Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

14016results about How to "Guarantee product quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

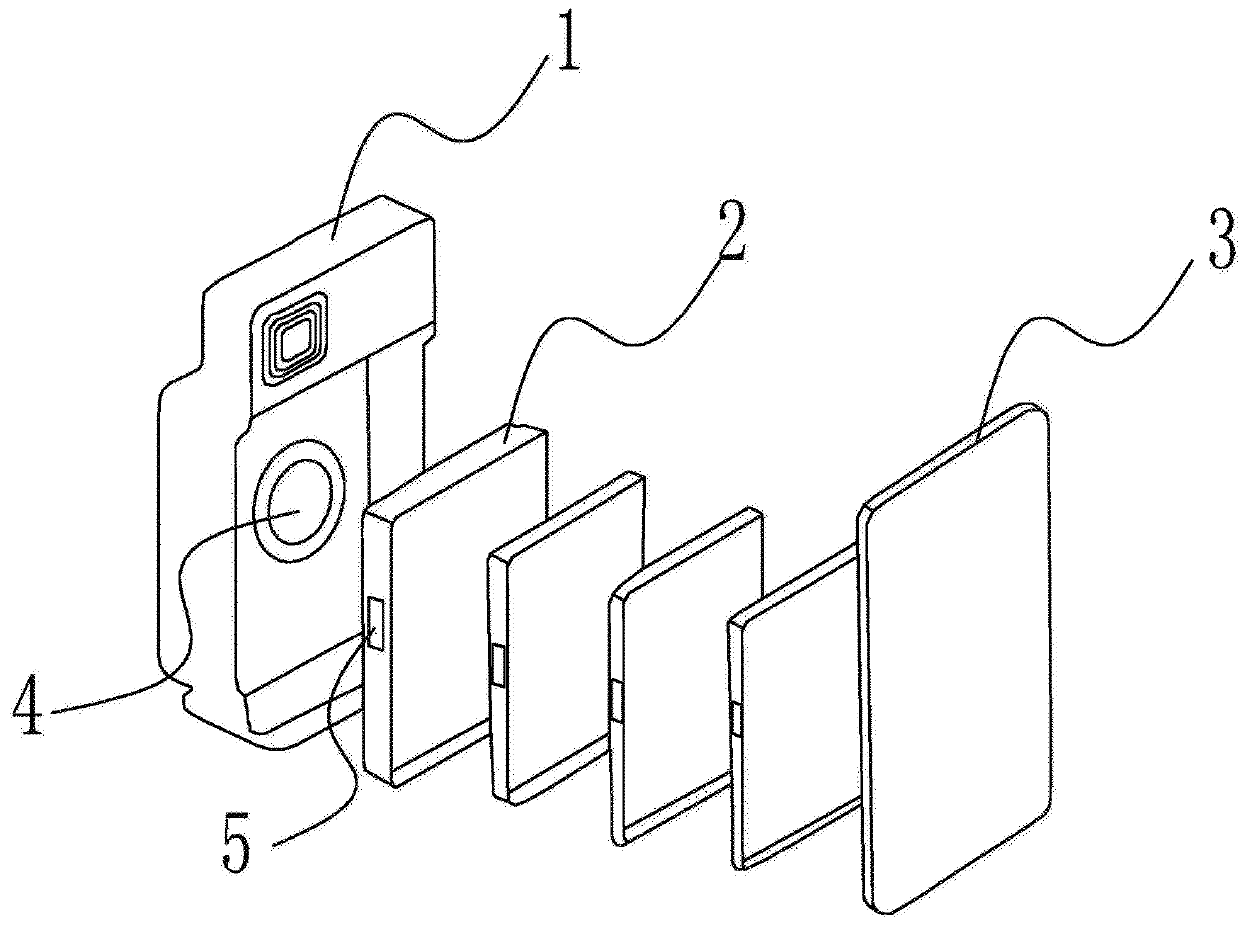

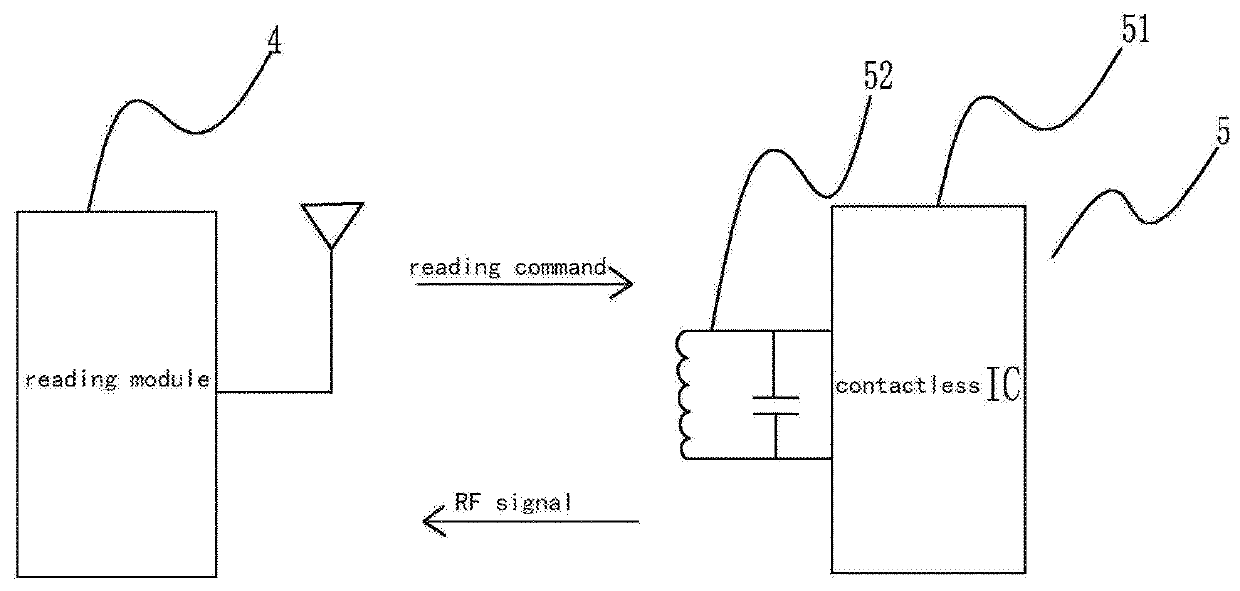

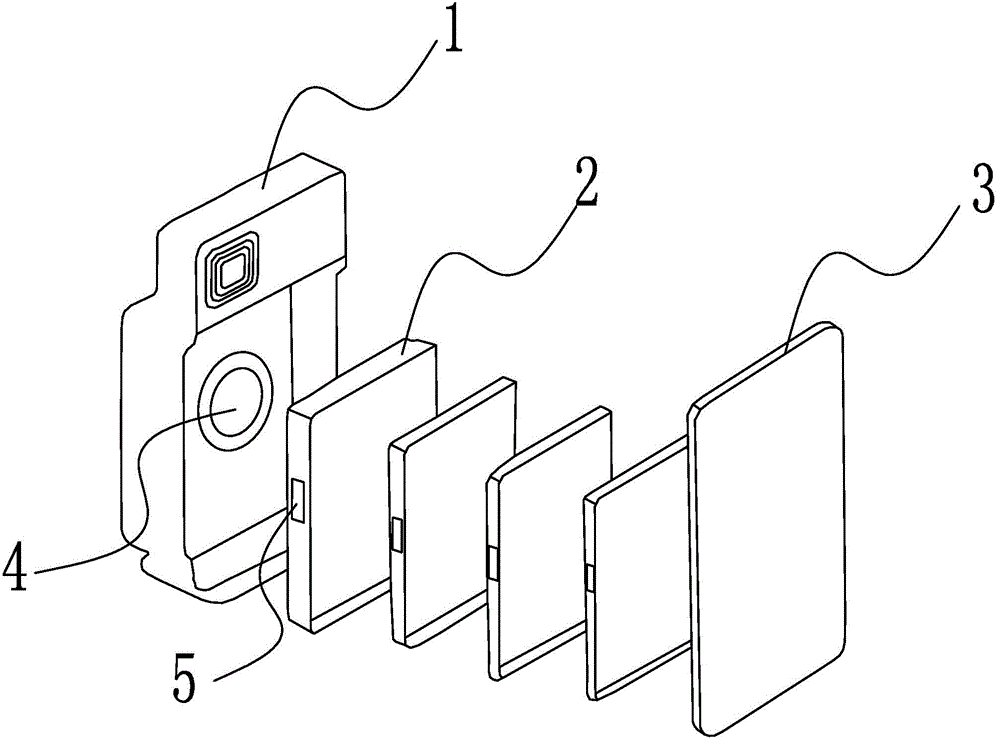

Air purifier based on filter Anti-counterfeiting identification

InactiveUS20180161716A1Guarantee product qualityPrevent counterfeitingDispersed particle filtrationTransportation and packagingAir purifiersPairing

Disclosed is an air purifier based on filter anti-counterfeiting identification, comprising a purifier body (1) in which control circuitry and a purifying chamber are provided; a filter (2) is arranged in the purifying chamber; the filters (2) are paired and coupled with the purifier body (1) via an identification unit; the identification unit comprises an identification chip configured on the filter (2) and an identifier configured on the purifier body (1); the identifier is connected with the control circuitry; the control circuitry is powered on and starts to operate until the pairing between the identification chip and the identifier succeeds. The identification process can identify multiple objects without manual intervention. Moreover, it responds quickly and no mechanical malfunction will happen. Thus, the air purifier can operate under harsh environment and serve for a long time. In this manner, counterfeits can be effectively prevented and quality of products can be guaranteed.

Owner:SHUNDE APOLLO AIR CLEANER

Continuous long fiber reinforced fire-retardant thermoplastic resin and its prepn

ActiveCN1810862ASimple recipeSimple process controlLong-fiber-reinforced thermoplasticPolymer chemistry

The present invention discloses one kind of continuous long fiber reinforced fire-retardant thermoplastic resin and its preparation process. It is prepared through mixing continuous long fiber reinforced thermoplastic resin agglomerate, which has reinforcing fiber content of 30-80 wt% and agglomerate length of 3-30 mm, and fire-retardant agglomerate, which has thermoplastic resin as carrier, fire retardant in 20-60 wt%, fire-retarding synergist 5-20 wt% and other additive 0-5 wt%. The continuous long fiber reinforced fire-retardant thermoplastic resin has continuous long fiber content of 5-60 wt%. The continuous long fiber reinforced fire-retardant thermoplastic resin has excellent mechanical performance, especially impact resistance, and excellent fire-retarding performance.

