Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7933results about "Thermal insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

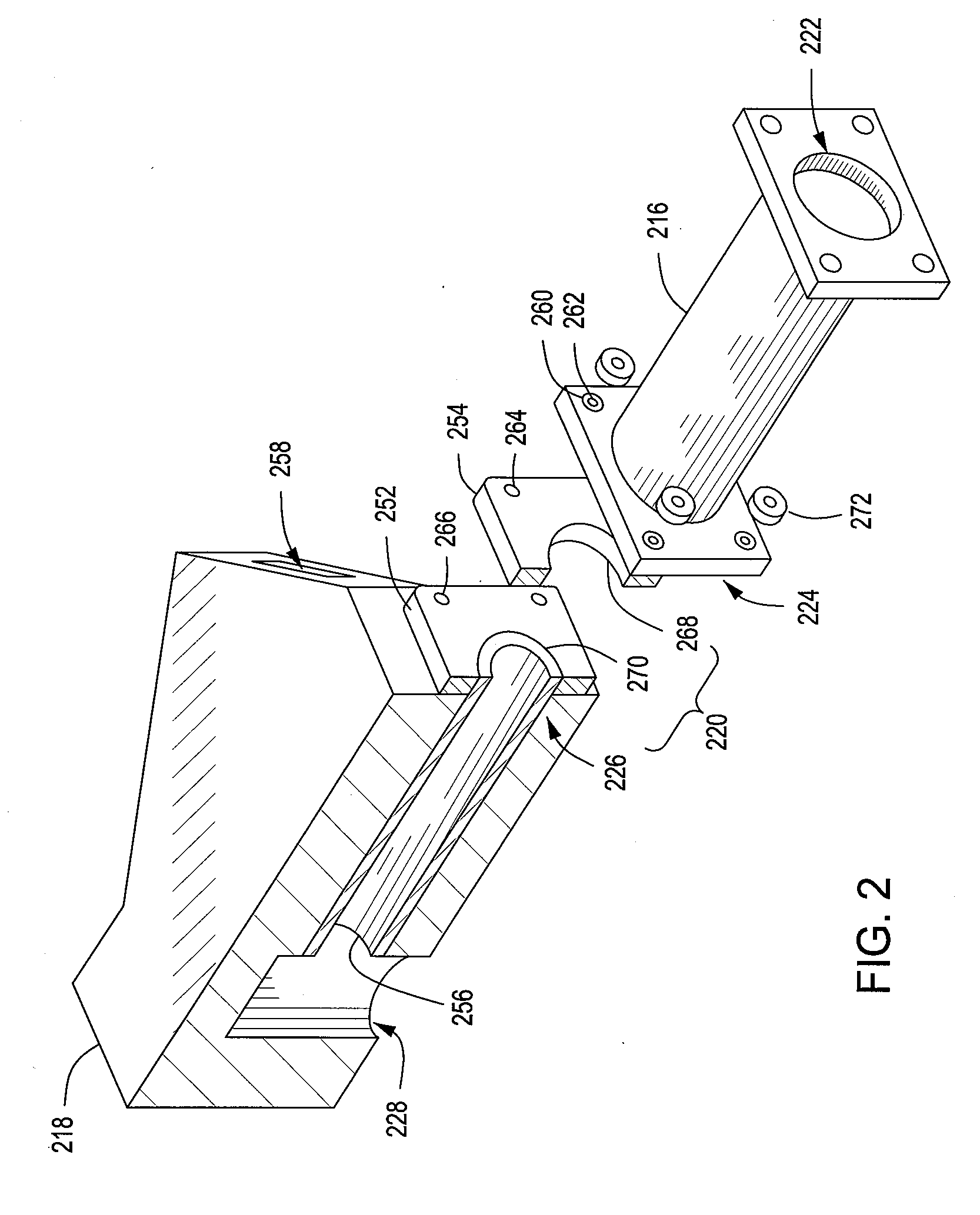

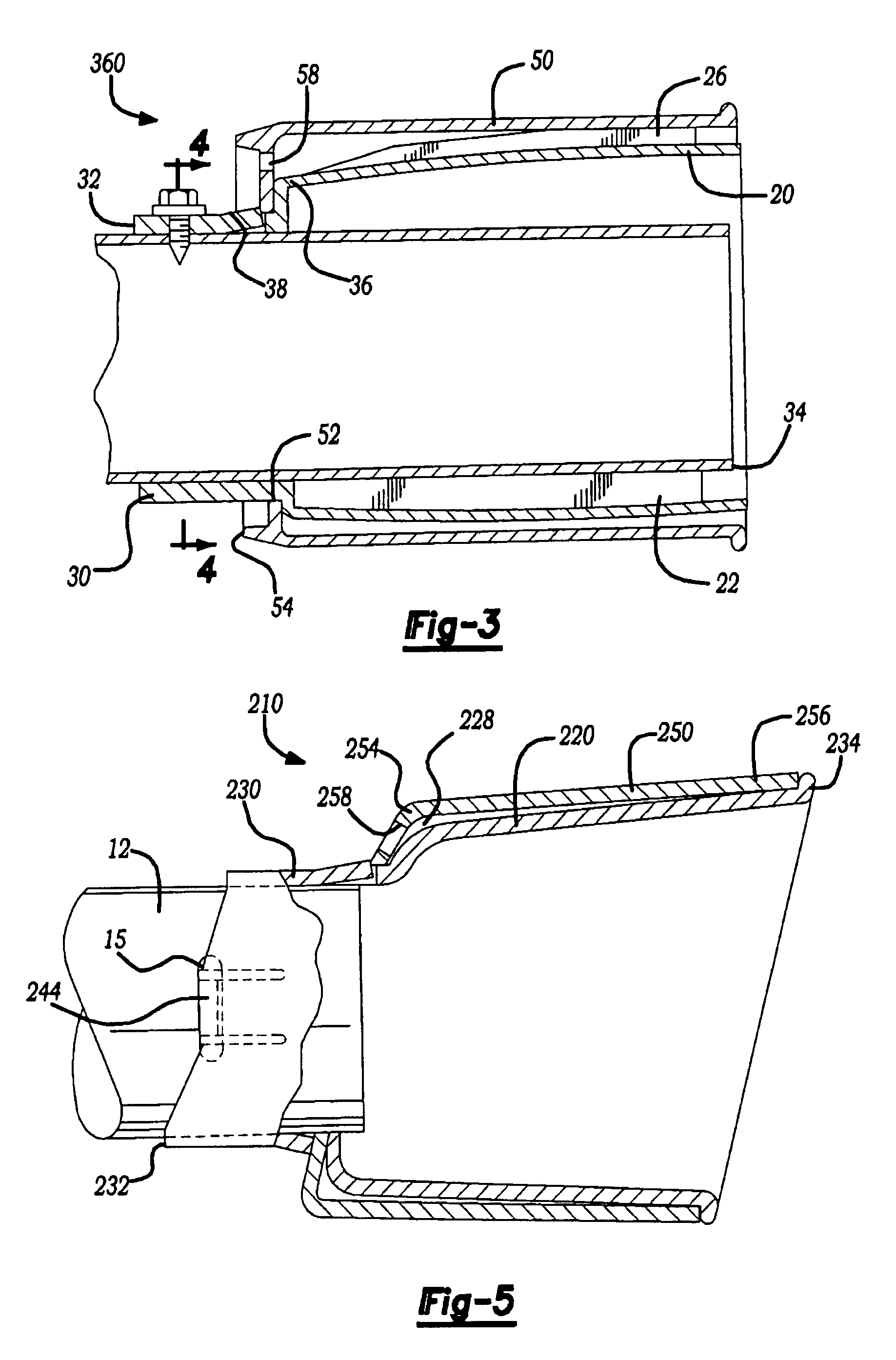

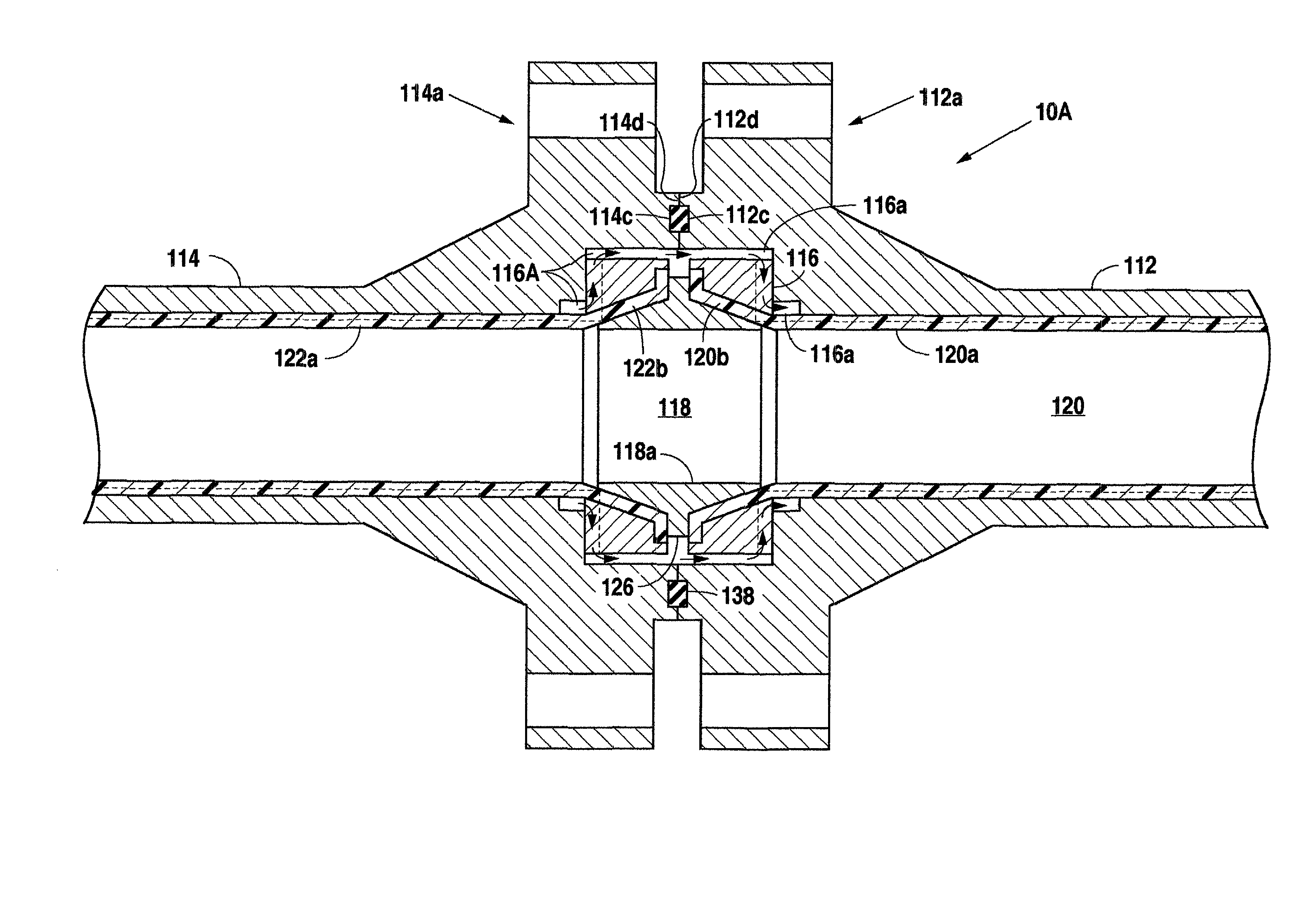

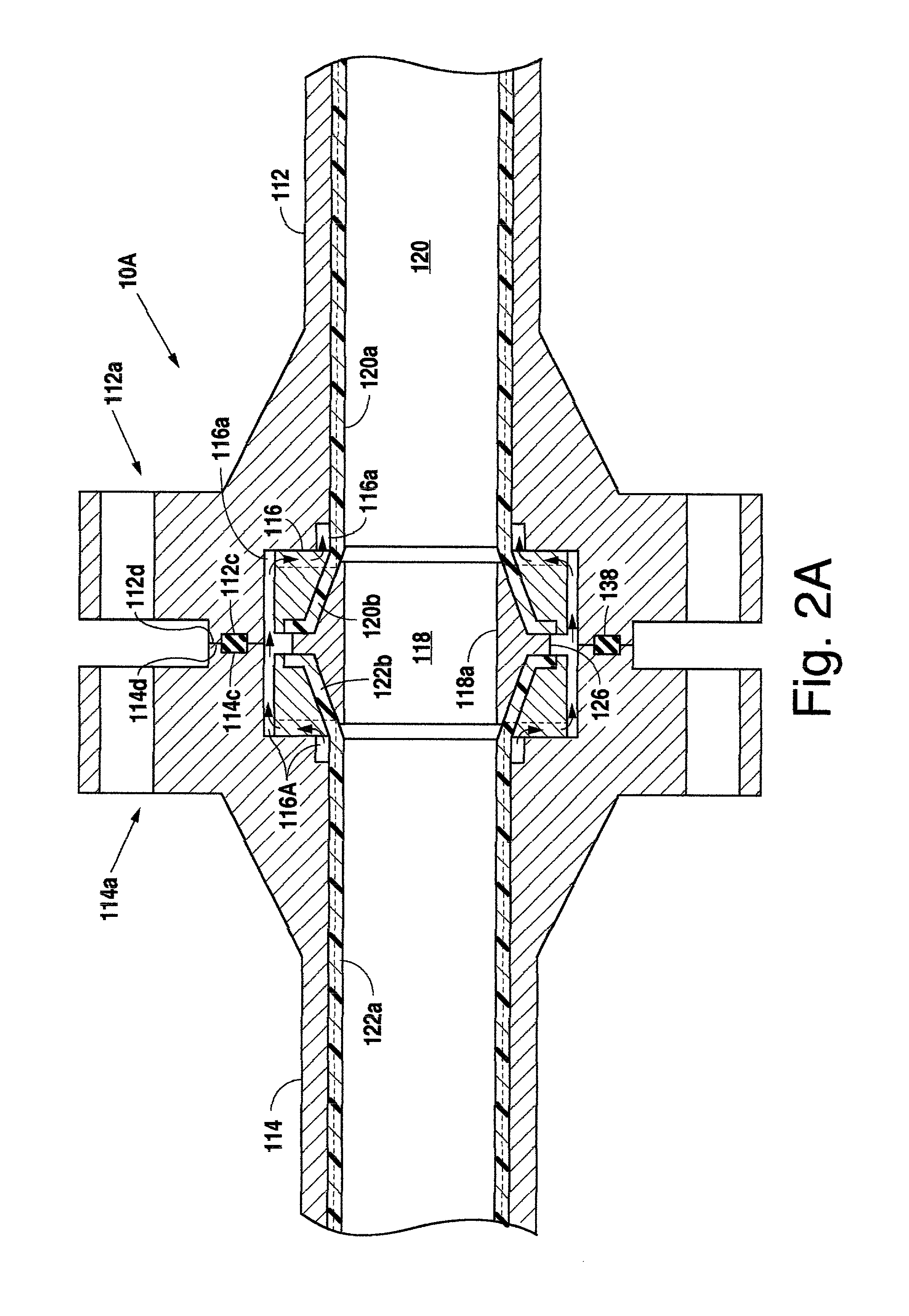

Manifold assembly

Embodiments of a manifold assembly are provided herein. In some embodiments, a manifold assembly includes a first manifold having a first inlet, for coupling to a high temperature fluid source, and a first outlet; a second manifold having a second inlet and a second outlet; and a connector portion coupling the first outlet of the first manifold to the second inlet of the second manifold, the connector portion includes a polymer block; and a thermal isolator disposed between the polymer block and the first manifold.

Owner:APPLIED MATERIALS INC

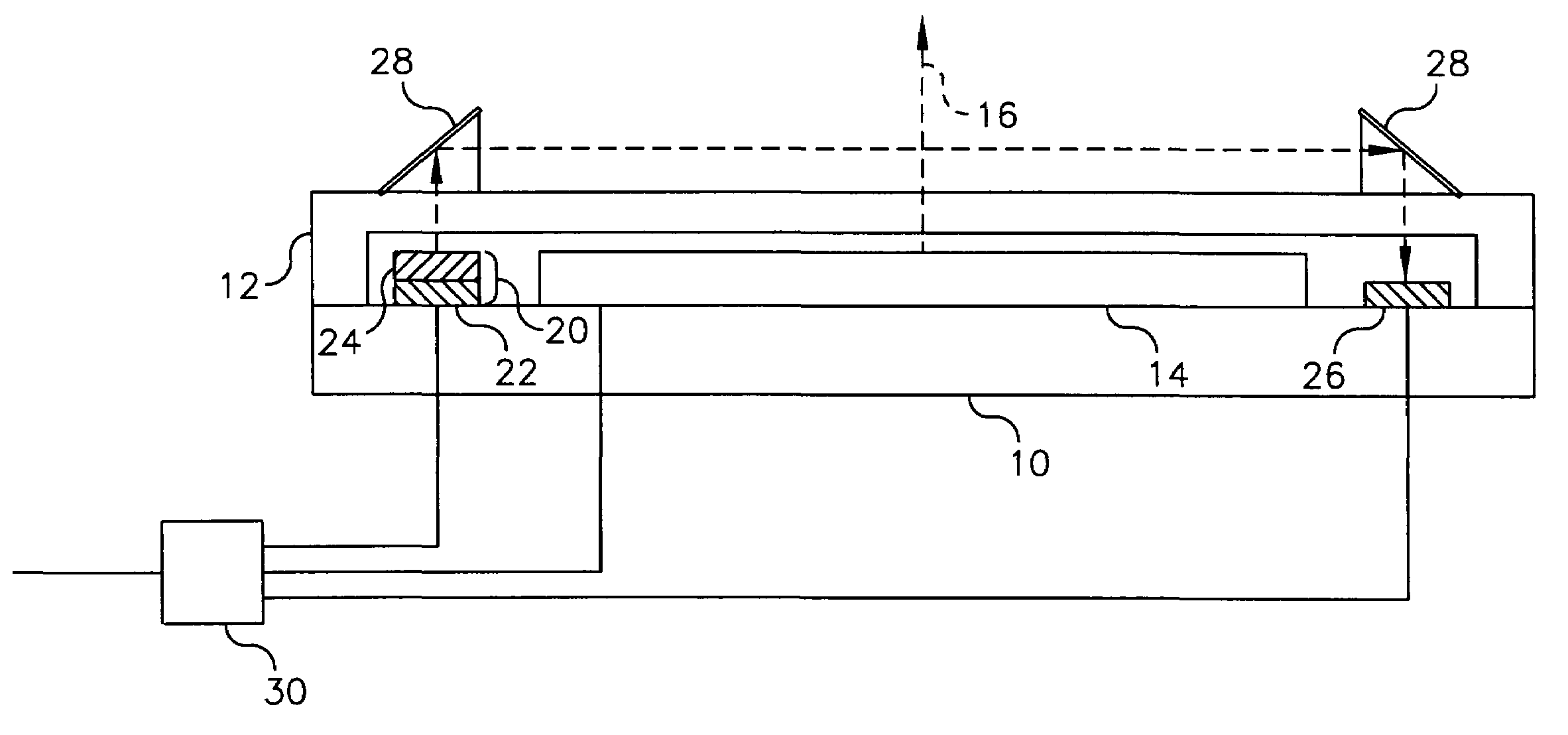

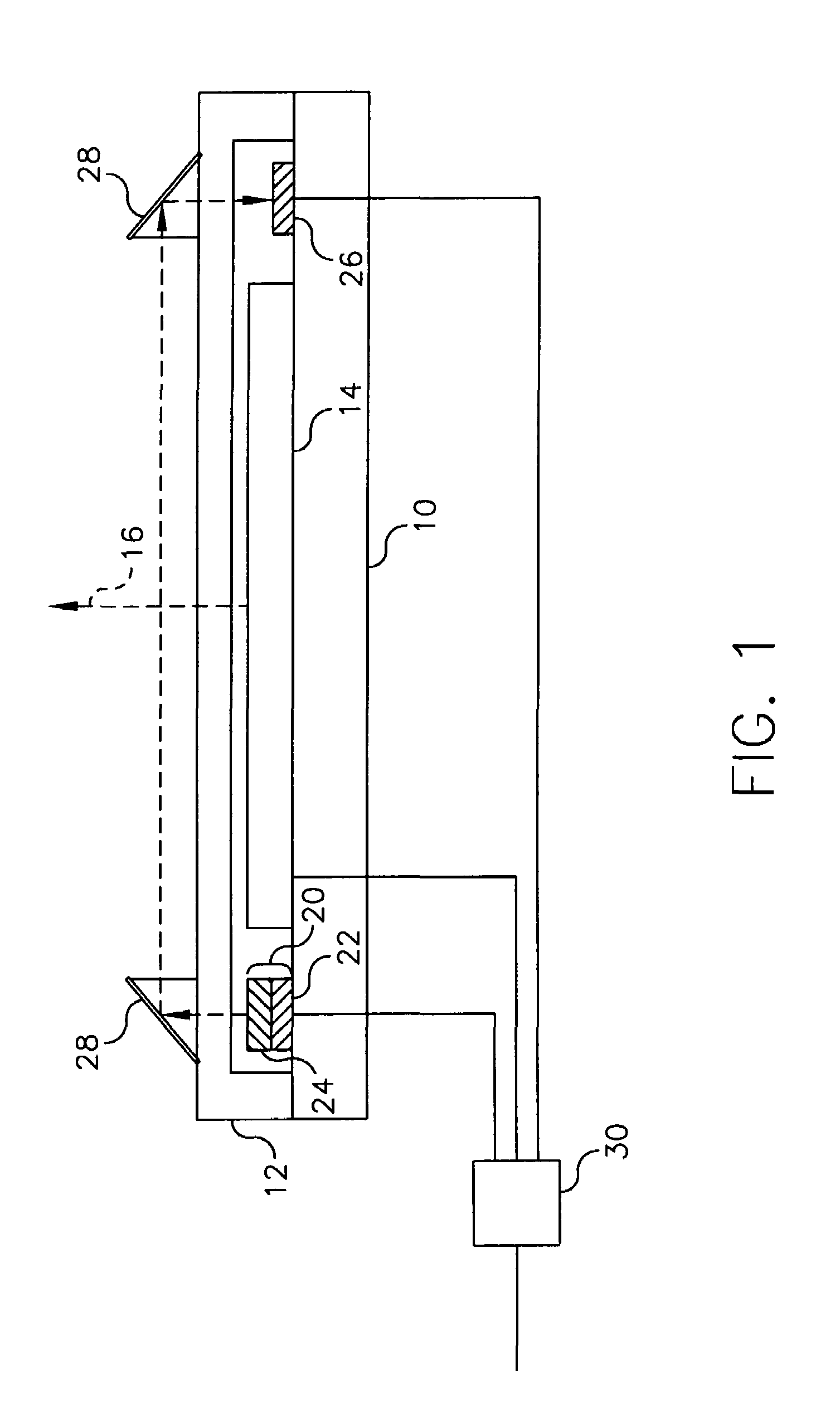

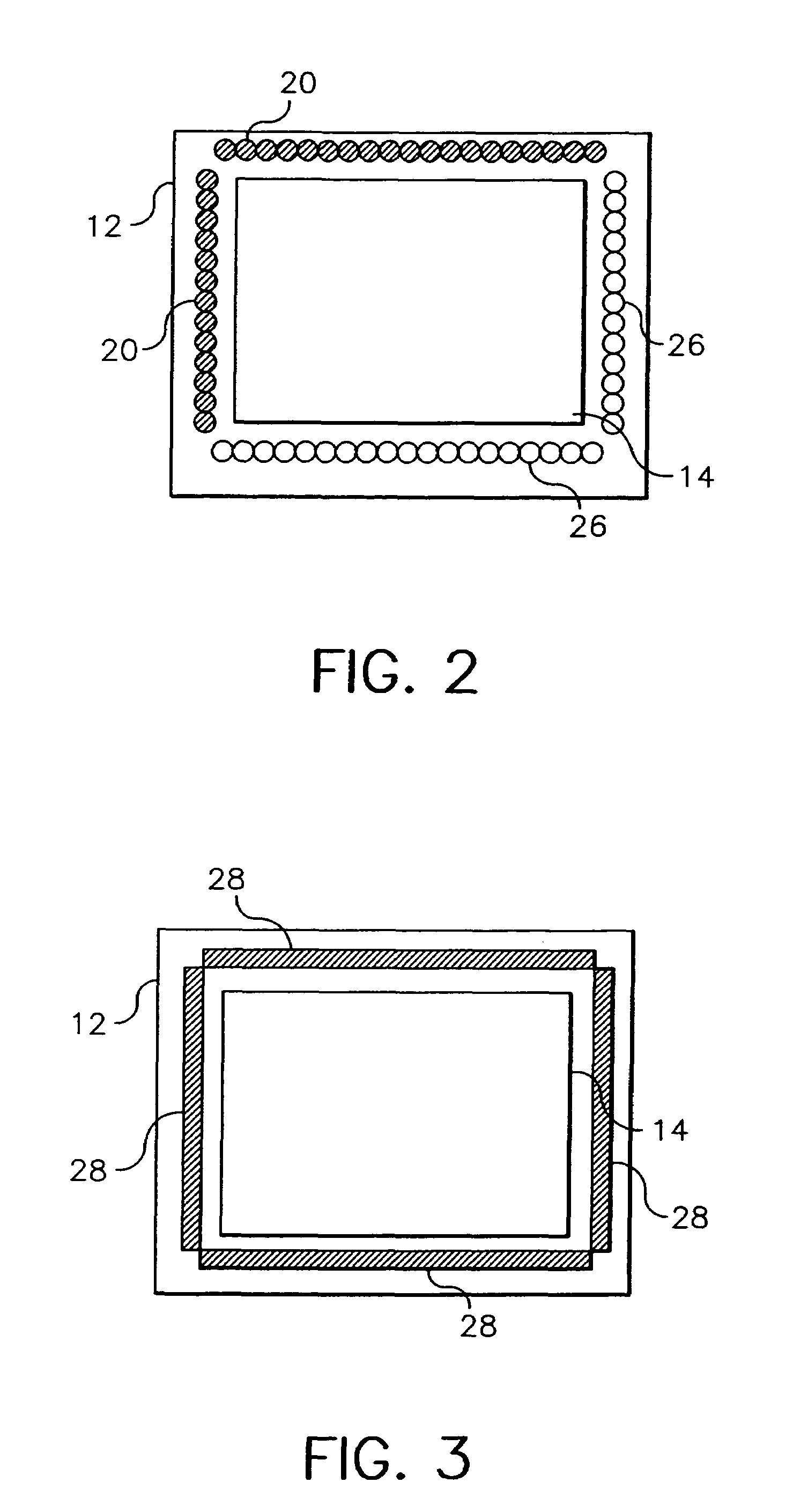

OLED display and touch screen

An OLED display and touch screen system includes a substrate; an OLED display including an array of individually addressable OLEDs formed on the substrate; and a touch screen including an OLED laser light emitter formed on the substrate, a light sensor formed on the substrate across the display from the light emitter, and optics located around the display above the light emitter and the light sensor for directing light emitted from the OLED laser light emitter across the display to the light sensor.

Owner:GLOBAL OLED TECH

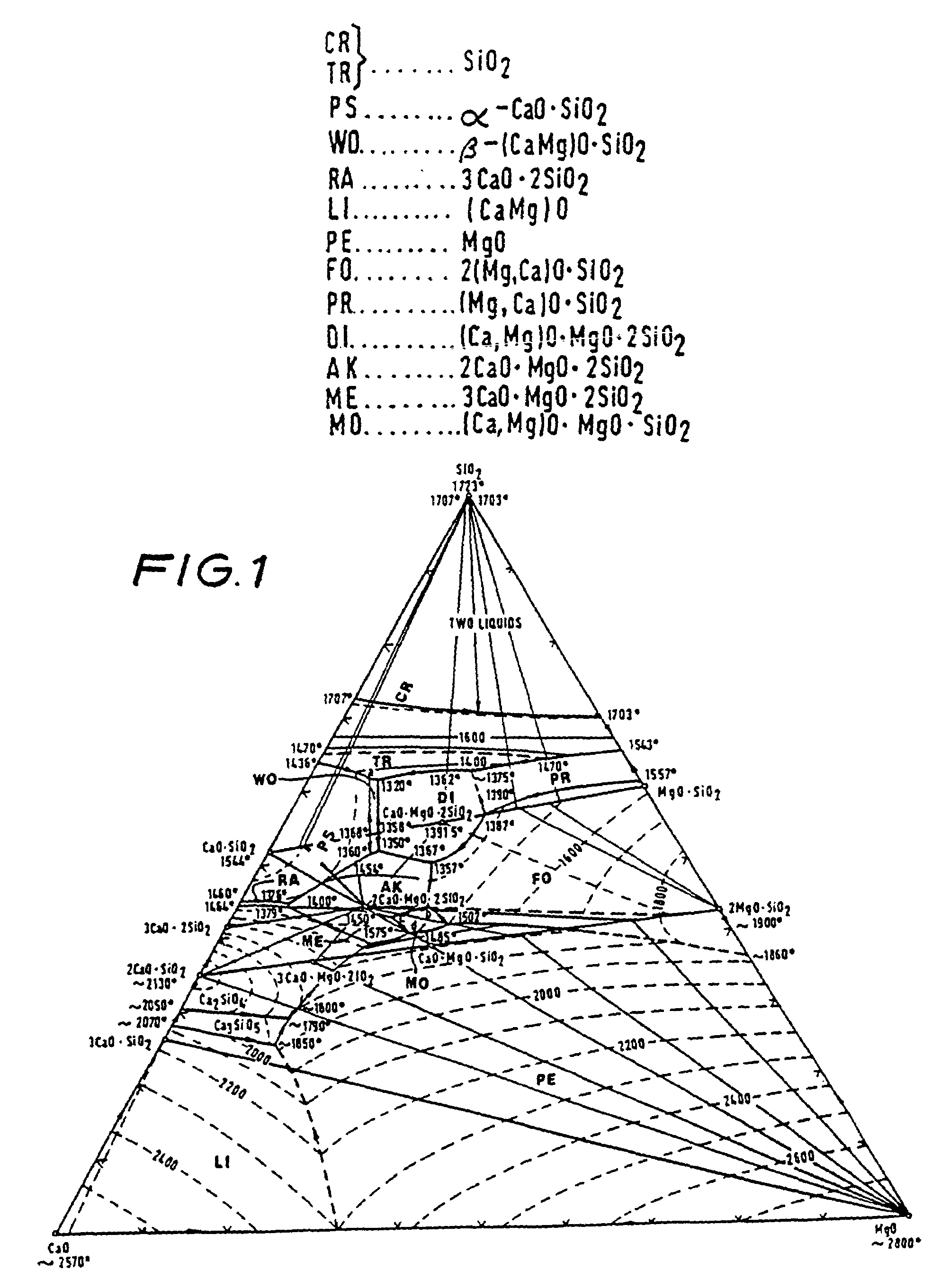

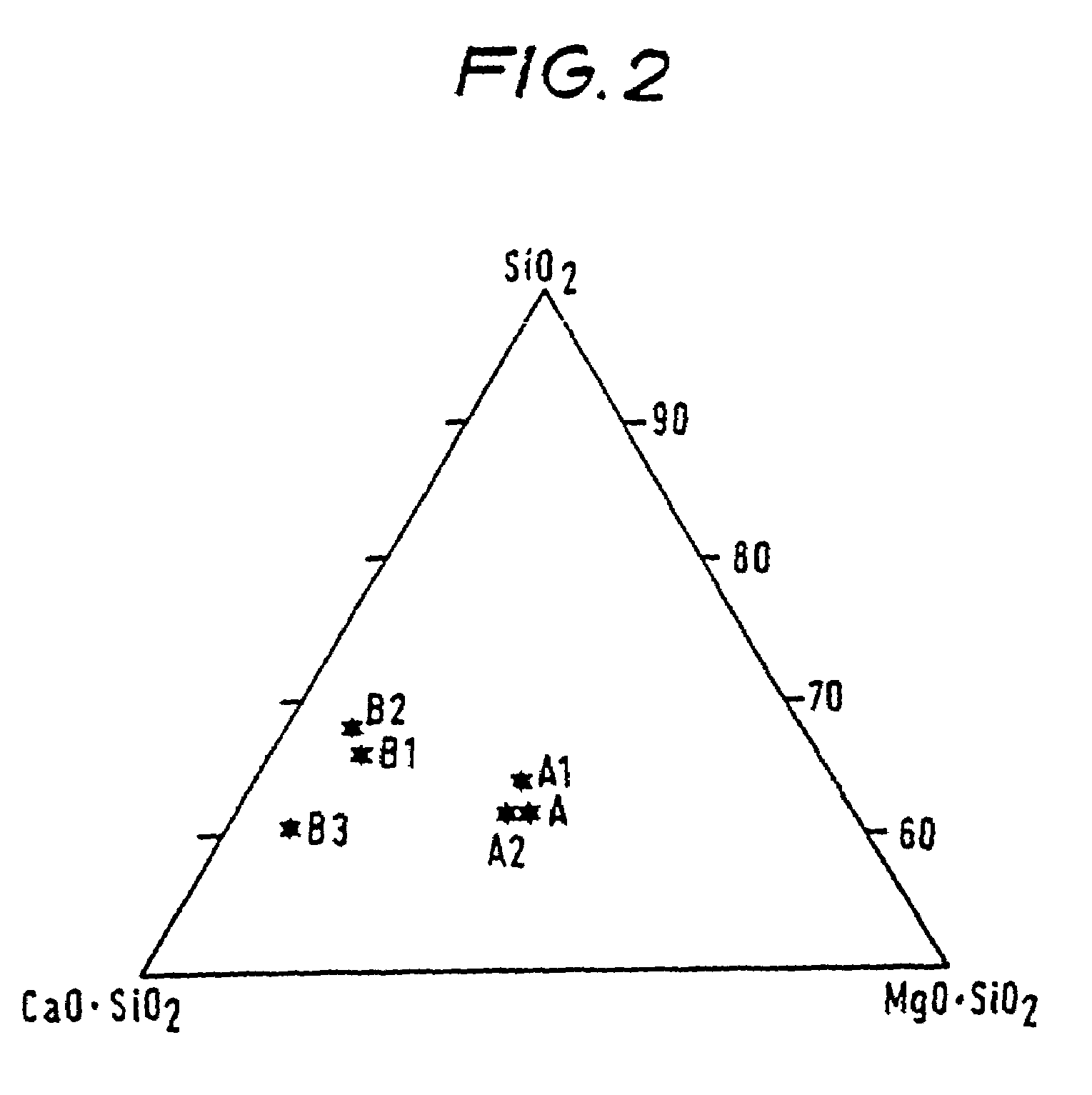

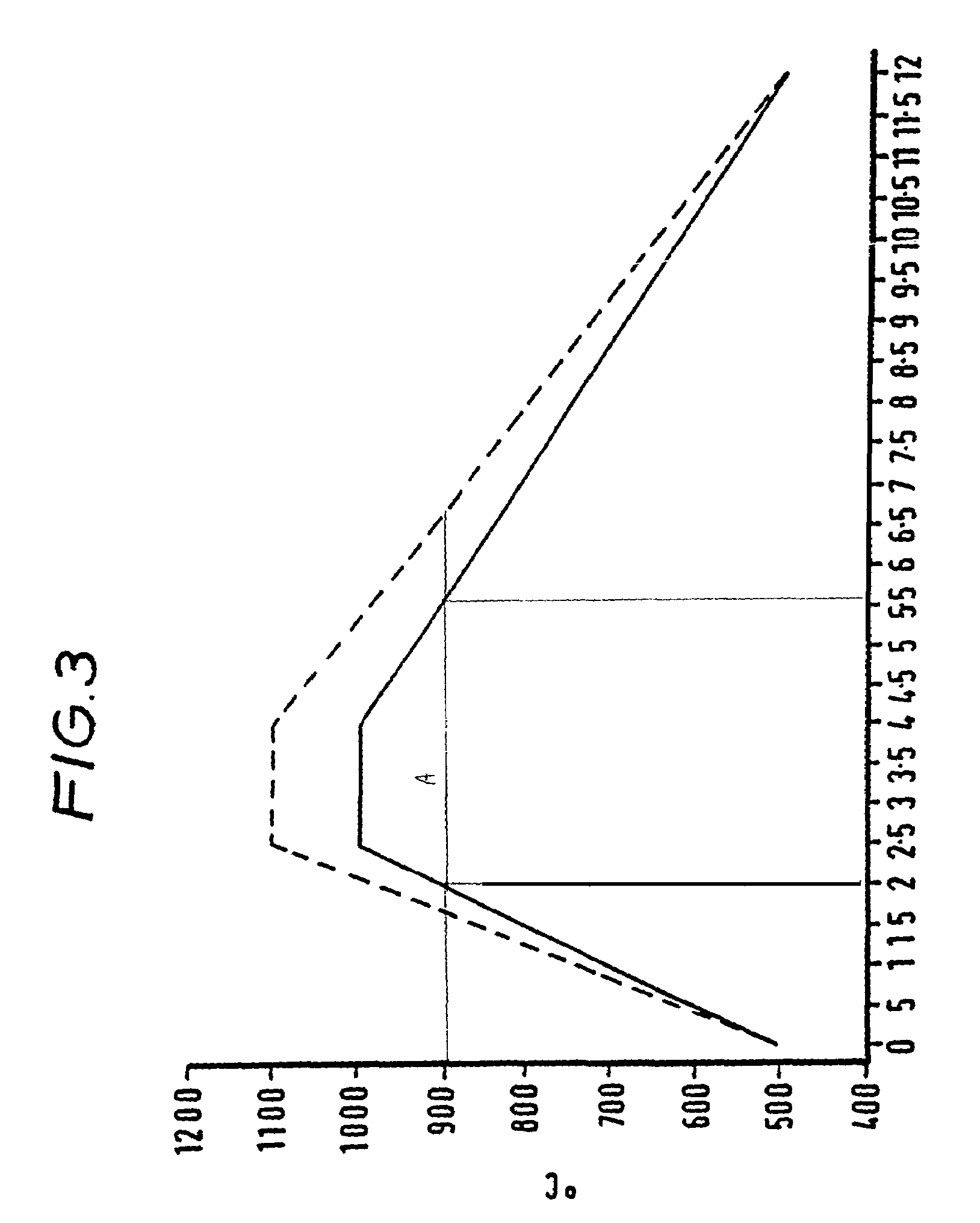

Saline soluble inorganic fibers

A method for insulating an article requiring resistance against repeated exposure to temperatures exceeding 900° C. uses saline soluble, non-metallic, amorphous, inorganic oxide, refractory fibrous materials as thermal insulation. The compositions that can be used for that purpose include vitreous fibers based on SiO2, CaO, MgO, and optionally, A2O3.

