Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53 results about "Chloride corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chloride stress corrosion cracking (CSCC) is a type of intergranular corrosion. Chloride stress corrosion involves selective attack of a metal along its grain boundaries. It occurs in austenitic stainless steel under tensile stress in the presence of oxygen, chloride ions and high temperature.

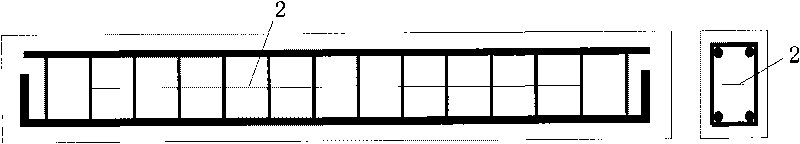

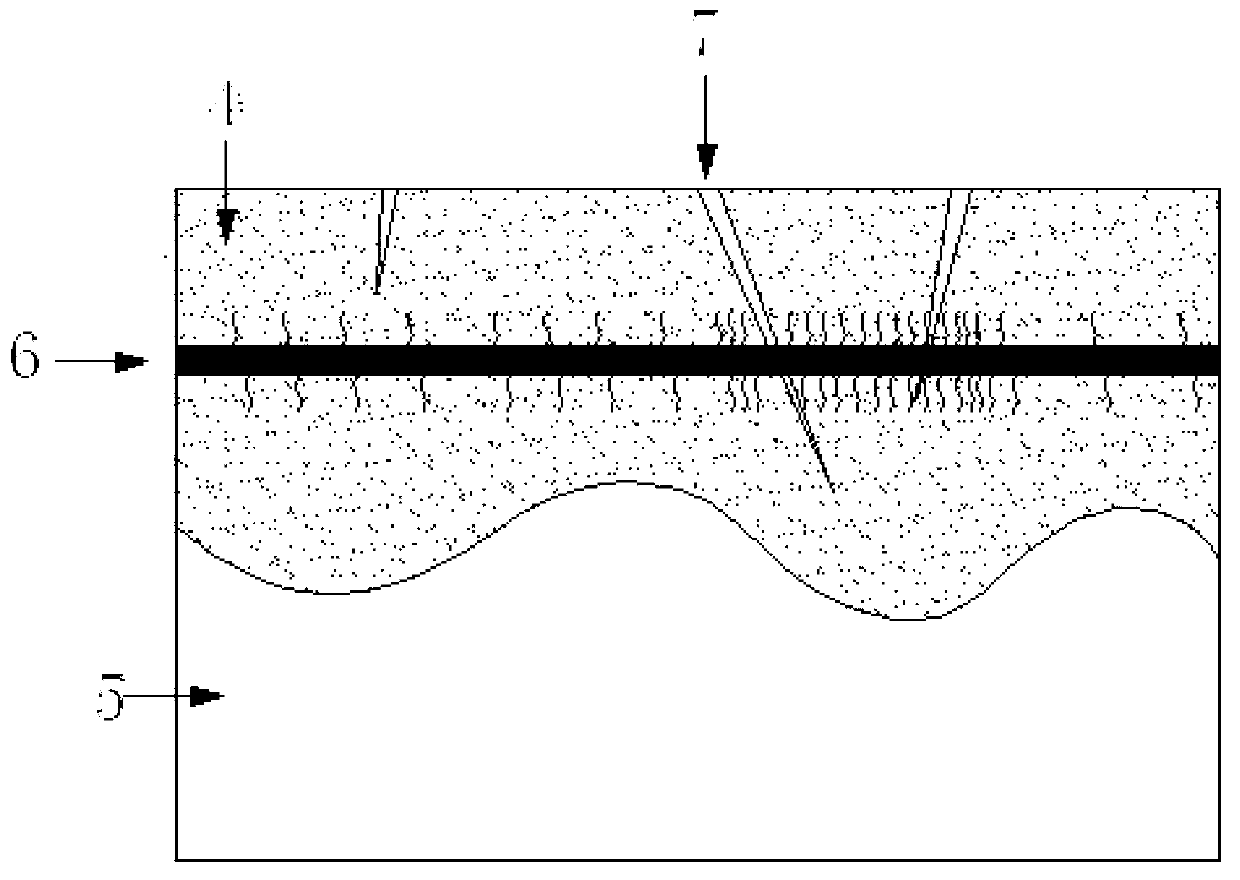

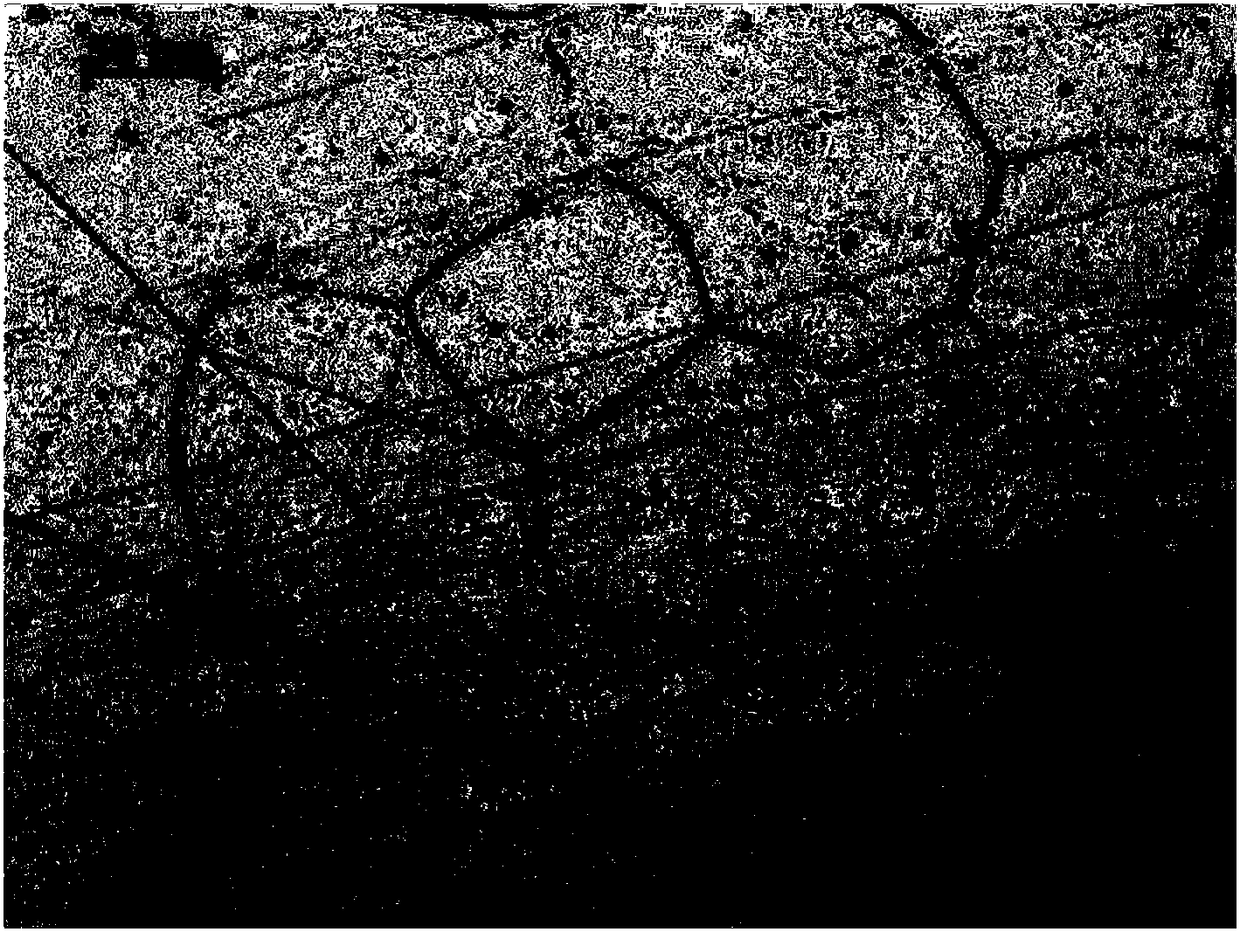

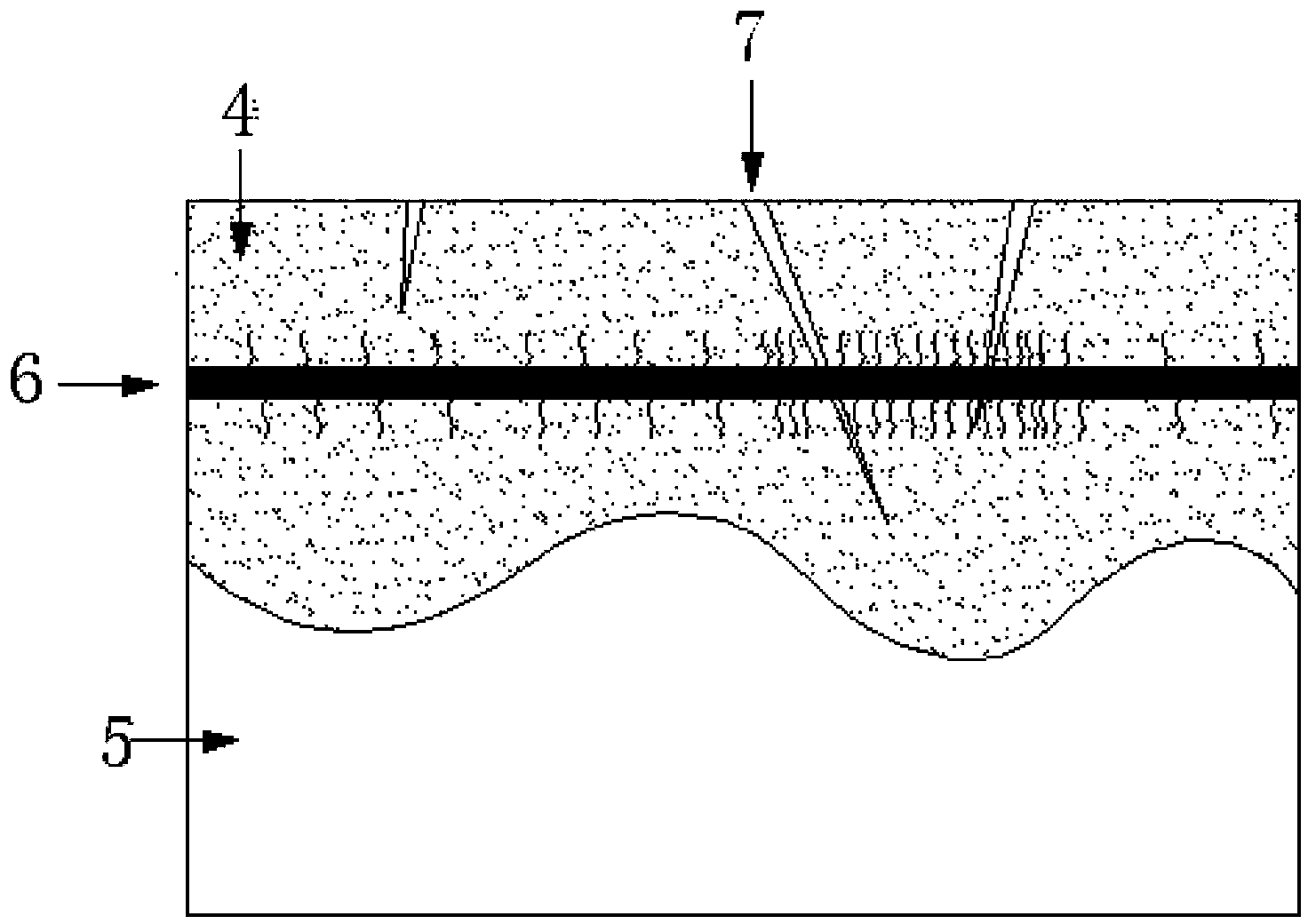

Accelerated test method of non-uniform corrosion in inbuilt electrode simulation concrete

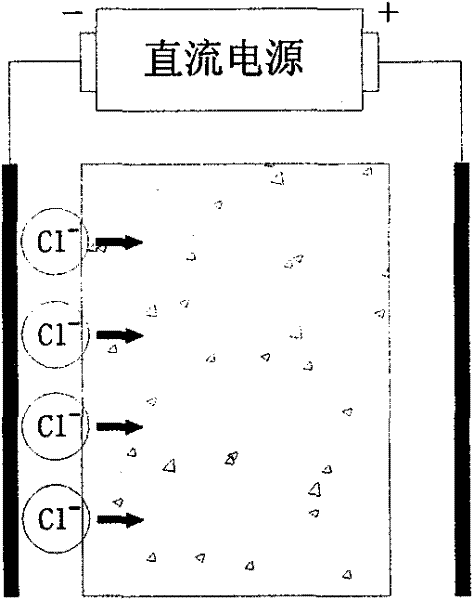

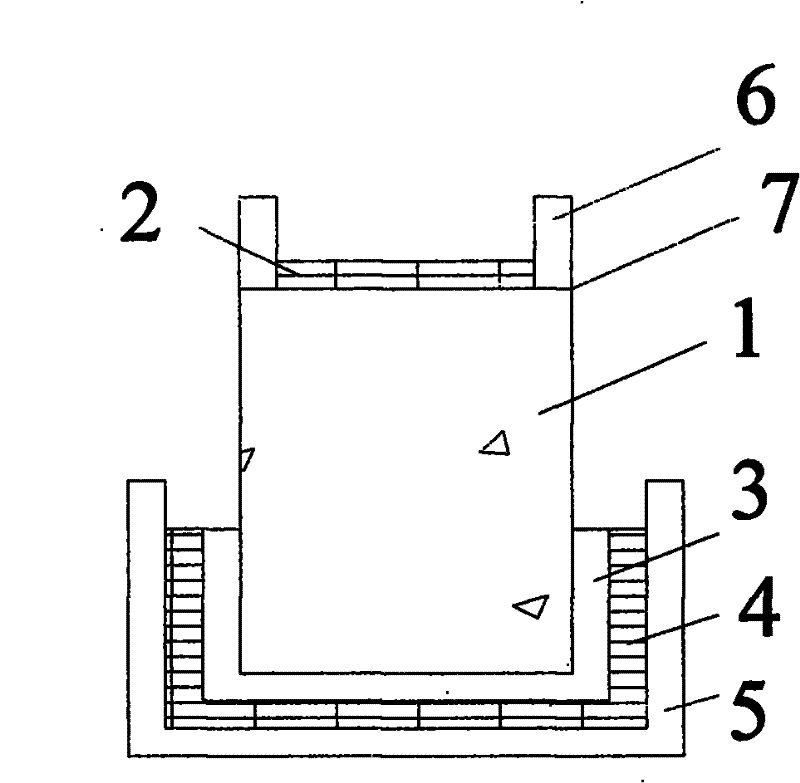

The invention discloses an accelerated test method of non-uniform corrosion in inbuilt electrode simulation concrete. After a concrete test piece is prepared by precating stainless steel sheets in concrete, the concrete test piece is successively performed with electroosmosis treatment, drying and watering cycle and constant-current energization treatment. Under the action of an electric field, chlorid ions accelerate to move into a concrete structure, and reinforcing steel bars in concrete reach the corrosion threshold value in advance so as to simulate the process that chlorid ions enter the concrete structure in the engineering environment. The drying and watering cycle process and little corrosion current speed up to corrode the reinforcing steel bars in the concrete structure, and the developing process of practical corrosion-induced expansive cracks is simulated. The method of the invention can simulate the diffusion process of chlorid ions to concrete in the chloride corrosion environment to realize the non-uniform corrosion and the single-surface corrosion of reinforcing steel bars in concrete, truly reflects the developing process of corrosion-induced expansive cracks in a reinforced concrete structure, and provides an accelerated test method for accessing the corroded property of the reinforced concrete structure.

