Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

453 results about "Manufacturing data" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

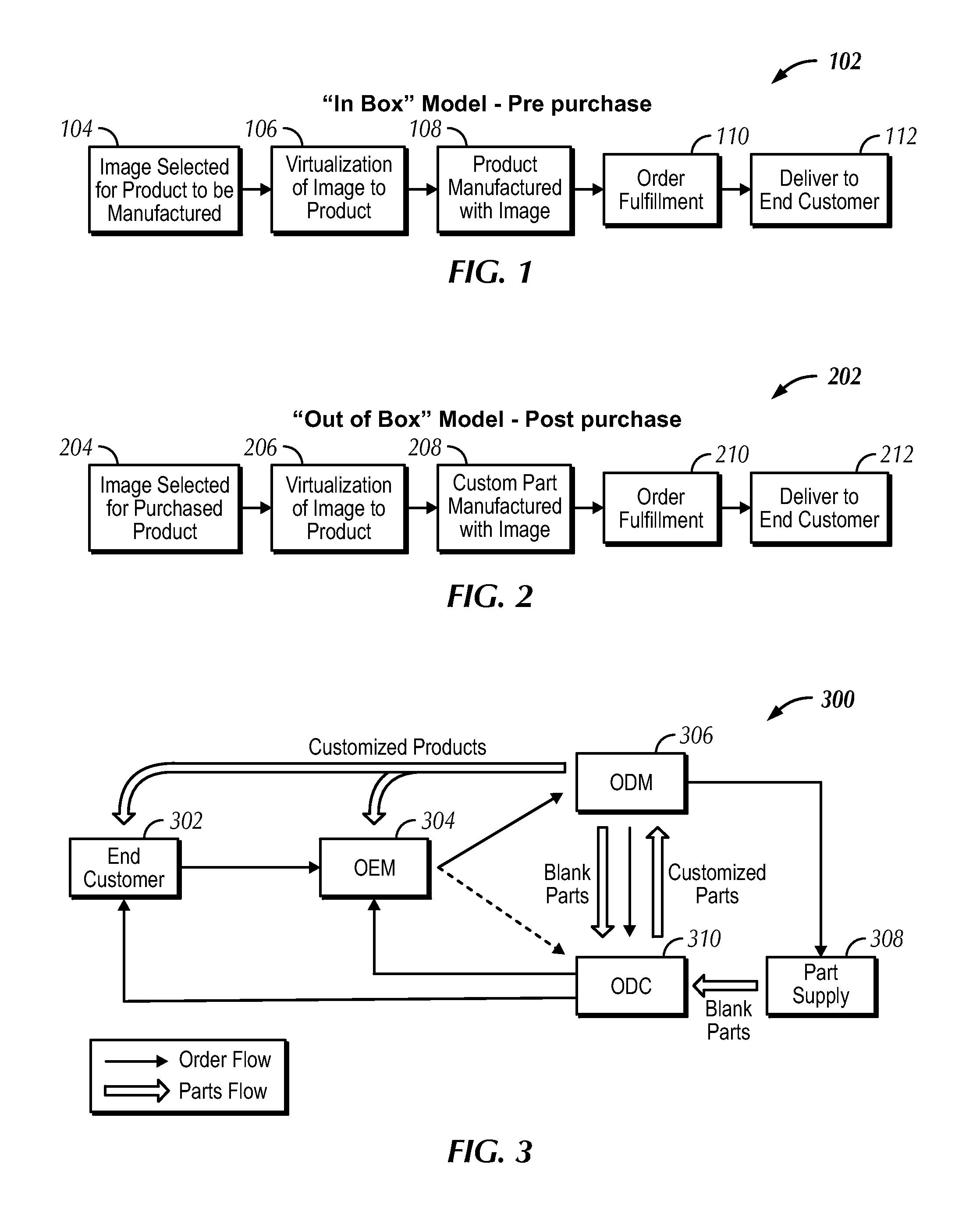

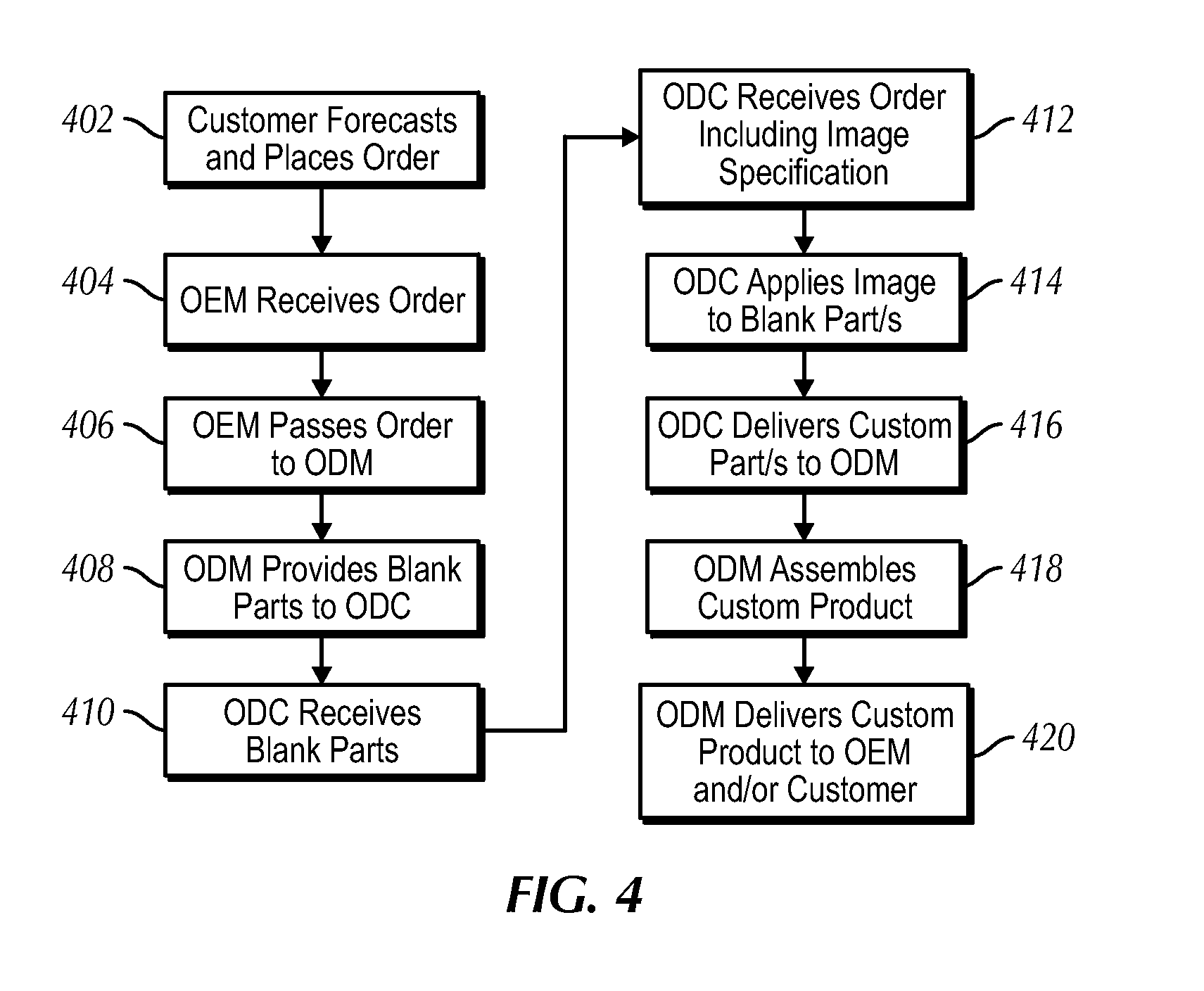

Systems and methods of on demand manufacturing of customized products

Systems and methods are described herein relating to managing an on-demand manufacturing supply chain personalization process. In some embodiments, the management system and method is described in order to manufacturing customized products according to image and customization data with images applied to parts using a post mold image application process. In other embodiments, customized products are defined by electronic orders that specify product manufacturing data including imagery to be applied to the products. In other embodiments, manufacturing methods are described in which an original equipment manufacturer (OEM) or an original design manufacturer (ODM) leverages use of an on demand customizing entity in the manufacturing supply chain. In other embodiments, customized products are described in which imagery spans across multiple components of the products. In other embodiments, re-usable tracking devices and scheduling processes based on filtered options are additionally described. Some embodiments combine one of more of these mentioned embodiments.

Owner:SKINIT

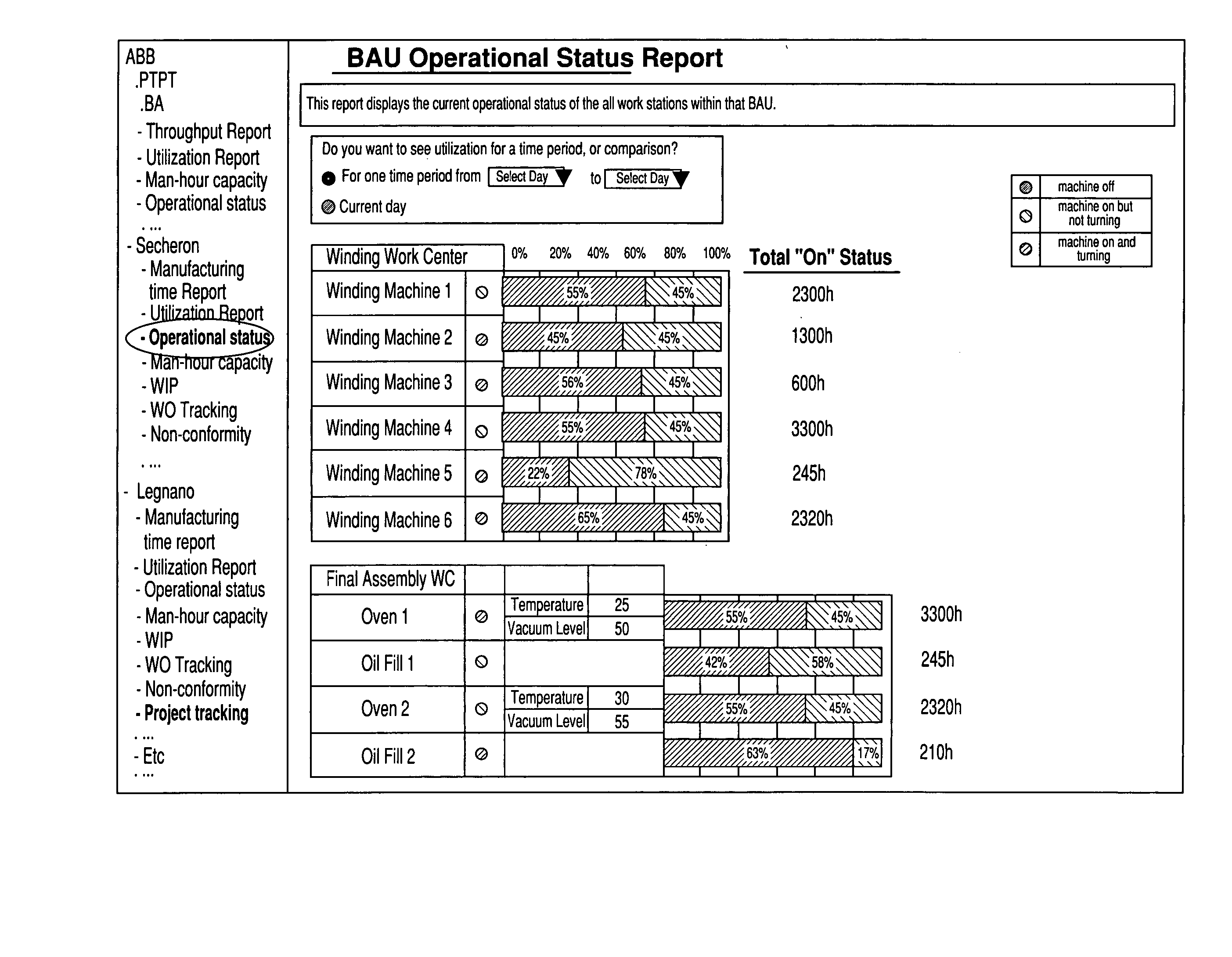

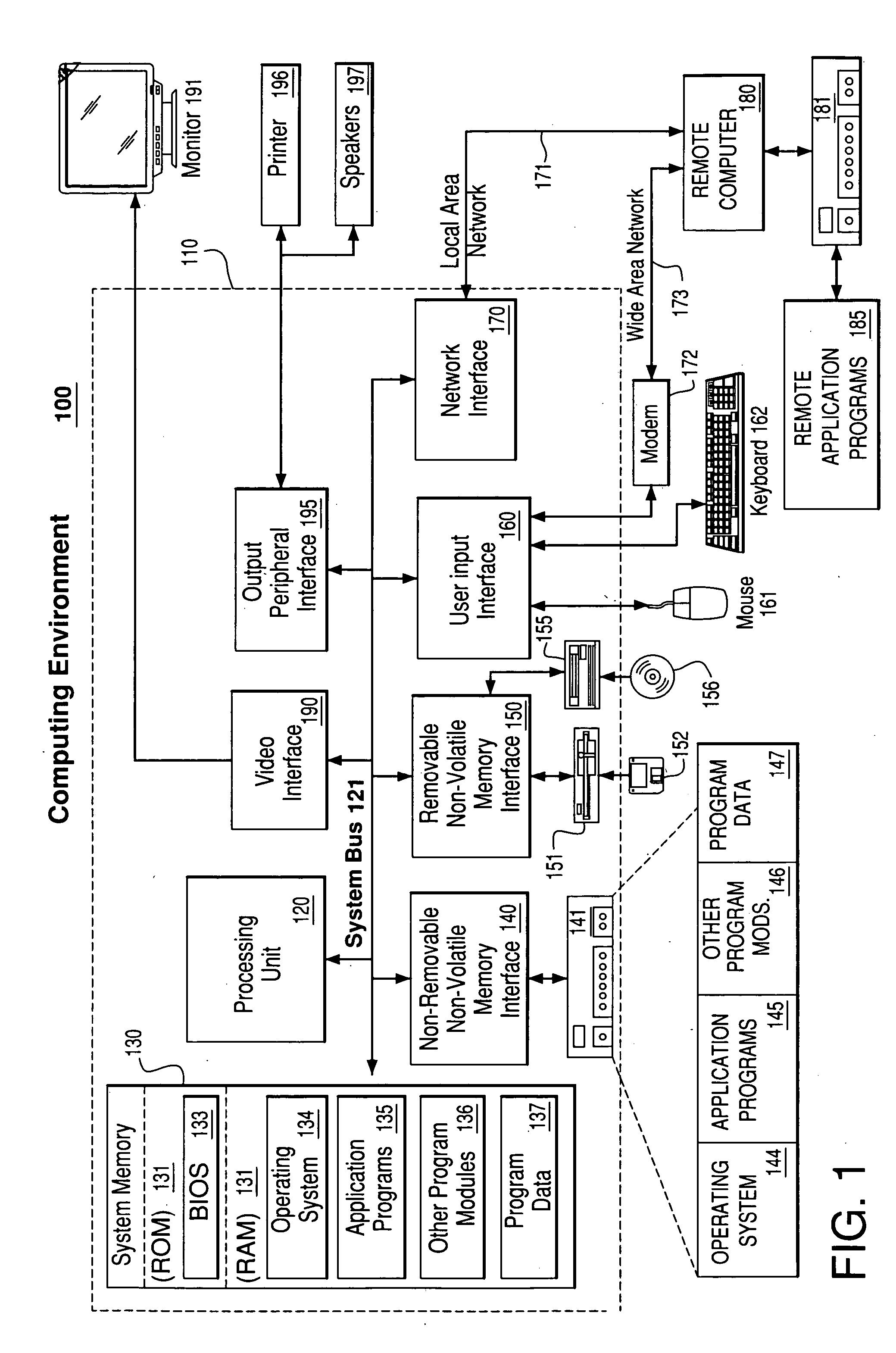

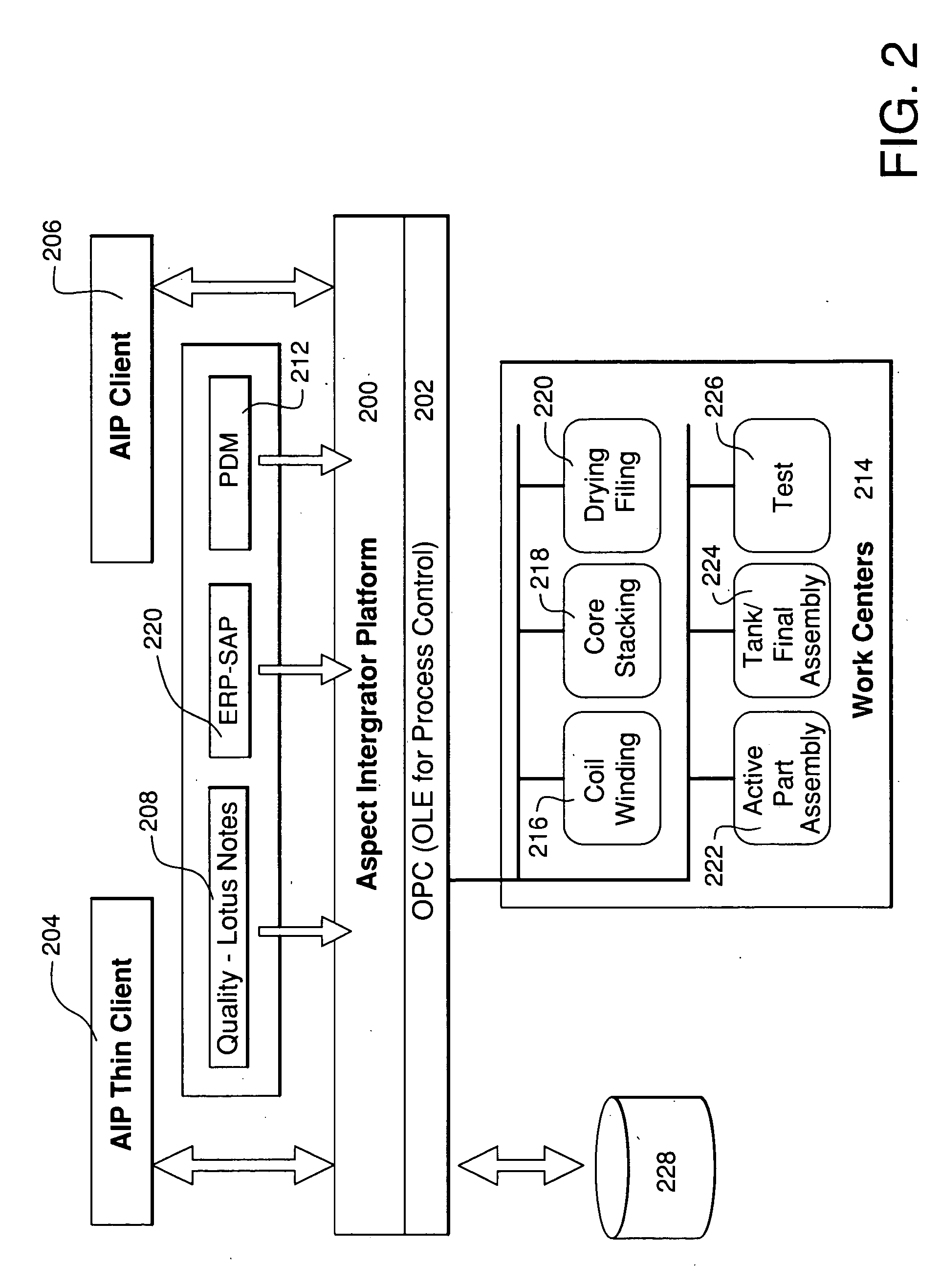

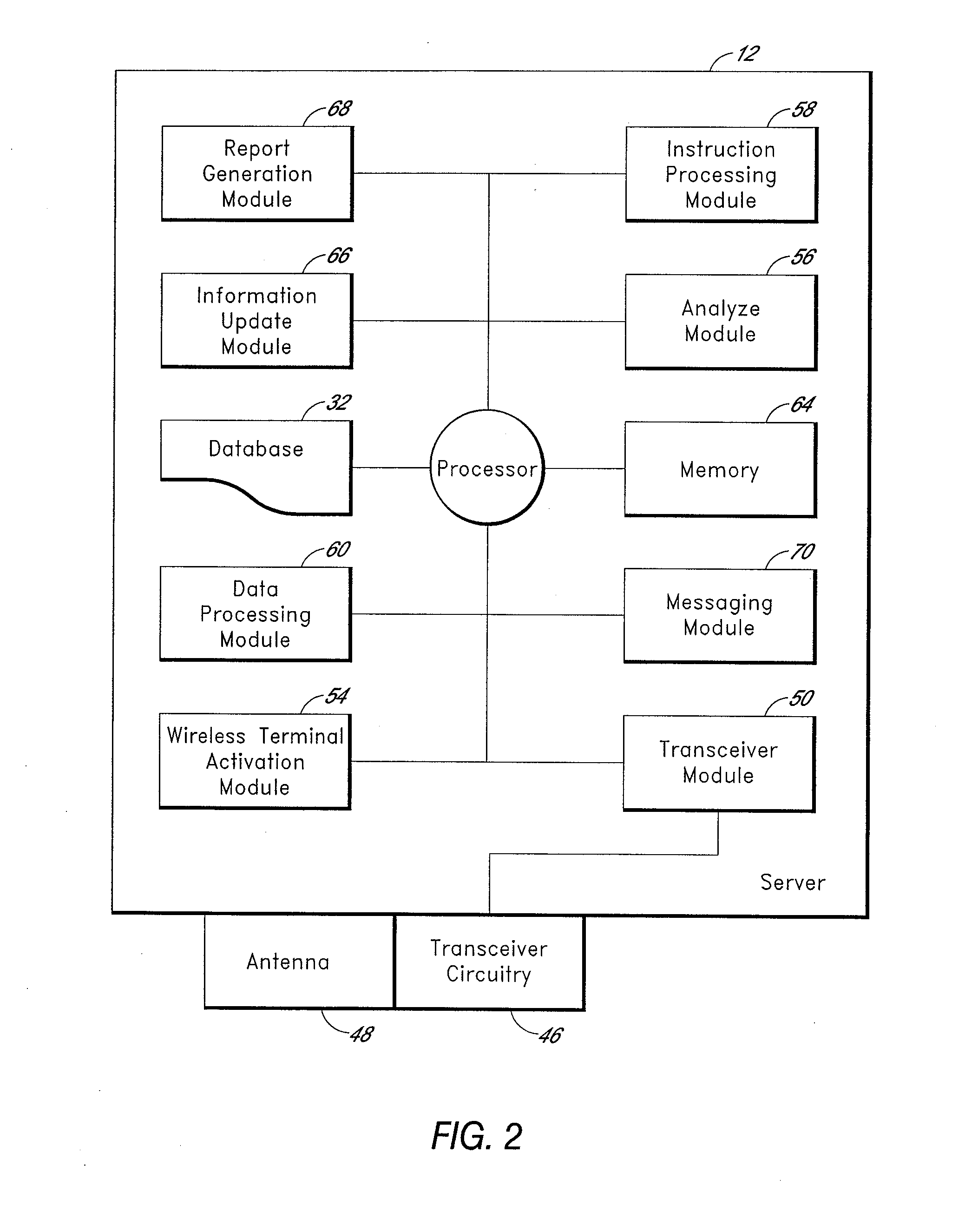

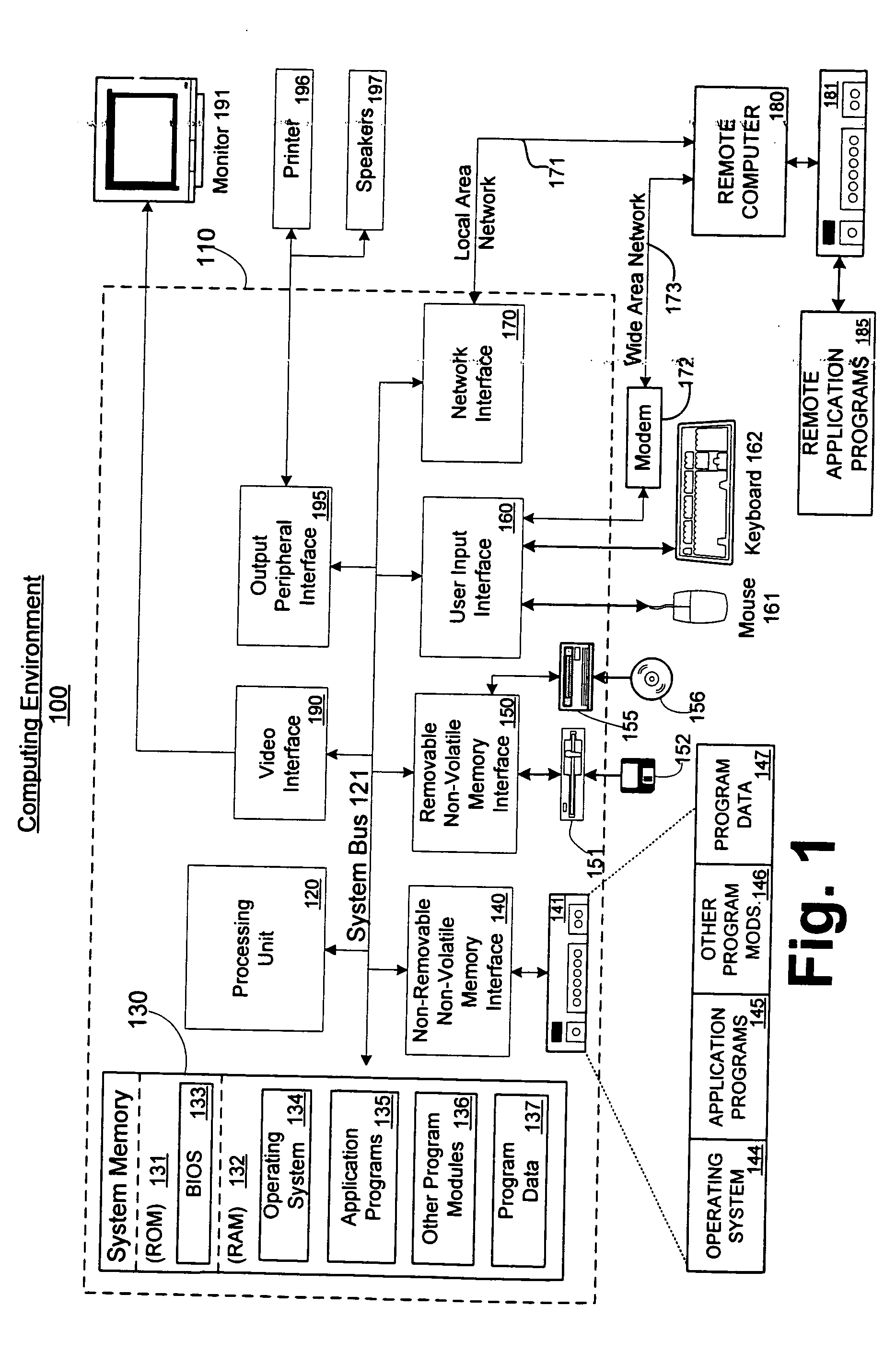

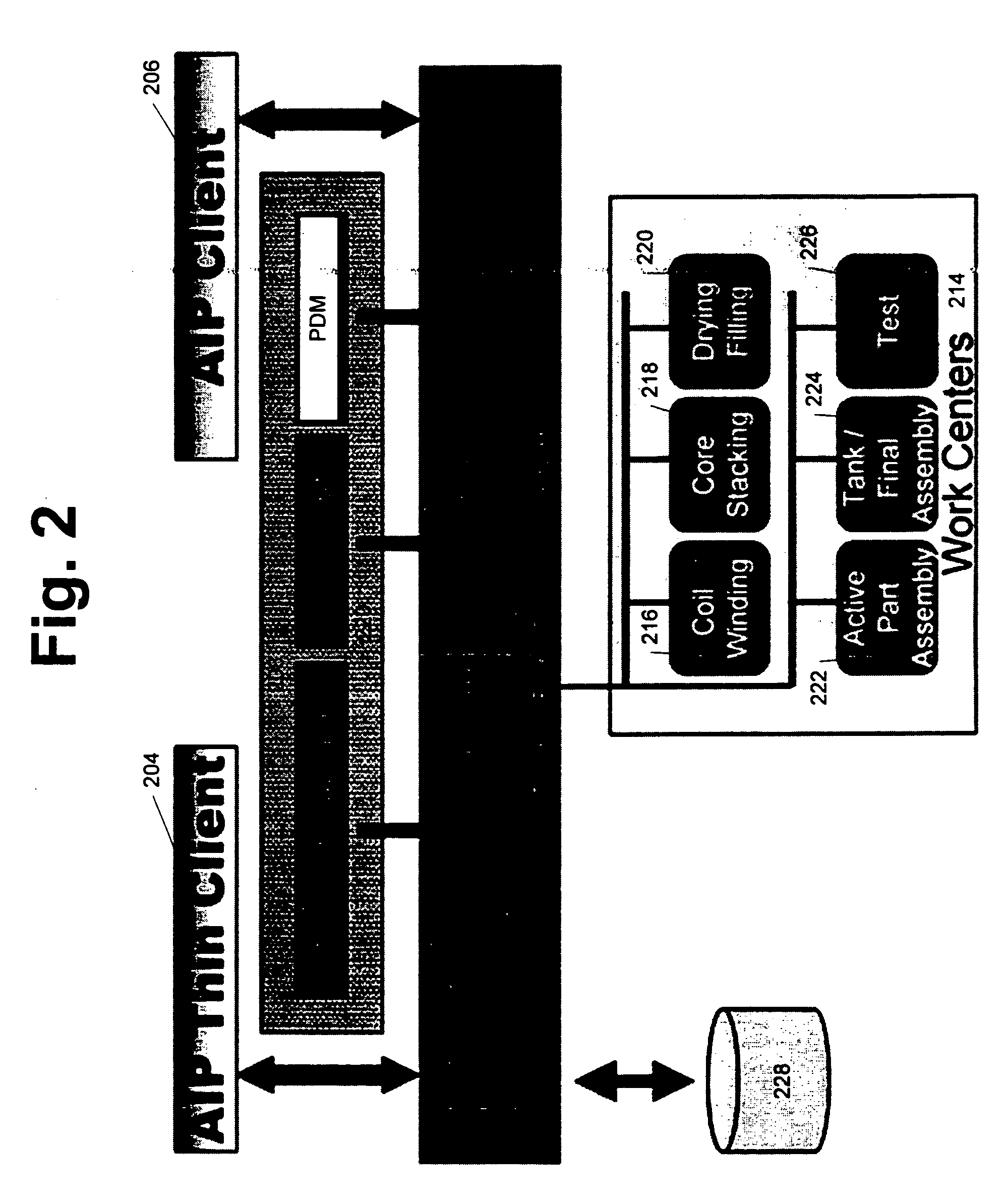

Object-oriented system for monitoring from the work-station to the boardroom

Systems and methods for visually displaying real-time enterprise management information over all levels of a corporate organizational structure of an enterprise. An application integration platform receives plural types of data from manufacturing and information systems within the enterprise and analyzes the plural types of data to determine key performance indicators. A process control server receives manufacturing data from at least one work center and forwards the manufacturing data to the application integration platform. A database contains information related to manufacturing processes performed at the at least one work center. A graphical user interface that interfaces with the application integration platform to provide a visual display of the key performance indicators in accordance with the class of user interacting therewith. The levels of the corporate organizational structure are modeled as objects having methods and variables. In addition, the objects may be created using an organizational hierarchical structure of the enterprise to be monitored together with respective states and behaviors of components within each level of the corporate structure.

Owner:ABB RES LTD

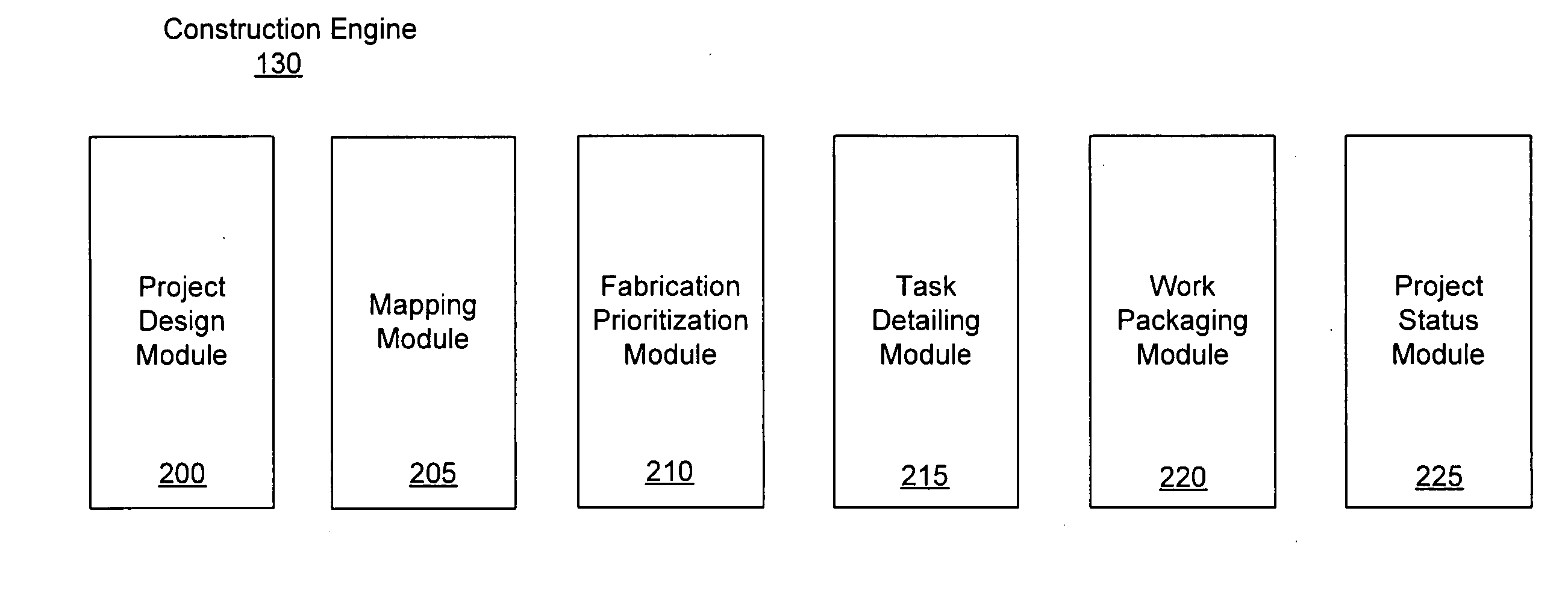

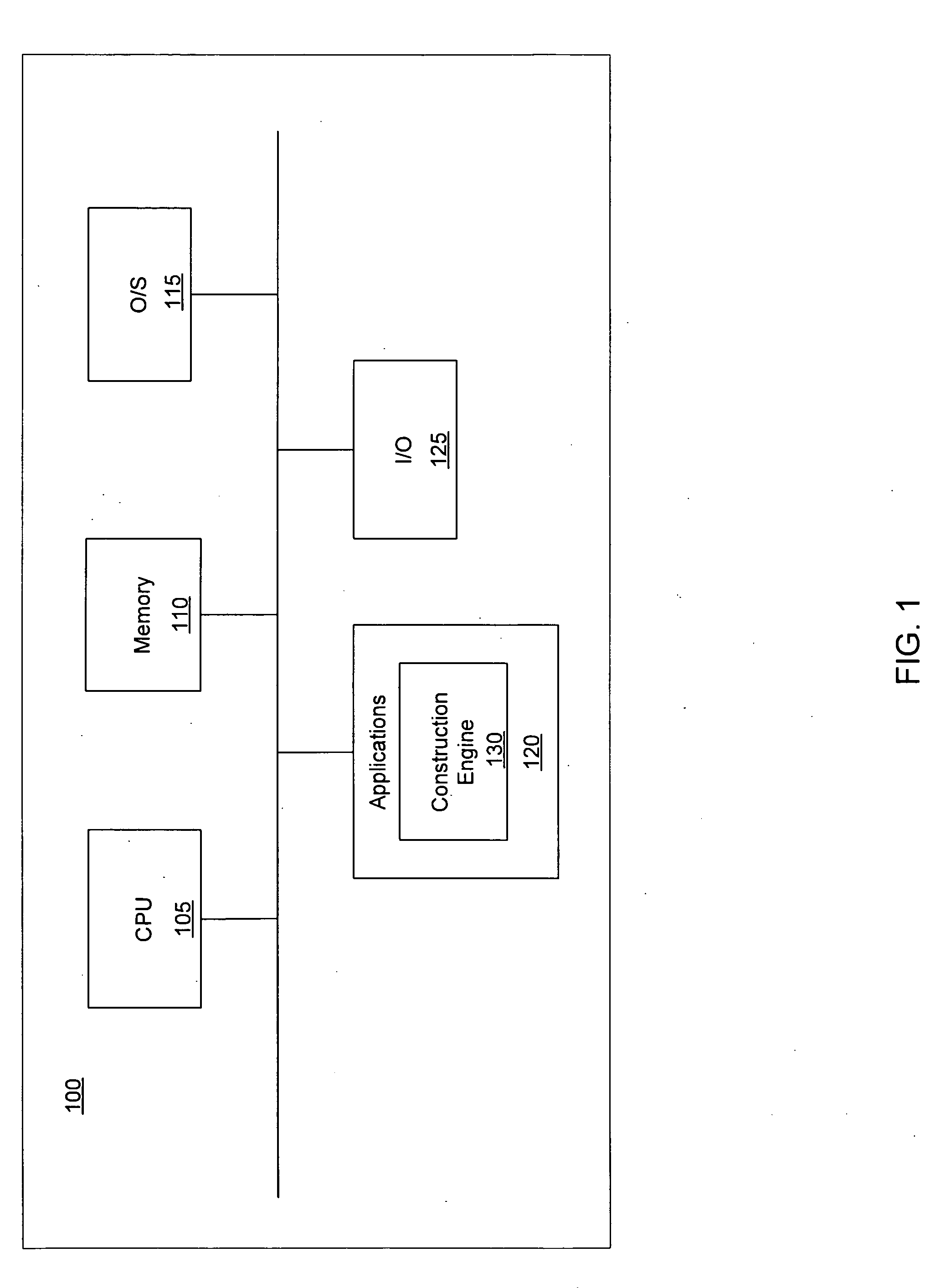

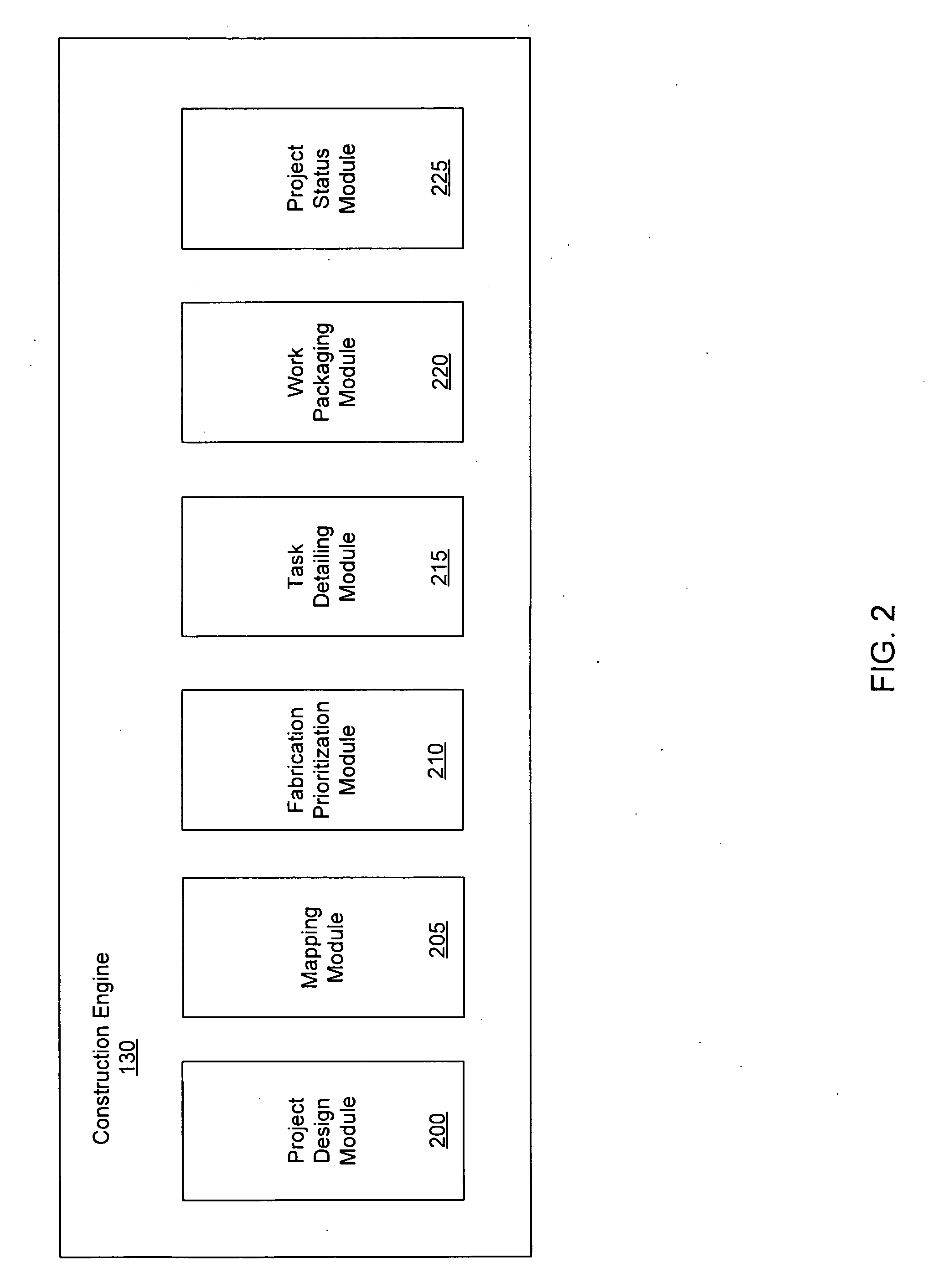

Construction project management system and method

InactiveUS20050171790A1ResourcesSpecial data processing applicationsGraphicsGraphical user interface

A construction project management system generates a computerized simulation model of a construction project based on data accessed in project databases. The system maps engineering data into constructible elements in the computerized simulation model based on manufacturing data and organizes the constructible elements by construction crafts, construction areas, and systems for testing and turnover. Additionally, the system matches the constructible elements with one or more work steps based on project controls data and generates a visual display of the construction project. A user selects construction areas in the visual display of the construction project and selects constructible elements within the construction areas, via a graphical user interface of the system, to create work packages for work crews. Each work package comprises work steps for the constructible elements in the work package, and can include an estimated time and cost for executing the work steps in the work package.