Owner:THE MORGAN CRUCIBLE CO PLC

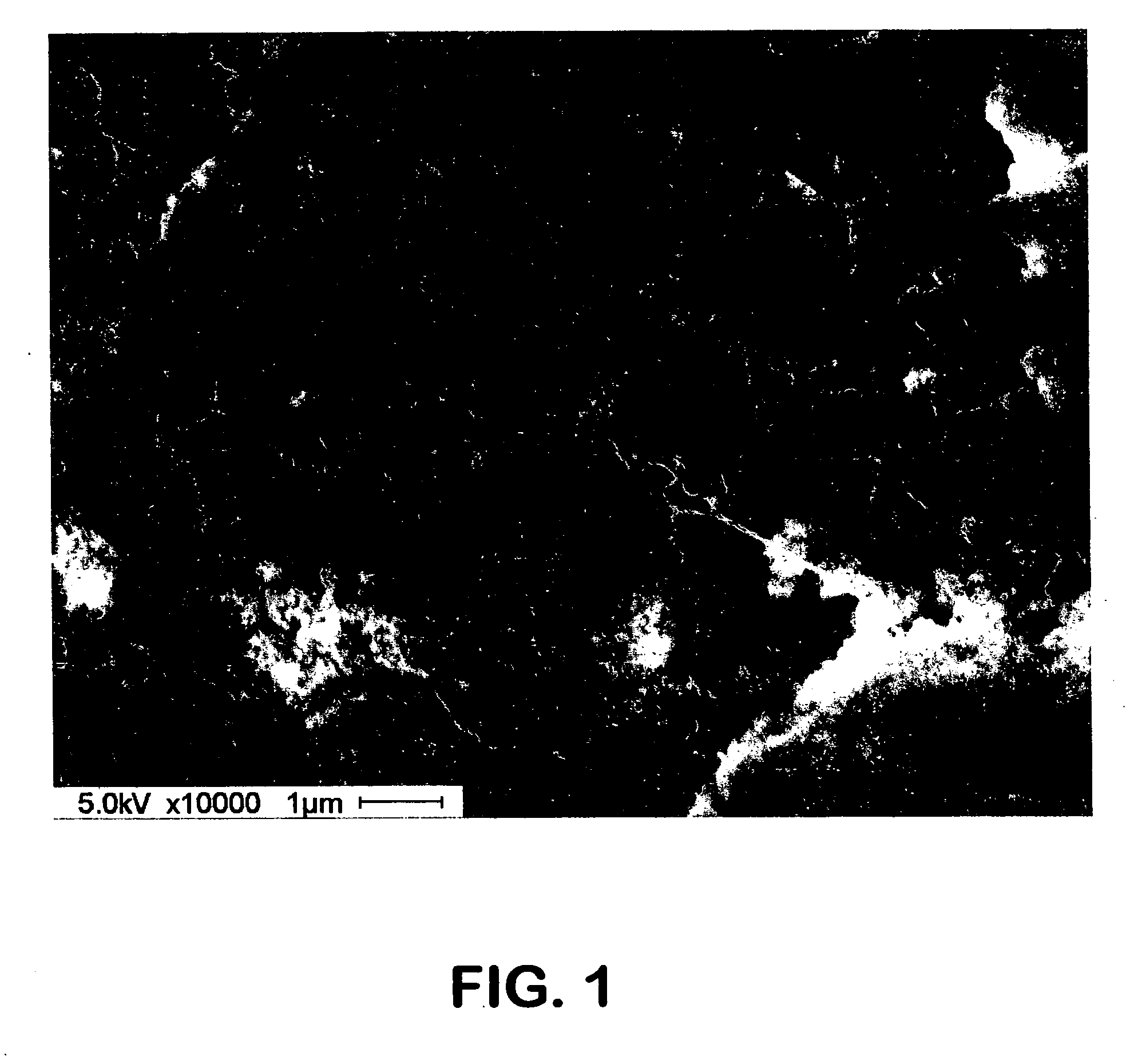

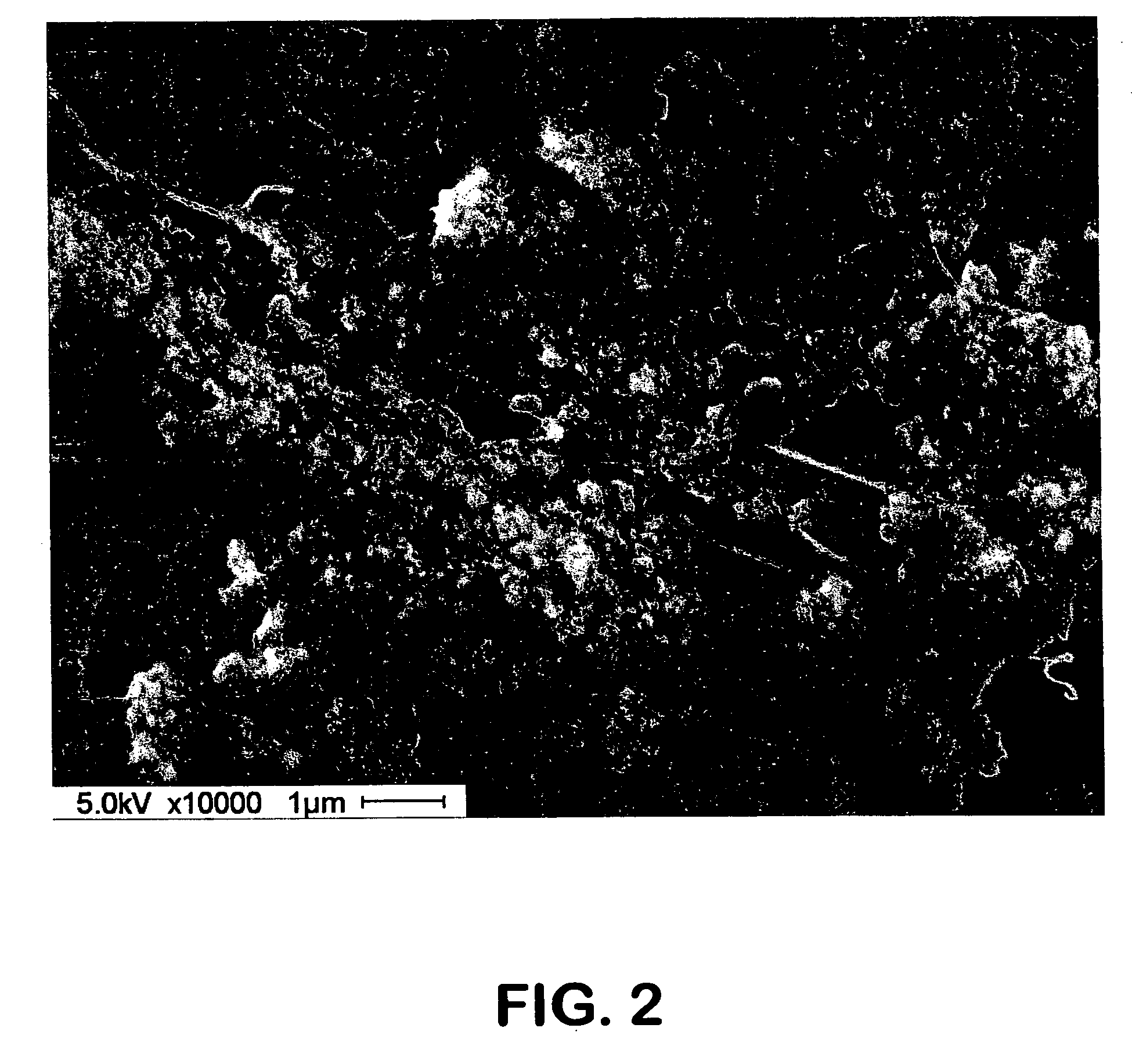

Aerogel/PTFE composite insulating material

ActiveUS20050100728A1Increase flexibilityHigh strengthDigital data processing detailsAdhesive articlesInto-structureMaterials science

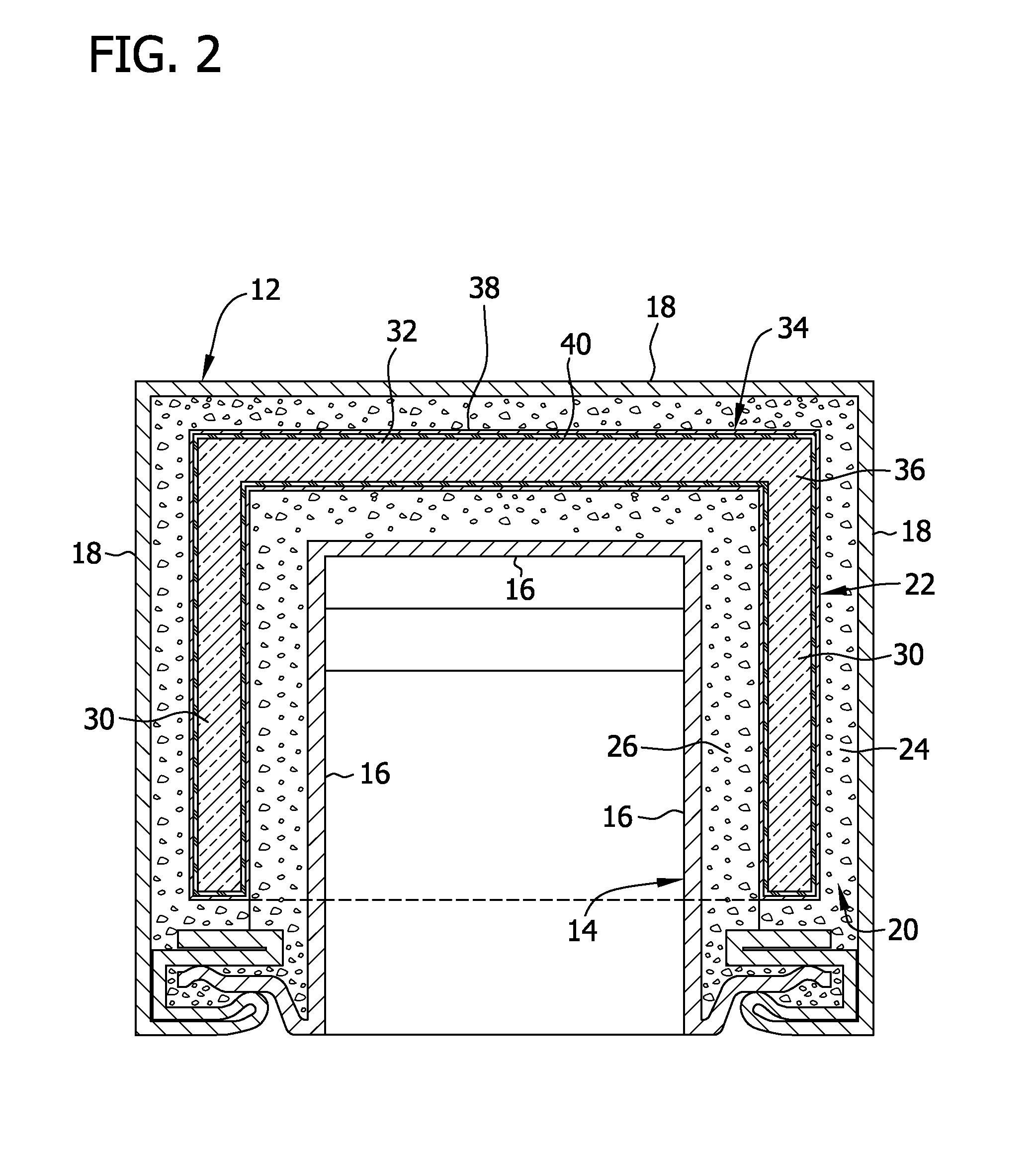

A material comprising aerogel particles and a polytetrafluoroethylene (PTFE) binder is formed having a thermal conductivity of less than or equal to 25 mW / m K at atmospheric conditions. The material is moldable or formable, having little or no shedding of filler particles, and may be formed into structures such as tapes or composites, for example, by bonding the material between two outer layers. Advantageously, composites may be flexed, stretched, or bent without significant dusting or loss of insulating properties.

Owner:WL GORE & ASSOC INC

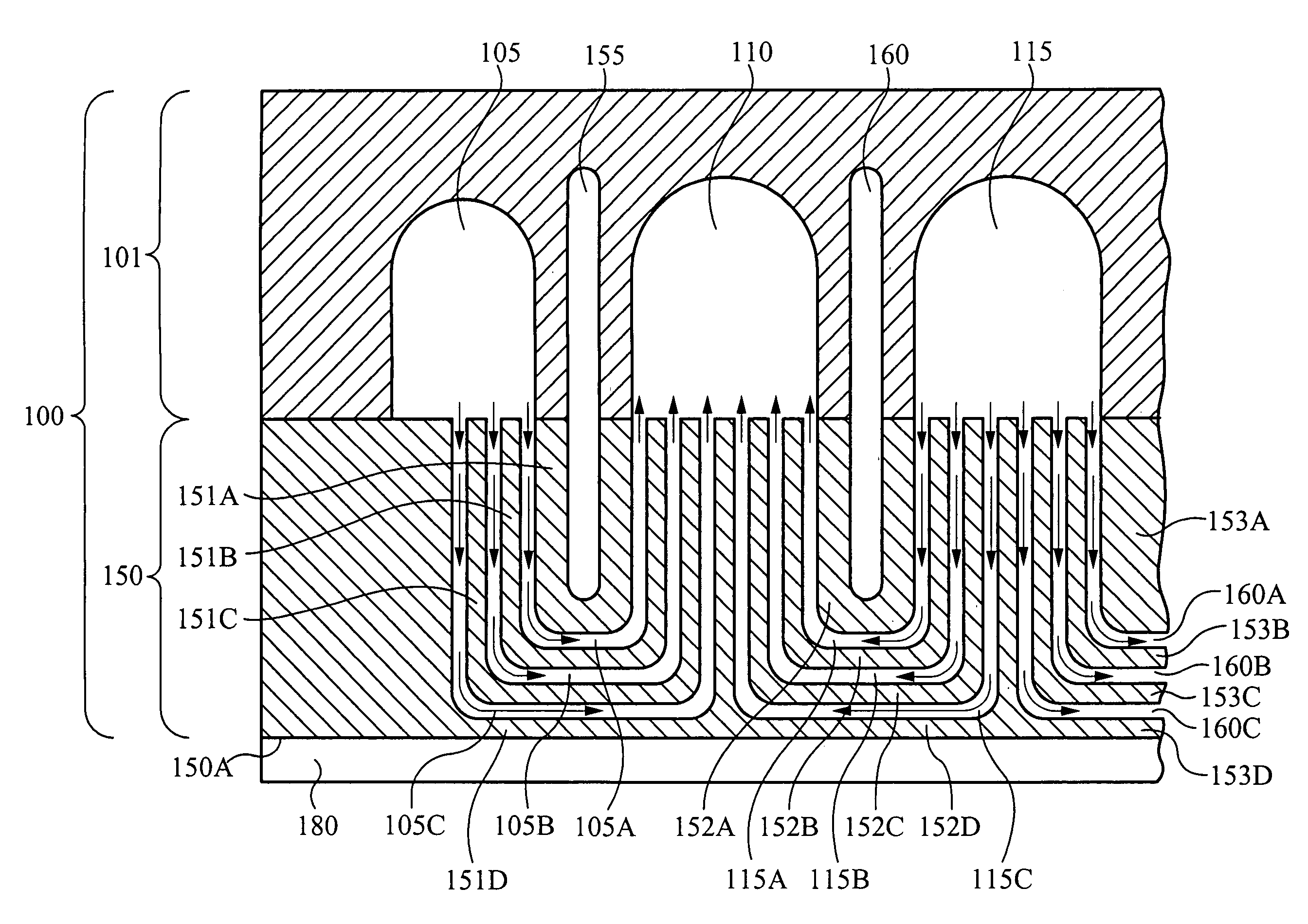

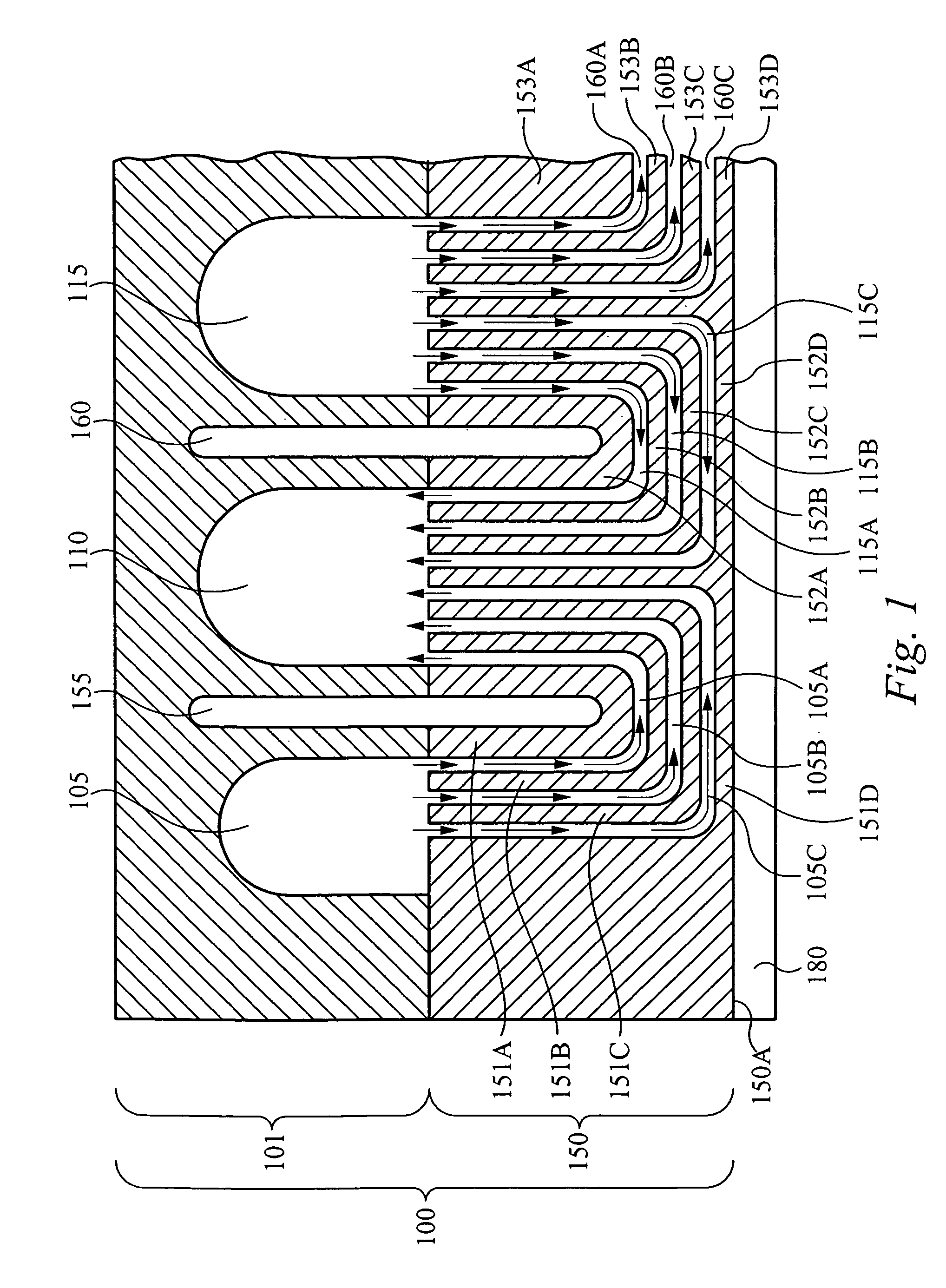

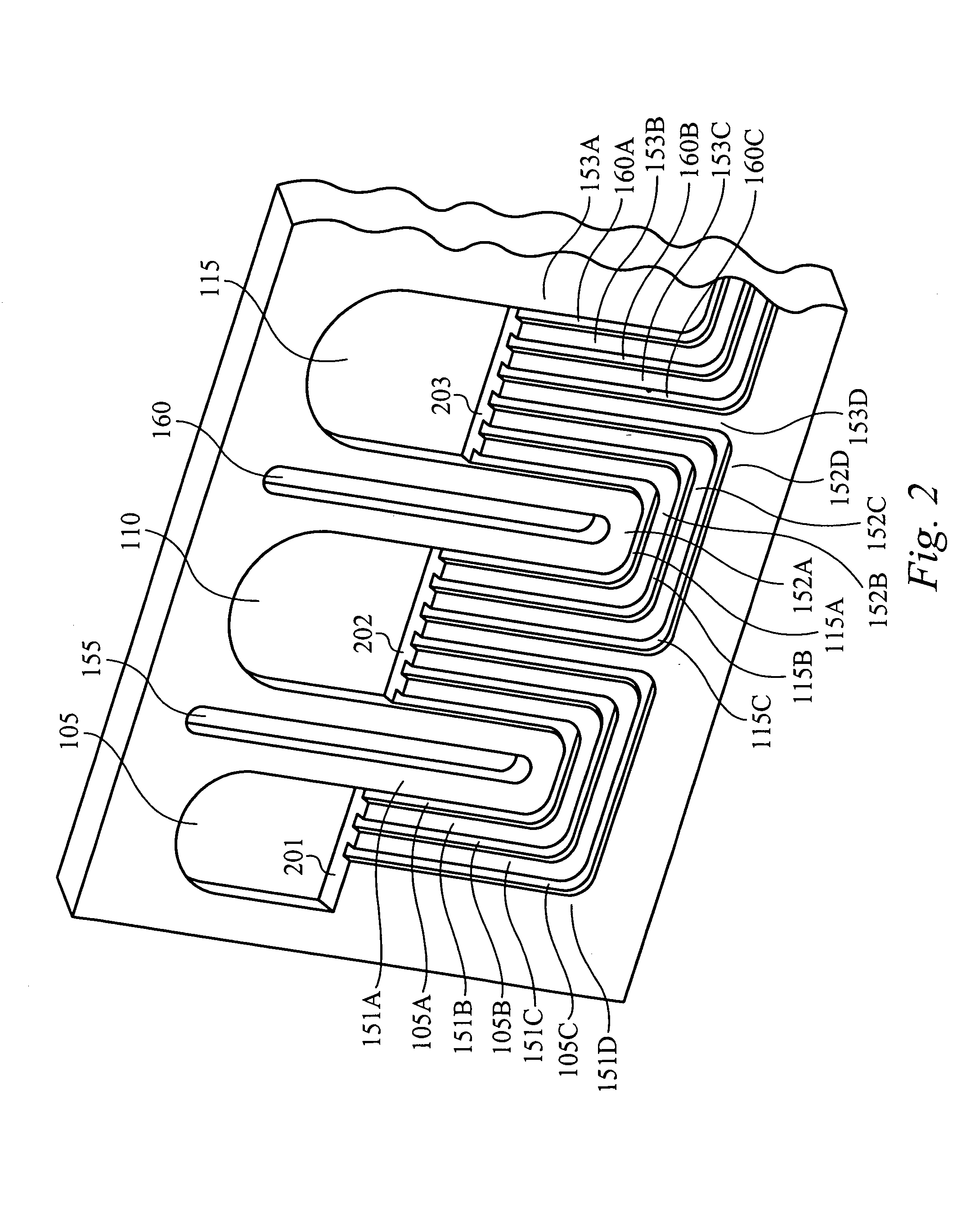

Multi-level microchannel heat exchangers

ActiveUS7156159B2Uniform pressure flowAccurate concentrationThermal insulationSemiconductor/solid-state device detailsInterface layerInlet manifold

An apparatus and method of circulating a heat-absorbing material within a heat exchanger. The apparatus comprises a manifold layer coupled to an interface layer. The manifold layer comprises an inlet manifold and an outlet manifold. The interface layer comprises a plurality of channels that extend from the inlet manifold, toward a heat-exchanging plane, and turn away from the heat-exchanging plane, terminating at the outlet manifold. The plurality of channels are stacked in a plane non-parallel to the heat-exchanging plane. Each of the channels is adjacent to another, thus allowing heat radiated from a heat-generating device to be conducted to a cooling material circulating within the channels, away from the heat-generating device. Preferably, each of the channels has a U-shape or an elongated U-shape.

Owner:VERTIV CORP

Vacuum insulating material and device using the same

Vacuum heat insulator comprising a laminated core made of a plurality of sheets of inorganic fibers having 10 μm or smaller in diameter and a certain composition including SiO2 as a main component, Al2O3, CaO, and MgO, a gas barrier enveloping member, and an absorbent. The vacuum heat insulator is characterized by having at least one groove formed therein after fabrication of the vacuum heat insulator. Further, the vacuum heat insulator is characterized by using inorganic fiber core of which a peak of distribution in fiber diameter lies between 1 μm or smaller and 0.1 μm or larger, and not containing binding material for binding the fiber material. Electronic apparatuses use the vacuum heat insulator. With use of the vacuum heat insulator, electronic and electric apparatuses superior in energy saving and not to present uncomfortable feeling to the user can be provided.

Owner:PANASONIC CORP

Binder compositions and associated methods

Disclosed are formaldehyde-free, thermally-curable, alkaline, aqueous binder compositions, curable to formaldehyde-free, water-insoluble thermoset polyester resins, and uses thereof as binders for non-woven fibers and fiber materials.

Owner:KNAUF INSULATION LLC

Insulated panels and shipping container incorporating said panels

The invention relates to an insulation panel for use in thermally insulated shipping containers, the panel comprising a rigid core of an insulation material, the core being wholly encompassed within a polyethylene foam envelope. A container made from the panels and a shipping carton is also described.

