Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51 results about "Virtual metrology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

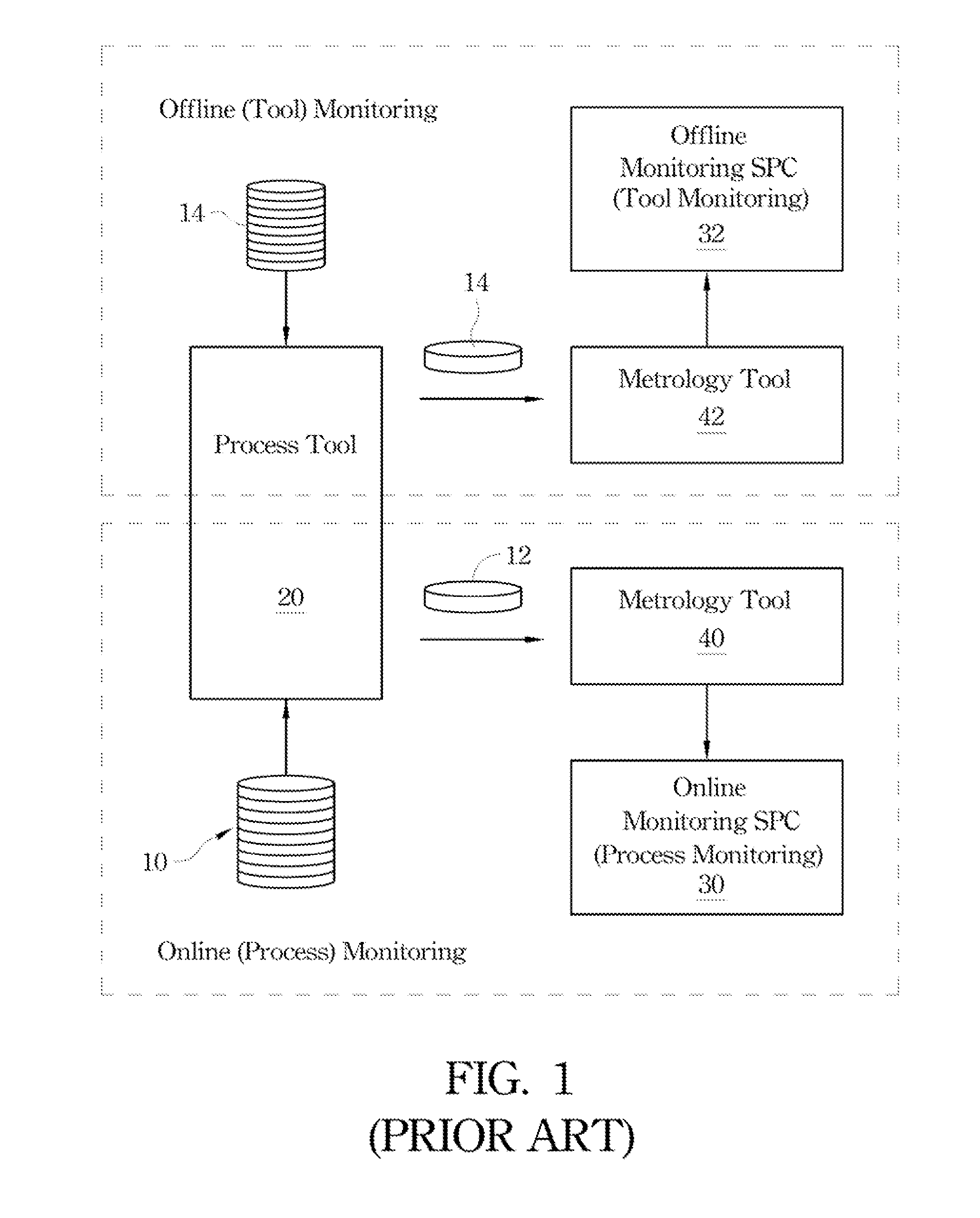

In semiconductor manufacturing, virtual metrology refers to methods to predict the properties of a wafer based on machine parameters and sensor data in the production equipment, without performing the (costly) physical measurement of the wafer properties. Statistical methods such as classification and regression are used to perform such a task. Examples of virtual metrology include: the prediction of the silicon nitride (Si₃N₄) layer thickness in the chemical vapor deposition process (CVD), using multivariate regression methods; the prediction of critical dimension in photolithography, using multi-level and regularization approaches; the prediction of layer width in etching.

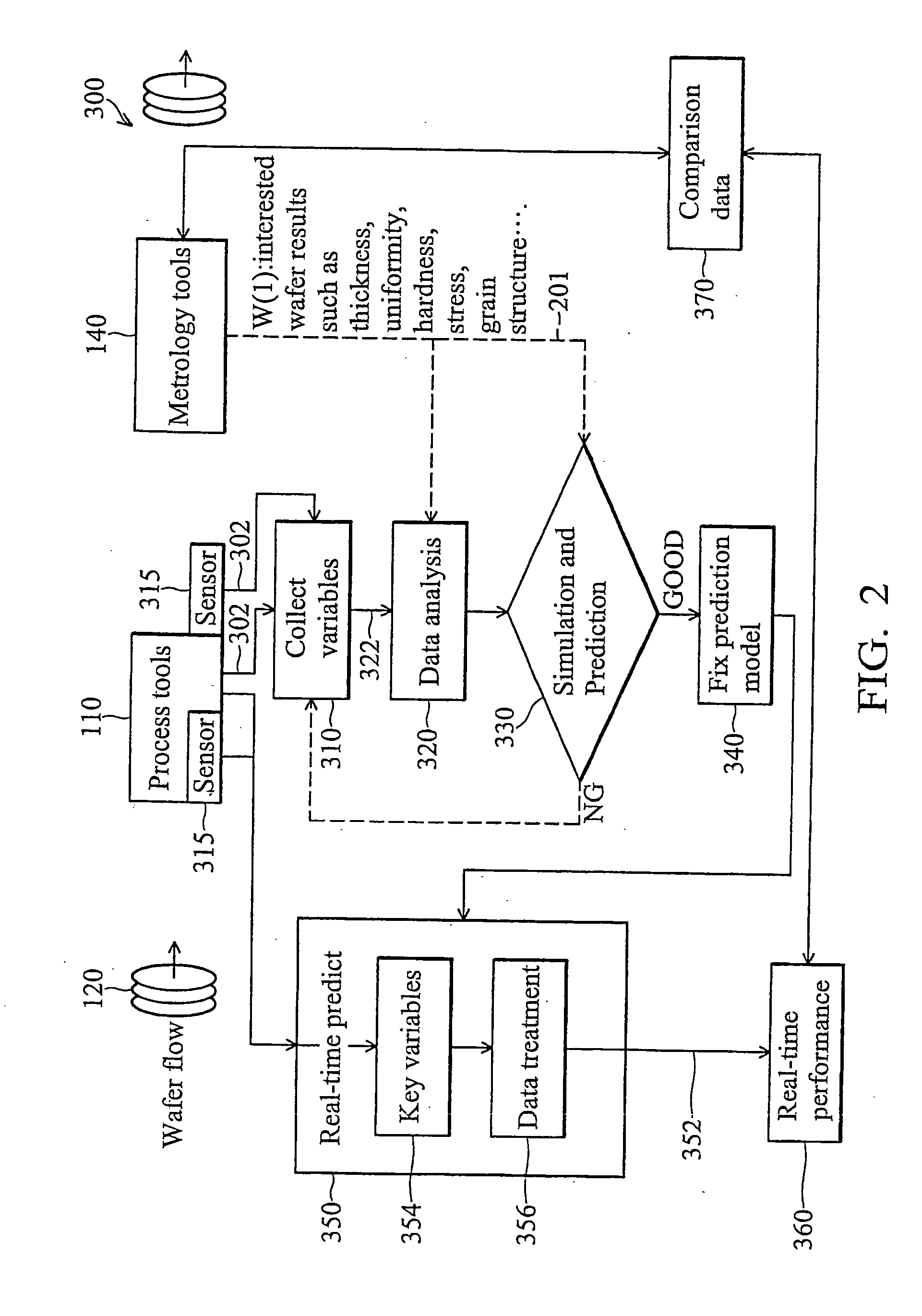

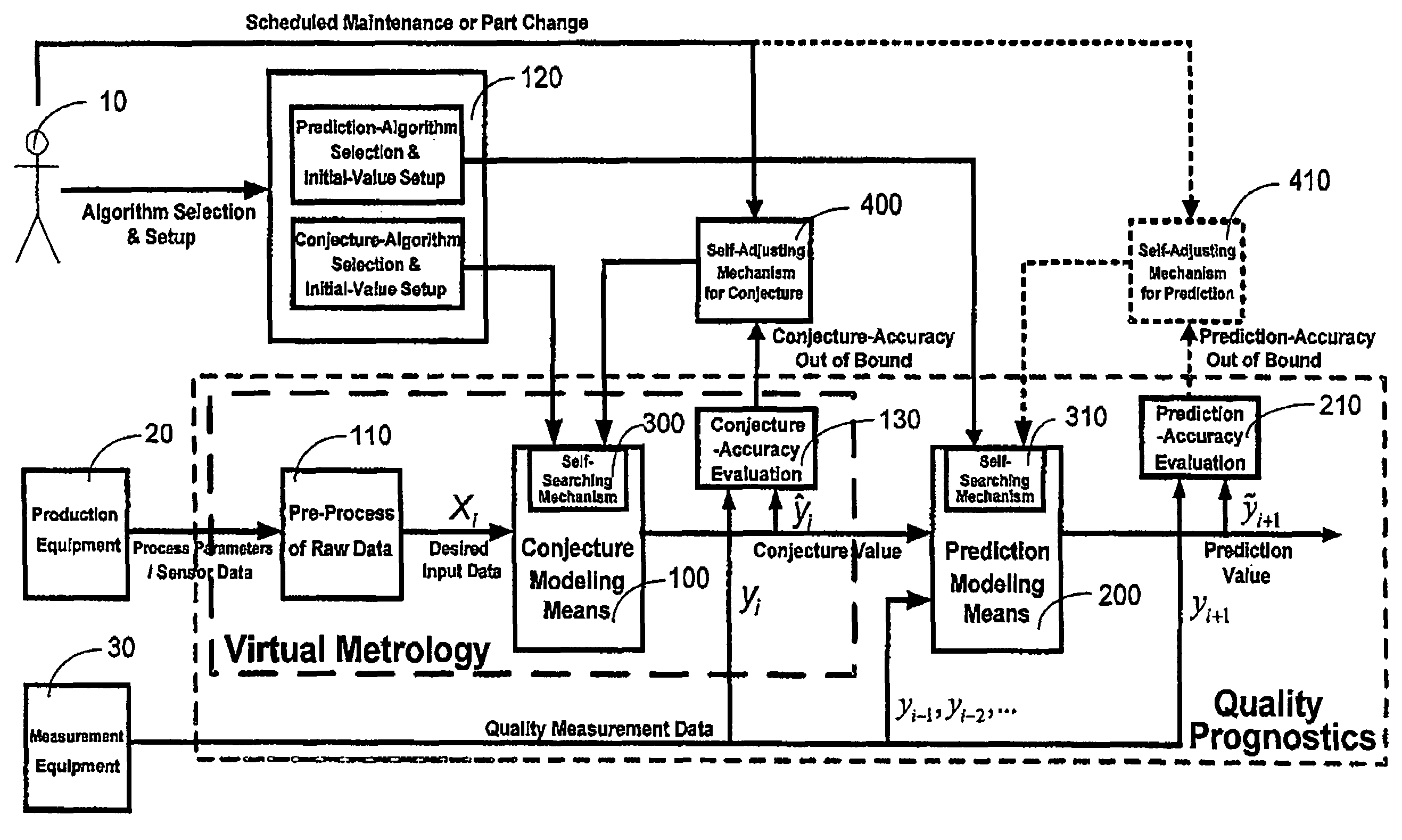

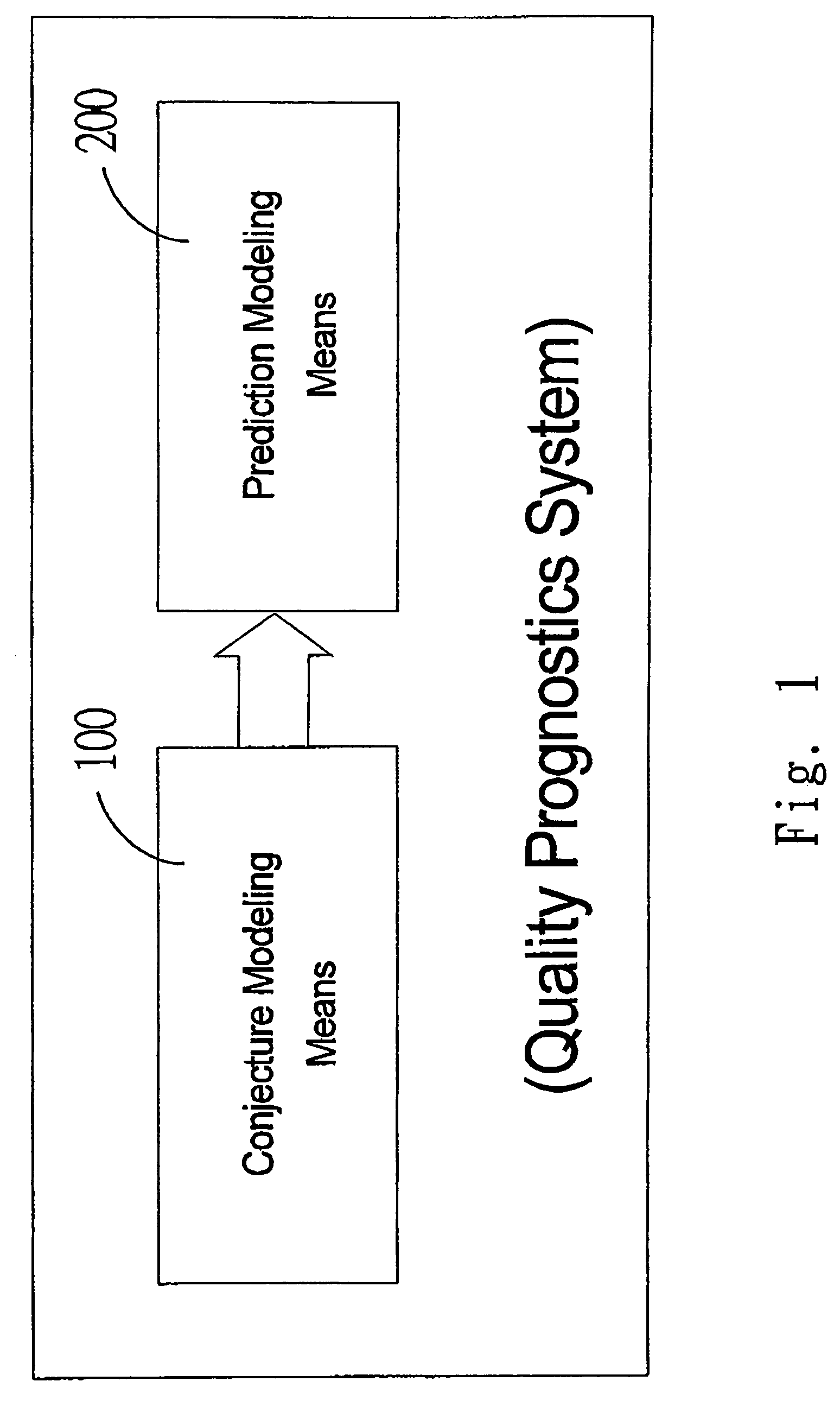

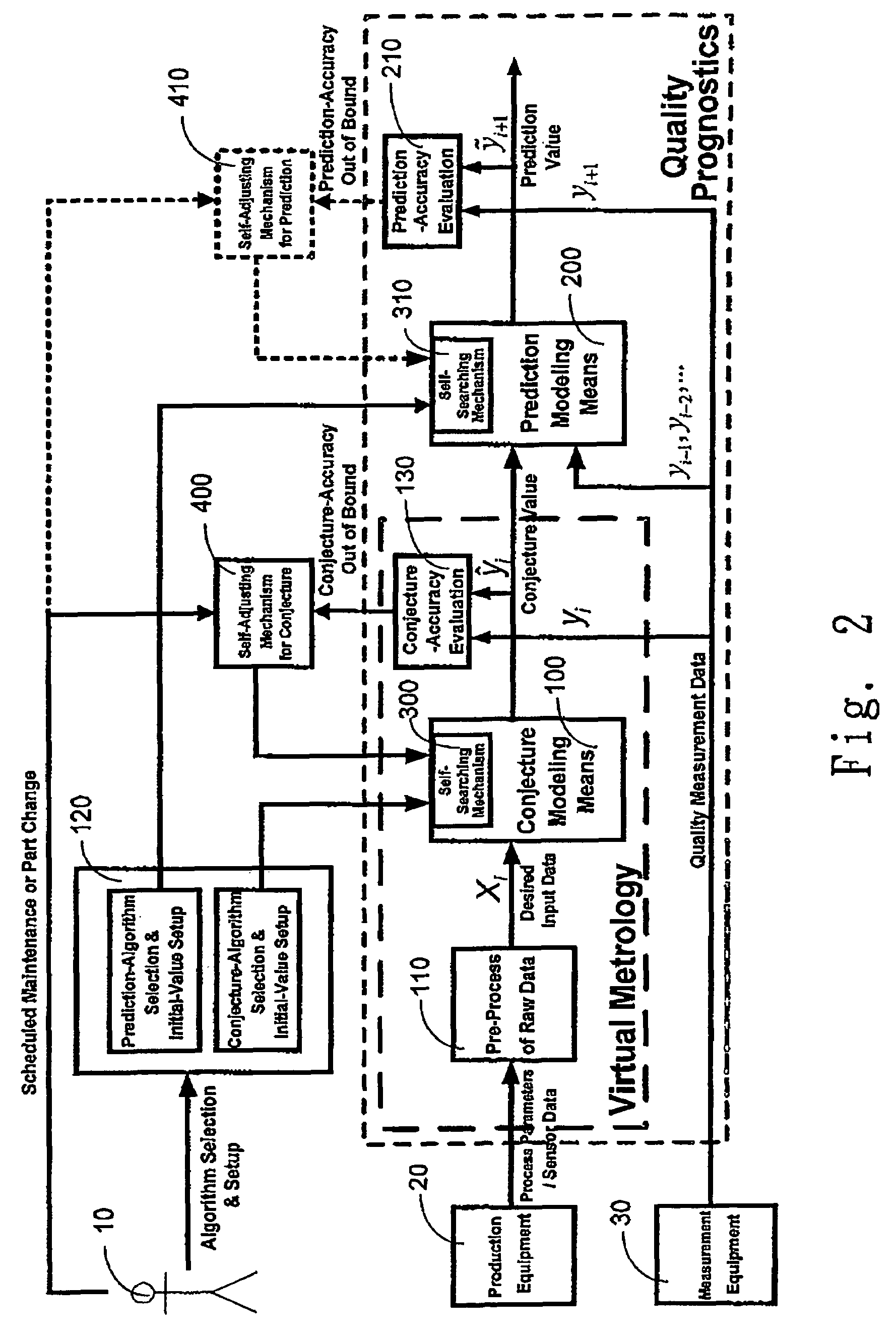

Quality prognostics system and method for manufacturing processes

ActiveUS20050288812A1Reduce disadvantagesImprove availabilityDigital computer detailsSemiconductor/solid-state device manufacturingPredictive systemsPrediction algorithms

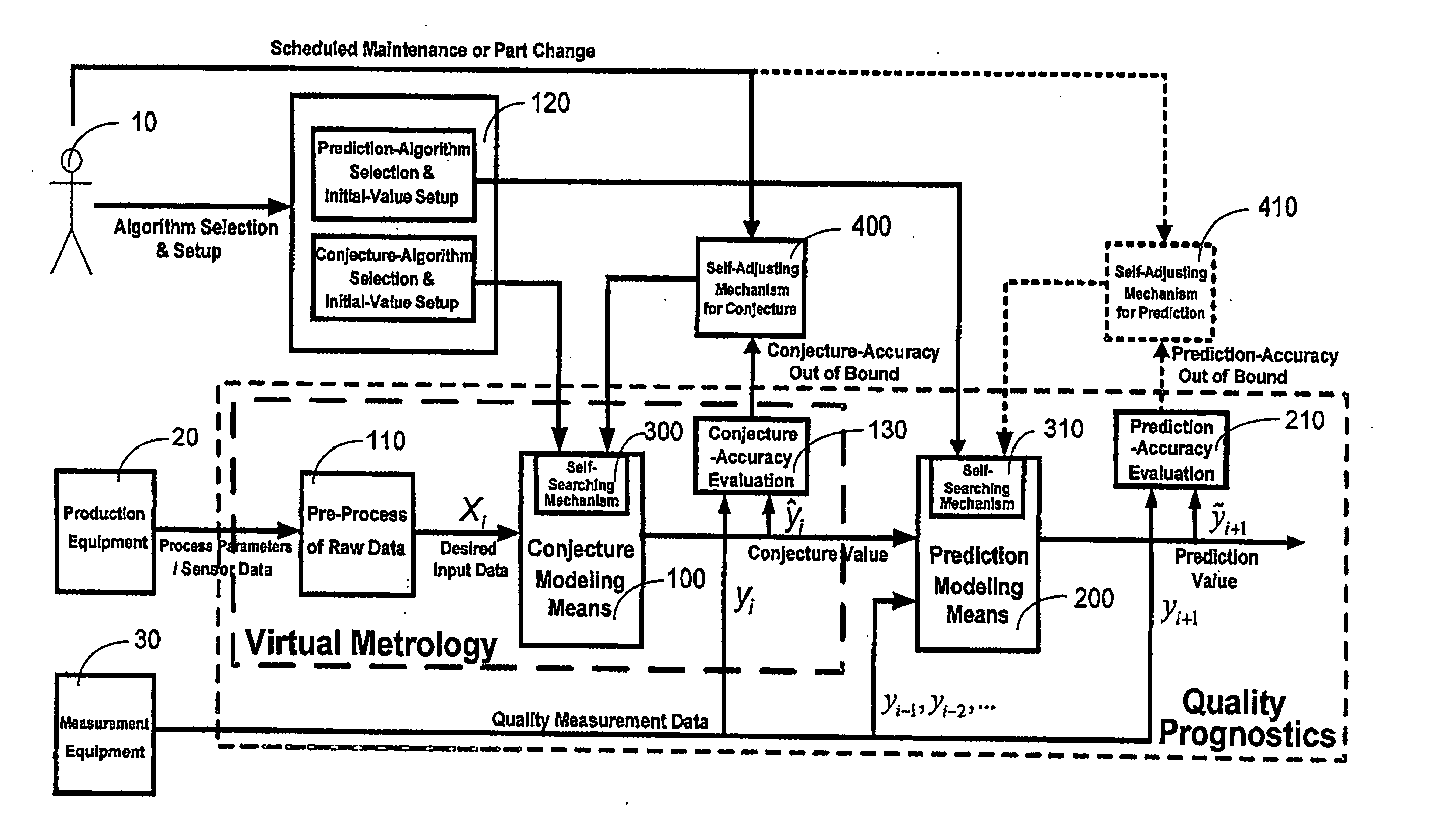

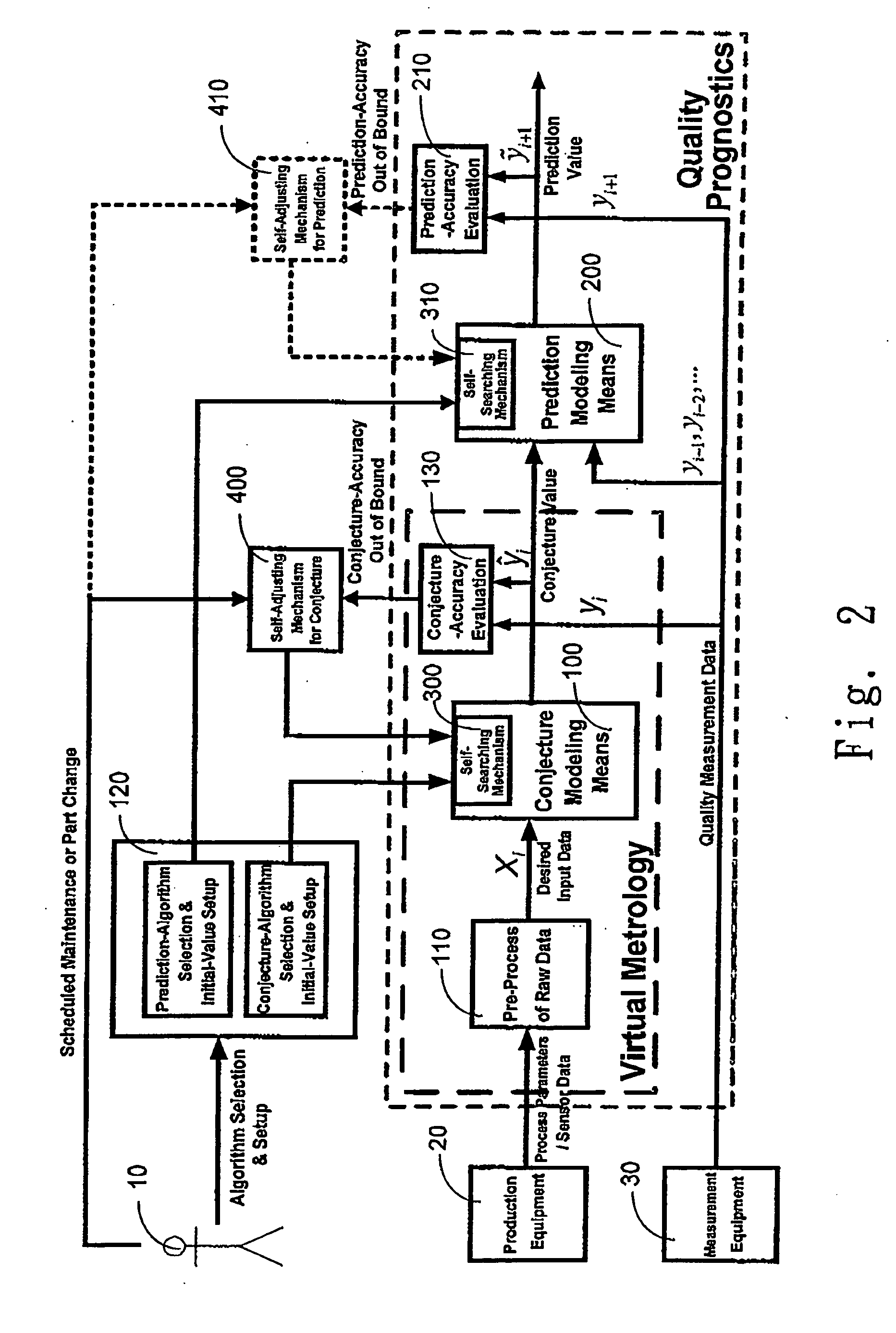

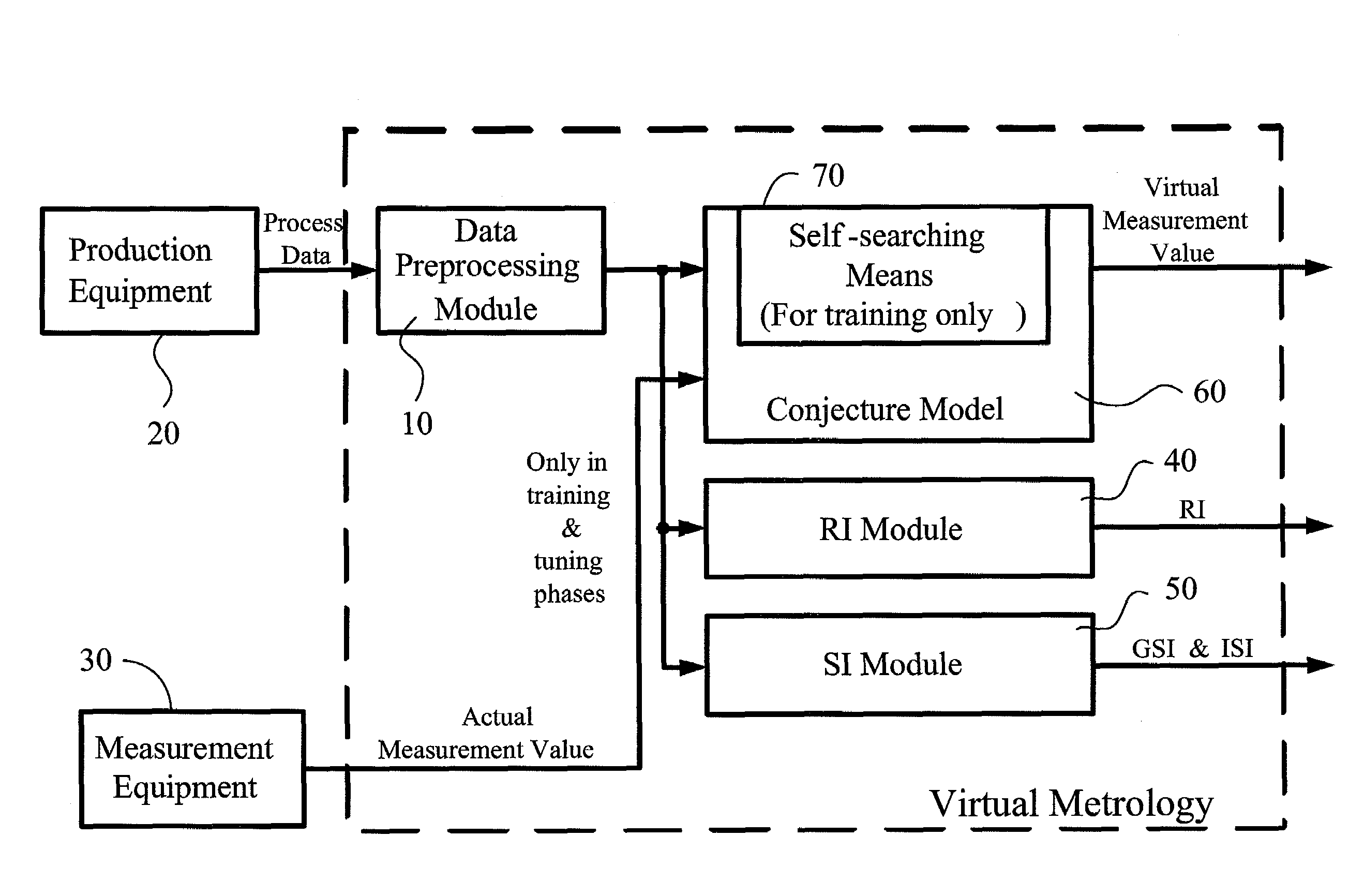

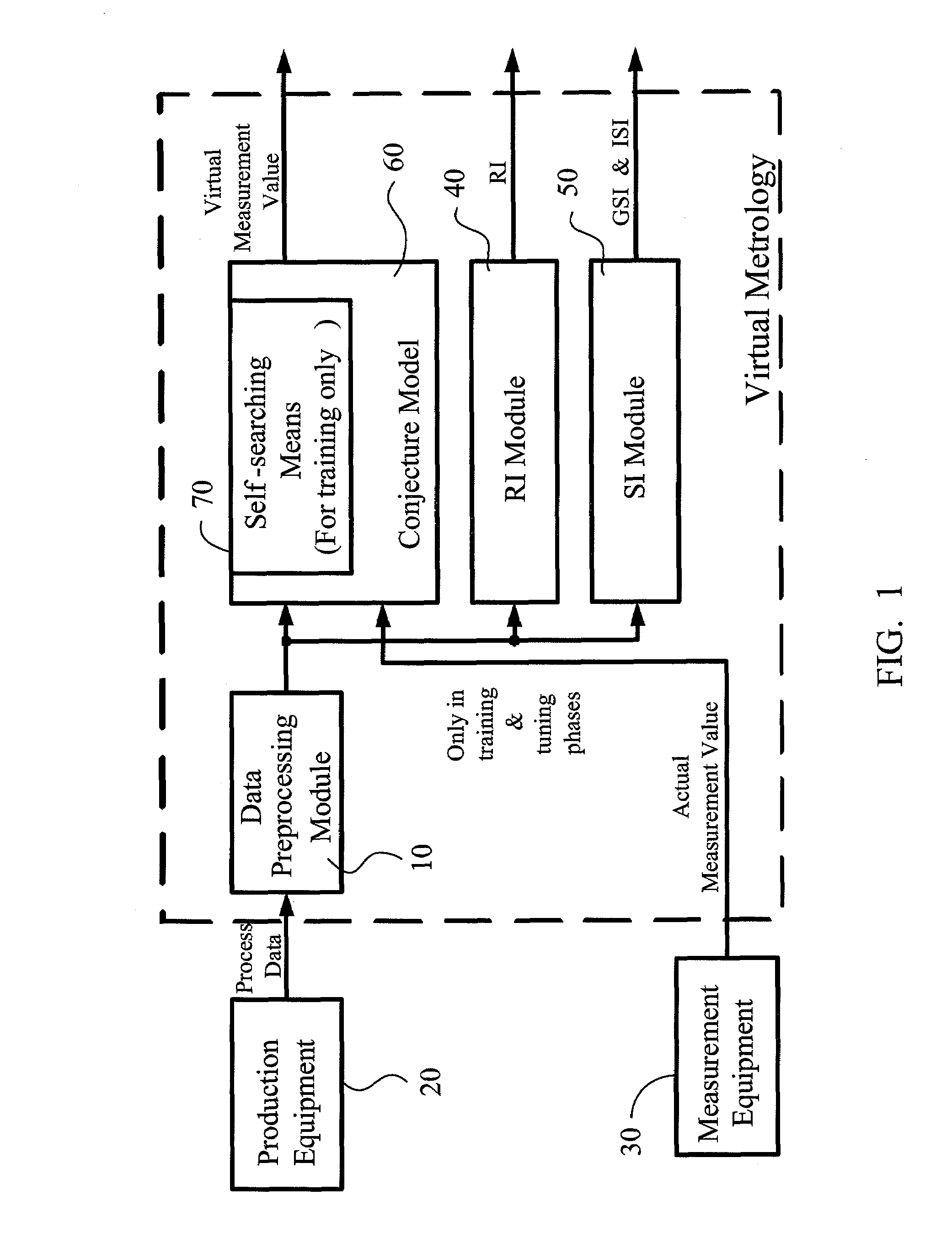

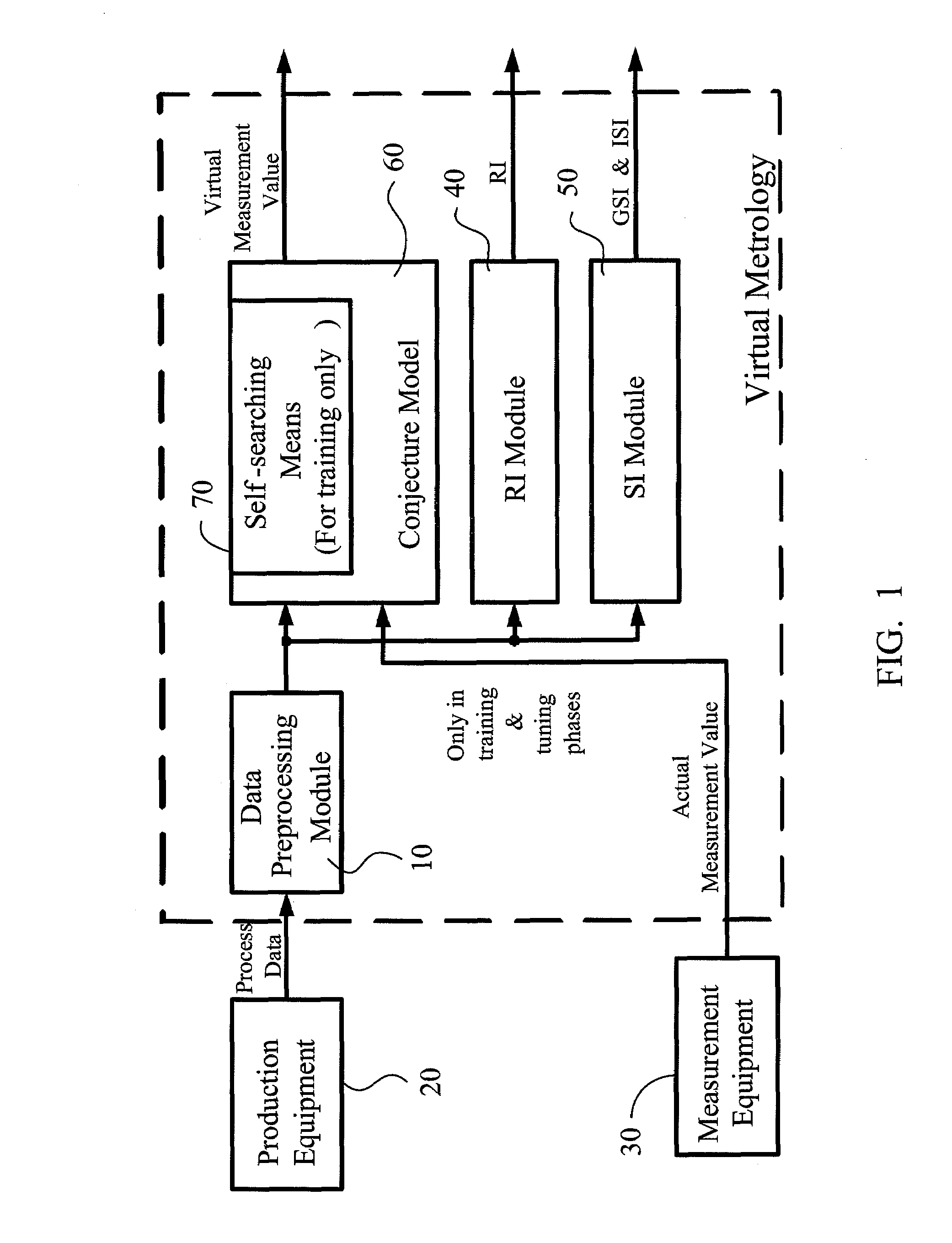

A quality prognostics system and a quality prognostics method for predicting the product quality during manufacturing processes are disclosed. The present invention utilizes the current production tool parameters sensed during the manufacturing process and several previous quality data collected from the measurement tool to predict the future product quality. The quality prognostics system is composed of conjecture modeling means and prediction modeling means. The conjecture modeling means itself also can be applied for the purpose of virtual metrology. Further, the quality prognostics method possesses a self-searching means and a self-adjusting means for searching the best combination of various parameters / functions used by the conjecture algorithm or prediction algorithm; and meeting the requirements of new equipment parameters and conjecture / prediction accuracy.

