Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

148 results about "Waste-to-energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waste-to-energy (WtE) or energy-from-waste (EfW) is the process of generating energy in the form of electricity and/or heat from the primary treatment of waste, or the processing of waste into a fuel source. WtE is a form of energy recovery. Most WtE processes generate electricity and/or heat directly through combustion, or produce a combustible fuel commodity, such as methane, methanol, ethanol or synthetic fuels.

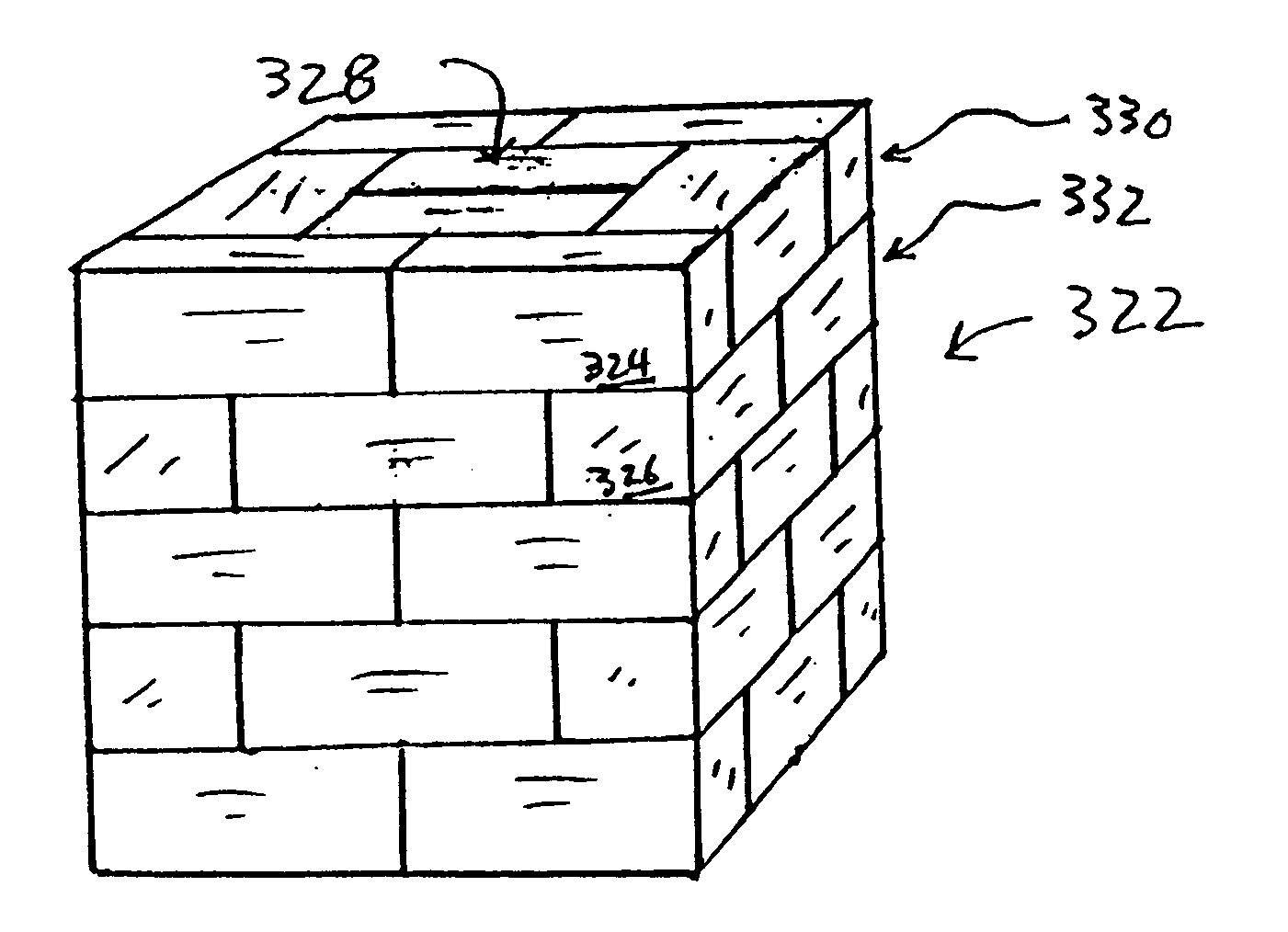

Municipal waste briquetting system and method of filling land

InactiveUS6692544B1Conveniently and economically transportedReduce the impactBiofuelsSolid fuelsRefuse-derived fuelMunicipal sewage

Mechanically and biologically stable briquettes and pellets are obtained from either municipal solid waste (MSW), Refuse Derived Fuel (RDF) or municipal sewage sludge and their combination for purposes of disposing said briquettes and pellets as fuel in waste-to-energy processes such as the one described herein or to form geometric aggregates with such briquettes for their disposal at landfill sites. The use of binding material is not required whereas fuel additives such as crushed coal and petroleum residues may be added to enhance fuel performance but are not needed to improve waste processing or product stability and mechanical properties.

Owner:ECOSYST PROJECTS

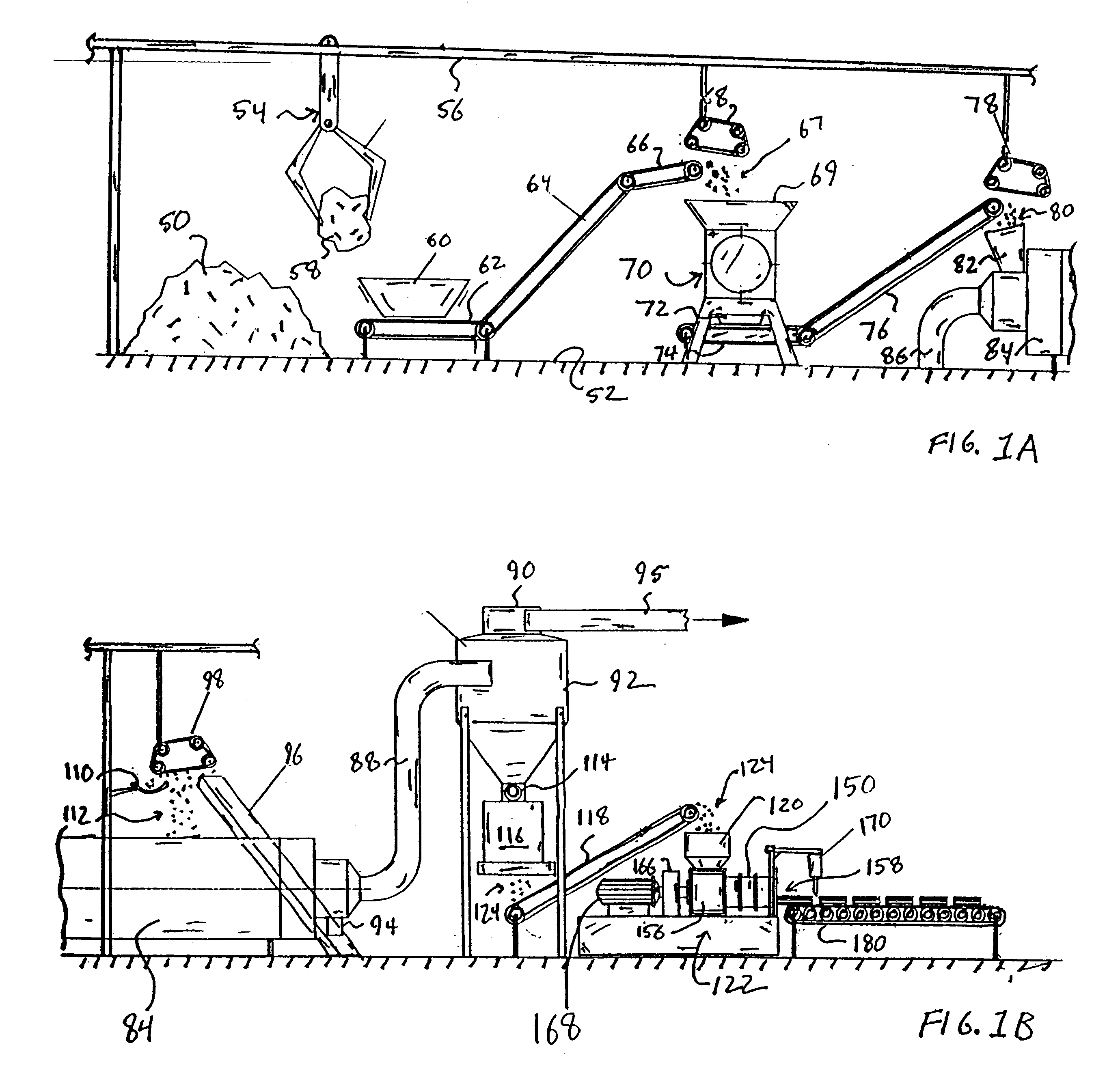

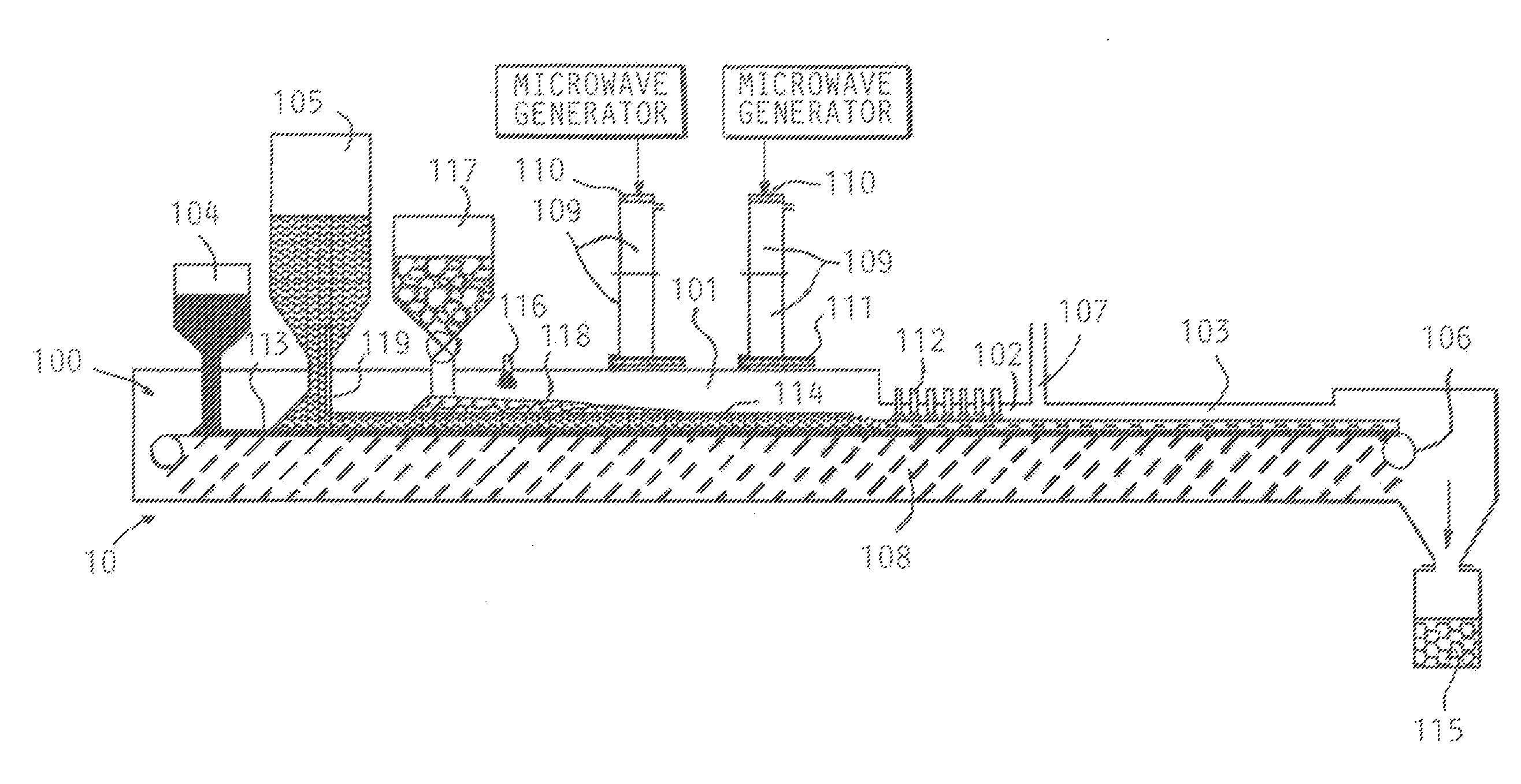

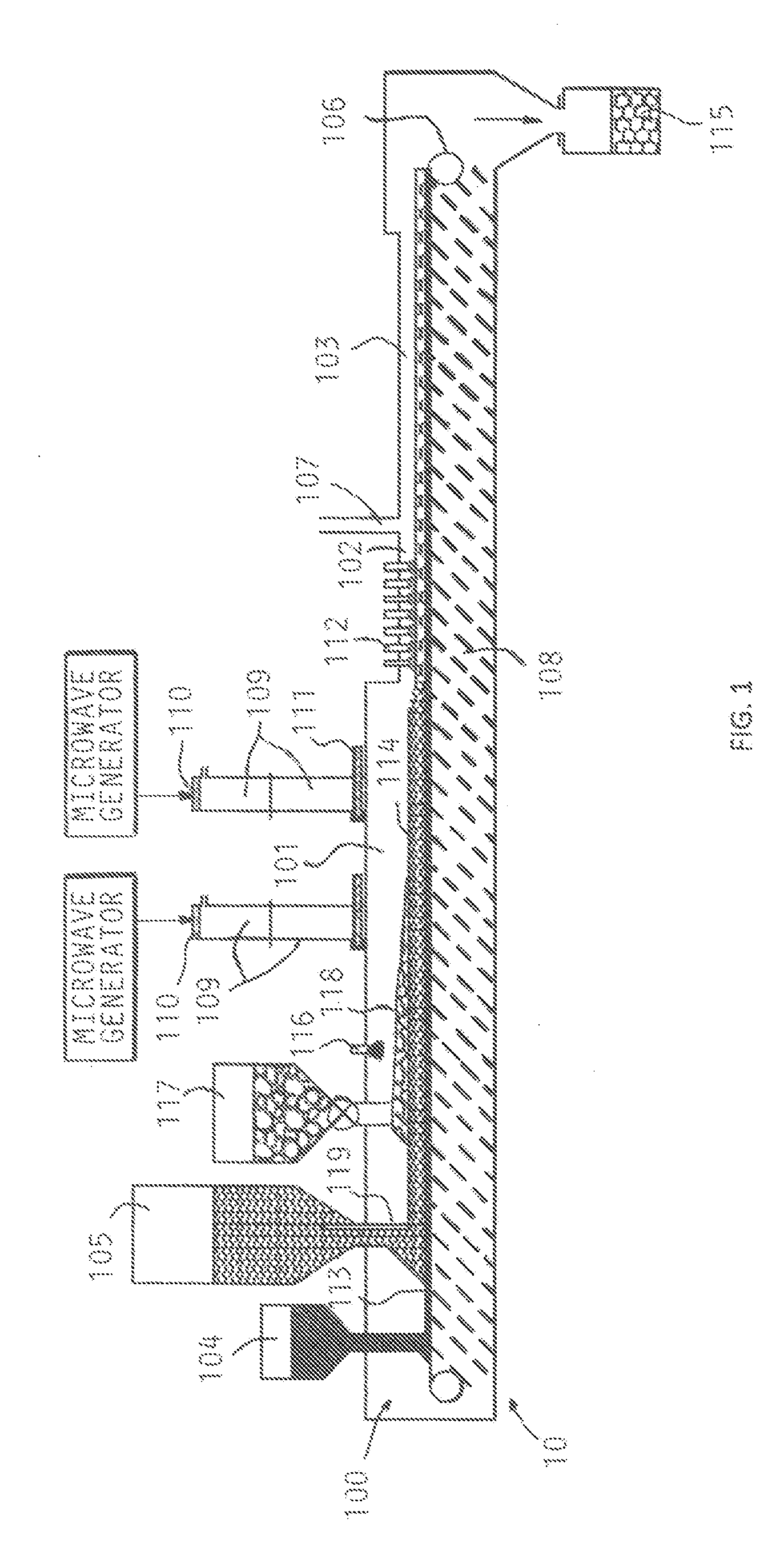

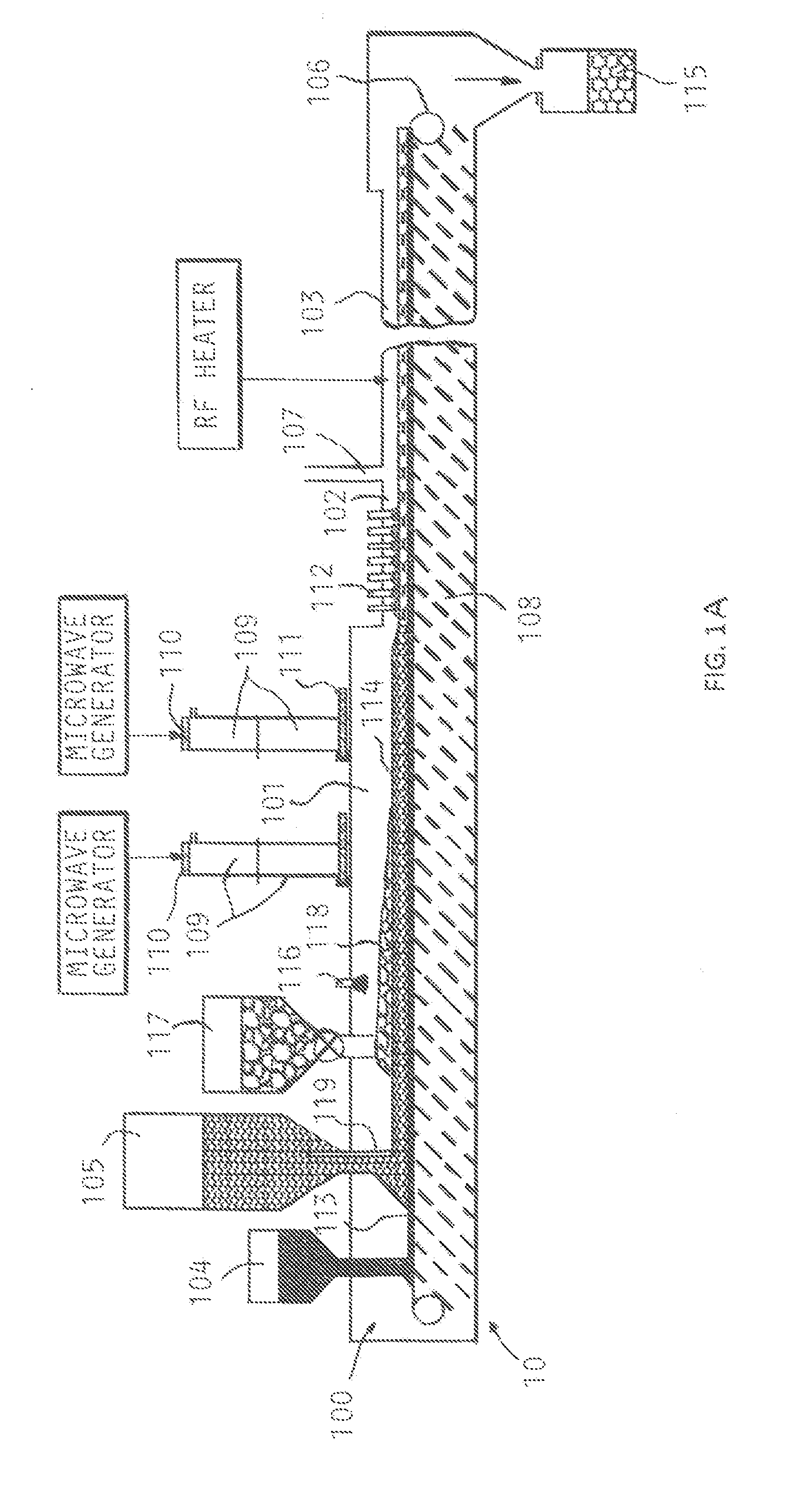

Method and Apparatus For Coproduction of Pig Iron and High Quality Syngas

ActiveUS20120031232A1Improve microwave absorption performanceHeating up fastBlast furnace detailsCharge manipulationSludgeLiquid fuel

Combined microwave heating and plasma / electric arc heating is utilized in several processes and apparatus which involve co-production of pig iron and high quality syngas, biomass to liquid fuel production, coal to liquid fuel production, co-gasification of biomass and coal, municipal solid waste treatment, waste-to-energy (agriculture waste, ASR and PEF), EAF dust and BOF sludge treatment to recover zinc and iron, hazardous bottom ash vitrification, and bromine, chlorine and sulfur removal / recycling.

