Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about How to "Meet quality control requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Smelting method for stably increasing content of boron in boron-containing steel

The invention relates to a smelting method for stably increasing the content of boron in boron-containing steel. The smelting method is characterized in that high-carbon ferromanganese, high-carbon ferrochromium and iron-core aluminum are subjected to the deoxidation alloying in the steel tapping process of a converter, and a whole-course bottom argon blowing and wash heat technology is adopted for reducing oxygen content and nitrogen content in the steel; after steel tapping is completed, molten steel is lifted to an argon station, and the molten steel is converted to an LF (Ladle Furnace) after ferroaluminium is added for adjusting the activity of oxygen in the steel to a required control range; and submerged arc operation, soft argon blowing control, a deep deoxidation technology and a titanium alloy technology are adopted for refining in the LF, then boron alloying is carried out, and later the long-time soft argon blowing is carried out, thus the recovery rate of boron in the steel reaches 82%-86%, the problems of low and instable recovery rate of boron are solved, the fluctuation quantity between the furnaces is less than 0.0005%, the ideal control level is achieved, the dependence of boron alloying on vacuum refining is eliminated, and the requirement of subsequent process for the quality of the boron-containing steel is ensured.

Owner:WUKUN STEEL

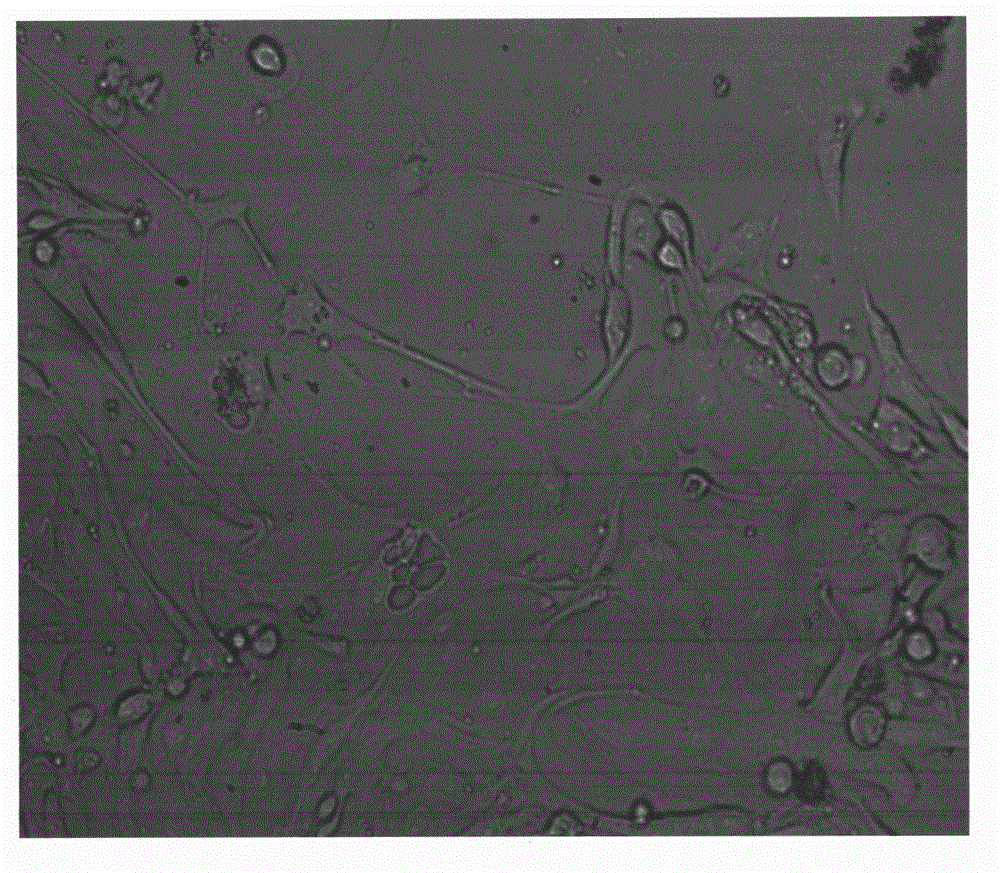

Culture medium and method for NK cell expansion in vitro

InactiveCN105567634AClinical diagnostic safetyAchieve explosive proliferationBlood/immune system cellsCell culture active agentsLymphocyteQuality control

The invention relates to a culture medium and method for NK cell expansion in vitro. The culture medium is prepared from, by volume, 100% of a lymphocyte serum-free culture medium or the mixture of 1-90% of an RPMI1640 culture medium and 10-99% of a lymphocyte serum-free culture medium, a serum substitute and interleukin 2, wherein the concentration of the serum substitute is 0.5-4g / L, and the concentration of the interleukin 2 is 50-500 micrograms / mL. According to the culture medium and the preparation method, explosive expansion of NK cells in a short time can be achieved, the cost is low, the expanded cells are extremely high in destruction, and the requirement for application of three kinds of medical technologies and the requirement for somatic cell treatment medicine quality control are met.

Owner:上海润泉生物技术有限公司

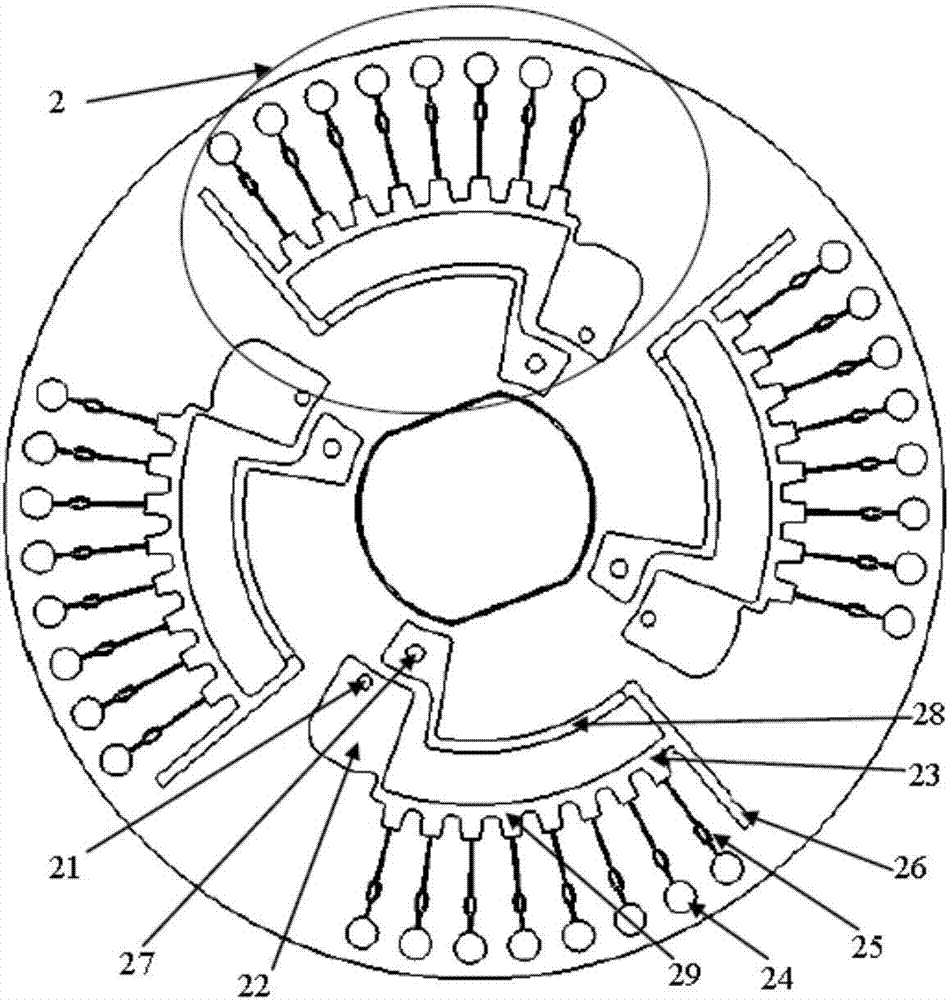

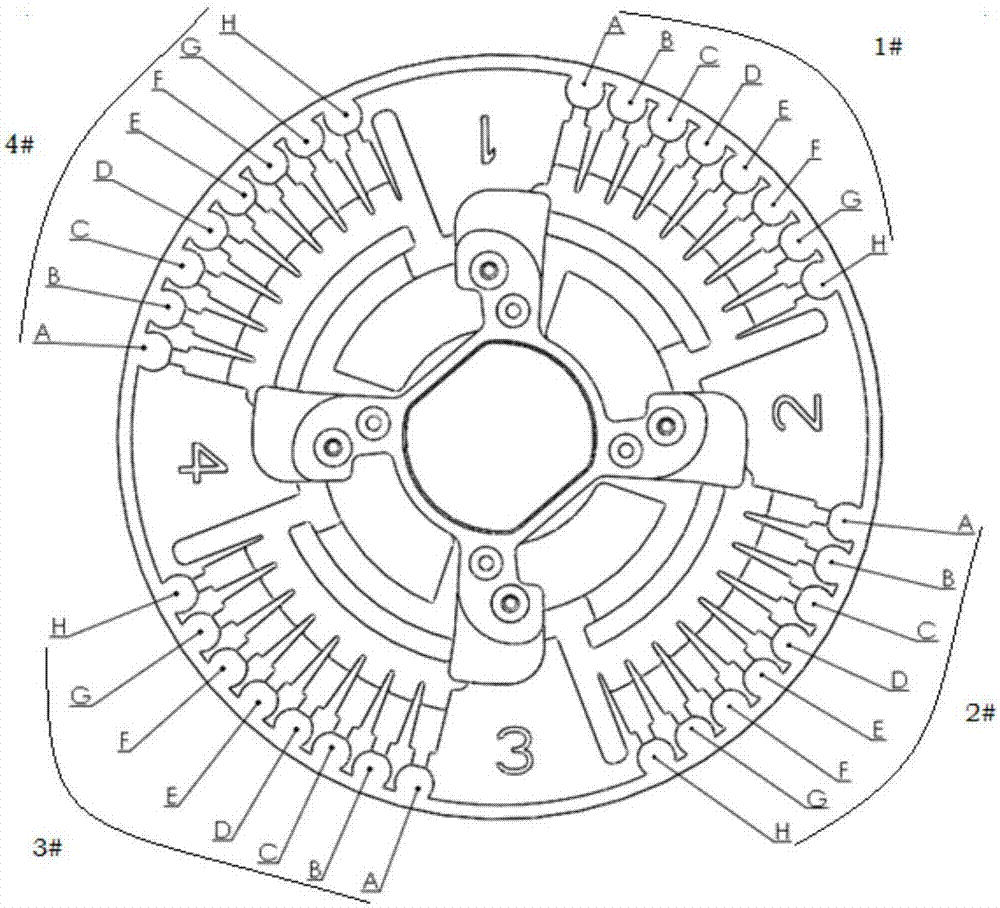

LAMP primer composite for detecting respiratory pathogens and kit of LAMP primer composite

InactiveCN107099619ADoes not affect amplificationMeet quality control requirementsMicrobiological testing/measurementMicroorganism based processesColor changesBiology

The invention relates to a primer composite for detecting respiratory pathogens. The primer composite comprises at least one group of a mycoplasma pneumoniae group, a chlamydia pneumoniae primer group, an influenza A / B virus primer group, a parainfluenza virus primer group, an adenovirus primer group and a respiratory syncytial virus primer group. The invention further relates to a kit comprising the primer composite. The kit further comprises a micro-fluidic chip wrapping primers, and a macroscopic indicator. The invention further relates to a detection method adopting the primer composite. The detection method comprises the steps of primer composite coating, to-be-detected sample nucleic acid extraction, LAMP reaction and visual result interpretation. The kit and the method are applied to the micro-fluidic chip for visual judgment, instant detection of the seven respiratory pathogens is rapidly and accurately realized, and a result is judged by a naked eye by color change, so that the kit and the method are simpler, more convenient and quicker in practical applications, are easy to operate, and are suitable for site operation.

Owner:SHANGHAI IGENETEC DIAGNOSTICS CO LTD

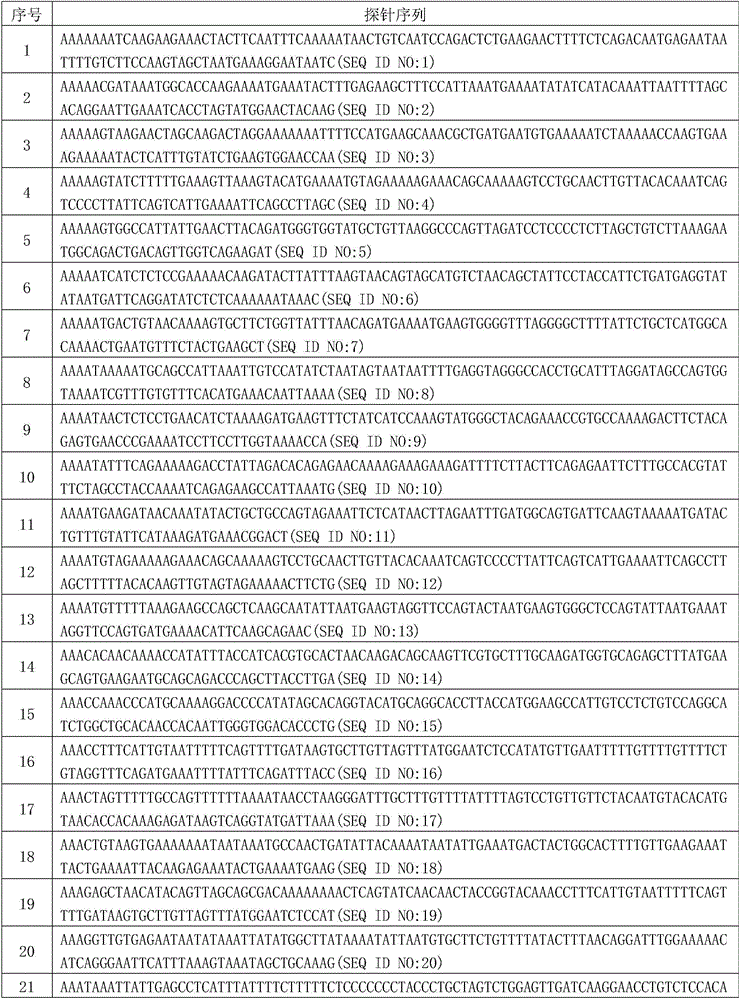

Quality control method for detecting human BRCA1/2 genovariation based on high-throughput sequencing and reagent kit

ActiveCN106381334AMeet quality control requirementsConducive to controlling the accuracy of analysisMicrobiological testing/measurementSanger sequencingNegative control

The invention relates to a quality control method for detecting human BRCA1 / 2 genovariation based on high-throughput sequencing, a reagent kit, and an application thereof. In the quality control method, a plurality of genome DNAs of a human tumor cell line with positive BRCA1 / 2 genovariation are extracted, and are determined by means of a Sanger sequencing method, wherein a variation positive locus is used as a positive comparison locus while a wild type locus is a negative comparison locus; the genome DNAs are mixed at a certain ratio to obtain a quality control product that can be used for detecting human BRCA1 / 2 genovariation through high-throughput sequencing. The reagent kit disclosed by the invention comprises the quality control product for detecting human BRCA1 / 2 genovariation.

Owner:上海思路迪医学检验所有限公司

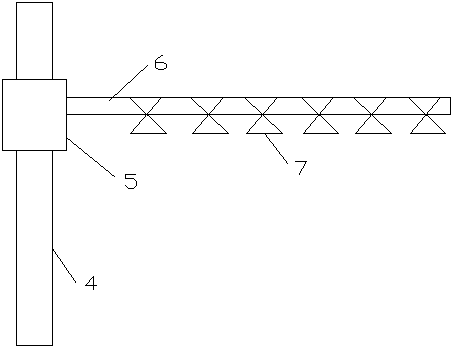

Flexible ironing groove structure of groove type ironing machine

ActiveCN104018329AReduce manufacturing difficultyAchieve machine flexibilityIroning machinesTextiles and paperEngineeringTemperature control

The invention discloses a flexible ironing groove structure of a groove type ironing machine. The ironing machine comprises a cylindrical roller horizontally arranged, and a semicircular ironing groove formed below the roller, wherein the ironing groove is formed by splicing tile-shaped heating blocks which are divided into a plurality of sections in the axial direction, and each section of the tile-shaped heating blocks is divided into a plurality of blocks in the peripheral direction; an ironing groove support frame with an upward opening is arranged below the ironing groove; the length direction of a groove cavity of the ironing groove support frame is accordant with the axial direction of the ironing groove; pairs of ejection elements are respectively arranged between all the heating blocks and the ironing groove support frame close to the two ends of the heating blocks in the axial direction of the ironing groove; the axial lines of the ejection elements are accordant with the radial direction of the ironing groove; and the upper ends / lower ends of the ejection elements are rotationally connected with the heating blocks. The flexible ironing groove structure provides an ironing mode of active three-dimensional pressure servo adjustment and temperature control for ironing linen, and can satisfy different process control requirements of different linen types on the ironing quality.