Owner:ZHEJIANG UNIV

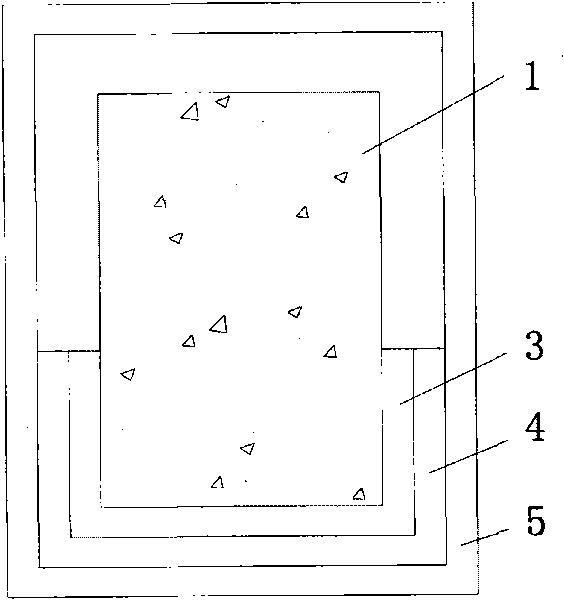

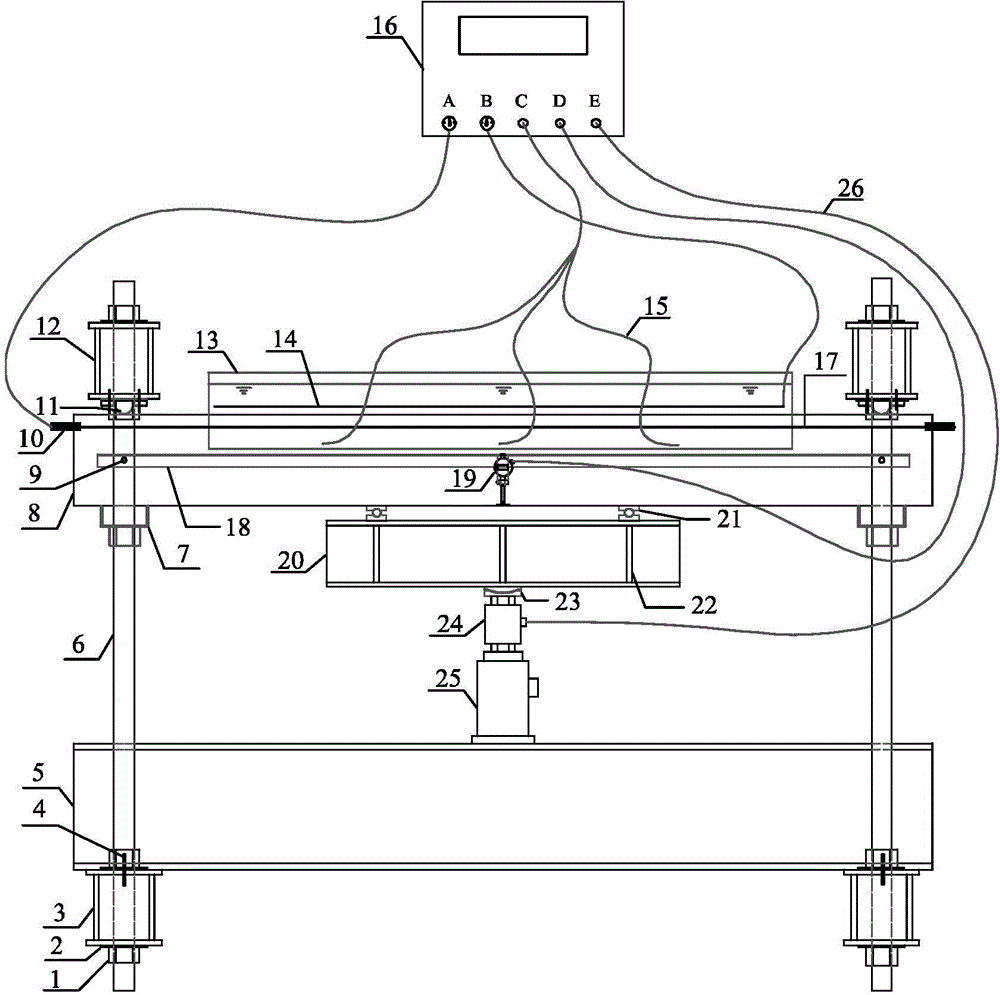

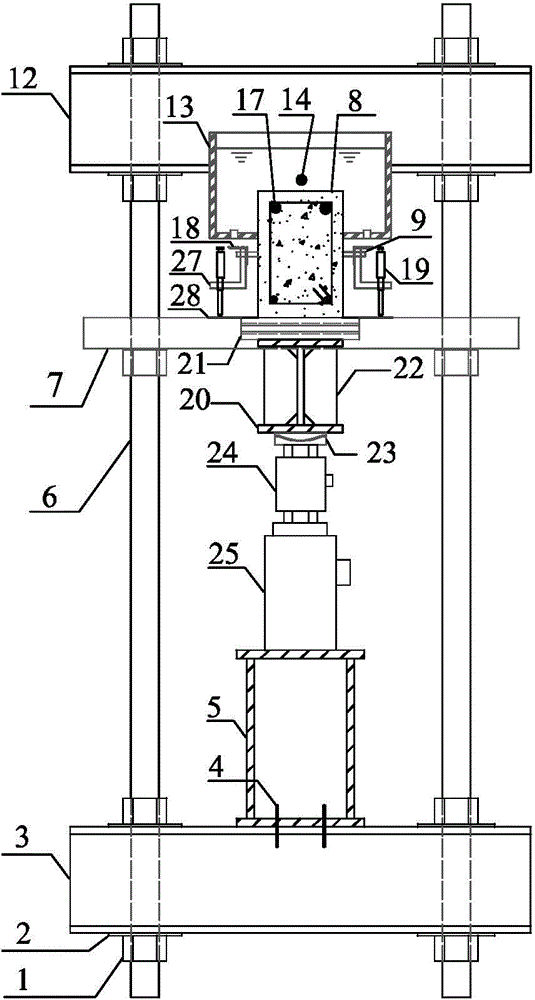

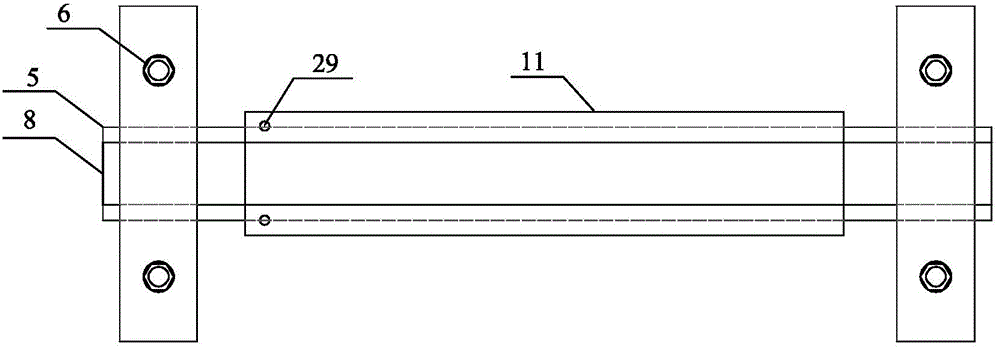

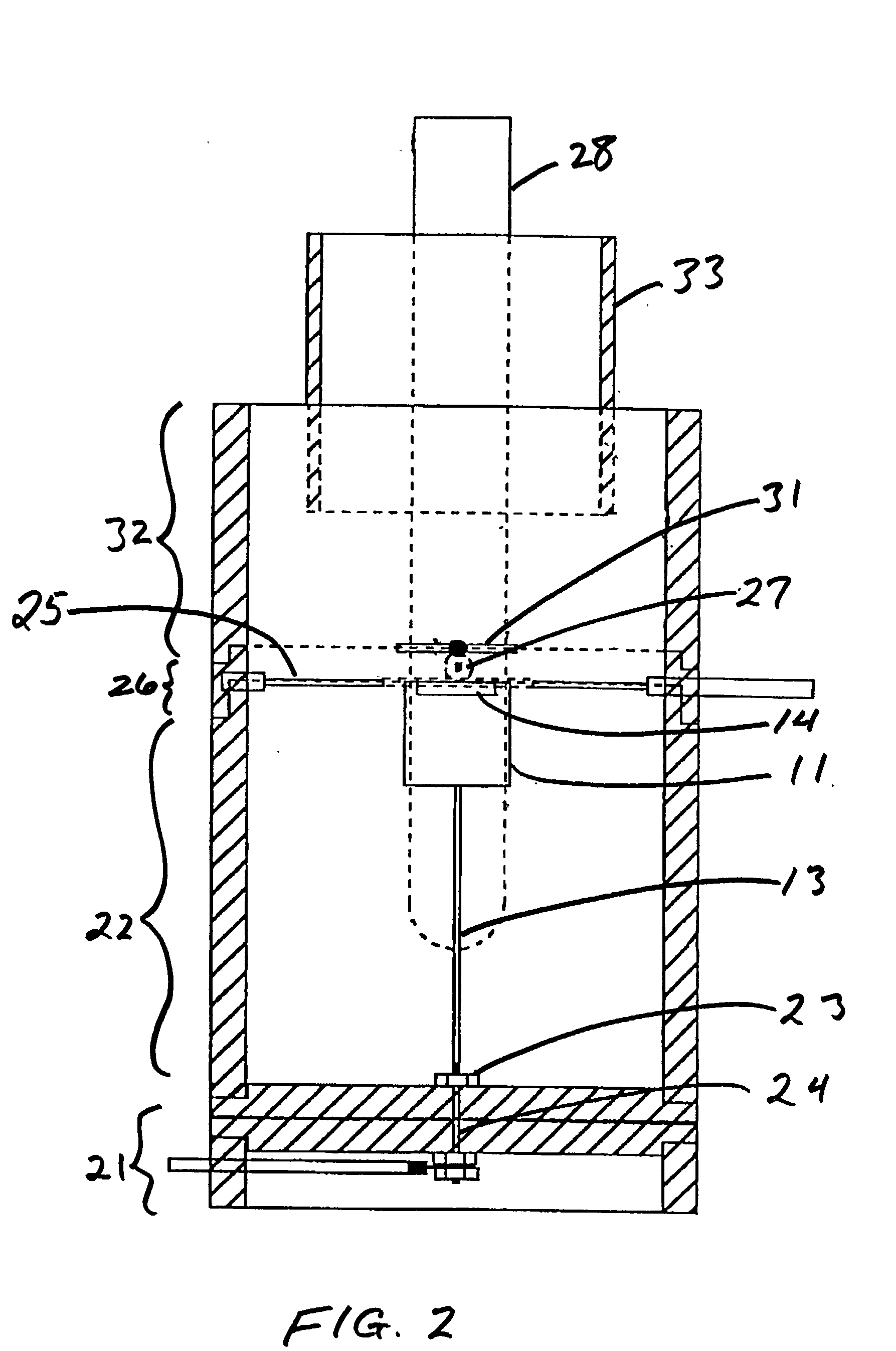

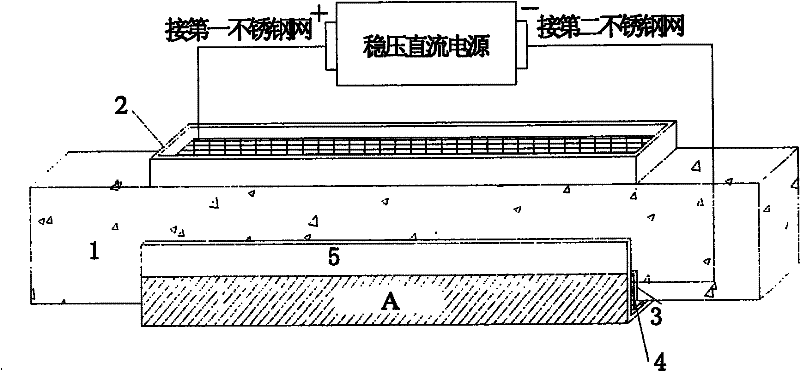

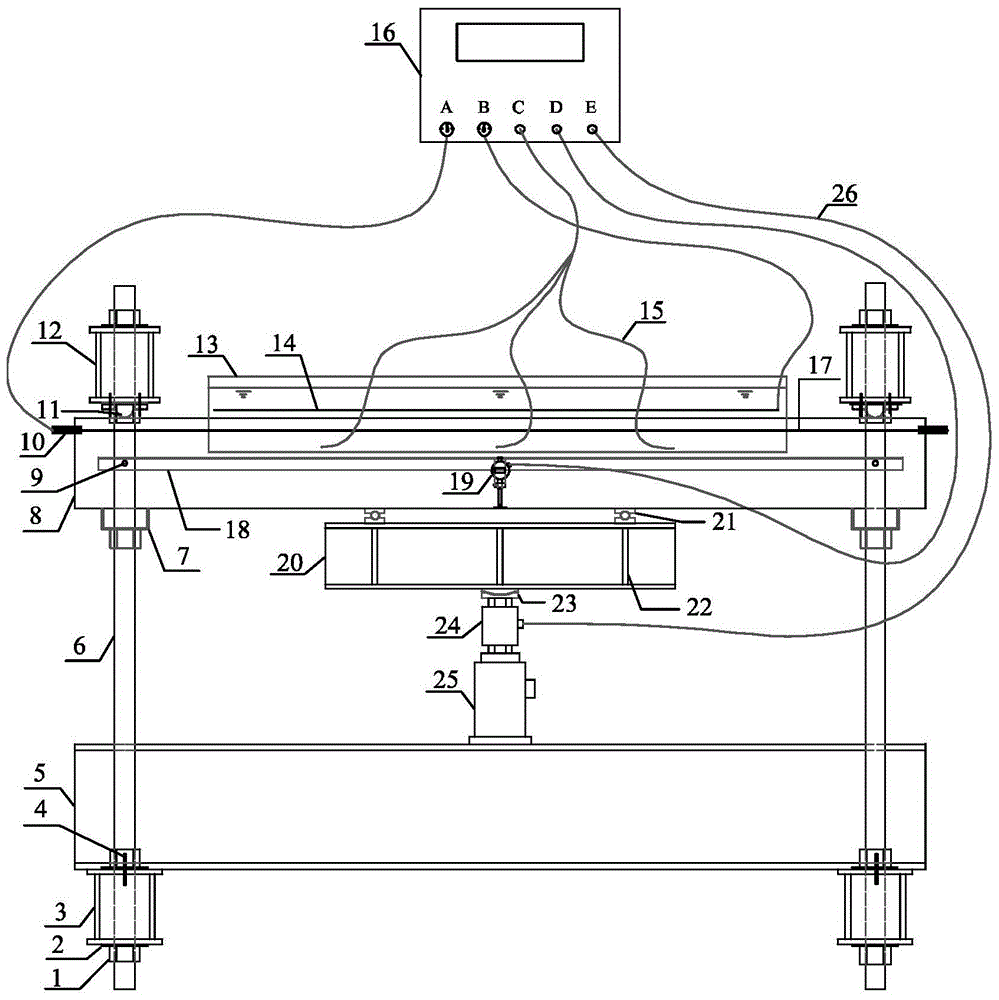

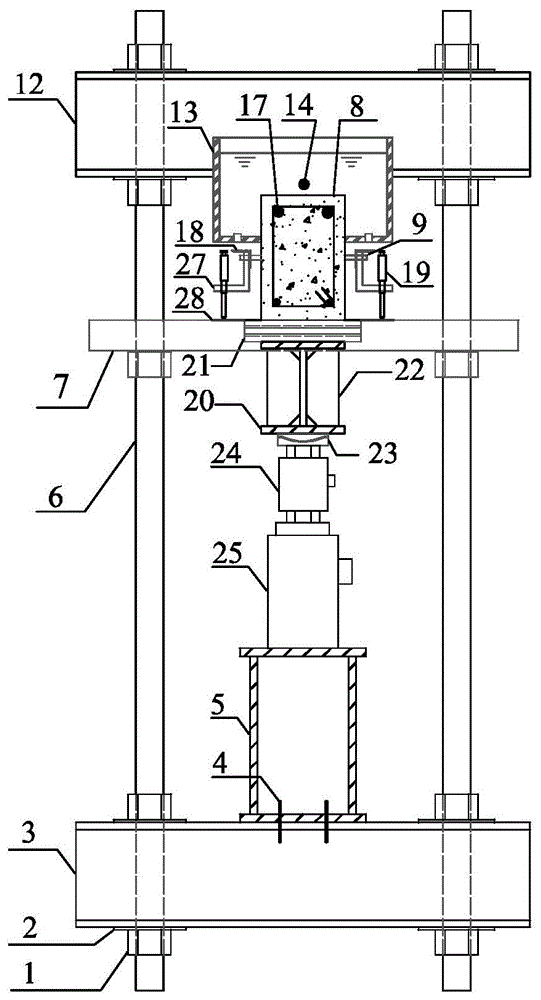

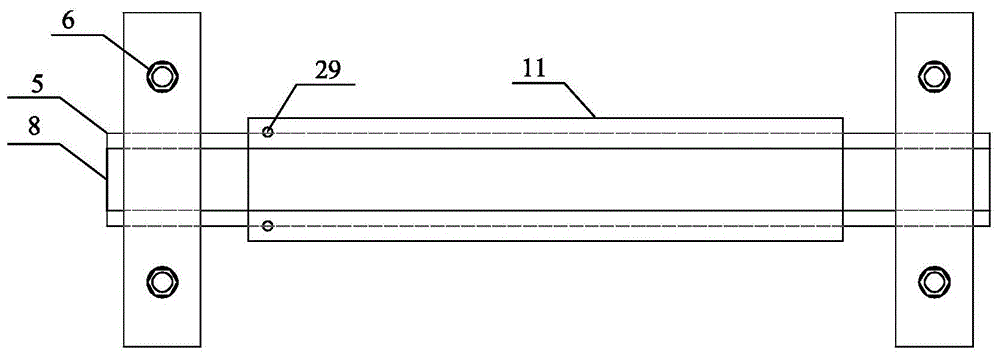

Device and method for testing chloride corrosion of reinforced concrete member under continuous load

ActiveCN104132847ATroubleshoot test setup issuesSolve the real problemMaterial strength using tensile/compressive forcesMicrocontrollerData acquisition

The invention provides a device and method for testing chloride corrosion of a reinforced concrete member under a continuous load. The device comprises a continuous load loading device, a rapid chloride corrosion device and a measurement and control device. A continuous load is applied by a loading frame and a drive device, a frame body is filled with a chloride solution and is fixed at the upper-middle part of a test beam in a sealing manner, air is continuously injected in the chloride solution by adopting an air pump, and direct current is introduced into reinforced steel bars of the test beam to implement the rapid corrosion. Relevant data acquirers, electrochemical testers and output equipment which are controlled through a single chip microcomputer in a unified manner are integrated in the main control box, the continuous load is measured in real time, and periodically corrected to a target level, corrosion behaviors of a corroded member are periodically tested, and data are acquired, displayed, stored, printed and output in real time. The device is capable of effectively simulating an actual corrosion working condition of the on-active service reinforced concrete structure member under the coupling effect of a chloride environment and the load, and provides a scientific basis for evaluating the durability of engineering structures under chloride environments such as sea and salt lakes.

Owner:HOHAI UNIV

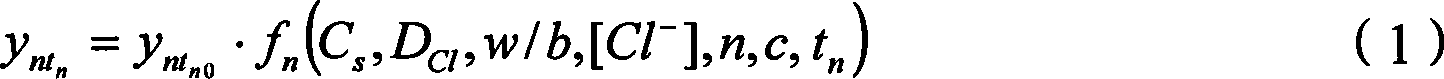

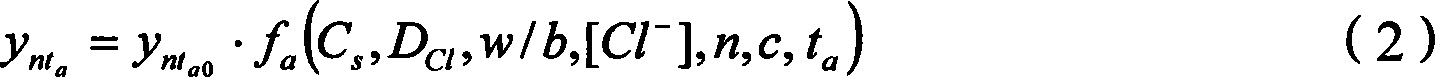

Multiple environment time chloride corrosion concrete evaluation method

InactiveCN101183059AWeather/light/corrosion resistanceMaterial testing goodsThird partyField conditions

The present invention relates to a evaluation method for the durability of chloride corrosion concrete, in particular to an evaluation method for similarity chloride corrosion concrete with multiple environment time. A third party reference object which is provided with the similar environment situation with the research object and serves for a plurality of years is selected. The boundary condition of each influence factor at the serving initial time of the research object, the third party reference object and the material of the research object are collected. The performance degradation relationship of the time of the third party reference object under spot environment and the corresponding concrete test piece in artificial climate simulation laboratory is compared and analyzed. The performance degradation time similar relationship of concrete structure durability in artificial simulation environment and spot environment is established. According to the boundary condition of the research object and the durability parameters of the corresponding concrete test piece obtained in acceleration condition, the performance degradation similar relationship of concrete structure durability in two environments is utilized, the durability evaluation and the life prediction are carried out to the research object on a spot condition.

Owner:ZHEJIANG UNIV

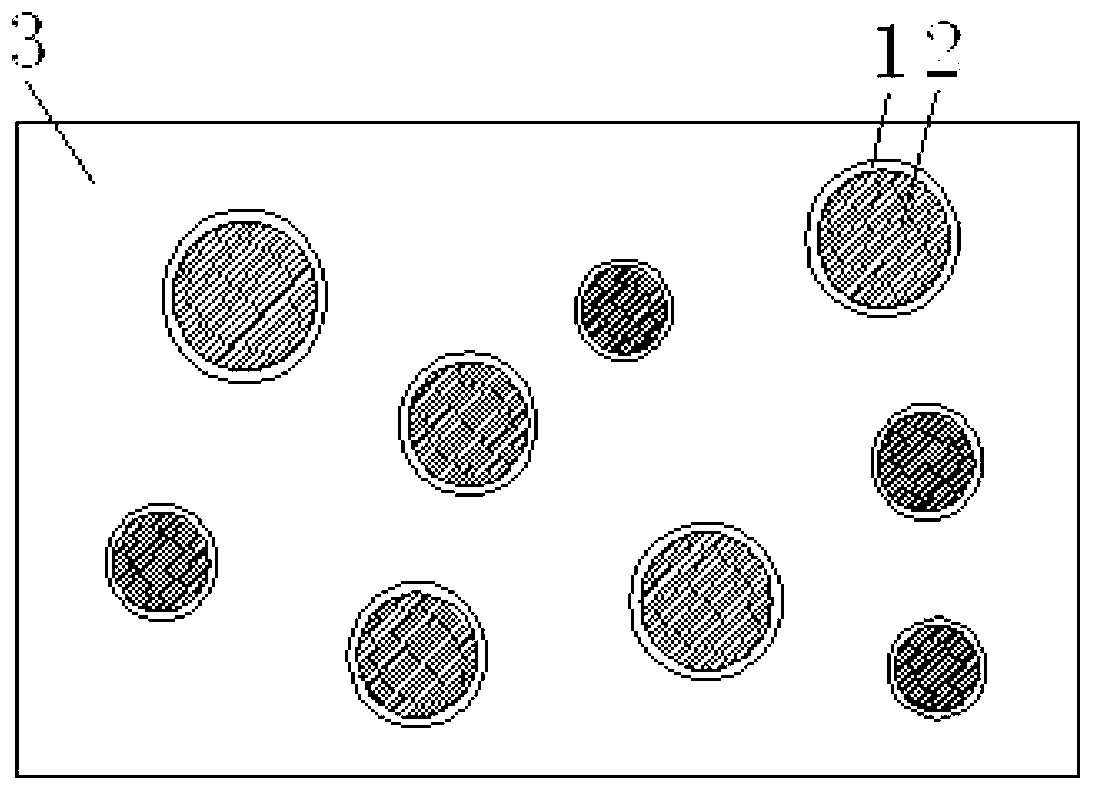

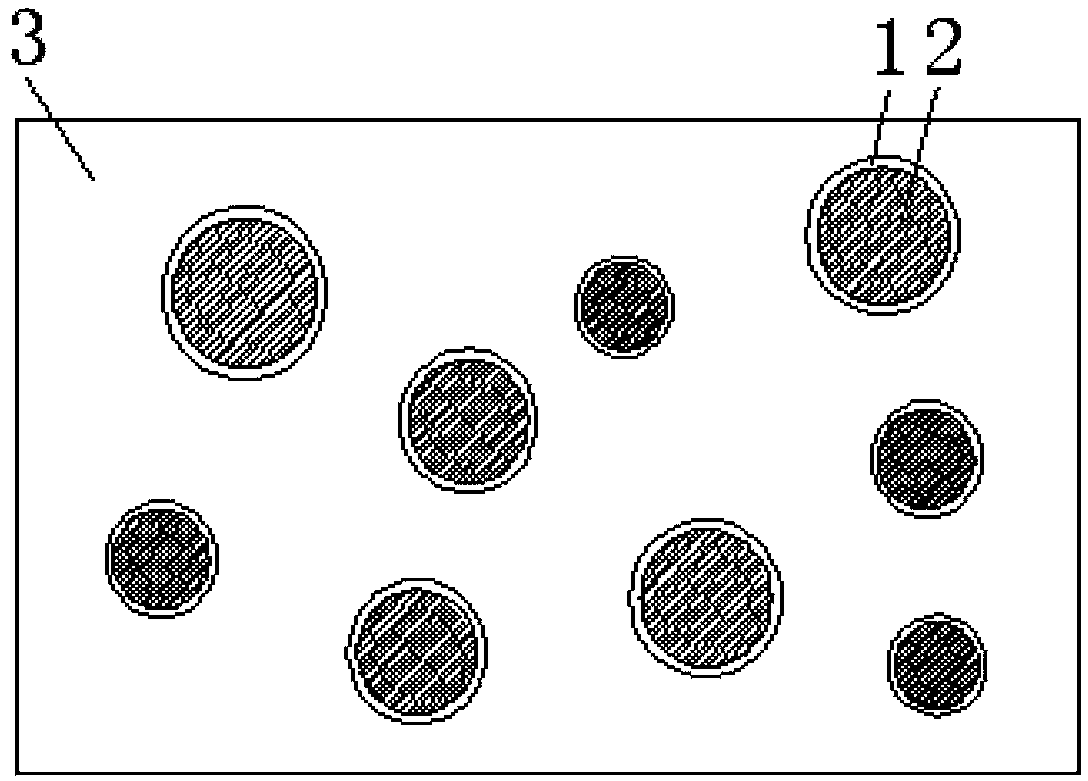

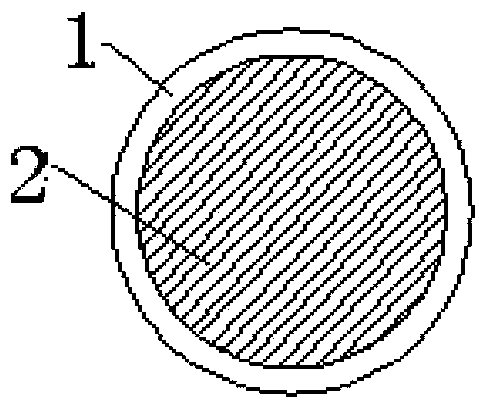

Chlorine salt corrosion resistant system with chemical microcapsule for underground structure concrete

ActiveCN102992673AAvoid problems such as downtimeImprove securityPhysical chemistryChloride corrosion

The invention relates to the field of concrete engineering, and especially relates to a chlorine salt corrosion resistant system with chemical microcapsule for underground structure concrete. The invention relates to the field of concrete engineering, and especially relates to a chlorine salt corrosion resistant system with chemical microcapsule for underground structure concrete. Compared with an existing chloride corrosion resistance method, the chloride corrosion resistance system provided by the invention has the following advantages: the system can realize intelligent control of chloride concentration by concrete, reduce chlorine salt corrosion, and produce precipitate to block a channel corroded by chlorine salt while reducing the chloride ion concentration; the microcapsules can protect the internal repair agent from outside influence, so as to realize long-time effectiveness of chlorine salt corrosion resistance of the repair agent; and compared with an anticorrosive coating, the chlorine salt corrosion resistant system can realize large-scale multiple rehabilitation due to a large amount of chemical microcapsules evenly distributed in the concrete matrix.

