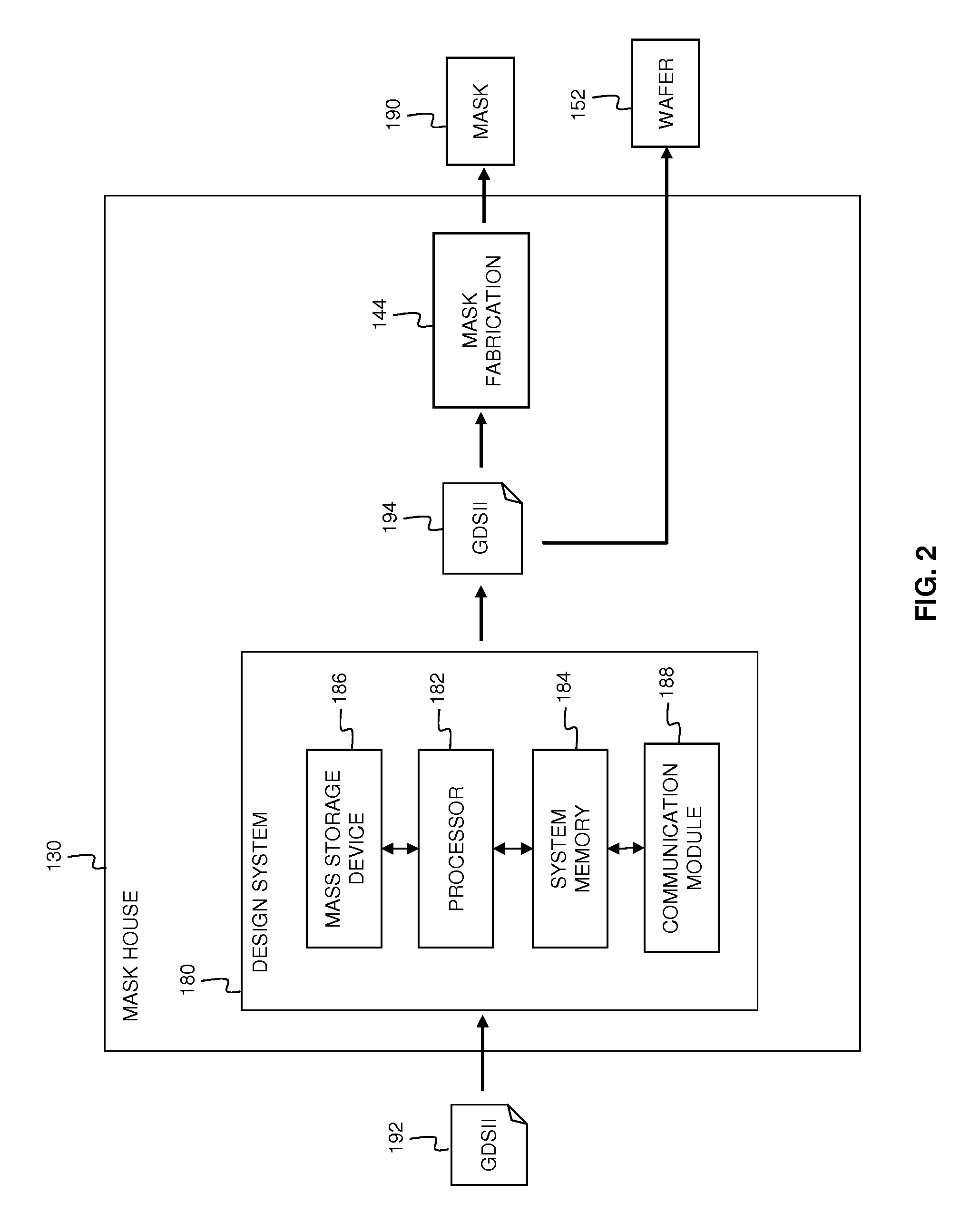

System and Method for Integrated Circuit Manufacturing

ActiveUS20150278429A1Photomechanical apparatusDesign optimisation/simulationMask inspectionIntegrated circuit manufacturing

Provided is an integrated circuit (IC) manufacturing method. The method includes receiving a design layout of an IC, the design layout having a main feature; performing a process correction to the main feature thereby generating a modified main feature; using a computer, generating a simulated contour of the modified main feature, the simulated contour having a plurality of points; generating a plurality of assistant data in computer readable format, wherein each assistant data includes at least one process performance factor associated with one of the points; and keeping the simulated contour and the assistant data for use by a further process stage, such as mask making, mask inspection, mask repairing, wafer direct writing, wafer inspection, and wafer repairing.

Owner:TAIWAN SEMICON MFG CO LTD

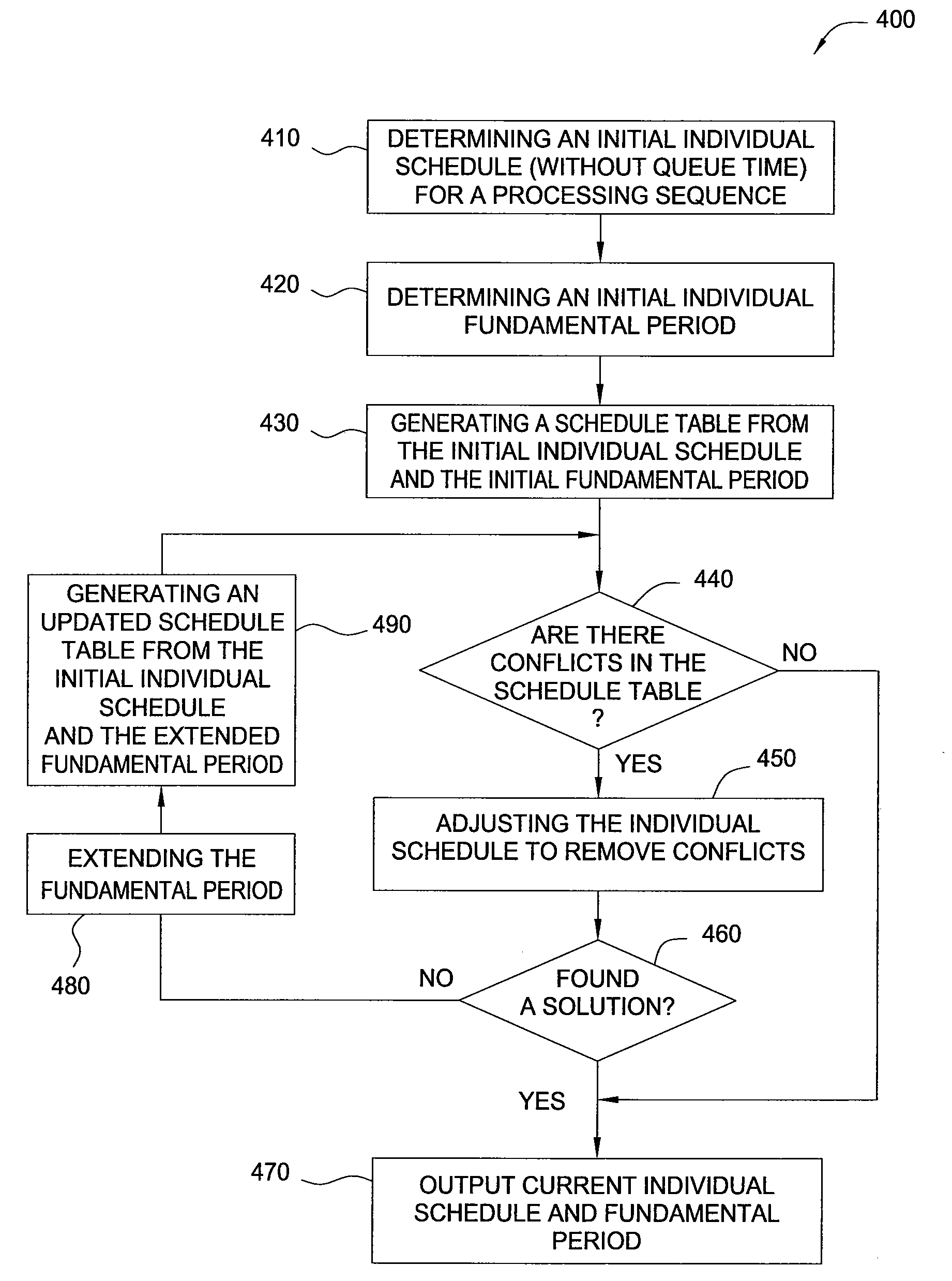

Software sequencer for integrated substrate processing system

InactiveUS20080216077A1Programme controlSemiconductor/solid-state device manufacturingProgram planningDistributed computing

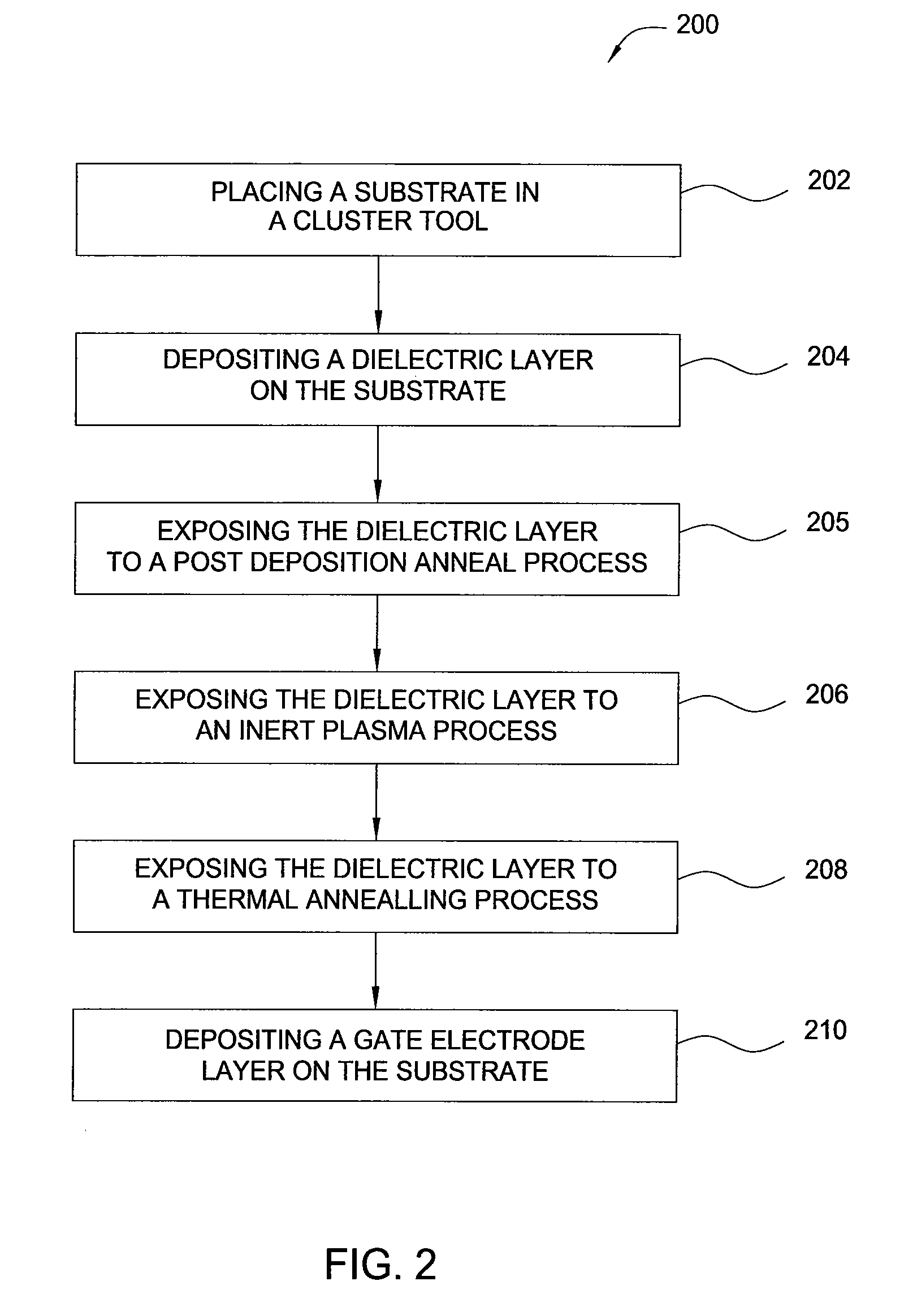

Embodiments of the invention generally provide apparatus and method for scheduling a process sequence to achieve maximum throughput and process consistency in a cluster tool having a set of constraints. One embodiment of the present invention provides a method for scheduling a process sequence comprising determining an initial individual schedule by assigning resources to perform the process sequence, calculating a fundamental period, detecting resource conflicts in a schedule generated from the individual schedule and the fundamental period, and adjusting the individual schedule to remove the resource conflicts.

Owner:APPLIED MATERIALS INC

Purged vacuum chuck with proximity pins

InactiveUS20060130767A1Reduce the overall heightImprove heat transfer rateProgramme controlSemiconductor/solid-state device testing/measurementEngineeringFree space

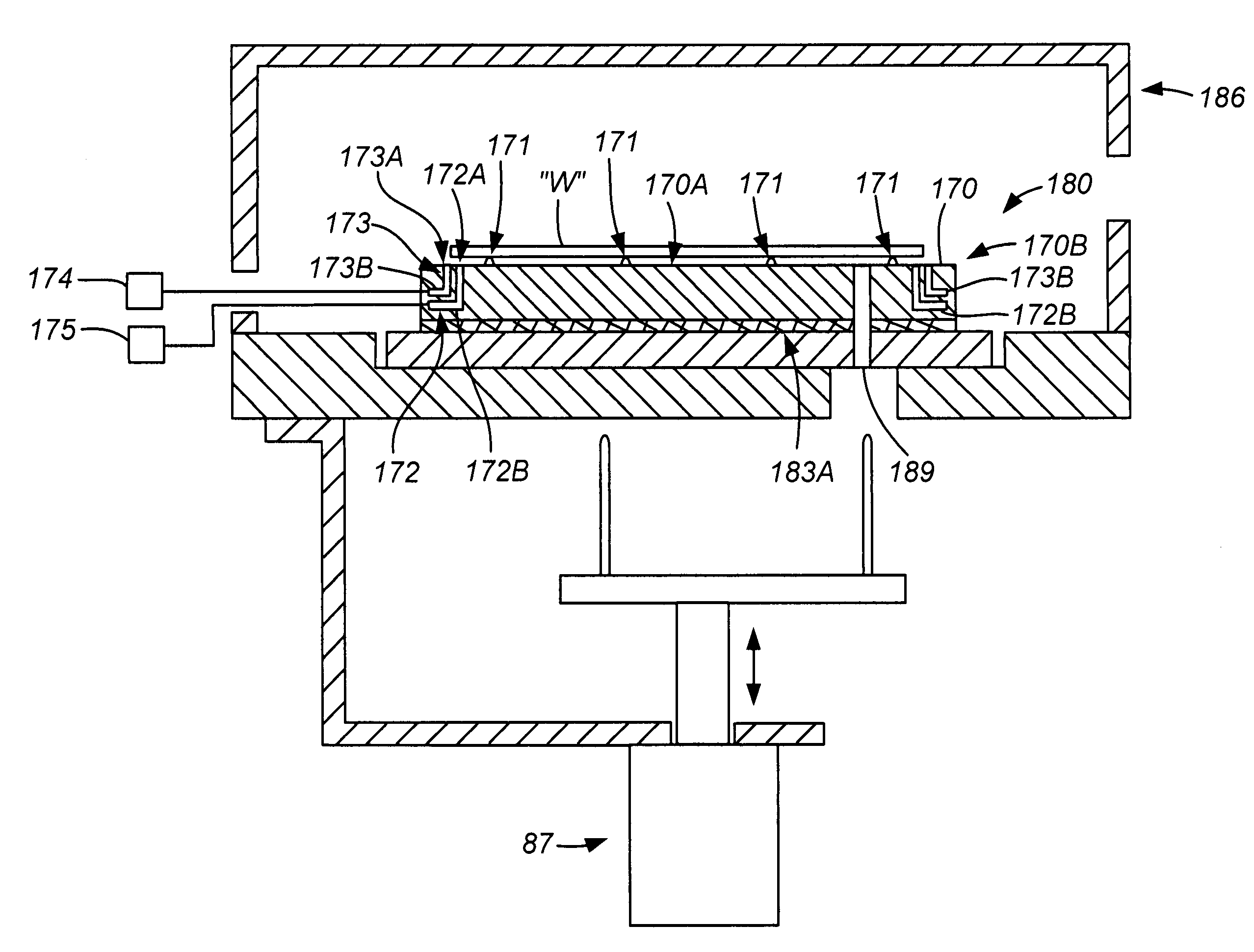

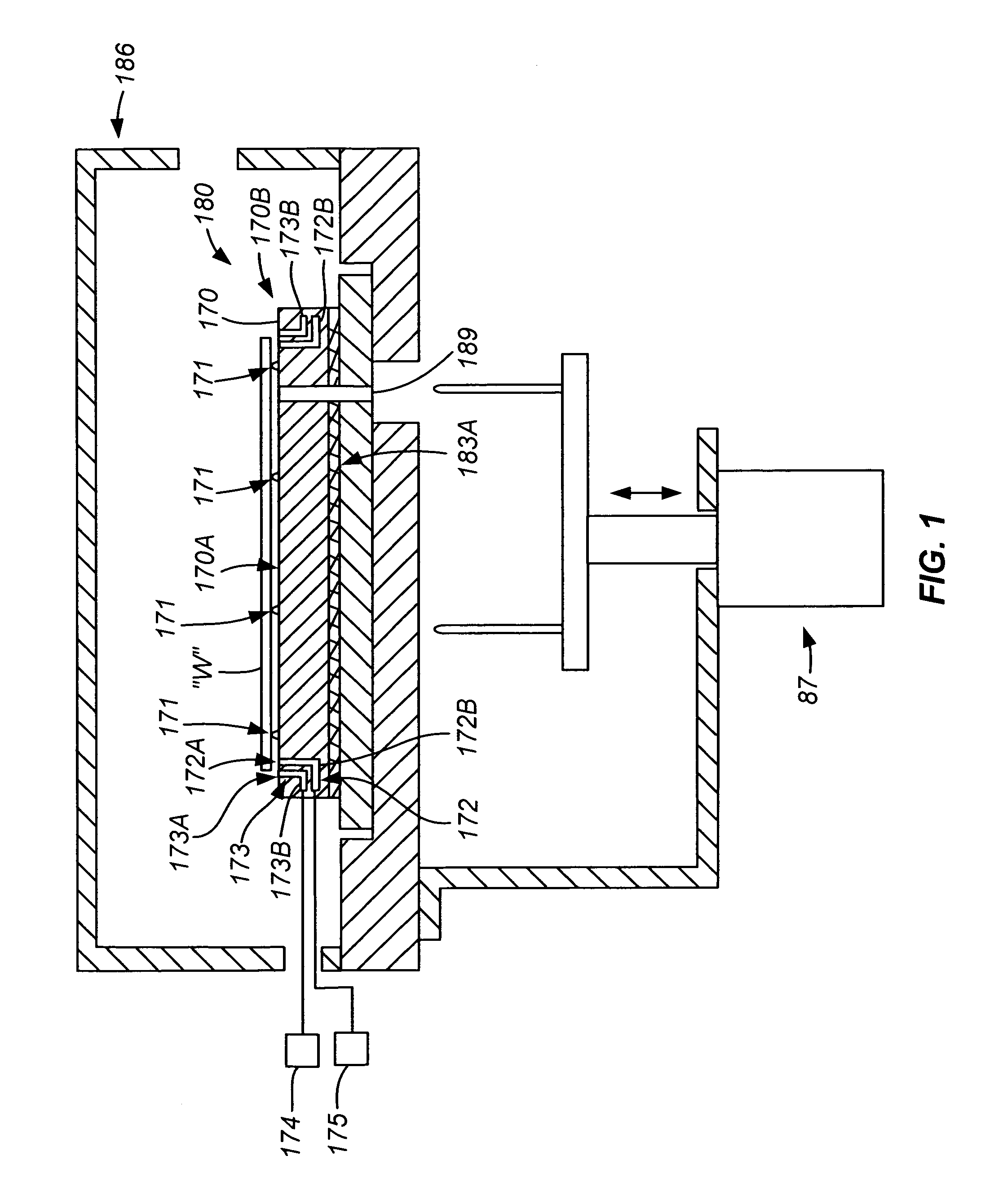

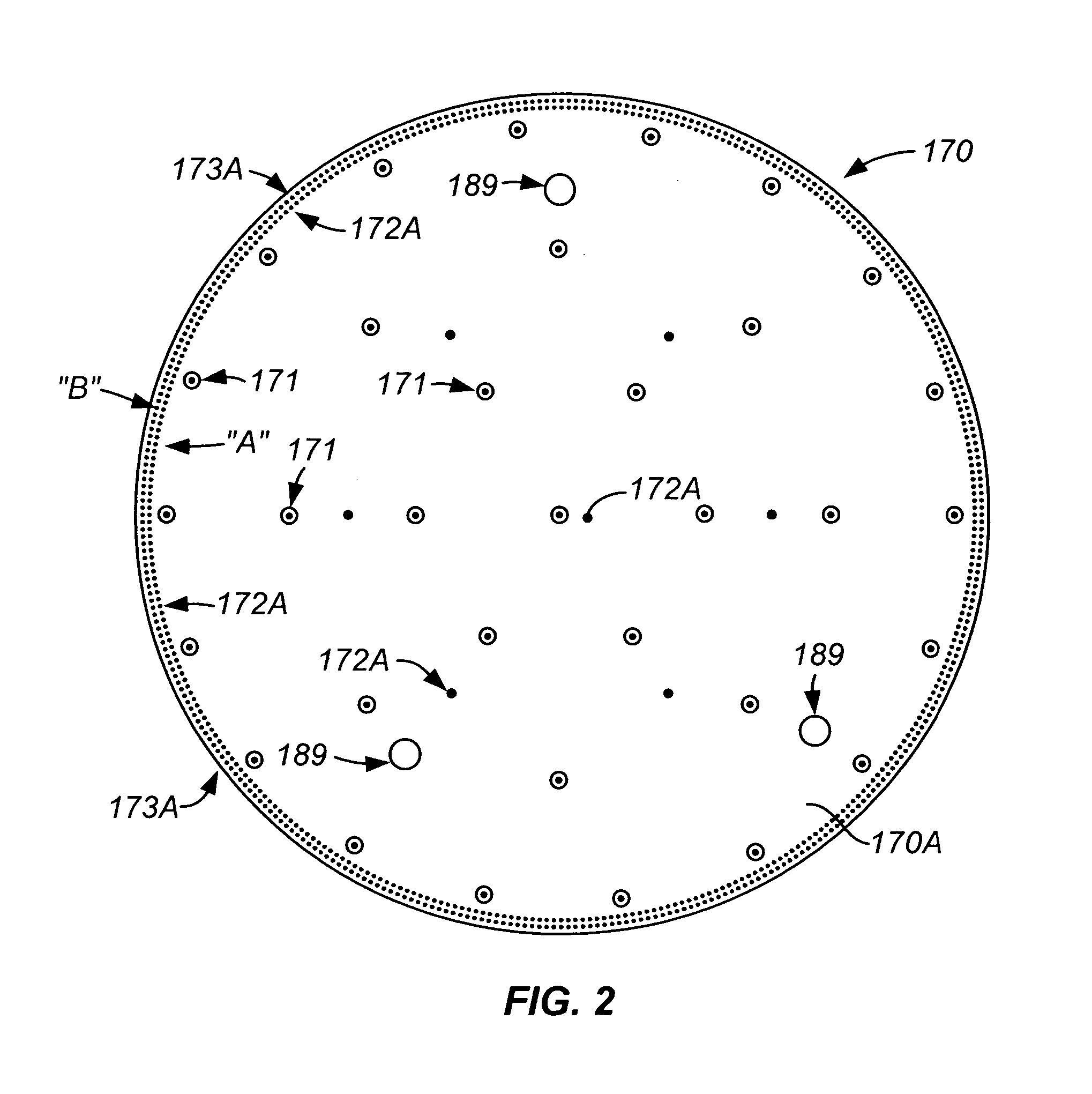

A substrate support structure comprising a first surface and a second surface opposite the first surface. The substrate support structure also comprises a plurality of proximity pins projecting to a first height above the first surface, the first height being less than 100 μm. In addition, the substrate support structure further comprises a plurality of purge ports passing from the second surface to the first surface and a plurality of vacuum ports passing from the second surface to the first surface. In one embodiment, the plurality of purge ports are arranged in a first circular pattern, the first circular pattern having a first radial dimension less than the radius of the substrate support, and the plurality of vacuum ports are arranged in a second circular pattern, the second circular pattern having a second radial dimension less than the first radial dimension.

