Desalination plant by using engine end gas

An engine and exhaust gas technology, applied in seawater treatment, water/sewage treatment, general water supply conservation, etc., can solve the problems of ineffective use of waste energy, energy waste, complex devices, etc., and achieve easy operation and maintenance, and simple operation , The effect of less power part demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

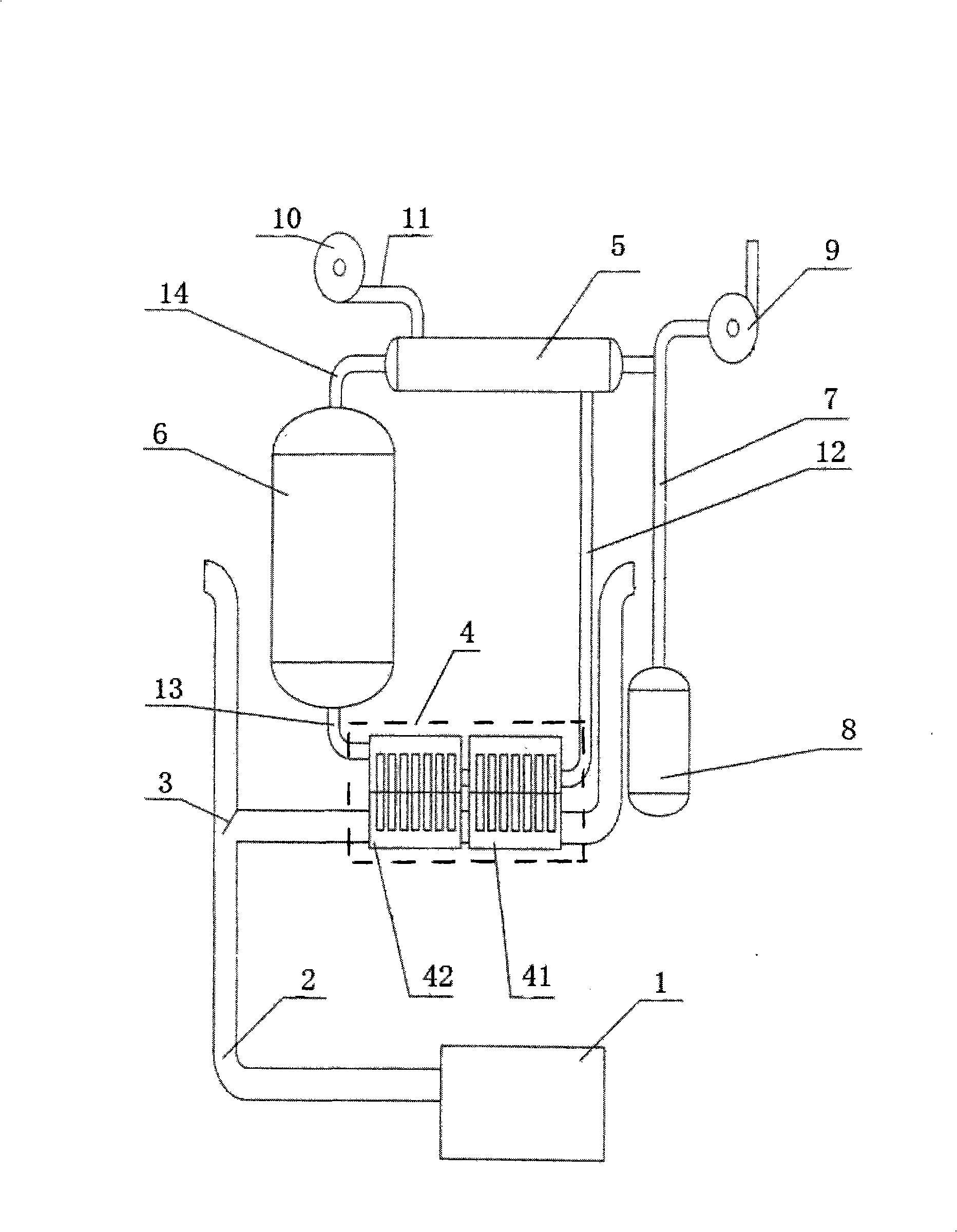

[0027] The present invention includes a superconducting heat exchanger 4, a vacuum evaporation tank 6 and a condenser 5 connected in sequence, wherein the superconducting heat exchanger 4 is formed in series by a primary heat exchanger 41 and a secondary heat exchanger 42, and the secondary heat exchanger The heater 42 is connected to the exhaust pipe 2 of the engine 1 through the flue gas steering valve 3 , the condenser 5 is equipped with a seawater supply pump 10 to replenish fresh seawater, and the condensed water outlet of the condenser 5 is connected to the vacuum pump 9 and the fresh water collection tank 8 .

[0028] The present invention can produce fresh water uninterruptedly as long as the engine is running normally. If it is not necessary to prepare fresh water, the flue gas steering valve 3 can be turned directly so that the flue gas can be directly discharged into the atmosphere through the engine exhaust pipe without passing through the superconducting pipe heat e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com