Owner:TONGJI UNIV

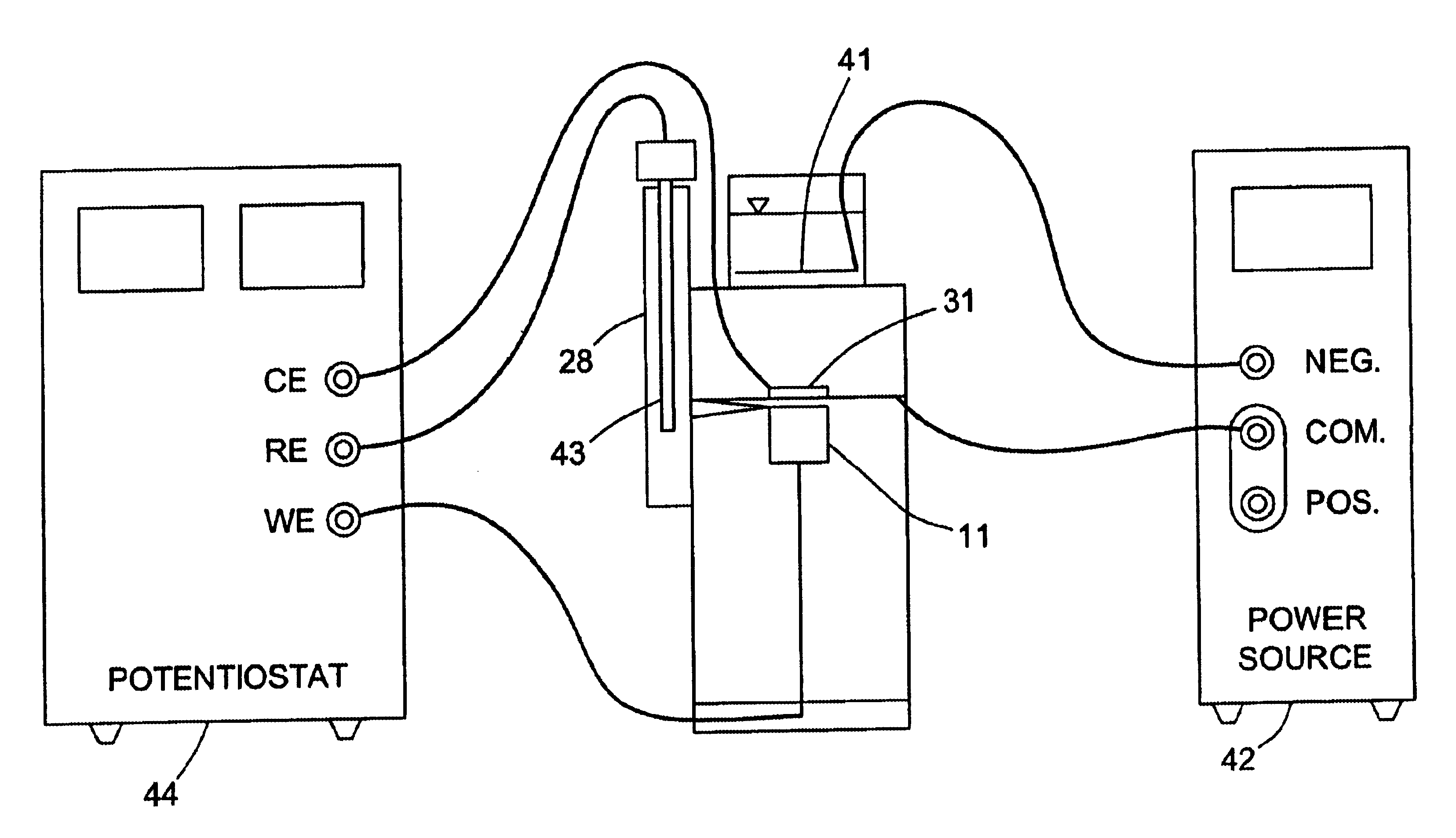

Determination of chloride corrosion threshold for metals embedded in cementitious material

InactiveUS20030011387A1Weather/light/corrosion resistanceResistance/reactance/impedenceMetal chloridePhysical chemistry

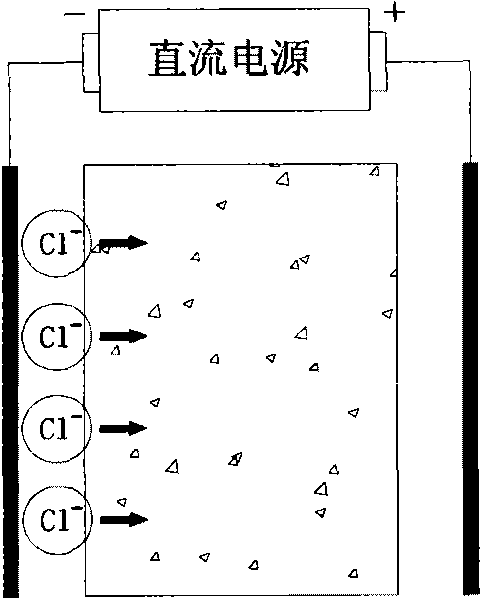

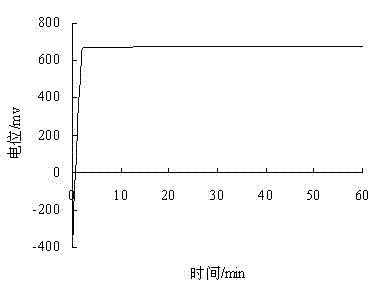

The chloride corrosion threshold of a metal embedded in a cementitious structure is determined in an accelerated manner by using an electric field to increase the rate of migration of chloride ion into the structure and monitoring the interface between the metal and the cementitious material to detect the onset of corrosion, then determining the chloride corrosion threshold, which is defined as the chloride content of the cementitious material once corrosion has begun. This determination can be performed over a time period of as little as 2 to 3 weeks rather than the months or years required by conventional chloride corrosion test procedures.

Owner:CMC STEEL FABTORS +1

Antifreeze anticorrosion durable concrete and preparation method thereof

The invention discloses an antifreeze anticorrosion durable concrete. The concrete comprises the following components, by weight, 500 parts of a gelling material, 700-715 parts of medium sand, 1050 parts of broken stone, 164 parts of water and 10.56-18 parts of a water reducer, wherein the gelling material comprises 54-56wt% of cement and 44-46wt% of powder A; and the powder A comprises the following components: 30-35wt% of slag, 20-25wt% of zeolite, 35-40wt% of coal ash, 5-10wt% of long bluestone and 0-7wt% of quicklime. The invention also discloses a preparation method of the concrete. The preparation method comprises the following steps: 1, weighing raw materials of the components of the powder A according to above proportions, crushing by an ultrafine mill, and uniformly mixing; 2, weighing raw materials of the components of the concrete according to above proportions; 3, sequentially adding ordinary Portland cement, the powder A, the medium sand and the broken stone to a concrete stirring device, and stirring for 2-3min to fully and uniformly mix; and 4, slowly adding well weighed water and the well weighed water reducer to the obtained mixture while stirring, and continuously stirring for 1-2min to obtain the concrete. The concrete of the invention is high performance concrete which can resist strong sulfate corrosion, strong chloride corrosion, freeze-thaw cycles and drying and wetting cycles.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

Determination of chloride corrosion threshold for metals embedded in cementitious material

InactiveUS6646427B2Weather/light/corrosion resistanceResistance/reactance/impedenceMetal chlorideTest procedures

The chloride corrosion threshold of a metal embedded in a cementitious structure is determined in an accelerated manner by using an electric field to increase the rate of migration of chloride ion into the structure and monitoring the interface between the metal and the cementitious material to detect the onset of corrosion, then determining the chloride corrosion threshold, which is defined as the chloride content of the cementitious material once corrosion has begun. This determination can be performed over a time period of as little as 2 to 3 weeks rather than the months or years required by conventional chloride corrosion test procedures.

Owner:CMC STEEL FABTORS +1

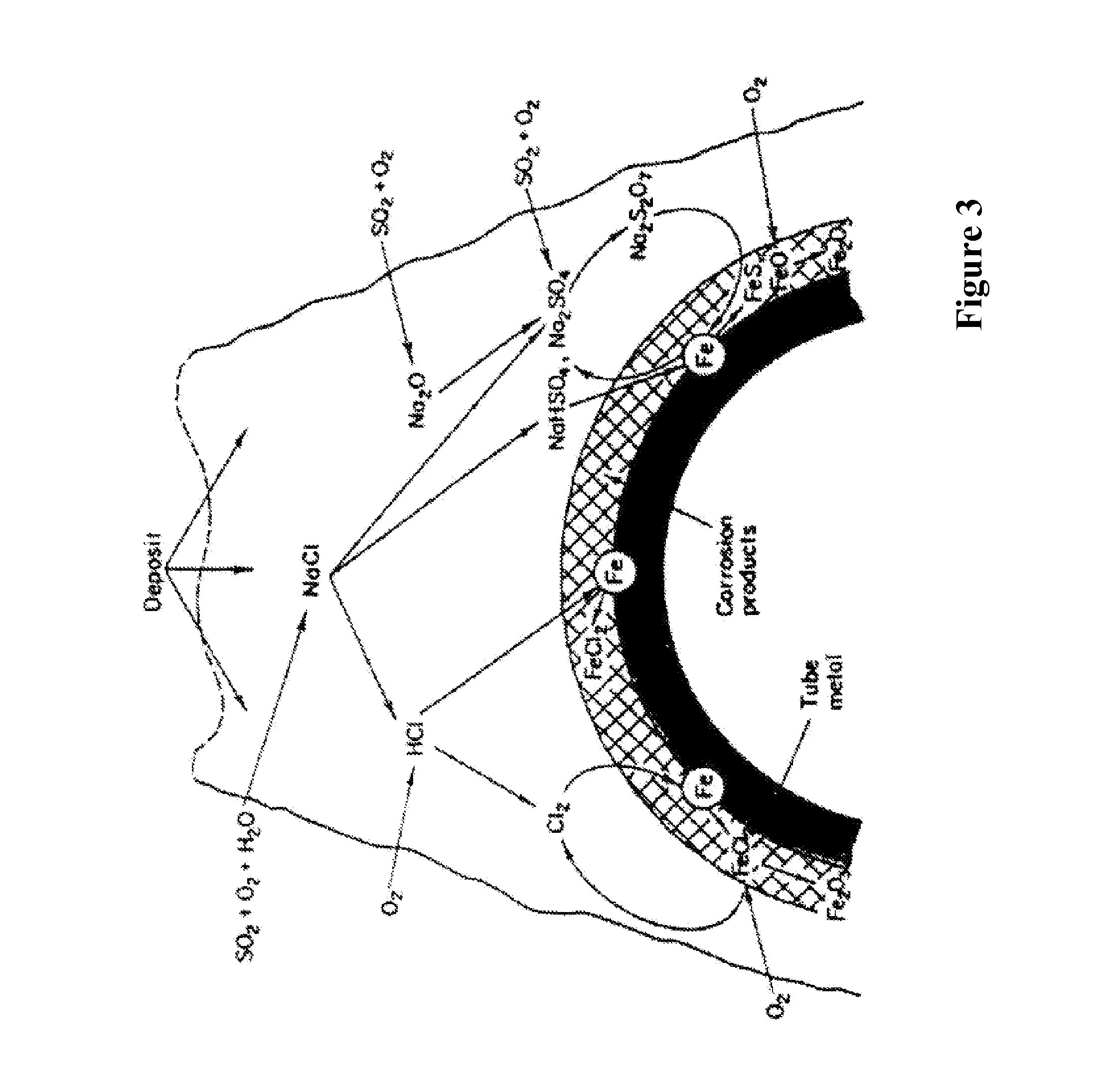

Process for corrosion control in boilers

InactiveUS20060290935A1Reduce corrosionWaste of energyWeather/light/corrosion resistanceSpecific water treatment objectivesRegimenCombustion

A corrosion control process is described. The process is especially useful in the control of chloride corrosion in waste to energy boilers. Corrosion of high temperature surfaces can be assessed by the monitor and controlled introduction of treatment chemicals by targeted in furnace injection reduces corrosion while maximizing combustion efficiency. A corrosion monitor is also described. Before and following selection of corrosion control chemicals and the locations for targeted in furnace injection, injection regimen and chemical selection and introduction parameters are monitored with the aid of the method and apparatus of the invention to adjust one or more control parameters to reduce corrosion. A preferred method will employ a treatment chemical that comprises an SO2 or SO3 reagent, e.g., sulfuric acid, sulfur, a sulfate salt or a bisulfite salt.

Owner:FUEL TECH

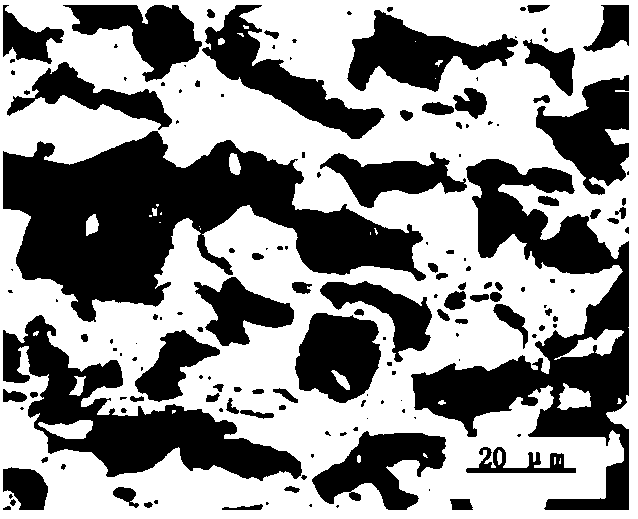

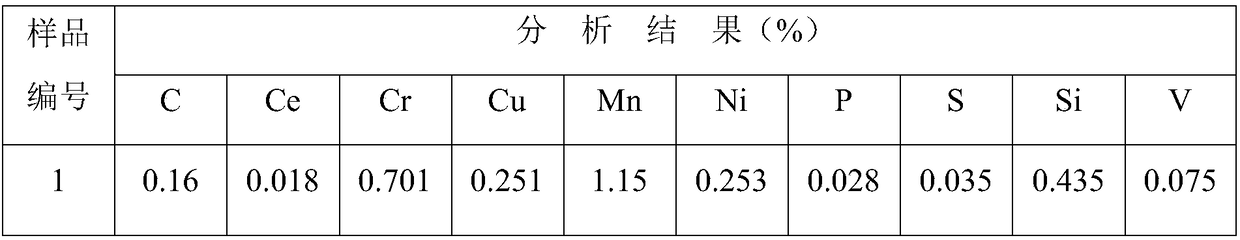

400MP class a seismic chloride-corrosion-resistant reinforcing steel bar and manufacturing method thereof

InactiveCN109023041AImprove corrosion resistanceHigh strengthManufacturing convertersChemical compositionRebar

The invention relates to a 400MP class a seismic chloride-corrosion-resistant reinforcing steel bar and a manufacturing method thereof. The 400MP class a seismic chloride-corrosion-resistant reinforcing steel bar comprises the chemical compositions of, by weight, 0.13-0.18% of C, 0.20-0.60% of Si, 0.95-2.0% of Mn, 0.10-12.0% of Cu, 0.20-2.50% of Cr, 0.0-2.0% of Ni, 0.0-2.8% of V and 0.0-2.0% of RE, the balance Fe and inevitable impurities elements. The reinforcing steel bar has the following advantages that the corrosion resistance of the reinforcing steel bar is good, the strength of the reinforcing steel bar is further improved, and the service life of the reinforcing steel bar is further prolonged.

Owner:BAOTOU IRON & STEEL GRP

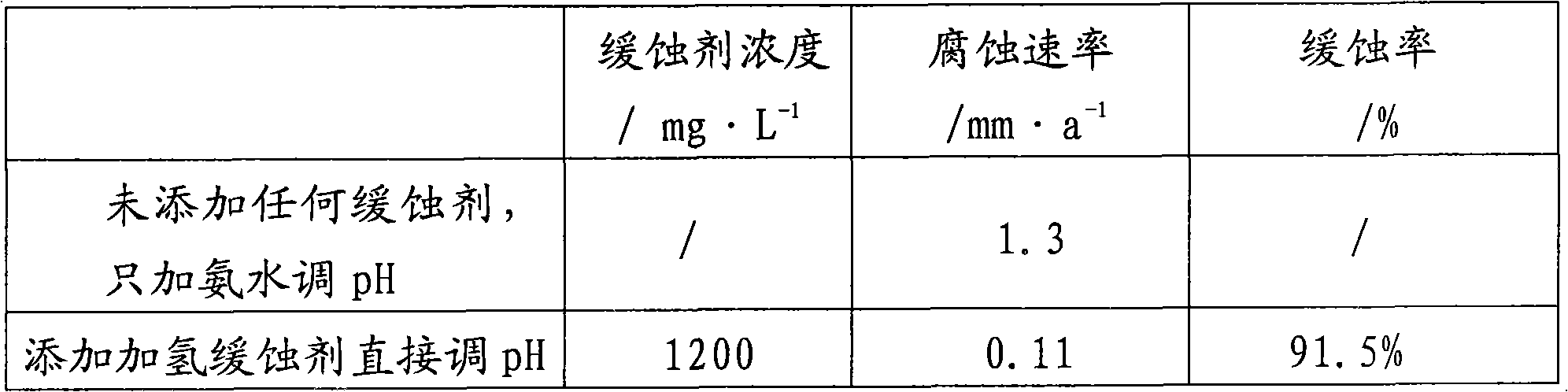

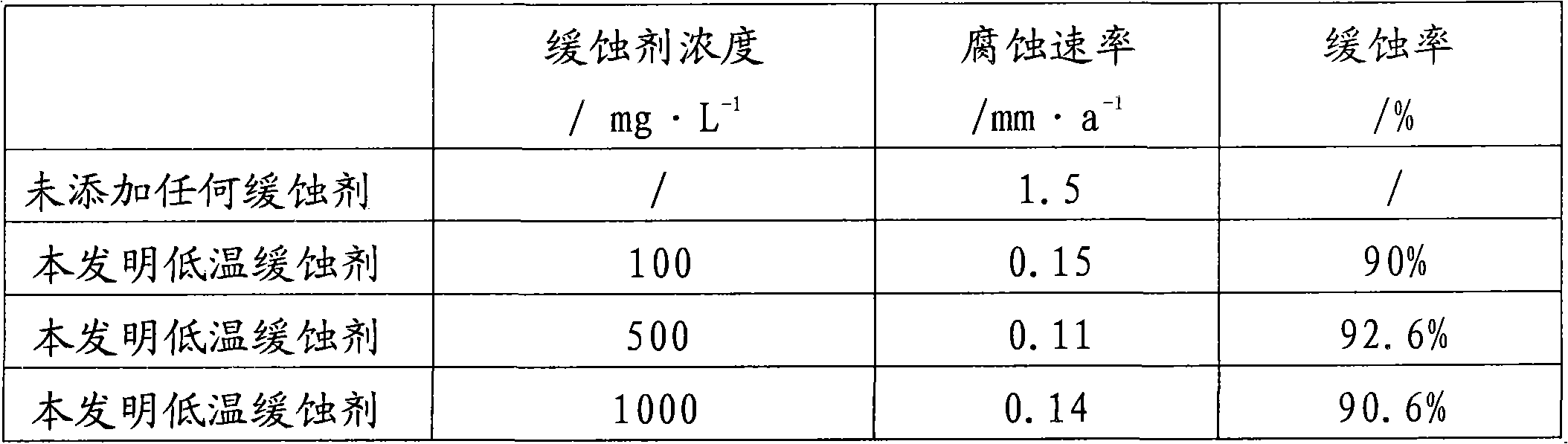

Low-temperature corrosion inhibitor

The invention belongs to the field of chemical additives and discloses a low-temperature corrosion inhibitor. The low-temperature corrosion inhibitor comprises the following ingredients of: by weight, 30-50% of a water-soluble imidazoline compound, 3-15% of an alkynol compound, 12-45% of a nitrogen-containing adsorption-type corrosion inhibitor, and 20-40% of a compounded solvent. The low-temperature corrosion inhibitor provided by the invention is resistant to high-density wet hydrogen sulfide and chloride corrosion, is safe and sanitary, and has no pollution.