Owner:BENTLEY SYST INC

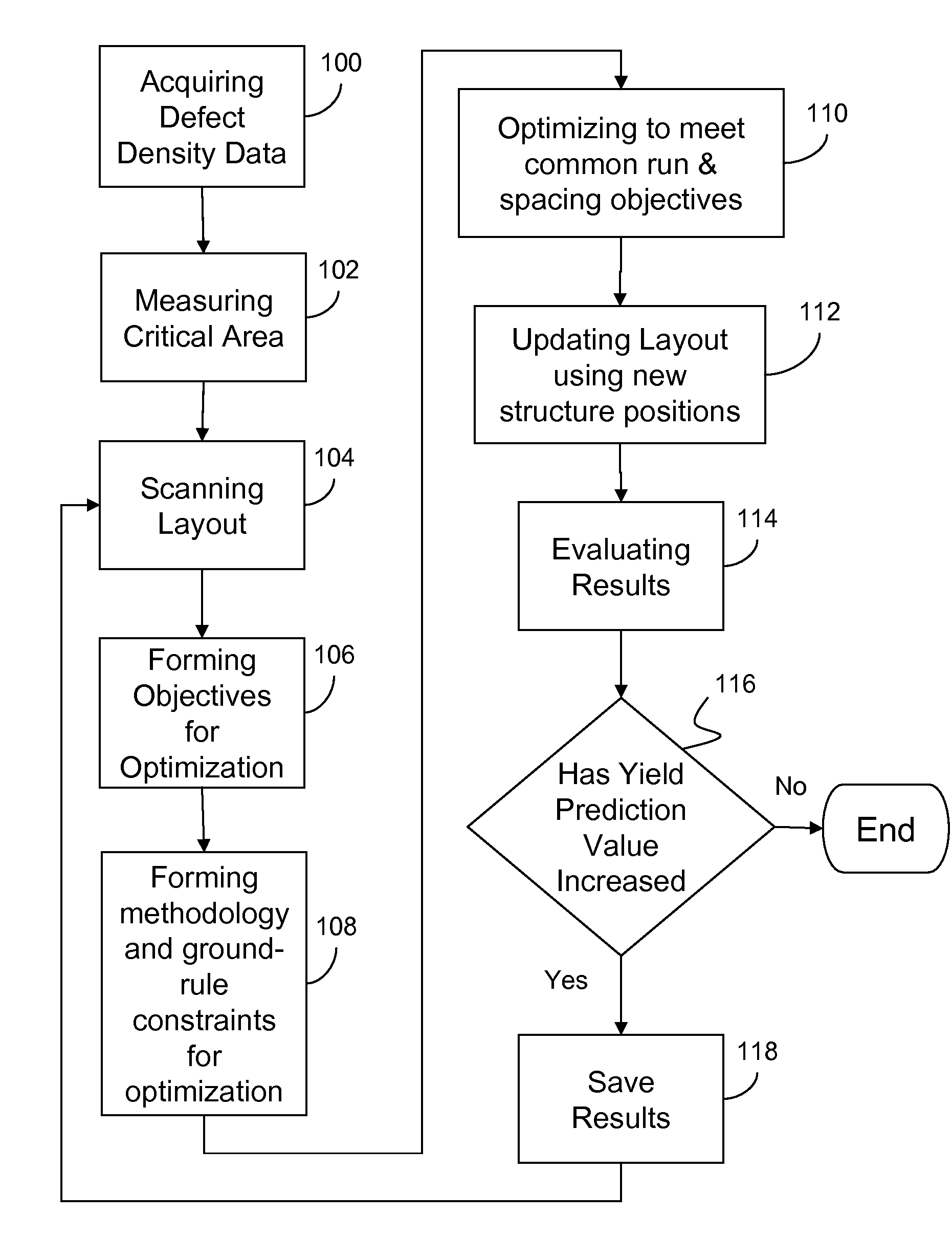

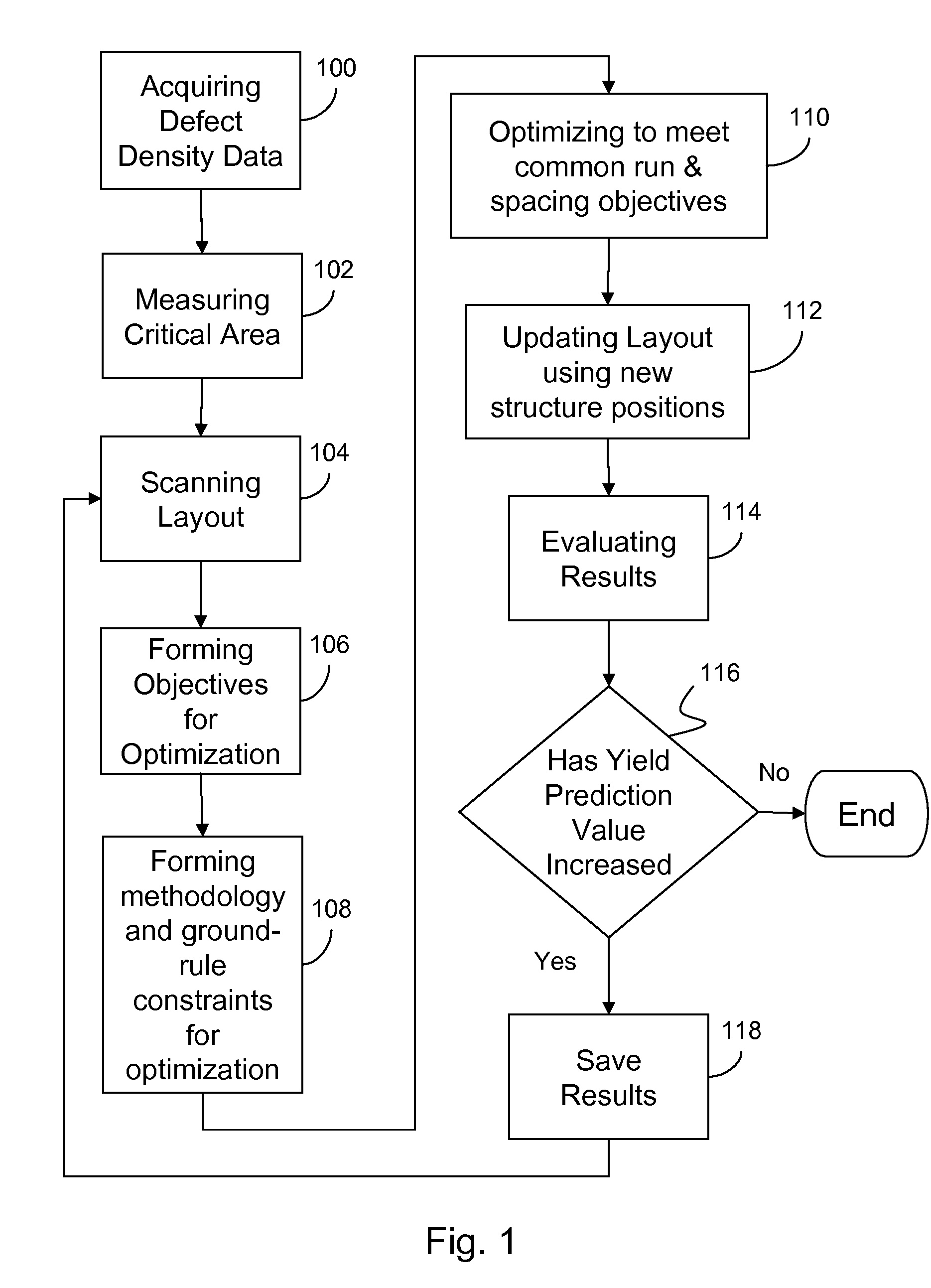

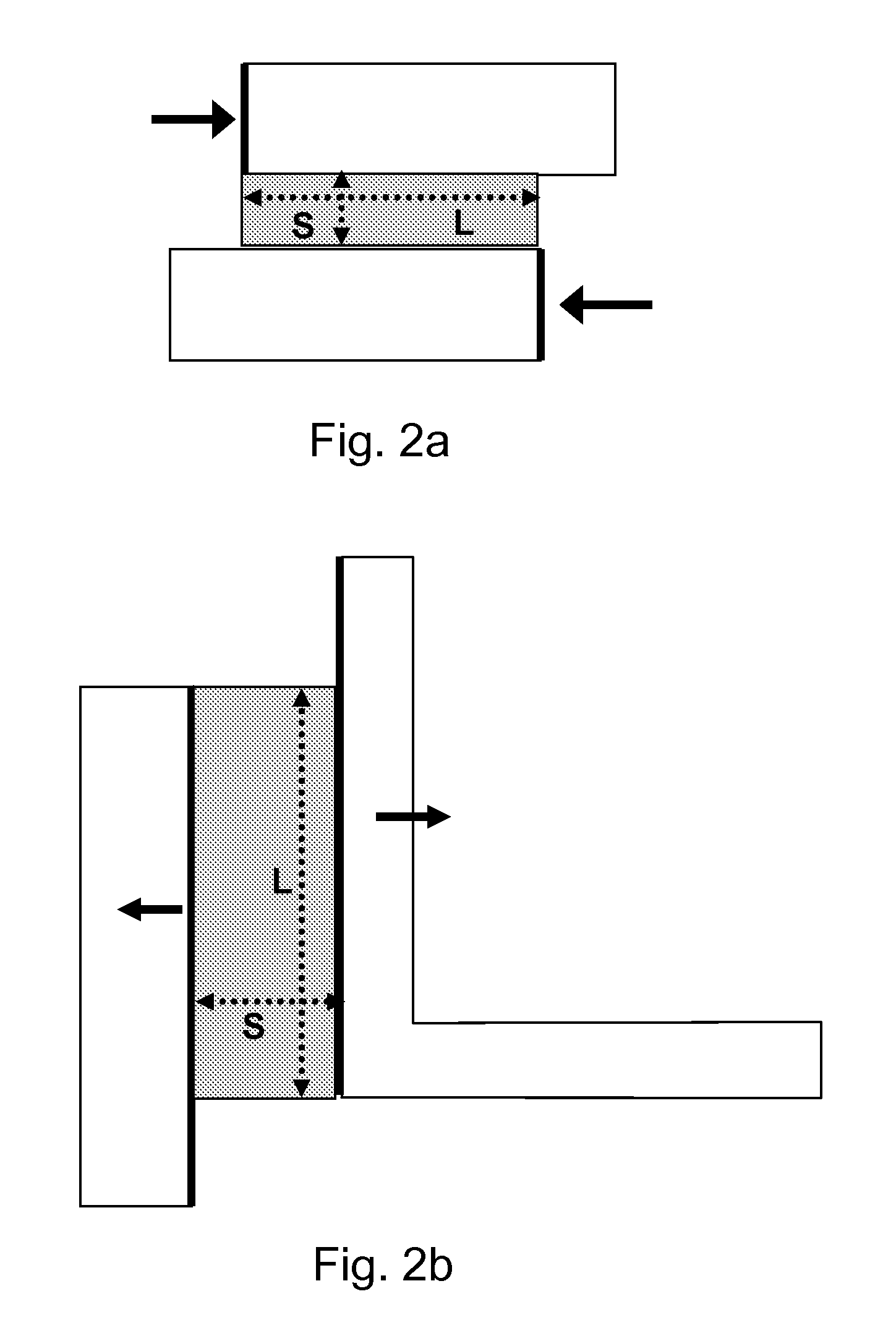

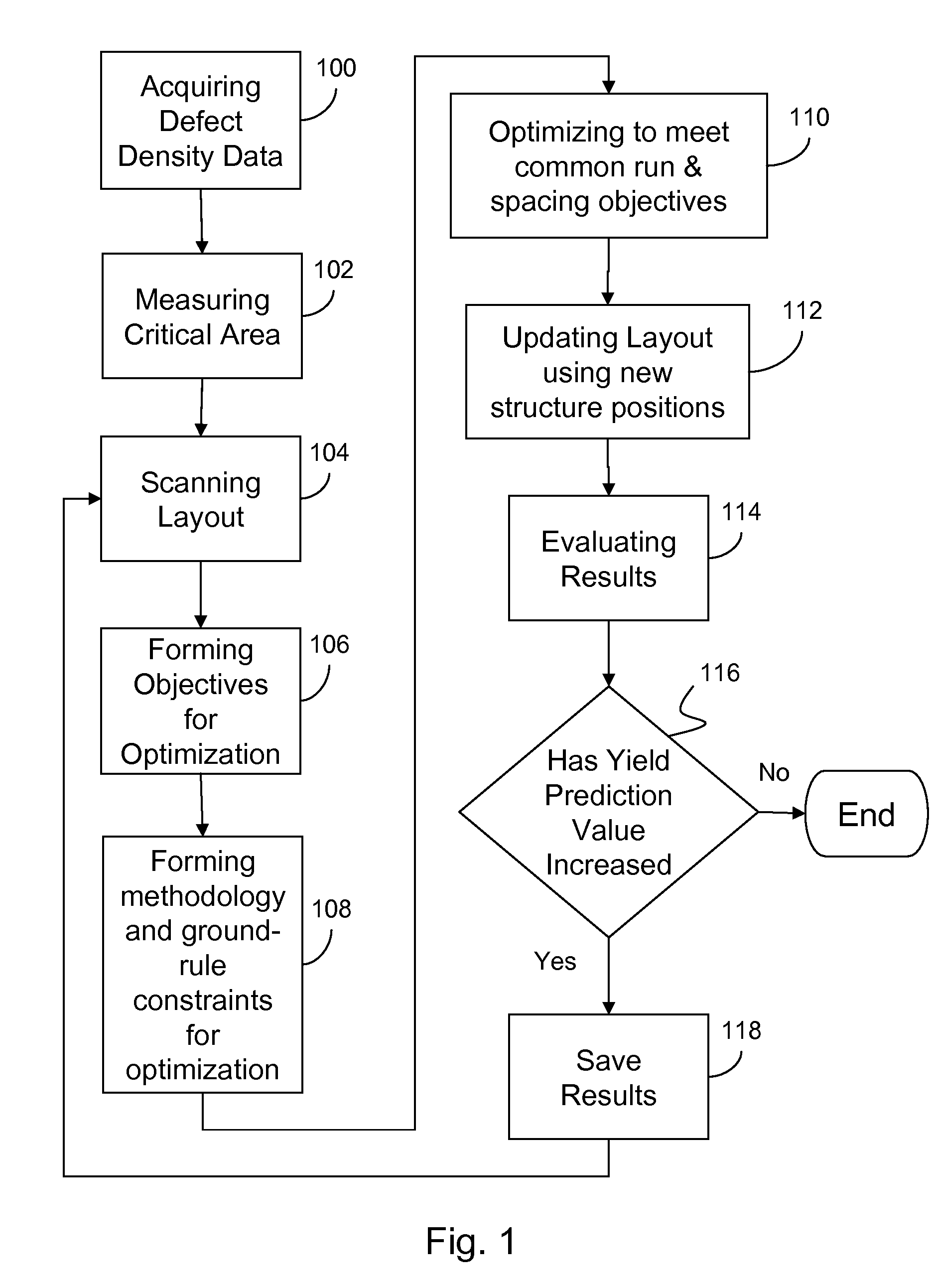

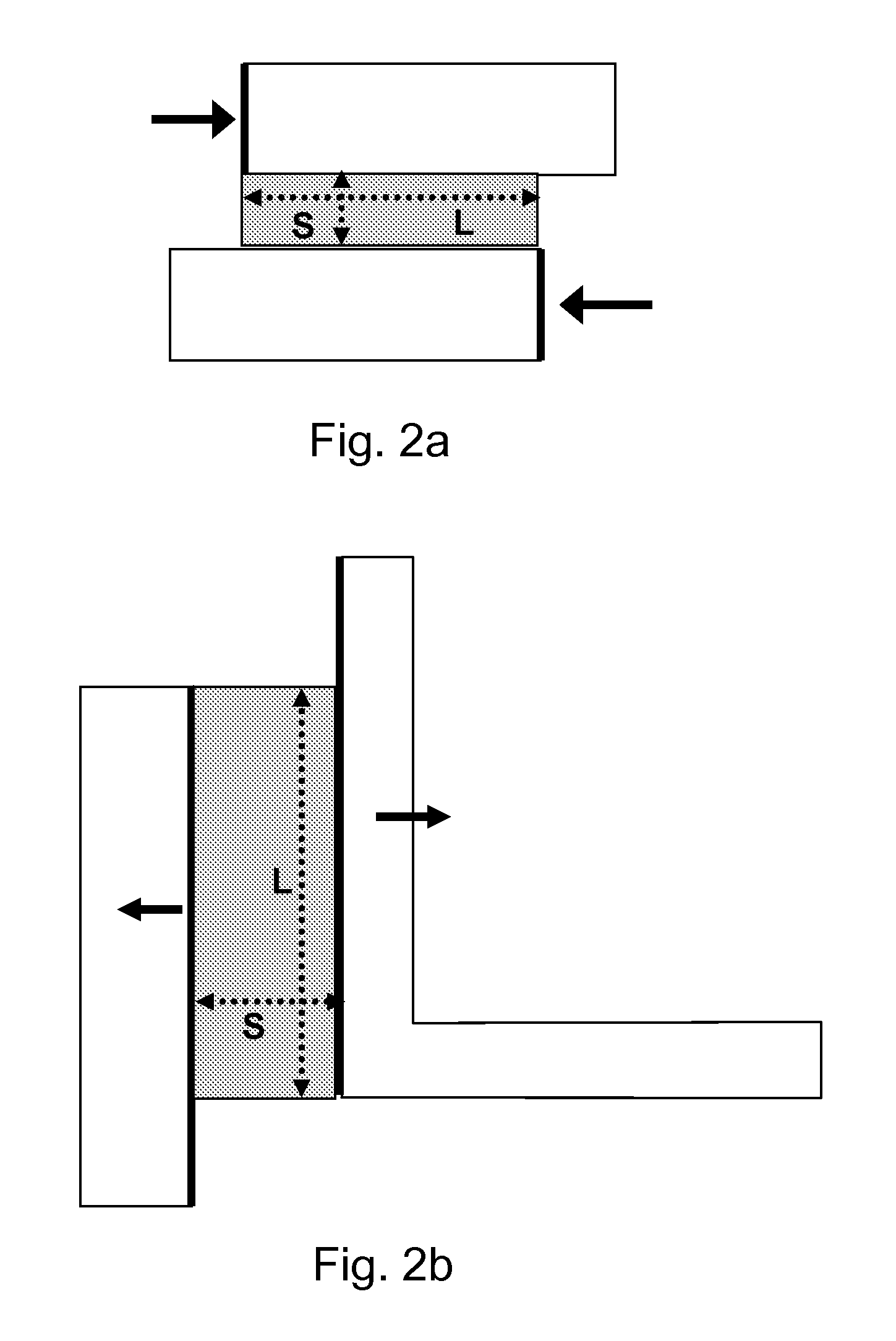

IC layout optimization to improve yield

InactiveUS7503020B2Low costReduce layout areaCAD circuit designSoftware simulation/interpretation/emulationHigh probabilityManufacturing data

A method of and service for optimizing an integrated circuit design to improve manufacturing yield. The invention uses manufacturing data and algorithms to identify areas with high probability of failures, i.e. critical areas. The invention further changes the layout of the circuit design to reduce critical area thereby reducing the probability of a fault occurring during manufacturing. Methods of identifying critical area include common run, geometry mapping, and Voronoi diagrams. Optimization includes but is not limited to incremental movement and adjustment of shape dimensions until optimization objectives are achieved and critical area is reduced.

Owner:GLOBALFOUNDRIES INC

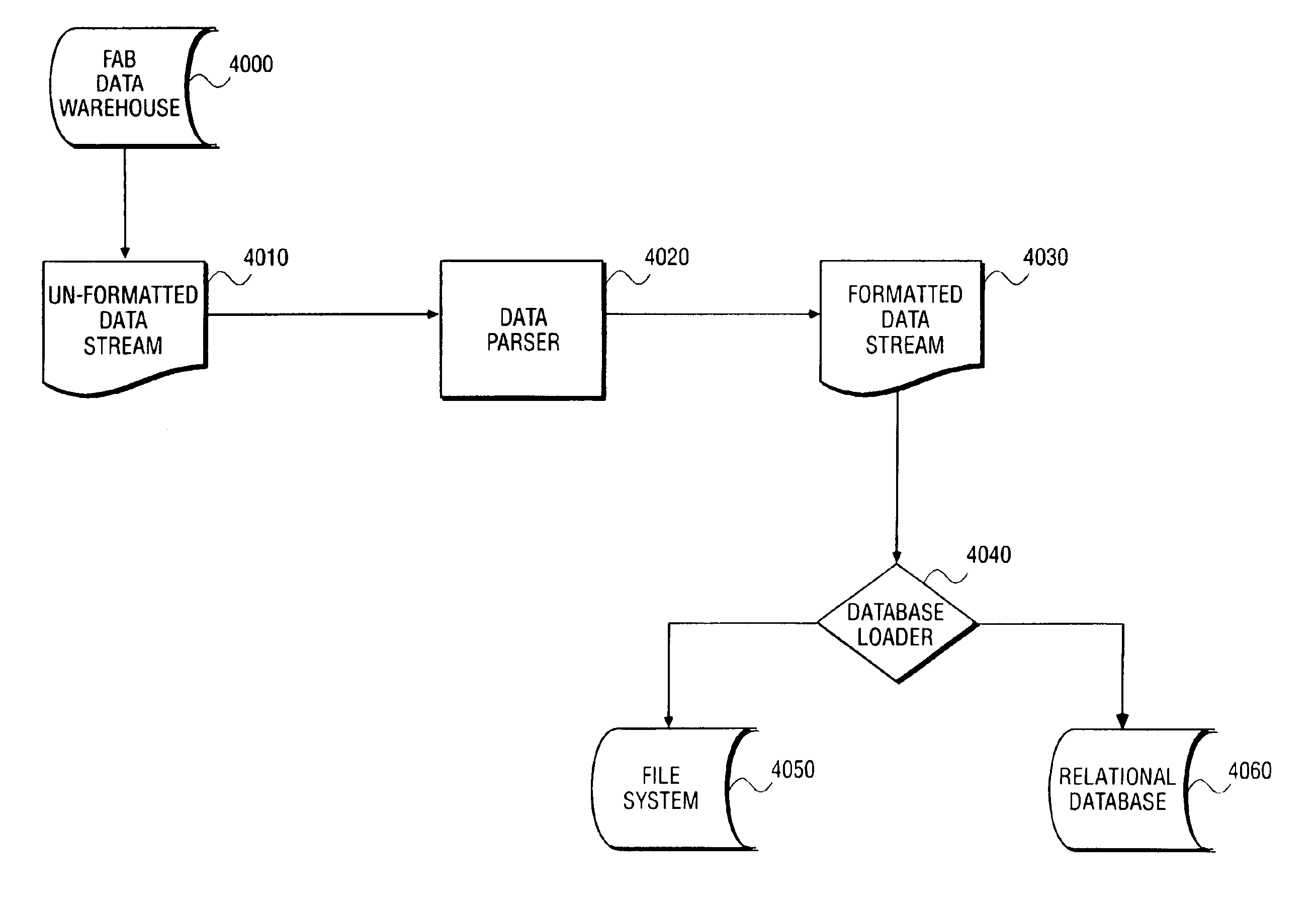

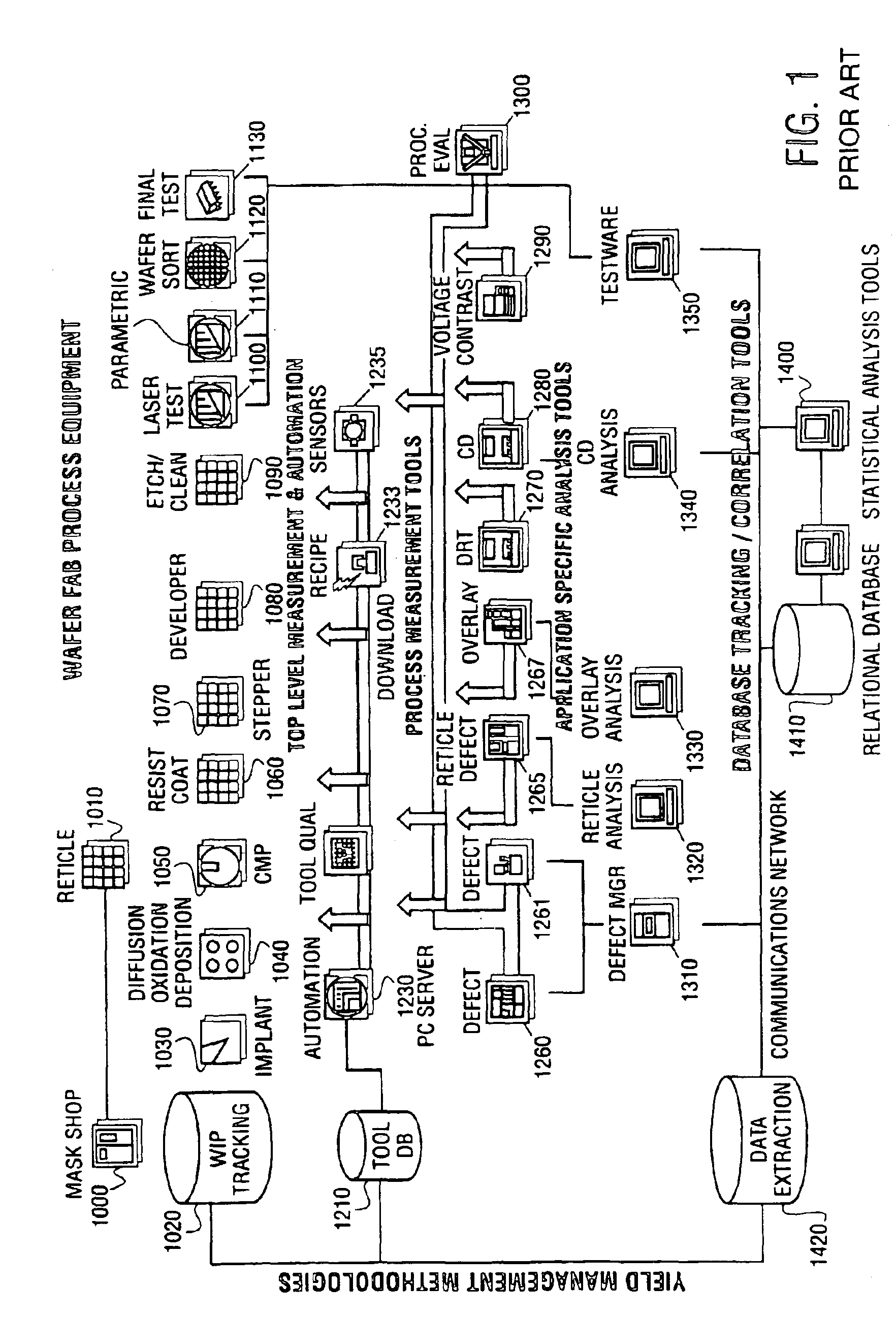

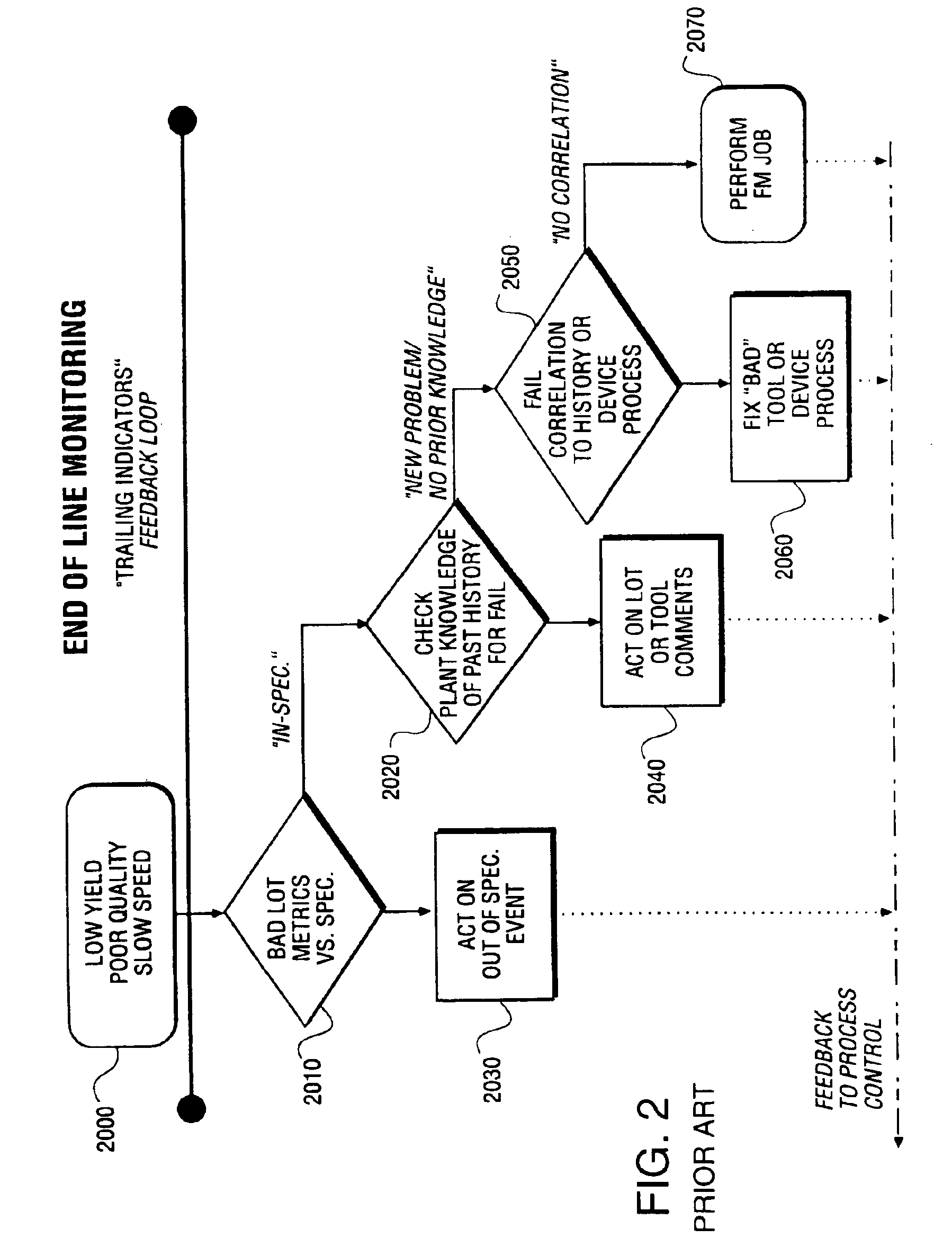

Method and apparatus for analyzing manufacturing data

A method for data mining information obtained in an integrated circuit fabrication factory (“fab”) that includes steps of: (a) gathering data from the fab from one or more of systems, tools, and databases that produce data in the fab or collect data from the fab; (b) formatting the data and storing the formatted data in a source database; (c) extracting portions of the data for use in data mining in accordance with a user specified configuration file; (d) data mining the extracted portions of data in response to a user specified analysis configuration file; (e) storing results of data mining in a results database; and (f) providing access to the results.

