Manufacture method for rock samples

A technology of rock sample and production method, which is applied in the field of test sample production, can solve problems such as troubles, and achieve fast results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

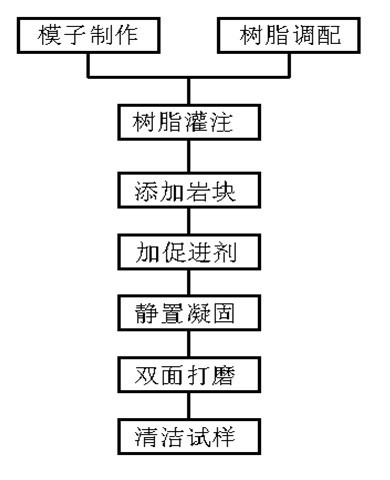

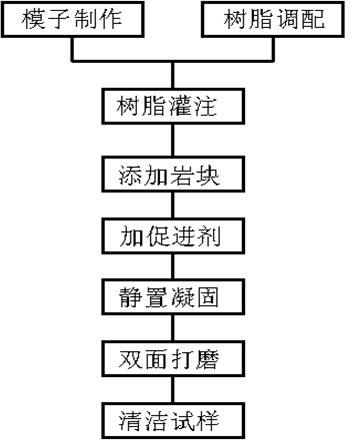

Method used

Image

Examples

Embodiment 1

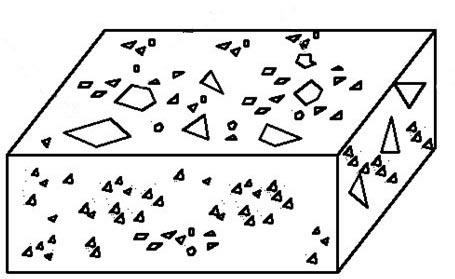

[0030] (1) Make a thin plexiglass plate into a cuboid mold with an upper opening. The size of the cuboid mold is L×W×H=40cm×40cm×15cm, which can be bonded with glue.

[0031] (2) Mix epoxy resin and amine curing agent in a certain proportion to form a certain volume of fluid, pour it into the mold, and then immediately pour the irregular rock blocks into the mold.

[0032] (3) Stand for a period of time, waiting for the resin to fully solidify.

[0033] (4) After the resin is solidified, put the mold filled with resin on the grinder for grinding. When grinding, grind both sides of the mold at the same time, and when there are more rock smooth surfaces on the grinding surface, the grinding can be stopped.

[0034] (5) Wipe off the debris on the grinding surface so that the surface of the rock can be clearly seen, so that the sample is completed.

Embodiment 2

[0036] (1) Make a thin plexiglass plate into a cylindrical mold with an upper opening. The size of the cylindrical mold is R×H=20cm×15cm, which can be bonded with glue.

[0037] (2) Mix epoxy resin and amine curing agent in a certain proportion to form a certain volume of fluid, pour it into the mold, and then immediately pour the irregular rock blocks into the mold.

[0038] (3) Stand for a period of time, waiting for the resin to fully solidify.

[0039] (4) After the resin is solidified, put the mold filled with resin on the grinder for grinding. When grinding, grind both sides of the mold at the same time, and when there are more rock smooth surfaces on the grinding surface, the grinding can be stopped.

[0040] (5) Wipe off the debris on the grinding surface so that the surface of the rock can be clearly seen, so that the sample is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com