Owner:NAT CHENG KUNG UNIV

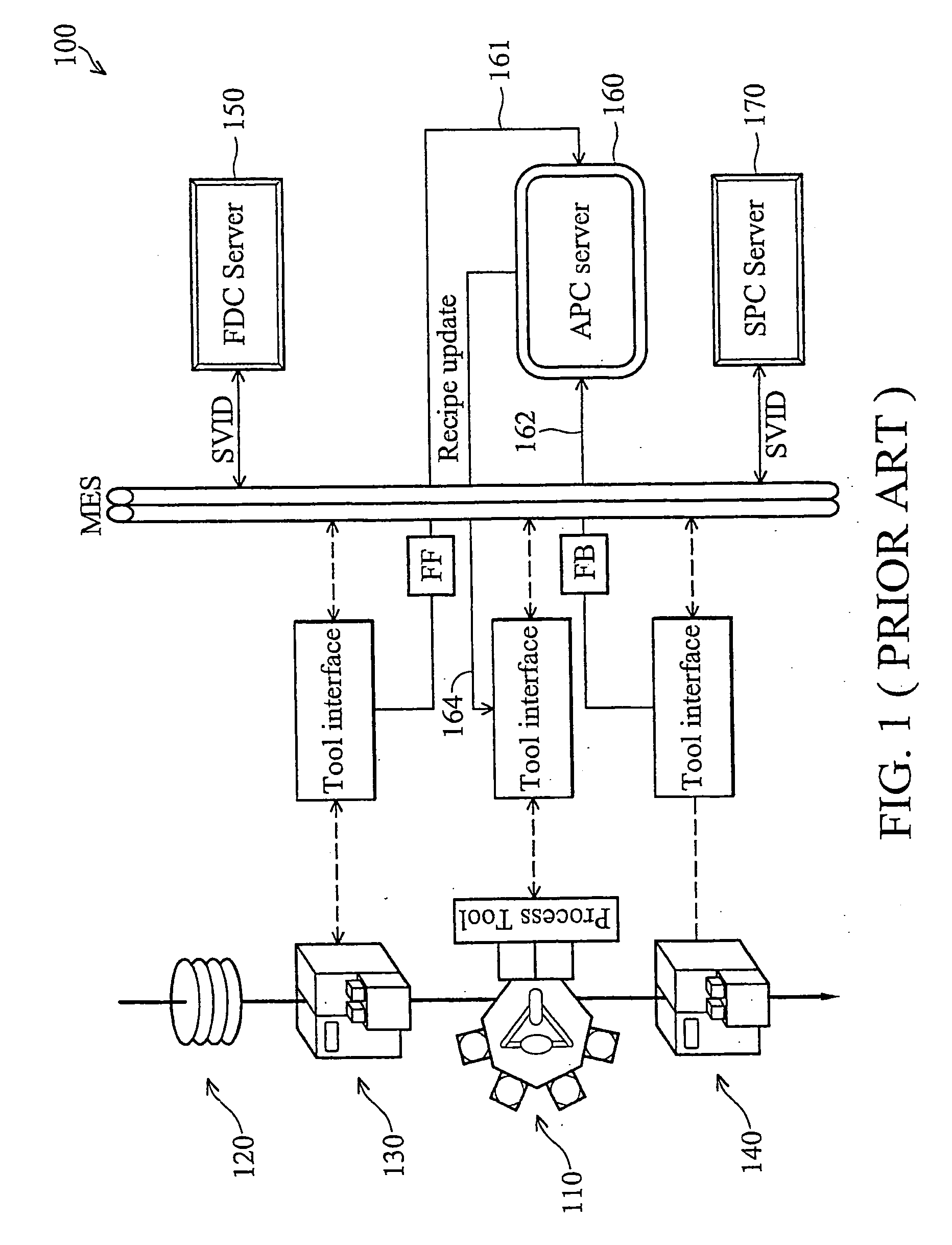

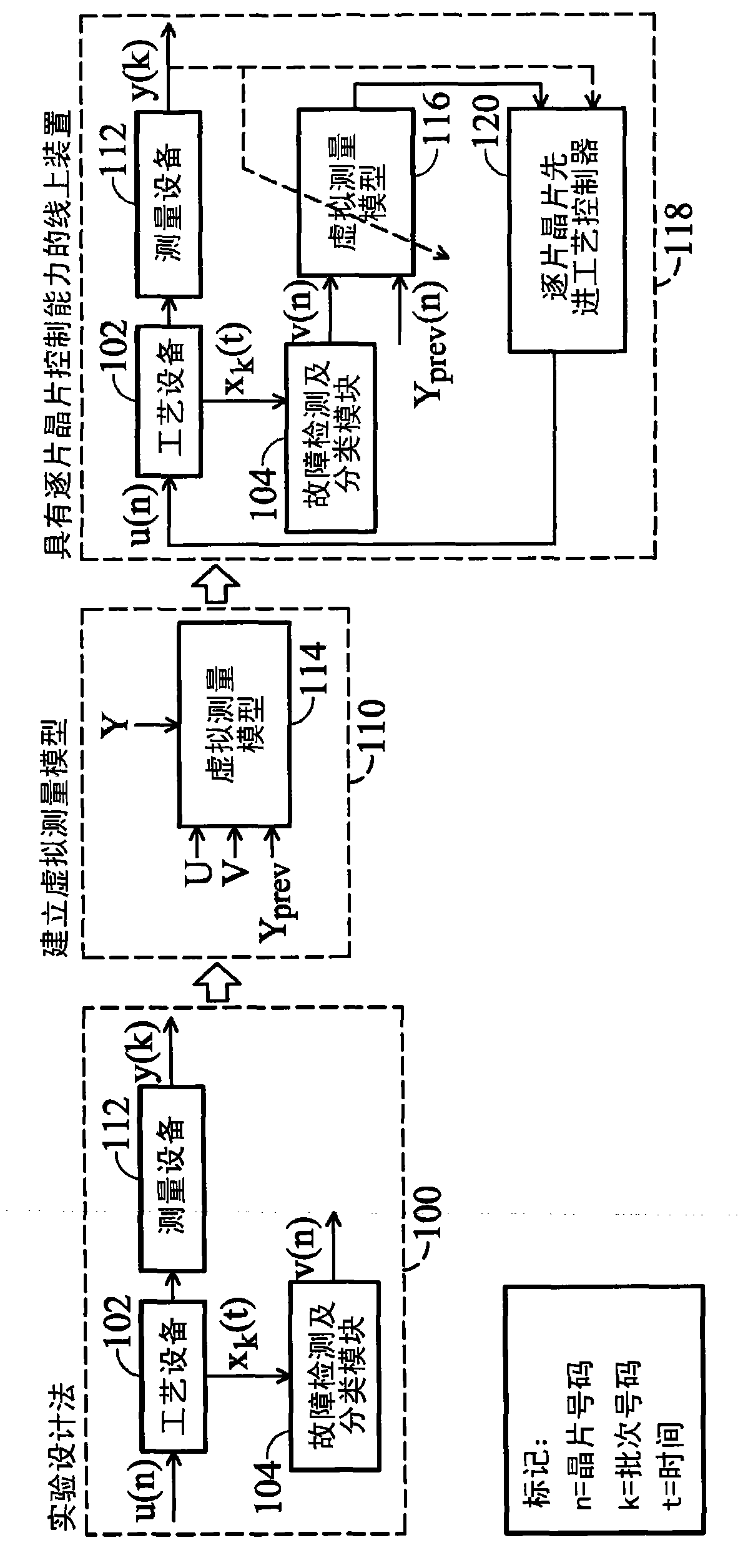

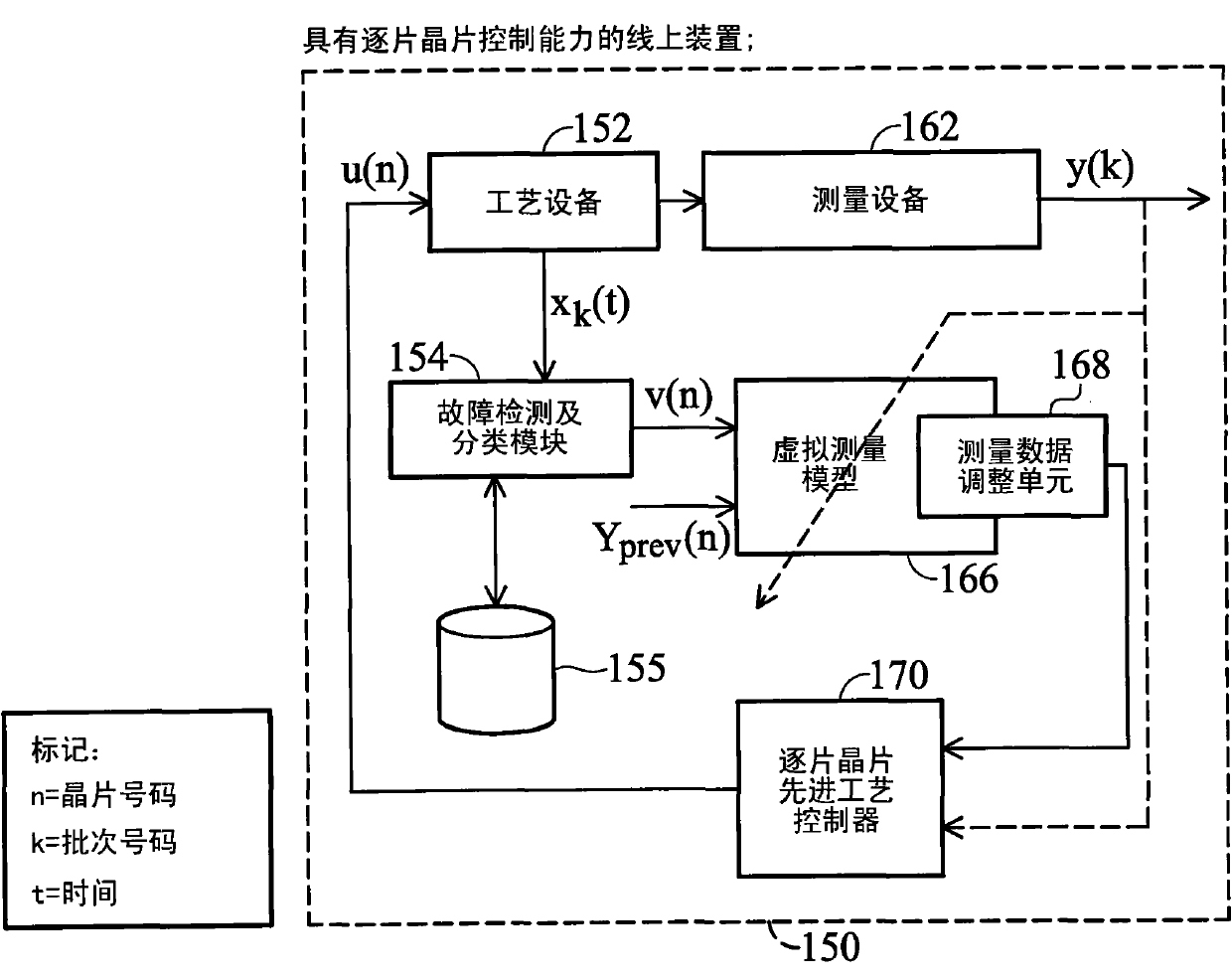

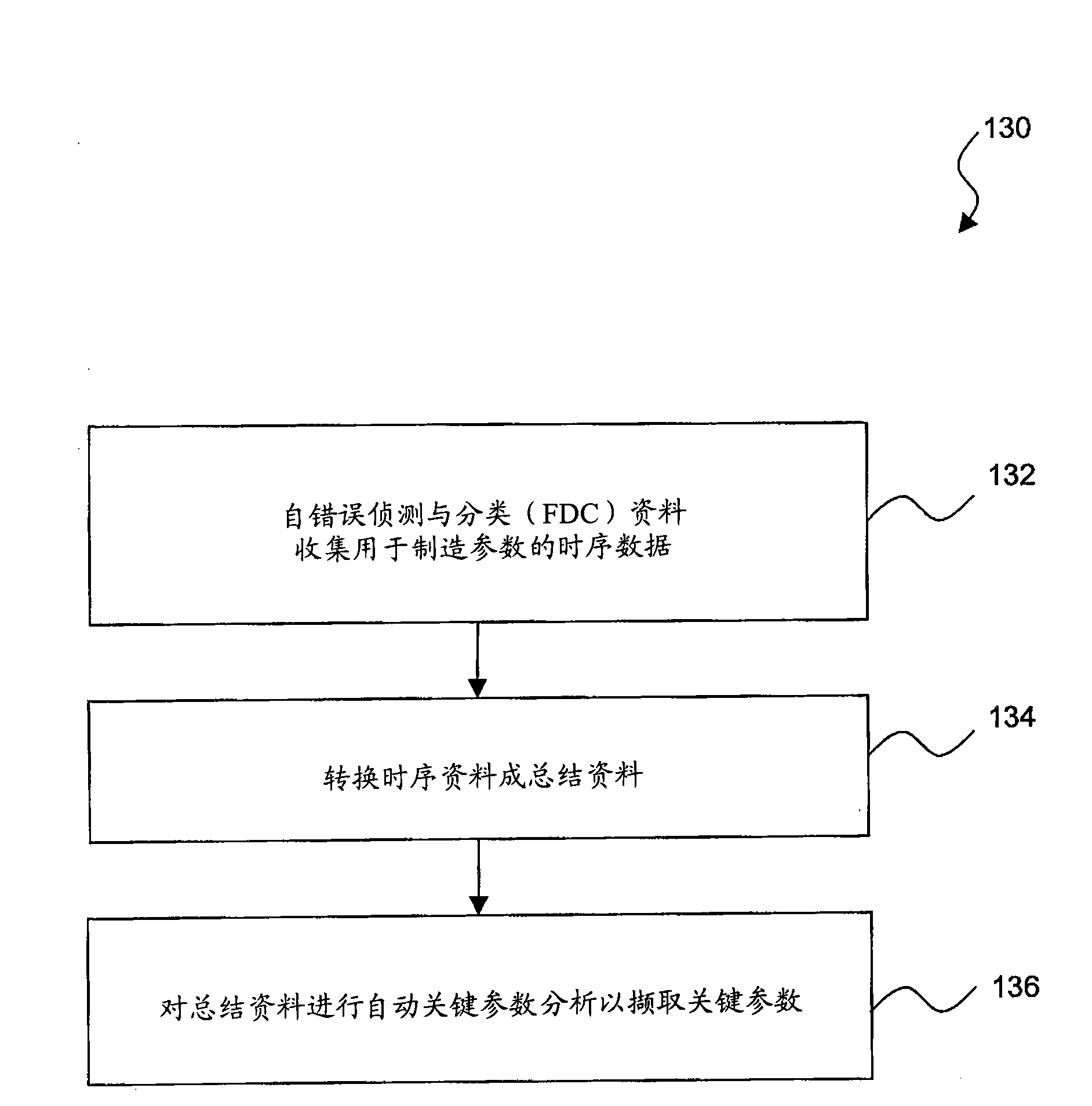

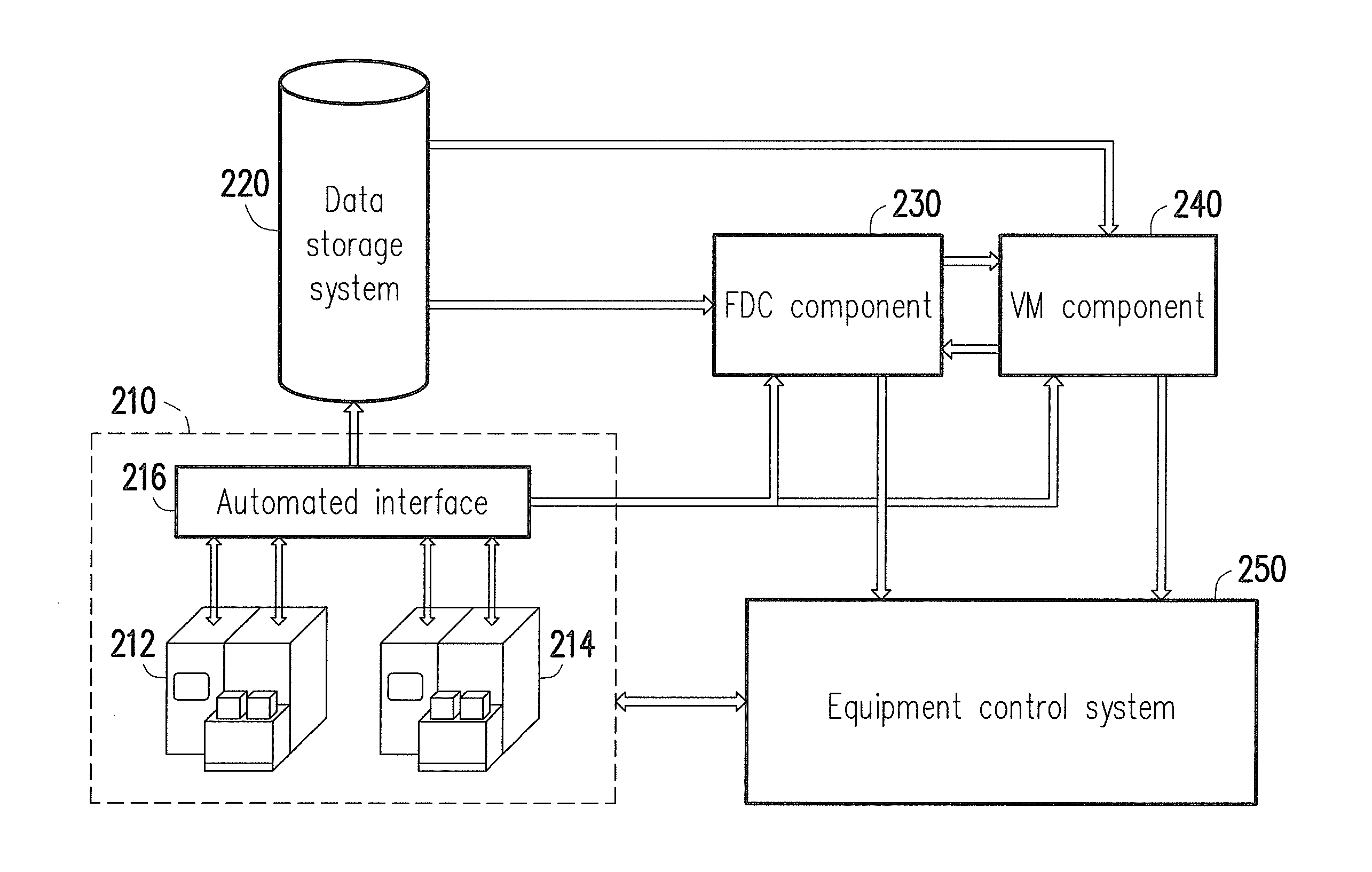

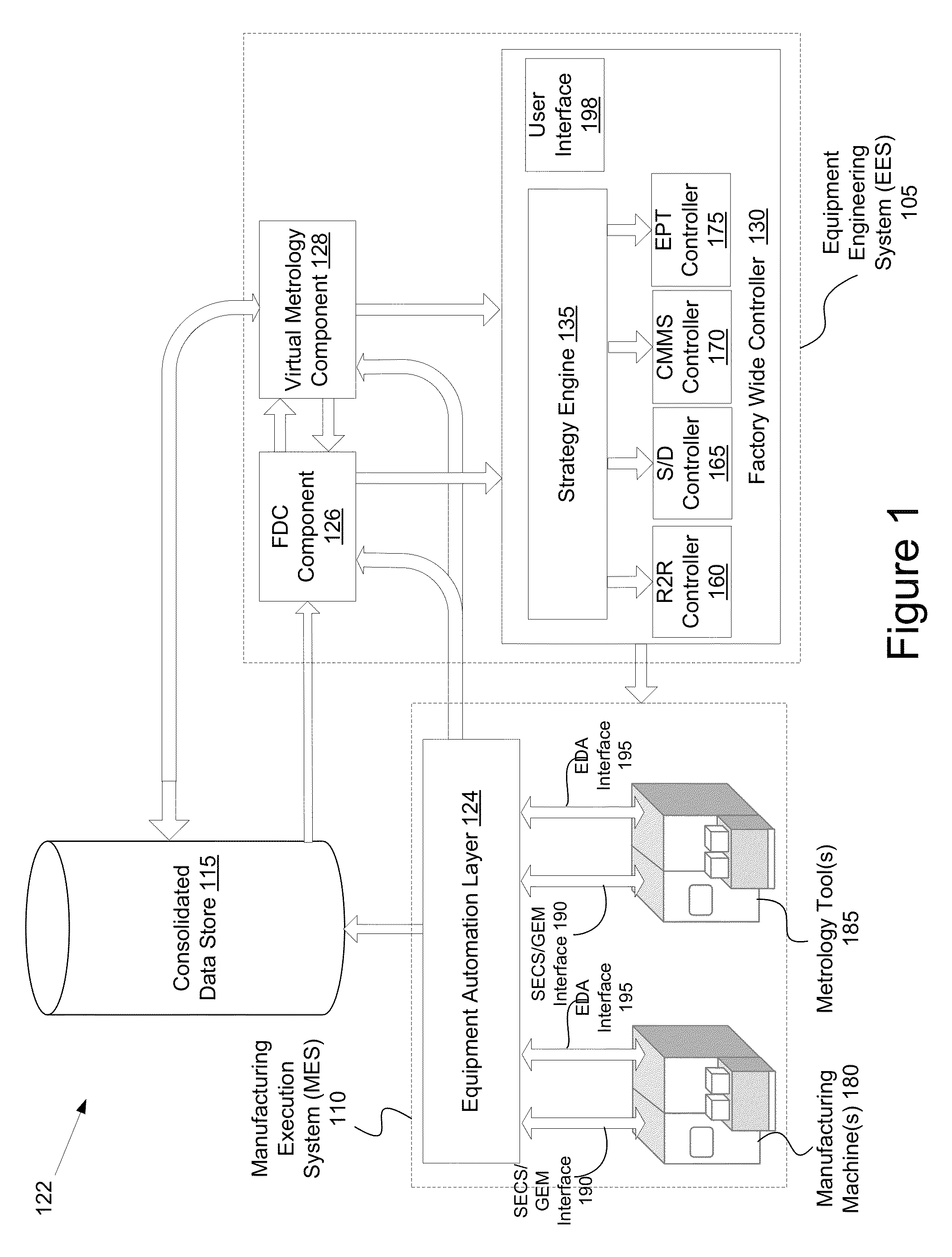

Novel method and apparatus for integrating fault detection and real-time virtual metrology in an advanced process control framework

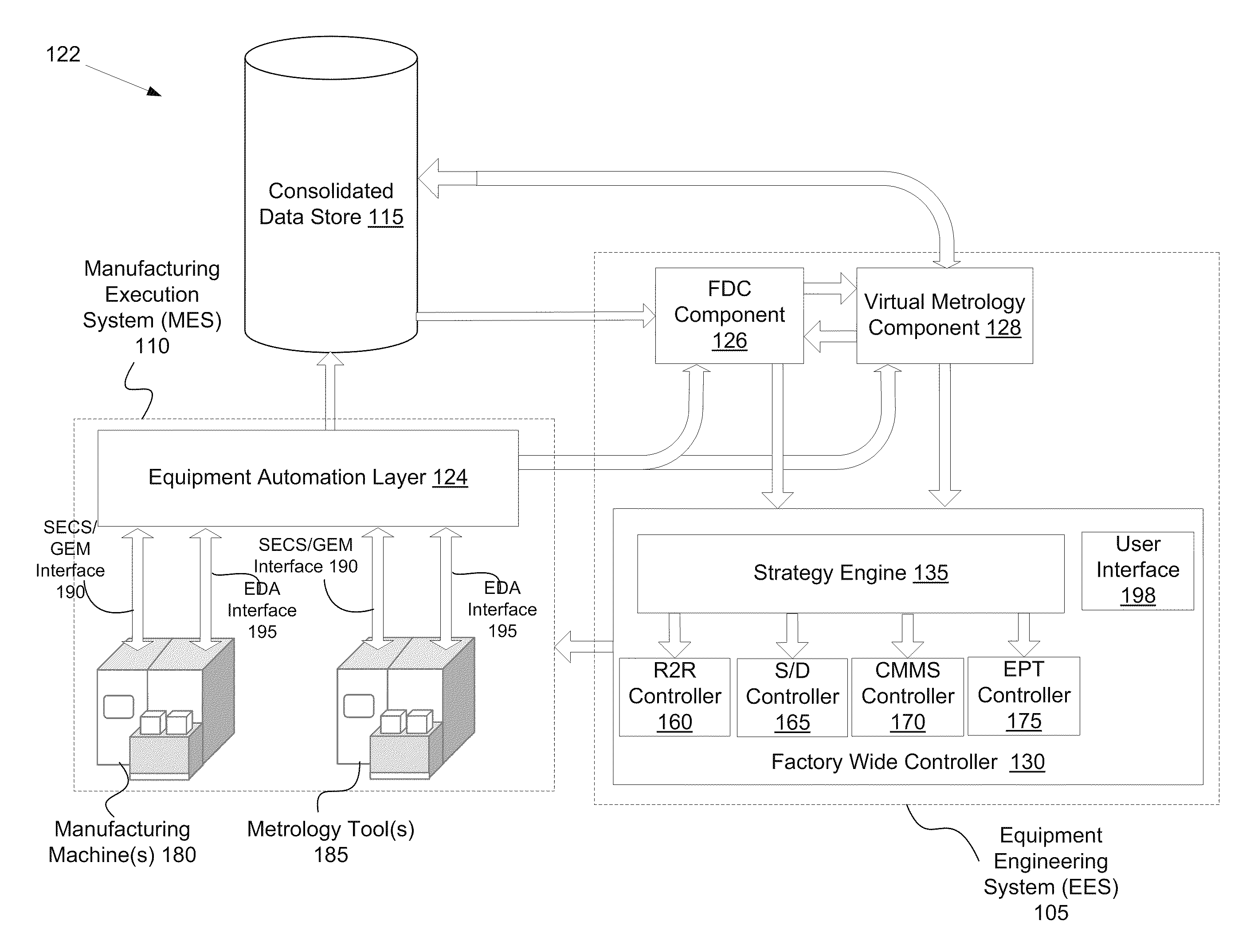

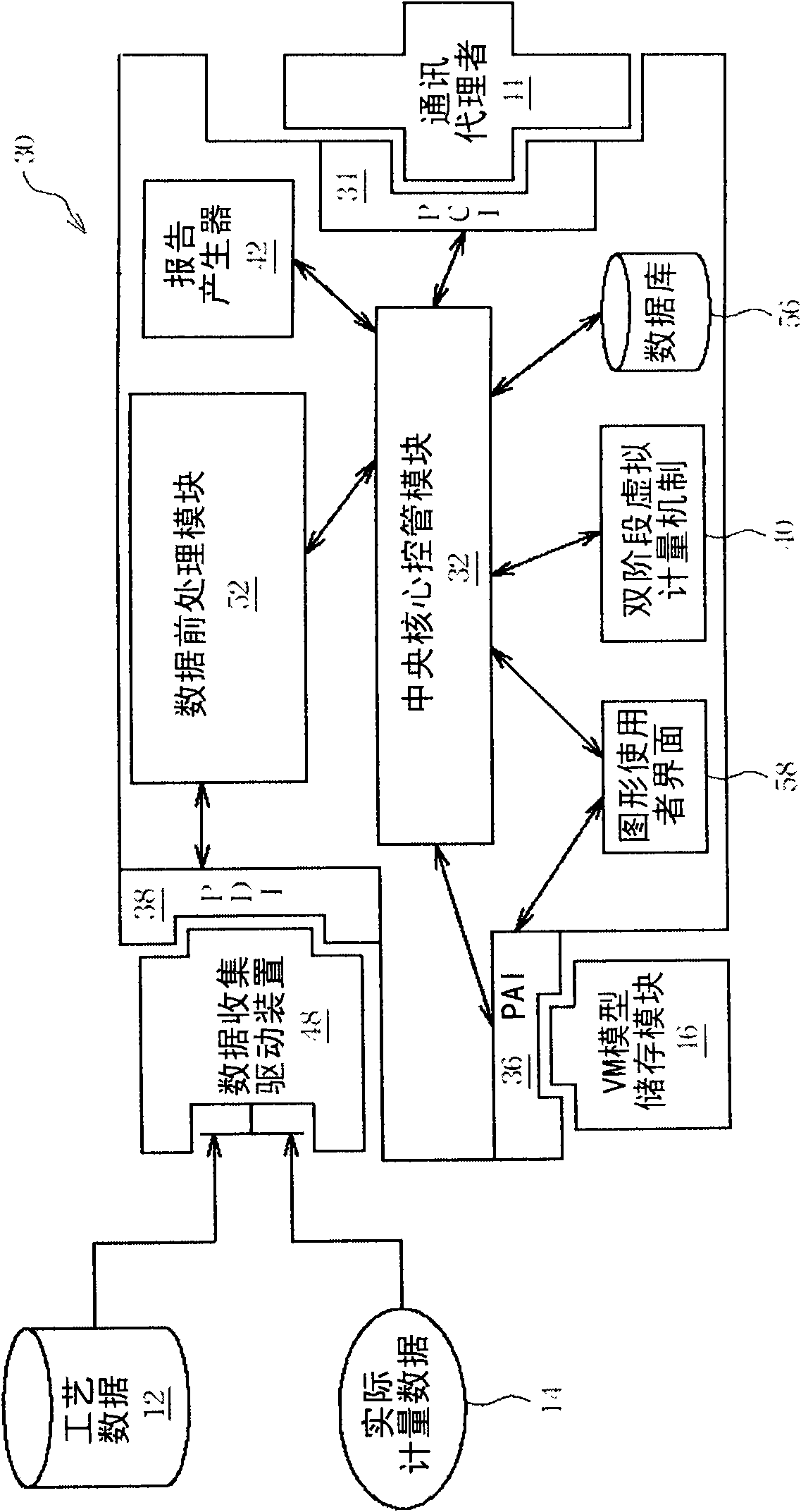

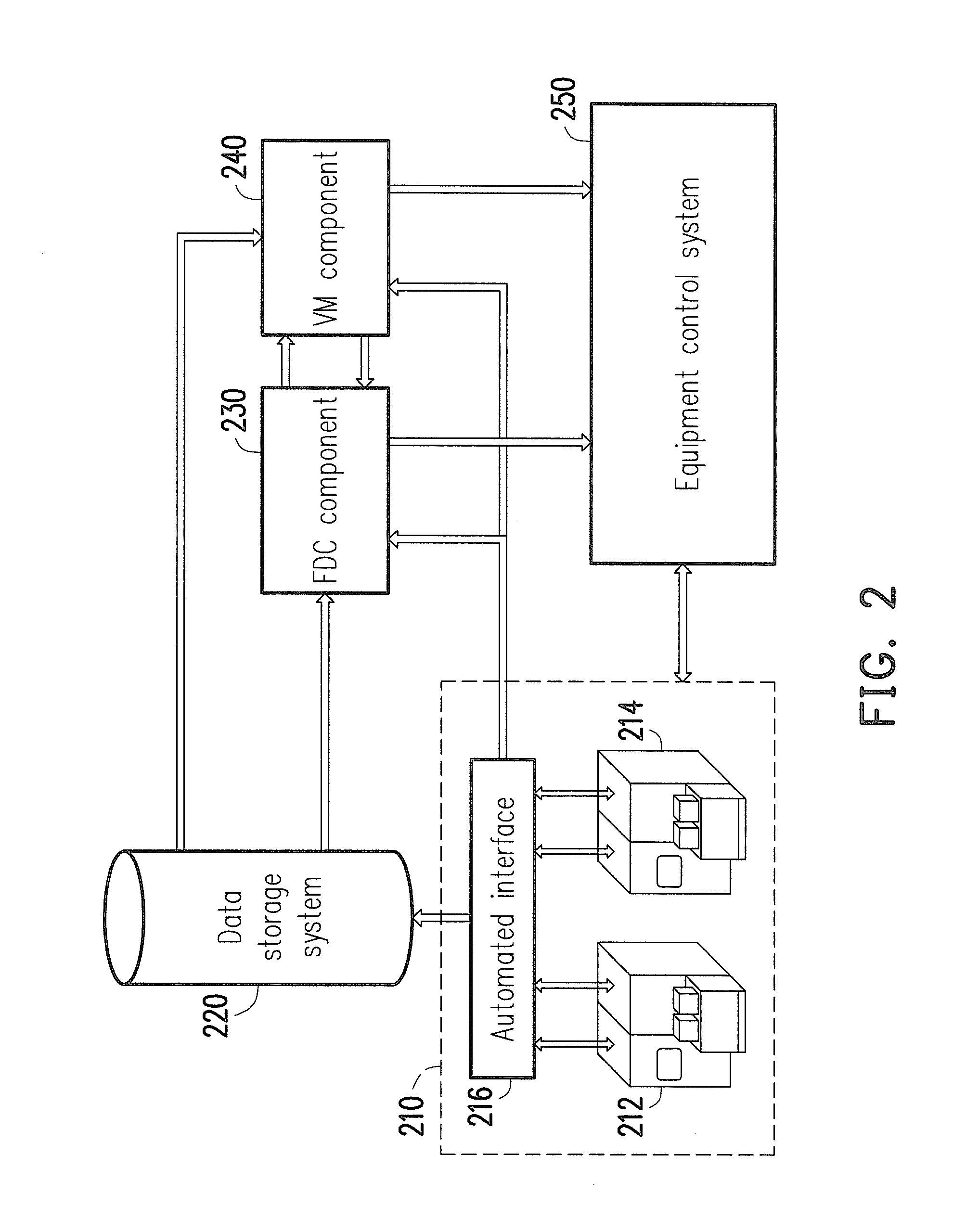

InactiveUS20060129257A1Optimize preventative maintenance scheduleReduce the amount of controlProgramme controlTotal factory controlData acquisitionData system

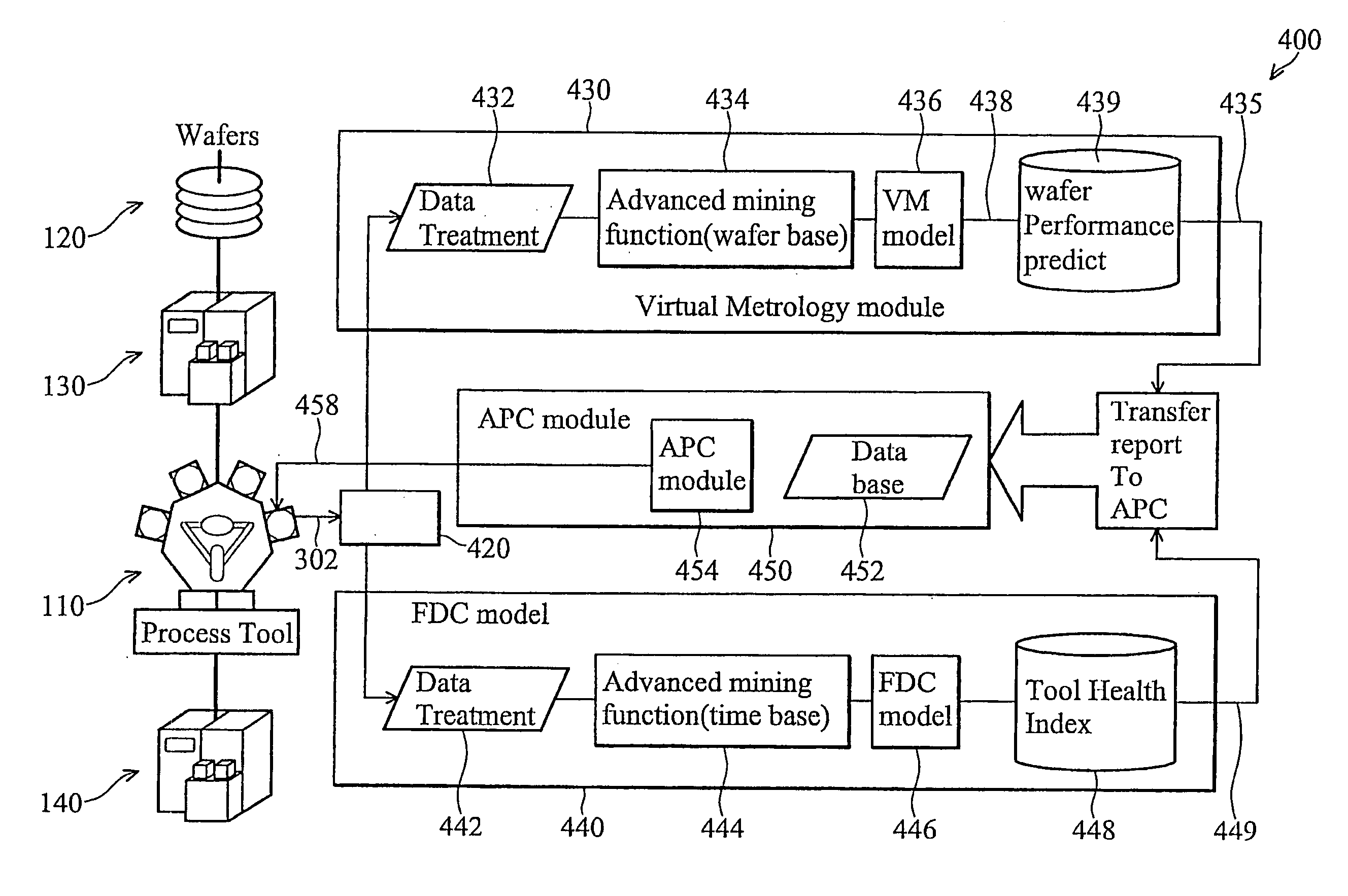

A semiconductor manufacturing information framework to operate a processing tool includes a data acquisition system (DAS), a virtual metrology (VM) system, a fault detection and classification (FDC) system and an advanced process control (APC) system. The DAS is operable to receive data related to the processing of a workpiece by the processing tool or sensors coupled on tool. The VM system is operable to receive the data from the DAS and predict results of the workpiece processed by the processing tool or sensors. The VM system generates at least one first output indicative of the results. The FDC system is operable to receive the data and generate at least one second output indicative of an operating status of the processing tool. The APC system is operable to receive the at least one first or second outputs, and, in response, generate at least one third output to control the processing tool.