Owner:APPLIED MATERIALS INC

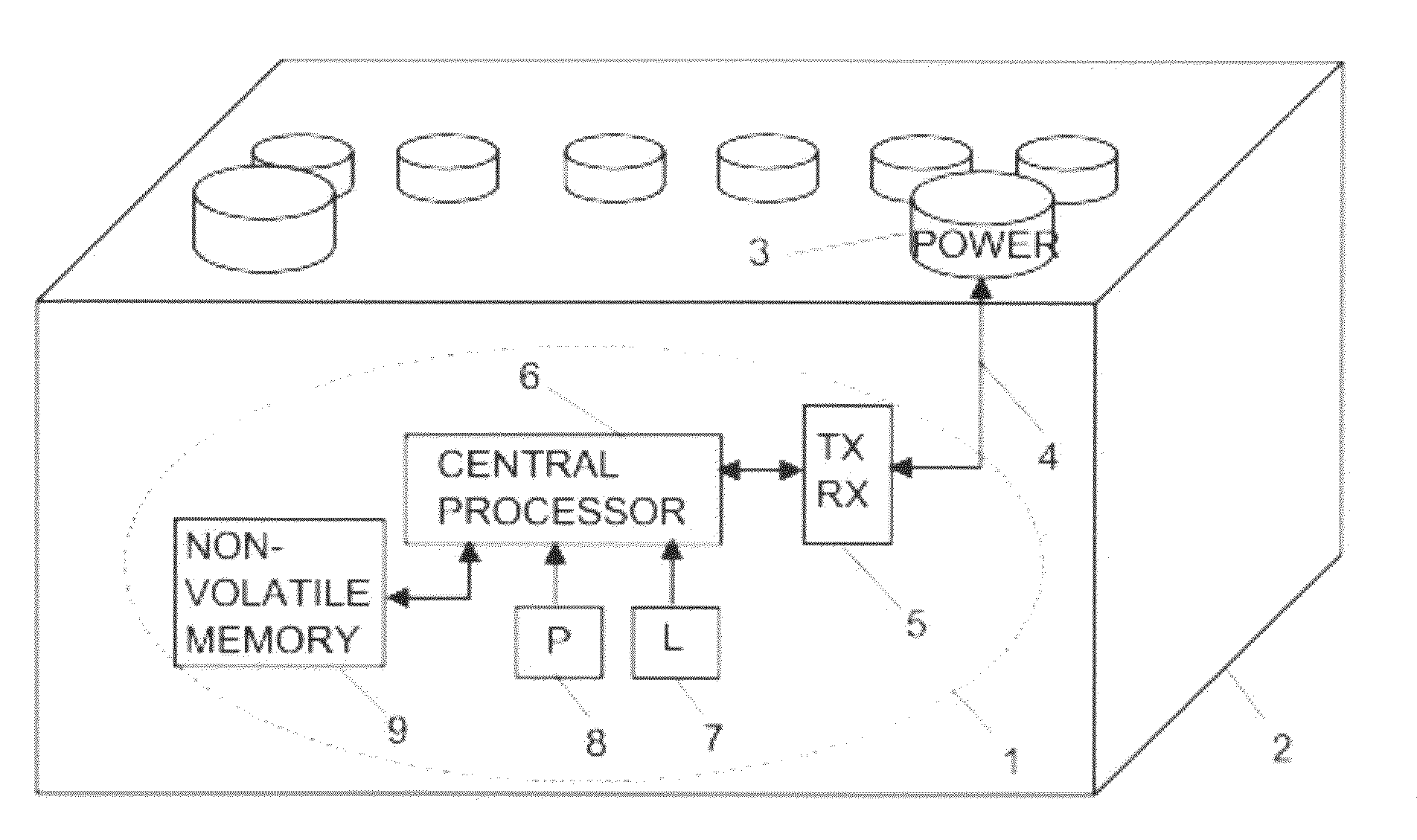

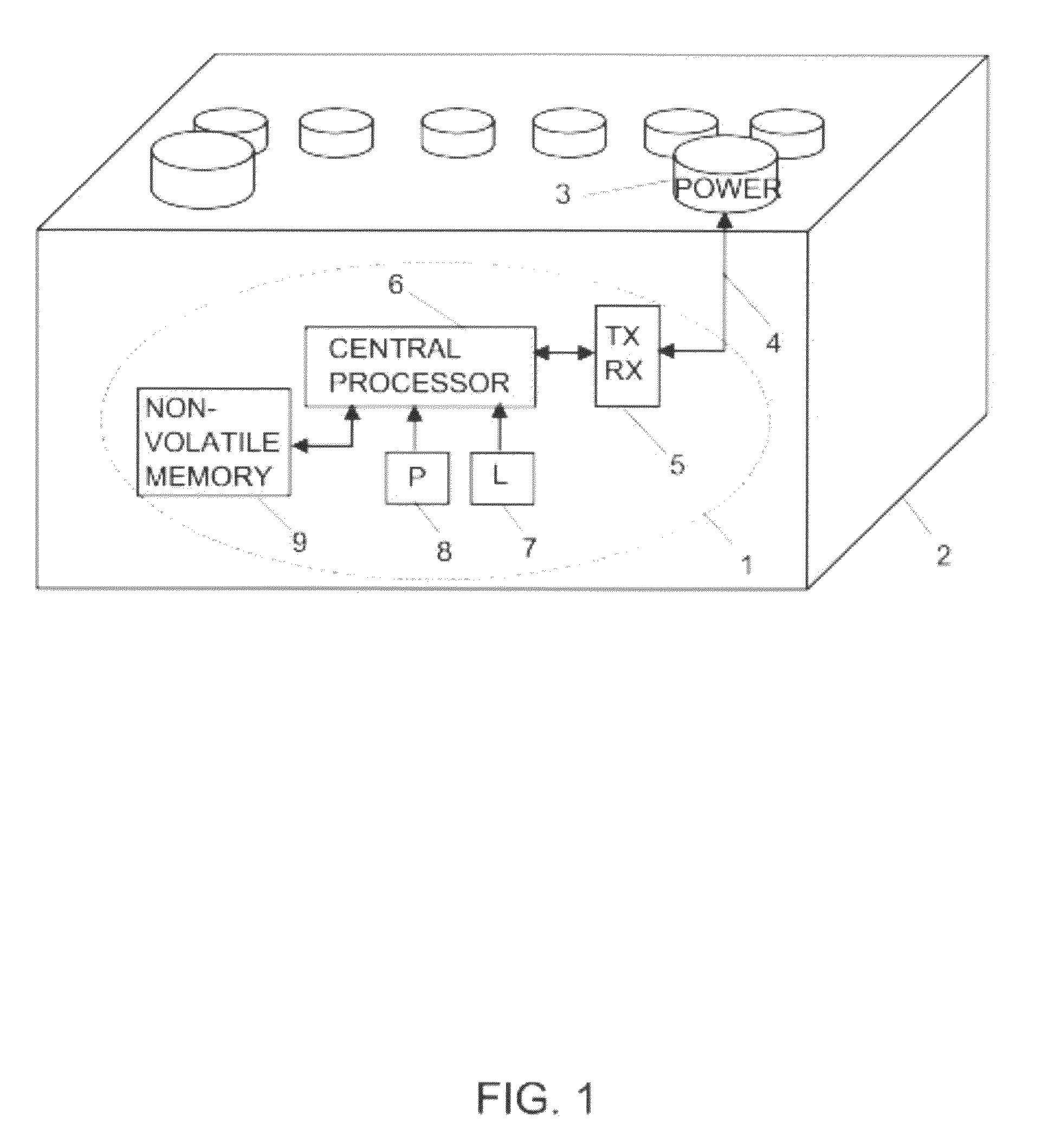

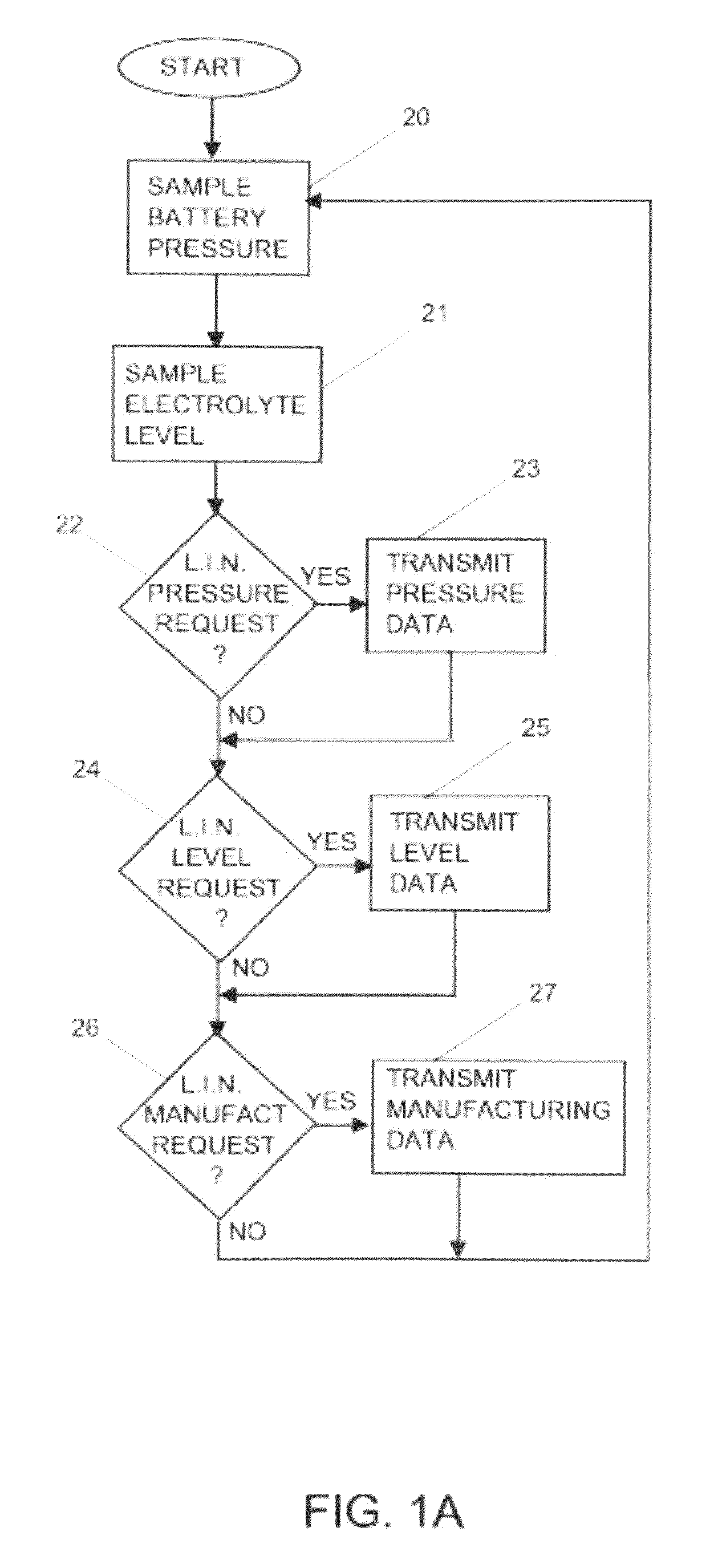

Embedded microprocessor system for vehicular batteries

InactiveUS20100217551A1Batteries circuit arrangementsError detection/correctionElectrical batteryComputerized system

A computer system embedded inside a starter or deep cycle battery that includes manufacturing data, the means to monitor battery pressure, the means to monitor electrolyte level and the means to transfer information to an external device.