Owner:SOKUDO CO LTD

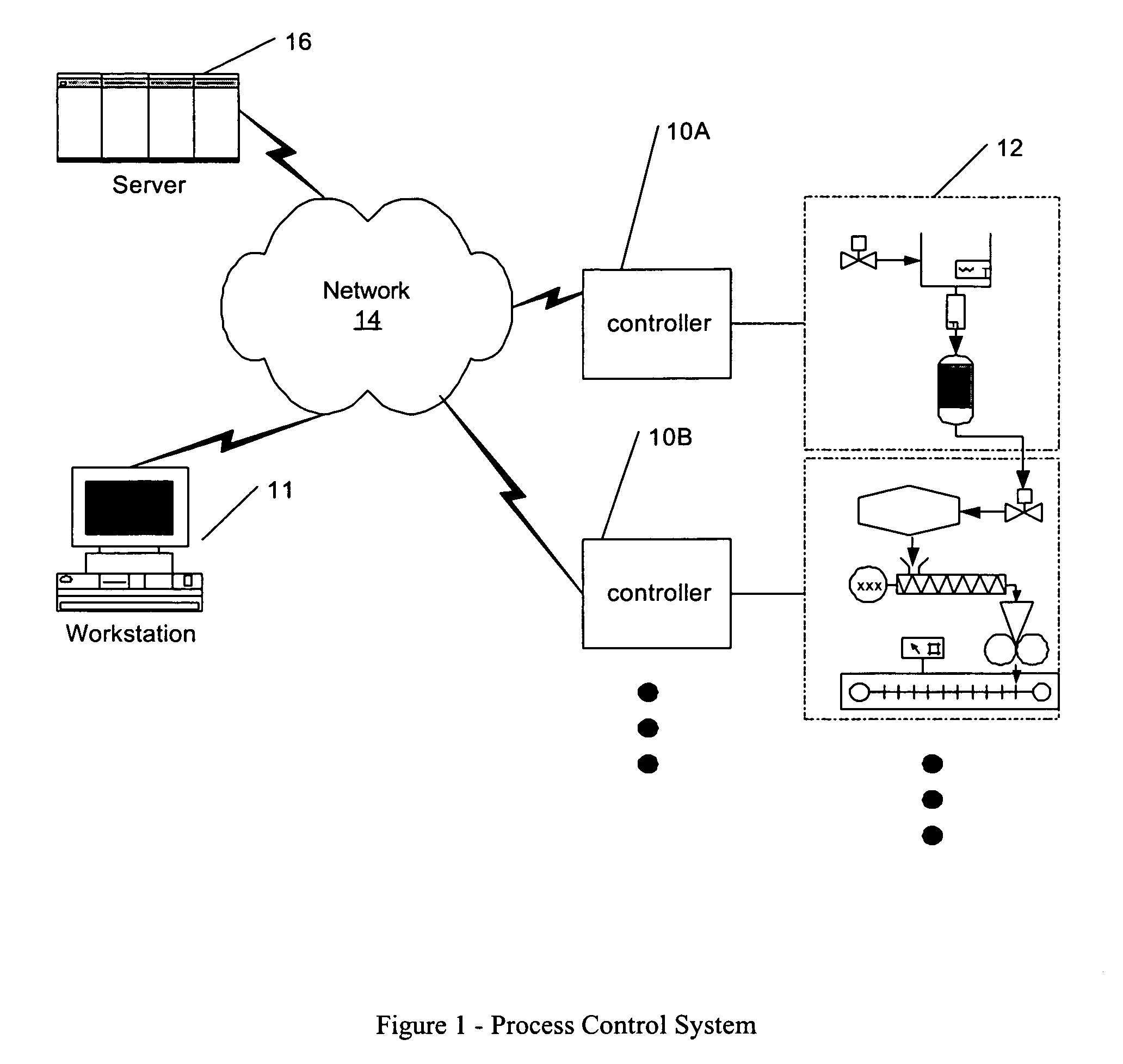

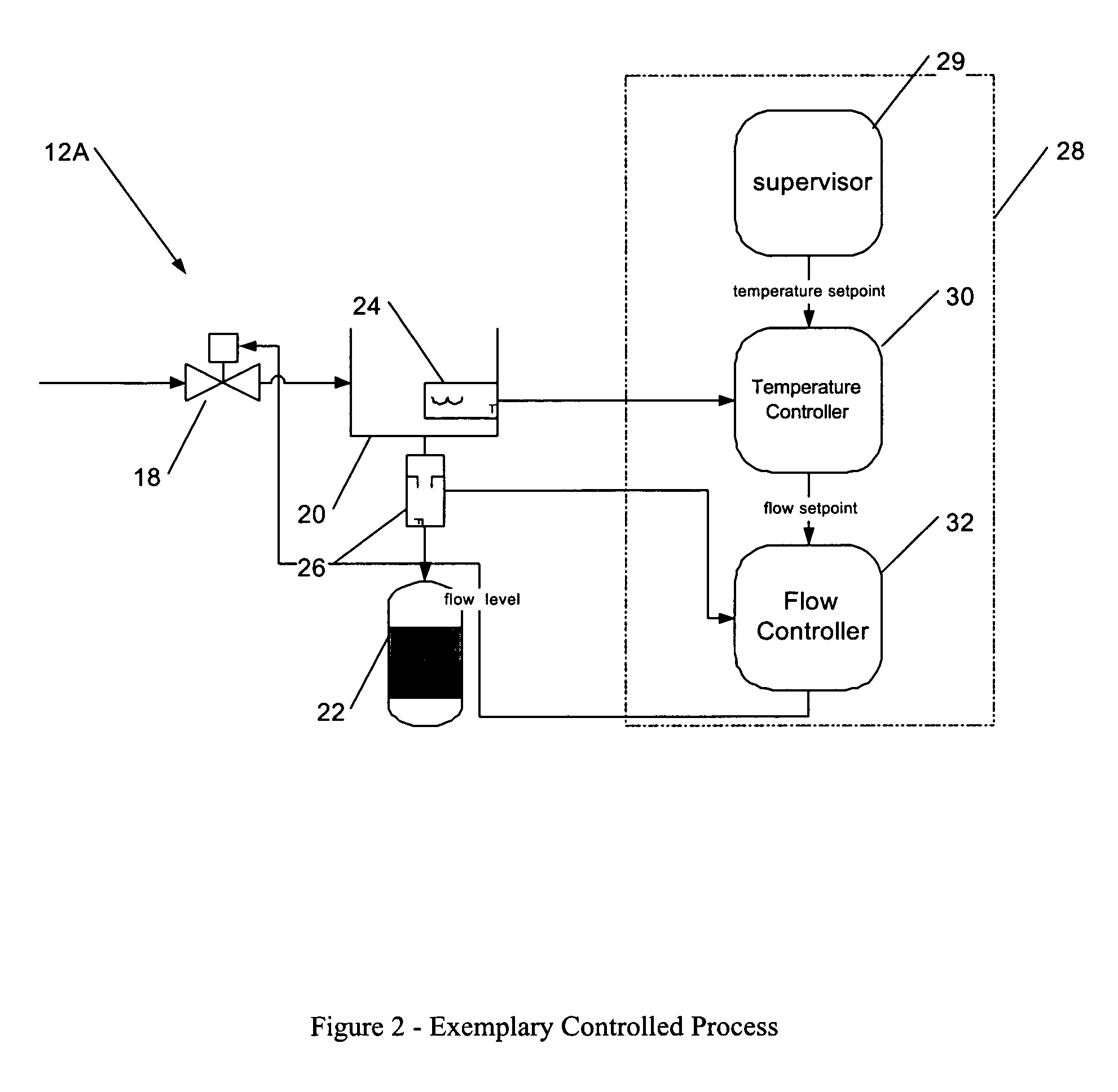

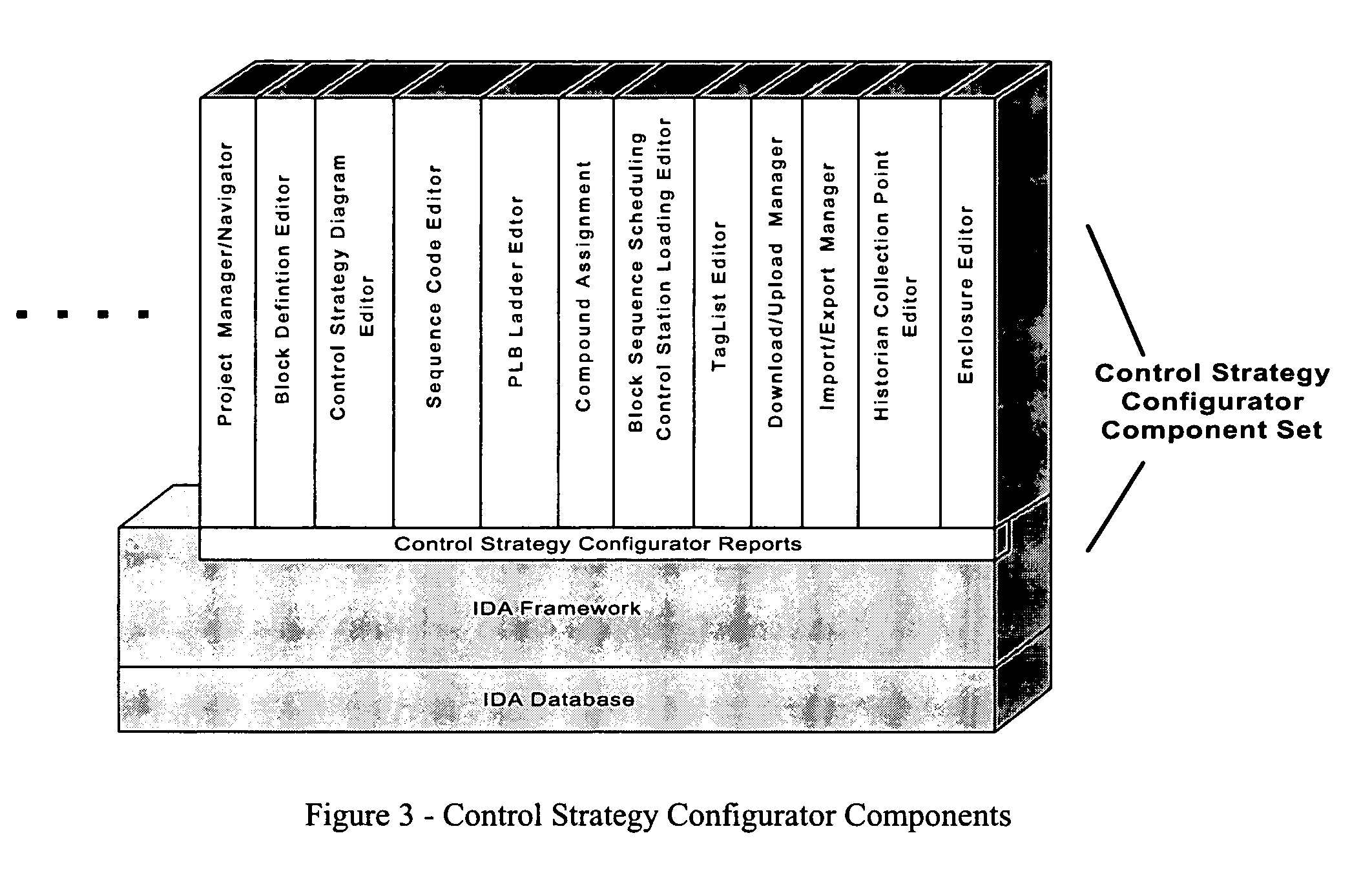

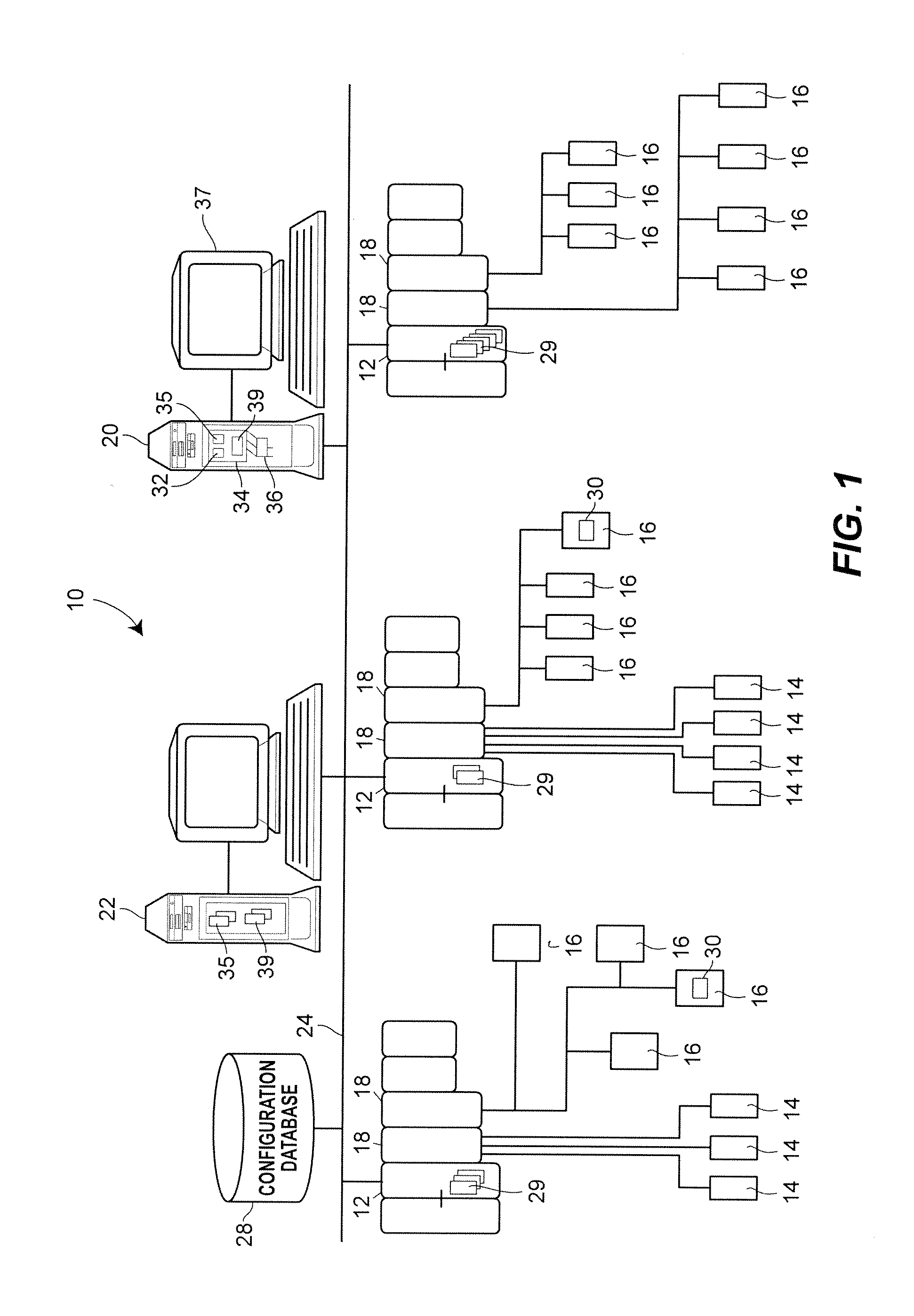

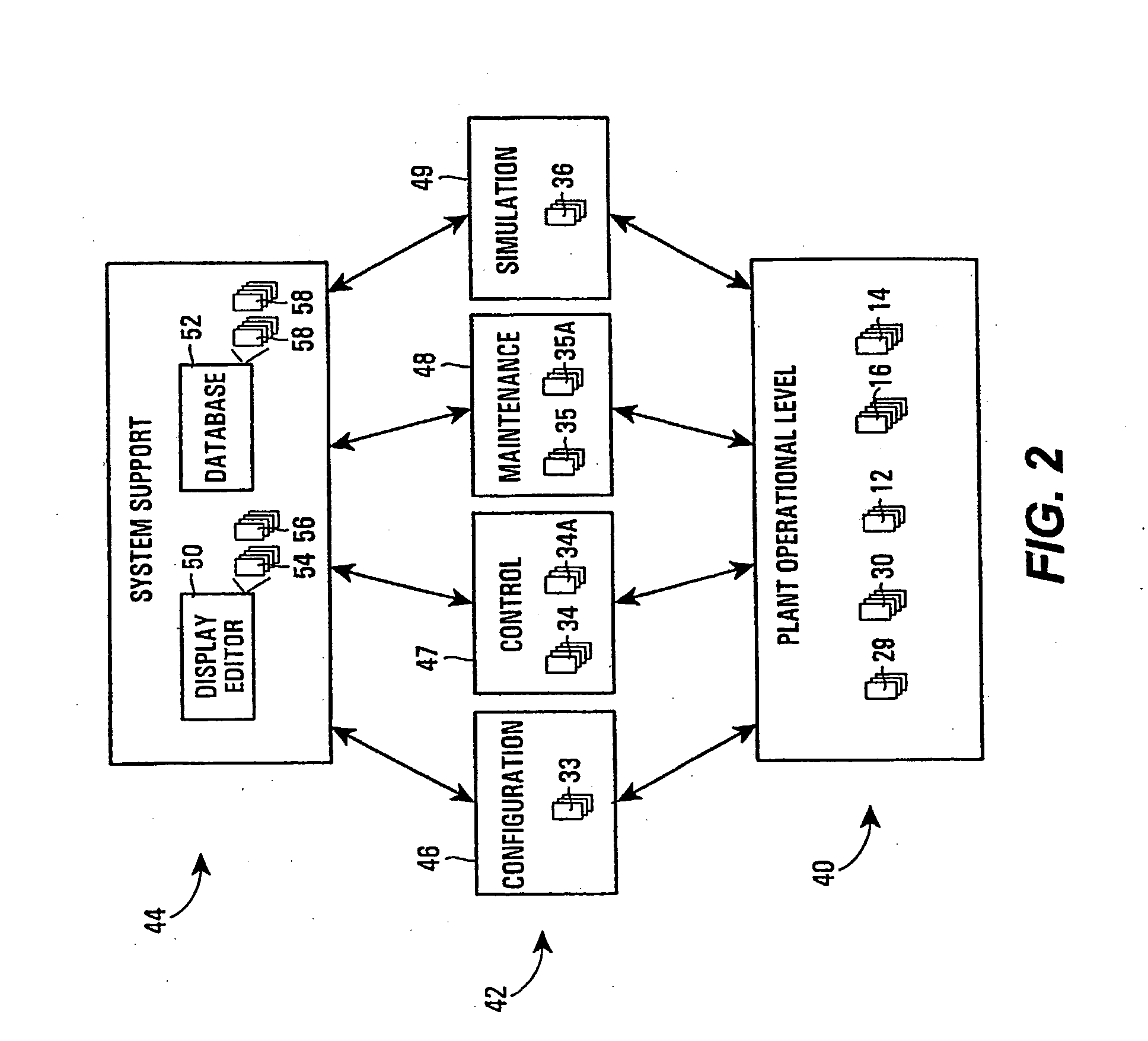

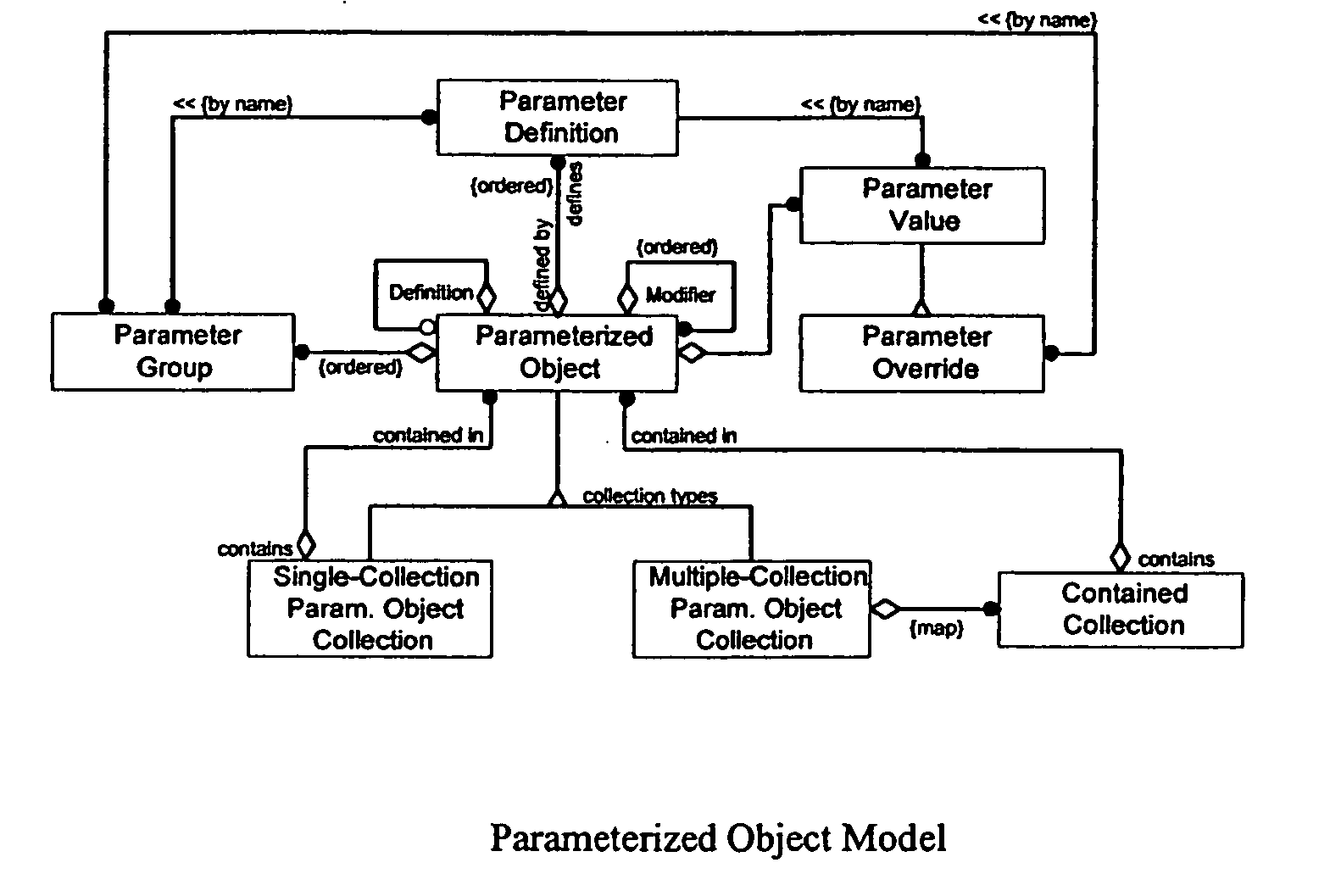

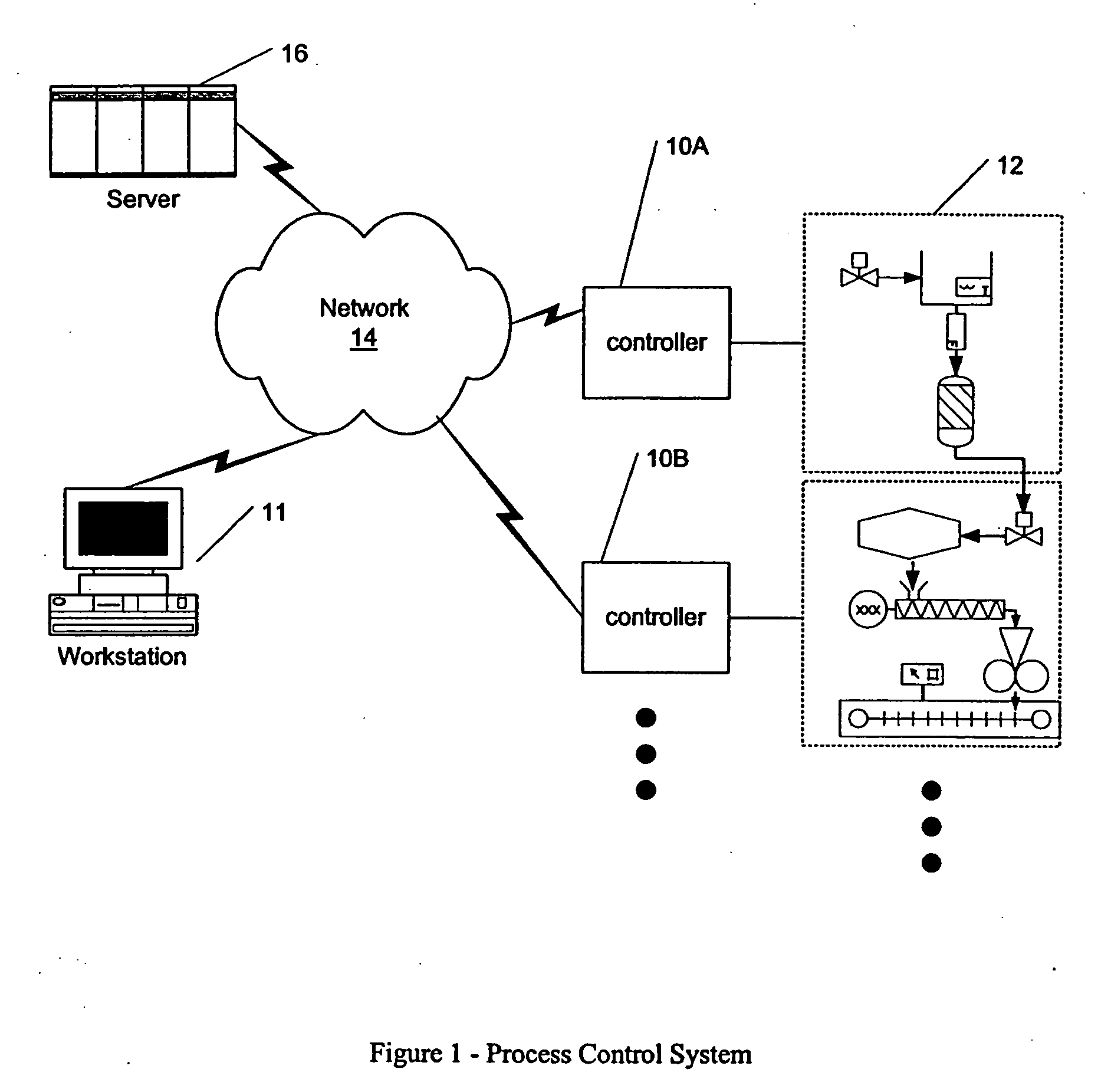

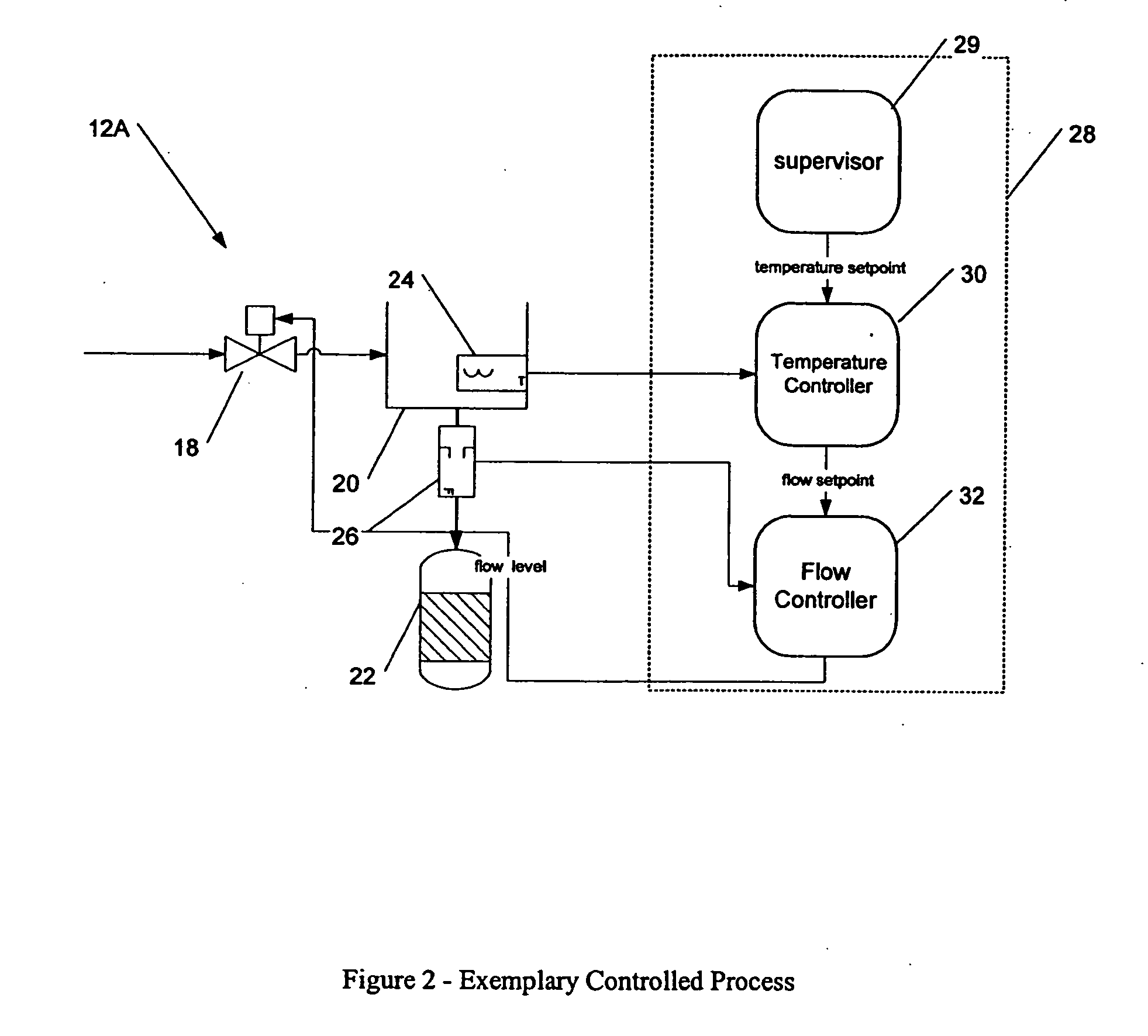

Process control configuration system with connection validation and configuration

Connection objects or other such data structures facilitate establishing and configuring connections between objects that model components in a process control system. A first set of data structures (e.g. the object connection type structures) identify valid types for component-to-component pairings and the respective roles of each component in the pairing (e.g., parent or child, source or sink). A second set of data structures (e.g., the parameter connection type structures) supply similar information for parameter-to-parameter connections. Together, these data structures can be used, for example, to validate component-to-component connections suggested by the user and to automatically configure parameter-to-parameter connections. Actual connections, both at the component or parameter level, are reflected using parameter overrides within the parameterized object model—with which the connection objects are constructed.

Owner:SCHNEIDER ELECTRIC SYST USA INC

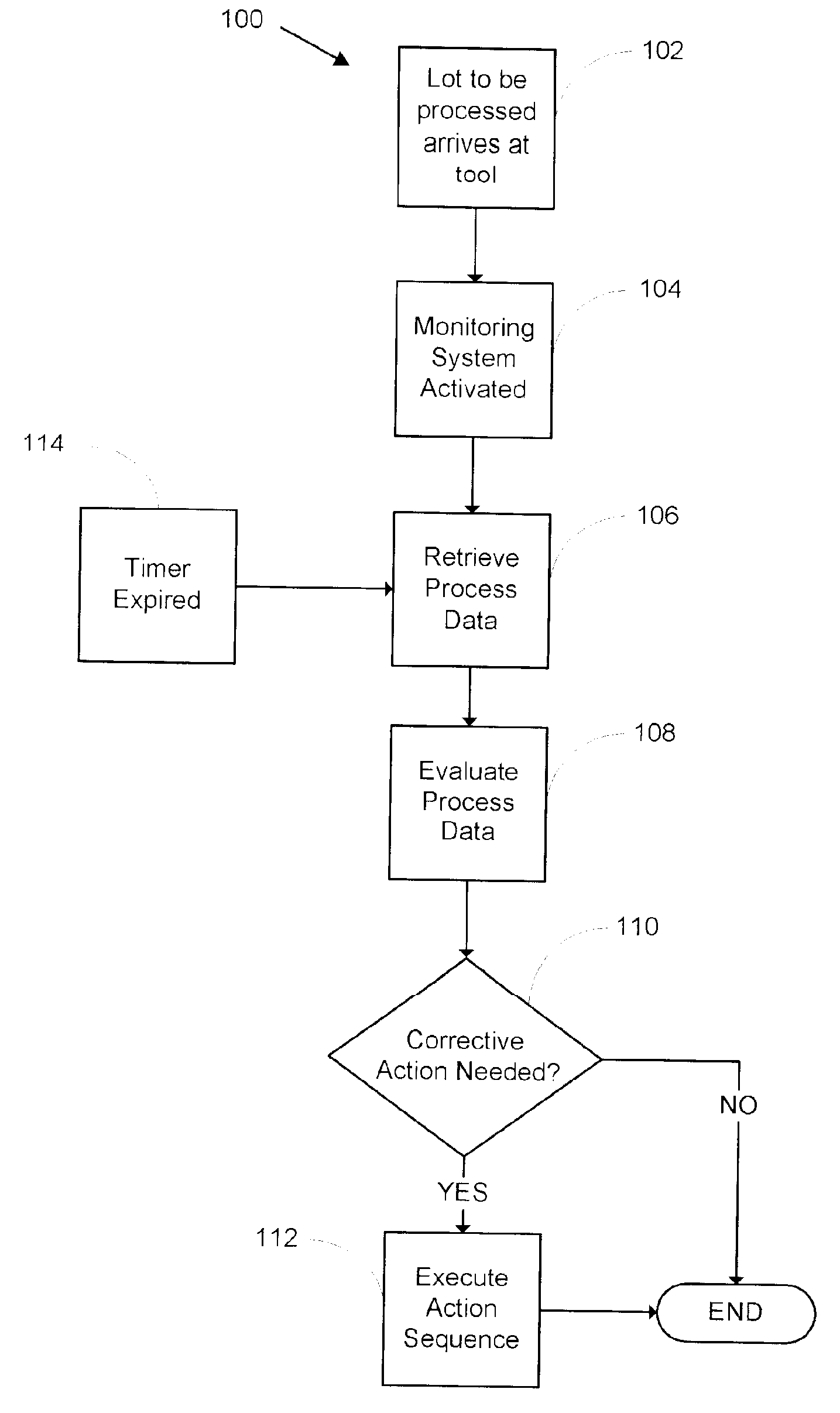

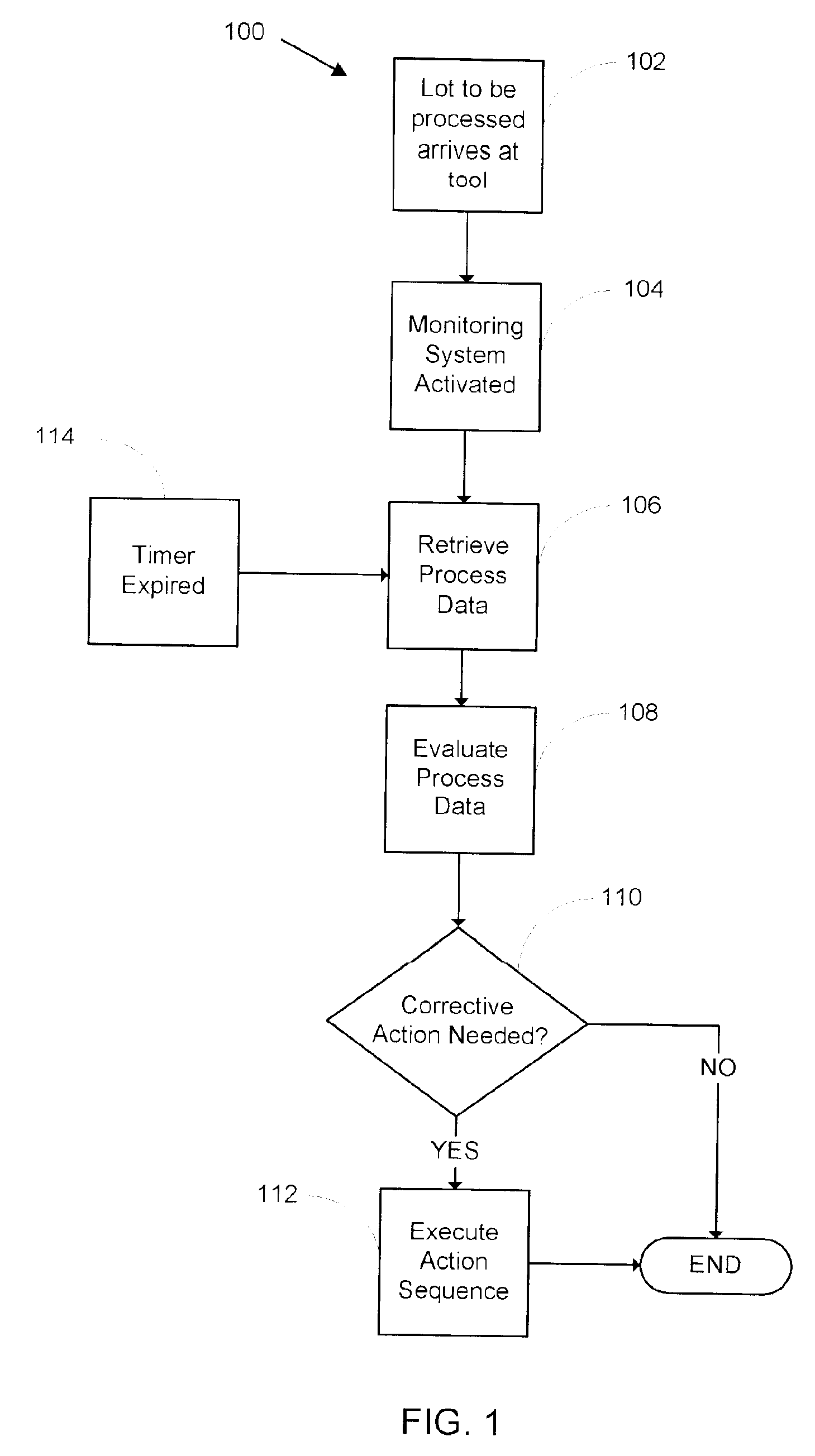

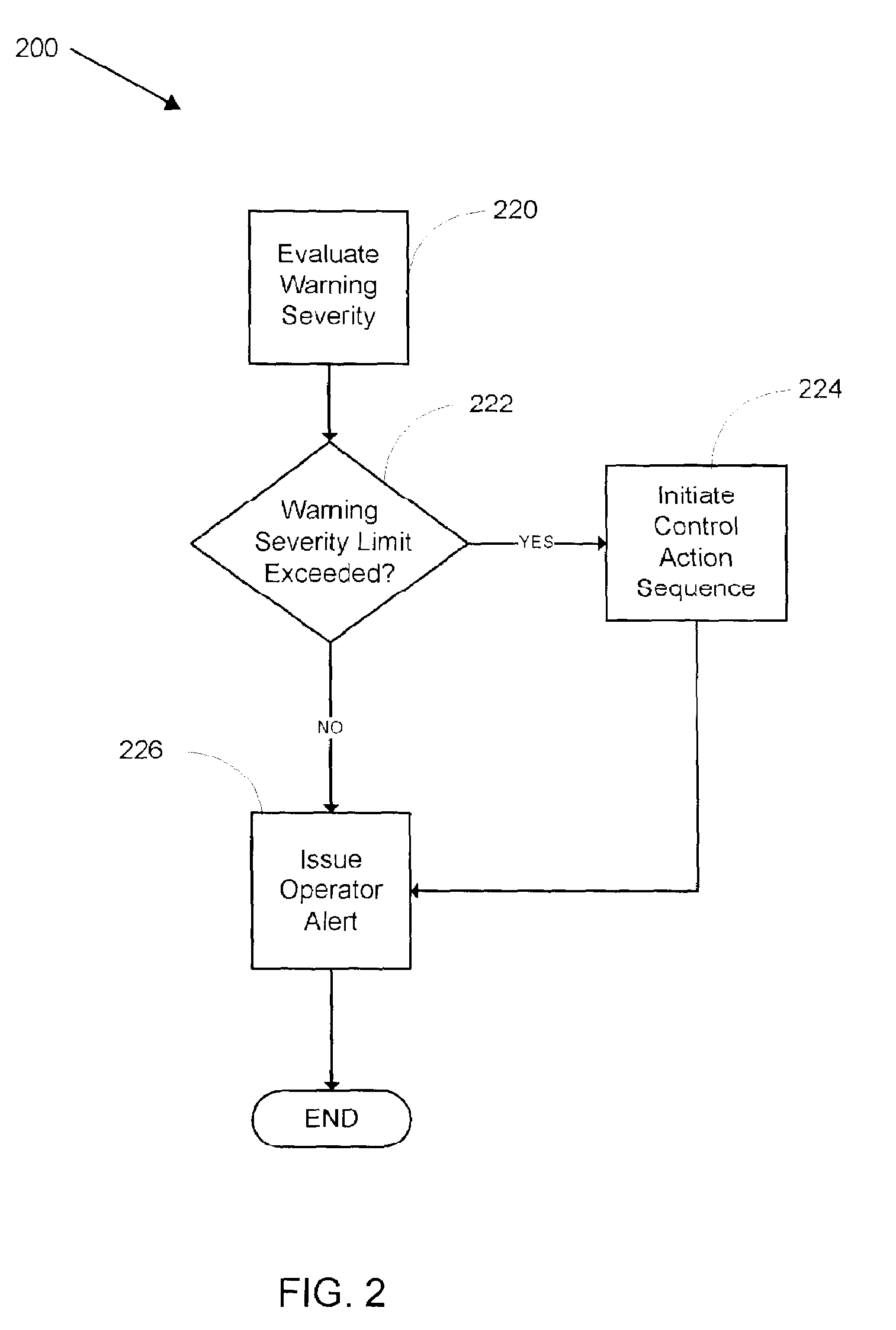

Semiconductor manufacturing process monitoring

A system and method for monitoring a semiconductor manufacturing process is disclosed. The system communicates with one or more process tools, and monitors each tool during a predetermined process window time. Errors and warnings are provided to users, allowing corrective action to be taken. Additionally, the system of the present invention can initiate automatic adjustment of the process tools to maintain an efficient manufacturing operation.

Owner:GLOBALFOUNDRIES INC

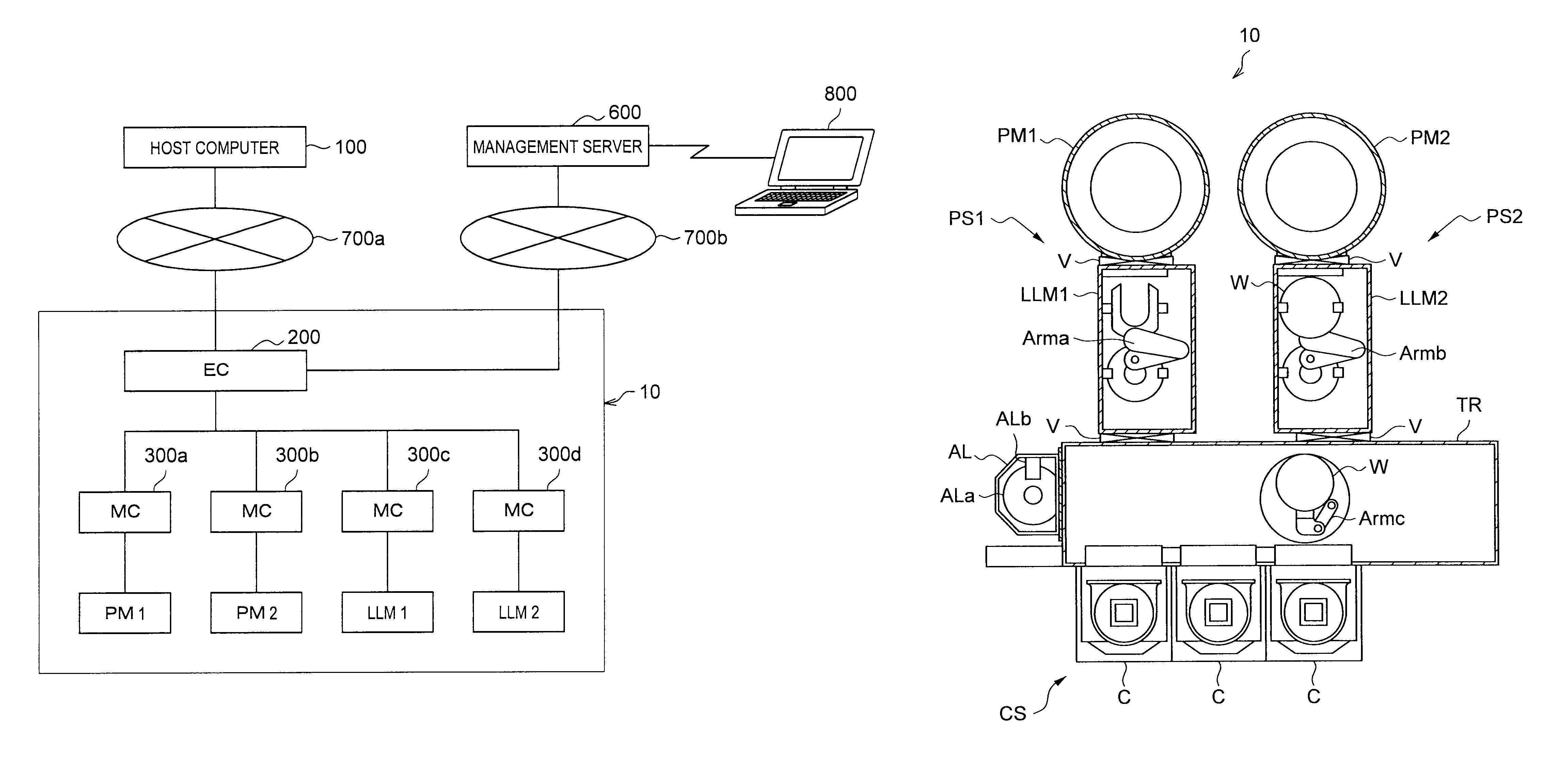

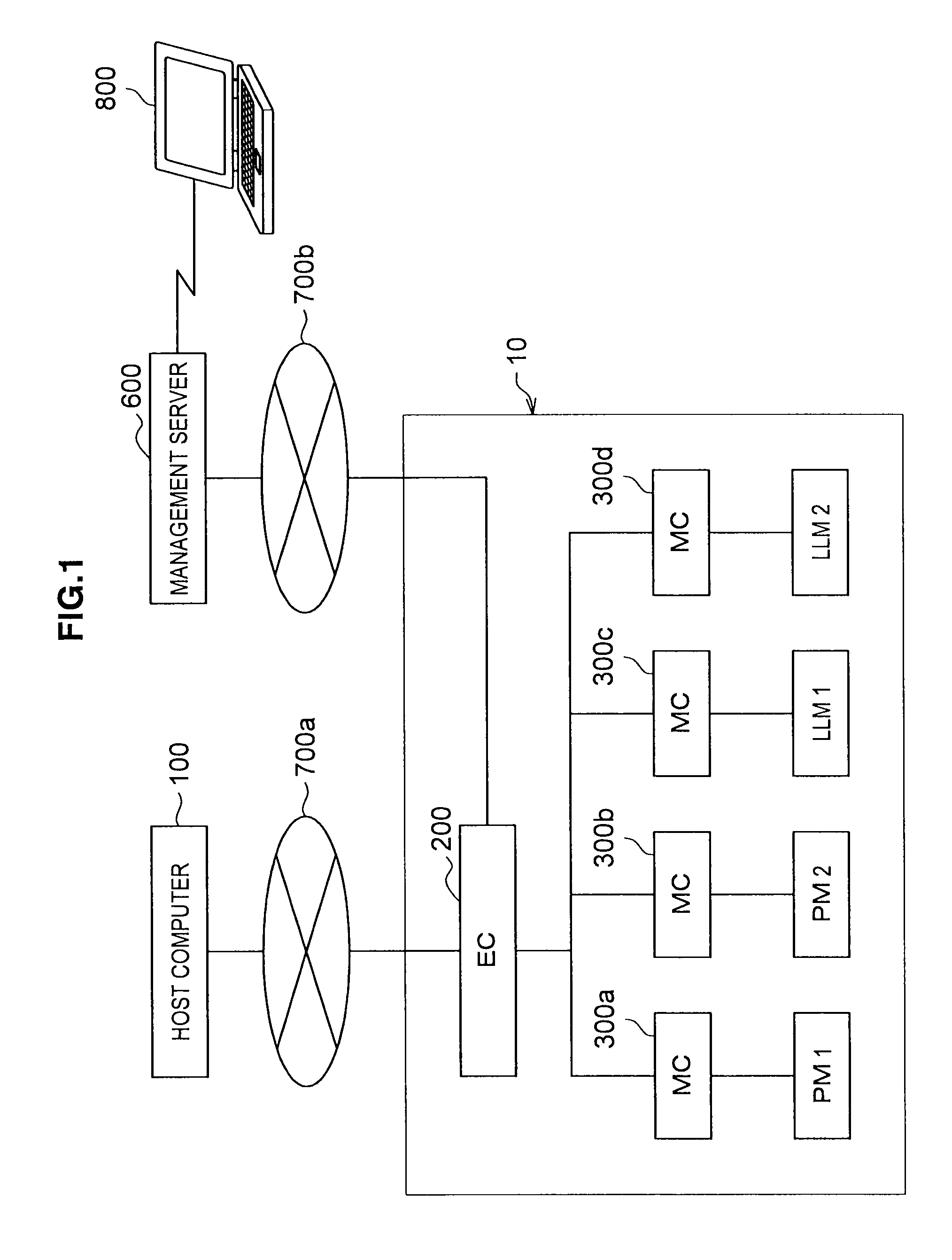

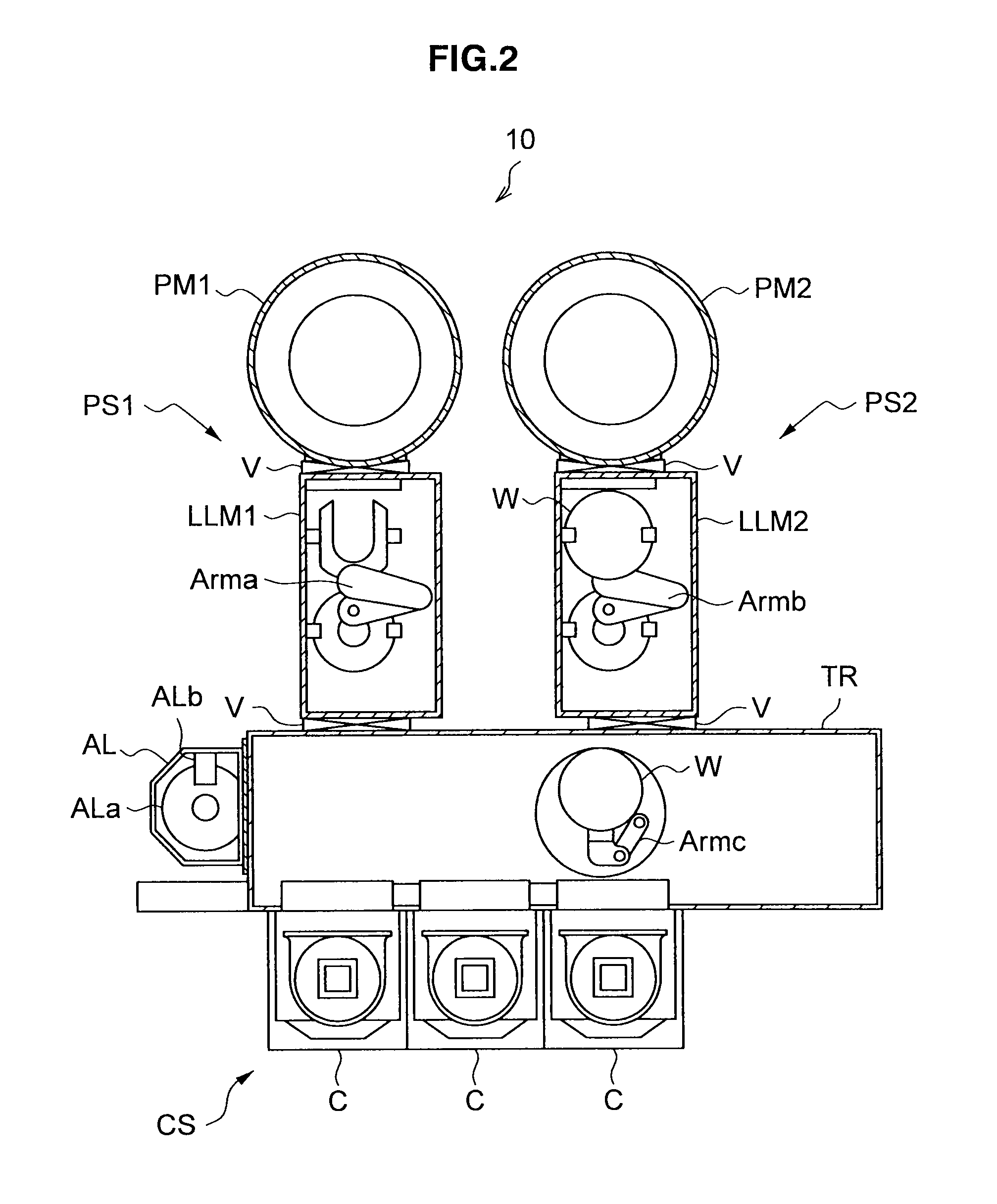

Device for controlling processing system, method for controlling processing system and computer-readable storage medium stored processing program

ActiveUS8055378B2Production of product can be suppressedIncrease productionProgramme controlDigital data processing detailsProcess moduleComputer module

A processing system includes process modules, load lock modules, an equipment controller, and a machine controller. The equipment controller controls transfer and processing of wafers in the processing system. A transfer destination determining portion determines the transfer destination of each wafer such that each wafer is sequentially transferred to a normally operating process module. When an abnormality occurs in a process module, an evacuation portion temporarily evacuates to a cassette stage the wafer determined is to be transferred to the abnormal process module and that has not yet been transferred to the abnormal process module. When a new transfer destination of the evacuated wafer is determined, if a process that is performed immediately before processing the evacuated wafer in the processing module as the new transfer destination satisfies a predetermined condition, a transfer inhibition portion inhibits the transfer of the evacuated wafer to the new transfer destination.