Owner:TAIWAN SEMICON MFG CO LTD

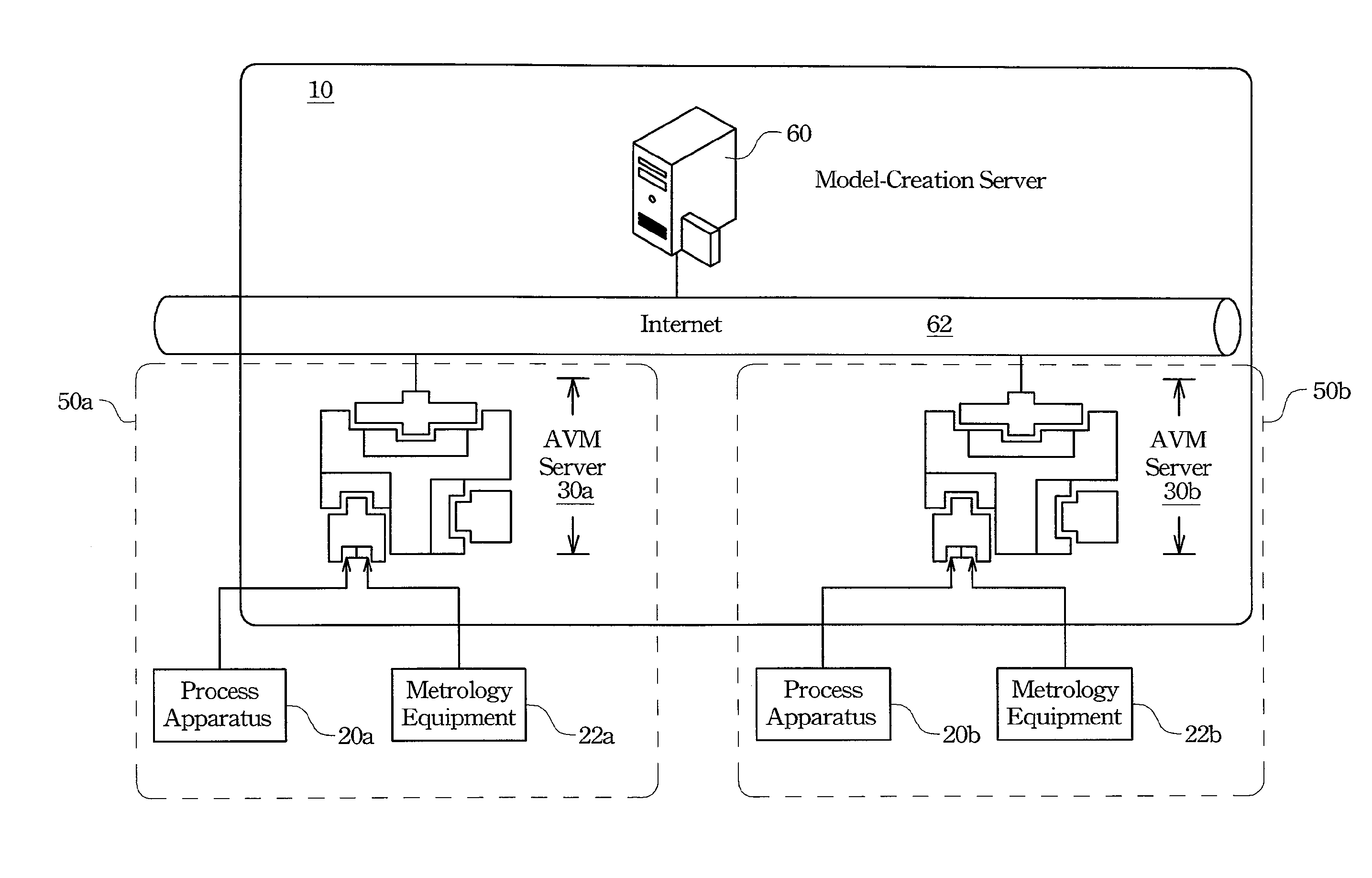

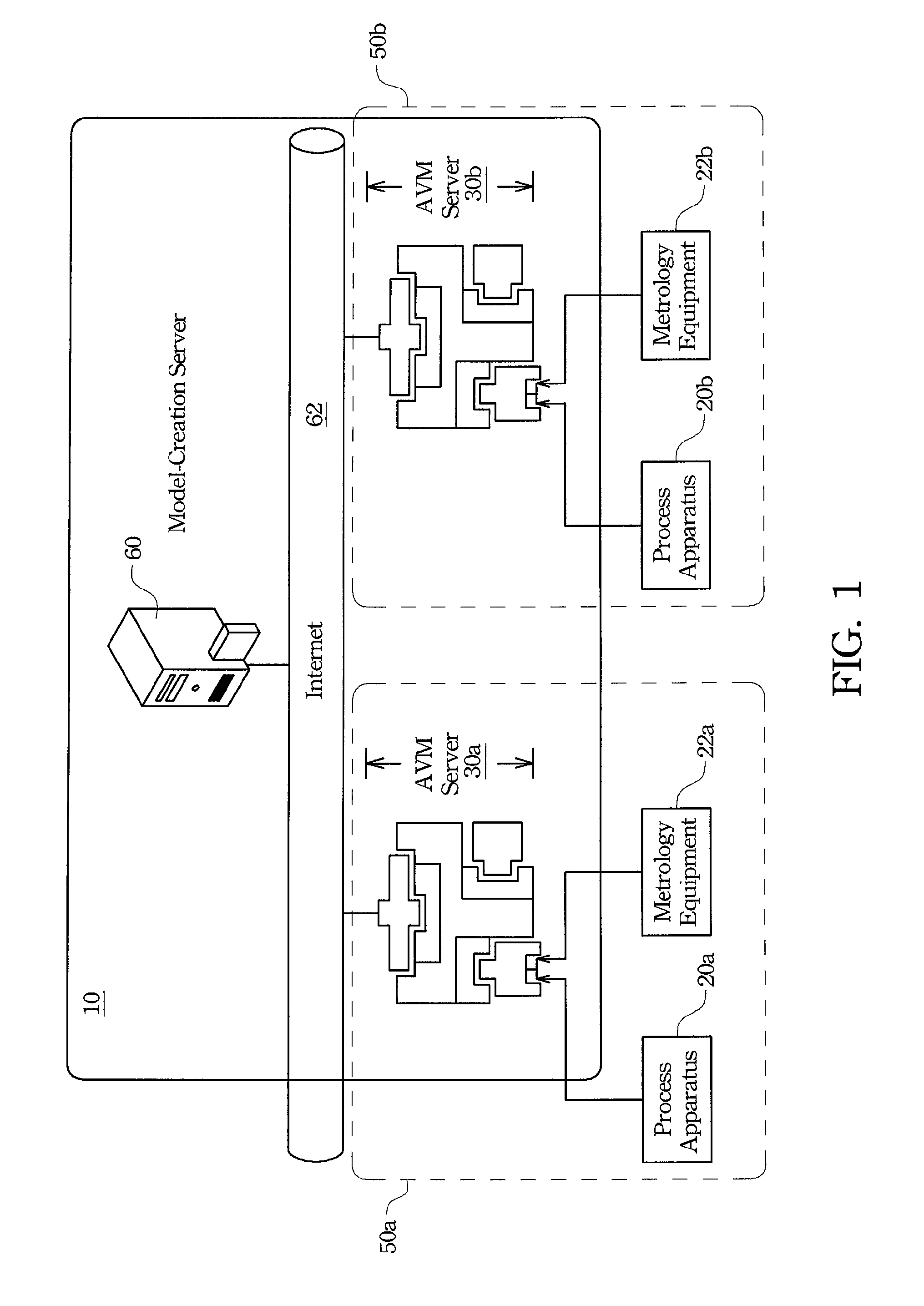

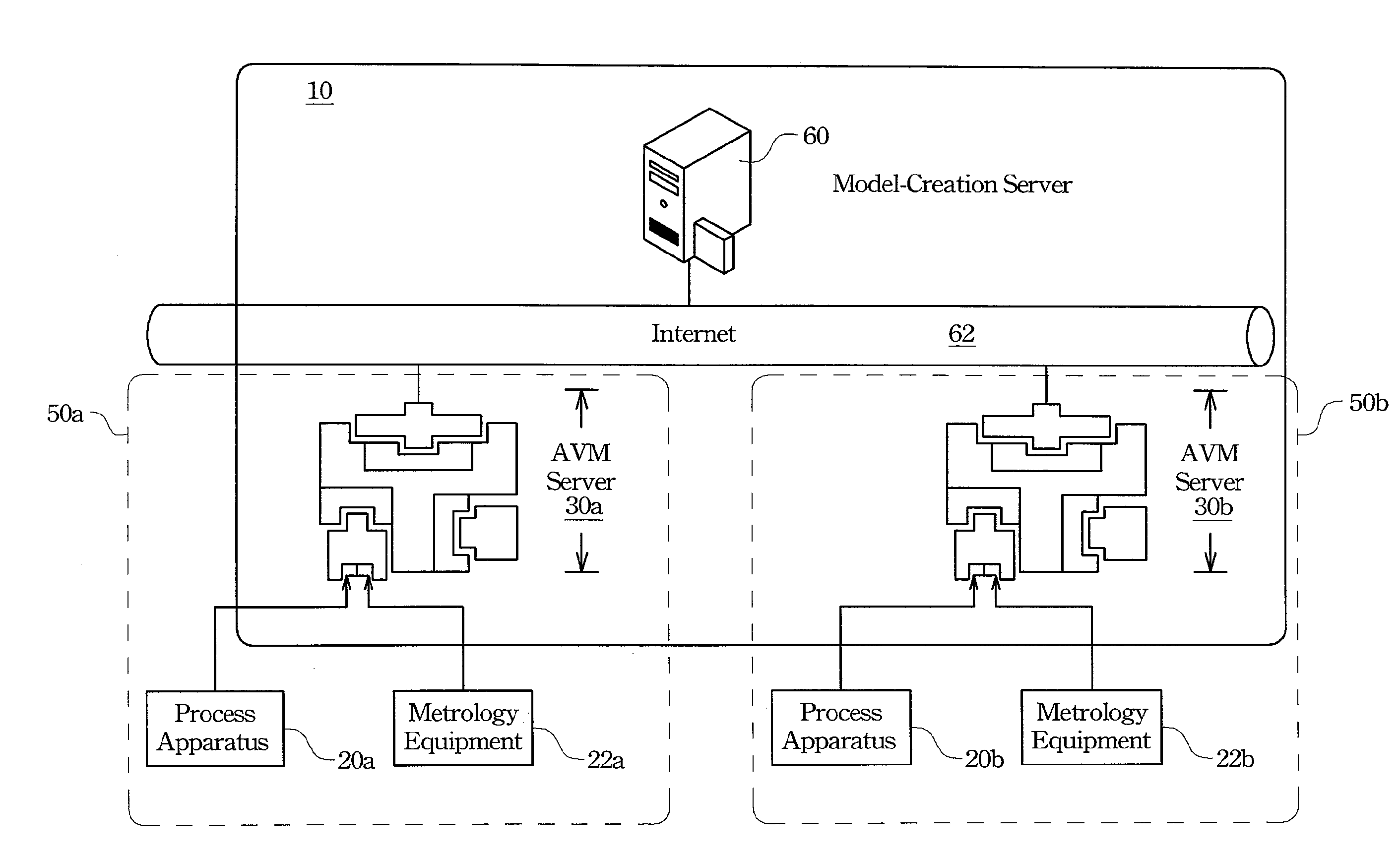

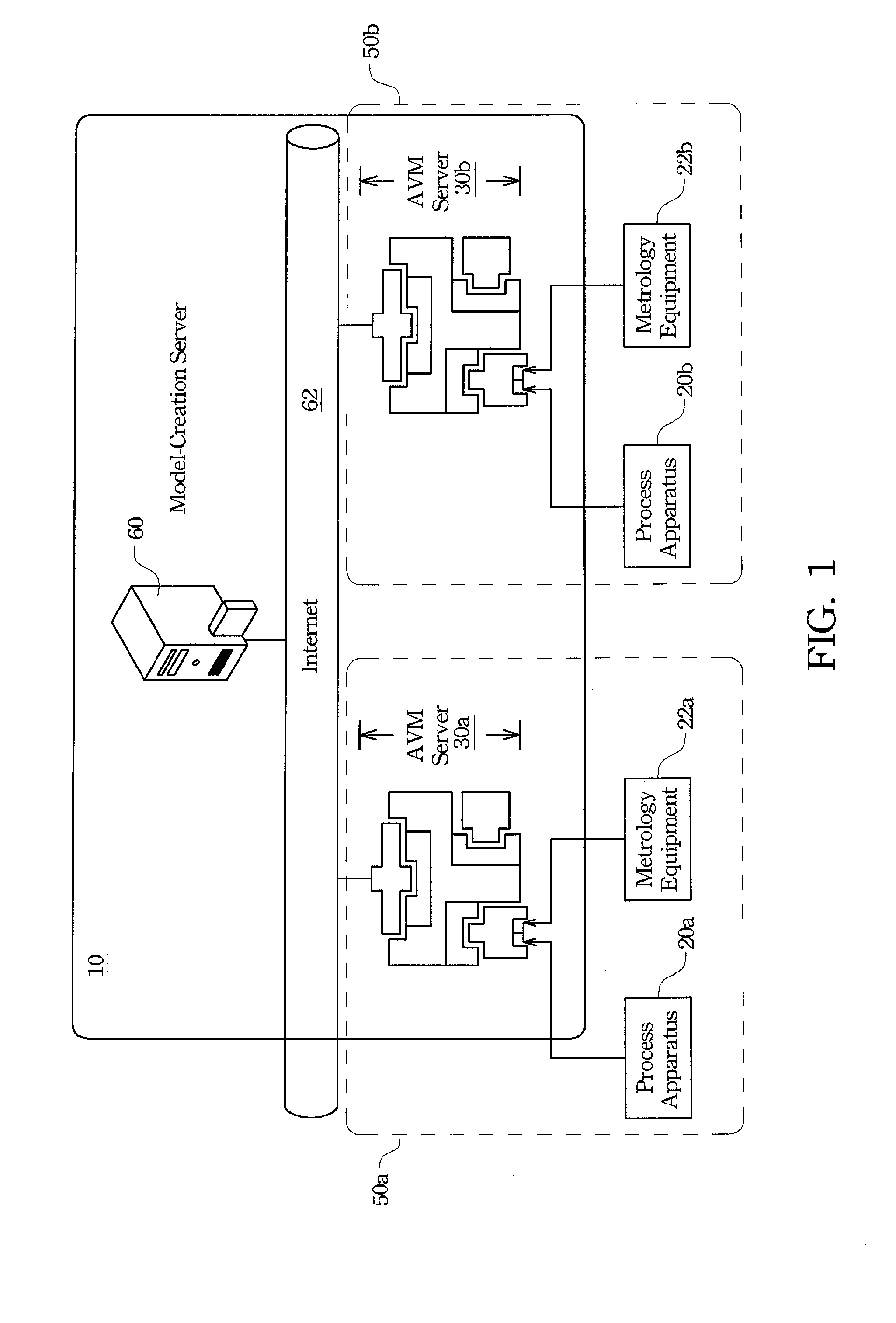

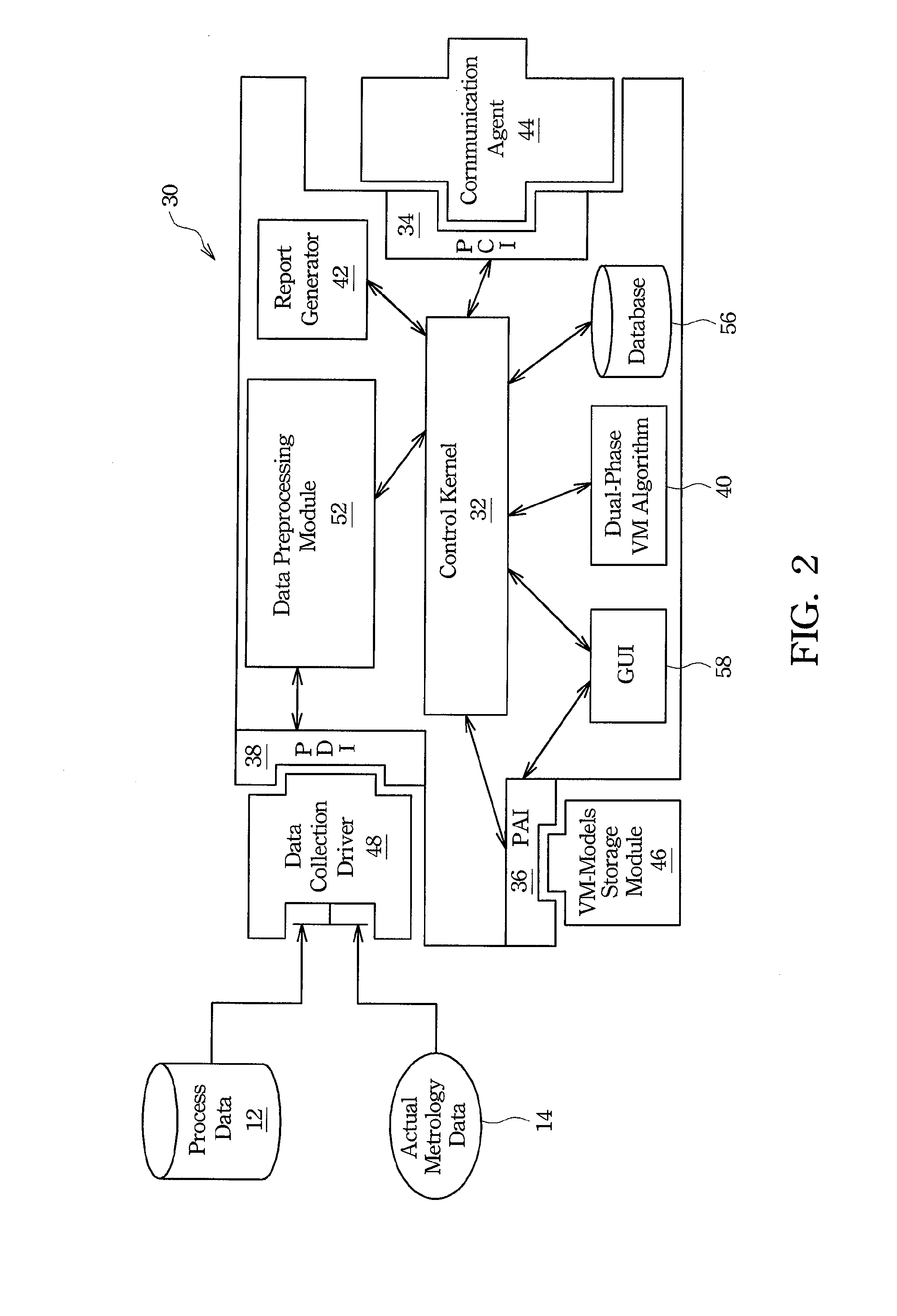

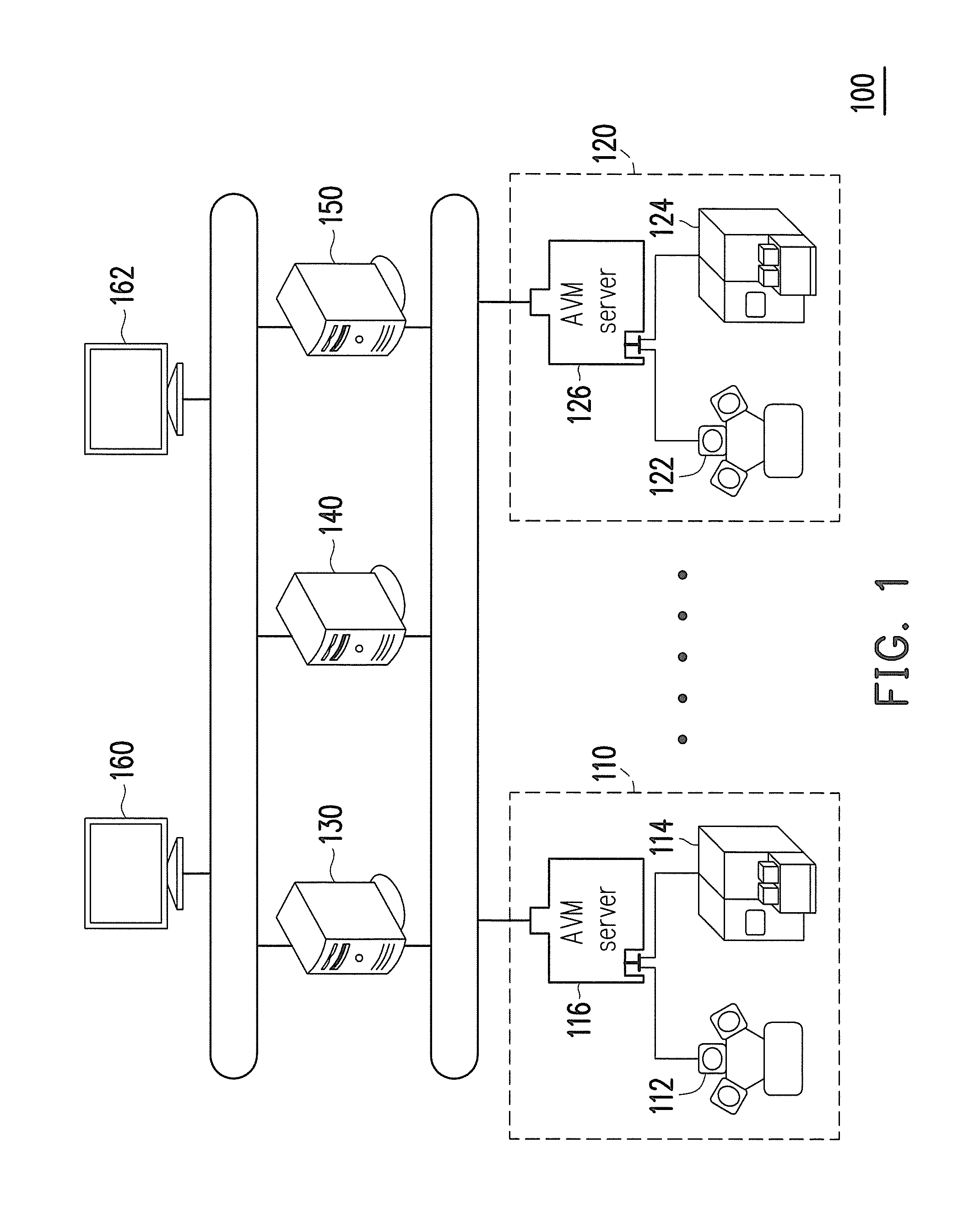

System and method for automatic virtual metrology

ActiveUS8095484B2Shorten the timeMaintaining desirable accuracyMeasurement devicesSemiconductor/solid-state device testing/measurementDevice typeMetrology

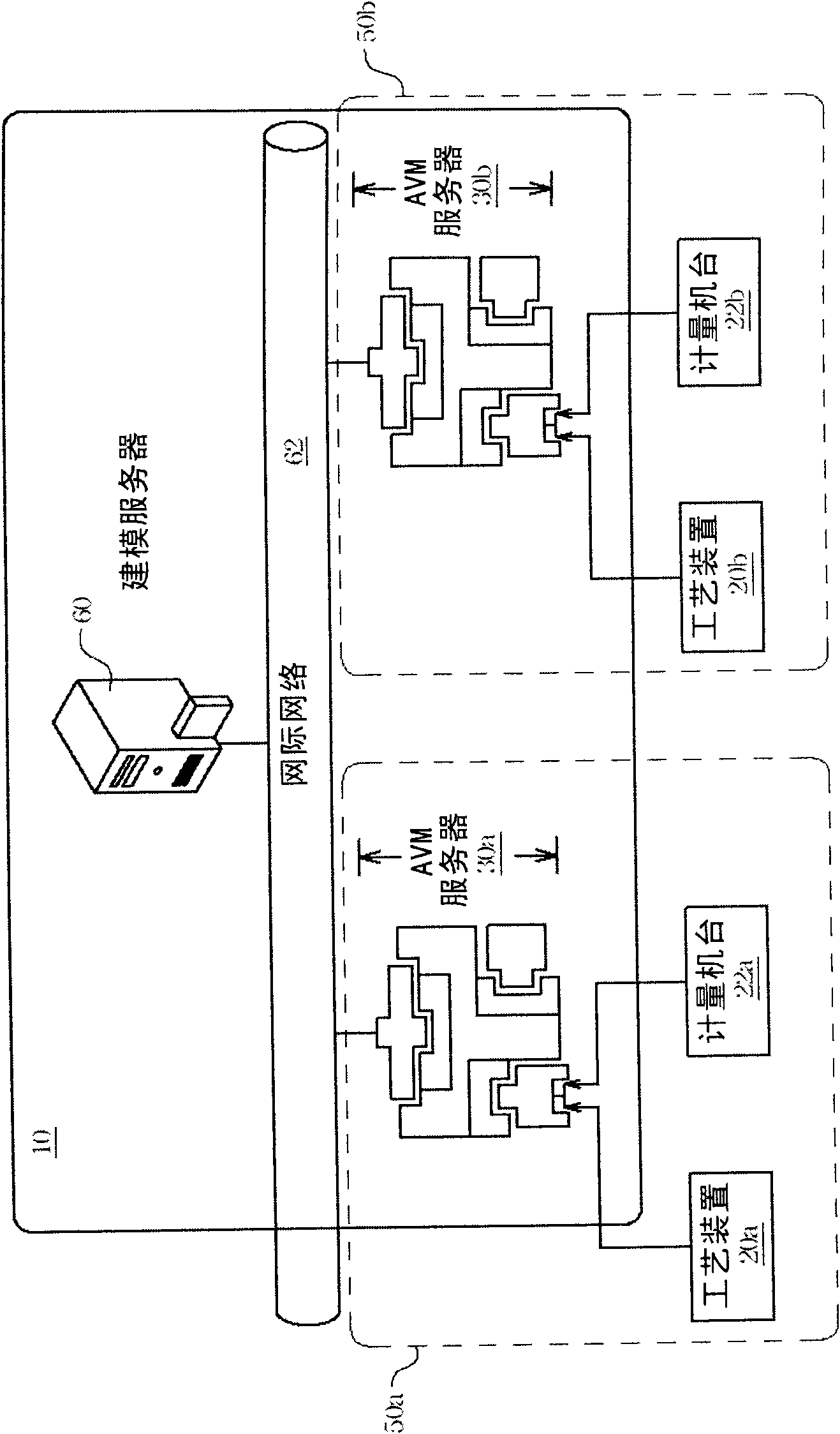

A server, a system and a method for automatic virtual metrology (AVM) are disclosed. The AVM system comprises a model-creation server and a plurality of AVM servers. The model-creation server is used to construct the first set of virtual metrology (VM) models (of a certain equipment type) including a VM conjecture model, a RI (Reliance Index) model, a GSI (Global Similarity Index) model, a DQIx (Process Data Quality Index) model, and a DQIy (Metrology Data Quality Index) model. In the AVM method, the model-creation server also can fan out or port the first set of VM models generated to other AVM servers of the same process apparatus (equipment) type, and each individual fan-out-acceptor's AVM server can perform automatic model refreshing processes so as to gain and maintain its VM models' accuracy.

Owner:NAT CHENG KUNG UNIV

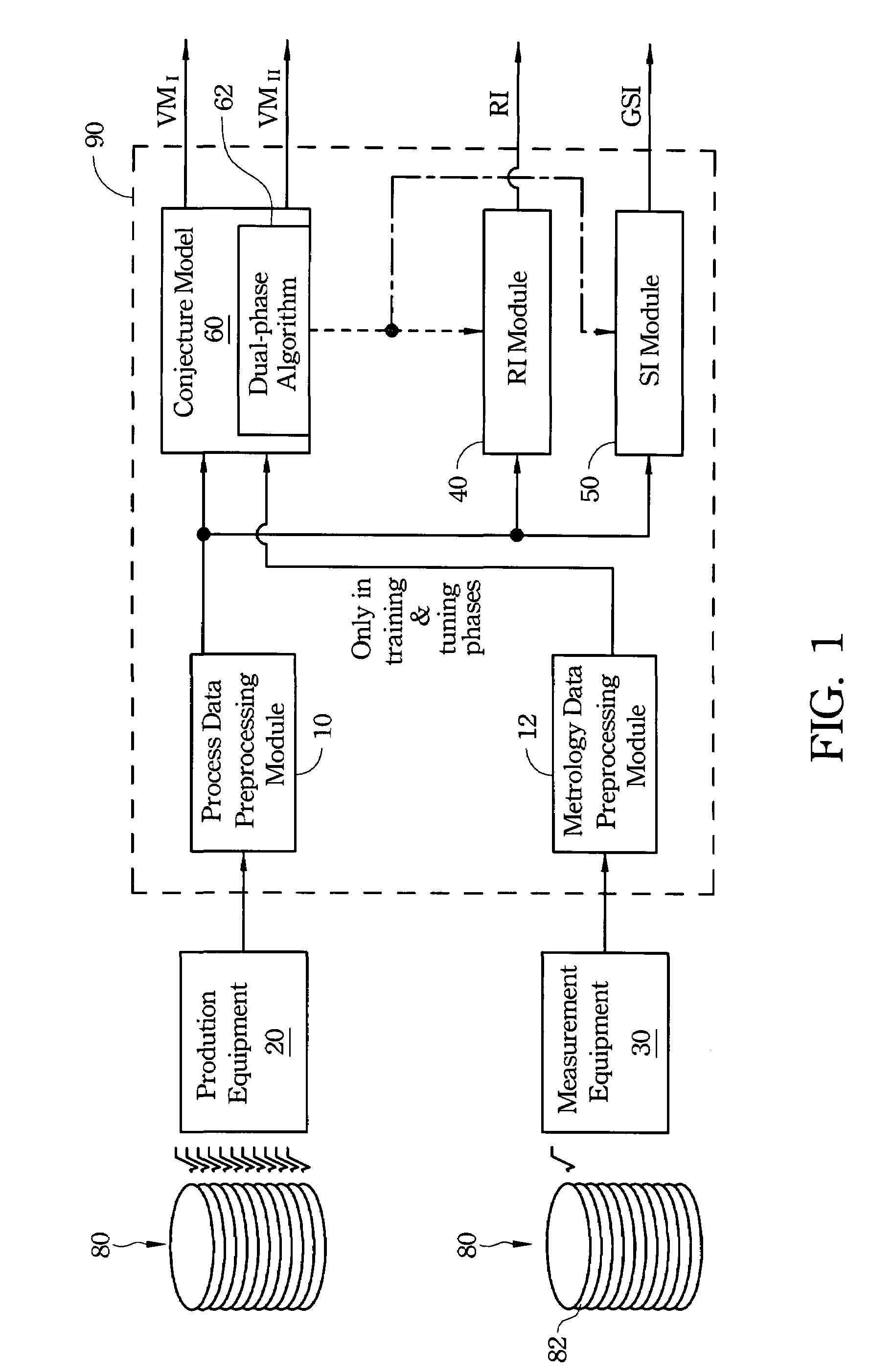

Quality prognostics system and method for manufacturing processes

ActiveUS7493185B2Improve availabilityImprove efficiencyDigital computer detailsSemiconductor/solid-state device manufacturingPrediction algorithmsPredictive methods

A quality prognostics system and a quality prognostics method for predicting the product quality during manufacturing processes are disclosed, wherein the current production tool parameters sensed during the manufacturing process and several previous quality data collected from the measurement tool are utilized to predict the future product quality, and a conjecture modeling step and prediction modeling step are performed respectively. The conjecture modeling step itself also can be applied for the purpose of virtual metrology. Further, a self-searching step and a self-adjusting step are performed for searching the best combination of various parameters / functions used by the conjecture algorithm or prediction algorithm; and meeting the requirements of new equipment parameters and conjecture / prediction accuracy.

Owner:NAT CHENG KUNG UNIV

System and Method for Automatic Virtual Metrology

ActiveUS20090292386A1Shorten the timeMaintaining desirable accuracyMeasurement devicesSemiconductor/solid-state device testing/measurementDevice typeMetrology

A server, a system and a method for automatic virtual metrology (AVM) are disclosed. The AVM system comprises a model-creation server and a plurality of AVM servers. The model-creation server is used to construct the first set of virtual metrology (VM) models (of a certain equipment type) including a VM conjecture model, a RI (Reliance Index) model, a GSI (Global Similarity Index) model, a DQIx (Process Data Quality Index) model, and a DQIy (Metrology Data Quality Index) model. In the AVM method, the model-creation server also can fan out or port the first set of VM models generated to other AVM servers of the same process apparatus (equipment) type, and each individual fan-out-acceptor's AVM server can perform automatic model refreshing processes so as to gain and maintain its VM models' accuracy.

Owner:NAT CHENG KUNG UNIV

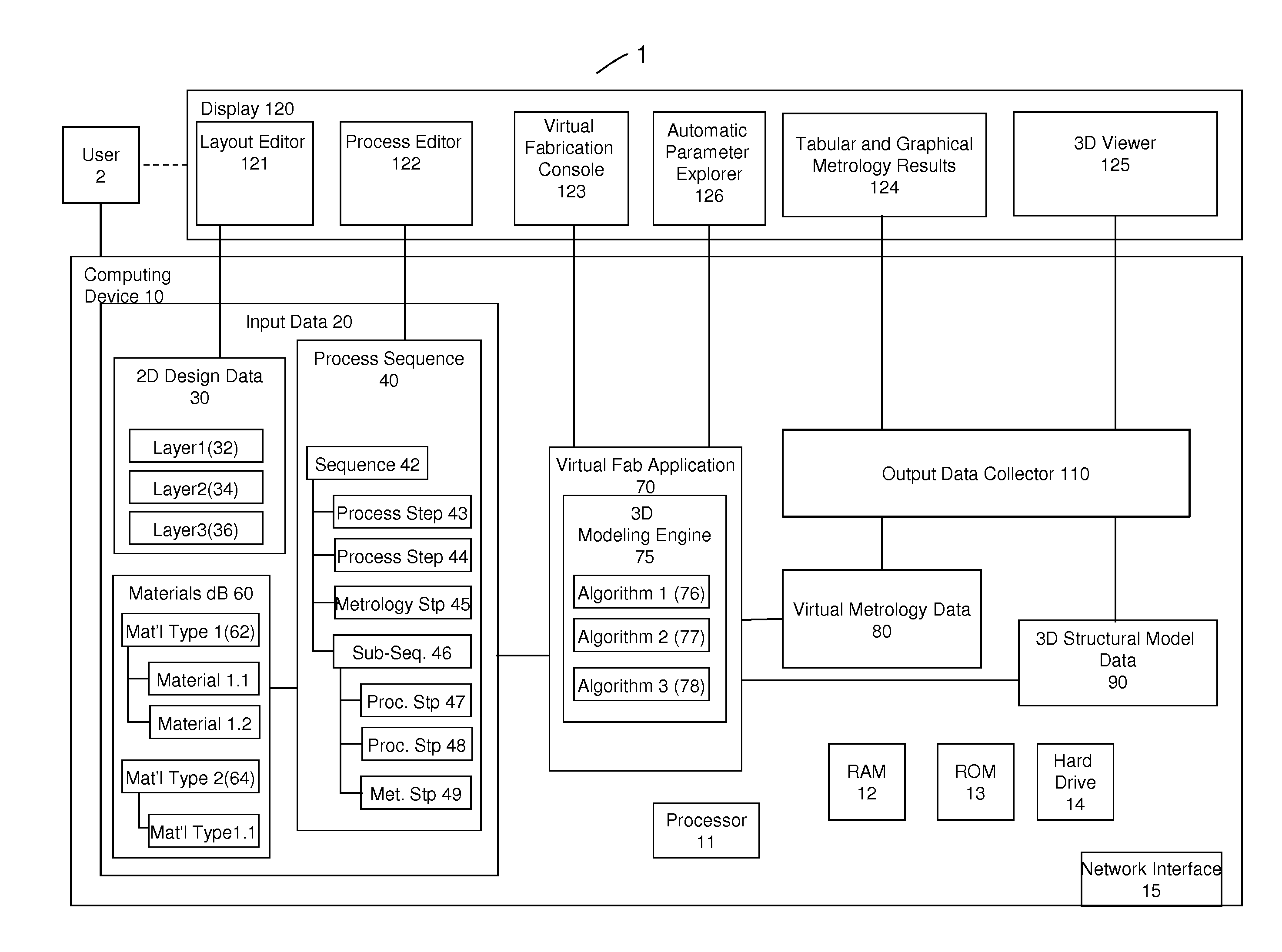

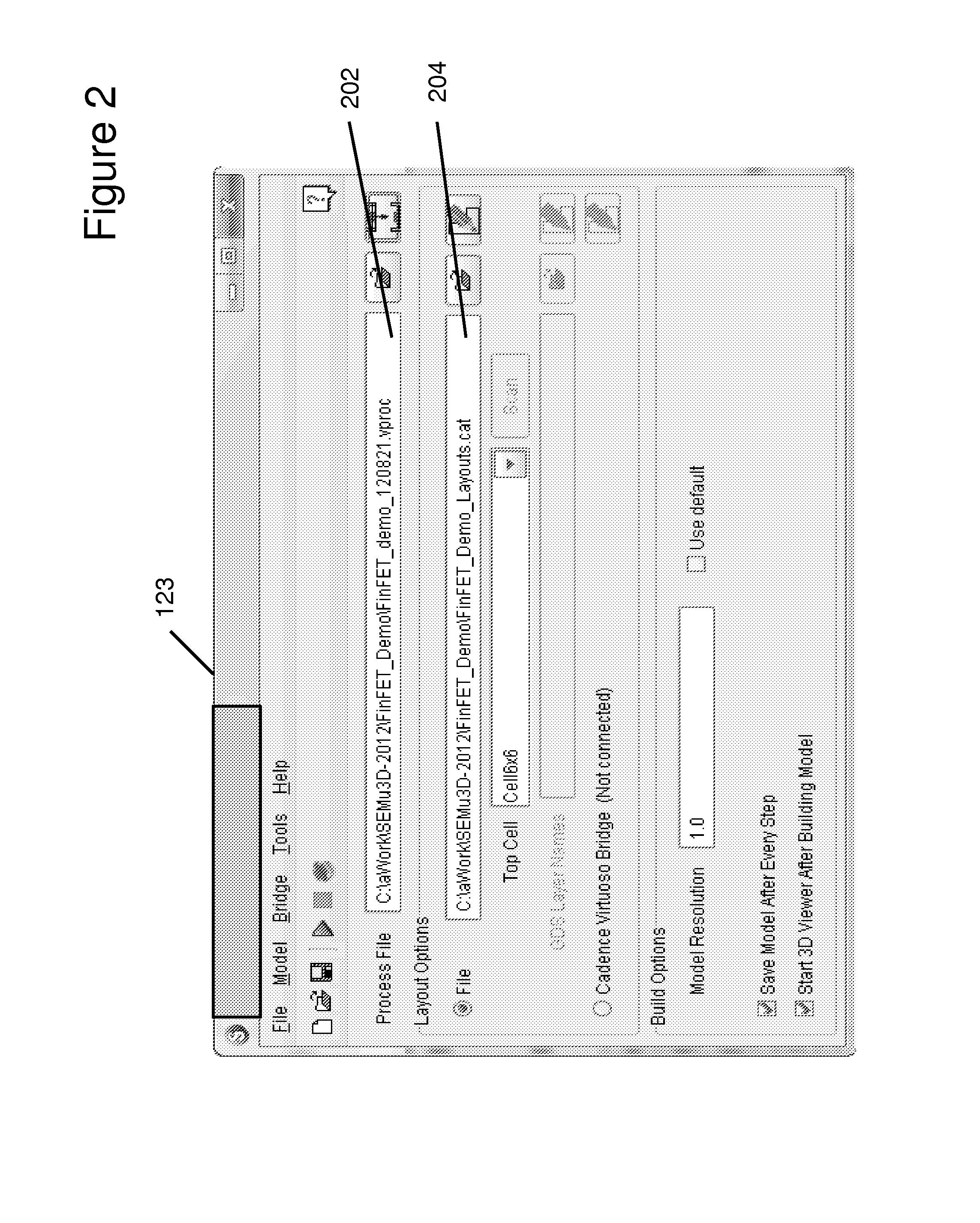

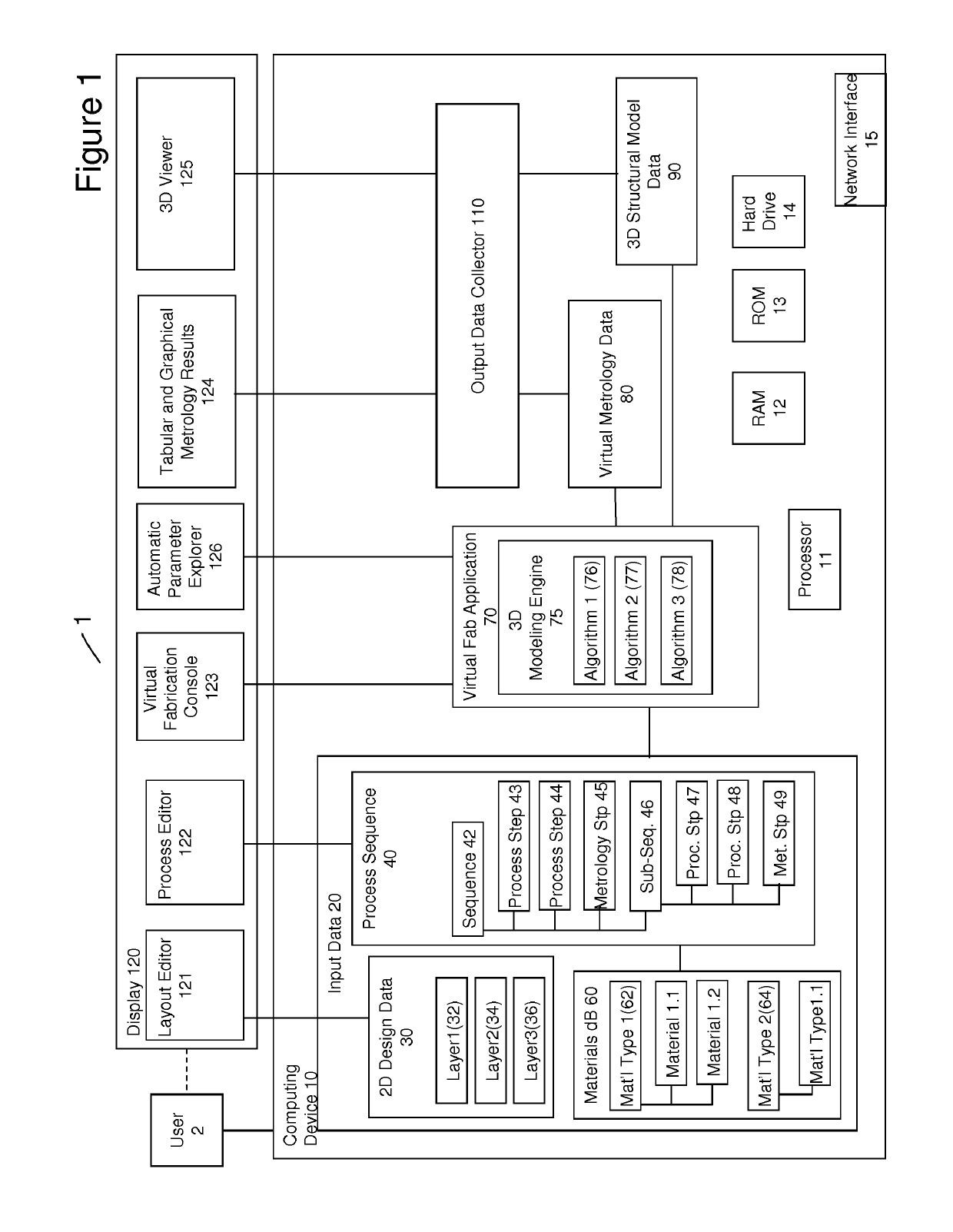

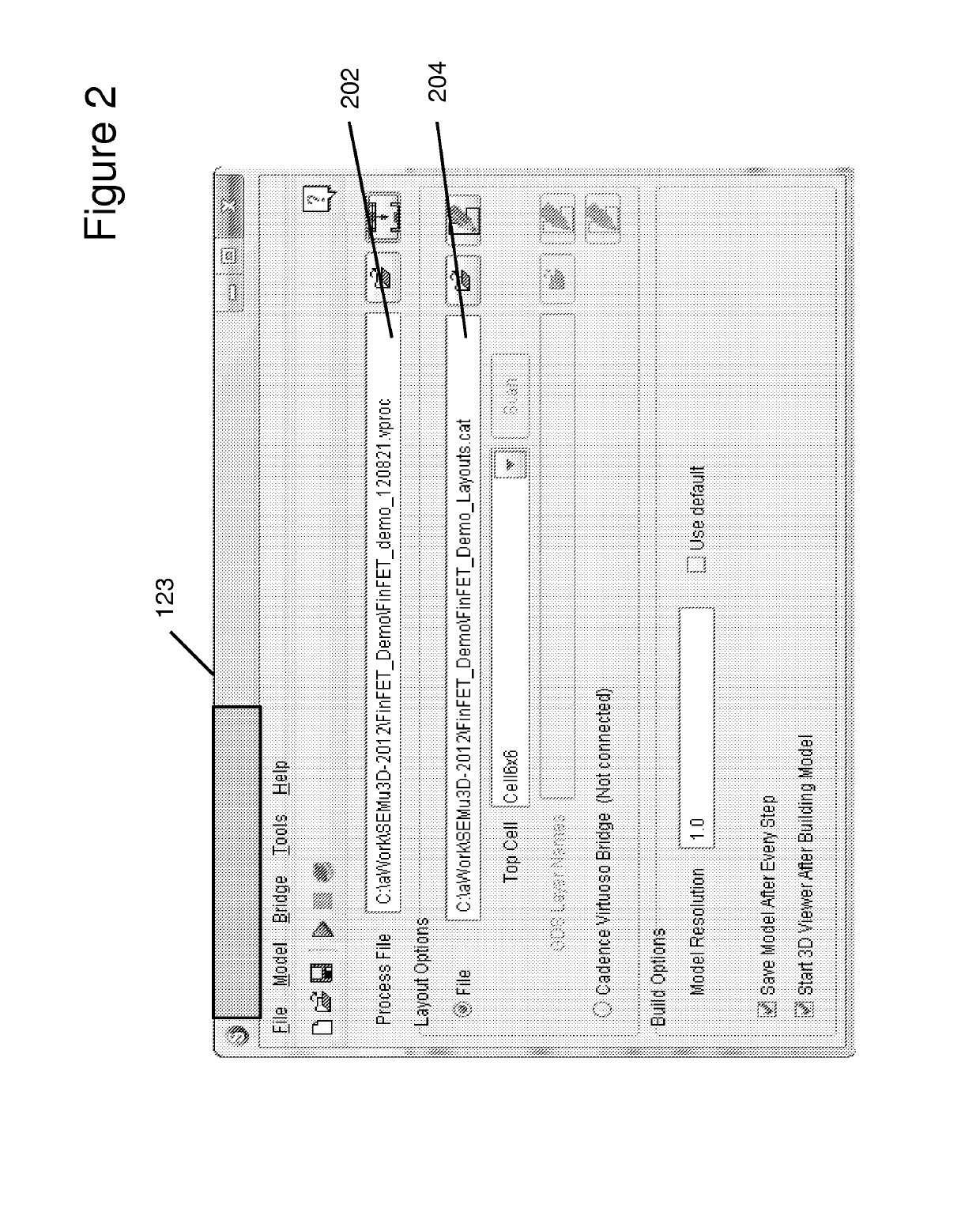

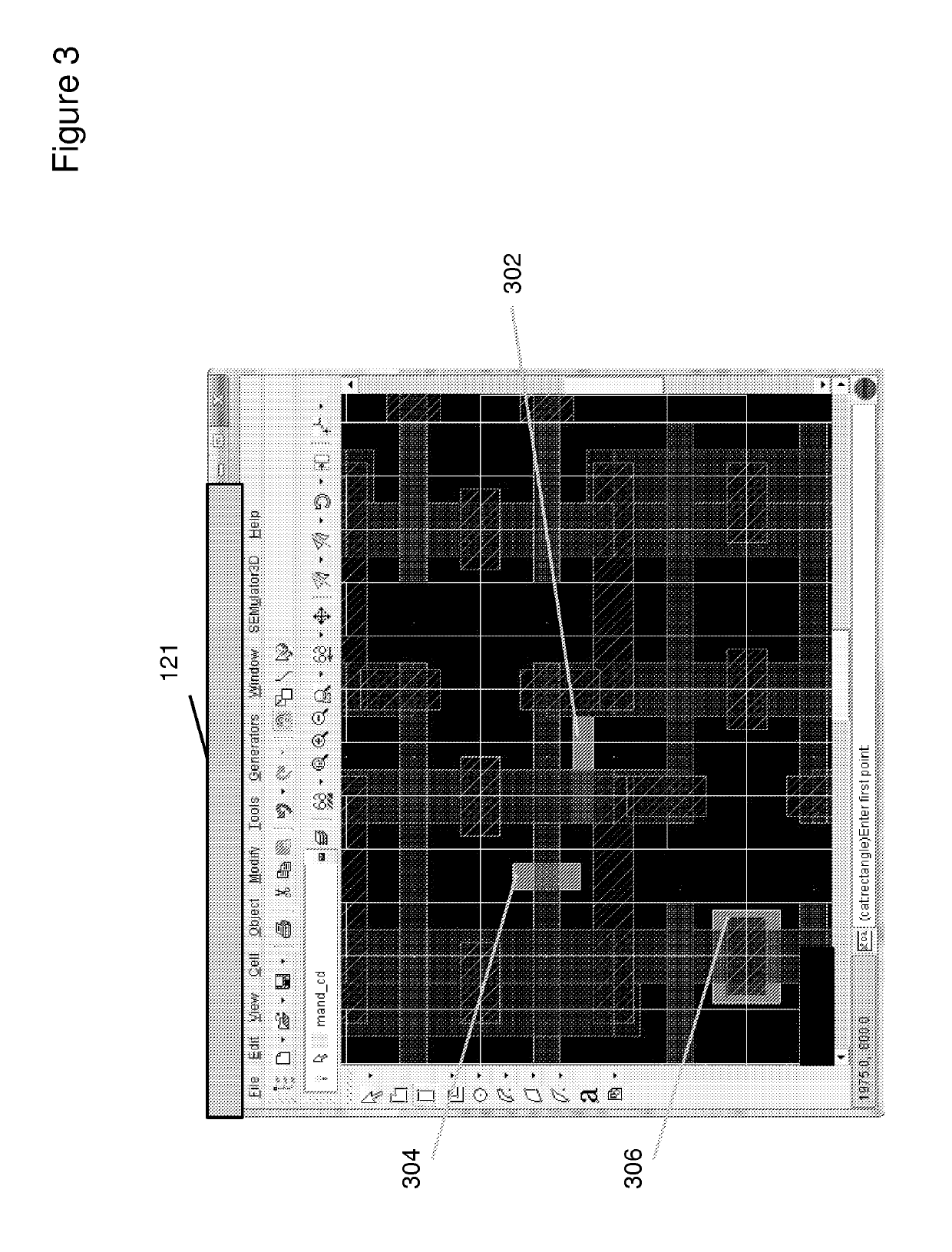

Predictive 3-d virtual fabrication system and method

ActiveUS20140282324A1More physically predictiveGeometric CADCAD circuit designEngineeringDesign space

A virtual fabrication environment for semiconductor device structures that includes the use of virtual metrology measurement data to optimize a virtual fabrication sequence is described. Further, calibration of the virtual fabrication environment is performed by comparing virtual metrology data generated from a virtual fabrication run with a subset of measurements performed in a physical fabrication environment. Additionally, virtual experiments conducted in the virtual fabrication environment of the present invention generate multiple device structure models using ranges of process and design parameter variations for an integrated process flow and design space of interest.

