Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7150results about How to "Simple recipe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Continuous long fiber reinforced fire-retardant thermoplastic resin and its prepn

ActiveCN1810862ASimple recipeSimple process controlLong-fiber-reinforced thermoplasticPolymer chemistry

The present invention discloses one kind of continuous long fiber reinforced fire-retardant thermoplastic resin and its preparation process. It is prepared through mixing continuous long fiber reinforced thermoplastic resin agglomerate, which has reinforcing fiber content of 30-80 wt% and agglomerate length of 3-30 mm, and fire-retardant agglomerate, which has thermoplastic resin as carrier, fire retardant in 20-60 wt%, fire-retarding synergist 5-20 wt% and other additive 0-5 wt%. The continuous long fiber reinforced fire-retardant thermoplastic resin has continuous long fiber content of 5-60 wt%. The continuous long fiber reinforced fire-retardant thermoplastic resin has excellent mechanical performance, especially impact resistance, and excellent fire-retarding performance.

Owner:KINGFA SCI & TECH CO LTD +1

Metal deoiling agent and deoiling method thereof

InactiveCN102108321ASimple recipeLow costInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsMetallic materialsDicarboxylic acid

The invention provides a metal deoiling agent. The deoiling agent contains anionic surfactant, nonionic surfactants, solubilizer and corrosion inhibitor, wherein corrosion inhibitor contains monocarboxylic acid and dicarboxylic acid and the weight ratio of monocarboxylic acid to dicarboxylic acid is 10-1:1. The invention also provides a deoiling method. The deoiling method is as follows: soaking a metal material in the deoiling agent to perform ultrasonic deoiling for 1-3min, wherein the temperature of the deoiling agent is 50-80 DEG C and the metal deoiling agent is the metal deoiling agent in the claim 1. The deoiling agent of the invention can be used to effectively remove greasy dirts on the surface of metal in a short time can not corrode metal; and the deoiling agent has simple formula, low cost and stable performance.

Owner:CHANGSHA TOPWELLWEAR METAL MATERIAL SCI

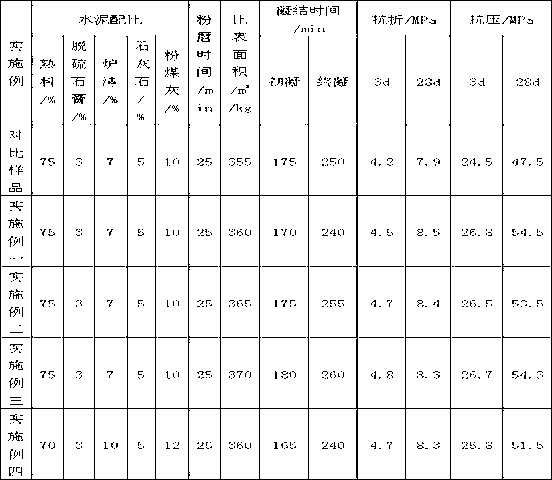

Liquid compound reinforced type cement grinding aid and preparation method thereof

The invention discloses a liquid compound reinforced type cement grinding aid. The liquid compound reinforced type cement grinding aid is prepared by the following ingredients in part by weight: 5 to 15 parts of reinforced compounds, 20 to 40 parts of grinding aiding compound, 0.1 to 1 part of silicon-contained compound, 10 to 50 parts of stable compounds, and the balance of water. The invention also discloses a preparation method of the liquid compound reinforced type cement grinding aid. The preparation method comprises the following steps: 1, adding water to a reacting kettle, and heating to reach 50 to 60 DEG C; 2, sequentially adding the reinforced component and the silicon-contained compound, and stirring for 30 minutes; 3, adding the stabile component and the grinding aiding component, and stirring for 10 minutes; and 4, adjusting the pH (Potential Of Hydrogen) of the solution to 8 to 9, and stirring for 10 minutes. The cement grinding aid disclosed by the invention can improve the physical and mechanical performances, and is low in dosage and free from harmful ingredients such as chlorine salt; and the preparation method of the cement grinding aid is simple in technological preparation and low in cost.

Owner:KZJ NEW MATERIALS GROUP CO LTD +1

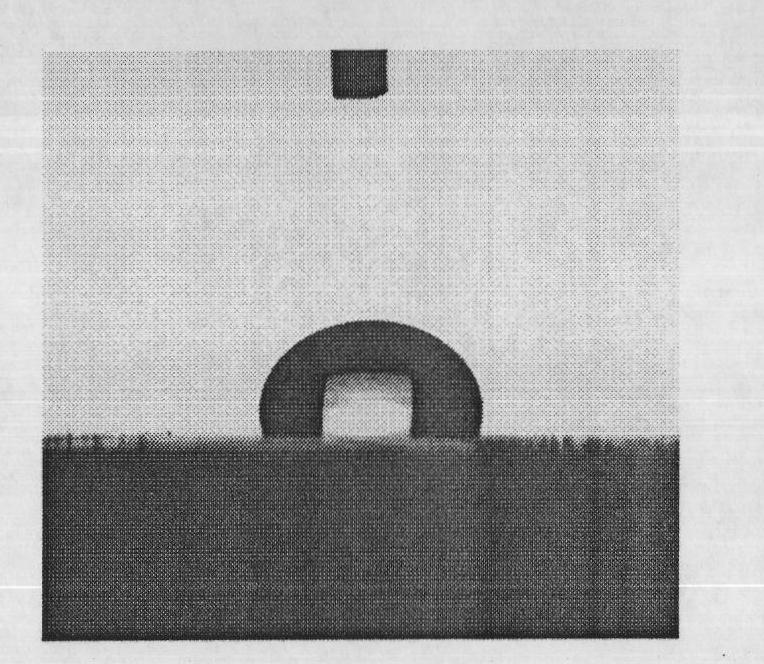

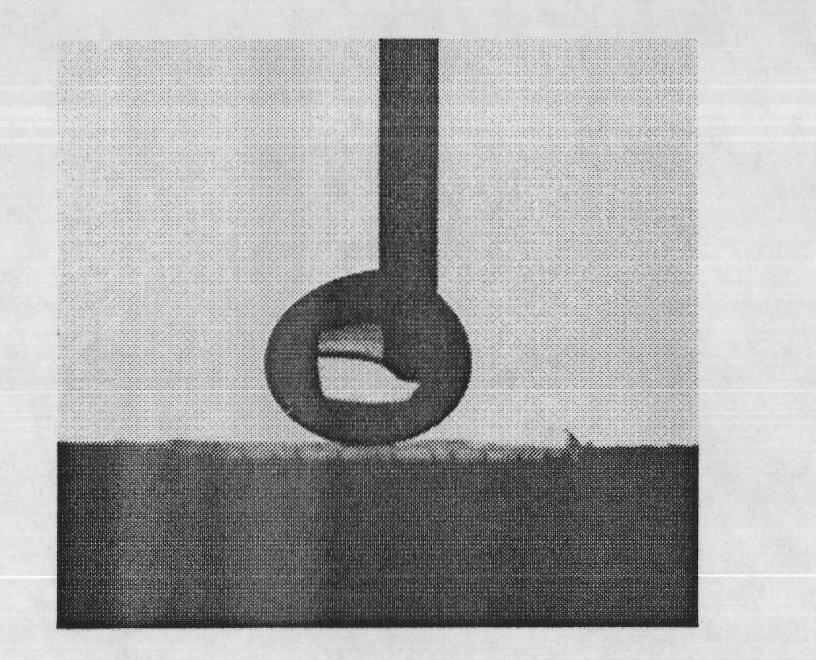

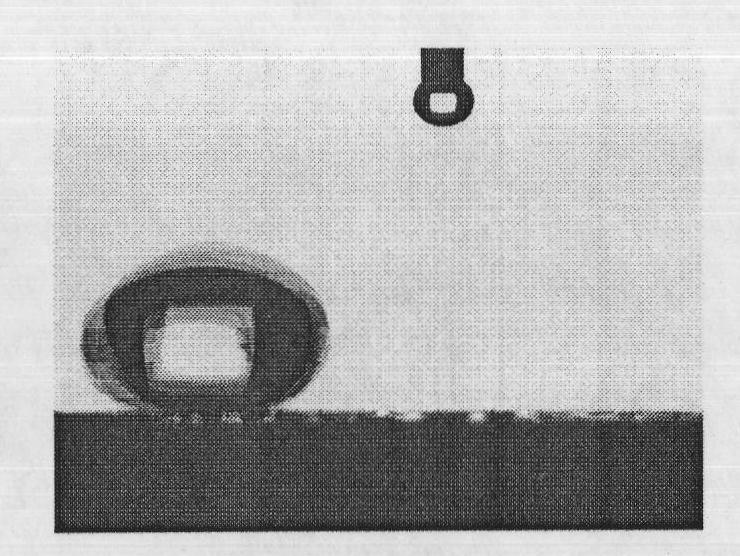

Super-hydrophobic nano-composite coating and preparation method thereof

InactiveCN101845242AExcellent superhydrophobic propertiesAchieve self-cleaning effectCoatingsProcess equipmentHydrophobic polymer

The invention discloses a super-hydrophobic nano-composite coating comprising the following components in percentage by weight: 0.5-10.5 percent of hydrophobic silicon dioxide, 0.2-5.4 percent of hydrophobic polymer material and 86.5-99.3 percent of solvent, wherein a contact angle of a water drop on a membrane surface prepared by the coating is 152-169 degrees, and a rolling angle is 1-9 degrees. When the coating is transparent, the visible light transmission of the membrane prepared from the coating is 80-94 percent. The invention also discloses a preparation method of the super-hydrophobic nano-composite coating. The nano-composite coating not only has excellent super-hydrophobicity and low cost of products, but also can obtain higher transparency by reducing the contents of the hydrophobic silicon dioxide and the hydrophobic polymer material and has simple preparation processing equipment and high production efficiency.