Owner:4 PEAKS TECH

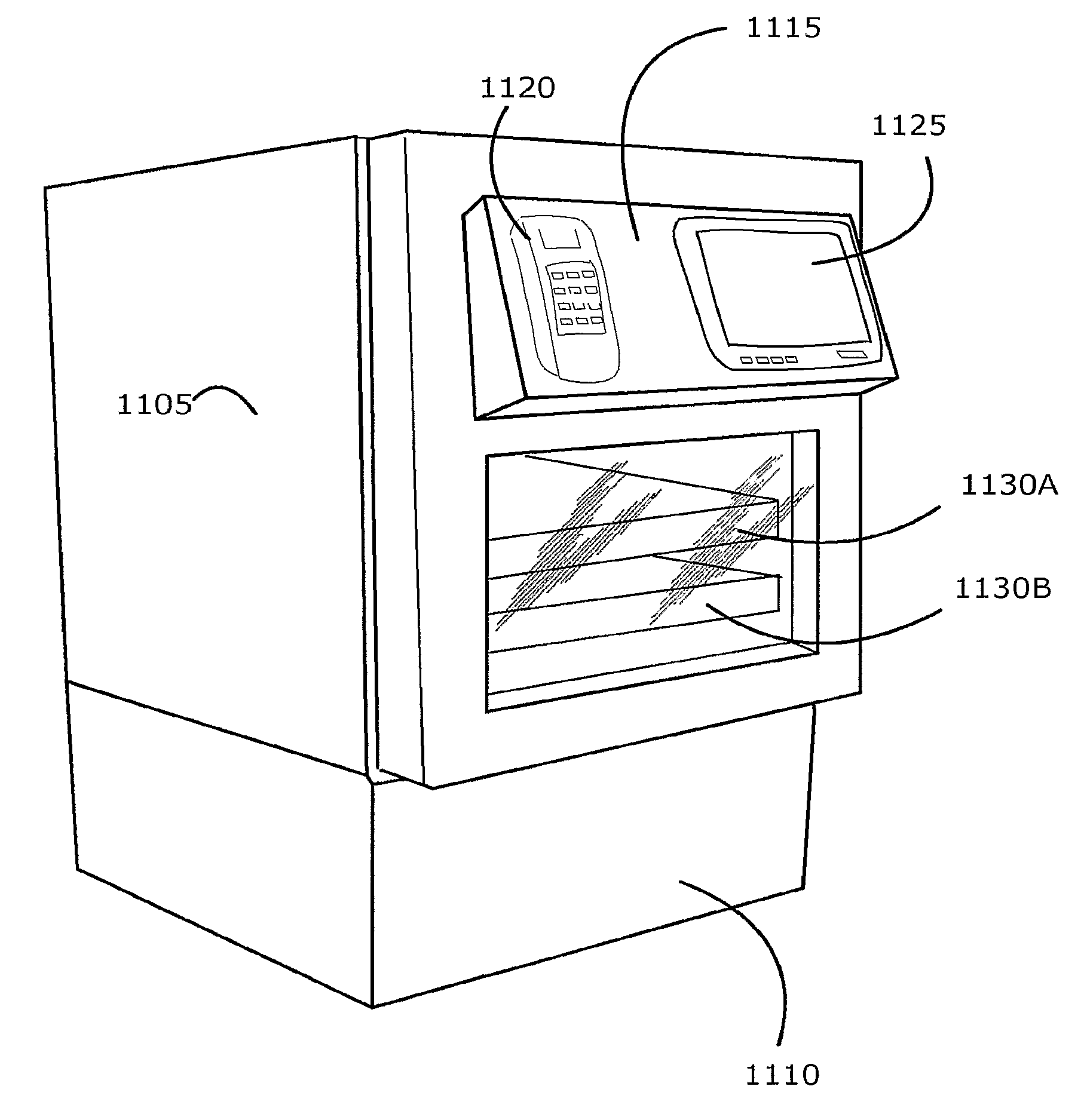

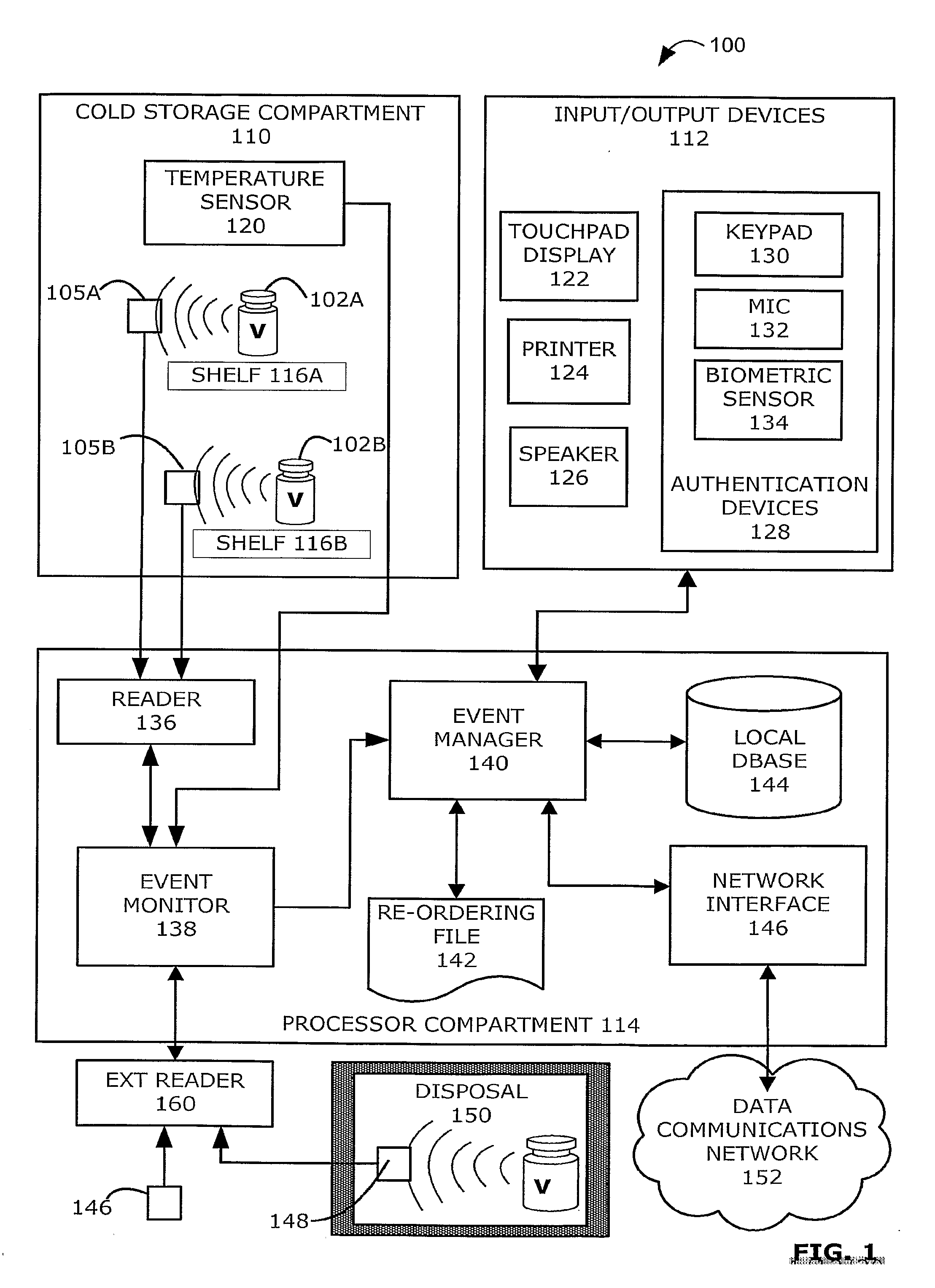

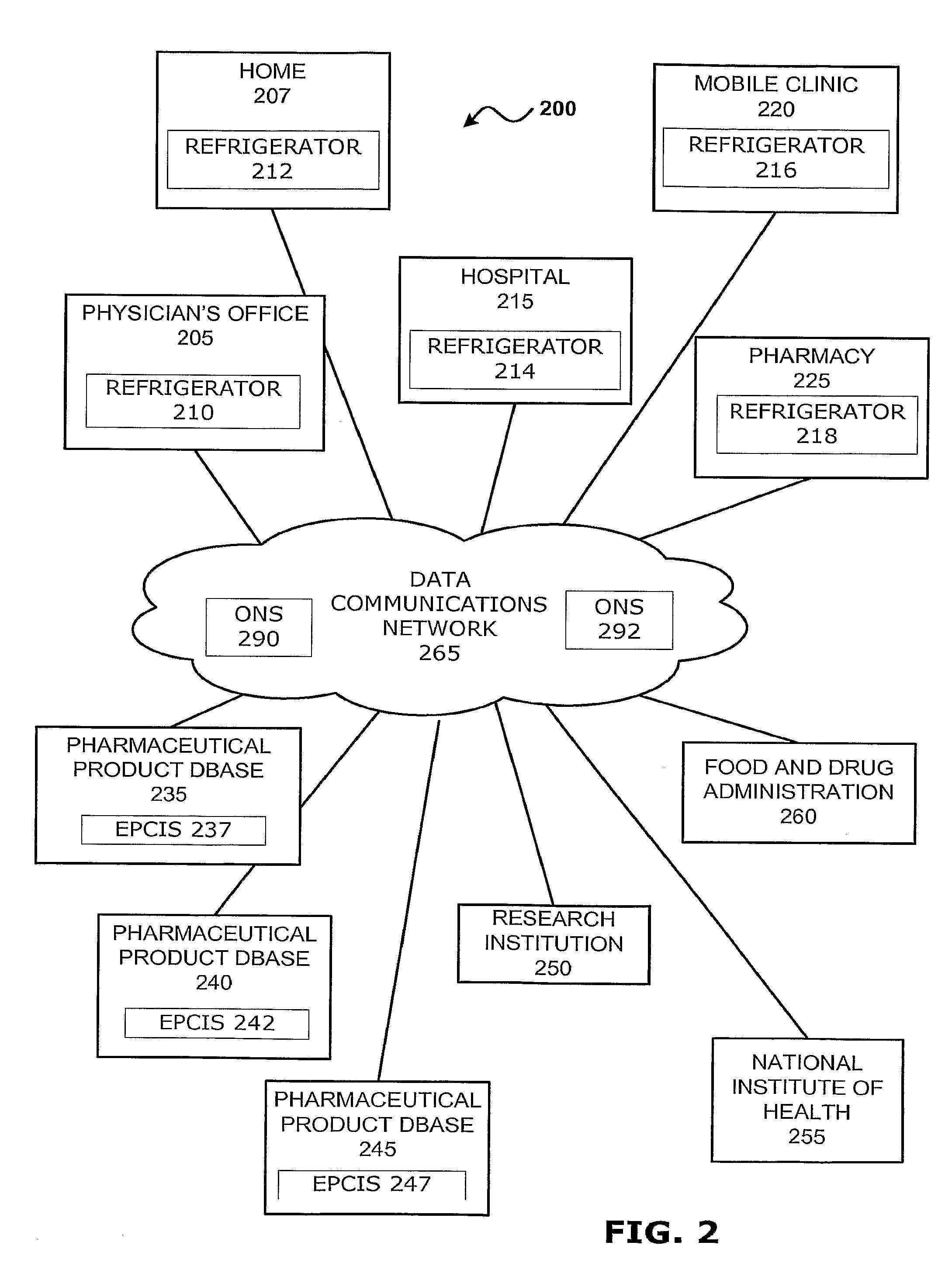

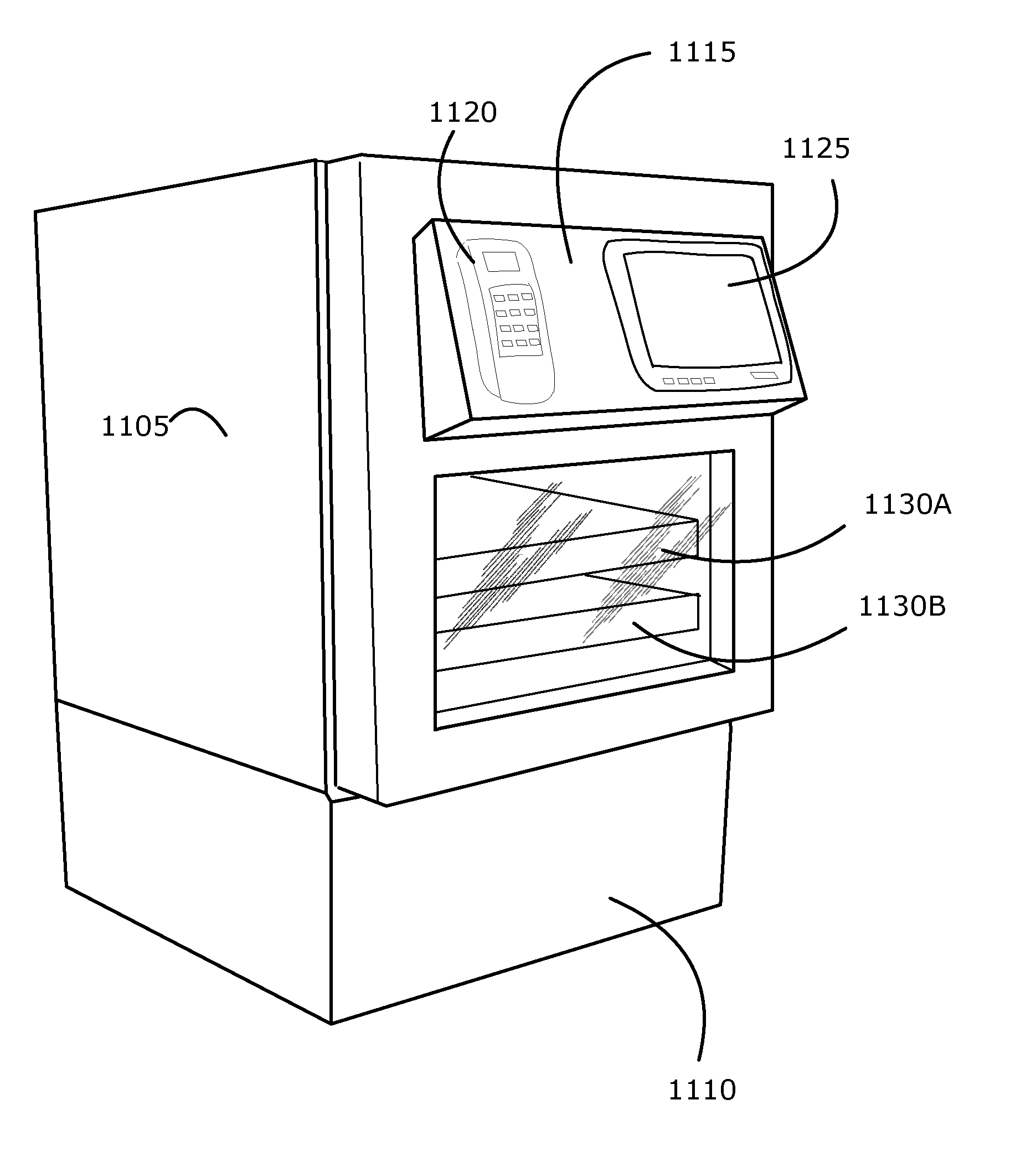

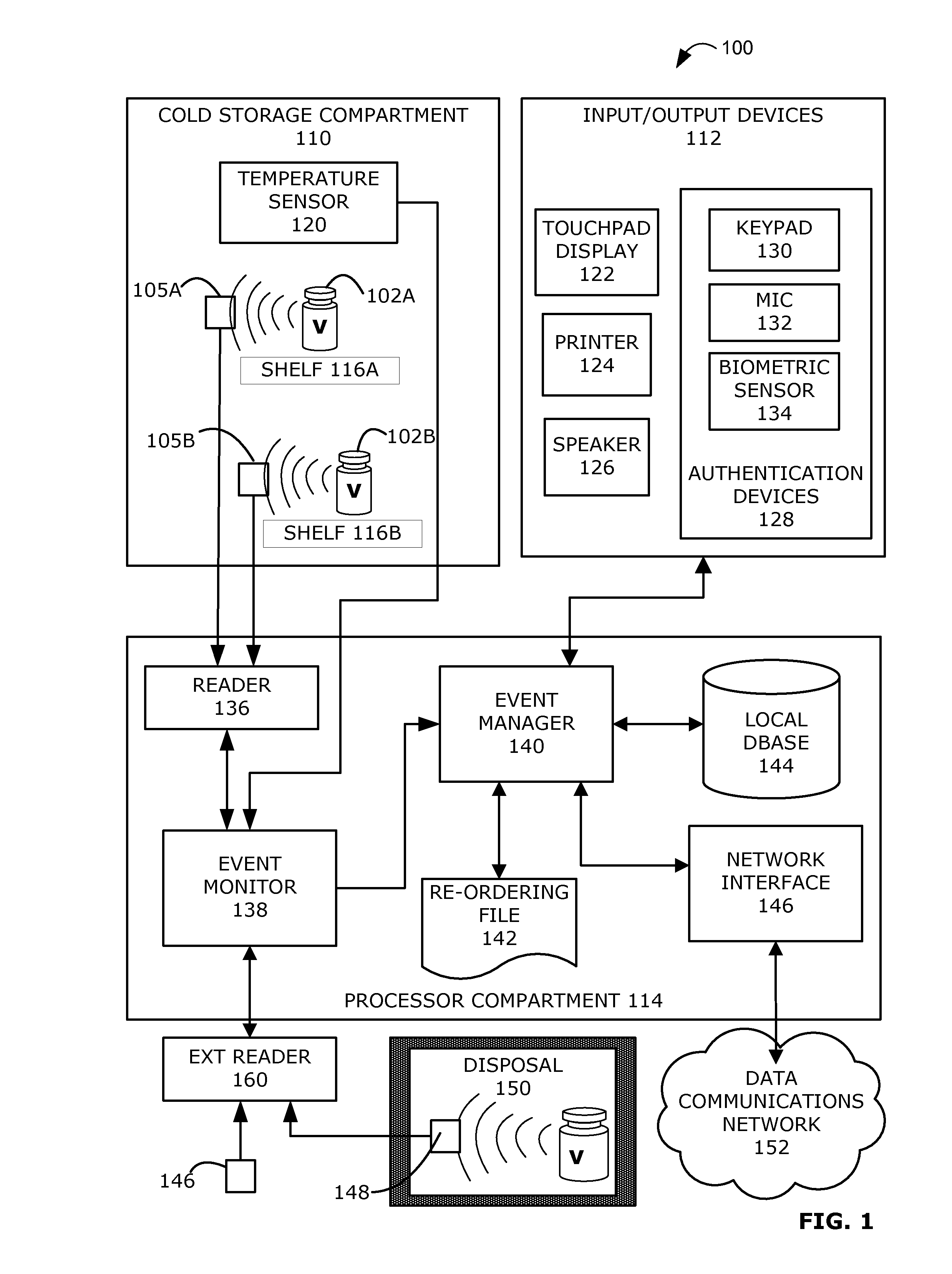

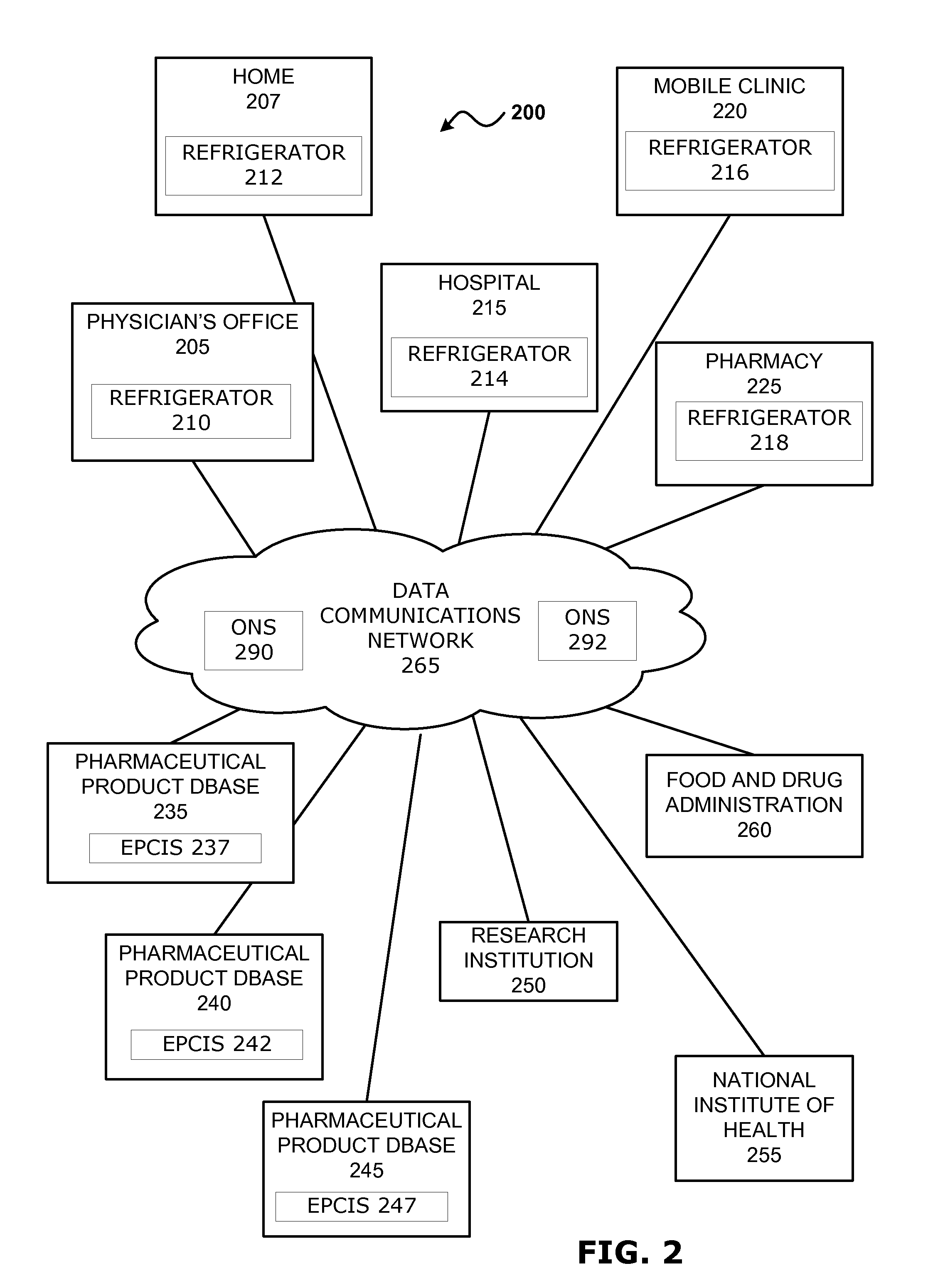

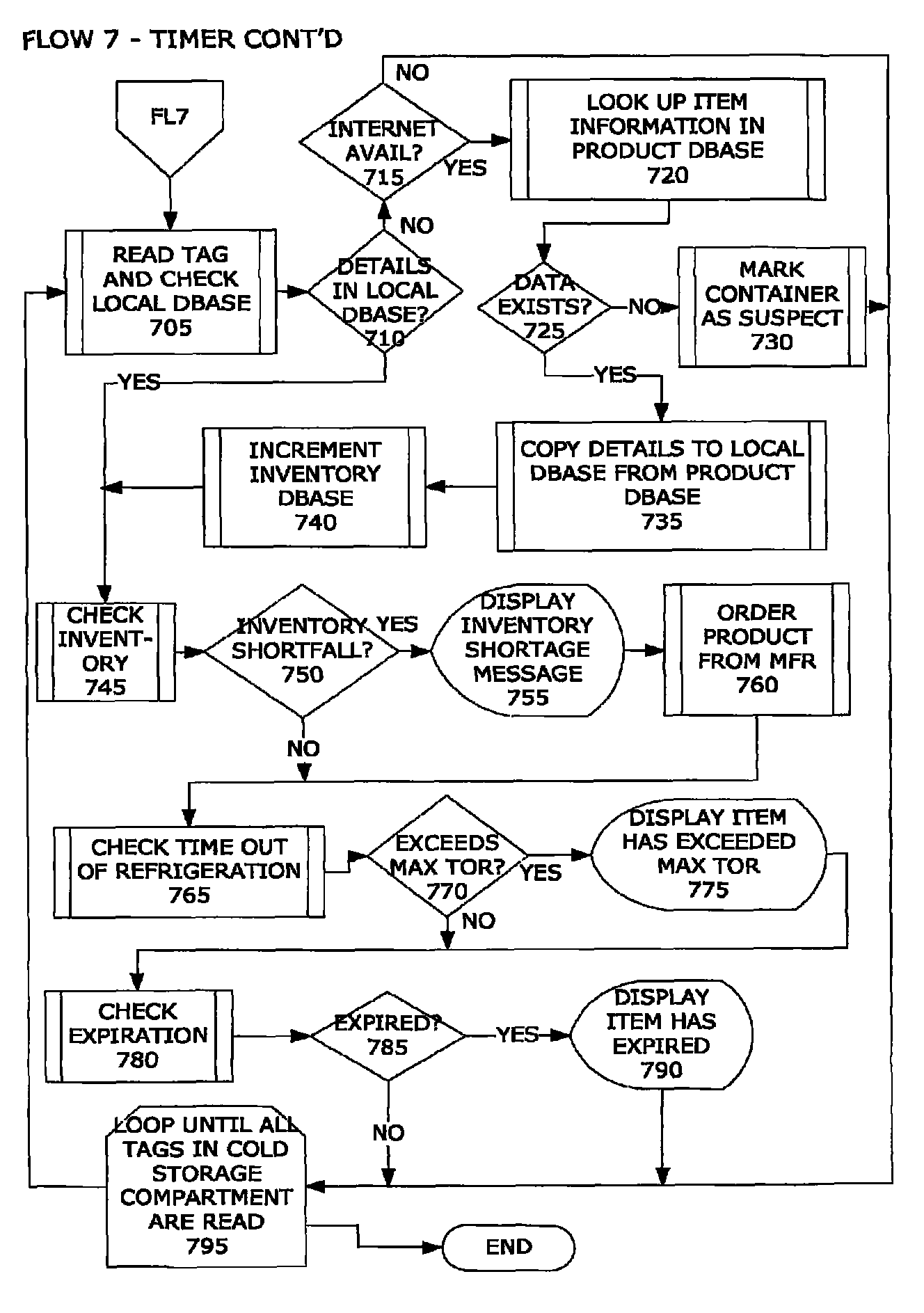

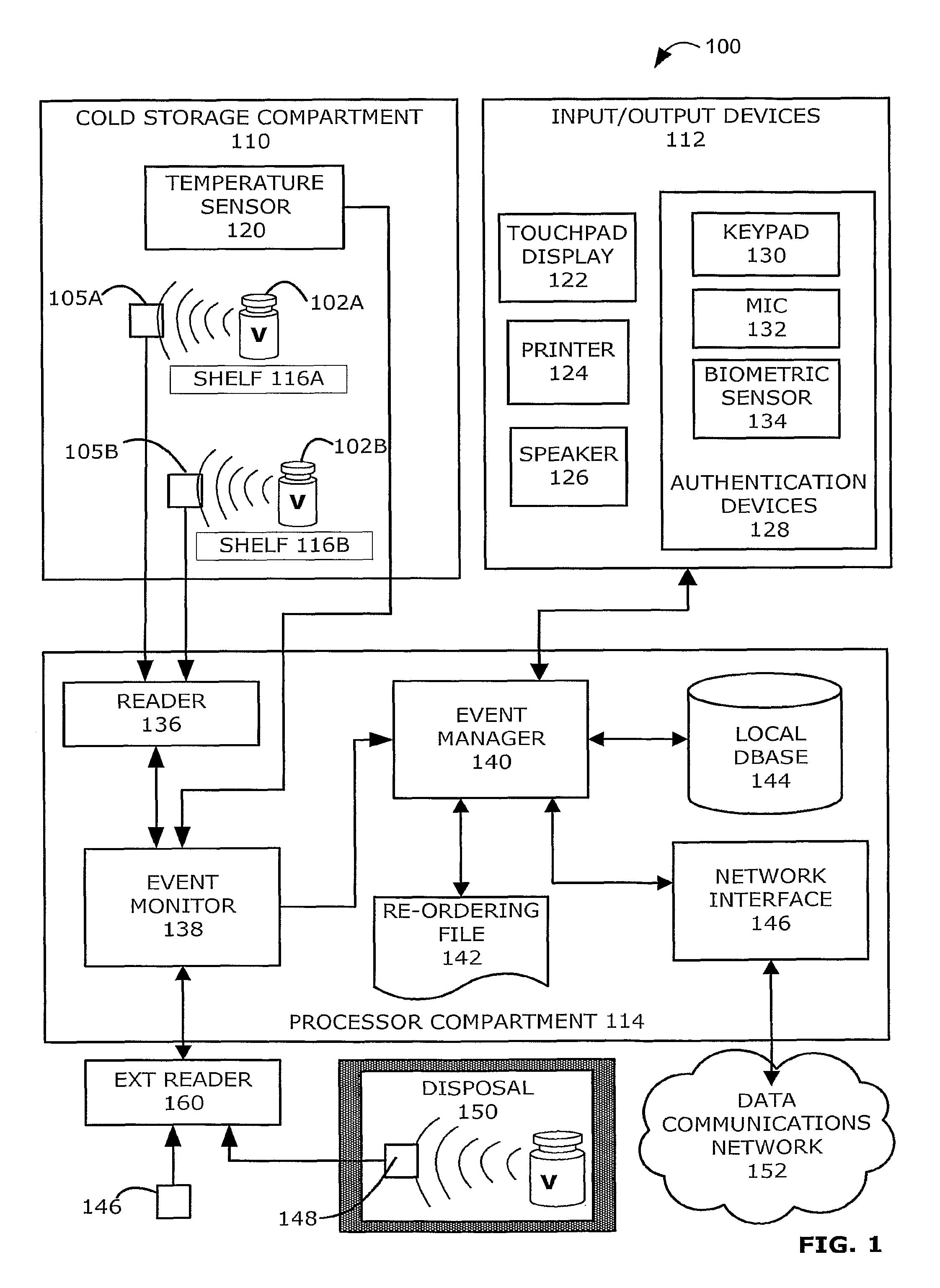

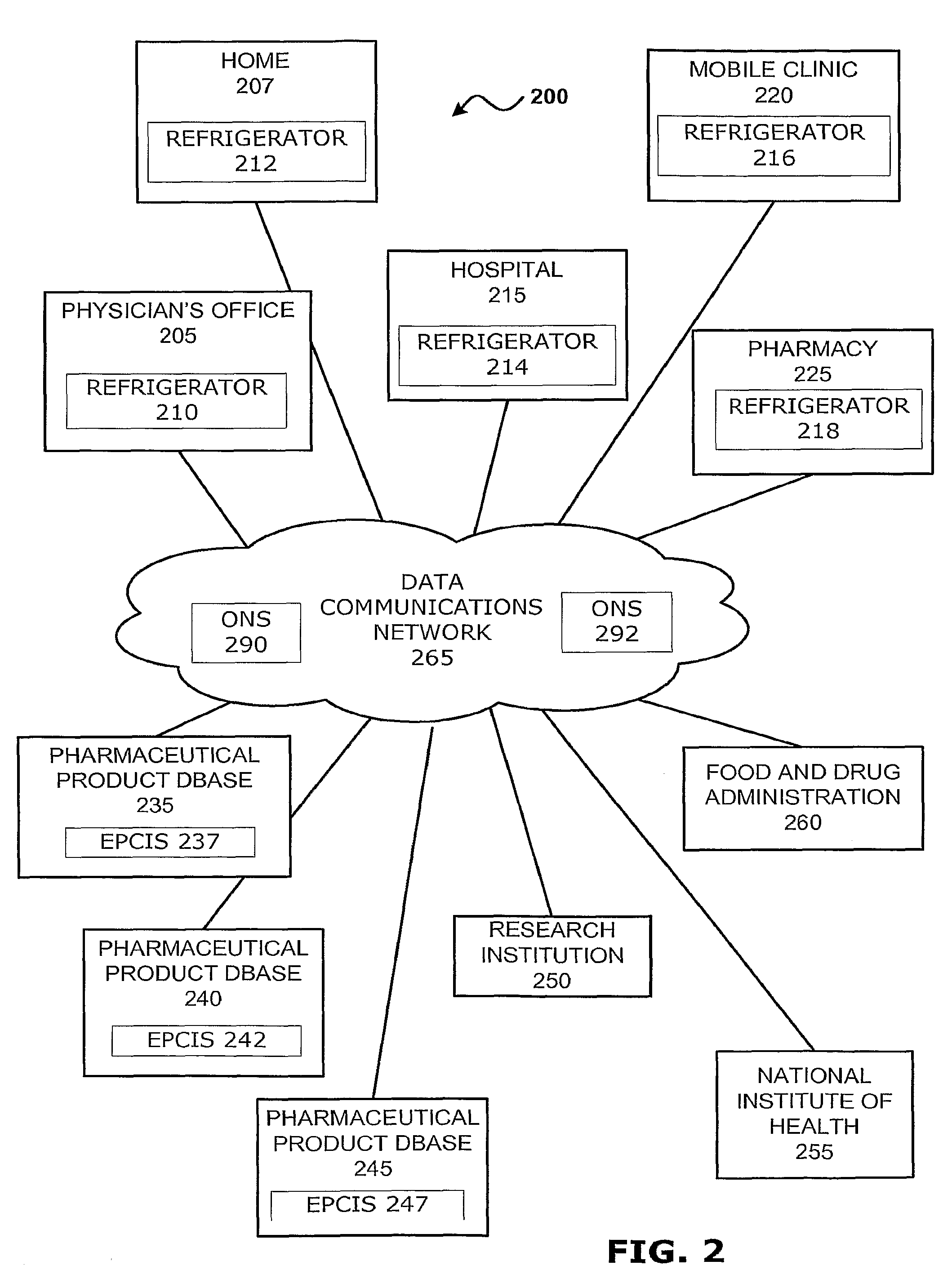

Intelligent Refrigerator for Storing Pharmaceutical Product Containers

Intelligent refrigerator system for storing pharmaceutical product containers, such as vials, ampules, syringes, bottles, medication tubes, blister packs and cartons, at the point of dispensing. Embodiments of the invention use product identification technology, such as radio-frequency identification (RFID) tags and readers, to uniquely identify containers as they are added to or removed from the cold storage compartment of the refrigerator, and automatically retrieve from a local or remote database a variety of details associated with the containers and their contents, such as manufacturing data, expiration dates, time out of refrigeration, inventory levels, safety information, usage statistics, known contraindications and warnings, etc. If the details indicate that there is a problem with a particular pharmaceutical (e.g., that it is counterfeit, expired, suspect, spoiled, recalled or almost depleted), then a message or warning is automatically delivered to a human operator via an attached output device, such as a display screen, speaker or printer. Embodiments of the invention may also be configured to monitor and report temperature faults, power failures and other anomalies associated with the refrigerator or cold storage compartment.

Owner:MERCK SHARP & DOHME LLC

Intelligent refrigerator for storing pharmaceutical product containers

Intelligent refrigerator system for storing pharmaceutical product containers, such as vials, ampules, syringes, bottles, medication tubes, blister packs and cartons, at the point of dispensing. Embodiments of the invention use product identification technology, such as radio-frequency identification (RFID) tags and readers, to uniquely identify containers as they are added to or removed from the cold storage compartment of the refrigerator, and automatically retrieve from a local or remote database a variety of details associated with the containers and their contents, such as manufacturing data, expiration dates, time out of refrigeration, inventory levels, safety information, usage statistics, known contraindications and warnings, etc. If the details indicate that there is a problem with a particular pharmaceutical (e.g., that it is counterfeit, expired, suspect, spoiled, recalled or almost depleted), then a message or warning is automatically delivered to a human operator via an attached output device, such as a display screen, speaker or printer. Embodiments of the invention may also be configured to monitor and report temperature faults, power failures and other anomalies associated with the refrigerator or cold storage compartment.

Owner:MERCK SHARP & DOHME LLC

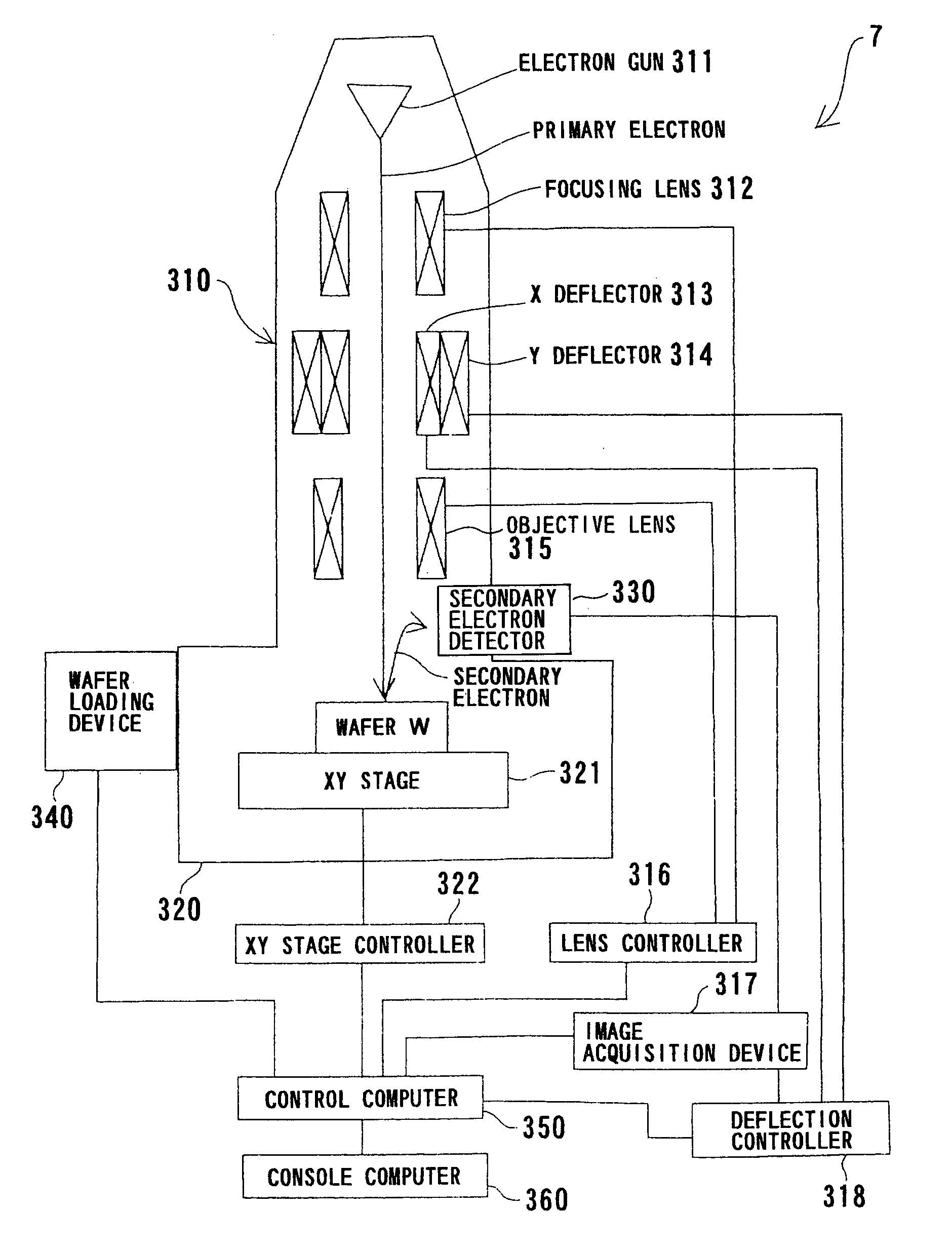

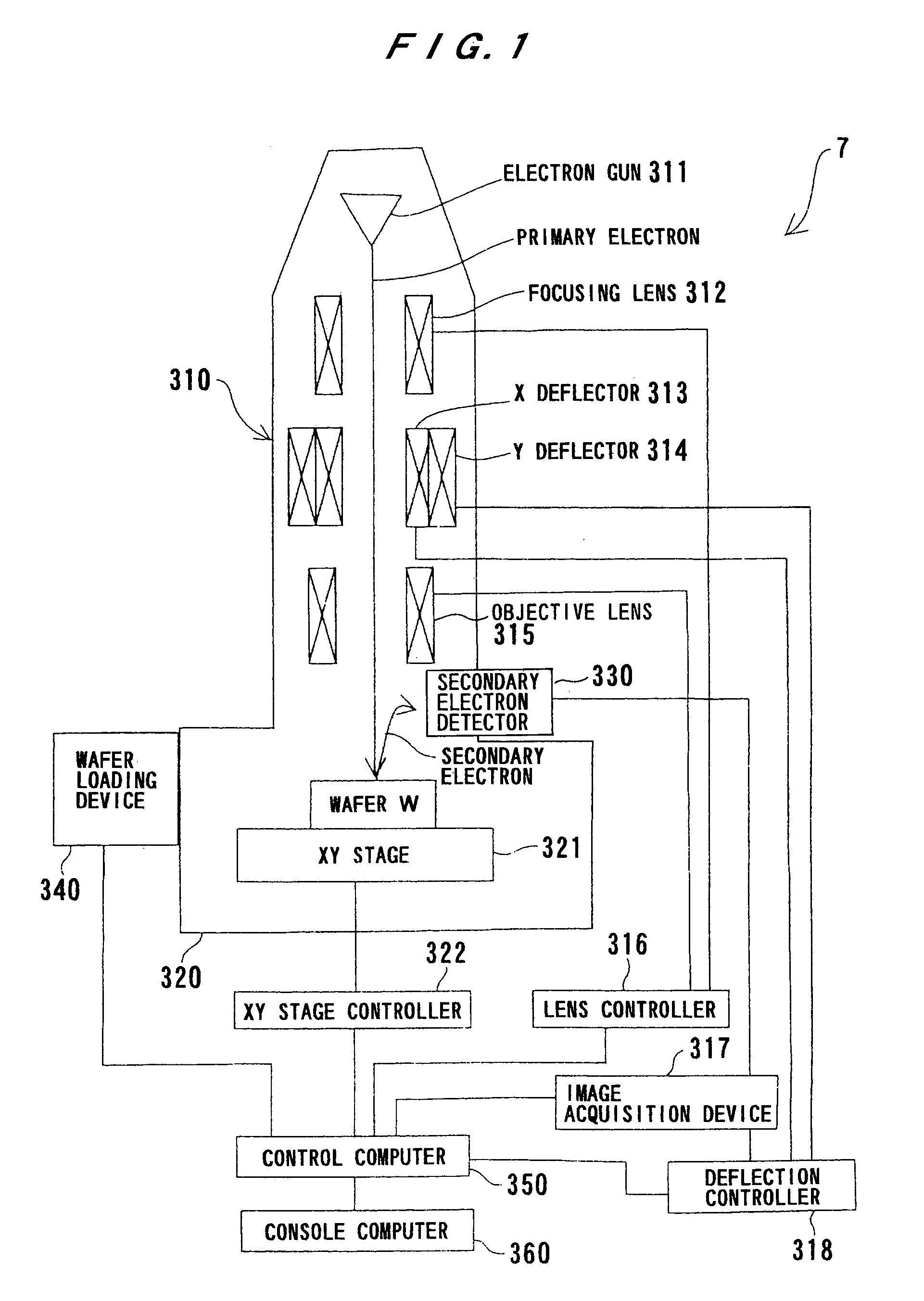

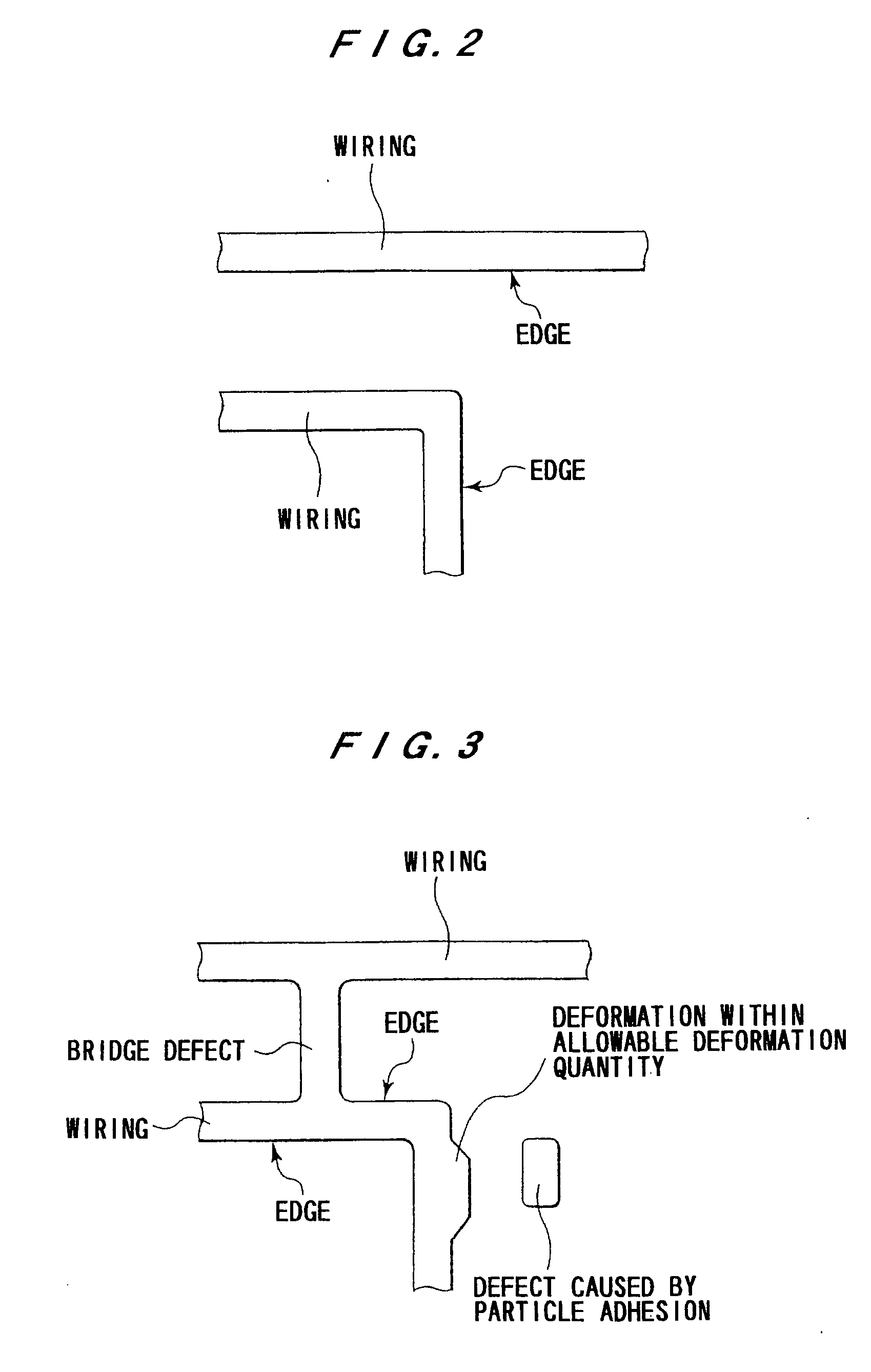

Pattern inspection apparatus and method

InactiveUS20080130982A1Obtaining repeatabilityImage enhancementImage analysisReference patternsManufacturing data

A pattern inspection apparatus is used for inspecting a fine pattern, such as a semiconductor integrated circuit (LSI), a liquid crystal panel, and a photomask (reticle) for the semiconductor or the liquid crystal panel, which are fabricated based on data for fabricating the fine pattern such as design data. The pattern inspection apparatus includes a reference pattern generation device configured to generate a reference pattern represented by one or more lines, comprising one of a line segment and a curve, from the data, an image generation device configured to generate the image of the pattern to-be-inspected, a detecting device configured to detect an edge of the image of the pattern to-be-inspected, and an inspection device configured to inspect the pattern to-be-inspected by comparing the edge of the image of the pattern to-be-inspected with the one or more lines of the reference pattern.

Owner:TASMIT INC

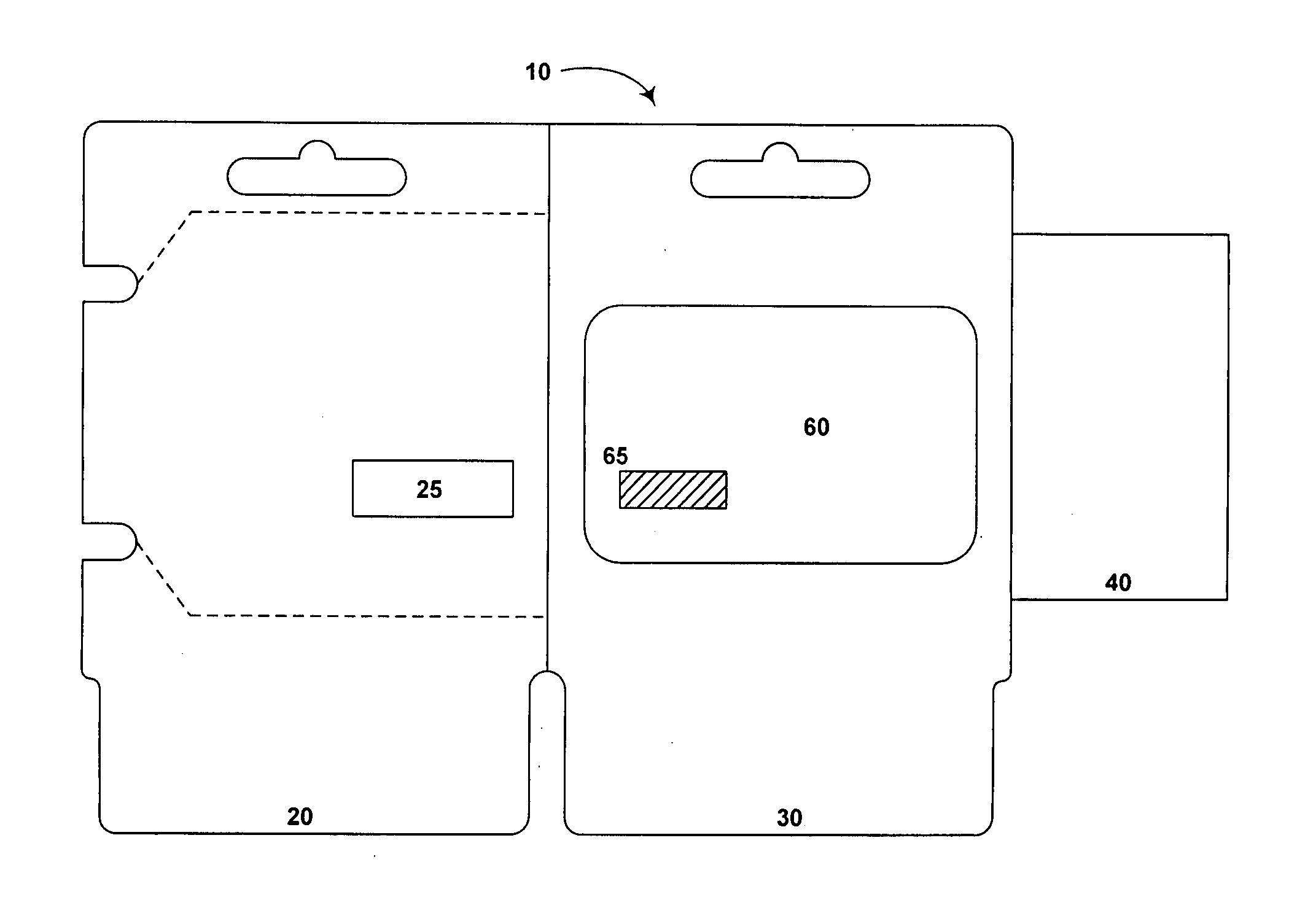

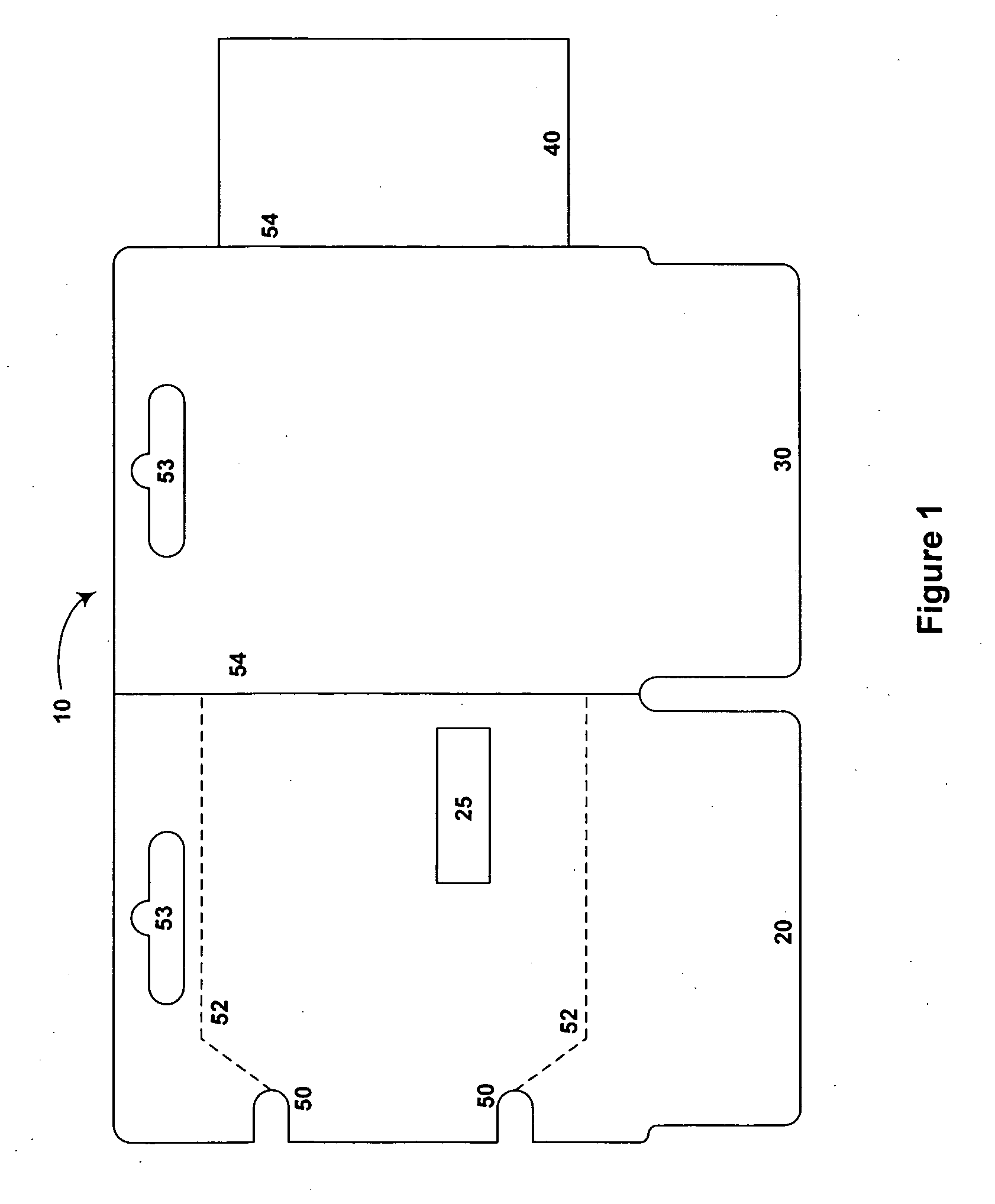

Activation number generation and association

ActiveUS20070063021A1Credit registering devices actuationCard-filingComputer hardwareManufacturing data

The present invention is generally directed to methods of manufacturing data card assemblies. These methods generally comprise manufacturing or purchasing a data card comprising a special number, wherein the special number is associated with a particular data card account; packaging the data cards in a package such that the special number is visible; generating activation information; reading the special number on the data card; recording the activation information on the package; and associating the special number with the particular activation information recorded on the package. Some embodiments of the present invention may further comprise conveying the association between the activation information and the special number to an intermediary managing the data card accounts. Some embodiments of the present invention may further comprise generating a special number associated with a particular data card account; and generating activation information associated with a particular special number.

Owner:E2INTERACTIVE INC D B A E2INTERACTIVE

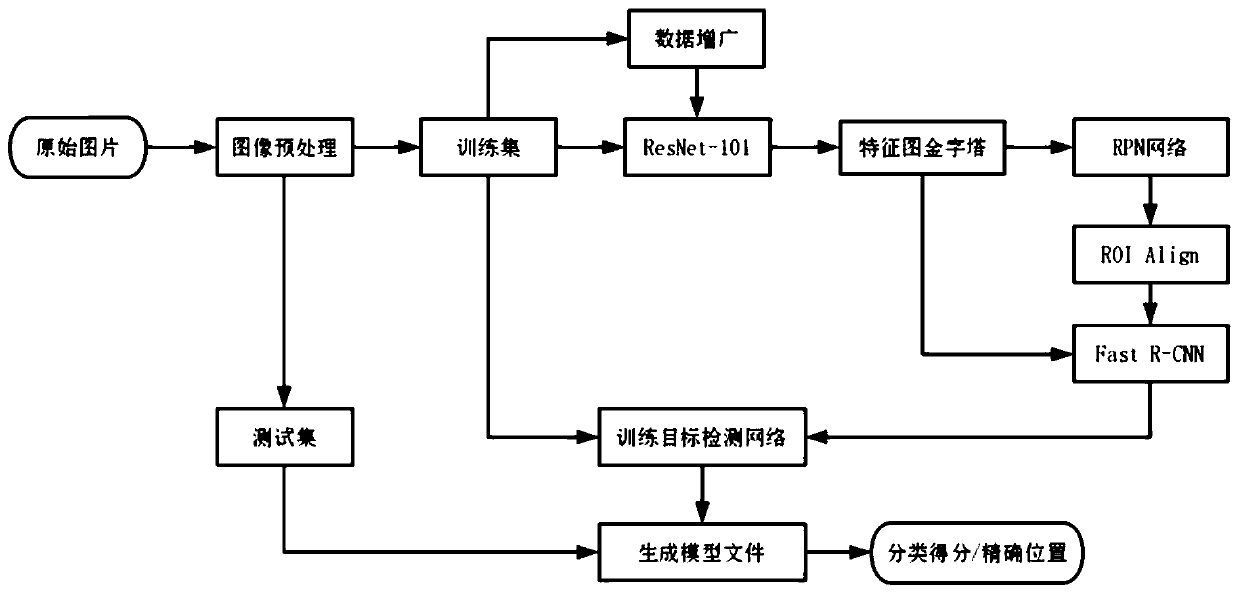

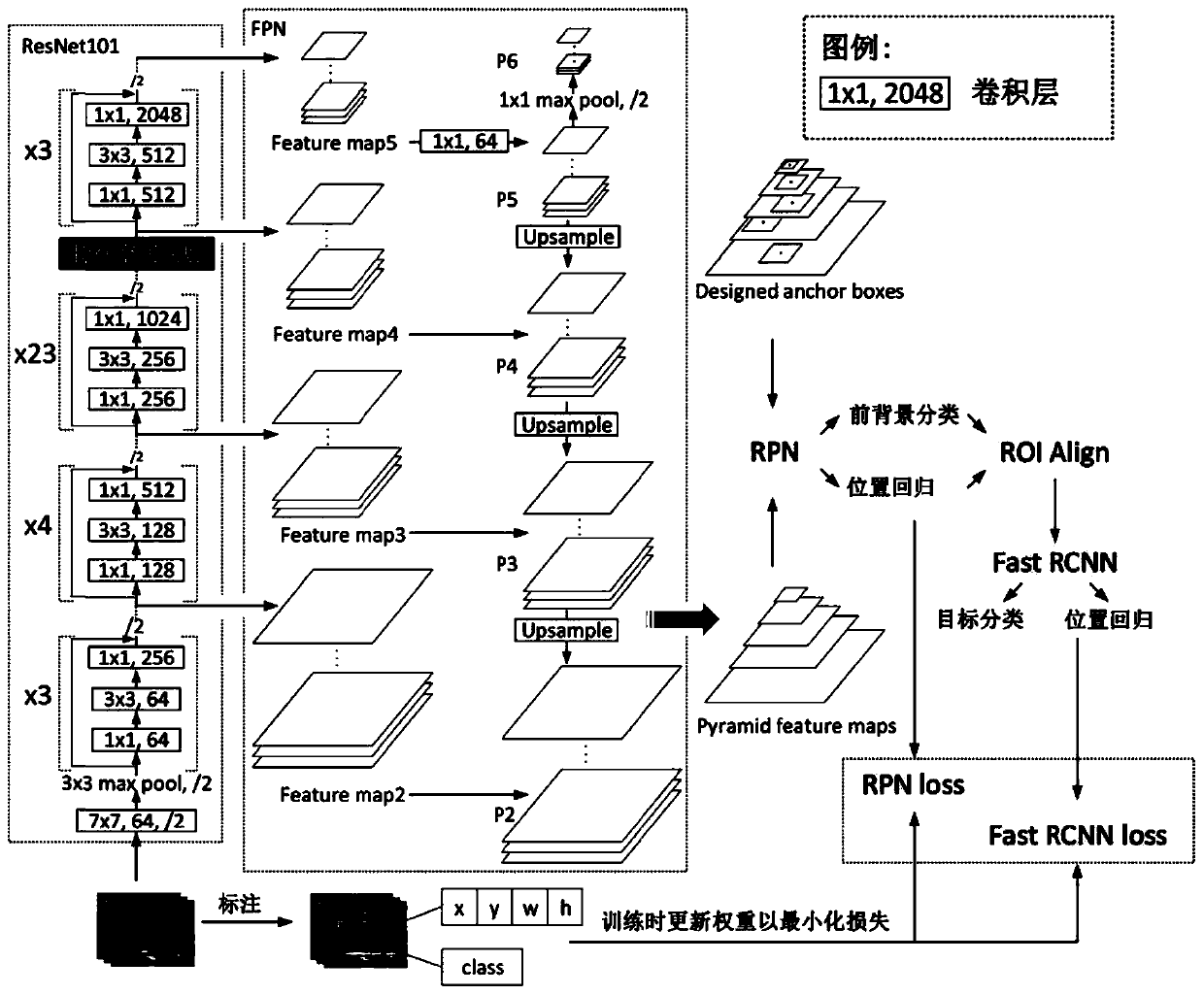

Automatic detection method for multi-scale polymorphic target in two-dimensional image

ActiveCN111027547AImprove robustnessCharacter and pattern recognitionNeural architecturesFeature extractionData set

The invention provides an automatic detection method for a multi-scale polymorphic target in a two-dimensional image. The automatic detection method comprises the following steps: preprocessing the two-dimensional image; performing target labeling on the preprocessed image to complete the production of a data set; adding a spatial mapping layer into a basic feature extraction network of the targetdetection network, and fusing the feature map after spatial mapping and other feature maps together to form a feature pyramid to adapt to the change of a target in the two-dimensional image; completing region recommendation on a feature pyramid formed by the plurality of fused feature maps by using an anchor box with good prior; training the improved target detection network by using the manufactured data set, and carrying out cross validation for multiple times; and using the trained target detection model to detect the picture possibly containing the target, selecting a threshold to screenout a detection box with relatively high possibility of containing the target, carrying out non-maximum suppression on the screened detection box, and removing an overlapping box to obtain a final target detection result with relatively high accuracy.