Owner:KINGFA SCI & TECH CO LTD +1

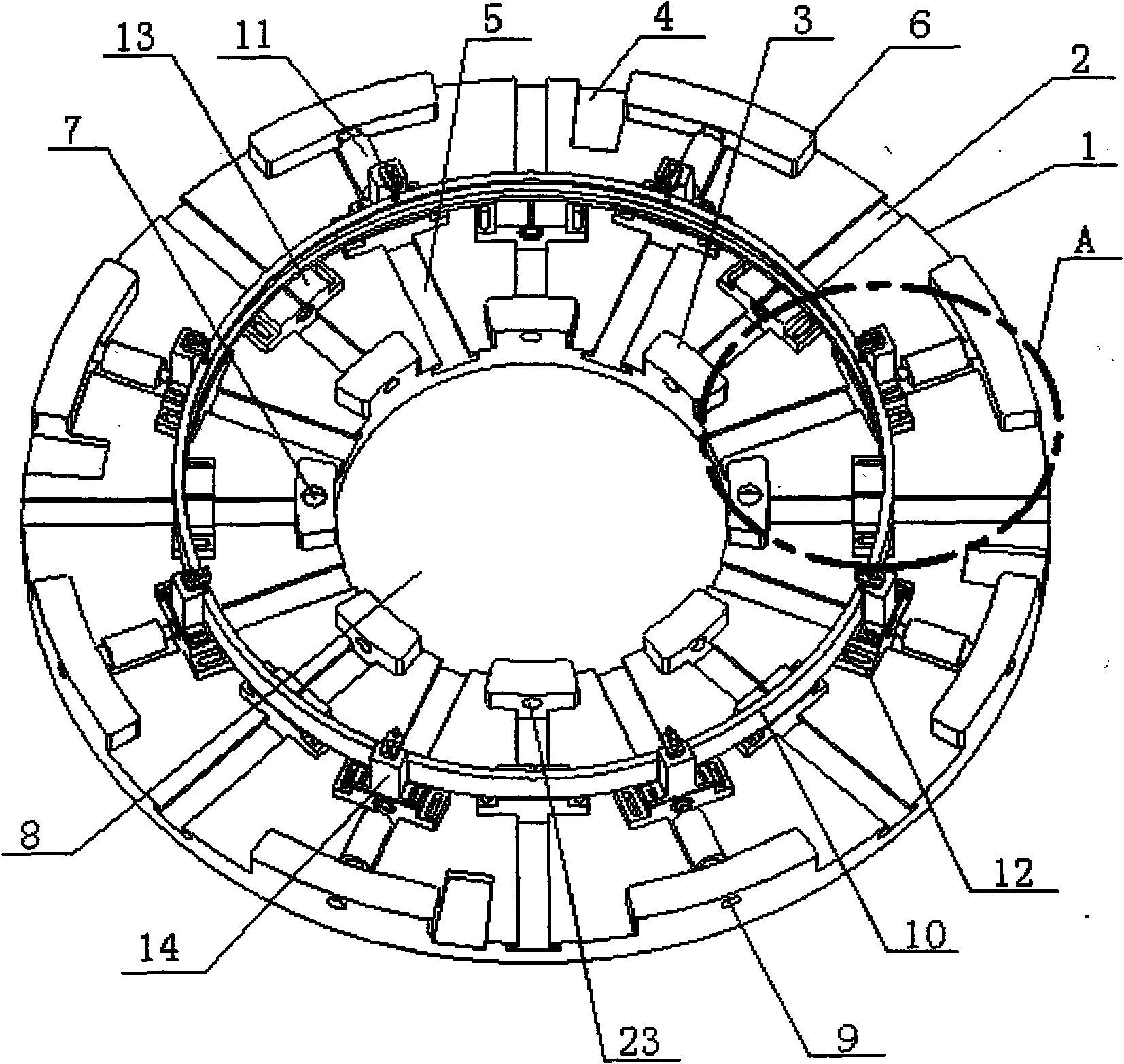

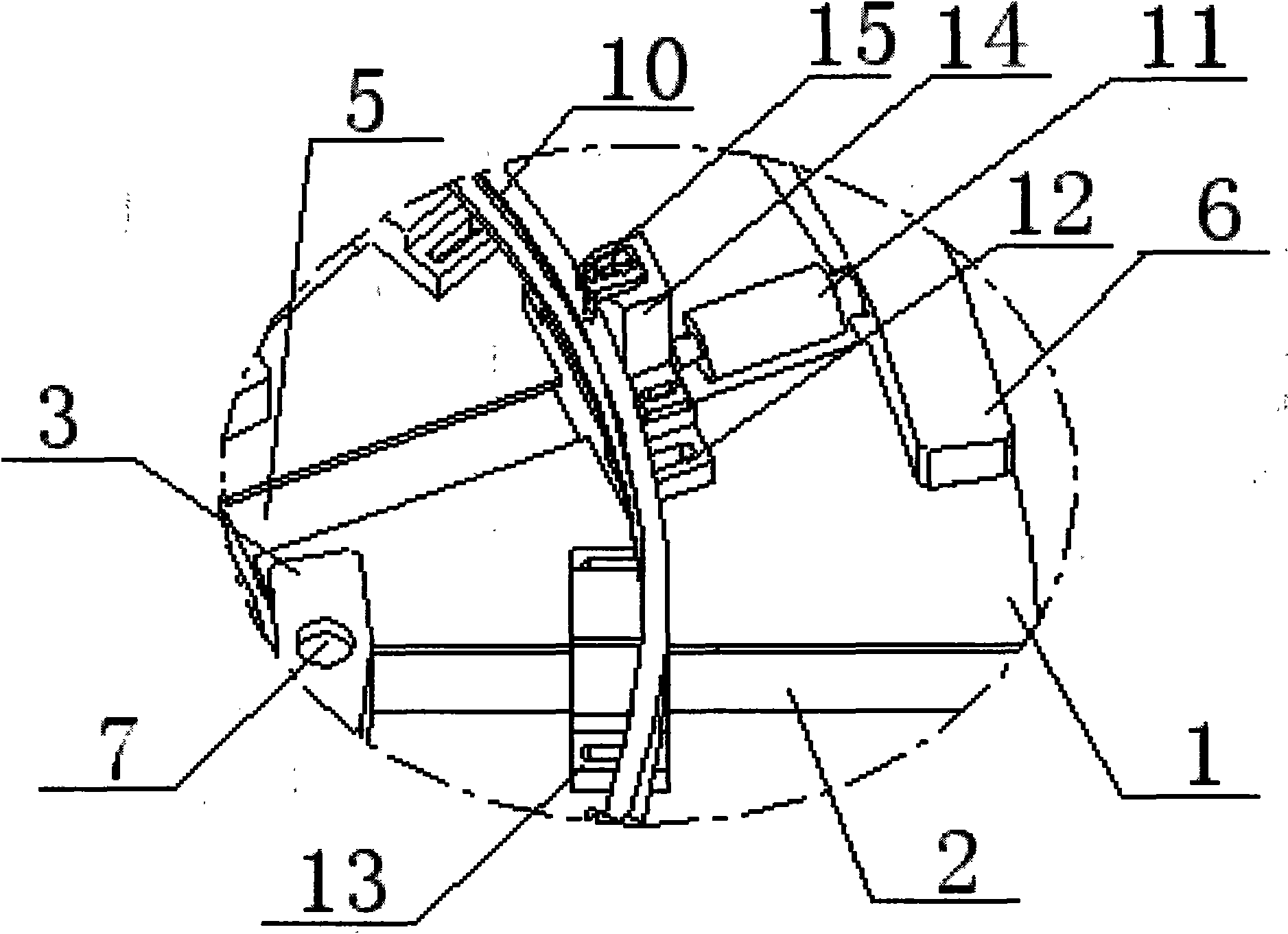

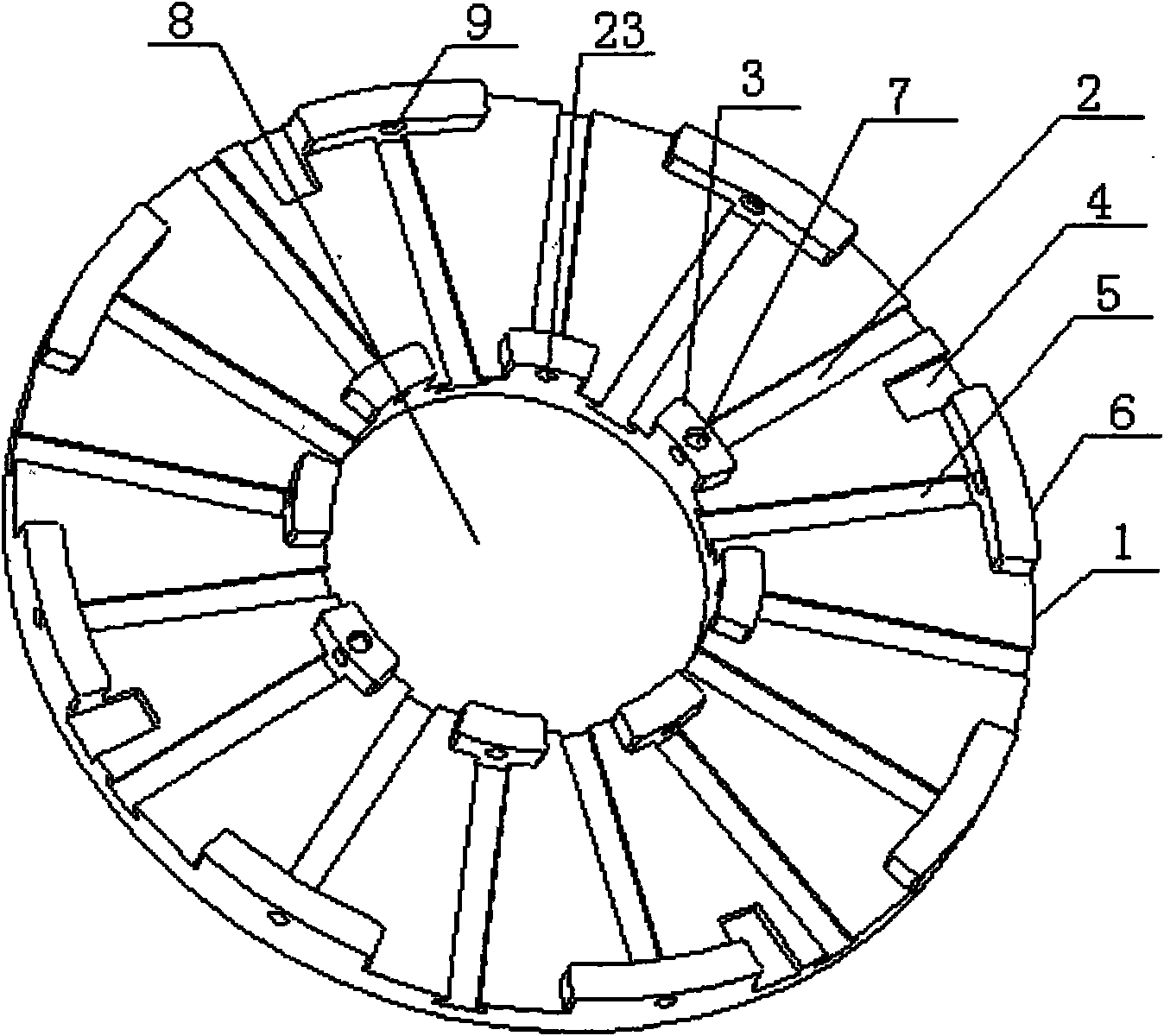

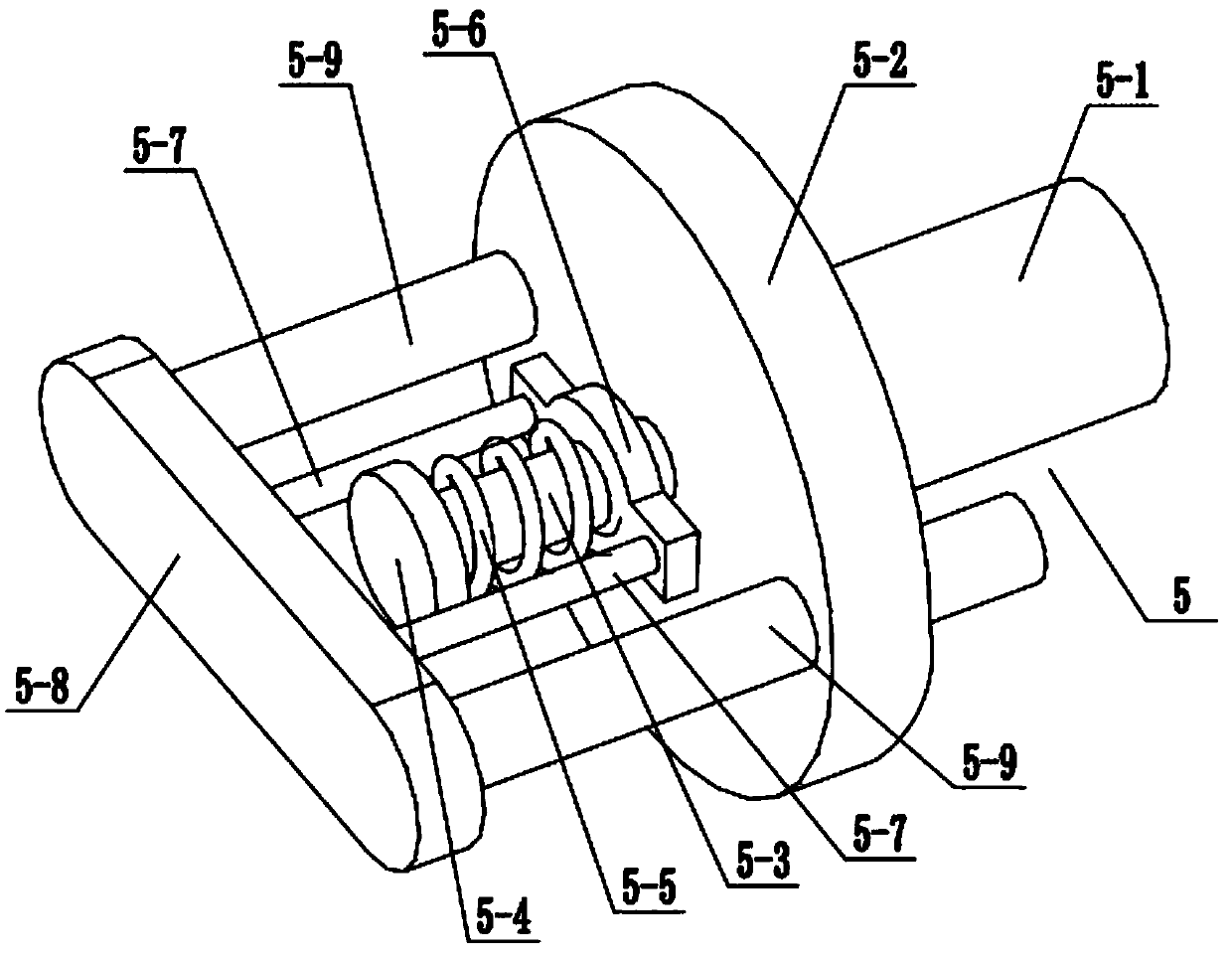

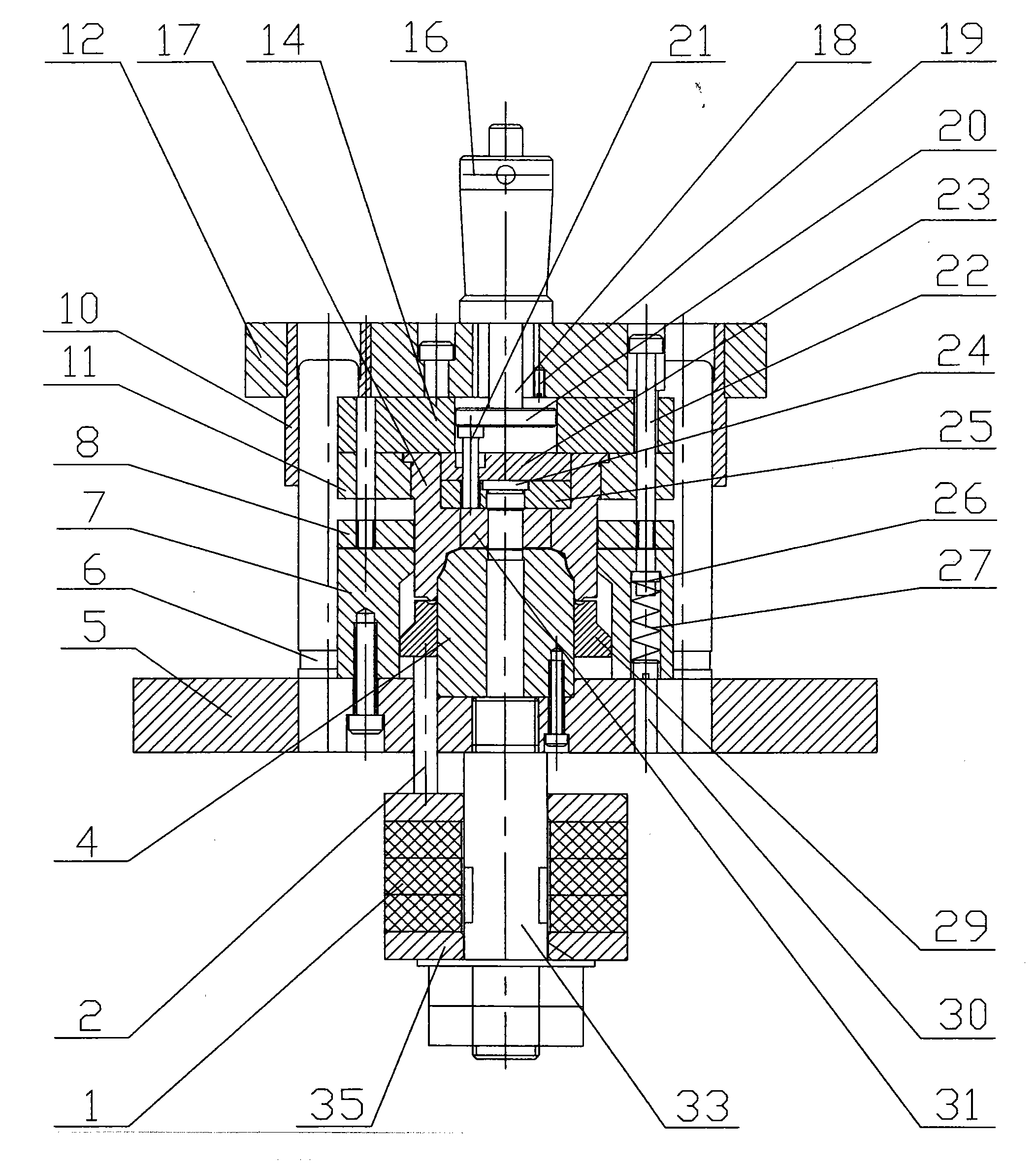

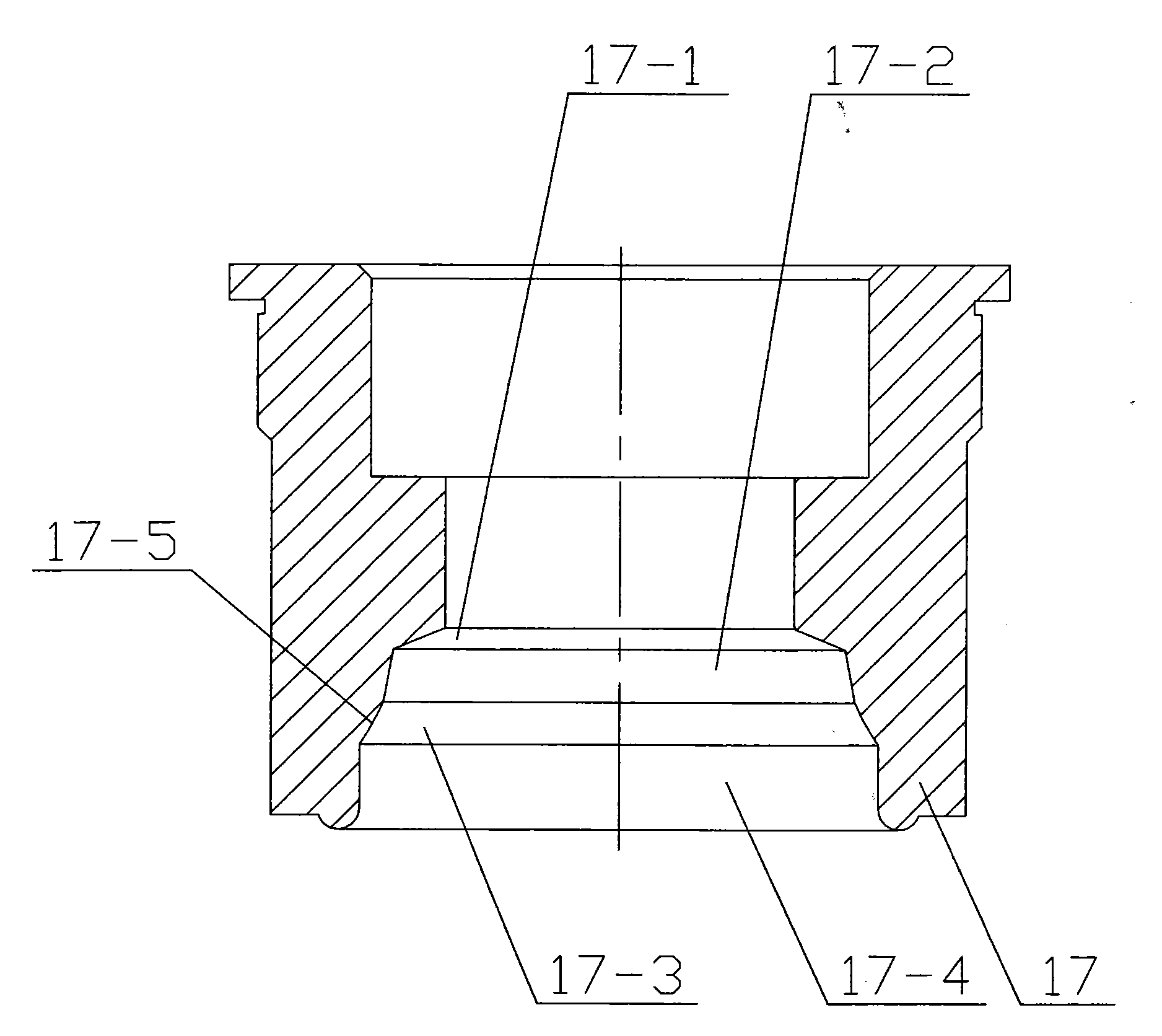

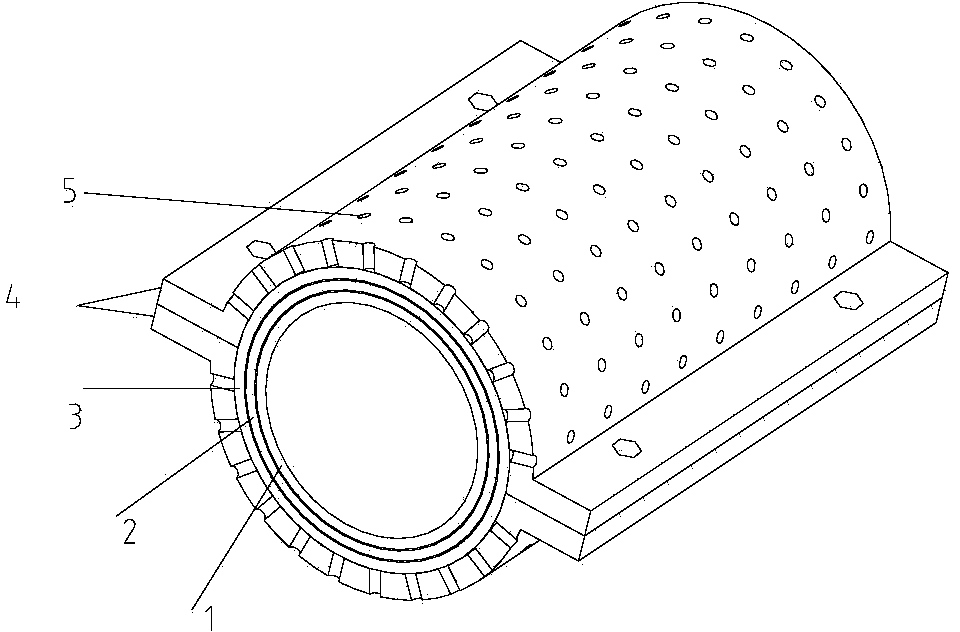

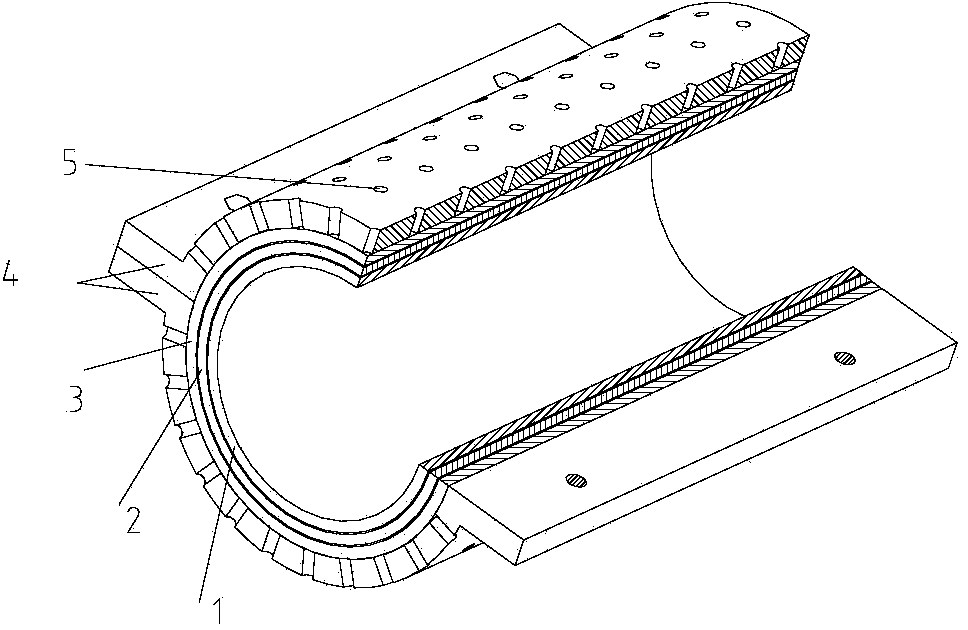

Annular thin-wall article clamping device and using method thereof

ActiveCN101954604AGuaranteed accuracyReduce labor intensityAutomatic conveying/guiding stockPositioning apparatusEngineeringThin walled

The invention provides an annular thin-wall article clamping device and a using method of the device. The clamping device comprises an annular chassis; the chassis is provided with a radial regulation mechanism of a locating workpiece; the radial regulation mechanism is divided into an inner radial regulation mechanism and an outer radial mechanism; two radial regulation mechanisms position workpiece respectively from the inner side or the outer side of the workpiece; the chassis is respectively provided with track-directed sliding grooves for the two radial adjustment mechanisms; the inner end of the sliding groove of the inner radial regulation mechanism is provided with a stopping block; the outer end of the sliding groove of the outer radial regulation mechanism is provided with the stopping block; the sliding grooves of the two groups of radial regulation mechanisms are disposed at intervals; one of the two groups of radial regulation mechanisms is provided with an axial compacting mechanism for fixing the workpiece; and the axial compacting mechanism is displaced alternatively between the two groups of radial regulation mechanisms when turning the workpiece. The clamping device can realize the processing of two side walls of the workpiece by clamping the workpiece once, and is fit for the clamping of the workpieces with different specifications. The device has the characteristics of high use rate, strong practical applicability, good generality, time saving and labor saving, light labor intensity, high production efficiency and the like.

Owner:DONGFANG TURBINE CO LTD

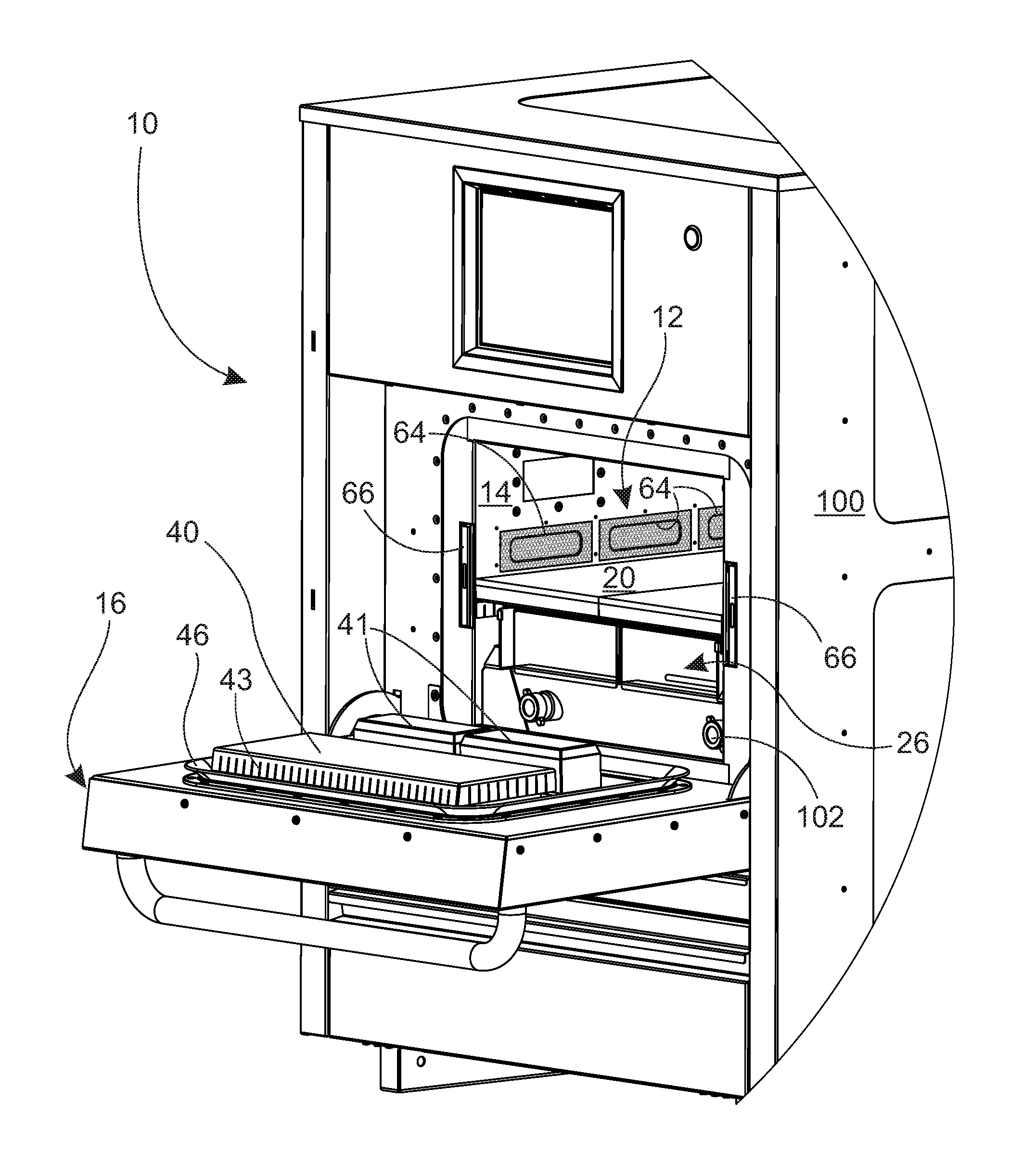

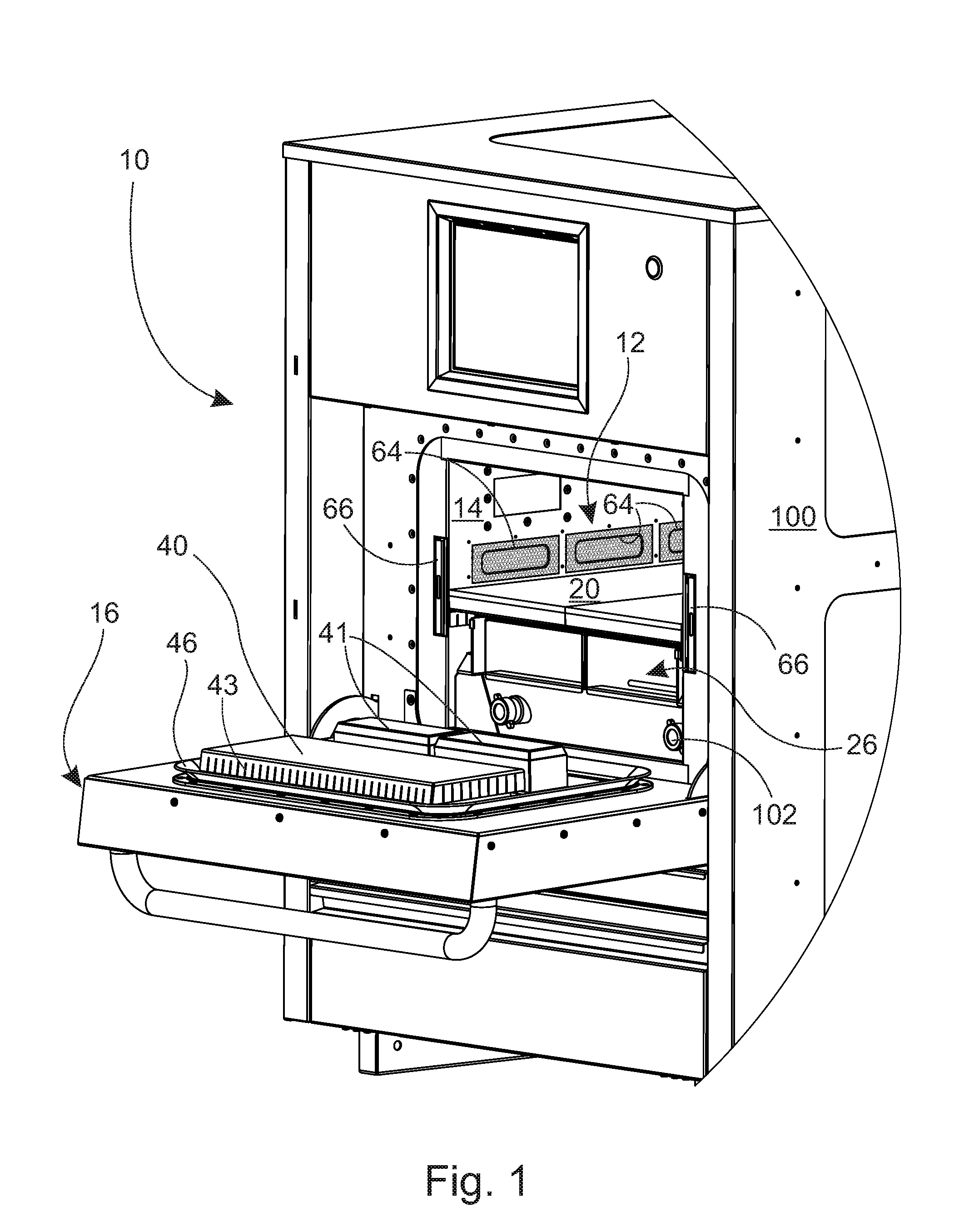

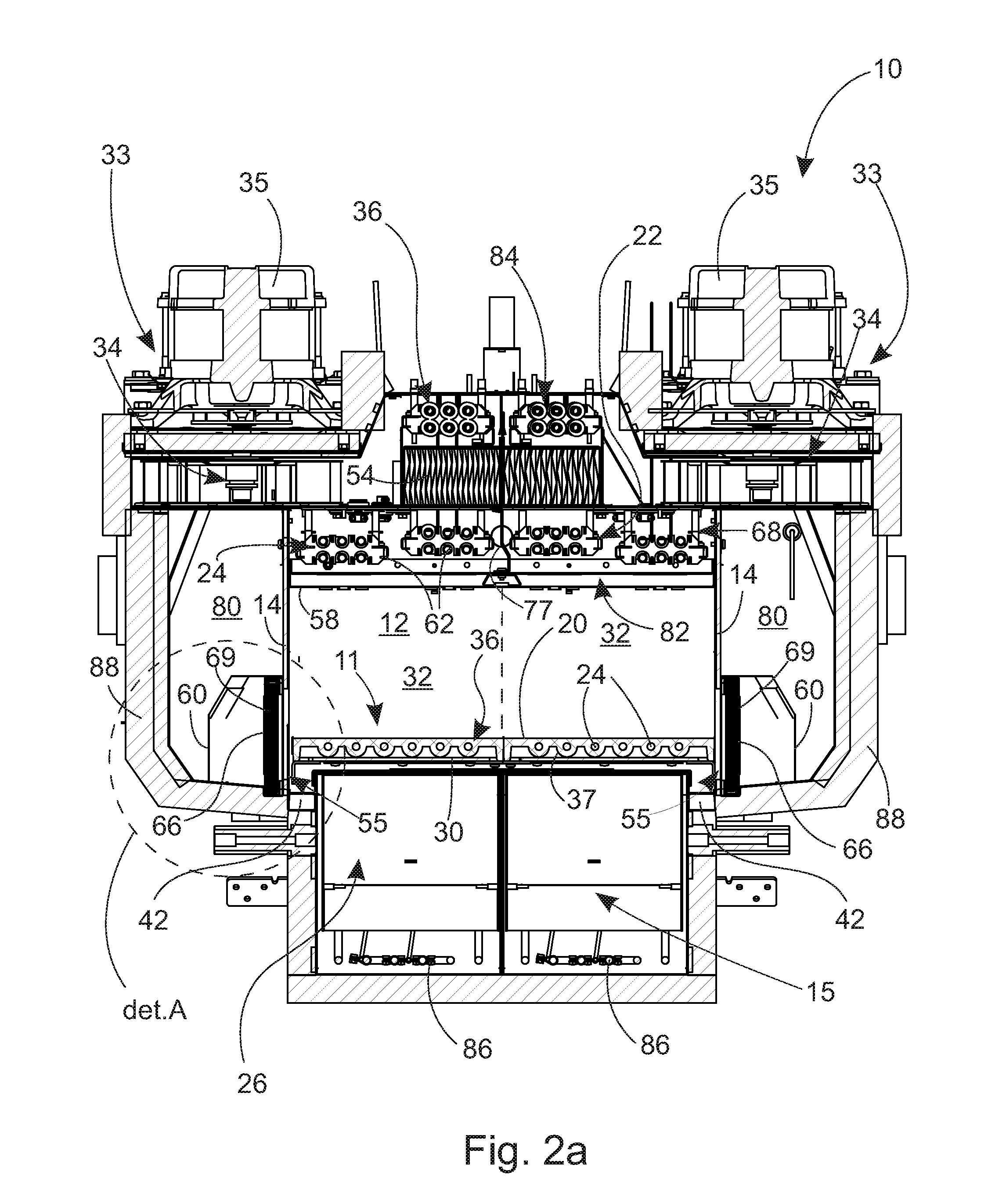

Oven for heating and frying food

ActiveUS20160316525A1Guarantee product qualityTime of keeping in accurateDomestic stoves or rangesLighting and heating apparatusMicrowaveThermal insulation

An oven for heating and frying food, particularly a rapid cook oven, includes walls and an openable oven door delimiting an oven space and heaters to heat food in the oven space. Such heaters including: microwave radiation devices, a frying plate having an undersurface, and heat circulating-air devices comprising a flow duct for removing circulating air from the oven space and leading it back into the oven space after cleaning, and a fan installed in the flow duct for creating a circulating-air flow in the said flow duct. The oven additionally includes structure delimiting a cooker space, thermal insulation between the oven space and the cooker space and a heater comprising a cooker situated in the cooker space.

Owner:R MENU

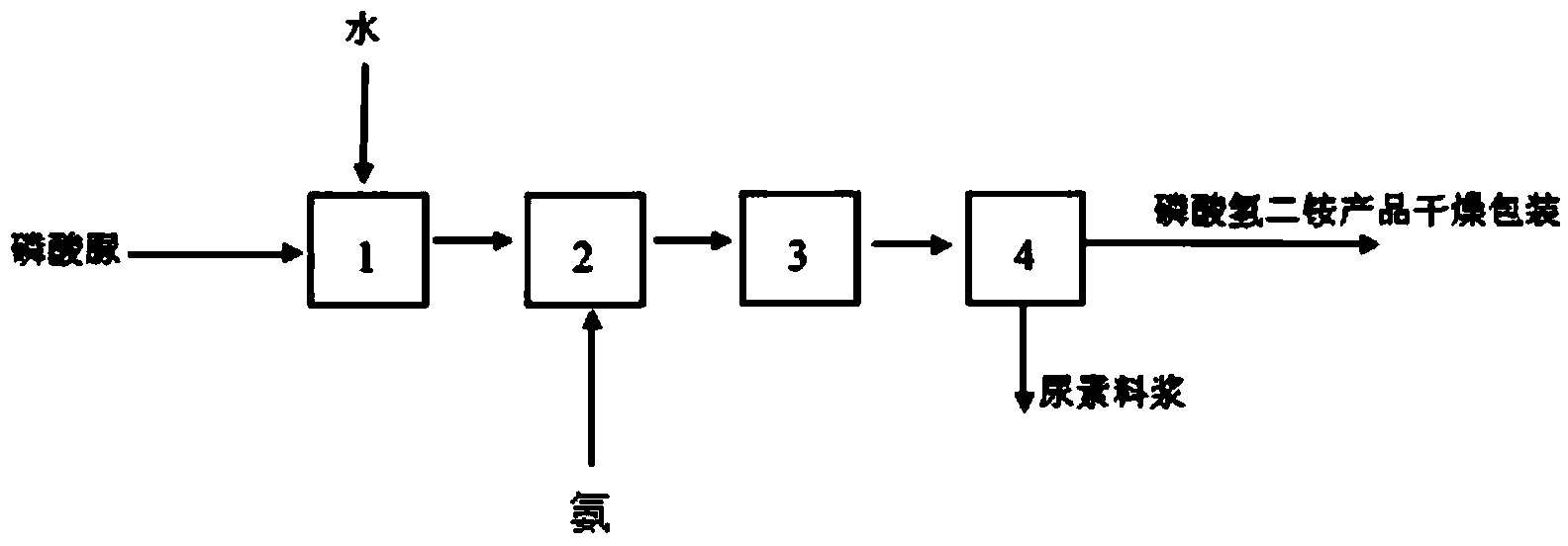

Production method for monoammonium phosphate

InactiveCN104016323AReduce energy consumptionReduce manufacturing costPhosphatesWater insolubleDecomposition

The invention relates to the technical field of chemical engineering, and particularly relates to a production method for monoammonium phosphate. A monoammonium phosphate product is prepared by directly subjecting high pure urea phosphate and ammonia to a double decomposition reaction and reacting for 20-60 min with stirring by controlling a reaction temperature at 40-80 DEG C and a pH value at a reaction endpoint being 4.2-4.6, and through the steps of cooling for crystallization; separating by centrifugation and drying. Measurements of physical and chemical indexes of the produced product show that the physical and chemical indexes of the produced monoammonium phosphate product meet an industrial first level standard. Specifically, the total nutrient content of monoammonium phosphate is higher than 73%; the content of total nitrogen is 12.01-12.23%; the content of phosphorus pentoxide is 61.05-61.25%; the content of moisture is 0.35-0.52%; a pH value is 4.2-4.6; the content of water insoluble materials is 0.090-0.096%; and the content of fluoride is 0.15-0.19%.

