Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Rapid Quality Inspection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

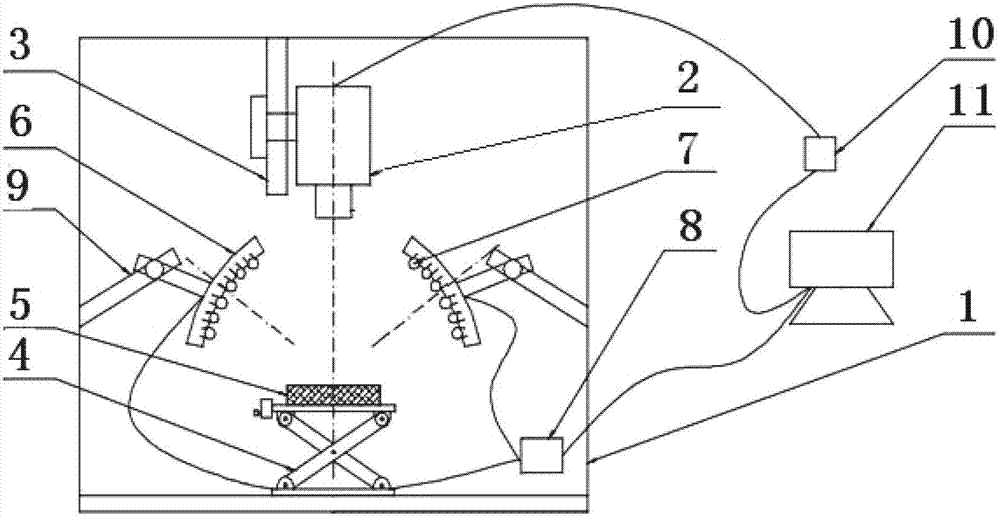

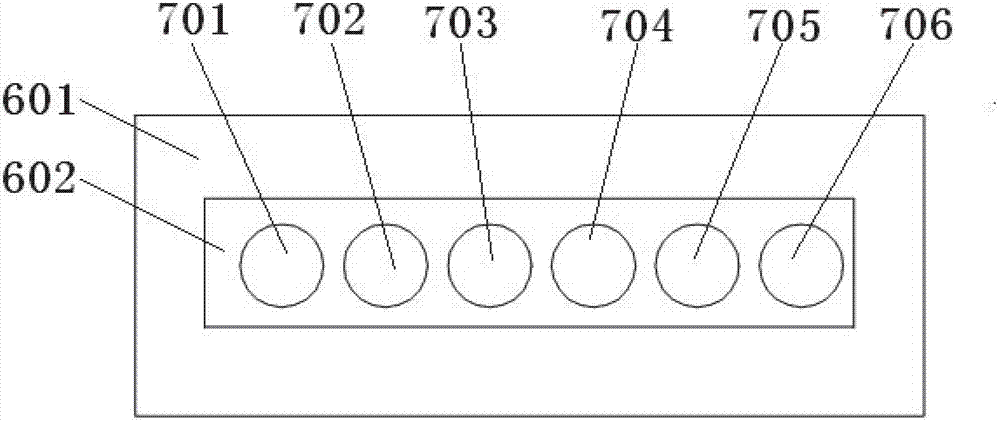

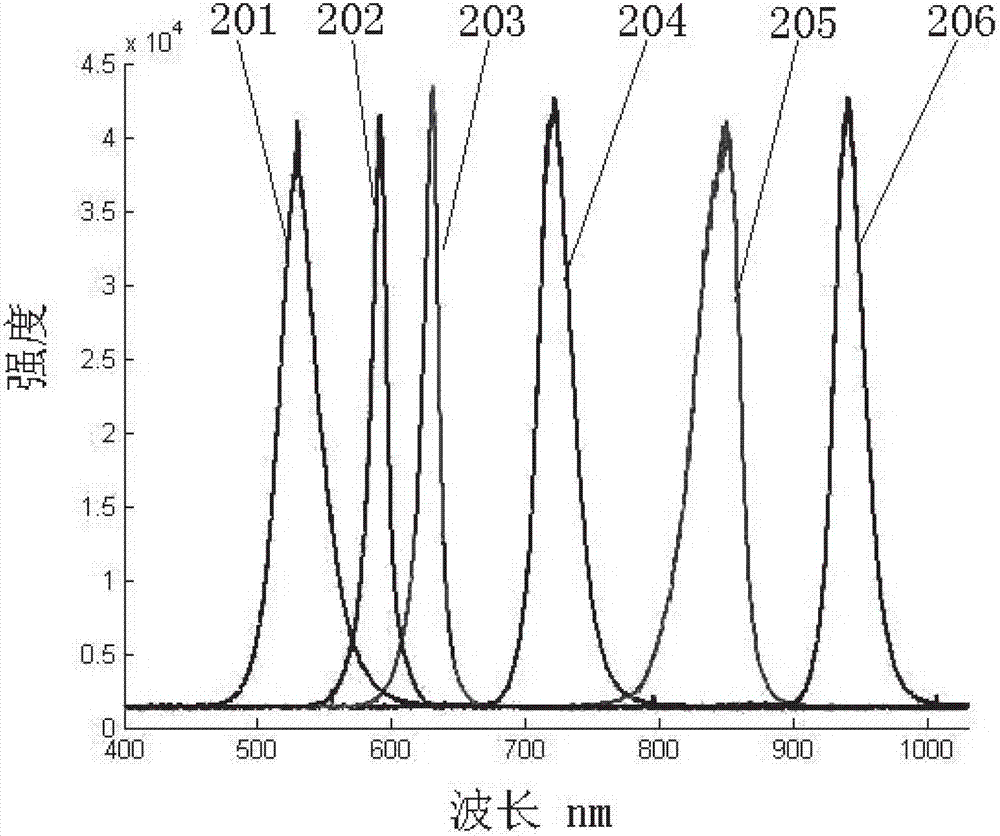

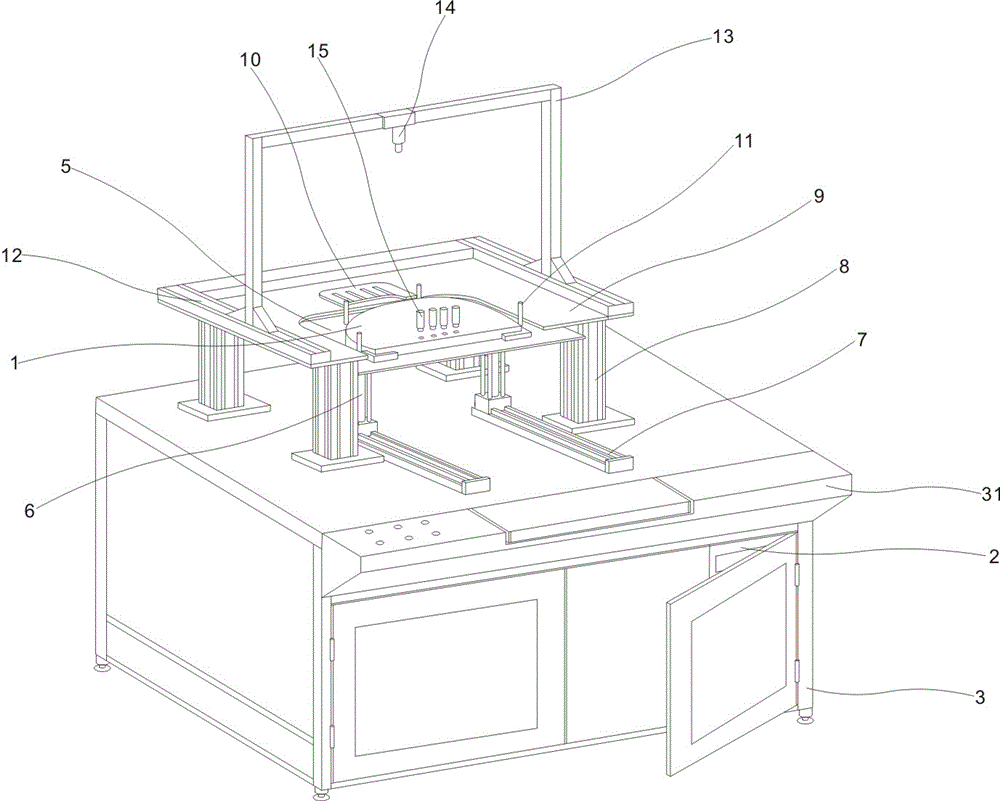

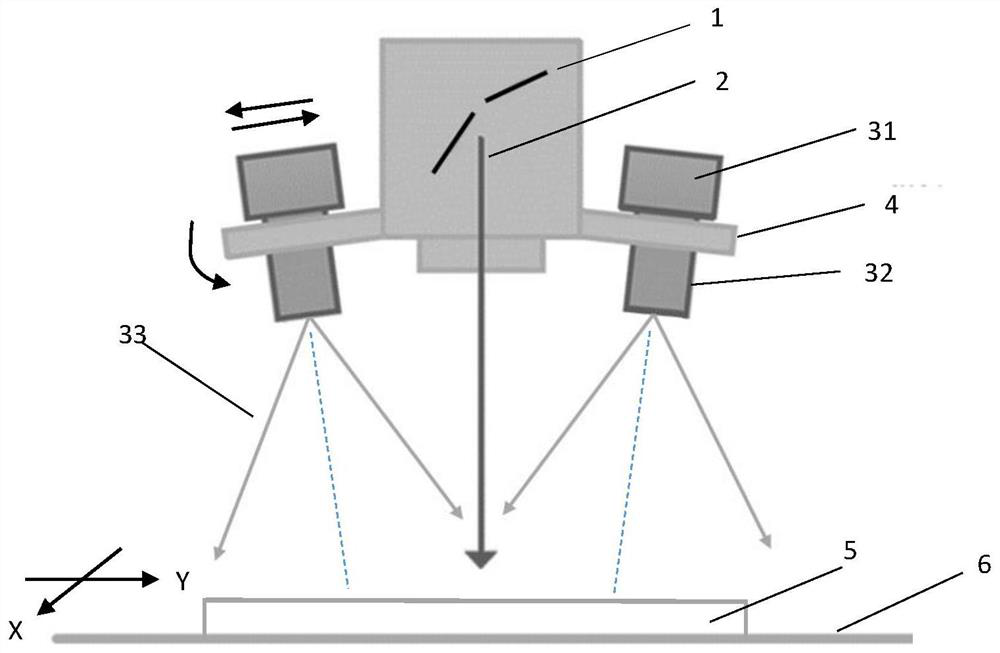

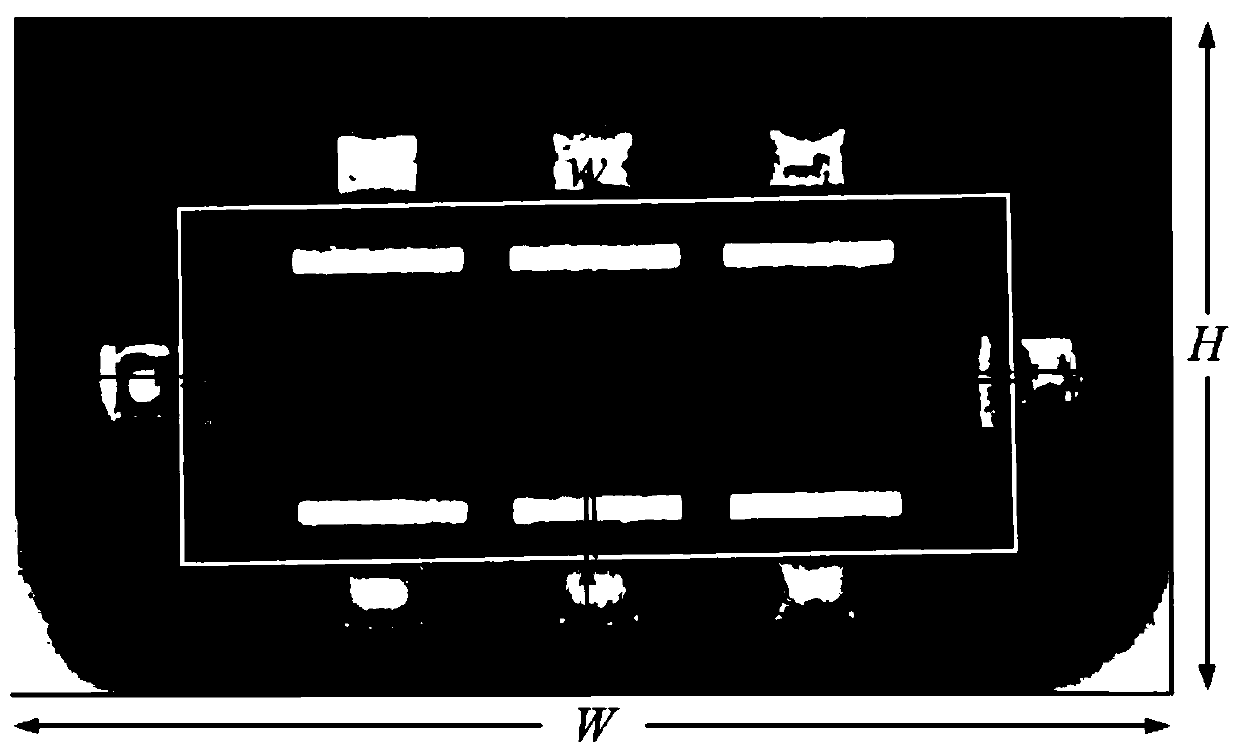

Detection and grading system for tenderness of fresh beef based on multispectral imagery

InactiveCN102854148AEasy to detectAchieve ratingColor/spectral properties measurementsCamera lensLean meat

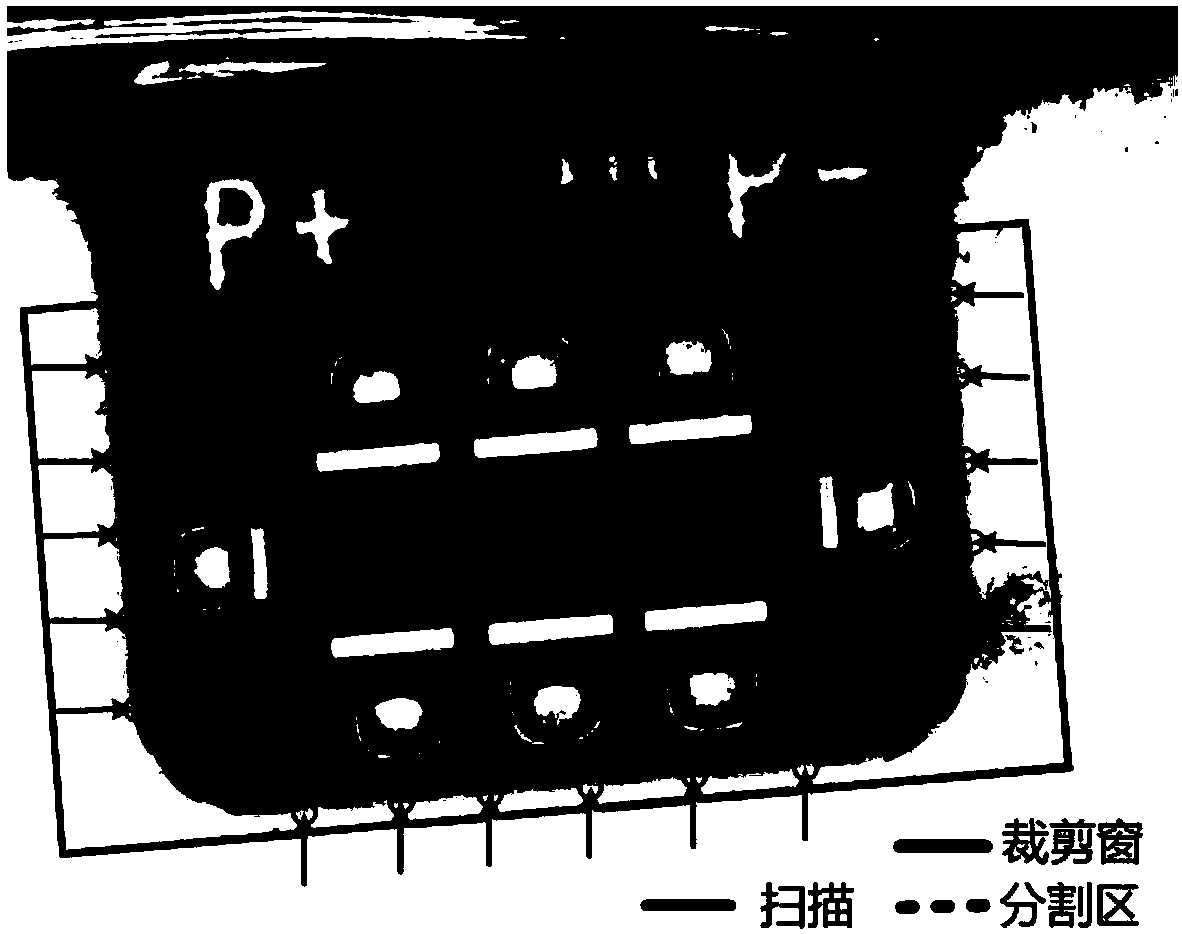

The invention relates to a detection and grading system for tenderness of fresh beef based on multispectral imagery, which belongs to the technical field of detection of food quality. In a dark box, the lens of a CCD industrial camera is aligned with the center of a table board of a height-adjustable objective table, two multispectral light source assemblies are symmetrically arranged at a left sidewall and a right sidewall of the dark box respectively through two light source fixing supports, and a large power LED array on each of multispectral light source assemblies is composed of LEDs of 6 kinds of wave bands; during detection, a sample to be detected is put on the table board of the height-adjustable objective table, the LEDs of 6 kinds of wave bands alternately radiate in order, the CCD industrial camera acquires multispectral images of the sample to be detected, a multispectral beef sample reflection image in an interested area of a lean meat part is extracted through computer image processing, and therefore, marbling of beef is extracted, and evaluation and grading of content of marbling of the beef are carried out, and tenderness of the beef is predicted. The detection and grading system provided by the invention is applicable to companies dealing with cutting, marketing, processing and import and export of fresh beef and to market supervision by quality and technical supervision departments.