Owner:SICHUAN UNIV

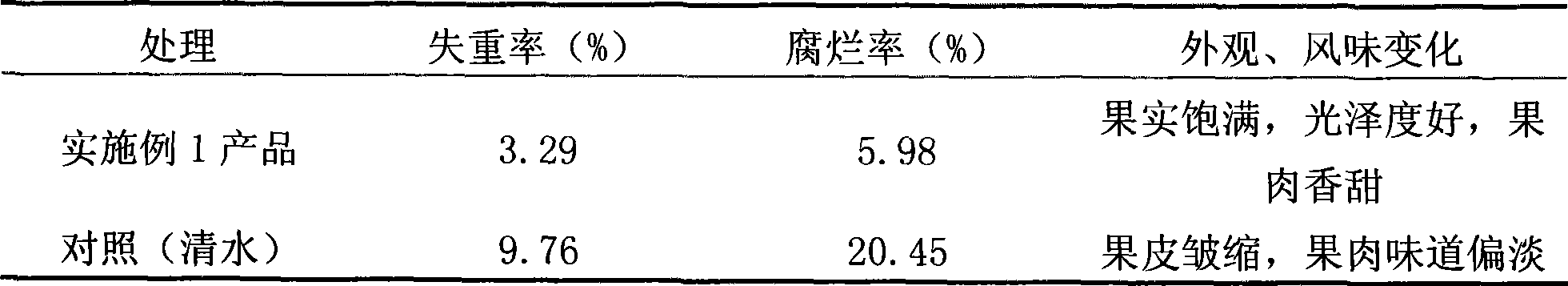

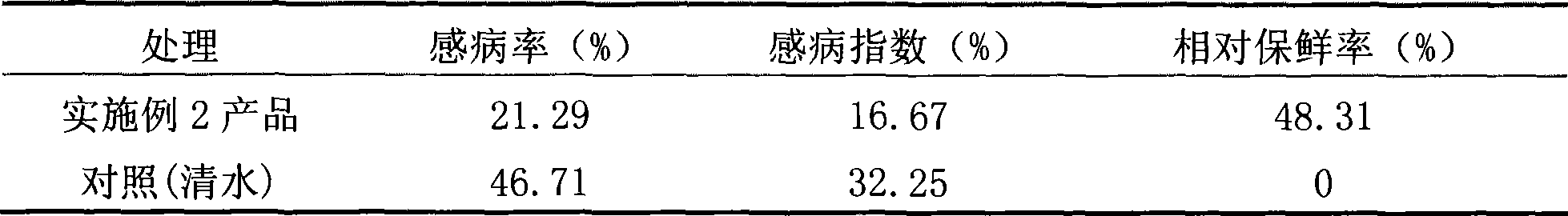

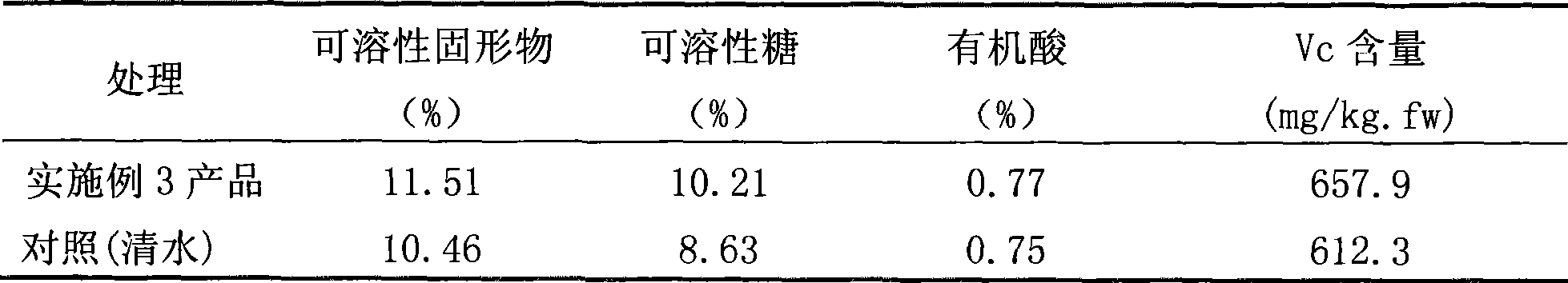

Fruit-vegetables antistaling agent, preparation and application thereof

InactiveCN101366411AAnti agingInhibit spoilage and mildewFruit and vegetables preservationAdditive ingredientSalicylic acid

The invention provides a fruit and vegetable fresh-keeping agent, a preparation method and application thereof. The fresh-keeping agent uses burdock fructo-oligosaccharides as main composition and combines aqueous solution prepared by chitosan, ascorbic acid, salicylic acid, calcium chloride and acetic acid to treat fruit and vegetable, so that a fruit and vegetable system can obtain the improved resistance, and a hyaloplasmic fresh-keeping membrane is formed on the surface of the fruit and the vegetable so as to effectively inhibit the growth of microbe, prevent moisture dissipation and contact between the fruit and the vegetable and air, and inhibit breath and transpiration, thereby greatly deferring aging of the fruit and the vegetable, and inhibiting putridity, mildew and rot. The fruit and vegetable fresh-keeping agent is applicable to storage and fresh-keeping for various fruits and vegetables with long fresh-keeping period and small consumption of nutrient materials.

Owner:SHANDONG UNIV

Traditional Chinese medicine for treating deficiency of the kidney and lumbago

Disclosed is a Chinese medicament for treating lumbago caused by deficiency of the kidney, wherein the recipe includes pubescent angelica root, large-leaf gentian root, Chinese angelica root, root of herbaceous peony, prepared rhizome of rehmannia each 12g, Loranthus mulberry mistletoe 18g, drynaria, eucommia bark, achyranthes root, pilose asiabell root, dipsacus root, Clematis chinensis each 15g, ledebouriella root, rhizome of Sichuan lovage each 9g, astragalus root 30g, cinnamon twig 6g, bitter cardamon, lindera root each 12g, asaryl, processed radix aconiti each 15g, prepared aconite root, dried ginger each 18g, curculigo rhizome, epimedium each 12g, spatholobus stem, safflower, curcuma aromatica, red peony root each 10g. The Chinese medicament has simplified recipe, easy preparing process and low price.

Owner:尹克山

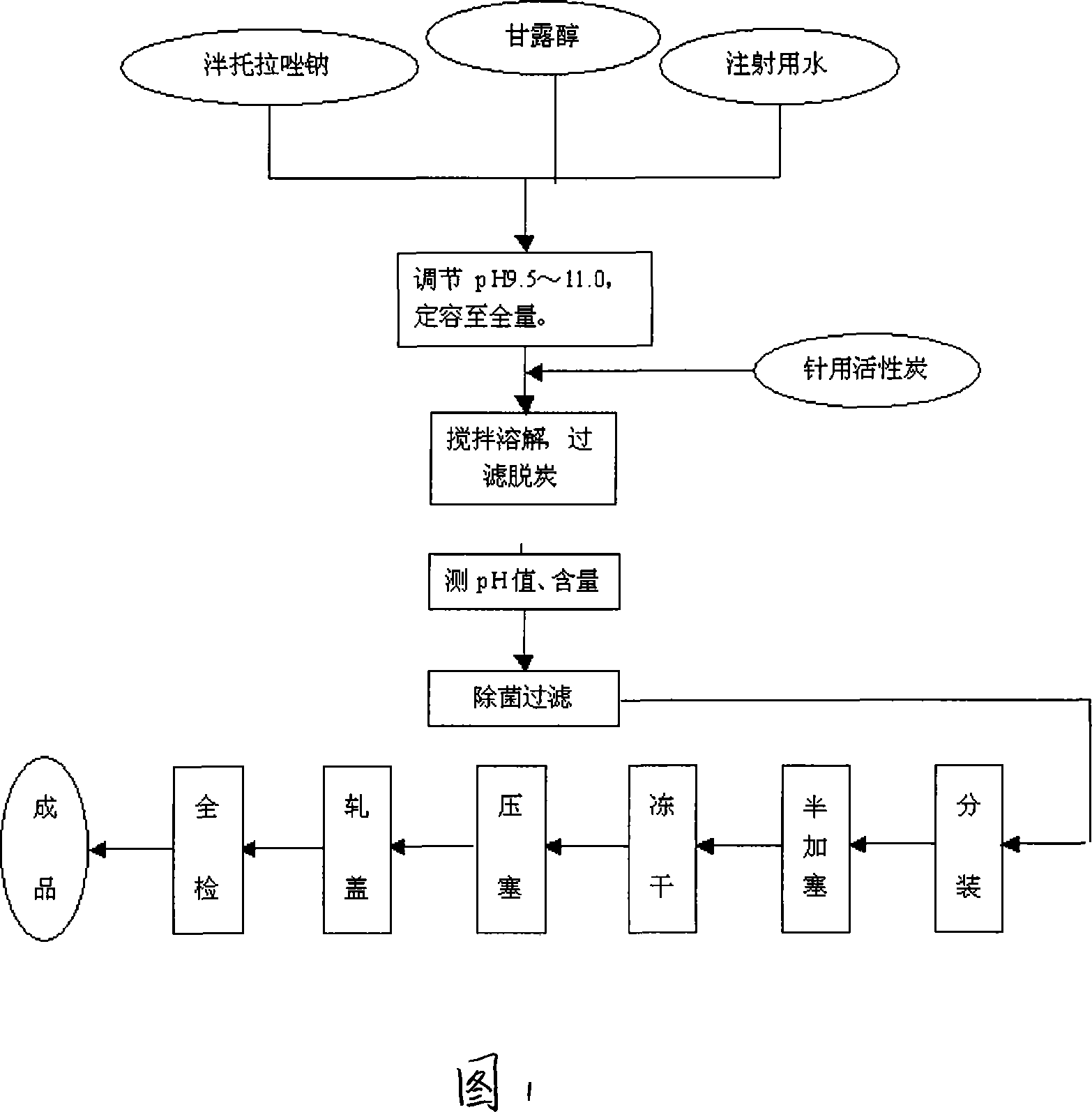

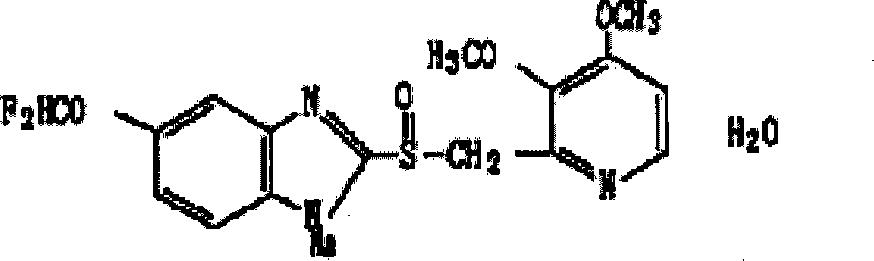

Pantoprazole sodium freeze-dried powder injection and preparing method thereof

ActiveCN101229138ASimple recipeLittle side effectsPowder deliveryOrganic active ingredientsSolubilityMANNITOL/SORBITOL

The invention aims at providing a pantoprazole sodium freeze-dried powder injection and comprises pantoprazole sodium and mannitol with the weight ratio of 1: 2 to 5. The invention is simple in formula and little in side effect; products prepared by the method are plump in appearance, good in complex solubility and excellent in quality with the adoption of an advanced freezing and drying process.