Owner:HUANG XIAODI +1

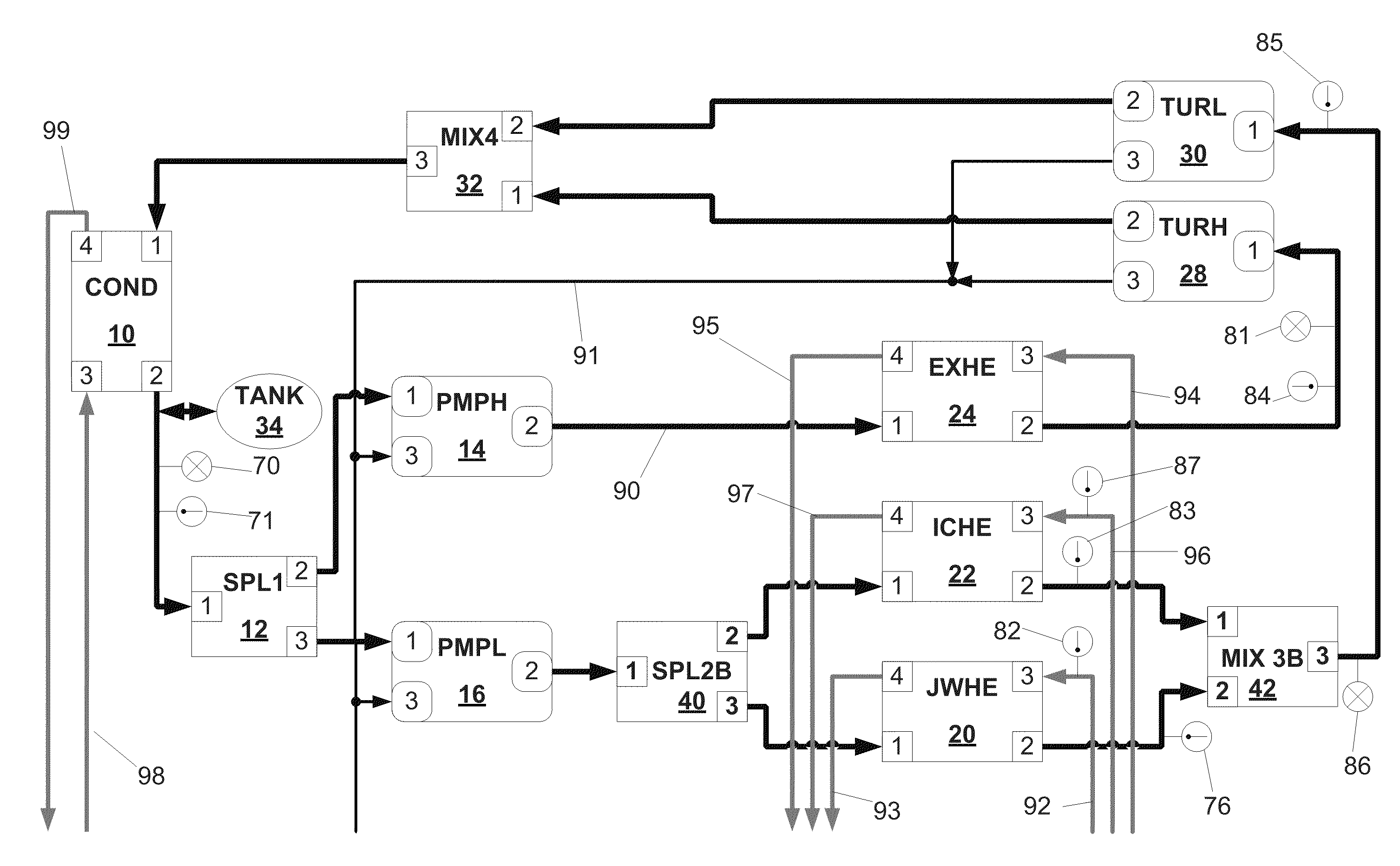

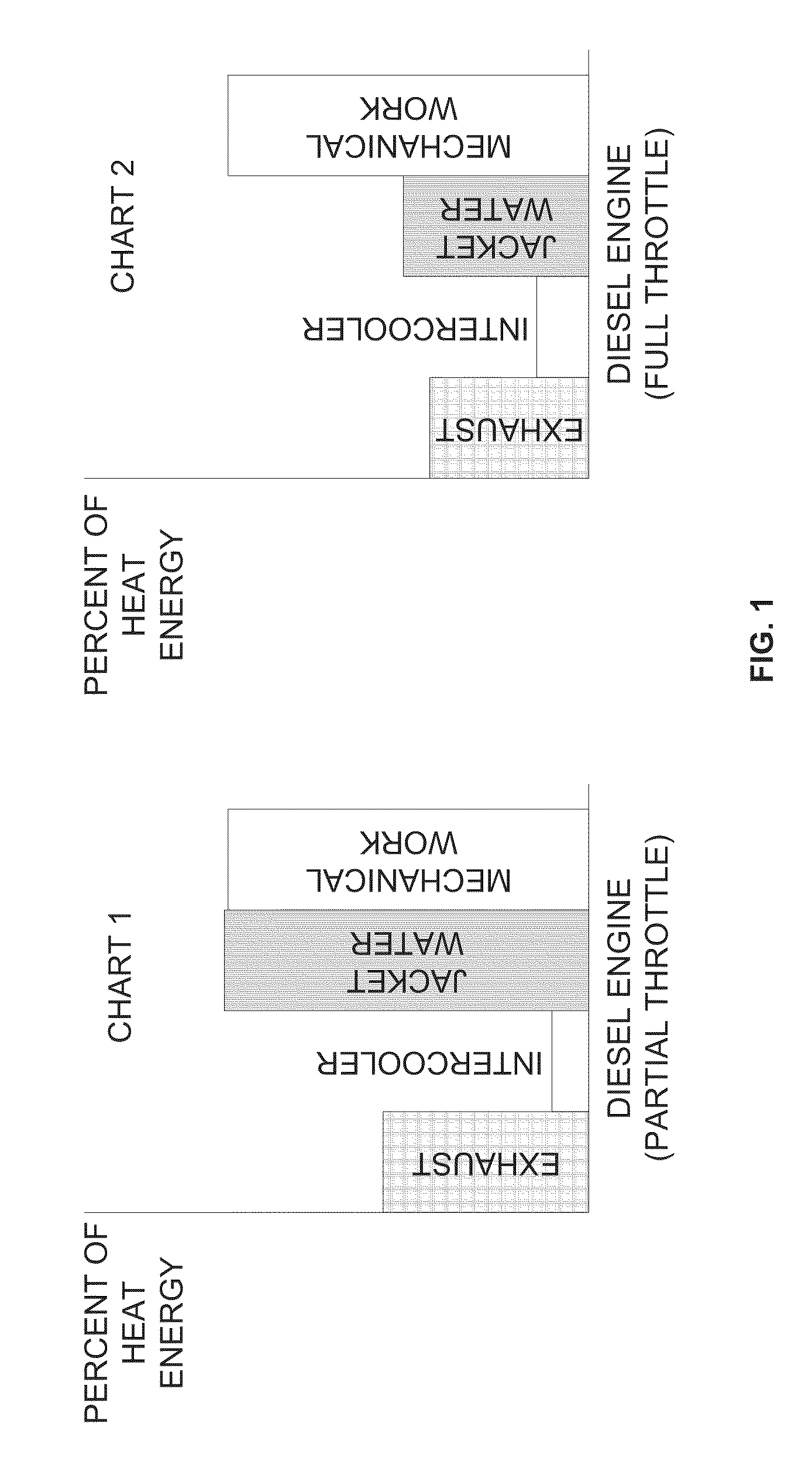

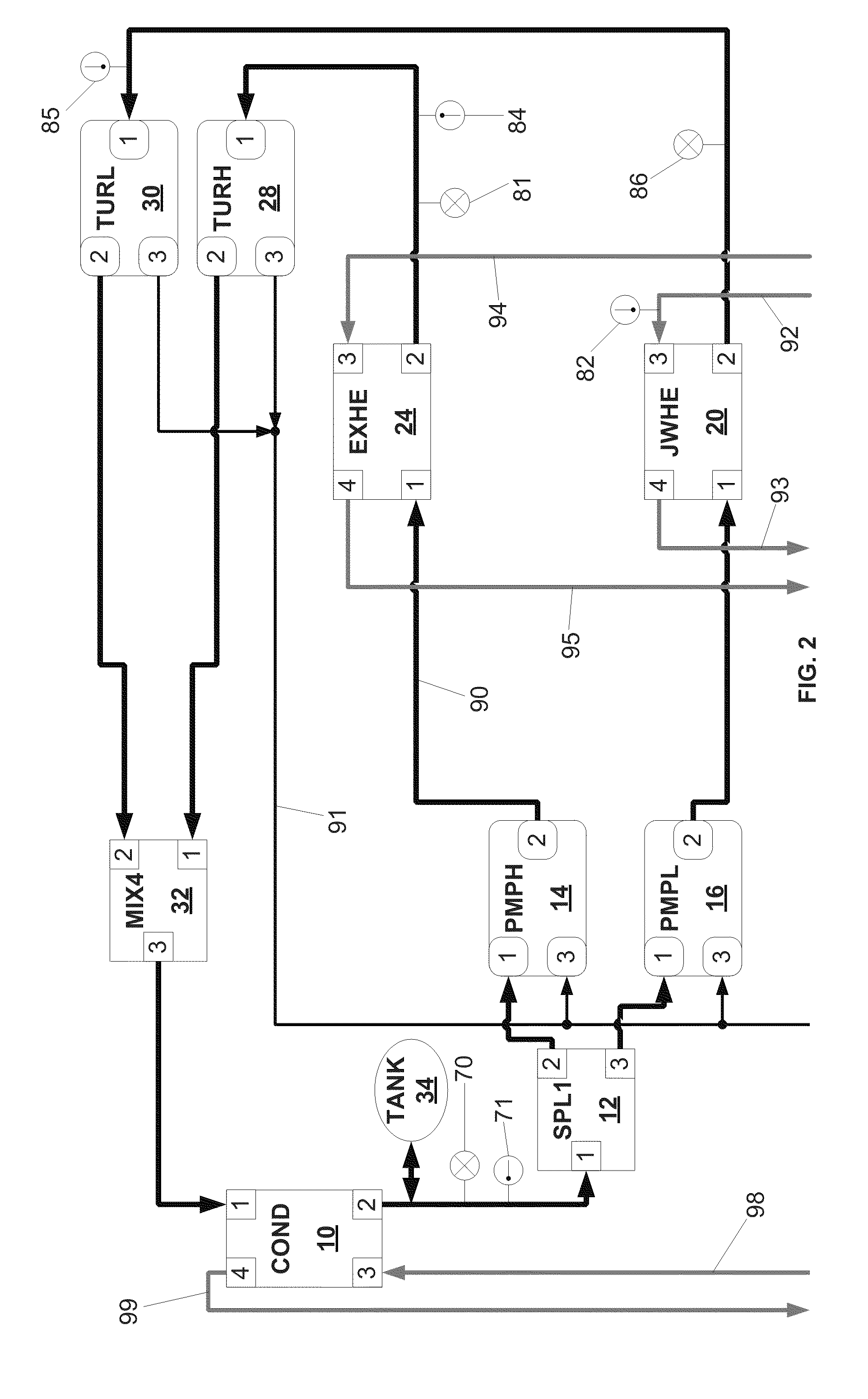

Waste heat recovery system

ActiveUS20110072818A1Reduce complexityLow costSteam engine plantsWorking fluidExternal combustion engine

To mitigate the potential significant impact on our society due to the continued reliance on high-cost diesel hydrocarbon fuel and the implementation of increasingly strict emission controls, an apparatus is disclosed which provides the means for extracting additional heat from an internal combustion engine while providing the cooling needed to meet stricter emissions standards. The present disclosure describes an apparatus operating on a Rankine cycle for recovering waste heat energy from an internal combustion engine, the apparatus including a closed loop for a working fluid with a single shared low pressure condenser serving a pair of independent high pressure circuits each containing zero or more controlled or passive fluid splitters and mixers, one or more pressure pumps, one or more heat exchangers, and one or more expanders, and the means for controlling said apparatus.

Owner:SANCHEZ SANDRA I

Methods for recovering waste energy from bleed air ducts

ActiveUS20150047684A1Power installationsThermoelectric device with peltier/seeback effectThermal energyBleed air

A thermal energy harvester and power conversion system employs a bleed air duct containing the flow of high temperature air from an engine. A lower temperature air source is included with an energy conversion device having a hot interface operably engaged to the bleed air duct and a cold interface operably engaged to the lower temperature air source. The energy conversion device generates electrical power from a thermal gradient between the bleed air duct and the lower temperature air source and the electrical power is routed to a power feeder.

Owner:UNKNOWN

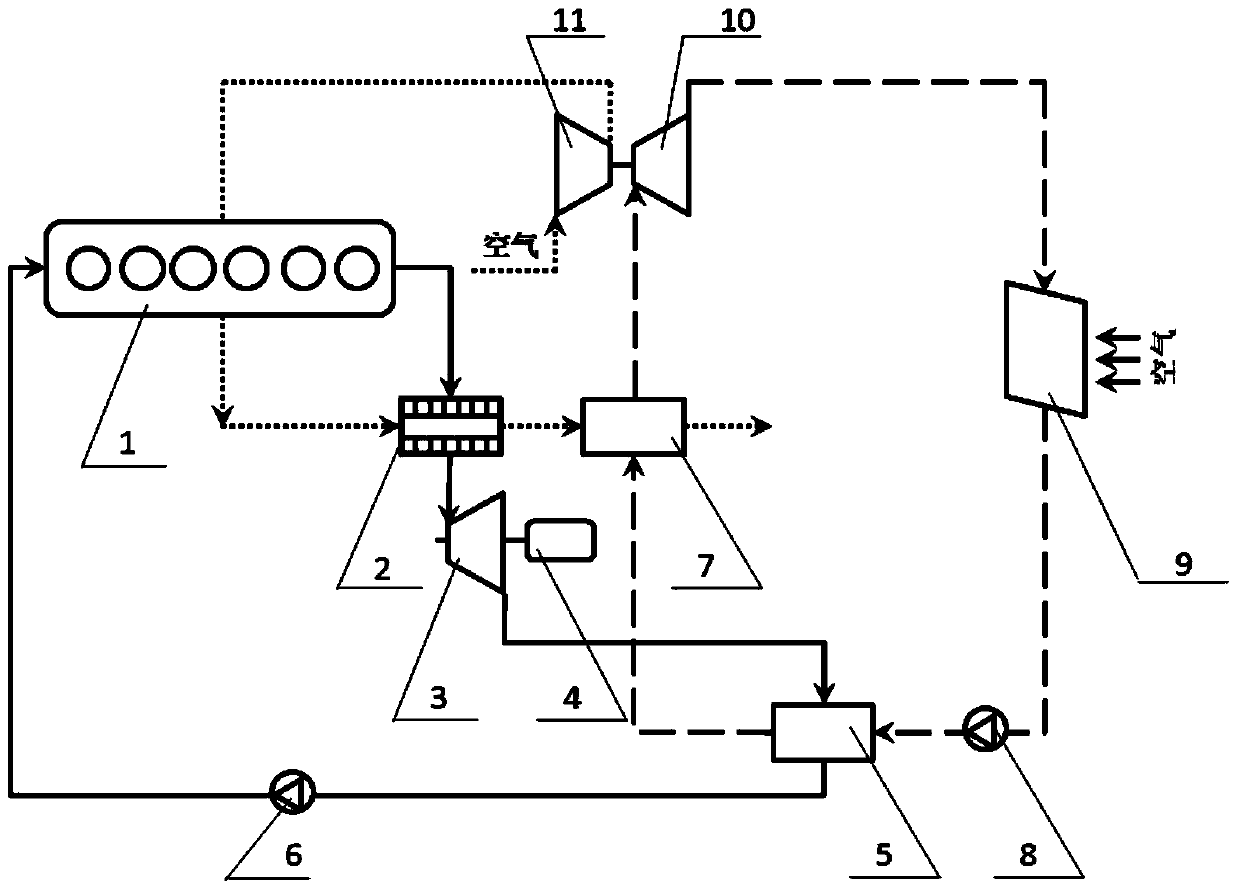

Internal combustion engine vapor supercharging waste heat recovery system

ActiveCN103742293AIncrease the effective working rangeEfficient use ofInternal combustion piston enginesEngine componentsWaste heat recovery unitOrganic Rankine cycle

The invention discloses an internal combustion engine vapor supercharging waste heat recovery system. According to the technical scheme, internal combustion engine cylinder sleeve cooling water is in tandem connection with the cold end of a thermoelectric generator, an expansion machine, a preheater and a circulating water pump sequentially through pipelines to form into a cooling water heat utilization circulating system; air performed air suction compression through a compressor is sent to an internal combustion engine; an exhaust pipe of the internal combustion engine is in tandem connection with the thermal end of the thermoelectric generator, the gas side of an evaporator sequentially to form into an exhaust thermal utilization system; a preheater is in tandem connection with the working medium side of the evaporator, a turbine expansion machine, the working medium side of the condenser and a working medium pump sequentially to form into an organic rankine cycle system; the compressor is in shaft connection with a turbo machine to form into a turbosupercharger. The internal combustion engine vapor supercharging waste heat recovery system has the advantages of breaking the temperature limit of the recycle source of the organic rankine cycle, recycling the waste heat energy of the exhaust and the cooling water, achieving efficient utilization of the waste heat, avoiding the condition that the exhaust energy is not enough to drive a supercharging system when the load is low, increasing the effective working range of the supercharging system and achieving the purpose of efficiently recycling the waste heat energy.