Owner:GUIYANG KAILIN FERTILIZER CO LTD

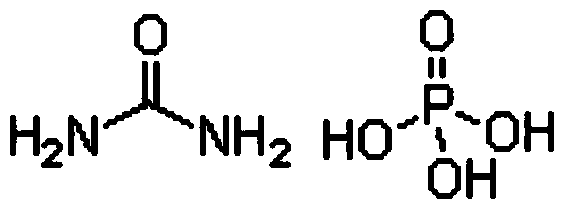

Manufacturing process of adjusting nut

InactiveCN101618498ALess consumablesCompact structureNutsMetal-working apparatusWire rodMolding machine

The invention discloses a manufacturing process of an adjusting nut. The steel billet raw materials are manufactured into wire rod materials, surface treatment is performed on the wire rod materials by using phosphate, spheroidizing annealing, phosphating and fine-drawing and sizing treatment are respectively performed on the wire rod materials after roughing, and finally, the molding working procedure of the adjusting nut is carried out in a cold-heading molding machine; the molding working procedure of the adjusting nut comprises the following steps: material fracturing; material shaping and upsetting, upsetting an inner chamfer at the upper end; material turning, shaping and upsetting a positioning hole at the upper end and an inner chamfer at the lower end; material translating, upsetting a counterbore at the front end and a positioning hole at the rear end; material turning, upsetting a counterbore at the other end; material translating, upsetting a plane in the middle by using the PKO male die technology; discharging the residual scrap iron at a middle hole out and manufacturing a through hole product; and performing tapping to an inner hole of a blank of the adjusting nut. The invention is molded at one time by adopting a cold heading machine, thereby improving the production efficiency and the product quality of the adjusting nut, saving the raw material and reducing the manufacturing cost.

Owner:NINGBO ANCHOR FASTENERS INDAL

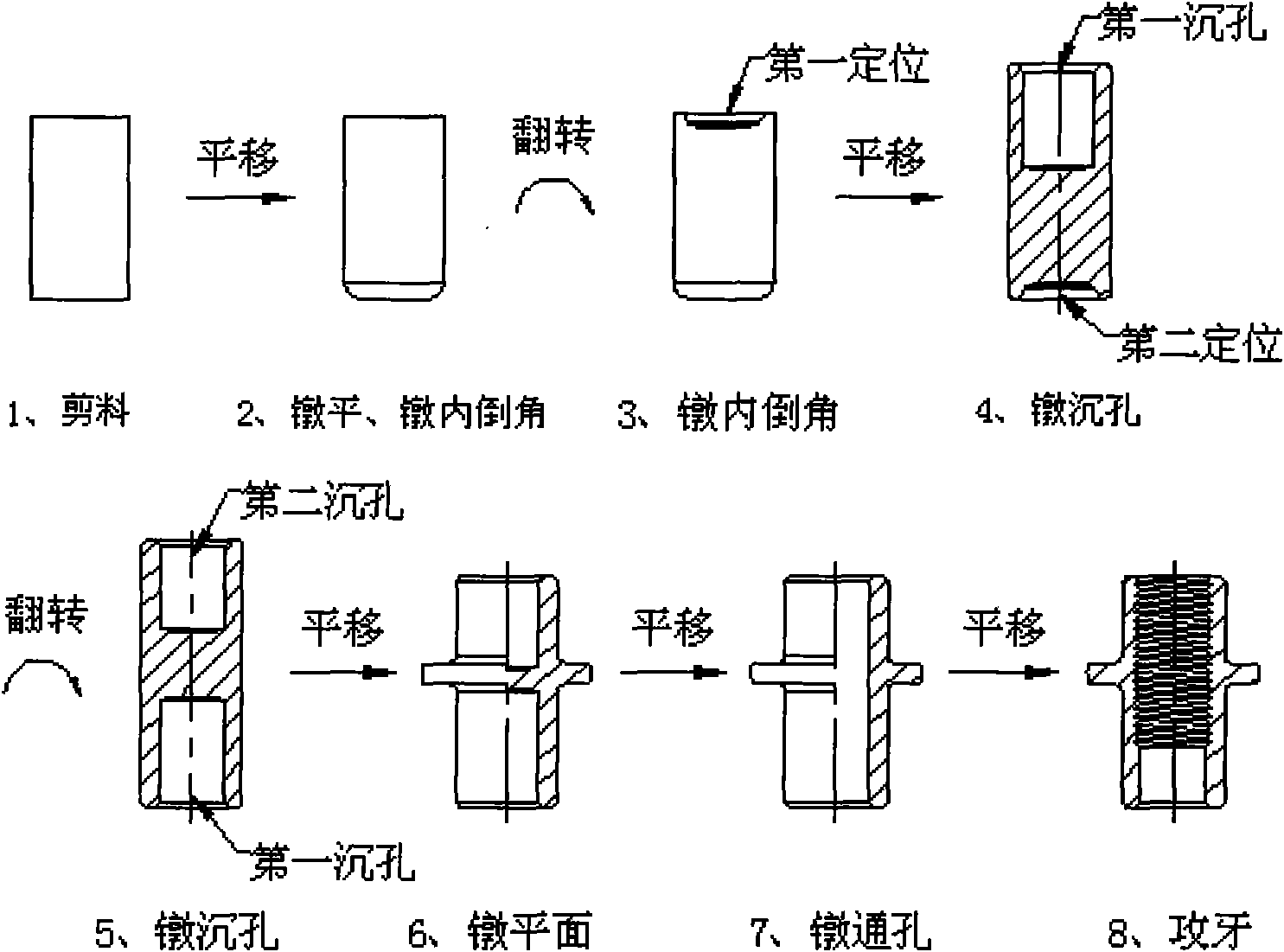

Method and system for treating construction waste

InactiveCN102838307AAchieve pre-separationReduce micronized contentSolid waste managementEngineeringNational standard

The invention discloses a method for treating construction waste, comprising the following steps of: performing feeding and dregs pre-screening, primary crushing, secondary crushing and product screening on a material in sequence; performing sorting and impurity removing treatment on the material subjected to the primary crushing; performing material returning screening on the material subjected to the sorting and impurity removing treatment, performing particle shaping on the material screened down after the material returning screening treatment, and returning the oversize material to the secondary crushing; and combining the material subjected to the secondary crushing with the material in the sorting and impurity removing treatment. The system and method treating construction waste, provided by the invention, have high-efficiency and systemic sorting and impurity-removing functions; the generated construction waste recycled aggregate product meets the requirements of national standard 'recycled coarse aggregate for concrete'(GB / T 25177-2010), 'recycled fine aggregate for concrete and mortar' (GB / T 25176-2010) and other recycled aggregate product raw materials.

Owner:SHOUGANG CORPORATION

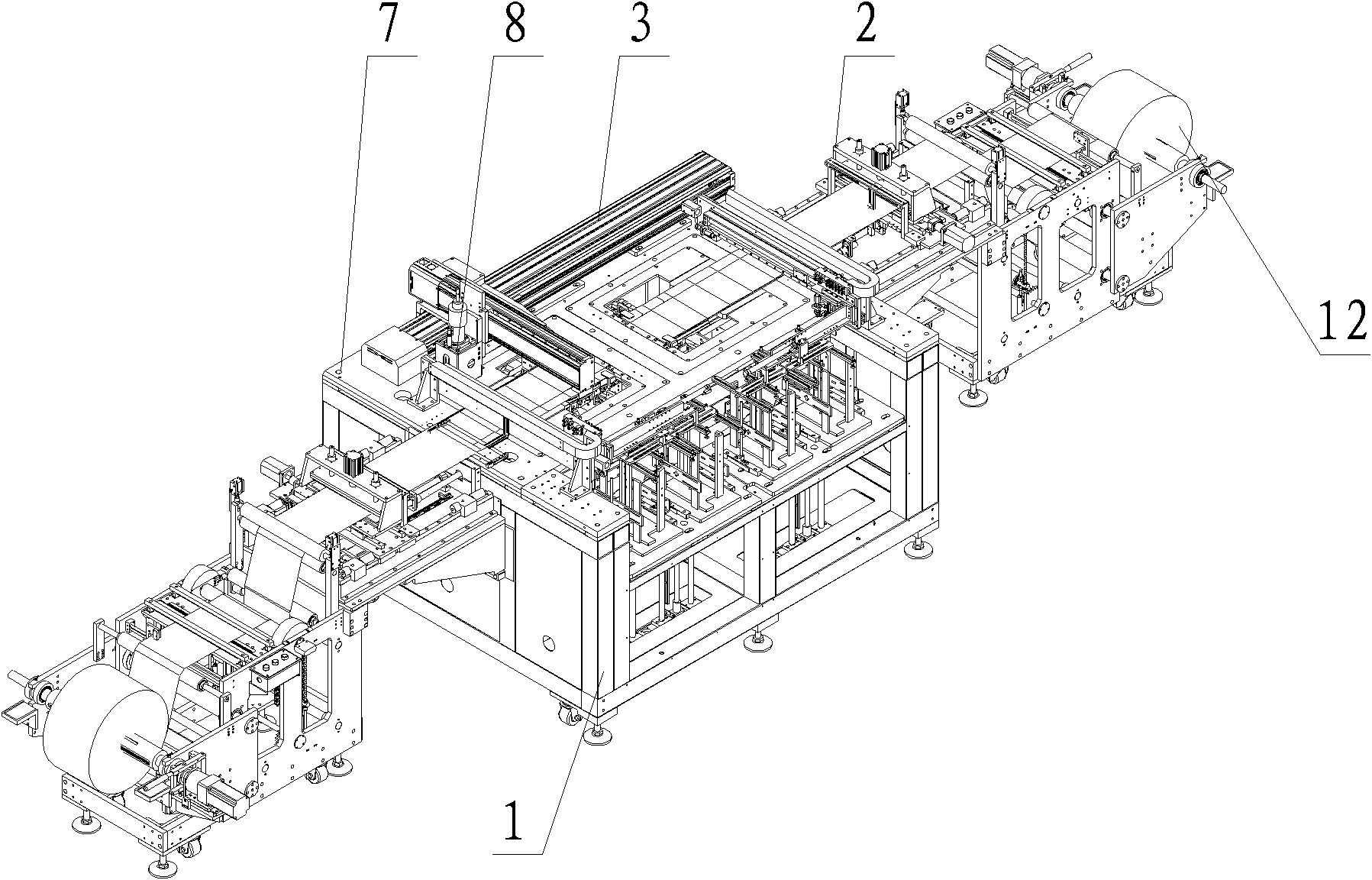

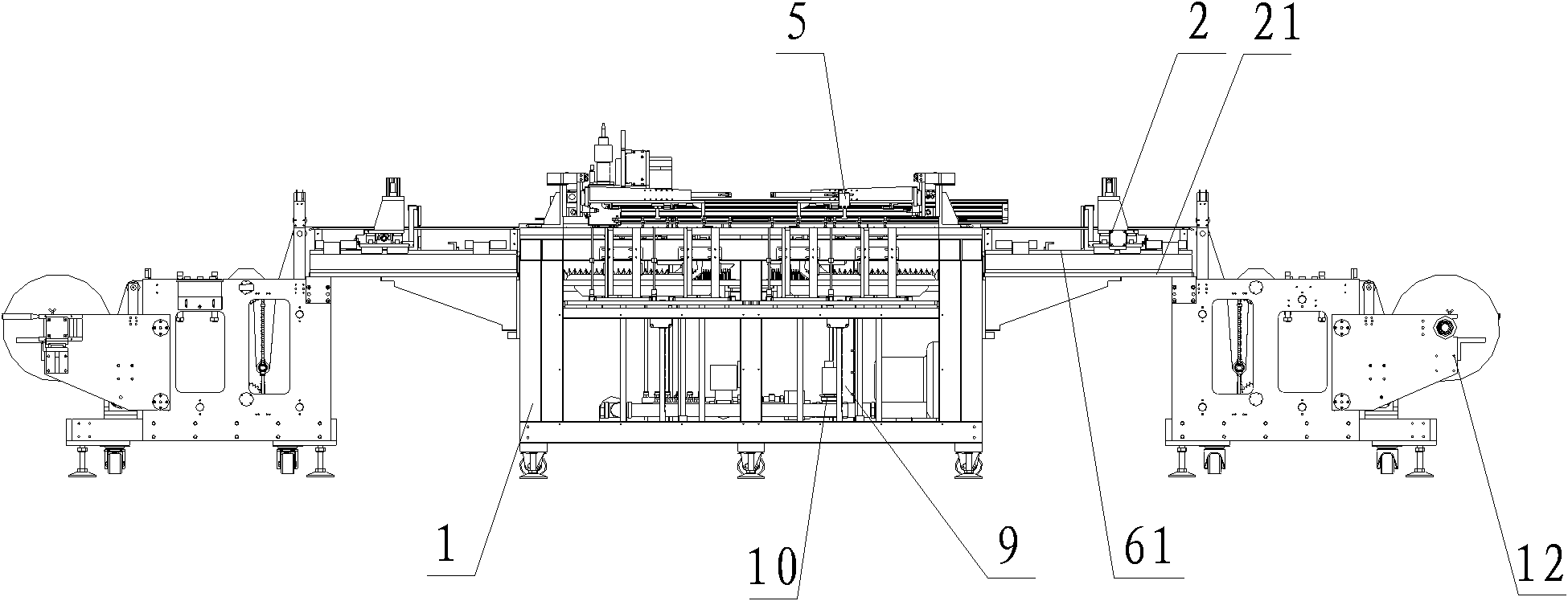

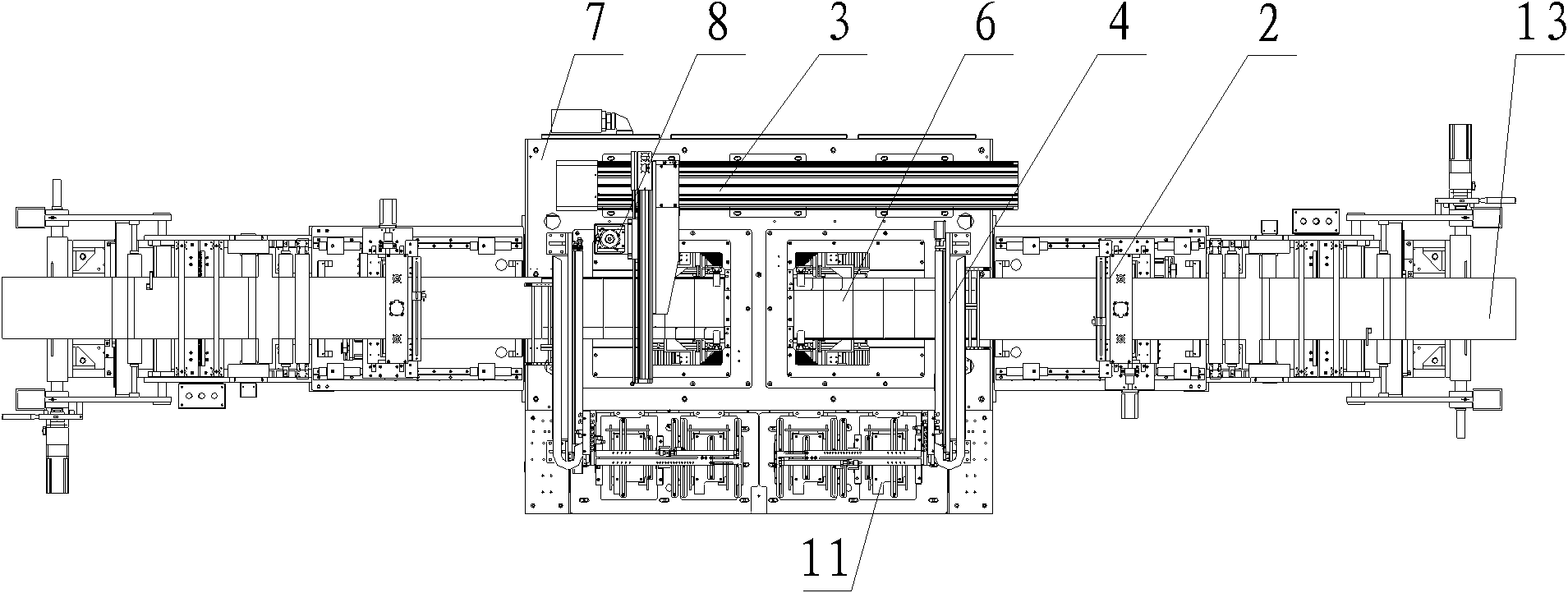

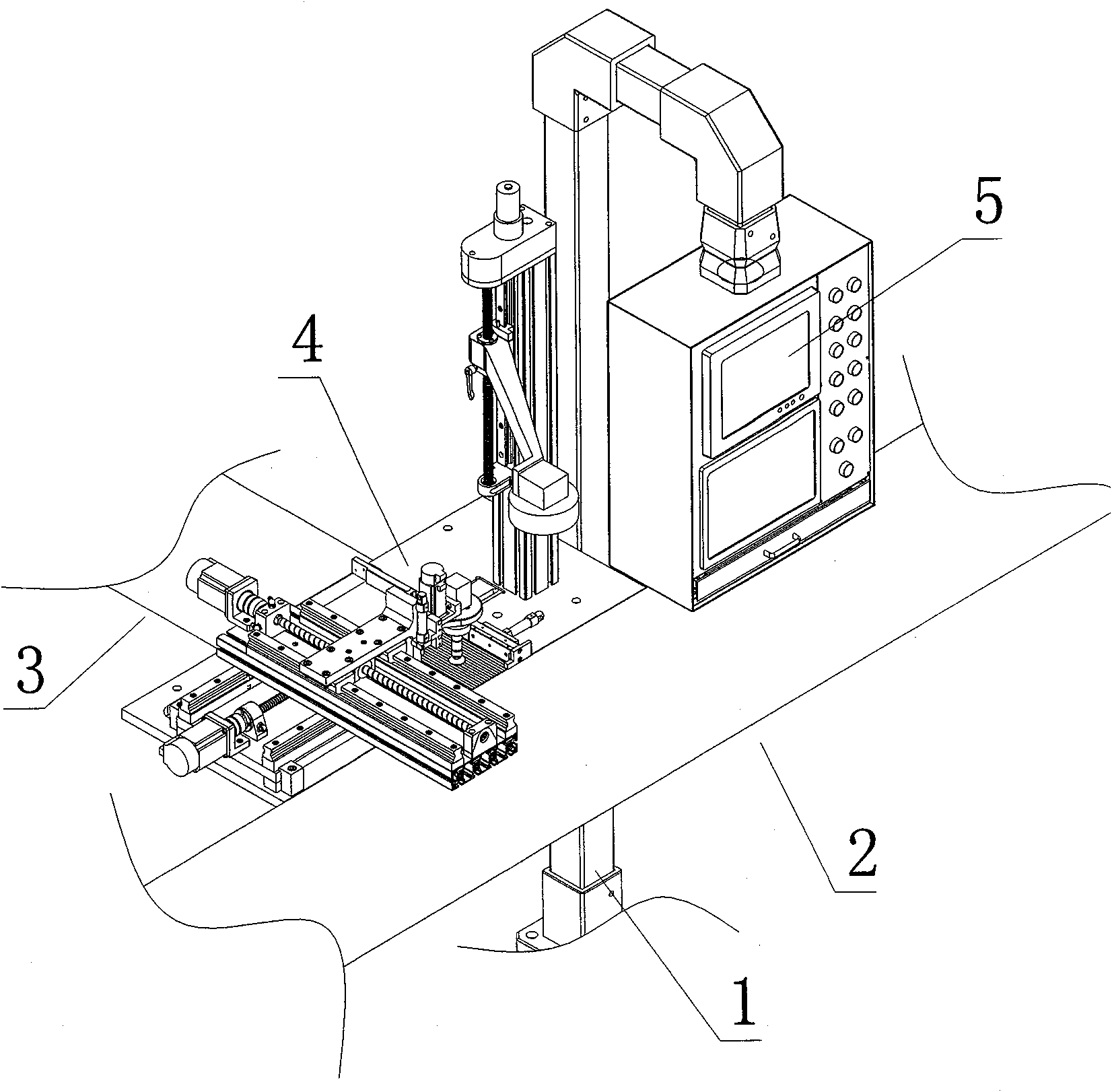

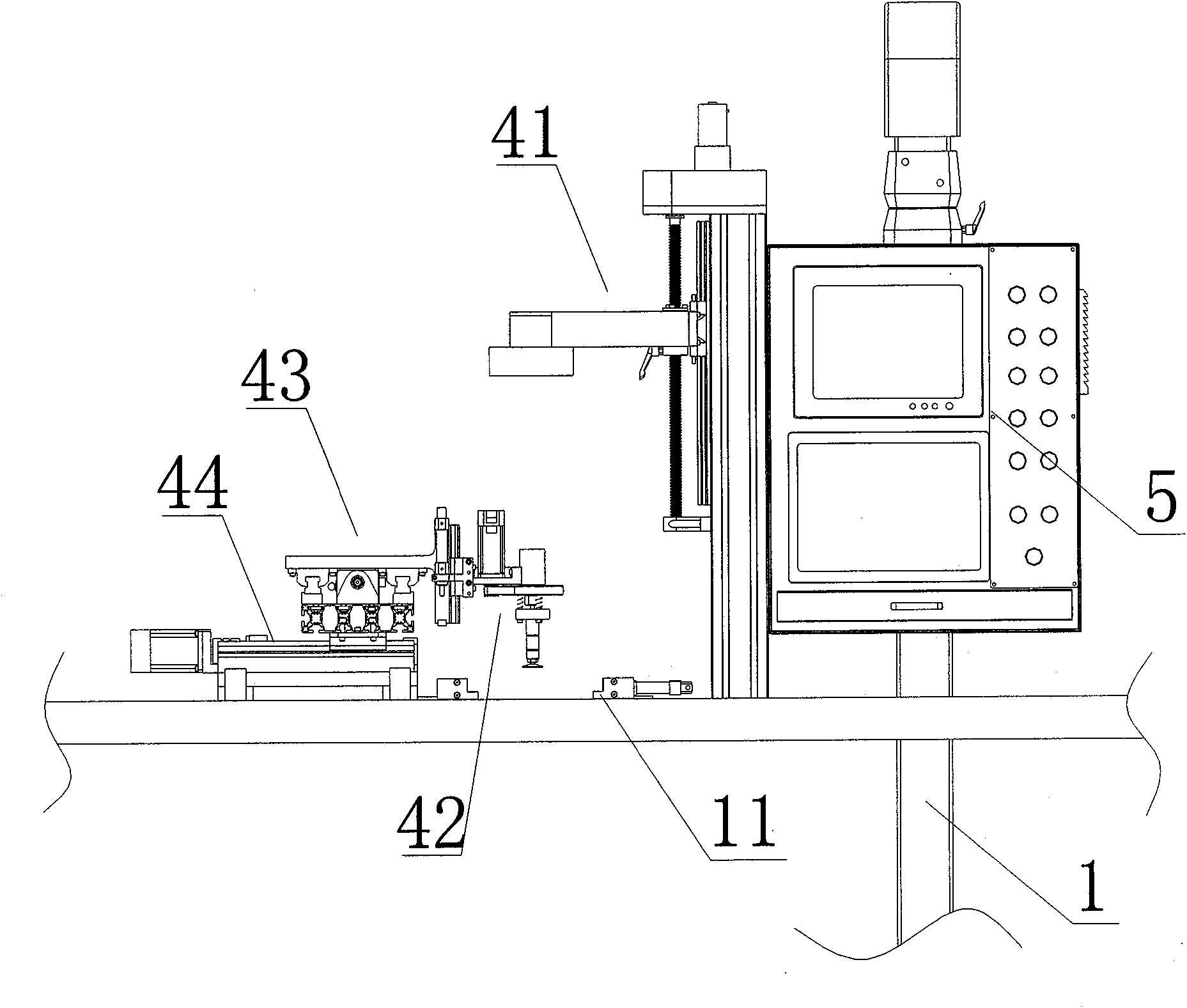

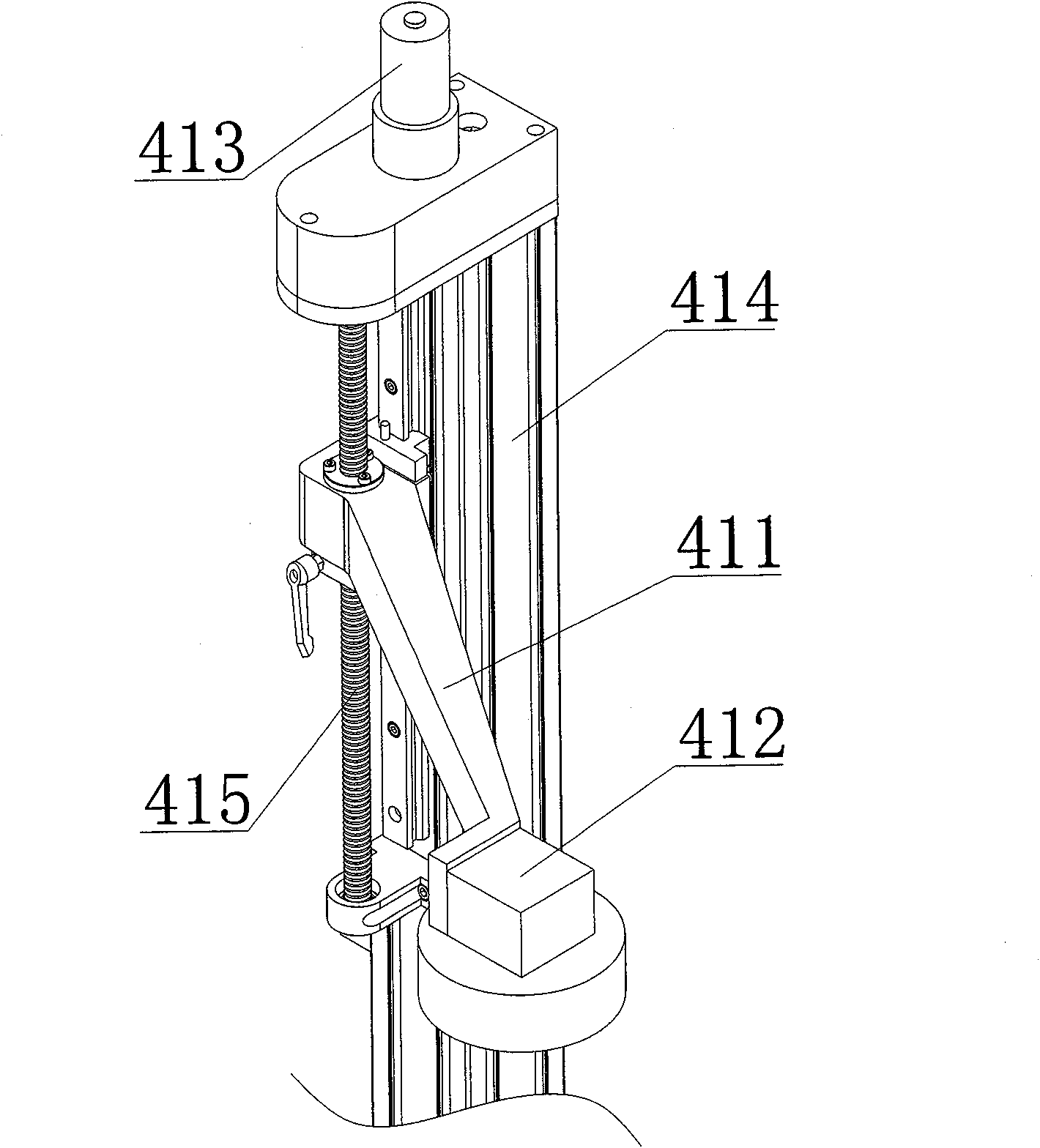

Pole piece laser cutting machine

ActiveCN102642089AOvercome deformationSmall size errorProgramme-controlled manipulatorElectrode manufacturing processesCapacitanceLaser technology