Owner:WUHAN RUNERHUA TECH

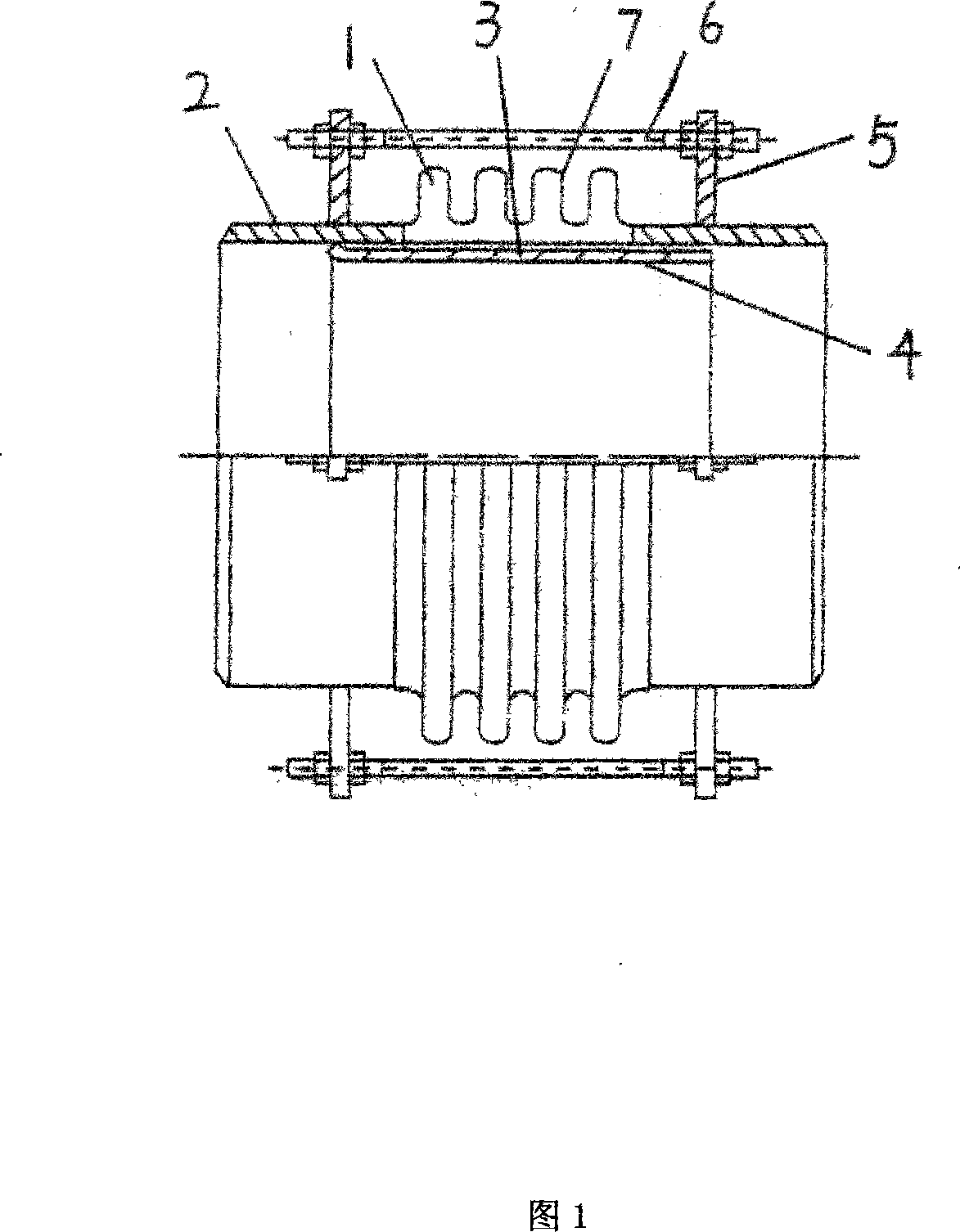

Ripple compensator against vibration

InactiveCN101230945ACompact structureStrong pressure capacityFlanged jointsPipeline expansion-compensationEngineeringFlanging

The invention relates to the technical field of a corrugation compensator, especially a vibration-proof corrugation compensator, which comprises a sylphon bellowss and a side tube which are connected into an integral structure. The invention is characterized in that an inner sleeve is arranged in the sylphon bellowss, and the inner surface of the inner sleeve is uniformly sprayed with an anticorrosion coating. The external surfaces of both ends of the side tube are provided with a flanging which is integrated with the side tube, and a plurality of stiffeners are arranged on the flanging. The invention has the advantages of compact structure, strong pressure bearing capacity, acid, alkali and chloride corrosion prevention, high temperature resistance, heat insulation prevention, etc, which prevents the flow resistance of flow media in the compensator and the induced vibration of the sylphon bellowss caused by high speed flow of the media and extends the service life.

Owner:SHANGHAI HUQIANG PIPELINE EQUIP

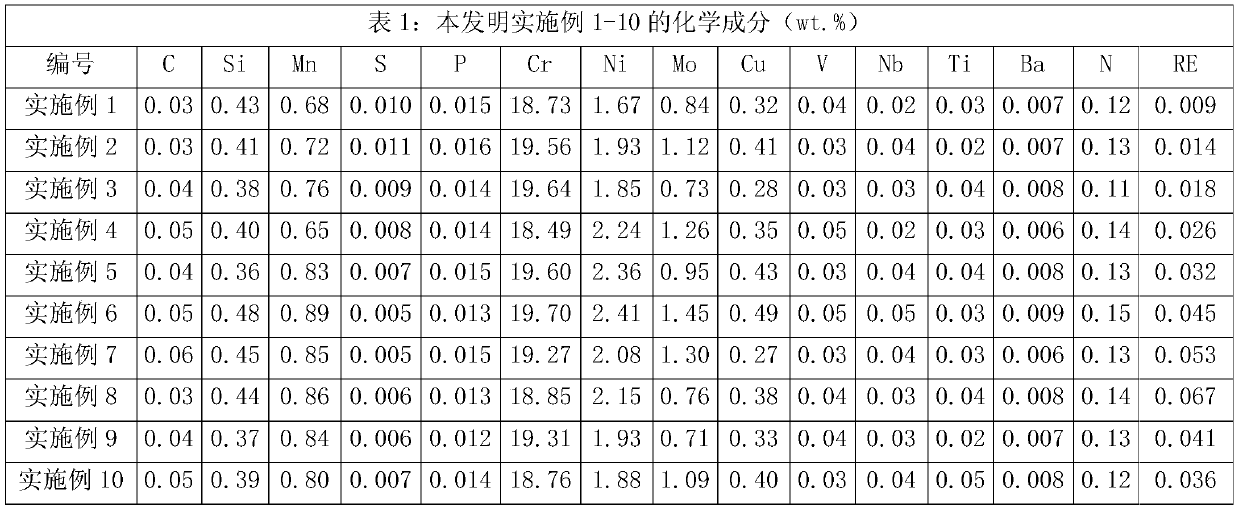

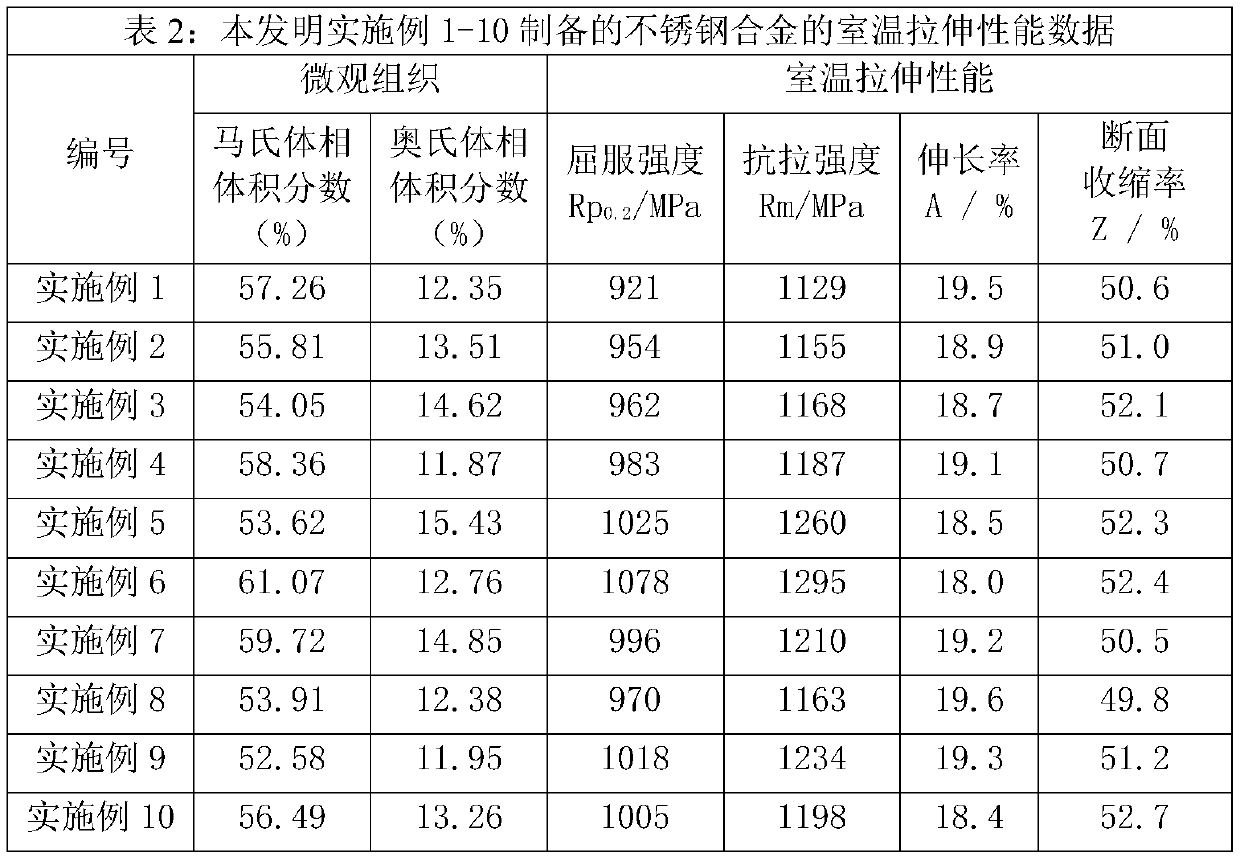

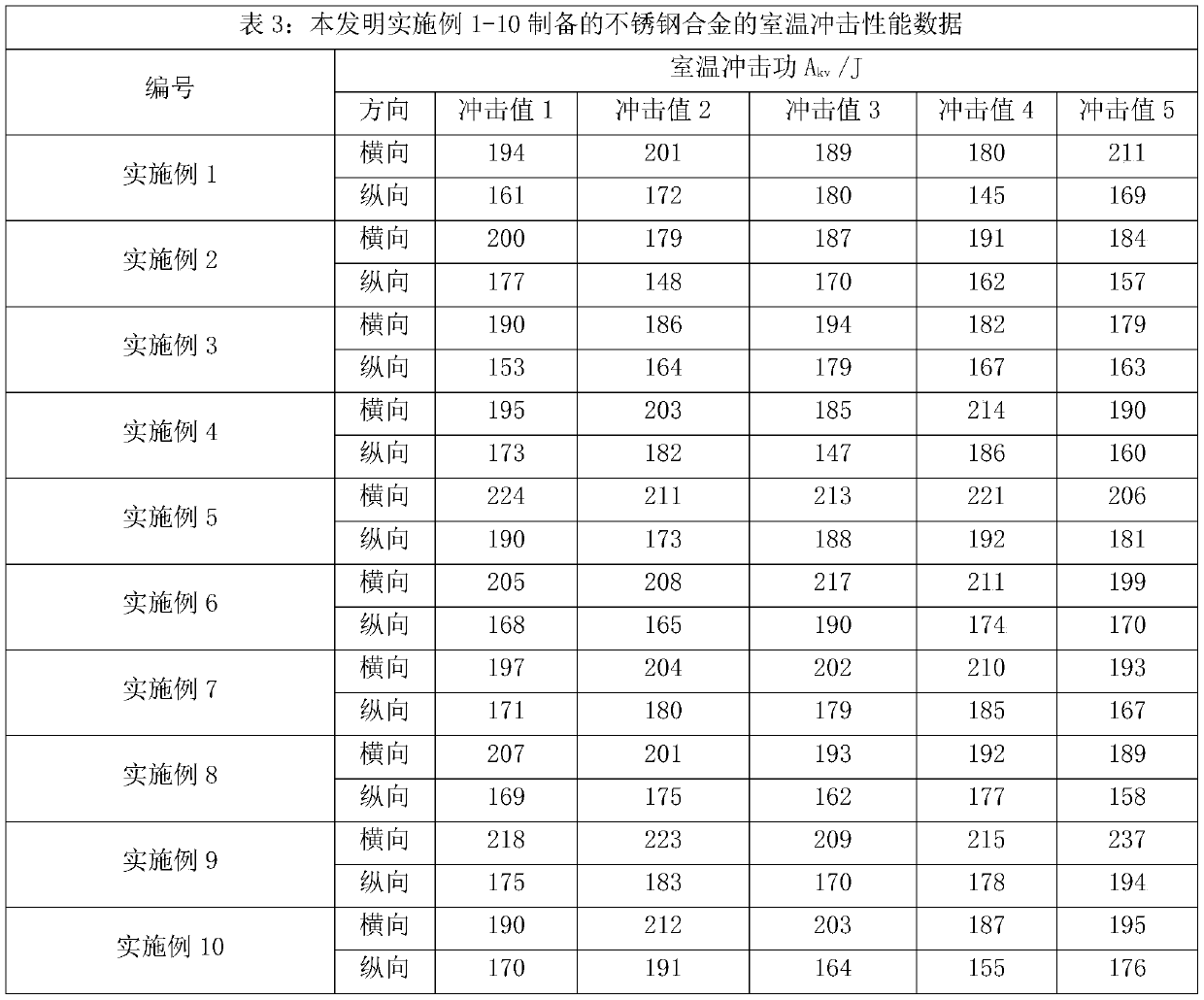

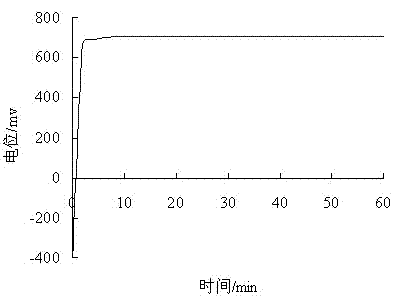

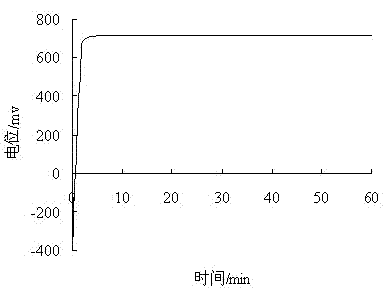

High-strength martensitic stainless steel and manufacturing process thereof

ActiveCN109811252AImprove the effect of solid solution strengtheningReduce segregationIngot castingMartensitic stainless steel

The invention discloses high-strength martensitic stainless steel. The high-strength martensitic stainless steel is prepared from the following components in percentage by weight: less than or equal to 0.1 percent of C, less than or equal to 0.02 percent of S, less than or equal to 0.02 percent of P, 0.1 percent to 0.5 percent of Si, 0.6 percent to 0.9 percent of Mn, 18.0 percent to 20.0 percent of Cr, 1.5 percent to 2.5 percent of Ni, 0.5 percent to 1.5 percent of Mo, 0.1 percent to 0.5 percent of Cu, 0.01 percent to 0.05 percent of V, 0.01 percent to 0.05 percent of Nb, 0.01 percent to 0.05percent of Ti, 0.001 percent to 0.1 percent of Ba, 0.1 percent to 0.15 percent of N, 0.001 percent to 0.1 percent of rear earth element RE, and the balance of Fe. The manufacturing process of the high-strength martensitic stainless steel comprises the following steps: melting, ingot-casting or ingot-casting cogging, hot-rolling, post-rolling thermal treatment and the like. A stainless alloy is high in strength and higher in corrosion resistance, is high in machining performance and is easy to form; and moreover, the stainless alloy has high CO2 and chloride corrosion resistant performance under a good high-temperature environment.

Owner:JIANGSU XIHU SPECIAL STEEL

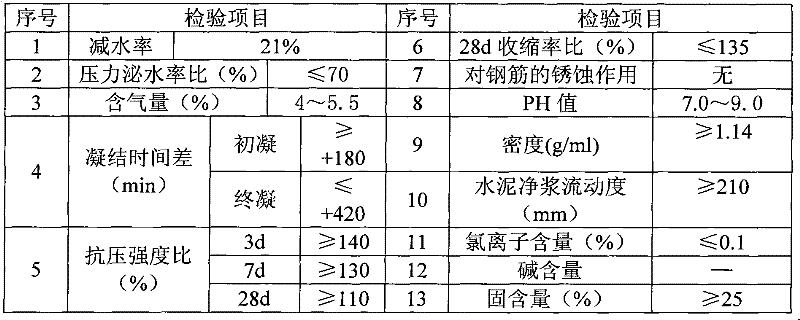

Polycarboxylate-based water-reducing agent with effect of inhibiting corrosion of steel bars and preparation method thereof

The invention discloses a polycarboxylate-based water-reducing agent with an effect of inhibiting corrosion of steel bars and a preparation method thereof, and belongs to the field of concrete additives. The water-reducing agent is prepared based on a modified ether polycarboxylate-based water-reducing agent; and the pH value of the modified ether polycarboxylate-based water-reducing agent is adjusted by use of a preferred alkanolamine organic monomer which has a corrosion-inhibiting effect on steel bars, and then preferred corrosion-inhibiting functional components are compounded. The modified ether polycarboxylate-based water-reducing agent is obtained by free radical induced polymerization of modified polyether and acrylic acid / methyl methacrylate in a water medium. The polycarboxylate-based water-reducing agent which is prepared by the method provided by the invention has the characteristics of high water-reducing rate, low alkali content, good product stability and good capability of inhibiting corrosion of steel bars, is particularly suitable for being used in steel reinforced concrete structures with alkali-aggregate reaction risks and in chloride corrosion environments, and helps improve durability of concrete structures.

Owner:NANJING RUIDI HIGH TECH

Ultralow-dosage corrosion inhibitor and preparation method thereof

The invention relates to an ultralow-dosage corrosion inhibitor and a preparation method thereof, belonging to the technical field of building materials. The ultralow-dosage corrosion inhibitor is prepared from the following components: by mass percent, 0.4% to 1% of sodium monoflurophosphate and 99.6% to 99% of mineral admixtures. The corrosion inhibitor does not contain nitrite, poses no harm to the environment and human bodies and can improve concrete strength. Compared to traditional corrosion inhibitors, the corrosion inhibitor provided in the invention has the advantages of excellent anticorrosion performance, capacity of improving concrete strength, environment friendliness, no harm and the like and is widely applicable to industrial and civil buildings which mainly suffer from chloride corrosion, e.g., buildings in marine environment areas and a steel bar retarding concrete structure which adopts deicing salts.