Owner:COVENTOR

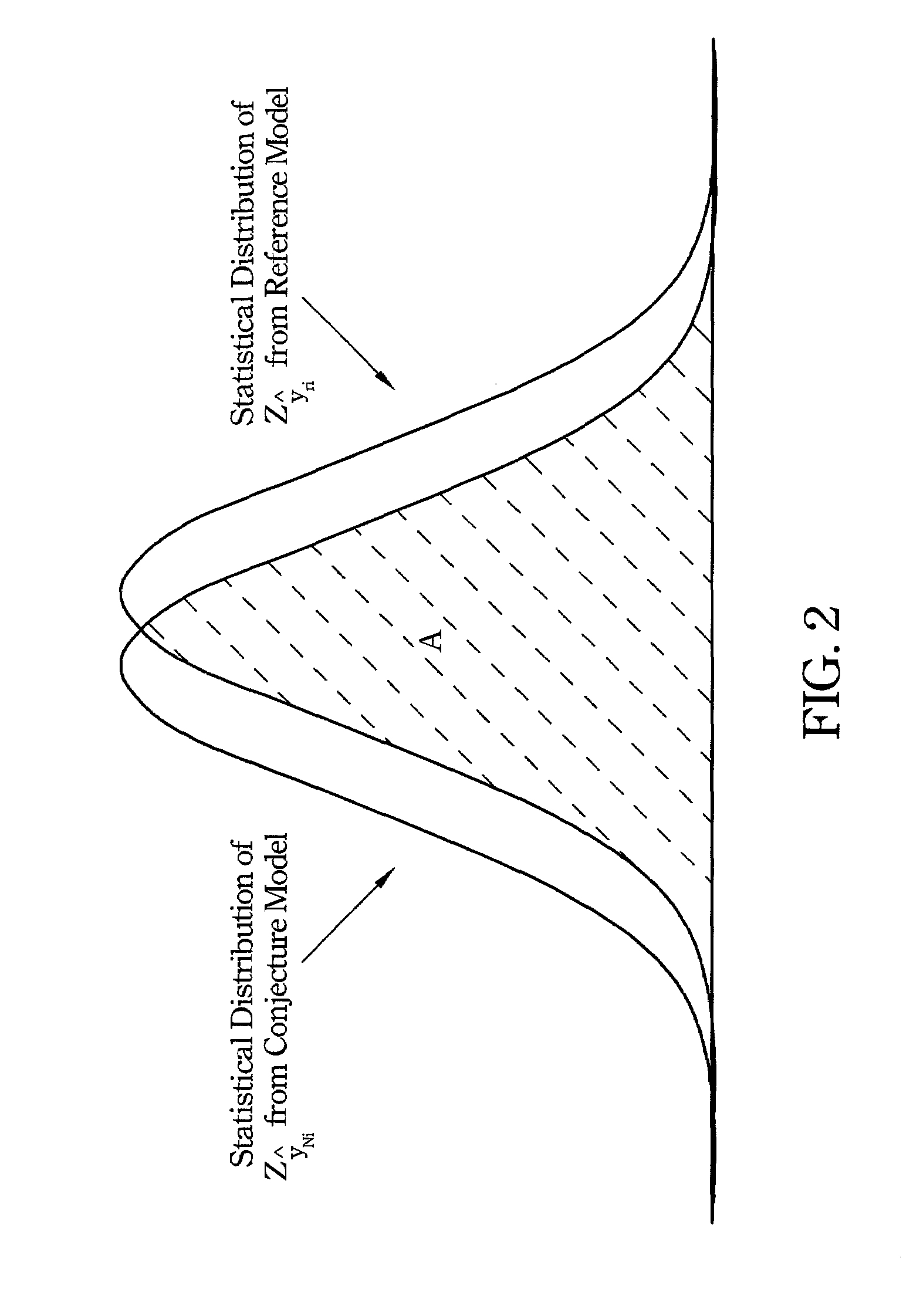

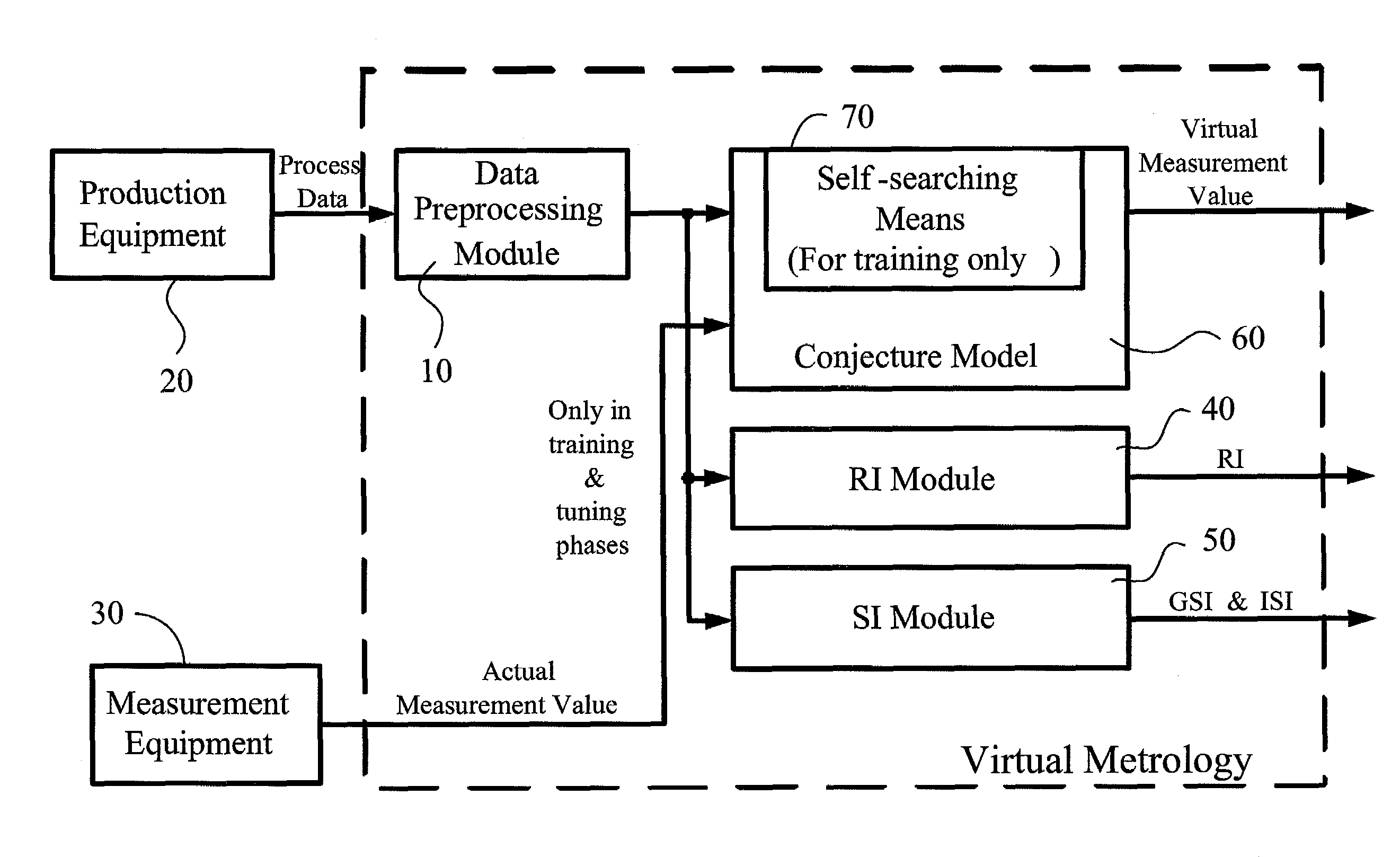

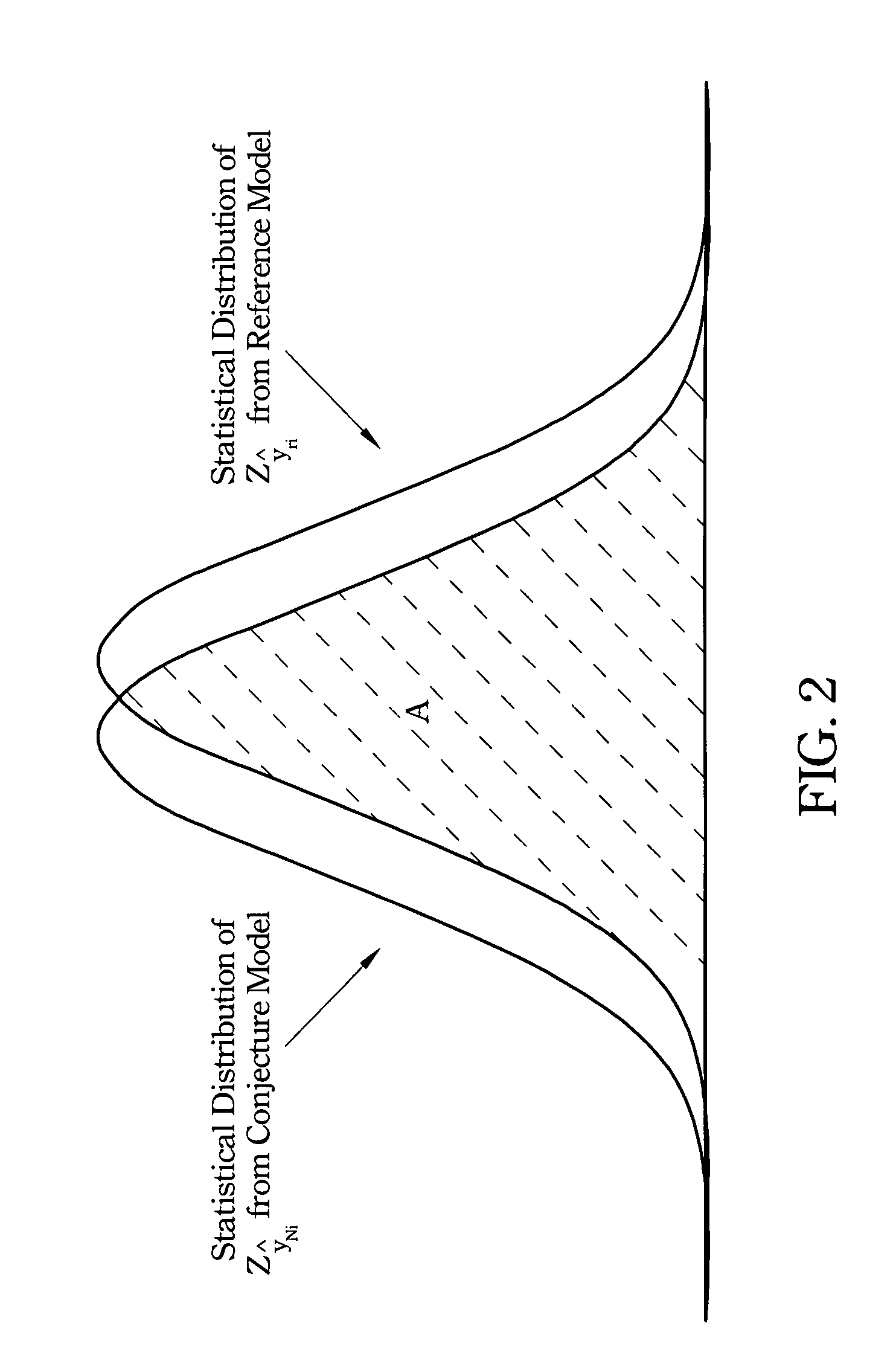

Method for Evaluating Reliance Level of a Virtual Metrology System

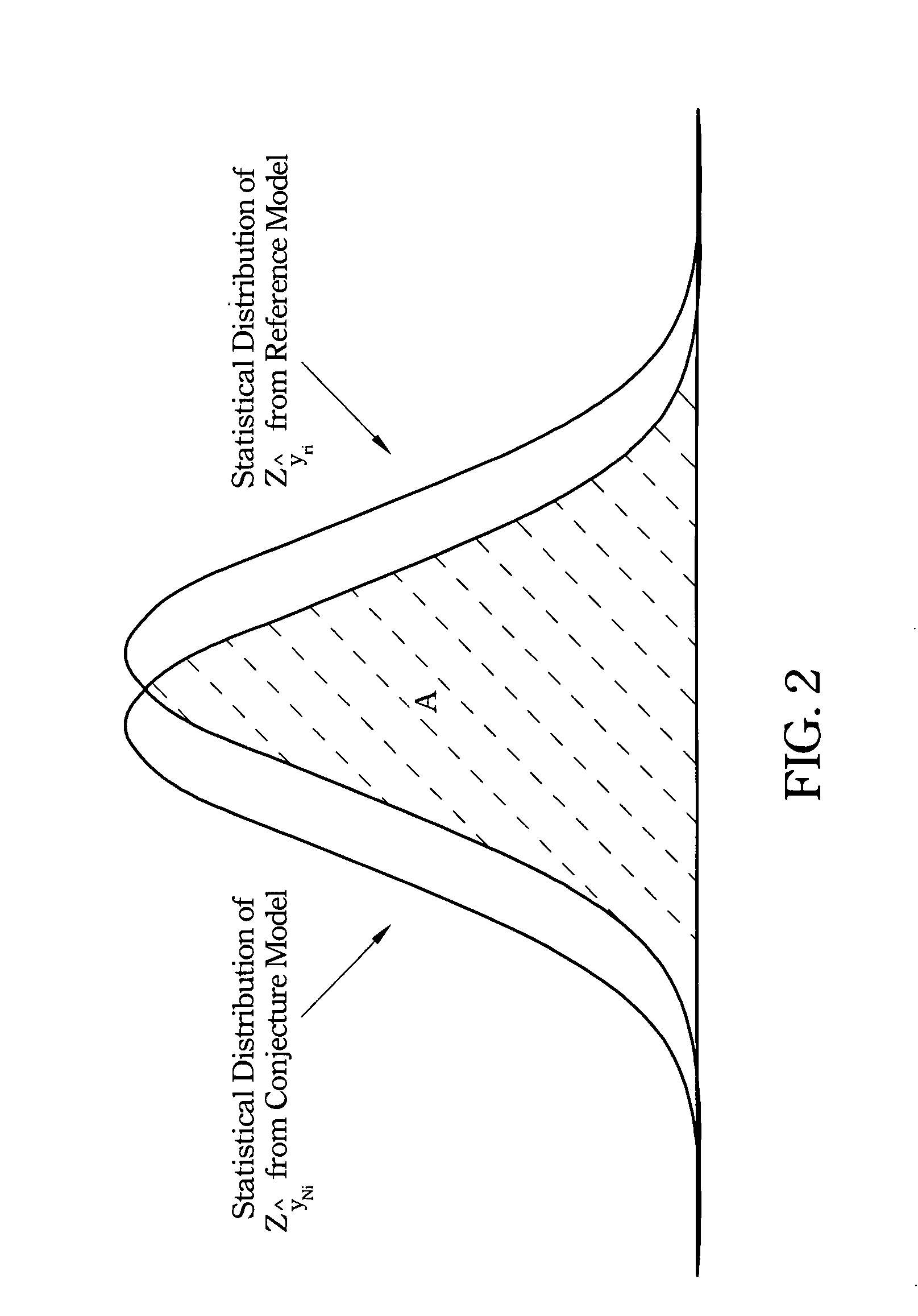

ActiveUS20070282767A1Improve the level ofTesting/monitoring control systemsDigital computer detailsData setDegree of similarity

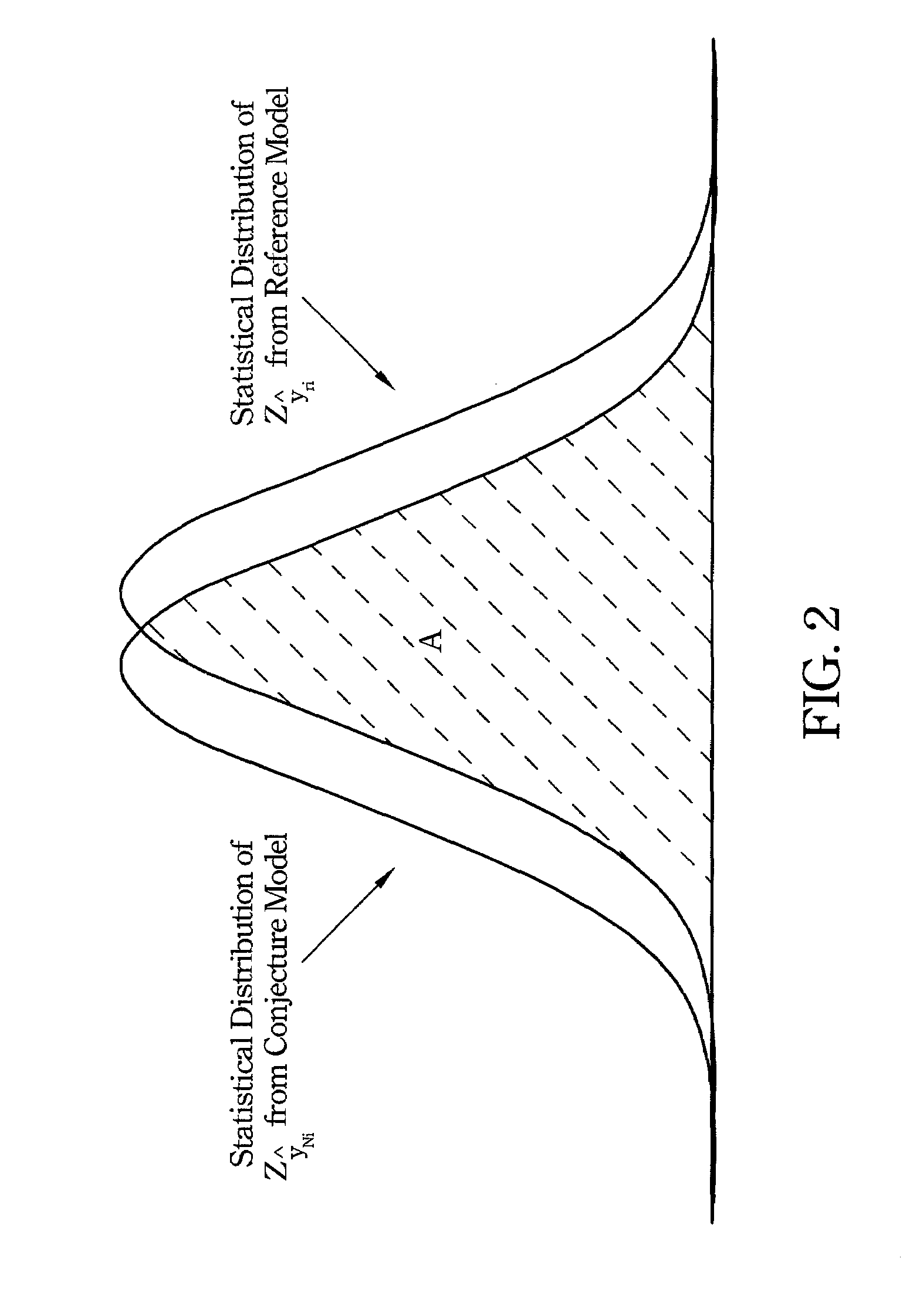

A method for evaluating reliance level of a virtual metrology system is disclosed. In this method, a reliance index (RI) and a RI threshold value are calculated by analyzing the process data of production equipment, thereby determining if the virtual metrology result is reliable. Besides, in this method, a global similarity index (GSI) and individual similarity indexes (ISI) are also provided for defining the degree of similarity between the current set of process data and all of the sets of historical process data used for establishing the conjecture model, thereby assisting the RI in gauging the degree of reliance and locating the key parameter(s) that cause major deviation.

Owner:NAT CHENG KUNG UNIV

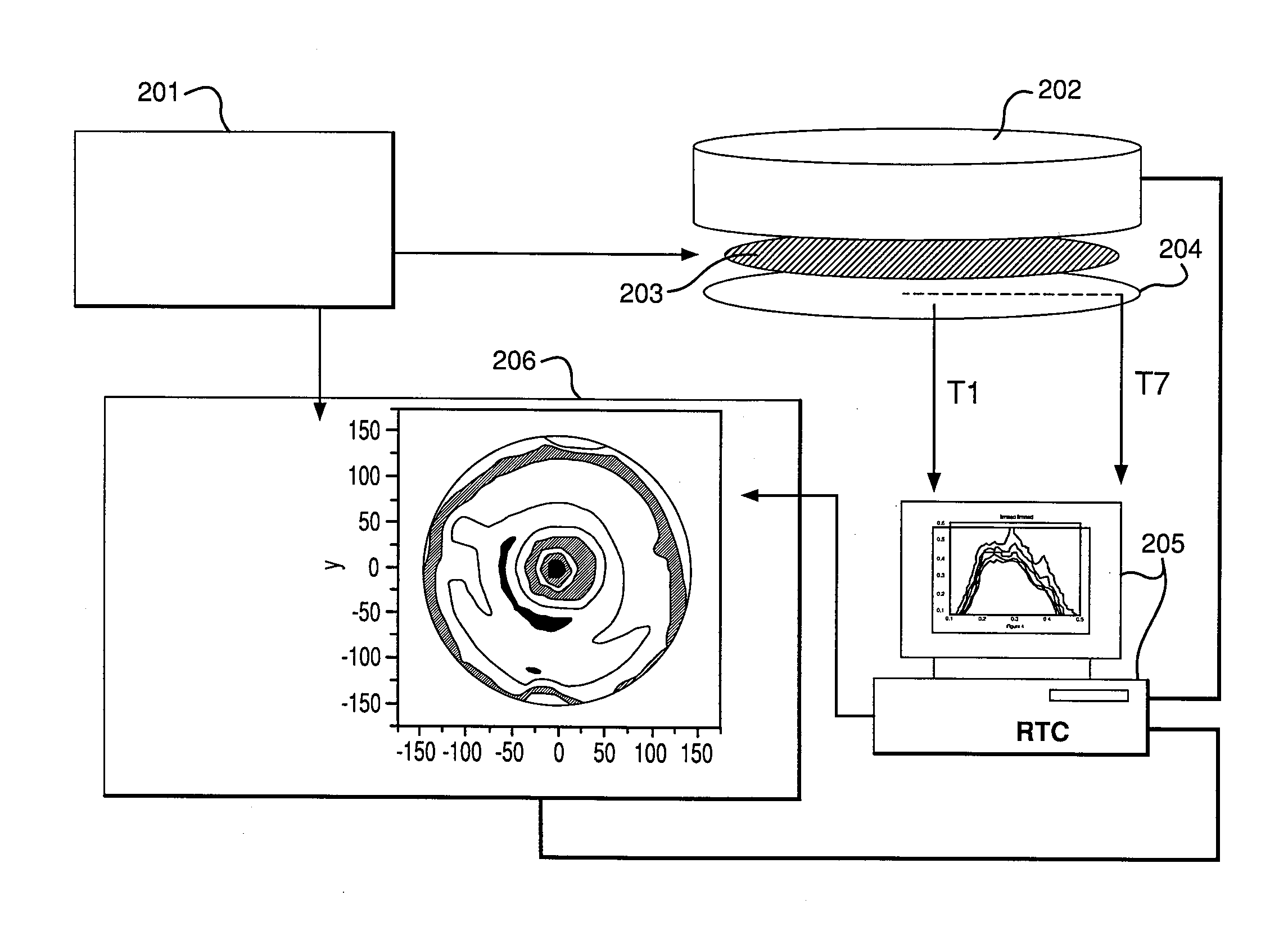

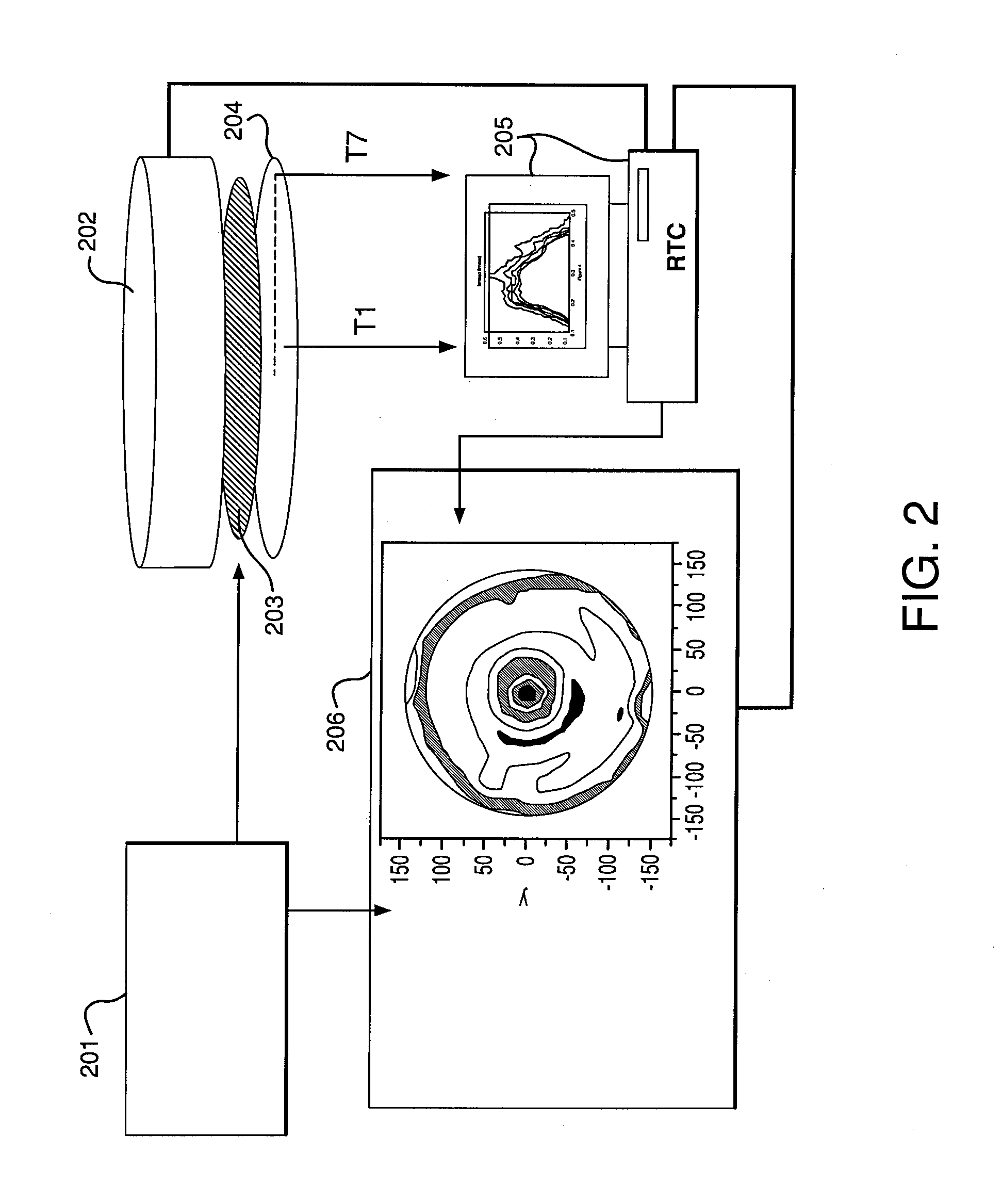

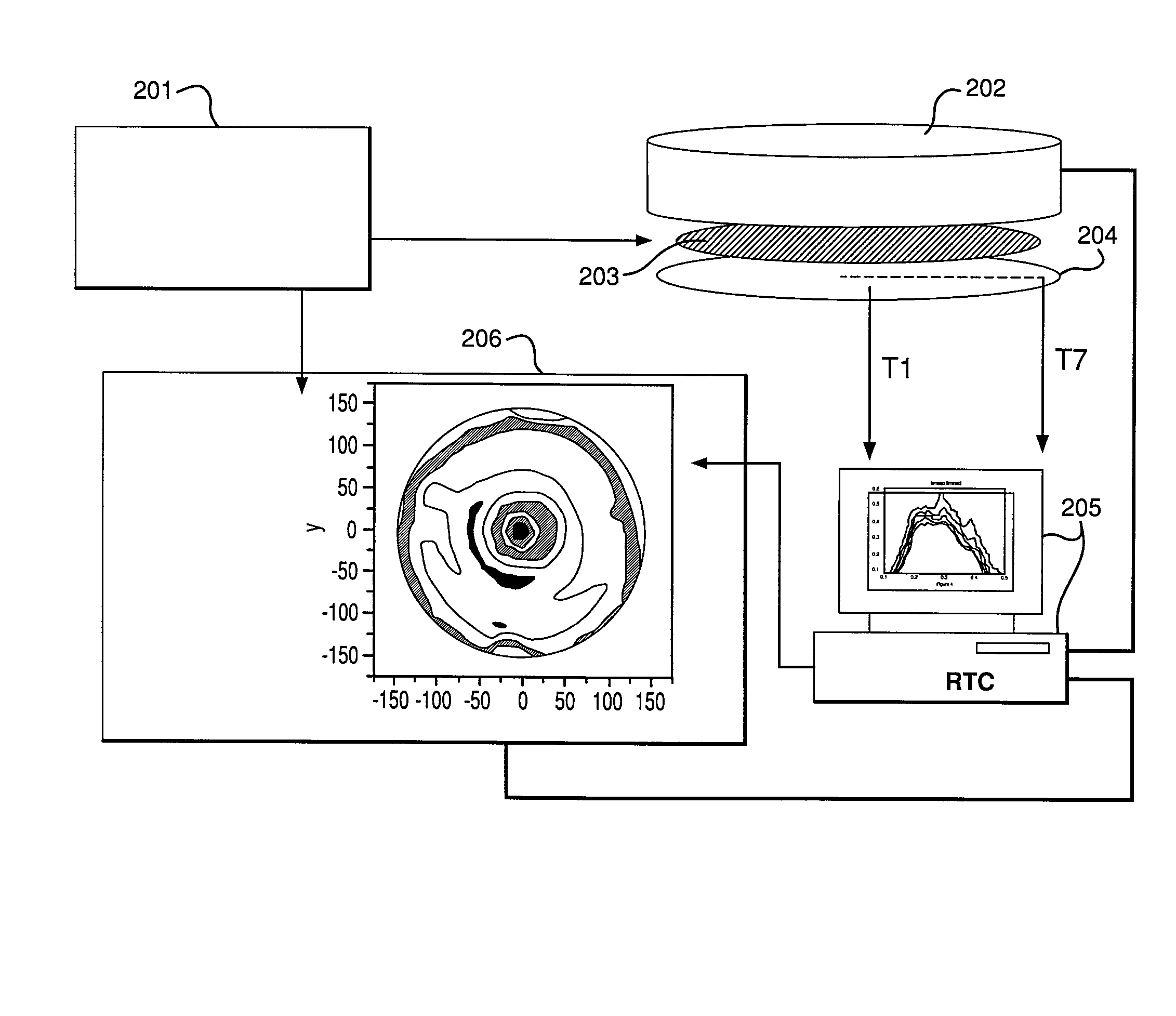

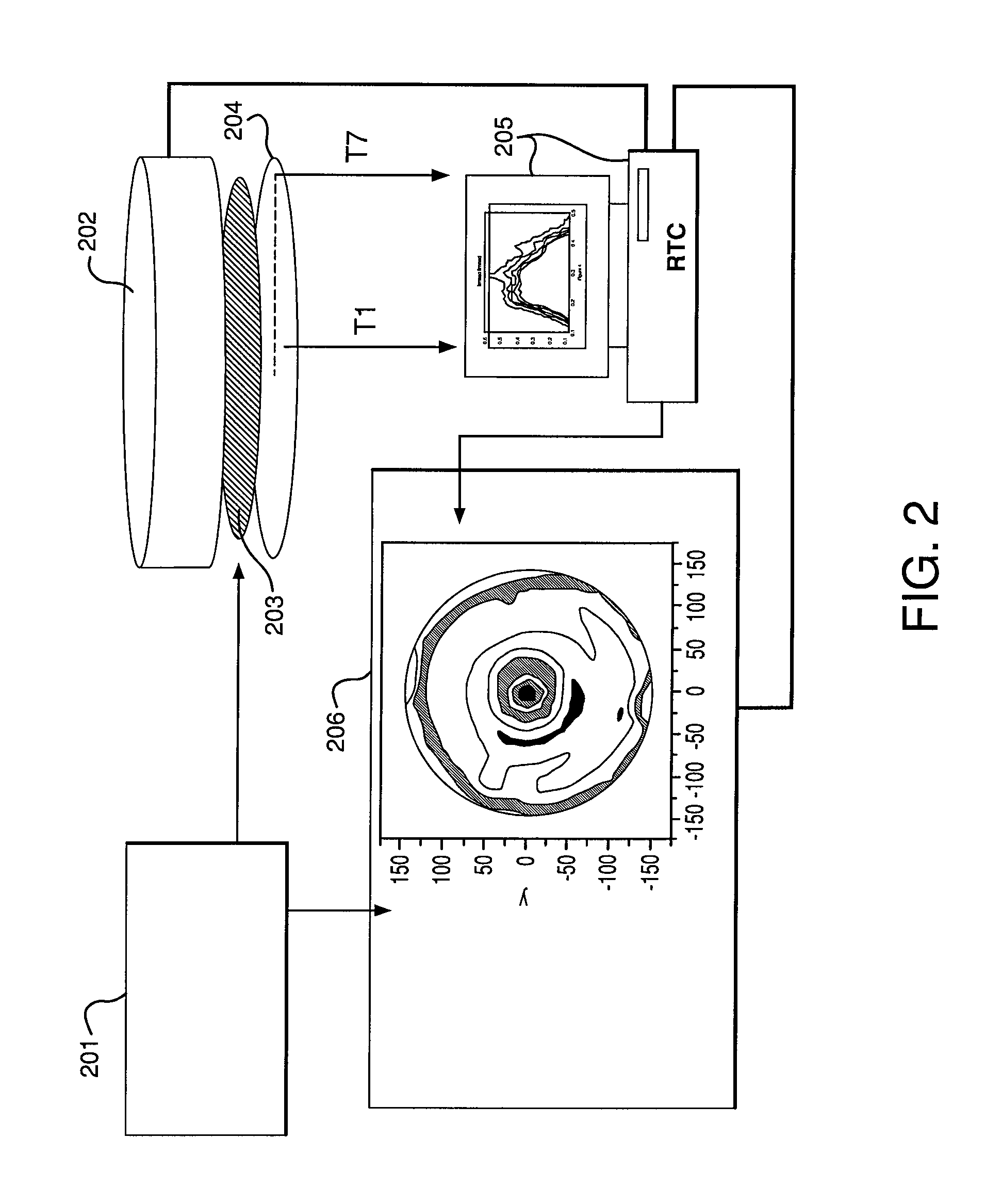

Temperature uniformity measurement during thermal processing

InactiveUS20100124249A1Operation be interruptThermometer detailsThermometers using material expansion/contactionMetrologyEngineering

Methods and systems for determining a radial differential metrology profile of a substrate heated in a process chamber is provided. Methods and systems for determining an angular or azimuthal differential metrology profile of a rotating substrate in a processing chamber are also provided. The radial and azimuthal differential metrology profiles are applied to adjust a reference metrology profile to provide a Virtual metrology of the process chamber. The virtual metrology is applied to control the performance of the process chamber.

