Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

84 results about "Chloride levels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nitrile rubbers

ActiveUS20080293889A1Easy to processEnhance the imageGroup 4/14 element organic compoundsConductive materialNitrile rubberPhotochemistry

An improved polymerization and work-up process makes it possible to produce specific nitrile rubbers which have a specific calcium and chloride content and have a particularly high storage stability.

Owner:ARLANXEO DEUT GMBH

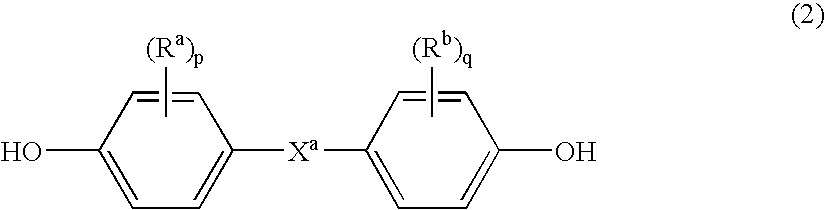

9, 10- dihydro-9- oxa -10- phosphine hetero- phenanthrene -10- oxide compound and its derivant and method of preparing the same

InactiveCN101108864ALight colorHigh yieldGroup 5/15 element organic compoundsGlycol synthesisPhosphorus trichloride

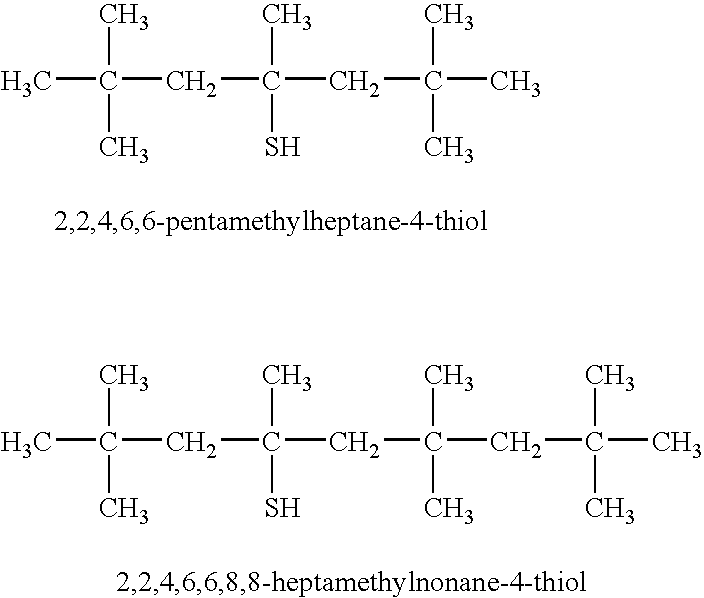

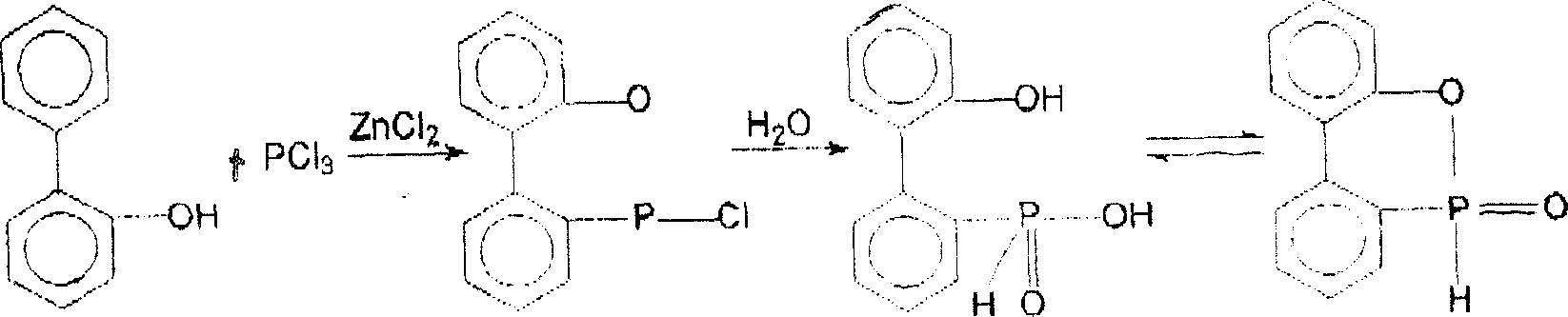

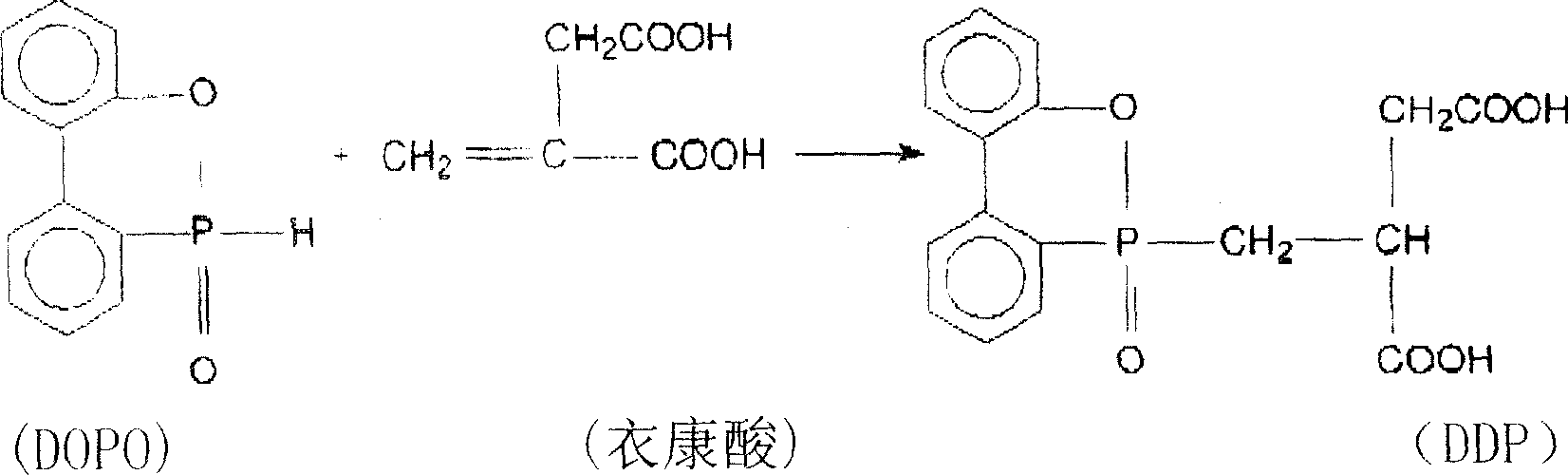

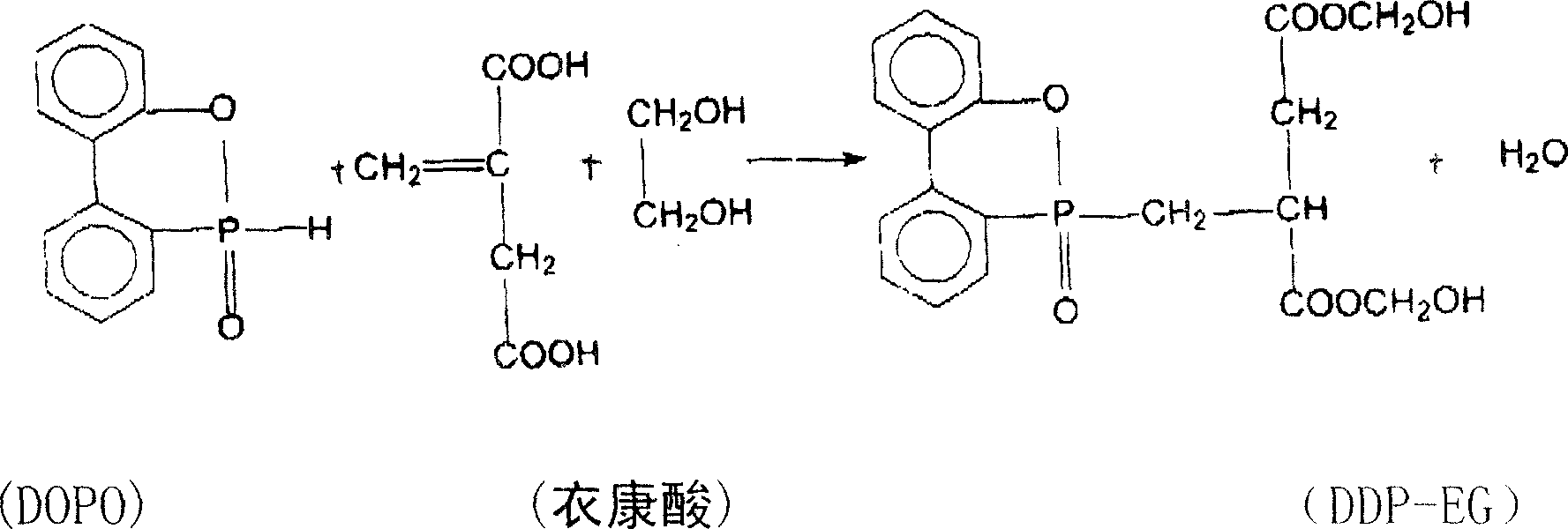

The invention discloses a preparation method of the 9, 10-dihydro-9-oxa-10-phosphahenanthrene-10-oxide and the derivatives DDP, DDP-EG and DOPO-BQ. The invention has three steps to synthesize the DOPO: (1) preparation of CDOP, the O-phenylphenol (OPP) reacts with the Phosphorus trichloride (PCl3) with ZnCl2 as the catalyst. (2) purification of CDOP, vacuum distillation is carried out. (3) DOPO with high purity and yield is gained through the hydrolysis and crystallization. The preparation materials comprises the O-phenylphenol, the Phosphorus trichloride, the toluene, the alcohol, the deionized water, the itaconic acid, the ethylene glycol, the p-benzoquinone and the acetone. The invention simplifies the process conditions, improves the product purity with good production stability and repeatability. The purity of the product reaches over 99.0 per cent, the content of the chloride is below 50ppm, the OPP is about 0.01 per cent, the color is about 10 (10 per cent solution of acetone), the zinc-ion is less than 10ppm. The preparation method of the derivatives DDP, DDP-EG, DOPO-BQ is simple, good in stability and high in yield.

