Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43009results about "Silencing apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

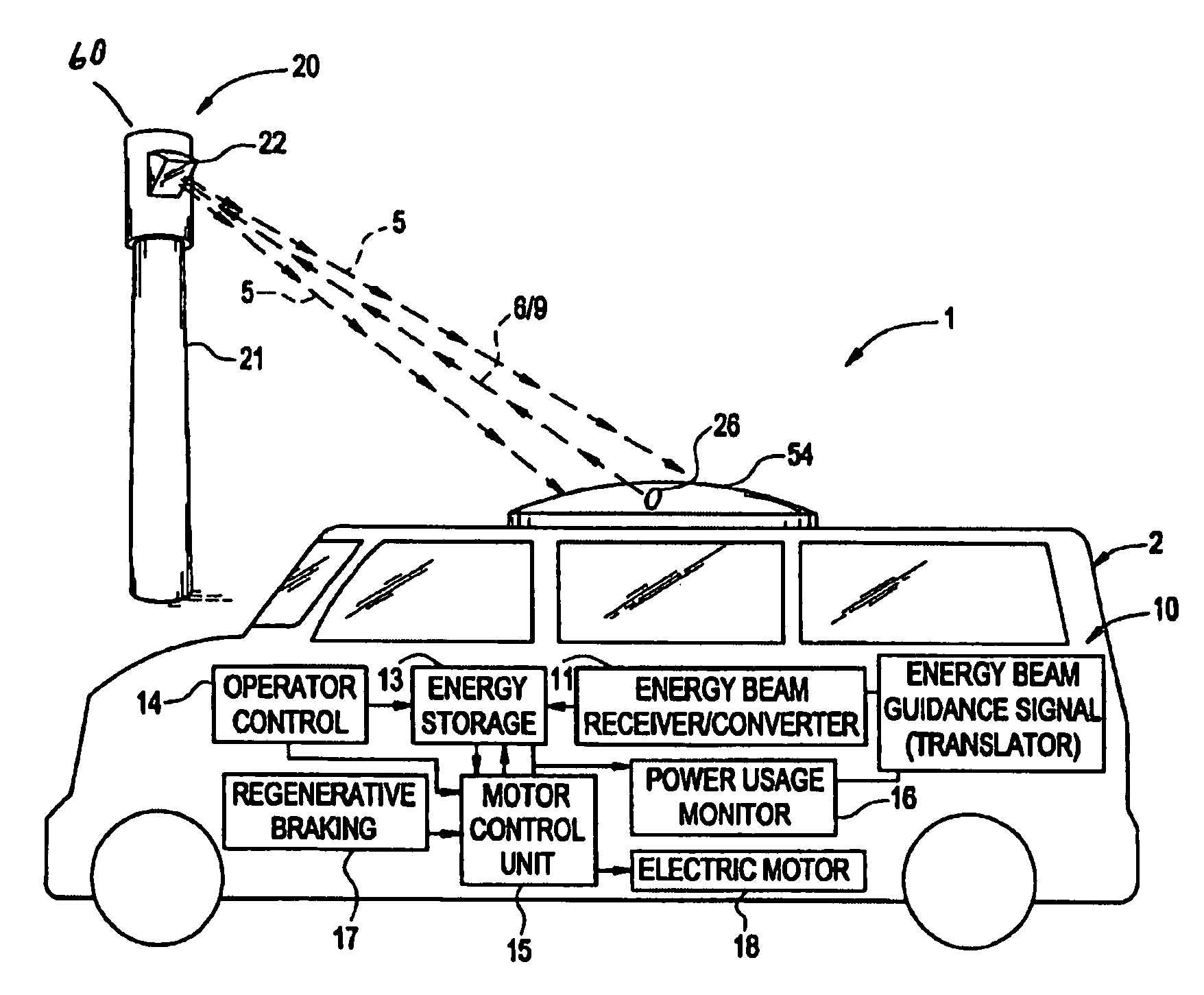

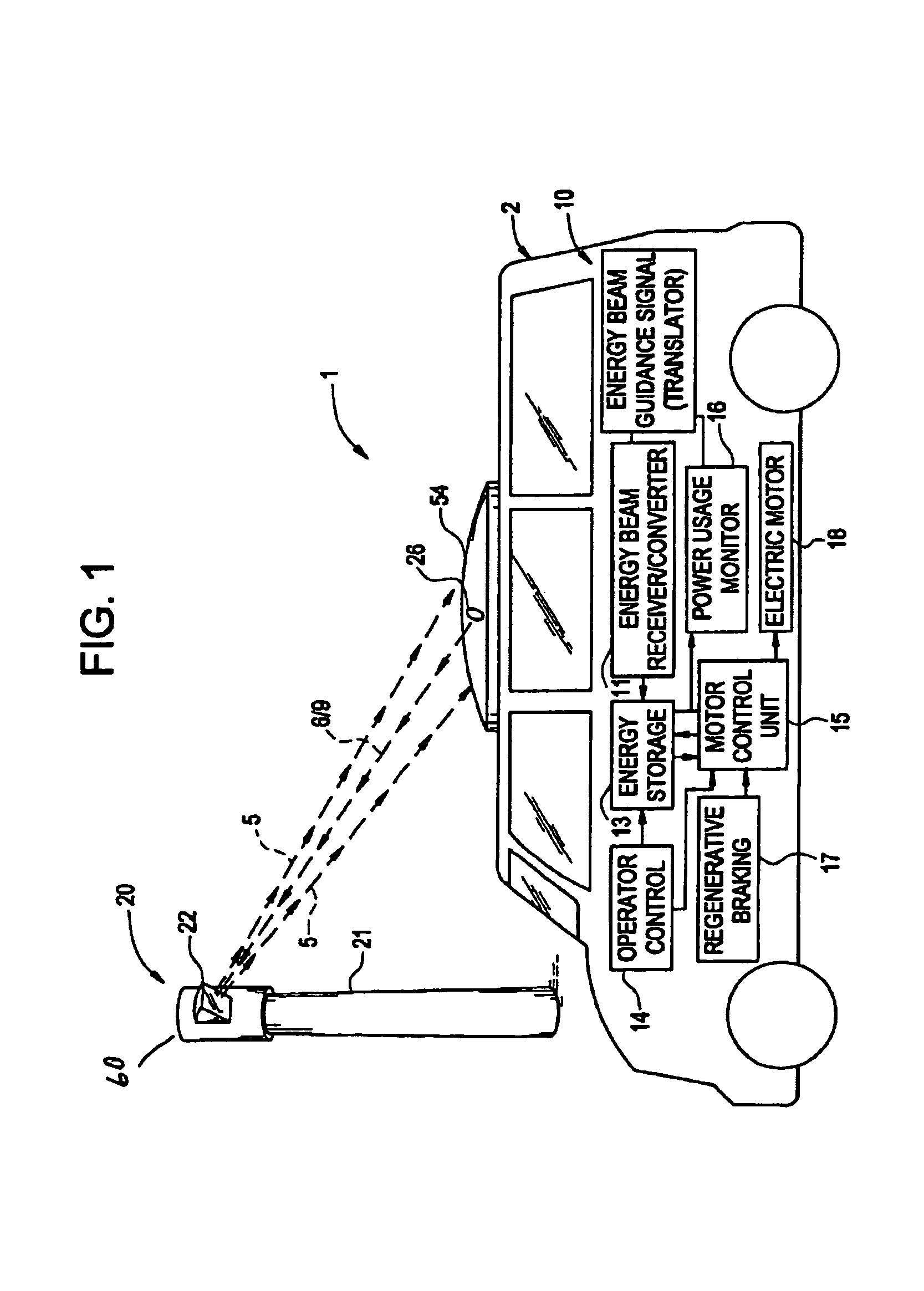

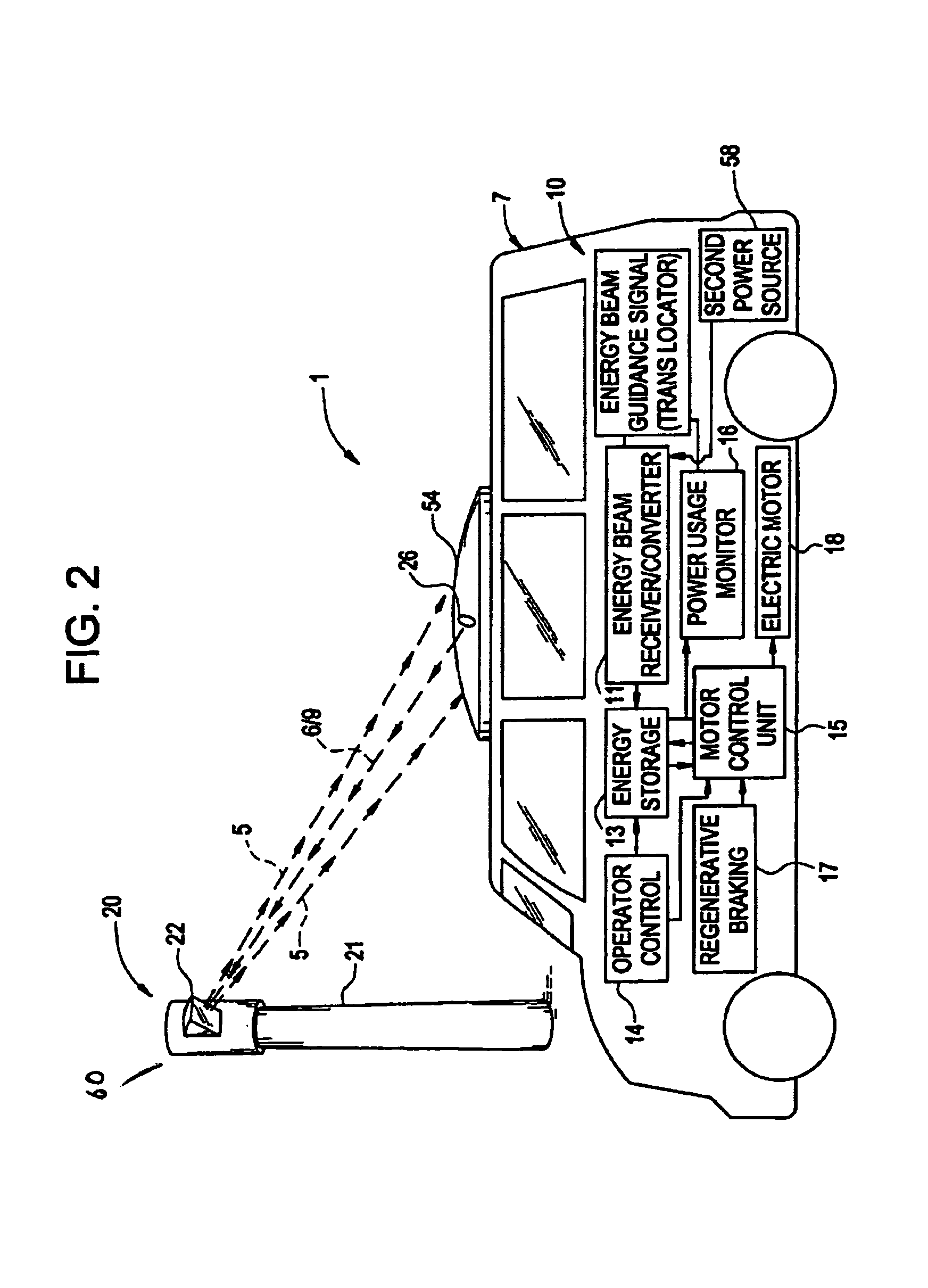

Remote power recharge for electronic equipment

InactiveUS7068991B2Batteries circuit arrangementsInternal combustion piston enginesElectric power transmissionElectrical conductor

A conductorless charging and power system for electronic appliances and method for communicating power to a power receiver employing wireless energy transmission are disclosed. The remote charging system includes a power transmission unit, which transmits energy as a directional power beam, and a power receiver system that receives the transmitted energy. The power receiver system is preferably incorporated in an appliance and includes an energy receptor capable of receiving the wireless power beam and transferring the energy from the beam to an energy storage device included in the appliance. The power transmission unit receives and tracks a power request signal from the power receiver system to track the power receiver system location during energy transmission. Data streams may be incorporated into the wireless signals of the remote charging system, allowing the remote charging system to function as a communications pathway as well as a power delivery system.

Owner:PARISE RONALD J

Pt-Pd diesel oxidation catalyst with CO/HC light-off and HC storage function

ActiveUS20080045405A1Nitrous oxide captureMolecular sieve catalystsExhaust gas emissionsNitrogen oxide

The present invention is directed to a diesel oxidation catalyst for the treatment of exhaust gas emissions, such as the oxidation of unburned hydrocarbons (HC), and carbon monoxide (CO) and the reduction of nitrogen oxides (NOx). More particularly, the present invention is directed to a novel washcoat composition comprising two distinct washcoat layers containing two distinctly different ratios of Pt:Pd.

Owner:BASF CATALYSTS LLC

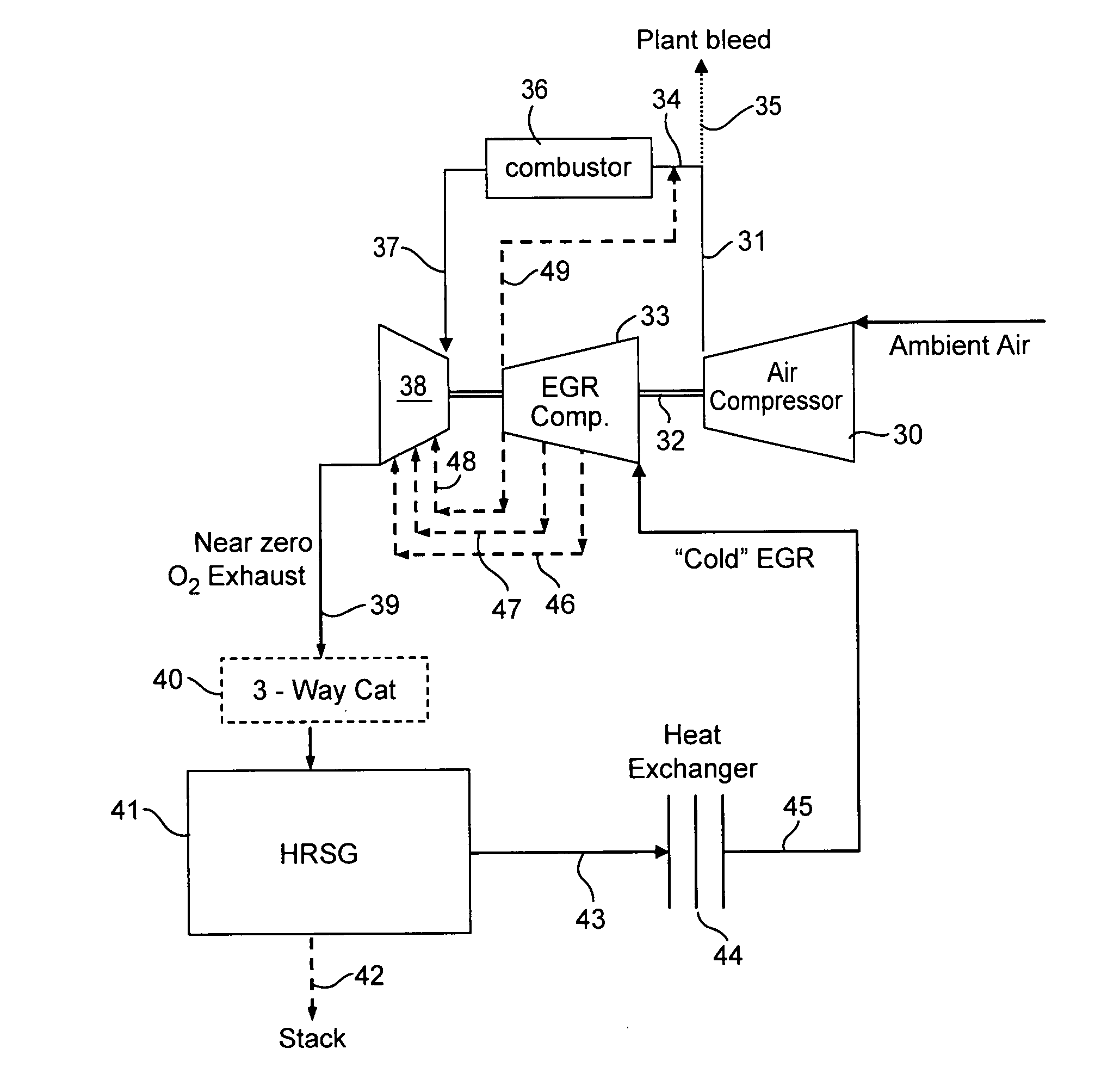

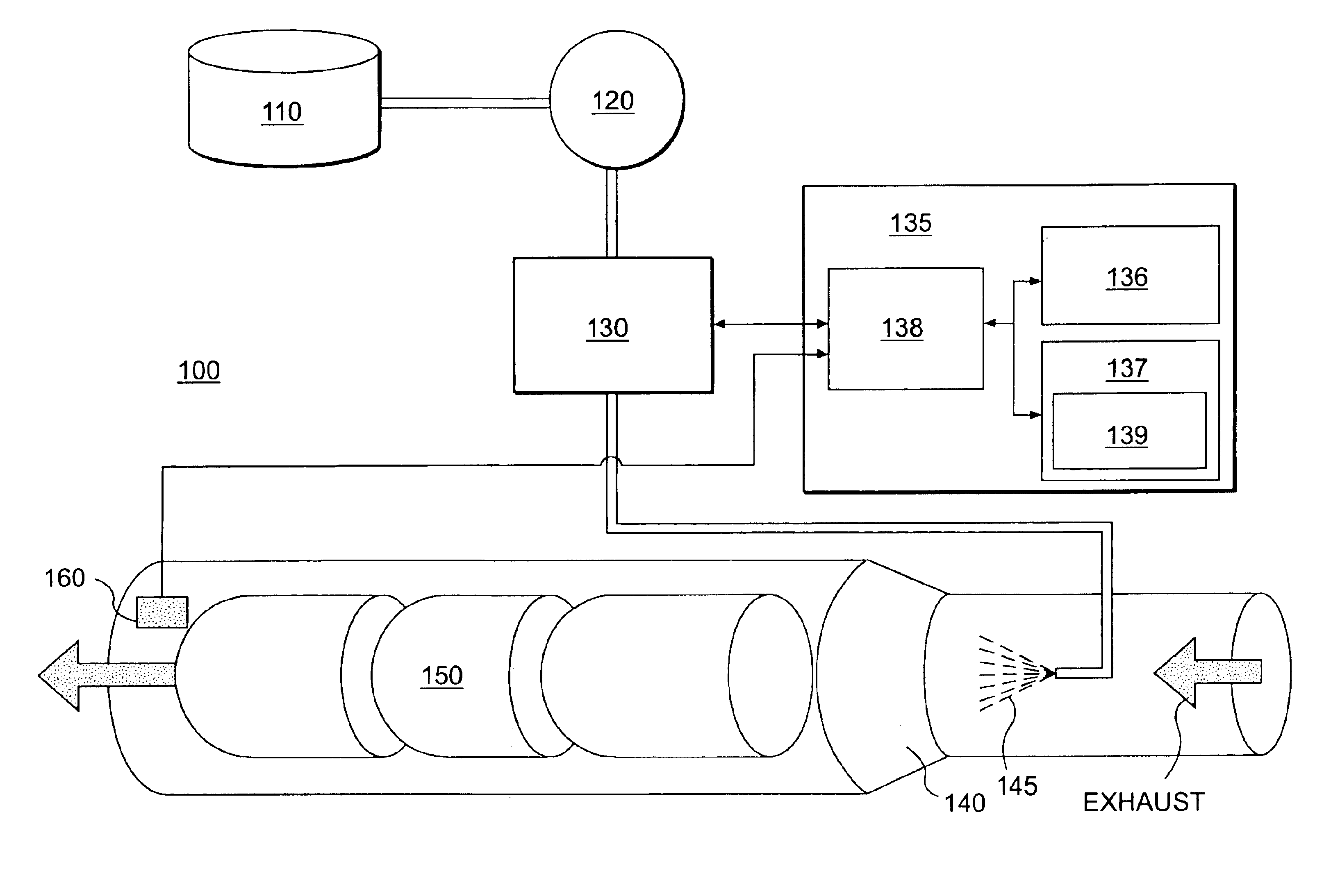

Dry 3-way catalytic reduction of gas turbine NOx

ActiveUS20090284013A1Reduction in amount of NOxIncrease carbon dioxide concentrationInternal combustion piston enginesExhaust apparatusCombustion chamberGas compressor

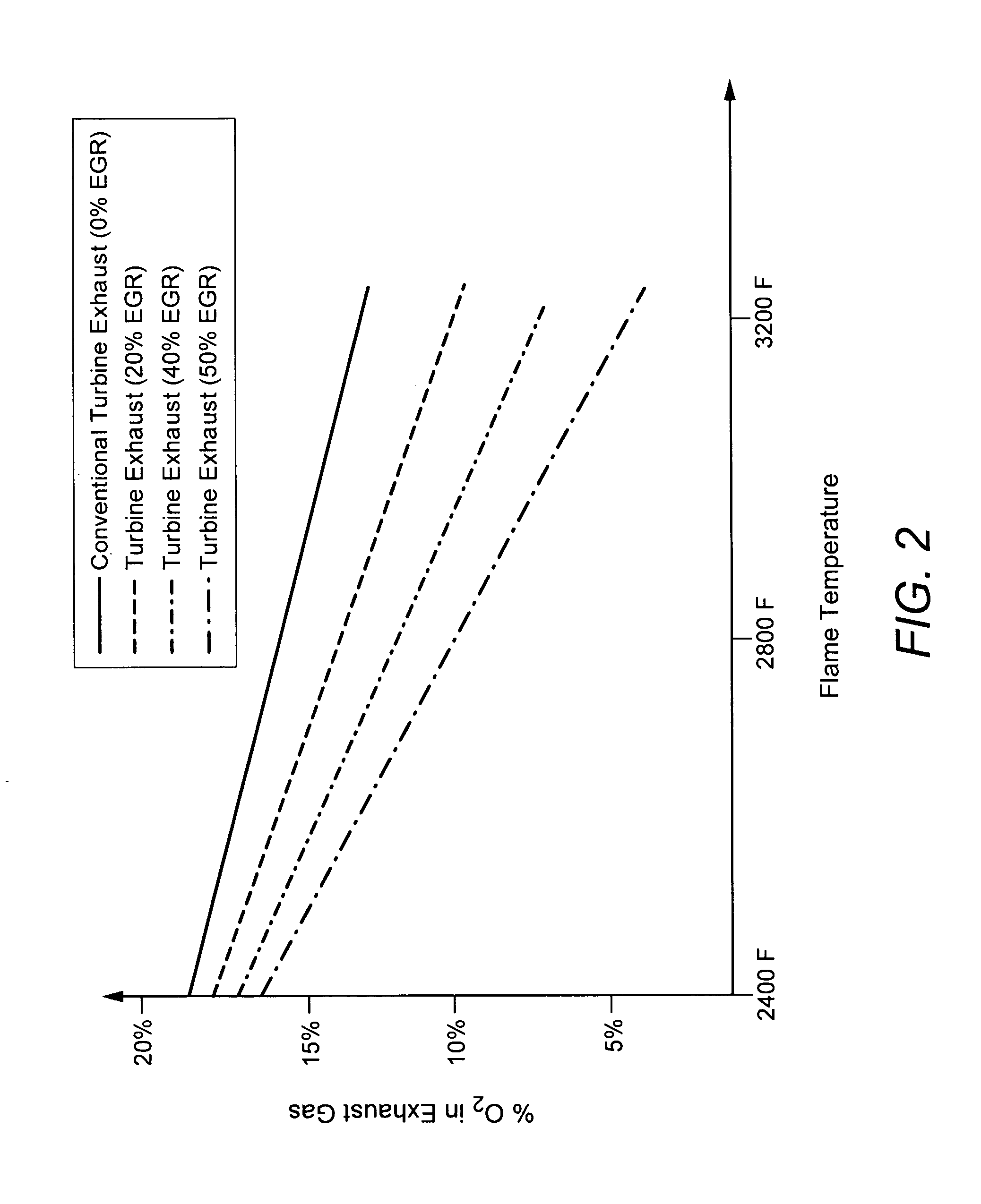

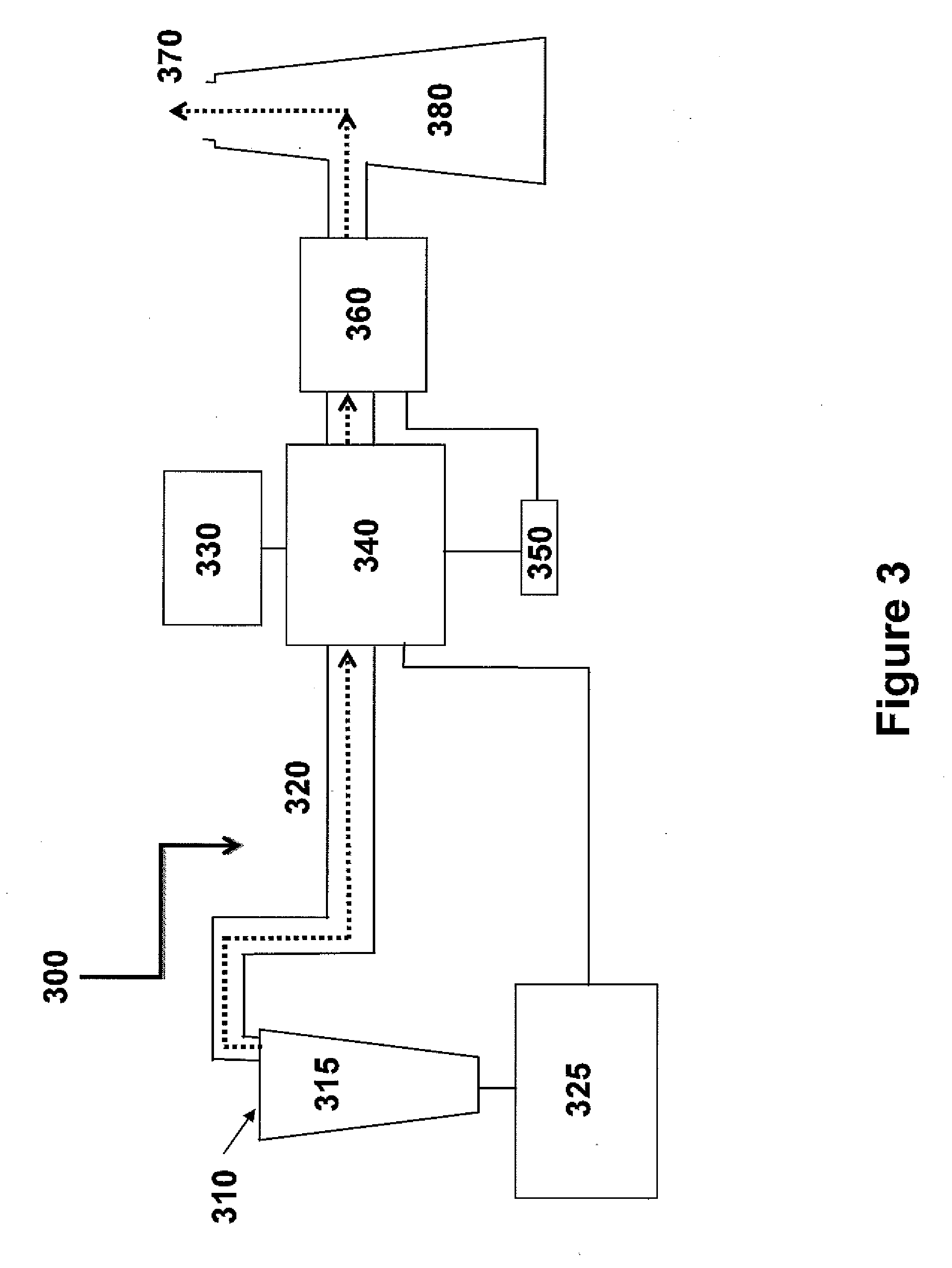

A power generation system capable of eliminating NO, components in the exhaust gas by using a 3-way catalyst, comprising a gas compressor to increase the pressure of ambient air fed to the system; a combustor capable of oxidizing a mixture of fuel and compressed air to generate an expanded, high temperature exhaust gas; a gas turbine engine that uses the force of the high temperature gas; an exhaust gas recycle (EGR) stream back to the combustor; a 3-way catalytic reactor downstream of the gas turbine engine outlet which treats the exhaust gas stream to remove substantially all of the NOx components; a heat recovery steam generator (HRSG); an EGR compressor; and an electrical generator.

