Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

12027 results about "Air tightness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Air Tightness. Air tightness is needed, as air exchange through the envelope increases the heat loss from the building. In extreme cases it may equal the transmission loss. Lack of air tightness may also cause moisture damage when heated moist air causes condensation in the construction.

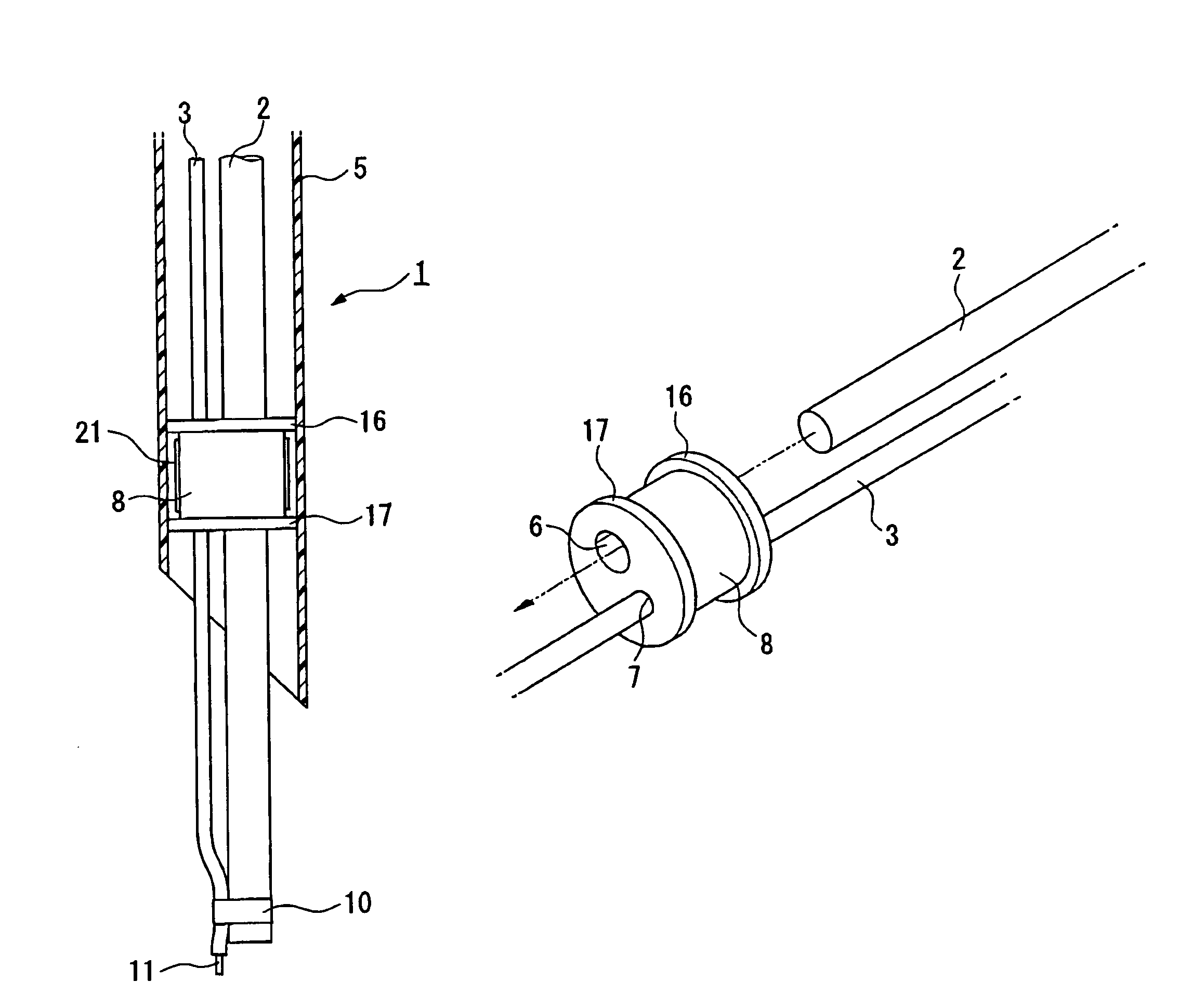

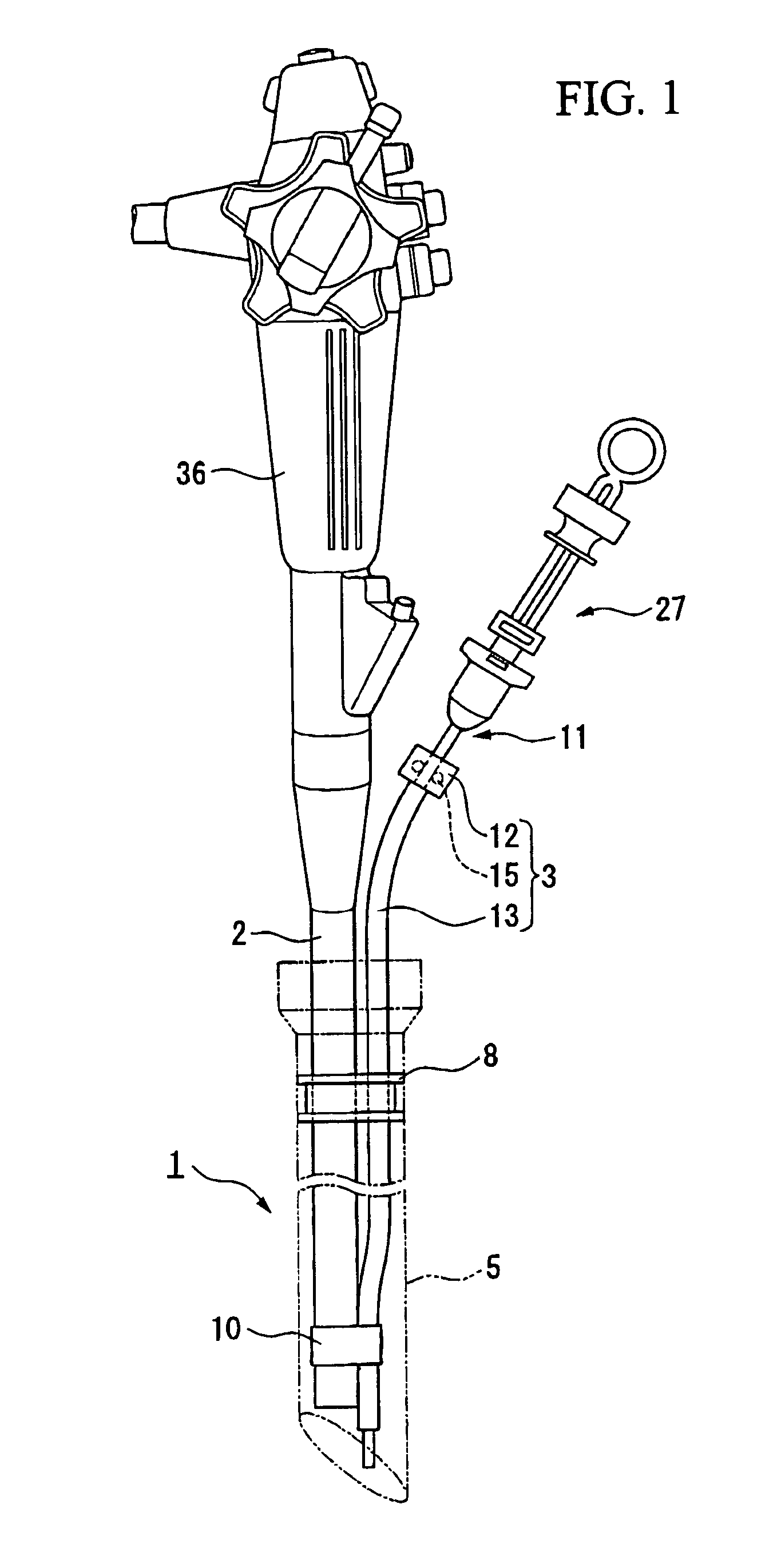

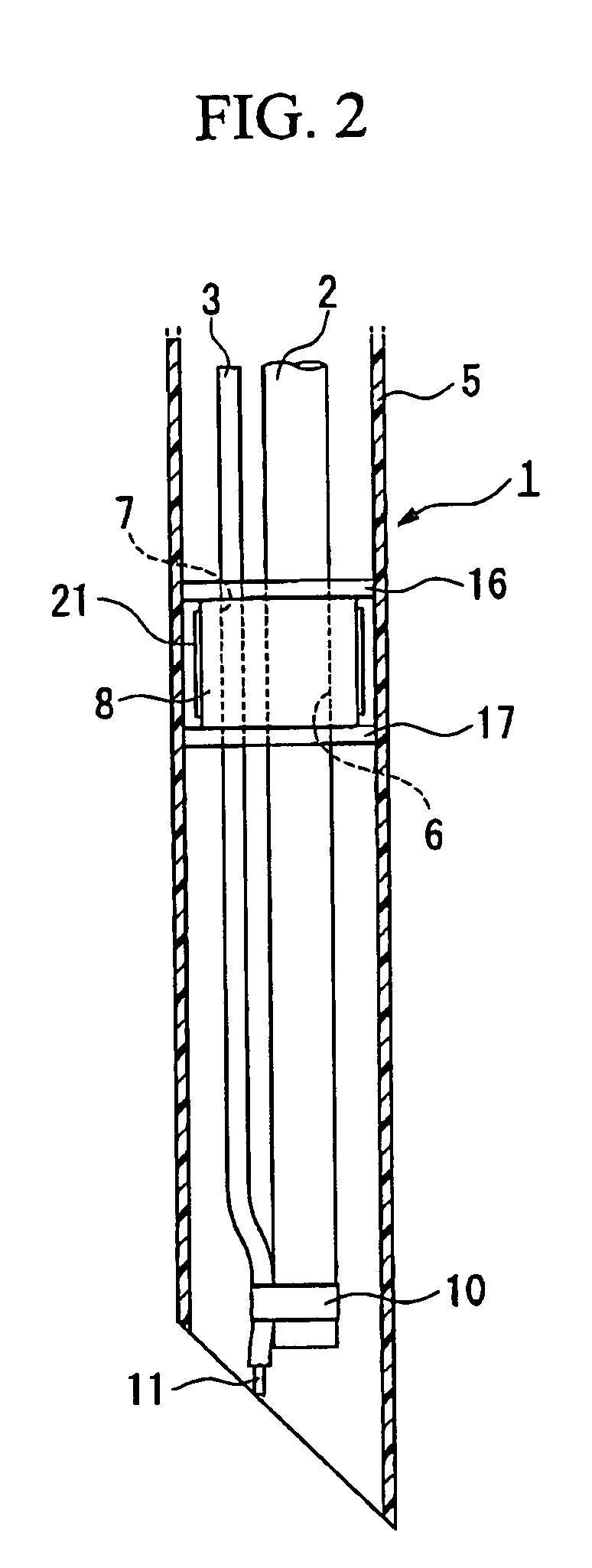

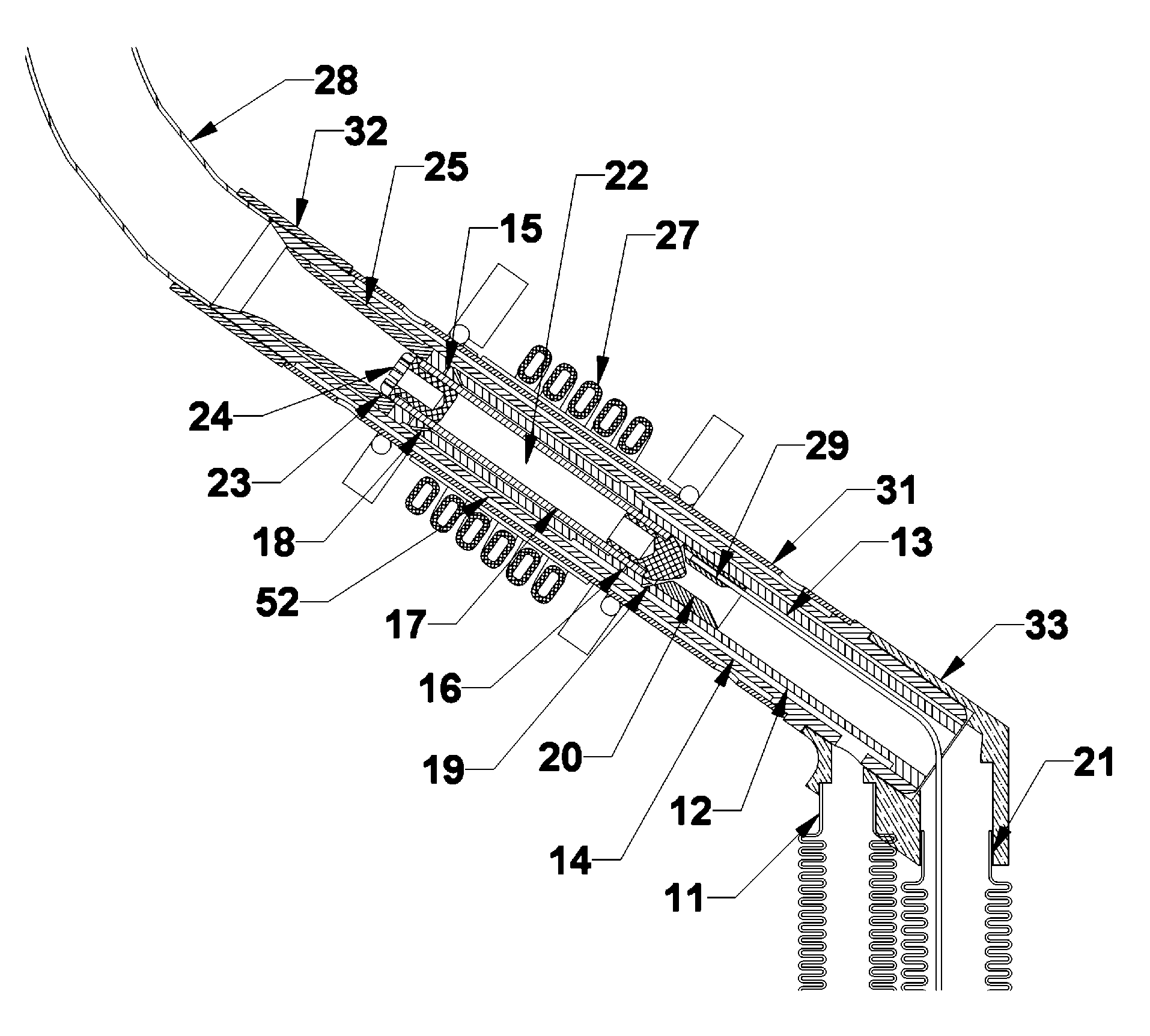

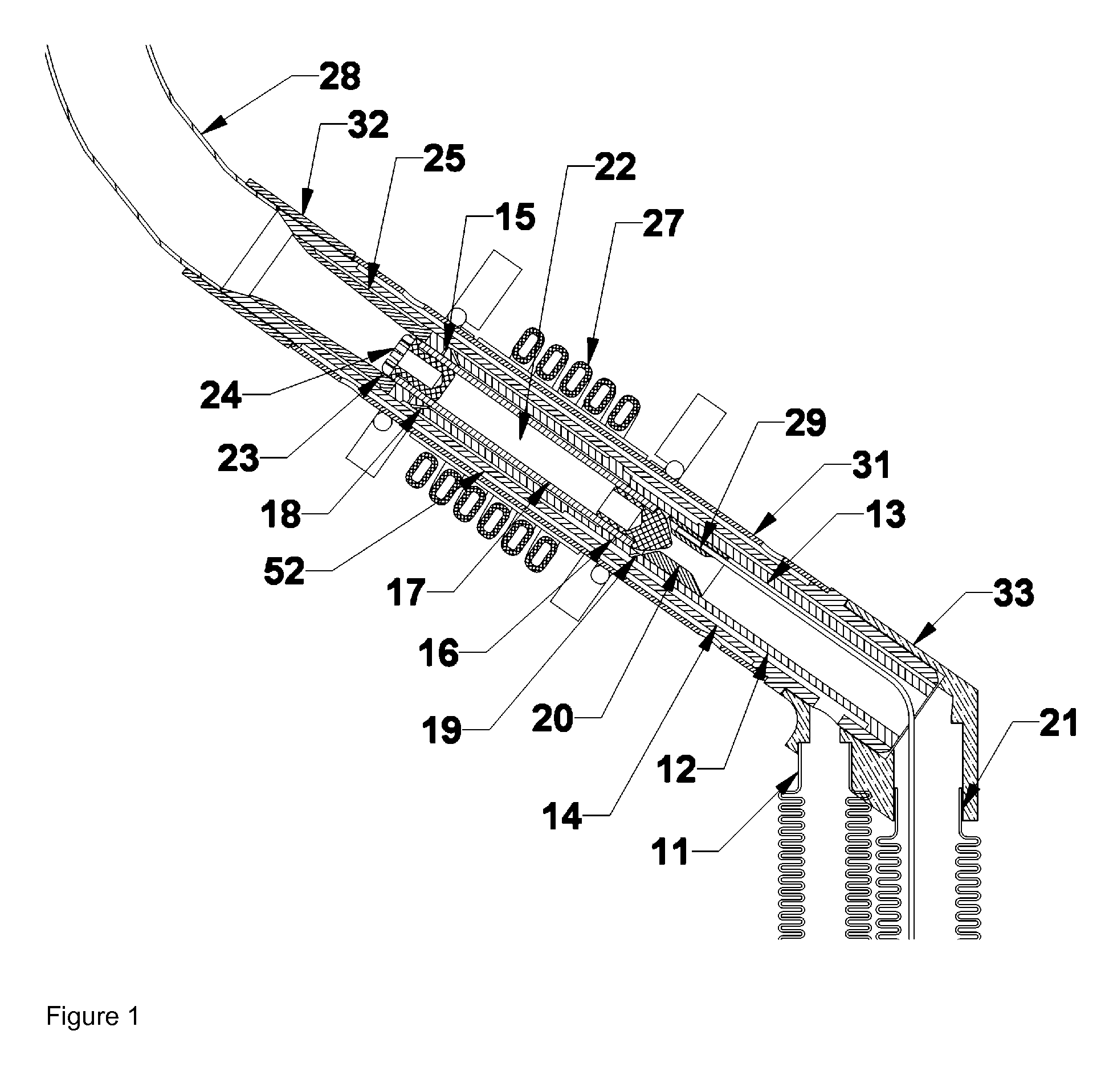

Insertion auxiliary implement

An insertion auxiliary implement of the present invention includes: a tubular part into which a flexible endoscope insertion part which is insertable into a body cavity, and one of a treatment tool and a channel into which the treatment tool is insertable, are insertable; and a sealing member which has through holes for supporting the endoscope insertion part and one of the treatment tool and the channel in the tubular part, and which airtightly and movably contacts each of a periphery of the endoscope insertion part, a periphery of the treatment tool or a periphery of the channel, and an inner surface of the tubular part, and thereby maintains airtightness between a distal end and a proximal end inside the tubular part.

Owner:OLYMPUS CORP

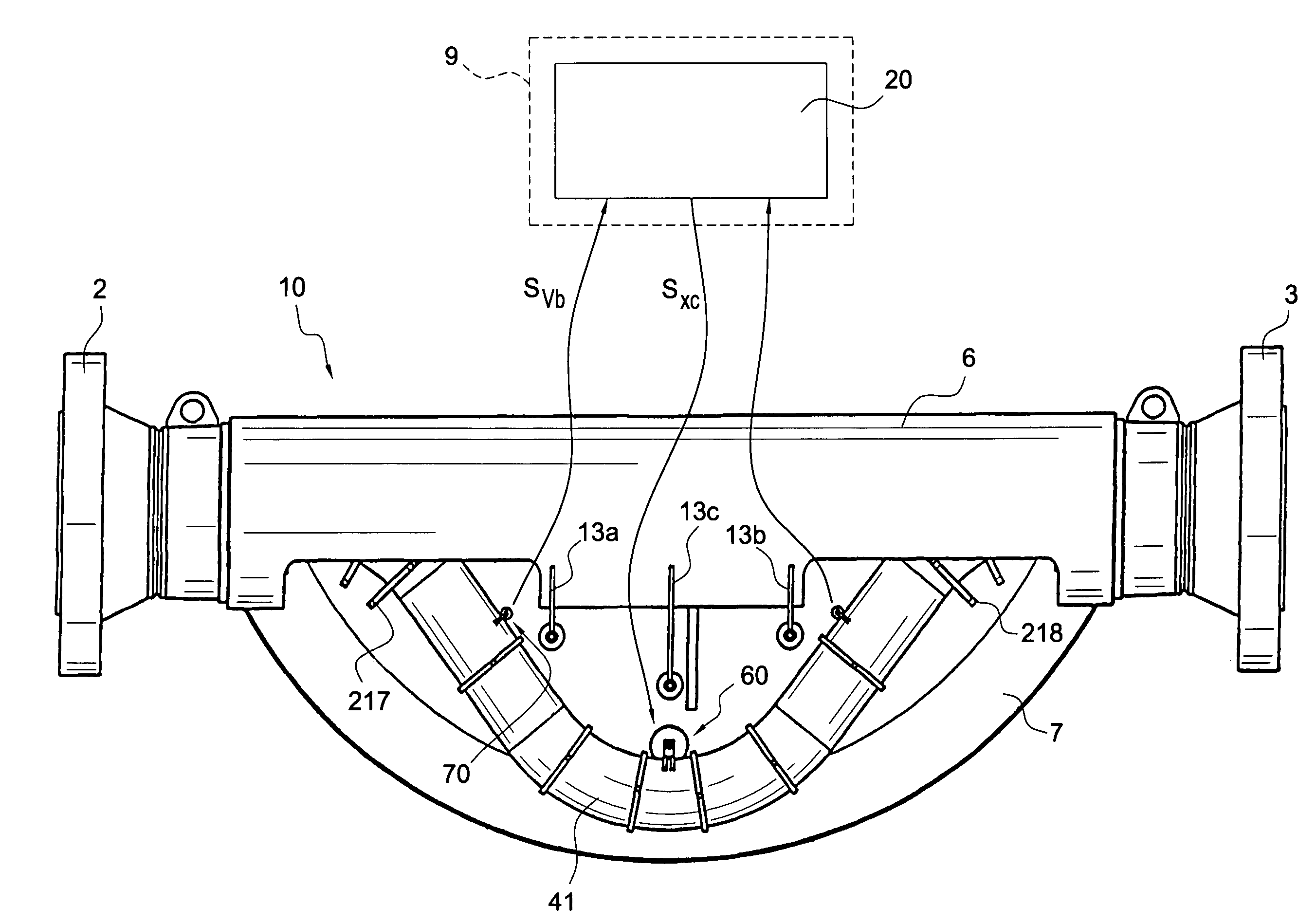

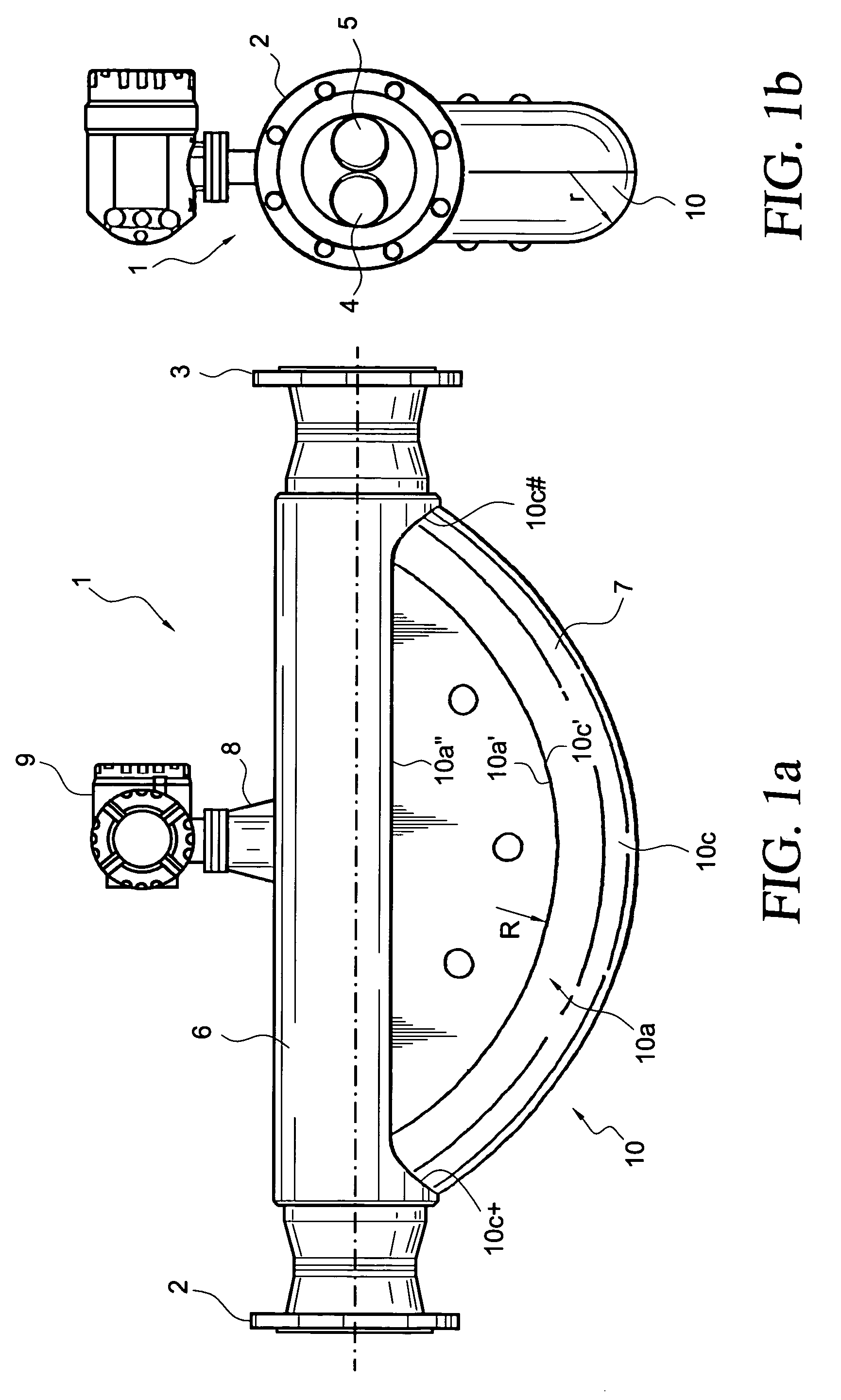

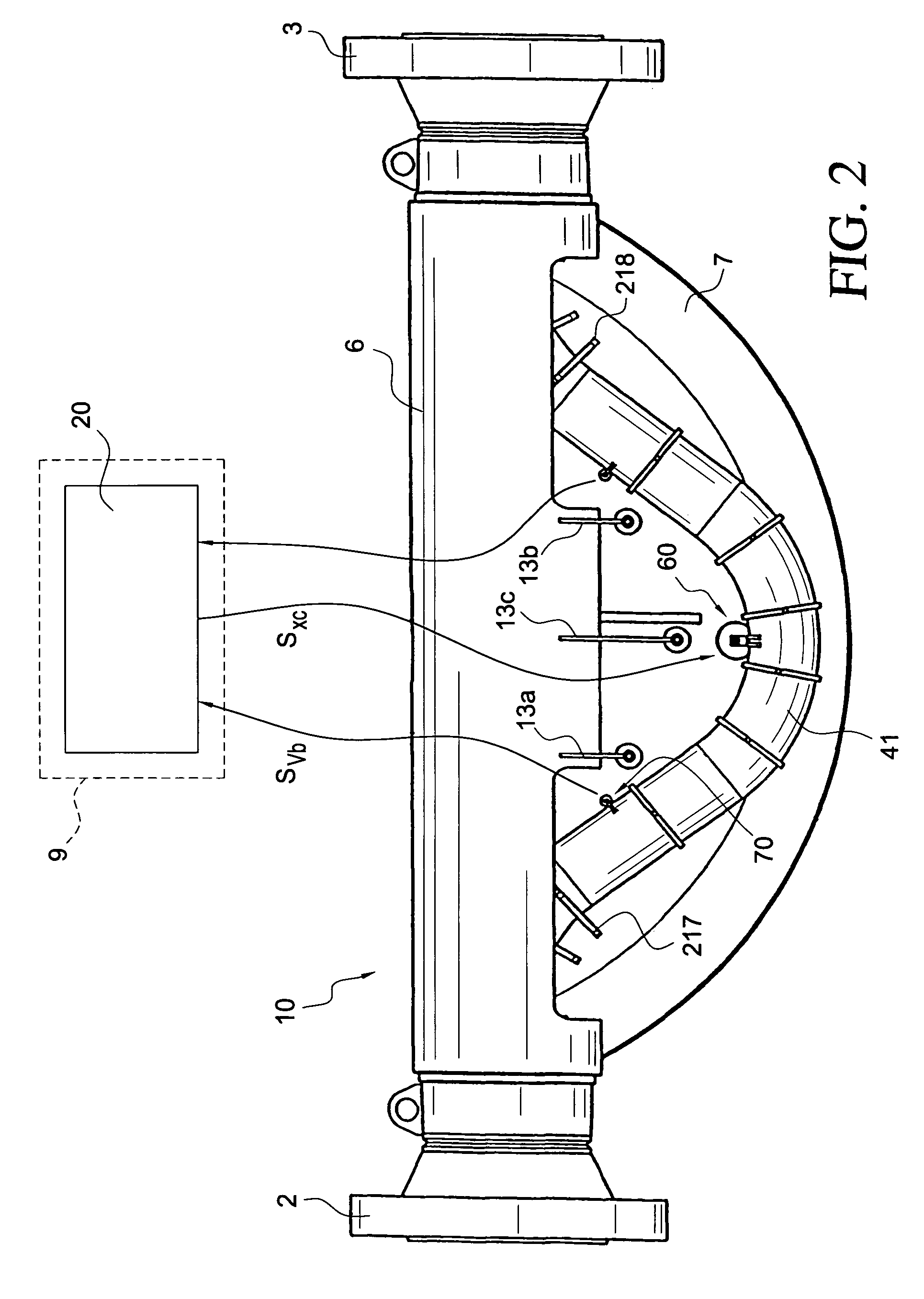

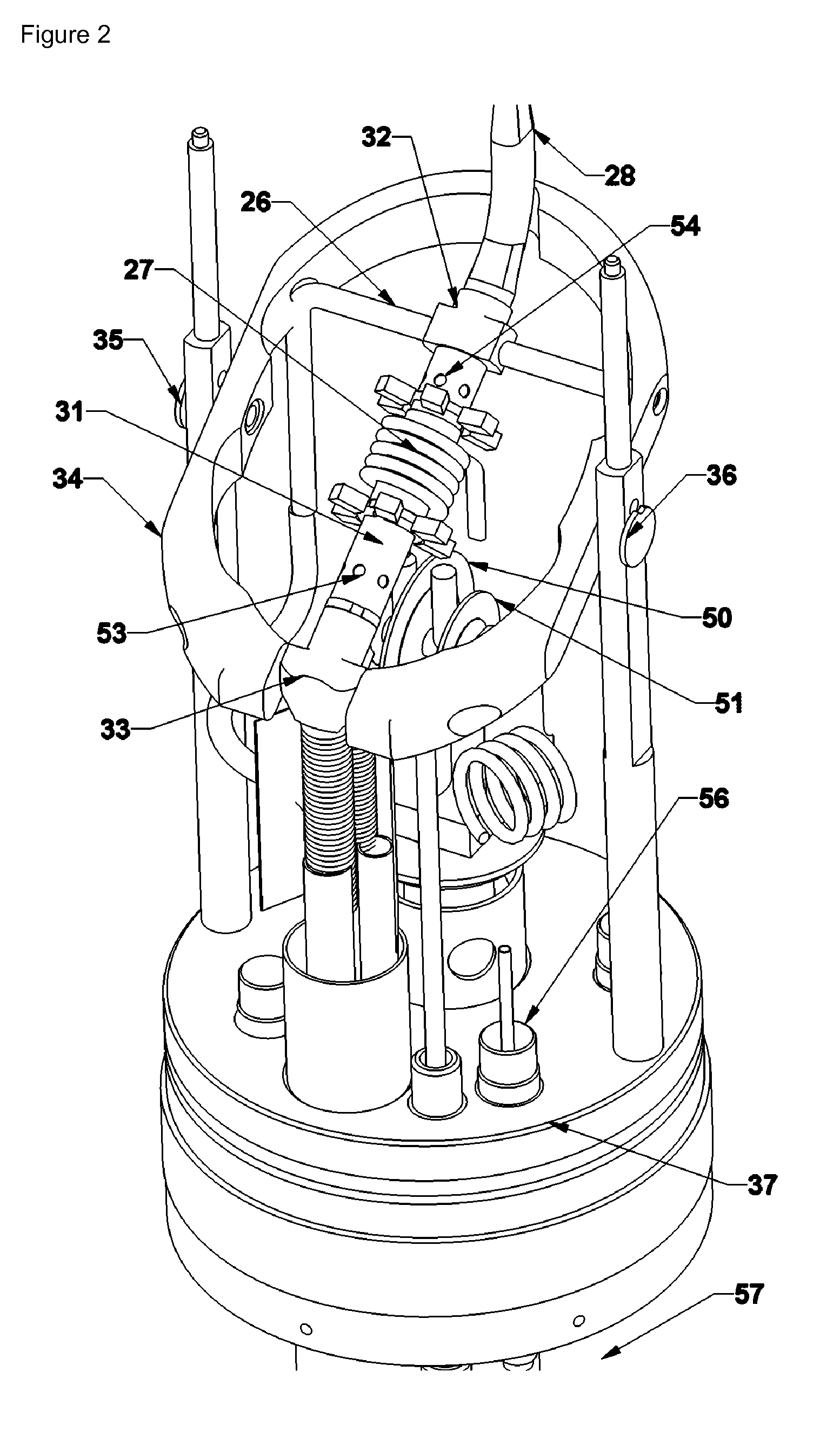

Inline measuring device with a vibration-type measurement pickup

An inline measuring device serves for measuring a medium, especially a gaseous and / or liquid medium, in a pipeline. It includes, a vibration-type measurement pickup and a measuring device electronics electrically coupled with the measurement pickup. The measurement pickup has at least one measuring tube vibrating during operation and communicating with the pipeline, an electromechanical, especially electrodynamic, exciter mechanism acting on the at least one measuring tube for producing and maintaining mechanical oscillations of the measuring tube, a sensor arrangement for producing at least one oscillation measurement signal representing oscillations of the measuring tube and having at least one oscillation sensor arranged on the measuring tube or in its vicinity, and a measurement pickup housing. In an inline measuring device of the invention, it is additionally provided that the measuring device electronics monitors a static internal pressure within the measurement pickup housing and / or a hermeticity of the at least one measuring tube.