Owner:SHANGHAI WEISHI MACHINERY

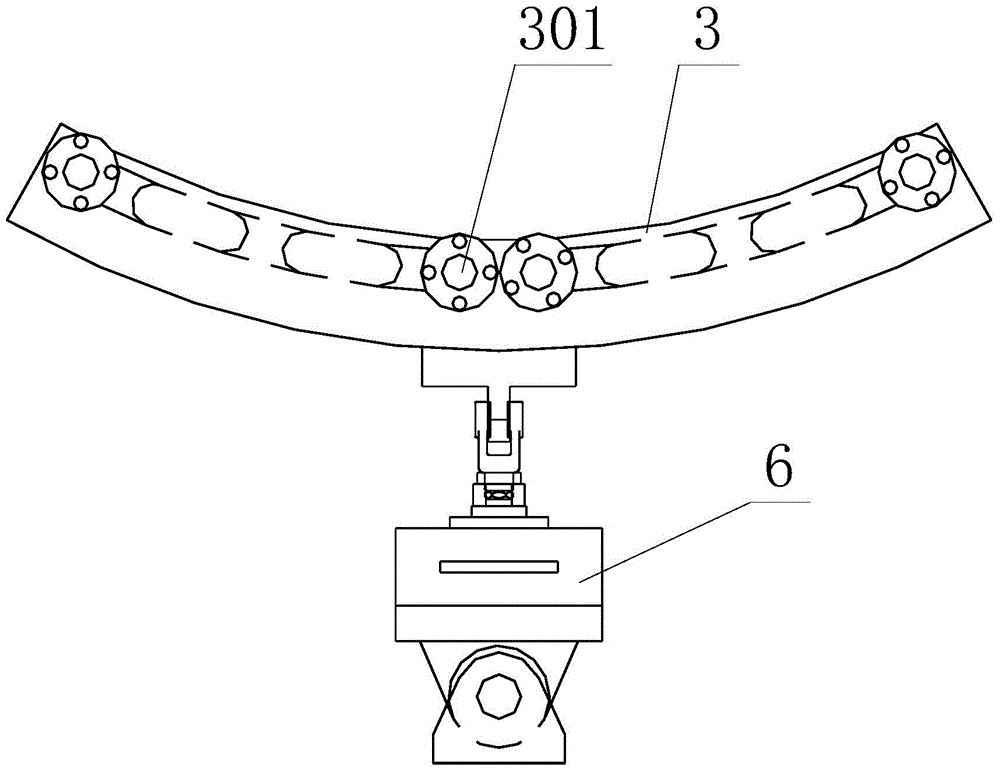

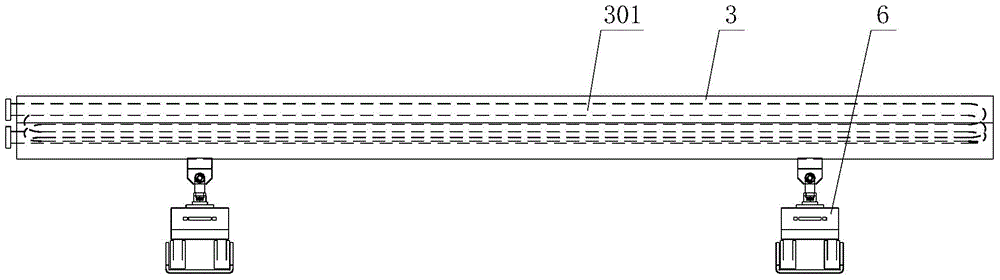

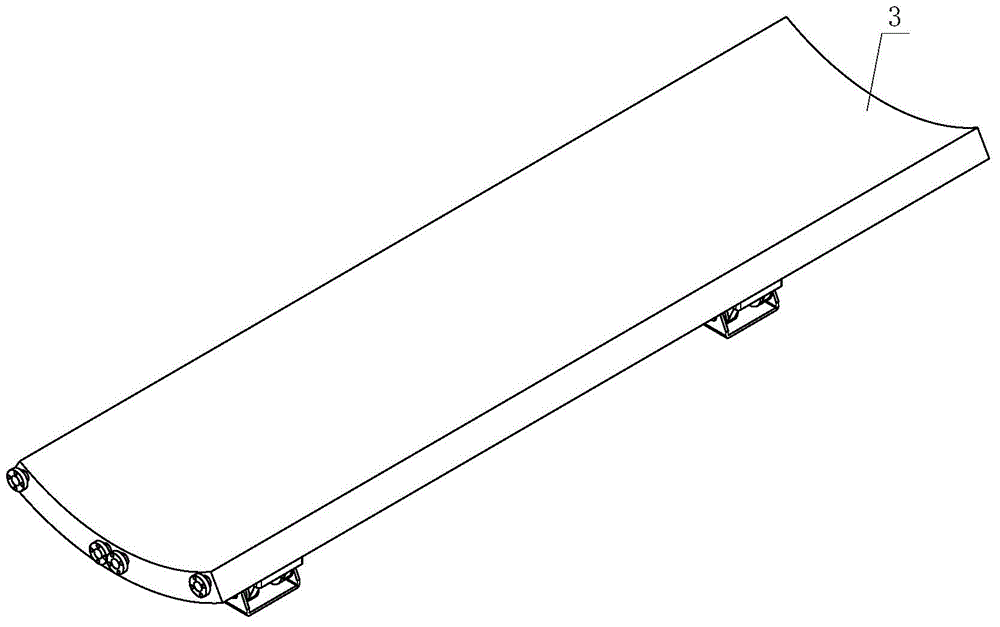

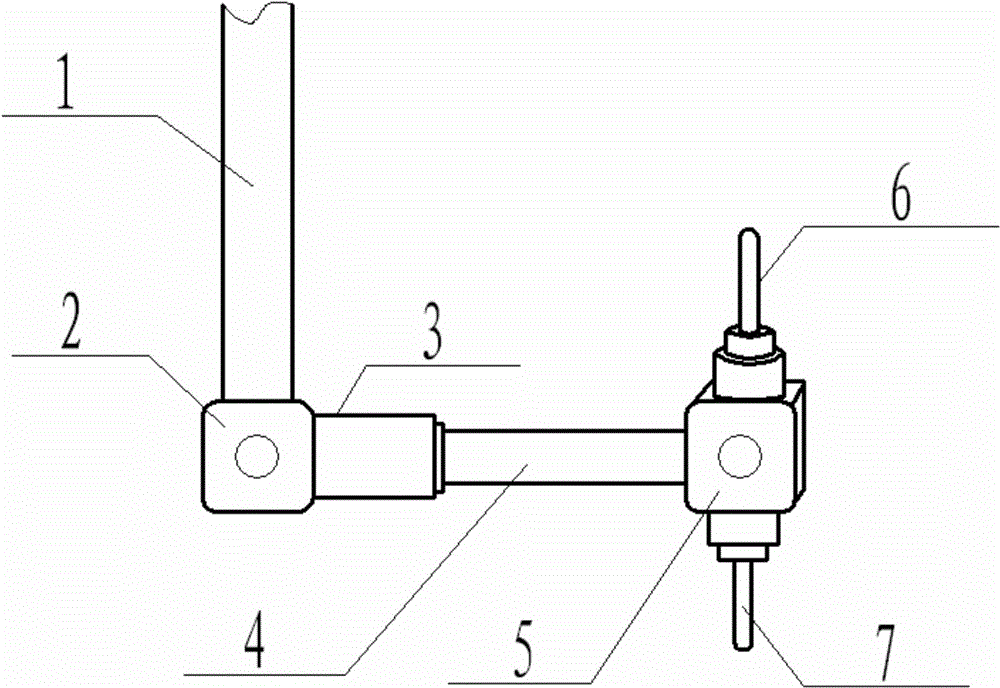

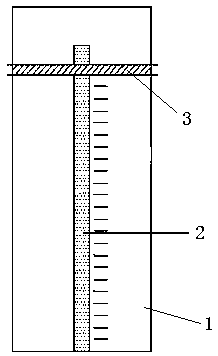

Cylindrical probe and method for measuring and scanning blade profile of blisk

InactiveCN105651234AAvoid stitching errorsRealize high-efficiency and high-precision measurementMeasurement devicesObservational errorContinuous scanning

Disclosed are a cylindrical probe and a method for measuring and scanning the blade profile of a blisk. The cylindrical probe is composed of an extension bar I (1), a five-dimension adapter I (2), a universal joint (3), an extension rod II (4), a five-dimension adapter II (5) and a cylindrical probe I (6). One end of the extension rod II (4) is connected with the extension bar I (1) through the five-dimension adapter I (2) and the universal joint (3). The problems of data discontinuity and large measurement error are solved, data splicing error is avoided, and the efficiency of measurement is improved. With the cylindrical probe and the method for measuring and scanning the blade profile of a blisk, continuous scanning measurement of the blade profile of a blisk can be completed at one attempt. Data is continuous and complete, there is no data missed, and there is no cohesion error. The measurement precision and speed are high, and the stability is good. High-efficiency and high-precision measurement of blisks is realized. The cylindrical probe and the method satisfy the aero-engine blisk quality control requirements, and adapt to the progress demand of batch production on the production site for measurement.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

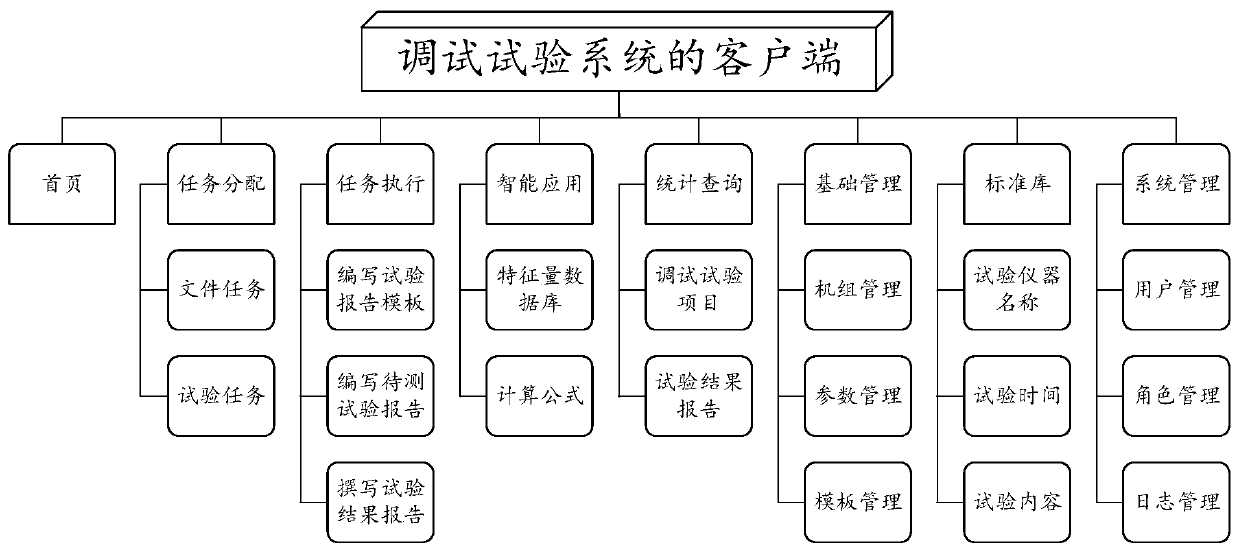

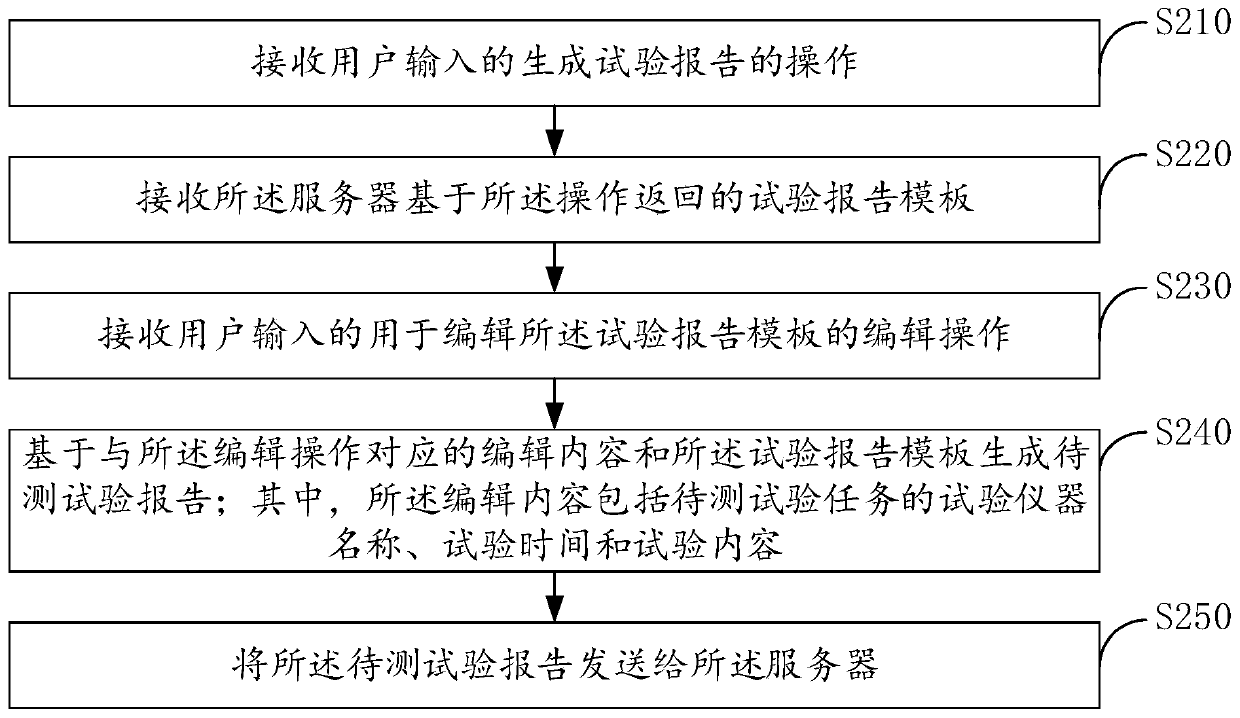

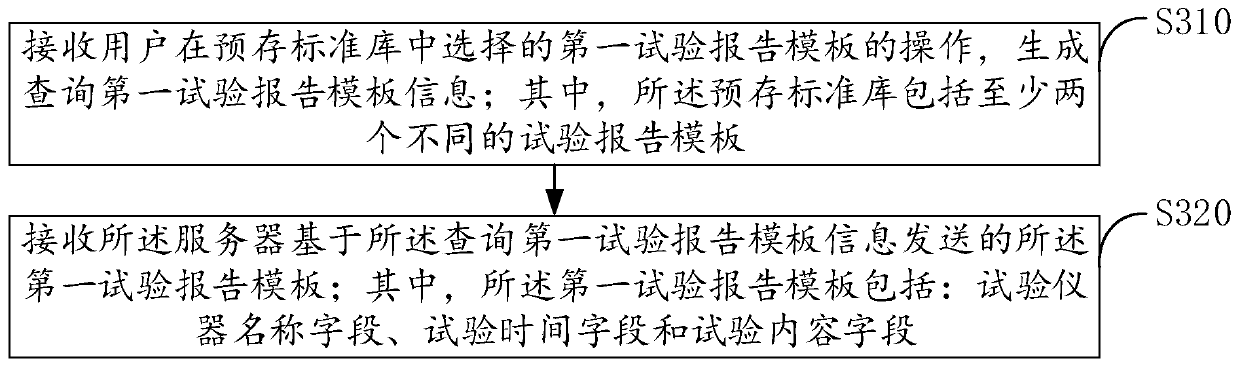

Method for generating a test repor

PendingCN109800387AReduce error rateMeet quality control requirementsDigital data information retrievalOffice automationNuclear powerSoftware engineering

The invention provides a method for generating a test report, and relates to the technical field of nuclear power tests. The method for generating the test report is applied to a client of a debuggingtest system, the client is in communication connection with a server, and the method comprises the following steps: receiving a test report generation operation input by a user; receiving a test report template returned by the server based on the operation; receiving an editing operation which is input by a user and is used for editing the test report template; generating a to-be-tested test report based on the editing content corresponding to the editing operation and the test report template; wherein the editing content comprises the test instrument name, the test time and the test contentof the test task to be tested; and sending the test report to be tested to the server. By converting the paper debugging test report into the electronic debugging test report, the defects of the paperreport can be overcome, the error rate of the debugging test report of the nuclear power engineering is reduced, and thus the quality control requirement of the debugging test report is met.