Owner:TOKYO ELECTRON LTD

Dynamic User Interface for Configuring and Managing a Process Control System

ActiveUS20120029661A1Reduce the number of timesImprove convenienceElectric controllersIgnition automatic controlControl systemComputerized system

A process control management method in a computer system for configuring and supervising a process plant includes providing an interactive user interface to manage a plurality of objects in the process plant, where each of the plurality of objects corresponds to a physical or logical entity in the process plant, including generating a navigation pane to display a set of selectable items, each in the set of selectable items corresponding to a respective one of the plurality of objects, and generating a command pane to display a set of selectable controls, each in the set of selectable controls corresponding to a task to be performed on at least one of the plurality of objects in the process plant; receiving a selection of one of an item in the set of selectable items via the navigation panel and a control in the set of selectable controls via the command panel; determining an operational context based on the received selection, wherein the operational context corresponds to one of a range of actions applicable to the selection if the selection is an item selection, or a range of items to which the selection is applicable if the selection is a control selection; and adjusting one of the navigation pane or the command pane according to the operational context, including displaying a subset of selectable items in the navigational pane, wherein each in the subset of selectable items is within the range applicable to the selection, if the selection is a control selection, and displaying a subset of selectable controls in the command pane, wherein each in the subset of selectable controls is within the range applicable to the selection, if the selection is an item selection.

Owner:FISHER-ROSEMOUNT SYST INC

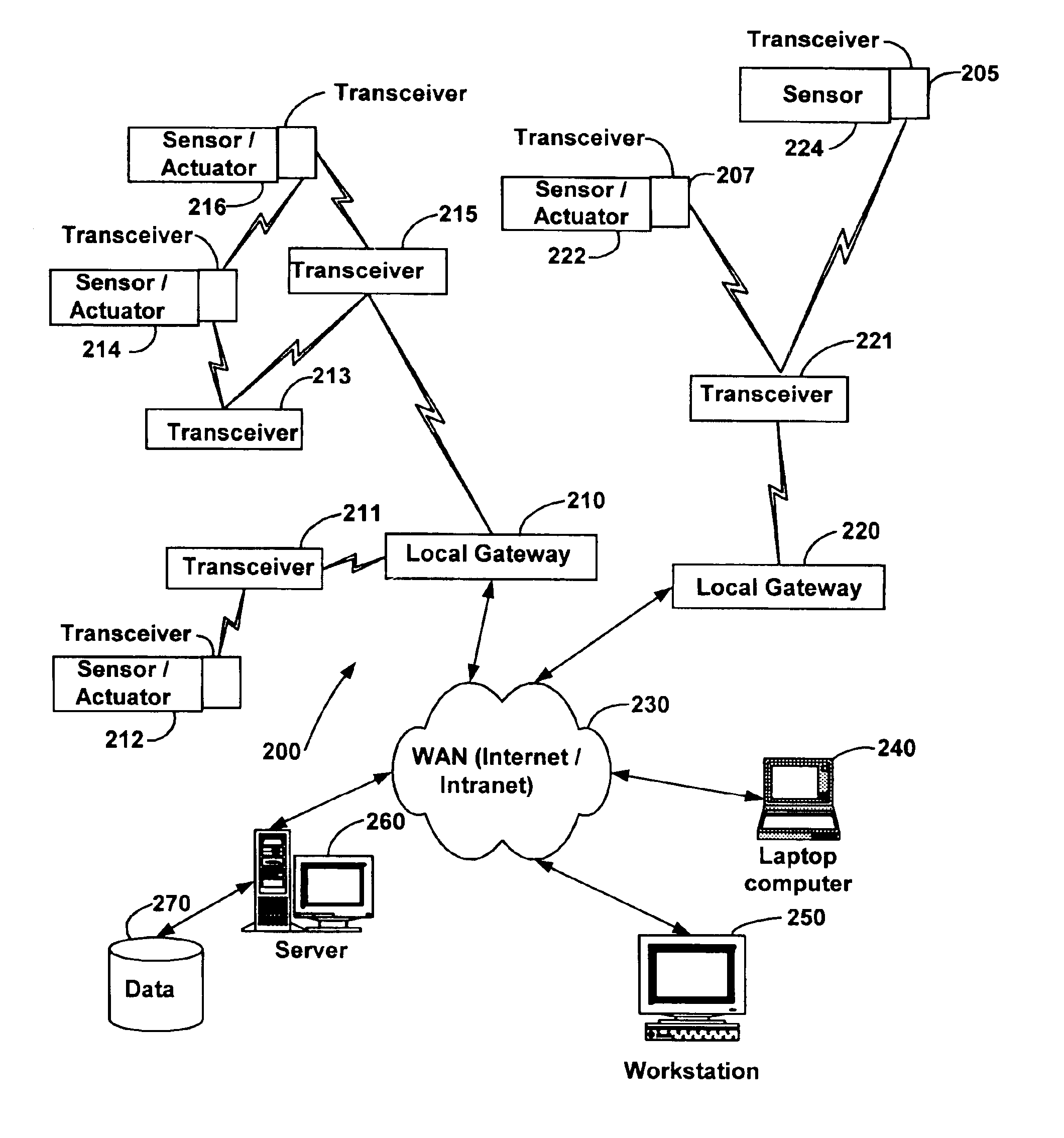

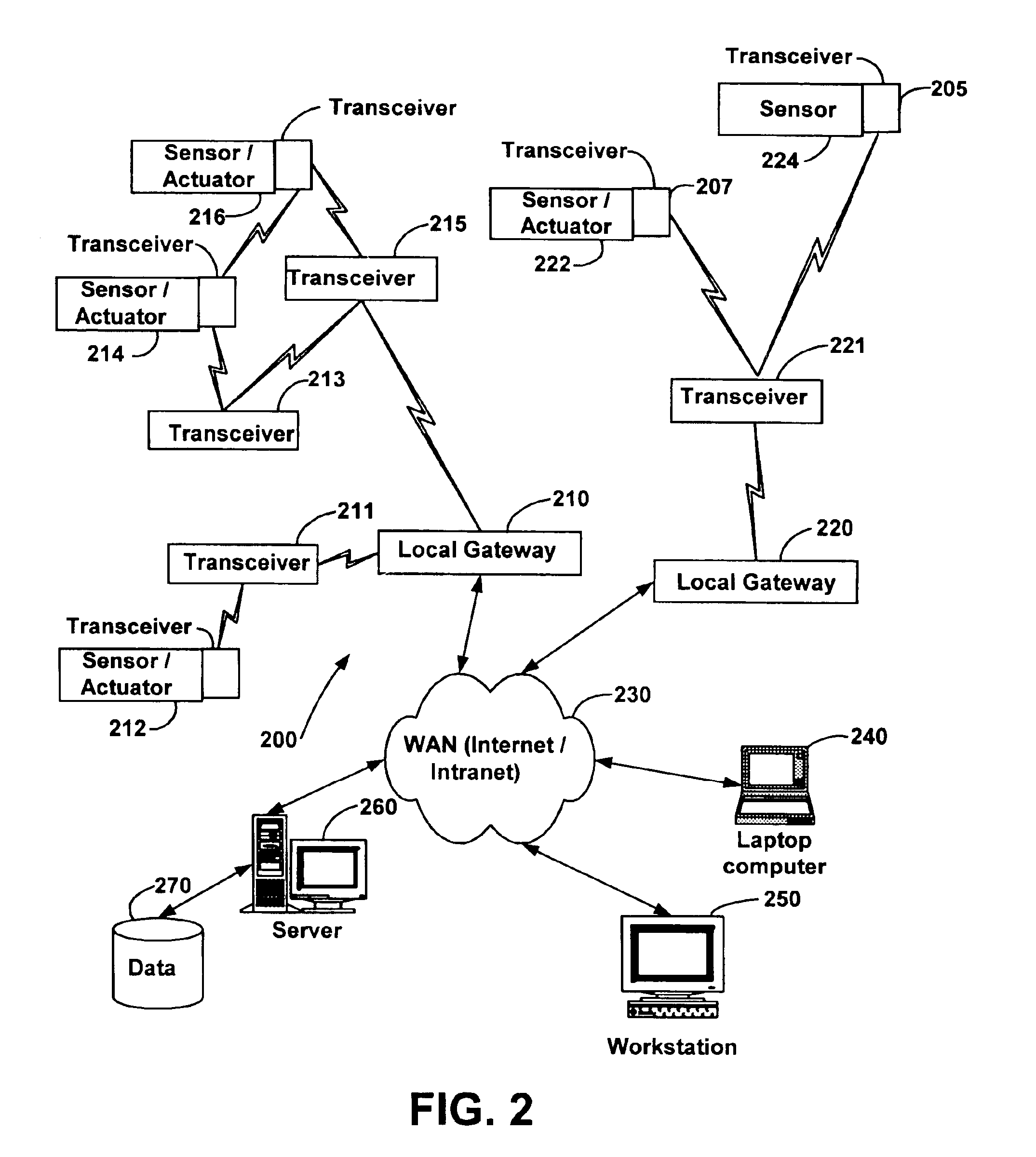

System and method for monitoring and controlling remote devices

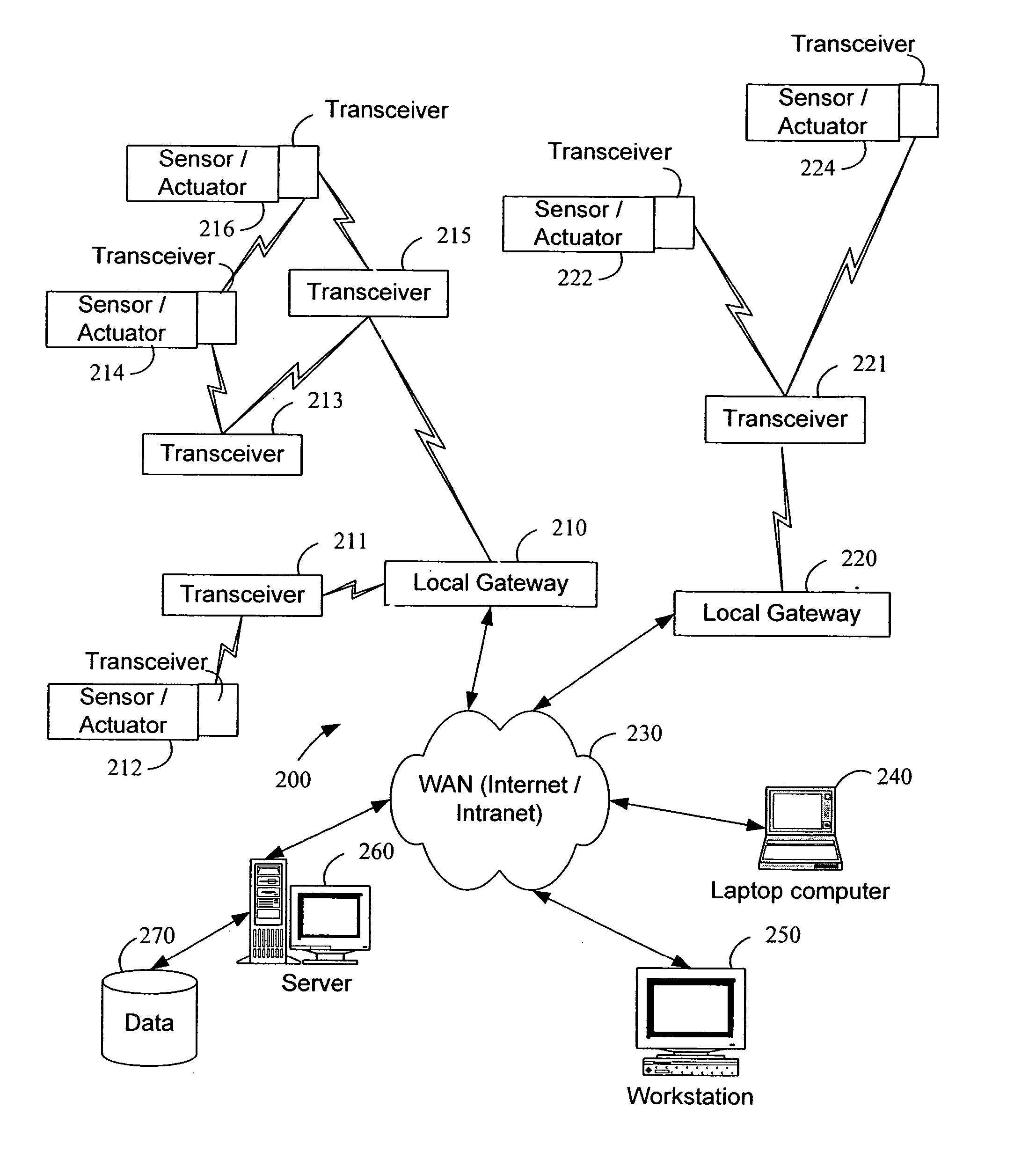

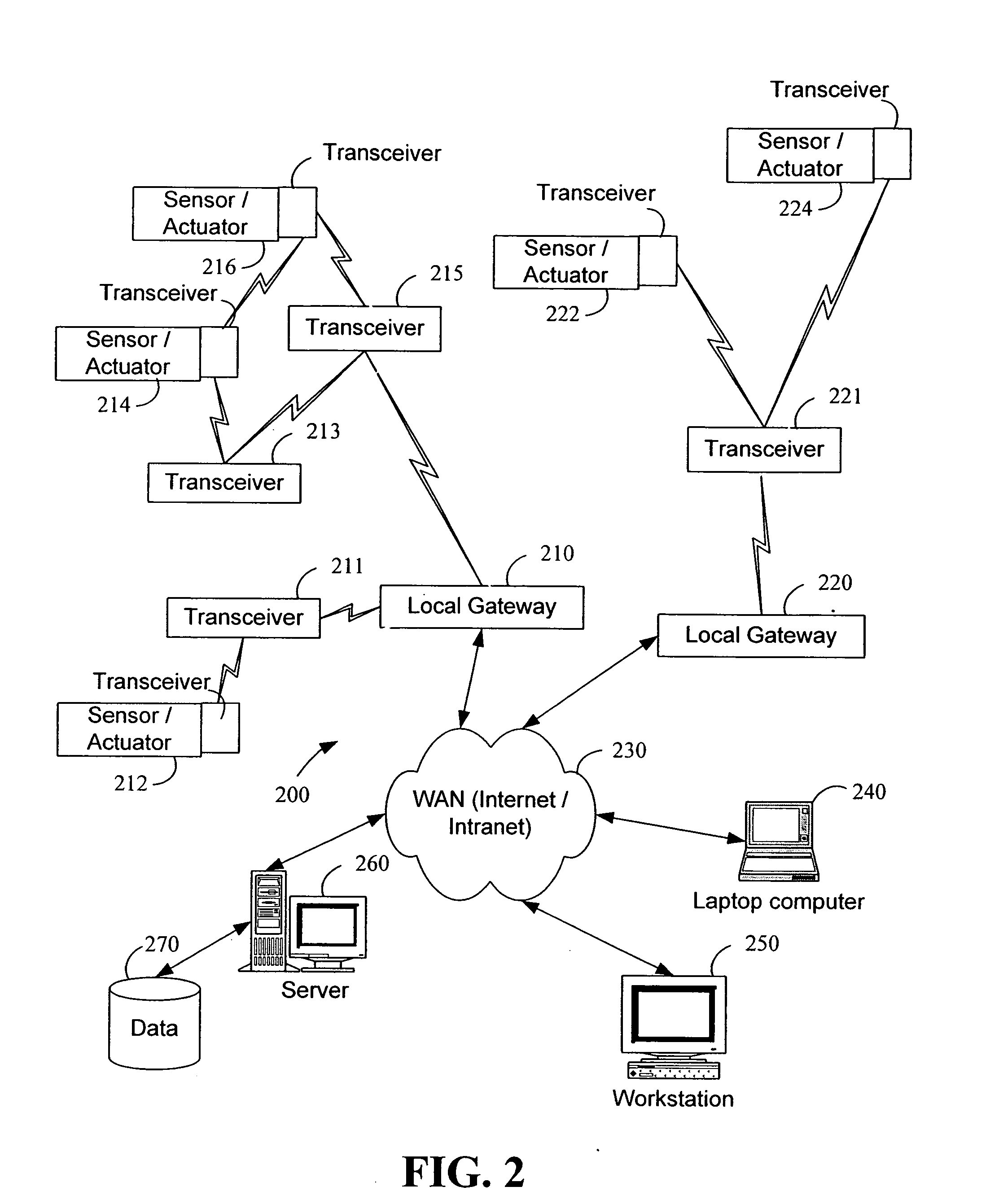

InactiveUS20060181406A1Closed feedback loopIntegrated inexpensivelyFrequency-division multiplex detailsRegistering/indicating working of vehiclesTransceiverControl signal

The present invention is generally directed to a system for monitoring a variety of environmental and / or other conditions within a defined remotely located region. In accordance with one aspect of the invention, a system is configured to monitor utility meters in a defined area. The system is implemented by using a plurality of wireless transmitters, wherein each wireless transmitter is integrated into a sensor adapted to monitor a particular data input. The system also includes a plurality of transceivers that are dispersed throughout the region at defined locations. The system uses a local gateway to translate and transfer information from the transmitters to a dedicated computer on a network. The dedicated computer, collects, compiles, and stores the data for retrieval upon client demand across the network. The computer further includes means for evaluating the received information and identifying an appropriate control signal, the system further including means for applying the control signal at a designated actuator.

Owner:SIPCO

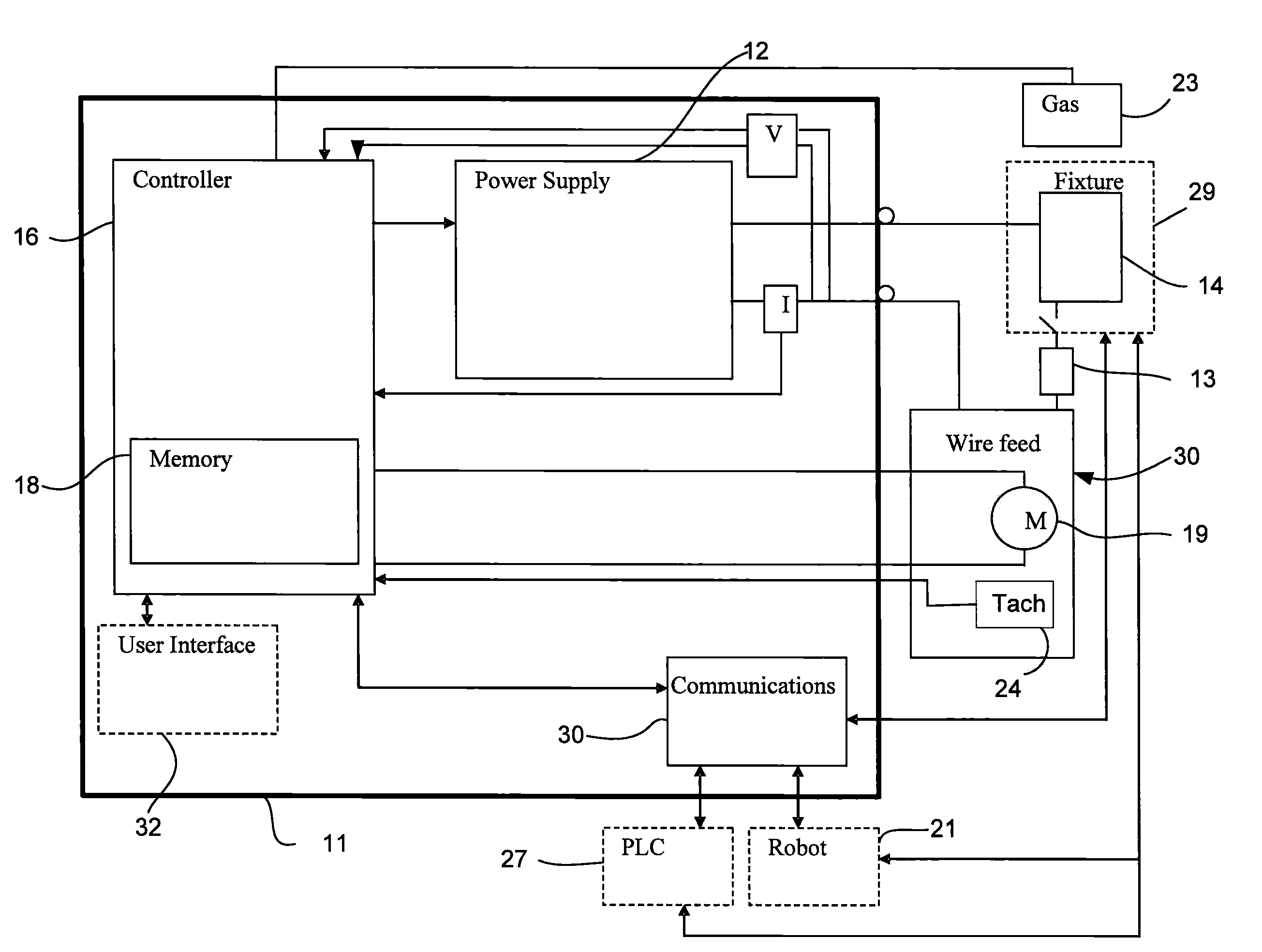

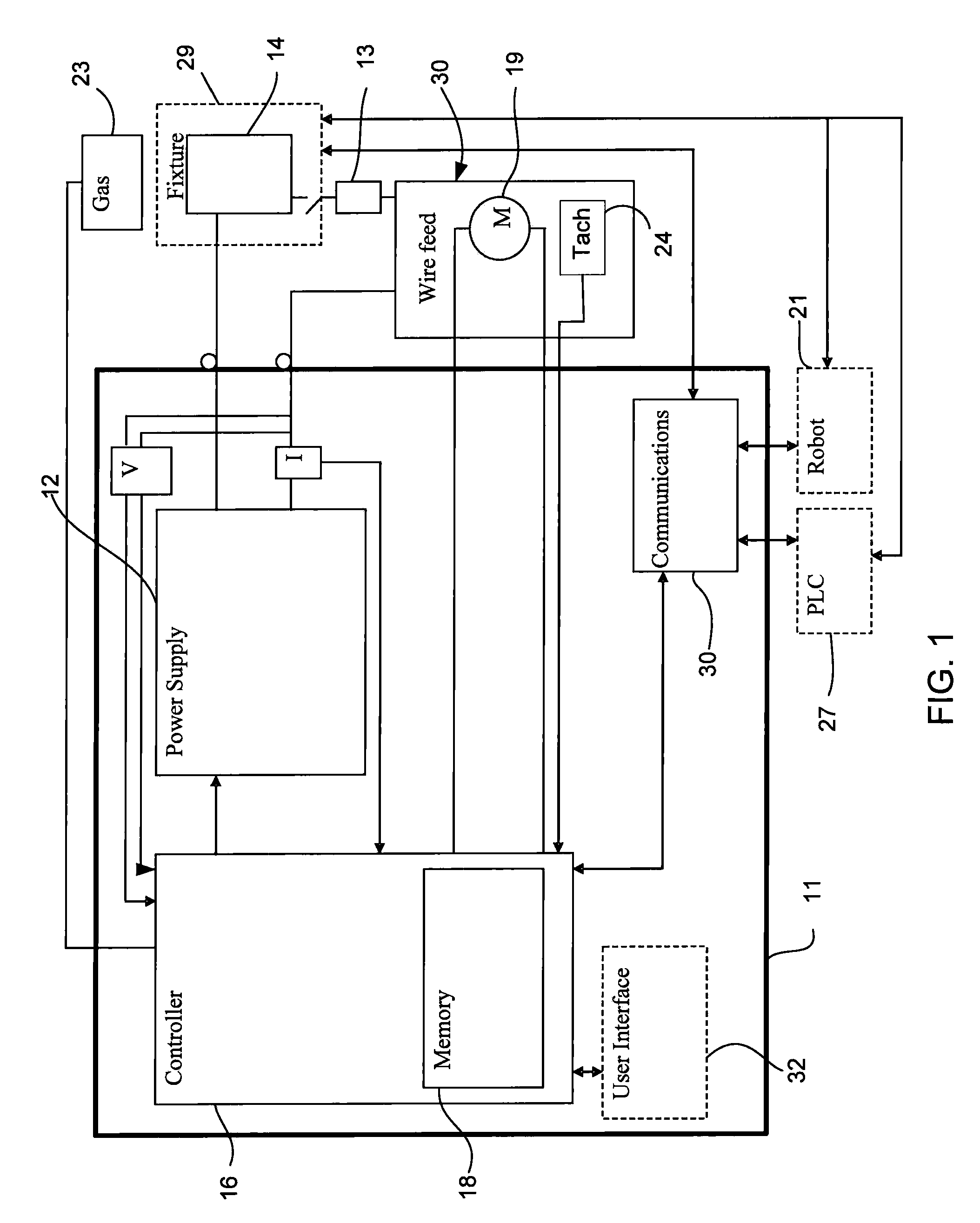

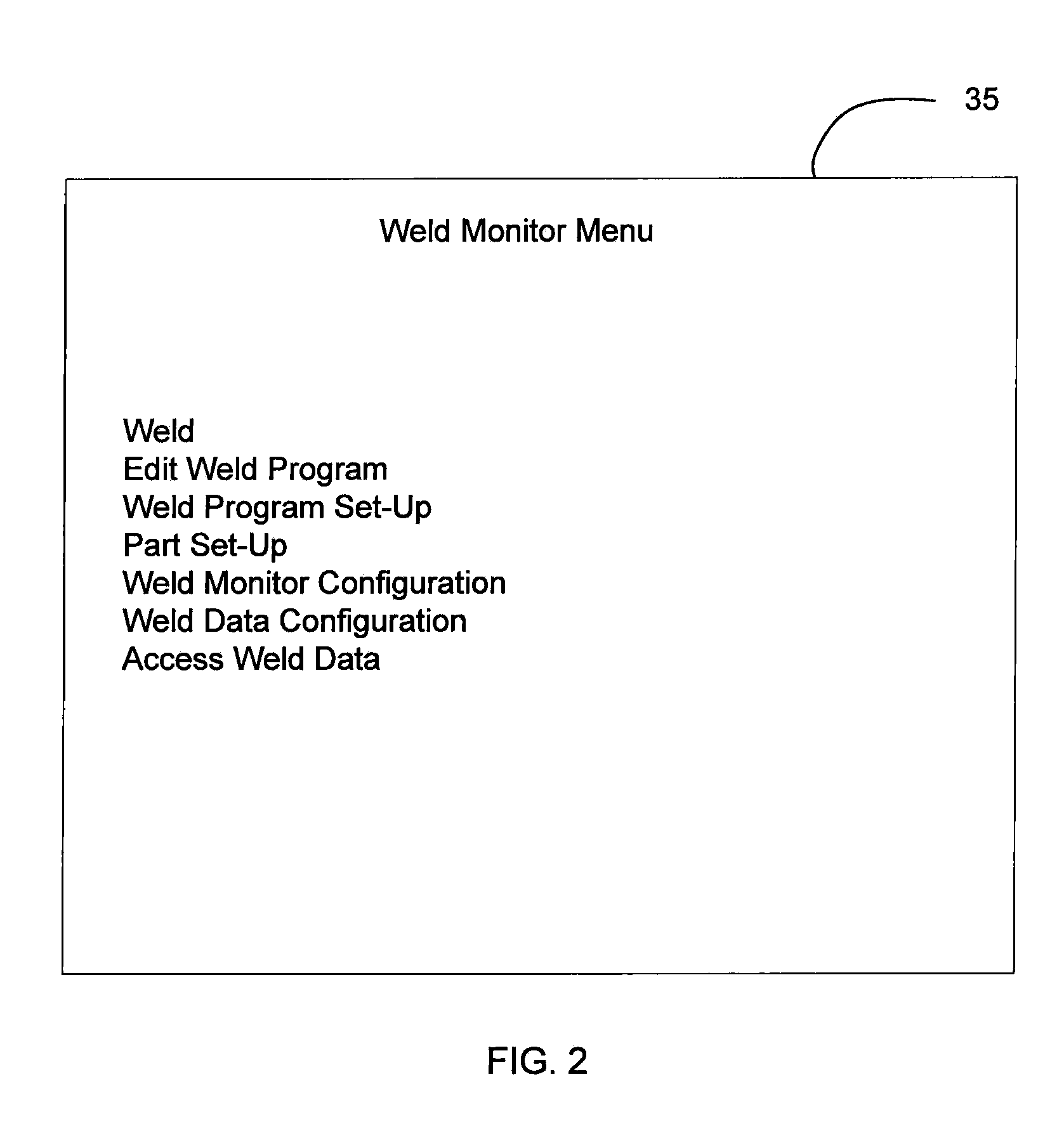

Automatic Weld Arc Monitoring System

A welding system including an arc monitoring, training, and control system is disclosed. The welding system includes a power supply, controller, and associated memory. When a weld is performed, the weld command and weld feedback parameters can be stored in the memory, along with associated alarm limit values. During subsequent welds, the input weld commands and actual feedback values can be compared to the established limits, and a fault signal provided to an operator or supervisor when the value exceeds the established limits. The fault signals can be used for training operators, as well as providing monitoring signals, and can be stored with weld data in a database for later analysis. In addition, collected weld data can be used to determine when to clean, repair, or replace consumables, including, for example, contact tips, wire drive liners, and drive rolls, and to monitor usage of wire and gas.