Owner:武汉三源特种建材有限责任公司

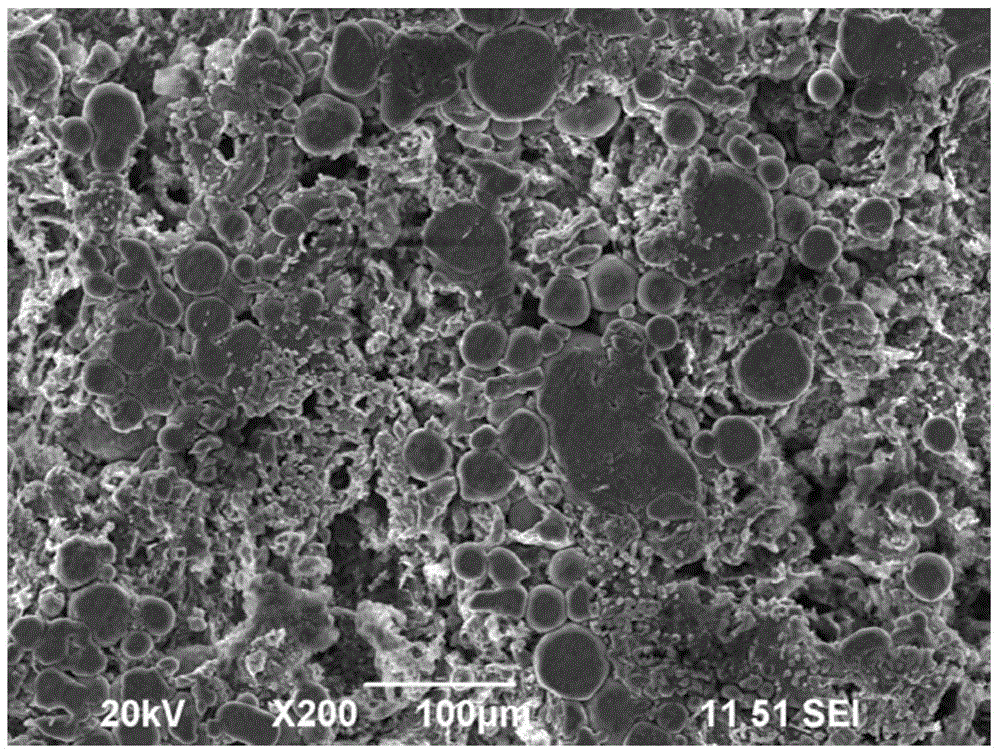

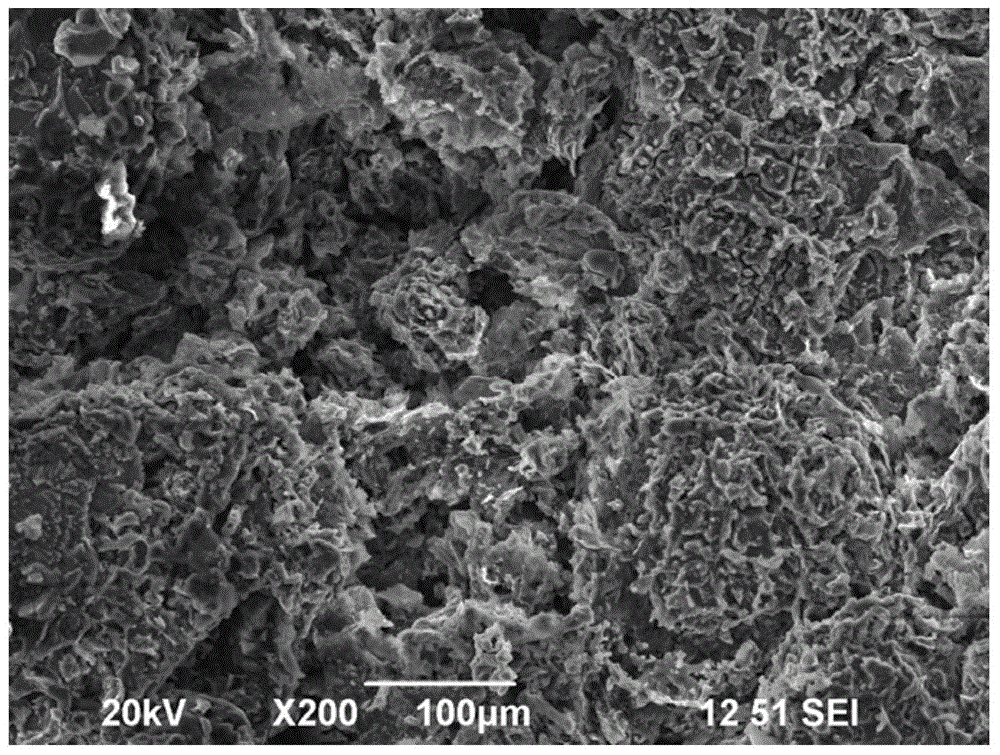

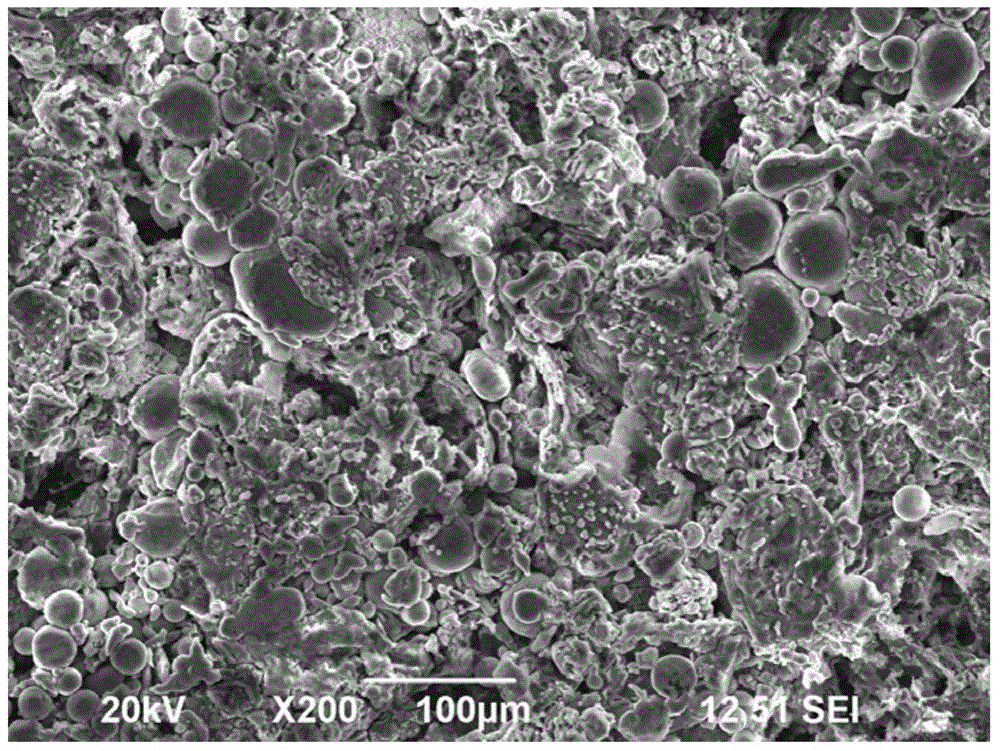

Al-Mg alloy porous material and preparation method thereof

The invention discloses an Al-Mg alloy porous material and a preparation method thereof. The Al-Mg alloy porous material is formed through sintering of an Al metal material and an Mg metal material, wherein the weight of Al accounts for 30%-70% of the weight of the material, and the balance is Mg. The material comprises one or more of four phases including alpha (Al), beta (Al3Mg2), gamma (Al12Mg17) and delta (Mg). The preparation method comprises main steps: firstly, 30%-70% of Al powder with grain sizes of 100-300 meshes and the balance of Mg powder with grain sizes of 100-300 meshes are mixed for 10 hours; the mixed powder of the Al powder and the Mg powder is subjected to pressure forming and kept at the forming pressure of 30-150 MPa for 20-120 seconds, and a pressed blank is obtained through pressing forming; finally, the pressed blank is placed in a vacuum sintering furnace to be sintered, and the vacuum degree is 1-10<-3> Pa. The alloy porous material has higher strength and excellent chloride corrosion resistance and has higher porosity and rich communication pores.

Owner:XIANGTAN UNIV

Method for detecting content of chloride in water

InactiveCN106908566AEliminate distractionsAvoid Titration EffectsChemical analysis using titrationPreparing sample for investigationSulfurPotentiometric titration

The invention relates to a method for detecting the content of chloride in water. The method comprises the following steps: heating a to-be-detected sample when the pH value is 8-9, continuing to regulate the pH value to be 2-6, and heating; adding hydrogen peroxide into the sample, and heating; regulating the pH value to be 2-3 after the sample is cooled to room temperature, and performing potentiometric titration with a silver nitrate standard solution; and calculating the content of chloride in the to-be-detected sample according to the volume of the consumed silver nitrate standard solution when the titration destination is reached. The method is applicable to detection of content of chloride in high-sulfur condensate of a refining device, fills up the blank that high-sulfur condensate of the refining device cannot be accurately detected, and provides more accurate reference basis for regulating anti-corrosion measure of the device, so that a preventive anti-corrosion measure is adopted, and potential corrosion hazard of the equipment can be found and eliminated; and a certain reference effect is achieved for detecting corrosion of chloride in condensate of similar devices in China.

Owner:PETROCHINA CO LTD

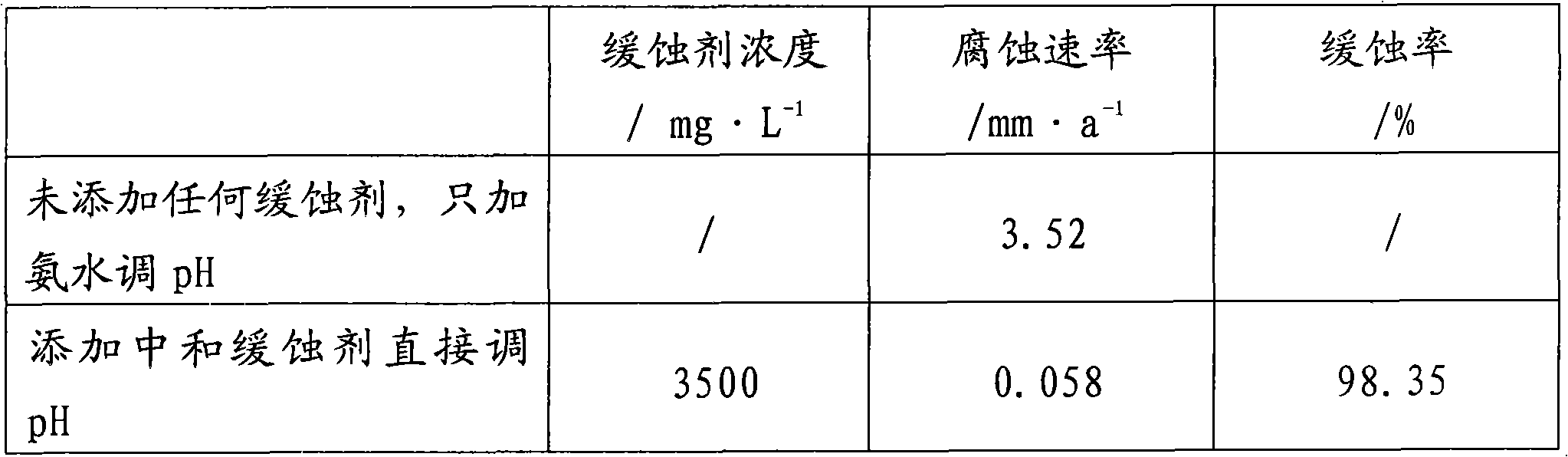

Corrosion inhibitor capable of preventing high-strength low-alloy steel from being corroded in chloride-containing corrosive medium

InactiveCN106544679AInhibition of localized corrosionMitigate uniform corrosionRare-earth elementCerium nitrate

The invention provides a corrosion inhibitor capable of preventing high-strength low-alloy steel from being corroded in a chloride-containing corrosive medium and belongs to the field of inhibitors. The corrosion inhibitor comprises phosphate with the concentration being 300-600 ppm, sodium tripolyphosphate with the content being 200-400 ppm, sodium phosphate with the content being 100-200 ppm, a sodium nitrite compound with the concentration being 20-60 ppm and a cerium compound with the concentration being 30-80 ppm, wherein the cerium compound is cerium chloride, or cerium sulfate or cerium nitrate, and the valence state of cerium is +3. The corrosion inhibitor containing the rare earth element, namely cerium with the valence state being +3, is developed for preventing the high-strength low-alloy steel from being corroded in the chloride-containing corrosive medium so as to meet requirements of oceaneering and ship engineering in the ocean resource development process.