Owner:WUHAN RUILAIBAO ENERGY TECH

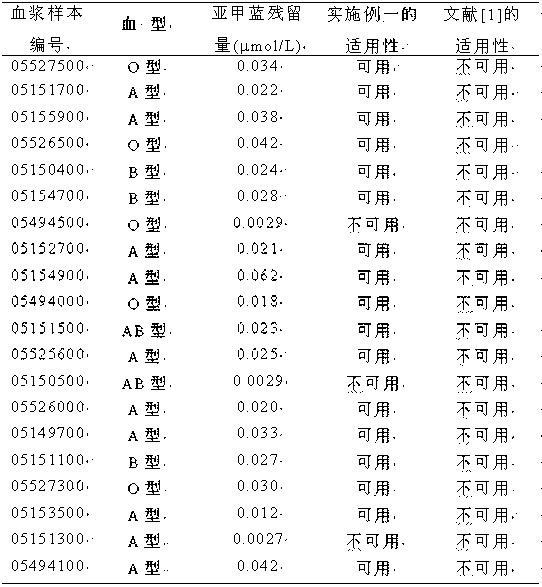

Method for detecting content of methylene blue in blood plasma

InactiveCN102706844AReduce consumptionThe determination method is simpleFluorescence/phosphorescenceFluorescenceBlood plasma

The invention discloses a method for detecting the content of methylene blue in blood plasma. The method comprises the following steps of: (a) adding carboxymethyl-beta-cyclodextrin saturated solution into blank blood plasma, enabling the concentration of the mixed solution to reach 1-4.5mmol / L and maintaining the constant volume to obtain a blood plasma blank sample; (b) adding quantitative methylene blue solution into the blank blood plasma and adding the carboxymethyl-beta-cyclodextrin saturated solution to obtain a standard blood plasma sample containing the methylene blue with the concentration of Cs; and (c) adding the carboxymethyl-beta-cyclodextrin saturated solution in a blood plasma sample containing the methylene blue to obtain a blood plasma to-be-measured sample containing the methylene blue with the concentration of Cs; detecting the strength or the area of a fluorescence peak of the sample; and then calculating according to a reference substance comparison method to obtain the concentration Cs of the methylene blue in the blood plasma to-be-measured sample. According to the method disclosed by the invention, the lowest detectable limit is 0.012mumol / L and the unexpected effect is obtained.

Owner:苏州市中心血站 +1

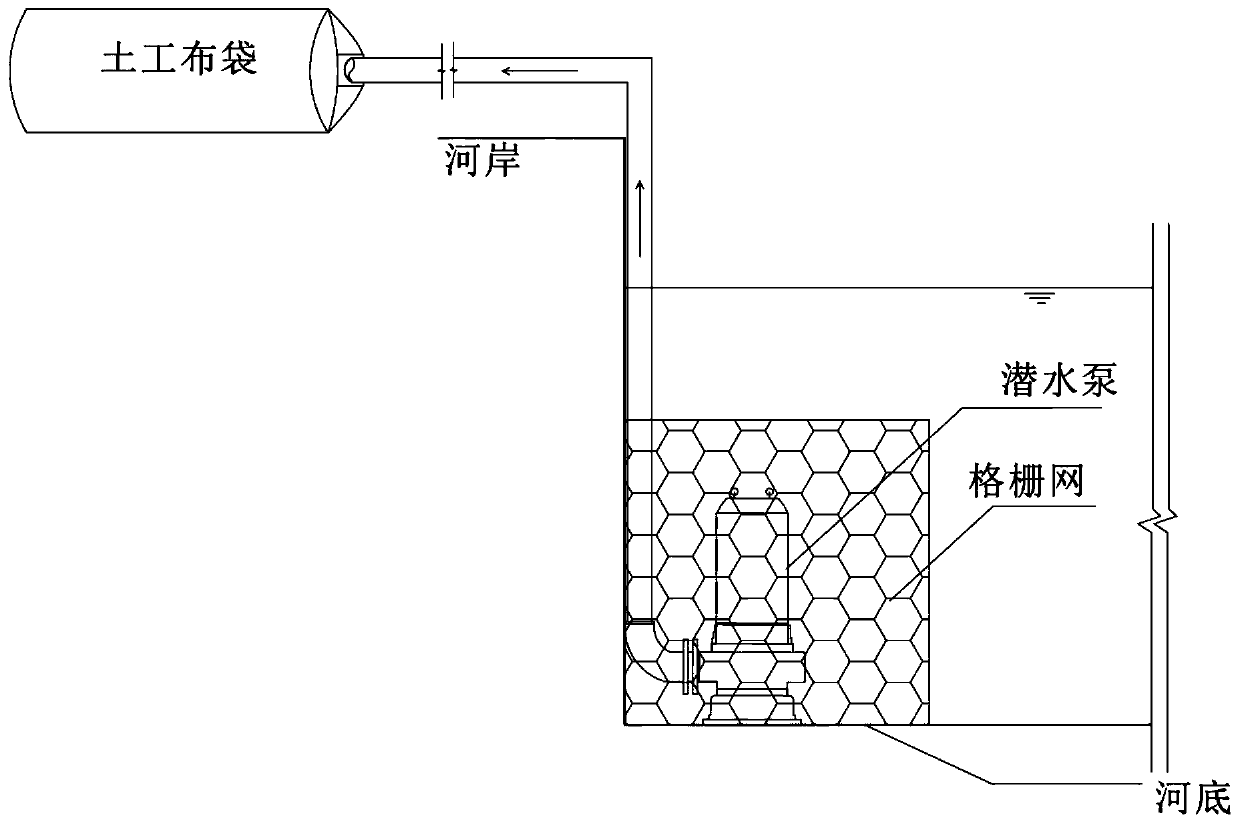

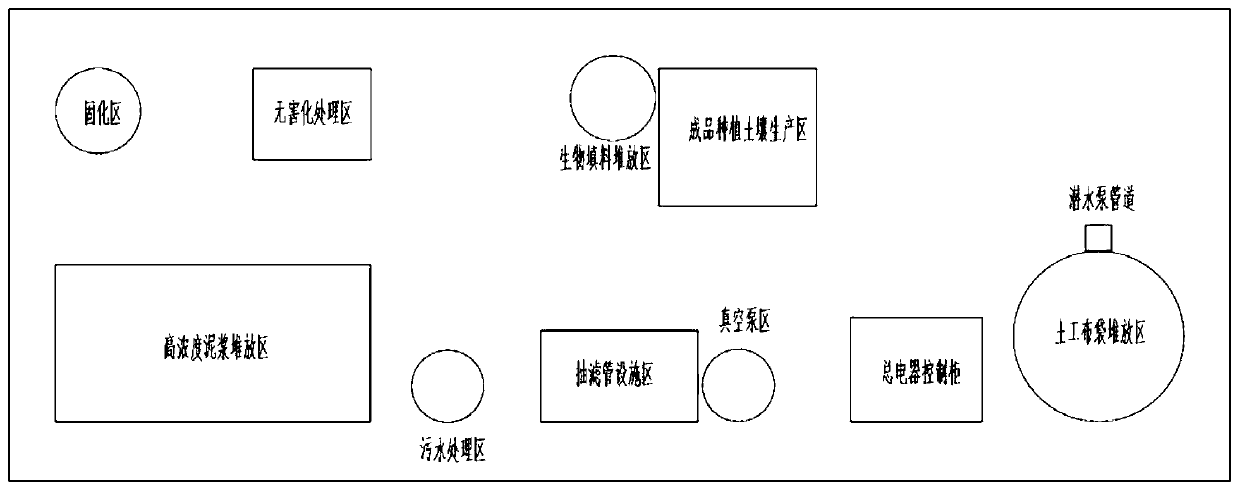

Method for applying treated river and lake silt to land-water ecotone plant planting medium

InactiveCN110839509AFull of nutritionMeet quality control requirementsGrowth substratesCulture mediaMicroorganismMuck

The invention discloses a method for applying treated river and lake silt to a land-water ecotone plant planting medium. By adoption of the method, final planting soil is obtained by S1 sediment dredging, S2 mud-water separation, S3 silt solidifying, S4 harmless treatment and S5 planting soil formation sequentially. According to the method, firstly, a rapid mud-water separation technique is designed for low-concentration dredged mud and integrated with a subsequent silt solidifying treatment technique to form an integrated sediment dredging treatment and utilization technique to turn dredged sediment into soil; then, by a sediment microbial technique, the polluted river and lake silt is subjected to harmless treatment to meet planting soil quality control requirements, and the characteristic of rich nutrition of the river and lake sediment can be given into full play, and high-quality organic planting soil is formed.

Owner:JIANGSU AOYANG ECOLOGICAL LANDSCAPE CO LTD

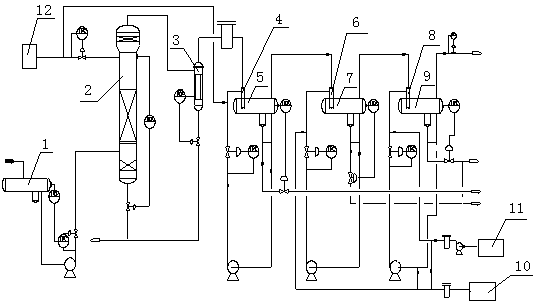

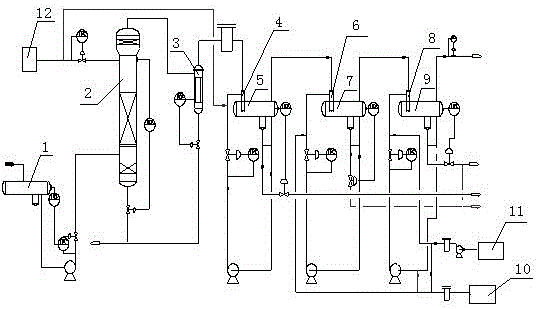

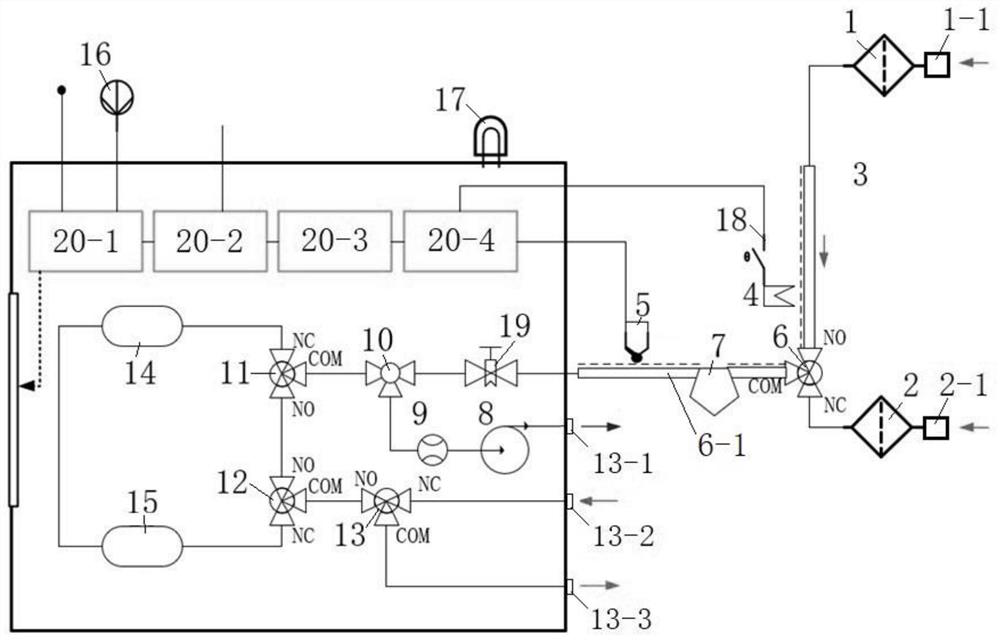

Liquefied gas desulfurization refining device and liquefied gas desulfurization refining method in oil refinery

ActiveCN103805274AGuaranteed recyclingReduce consumptionGaseous mixture working upFiberWater storage tank

The invention relates to a liquefied gas desulfurization refining device in an oil refinery. The device comprises a buffer tank, an extraction tower, an MDEA (methyldiethanolamine) solvent storage tank, an alkaline liquor storage tank, a water storage tank, a primary extraction settling tank, a secondary extraction settling tank and a tertiary extraction settling tank, wherein the outlet of the buffer tank is connected with the bottom inlet of the extraction tower; the top outlet of the extraction tower is connected to the primary extraction settling tank by virtue of a coalescer and a primary fiber membrane contactor; the MDEA solvent storage tank is respectively communicated with the upper outlet of the extraction tower and the primary fiber membrane contactor; a top outlet of the primary extraction settling tank is connected to the secondary extraction settling tank by virtue of a secondary fiber membrane contactor; the top outlet of the secondary extraction settling tank is connected to the tertiary extraction settling tank by virtue of a tertiary fiber membrane contactor; the alkaline liquor storage tank is respectively communicated with the secondary fiber membrane contactor and the tertiary fiber membrane contactor; the water storage tank is communicated with the tertiary fiber membrane contactor. According to the device, when the liquefied gas is subjected to desulfurization refining, the desulfurization effect is good, the consumption of the solvent and alkaline liquor is low, and the cost is greatly saved.

Owner:CHINA PETROLEUM & CHEM CORP

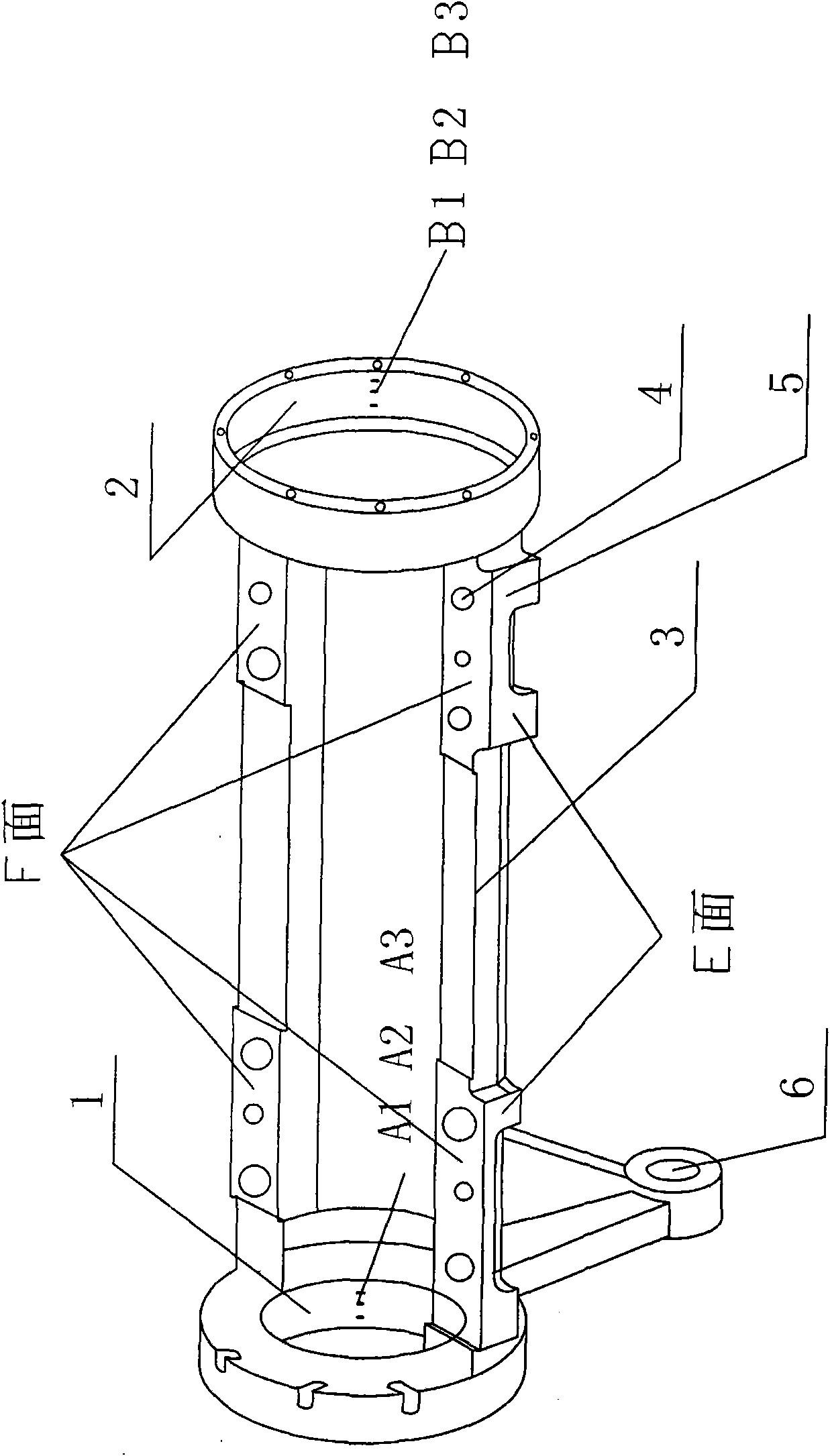

Method for measuring bearing hole concentricity of axle-hang box of locomotive

ActiveCN101625227AAccurately reflect quality statusReflect the quality statusMechanical measuring arrangementsQuality controlEngineering

The invention relates to the technical field of axle-hang boxes of locomotives, in particular to a method for measuring bearing hole concentricity of an axle-hang box of a locomotive, comprising the following steps: 1. in the three-dimensional measuring process of the bearing hole concentricity of the axle-hang box of the locomotive, measuring an F mounting plane and an E mounting plane, and using an intersecting line L of the F plane and the E plane as a directional standard for measuring the concentricity; 2. measuring three section circles A1, A2, A3 and B1, B2, B3 respectively on bearing holes A and B; 3. calculating the concentricity value of B1, B2 and B3 to A1, A2 and A3 in an L direction of the intersecting line L of the F and E planes; and 4. acquiring the maximum concentricity, i.e. the measuring value of the bearing hole concentricity of axle-hang box of the locomotive. The measuring method can objectively and accurately reflect the quality condition of the axle-hang box of the locomotive, satisfy the quality control requirement of products and reduce erroneous judgment as much as possible.