Owner:APPLIED MATERIALS INC

Method for evaluating reliance level of a virtual metrology system in product manufacturing

ActiveUS7593912B2Improve the level ofTesting/monitoring control systemsDigital computer detailsData setDegree of similarity

A method for evaluating reliance level of a virtual metrology system is disclosed. In this method, a reliance index (RI) and a RI threshold value are calculated by analyzing the process data of production equipment, thereby determining if the virtual metrology result is reliable. Besides, in this method, a global similarity index (GSI) and individual similarity indexes (ISI) are also provided for defining the degree of similarity between the current set of process data and all of the sets of historical process data used for establishing the conjecture model, thereby assisting the RI in gauging the degree of reliance and locating the key parameter(s) that cause major deviation.

Owner:NAT CHENG KUNG UNIV

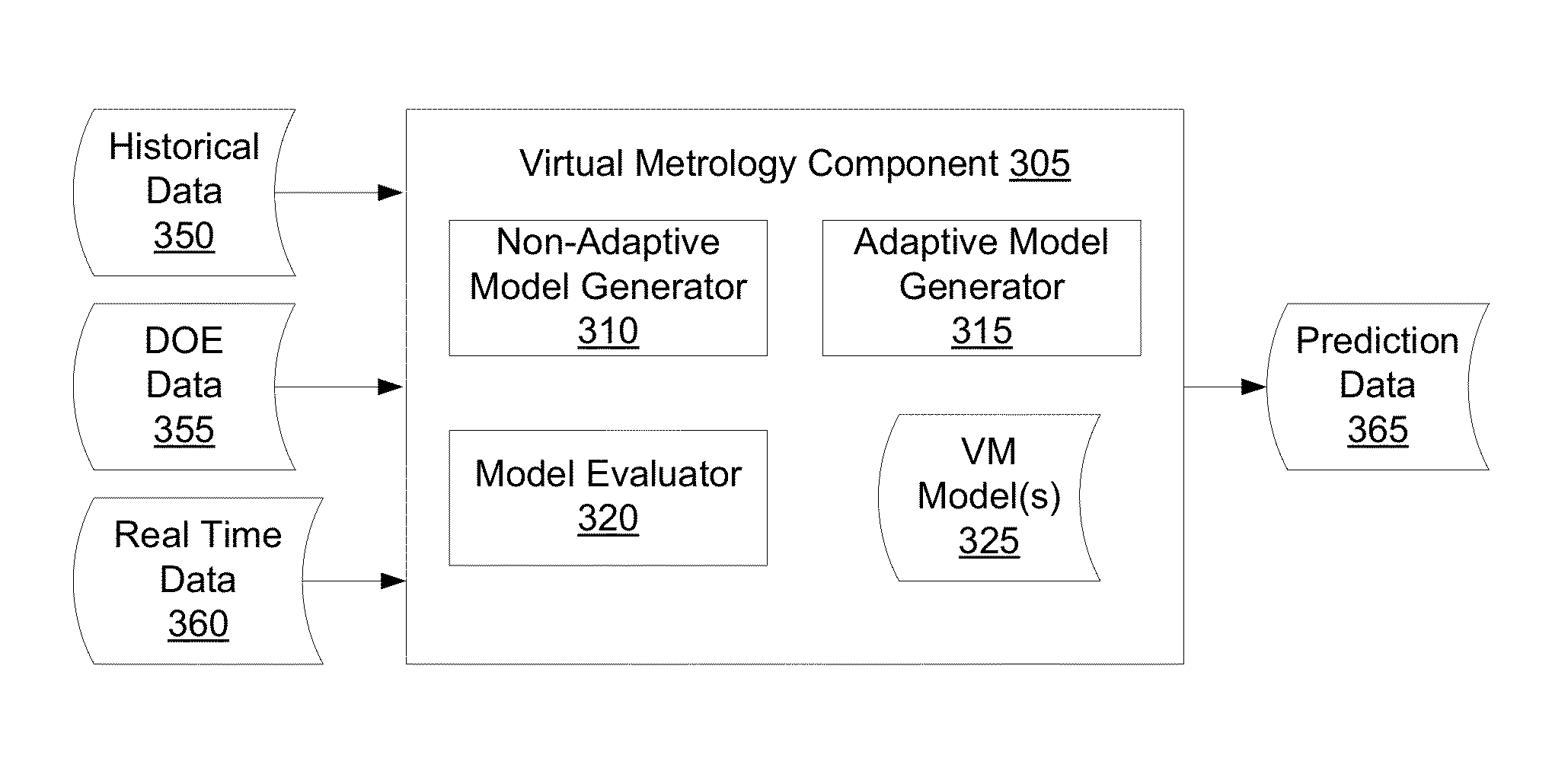

Method and apparatus for developing, improving and verifying virtual metrology models in a manufacturing system

A computing device develops a first non-adaptive virtual metrology (VM) model for a manufacturing process based on performing a non-adaptive regression using a first data set. Upon determining that an accuracy of the first non-adaptive VM model satisfies a first quality criterion, the computing device develops an adaptive VM model for the manufacturing process based on performing an adaptive regression using at least one of the first data set or a second data set. The computing device evaluates an accuracy of the adaptive VM model using a third data set that is larger than the first data set and the second data set. The computing device determines that the adaptive VM model is ready for use in production upon determining that an accuracy of the first adaptive VM model satisfies a second quality criterion that is more stringent than the first quality criterion.

Owner:APPLIED MATERIALS INC

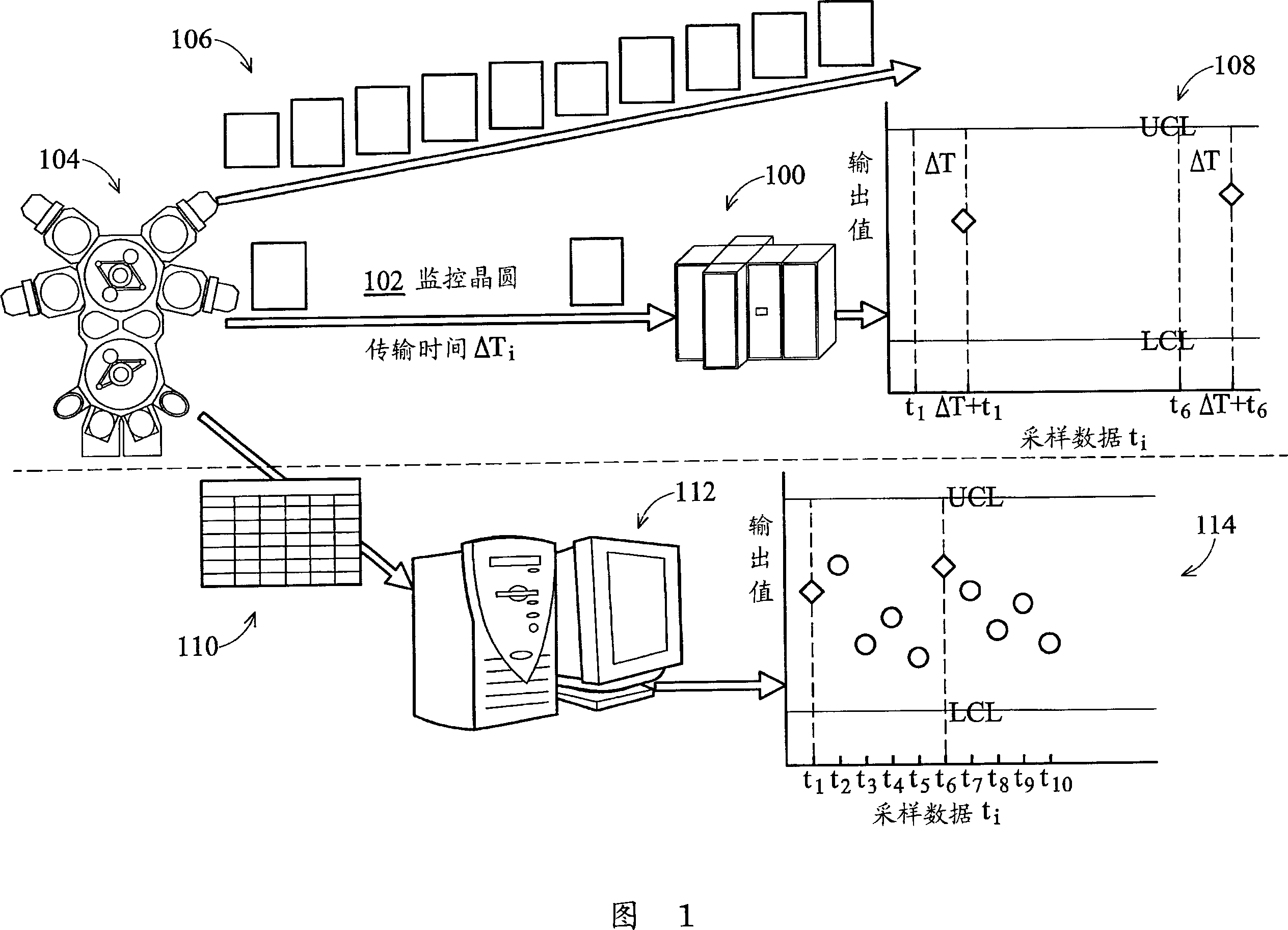

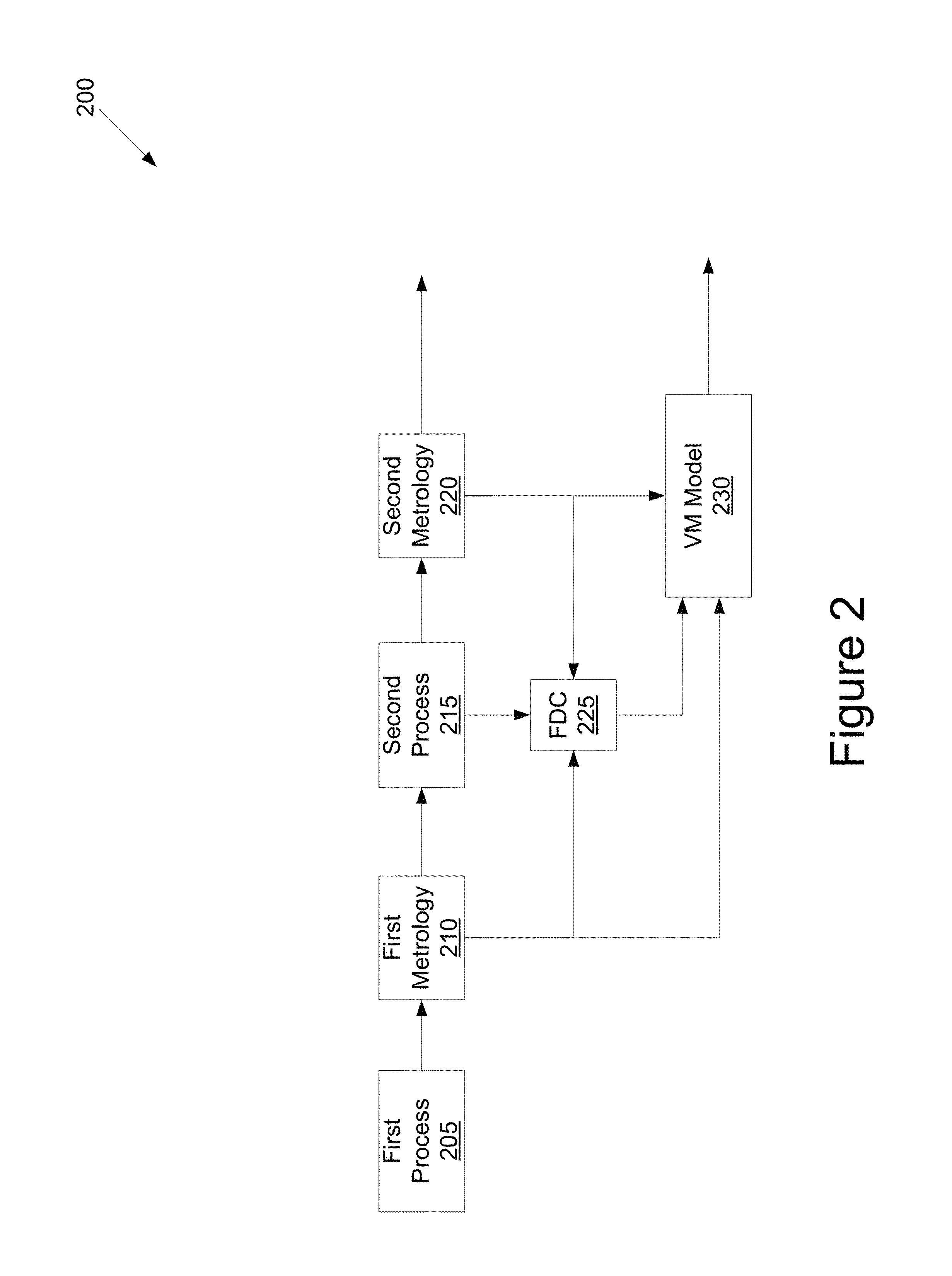

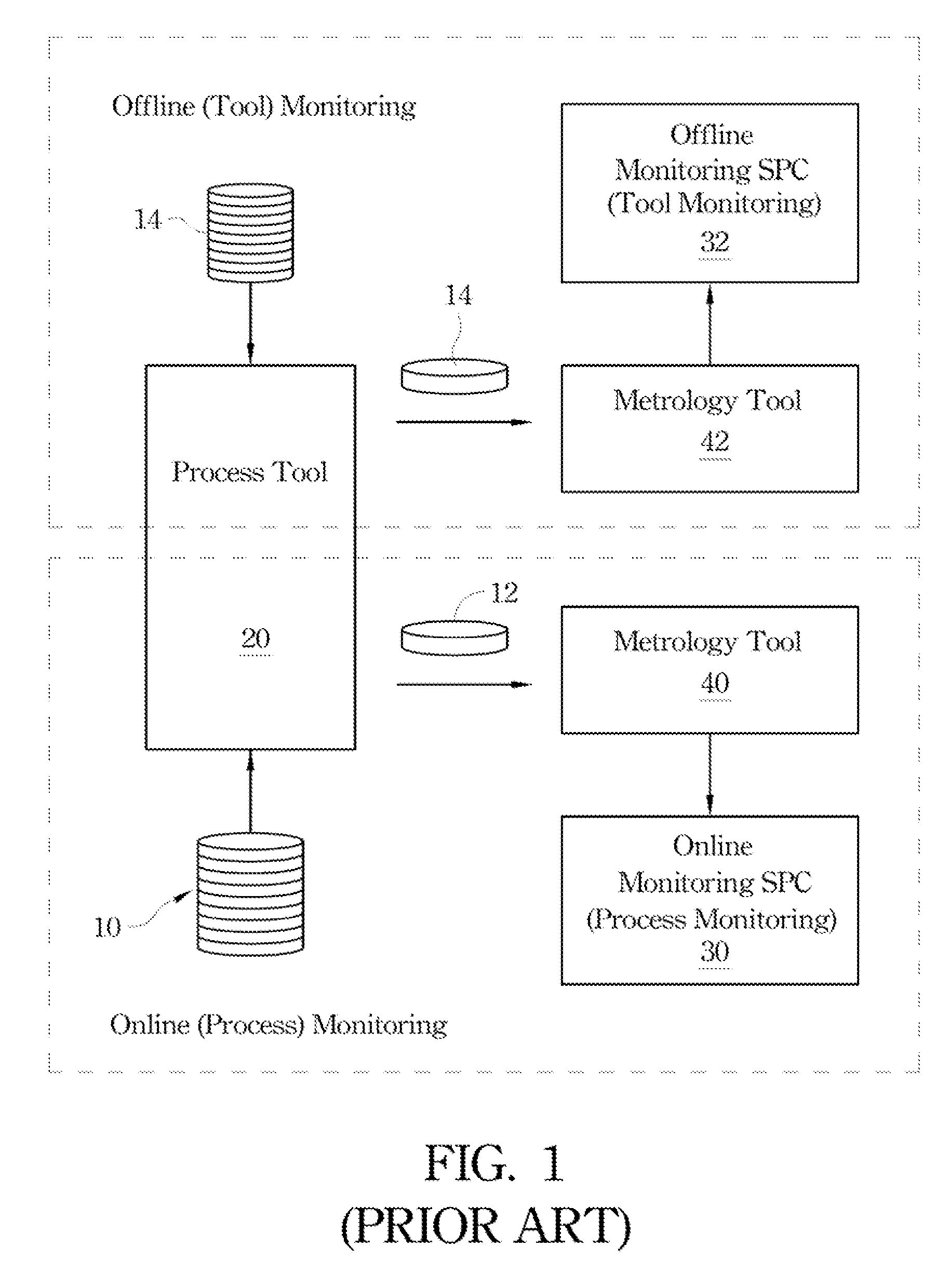

Method and system for virtual metrology

The present invention provides a method and a metrology system which are especially suitable for semiconductor manufacturing are provided in this patent. Process data and metrology data are received. Prediction data is generated from the process data and metrology data using a learning control model. The virtual measuring system which is suitable for manufacturers is composed of a fault detection and classification system which receives process data, a statistical process control system which performs statistical process control on a history of physical metrology data to form metrology data, a virtual metrology application system which generates prediction data based on the process data and the metrology data using a learning control model. The method and the metrology system presented in this patent can shorten production period through lowering application procedures or tool measuring parameters.

Owner:TAIWAN SEMICON MFG CO LTD

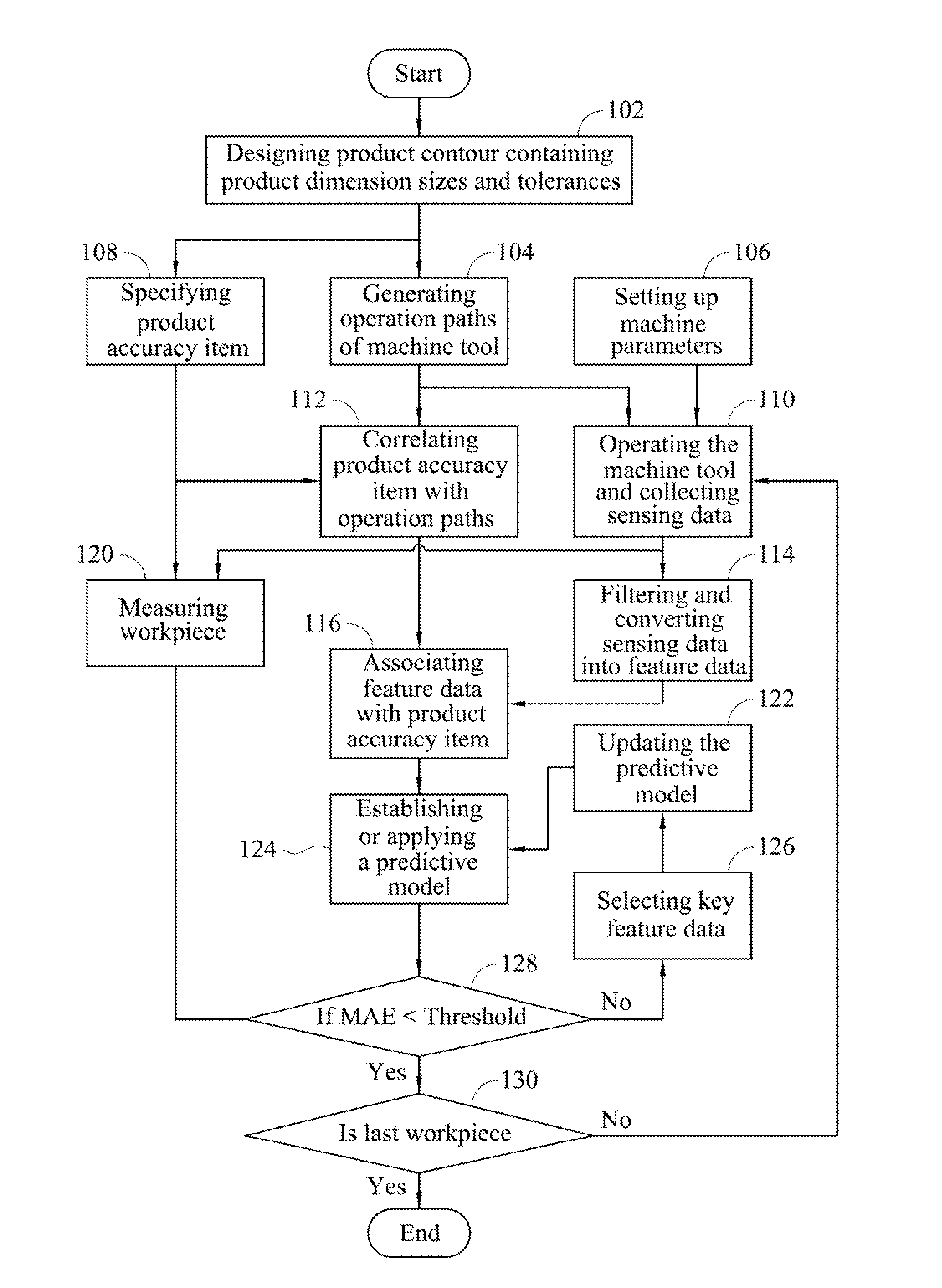

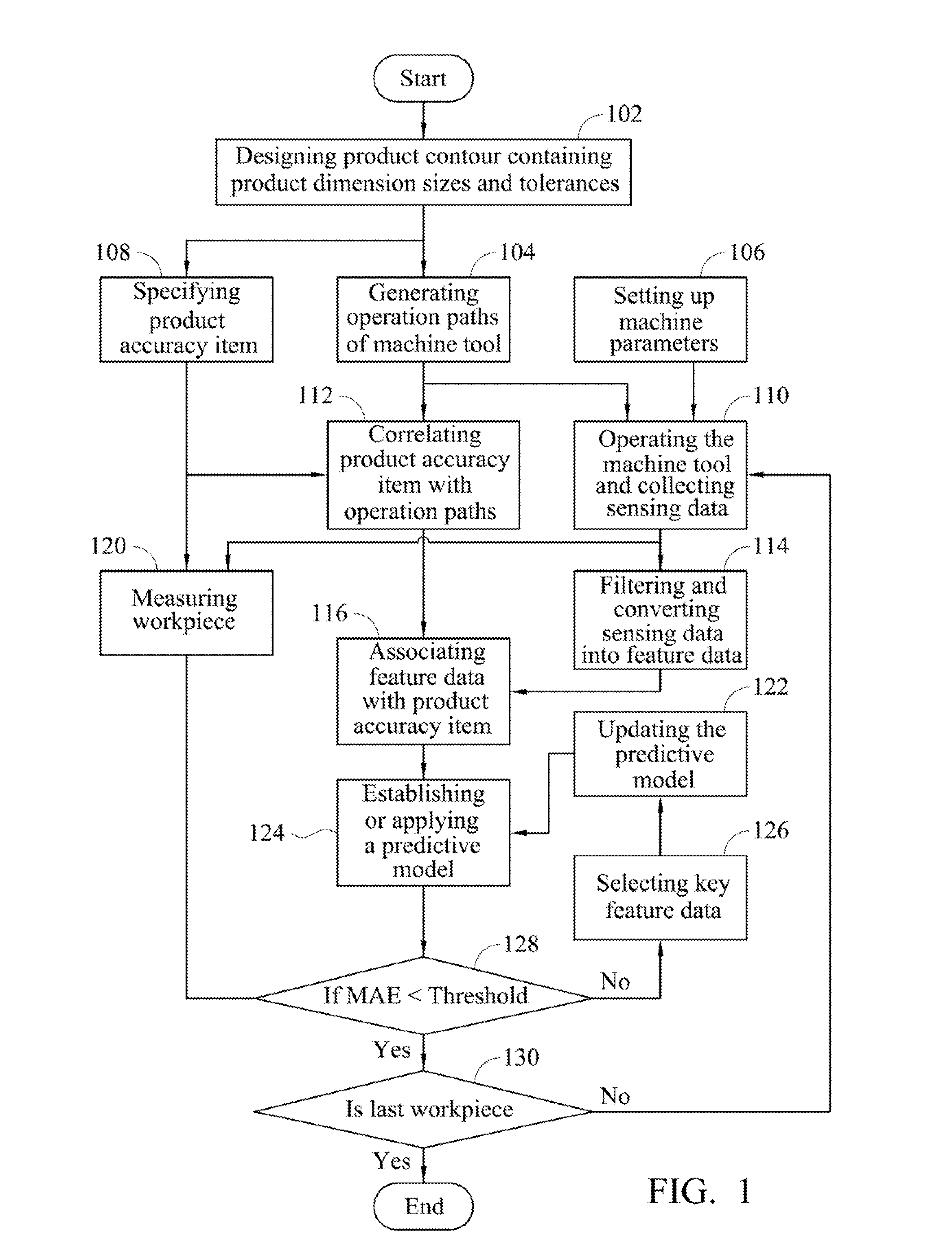

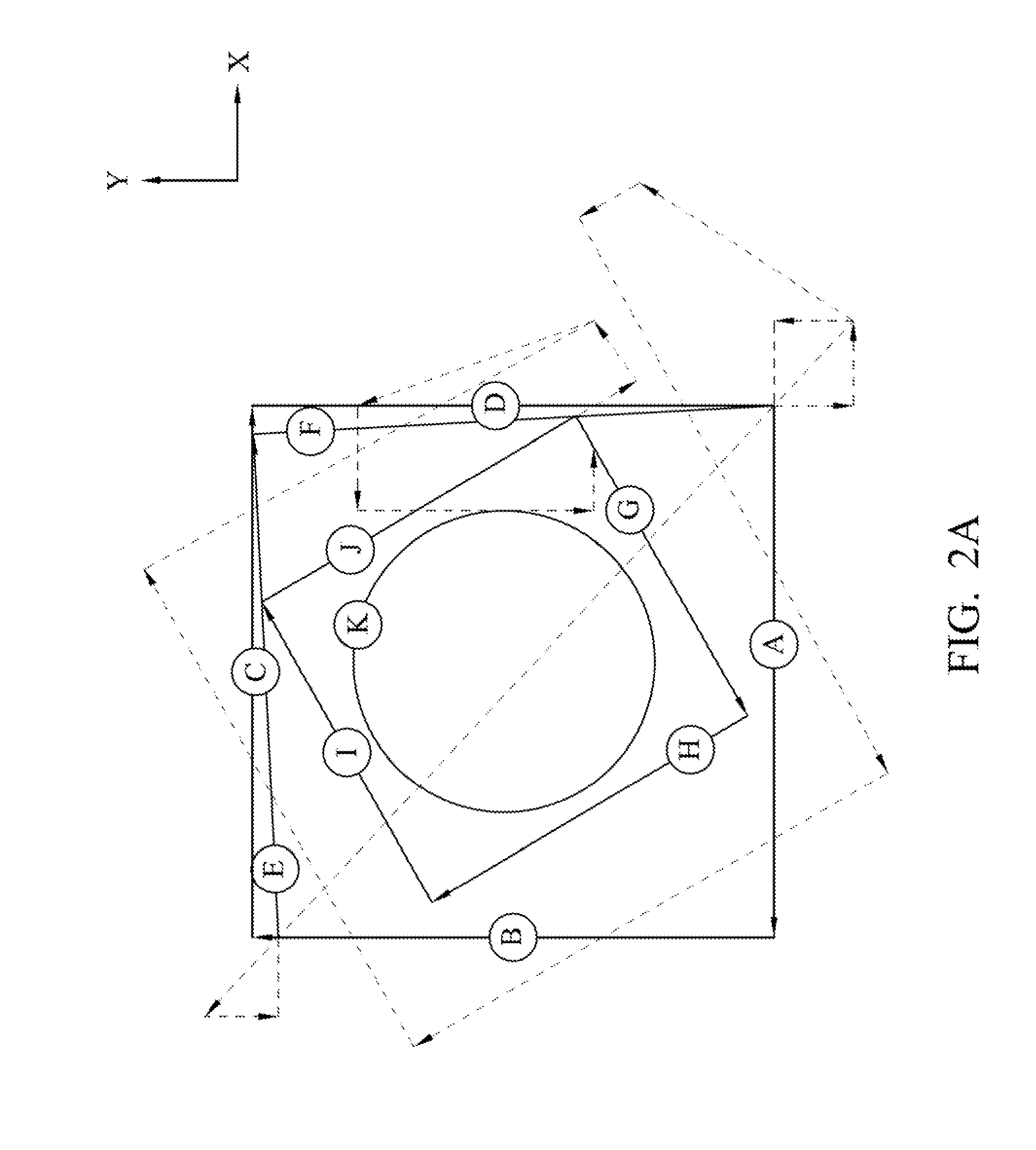

Method for predicting machining quality of machine tool

ActiveUS20140129503A1Effective valuePredicting machining quality of machineKnowledge representationInference methodsSensing dataFeature data

A virtual metrology based method for predicting machining quality of a machine tool is provided. In this method, each product accuracy item is correlated with operation paths of the machine tool. During a modeling stage, the machine tool is operated to process workpiece samples, and sample sensing data of the workpiece samples associated with the operation paths are collected during the operation of the machine tool. The sample sensing data of each workpiece sample is de-noised and converted into the sample feature data corresponding to each feature type. The workpiece samples are measured with respect to the product accuracy item and integrated into the feature data for building a predictive model, thereby obtaining quality predicted data for each product accuracy item. During a usage stage, accuracy item values of a workpiece are predicted using the feature data during processing the workpiece in accordance with the predictive models.

Owner:NAT CHENG KUNG UNIV

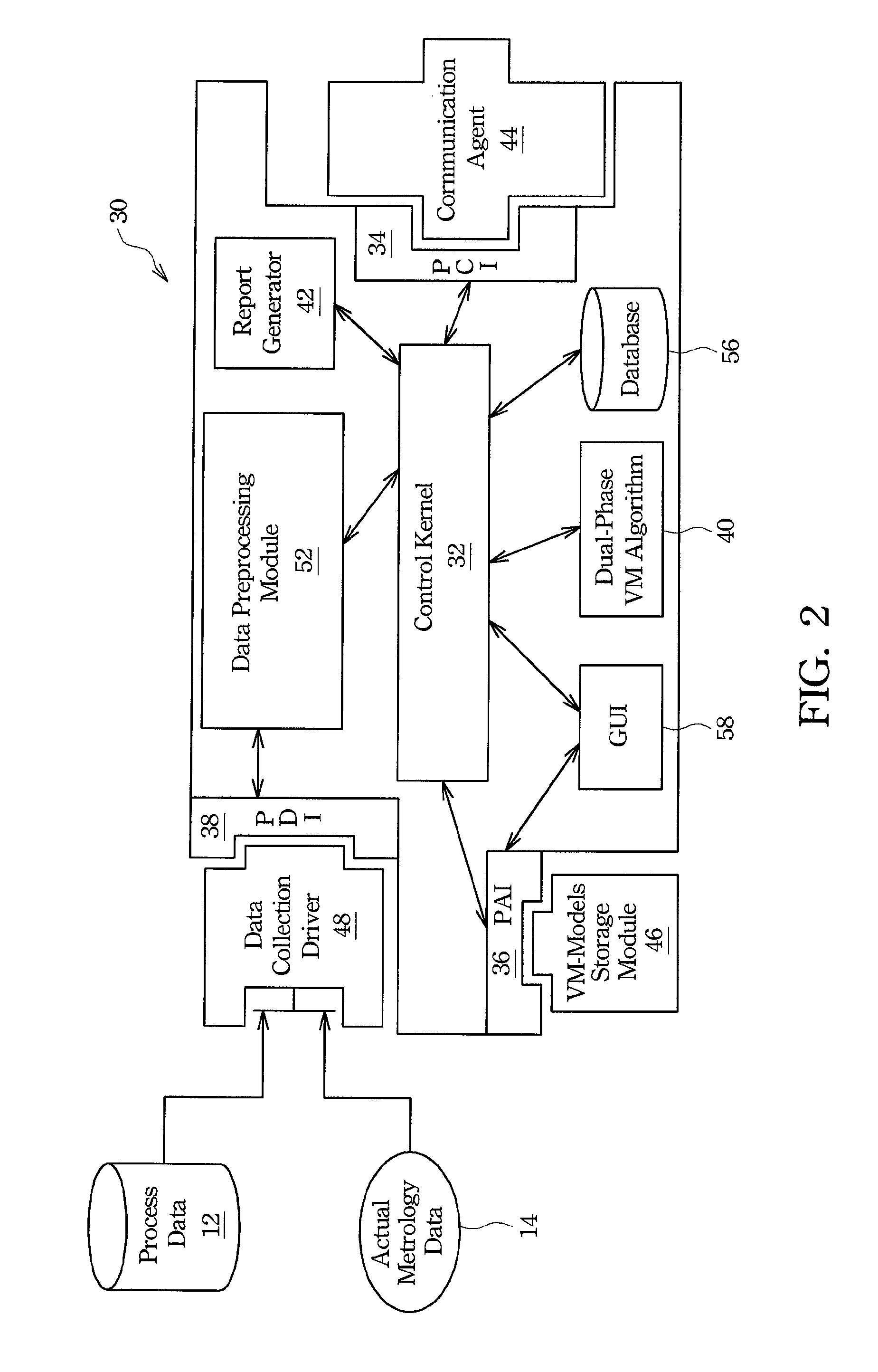

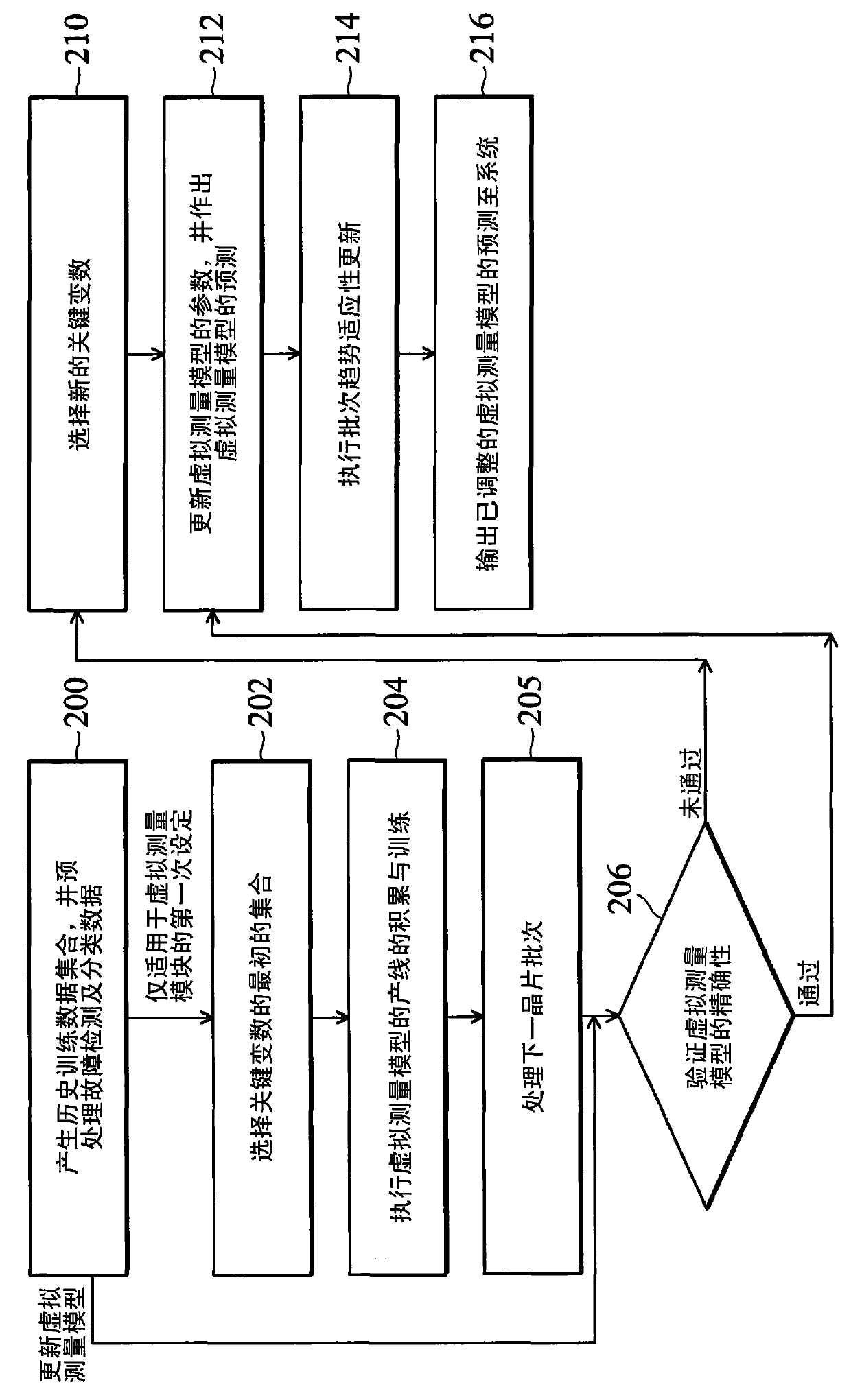

System and method for implementing a virtual metrology advanced process control platform

ActiveCN101908495ASemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingProcess equipmentMetrology

System and method for implementing a Virtual Metrology ('VM') Advanced Process Control ('APC') platform are described. In one embodiment, the VM APC system comprises a process tool for processing a plurality of wafers, a metrology tool for measuring a sample wafer of the plurality of wafers and generating actual metrology data therefor, and a VM model for predicting metrology data for each of the plurality of wafers. The system also includes an APC controller for receiving the predicted metrology data and the actual metrology data and generating a process input of the process tool based on the received data. In the inventive VM APC system, process parameters after updating or modulating are not needed to perfrom individual measurement procedure, based on chip by chip control.