Owner:ENDRESS HAUSER FLOWTEC AG

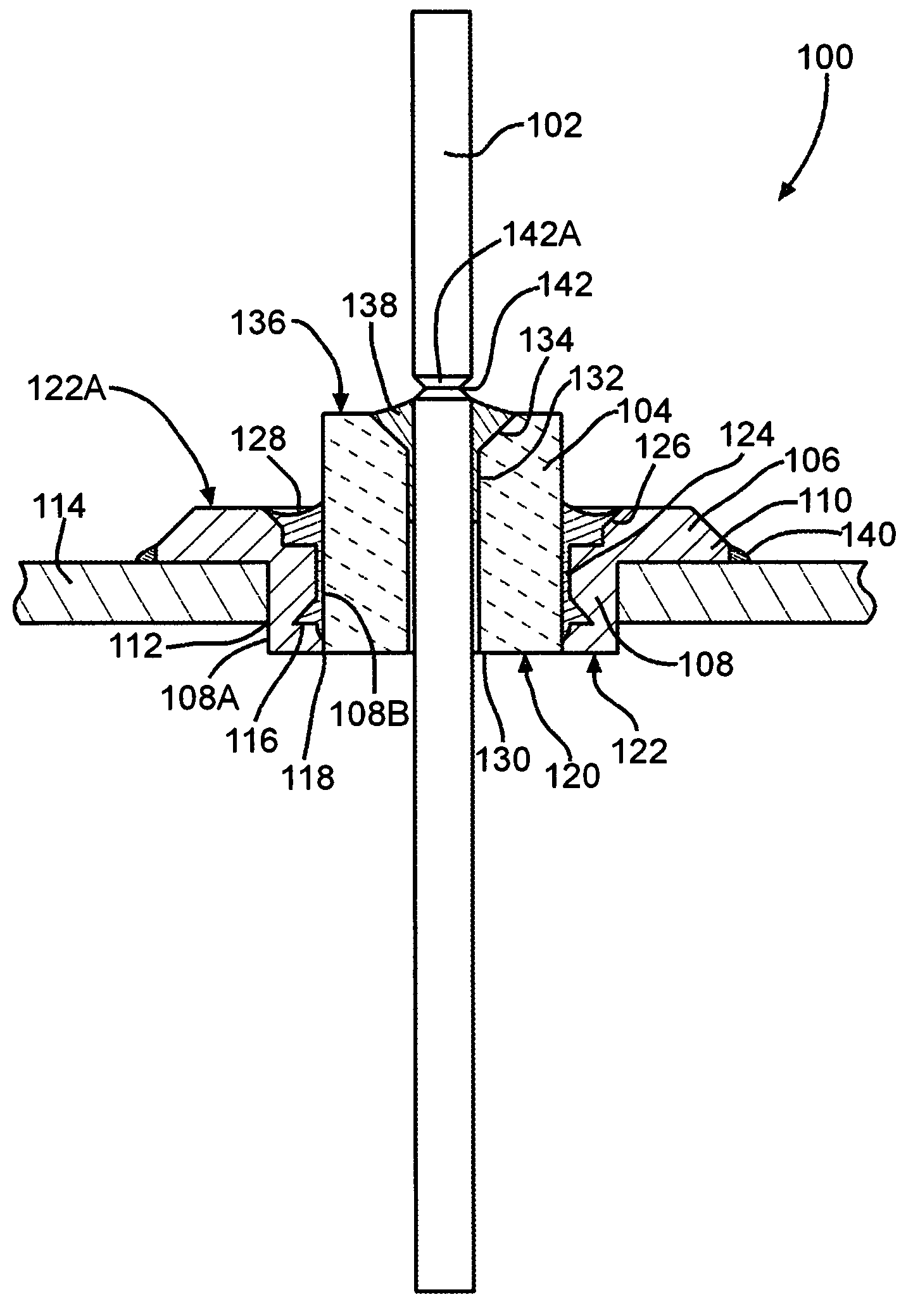

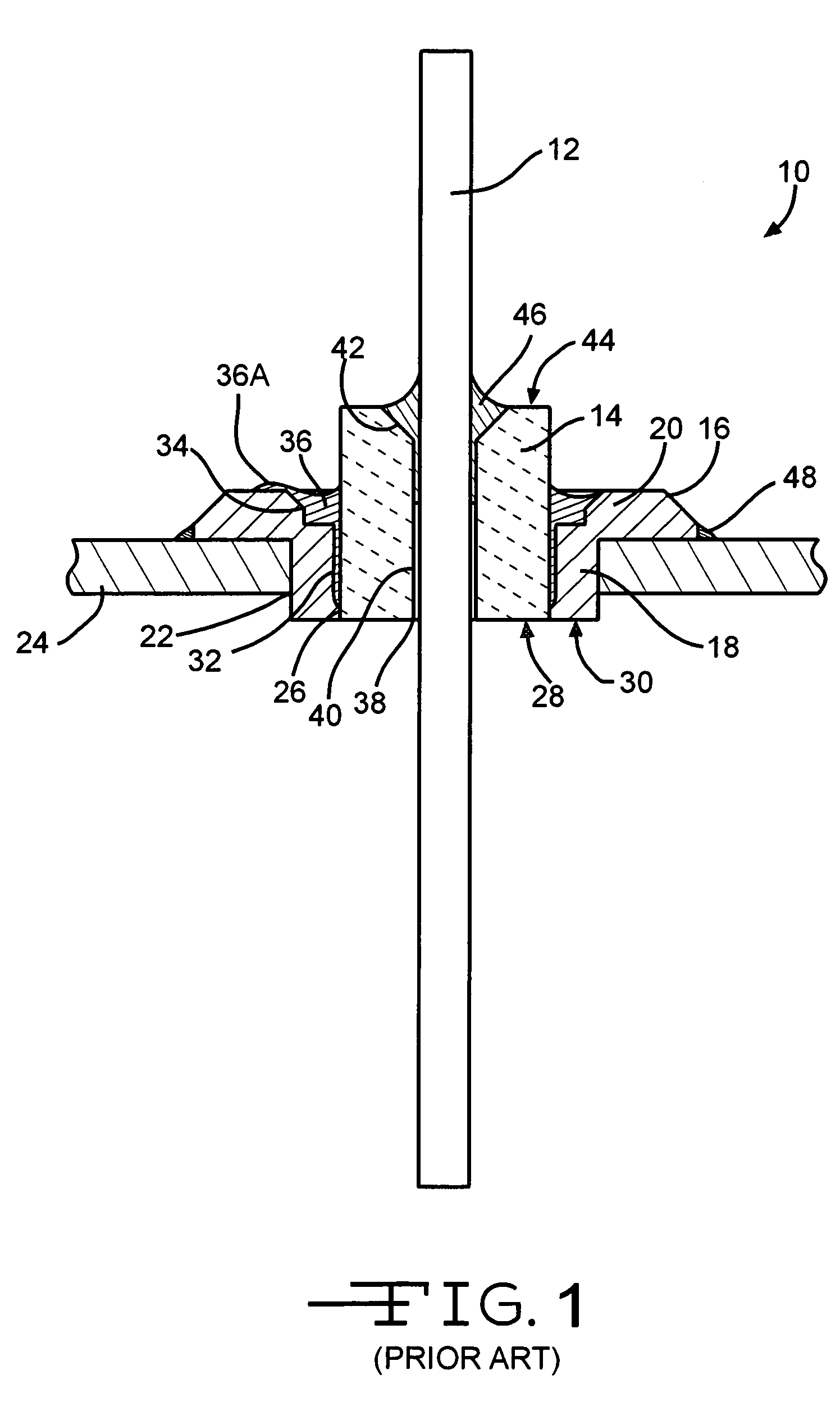

Method for minimizing stress in feedthrough capacitor filter assemblies

A feedthrough terminal pin assembly includes an outer ferrule hermetically sealed through a braze joint to an insulator seated within the ferrule is described. The insulator is also hermetically brazed to at least one terminal pin. The terminal pin is provided with a braze retention structure such as an annular groove that prevents braze material from filleting past the groove. Similarly, either the ferrule or the insulator is provided with a retention structure such as an annular groove that prevents braze material spill out from the insulator / ferrule interface. In that manner, the braze retention structures keep braze material from accumulating in unwanted areas where it could adversely affect hermeticity as well as proper attachment of an EMI filter to the feedthrough assembly.

Owner:WILSON GREATBATCH LTD

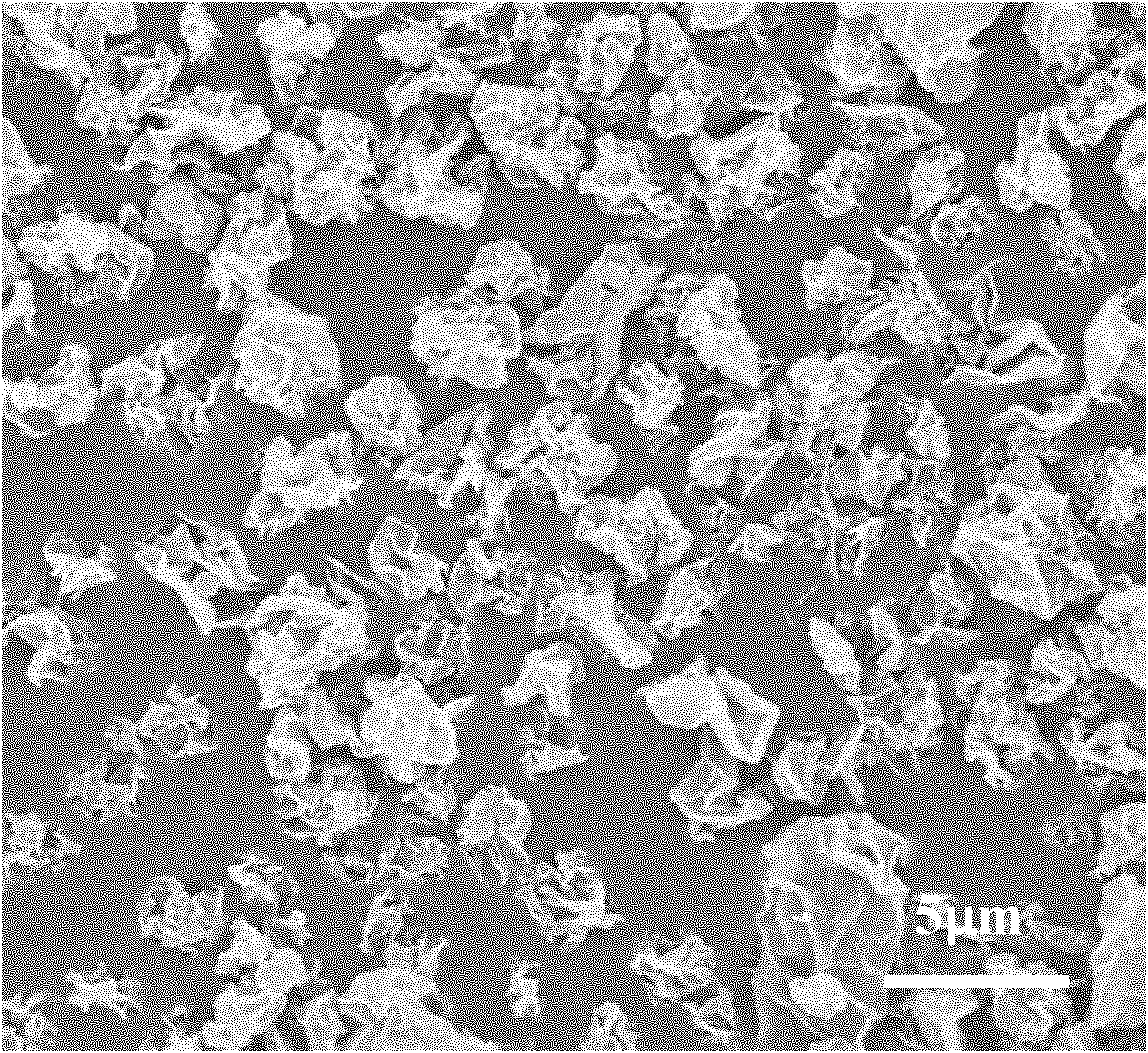

Method for preparing graphene powder

The invention relates to a method for preparing graphene powder in large scale, which is characterized by comprising the following steps of: firstly, uniformly peeling graphene oxide into a graphene oxide suspension solution; then, atomizing the graphene oxide solution by using the spray drying technology comprising spray pyrolysis drying and spray freeze drying, and removing a solvent to obtain graphene oxide powder; and finally, oxidizing grapheme by using the non-expansion heat treatment process to obtain non-agglomerative graphene powder. The continuous preparation process of the spray technology and the non-expansion heat treatment process ensure the large-scale preparation of the graphene powder. The prepared graphene powder comprising intermediate product graphene oxide powder does not have agglomeration and has good dispersivity in the solvent. The graphene powder is used as a filling material to prepare high strength composite materials, conductive composite materials, novel air-tight flame-retardant composite materials, novel nanodevices and the like.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

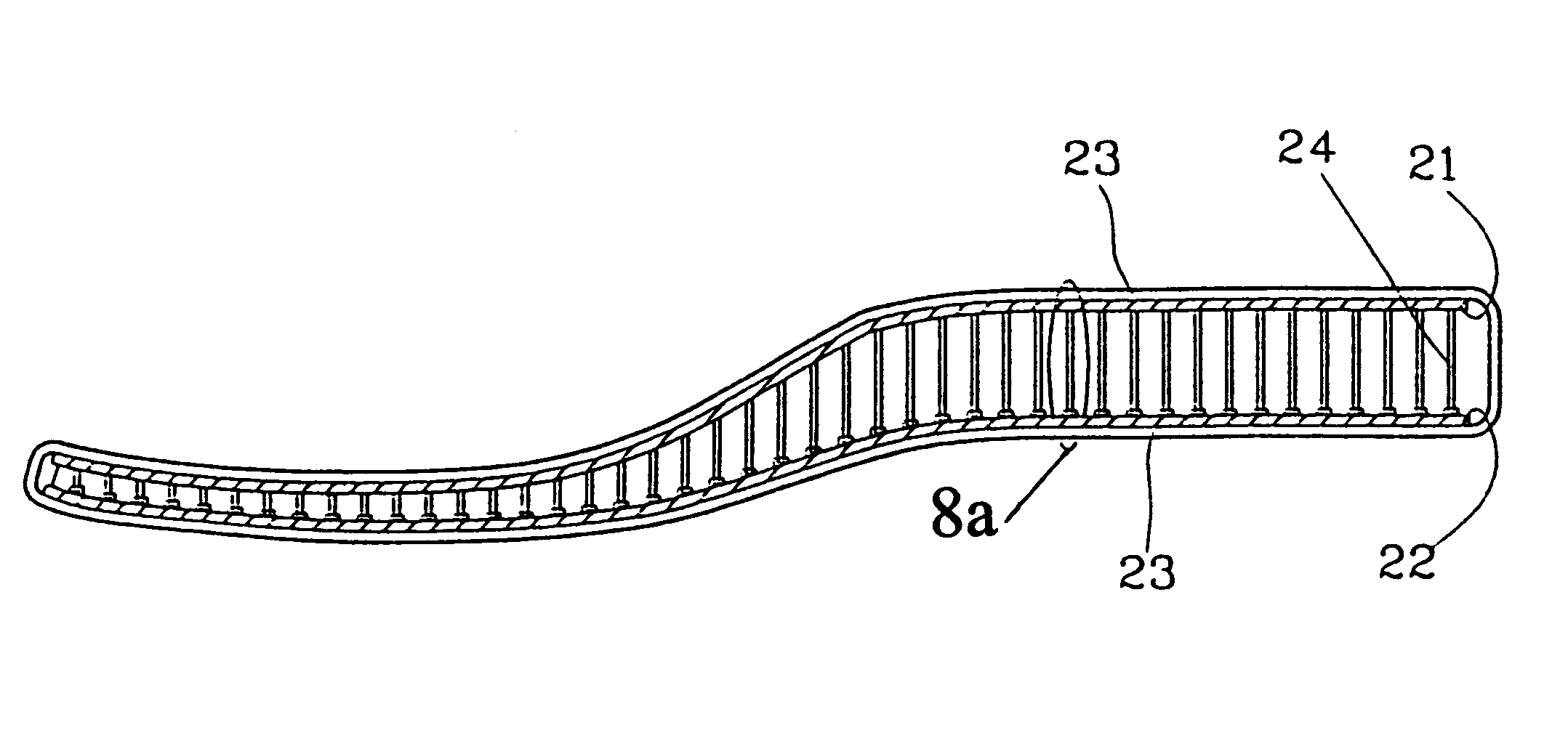

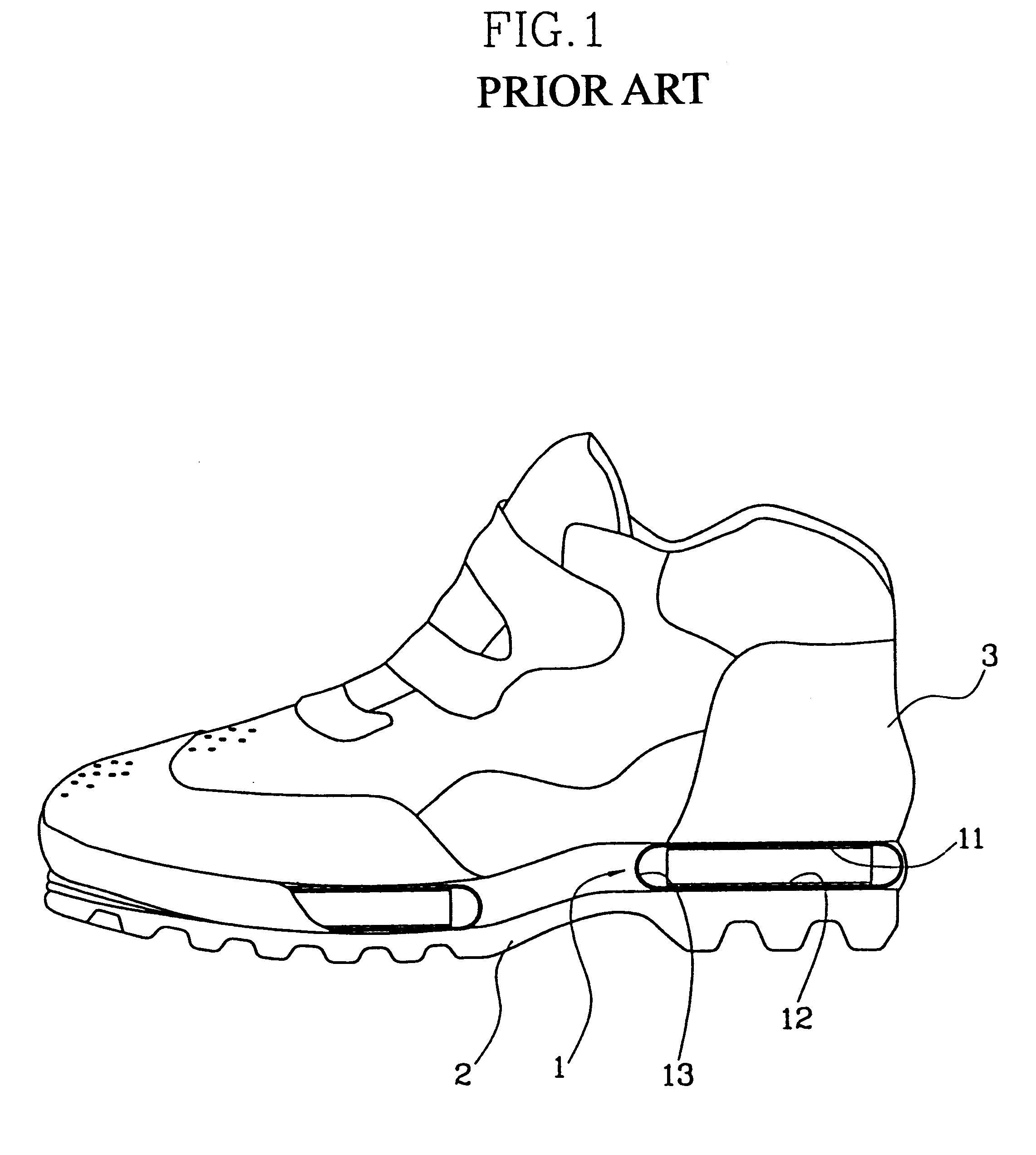

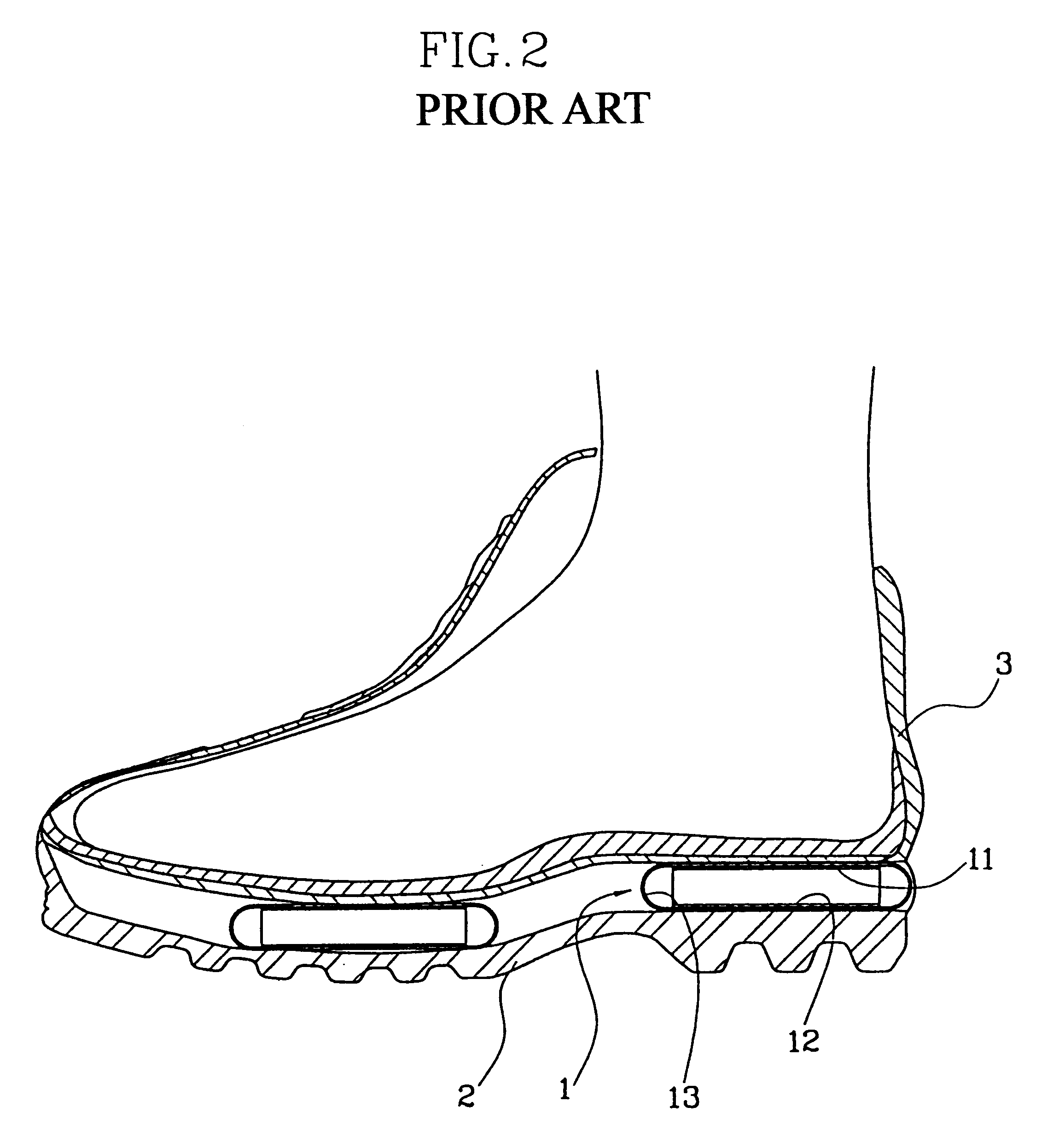

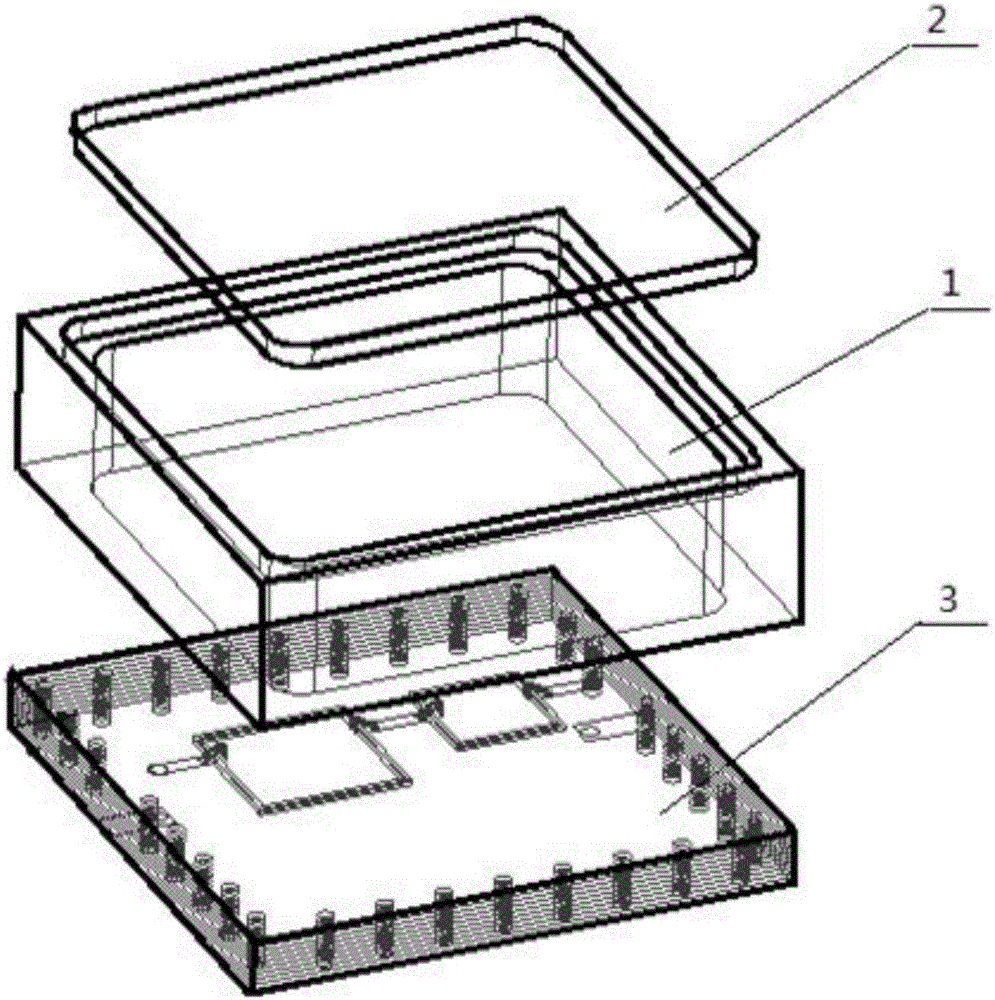

Air cushion having support pin structure for shock-absorbing, method for manufacturing the air cushion, and footgear comprising the air cushion

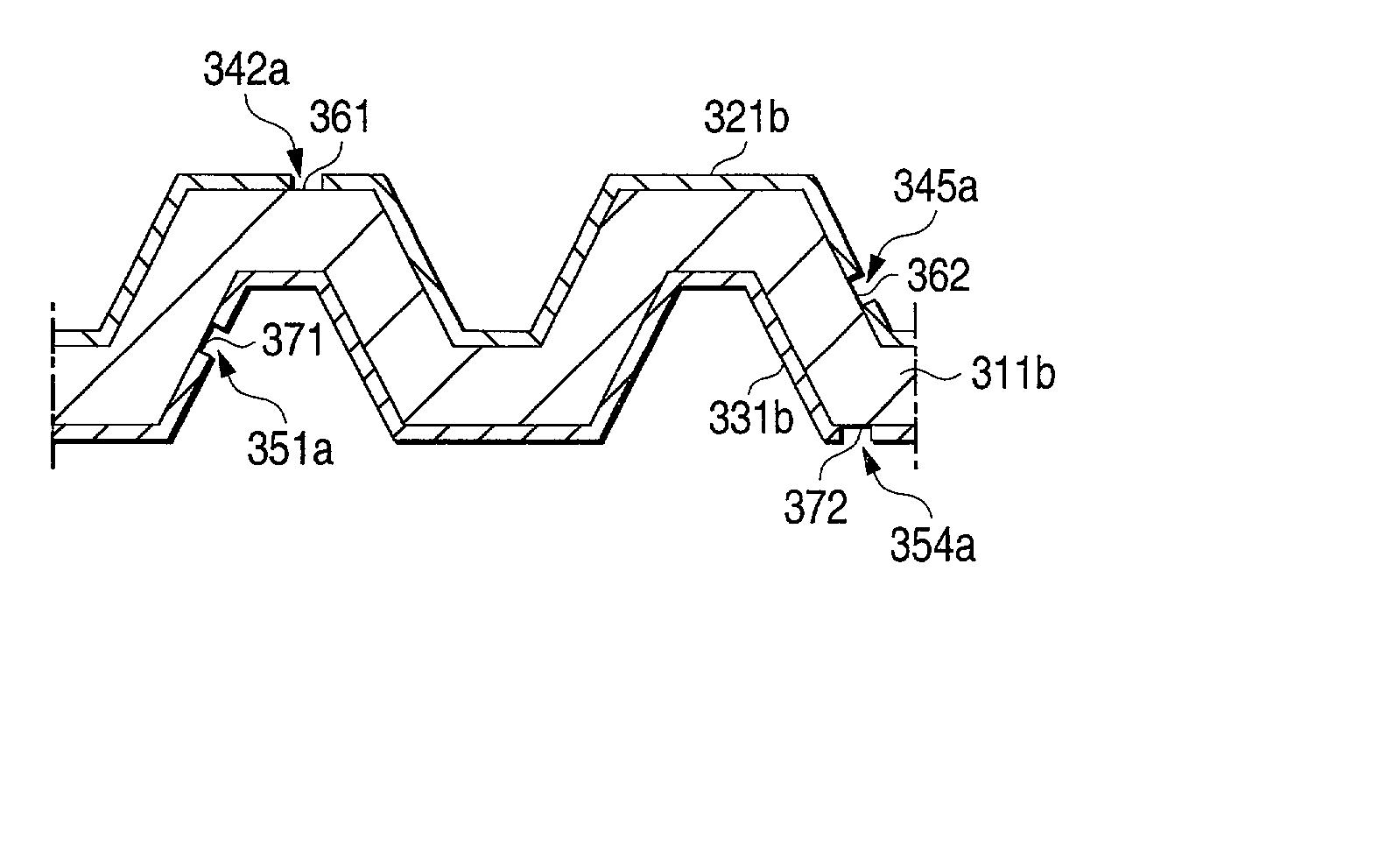

Disclosed is an air cushion having a support pin structure for absorbing shock, a method for manufacturing the air cushion, and footgear comprising the air cushion which does not exhibit any bulging effect, even upon application of an external pressure, to thereby improve the stability thereof. The air cushion includes: an upper plate having a plurality of support pins arranged at the same height or different height in a downward direction on the bottom surface thereof; a lower plate having a plurality of pin receiving bodies on the top surface thereof opposite to the upper plate, each of the pin receiving bodies having a groove into which each of the support pins is inserted; and a cushion body adapted to surround the coupled state of the upper plate with the lower plate where the support pins are received and fixed into the pin receiving bodies, thereby maintaining the air-tightness therein.