Owner:CRRC QISHUYAN CO LTD

Reverse-flow type rapid extraction device for sediment organic matter

InactiveCN106153430AImprove extraction efficiencyEasy temperature controlPreparing sample for investigationGas phaseEnvironmental studies

The invention discloses a reverse-flow type rapid extraction device for sediment organic matter and belongs to the field of environmental studies. The device comprises a sample treatment system (two round-bottom flasks containing a sediment sample and an organic extraction solvent respectively), a reverse-flow collecting system and a condensation reverse-flow system. The sediment sample, an ultrapure water mixture and the organic extraction solvent in the round-bottom flasks are heated respectively, the organic extraction solvent and target objects ascend to a condenser pipe at the upper end from a glass reverse-flow pipe in a gas state and a flow guiding mode, the organic extraction solvent extracts the target organic contaminants in a gas phase state, the target organic contaminants are condensed under the action of circulating cooling water and fall back into the reverse-flow collecting system, and due to the density difference between the organic extraction solvent and a water phase, an effective laying is obtained. The water phase and the organic phase return into the round-bottom flasks through return-flow catheters with different oblique angles, over and over again, the target organic contaminants are constantly extracted through the pure solvent, and the target organic contaminant is collected in the reverse-flow system. After extraction is completed, the organic phase containing the target objects is discharged through a liquid separating switch, components are collected, and therefore the target organic contaminants in the sediment sample are effectively extracted.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

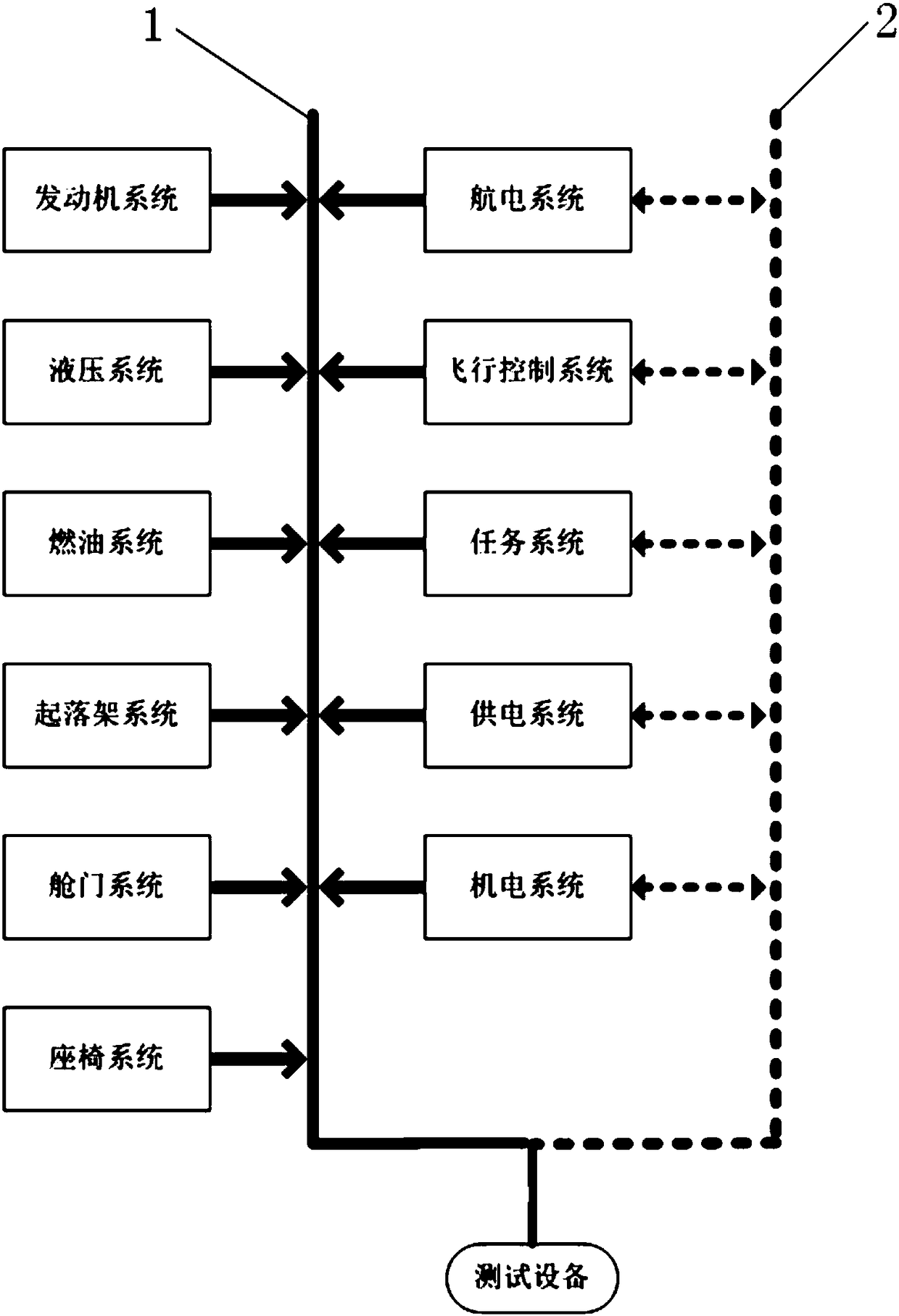

Method for data interaction of aircraft whole avionics equipment

InactiveCN108241358AIntegrity guaranteedGuaranteed reliabilityProgramme controlElectric testing/monitoringComplete dataAviation

The present invention provides a method for the data interaction of aircraft whole avionics equipment. In order to collect complete data of the aircraft whole avionics equipment, a cable plug end connected to a flight parameter recording device is used as an interface of the data interaction, test equipment is connected, signals of a bus, a discrete amount, a switch quantity and the like are collected in real time, and at the same time, corresponding bus data can be inputted via a simulation stimulus function of the test equipment. Through an above data interaction mode, the purpose of closed-loop online detection is achieved. The collected data of original aircraft avionics equipment does not need to be transferred and processed, and the integrity and reliability of the data are ensured.

Owner:XIAN AIRCRAFT IND GROUP

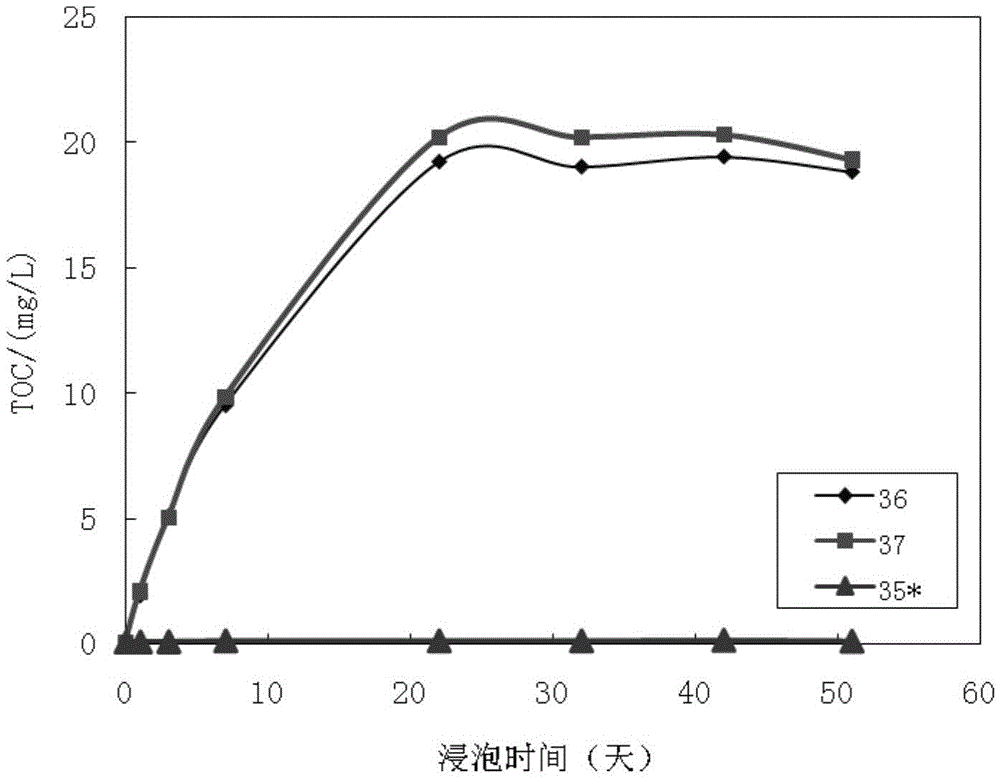

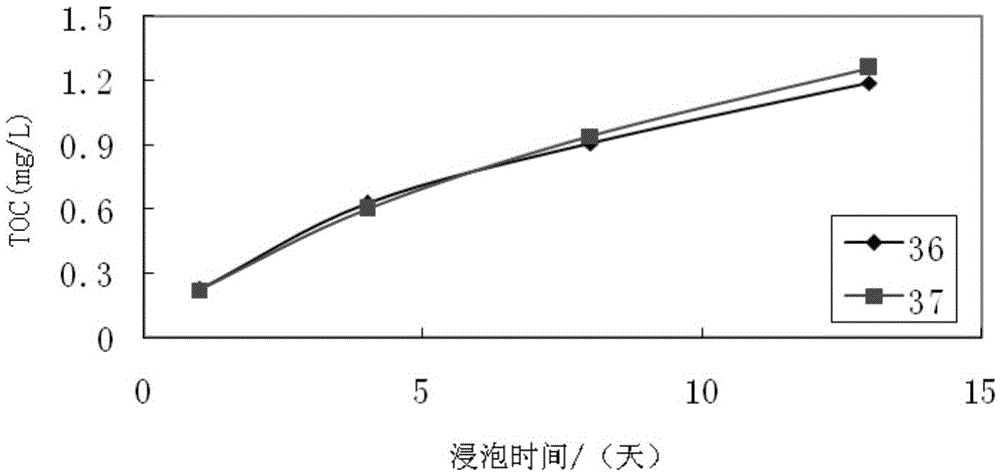

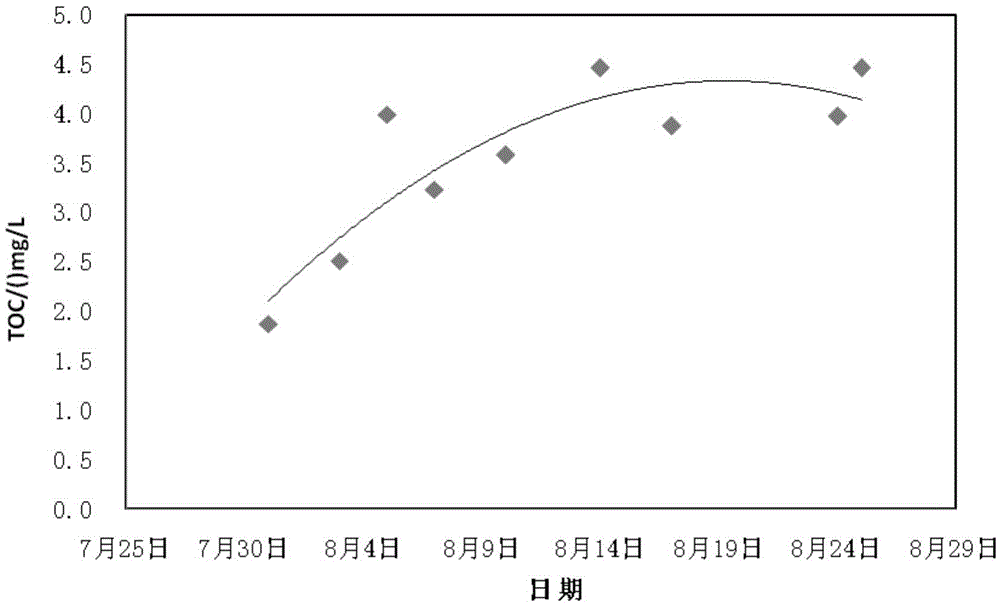

Water tank antirot material dissolvent characteristic detection test method

InactiveCN105628562AGuaranteed reliabilityGuaranteed accuracySurface/boundary effectSolventTotal organic carbon

The invention provides a water tank antirot material dissolvent characteristic detection test method, comprising the following steps: sample pretreatment: taking an antirot coating sample, weighing, and obtaining the size; initial dissolvent: soaking the sample in test water, sampling at a soaking time interval of 1 to 3 days in the first 15 soaking days, then sampling for 3 to 5 times at an interval of 3 to 5 days, and then sampling at an interval of 10 to 15 days, and detecting concentration of dissolved total organic carbon each time; deep dissolvent: talking out a test block, soaking in the test water again, taking a soak solvent at an interval of 1 to 3 days in the first 15 soaking days for detection, then sampling for 3 to 5 times at an interval of 3 to 5 days, detecting concentration Cs of dissolved total organic carbon each time, and when the soak solvent is taken for the last time, detecting other ion concentrations; data processing: performing analytical processing on a detection result of a dissolved matter, and respectively calculating dissolvent rates of total organic carbon of the test block in the initial dissolvent stage and the deep dissolvent stage, thus obtaining water tank antirot material dissolvent characteristics.

Owner:NORTH CHINA ELECTRICAL POWER RES INST +1

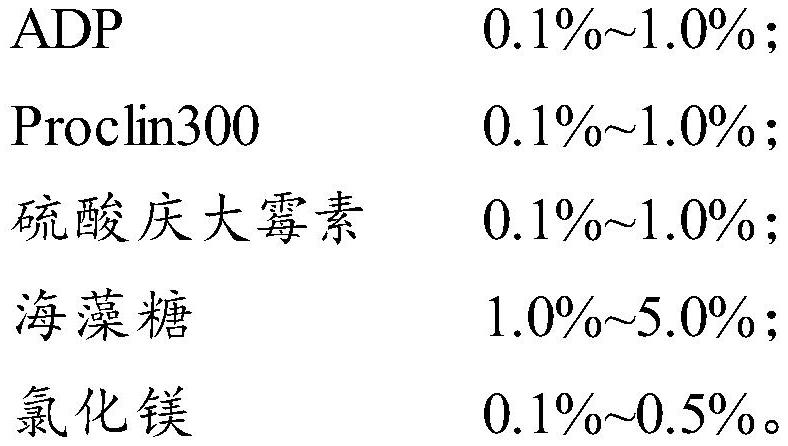

Stable NSE quality control product and preparation method thereof

PendingCN112595848ADecrease speed of descentGood stabilityBiological material analysisBlood serumAntigenic protein

The invention relates to the technical field of biology, in particular to a stable NSE quality control product and a preparation method thereof. The NSE quality control product provided by the invention is prepared from an NSE antigen, a protein protective agent, a preservative, an antibiotic, a freeze-drying protective agent, magnesium ions and human serum. The product can effectively weaken thedescending speed of a tumor marker NSE in a matrix liquid, has good product uniformity, long-term storage stability and stability after redissolution, is not influenced by transportation, temperatureand other factors, has long stabilization time in the detection process after redissolution, has detection repeatability and high accuracy, and can be suitable for the quantitative detection of different instrument models and different reagents. The product can be used for detecting by operators in different regions and different laboratories, can be suitable for quantitative detection kits of different brands, can meet the clinical quality control requirement on the tumor marker NSE, and can more accurately detect the accuracy of a clinical sample detection result.

