Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2332results about How to "Heat resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

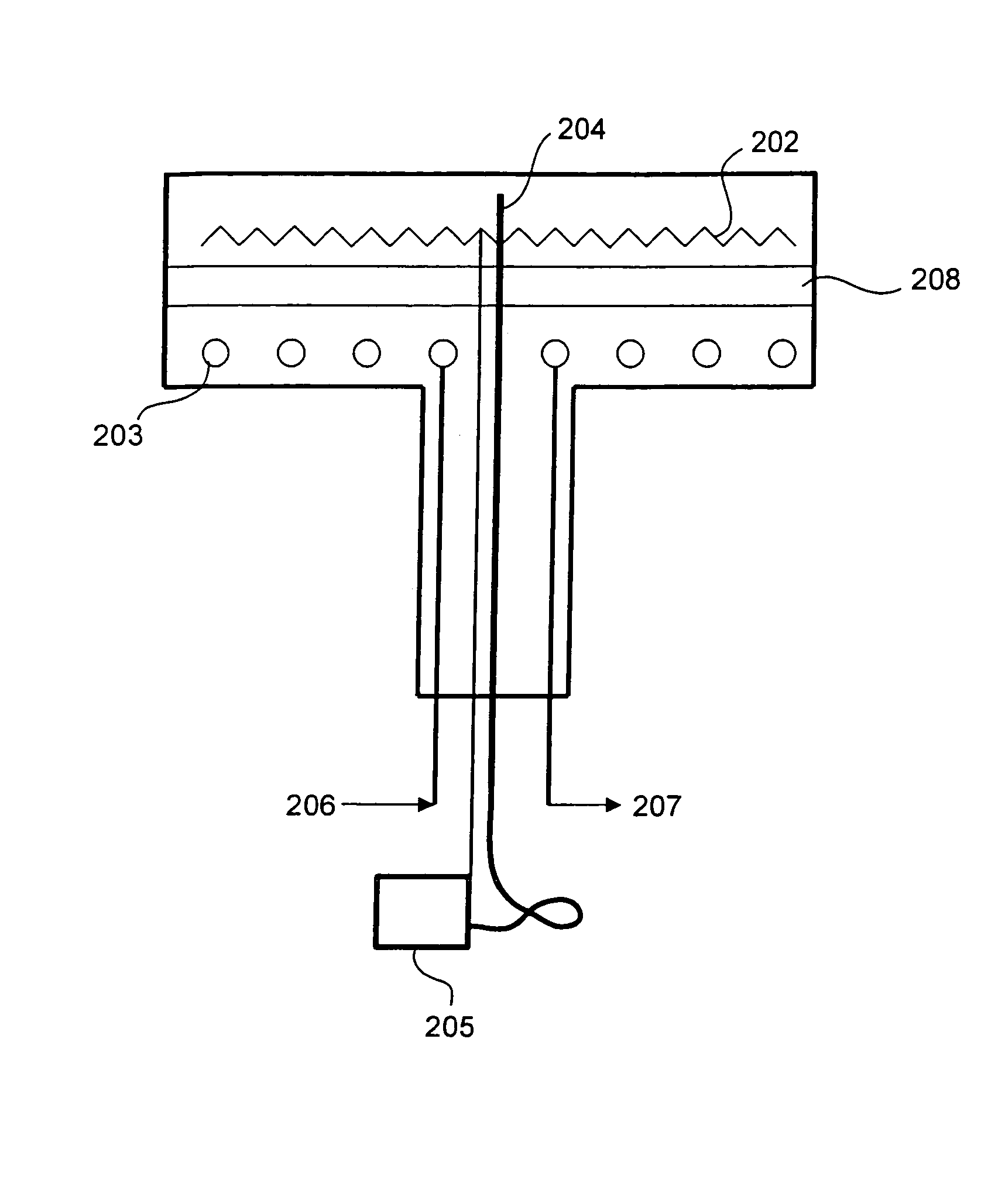

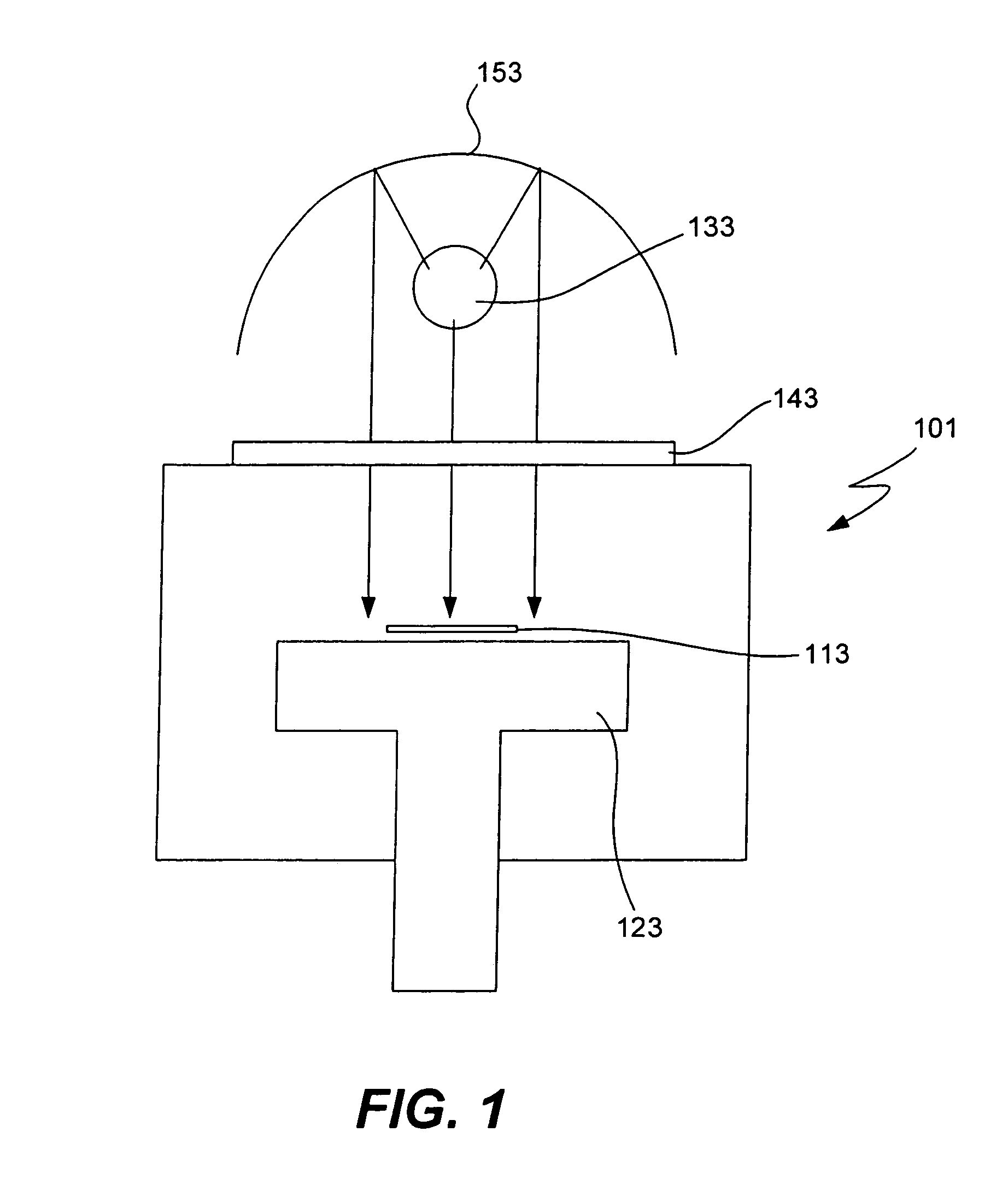

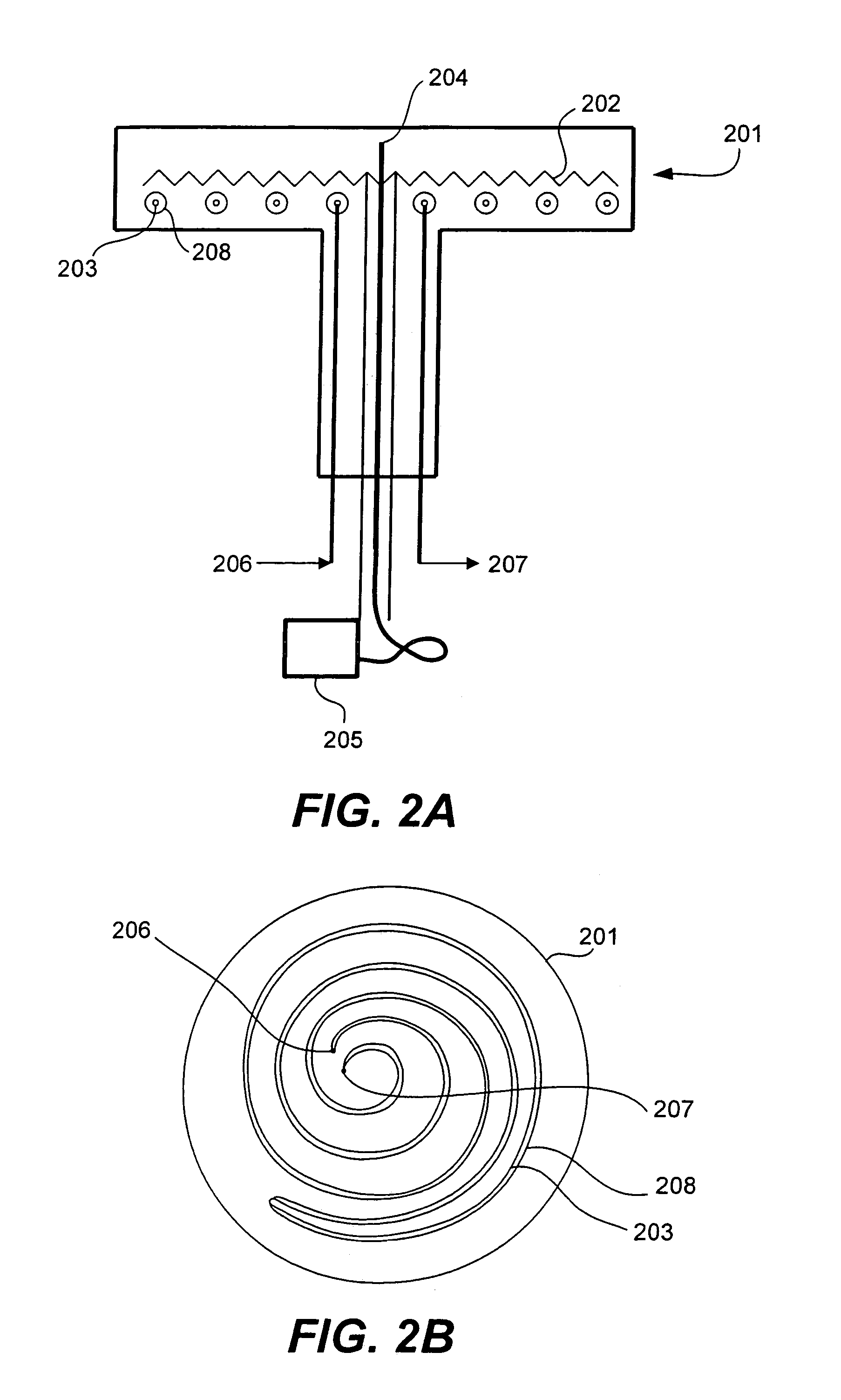

Cast pedestal with heating element and coaxial heat exchanger

ActiveUS7327948B1High-temperature gradientHeat resistantSemiconductor/solid-state device manufacturingHigh-frequency/infra-red heating bakingHeat resistanceEngineering

The present invention provides a heat transfer assembly that, when coupled to an object, is capable of keeping the object at a uniform elevated temperature while removing large amounts of heat from an external source. The assembly may be contained in a pedestal for use in a UV-cure chamber. The heat transfer assembly includes a heating element to control the wafer temperature and a cooling element to remove incident IR heat from the wafer and pedestal. A heat resistant layer having a calibrated heat resistance is located between the heating and cooling elements and between the wafer and the cooling elements. The heat resistant layer is able to sustain high temperature gradient from the wafer to the coolant so that the coolant does not boil while permitting enough heat to be conducted away from the wafer to maintain the desired set-point temperature.

Owner:NOVELLUS SYSTEMS

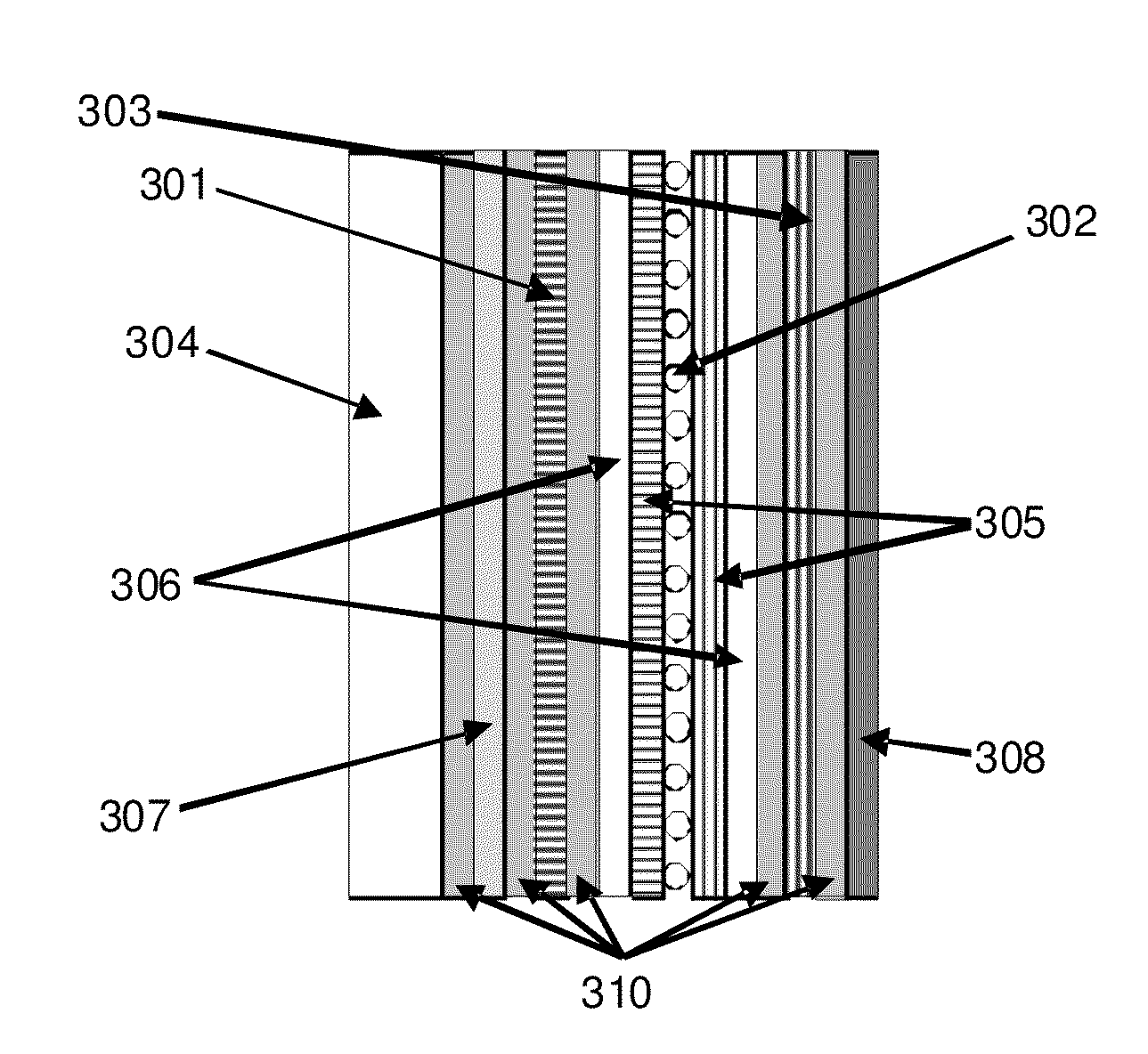

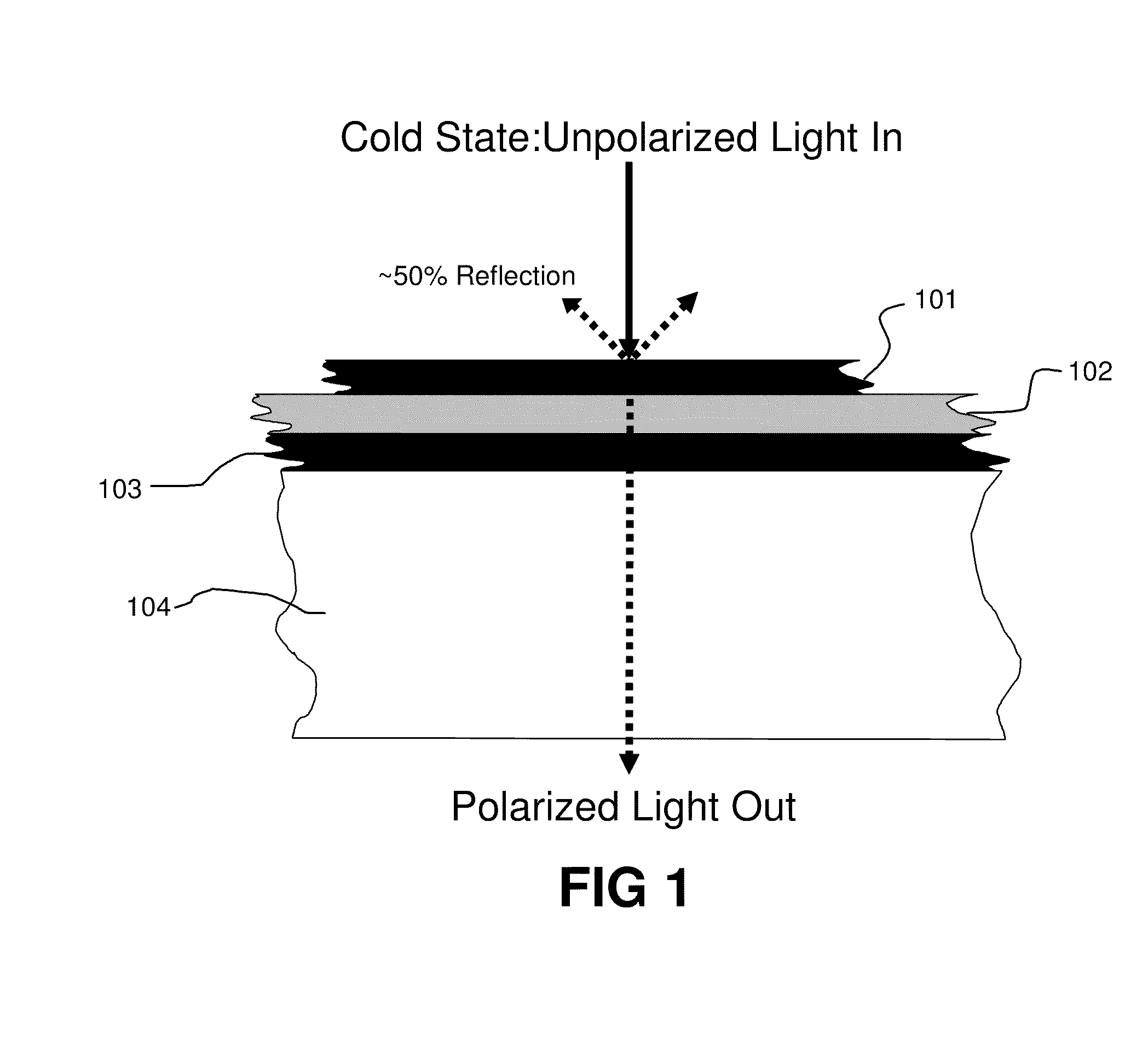

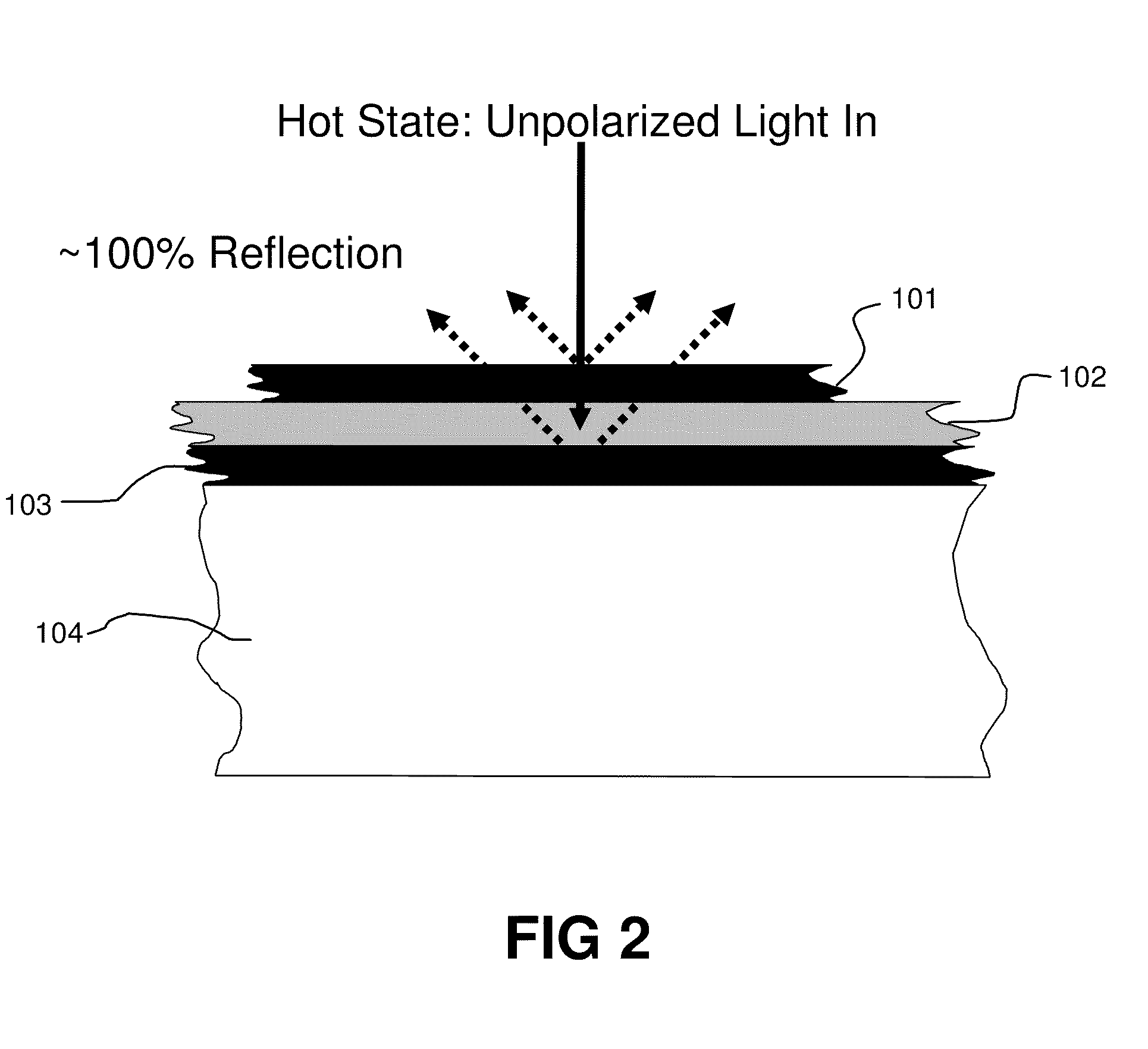

Methods for Fabricating Thermochromic Filters

InactiveUS20100045924A1Easy and less-expensive to manufactureEasy to installSolar heating energySolar heat collector controllersSelective reflectionElectrical polarity

Thermochromic liquid crystal filters are fabricated by providing two polarizers oriented at offset polarity with respect to each other; providing alignment structures adjacent the inner surfaces of the polarizers; placing a plurality of spacers between the polarizers; and filling a space created by the spacers with a thermotropic liquid crystal that acts as a wave block in an isotropic state and acts as a depolarizer in a nematic state. Alternatively, the filters can be created by encapsulating a thermochromic liquid crystal with a polymer material to form a flexible film and orienting the thermochromic liquid crystal in the polymer material to create a structure that functions as a thermochromic optical filter. Such filters can control the flow of light and radiant heat through selective reflection, transmission, absorption, and / or re-emission. The filters have particular application in passive or active light-regulating and temperature-regulating films, materials, and devices, and particularly as construction materials.