The invention discloses a pole piece laser cutting machine. The machine comprises a base frame part, a laser cutter, a cutting manipulator part, a control system and at least a piece feeding component, wherein the cutting manipulator part is used for driving the laser cutter; each piece feeding component comprises a material clamping manipulator part, a feeding fixed-length part and an emptying part; the cutting manipulator part and the material clamping manipulator part are installed on the base frame part; the feeding fixed-length part is arranged between the material clamping manipulator part and the emptying part; and the control system is connected with the cutting manipulator part, the material clamping manipulator part and the feeding fixed-length part. The machine has the following beneficial effects: the machine realizes the piece preparation processes of the lithium ion batteries or super capacitors by adopting the laser technology, can solve the problem that the pole pieces are easy to deform and have bigger burrs as the traditional cutting processes are adopted in the prior art, simultaneously improves the piece preparation process quality under the control of the control system and increases the yield.

Owner:SHENZHEN GEESUN INTELLIGENT TECHNOLOGY CO LTD

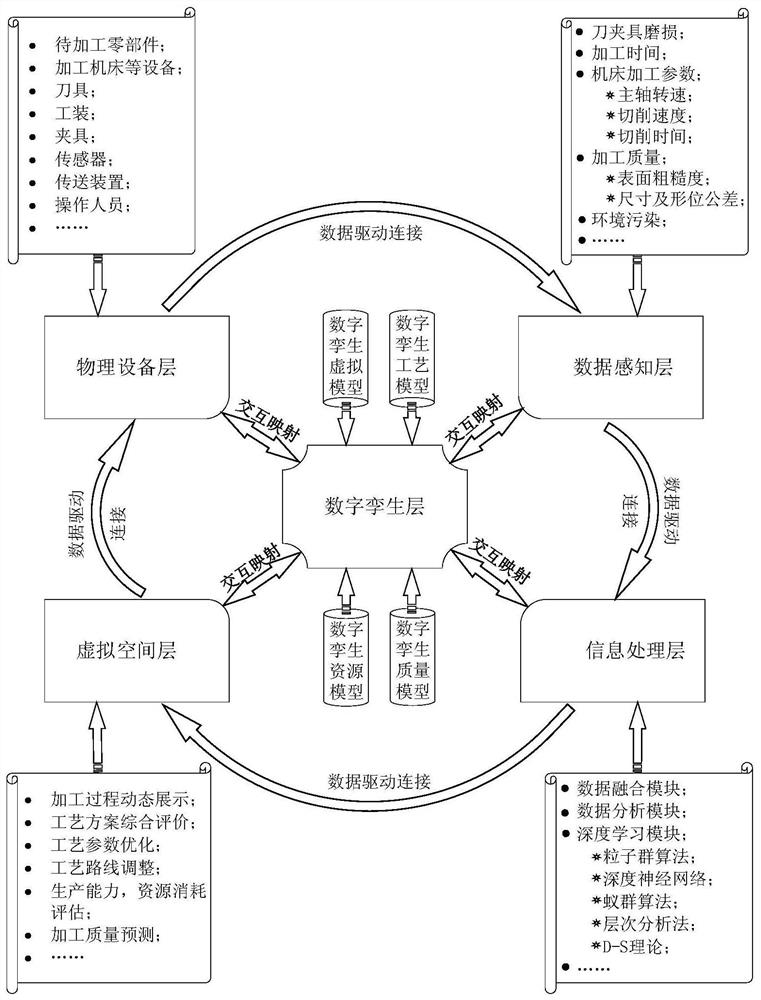

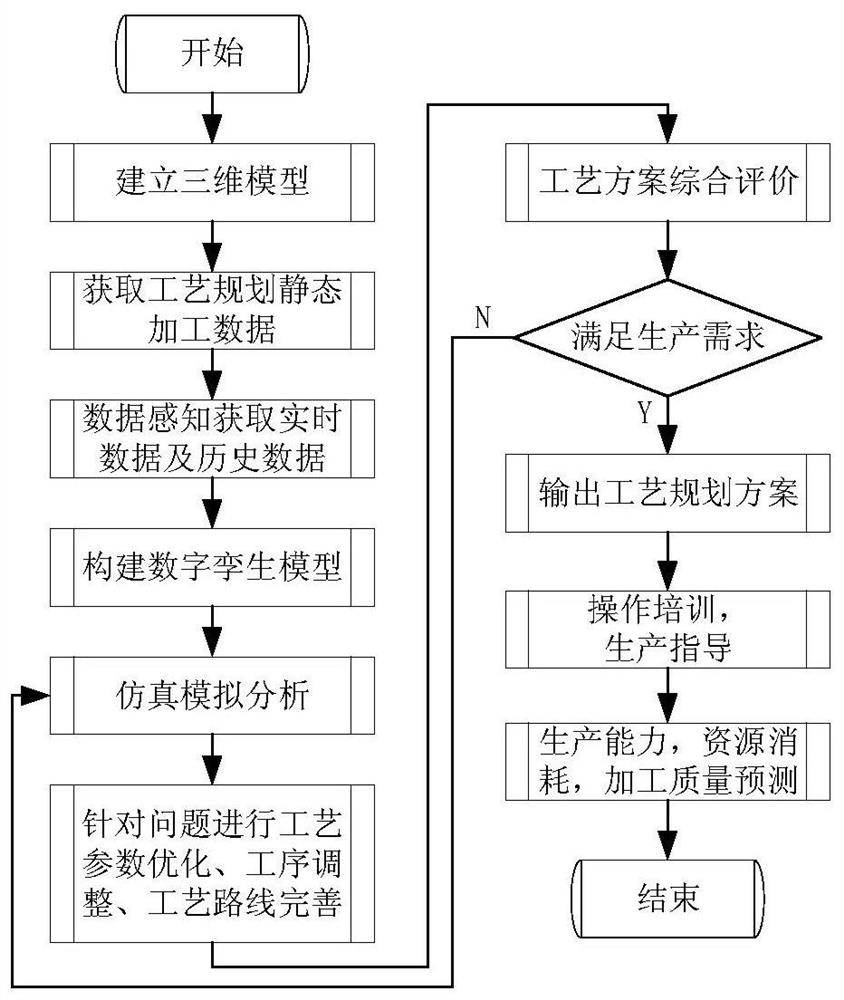

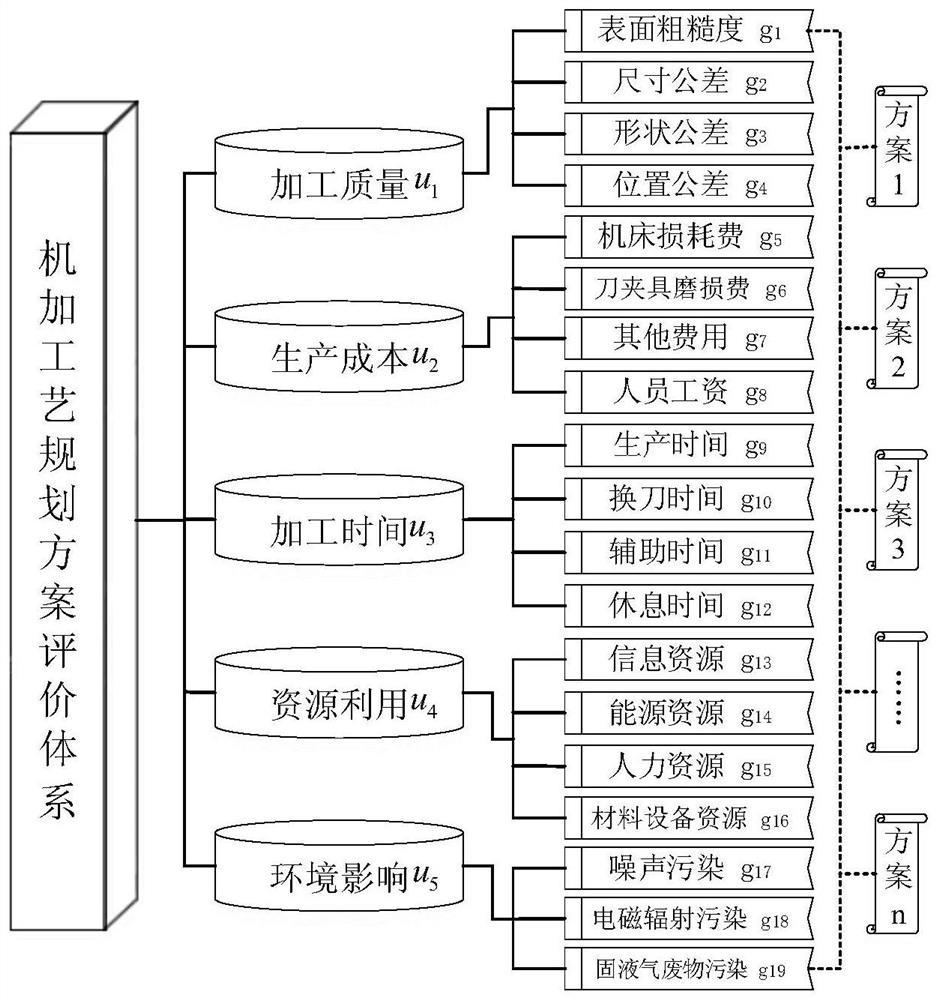

Multi-process planning comprehensive evaluation system and method based on digital twinning and deep learning

PendingCN111695734AOptimize schedulingEasy to controlForecastingDesign optimisation/simulationInformation processingVirtual space

The invention relates to a multi-process planning comprehensive evaluation system and method based on digital twinning and deep learning, and belongs to the field of process planning virtual simulation. The system comprises a physical equipment layer, a data sensing layer, an information processing layer, a virtual space layer and a digital twinning layer, the data sensing layer collects related real-time data and historical data of the physical equipment layer in the machining process and sends the data to the information processing layer for data fusion analysis and processing; meanwhile, the acquired data is transmitted to a virtual space layer, and a dynamic virtual model corresponding to the physical entity is constructed under the guidance of requirements of related models in a digital twinning layer; the digital twinning layer is used for leading the other layers together, carrying out virtual-real interaction feedback, fusion analysis and iterative optimization, and carrying out comprehensive evaluation analysis on different process schemes of the to-be-processed part, so that process parameter optimization and process route improvement are realized. According to the method, the flexibility and dynamic adaptability of process planning are improved, the resource utilization rate can be improved, the processing period is shortened, and the production cost is reduced.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI +1

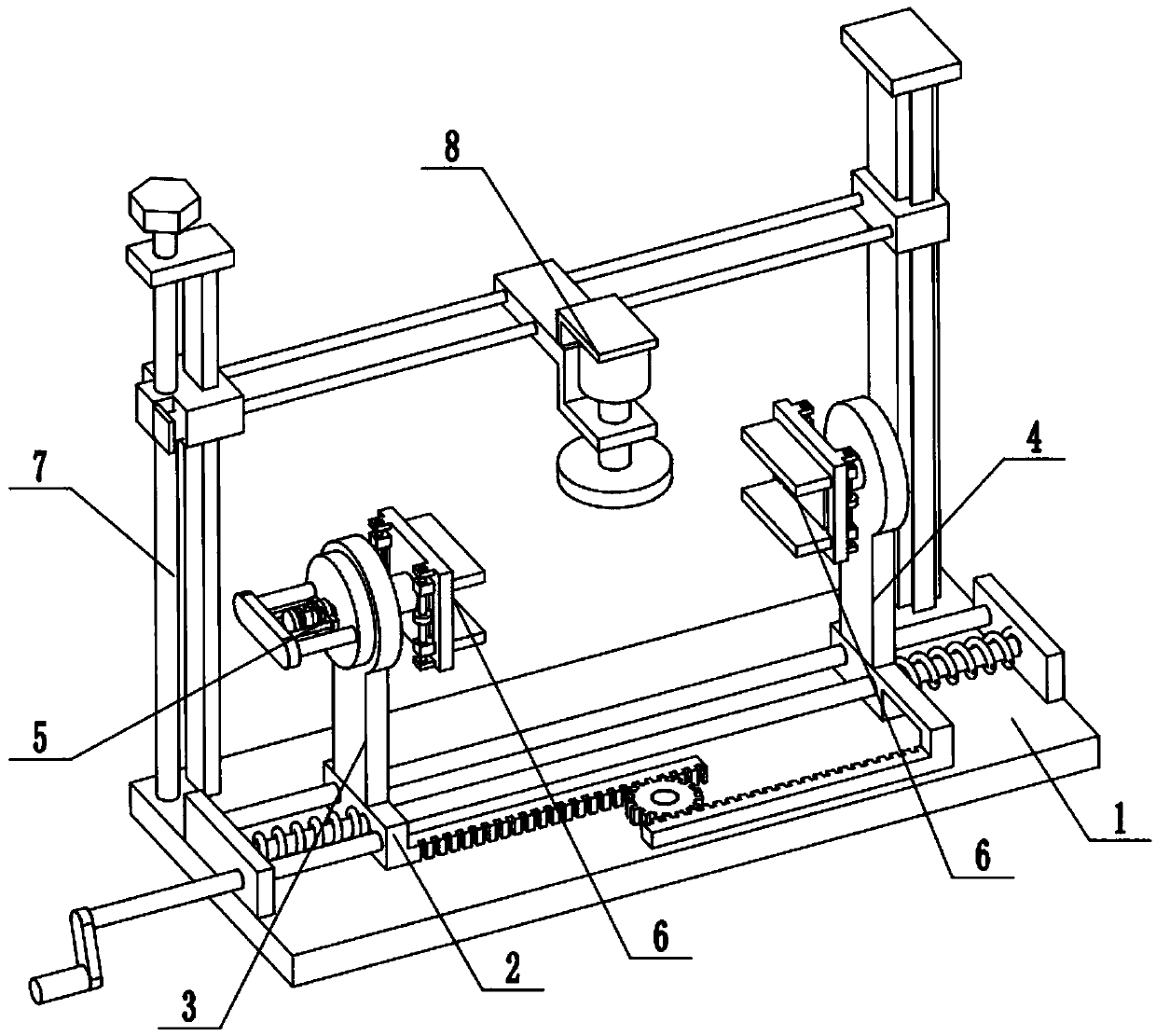

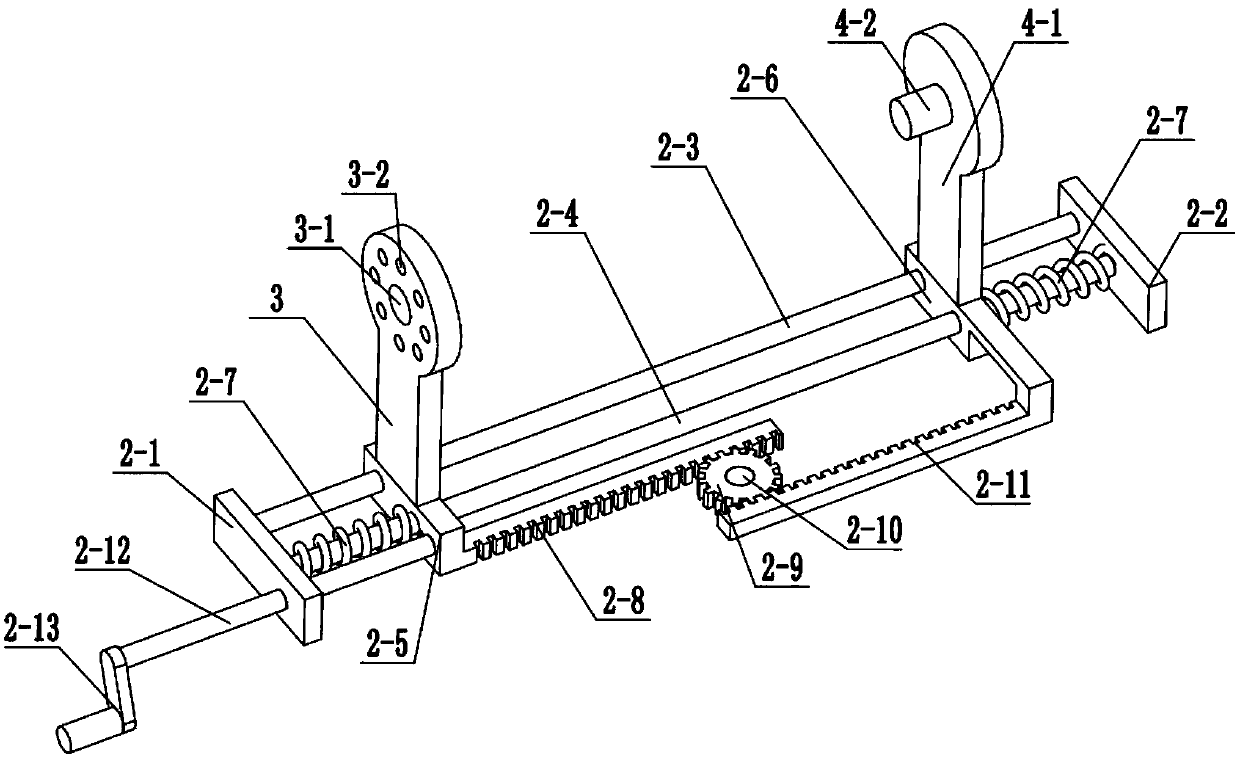

Multi-angle plate polishing device

InactiveCN109571180ARealize multi-degree-of-freedom grindingImprove grinding limitationsEdge grinding machinesGrinding carriagesMulti degree of freedomEngineering

The invention relates to the field of plate processing, in particular to a multi-angle plate polishing device. The multi-angle polishing device is characterized in that a length adjusting component isfixedly connected to the front end of a base; a left plate and a right plate are separately fixedly connected to the two ends of the length adjusting component; an angle adjusting component is connected to the upper end of the left plate; the number of plate clamping pieces is two; the two plate clamping pieces are separately fixedly connected to the inner sides of the angle adjusting component and the right plate; a grinding plate sliding seat component is fixedly connected to the rear end of the base; and a grinding component is connected onto the grinding plate sliding seat component in asliding manner. A plate can be polished from multiple angles and in multiple directions according to the self characteristics and the grinding requirements of a product, the multi-degree of freedom polishing of the plate is realized, or the omni-directional polishing and local polishing of the plate are realized, the polishing limitation of an existing automatic polishing machine is improved, andmanual operation is replaced with mechanical automatic processing, so that the production efficiency is improved, and the production quality of the product is ensured; and the multi-angle plate polishing device is applicable to plates of different sizes or shapes.

Owner:张馨文

Method for non-contact laser cutting of quartz glass product and device thereof

InactiveCN102898014AEnsure consistencyReduce labor intensityGlass severing apparatusLaser beam welding apparatusCrevasseEngineering

The invention discloses a method for non-contact laser cutting of a quartz glass product and a device thereof. The method comprises the following steps: firstly firing the quartz glass product with a laser beam emitted by a laser generator to form a groove, and then cutting off by using a pneumatic unit. The device provided by the invention comprises a laser automatic cutting unit and the pneumatic unit. According to the invention, the product quality can be guaranteed, crevasses can be reduced, the consistency of the kerf and the kerf section can be guaranteed, waste is reduced, thus the operation is safe; and the laser cutting has noncontact with the quartz glass tube or quartz glass rod, thus the speed of drawing is raised, the production cost is reduced, the labor intensity is reduced, and the yield is raised.

Owner:JIANGSU PACIFIC QUARTZ

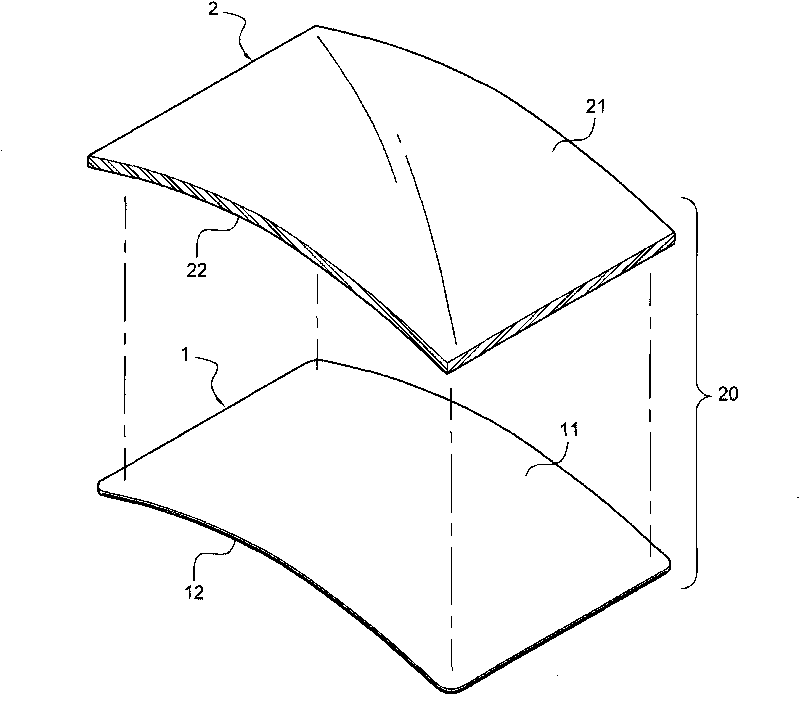

Manufacturing method and structure of camber-shaped capacitance type touch-control plate

ActiveCN101727249AControllable shapeReduce processing difficultyInput/output processes for data processingCompression moldingCapacitance

The invention provides a manufacturing method and a structure of a camber-shaped capacitance type touch-control plate. The manufacturing method comprises the following steps of: firstly providing a planar flexible circuit board with a capacitance type touch-control function; then compressing and molding the planar flexible circuit board into a camber-shaped flexible circuit board in a compression molding way; then providing a camber-shaped base plate, and coupling and attaching the outer camber of the camber-shaped flexible circuit board to the inner camber of the base plate, thus the camber-shaped capacitance type touch-control plate is assembled.

Owner:TPK ADVANCED SOLUTIONS

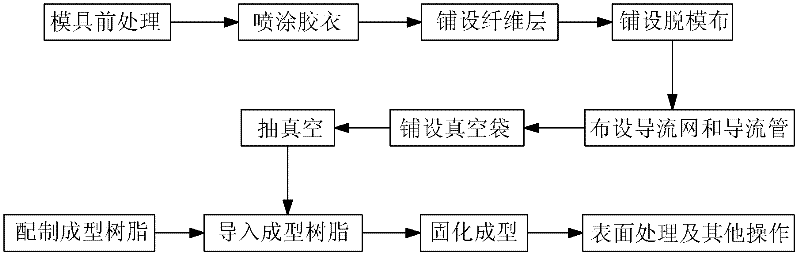

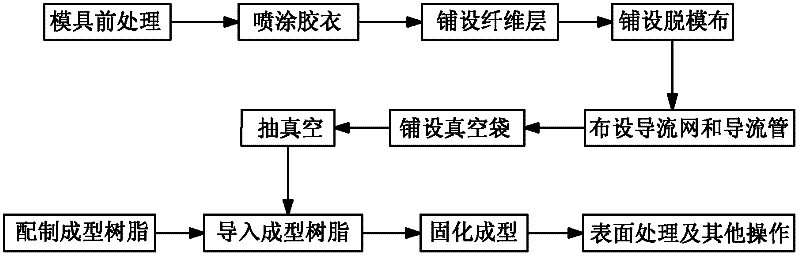

Production method of composite material automobile parts

The invention discloses a production method of composite material automobile parts. The method comprises the following steps: performing pretreatment on a die, coating gel coat on the die, configuring molding resin, baking raw fiber cloth, laying a fiber cloth layer in the die, sequentially laying demolding cloth and a guide mesh on the fiber cloth layer, arranging winding pipes on the periphery of the die, leading in molding resin in a vacuum pouring mode, performing curing molding, and performing surface treatment and other operation on molded products. The composite material product prepared by the method has high surface brightness and is level, compared with the traditional metal parts, the weight of the produced product is reduced by 30 to 60 percent, so that the mass of an automobile body is reduced, and the method has the effects of energy saving and emission deduction. In addition, the method of leading in molding resin in the vacuum pouring mode to be compounded with fiber can reduce the concentration of organic escaping gas in the operating environment and reduce the injury on operators.