Owner:CHINA AGRI UNIV

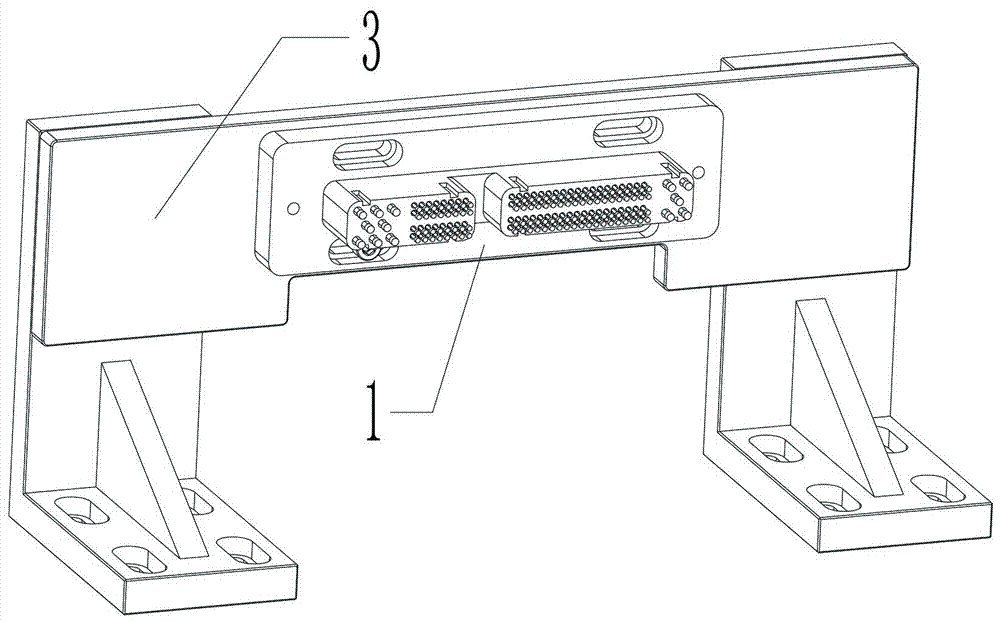

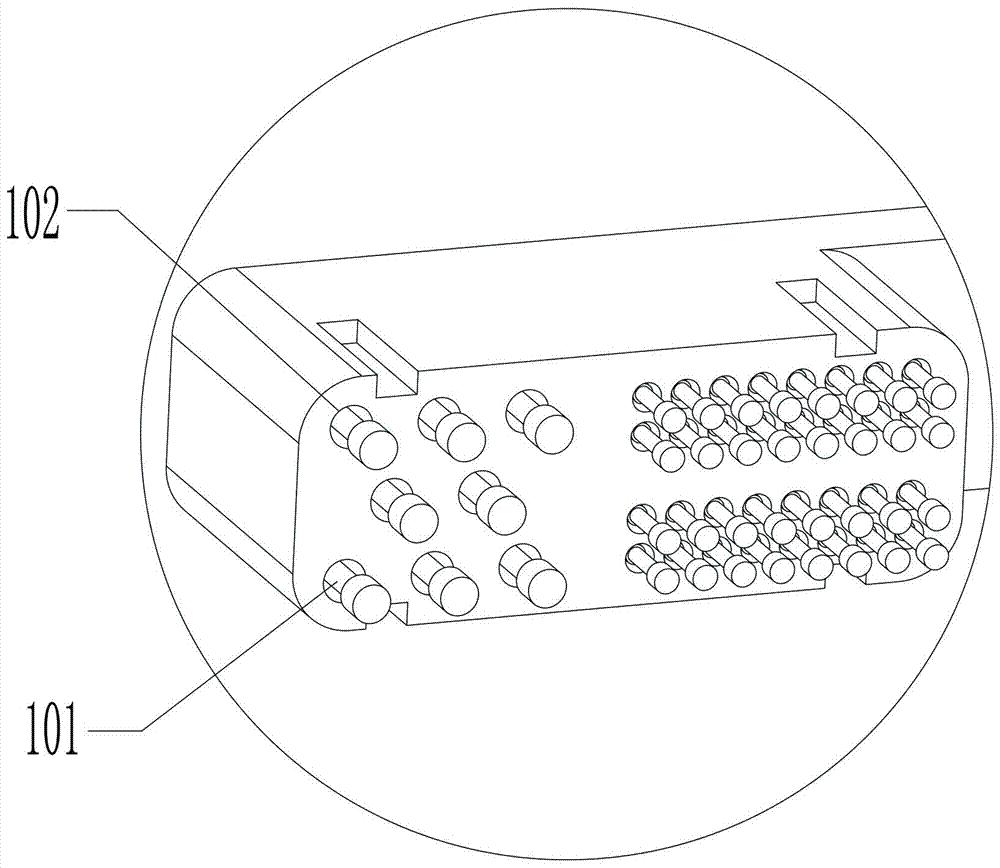

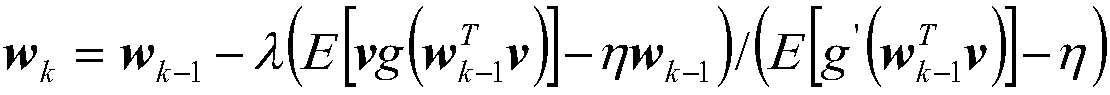

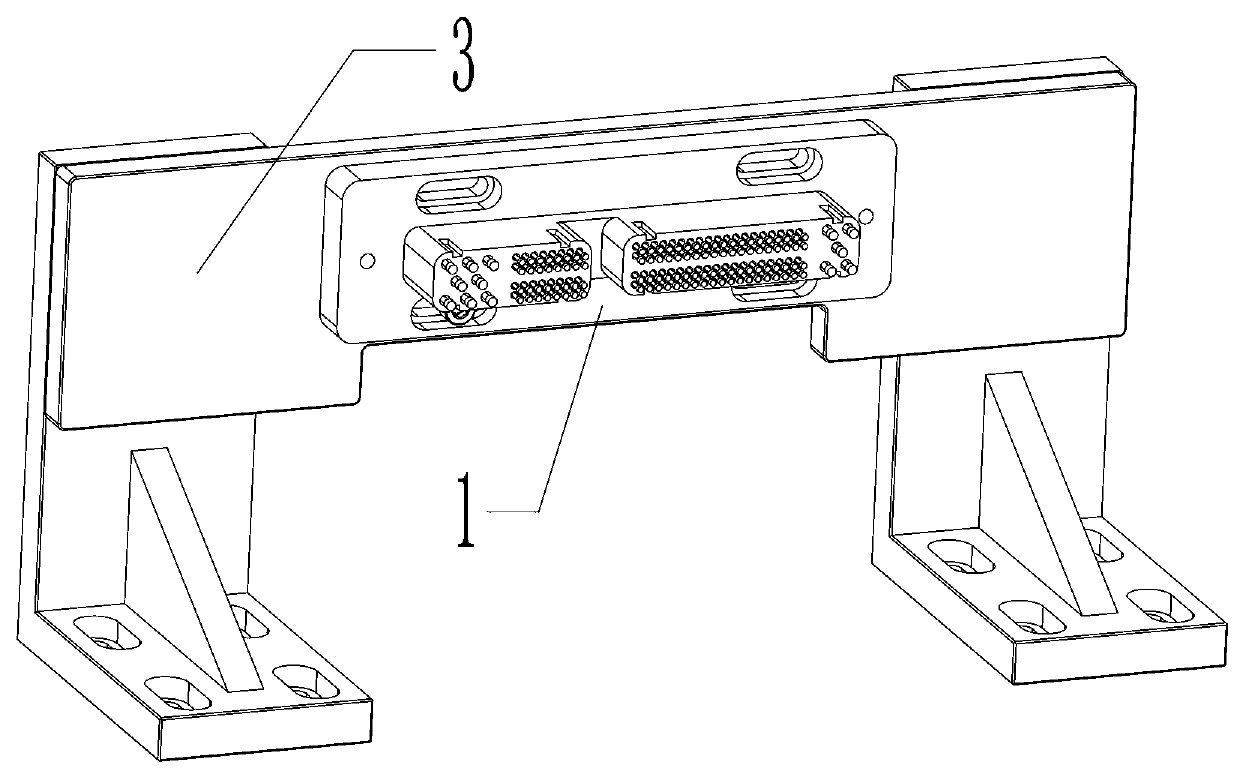

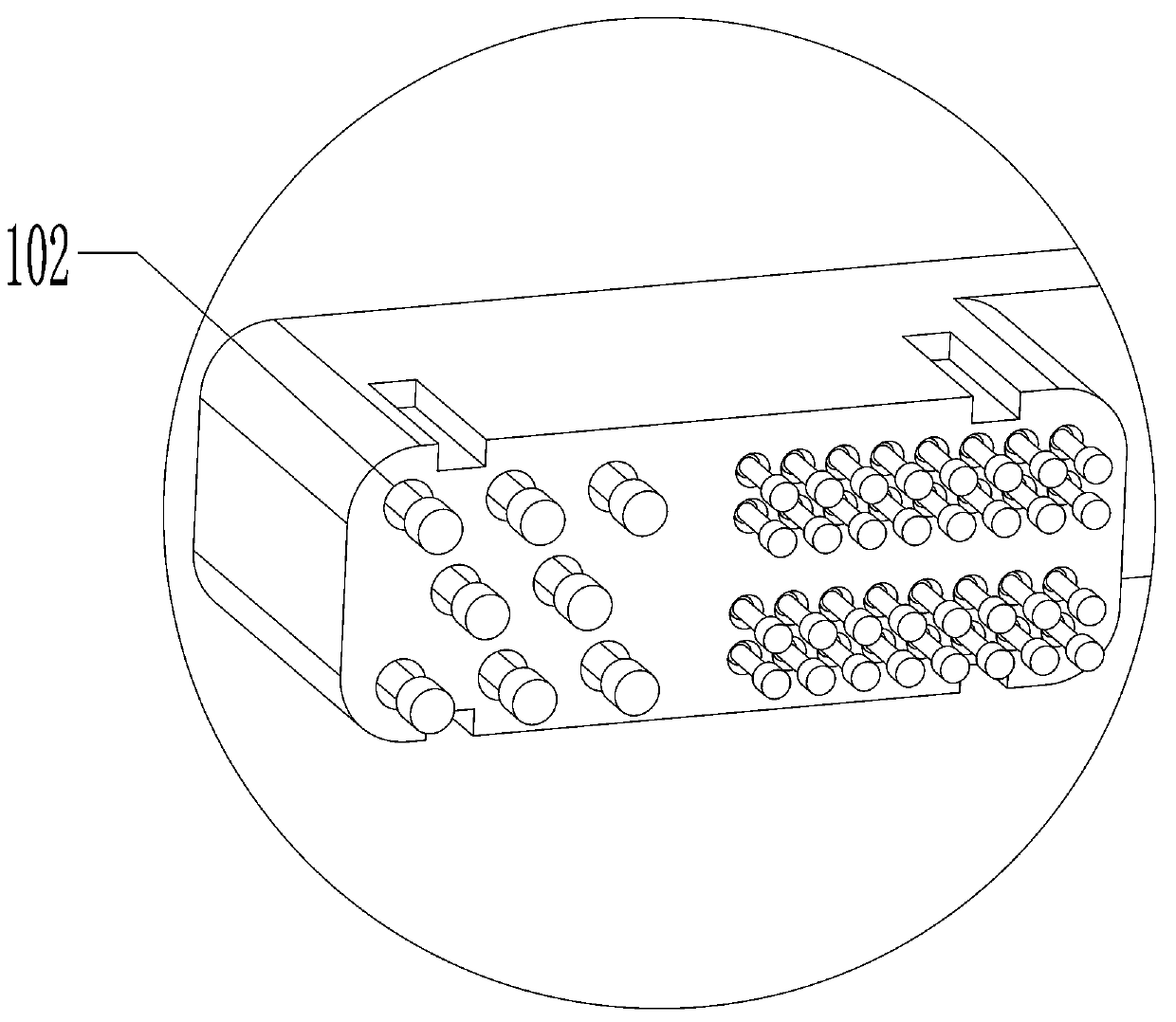

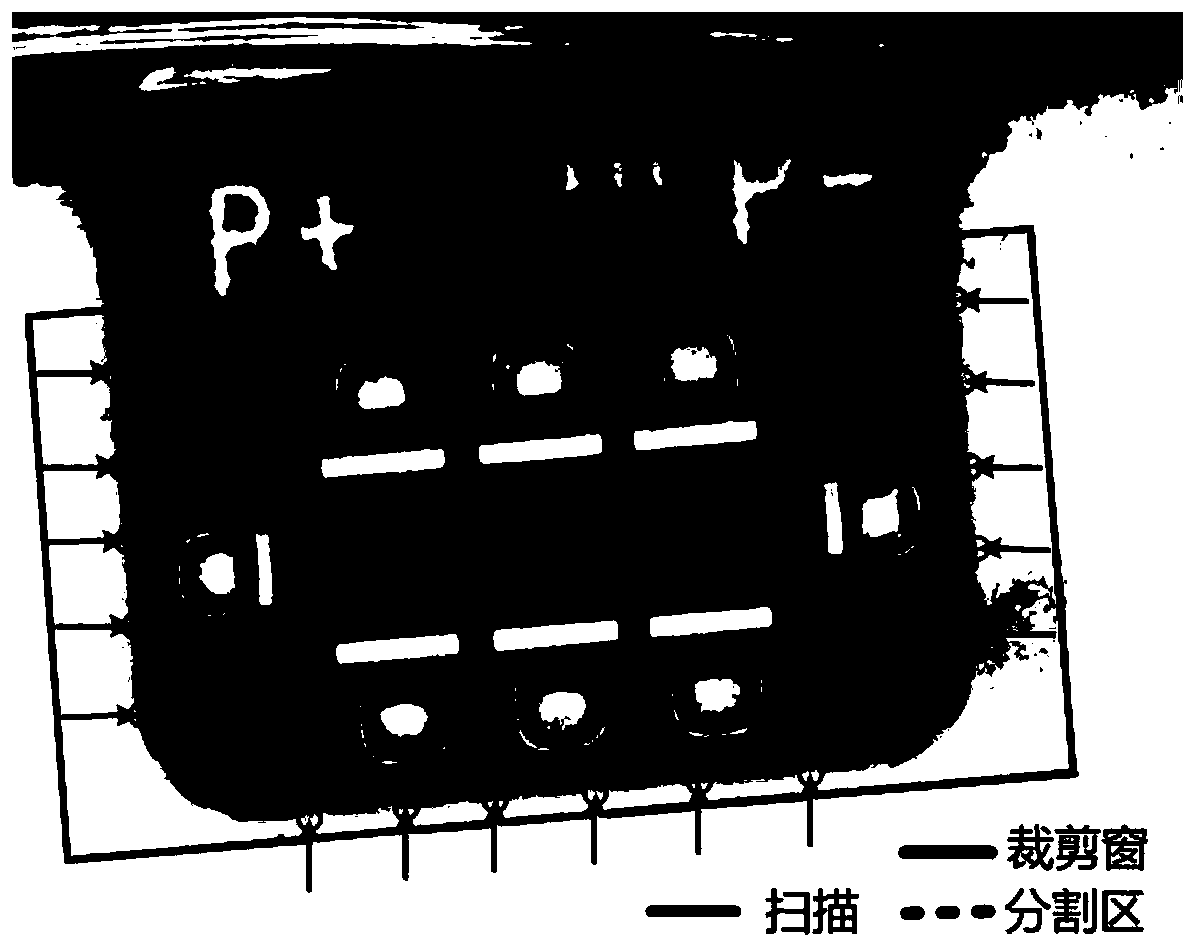

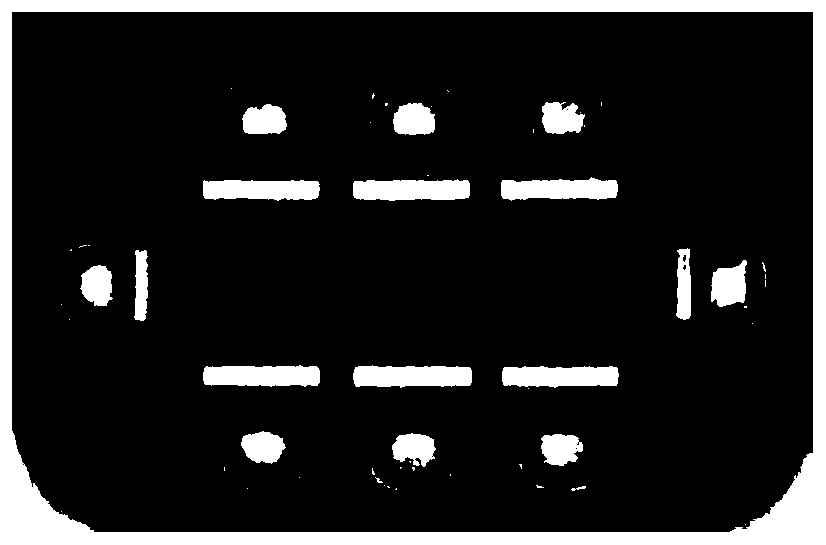

Battery connector quality detecting method based on machine vision

ActiveCN108355981ARapid Quality InspectionNo human intervention requiredSortingData setMachine vision

The invention discloses a battery connector quality detecting method based on machine vision. A connector template data set is built; images of detected connectors are acquired; acquired original images of the battery connectors are cut to obtain images of rectangular window areas; the cut images are aslant corrected to obtain corrected images; the images are reconstructed until the images finishpretreatment; after the images are pretreated, positions of the connectors, connector FPC substrate copper exposure, connector central area defects, connector hardware part defects and connector plastic part detects are respectively detected by adopting independent detecting methods; detecting templates are updated in real time by adopting dynamic template update mechanisms; a coordinate system isbuilt based on the corrected images; the defects are classified, positioned and marked; detecting results are output; common quality problems of inclination / deflection, FPC plate copper exposure, hardware defects, plastic defects and central area defects of the connectors can be detected; and excellent instantaneity and higher detecting rate are achieved.

Owner:XI AN JIAOTONG UNIV

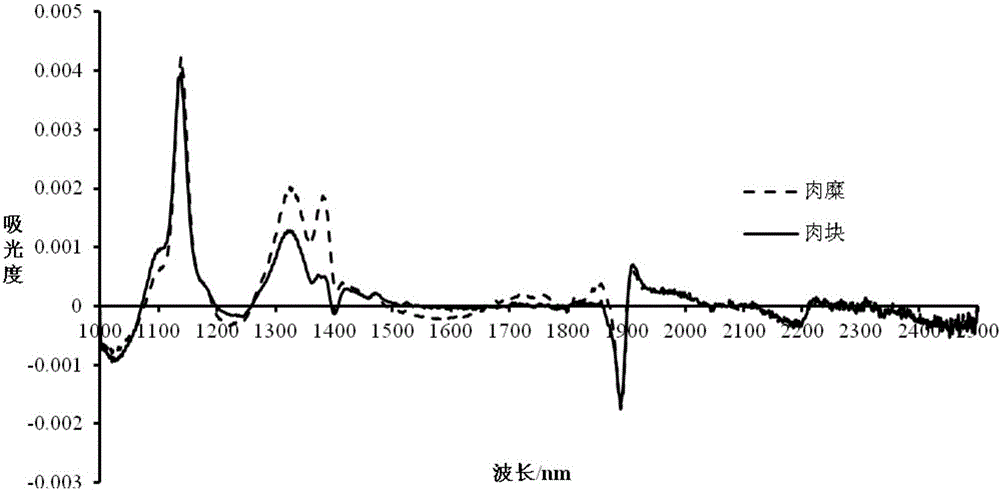

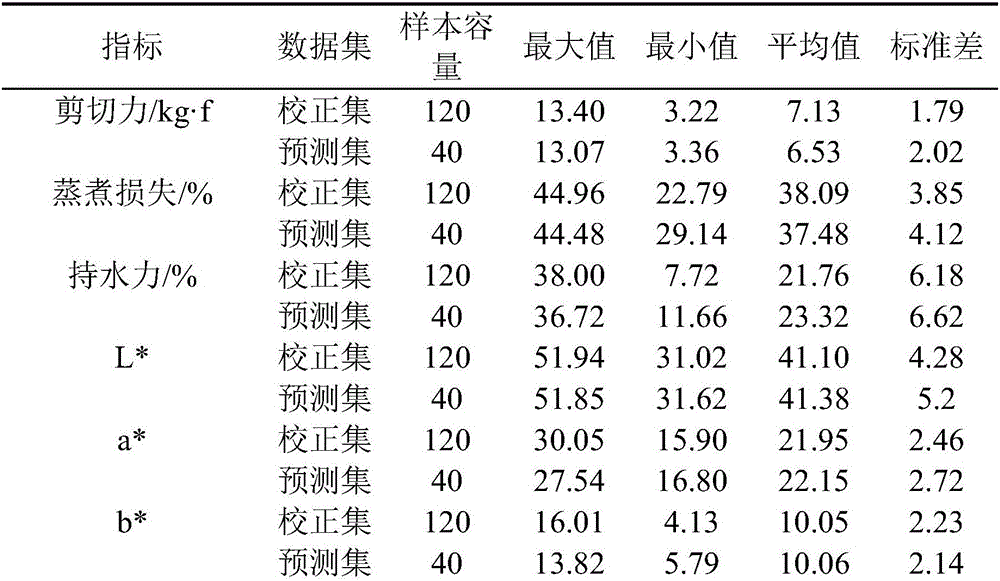

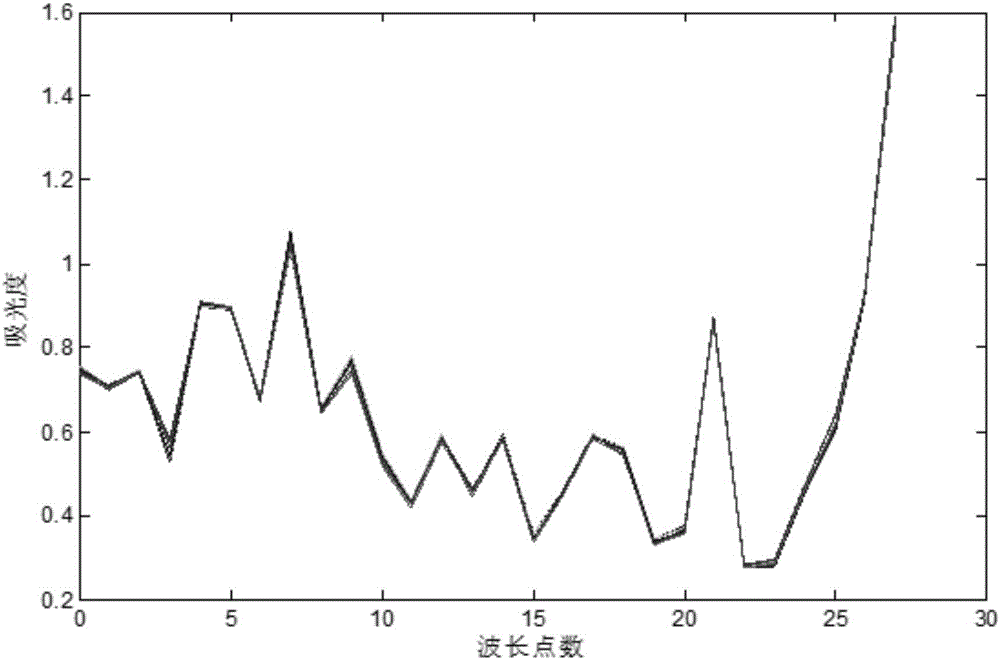

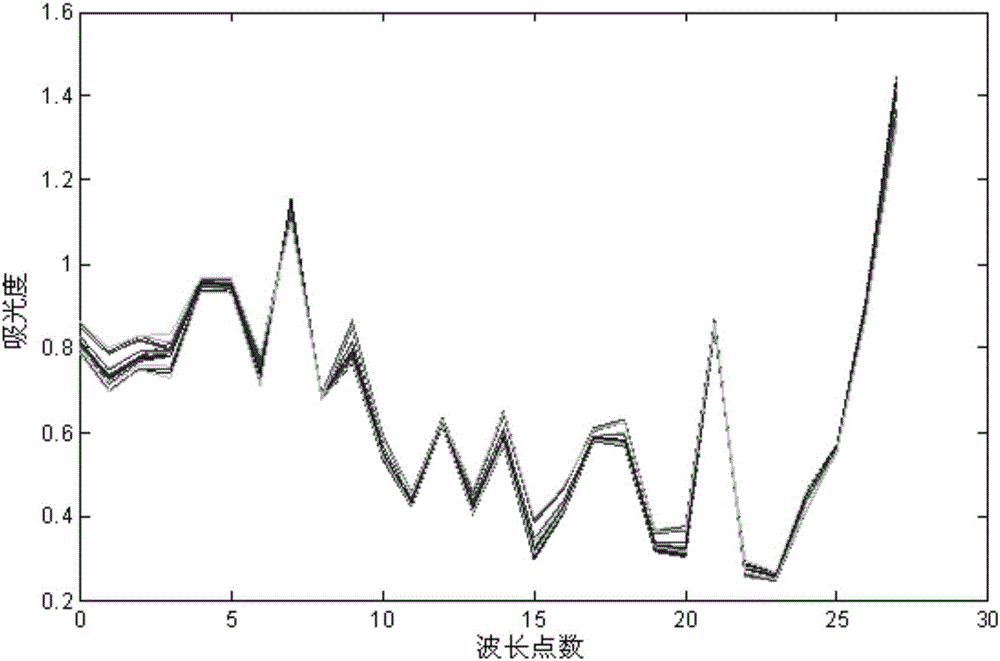

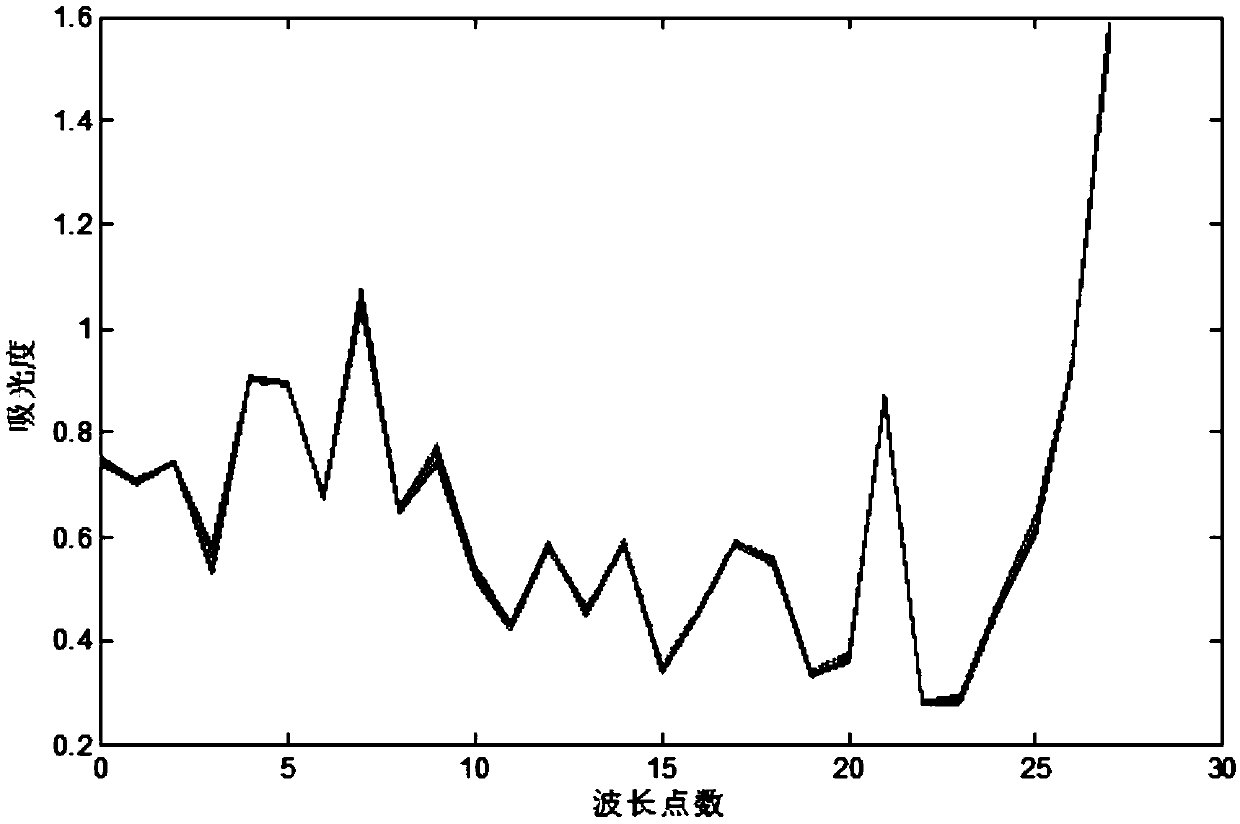

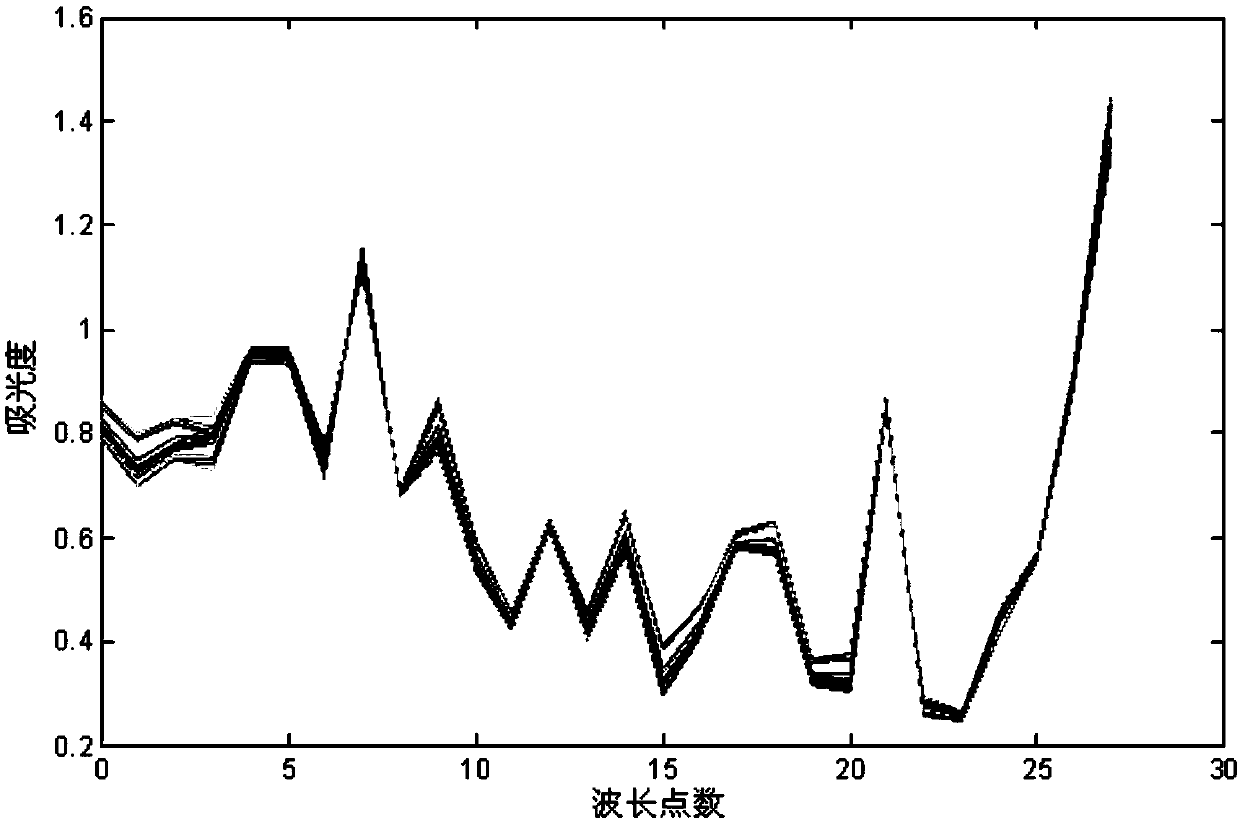

Method for establishing data model using near-infrared spectrum information to evaluate beef quality and application

InactiveCN106501211AFast operationGood repeatabilityMaterial analysis by optical meansWater contentProtein content

The invention relates to the technical field of meat product quality inspection, in particular to a method for establishing a data model using a near-infrared spectrum information system to evaluate beef quality, and application of the method in evaluation of beef quality. The method comprises the following steps of (1) establishing large sample data of beef near-infrared spectrum, and inspecting related parameters of the beef quality; (2) according to the corresponding relationship of the large sample data of near-infrared spectrum and the related parameters of the beef quality, establishing a near-infrared spectrum data model, wherein the related parameters of the beef quality include main chemical component indexes and / or quality indexes; the main chemical component indexes comprise one or multiple of protein content, fat content and water content; the quality indexes comprise one or multiple of shear force value, cooking loss rate, water-retaining capability, and color differences L*, a* and b*.