Owner:RAVENBRICK

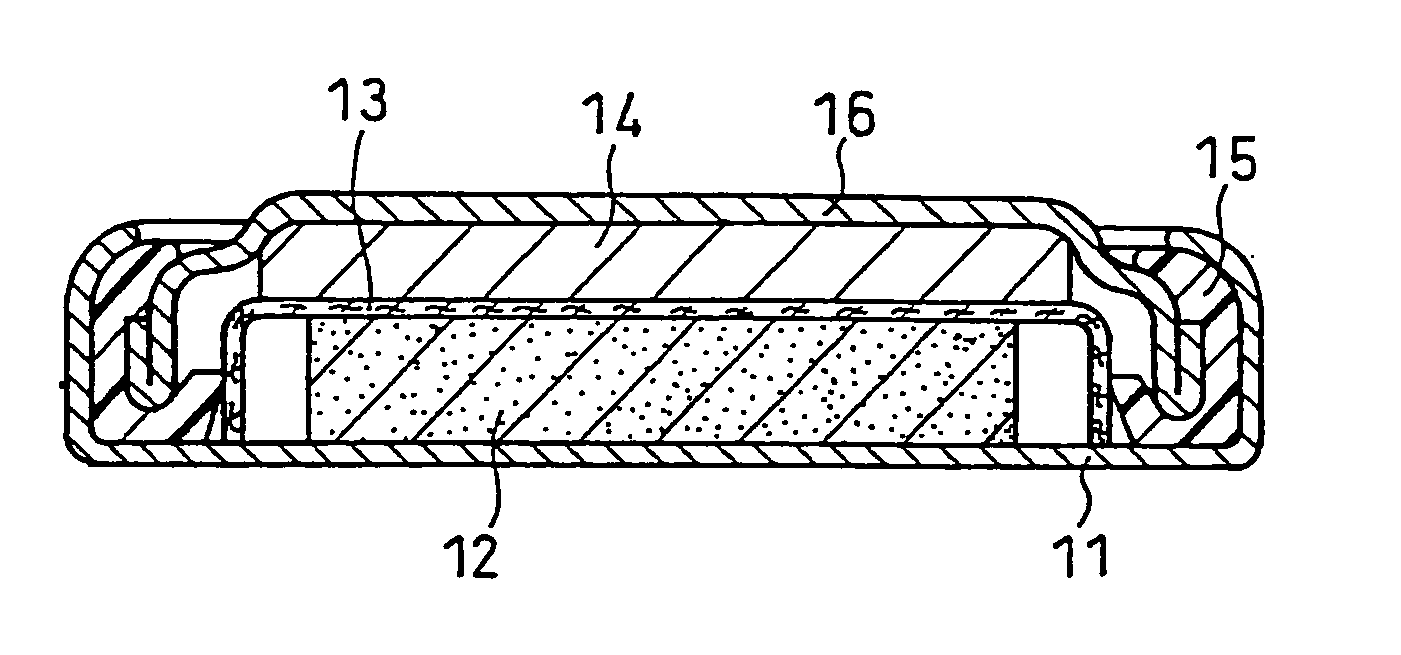

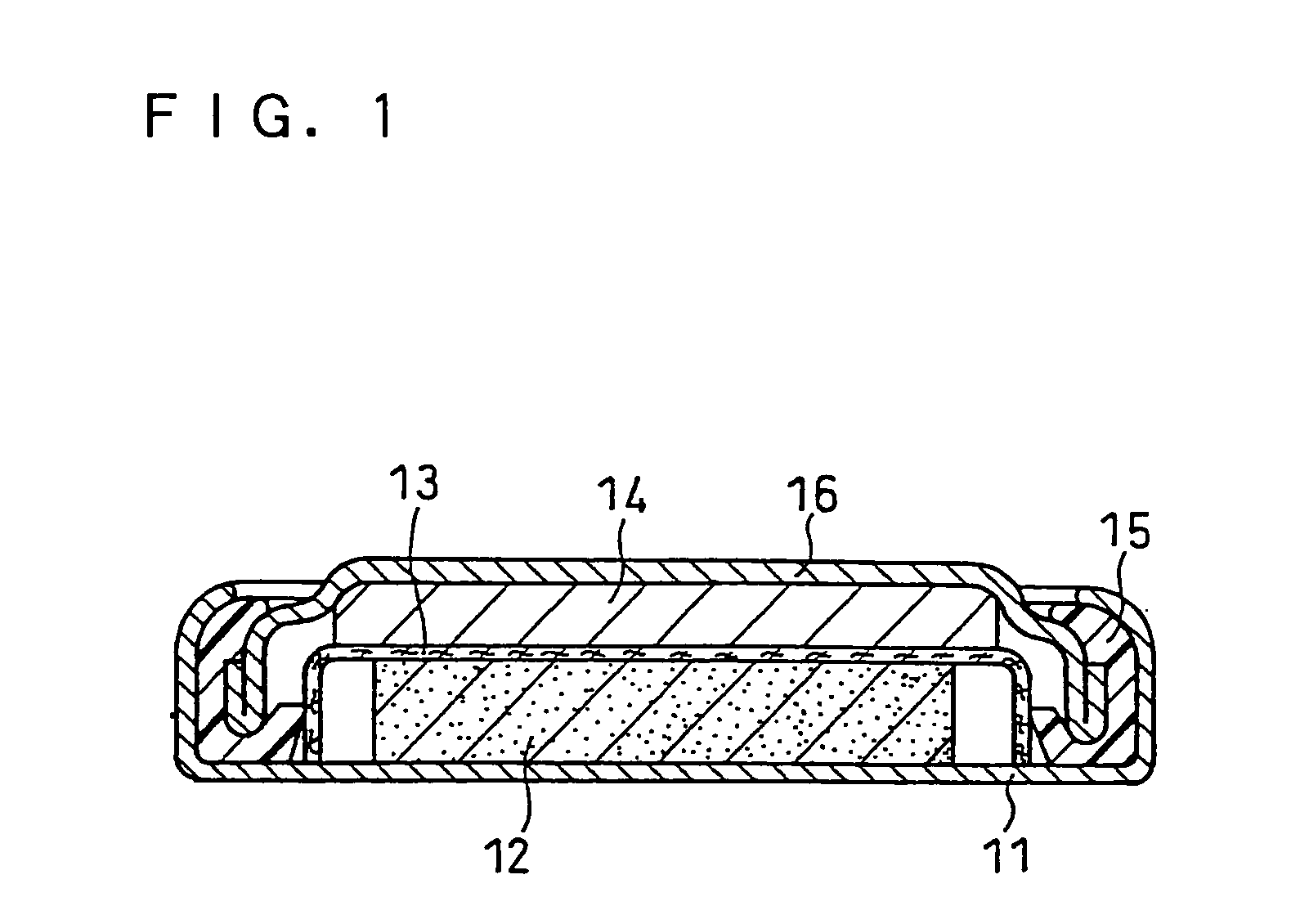

Lithium rechargeable battery

ActiveUS20070020525A1Excellent thermal and electrical propertyLittle thicknessCell electrodesSecondary cellsPorous membraneNon aqueous electrolytes

A lithium rechargeable battery includes a separator that shows excellent safety characteristics such as short circuit resistance and heat resistance. The lithium rechargeable battery includes a cathode, an anode, a separator that separates the cathode and the anode from each other, and a non-aqueous electrolyte, wherein the separator includes a porous membrane formed of a ceramic material and a binder, and wherein the binder includes at least one crystalline resin having a crystal melting temperature of 250° C. or higher or at least one non-crystalline resin having an initial decomposition temperature of 250° C. or higher.

Owner:SAMSUNG SDI CO LTD

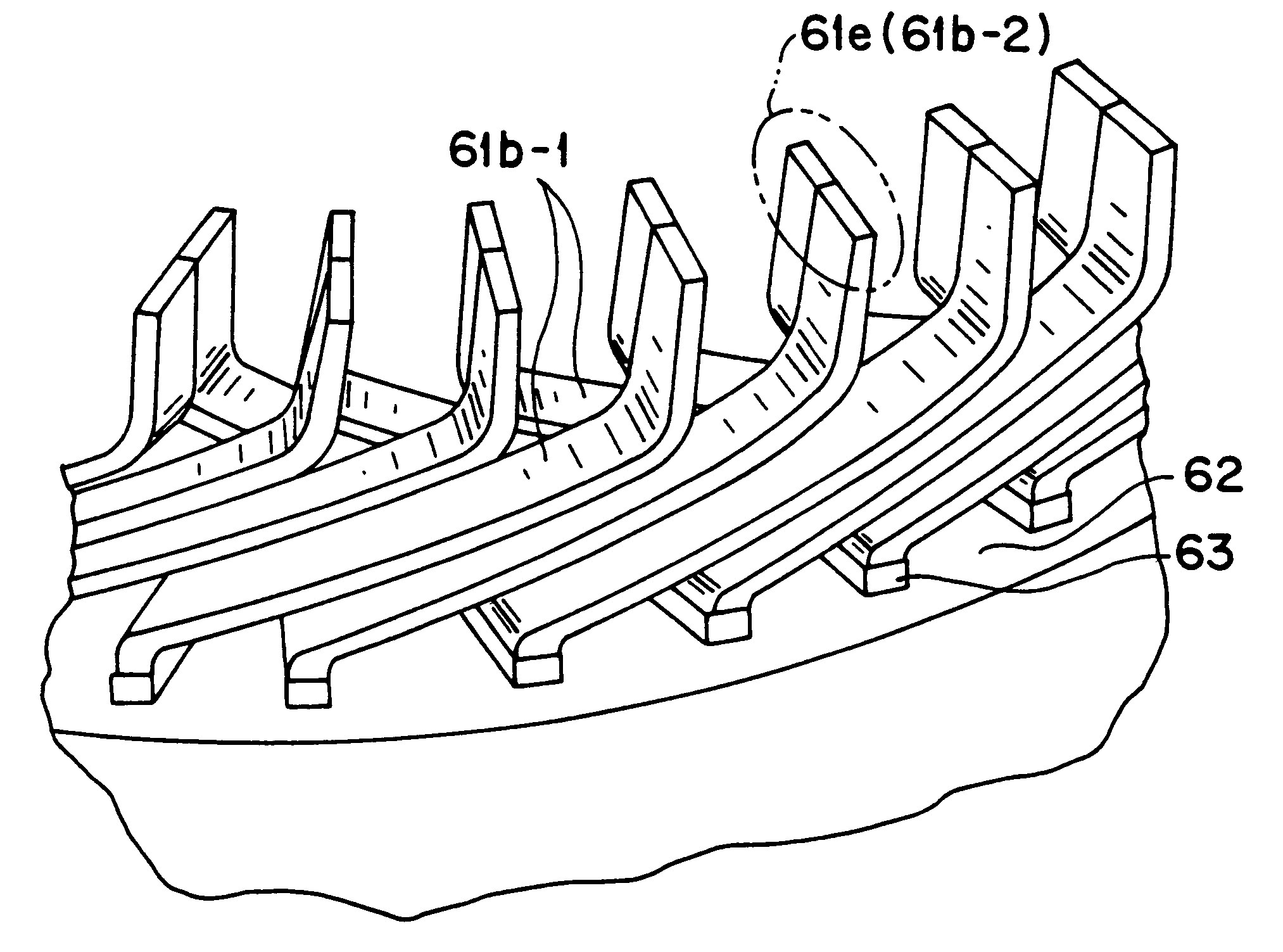

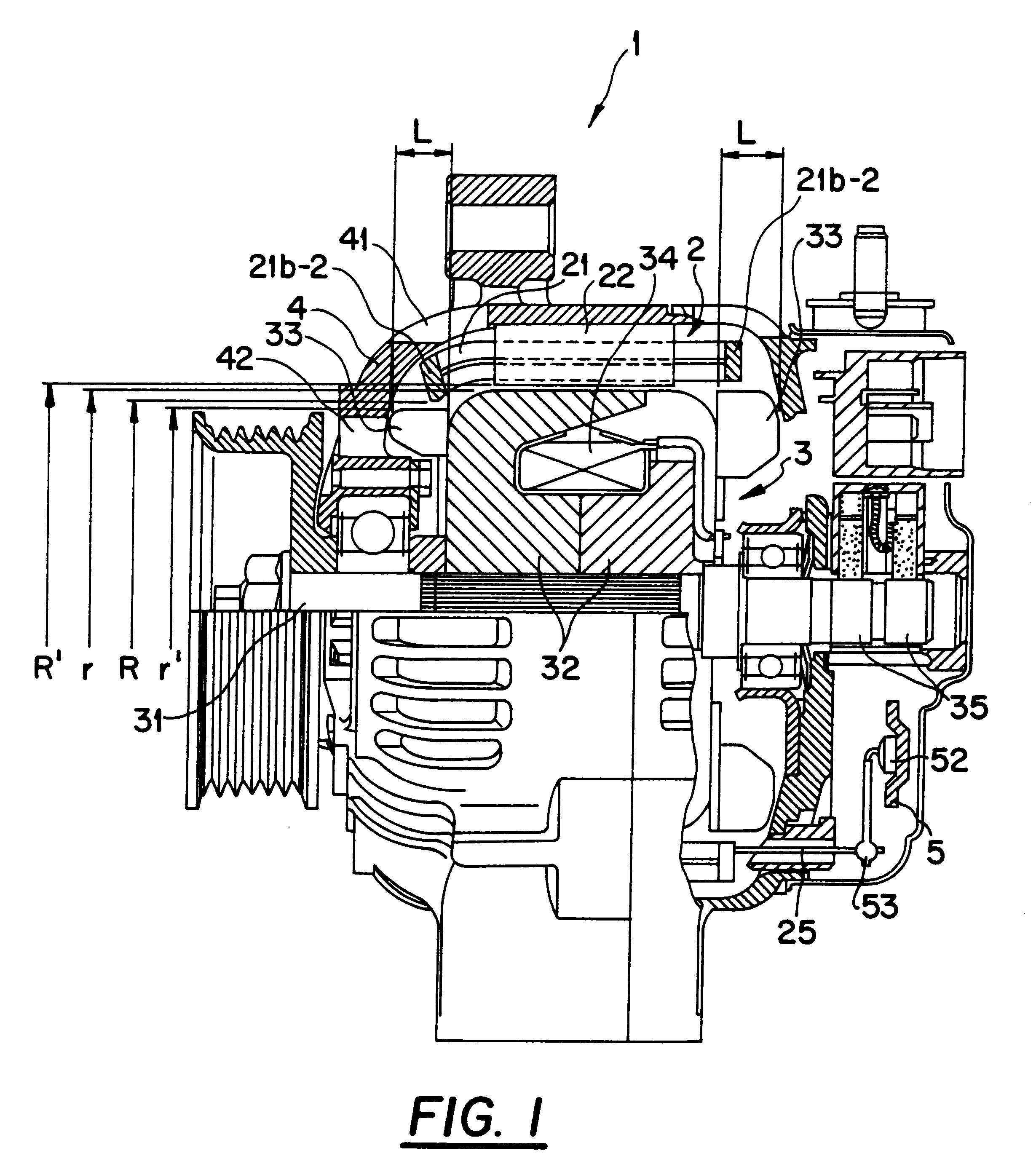

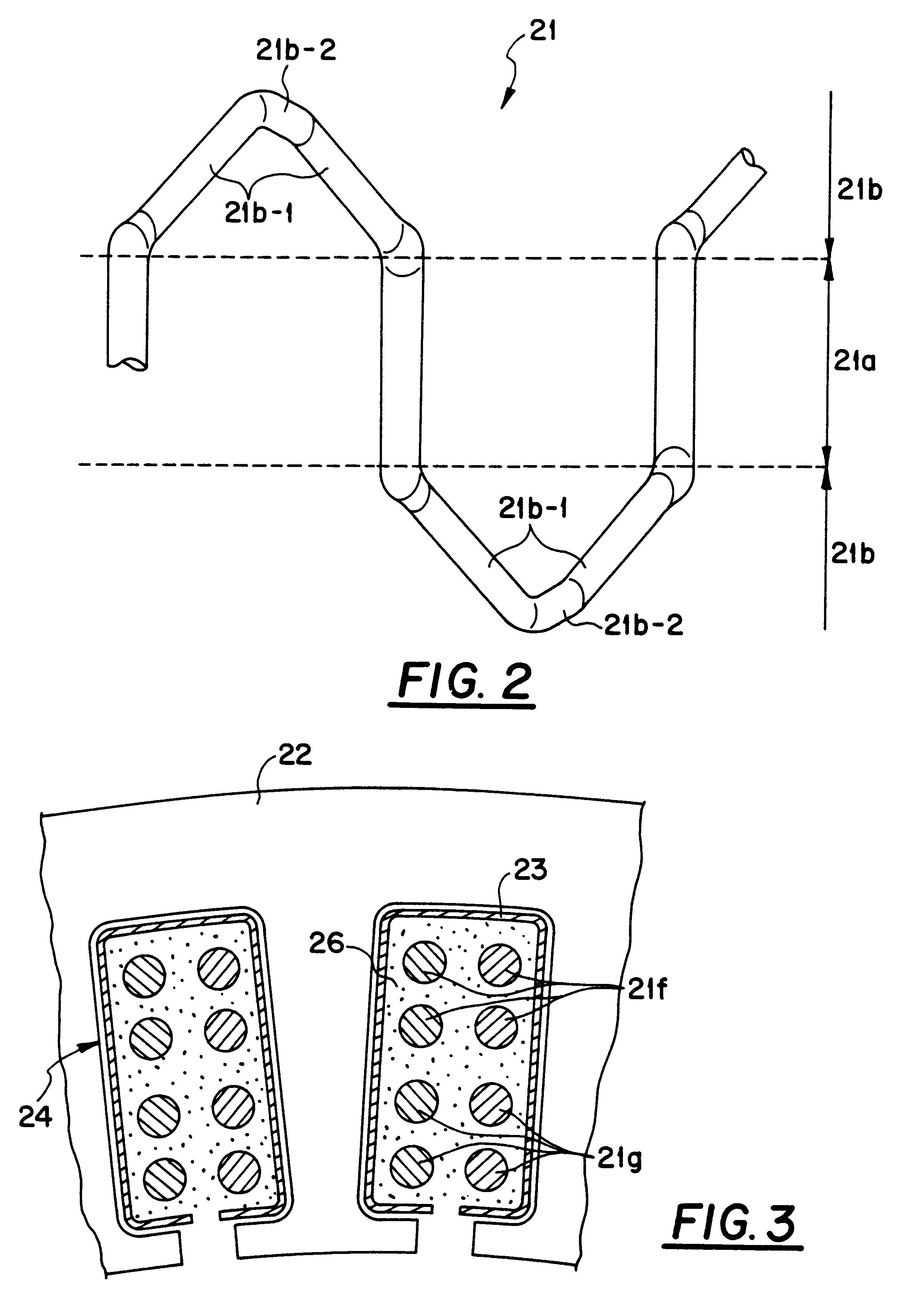

Alternator for vehicle

InactiveUS6181045B1Heat resistantIncrease heat radiationSynchronous generatorsWindings insulation shape/form/constructionElectrical conductorAlternator

It is an object of this invention to provide an alternator for a vehicle in which all electric conductors forming bridge portions are sufficiently exposed to cooling winds so that the cooling performance is remarkably improved. It is another object of this invention to provide an alternator for a vehicle which is excellent in cooling performance, insulating characteristic, and heat resisting property. An alternator for a vehicle includes a stator. The stator includes an iron core 22, an electric conductor 21, and an insulator 23. The electric conductor 21 forms a winding on the iron core 22. The insulator 23 provides electric insulation between the electric conductor 21 and the iron core 22. The stator is supported by a housing. The dimension of openings of slots in the iron core 22 is smaller than the distance between inner side surfaces of the slots. The electric conductor 21 has accommodated portions accommodated in the slots, and bridge portions connecting the accommodated portions. Pieces of the electric conductor which extend out of the slots are approximately separated into a conductor groups 21f located on outer radial sides of the slots and a conductor group 21g located on inner radial sides of the slots, and form the bridge portions. Predetermined gaps are provided between pieces of the electric conductor in the bridge portions. The bridge portions have ridge portions inclined in a same circumferential direction in each of the outer radial side and the inner radial side, and top portions connecting the ridge portions along an axial and radial direction.

Owner:DENSO CORP

Negative electrode for non-aqueous electrolyte secondary battery, producing method therefor, and non-aqueous electrolyte secondary battery

InactiveUS20070048609A1Improve abilitiesImprove heat resistanceSecondary cellsNon-aqueous electrolyte accumulator electrodesConductive materialsMaterials science

A negative electrode for a non-aqueous electrolyte secondary battery in the present invention includes an active material including Si, a conductive material, and a binder. The binder is polyimide and polyacrylic acid, and the conductive material is a carbon material.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

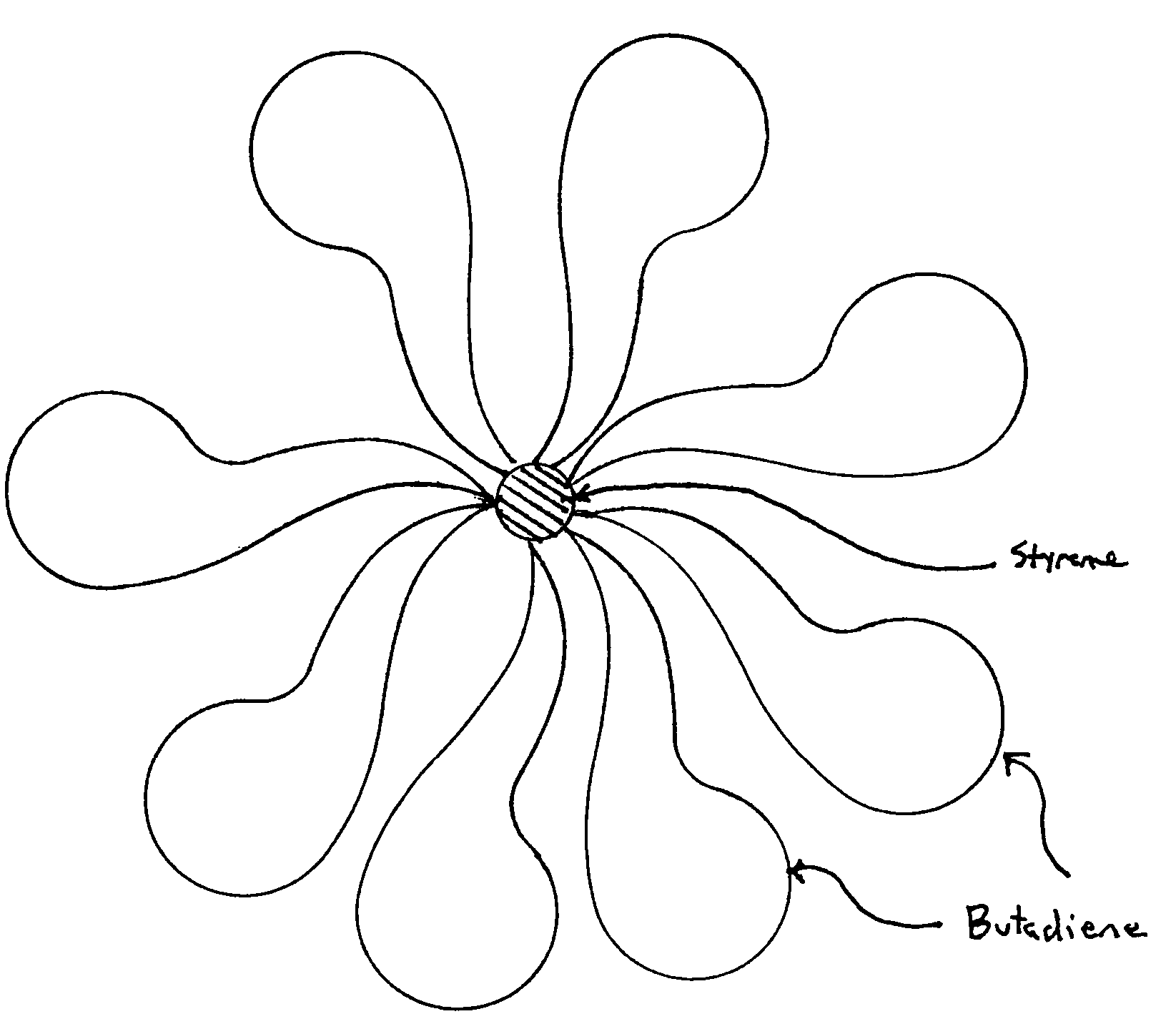

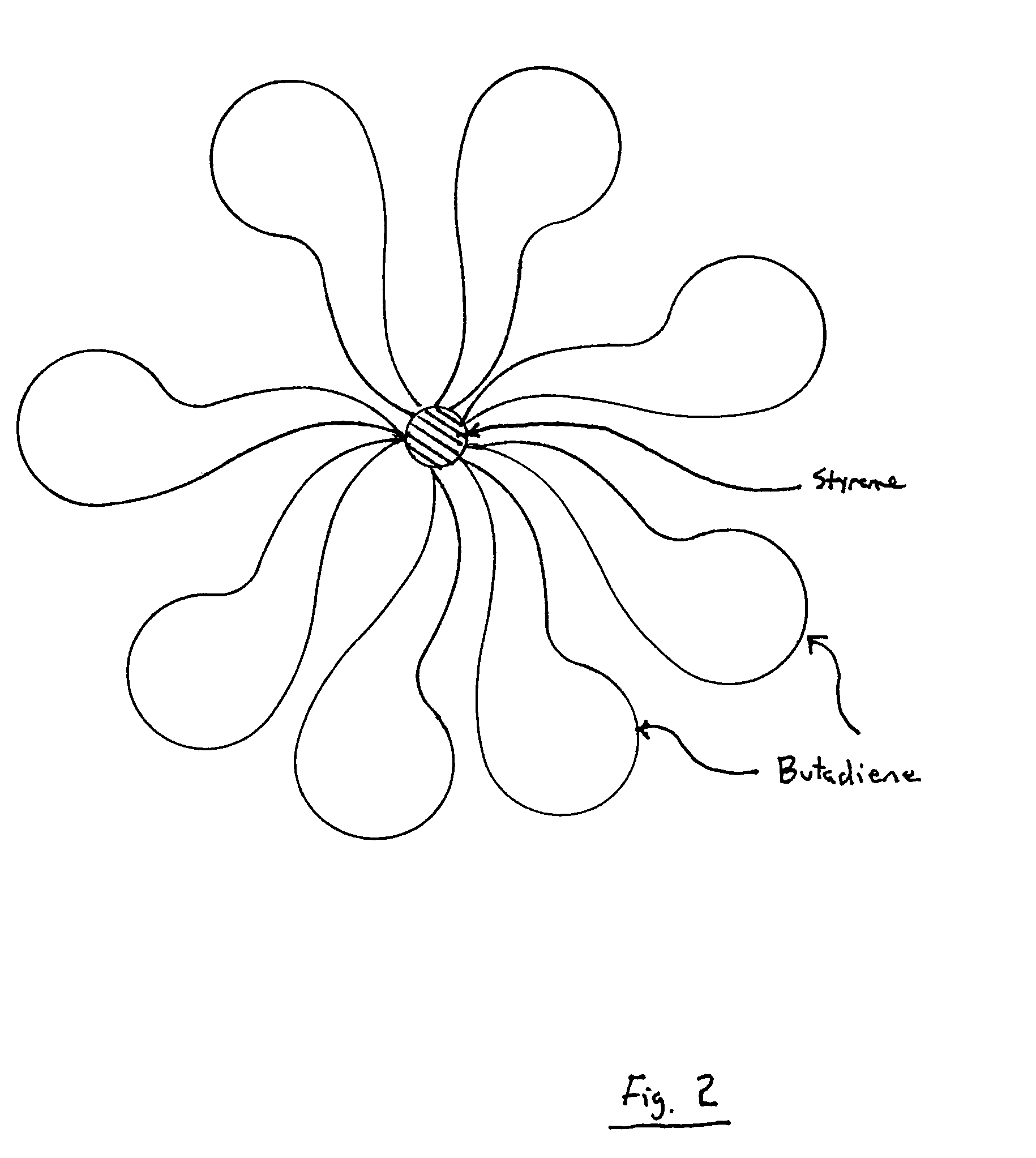

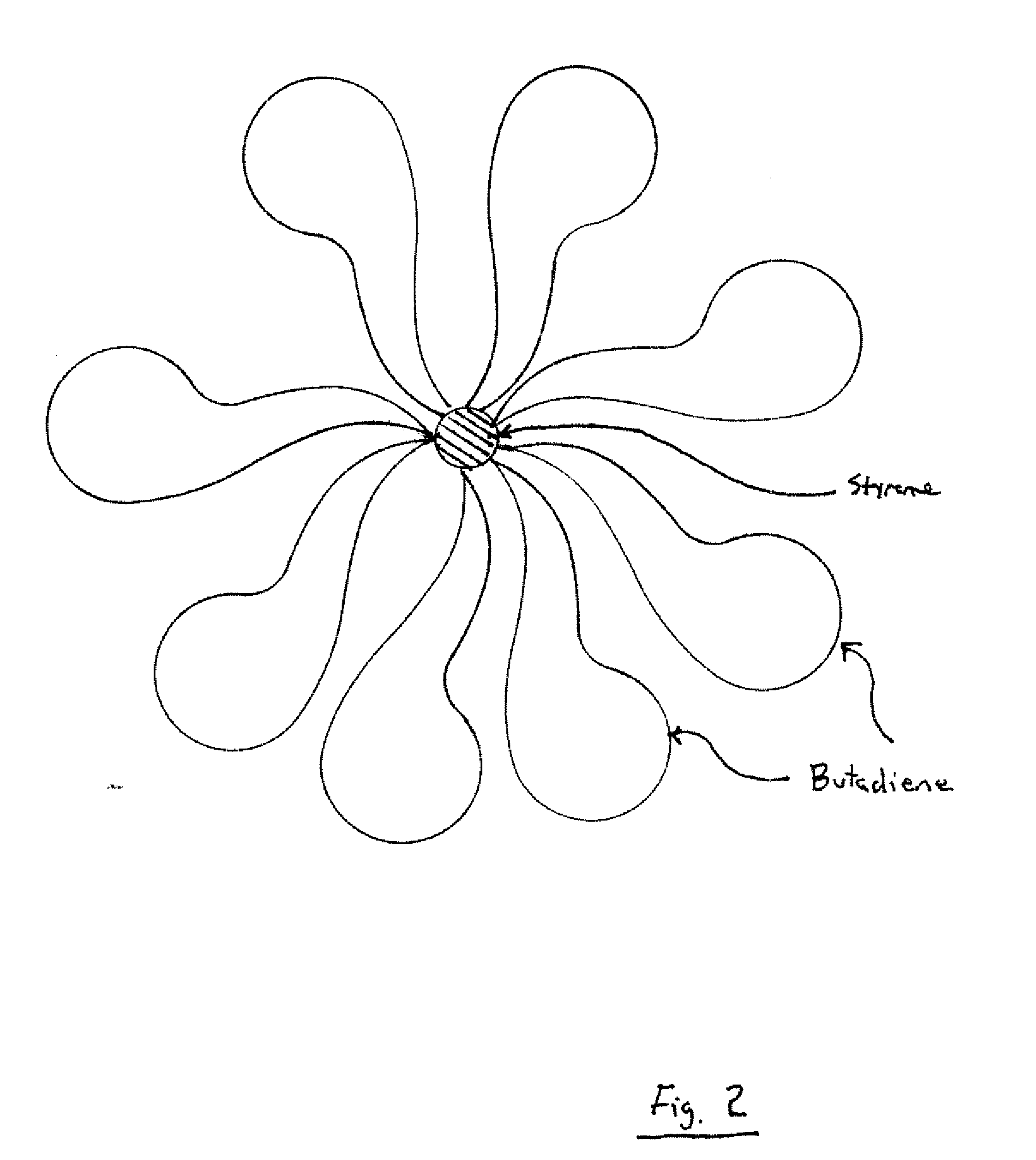

Polymeric nano-particles of flower-like structure and applications

InactiveUS7205370B2Super soft propertyHeat resistantPlastic/resin/waxes insulatorsThermoplasticElastomer

A flower-like nano-particle composition including a poly (alkenylbenzene) core and a poly (conjugated diene) or a poly(alkylene) surface layer is provided. The nano-particles have a mean average diameter less than about 100 nm and are substantially free of chain ends. The nano-particles can be modified via, for example, hydrogenation. The nano-particles can advantageously be incorporated into rubbers, elastomers, and thermoplastics.