Owner:SHANDONG LUOXIN PARMACEUTICAL GROUP STOCK CO LTD +1

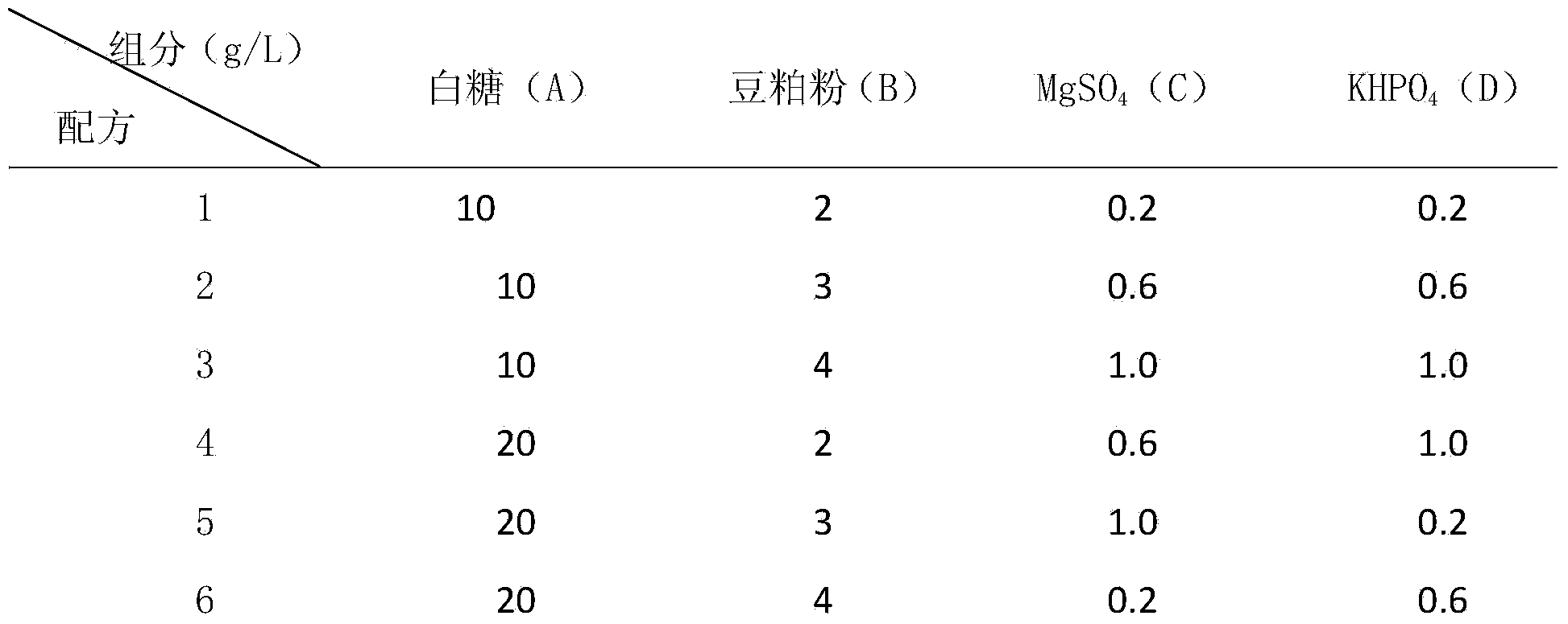

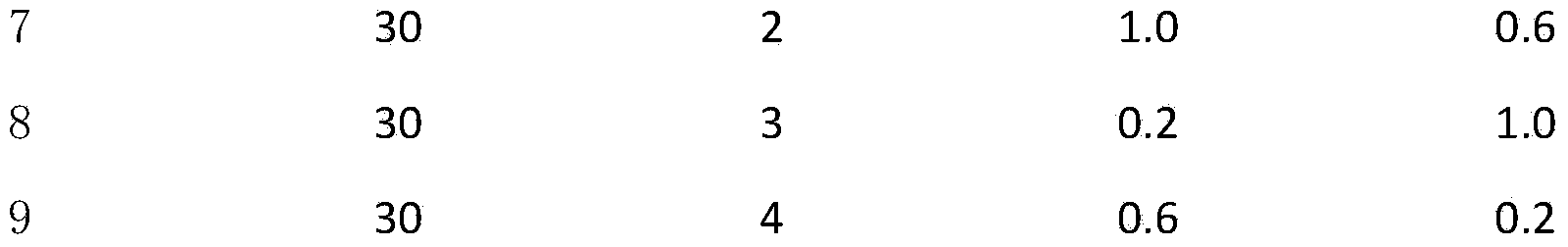

Method for cultivating pleurotus eryngii liquid strains

The invention discloses a method for cultivating pleurotus eryngii liquid strains. The method comprises the steps that firstly, liquid mother culture is prepared, then the liquid strains are cultured through fermentation cylinders, and finally, the obtained liquid strains through preparation can be injected into cultivation bottles or cultivation bags for cultivation through an injecting machine.

Owner:SHANGHAI ACAD OF AGRI SCI +2

Composite fiber reinforced foam concrete and preparation method thereof

InactiveCN102199044APrevent shrinkage crackingImprove flexural strengthSolid waste managementCeramicwareFoam concreteFoaming agent

The invention relates to composite fiber reinforced foam concrete and a preparation method thereof. The foam concrete comprises the following components in parts by weight: 0-400 parts of fly ash, 100-900 parts of cement, 500-1000 parts of sands, 300-600 parts of water, 0.4-1 part of organic fiber, 1-3 parts of plant fiber, 0.2-15 parts of early strength agent, 3-20 parts of foaming agent, 0.5-4 parts of water reducing agent and 0.5-2 parts of water retention agent. The preparation method of the foam concrete comprises the following steps of: generating foams by using the foaming agent, adding the foams to fully stirred cement mortar containing composite fibers and the like and keeping stirring so that the foams are dispersed in the mortar uniformly, measuring the volume weight and carrying out casting forming or coating forming and carrying out standard curing for 28 days. In the invention, industrial and agricultural wastes, such as fly ash, plant fiber and the like, are used, shrinkage crack of the foam concrete is inhibited obviously, and the composite fiber reinforced foam concrete has low price; and the foam concrete has simple formula, good workability, long foam stabilizing time, light weight and low coefficient of thermal conductivity and is suitable for exterior wall thermal insulation, roof thermal insulation and non-load-bearing wall manufacturing.

Owner:TONGJI UNIV

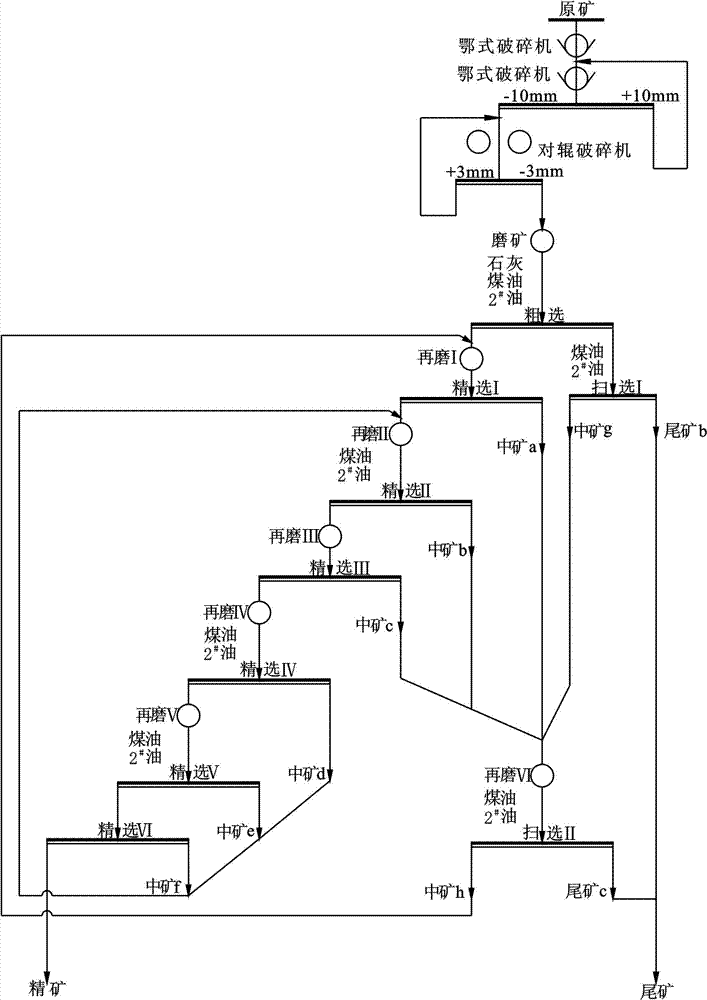

Fine flaky-cryptocrystalline mixed graphite separation technique

The invention discloses a fine flaky-cryptocrystalline mixed graphite separation technique which comprises the following steps: primary rough grinding and rough separation, quintic regrinding and sextic concentrating, and middling centralized processing. According to the technique, in the rough separation step, the grinding fineness is -0.074mm, and the content is 90-95%; in the concentrating step, the regrinding fineness is -0.045mm, and the content is 90-95%; and thus, the graphite monomer is sufficiently dissociated, thereby sufficiently ensuring the fixed carbon content and recovery rate of the concentrated concentrate. The technique adopts gradually decreased low concentrating concentrations in multiple concentrating process to ensure the dispersity of ore slurry, thereby solving thesevere problem of entrapped impurities in floatation foam; and thus, in the final concentrate, the fixed carbon content is 91.35%, and the recovery rate is 91.30%, thereby solving the problems of lowtechnical indexes, low grade, low recovery rate and high cost in the fine flaky-cryptocrystalline mixed graphite concentrate separation, so that the fine flaky-cryptocrystalline mixed graphite ores are utilized in an efficient, economical and reasonable way.