Owner:YANG SOO DONG

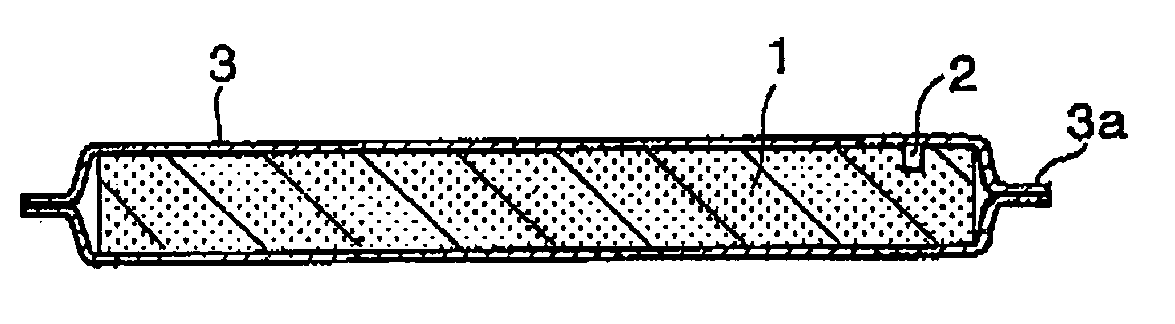

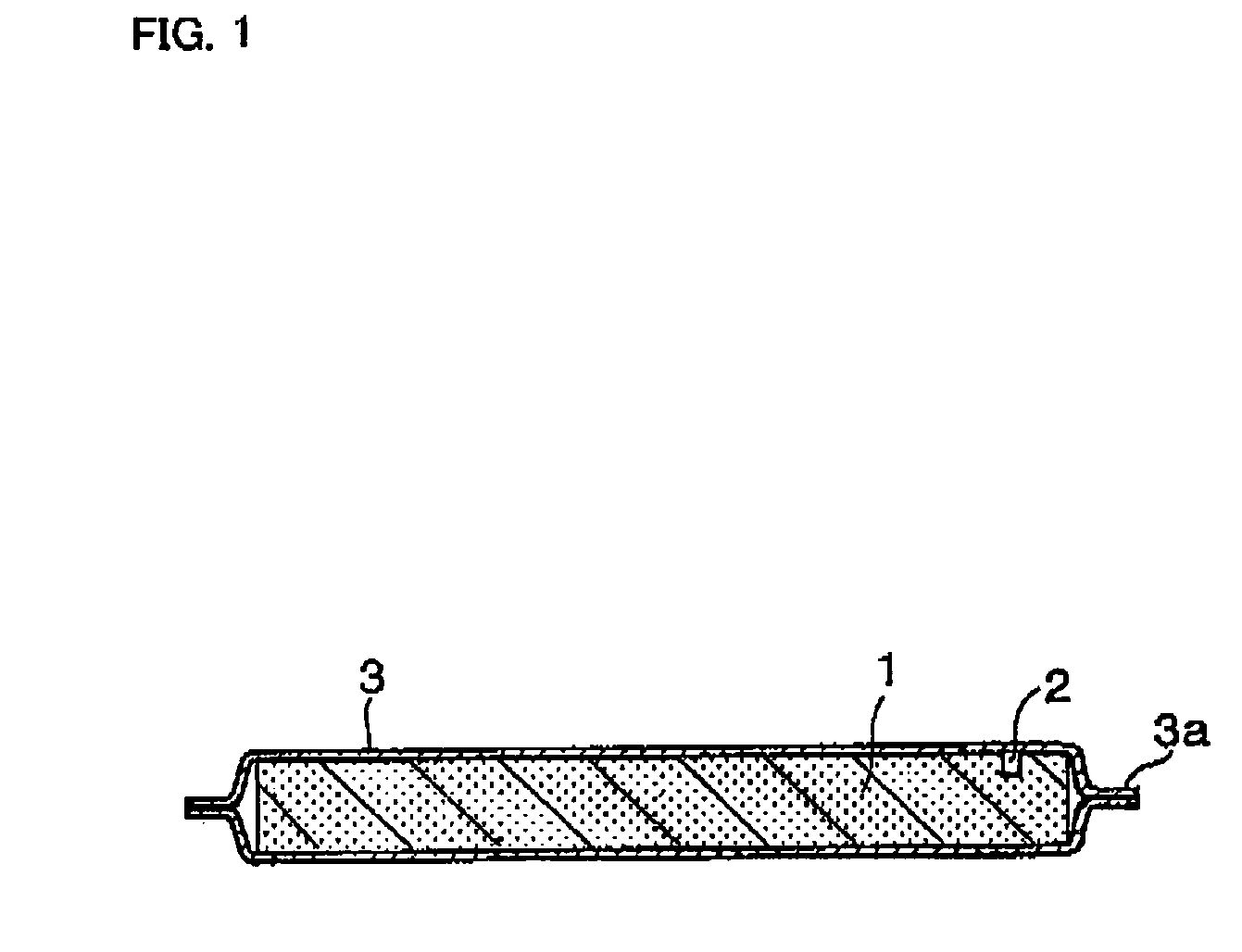

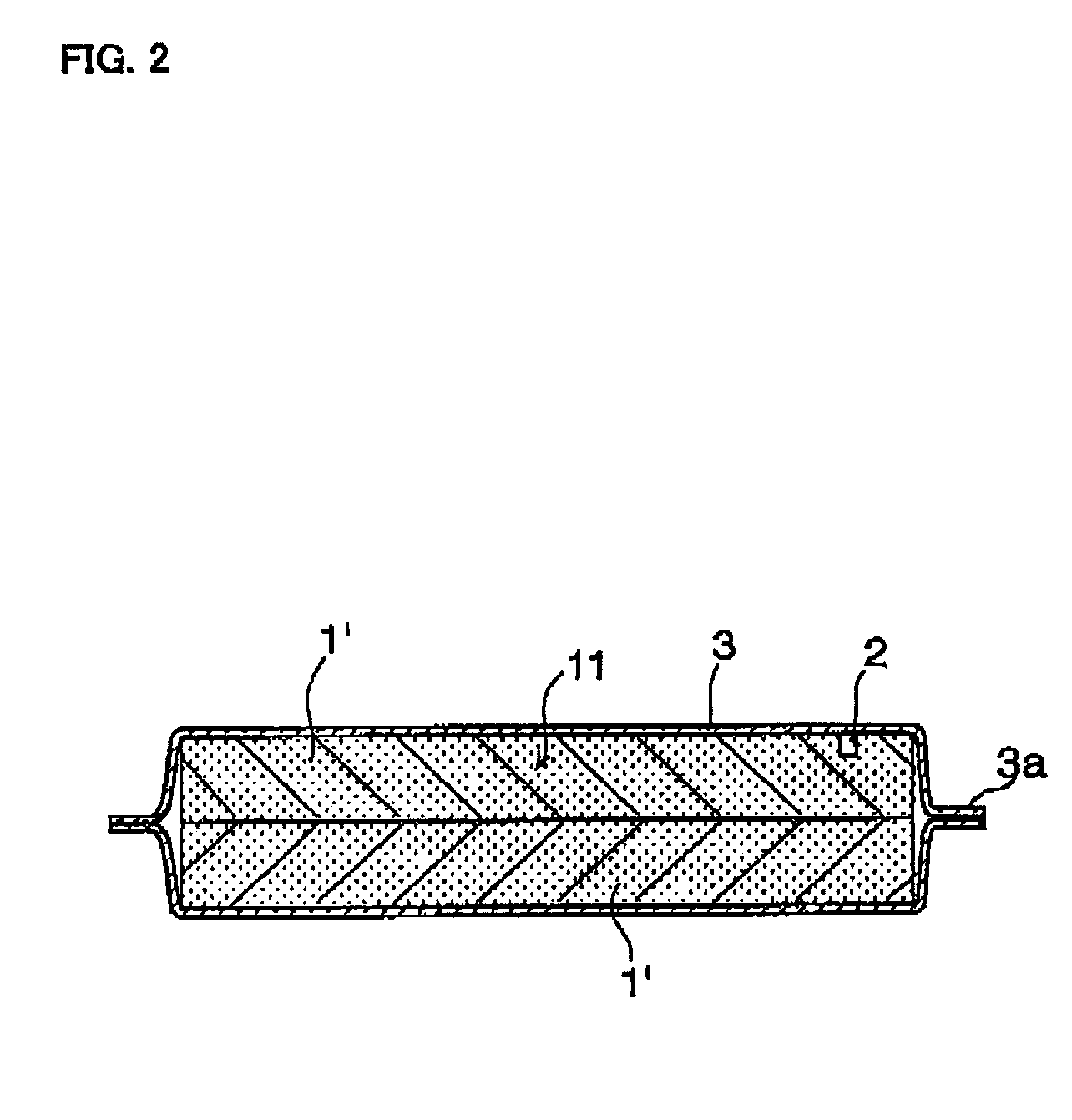

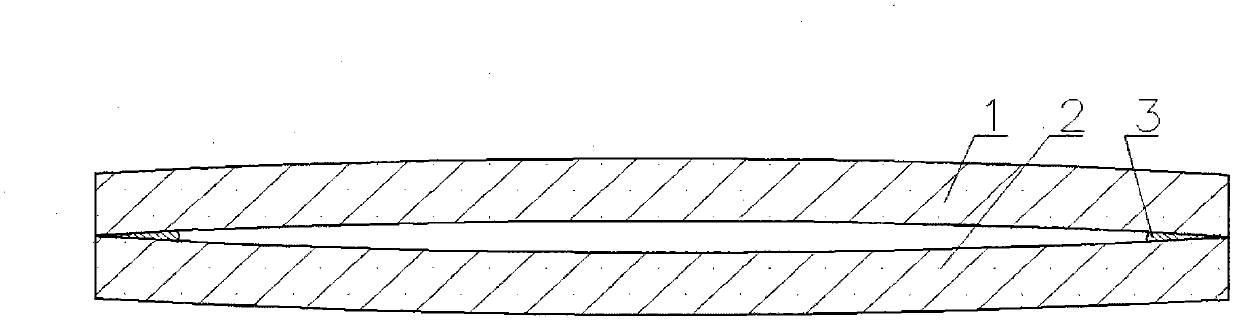

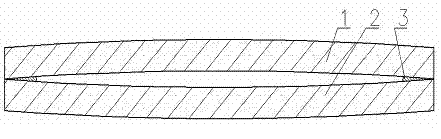

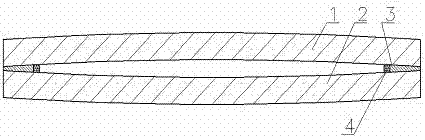

Vacuum heat insulating material and manufacturing method therefor

InactiveUS20040253406A1Improve performanceLow thermal conductivityThermal insulationDomestic cooling apparatusSorbentDecreased pressure

Provided is a vacuum heat insulating material, using inorganic fibers as a core material, high in heat insulating performance (low in thermal conductivity), capable of maintaining the heat insulating performance for a long period, free of defects such as projections and depressions on a large scale on a surface thereof, short in manufacturing time and advantageous in terms of cost; and a manufacturing method therefor. A vacuum heat insulating material of the present invention is of a construction in which a core material 1 and a gas adsorbent 2 are housed in a bag 3 made from a gas barrier film and the interior thereof is reduced in internal pressure thereof and air-tightly sealed, wherein the core material 1 is a molded product obtained by coating a binder B on inorganic fibers having an average fiber diameter in the range of from 3 to 5 mum at a coating amount in the range of from 0.5 to 1.5 wt % relative to the fibers and heat pressing the inorganic fibers, or a laminate fabricated by stacking two or more sheets of the molded product.

Owner:ASAHI FIBER GLASS CO LTD

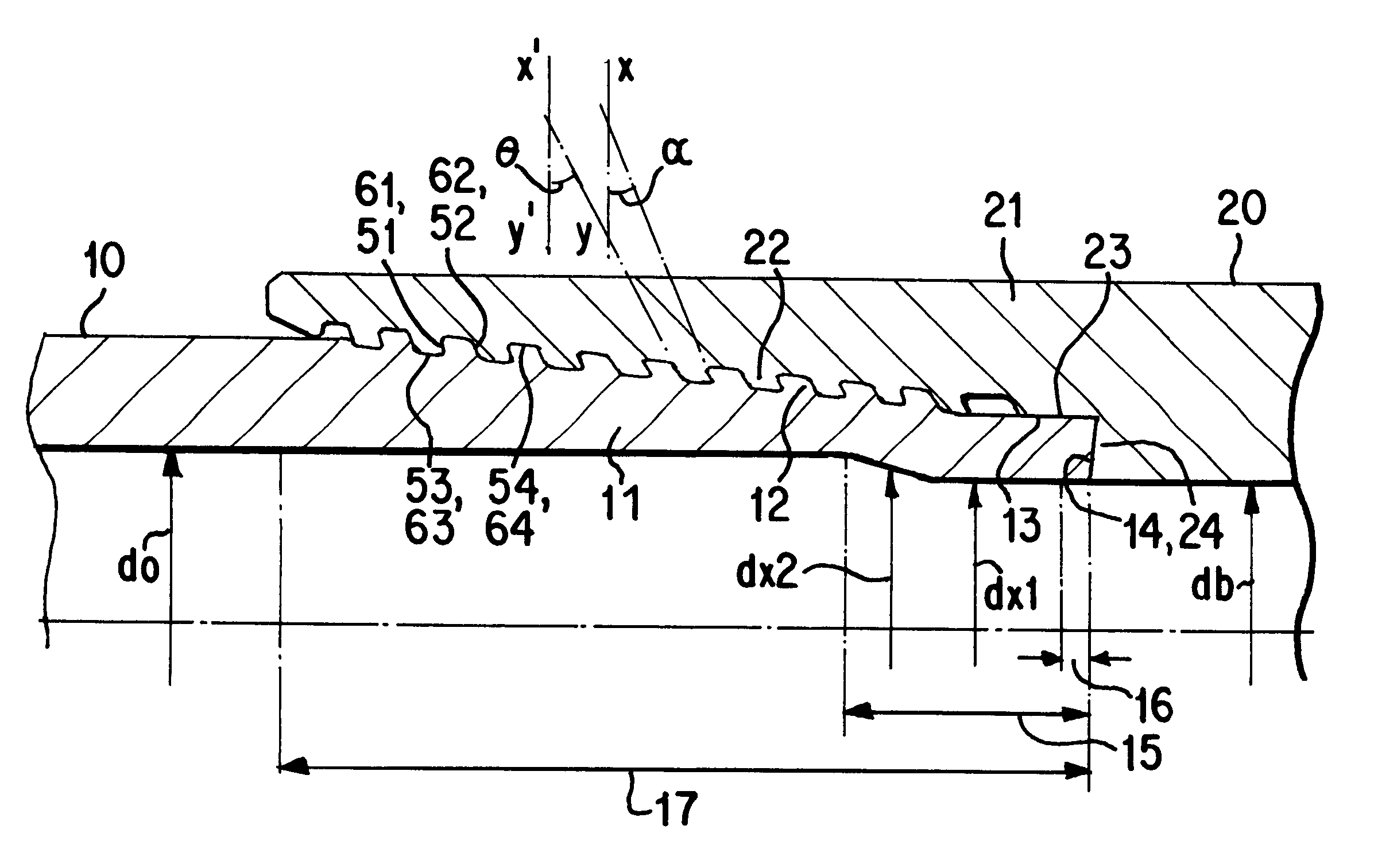

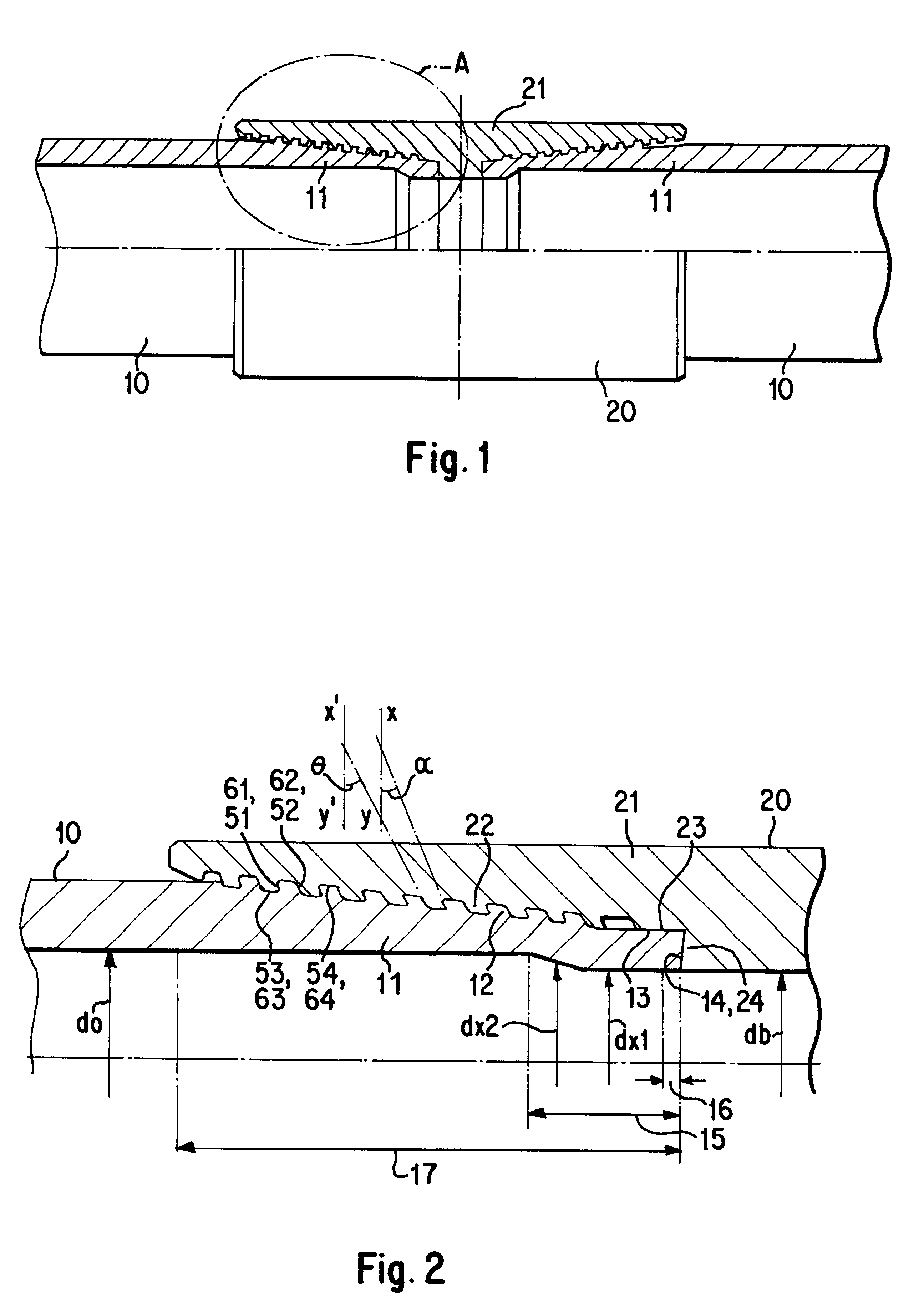

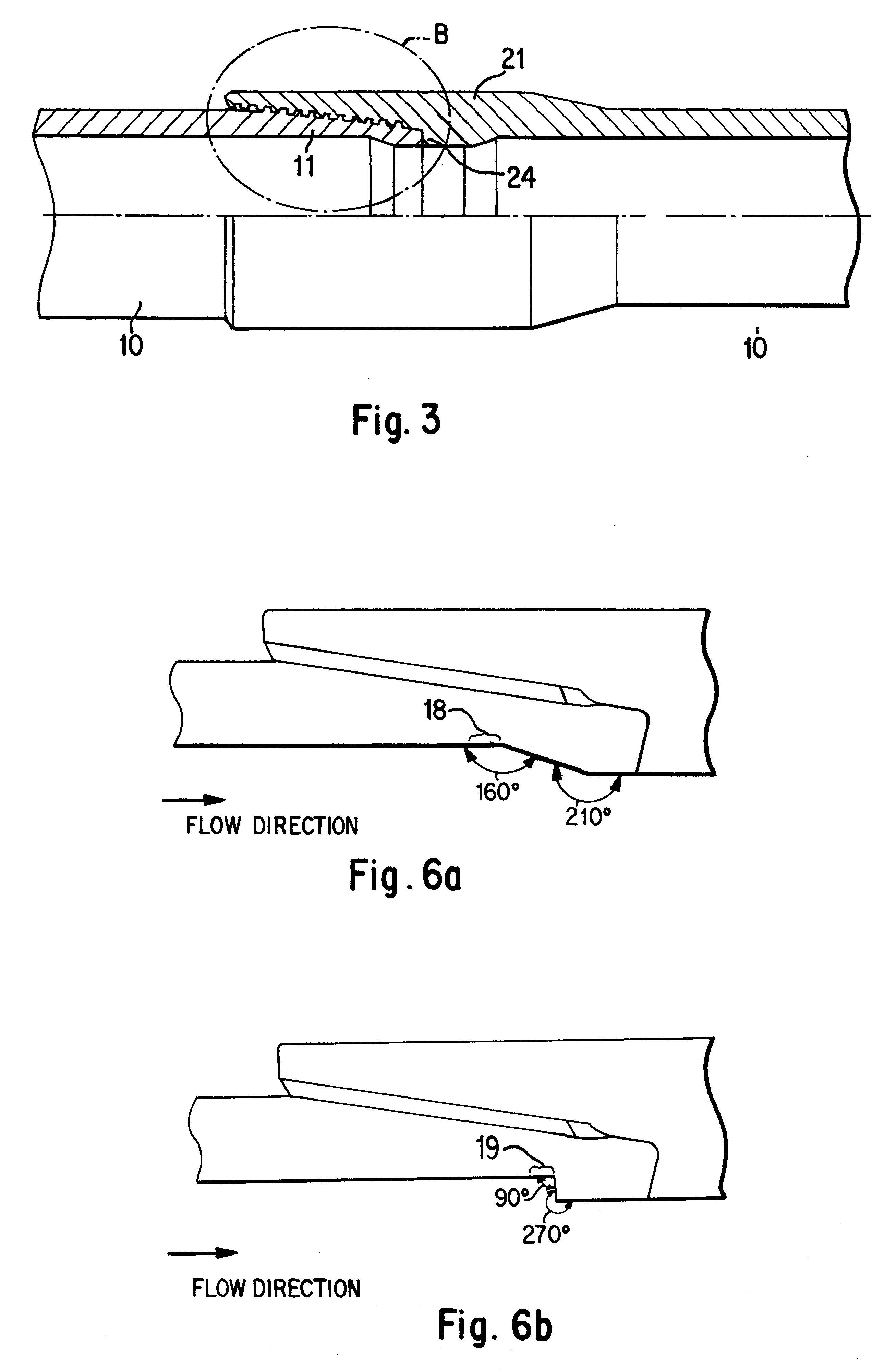

Threaded connection for oil country tubular goods and its method of manufacturing

[Purpose]To provide a threaded connection capable of preventing deterioration of gas tightness from occurring when a tensile stress acts thereon after a compressive force in the direction of the axis of a pipe is applied.[Means of Solving Problems](1) A threaded connection for oil country tubular goods wherein a length (15) of a thick walled portion with a diameter defined in the formula (1), is longer than the length (16) from seal contact to the extremist of the pin section, shorter than a half of the length (17) of the pin section, the rest of inside diameter is equal to the inside diameter of pipe proper, having smooth tapered inner wall between thick walled portion and pipe proper. The inside diameter of the box section of torque shoulder section is the same as inside diameter of thick wall.Where dx(mm)=inside diameter of the thick walled portion of the pin section, and d0(mm)=inside diameter of the pipe proper.

Owner:SUMITOMO METAL IND LTD +1

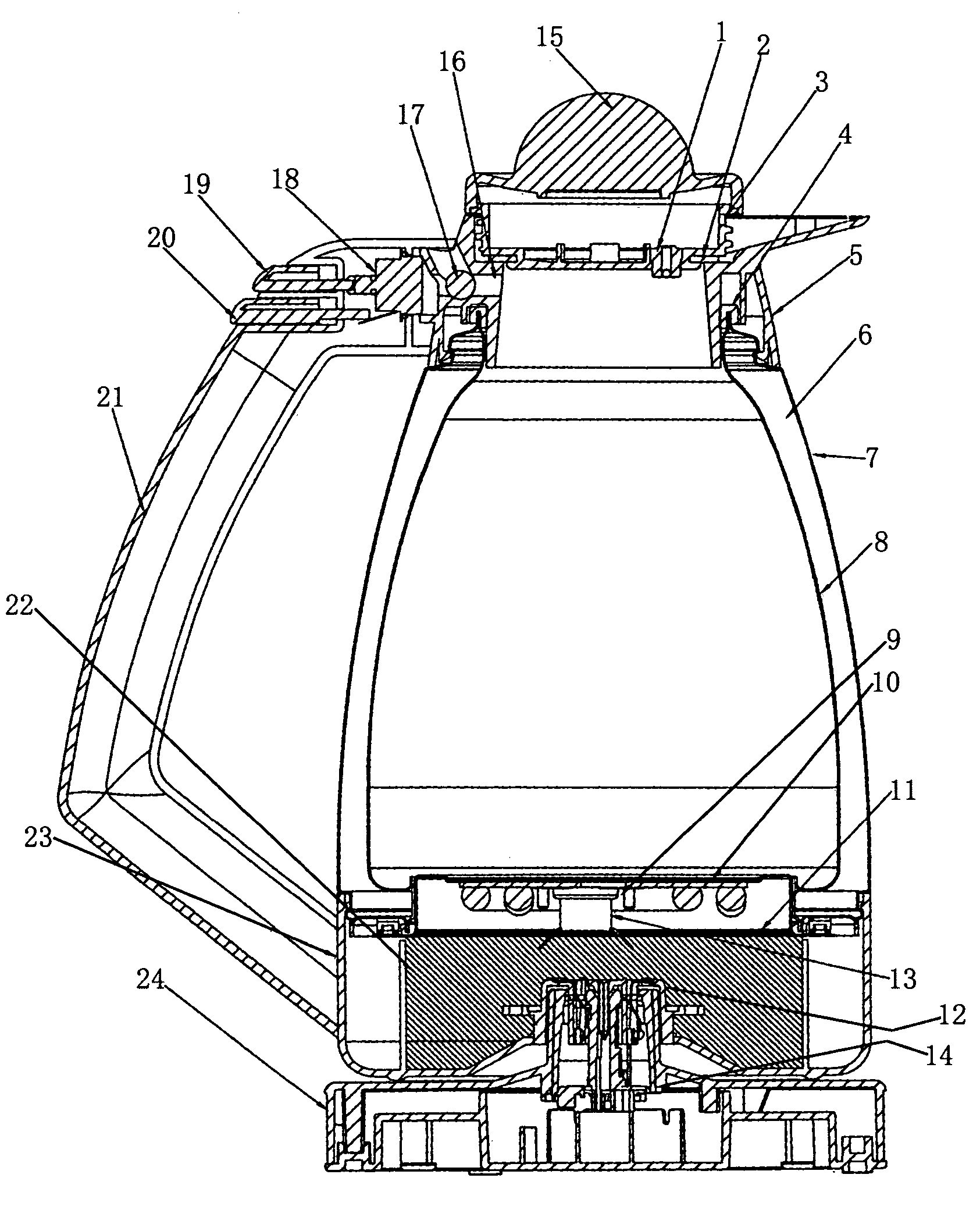

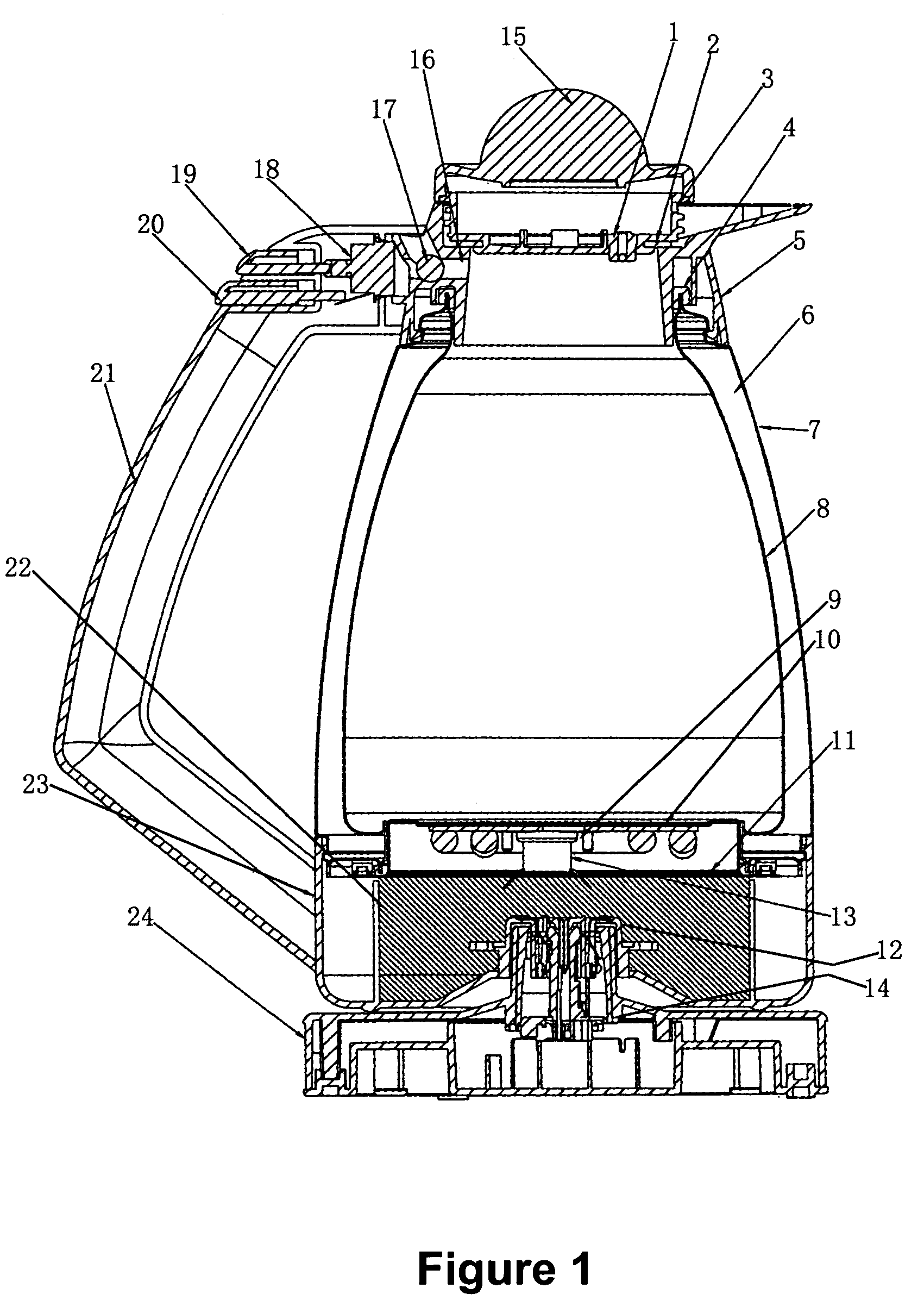

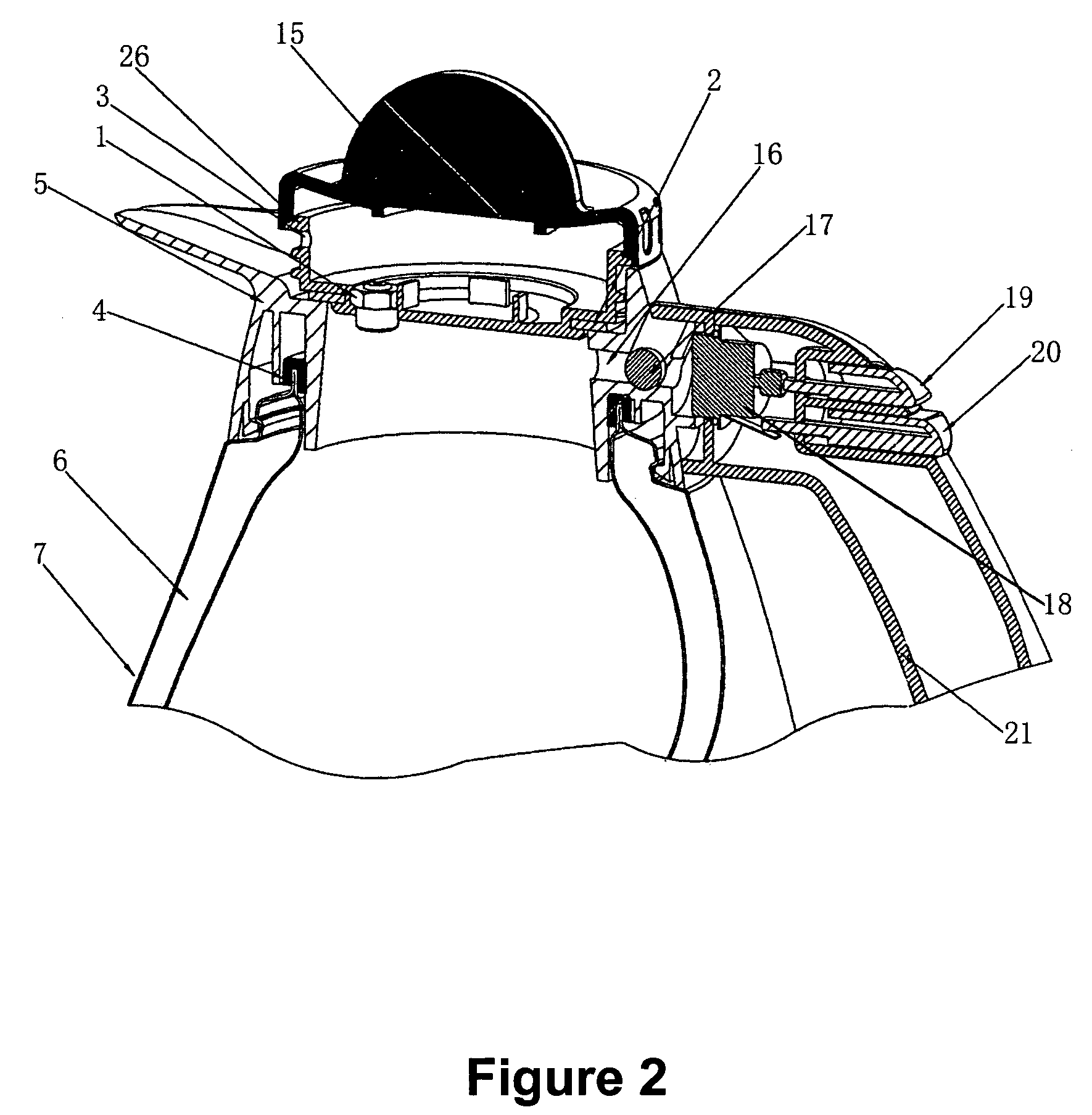

Electric thermos jug

InactiveUS7091455B2Improve air tightnessEasy to useCooking-vessel materialsDomestic cooling apparatusElectricityWater quality