Owner:GENERAL ELECTRIC CO

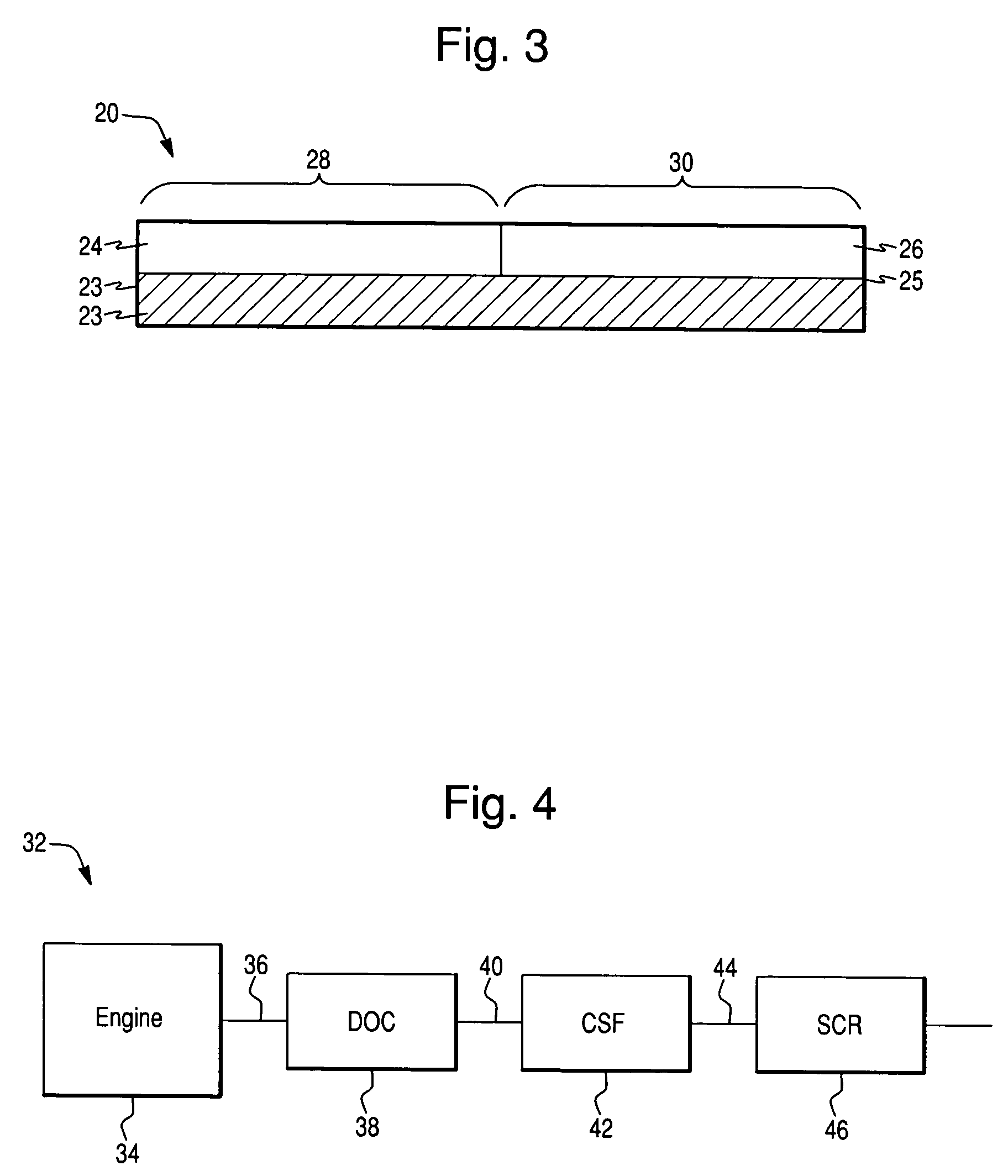

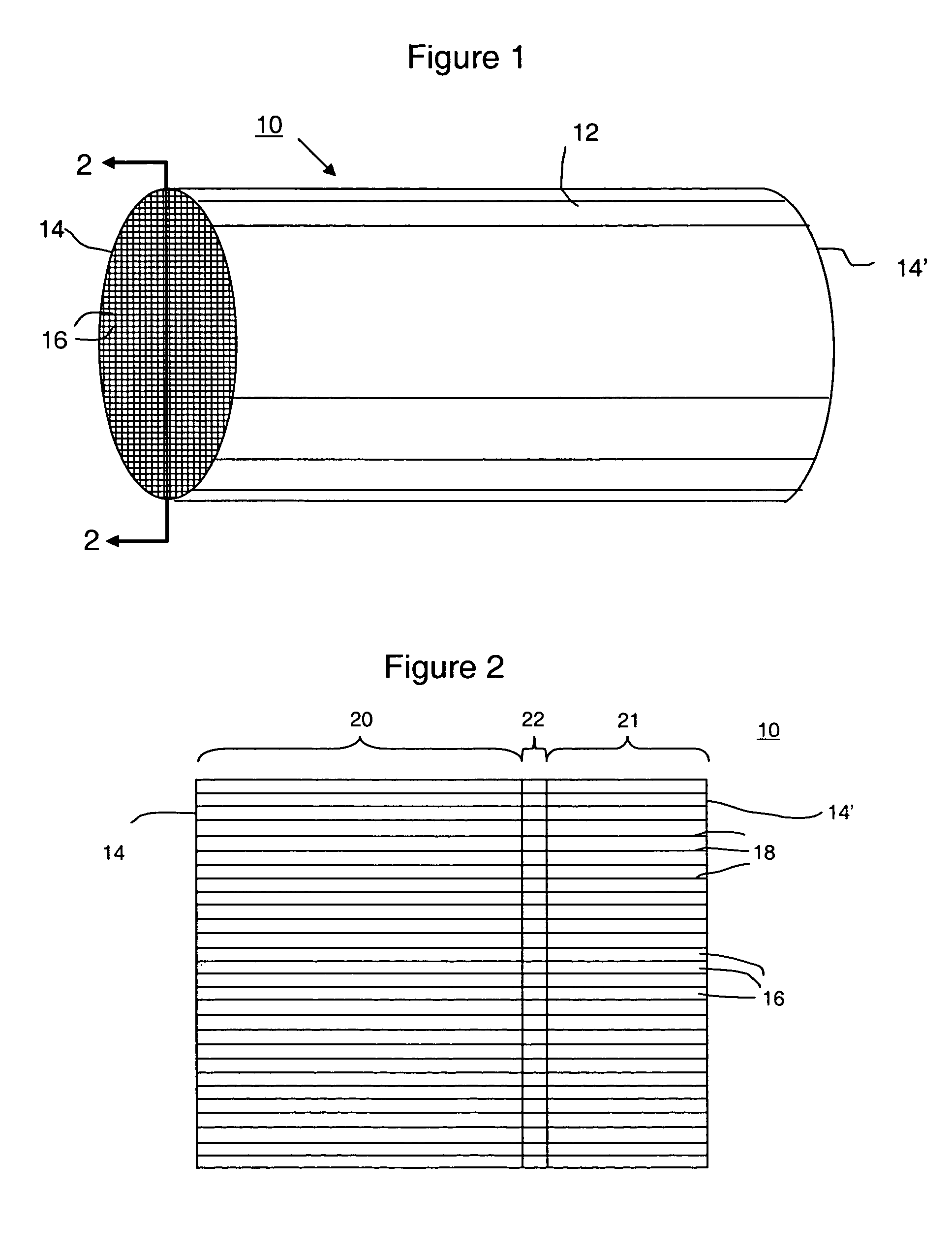

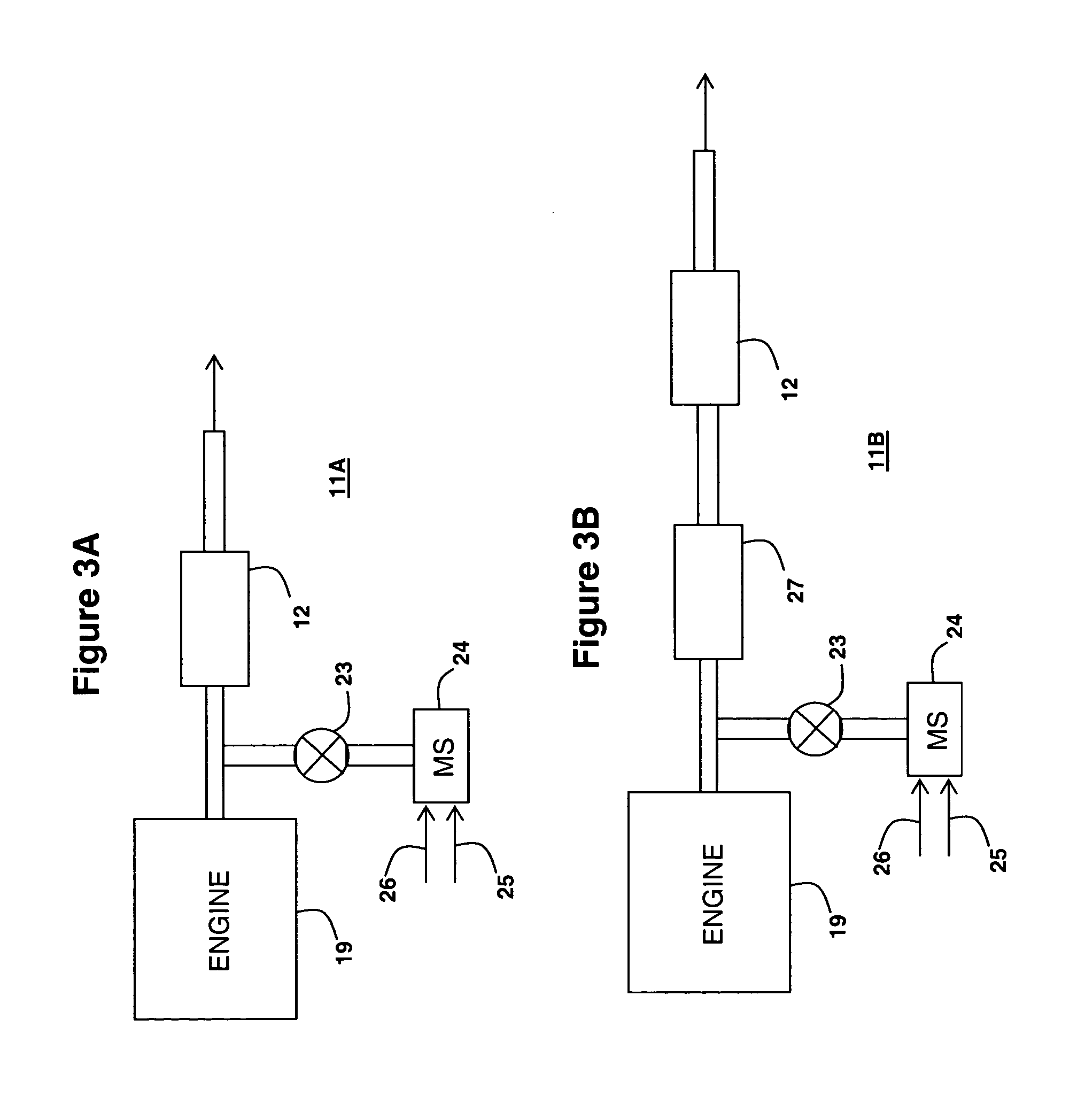

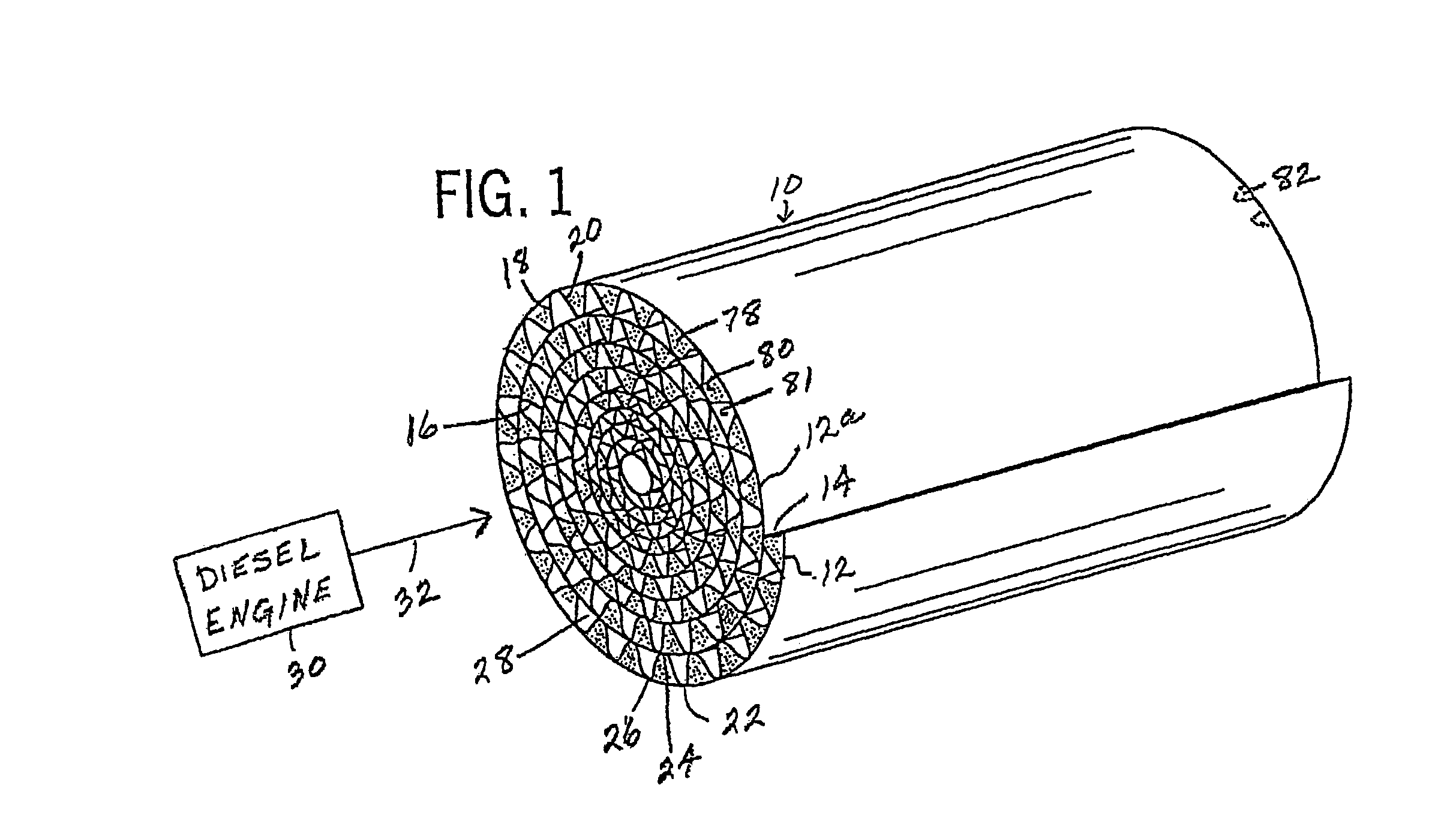

Catalyzed SCR filter and emission treatment system

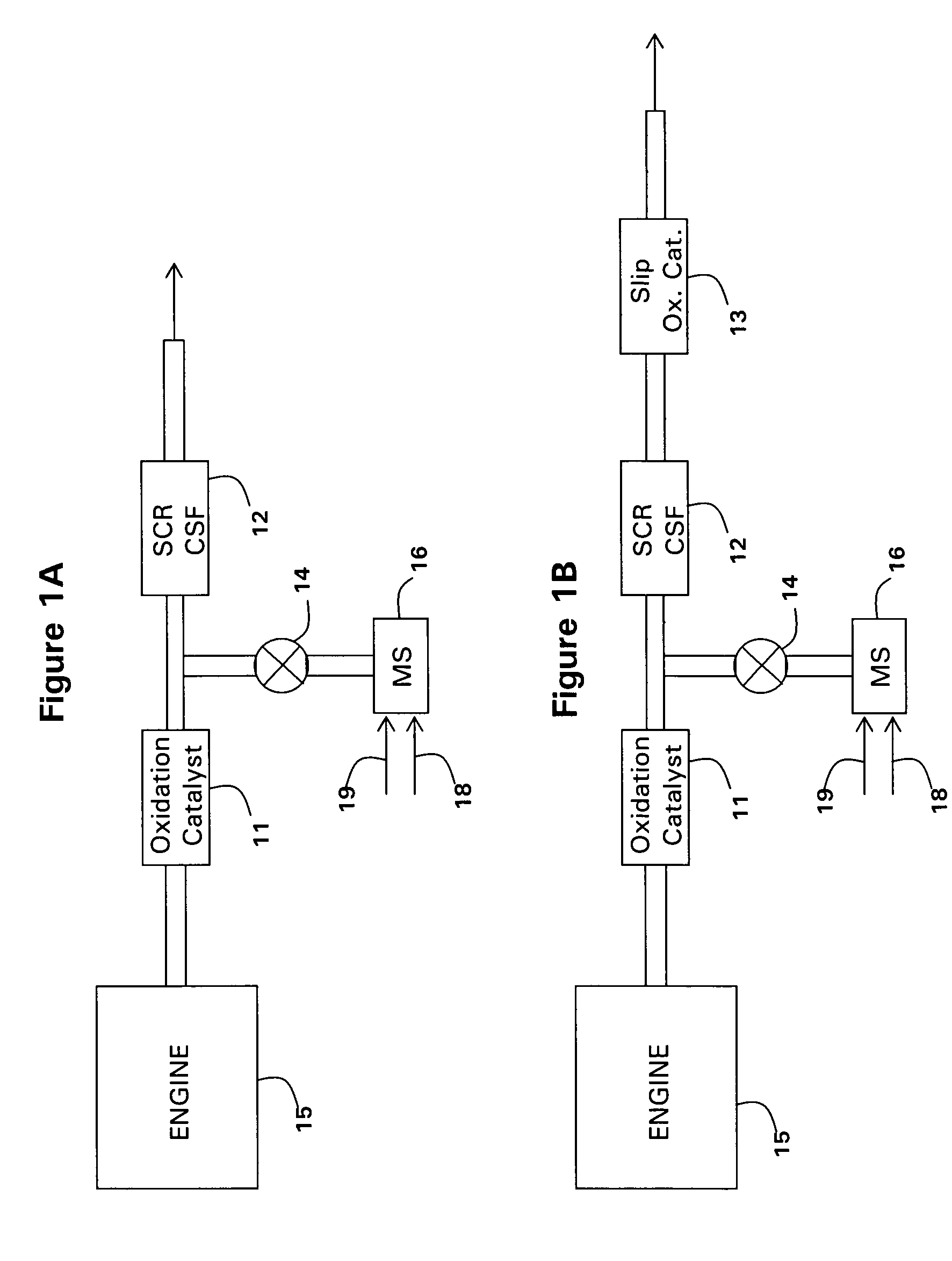

ActiveUS7229597B2Reduce the temperaturePromote regenerationCombination devicesLiquid degasification with auxillary substancesNitrogen oxideSoot

Provided is an emission treatment system and method for simultaneously remediating the nitrogen oxides (NOx), particulate matter, and gaseous hydrocarbons present in diesel engine exhaust streams. The emission treatment system has an oxidation catalyst upstream of a soot filter coated with a material effective in the Selective Catalytic Reduction (SCR) of NOx by a reductant, e.g., ammonia. Also provided is a method for disposing an SCR catalyst composition on a wall flow monolith that provides adequate catalyst loading, but does not result in unsuitable back pressures in the exhaust.

Owner:BASF CORP

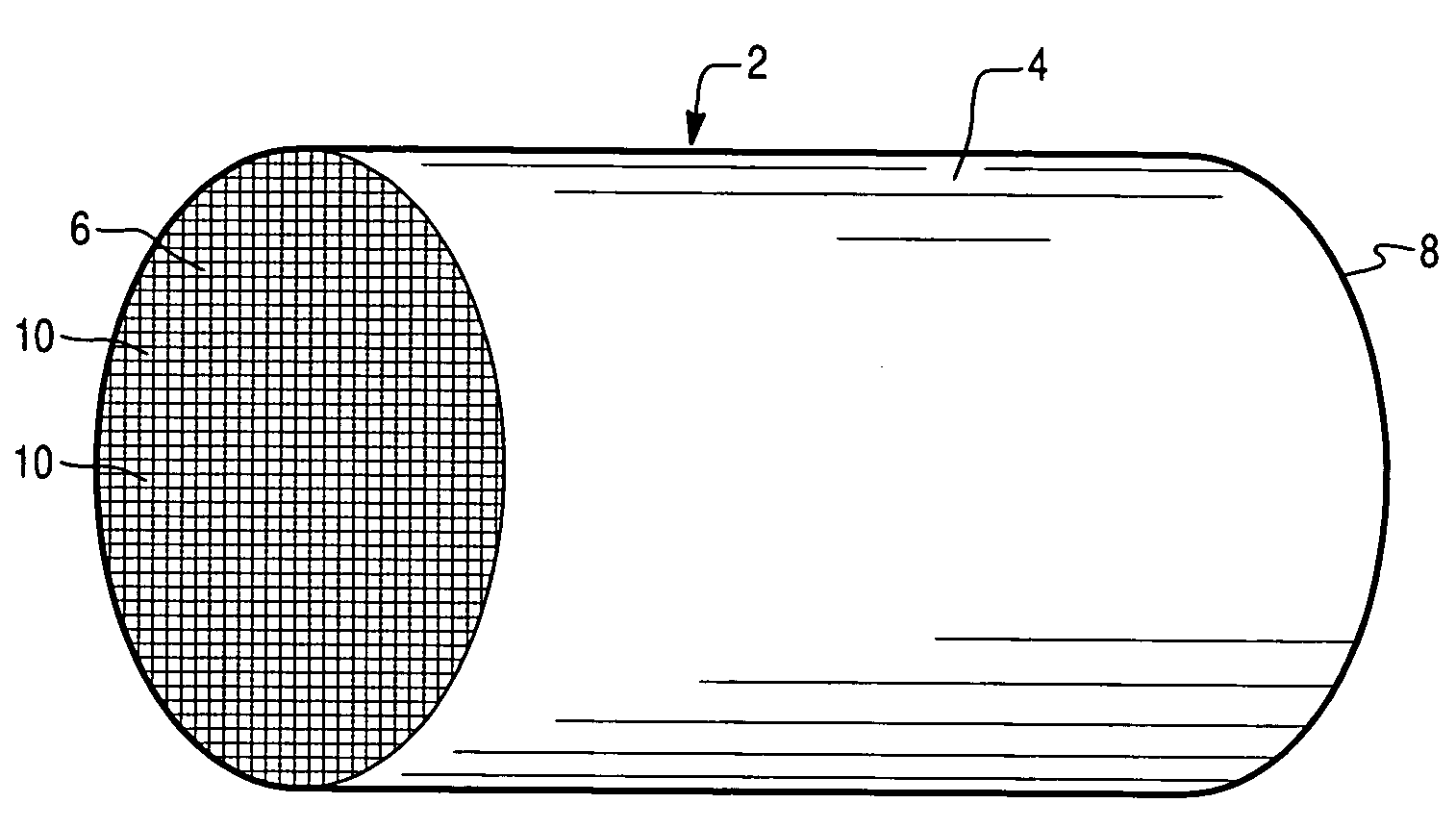

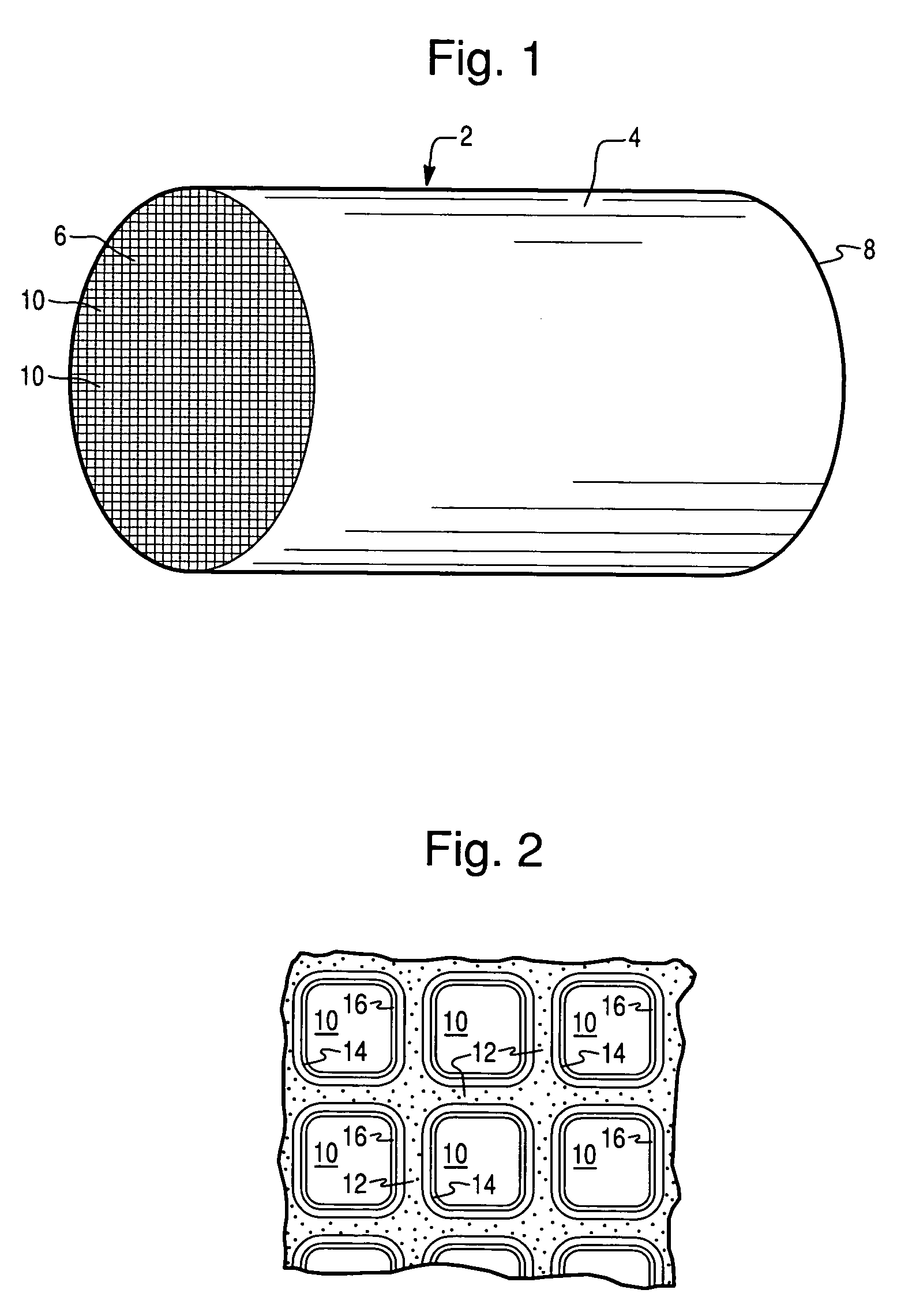

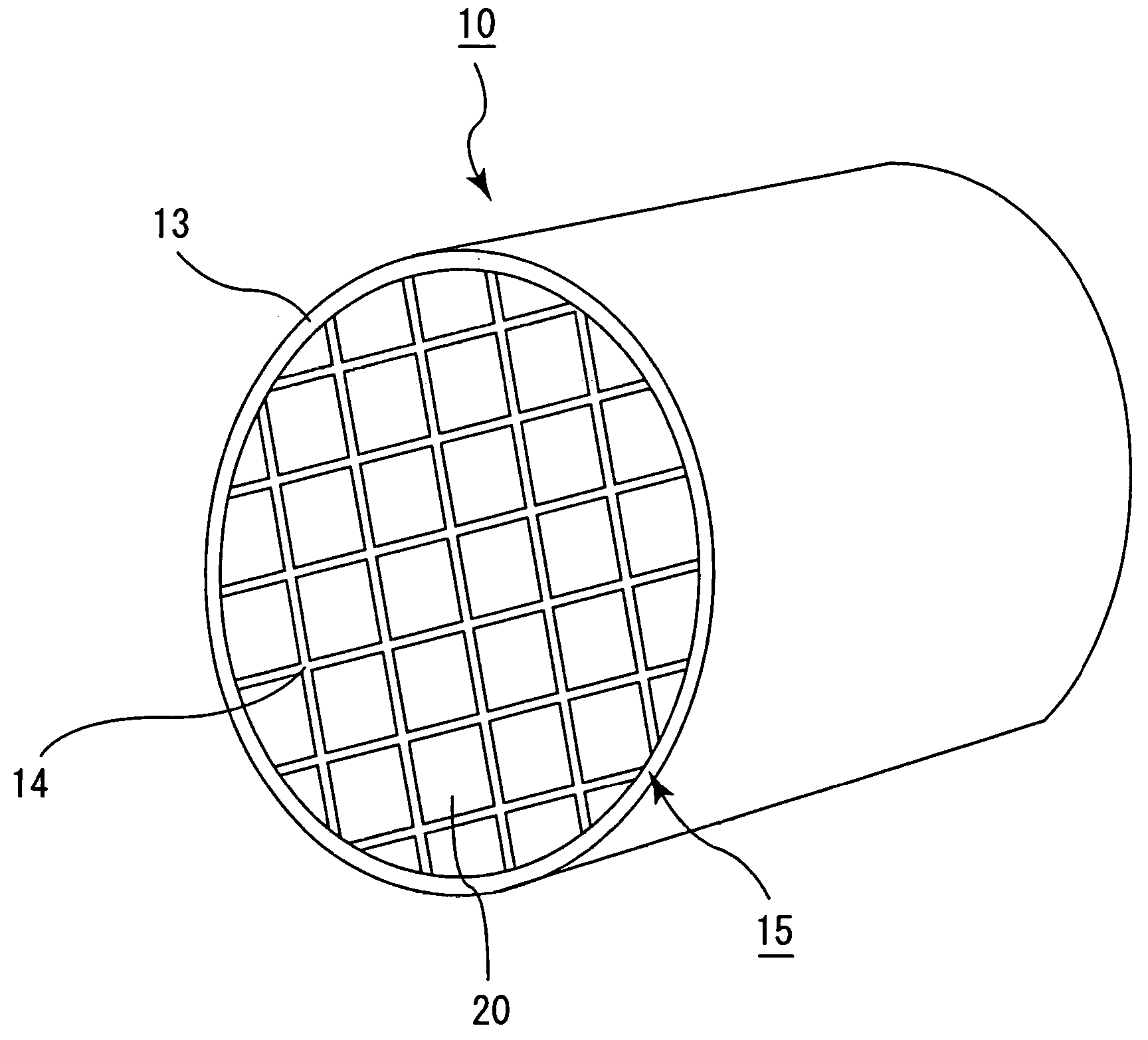

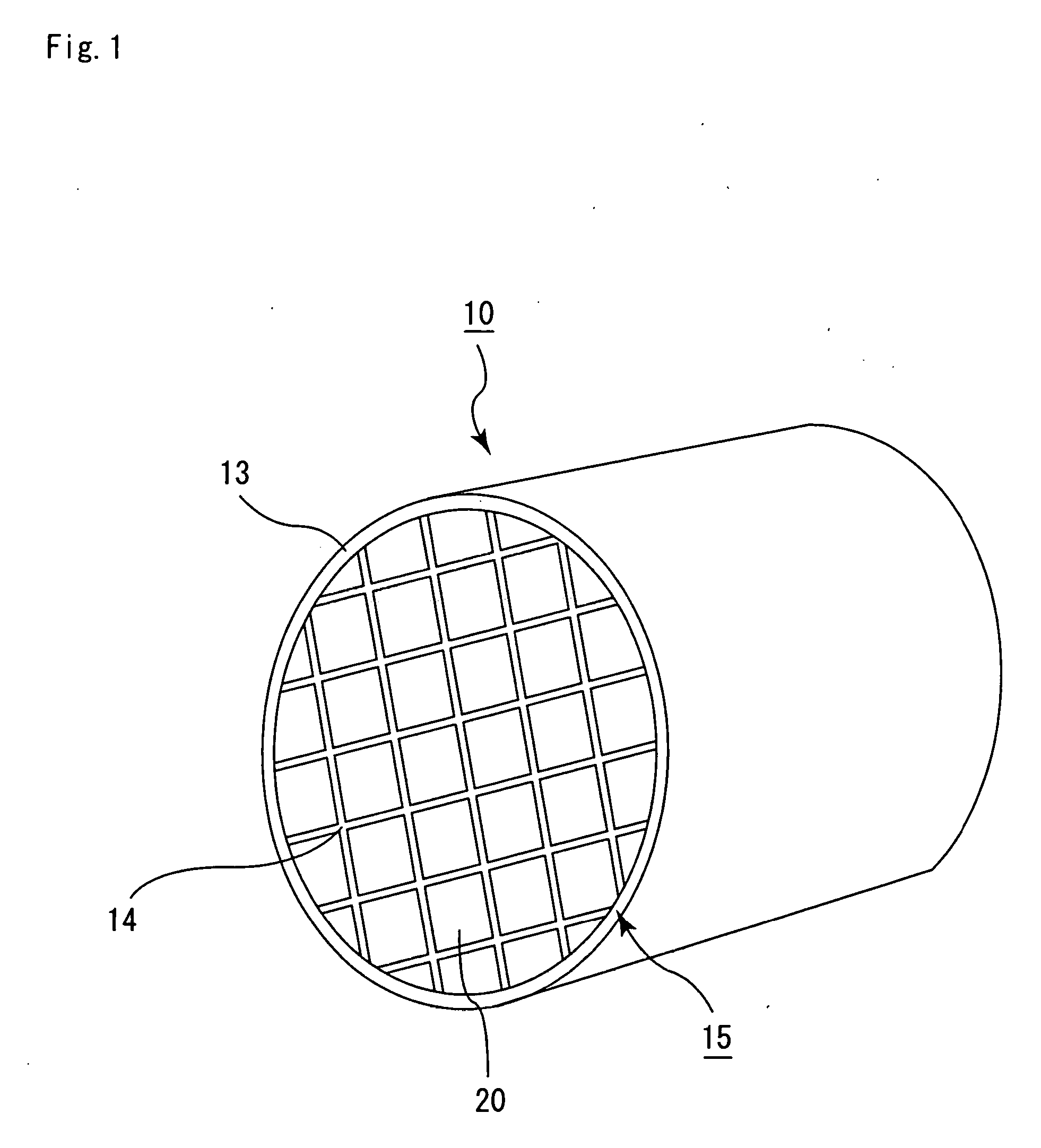

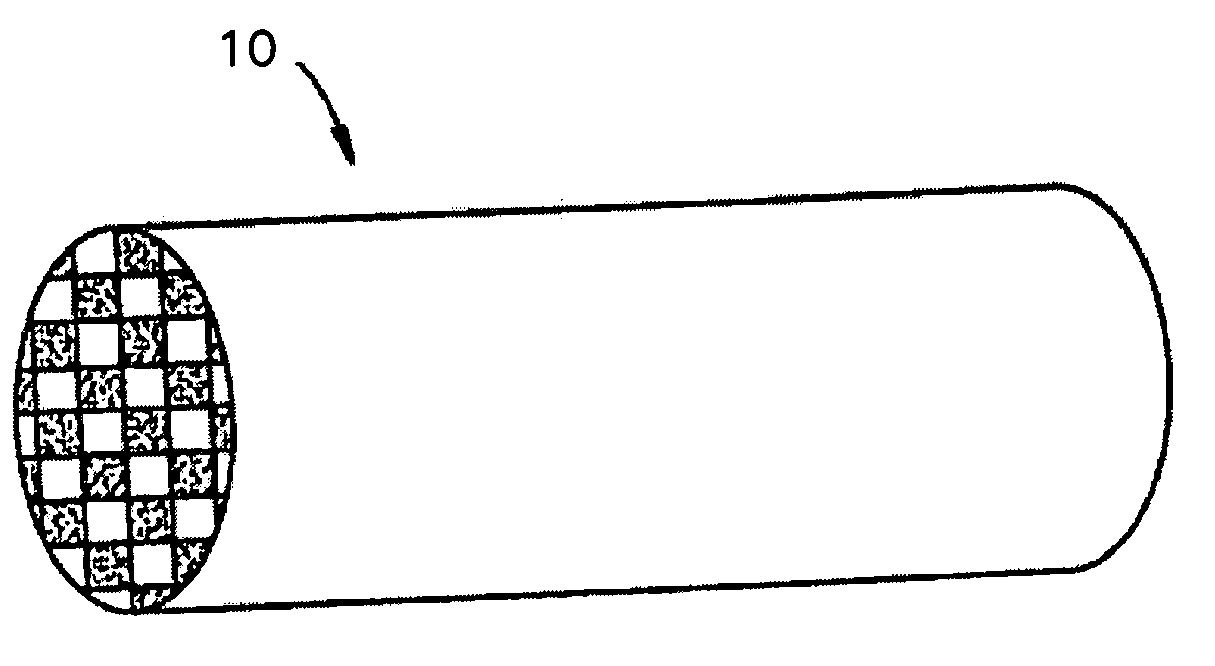

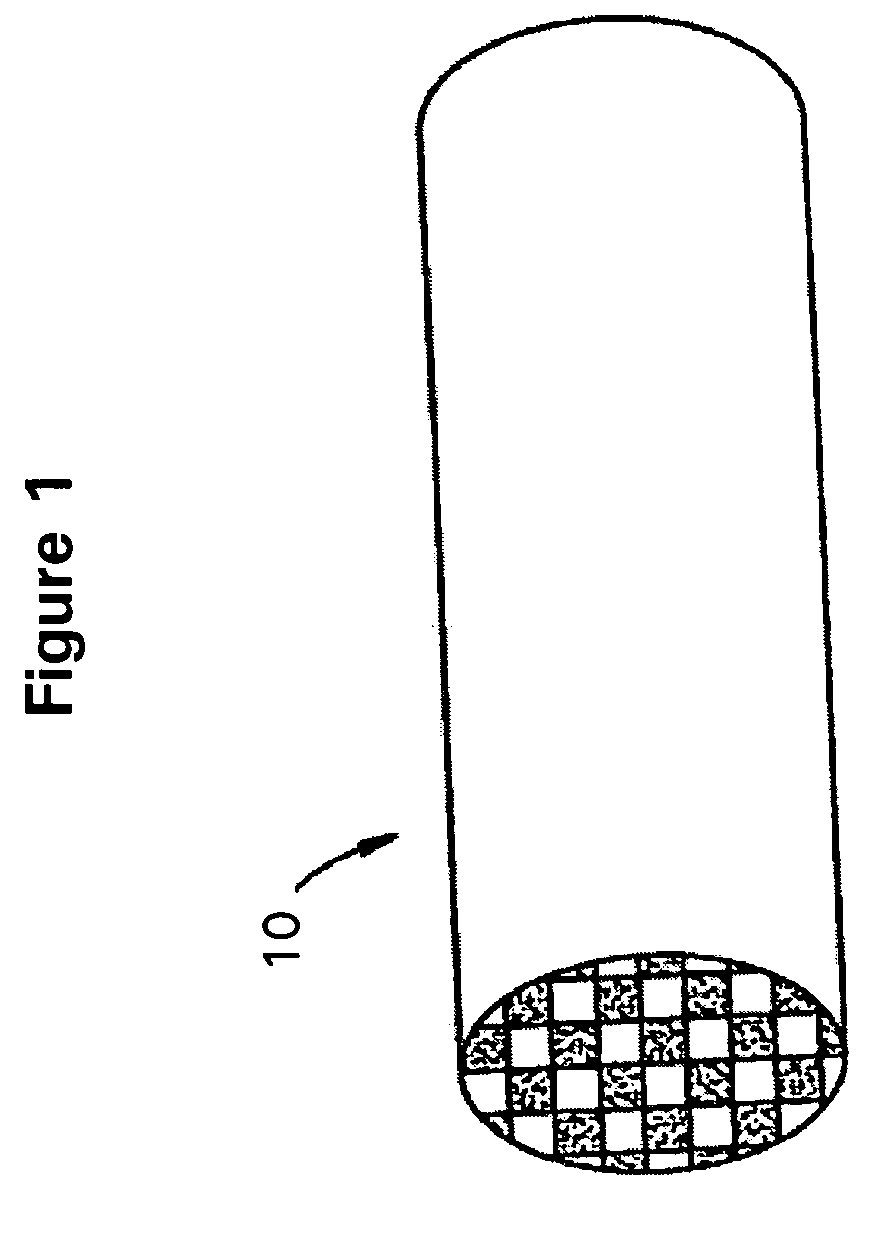

Honeycomb filter for exhaust gas decontamination, adhesive, coating material and process for producing honeycomb filter for exhaust gas decontamination