Owner:INST OF QUALITY STANDARD & TESTING TECH FOR AGRO PROD OF CAAS

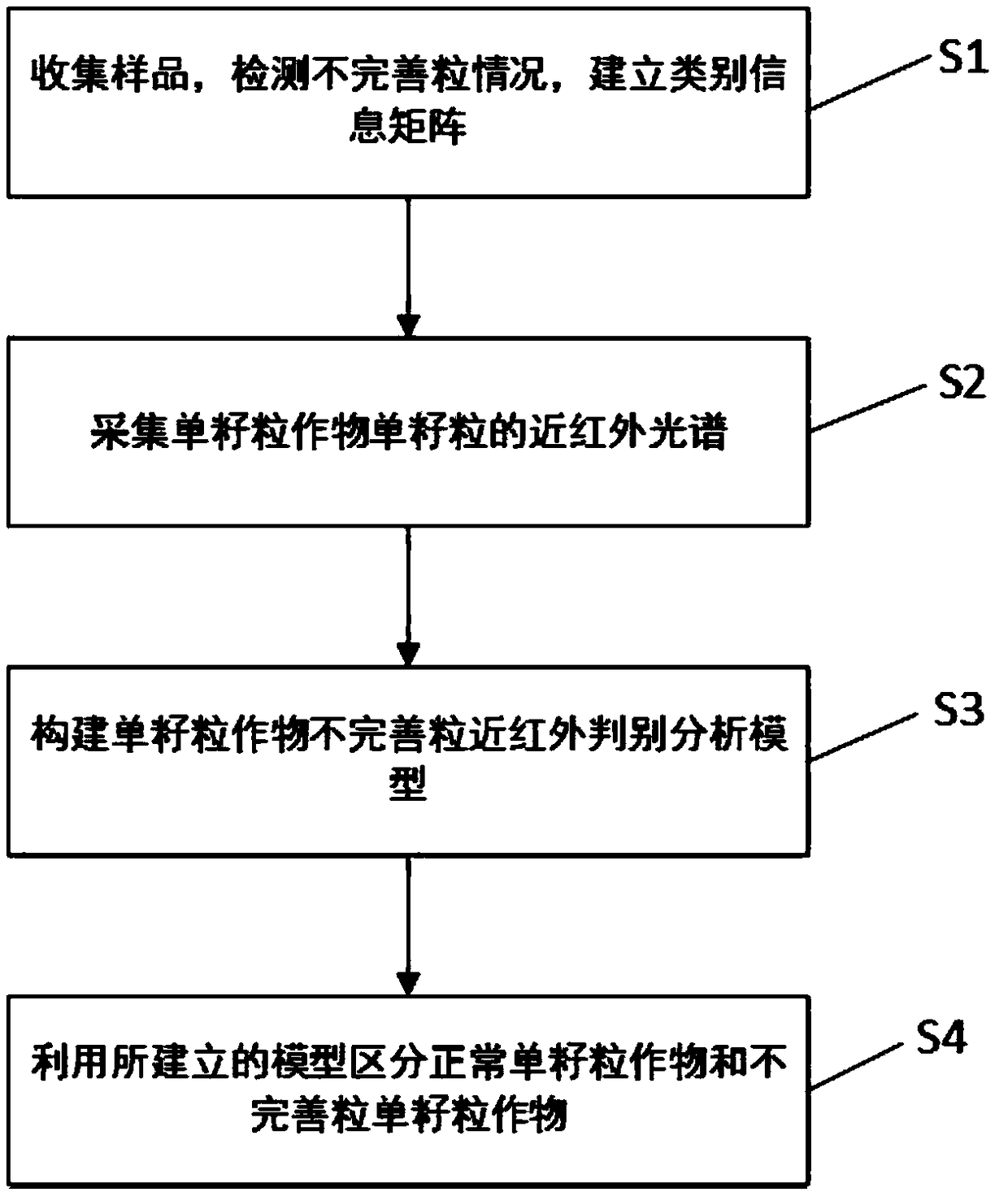

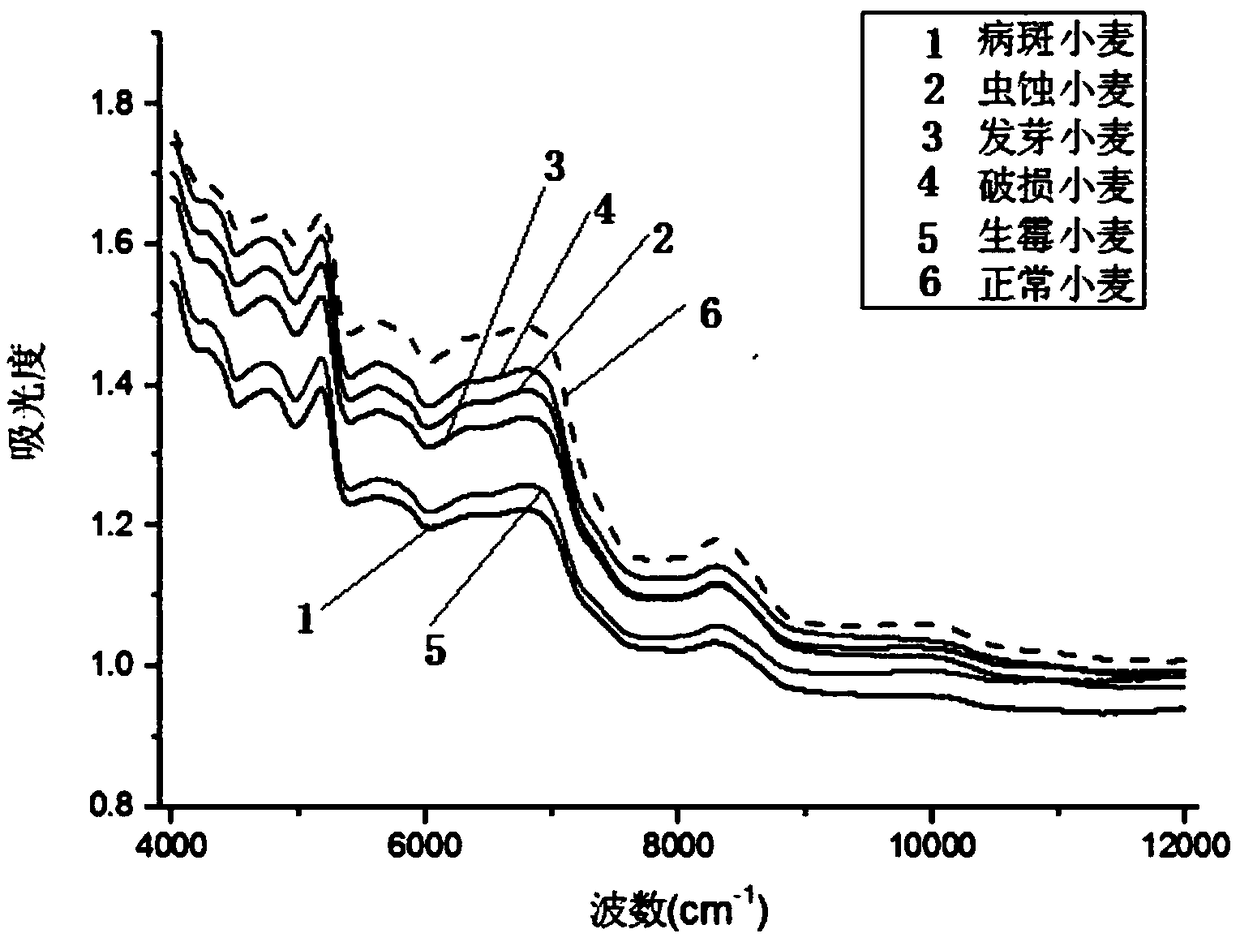

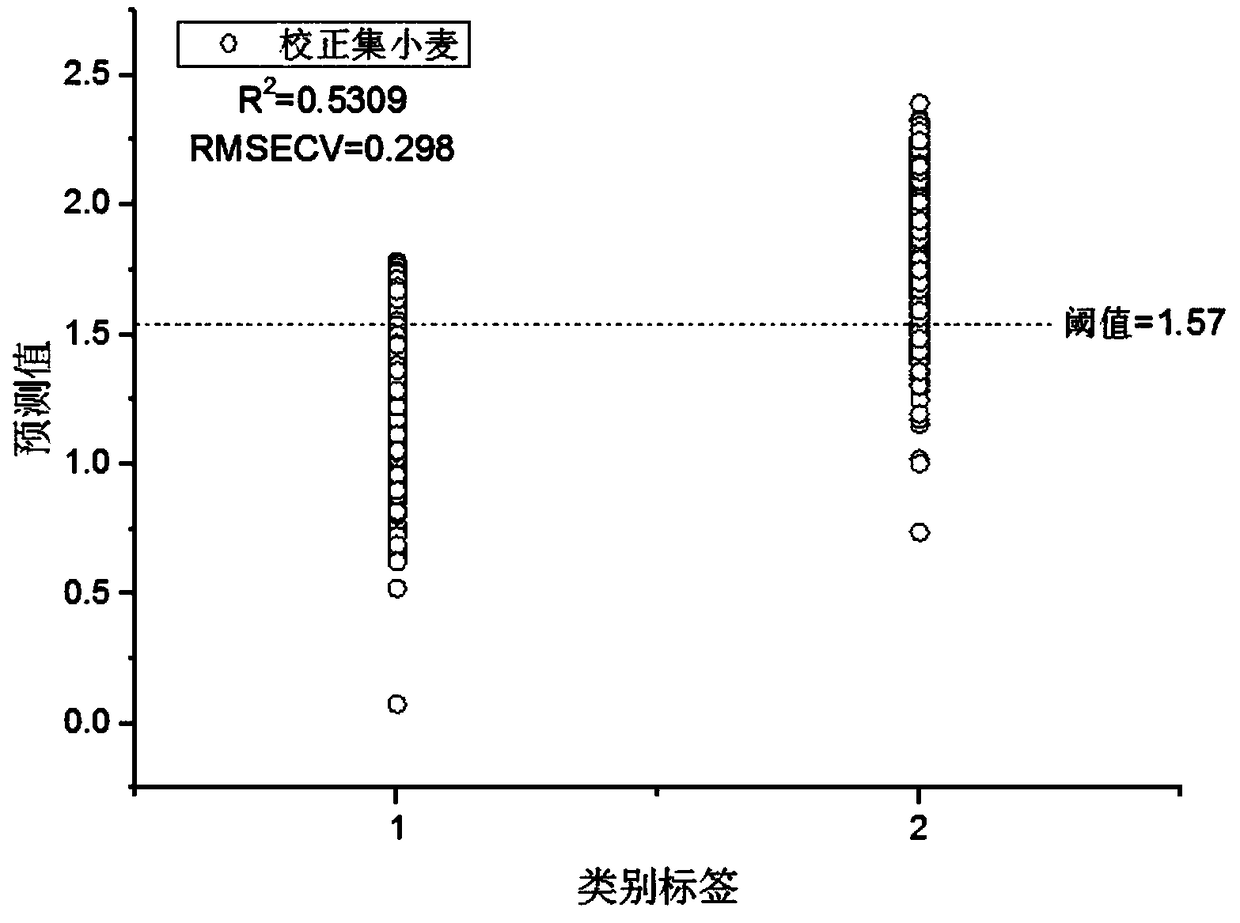

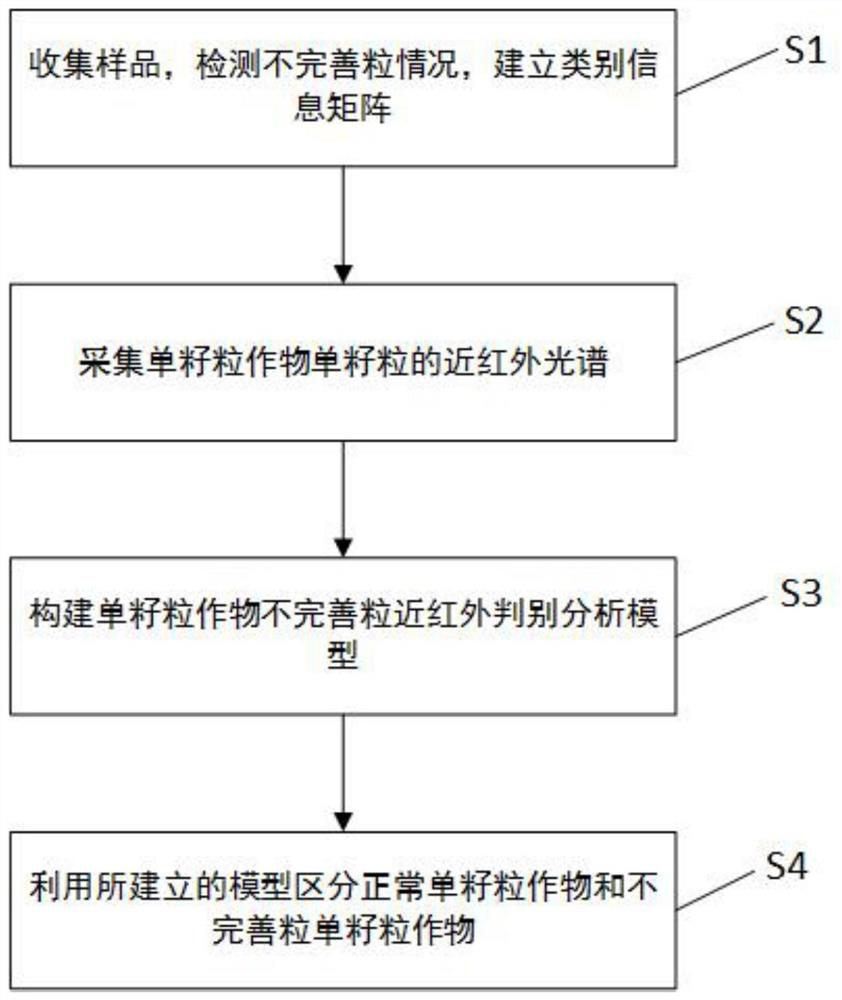

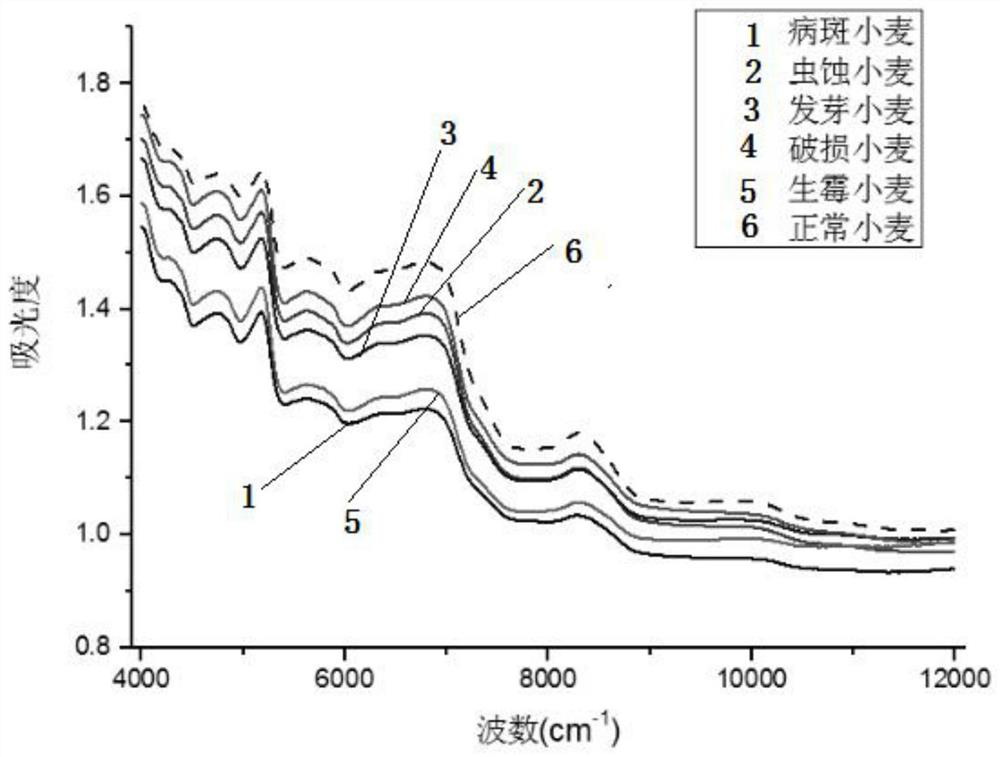

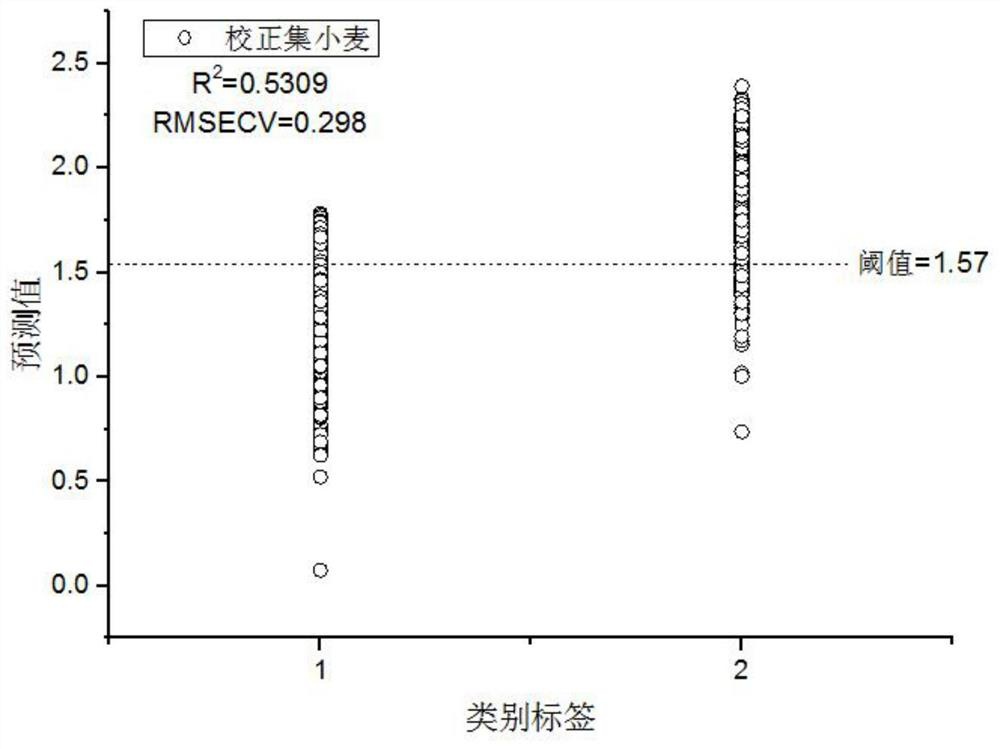

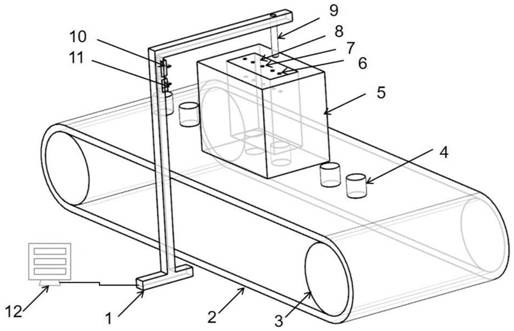

Quick non-destructive judging method for unsound grains of single kernel crop

ActiveCN109470648AEfficient discriminationThe test results are objective and accurateMaterial analysis by optical meansNon destructiveComputer science

The invention discloses a quick non-destructive judging method for unsound grains of a single kernel crop. The method comprises the following steps: S1, collecting a single kernel crop sample, detecting unsound grain condition of each single kernel crop and establishing a class information matrix; S2, collecting a near infrared spectrum of single grains of the single kernel crop; S3, constructinga near infrared judging and analyzing model of unsound grains of the single kernel crop; and S4, differentiating normal single kernel crop and unsound grain single kernel crop by means of the established model. The method has the advantages of being objective and accurate in detection result, free of damage to the sample in the detection process, quick and simple, and can judge the unsound grainsof the single kernel crop efficiently in a through manner.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