Owner:ILLINOIS TOOL WORKS INC

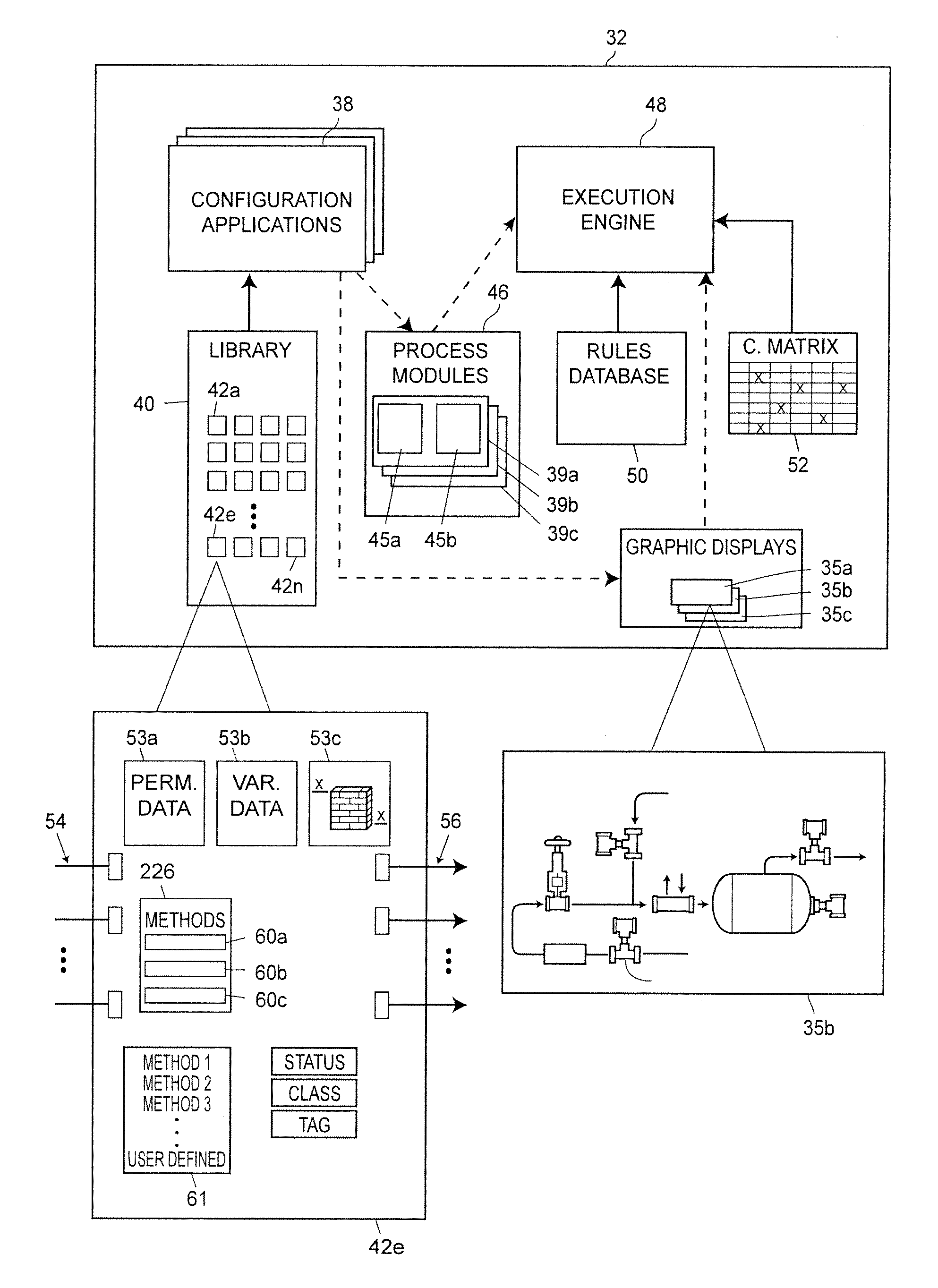

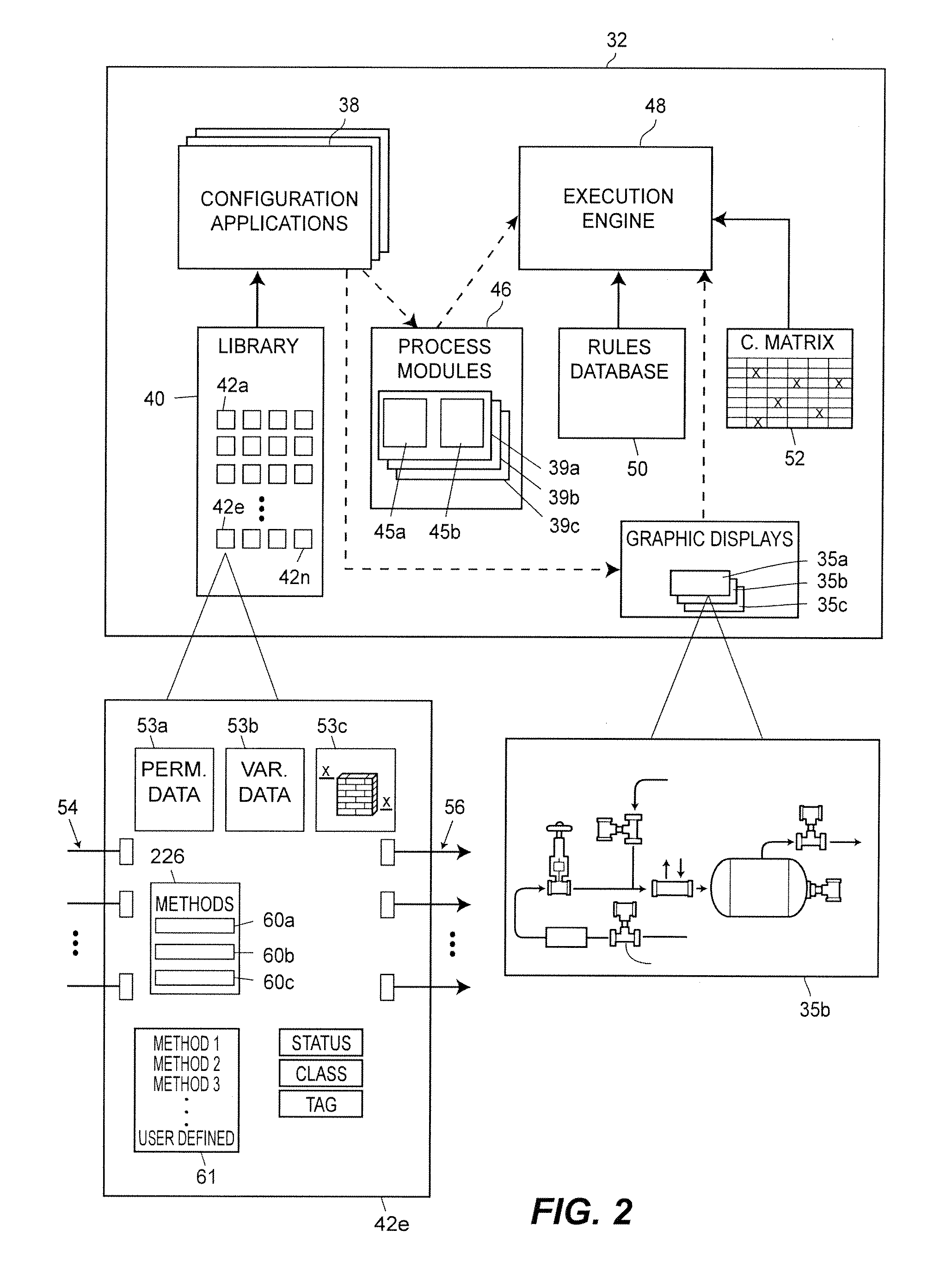

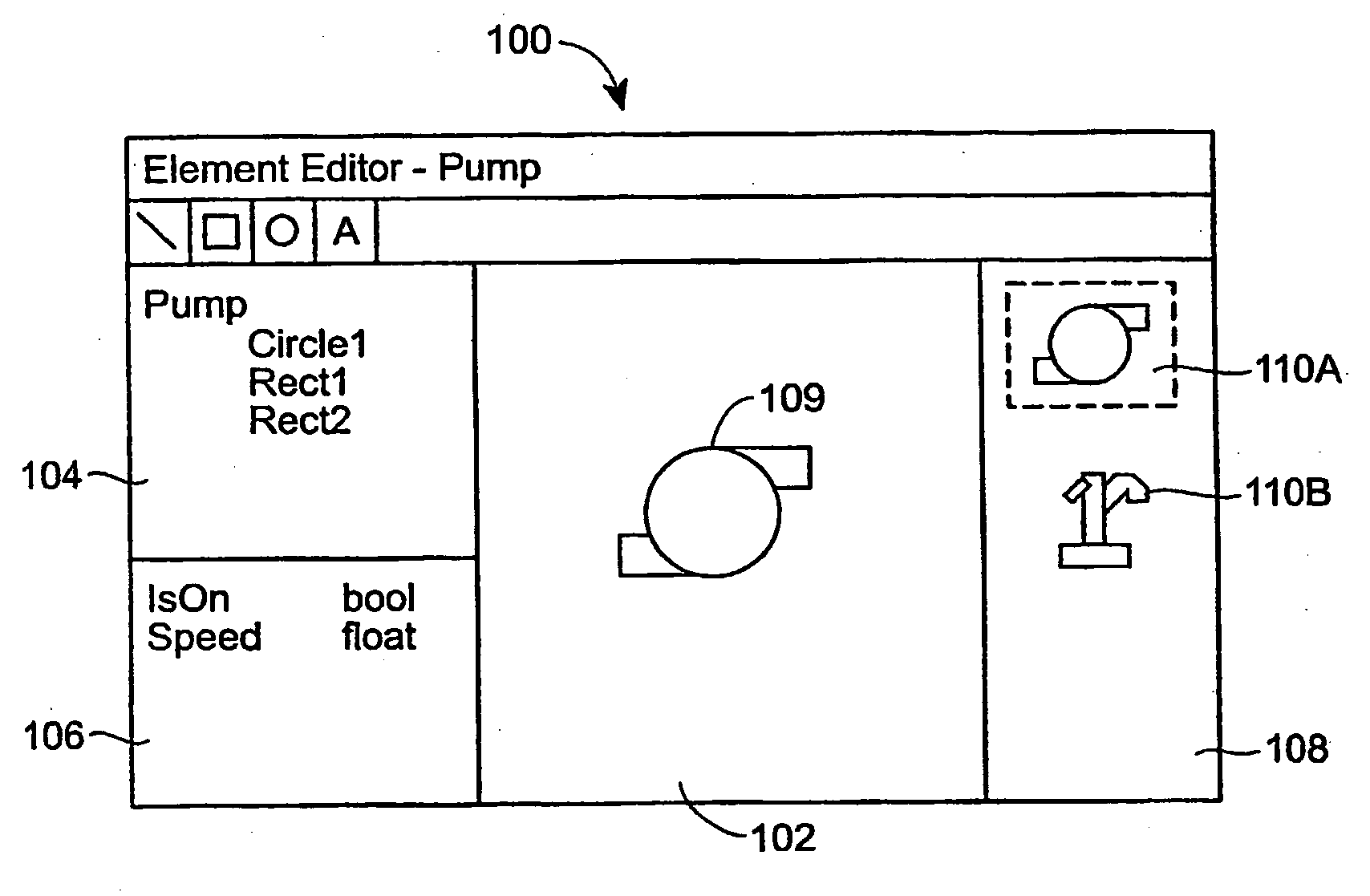

Graphic element with multiple visualizations in a process environment

ActiveUS20070132779A1Graphic element more versatileTechnology managementProgram controlGraphicsDisplay design

Smart graphic elements are provided for use as portions or components of one or more graphic displays, which may be executed in a process plant to display information to users about the process plant environment, such as the current state of devices within the process plant. Each of the graphic elements is an executable object that includes a property or a variable that may be bound to an associated process entity, like a field device, and that includes multiple visualizations, each of which may be used to graphically depict the associated process entity on a user interface when the graphic element is executed as part of the graphic display. Any of the graphic element visualizations may be used in any particular graphic display and the same graphic display may use different ones of the visualizations at different times. The different visualizations associated with a graphic element make the graphic element more versatile, at they allow the same graphic element to be used in different displays using different graphical styles or norms. These visualizations also enable the same graphic element to be used in displays designed for different types of display devices, such as display devices having large display screens, standard computer screens and very small display screens, such as PDA and telephone display screens.

Owner:FISHER-ROSEMOUNT SYST INC

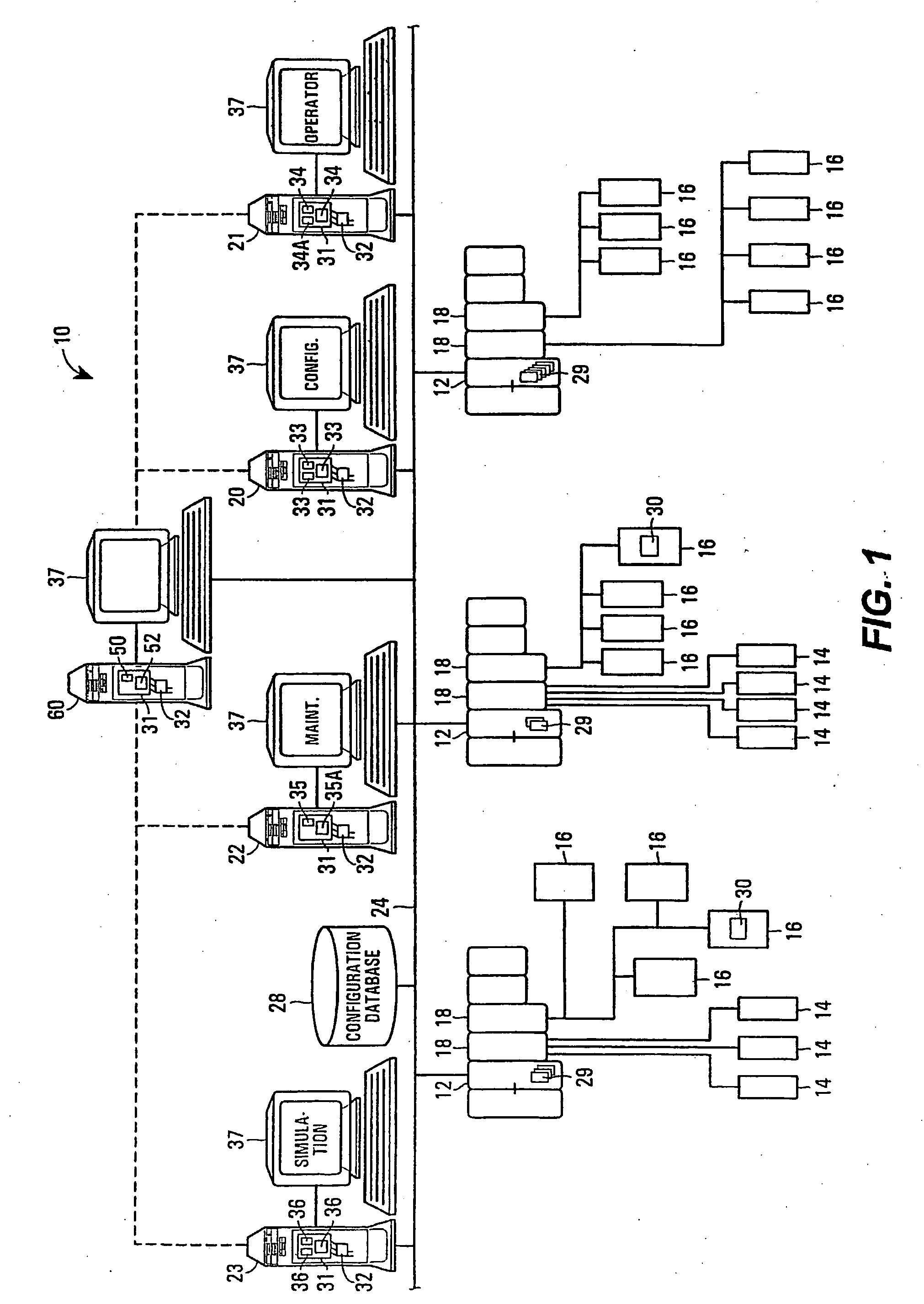

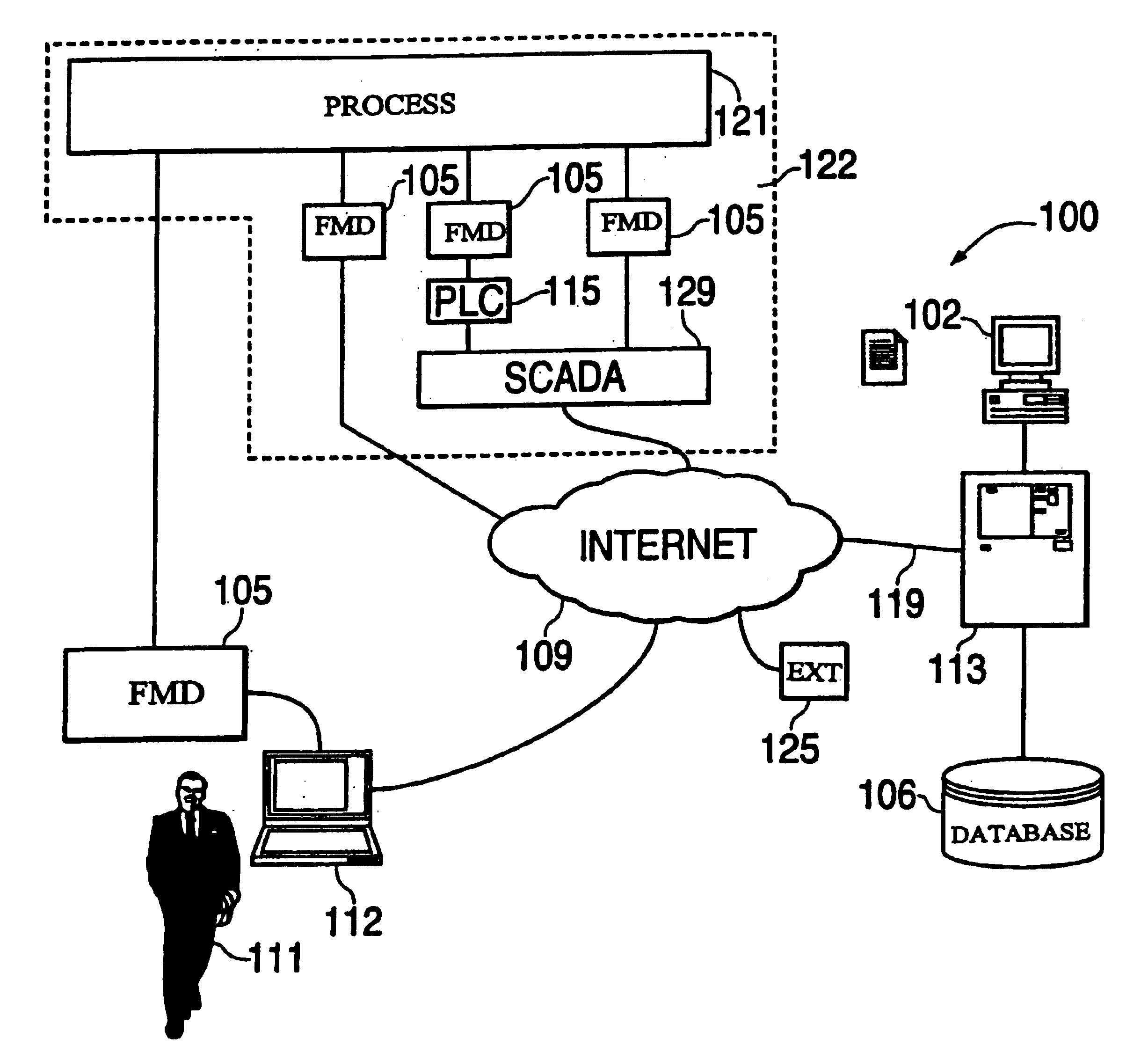

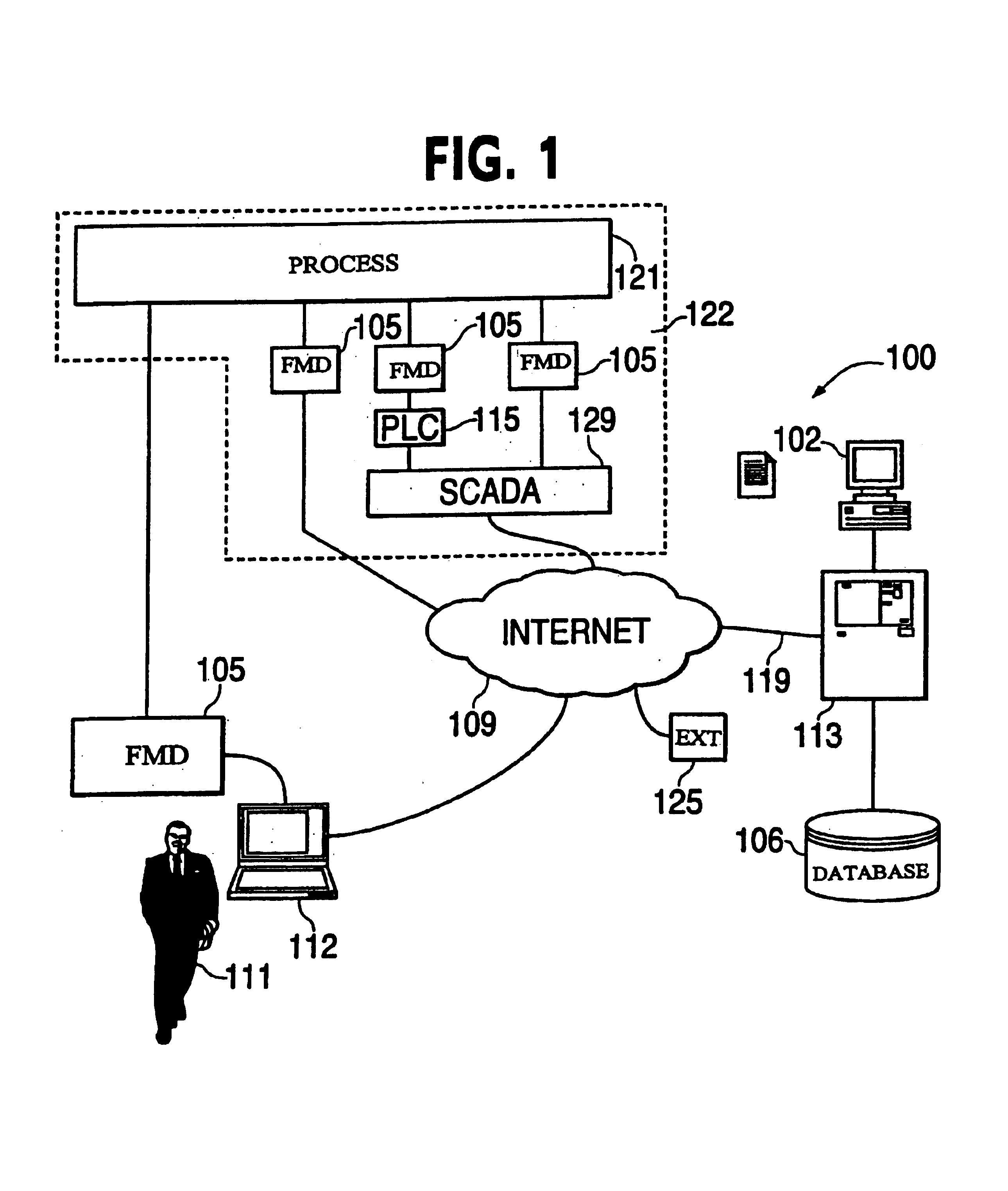

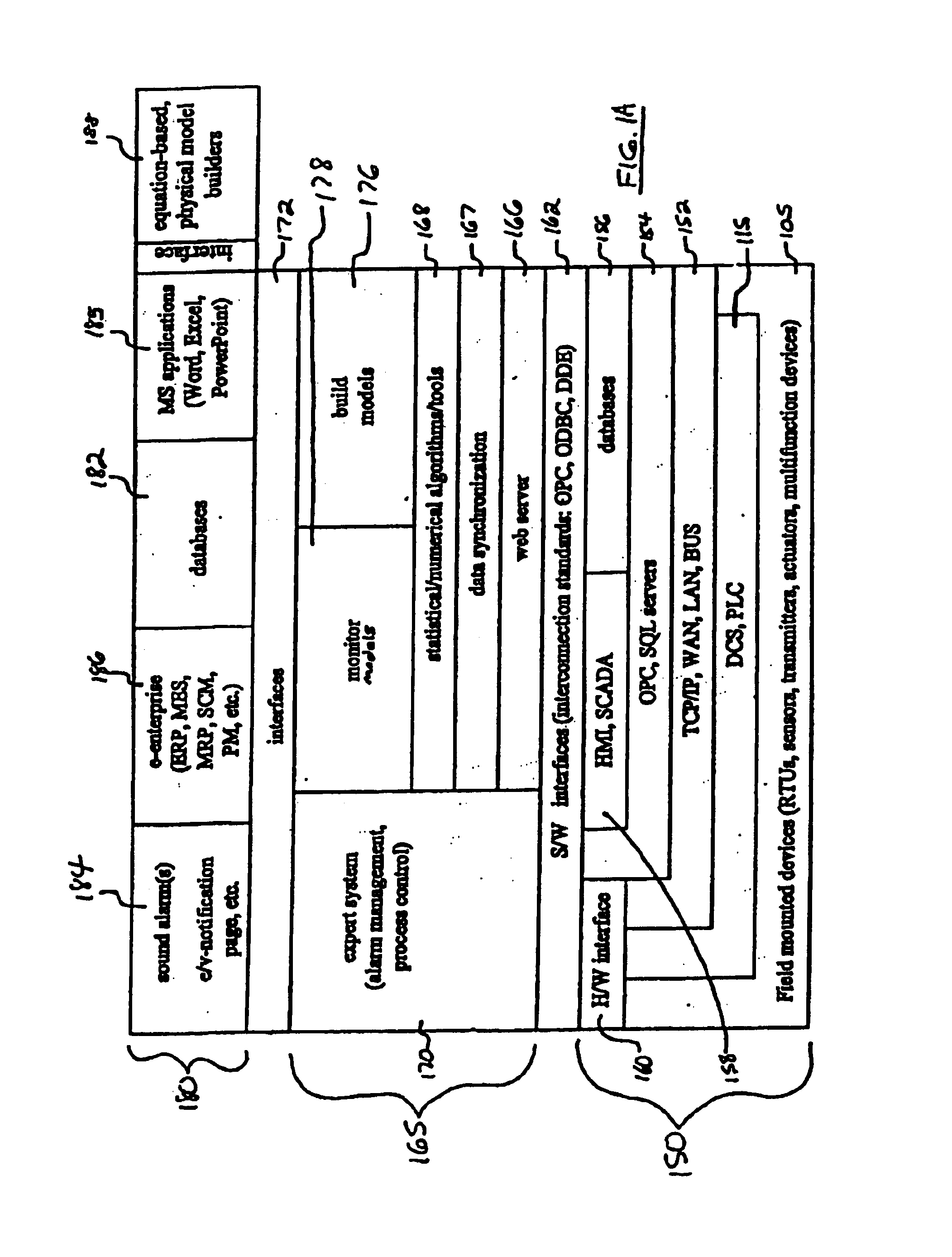

Method and apparatus for the creation of personalized supervisory and control data acquisition systems for the management and integration of real-time enterprise-wide applications and systems

A system and method provide for the creation and operation of real-time enterprise-wide, personalize supervisory and control data acquisition systems. Personalized SCADA applications are constructed from a virtual application service and a personal agent framework using simple drag and drop operations or other high level action. The virtual application service includes a communications gateway that communicates with disparate and non-interoperable systems and external field devices to communicate low level time data collected from such systems into the application environment transforming the collected data in a single common data format. The virtual application service includes application cells that receive the reformatted data and process it to provide high level analysis and context, storing the processed data in an object server. The object server provides a unified, hierarchical object model for all of the data received from the underlying devices and systems. The virtual application service communicates with personal agent frameworks containing presentation cells and service agents. The service agents are representative of the virtual application service, and provide the personal agent framework with access to the object server to receive and send data from the object server to the presentation cells. The presentation cells subscribe to the object server's data objects via the service agent. Presentation cell provide a graphical representation and mapping of data objects and hence underlying devices and systems, to allow a user to manage and control such systems.

Owner:EUTECH CYBERNETICS PTE

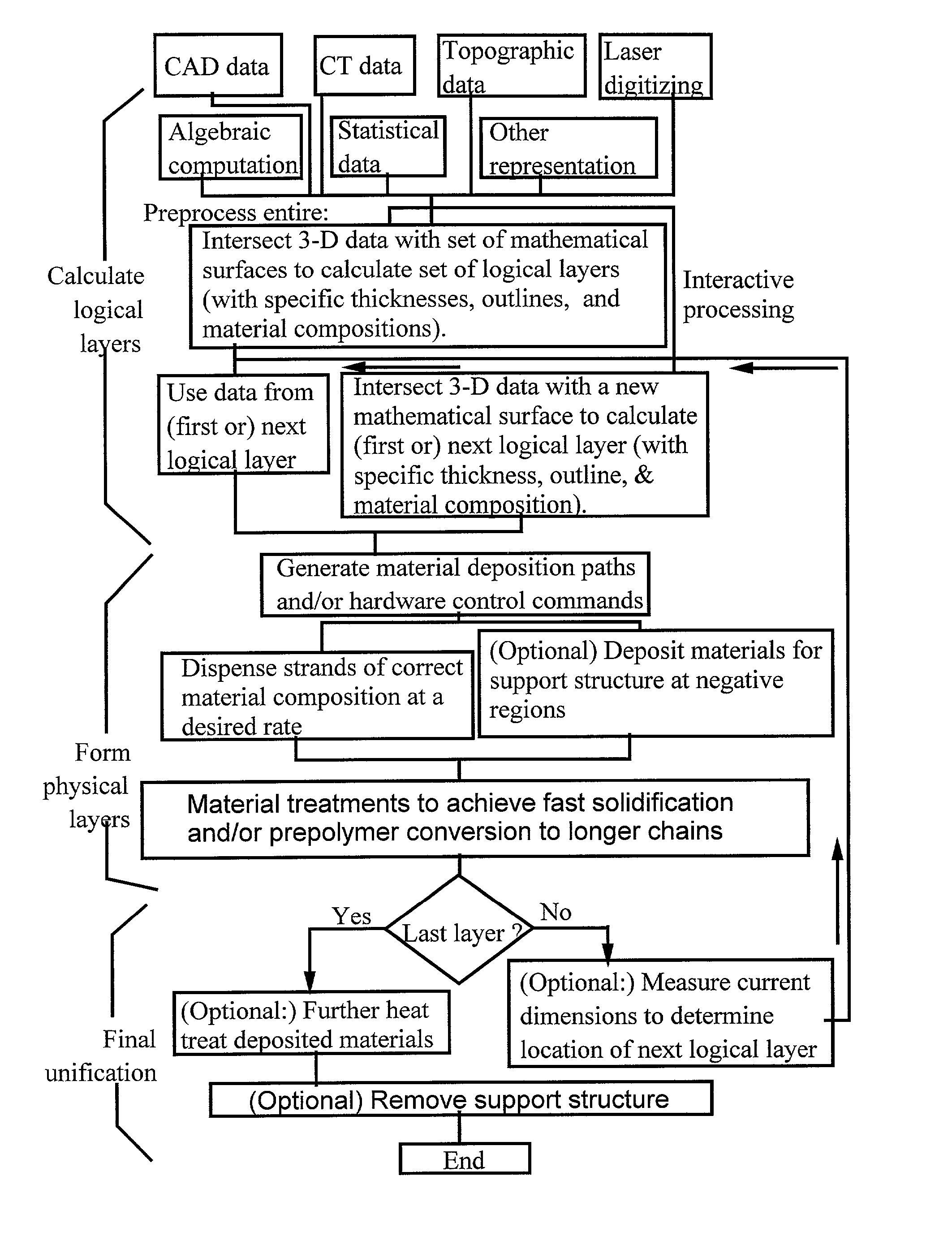

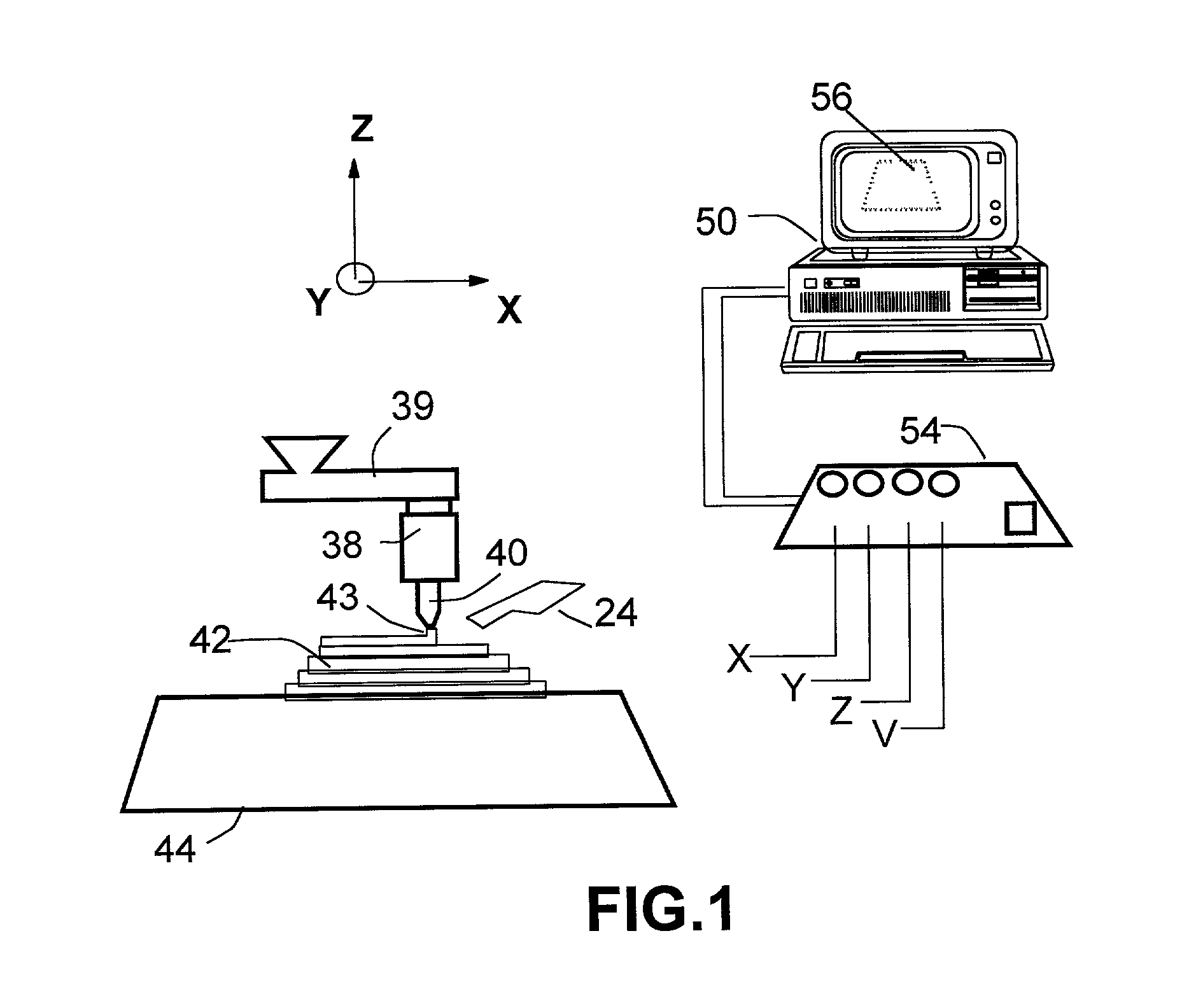

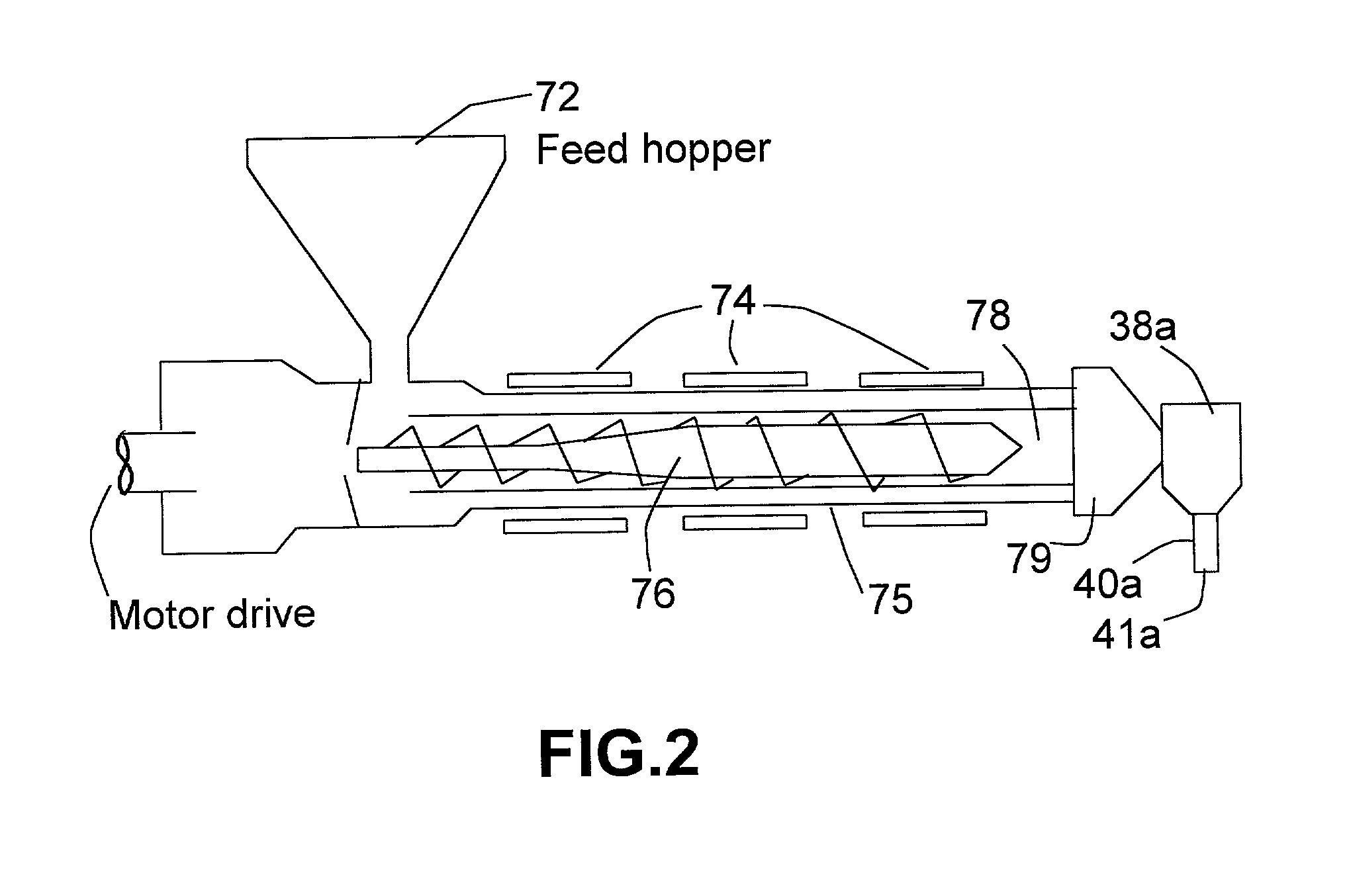

Freeform fabrication method using extrusion of non-cross-linking reactive prepolymers

InactiveUS20020113331A1Fast formingDifficult to prepareProgramme controlComputer controlCross-linkThermoplastic

An extrusion-based freeform fabrication method for making a three-dimensional object from a design created on a computer, including (a) providing a support member; (b) operating a dispensing head having at least one dispensing nozzle with a discharge orifice for dispensing continuous strands of a material composition in a fluent state at a first temperature onto the support member, the material composition including a reactive prepolymer with a melting point above 23° C. and the first temperature being greater than the prepolymer melting point; (c) operating material treatment devices for causing the dispensed strands of material composition to rapidly achieve a rigid state in which the material composition is substantially solidified to build up the 3-D object, the material treatment devices also working to convert the reactive prepolymer to a higher molecular weight thermoplastic resin; and (d) operating control devices for generating control signals in response to coordinates of the object design to control the movement of the dispensing nozzle relative to the support member and for controlling the strand dispensing of the material composition to construct the 3-D object.