Owner:TIANJIN UNIV

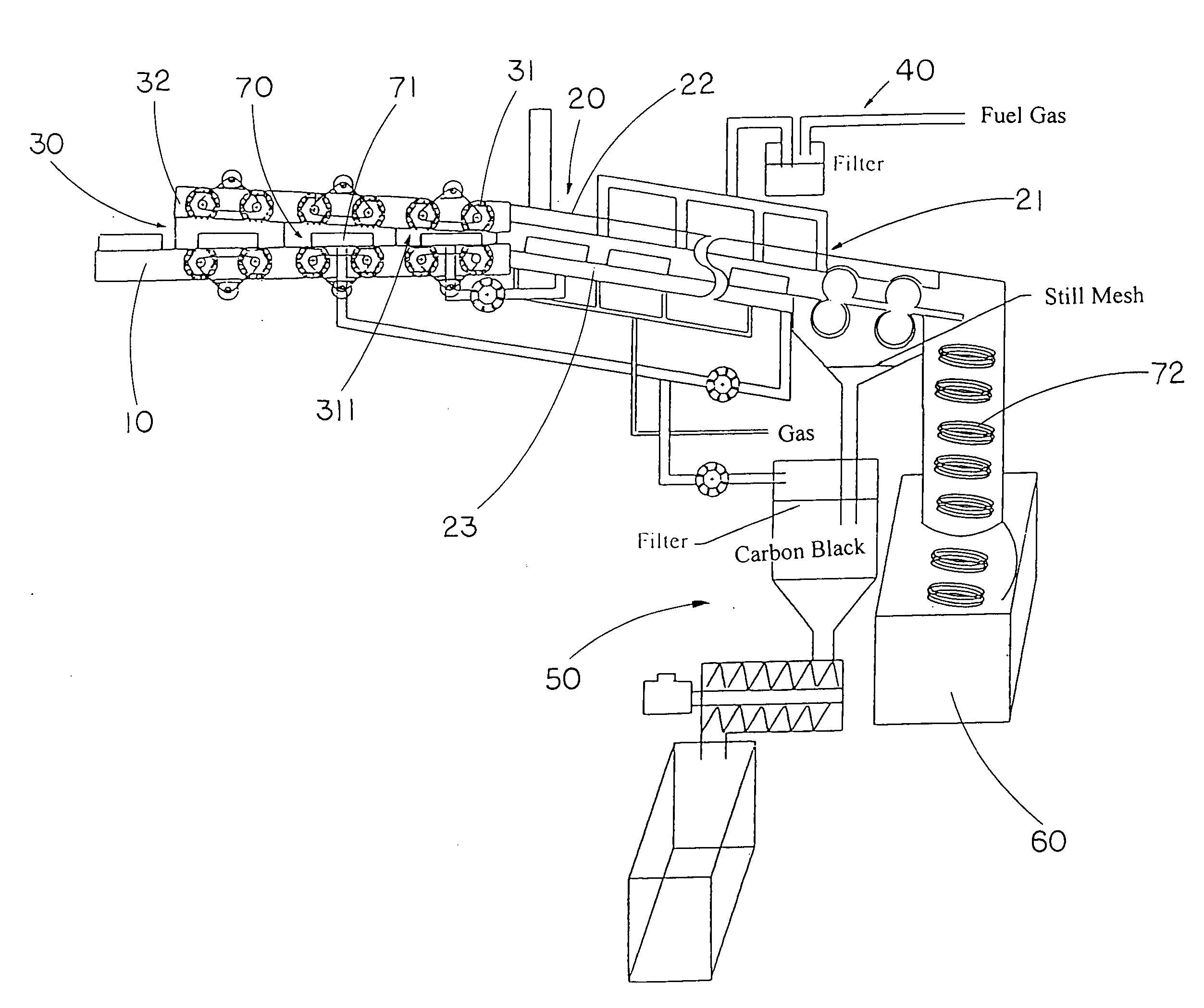

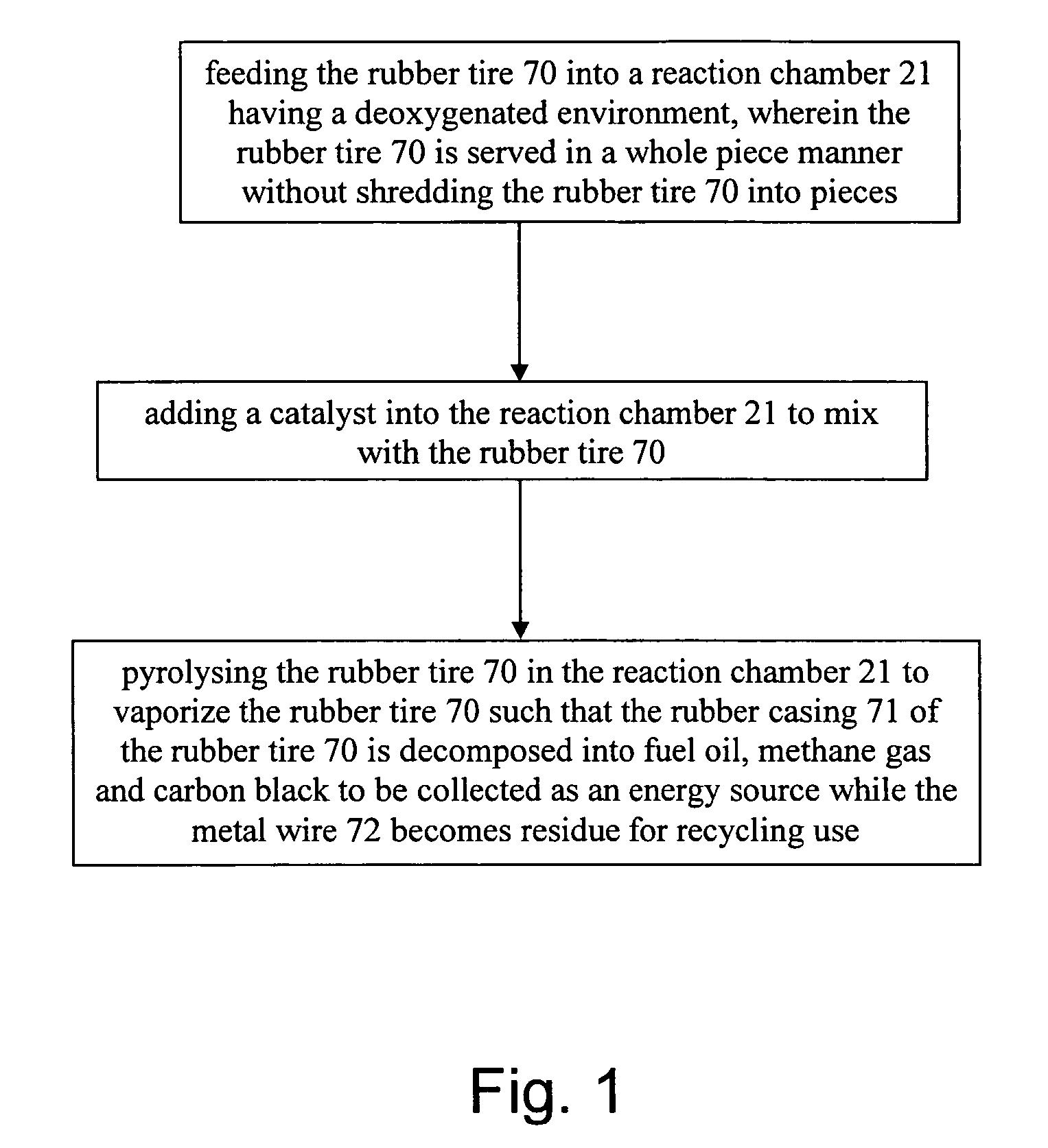

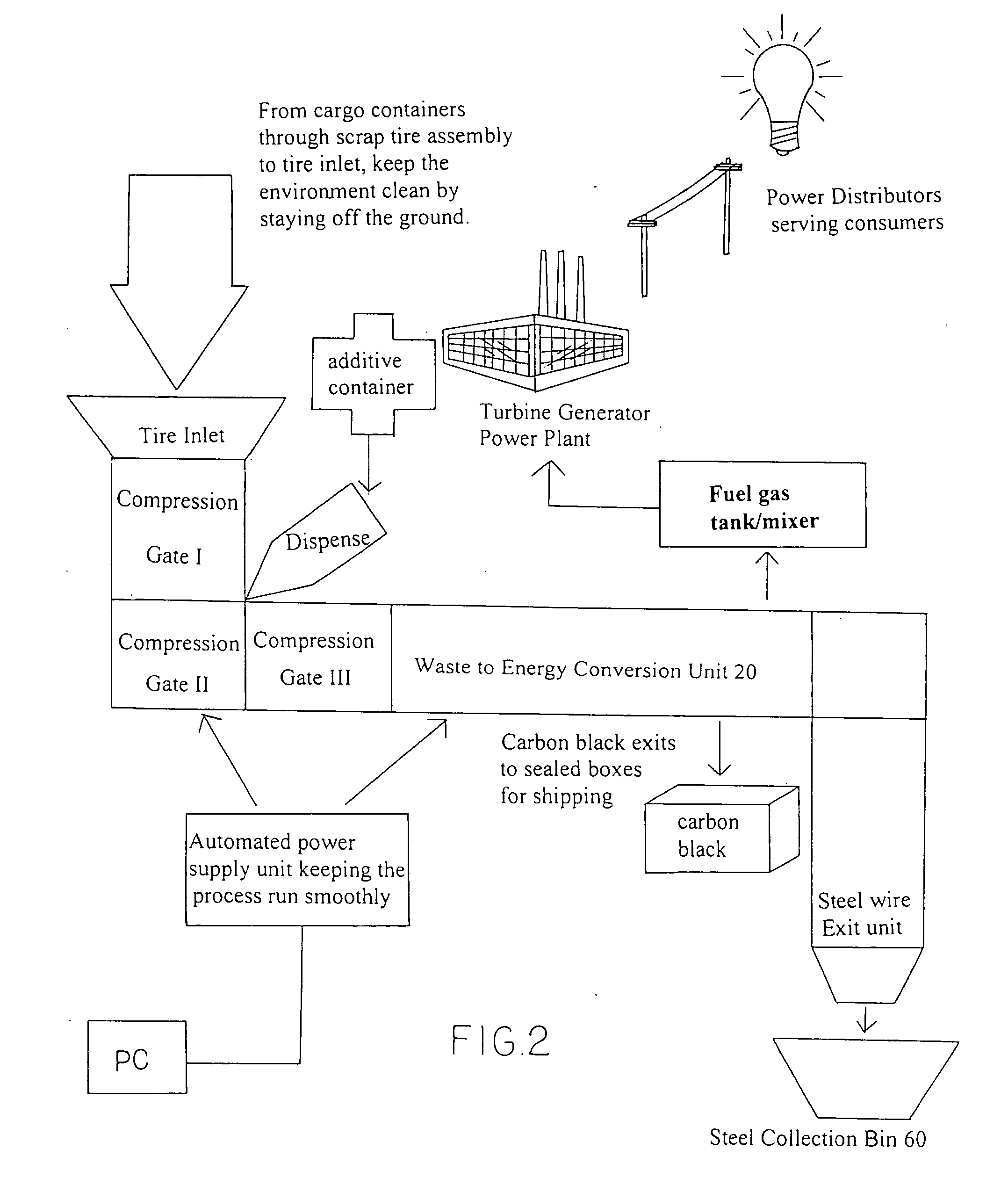

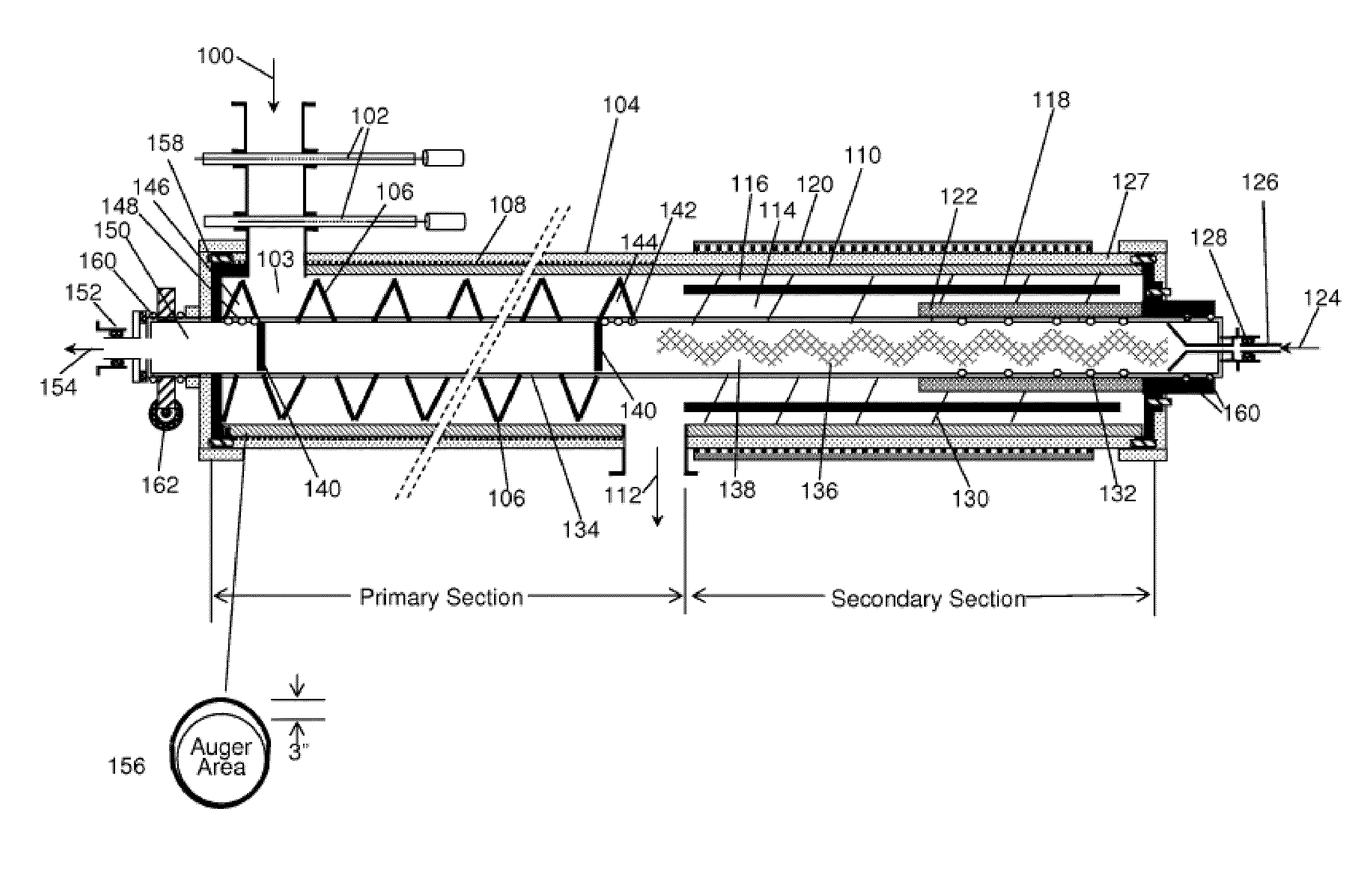

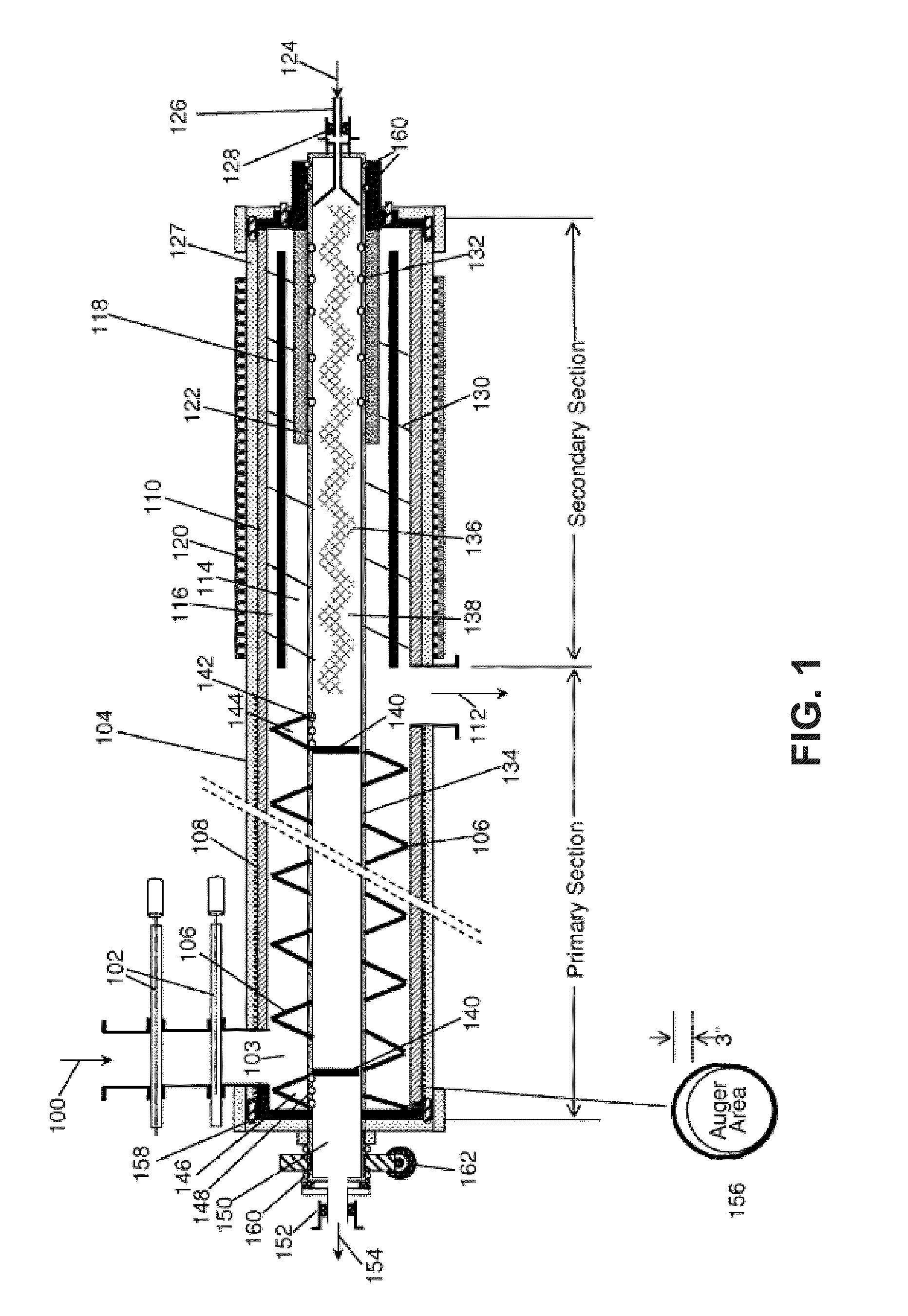

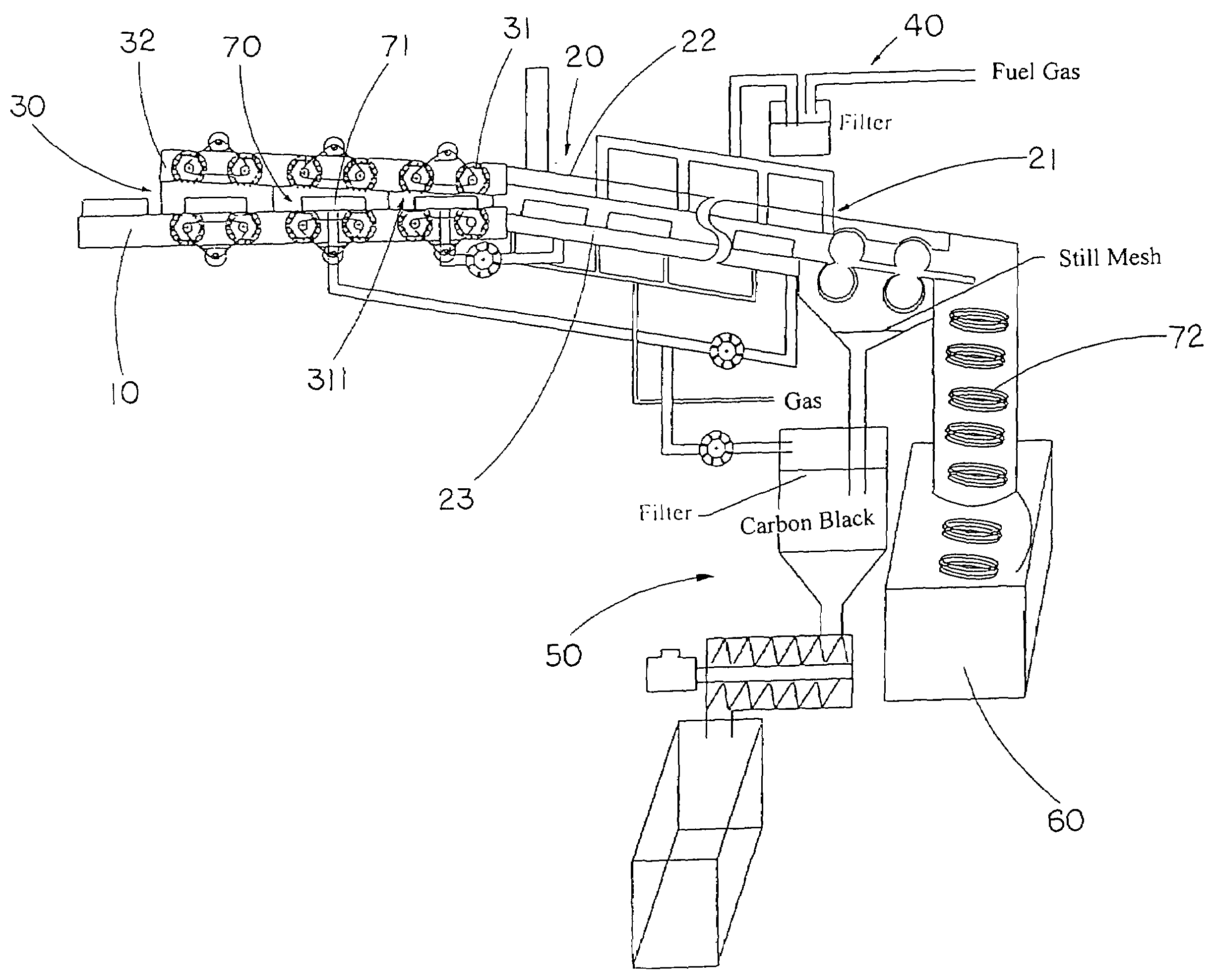

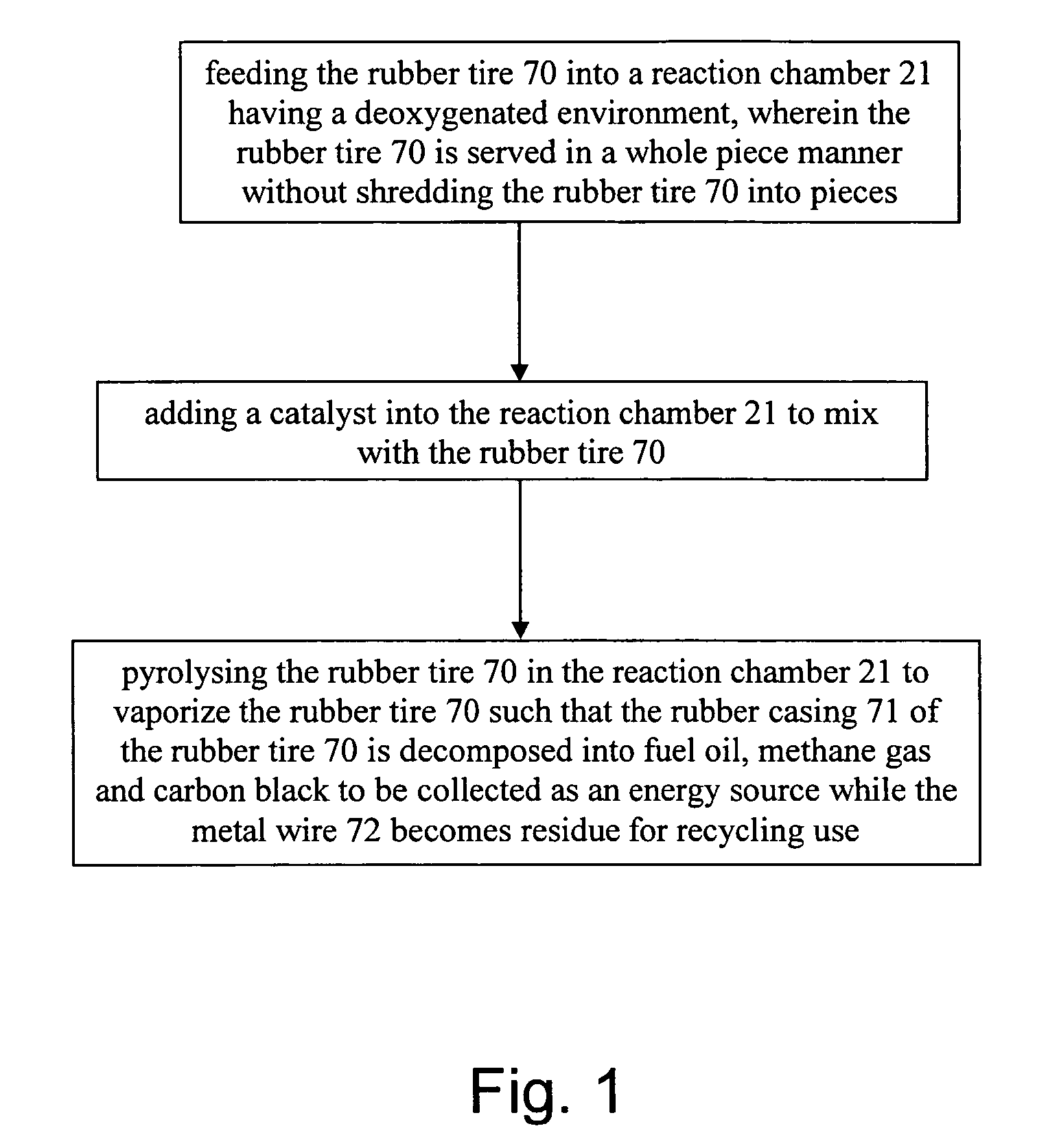

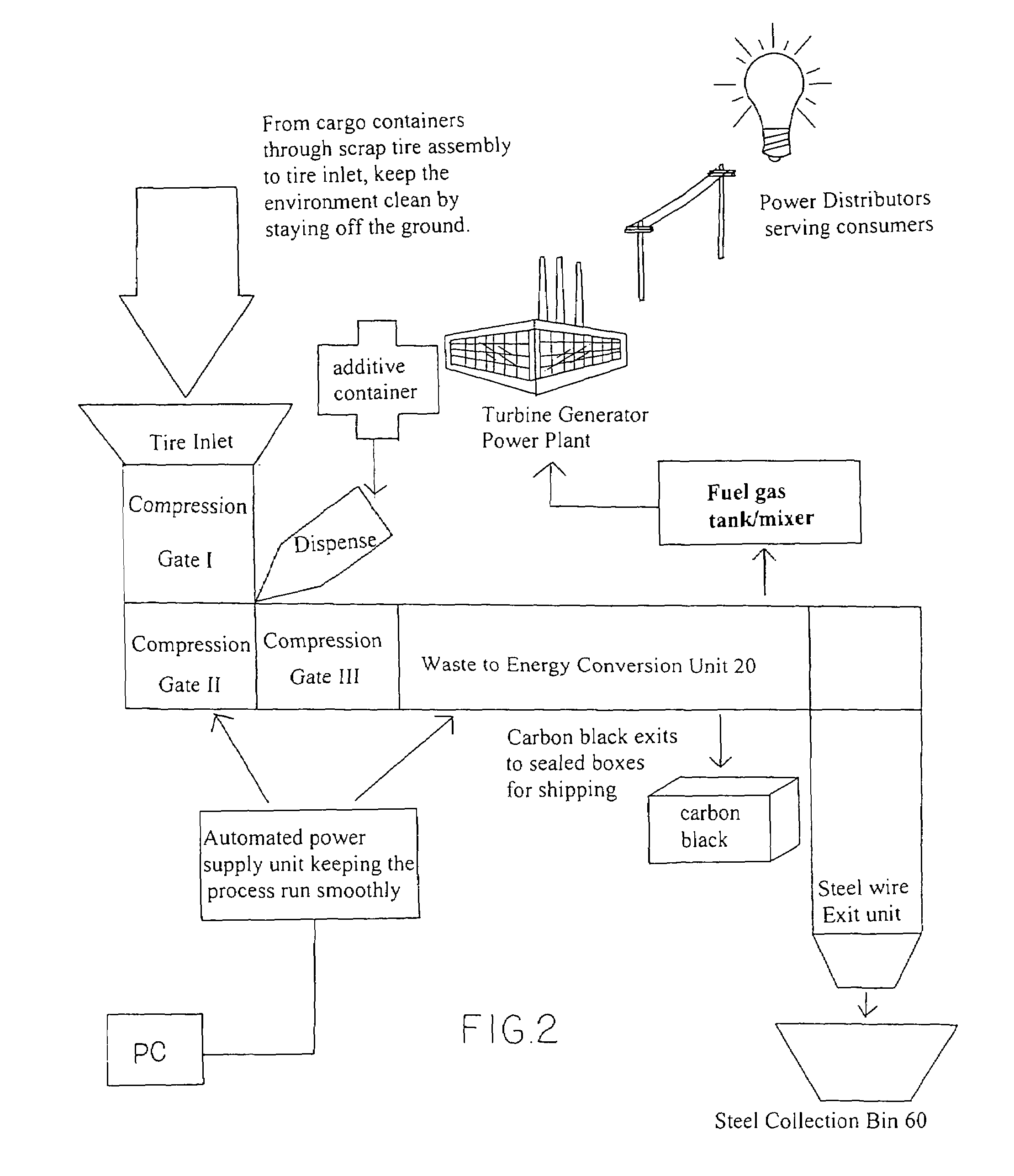

Rubber tire to energy pyrolysis system and method thereof

InactiveUS20060211899A1Maximize applicationLow costIndirect and direct heating destructive distillationRetortsFuel oilMethane gas

The present invention provides a pyrolysis system and method thereof which are capable of converting an entire rubber tire into several energy resources in an environmentally-friendly manner. The system includes a tire transporting unit, a waste to energy conversion unit, and a energy collection unit. The waste to energy conversion unit includes a conversion housing having a reaction chamber for receiving the rubber tire for pyrolysis processing to decompose the rubber tire into fuel oil, methane gas and carbon black, while metal wire from the rubber tire are resided for recycling use.

Owner:LEE ERNEST

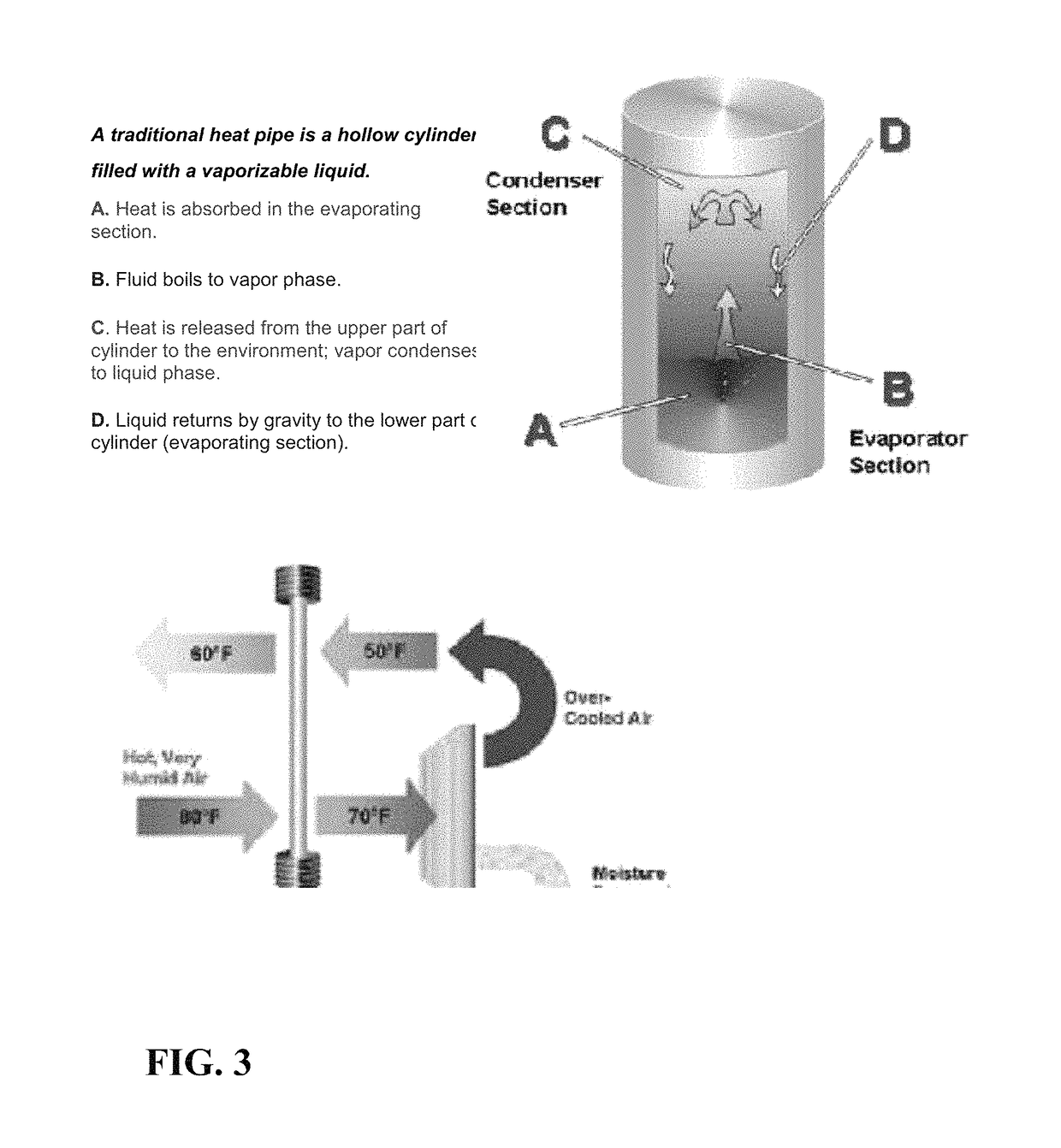

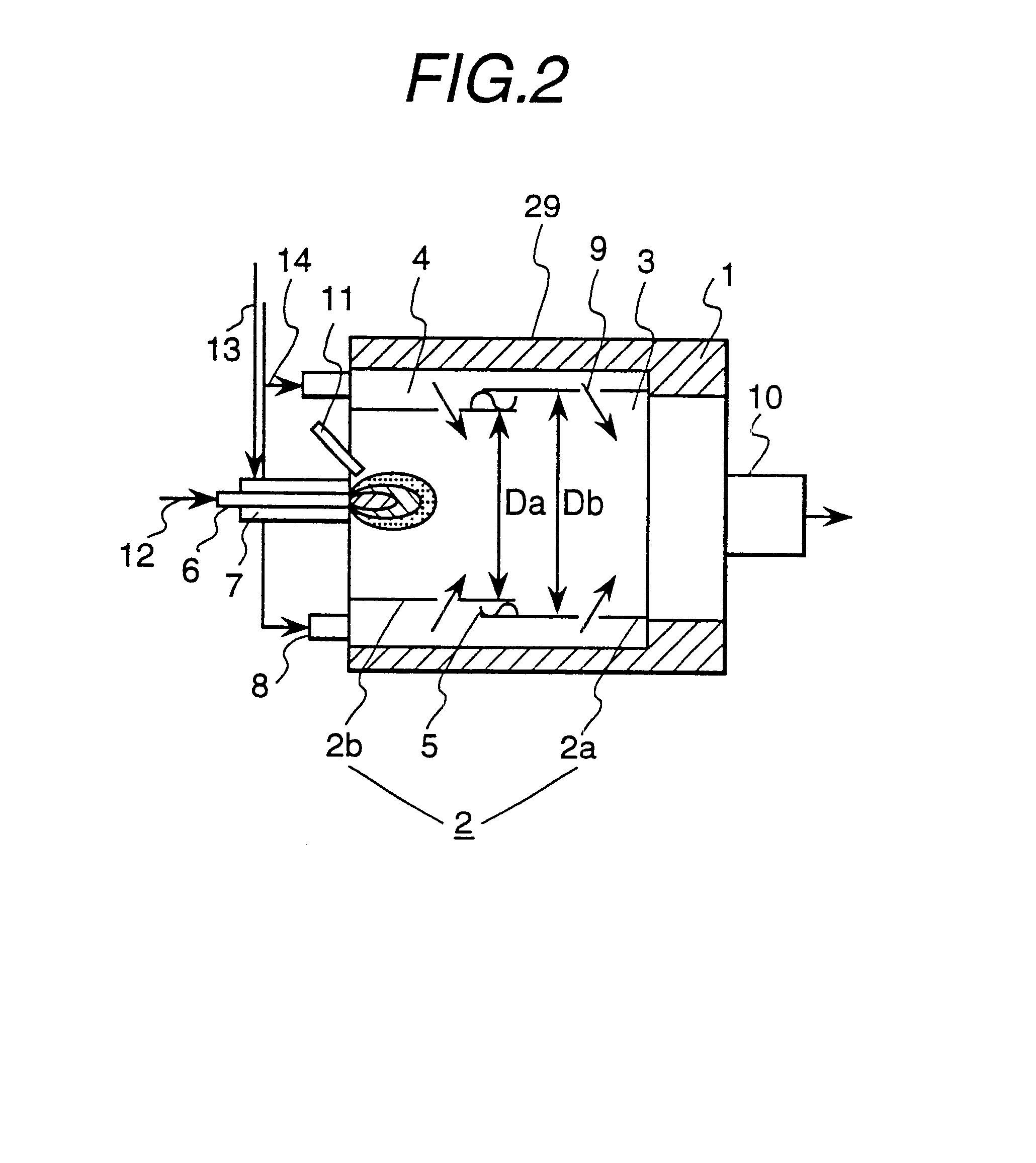

Waste energy recovery method and waste energy recovery system

InactiveUS20070074515A1Recovers waste heat energyOptimize energy useLiquid coolingInternal combustion piston enginesTurbochargerBoiling point