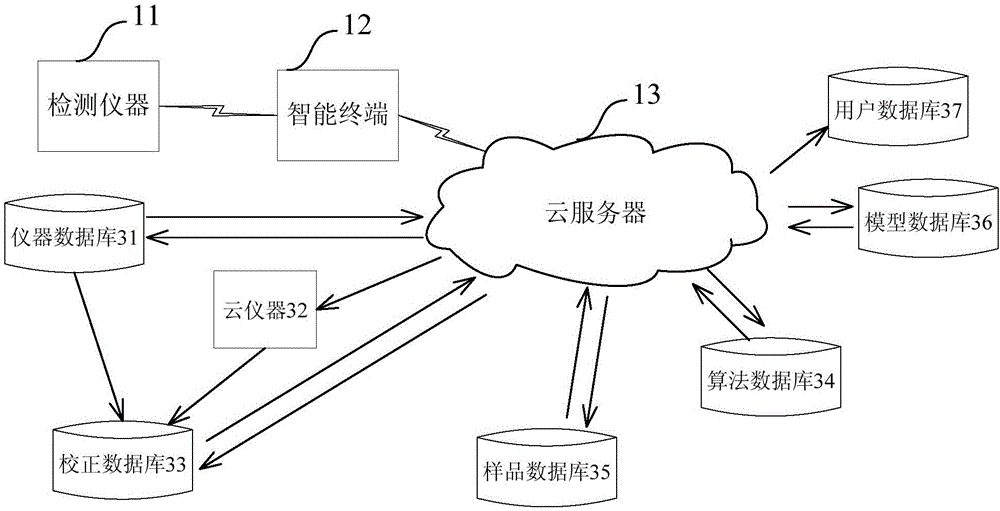

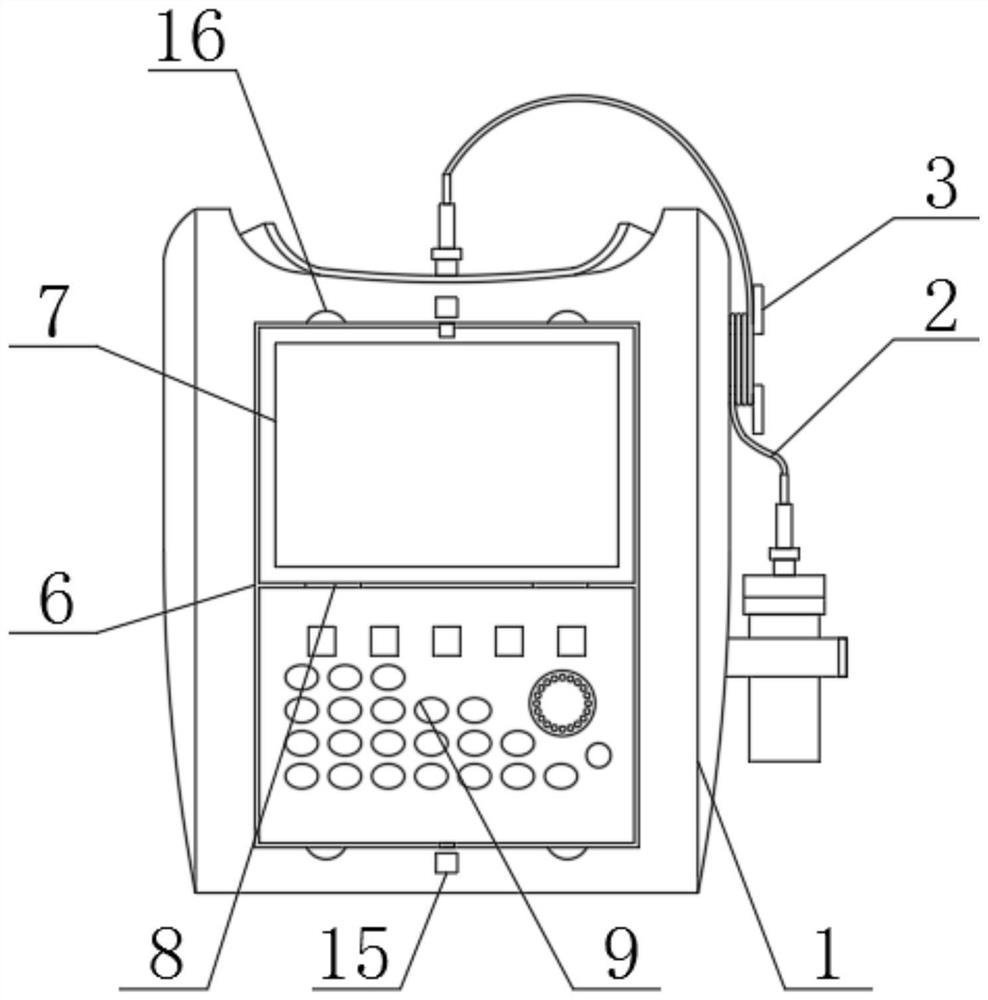

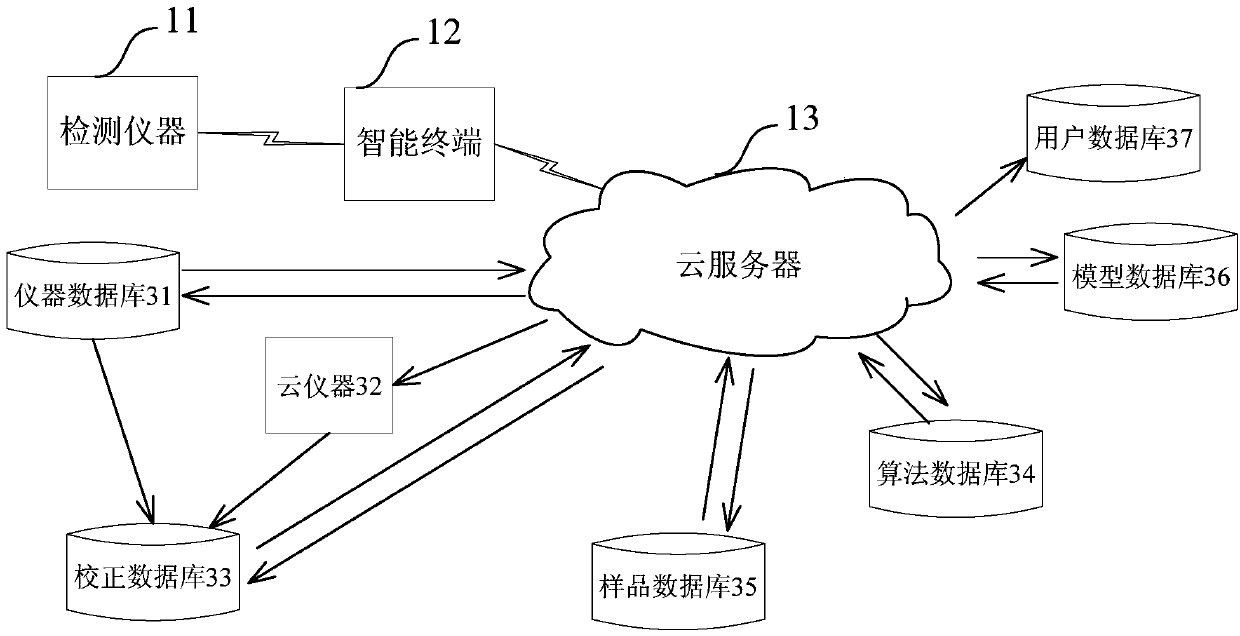

Quality detection system based on cloud server

ActiveCN106323889ARapid quality inspectionSimplify networkingRaman scatteringColor/spectral properties measurementsInstrumentationData library

The invention discloses a quality detection system based on a cloud server. The system comprises a detection instrument, an intelligent terminal and the cloud server. The detection instrument is used for detecting a to-be-detected sample. The cloud server is used for receiving an instrument serial number obtained by the intelligent terminal and inquiring the state of the detection instrument in an instrument database according to the received instrument serial number so as to judge whether the detection instrument needs to be corrected or not; if the detection instrument needs to be corrected, the cloud server calls a cloud instrument to correct the detection instrument, a correction model is formed and stored in a correction database, then properties of the to-be-detected sample are predicted, and a prediction result is returned to the intelligent terminal; if the detection instrument does not need to be corrected, the cloud server calls a sample property prediction model stored in the model database to predict the properties of the to-be-detected sample, and a prediction result is returned to the intelligent terminal. The detection instrument is connected through the internet, so product quality detection is quick, easy and networked, and quality detection efficiency is improved.

Owner:上海赛诚医药科技有限公司

Automobile instrument automatic detection equipment based on machine vision

InactiveCN105588598AReal-time deliveryAchieve traceabilityInstrumentsMachine visionPersonal computer

The invention provides a piece of automobile instrument automatic detection equipment based on machine vision. The equipment comprises an industrial personal computer, a control cabinet, a support, a camera, a positioning base, conveying guide rails, locking cylinders, a test base plate, a test probe base and a mechanical finger. The test base plate is provided with a through hole for installing the test probe base, the test probe base is installed in the through hole, and a test probe is installed in the test probe base. The upper part of the test base plate is equipped with a limiting support base matching the universal shape of an automobile instrument. The cross bar in the upper part of the support is equipped with a light source. The camera is arranged in the middle of the cross bar. The mechanical finger is installed above the rear part of an instrument test station. The industrial personal computer is installed in the control cabinet. The industrial personal computer, the camera and the mechanical finger cooperate together to complete test of the automobile instrument. With the equipment, intelligent, full-automatic, high-precision and quick quality detection of an automobile instrument panel is realized, various errors caused by manual detection are avoided, and the production efficiency is improved greatly.

Owner:ZHENGZHOU JINGYIDA AUTO PARTS

Metal weldment quality detection device and method

PendingCN112730630AQuick fixConvenient folding protection functionAnalysing solids using sonic/ultrasonic/infrasonic wavesShock waveButt joint

The invention discloses a metal weldment quality detection device and method. The metal weldment quality detection device comprises a main body and a pulling groove, wherein one side of the main body is connected with a connecting wire, one end of the connecting wire is connected with a detector, one side, close to the connecting wire, of the main body is connected with a fixing block, and one side, close to the detector, of the main body is connected with a fixing ring. According to the metal weldment quality detection device and method, the fixed block can be wound by pulling the connecting wire, the connecting wire can be limited through the L shape of the fixed block during winding, and the detector is pulled to be in butt joint with the fixed ring after the connecting wire is wound; when the detector is in butt joint with the fixing ring, the detector is pressed to extrude the notch in one side of the fixing ring, the aluminum alloy profile weldment is detected through a shock wave vibration detection method, rapid quality detection of the aluminum alloy weldment can be achieved before the aluminum alloy weldment is put into use, and the aluminum alloy profile weldment does not need to be disassembled in regular safety detection in the service process; and in-situ safety detection is conducted on the aluminum alloy weldment.