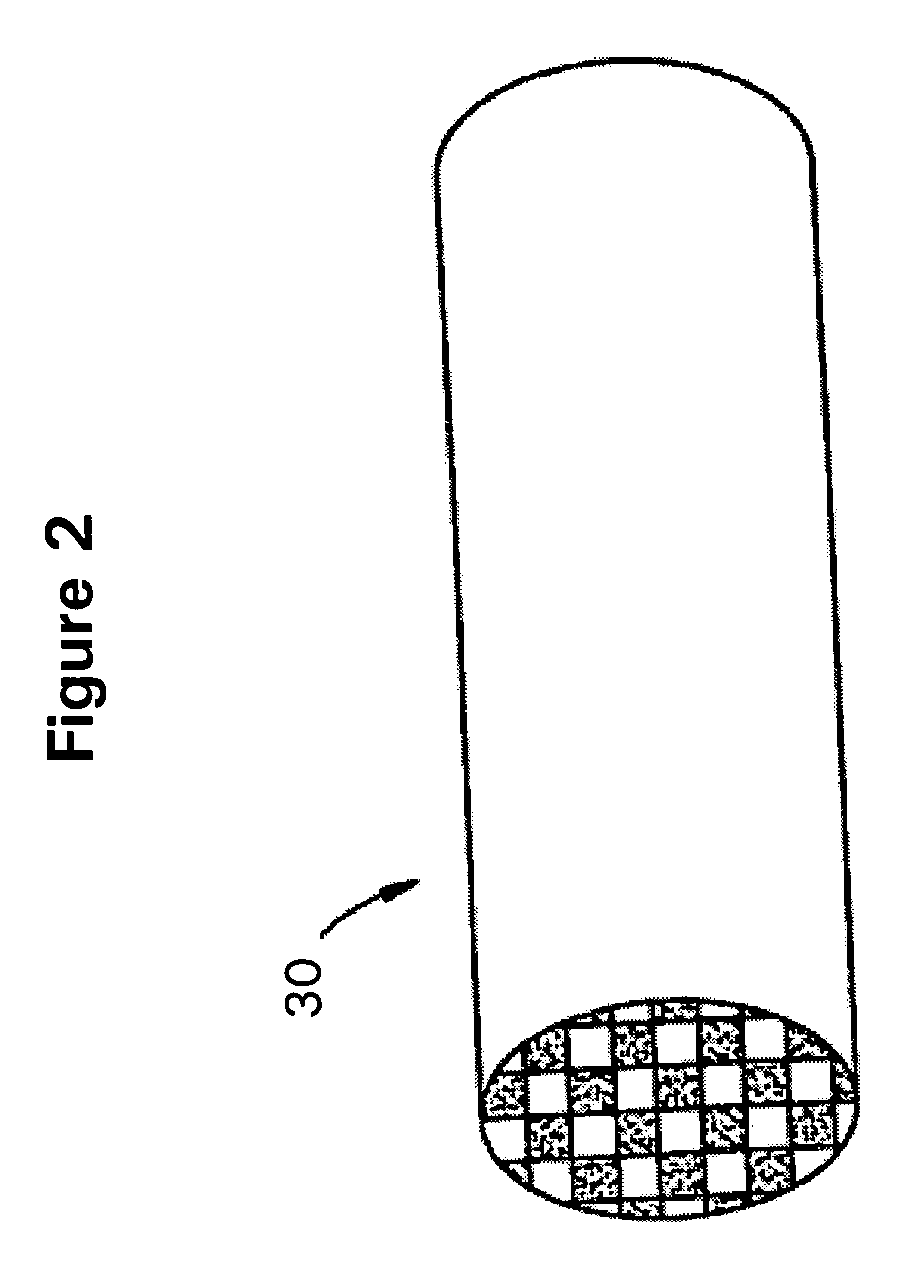

ActiveUS20050109023A1Reduce thermal stressAlleviating generated thermal stressCombination devicesDispersed particle filtrationParticulatesAdhesive

An object of the present invention is to provide a honeycomb filter for purifying exhaust gases which makes it possible to alleviate a thermal stress generated due to occurrence of a local temperature change and which is less likely to generate cracks and superior in strength and durability, an adhesive that has a low thermal capacity and is capable of alleviating the thermal stress, a coating material that has a low thermal capacity with a superior heat insulating property and is capable of alleviating the thermal stress, and a manufacturing method of the honeycomb filter for purifying exhaust gases that can improve precision in the outside dimension, and reduce damages in the manufacturing processes. The present invention relates to a honeycomb filter for purifying exhaust gases, having a structure in that a plurality of column-shaped porous ceramic members, each having a number of through holes that are placed side by side in the length direction with partition wall interposed therebetween, are combined with one another through adhesive layers so that the partition wall that separate the through holes are allowed to function as a filter for collecting particulates, and in this structure, the thermal expansion coefficient αL of the adhesive layer and the thermal expansion coefficient αF of the porous ceramic member are designed to have the following relationship: 0.01<|αL−αF| / αF<1.0.

Owner:IBIDEN CO LTD

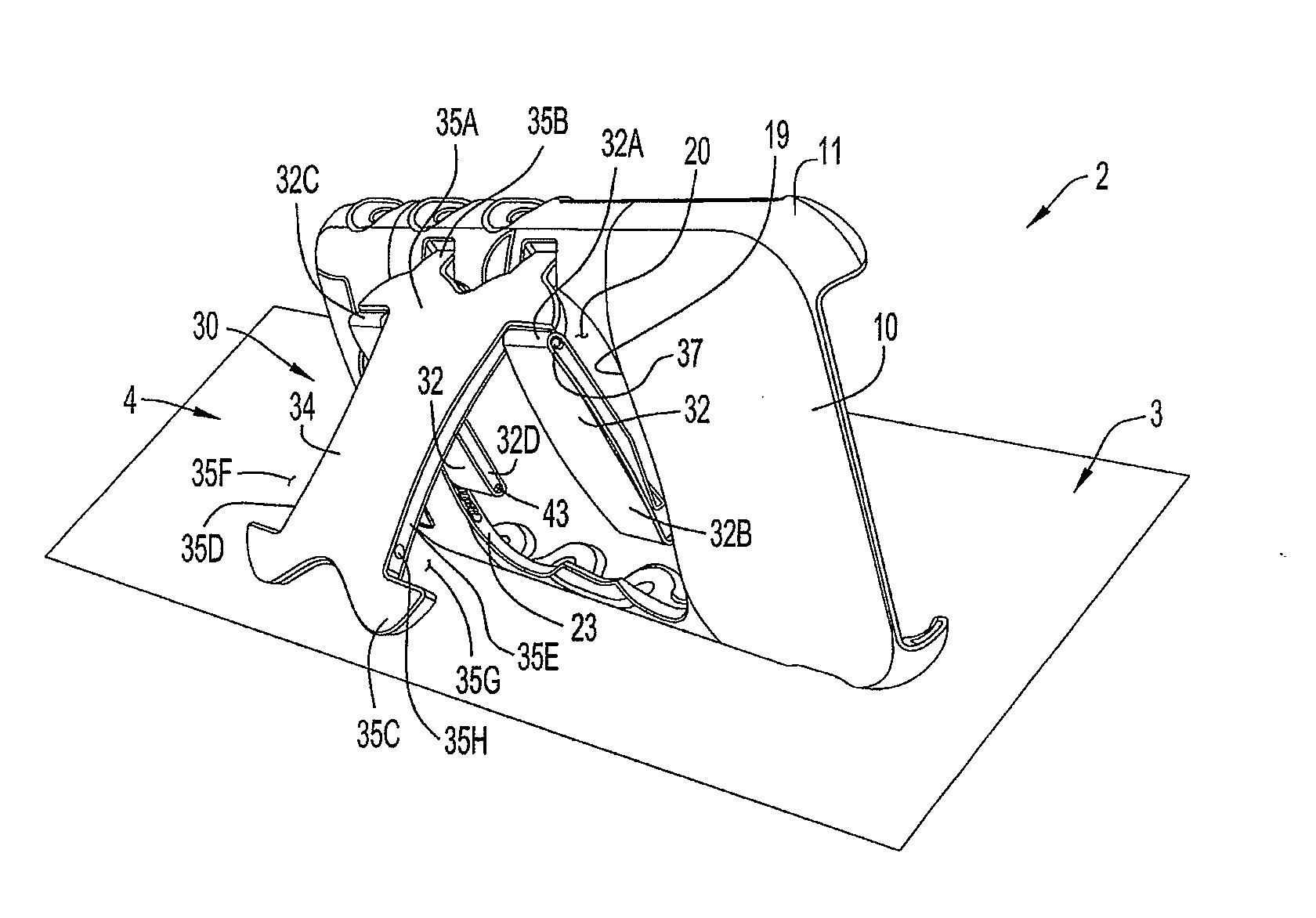

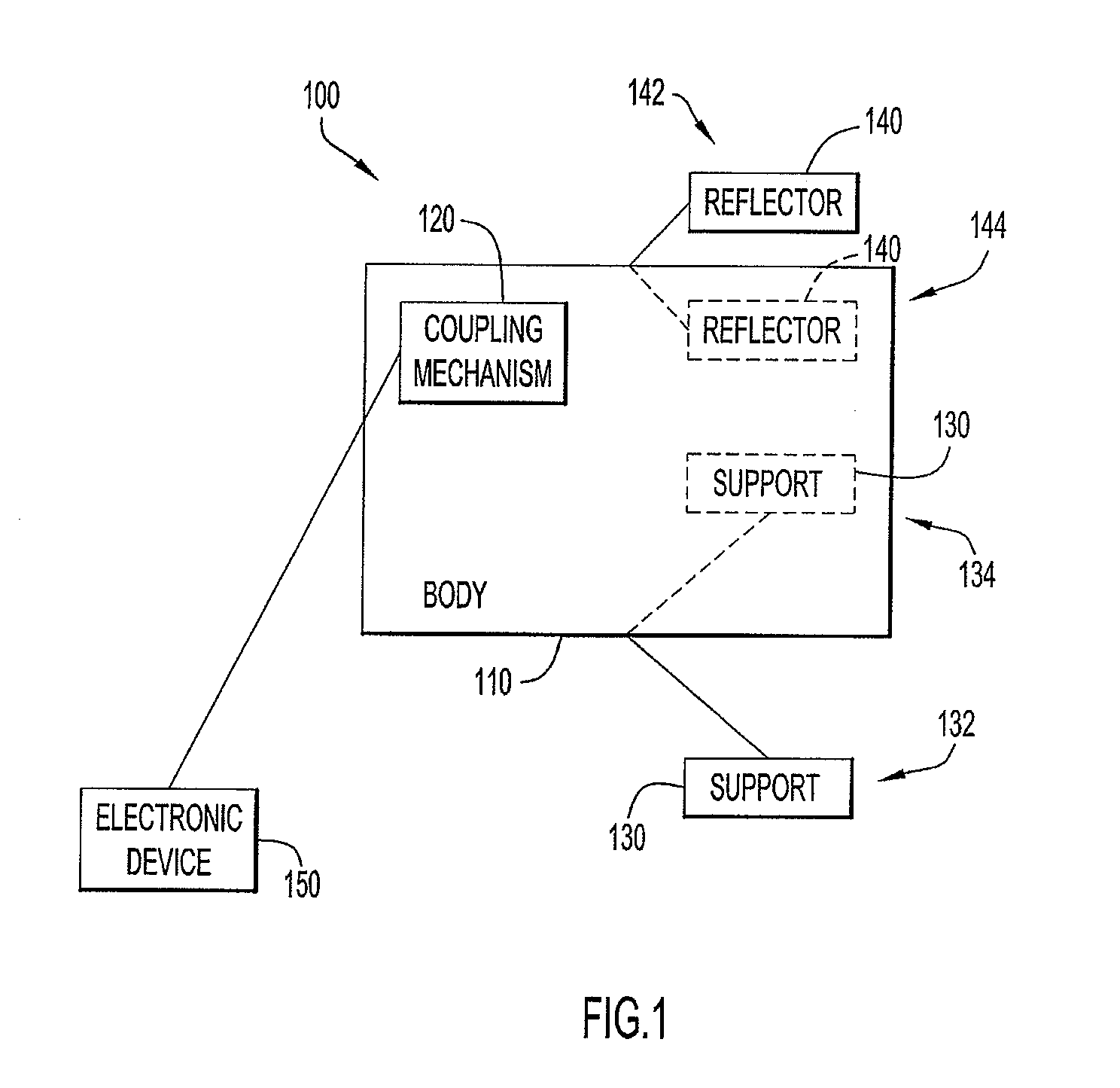

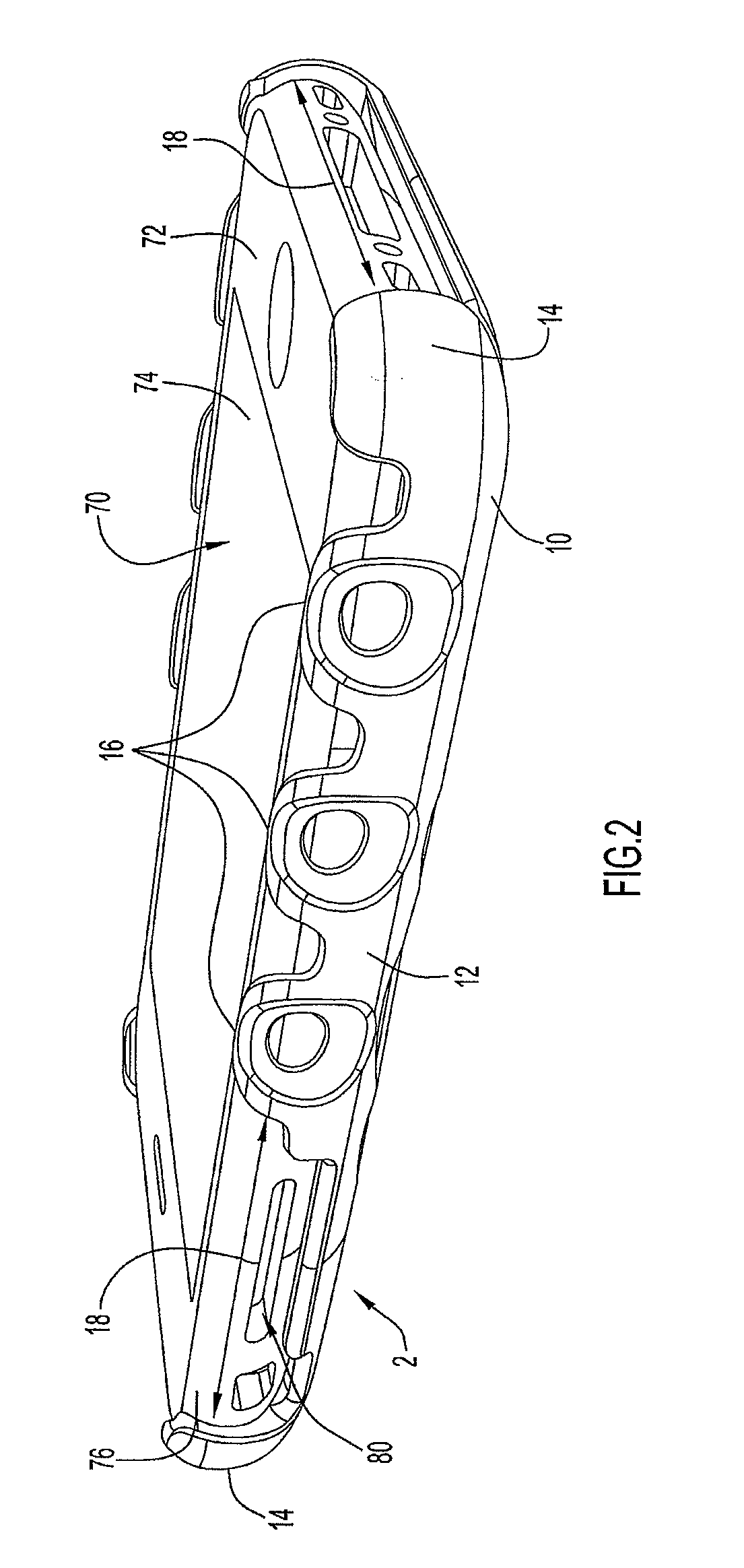

Holder for Electronic Device with Support

InactiveUS20100072334A1Easy to cleanImprove audio performanceTravelling carriersHoldersTablet computerDisplay device

A protective holder for the iPhone®, iPod Touch™, electronic books, electronic tablet computers and other portable devices having a frontal LCD, OLED, touch screen, or other display that employs a form-fitting backplate with corner frames for cradling the device while leaving the entire frontal aspect unobstructed is disclosed. The holder may include a series of contoured side grippers on each side of the backplate for clamping the device in place without obstructing the LCD screen (or access to it for cleaning or otherwise). The holder may include a fully-adjustable kickstand for upright hands-free viewing of the device at several landscape and portrait angles and the holder may also include a built-in moveable directional sound reflector and noise shield improves audio performance, and a detachable belt clip allows belt wearing. The holder has an extreme slimline folded profile to facilitate pocket insertion, minimize bulk and create an eye-catching aesthetic.

Owner:ZERO CHROMA

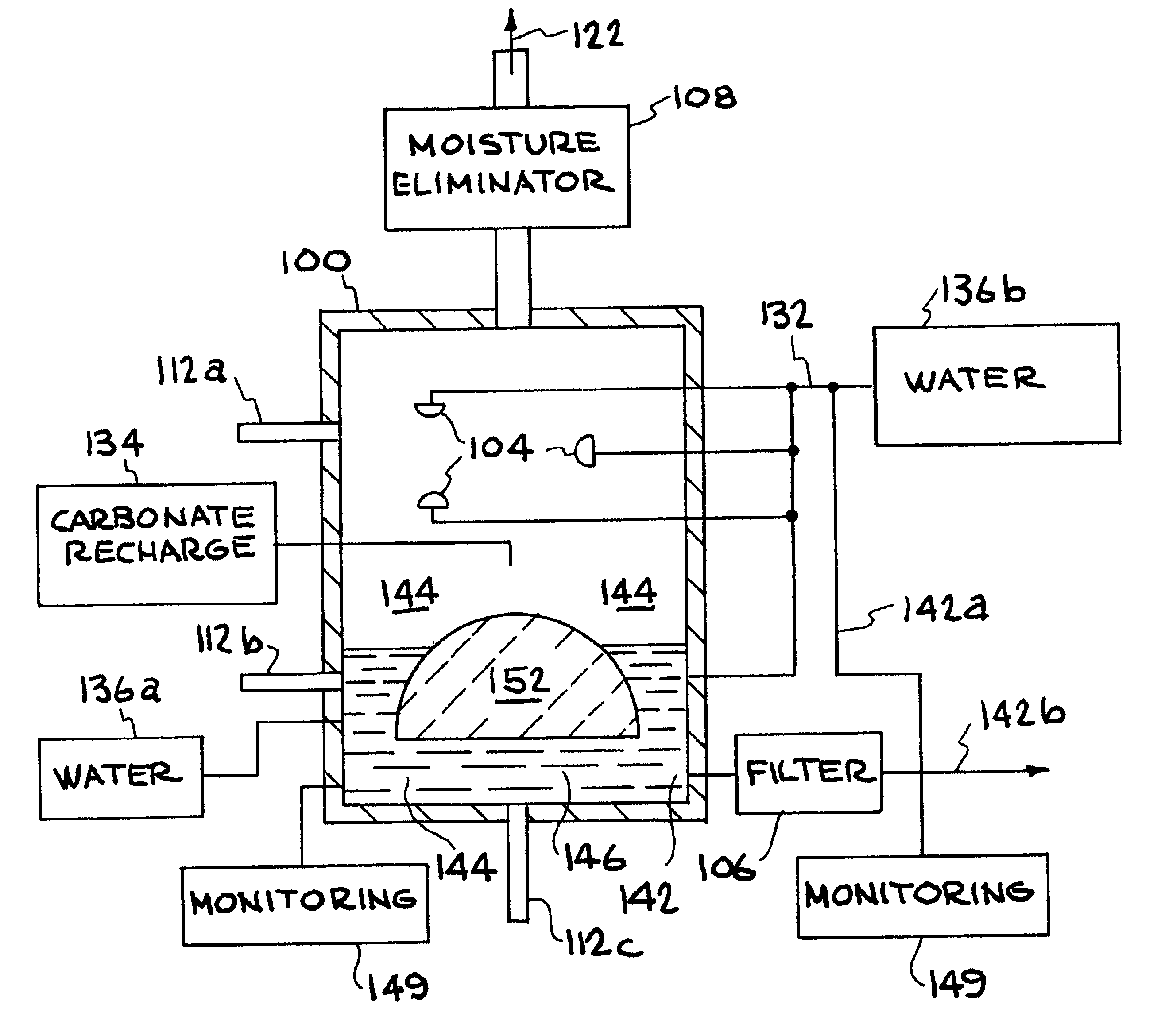

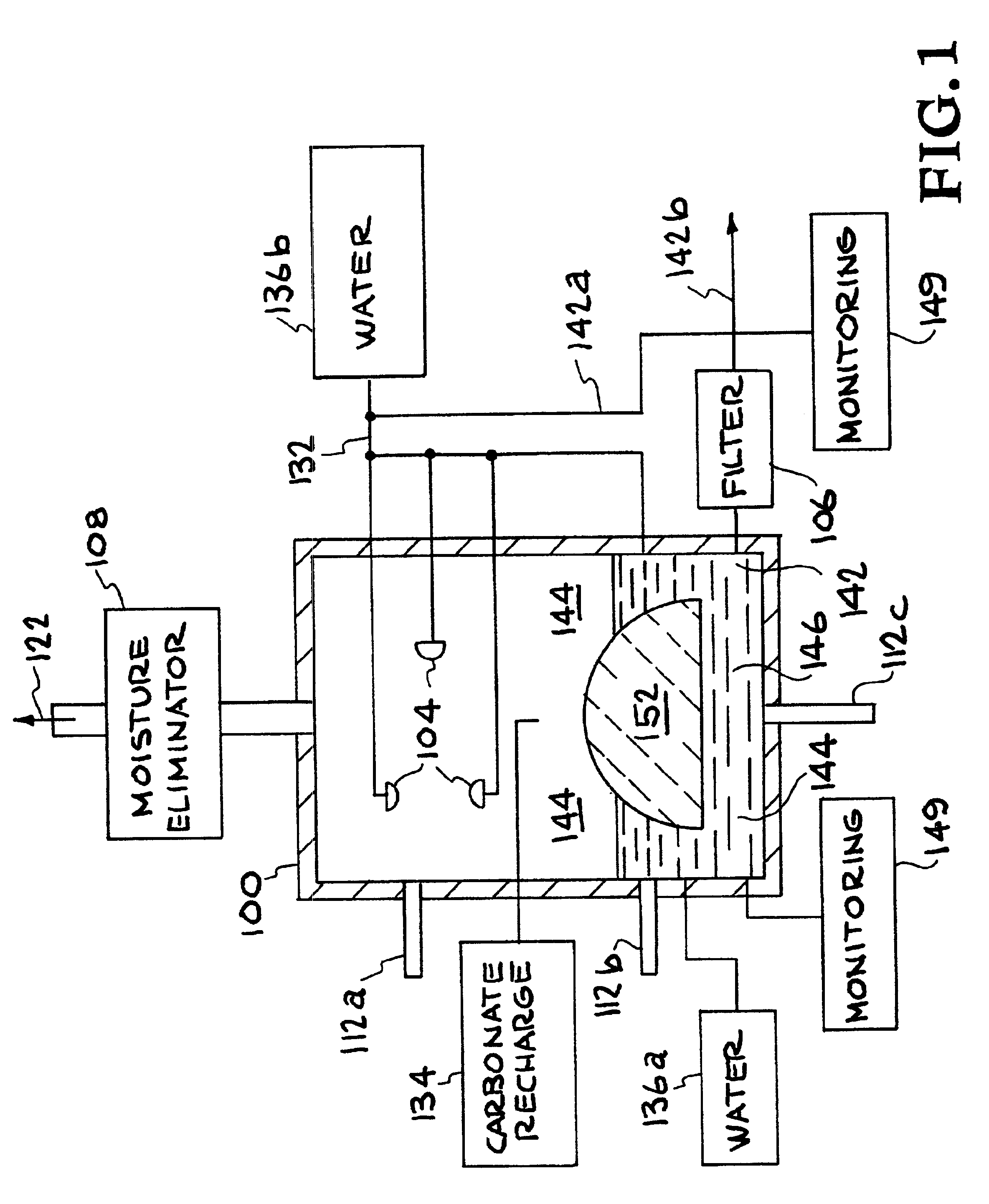

Method for extracting and sequestering carbon dioxide

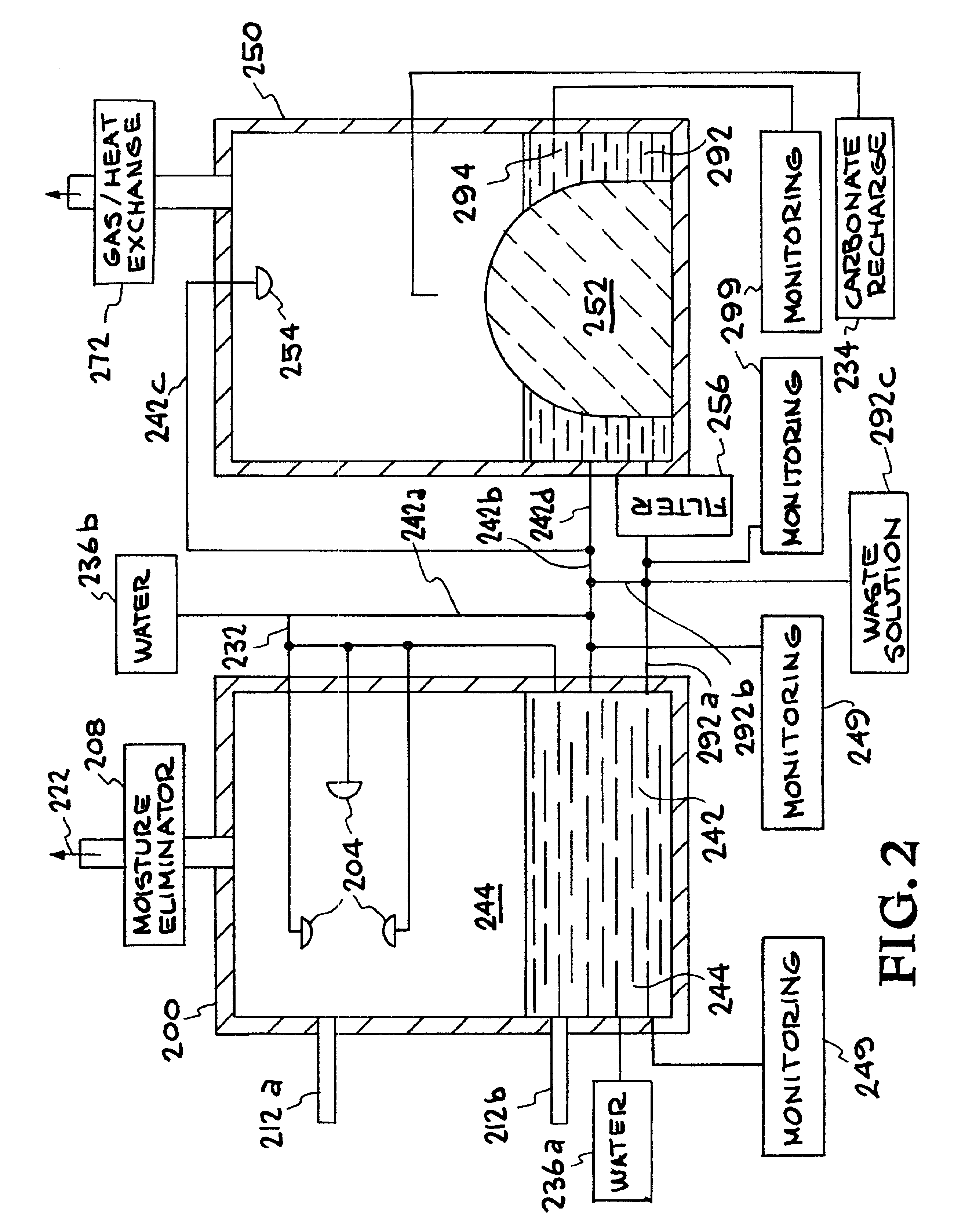

InactiveUS6890497B2Reduce CO burdenWithout significant expenditureCalcium/strontium/barium carbonatesCombination devicesDicarbonateAlkaline earth metal