Owner:SICHUAN PILOT GRAPHITE PROD

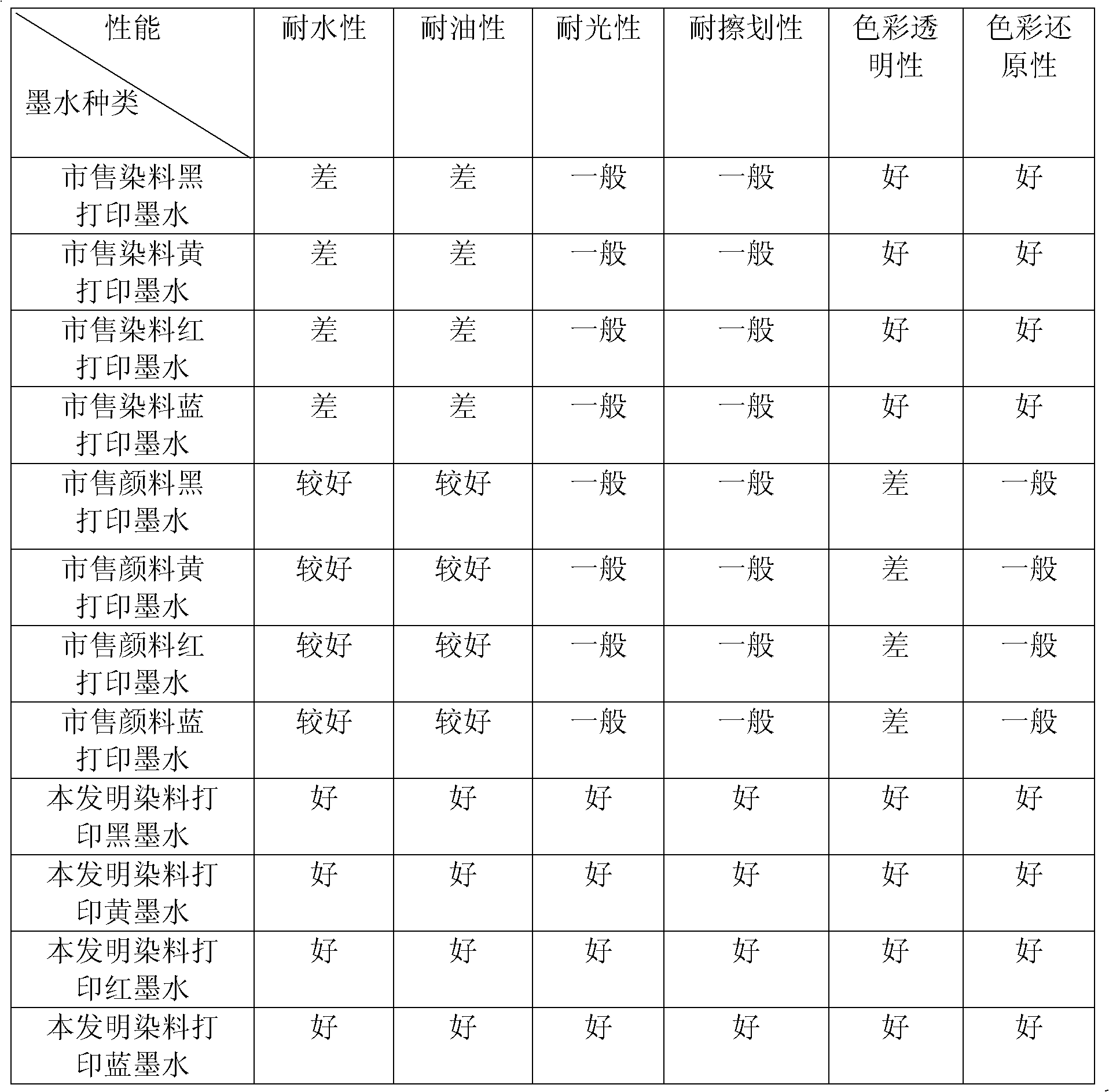

Water-based dye ink and application thereof

InactiveCN101805542AOvercome LightfastnessOvercome fading under lightInksDyeing processTextile printerWater based

The invention discloses a water-based dye ink and an application thereof. The water-based dye ink comprises the following components in percent by weight: 0.2 to 12 percent of water-soluble dye, 55 to 80 percent of modified acrylic resin emulsion, 0.01 to 1 percent of ultraviolet absorbent and balance of water, and different additives can be added. The dye ink can be applicable to the fields such as jet ink, cipher paint ink, textile printing ink, water-type printing ink, fountain pen ink and water ball pen ink, and has the advantages of water resistance, oil resistance, scratch resistance, illumination resistance, high temperature resistance, low temperature resistance, good color reducibility, duration and the like.

Owner:鲁继烈

Radiation vulcanizing method for environment-friendly type medical rubber products

InactiveCN101104700ANo precipitationSimple recipePharmaceutical containersMedical packagingCross-linkPolymer science

The invention relates to a process method of radiation vulcanization which applies the high energy radiation technology in medical rubber products, in particular to a vulcanization method of the environment protecting medical rubber products that can improve the safety and not-pollution property of the medical rubber products. Green rubber compound, reactive environment protecting cross-linking coagent, filler and compounding agent are mixed in a regulated weight ratio, and then are mixed in a mixing facility, so that non cross-linked rubber profiles are formed preliminarily. The non cross-linked rubber profiles are treated in radiation vulcanization for once or a plurality of times and then become the medical rubber products. The invention has the advantages of good safety, high chemical stability, air tightness and cleanness, no residue precipitation with irritability, volatility and anaphylaxis, ozonation resistance, crack resistance, heat resistance and fine mechanical property, and also has the advantages that the time of the radiation vulcanization is reduces, the energy is saved, fast radiation disinfection proposal method can be accepted.