Owner:无锡通测检测技术有限公司

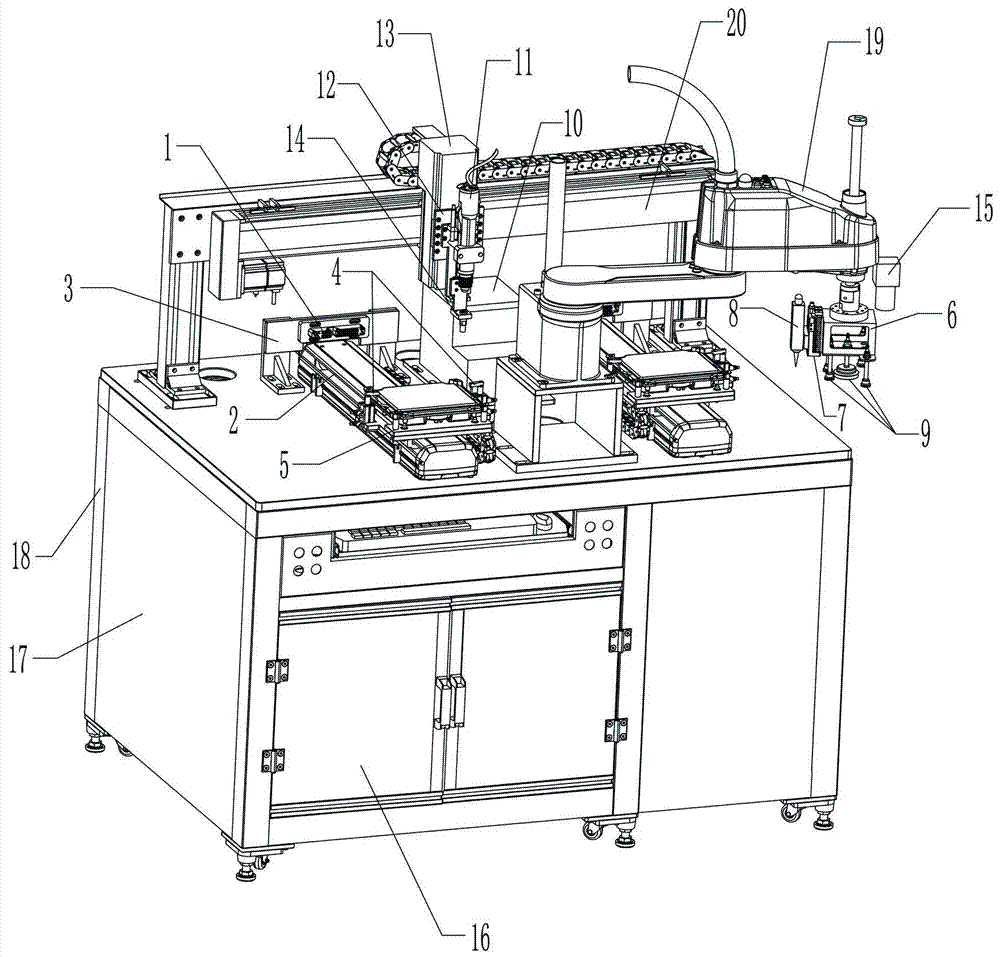

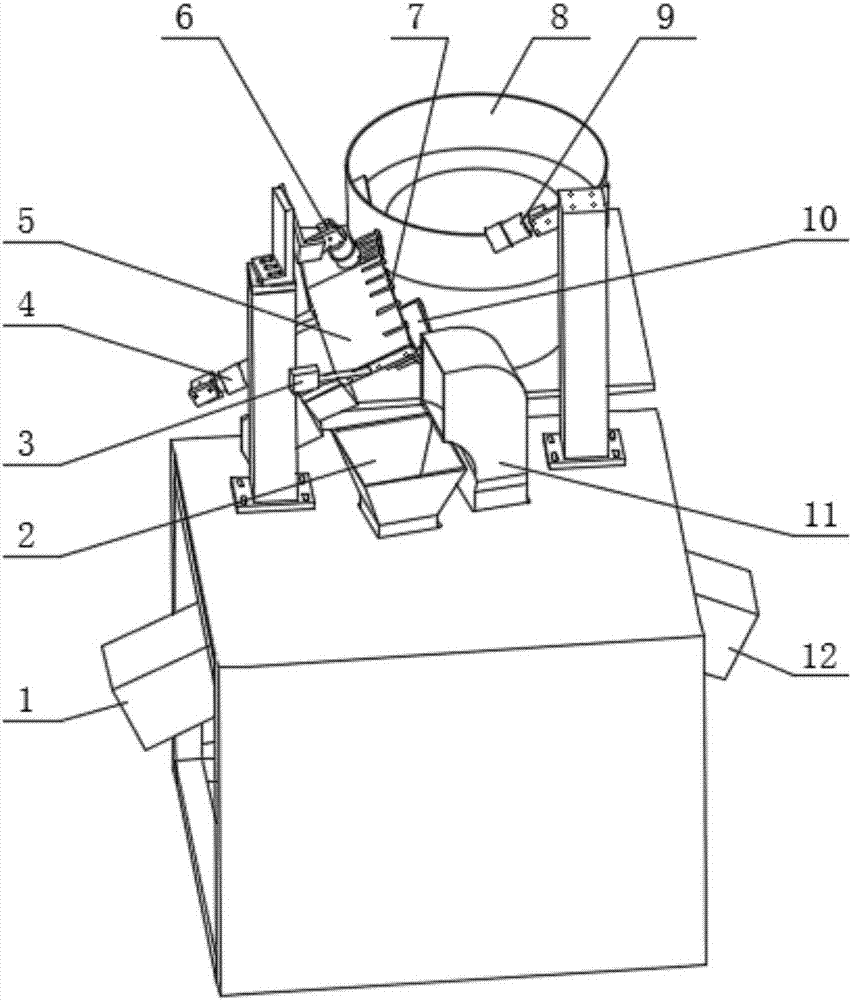

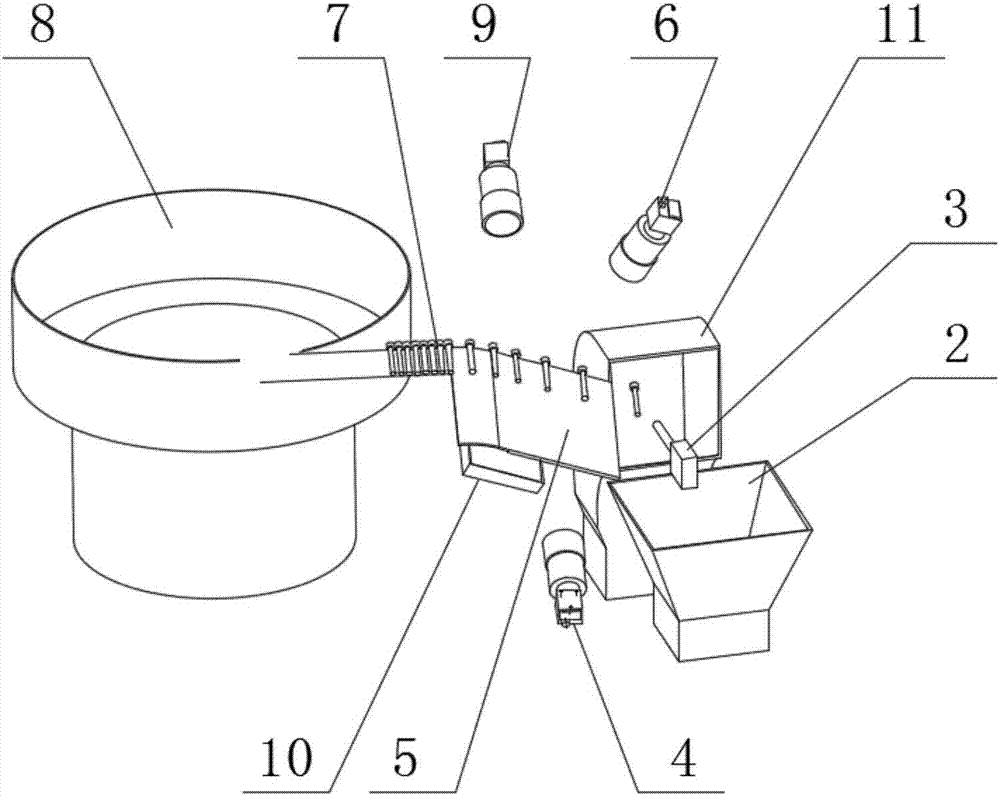

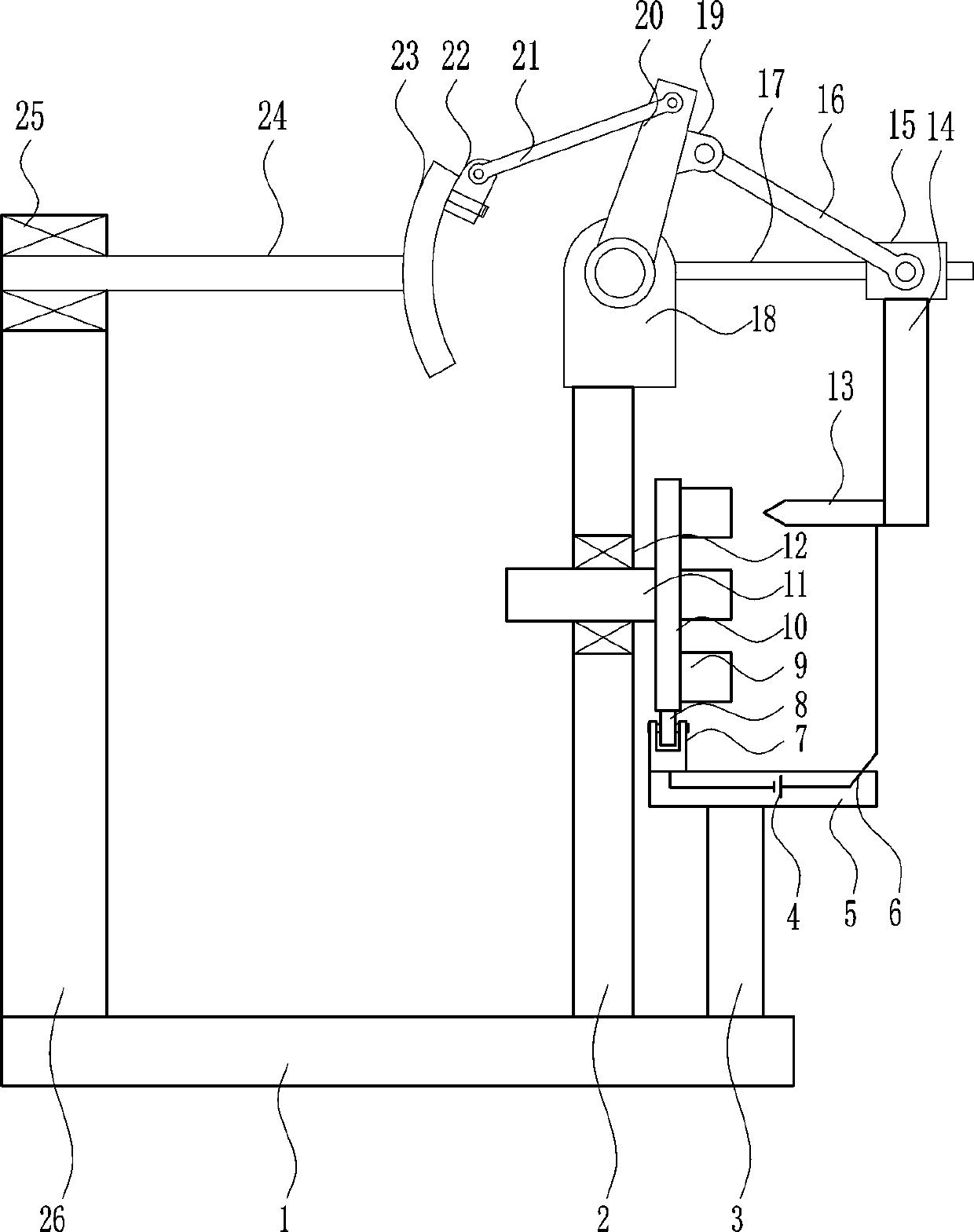

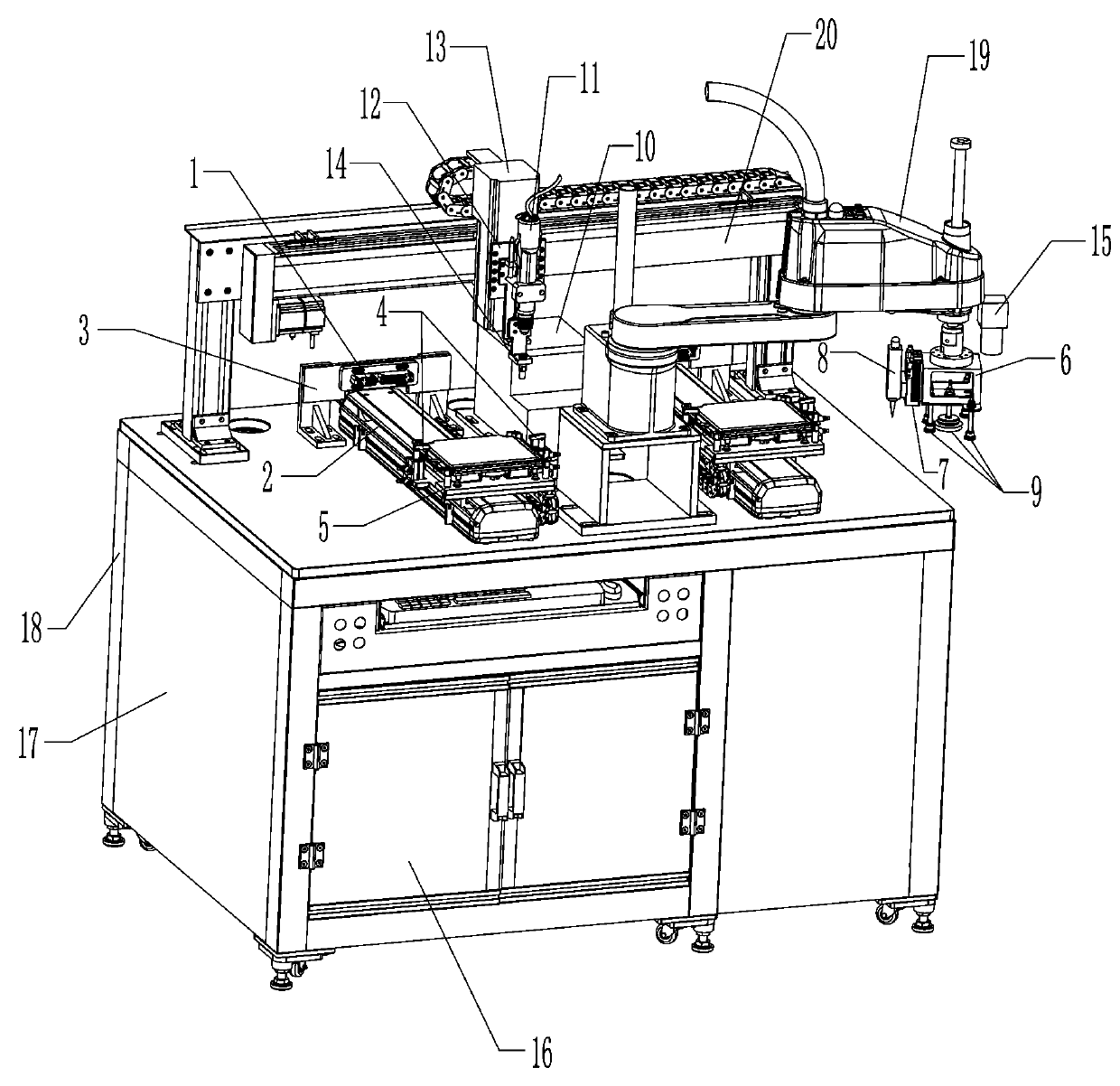

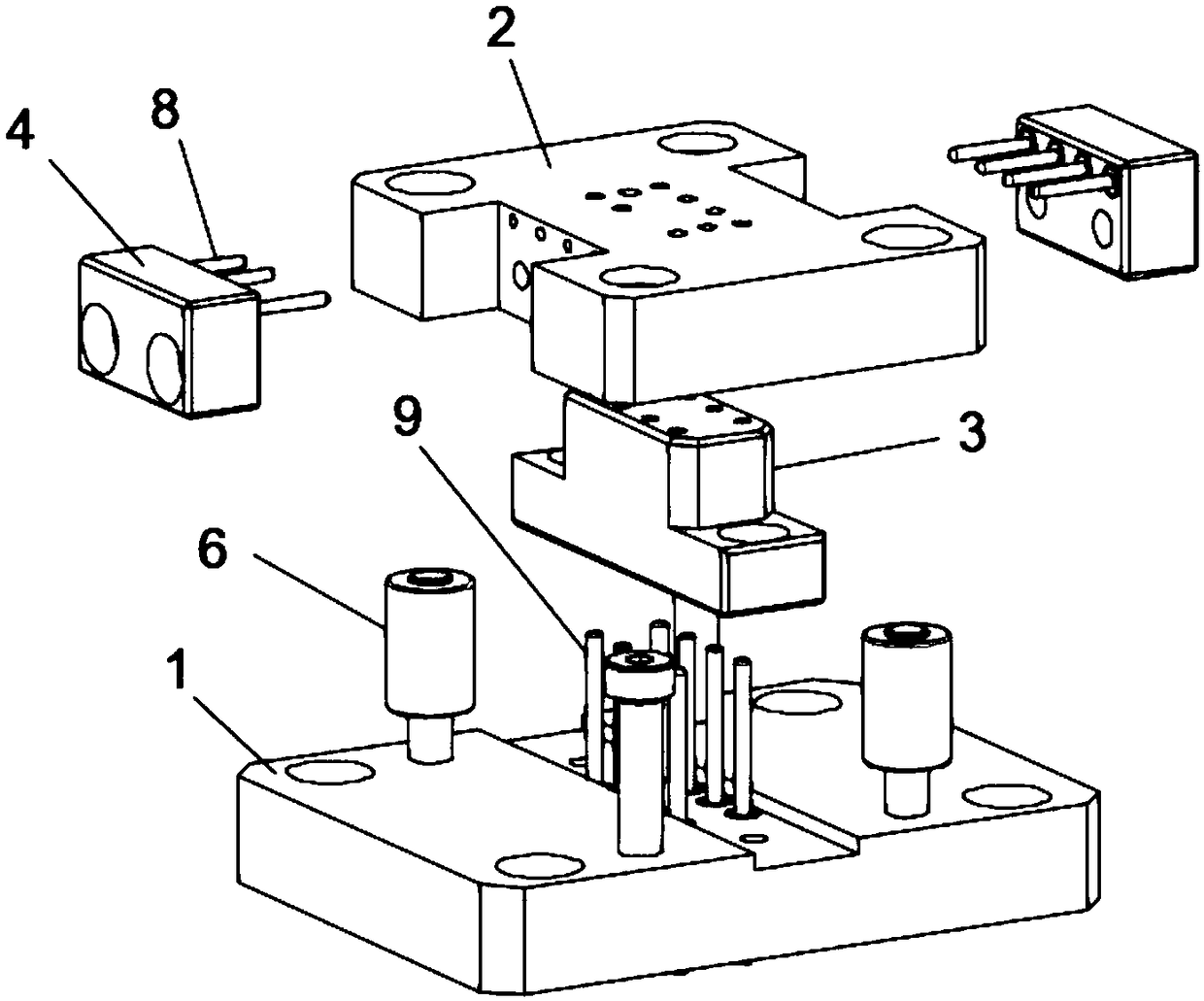

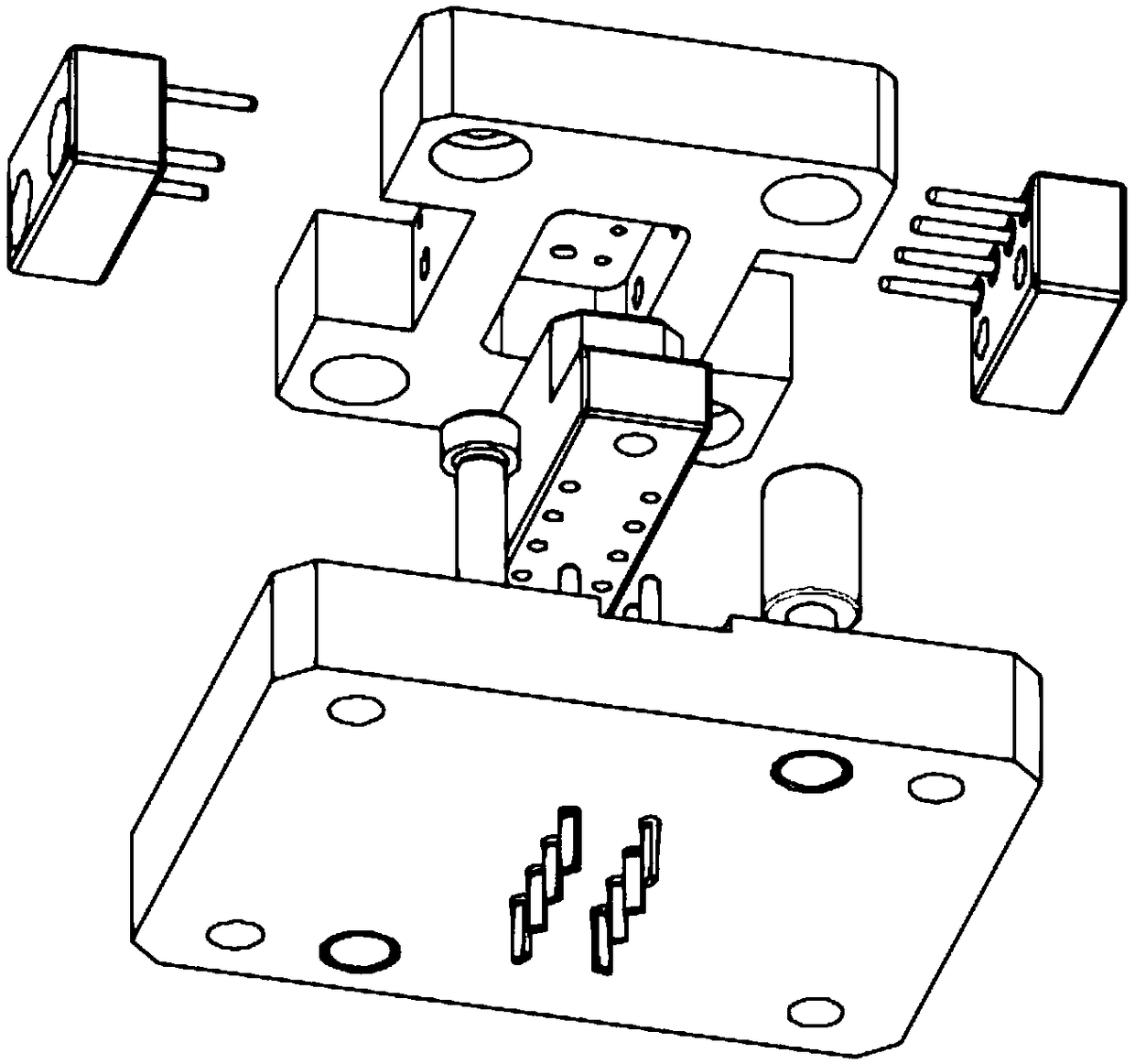

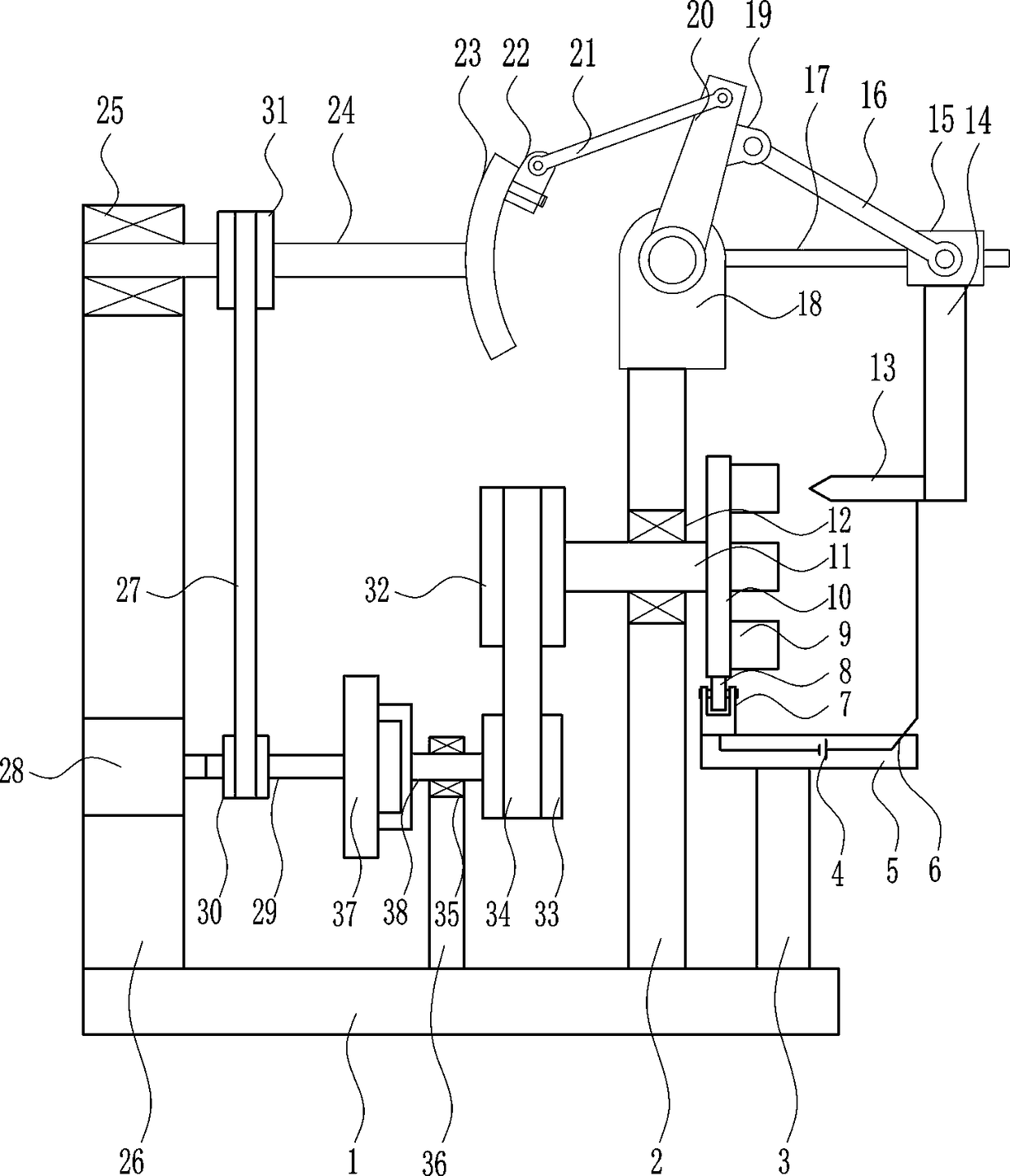

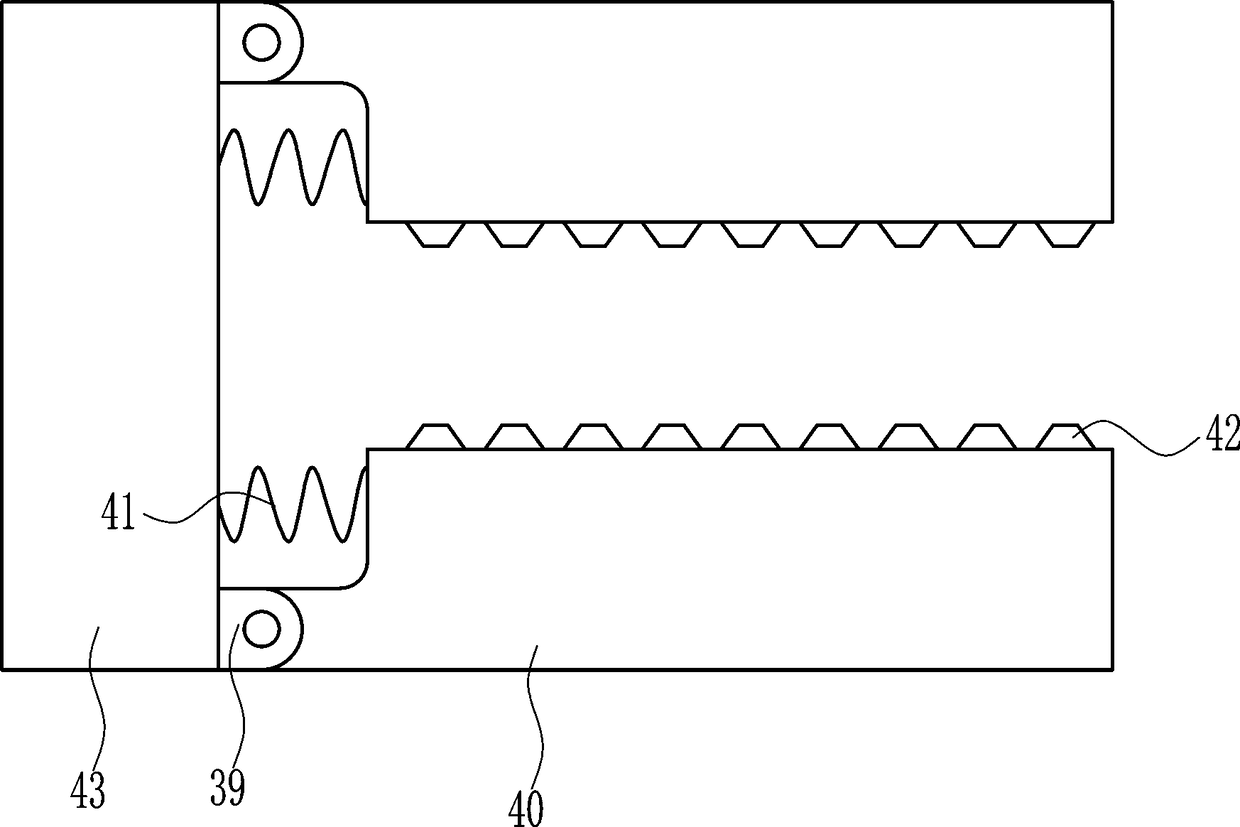

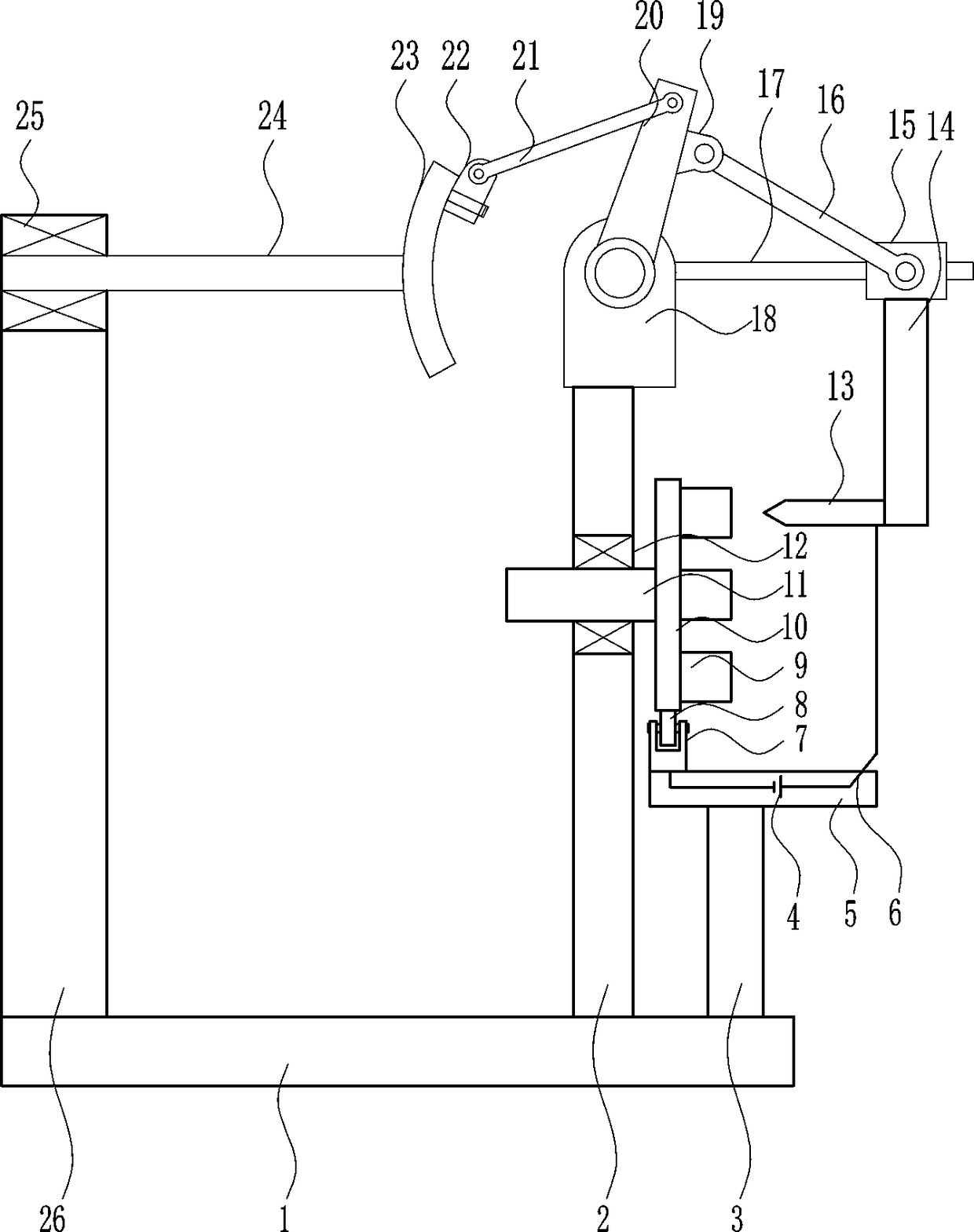

Online full-automatic assembly detection equipment for automobile body controller

ActiveCN107992032AReduce handlingIncrease productivityProgramme controlElectric testing/monitoringProduct testingAdhesive

The invention discloses online full-automatic assembly detection equipment for an automobile body controller. The equipment comprises assembly testing modules, an assembly adhesive dispensing module,a manipulator, a screw assembly module, an X-axis electric module, an industrial computer, a robot controller and a control cabinet, wherein two assembly testing modules are arranged on two sides of the manipulator; the assembly adhesive dispensing module is mounted on the manipulator; the screw assembly module is arranged on the X-axis electric module; the X-axis electric module, the assembly testing modules, the assembly adhesive dispensing modules, the manipulator and the screw assembly module are all arranged on the control cabinet, and the industrial computer and the robot controller arearranged in the control cabinet. Technologies about mechanical movement, robot control and the like are integrated, so that the automobile body controller is automatically assembled from different parts according to the production process and then is automatically sent to a certain position, and the industrial computer system simulates the whole automobile for product testing.

Owner:ZHENGZHOU JINGYIDA AUTO PARTS

Intelligent food quality fast detection system

InactiveCN108627621ARapid Quality InspectionEnsure health and safetyTesting foodPesticide residueFood safety

The invention belongs to the technical field of food safety, and discloses an intelligent food quality fast detection system. The intelligent food quality fast detection system is provided with a foodsafety system control end; the food safety system control end is connected with an intelligent food classification instrument through a data wire; the intelligent food classification instrument is connected with an aquatic product detection module, a meat detection module, a fruit and vegetable detection module and an other food monitoring module; the aquatic product detection module, the meat detection module, the fruit and vegetable detection module and the other food monitoring module are connected with an enzyme linked immunosorbent assay detection module; the enzyme linked immunosorbentassay detection module is connected with a pesticide residue compound detection module, a microorganism module, a fluorescent quantitative PCR module and a food attribution module through data wires.According to the intelligent food quality fast detection system provided by the invention, the food is classified, so that the food quality detection is faster; through the enzyme linked immunosorbentassay detection module, an antibody and an enzyme compound are combined; whether food is transgenic food or not is detected through color development; the food health and safety are ensured, so thatconsumers are relieved.

Owner:ZUNYI INST OF PROD QUALITY INSPECTION & TESTING

Kaolin reagent quality control product and preparation method and application thereof

ActiveCN109541242AMeet quality control requirementsIncreased sensitivityPreparing sample for investigationBiological testingQuality controlBlood plasma

The invention discloses a kaolin reagent quality control product. The quality control product is lyophilized formulation, and the raw material of the lyophilized formulation includes platelet-deficient animal plasma. The R value of the quality control product is 6-8 min, the K value is 2-5 min, the Angle value is 60 DEG-80 DEG, and the MA value is 23-45 mm. The kaolin reagent quality control product is sensitive to the kaolin reagent reaction, so the accuracy of the quality detection is high, and the quality control requirements for the kaolin preparation in thromboelastography test are met. The quality control product has good reconstitution stability and can be stored for a long time under low temperature. The quality control product uses animal plasma as raw material, thus reducing thecost of the quality control and improving the safety of the quality control operations. The invention also discloses a preparation method of a kaolin reagent quality control product, which can preparethe kaolin reagent quality control product with accurate detection results and high stability. The preparation method is stable and reliable, the preparation process is simple and easy to operate, and the preparation method is suitable for the production and application of kaolin reagent quality control products.

Owner:中科精瓒(武汉)医疗技术有限公司

Detecting device use for columnar products

The invention provides a detecting device use for columnar products. The detecting device comprises a charging mechanism, a visual detecting mechanism and a distribution mechanism. The visual detecting mechanism comprises a transparent plate, a control unit and a camera assembly. The transparent plate is in butt joint with a discharging outlet of the charging mechanism and is inclined downwards by a preset angle and used for enabling the columnar products to move on the transparent plate in a rotating mode. The camera assembly is used for collecting the surface images of the columnar products. The distribution mechanism comprises a blowing unit, a qualified product collecting unit and a reject collecting unit. The blowing unit is arranged under the transparent plate and used for generating pulse airflow so as to blow rejects into the reject collecting unit. The detecting device provided by the invention is convenient to use, high in precision and speed, stable in operation and simple in structure.