Owner:TAIWAN SEMICON MFG CO LTD

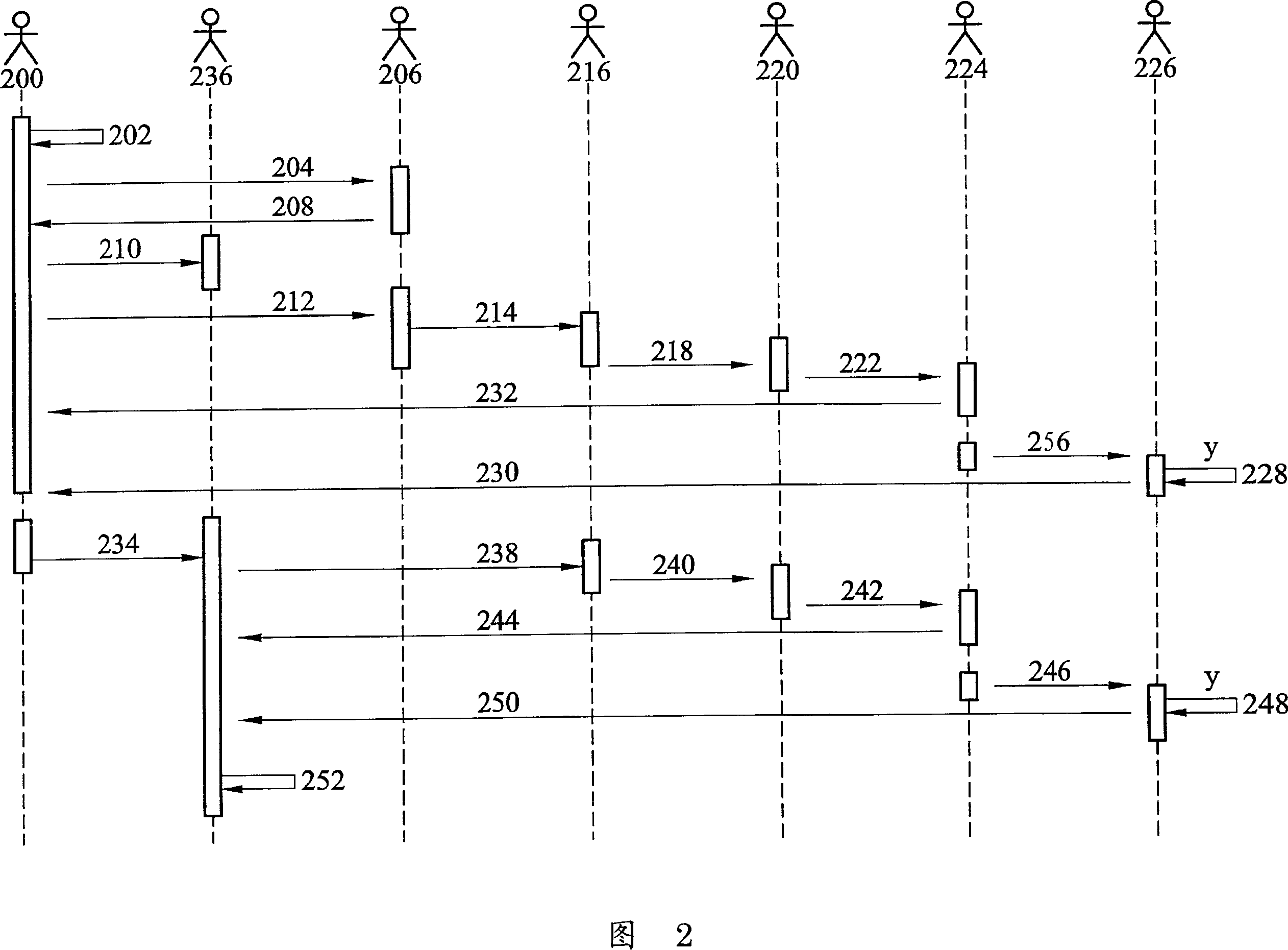

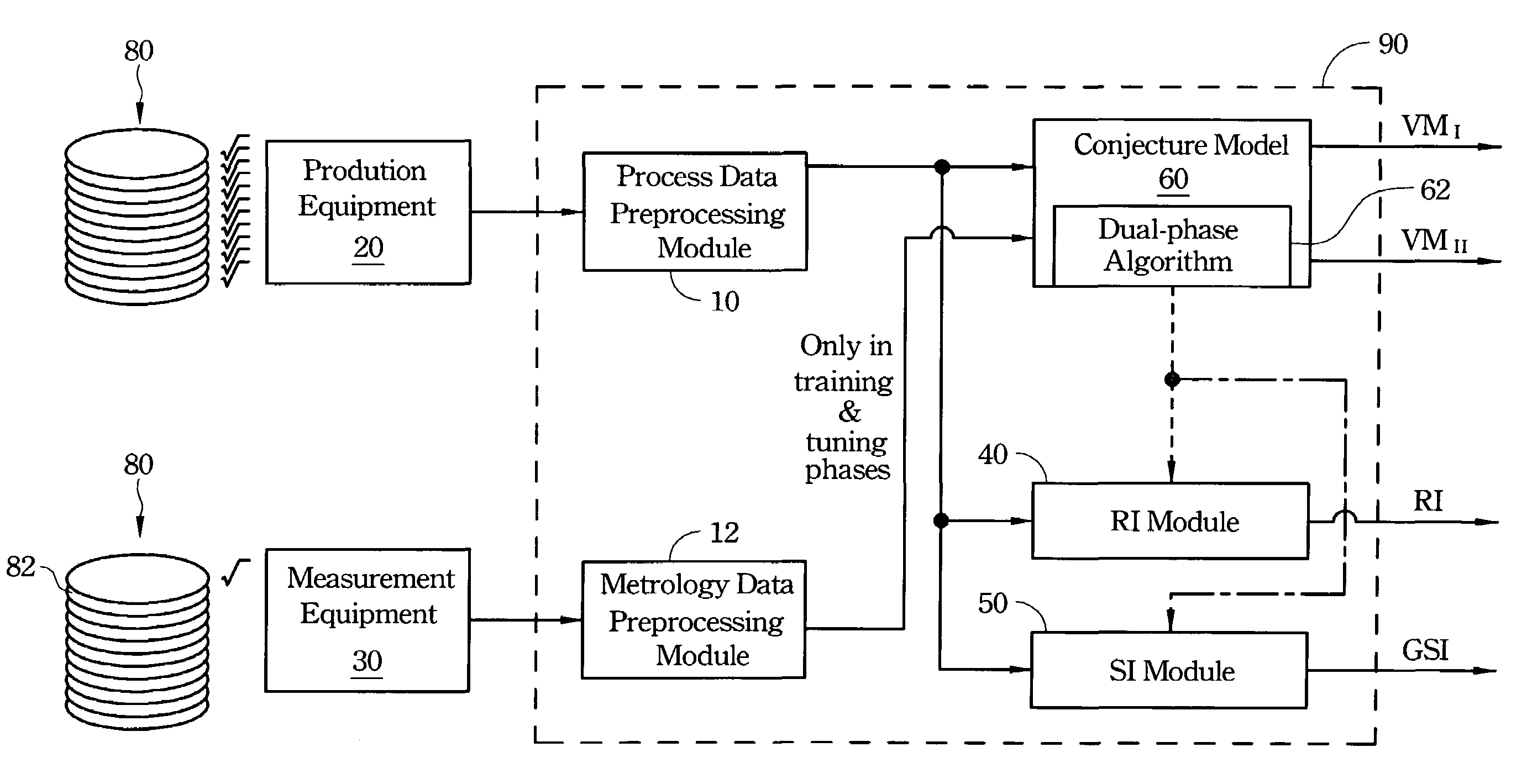

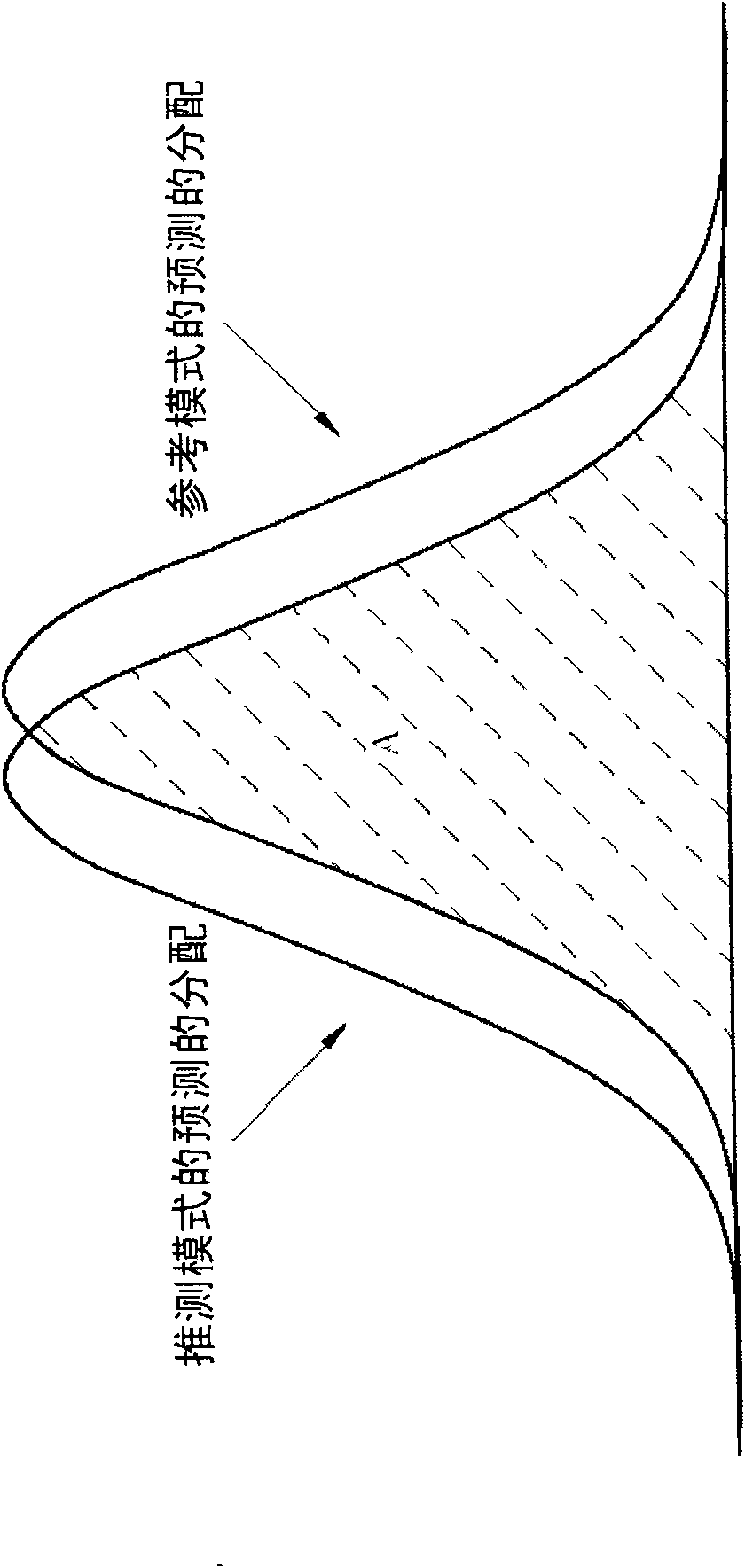

Dual-phase virtual metrology method

ActiveUS7603328B2Programme controlSemiconductor/solid-state device testing/measurementMetrologySoftware engineering

A dual-phase virtual metrology method is disclosed for considering both promptness and accuracy by generating dual-phase virtual metrology (VM) values, wherein a Phase-I conjecture step emphasizes promptness by immediately calculating the Phase-I virtual metrology value (VMI) of a workpiece once the entire process data of the workpiece are completely collected; and a Phase-II conjecture step intensifies accuracy, which does not re-calculate the Phase-II virtual metrology values (VMII) of all the workpieces in the cassette until an actual metrology value (required for tuning or re-training purposes) of a selected workpiece in the same cassette is collected. Besides, the accompanying reliance index (RI) and global similarity index (GSI) of each VMI and VMII are also generated.

Owner:NAT CHENG KUNG UNIV

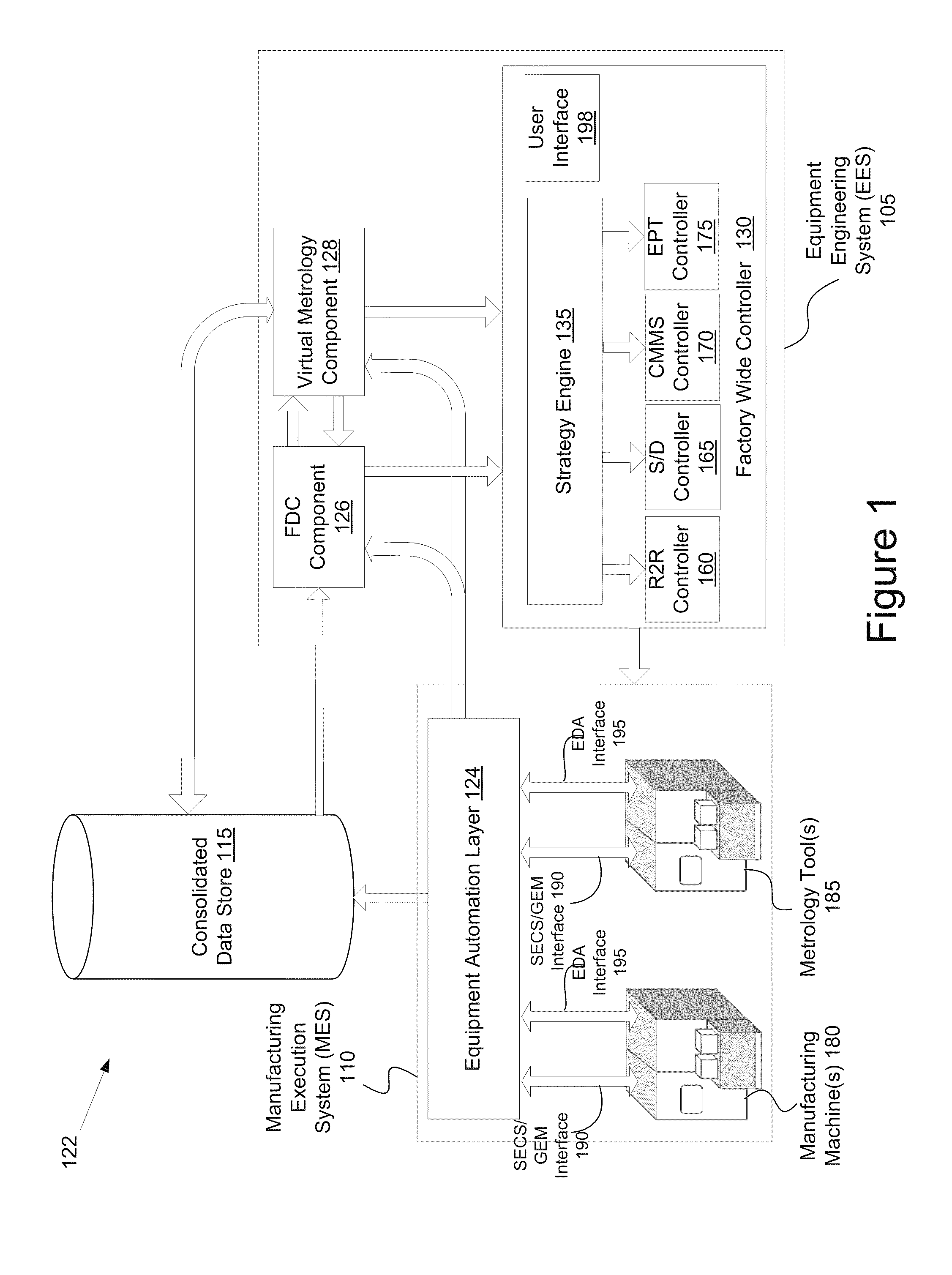

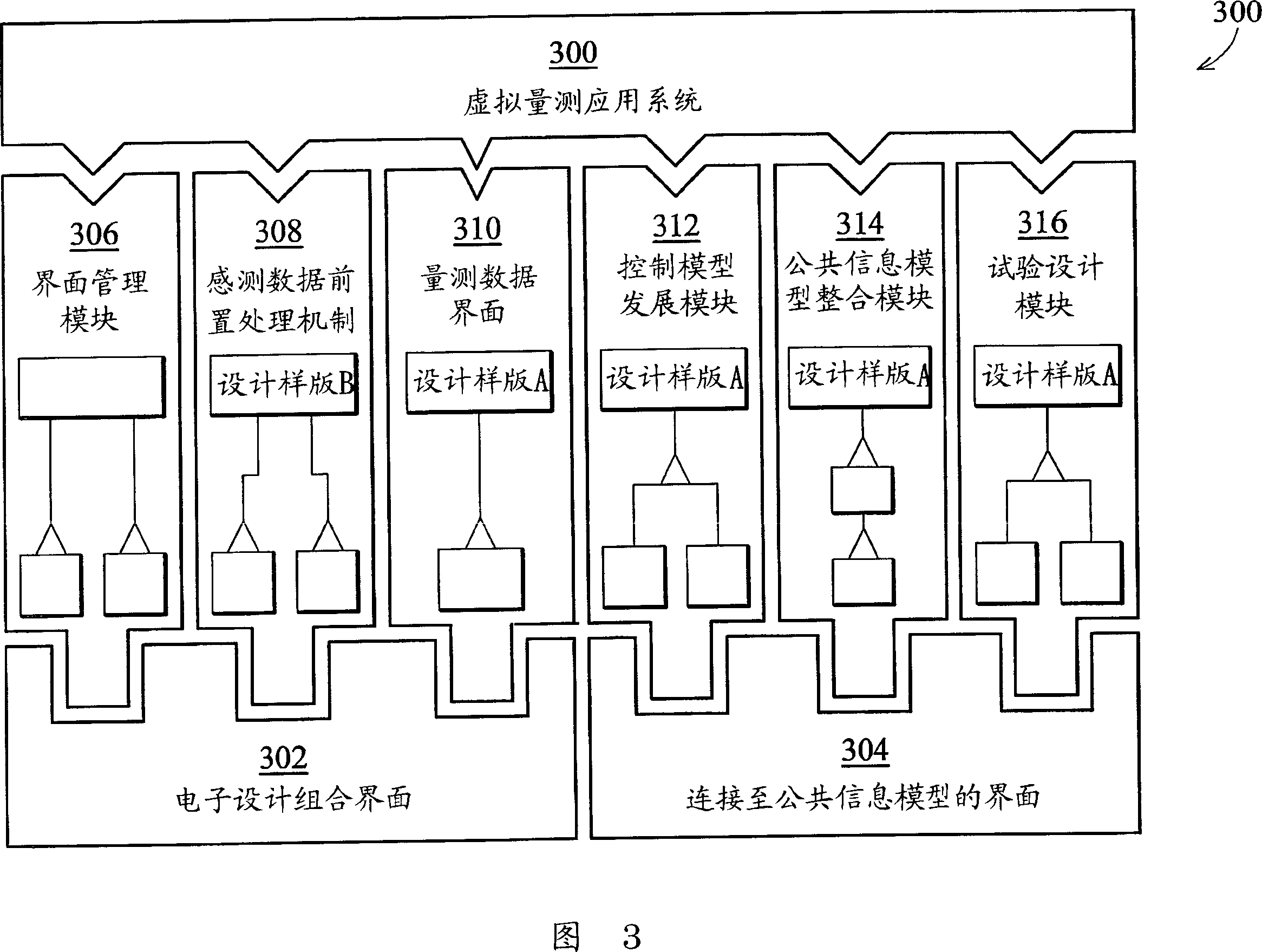

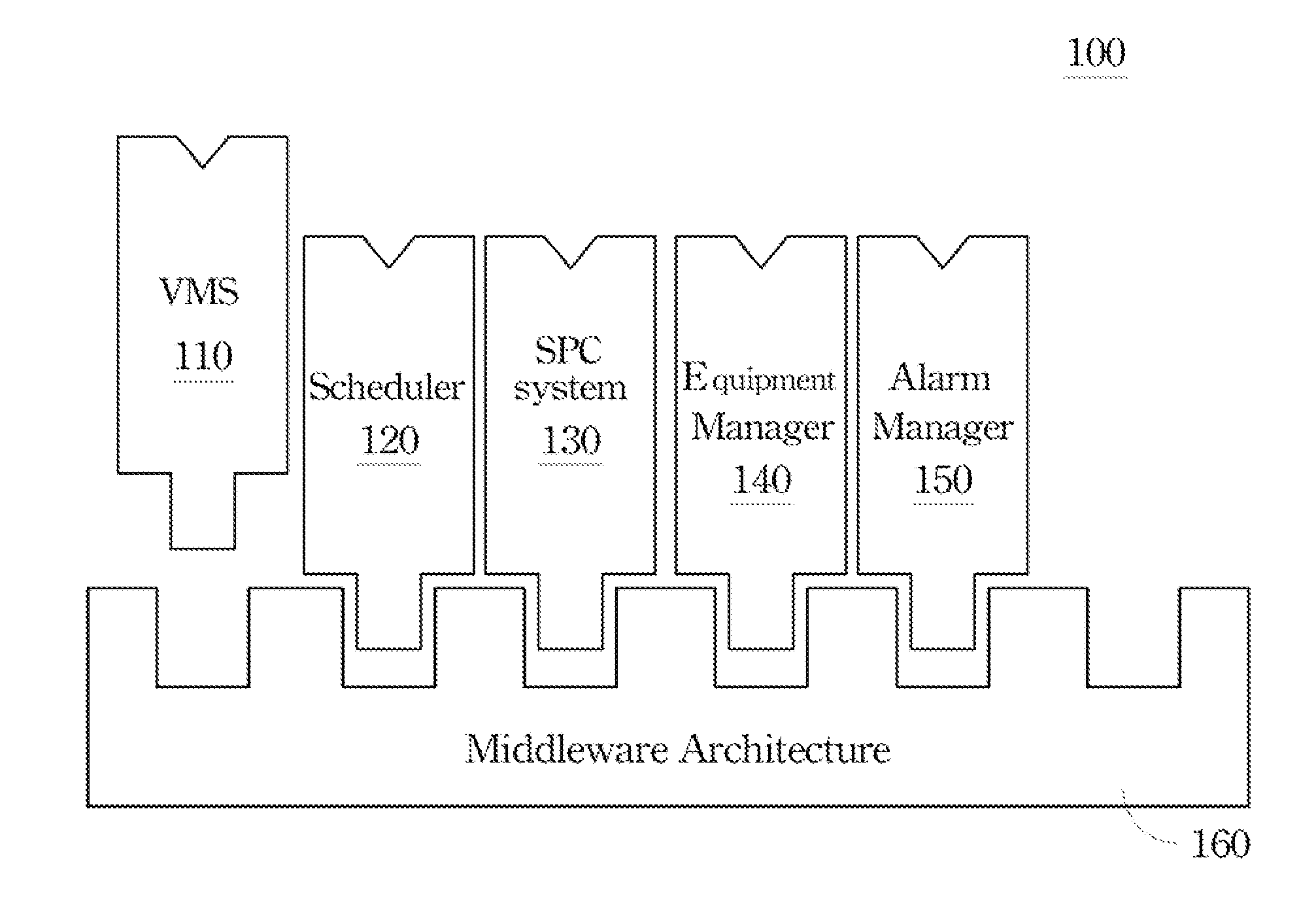

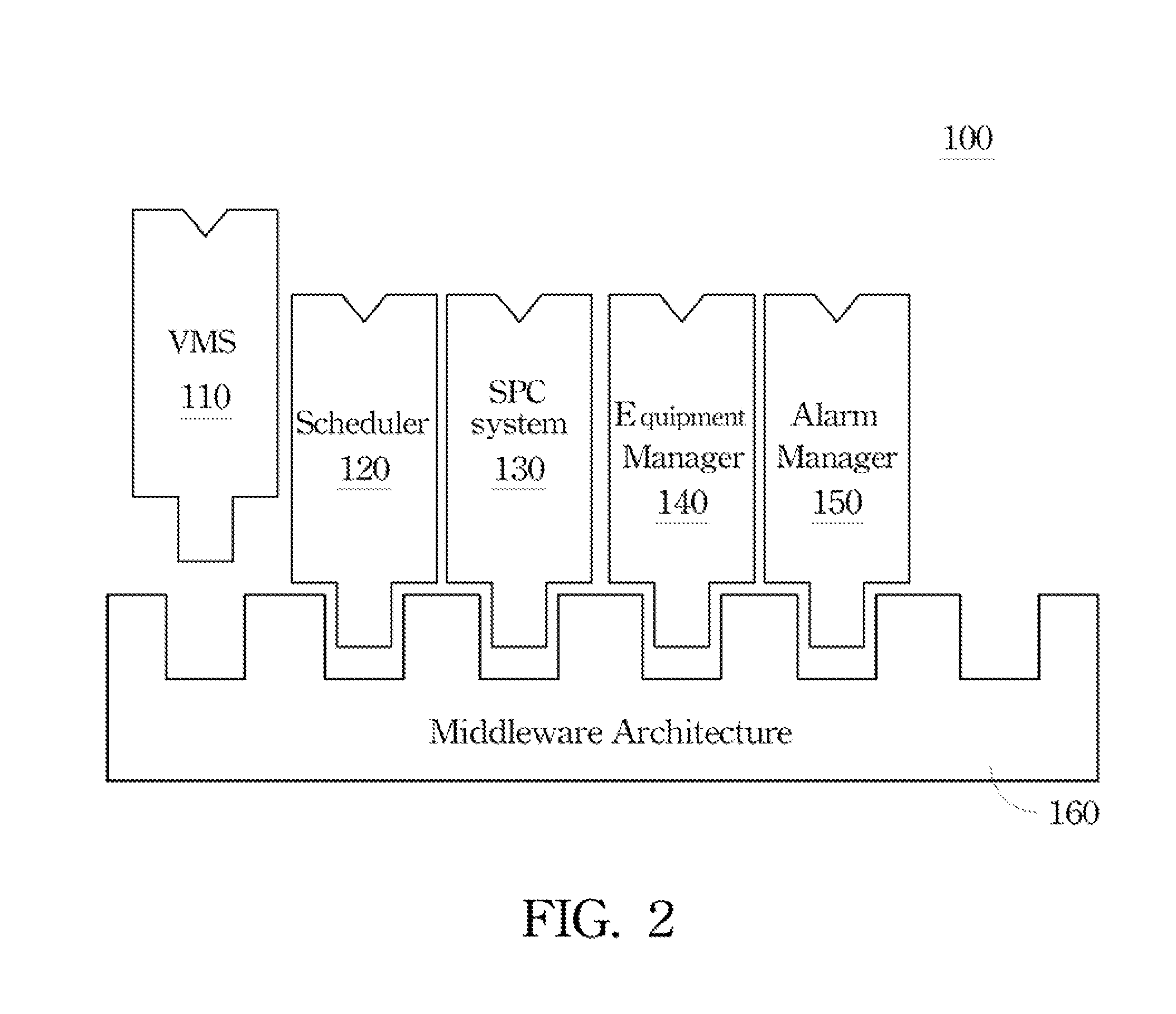

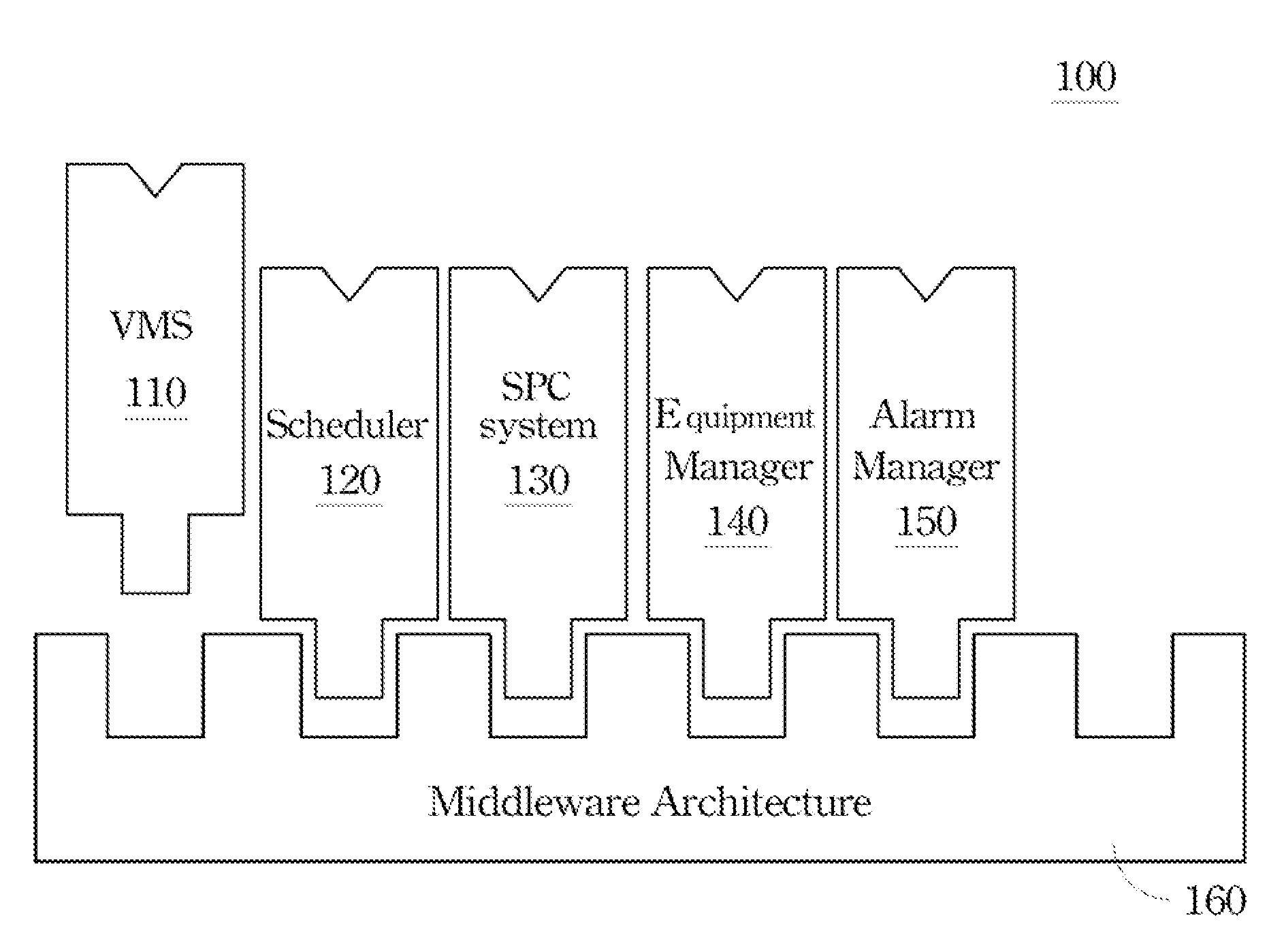

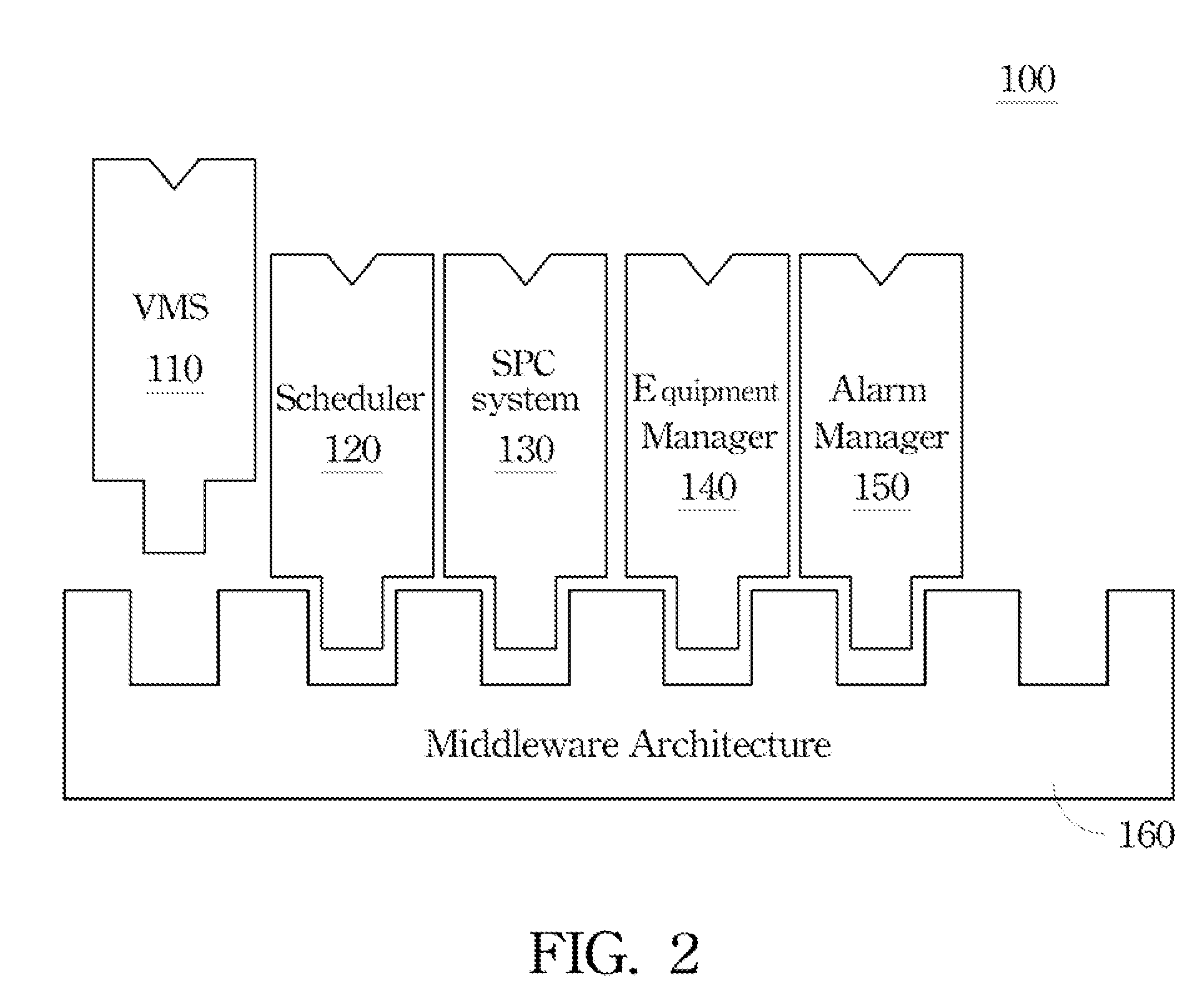

Manufacturing execution system with virtual-metrology capabilities and manufacturing system including the same

ActiveUS20110251707A1Guarantee product qualityLow costProgramme controlTotal factory controlManufacture execution systemMetrology

A manufacturing execution system (MES) with virtual-metrology capabilities and a manufacturing system including the MES are provided. The MES is built on a middleware architecture (such as an object request broker architecture), and includes an equipment manager, a virtual metrology system (VMS), a statistical process control (SPC) system, an alarm manager and a scheduler. The manufacturing system includes a first process tool, a second process tool, a metrology tool, the aforementioned MES, a first R2R (Run-to-Run) controller and a second R2R controller.

Owner:NAT CHENG KUNG UNIV

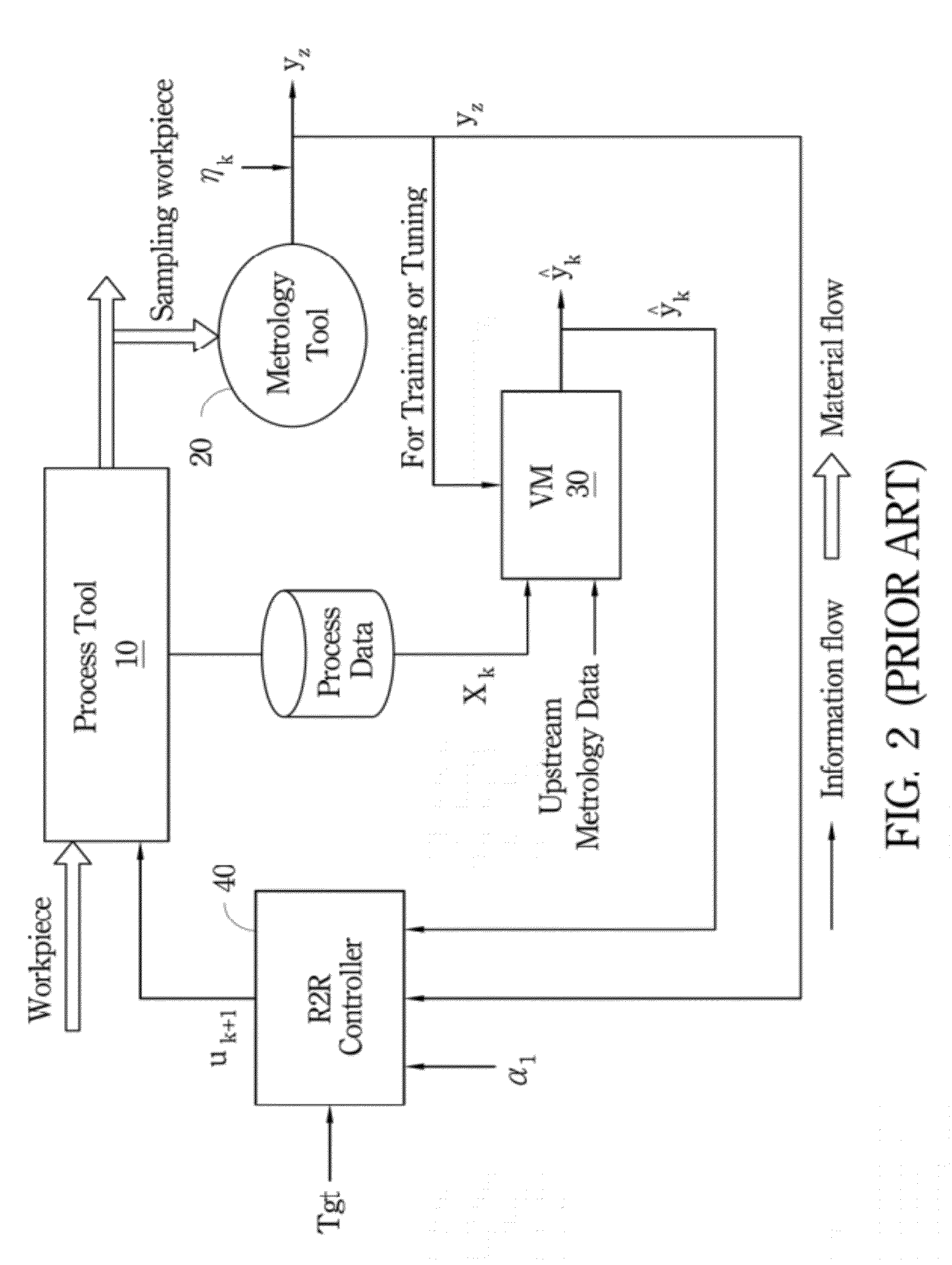

Advanced process control system and method utilizing virtual metrology with reliance index

ActiveUS20120029662A1Upgrading APC performanceConsider qualityTotal factory controlAdaptive controlData setEngineering

An advanced process control (APC) system, an APC method, and a computer program product, which, when executed, performs an APC method are provided for incorporating virtual metrology (VM) into APC. The present inventions uses a reliance index (RI) and a global similarity index (GSI) to adjust at least one controller gain of a run-to-run (R2R) controller when the VM value of a workpiece is adopted to replace the actual measurement value of the workpiece. The RI is used for gauging the reliability of the VM value, and the GSI is used for assessing the degree of similarity between the set of process data for generating the VM value and all the sets of historical process data used for building the conjecturing model.