Owner:QINGDAO UNIV OF SCI & TECH

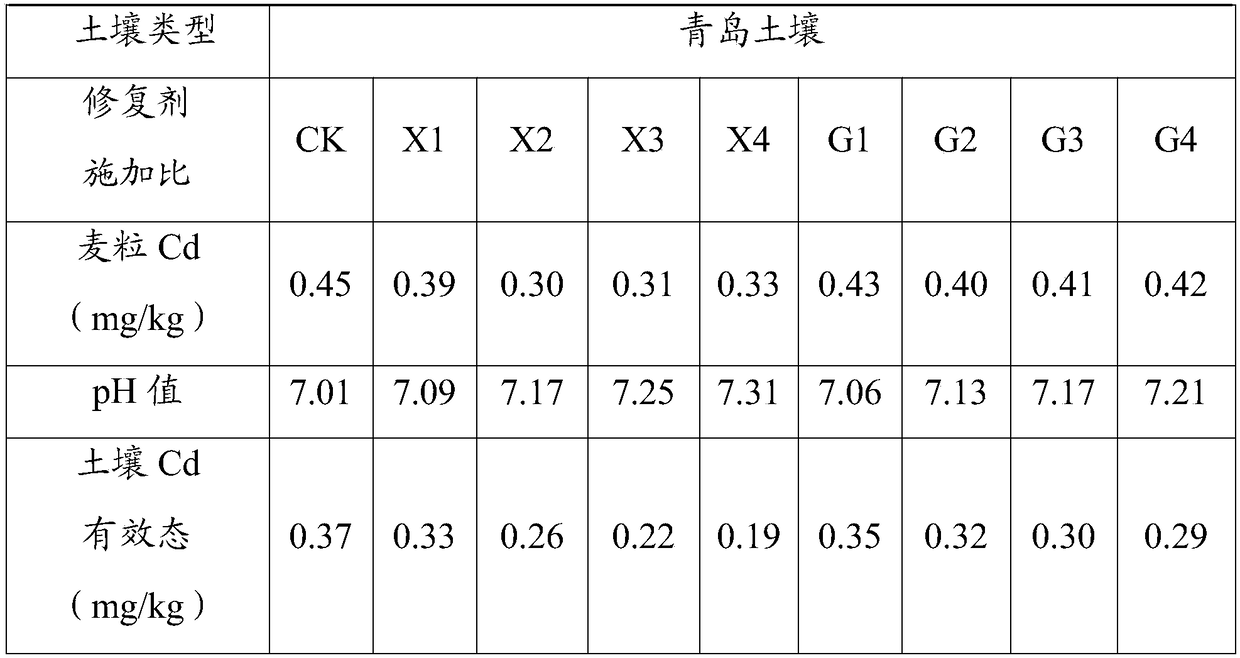

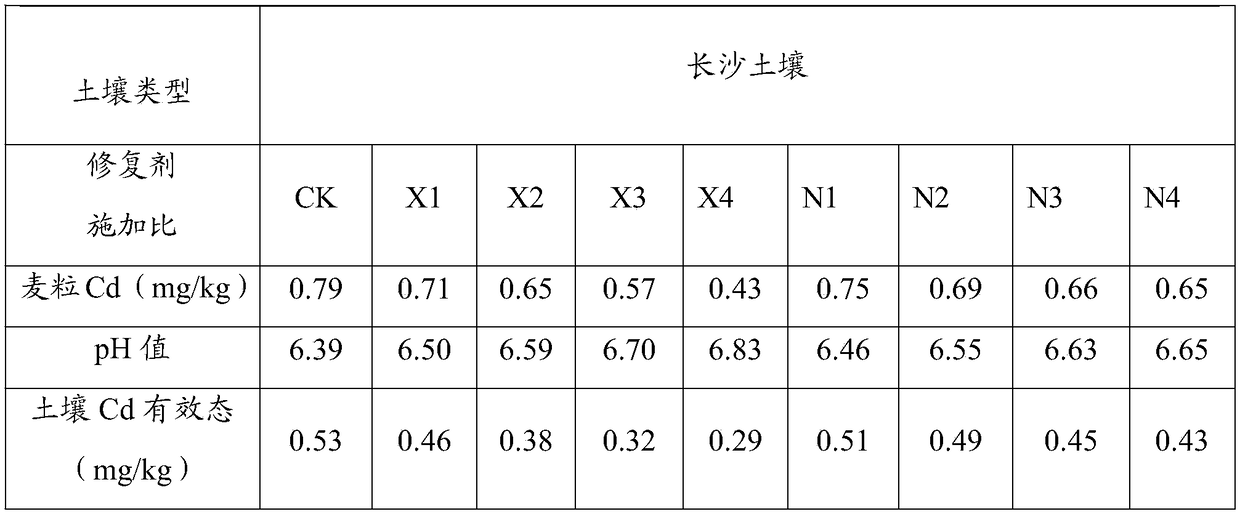

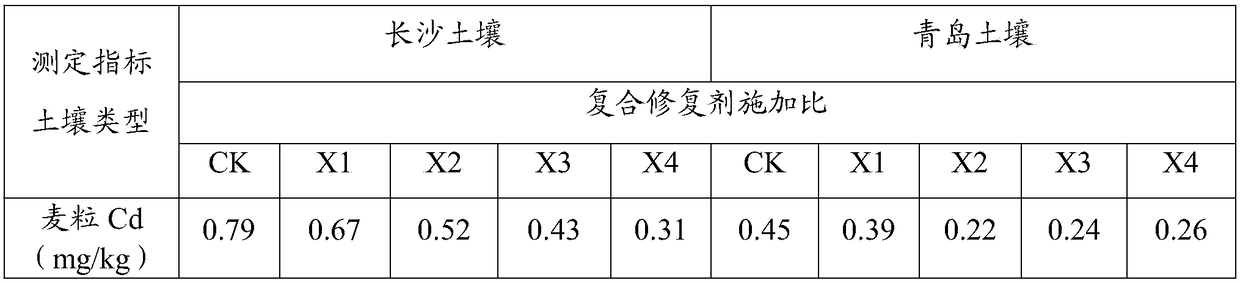

Composite repair agent for soil heavy metal pollution and application thereof

InactiveCN108085010AWide variety of sourcesImprove efficiencyContaminated soil reclamationOrganic fertilisersSodium BentoniteOyster

The invention provides a composite repair agent for soil heavy metal pollution as well as a preparation method and application thereof, and belongs to the technical field of soil improvement and environmental protection. A composite repair agent for soil cadmium pollution is prepared from the following components in parts by weight: 10 to 30 parts of sodium bentonite, 5 to 15 parts of bone powder,5 to 25 parts of chitosan, 5 to 30 parts of oyster shell powder, 10 to 40 parts of graphene-modified crop straw biochar, 10 to 30 parts of bio-organic fertilizer, 15 to 45 parts of sodium silicate, 1to 15 parts of nano-FeO, 1 to 8 parts of carbon nanotubes, and 1 to 10 parts of microbial inoculants. The number of each 10 mg colonies of rhodotorula mucilaginosa OP11 in the microbial inoculum is 2.25*10 <8> to 2.5*10<9> CFU; the preservation number of the rhodotorula mucilaginosa OP11 is CGMCC No. 13540. The application of the composite repair agent is in remediation of heavy metal contaminated soil.

Owner:QINGDAO AGRI UNIV +1

Powdery paint for aluminum profile and preparation method thereof

ActiveCN102516855AStrong adhesionSimple recipePowdery paintsPolyester coatingsComminutionOrganic matter

The invention discloses a powdery paint for aluminum profile and a preparation method thereof. The powdery paint is composed of carboxyl-terminated saturated polyester resin, triglycidyl isocyanurate (TGIC), titanium dioxide, precipitated barium sulfate, a brightener, a leveling agent and benzoin. The preparation method contains the following steps of: batch mixing, melt extrusion, crushing and ultrafine comminution. The powdery paint for aluminum profile has low curing temperature. By the adoption of the powdery paint, volatilization amount of residual TCIC low molecular organic matter is reduced. The powdery paint is beneficial to environmental protection and the health of human body. In addition, the appearance of the film is more flattening and fine.

Owner:广东华江粉末科技有限公司

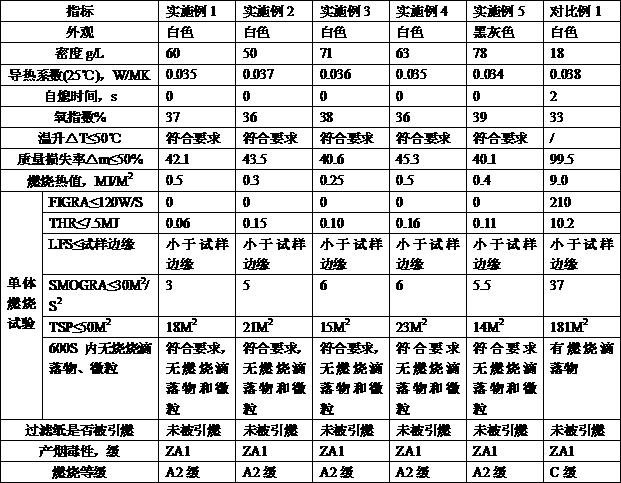

High-flame-retardance composite heat-insulating foam material and preparation method thereof

The invention relates to the technical field of polystyrene foam materials, in particular to a high-flame-retardance composite heat-insulating foam material and a preparation method thereof. The high-flame-retardance composite heat-insulating foam material comprises polystyrene foaming particles with the density of 18 to 20 g / L and a flame-retardant composite layer wrapped on the surface of the polystyrene foaming particles, wherein the flame-retardant composite layer consists of a flame-retardant binder of 5 to 50 g / L and an inorganic flame retardant of 5 to 75 g / L. Compared with the prior art, the invention optimizes the formula of the flame retardant and adopts environment-friendly, non-toxic and low-price organic and inorganic flame retardants. The prepared composite heat-insulating material has low production cost. After the product is combusted, the product has the advantages of alveolate skeleton structure, no melted drop, low smoke output quantity, no combustion dripping substance and no particle, so the flame-retardant performance and the flame-retardant grade of the product are obviously improved and the product has wide development prospect in the heat insulation field of buildings such as roofs and walls.

Owner:宁波龙利钜能新材料有限公司 +1

Hemp seed beverage and preparation method thereof

InactiveCN101313770AReduce cholesterolIncrease milk flavorMilk preparationFood preparationCannabisSlurry

The invention relates to a fructus cannabis beverage, which is mainly made from fructus cannabis and condensed milk, to which an appropriate amount of white sugar, emulsifier and stabilizer are added. A method for preparing the fructus cannabis beverage adopts a disc-type vegetable stuffing machine to grind the fructus cannabis, which can prevent fructus cannabis shells from being ground excessively and becoming nigrescent in color, so as to ensure that fructus cannabis slurry is pure white and closer to the primary color of milk slurry. The fructus cannabis beverage is simple in formula, convenient in making process, low in production cost and suitable for industrial production.

Owner:刘国铨

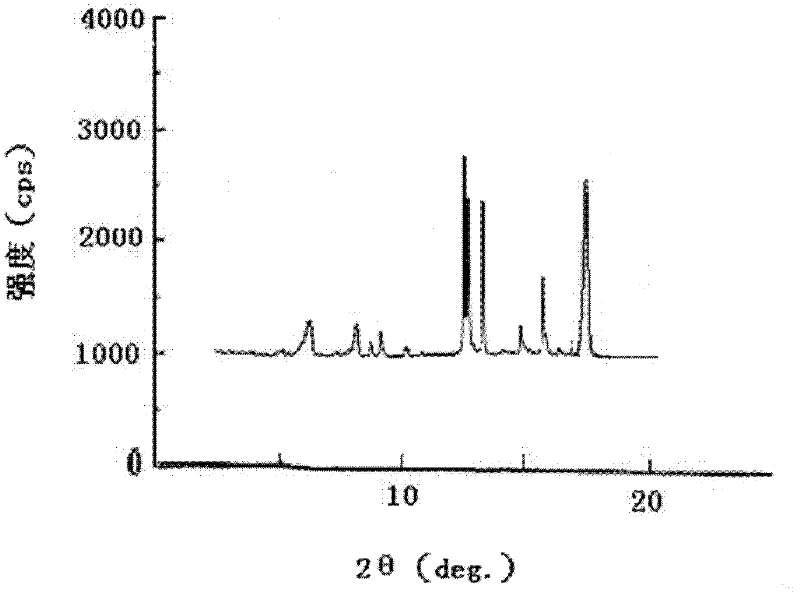

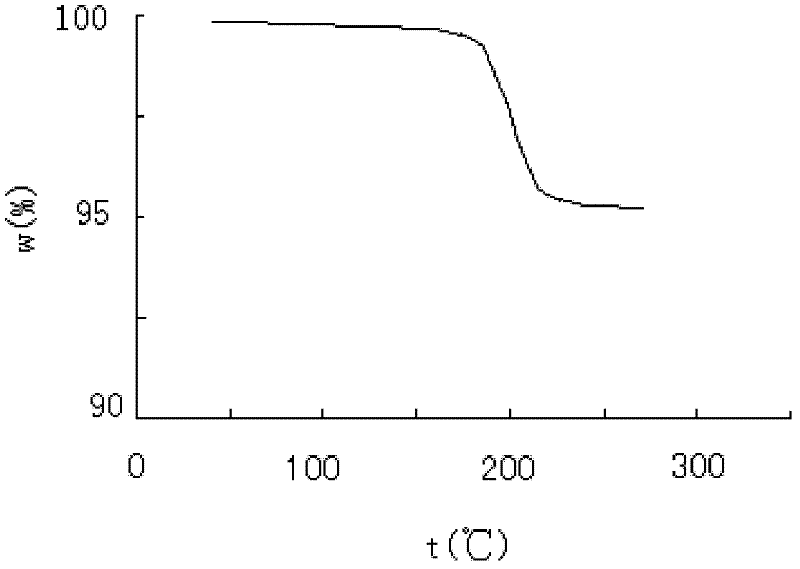

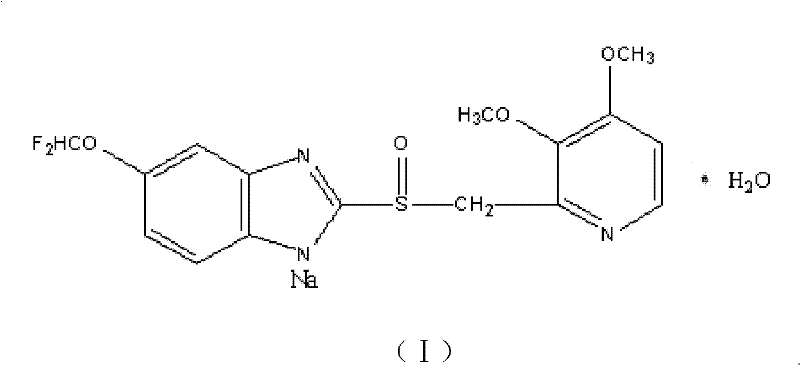

Pantoprazole sodium compound and pharmaceutical composition thereof

ActiveCN102351844AStable moisture contentNo changeOrganic active ingredientsPowder deliveryFreeze-dryingX-ray