Owner:ZHANG TAN +3

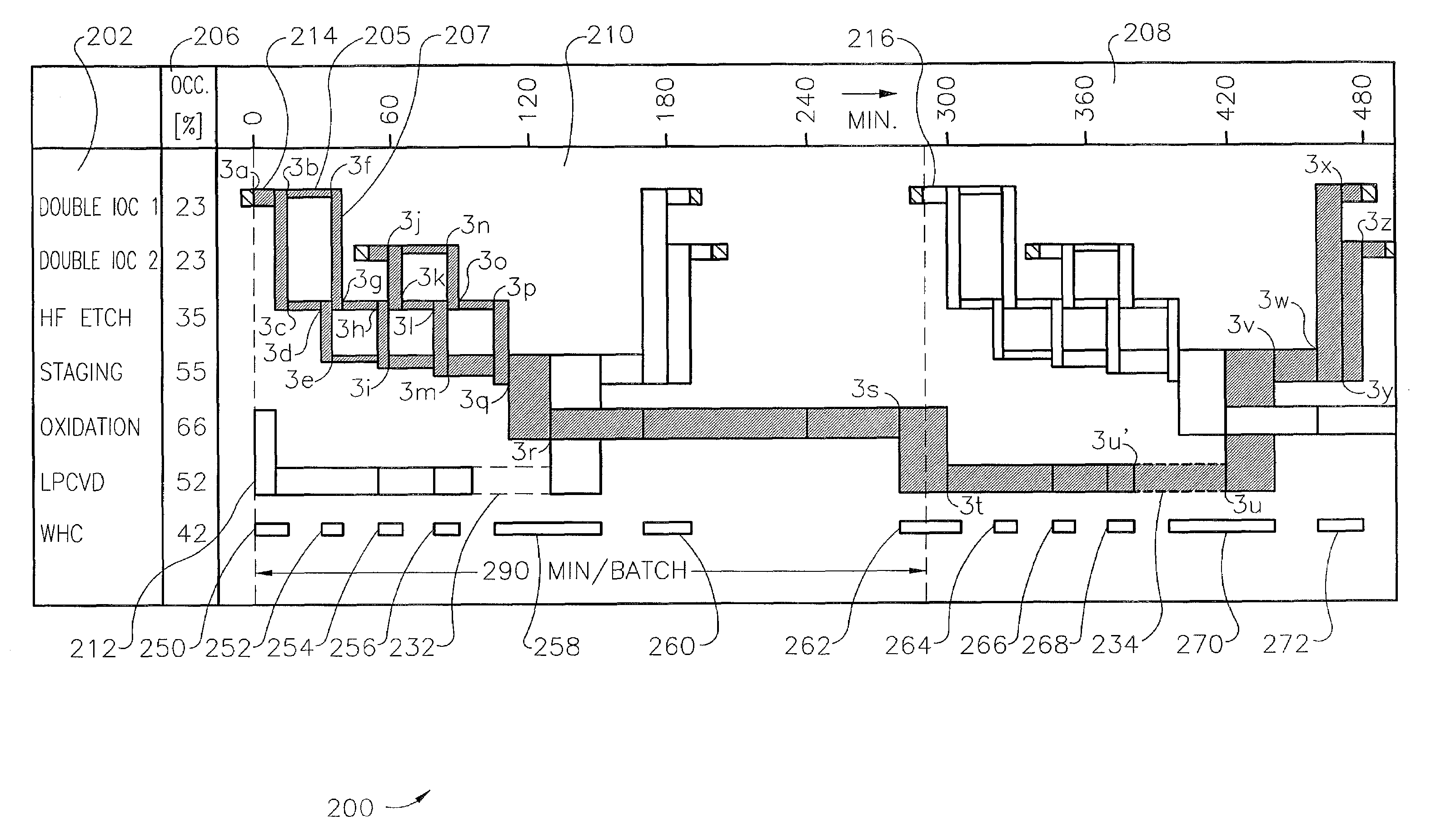

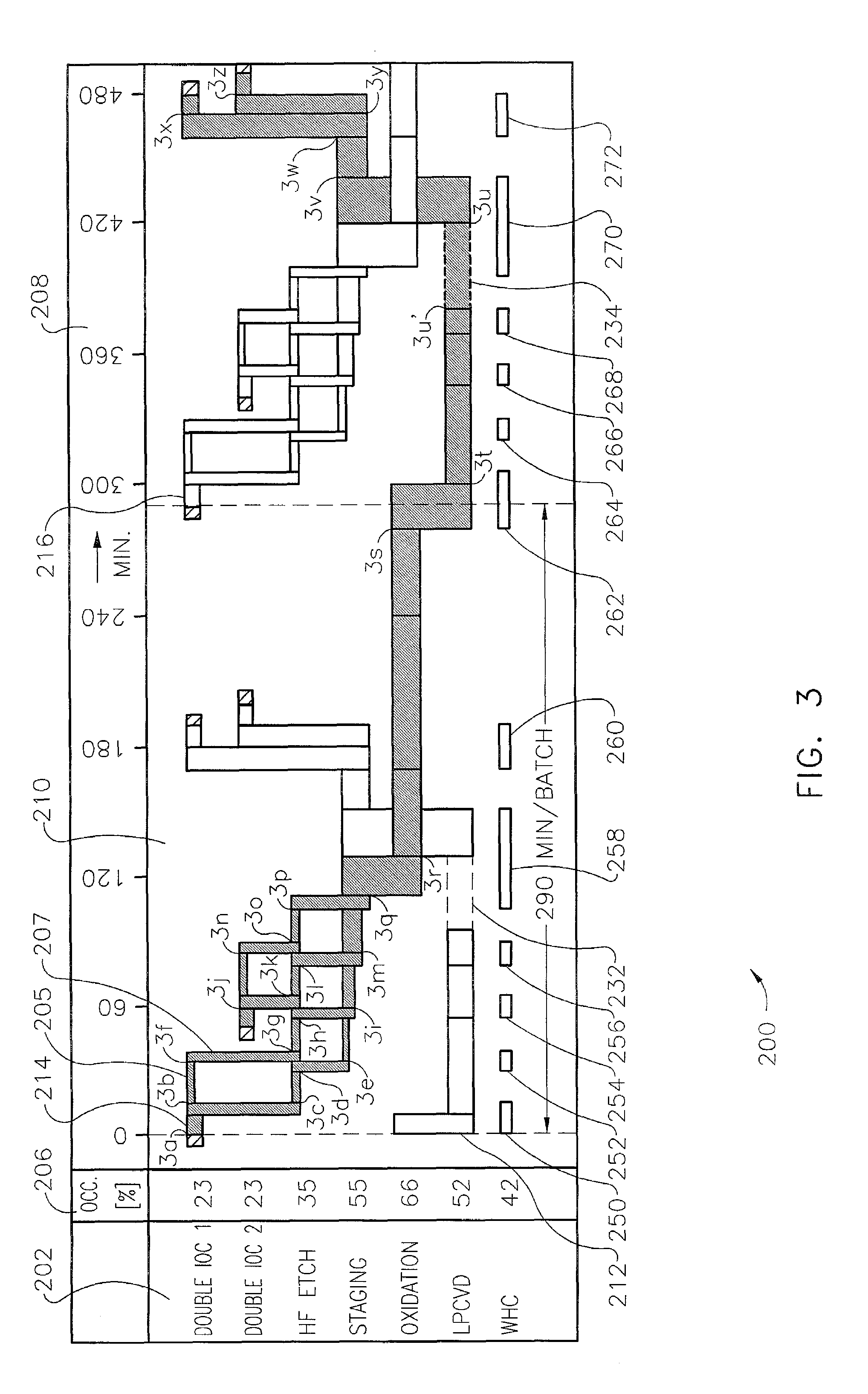

Graphical representation of a wafer processing process

A method for graphically representing the progress of wafers being processed in a plurality of process stations is disclosed. In one step, the start of a process performed on the wafers in one of the plurality of process stations is determined. Then, the generation of a first line segment parallel to a first axis is initiated. Next, the end of the process in one of the plurality of process stations is determined. Then the generation of the first line segment parallel to the first axis is terminated. The start of a transfer of the wafers from one of the plurality of process stations to another one of the plurality of process stations is detected in a next step. Then, the formation of a second line segment connected with the first line segment and substantially perpendicular to the first axis is initiated. The completion of the transfer of the wafers is then determined and the formation of the second line segment perpendicular to the first axis is terminated. The process is then repeated for each process station until the wafers have been processed through all the process stations.

Owner:ASM INTERNATIONAL

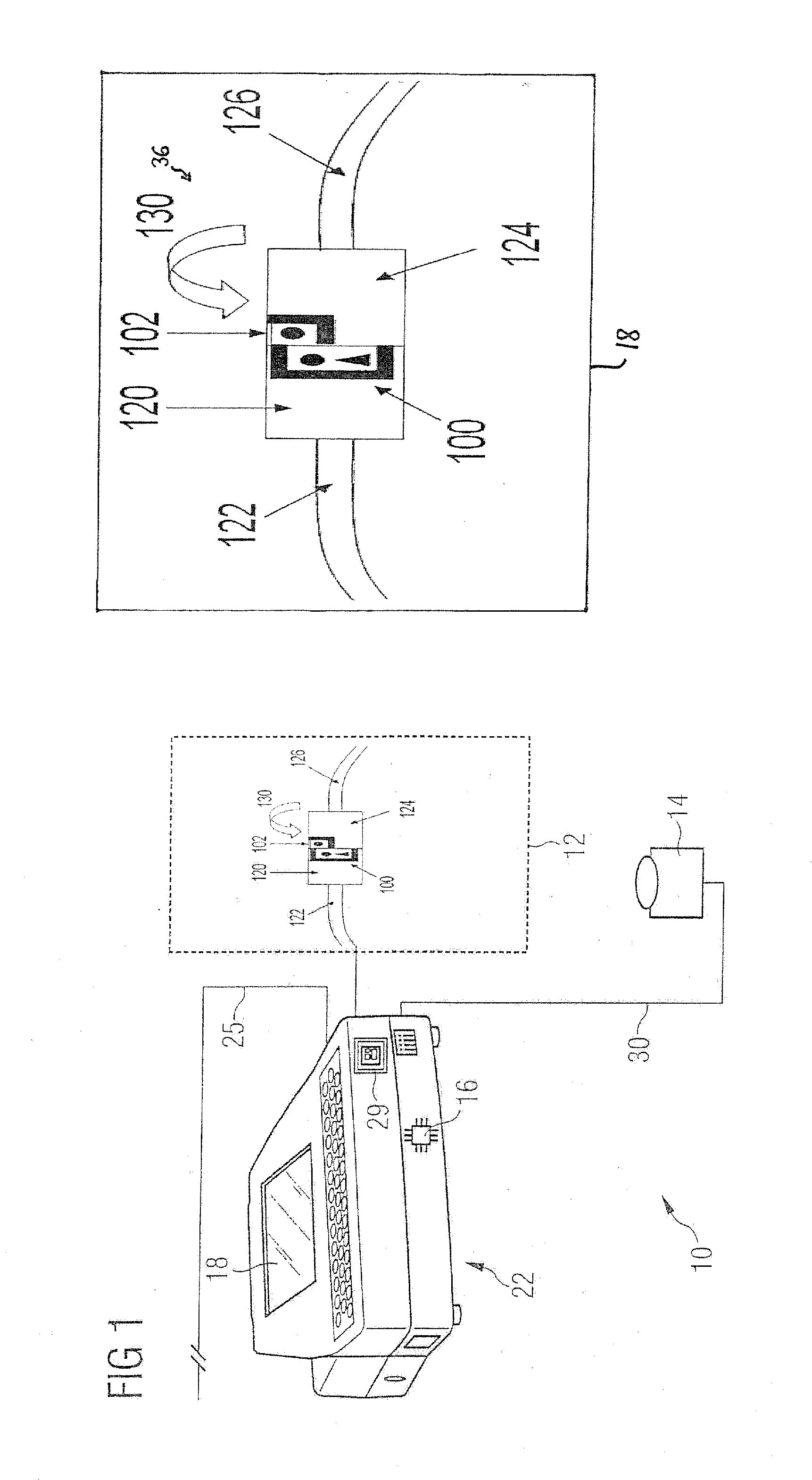

Location Dependent Control Access in a Process Control System

ActiveUS20090065578A1Avoid changeProvide securityIndividual entry/exit registersTotal factory controlControl systemPosition dependent

A method of accessing an element in a process control environment using a portable communicator includes defining a plurality of control areas within the process control environment, determining a position of a user operating a portable communicator with respect to one or more of the control areas, establishing an identity of the user, and selectively allowing the user to access an element within the process control environment via the portable communicator depending on the determined position of the user with respect to the one or more control areas and on the identity of the user.

Owner:FISHER-ROSEMOUNT SYST INC

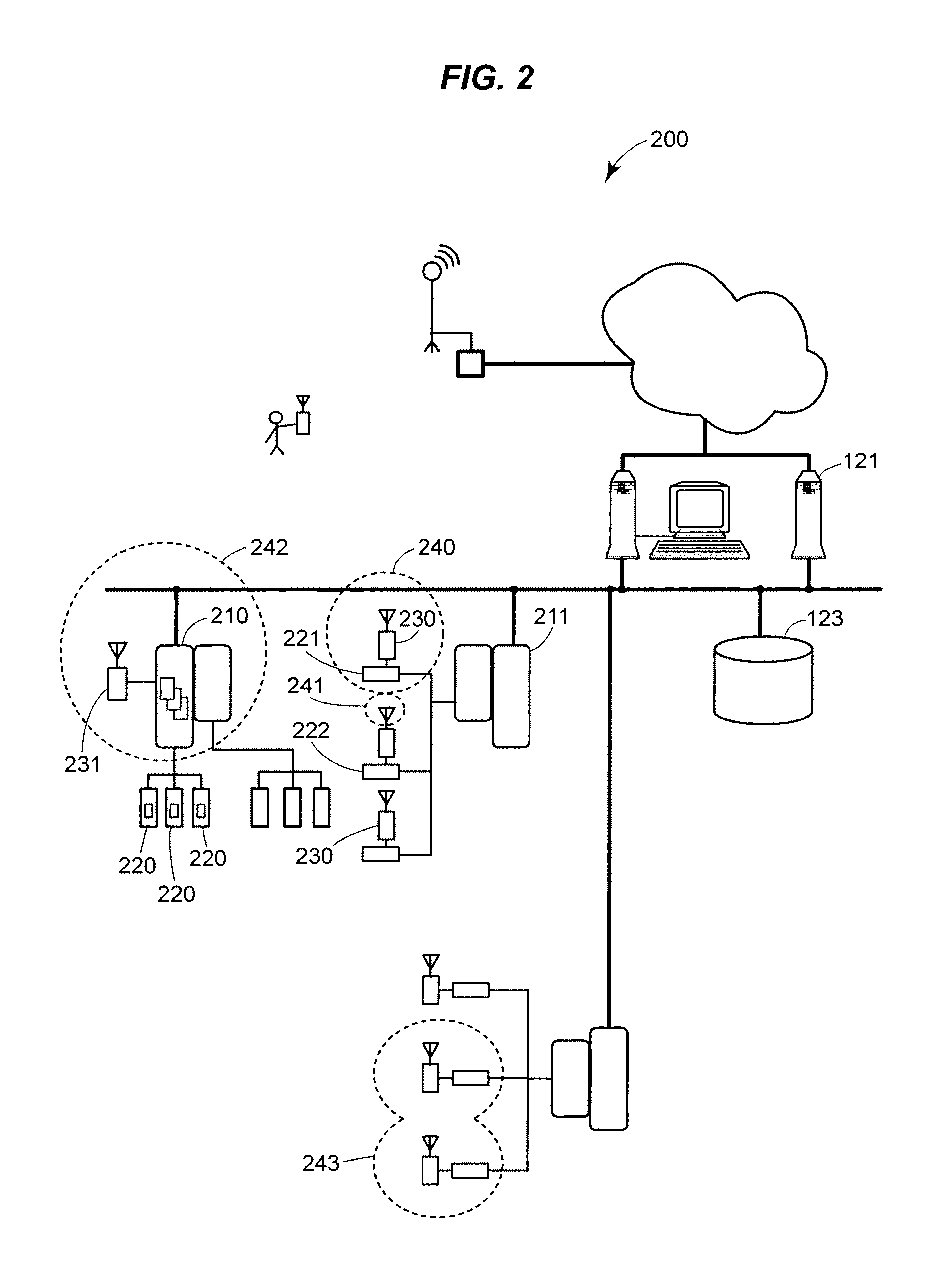

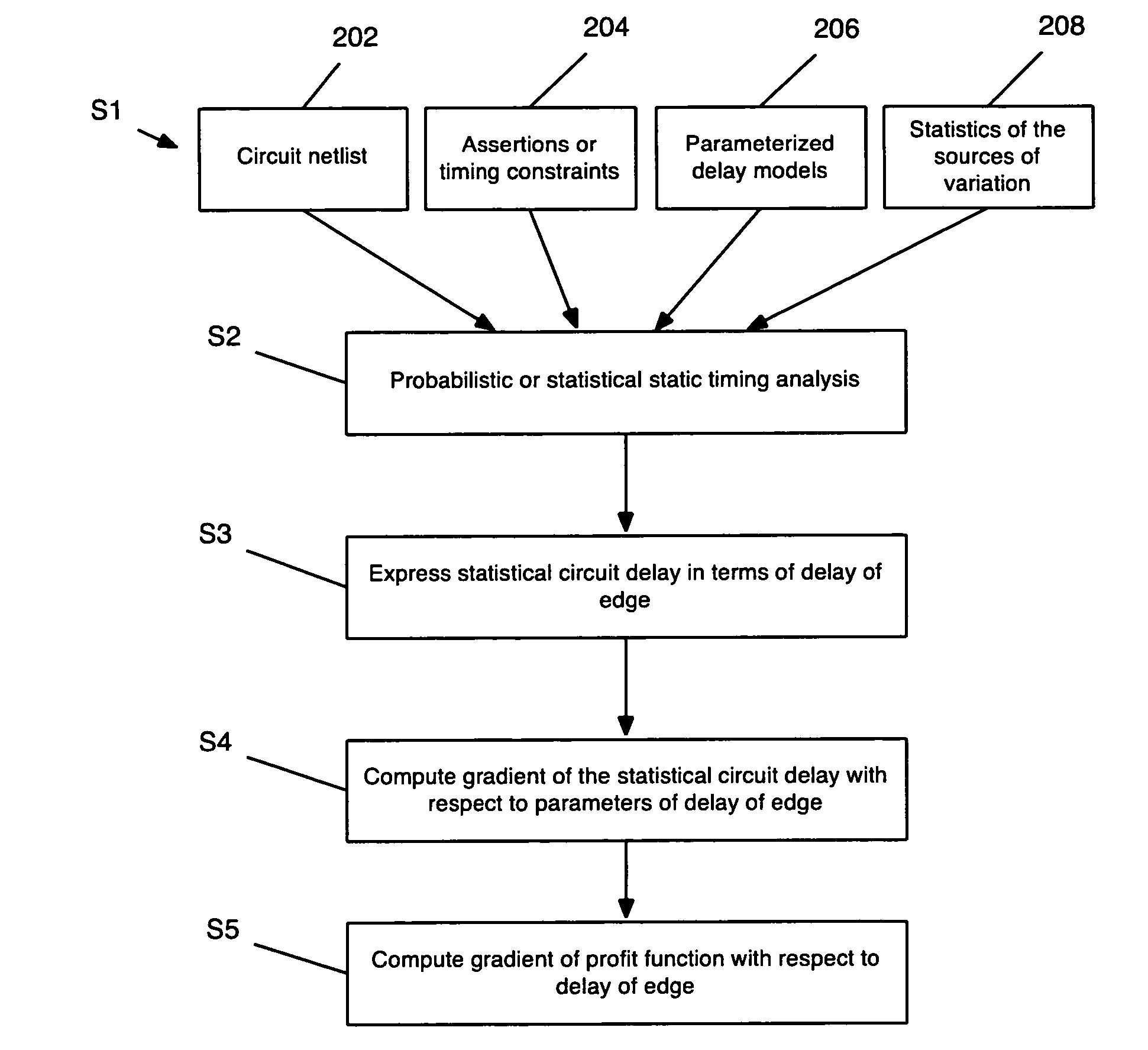

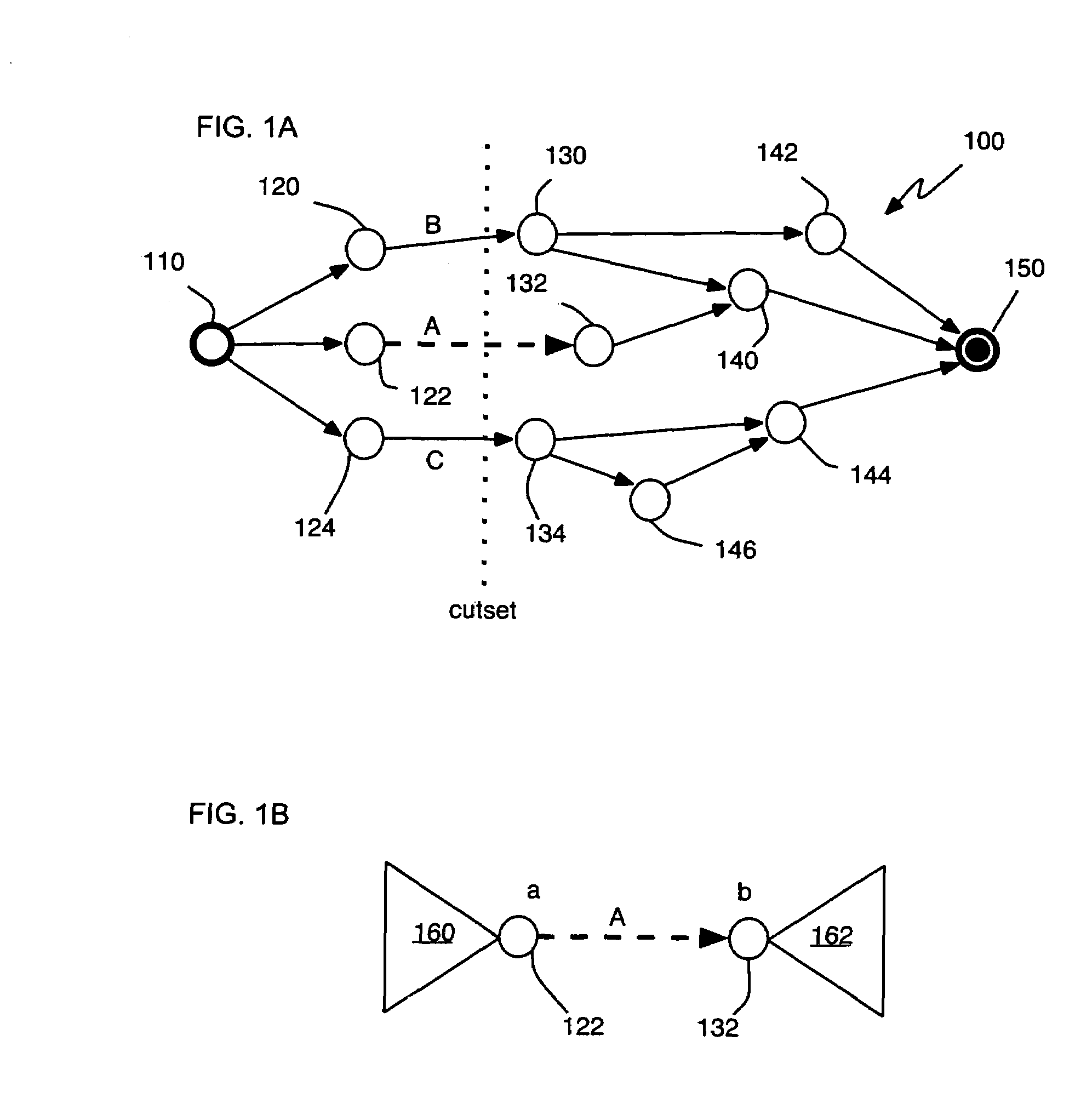

Method, system, and program product for computing a yield gradient from statistical timing

InactiveUS7480880B2Geometric CADComputation using non-denominational number representationCircuit delayComputer science

The invention provides a method, system, and program product for determining a gradient of a parametric yield of an integrated circuit with respect to parameters of a delay of an edge of a timing graph of the circuit. A first aspect of the invention provides a method for determining a gradient of a parametric yield of an integrated circuit with respect to parameters of a delay of an edge of a timing graph of the circuit, the method comprising: conducting a statistical timing analysis; expressing a statistical circuit delay in terms of a delay of the edge; and computing a gradient of the statistical circuit delay with respect to parameters of the delay of the edge.

Owner:GLOBALFOUNDRIES INC

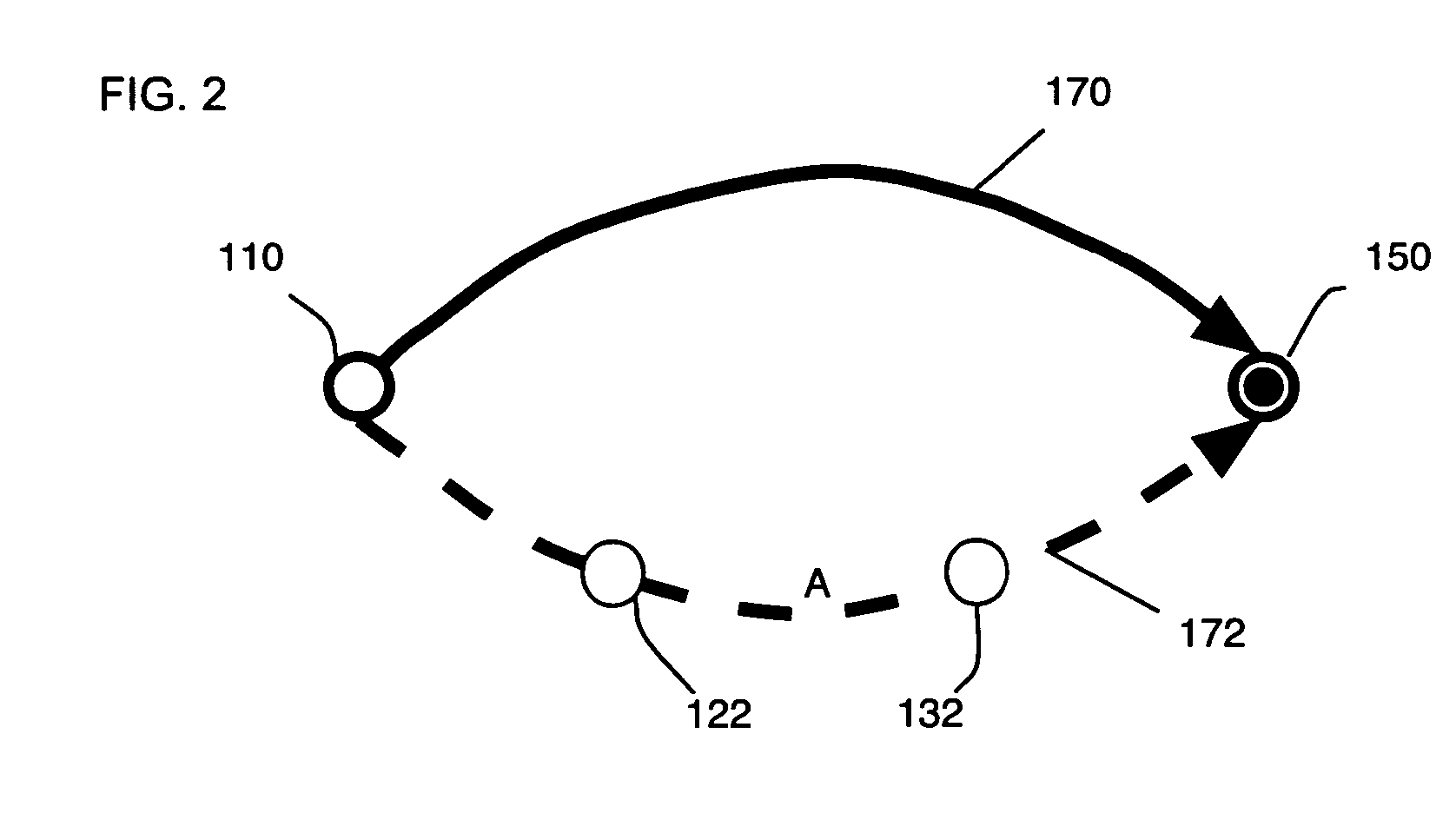

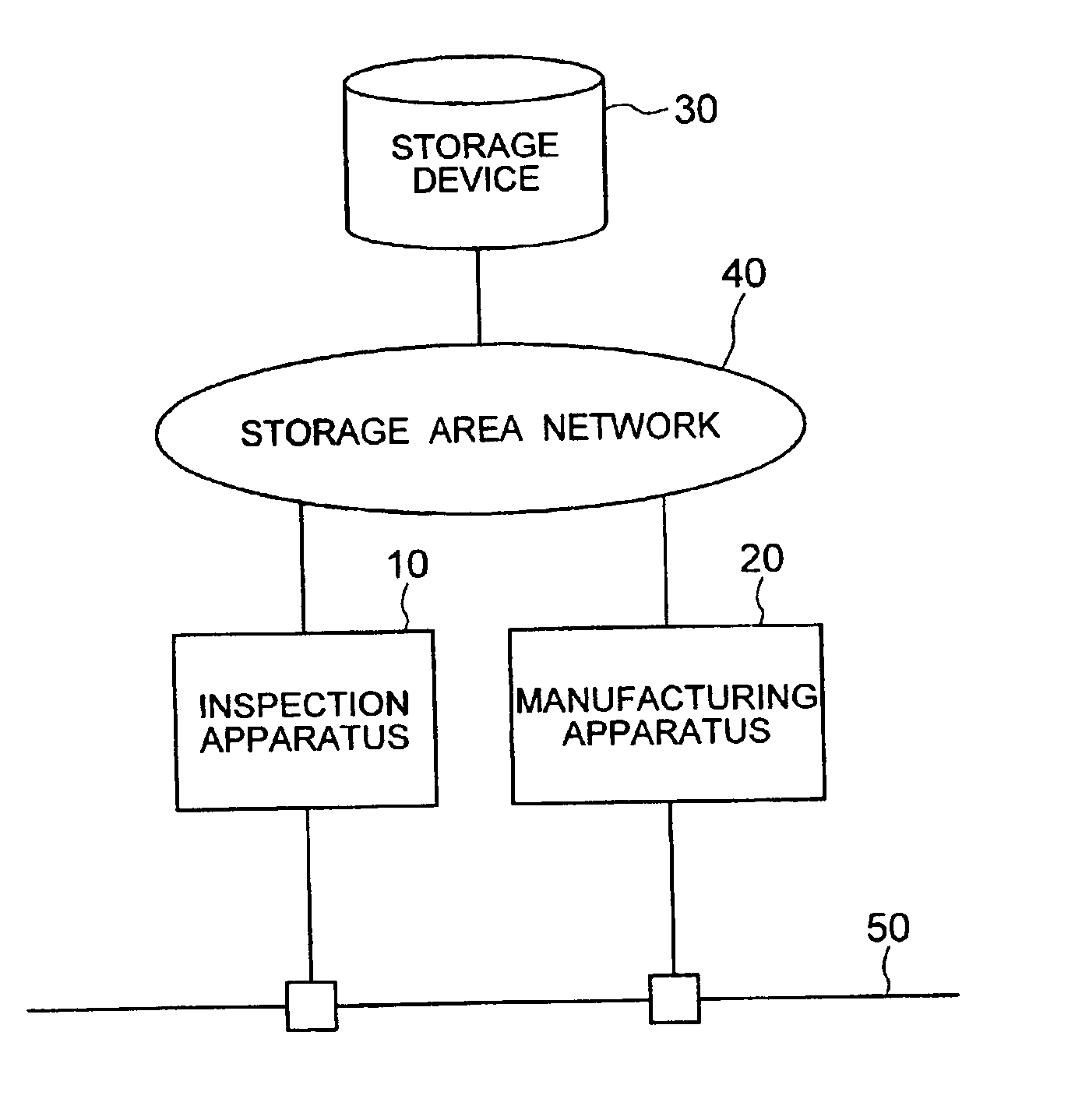

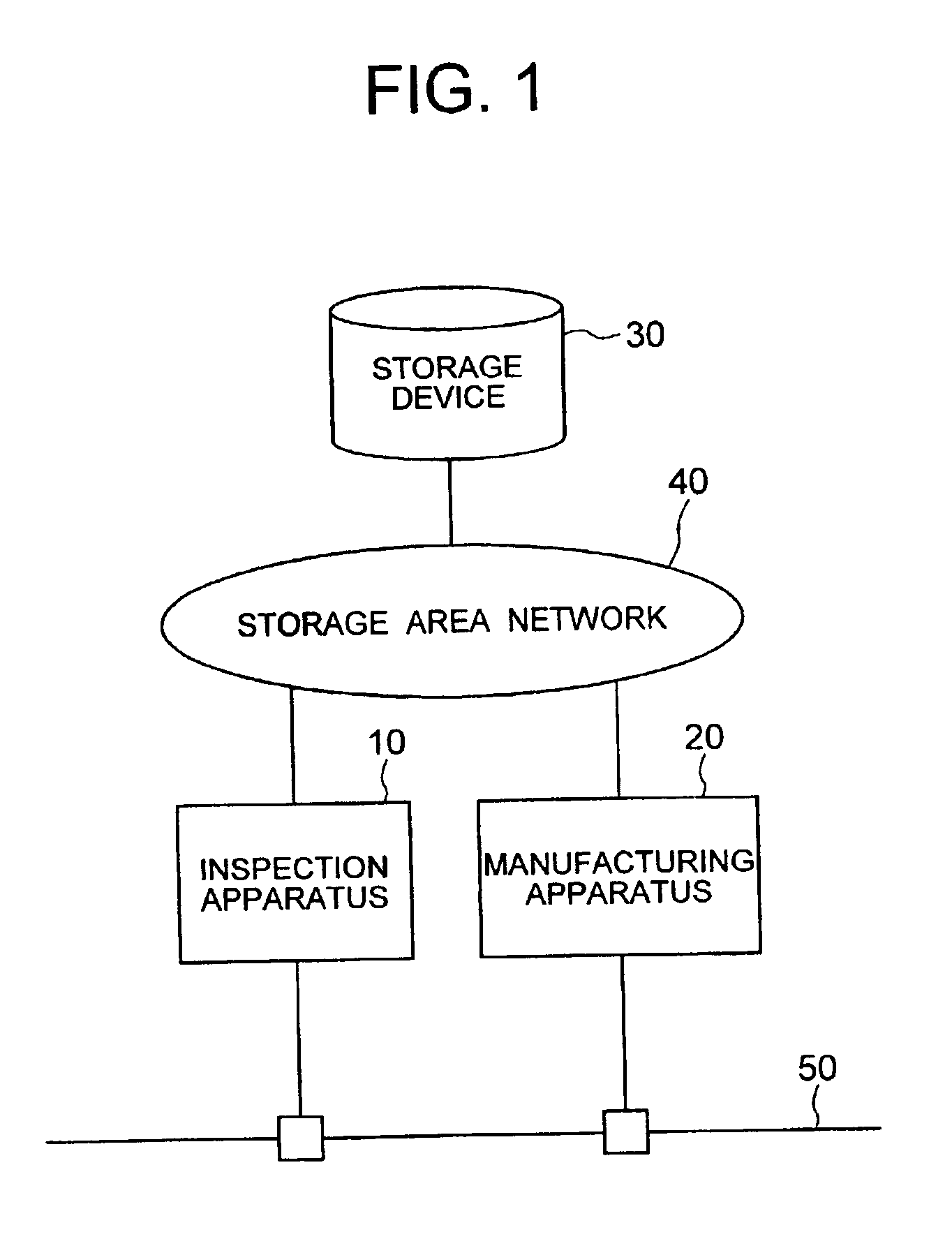

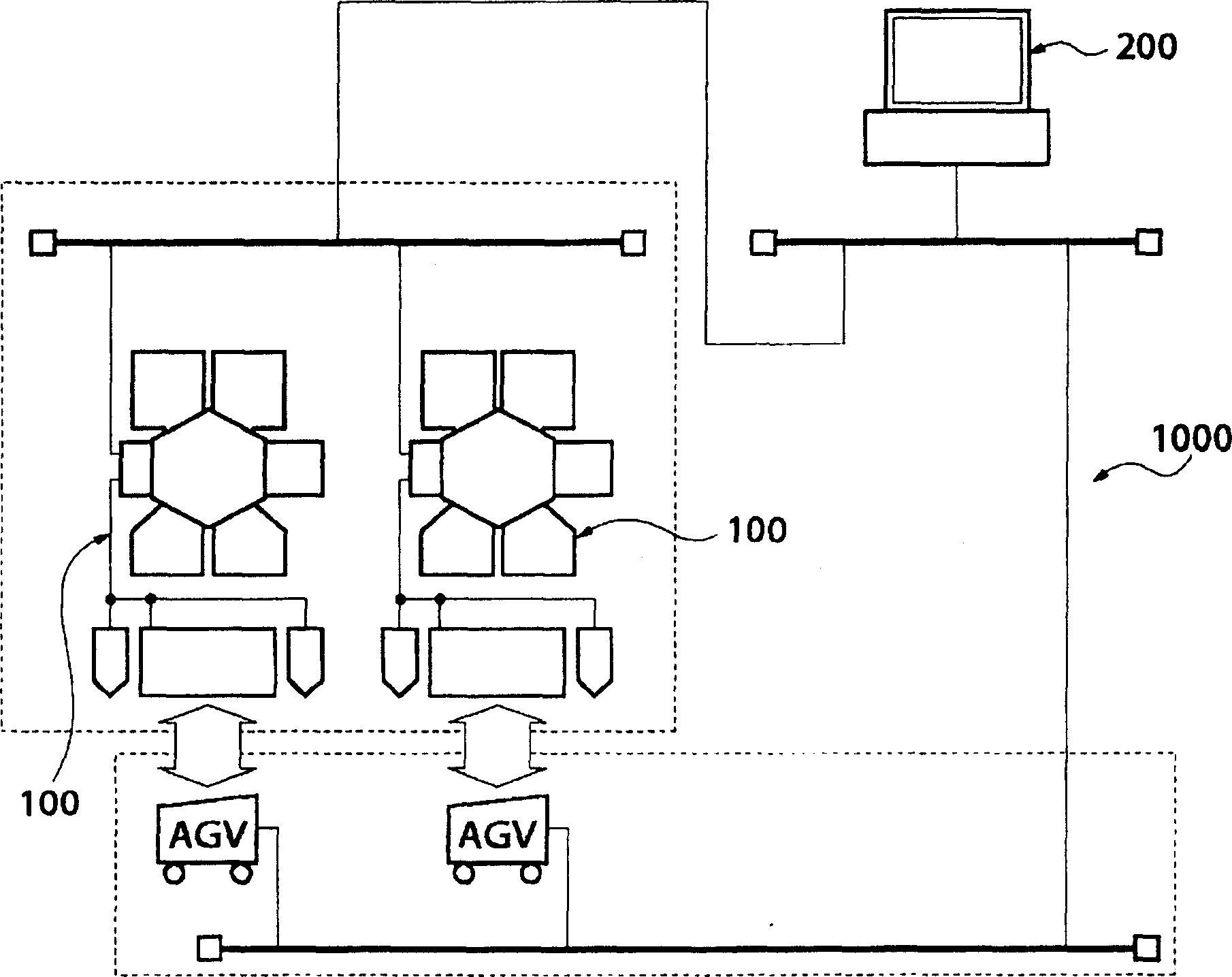

Semiconductor production system

InactiveUS6850854B2Improve system throughputIncrease in sizeSemiconductor/solid-state device testing/measurementElectronic circuit testingStorage area networkObservation unit

A semiconductor production system has a semiconductor manufacturing apparatus having an exposure unit, a control unit for controlling the exposure unit and a storage device; a semiconductor inspection apparatus having an observation unit, a control unit for controlling the observation unit and a storage device; and a storage device commonly used by the semiconductor manufacturing apparatus and the semiconductor inspection apparatus. The manufacturing apparatus, the inspection apparatus and the commonly used storage device are interconnected via a storage area network. With the semiconductor manufacturing apparatus and the storage device linked together via the storage area network, a large volume of image data or design data can be communicated at high speed, thus improving the system throughput.