A method and apparatus to extract and sequester carbon dioxide (CO2) from a stream or volume of gas wherein said method and apparatus hydrates CO2, and reacts the resulting carbonic acid with carbonate. Suitable carbonates include, but are not limited to, carbonates of alkali metals and alkaline earth metals, preferably carbonates of calcium and magnesium. Waste products are metal cations and bicarbonate in solution or dehydrated metal salts, which when disposed of in a large body of water provide an effective way of sequestering CO2 from a gaseous environment.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

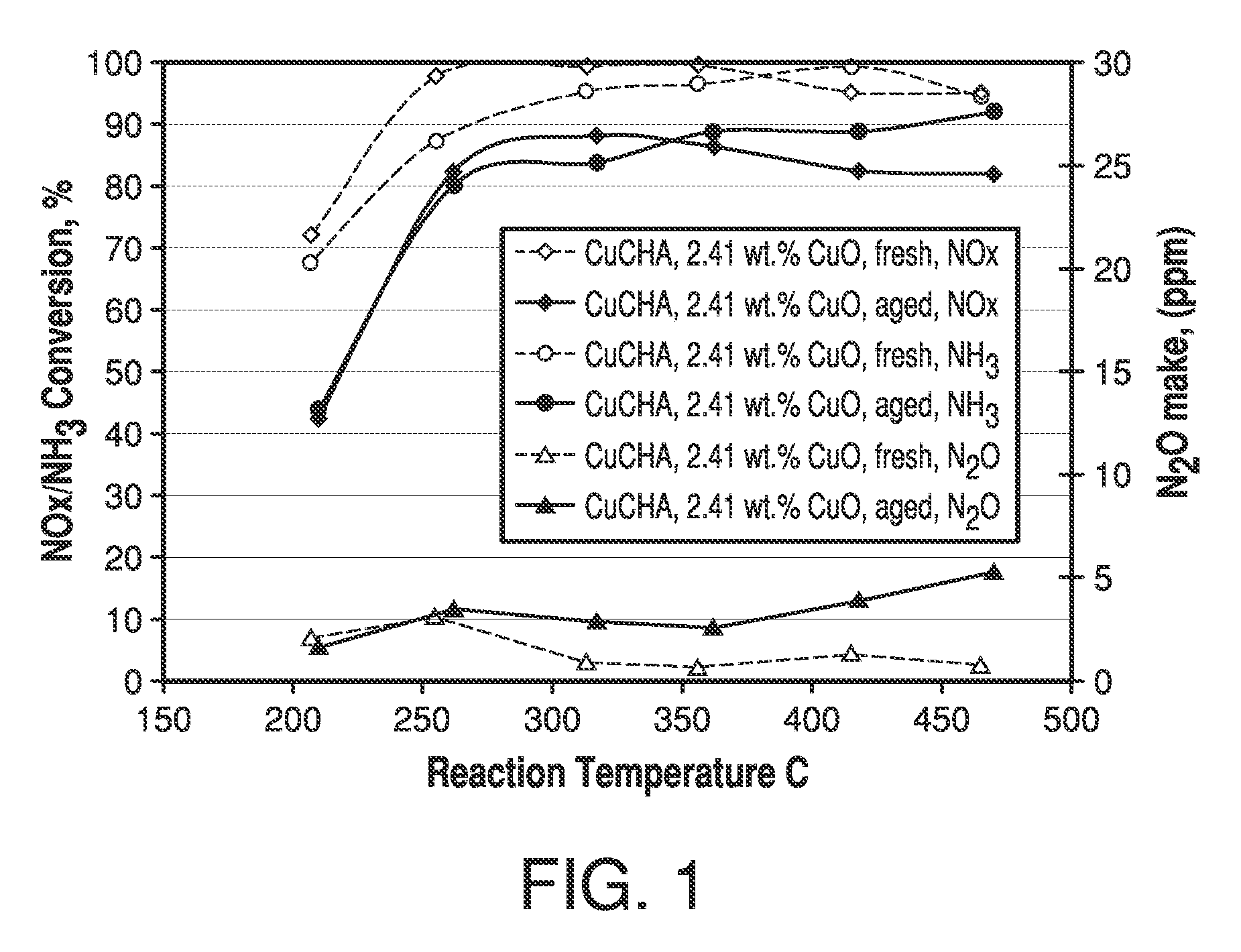

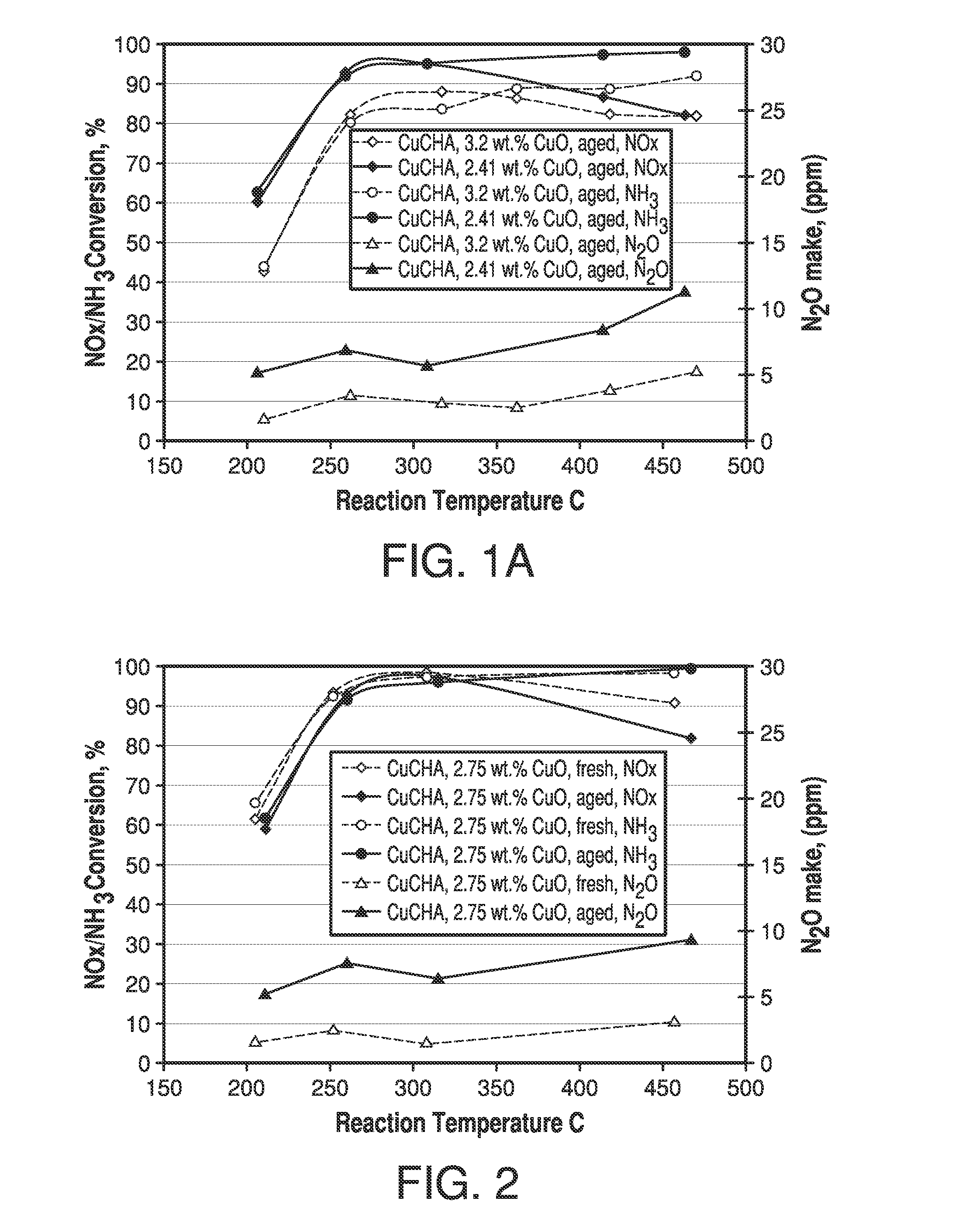

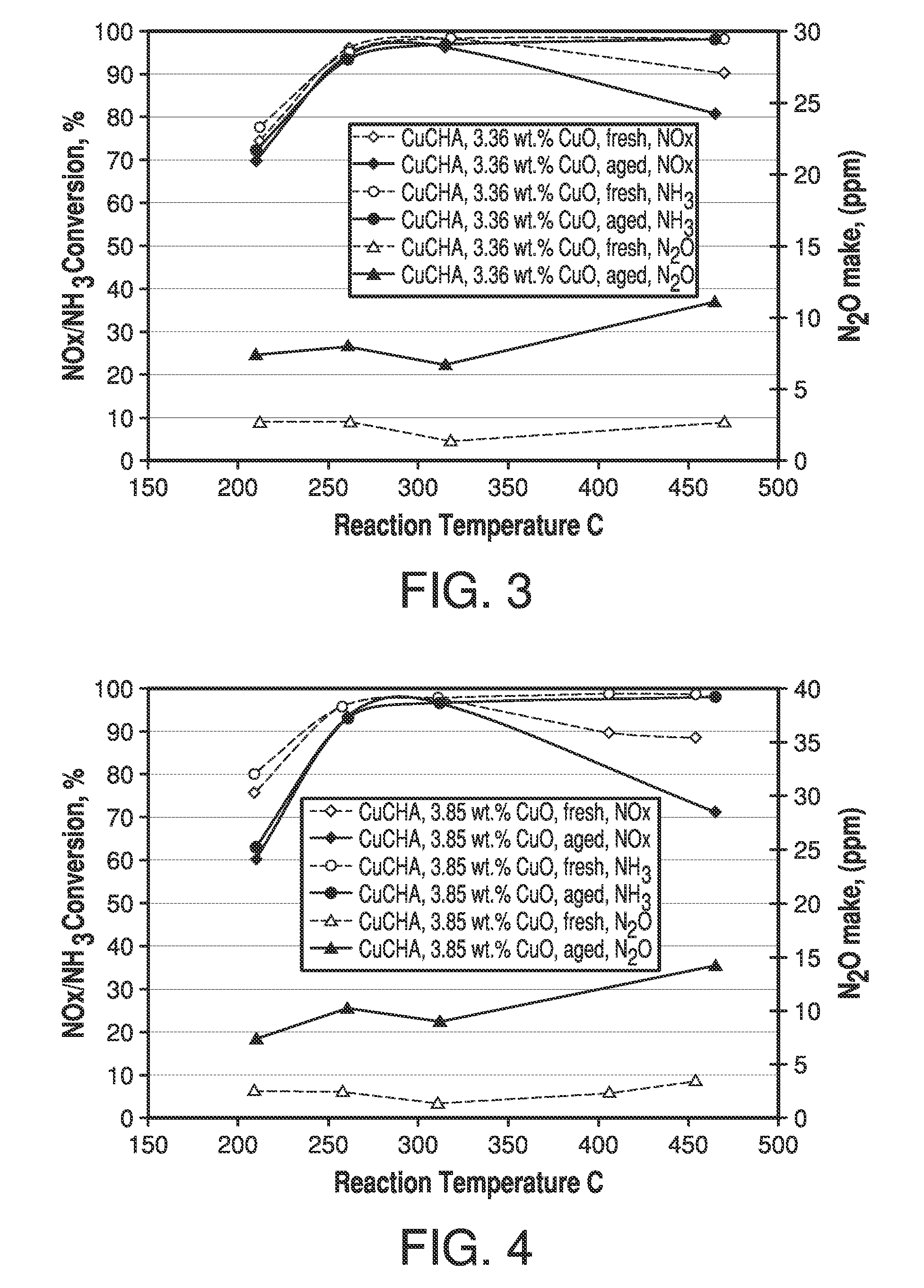

Copper CHA zeolite catalysts

ActiveUS7601662B2Good hydrothermal stabilityHigh catalytic activityCombination devicesAluminium compoundsReaction temperatureCrystal structure

Zeolite catalysts and systems and methods for preparing and using zeolite catalysts having the CHA crystal structure are disclosed. The catalysts can be used to remove nitrogen oxides from a gaseous medium across a broad temperature range and exhibit hydrothermal stable at high reaction temperatures. The zeolite catalysts include a zeolite carrier having a silica to alumina ratio from about 15:1 to about 256:1 and a copper to alumina ratio from about 0.25:1 to about 1:1.

Owner:BASF CORP

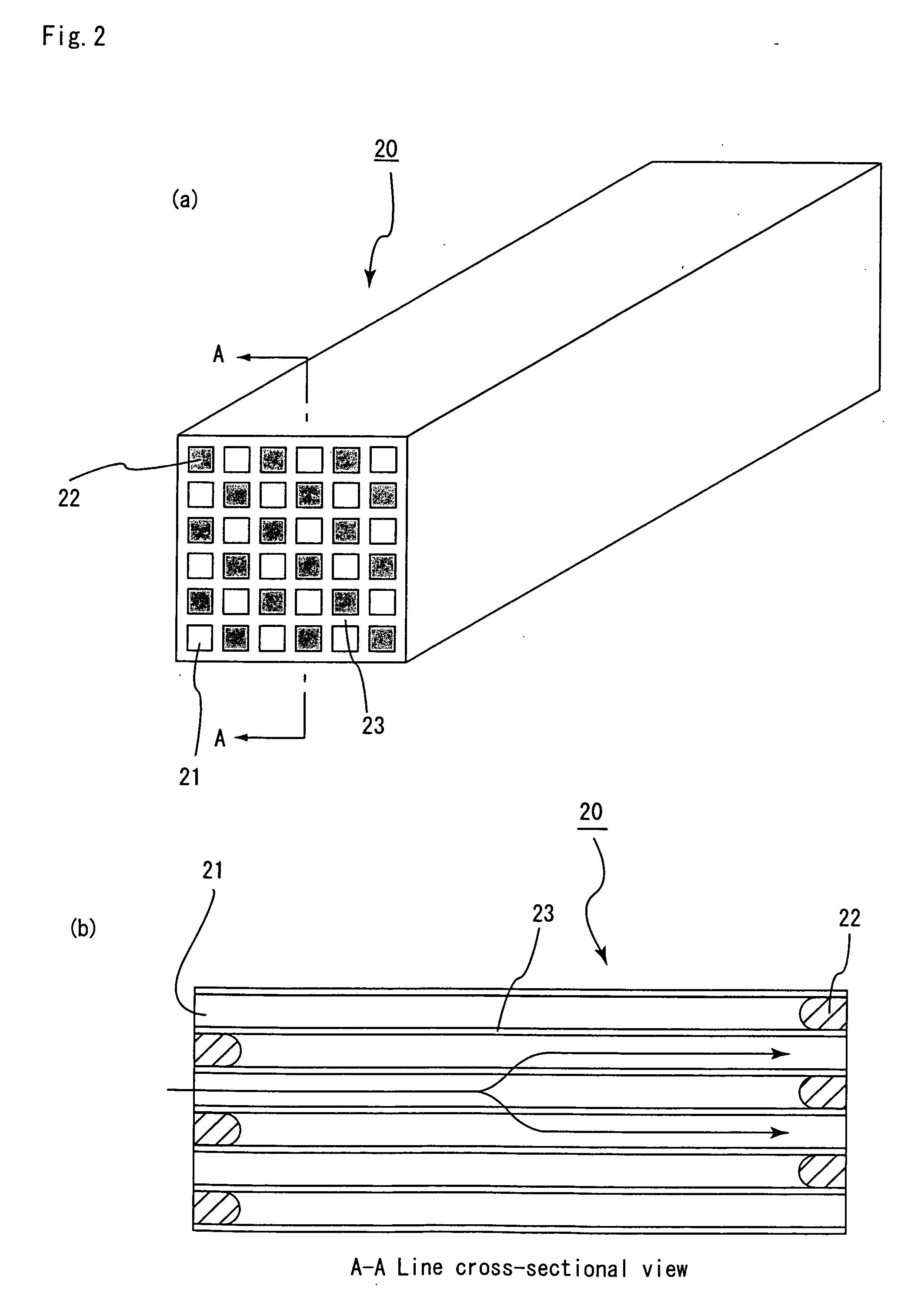

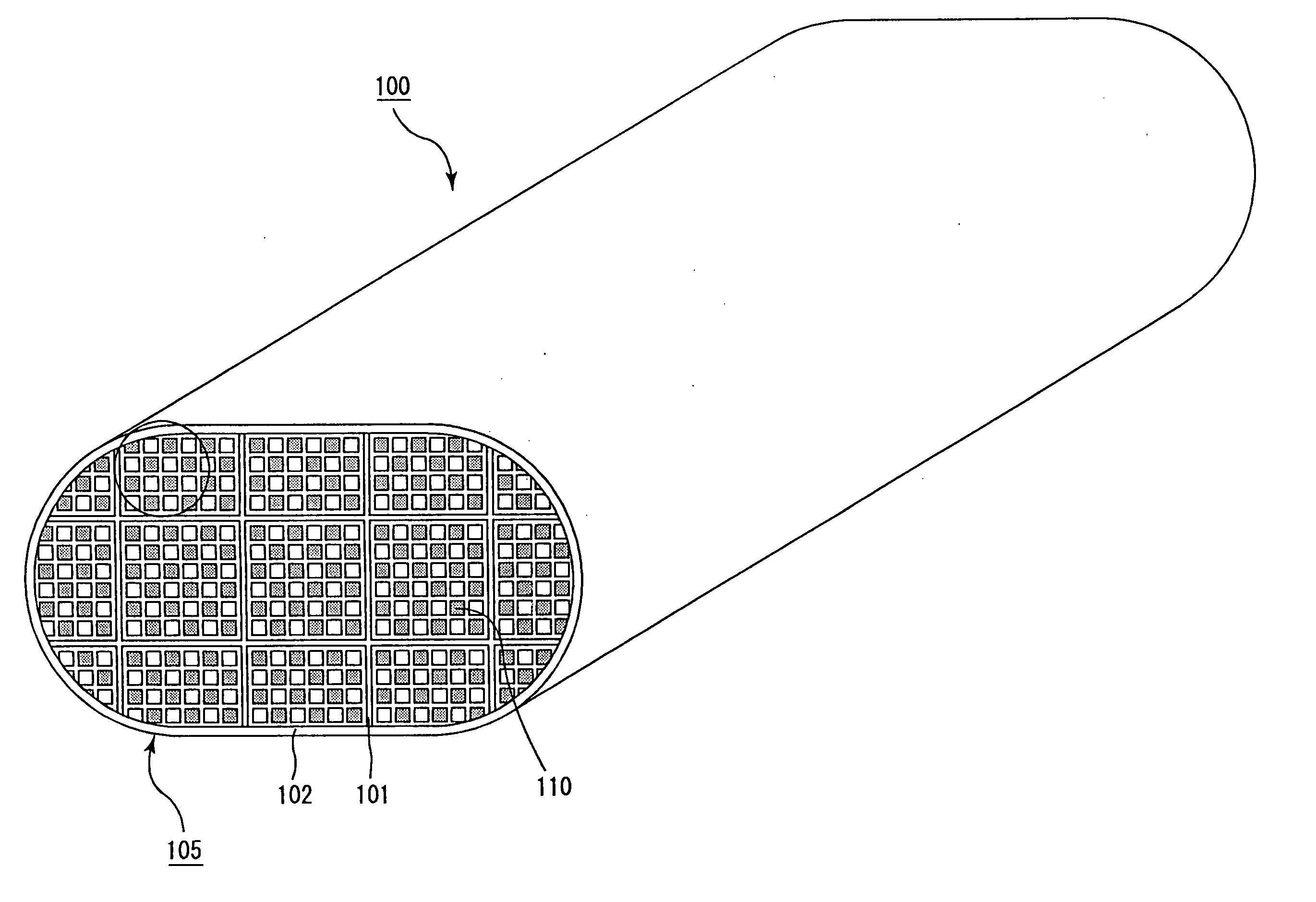

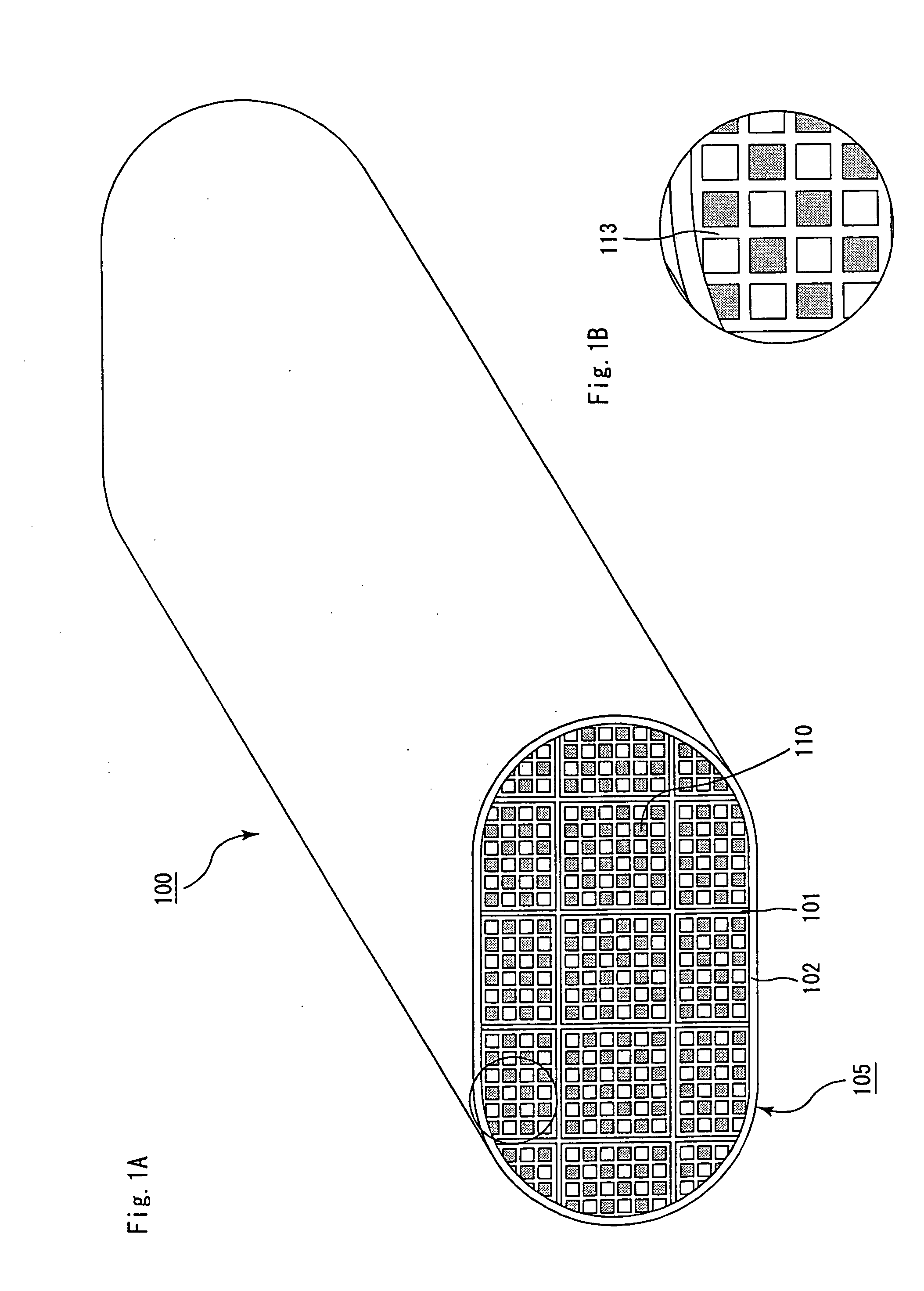

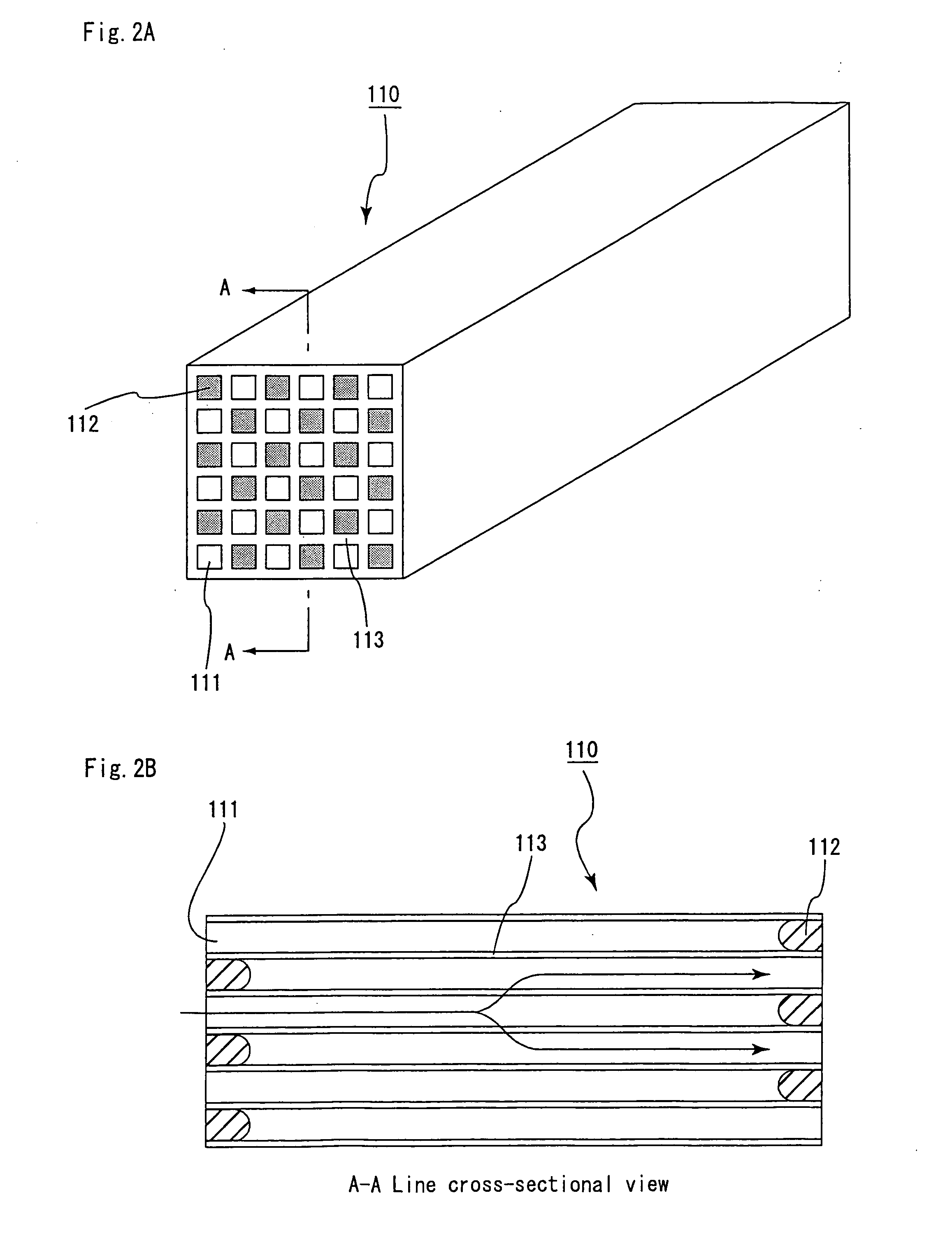

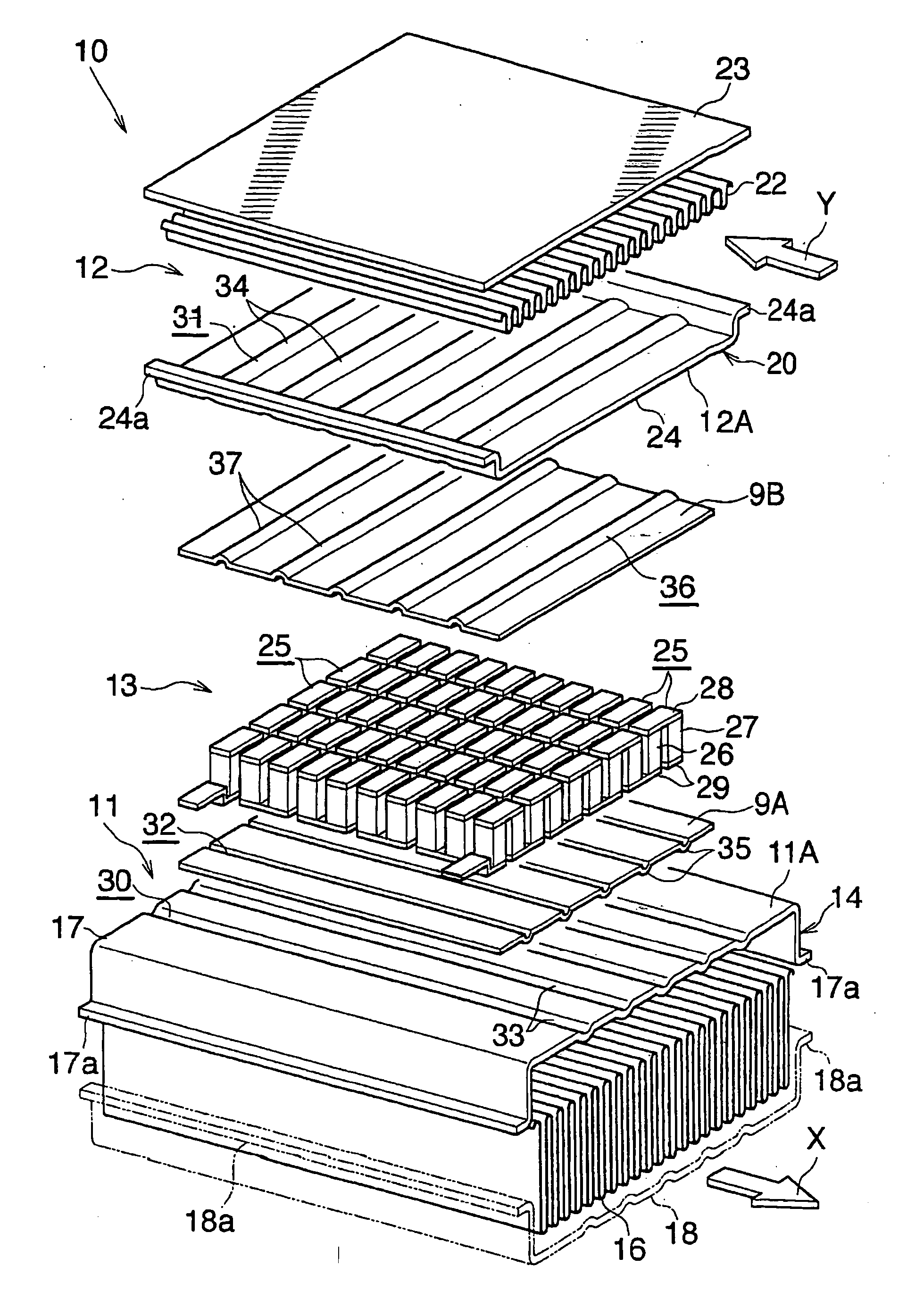

Honeycomb structural body and manufacturing method thereof

ActiveUS20050247038A1Great resistance to physical impactIncreased durabilityCatalyst carriersGas treatmentDiagonalHoneycomb structure

A honeycomb structural body comprising: a ceramic block having a flat shape in which a plurality of honeycomb units are bonded to each other through a sealing material layer, said honeycomb unit mainly comprises porous ceramic and includes a large number of through holes placed in parallel with one another in a longitudinal direction with a partition wall interposed therebetween; and a sealing material layer formed on a peripheral portion thereof, wherein the sealing material layer among the honeycomb units on a cross section perpendicular to the longitudinal direction has a pattern that is formed in a diagonal direction with respect to a major axis of a shape forming a contour of the cross section.