Owner:CHERY AUTOMOBILE CO LTD

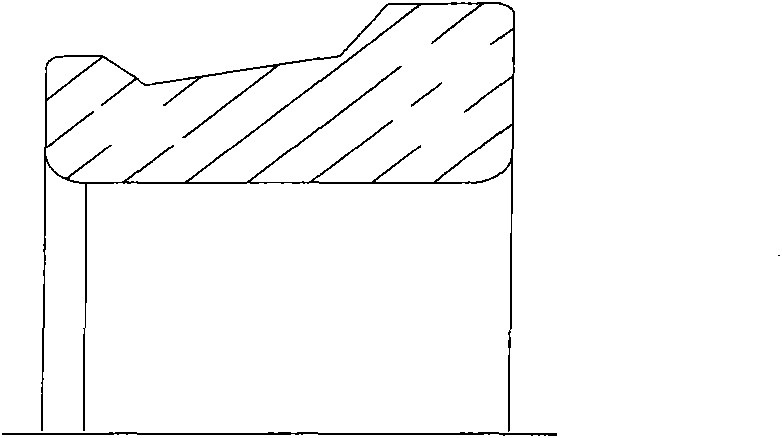

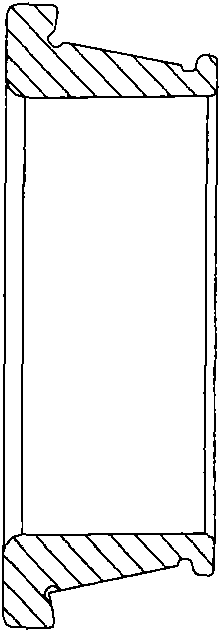

Composite machining process for inner and outer rings of narrow-series thin-walled high-precision conical thin-walled bearings

The invention discloses a composite machining process for inner and outer rings of narrow-series thin-walled high-precision conical thin-walled bearings, belongs to the technical field of forging, turning, heating and grinding machining of the inner and outer rings of bearing components, and mainly solves the problems of low production efficiency and high rejection rate in a conventional machining method. The composite machining process is mainly characterized by comprising the following steps of: (1) cutting bar stock into straight material sections; (2) after heating, forming a single-forged inner ring and double combined-forged outer rings by using a pressing machine; (3) spheroidizing and annealing; (4) performing shot blasting to remove surface oxide scales; (5) after cutting the double outer rings, performing rough turning and soft grinding; (6) performing additional tempering; (7) performing the soft grinding on the outside diameter of the outer rings, and performing finish turning and rolling; (8) performing heat treatment in quenching and tempering furnaces, and performing shot blasting again; and (9) performing rough grinding machining, the additional tempering, finish grinding machining, super-finishing, cleaning and assembling. The composite machining process has the characteristics of great improvement on product qualification rate and production efficiency, and suitability for batch production on the premise of no increase of equipment investment, and is mainly used for machining the inner and outer rings of the narrow-series thin-walled high-precision conical thin-walled bearings.

Owner:XIANGYANG AUTOMOBILE BEARING CO LTD

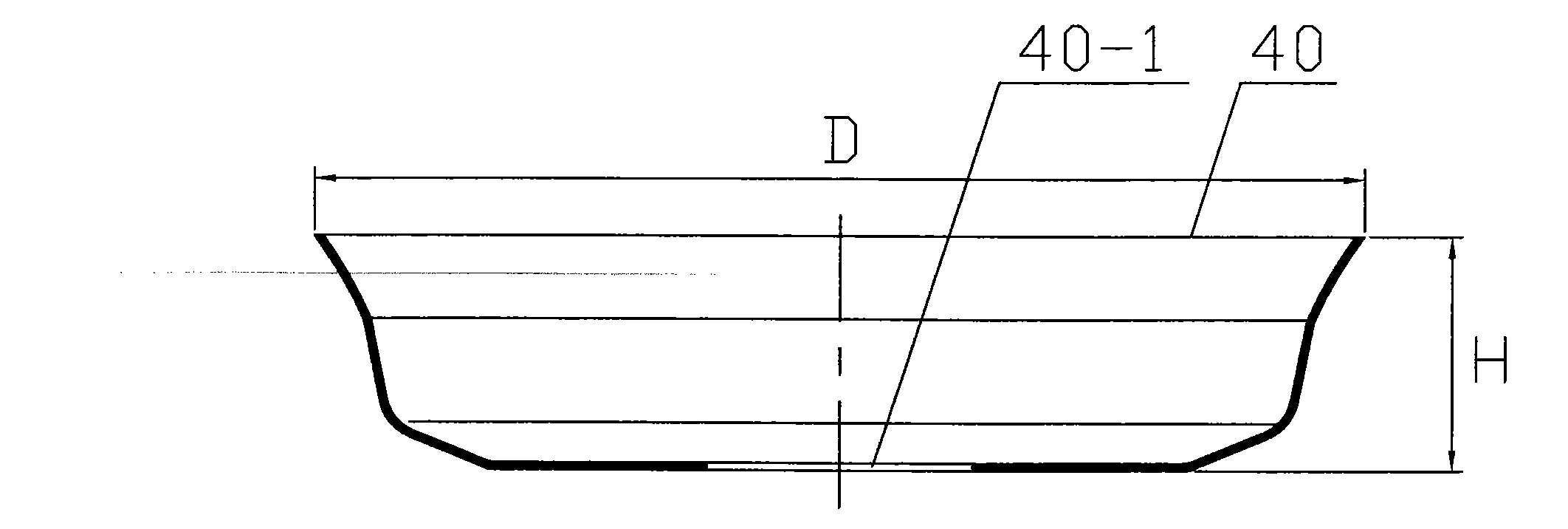

Deep drawing forming composite die for shallow conical pieces with sunken side walls

ActiveCN102371309AIncrease productivityGuarantee product qualityShaping toolsInterference fitPunching

The invention discloses a deep drawing forming composite die for shallow conical pieces with sunken side walls, and relates to a deep drawing forming composite die. The problem that the conventional die is difficult in forming the shallow conical pieces with the sunken side walls is solved. The upper end of a guide sleeve is in sliding fit with a guide post, and the lower end of the guide sleeve is in interference fit with a lower guide post hole of a lower template; a blanking female die is arranged on the lower template; an upper convex-concave die is connected with a fixed plate; a backingring is positioned between an upper template and the fixed plate; the upper convex-concave die is placed in the blanking female die; a spring and a baffle pin are arranged in circular bead through holes of the blanking female die; a limiting screw is arranged on the lower template; an ejection plate is arranged in the backing ring; a stripping rod is arranged on the backing ring; a punching male die fixed plate and a shim plate are arranged in the upper convex-concave die; a punching male die is arranged in a lower convex-concave die; the lower convex-concave die is arranged in a profile holeof the upper convex-concave die; a return plate is sleeved on the punching male die; a blank holder is sleeved on the lower convex-concave die; and a side pressing rubber pad and a supporting plate are sleeved on a solenoid. The die is used for deep drawing forming of the shallow conical pieces with the sunken side walls.

Owner:HARBIN JIANCHENG GRP

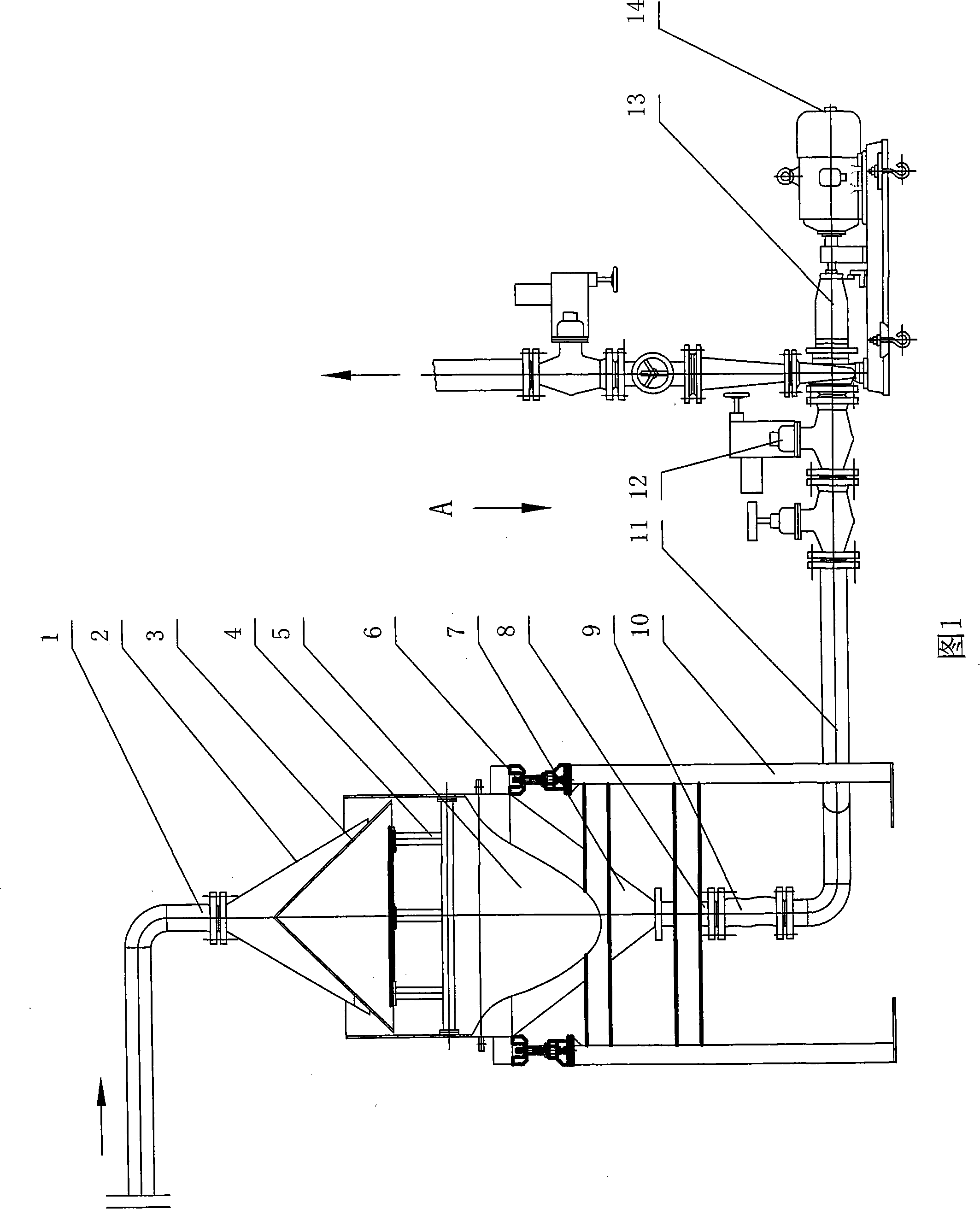

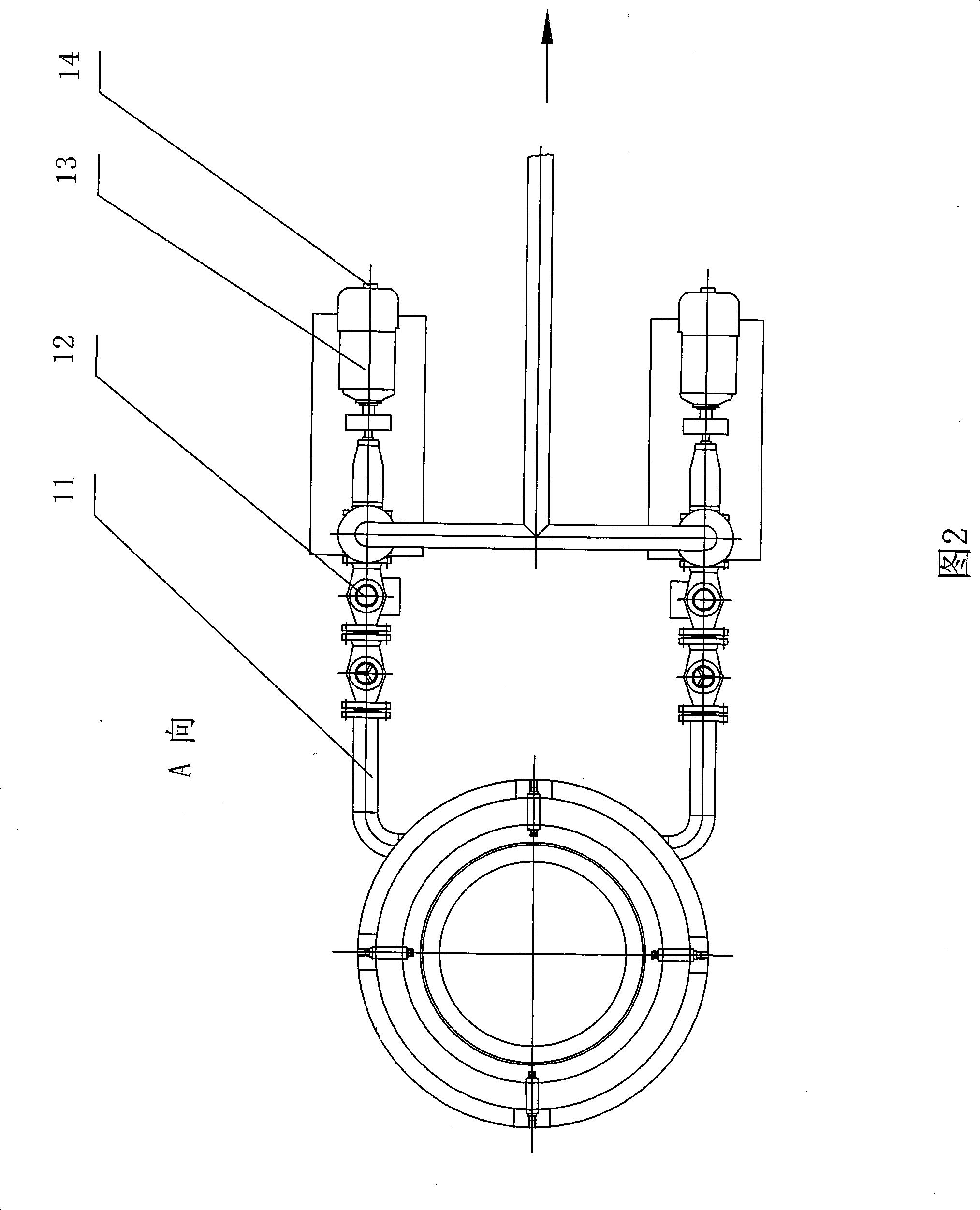

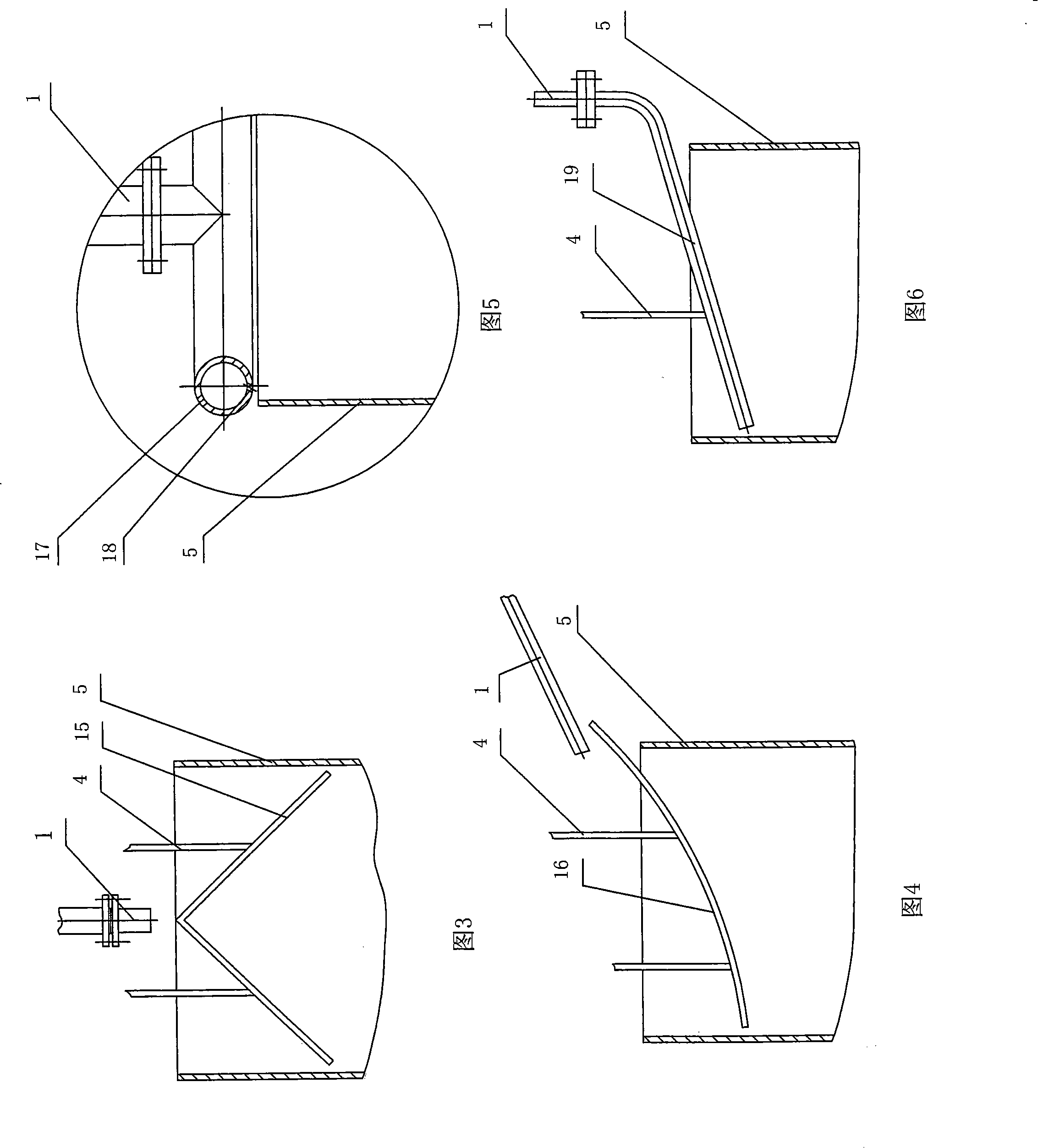

Mineral slurry flux on-line detecting device and multi-parameter on-line detecting integrated system

InactiveCN101251395AAccurate measurementEliminate wear and tearVolume/mass flow measurementMaterial analysis by electric/magnetic meansLiquid productMeasurement device

The invention provides an online detection device for the pulp flow rate and a multi-parameter online detection integration system, which comprise a pulp container which has a feed port and a discharge port and is arranged on a support through a, weighing cell, a pulp flow rate detection device which is provided with a soft connector at the discharge port, and / or a pulp density measuring device, a pulp grain size measuring device and a pulp grade measuring device. The online detection device for the pulp flow rate and a multi-parameter online detection integration system can not only measure any single index of the flow rate, density, grain size and grade of the pulp according to requirements, but also simultaneously measure two or above two or even all of the indexes with high measuring accuracy, good stability and reliability. The online detection device for the pulp flow rate and a multi-parameter online detection integration system also have the advantages of simple structure, high working efficiency, low labor intensity, wide application range, etc., thereby being capable of providing the highly reliable flow rate, density, grain size and grade control parameters for liquid products to ensure product quality, reduce cost and improve working efficiency, and providing a highly guaranteed measuring device and system for full automatic control.

Owner:罗放明

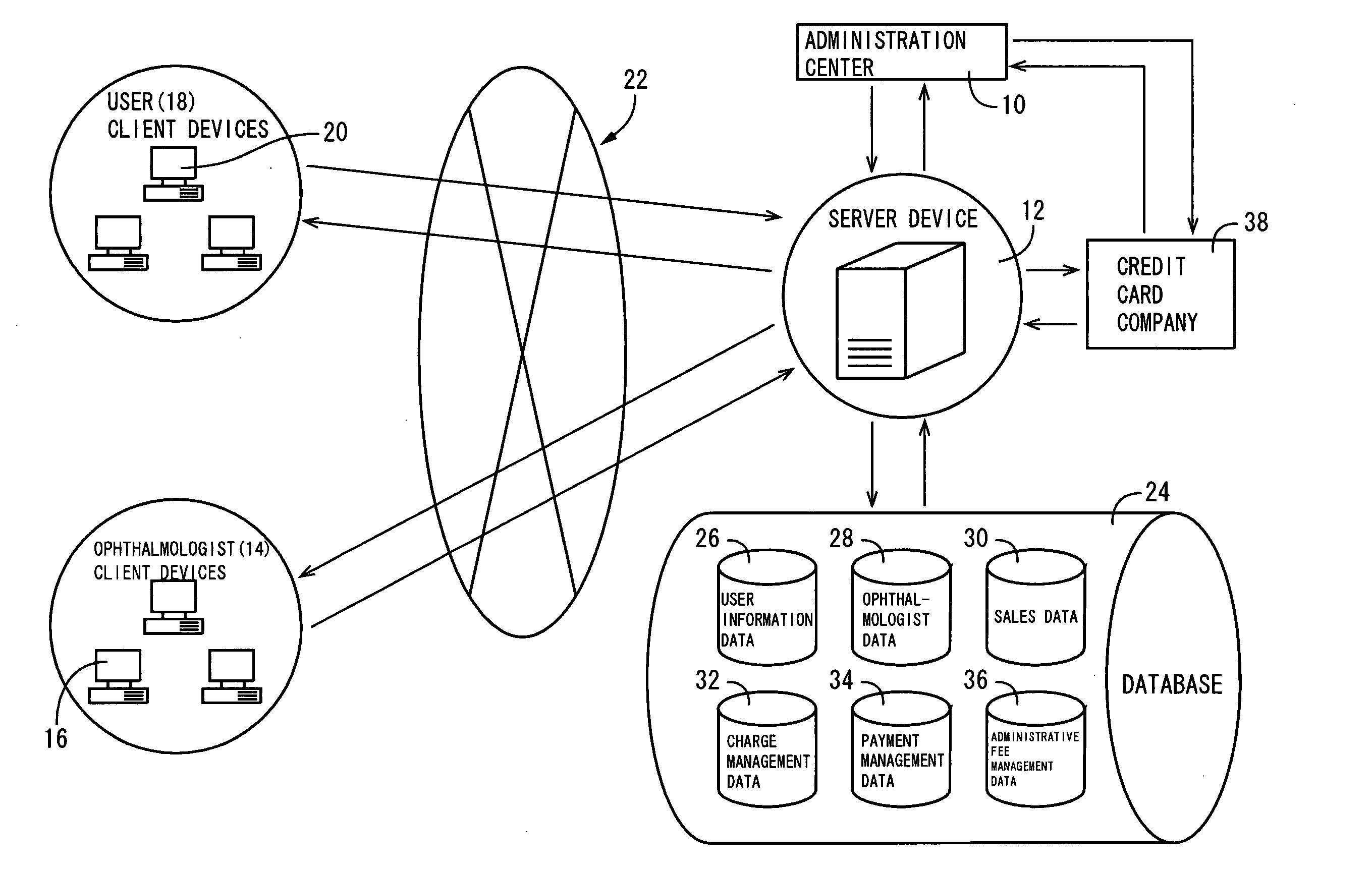

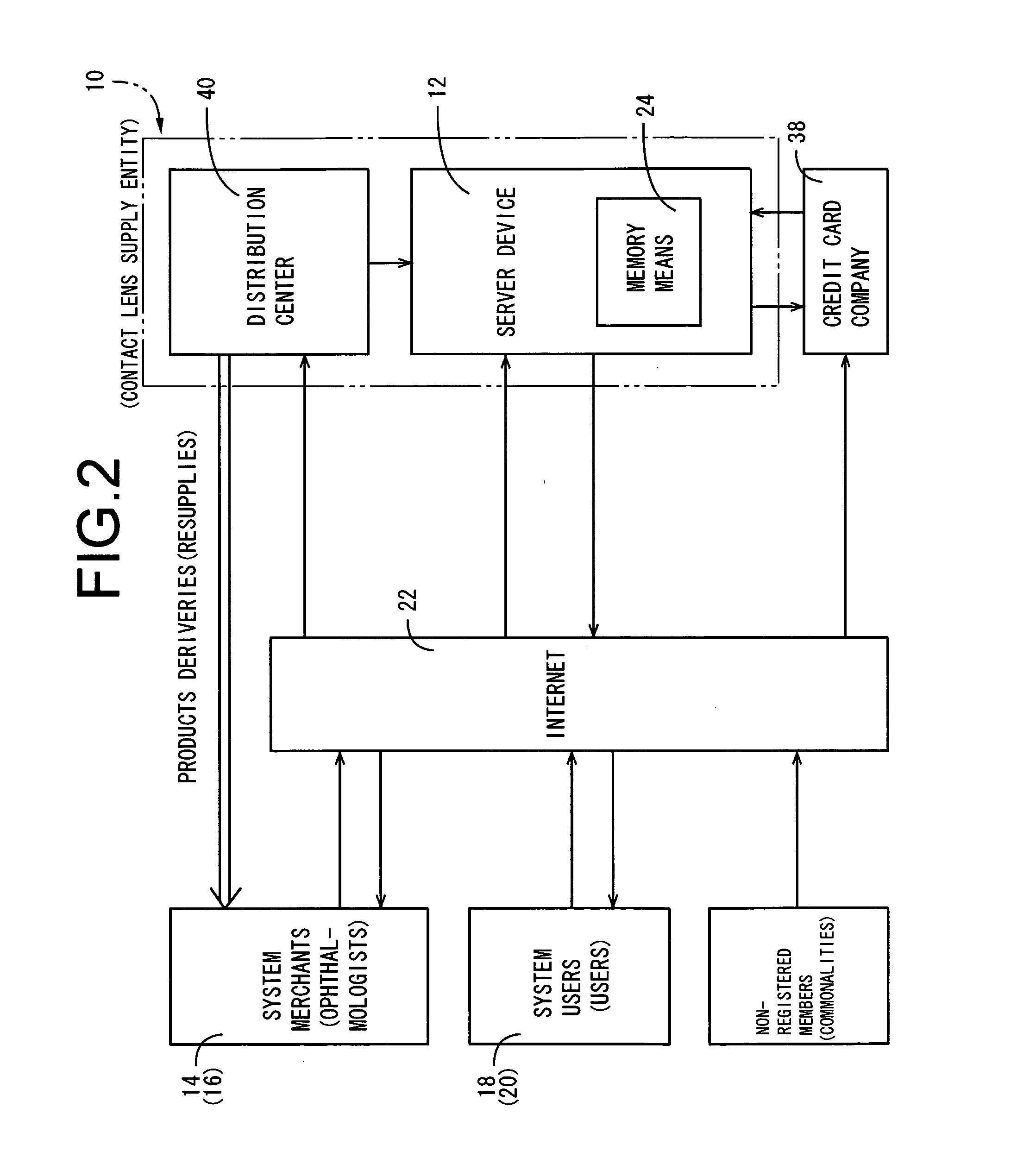

Supply and examination system for contact lenses

InactiveUS20050060196A1Safely provideNo need to impose a burdensome workload on individual usersSpectales/gogglesMechanical/radiation/invasive therapiesComputer scienceEye examination

Provides a novel supply and examination system by which it is possible to safely provide users with contact lenses having a predetermined expiration date, without imposing an excessive burden on users and on ophthalmologists. A user 18 is assessed a periodic membership fee on the one hand, while the user 18 is supplied with contact lenses through a designated pre-selected merchant 14. That is, member users 18 who pay a periodic membership fee on a continuing basis are supplied with new replacement contact lenses without any special procedure, simply by visiting the merchant 14. When receiving supply of lenses, user 18 received periodic eye examinations at the merchant 14. Various kinds of information including personal user information are managed by the contact lens supplying entity 10 to build a database 24.