Owner:BRIDGESTONE AMERICAS HLDG

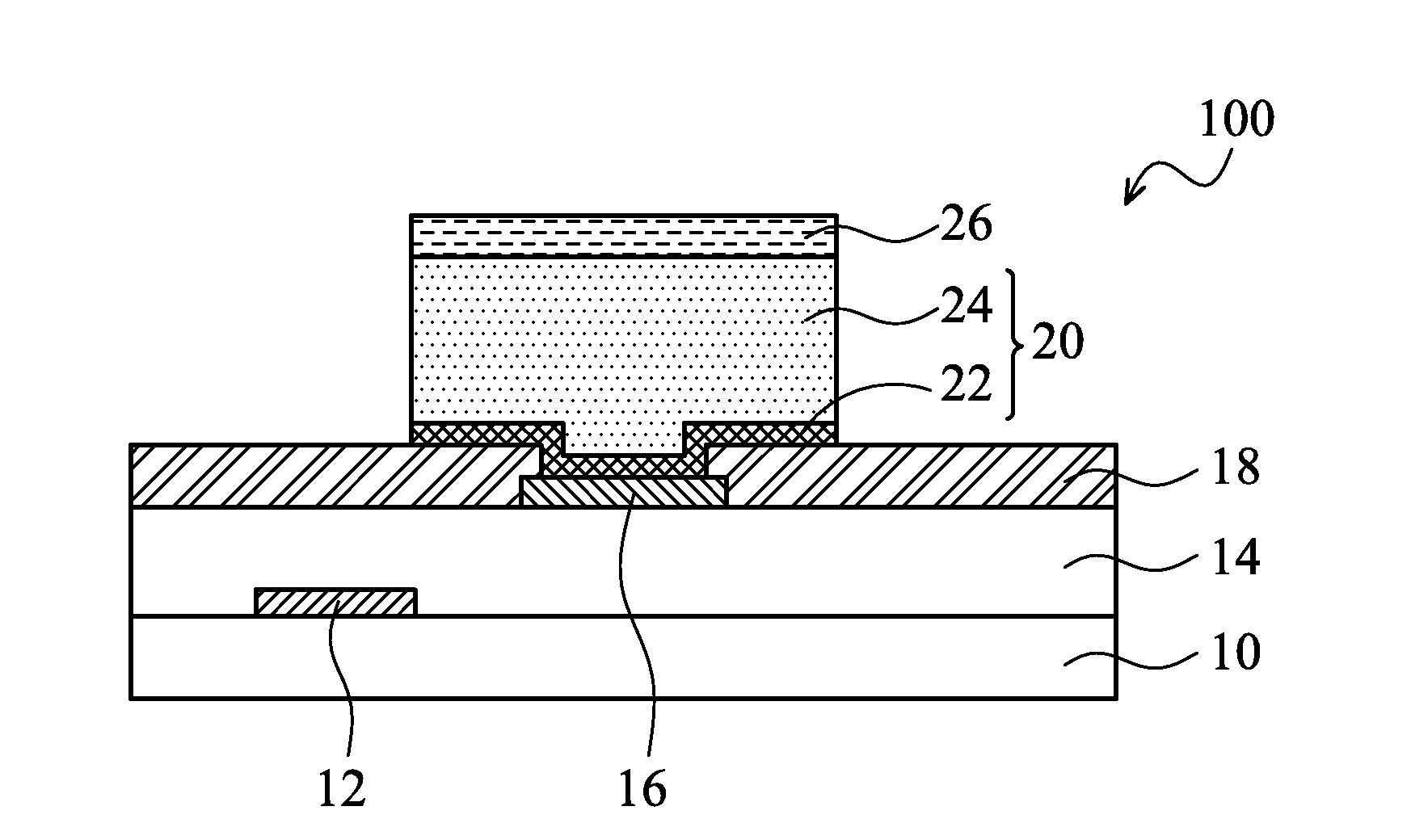

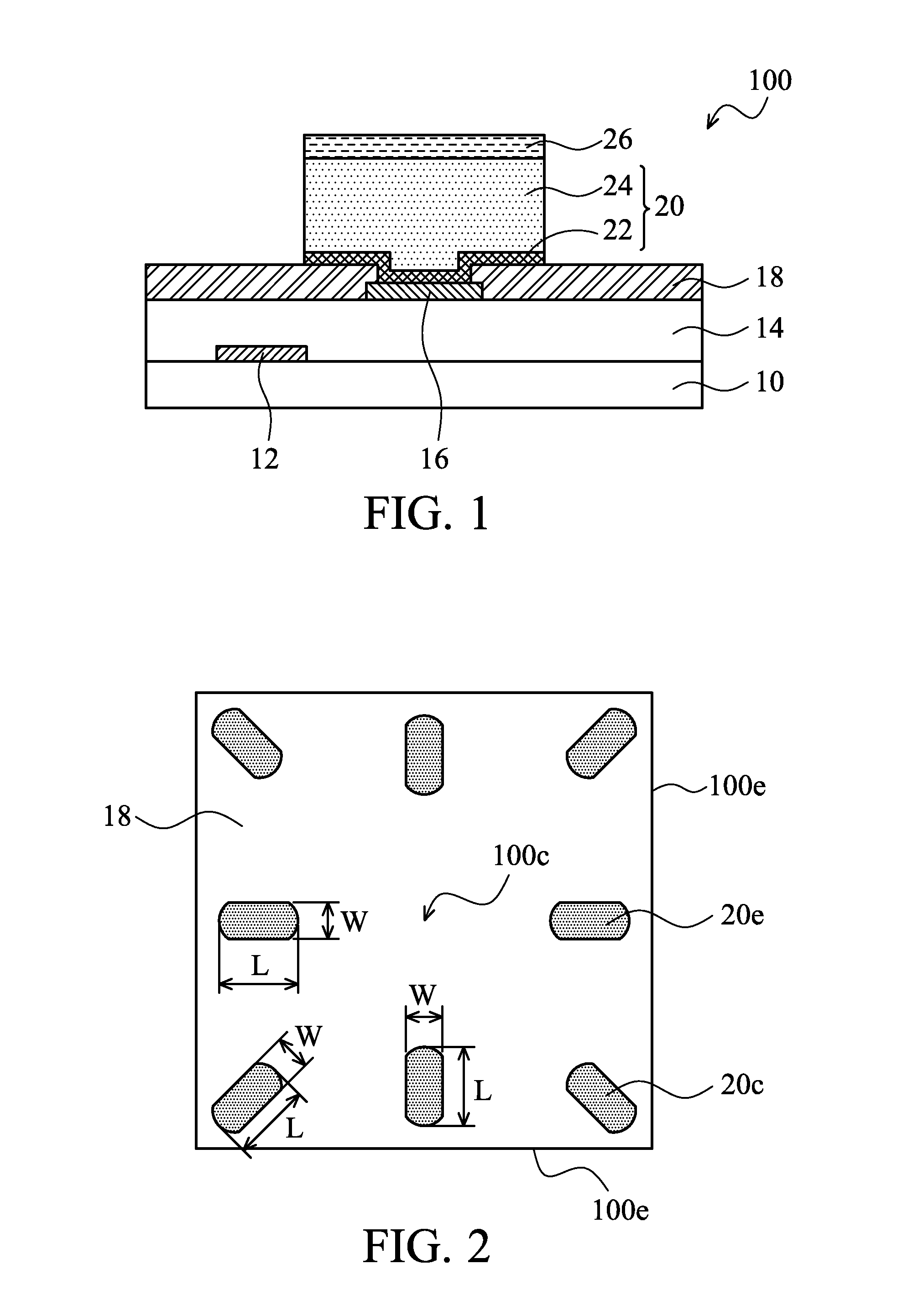

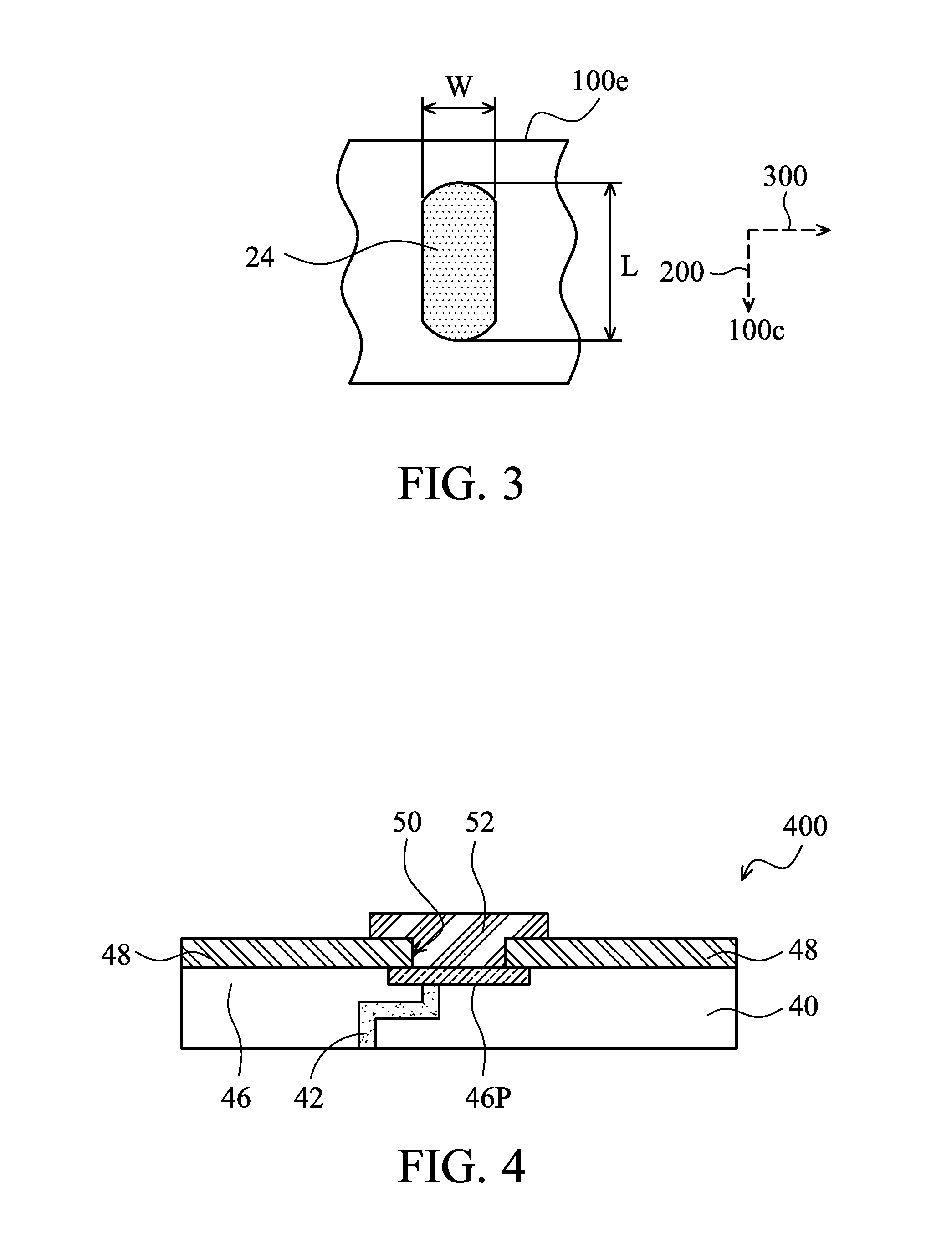

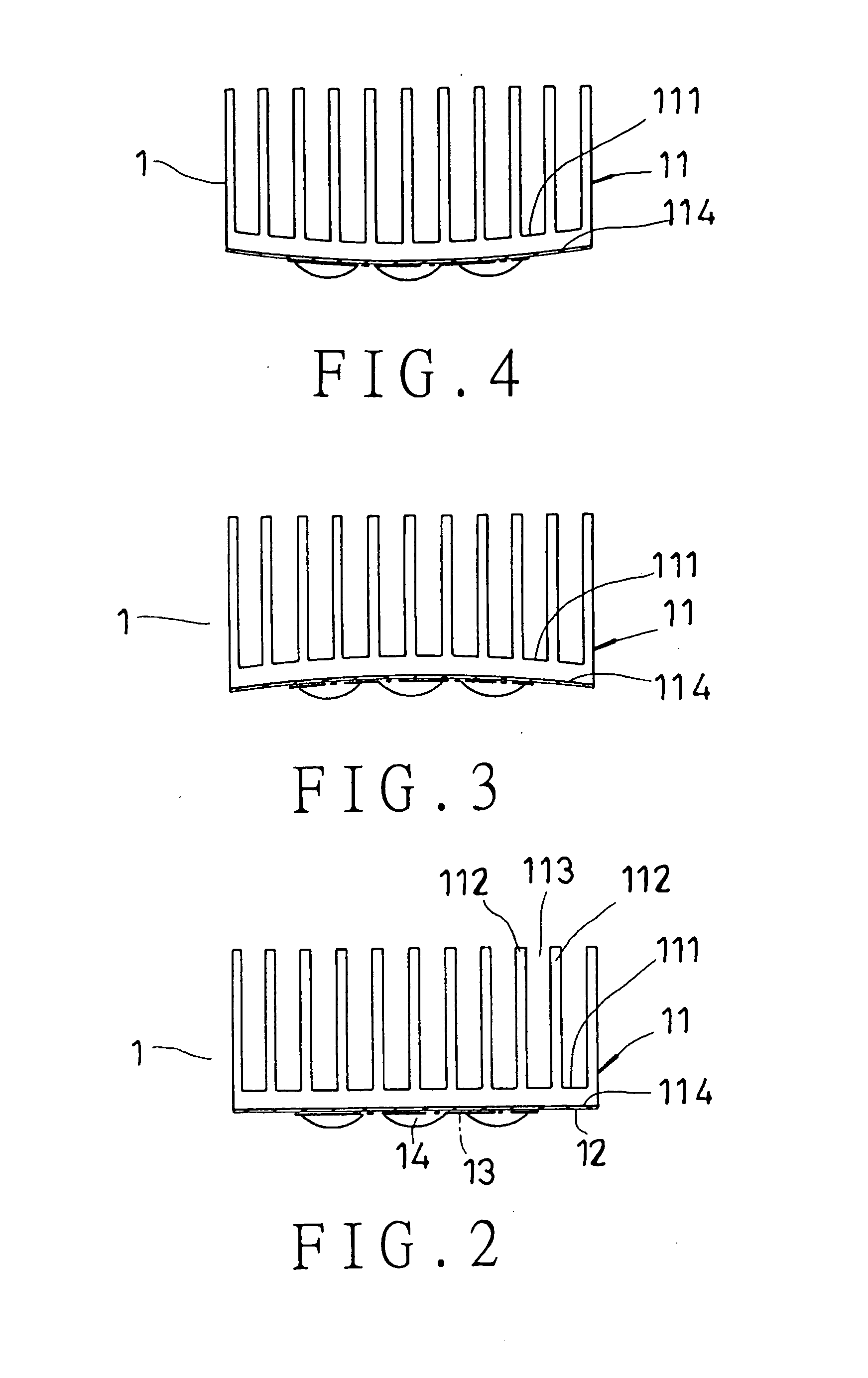

Elongated bump structure in semiconductor device

ActiveUS20130062755A1Heat resistantHigher-speed deviceSemiconductor/solid-state device detailsSolid-state devicesInterconnectionSemiconductor

A device includes a chip attached to a substrate. The chip includes a conductive pillar having a length (L) measured along a long axis of the conductive pillar and a width (W) measured along a short axis of the conductive pillar. The substrate includes a conductive trace and a mask layer overlying the conductive trace, wherein the mask layer has an opening exposing a portion of the conductive trace. An interconnection is formed between the conductive pillar and the exposed portion of the conductive trace. The opening has a first dimension (d1) measured along the long axis of the conductive pillar and a second dimension (d2) measured along the short axis of the conductive pillar. A ratio of L to d1 is greater than a ratio of W to d2.

Owner:TAIWAN SEMICON MFG CO LTD

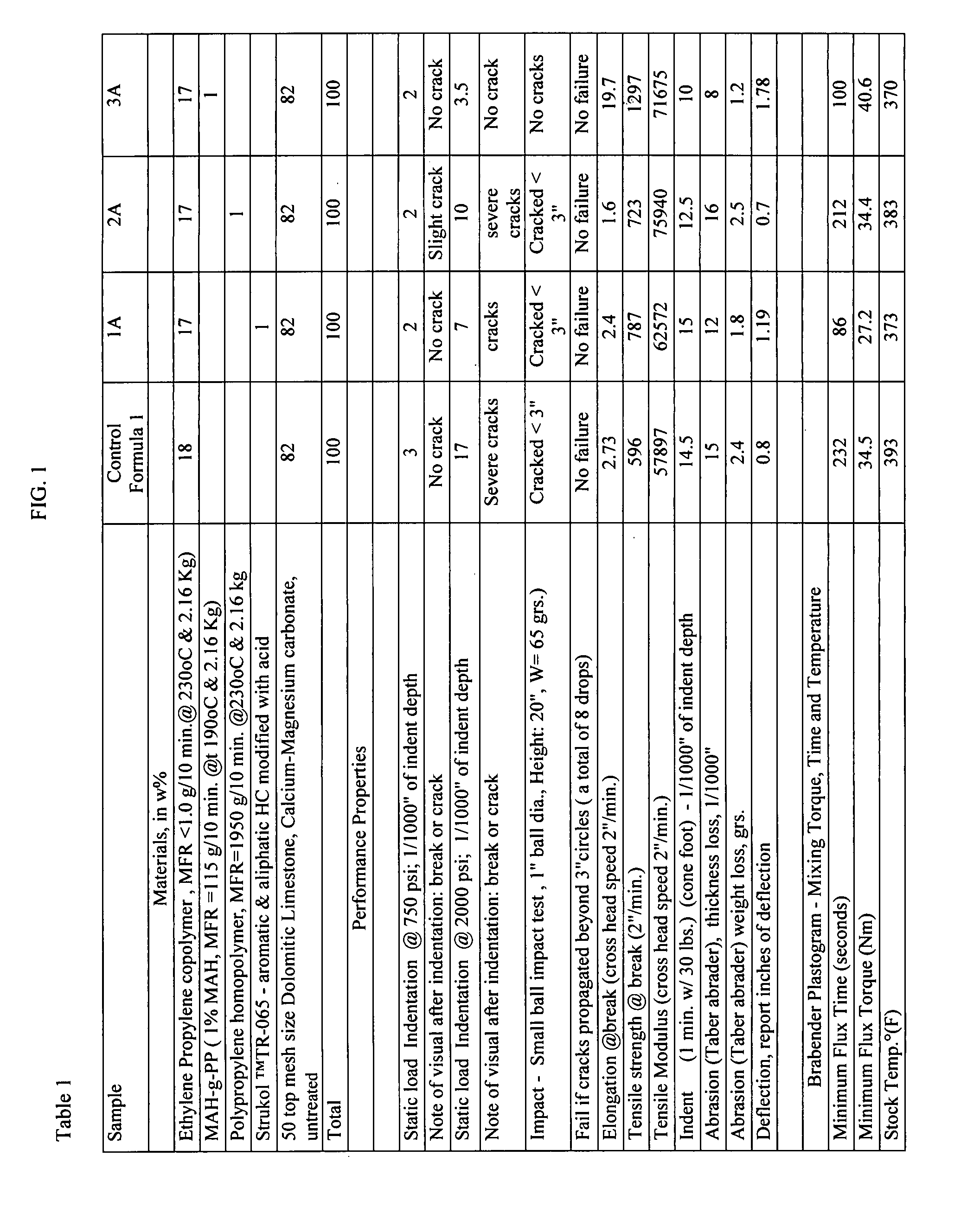

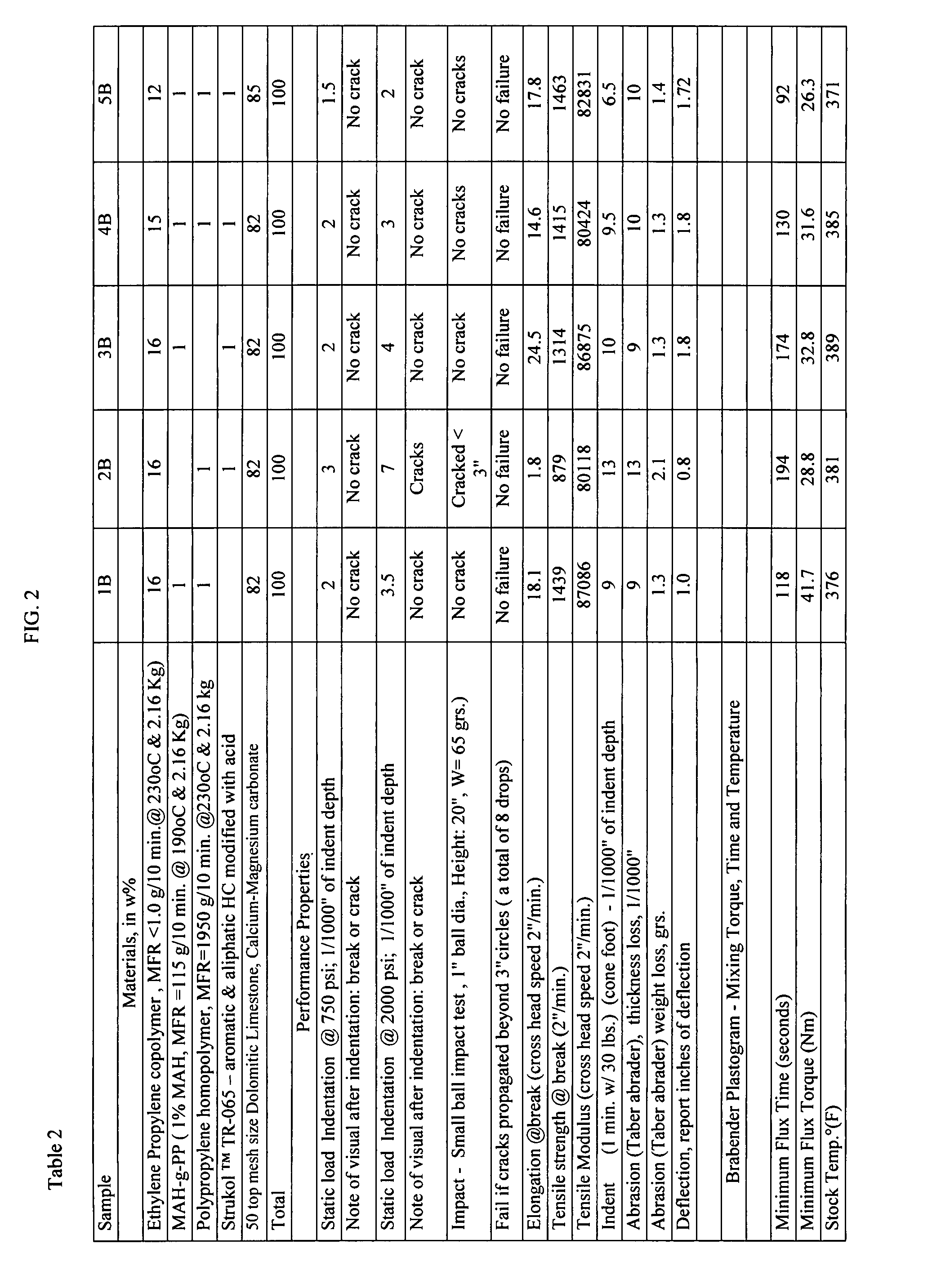

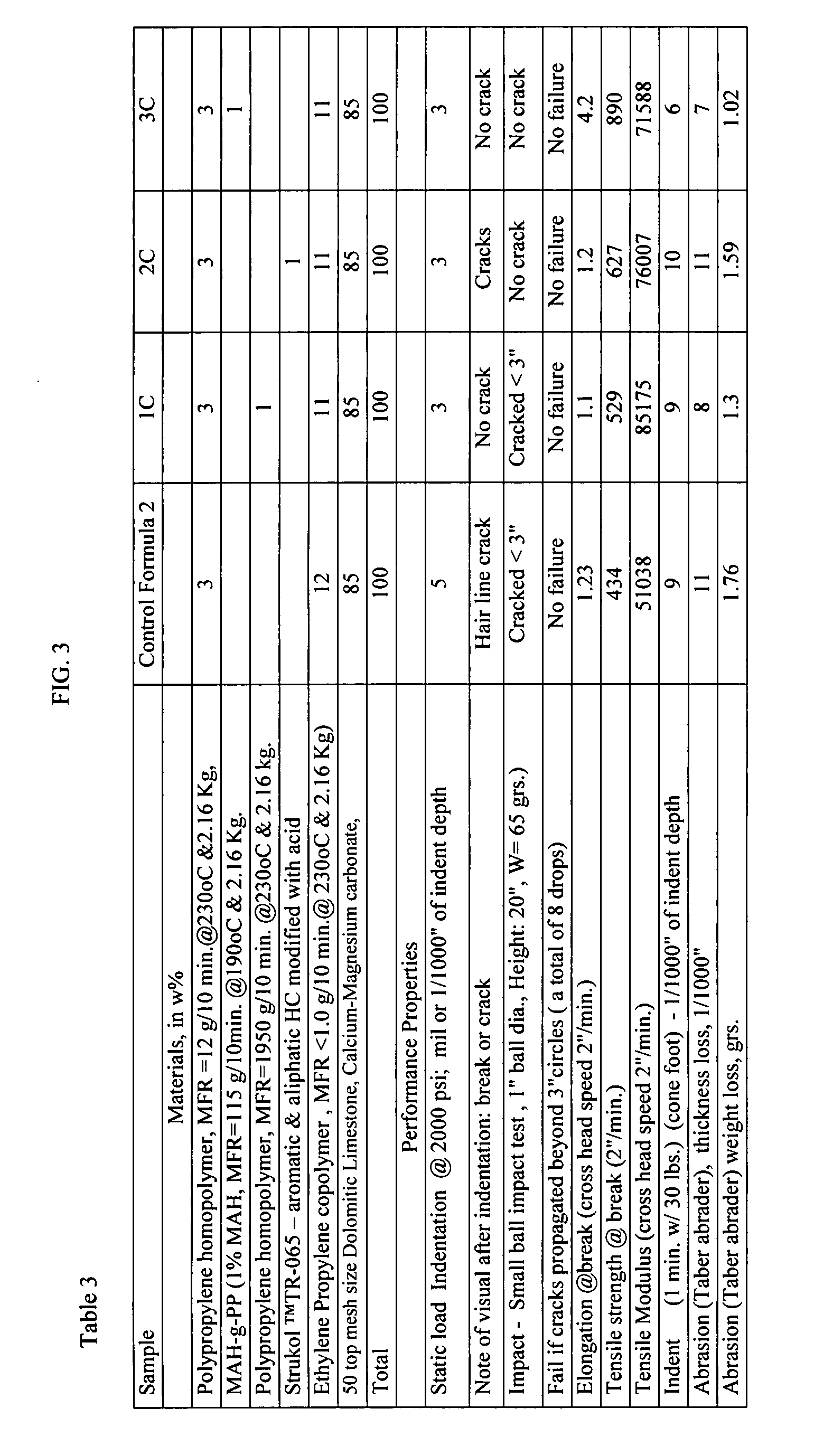

Olefin based compositions and floor coverings containing the same

ActiveUS20080206583A1Improve performanceEliminating and decreasing needSynthetic resin layered productsThin material handlingPolyolefinFloor covering

A composition is described that includes at least one compatibilizer having at least one polyolefin and at least one polar group. The composition can include a blend of polymers. Surface coverings and floor coverings, such as laminated floor coverings, having the composition, are also described.