An oil cooler for cooling hydraulic oil that has increased in temperature due to energy loss in a hydraulic circuit a radiator for cooling engine cooling water that has increased in temperature as a result of cooling an engine and an ATAAC for cooling engine intake air that has increased in temperature as a result of being compressed by a turbocharger, are provided with heat pipes for vaporizing low-boiling medium by absorbing heat from the oil cooler the radiator and the ATAAC. A power recovery turbine is rotated by energy provided by vaporized low-boiling medium is provided for the engine. A low-boiling medium circuit is provided so as to drive the turbine by feeding the low-boiling medium that has been vaporized by waste heat energy. The low-boiling medium circuit includes the heat pipes of the oil cooler the radiator, and the ATAAC, as well as the turbine.

Owner:SHIN CATERPILLAR MITSUBISHI LTD CORP

Waste recovery cogenerator

InactiveUS20110036320A1Easy to remove waterImprove filtering effectInternal combustion piston enginesExhaust apparatusThermal energyParticulates

A waste-to-energy cogeneration system is described in various embodiments. The system can convert certain fuel-laden waste to thermal energy and electrical power. In certain embodiments, fuel-laden waste which has not been pre-filtered or pre-treated to remove particulates and water is deposited in the cogeneration system and prepared by the system for combustion in an unmodified diesel engine. The fuel-laden waste can comprise oils, greases and fats from food preparation which are contaminated with water and particulates. Thermal and mechanical energy produced by the engine are utilized to provide thermal energy and electrical power external to the cogeneration system.