Owner:IBIDEN CO LTD

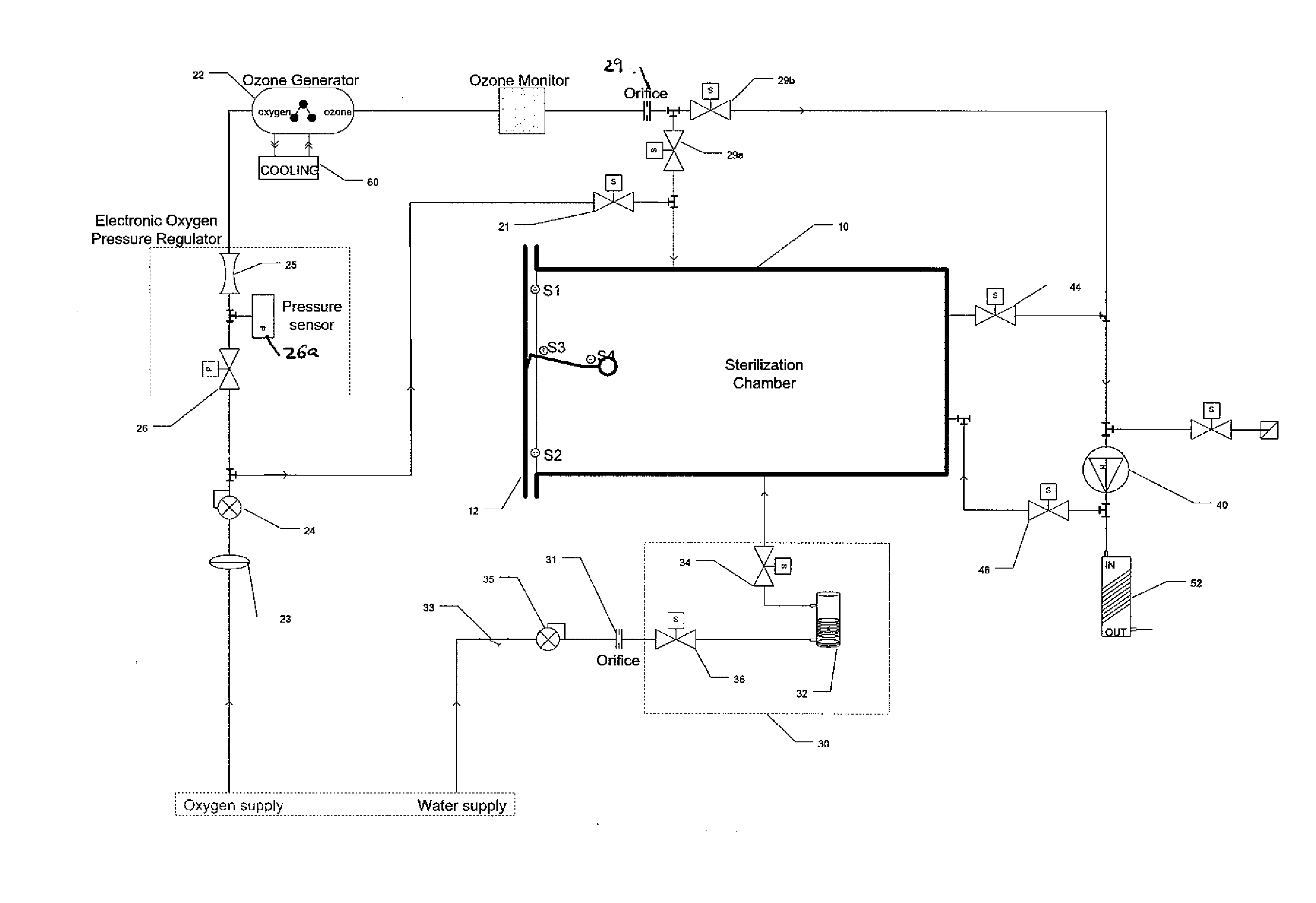

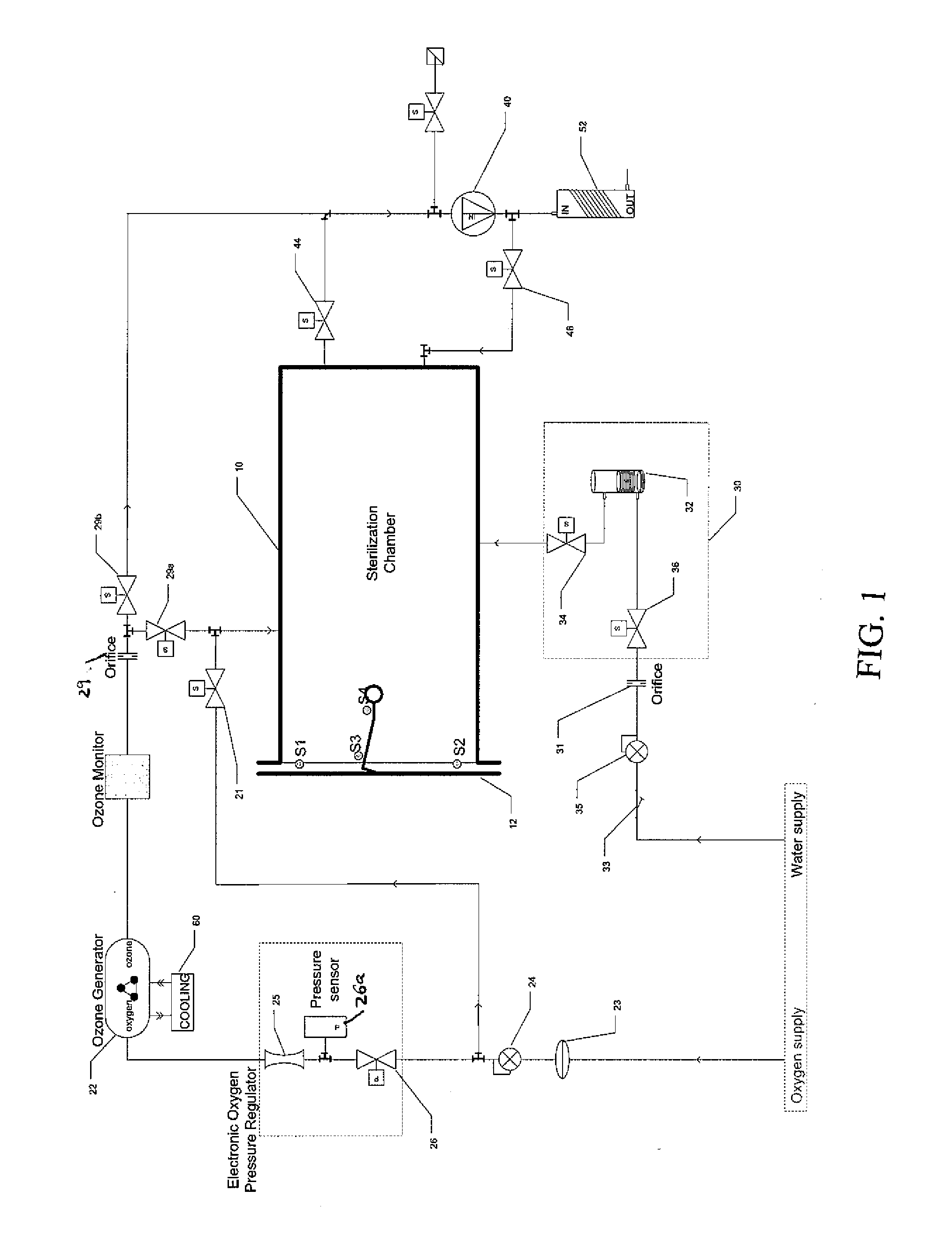

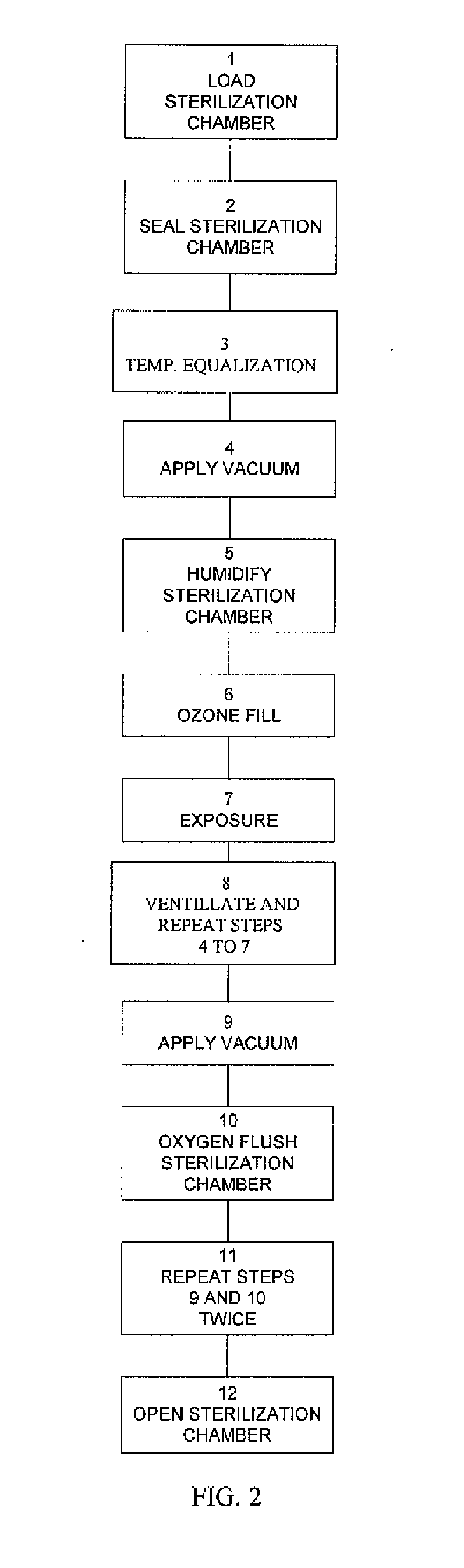

Method and apparatus for ozone sterilization

InactiveUS20070258855A1Avoid condensationPrevent water condensationElectrolysis componentsExhaust apparatusVacuum pressureWater vapor

The present invention provides a method and apparatus for sterilizing articles using an ozone-containing gas, where condensation of water from the sterilization atmosphere during the sterilization process is substantially prevented. The inventive sterilization method includes providing a sterilization chamber and placing an article into the sterilization chamber. The sterilization chamber is sealed prior to equalizing the temperature of the article and the atmosphere in the sterilization chamber. A vacuum is applied to achieve a preselected vacuum pressure in the sterilization chamber. Once the vacuum pressure is set, water vapour is supplied to the sterilization chamber. Ozone-containing gas is then supplied to the sterilization chamber and the sterilization chamber remains sealed for a preselected treatment period, where the sterilization chamber remains sealed throughout the whole process. Finally, vacuum in the sterilization chamber is released.

Owner:STRYKER CORP

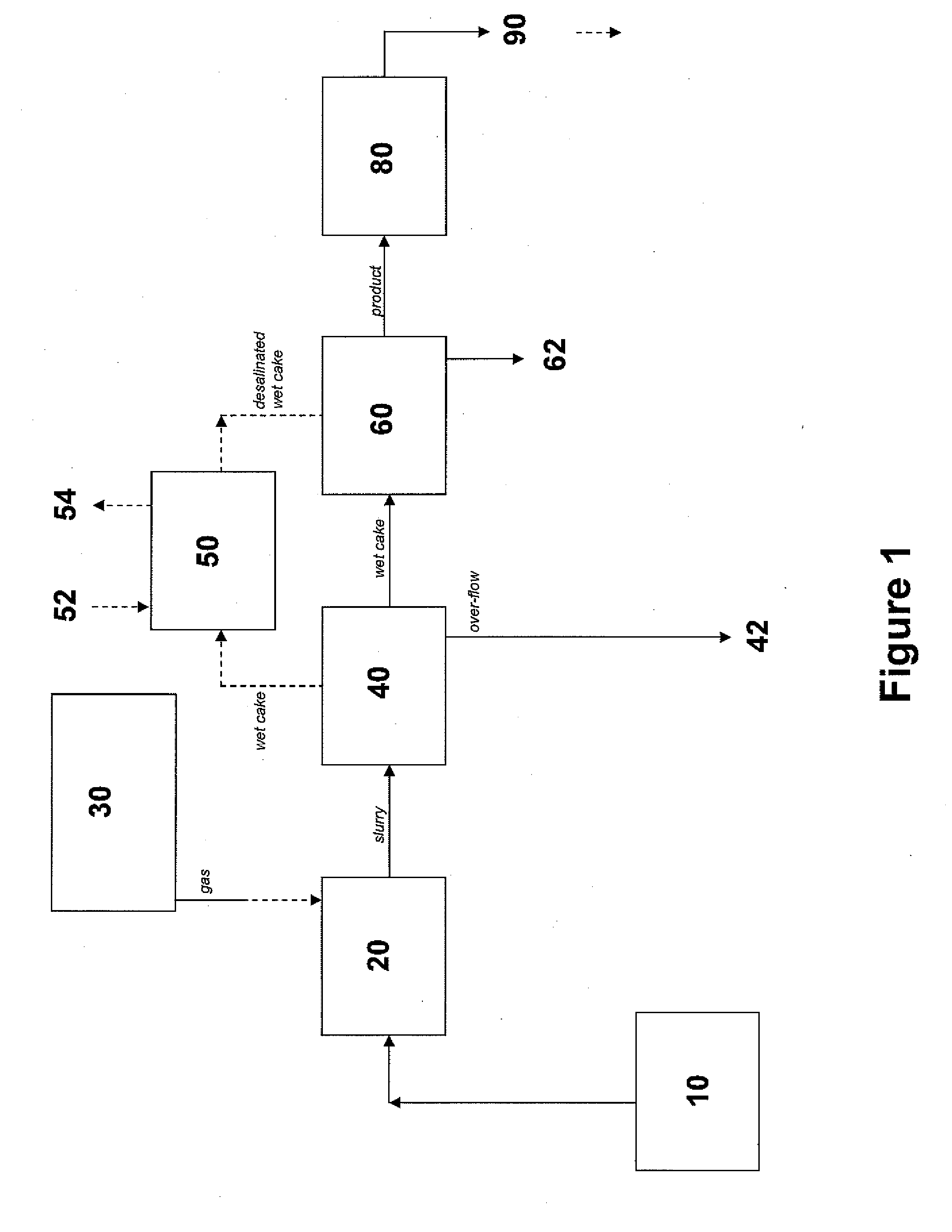

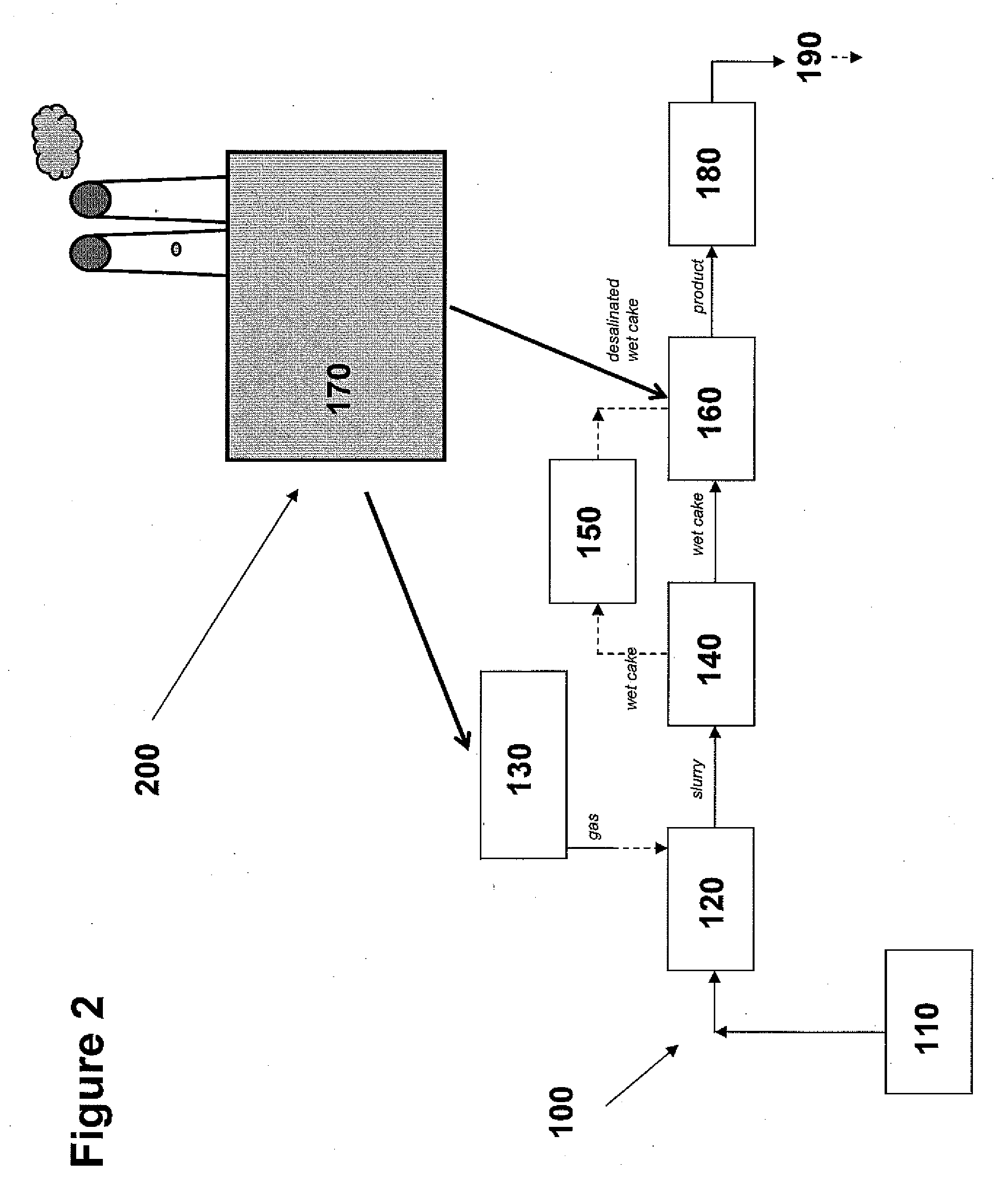

Methods of sequestering co2

Methods of sequestering carbon dioxide (CO2) are provided. Aspects of the methods include precipitating a storage stable carbon dioxide sequestering product from an alkaline-earth-metal-containing water and then disposing of the product, e.g., by placing the product in a disposal location or using the product as a component of a manufactured composition. Also provided are systems for practicing methods of the invention.

Owner:ARELAC INC

Smart disposable plastic lab-on-a-chip for point-of-care testing

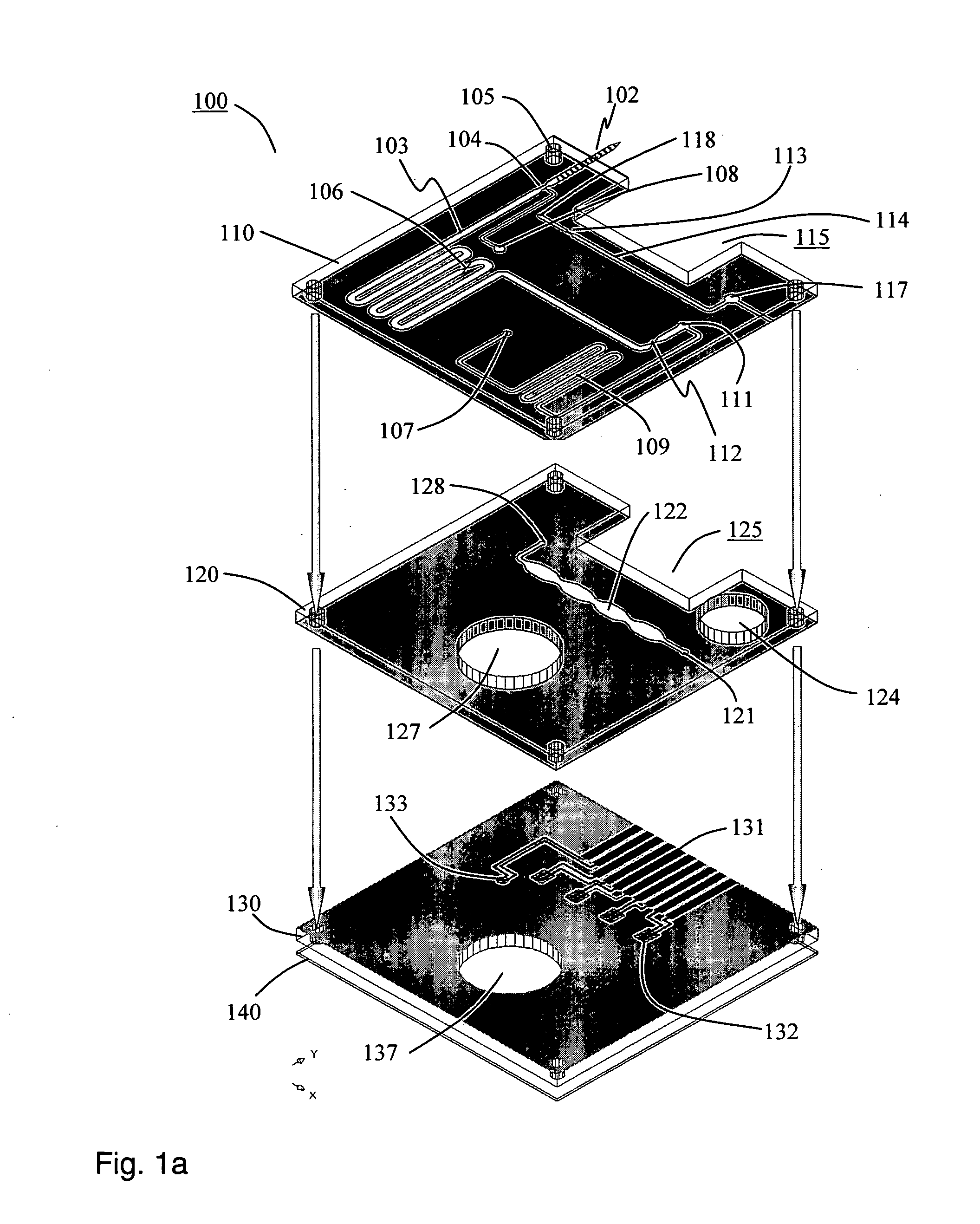

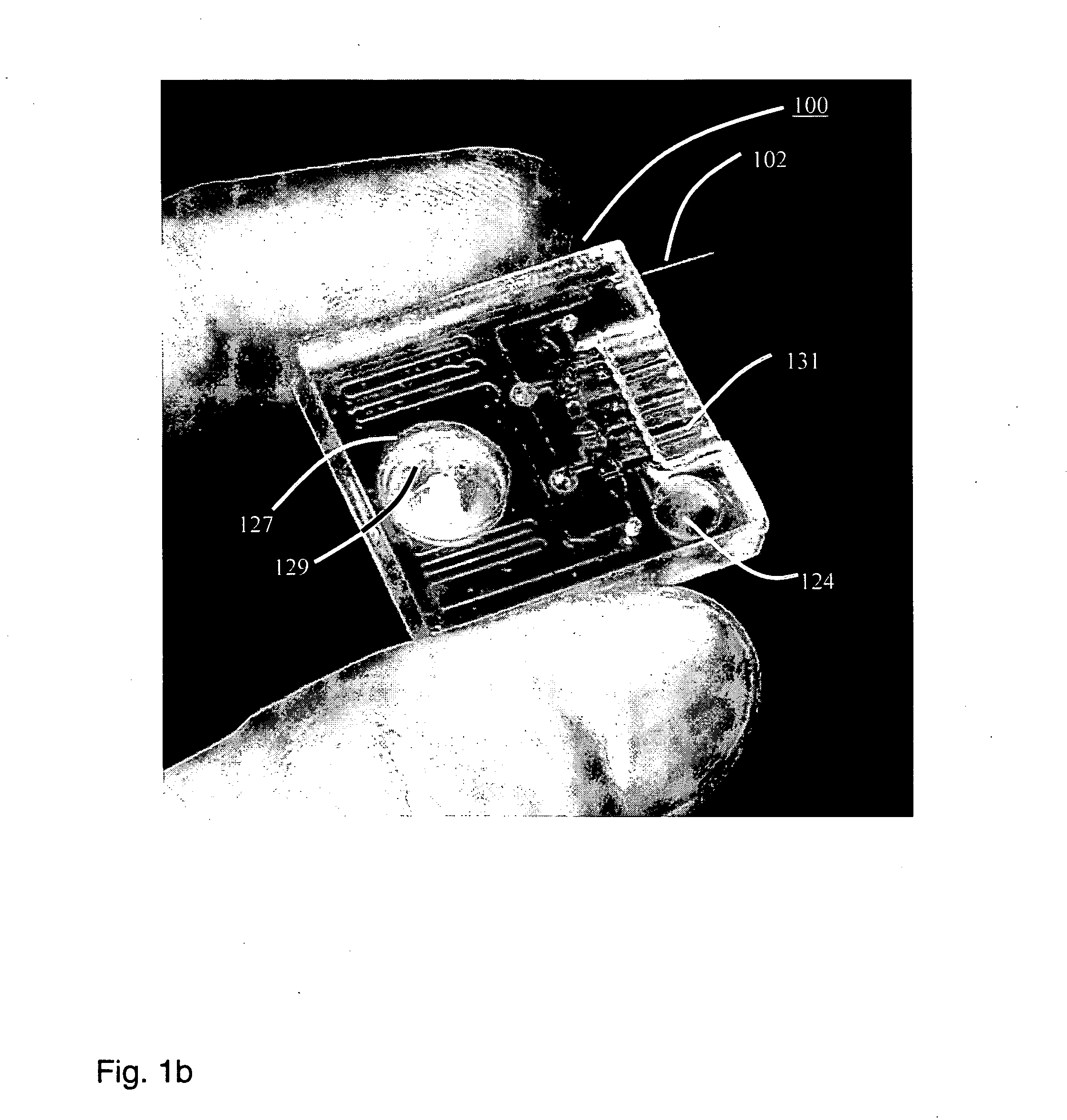

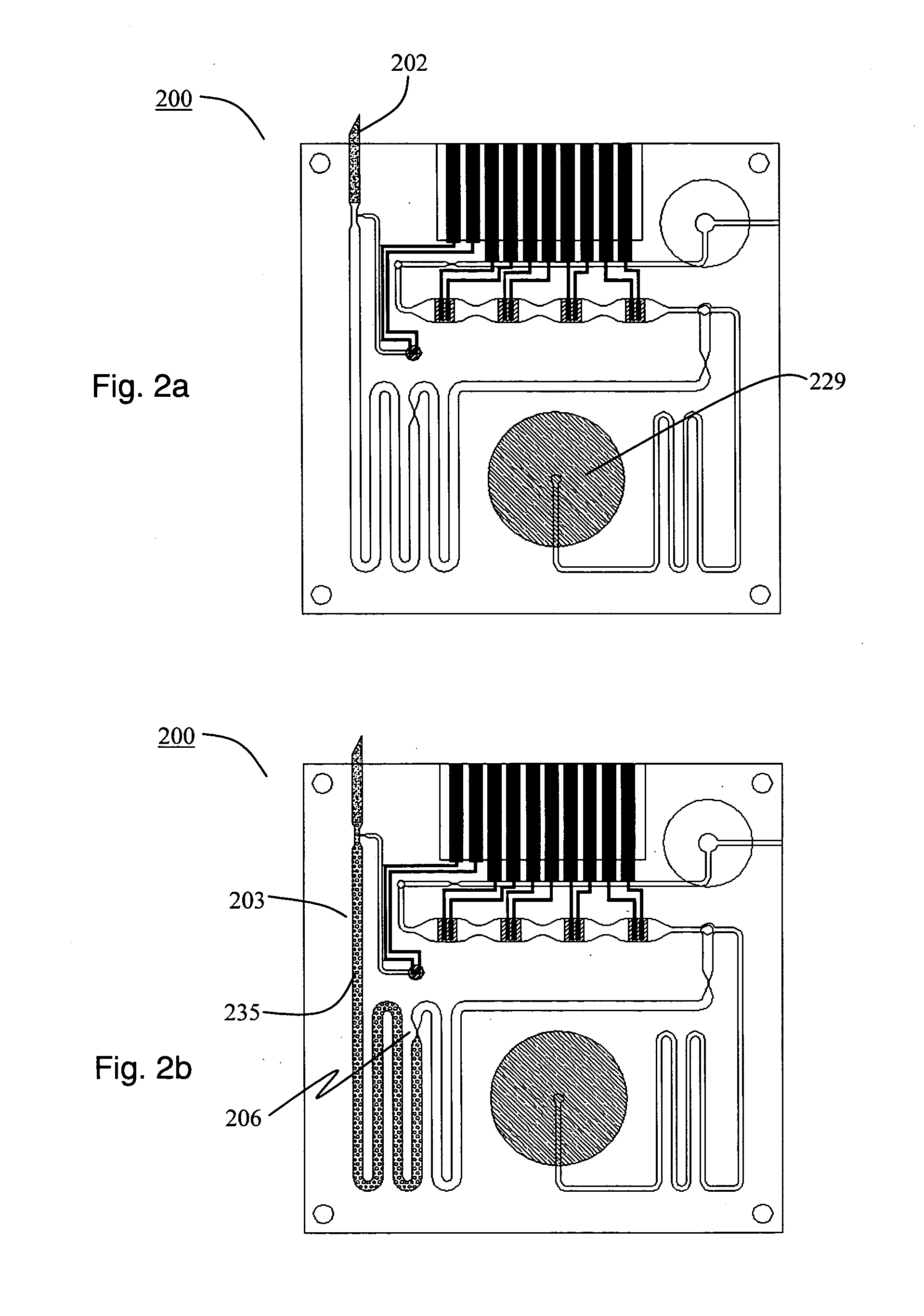

InactiveUS20050130292A1None of measures has been particularly successfulRelieve painBioreactor/fermenter combinationsCombination devicesVenous bloodLab-on-a-chip

Disclosed herein is a fully-integrated, disposable biochip for point-of-care testing of clinically relevant parameters. Specifically, in accordance with an embodiment of the present invention, the biochip is designed for POCT (point-of-care-testing) of an array of metabolic parameters including partial pressure of oxygen, Glucose, and Lactate concentration from venous blood samples. The biochip is fabricated on a low-cost plastic substrate using mass manufacturing compatible fabrication processes. Furthermore, the biochip contains a fully-integrated metallic micro-needle for blood sampling. The biochip also uses smart passive microfluidics in conjunction with low-power functional on-chip pressure generators for microfluidic sequencing. The design, configuration, assembly and operation of the biochip are ideally suited for a disposable biochip specifically targeted towards POCT applications.