Owner:NANJING UNIV +1

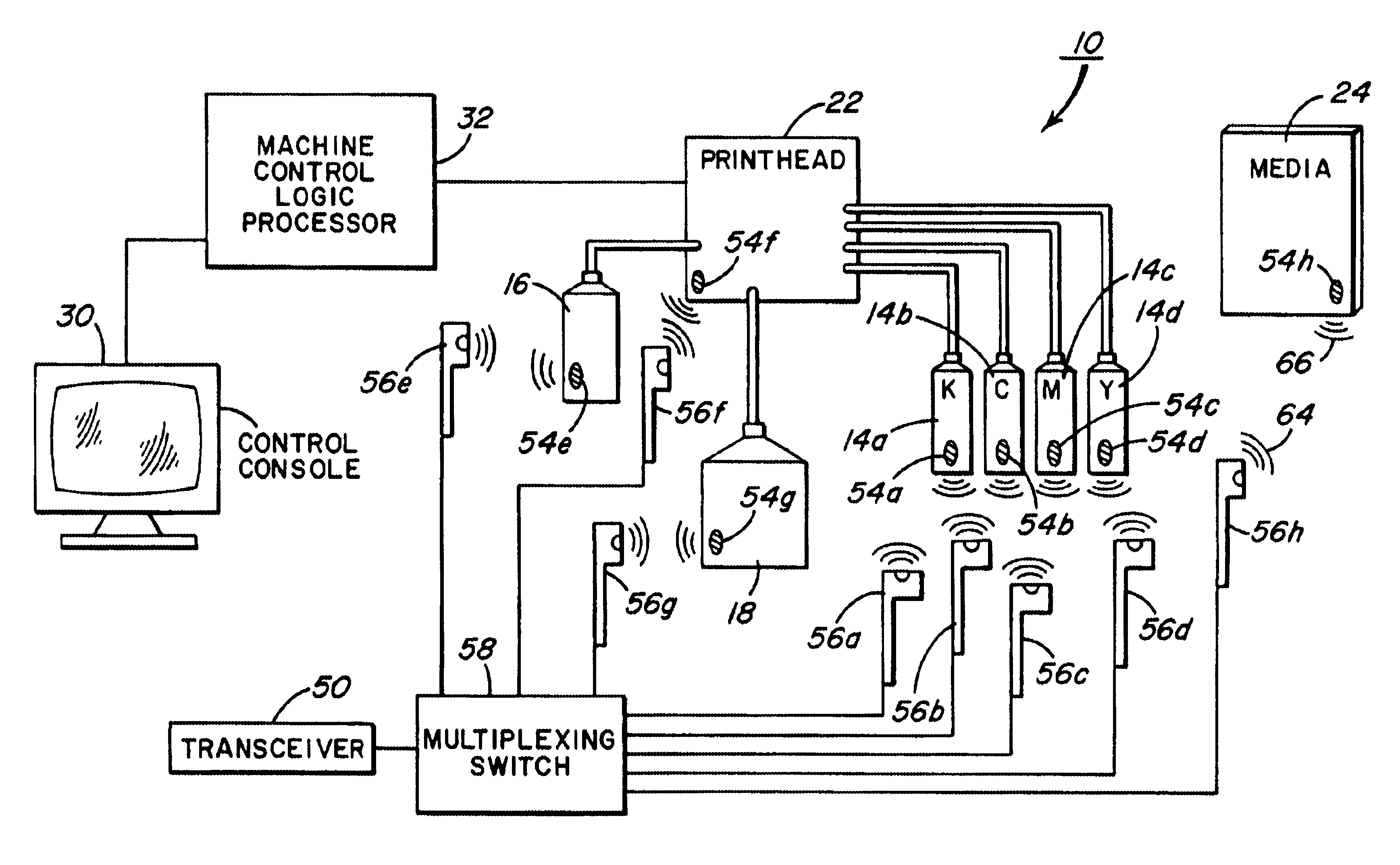

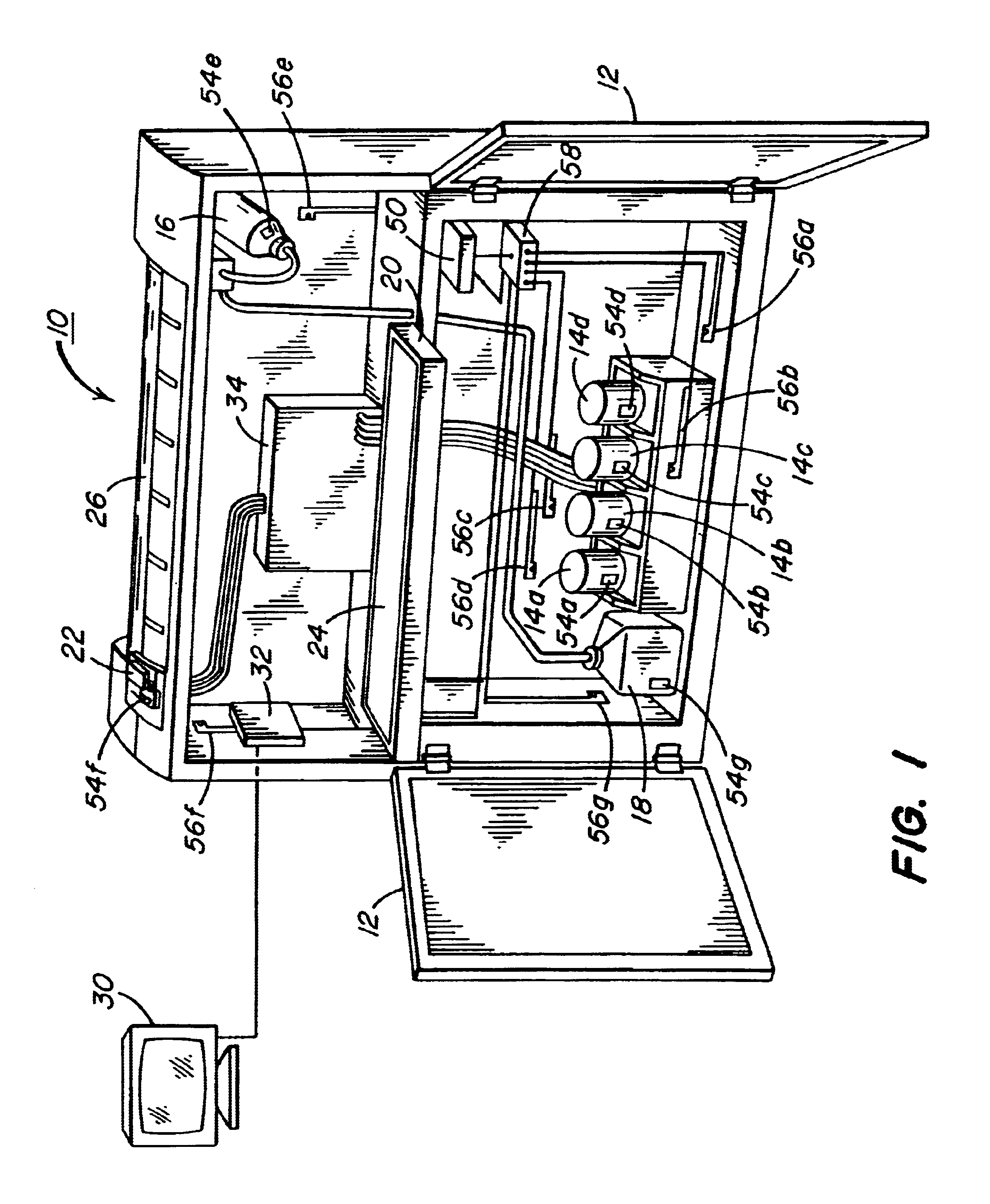

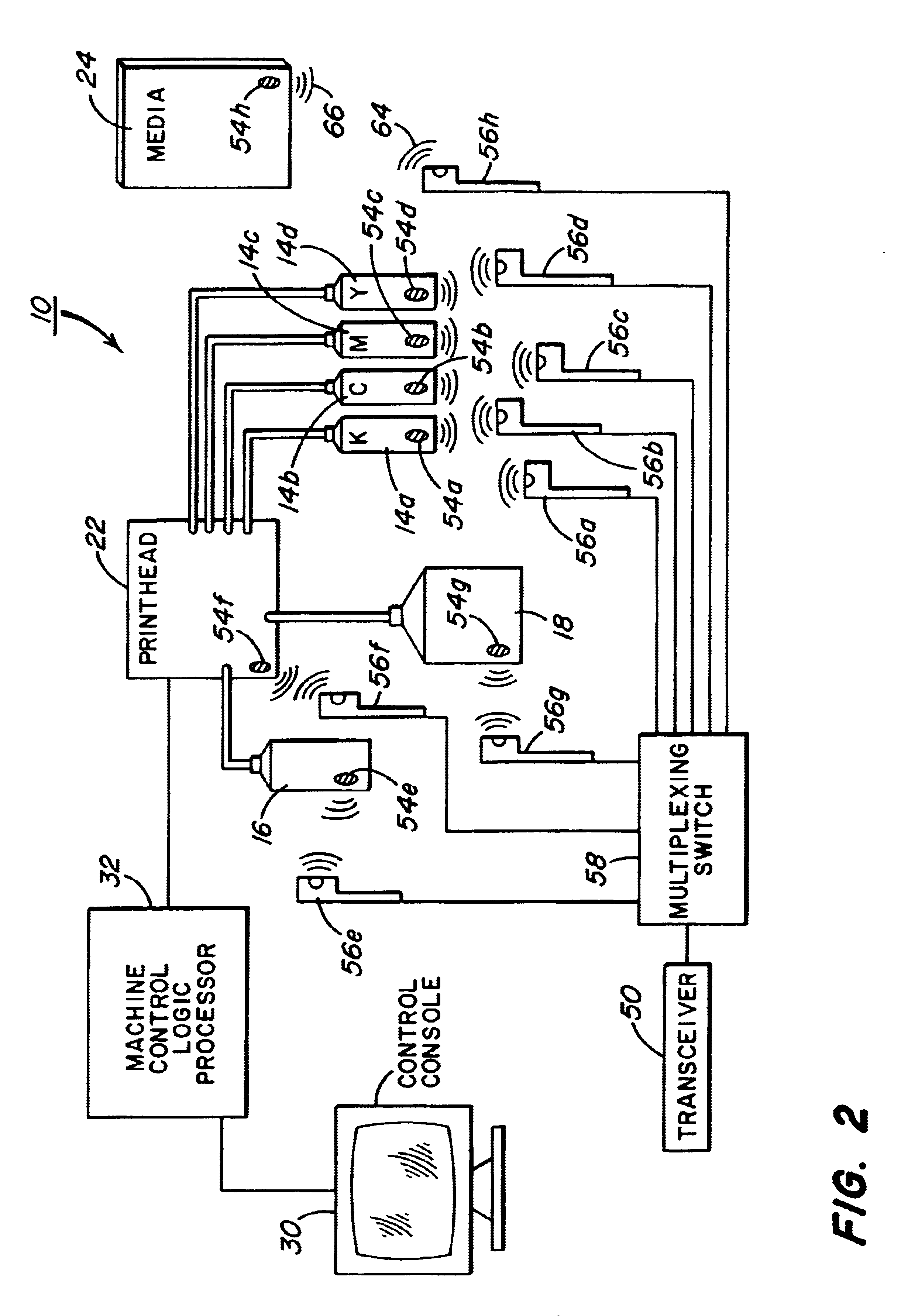

Printer and method therefor adapted to sense data uniquely associated with a consumable loaded into the printer

An inkjet printer adapted to sense type of supplied consumable receiver media, inks, printhead, and cleaning fluid. A transponder attached to a consumable is coupled to a memory device capable of storing information characteristic of the consumable. A transceiver is disposed within the inkjet printer, with antennae disposed for polling an individual transponder attached to each consumable. The transponder is capable of receiving a first RF frequency electromagnetic field from the transceiver and deriving power and address information from the first frequency, then generating a second RF frequency electromagnetic field in response, where the second electromagnetic field is characteristic of the data stored in memory. As instructed by a machine control logic processor, the transceiver can both read manufacturing data from the transponder about the consumable and write usage and processing data to the transponder for storage in memory. The transponder can also be coupled with a transducer for taking measurements from the consumable.

Owner:EASTMAN KODAK CO

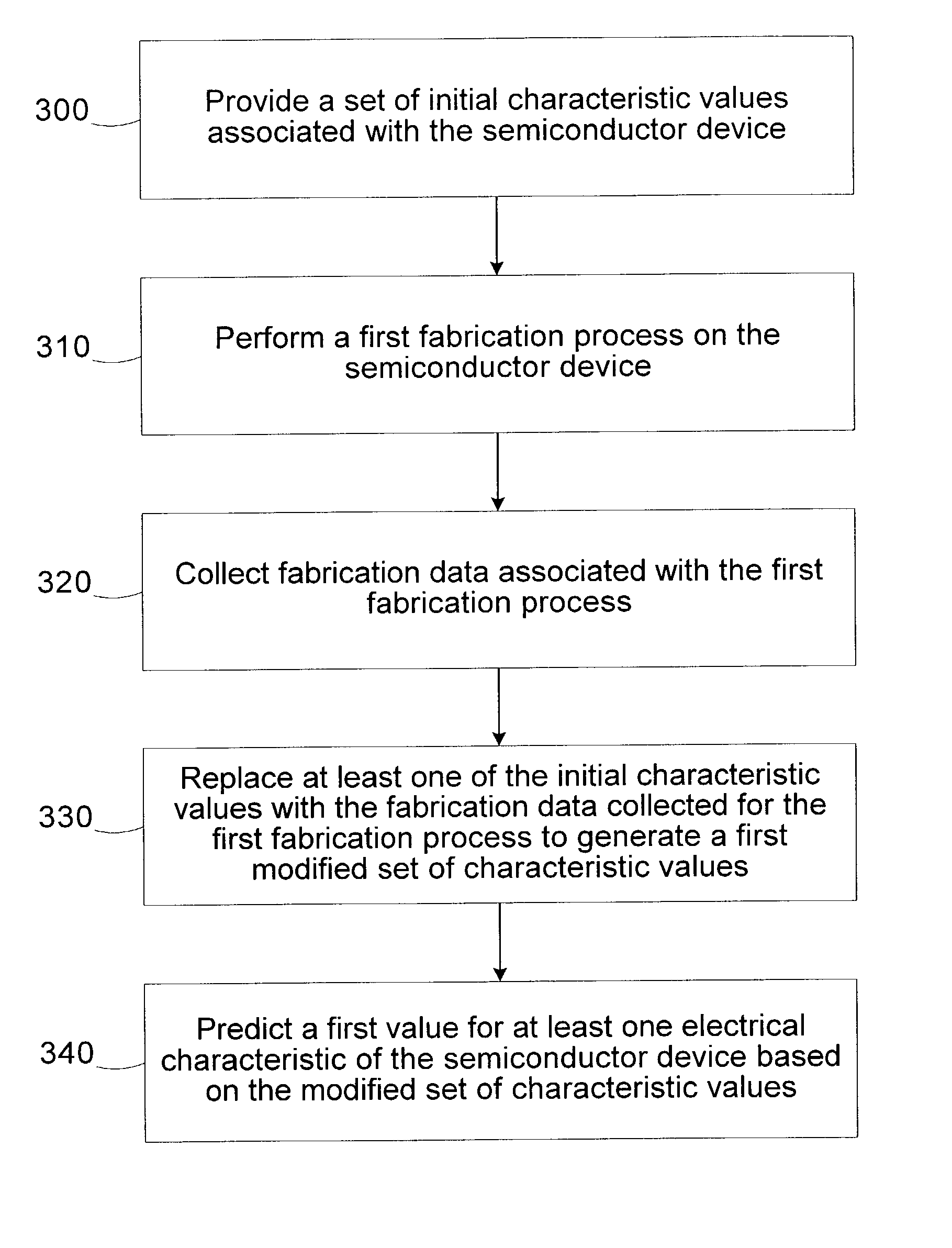

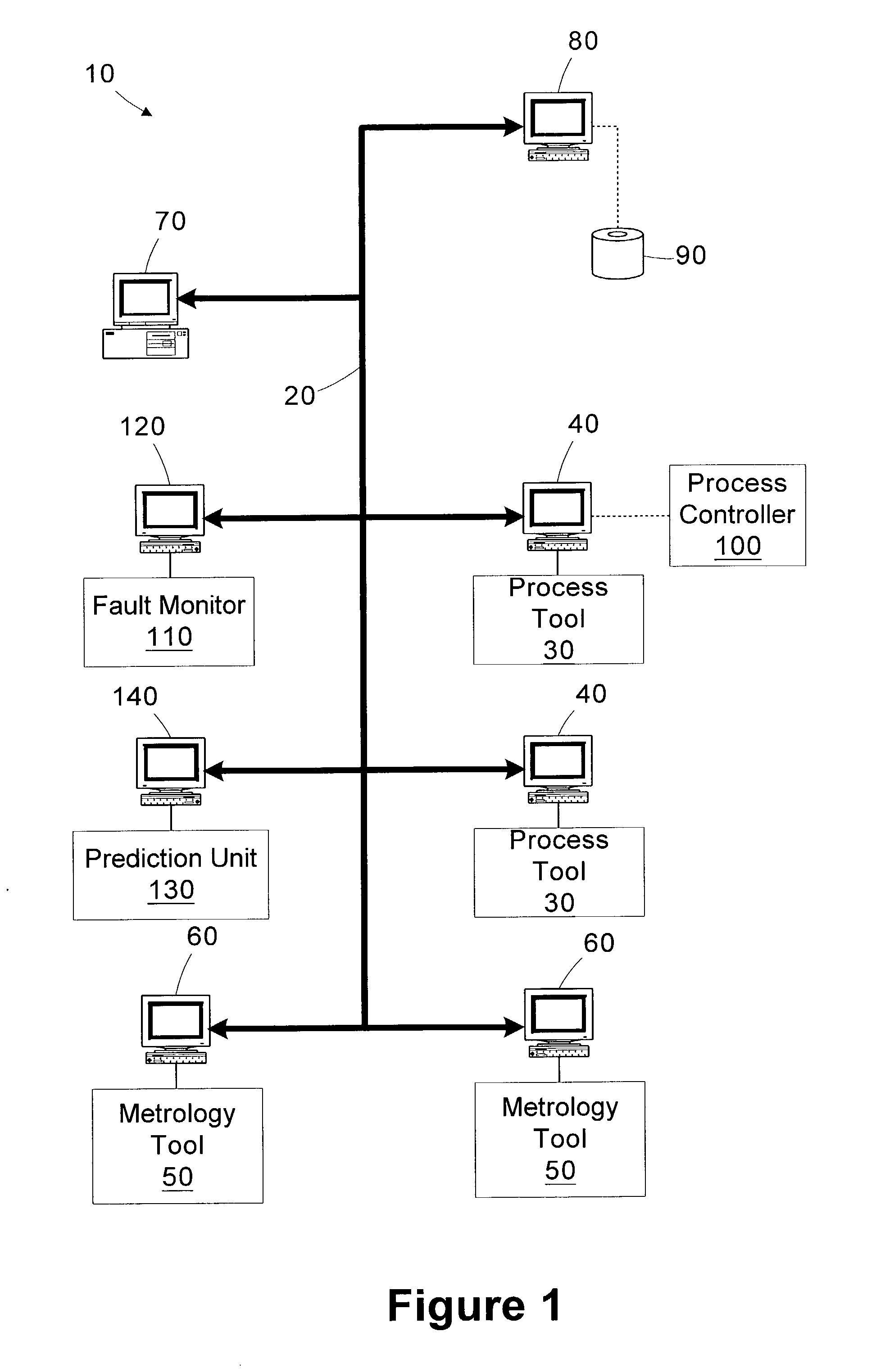

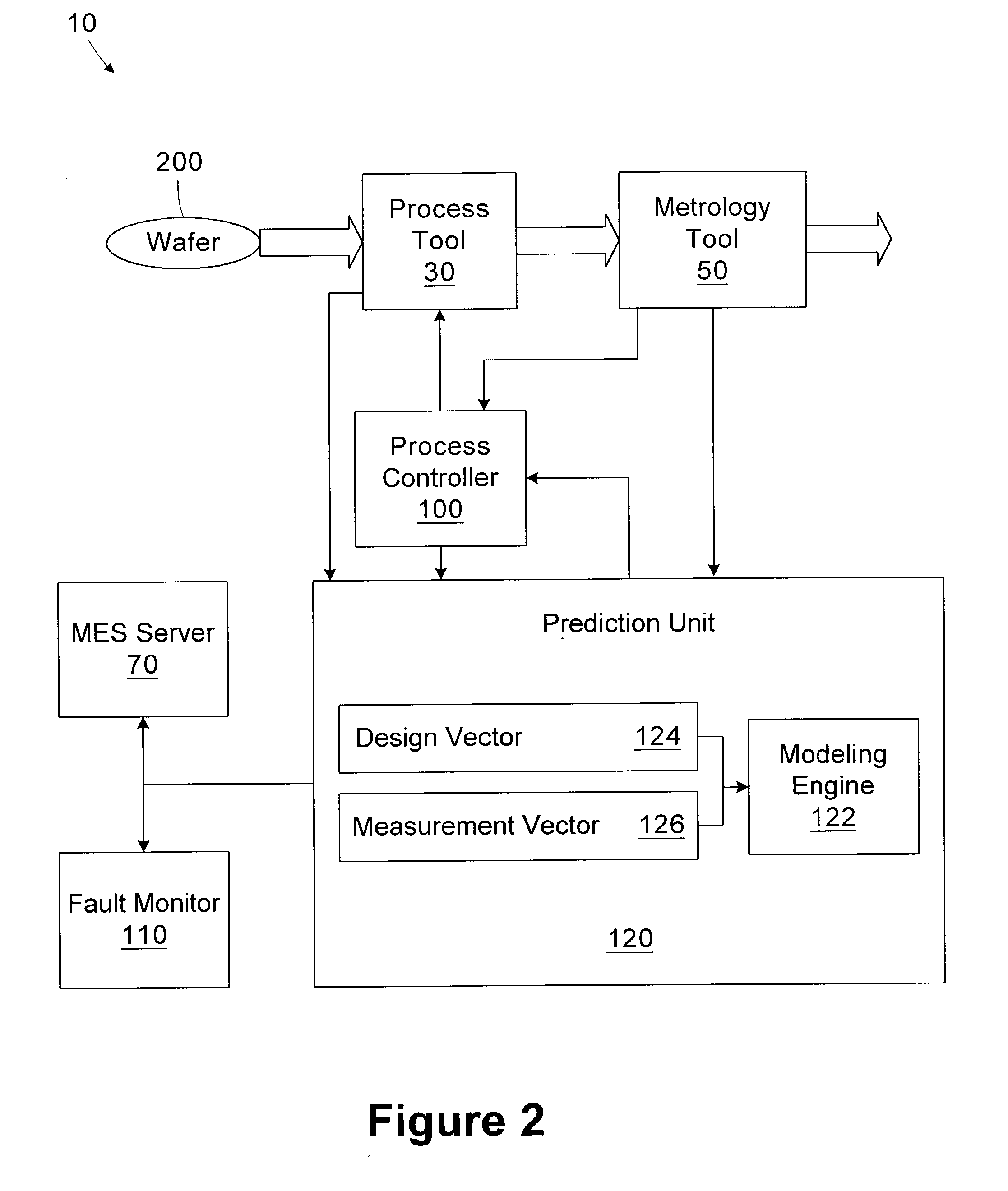

Method and apparatus for predicting device electrical parameters during fabrication

ActiveUS20040040001A1Semiconductor/solid-state device testing/measurementDetecting faulty computer hardwareManufacturing dataEngineering

A method includes providing a set of initial characteristic values associated with the semiconductor device. A first fabrication process is performed on the semiconductor device. Fabrication data associated with the first fabrication process is collected. At least one of the initial characteristic values is replaced with the fabrication data collected for the first fabrication process to generate a first modified set of characteristic values. A first value for at least one electrical characteristic of the semiconductor device is predicted based on the modified set of characteristic values. A system includes a first process tool, a first data collection unit, and a prediction unit. The first process tool is configured to perform a first fabrication process on the semiconductor device. The first data collection unit is configured to collect fabrication data associated with the first fabrication process. The prediction unit is configured to provide a set of initial characteristic values associated with the semiconductor device, replace at least one of the initial characteristic values with the fabrication data collected for the first fabrication process to generate a first modified set of characteristic values, and predict a first value for at least one electrical characteristic of the semiconductor device based on the modified set of characteristic values.

Owner:ADVANCED MICRO DEVICES INC

Intelligent refrigerator for storing pharmaceutical product containers

Intelligent refrigerator system for storing pharmaceutical product containers, such as vials, ampules, syringes, bottles, medication tubes, blister packs and cartons, at the point of dispensing. Embodiments of the invention use product identification technology, such as radio-frequency identification (RFID) tags and readers, to uniquely identify containers as they are added to or removed from the cold storage compartment of the refrigerator, and automatically retrieve from a local or remote database a variety of details associated with the containers and their contents, such as manufacturing data, expiration dates, time out of refrigeration, inventory levels, safety information, usage statistics, known contraindications and warnings, etc. If the details indicate that there is a problem with a particular pharmaceutical (e.g., that it is counterfeit, expired, suspect, spoiled, recalled or almost depleted), then a message or warning is automatically delivered to a human operator via an attached output device, such as a display screen, speaker or printer. Embodiments of the invention may also be configured to monitor and report temperature faults, power failures and other anomalies associated with the refrigerator or cold storage compartment.

Owner:MERCK SHARP & DOHME LLC

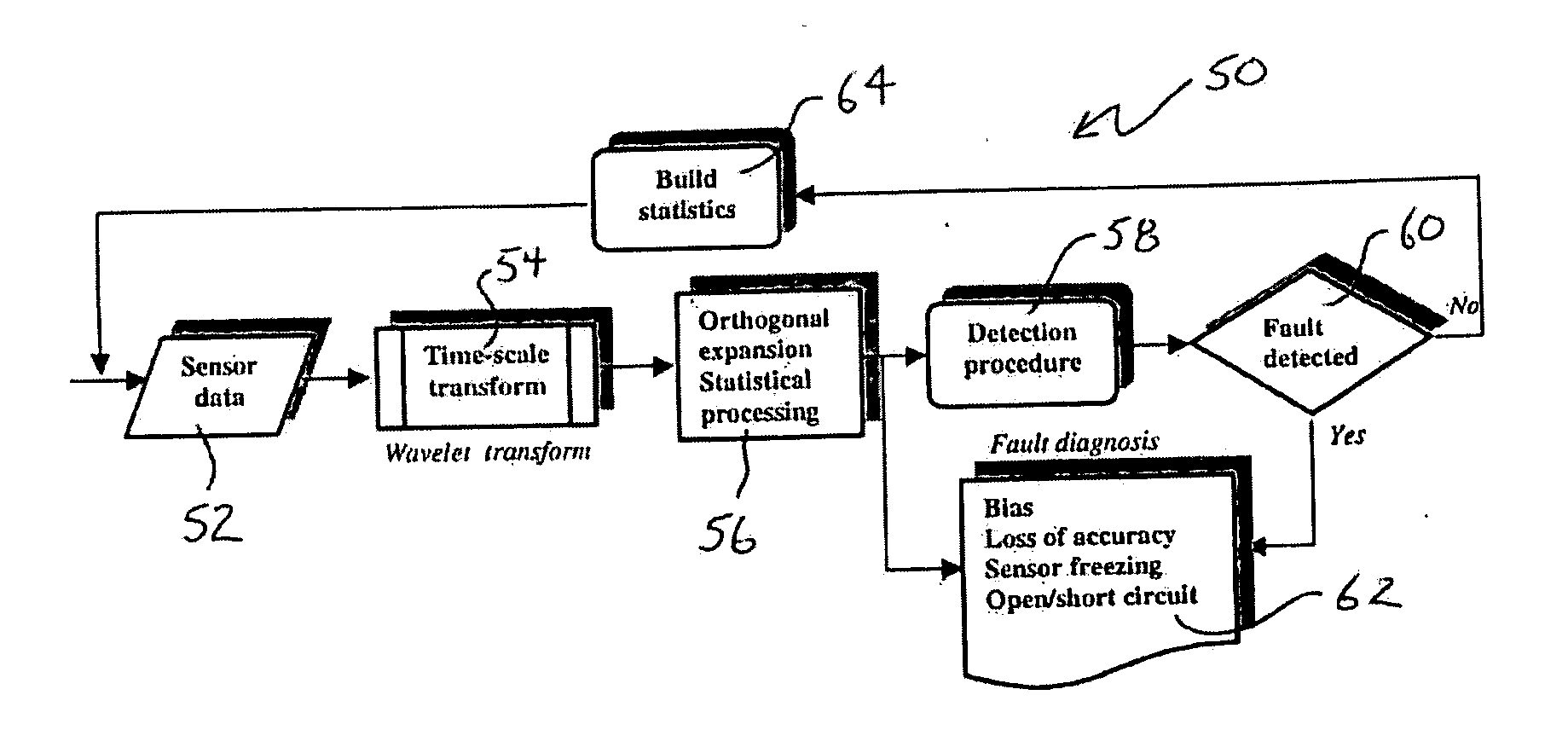

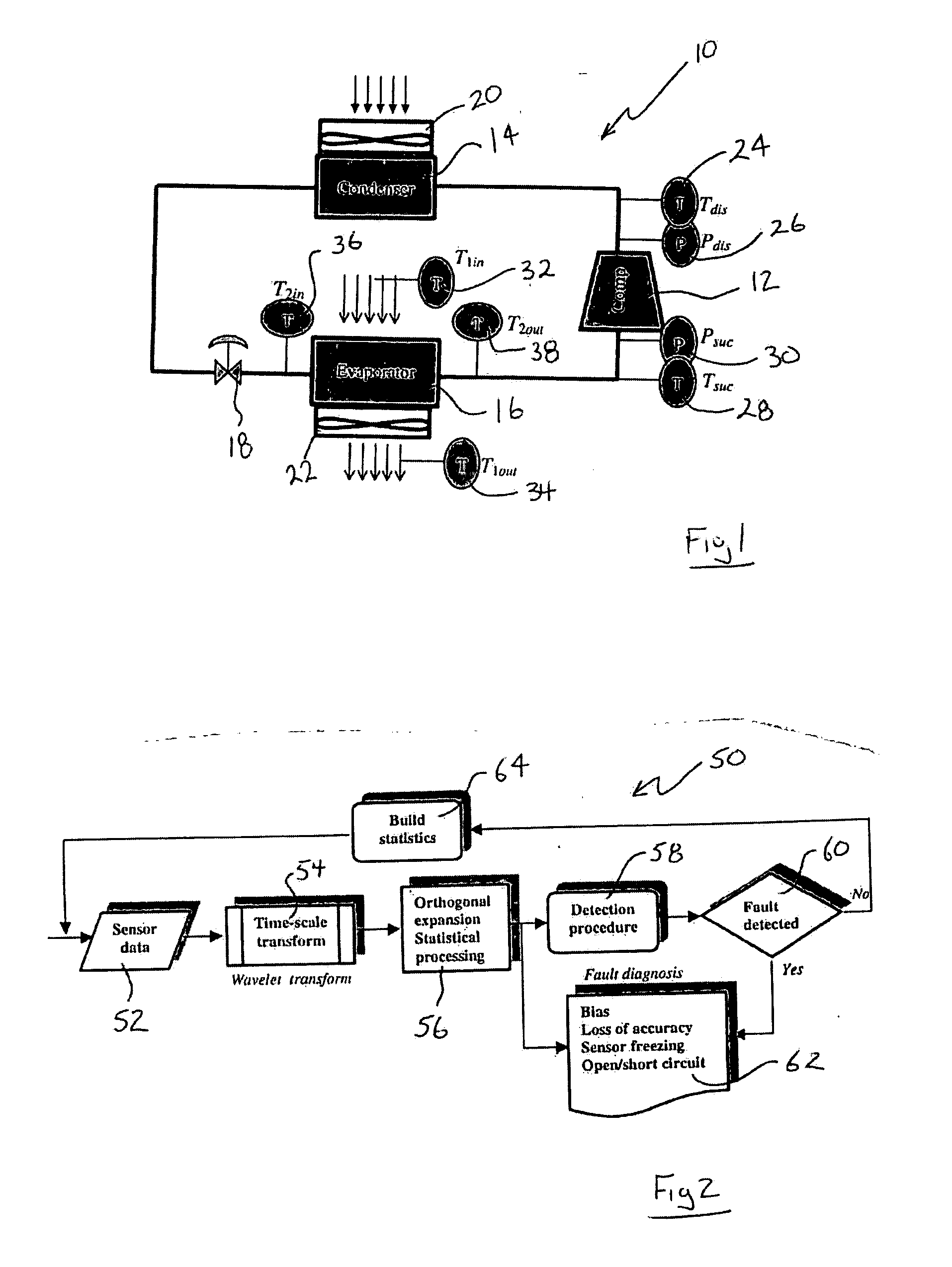

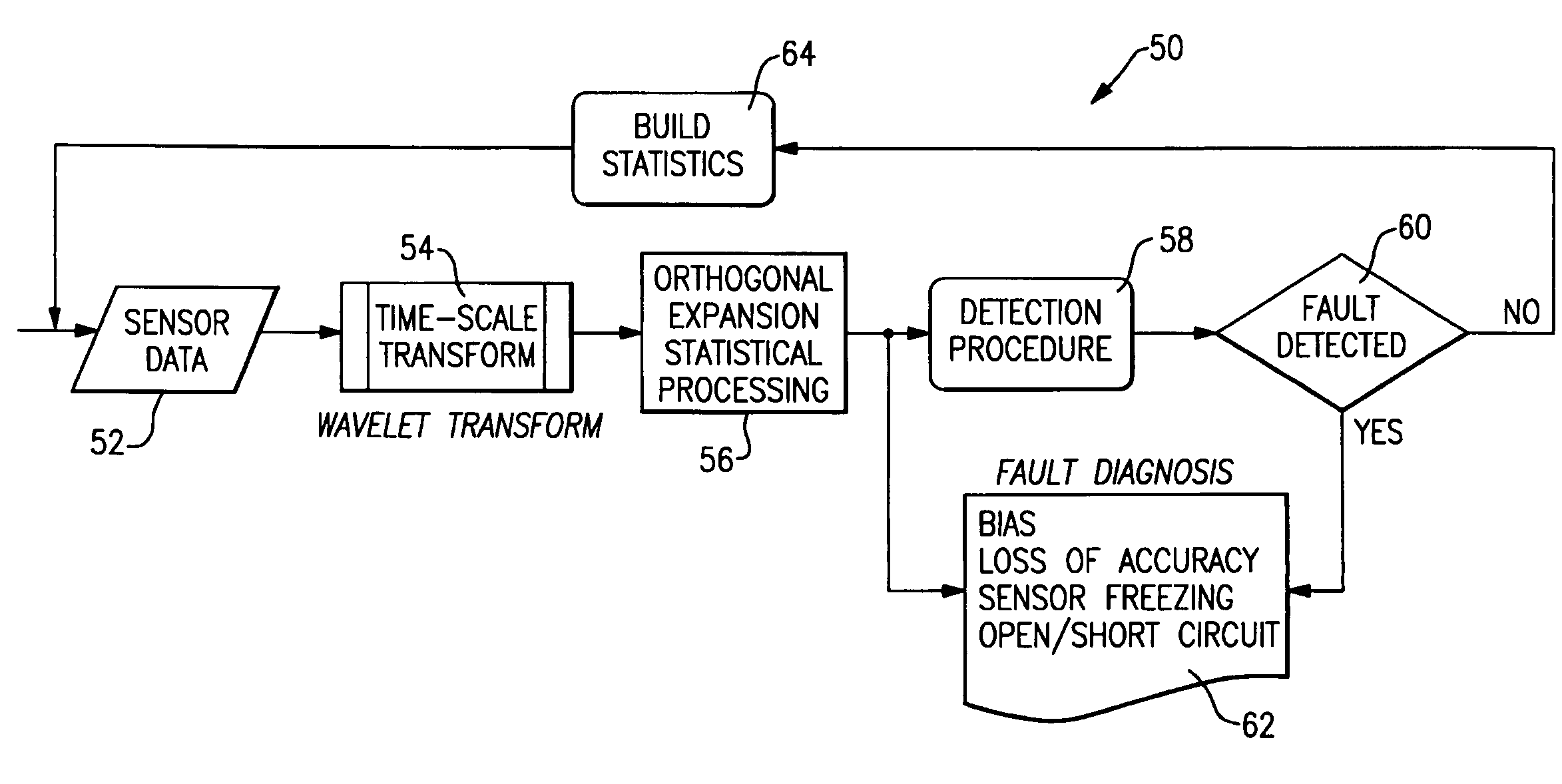

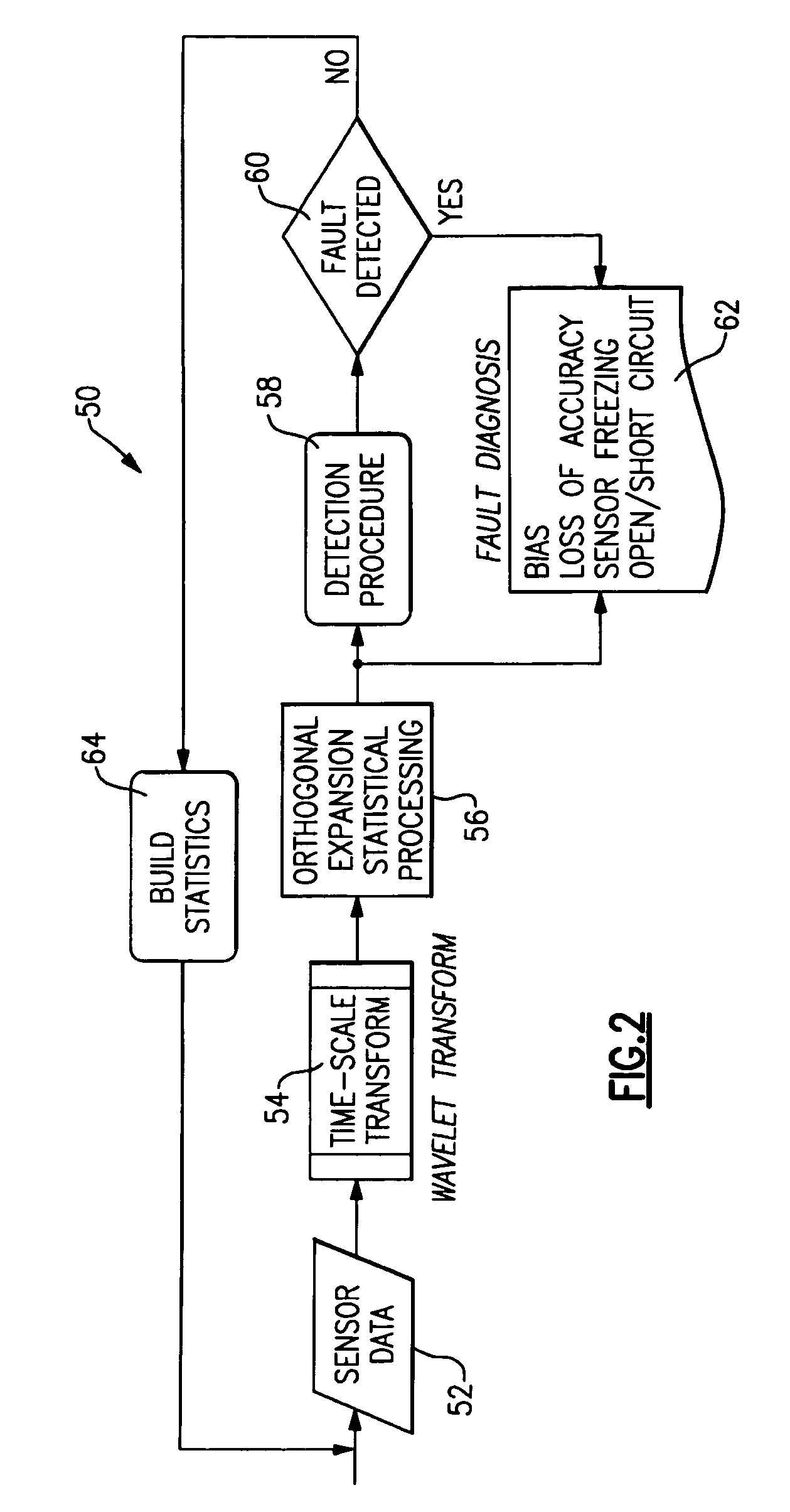

Sensor fault diagnostics and prognostics using component model and time scale orthogonal expansions

InactiveUS20050251364A1Effective economicalReliable methodProgramme controlSafety arrangmentsElectrical FailureRemedial action

A method of diagnosing sensor faults for a heating, ventilation and air conditioning system includes the steps of creating a component model for a specific component within the system. The component model is created through the use of commonly available manufacturing data. Data within the system is input into the component model and compared to calculated and predicted values that are also calculated using the identical component models. Differences between the calculated and actual values is determined and compared to a threshold difference value. If the difference exceeds the threshold value, then a fault is detected. The specific type of sensor fault is determined using probability distribution analysis. Each type of sensor fault produces a different type of statistical deviation from normal distribution. By recognizing these patterns of deviations from the normal distribution, the specific type of fault such as electrical, intermittent or freezing of the sensor can be determined to provide initial information as to the severity and type of remedial action required.