Owner:MANNINGTON MILLS

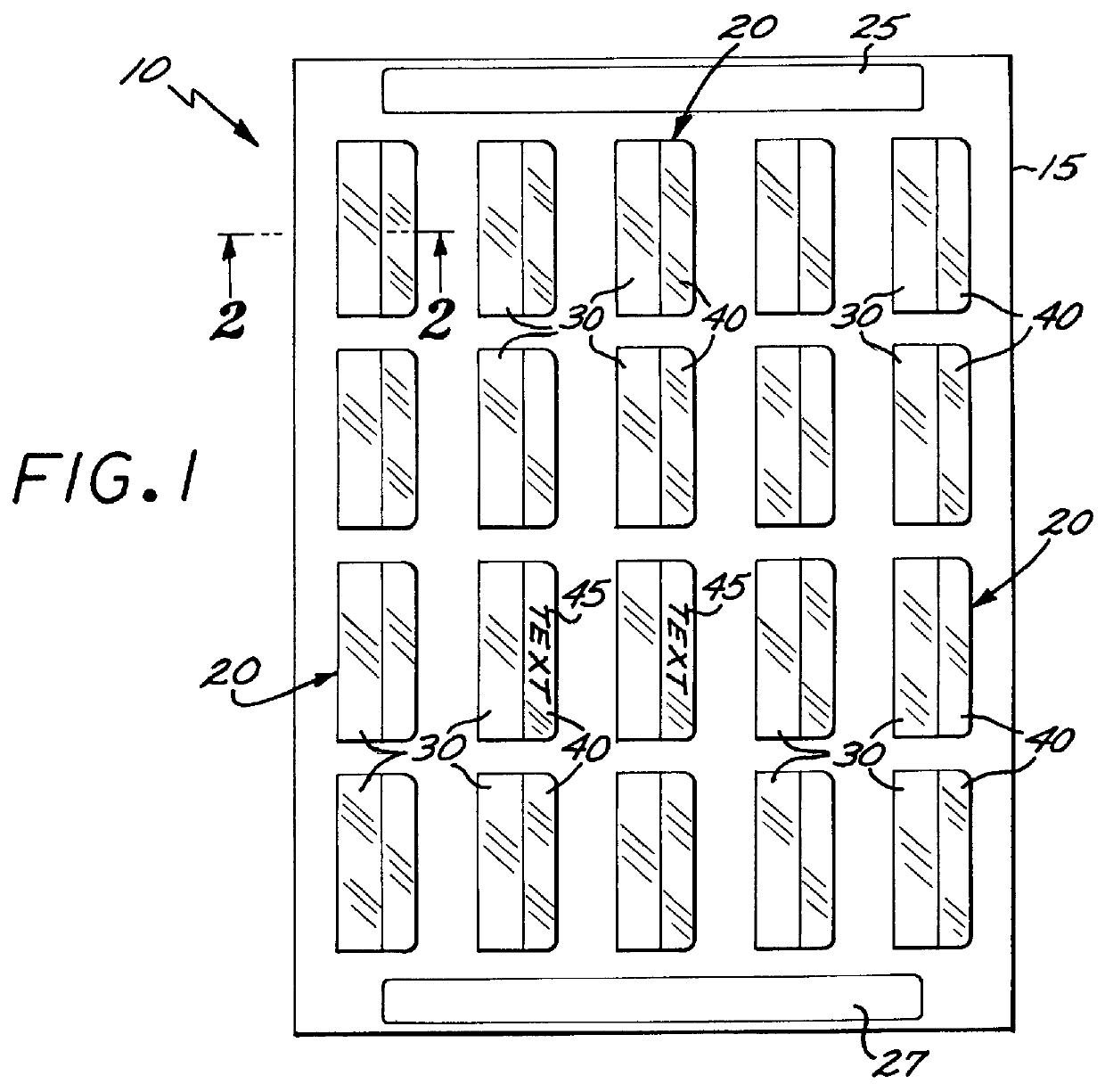

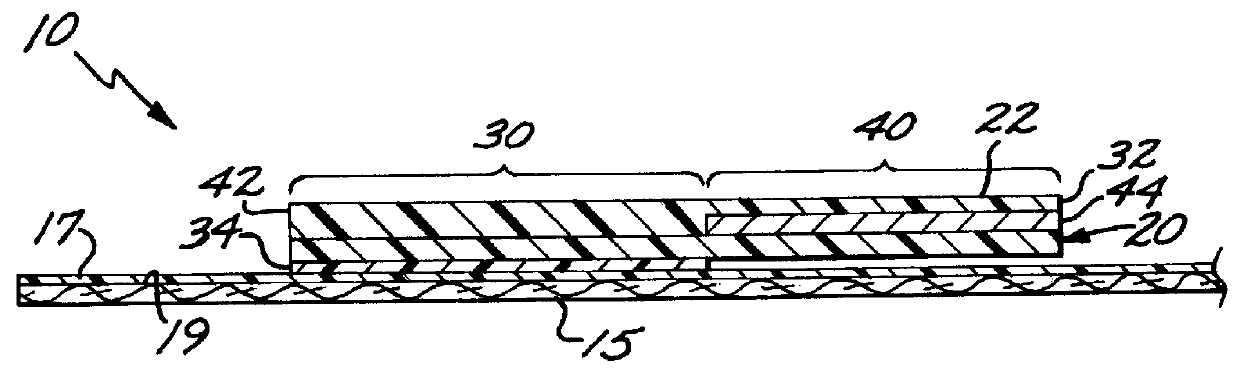

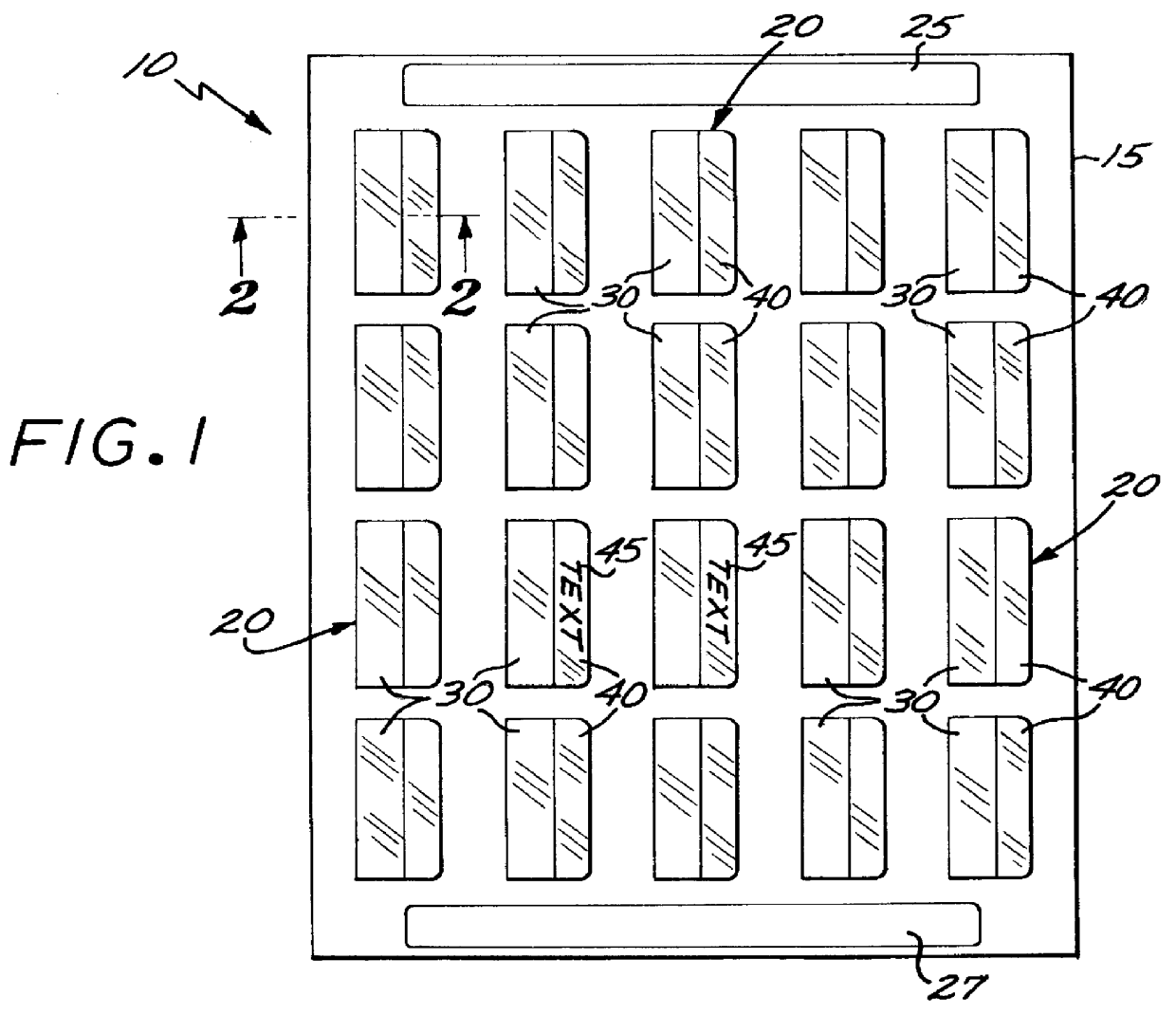

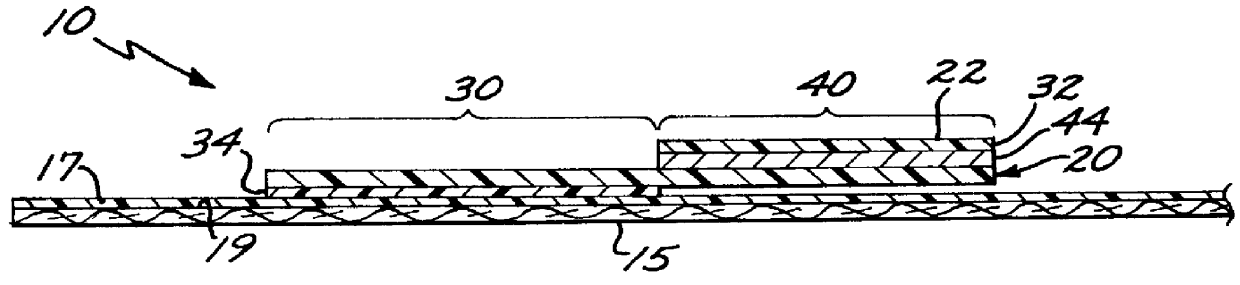

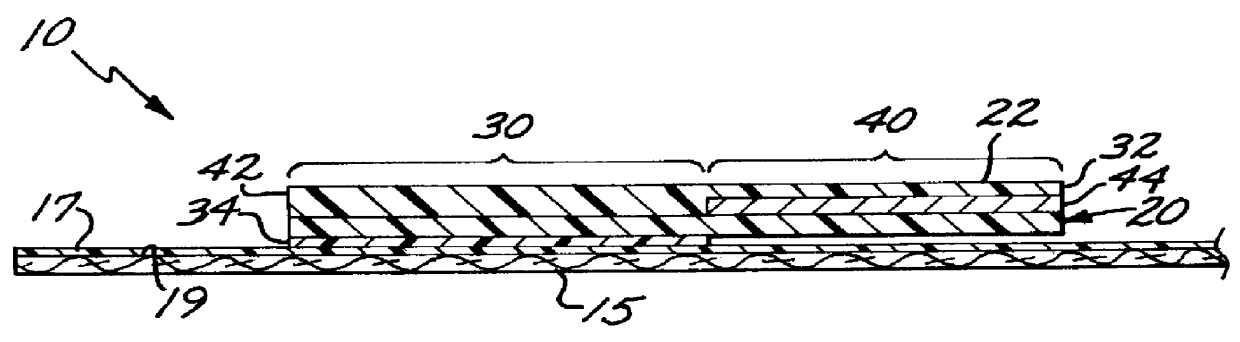

Transferable index tabs

A computer printer compatible index tabs assembly that includes a carrier sheet recognizable by any of a wide variety of computer compatible printing devices. The carrier sheet includes a plurality of self-adhesively secured tabs each formed from a resilient, durable thin film. The self-adhesive is formulated to either permanently or releasably adhere to a peripheral edge of a sheet of material which is to be tagged, labeled or indexed. After printing, the index tab is transferred from the carrier sheet and positioned with the self-adhesive securing the index tab to the sheet of material and with the indicia projecting outwardly from the edge for convenient display.

Owner:IDG

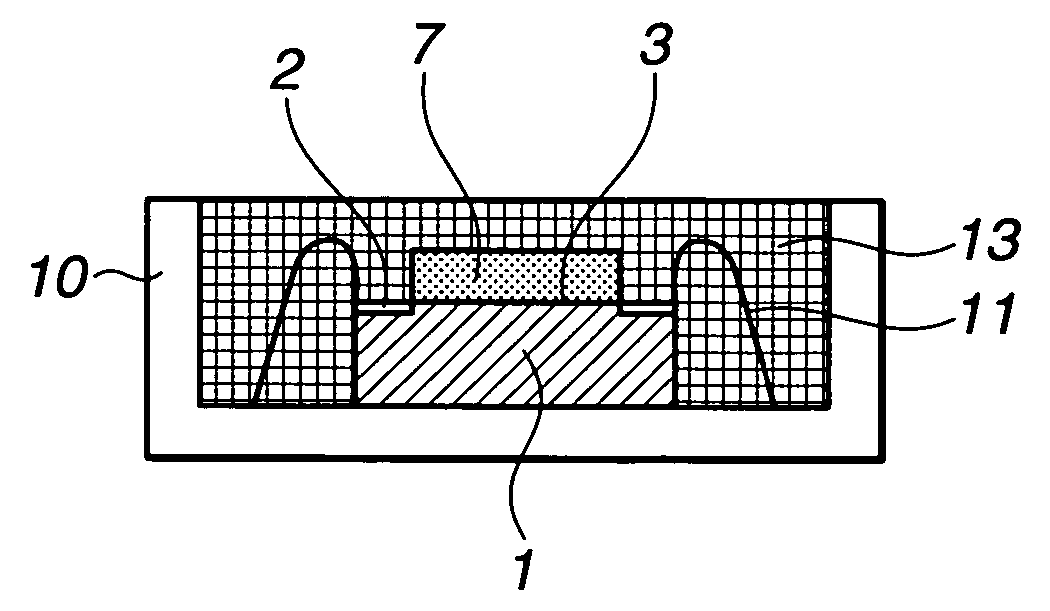

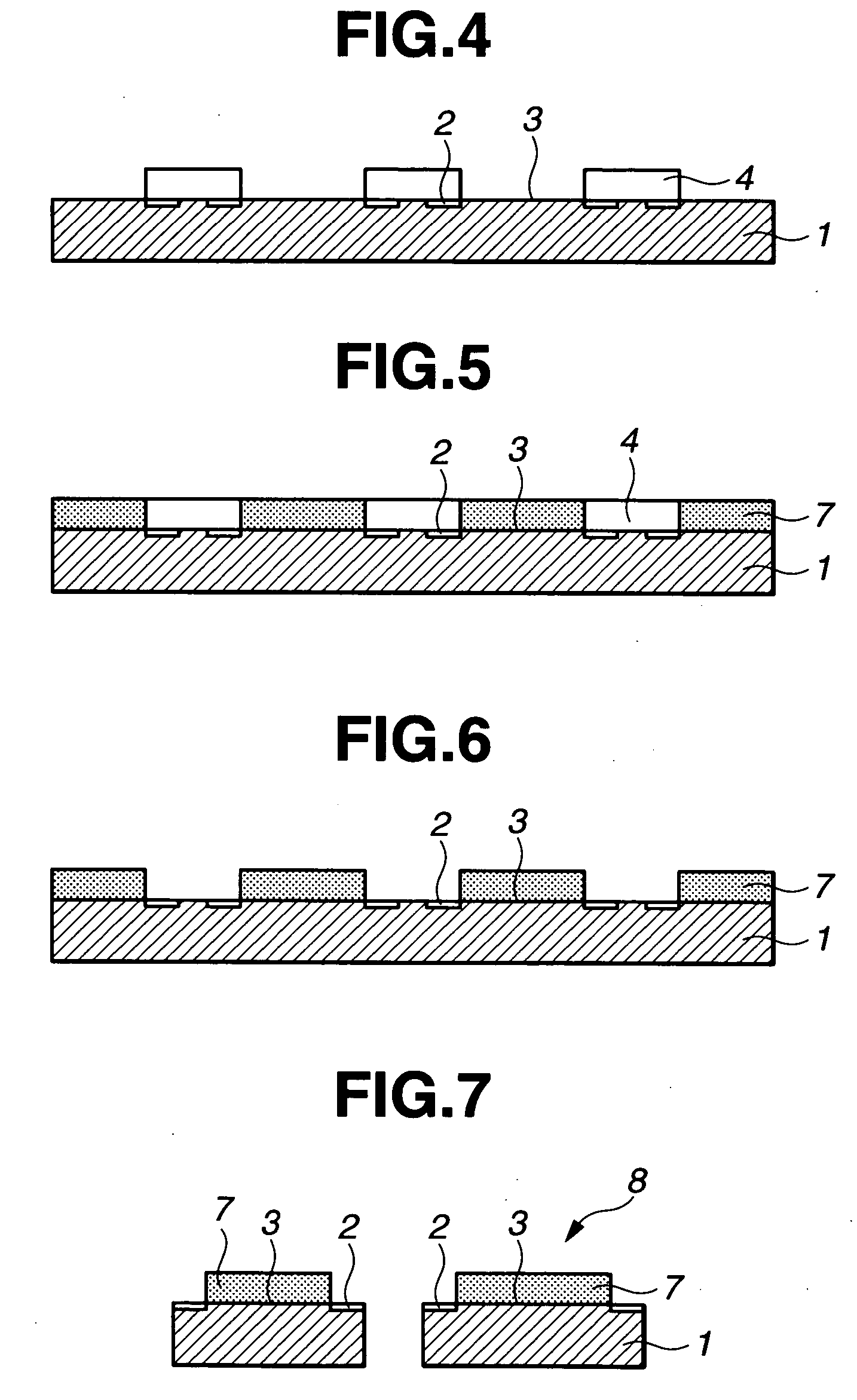

Method for sealing semiconductor component

ActiveUS20050009244A1Heat resistantImprove adhesionSemiconductor/solid-state device detailsSolid-state devicesResistSolvent

In connection with a semiconductor component having a circuit region and electrodes formed on a substrate surface, the circuit region is sealed by (1) applying a resist material onto the substrate surface to form a resist layer, (2) selectively exposing the resist layer to radiation and developing the resist with a liquid developer for thereby removing only the portion of the resist layer which overlies the circuit region, (3) applying a resin sealant onto the circuit region and curing the resin sealant into a cured resin layer that covers the circuit region, and (4) removing the residual resist layer using a solvent.

Owner:SHIN ETSU CHEM IND CO LTD

Water-based ultra-thin fire-retardant coating for steel structures and preparation method of fire-retardant coating

The invention discloses a water-based ultra-thin fire-retardant coating for steel structures. The fire-retardant coating comprises components as follows: a binder emulsion, an intumescent flame retardant system, filler, deionized water and additives, wherein the additives comprise a dispersing agent, an antifoaming agent, a mold inhibitor, an anti-flash-rust agent, a coalescing agent, a leveling agent and a thickener; the intumescent flame retardant system comprises a dehydration catalyst, a carbonizing agent and a foaming agent. The invention further designs a preparation method of the water-based ultra-thin fire-retardant coating for the steel structures. The components are mixed sequentially to be prepared into the water-based ultra-thin fire-retardant coating for the steel structures in a vertical sand mill and a dispersing tank. The prepared coating is large in adhesive force, high in hardness, good in fireproof property, good in anti-scratch performance and excellent in weather resistance and water resistance, the surface layer of the coating is fine and smooth, the decoration performance is improved significantly, and the preparation method is low in energy consumption and has the advantages that the harm to human bodies and the pollution to the environment during preparation are small and the like.