Owner:魏铭杉

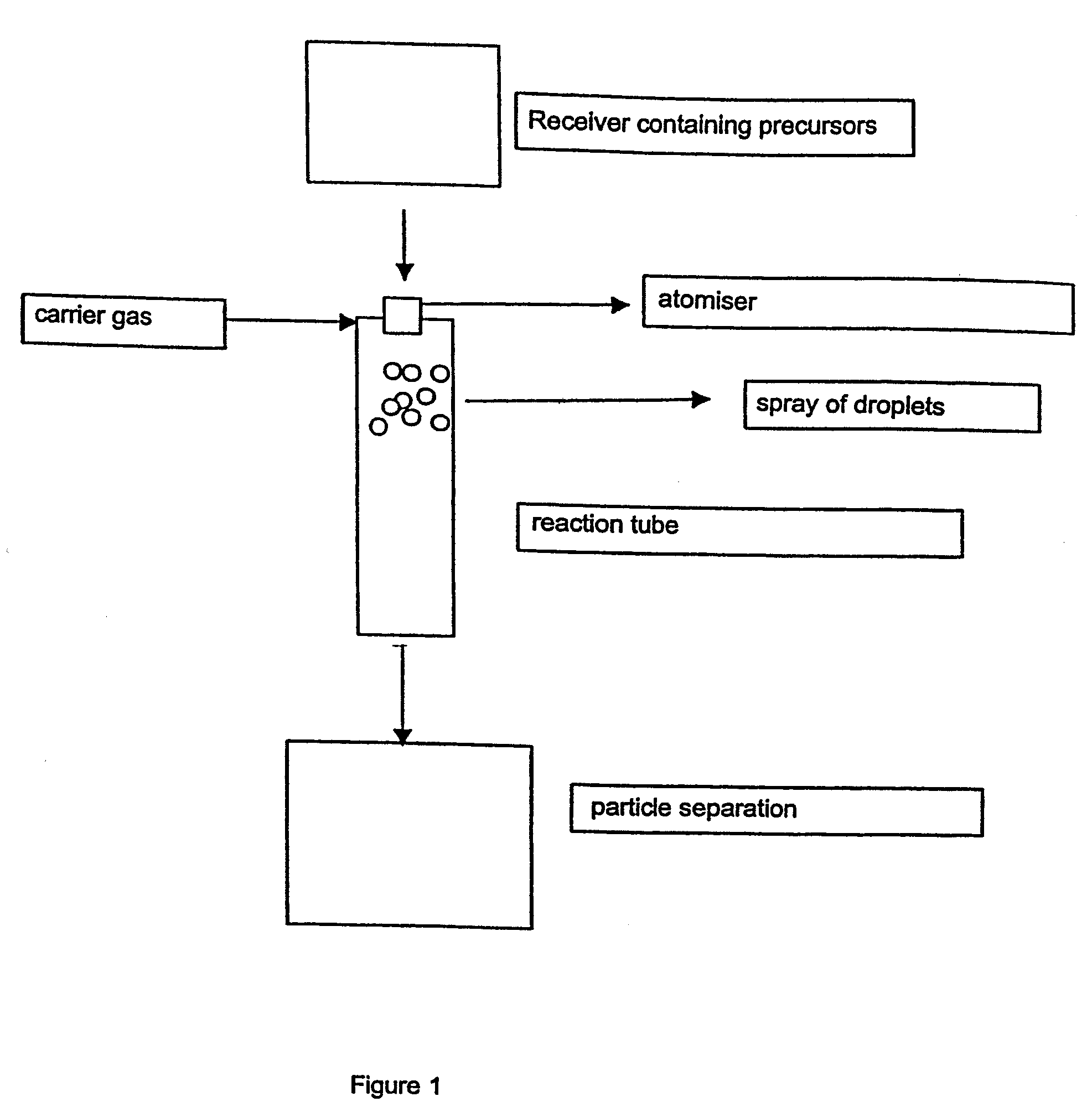

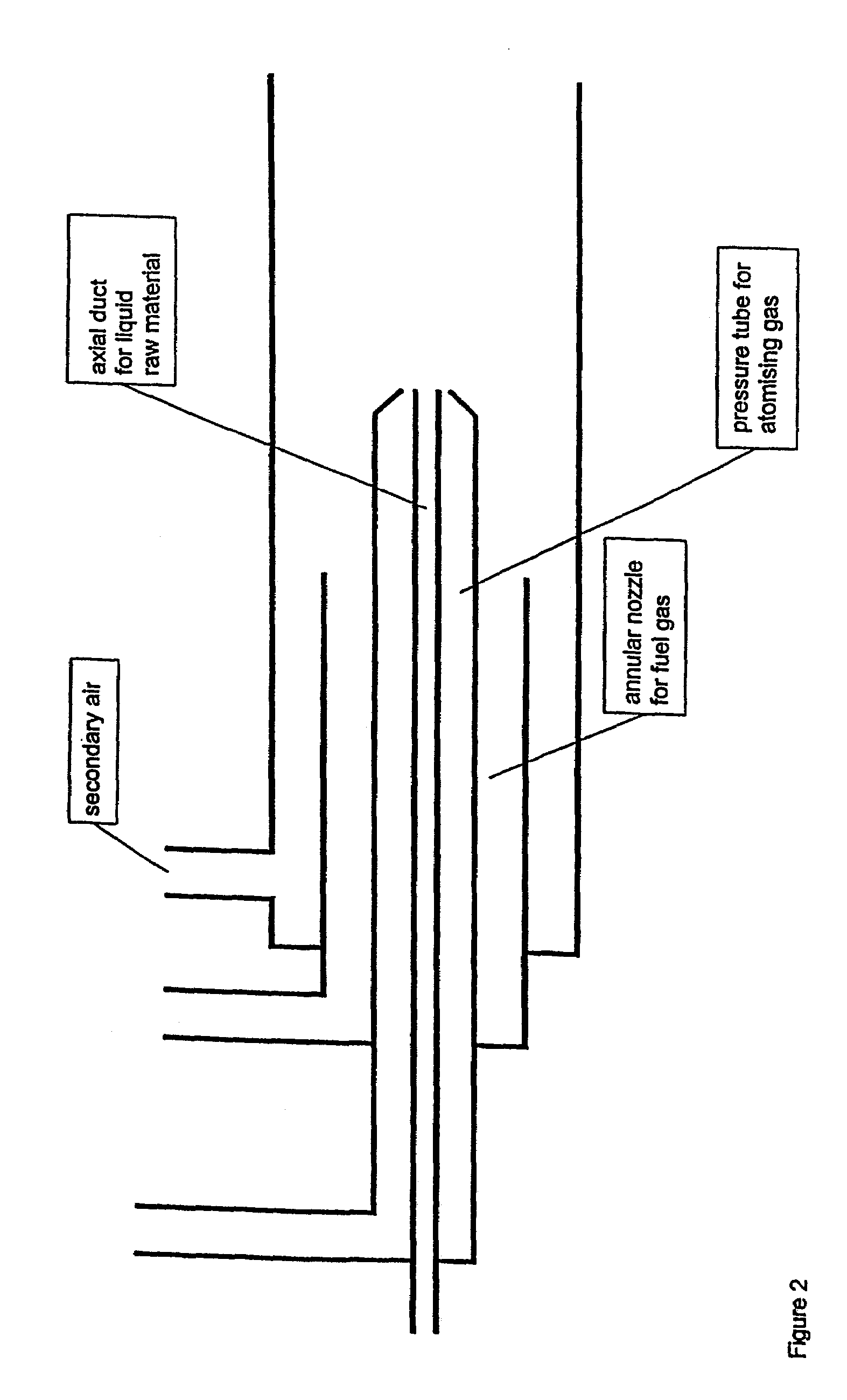

Nanoscale pyrogenic oxides

InactiveUS20070175362A1Low chloride contentMaterial nanotechnologyAluminium compoundsChloride levelsMetal

Nanoscale, pyrogenically produced oxides and / or mixed oxides having a BET surface area of between 1 m2 / g and 600 m2 / g and a chloride content of less than 0.05 wt. % are produced by converting organometallic and / or organometalloid substances into the oxides at temperatures of above 200° C. The oxides may be used as a polishing agent in the electronics industry (CMP).

Owner:EVONIK DEGUSSA GMBH

Synthesis of gallium and indium alkoxides

InactiveUS20090112012A1Eliminate chlorine contaminationGroup 4/14 element organic compoundsOrganic compound preparationAlkaline earth metalPotassium

A method of synthesising gallium or indium alkoxide from the corresponding gallium or indium halide, the method comprising the step of reacting the gallium or indium metal halide with the alkoxide of an alkali earth metal, to produce the desired metal alkoxide essentially free of chlorine contamination. The method provides a composition comprising a solution of gallium or indium alkoxide of high purity, the composition having a chloride content of less than 30 ppm, a barium or strontium content of less than 30 ppm, and a sodium or potassium content of less than 30 ppm, without requiring any additional steps.

Owner:MULTIVALENT

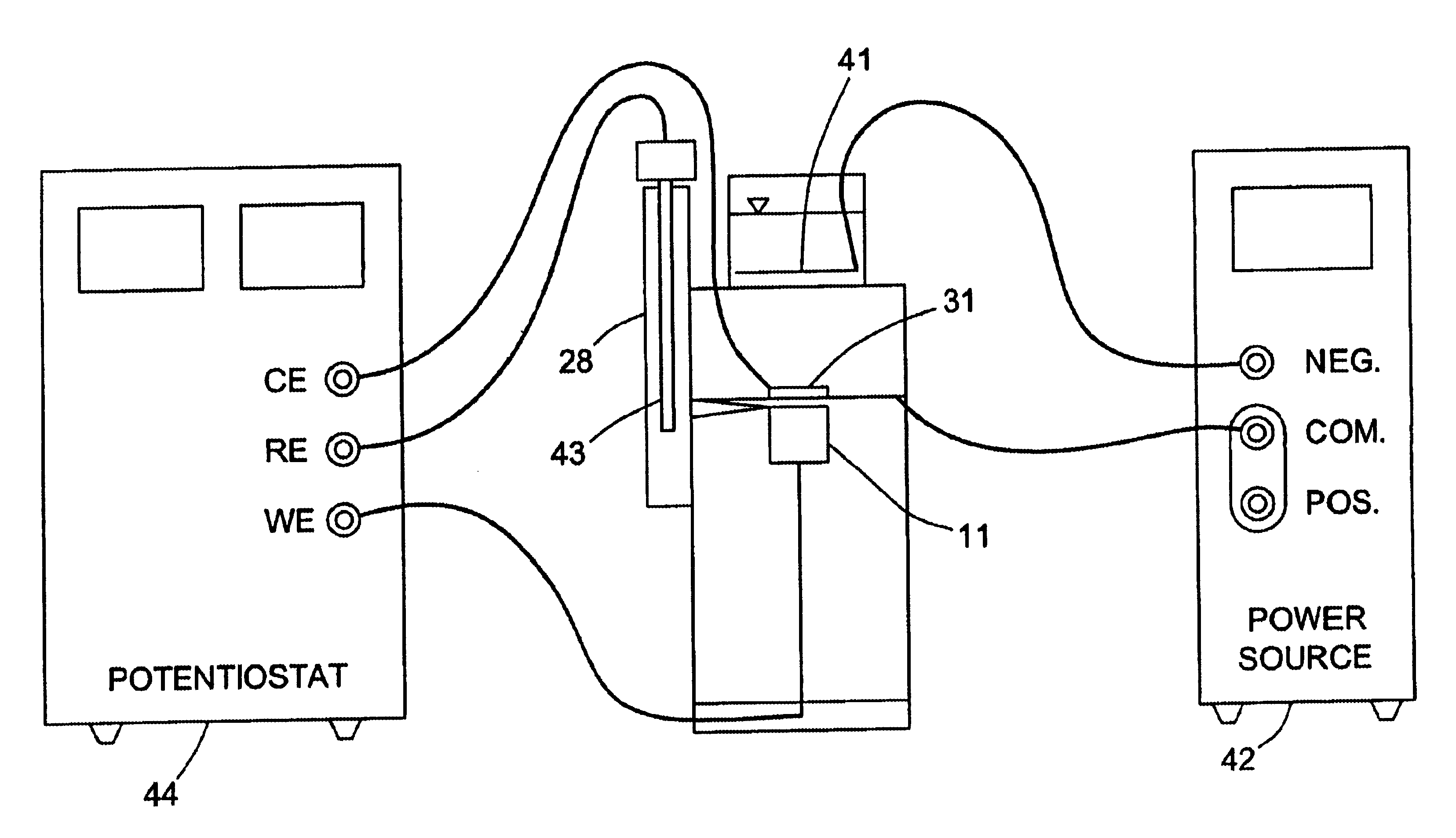

Determination of chloride corrosion threshold for metals embedded in cementitious material

InactiveUS20030011387A1Weather/light/corrosion resistanceResistance/reactance/impedenceMetal chloridePhysical chemistry

The chloride corrosion threshold of a metal embedded in a cementitious structure is determined in an accelerated manner by using an electric field to increase the rate of migration of chloride ion into the structure and monitoring the interface between the metal and the cementitious material to detect the onset of corrosion, then determining the chloride corrosion threshold, which is defined as the chloride content of the cementitious material once corrosion has begun. This determination can be performed over a time period of as little as 2 to 3 weeks rather than the months or years required by conventional chloride corrosion test procedures.