Owner:BEIJING UNIV OF CHEM TECH +1

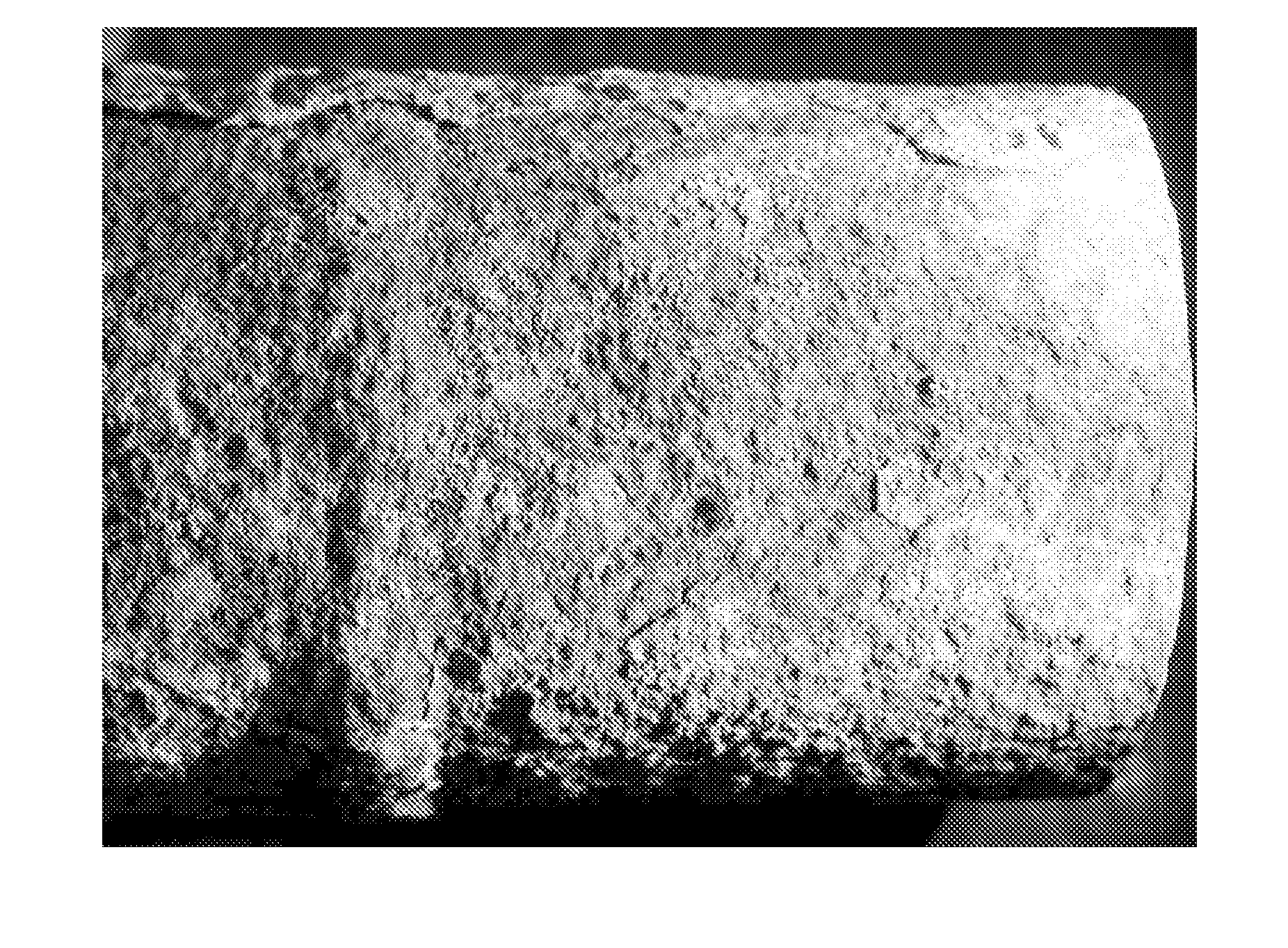

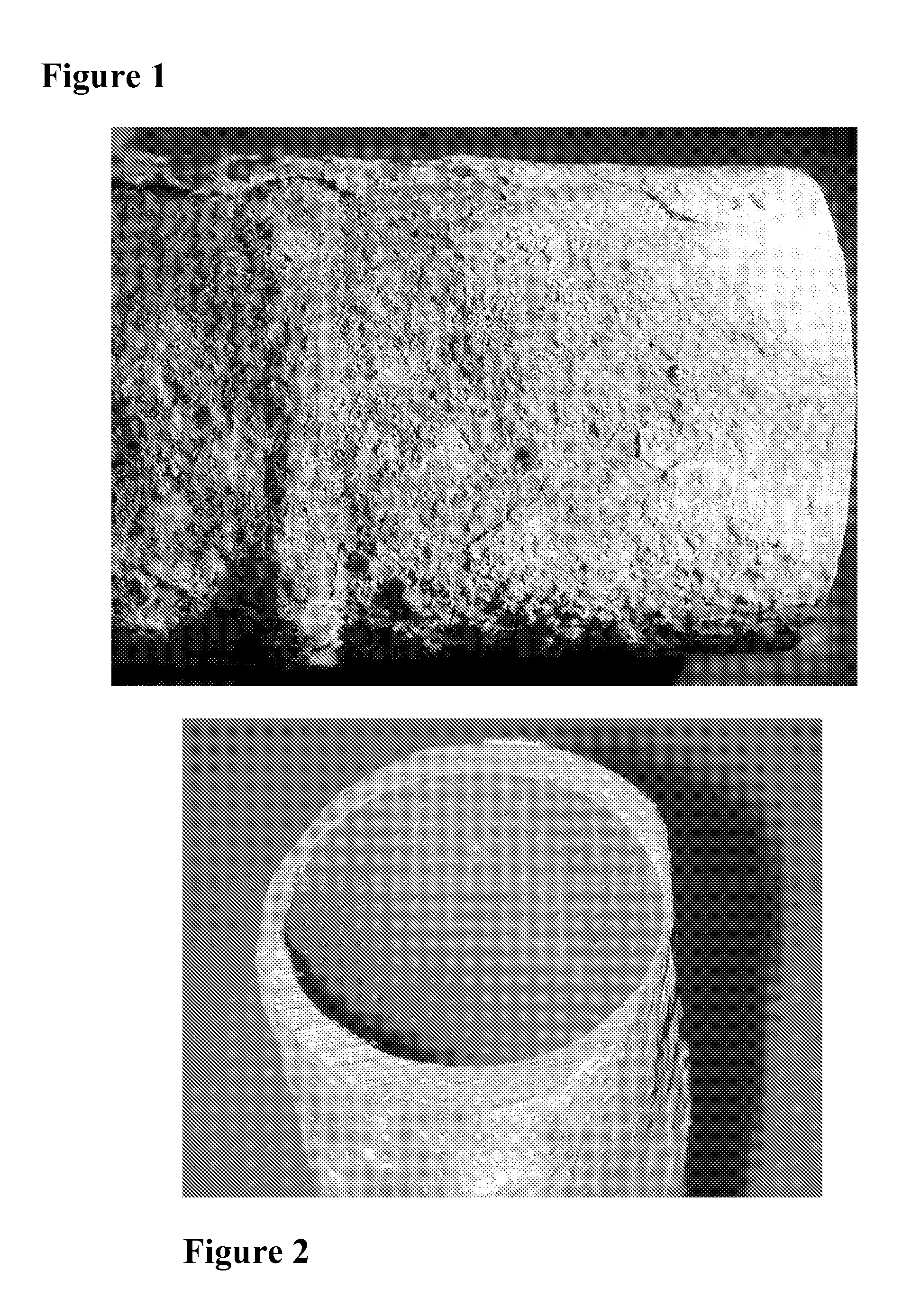

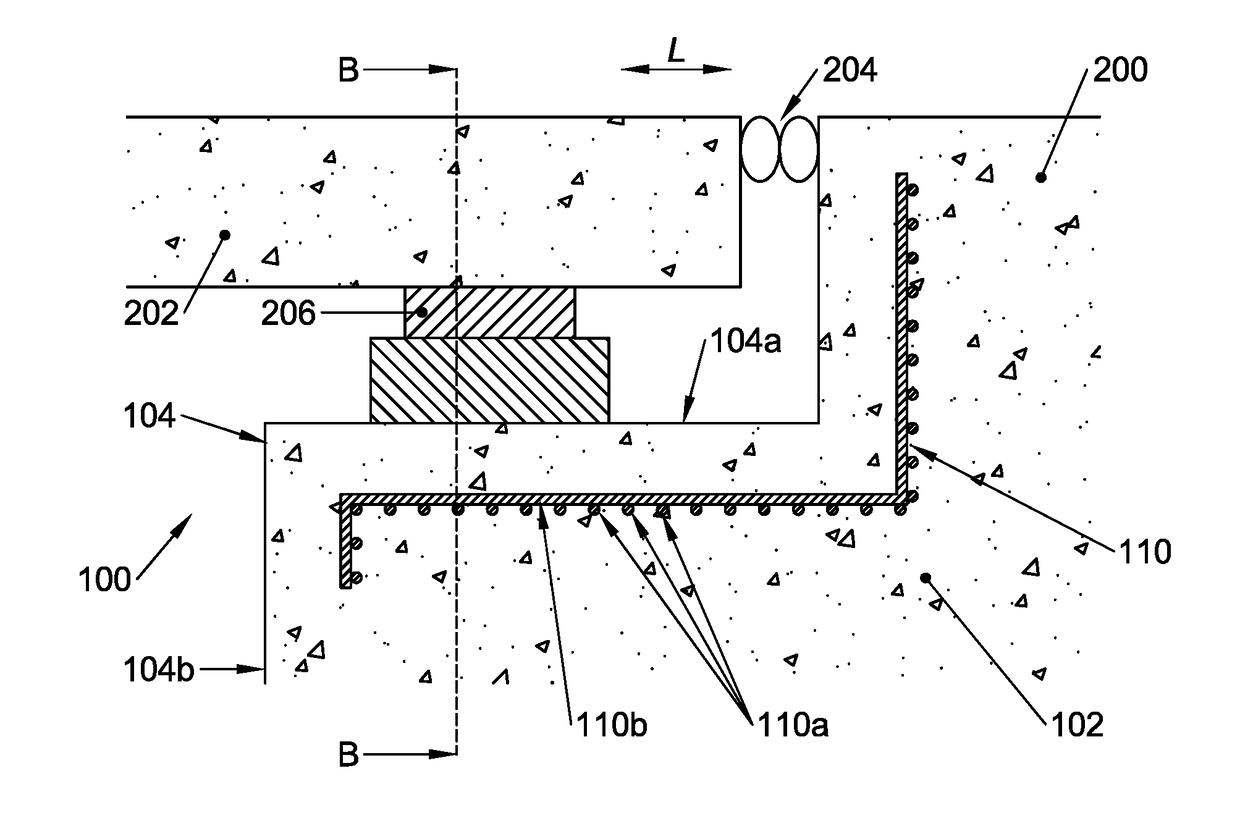

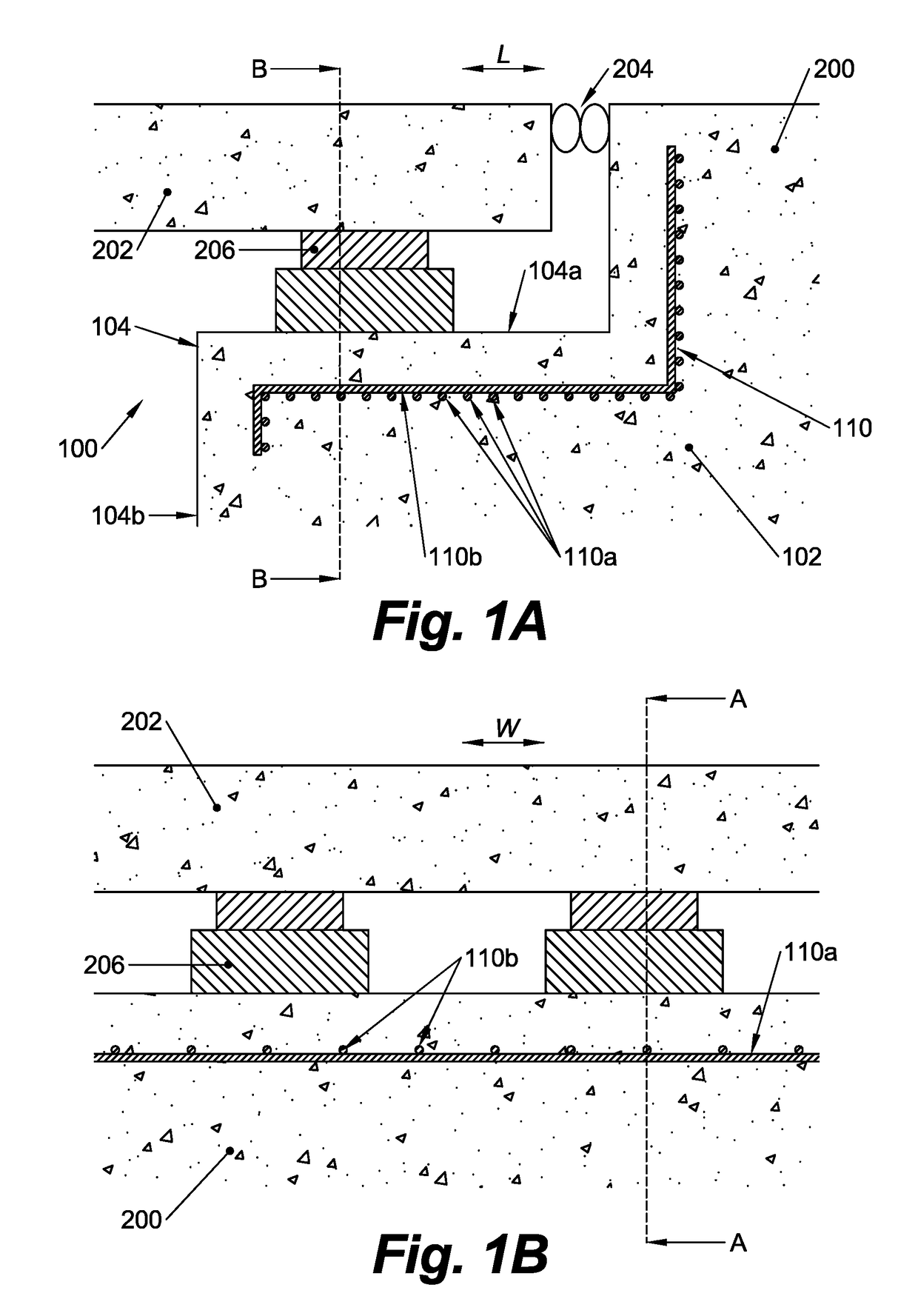

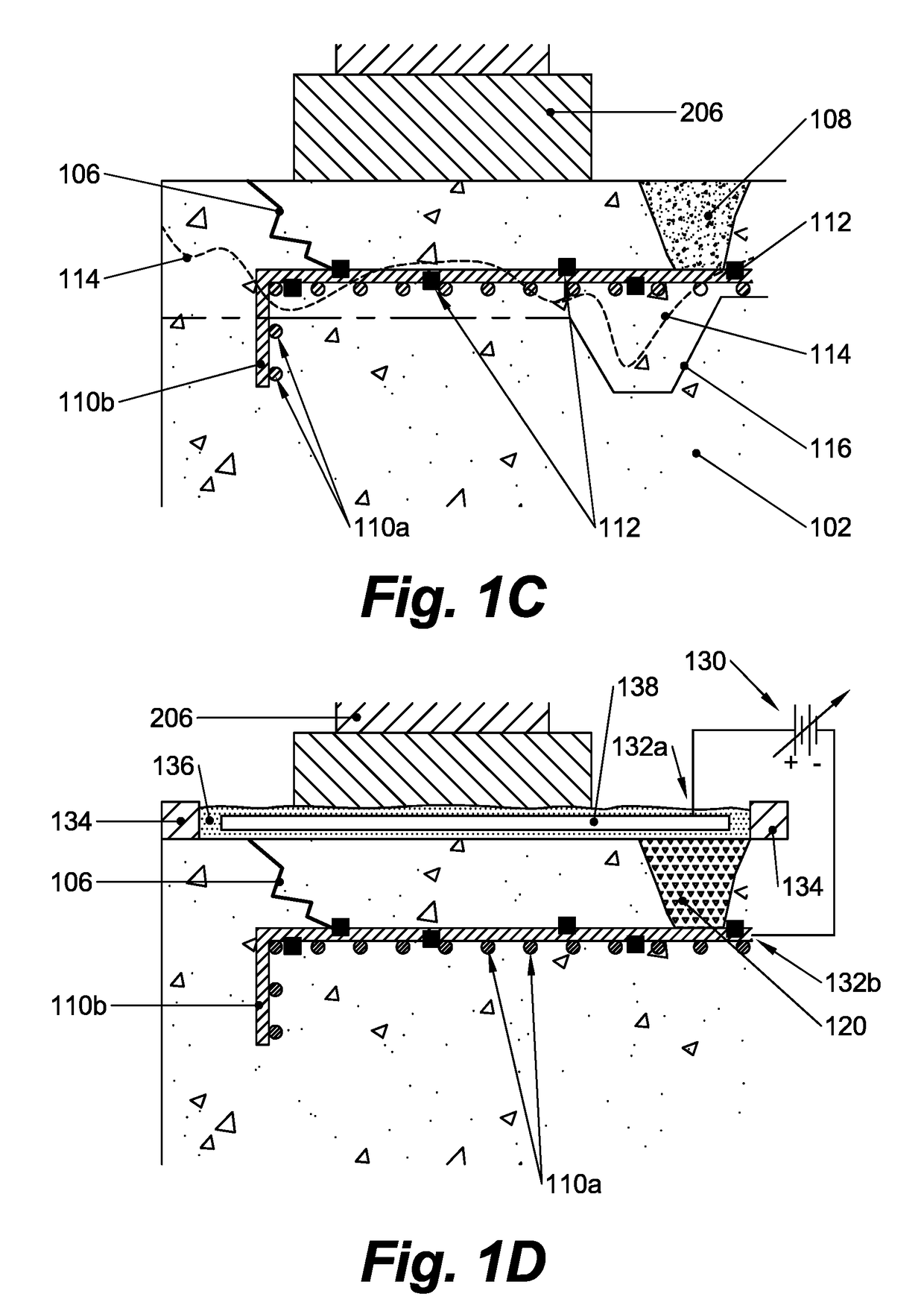

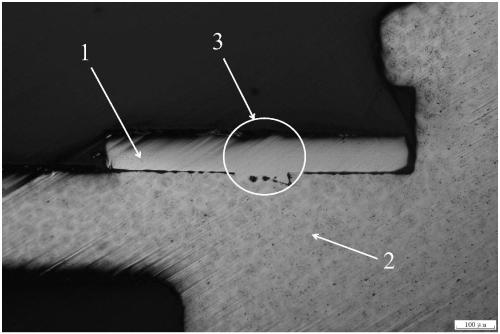

Method of repairing steel reinforced concrete structure affected by chloride induced corrosion

A method of repairing a steel reinforced concrete structure (100) affected by chloride induced corrosion, comprising:subjecting the reinforced concrete structure (100) to an electrochemical treatment so as to enrich material (102, 120, 140) embedding the steel reinforcement (110) with chlorides originating from corrosion pits (112) in the steel reinforcement; andreplacing the material (102, 120, 140) embedding the steel reinforcement (110), which has been enriched with chlorides during the electrochemical treatment, with a repair material (124) that is relatively poor in chlorides.

Owner:NEDERLANDSE ORG VOOR TOEGEPAST-NATUURWETENSCHAPPELIJK ONDERZOEK (TNO) +1

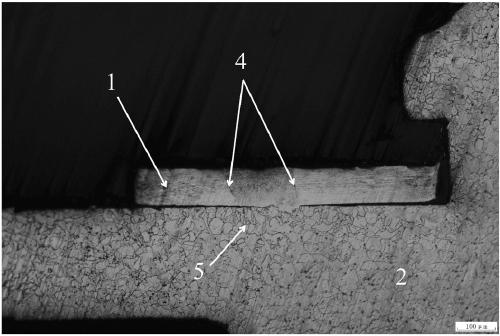

Stainless steel metallographic corrosion agent and application method thereof

ActiveCN109628933AThe corrosion process is smooth and slowEasy to detectPreparing sample for investigationMaterial analysis by optical meansAnhydrous ethanolIron chloride

The invention relates to the technical field of metallographic corrosion of stainless steel materials, and particularly relates to a stainless steel metallographic corrosion agent and an application method thereof. The metallographic corrosion agent comprises the following components: by volume ratio, 12-25% of concentrated nitric acid solution, 47-70% of anhydrous ethanol solution, and 16-30% offerric chloride solution, and the mass fraction of iron chloride in ferric chloride solution is 40-58%. Through the mutual synergy between different solution, the phase boundary of deformed stainlesssteel and the grain boundary of powder metallurgy stainless steel can be displayed quickly and obviously, compared with existing dilute aqua regia or ferric chloride corrosion agent, the corrosion process of the stainless steel metallographic corrosion agent is steady and slow, the grain boundary of powder metallurgy stainless steel cannot be corroded during corroding of the phase boundary of thedeformed stainless steel, and great convenience is provided for the follow-up inspection of the welding quality.

Owner:HANS LASER TECH IND GRP CO LTD

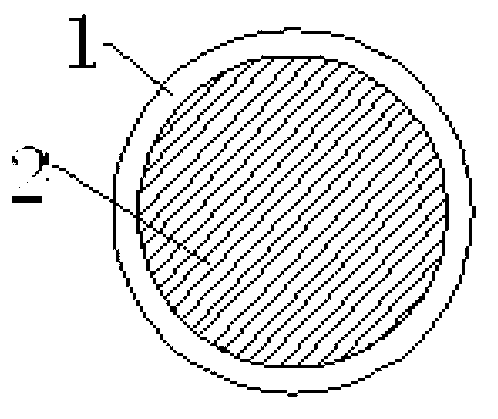

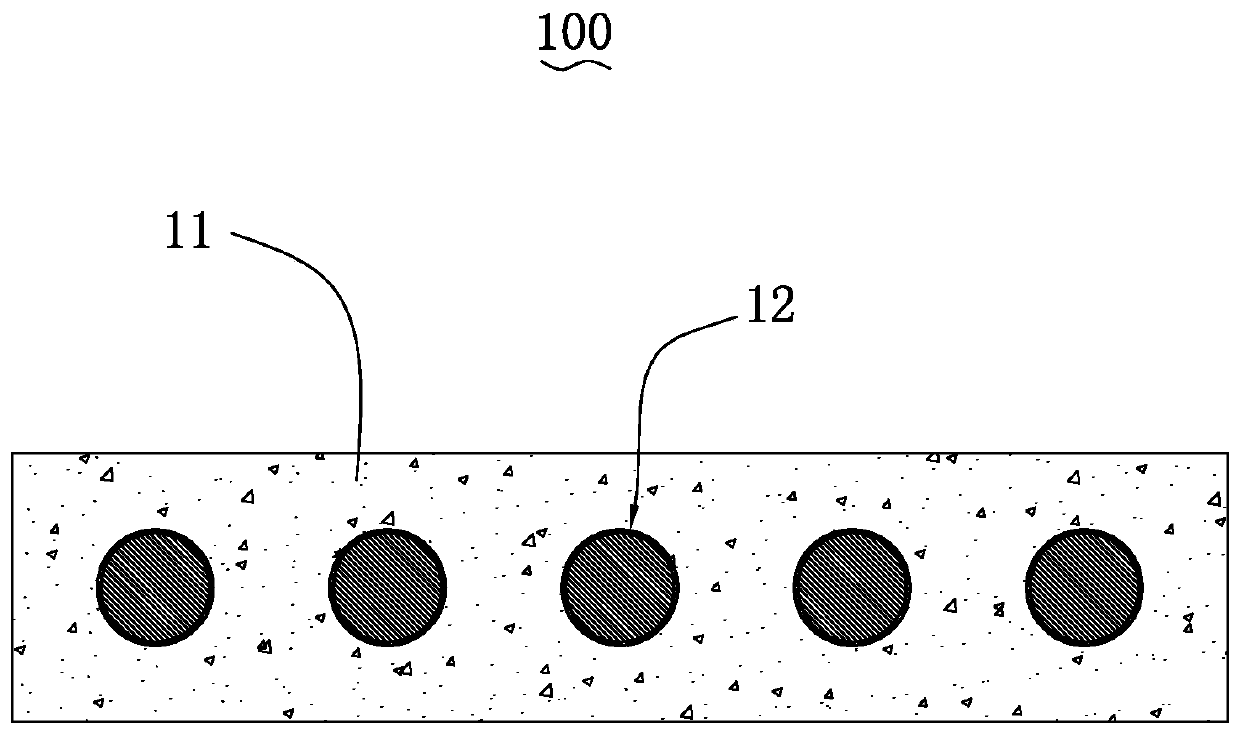

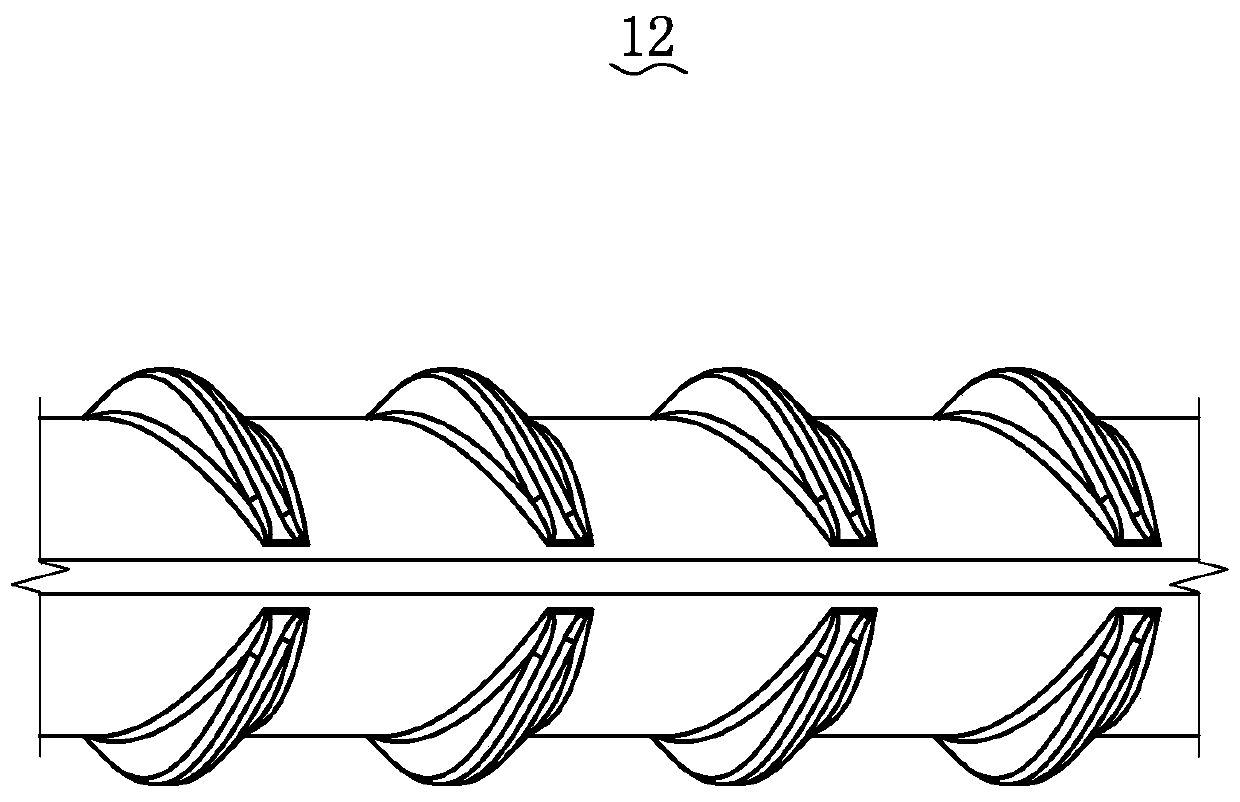

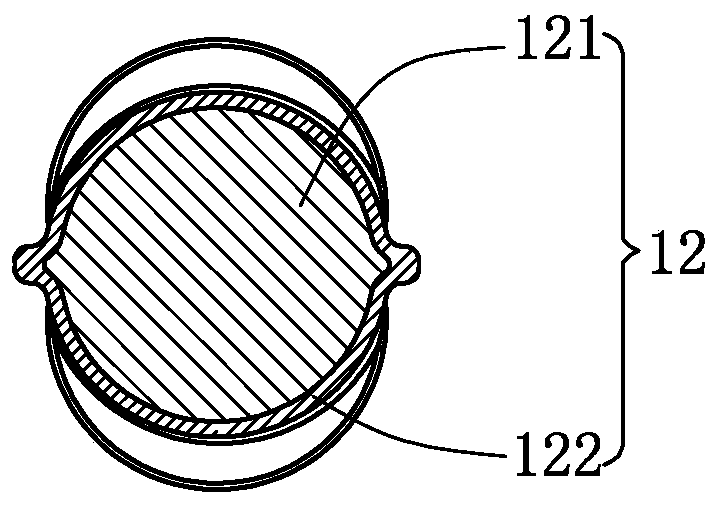

Sea-mixed sea-cured reinforced concrete adopting stainless steel coated steel bars

InactiveCN109914414AImprove anti-corrosion performanceHigh compressive strengthFoundation engineeringSS - Stainless steelRebar

The invention discloses sea-mixed sea-cured reinforced concrete adopting stainless steel coated steel bars. The concrete comprises a concrete base body and coated steel bars arranged in the concrete base body, and the concrete base body is prepared from cement as a main cementing material, sea sand and coral reef chippings as aggregates and seawater as mixing water; and each coated steel bar comprises a core steel bar and a stainless steel coating layer coated on the surface of the core steel bar. According to the sea-mixed sea-culture reinforced concrete adopting the stainless steel coated steel bars, the stainless steel coating layer is coated on the surface of the common steel bar, so that the coated steel bars have excellent corrosion resistance, and the reinforced concrete has excellent marine chloride corrosion resistance; and the core steel bars of the coated steel bars are threaded steel carbon steel bars, so that the coated steel bars have the same mechanical property as common steel bars, high compressive strength, high tensile strength and high yield strength of the reinforced concrete are ensured, and the amount of reinforcements does not need to be additionally increased.

