Chloride content test rod and preparation method thereof

A test rod and chloride technology, which is applied in the direction of chemical reaction of materials and material analysis by observing the influence of chemical indicators, can solve the problem that the operation level of testing equipment and testing personnel is relatively high, and it is difficult to promote and other problems, to achieve the effect of less time-consuming, simple and convenient operation, and fast speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A manufacturing process for a chloride content test rod, comprising the following steps:

[0030] a) Preparation of impregnating solution: fill the chemical reaction tank with a silver nitrate solution of 2.45% by mass, the length of the chemical reaction tank is not less than 1000mm, the width is not less than 500mm, and the stirring temperature of the chemical tank is 20±0.5°C;

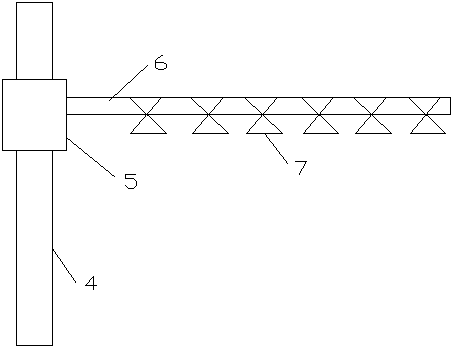

[0031] b) Preparation of spray treatment liquid: put potassium chromate solution with a mass percentage of 7.8% into the anti-corrosion solution tank of the automatic sprayer, and the flow rate of the automatic sprayer is set at 10mL / min-30mL / min;

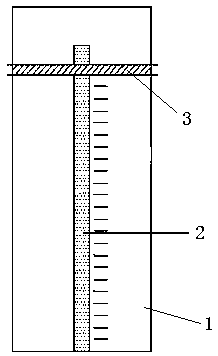

[0032] c), hanging: clip the entire reaction test paper 2 substrates on the wooden clips of the movable frame respectively;

[0033] d), impregnation: immerse the lower end of the base material of the reaction test paper 2 into the silver nitrate solution, and the silver nitrate solution rises to the entire reaction test paper 2 under capillary ac...

Embodiment 2

[0044] A manufacturing process for a chloride content test rod, comprising the following steps:

[0045]a) Preparation of impregnating solution: Fill a chemical reaction tank with a silver nitrate solution of 0.245% by mass, the length of the chemical reaction tank is not less than 1000mm, the width is not less than 500mm, and the stirring temperature of the chemical tank is 20±0.5°C;

[0046] b) Preparation of spray treatment liquid: put potassium chromate solution with a mass percentage of 0.78% into the anti-corrosion solution tank of the automatic sprayer, and the flow rate of the automatic sprayer is set at 10mL / min-30mL / min;

[0047] c), hanging: clip the entire reaction test paper substrate 2 on the wooden clips of the movable frame;

[0048] d), impregnation: immerse the lower end of the base material of the reaction test paper 2 into the silver nitrate solution, and the silver nitrate solution rises to the entire reaction test paper 2 under capillary action;

[0049]...

Embodiment 3

[0059] A manufacturing process for a chloride content test rod, comprising the following steps:

[0060] a) Preparation of impregnating solution: fill the chemical reaction tank with a silver nitrate solution of 15.0% by mass, the length of the chemical reaction tank is not less than 1000mm, the width is not less than 500mm, and the stirring temperature of the chemical tank is 20±0.5°C;

[0061] b) Preparation of spray treatment liquid: put potassium chromate solution with a mass percentage of 45.5% into the anti-corrosion solution tank of the automatic sprayer, and the flow rate of the automatic sprayer is set at 10mL / min-30mL / min;

[0062] c), hanging: clip the entire reaction test paper 2 substrates on the wooden clips of the movable frame respectively;

[0063] d), impregnation: immerse the lower end of the base material of the reaction test paper 2 into the silver nitrate solution, and the silver nitrate solution rises to the entire reaction test paper 2 under capillary a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com