Owner:CMC STEEL FABTORS +1

Method for preparing light aggregate through burning fly ash by using garbage

InactiveCN1654403ASolve the problem of poor pollution controlFulfil requirementsSolid waste managementSolid waste disposalAdhesiveFly ash

The present invention is method of utilizing garbage incinerating flyash in producing light aggregate, and belongs to the technology of treating and utilizing harmful heavy metal waste. The method includes extraction and separation to eliminate great amount of soluble chlorates; controlling the extractant amount and extracting liquid pH value to reduce the migration of heavy metal matter to extracted liquid phase; and obtaining light aggregate through adding adhesive, pelletizing and sintering. The present invention provides one extracting desalting combined sintering process to ensure the strength of sintered matter. In addition, the present invention can decompose dioxin and similar pollutant in the material and cure heavy metal in the sintered product.

Owner:TSINGHUA UNIV

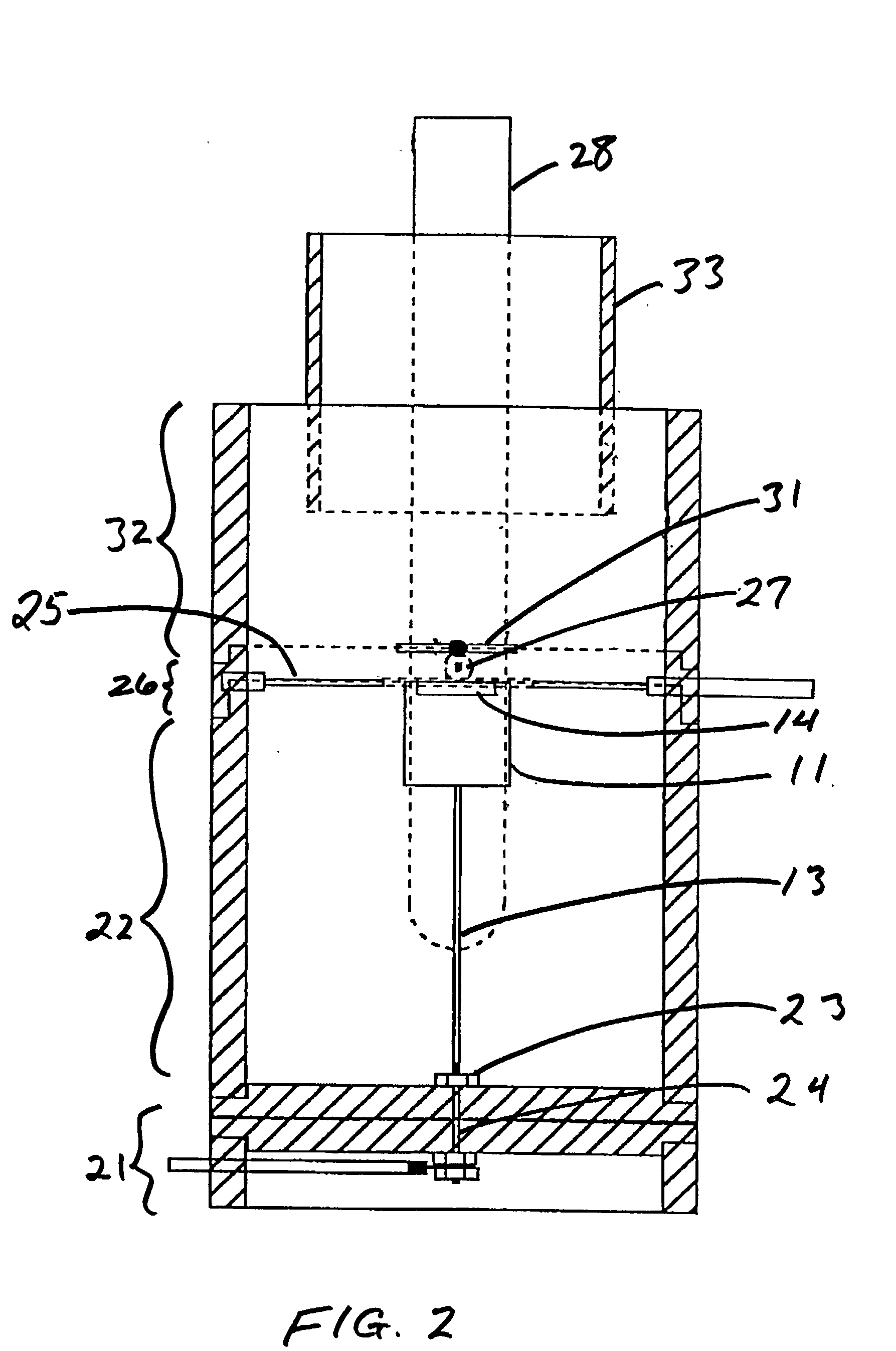

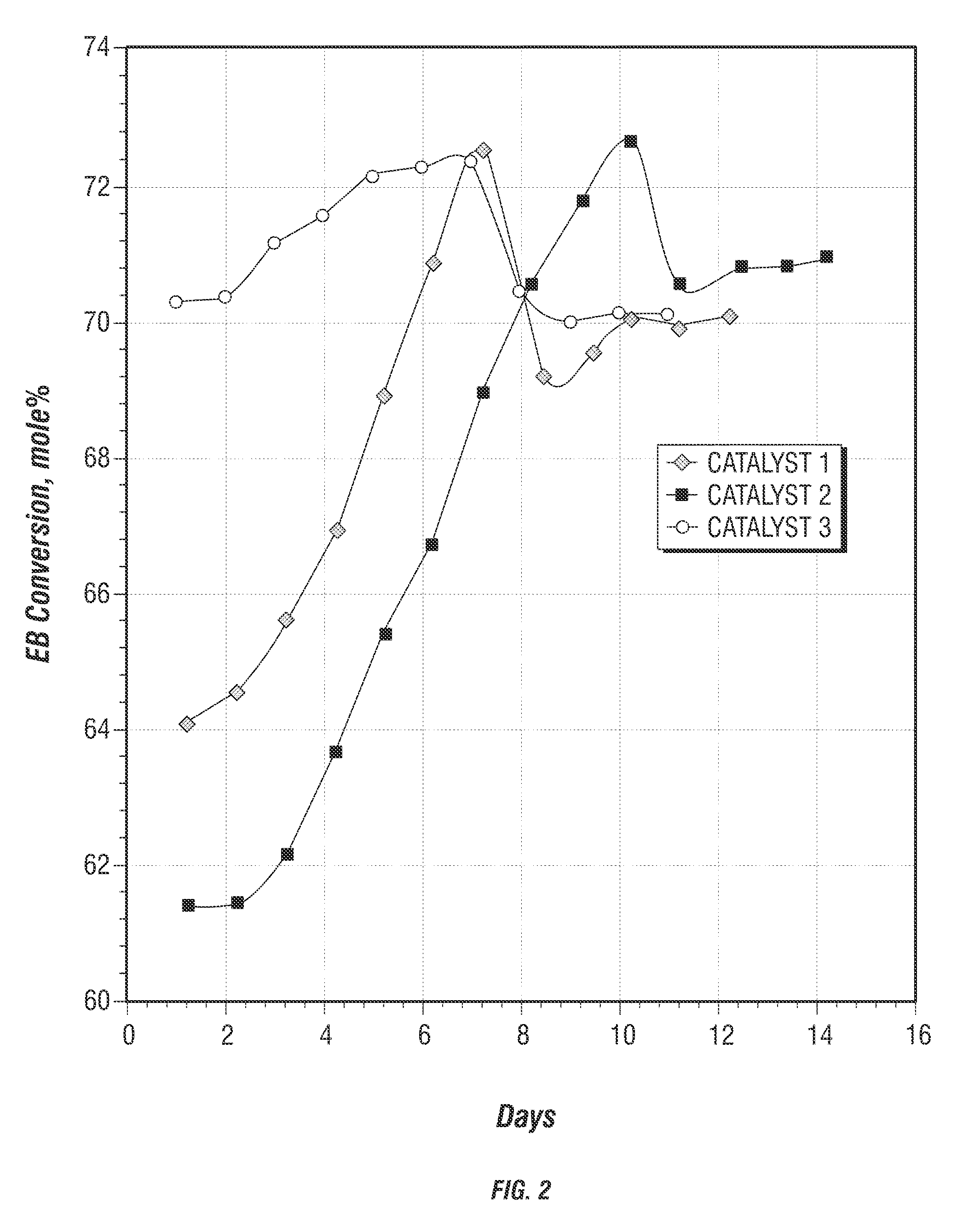

Dehydrogenation catalyst, process for preparation, and a method of use thereof

InactiveUS20080200741A1Easy to operateMaterial nanotechnologyCatalystsDehydrogenationChloride levels

A process for preparing a dehydrogenation catalyst comprising preparing a mixture comprising a treated regenerator iron oxide and at least one additional catalyst component; and calcining the mixture wherein the treated regenerator iron oxide is prepared by washing a regenerator iron oxide at a temperature below 350° C. such that the treated regenerator iron oxide has a chloride content of at most 500 ppmw relative to the weight of iron oxide, calculated as Fe2O3; the catalyst prepared by this process and the use of the catalyst in a dehydrogenation process.