Owner:FUNG SHIU PO

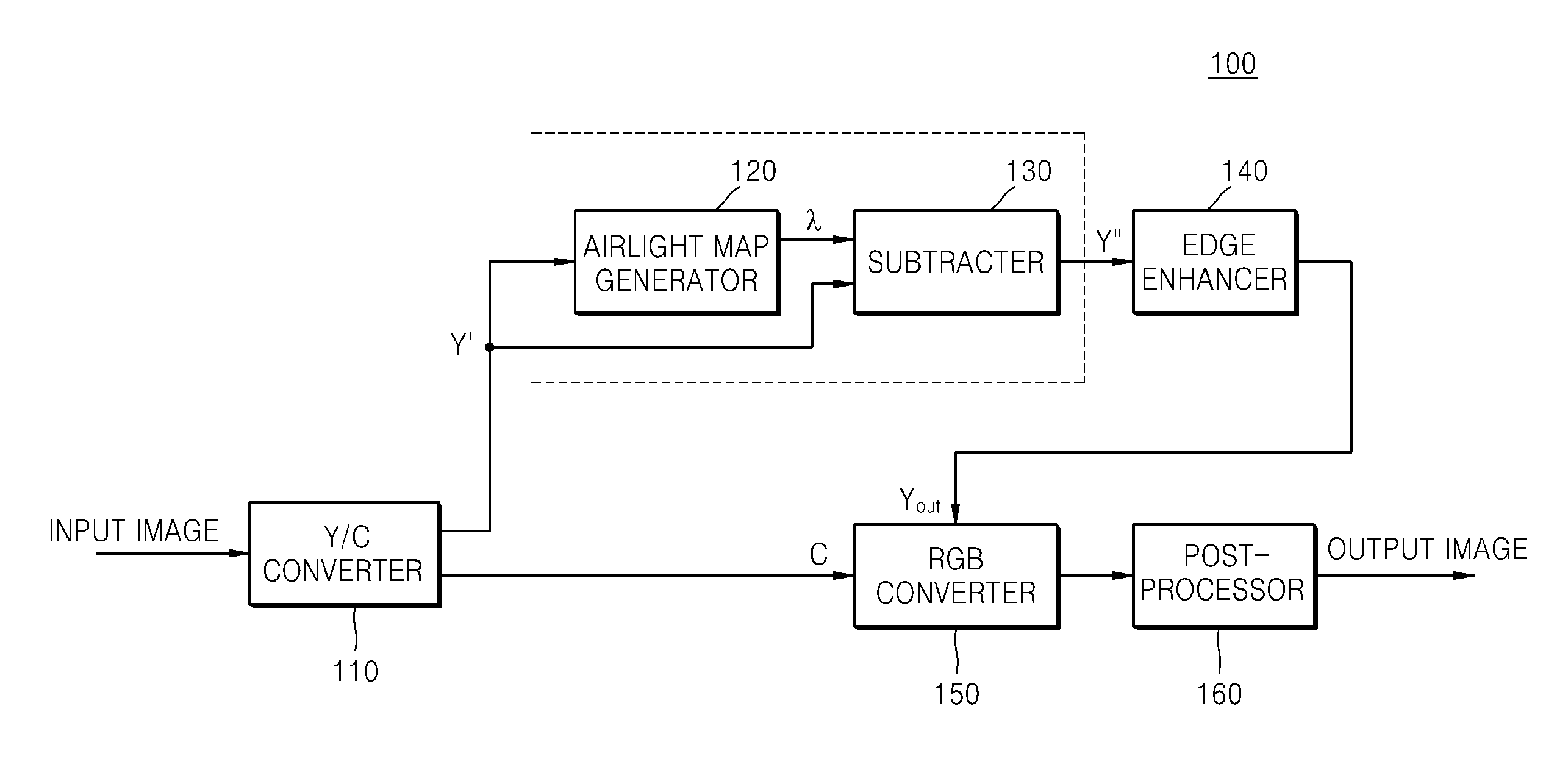

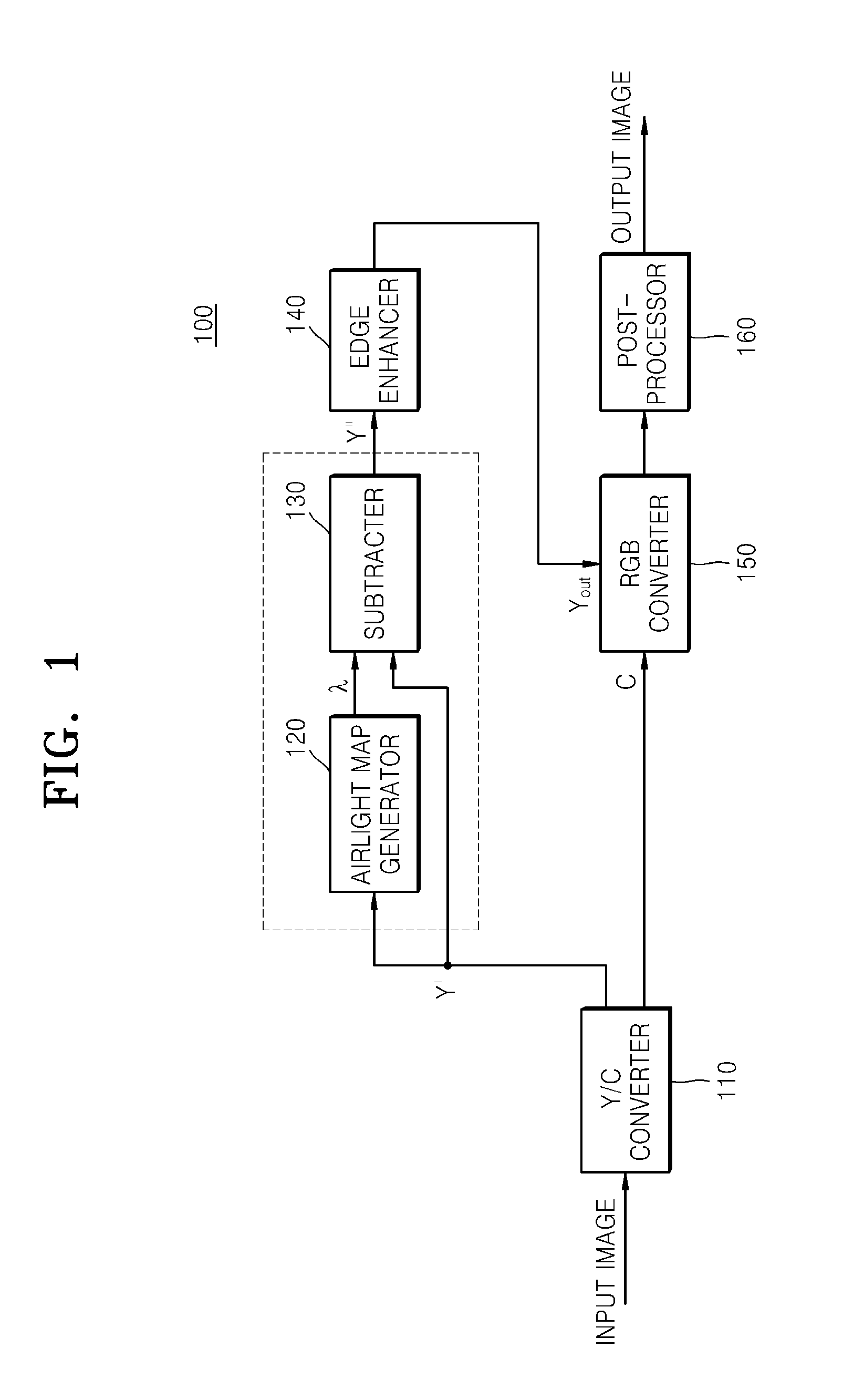

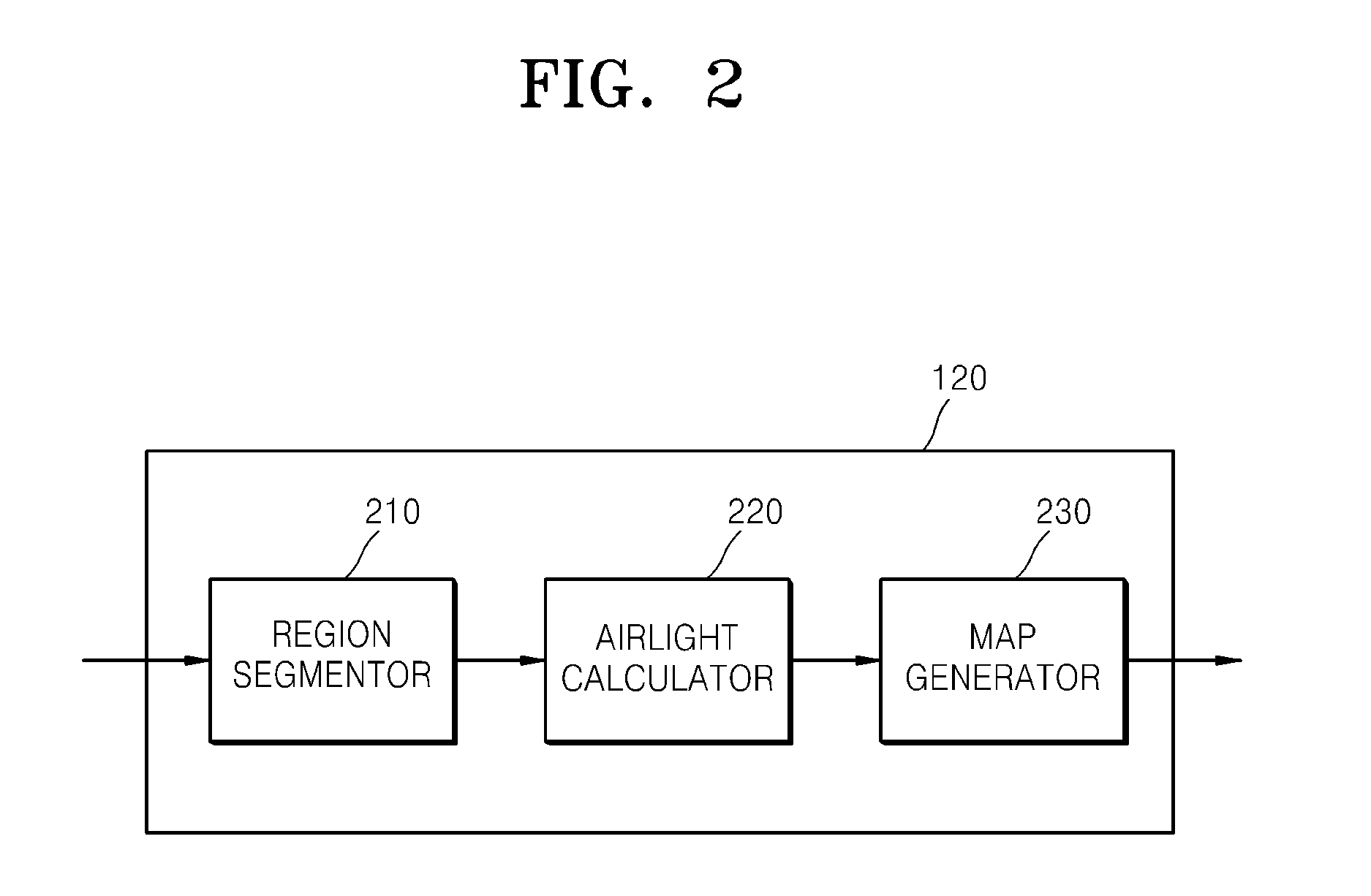

Image processing method and apparatus for correcting distortion caused by air particles as in fog

ActiveUS20100040300A1Enhance the imageComponent can be removedImage enhancementTelevision system detailsImaging processingAir tightness

Provided are a method and apparatus for processing an image. The method includes receiving a first luminance image of an image including airlight, which is a type of light that occurs in a foggy environment, and generating an airtight map based on a ratio between an average luminance of the first luminance image, and a standard deviation; and removing the airtight by subtracting the airtight map from the first luminance image and outputting a second luminance image. According to the present invention, airlight components may be effectively removed.

Owner:KOREA UNIV IND & ACADEMIC CALLABORATION FOUND +1

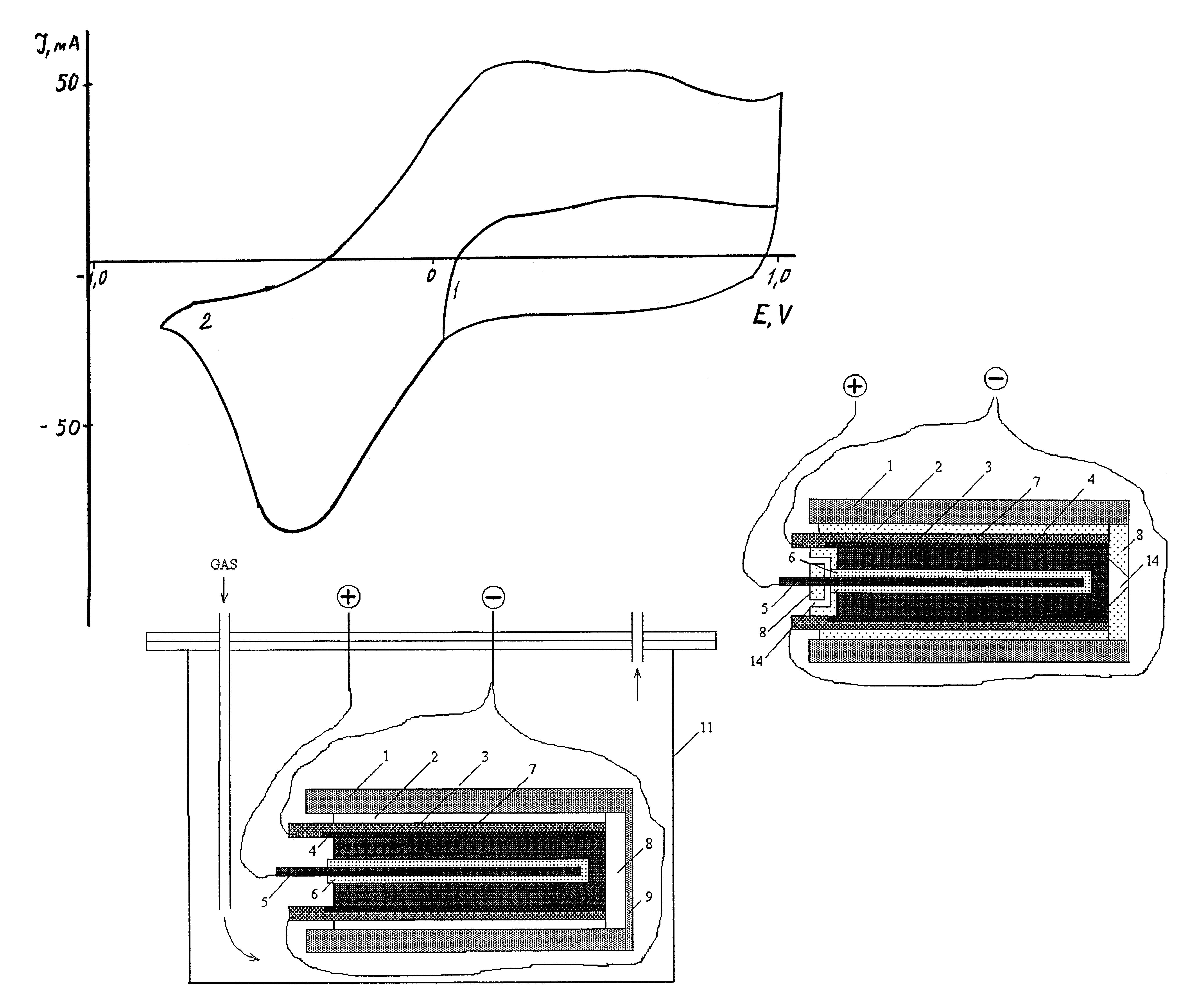

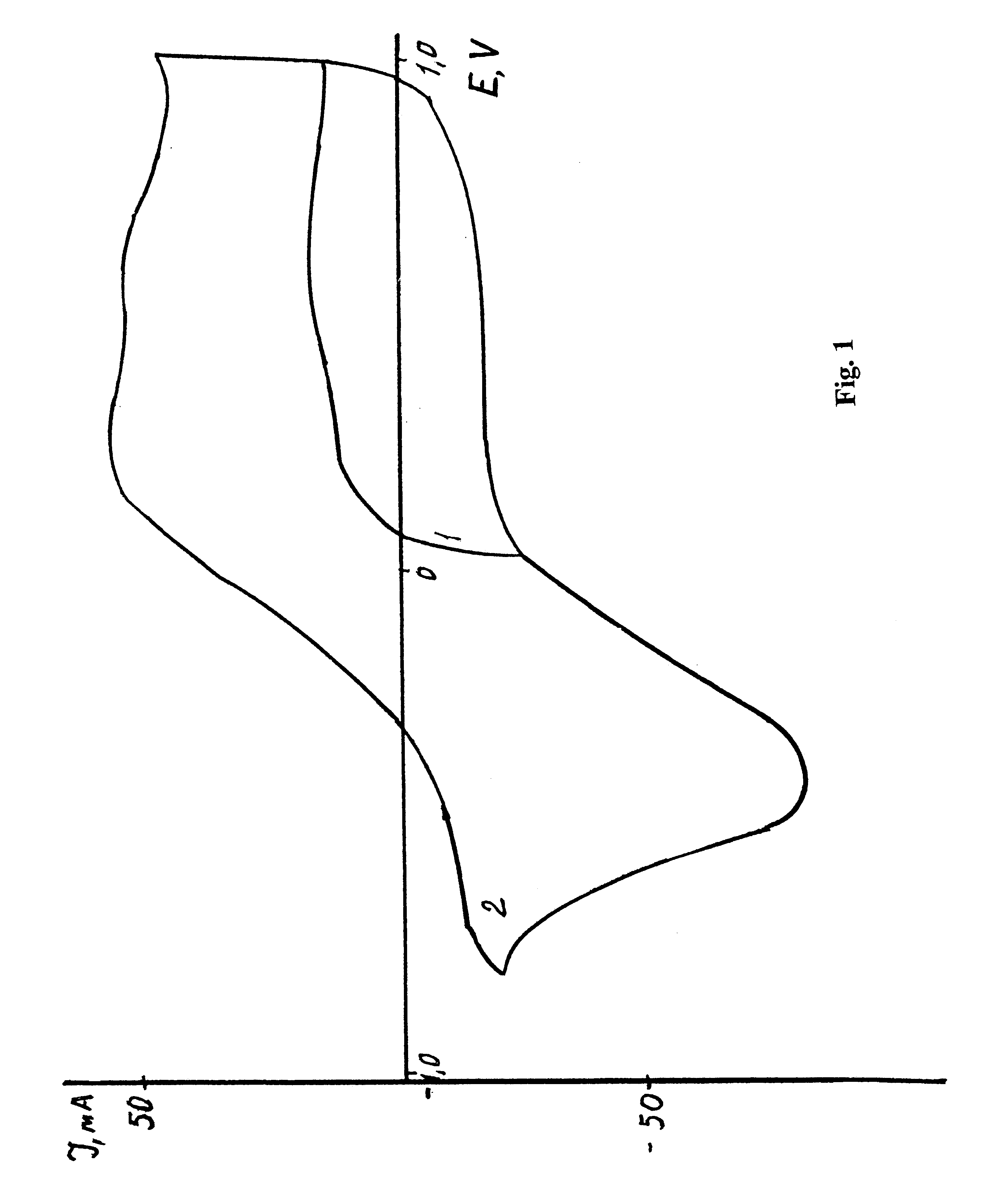

Method of formation and charge of the negative polarizable carbon electrode in an electric double layer capacitor

InactiveUS6706079B1Protecting/adjusting hybrid/EDL capacitorDouble layer capacitorsCapacitanceHydrogen

A method of formation and charge of a negative polarizable electrode of an electric double layer capacitor. The method can be used for manufacturing of high capacitance capacitors utilizing the energy of the electric double layer. The methods achieve hydrogen evolution on carbonaceous materials using very negative potentials. The methods provide an EDL capacitor, employing an aqueous electrolyte, with improved specific energy. The methods may also ensure the hermeticity of the capacitor. The methods include pretreating the electric double layer capacitor by keeping the negative polarizable electrode at a desired minimum potential prior to use. Desirably, the minimum potential ranges from about -0.25 to about -1.2 V vs. a reference hydrogen electrode.

Owner:WAINWRIGHT D WALKER

Water-proof acid resistant heat resistant light heat insulating casting material and its manufacturing method

InactiveCN1537821AReduce intensityGood impermeability and antifreeze performanceSolid waste managementCeramic shaping apparatusHigh resistancePolymer science

A water-proof light-weight insulating casting material resisting acid and high temp for the liner of chimney is prepared from the inorganic light aggregate particles resisting acid and high temp, the acid and high temp resistant powder, the acid and high temp resistant adhesive and additive through proportional mixing, stirring, casting in mould for 1-5 days, demoulding, and natural drying and curing. Its advantages are high volume density and strength, light weight and high resistance to water, acid and high temp.

Owner:张东辉 +1

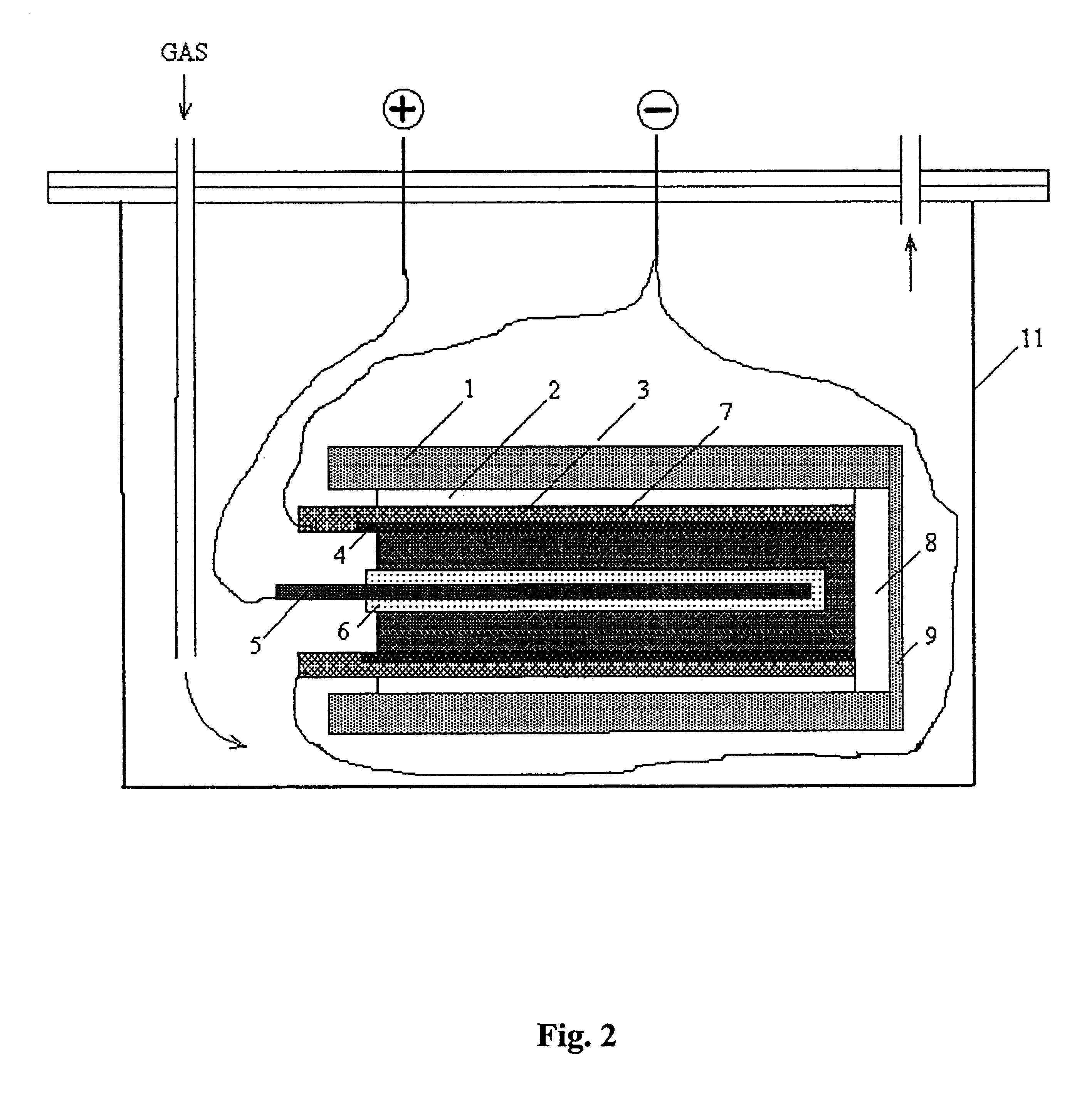

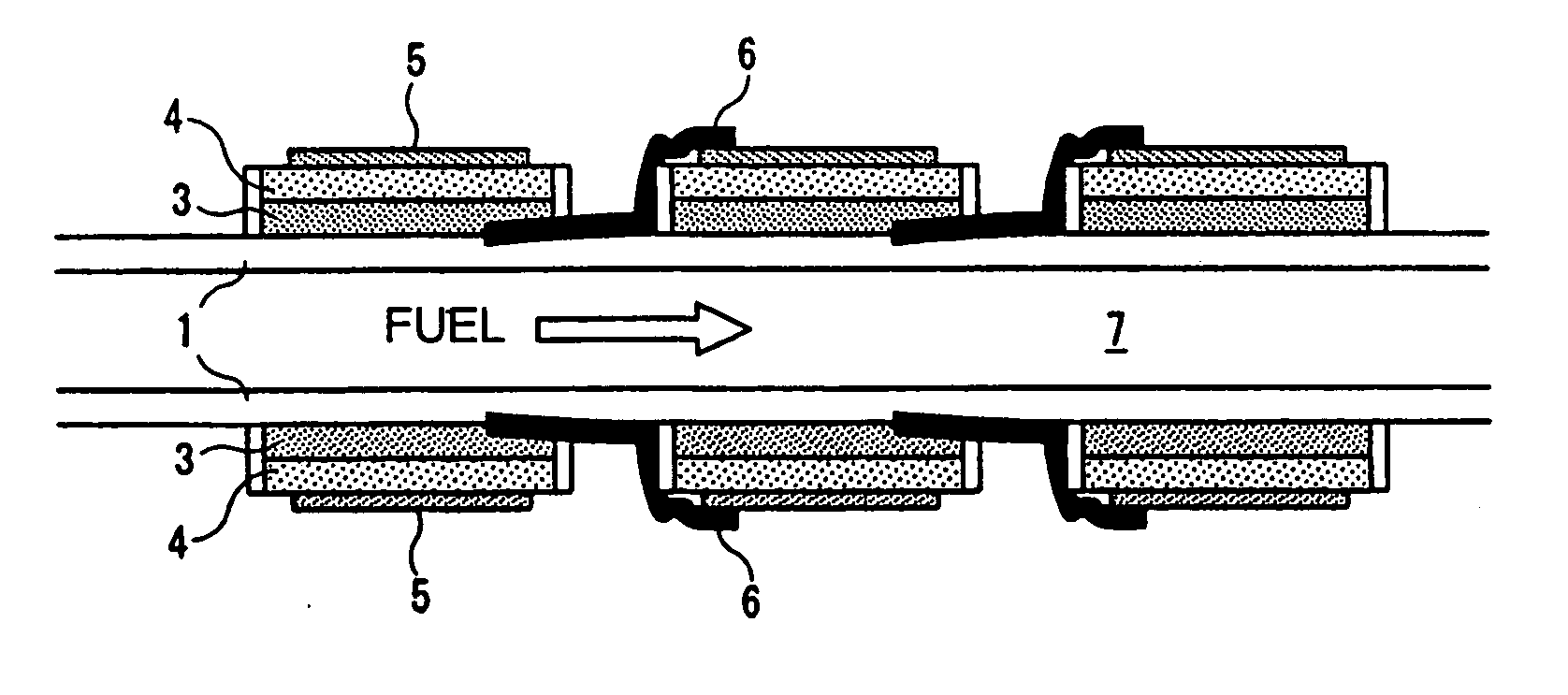

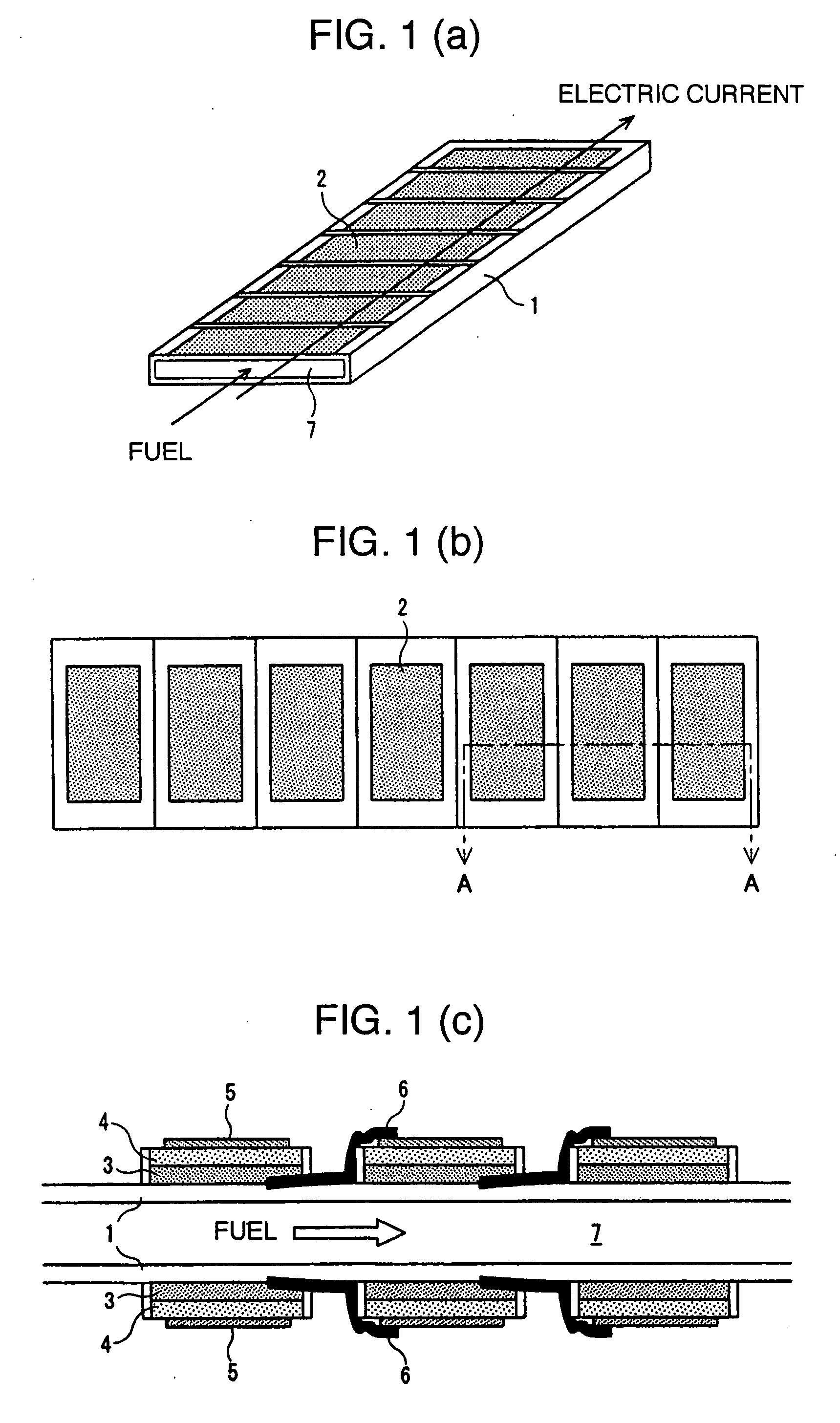

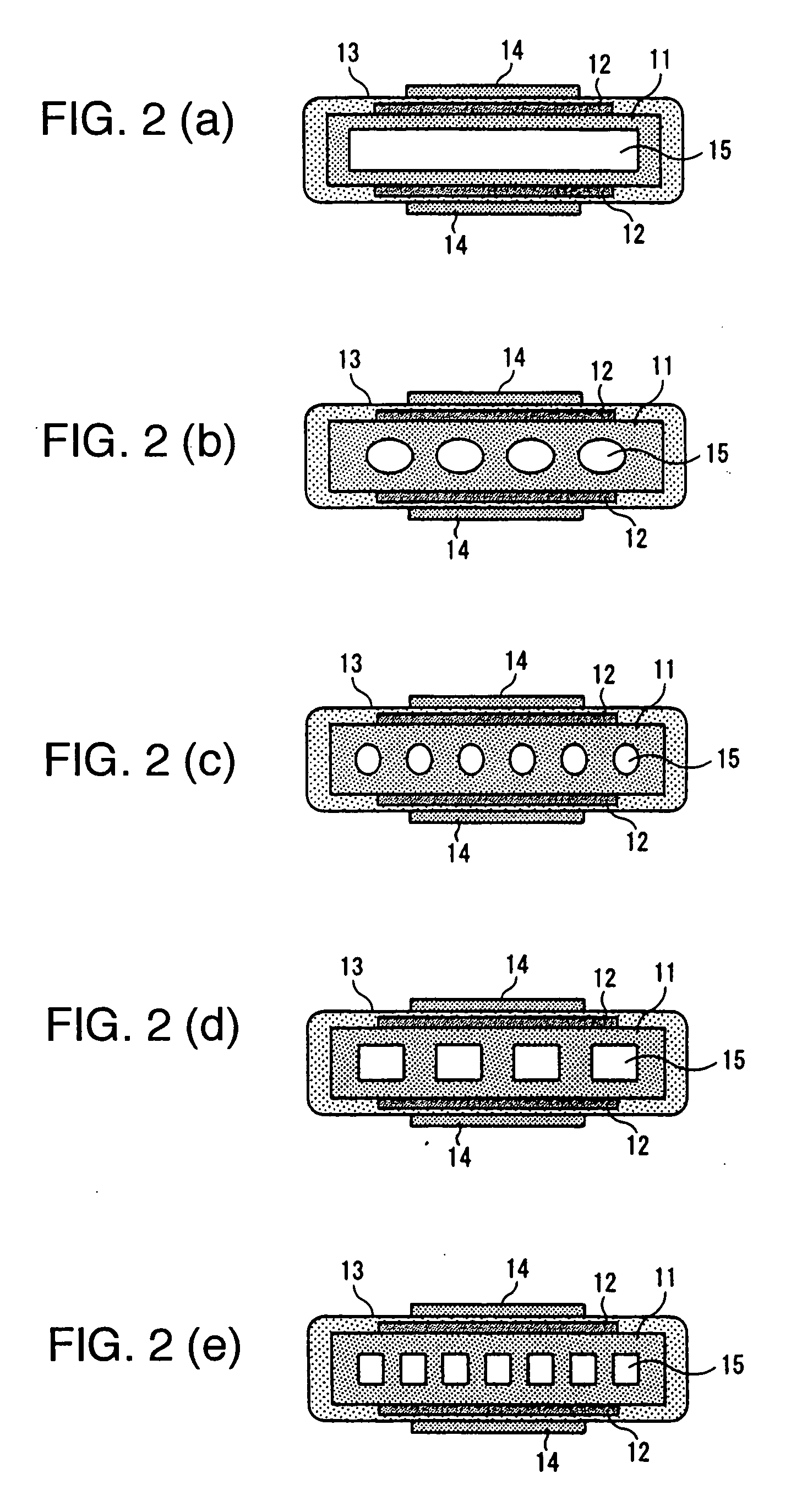

Method for fabricating solid oxide fuel cell module

ActiveUS20060153974A1High gas-sealing performanceImprove productivityFuel cells groupingFinal product manufactureProduction rateElectricity

There is provided a method of manufacturing a solid oxide fuel cell module comprising a plurality of cells each made up of a fuel electrode, an electrolyte, and an air electrode sequentially formed on a surface of a substrate with an internal fuel flow part provided therein, at least a face of the substrate, in contact with the cells, and interconnectors, being an insulator, and the cells adjacent to each other, being electrically connected in series through the intermediary of the respective interconnectors, said method of manufacturing the solid oxide fuel cell module comprising the steps of co-sintering the respective fuel electrodes, and the respective electrolytes, subsequently forming a dense interconnector out of a dense interconnector material, or an interconnector material turning dense by sintering in at least parts of the solid oxide fuel cell module, in contact with the respective fuel electrodes, and the respective electrolyte, and forming an air electrode on the respective electrolytes before electrically connecting the air electrode with the respective dense interconnectors. With the invention, it is possible to solve various problems of sinterability, encountered in the process of manufacturing the solid oxide fuel cell module of a multi-segment type, and to secure electrical contact of the parts of the respective dense interconnectors, in contact with the fuel electrodes while attaining high gas-sealing performance by the agency of the respective dense interconnectors, and electrolytes, thereby enhancing productivity.