Owner:UNIV OF MIAMI

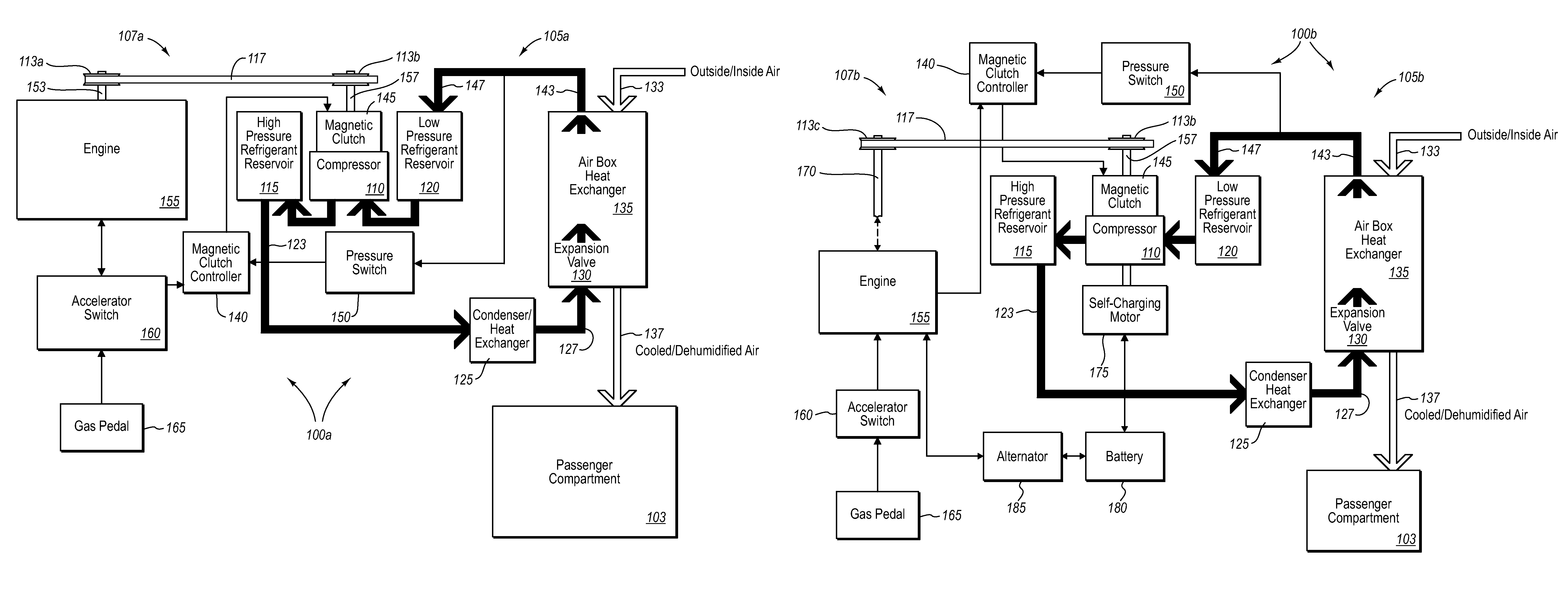

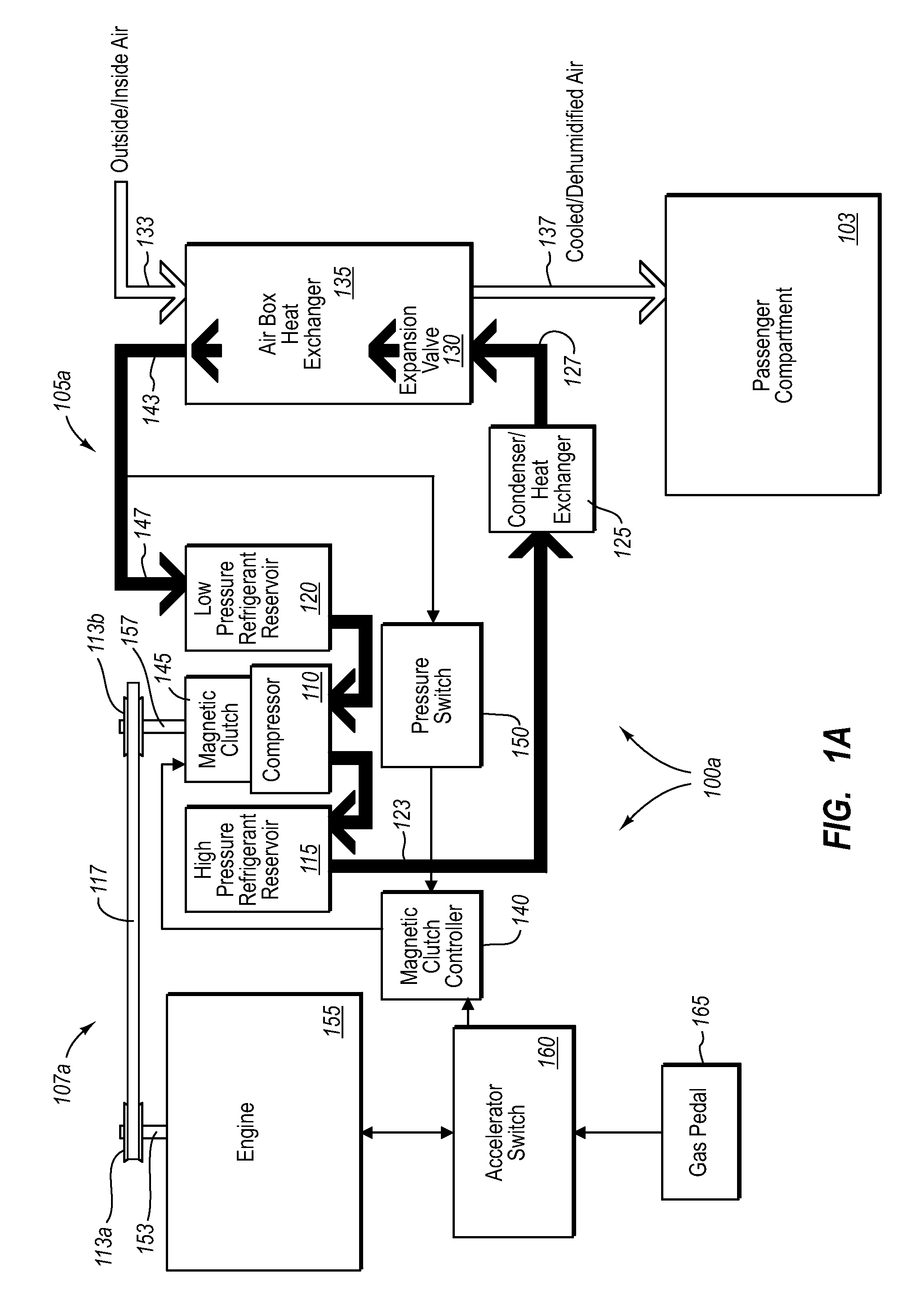

Air conditioning system operating on vehicle waste energy

InactiveUS20070204639A1Mitigate fuel economy issueEasily and inexpensively configuredReciprocating combination enginesAir-treating devicesDrive shaftElectrical battery

A waste energy-based vehicle air conditioning system includes efficient compression driving means coupled to refrigeration means. In one implementation, the compression driving means includes a controller (e.g., magnetic clutch) that couples mechanical waste energy from an engine fan axle, a vehicle drive shaft, or a transmission shaft to an axle of a refrigerant compressor. Alternatively, the controller can also include a battery that is charged from the mechanical waste energy. Upon detecting certain pressure values, the controller powers the refrigerant compressor with a rotating axle (e.g., during deceleration) or with battery power, as appropriate. In one implementation, the controller is configured to engage compression immediately upon detecting that the vehicle is decelerating. One or more kits can be used to retrofit existing vehicles to operate the respective air conditioning systems principally on waste energy.

Owner:HARRISON THOMAS D

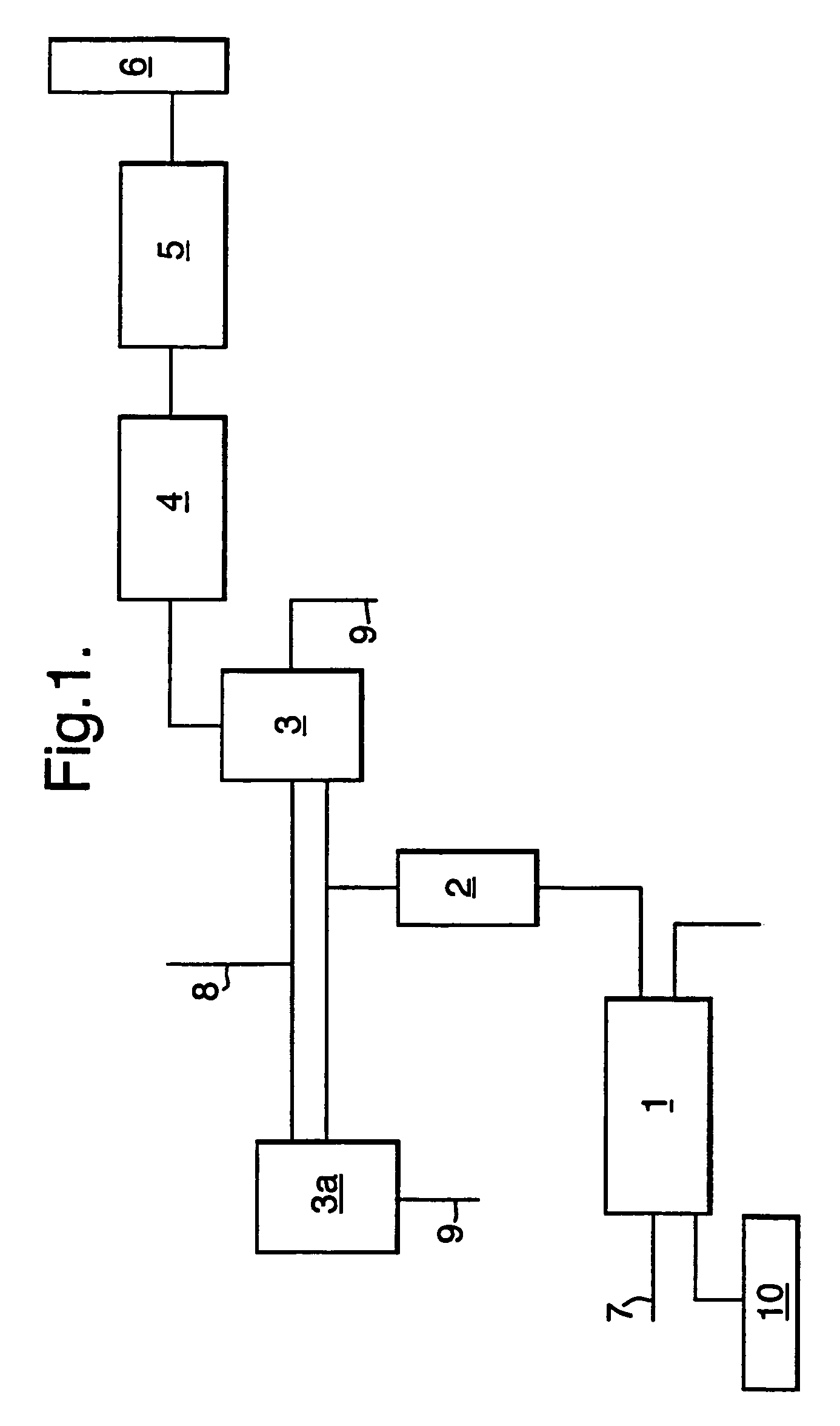

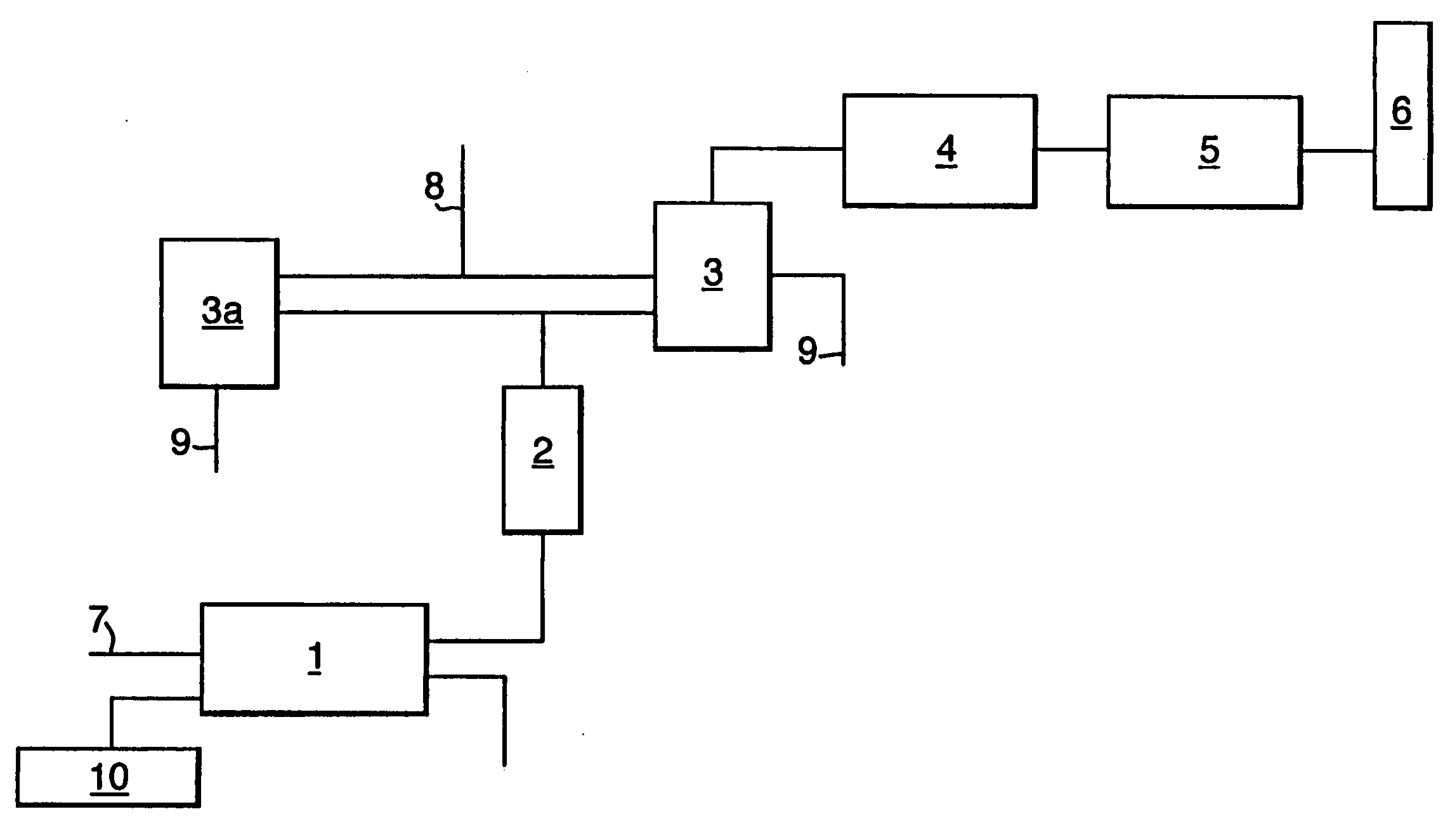

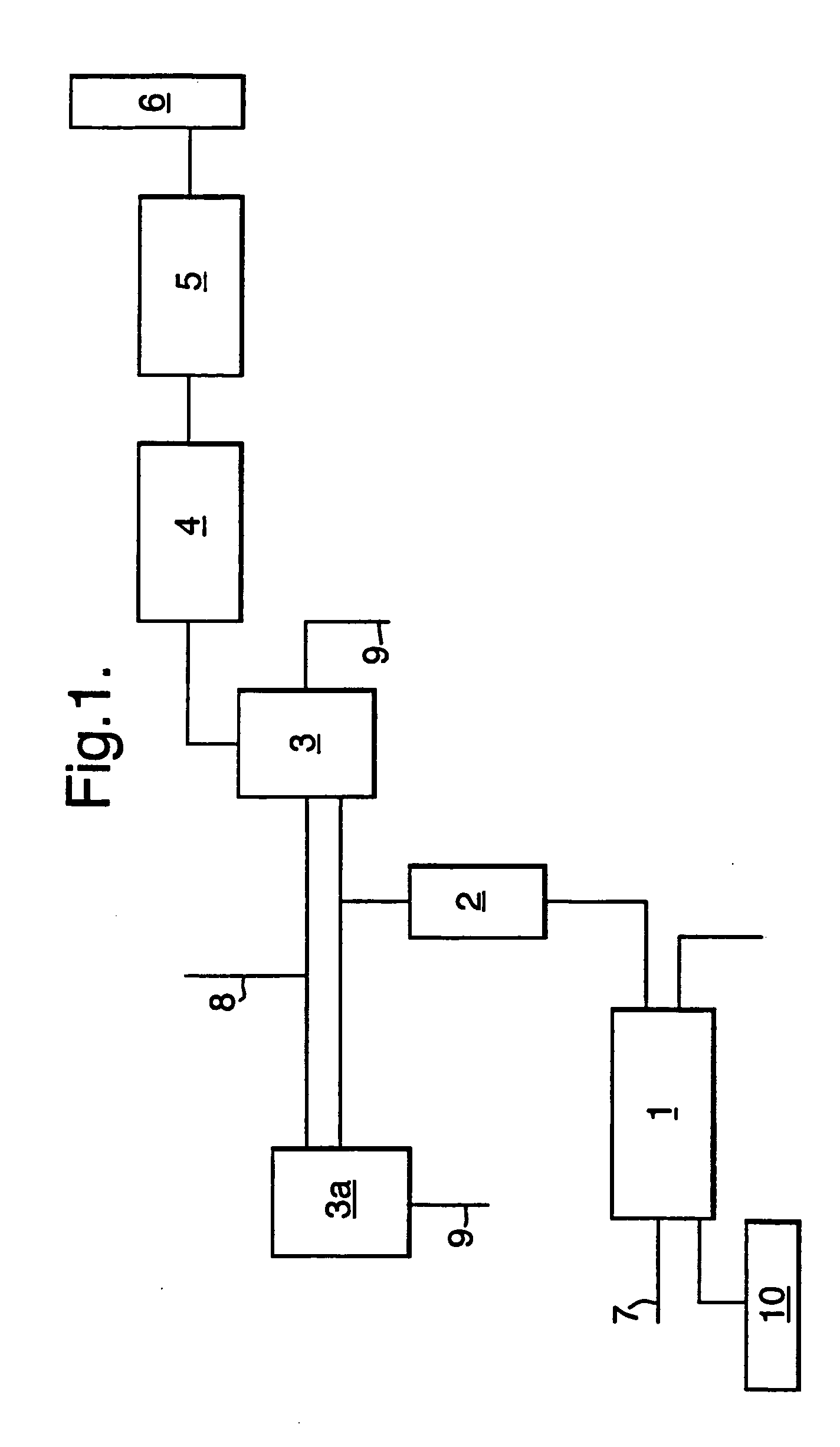

Method and process for co-combustion in a waste to-energy facility

InactiveUS7189074B2Reduce chanceImprove usabilityRotary drum furnacesCeramic production plantsCombustion chamberSlag

The co-combustion process may comprise the following unit operations: routing of hot gas (10) generated in the clinker cooling process to a rotary kiln (1); use of part of the rotary kiln exhaust gas to dry solid wastes in rotary dryers; leading the gases from both the dryer and the combustion kiln to the secondary combustion chamber (2); use of additional fuel to boost up the secondary combustion chamber reaction temperature to as high as 1200° C.; primary dry gas scrubbing in a precalciner or precalciners (3, 3a); heat recovery (4) and power generation; secondary gas scrubbing (5) in a semi-dry scrubber; bag filtering after activated carbon injection and returning of all the collected ash and used carbon into the waste kiln and / or a cement kiln. Detrimental materials for cement processing generated by waste combustion can be by-passed to a scrubbing system and a cement kiln. Residue slag from waste kilns can be treated and reused.