Owner:CARRIER CORP

Optical markings

InactiveUS20080217391A1Input/output to record carriersComputer-assisted medical data acquisitionPatient dataManufacturing data

A method and system for cumulatively associating manufacture data and patient data with disposable equipment, particularly sample collection containers, in a medical or laboratory environment by permanently affixing unique code labels to the disposable equipment.

Owner:PATIENTSAFE SOLUTIONS

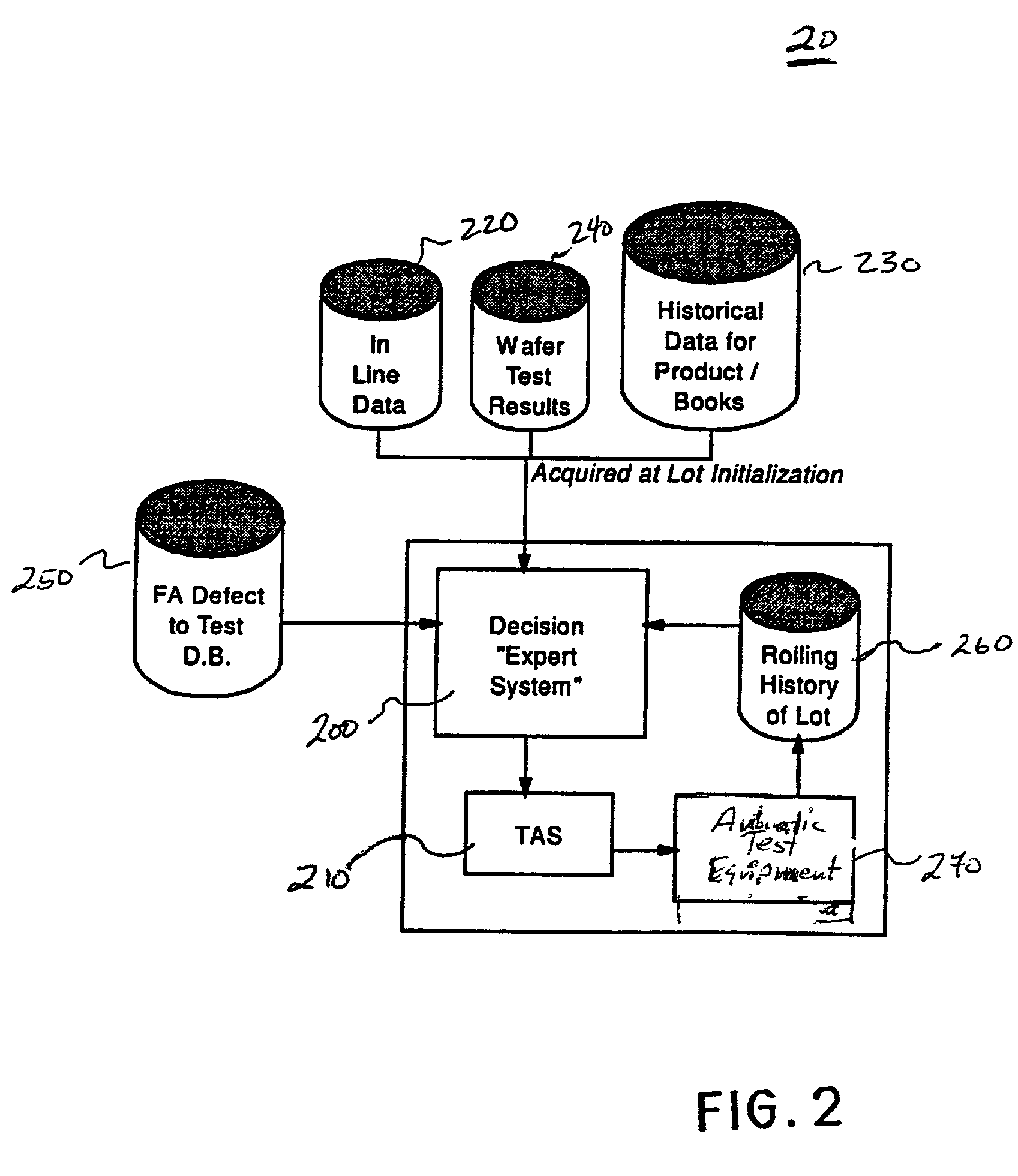

Method for test optimization using historical and actual fabrication test data

InactiveUS20020155628A1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingQuality levelWafer fabrication

A method and system are provided that minimize wafer or package level test time without adversely impacting yields in downstream manufacturing processes or degrading outgoing quality levels. The method provides optimization by determining, a priority, the most effective set of tests for a given lot or wafer. The invention implements a method using a processor-based system involving the integration of multiple sources of data that include: historical and realtime, product specific and lot specific, from wafer fabrication data (i.e., process measurements, defect inspections, and parametric testing), product qualification test results, physical failure analysis results and manufacturing functional test results. These various forms of data are used to determine an optimal set of tests to run using a test application sequence, on a given product to optimize test time with minimum risk to yield or product quality.

Owner:CADENCE DESIGN SYST INC

Dynamic targeting for a process control system

InactiveUS20040029299A1Semiconductor/solid-state device testing/measurementSolid-state devicesMetrologyControl system

A method and an apparatus for dynamic targeting for a process control system. A process step is performed upon a first workpiece in a batch based upon a process target setting. The process target setting comprises at least one parameter relating to a target characteristic of the first workpiece. Manufacturing data relating to processing of the first workpiece is acquired. The manufacturing data comprises at least one of a metrology data relating to the processed first workpiece and a tool state data relating to the tool state of a processing tool. Electrical data relating to the processed first workpiece is acquired at least partially during processing of a second workpiece in the batch. The process target setting is adjusted dynamically based upon a correlation of the electrical data with the manufacturing data.

Owner:GLOBALFOUNDRIES INC

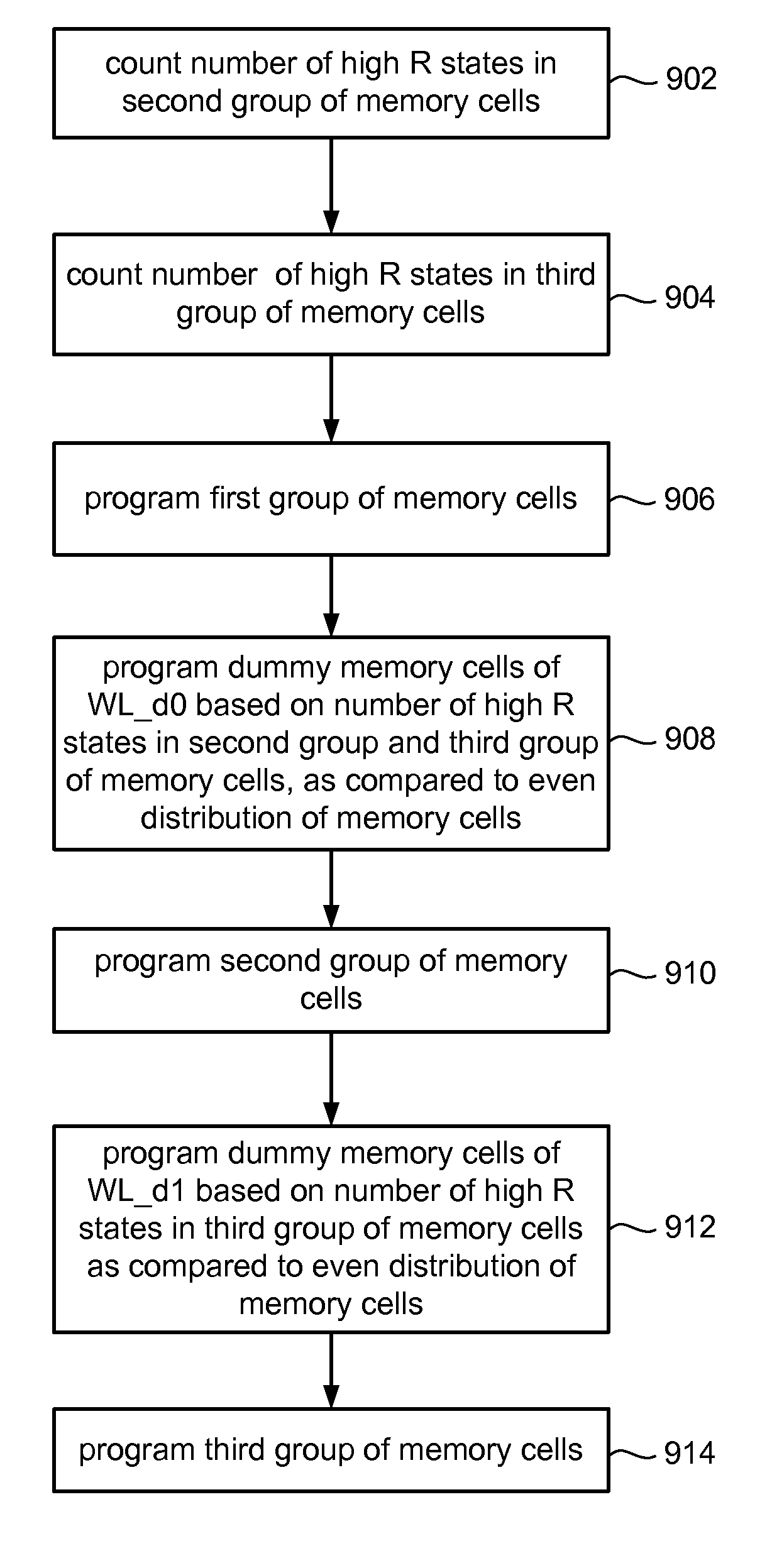

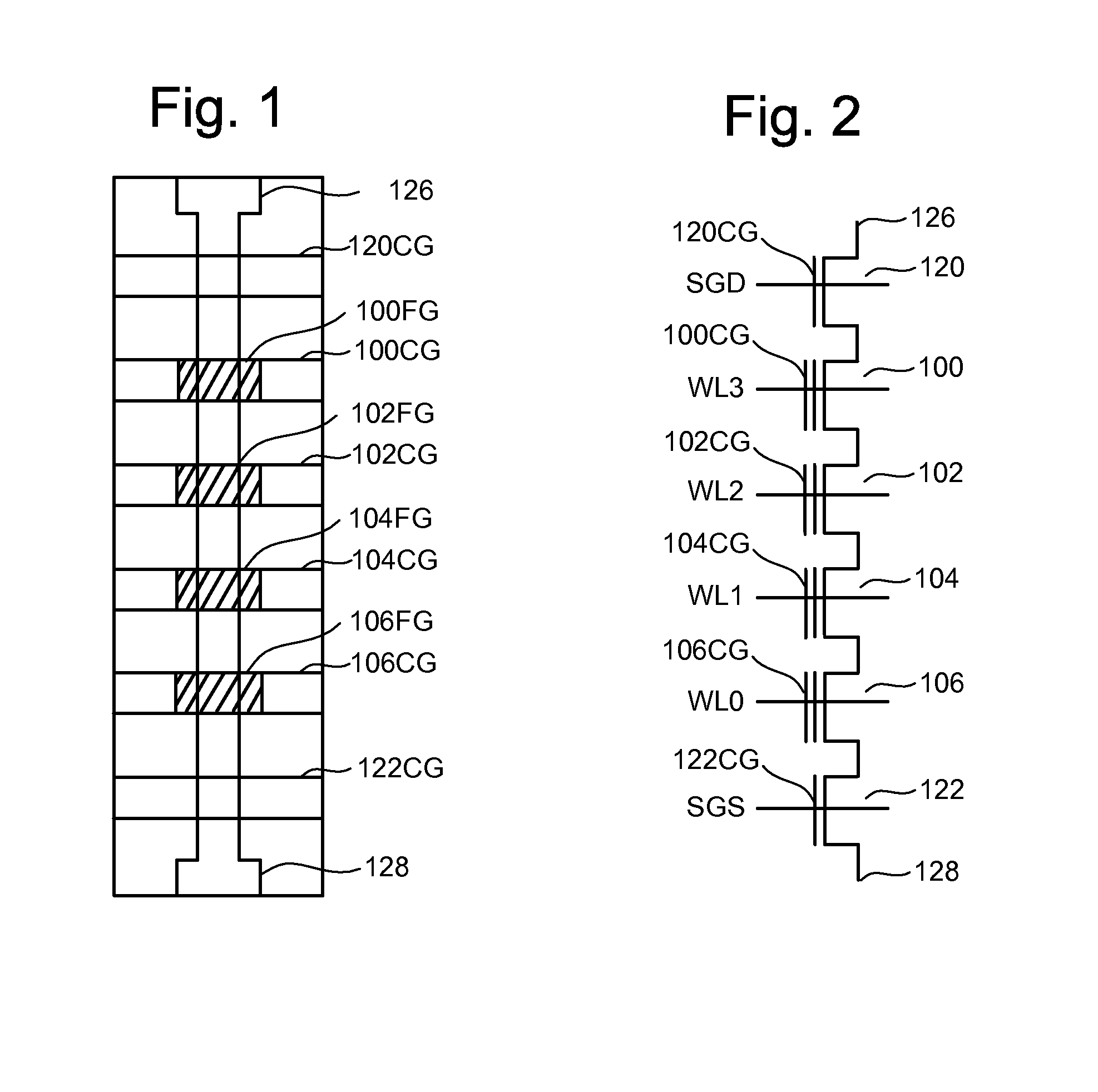

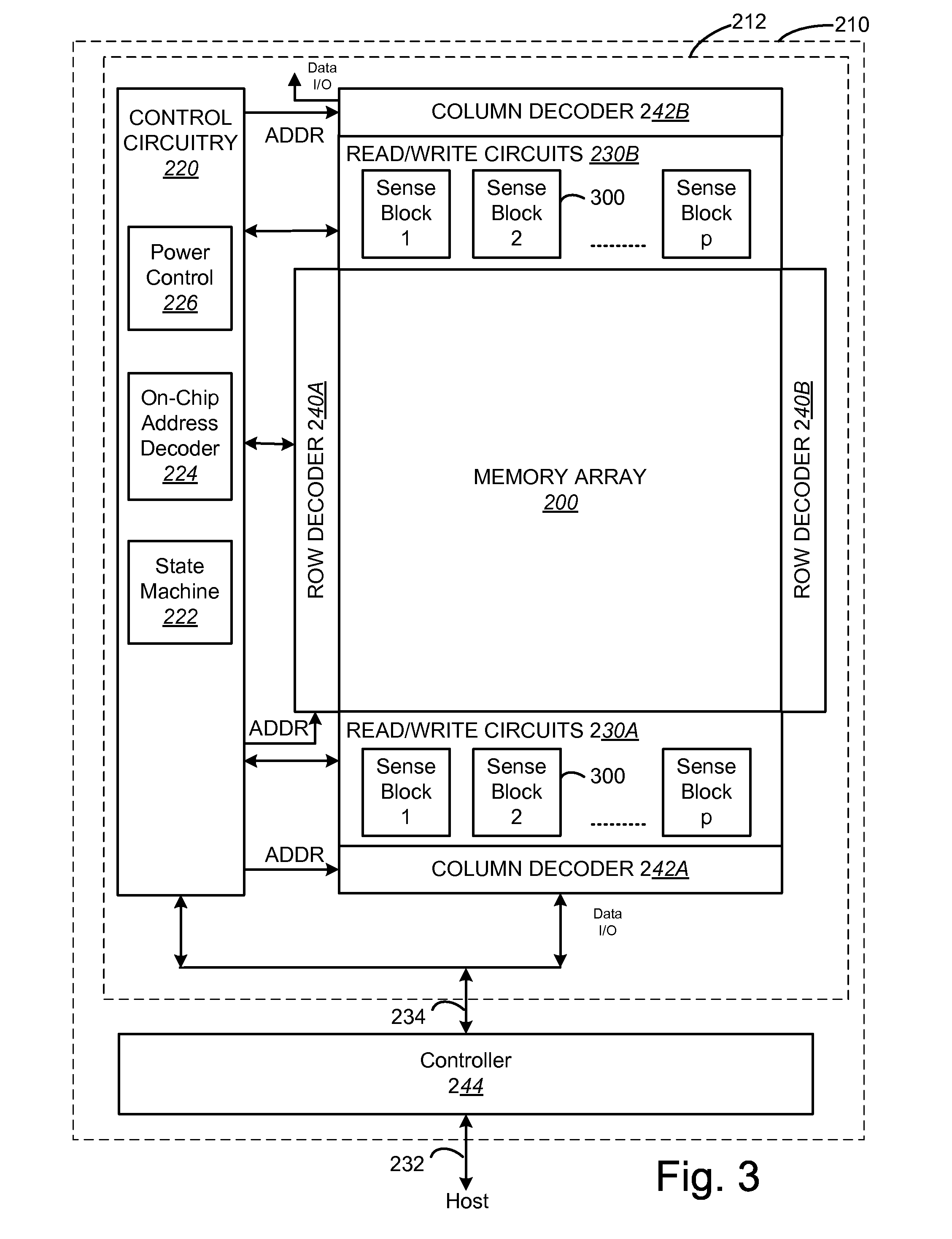

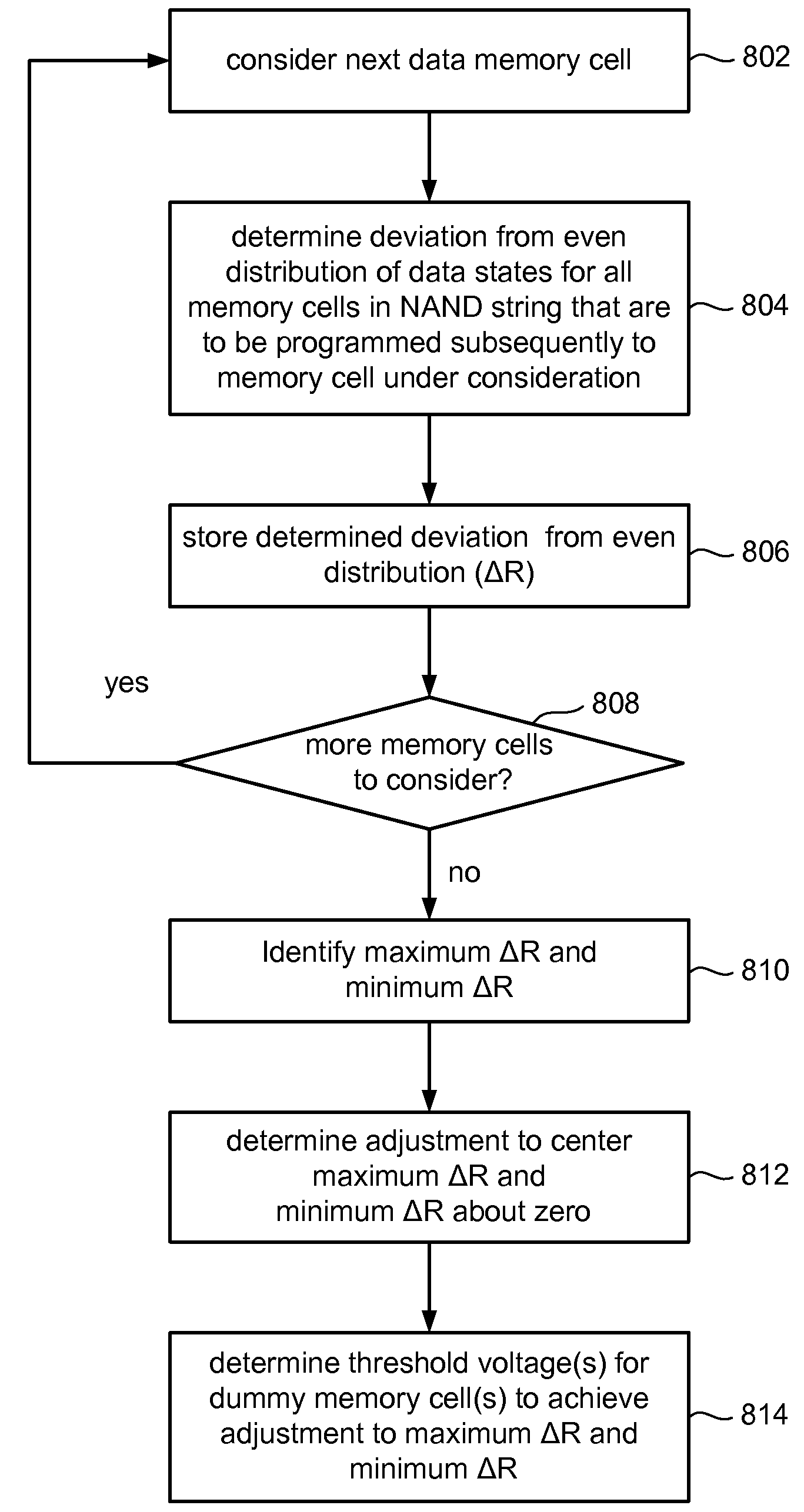

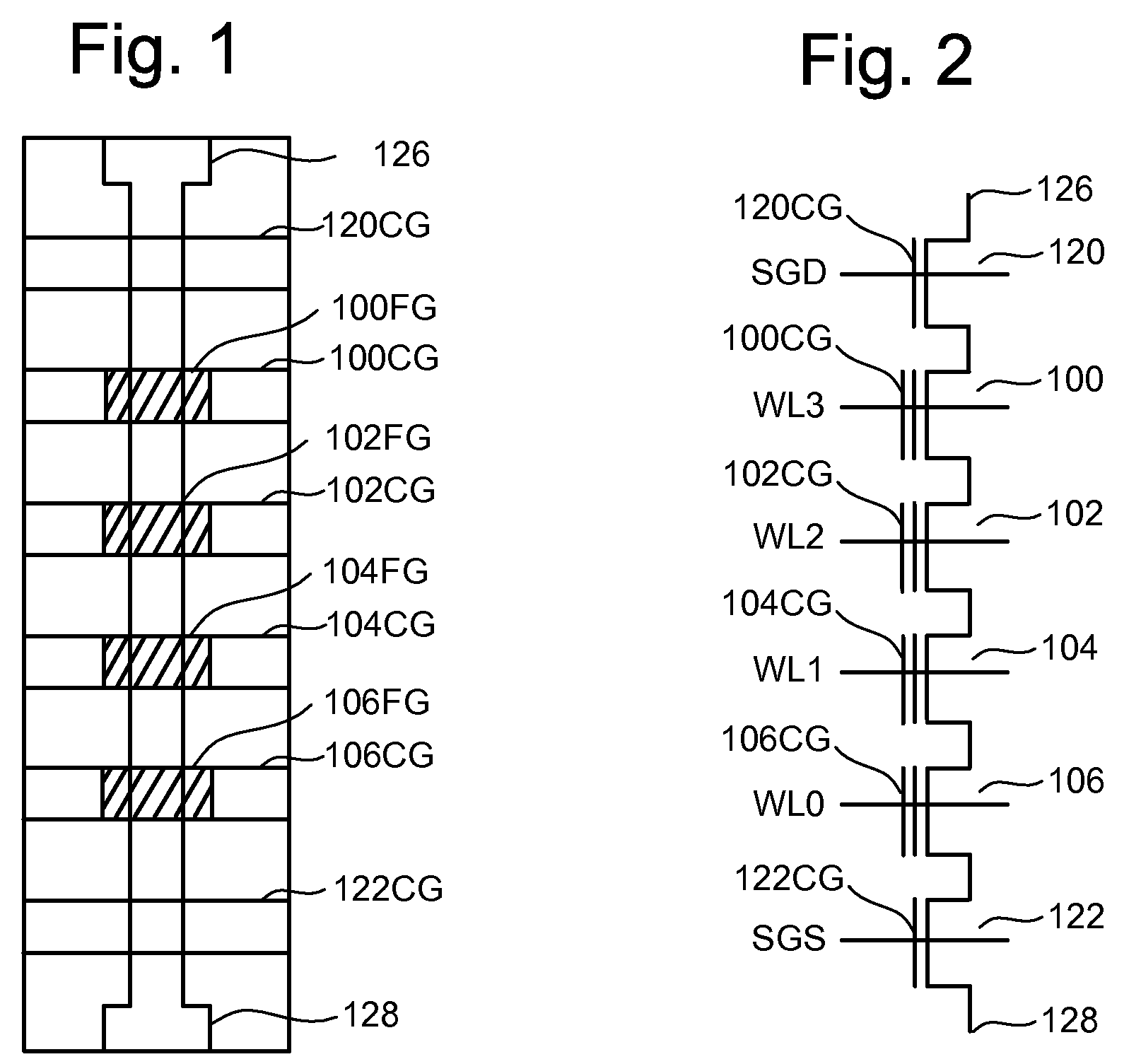

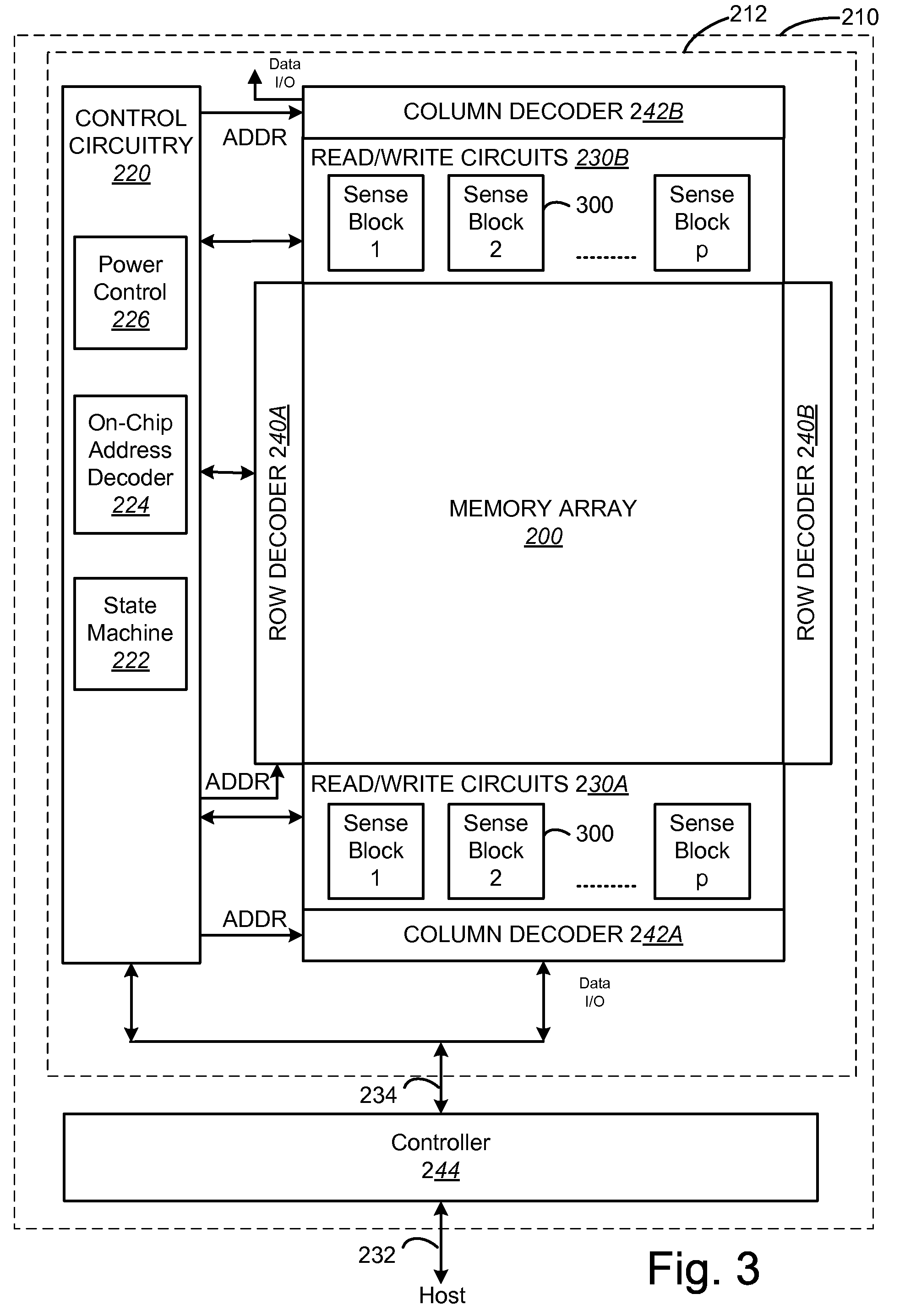

Adjusting resistance of non-volatile memory using dummy memory cells

In some non-volatile storage systems, a block of data memory cells is manufactured with a dummy word line at the bottom of the block, at the top of the block, and / or at other locations. By selectively programming memory cells on the dummy word line(s), the resistances associated with the data memory cells can be changed to account for different programmed data patterns.

Owner:SANDISK TECH LLC

Sensor fault diagnostics and prognostics using component model and time scale orthogonal expansions

InactiveUS7200524B2Effective and economical sensor fault diagnostic and prognostic techniqueReliable methodProgramme controlInput/output for user-computer interactionRemedial actionManufacturing data

A method of diagnosing sensor faults for a heating, ventilation and air conditioning system includes the steps of creating a component model for a specific component within the system. The component model is created through the use of commonly available manufacturing data. Data within the system is input into the component model and compared to calculated and predicted values that are also calculated using the identical component models. Differences between the calculated and actual values is determined and compared to a threshold difference value. If the difference exceeds the threshold value, then a fault is detected. The specific type of sensor fault is determined using probability distribution analysis. Each type of sensor fault produces a different type of statistical deviation from normal distribution. By recognizing these patterns of deviations from the normal distribution, the specific type of fault such as electrical, intermittent or freezing of the sensor can be determined to provide initial information as to the severity and type of remedial action required.

Owner:CARRIER CORP

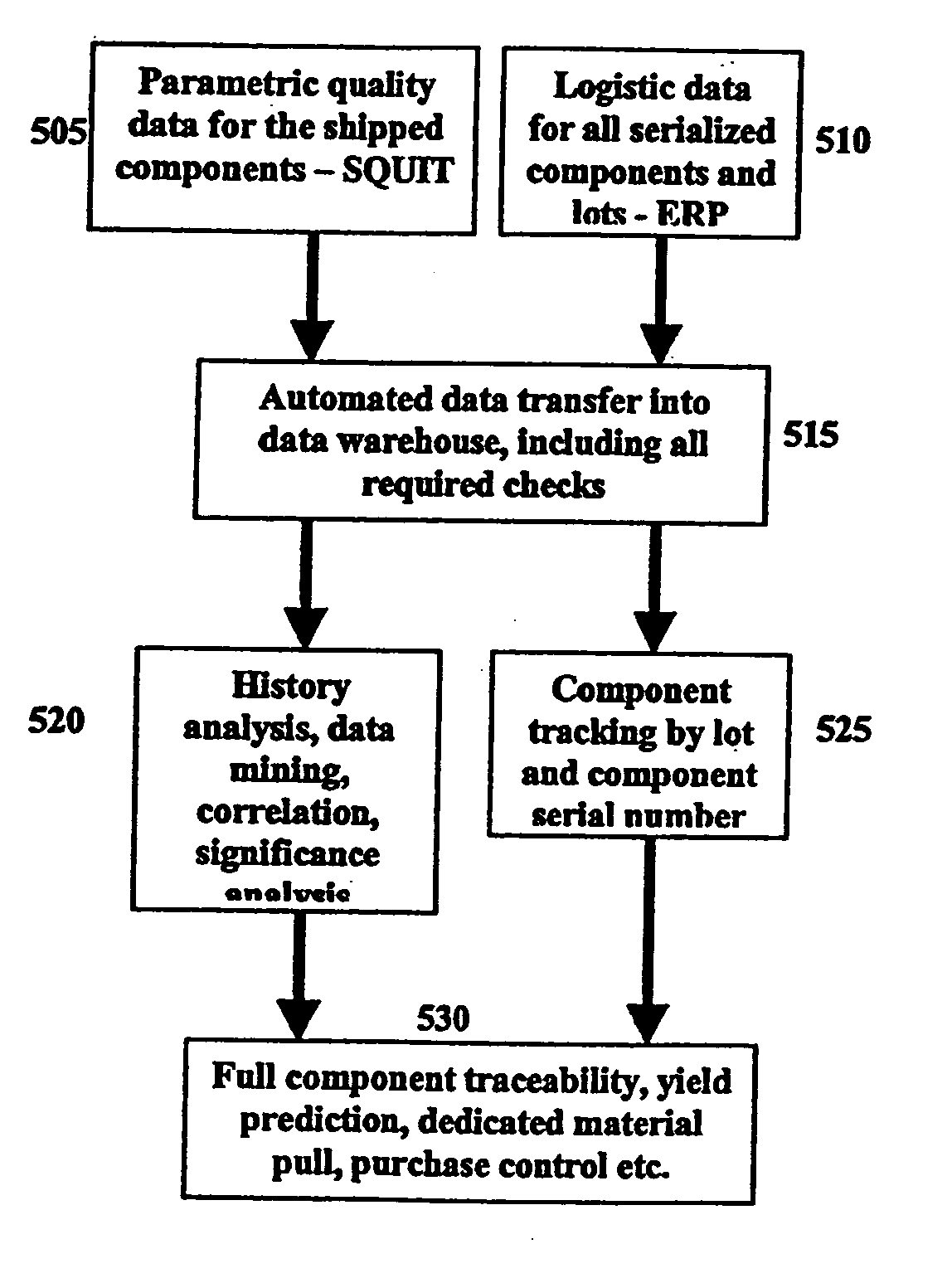

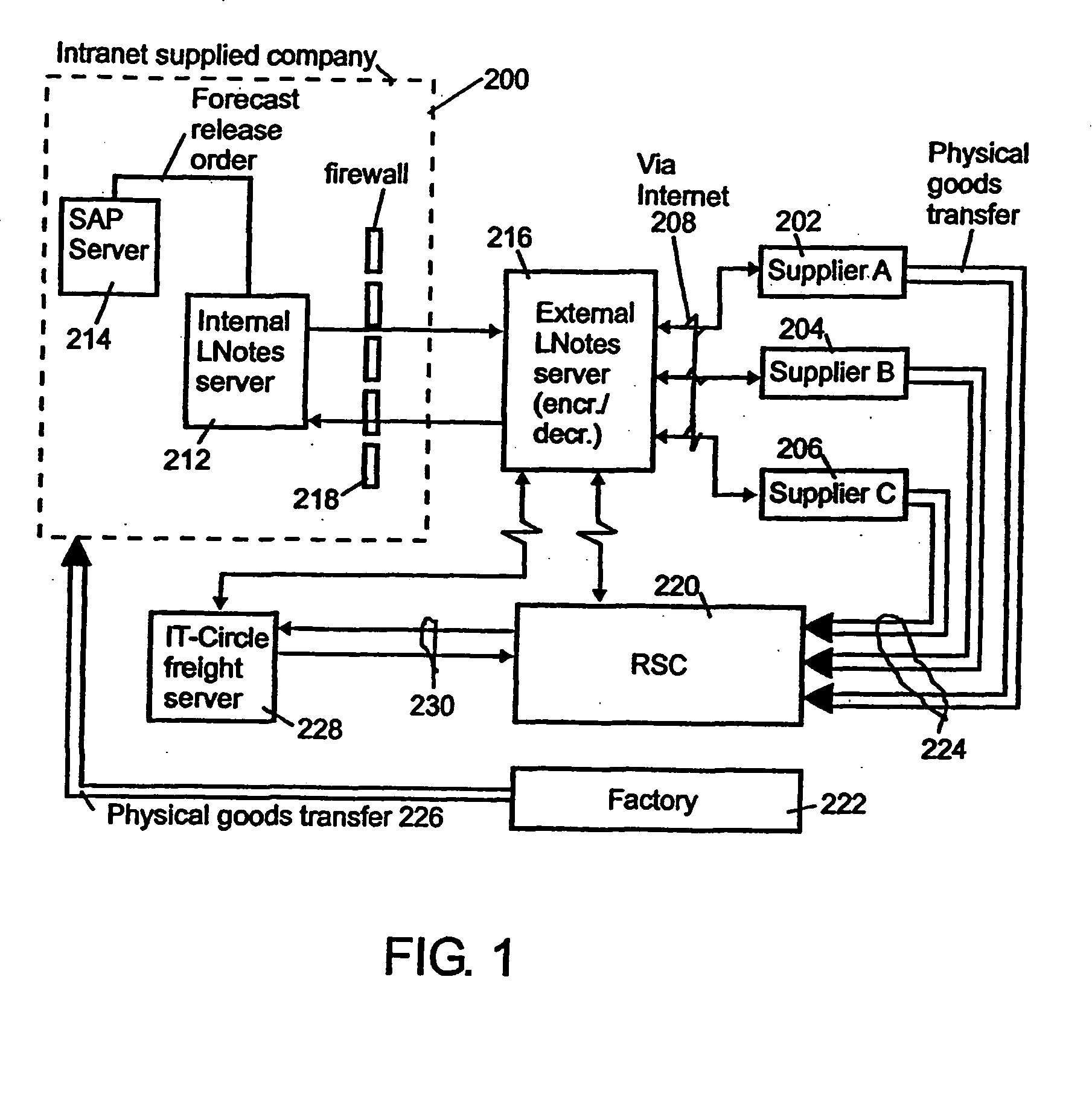

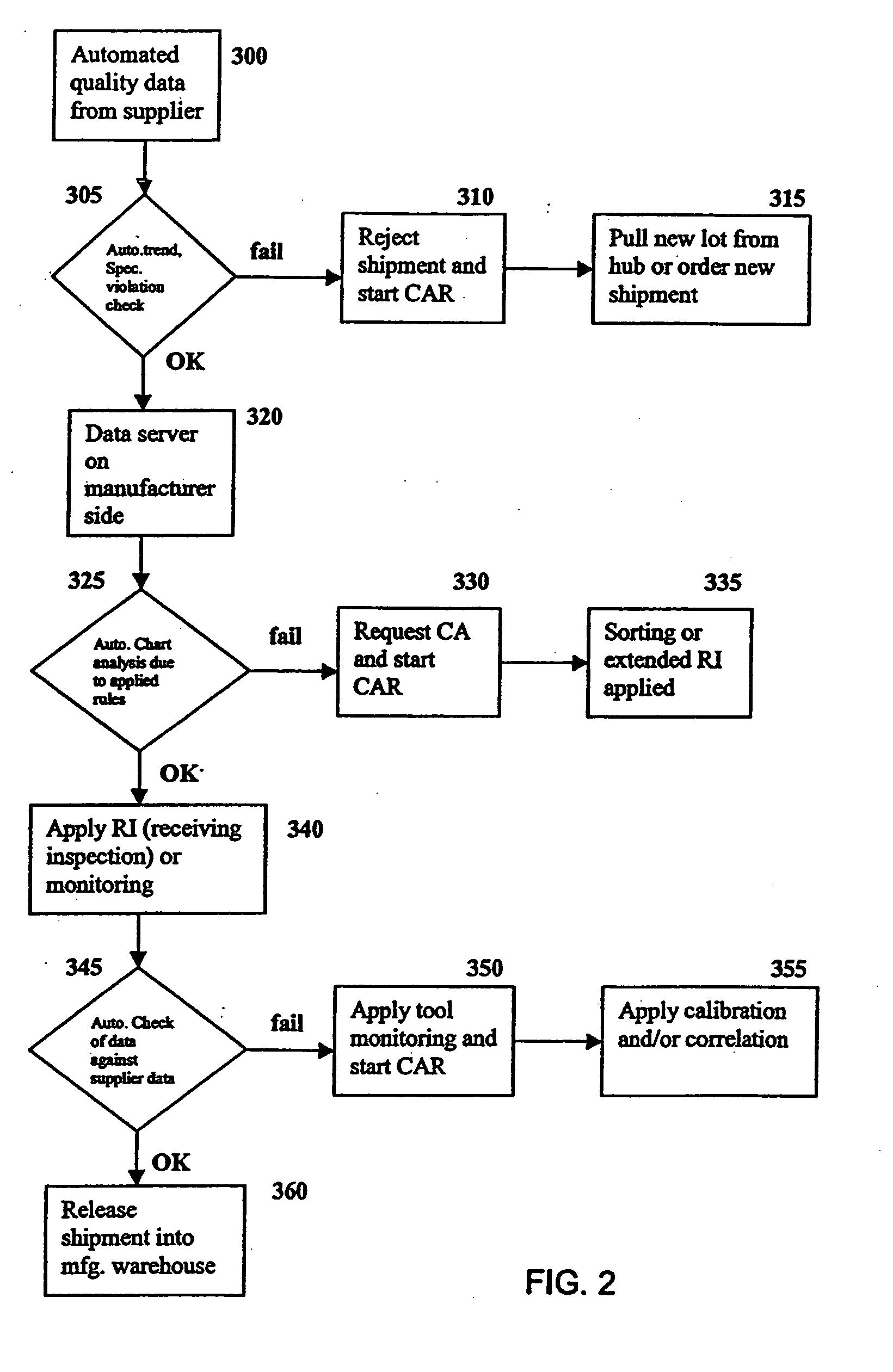

Method and system for computerizing quality management of a supply chain

InactiveUS20050159973A1Quality improvementYield predictionTechnology managementResourcesOriginal dataFeedback control