Owner:FAGERDALA SINGAPORE PTE

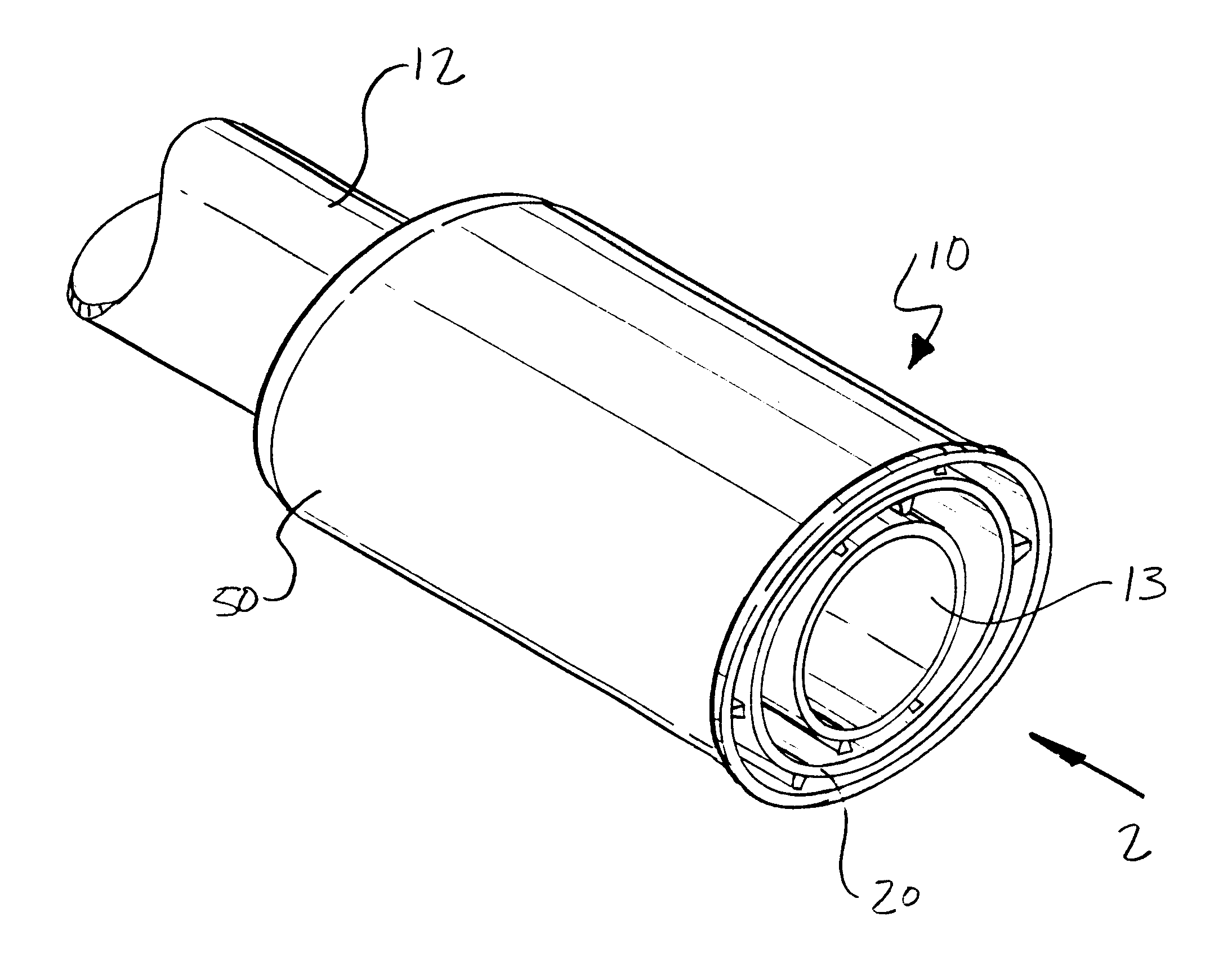

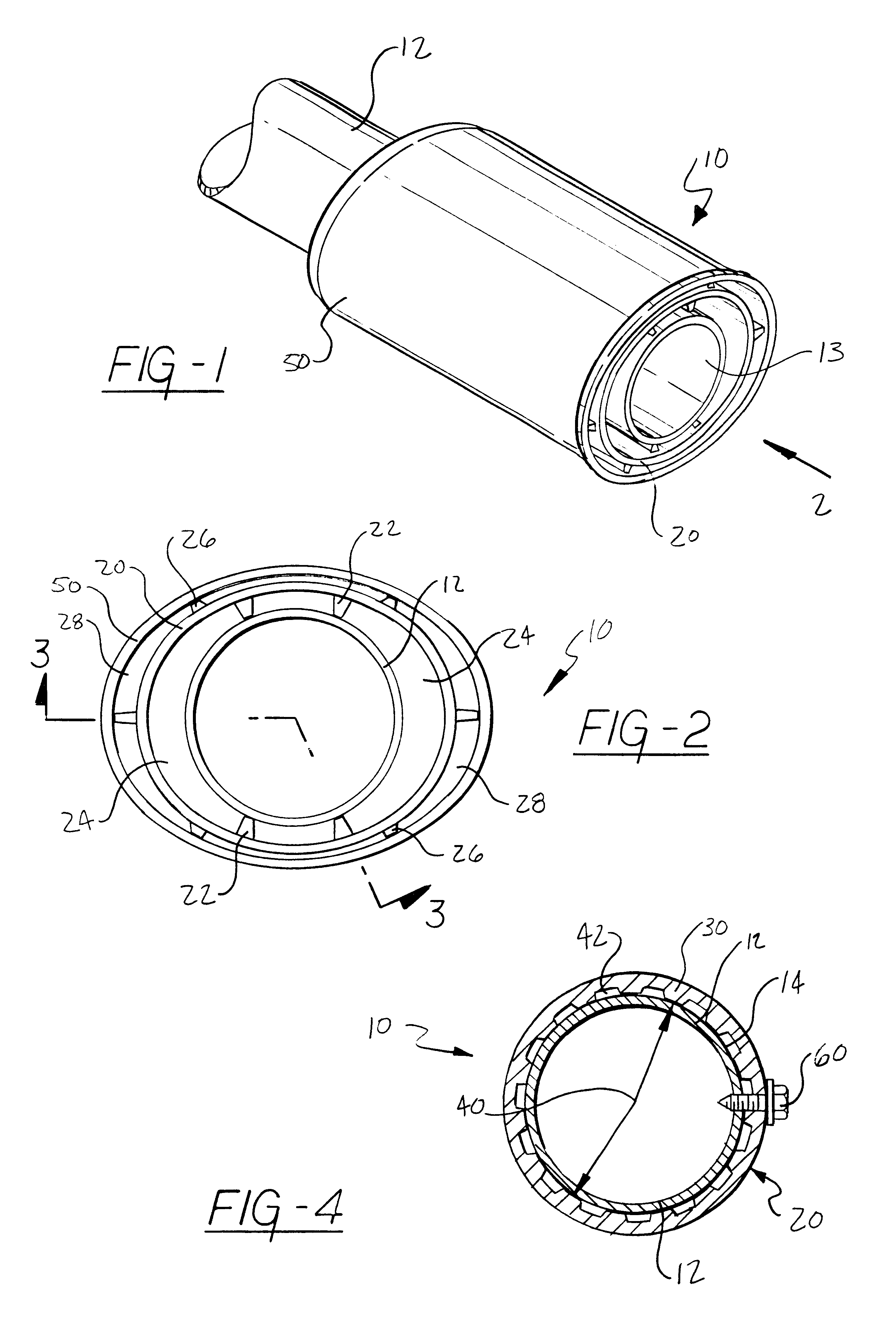

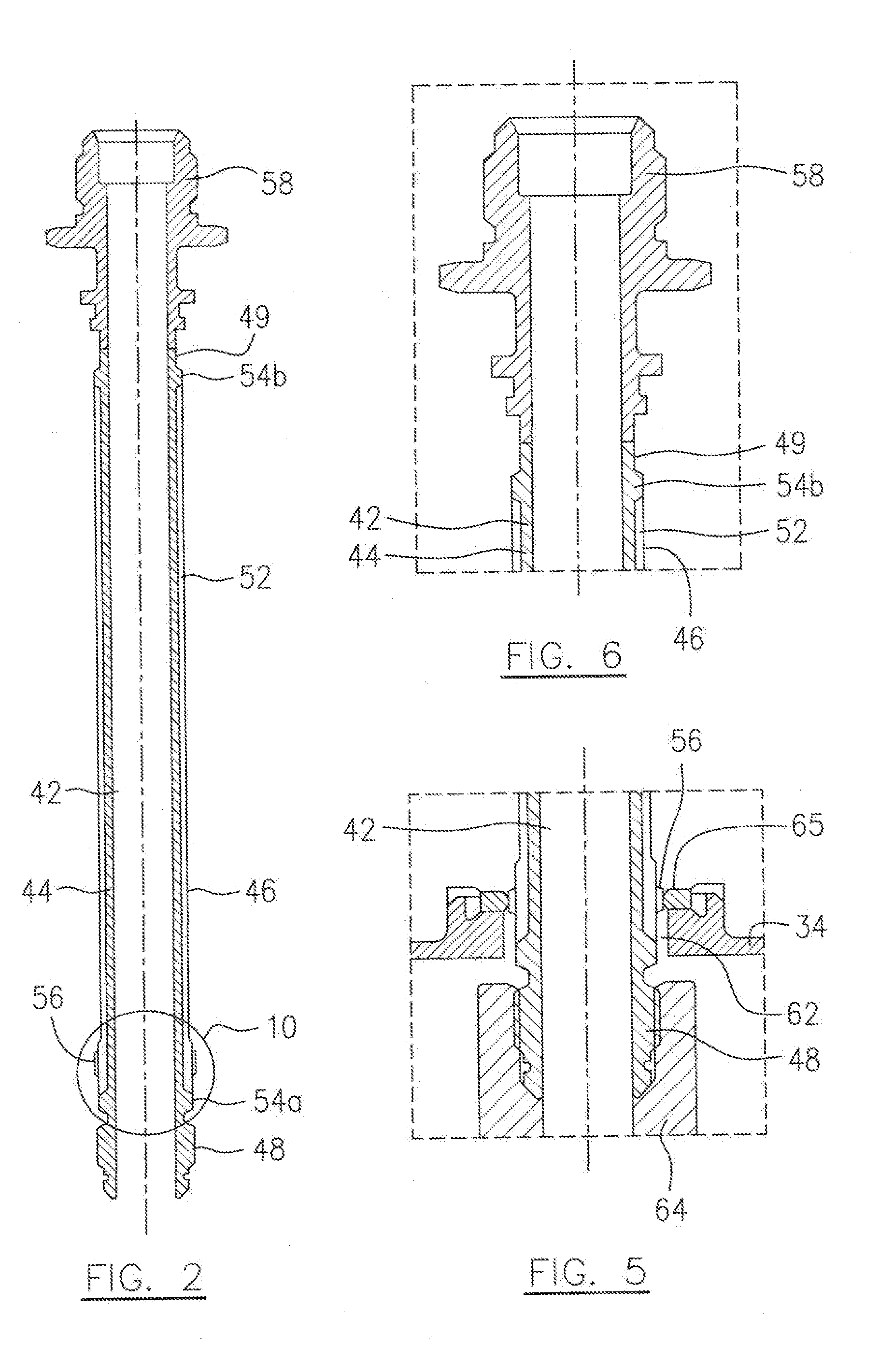

Exhaust tip

InactiveUS7007720B1Severe design restrictionOverall design flexibilityThermal insulationSilencing apparatusEngineeringThermal effect

An exhaust tip for attachment to a tailpipe that includes a thermoset heat shield at least partially surrounding and fastened to the tailpipe, and a thermoplastic decorative cover at least partially surrounding and fastened to the thermoset heat shield. The thermoset heat shield insulates the thermoplastic decorative cover from thermal effects of the tailpipe and spaces the thermoplastic decorative cover a predetermined distance away from the tailpipe.

Owner:LACKS INDUSTRIES INC

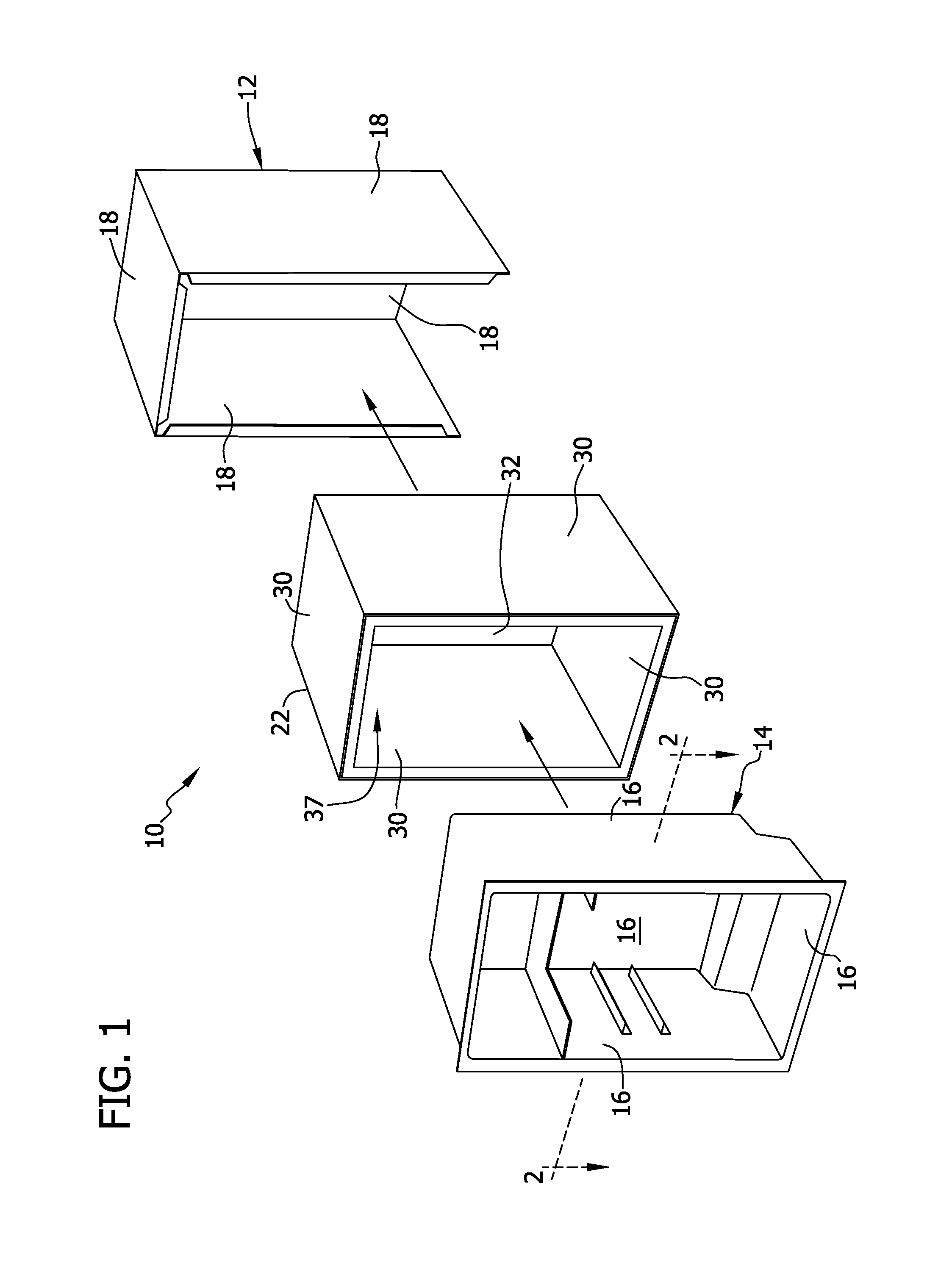

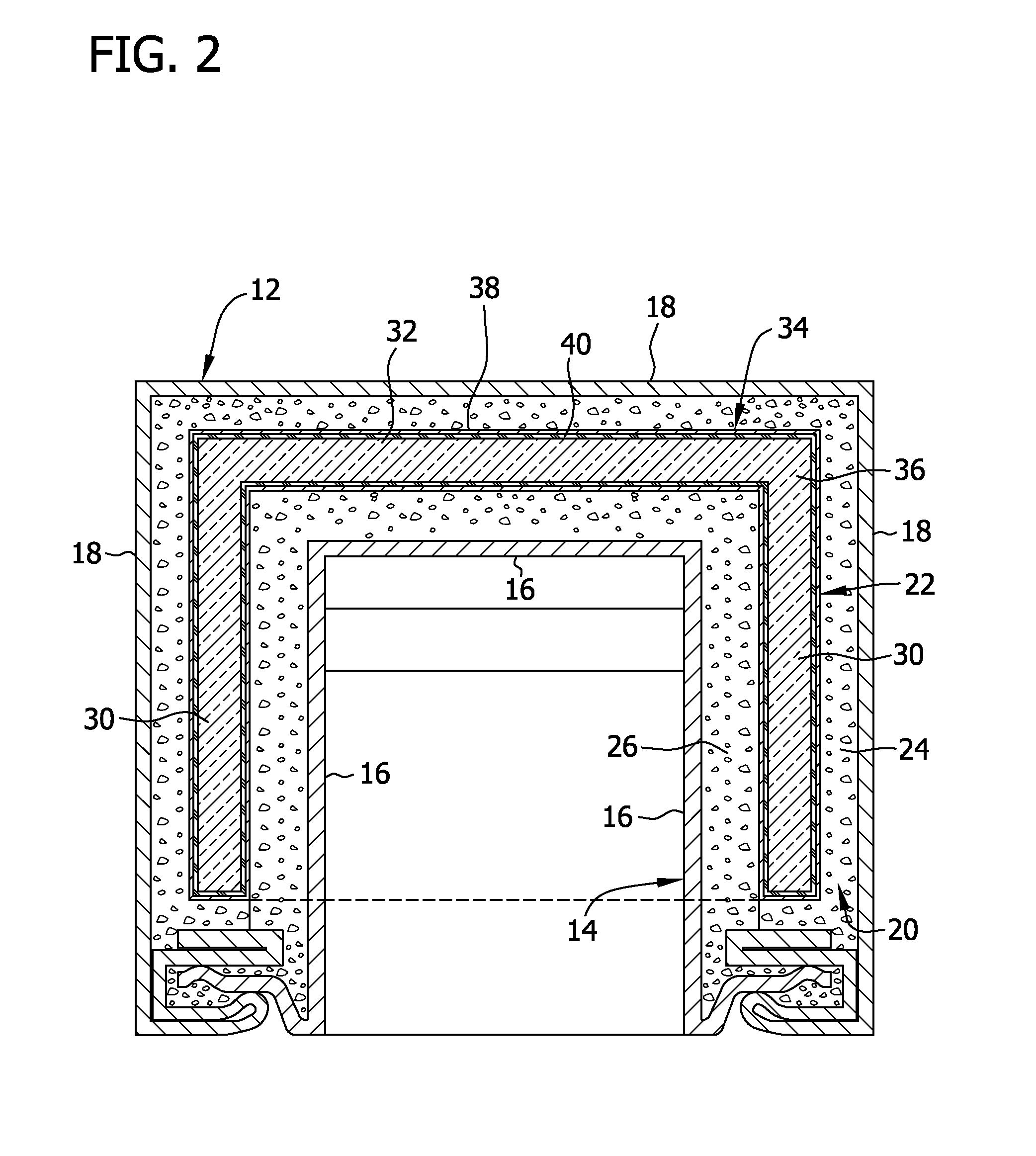

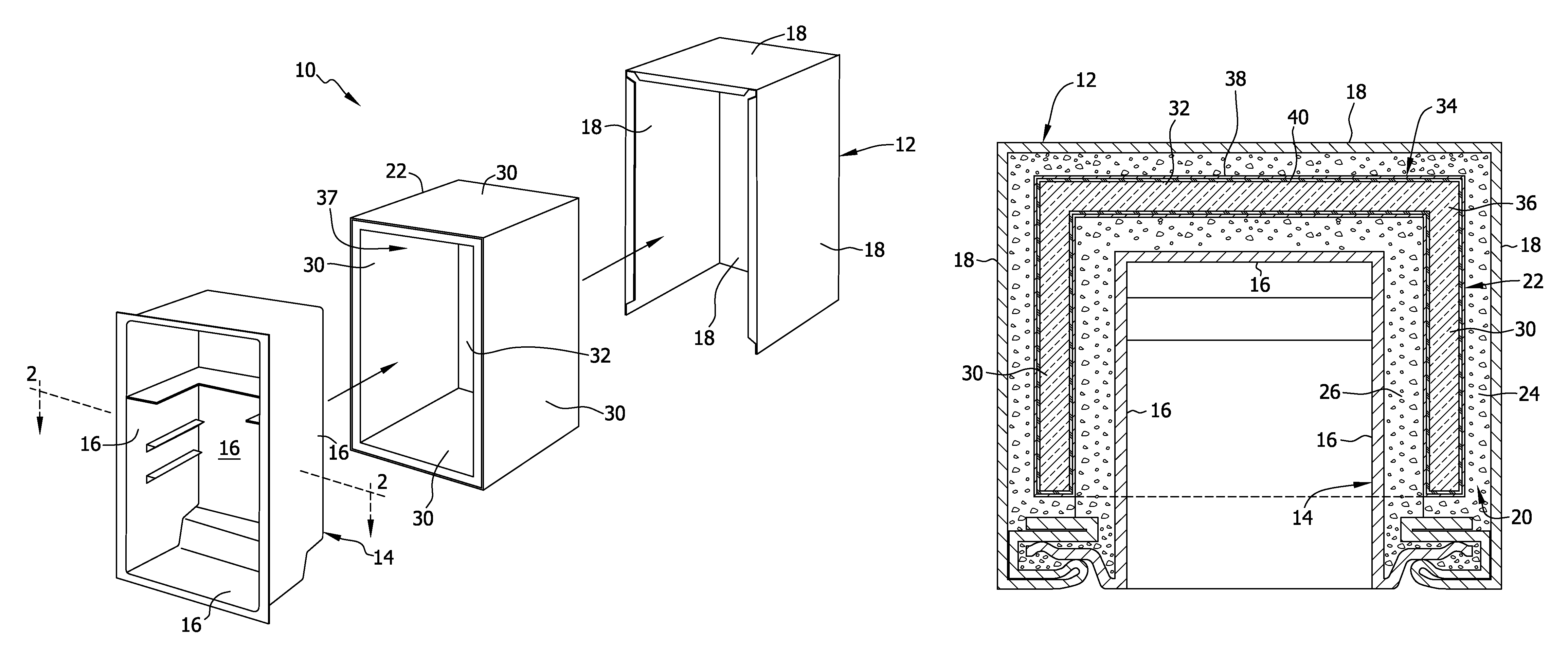

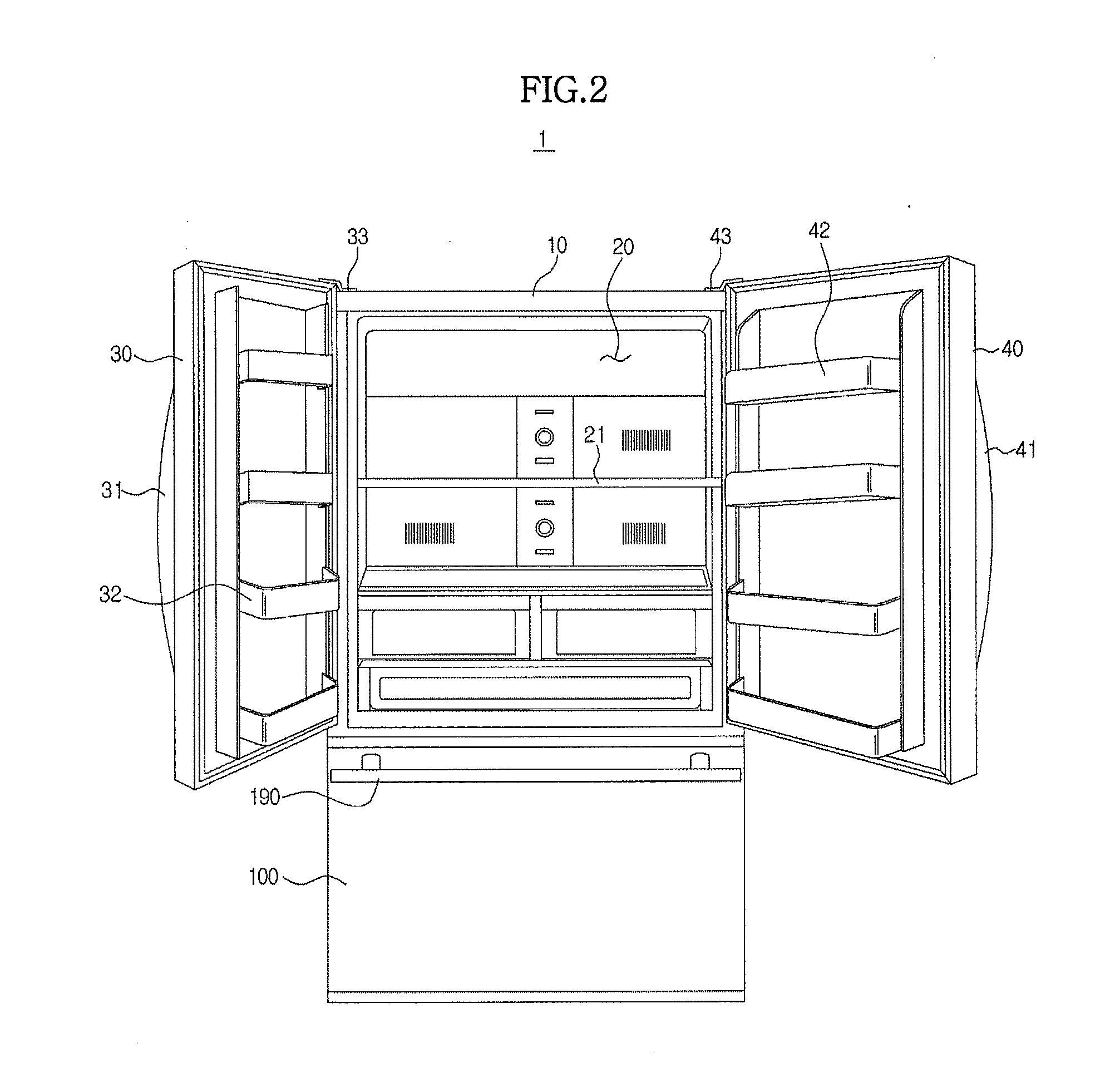

Method and apparatus for insulating a refrigeration appliance

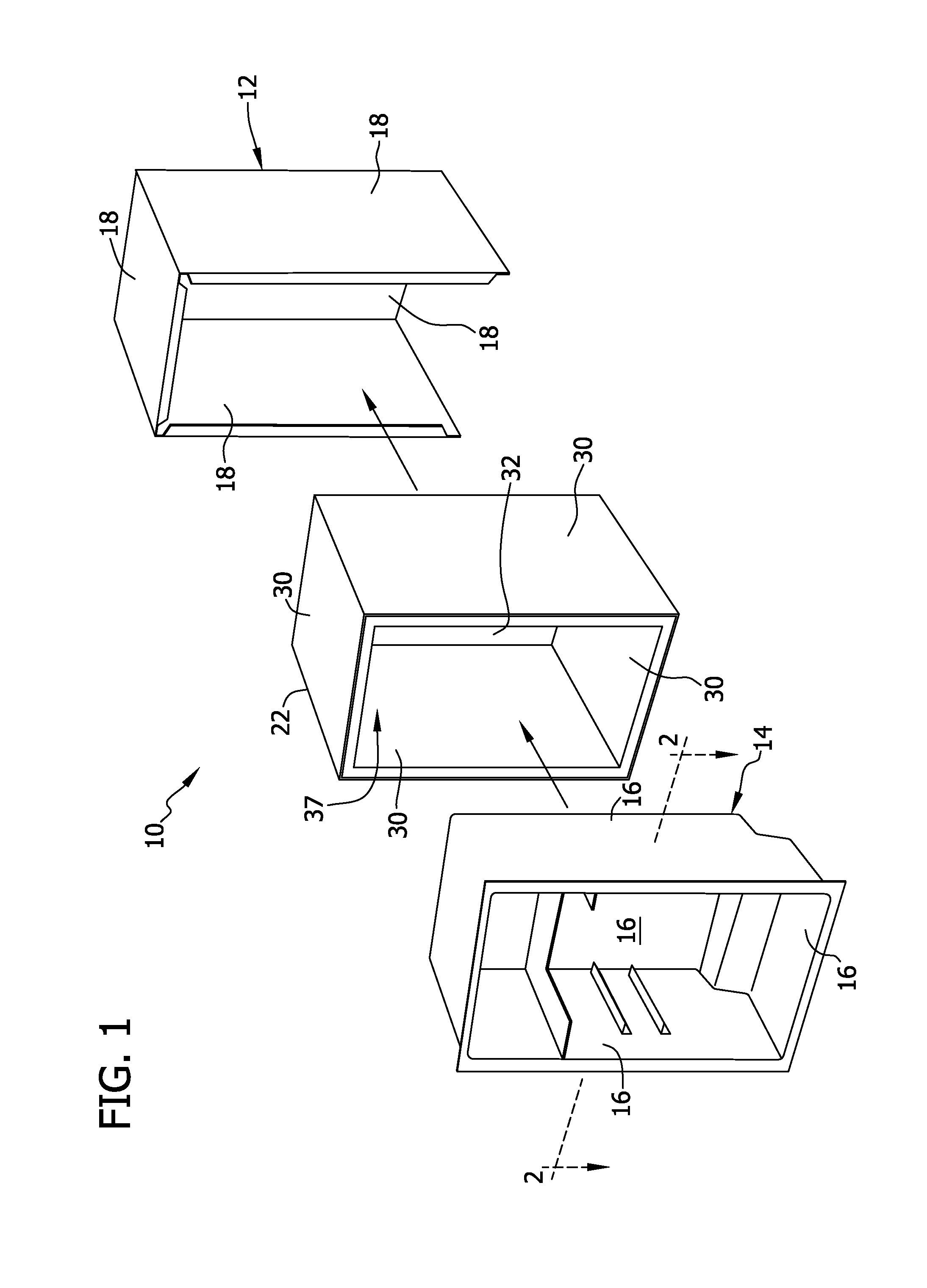

A method of insulating a refrigeration appliance. The refrigeration appliance includes a case, a liner, and a five-sided, box like vacuum panel. The liner is formed to be inserted into the case forming a chamber between the liner and the case. The five sides of the vacuum panel define a cavity. The method includes in one embodiment, positioning the five-sided vacuum panel in the chamber between the case and the liner, injecting foam into the chamber, and curing the foam to attach the five sided vacuum panel to the case and the liner.

Owner:HAIER US APPLIANCE SOLUTIONS INC

Internally insulated, corrosion resistant pipeline

An internally insulated, corrosion resistant pipeline. An inner fluid barrier is formed preferably by a polymer liner. The outer pipe may be a steel pipe. The liner is provided with a plurality of passages or an open annulus. The passages in the liner or annulus between the pipe and liner are filled with an insulation material.

Owner:J RAY MCCDERMOTT SA

Free flowing dry back-up insulating material

Disclosed is a free flowing dry back-up material which comprises:from 67 to 96% by weight of fly-ash;from 2 to 15% by weight of a heat sensitive binder such as boric acid;from 2 to 7% by weight of a non-wetting agent such as calcium fluoride;from 0 to 10% by weight of a heat expandable material, viz. a material expandable as a function of the temperature such as vermiculite or graphite; andfrom 0 to 1% by weight of a dust suppressant such as kerosene.This material which is useful in particular in the aluminum industry has the advantages of being water free and free flowing, such avoiding the use of vibrator to position it into a shell. It also has a low density and a low thermal conductivity. Moreover, it is organic free as compared to the existing materials which use an organic binder to ensure a low temperature set; and it sets at a temperature lower than 400° F.