Owner:SHELL OIL CO

Method for preparing sodium carboxymethylcellulose from residues generated by producing biobutanol from maize straw

The invention discloses a method for preparing sodium carboxymethylcellulose from residues generated by producing biobutanol from maize straw. A by-product fiber slurry during production of biobutanol from the maize straw is taken as a raw material, and is subjected to pulverization, basification, etherification, washing, centrifugation, drying, pulverization and sieving to prepare the finished sodium carboxymethylcellulose. The residues generated in the process of producing the biobutanol from the maize straw are utilized fully and changed into treasure, so the industrial development of the production of the biobutanol from the maize straw is promoted, and the problems of deficient raw materials and high production cost during the production of the sodium carboxymethylcellulose are solved. The appearance of the prepared sodium carboxymethylcellulose is white or faint yellow powder, the pH value is between 6.0 and 8.5, the moisture content is less than or equal to 10 percent, the degree of substitution is between 0.6 and 1.2, the viscosity is between 35 and 6,500 mPa.s, and the chloride content is less than or equal to 1.2 percent; and the sodium carboxymethylcellulose has excellent performance, and can be applied in the industry such as daily chemical engineering, papermaking, oil exploitation and the like.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

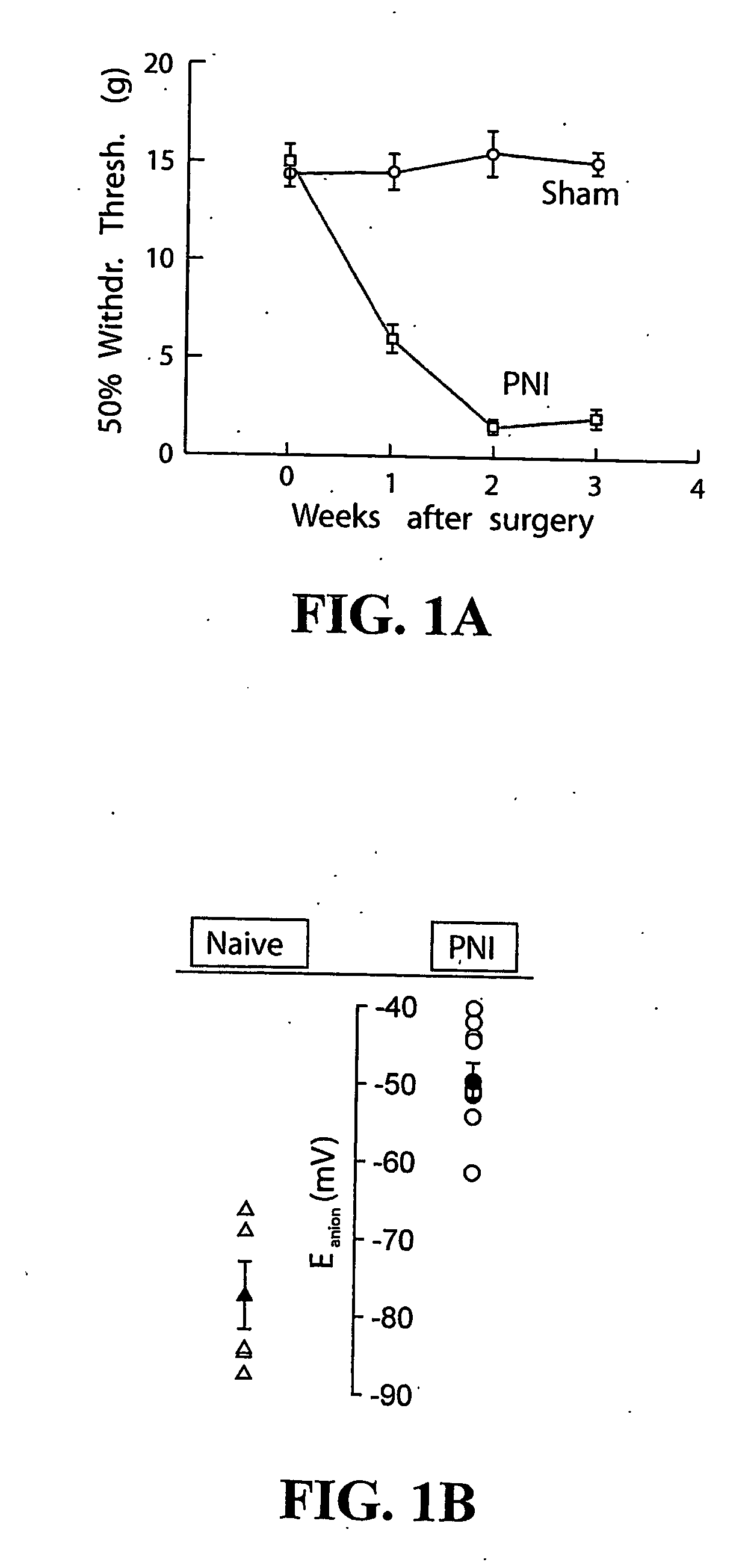

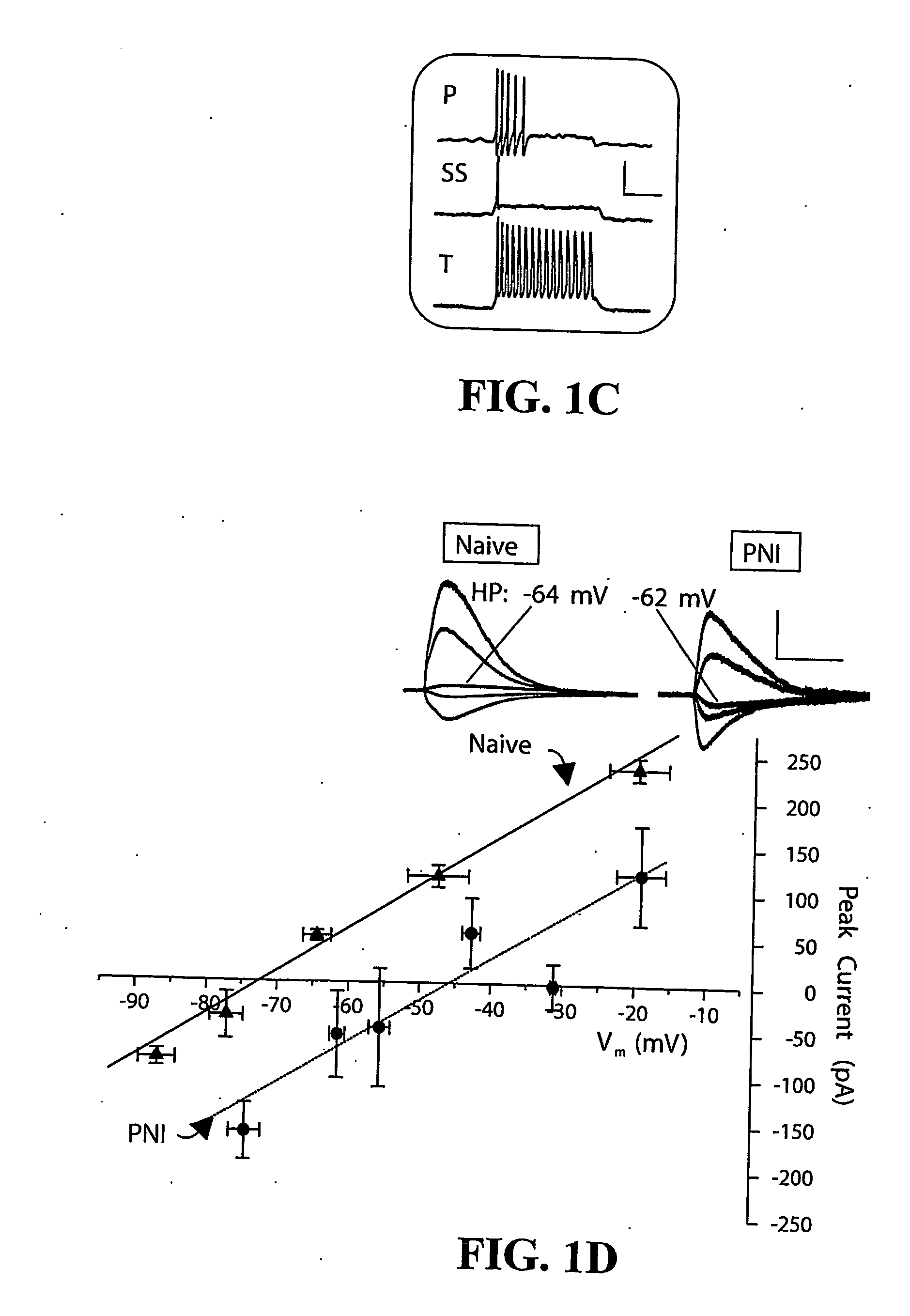

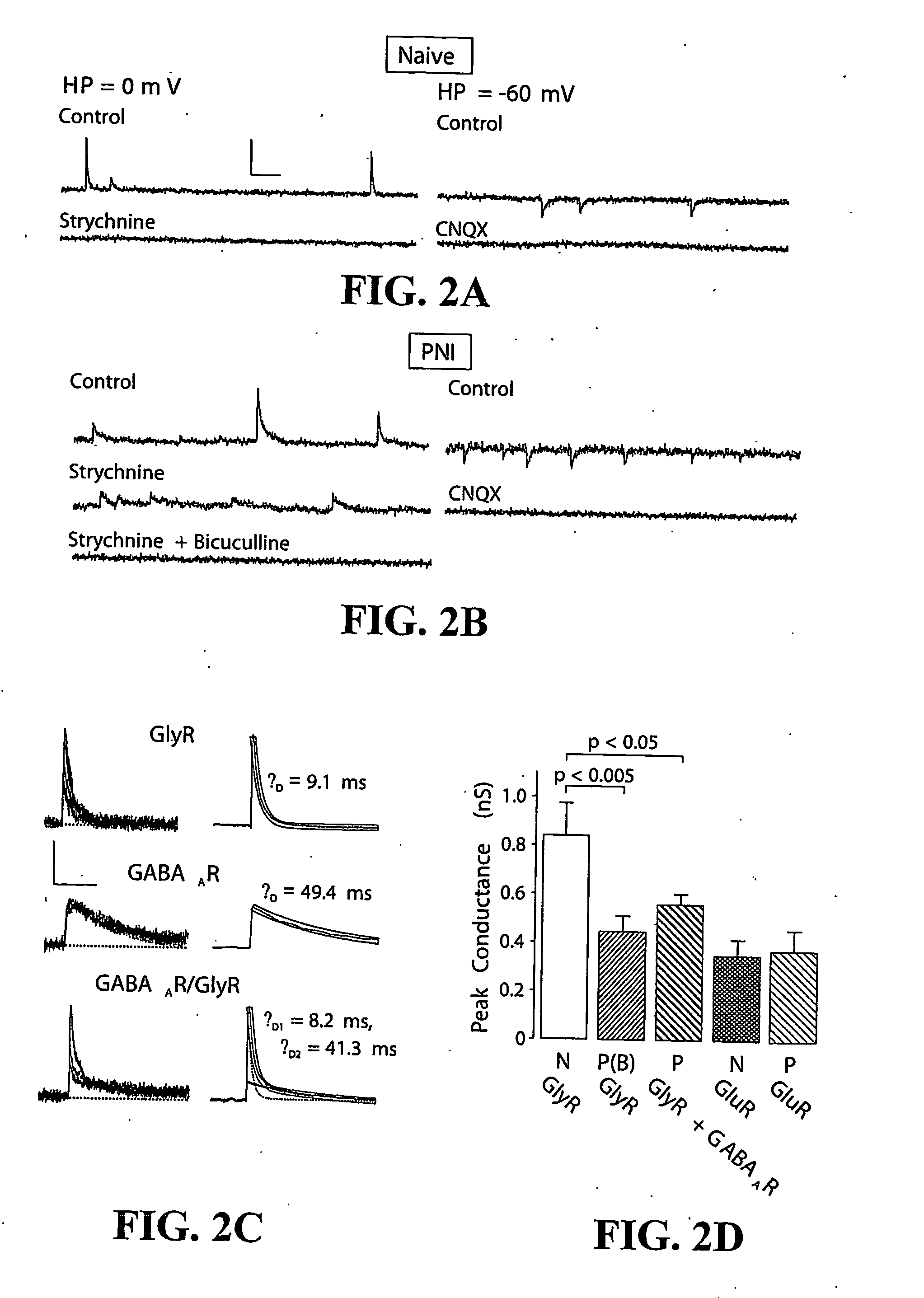

Cns chloride modulation and uses thereof

InactiveUS20070092510A1Decreasing chloride levelModulating activityCompounds screening/testingOrganic active ingredientsUltrasound attenuationChloride transporter

Methods and products for the attenuation or treatment of pain and the reduction of nociception are described. The methods and products are based on the modulation of CNS intracellular chloride levels. The methods and products may also relate to modulation of the activity and / or expression of a chloride transporter, such as the KCC2 potassium-chloride cotransporter. Also described herein are commercial packages and uses based on such modulation. Related methods for identifying or characterizing a compound for the treatment of pain, the reduction of nociception and the diagnosis and prognostication of pain are also described.