Owner:JIANGSU MARINE VICTORY COATING

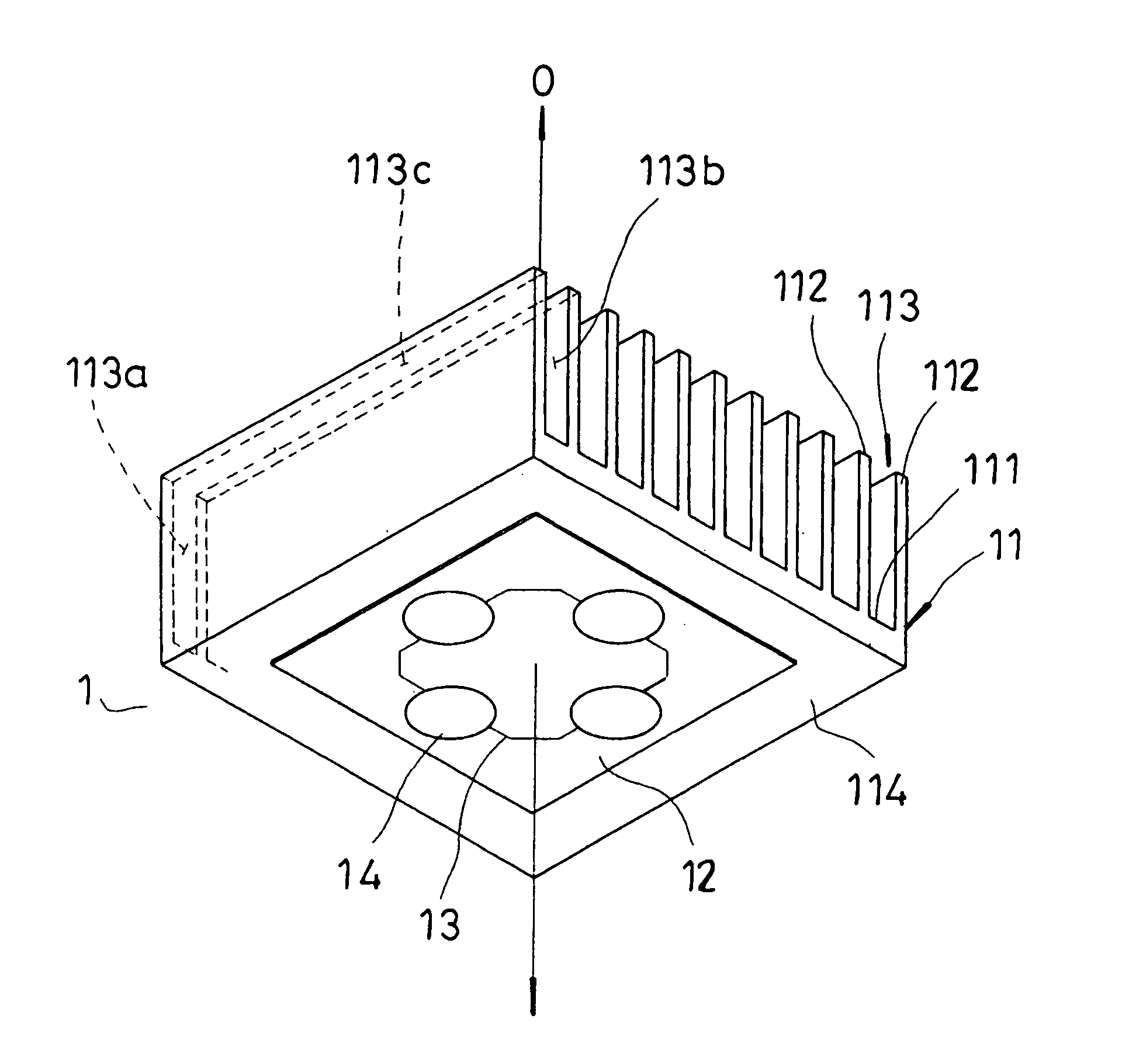

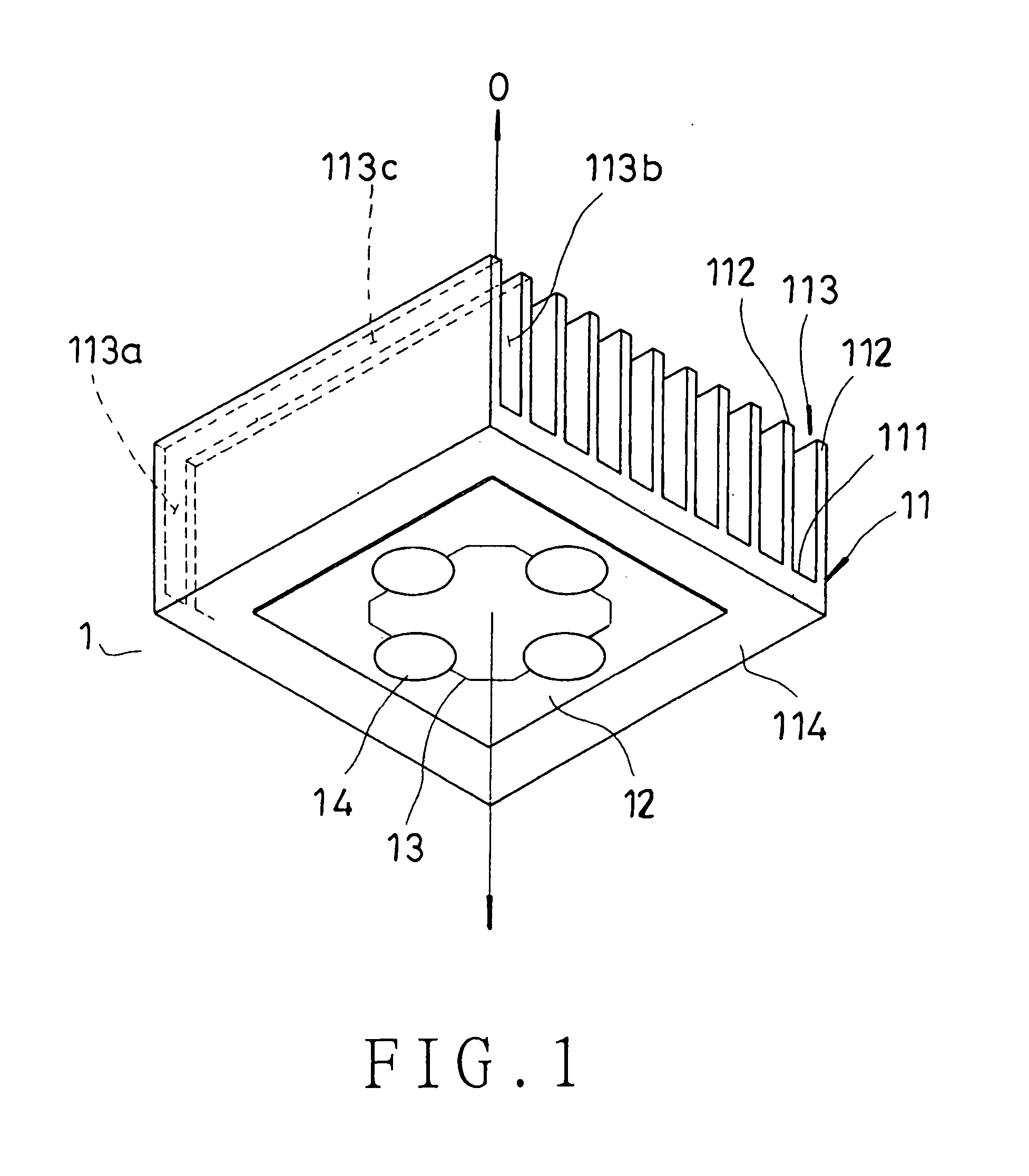

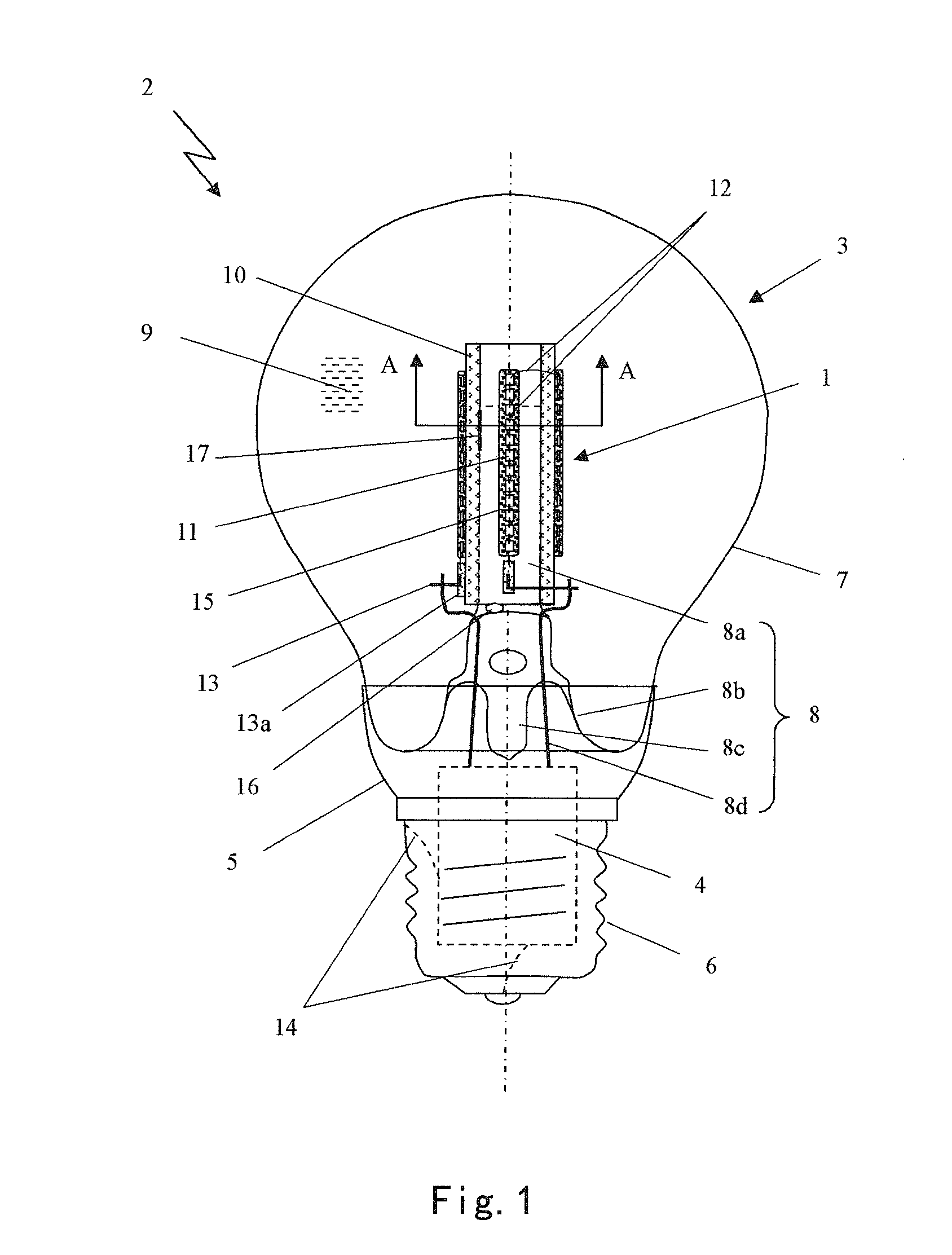

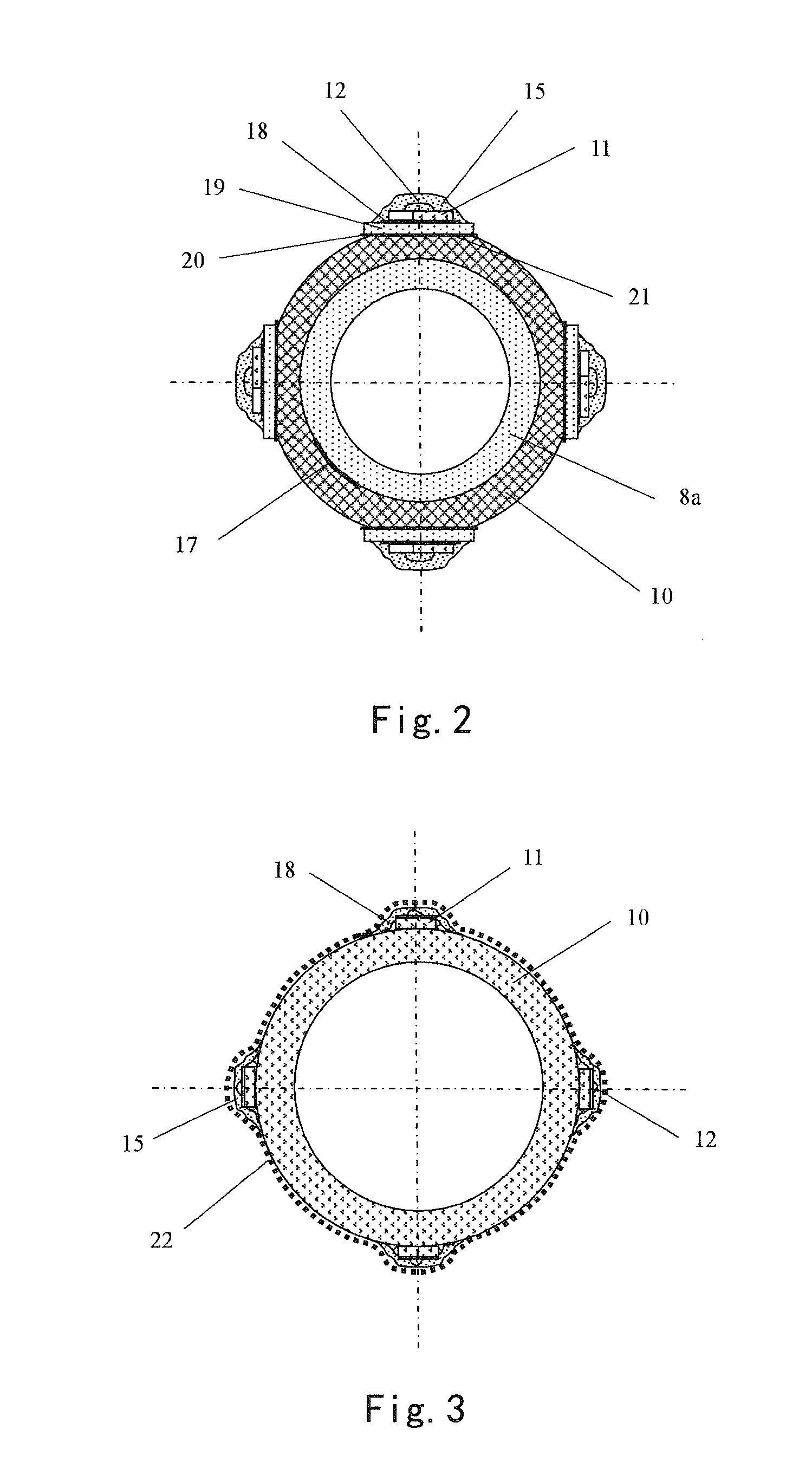

Light emitting diode lamp with high heat-dissipation capacity

InactiveUS20090303735A1Improve cooling effectHeat resistantMechanical apparatusPoint-like light sourceElectricityInsulation layer

This invention relates to a light emitting diode lamp with high heat-dissipation capacity wherein the lamp has at -least one heat-dissipating unit, a plurality of air-flow channels being provided within each heat sink unit, an electrical insulation layer with high heat-conductivity being provided on the surface of the light emitting diode mounted with heat-dissipating unit, a metal circuit being formed on the electrical insulation layer with high heat-conductivity according to demand, at least one light emitting diode being packaged on the metal circuit such that provision of circuit board or coating of heat sink paste become unnecessary for the lamp.

Owner:CHEN HON WEN

Binder for electrode formation, slurry for electrode formation using the binder, electrode using the slurry, rechargeable battery using the electrode, and capacitor using the electrode

InactiveUS20090325069A1Improve cycle performanceHeat resistantElectrode manufacturing processesHybrid capacitor electrodesPolyolefinUnsaturated hydrocarbon

Disclosed is a binder for electrode formation, which is obtained by dispersing a polyolefin resin containing 50 to 98% by mass of an unsaturated hydrocarbon having 3 to 6 carbon atoms and 0.5 to 20% by mass of an unsaturated carboxylic acid unit in an aqueous medium together with a basic compound. This binder for electrode formation is also characterized in that the content of a nonvolatile water-compatibilizing agent is 5 parts by mass or less per 100 parts by mass of the polyolefin resin.

Owner:UNITIKA LTD

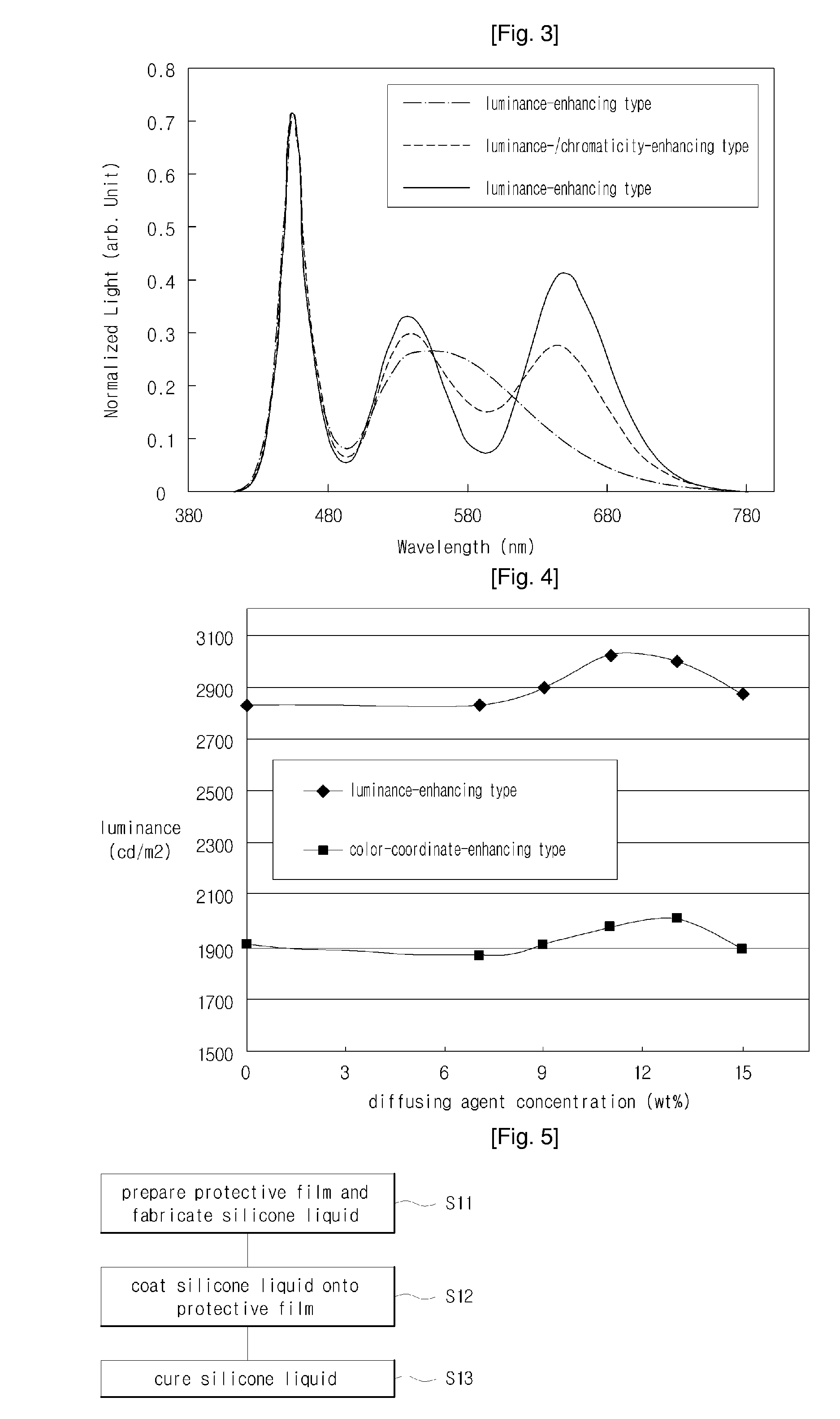

Photoluminescent Sheet

ActiveUS20090212257A1Improve the immunityUneven levelDischarge tube luminescnet screensSidewalk pavingsPhotoluminescencePhosphor

A photoluminescent sheet is disclosed. A photoluminescent sheet that includes a matrix resin layer, which is a thermosetting resin; a phosphor, which is included in the matrix resin layer and which converts the wavelength of light emitted from a blue LED; a curing agent, which is included in the matrix resin layer and which cures liquid thermosetting resin; and an additive, which is included in the matrix resin layer and which disperses the phosphor uniformly within the matrix resin layer, can implement white light from light having wavelengths corresponding to blue color.

Owner:SUZHOU LEKIN SEMICON CO LTD

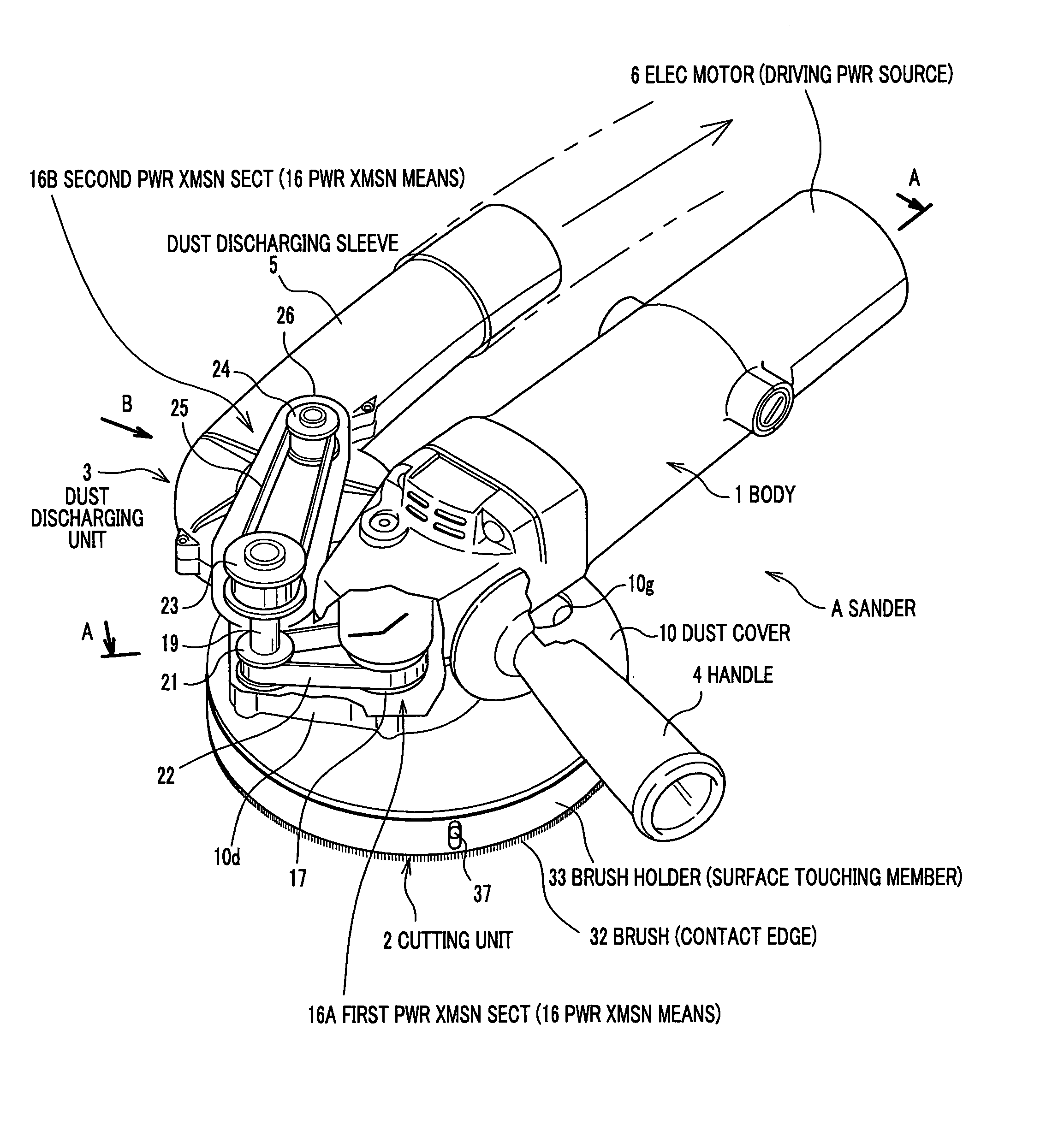

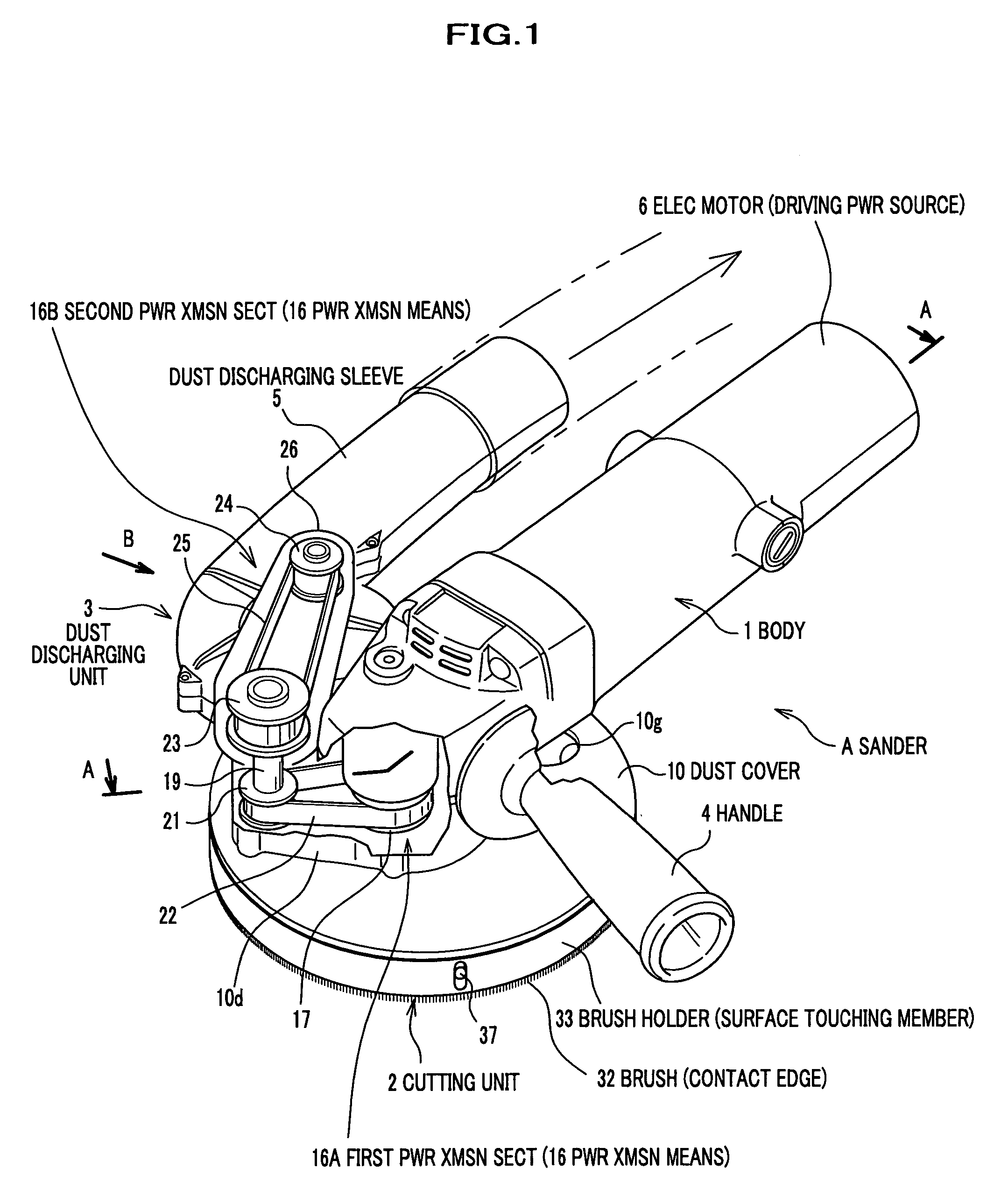

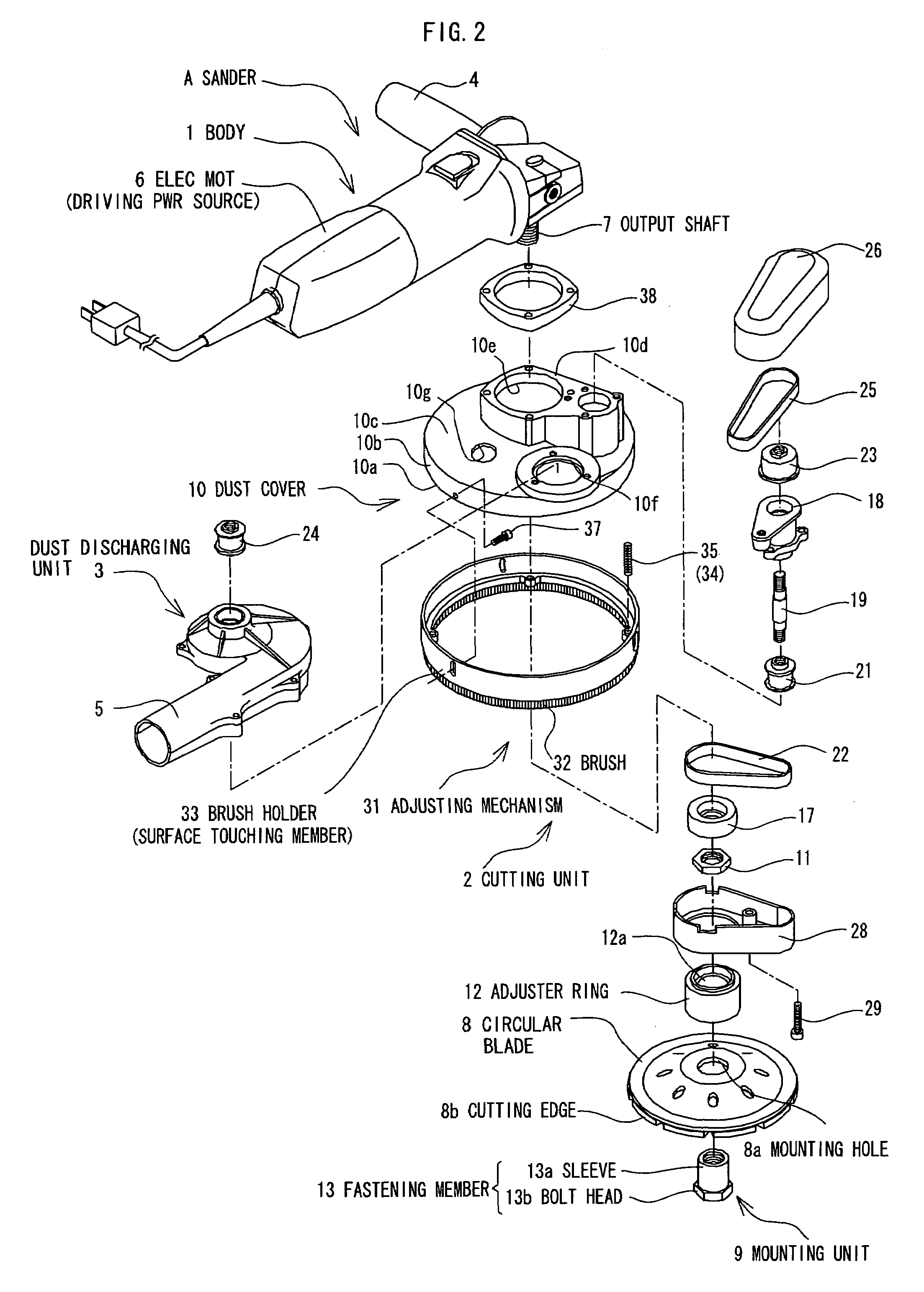

Cutting apparatus with dust discharging

InactiveUS7223161B2Increase flexibilityImprove sealing propertiesPortable grinding machinesPlane surface grinding machinesTransmitted powerPulley

In a cutting apparatus having a circular blade with a dust discharging unit for, during cutting, discharging chips (dust) within a dust cover covering the circular blade, a pulley is fixed to an output shaft of a power source, and a flat belt for transmitting power to the dust discharging unit is engaged with the pulley. The pulley and the flat belt are covered with an inner cover within the dust cover. The inner cover has a through hole for allowing the output shaft to protrude the inner cover therethrough with a seal made of felt to prevent dust from entering the inside of the inner cover. A surface touching member is provided around an opening edge of the dust cover movable along an axial direction of the output shaft by spring-loading, which automatically reduces the gap between the dust cover and the object to prevent dust from being scattered.