Owner:LES PROD CHIMS INDS DE HAUTE TEMPERATURE PYROTEK

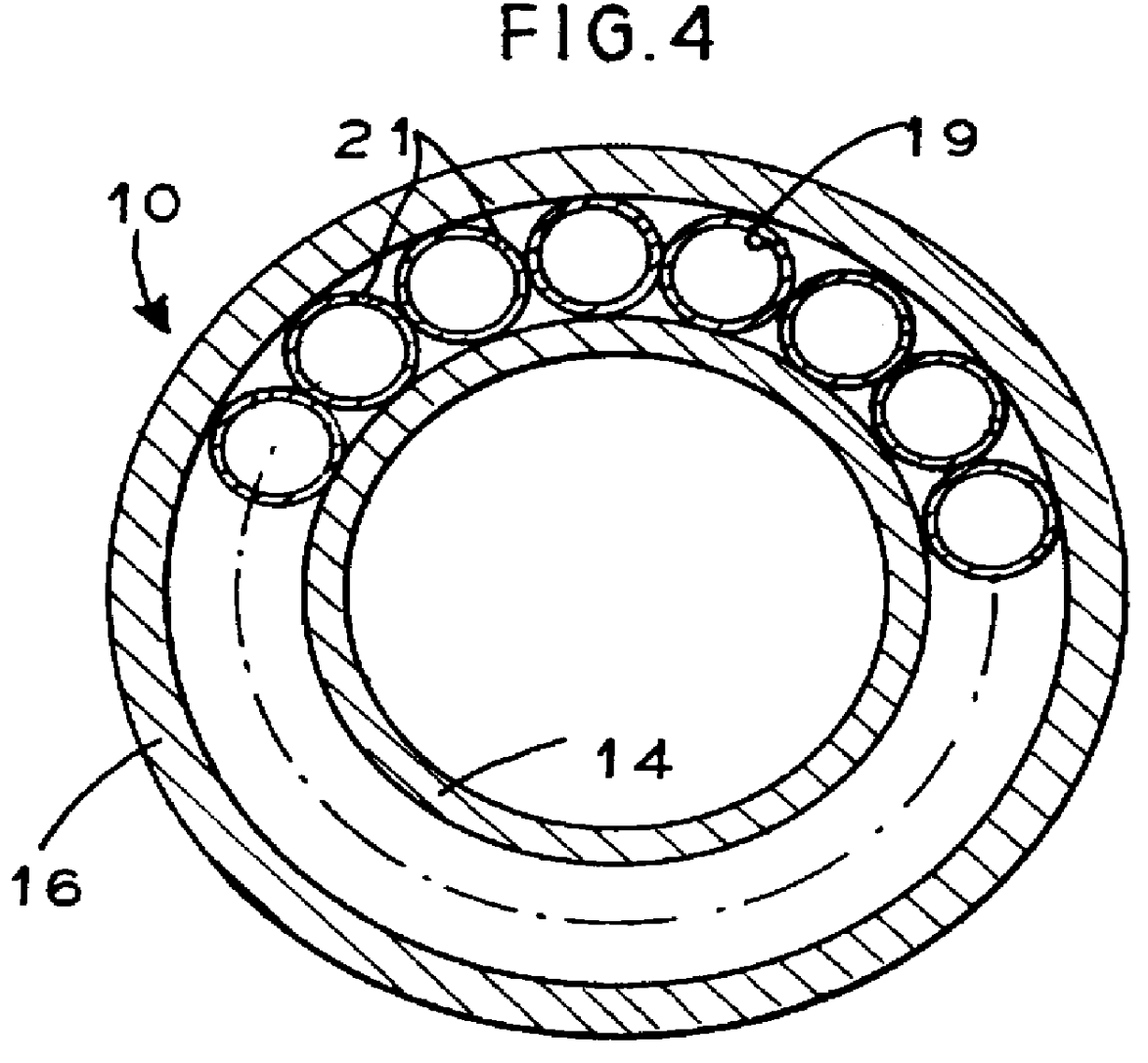

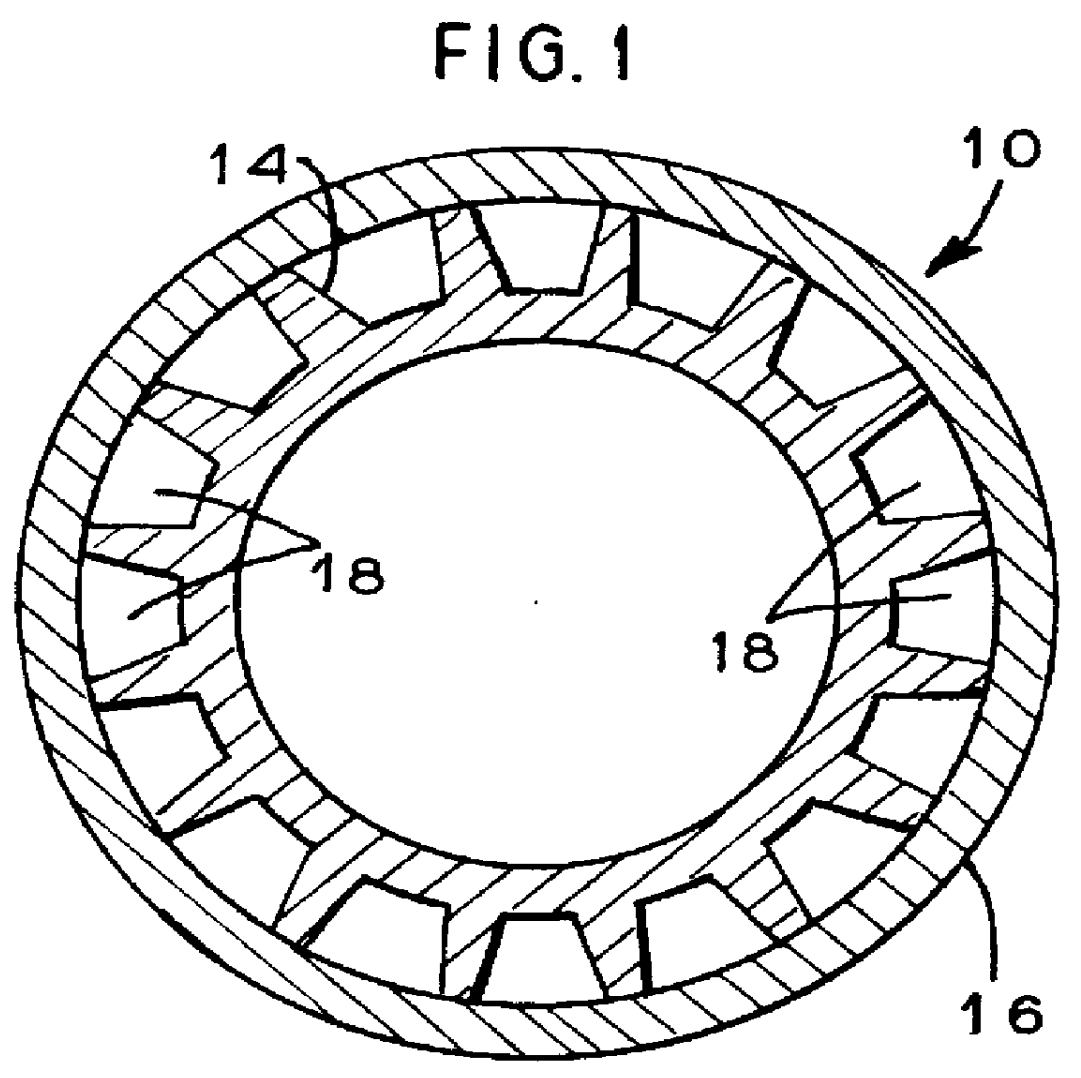

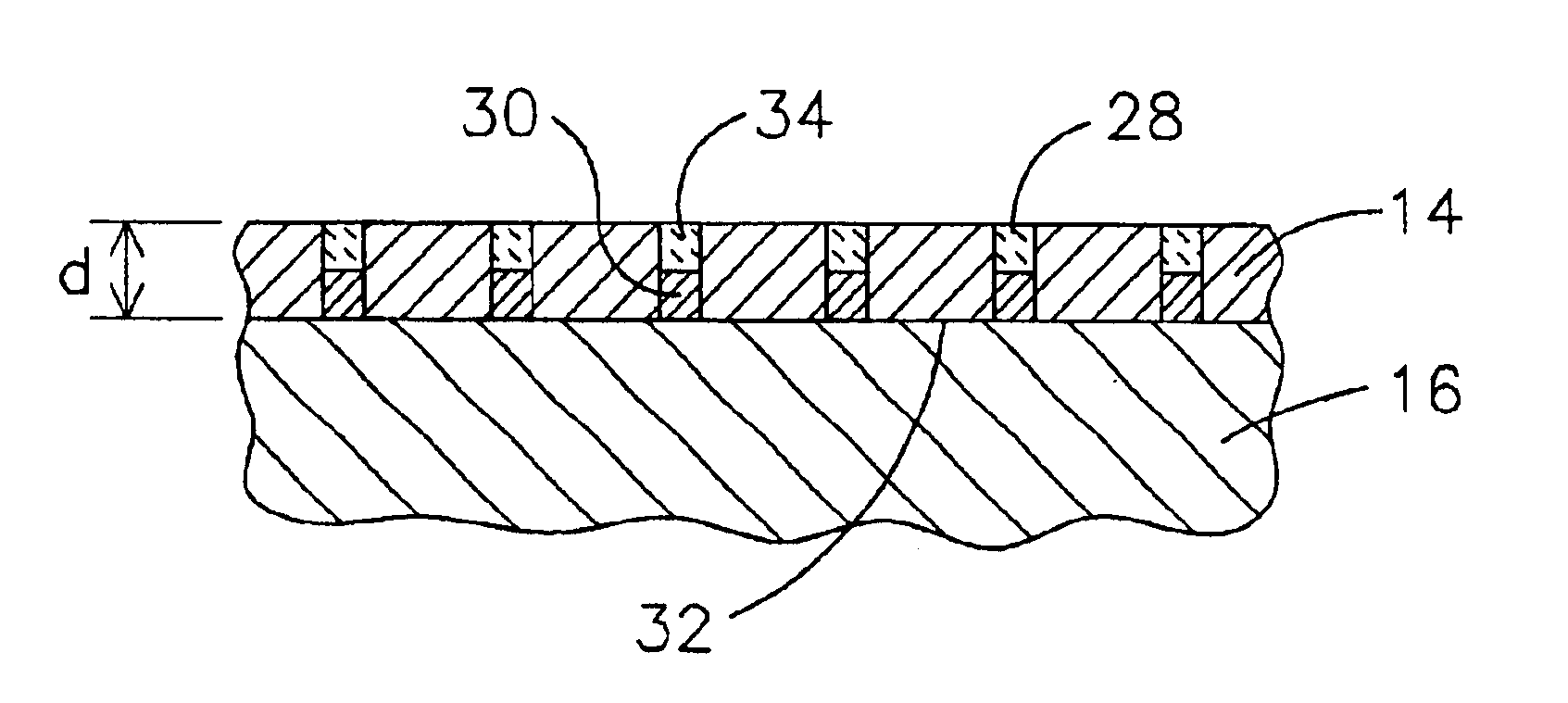

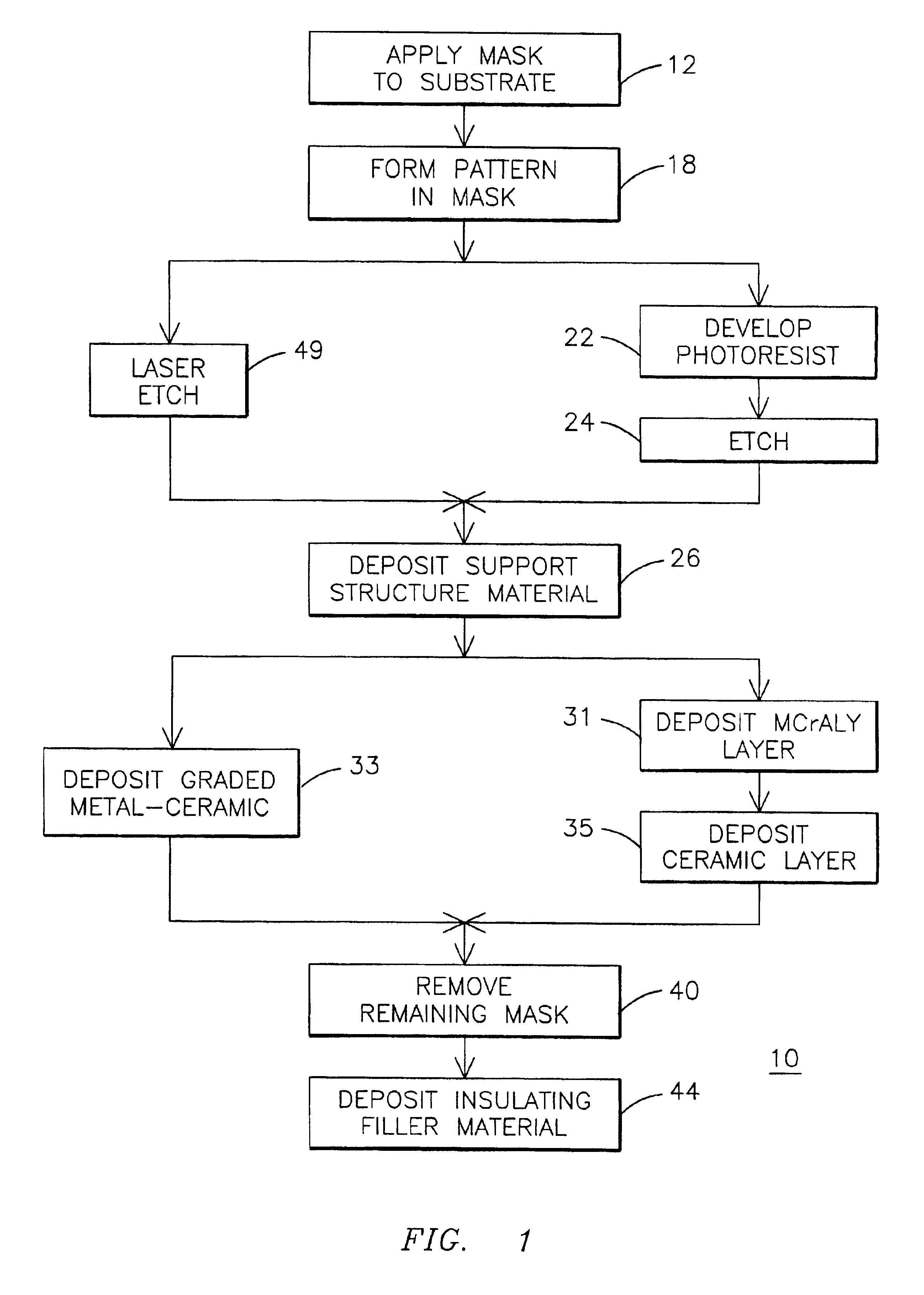

Honeycomb structure thermal barrier coating

InactiveUS6846574B2Minimize heat transfer rateConvenient coatingMolten spray coatingRecord information storageForeign matterLaser etching

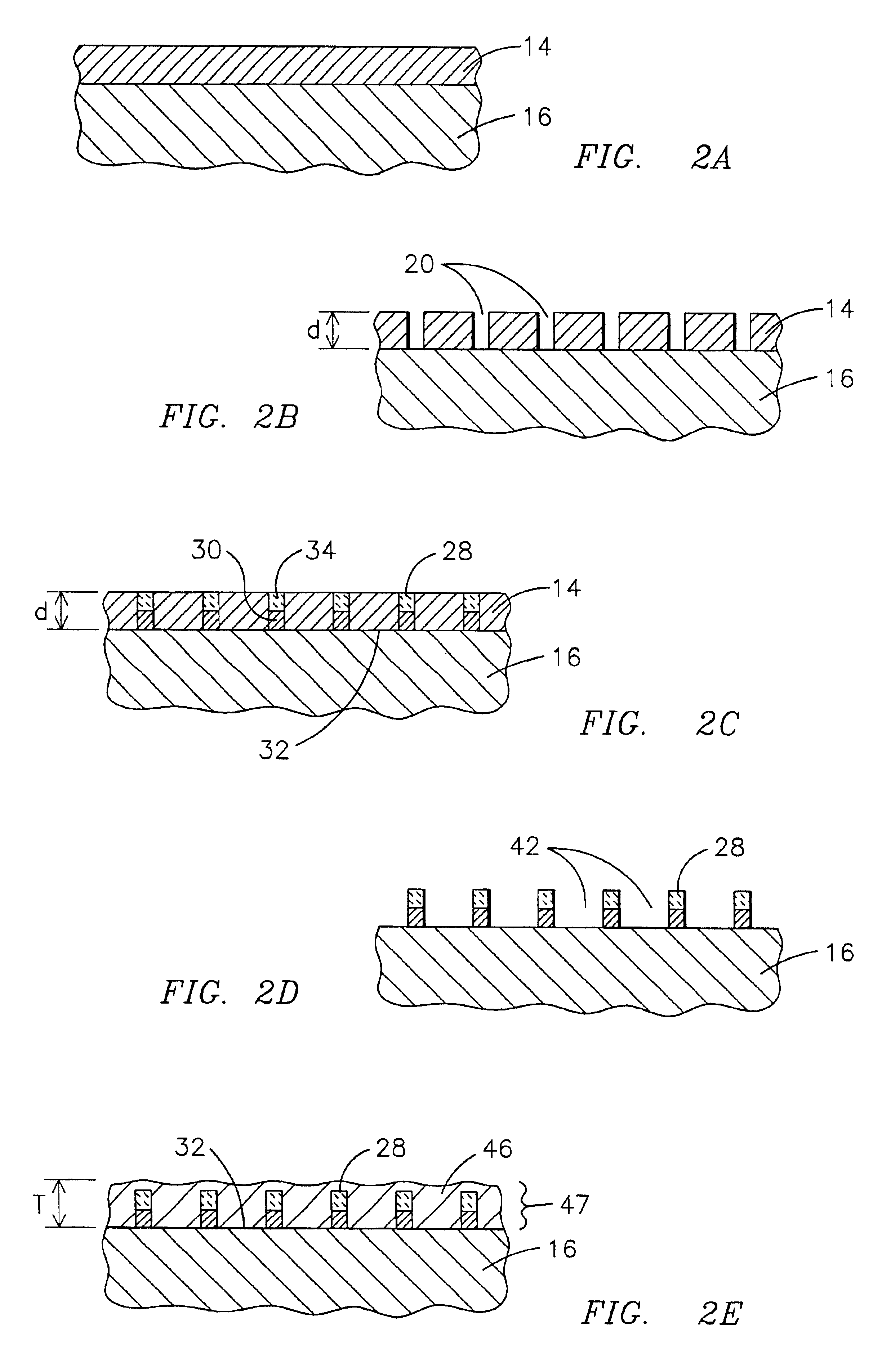

A device having an improved thermal barrier coating (46) and a process for manufacturing the same. A support structure (28) for retaining a ceramic insulating material (46) on a substrate (16) is formed by the deposition of a support structure material through a patterned masking material (14). The support structure can define cells into which the ceramic insulating material is deposited following removal of the masking material. The masking material may be patterned by known photolithographic techniques (22,24) or by laser etching (48). The support structure (28) may be a composite metal-ceramic material having either discreet layers (30,34) or a graded composition and may be deposited by an electro-desposition process followed by a heat treatment to form a solid state diffusion bond with the substrate. The ceramic filler material may be deposited (44) by the electrophoretic deposition of ceramic particles coated with a bonding material that is subsequently heated to oxidize and to bond the particles together. The support structure may be provided with included walls in order to improve its resistance to foreign object impact damage.

Owner:SIEMENS ENERGY INC

Fixed vacuum insulation panel

InactiveUS6164030ASimple wayReliable anchoringThermal insulationInsulation for cooling apparatusEngineeringOpen cell

An apparatus is described which consists of a rigid plate and a vacuum insulation panel, in which the vacuum insulation panel is fixed to the rigid plate by a polyurethane foam applied as a liquid reaction mixture, wherein the vacuum insulation panel contains open-cell rigid plastics foam and / or open-cell rigid plastics foam recyclate. A refrigerated cabinet element containing said apparatus is additionally described.

Owner:KARL WERNER DIETRICH

Free flowing dry back-up insulating material

ActiveUS20050116398A1Reduce the temperatureSolid waste managementThermal insulationKeroseneNon wetting

Disclosed is a free flowing dry back-up material which comprises: from 67 to 96% by weight of fly-ash; from 2 to 15% by weight of a heat sensitive binder such as boric acid; from 2 to 7% by weight of a non-wetting agent such as calcium fluoride; from 0 to 10% by weight of a heat expandable material, viz. a material expandable as a function of the temperature such as vermiculite or graphite; and from 0 to 1% by weight of a dust suppressant such as kerosene. This material which is useful in particular in the aluminum industry has the advantages of being water free and free flowing, such avoiding the use of vibrator to position it into a shell. It also has a low density and a low thermal conductivity. Moreover, it is organic free as compared to the existing materials which use an organic binder to ensure a low temperature set; and it sets at a temperature lower than 400° F.

Owner:LES PROD CHIMS INDS DE HAUTE TEMPERATURE PYROTEK

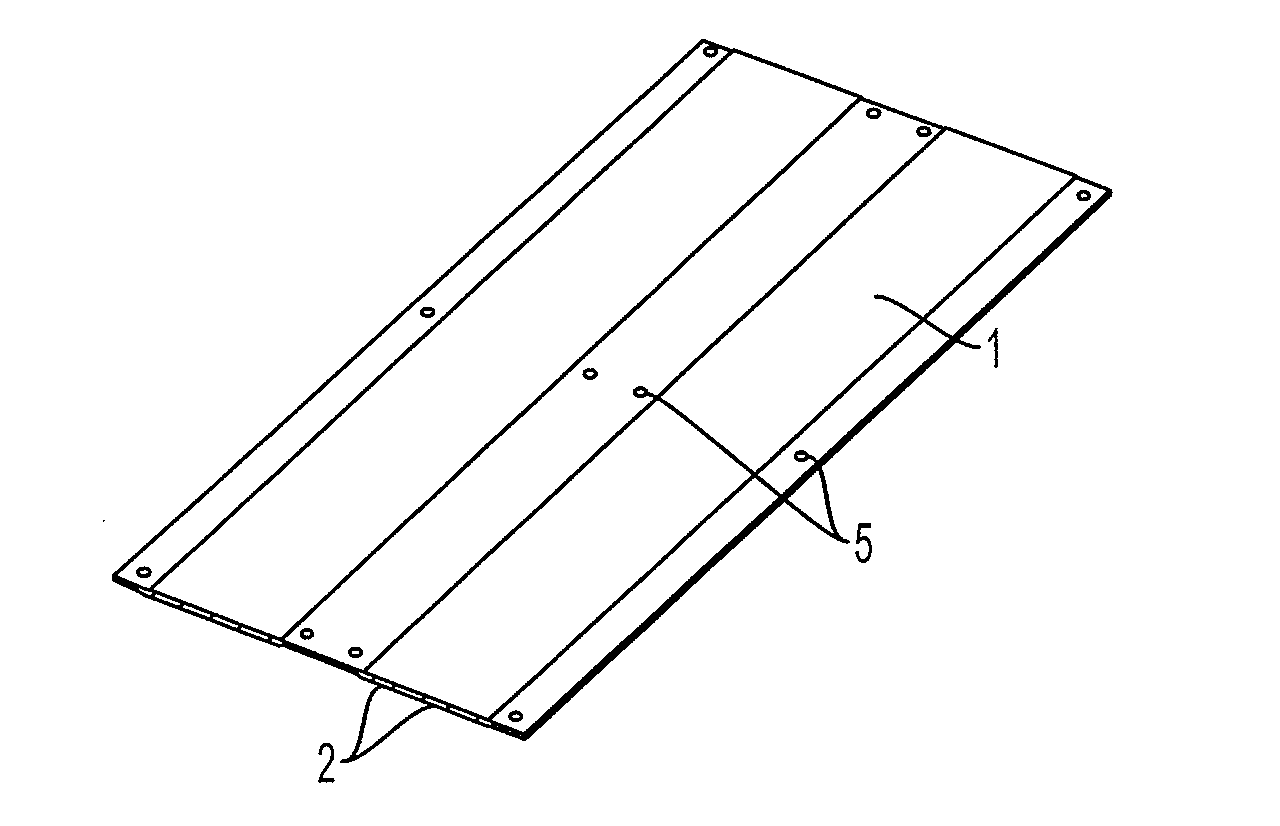

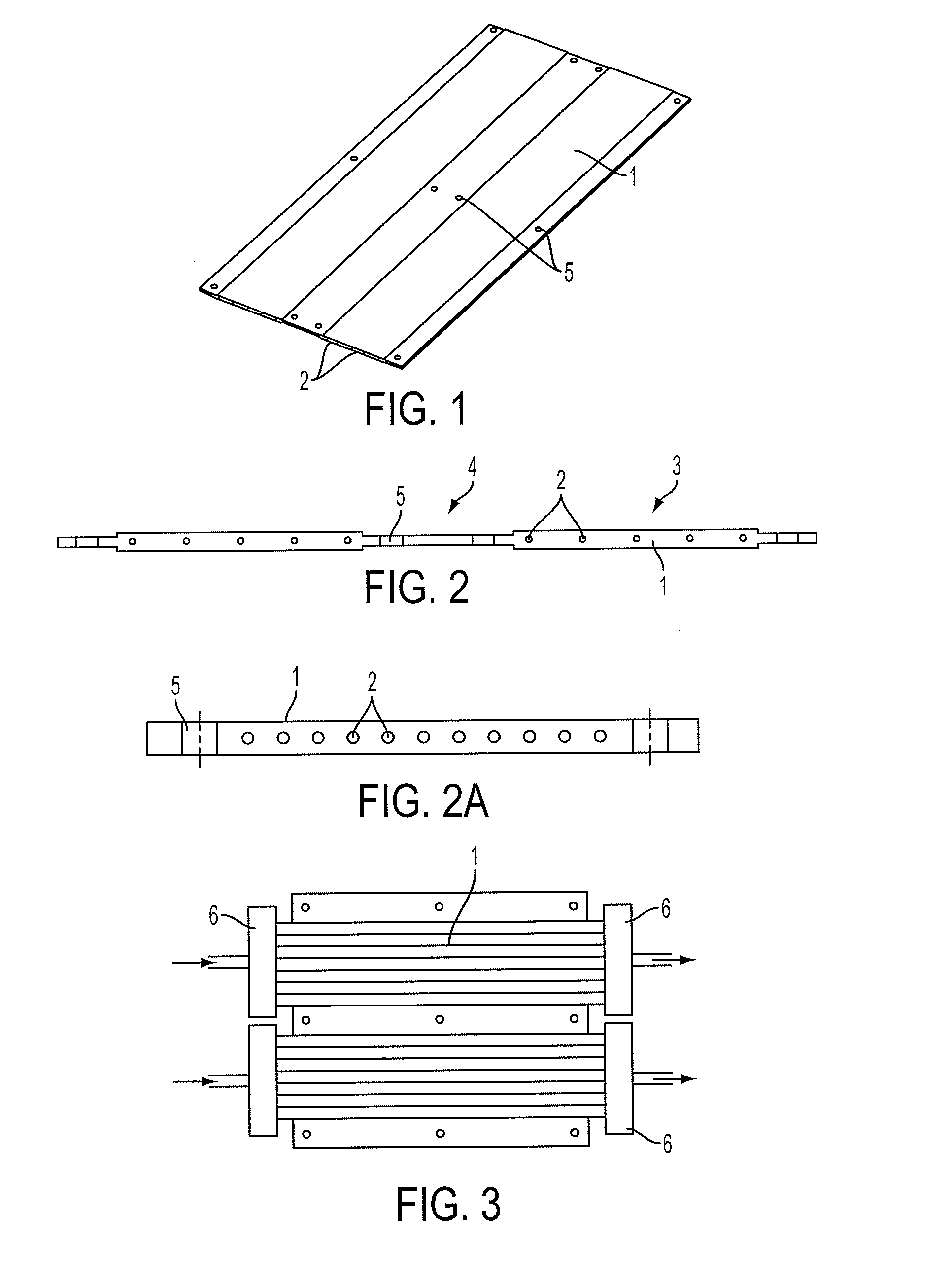

Device for cooling a vehicle battery

InactiveUS20110132580A1Effective and reliable coolingImprove pressure resistanceFuel cell heat exchangeThermal insulationElectricityElectrical battery

A device for cooling a vehicle battery is provided that includes a plurality of electrical storage elements, and a cooling element having ducts for a fluid to flow through, wherein the electrical storage elements are in thermal contact with the cooling elements and heat can be transmitted from the storage elements to the fluid, and wherein the cooling element which comprises the ducts is embodied as at least one extruded profile.