Owner:UNIV LAVAL

Feed supplement for increasing the plasma amino acid level of ruminant livestock and method of administration

ActiveUS7318943B2Specific productive resultGood for healthAnimal feeding stuffAccessory food factorsAmino acid supplementBlood plasma

A feed supplement for increasing the plasma amino acid level of animals, including animal feed and liquid lysine base, where the liquid lysine base has a concentration between about 45% and about 55%, and has a pH level of between about 9.5 and about 10.5, a chloride content between about 0.10% and about 0.15%, a bulk density of between about 1.14 and about 1.17 g / cm3, and a maximum moisture level of between about 42% and about 48%. The animal feed may either be dry feed, liquid feed, drinking water or milk replacers, or a combination thereof. The present invention also includes a method of increasing the plasma amino acid level of animals, including the steps of providing animal feed, and supplementing the animal feed with an amino acid supplement comprising liquid lysine base having a concentration between about 45% and about 55%, and having a pH level of between about 9.5 and about 10.5.

Owner:ARCHER DANIELS MIDLAND CO

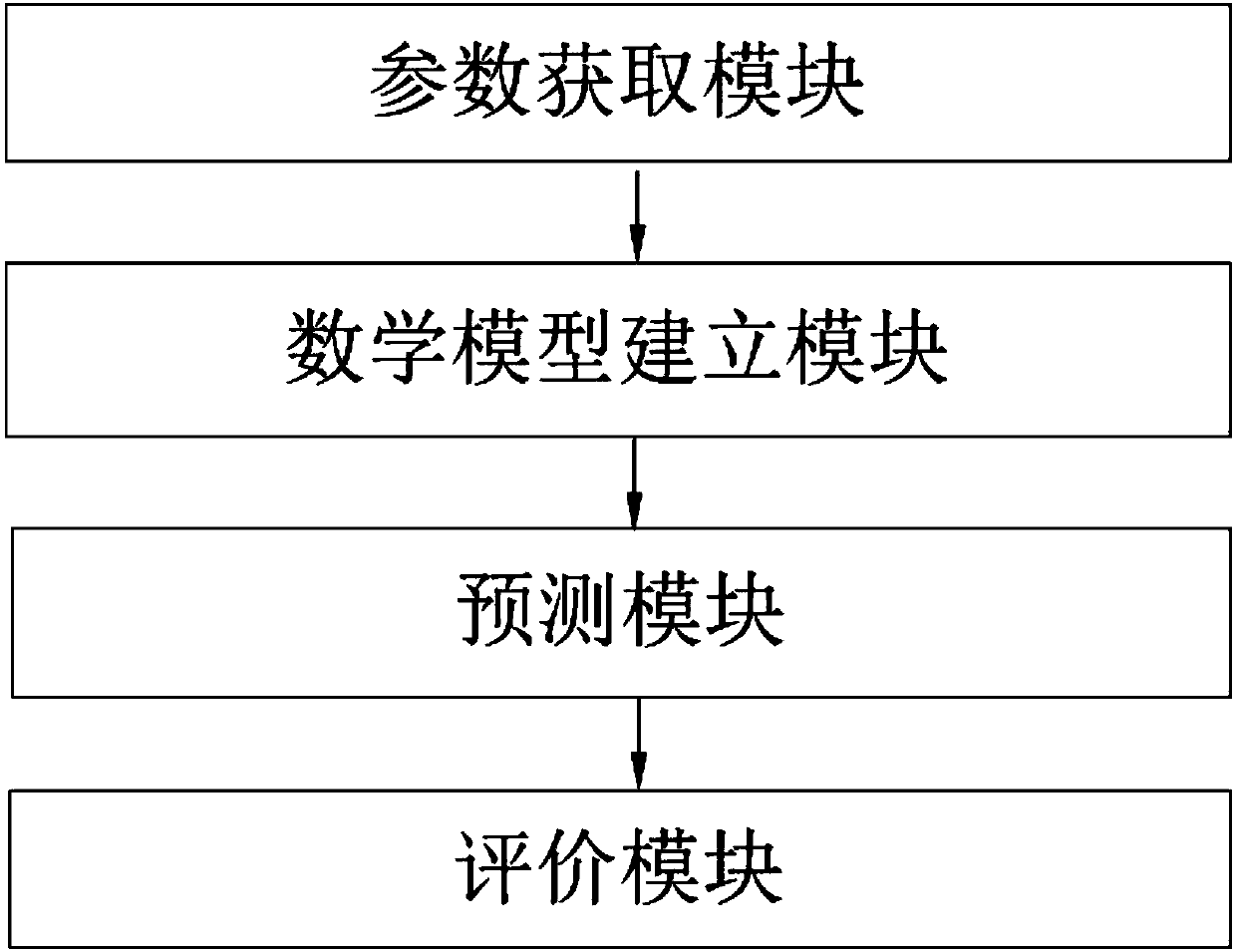

Method and apparatus for dynamically and safely determining corrosive defects inside conveying pipeline

ActiveCN107063991ARapid assessmentAccurate assessmentWeather/light/corrosion resistanceTesting metalsMathematical modelMetallic materials

The invention provides a method and an apparatus for dynamically and safely determining corrosive defects inside a conveying pipeline. The method comprises the following steps: acquiring a corrosion expansion rate of a conventional metal material for a conveying pipeline under different CO2 partial pressure, H2S partial pressure, chloride contents and different stress levels; establishing a mathematic model of the corrosion expansion rate by utilizing a self-adaptive neural-fuzzy inference system according to the acquired corrosion expansion rate; acquiring the CO2 partial pressure, a H2S content, the chloride content and the stress level of a pipe section at which a corroded portion of the pipeline is located, and predicting the corrosion expansion rate according to the established mathematic model; and establishing a pipeline limit-state equation, and acquiring a safety state of the pipeline. The invention also provides the apparatus for dynamically and safely determining the corrosion defects inside the conveying pipeline. By adopting the method and the apparatus for dynamically and safely determining the corrosion defects inside the conveying pipeline, the problem that the safety state of the oil-gas conveying pipeline containing the corrosion defects is difficult to determine dynamically and accurately can be solved.

Owner:PETROCHINA CO LTD

High-temperature dechlorination agent and preparation method thereof

InactiveCN102485837ALow chlorine content after removalHigh chlorine capacityHydrocarbon oils refiningSodium BentonitePolyvinyl alcohol

The invention discloses a high-temperature dechlorination agent and a preparation method thereof. The high-temperature dechlorination agent is suitable for an environment at a temperature of 200 to 500 DEG C. The high-temperature dechlorination agent is prepared from 20 to 30% of Na2CO3, 20 to 30% of NaOH, 20 to 40% of bentonite, 2 to 10% of polyvinyl alcohol and 1 to 2% of (NH4)2CO3 by mixing. The high-temperature dechlorination agent has the advantages that component compatibility is good so that all technical indexes are high; through the high-temperature dechlorination agent, chloride content of raw material oil is reduced to content below 0.45mg / L from content above 10mg / L; a dechlorination ratio reaches above 95%; a chloride capacity reaches 53%; all the technical indexes are superior to technical indexes of congeneric products; raw material oil feeding requirements from a device can be satisfied; and the solution of device chlorine-corrosion problems is promoted.

Owner:PETROCHINA CO LTD

Snowmelt agent

InactiveCN101671539AImprove snow removal effectGood snow removal effectOther chemical processesRoad surfaceSnowmelt

The invention relates to a snowmelt agent, which is a composite snowmelt agent and comprises the following components and contents (weight) in percentage by weight: 80 to 95 percent of acetate and 5 to 20 percent of chloride. Compared with the prior art, the snowmelt agent has good snow removing effect and low chloride content, can reduce the corrosivity of the snowmelt agent obviously, effectively protects pavement and bridges, prolongs the service life of public facilities and reduces the cost while achieving excellent snow removing effect.

Owner:SHANGHAI CITY CHANGNING DISTRICT JUNIOR SCI &TECH GUIDANCE STATION +2

Nanoscalar pyrogenically produced yttrium-zirconium mixed oxide

Nanoscalar, pyrogenically produced yttrium-zirconium mixed oxide which has a BET surface area of between 1 and 600 m2 / g, a total chloride content of less than 0.05 wt. % and does not exhibit a conversion into the monoclinic phase during storage is produced by atomizing yttrium compounds and zirconium compounds and reacting them in a flame. The mixed oxide can be used as ceramic raw material.

Owner:EVONIK OPERATIONS GMBH

Process for preparing sodium chlorite

InactiveCN1378973AGenerate fastHigh Goal Conversion RateChlorous acidHypochloriteSodium chlorateOxygen

A process for preparing sodium chlorite includes such steps as dissolving hydrogen peroxide and solid sodium chlorate in water, adding the resultant solution along with sulfuric acid to a ClO2 generator to generate the mixture of ClO2 and oxygen, loading the mixed absorbing liquid containing sodium hydroxide and hydrogen peroxide into an absorbing tower, adding ClO2 to the absorbing tower while escaping oxygen, and finally generating sodium chlorite. Its advantages are high output rate (more than 95%) and high purity (more than 95%) of product.

Owner:SOUTH CHINA UNIV OF TECH

Method for determining chemical oxygen demand of liquid sample and analyzer

InactiveCN104345034AWater treatment parameter controlMaterial analysis by observing effect on chemical indicatorChemical oxygen demandReagent

The invention relates to a method for determining the chemical oxygen demand of a liquid sample and an analyzer. The invention describes a method for determining the chemical oxygen demand of a liquid sample by means of an automatic analyzer. The method comprises: -adding a predetermined amount of a reagent to the liquid sample for masking chloride or for the separation of chloride from the liquid sample; -then determining the chemical oxygen demand of the liquid sample; and characterized in that an evaluation and control device of the analyzer determines the predetermined amount of the reagent based on at least one of a chloride content of the liquid sample representing the measured value. The invention also describes an analyzer for carrying out the method.

Owner:ENDRESS HAUSER CONDUCTA GESELLSCHAFT FUER MESS UND REGELTECHNIK MBH CO KG

Determination of chloride corrosion threshold for metals embedded in cementitious material

InactiveUS6646427B2Weather/light/corrosion resistanceResistance/reactance/impedenceMetal chlorideTest procedures

The chloride corrosion threshold of a metal embedded in a cementitious structure is determined in an accelerated manner by using an electric field to increase the rate of migration of chloride ion into the structure and monitoring the interface between the metal and the cementitious material to detect the onset of corrosion, then determining the chloride corrosion threshold, which is defined as the chloride content of the cementitious material once corrosion has begun. This determination can be performed over a time period of as little as 2 to 3 weeks rather than the months or years required by conventional chloride corrosion test procedures.