Owner:GREEN ISLAND ENVIRONMENTAL +1

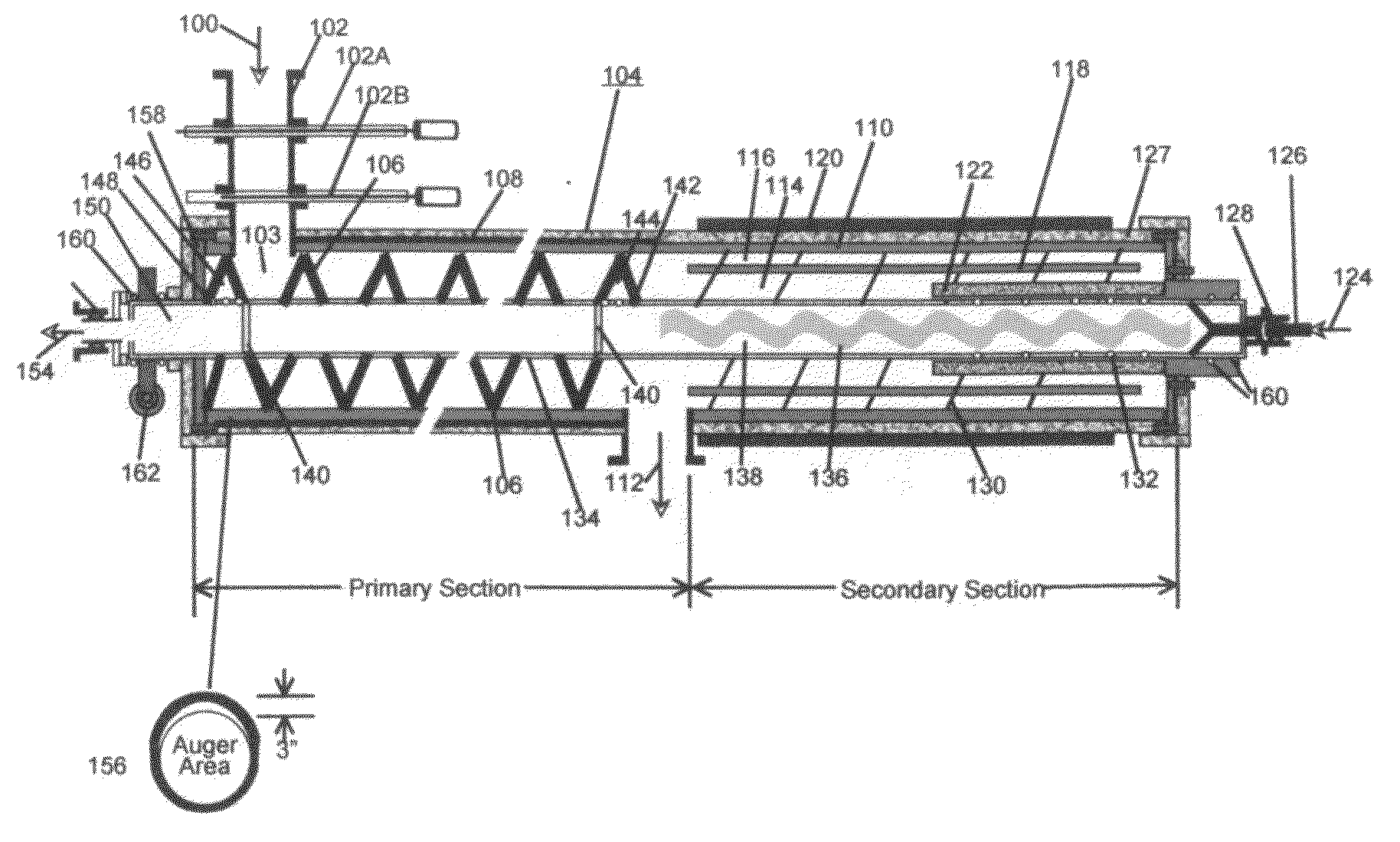

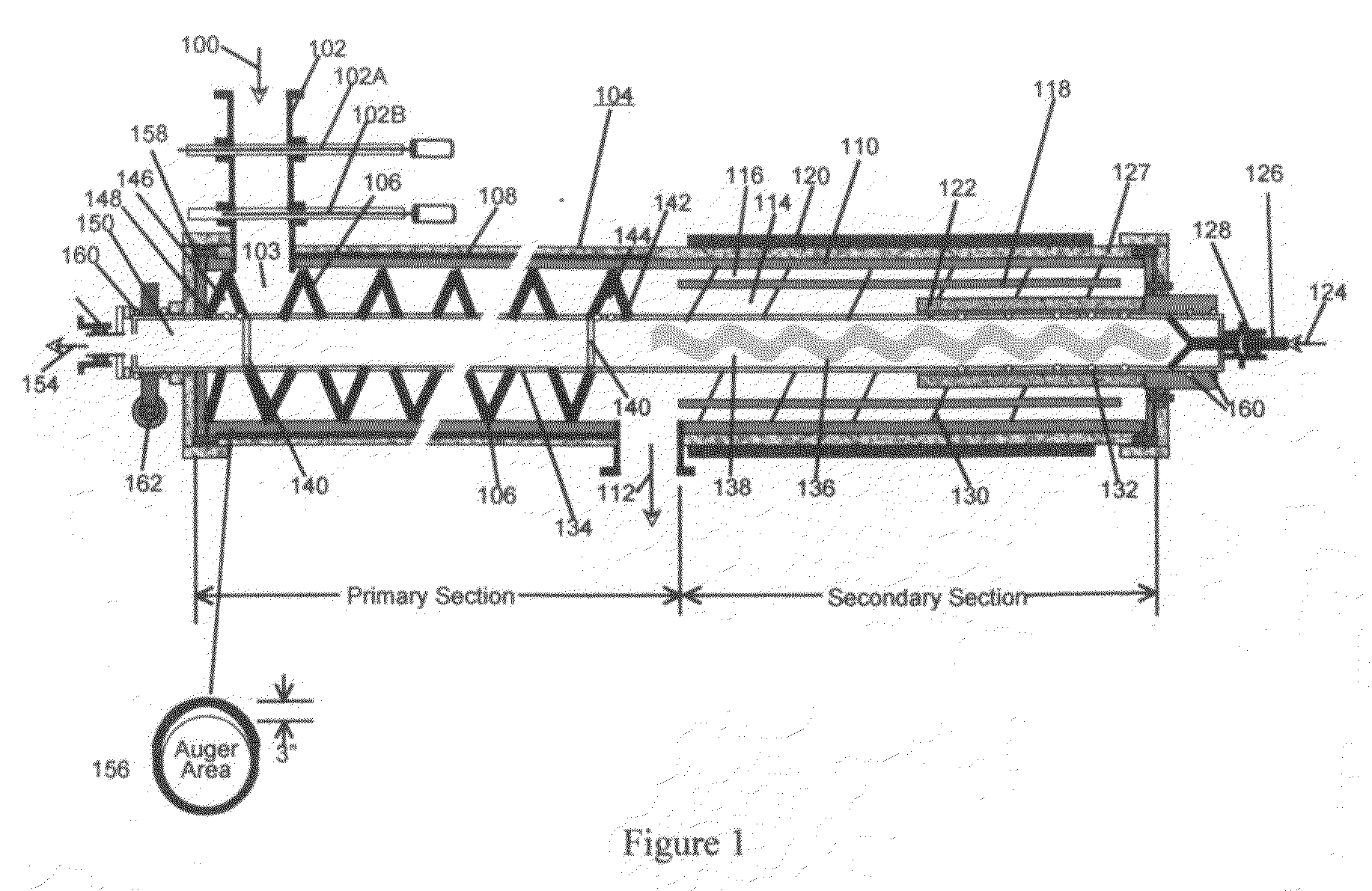

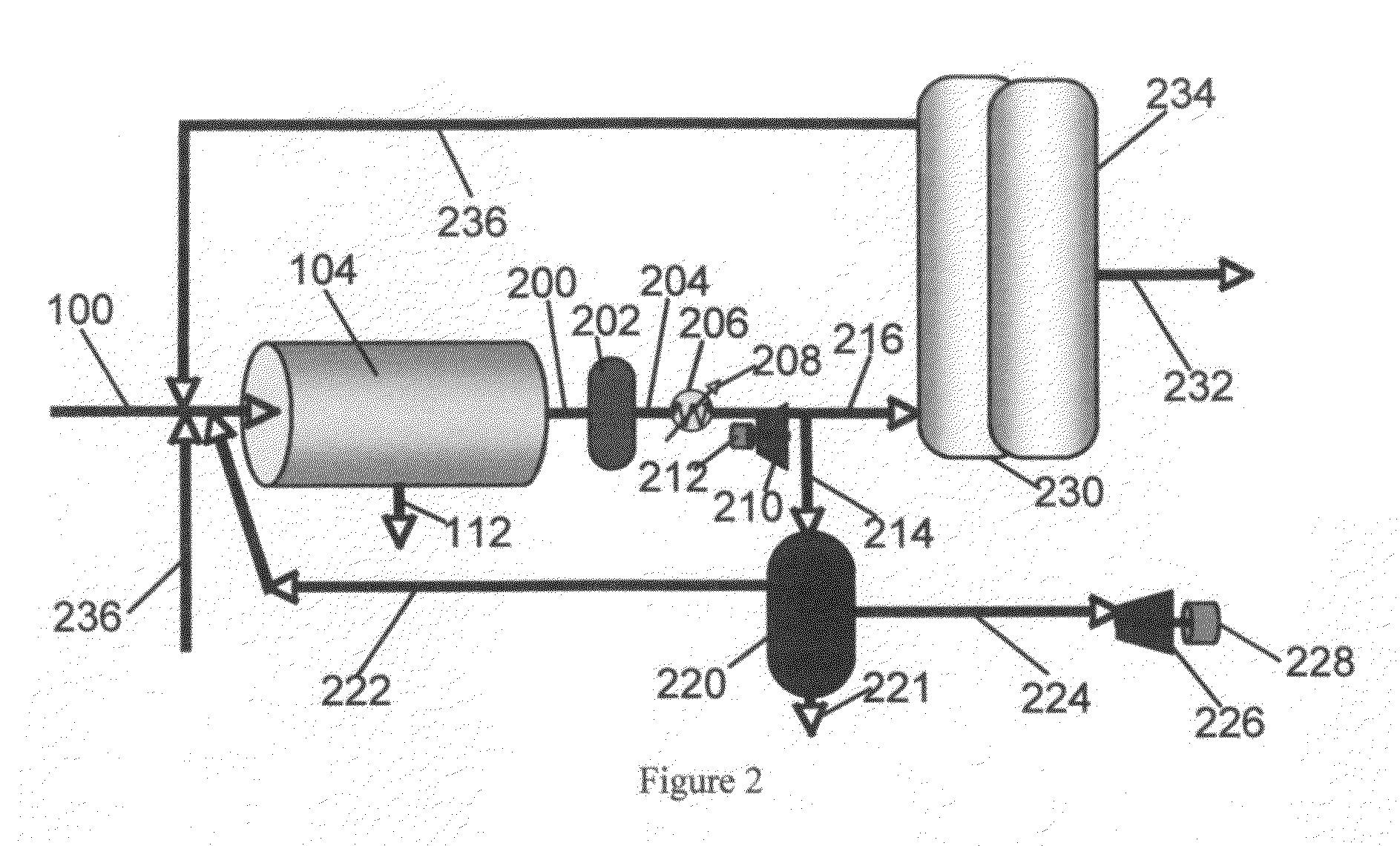

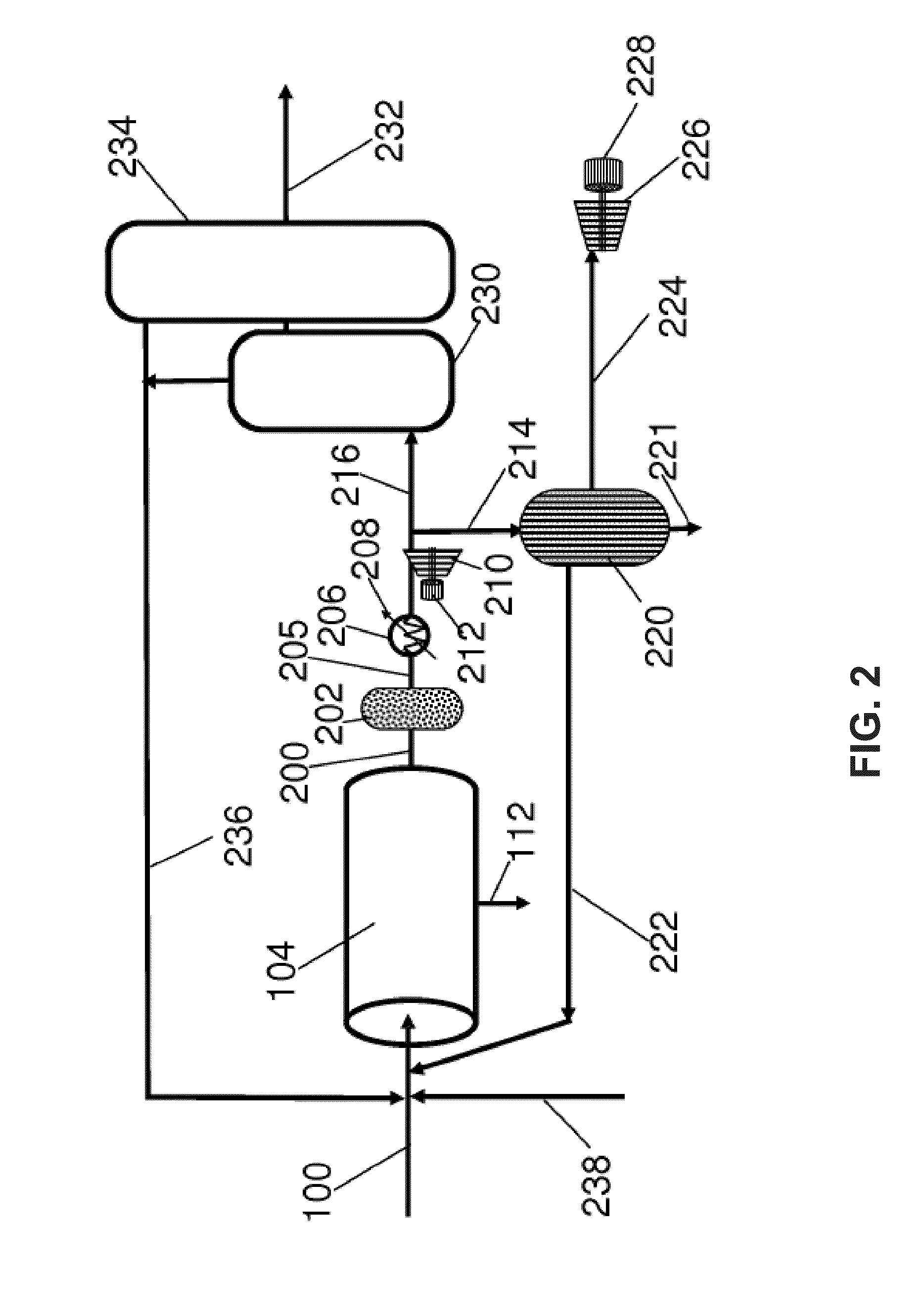

Process and System for Converting Waste to Energy Without Burning

ActiveUS20120277329A1Large emissionsGasifier mechanical detailsCombustible gas catalytic treatmentHigh carbonWaste stream

This invention relates to a power recovery process in waste steam / CO2 reformers whereby a waste stream can be made to release energy without having to burn the waste or the syngas. This invention does not make use of fuel cells as its critical component but makes use of highly exothermic chemical reactors using syngas to produce large amounts of heat, such as Fischer-Tropsch. It also relates to control or elimination of the emissions of greenhouse gases in the power recovery process of this invention with the goal of producing energy in the future carbonless world economy. A New Concept for a duplex kiln was developed that has the combined functionality of steam / CO2 reforming, heat transfer, solids removal, filtration, and heat recovery. New methods of carbon-sequestering where the syngas produced by steam / CO2 reforming can be used in Fischer-Tropsch processes that make high-carbon content compounds while recycling the methane and lighter hydrocarbons back to the reformer to further produce syngas at a higher H2 / CO ratio.

Owner:RAVEN SR INC

System for recycling waste heat energy of exhaust gas of internal combustion engine by using air circulation

InactiveCN102840026AImprove powerImprove economyInternal combustion piston enginesExhaust apparatusAir cycleExternal combustion engine

The invention discloses a system for recycling waste heat energy of exhaust gas of an internal combustion engine by using air circulation. One set of air circulation (Brayton Air Cycle) system is additionally arranged on an internal combustion engine exhaust pipe to recycle the waste heat energy of the exhaust gas and convert the waste heat energy into effective work. A technical scheme is as follows: after being pressurized to a certain pressure by a compressor, the air is heated in a heat exchanger to form a high temperature and high pressure gas, and then the high temperature and high pressure gas is expanded in a turbine to do work. Turbine output work is used for driving an air compressor of an internal combustion engine air intake system to supercharge inlet air and can be also used for driving a high speed motor to generate power. In addition, the system disclosed by the invention can be also designed in a heat return circulation mode, so that energy recycling efficiency is further increased through two-stage heating. An internal combustion engine electronic control system is used for adjusting working pressure and flow of air circulation in real time according to an exhaust state, so as to optimize circulating efficiency. The system for recycling the waste heat energy of the exhaust gas of the internal combustion engine by using the air circulation, disclosed by the invention, can obtain an energy saving and environment friendly effect by using air as a working medium and has the advantages of comparatively simple structure and better application value.