Owner:BEHR GMBH & CO KG

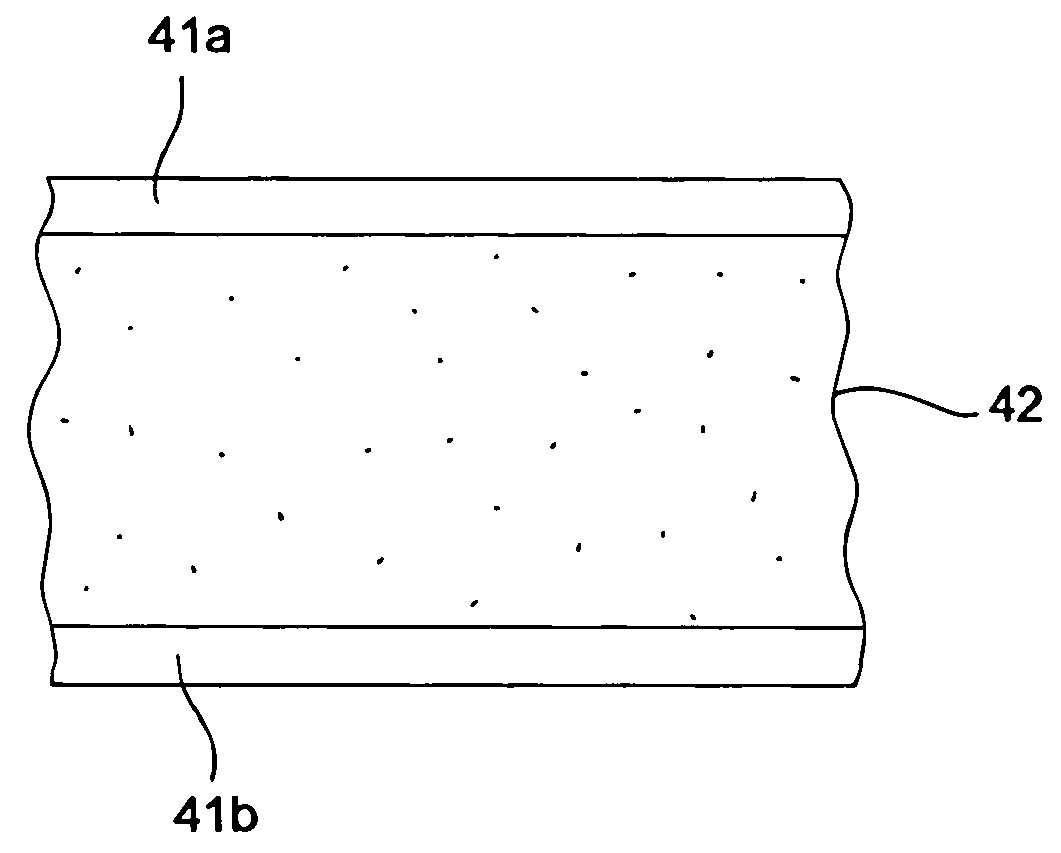

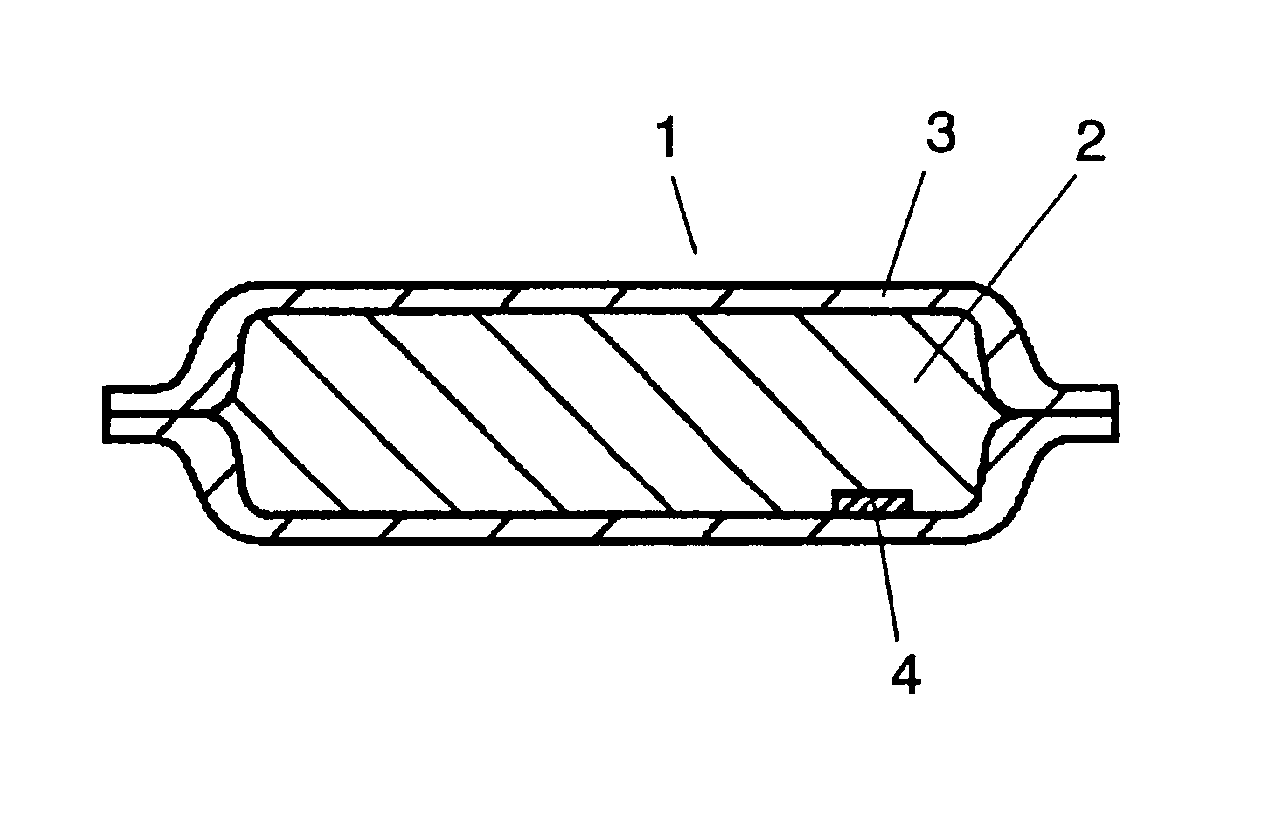

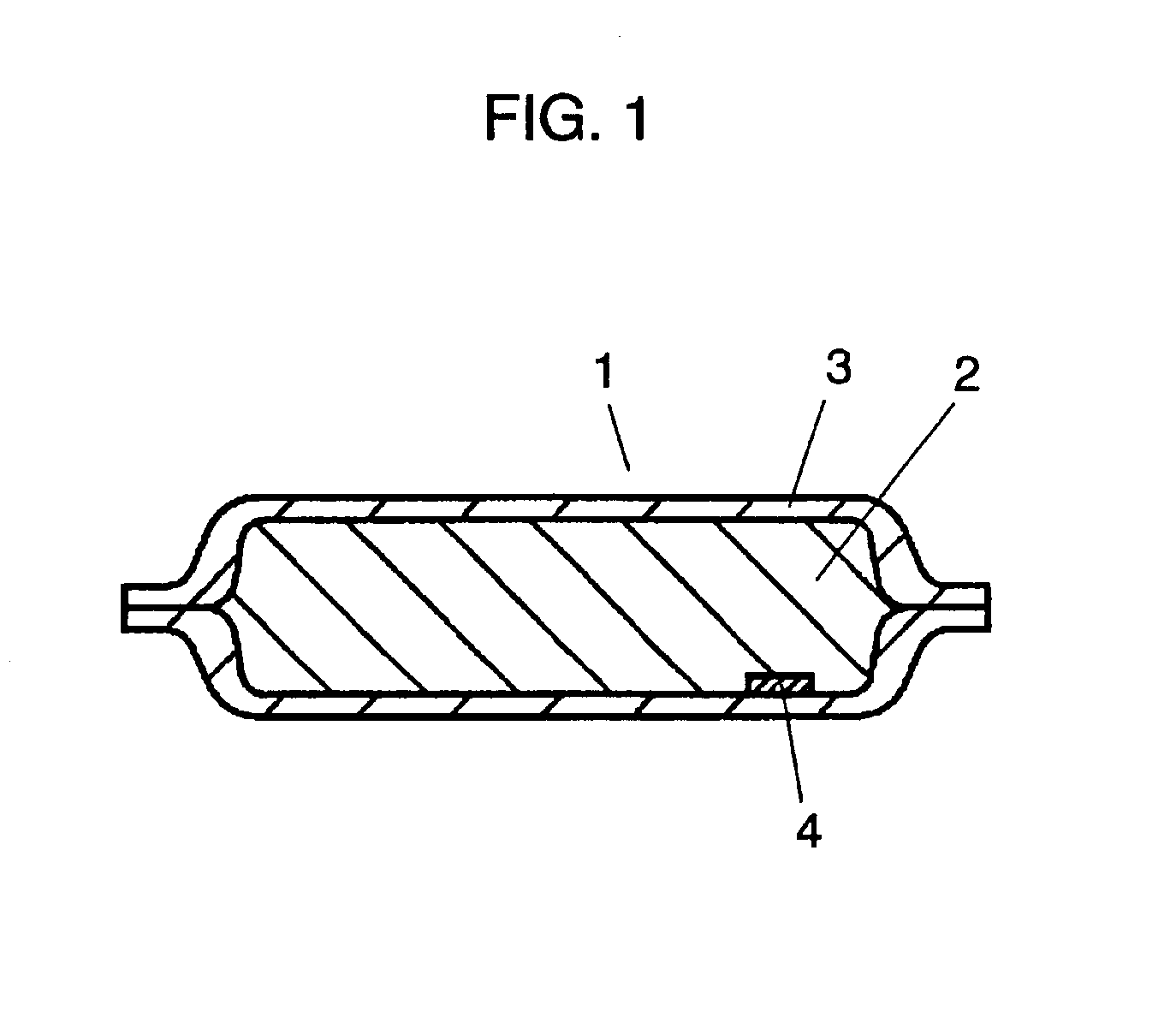

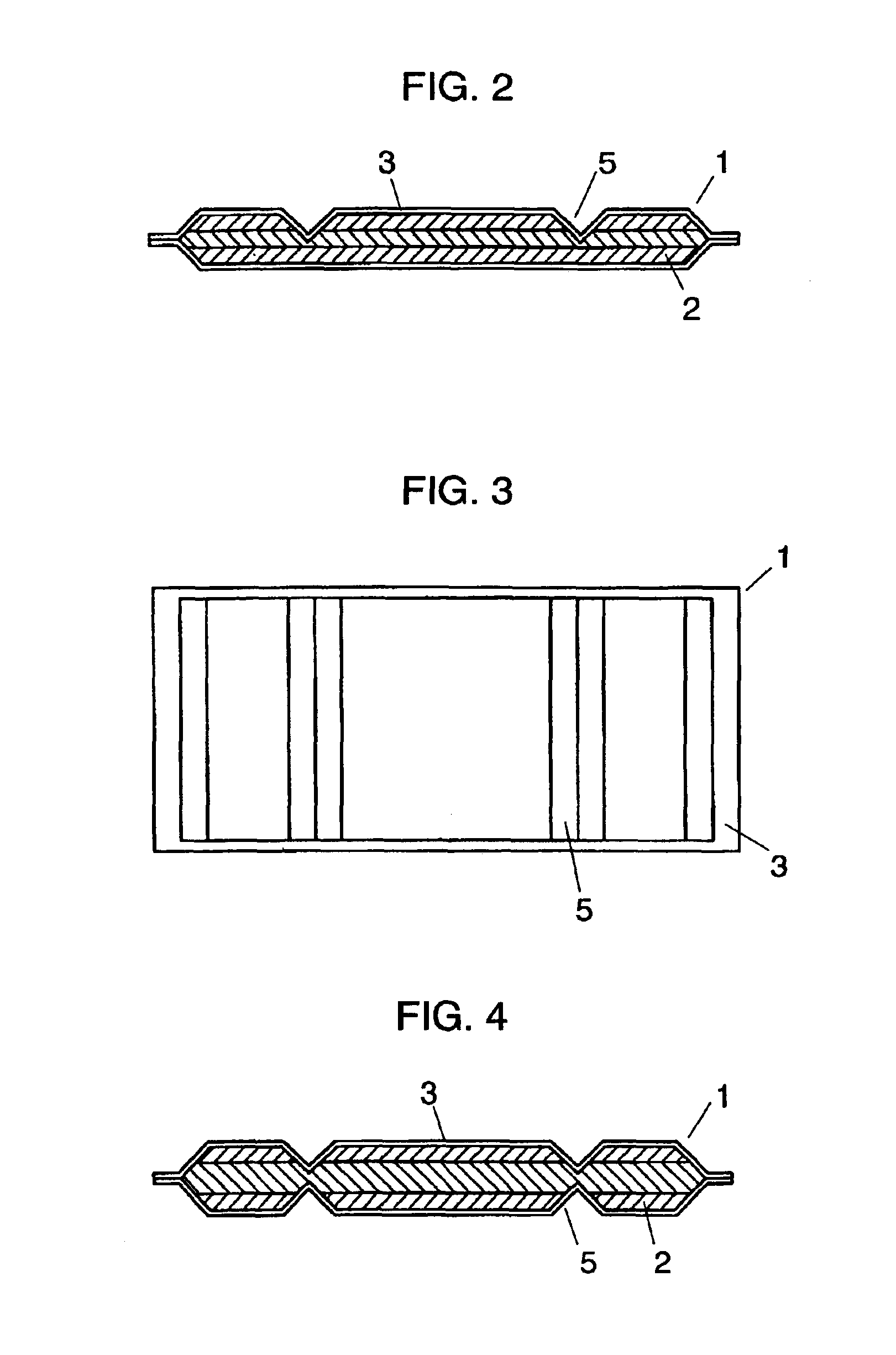

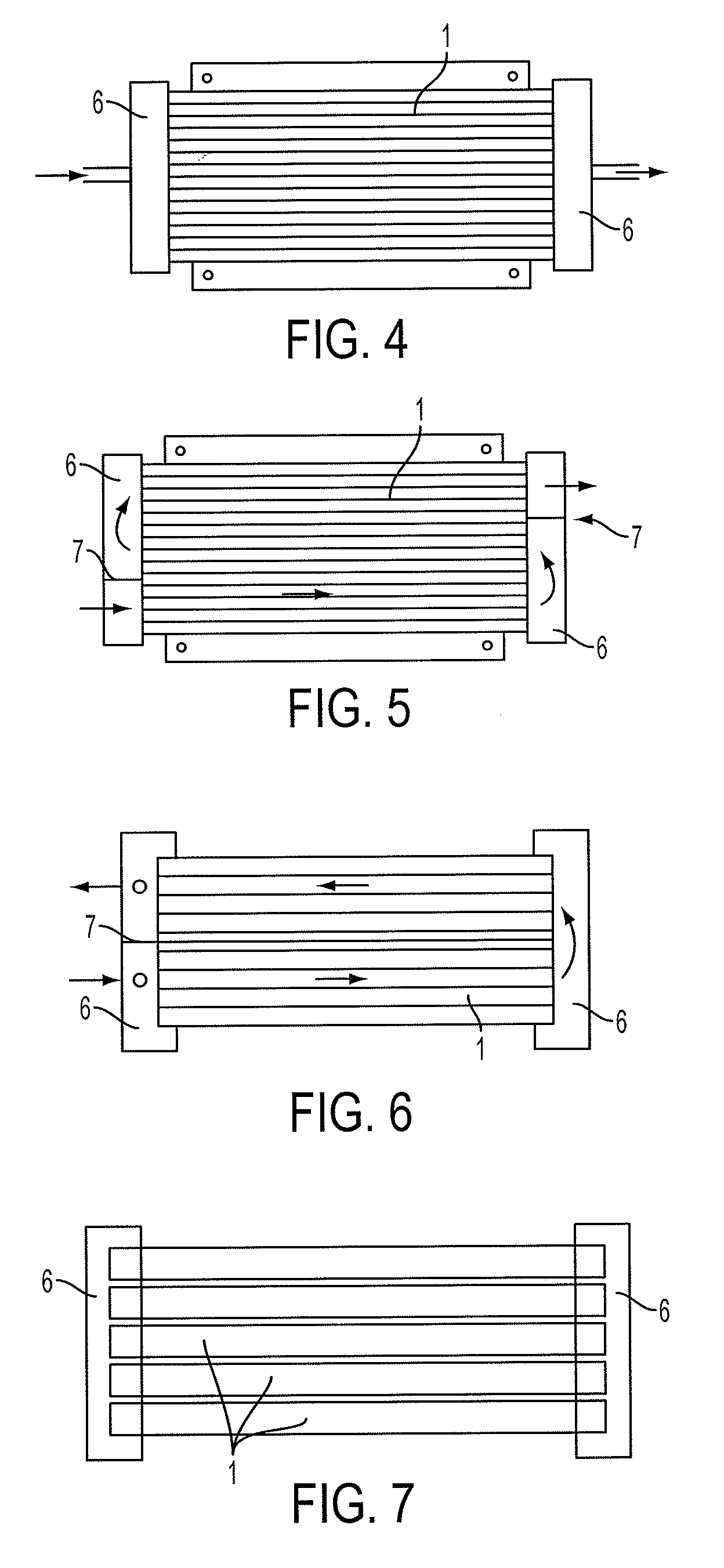

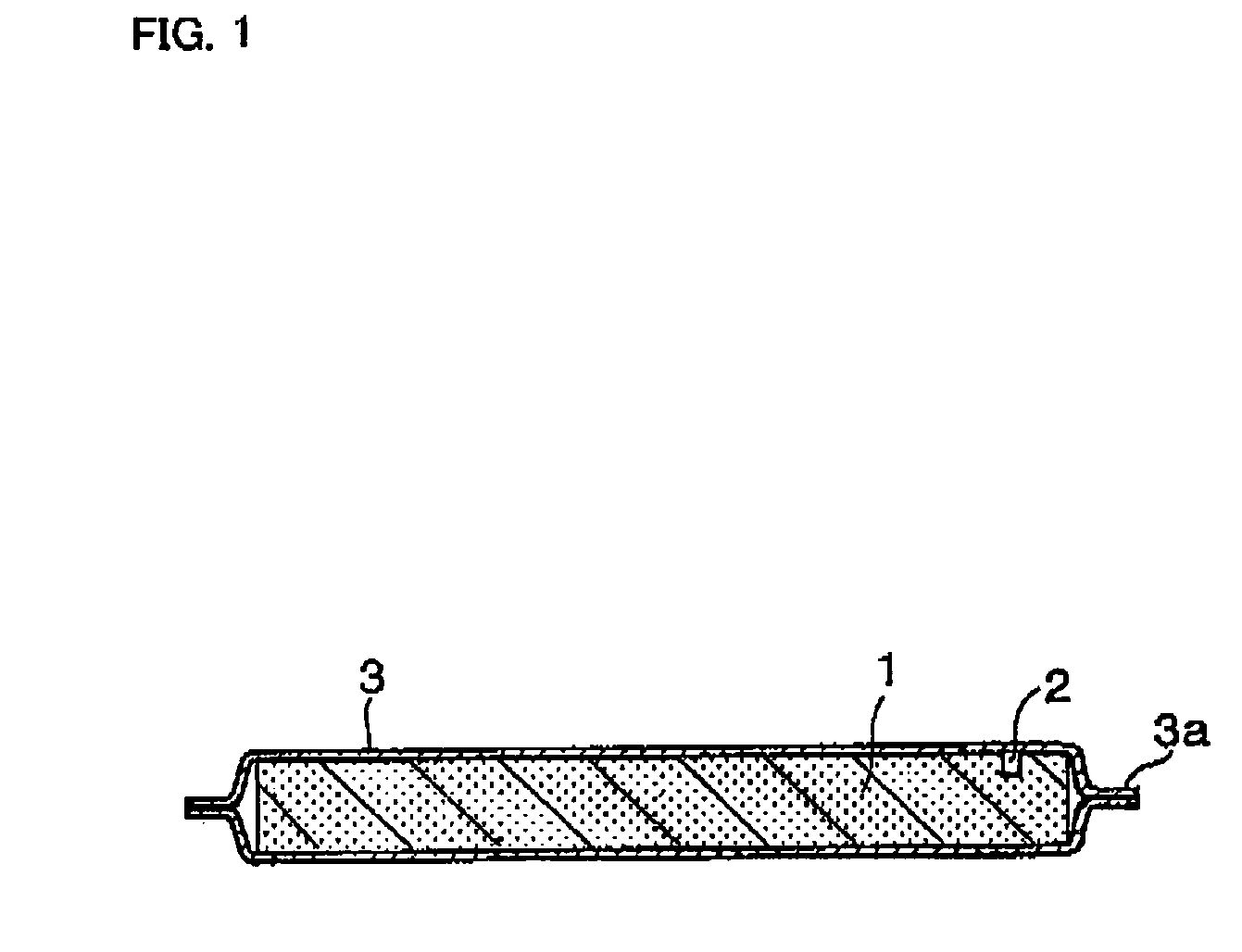

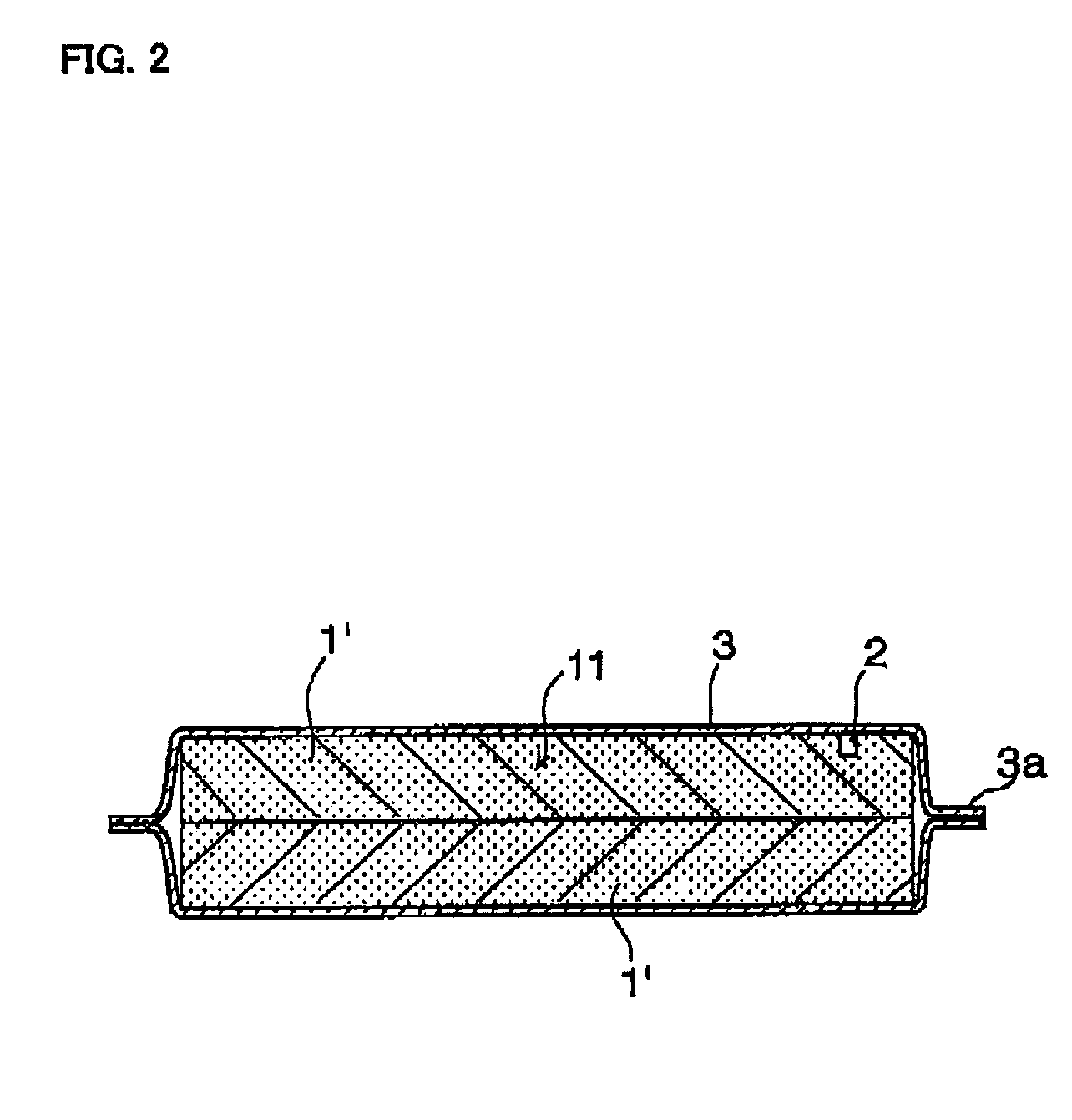

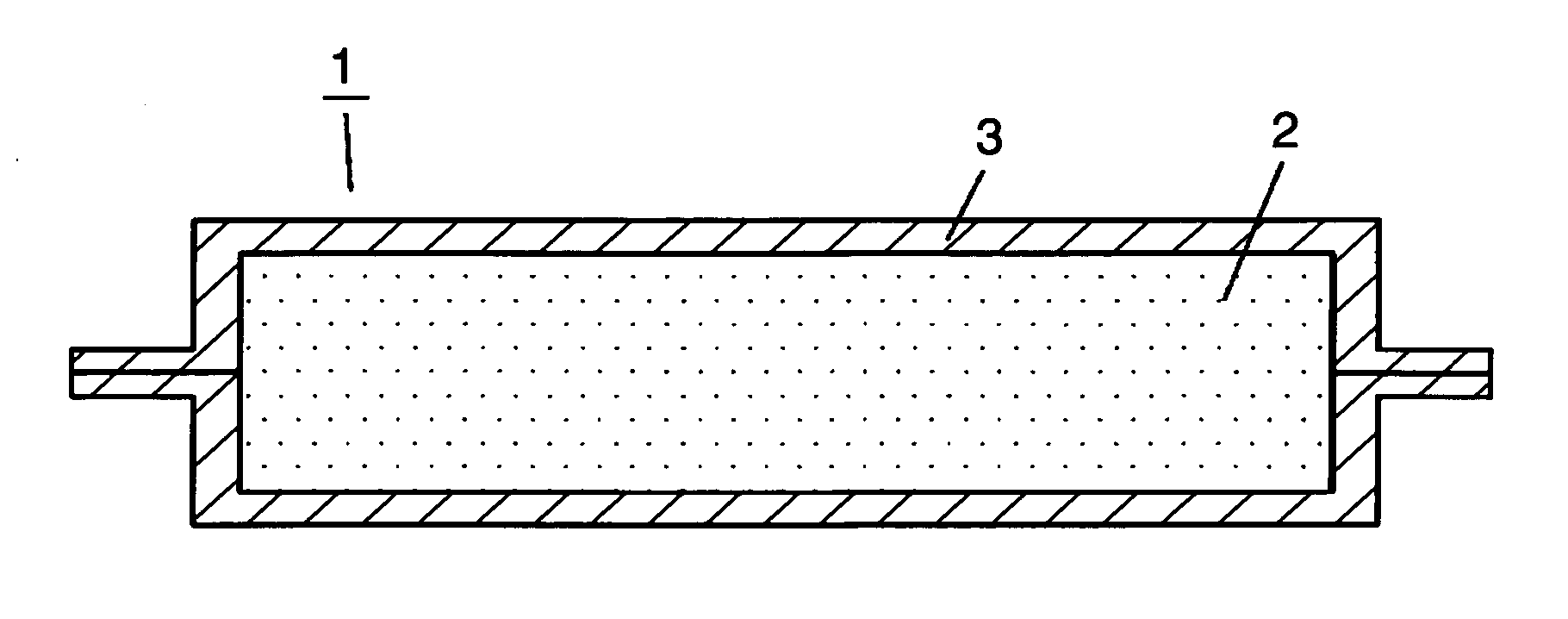

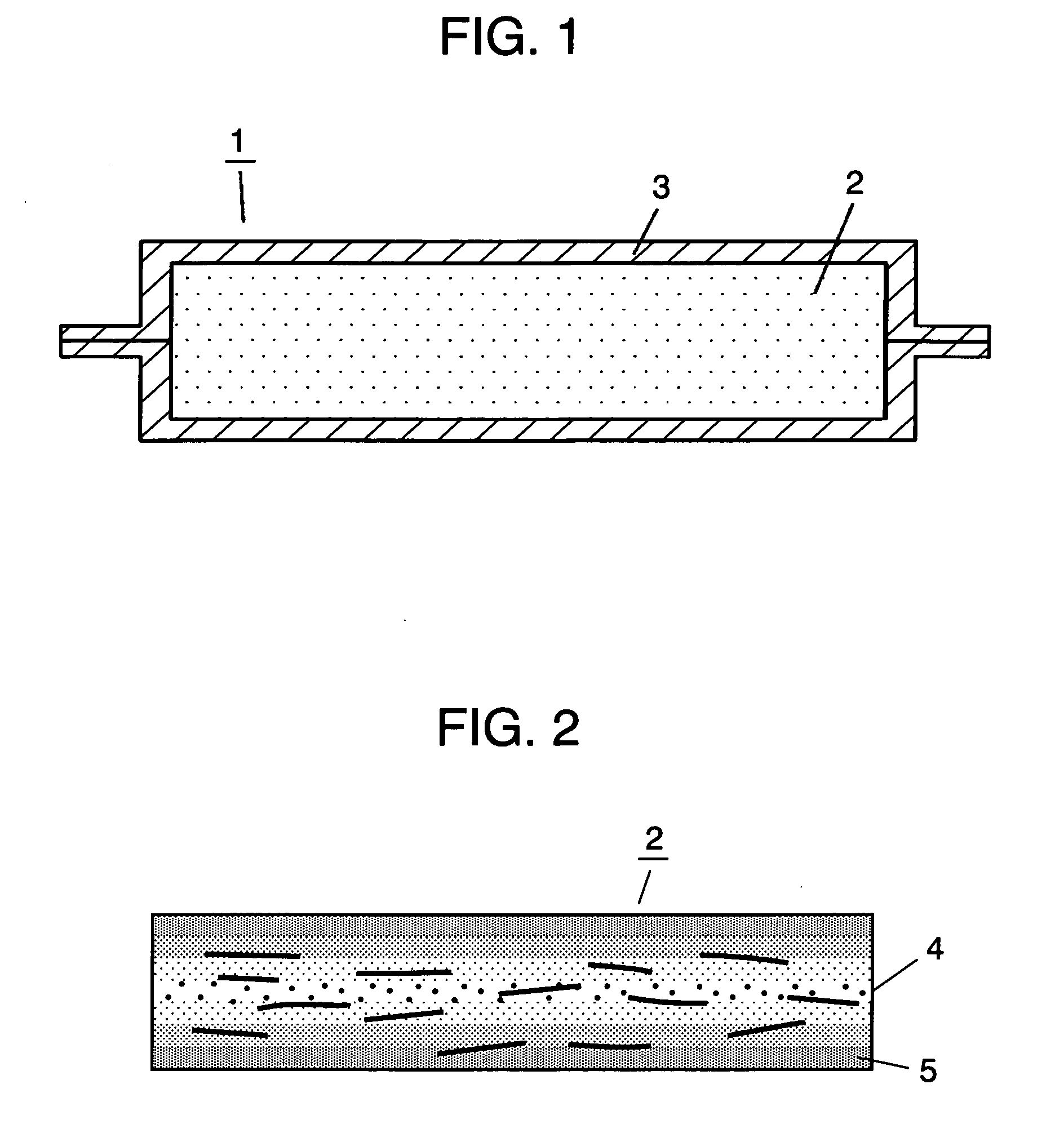

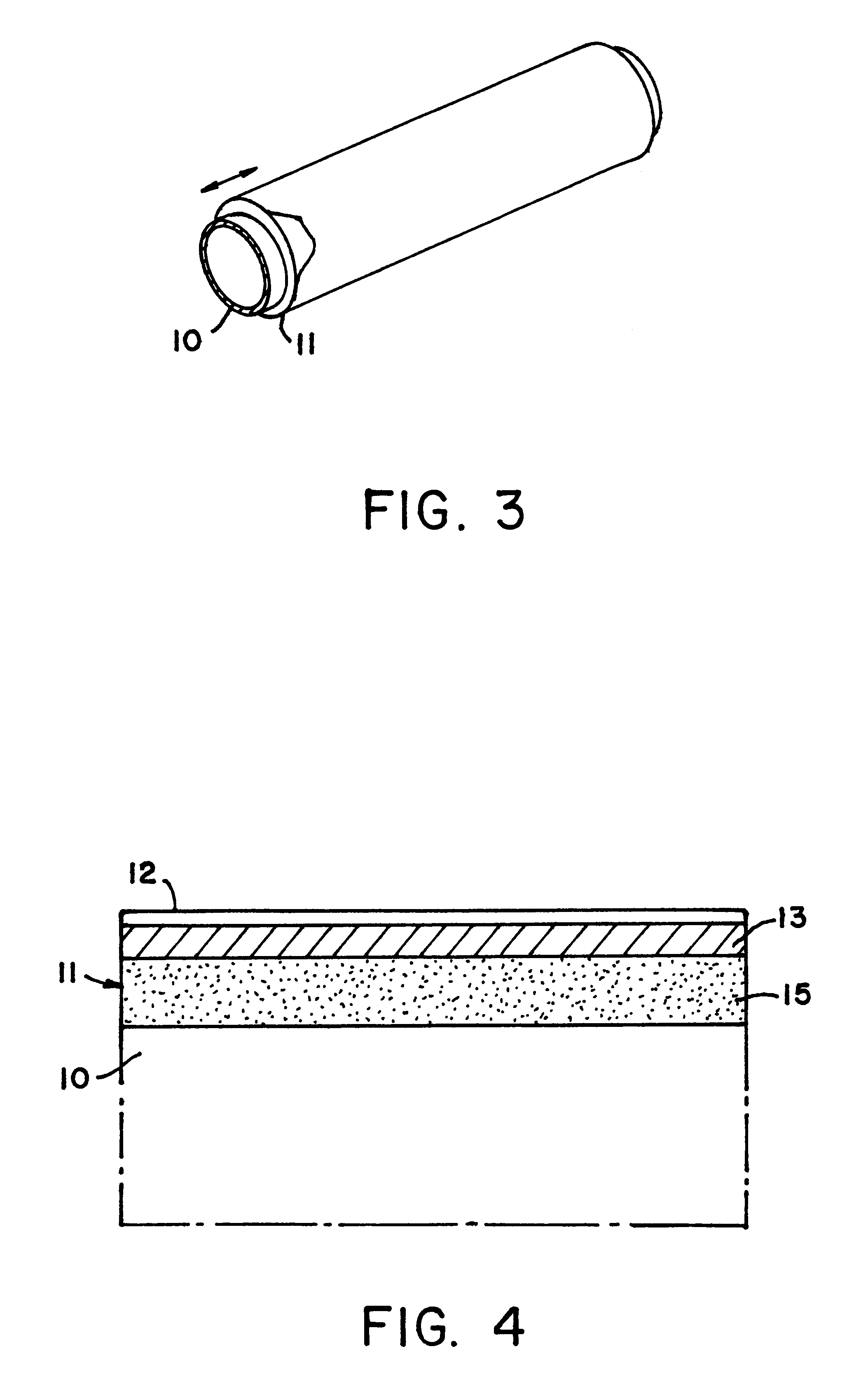

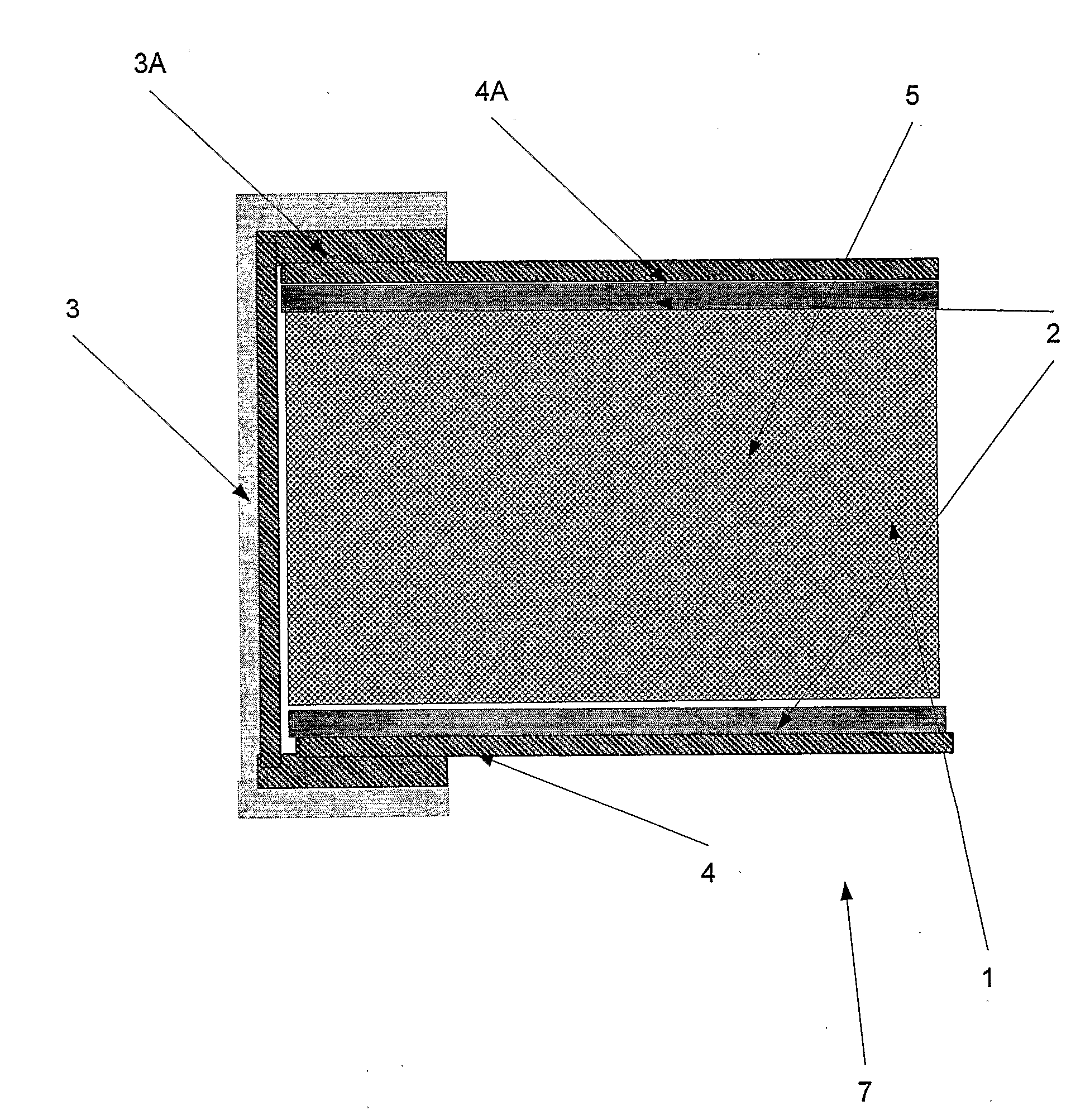

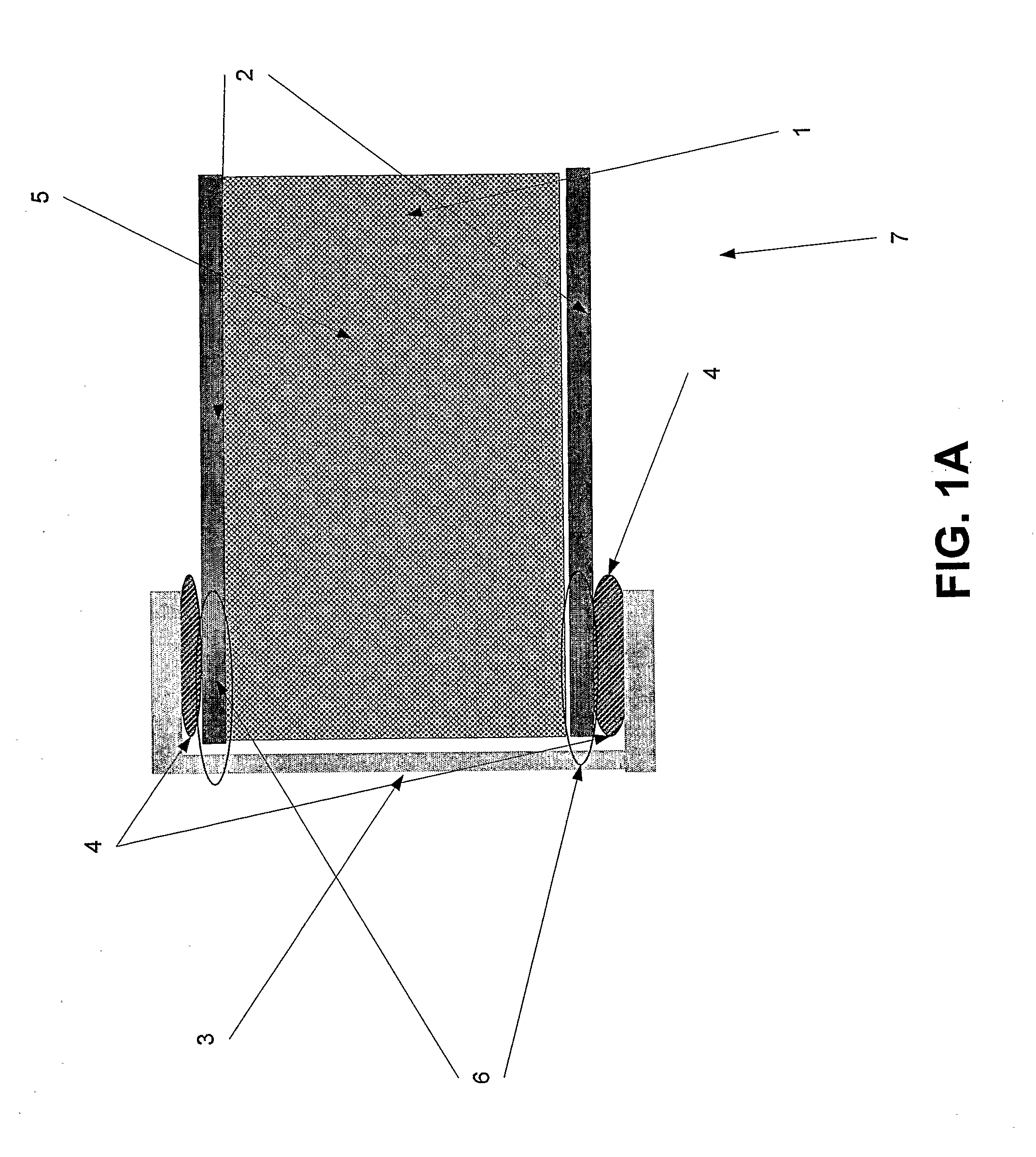

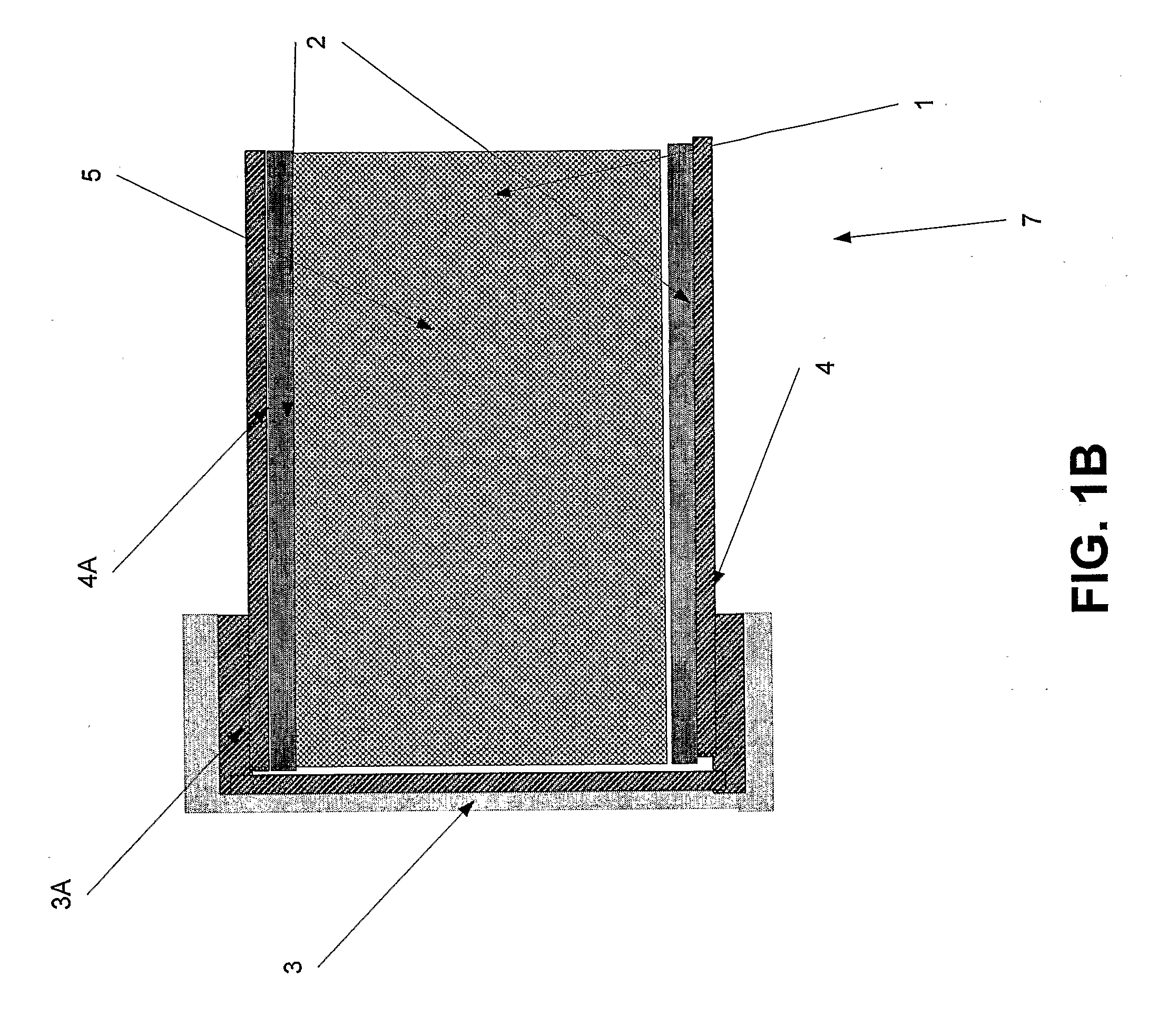

Vacuum heat insulating material and manufacturing method therefor

InactiveUS20040253406A1Improve performanceLow thermal conductivityThermal insulationDomestic cooling apparatusSorbentDecreased pressure

Provided is a vacuum heat insulating material, using inorganic fibers as a core material, high in heat insulating performance (low in thermal conductivity), capable of maintaining the heat insulating performance for a long period, free of defects such as projections and depressions on a large scale on a surface thereof, short in manufacturing time and advantageous in terms of cost; and a manufacturing method therefor. A vacuum heat insulating material of the present invention is of a construction in which a core material 1 and a gas adsorbent 2 are housed in a bag 3 made from a gas barrier film and the interior thereof is reduced in internal pressure thereof and air-tightly sealed, wherein the core material 1 is a molded product obtained by coating a binder B on inorganic fibers having an average fiber diameter in the range of from 3 to 5 mum at a coating amount in the range of from 0.5 to 1.5 wt % relative to the fibers and heat pressing the inorganic fibers, or a laminate fabricated by stacking two or more sheets of the molded product.

Owner:ASAHI FIBER GLASS CO LTD

Nanometer multiple-layer composite thermal insulation material and preparation method thereof

ActiveCN101799099AEasy to useInhibition of high temperature radiative heat transferThermal insulationPipe protection by thermal insulationAdhesiveMetal foil

The invention discloses a nanometer multiple-layer composite thermal insulation material and a preparation method thereof. The nanometer multiple-layer thermal insulation composite material is formed by alternatively overlapping an infrared reflecting screen and a spacer; the ratio of total layer amounts n of the infrared reflecting screens and the spacers to the total thickness of the nanometer multiple-layer composite thermal insulation material is 0.5-4; the infrared reflecting screen is a metal foil or a metal plated foil; the spacer is a thermostability nanometer porous aerogel composite thermal insulation material; the infrared reflecting screen and the spacer are combined by being adhered with thermostability adhesives or in puncturing connection by thermostability sewing threads. The invention also comprises the preparation method of the nanometer multiple-layer composite thermal insulation material. The nanometer multiple-layer composite thermal insulation material of the invention has low density, favorable mechanical property and favorable high-temperature thermal insulation property, lowers requirements on the vacuum degree by a VIP plate when being used as vacuum thermal insulation plate core materials, does not need getter and can satisfy harsh high-efficiency thermal insulation using requirements on materials by aviation, aerospace and civil fields. The method of the invention can prepare thermal insulation material members with large size and complex shape.