Owner:CMC STEEL FABTORS +1

Method for refining crude glycerol as byproduct generated in high-pressure hydrolysis of grease

InactiveCN103896735AReduce energy consumptionReduce the risk of excessive chloride levelsHydroxy compound separation/purificationWater bathsDistillation

The invention discloses a method for refining crude glycerol as a byproduct generated in the high-pressure hydrolysis of grease. The method comprises the following steps of (a) firstly introducing crude glycerin containing high-pressure hydrolysis byproduct of grease into a thermostatic water bath and then heating to 50-70 DEG C, adjusting pH to 3-4 with hydrochloric acid, and then standing; (2) after standing is completed, removing an upper layer of grease, adjusting pH to 5-6.5 by adding soda ash, then adding sodium metaaluminate, adding a flocculant after a large amount of flocculate is generated, stirring for 5-30 minutes and filtering; and (3) enabling the filtered high-pressure hydrolysis byproduct of grease to sequentially pass through a chromatographic column filled with a cation exchange resin, an anion exchange resin and a cation-anion exchange resin to obtain a purified glycerol. The method for refining crude glycerol as a byproduct generated in the high-pressure hydrolysis of grease is clean and green, the energy consumption of the distillation and rectification section can be reduced and the risk of excessive chloride content in glycerol caused by the liquid-foam entrainment in the distillation process can be reduced.

Owner:NANJING COLLEGE OF CHEM TECH

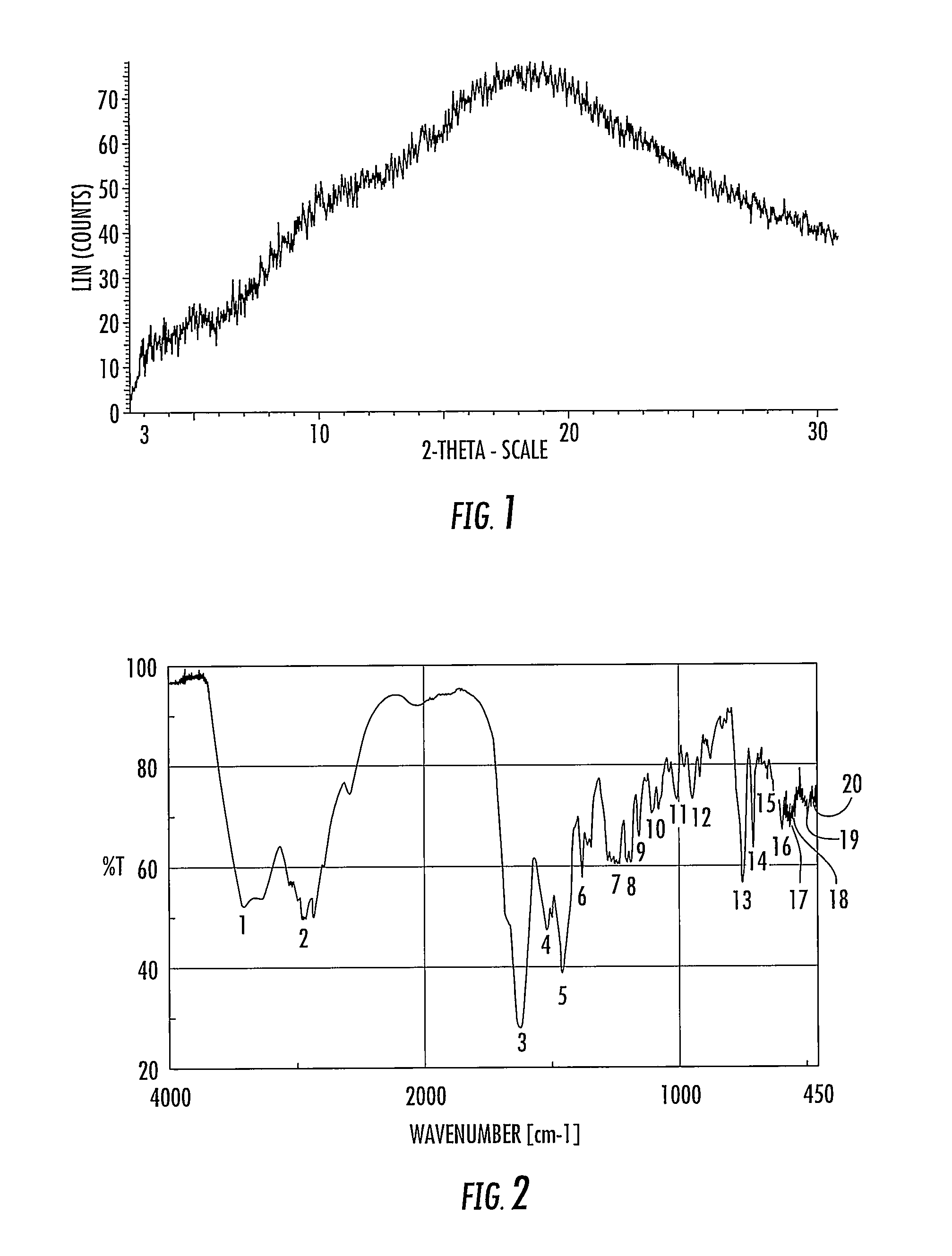

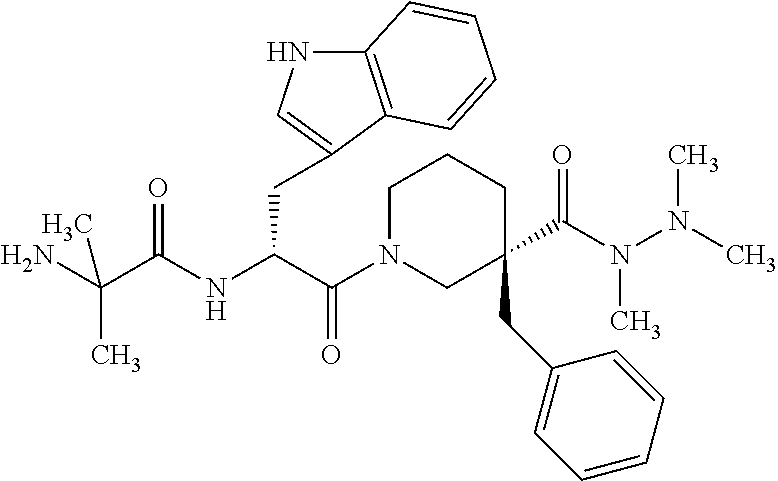

Methods of producing anamorelin hydrochloride having controlled chloride content

ActiveUS9403867B2Precise and Efficient ControlIncrease productionDipeptide ingredientsMetabolism disorderFine particulatePharmaceutical Substances

Owner:HELSINN HEALTHCARE SA +1

Branched polycarbonates and processes for producing the same

Owner:SHPP GLOBAL TECH BV

Method for producing sodium permanganate

ActiveCN101880064AImprove product qualityReduce Chloride ContentManganates/permanganatesChemical industryFiltration

The invention belongs to the field of chemical industry, and relates to a method for producing sodium permanganate. The method comprises the following steps of: adding water into sodium fluosilicate and potassium permanganate serving as raw materials to perform reaction at the temperature of between 70 and 95 DEG C to obtain the sodium permanganate, performing heating concentration, cooling and filtration on crude solution to obtain 50 to 52Be sodium permanganate concentrate, and diluting the sodium permanganate concentrate to obtain 40.0 to 40.5 percent sodium permanganate solution product. The production method generates the sodium fluosilicate in one step without adopting chlorine oxidation, so the production method is safe and environment-friendly; the product has good quality, and particularly has low chloride content; the reaction is finished under normal pressure, and the reaction conditions are easy to control; and the method has the advantages of simple production process, short flow and no three-waste discharge.

Owner:广东航鑫科技股份公司

Methods of Producing Anamorelin Hydrochloride Having Controlled Chloride Content

InactiveUS20140018391A1Reduce productionExcellent reduction in solvent levelBiocideDipeptide ingredientsFine particulateMedicinal chemistry

The present invention relates to particulate forms of anamorelin monohydrochloride or a composition comprising anamorelin monohydrochloride having controlled chloride content, preferably isolated in an amorphous and / or fine particulate state, processes for making the particulate forms, and pharmaceutical compositions comprising the particulate forms.

Owner:HELSINN HEALTHCARE SA +1

Method for Producing Iron Powder Respectively Microalloyed Steel Powder Mainly for Metallurgical Applications and Method for Producing Thereof

A method for manufacturing of iron- respectively micro-alloyed steel powders, starting from fluffy spray roasted iron oxides exhibiting a specific surface area in excess of 2.0 m2 / g and residual chloride contents over 440 ppm Cl′, decrease the chloride content in two steps to less than 100 ppm, the specific surface area (BET) of to a pre-selected value of less than 10.0 m2 / g, preferably between 0.1 and 2.0 m2 / g and reduce the pre-sintered granules exhibiting a bulk density in excess of 1.200 g / dm3.

Owner:RUTHNER MICHAEL J

Method for recovering and reutilizing copper etching agent containing amino-soda by metal aluminum

InactiveCN1982505AEasy to controlGood response controlWater treatment parameter controlTreatment involving filtrationControl channelCopper

Method for recovering and re-utilizing refused copper etching agent containing ammonia-soda from metal aluminum is carried out by controlling process parameter by control channel and removing copper by one or multiple independent reactive kettle with aluminum. The process parameter consists of temperature, copper concentration, pH value, specific weight, ammonia capacity, chloride content and circulating speed. The reactive kettles could be series, paralleled or mixed arranged and have independent filter with solid reactant selectively.