Owner:NAT CHENG KUNG UNIV +1

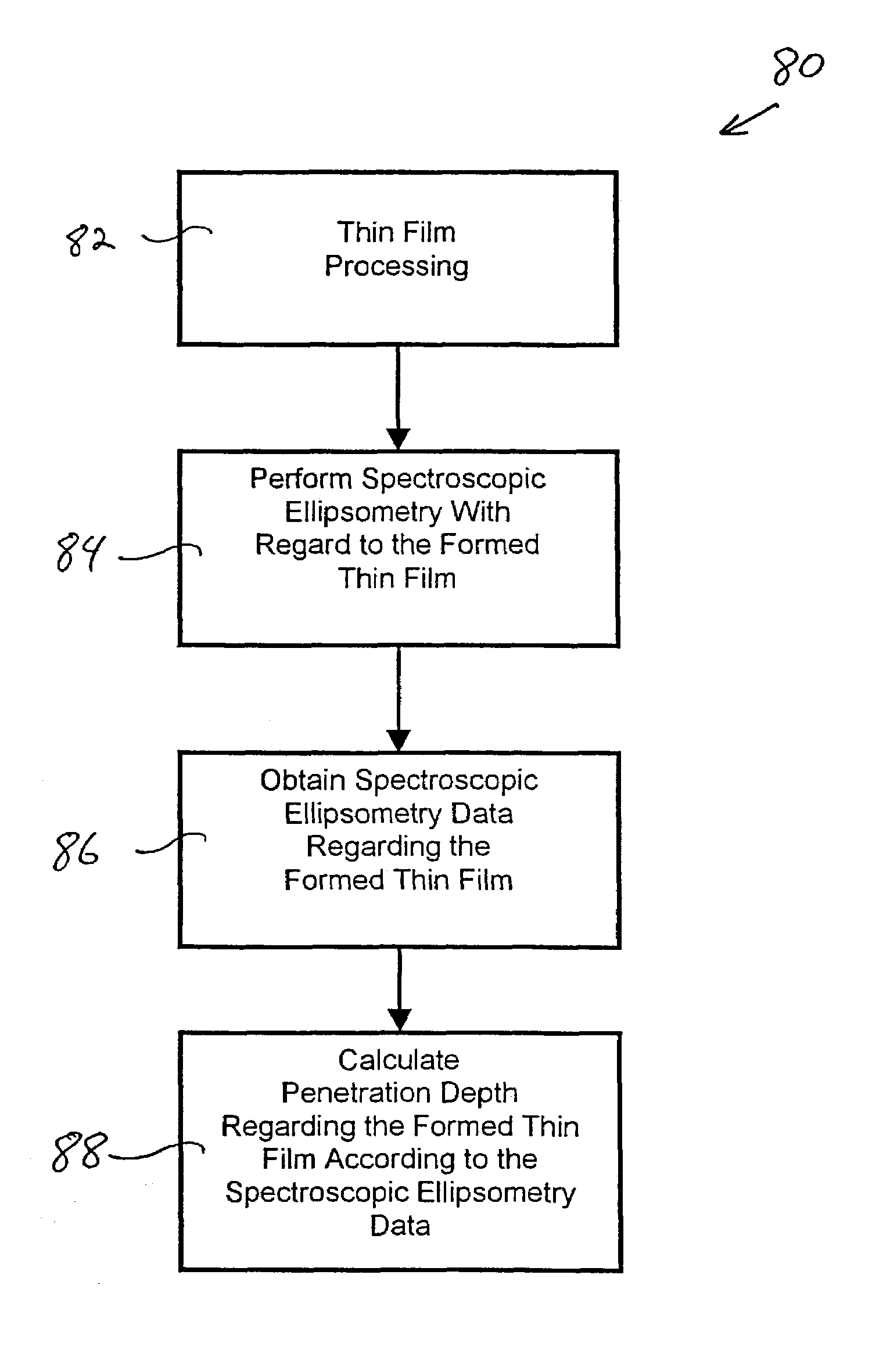

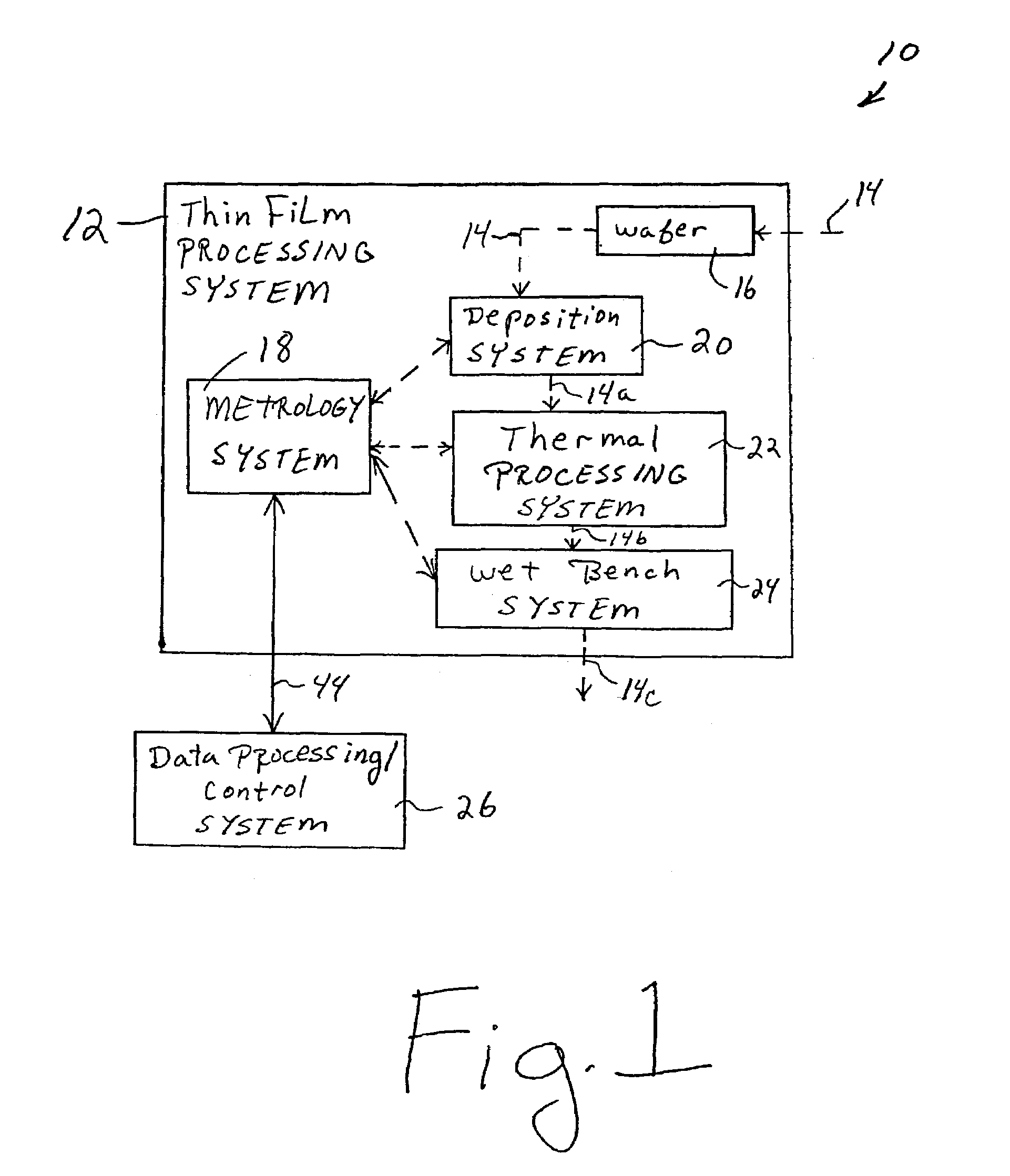

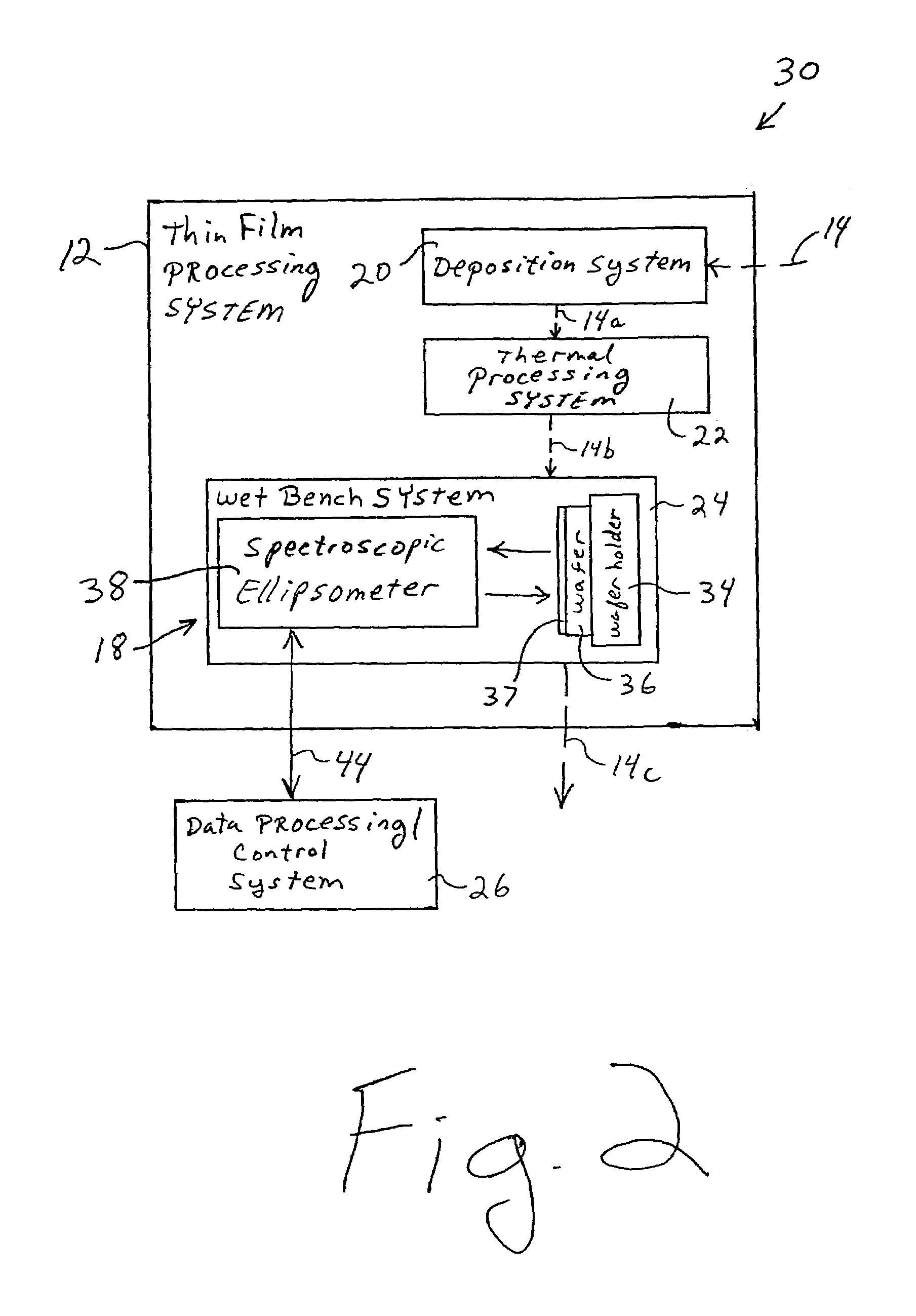

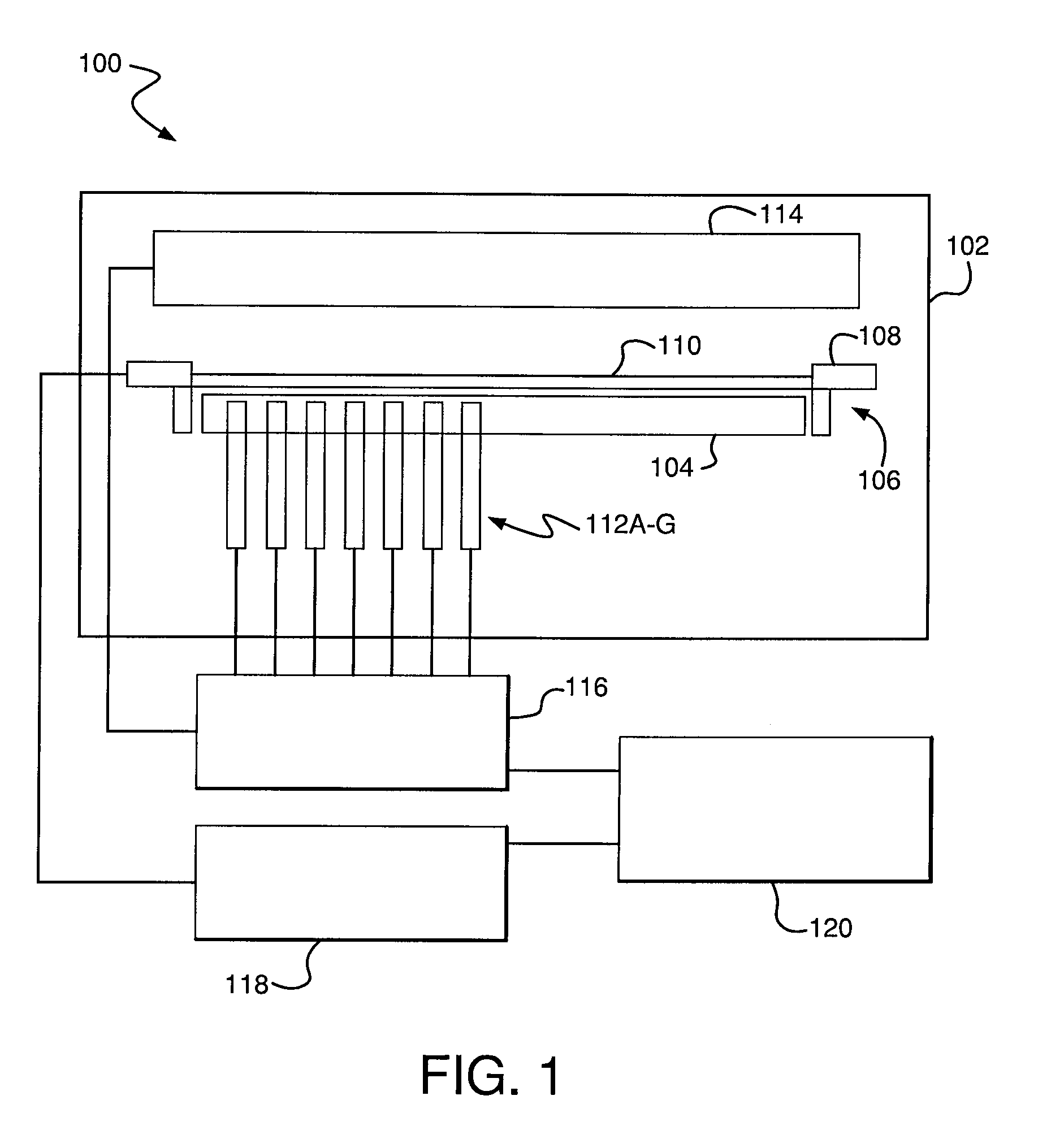

In-situ metrology system and method for monitoring metalization and other thin film formation

InactiveUS7414721B1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingNon destructiveMetrology

An in-line, in-process or in-situ and non-destructive metrology system, apparatus and method provides composition, quality and / or thickness measurement of a thin film or multi-layer thin film formed on a substrate in a thin film processing system. Particularly, the subject invention provides a spectroscopic ellipsometer performing spectroscopic ellipsometry while the wafer is in a thin film processing system. In one form, the spectroscopic ellipsometer is associated with a wet bench system portion of the thin film processing system. The spectroscopic ellipsometer obtains characteristic data regarding the formed thin film to calculate penetration depth (Dp) for a thin film formed on the substrate. Particularly, the ellipsometer obtains an extinction coefficient (k) which is used to calculate penetration depth (Dp). Penetration depth (Dp), being a unique function of the extinction coefficient (k) provides the information for the composition, quality and / or thickness monitoring of the thin film.

Owner:BELL SEMICON LLC

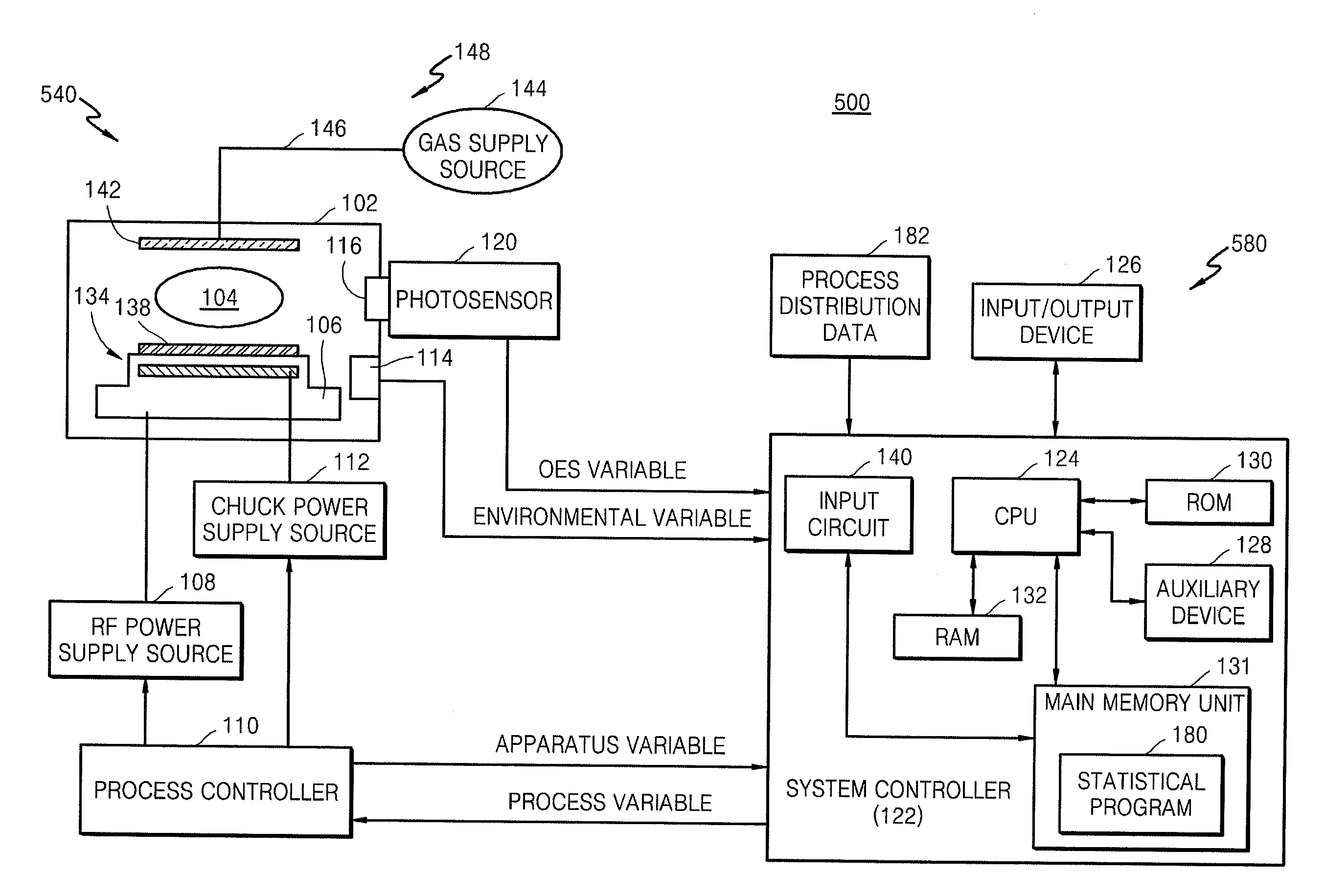

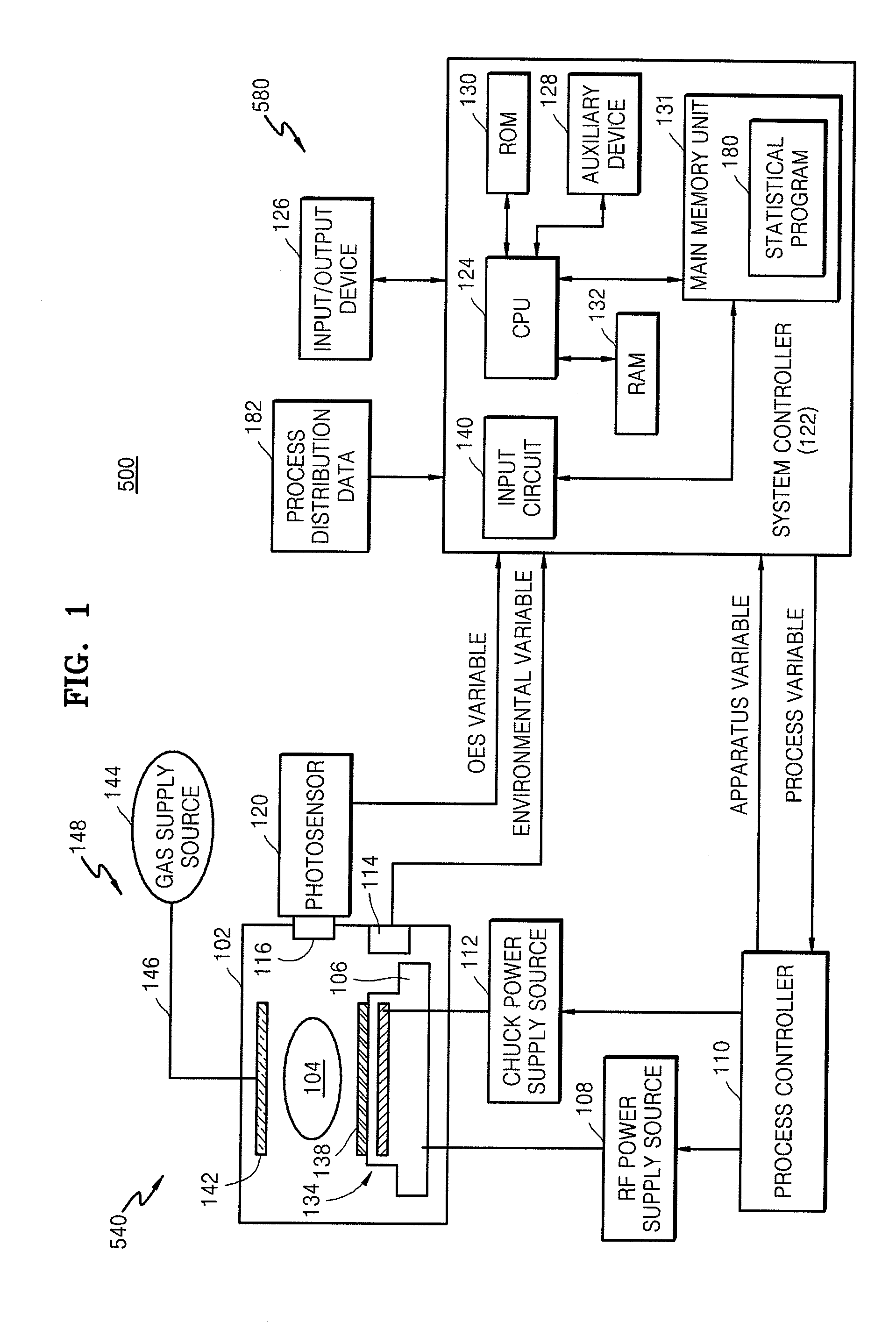

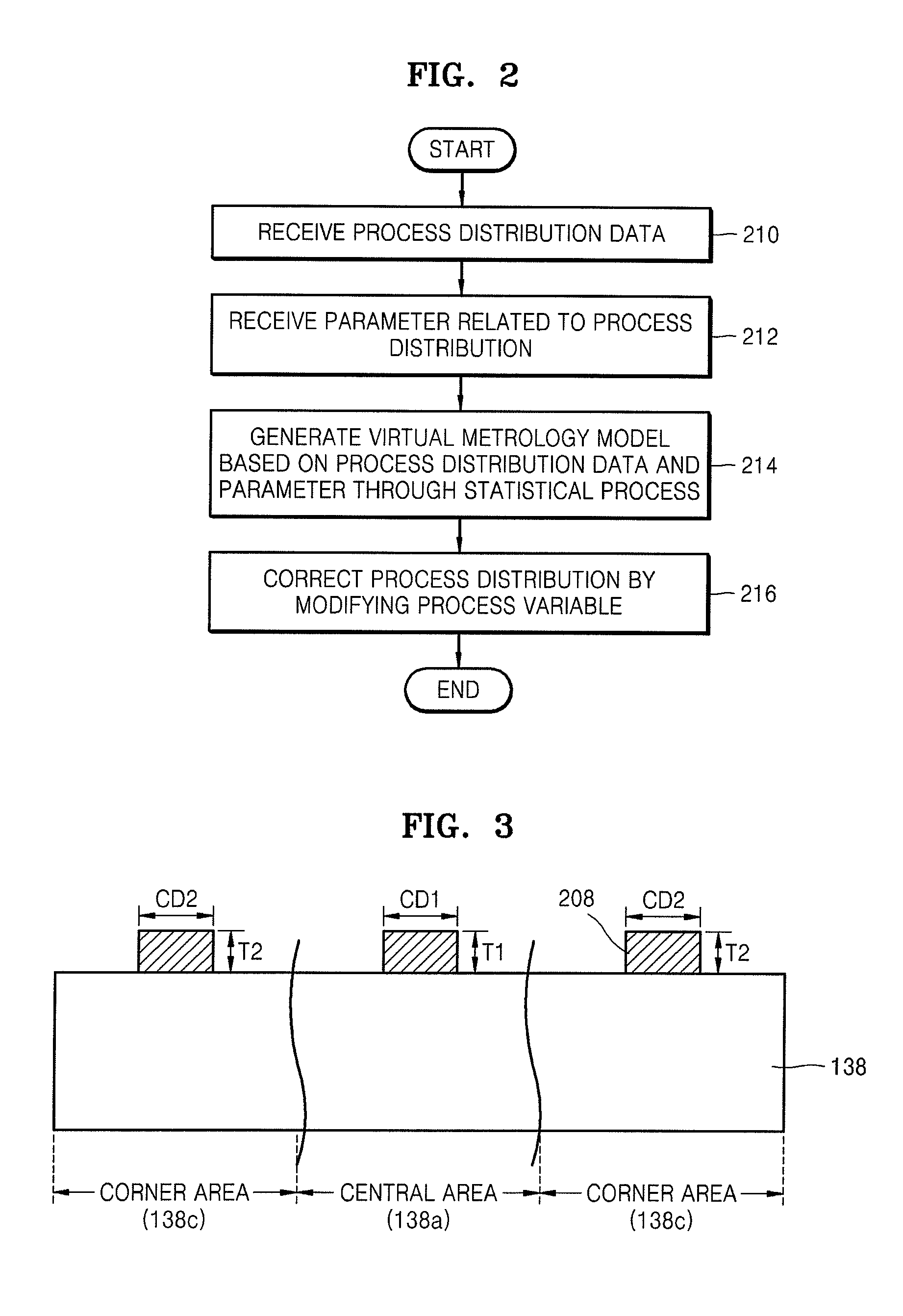

Method of controlling semiconductor process distribution

ActiveUS20120150330A1Programme controlSampled-variable control systemsModel modificationComputer science

A method of controlling process distribution of a semiconductor process includes receiving process distribution data representing the process distribution of the semiconductor process, receiving a parameter related to the process distribution, generating a virtual metrology model corresponding to the process distribution based on a relationship between the process distribution data and the parameter, and modifying a process variable affecting the process distribution based on the virtual metrology model.

Owner:SAMSUNG ELECTRONICS CO LTD

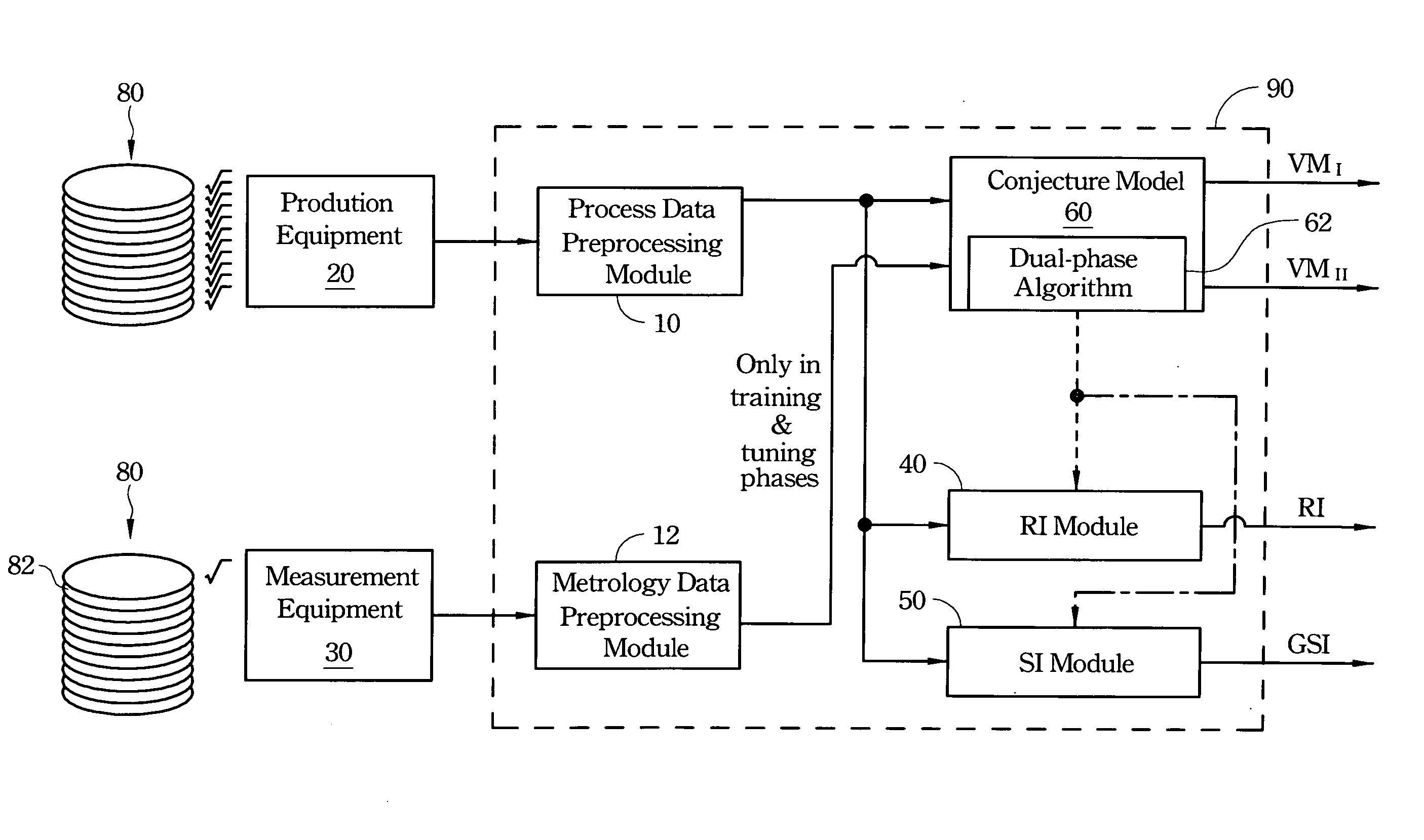

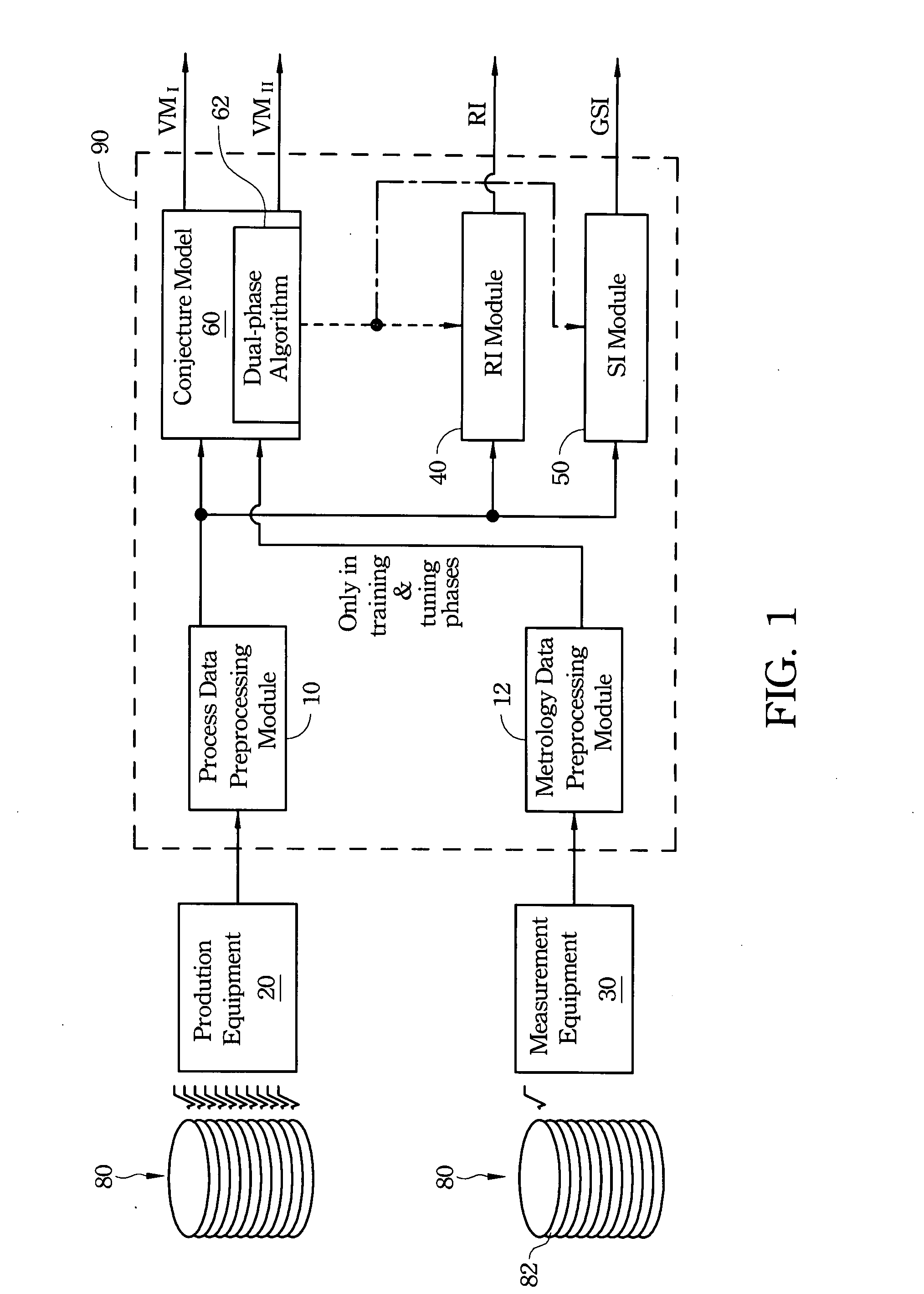

Dual-phase virtual metrology method

ActiveUS20080306625A1Meet the requirementsProgramme controlSemiconductor/solid-state device testing/measurementMetrologySoftware engineering

A dual-phase virtual metrology method is disclosed for considering both promptness and accuracy by generating dual-phase virtual metrology (VM) values, wherein a Phase-I conjecture step emphasizes promptness by immediately calculating the Phase-I virtual metrology value (VMI) of a workpiece once the entire process data of the workpiece are completely collected; and a Phase-II conjecture step intensifies accuracy, which does not re-calculate the Phase-II virtual metrology values (VMII) of all the workpieces in the cassette until an actual metrology value (required for tuning or re-training purposes) of a selected workpiece in the same cassette is collected. Besides, the accompanying reliance index (RI) and global similarity index (GSI) of each VMI and VMII are also generated.