Owner:NAT UNIV OF DEFENSE TECH

Insulated pipe and method for preparing same

The invention provides an insulated pipe-in-pipe assembly comprising (a) at least one inner pipe, (b) an outer pipe disposed around the at least one inner pipe so as to create an annular space between the outer and inner pipes, (c) porous, resilient, compressible material disposed in the annular space, and (d) a remnant of a container that previously was positioned in the annular space and previously held the compressible material in a volume less than the volume of the compressible material in the annular space. The invention also provides a method for making such an insulated pipe-in-pipe assembly.

Owner:CABOT CORP

Vacuum thermal insulating material, process for producing the same and refrigerator including the same

A vacuum heat insulator according to the present invention includes a core molded to be plate-shaped with the use of a binding agent. The vacuum heat insulator assumes any one of the following configurations. A) The core is formed by curing a fiber aggregate by means of a binding agent. The fibers have an average fiber diameter of at least 0.1 μm but at most 10 μm, and voids defined by fibers have a void diameter of at most 40 μm. The core has a percentage of the voids of at least 80%. B) The binding agent is varied in concentration in a through-thickness direction of the core. C) A cured layer solidified by the binding agent is formed on at least one side surface of the core. D) The core contains fibers having a length of at most 100 μm. The fibers are oriented perpendicular to a direction of heat transmission. Such vacuum heat insulator is excellent in adiabatic property. Refrigerators, to which such a vacuum heat insulator is applied, are made small in size, or have a large inner volume, or contribute to energy saving.

Owner:PANASONIC CORP

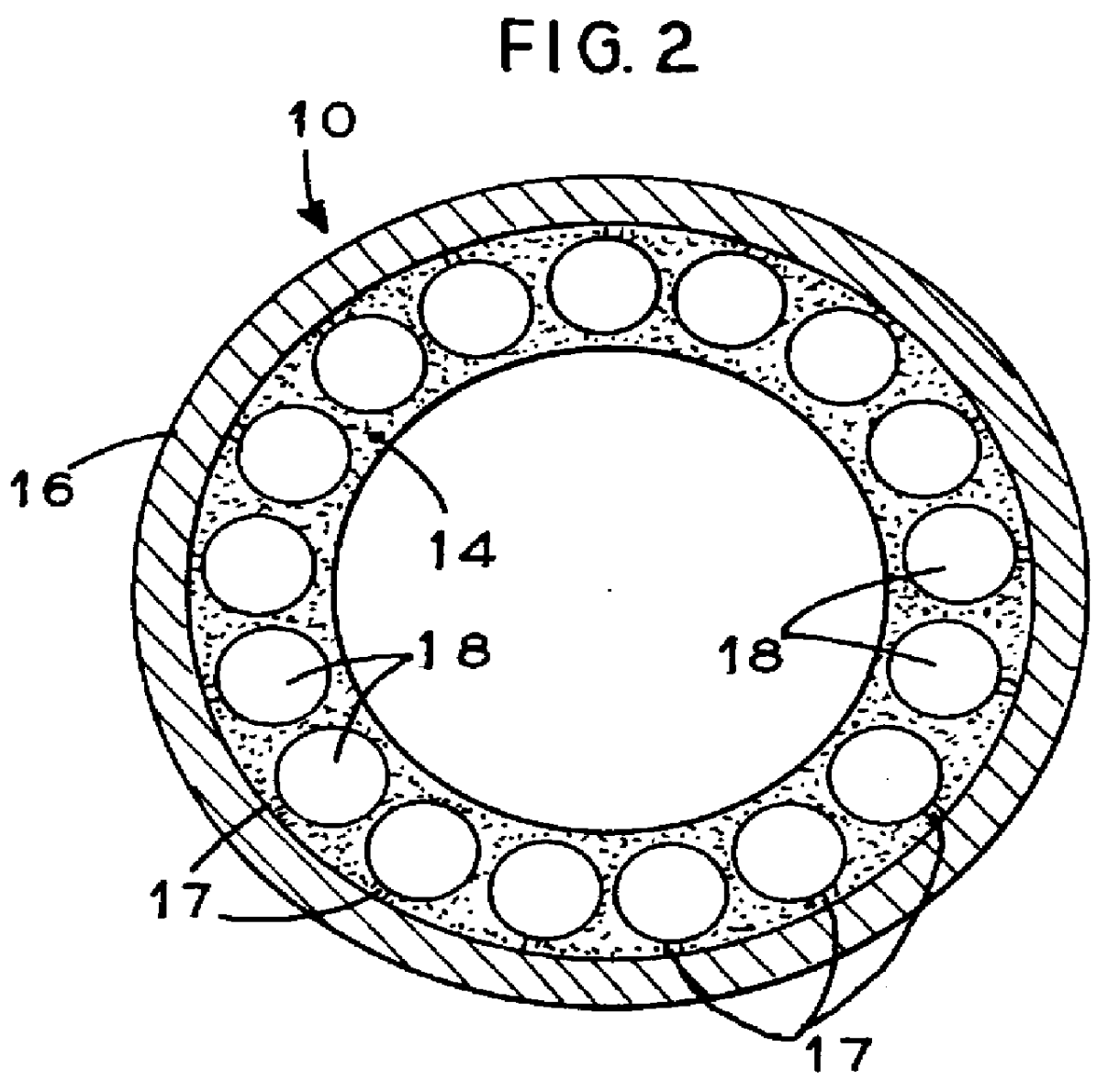

Microsphere insulation systems

InactiveUS6858280B2Reduce the impactIncreases insulation valueLayered productsContainer filling methodsMicrosphereEngineering

A new insulation system is provided that contains microspheres. This insulation system can be used to provide insulated panels and clamshells, and to insulate annular spaces around objects used to transfer, store, or transport cryogens and other temperature-sensitive materials. This insulation system provides better performance with reduced maintenance than current insulation systems.

Owner:TECH APPL

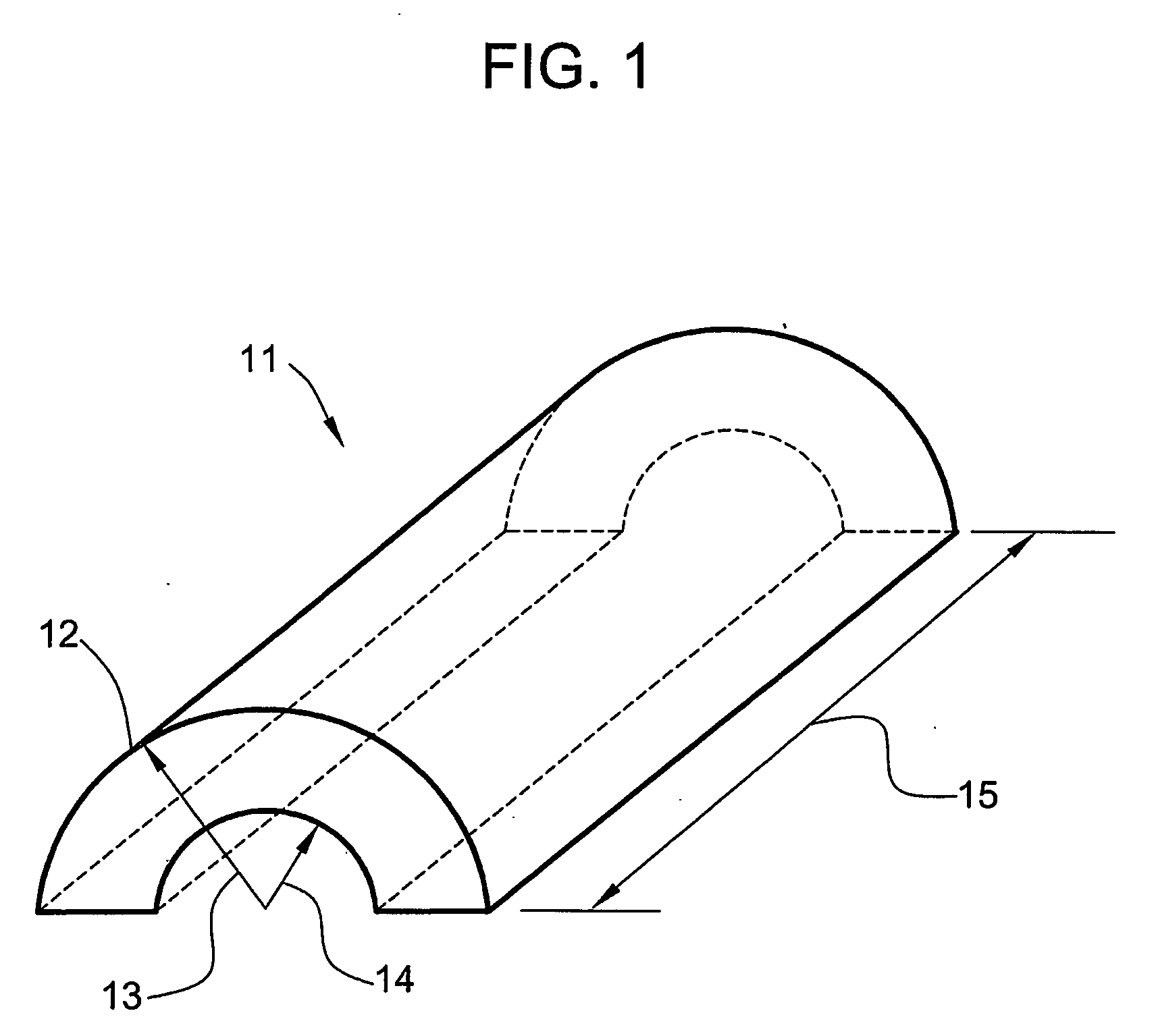

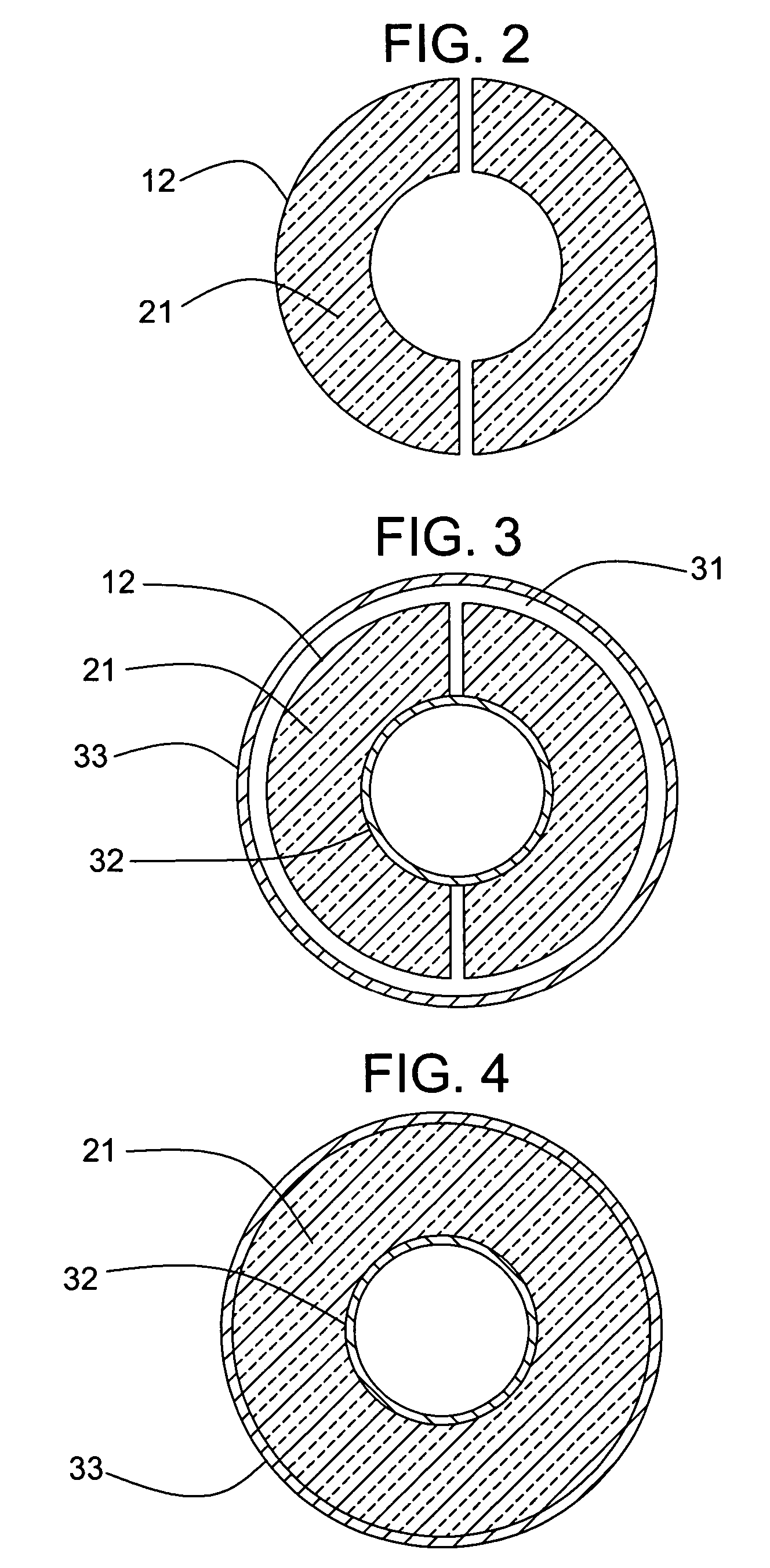

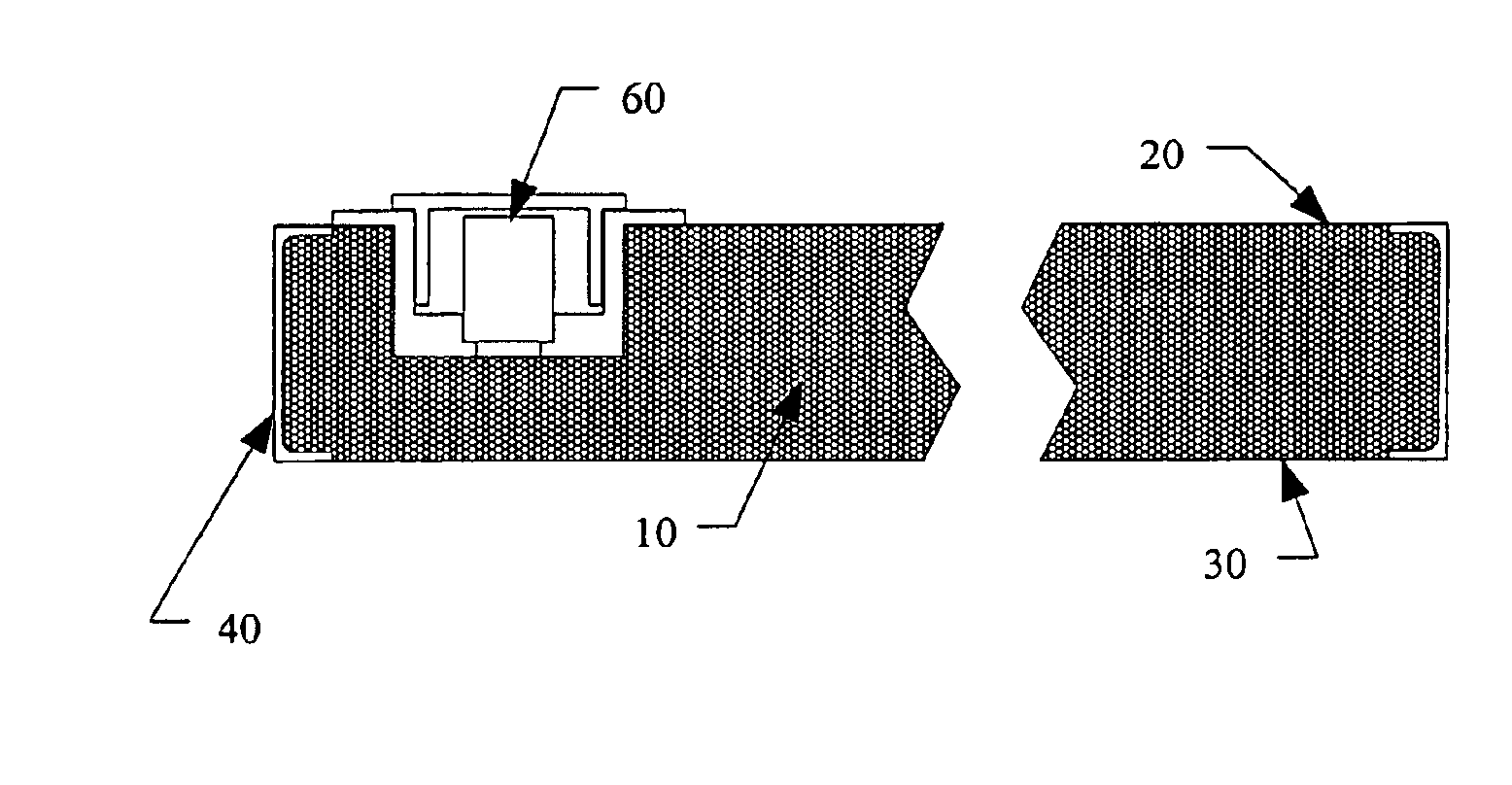

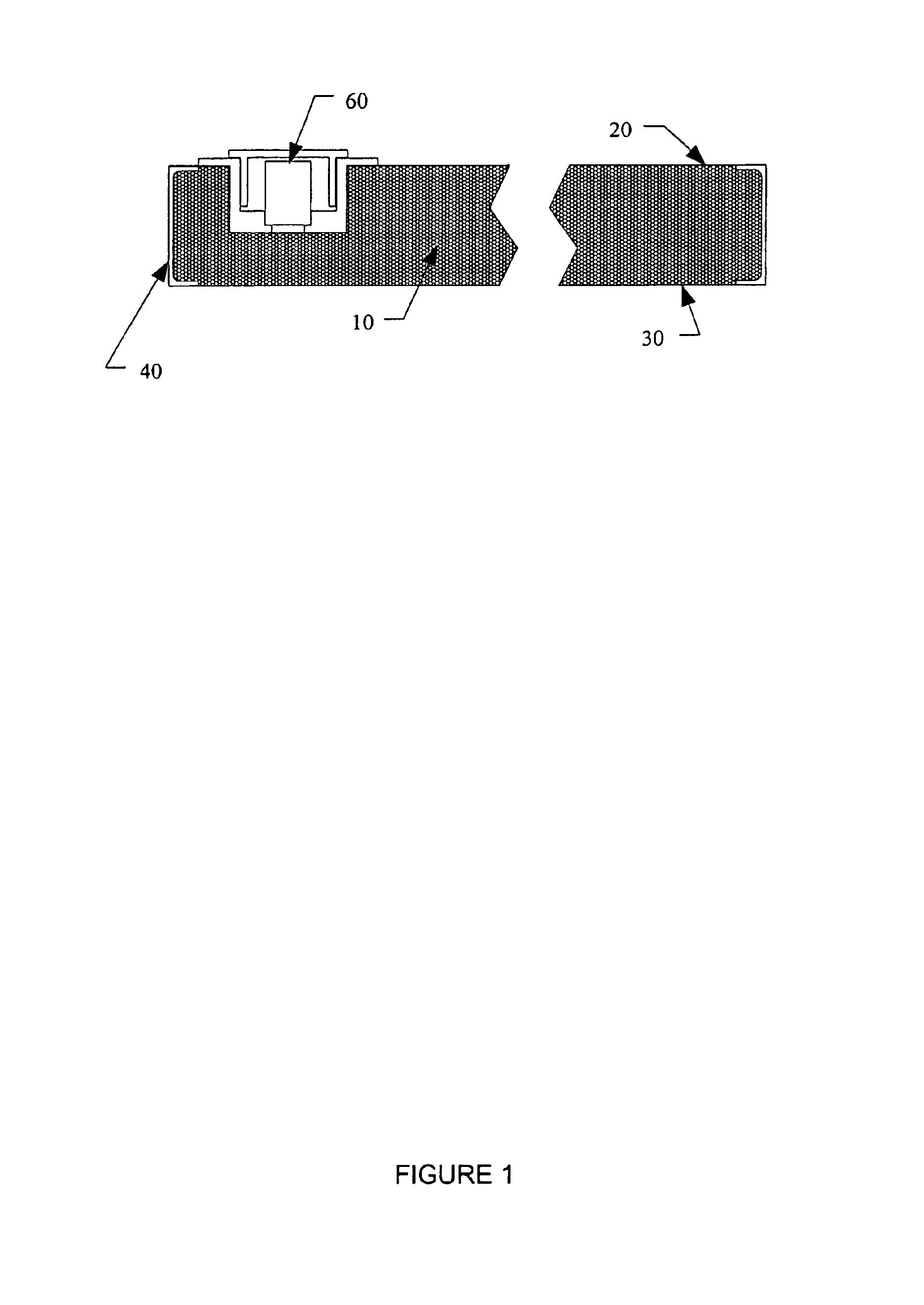

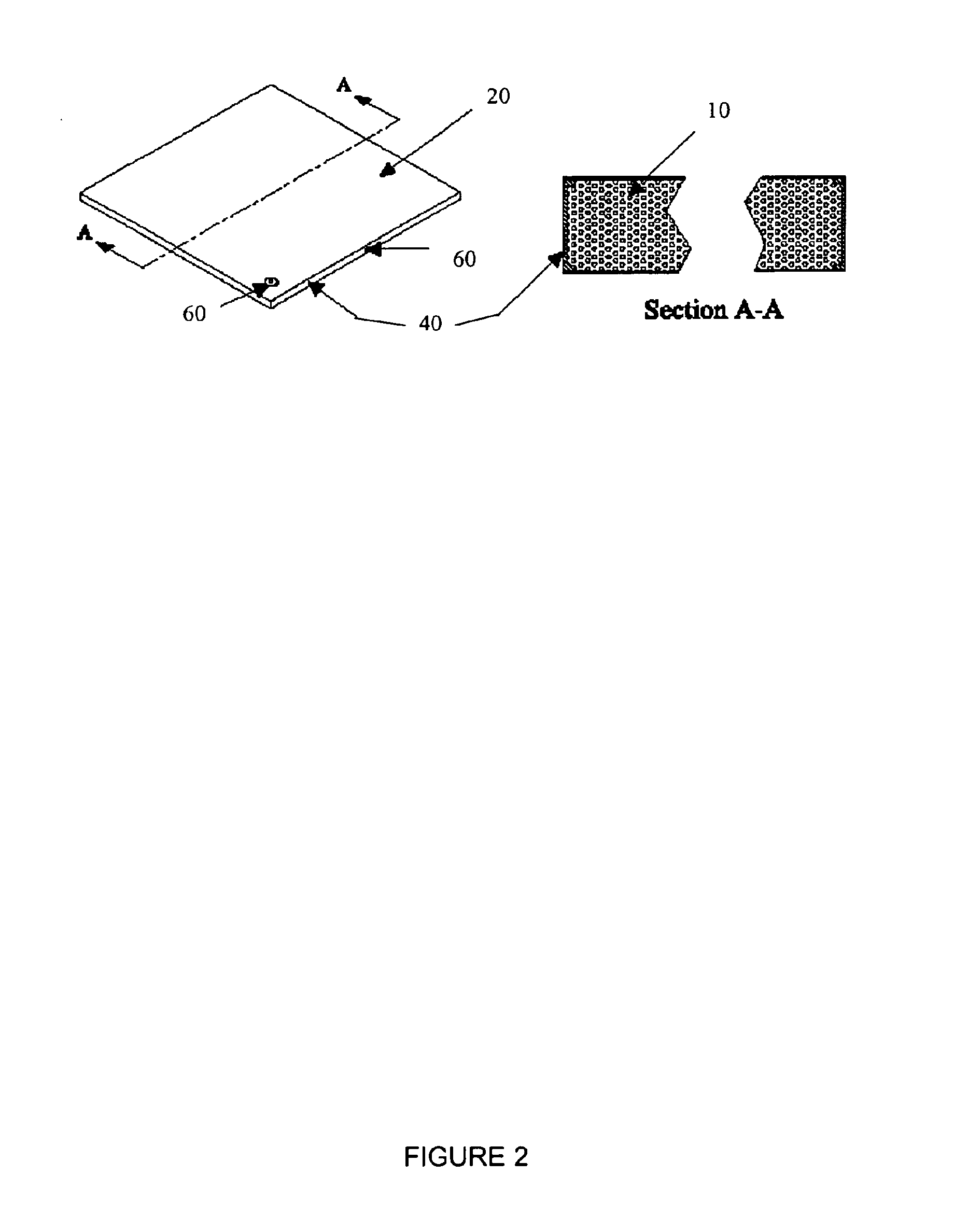

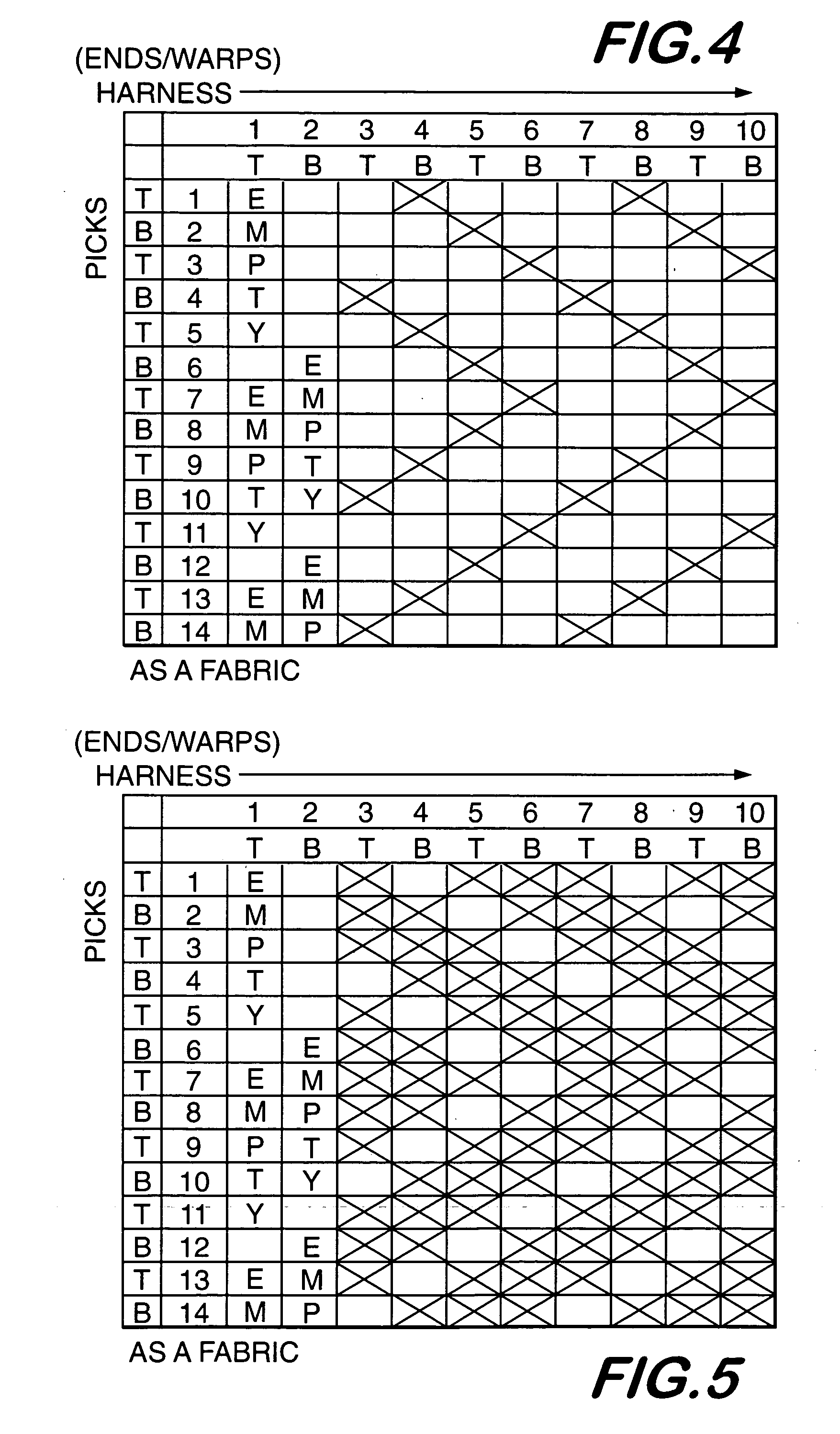

Self-curling sleeve

ActiveUS20060016507A1Thermal insulationPipe protection by thermal insulationEngineeringPerpendicular direction

A substrate including a plurality of monofilaments, or a combination of monofilaments and multi-filament yarns oriented in perpendicular directions, has a tendency to curl around a central space. When all monofilaments are used, the monofilaments along one direction may have a larger diameter than the monofilaments along the other direction. The monofilaments are woven such that the larger diameter monofilaments form floats predominantly on one side of the substrate. For the monofilament-multifilament combination the monofilaments form floats predominantly on one side of the substrate. The substrate curls about an axis parallel to the monofilaments forming the floats. The side having the floats faces outwardly away from the central space. Preferably, the monofilaments are oriented in the warp direction along the substrate. The filaments may be woven in a herringbone twill weave, a double cloth herringbone twill weave or a satin weave to provide the floats.

Owner:FEDERAL MOGUL WORLD WIDE LLC

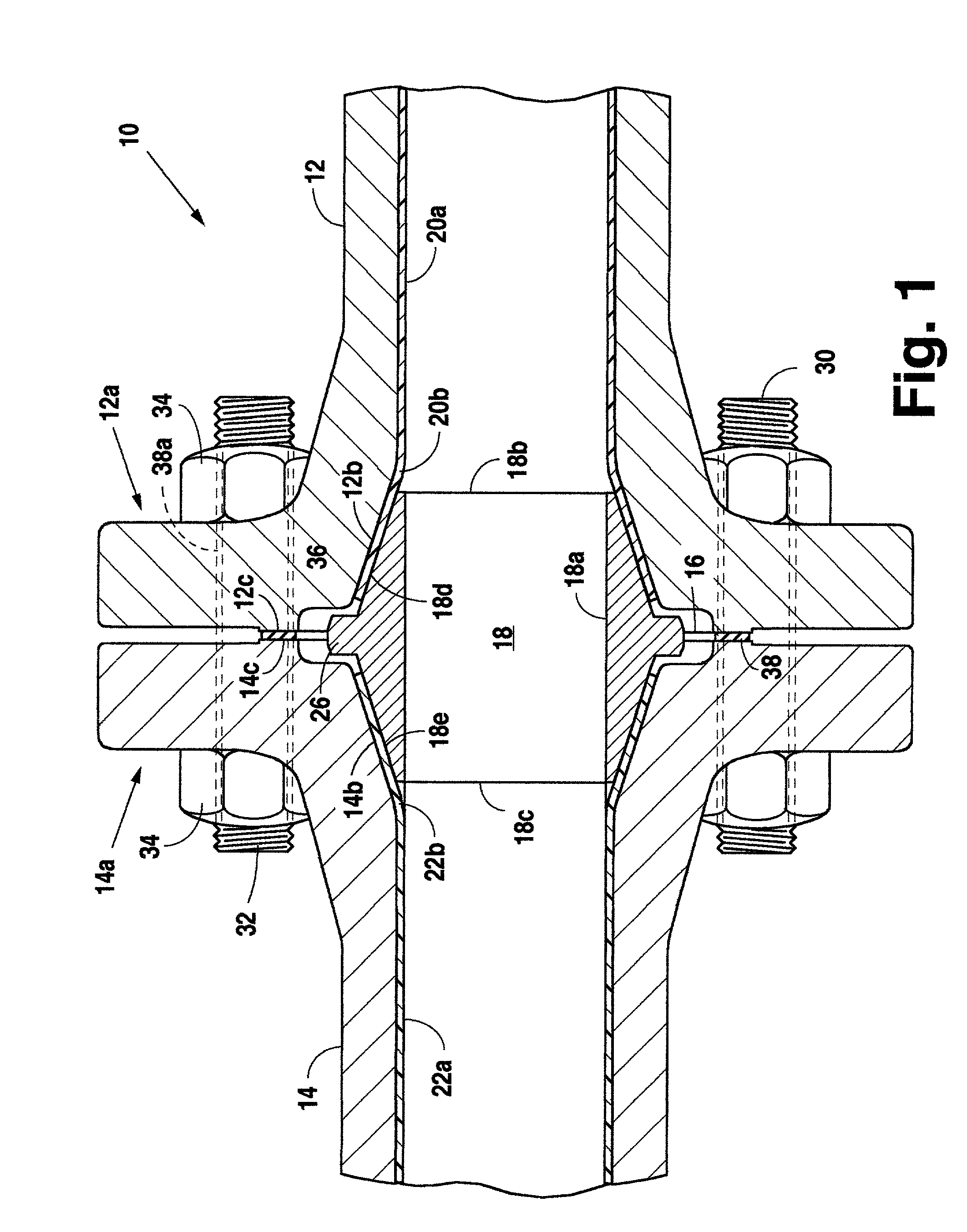

Method and a coupler for joining two steel pipes

InactiveUS7107662B1Improve sealingPipe elementsPipe protection by thermal insulationMechanical engineering

A method and apparatus for coupling together the ends of two steel pipe sections, each of which contains a permeable inner liner, in which not only are the pipe ends held in abutting engagement, but gas contained within the liner of one pipe section is effectively channeled into the liner of the other pipe section.