Owner:HUNAN 3T NEW MATERIAL

Accelerated test method for simulating non-uniform corrosion of steel bar in reinforced concrete by external electrode

The invention discloses an accelerated test method for simulating non-uniform corrosion of a steel bar in concrete by an external electrode, which comprises the following steps: serving the concrete surface as a bottom surface on one side of a concrete sample away from the steel bar to be corroded; arranging a water tank of which the length is the same as that of the area to be corroded and the width is the same as that of the concrete sample at the periphery; sealing the periphery of the water tank and the concrete sample by using epoxy resin; arranging an external stainless steel mesh with the same length as an area to be corroded at the bottom of the water tank; and performing electroosmosis treatment, drying and watering cycle, and constant current power-on treatment on the concrete sample in turn. The accelerated test method can simulate the process of diffusing chloridions to the concrete under the chloride corrosion environment, realize non-uniform corrosion and single-side corrosion of the steel bar in the concrete, really reflect the process of developing a corrosion expansion crack in the corroded reinforced concrete structure, and is the accelerated test method for evaluating the performance of the corroded reinforced concrete structure.

Owner:ZHEJIANG UNIV

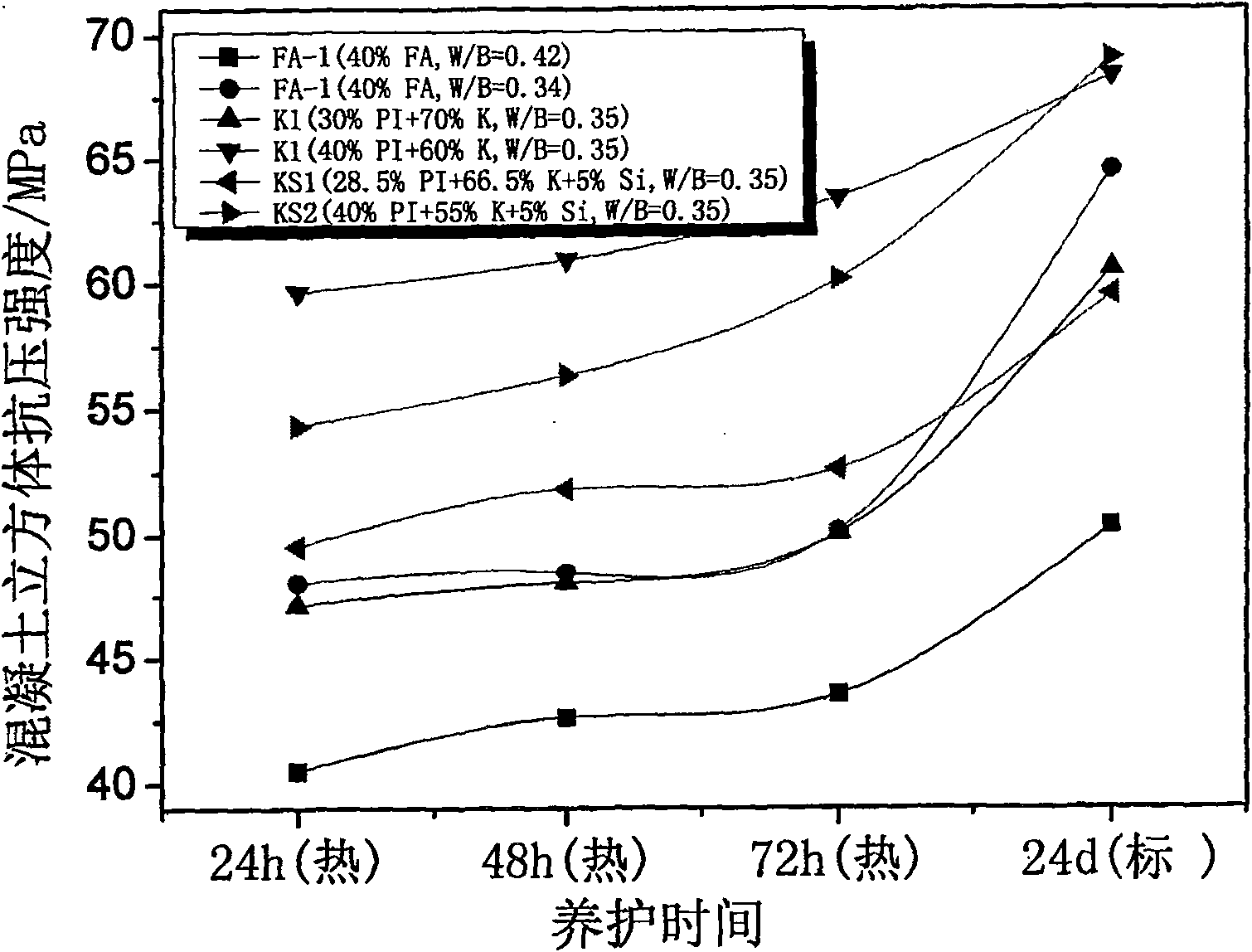

Method for testing capacity of concrete resisting chlorides corrosion

InactiveCN100575922CShorten the regular maintenance periodPromote maturityWeather/light/corrosion resistanceMaterial testing goodsDiffusionChloride corrosion

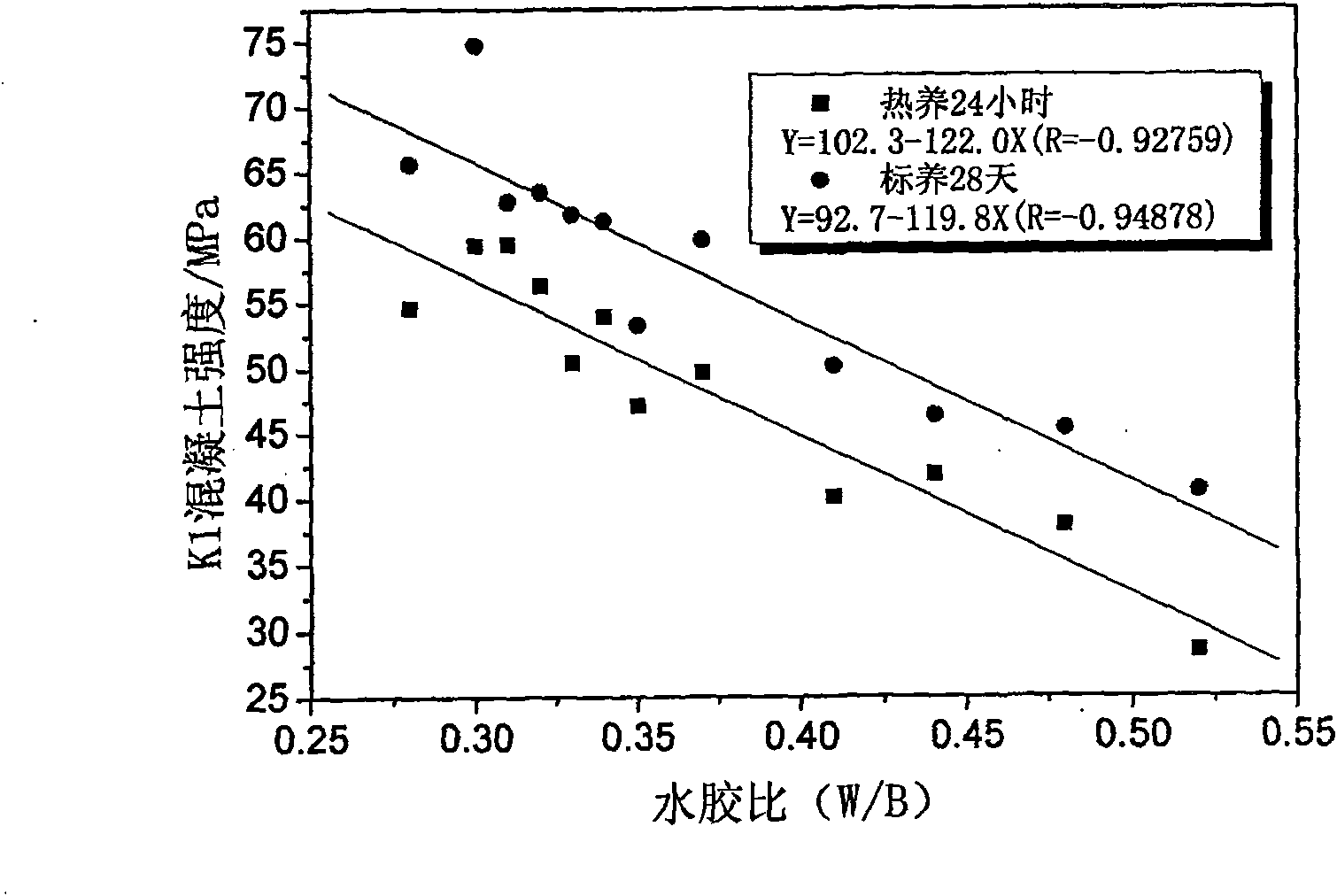

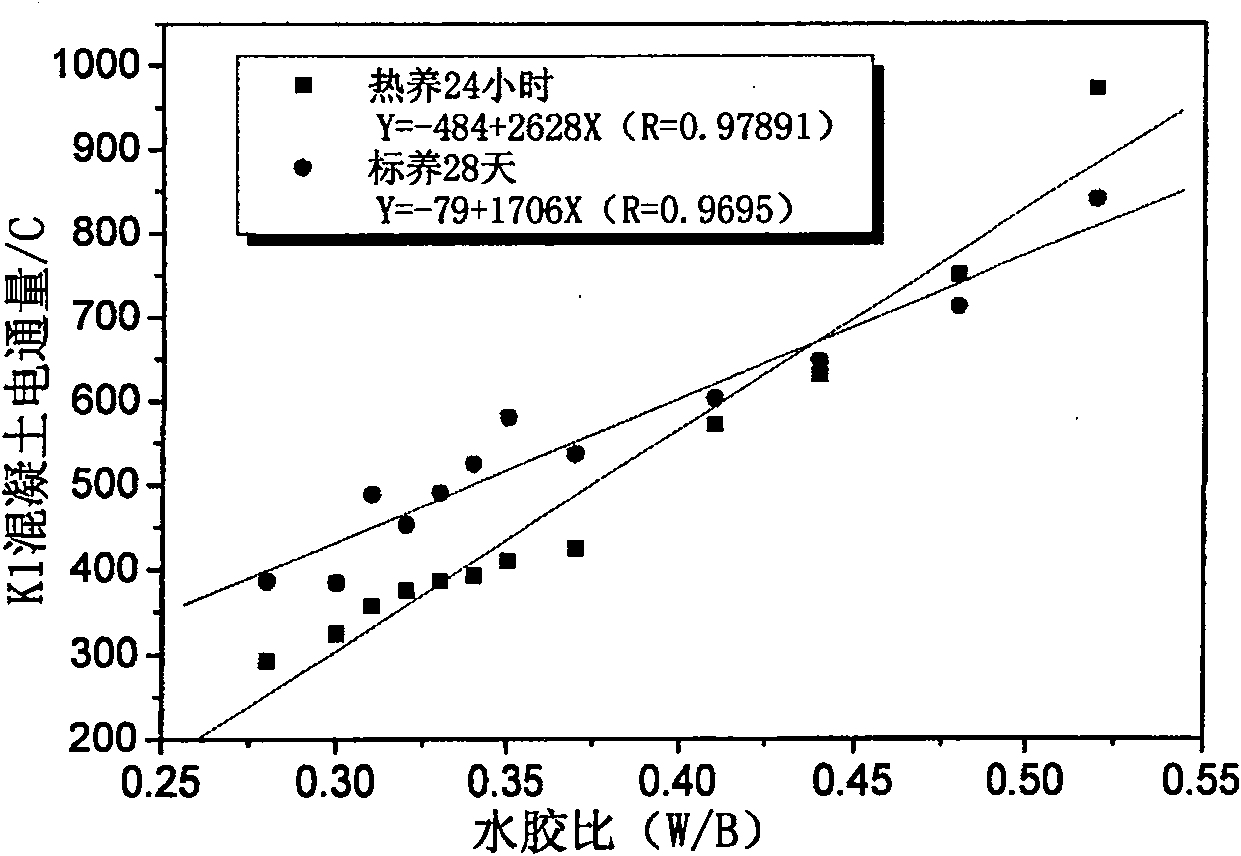

The invention discloses a kind of method of testing the concrete erosion-chloride resisting ability. It is characterized in that: concluding the follow steps: A. makes the concrete material after hot curing at 60-90deg.C as the test piece and at time of hot curing the weight ratio of the water and the jelling material is 0.28-0.54; B. after hot curing the concrete assays the value of flux and chloride ion diffusion coefficient individually; C. accords the formula Qstandard=M+NQhot to impute the value of concrete flux with the standard curing and in the formula Qstandard is the value of concrete flux with the standard curing and the Qhot is the flux measured at step B and the M,N are constants; D. accords the formula Destandard=M1+N1Dehot to calculate the chloride ion diffusion coefficient of standard curing concrete and in the formula Destandard is the value of chloride ion diffusion coefficient of standard curing concrete and the Dehot is the chloride ion diffusion coefficient measured at step B and the M1,N1 are constants. The method of the invention can test the concrete erosion-chloride resisting ability quickly.

Owner:CCCC SHANGHAI THIRD HARBOR SCI RES INST CO LTD +3

High-strength concrete admixture used for municipal construction

InactiveCN109399997AImprove the corrosion resistance of chlorine saltIncreased durabilityHigh strength concreteEpoxy

A high-strength concrete admixture used for municipal construction includes: 10-30 parts of nano composite filler, 12-17 parts of epoxy-modified polysiloxane, 22-25 parts of polypropylmethylsesquiloxane, 0.5-1.5 parts of alkoxy silane, 2-8 parts of nano-SiO2, 1.2-1.8 parts of a thickener, 2.5-5.5 parts of a hydrophobic agent, 17-23 parts of silica fume, 12-13 parts of fly ash, 55-85 parts of granularity, 0.2-1.1 parts of redispersible rubber powder, 3.5-5 parts of raw gypsum powder, 11-14 parts of a water reducing agent, 13-18 parts of nano-TiO2, 13-17 parts of fatty amine polyoxyethylene ether, and 20-23 parts of polyoxyethylene stearate. The concrete admixture can effectively enhance anti-chloride-corrosion performance of concrete, thereby significantly improving the durability of the concrete and achieving excellent compression strength and water permeability.

Owner:江苏兆佳建材科技有限公司

Manufacturing technology for autoclaving-free pole

InactiveCN108908685AImprove qualityGuaranteed physical and mechanical propertiesShaping reinforcementsManufacturing technologySuperplasticizer

The invention provides a manufacturing technology for an autoclaving-free pole. The specific machining technology comprises the following steps that one, prestressed steel bars and screw-thread steelare machined; two, a steel bar framework is manufactured; three, a concrete mixture is manufactured; four, mold closing and formation of the autoclaving-free pole are conducted; five, natural curing is conducted; six, mold removing is conducted; and seven, finished product inspection is conducted. The manufacturing technology for the autoclaving-free pole has the beneficial effects that by means of improvement of raw material quality, optimization of mixing proportion and adoption of an efficient water reducing agent, a large amount of energy consumption is saved on the premise that physical and mechanical properties, durability and production time of the pole are guaranteed; a cost ranging from 30 rmb to 60 rmb can be saved by each pole; production cost is reduced greatly; the history ofhigh energy consumption of the pole is changed completely; a novel breakthrough of the pole is achieved; the concrete of the autoclaving-free pole is high in durability such as chloride corrosion resistance property, freezing resistance and the like and high in latter strength; a strength loss of 17% of steam curing is avoided; the autoclaving-free pole is artistic in appearance; a non-pulp-pouring technology is adopted; meanwhile, numerous troubles of the remaining pulp are avoided; and the manufacturing technology is environmentally friendly.

Owner:泰州桓通管业有限公司

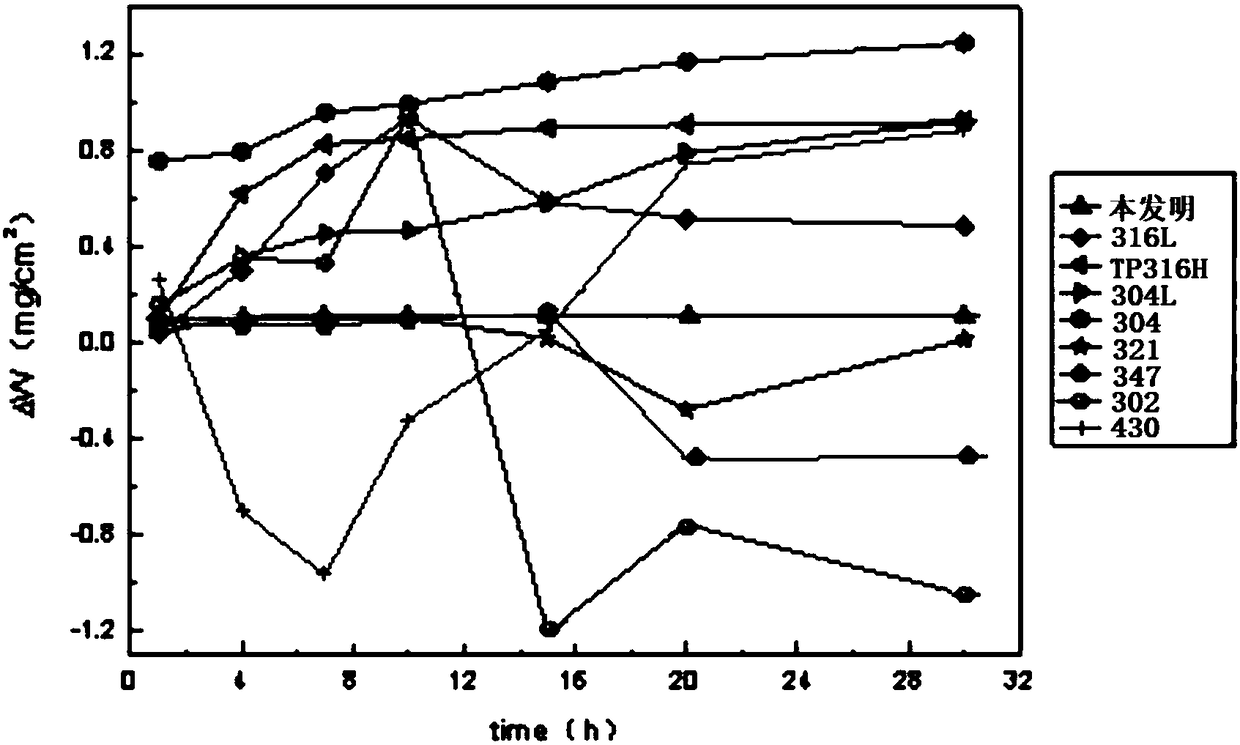

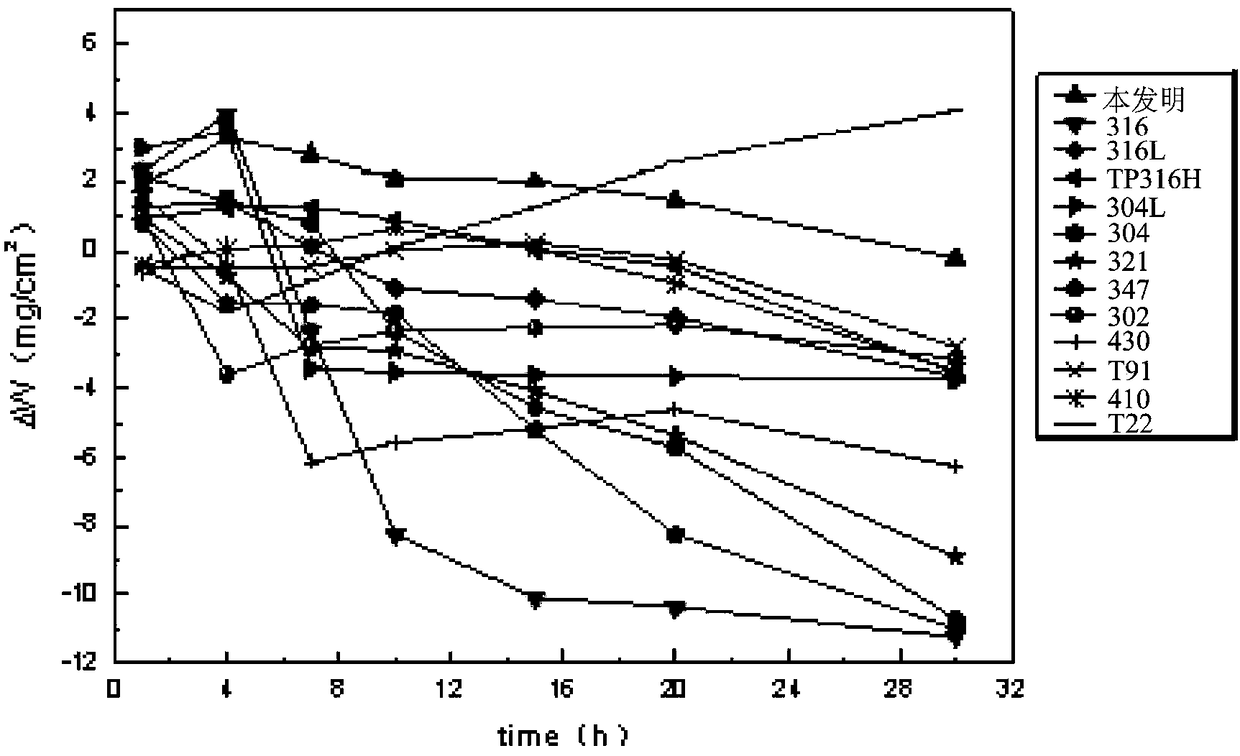

Carbon fiber reinforced alloy composite and preparation method thereof

ActiveCN108193149AExcellent resistance to high temperature potassium chloride corrosion performanceGood corrosion resistance to high temperature potassium chlorideRigid pipesFiberCarbon fibers

The invention belongs to the field of metal materials, particularly relates to a carbon fiber reinforced alloy composite and a preparation method thereof, and provides the carbon fiber reinforced alloy composite. The carbon fiber reinforced alloy composite is prepared by adopting alloy as a matrix and adopting carbon fibers for reinforcement. The alloy comprises, by mass, 20-22% of Cr, 0.5-2% of Al, 2-8% of Ni, 0.02-0.08% of C, 0.2-0.8% of Ti, 0.2-0.8% of Nb and the balance Fe. High temperature corrosion dynamic tests and high temperature oxidation dynamic tests show that the weight increase change of the carbon fiber reinforced alloy composite is mainly concentrated in the range of 1.3-2.9 mg / cm<2>, and the carbon fiber reinforced alloy composite has high temperature potassium chloride corrosion resistance which is obvious better than that of commercial metal products such as TP316.