Owner:UNIVERSITY OF CINCINNATI

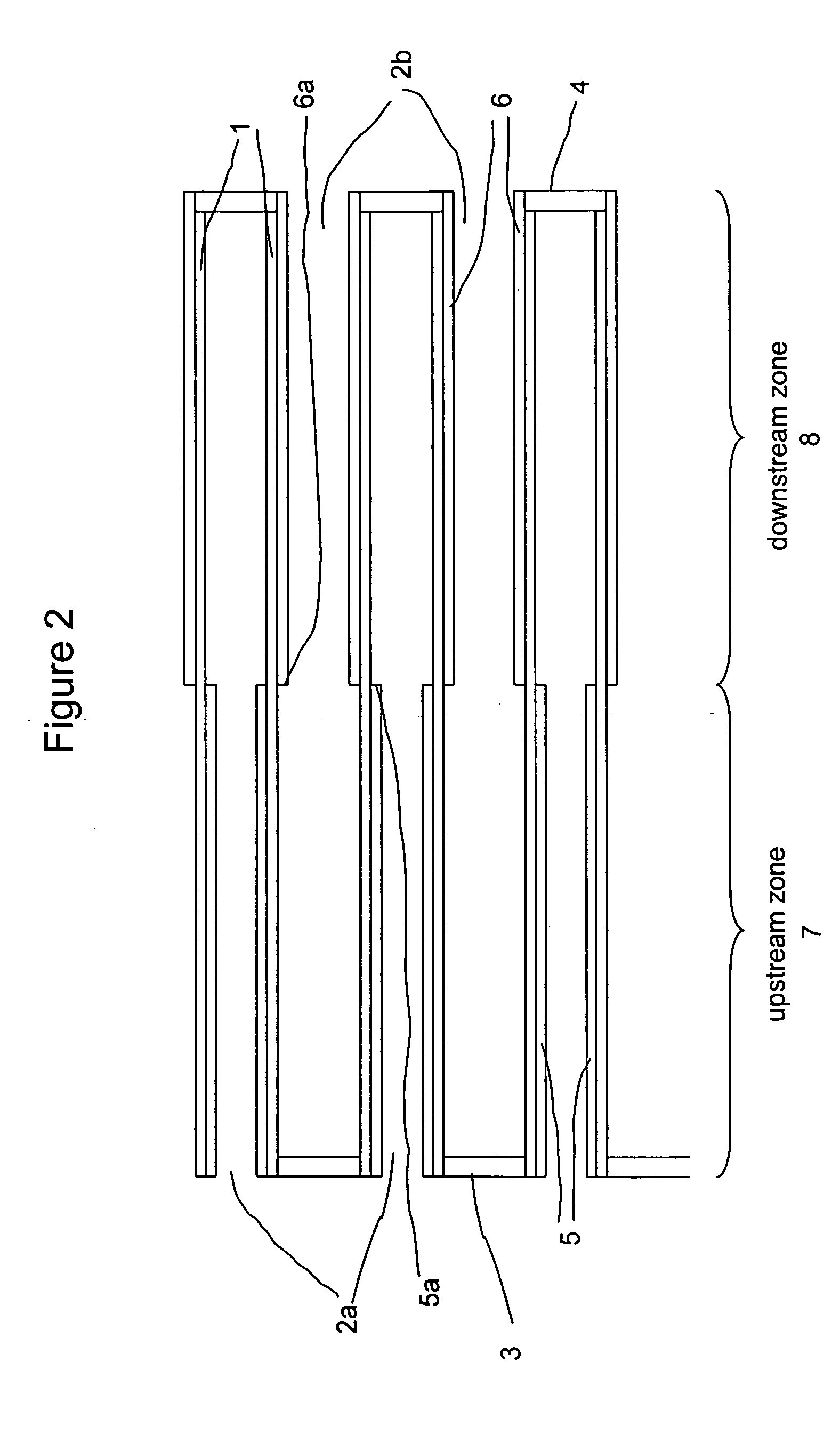

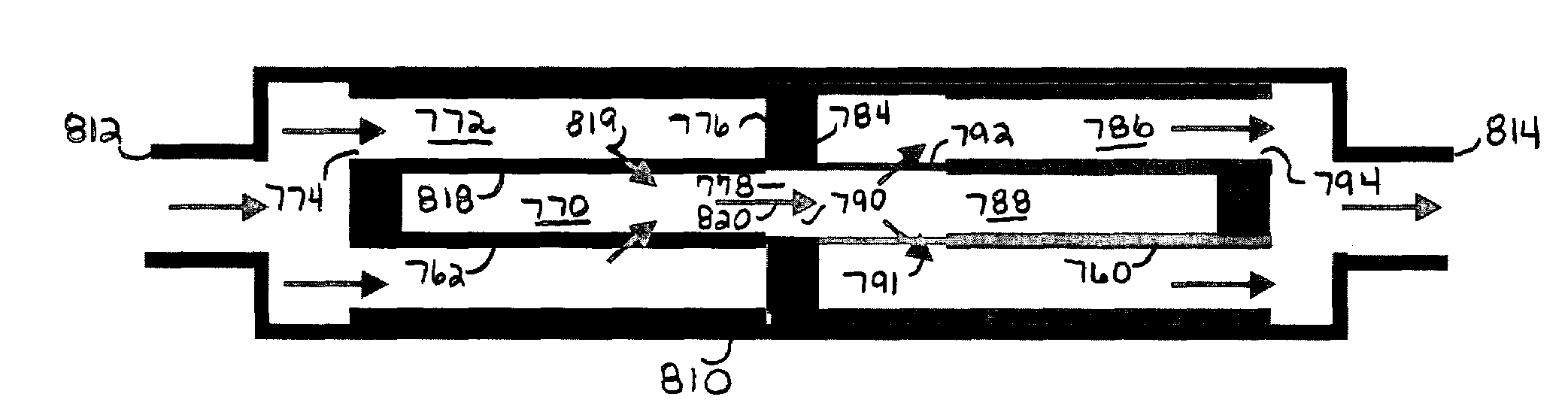

Zone coated catalyst to simultaneously reduce NOx and unreacted ammonia

ActiveUS20060039843A1Efficient conversionReduce riskCombination devicesNitrogen compoundsEngineeringInternal combustion engine

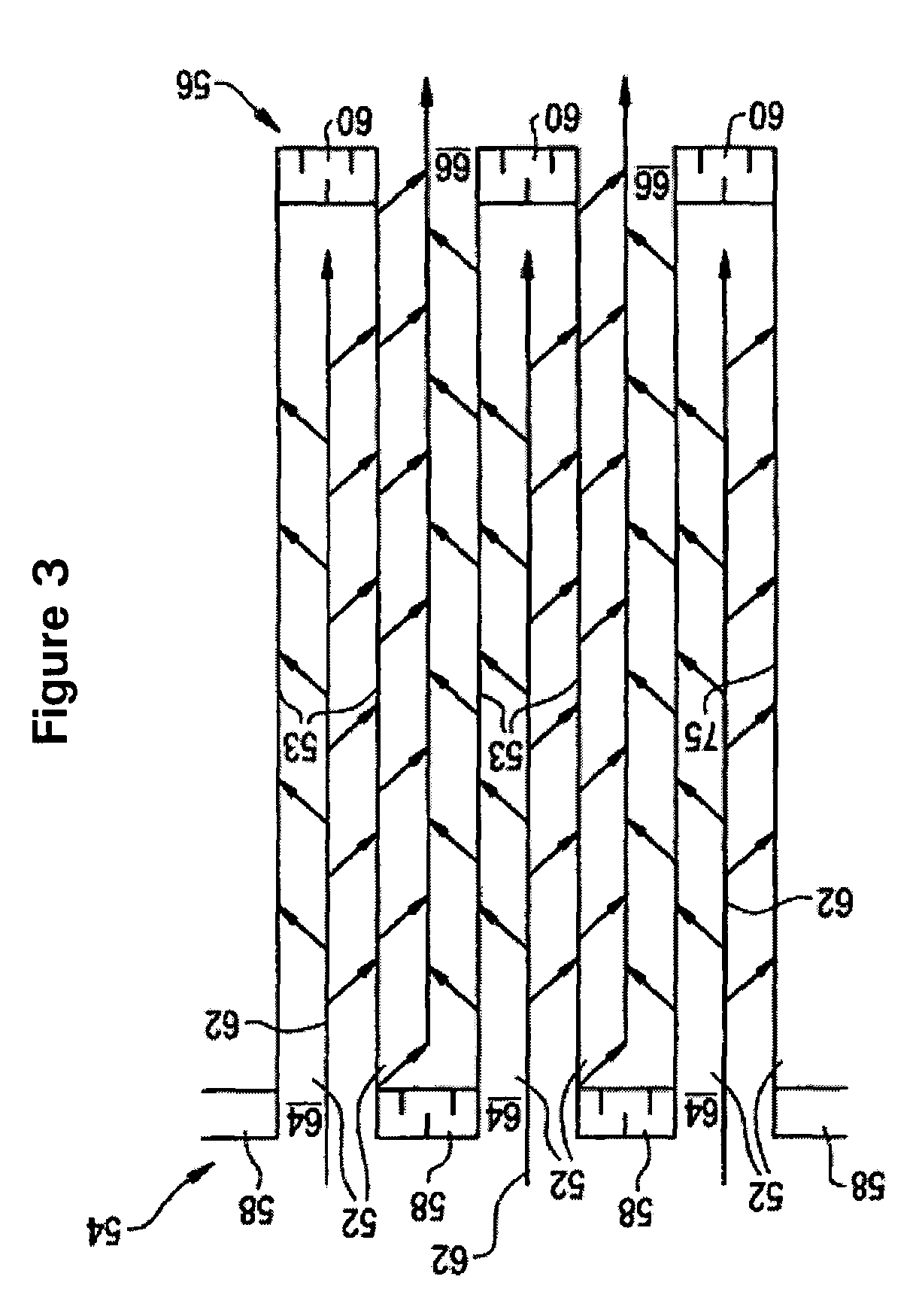

Provided is an emissions treatment system and method for reducing NOx emissions in the exhaust stream produced from an internal combustion engine. The system has an injector for periodically metering ammonia or an ammonia precursor into an exhaust stream; and a first substrate with a first SCR catalyst composition, downstream of the injector. The first substrate has an inlet end, an outlet end, a length extending between the inlet end to the outlet end, wall elements and a plurality of passages defined by the wall elements. The first SCR catalyst composition is disposed on the wall elements from the inlet end toward the outlet end to a length that is less than the substrate's axial length to form an inlet zone. The first substrate also has an NH3 destruction catalyst composition with a platinum group metal component dispersed on a refractory metal oxide. The NH3 destruction catalyst is disposed on the wall elements from the outlet end toward the inlet end to a length that is less than the substrate's axial length to form an outlet zone. Generally, there is from 0.1 to 10 g / ft3 of platinum group metal component in the outlet zone.

Owner:BASF CATALYSTS LLC

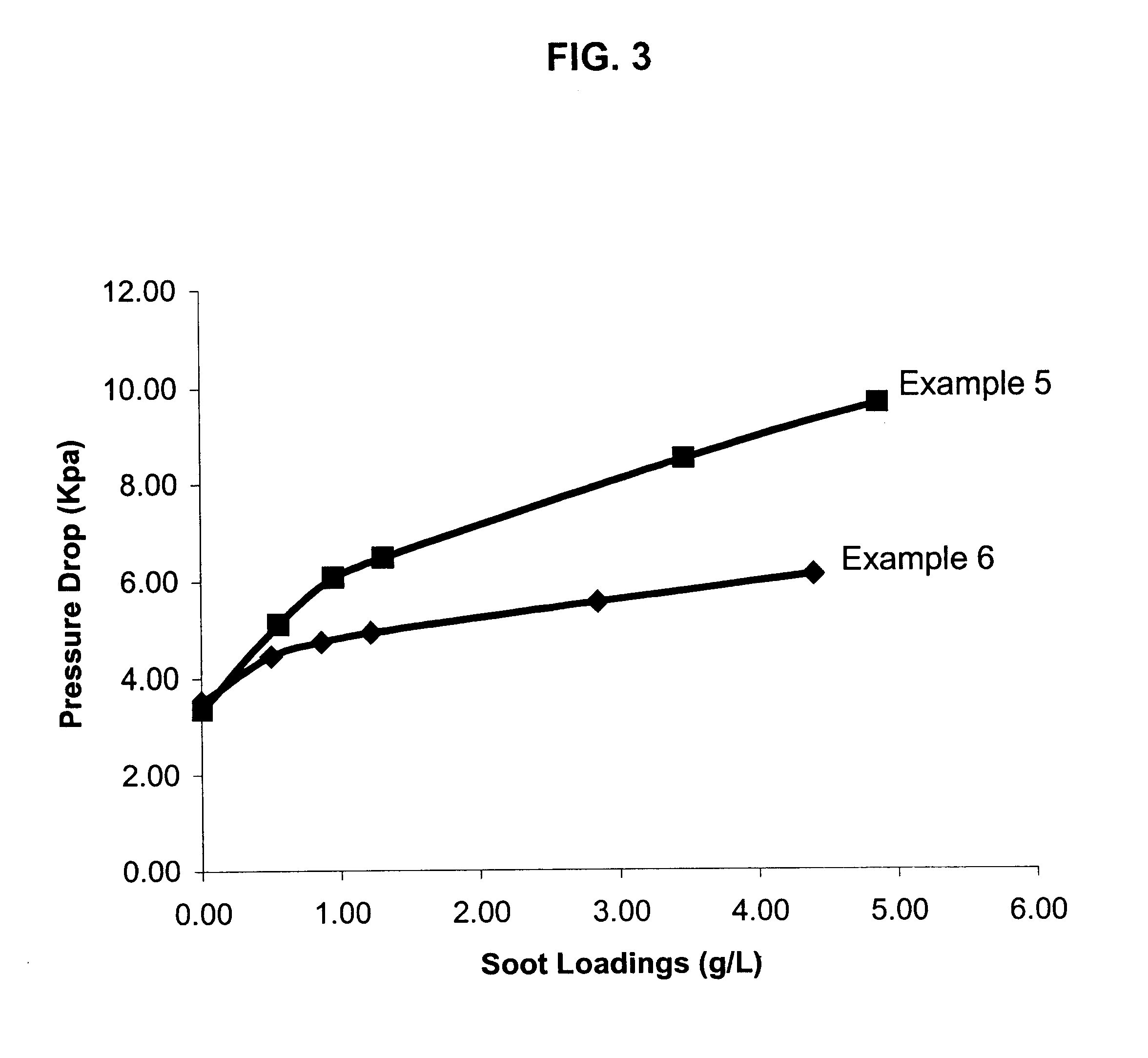

Pressure-balanced, catalyzed soot filter

ActiveUS20060057046A1Minimal overall platinum group metal component material costSpeed up the conversion processCombination devicesMolecular sieve catalystsParticulatesCatalytic function

The invention provides a catalyzed soot filter formed on a wall flow substrate having internal walls coated with catalyst compositions. The soot filter maintains a homogeneous flow of the exhaust gases through the internal walls of the substrate along the length of the filter due to the coating design. Both the efficiency and the durability of the catalytic function are increased over conventionally designed catalyzed soot filters. The catalyzed soot filter provides an integrated function for simultaneously treating the gaseous components of the exhaust (e.g., CO and HC) and the particulate matter deposited in the filter.

Owner:BASF CATALYSTS LLC

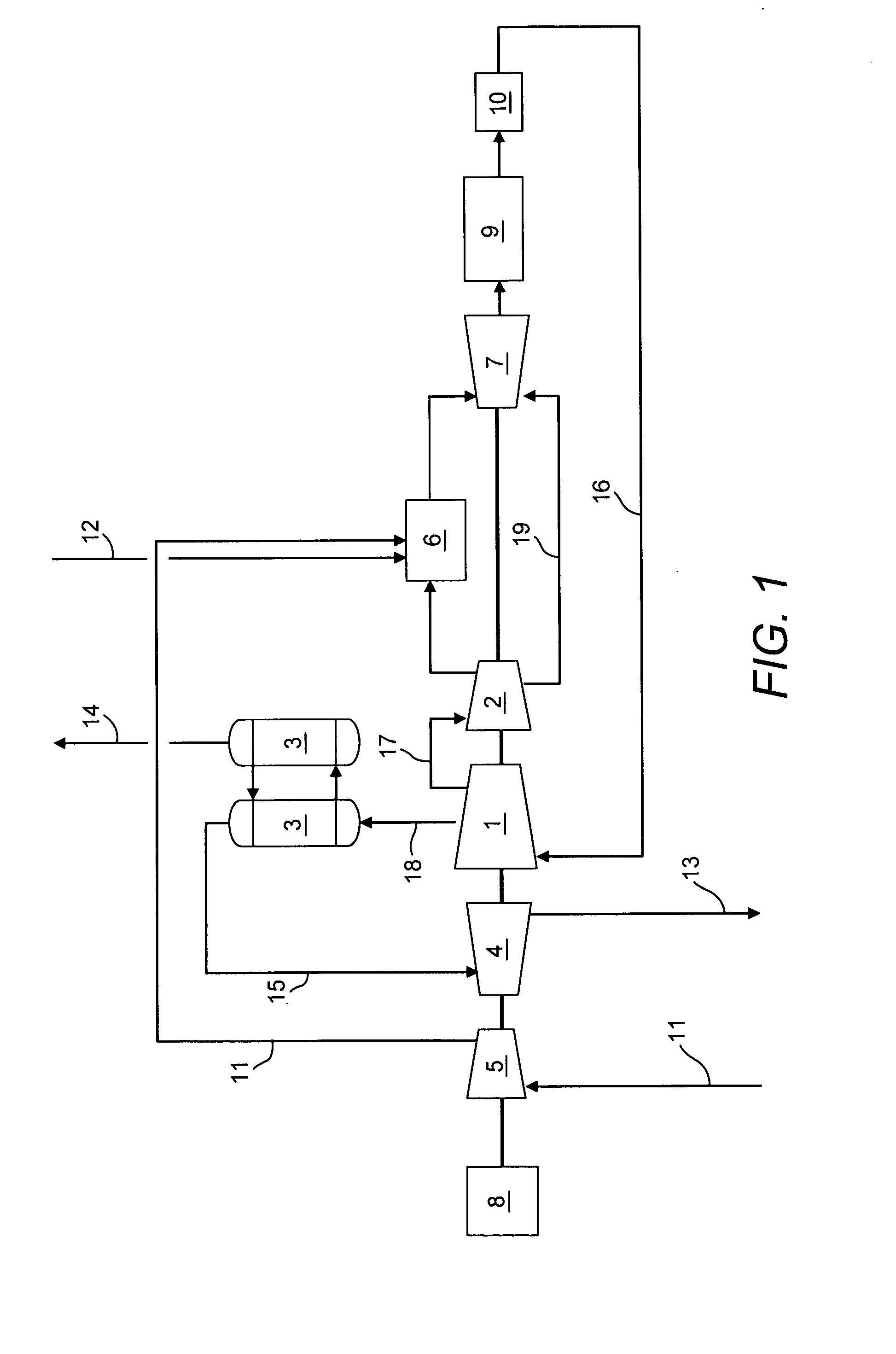

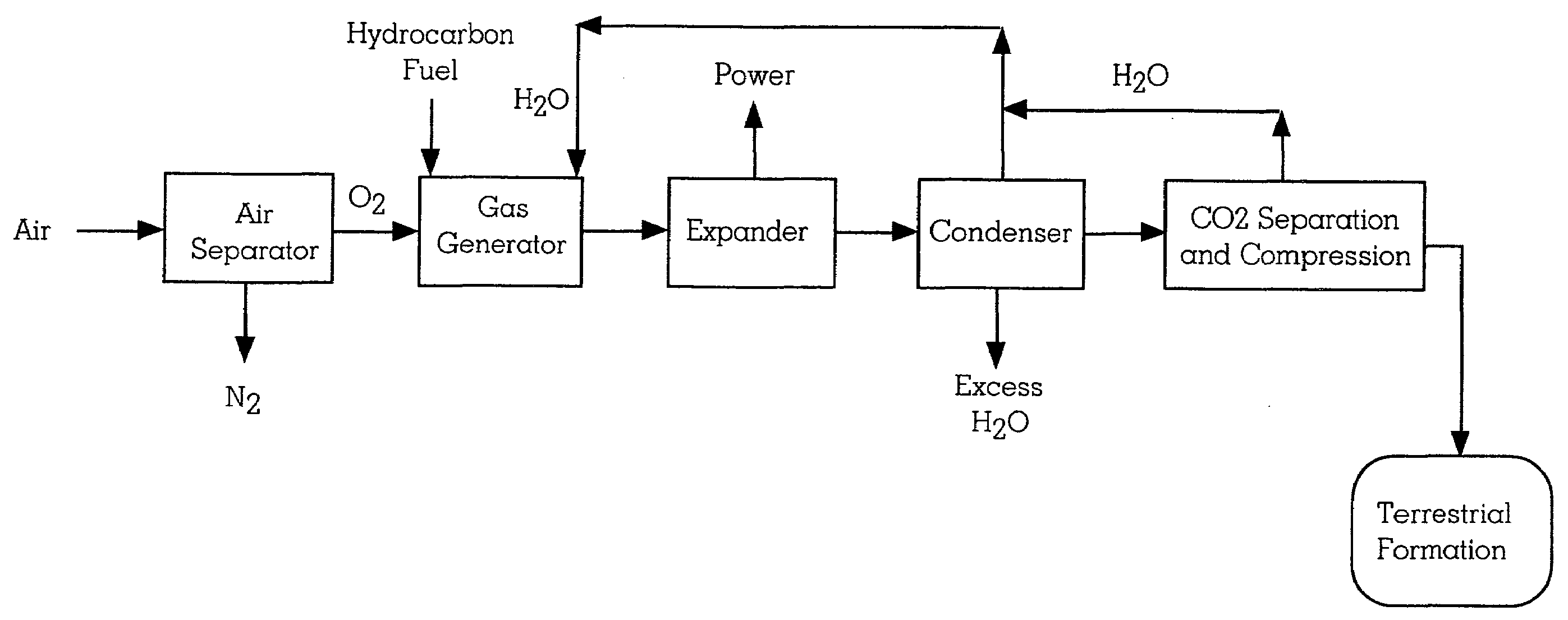

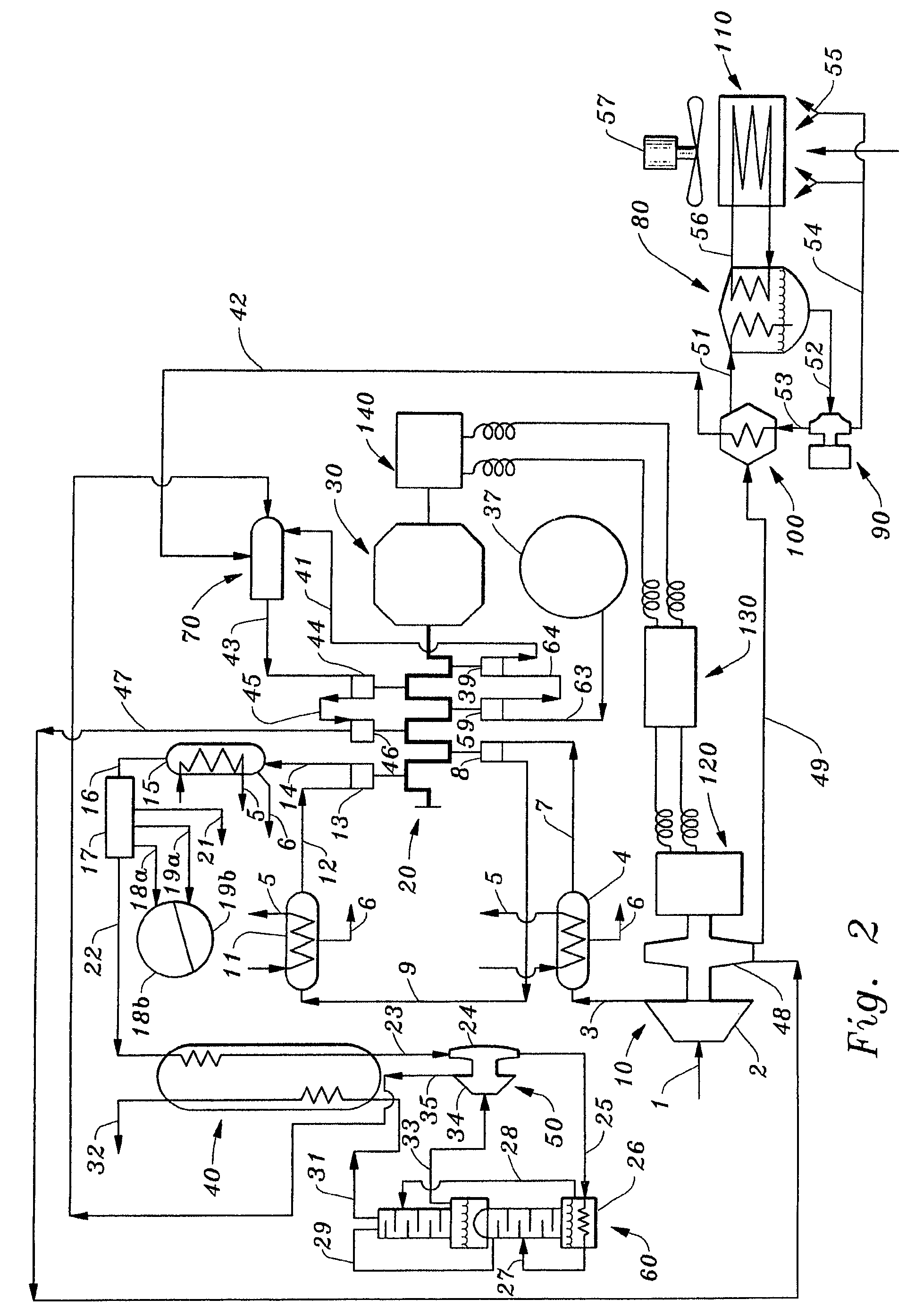

Hydrocarbon combustion power generation system with CO2 sequestration

InactiveUS7043920B2Eliminate needReduce electricity demandReciprocating combination enginesSolidificationAtmospheric airOxygen

A low or no pollution engine is provided for delivering power for vehicles or other power applications. The engine has an air inlet which collects air from a surrounding environment. At least a portion of the nitrogen in the air is removed. The remaining gas is primarily oxygen, which is then routed to a gas generator. The gas generator has inputs for the oxygen and a hydrocarbon fuel. The fuel and oxygen are combusted within the gas generator, forming water and carbon dioxide. The combustion products are then expanded through a power generating device, such as a turbine or piston expander to deliver output power for operation of a vehicle or other power uses. The combustion products are then passed through a condenser where the steam is condensed and the carbon dioxide is collected or discharged. A portion of the water is routed back to the gas generator. The carbon dioxide is compressed and delivered to a terrestrial formation from which return of the CO2 into the atmosphere is inhibited.