Owner:王亚辉

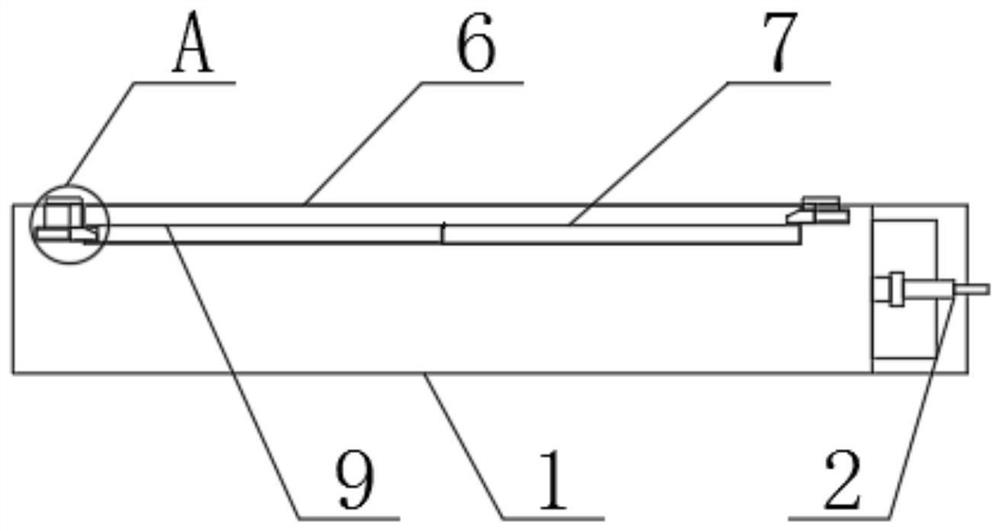

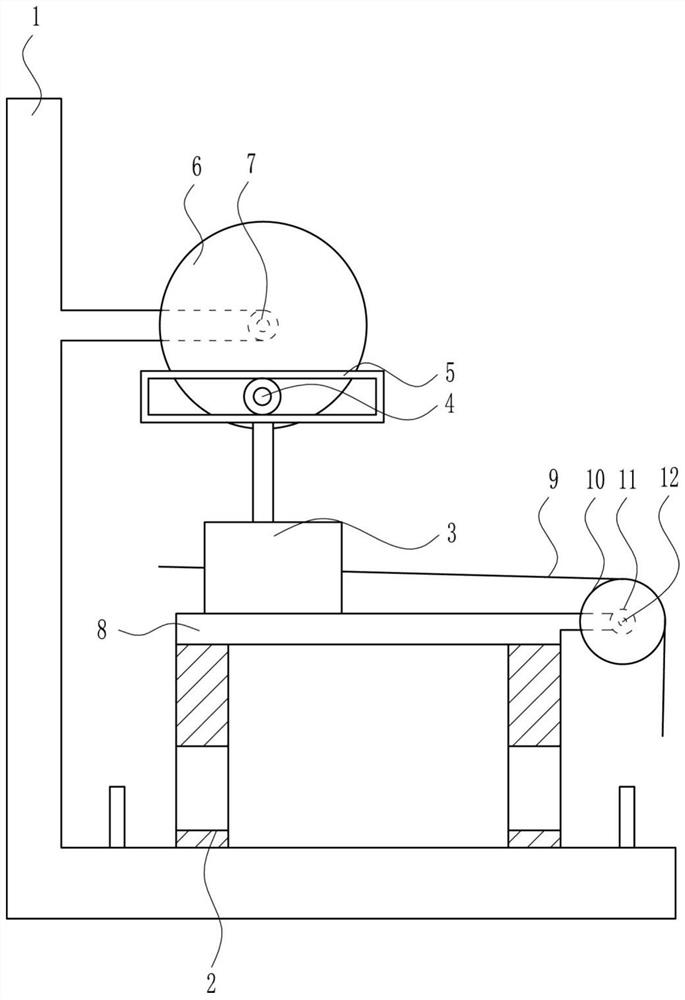

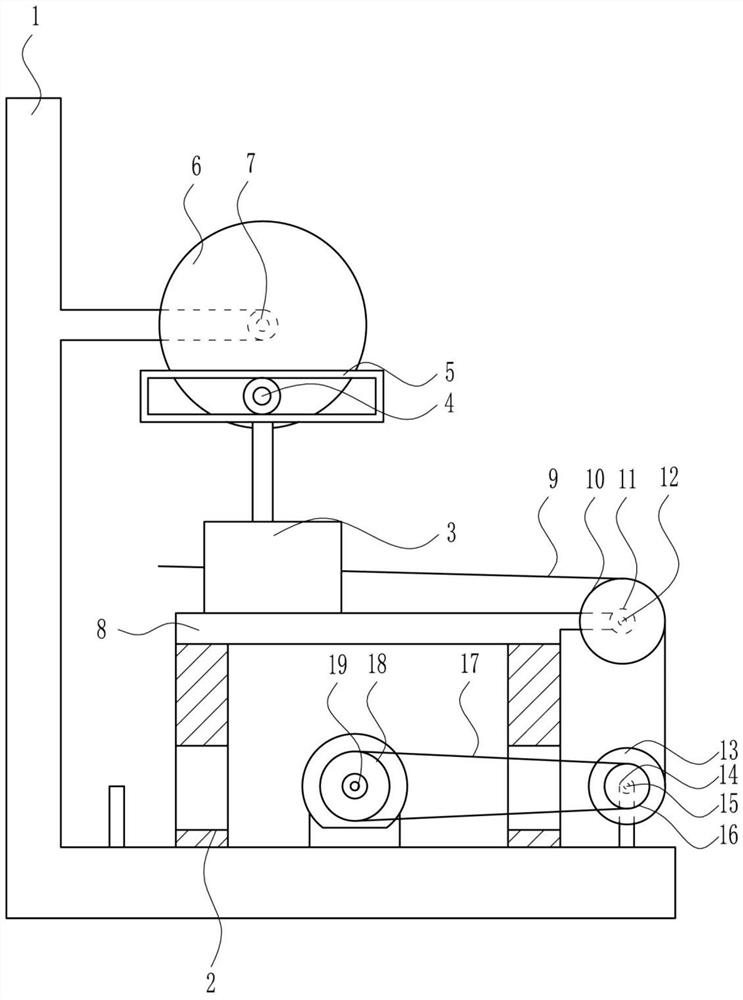

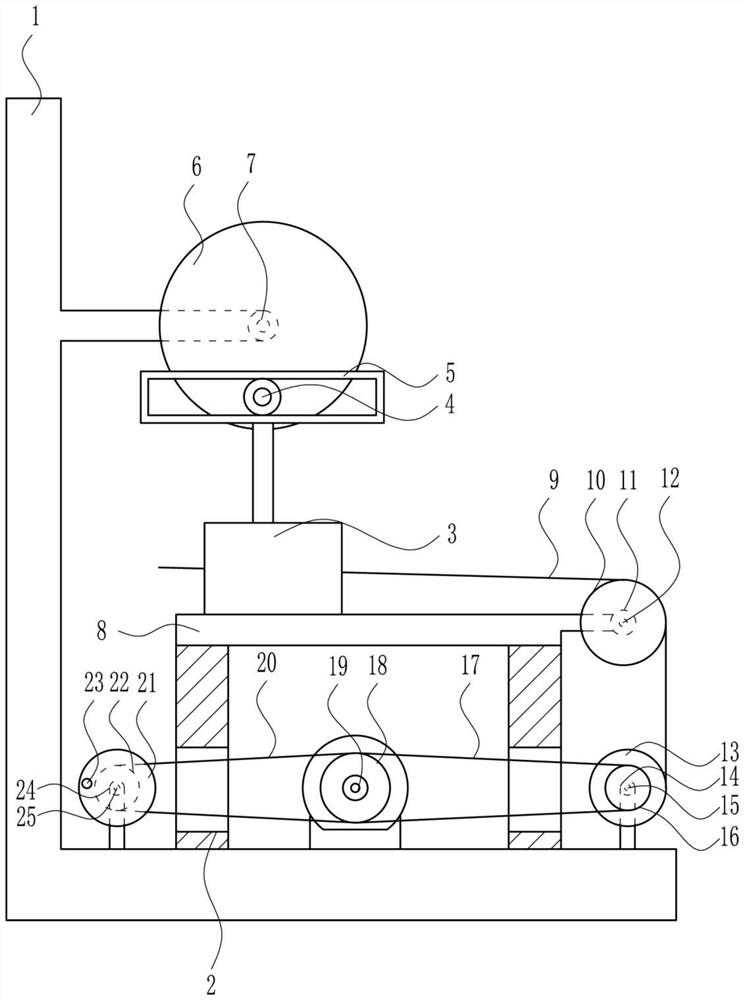

A cable skin quality detection device

ActiveCN108152157BRapid Quality InspectionLow costInvestigating material hardnessCircular discFixed frame

The invention relates to a detecting device, in particular to a cable coat quality detecting device. In order to solve the technical problems, the invention provides the cable coat quality detecting device which can effectively detect cable coat hardness, is convenient to use, and is safe to use. The cable coat quality detecting device comprises a fixed frame, a supporting rod, a pressing device,a roller, a movable frame, a circular disc and the like, wherein a first motor is mounted on the left upper part of the fixed frame; the circular disc is mounted on the first motor; the roller is mounted on the circular disc; the supporting rod is mounted on the lower part of the fixed frame; a workbench is mounted on the upper part of the supporting rod; and the pressing device is mounted on theupper part of the workbench. The cable coat quality detecting device achieves the effects of being capable of effectively detecting cable coat hardness, and being convenient to use and safe to use, can be used for quickly performing quality detection on cable coat, a great deal of manual labor power is saved, the cable coat quality detecting device is strong in detecting practicability, guaranteesis provided for our life safety, and a great deal of cost for a plant is reduced.

Owner:义乌市添诚科技有限公司

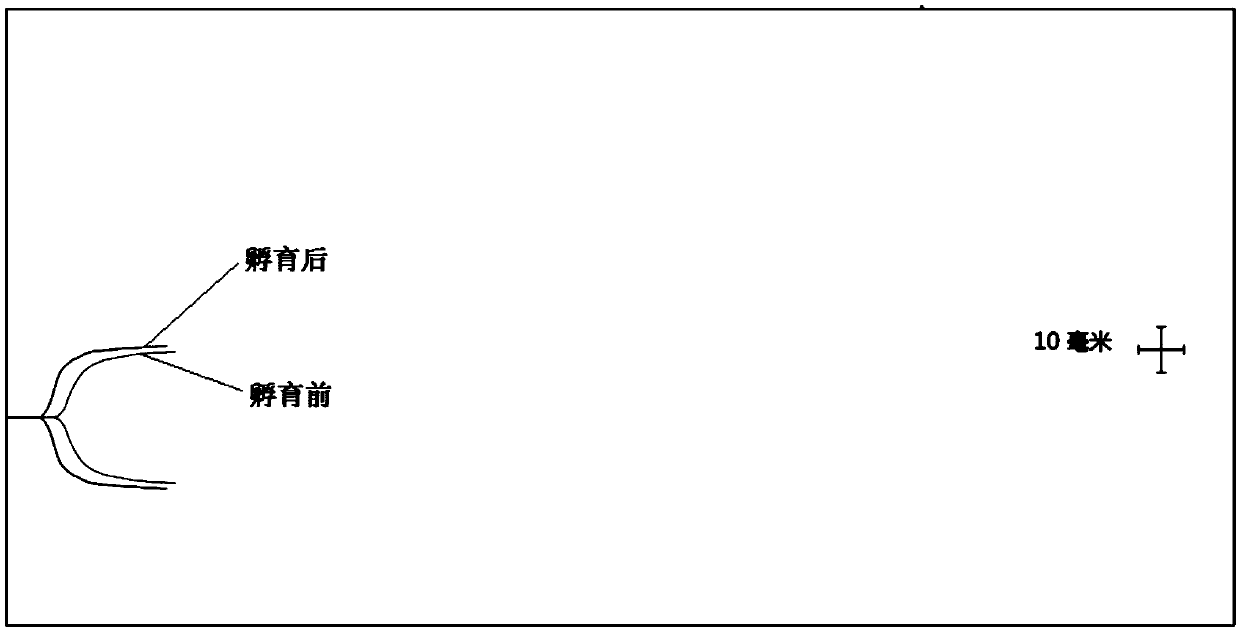

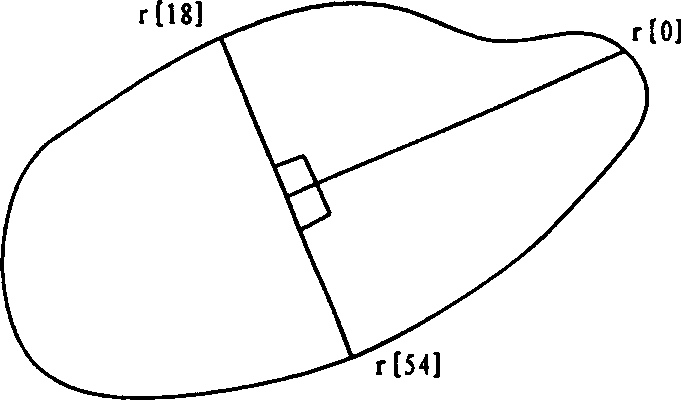

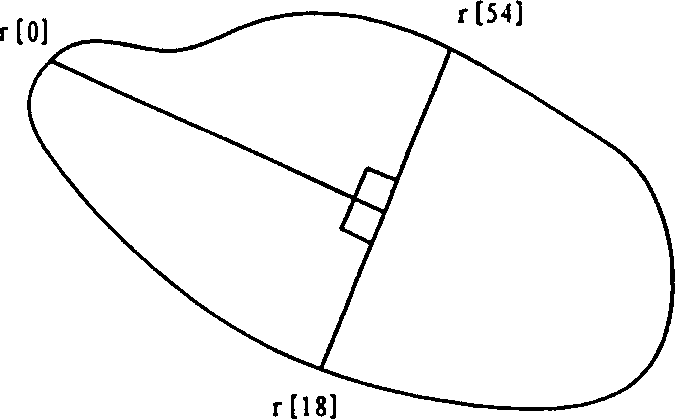

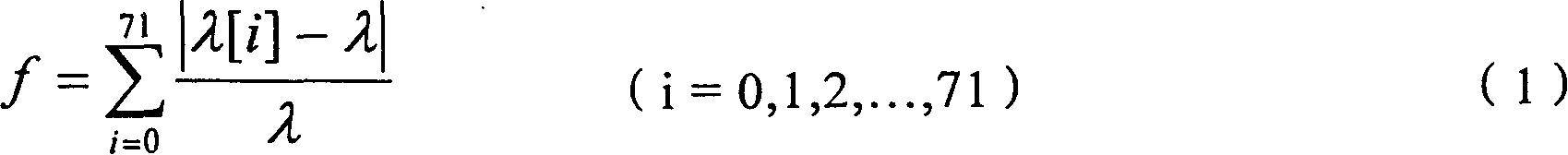

Automatic identification method for milled rice

InactiveCN1281952CQuick identificationAccurate identificationCharacter and pattern recognitionFuzzy logic based systemsPaddy fieldComputer science

The invention discloses a method for automatic identification of polished rice, comprising: placing a rice sample in an image collector to collect original image information; reading the original image information, storing the coordinates of each point on the individual contour of the rice sample, and obtaining The geometric mean of the coordinates of these points is used as the center point of the rice sample individual; the connection line between the center point and the contour point is used as the radius of the rice grain; with the longest radius as the reference direction, a radius is stored every 5 degrees counterclockwise, stored in In the counterclockwise radius table; calculate a standard meter according to the data stored in the rice grain radius table; carry out the judgment of the polished rice: distinguish each rice sample in the bitmap file respectively, if the grain length is greater than or equal to 73% of the standard rice grain length, it is regarded as the polished rice Selected; if the grain length is less than 73% of the standard grain length, it is regarded as untreated rice. The method of the invention can quickly, objectively and correctly identify the whole polished rice in the polished rice, and meets the requirements of fast, objective and high accuracy quality detection in the on-site purchase of rice and market transactions.

Owner:CHINA AGRI UNIV

Automatic detection system for transparent bottle

InactiveCN110865081AImprove light concentratingIncrease brightnessOptically investigating flaws/contaminationImage resolutionRadiology

The invention discloses an automatic detection system for a transparent bottle. The automatic detection system comprises the followings: an optical illumination system providing uniform illumination for an image acquisition system, the image acquisition system collecting a surface image of the transparent bottle and outputting a video signal from a system unit for processing by an image processingunit; and an image processing software system segmenting and positioning a defect area, detecting and judging the transparent bottle, and sending a removal signal for an unqualified product. The automatic detection system not only improves the view angle of a lens, increases a shooting range and improves imaging resolution, but also reduces a calculation process through image segmentation, thereby greatly improving the accuracy and speed of detection.

Owner:DONGGUAN XIANGFEI INTELLIGENT EQUIP TECH CO LTD

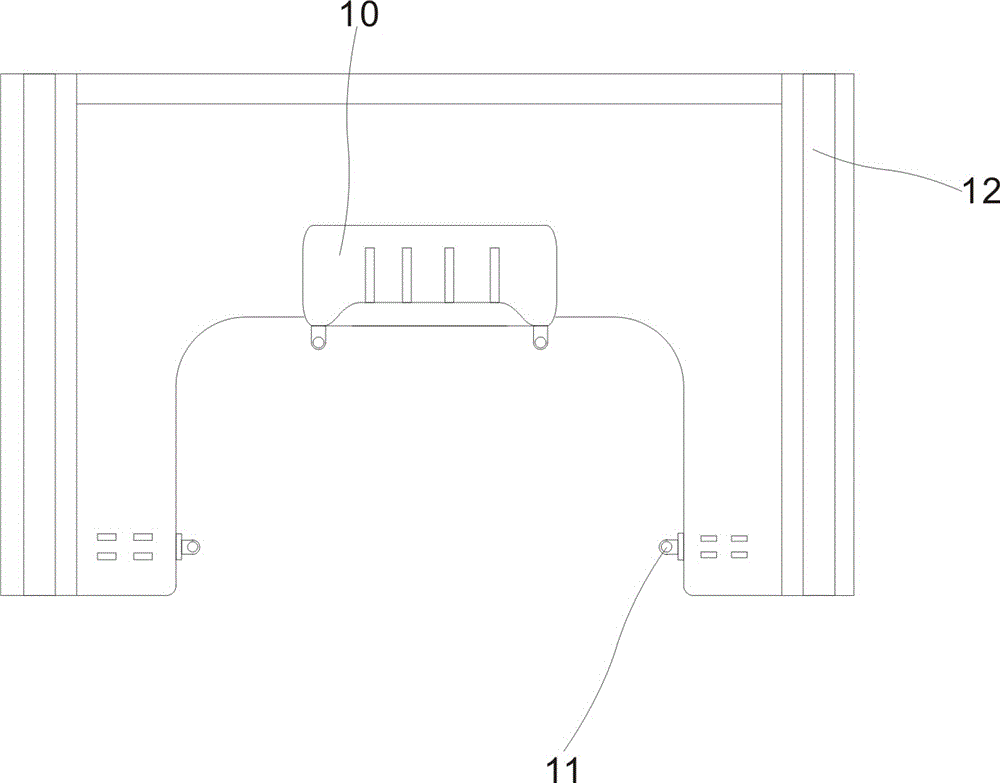

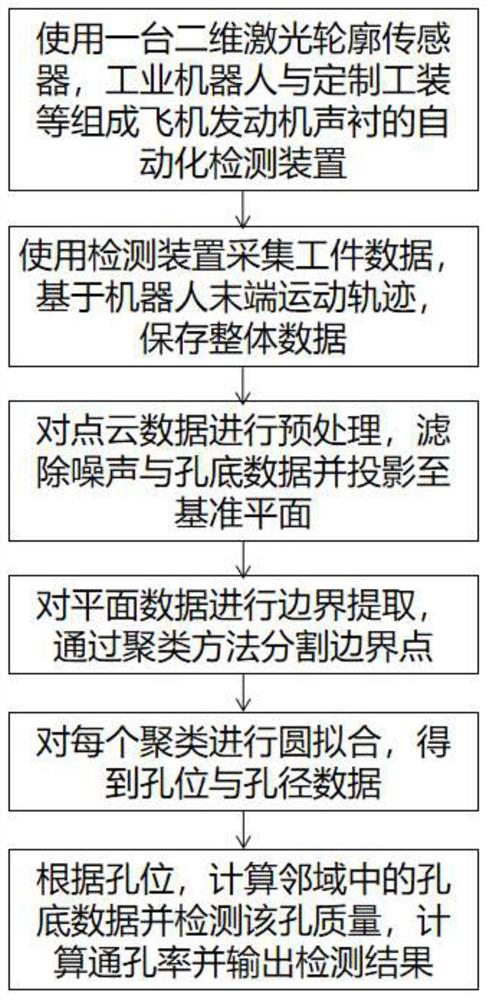

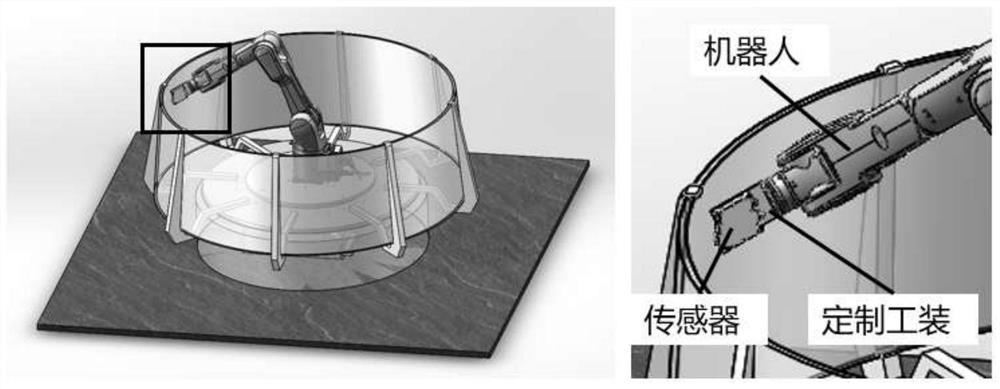

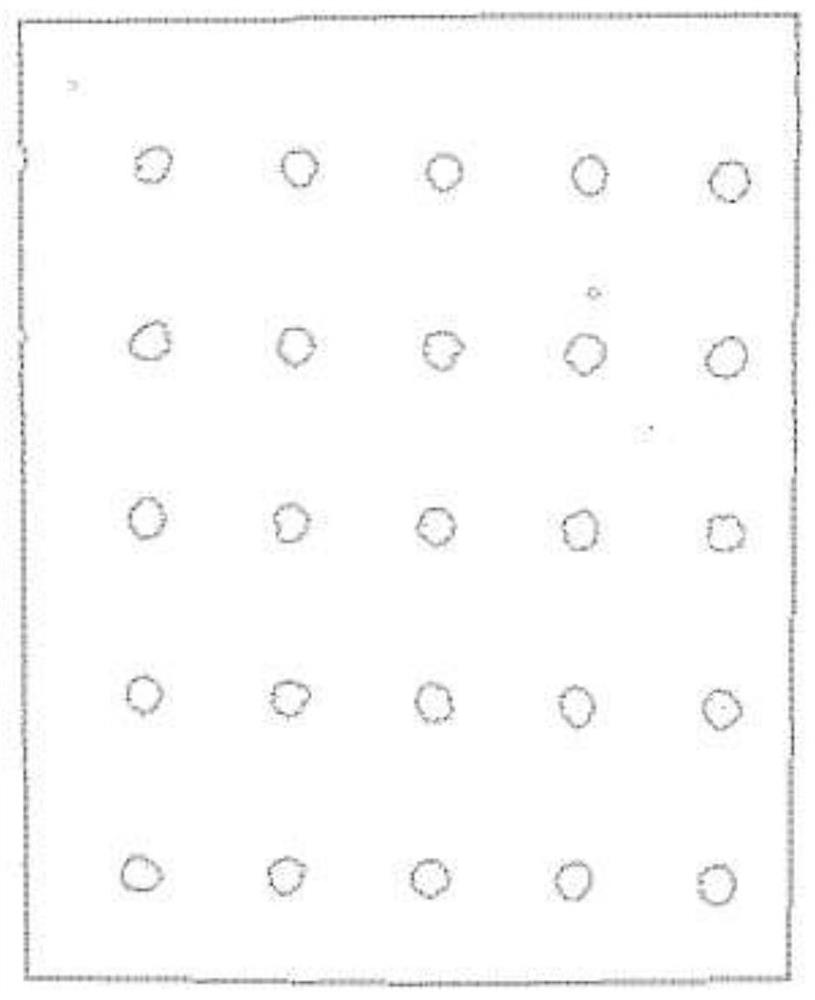

Automatic detection device and method for through hole rate of honeycomb sandwich composite acoustic liner