Owner:郑州标源生物科技有限公司

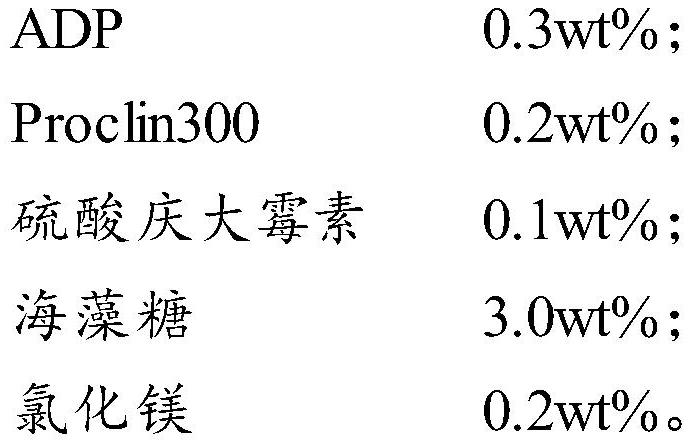

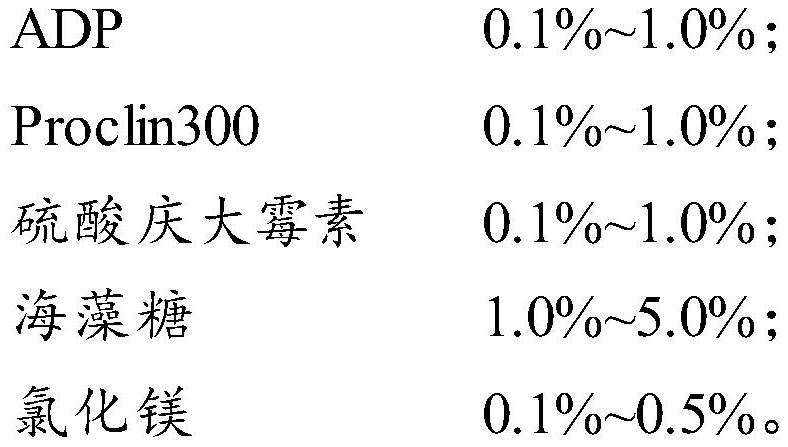

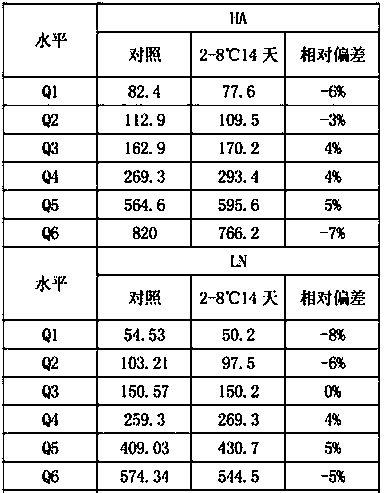

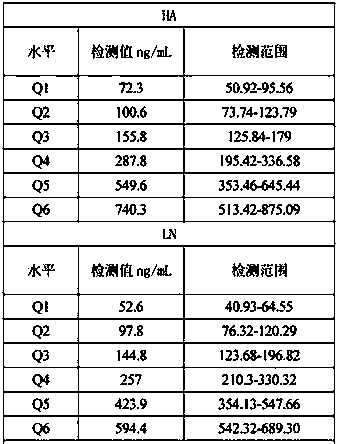

Liver fibrosis marker control material and preparation method thereof

InactiveCN109443876AImprove uniformityImprove stabilityChemiluminescene/bioluminescencePreparing sample for investigationMedicineDiluent

The invention discloses a liver fibrosis marker control material. The liver fibrosis marker control material is a lyophilized product prepared from matrix diluent, hyaluronic acid (HA), laminin (LN),type III procollagen (PIIINP), type IV collagen (Col IV) and glycocholic acid (CG). The control material prepared by the invention has the advantages of good uniformity and stability, free from influence of transportation, temperature and the like, suitability for quantitative detection of different instrument models and different reagents, as well as detection operation of different laboratory personnel in different regions. After the control material is redissolved, the detection process has a longer stable time, detection repeatability and high accuracy are realised; the quality control requirements of clinical detection of a liver fibrosis marker can be met and further the accuracy of clinical sample test results can be detected more accurately.

Owner:AUTOBIO DIAGNOSTICS CO LTD

Kaolin reagent quality control product and preparation method and application thereof

ActiveCN109541242AMeet quality control requirementsIncreased sensitivityPreparing sample for investigationBiological testingQuality controlBlood plasma

The invention discloses a kaolin reagent quality control product. The quality control product is lyophilized formulation, and the raw material of the lyophilized formulation includes platelet-deficient animal plasma. The R value of the quality control product is 6-8 min, the K value is 2-5 min, the Angle value is 60 DEG-80 DEG, and the MA value is 23-45 mm. The kaolin reagent quality control product is sensitive to the kaolin reagent reaction, so the accuracy of the quality detection is high, and the quality control requirements for the kaolin preparation in thromboelastography test are met. The quality control product has good reconstitution stability and can be stored for a long time under low temperature. The quality control product uses animal plasma as raw material, thus reducing thecost of the quality control and improving the safety of the quality control operations. The invention also discloses a preparation method of a kaolin reagent quality control product, which can preparethe kaolin reagent quality control product with accurate detection results and high stability. The preparation method is stable and reliable, the preparation process is simple and easy to operate, and the preparation method is suitable for the production and application of kaolin reagent quality control products.

Owner:中科精瓒(武汉)医疗技术有限公司

A device and method for desulfurization and refining of liquefied gas in an oil refinery

The invention relates to a liquefied gas desulfurization refining device in an oil refinery. The device comprises a buffer tank, an extraction tower, an MDEA (methyldiethanolamine) solvent storage tank, an alkaline liquor storage tank, a water storage tank, a primary extraction settling tank, a secondary extraction settling tank and a tertiary extraction settling tank, wherein the outlet of the buffer tank is connected with the bottom inlet of the extraction tower; the top outlet of the extraction tower is connected to the primary extraction settling tank by virtue of a coalescer and a primary fiber membrane contactor; the MDEA solvent storage tank is respectively communicated with the upper outlet of the extraction tower and the primary fiber membrane contactor; a top outlet of the primary extraction settling tank is connected to the secondary extraction settling tank by virtue of a secondary fiber membrane contactor; the top outlet of the secondary extraction settling tank is connected to the tertiary extraction settling tank by virtue of a tertiary fiber membrane contactor; the alkaline liquor storage tank is respectively communicated with the secondary fiber membrane contactor and the tertiary fiber membrane contactor; the water storage tank is communicated with the tertiary fiber membrane contactor. According to the device, when the liquefied gas is subjected to desulfurization refining, the desulfurization effect is good, the consumption of the solvent and alkaline liquor is low, and the cost is greatly saved.

Owner:CHINA PETROLEUM & CHEM CORP

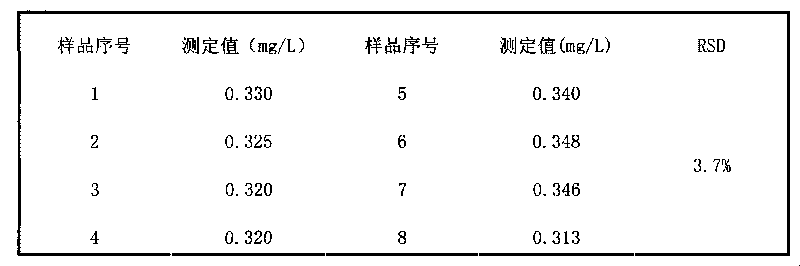

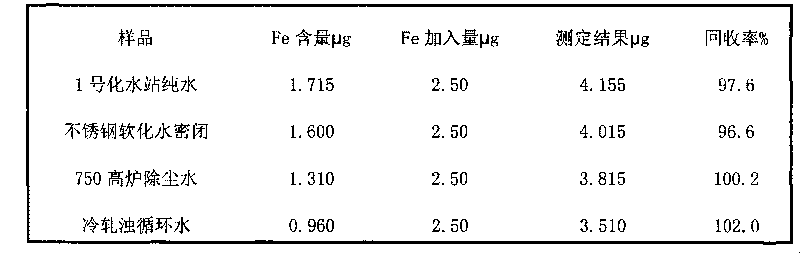

Method for digesting total iron in water sample

InactiveCN101726434AMeet quality control requirementsPromote digestionPreparing sample for investigationAnalysis by thermal excitationDigestionWater sample

The invention relates to monitoring and analysis of a water body, in particular to a method for digesting total iron in a water body. The method comprises the following steps of: 1, adding the water sample to a sealed, pressure resistant and temperature resistant container, and adding nitric acid to obtain a standard water sample; 2, heating the standard water sample, obtained by the step 1, at temperature of between 130 and 150 DEG C for digestion, wherein the digested standard water sample is at a sub-boiling state until the standard water sample is completely clear; and 3, standing and cooling the standard water sample, obtained by the step 2, and measuring supernatant by a plasma emission spectrometer.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

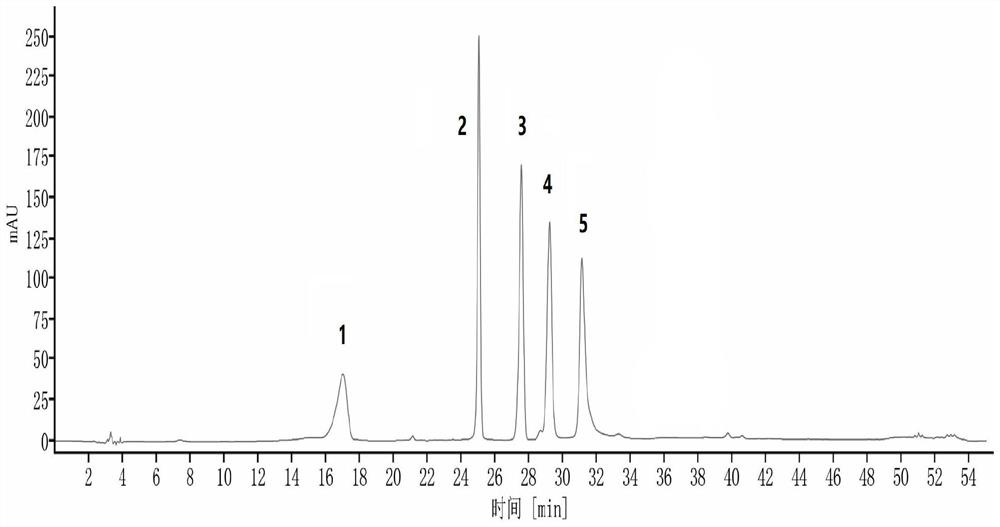

Detection method of rose polyphenol

ActiveCN113484434AMeet quality control requirementsComponent separationAgainst vector-borne diseasesPolyphenolBiology

The invention discloses a detection method of rose polyphenols. The method comprises the following steps that: a high performance liquid chromatography and an ultraviolet detector are selected to carry out characteristic spectrum analysis on rose polyphenol by using five index components, namely cyanidin-3-O-glucoside, quercetin-3-O-beta-D-sophoroside, kaempferol-3-O-beta-D-sophoroside, ellagic acid, kaempferol-3-O-(6 ''-galloyl)-beta-D-glucoside and the like; and the total content of the rose polyphenols in the ellagic acid, quercetin and kaempferol is quantitatively analyzed by adopting a sample acid hydrolysis treatment method. Based on characteristic index components in roses, a qualitative and quantitative analysis method for specificity of the roses is established, and the method has the remarkable advantages of being easy and convenient to operate and use, easy to popularize and use and the like, and can be applied to quality analysis and control of the roses, extracts of the roses and other related products.

Owner:SUZHOU QIUSHI HERBAL HEALTH TECH CO LTD

Chloride content test rod and preparation method thereof

PendingCN109884043AAccelerateHigh precisionMaterial analysis by observing effect on chemical indicatorPaper sheetEngineering

The invention relates to a chloride content test rod and a production and manufacturing process thereof. The chloride content test rod comprises a plastic package shell, reaction test paper and a detection time indication strip; the plastic package shell is composed of transparent plastic; holes are formed in the bottom and the two sides of the plastic package shell; scales are marked on the plastic package shell in the longitudinal direction; a base material of the reaction test paper is raw wood pulp paper or a fiber material; silver chromate and silver nitrate are uniformly distributed on the surface of the reaction test paper and inside the reaction test paper; a base material of the time indication strip is a chemical fiber; the length of the time indication strip is matched with thewidth of the plastic package shell and does not exceed the edge of the plastic package shell; and copper sulfate powder is attached to the surface of the chemical fiber. The chloride content test rodhas the advantages that the operation is easy, the precision is high, the detection process consumes less time, the detection precision meets the requirements of concrete and mortar quality control, the chloride content test rod is suitable for large-scale production, and the like.

Owner:NANTONG ACADEMY OF BUILDING RES +2

Volatile organic compound detection quality control device and method

PendingCN112881610AChange flow rateAvoid condensationGas analyser construction detailsAir quality improvementMoisture condensationQuality control

The invention provides a volatile organic compound detection quality control device and method. The device comprises an outdoor gas tetrafluoride filter, an indoor gas tetrafluoride filter and an indoor and outdoor sample injection electromagnetic switching valve. The detection quality control operation of the volatile organic compounds is realized by periodically switching the sample gas channel, the zero gas channel and the standard gas channel; the environment temperature is monitored in real time, the heat preservation temperature of the sampling pipeline is adjusted at any time, what is guaranteed is that the detected outdoor gas is consistent with the detected environment temperature, and water vapor condensation caused by too high dew point is avoided; the situation of inaccurate detection data caused by retention loss of formaldehyde, formic acid and the like with relatively high viscosity in the detected volatile organic compound in the pipeline can be reduced; sampling environment conditions are judged in real time, indoor and outdoor sampling channels are switched in time, and invalid sampling and sampling hidden dangers can be avoided; meanwhile, the variable adjustment of the drainage flow is more suitable for being applied to different sites; and by monitoring the pressure of the sampling pipeline, the smoothness of the sampling channel is effectively ensured, and the quality control requirement is met.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

