Detection and grading system for tenderness of fresh beef based on multispectral imagery

A multi-spectral image and grading system technology, which is applied in the field of fresh beef tenderness detection and grading system, can solve the problems of limited wavelength precision filter specifications, unstable hardware system, slow speed of multi-hole wheel, etc., to achieve fast Non-destructive quality inspection, the effect of ensuring the quality of beef products and improving the accuracy of detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings.

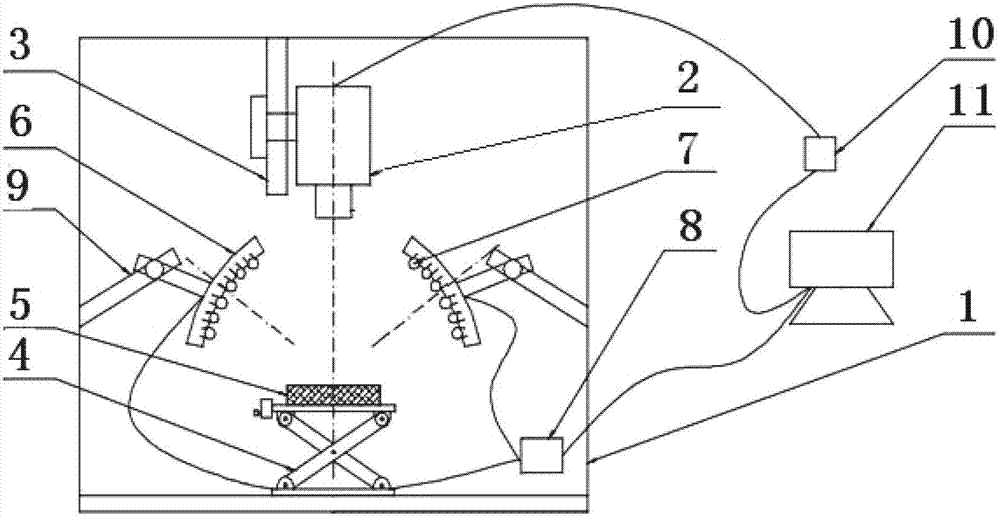

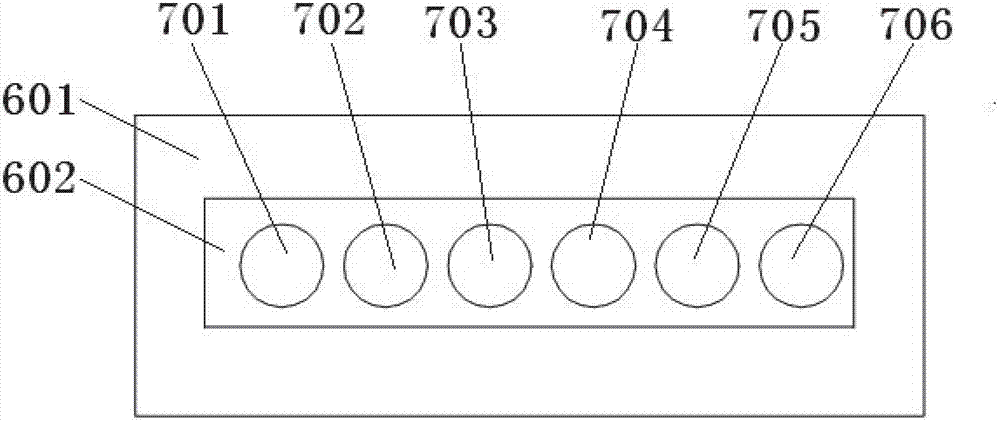

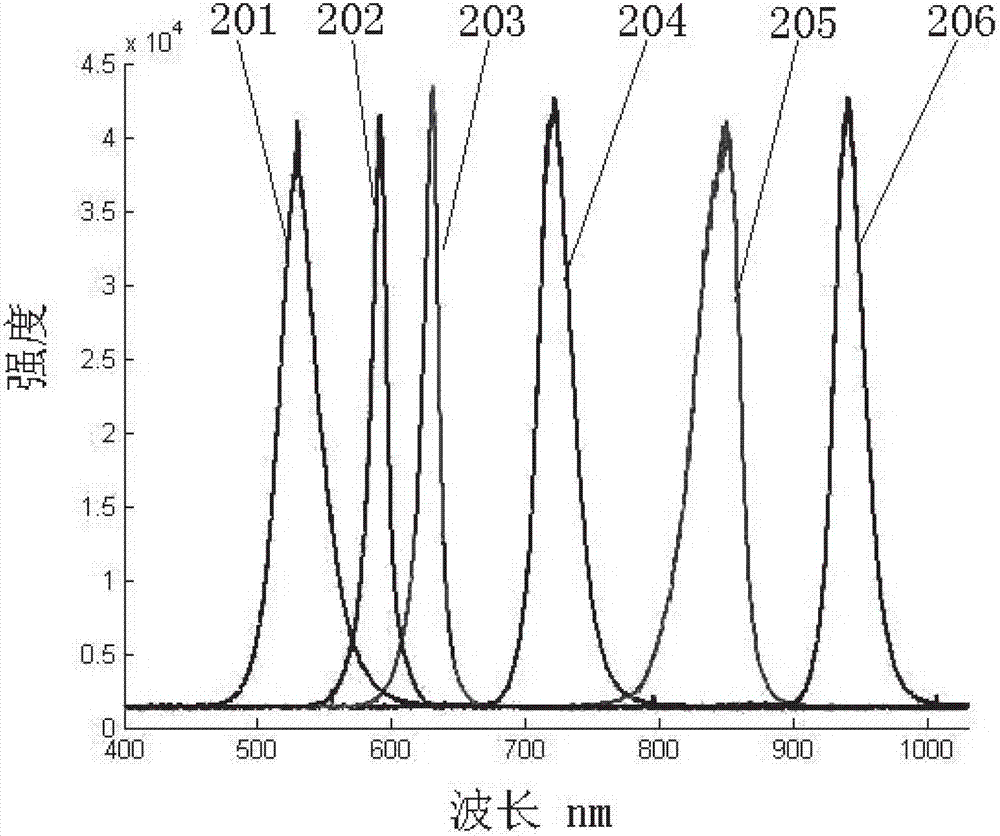

[0035] figure 1 It is a structural schematic diagram of an embodiment of the present invention. As shown in the figure, the image acquisition card 10 and the computer 11 are placed outside the dark box 1, and in the dark box 1, the height-adjustable stage 4 is placed at the center of the bottom plate of the dark box, and the sample 5 to be tested is placed on the height-adjustable carrier during detection. On the table of the object stage 4, the camera fixing bracket 3 is fixed on the top plate of the dark box, the lens of the CCD industrial camera 2 is installed downward on the camera fixing bracket 3, and the lens of the CCD industrial camera 2 is aligned with the height-adjustable stage 4 table. In the center, two light source fixing brackets 9 are symmetrically fixed on the left and right side walls of the dark box 1, and two multispe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com