ActiveCN113865508AReduce workloadImprove detection efficiencyProgramme controlProgramme-controlled manipulatorData acquisitionEngineering

The invention discloses an automatic detection device and method for the through hole rate of a honeycomb sandwich composite acoustic liner. The detection device is composed of a customized tool data acquisition system, a moving mechanism system and a data processing system. The data acquisition system uses a two-dimensional laser contour sensor to acquire surface three-dimensional point cloud data of a to-be-detected sample piece in a parallel movement shooting mode, is connected with a high-performance graphic workstation, and imports the acquired data for subsequent processing; the moving mechanism system is composed of an industrial robot, and a two-dimensional laser contour sensor is fixed to the tail end of the moving mechanism system and used for supporting the data acquisition system to conduct translation scanning. The data processing system is composed of the high-performance graphic workstation, plays a role in path planning and data storage in the data acquisition process, and outputs a detection result through a proposed improved algorithm. The device and the method can be used for automatic and rapid quality detection of large workpieces with digital models, and are especially suitable for measurement scenes of rapid detection of surface holes of acoustic liners of aircraft engines.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

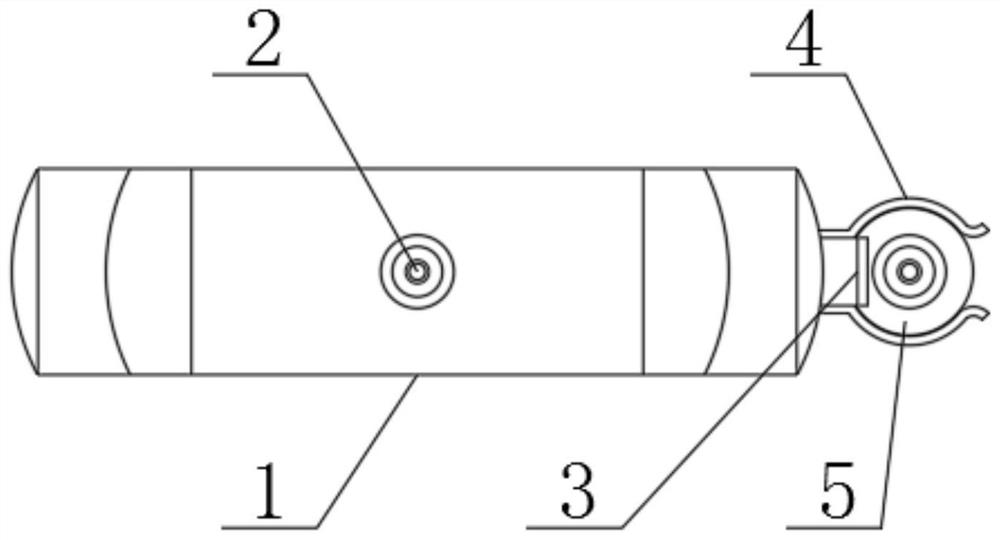

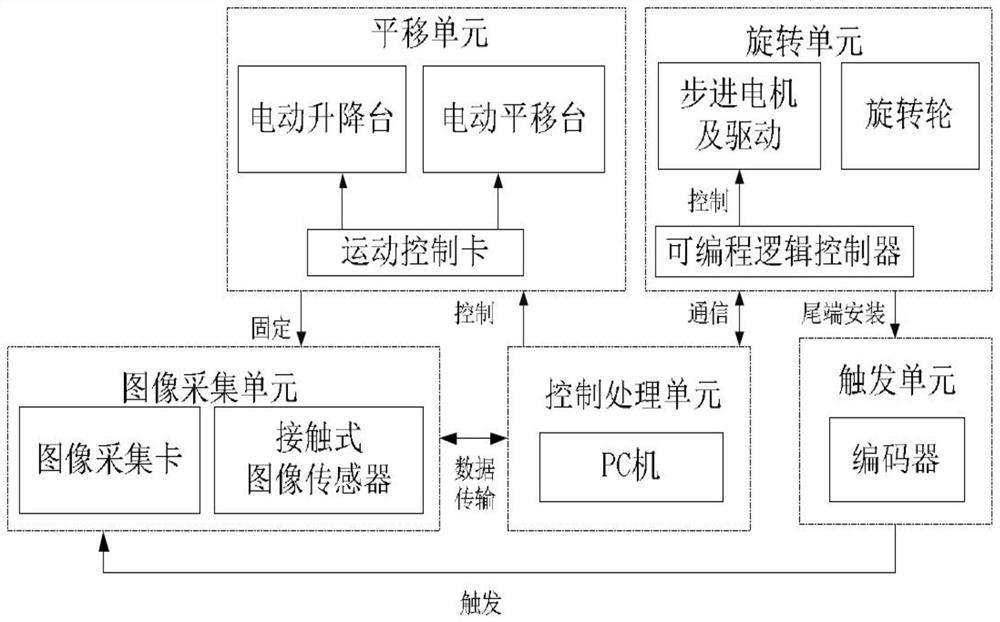

High-pressure gas cylinder inner surface defect detection system based on machine vision

PendingCN112051272ASolve image distortionRapid Quality InspectionOptically investigating flaws/contaminationMachine visionFire protection

The invention relates to the field of high-pressure gas cylinder on-line detection systems for industries such as fire protection, medical treatment and automobiles, in particular to a high-pressure gas cylinder inner surface defect on-line detection system based on machine vision. The problems that imaging is difficult due to the small radial size of the gas cylinder and area-array camera imagingdistortion is caused by the arc-shaped surface are solved. The system comprises an image acquisition unit, a control processing unit, a rotating unit, a triggering unit and a translation unit. The image acquisition unit is connected with the control processing unit, the control processing unit is respectively connected with the rotating unit and the translation unit, the rotating unit is connected with the triggering unit, the triggering unit is connected with the image acquisition unit, and the image acquisition unit is installed on the translation unit.

Owner:SHENYANG POLYTECHNIC UNIV

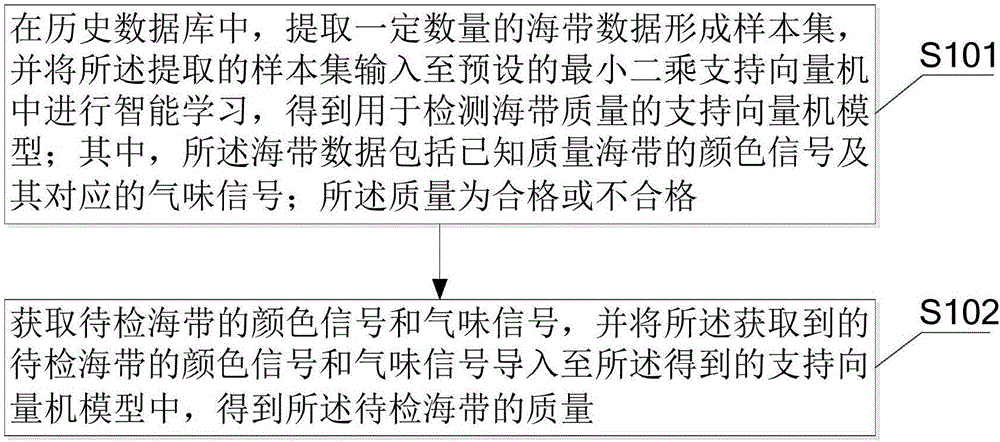

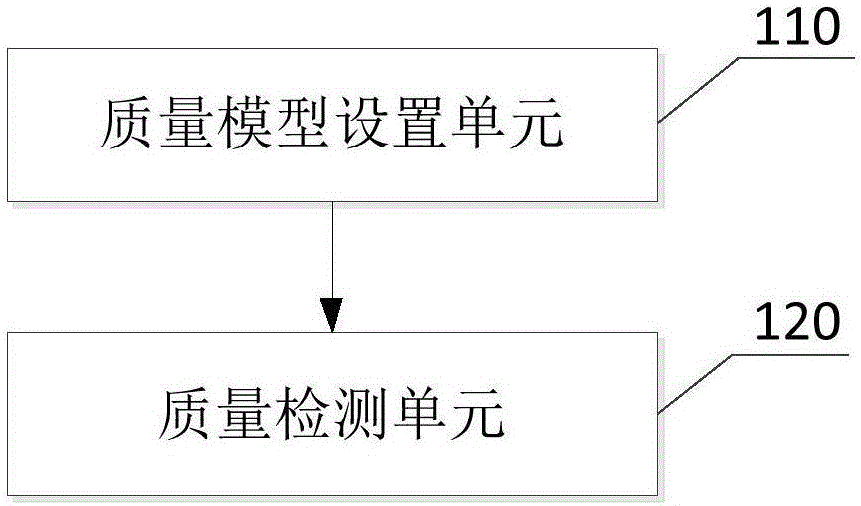

Method and system for detecting quality of kelps

InactiveCN107525772ARapid Quality InspectionEffective Quality InspectionColor/spectral properties measurementsMachine learningLeast squares support vector machineColor signal

The embodiment of the invention discloses a method for detecting the quality of kelps. The method comprises the following steps: in a historical database, extracting a certain amount of kelp data to form a sample set, inputting the extracted sample set into a preset least square support vector machine to carry out intelligent learning, and thus obtaining a support vector machine model for detecting the quality of the kelps, wherein the kelp data includes color signals and corresponding odor signals of the kelps with known quality, and the quality is qualified or unqualified; and acquiring color signals and odor signals of the kelps to be detected, and transmitting the color signals and the odor signals of the kelps to be detected into the support vector machine model to obtain the quality of the kelps to be detected. The method disclosed by the embodiment of the invention has the characteristics that fast and effective quality detection for the kelps can be realized, simultaneously the detecting capability is strong, the false detection ratio is low, the time and the labor are saved and the like.

Owner:WENZHOU UNIVERSITY

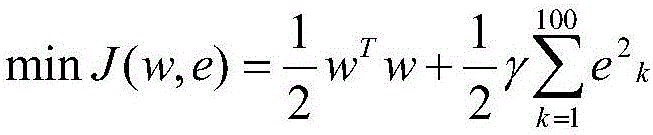

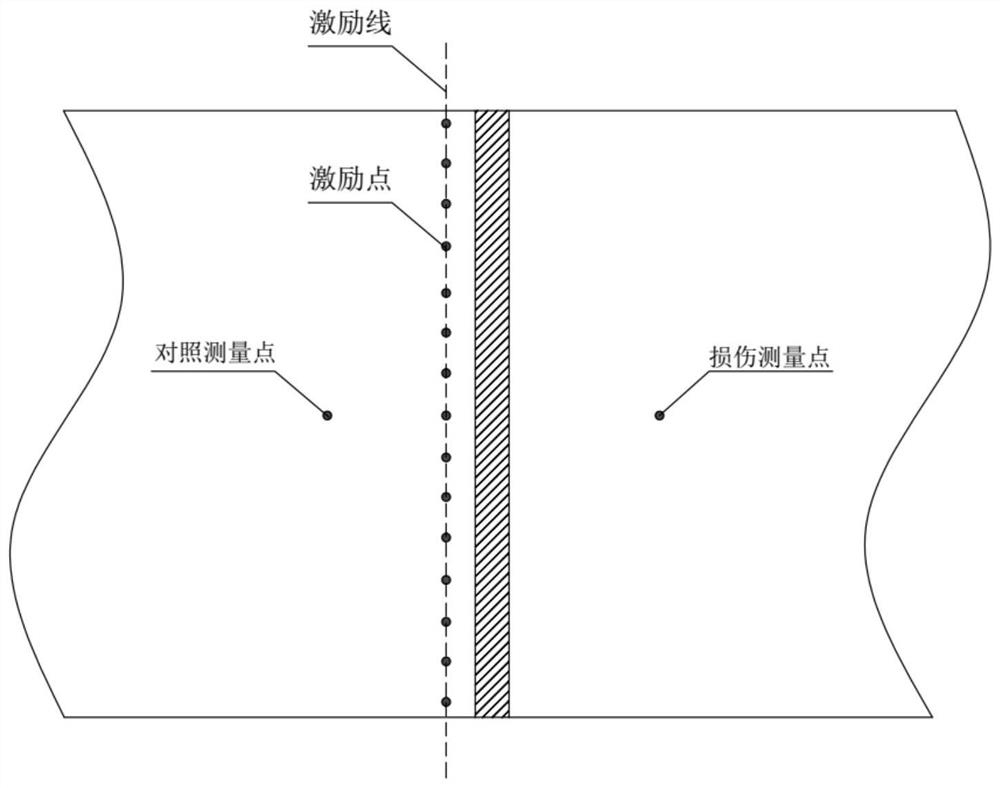

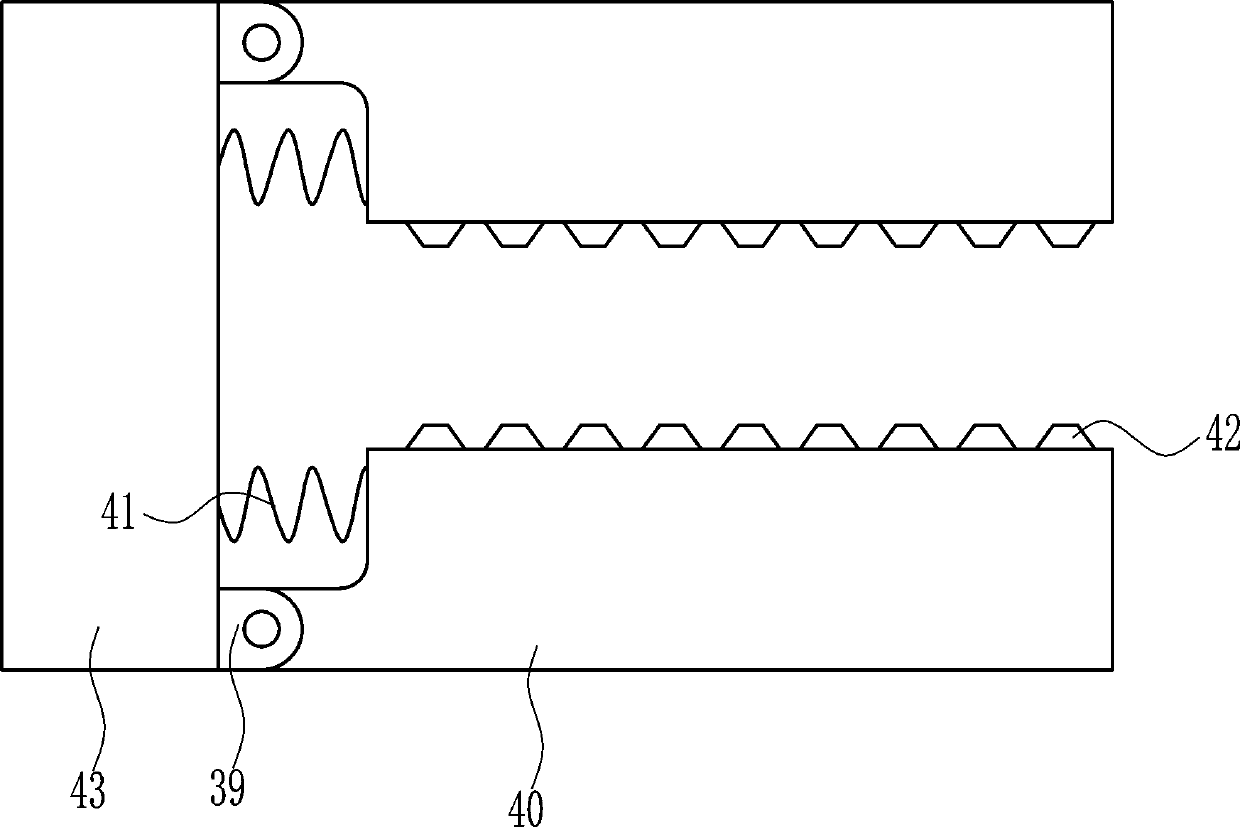

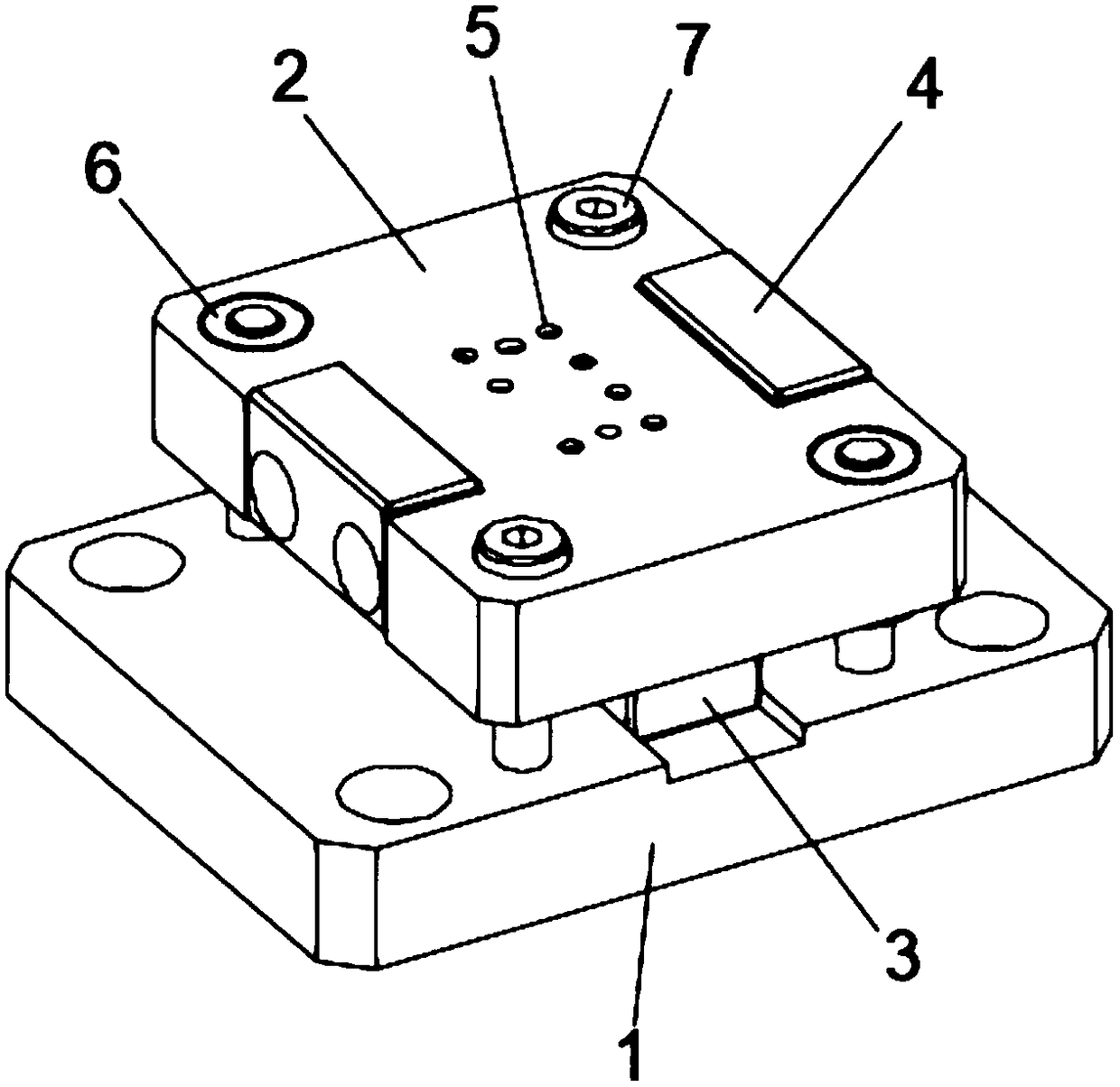

Apparatus and method for quality inspection of welded parts

ActiveCN110988138BRapid Quality InspectionNo need to disassembleAnalysing solids using sonic/ultrasonic/infrasonic wavesTime domainFrequency spectrum

The invention relates to a weldment quality inspection device and method, including an excitation device for performing multiple percussion excitations on the weldment, and obtaining frequency spectrum signals of each percussion force; a measuring device for collecting each percussion The vibration response signal of the damage measurement point M of the percussion excitation; the control device is connected with the excitation device and the measurement device circuit, and is used to calculate the time domain duration, each The order modal frequency and the center frequency of the power spectrum. The invention adopts the shock wave vibration detection method to detect the welded parts of aluminum alloy profiles, which can not only realize the rapid quality detection of the welded parts of aluminum alloys before they are put into use, but also can detect the aluminum alloy profiles without disassembly during regular safety inspections during service In-situ safety testing of alloy weldments.

Owner:CRRC QINGDAO SIFANG CO LTD

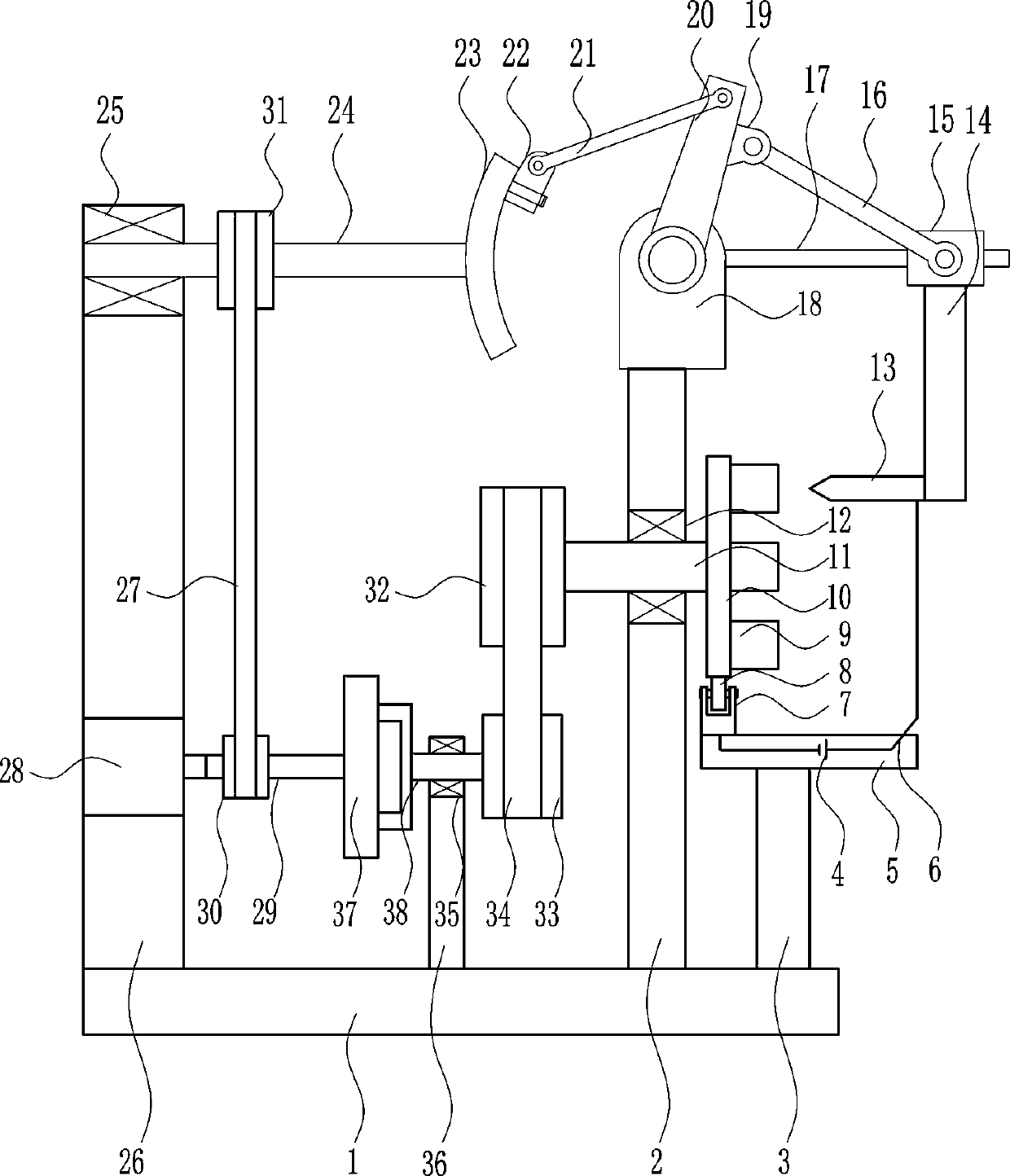

A quality inspection device for electronic components

ActiveCN109060333BShorten the timeRapid Quality InspectionMachine part testingCircular discEconomic benefits

The invention relates to a quality detection device, in particular to an electronic component quality detection device. The invention aims to provide the electronic component quality detection devicewhich is convenient to use, high in detection efficiency and time-saving for solving technical problems. According to the technical scheme, the electronic component quality detection device comprisesa base, a first supporting rod, a second supporting rod, a battery, a supporting plate, a wire, a first fixed base, a rolling wheel, a clamp, a first circular disc, a first rotating shaft and the like; and a third supporting rod, a first supporting rod and a second supporting rod are sequentially installed on the upper portion of the base from left to right; and a second bearing is installed on the upper portion of the third supporting rod. According to the device, the effects of being convenient to use, high in detection efficiency and time saving are achieved, quality detection can be carried out on a large number of electronic components quickly, the use is convenient, the time of workers is saved, and higher economic benefits are provided for factories; and the device is precise in structure, exquisite in design and long in service life.