Owner:HUNAN UNIV

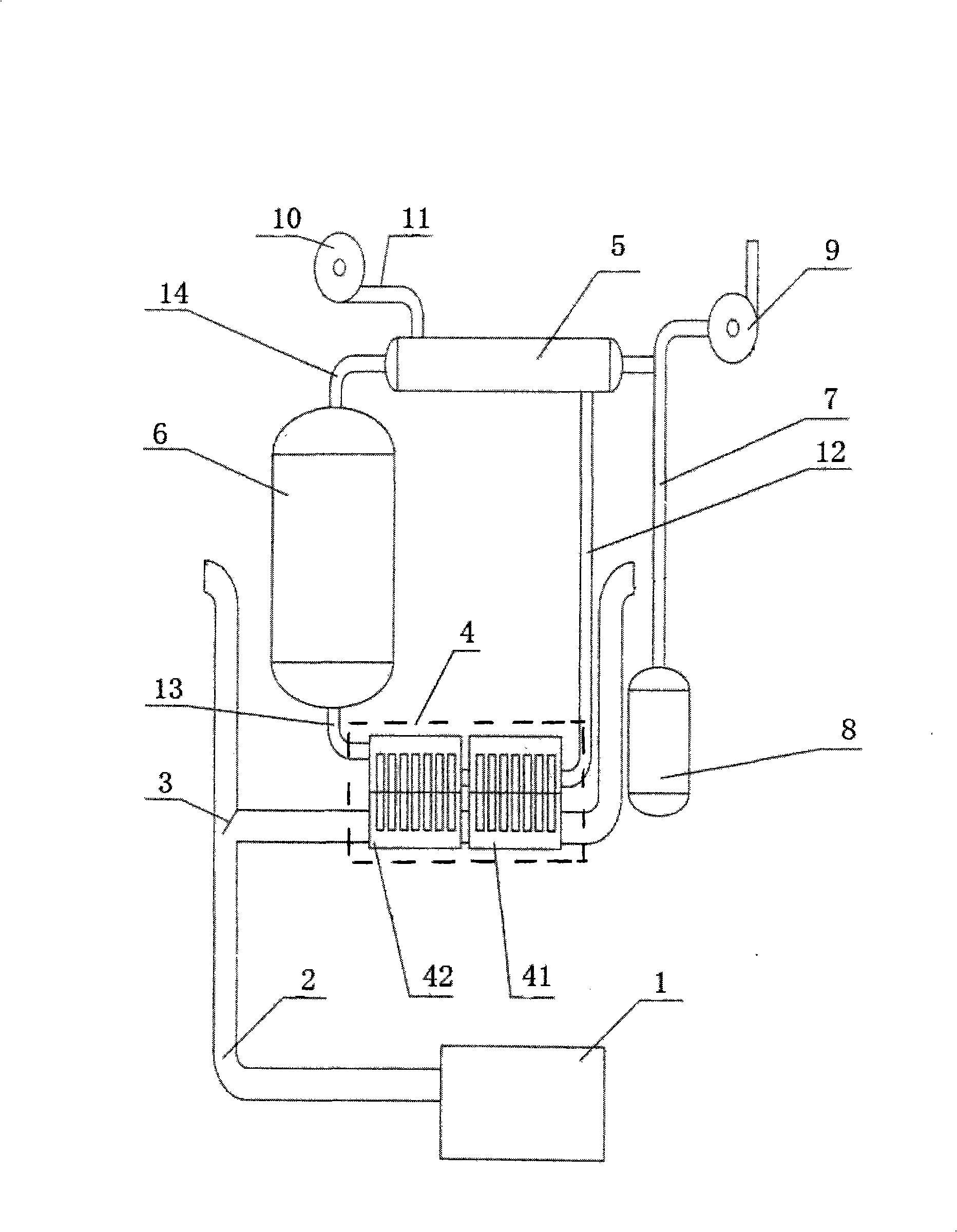

Desalination plant by using engine end gas

InactiveCN101306846ATake advantage ofFast heat transfer and heat exchangeGeneral water supply conservationSeawater treatmentThermal energyEngineering

The invention discloses a seawater desalting device for tail gas of an engine. The device comprises a superconductive pipe heat exchanger(4), a vacuum evaporating pot(6) and a condenser(5) which are orderly connected as a whole, wherein the superconductive pipe heat exchanger(4) is communicated with an exhaust pipe(2) of the engine through a flue gas diversion valve(3), and the condenser(5) has a seawater inlet provided with a sea water replenishing pump(10) and a condensed water outlet provided with a vacuum pump(9) and a fresh water collection pot(8). The invention utilizes the tail gas of the engine which is the waste energy to produce fresh water by the distillation method, which fully utilizes the energy, reduces the emission of pollutants and fully utilizes the heat energy of the tail gas; the seawater desalting device has the advantages of simple running, easy operation and maintenance, low cost, small volume and few requirements of the power section, and can effectively resolve the water supply problem for sailing warships, civilian ships and oil drilling platforms which use engines as power sources or use other devices the temperature of the tail gases of which is more than 80 DEG C, as power sources.

Owner:普瑞特机械制造股份有限公司

Process and system for converting waste to energy without burning

InactiveUS20150122243A1Large emissionsExothermal chemical reaction heat productionOther heat production devicesWaste streamFiltration

This invention relates to a power recovery process in waste steam / CO2 reformers whereby a waste stream can be made to release energy without having to burn the waste or the syngas. This invention does not make use of fuel cells as its critical component but makes use of highly exothermic chemical reactors using syngas to produce large amounts of heat, such as Fischer-Tropsch. It also relates to control or elimination of the emissions of greenhouse gases in the power recovery process of this invention with the goal of producing energy in the future carbonless world economy. A New Concept for a duplex kiln was developed that has the combined functionality of steam / CO2 reforming, heat transfer, solids removal, filtration, and heat recovery. New methods of carbon-sequestering where the syngas produced by steam / CO2 reforming can be used in Fischer-Tropsch processes that make high-carbon content compounds while recycling the methane and lighter hydrocarbons back to the reformer to further produce syngas at a higher H2 / CO ratio.

Owner:INTELLERGY INC

Waste to energy process and plant

A plant produces electrical energy from municipal solid waste without exhausting a carbon dioxide or other carbon based gas to the atmosphere. The plant includes a source of artificial light powered by electrical energy, and a reactor into which the municipal solid waste is fed and which is operated under temperature, pressure and flow rate conditions to produced a syngas. An electrical energy generating station at which the syngas is burned produces the electrical energy and a flue gas comprising carbon dioxide and other products of combustion. At least a portion of the electrical energy is used to power the artificial light source. A carbon dioxide collector separates the carbon dioxide from the other products of combustion in the flue gas to provide a clean carbon dioxide suitable as a nutrient for microorganisms, and a farm of the microorganisms is illuminated essentially constantly, alternately with sunlight and artificial light from said source.

Owner:PACIFIC WASTE

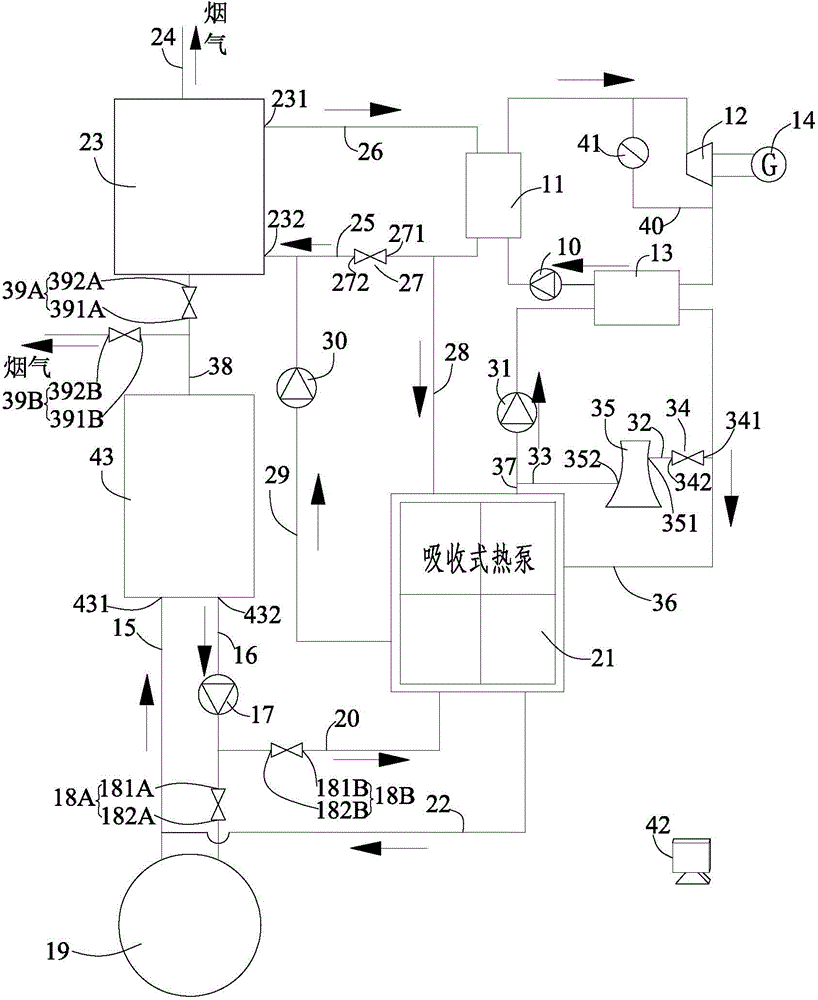

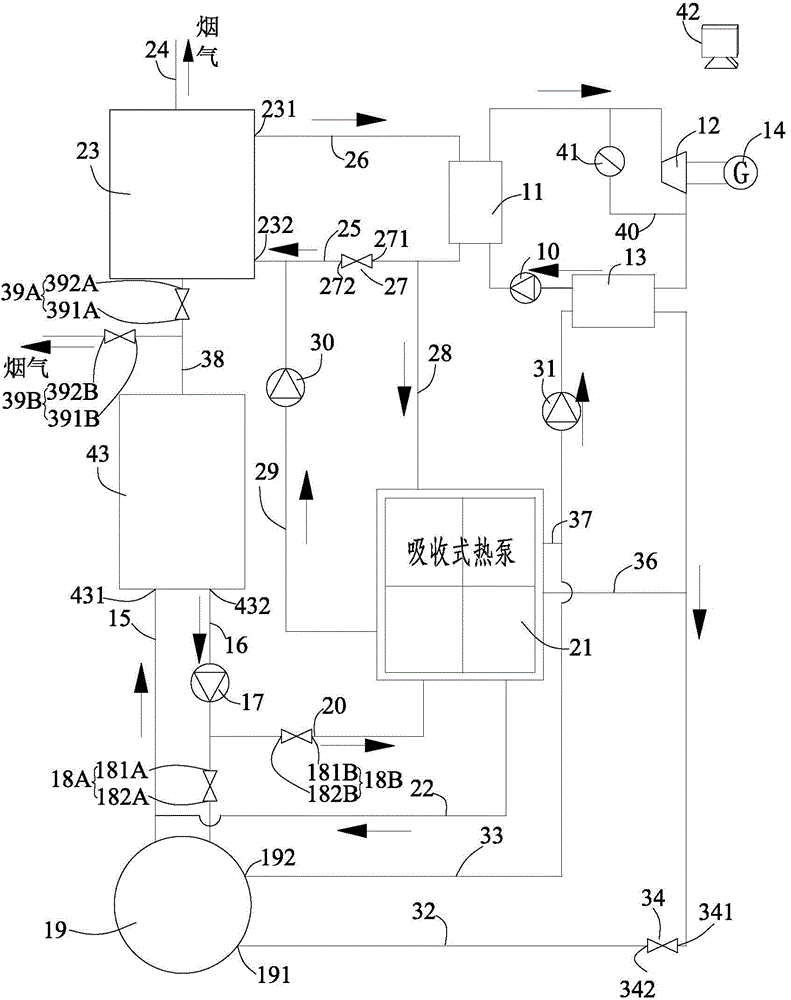

Comprehensive waste heat utilization system of internal combustion engine

ActiveCN104564194AImprove the comprehensive utilization efficiency of waste heatImprove power generation efficiencyInternal combustion piston enginesHeat recovery systemsCooling towerExternal combustion engine

The invention provides a comprehensive waste heat utilization system of an internal combustion engine. The system comprises an organic working medium pump, a first heat exchanger, an expansion machine, a second heat exchanger, a generator, a water inlet pipe, a water outlet pipe, a cooling water pump, a first stop valve, a first cooling tower, a second stop valve, a first inlet pipe, an absorption type heat pump unit, a first outlet pipe, a flue gas waste-heat heat exchanger, a flue gas emission pipeline, a fluid circulation inlet pipe, a fluid circulation outlet pipe, a third stop valve, a second outlet pipe and a fluid pump. The flue gas waste-heat heat exchanger and the absorption type heat pump unit are used for recovering waste heat of flue gas emitted by the internal combustion engine and waste heat of cooling water of the internal combustion engine for heating organic working medium, and the organic working medium is enabled to evaporate to overheating gaseous organic working medium under pressure for driving the expansion machine to act. Based on Rankine cycle of the organic working medium, waste heat energy of the internal combustion engine is recovered comprehensively, and comprehensive waste heat utilization efficiency of the internal combustion engine and power generation efficiency of an organic working medium Rankine cycle system can be improved.

Owner:DINGLI SHICHUANG INTELLIGENT CONTROL TECH BEIJING CO LTD

Method and process for co-combustion in a waste to-energy facility

InactiveUS20050039638A1High degreeReduce chanceRotary drum furnacesCeramic production plantsCombustion chamberSlag

The co-combustion process may comprise the following unit operations: routing of hot gas (10) generated in the clinker cooling process to a rotary kiln (1); use of part of the rotary kiln exhaust gas to dry solid wastes in rotary dryers; leading the gases from both the dryer and the combustion kiln to the secondary combustion chamber (2); use of additional fuel to boost up the secondary combustion chamber reaction temperature to as high as 1200° C.; primary dry gas scrubbing in a precalciner or precalciners (3, 3a); heat recovery (4) and power generation; secondary gas scrubbing (5) in a semi-dry scrubber, bag filtering after activated carbon injection and returning of all the collected ash and used carbon into the waste kiln and / or a cement kiln. Detrimental materials for cement processing generated by waste combustion can be by-passed to a scrubbing system and a cement kiln. Residue slag from waste kilns can be treated and reused.

Owner:GREEN ISLAND ENVIRONMENTAL +1

Air conditioning system operating on vehicle waste energy

InactiveUS7260947B1Mitigate fuel economy issueEasily and inexpensively configuredReciprocating combination enginesAir-treating devicesElectrical batteryDrive shaft

A waste energy-based vehicle air conditioning system includes efficient compression driving means coupled to refrigeration means. In one implementation, the compression driving means includes a controller (e.g., magnetic clutch) that couples mechanical waste energy from an engine fan axle, a vehicle drive shaft, or a transmission shaft to an axle of a refrigerant compressor. Alternatively, the controller can also include a battery that is charged from the mechanical waste energy. Upon detecting certain pressure values, the controller powers the refrigerant compressor with a rotating axle (e.g., during deceleration) or with battery power, as appropriate. In one implementation, the controller is configured to engage compression immediately upon detecting that the vehicle is decelerating. One or more kits can be used to retrofit existing vehicles to operate the respective air conditioning systems principally on waste energy.

Owner:HARRISON THOMAS D

Waste heat utilizing system of thermal power plant and thermal power unit

ActiveCN103574587AReduce coal consumptionReduce steam extractionLiquid degasificationFeed-water heatersAir preheaterEngineering

The invention provides a waste heat utilizing system of a thermal power plant and a power unit. The waste heat utilizing system of the thermal power plant comprises a boiler outlet flue gas waste heat utilizing system, an air preheater outlet flue gas waste heat utilizing system and a driving steam turbine steam exhaust waste heat utilizing system; the flue gas of the air preheater outlet is used for heating the condensed water from a low-pressure heater; the driving steam turbine steam exhaust waste heat utilizing system comprises a steam-water heat exchanger and an air-water heat exchanger which are formed into a steam-water-air heat exchange system; primary air and or secondary air of the air preheater inlet are or is heated by the steam exhaust of a driving steam turbine through the steam-water-air heat exchange system; the feed water and the condensed water are heated by part of high temperature flue gas of the boiler outlet. According to the waste heat utilizing system of the thermal power plant and the thermal power unit, the waste heat energy of the thermal power plant is effectively utilized and accordingly the efficiency of the thermal power plant is improved, meanwhile the coal consumption is reduced, and emissions of pollutants are reduced.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST

System for efficiently recovering waste heat energy from internal combustion engine

InactiveCN102305151ARaise the average endothermic temperatureImprove recycling efficiencyInternal combustion piston enginesEngine componentsSolenoid valveExternal combustion engine

The invention discloses a system for efficiently recovering waste heat energy from an internal combustion engine. The system comprises an internal combustion engine cooling system and an exhaust Rankine cycle system, wherein the circulation loop of the internal combustion engine cooling system is provided with a three-way valve, and the three-way valve is used for coupling the internal combustion engine cooling system with the exhaust Rankine cycle system; the exhaust Rankine cycle system is internally provided with a pumping system, and the pumping system is used for controlling the flow rate of working substances entering the exhaust Rankine cycle system so as to provide control freedom degree for adjustment of main steam parameters within the range of the surface working condition; the pumping system is composed of a variable-frequency feed water pump, a solenoid valve and a bypass check valve, and the variable-frequency feed water pump and the solenoid valve are sequentially connected to an evaporator in the exhaust Rankine cycle system through the three-way valve; and a cooling fluid bypass loop is arranged between the three-way valve and the evaporator, and the bypass check valve is arranged on the cooling fluid bypass loop. The system provided by the invention has the advantages that by improving the system layout and the pumping system, the cooling fluid energy recycling efficiency and the exhaust energy recycling efficiency are improved at the same time within the range of the surface working condition of the internal combustion engine.

Owner:TIANJIN UNIV

Waste heat recovery and optimized systems performance

ActiveUS9702634B1Considerable energy savingIncrease the effective surface areaFluid heatersEnergy recovery in ventilation and heatingOperational costsEnergy expenditure

Energy systems in different industrial applications including automotive applications experience between 20 to 50 percent of raw energy input as waste heat. in the form of hot exhaust gases, hot cooling water and lost heat from hot equipment surfaces including heated products. Continued efforts to improve systems energy efficiency, recovering waste heat losses provide attractive opportunities for reduced emission and less costly energy resources. This invention introduces other methods for higher performance of existing energy consuming systems by optimizing the performance of some of the system modules that contributes to the waste energy. in turn reduce energy consumption of these systems, reduces its operating cost, damages to the population health by reducing pollution improving the environment quality, and also reduces the cost of health care. Improving efficiency of the module's' which contribute large percentage of waste energy as by-product from the operation of these systems can improve the system efficiency.