Owner:CLEAN ENERGY SYST

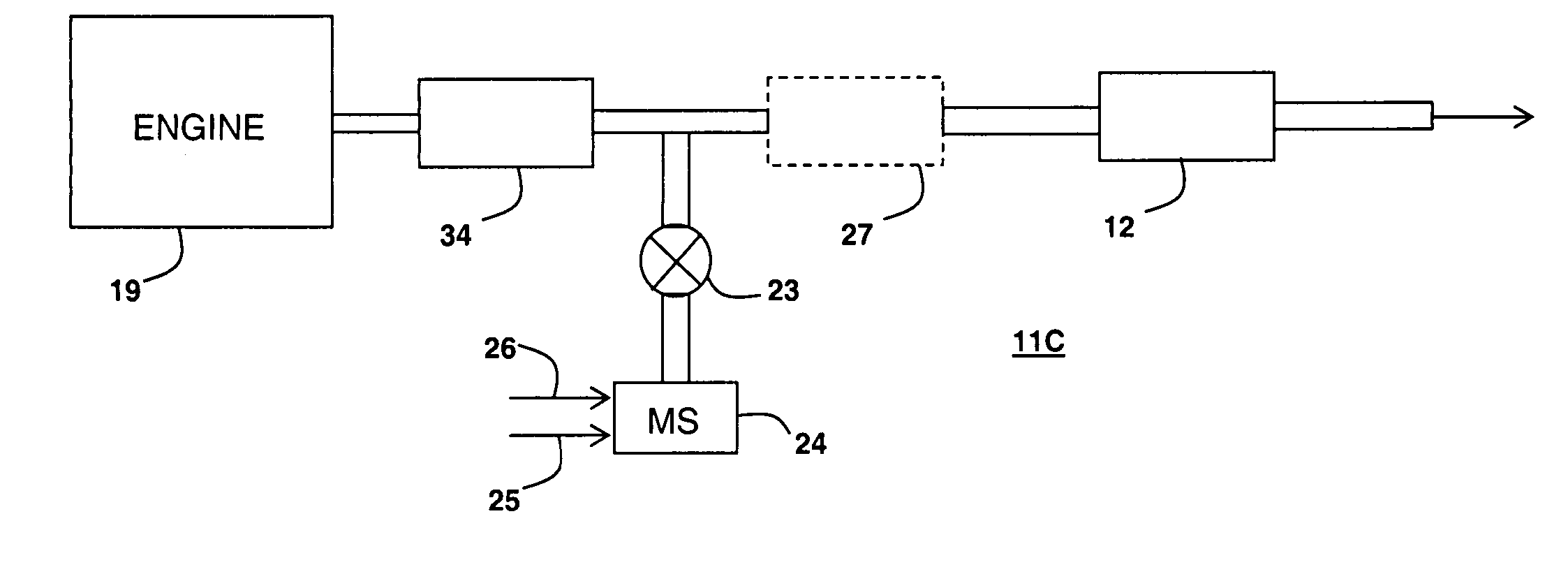

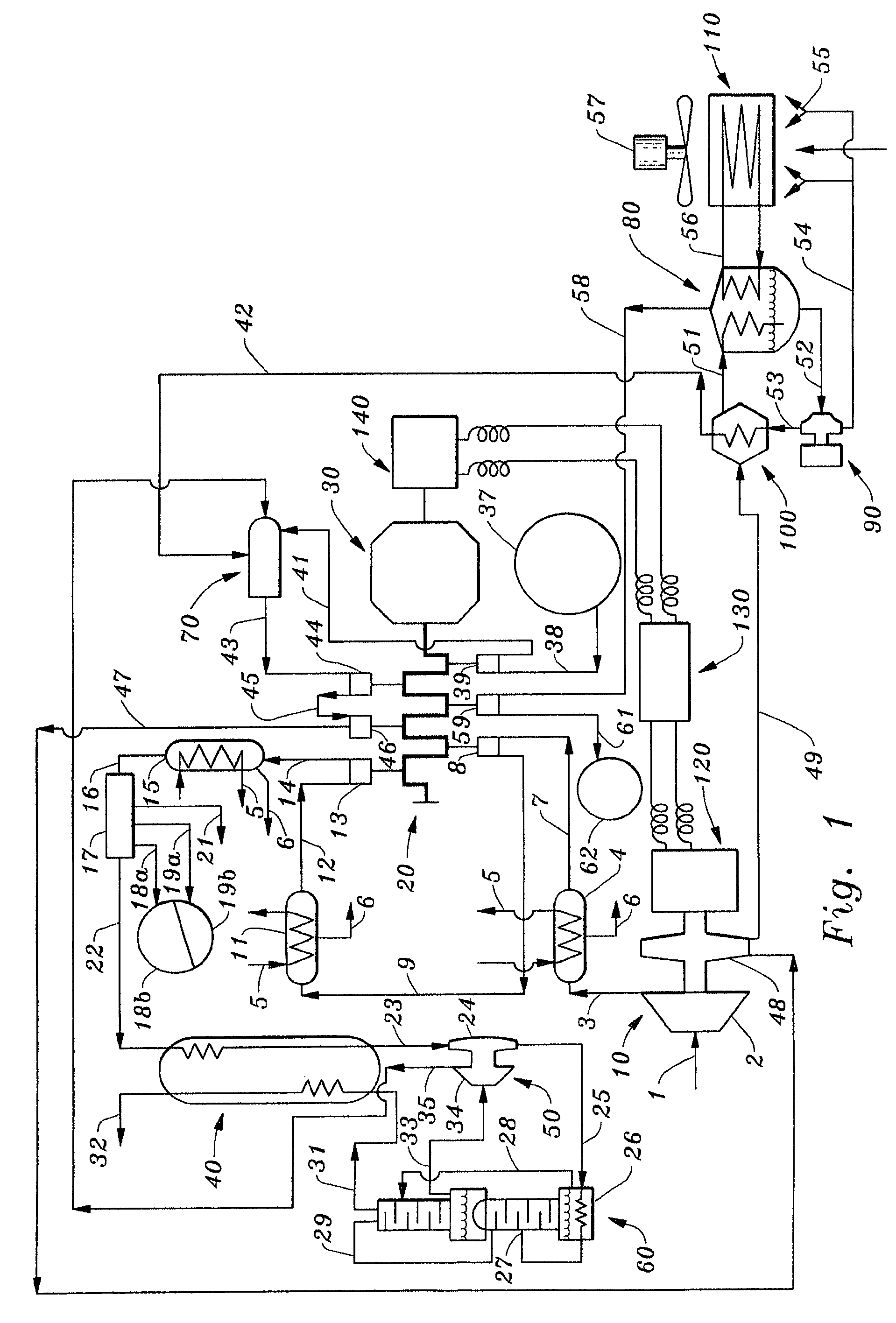

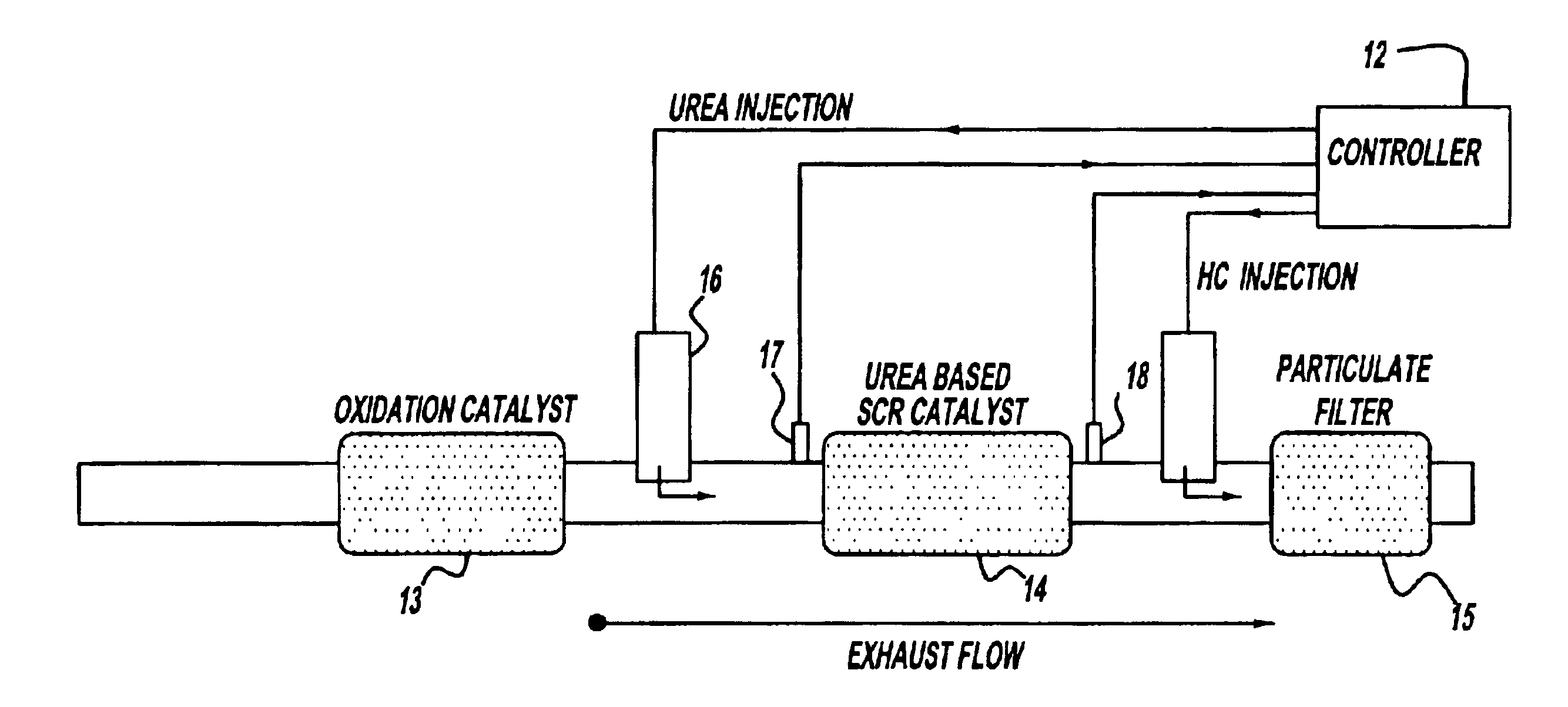

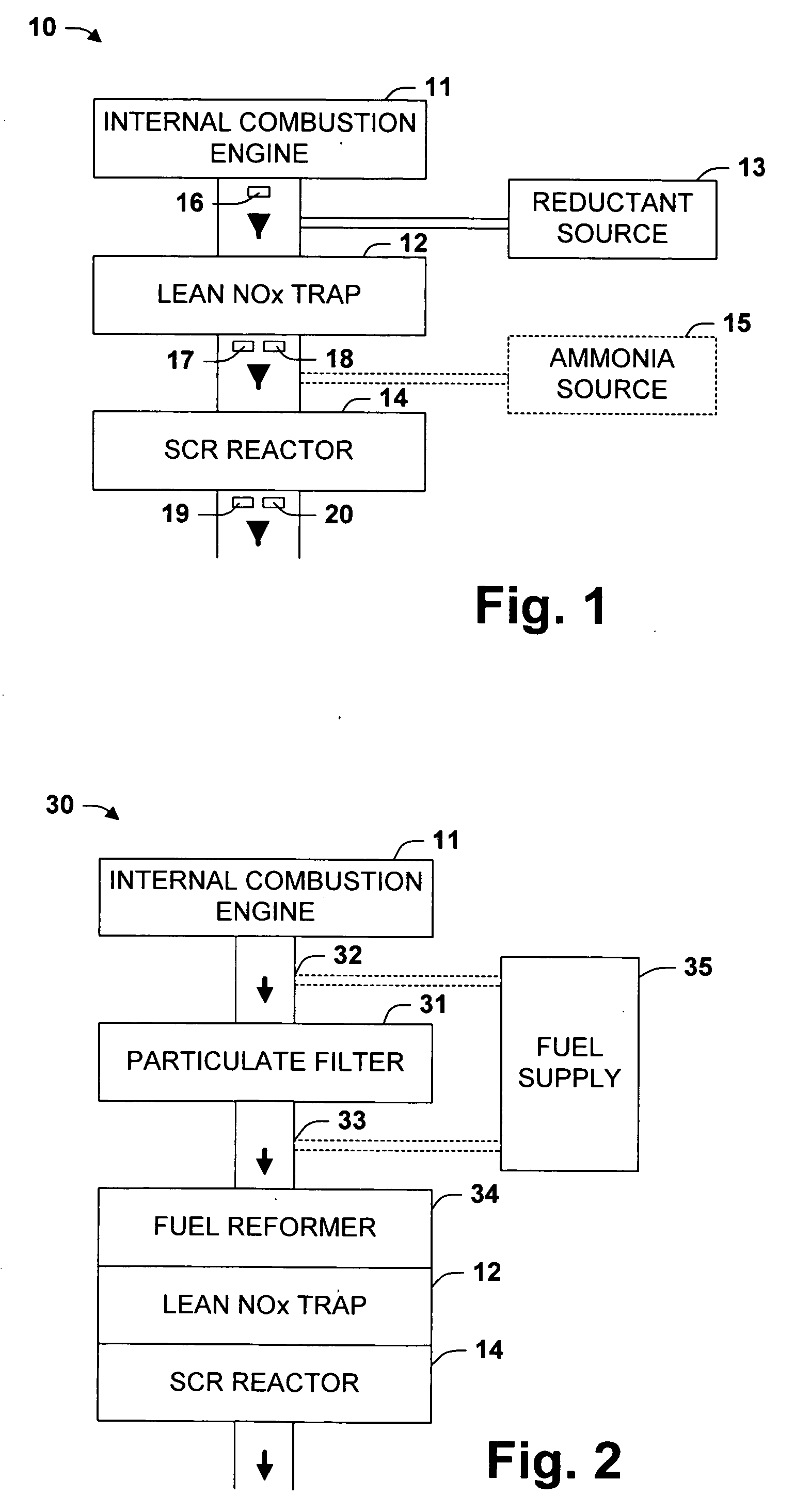

Exhaust gas aftertreatment systems

InactiveUS6928806B2Improve NOx conversion efficiencyHigh operating temperatureElectrical controlInternal combustion piston enginesExhaust fumesSystem configuration

A system for effective NOx and particulate matter control in a diesel or other lean burn internal combustion engine is presented. The system includes a urea-based SCR catalyst having an oxidation catalyst coupled upstream of it and a particulate filter coupled downstream of the SCR catalyst. This system configuration results in improved NOx conversion due to fast SCR catalyst warm-up and higher operating temperatures. Additionally, placing the particulate filter last in this system configuration reduces tailpipe ammonia emissions as well as prevents any thermal damage to the SCR catalyst due to the particulate filter regeneration.

Owner:FORD GLOBAL TECH LLC

Audio preview of music

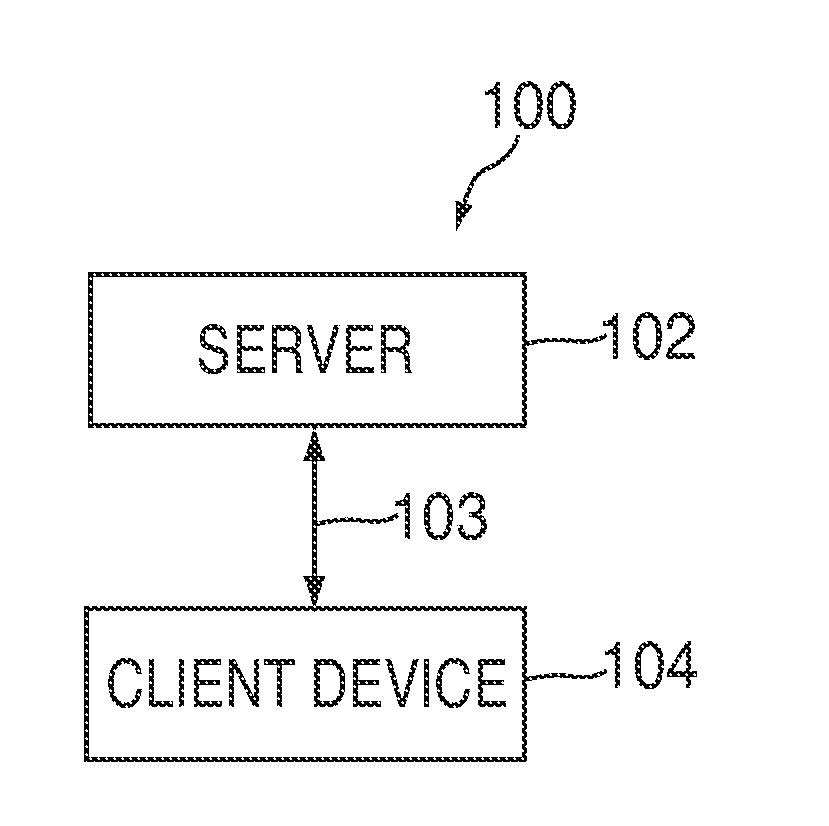

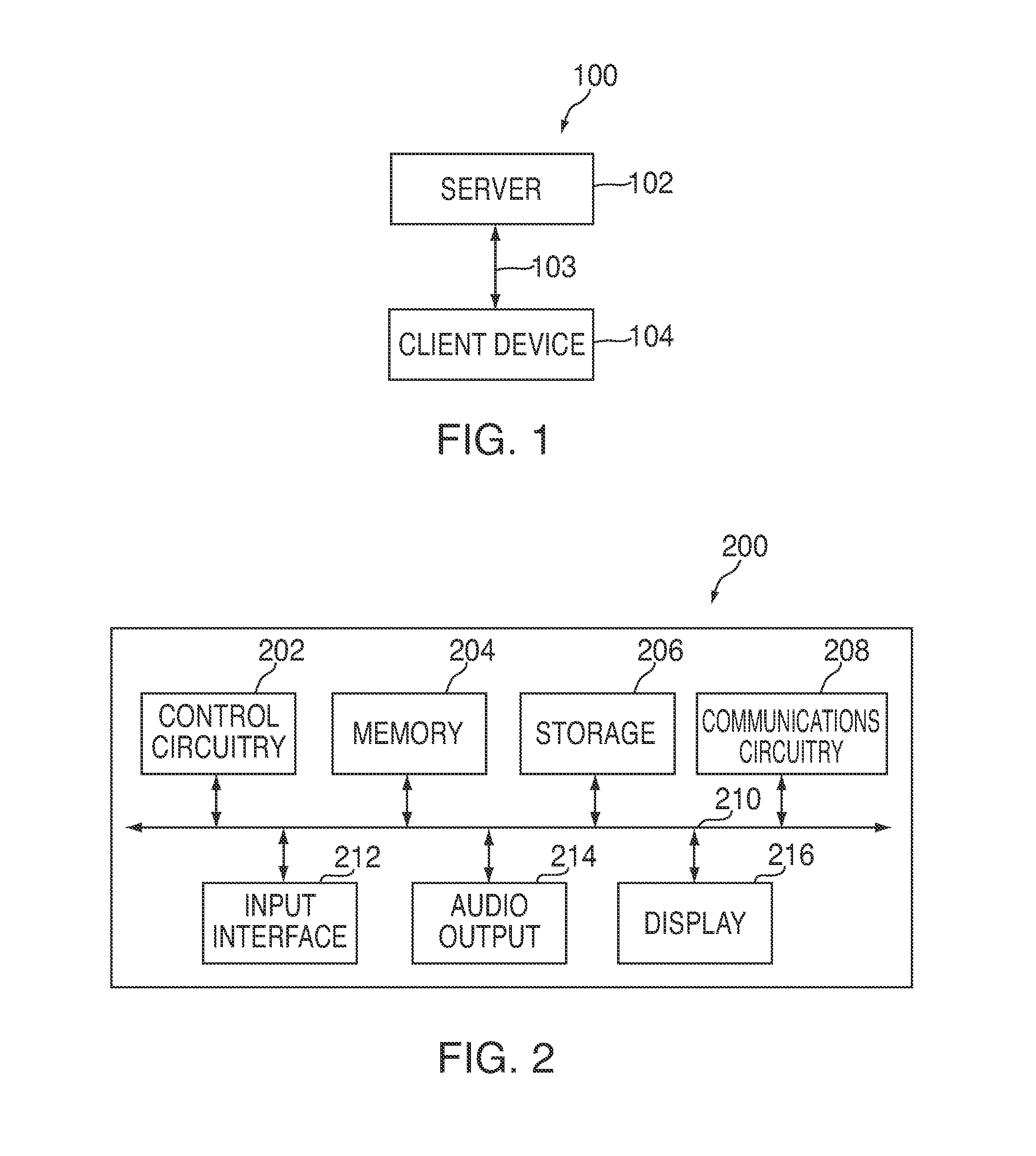

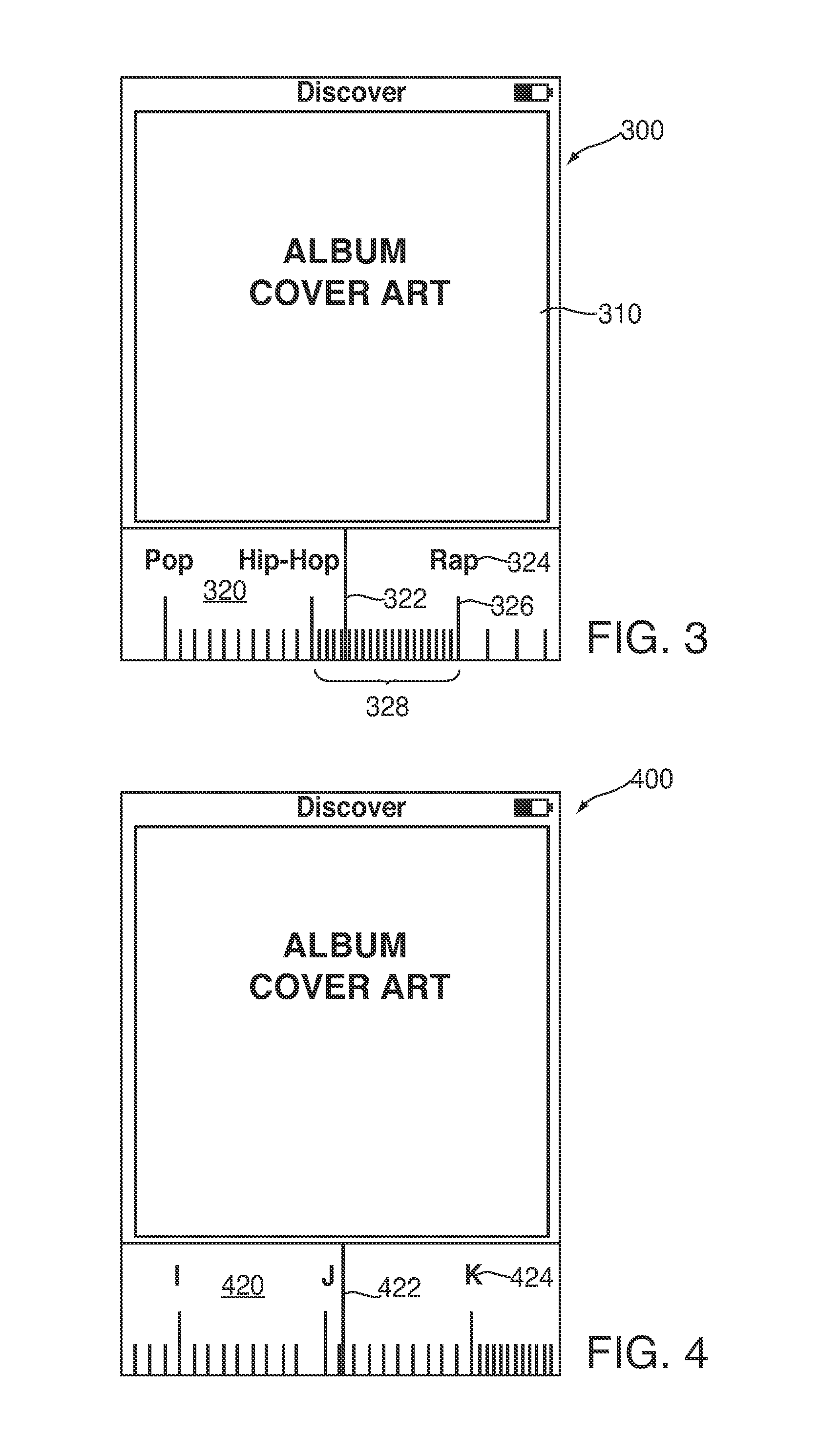

ActiveUS20110234480A1Easily effectively locateQuick ViewExhaust apparatusTransportation and packagingOperation modeVisual interface

Systems, methods, and machine-readable media are disclosed for providing an audio preview of songs and other audio elements. In some embodiments, an electronic device may operate in either a “play mode,” which allows a user to listen to songs in a normal fashion, or in a “preview mode,” which may be used to provide previews of songs to a user in succession. In some embodiments, the electronic device may seamlessly transition between play mode and preview mode. For example, the electronic device may pause a currently-playing song when the mode of operation switches from play mode to preview mode so that, if the user exits out of preview mode, the original song may be resumed from the pause point. In some embodiments, the electronic device may provide a multi-directional visual interface that allows a user to control the succession of previews provided in preview mode.

Owner:APPLE INC

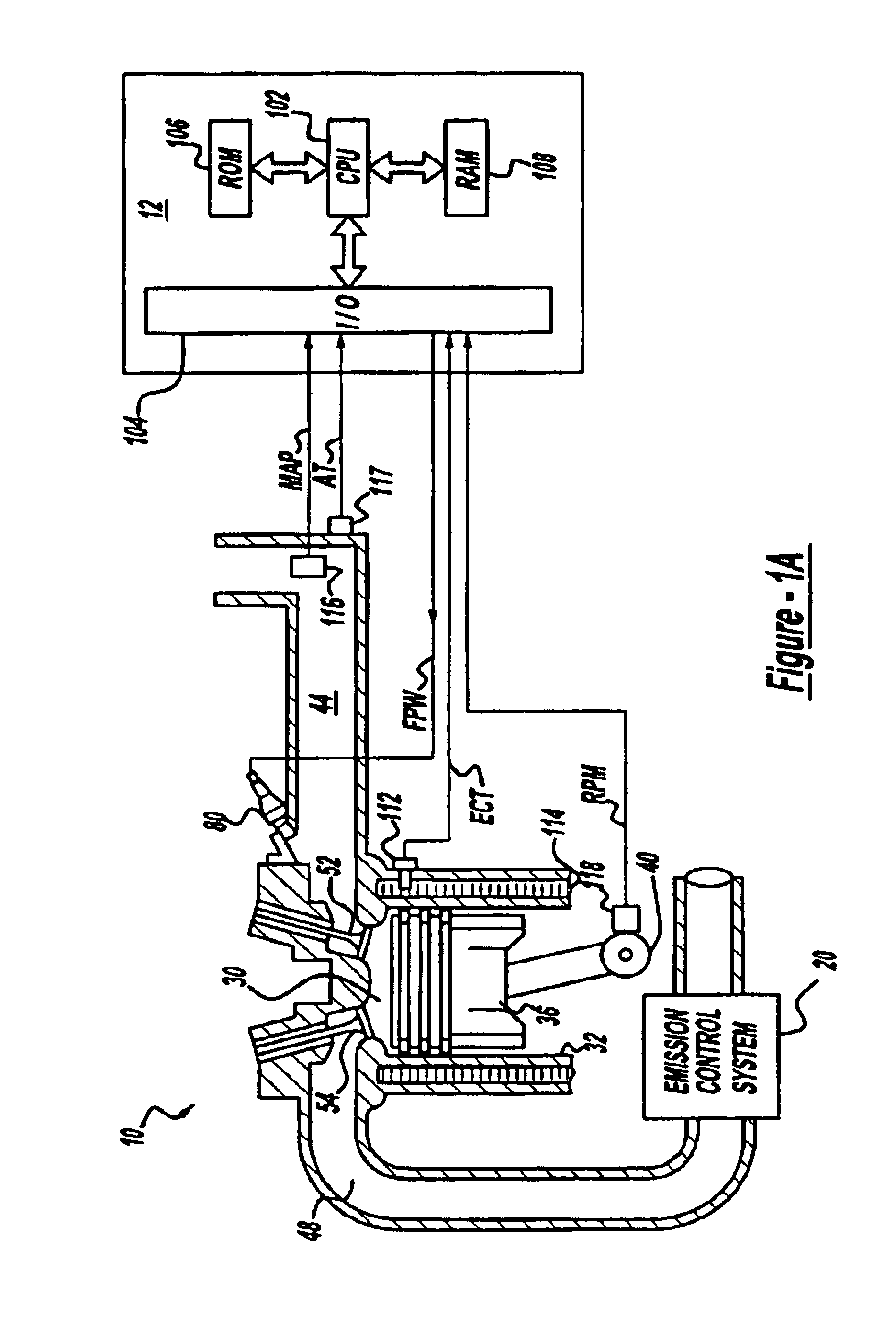

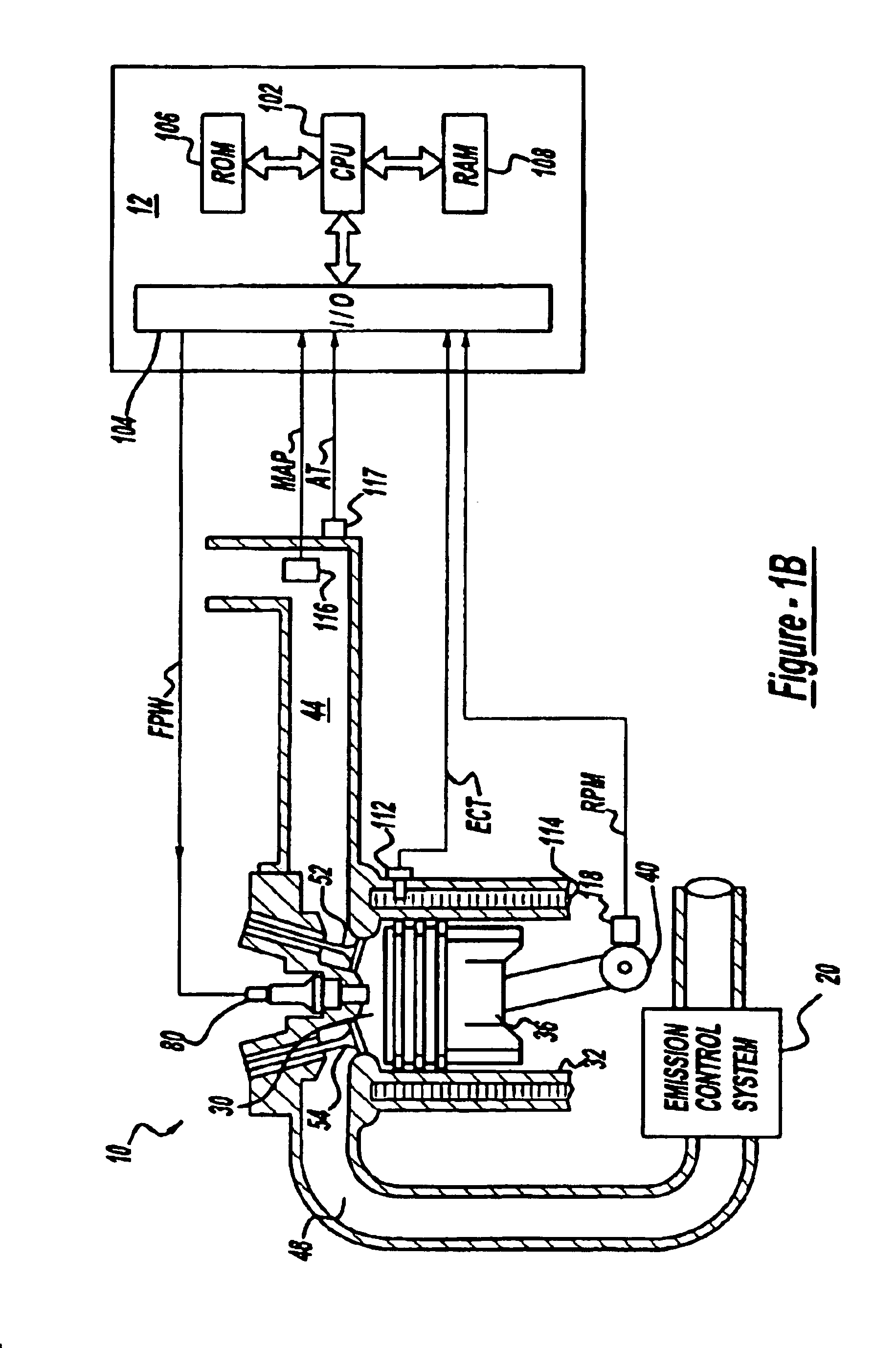

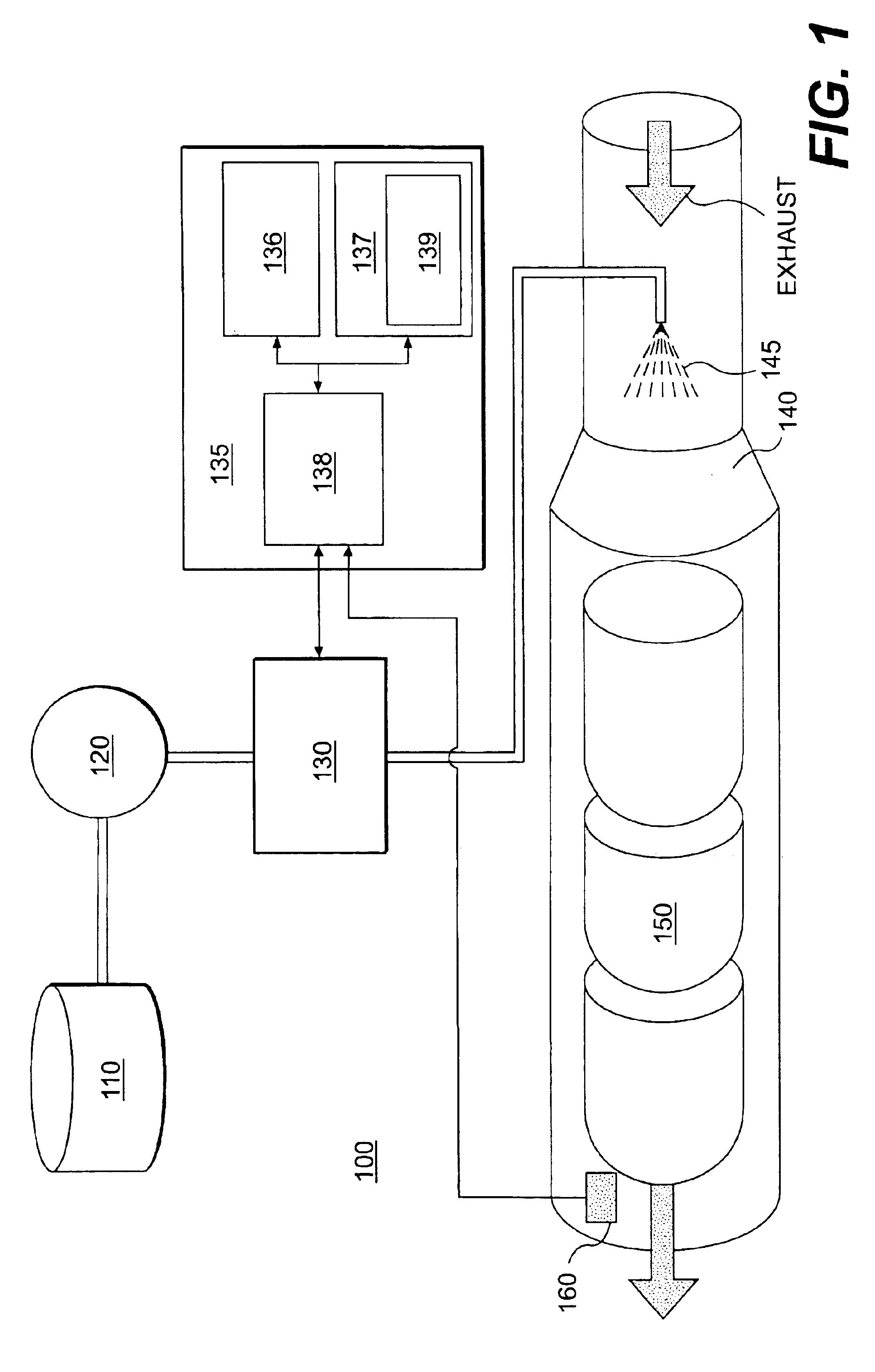

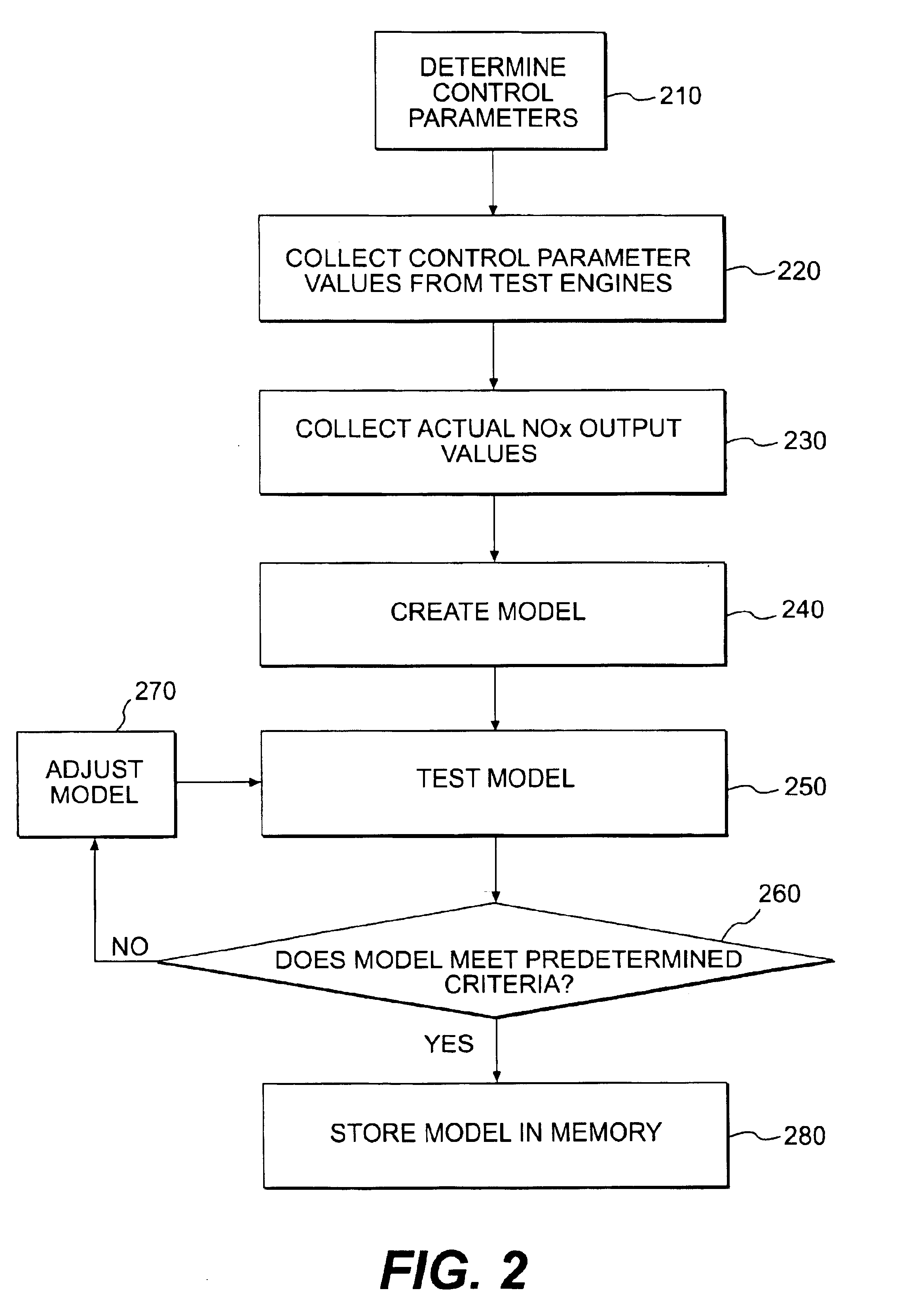

NOx emission-control system using a virtual sensor

InactiveUS6882929B2Reduce nitrogen oxide emissionsInternal combustion piston enginesDigital data processing detailsAmbient humidityControl system

A method and system may be provided to perform a process for controlling NOx emissions of an target engine. In one embodiment of the invention, the process may include determining predicted NOx values based on a model reflecting a predetermined relationship between control parameters and NOx emissions, wherein the control parameters include ambient humidity, manifold pressure, manifold temperature, fuel rate, and engine speed associated with the engine. Further, the process may include adjusting the model based on a determination of whether the predicted NOx values meet a predetermined criteria associated with actual NOx values. The adjusted model may be stored in a memory associated with the engine whereby NOx emissions exhausted from the engine may be reduced based on virtual NOx emission values determined from the adjusted model.