Owner:IBM CORP

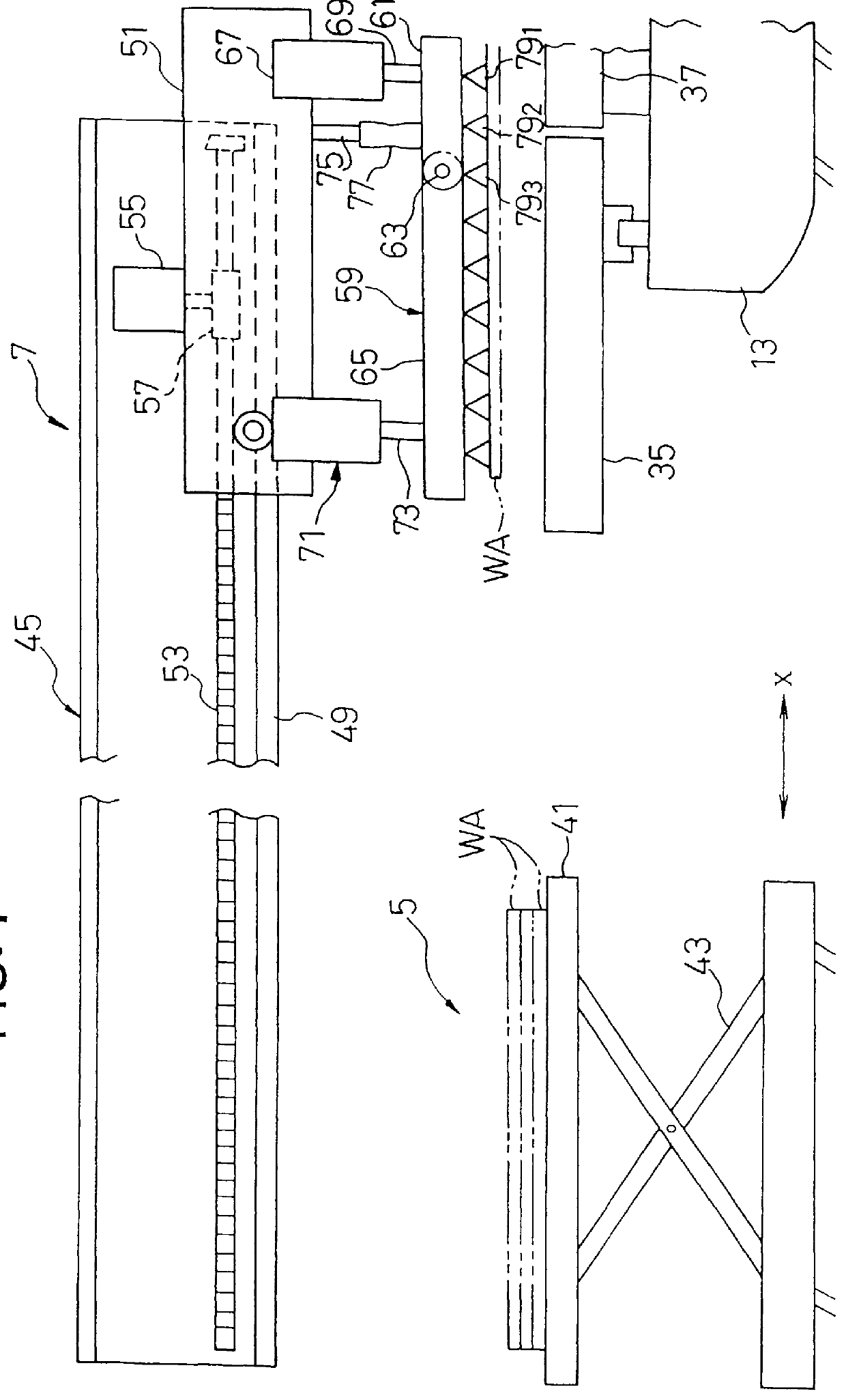

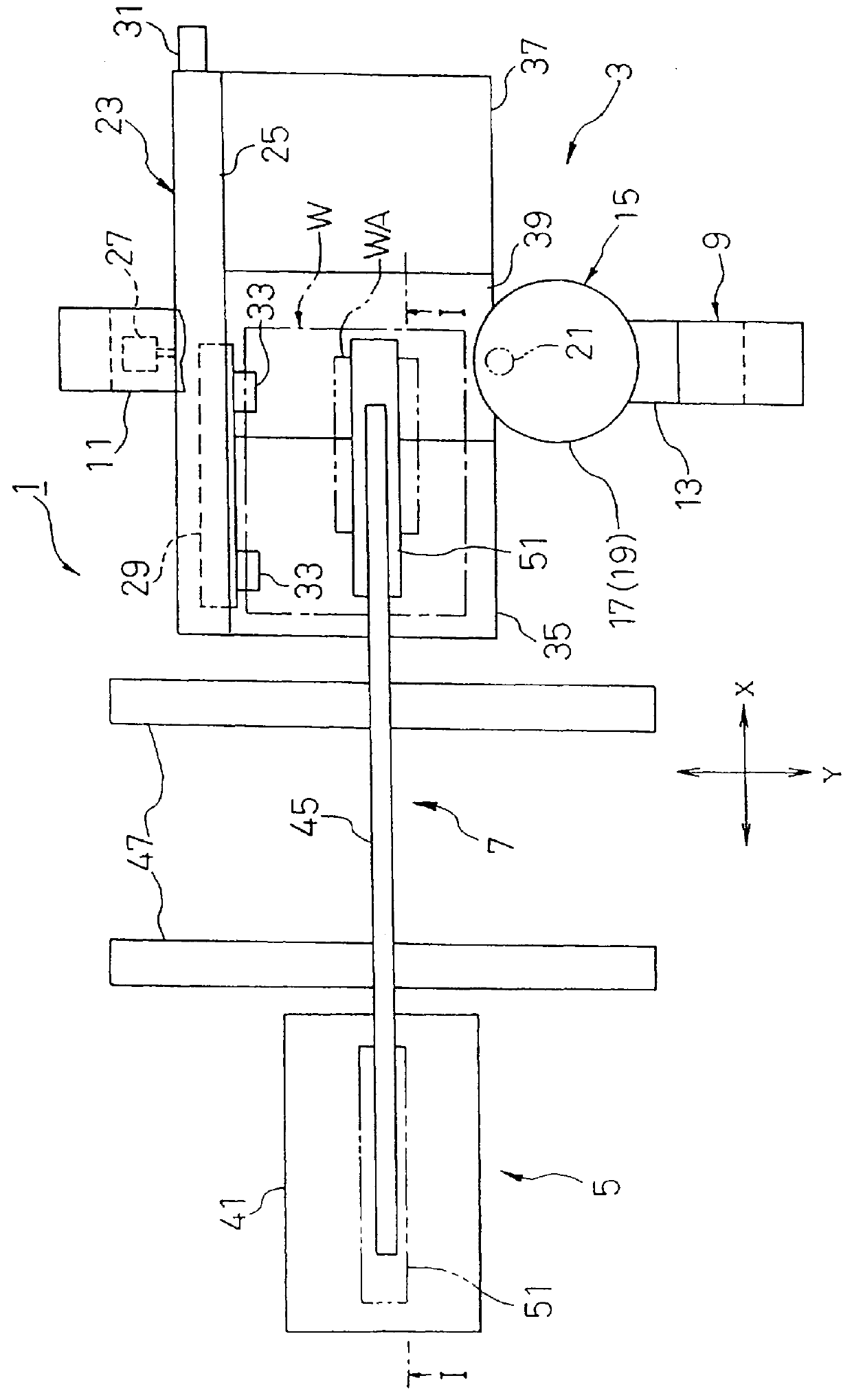

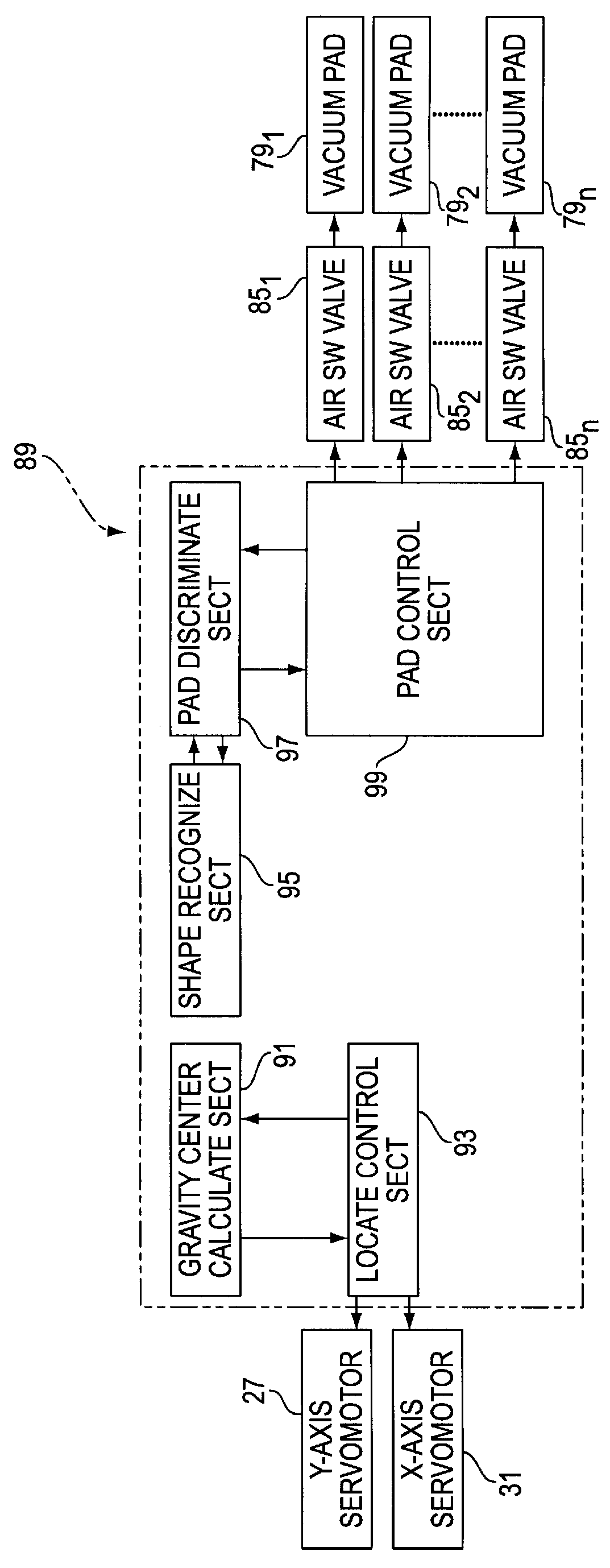

Punched plate material carrying-out system

InactiveUS6055895AReduce in quantitySmall sizeAutomatic control devicesMetal-working feeding devicesPunch pressManufacturing data

A slider of the punch carry out unit is moved in the X-axis direction adjacent a punching section of the punch press machine before or after a plate material is punched into a punched product by a punch press machine. At the same time, a gravity center and a shape of the punched product are calculated and recognized on the basis of the manufacturing data. On the basis of the obtained gravity center and the shape of the punched product, the gravity center of the punched product is moved under the lift arm by the X- and Y-axis locating mechanism. Vacuum pads located just over the punched product are selected or discriminated. Then, the lift arm is lowered and the punched product is held by actuating only the discriminated vacuum pads. During this lift motion, it is preferable to bend one end of the punched product slightly upward to easily separate the punched product from the remaining flat plate material. After the punched product has been lifted, the punched product is moved horizontally away from the punch press, and is then lowered on the punched product supporting unit by releasing only the actuated vacuum pads. Since only the vicinity of the gravity center of the punched product is held by a minimum possible number of the vacuum pads, irrespective of the size and shape of the punched products, the number of the vacuum pads can be reduced.

Owner:U S AMADA

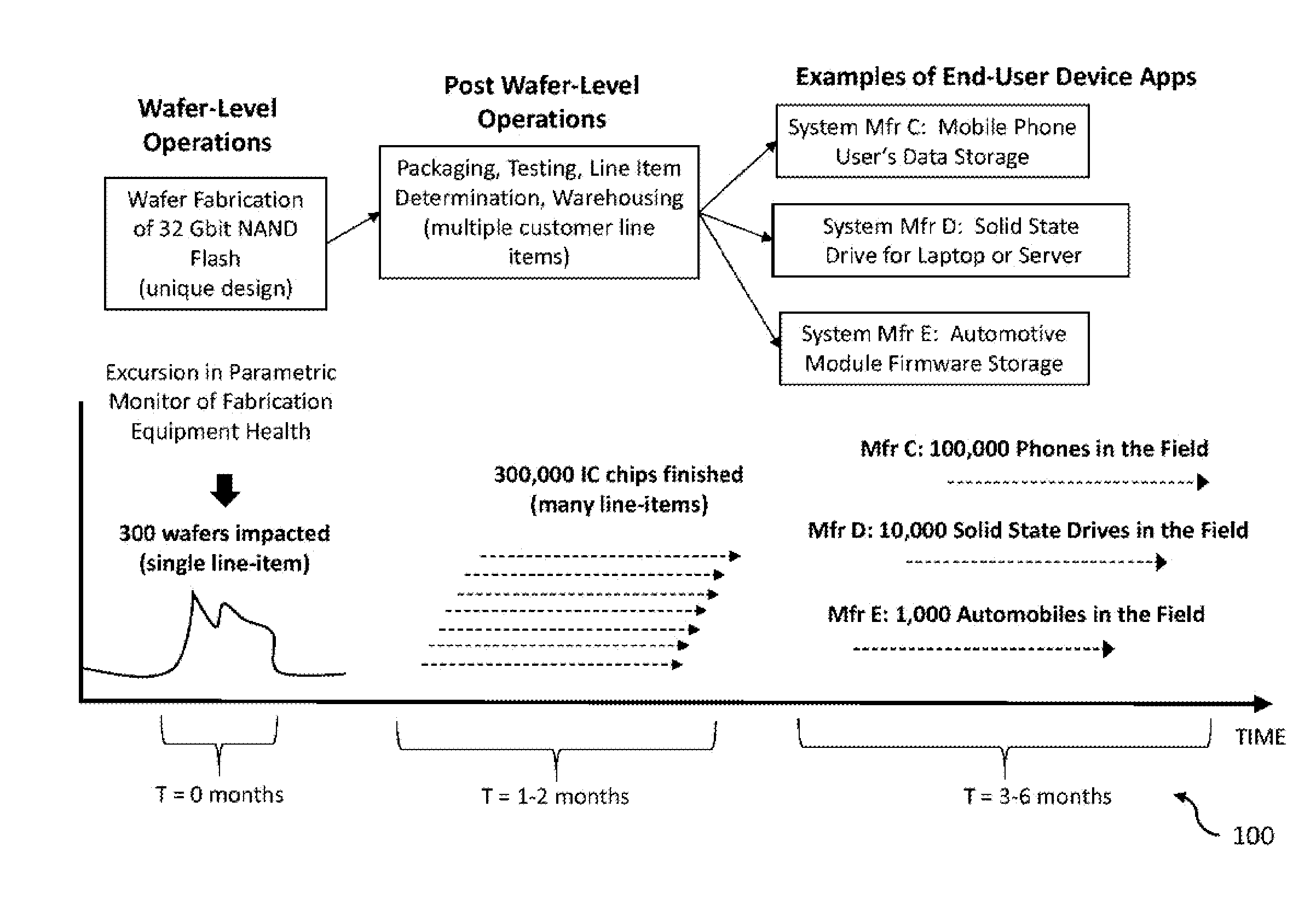

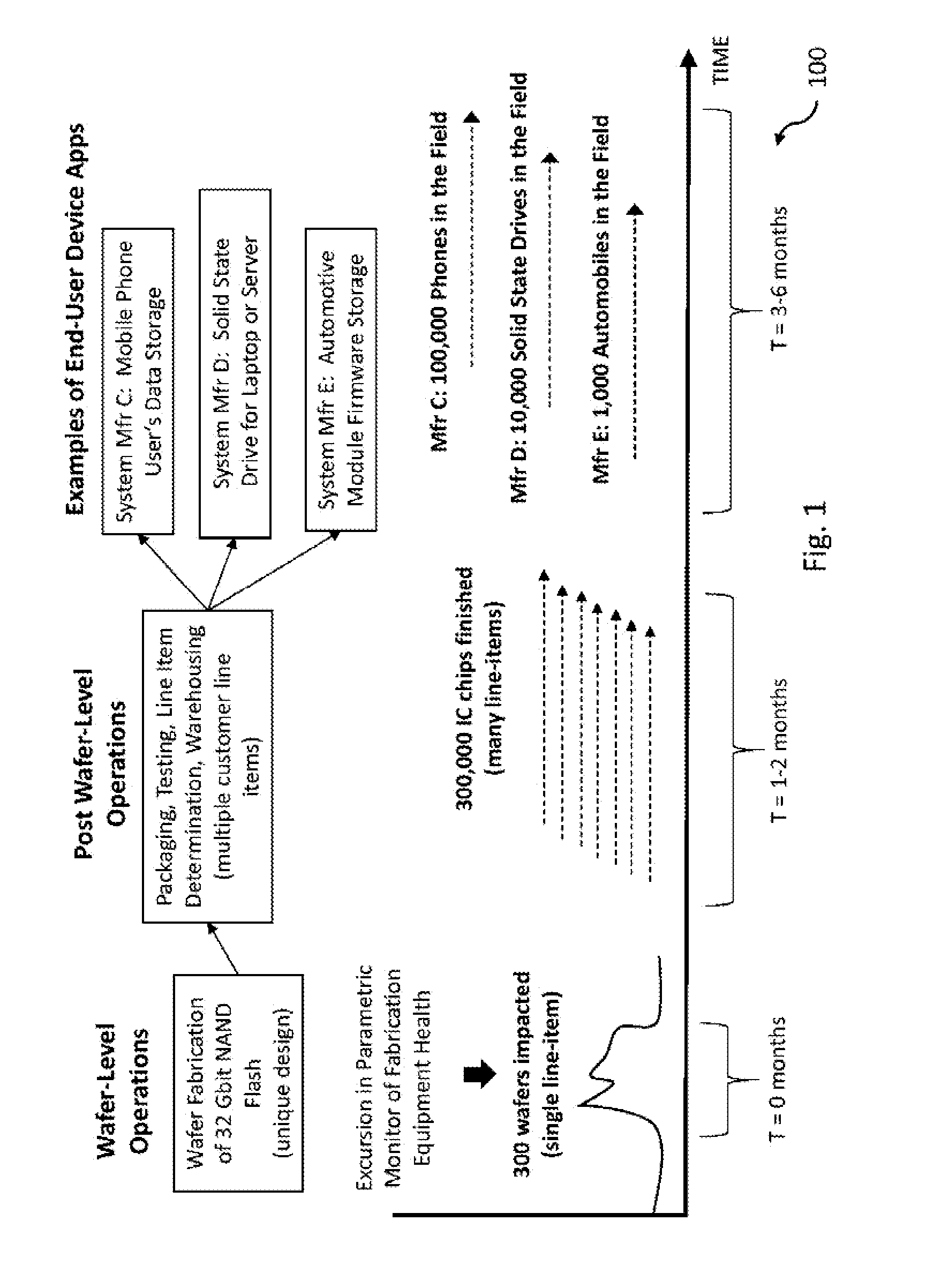

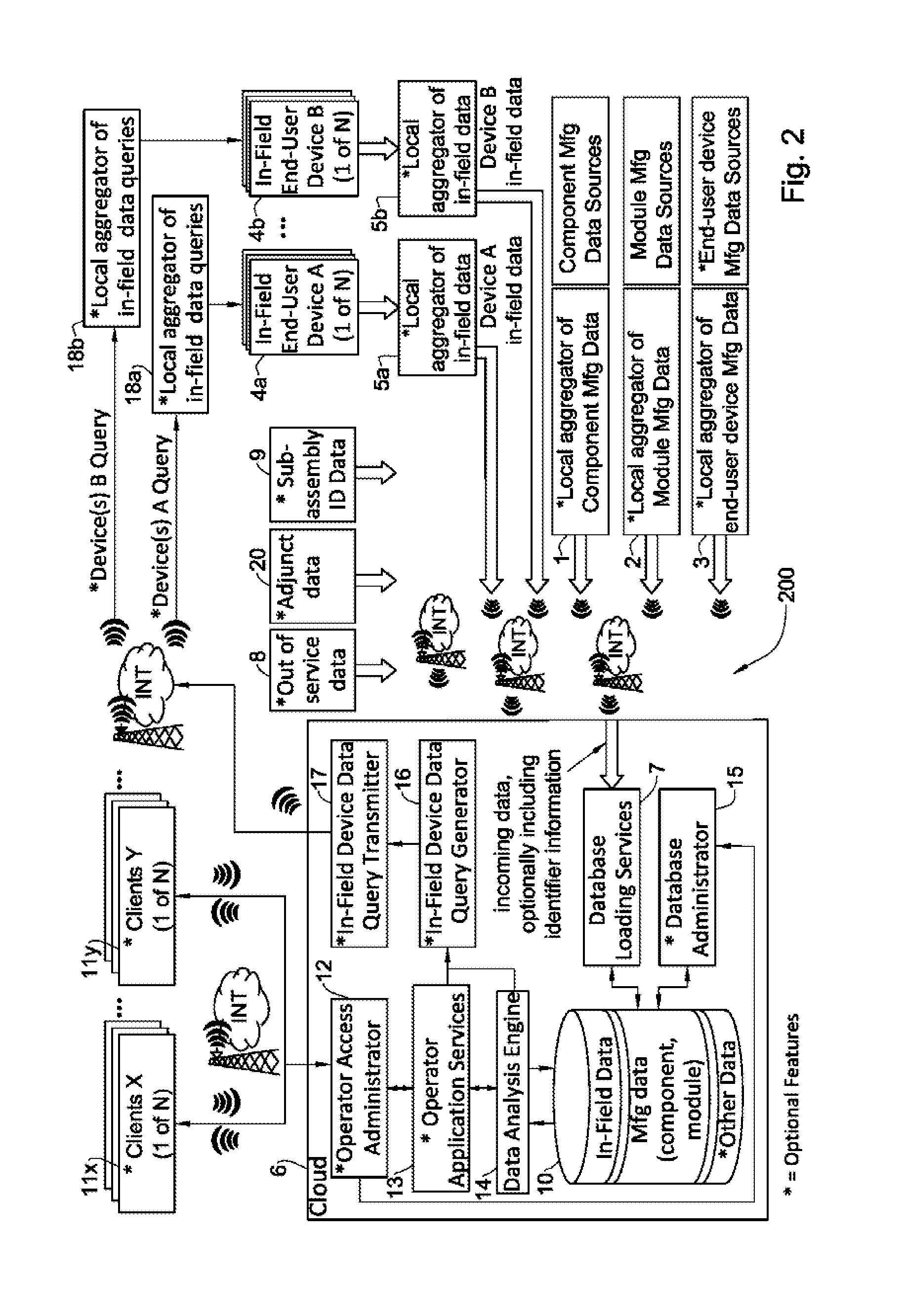

Correlation between manufacturing segment and end- user device performance

InactiveUS20160321594A1Reliability/availability analysisTechnology managementUser deviceManufacturing data

Disclosed are methods, systems and computer program products for concluding whether or not there is a correlation between a set of manufacturing condition(s) and performance of in-field end user devices. Also disclosed are methods, systems and computer program products for concluding whether or not there is an inconsistency in in-field end user devices data and / or manufacturing data associated with electronic elements included in end-user devices. In one example, a method includes analyzing received in-field data and / or data computed based on received in-field data, in order to determine whether or not there is a statistically significant difference in in-field performance between end-user devices including elements from a first population and end-user devices including elements from a second population, where manufacturing of the first population corresponds to a set of one or more manufacturing conditions, but manufacturing of the second population does not correspond to the set.

Owner:OPTIMAL PLUS

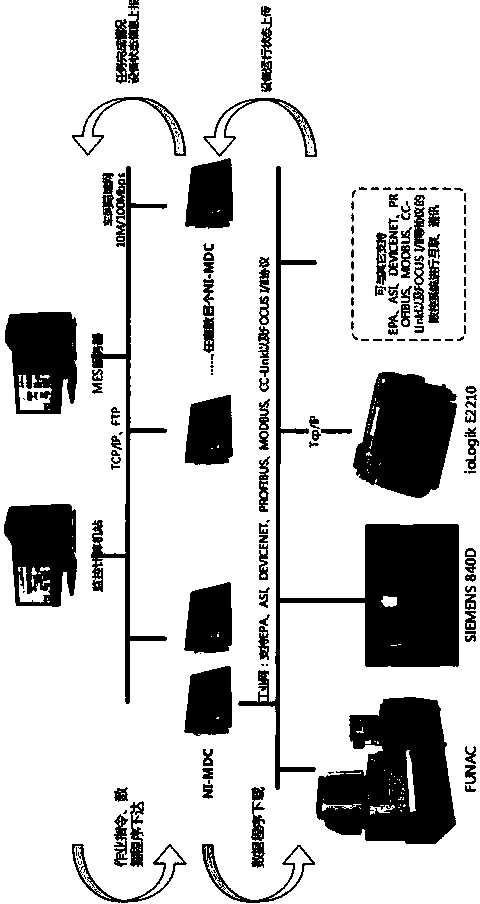

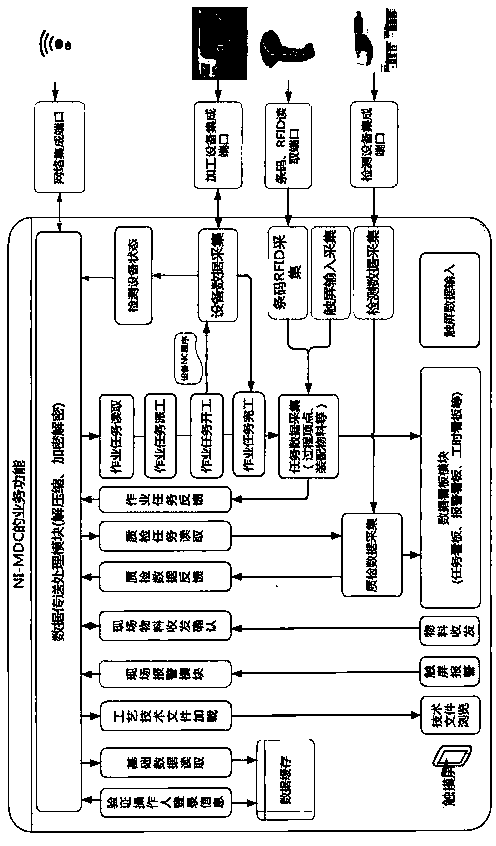

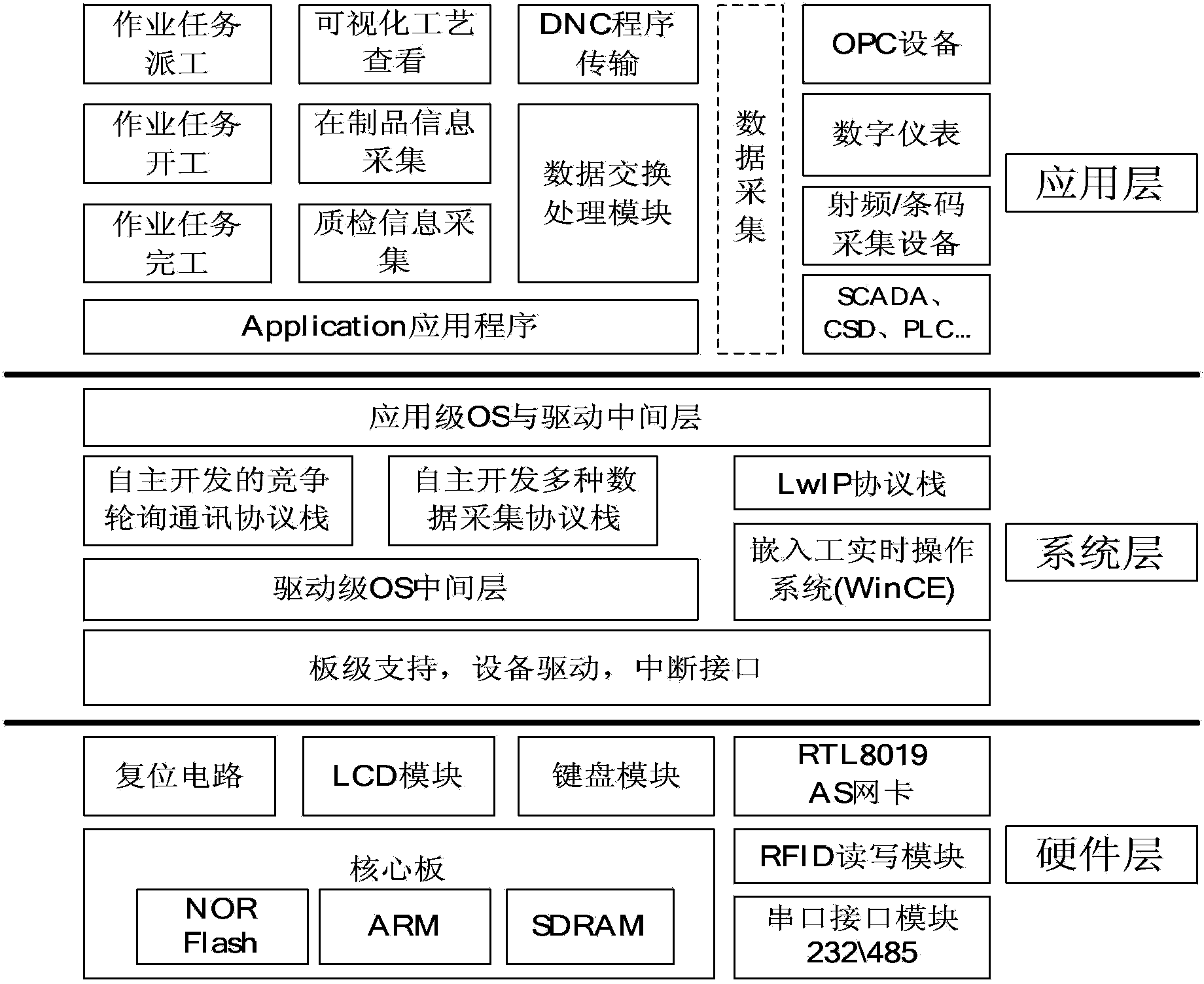

Embedded type integratedly-manufactured data collecting terminal based on network

The invention discloses an embedded type integratedly-manufactured data collecting terminal (NI-MDC) based on a network. The NI-MDC comprises an NI-MDC system platform and an NI-MDC drive software system, wherein the NI-MDC system platform comprises a core board, a reset circuit, an LCD module, touch screen equipment, a keyboard module, a DM9000 network card, an RFID read-write module and a serial interface read-write module. By means of an on-site data collecting end, the NI-MDC can finish real-time collecting of work data, material data, quality data, equipment state data and the like, provides accurate original data timely for production operation management of enterprises after the data are filtered and gathered by a data processing module and transmitted to a management system such as an MES, can carry out practical and effective production monitoring on a production site, and is safe, reliable, simple and practical.