Owner:ARANT AS TRUSTEE MR GENE W +1

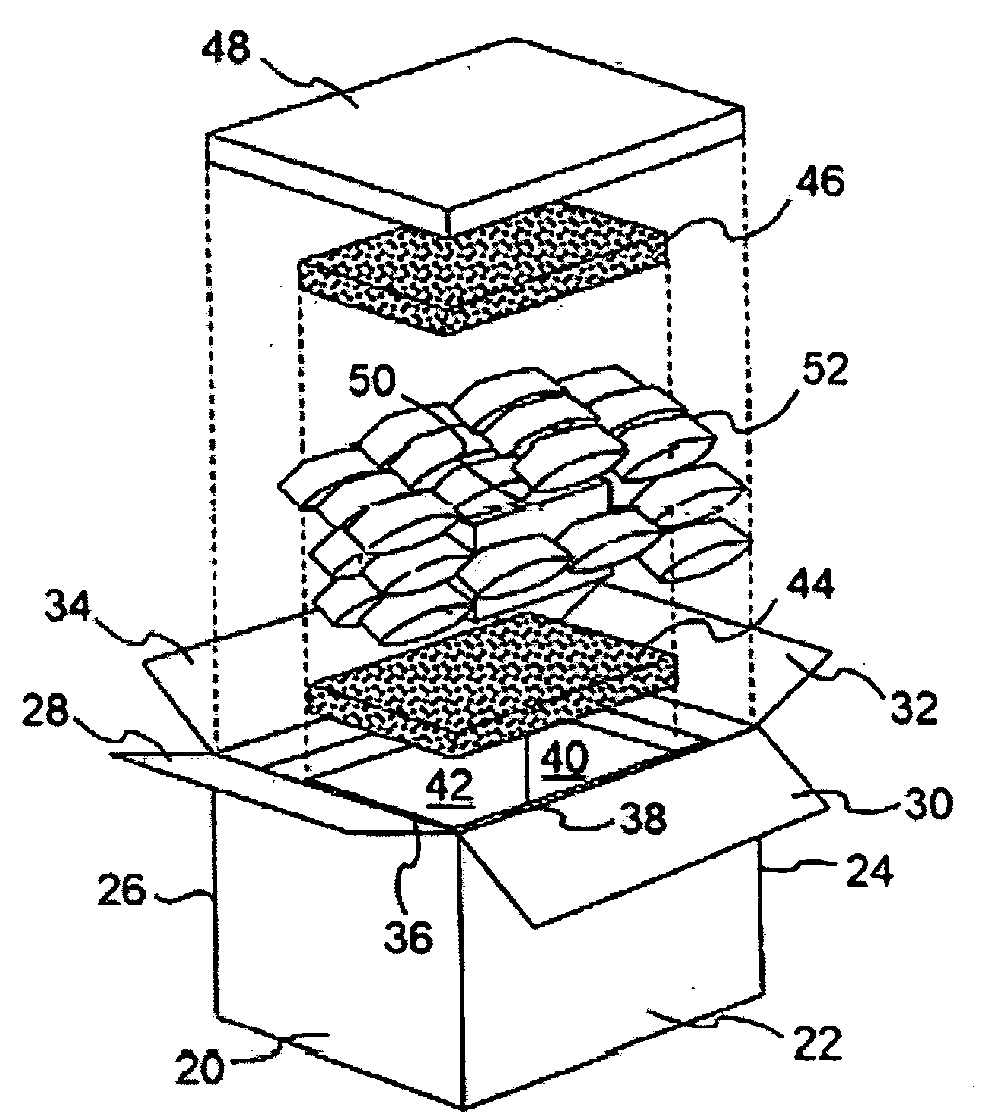

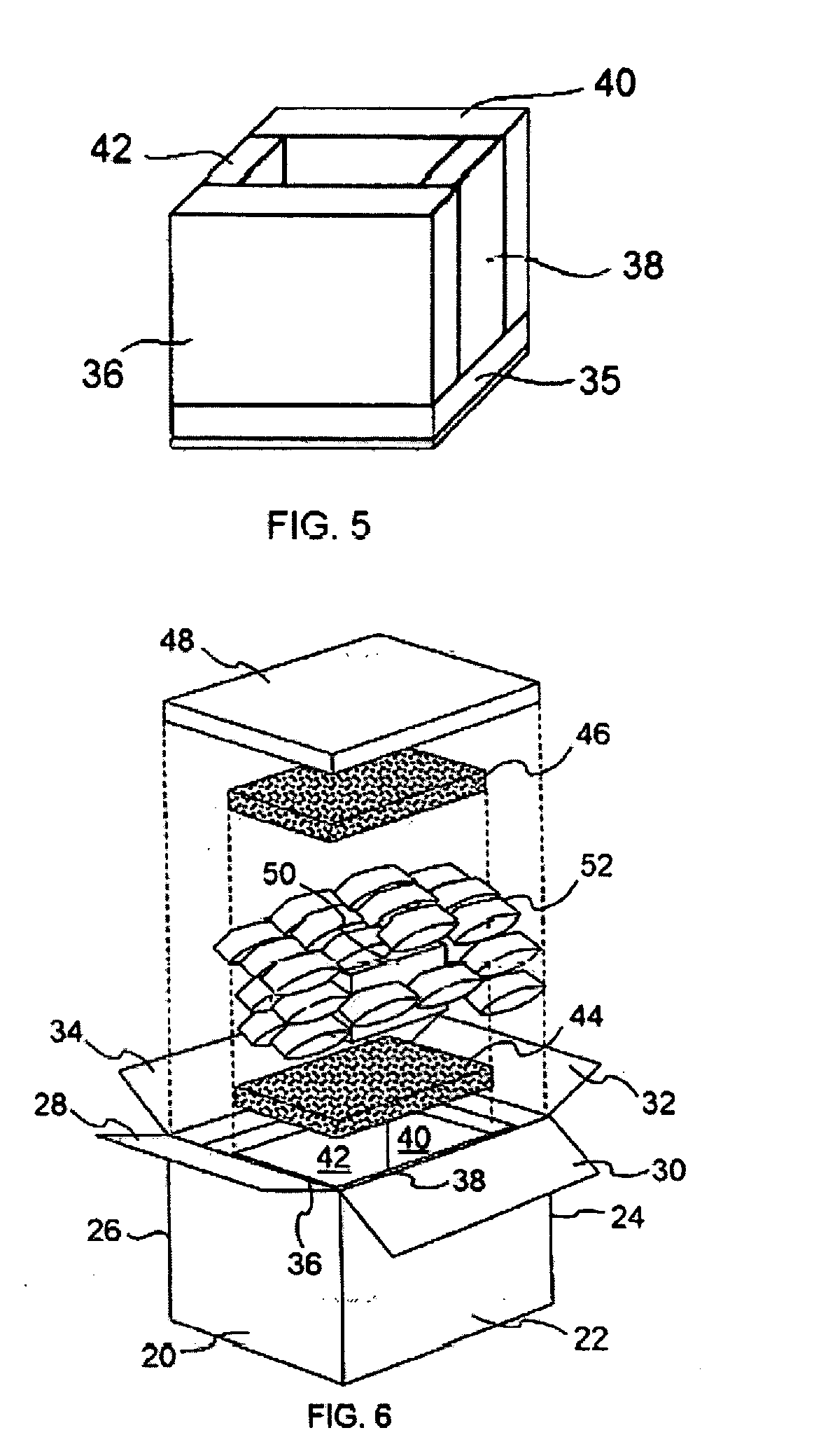

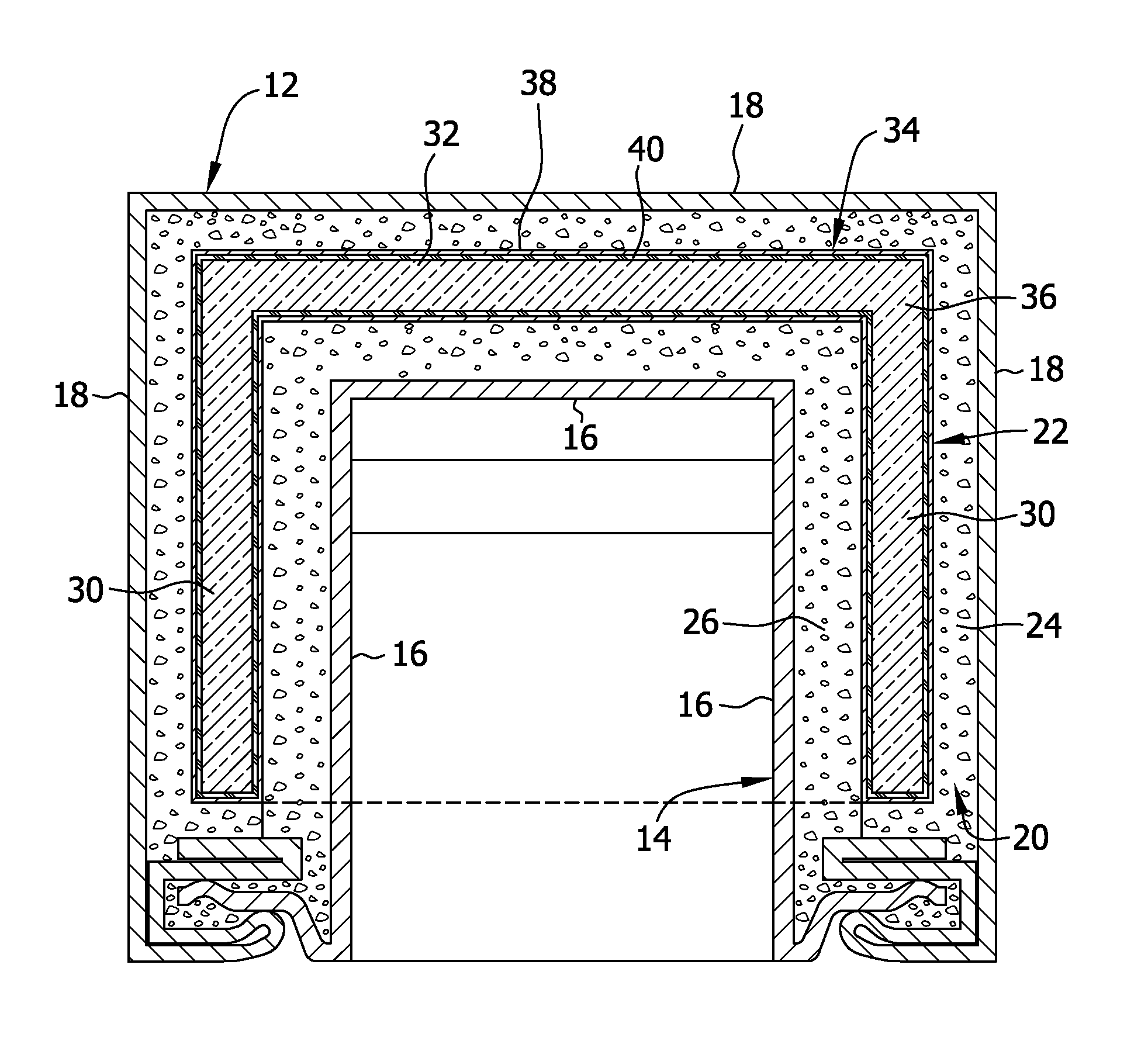

Method and apparatus for insulating a refrigeration appliance

ActiveUS8881398B2Envelopes/bags making machineryThermal insulationRefrigerationElectrical and Electronics engineering

A method of insulating a refrigeration appliance. The refrigeration appliance includes a case, a liner, and a five-sided, box like vacuum panel. The liner is formed to be inserted into the case forming a chamber between the liner and the case. The five sides of the vacuum panel define a cavity. The method includes in one embodiment, positioning the five-sided vacuum panel in the chamber between the case and the liner, injecting foam into the chamber, and curing the foam to attach the five sided vacuum panel to the case and the liner.

Owner:HAIER US APPLIANCE SOLUTIONS INC

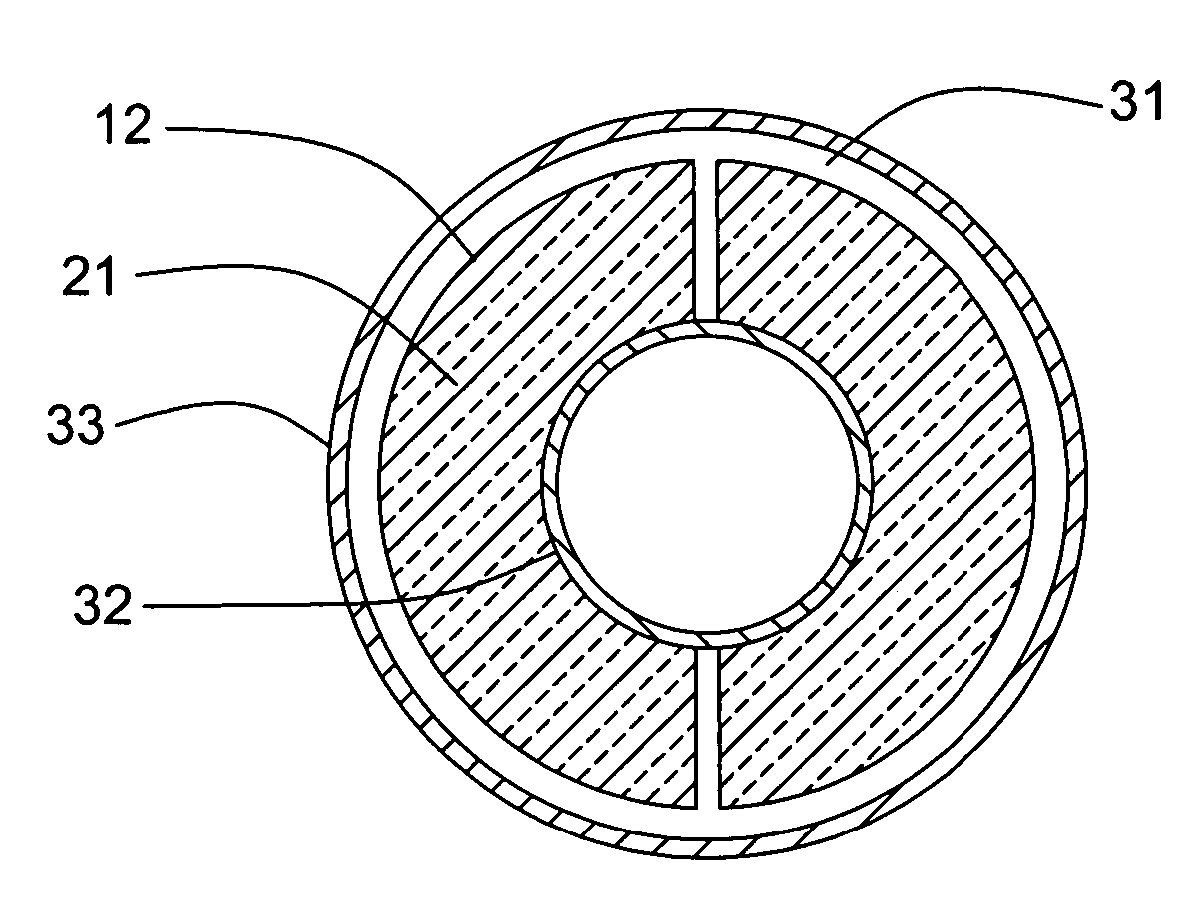

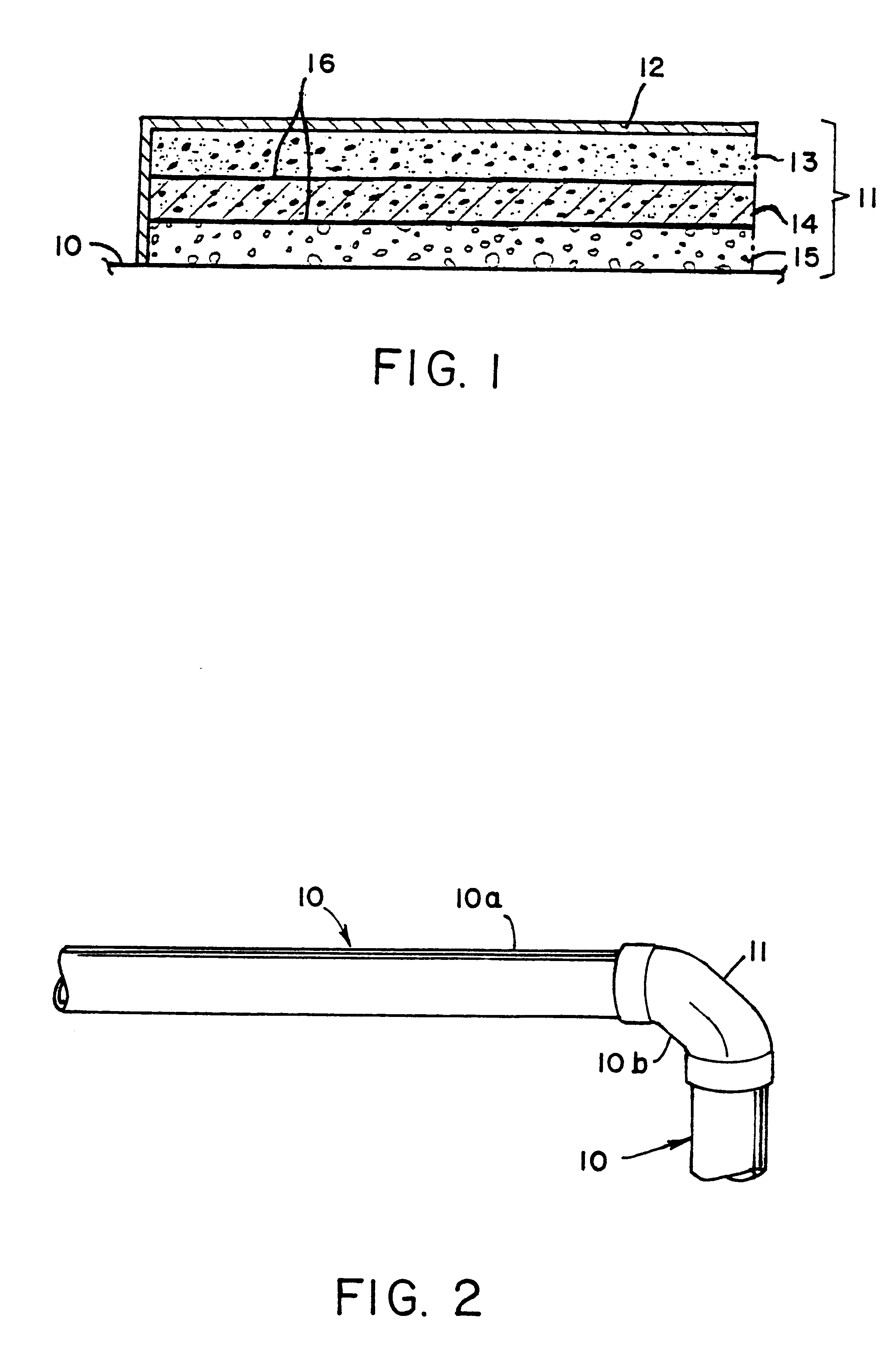

Acoustic damping pipe cover

InactiveUS6202702B1Easy to handleImprove damping performanceThermal insulationPipe protection by thermal insulationInsulation layerNoise level

A generally tubular laminated acoustic damping pipe cover to be used on a water pipe to reduce the noise level of the pipe, having a sound insulation layer whose area density is 1.5-5.0 kg / m2 and a sound absorptive layer whose thickness is 4.0-10.0 mm, covered with a heat-contractile film which when heat treated will tighten the acoustic damping pipe cover on the water pipe but hold the pipe cover in a sliding fashion. The acoustic damping pipe cover is lightweight and easy to manipulate, and provides an excellent acoustic damping performance.

Owner:SHISHIAI KK

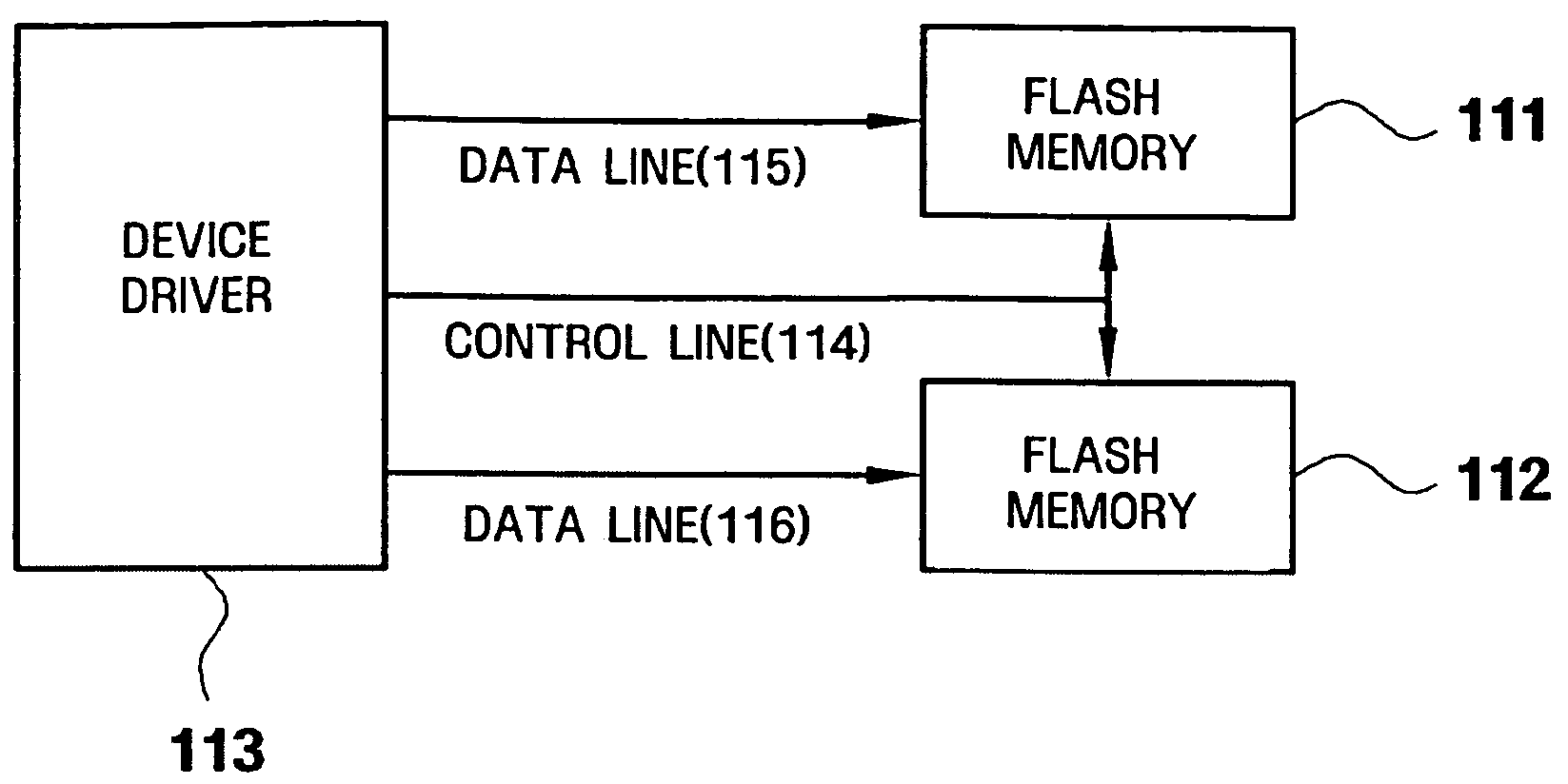

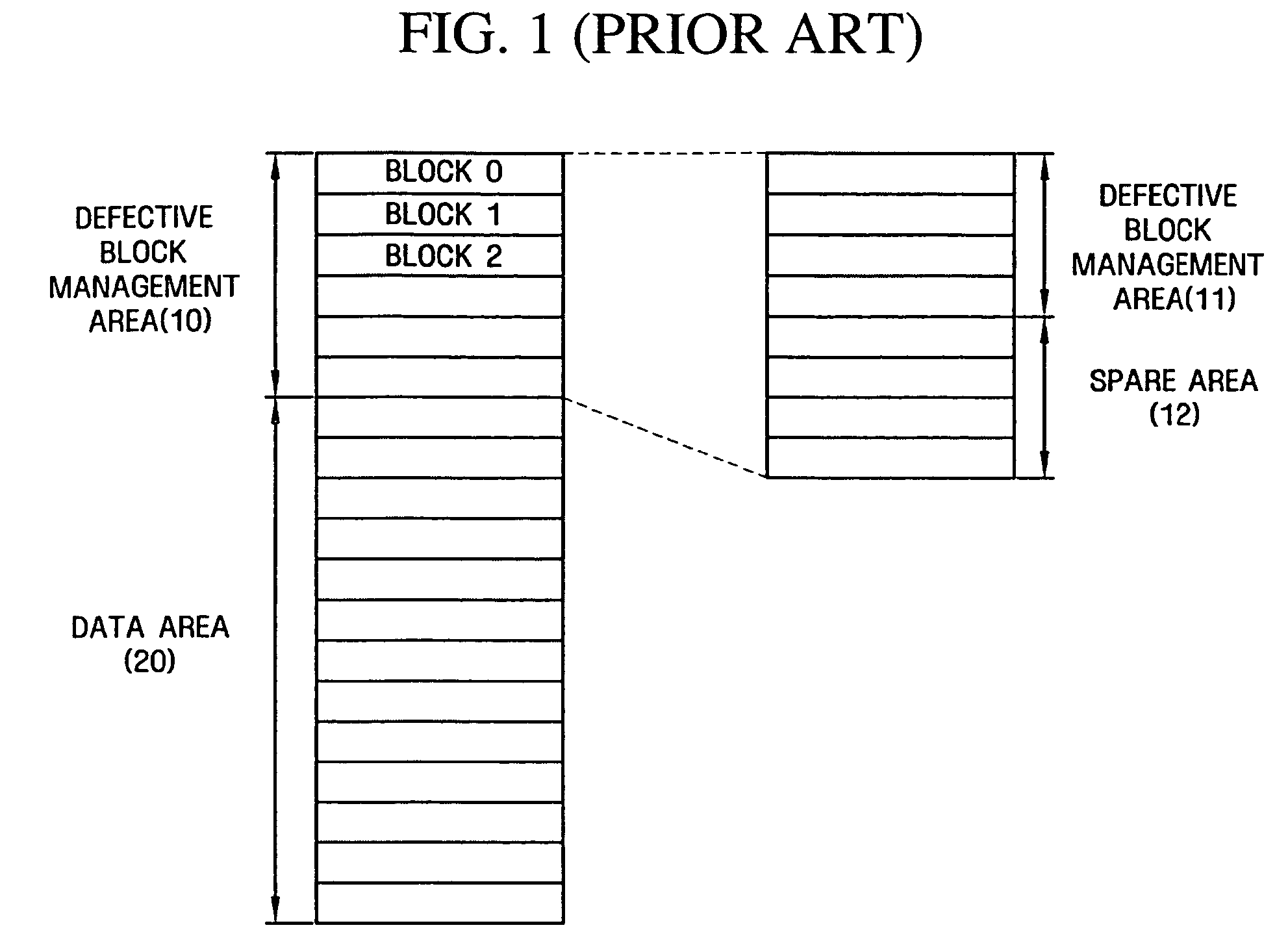

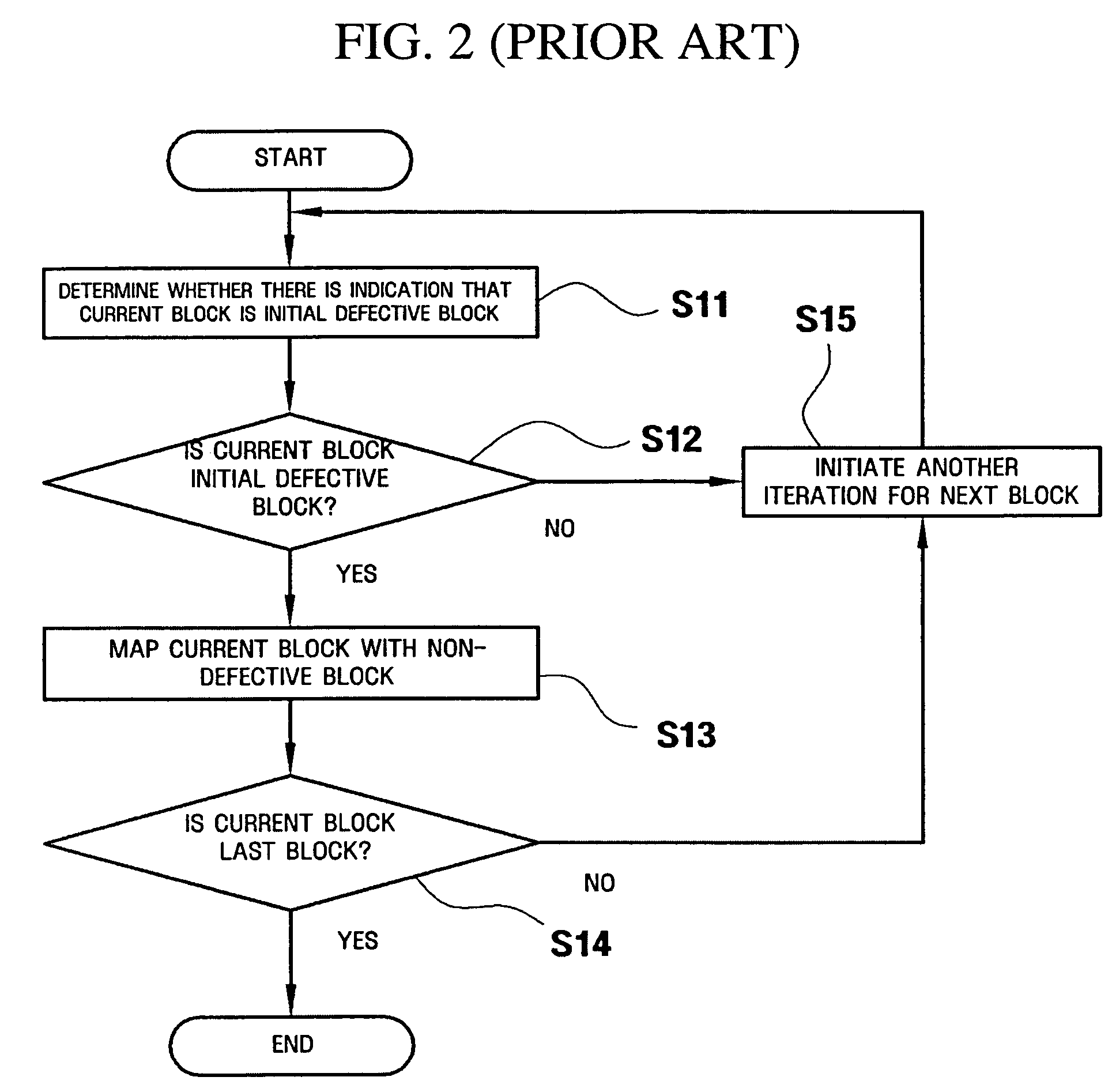

Data management apparatus and method of flash memory

A data management apparatus and method used in a system using one or more flash memories, which can deal with defective blocks in each of the flash memories using different methods depending on how the system manages data stored in each of the flash memories. The data management apparatus includes a device driver, which controls the operation of one or more flash memories, and a controller, which transfers data stored in a defective block of one of the flash memories to a predetermined block in the flash memory.