Owner:TOKYO GAS CO LTD

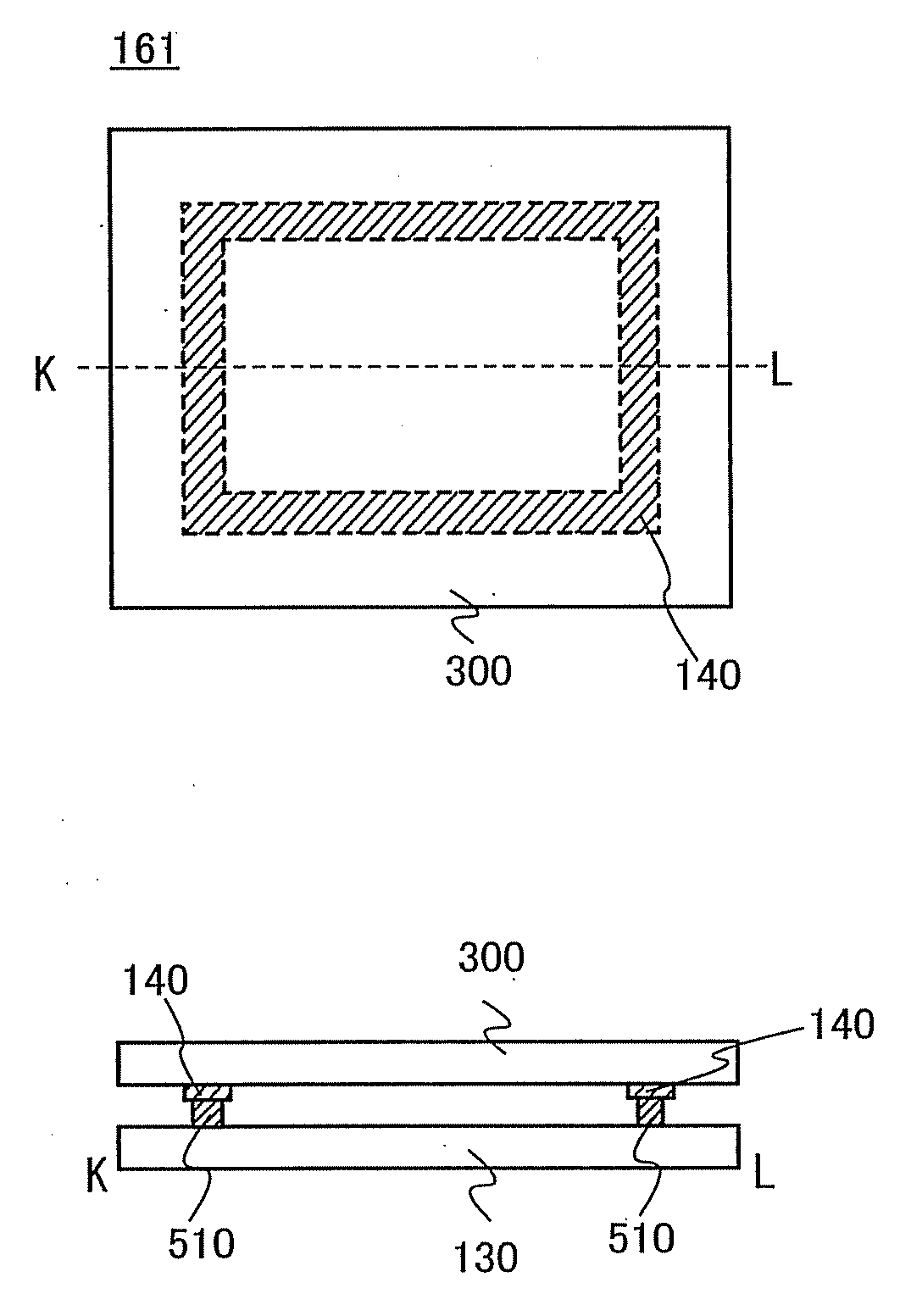

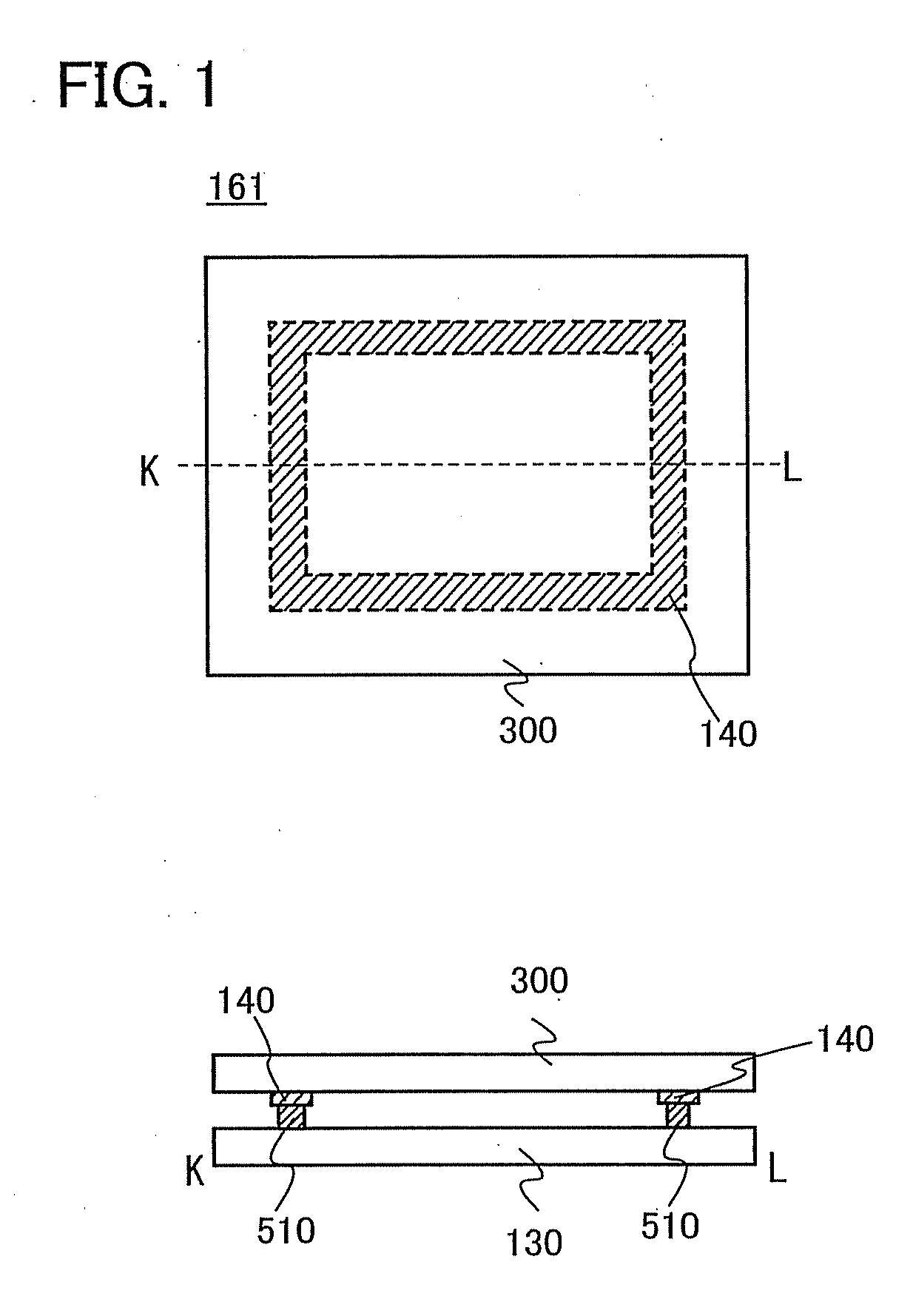

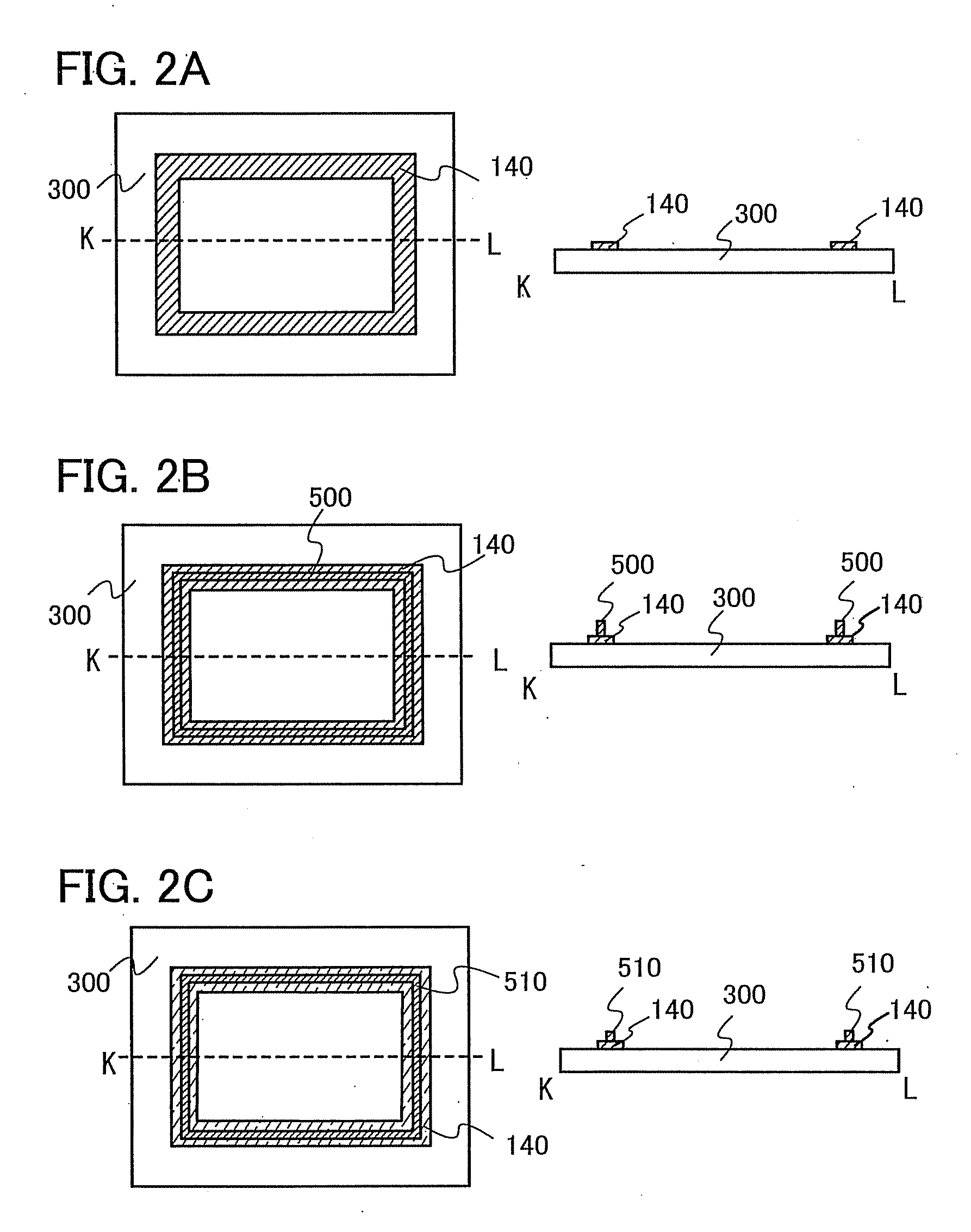

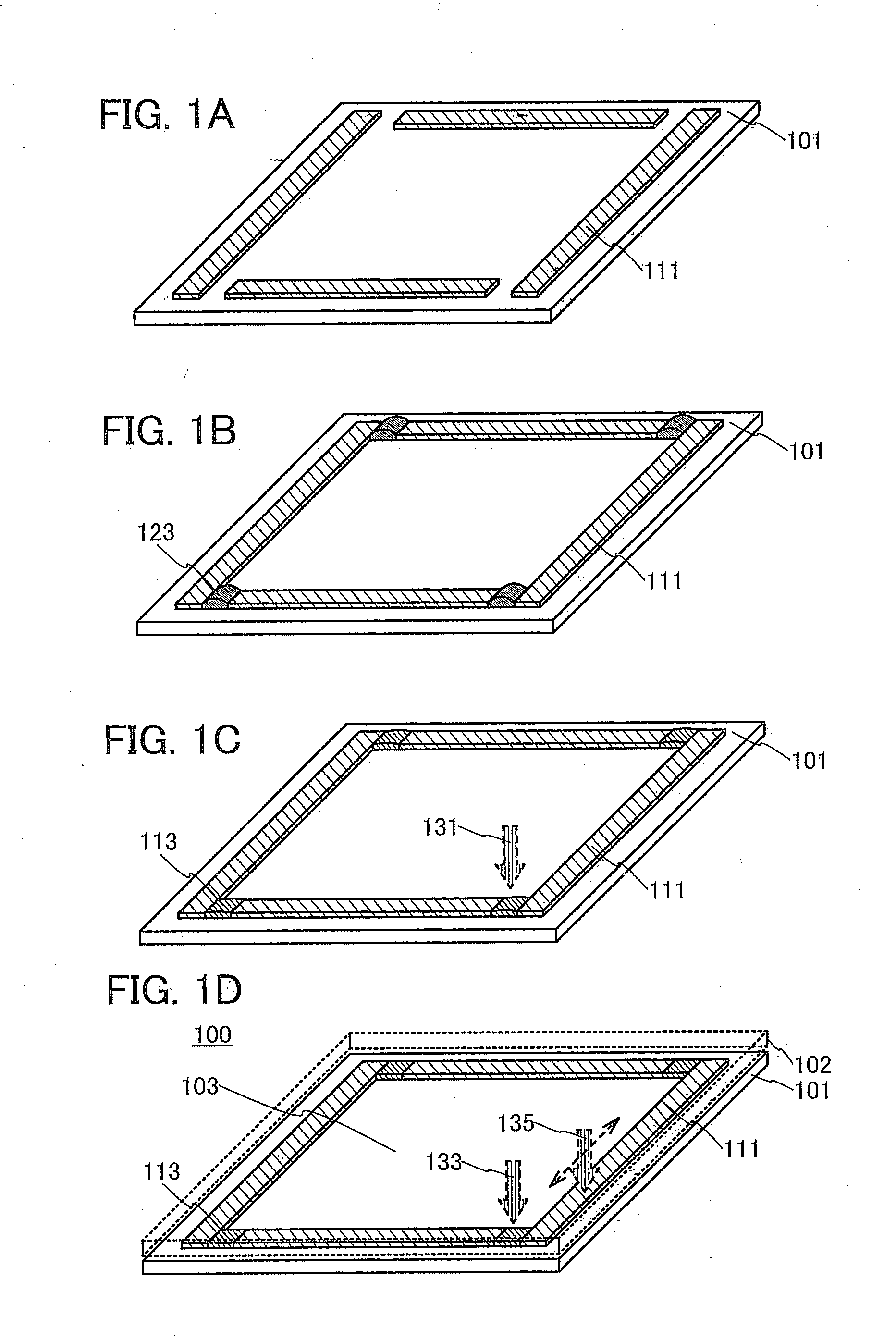

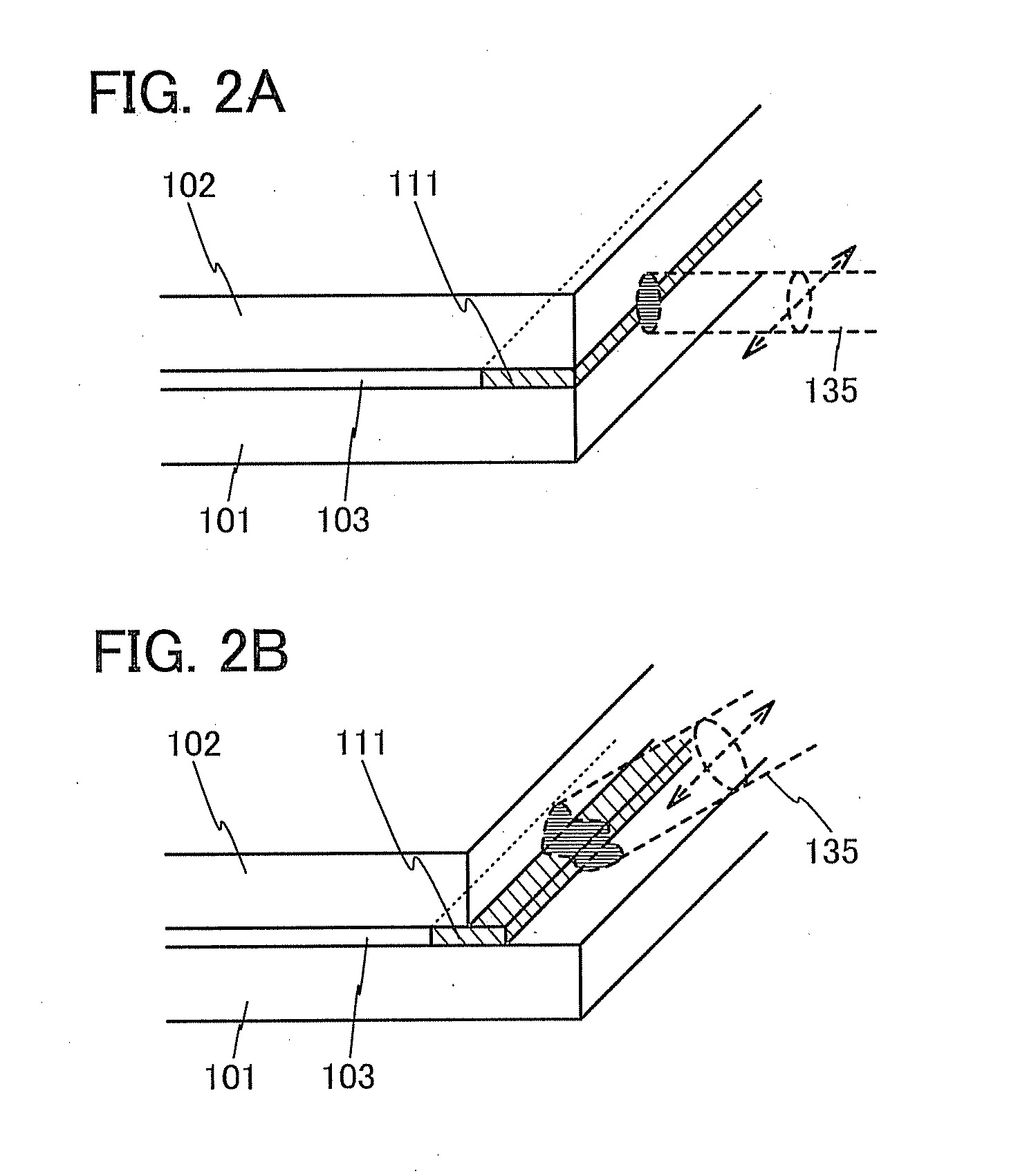

Method of manufacturing light-emitting device

ActiveUS20120318023A1Improve reliabilityImprove air tightnessGlass reforming apparatusFritLaser light

A method of manufacturing a sealed structure with excellent hermeticity and a method of manufacturing a light-emitting device sealed with the sealed structure. In the methods of manufacturing a sealed structure and a light-emitting device using a glass frit layer, a first step of forming a buffer layer for preventing a crack generated in a substrate and the glass frit layer by laser light irradiation, a second step of forming the glass frit layer to overlap with the buffer layer over the substrate, and a third step of welding the substrates by irradiating the glass frit layer or the buffer layer with laser light are performed, whereby a sealed structure with high hermeticity and a reliable light-emitting device sealed with the sealed structure can be manufactured. By applying the method of manufacturing a light-emitting device especially to an organic EL element, a highly reliable light-emitting device can be obtained.

Owner:SEMICON ENERGY LAB CO LTD

Glass Pattern and Method for Forming the Same, Sealed Body and Method for Manufacturing the Same, and Light-Emitting Device

InactiveUS20130134396A1Low heat resistanceImprove productivityLayered productsSolid-state devicesProduction rateFrit

A glass pattern that can be used for a substrate provided with a material having low heat resistance and has increased productivity is provided. Further, a sealed body having high hermeticity and increased productivity is provided. Furthermore, a light-emitting device with high reliability including such a sealed body is provided. A glass sheet is used for a main portion of a glass pattern such as a straight line portion and a curved portion. In a joint portion of two glass sheets arranged in the corner portion, the straight line portion, or the like of the glass pattern, a frit paste is provided in contact with the glass sheets and is locally heated to remove the binder from the frit paste and to form a glass layer; thus, the glass sheets are fused to each other without any space provided therebetween.

Owner:SEMICON ENERGY LAB CO LTD

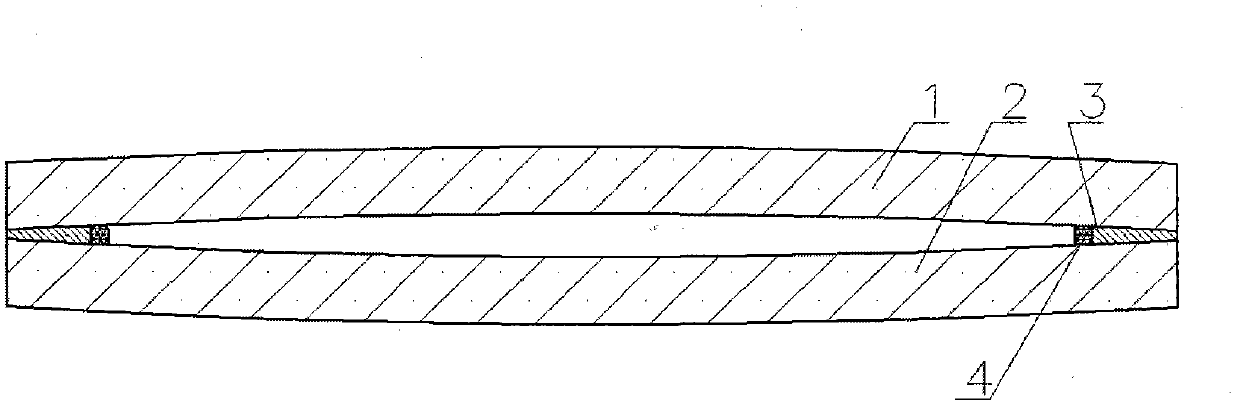

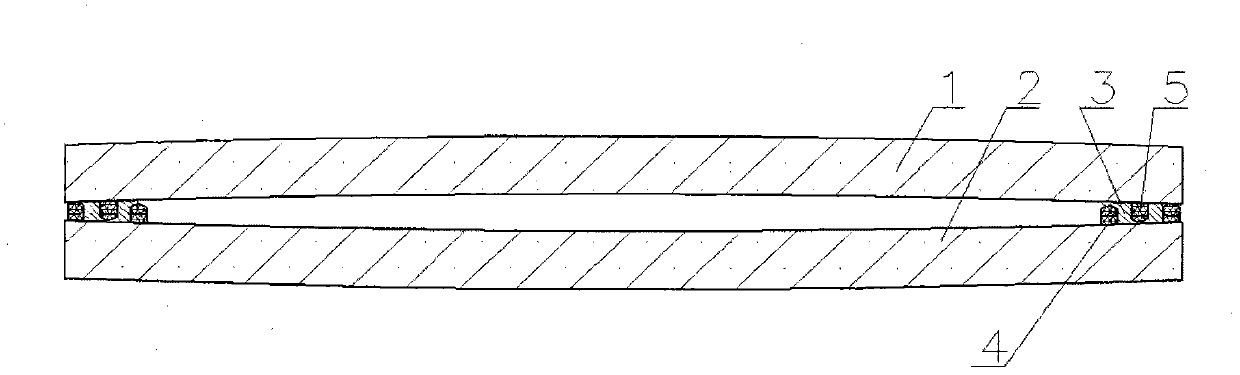

Convex vacuum glass, flat plate vacuum glass and preparation method thereof

ActiveCN102701575ASimple manufacturing processIncrease production costWindows/door improvementGlass reforming apparatusLight pollutionUltimate tensile strength

The invention provides convex vacuum glass, which comprises upper glass and lower glass, wherein peripheries of the upper glass and the lower glass are welded together through low-temperature solder; a sealed vacuum layer is formed between the upper glass and the lower glass; the upper glass and the lower glass are convex glass; and the convex surface is toward the outer side. The manufacture method of the vacuum glass disclosed by the invention is simple in process; and with the adoption of the prepared vacuum glass and toughened vacuum glass, the defects in the prior art can be overcome, the gas tightness of the vacuum glass can be effectively ensured, the transparency, the strength and heat-insulation and sound-insulation performances can be can increased, and light pollution of a glass curtain wall also can be reduced.

Owner:WEIHAI RUNFENG GLASS

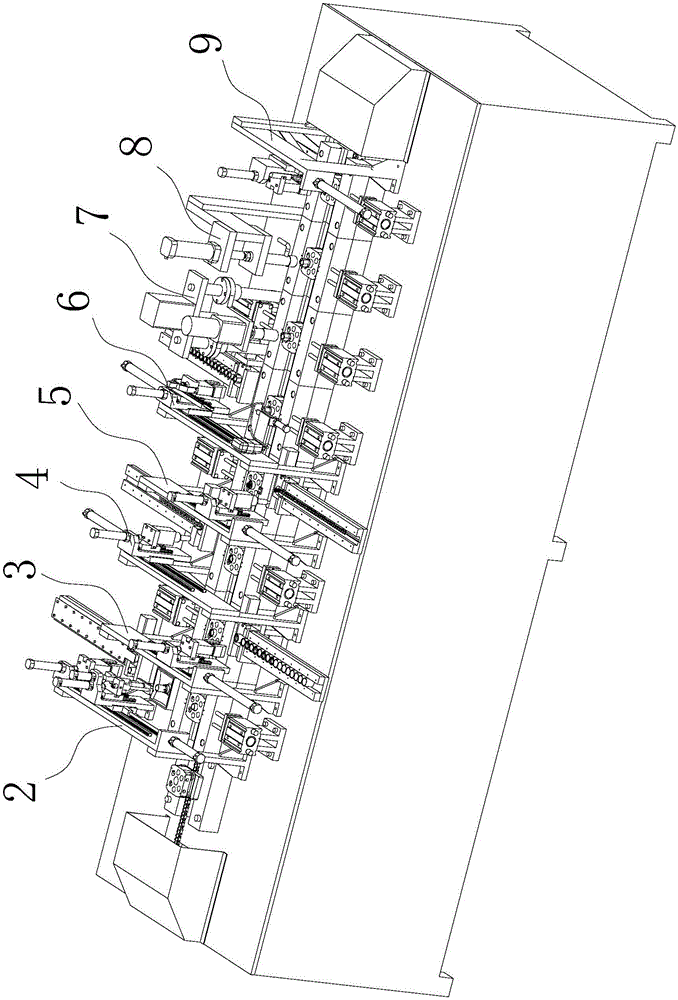

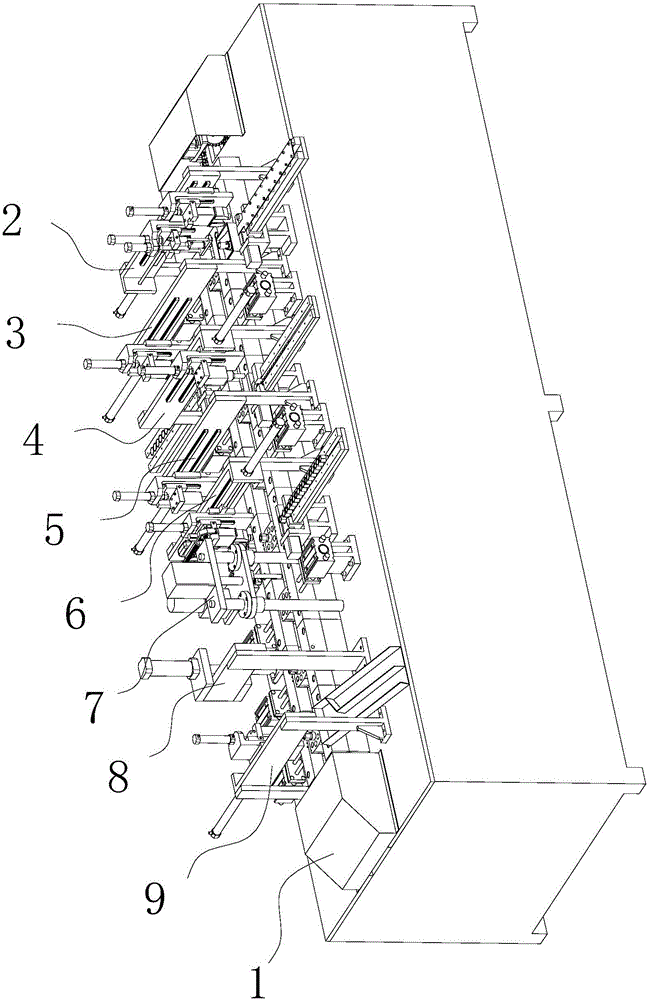

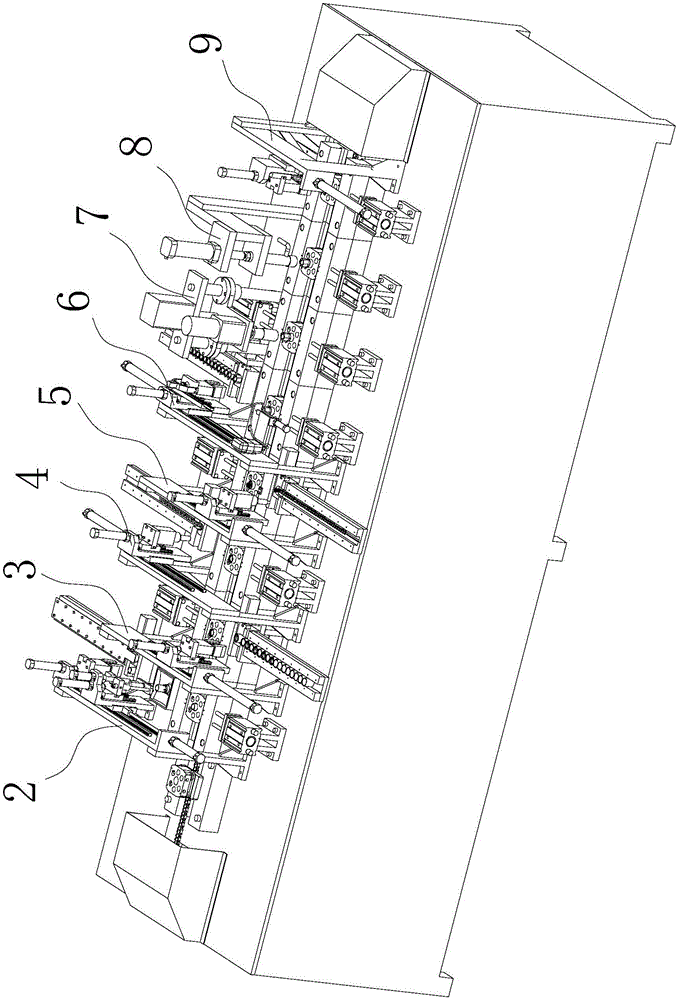

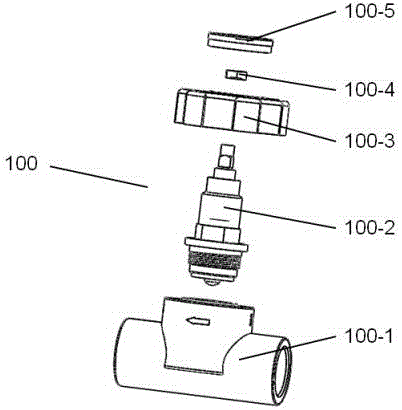

Nut mounting station of quick joint automatic assembly machine

ActiveCN105817873AThe air tightness index is qualifiedImplement step-by-step jobsMetal working apparatusAir tightnessSealant

The invention relates to the technical field of quick joint assembly equipment, in particular to a nut mounting station of a quick joint automatic assembly machine. The nut mounting station comprises a nut feeding pre-screwing station and a nut screwing station which are arranged in the material flow direction of the automatic assembly machine. The nut feeding pre-screwing station comprises a nut feeding mechanism, a nut feeding pre-screwing mechanical arm, a nut gluing mechanism and a nut pre-screwing mechanism. Nut accessories are conveyed to the specified position through the nut feeding pre-screwing mechanical arm. The nut pre-screwing mechanism and the nut gluing mechanism cooperate to firstly complete the action of coating the nut accessories with sealant, and after the sealant coating action is completed, the nut feeding pre-screwing mechanical arm completes the assembly action of the nut accessories in cooperation with the nut pre-screwing mechanism. The nut screwing station is used for locking the pre-screwed nut accessories. Step-by-step work in the nut mounting process is achieved, it is guaranteed that the nut accessories are mounted in place, and it is ensured that the air tightness index of a quick joint is qualified.