The invention discloses a pantoprazole sodium compound, which is crystal. In X-ray powder diffraction pattern obtained through Cu-Kalpha ray measurement, the characteristic peaks of the pantoprazole sodium compound are shown in positions where 2theta is 12.5, 12.6, 13.2, 16.2 and 17.3. The pantoprazole sodium compound can be used together with multiple freeze-drying supporting agents, the prepared freeze-dried powder injection has the advantages of good redissolution, good transparency after redissolution, low impurity content and the like; and moreover, the use amount of the freeze-drying supporting agent is lower, thus saving the pharmaceutical cost and improving the stability of a drug preparation. The invention also discloses a pharmaceutical composition. The pharmaceutical composition comprises a pharmaceutical active ingredient and pharmaceutical auxiliary materials, wherein the pharmaceutical active ingredient is the pantoprazole sodium compound. The stability of the pharmaceutical composition is obviously superior to that of commercial products, and especially, the stability duration of the pharmaceutical composition after being matched with common infusion fluid is prolonged, thus facilitating the clinical application.

Owner:江西新先锋医药有限公司

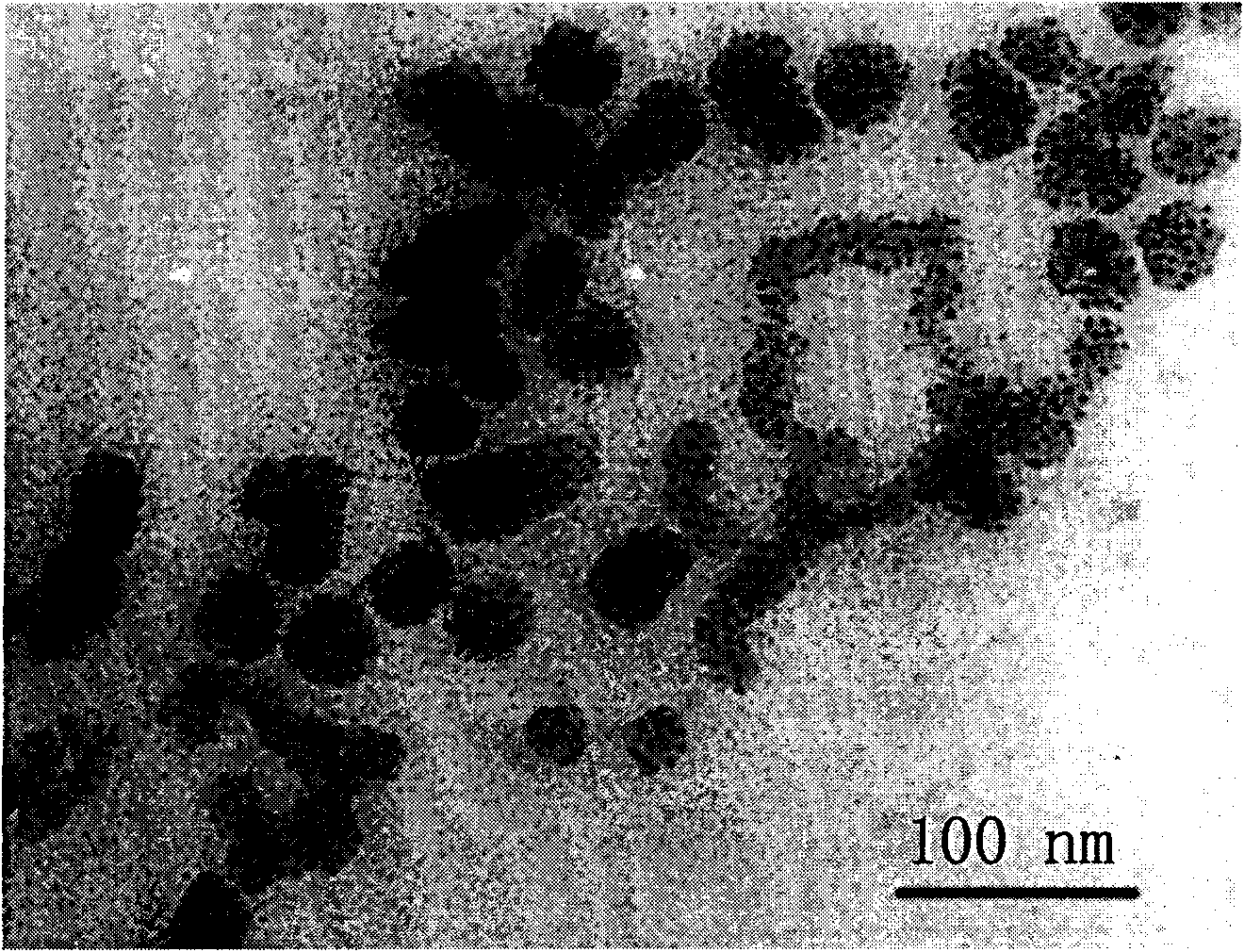

Antibacterial supermolecule aquogel and preparation method and application thereof

InactiveCN101564400AEasy to prepareEasy to operateAntibacterial agentsInorganic active ingredientsBiocompatibility TestingSILVER NITRATE CRYSTALS

The invention discloses a method for in-situ preparing antibacterial supermolecule aquogel. The method comprises the following operation steps: silver nitrate crystal and polyethyleneglycol-polypropylene glycol-polyethyleneglycol triblock copolymer solution are mixed and stirred to obtain mixed solution; the steps of stirring the mixed solution for 15 minutes and ultrasonically dispersing the mixed solution for 5 minutes are alternatively carried out for 2-4 hours to obtain nano silver sol; and the nano silver sol and Alpha-cyclodextrin solution are mixed, stirred and stands at the room temperature to obtain hydrogel. The hydrogel can be used for preparing injectable drug carriers. The invention has the advantages of simple operation, adjustable gel strength and the gelation time, room temperature forming, no involvement of chemical cross linking reaction and the usage of organic solvent, favorable biocompatibility and antibacterial property of obtained gel, and the like and is prospective to be widely applied in the field of biomedical engineering materials.

