Method and system for detecting defects on a printed circuit board

A technology for printed circuit boards and defects, applied to printed circuits, printed circuit manufacturing, electrical components, etc., can solve problems such as difficulty in collecting quantitative information and slow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

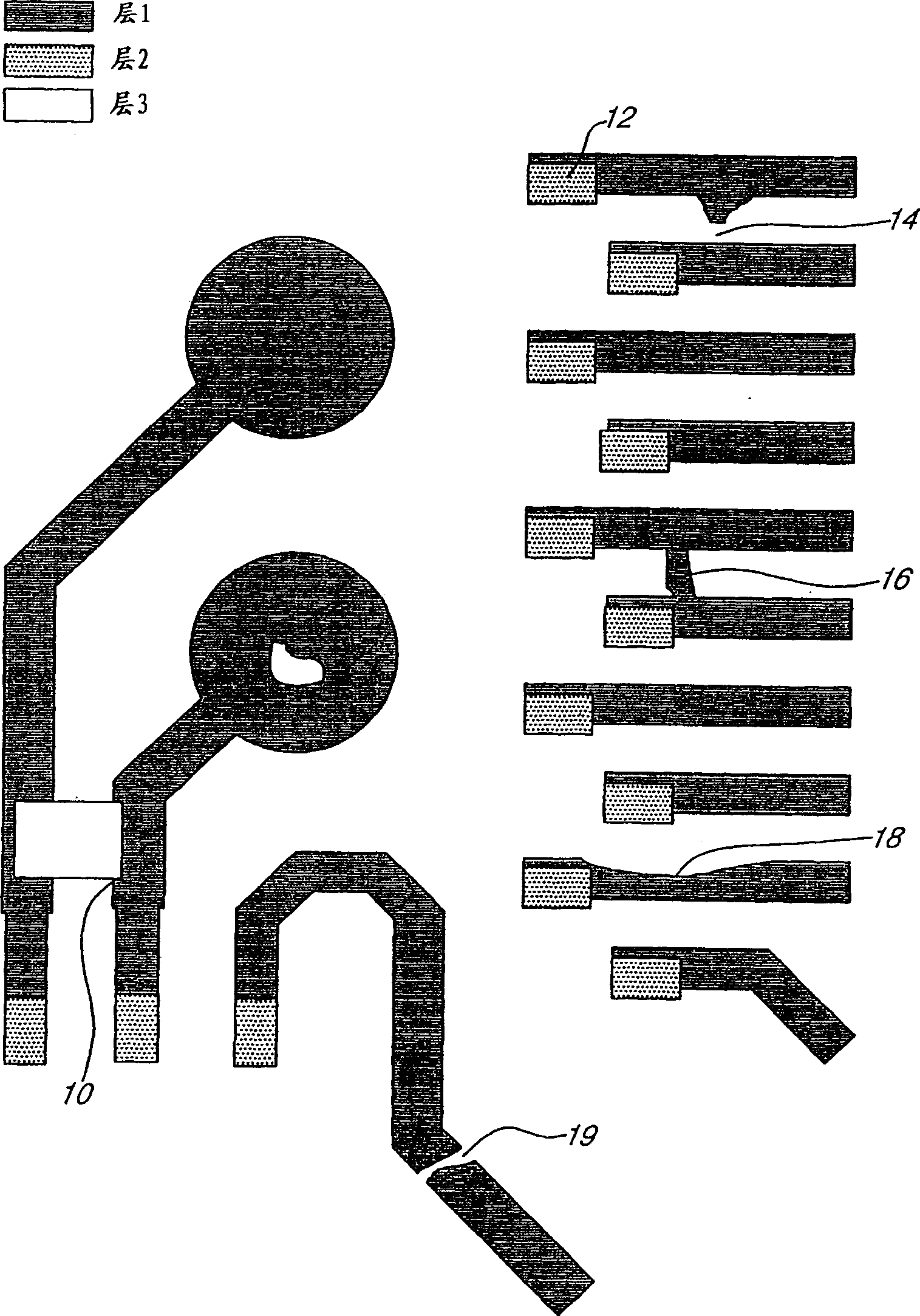

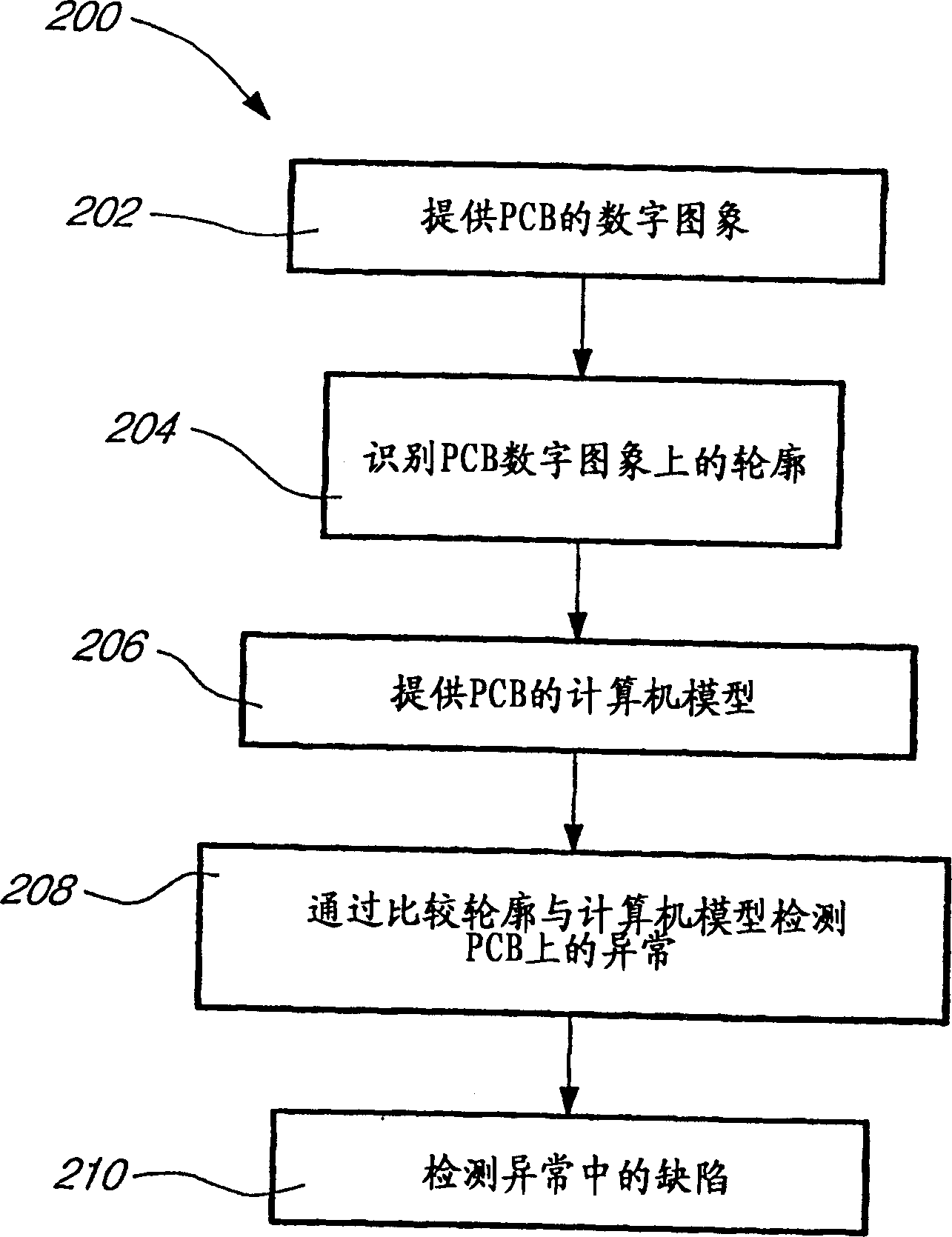

[0052] In general, a method for detecting PCB surface defects according to an embodiment of the present invention includes 1) identifying edges on a digital image of the PCB, 2) detecting anomalies by comparing the identified edges with a computer model of the PCB, and 3) detecting anomalies by The characterization of each anomaly determines whether the detected anomaly corresponds to a defect in the surface.

[0053] The method according to the invention thus proposes two levels of inspection: a first level, which allows rapid identification of anomalies and requires relatively little computation time, and a second level, which is a more refined inspection, comparing identified anomalies with design specifications, in order to characterize the detected defects.