Owner:GOEI

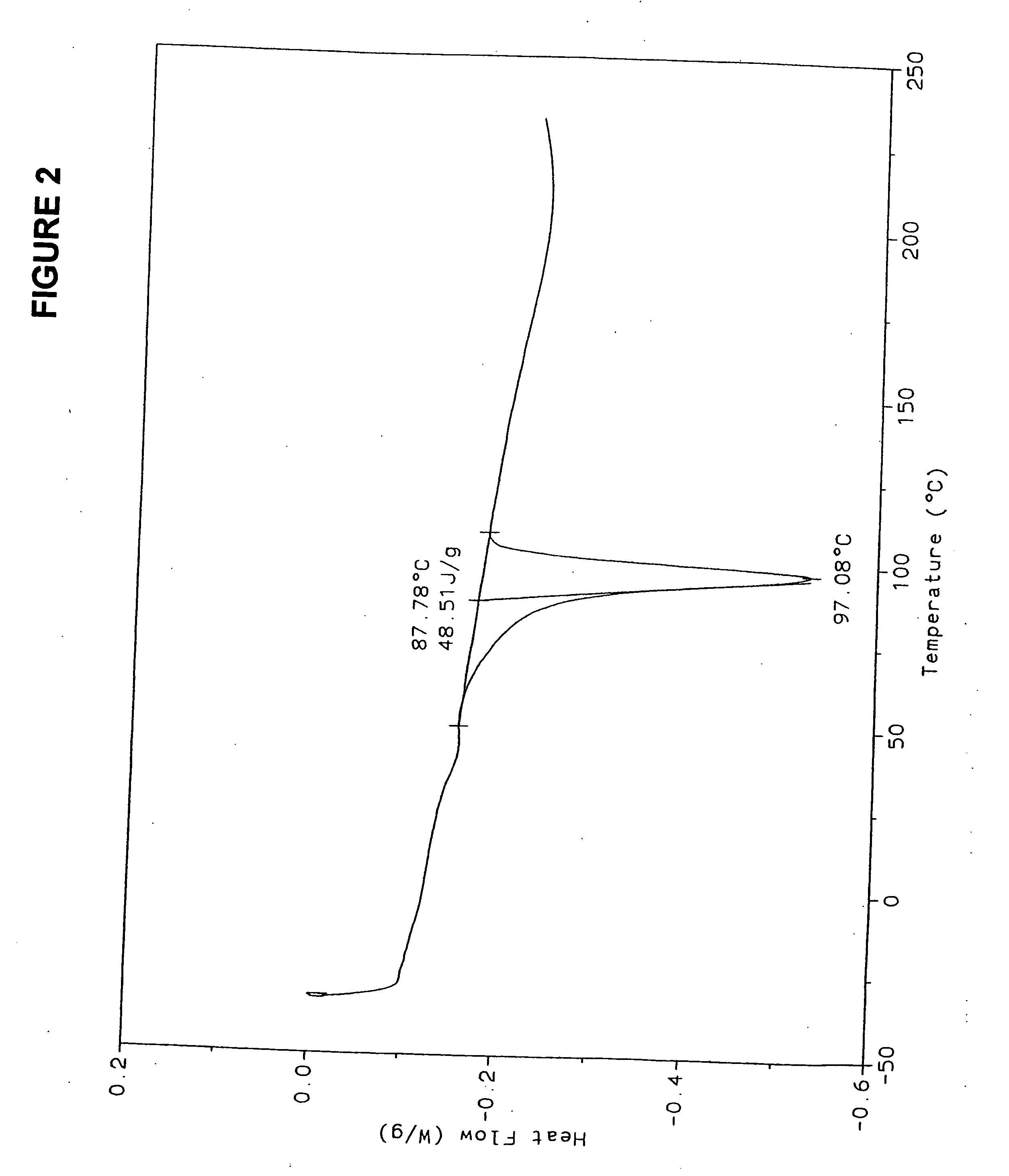

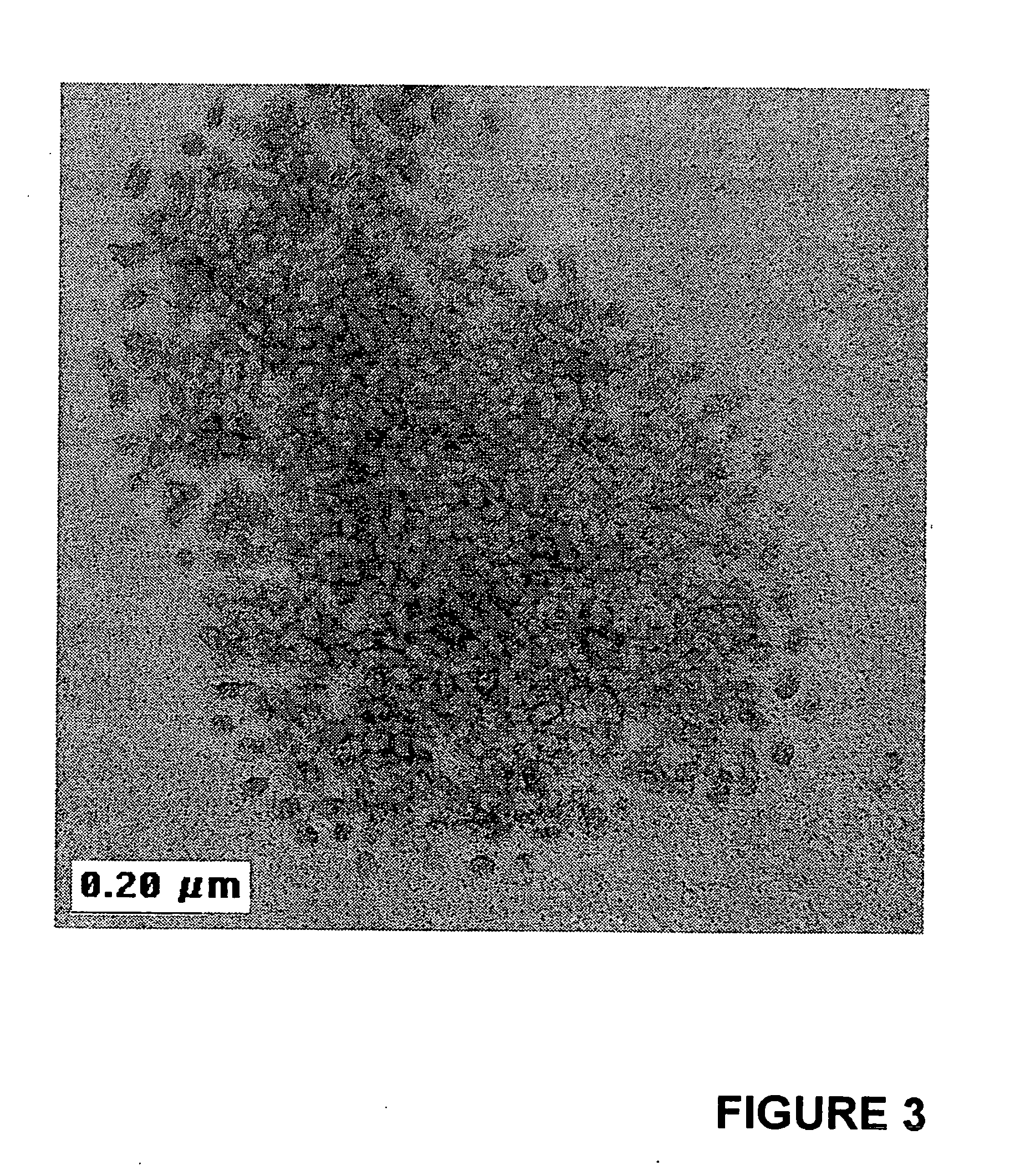

Nano-particle preparation and applications

InactiveUS20050192408A1Super soft propertyHeat resistantMaterial nanotechnologyGlass/slag layered productsElastomerThermoplastic

A nano-particle composition including a poly(alkenylbenzene) core and a poly (conjugated diene) or a poly(alkylene) surface layer is provided. The nano-particles have a mean average diameter less than about 100 nm. The nano-particles can be modified via, for example, hydrogenation or functionalization. The nano-particles can advantageously be incorporated into rubbers, elastomers, and thermoplastics.

Owner:BRIDGESTONE FIRESTONE NORTH AMERICAN TIRE

Heat-shrinkable laminated film, molded product and heat-shrinkable label comprising the film, and container

ActiveUS20130224412A1Good heat shrinkabilitySolve easy peelingBottlesSynthetic resin layered productsPolyesterRoom temperature

A heat-shrinkable laminated film having: (A) layer mainly having a polyester series resin; (C) layer mainly having a polystyrene series resin or mixture of polyester series and polystyrene series resins; and (B) layer mainly having polyester series and polystyrene series resins and disposed between (A) and (C) layers, the film having excellent heat-shrinkability, transparency, and interlayer-adhesiveness at room temperature, not easily peeled in a high-temperature treatment, inhibited from whitening when bent during processing, and suitable for shrinkage-packaging, shrink-bond-packaging, etc., with (B) layer having: a hard polyester series resin or mixture of hard polyester series and soft polyester series resins; and soft styrene series resin, hard styrene series resin, or mixture thereof, or with a content of the (B) layer polyester series resin smaller than that of the (A) layer one, and a content of the (C) layer polyester series resin smaller than that of the (B) layer one.

Owner:MITSUBISHI CHEM CORP

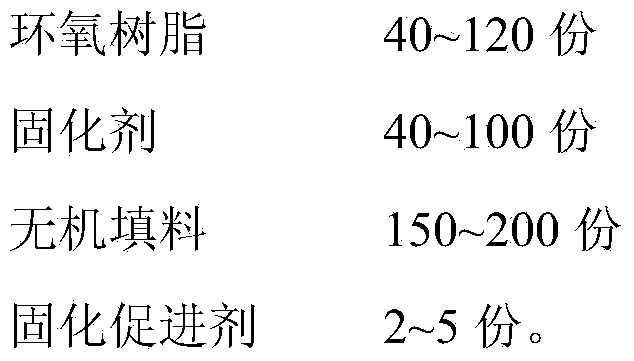

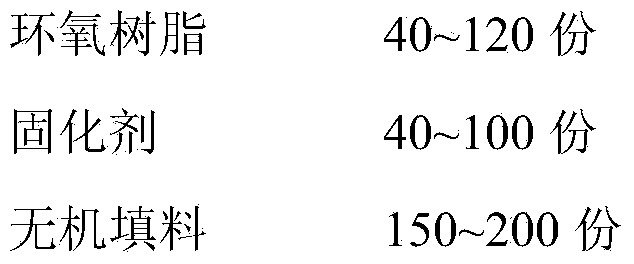

Outdoor electric-insulation modified epoxy resin composition

The invention discloses an outdoor electric-insulation modified epoxy resin composition which comprises an epoxy resin, a curing agent, a curing accelerator and an inorganic filler. The outdoor electric-insulation modified epoxy resin composition has the advantages of high weather resistance, favorable hydrophobicity, high volume resistivity, high tracking resistance, high arc resistance, low thermal expansivity and the like, and can be used for manufacturing suspension insulators for alternating current transmission lines as well as umbrella skirts of cross arms and other outdoor insulation parts. Compared with the silicon rubber umbrella skirt, the umbrella skirt prepared from the composition can prevent birds from damage, resist line walking trampling, avoid shipping damage and the like.

Owner:赛思迈(上海)新材料科技有限公司

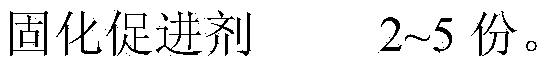

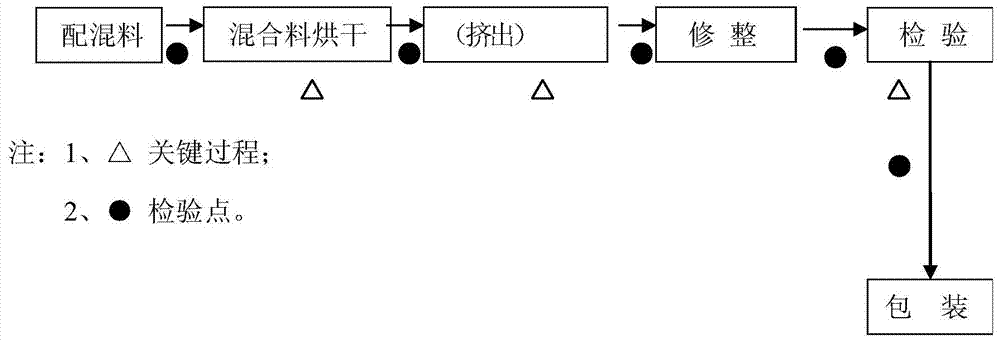

High-temperature, temperature-resisting and wear-resisting polyethylene pipe

The invention discloses a high-temperature, temperature-resisting and wear-resisting polyethylene pipe. The high-temperature, temperature-resisting and wear-resisting polyethylene pipe sequentially comprises a micron-grade modified ultra-high molecular weight polyethylene layer, a high molecular weight modified material layer of high density polyethylene and inorganic minerals and a polyethylene felt layer from inside to outside. The polyethylene felt layer is composed of the following raw materials: 100 parts of the polyethylene, 10-20 parts of nano materials, 1-3 parts of a compatilizer, 1-3 parts of a toughening agent, 1-2 parts of a coupling agent, 1-1.5 parts of a processing lubricant and 1-1.5 parts of an antioxidant. The high-temperature, temperature-resisting and wear-resisting polyethylene pipe has the advantages that nano particles are sufficiently dispersed in plastic resin so that the heat resistance, the weather resistance, the wear resistance and the like of the plastic are effectively improved.

Owner:NINGBO BOER PIPE IND DEV

Computer printer compatible index tabs

InactiveUS6132831AEasy to useOvercome disadvantagesStampsFlexible coversComputer printingEngineering

A computer printer compatible index tabs assembly that includes a carrier sheet recognizable by any of a wide variety of computer compatible printing devices. The carrier sheet includes a plurality of self-adhesively secured tabs each formed from a resilient, durable thin film. The self-adhesive is formulated to either permanently or releasably adhere to a peripheral edge of a sheet of material which is to be tagged, labeled or indexed. After printing, the index tab is transferred from the carrier sheet and positioned with the self-adhesive securing the index tab to the sheet of material and with the indicia projecting outwardly from the edge for convenient display.

Owner:IDG

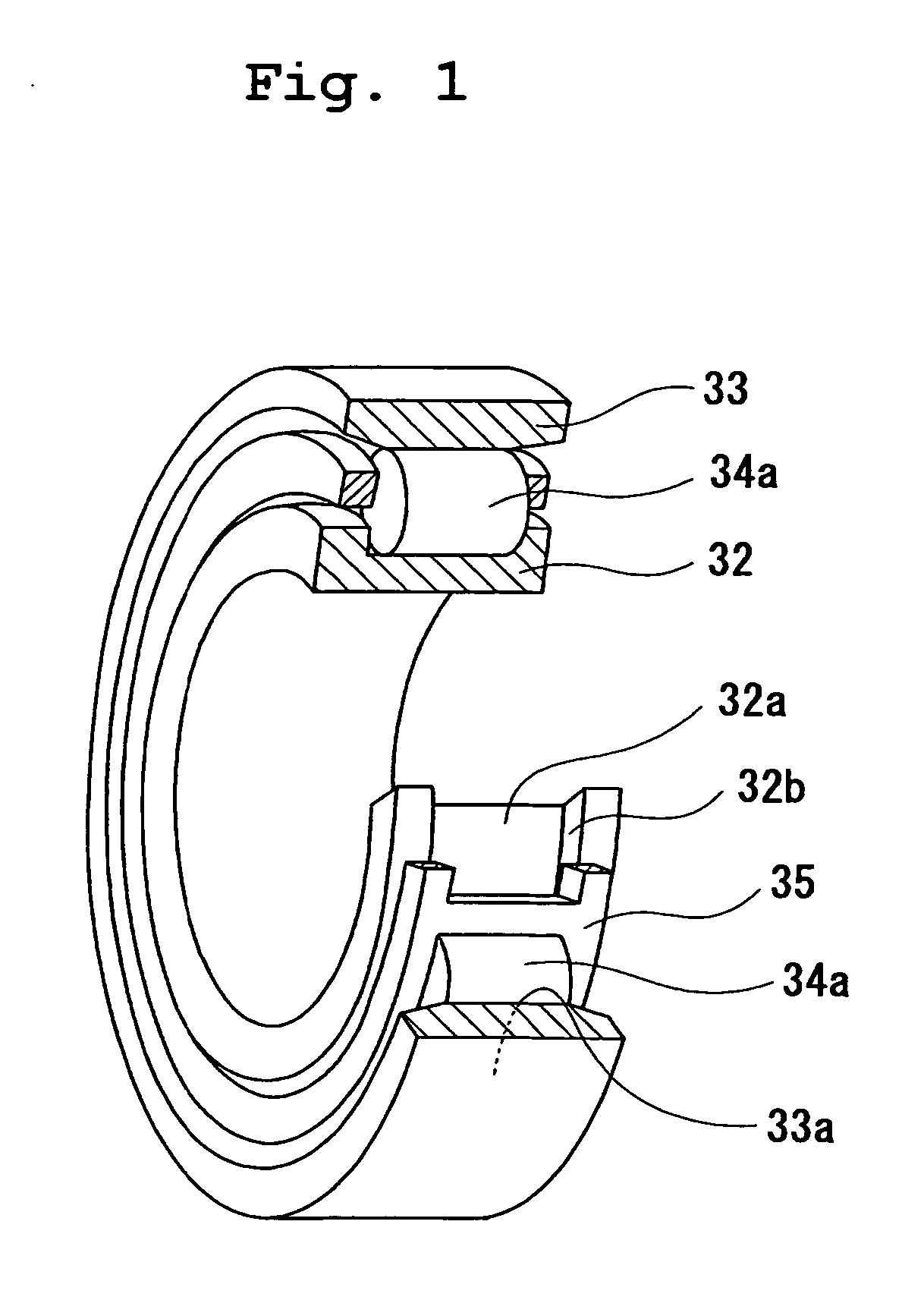

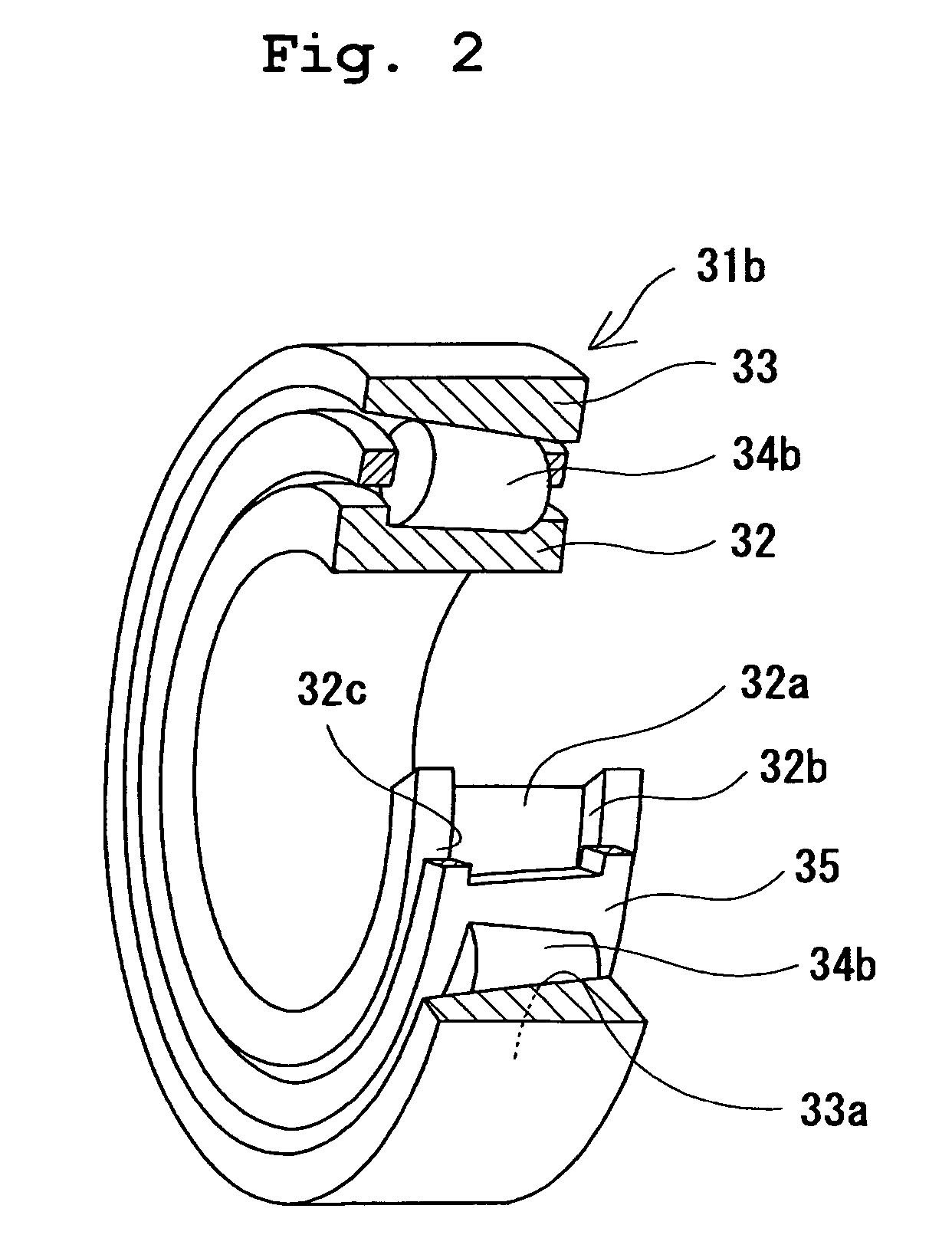

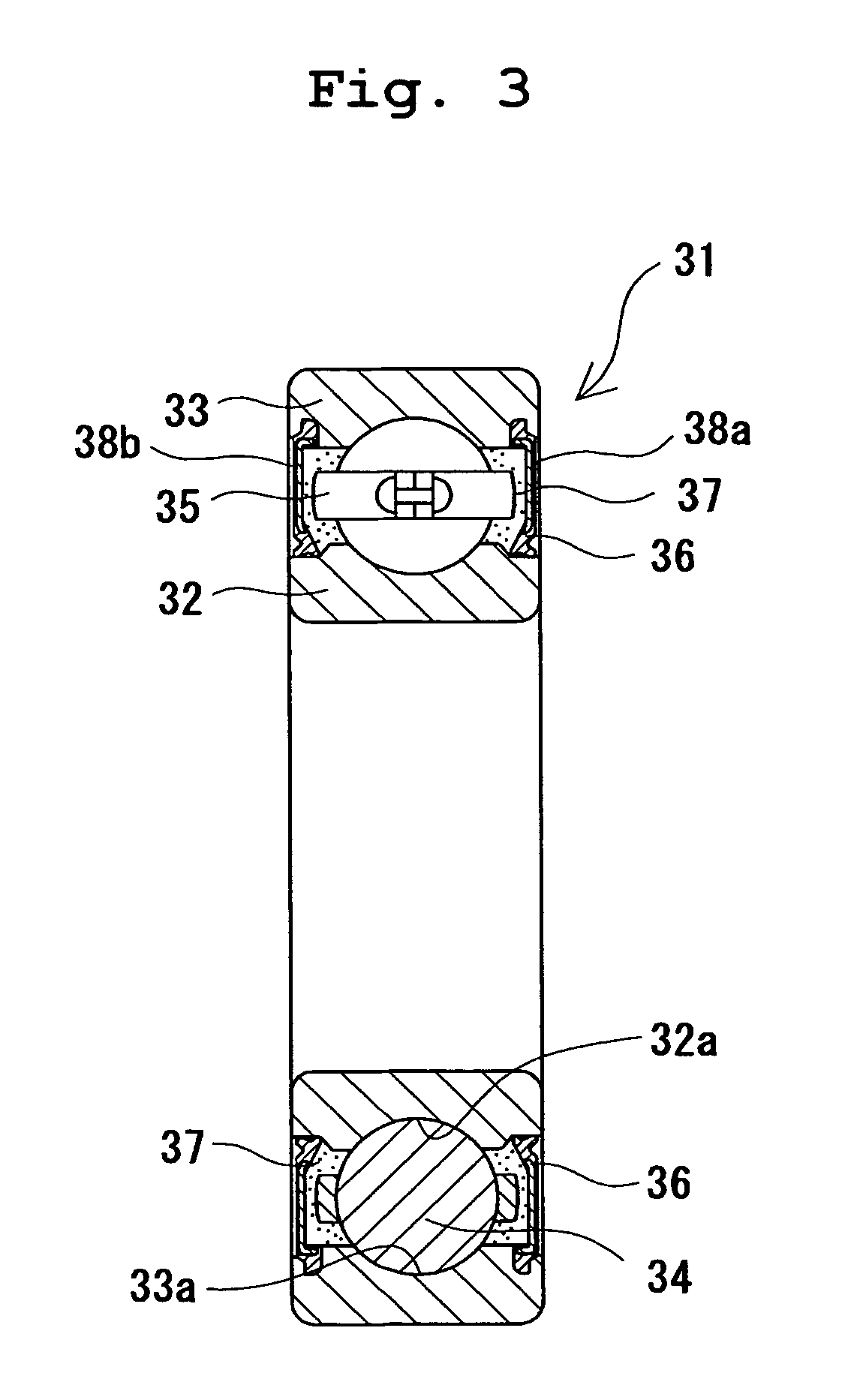

Grease, rolling bearing, constant velocity joint and rolling parts

InactiveUS20070154128A1Resistance to durabilityHeat resistantClutchesMachines/enginesBismuth compoundSulfate

The present invention provides grease which prevents frictional wear on a lubricating surface and excellent in performance of preventing occurrence of flaking, heat-resistant performance, and long-term durability, a grease-enclosed rolling bearing, a constant velocity joint, and rolling parts. Grease is composed of base grease, essentially containing a thickener, to which at least 0.01 to 15 wt % of one substance selected from among bismuth and inorganic bismuth compounds is added. The inorganic bismuth compounds are at least one inorganic bismuth selected from among bismuth sulfate, bismuth trioxide, bismuth carbonate, and sodium bismuthate. The above-described grease is used for the rolling bearing and the constant velocity joint. A coating film of at least one substance selected from among the bismuth and the inorganic bismuth is formed on surfaces of the rolling parts.