Owner:MENICON CO LTD

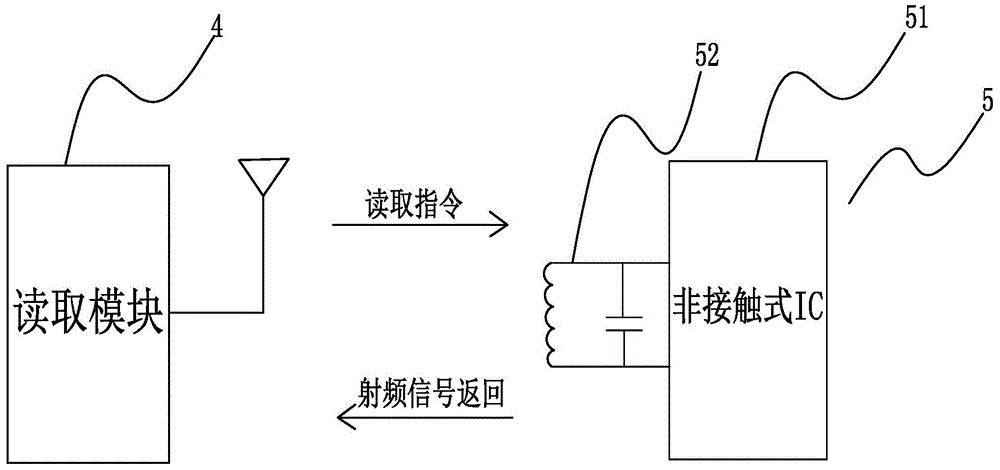

Air purifier capable of preventing faking based on filter element recognition

InactiveCN104436911AEffective strikeNo mechanical failureDispersed particle filtrationTransportation and packagingIdentity recognitionAir purifiers

The invention discloses an air purifier capable of preventing faking based on filter element recognition. The air purifier comprises an air purifier main body, wherein a control circuit and a purifying cavity are arranged in the purifier main body; multiple layers of filter elements are arranged in the purifying cavity and are in matched connection with the air purifier main body through an identity recognition unit; the identity recognition unit comprises identity recognition chips and an identity recognition device; the identity recognition chips are arranged on the filter elements, and the identity recognition device is arranged on the purifier main body and is connected with the control circuit and drives the control circuit to work only after the identity recognition chips are successfully matched with the identity recognition device. The identity recognition unit serves as an authentication device, so that the air purifier is capable of automatically recognizing filter element products without manual intervention, acquiring relevant data and simultaneously recognizing multiple targets, is high in response speed and long in service life, has no mechanical fault and can resist the severe environment, counterfeited products can be effectively combated, and the product quality is guaranteed.

Owner:SHUNDE APOLLO AIR CLEANER

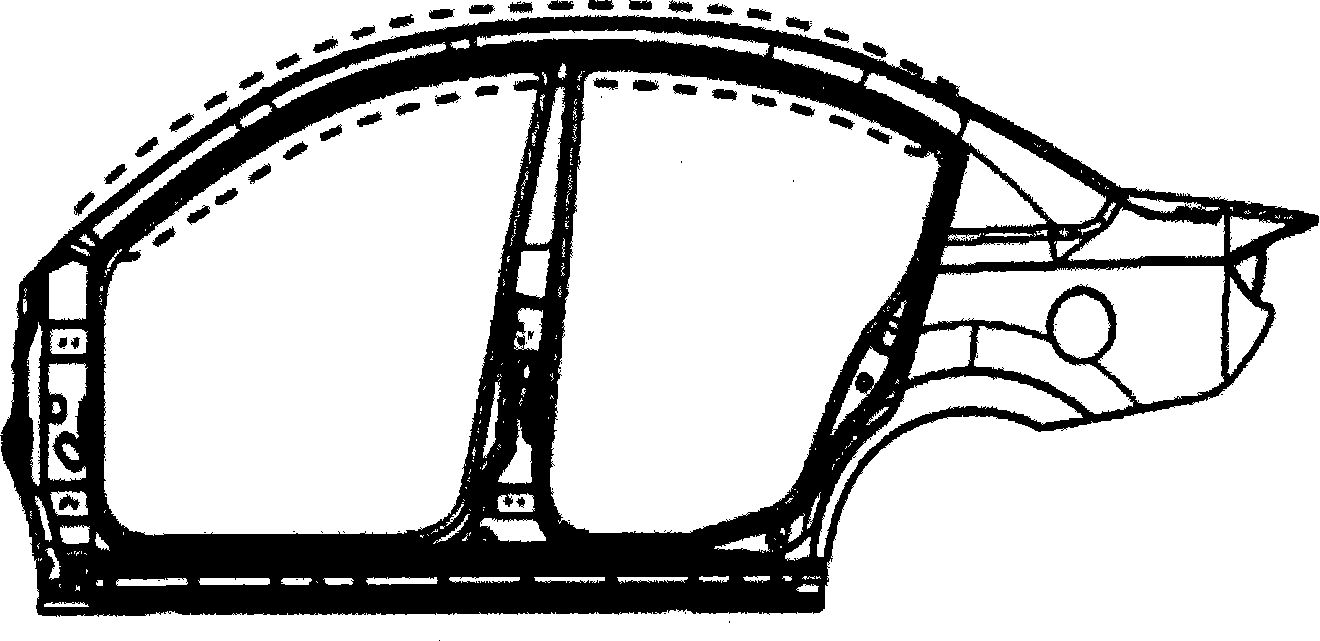

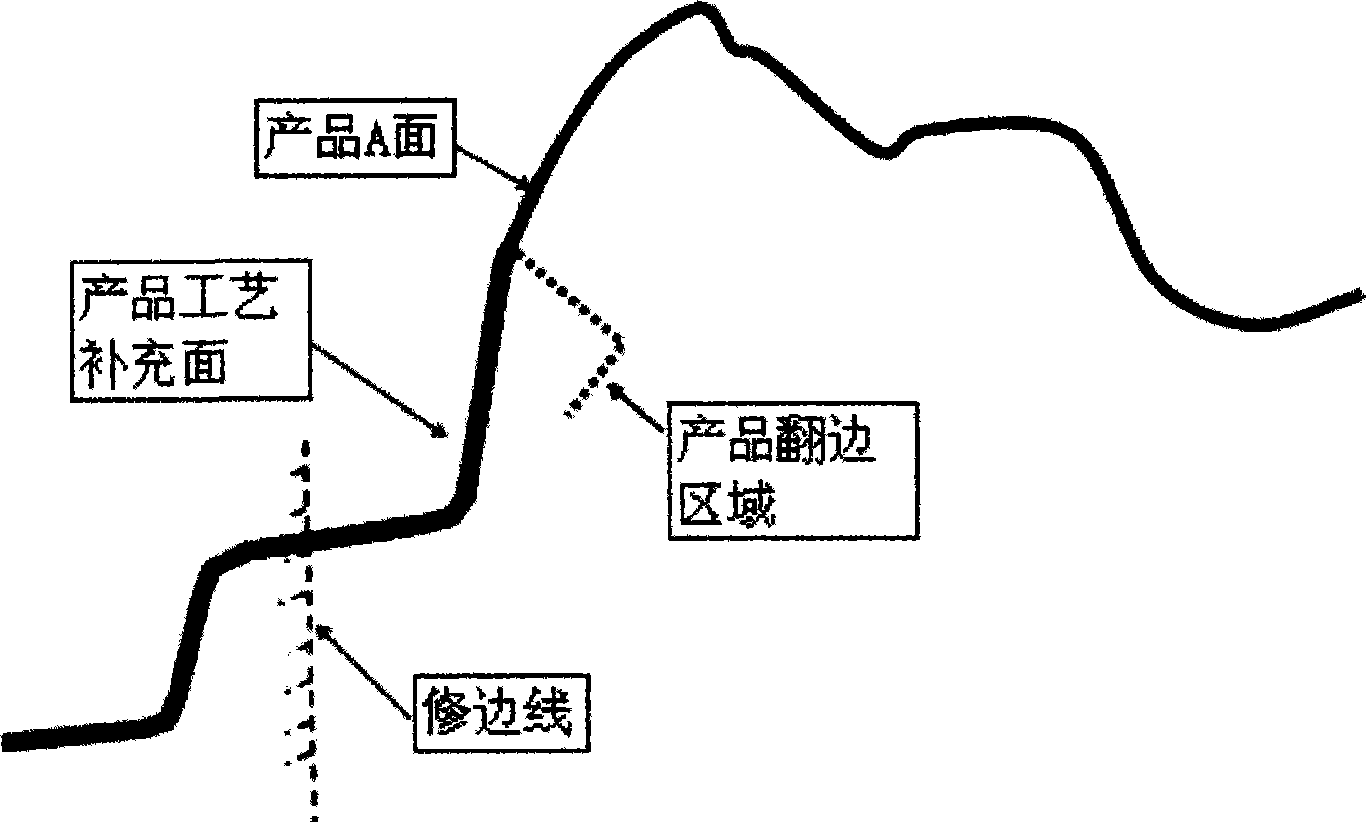

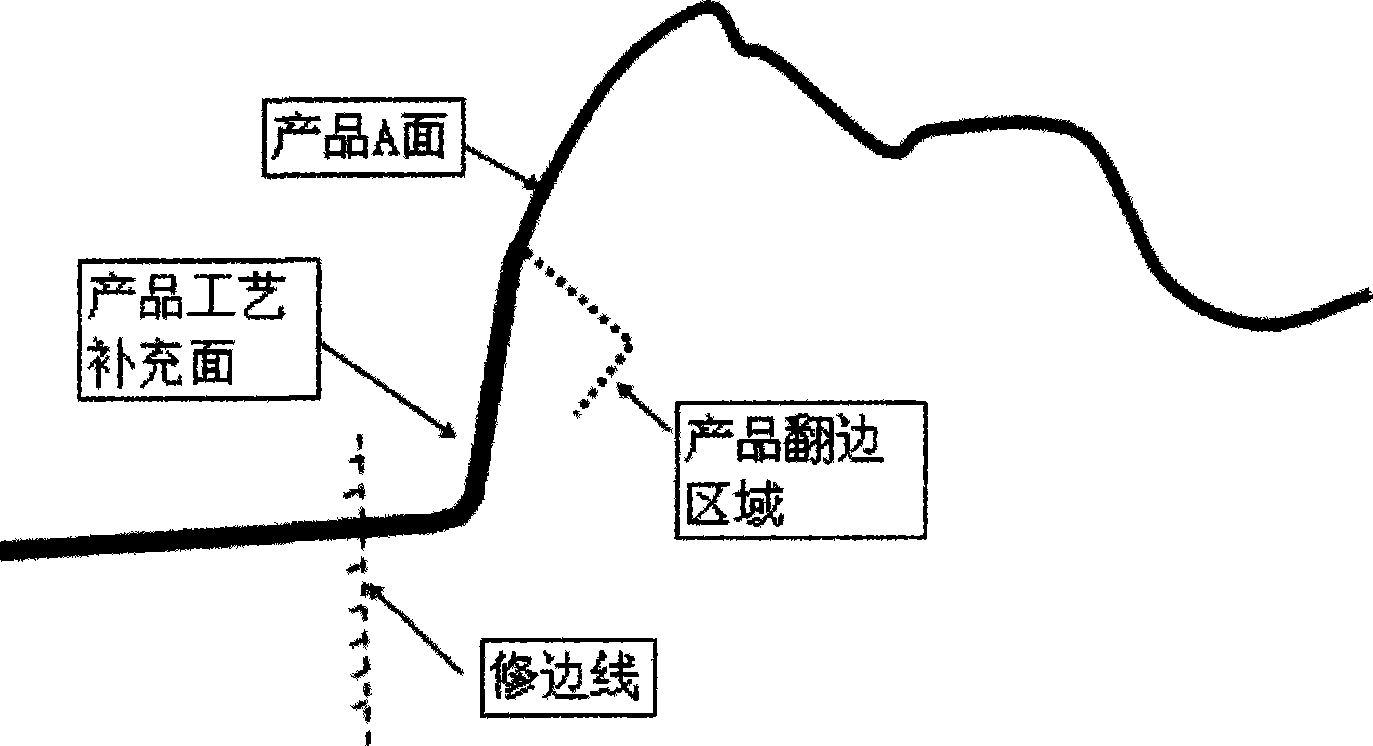

Stamping processing method for related joint of vehicle side-frame outer plate and roof board

The invention discloses a punching treating method for a lapping position between a side-frame outer panel and a head cover of an automobile, comprising the manufacturing of a die face during the drawing of the side-frame outer panel, the lateral trimming on the die face and the lateral shaping on the die face. In the manufacturing of the drawing die face, a step is designed on an addendum surface at the outside of a trimming line of the die face at first. In the formation of the step, the boundary of side A of the side-frame outer panel extends outwards along the tangency direction with the side A firstly; the length is less than or equal to 10nm; the addendum surface is manufactured at the direction which forms a 3-20 degree angle with the punching direction; the step is formed at 3-20nm away from the trimming line on the addendum surface. The boundary of the side A of the side-frame outer panel refers to an intersecting part between the side A of the side-frame outer panel and a flange of the side-frame outer panel. The side A refers to the appearance surface of an external surface part. With the method provided by the invention adopted, the deformation of the side A at the lapping position between the side-frame outer panel and the head cover can be prevented. The product quality can be ensured. Influences of a primary impact line and a secondary impact line can be eliminated. Meanwhile, the most reasonable material utilization can be achieved.

Owner:CHERY AUTOMOBILE CO LTD

Automatic paper box positioning and processing method and device for implementing same

ActiveCN101628488ASimple structureReduce labor intensityBox making operationsPaper-makingAutomatic controlControl system

The invention discloses an automatic paper box positioning and processing method which comprises a paper box to be coated and glue costing cover paper which is adapted to the paper box to be coated. The automatic paper box positioning and processing method comprises the following steps: 1, setting a paper box transporting device; 2, setting a surface paper transporting device; 3, setting an automatic positioning system; 4, setting an automatic control system, wherein the automatic control system is respectively connected with the paper box transporting device, the surface paper transporting device and the automatic positioning system and controls a work state; and the invention also discloses a device for implementing the method. The method of the invention can complete the positioning and processing action of the paper box in full-automation, high-speed and high accuracy modes; the device of the invention is applied in a mechanical automation mode, corresponding parameters and control instructions are input on the automatic control system in order to control the operation of the paper box transporting device, the surface paper transporting device and the automatic positioning system, and the automatic paper box positioning and processing method reduces labor intensity, greatly increases production efficiency, ensures product quality and reinforces competitive capacity of enterprises.

Owner:DONGGUAN HONGMING MACHINERY

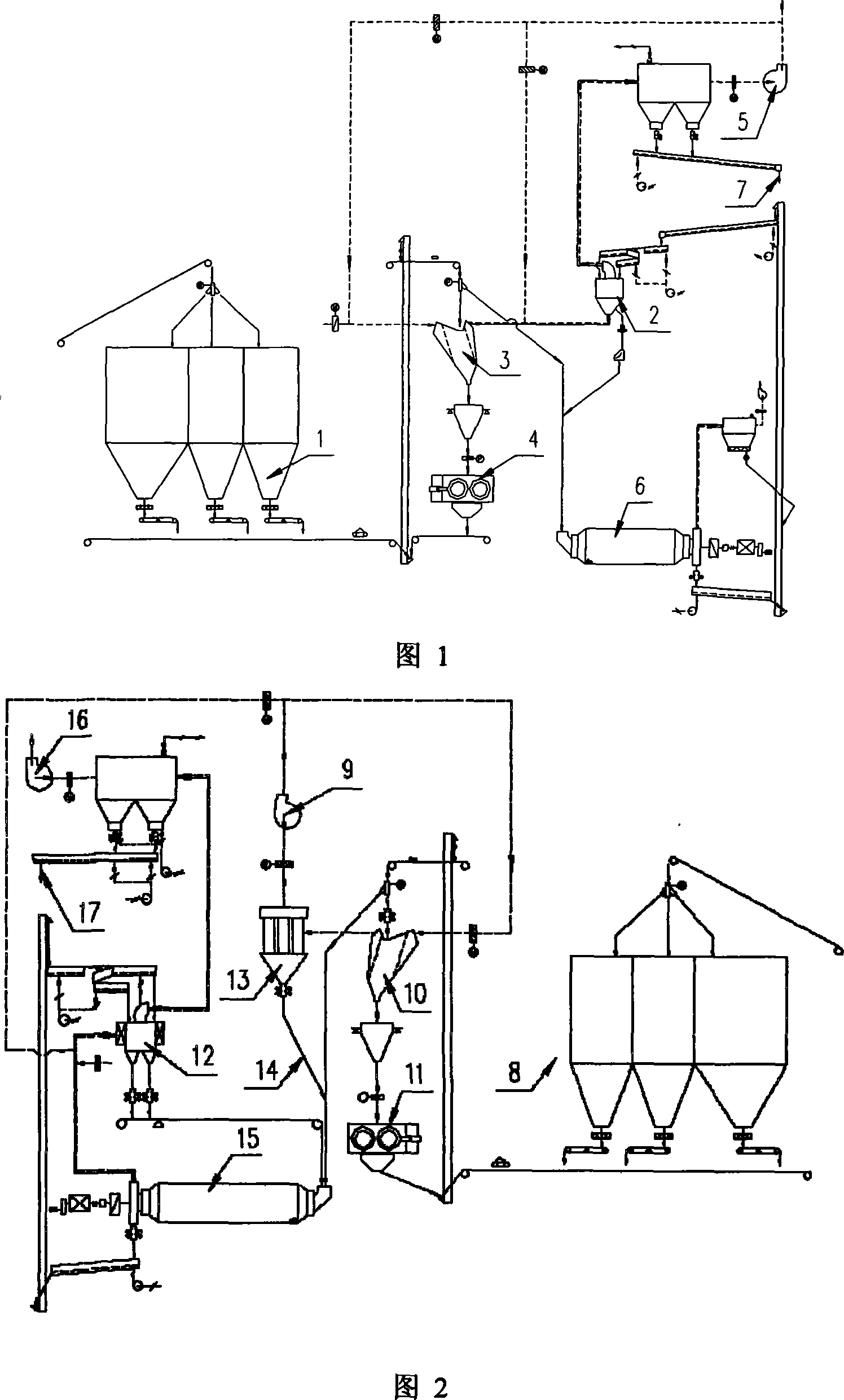

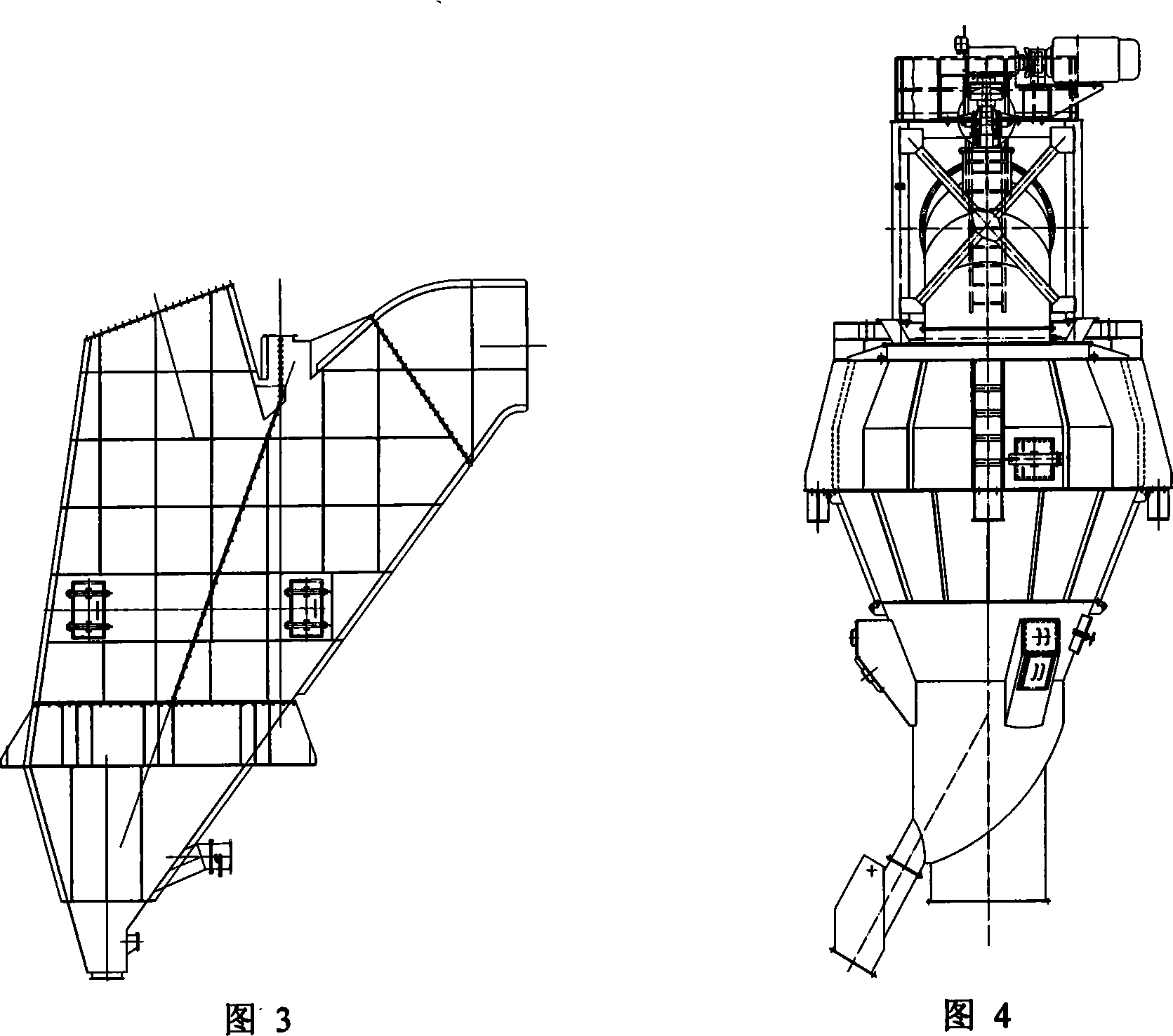

Roller press combination grinding device

ActiveCN101134175AEliminate wear and tearAdapt to the requirements of different statesGrain treatmentsMetallic materialsOperation mode

The present invention relates to one kind of combined rolling press grinding apparatus, and belongs to the field of inorganic non-metal material grinding technology. The combined rolling press grinding apparatus includes one dispensing mechanism, one lifting and conveying mechanism, one rolling press, one ball mill, one powder concentrator, one dust collector and one fan. The present invention has the advantages of low milling loss, simple structure, several operation mode, high grinding efficiency, low power consumption, etc.