Owner:NAT CHENG KUNG UNIV

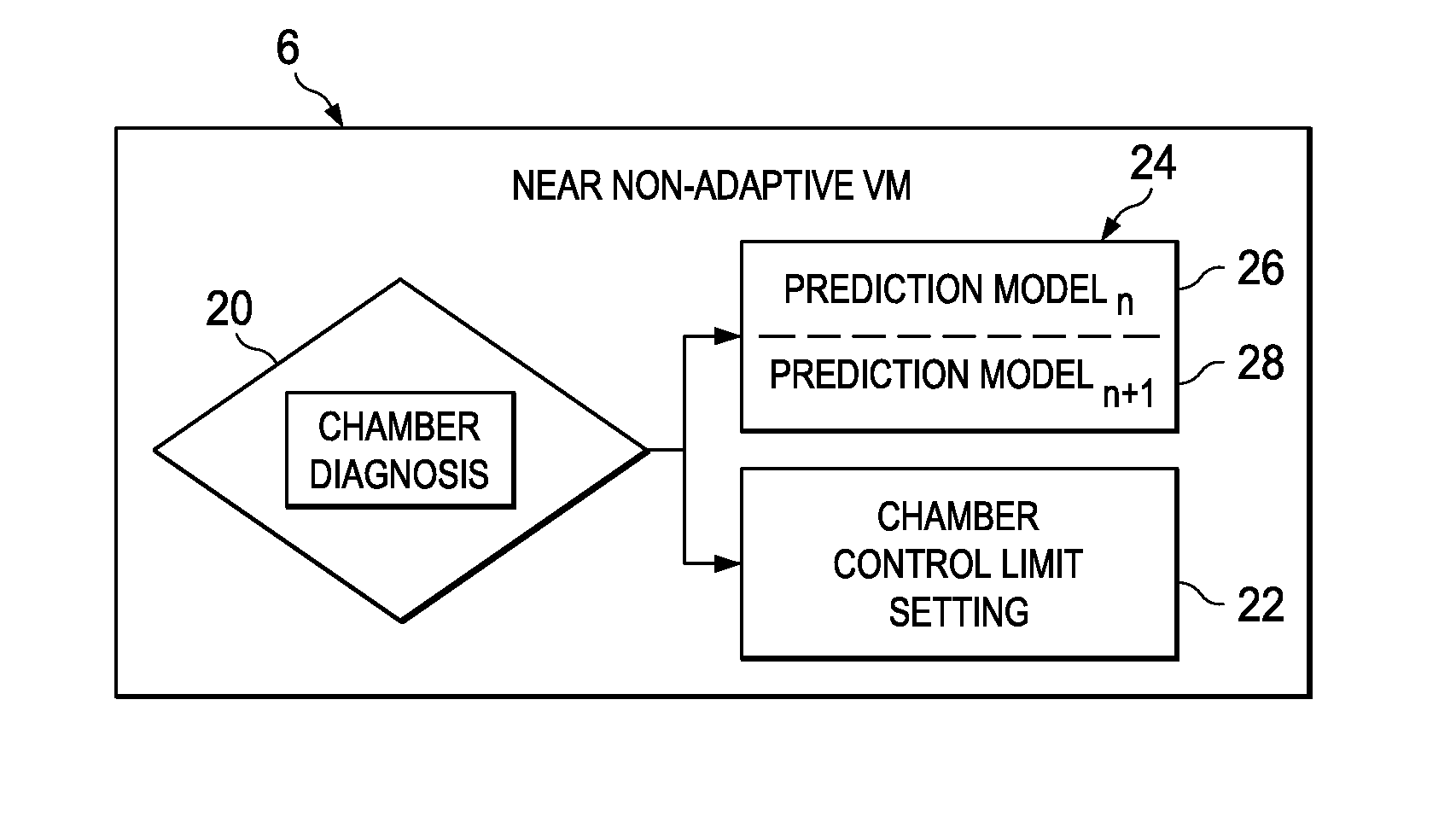

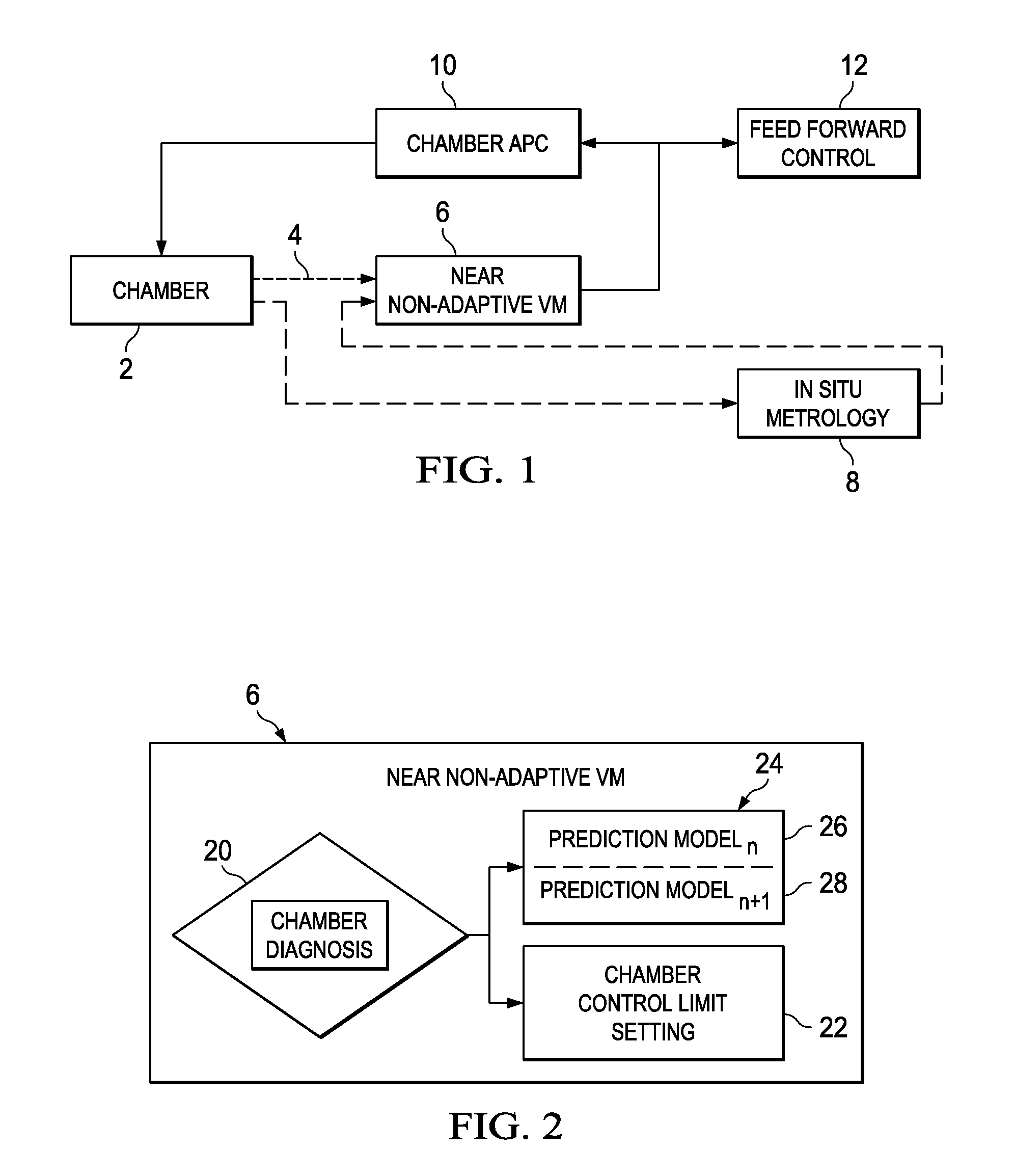

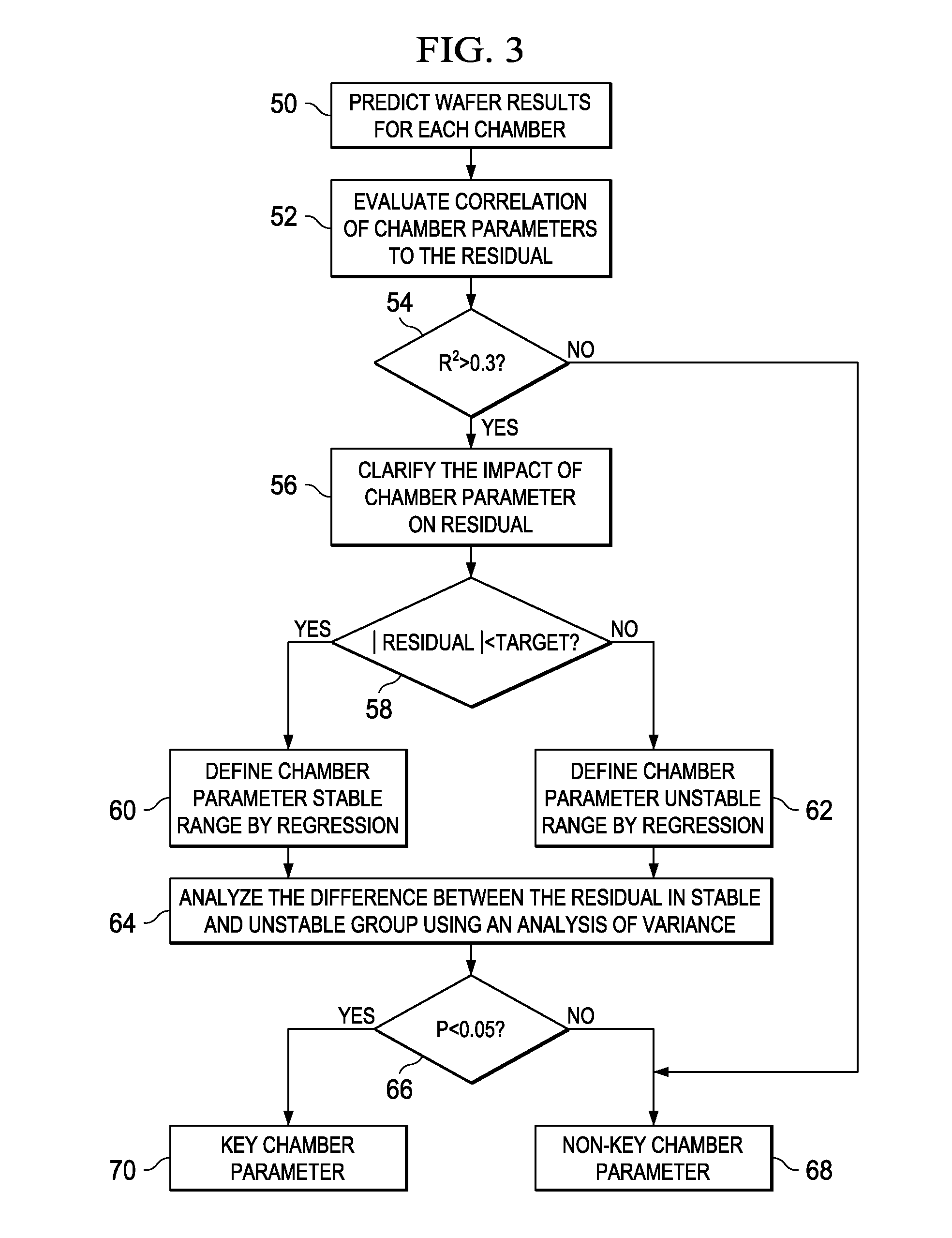

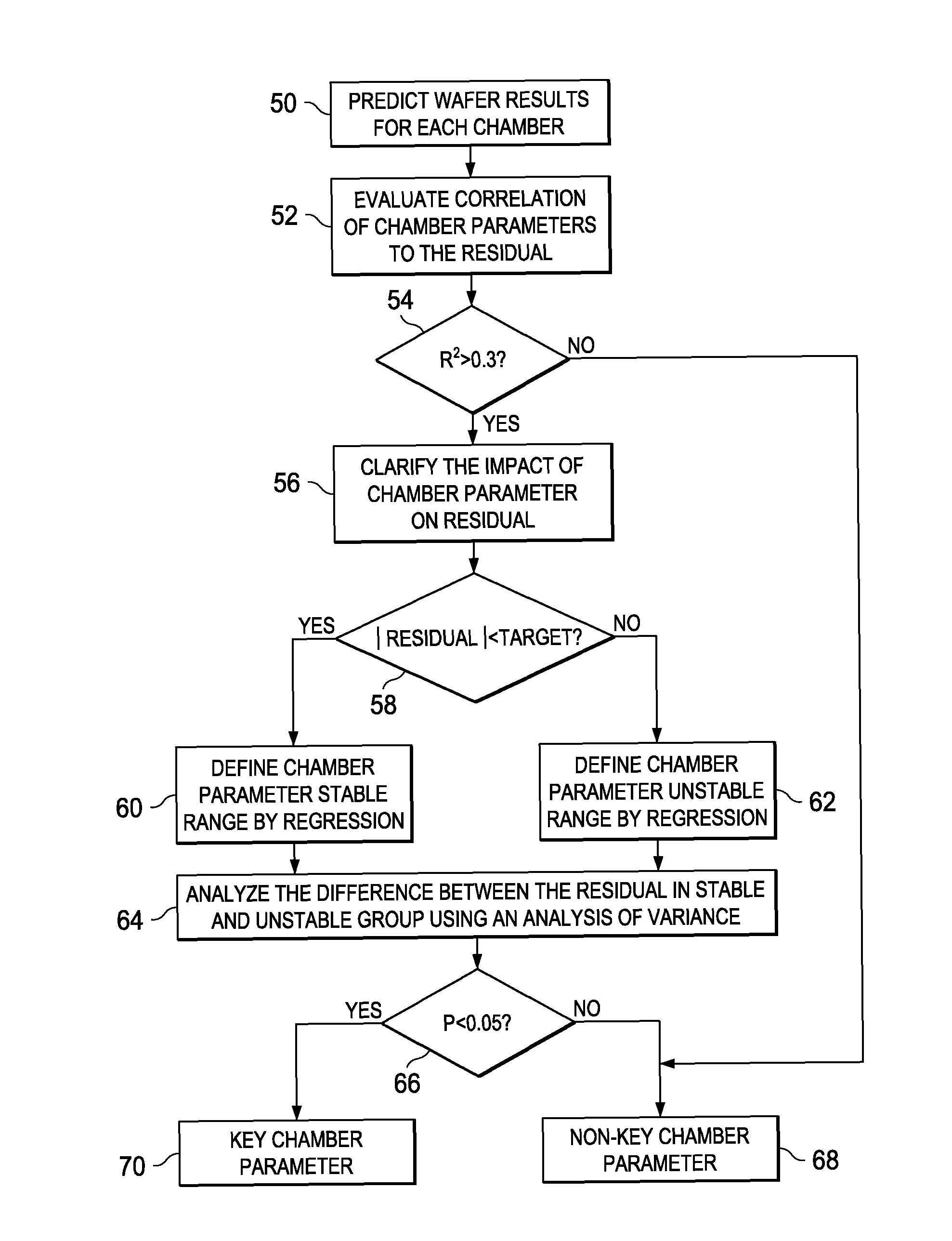

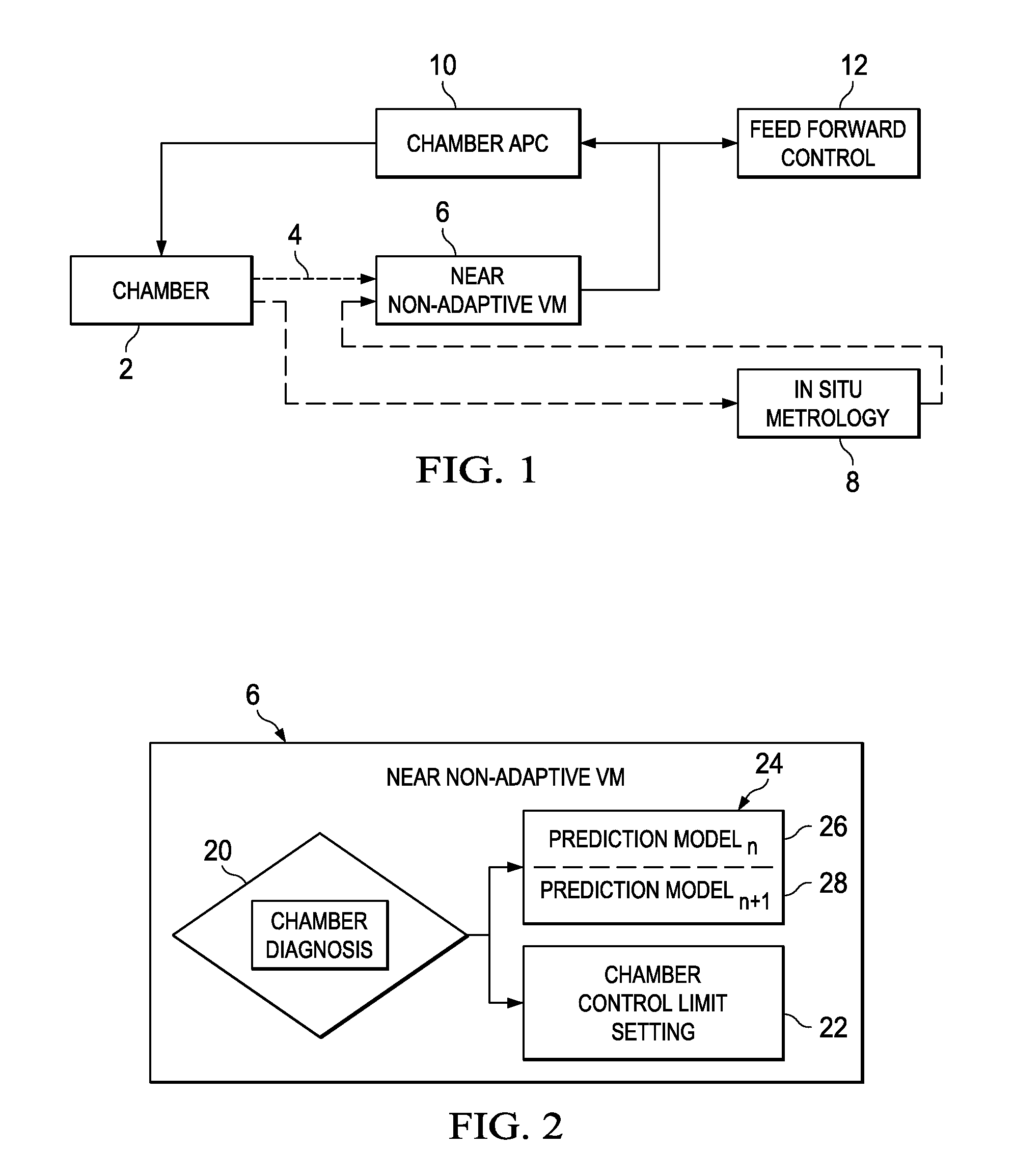

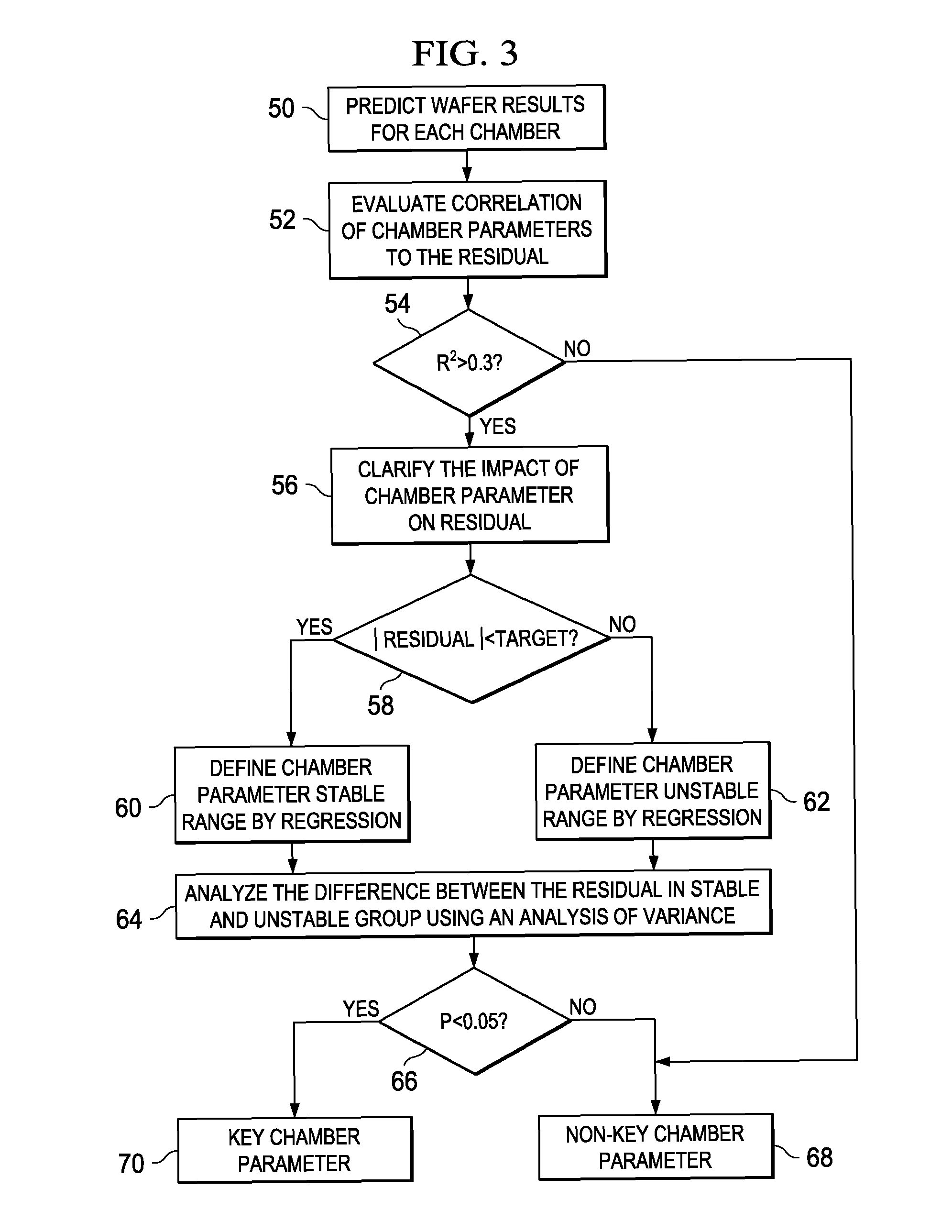

Near Non-Adaptive Virtual Metrology and Chamber Control

ActiveUS20110009998A1Special data processing applicationsAdaptive controlParameter controlSelf adaptive

Embodiments of the present invention relate to a method for a near non-adaptive virtual metrology for wafer processing control. In accordance with an embodiment of the present invention, a method for processing control comprises diagnosing a chamber of a processing tool that processes a wafer to identify a key chamber parameter, and controlling the chamber based on the key chamber parameter if the key chamber parameter can be controlled, or compensating a prediction model by changing to a secondary prediction model if the key chamber parameter cannot be sufficiently controlled.

Owner:TAIWAN SEMICON MFG CO LTD

System and method for automatic virtual metrology

ActiveCN101598754AGuaranteed accuracyShorten the timeElectrical testingOptical apparatus testingMetrologySimulation

The invention relates to a system and a method for automatic virtual metrology (AVM). The AVM system comprises a modeling server and a plurality of AVM servers. The modeling server is used for constructing the first set of virtual metrology model of a processing unit (machine) of a certain type, the set of the virtual metrology model comprises a virtual metrology inferring model, a reliance index (RI) model, a global similarity index (GSI) model, a process data quality index (DQIX) model and a metrology data quality index(DQIy) model. In the AVM method, the modeling server can also transplant the first set of the virtual metrology model of the processing unit of the type to other AVM servers of the processing unit of the same type. Each AVM server accepting the transplantation can refresh in an automatic die changing manner and maintains the precision of the virtual metrology model.

Owner:郑芳田

Advanced process control system and method utilizing virtual metrology with reliance index

ActiveUS8688256B2Consider qualityUpgrading the APC performanceTotal factory controlSpecial data processing applicationsData setEngineering

An advanced process control (APC) system, an APC method, and a computer program product, which, when executed, performs an APC method are provided for incorporating virtual metrology (VM) into APC. The present inventions uses a reliance index (RI) and a global similarity index (GSI) to adjust at least one controller gain of a run-to-run (R2R) controller when the VM value of a workpiece is adopted to replace the actual measurement value of the workpiece. The RI is used for gauging the reliability of the VM value, and the GSI is used for assessing the degree of similarity between the set of process data for generating the VM value and all the sets of historical process data used for building the conjecturing model.

Owner:NAT CHENG KUNG UNIV +1

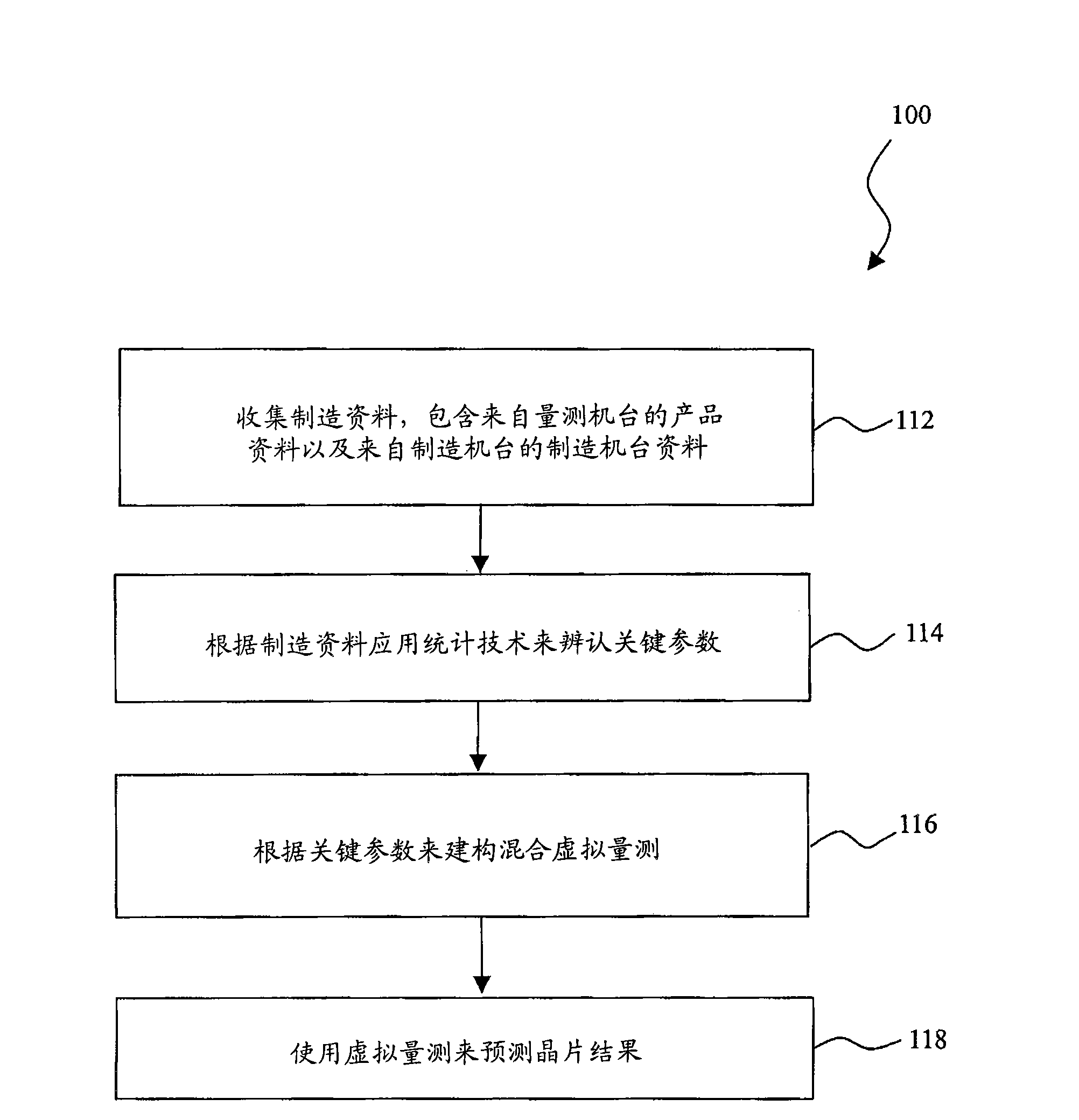

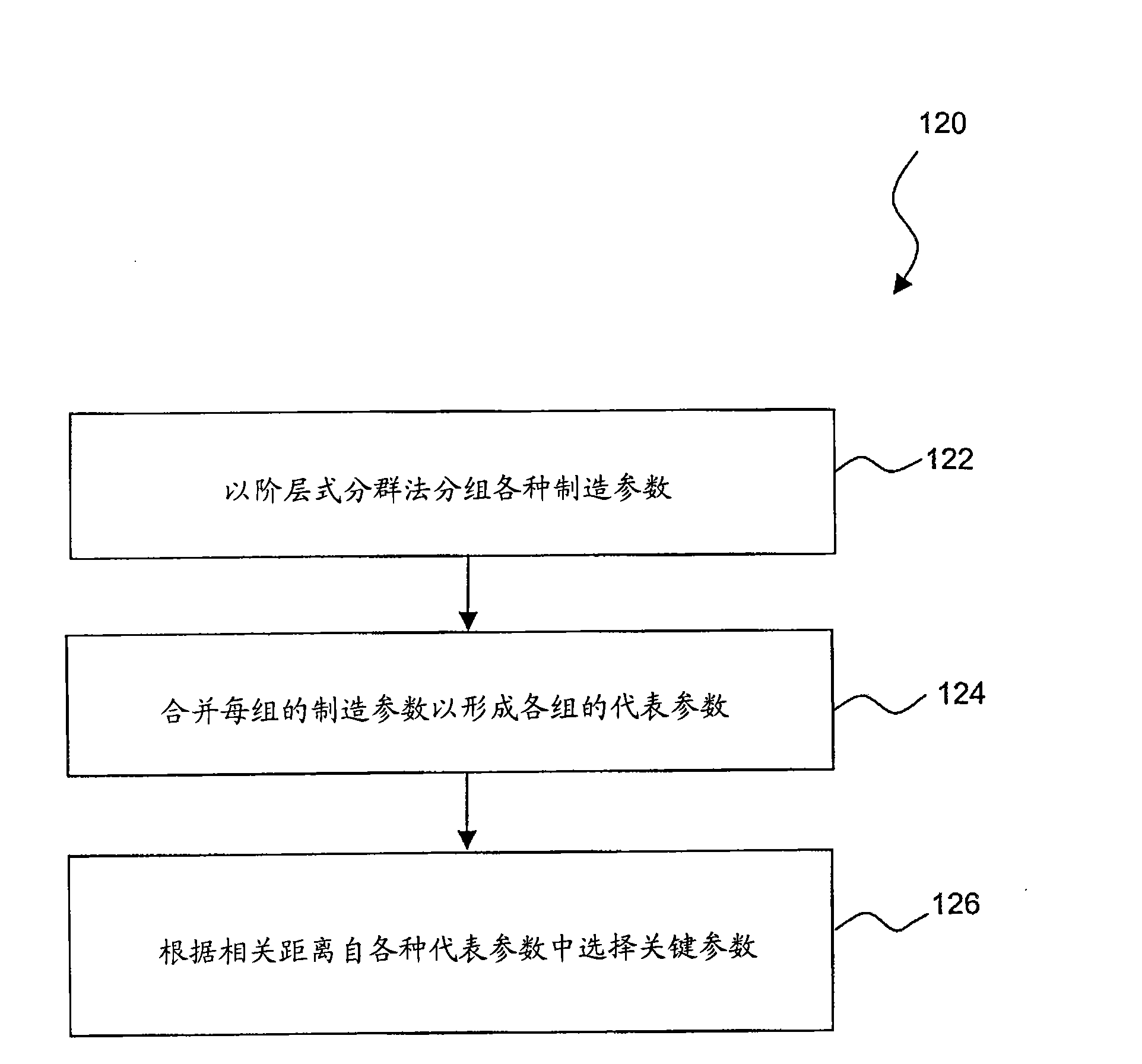

Novel methodology to realize automatic virtual metrology

ActiveCN101581930ASemiconductor/solid-state device manufacturingProgramme total factory controlMetrologyManufacturing data

The invention provides a method to enable wafer result prediction includes collecting manufacturing data from various semiconductor manufacturing tools and metrology tools; choosing key parameters using an autokey method based on the manufacturing data; building a virtual metrology based on the key parameters; and predicting wafer results using the virtual metrology.

Owner:TAIWAN SEMICON MFG CO LTD

Virtual metrology system and method

A virtual metrology system and a method therefor are provided herein. In the system, a set of process data is gathered and clustered according to a plurality of predetermined patterns. The clustered set of process data is calculated according to the corresponding pattern, so as to obtain a comparison result. If the obtained result meets a desired output, a corresponding step is performed based on the result. In one case, the corresponding step is a normal sampling step if the clustered set of process data meets the corresponding pattern. If the clustered set of process data does not meet the corresponding pattern, an alarm is generated thereby, and the corresponding equipment may be shut down. In another case, the corresponding step is a maintenance, repair, and overhaul step if the clustered set of process data meets the corresponding pattern.

Owner:MARLIN SEMICON LTD

Temperature uniformity measurement during thermal processing

InactiveUS8109669B2Thermometer detailsSemiconductor/solid-state device testing/measurementMetrologyEngineering

Methods and systems for determining a radial differential metrology profile of a substrate heated in a process chamber is provided. Methods and systems for determining an angular or azimuthal differential metrology profile of a rotating substrate in a processing chamber are also provided. The radial and azimuthal differential metrology profiles are applied to adjust a reference metrology profile to provide a Virtual metrology of the process chamber. The virtual metrology is applied to control the performance of the process chamber.

Owner:APPLIED MATERIALS INC

Method and apparatus for developing, improving and verifying virtual metrology models in a manufacturing system

Owner:APPLIED MATERIALS INC

Predictive 3-D virtual fabrication system and method

ActiveUS10242142B2More physically predictiveCAD circuit designTotal factory controlEngineeringDesign space

A virtual fabrication environment for semiconductor device structures that includes the use of virtual metrology measurement data to optimize a virtual fabrication sequence is described. Further, calibration of the virtual fabrication environment is performed by comparing virtual metrology data generated from a virtual fabrication run with a subset of measurements performed in a physical fabrication environment. Additionally, virtual experiments conducted in the virtual fabrication environment of the present invention generate multiple device structure models using ranges of process and design parameter variations for an integrated process flow and design space of interest.

Owner:COVENTOR

Near non-adaptive virtual metrology and chamber control

ActiveUS8433434B2Special data processing applicationsAdaptive controlParameter controlEmbedded system

Owner:TAIWAN SEMICON MFG CO LTD

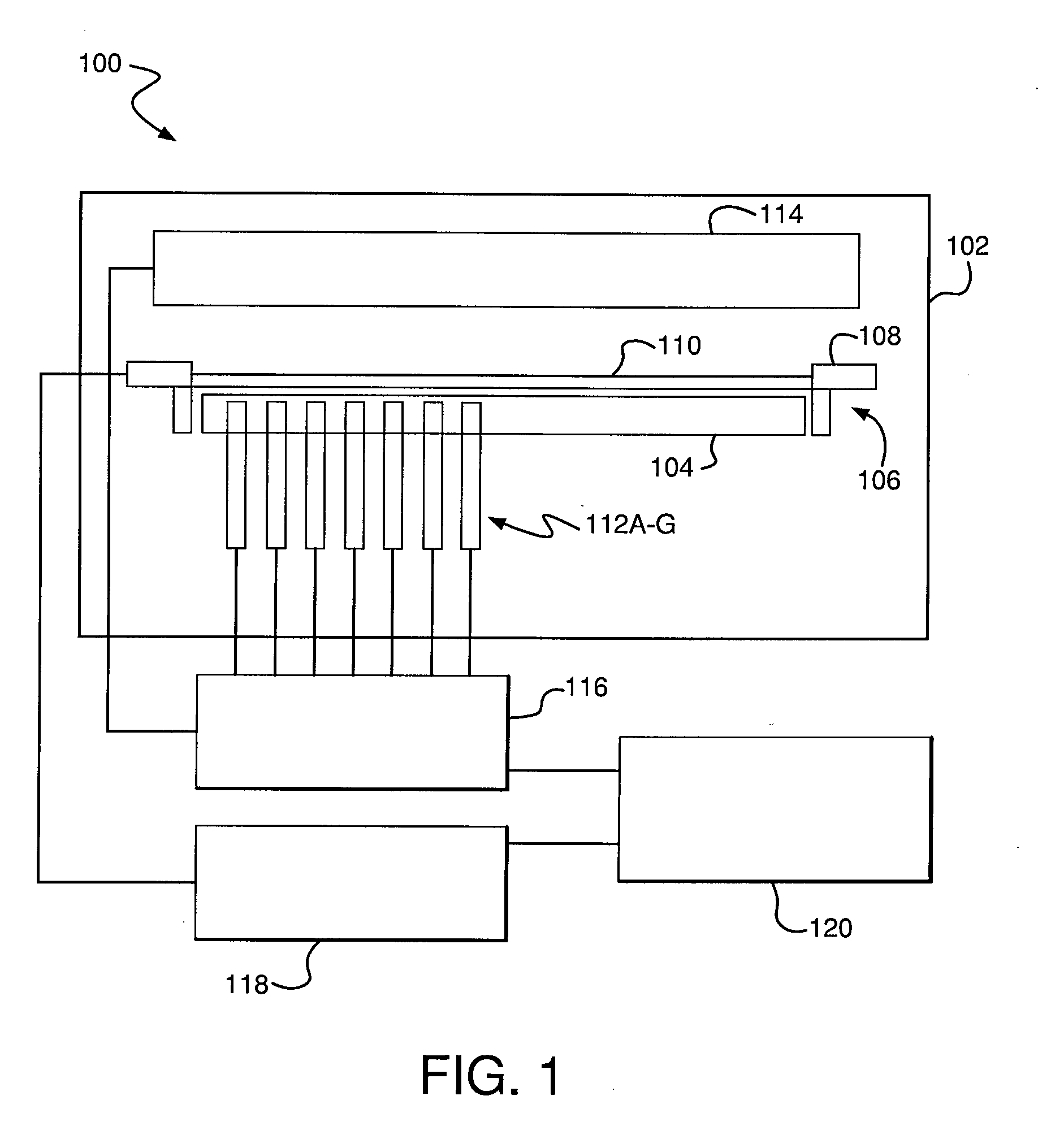

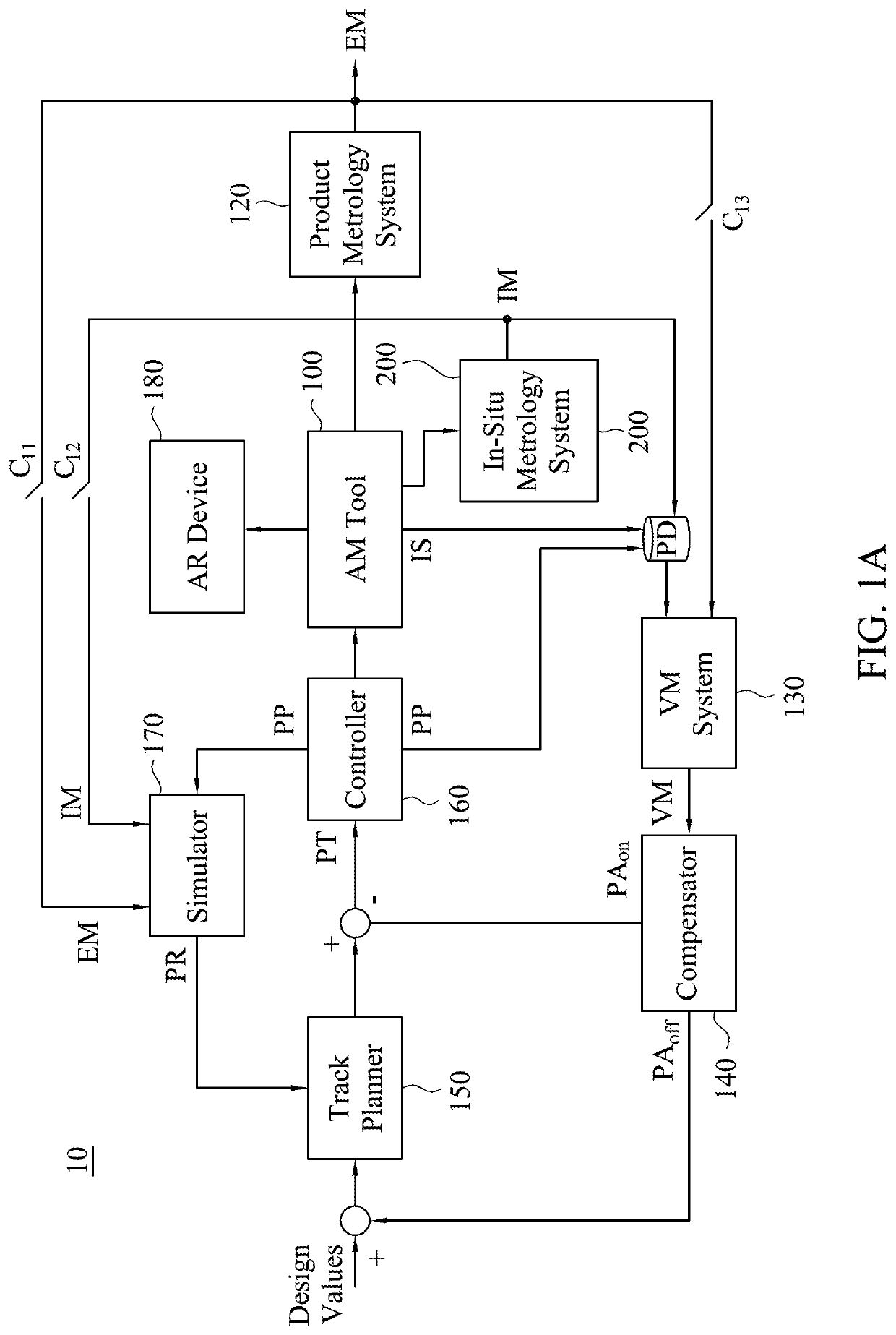

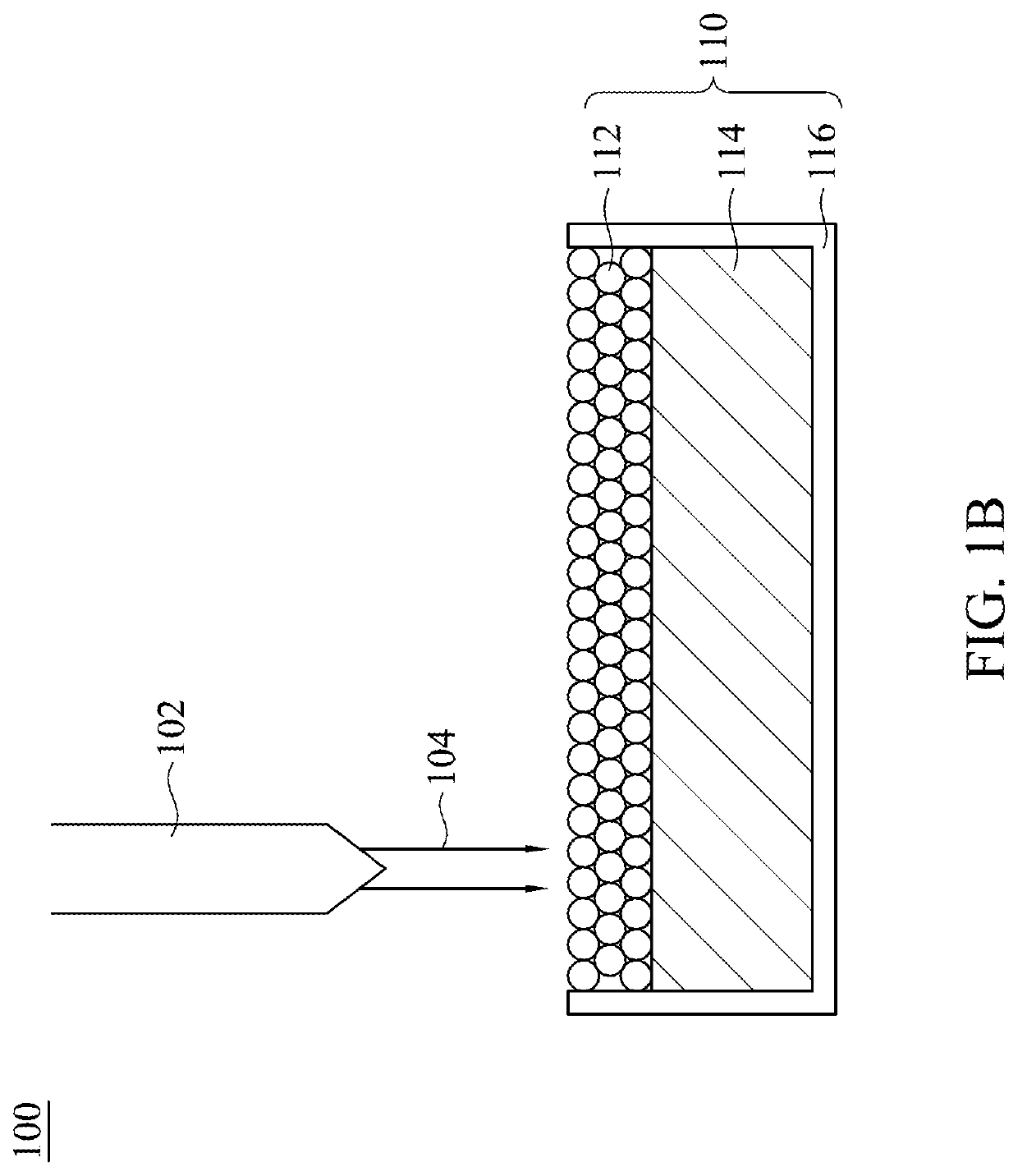

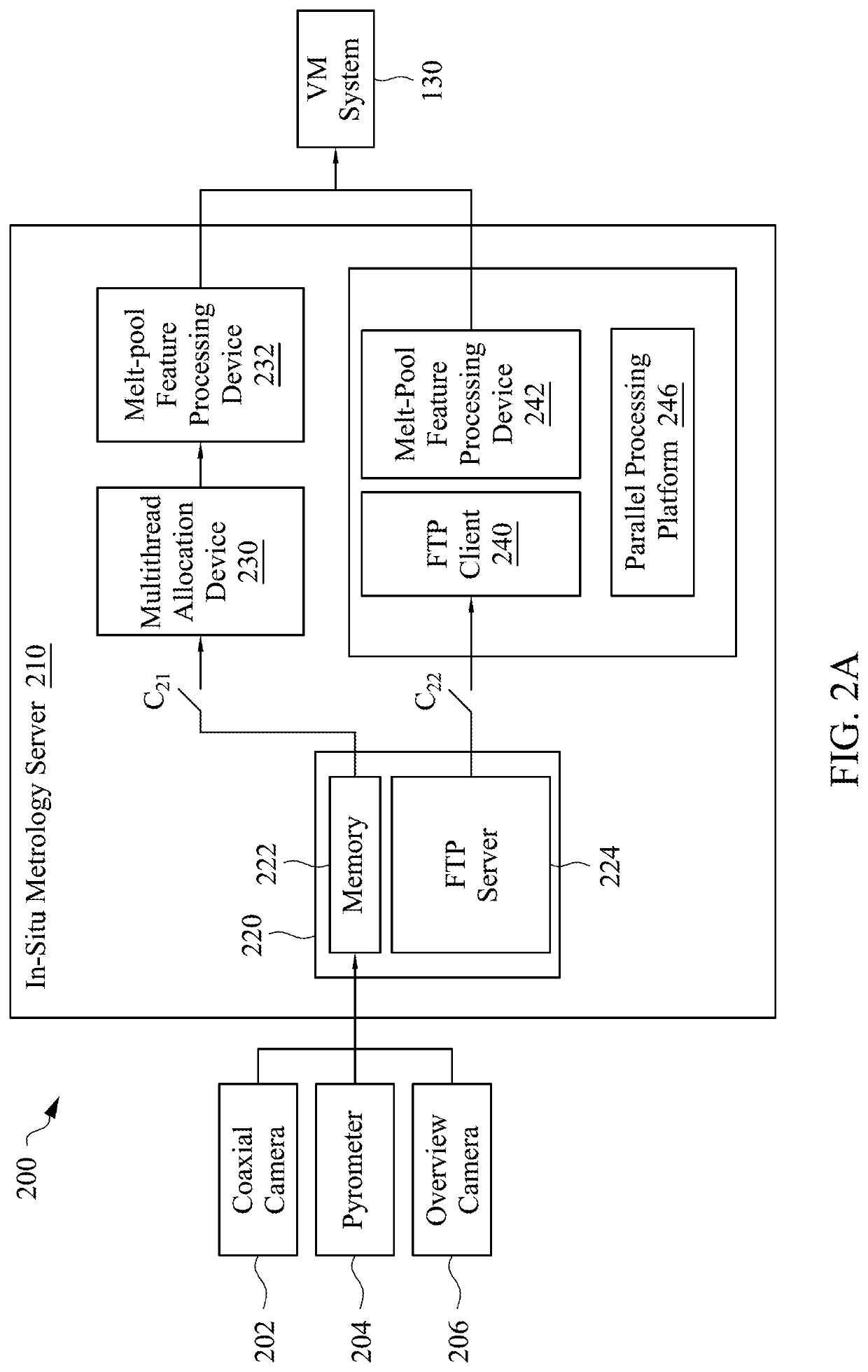

Additive manufacturing system and method and feature extraction method

ActiveUS20200147893A1Obtaining product qualityIncrease productionProgramme controlAdditive manufacturing apparatusFeature extractionPowder bed

An additive manufacturing (AM) system, an AM method, and an AM feature extraction method are provided. The AM system includes an AM tool, a product metrology system, an in-situ metrology system, a virtual metrology (VM) system, a compensator, a track planner, a controller, a simulator and an augmented reality (AR) device. The simulator is used to find feasible parameter ranges, while the AR device is used to support operations and maintenance of the AM tool. The product metrology system, the in-situ metrology system and the VM system are integrated to estimate the variation of material on a powder bed of the AM tool. The compensator is used for compensating the process variation by adjusting process parameters. The product metrology system is used to measure the quality of products. The in-situ metrology system is used to collect features of melt pools on the powder bed.

Owner:NAT CHENG KUNG UNIV

Manufacturing execution system with virtual-metrology capabilities and manufacturing system including the same

ActiveUS8983644B2Low costMore production timeDigital computer detailsBiological neural network modelsManufacture execution systemMetrology

A manufacturing execution system (MES) with virtual-metrology capabilities and a manufacturing system including the MES are provided. The MES is built on a middleware architecture (such as an object request broker architecture), and includes an equipment manager, a virtual metrology system (VMS), a statistical process control (SPC) system, an alarm manager and a scheduler. The manufacturing system includes a first process tool, a second process tool, a metrology tool, the aforementioned MES, a first R2R (Run-to-Run) controller and a second R2R controller.

Owner:NAT CHENG KUNG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com