Owner:HITACHI LTD

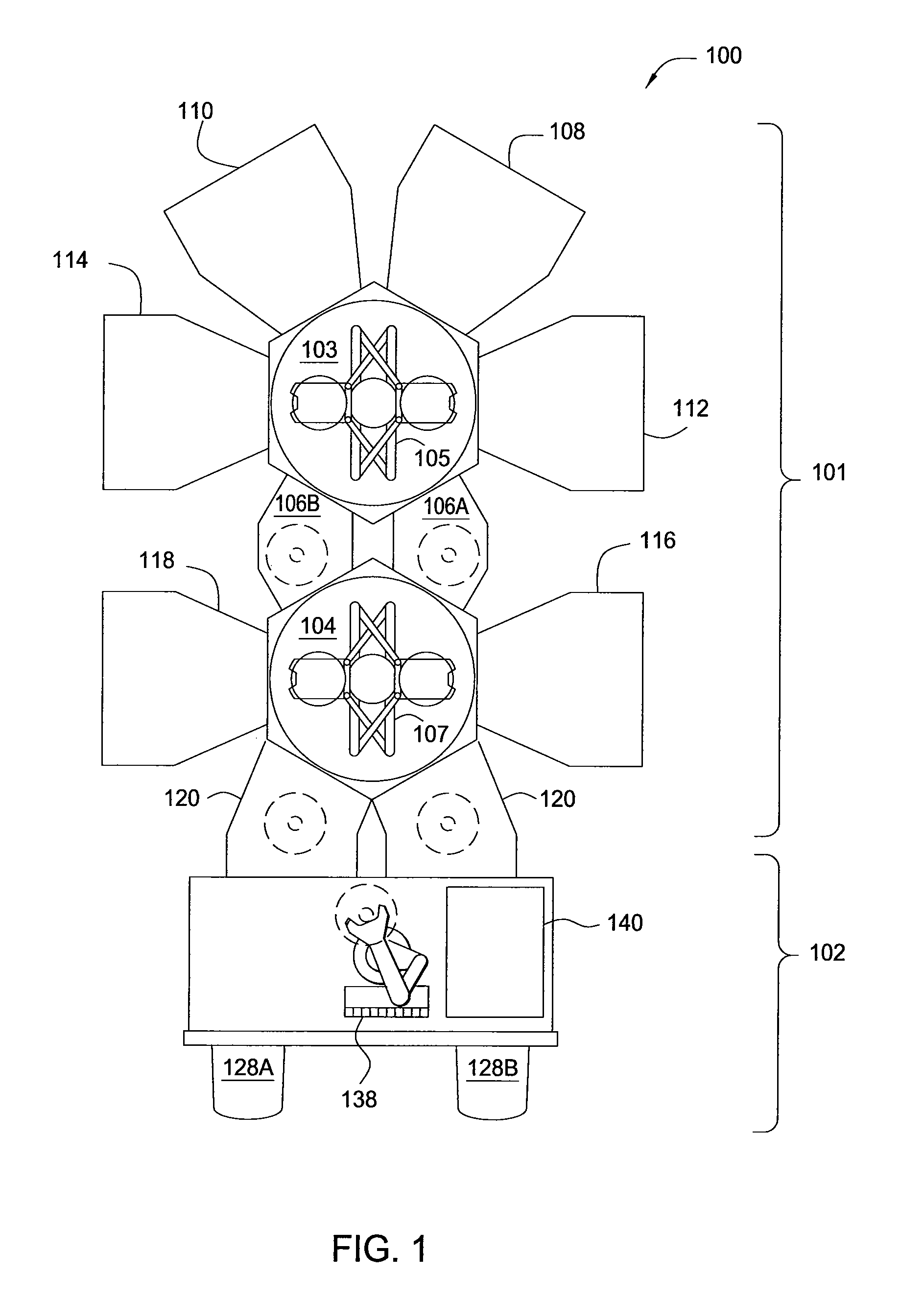

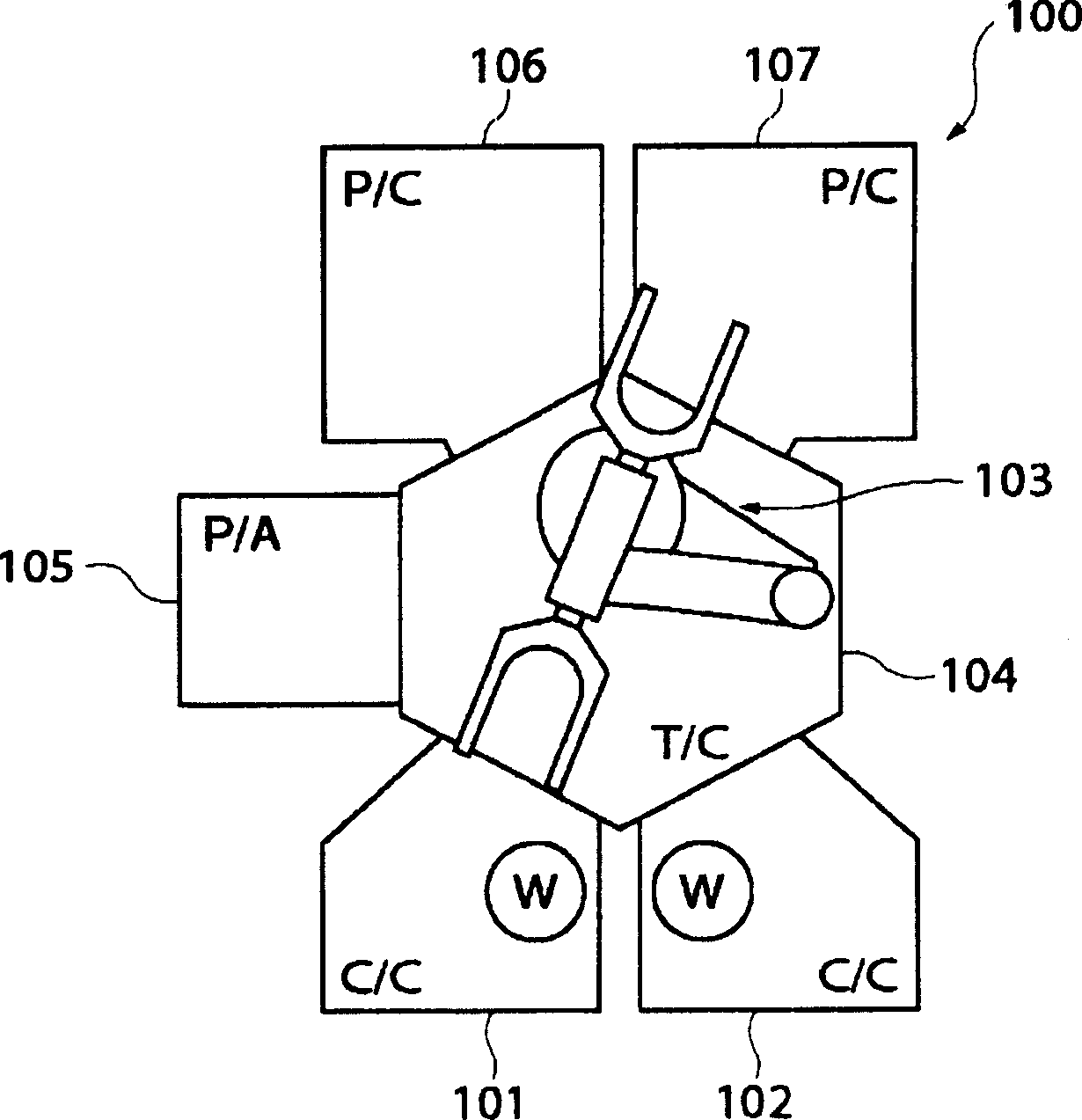

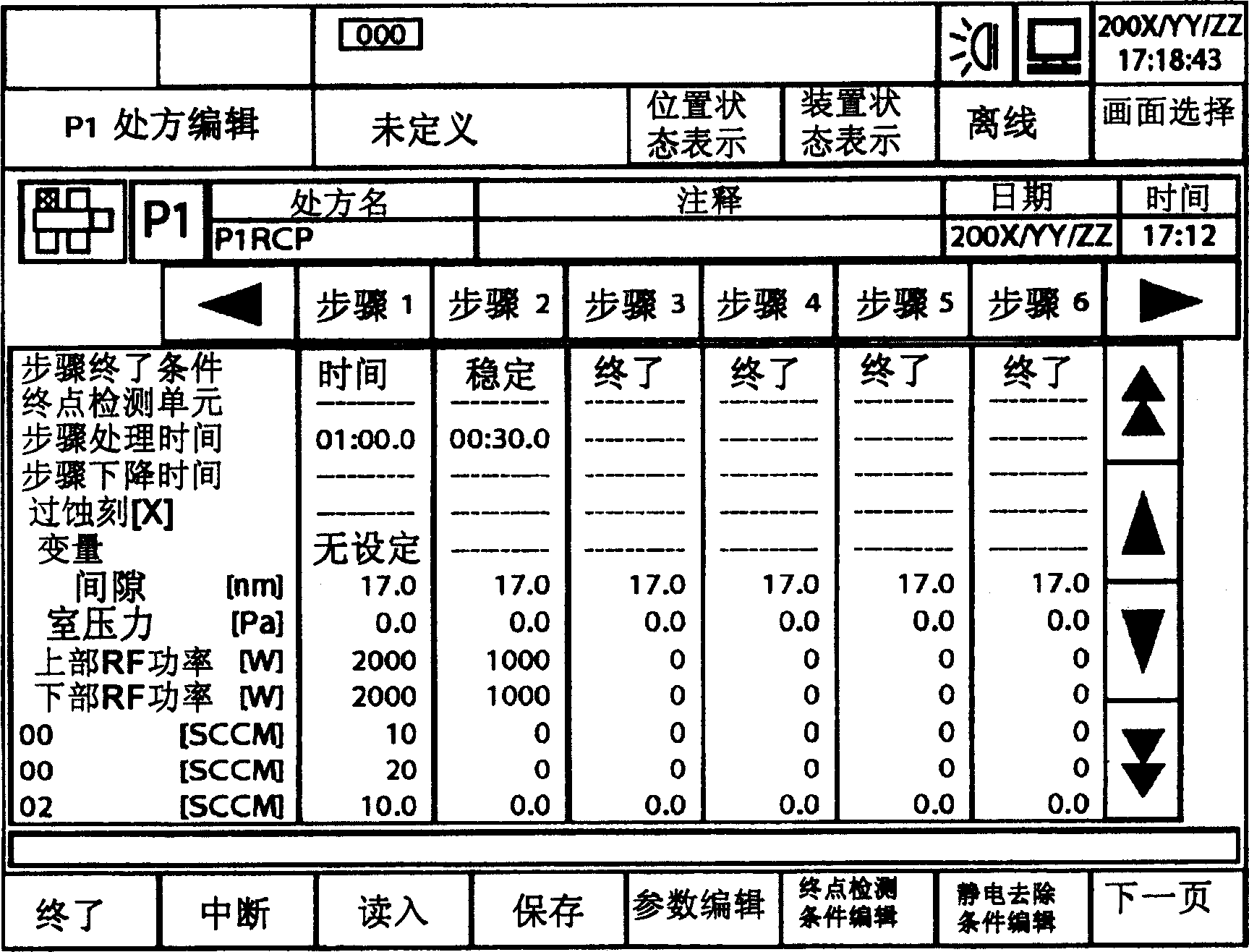

Base plate processing device,base plate processing method and progarm

ActiveCN1664987AIncrease production capacityIndeed implement the requirementsComputer controlSemiconductor/solid-state device manufacturingStable stateProduct processing

An etching apparatus 100 as the substrate processing apparatus is provided with a rotary arm 103 for carrying a substrate included in a lot, and process chambers 106 and 107 for carrying out etching to the substrate as product processing. The etching apparatus 100 is controlled by a host computer 200 in which a transportation recipe, a recipe for product processing and a recipe for dummy processing are registered. When a chamber neglecting time being each neglecting time of the process chambers 106 and 107 does not become time out, the host computer 200 discriminates that processing atmosphere in the process chambers used for etching to the lot is stable, omits the execution of the dummy processing, and executes etching to the substrate of the lot.

Owner:TOKYO ELECTRON LTD

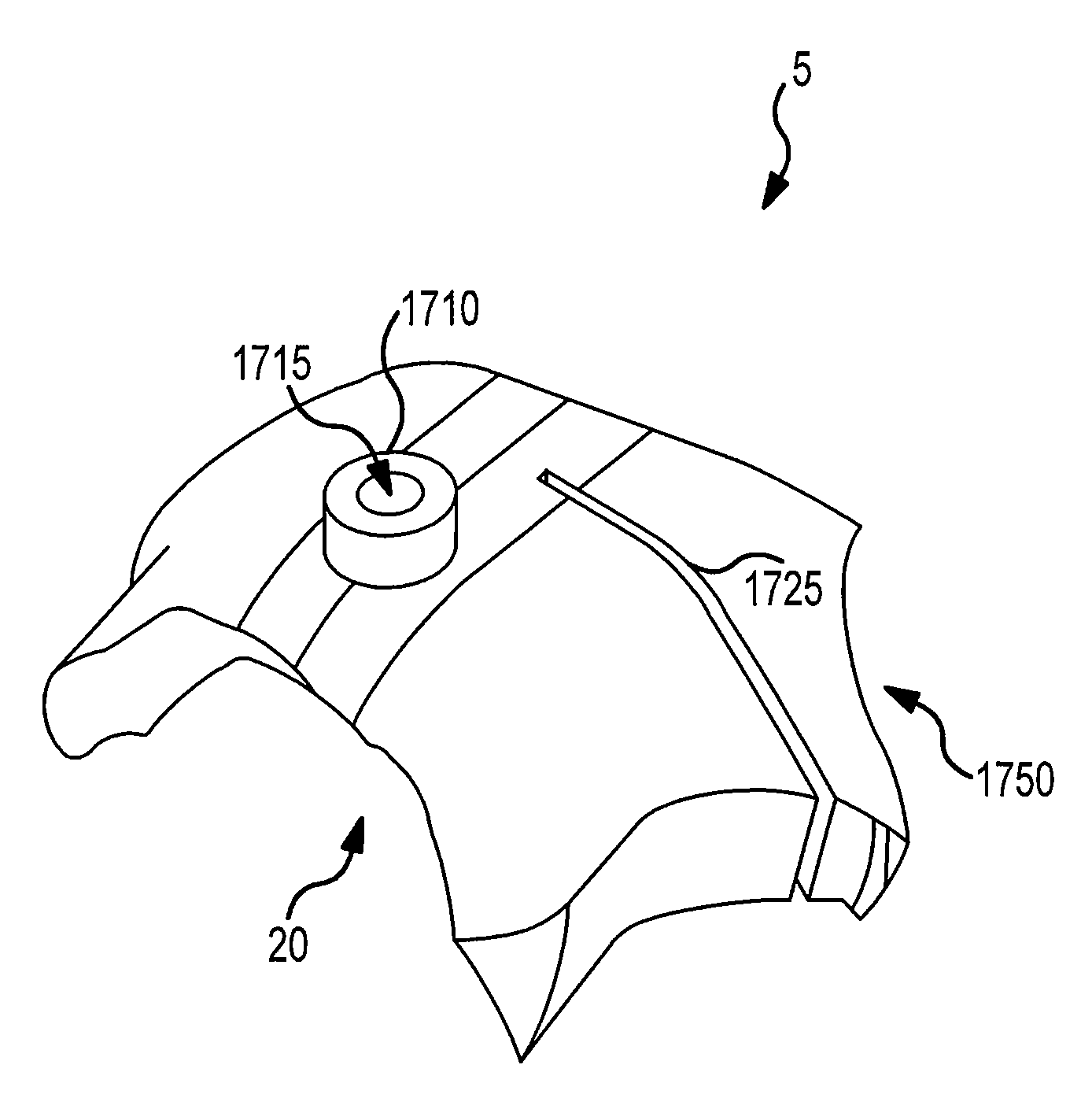

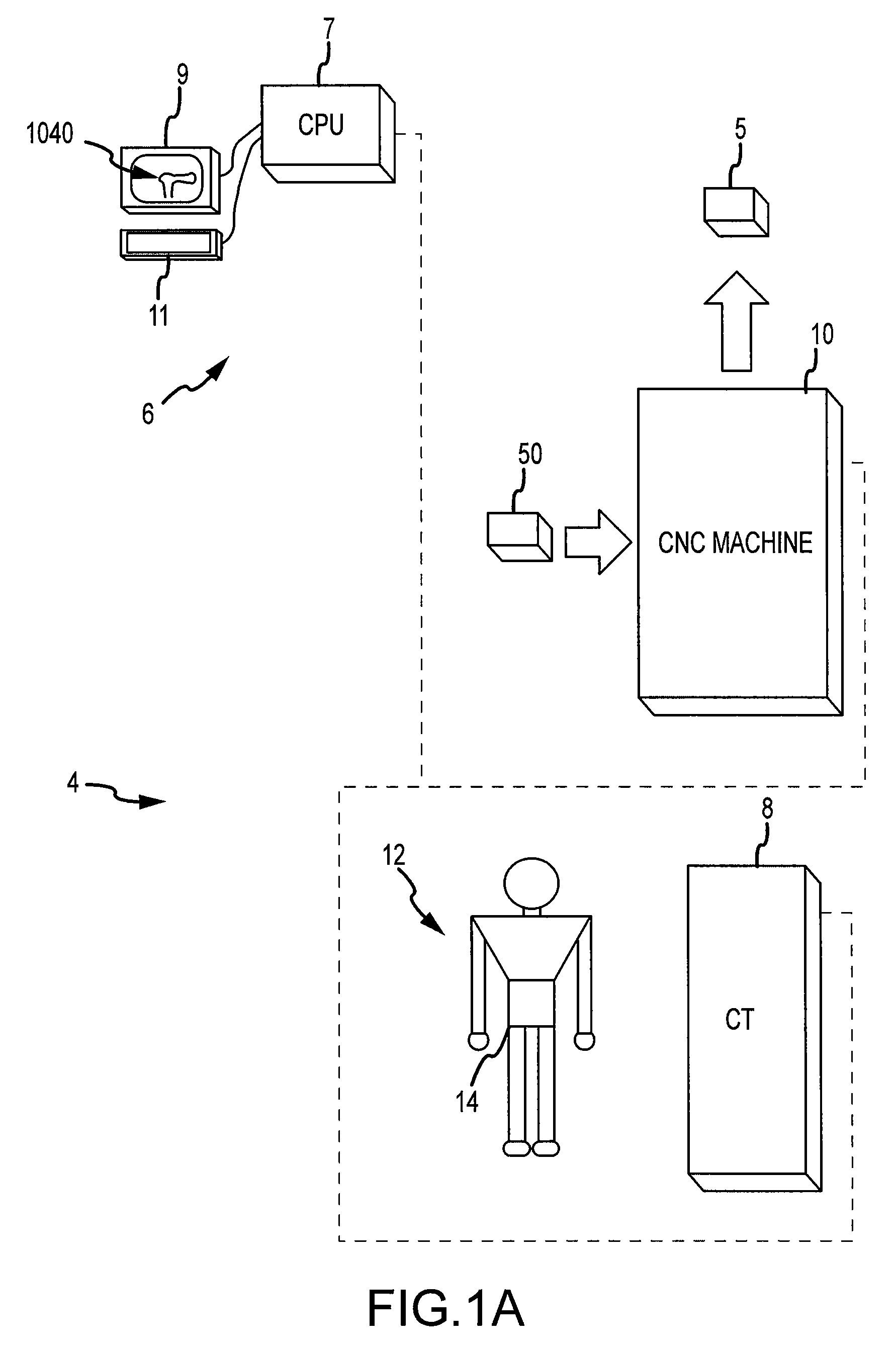

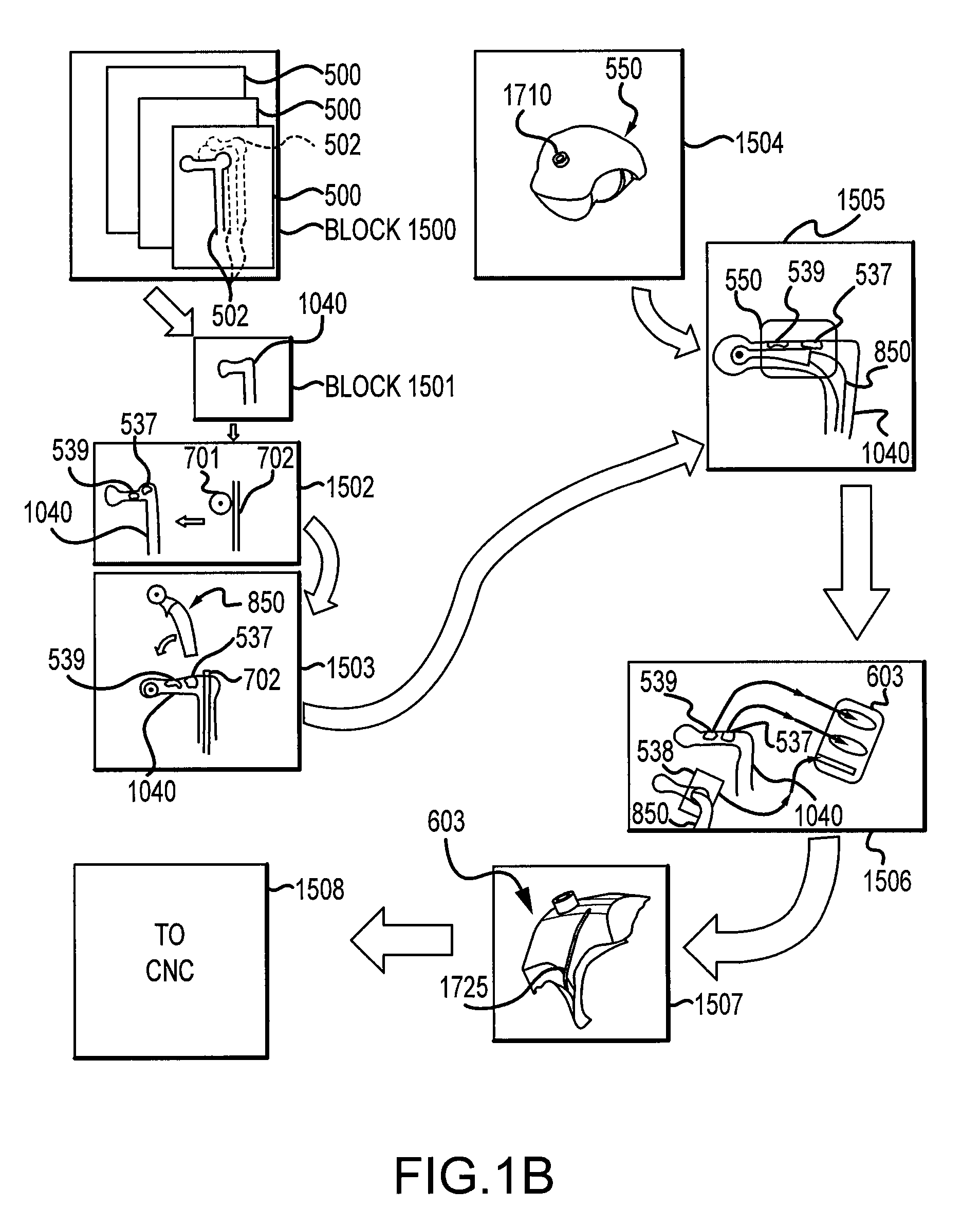

Total hip replacement surgical guide tool

Disclosed herein is a surgical guide tool for use in total hip replacement surgery. The surgical guide tool may include a customized mating region and a resection guide. The customized mating region and the resection guide are referenced to each other such that, when the customized mating region matingly engages a surface area of a proximal femur, the resection guide will be aligned to guide a resectioning of the proximal femur along a preoperatively planned resection plane.

Owner:HOWMEDICA OSTEONICS CORP

System for providing control to an industrial process using one or more multidimensional variables

InactiveUS6865509B1Quick analysisHigh reliability and precisionElement comparisonElectric testing/monitoringComputer-aidedComputer aid

Owner:SMITHS DETECTION

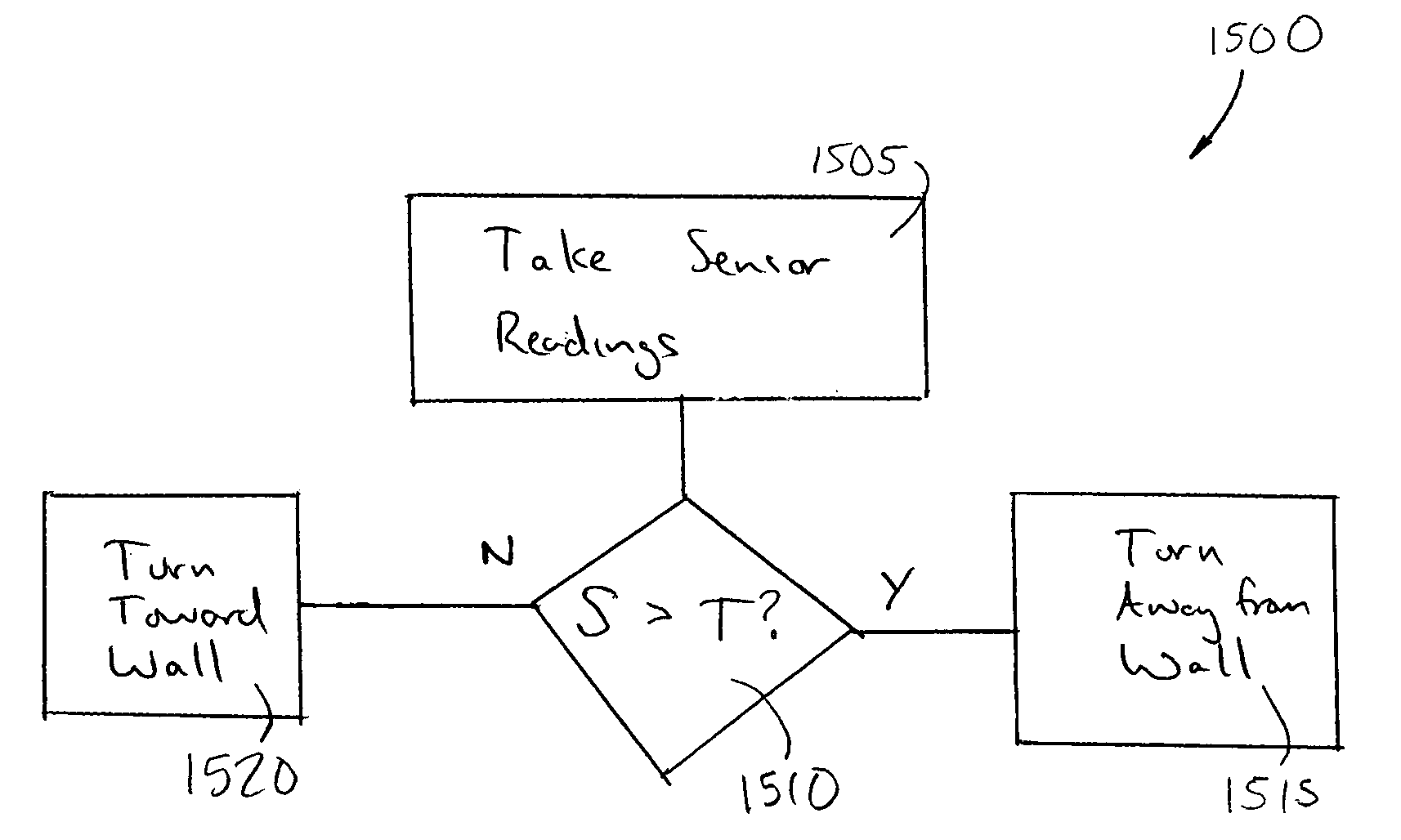

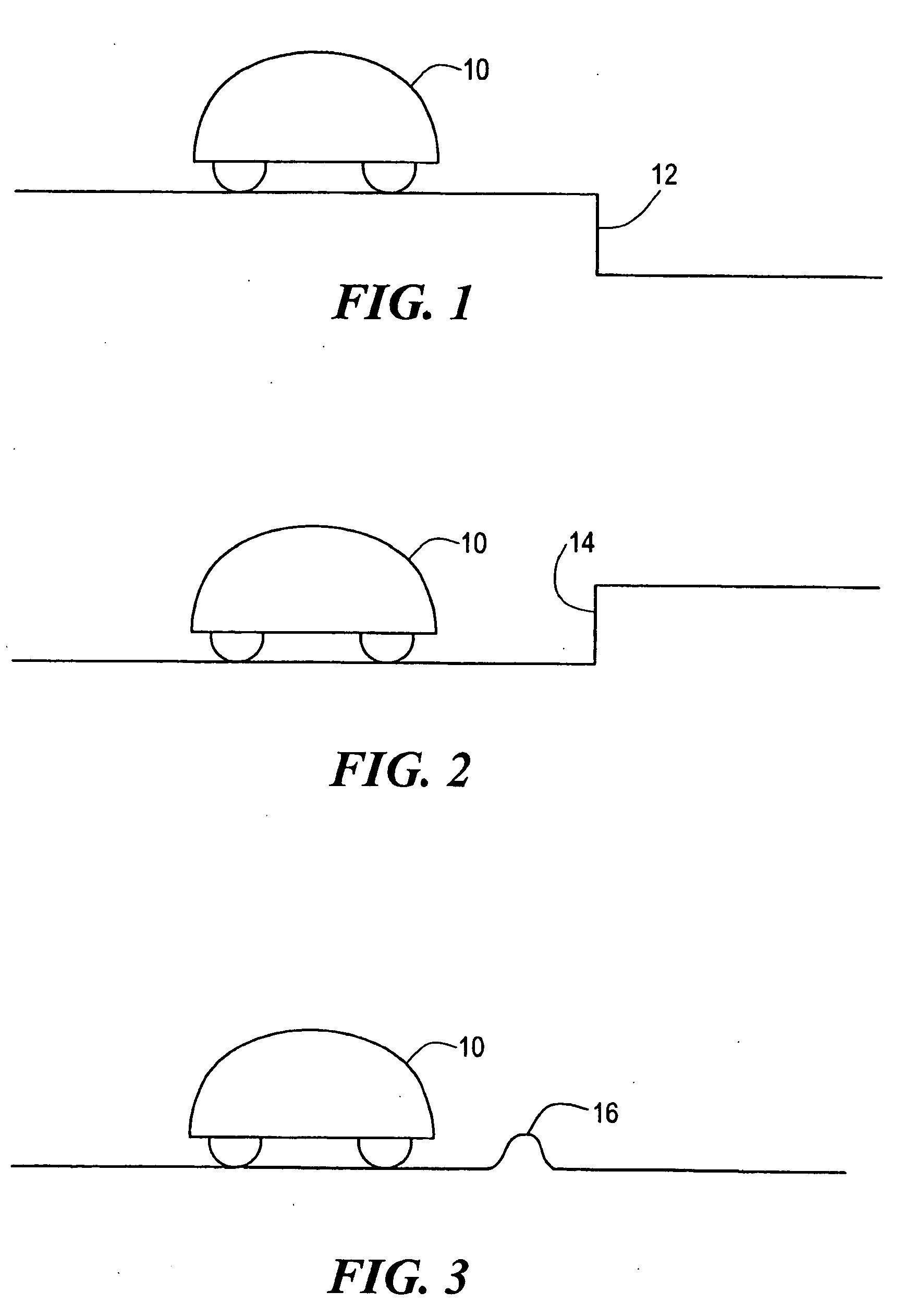

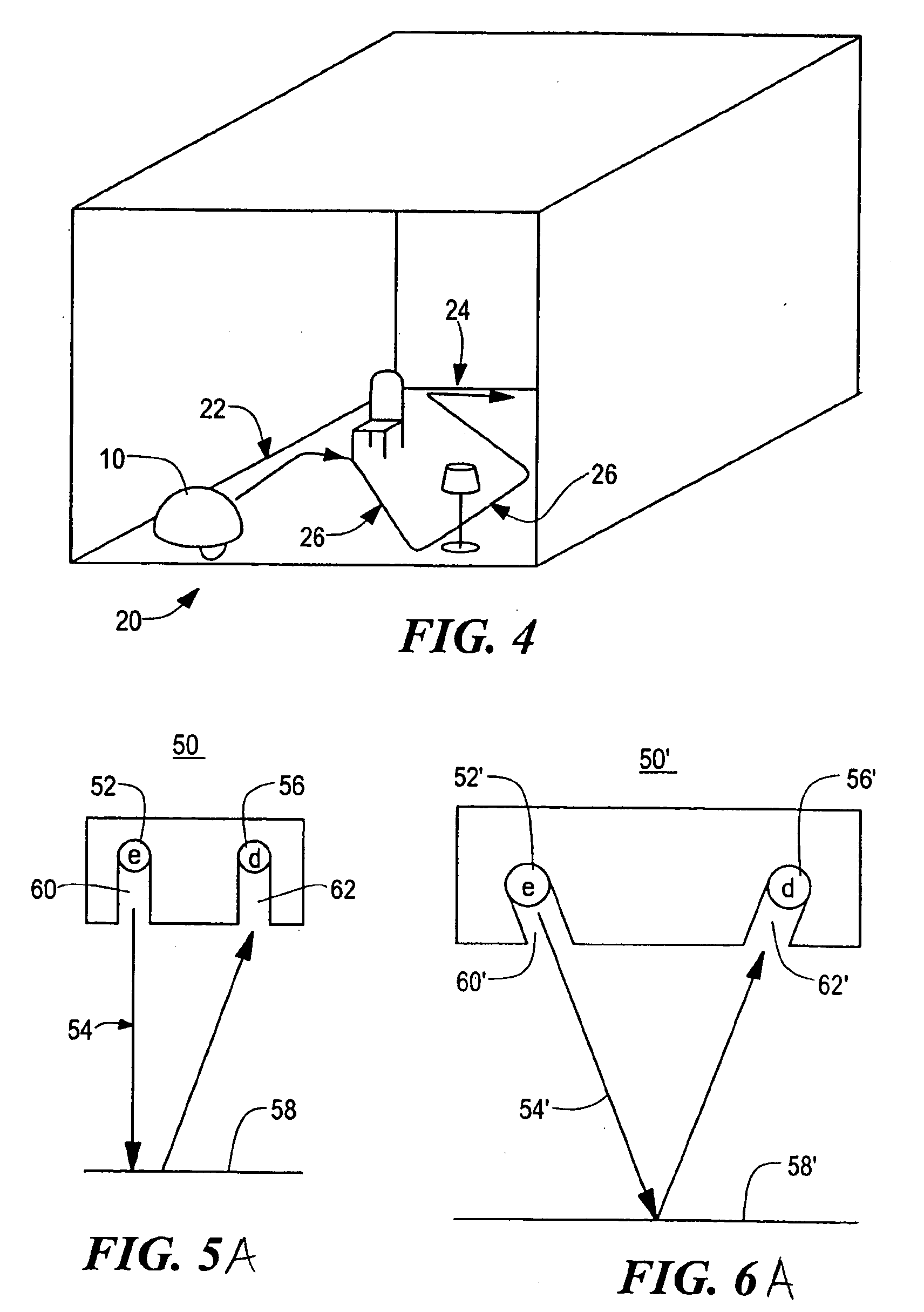

Obstacle following sensor scheme for a mobile robot

ActiveUS20050251292A1Simple designLow costProgramme-controlled manipulatorAutomatic obstacle detectionProximateEngineering

A robot obstacle detection system including a robot housing which navigates with respect to a surface and a sensor subsystem aimed at the surface for detecting the surface. The sensor subsystem includes an emitter which emits a signal having a field of emission and a photon detector having a field of view which intersects the field of emission at a region. The subsystem detects the presence of an object proximate the mobile robot and determines a value of a signal corresponding to the object. It compares the value to a predetermined value, moves the mobile robot in response to the comparison, and updates the predetermined value upon the occurrence of an event.