Owner:天津椿本输送机械有限公司 +1

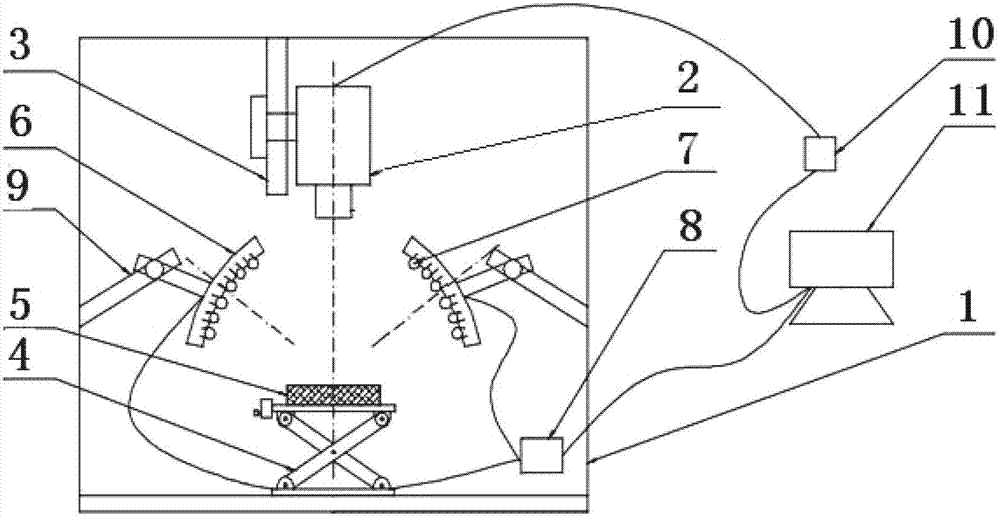

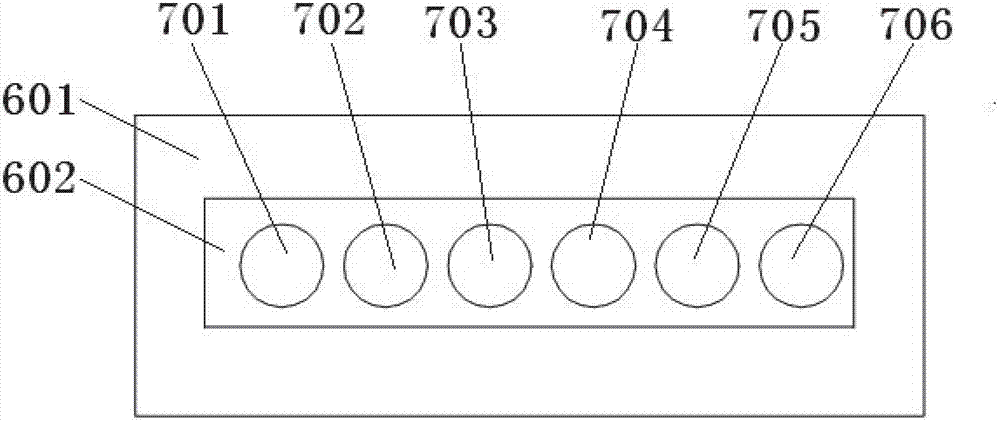

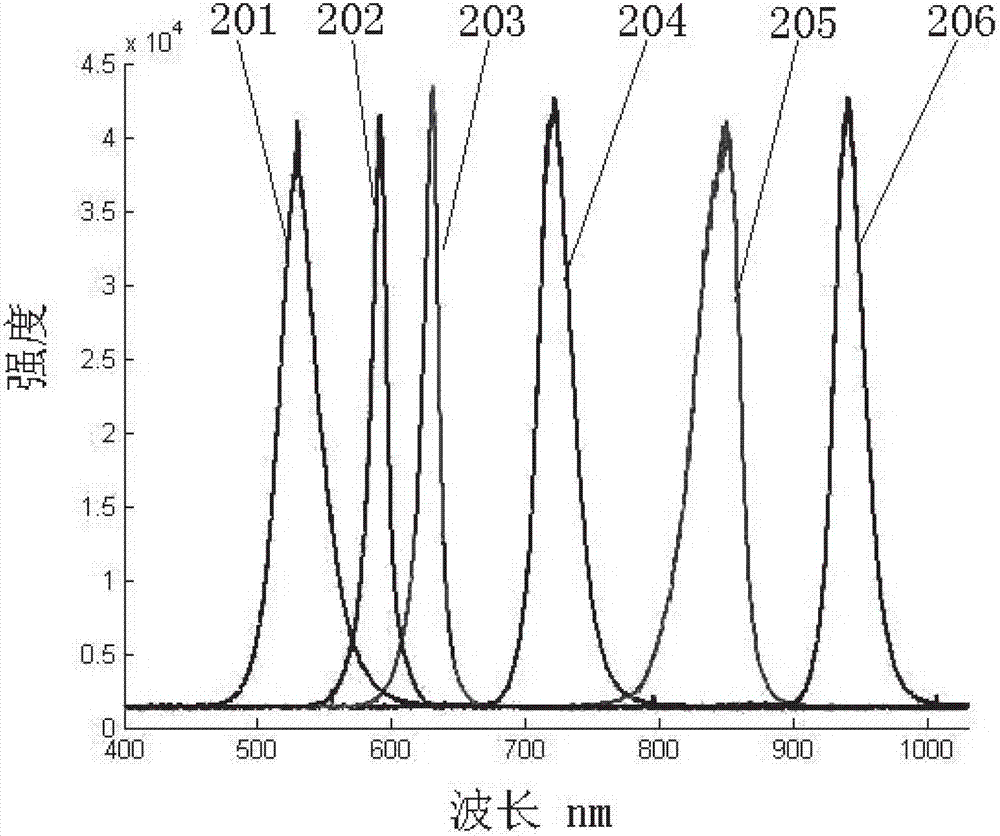

Detection and grading system for tenderness of fresh beef based on multispectral imagery

InactiveCN102854148AEasy to detectAchieve ratingColor/spectral properties measurementsCamera lensLean meat

The invention relates to a detection and grading system for tenderness of fresh beef based on multispectral imagery, which belongs to the technical field of detection of food quality. In a dark box, the lens of a CCD industrial camera is aligned with the center of a table board of a height-adjustable objective table, two multispectral light source assemblies are symmetrically arranged at a left sidewall and a right sidewall of the dark box respectively through two light source fixing supports, and a large power LED array on each of multispectral light source assemblies is composed of LEDs of 6 kinds of wave bands; during detection, a sample to be detected is put on the table board of the height-adjustable objective table, the LEDs of 6 kinds of wave bands alternately radiate in order, the CCD industrial camera acquires multispectral images of the sample to be detected, a multispectral beef sample reflection image in an interested area of a lean meat part is extracted through computer image processing, and therefore, marbling of beef is extracted, and evaluation and grading of content of marbling of the beef are carried out, and tenderness of the beef is predicted. The detection and grading system provided by the invention is applicable to companies dealing with cutting, marketing, processing and import and export of fresh beef and to market supervision by quality and technical supervision departments.

Owner:CHINA AGRI UNIV

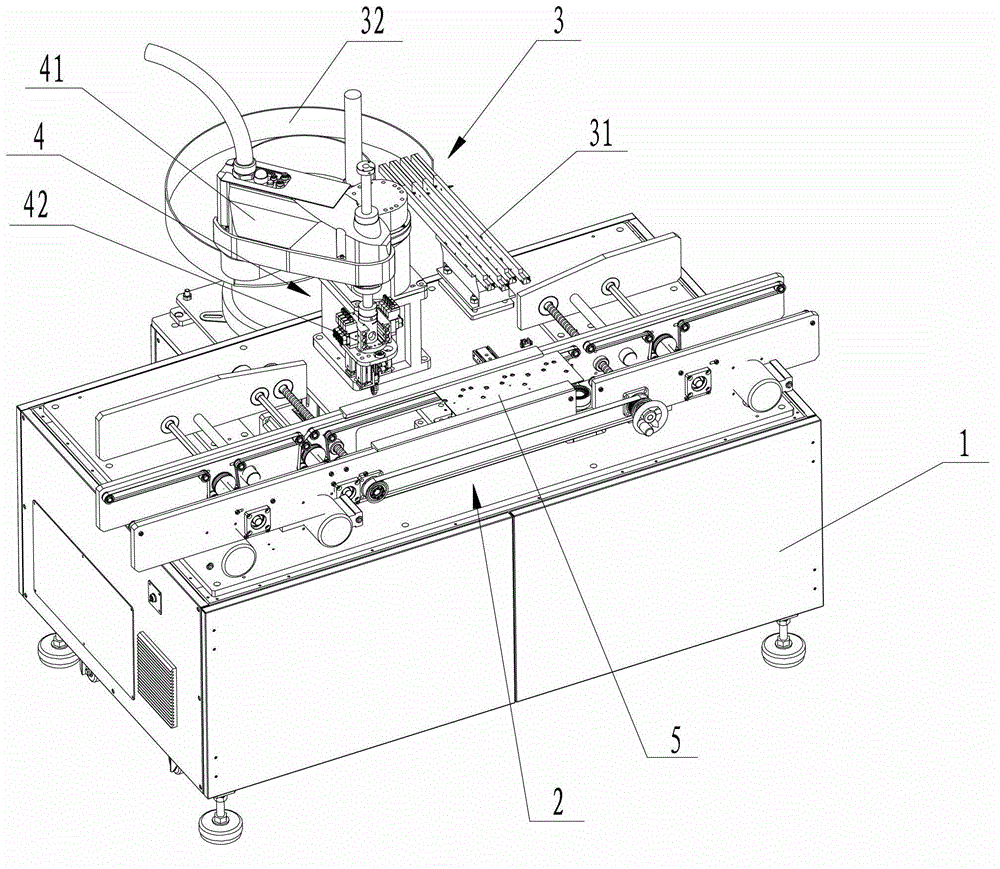

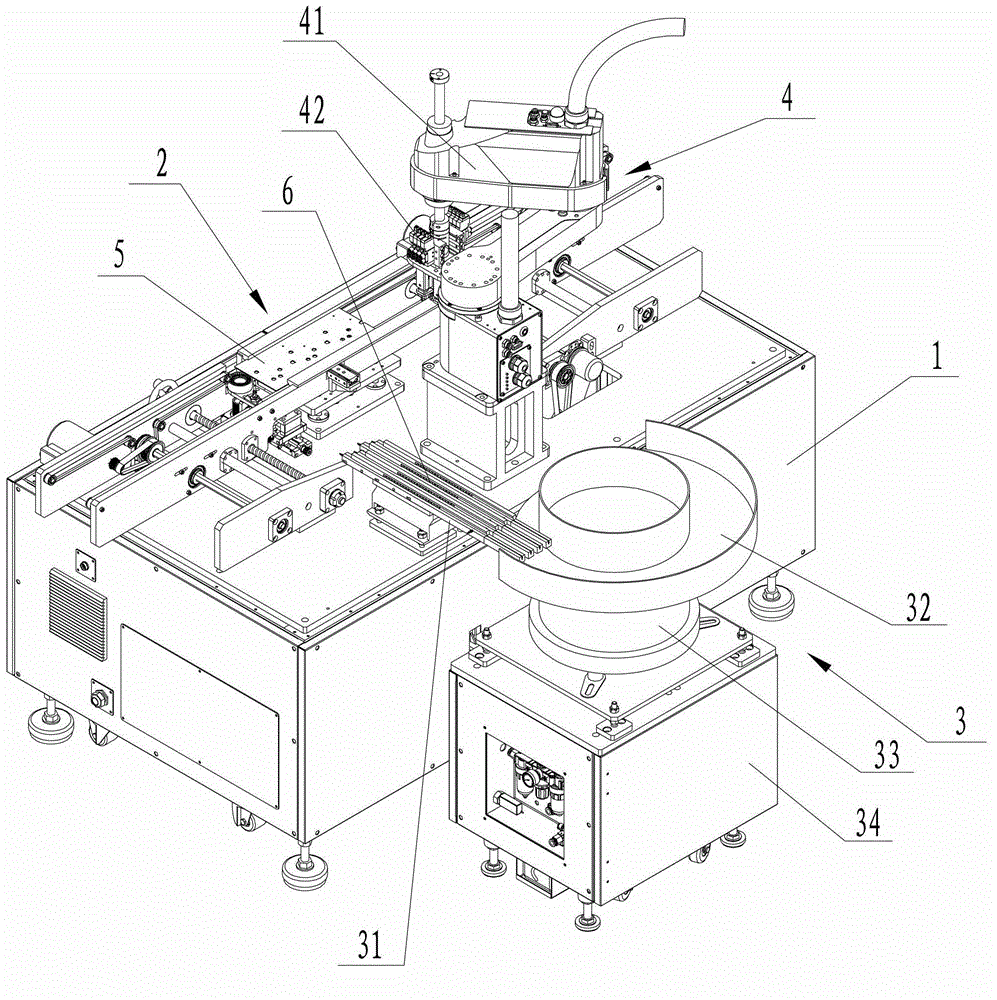

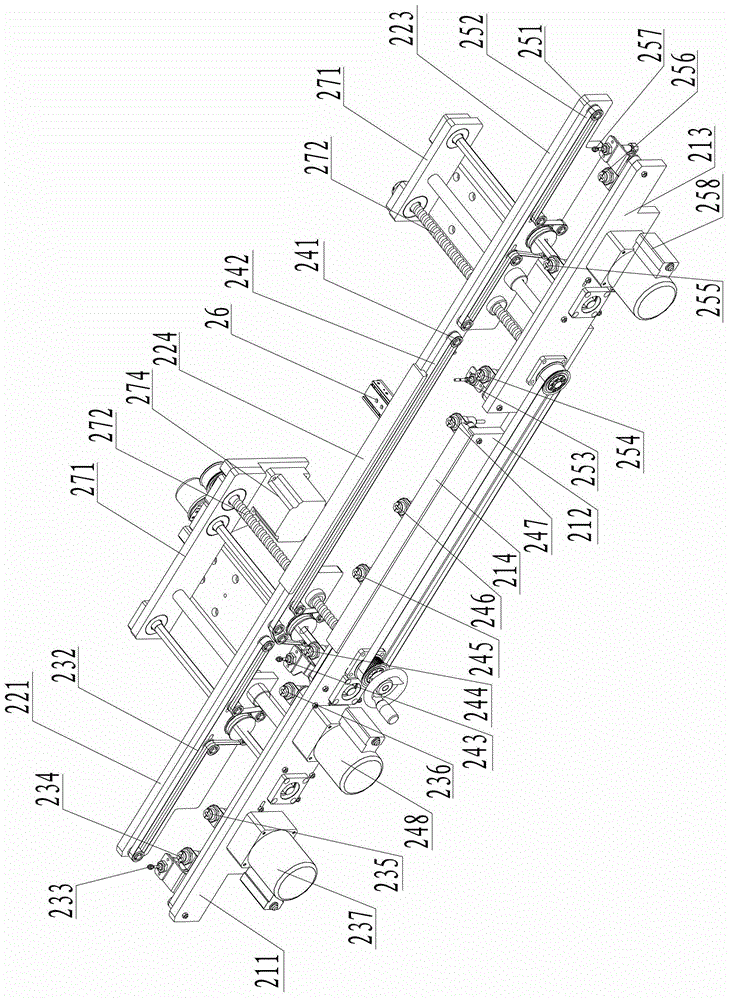

Automatic plug-in machine for plug-in production of specially-shaped electronic elements of electronic products

ActiveCN103338627AIncrease productivityGuarantee product qualityElectrical componentsElectronic componentSi substrate

The invention discloses an automatic plug-in machine for plug-in production of specially-shaped electronic elements of electronic products. The automatic plug-in machine is provided with a substrate feeding device used for transmitting substrates, an element feeding device used for transmitting electronic elements to be plugged, an element pick-up device used for picking up the electronic elements from the element feeding device and plugging the electronic elements in the substrates, and a controller used for controlling working state of the element pick-up device. In the production process, the substrates are sequentially transmitted from front to back by the substrate feeding device in the horizontal direction, the electronic elements to be plugged are sequentially transmitted to the pick-up position by the element feeding device, when the substrates are transmitted to the position to be plugged, the electronic elements to be plugged are taken out from the pick-up position by the element pick-up device and plugged into the substrates, and after plug-in, the electronic products are transmitted out by the substrate feeding device to be collected. The automatic plug-in machine can realize automatic production of plug-in units of the electronic products, and greatly improves the product production efficiency.

Owner:SUZHOU MENGCHUAN AUTOMATION TECH

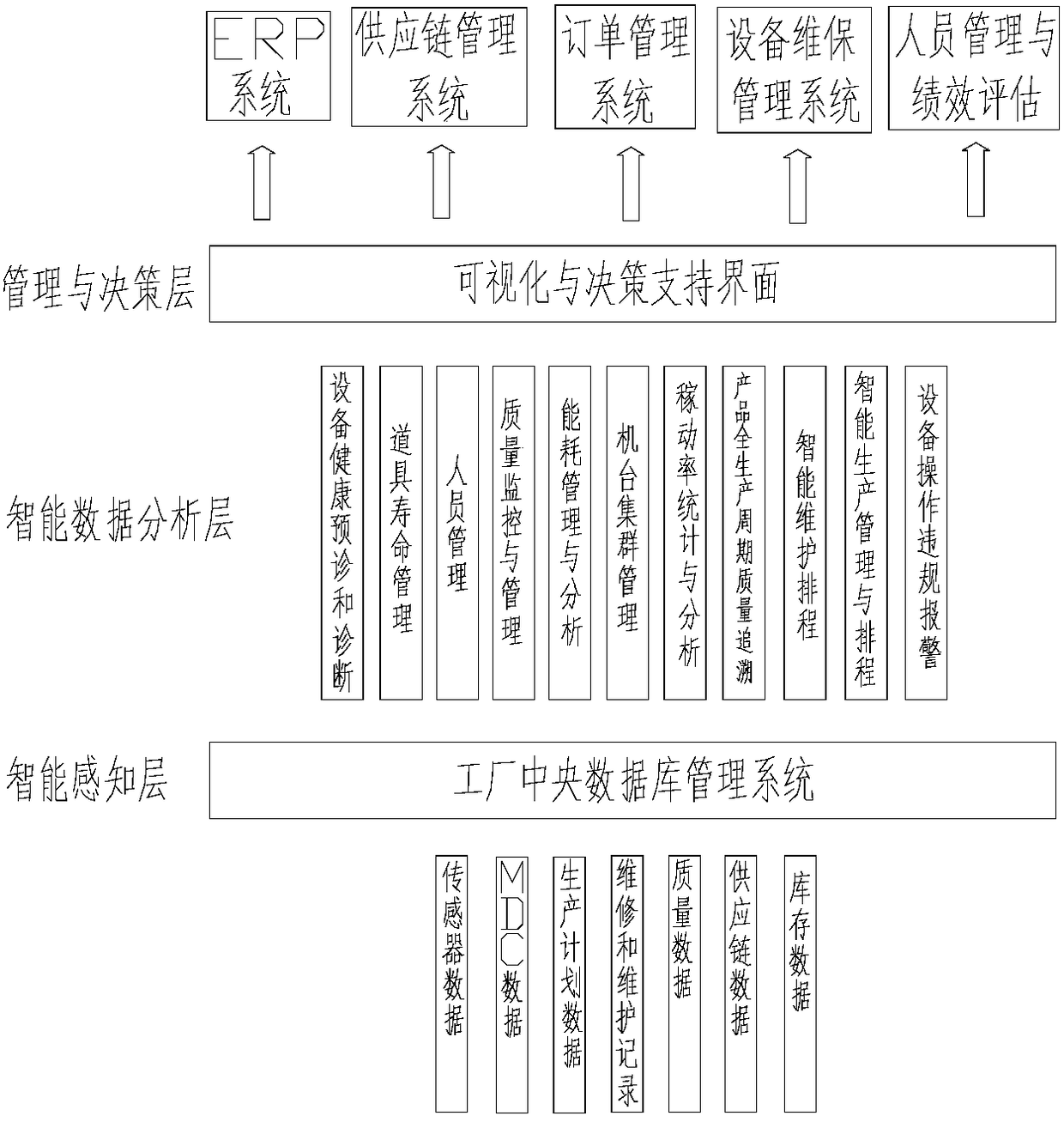

Smart factory management platform system

InactiveCN108241343AAvoid failureReduce operation and maintenance costsTechnology managementTotal factory controlReal time analysisInteraction interface

The invention relates to a smart factory management platform system comprising an intelligent sensing layer for collecting, arranging and storing data of all information sources during a production process, an intelligent data analysis layer for carrying real-time analyses on various collected data, monitoring, evaluating, and predicting healthy states of equipment and product quality states, displaying analysis results at a visual human-computer interaction interface, and generating corresponding decision-making support suggestions, and a management and decision-making layer for pushing the analysis results and decision-making suggestions to all departments under jurisdiction of a company and providing a decision-making and planning basis for a superior information system. According to the invention, historical and real-time monitoring data and production data are dug fully and health states of the equipment are analyzed and controlled precisely and quantitatively; a reasonable production plan and a reasonable maintenance plan are made based on the predictive analysis of the states of the equipment; failures of the equipment and products due to faults can be prevented; the operation and maintenance costs are lowered effectively; the production efficiency is improved; the product quality is guaranteed; and the comprehensive competitiveness of the market is strengthened.

Owner:QINGDAO HAIER MOLDS

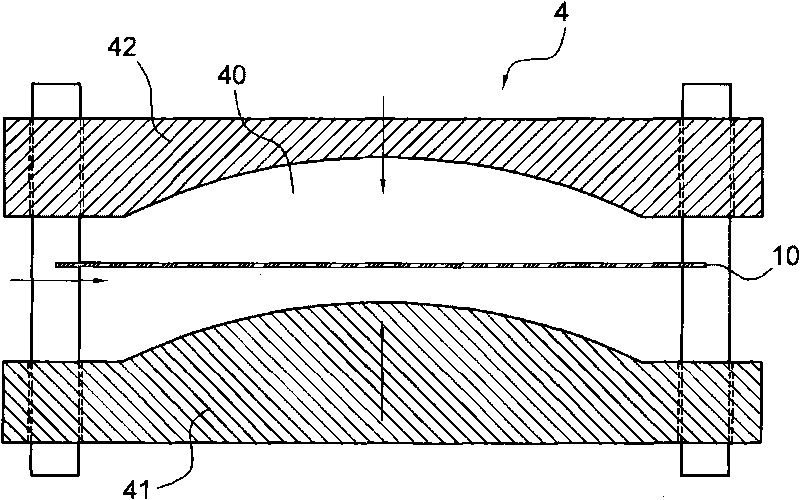

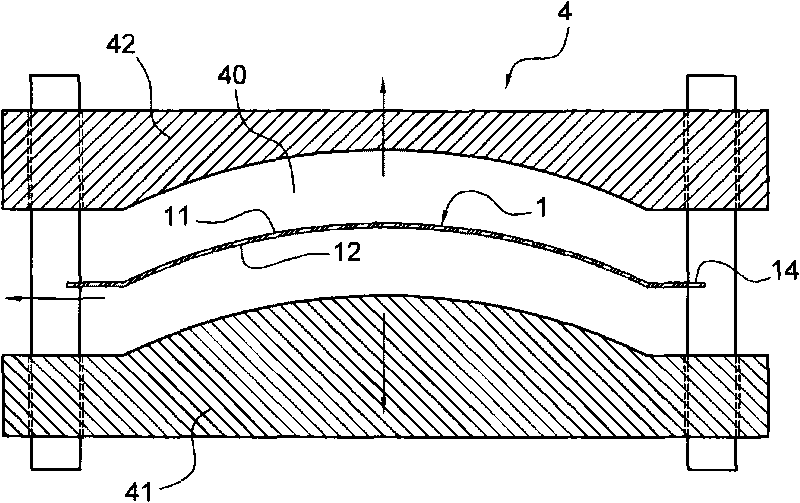

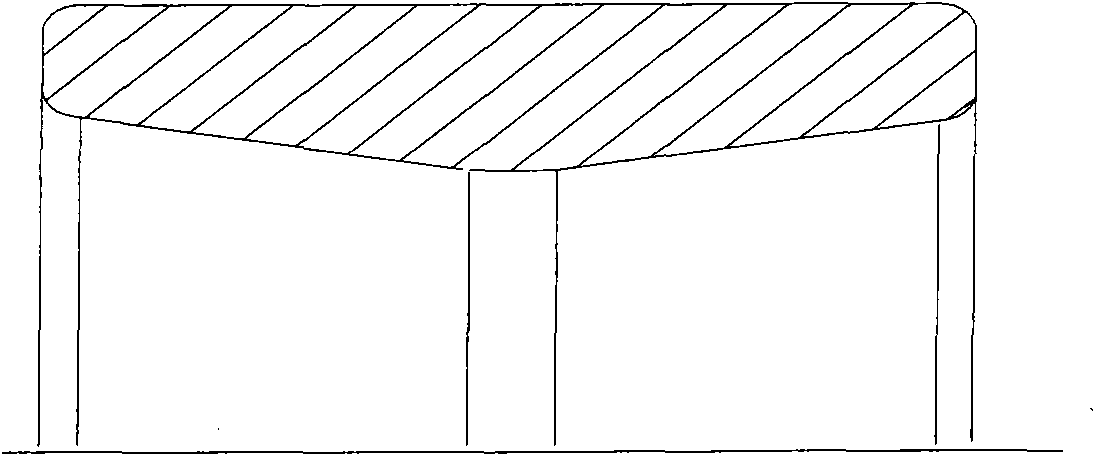

Method for forming composite material pipe mold element by pressurizing air bags with assistance of resin film transfer

InactiveCN104070687AGet rid of usingReduce manufacturing costTubular articlesManufacturing cost reductionManufacturing technology

The invention belongs to the technical field of manufacture engineering, relates to a manufacture technology method of a high-performance composite material pipe mold element, and particularly relates to a method for forming a composite material pipe mold element by pressurizing air bags with assistance of resin film transfer. According to the invention, a dry state fiber fabric and a thermoset resin adhesive film act as a base of a material, so that the method has the multiple advantages of reducing the manufacture cost obviously, improving the production efficiency effectively, expanding the application range of the manufacture technology extremely and the like. Compared with the traditional prepreg-autoclave technology, the fiber / adhesive film pre-dipping process is saved, so that on one hand, the using of a pre-dipping machine is prevented, and the cost of production equipment is reduced obviously, and on the other hand, the reduction of manufacture links improves the production efficiency effectively; additionally, most importantly, as for manufacture of pipe mold elements with the dry state fiber structure incapable of being treated by the pre-dipping mode, such as fiber 2.5D / 3D braided structure, the technology provided by the invention can also be used, and the technology application range is expanded extremely.