Owner:SAMSUNG ELECTRONICS CO LTD

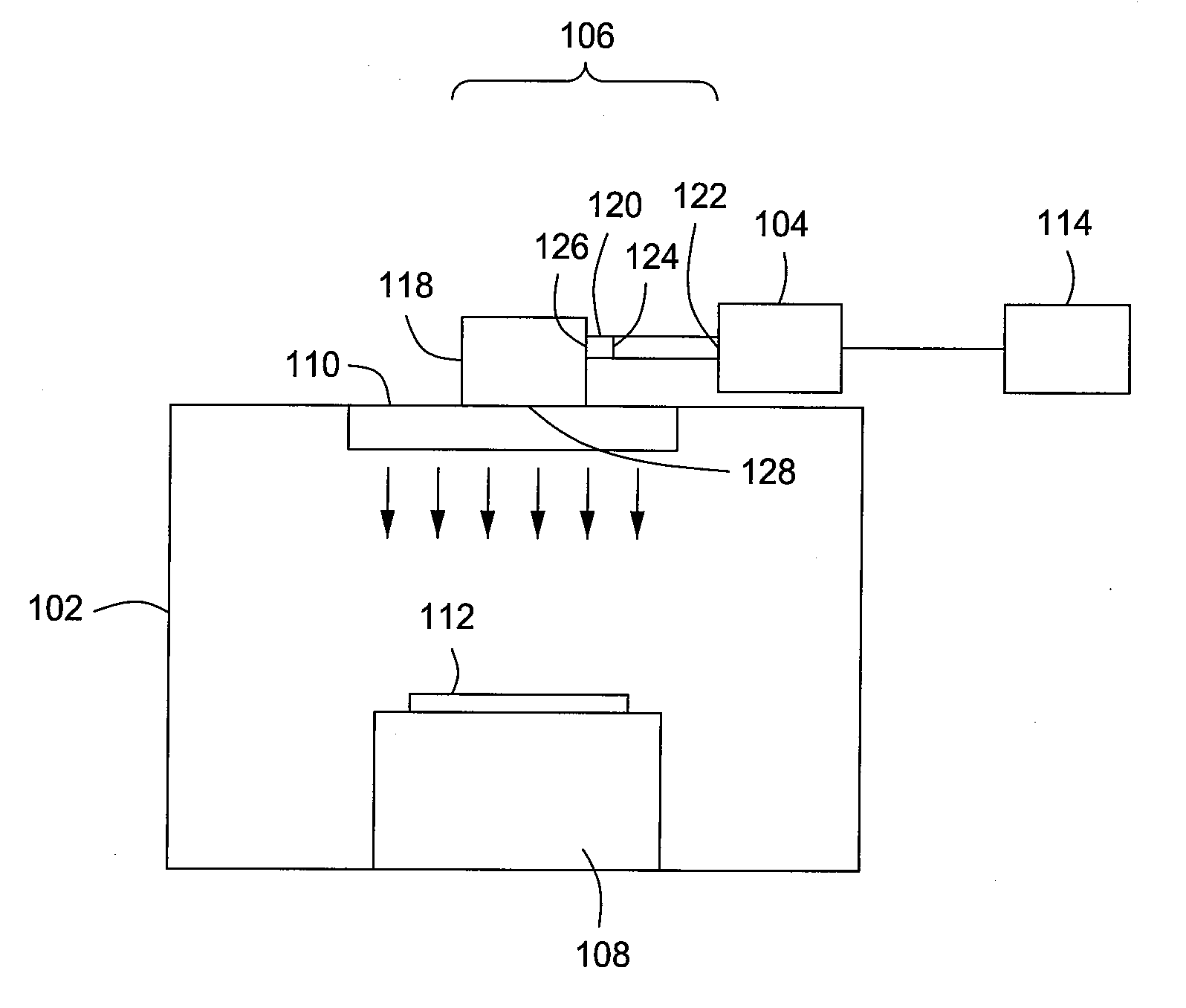

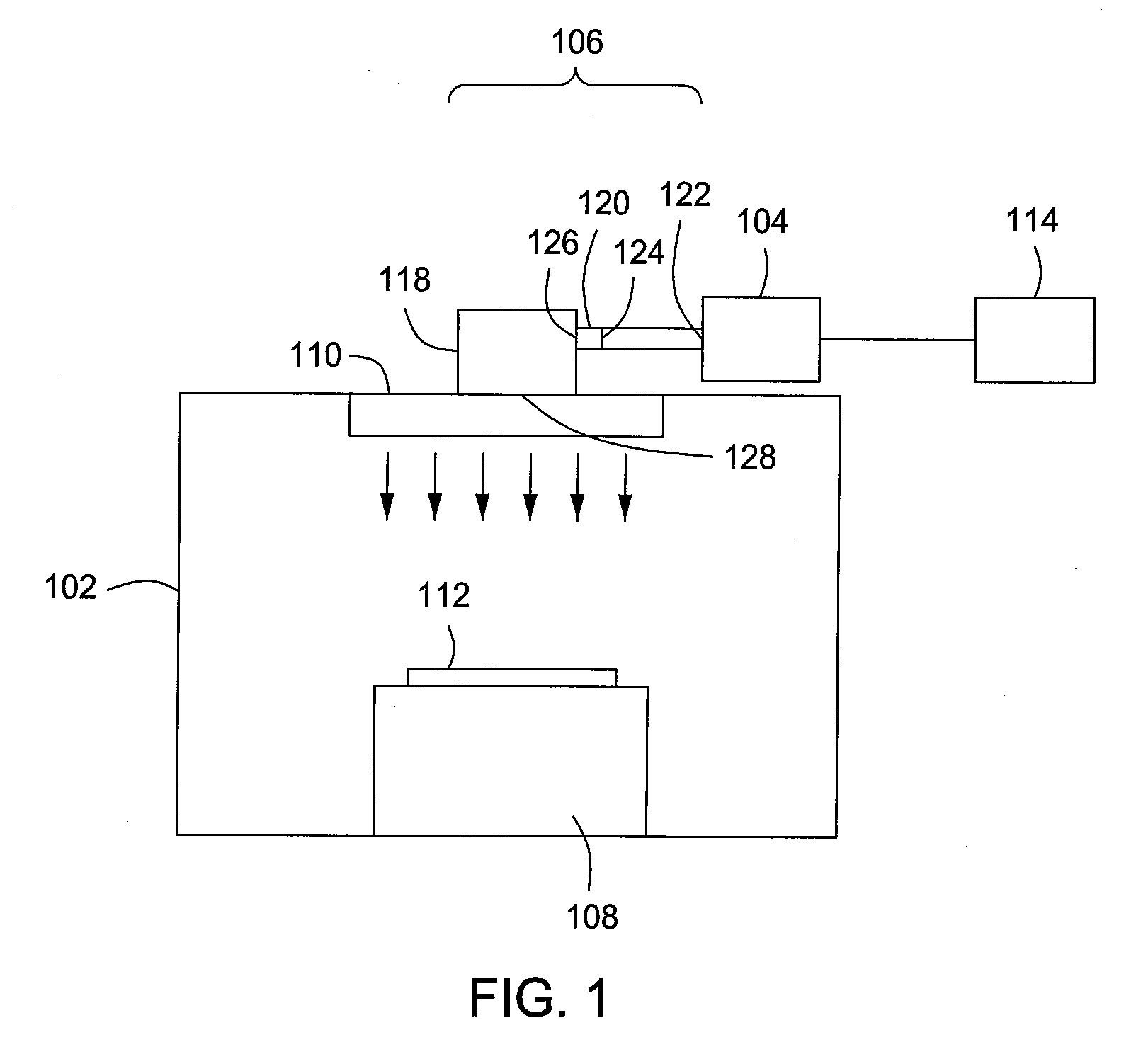

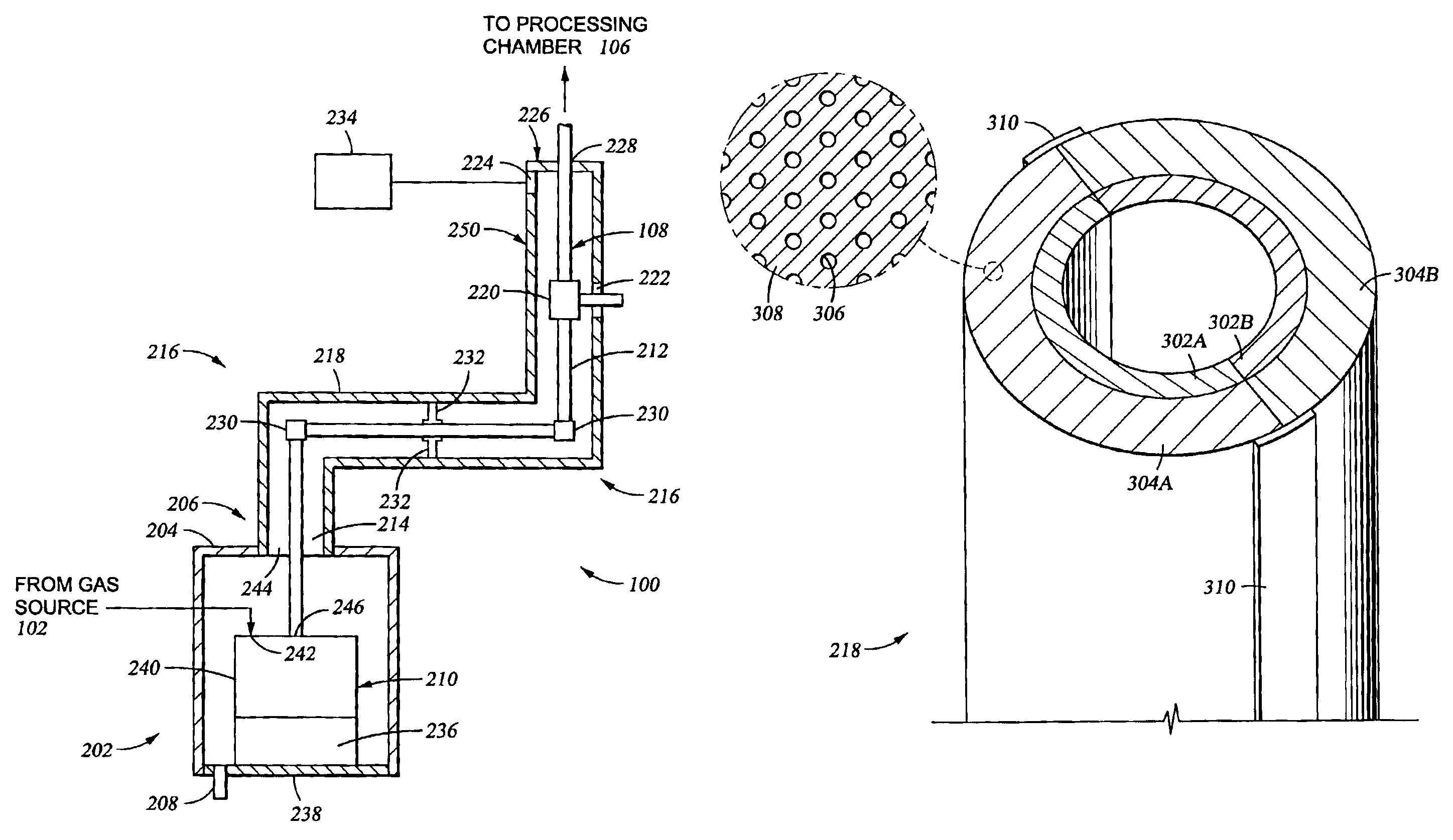

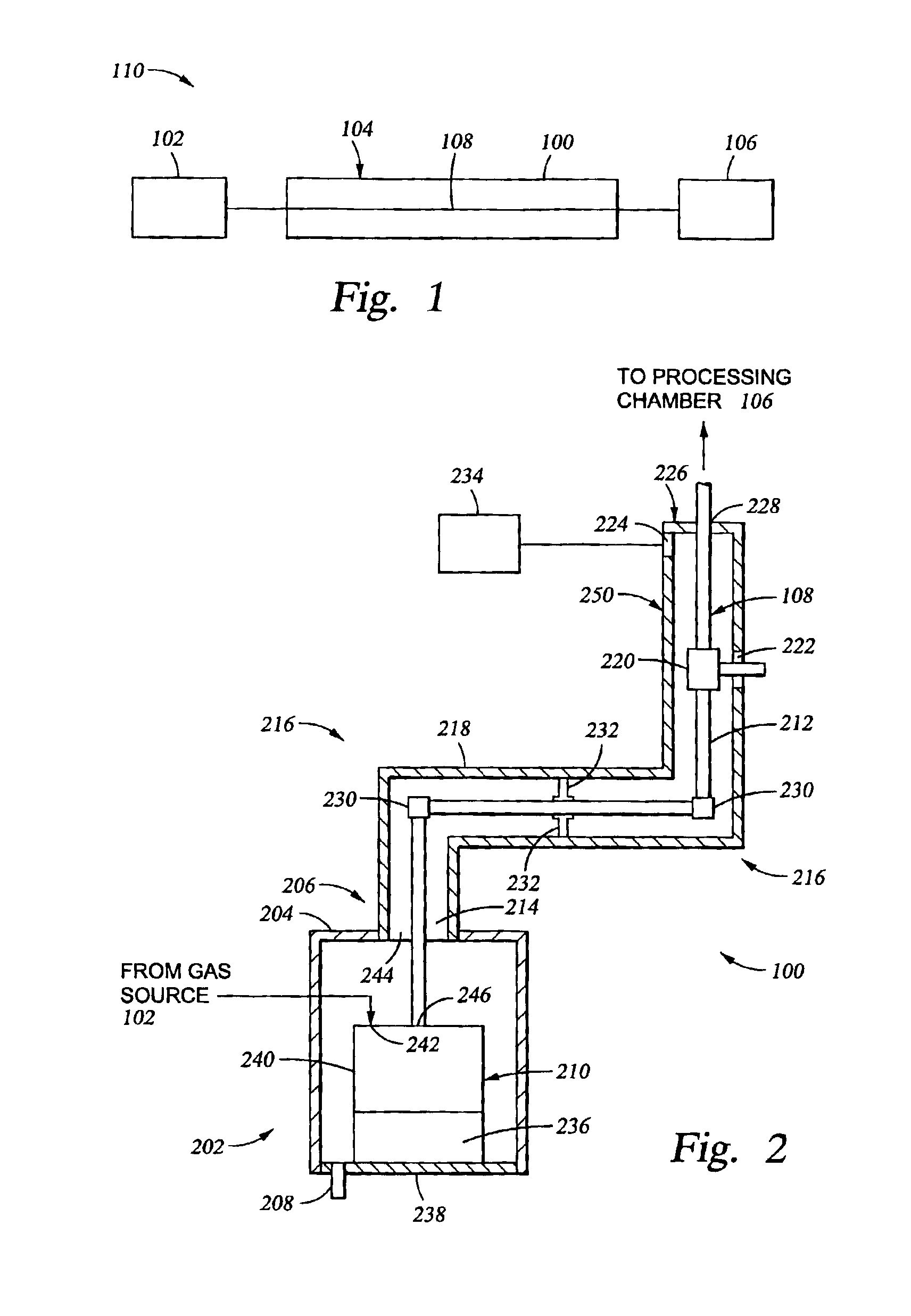

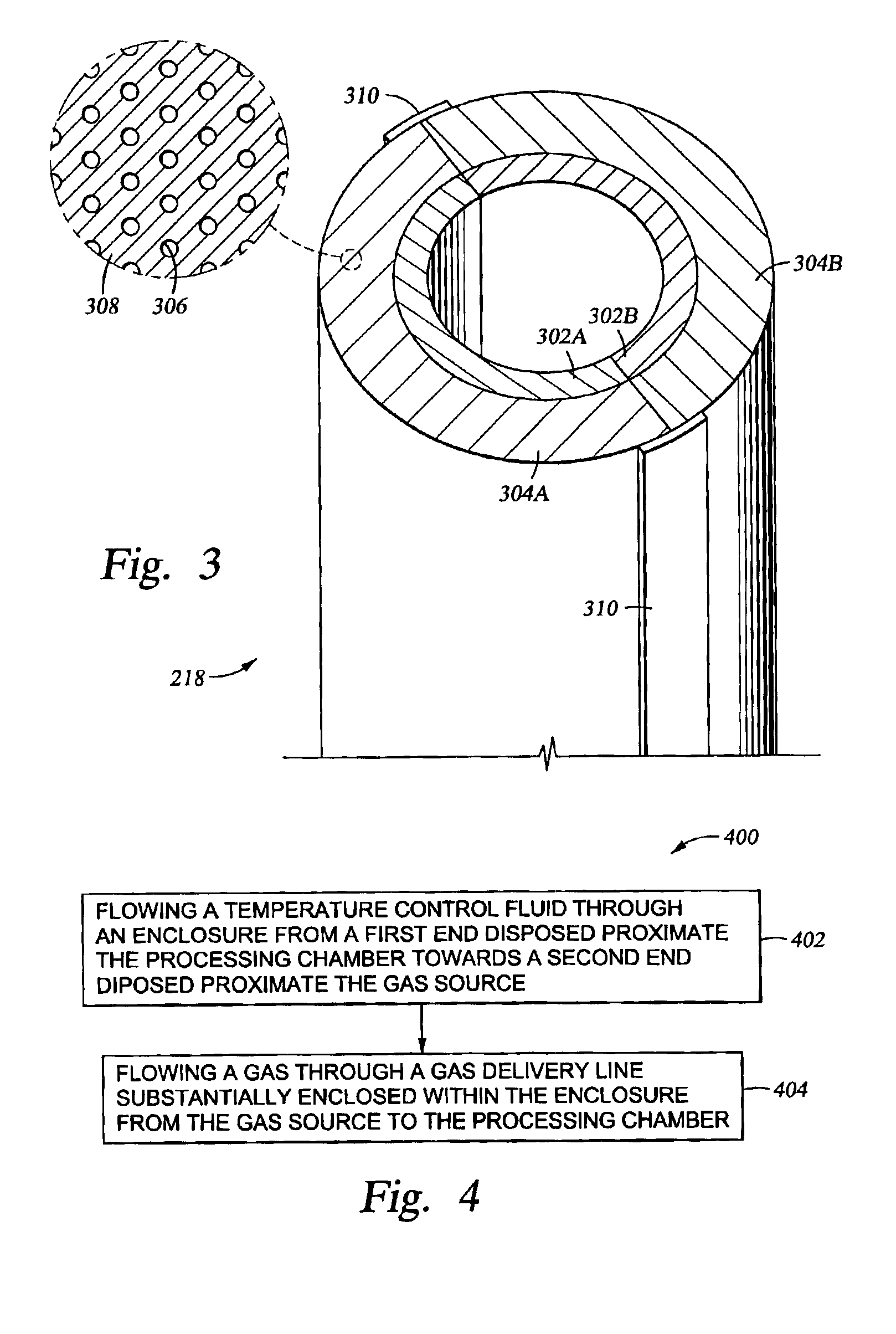

Method and apparatus for gas temperature control in a semiconductor processing system

A method and apparatus for controlling the temperature of at least one gas flowing into a processing chamber is provided. In one embodiment, a gas temperature control apparatus for semiconductor processing includes a gas delivery line coupled between a processing chamber and a gas source. An enclosure substantially encloses the gas delivery line and is adapted to flow a heat transfer fluid away from the processing chamber.

Owner:APPLIED MATERIALS INC

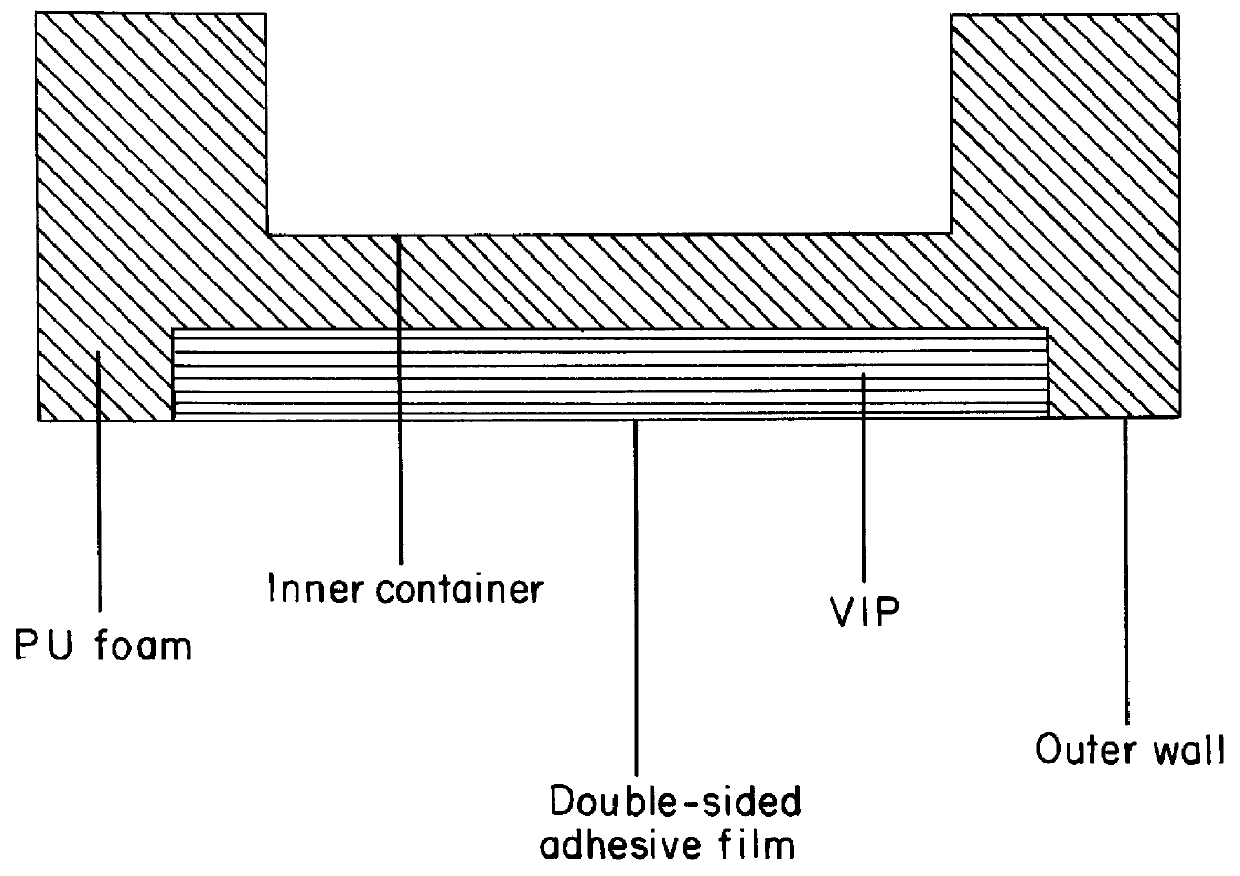

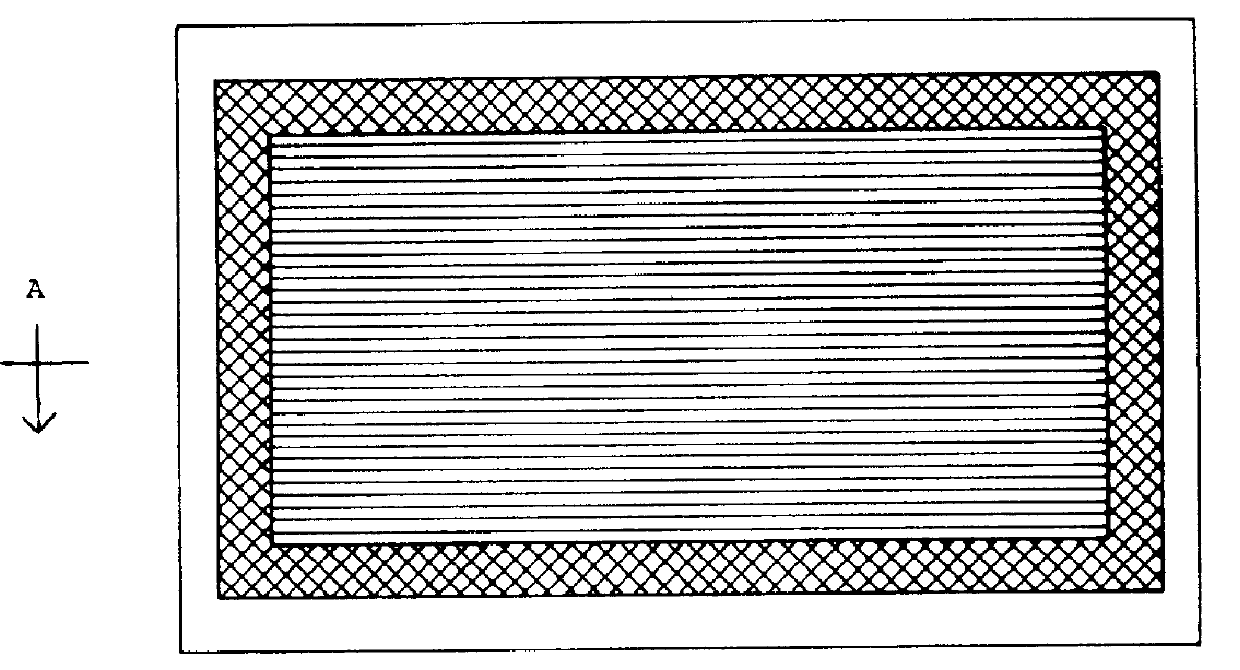

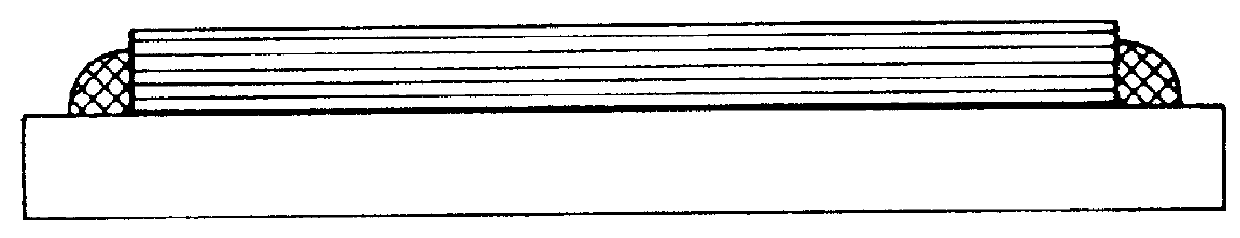

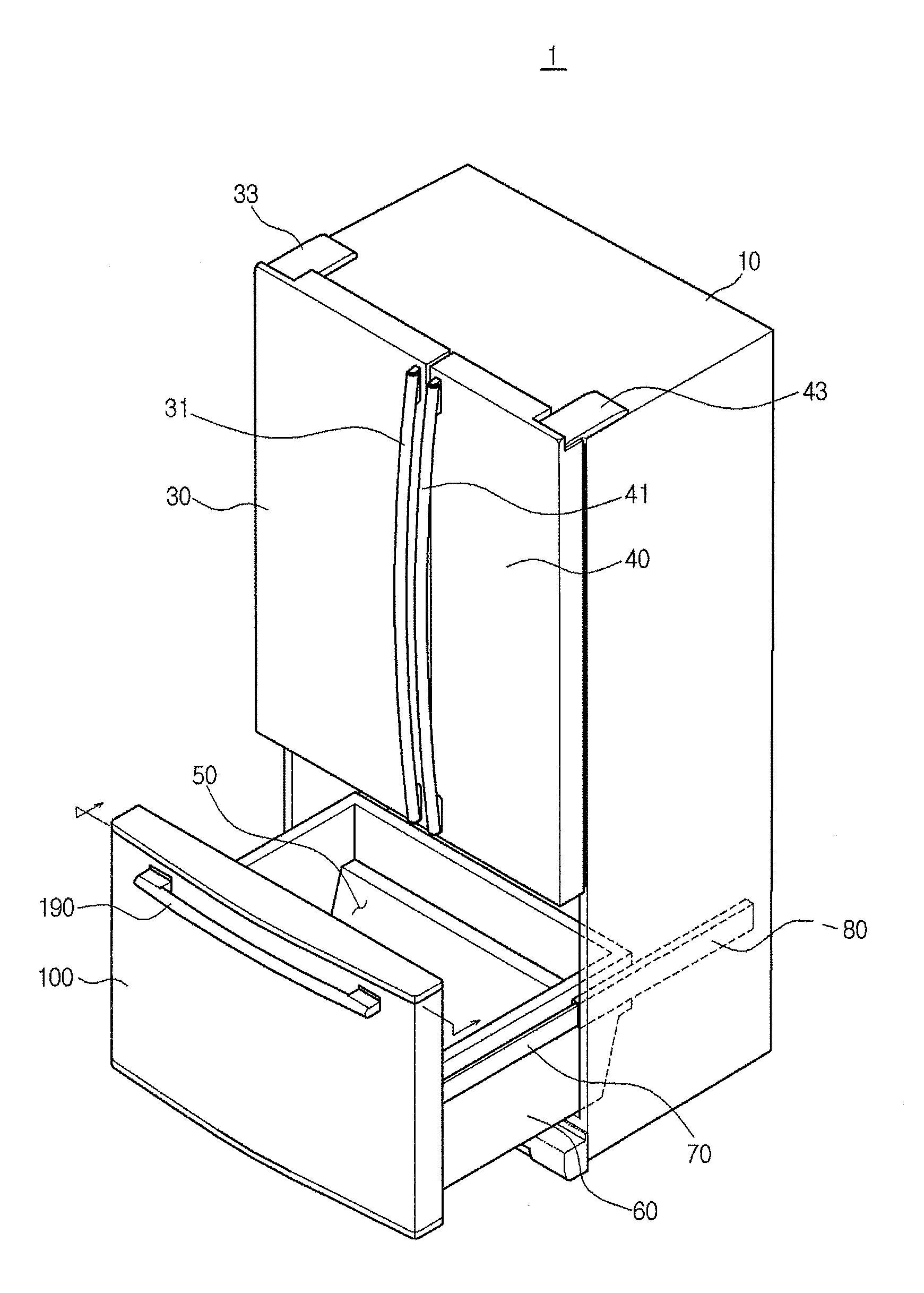

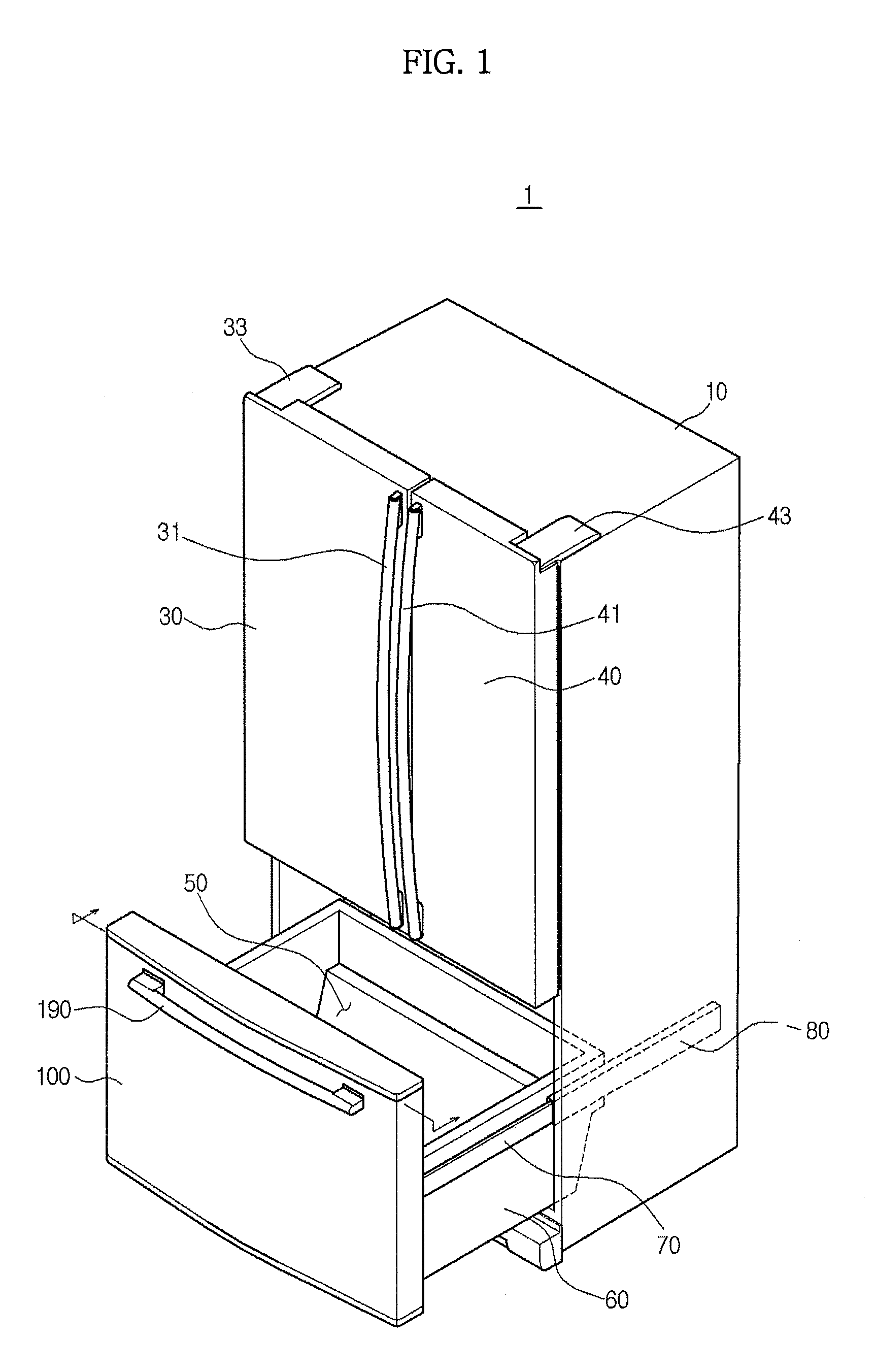

Refrigerator and method of manufacturing door thereof

ActiveUS20130293080A1Prevented from being shakenThermal insulationMetal-working apparatusRefrigerated temperatureElectrical and Electronics engineering

Owner:SAMSUNG ELECTRONICS CO LTD

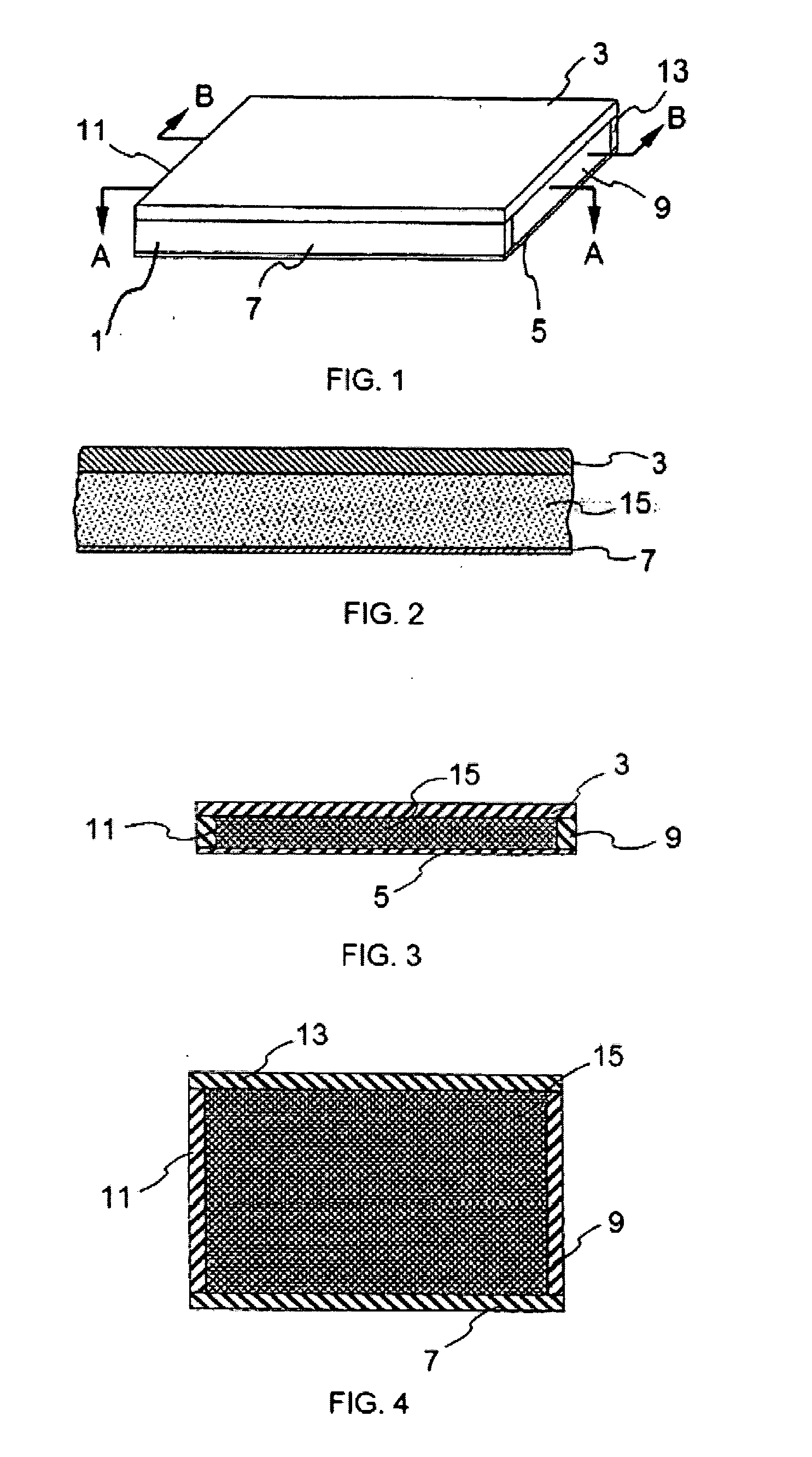

Evacuated Thermal Insulation Panel

InactiveUS20090031659A1Easy accessMaterial nanotechnologyFunctional valve typesThermal insulationWater vapor

A sealed vacuum thermal insulation panel having a thermal barrier that comprises a core made of thermal insulation material and two panel walls made of a barrier material substantially impermeable to atmospheric gases and water vapors. The two panel walls covers opposite sides of the core. The sealed panel further comprises at least one lateral strip of substantially impermeable to atmospheric gases and water vapor. The lateral strip is adapted to sealably enfold the edges of the obverse side of the two panel walls. Additionally, the sealed panel further comprises at least one sealing strip, each comprising sealing material. The sealing strip is adapted to sealably join the edges to the inner side of the lateral strip.

Owner:THERMOVAC LTD

Oil tube with integrated heat shield

A gas turbine engine has an oil tube for delivering oil through a high temperature zone of the engine to an engine component for cooling and lubrication. An insulation tube surrounds the oil tube and extends in a substantial length of the oil tube. The opposed ends of the insulation tube are integrally and sealingly connected to respective end portions of the oil tube to form a dead air annulus between the oil tube and the insulation tube.

Owner:PRATT & WHITNEY CANADA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com