Owner:IROBOT CORP

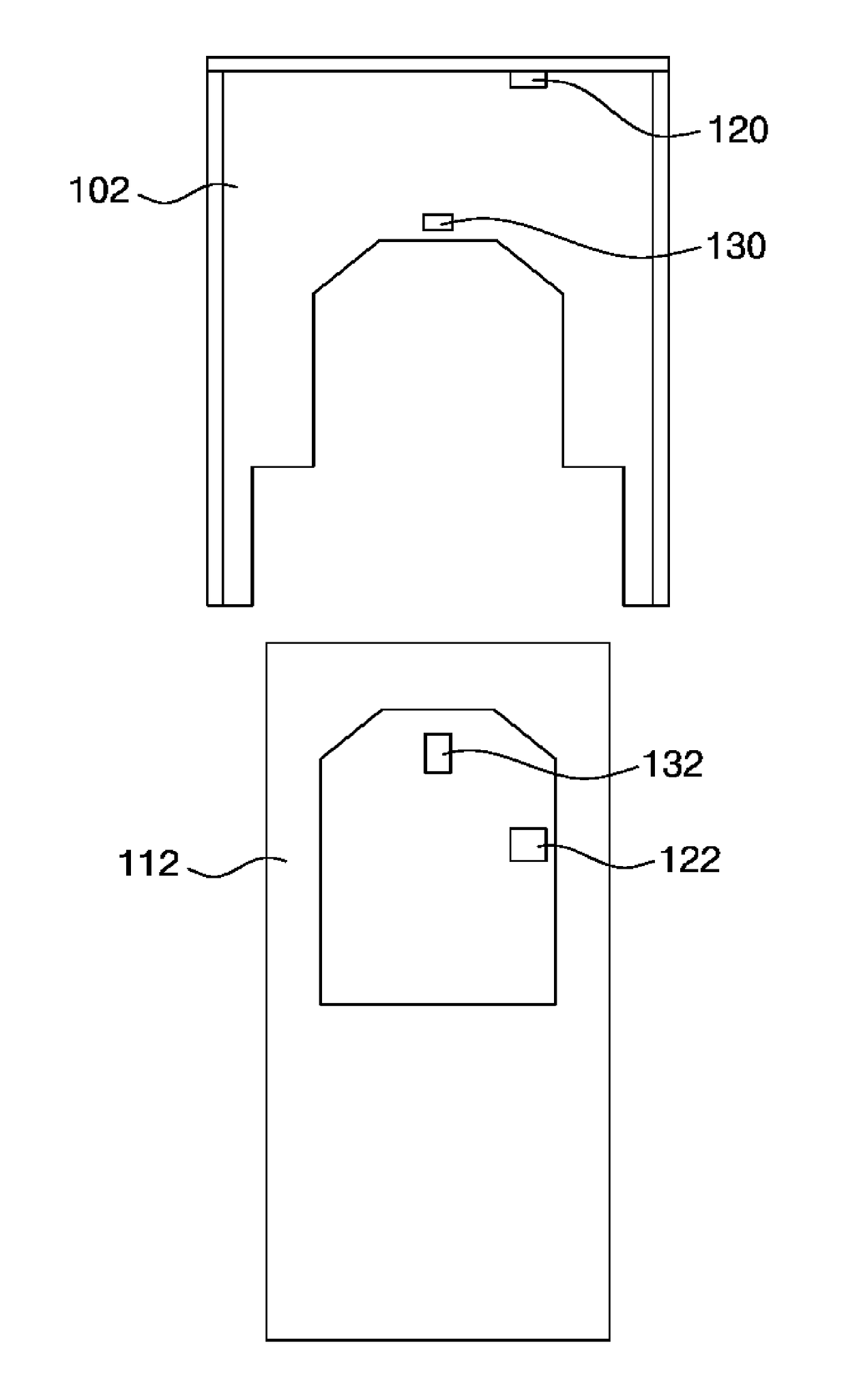

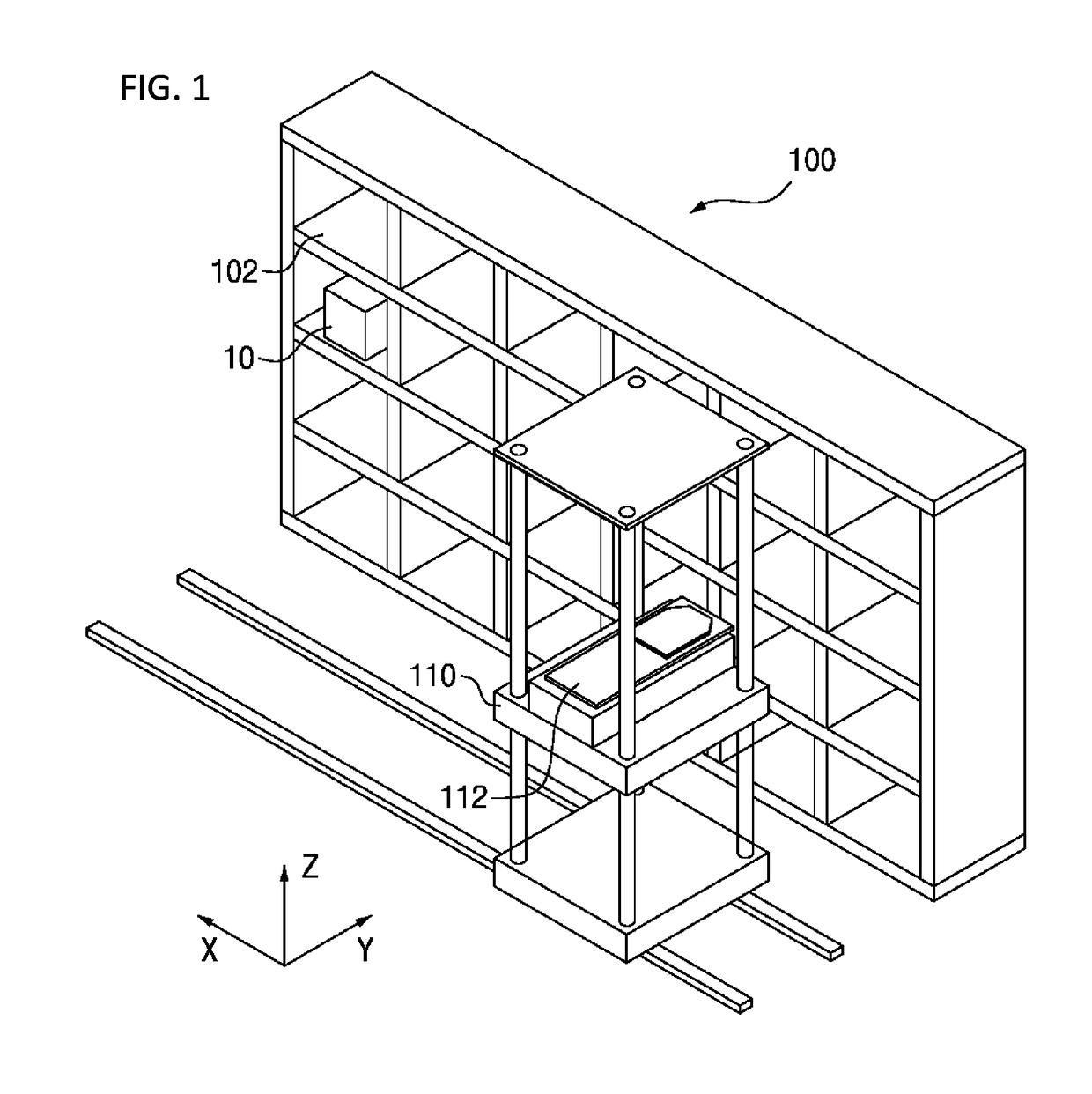

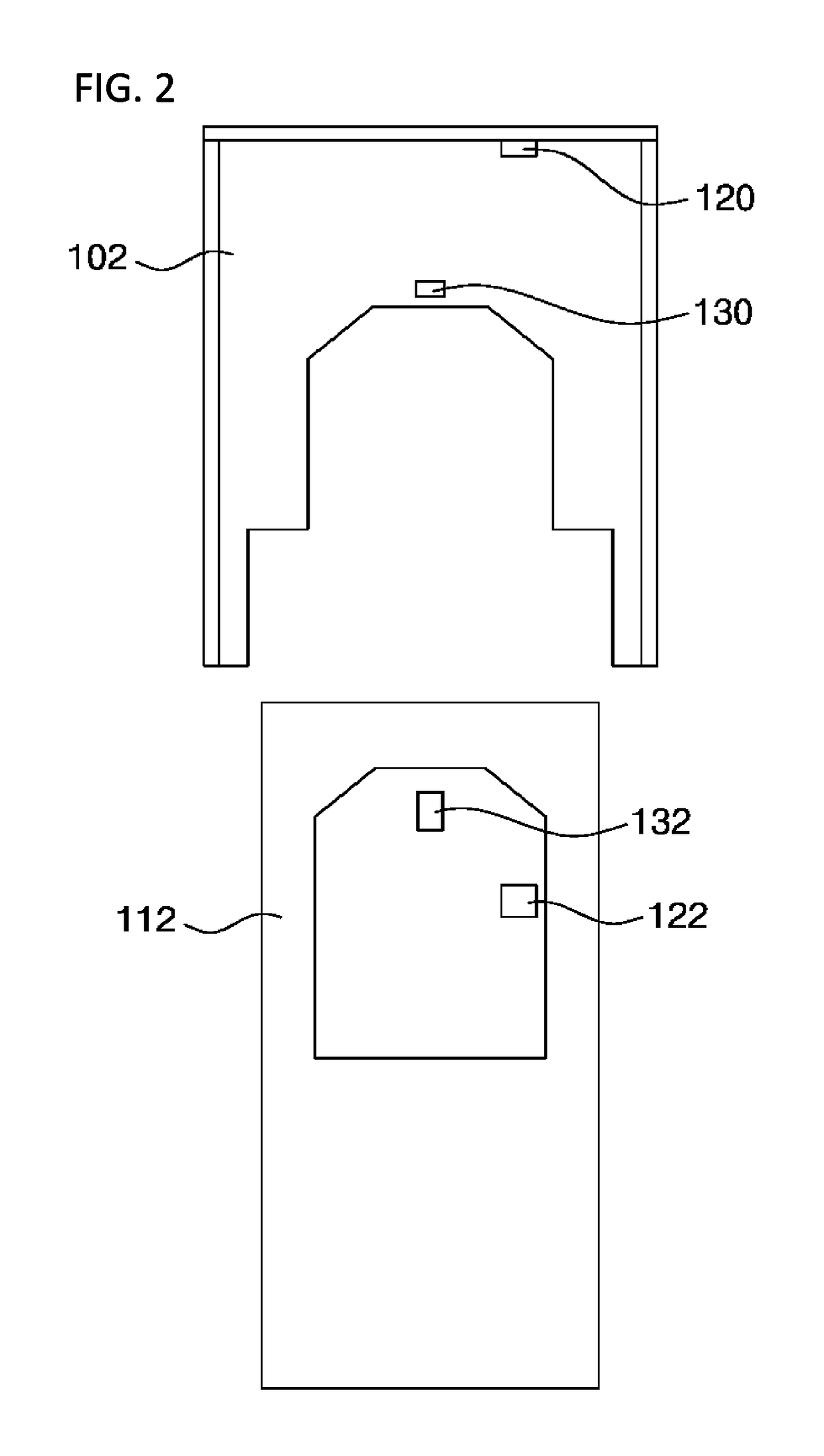

Stocker for receiving cassettes and method of teaching a stocker robot disposed therein

ActiveUS9987747B2Rapidly and easily teachingEasy to implementProgramme controlProgramme-controlled manipulatorSimulation

Disclosed is a stocker for receiving a cassette. The stocker includes a shelf for receiving a cassette, a stocker robot, a teaching jig, and a teaching unit. The stocker robot includes a robot arm configured to load the cassette in the shelf and to unload the cassette from the shelf. The teaching jig is disposed in the shelf to teach the stocker robot. The teaching unit is disposed on the robot arm to acquire information for teaching the stocker robot using the teaching jig.

Owner:SEMES CO LTD

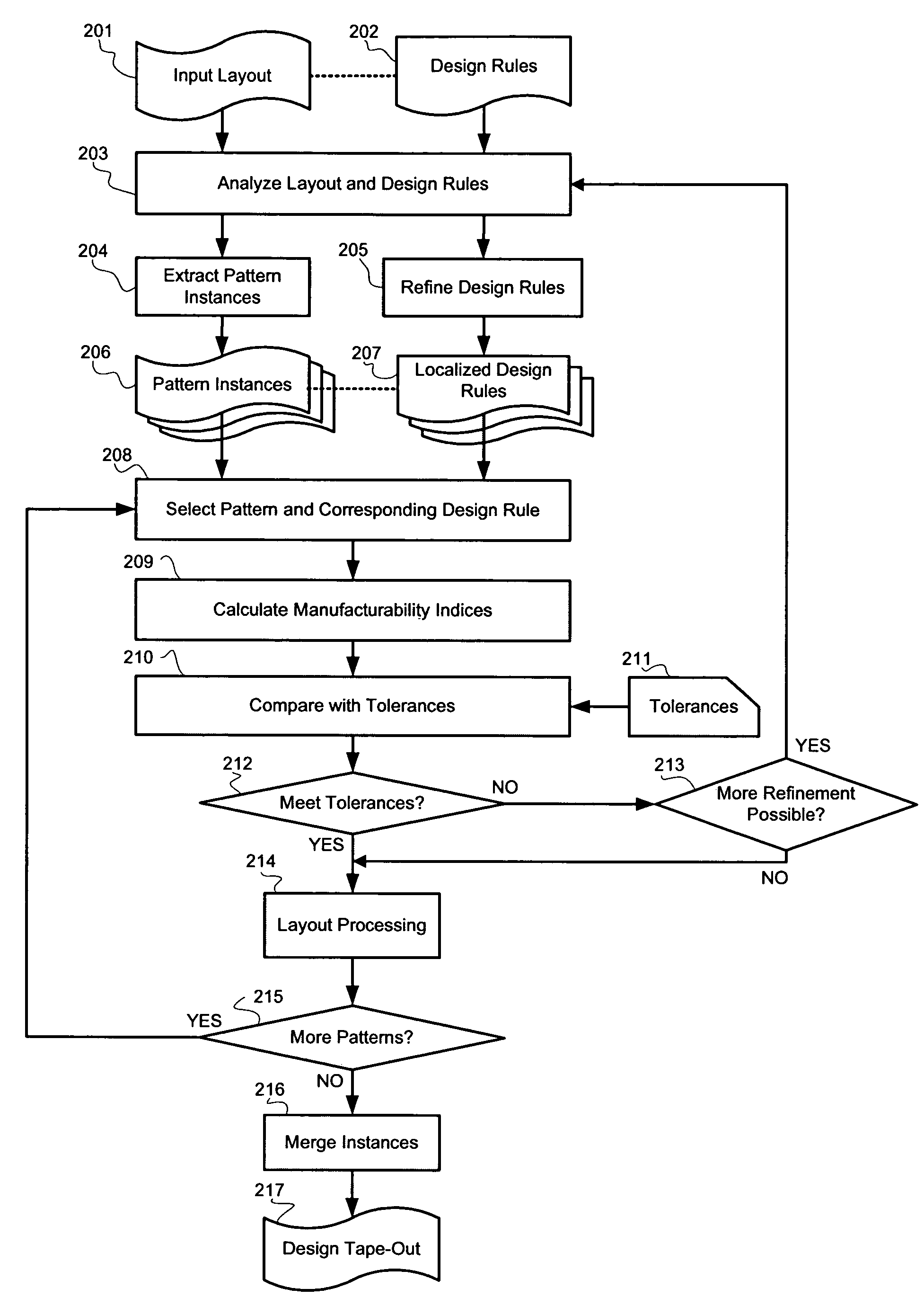

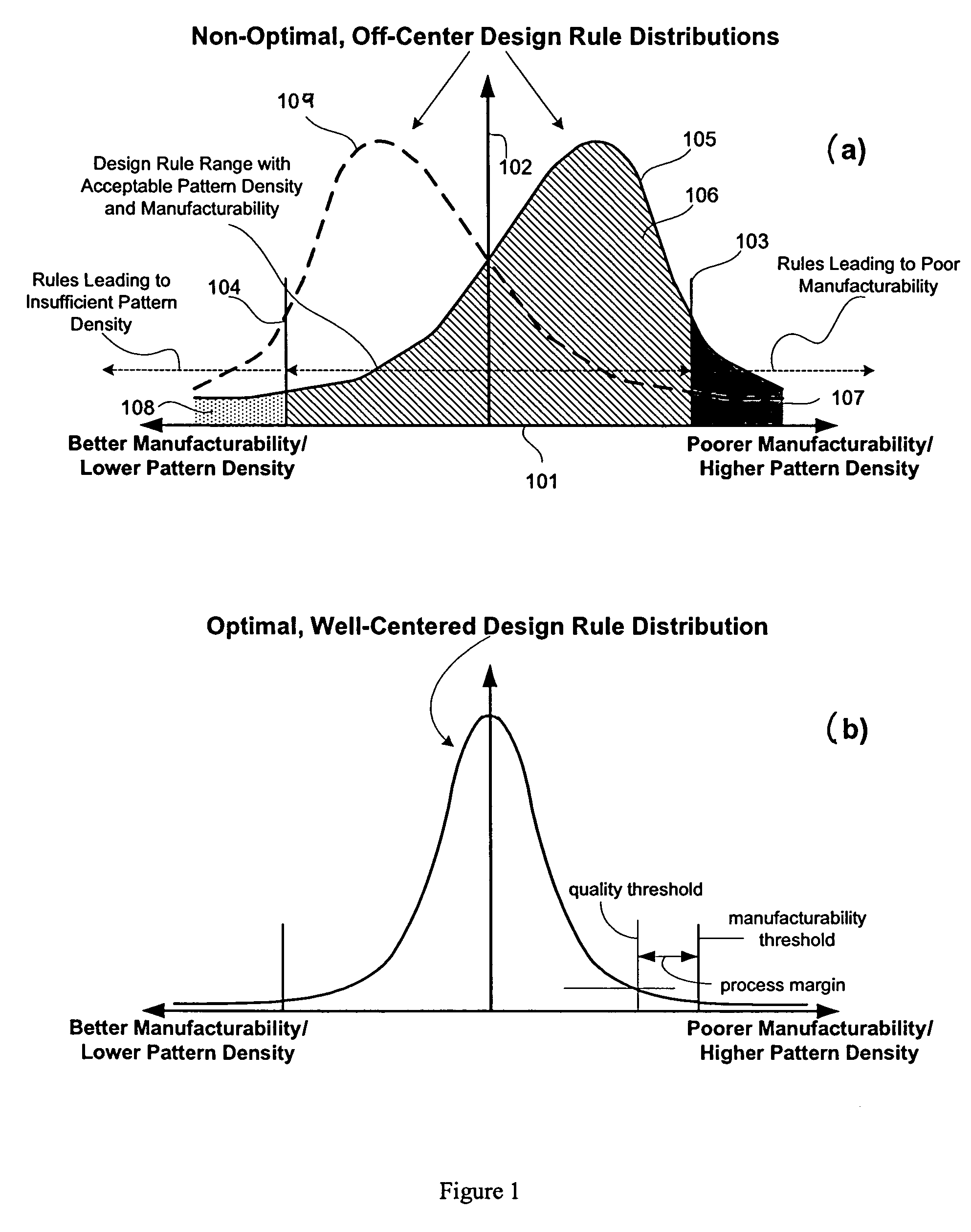

System for designing integrated circuits with enhanced manufacturability

ActiveUS7523429B2Improve manufacturabilityLittle interferencePressersMattress sewingGranularityEngineering

A system and method for integrated circuit design are disclosed to enhance manufacturability of circuit layouts through generation of hierarchical design rules which capture localized layout requirements. In contrast to conventional techniques which apply global design rules, the disclosed IC design system and method partition the original design layout into a desired level of granularity based on specified layout and integrated circuit properties. At that localized level, the design rules are adjusted appropriately to capture the critical aspects from a manufacturability standpoint. These adjusted design rules are then used to perform localized layout manipulation and mask data conversion.

Owner:APPLIED MATERIALS INC

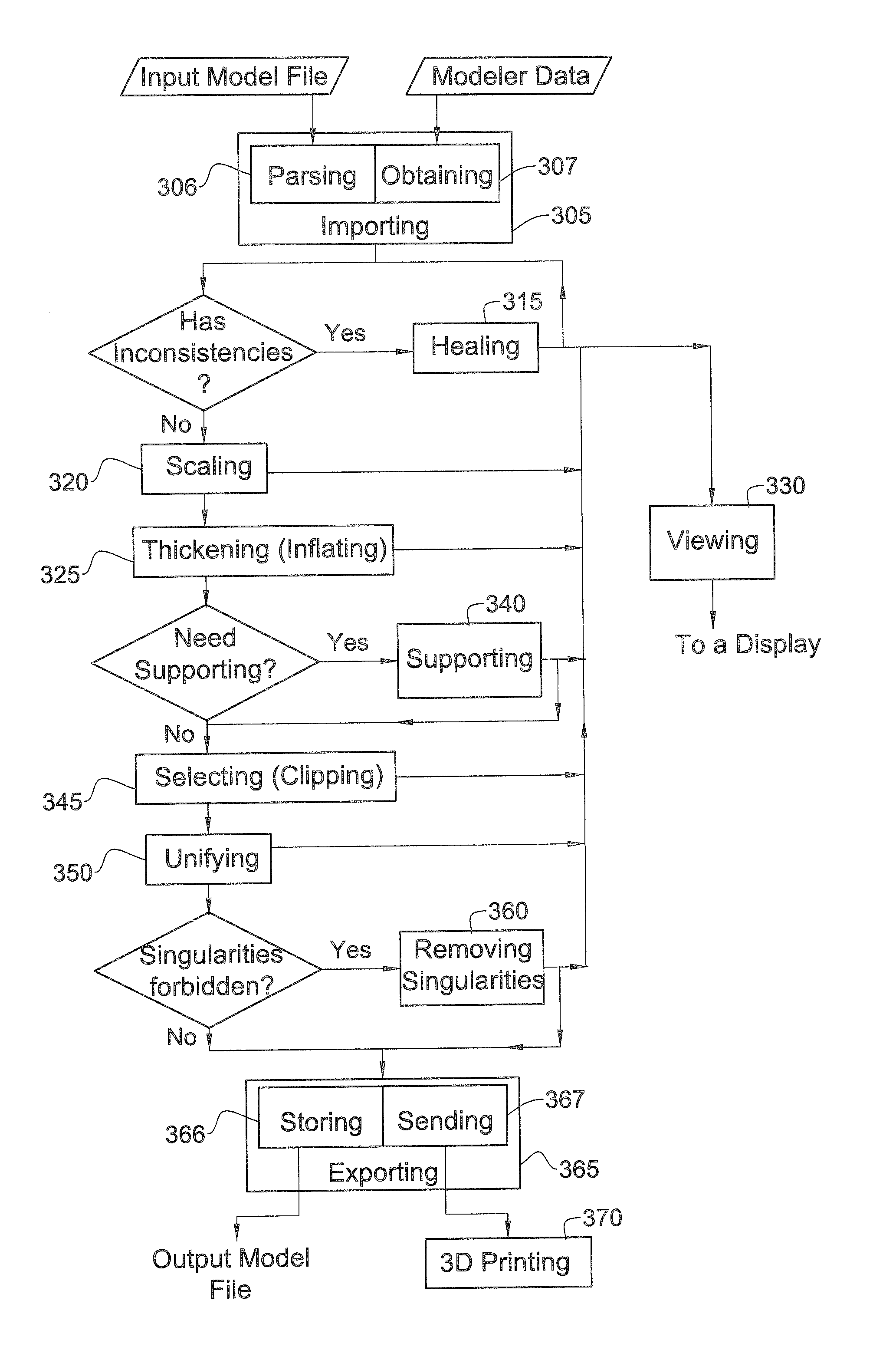

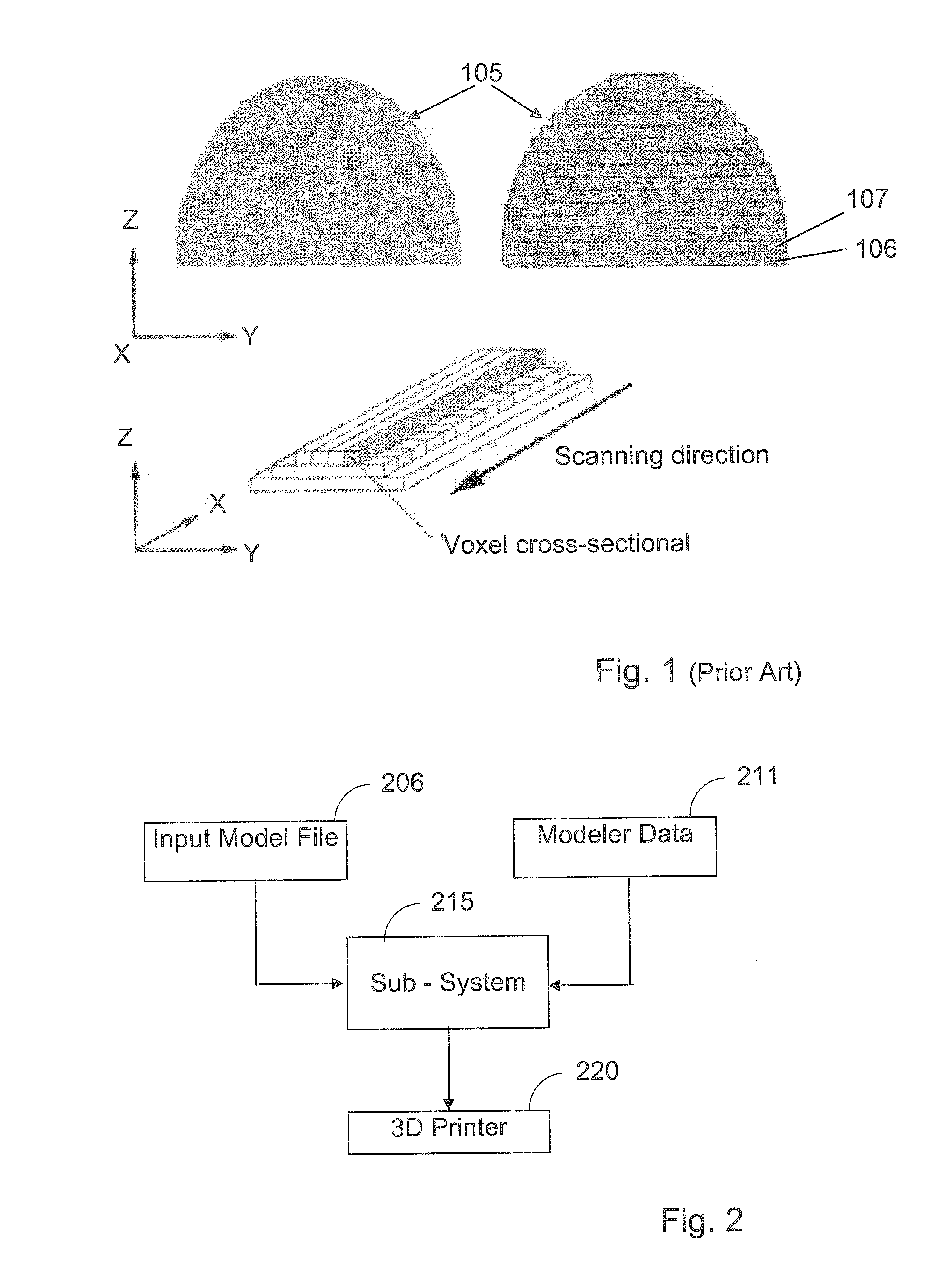

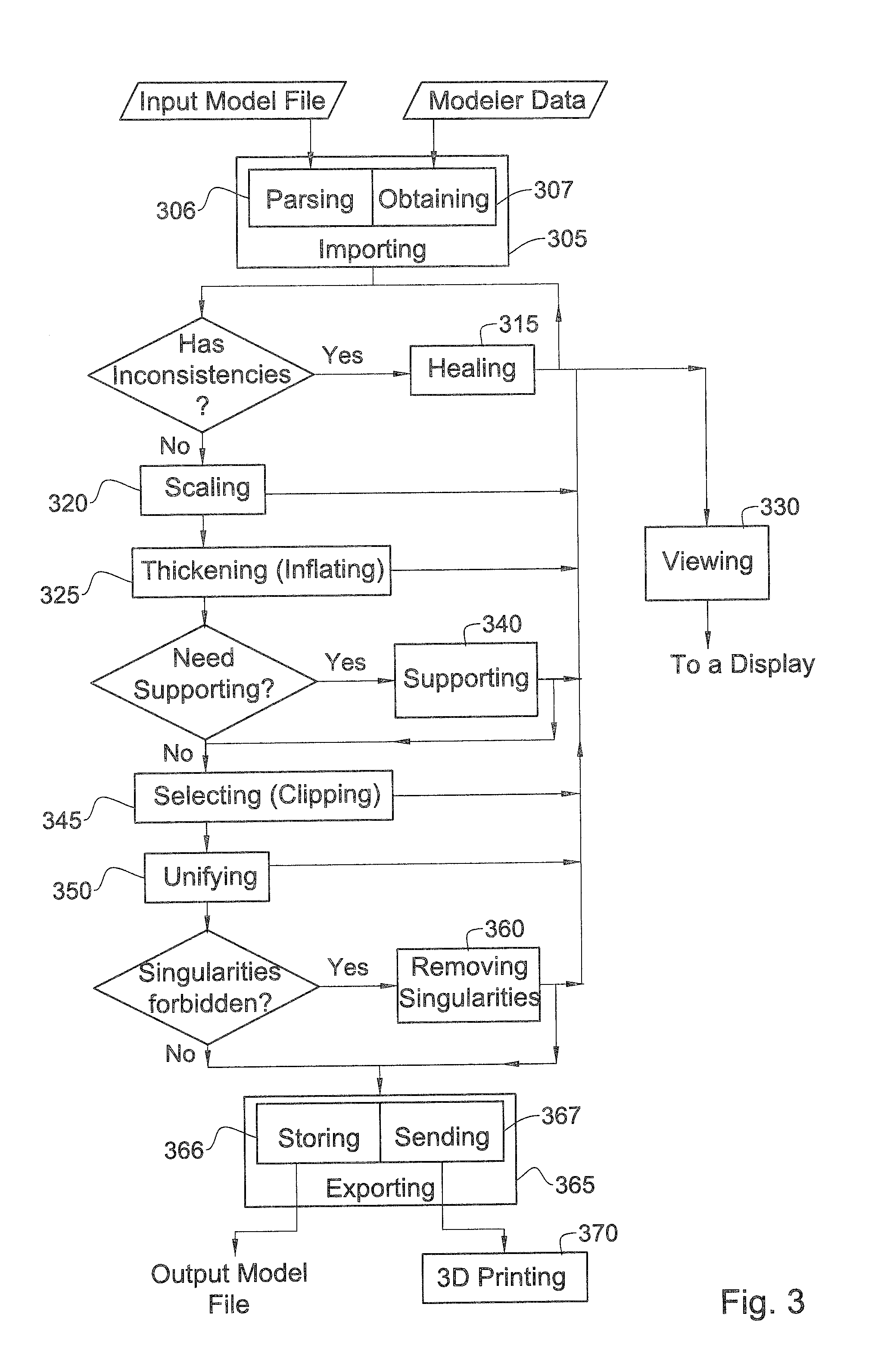

Methods and system for enabling printing three-dimensional object models

InactiveUS20110087350A1Additive manufacturing apparatusComputer aided designComputer scienceObject model

The present invention relates to a system and method of transforming an inconsistent 3D (three-dimensional) model of one or more 3D objects into a valid printable 3D model, said method comprising: (a) receiving an input model file and / or receiving modeler data, giving rise to an input 3D model having one or more parts; (b) analyzing said input 3D model and removing its one or more inconsistencies; (c) thickening the one or more parts of said 3D model, while preserving their functionality; and (d) unifying the union of interior volumes of said one or more parts, thereby removing self intersections and / or intersections between the two or more parts, giving rise to a valid printable 3D model.

Owner:3D M T P

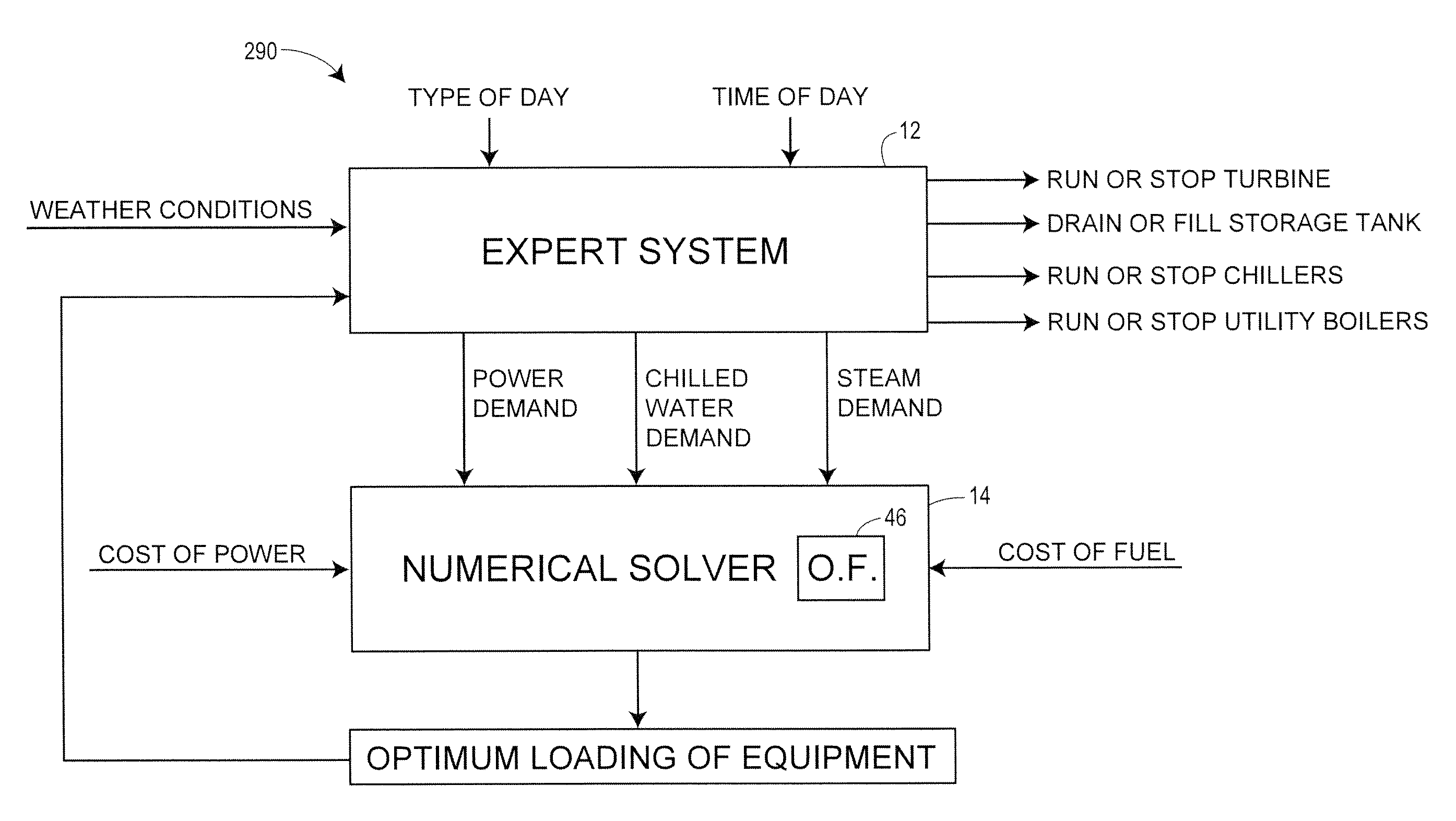

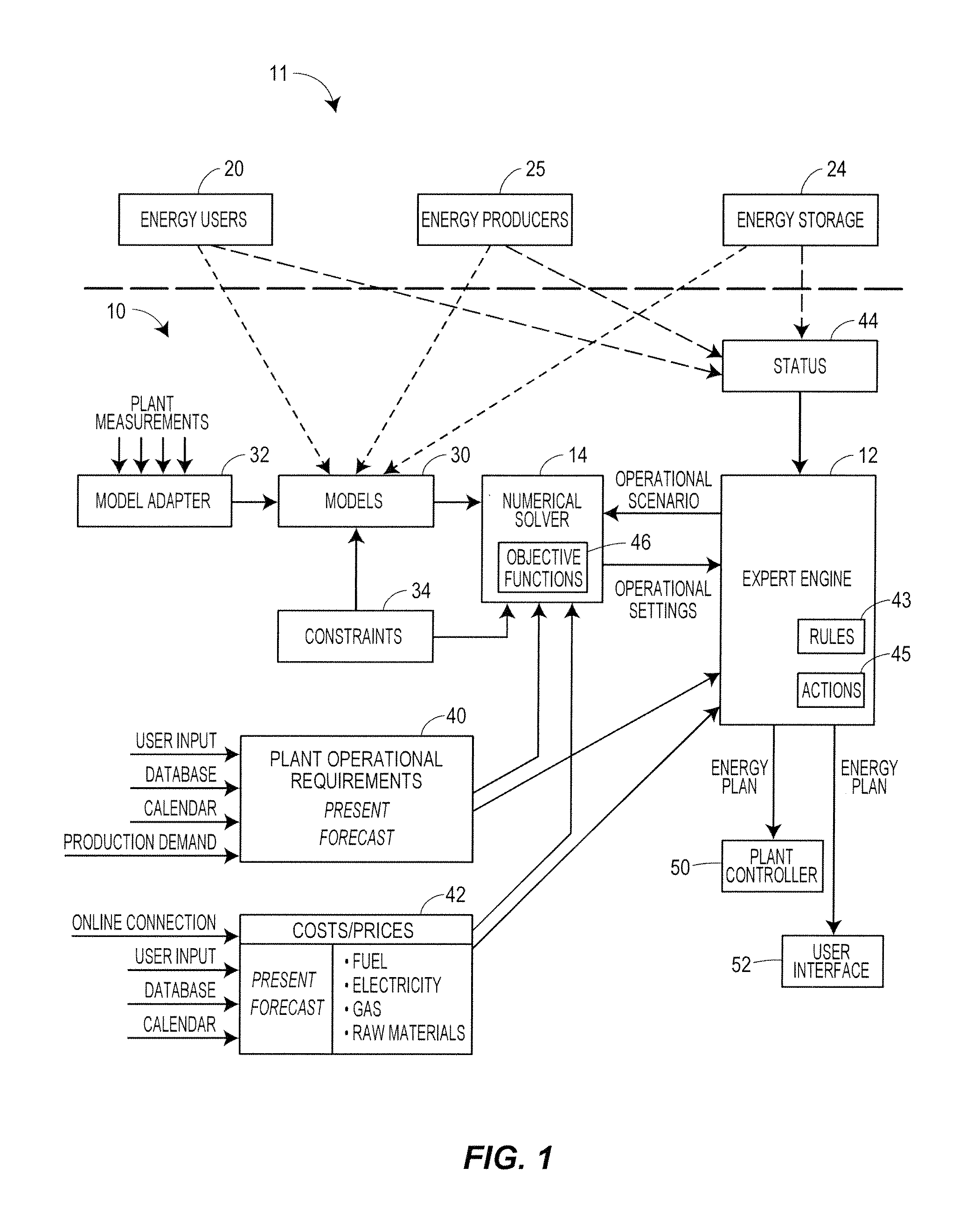

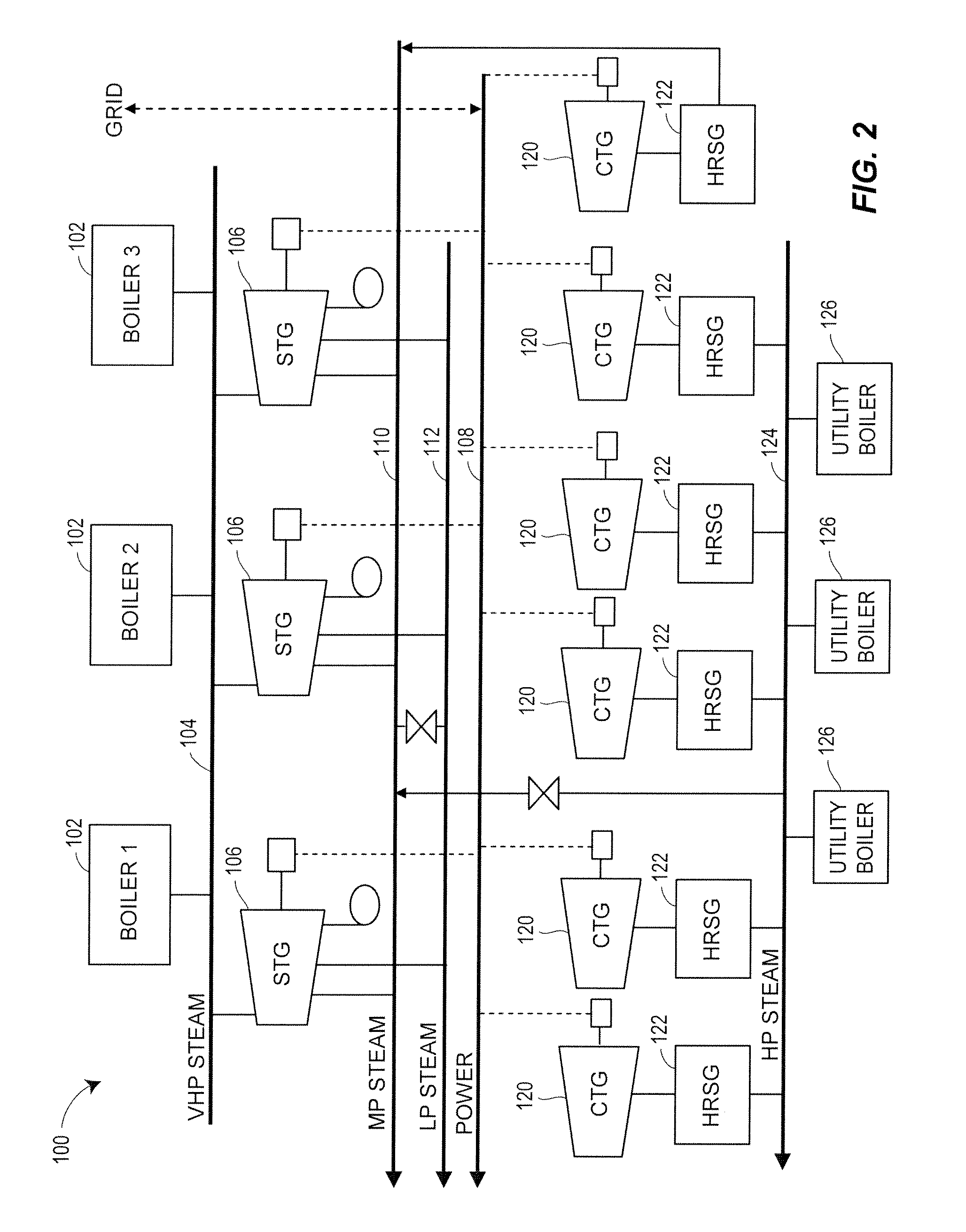

Energy management system

ActiveUS20120010757A1Reduce and optimize energy costLow costLevel controlVolume/mass flow measurementOperational systemEnergy depletion

An energy management system uses an expert engine and a numerical solver to determine an optimal manner of using and controlling the various energy consumption, producing and storage equipment in a plant / communities in order to for example reduce energy costs within the plant, and is especially applicable to plants that require or that are capable of using and / or producing different types of energy at different times. The energy management system operates the various energy manufacturing and energy usage components of the plant to minimize the cost of energy over time, or at various different times, while still meeting certain constraints or requirements within the operational system, such as producing a certain amount of heat or cooling, a certain power level, a certain level of production, etc. In some cases, the energy management system may cause the operational equipment of the plant to produce unneeded energy that can be stored until a later time and then used, or that can be sold back to a public utility, for example, so as to reduce the overall cost of energy within the plant.