Owner:DAREN TECH

Method for preparing stabilizing agent for silicon antifreeze

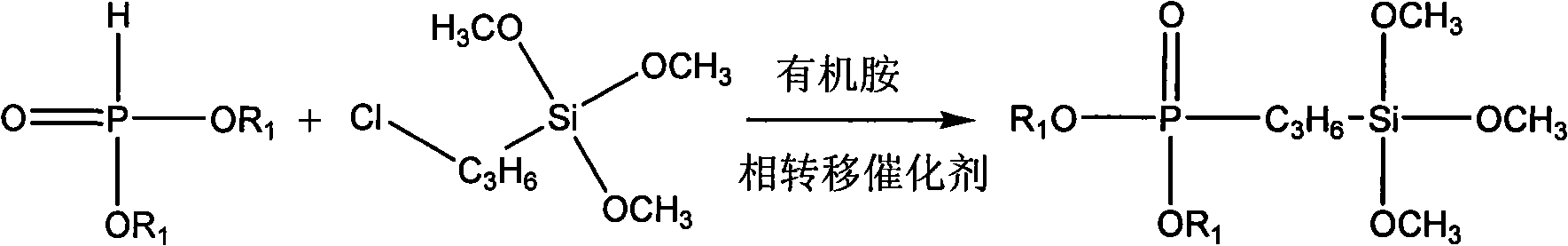

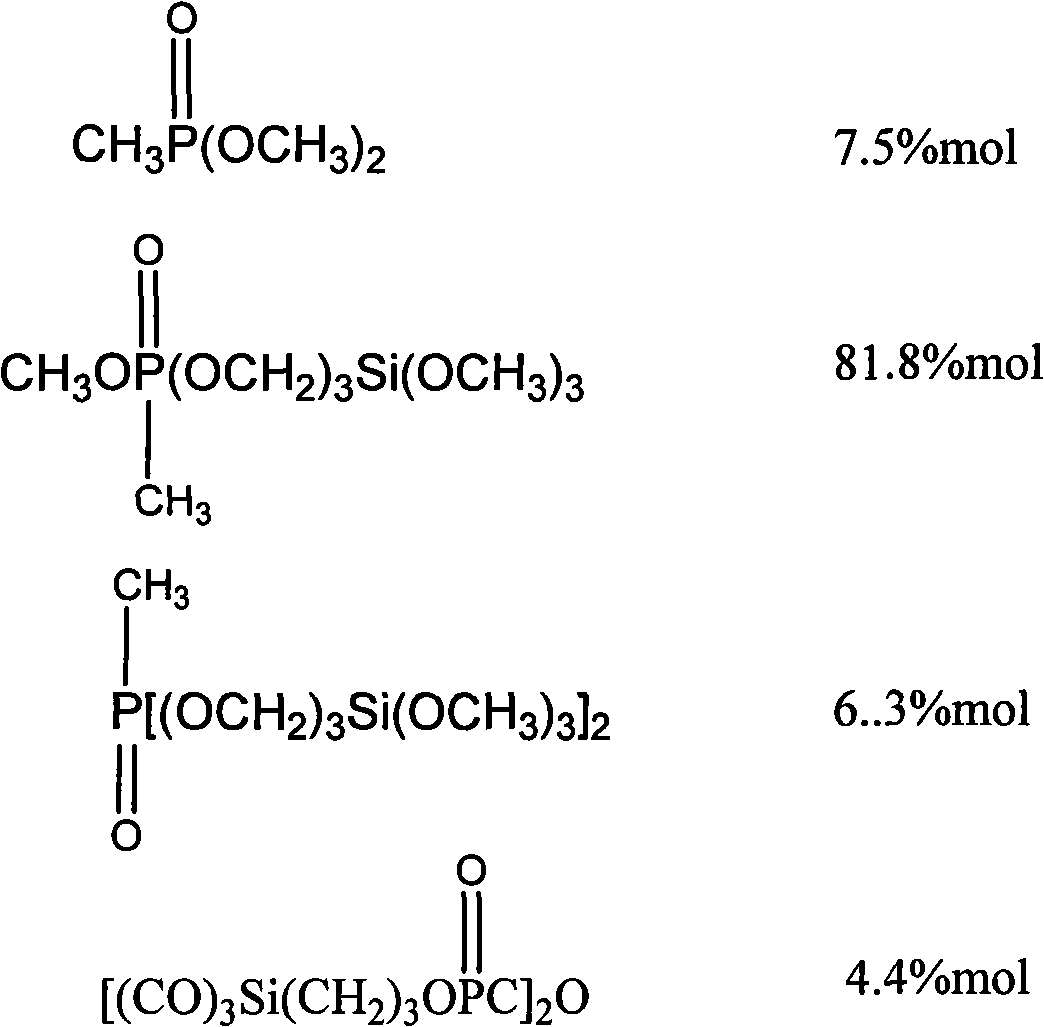

ActiveCN101575350AHigh selectivityHigh yieldGroup 5/15 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsOrganic synthesisSilanes

The invention relates to a method for preparing a stabilizing agent for an antifreeze, in particular to a method for preparing a stabilizing agent for a silicon antifreeze, and belongs to the technical field of organic synthesis. The preparation method comprises the following steps: adopting a phase transfer catalyst as a catalyst accelerator to accelerate the reaction of halogenated silane and organic phosphonate, and removing chloride contents in a residual product through nitrogen and flash evaporation. The method has the advantages that the method can effectively improve the selectivity and yield of the reaction under the proper temperature, mainly can effectively reduce the content of chlorine hydride in the product to obtain the stabilizing agent applicable to the silicon antifreeze, and has high yield; and the purity of the obtained stabilizing agent for the silicon antifreeze is not less than 76 percent per mole.

Owner:JIANGSU LOPALTECH

Method for treating liquid flows at a chemical pulp mill

ActiveCN101688362AReach the brightness levelPulp liquor regenerationWashing/displacing pulp-treating liquorsEvaporationChemical recovery

The present invention relates to a method for treating liquid flows at a chemical pulp mill comprising at least an alkaline cooking process for producing pulp, brown stock treatment with essentially closed liquid cycles, a pulp bleaching plant using ECF-bleaching, a chemical recovery plant comprising a chemical recovery boiler, and effluent purification. Chloride-containing bleaching plant effluents are led to the effluent purification, where they are treated in order to decrease the organic matter content thereof. At least 20 % of the purified effluent is returned to a pulp mill process and purified effluent is used in a last washing stage included in brown stock treatment. In the brown stock treatment the liquid flow is passed counter-currently to evaporation, wherefrom it is led for treatment to a recovery boiler process, wherein a separation process for chlorides is arranged for controlling the chloride level of the liquor cycle.

Owner:ANDRITZ AG

Method for detecting content of chloride in water

InactiveCN106908566AEliminate distractionsAvoid Titration EffectsChemical analysis using titrationPreparing sample for investigationSulfurPotentiometric titration

The invention relates to a method for detecting the content of chloride in water. The method comprises the following steps: heating a to-be-detected sample when the pH value is 8-9, continuing to regulate the pH value to be 2-6, and heating; adding hydrogen peroxide into the sample, and heating; regulating the pH value to be 2-3 after the sample is cooled to room temperature, and performing potentiometric titration with a silver nitrate standard solution; and calculating the content of chloride in the to-be-detected sample according to the volume of the consumed silver nitrate standard solution when the titration destination is reached. The method is applicable to detection of content of chloride in high-sulfur condensate of a refining device, fills up the blank that high-sulfur condensate of the refining device cannot be accurately detected, and provides more accurate reference basis for regulating anti-corrosion measure of the device, so that a preventive anti-corrosion measure is adopted, and potential corrosion hazard of the equipment can be found and eliminated; and a certain reference effect is achieved for detecting corrosion of chloride in condensate of similar devices in China.

Owner:PETROCHINA CO LTD

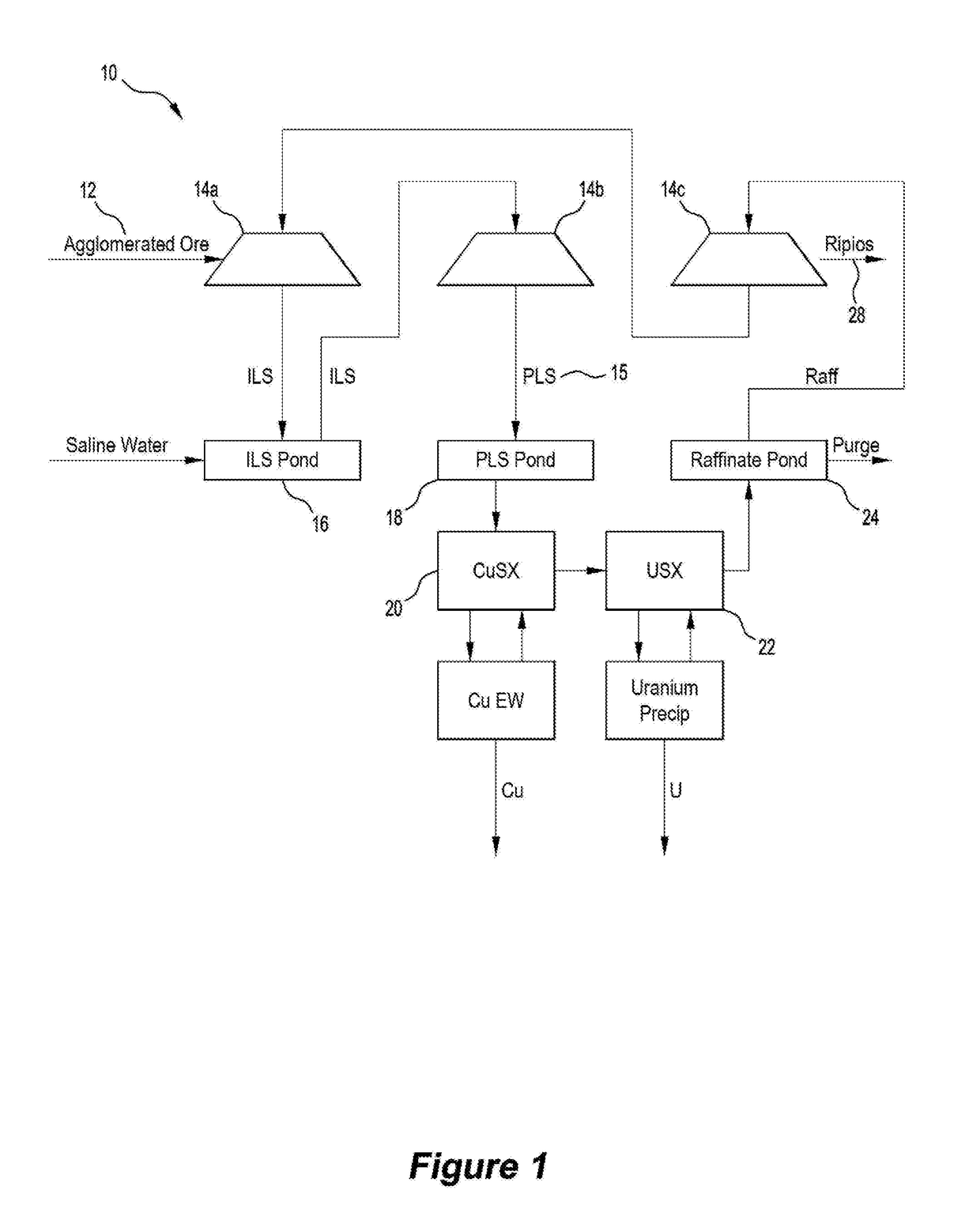

Heap Leaching Method

ActiveUS20170349972A1High solution redox potentialSolve highProcess efficiency improvementPregnant leach solutionHeap leaching

A method for recovering one or more of copper, uranium and a precious metal from an ore material, including: (a) forming a heap of the ore material; (b) during active heap irrigation, contacting the heap of the ore material with an iron containing acidic leach liquor having a high chloride content in the presence of an oxygen containing gas, and producing a pregnant leach solution; and (c) recovering one or more of copper, uranium and a precious metal from the pregnant leach solution.