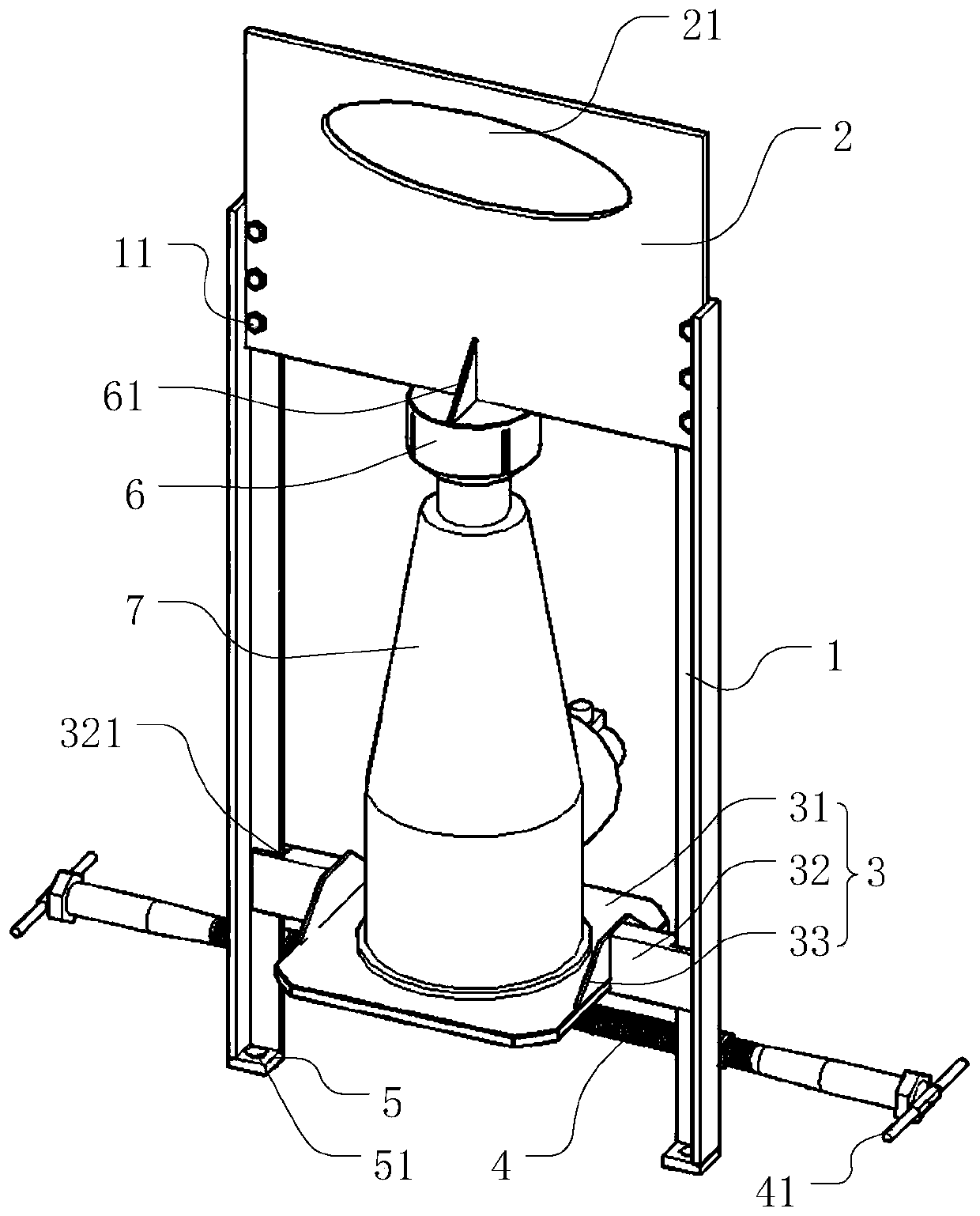

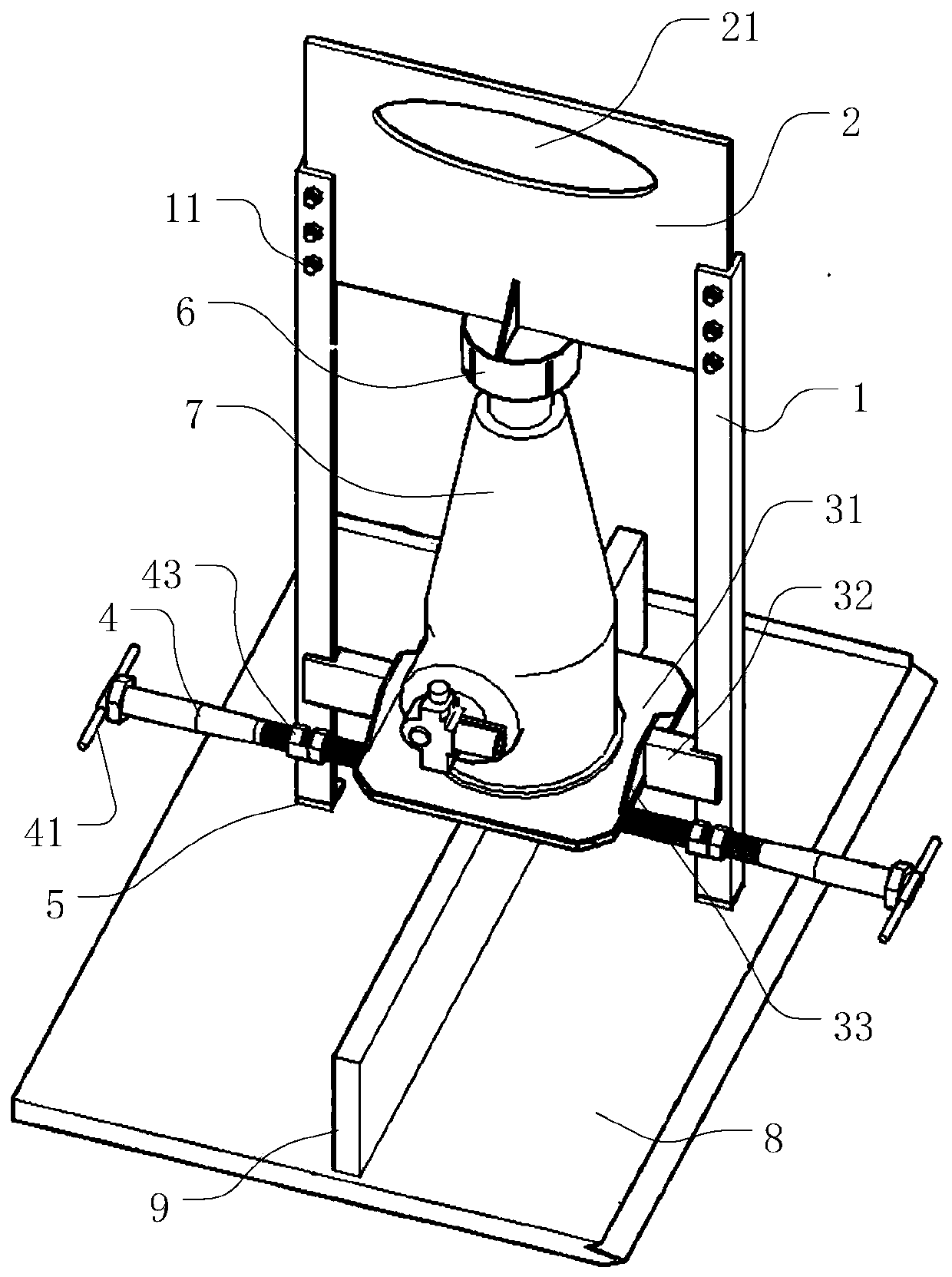

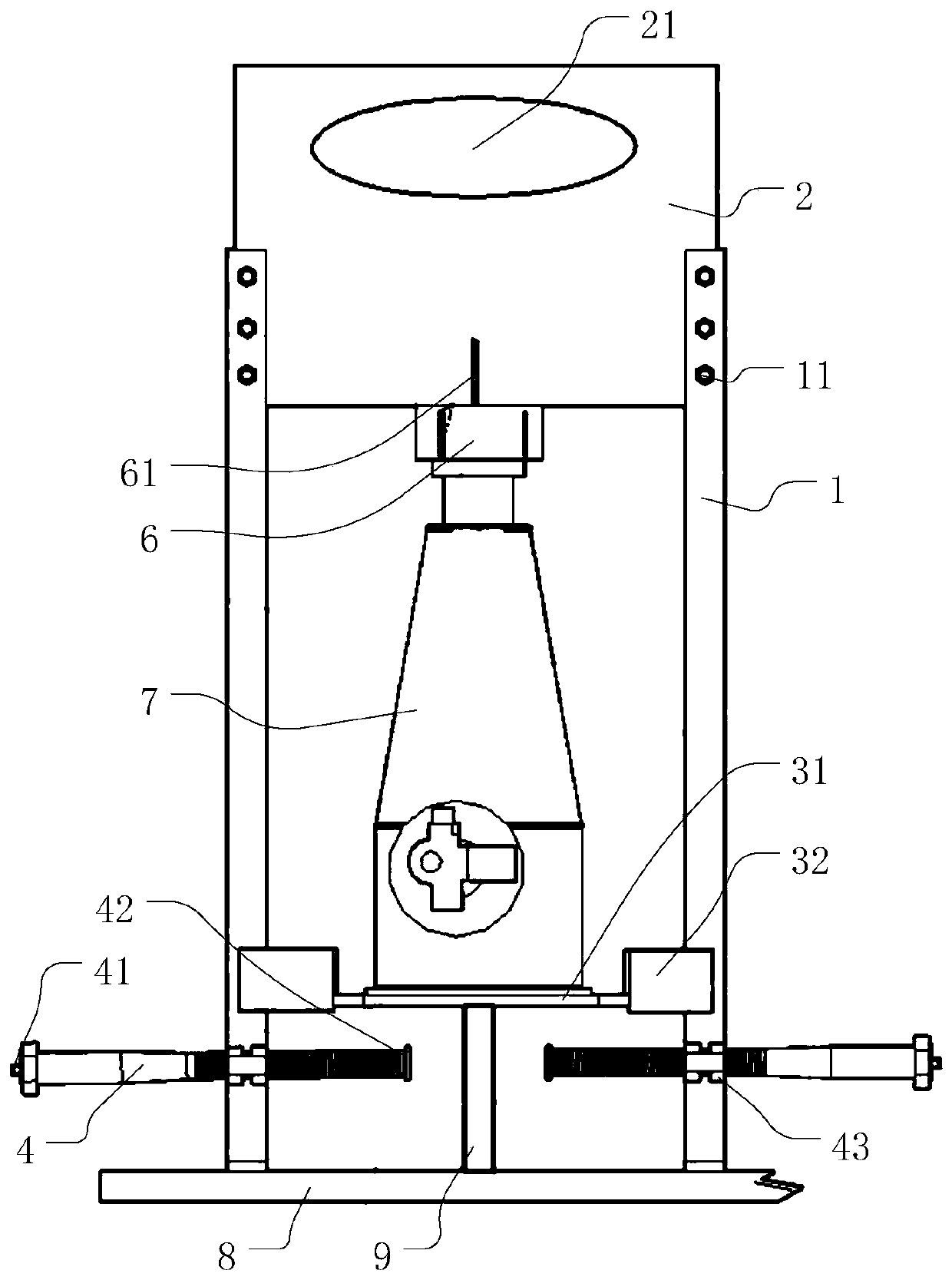

Tightening device used for joint between steel plates during steel structure welding

PendingCN110202298AAvoid more serious problems with deformationGuaranteed flatnessWelding/cutting auxillary devicesAuxillary welding devicesSheet steelArchitectural engineering

The invention relates to a tightening device used for a joint between steel plates during steel structure welding. The tightening device comprises a door-shaped frame, a tray rack, a lifting jack anda rib plate perpendicularity regulating mechanism, wherein two fixed supporting legs of the door-shaped frame are fixedly connected to steel plates; the tray rack is in sliding connection on two fixedsupporting legs of the door-shaped frame in a vertical direction; the lifting jack is placed between the tray rack and a limiting top plate of the door-shaped frame; the lifting jack jacks the tray rack to generate downward acting force, so that the tray rack can press a rib plate which needs to be perpendicularly welded with the steel plates; and the rib plate perpendicularity regulating mechanism is arranged on the two fixed supporting legs for clamping the rib plate and regulating perpendicularity of the rib plate. The tightening device used for the joint between steel plates during steelplate welding can realize effective fitting between the steel plates and the rib plate, tightens the joint between the rib plate and the steel plates, avoids uneven welding seams, and meets quality requirements in a construction process.

Owner:CHINA MCC 2 GRP CO LTD

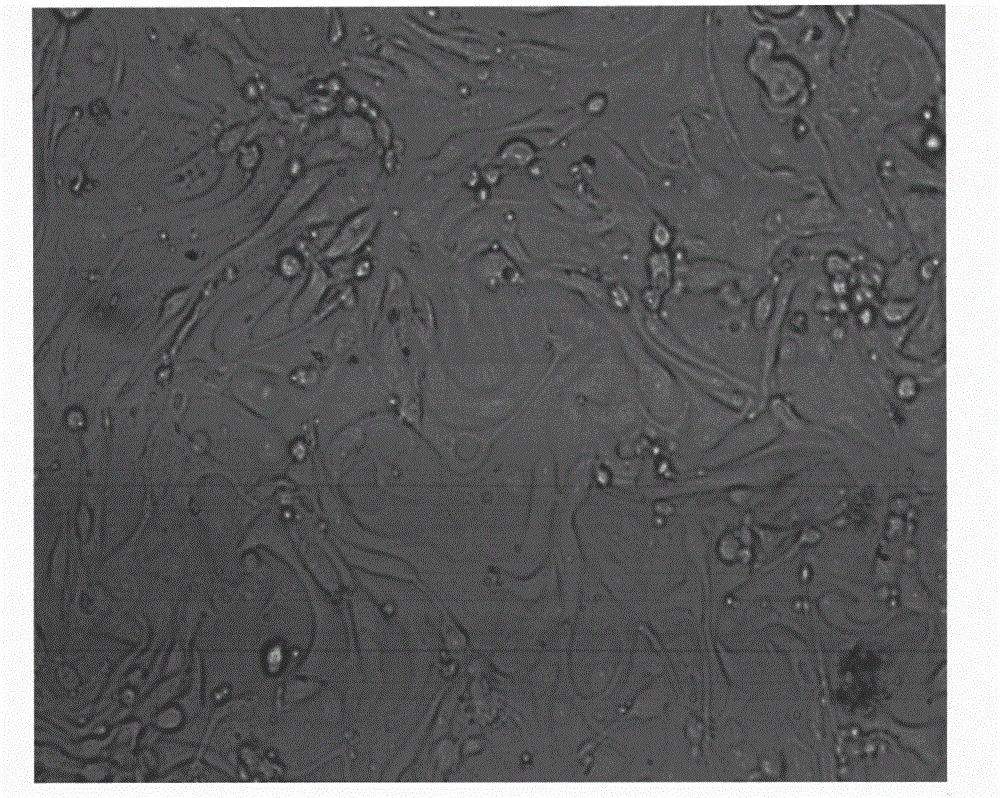

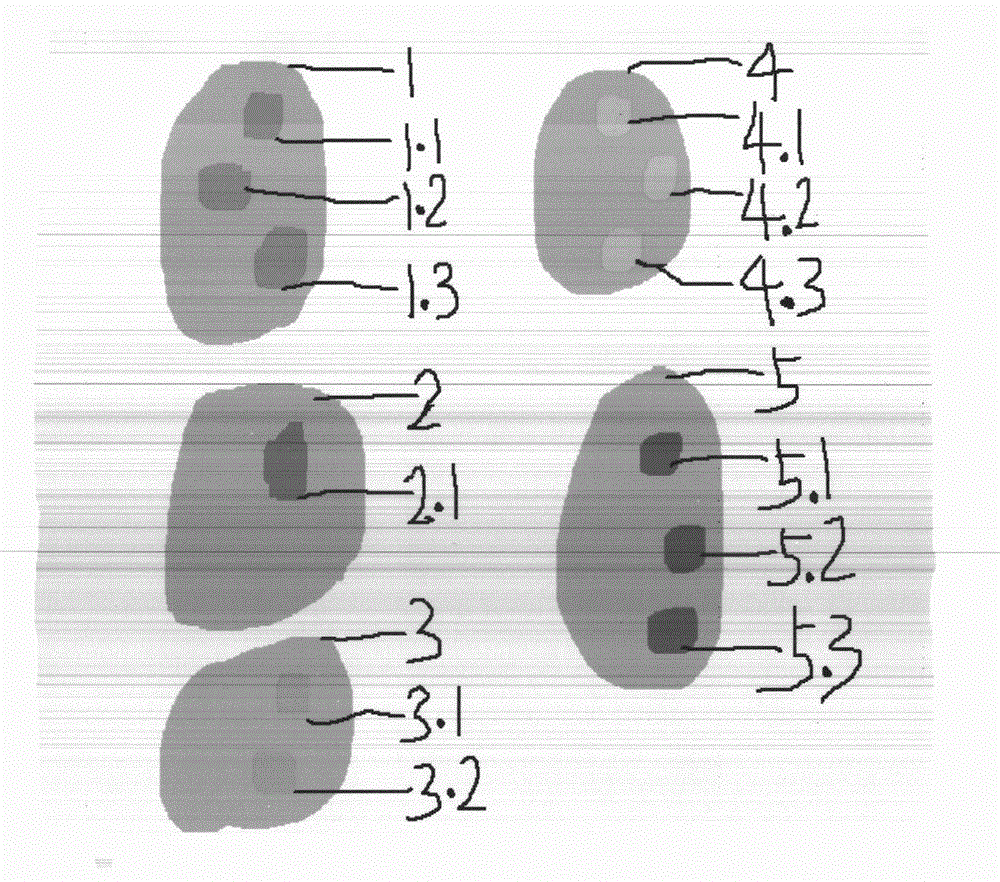

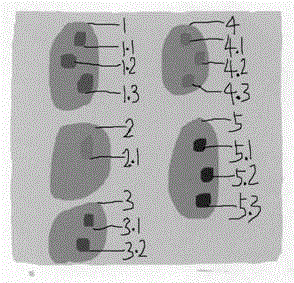

Diagnosis quality-control cell strain for common numerical abnormalities of chromosomes and preparation method thereof

InactiveCN104059883ALive foreverMeet quality control requirementsMicrobiological testing/measurementVector-based foreign material introductionControl cellDifferential diagnosis

The invention relates to a diagnosis quality-control cell strain for common numerical abnormalities of chromosomes and a preparation method thereof. The invention is mainly characterized in that the preparation method comprises: taking residual attached living cells which are used for chromosomal disease diagnosis as needed by clinical diagnosis and treatment and are definitely diagnosed to have 21-trisomy, 18-trisomy, 13-trisomy, X or Y chromosome abnormalities, introducing, through transgenosis, SV40LTag-pcDNA3.1(-) plasmid constructed by SV40LTag DNA and pcDNA3.1(-) connected by T4DNA ligase and digested by BamHI, allowing the plasmid to integrate with the cell DNA, screening cell strains integrated with recons by G418, performing subculture amplification and cryopreservation, then extracting the cell strains with numerical abnormalities of chromosomes, mixing the cell strains according to a required ratio for quality control so as to convert each original cell strain with a single numerical abnormality of chromosomes into a chimera quality-control cell strain with a certain ratio of five numerical abnormalities of chromosomes. Therefore, the difficulty for differential diagnosis and chimera diagnosis is increased; the cell strain is used as a quality-control cell strain for diagnosis of common numerical abnormalities of chromosomes; samples are easily available; and waste residual cells are converted into effective immortalized quality-control cells.