Owner:NINGBO SINPPA TOOLS CO LTD

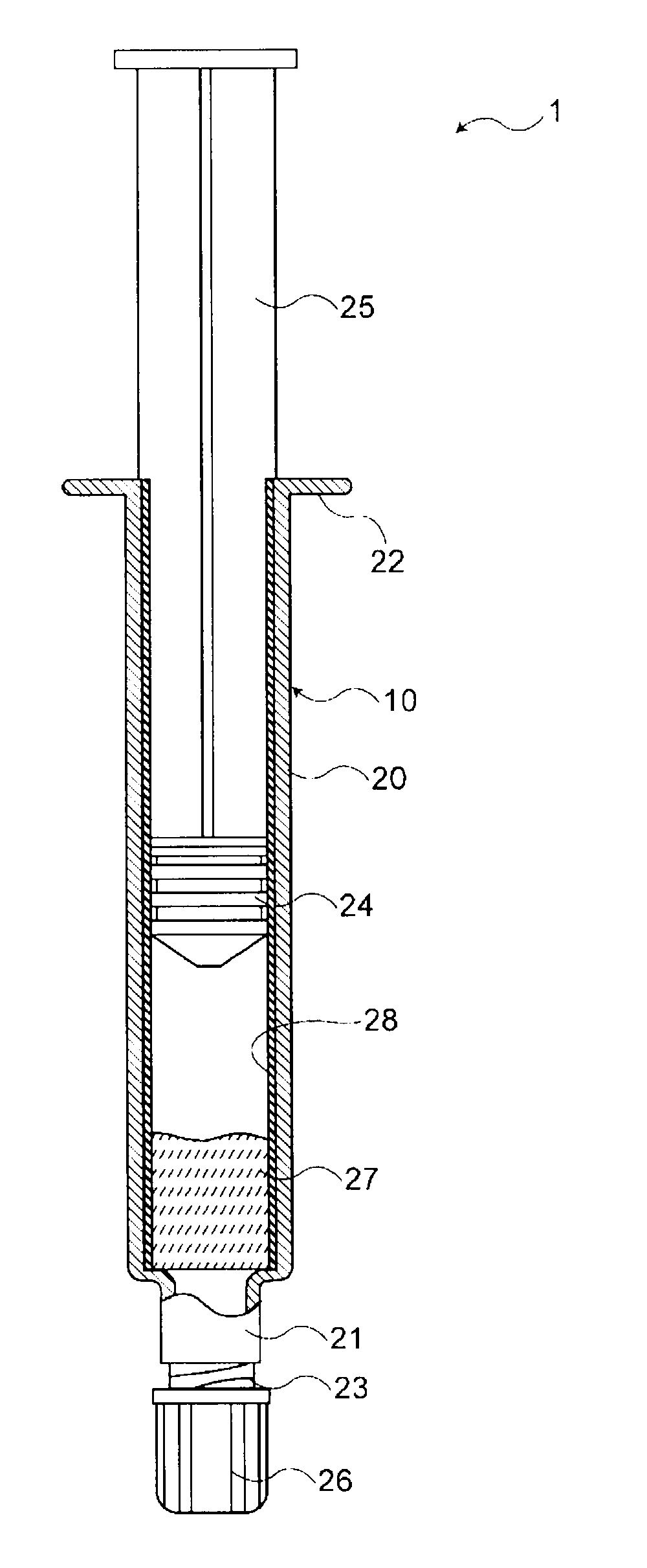

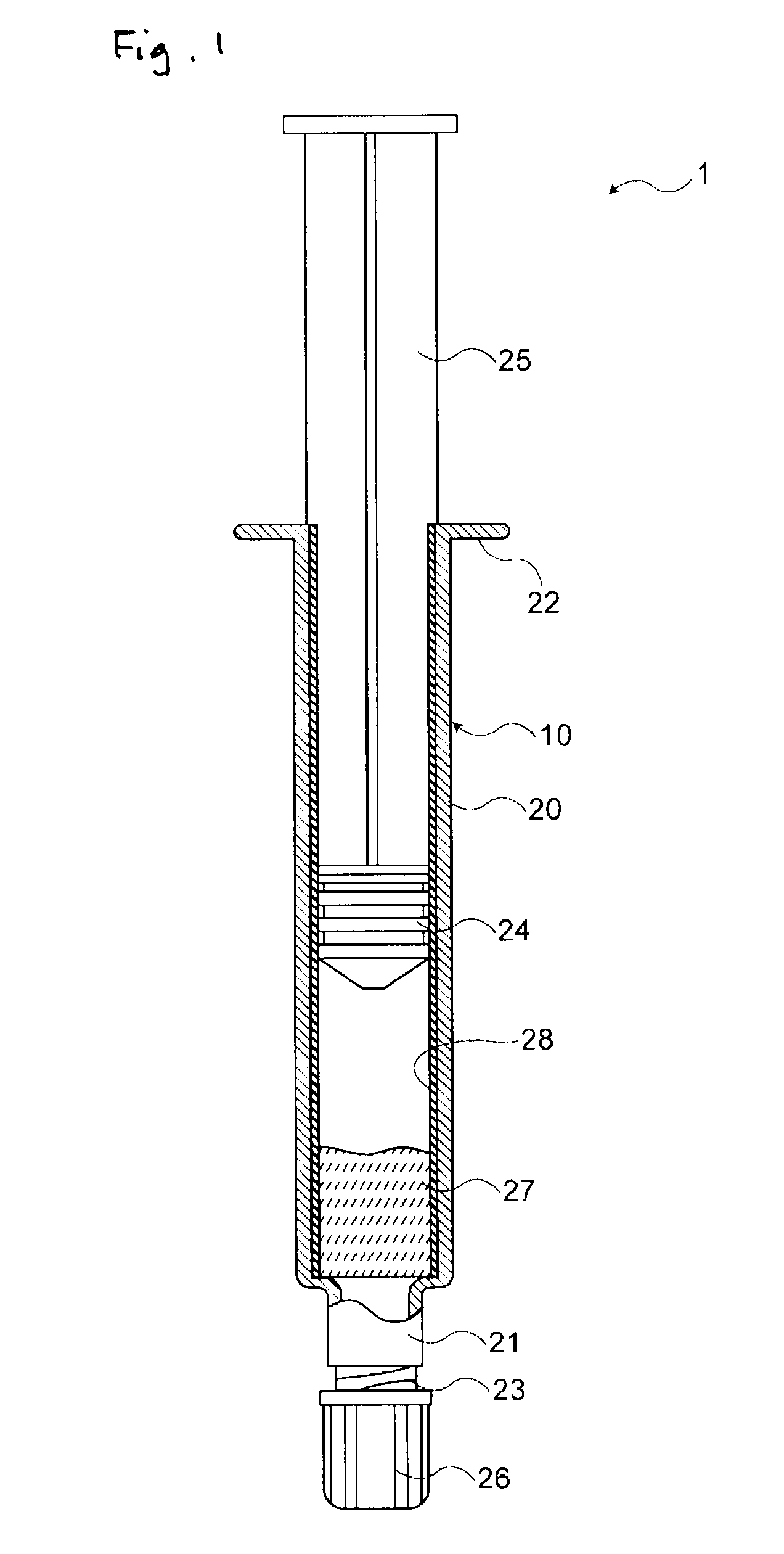

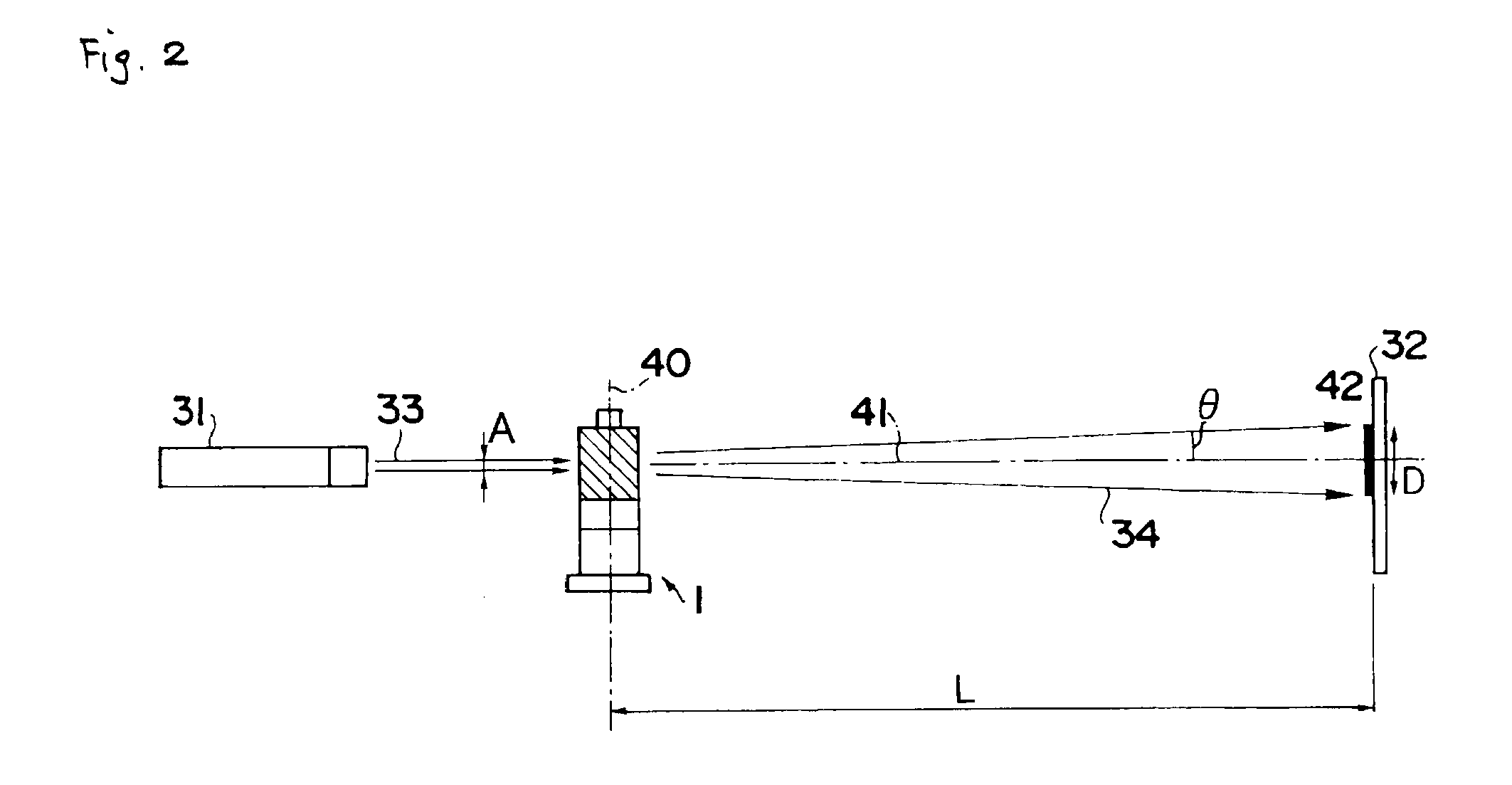

Syringe

InactiveUS20110276005A1Reduce riskSufficient gasket slidability and sealing propertyAmpoule syringesLiquid surface applicatorsVisual inspectionEngineering

Provided is a syringe with which it is possible to hold with greater stability a liquid inside the barrel while maintaining the slidability and air-tightness between the barrel and the gasket without requiring fixation of silicone oil, and which is excellent in terms of accuracy of visual inspection. The syringe has a resin barrel, a gasket slidably inserted inside the barrel, a plunger attached to the gasket, and a silicone film obtained by applying silicone oil having a kinematic viscosity of 500 to 10,000 cSt over the inner peripheral surface of the barrel in an amount of 5 to 50 μg per 1 cm2of area.

Owner:DENKA CO LTD +1

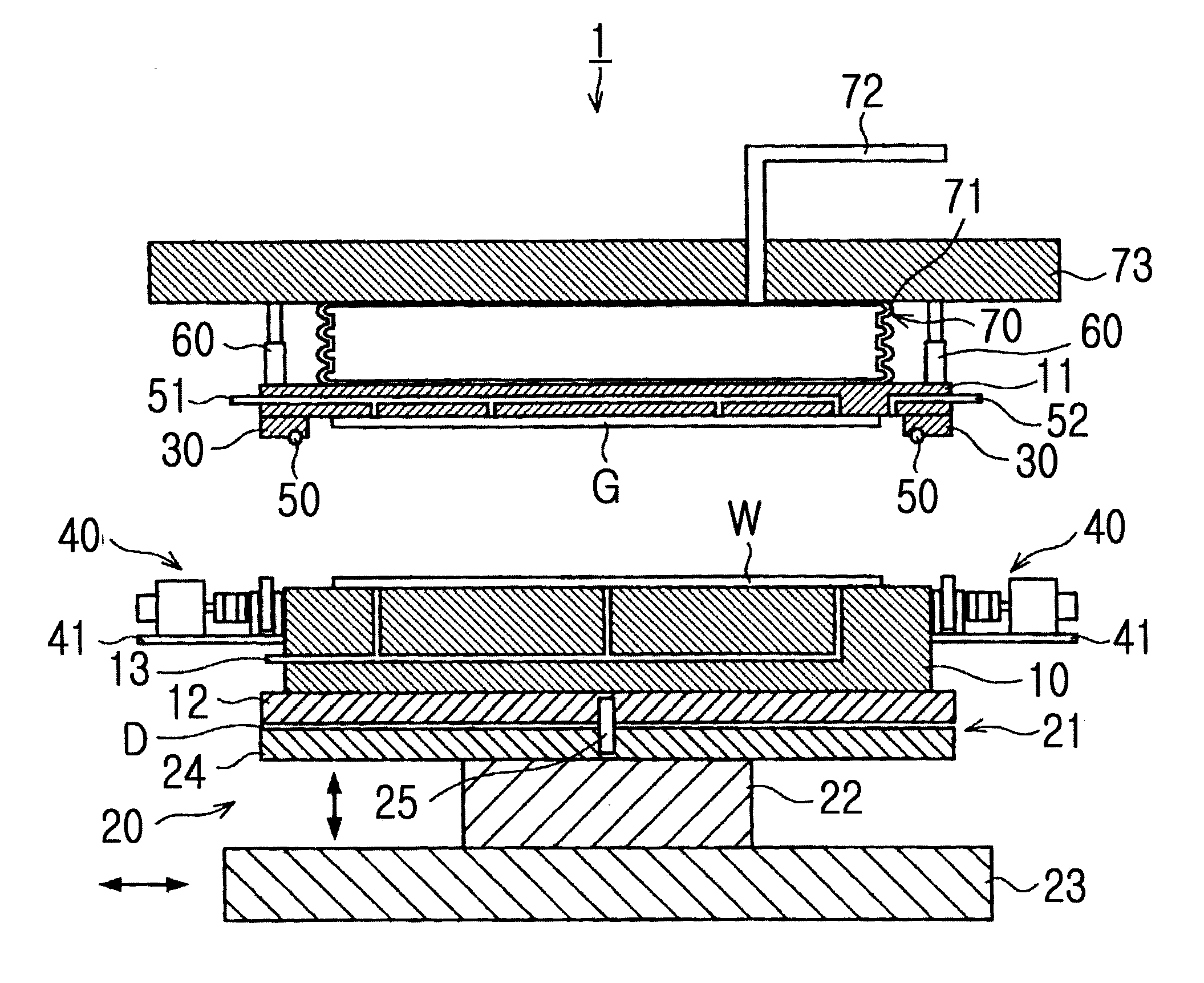

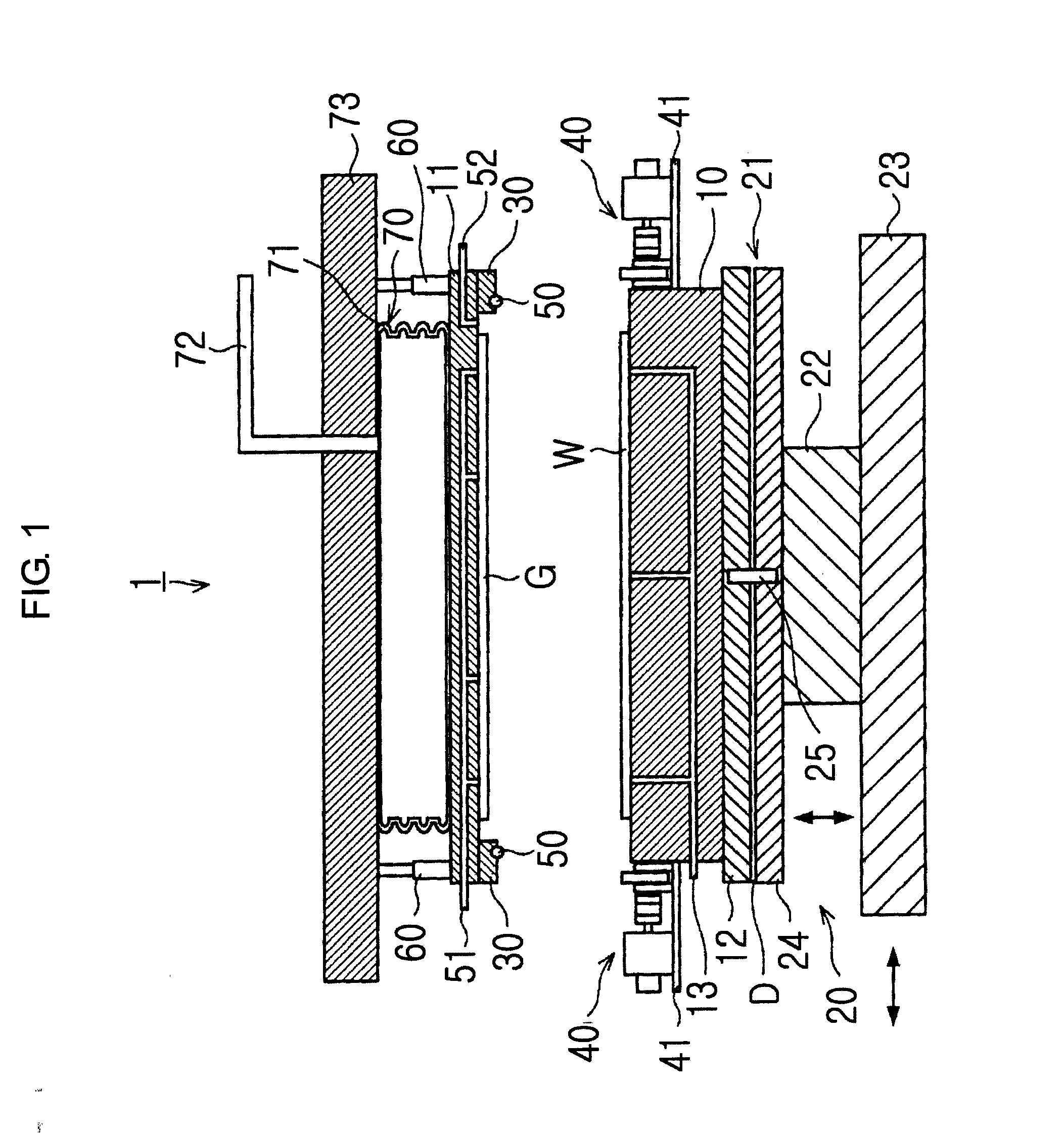

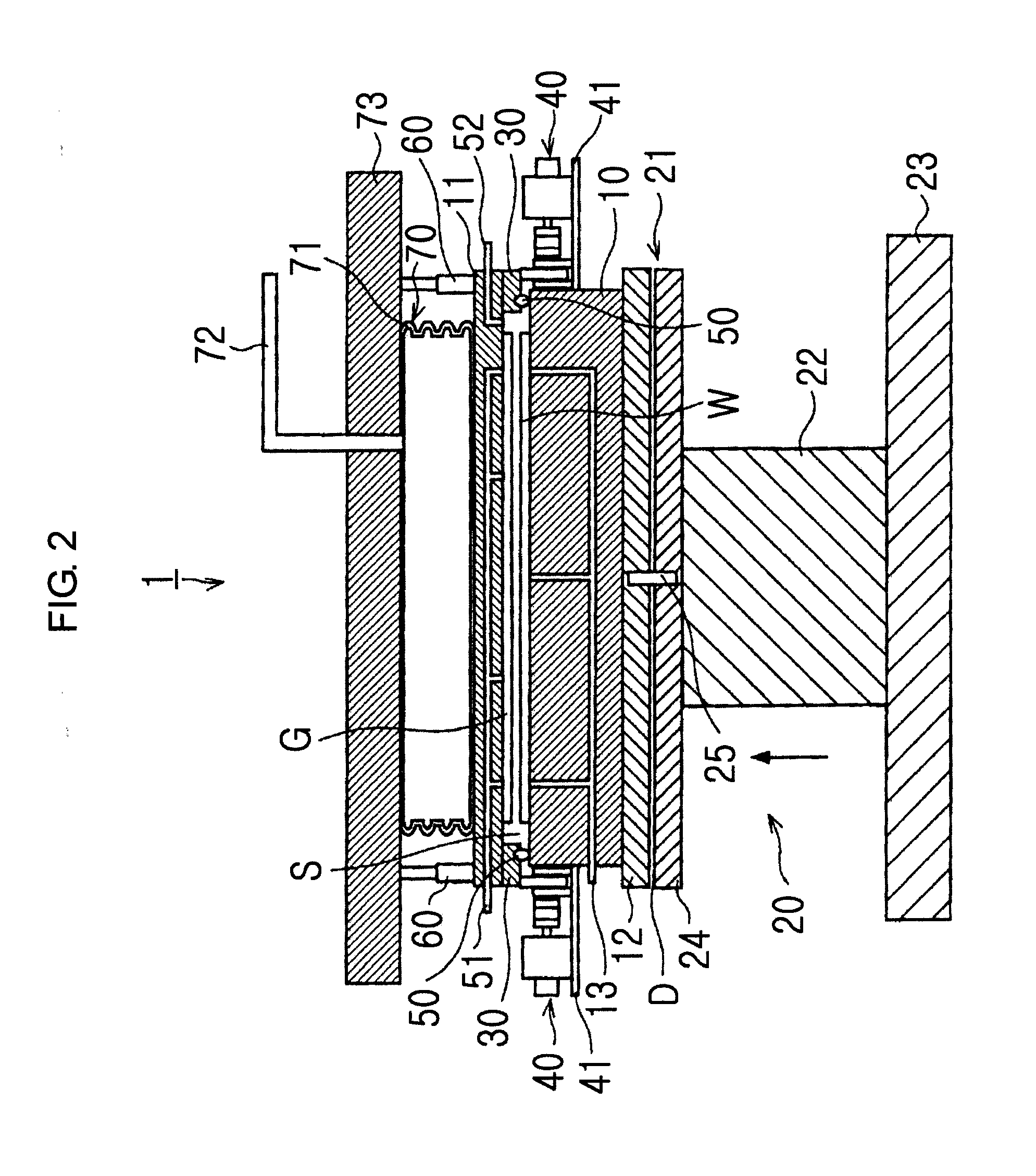

Bonding apparatus and bonding method

InactiveUS20110214809A1Efficient executionAvoid it happening againLaminationSemiconductor/solid-state device manufacturingEngineeringAir tightness

A bonding apparatus includes a first holding section which places and holds a first member on an upper surface, and a second holding section which adsorbs and holds a second member on a lower surface. The second holding section is configured such that a center section bends due to a predetermined pressure. The second holding section includes an intake mechanism which sucks atmosphere of a bonding space between the first holding section and the second holding section. A protrusion which protrudes downward along an outer circumferential lower surface of the second holding section is formed on the outer circumferential lower surface. A sealing member which holds an air-tightness of the bonding space and has elasticity is formed in a lower surface of the protrusion. A height adjusting mechanism which abuts on the protrusion and can adjust the vertical distance between the first member and the second member is formed on a side surface of the first holding section.

Owner:TOKYO ELECTRON LTD

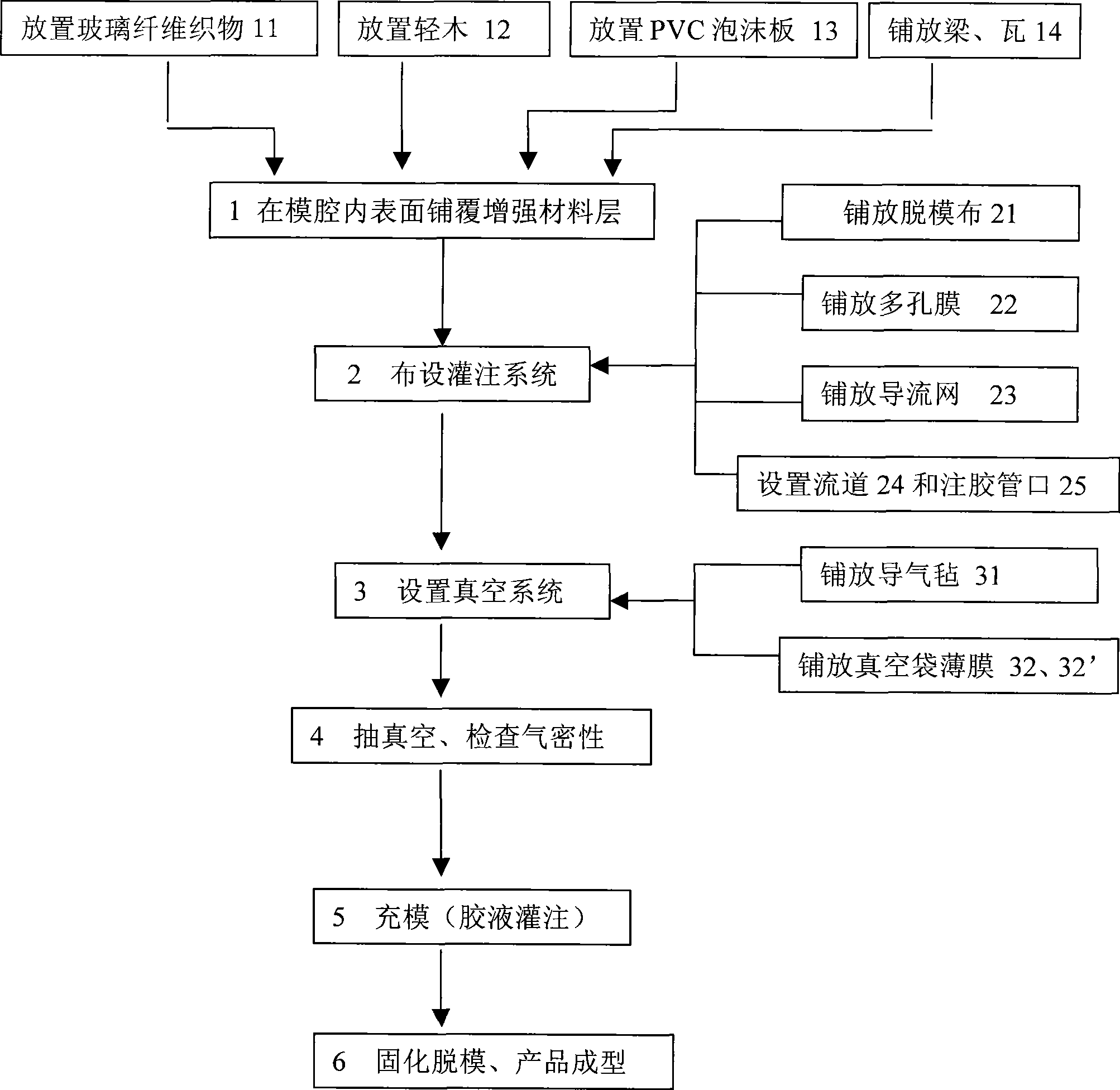

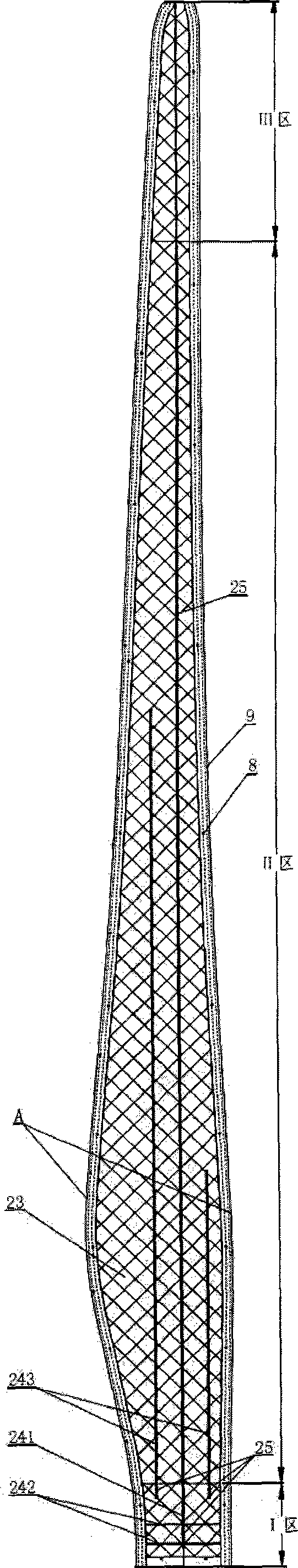

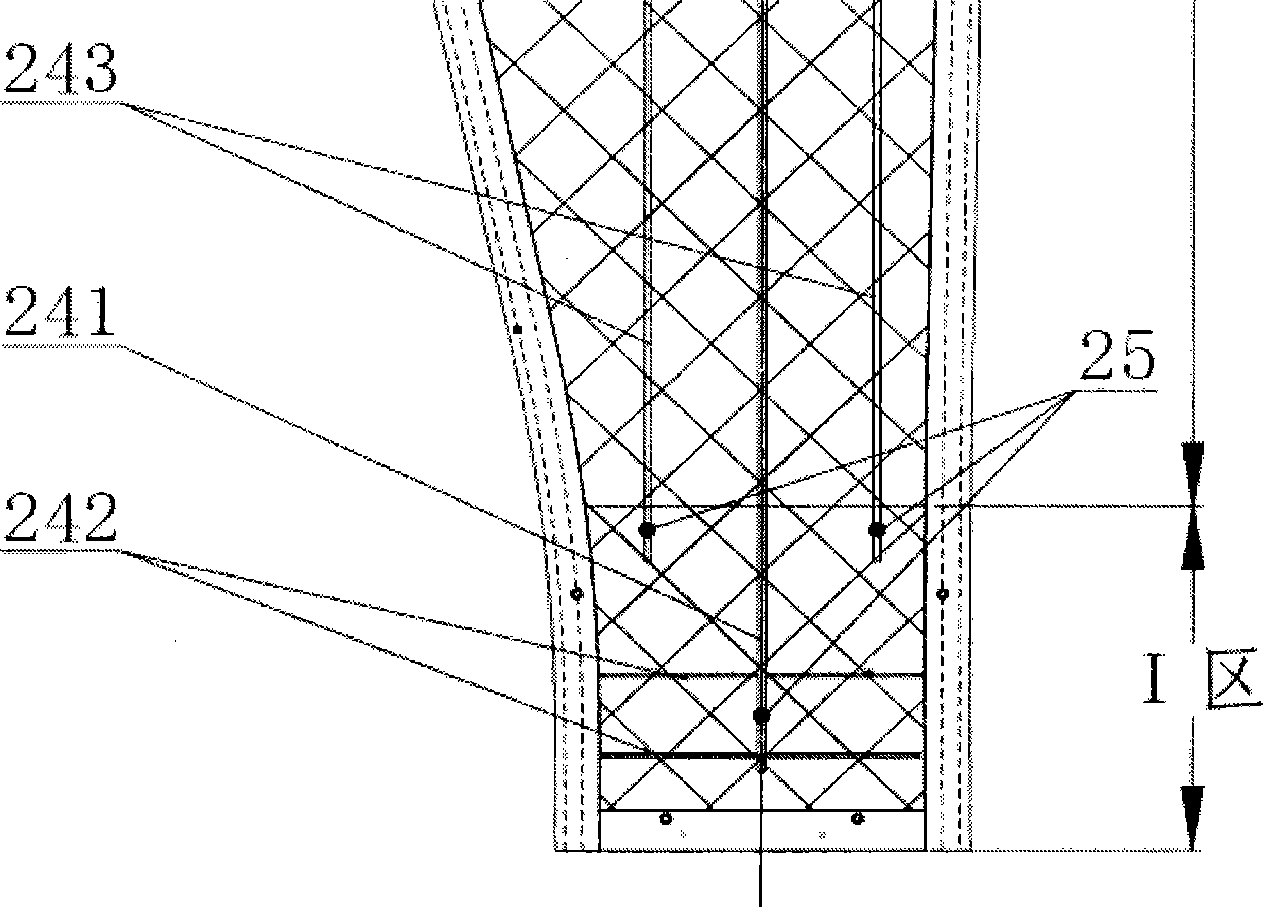

Megawatt level composite material wind electricity blade vacuum guiding and forming technique

ActiveCN101456256AHarm reductionImprove molding efficiencyFinal product manufactureDomestic articlesElectricityTurbine blade

The invention discloses a vacuum infusion forming process for a megawatt grade composite material wind turbine blade. The process comprises a step of spreading and cladding reinforced material layers in an upper mold cavity and a lower mold cavity of a mould of the blade respectively and a step of solidification, demoulding and product forming, and is characterized by comprises the following steps between the two steps: 1)distributing injection systems on the surfaces of the reinforced material layers; 2) distributing vacuum systems on the outer surface of the injection systems spread and covered with flow channels in the step 1); 3) checking the airtight performance of an vacuumizing opening; 4) mould filling ( filling rubber liquid); and 5), solidification, demoulding and product forming. The vacuum infusion process can complete mould filling in 1.5 hours, improves the forming efficiency of large blades, saves special equipment and achieves low production costs. Products formed by the process are uniform in quality distribution and good in process repeatability, and can reduce volatilization of harmful gases and environmental pollution and ensure heath of operators and are easy to promote and use compared with a hand lay up process and a wet spreading process.