Owner:AVIC COMPOSITES

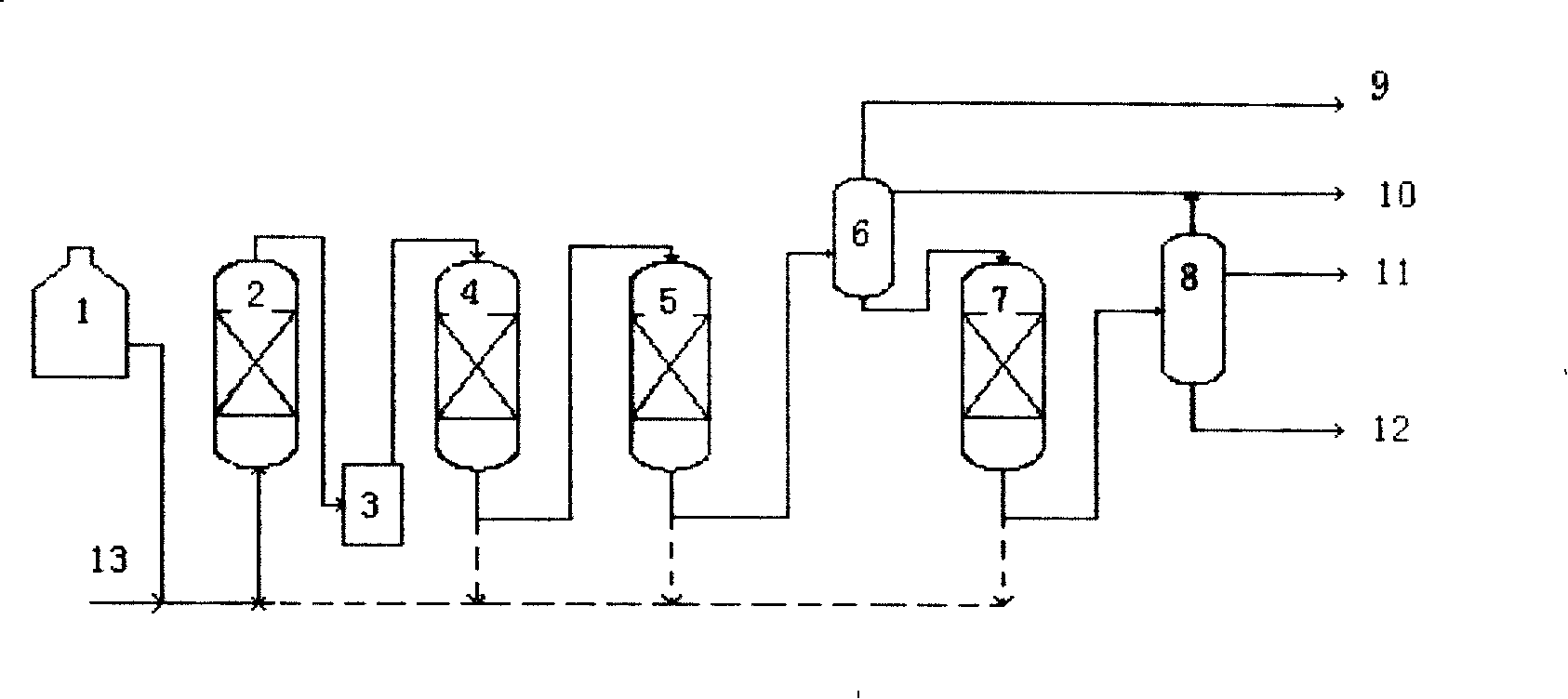

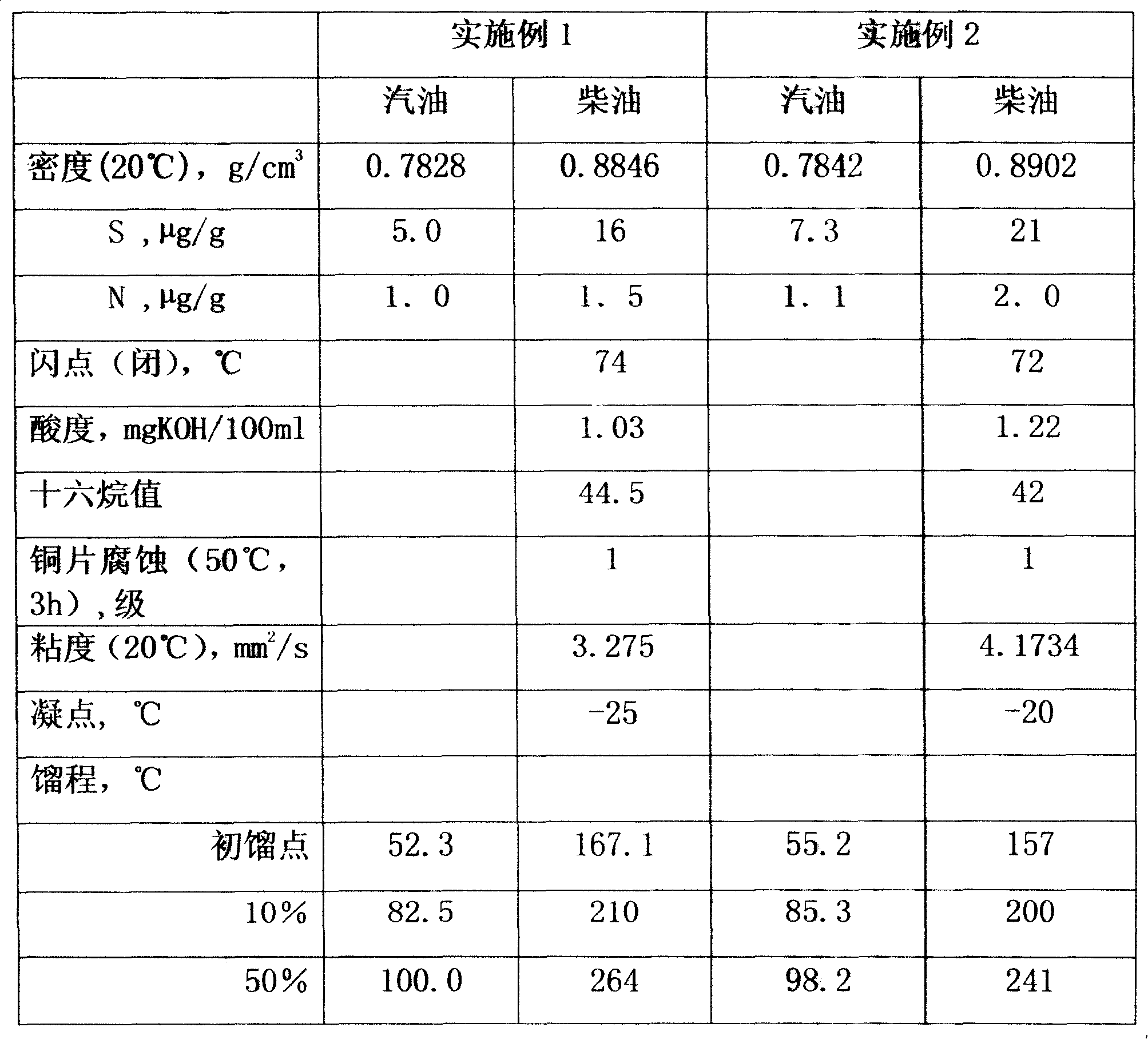

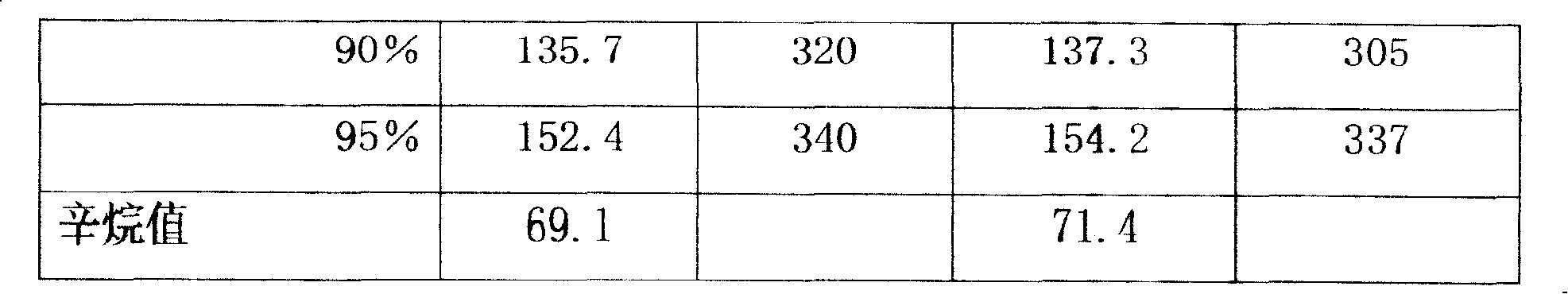

Coal tar multistage hydrogenation treatment technique

ActiveCN101240193AFully activeSolve cokingTreatment with hydrotreatment processesHydrogenation reactionGasoline

The invention discloses a coal-tar oil multistage hydrogenation craft, which belongs to coal chemical industry technology area. The method of the invention is that coal-tar oil fraction oils like impurities, sols, high content, asphaltenes, oxygen element, and so on, with high content or entire fraction are delivered into pre-hydrogenation reaction chamber by pump and are carried on pre-hydrogenation processing, then are successively followed by hydrogenation and demetallization, and depth hydrogenation reaction. After carried on separation of water and lightweight components, the generative fluid enters into a hydrocracking reactor, passes by a distiller to get gasoline fractions, diesel oil and hydrocracking tail oil out. Compared with the prior art, the invention can guarantee the long-period stability operation of the installation.

Owner:CHINA PETROLEUM & CHEM CORP +1

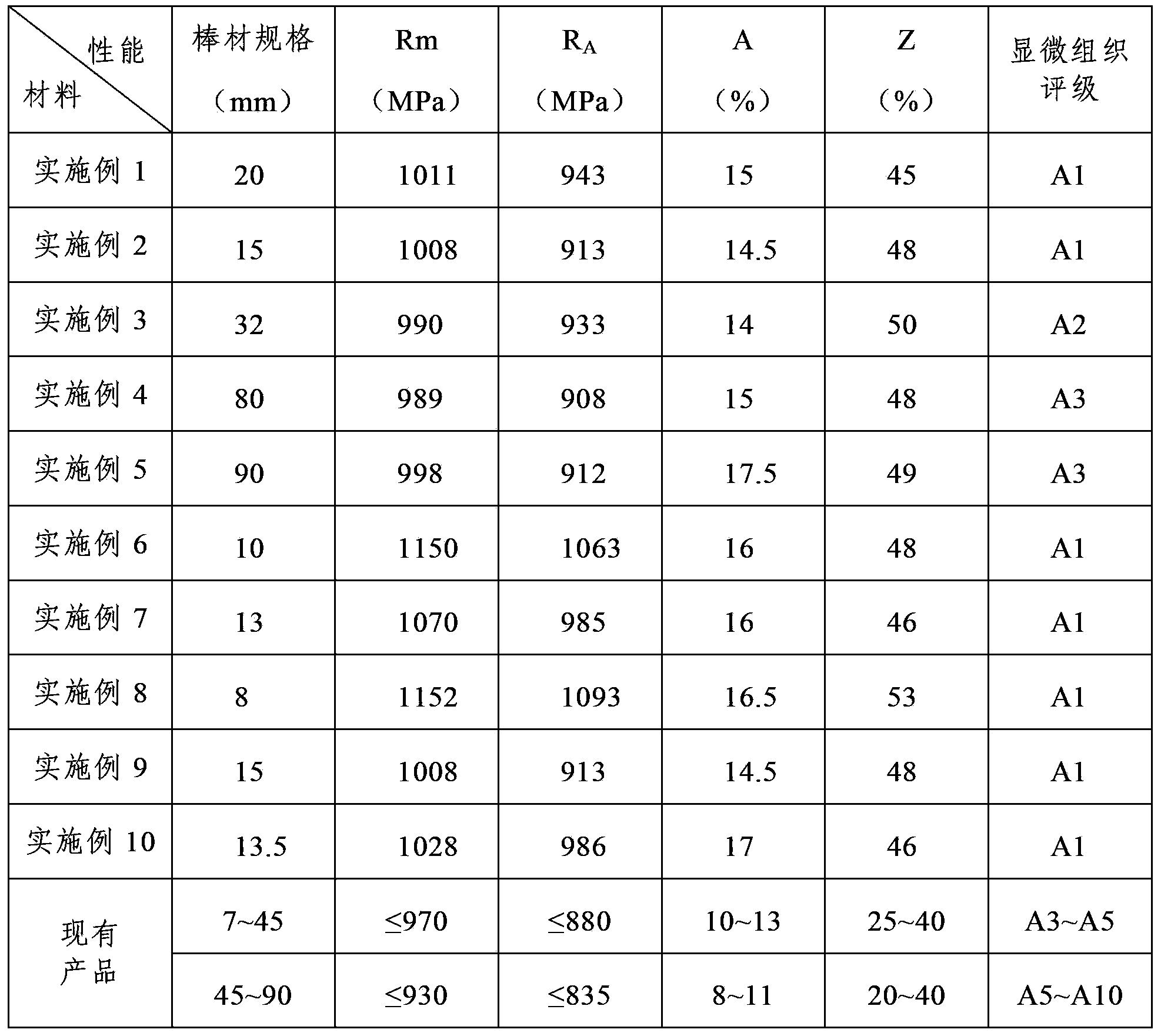

Preparation method of TC4ELI titanium alloy bar

The invention provides a preparation method of a TC4ELI titanium alloy bar. The preparation method comprises the following steps of: (1) carrying out cogging forging; (2) carrying out upsetting forging; (3) carrying out precise forging; (4) carrying out shearing, straightening and annealing treatment in sequence, thereby obtaining the cylindrical TC4ELI titanium alloy bar with the cross-section diameter of 15mm-90mm. The invention also provides a preparation method of the TC4ELI titanium alloy bar. The preparation method comprises the following steps of: (1) carrying out cogging forging; (2) carrying out upsetting forging; (3) carrying out precise forging; (4) rolling; (5) carrying out shearing, straightening and annealing treatment in sequence, thereby obtaining the cylindrical TC4ELI titanium alloy bar with the cross-section diameter of 8mm-15mm. The preparation method is simple in process, strong in repeatability and suitable for large-scale industrial production; the TC4ELI titanium alloy bar prepared by adopting the preparation method is uniform and fine in structure, high in microscopic structure level and excellent in mechanical property.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Micro-elastic memory face fabric and production process thereof

InactiveCN101338470APromote formationSuitable for mass productionWeft knittingLoomsEngineeringCompanion animal

The invention discloses micro-stretch memory fabric and a process thereof. The process comprises the selection of weaving equipment, warp and weft, weaving gray fabric, and dyeing and finishing. The invention is characterized in that the weaving equipment is a hydraulic loom or a jet loom; the warp is PTT memory filament or PET / 144F fine denier filament; the weft is PPT / PET compound blended fabric or PBT stretch yarn; and the quality ratio of the warp and the weft is 60 to 70 / 40 to 30. The gray fabric weaving adopts X55, CM800, T400 or the PBT stretch yarn of whole original weft supplier. Warp twisting is 6 to 8 twist / cm. Twisting speed is 8500 revolutions per minute. The temperature of setting twist is 75 DEG C and heat preservation lasts for an hour or scaling treatment lasts for 24 to 48 hours. The flow of the dyeing and finishing is as follows: open-width de-sizing, preshrinking, previous form definition, dying and subsequent form definition. The process of the micro-stretch improves the quality of a product, and reduces cost. In addition, the fabric has good elasticity and good size stability, and is comfortable to be wore and easy to be handled.

Owner:YANGZHOU JIYUAN TEXTILE +1

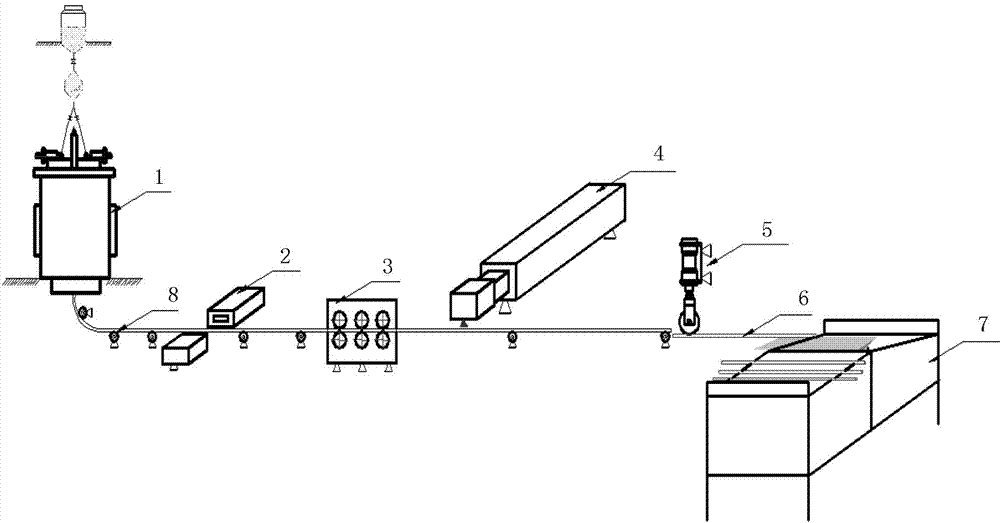

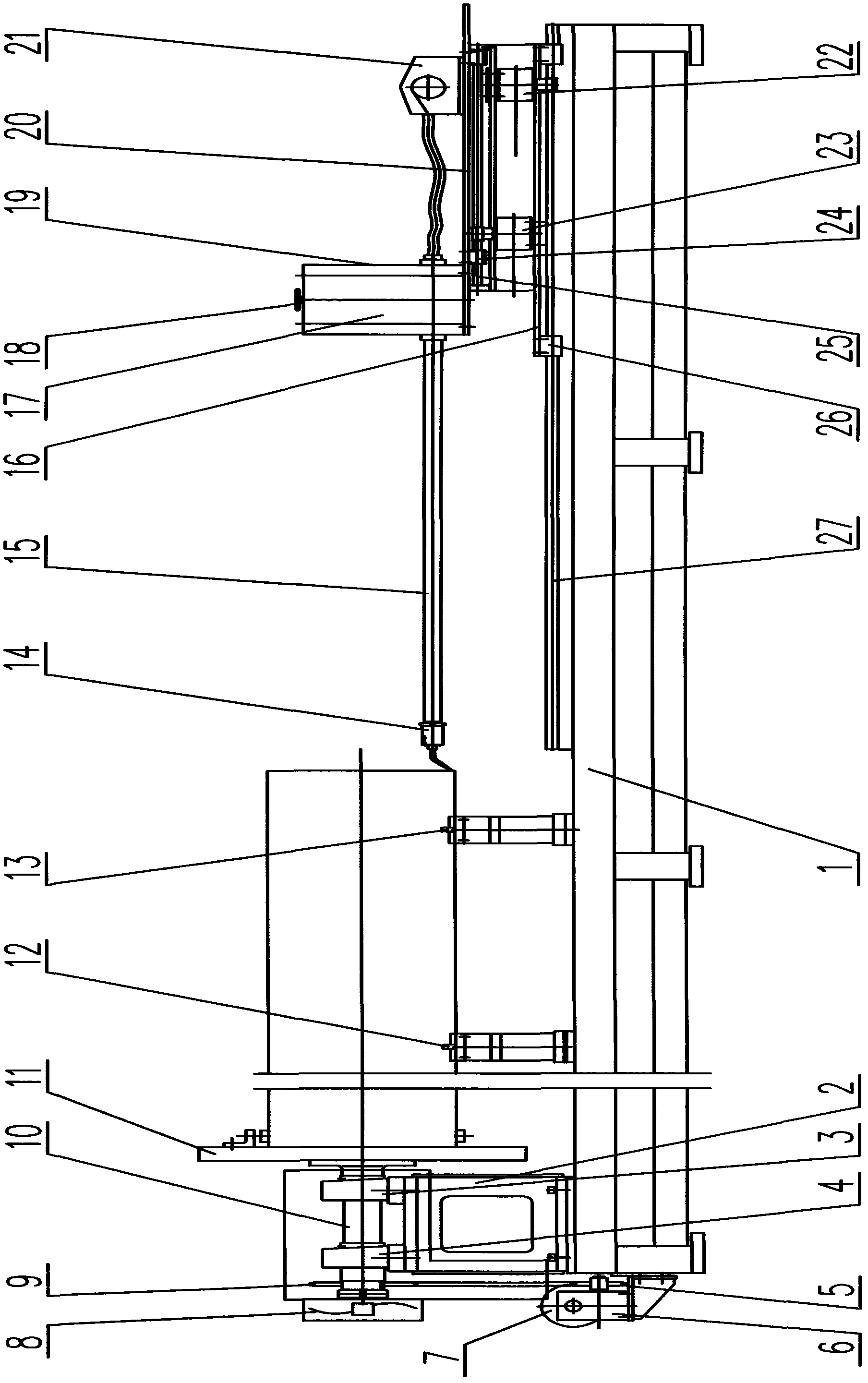

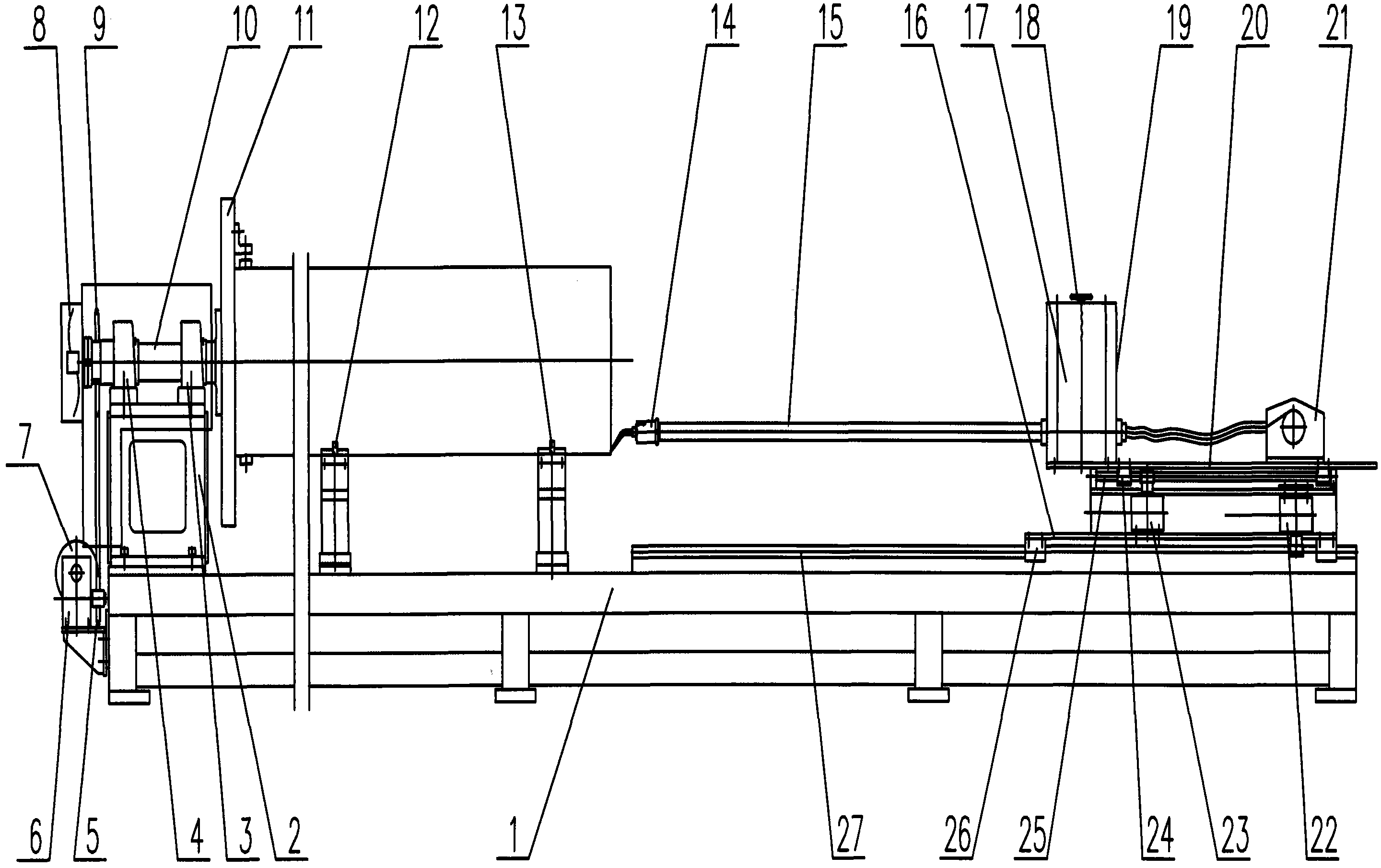

Automatic build-up welding equipment for abrasion-resistant layer on inner wall of pipeline and automatic build-up welding method

InactiveCN102049594ASmooth and reliable rotation speedGuaranteed uptimeWelding/cutting auxillary devicesAuxillary welding devicesAutomatic controlWelding power supply

The invention discloses automatic build-up welding equipment for an abrasion-resistant layer on an inner wall of a pipeline and an automatic build-up welding method for realizing efficient automatic production of high abrasion-resistant composite conveying pipelines. The equipment comprises a host, a direct-current gas protective welding power supply, a protective gas storage tank and a control box with a built-in automatic control device; one end of a base is provided with a head, a main shaft, a chuck and an adjustable roller bracket; the other end of the base is provided with a welding gun running execution device, and the device comprises a driving and reversing platform, a swing platform, a welding gun lifting mechanism, a wire feeder and a welding gun; the front end of the welding gun is provided with a welding torch, and a welding wire and a protective gas conveying pipe are communicated to the front end of the welding gun; the anode of the welding power supply is connected with the welding torch, and the cathode of the welding power supply is connected with a workpiece; and the moving parts are driven by a step motor through the automatic control device. The operation process comprises early preparation, parameter setting, welding and reset stopping; and by setting control parameters, the execution parts run according to the set parameters to form build-up welding layers tightly arranged and uniformly distributed in a spiral motion locus.

Owner:济南杰瑞复盛机电设备有限公司

High-temperature-resistant wave-transparent silicon nitride fiber-reinforced composite material and preparation method thereof

The invention relates to a high-temperature-resistant wave-transparent silicon nitride fiber-reinforced composite material and a preparation method thereof. The method comprises the following steps: by using a two-dimensional fabric laying or three-dimensional four-direction knitted continuous silicon nitride fiber preform as a reinforcing body, carrying out interface coating preparation on the reinforcing body fiber surface with a polyboron azane precursor by half-vitrification; compounding the precursor mainly composed of polyboron azane with an impregnation liquid to prepare a base; and carrying out vacuum pressure impregnation, desolventization, pressure crosslinking curing and cracking densification to obtain the final silicon nitride fiber-reinforced composite material. The preparation method greatly enhances the impregnation efficiency, enhances the material density by 18-40%, and finally obtains the novel wave-transparent material system with excellent high temperature resistance. The strength retention rate of the material at 1200 DEG C and 1500 DEG C is 70-94%. Compared with the silicon nitride ceramic material, the novel wave-transparent material has obviously higher breaking strain.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com