Owner:翁炳焕

hTERT and SV40 transduced quality-control cell for molecular genetics diagnosis and preparation method thereof

InactiveCN104059885ALive foreverMeet quality control requirementsForeign genetic material cellsSimian Vacuolating Virus 40Liposome

The invention relates to an hTERT and SV40 transduced quality-control cell for molecular genetics diagnosis and a preparation method thereof. The invention is mainly characterized in that the preparation method comprises: connecting recons of SV40LTag-pcDNA3.1(-) and pLXSNneo-hTERT by T4DNA, introducing tissue cells with common numerical abnormalities of chromosomes by liposome, screening cells integrated with the recons by G418, performing subculture amplification and cryopreservation, mixing the cells according to a required ratio for quality control when in use so as to convert each original cell with only one type of numerical abnormalities of chromosomes into a chimera quality-control cell with a certain ratio of 2-5 types of numerical abnormalities of chromosomes. Therefore, the difficulty for differential diagnosis and chimera diagnosis is increased; the original cells are easily available; waste residual cells are converted into effective immortalized quality-control cells; difficult quality-control cells are used for external quality assessment and internal quality control; and the quality-control cell of the invention has important significance on in-time discovery and solution of quality problems, and diagnostic level improvement.

Owner:翁炳焕

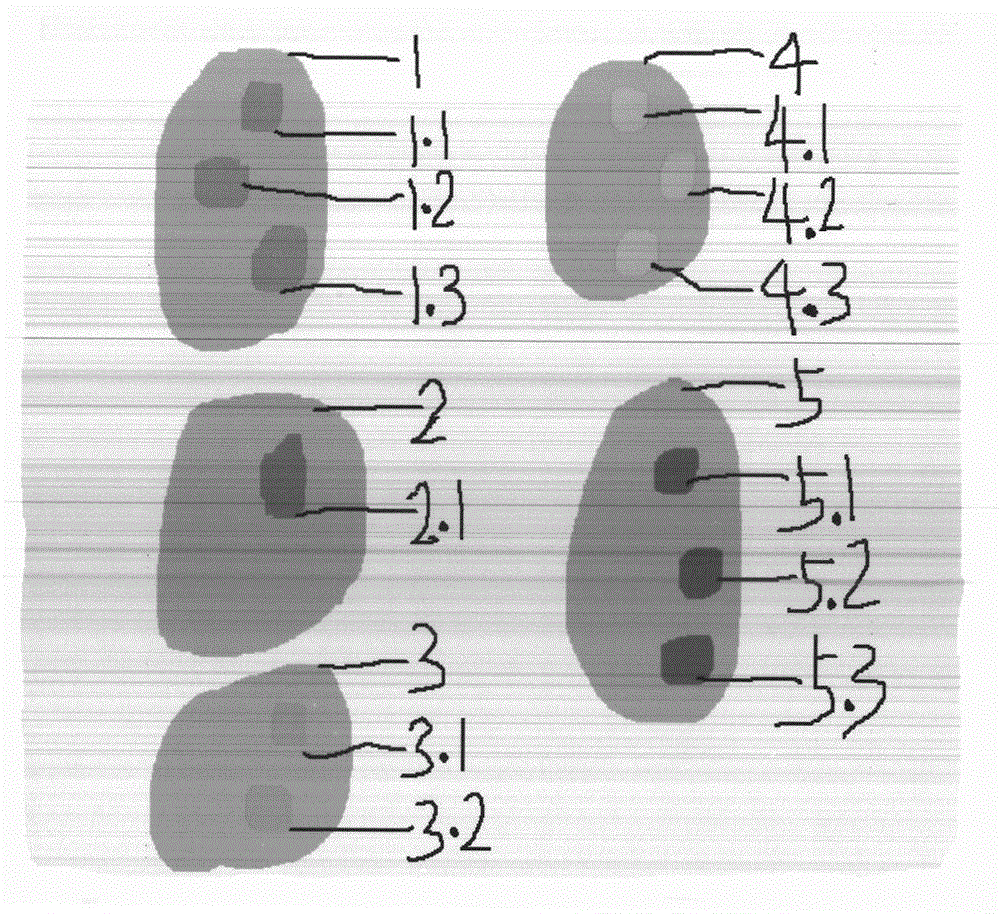

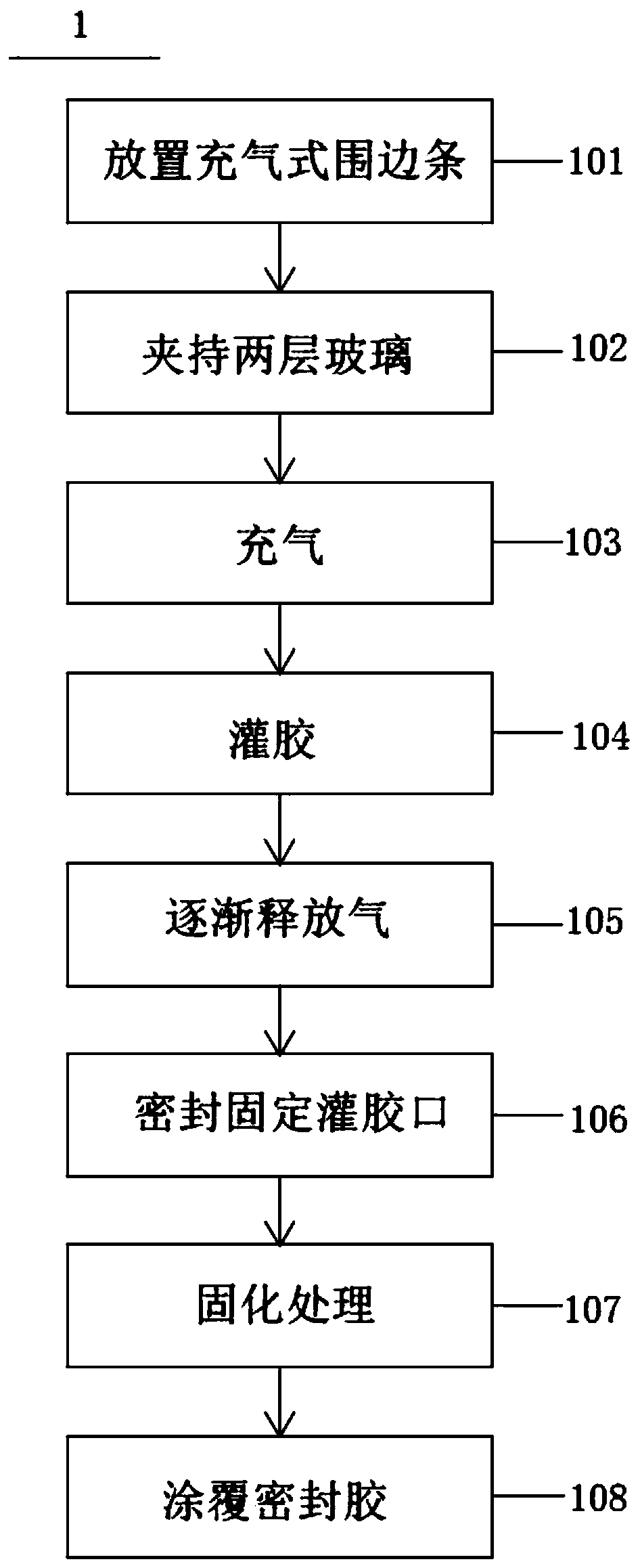

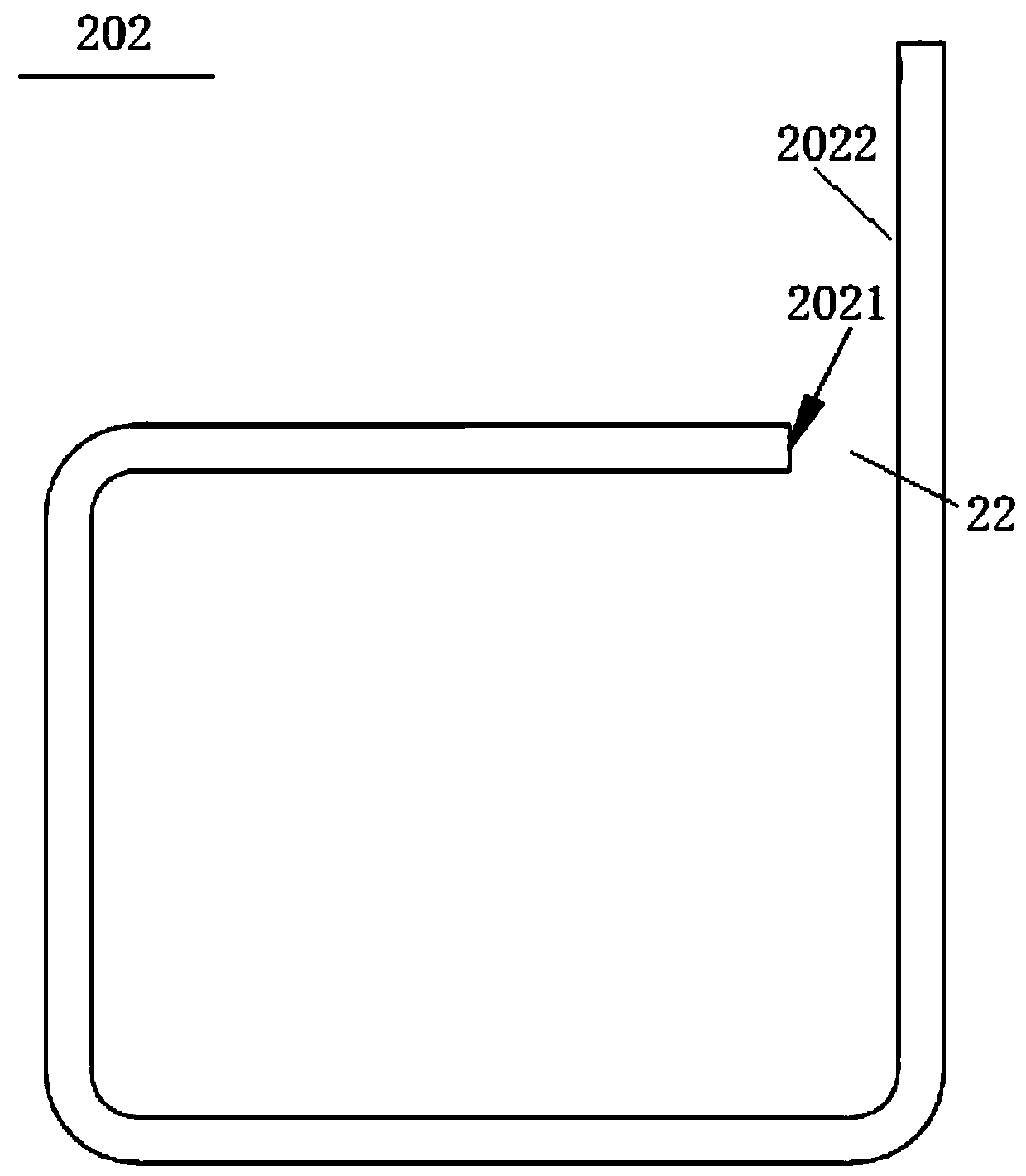

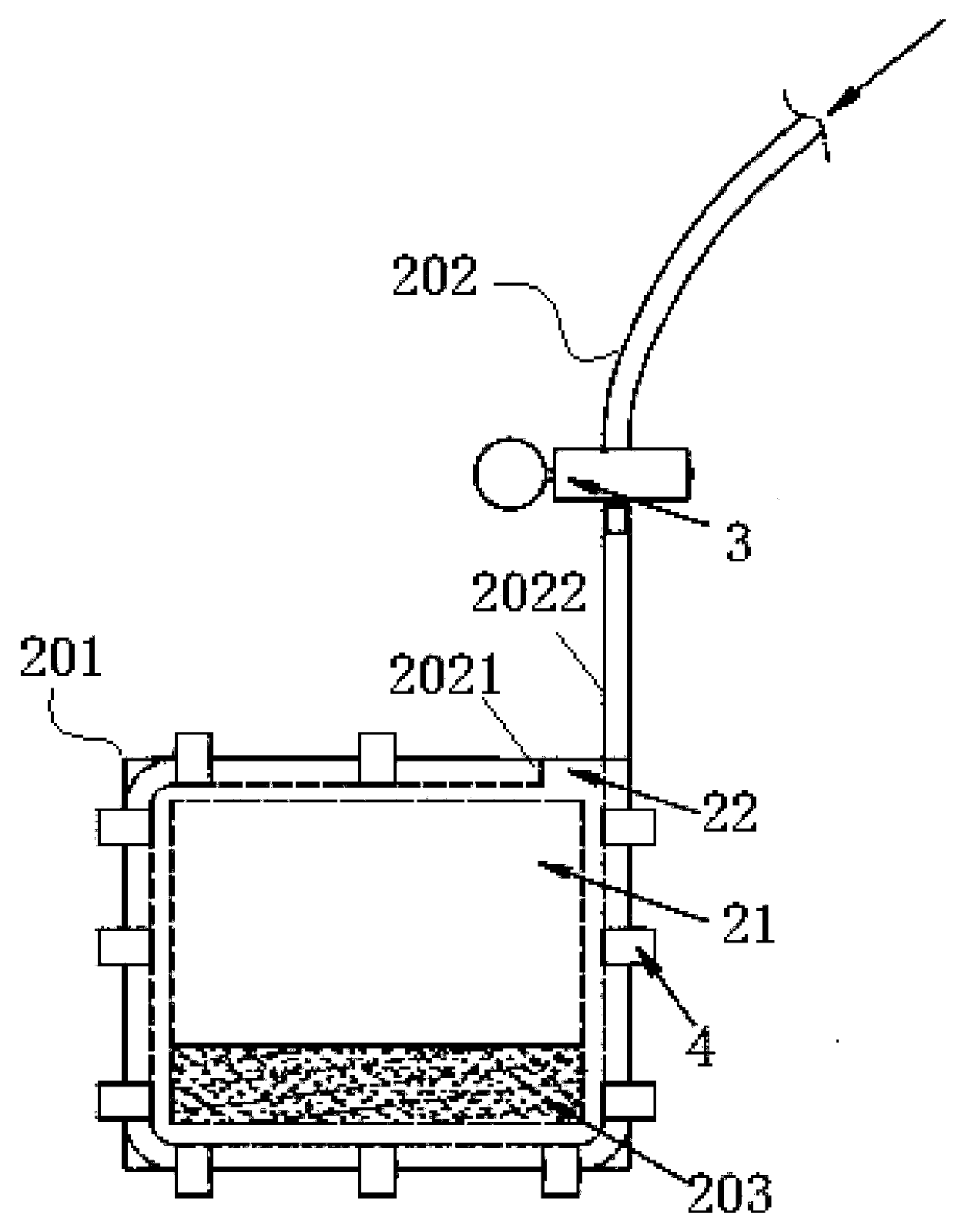

Wet-process laminated glass using inflatable surrounding edge strip and preparation method of wet-process laminated glass

PendingCN111361239AIncrease productivityMeet quality control requirementsLamination ancillary operationsLaminationBatch productionManufacturing engineering

The invention relates to wet-process laminated glass using an inflatable surrounding edge strip and a preparation method thereof. The preparation method of the wet-process laminated glass comprises the following steps: embedding the inflatable surrounding edge strip between two layers of glass to form a cavity gap between the two layers of glass; clamping the peripheries of the two layers of glassto enable the two layers of glass to extrude the inflatable surrounding edge strip; inflating gas into the inflatable surrounding edge strip to enable the inflatable surrounding edge strip to expandthe two layers of glass; obliquely placing the glass, and pouring a glue solution into the cavity gap through a glue pouring port; gradually releasing gas in the inflatable surrounding edge strip so as to gradually reduce the cavity gap; after the cavity gap is reduced to a preset gap size, horizontally placing the glass, and after a visible area of the glass is filled with the glue solution, sealing and fixing the glue pouring port; and carrying out polymerization curing treatment on the glass. By improving the pouring process, production efficiency is improved, quality control requirements are met, operation is safe and easy, and the method is suitable for batch production and has important commercial value and practical significance.