Owner:SINOMATECH WIND POWER BLADE

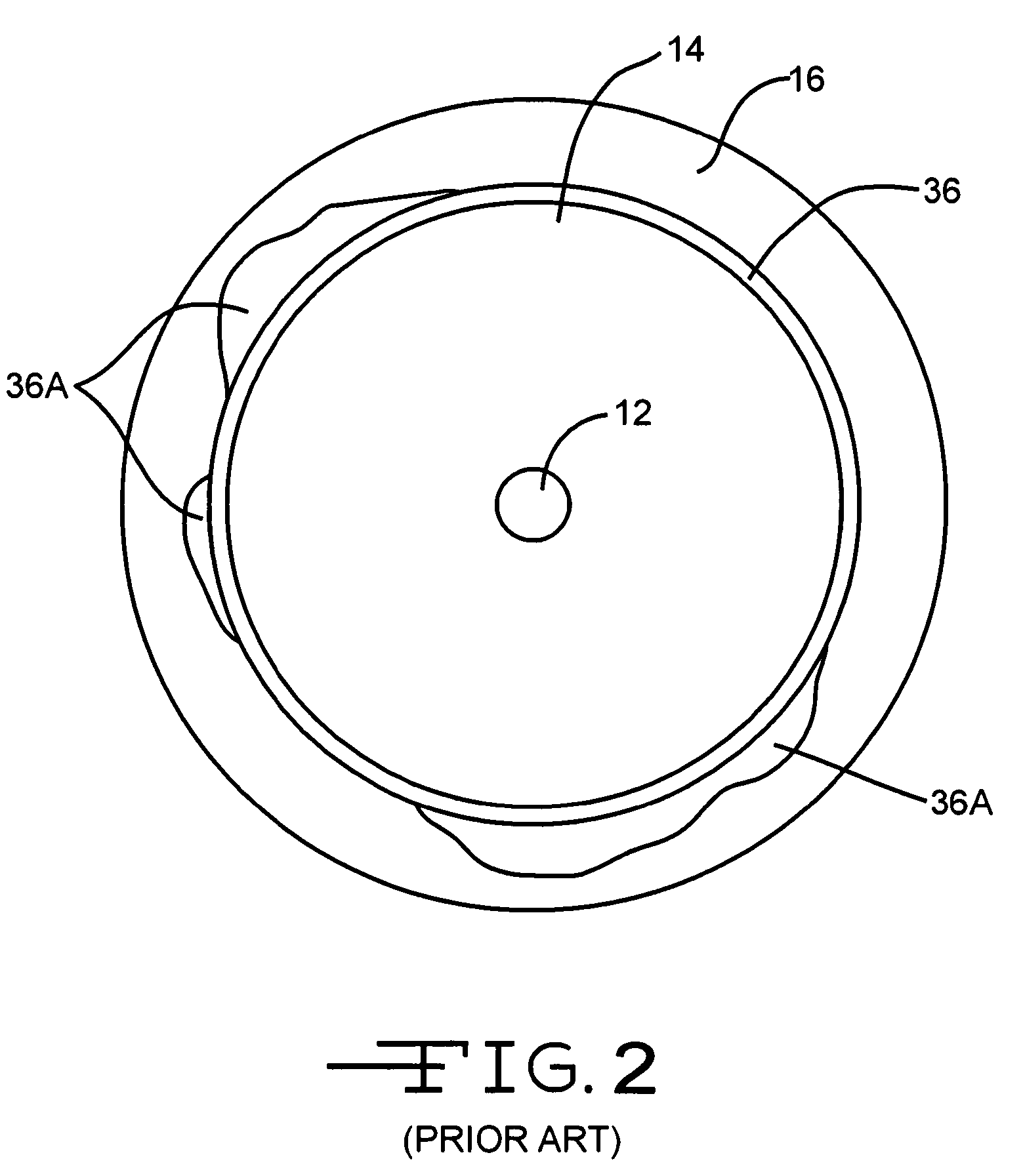

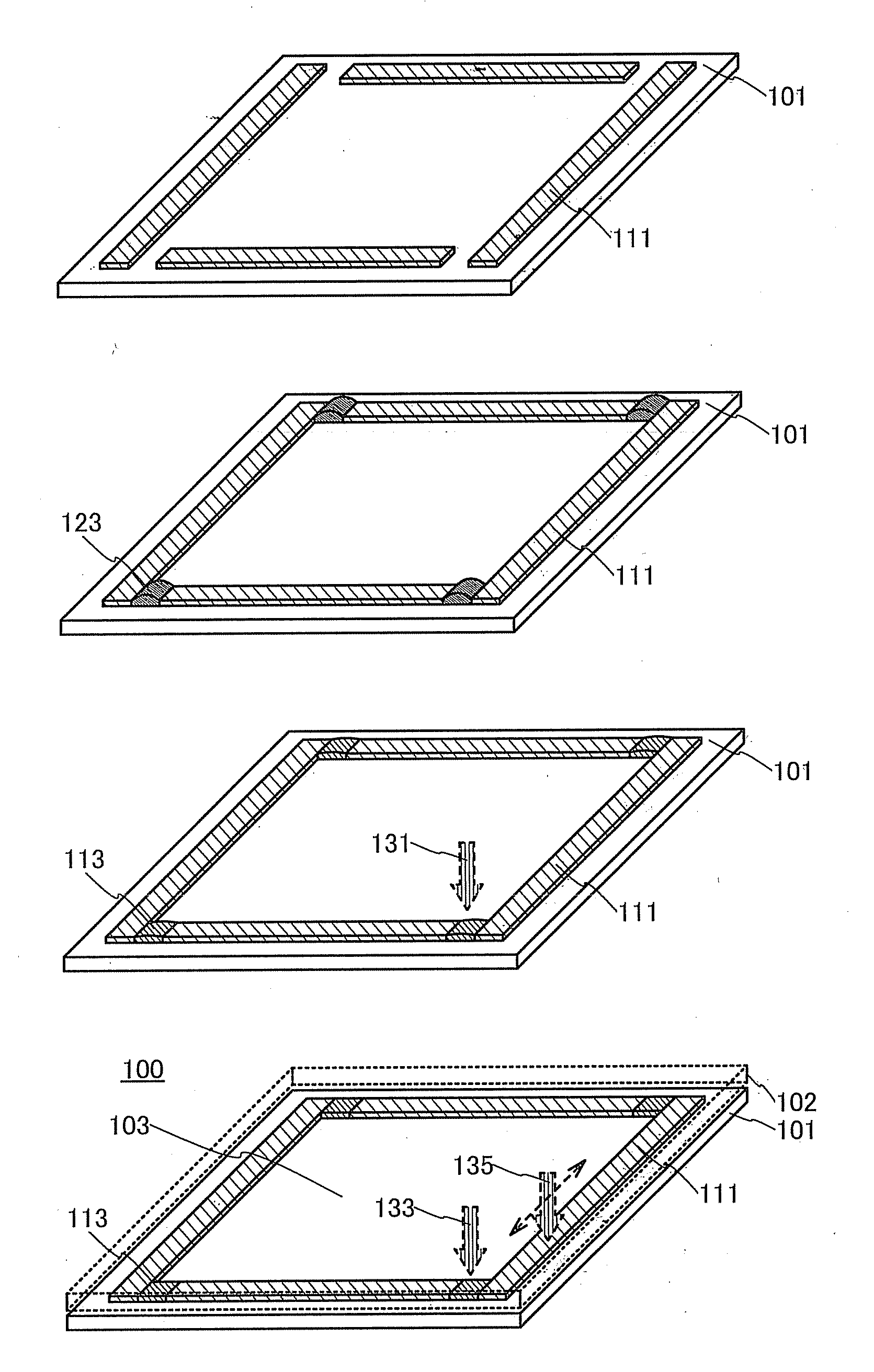

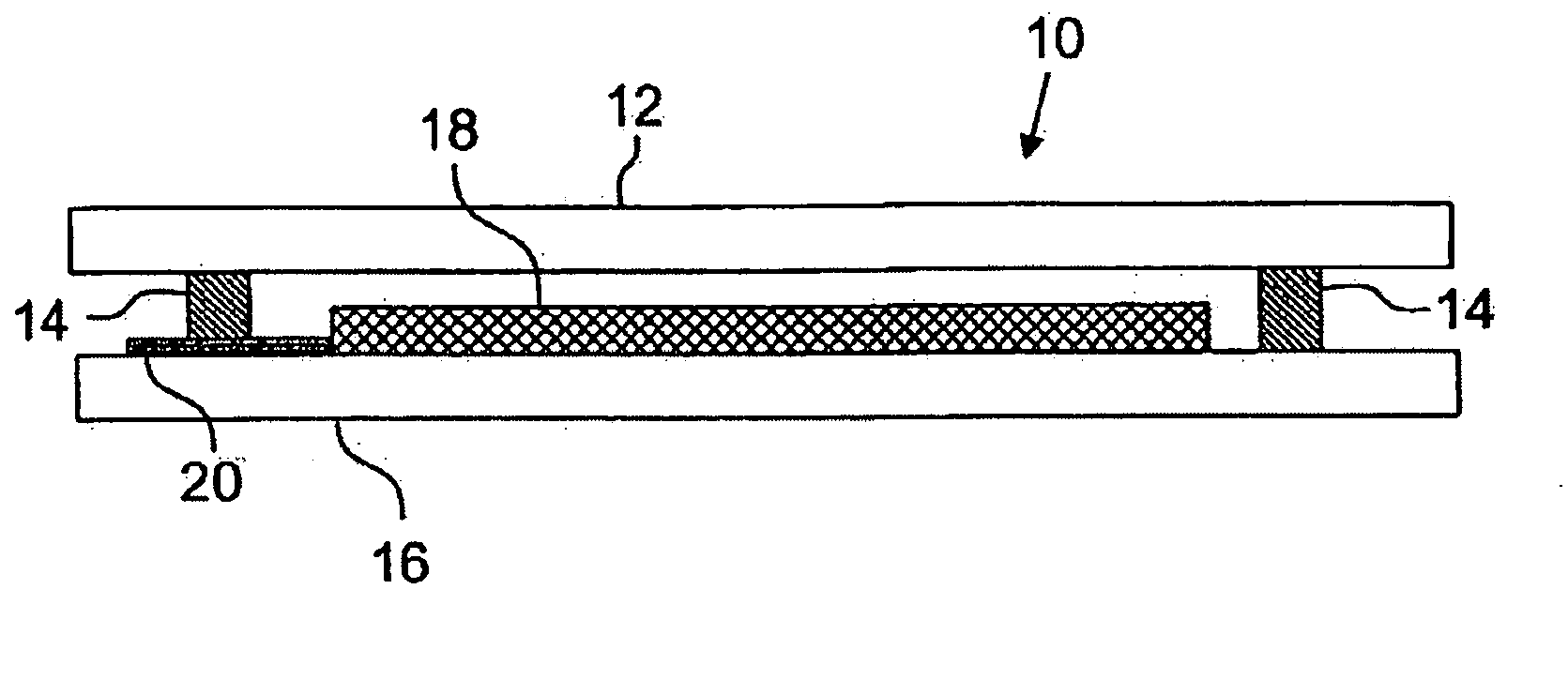

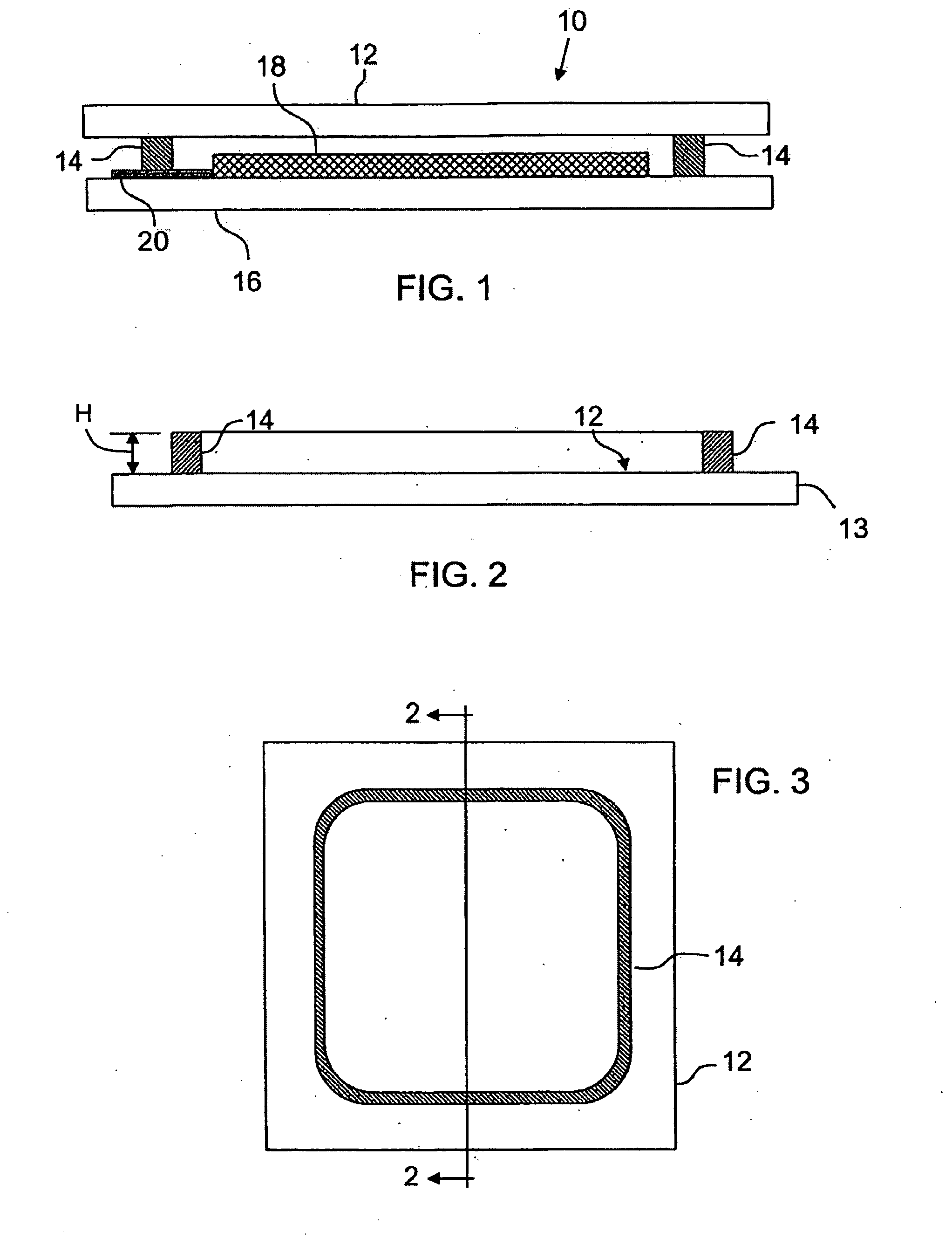

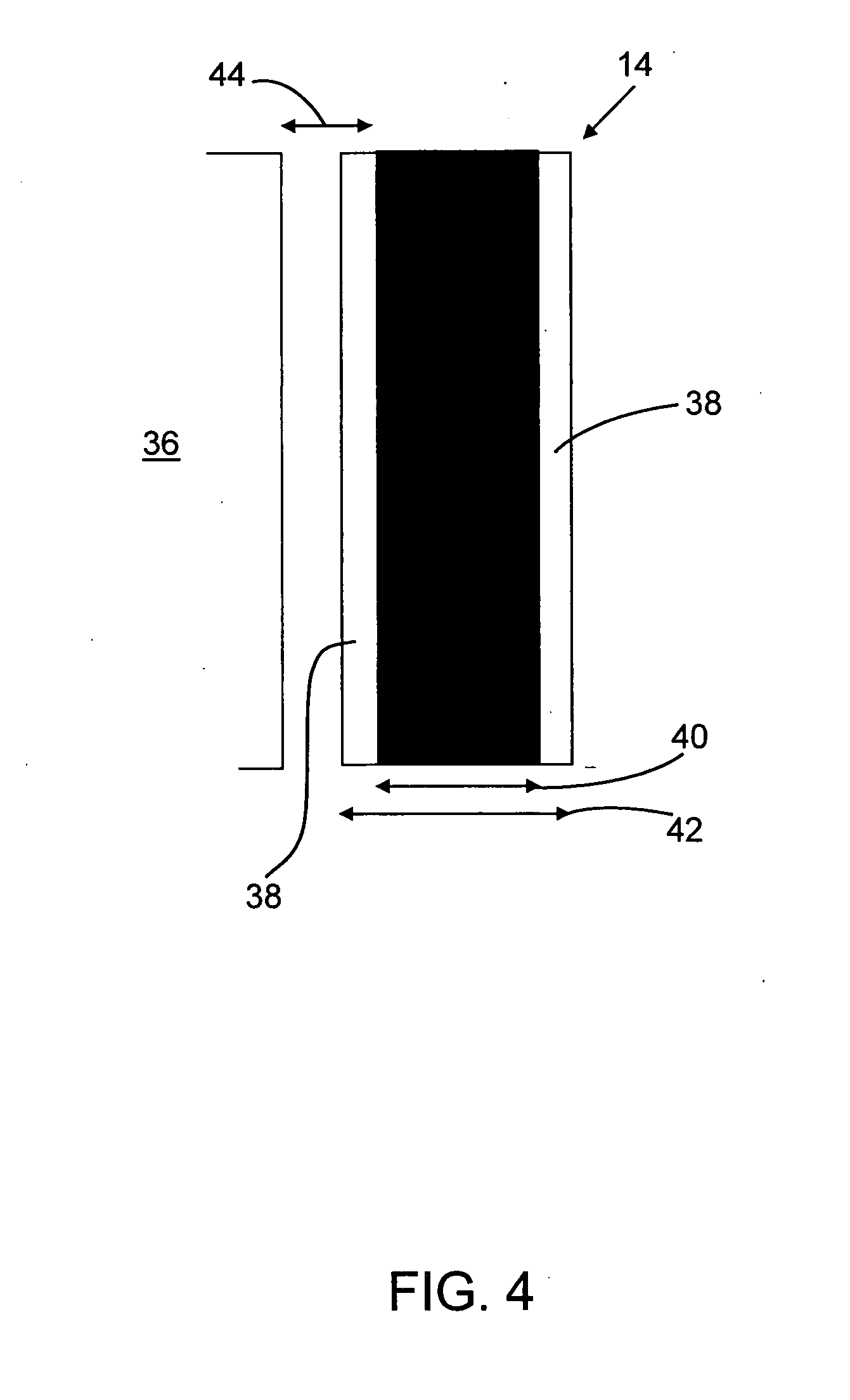

Methods and apparatus for packaging electronic components

InactiveUS20090142984A1Easy to passDischarge tube luminescnet screensElectroluminescent light sourcesFritElectronic component

Packages for elements, e.g., OLEDs, that are temperature sensitive are provided. The packages have a first glass substrate (12), a second glass substrate (16), and a wall (14) that separates the first and second substrates (12,16) and hermetically seals at least one temperature sensitive element (18,28,36) between the substrates (12,16). The wall (14) comprises a sintered frit and at least a portion of the wall is laser sealed to the second substrate (16) by melting a glass component of the sintered frit. The minimum width (40) of the laser-sealed portion of the wall (14) at any location along the wall (14) is greater than or equal to 2 millimeters so as to provide greater hermeticity and strength to the package. The laser sealing is performed without substantially degrading the temperature sensitive element(s) (18,28,36) housed in the package.

Owner:CORNING INC

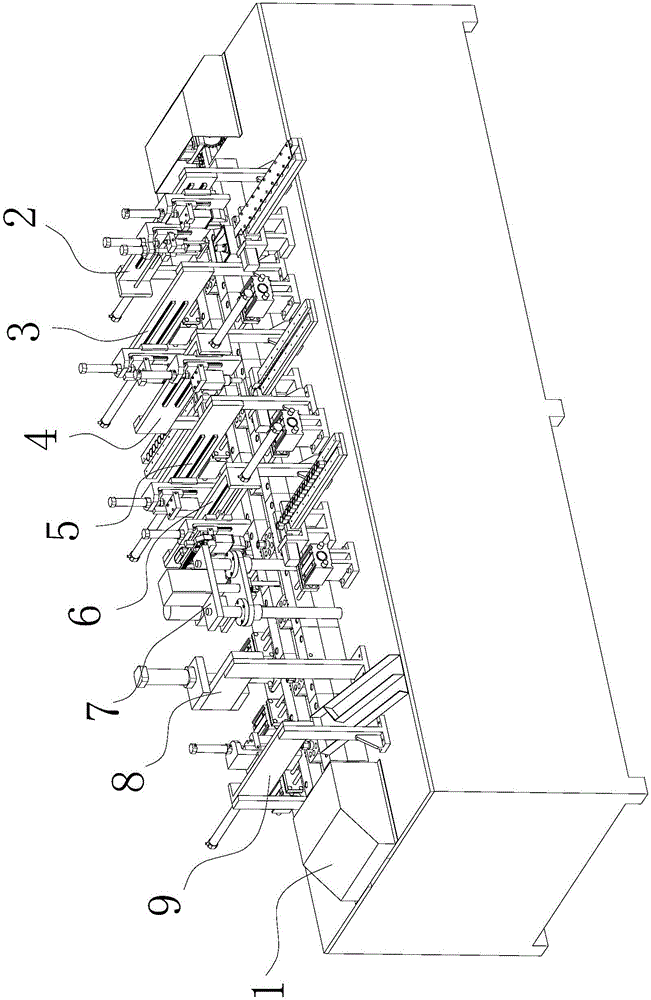

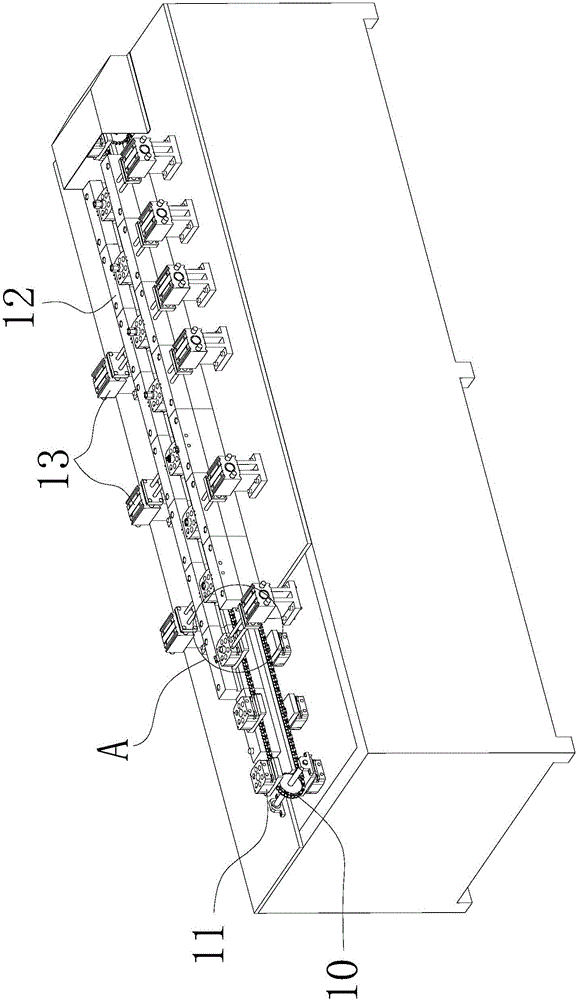

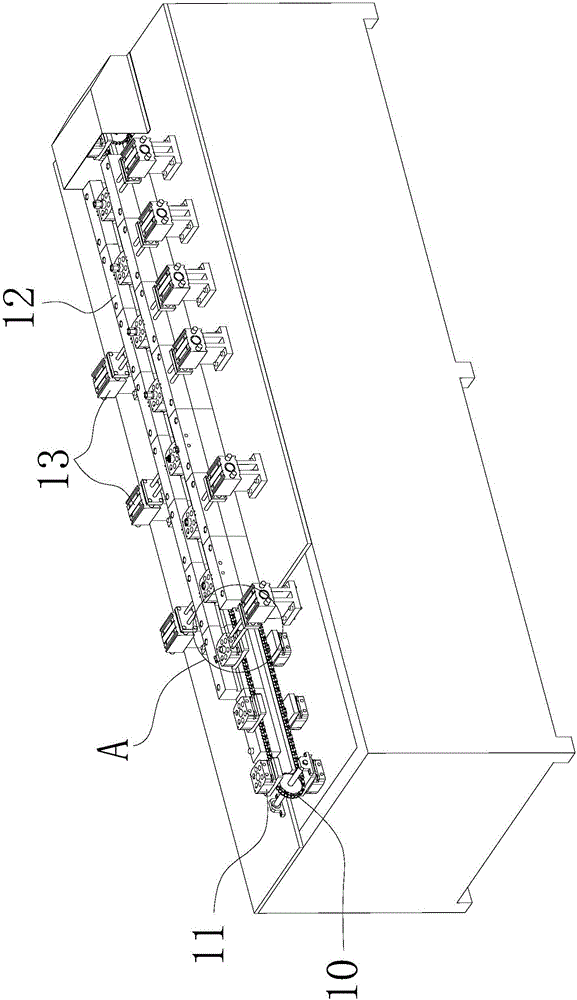

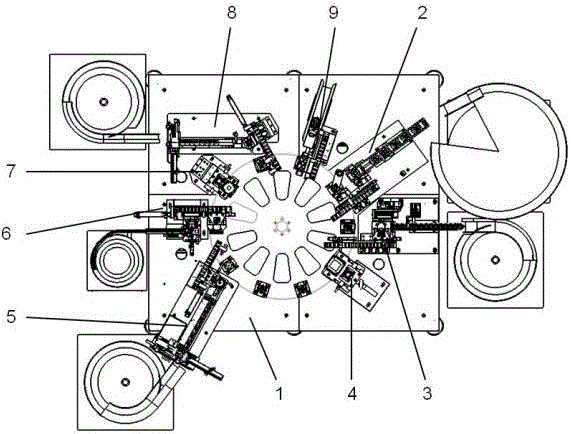

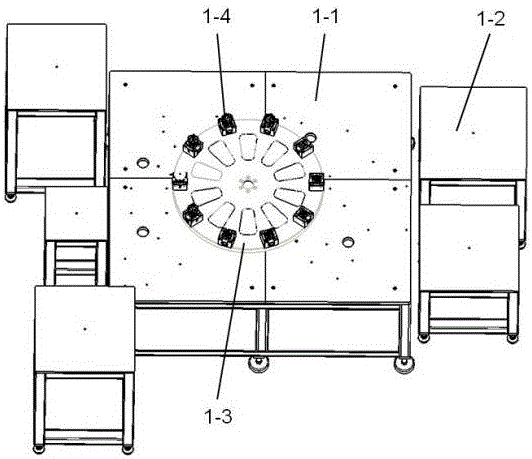

Multi-station automatic assembly machine for quick coupler

ActiveCN105834711AImprove assembly efficiencyAvoid mixingAssembly machinesMetal working apparatusAir tightnessAssembly machine

The invention relates to the technical field of quick coupler assembly equipment, in particular to a multi-station automatic assembly machine for a quick coupler. The multi-station automatic assembly machine comprises a workpiece transport mechanism which is driven by a step motor to realize step type motion, wherein a central loading station, an outer loading station, a sealing pad loading station, a valve element loading station, a nut loading and pre-twisting station, a nut locking station, an air tightness detecting station and a delivery station are sequentially arranged in a transport direction of the workpiece transport mechanism. The multi-station automatic assembly machine realizes quick assembly, air tightness online monitoring and unqualified product automatic sorting of the quick coupler, so that the assembly efficiency of the quick coupler is improved, the defective rate is reduced, and the unqualified products are effectively prevented from being mixed in a qualified product batch.

Owner:NINGBO SINPPA TOOLS CO LTD

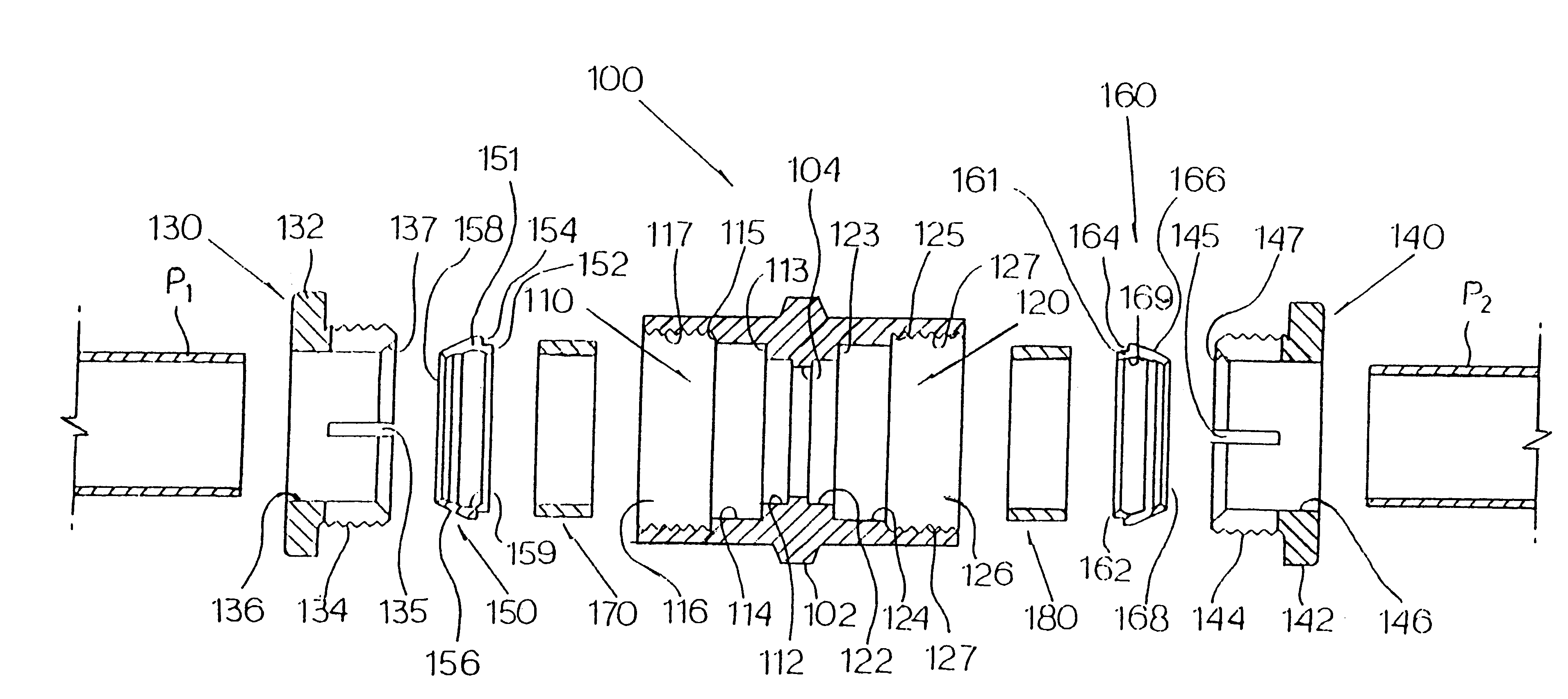

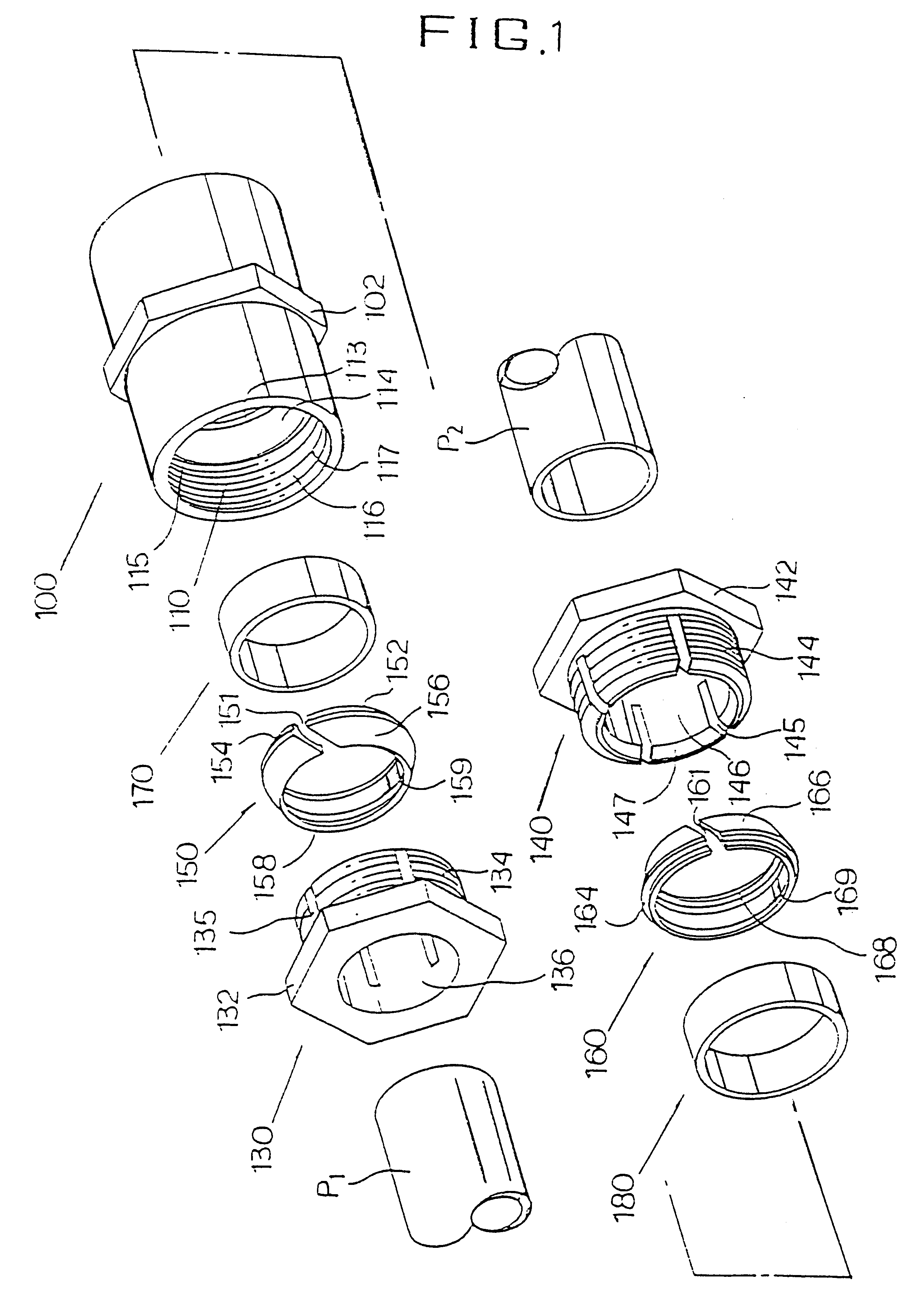

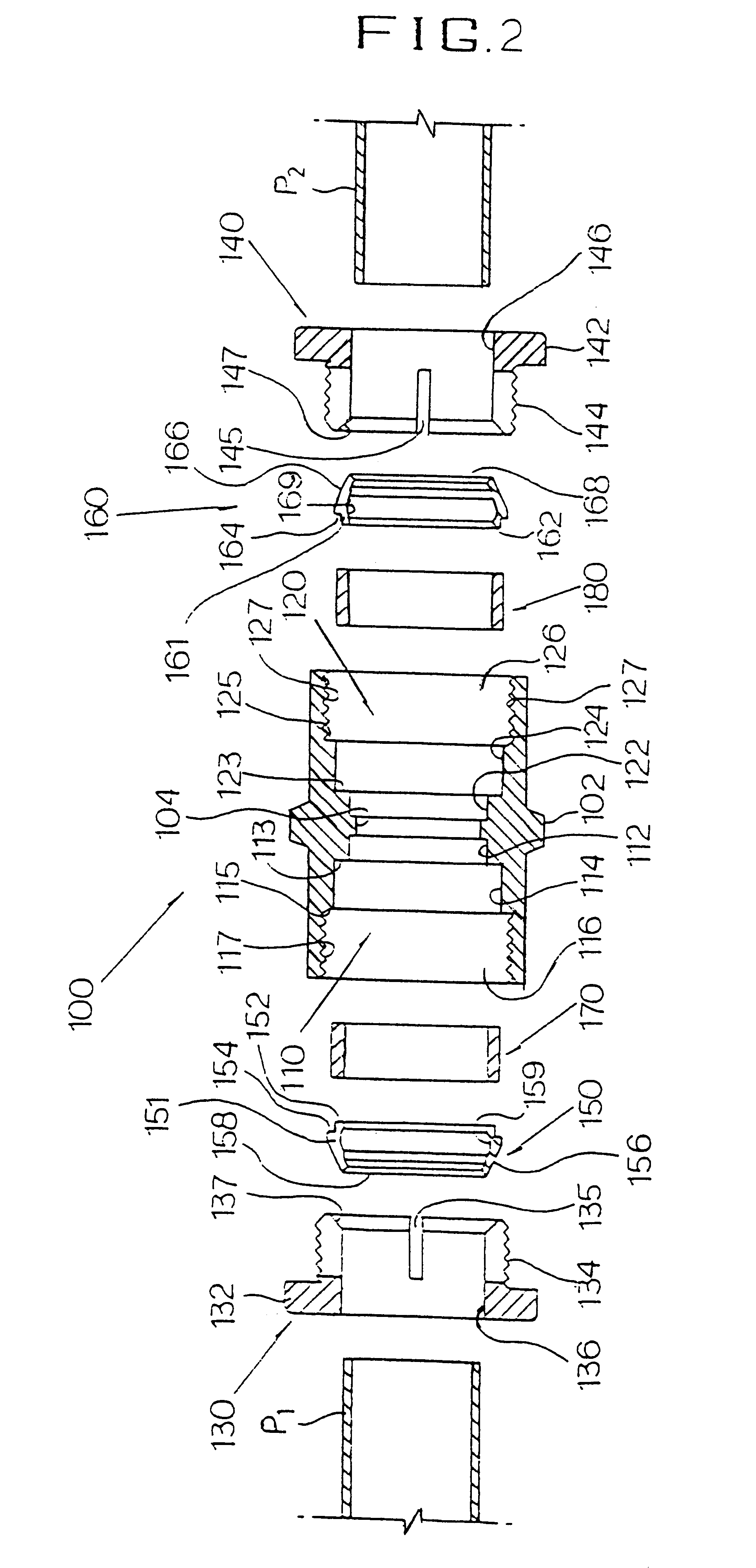

Piping joint and integrated valve with it

InactiveUS6488318B1Easy maintenanceImprove water tightnessSleeve/socket jointsFluid pressure sealed jointsThree-phaseEngineering

The present invention provides a piping joint and integrated valve with the piping joint, which improve airtight and watertight, maintain connection firm, and keep constant quality regardless repeated user. In connecting part (110, 120) of the joint body (100), the first holes (112, 113), the second packing holes (114, 124) where the first packing rings (170, 180) are inserted, the third holes (116, 126) with a female threaded part inside conjoining the second packing rings (150, 160) and bushes (130, 140), having three holes formed three phases outward on the concentric circle. The first packing rings (170, 180) are made of silicon or Teflon(R) that is flexible and sustainable against heat. One side of said second packing rings (150, 160) contact the first packing rings (170, 180), and ground the contact parts (152, 162) stoppers (154, 164) are placed to prevent the second packing rings (150, 160) from inserting too deeply into inside of the connecting parts (110, 120) of the joint body (100) and the other sides are tapered down in a certain angle to contact the slant (137, 147) of edges or bushes (130, 140), and the tapered parts (156, 166) are equipped with projections (158, 168) inside to hold pipes (P1, P2) firm.

