Hydraulic cylinder capable of being started under assistance of waste energy

A technology of hydraulic cylinders and waste energy, applied in the field of hydraulic cylinders, can solve the problems of high energy consumption and energy consumption that cannot be reused.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

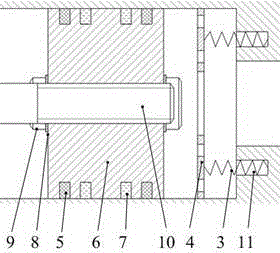

[0016] Such as figure 1 As shown, a hydraulic cylinder using waste energy to start auxiliary of the present invention mainly includes a cylinder barrel 2, an end cover, a piston 6, a piston rod 10, a guide sleeve 13, a buffer plate 4 and a spring 3, and the end cover is divided into an end cover A1 and end cap B14. The end cap A1 and the end cap B14 are disc-shaped structures with internal threads, and the middle part of the end cap B14 has a through hole and a dust-proof ring 15 is installed therein. The two ends of the cylinder 2 are provided with external threads connected with the end cover A1 and the end cover B14. There are oil port A17 and oil port B16 on the side of the cylinder 2, and there are 4 inside the cylinder 2 on the side of the oil port A17. Circumferentially uniform buffer grooves 11. One end of the piston rod 10 is provided with an external thread. The inside of the guide sleeve 13 is provided with a stepped hole, its end surface is provided with an annu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com