Owner:信华信技术股份有限公司

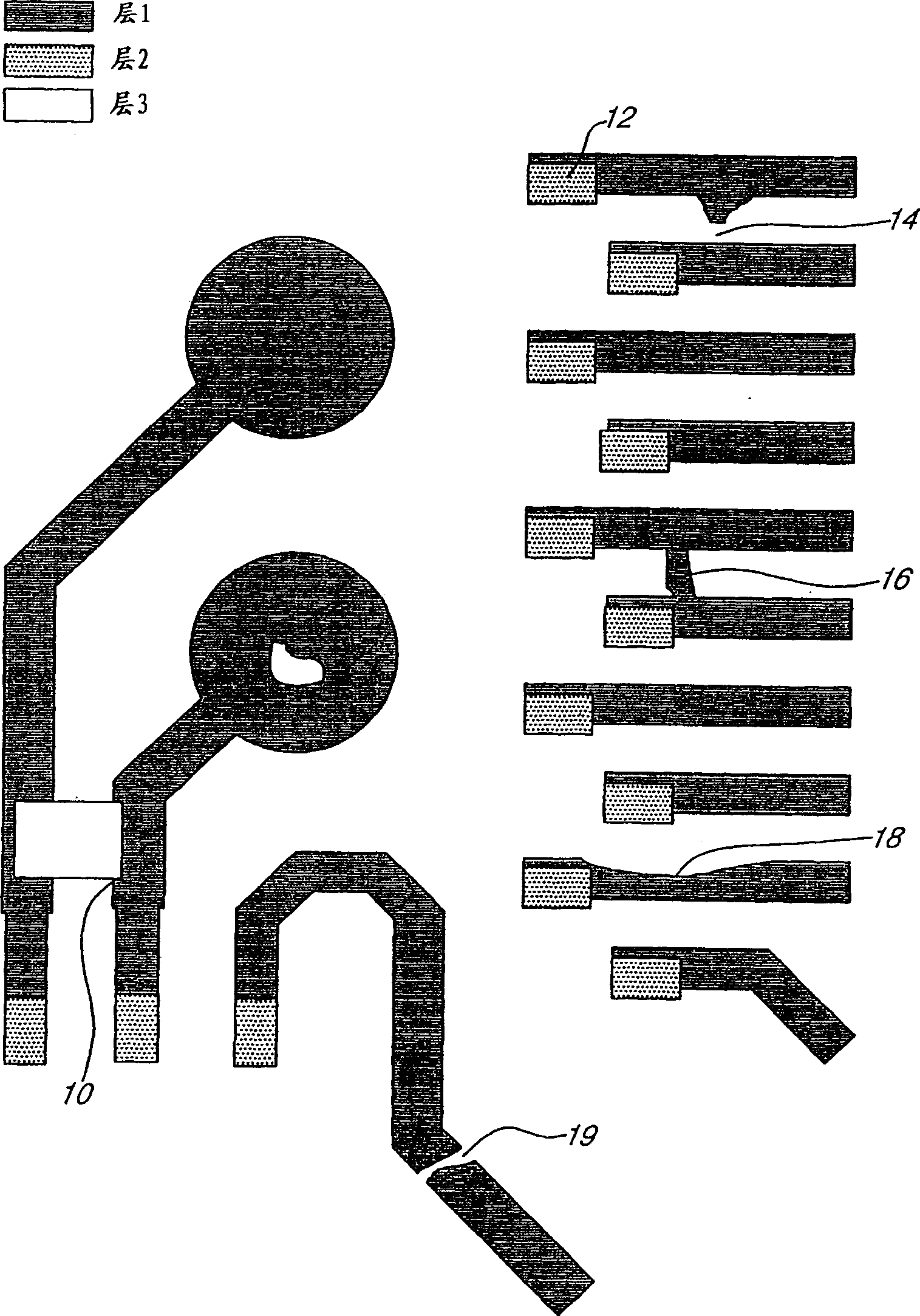

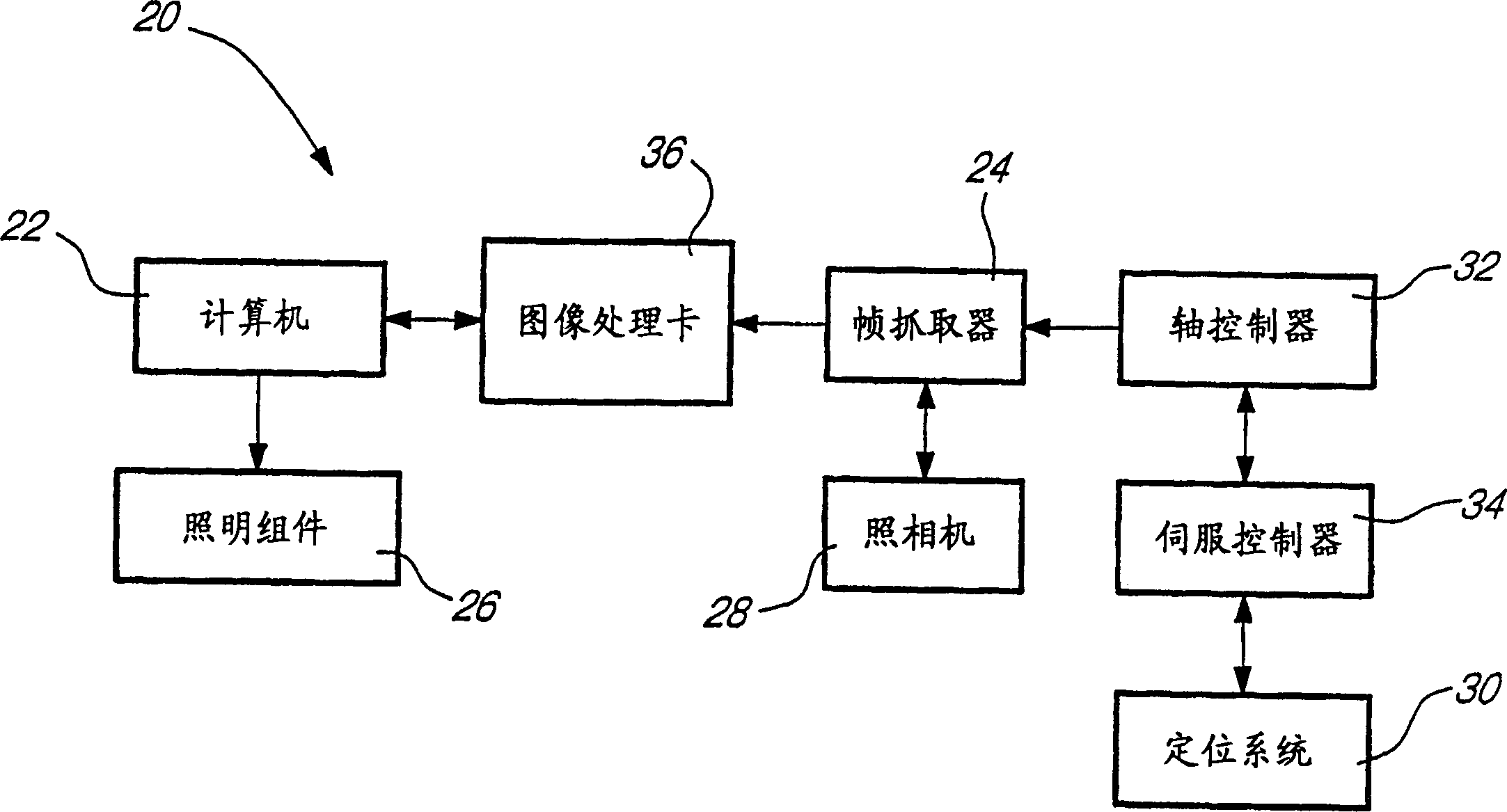

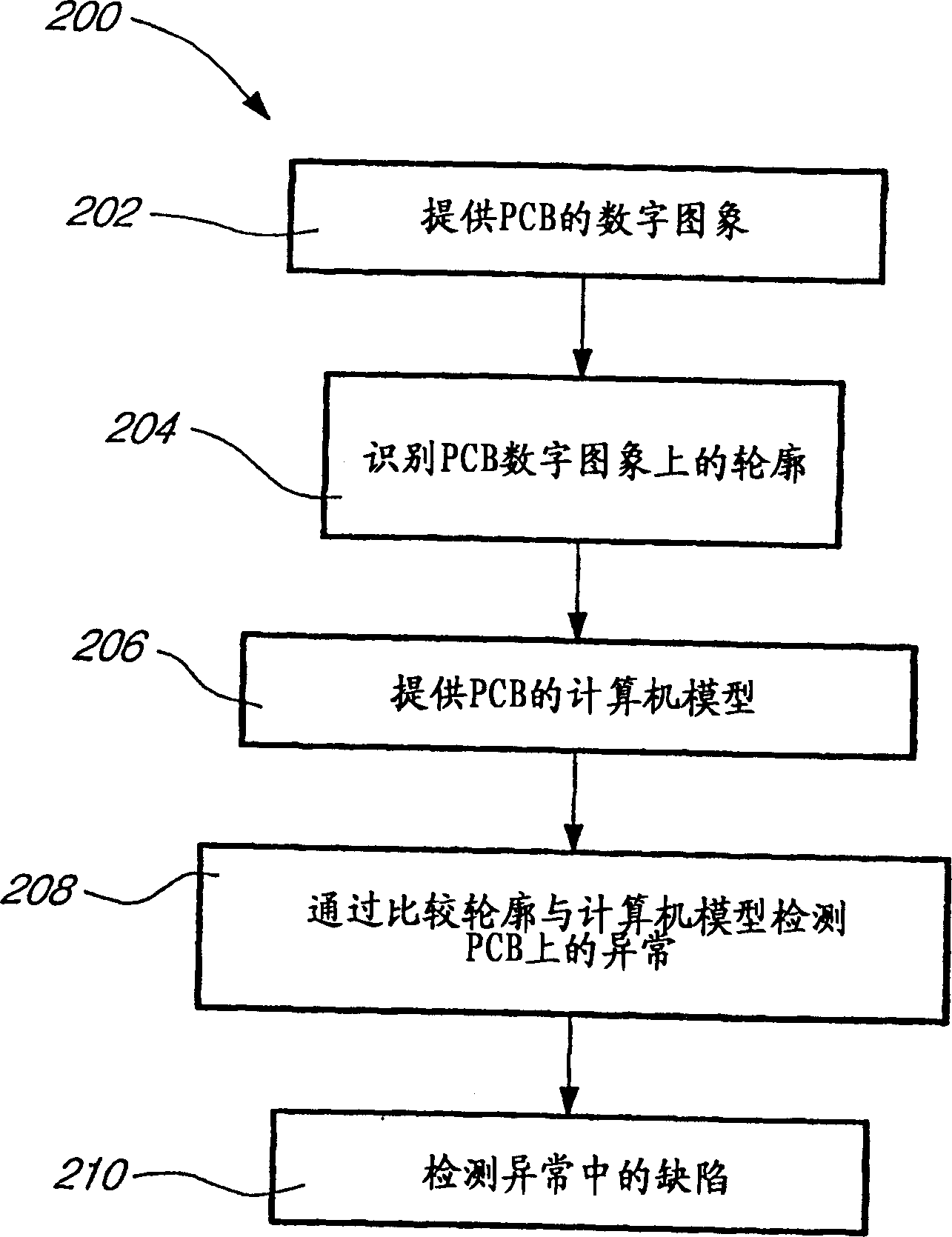

Method and system for detecting defects on a printed circuit board

A method and a system for detecting surface defects on electronic circuits, such as Printed Circuit Boards (PCB), are described herein. The method first comprises identifying contours on a digital image of the PCB. Then anomalies are detected on the PCB image by comparing the identified contours to contours on a vectorial model of the PCB. Each detected anomally is compared to manufacturing data to verify it if corresponds to a defect.

Owner:SOLVISION

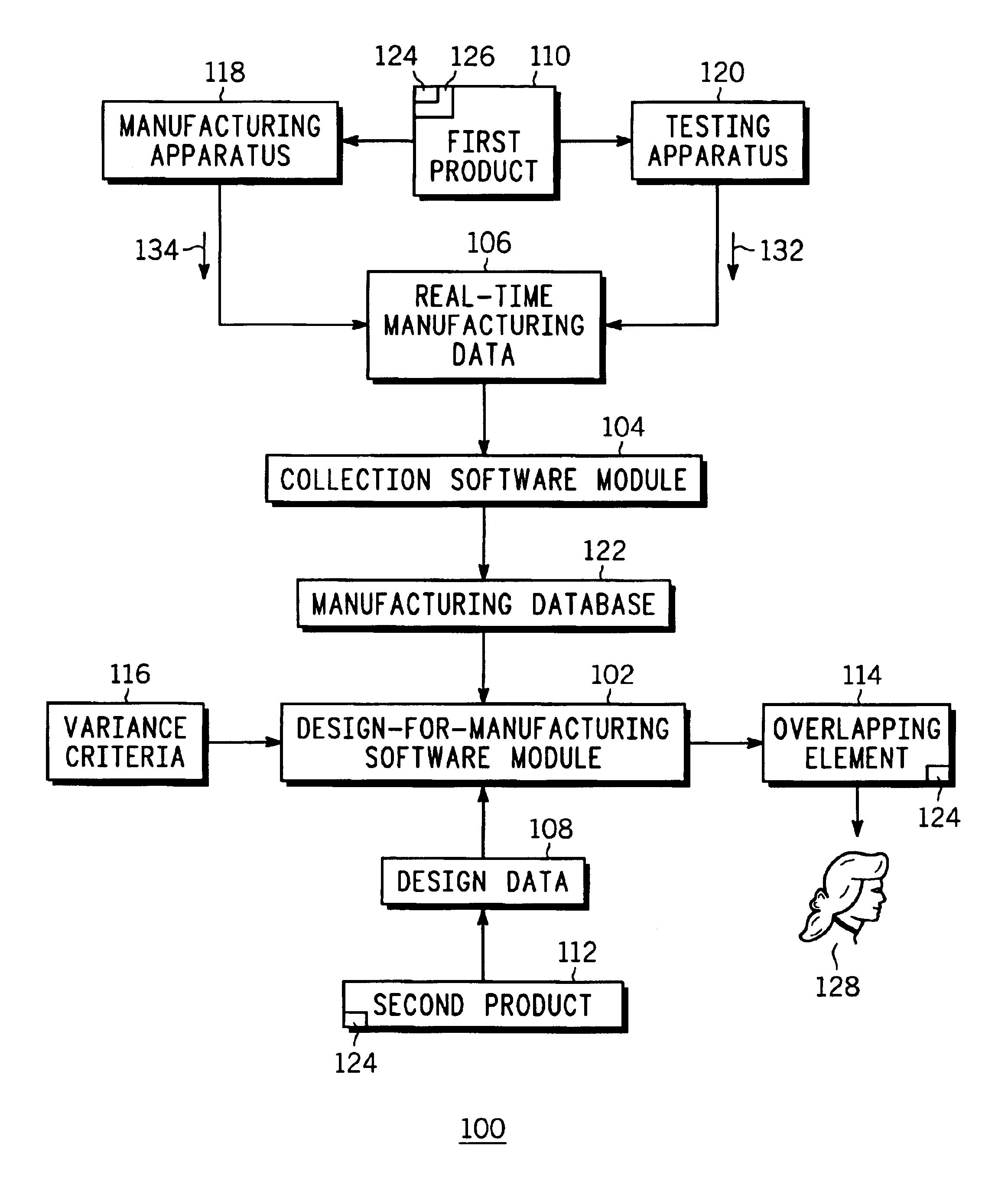

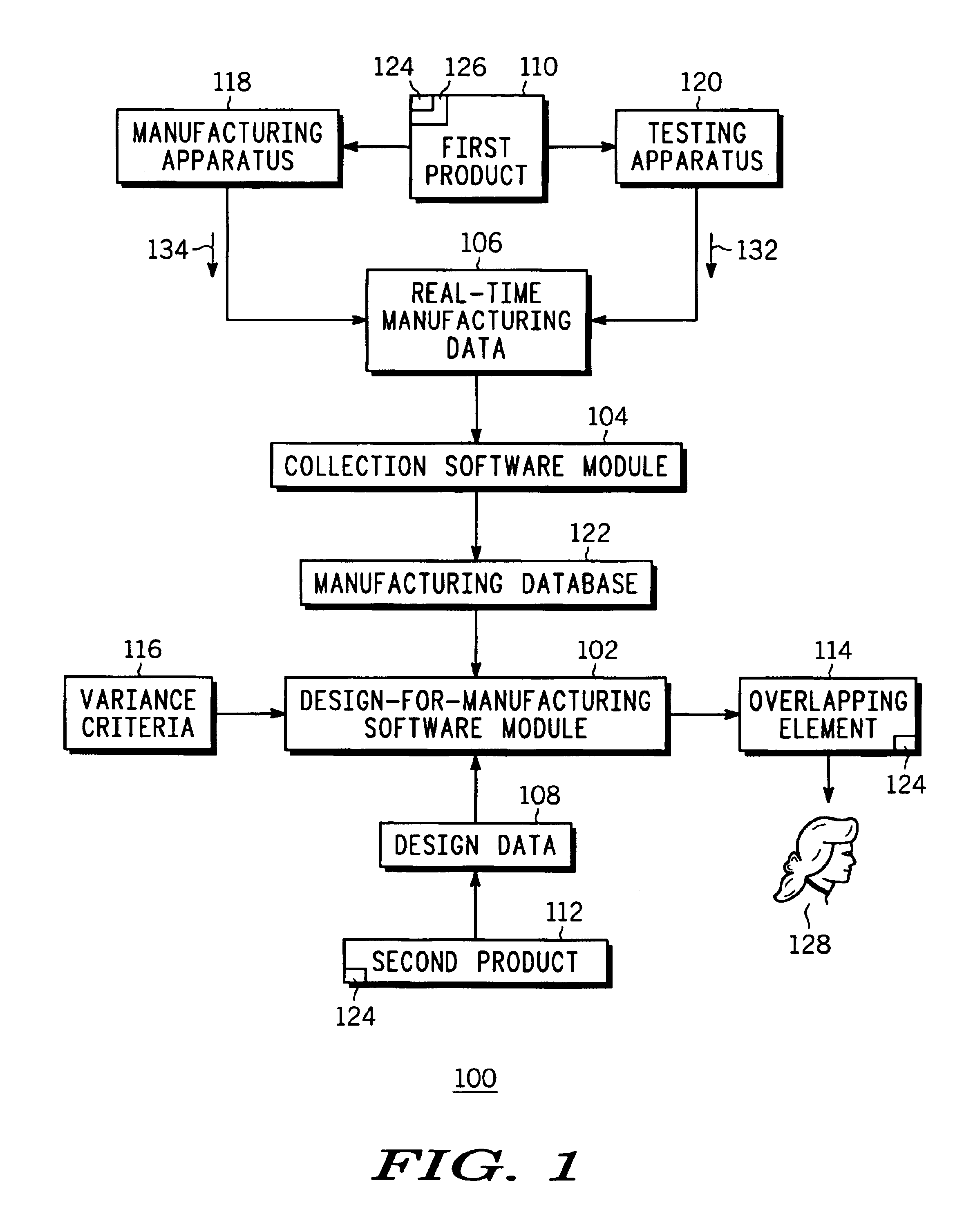

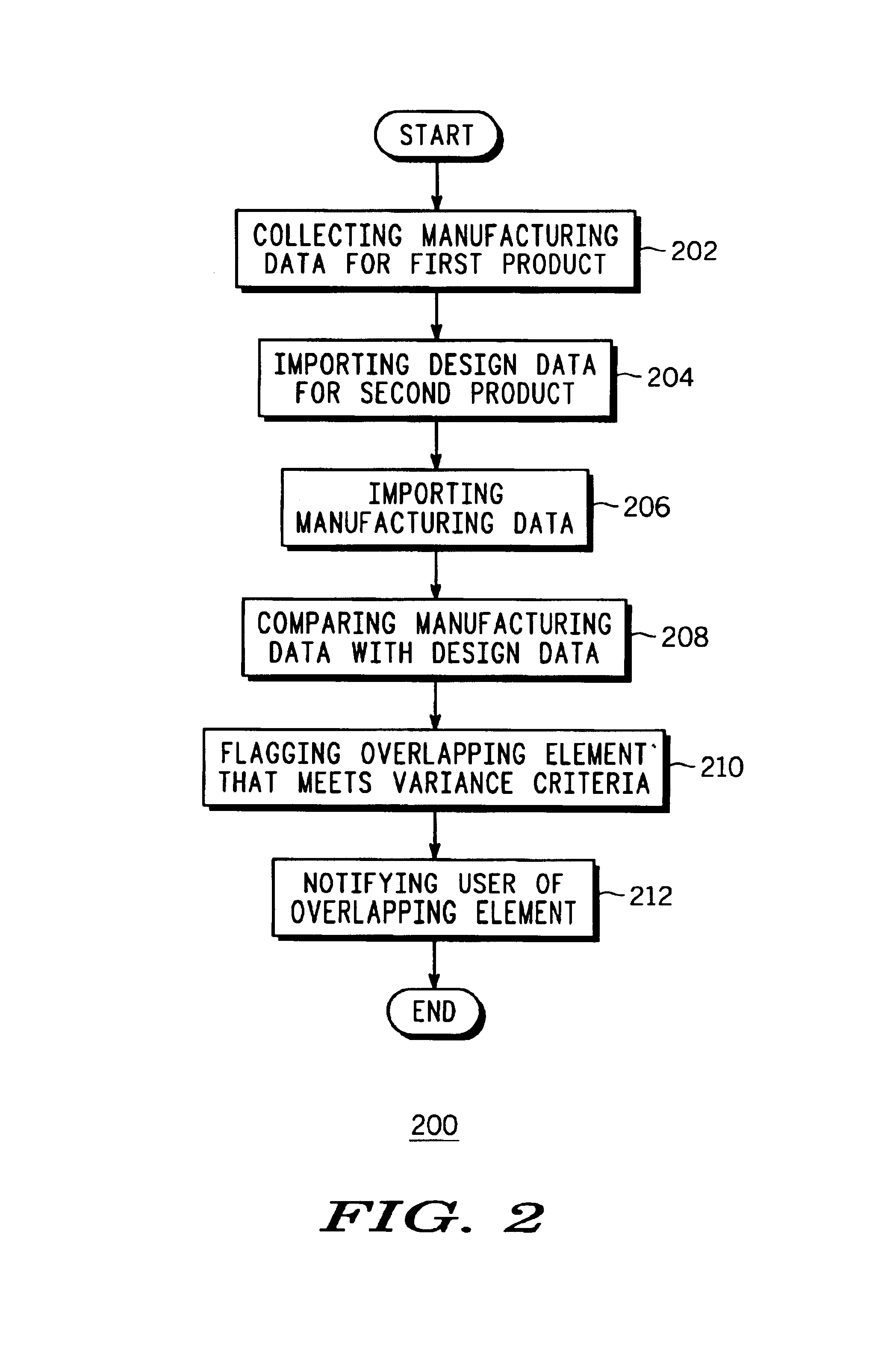

Method and apparatus for design for manufacturing

A method and apparatus for design for manufacturing includes importing real-time manufacturing data (106) for a first product (110) into a design-for-manufacturing software module (102), importing design data (108) for a second product (112) into the design-for-manufacturing software module (102). Design-for-manufacturing software module (102) compares the real-time manufacturing data to the design data and flags an overlapping element (114) of the real-time manufacturing data and the design data, wherein the overlapping element meets a variance criteria (116).

Owner:CONTINENTAL AUTOMOTIVE SYST INC

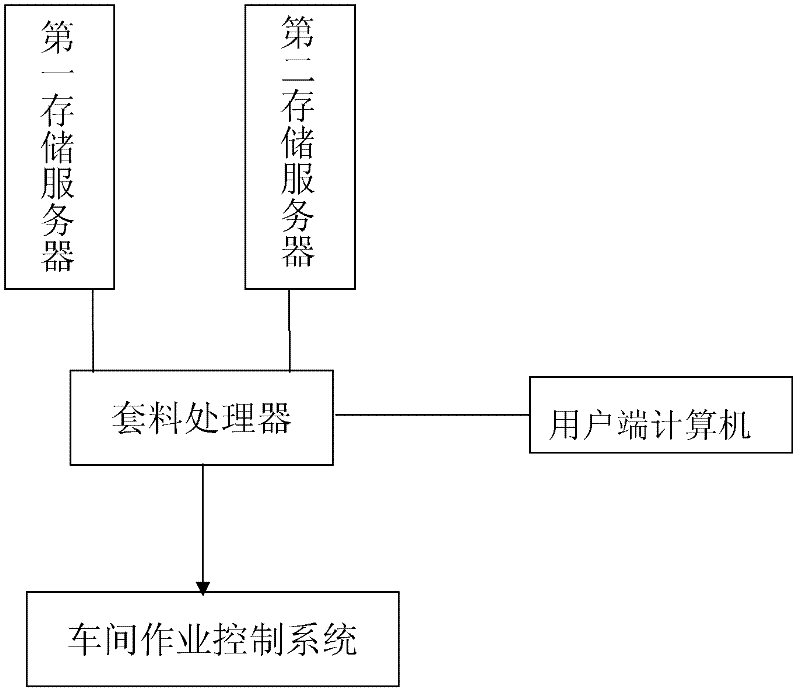

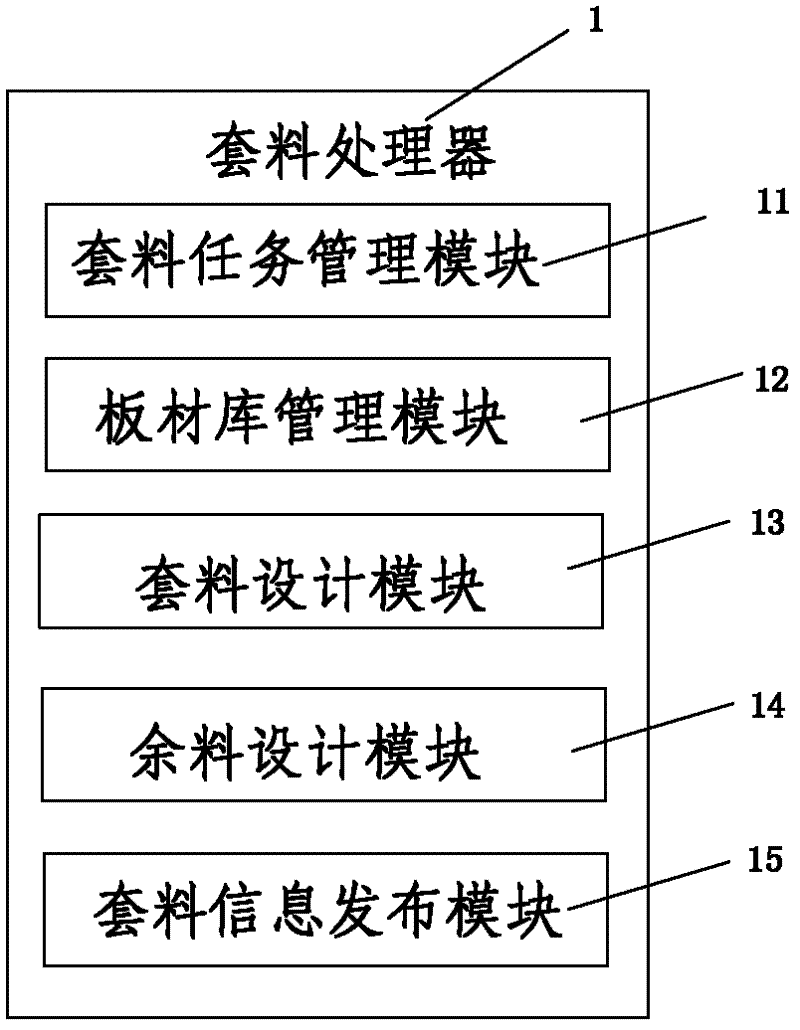

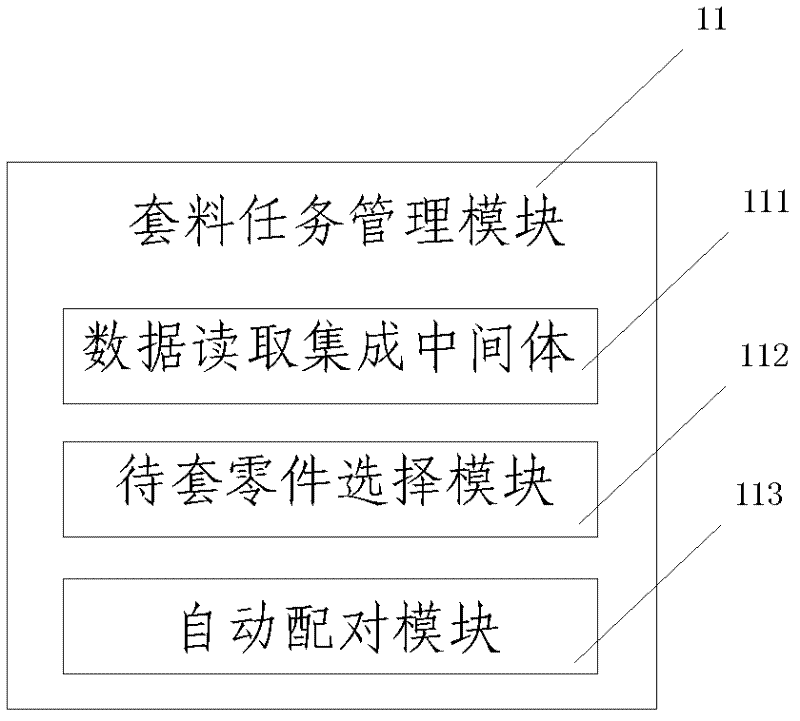

Automatic sheet metal part integrated nesting system and method thereof

InactiveCN102521459AEasy to operateShorten the time periodSpecial data processing applicationsNumerical controlData synchronization

The invention relates to an automatic sheet metal part integrated nesting system and a method thereof. The method includes: particularly, building a part model database of products on the basis of three-dimensional design software according to requirements of clients; selecting and creating a nesting task in a grouped manner by reading information of part models and process in the part model database, reading a purchase list database, filtering data of required plates from the purchase list according to goods codes of nesting task materials, and creating an internal nesting task by matching with materials, parts with identical plate thickness and plates in the nesting task according to the filtered data of the plates; disposing parts to be trepanned in the internal nesting task on the plates according to the layout requirement of no stacking; defining cutting paths of parts, simulating cutting, generating numerical-control commands and sending the same to a numerical-control lathe. By the automatic sheet metal part integrated nesting system and the method thereof, the problem of asynchrony among the nesting design and manufacturing data and a plate warehouse is solved, and the automatic sheet metal part integrated nesting system has the advantages that data are synchronous and work efficiency is improved and the like.

Owner:WUHAN WUCHUAN INFORMATION INTEGRATION

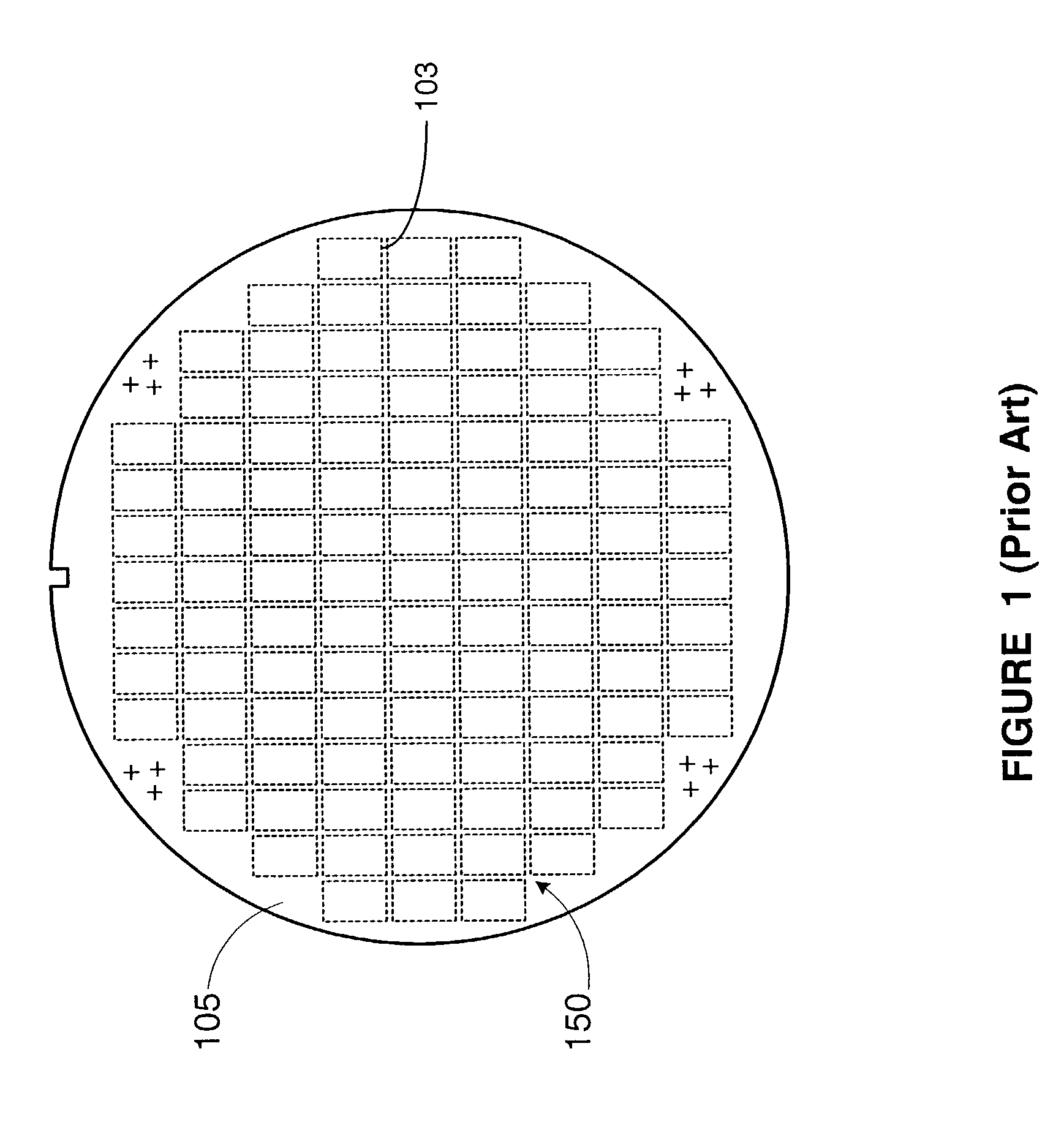

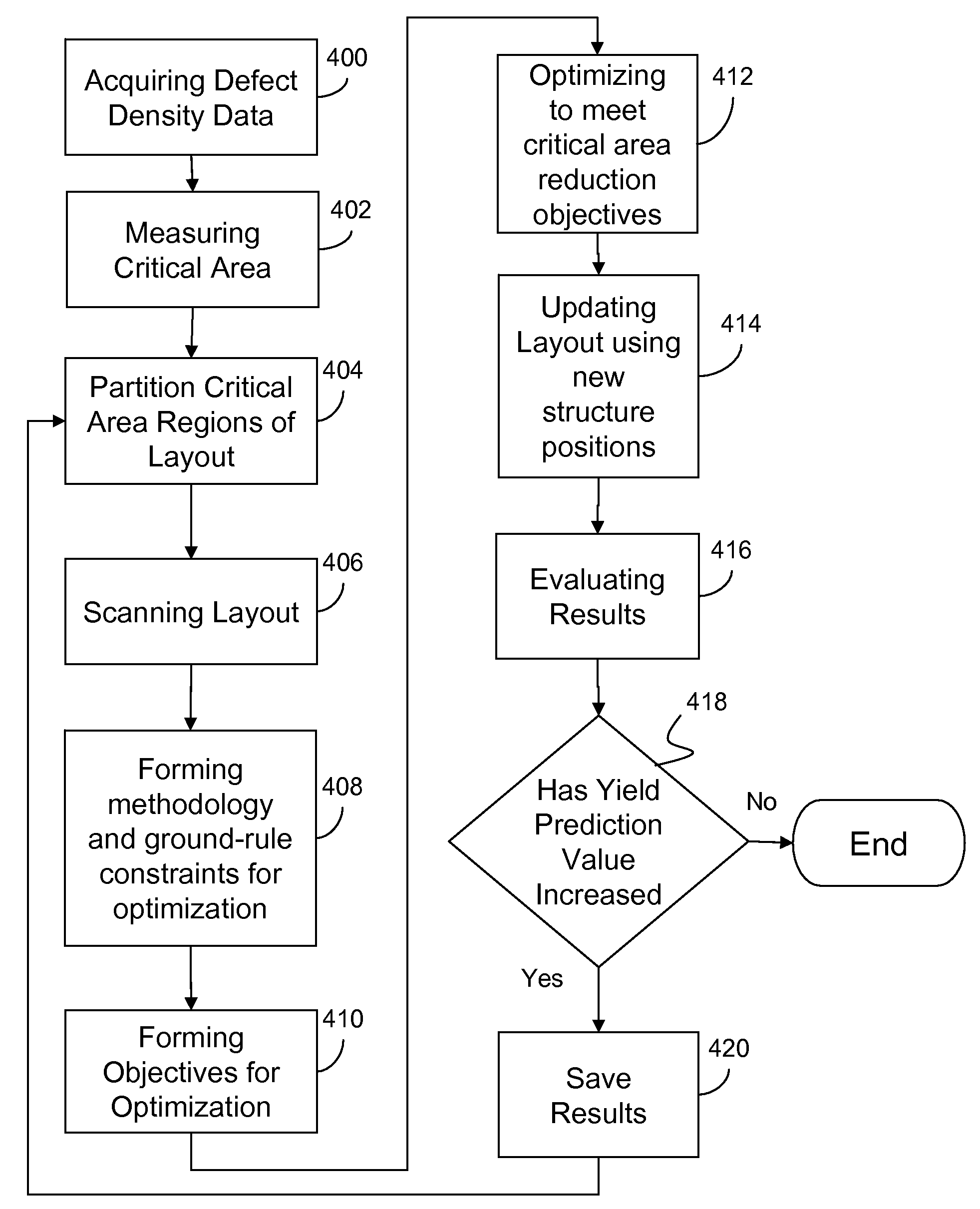

IC Layout Optimization To Improve Yield

InactiveUS20070294648A1Reduce critical area contribution costLow costCAD circuit designSoftware simulation/interpretation/emulationHigh probabilityManufacturing data

A method of and service for optimizing an integrated circuit design to improve manufacturing yield. The invention uses manufacturing data and algorithms to identify areas with high probability of failures, i.e. critical areas. The invention further changes the layout of the circuit design to reduce critical area thereby reducing the probability of a fault occurring during manufacturing. Methods of identifying critical area include common run, geometry mapping, and Voronoi diagrams. Optimization includes but is not limited to incremental movement and adjustment of shape dimensions until optimization objectives are achieved and critical area is reduced.

Owner:GLOBALFOUNDRIES INC

Adjusting resistance of non-volatile memory using dummy memory cells

In some non-volatile storage systems, a block of data memory cells is manufactured with a dummy word line at the bottom of the block, at the top of the block, and / or at other locations. By selectively programming memory cells on the dummy word line(s), the resistances associated with the data memory cells can be changed to account for different programmed data patterns.

Owner:SANDISK TECH LLC

Real time monitoring manufacturing scheduling and control

InactiveUS20060031840A1Minimize the numberMultiprogramming arrangementsMemory systemsCompletion timeBusiness management

A method and system for visually displaying real-time enterprise management information is provided. An application integration platform receives plural types of data from manufacturing and information systems within an enterprise and analyzes the plural types of data to determine key performance indicators, such as a number of tardy jobs. A process control server receives manufacturing data from at least one work center and forwards the manufacturing data to the application integration platform. A user interface that interfaces with the application integration platform provides a visual display of the number of tardy jobs in accordance with the class of user interacting therewith. The user may then reschedule the tardy jobs on alternate machines and determine how such rescheduling will affect the expected completion times of all jobs running on all machines.

Owner:ABB RES LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com