Owner:NTN CORP

Polymeric Nano-Particles Of Flower-Like Structure And Applications

InactiveUS20070185273A1Super soft propertyHeat resistantPlastic/resin/waxes insulatorsCrystallographyElastomer

Owner:BRIDGESTONE CORP

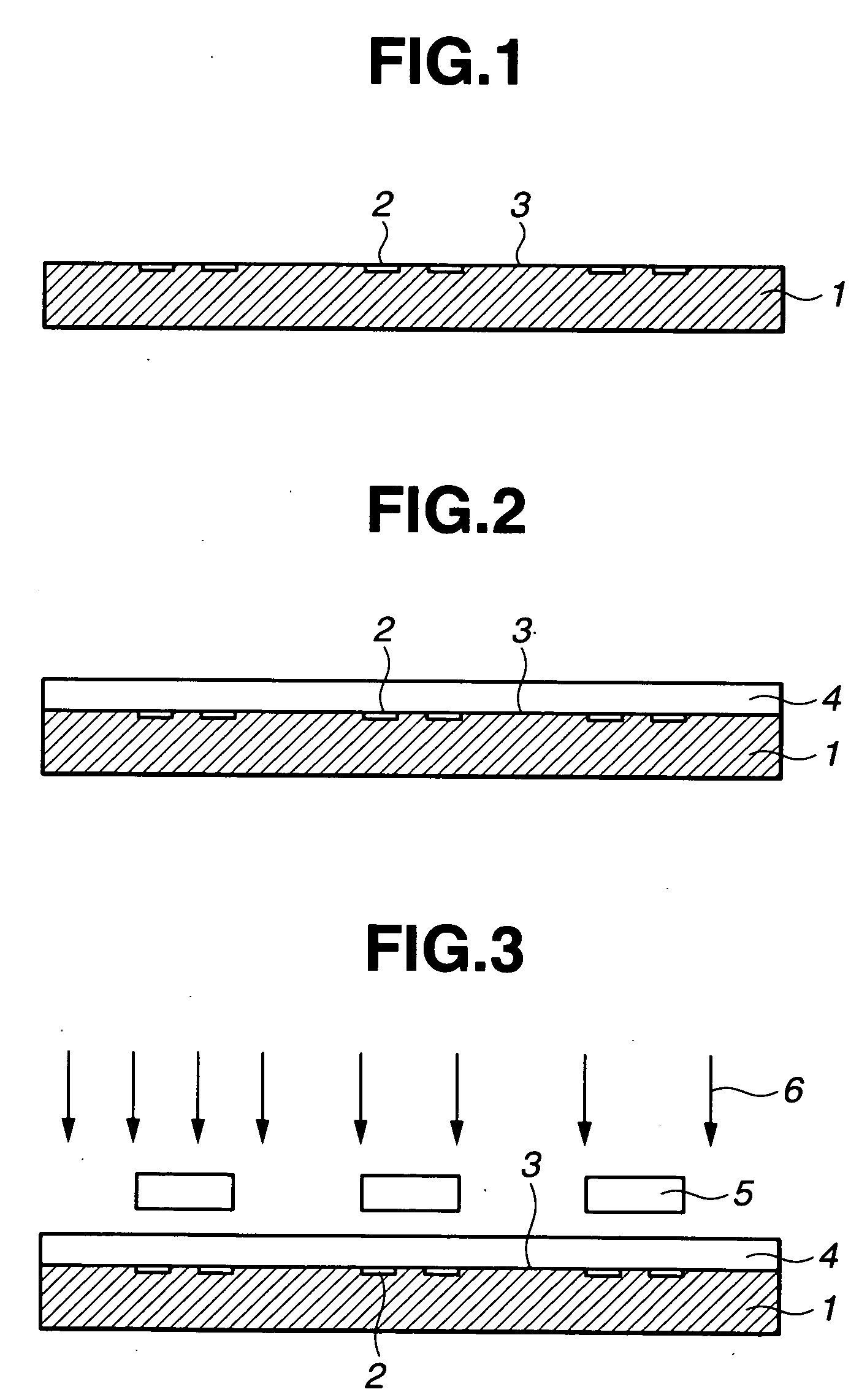

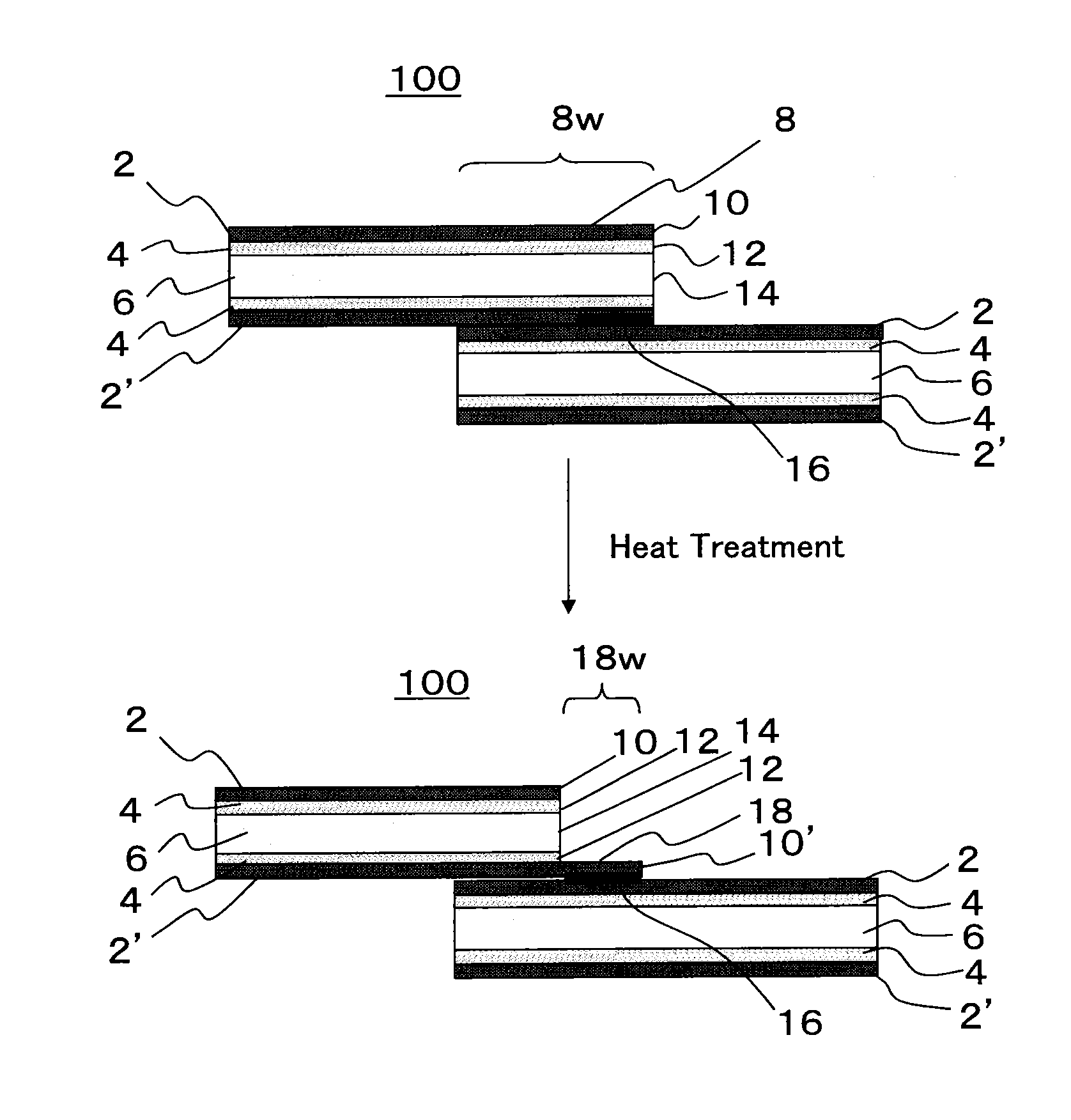

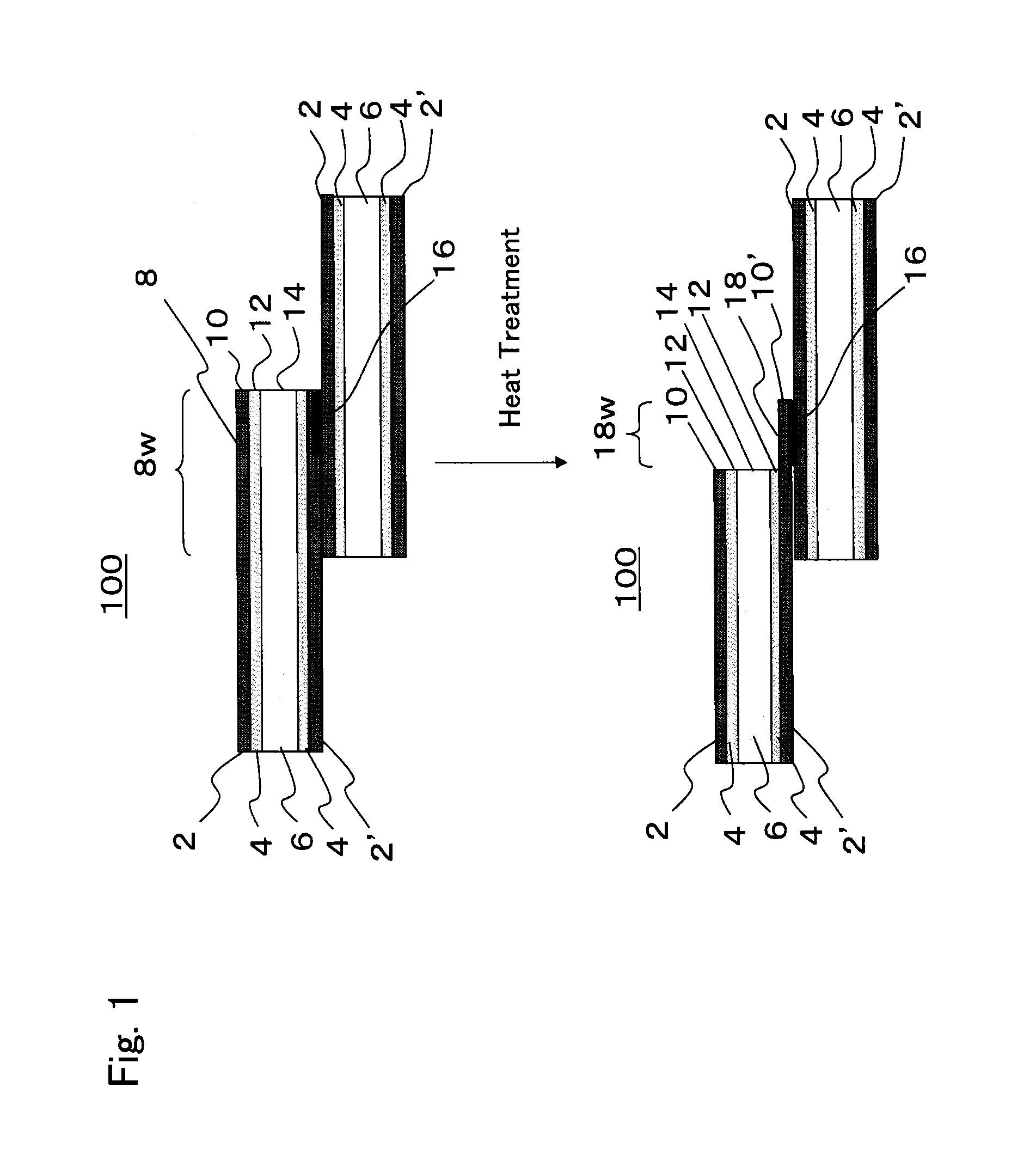

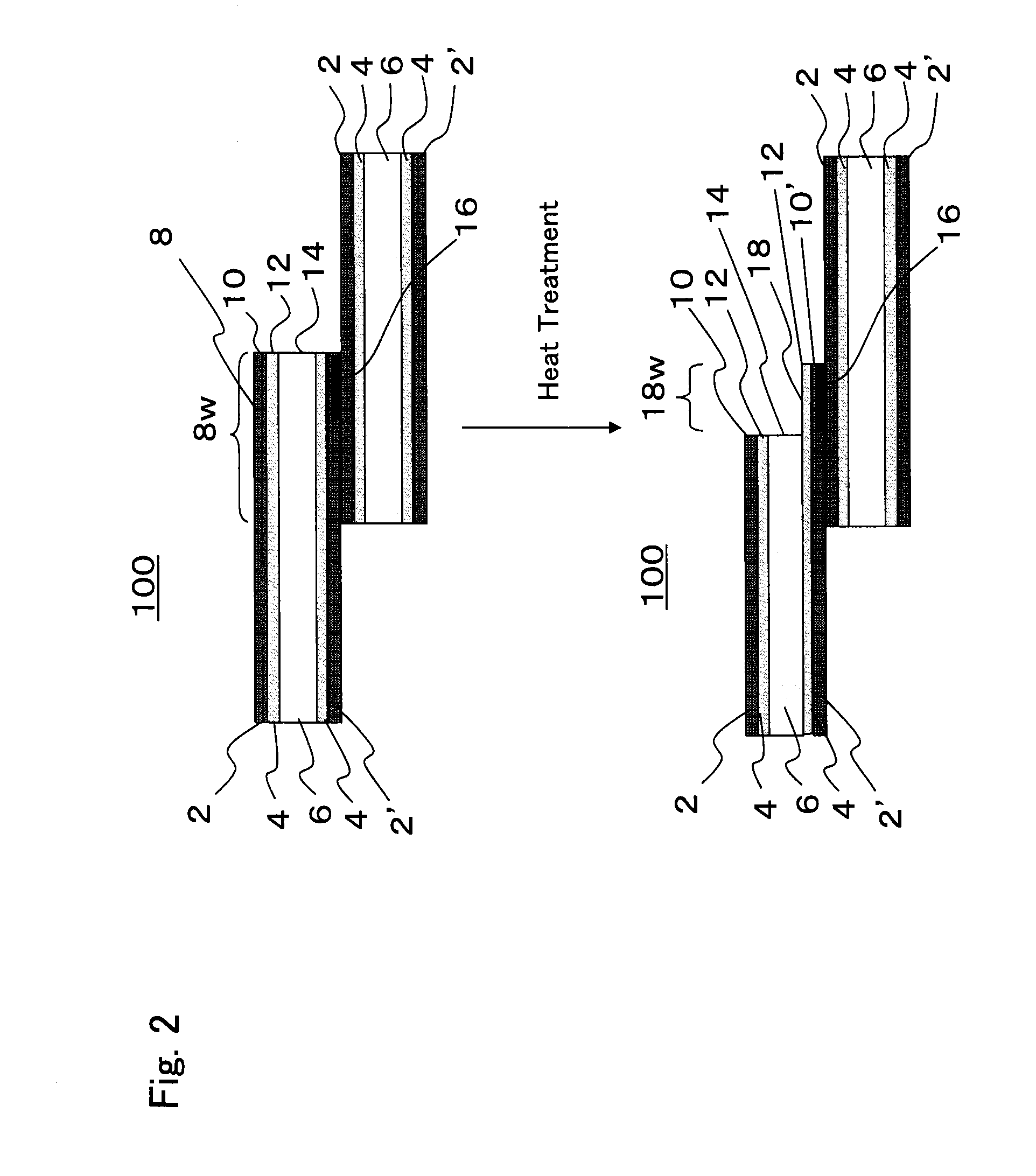

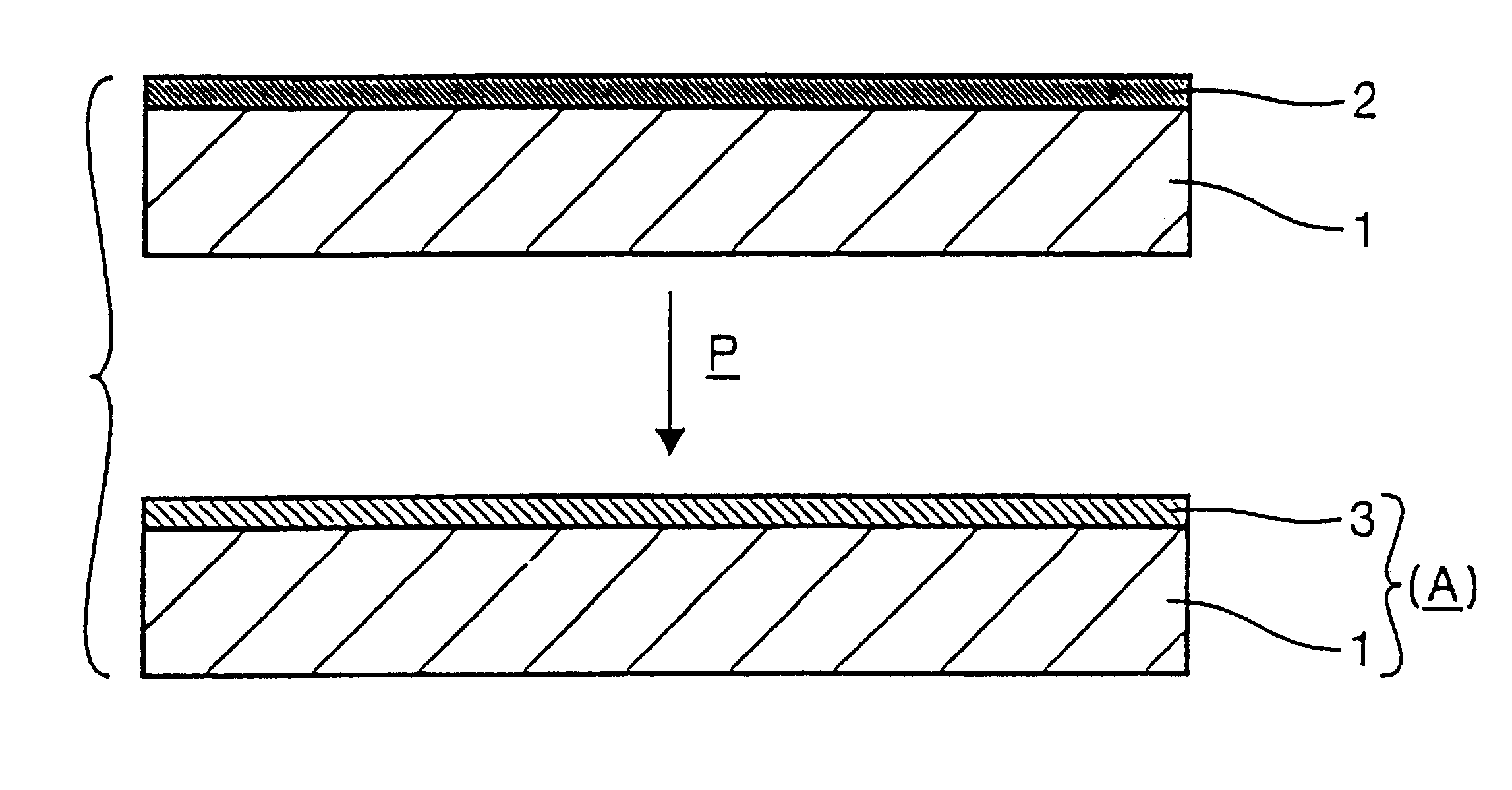

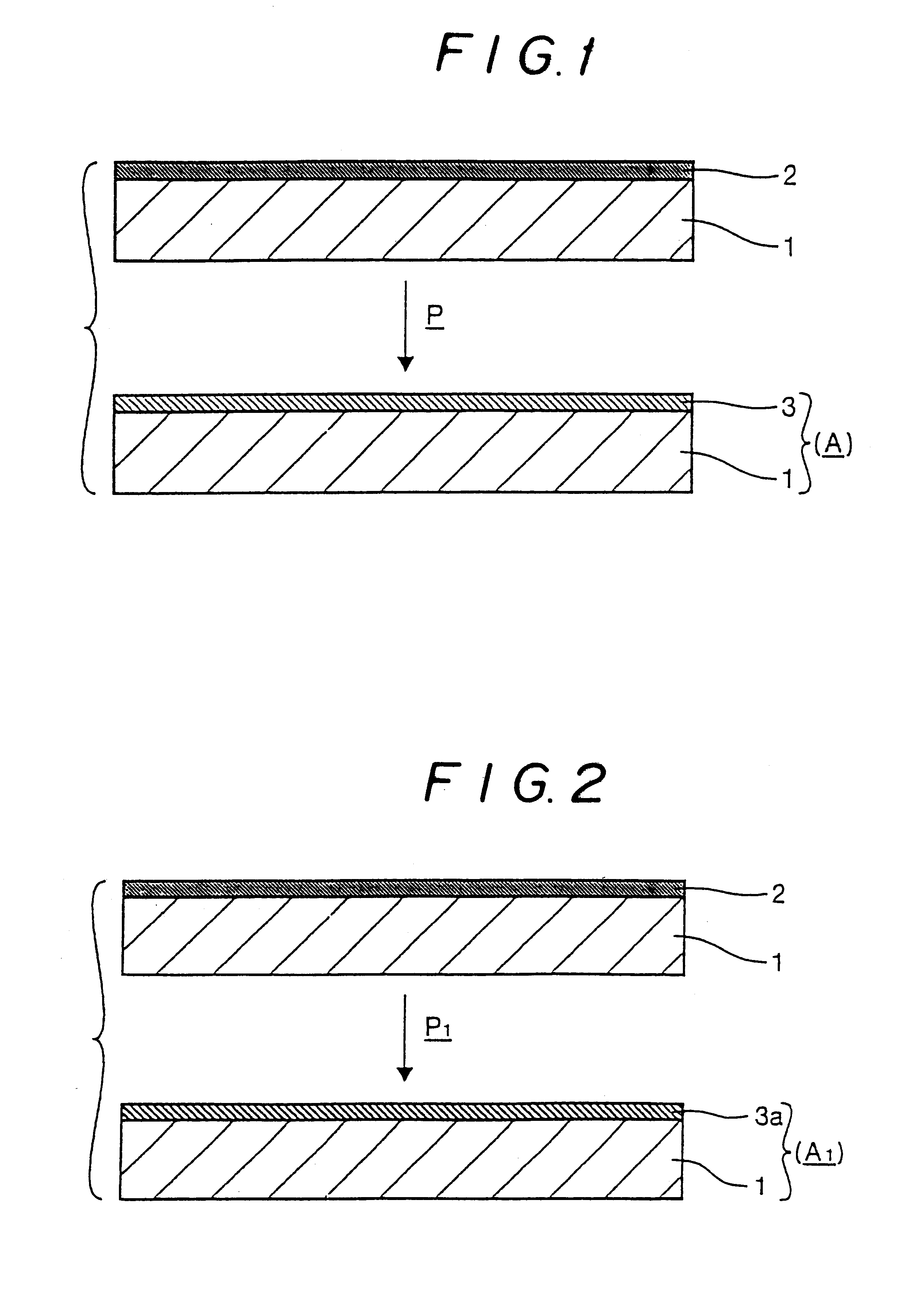

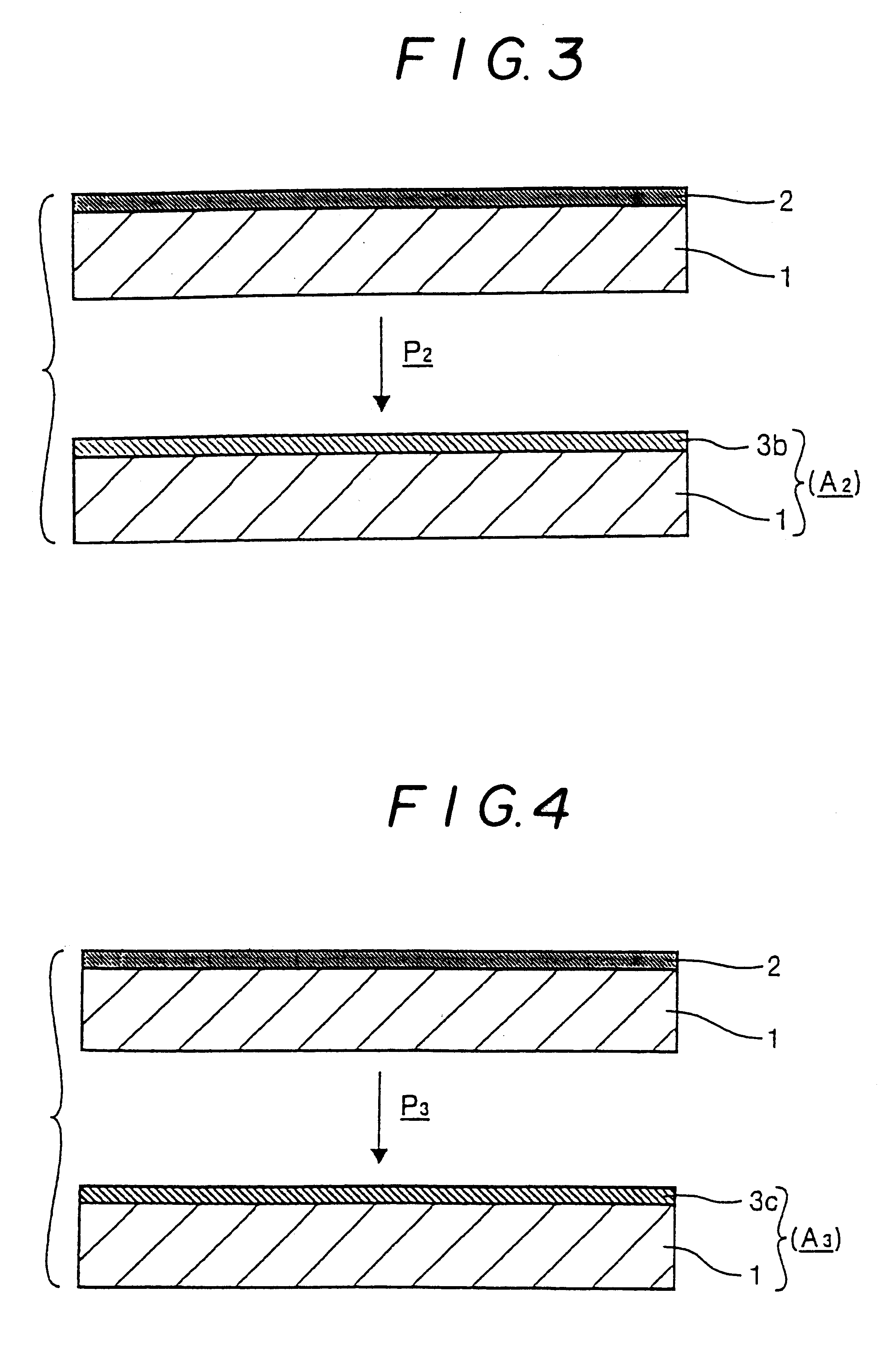

Barrier film and method for production thereof

InactiveUS6720097B2Degree of improvementHigh transparencyFlexible coversWrappersPermeationOxygen permeability