Owner:AMERICAN INNOVATION CORP

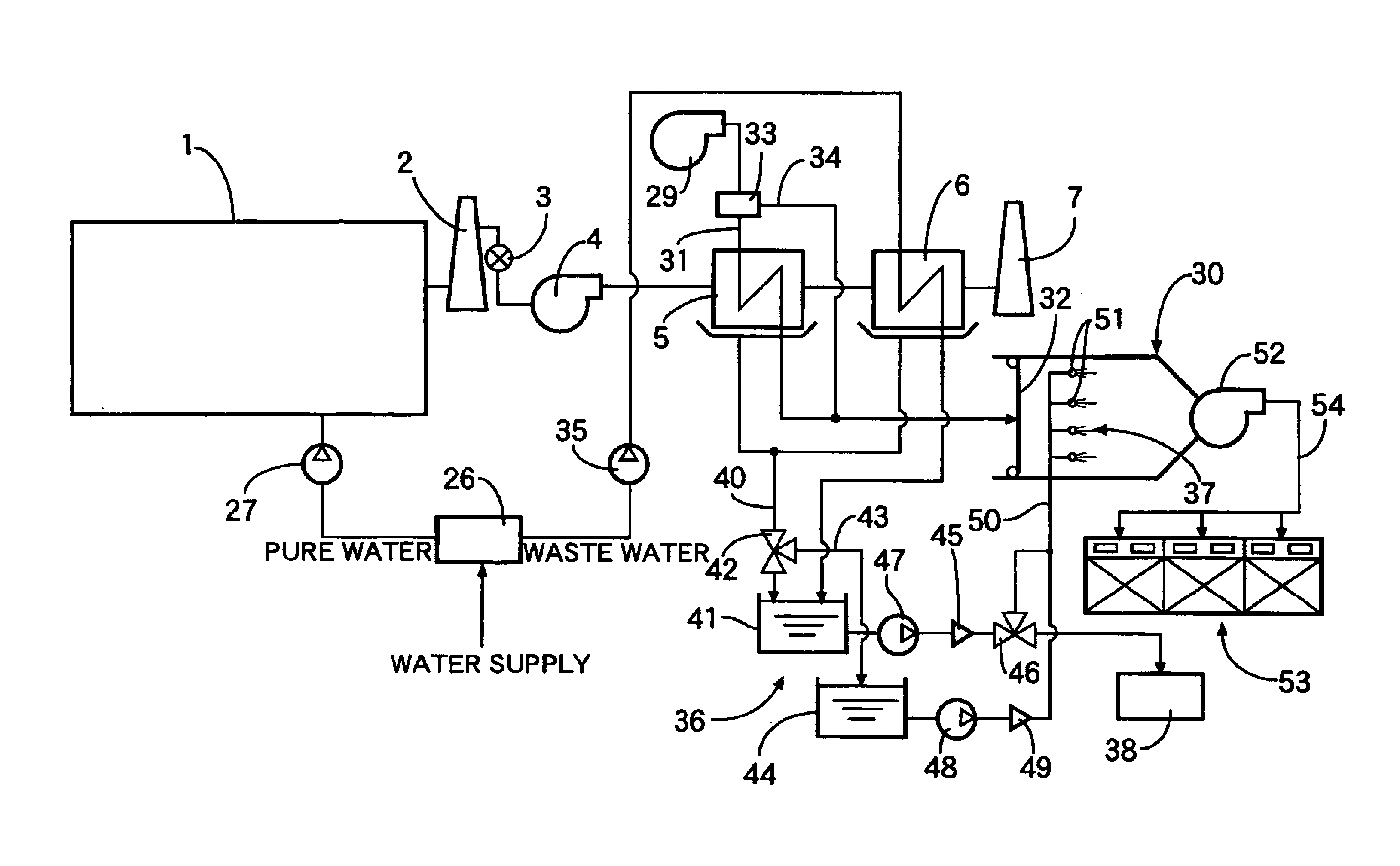

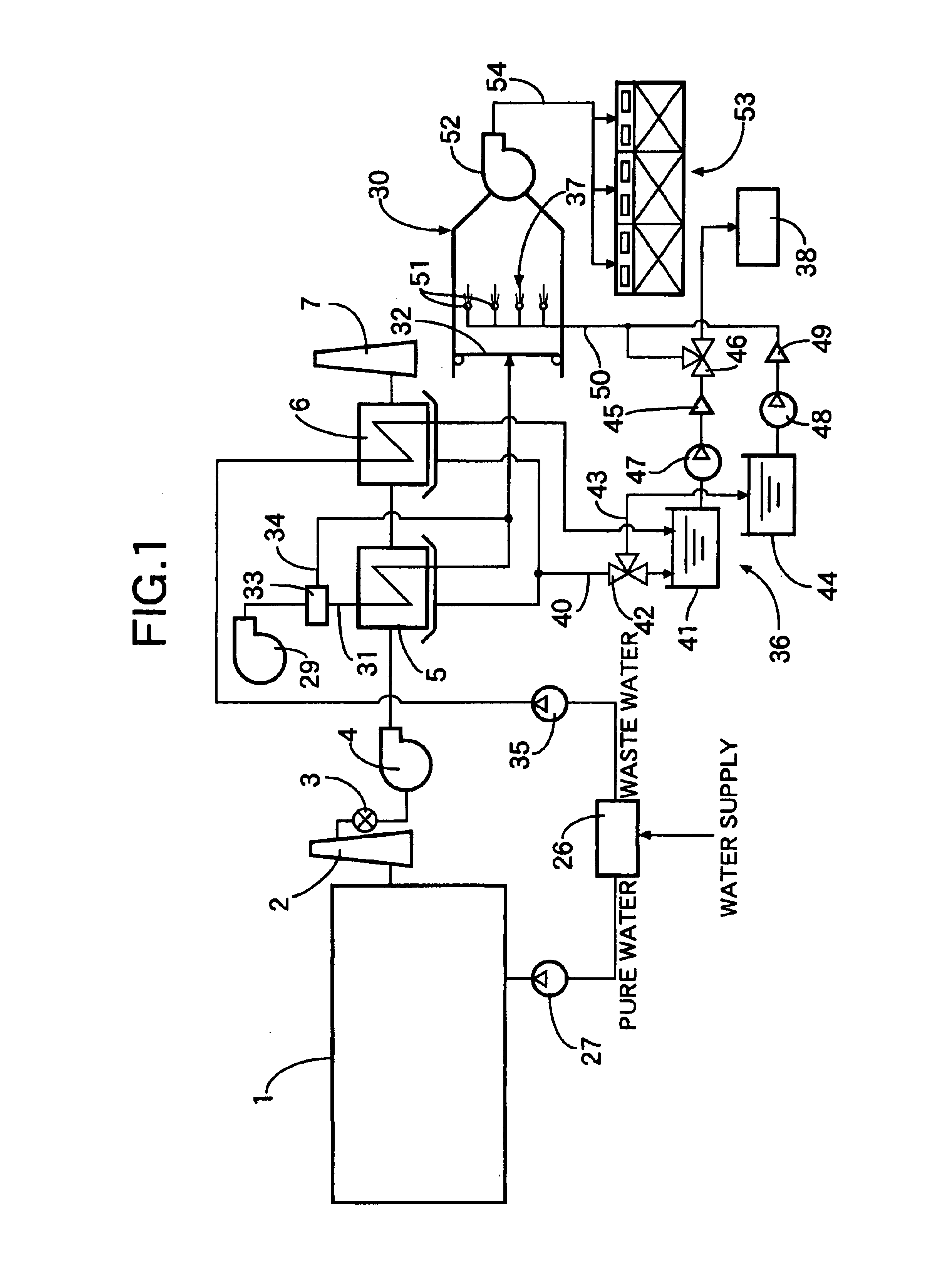

Cogeneration device

InactiveUS6948319B2Efficient use ofBroaden applicationInternal combustion piston enginesGas turbine plantsThermal energyCombustion

A cogeneration system is provided which includes a prime mover for obtaining power for driving a generator by combustion of a fuel, a waste heat boiler for recovering thermal energy from exhaust gas discharged from the prime mover, and a heat exchanger for heating air that is to be fed into an air conditioner by heat exchange with the exhaust gas discharged from the waste heat boiler. Drain water that is generated from the exhaust gas cooled by heat exchange in the air-heating heat exchanger (5) with the air that is to be fed into the air conditioner (30) is recovered by drain water recovery / supply means (36). The drain water recovery / supply means (36) supplies the drain water thus recovered to appliances (37, 38) that require comparatively high temperature water. Thermal energy can thus be recovered effectively from the drain water discharged from the heat exchanger on the downstream side of the waste heat boiler, thereby improving the efficiency of recovery of waste heat energy.

Owner:HONDA MOTOR CO LTD

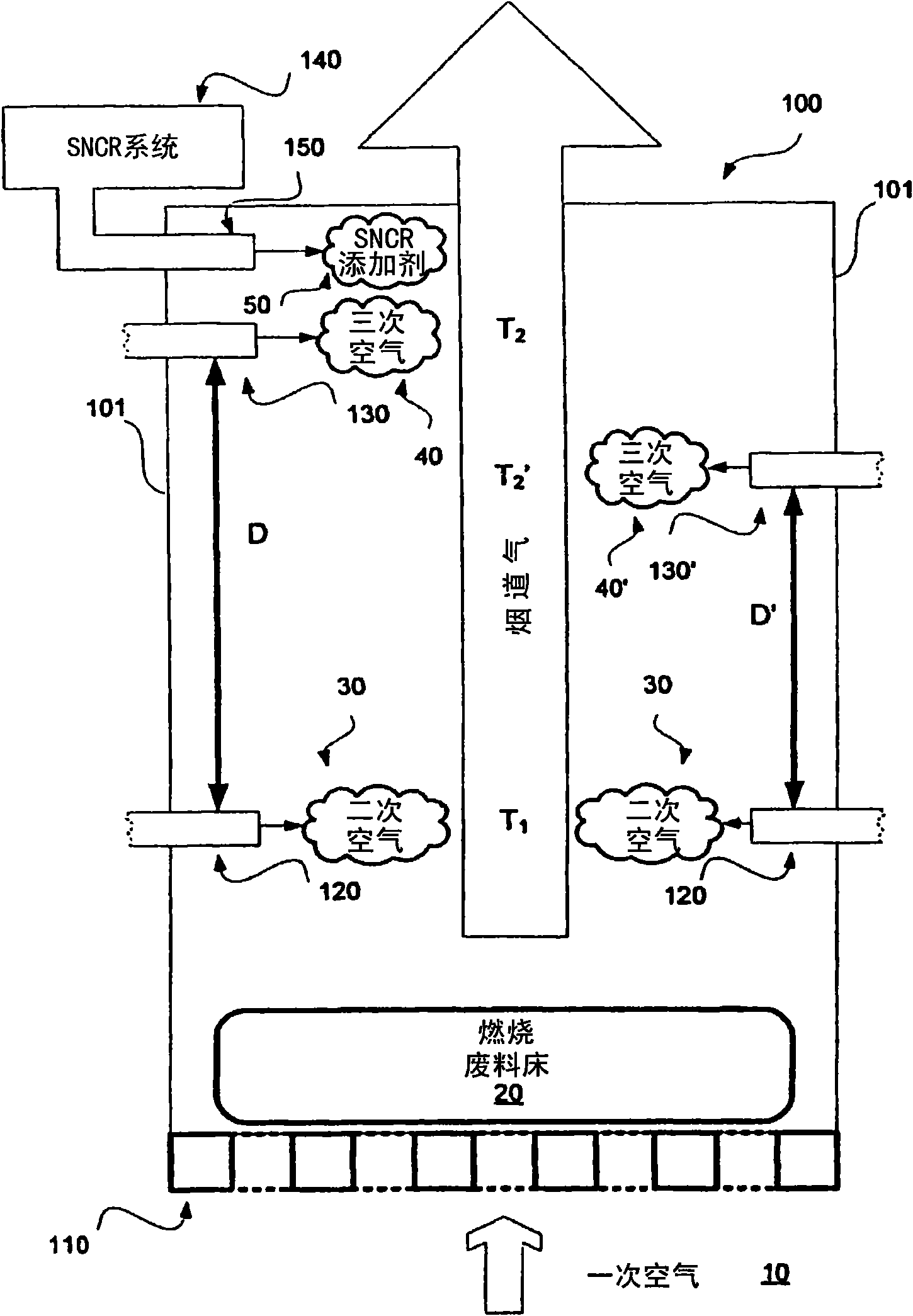

Tertiary air addition to solid waste-fired furnaces for nox control

ActiveCN101674874ADispersed particle separationAir/fuel supply for combustionPulp and paper industryAmmonia

Through the addition of tertiary air and a reduction of secondary air, NOx emissions from a waste-to-energy (WTE) boiler may be reduced. The tertiary air is added to the WTE at a distance from the secondary air, in a boiler region of relatively lower temperatures. A secondary NOx reduction system, such as a selective non-catalytic reduction (SNCR) system using ammonia or urea, may also be added to the boiler with tertiary air to achieve desirable high levels of NOx reductions. The SNCR additives are introduced to the WTE boiler proximate to the tertiary air.

Owner:COVANTA ENERGY CORPORATION

Waste to energy by way of hydrothermal decomposition and resource recycling

InactiveUS20110179981A1Improve energy efficiencyHigh removal rateTransportation and packagingBiofuelsHigh energySolid fuel

A method and an apparatus for disposing wastes comprising the steps of conducting a hydrothermal decomposition reaction of the wastes, separating the products into a solid fuel and waste water, combusting the solid fuel, scrubbing the combustion gas, generating steam using the heat generated by the combustion, and purifying the waste water, exhibit a high energy-efficiency, while exhibiting a high removal rate of the pollutants generated during the combustion.

Owner:VAN NAARDEN ROBERT +6

Hydraulic cylinder capable of being started under assistance of waste energy

InactiveCN105179372AAchieve sealingAchieving Buffer StillnessFluid-pressure actuatorsHydraulic cylinderPulp and paper industry

The invention provides a hydraulic cylinder capable of being started under assistance of waste energy. The hydraulic cylinder mainly comprises a cylinder barrel, end covers, a piston, a piston rod, a guide sleeve, a butter plate and a spring; the end covers comprise the end cover A and the end cover B; and the hydraulic cylinder is characterized in that waste energy generated after the piston stops moving is stored and converted into kinetic energy for assisting starting. Through the buffer plate with the spring, buffer static motion, waste energy storage and starting assistance of the piston are achieved; through an arc-shaped groove in the buffer plate, pressure balance of the two sides of the buffer plate is achieved; through a sealing ring on the outer side of the piston and an oil storage groove in the inner side of the piston, sealing and leaked oil temporary storage of the piston can be achieved.

Owner:UNIV OF JINAN

Rubber tire to energy pyrolysis system and method thereof

InactiveUS7375255B2Maximize applicationLow costIndirect and direct heating destructive distillationRetortsFuel oilProcess engineering

The present invention provides a pyrolysis system and method thereof which are capable of converting an entire rubber tire into several energy resources in an environmentally-friendly manner. The system includes a tire transporting unit, a waste to energy conversion unit, and a energy collection unit. The waste to energy conversion unit includes a conversion housing having a reaction chamber for receiving the rubber tire for pyrolysis processing to decompose the rubber tire into fuel oil, methane gas and carbon black, while metal wire from the rubber tire are resided for recycling use.

Owner:LEE ERNEST

Preparation and application of rare earth-containing nickel-based powder core wire material and coating

ActiveCN103924182AHeat and corrosion resistantGood heat and corrosion resistanceMolten spray coatingThermal sprayingRare earth

The invention discloses preparation and application of a rare earth-containing nickel-based powder core wire material and a coating, belonging to the field of thermal spraying in the material machining engineering. A core the following components in percentage by mass: 20-35% of pure metal chromium powder, 10-31% of nickel boron powder, 0.1-0.3% of rare earth and the balance of nickel, wherein the outer skin of the powder core wire material is made of a 80Ni-20Cr strip; the filling rate of the powder core wire material is 32%; when the rare earth-containing nickel-based coating is prepared in an electric arc spraying mode, a substrate needs to be pretreated; the spraying parameters are as follows: the voltage is 28-34V, the current is 160-220A, the spraying distance is 190-210mm, and the pressure of compressed air is 0.5-0.6MPa. A coating which is good in thermal conversion property and corrosion resistance can be obtained, and the service stability of a water-cooling wall tube and a superheater tube in a waste resource WTE (Waste To Energy) garbage incinerator is improved.

Owner:唐山宝航机械制造有限公司

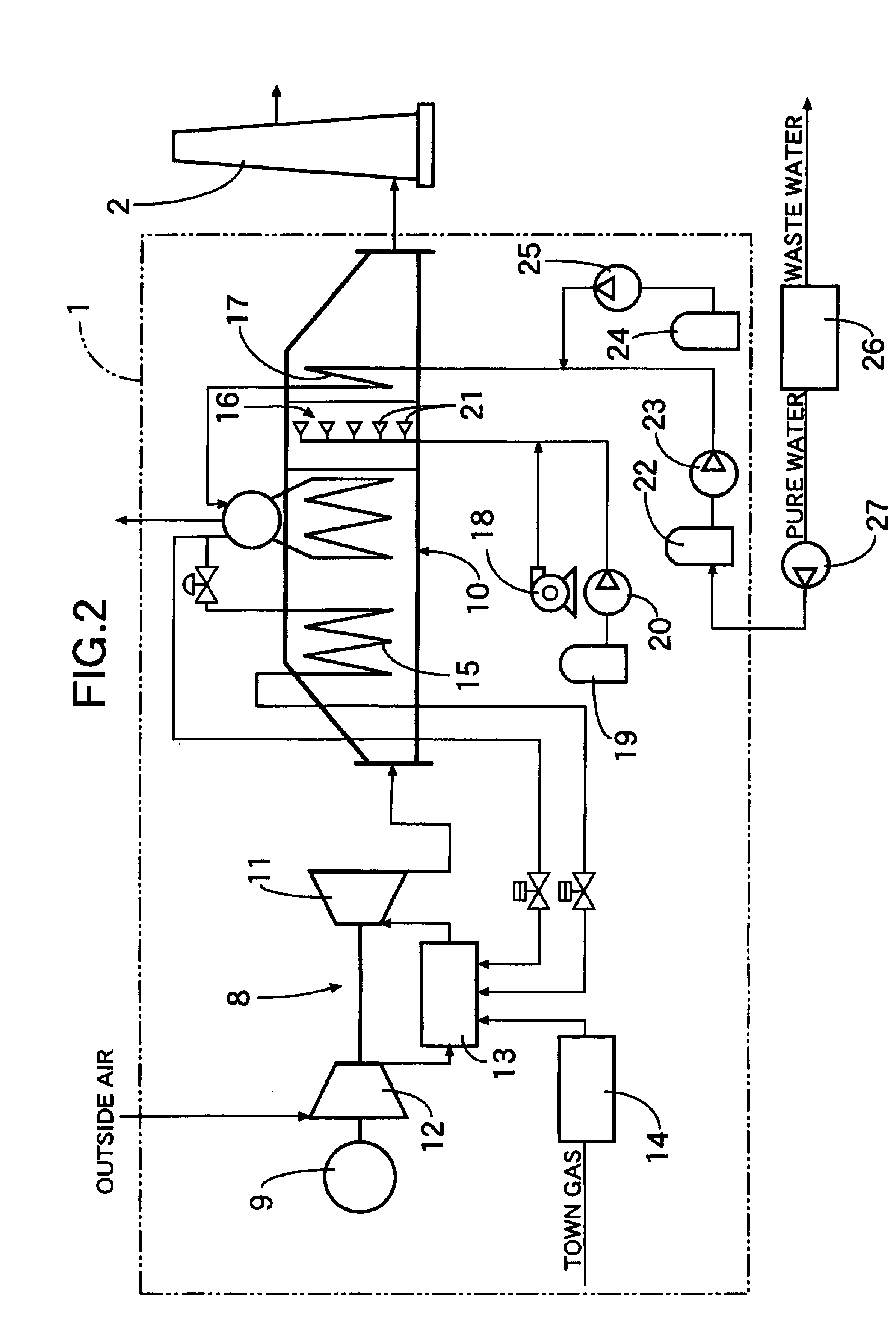

Waste processing system and fuel reformer used in the waste processing system

InactiveUS6282902B1Stable decompositionSuppresses the production of nitrogen oxidesHydrogenSteam engine plantsWaste processingCombustor

A waste-to-energy incineration system, in which the amount and heat value of exhaust gas largely changes in long and short periods, comprises an incinerator for burning waste, a boiler in the incinerator for generating steam with exhaust heat generated by the incinerator, a superheater for superheating steam generated in the boiler, a steam turbine driven by steam superheated by the superheater, a generator driven by the steam turbine, a fuel reformer for reforming source fuel, and a combustor burning fuel gas reformed by the fuel reformer and at least a part of exhaust gas led from the incinerator which is able to stably decompose generated dioxin in waste incineration exhaust gas.

Owner:HITACHI LTD

Multifunctional subsidiary agricultural product drying chamber

InactiveCN103471354AVersatileReasonable structureDrying gas arrangementsDrying chambers/containersRefrigerationMoisture

The invention belongs to the field of drying devices and provides a multifunctional subsidiary agricultural product drying chamber which is mainly characterized by utilizing a solar energy collector and an air energy hot pump to serve as primary heat supply devices, adopting separated waste heat in hot air and hot water in backflow to serve as circulation heat supply devices and separating exhausted moisture to serve as waste energy utilization devices, wherein waste energy includes regained moisture, regained fragrance, waste cold and the like. The multifunctional subsidiary agricultural product drying chamber has the advantages of being reasonable in structure, scientific in design, capable of saving energy, protecting the environment and recycling the waste energy, wide in application and multiple in functions, can achieve drying, refrigeration, moisture and fragrance regaining of various subsidiary agricultural products, and is good in effect proved by pilot run of a prototype.

Owner:邓州丰奇集团肥业有限公司

Sewage heat energy recovery system

ActiveCN103307909AExtended service lifeRegular automatic cleaningCorrosion preventionStationary tubular conduit assembliesEnergy recoveryPlate fin heat exchanger

The invention relates to the technical field of hot waste water recovery, in particular to a sewage heat energy recovery system. According to the system, heat energy recovery is realized by arranging a heat exchanging device which comprises a filtering device and a plurality of groups of heat exchangers, conducting filtering and recovery of the hot waste water, and arranging a corrugated heat exchanging tube to realize heat exchange of the hot waste water and normal temperature clean water. Compared with a traditional heat exchanging device, tubes communicating with the starting end heat exchanger and ending end heat exchanger are additionally arranged, so as to realize gradual temperature rising and heat exchanging of the normal temperature clean water and the hot waste water and improve heat exchanging efficiency, and in order to clean waste in the heat exchanger more efficiently, the heat exchanger is filled with filtering board with alumina balls which are driven by back washing water, so as to conduct filtering to the hot waste water, enable the waste not to enter in the heat exchanger, and improve the exchanging efficiency of the heat exchanger. The system can recover waste heat energy and save a large amount of water resource.

Owner:WUXI JINDESHENG ENERGY SAVING EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com