Owner:BHP OLYMPIC DAM CORP PTY LTD

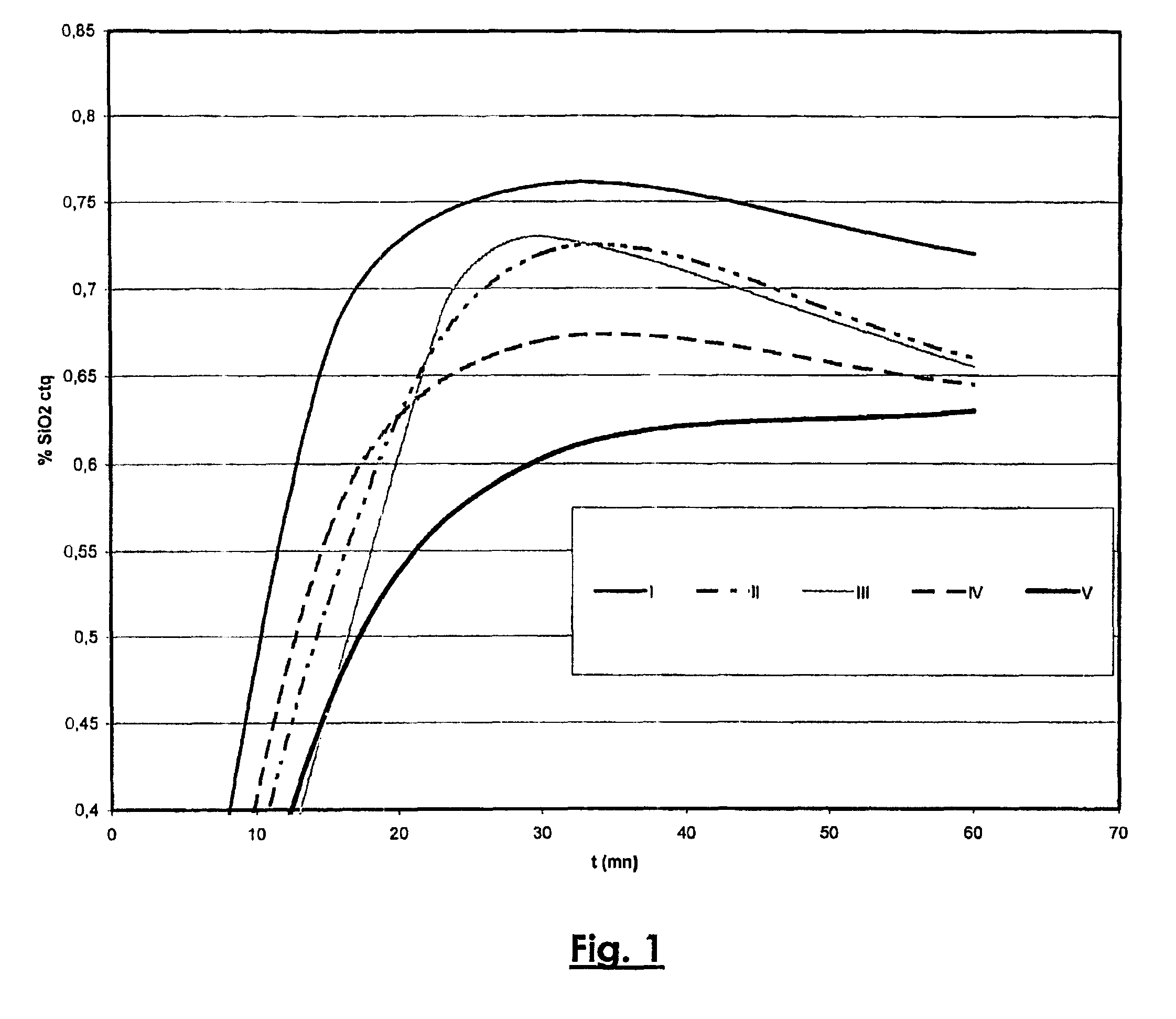

Bayer process for production of alumina trihydrate by alkaline digestion of bauxite, the process comprising a predesilication step

InactiveUS7704471B2Reduce solubilityImprove efficiencyAluminates/aluminium-oxide/aluminium-hydroxide purificationAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationSodium aluminateEvaporation

A Bayer process comprises grinding and then digestion of bauxite by bringing it into contact with a sodium aluminate liquor. Digestion consists of forming a slurry that is then treated to separate insoluble residues from the sodium aluminate liquor. The liquor is then crystallized and recycled back to green liquor after having been separated from the alumina trihydrate precipitated during crystallization. The process comprises a predesilication treatment during which the ground bauxite, before digestion, is brought into contact with an aqueous sodic solution that has a content of carbonates, sulphates and possibly chlorides which, expressed as a percentage related to the caustic concentration, has less than half of the corresponding impurities content of the spent liquor. Preferably, the pure caustic soda used to compensate for caustic soda losses in the Bayer circuit, previously injected just after evaporation, is now added in the aqueous sodic solution for the predesilication treatment.

Owner:ALUMINUM PECHINEY

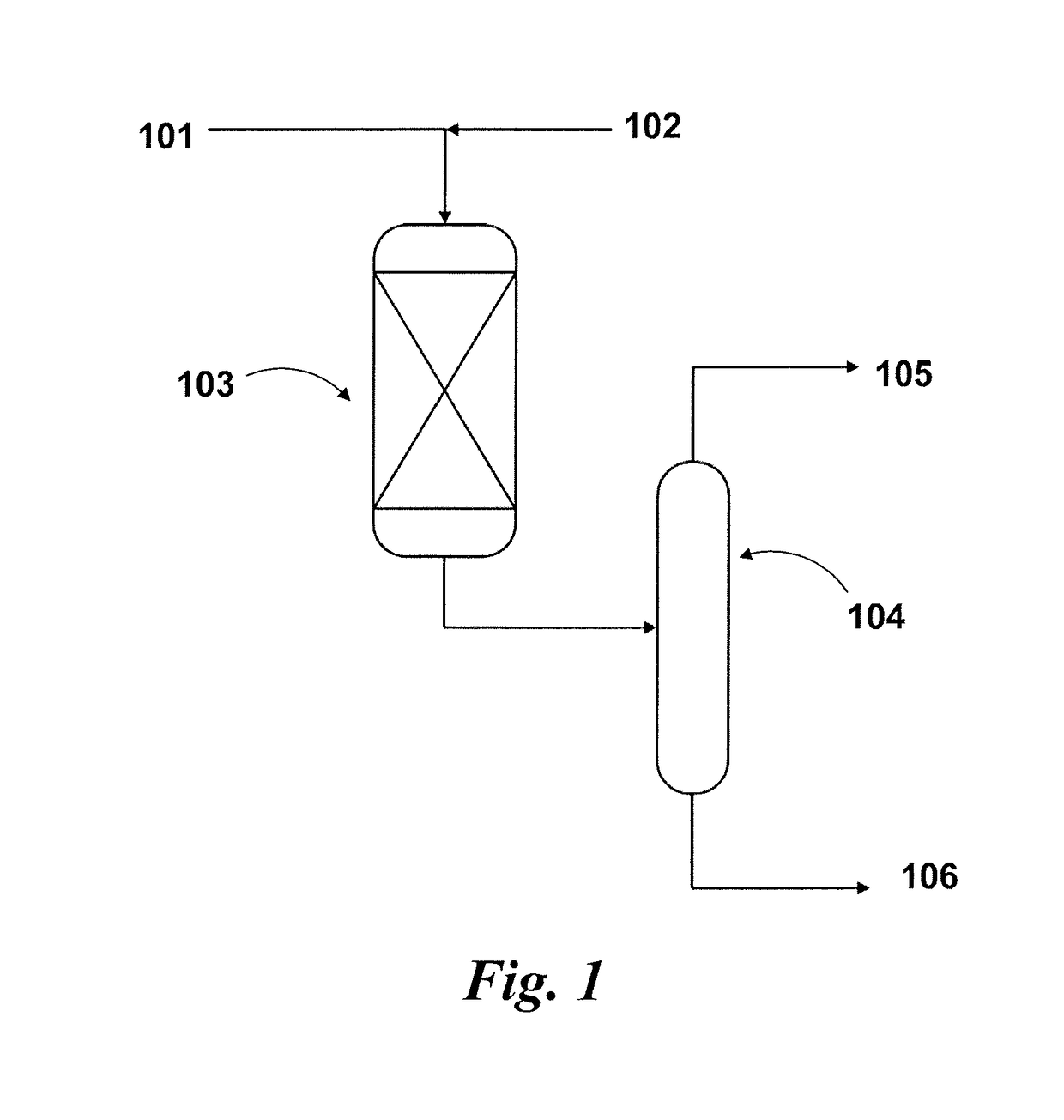

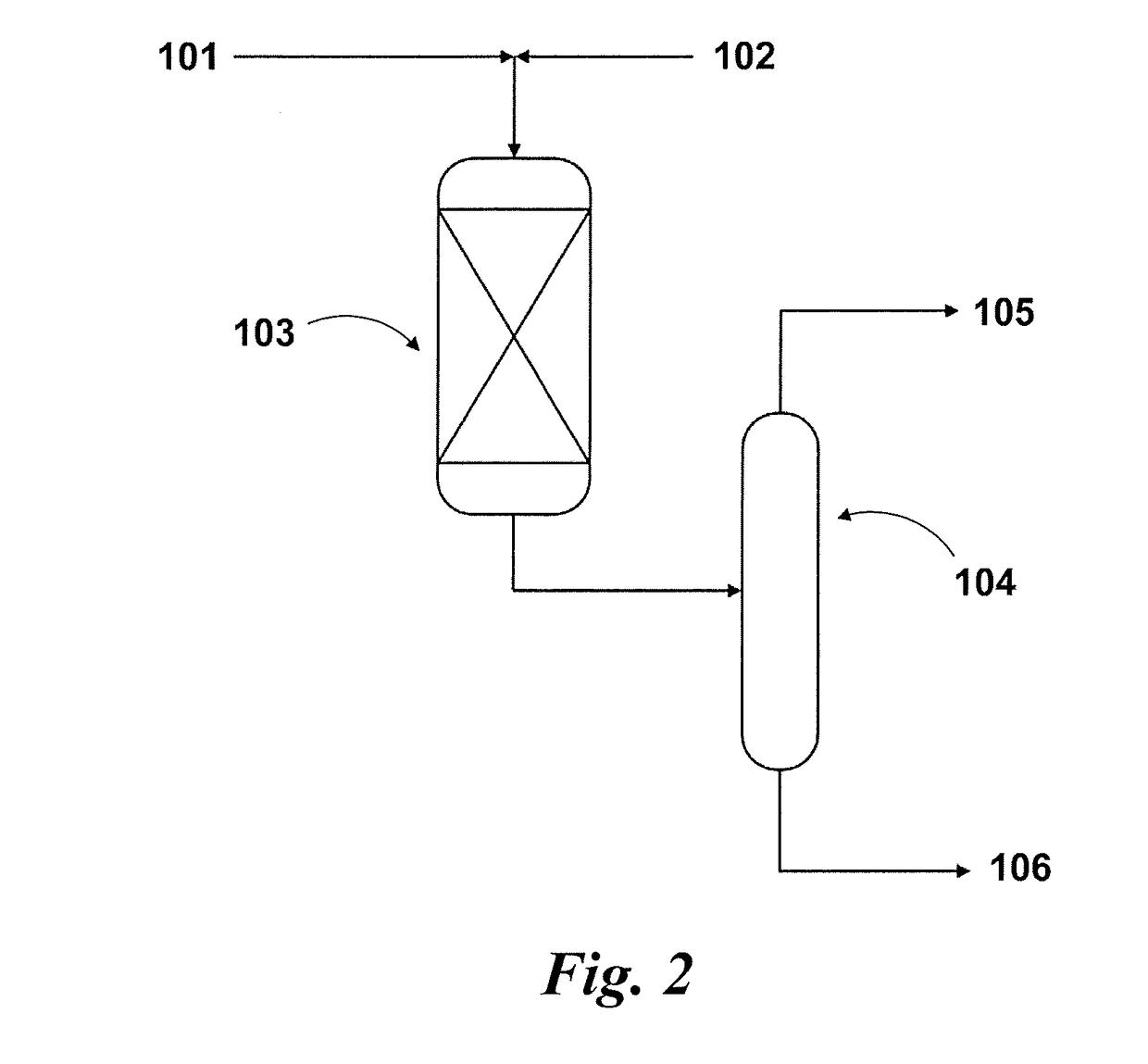

A catalytic process for reducing chloride content of a hydrocarbon feed stream

InactiveUS20190062646A1Reduce Chloride ContentReduce compoundingLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesHydrogenOrganic chloride compound

A process for reducing a chloride content of a hydrocarbon feed stream involving contacting a hydrocarbon feed stream comprising a chloride containing pyrolysis oil obtained by cracking a chloride containing thermoplastic material with a sulfided catalyst comprising at least one of Co, Mo, and Ni or a catalyst comprising Pd, Pt, Cu, and / or Zn on a catalyst support in the presence of hydrogen gas to reduce one or more organic chloride compounds present in the hydrocarbon feed stream and form a hydrocarbon product stream and HCl. The HCl is removed from the hydrocarbon product stream, wherein the hydrocarbon product stream has a lower chloride content than the hydrocarbon feed stream based on the total weight of the chloride and the total weight of the hydrocarbon feed stream.

Owner:SABIC GLOBAL TECH BV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com