Owner:GUANGDONG ELECTRIC POWER SCI RES INST ENERGY TECH CO LTD

Chlorine salt corrosion resistant system with chemical microcapsule for underground structure concrete

ActiveCN102992673BAvoid problems such as downtimeImprove securityPhysical chemistryChloride corrosion

The invention relates to the field of concrete engineering, and especially relates to a chlorine salt corrosion resistant system with chemical microcapsule for underground structure concrete. The invention relates to the field of concrete engineering, and especially relates to a chlorine salt corrosion resistant system with chemical microcapsule for underground structure concrete. Compared with an existing chloride corrosion resistance method, the chloride corrosion resistance system provided by the invention has the following advantages: the system can realize intelligent control of chloride concentration by concrete, reduce chlorine salt corrosion, and produce precipitate to block a channel corroded by chlorine salt while reducing the chloride ion concentration; the microcapsules can protect the internal repair agent from outside influence, so as to realize long-time effectiveness of chlorine salt corrosion resistance of the repair agent; and compared with an anticorrosive coating, the chlorine salt corrosion resistant system can realize large-scale multiple rehabilitation due to a large amount of chemical microcapsules evenly distributed in the concrete matrix.

Owner:TONGJI UNIV

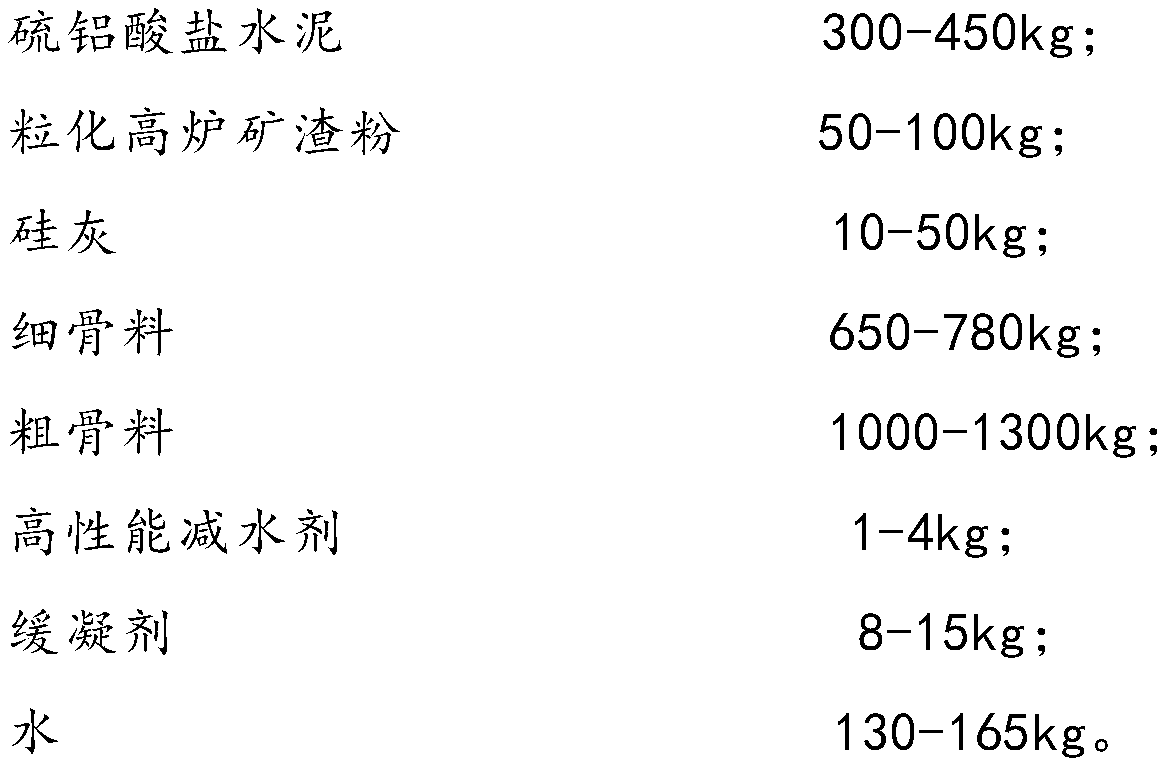

Concrete for rapid construction under marine environment and preparation method thereof

The invention discloses concrete for rapid construction under the marine environment. The concrete is prepared from, per cubic meter, 300-450 kg of sulphate aluminum cement, 50-100 kg of granulated blast-furnace slag powder, 10-50 kg of silica fume, 650-780 kg of fine aggregates, 1,000-1,300 kg of coarse aggregates, 1-4 kg of high-performance water reducer, 8-15 kg of retarder and 130-165 kg of water. The concrete for rapid construction under the marine environment achieves the demolding strength earlier under the normal temperature and low temperature conditions, and can be widely applied tothe environment under the low-temperature condition such as anti-chloride corrosion and freezing resistance in the North under the marine environment.

Owner:CCCC THIRD HARBOR ENG +2

A method of electroosmotic substitution pore solution for repairing chloride corrosion of concrete structures

The invention provides an electro-osmotic pore solution replacement method for repairing chloride corrosion in concrete structures. The method includes the steps of mixing well anionic surfactant and alkali pore solution to obtain electrolyte; soaking a reinforced concrete structure sample in the electrolyte to saturate the sample; placing the saturated reinforced concrete structure sample in an electrolytic cell, dividing the electrolytic cell into anodic cell and a cathodic cell, and placing an anode and a cathode in the anodic cell and the cathodic cell respectively at the same time; pouring electrolyte into the anodic cell and pouring deionized water into the cathodic cell; subjecting rears in the reinforced concrete structure sample to ground protection, externally connecting the anode and the cathode to positive and negative electrodes of a power source respectively, applying external voltage 1-6V / cm (relative to concrete width between the anode and the cathode) between the anode and the cathode to perform electro-osmotic pore solution replacement for 7-28 days at the temperature of 0-50 DEG C. The electro-osmotic pore solution replacement method for repairing chloride corrosion in concrete structures is simple in process, low in cost, capable of lossless repairing, and widely applicable.

Owner:HOHAI UNIV

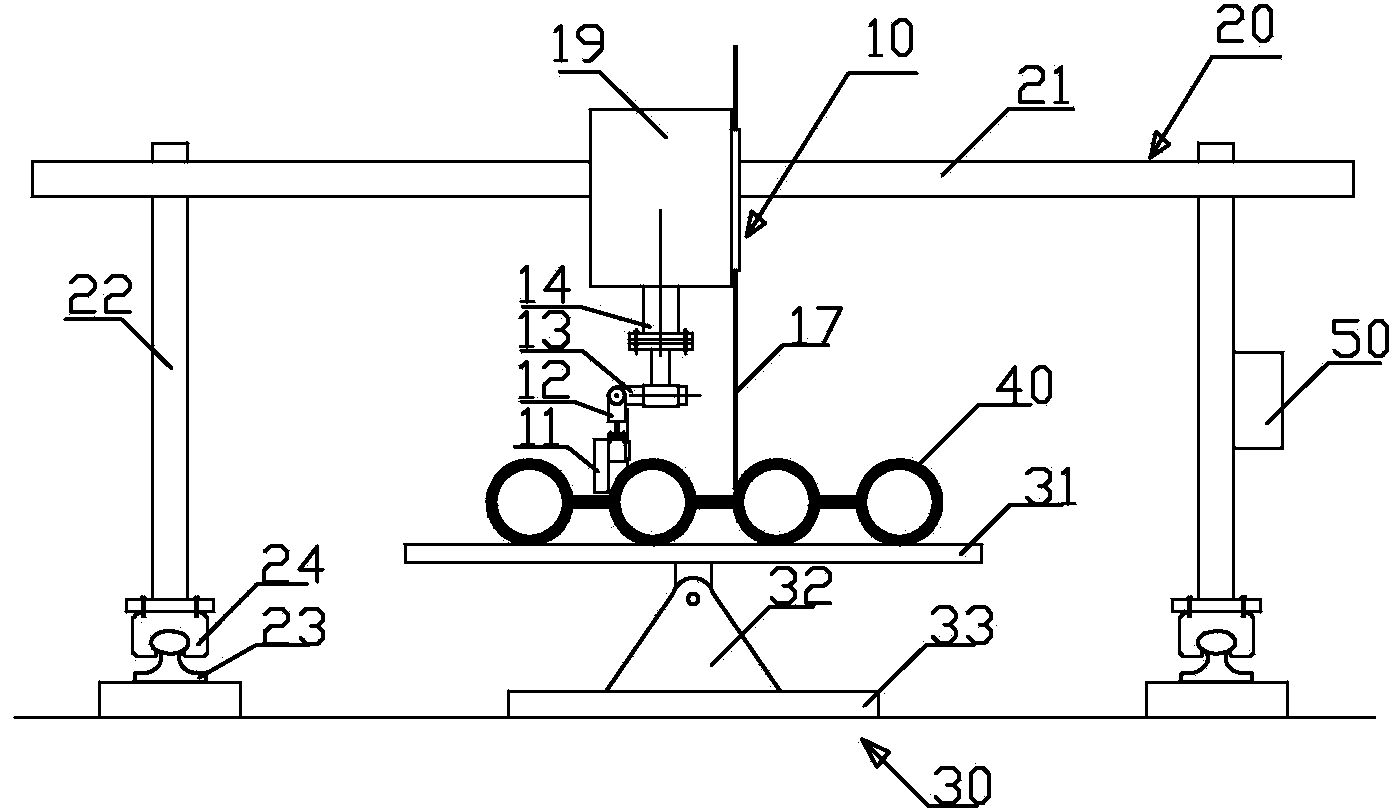

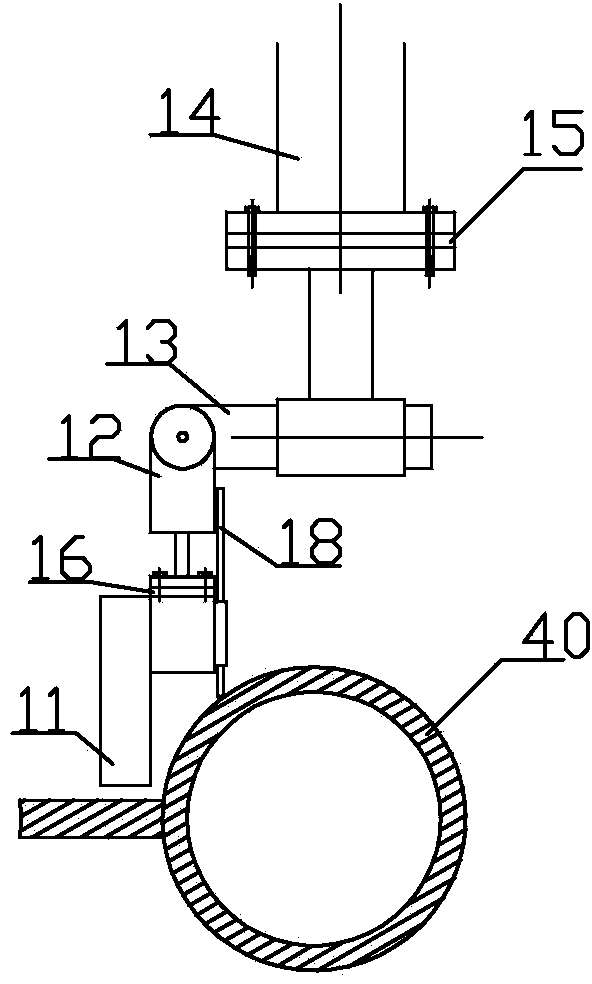

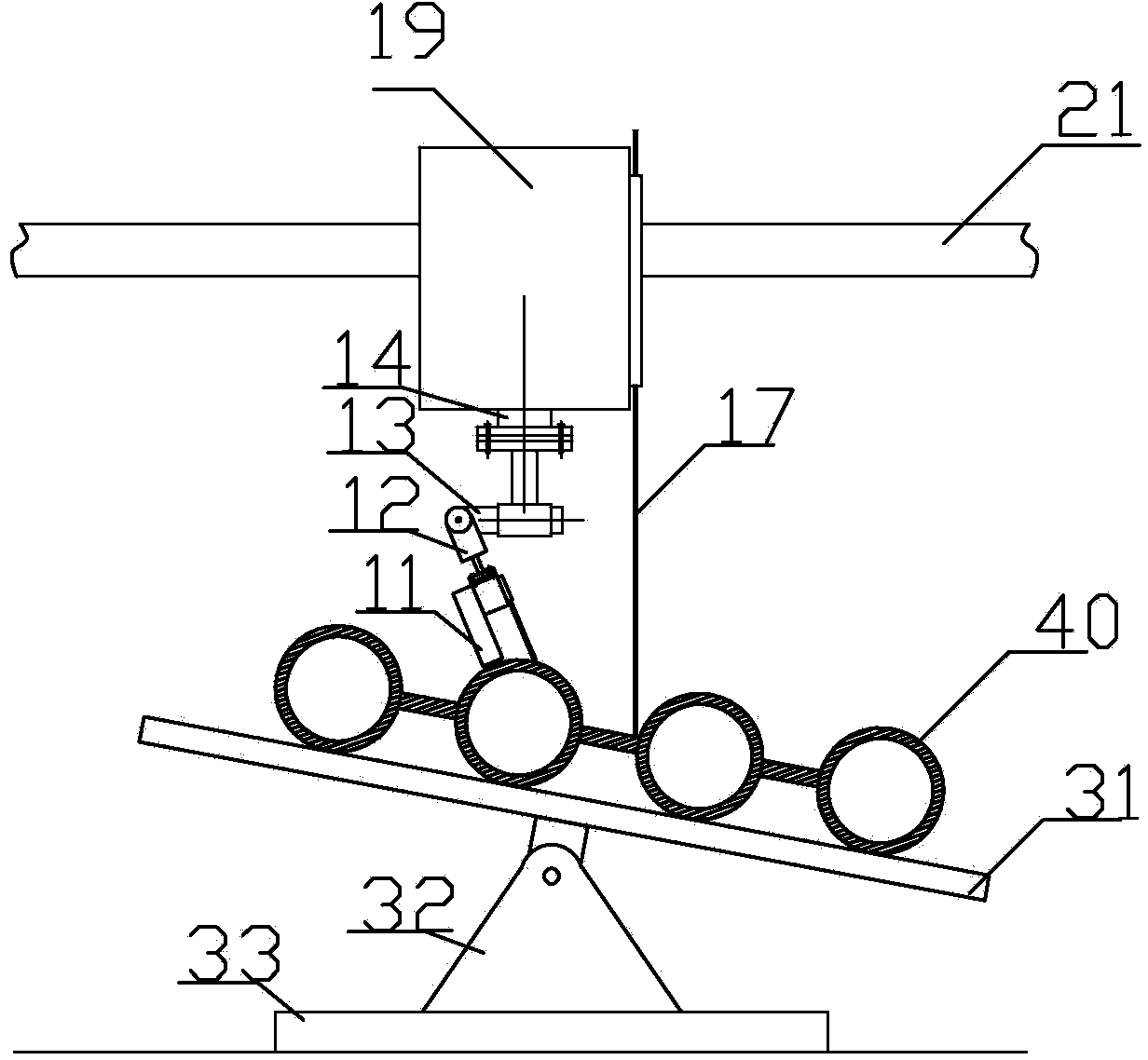

Automatic high temperature chloride corrosion resisting layer surfacing device of irregular surface and surfacing method

InactiveCN104384736AReduce labor intensityImprove yieldWelding/cutting auxillary devicesAuxillary welding devicesEngineeringChloride corrosion

The invention relates to an automatic high temperature chloride corrosion resisting layer surfacing device of an irregular surface and a surfacing method. The surfacing device comprises a stander, wherein the stander is provided with a position finding device, at least one positioning band electrode surfacing head component and a workpiece seat, wherein the positioning band electrode surfacing head component comprises a positioning band electrode surfacing head and a position adjusting device for adjusting the position of the positioning band electrode surfacing head, the position adjusting device comprises a longitudinal telescopic arm, a transverse telescopic arm and a direction regulation arm, the longitudinal telescopic arm is connected with the transverse telescopic arm, and one end of the direction regulation arm is hinged with one end of the longitudinal telescopic arm or one end of the transverse telescopic arm. By adopting the automatic high temperature chloride corrosion resisting layer surfacing device, the irregular surface can be automatically and mechanically welded, the distance and angle between the surface of the workpiece and the positioning band electrode surfacing head can be adjusted in multiple angles and multiple ways, the distance between the positioning band surfacing head and the surface of the workpiece is maintained constant, the yield of the product is high, and the consistency is good; moreover, simplicity in operation can be realized, the labor intensity of workers can be alleviated, and the product quality and the production efficiency can be greatly improved.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST

Test device and method for chloride salt corrosion of reinforced concrete members under continuous load

ActiveCN104132847BTroubleshoot test setup issuesSolve the real problemMaterial strength using tensile/compressive forcesMicrocontrollerAir pump

The invention provides a test device and a test method for chlorine salt corrosion of reinforced concrete components under continuous load. The device includes a continuous load loading device, a chlorine salt rapid corrosion device and a measurement and control device. Apply continuous load through the loading frame and driving device, fill the frame body sealed and fixed on the upper part of the test beam with chlorine salt solution, use the air pump to continuously inject air into the chlorine salt solution, and conduct rapid corrosion on the test beam steel bar through direct current . The main control box integrates relevant data acquisition instruments, electrochemical testers and output devices, and is controlled by a single-chip microcomputer to measure the continuous load in real time and regularly correct it to the target level, regularly test the corrosion behavior of the corroded components, collect, display, store and Print out the data. The invention can effectively simulate the actual corrosion working conditions of in-service reinforced concrete structural members under the coupling action of chloride salt environment and load, and provide scientific basis for durability evaluation of engineering structures in chloride salt environments such as oceans and salt lakes.

Owner:HOHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com