Owner:EMERSON PROCESS MANAGEMENT POWER & WATER SOLUTIONS

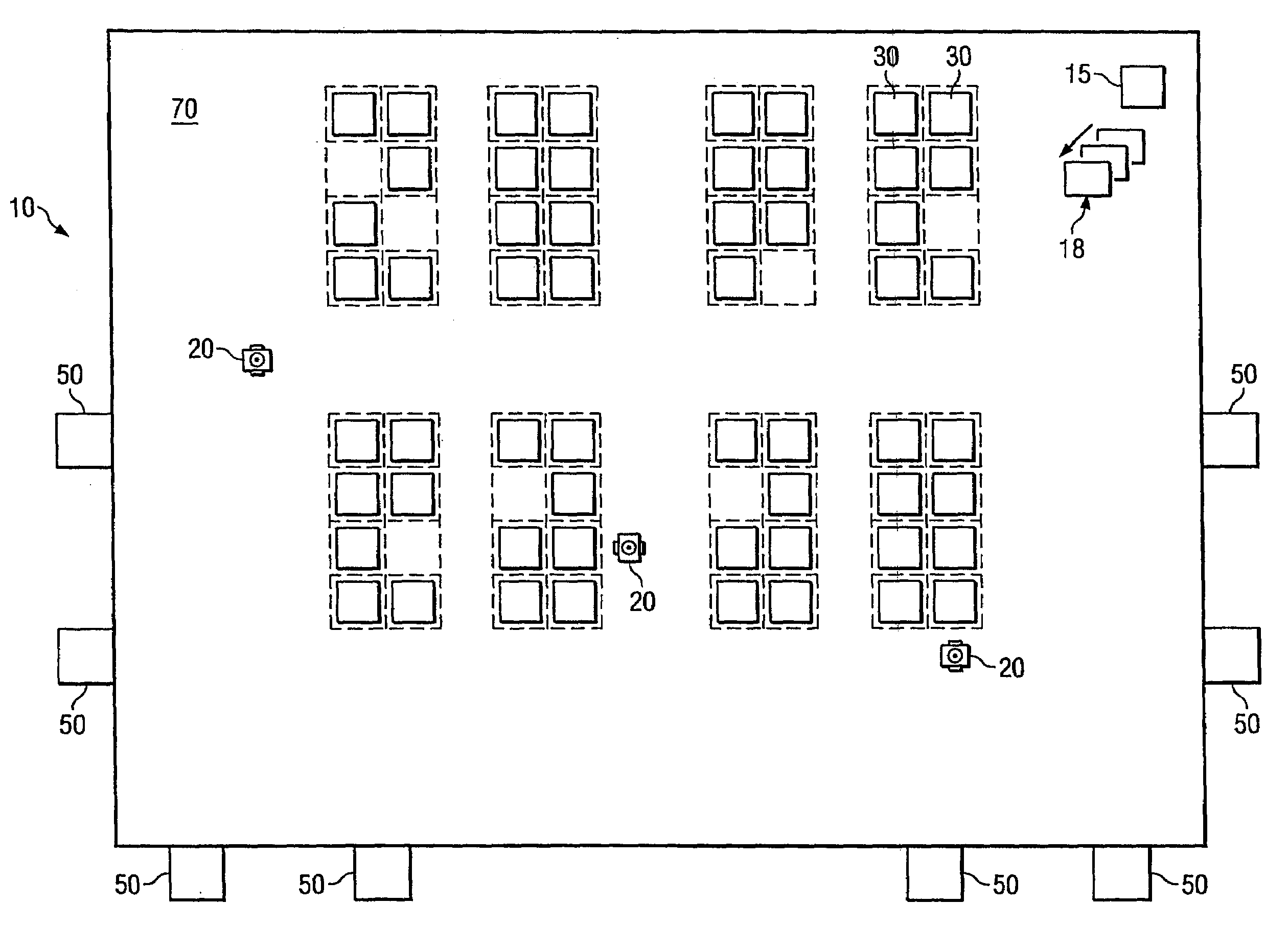

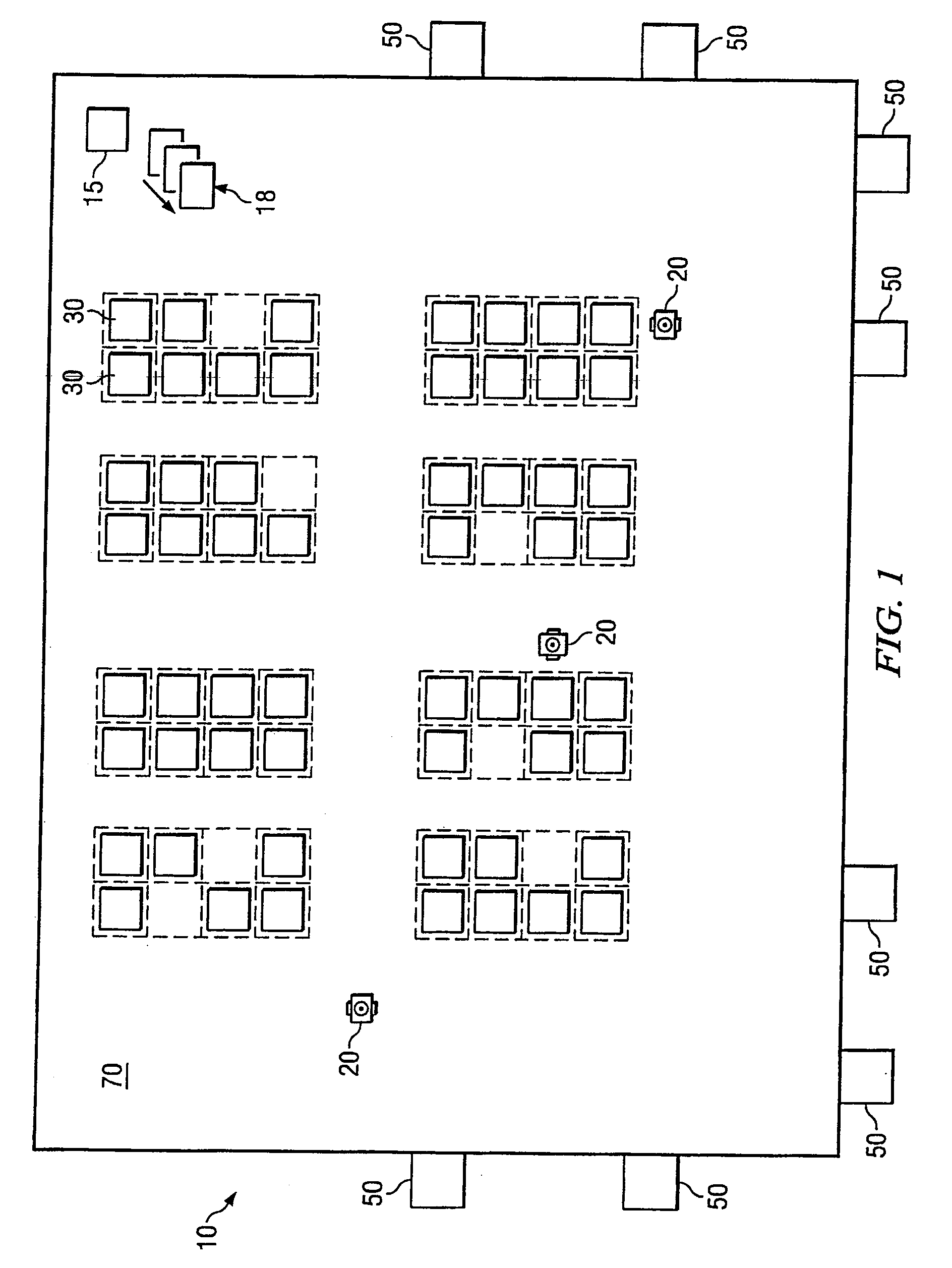

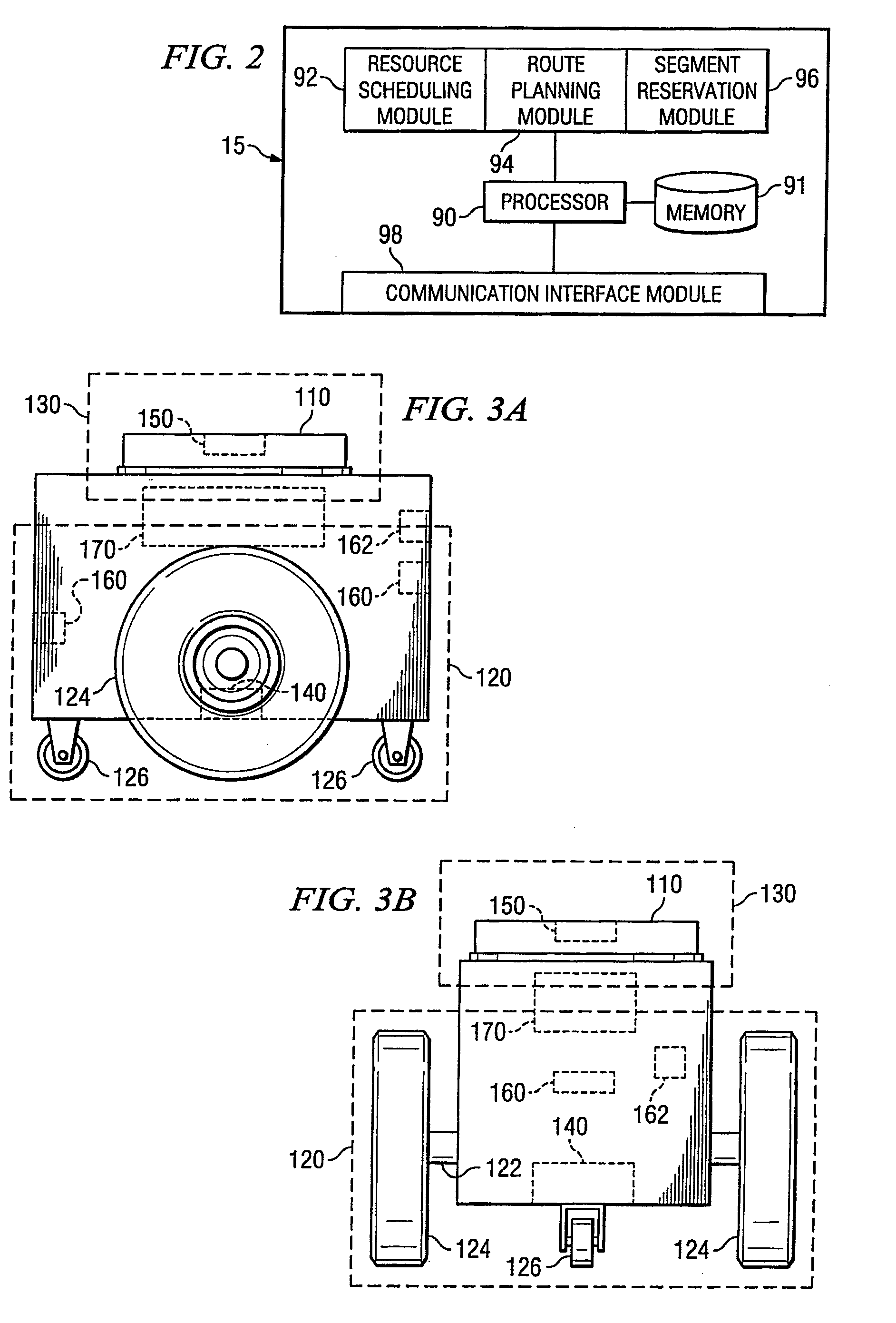

System and method for transporting inventory items

ActiveUS20070293978A1Disadvantages and reduced eliminatedInventory reduced eliminatedProgramme controlDigital data processing detailsWorkspaceTransport engineering

A method for transporting inventory items includes moving a mobile drive unit to a first point within a workspace. The first point is a location of an inventory holder. The method further includes docking the mobile drive unit with the inventory holder and moving the mobile drive unit and the inventory holder to a second point within the workspace. The second point is associated with conveyance equipment. The method further includes moving the inventory holder to a third point within the workspace using the conveyance equipment.

Owner:AMAZON TECH INC

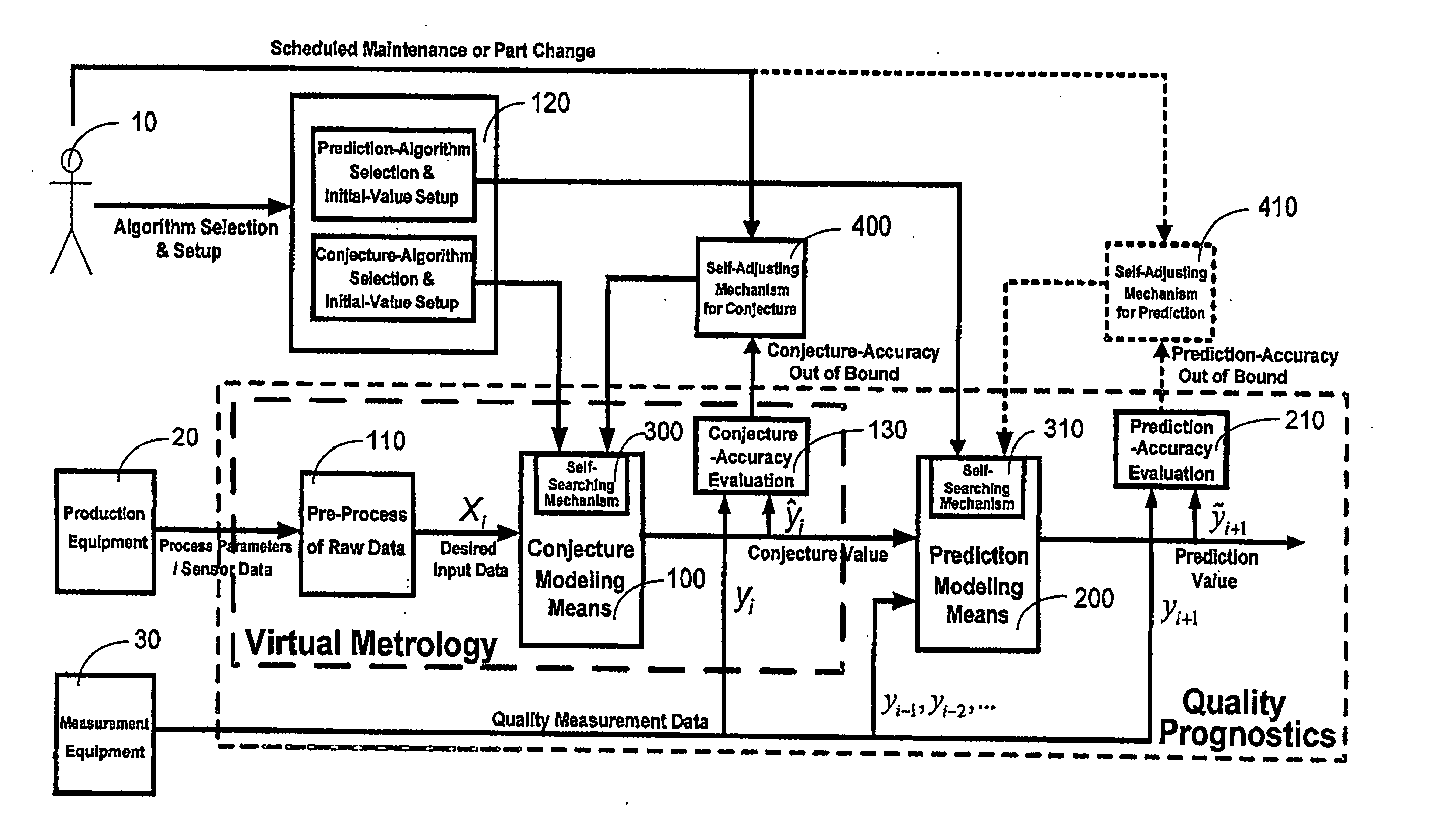

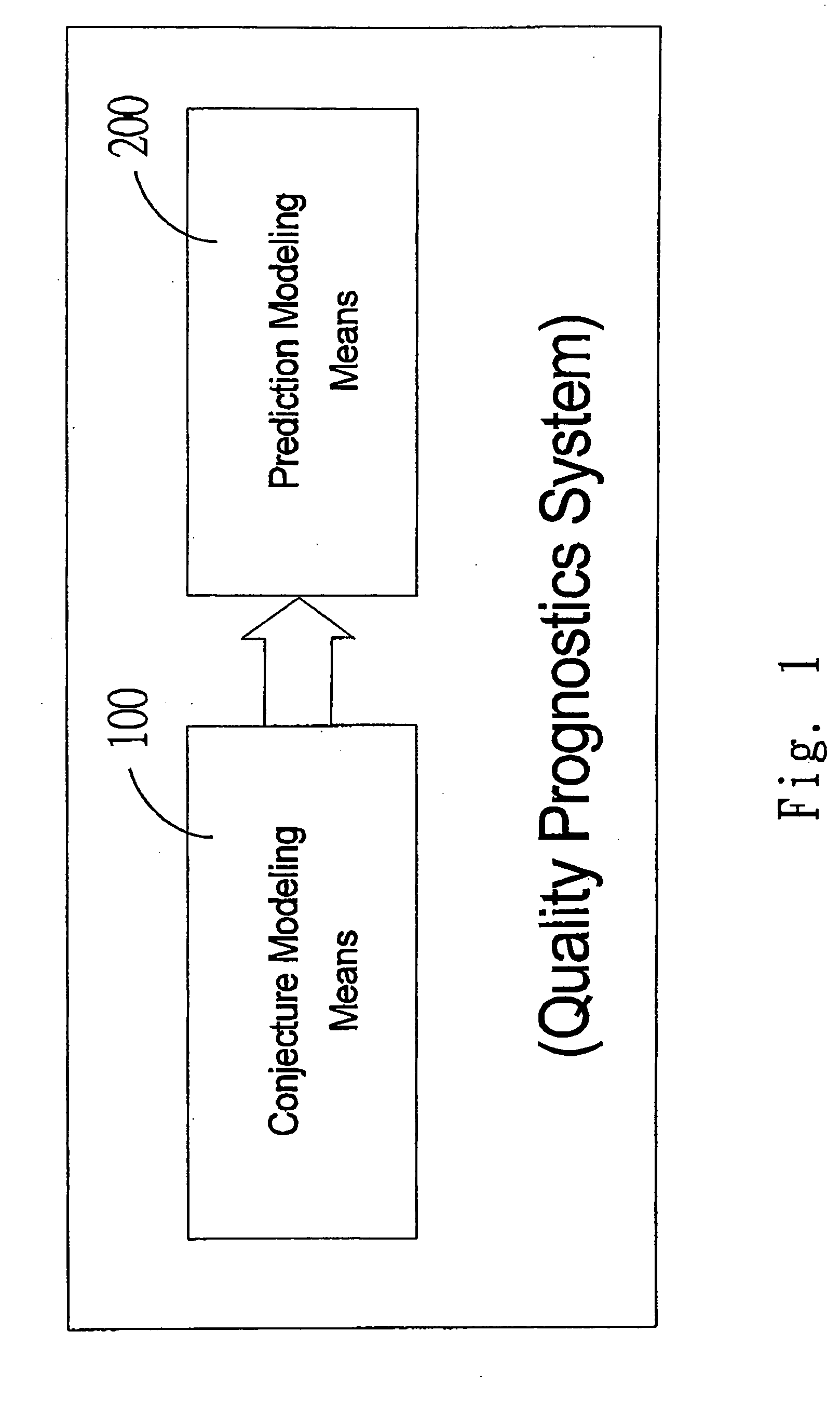

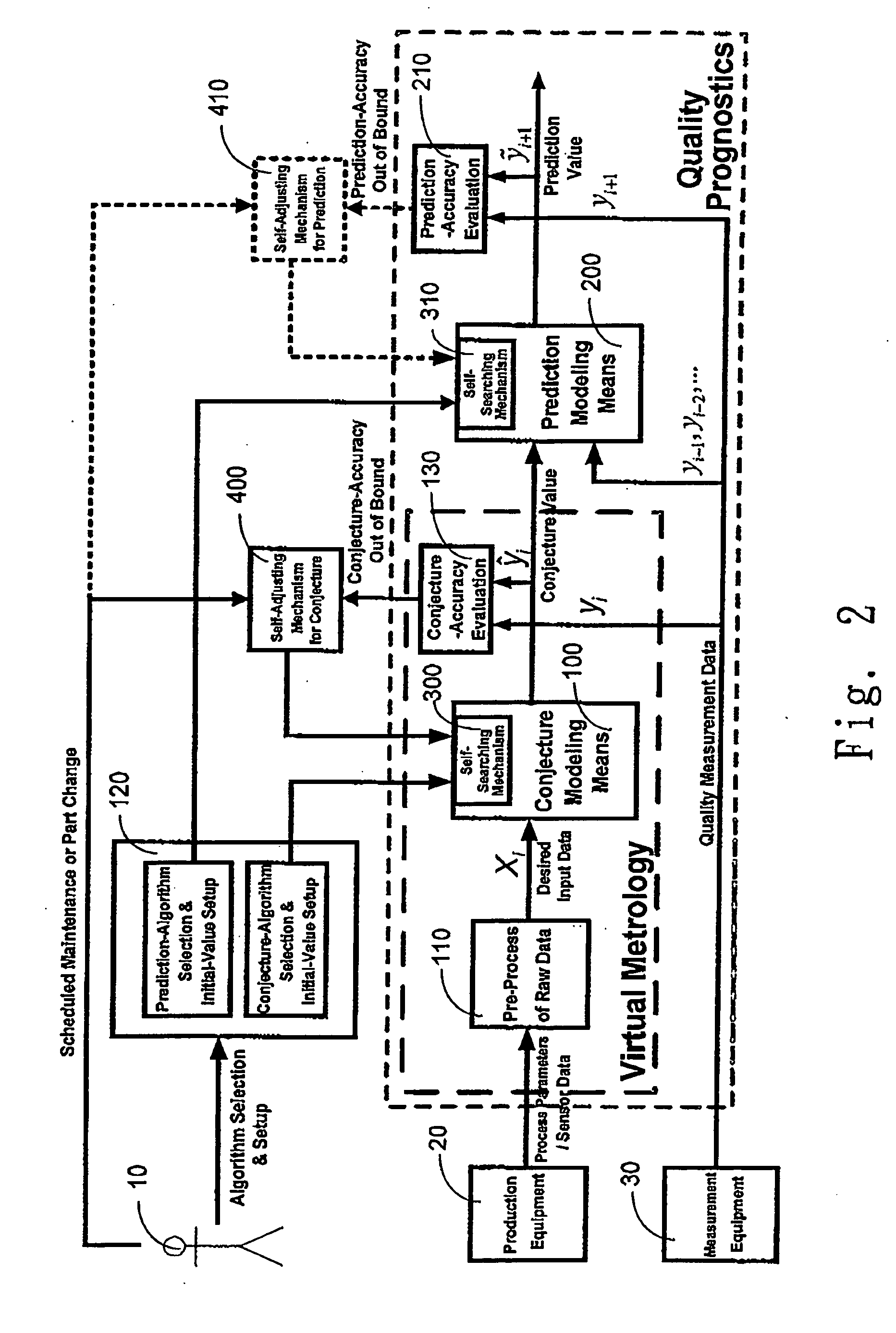

Quality prognostics system and method for manufacturing processes

ActiveUS20050288812A1Reduce disadvantagesImprove availabilityDigital computer detailsSemiconductor/solid-state device manufacturingPredictive systemsPrediction algorithms

A quality prognostics system and a quality prognostics method for predicting the product quality during manufacturing processes are disclosed. The present invention utilizes the current production tool parameters sensed during the manufacturing process and several previous quality data collected from the measurement tool to predict the future product quality. The quality prognostics system is composed of conjecture modeling means and prediction modeling means. The conjecture modeling means itself also can be applied for the purpose of virtual metrology. Further, the quality prognostics method possesses a self-searching means and a self-adjusting means for searching the best combination of various parameters / functions used by the conjecture algorithm or prediction algorithm; and meeting the requirements of new equipment parameters and conjecture / prediction accuracy.

Owner:NAT CHENG KUNG UNIV

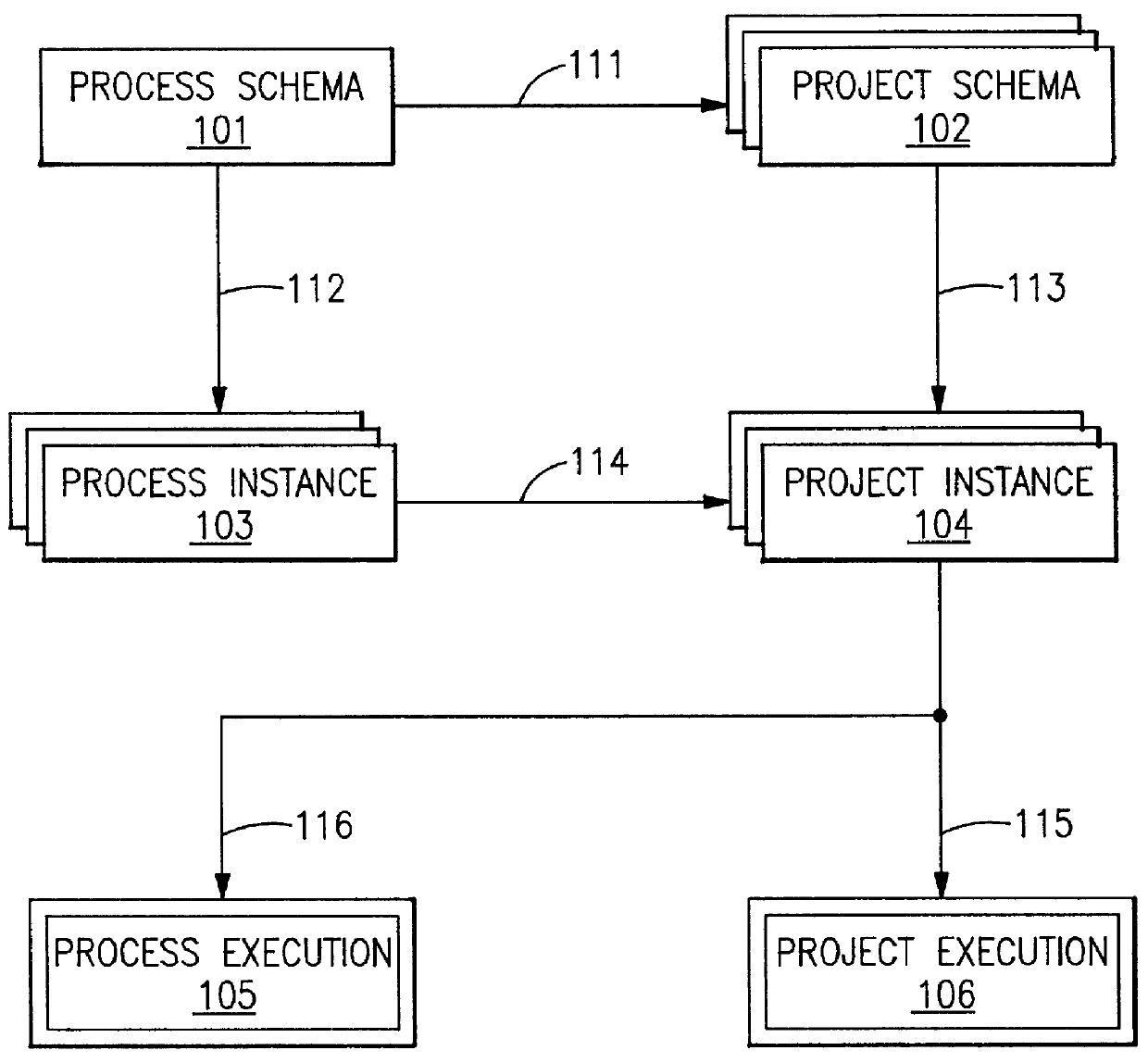

Method and apparatus for a process and project management computer system

InactiveUS6023702AReduce storageImprove performanceProgram control using stored programsResourcesDigital dataModularity

PCT No. PCT / EP95 / 03289 Sec. 371 Date Dec. 10, 1998 Sec. 102(e) Date Dec. 10, 1998 PCT Filed Aug. 18, 1995 PCT Pub. No. WO97 / 07472 PCT Pub. Date Feb. 27, 1997The inventive concept comprises a system platform for a synergistic, role modular work process environment. A work process object (WPO) (1001) is created, residing in a data base, and stored in a memory of the process and project management computer system (1030). All data concerning the process and project management are reported to said work process object (WPO) (1001) and said work process object (WPO) (1001) is used as a common data base. According to the inventive concept, each view must be supported by a specific workplace, represented by digital data and enforcing the rules for the specific role. A work process information model supports the dynamic definition and use of a data base object representing a work process, boch in its process and project planning modes and its execution. According to the inventive concept, one object supports simultaneously all modes delimited by dynamically moving boundaries. Workplace implementation enforces over-all rules for each role in the inventive system.

Owner:IBM CORP

Methods and apparatus for control configuration using live data

InactiveUS20060206866A1OptimizationOptimize system configurationData processing applicationsComputer controlGraphicsReal-time data

Methods and apparatus for configuring process, environmental, industrial and other control systems generate and / or utilize models representing configurations of control systems and / or the systems controlled by them. Records of changes to the models or the configurations represented by them are maintained, thereby, for example, providing bases for determining current states, prior states and histories of changes. Objects in the model have characteristics, such as an object type characteristic and an area characteristic. Users can have corresponding permissions. A security mechanism apparatus controls access by users to the objects. Composite objects are defined by definition objects and are displayed in encapsulated or expanded formats. Objects can include an edit control type identifier that determines how they are presented for editing. Functionality responds to user commands by transferring characteristics of a first object depicted by the graphical user interface to a second object. Configuration-time formulas contained objects are evaluated to constants prior to downloading to the control system.

Owner:INVENSYS SYST INC

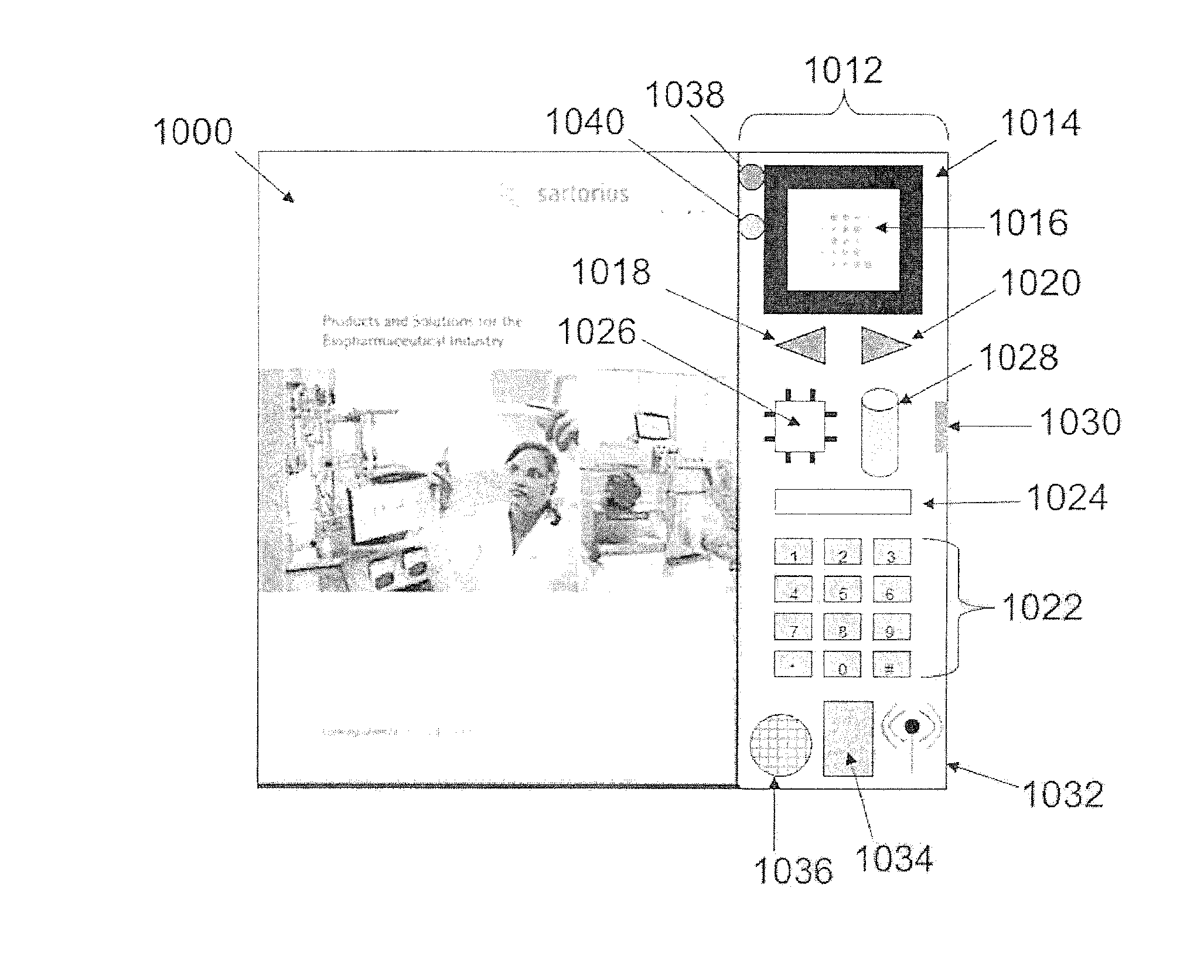

Assembling method, monitoring method, communication method, augmented reality system and computer program product

ActiveUS20130278635A1Reduce probabilityLow costProgramme controlCathode-ray tube indicatorsAugmented reality systemsComputer program

An augmented reality system, an assembling method for assembling a first set-up component to a second set-up component under the assistance of an augmented reality system, a method for monitoring a set-up component and a method for transmitting data from or to a set-up component are provided. The augmented realty system may capture a variable marker associated with the respective set-up component. The augmented reality system can recognize the location and / or status of the variable marker and thus decide whether the connection between the first and second set-up component is established correctly or not. Further, data can be transmitted by the variable marker monitored by the augmented reality system.

Owner:SARTORIUS STEDIM BIOTECH GMBH

Popular searches

Data switching by path configuration Radio/inductive link selection arrangements Alarms Wireless commuication services Time-division multiplex Messaging/mailboxes/announcements Seismic signal processing Vehicle position/course/altitude control Information technology support system Position/direction control

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com