Owner:JIANGSU IRON ANCHOR GLASS LTD BY SHARE LTD

Culture medium and method used for in-vitro large-scale amplification of NK cells

InactiveCN108660109ASolve the problem of preparation processIncreased anti-leukemia effectBlood/immune system cellsCell culture active agentsNatural Killer Cell Inhibitory ReceptorsHuman albumin

The invention relates to a culture medium and a method used for in-vitro large-scale amplification of NK cells. By volume percent, the culture medium comprises 100% of a lymphocyte serum-completely-free culture medium or a mixture including 1-95 % of DMEM / F12 culture medium and 5-99 % of the lymphocyte serum-completely-free medium, and human albumin and interleukin 2, wherein the concentration ofthe albumin is 0.1-2 g / L, and the concentration of the interleukin 2 is 100-600 [mu] g / mL. With the culture medium and the preparation method provided by the invention, the rapid large-scale amplification within a short period of the NK cells can be realized, the cost is low, and the amplification has very high lethality.

Owner:上海韵飞生物科技有限公司

Fluorescence in situ hybridization hTERT transfected external quality assessment cell line and preparation method thereof

InactiveCN104059882ALive foreverMeet quality control requirementsMicrobiological testing/measurementVector-based foreign material introductionFluorescenceDigestion

The invention relates to a fluorescence in situ hybridization hTERT transfected external quality assessment cell line for diagnosis quality control in medical genetics, and a preparation method thereof. The invention is mainly characterized in that the preparation method comprises: performing double digestion of plasmid pCIneo-hTERT and a carrier pLXSNneo by endonucleases of EcoR I and Xho I, connecting the digestion products of hTERT and pLXSNneo by Ligation Mix, constructing a pLXSNneo-hTERT recon, transfecting, by liposome, residual adherent living cells which are in logarithmic growth and are definitely diagnosed to have common numerical abnormalities of chromosomes as needed by clinical diagnosis and treatment, screening cell lines integrated with the recons by G418, performing subculture amplification and cryopreservation, then taking the cell lines, mixing the cell lines according to a required ratio for quality control so as to convert each original cell line with only one numerical abnormality of chromosomes into a chimera quality-control cell line with a certain ratio of common numerical abnormalities of chromosomes. Therefore, the difficulty for differential diagnosis and chimera diagnosis is increased; original cells are easily available; waste residual cells are converted into effective immortalized quality-control cells; external quality assessment is carried out by the difficult quality-control cells; and the cell line of the invention has important significance on in-time discovery and solution of quality problems, and diagnostic level improvement.

Owner:翁炳焕

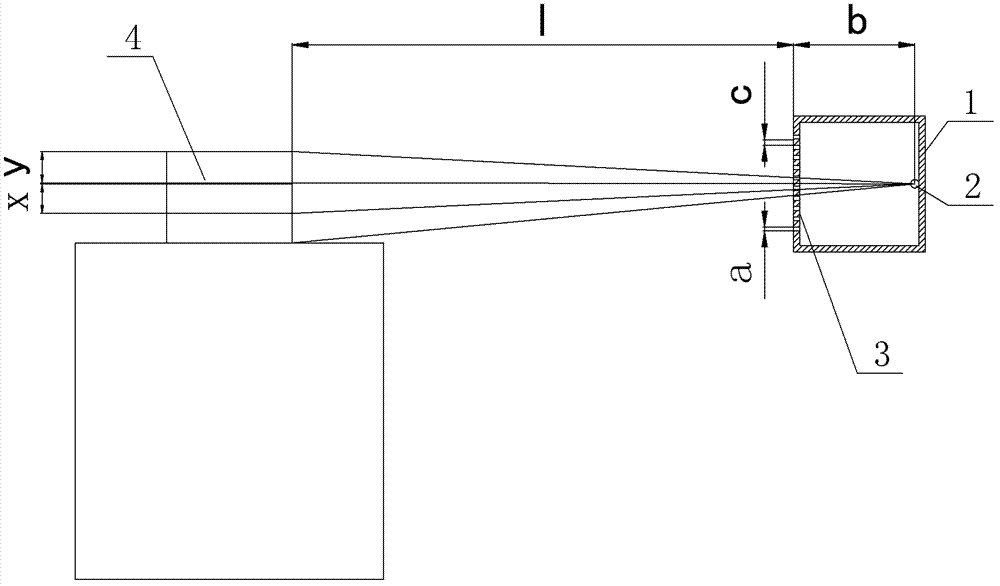

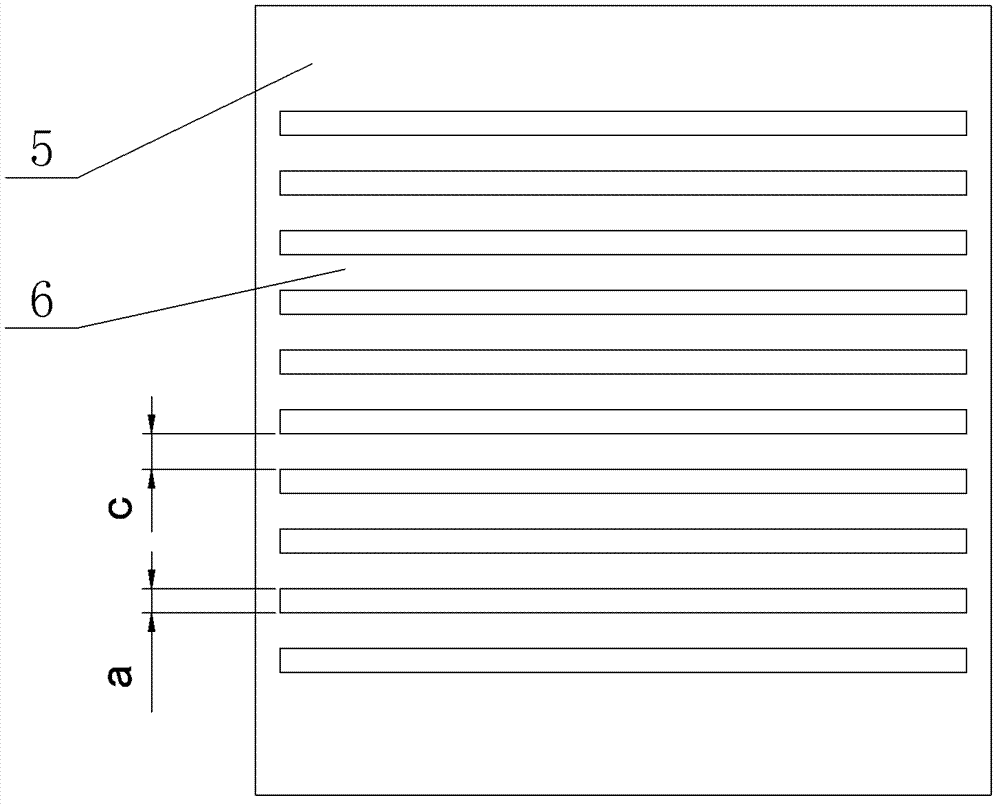

Non-contact hot rolled steel coil inner tower defect measuring method

ActiveCN102778462AReduce labor intensityReduce operational riskOptically investigating flaws/contaminationUsing optical meansMeasurement deviceEngineering

The invention relates to a non-contact hot rolled steel coil inner tower defect measuring method. By using measuring equipment for remote measuring of the length of a hot rolled steel coil inner tower, the method comprises: first setting a hollow box at a position of certain distance from the steel coil inner tower, with one box side facing the steel coil being a light-transmission plate and the other sides being lightproof, and disposing a light source on a box inner wall opposite to the light-transmission plate; and switching on a power supply, utilizing a triangle similarity principle to calculate the size of the inner tower. With the characteristics of simple measuring process and convenient operation, the invention has no need for close contact with a hot steel coil, thereby reducing the operation difficulty and providing guarantee for the work security of operation staff.

Owner:ANGANG STEEL CO LTD

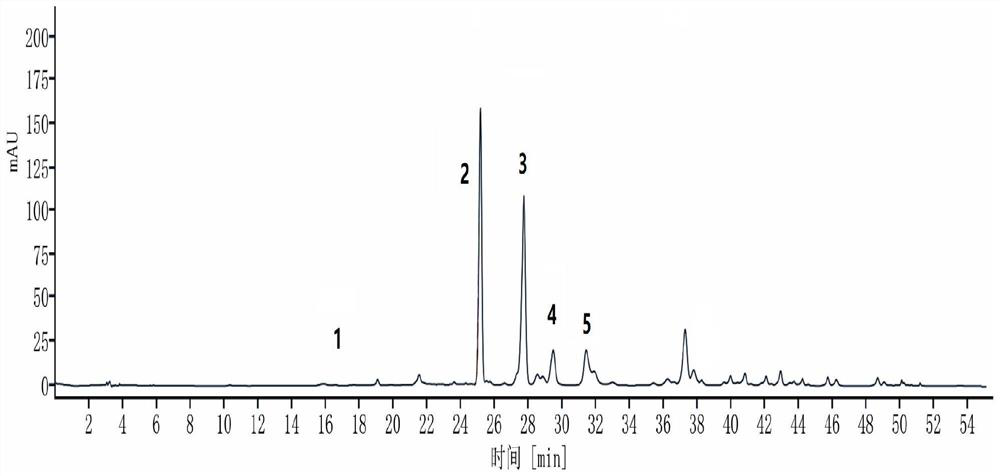

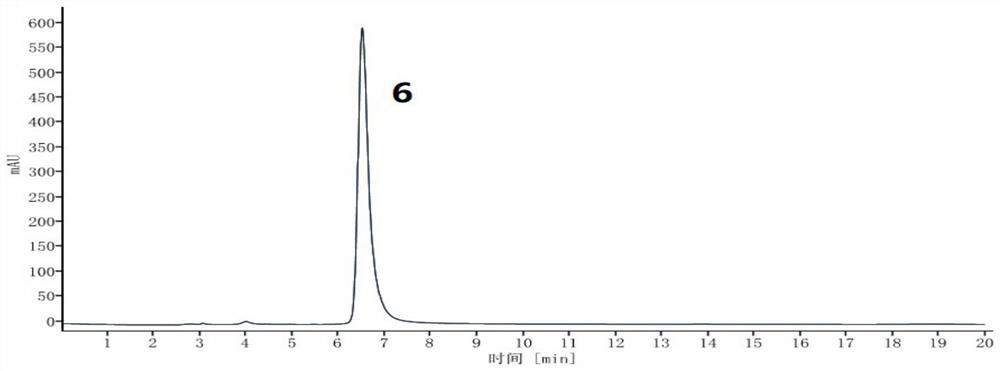

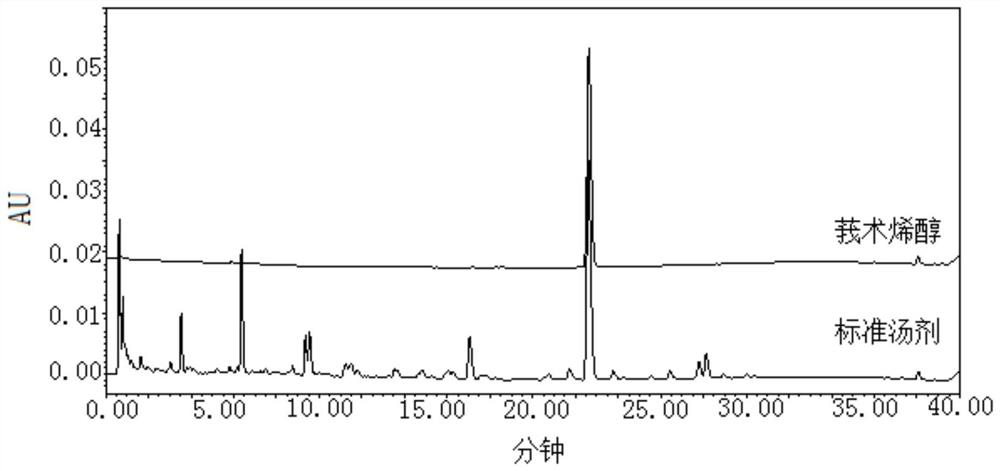

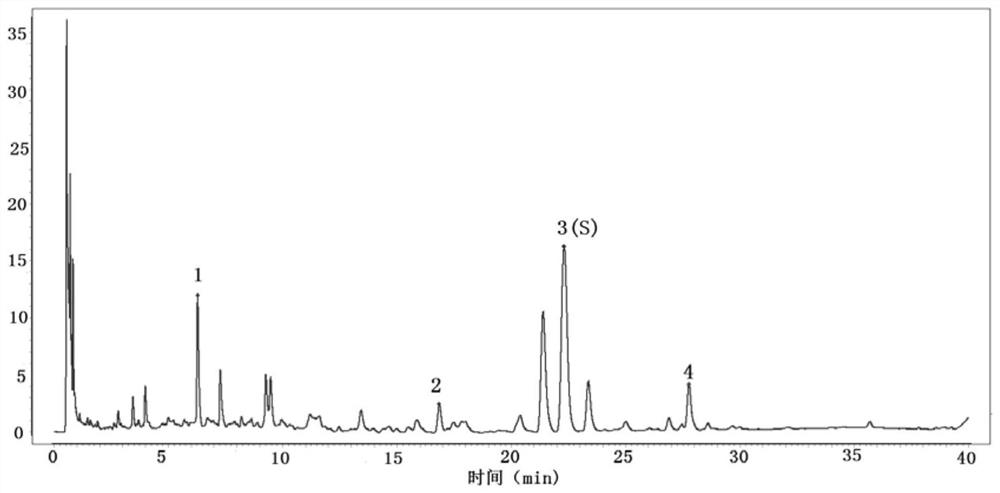

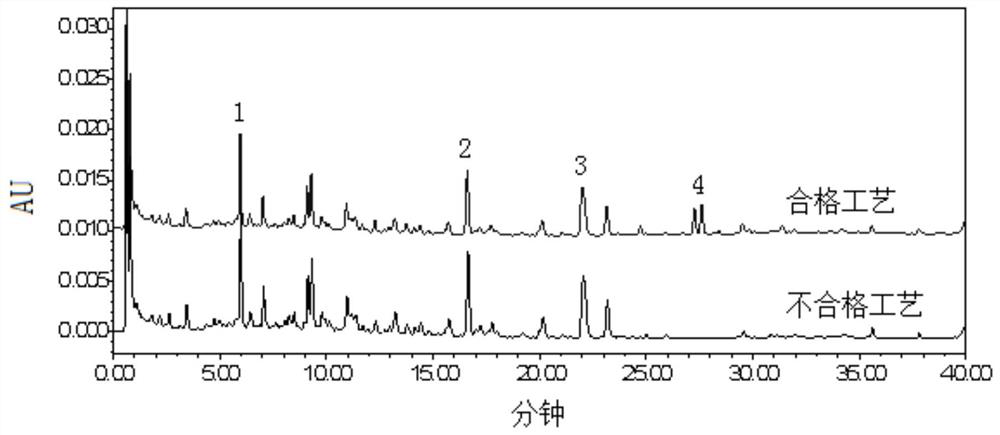

Quality control method of rhizoma wenyujin concisum formula granules

ActiveCN113759006ATo achieve the purpose of quality controlAccurate quality judgmentComponent separationFormularyFluid phase

The invention provides a quality control method of rhizoma wenyujin concisum formula granules, which comprises the following steps: obtaining a characteristic chromatogram of a test solution by adopting high performance liquid chromatography, calculating the relative retention time of each characteristic peak and the reference peak S by taking the chromatographic peak of curcumenol in the characteristic chromatogram as the reference peak S, wherein the relative retention time of at least three characteristic peaks is within + / -10% of specified values, and the specified values are 0.28, 0.76 and 1.25. The curcumenol which is relatively high in content and relatively stable is selected as a quality evaluation index component of the rhizoma wenyujin concisum formula granule, and the overall quality control of the rhizoma wenyujin concisum formula granule is realized in combination with common control of other quality evaluation index components; the method has the advantages that judgment is more accurate and objective, and clinical medication requirements are met.

Owner:BEIJING KANGRENTANG PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com