Owner:DAI NIPPON PRINTING CO LTD

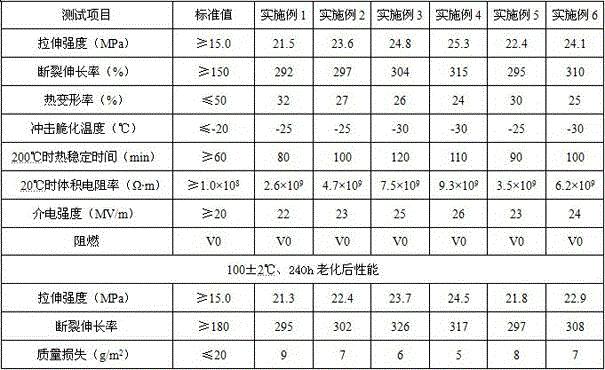

High-temperature resistant flame-retardant environment-friendly PVC (polyvinyl chloride) modified material and preparation method thereof

Owner:广东祺龙科技有限公司

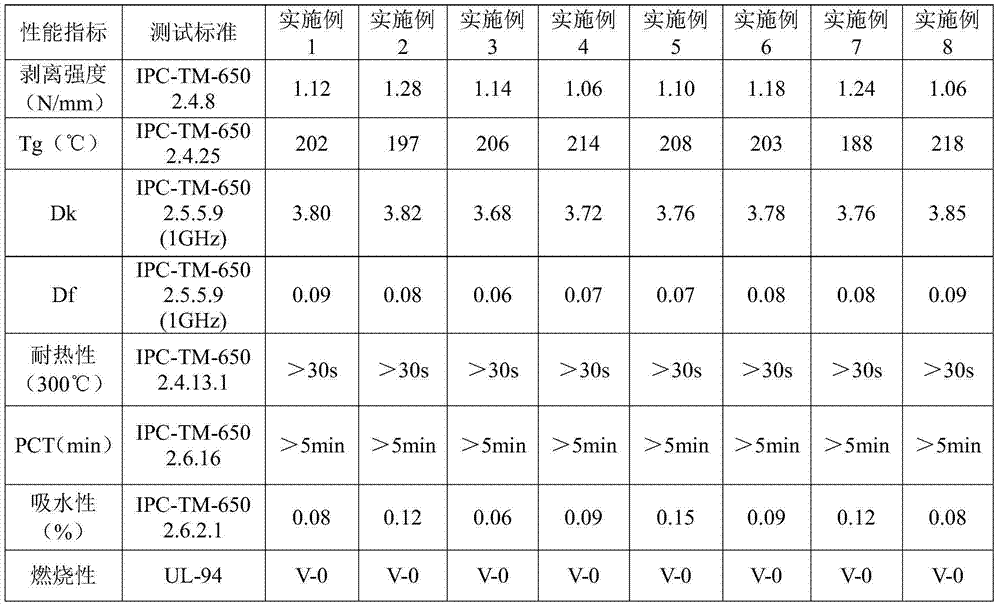

Thermosetting resin composition and method for manufacturing prepreg and laminated board by using thermosetting resin composition

InactiveCN103937156AGood dielectric propertiesImprove heat and humidity resistanceSynthetic resin layered productsMetal layered productsChemistryMetal foil

The present invention discloses a thermosetting resin composition and a method for manufacturing a prepreg and a laminated board by using the thermosetting resin composition. The thermosetting resin composition is prepared by dispersing the following components in an organic solvent, wherein the components comprise, by weight, 10-80 parts of an epoxy resin, 10-60 parts of cyanate, 10-60 parts of bismaleimide, 10-50 parts of polyphenylene oxide, 0.01-1.0 part of a curing accelerator, 1-40 parts of a fire retardation agent, and 0-100 parts of an inorganic filler, and the solid content of the resin composition is 30-70 wt%. The prepared prepreg and the metal foil-clad laminated board have characteristics of good heat resistance, good wet heat resistance, high glass-transition temperature, low water absorption rate, low dielectric constant, low dielectric loss factor and the like.

Owner:ZHEJIANG WAZAM NEW MATERIAL CO LTD

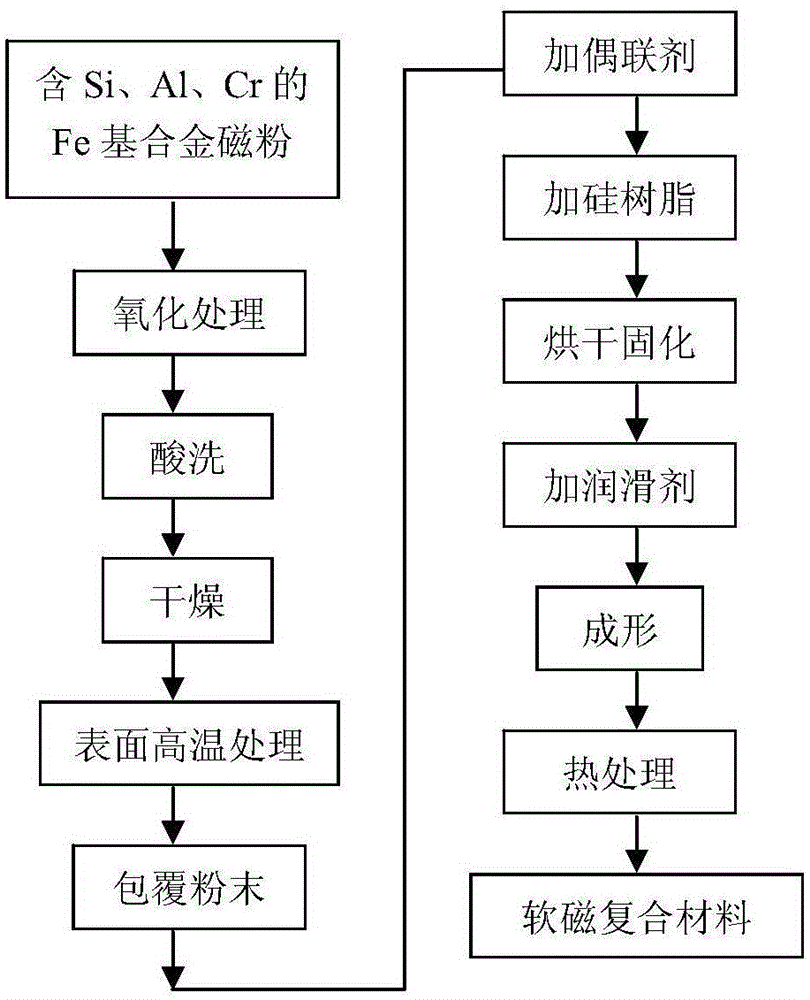

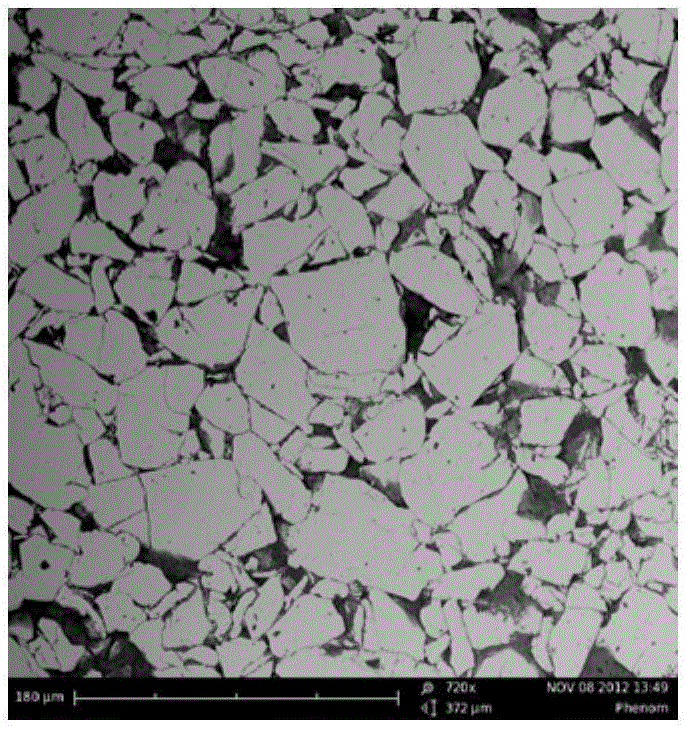

Coating method iron-based magnetically soft alloy powder and preparation method of soft magnet composite material

ActiveCN105149574AHigh resistivityImprove compactnessInorganic material magnetismMagnetic powderOxide

The invention relates to a coating method for iron-based magnetically soft alloy powder and a preparation method of soft magnet composite material. The coating method for iron-based magnetically soft alloy powder comprises the following steps: carrying out accelerated oxidation on iron-based magnetic metal powder at high temperature, forming an oxide layer on the surface of the powder and then carrying out acid pickling, thus obtaining powder with surface coated with SiO2, Al2O3 and Cr2O3 oxides. The preparation method of the soft magnet composite material comprises the following steps: adding coupling agent, silicon resin and lubricating agent to the coated powder, carrying out pressing forming, and then carrying out annealing heat treatment, thus obtaining the soft magnet composite material. According to the invention, the advantage that an oxide produced in reaction of elements including Si, Al and Cr contained in the iron-based magnetically soft alloy powder with oxygen is high in electrical resistivity, small in thermal expansion coefficient and steady in chemical performance and can resist high temperature is fully utilized; the adopted coating technology is to produce a coating layer in situ on the surface of the alloy magnetic powder, and is simple in process, easy to operate and low in cost; the metal soft magnet composite material prepared by adopting the method disclosed by the invention has good magnetic property and frequency stability.

Owner:CENT SOUTH UNIV

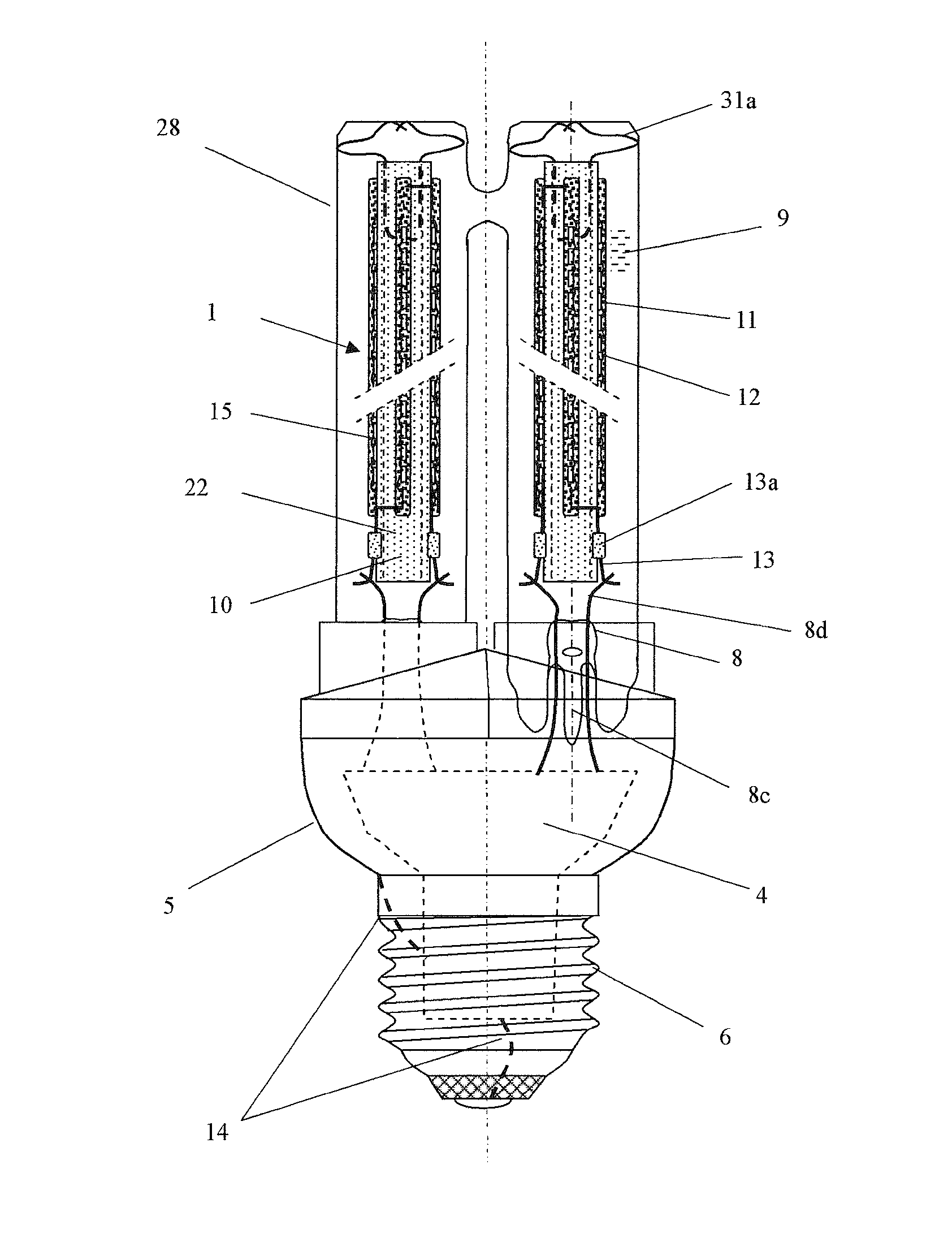

LED light-emitting column and LED light using the same

InactiveUS20150036341A1Improve featuresIncrease output brightnessLight source combinationsPoint-like light sourceShielding gasLight pillar

The present invention discloses a LED light-emitting column and a LED light using the same. The LED light-emitting column comprises a high thermal conductivity tube and at least one series of LED chips disposed on an outer surface of the high thermal conductivity tube. The LED light comprises a light-transmitting bulb shell vacuum-sealed and filled with a heat dissipation and protection gas, a LED driver and an electrical connector. The LED light-emitting column is fixed within the bulb shell. Electrical lead of the LED light-emitting column is connected with an outer power supply through the driver and the electrical connector. The LED light is a single bulb shell light, a multi-tube light or a U-type light.

Owner:ZHEJIANG LEDISON OPTOELECTRONICS

Ceramsite prepared by using smelting wastes, and preparation method thereof

ActiveCN103922698AHarmlessAchieve reductionCeramic materials productionClaywaresSocial benefitsSludge

The invention relates to the technical field of harmlessness treatment of smelting wastes, and especially relates to a ceramsite prepared by using smelting wastes, and a preparation method thereof. The ceramsite comprises 10-90% of smelting waste powder, 5-40% of municipal sludge, 4-20% of fly ash, 0-20% of gangue and 0.1-10% of a curing agent. The preparation method of the ceramsite comprises the following steps: 1, crushing the smelting wastes by using a crusher to prepare the smelting waste powder; 2, weighing the smelting waste powder, the municipal sludge, the fly ash, gangue and the curing agent, mixing, and uniformly stirring to prepare ceramsite powder; 3, conveying the ceramsite powder to a ball forming granulation machine, and carrying out granulation molding to prepare ceramsite balls; 4, drying the ceramsite balls; and 5, calcining he dried ceramsite balls to prepare the finished ceramsite. The ceramsite prepared in the invention has the advantages of light weight, environmental protection and wide uses; and the preparation method recycles the smelting wastes, and has good economic and social benefits.

Owner:DONGGUAN YICHENG ENVIRONMENTAL TECH

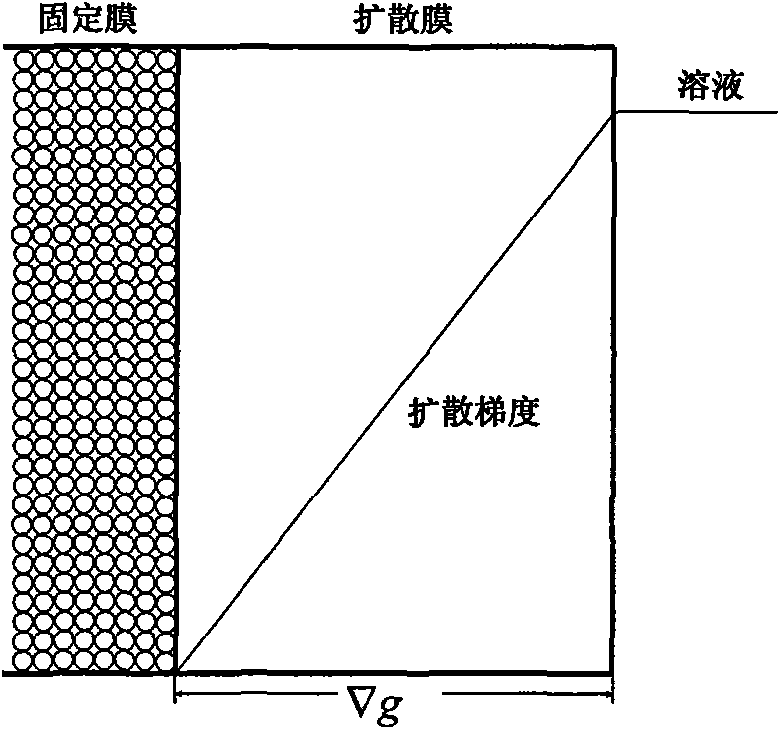

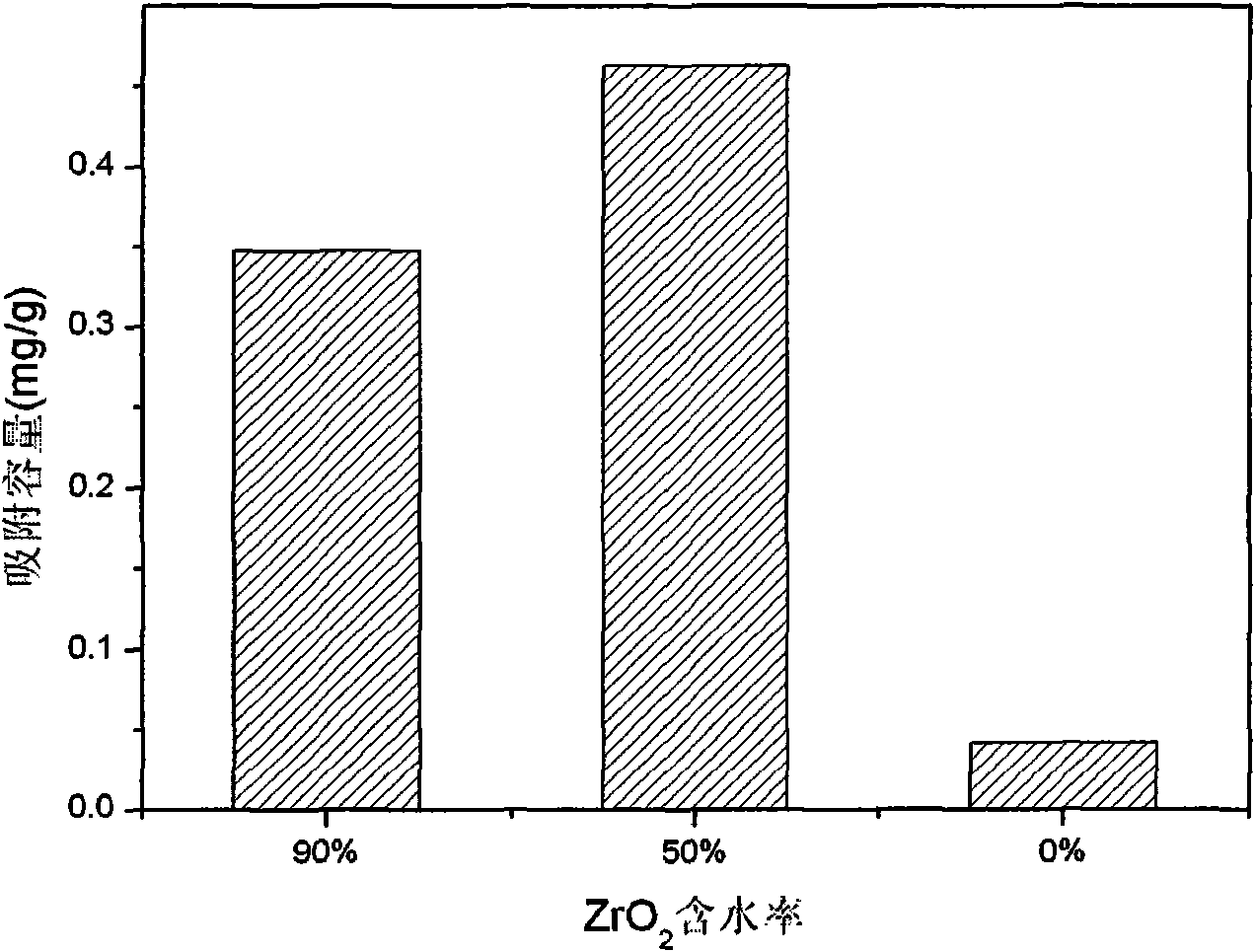

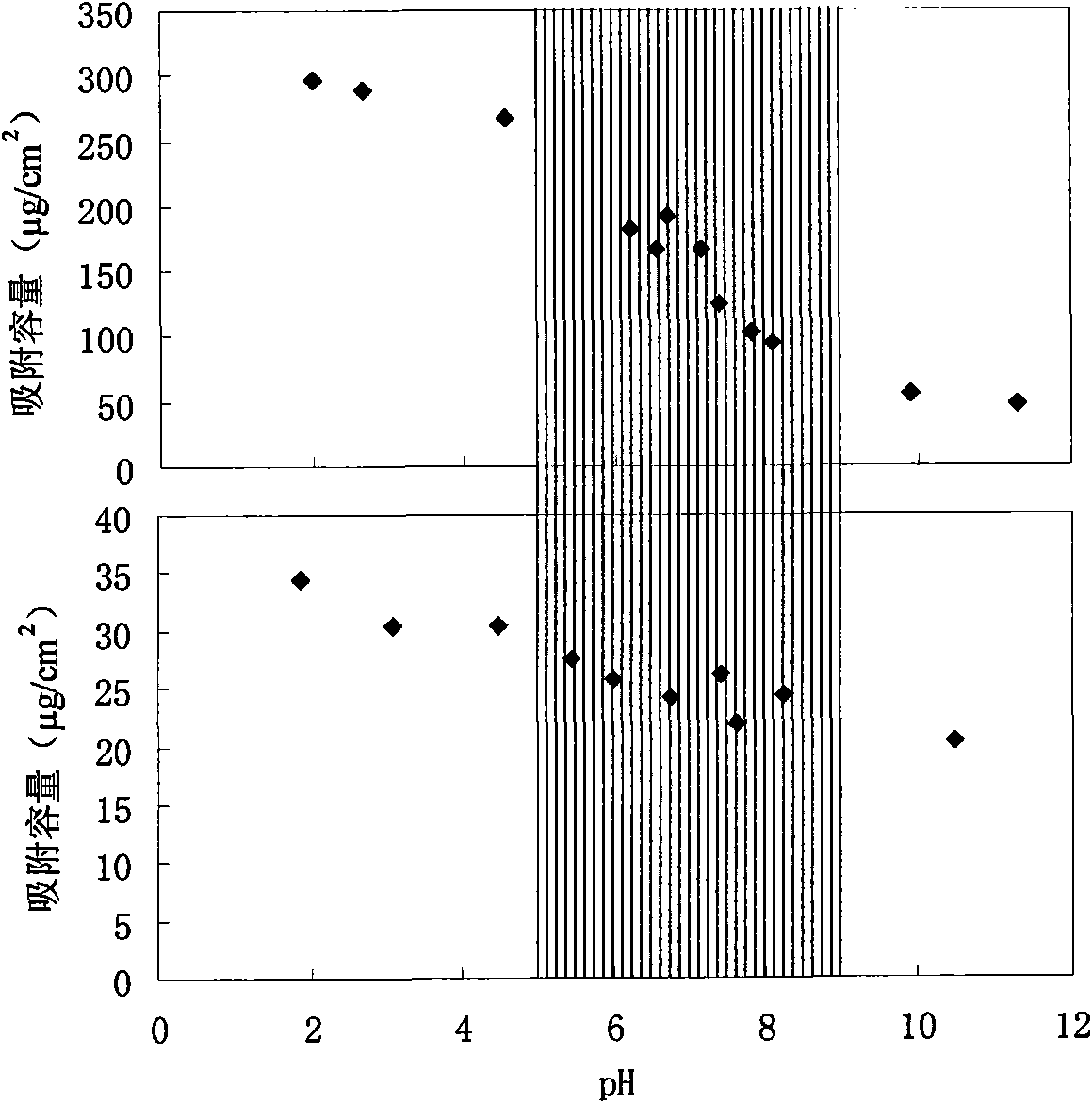

Phosphorus fixing film applied to diffusive gradients in thin-films measurement technology

InactiveCN101629881AHeat resistantChemically stablePreparing sample for investigationColor/spectral properties measurementsHigh absorptionAbsorption capacity

The invention relates to a phosphorus fixing film applied to diffusive gradients in thin-films measurement technology. A fixing film and dispersion film superposed structure is arranged in the diffusive gradients in thin-films measurement technology, ions pass through a dispersion film in a dispersion way and is captured by a fixing film immediately to form the linear gradient distribution on the dispersion film. The phosphorus fixing film capturing phosphorus ions is characterized by using zirconium dioxide powder and acrylamide as raw materials, the raw materials are uniformly mixed to form mixed solution according to the weight volume ratio of 1:1.5-1:4, the mixed solution is slowly infused into a clearance of two glass plates clamping a u-shaped plastic sheet, the glass plates are placed for 2-4h horizontally at lower temperature of 10-15 DEG C after bubbles are removed, the temperature is risen to 30-35 DEG C after the zirconium dioxide powder is freely settled so as to enable the mixed solution to be gelated to form a film, the film has higher absorption capacity ratio to phosphate radicals than the prior iron film material by at least 4 times under the condition that the pH value is 5-9, so the analysis requirement of the DGT technology to phosphorus in different environment media is completely met.

Owner:NANJING INST OF GEOGRAPHY & LIMNOLOGY

Radiation vulcanizing method for environment-friendly type medical rubber products

InactiveCN101104700ANo precipitationSimple recipePharmaceutical containersMedical packagingCross-linkPolymer science

The invention relates to a process method of radiation vulcanization which applies the high energy radiation technology in medical rubber products, in particular to a vulcanization method of the environment protecting medical rubber products that can improve the safety and not-pollution property of the medical rubber products. Green rubber compound, reactive environment protecting cross-linking coagent, filler and compounding agent are mixed in a regulated weight ratio, and then are mixed in a mixing facility, so that non cross-linked rubber profiles are formed preliminarily. The non cross-linked rubber profiles are treated in radiation vulcanization for once or a plurality of times and then become the medical rubber products. The invention has the advantages of good safety, high chemical stability, air tightness and cleanness, no residue precipitation with irritability, volatility and anaphylaxis, ozonation resistance, crack resistance, heat resistance and fine mechanical property, and also has the advantages that the time of the radiation vulcanization is reduces, the energy is saved, fast radiation disinfection proposal method can be accepted.

Owner:QINGDAO UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com