Owner:SUN YAT SEN UNIV

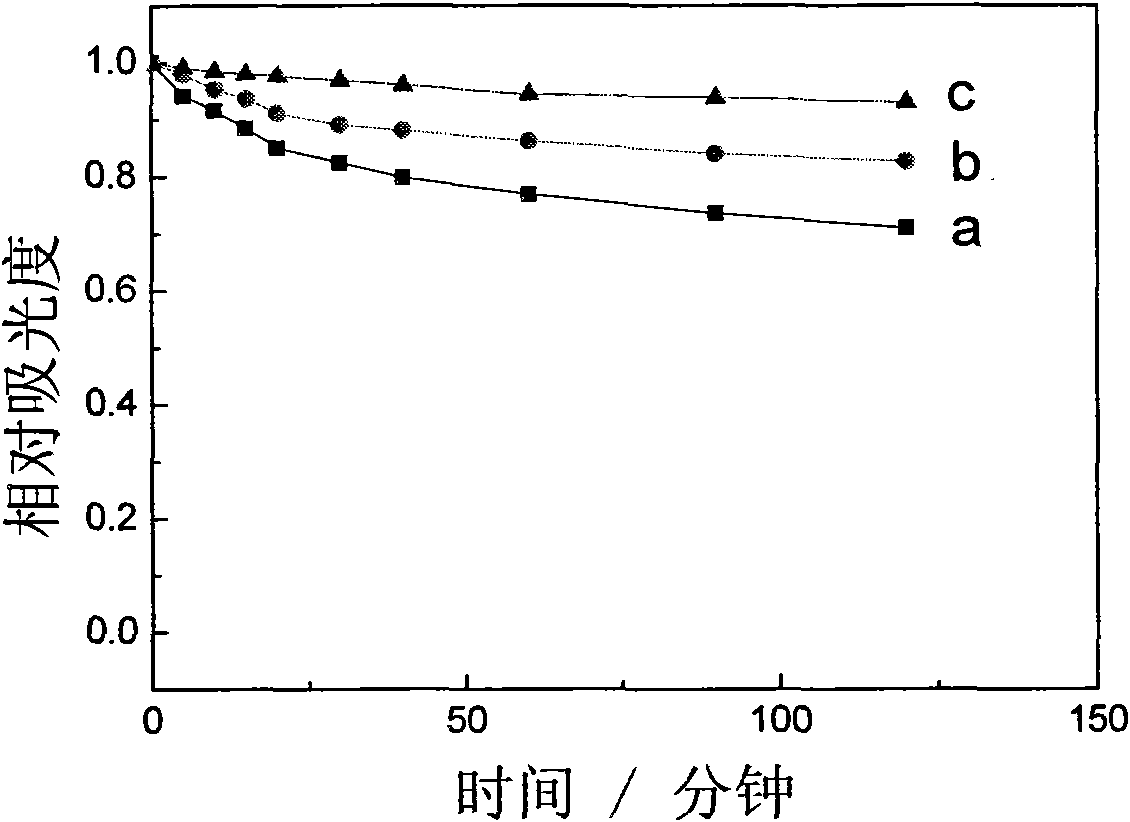

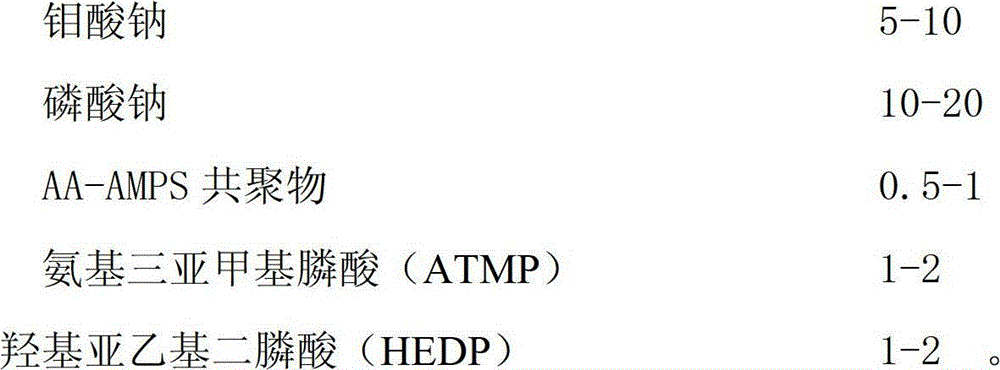

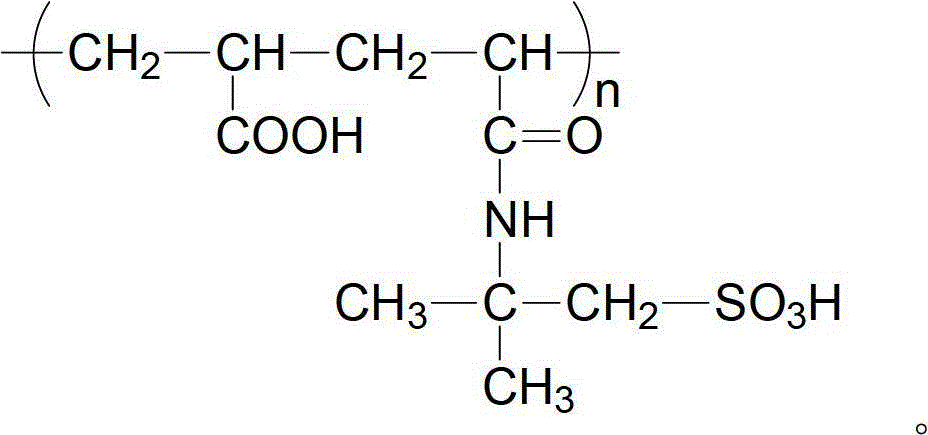

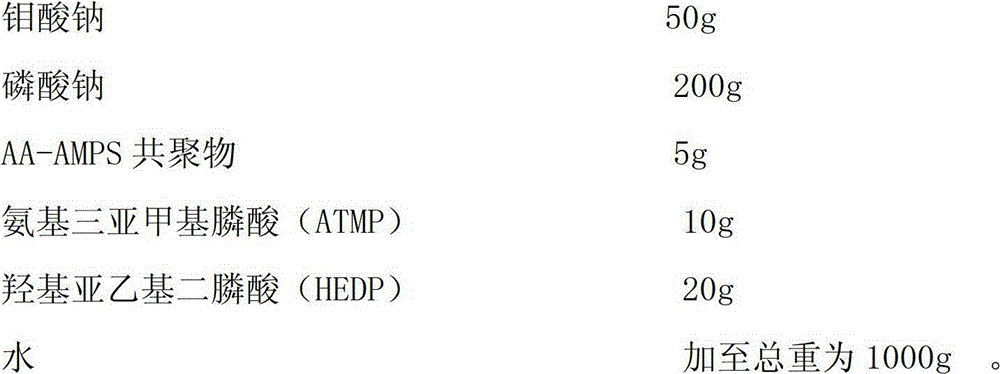

Oil field compound type anti-scale corrosion inhibitor and preparation method thereof

InactiveCN102911651AGood synergyGood scale and corrosion inhibitionBorehole/well accessoriesSodium phosphatesSimple component

The invention relates to an oil field compound type anti-scale corrosion inhibitor and a preparation method thereof, belonging to the technical field of corrosion inhibitor. The oil field compound type anti-scale corrosion inhibitor is characterized by comprising the components by mass percent: 5-10% of sodium molybdate, 10-20% of sodium phosphate, 0.5-1% of acrylic acid-2-acrylamido-2-methyl propane sulfonic acid (AA-AMPS) copolymer, 1-2% of amino trimethylene phosphonic acid and 1-2% of hydroxyl ethylidene diphosphonic acid (HEDP). The preparation method comprises the steps of: firstly, completely dissolving sodium molybdate and sodium phosphate by using water; then, adding the AA-AMPS copolymer under the condition of stirring until the copolymer is completely dissolved; subsequently, adding ATMP and the HEDP, and further stirring for dissolving; and finally, adding water until the concentration of the mixed solution is in accordance with the requirement, so as to obtain the oil field compound type anti-scale corrosion inhibitor. The inhibitor disclosed by the invention has the advantages of simple components, available raw materials, simple technology, high efficiency, low cost, low dosage, good scale inhibition, descaling and corrosion inhibition effects and the like, and is convenient to prepare, rapid.

Owner:E TECH ENERGY TECH DEV CORP

Extra-high voltage transformer oil and production process thereof

The invention relates to extra-high voltage transformer oil and a production process thereof. The extra-high voltage transformer oil comprises the following components in percentage by weight: 75wt%-85wt% of naphthenic-base base oil, 12wt%-22wt% of dodecyl benzene, 10ppm-200ppm of a metal de-activating agent and 0.1wt%-3wt% of a light stabilizer. Compared with the prior art, the extra-high voltage transformer oil is low in cost, simple in formula and production process, convenient to use, excellent in comprehensive performances and in particular suitable for being used as extra-high voltage transformer oil.

Owner:ANHUI KAIAO NEW ENERGY CO LTD

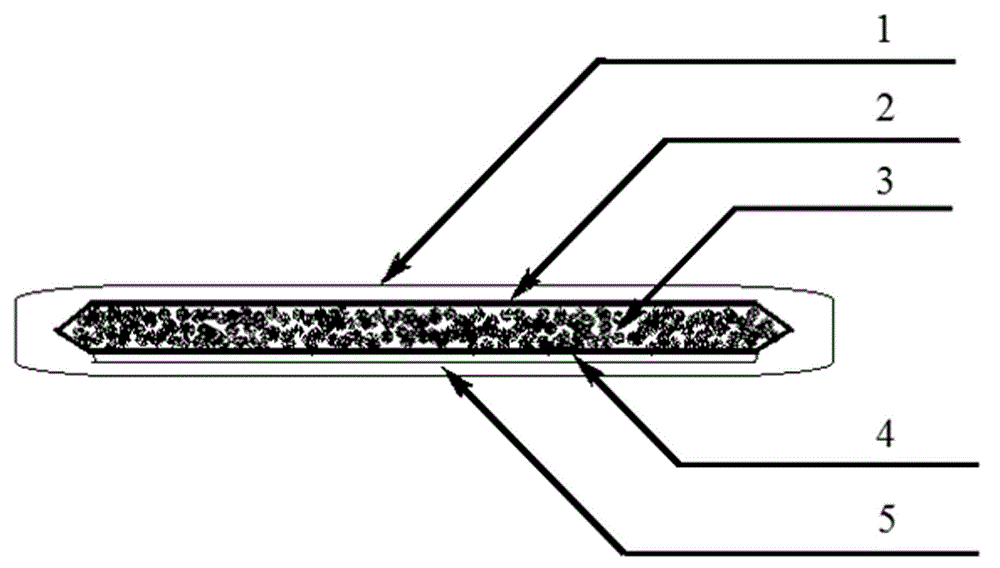

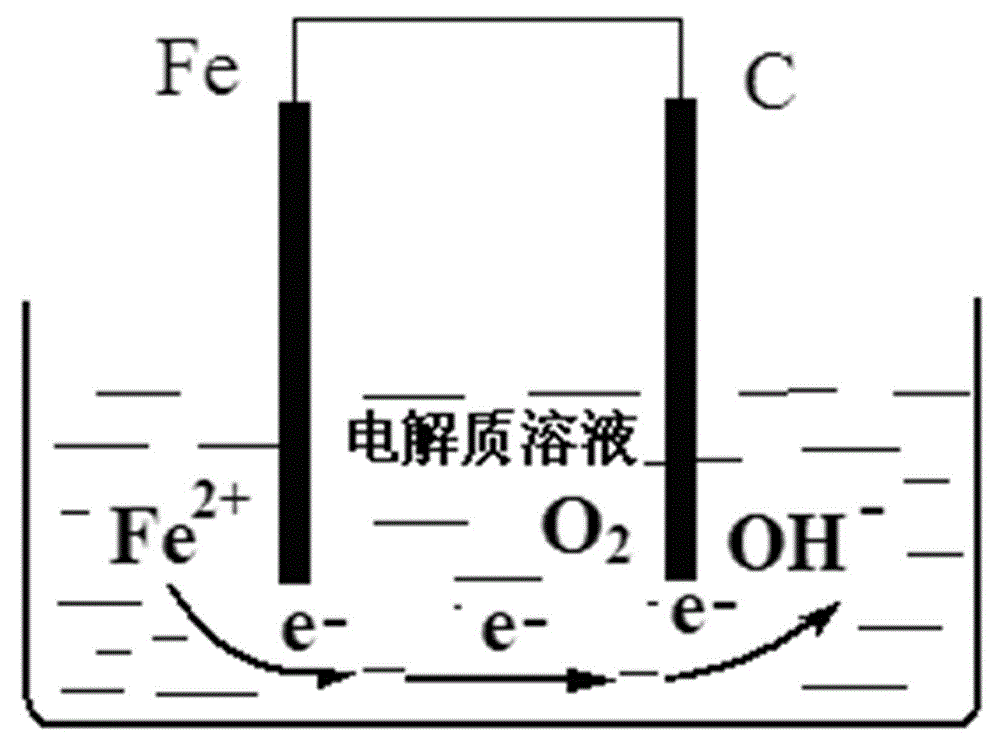

Self-heated type thermal paste

InactiveCN102715978AImprove insulation effectImprove water retentionHeat-exchange elementsTherapeutic coolingActivated carbonTap water