Owner:江苏省无锡交通高等职业技术学校

A kind of online automatic assembly and testing equipment for automobile body controller

ActiveCN107992032BReduce handlingIncrease productivityProgramme controlElectric testing/monitoringRobot handProduct testing

The invention discloses online full-automatic assembly detection equipment for an automobile body controller. The equipment comprises assembly testing modules, an assembly adhesive dispensing module,a manipulator, a screw assembly module, an X-axis electric module, an industrial computer, a robot controller and a control cabinet, wherein two assembly testing modules are arranged on two sides of the manipulator; the assembly adhesive dispensing module is mounted on the manipulator; the screw assembly module is arranged on the X-axis electric module; the X-axis electric module, the assembly testing modules, the assembly adhesive dispensing modules, the manipulator and the screw assembly module are all arranged on the control cabinet, and the industrial computer and the robot controller arearranged in the control cabinet. Technologies about mechanical movement, robot control and the like are integrated, so that the automobile body controller is automatically assembled from different parts according to the production process and then is automatically sent to a certain position, and the industrial computer system simulates the whole automobile for product testing.

Owner:ZHENGZHOU JINGYIDA AUTO PARTS

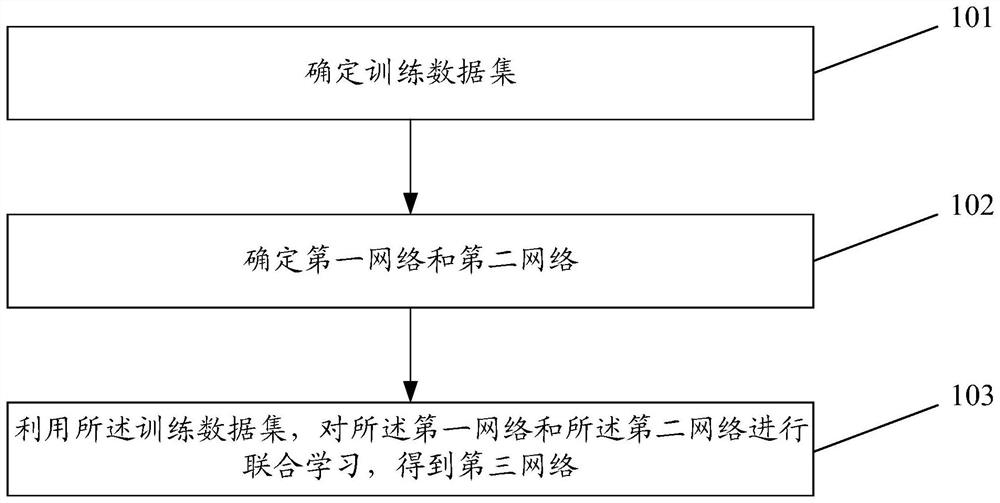

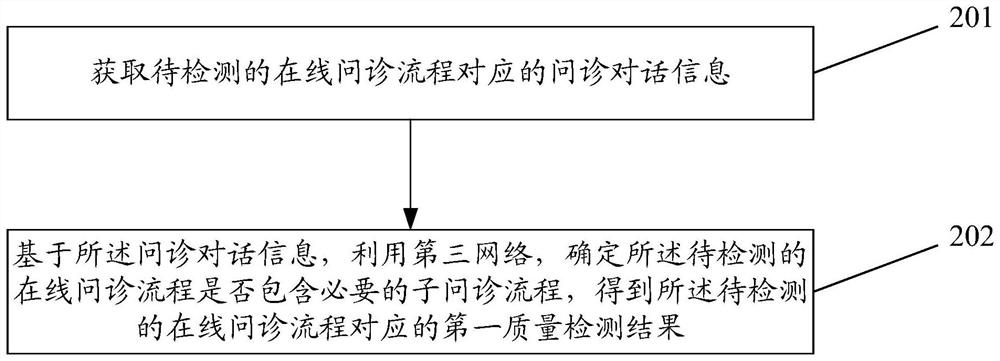

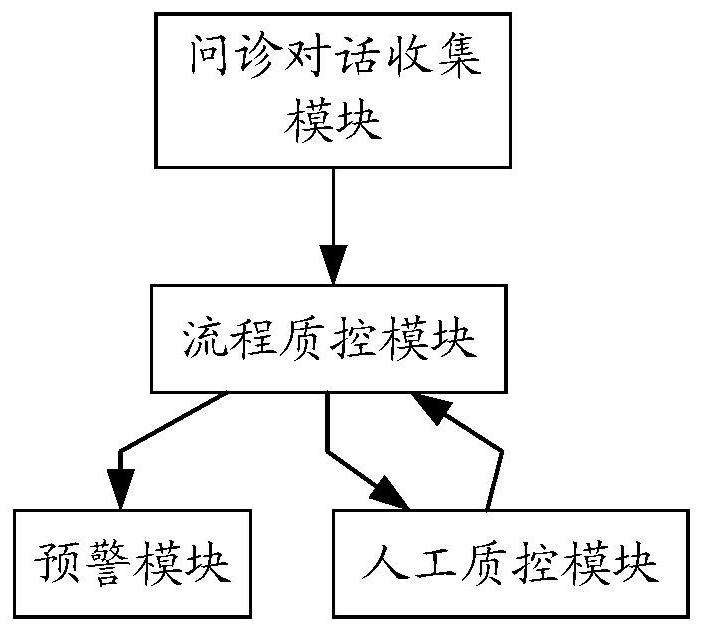

Quality detection method for online inquiry process, network training method and related device

PendingCN114334187ARapid Quality InspectionAccurate quality inspectionMedical communicationSemantic analysisData setEngineering

The invention discloses a network training method based on an online inquiry process, a quality detection method of the online inquiry process, a network training device based on the online inquiry process, a quality detection device of the online inquiry process, first electronic equipment, second electronic equipment and a storage medium. The network training method comprises the following steps: determining a training data set; the training data set comprises inquiry dialogue information and quality detection results corresponding to a plurality of online inquiry processes; determining a first network and a second network; the first network is used for determining a sub-inquiry process included in an online inquiry process; the second network is used for determining a necessary sub-inquiry process corresponding to an online inquiry process; performing joint learning on the first network and the second network by using the training data set to obtain a third network; and the third network is used for determining whether the online inquiry process contains necessary sub inquiry processes or not.

Owner:BEIJING JINGDONG TUOXIAN TECH CO LTD

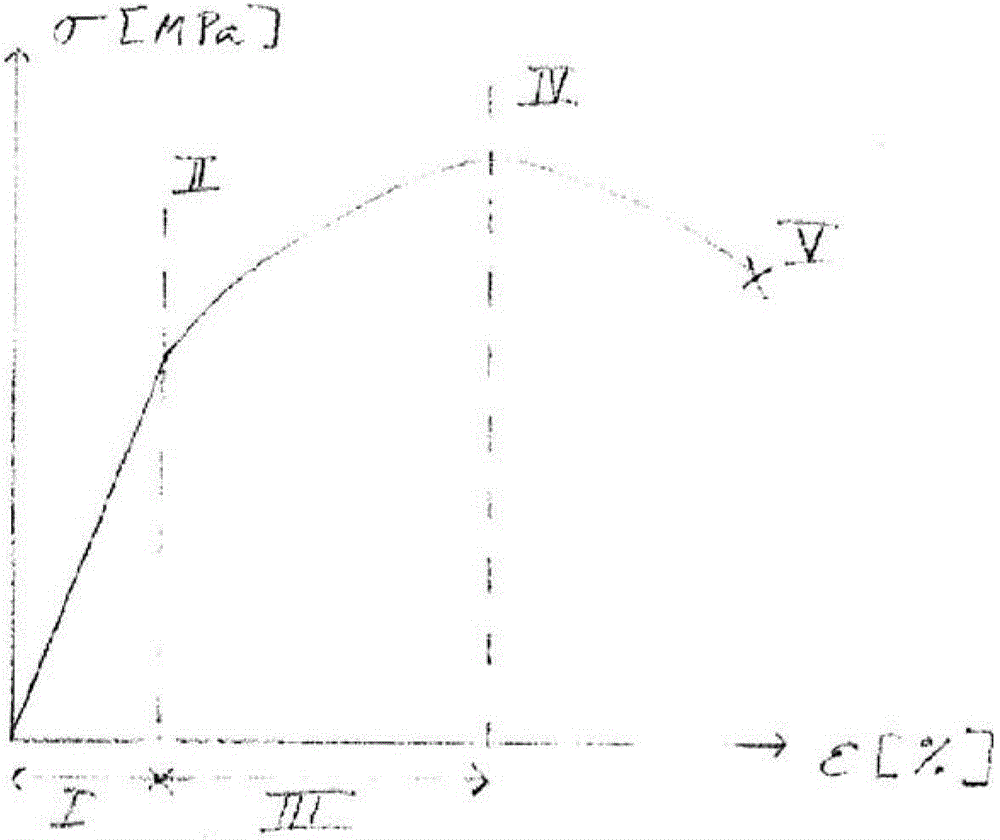

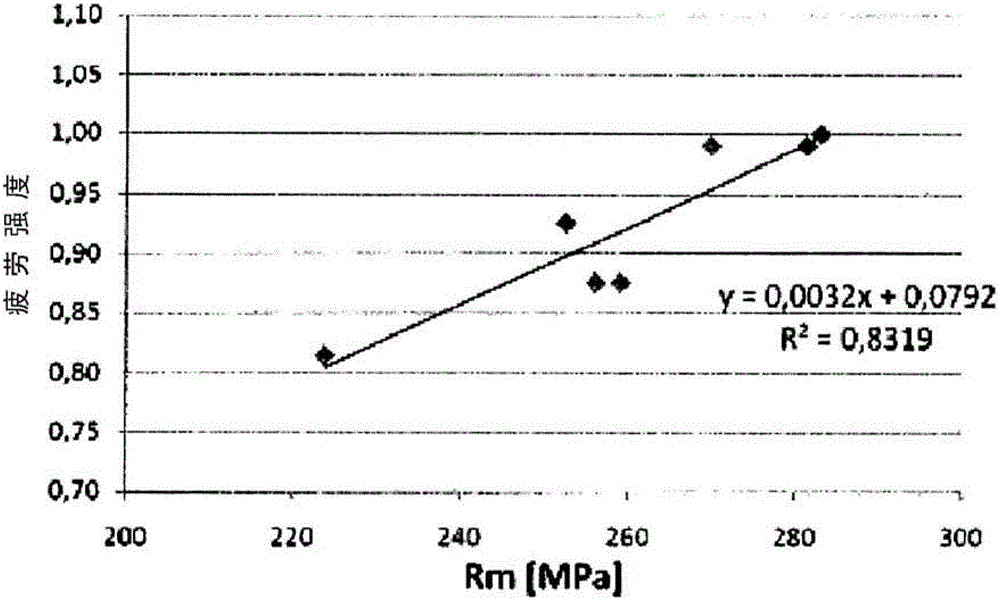

Method for determining fatigue strength of engine components

InactiveCN103339487ARapid Quality InspectionNo risk of damageEngine testingMaterial strength using tensile/compressive forcesEngineeringUltimate tensile strength

Owner:SCANIA CV AB

A fast and non-destructive method for judging imperfect kernels of single-grain crops

ActiveCN109470648BEfficient discriminationThe test results are objective and accurateMaterial analysis by optical meansNear infrared spectraBotany

The invention discloses a quick non-destructive judging method for unsound grains of a single kernel crop. The method comprises the following steps: S1, collecting a single kernel crop sample, detecting unsound grain condition of each single kernel crop and establishing a class information matrix; S2, collecting a near infrared spectrum of single grains of the single kernel crop; S3, constructinga near infrared judging and analyzing model of unsound grains of the single kernel crop; and S4, differentiating normal single kernel crop and unsound grain single kernel crop by means of the established model. The method has the advantages of being objective and accurate in detection result, free of damage to the sample in the detection process, quick and simple, and can judge the unsound grainsof the single kernel crop efficiently in a through manner.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Plugging device and method for powder clearing hole of selective laser melting forming wing rudder structure

PendingCN114147235AIncrease the level of automationImprove quality inspectionAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingControl engineering

The invention relates to a selective laser melting forming wing rudder structure powder clearing hole plugging device and method. The selective laser melting forming wing rudder structure powder clearing hole plugging device comprises a plugging support, a plugging device, a position recognition and feedback module, a quality detection module, a control terminal and a transmission module. Wherein the plugging support serves as a bearing structure of the plugging device, the position recognition and feedback module and the quality detection module, and the control terminal is connected with the plugging device, the position recognition and feedback module, the quality detection module and the transmission module and controls the plugging process. According to the technical scheme, high-quality and automatic high-efficiency plugging of the powder cleaning hole of the wing rudder structure can be achieved; the rapid quality detection of the plugging position can be realized; and the requirement for blocking batch powder clearing holes generated by batch production of selective laser wing rudder structures can be met, so that the automation level of the whole additive manufacturing process is improved.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

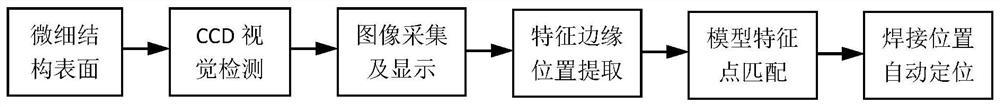

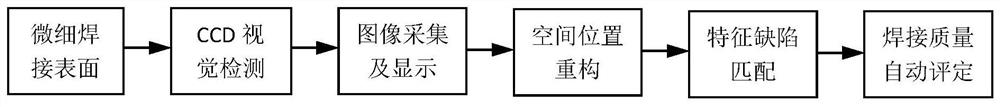

An automatic precision laser welding method based on ccd visual detection

ActiveCN110238520BRealize automatic positioningQuick feedbackLaser beam welding apparatusGraphicsVisual inspection

The invention discloses an automatic precision laser welding method based on CCD visual detection. In order to realize the automation and intelligent welding of microstructure precision parts and components, firstly, according to the technological requirements of welded parts and the technical requirements of dimensions, position, precision, etc., through CCD visual inspection, intelligent graphics processing and CNC platform precision motion control, The automatic positioning of parts welding is realized; for the parts after welding, the numerical control platform is driven, the welding quality inspection is directly performed by CCD, and the welding results are quickly fed back. The invention can meet the demand of high-precision automatic manufacturing in the field of high-end precision parts and components manufacturing.

Owner:苏州菲镭泰克激光技术有限公司

A quality inspection method for battery connectors based on machine vision

ActiveCN108355981BRapid Quality InspectionNo human intervention requiredSortingMachine visionData set

Owner:XI AN JIAOTONG UNIV

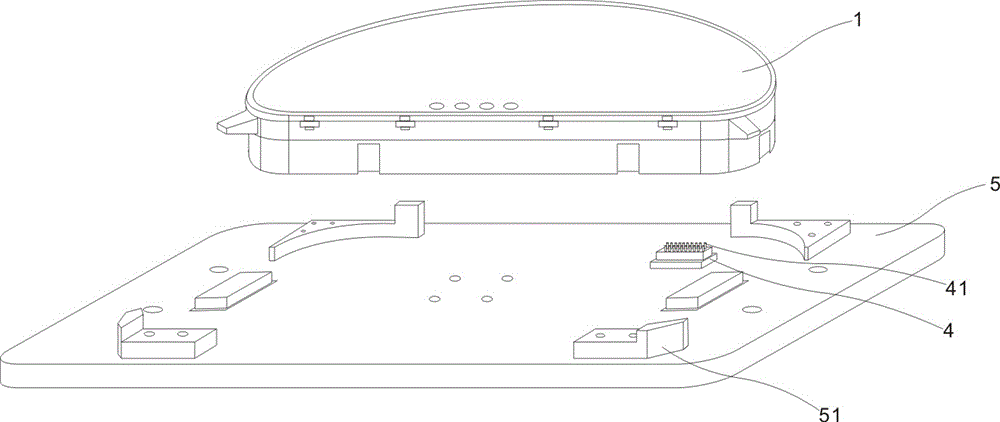

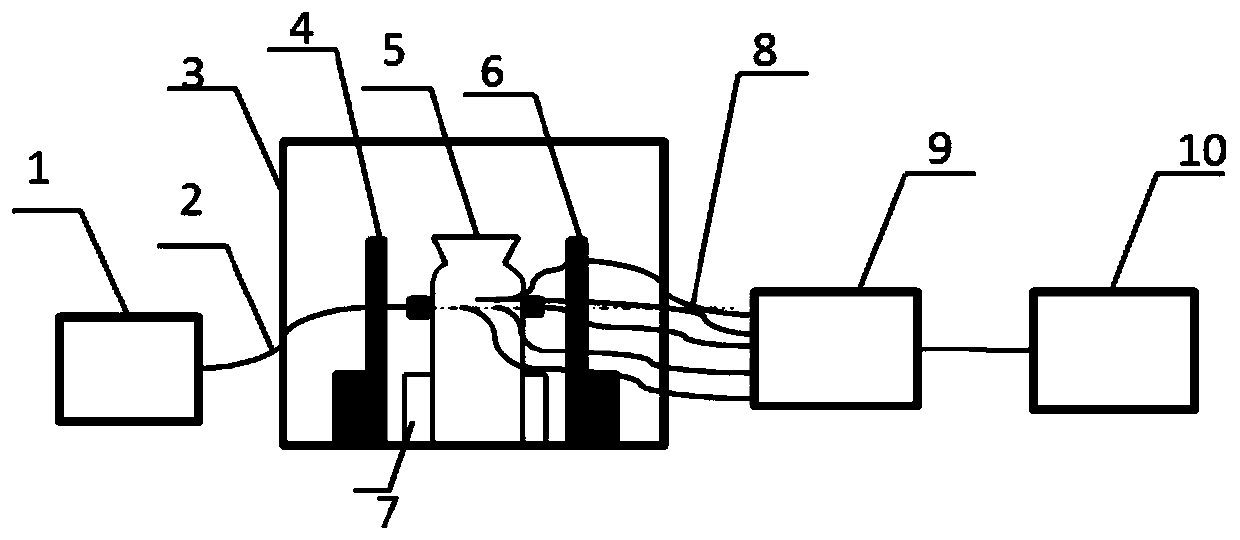

Near-infrared spectroscopy-based quality non-destructive rapid detection device for bottled oral liquid

InactiveCN110749569ARapid Quality InspectionImprove detection accuracyMaterial analysis by optical meansPhotodetectorEngineering

The invention discloses a near-infrared spectroscopy-based quality non-destructive rapid detection device for bottled oral liquid, and relates to the technical field of oral liquid quality analysis, and the device comprises a near-infrared light source, an incident optical fiber, a plurality of receiving optical fibers, a photodetector, a computer and a light-shielding device, wherein the near-infrared light source is transmitted to one end of the sample through the incident optical fiber, the other end of the sample is connected to the photodetector through the plurality of receiving opticalfibers, and the incident optical fiber and the plurality of receiving optical fibers are on the same level; the photodetector is also connected to the computer and is used to convert the scattered light and transmitted light transmitted by the receiving optical fibers into an electrical signal; the computer is used to obtain the electrical signal transmitted by the photodetector, and detect the quality of the sample according to the electrical signal. The device provided by the invention can realize fast and non-destructive oral liquid quality inspection on the spot without opening the bottle.

Owner:TIANJIN UNIV OF TRADITIONAL CHINESE MEDICINE

Device for detecting plastic cement PIN

InactiveCN108663716ARealize quality inspectionStable Quality InspectionElectric/magnetic detectionAcoustic wave reradiationEngineeringBuoyancy

The invention relates to a device for detecting plastic cement PIN, the device for detecting plastic PIN comprises a base and a buoyancy lift block; an insulating seat is arranged on the base below the buoyancy lift block; a locating plate for elastic blocks is embedded on the left and right ends of the buoyancy lift block respectively; a product jack is arranged on an upper surface of the buoyancy lift block; an upper detecting elastic block is arranged on an inner side of the locating plate for elastic blocks, and the upper detecting elastic block is inserted into the product jack through the buoyancy lift block transversely, and a lower detecting elastic block is further fixed on the base; the lower detecting elastic block is inserted into the insulating seat, the top end of the lower detecting elastic block is lower than the upper surface of the insulating seat, and the detecting hole is arranged at a corresponding position of the insulating seat, through the device for detecting the plastic cement PIN of the invention, when the PIN is pressed downwards, the PIN contacts the upper and lower detection elastic blocks to form a conduction test, and if conducted, ,qualified, and ifnot conducted, judged as a plastic PIN,, unqualified; the automation of detection is achieved instead of manual detection, so that more stable and fast quality testing of products is realized, and product accuracy and efficiency are improved.

Owner:KENTA ELECTRONIC MFG KUNSHAN CO LTD

Electronic component quality detection device

ActiveCN109060333AShorten the timeRapid Quality InspectionMachine part testingCircular discTime efficient

The invention relates to a quality detection device, in particular to an electronic component quality detection device. The invention aims to provide the electronic component quality detection devicewhich is convenient to use, high in detection efficiency and time-saving for solving technical problems. According to the technical scheme, the electronic component quality detection device comprisesa base, a first supporting rod, a second supporting rod, a battery, a supporting plate, a wire, a first fixed base, a rolling wheel, a clamp, a first circular disc, a first rotating shaft and the like; and a third supporting rod, a first supporting rod and a second supporting rod are sequentially installed on the upper portion of the base from left to right; and a second bearing is installed on the upper portion of the third supporting rod. According to the device, the effects of being convenient to use, high in detection efficiency and time saving are achieved, quality detection can be carried out on a large number of electronic components quickly, the use is convenient, the time of workers is saved, and higher economic benefits are provided for factories; and the device is precise in structure, exquisite in design and long in service life.

Owner:江苏省无锡交通高等职业技术学校

Quality inspection system based on cloud server

ActiveCN106323889BRapid Quality InspectionSimplified and networked quality inspectionRaman scatteringColor/spectral properties measurementsVisual inspectionThe Internet

Owner:上海赛诚医药科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com