Owner:JAE YOUNG SHIM

Convex-sided vacuum heat-insulating board, flattened vacuum heat-insulating board and preparation methods thereof

InactiveCN102953441AHigh compressive strengthSimple manufacturing processClimate change adaptationInsulation improvementConvex sideEngineering

The invention provides a vacuum heat-insulating board which comprises an upper heat-insulating board and a lower heat-insulating board, wherein the peripheries of the upper heat-insulating board and the lower heat-insulating board are welded together through using a welding flux, a closed vacuum layer is formed between the upper heat-insulating board and the lower heat-insulating board, the upper heat-insulating board and the lower heat-insulating board are flattened heat-insulating boards or convex-sided heat-insulating boards, and the convex side of each convex-sided heat-insulating board faces outwards. The production method of the vacuum heat-insulating board provided by the invention is simple in process, and the prepared vacuum heat-insulating board overcomes the defects of the existing heat-insulating board, so that the tightness of a vacuum layer of the vacuum heat-insulating board can be effectively guaranteed, the service life of the vacuum heat-insulating board is prolonged, and the strength and heat insulation, sound insulation and fire prevention properties of the vacuum heat-insulating board can be increased.

Owner:戴长虹

Corrosion-resistant metallic member, metallic separator for fuel cell comprising the same, and process for production thereof

InactiveUS20030068523A1A large amountIncrease contact resistanceFinal product manufacturePretreated surfacesAir tightnessContact resistance

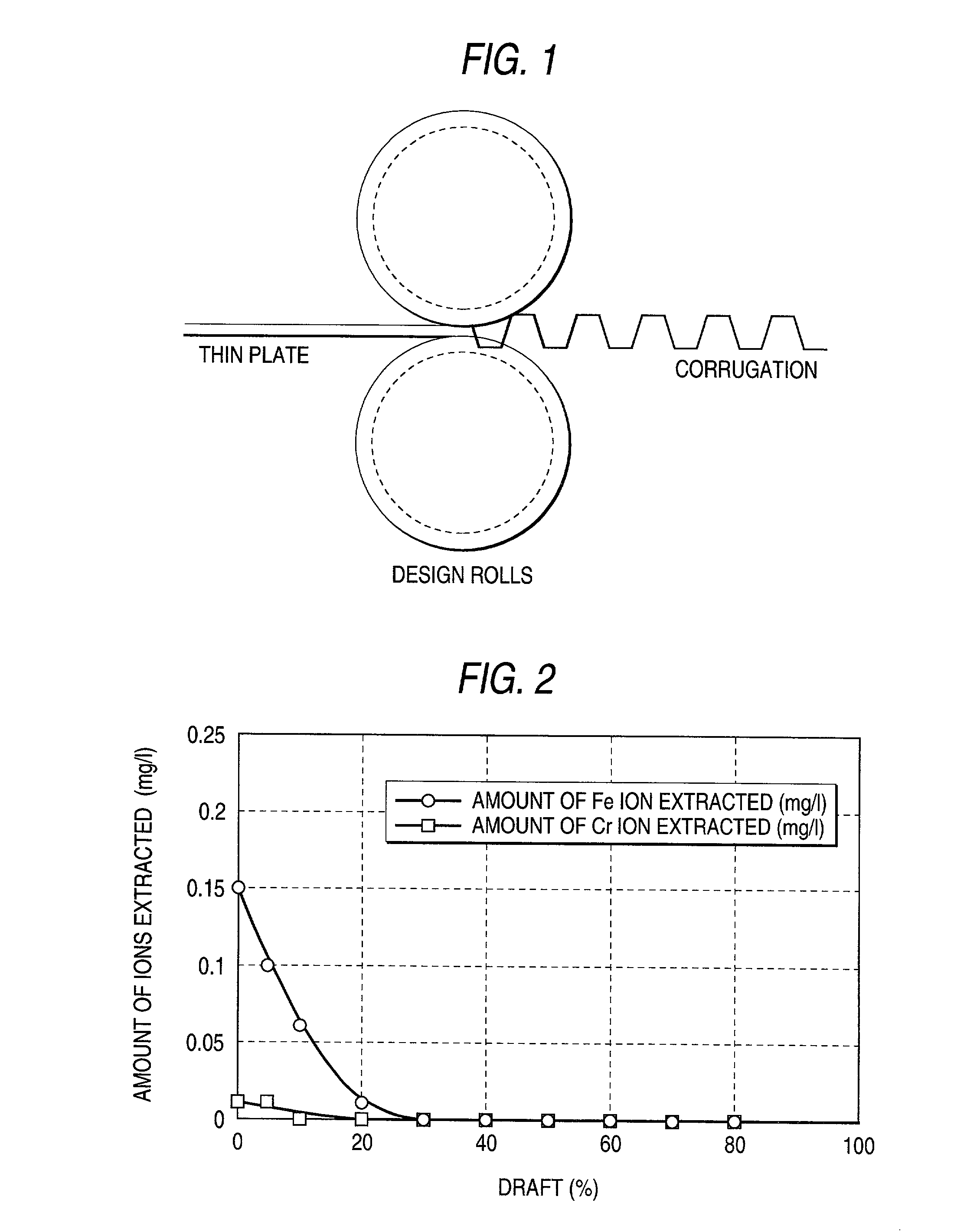

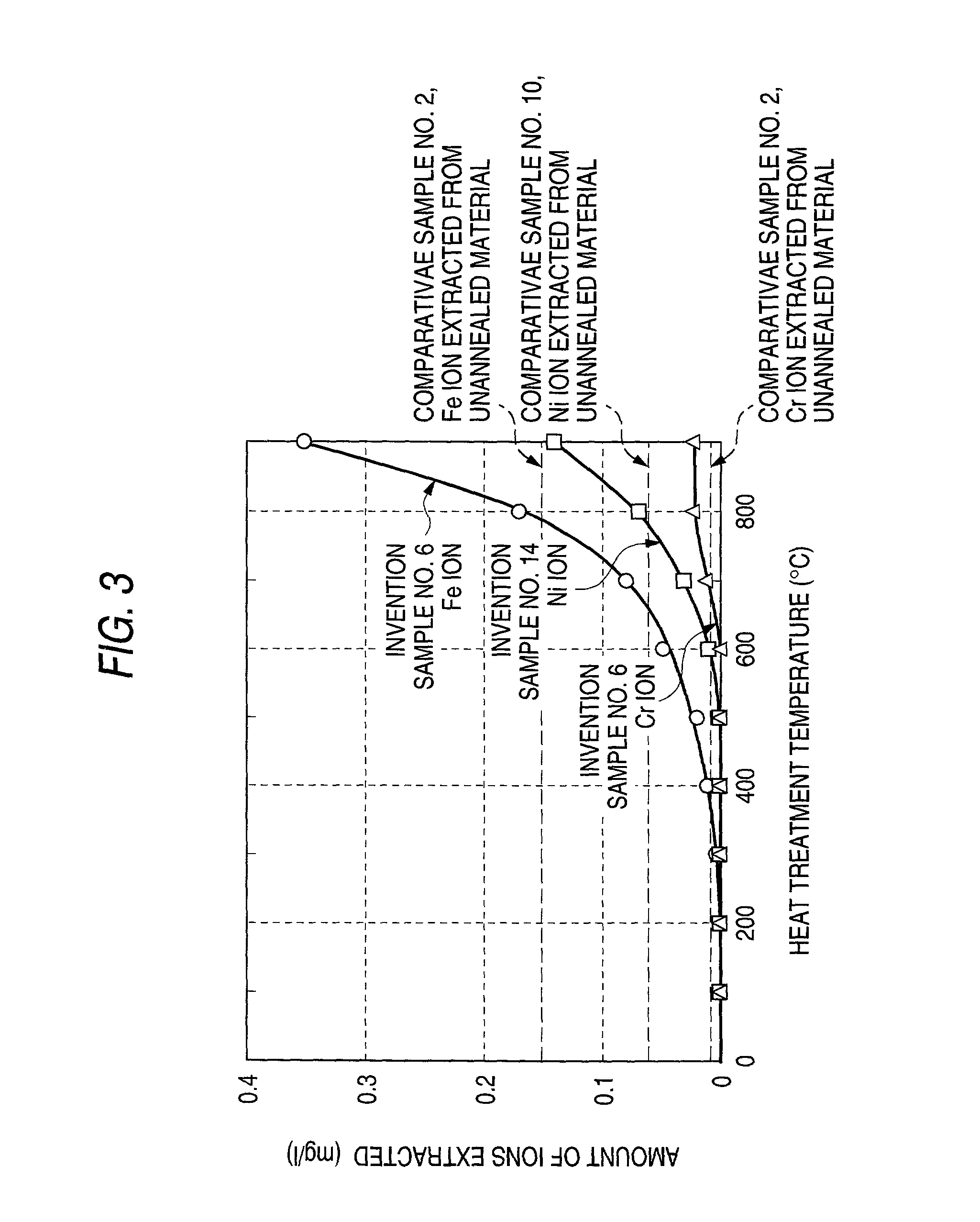

A highly corrosion-resistant material and a corrosion-resistant member which are improved in corrosion resistance, adhesion, contact electrical resistance, electrical conductivity, airtightness, etc. and are suitable for use as, e.g., a metallic separator for polymer electrolyte fuel cells (PEFC); and a process for producing them. A thin noble-metal layer is formed on the desired part of the surface of a metallic base and then subjected to compression working. The coated base may further be subjected to anticorrosive treatment with a liquid phase containing a peroxide or ozone or with an active gas atmosphere.

Owner:DAIDO STEEL CO LTD

Automatic assembly device for stop valve

InactiveCN105881450AImprove air tightnessImprove quality stabilityAssembly machinesMetal-working hand toolsClockwiseAir tightness

The invention discloses an automatic assembly device for a stop valve. The automatic assembly device for the stop valve comprises a rack. A rotary table of the rack is separated into ten working stations. A tee feeding module, a valve core feeding module, a valve core assembly module, a hand wheel assembly module, a nut feeding module, a nut assembly module, a plastic cap assembly module and a finished product discharging module are arranged in a clockwise direction around the rotary table in order. The assembly of the stop valve is in the order of feeding a tee, positioning the tee, assembling a valve core, detecting air tightness, assembling a hand wheel, assembling a nut, then assembling a plastic cap and finally discharging a finished product. According to the device, two working stations are obligated between the valve core assembly module and the hand wheel assembly module to detecting the air tightness, so that good air tightness of an assembled stop valve can be guaranteed. By means of the device, automatic feeding and assembly of five parts of the stop valve and automatic discharging of the finished product are realized, the stability of the quality of the stop valve and the production efficiency are improved, at the same time the labor cost is reduced.

Owner:TAIZHOU LIANFANG ELECTROMECHANICAL TECH

C/C and C/SiC composite material and metal connecting method

ActiveCN101143397AFirmly connectedSoldering apparatusWelding/soldering/cutting articlesParticulatesMetal fibers

The invention is a method of binding compound materials of the C / SiC and C / C, which belongs to the technology field of binding heterogeneous materials. The processing procedures are as following: 1. The surface of the e compound materials of the C / SiC and C / Cis pretreated, which comprise the surface of the connecting are grinding, cleaning, vacuum biscuit firing, preparation of double-layer metal film and microvacum heat treatment and so on. 2. The transition layer of the connecting area surface gradient of the compound materials of the C / SiC is coated and sintered. 3. The compound materials with the gradient transition layer as the felted phase is brazed with the metal in vacuum. The invention is characterized in that the gradient transition layer is directly used as the materials that bind the compound materials with the metal; the gradient transition layer is double-layered or multilayered (sub-layered) structure; from the inner basal body to the outer part of the compound materials, the melting points of active brazing alloy adopted by each sub-layer gradually lower, the coefficient of heat expansion that adjust volume percentage composition gradually lower and the coefficient of heat expansion of the sub-layers gradually rise. The brazing ceramic metal connecting piece of the invention has good strength, air tightness and wide application field, which is suitable for various non-metallic fibers, such as ceramics of SiC, Si3N4, Al2O3, AlN and so on and applicable for connecting the ceramic matrix compound materials with particulate reinforced with the metal.

Owner:GRIMAT ENG INST CO LTD

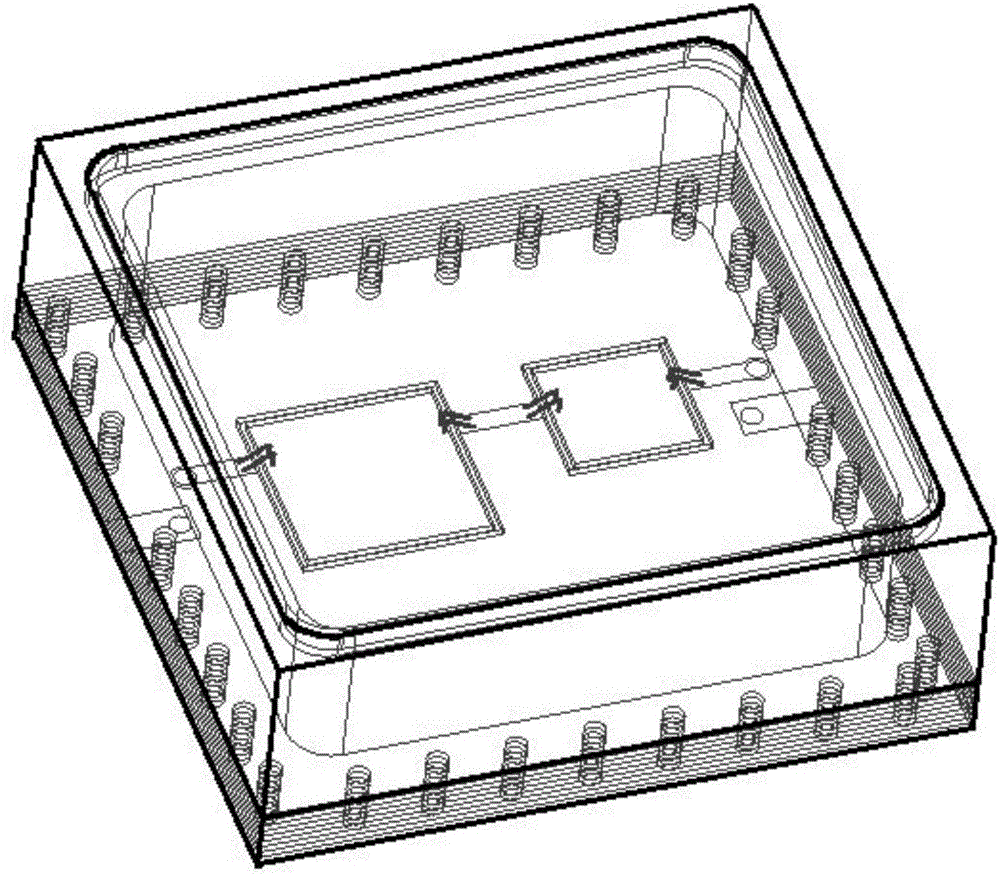

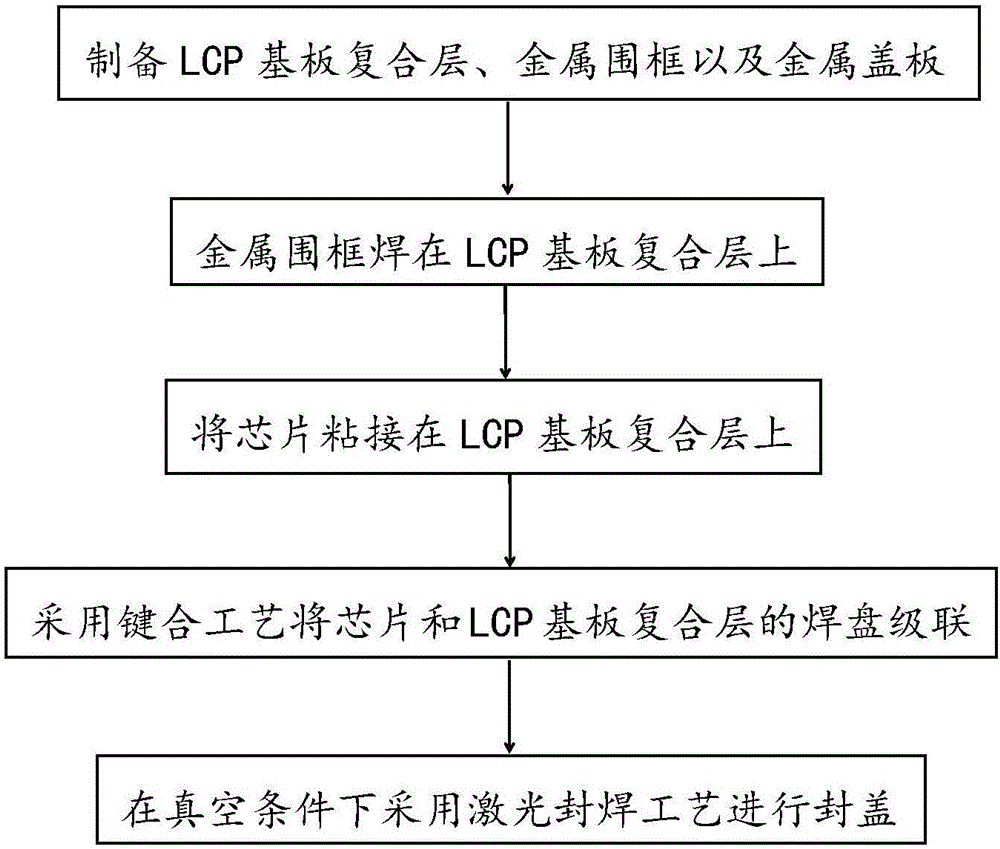

LCP substrate-based encapsulation shell and preparation method

InactiveCN106486427AImprove isolationInterconnectionSemiconductor/solid-state device detailsSolid-state devicesAdhesiveElectrical connection

The present invention relates to an LCP substrate-based encapsulation shell and a preparation method. The encapsulation shell comprises a metal enclosure, a LCP substrate composite layer which is arranged below the metal enclosure, and a metal cover plate which covers the metal enclosure; a plurality of LCP substrates which are connected with one another and are laminated so as to form the LCP substrate composite layer; the metal enclosure is in airtight connection with the LCP substrate composite layer; the metal cover plate is in airtight connection with the metal enclosure; the LCP substrate composite layer includes a chip adhesive layer, a gold wire bonding layer, components and a metal enclosure welding layer which are connected with one another sequentially; through holes are formed in the metal enclosure welding layer, so that excellent grounding and space isolation are realized; and electroplated solid holes are formed in each layer of the LCP substrate composite layer, so that electrical connection between any layers can be realized. The shell of the invention has the advantages of high air tightness, small size and light weight, and can be applied to high-frequency integrated circuits such as microwave and millimeter wave integrated circuits.

Owner:CHENGDU GANIDE TECH

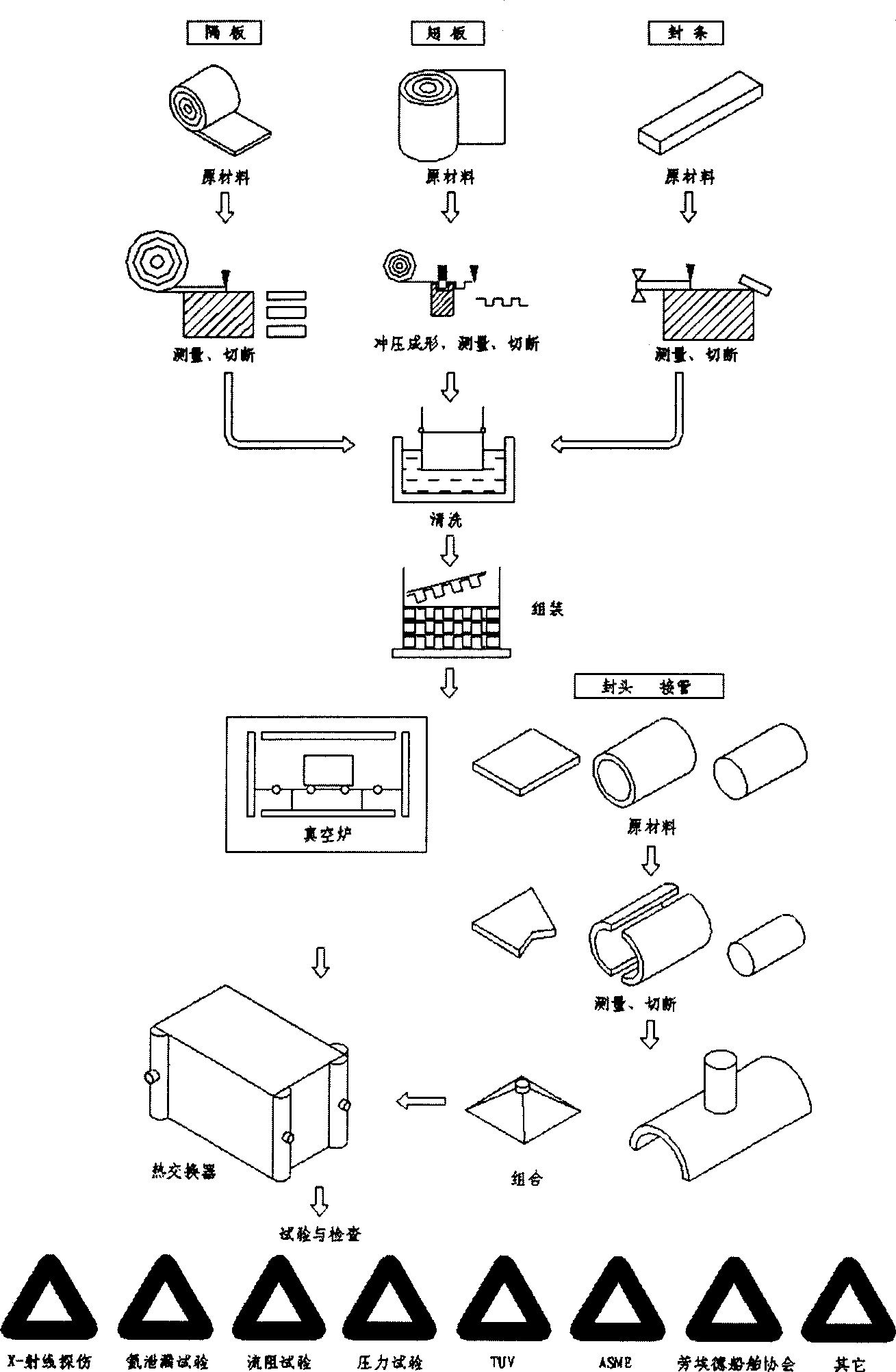

Manufacture of fine-type stainless steel plate heat exchanger

InactiveCN1375374AImprove wettabilityIngredients evenly distributedSoldering apparatusX-rayHigh pressure water

The production method of austenitic stainless steel plate fin heat exchanger includes the following steps: part preparation: partition, sealing strip, fin, sealing head and connecting pipe preparation; cleaning before welding; acid pickling to remove oil, dirt and oxide, and using high-pressure water to wash; element assembling and holding; vacuum braze welding, adopting argon arc welding to weldscaling head and connecting pipe, making general assembly; test and inspection, making x-ray inspection, helium leak detection, flow resistance test, pressure test, TUV, ASME and other test and inspection. Said invented process raise the production quality of said stainless steel plate fin heat exchanger, tensile-strength of connector and its service life.

Owner:NANJING UNIV OF TECH

NMR CryoMAS probe for high-field wide-bore magnets

InactiveUS7915893B2Low emissivityImprove fill factorElectric/magnetic detectionMeasurements using magnetic resonanceThermal insulationEngineering

All critical circuit components, including the sample coils, are located along with the spinner assembly in a region that may be evacuated to high vacuum for thermal insulation and high-voltage operation. A hermetically sealed spinner assembly simultaneously satisfies the requirements of hermeticity, low total emissivity, rf compatibility, spinning performance, magnetic compatibility, and high filling factor by utilizing metal construction except for the central region near the rf sample coils. Hence, it is possible to maintain high vacuum in the region external to the MAS spinner assembly even over a broad range of bearing and drive gas temperatures. A bundle of optical fibers is provided for tachometry for spin rates up to 60 kHz. The use of alumina disc capacitors allows the noise contributions from the most critical capacitors to be reduced to a minor fraction of the total and simplifies high voltage operation.

Owner:DOTY SCI

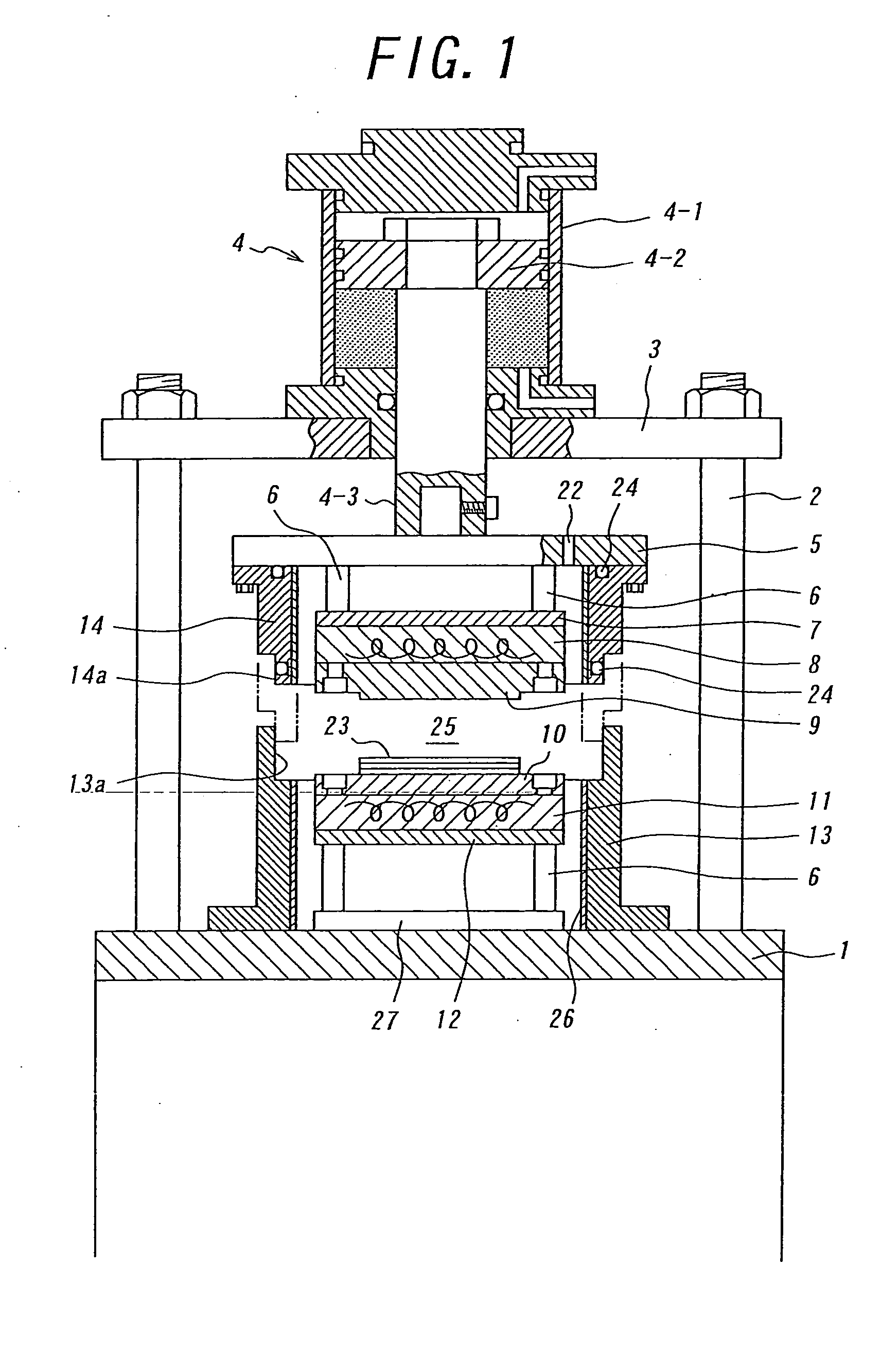

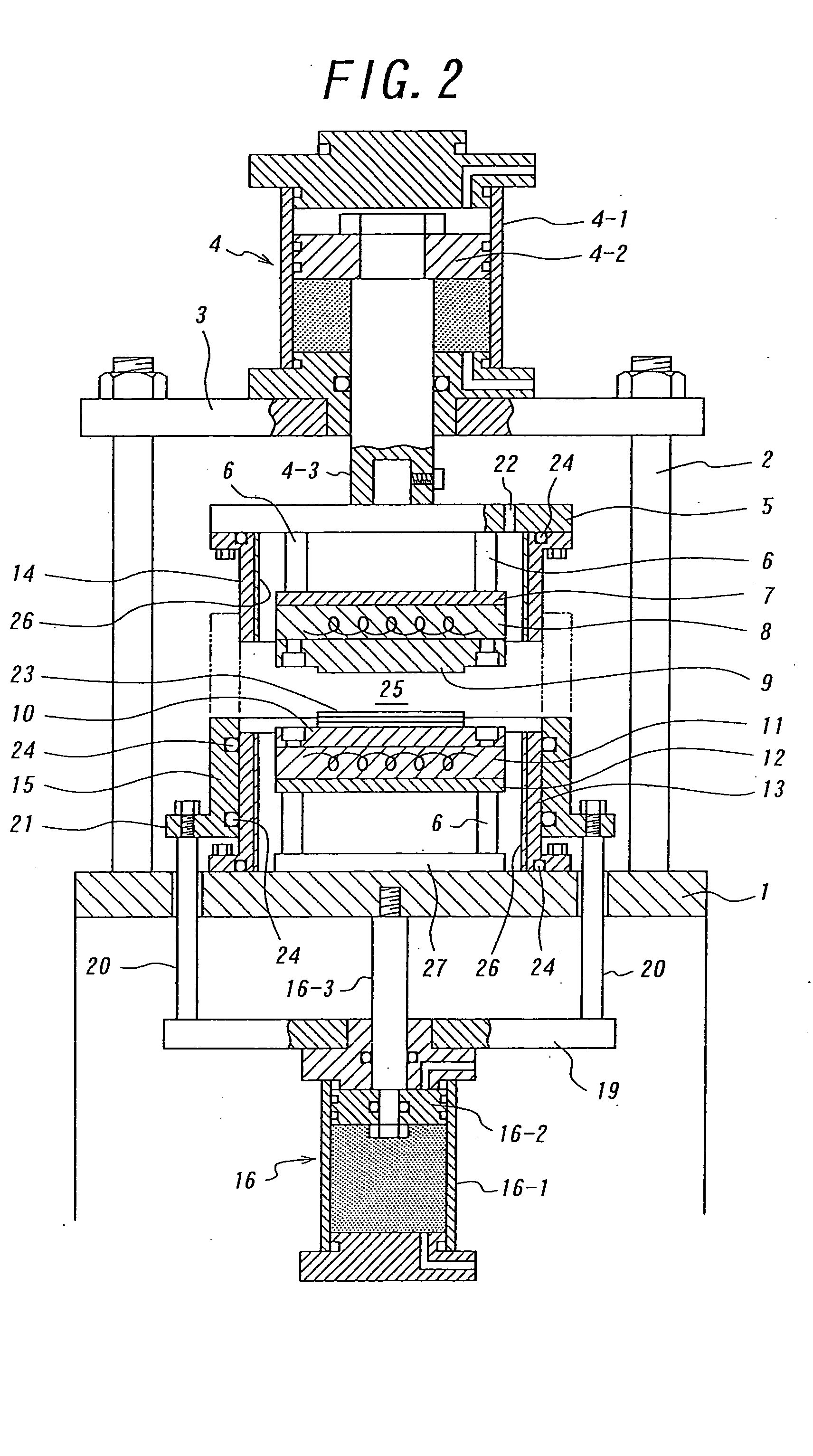

Heating-type vacuum press device

ActiveUS20050089597A1Vacuum pump can be miniaturizedConfectionerySweetmeatsVacuum pressureFixed frame

A heating-type vacuum press device which has a small vacuum isolation chamber in which pressing is performed under vacuum without damage to seal packing, while heating. A lower fixed frame and an upper movement frame constitute a wall portion of the isolation chamber. A gas-tight sliding mechanism ensures gas-tightness between the lower fixed frame and the upper movement frame. Thereby, the isolation chamber is formed in a space defined by the lower fixed frame, the upper movement frame, a base and a fitting plate. The lower fixed frame surrounds a receiving table equipped with a heater for a workpiece, and is arranged on the base such that the lower fixed frame is spaced from the receiving table. The upper movement frame is hanged from the fitting plate such that the upper movement frame is spaced from a pressing plate equipped with a heater, and surrounds the pressing plate. The isolation chamber is sucked to vacuum, and a workpiece on the receiving plate is pressed under heating and vacuum at a high temperature with a low thrusting force by descending the pressing plate. The present apparatus is suitable for bonding multi-functional laminated films having high heat-resistant temperature.

Owner:MIKADO TECHNOS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com