The invention provides a self-heated type thermal paste which comprises a vacuum external packaging bag and a breathable internal packaging bag. The internal packaging bag is filled with a heating material; one side of the internal packaging bag is provided with a gelatin layer; the gelatin layer is provided with a protecting film; the heating material is prepared from secondarily-reduced iron powder, sodium chloride, vermiculite, wood powder, active carbon powder and tap water at a certain proportion. Because the vermiculite is used as the heat preserving and insulating material of the self-heated type thermal paste, the heating time of the self-heated type thermal paste is prolonged greatly, and because the wood powder is used to prepare the self-heated type thermal paste, the heat preserving performance and the water retaining performance of the self-heated type thermal paste are improved effectively. A large number of experiments show that the self-heated type thermal paste can be heated to 40-50 DEG C, and the heat can be preserved for about 20 hours. In addition, the self-heated type thermal paste has the characteristics of low cost, easily-available raw materials, simple formula, quick long-time heating and balanced heat and can be used by people who can not tolerate cold and people who work or do activities outdoors in cold winter to keep warm.

Owner:GANSU RES INSTION OF CHEM IND GRICI

High blending flyash porcelain brick and its making method

InactiveCN1410386AImprove adhesionImprove plasticizing effectSolid waste managementClaywaresBrickGranularity

A ceramic tile with high content is flyash is prepared from flyash (60-700 wt.%), superfine kaolinite (25-40) prepared by the nano intercalation technique, and feldspar (0-10) through pretreating rawmaterials, compounding, pulping, baking, grinding, adding water and granulating, ageing, die pressing, baking, sintering and cooling. Its advantages are low cost, low hydroscopicity (less than 0.5%),and high modulus of rupture (more than 35 MPa).

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Low temperature curing epoxy low-gloss powder coating and preparation method thereof

InactiveCN101747826ASimple recipeLow curing temperaturePowdery paintsEpoxy resin coatingsPowder coatingEpoxy

The invention discloses a low temperature curing epoxy low-gloss powder coating, which comprises the following components in part by weight: 100 to 200 parts of epoxy resin, 1 to 10 parts of epoxy curing agent, 0 to 50 parts of delustering agent, 0 to 160 parts of inorganic filling and 0 to 10 parts of addition agent. The invention also discloses a method for preparing the powder coating. The low temperature curing epoxy low-gloss powder coating has the characteristics of simple formula, low curing temperature, stable gloss and free adjustment of a coat, good mechanical properties, good chemical resistance and the like.

Owner:GUANGZHOU QINGTIAN INDAL

Wound repair hydrogel material and preparation method thereof

The invention relates to a wound repair hydrogel material, composed of the following components by parts by weight: 10-20 parts of synthesized hydrophilic polymer compound, 2-6 parts of chitosan quaternary ammonium salt and 100 parts of water. The preparation method of the wound repair hydrogel material includes that raw materials are heated and dissolved according to prescription requirement andthen are subject to standing or ultrasound defoaming, solution is poured into a specific mould, the mould is horizontally placed under the condition of 0-20 DEG C, self crosslinking is carried out for1-7 days, sealing is carried out, cobat-60 or electron accelerator is used for irradiation, and irradiation dosage is 10-100KGy. The prescription of the invention has the advantages that: the prescription is safer and more efficient, chitosan quaternary ammonium salt can be directly fused with other components without adding acid, thus preparation process is simper. The preparation method of theinvention has the advantage that: the obtained wound repair hydrogel material has both good flexibility and high transparency, thus being convenient for medical care personnel to observe wound surface.

Owner:都本立

Shampoo and preparation method thereof

InactiveCN103211749ATemperatureStrong degreasing abilityCosmetic preparationsHair cosmeticsDiseasePreservative

The invention relates to the technical field of bath products in life, and in particular relates to shampoo and a preparation method thereof. The shampoo comprises the following components according to parts by weight: 7.5-17.5% of glutinous rice powder, 82-92% of water, 0.05-0.45% of strains, and proper amounts of a stabilizer, an anticorrosive and essence. The preparation method comprises the following steps of: cleaning glutinous rice, grinding the glutinous rice into powder to obtain glutinous rice powder, and sieving the glutinous rice powder through a sieve of 60-100 meshes; mixing 7.5-17.5% of glutinous rice powder and 82-92% of water according to weight percent, and stirring until the mixture is pasty, wherein the water temperature is 5-10 DEG C; adding strains, mixing uniformly, and fermenting 10-20 days under normal temperature, wherein the weight percentages of strains and glutinous rice powder are 0.05-0.45% and 7.5-17.5%; after fermentation, carrying out high-temperature sterilization; adding the proper amounts of stabilizer, anticorrosive and essence for mixing, and stirring uniformly; and hermetically packaging to obtain a finished product. Compared with the prior art, the shampoo not only can meet the cleaning requirement of regular shampoos but also is mild in nature, non-toxic and non-irritant and good in grease and contamination removal capacity, and can prevent diseases of head skin and nourish hair, so that the hair keeps lustrous and moist.

Owner:薛晨

Long carbon fiber enhanced high-heat-conductivity polymer composite and preparation method thereof

ActiveCN102477182AEnhancement effect is goodImprove continuityHeat-exchange elementsMasterbatchCarbon fibers

The invention discloses a long carbon fiber enhanced high-heat-conductivity polymer composite, which is made of, by weight, from 10 to 80 parts of long carbon fiber enhanced thermoplastic resin masterbatch and from 20 to 90 parts of heat-conducting masterbatch by means of mixing. The long carbon fiber enhanced thermoplastic resin masterbatch is made of from 30 to 80 parts of first thermoplastic resin, from 20 to 70 parts of continuous long carbon fibers, from 0.5 to 2 parts of first coupling agent, from 0.3 to 0.5 part of first antioxidant and from 0.5 to 1 part of first processing aid by means of pultrusion. The heat-conducting masterbatch is made of from 30 to 80 parts of second thermoplastic resin, from 20 to 70 parts of heat-conducting agent, from 0.5 to 2 parts of second coupling agent, from 0.3 to 0.5 part of second antioxidant and from 0.5 to 1 part of second processing aid by means of traditional extrusion process. The long carbon fiber enhanced high-heat-conductivity polymer composite has excellent heat conductivity and mechanical property, and continuity of a heat-conducting network can be effectively improved by means of the long carbon fibers.

Owner:上海事升新材料有限公司

Health-preserving tea

InactiveCN103478367AAlleviation of cold diarrheaGanping of cold diarrheaTea substituesMedicinal herbsPlant stem

The invention discloses a health-preserving tea, which includes Liupu Tea, chrysanthemum, honeysuckle, mulberry leaves, coralhead plant stem leaves, cassia seeds, acacia, roses, phyllanthus emblica, Momordica grosvenori, and radix puerariae. Liupu tea belongs to mild tea, can be used for neutralizing the cold medicinal materials chrysanthemum, honeysuckle, mulberry leaves, and roses, has warming and recuperating functions, and cannot cause influence to the body after long-term use of cold medicinal materials. Pan-fired cassia seeds have moderate cold diarrhea property, sweet taste and neutral nature. The coralhead plant stem leaves have good mouthfeel. Jasmine tea has faint scent, can enhance the tea aroma and make the mouthfeel of the tea better. The phyllanthus emblica can promote people's appetite, and the radix puerariae has very high edible and medicinal value. The health-preserving tea involved in the invention has a simple formula, uses medicinal and edible materials, is safe and reliable to eat, and has the health efficacy of drugs. Also, the raw materials have harmonious properties, are scientific and reasonable, and have mild drug properties. Thus, long-term drinking of the tea can achieve the health care effect of body building.

Owner:广西马山县姑娘江农产品加工厂

Preparation method of hemicellulose based edible film

The invention discloses a preparation method of a hemicellulose based edible film. The method includes taking hemicellulose or modified hemicellulose as a base material, adding additives such as an antibacterial agent, a plasticizer and a separator into hydrolysate of the base material, dissolving, mixing evenly, homogenizing, degassing, preparing a film, drying finally, and preparing the edible food packaging film with a certain intensity and water-solubility. The preparation method is simple, easy to industrialize, good in film formation and high in intensity; and the formed film has good separating performance and water resistance, and can satisfy packaging requirements of bread, cakes, fruit and other food.

Owner:KUNMING UNIV OF SCI & TECH

Wall fireproof insulating material and preparation method thereof

InactiveCN107162519ASimple recipeEasy to prepareClimate change adaptationHeat proofingPerliteMagnesium

The invention discloses a wall fireproof insulating material, comprising, by weight, 40-60 parts of cement, 30-40 parts of closed-cell expanded perlite, 20-30 parts of vitrified glass beads, 10-30 parts of glass fiber, 10-20 parts of sepiolite powder, 5-15 parts of a fiber, 15-25 parts of a silicate, 5-10 parts of mica powder, 2-8 parts of lightweight ceramsite, 5-15 parts of quartz sand, 3-8 parts of magnesium oxide, 5-15 parts of asbestos, 4-10 parts of heavy calcium carbonate, 3-10 parts of latex powder, 2-6 parts of a flame retardant, 1-5 parts of a mildew preventive, 3-8 parts of a foaming agent, and 60-80 parts of deionized water. The wall fireproof insulating material has simple formulation and is convenient to prepare, and has good fireproof and insulating properties.

Owner:HEFEI GUANGMIN BUILDING MATERIAL CO LTD

Pets food

InactiveCN1883292AImprove adhesionIncrease appetiteFood processingAnimal feeding stuffYeastAnimal science

Owner:NINGBO HAILUKONG ECO FOOD TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com