[0054]To implement this method, a digital image of the inspected PCB and a computer model of a similar PCB must be provided.

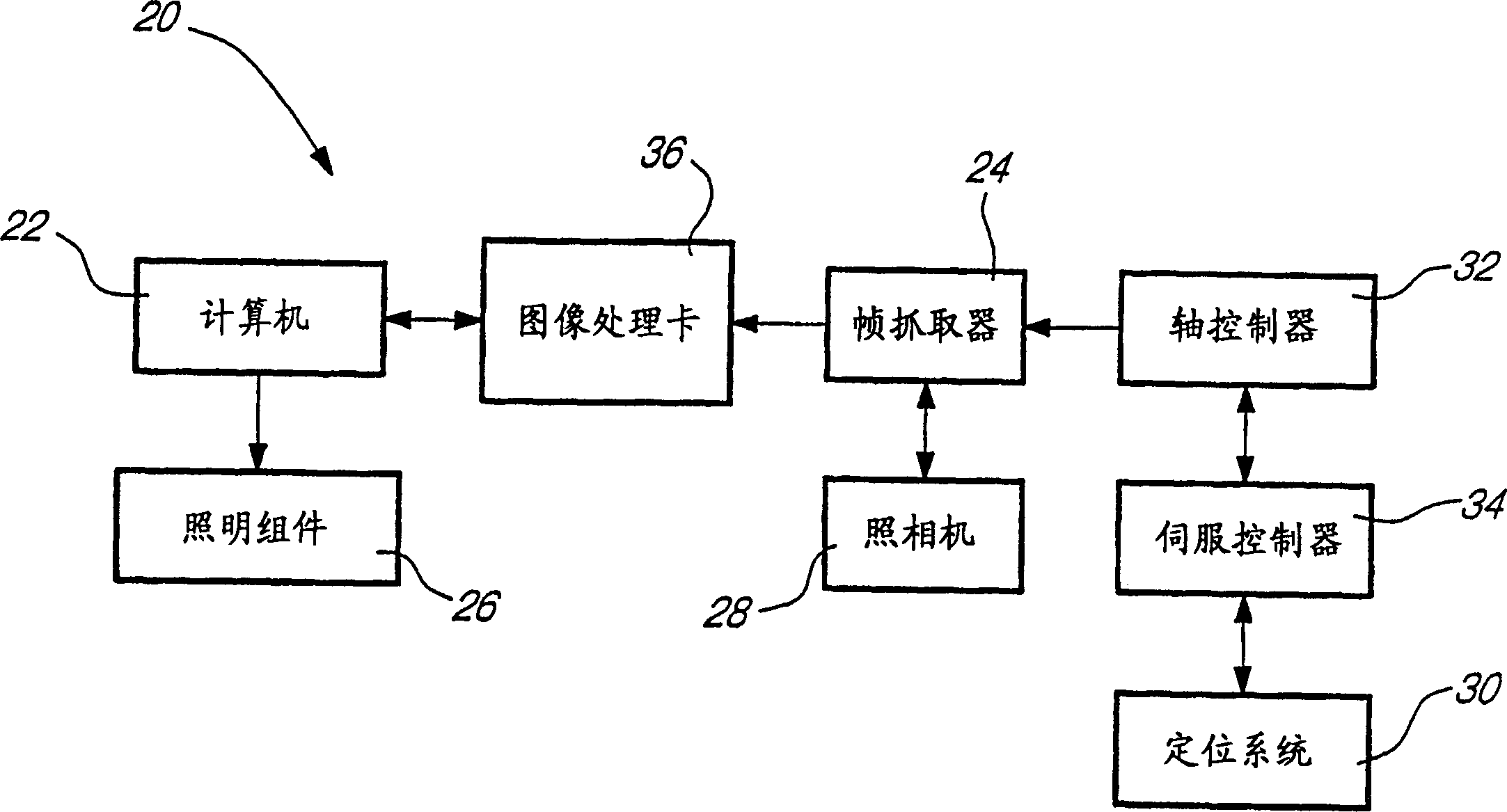

[0055] see attached figure 2 , a system 20 for detecting PCB surface defects according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com