Owner:CATERPILLAR INC

High temperature nanofilter, system and method

InactiveUS7052532B1More laminar flowShort pleat heightDispersed particle filtrationTransportation and packagingFiberNanoparticle

A filter, system and method is provided for filtering nanoparticles in a hot gas, namely particles <about 1 micron in a gas >about 200° C. and further particularly >about 450° C. including diesel exhaust. The filter includes filter media material composed of fibrous filter media having a plurality of fibers and granular filter media having a plurality of granules extending from the surfaces of the fibers. The filter is characterized by a permeability >about 3×10−12 m2 and an inertial resistance coefficient <about 1×106 m−1. The filter captures particles in the Most Penetrating Region (MPR). A filter system includes a nanoparticle filter in series with a diesel exhaust treatment element.

Owner:3M INNOVATIVE PROPERTIES CO +1

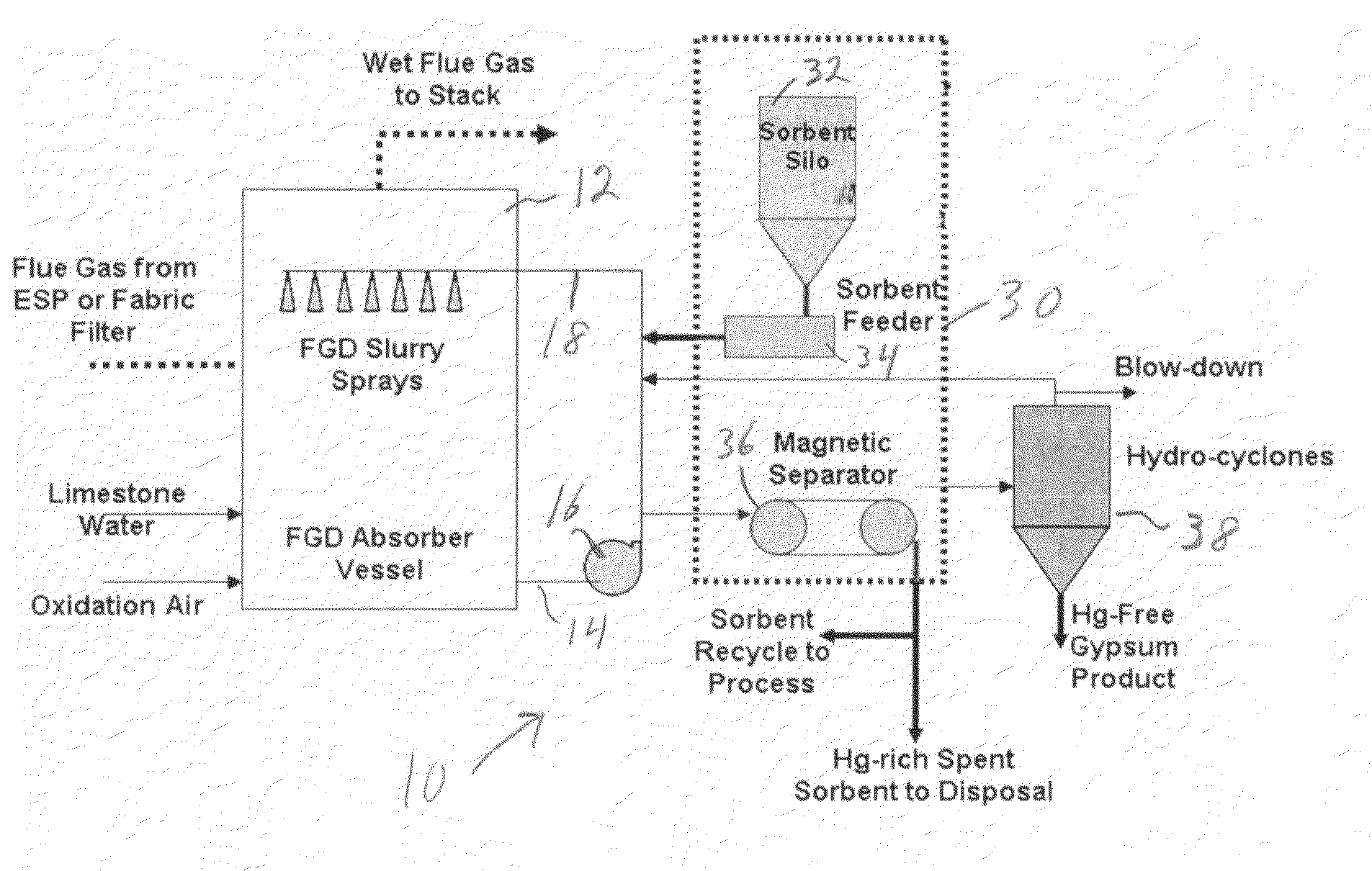

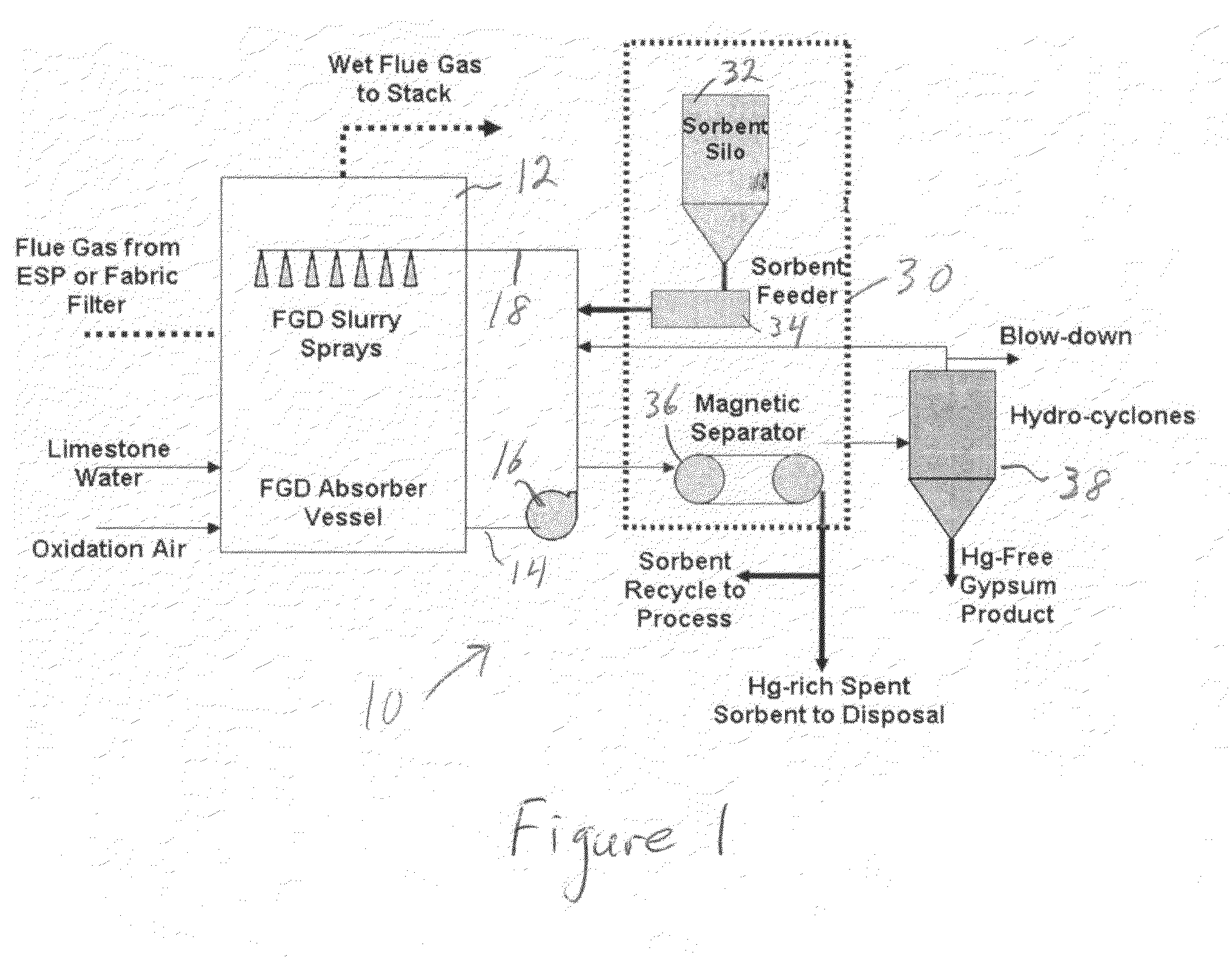

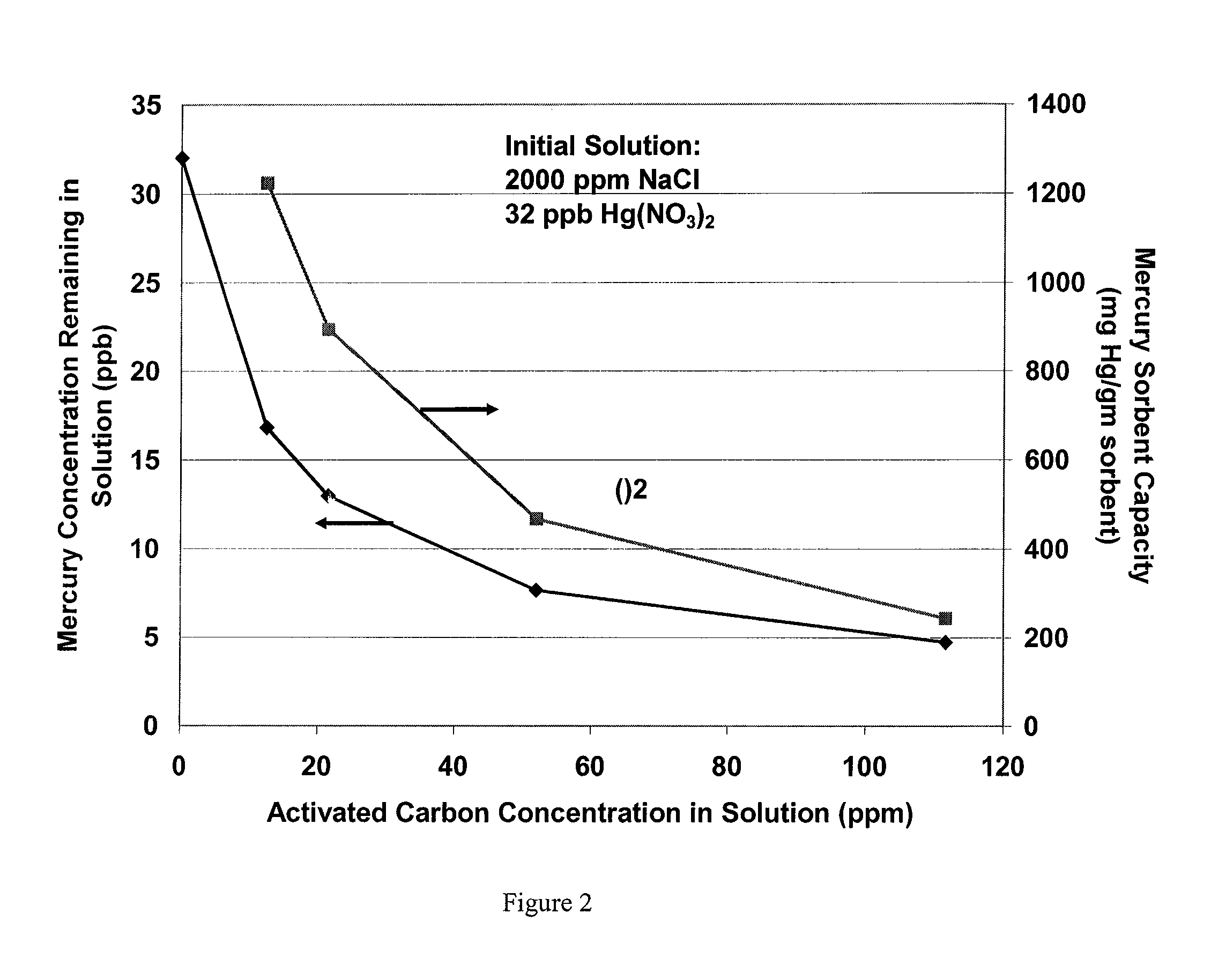

System and method for sequestration and separation of mercury in combustion exhaust gas aqueous scrubber systems

ActiveUS7722843B1Emission reductionMinimize re-emissionCombination devicesExhaust apparatusCombustionSorbent

A process, system and sorbent for removal of mercury from a combustion exhaust gas stream in a combustion exhaust gas purification scheme that includes a combustion exhaust scrubber system that uses an aqueous liquid to remove acid gases from the combustion exhaust gas. A powdered mercury sorbent is used. The sorbent is introduced into the aqueous scrubber liquid in the scrubber system. After introduction of the mercury sorbent into the scrubber liquid, at least some of the mercury sorbent is separated from the scrubber liquid.

Owner:SRINIVASACHAR SRIVATS

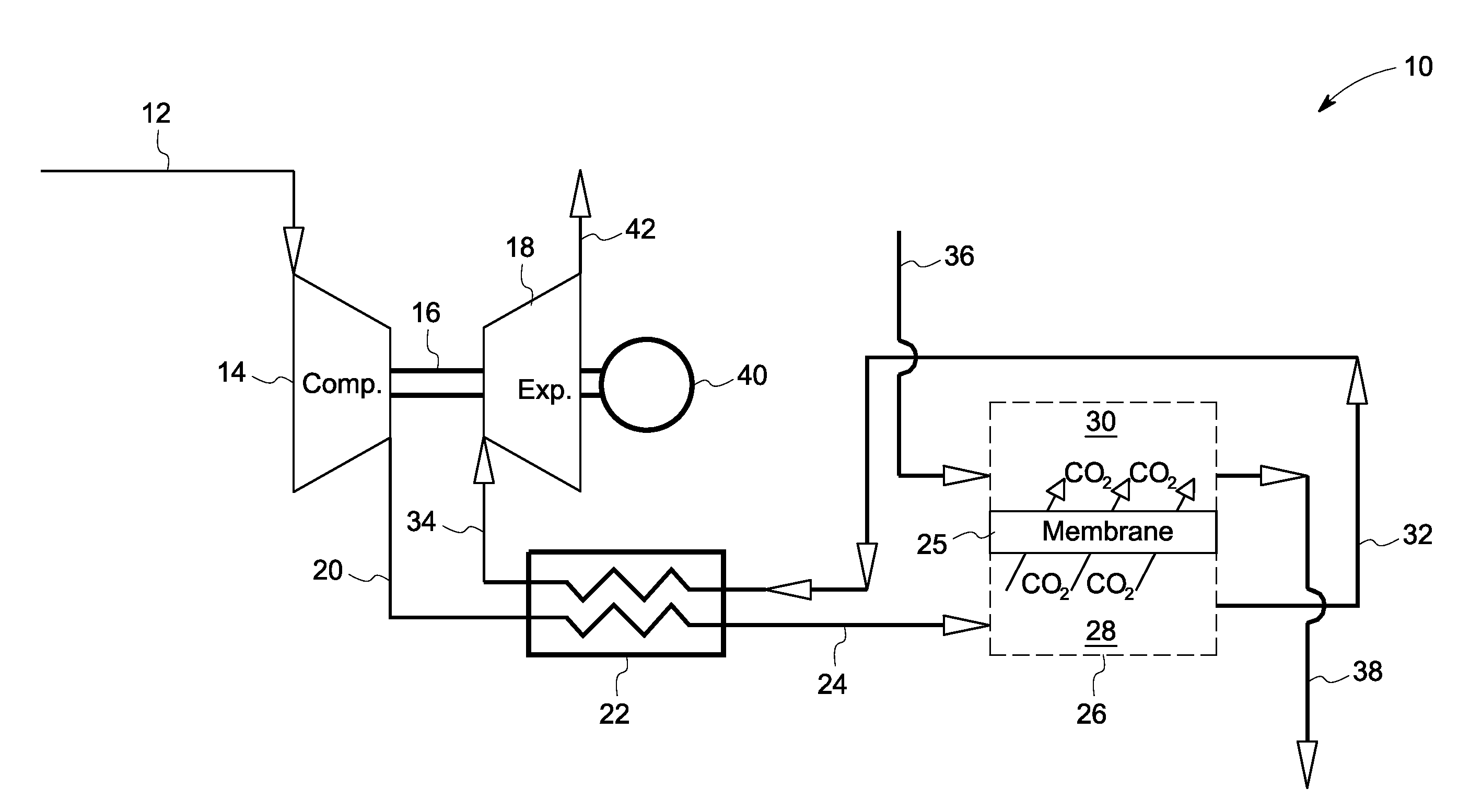

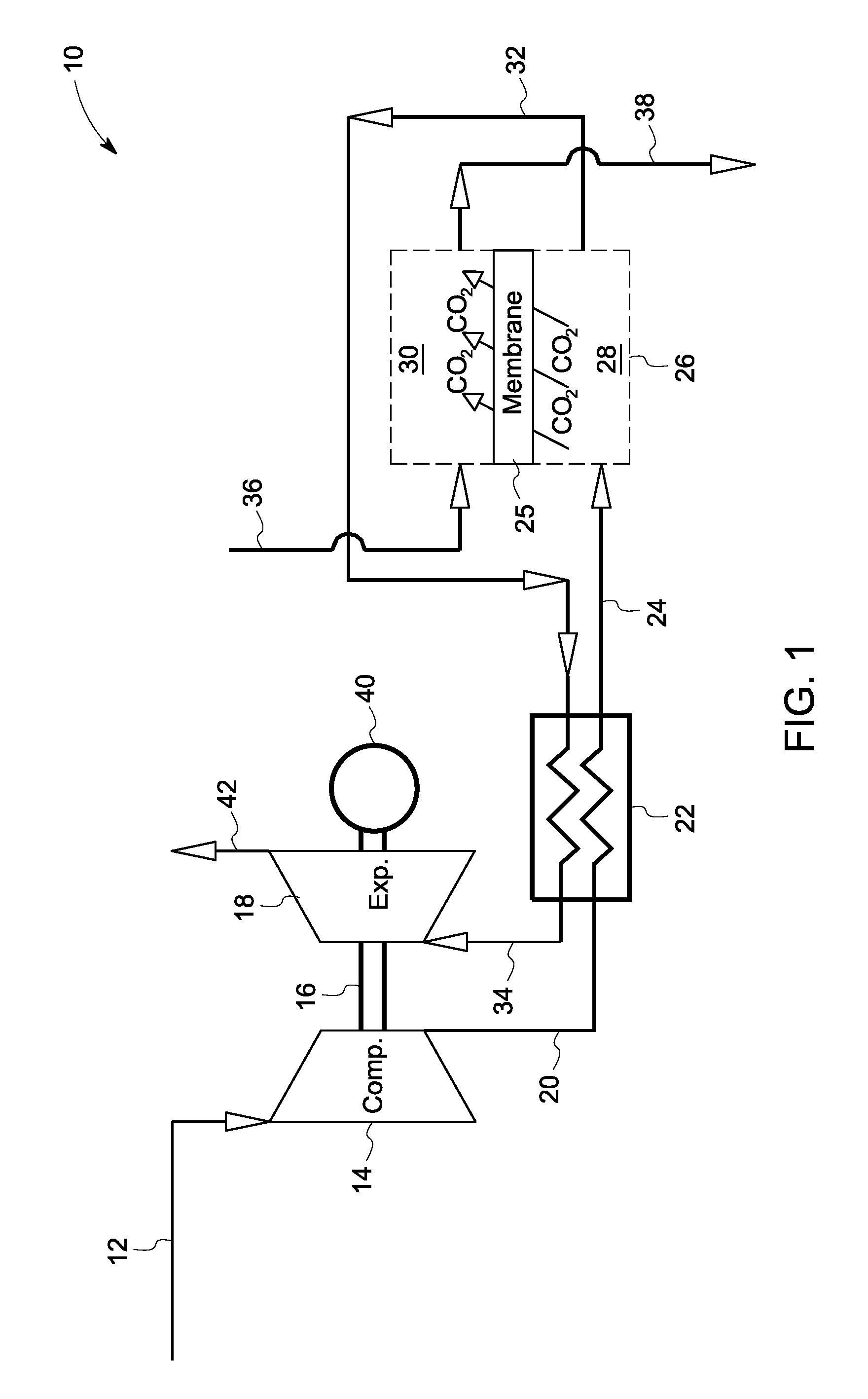

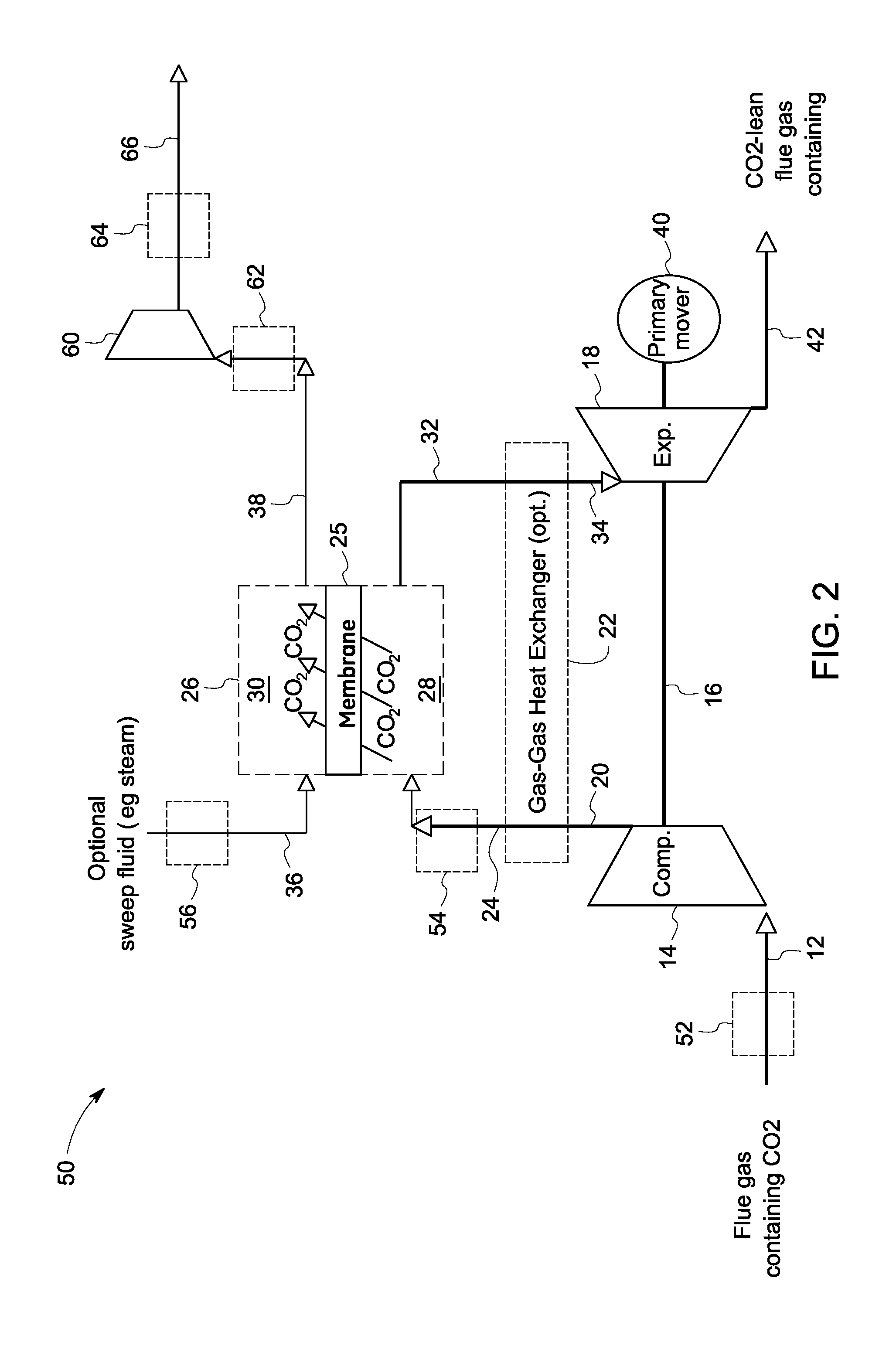

Carbon dioxide capture systems and methods

InactiveUS20080127632A1More cost-effectivelyEasy and cost-effectiveGas treatmentExhaust apparatusCarbon dioxide transportProcess engineering

A carbon dioxide separation system includes a compressor for receiving an exhaust gas comprising CO2 and generate a compressed exhaust gas and a separator configured to receive the compressed exhaust gas and generate a CO2 lean stream. The separator includes a first flow path for receiving the compressed exhaust gas, a second flow path for directing a sweep fluid therethrough, and a material with selective permeability of carbon dioxide for separating the first and the second flow paths and for promoting carbon dioxide transport therebetween. The system further includes an expander coupled to the compressor for receiving and expanding the CO2 lean stream to generate power and an expanded CO2 lean stream.

Owner:GENERAL ELECTRIC CO

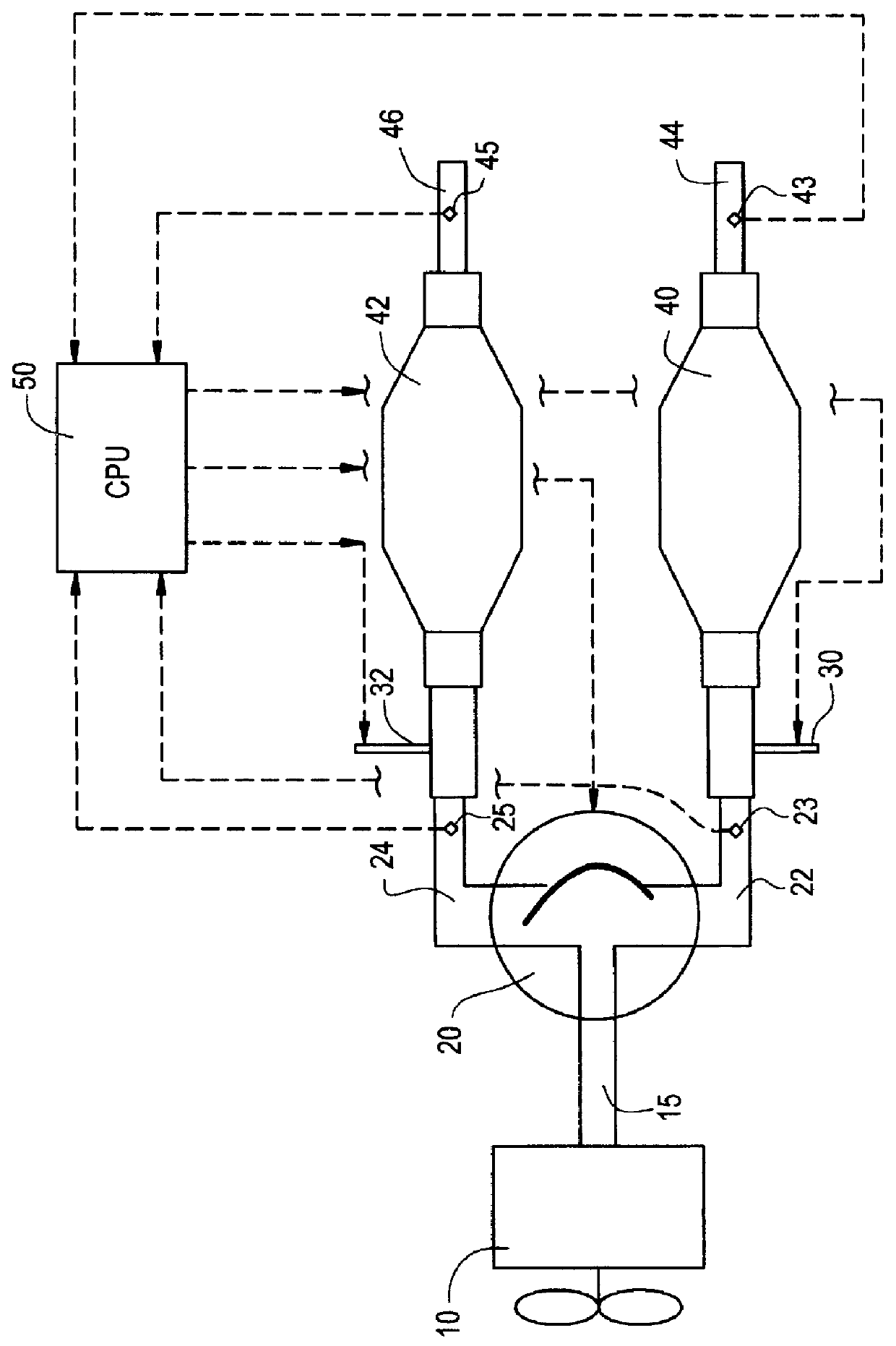

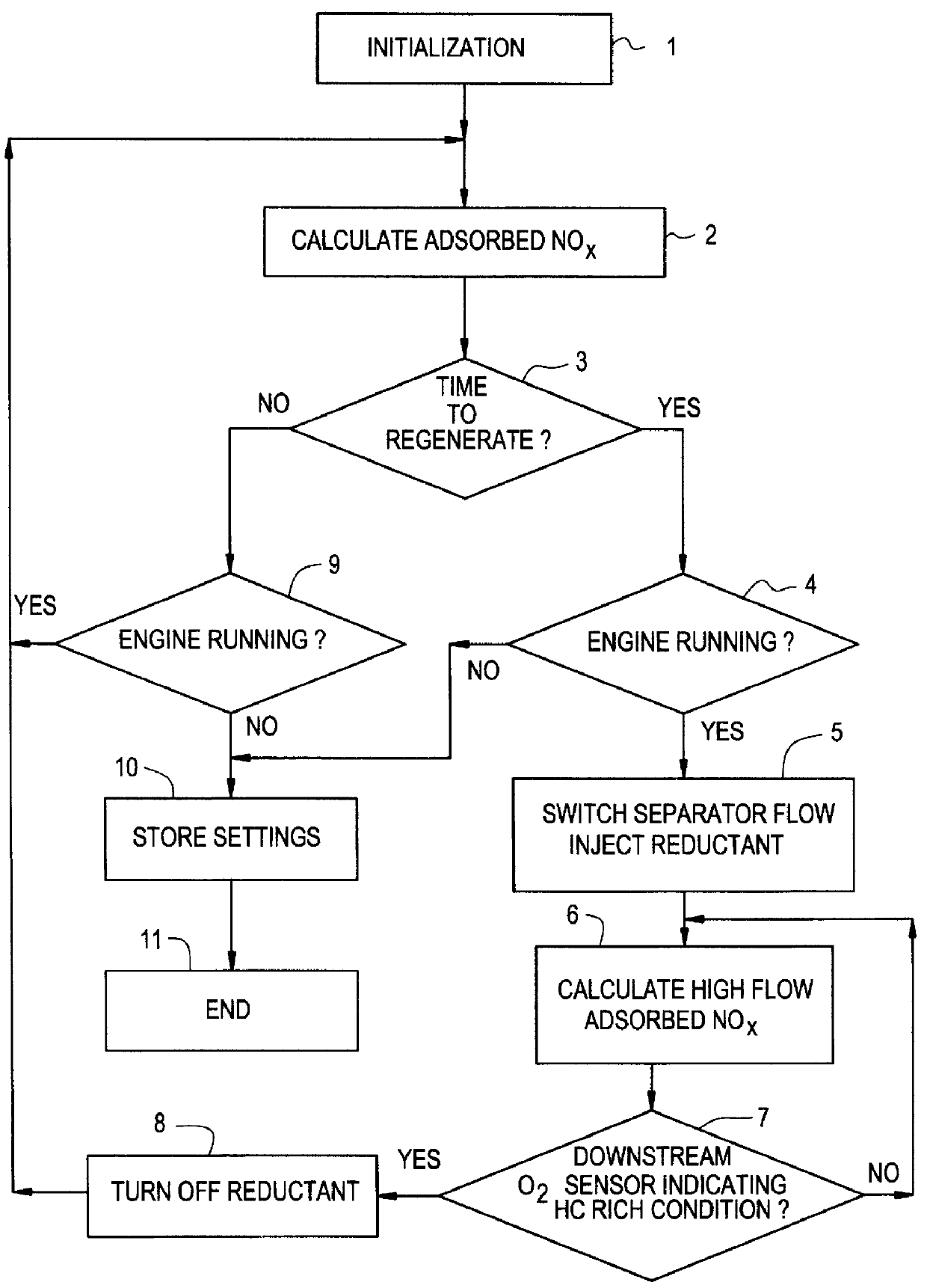

Apparatus, method, and system for concentrating adsorbable pollutants and abatement thereof

InactiveUS6105365ALess fuelLow oxygenGas treatmentInternal combustion piston enginesCombustionExhaust fumes

Owner:ENGELHARD CORP

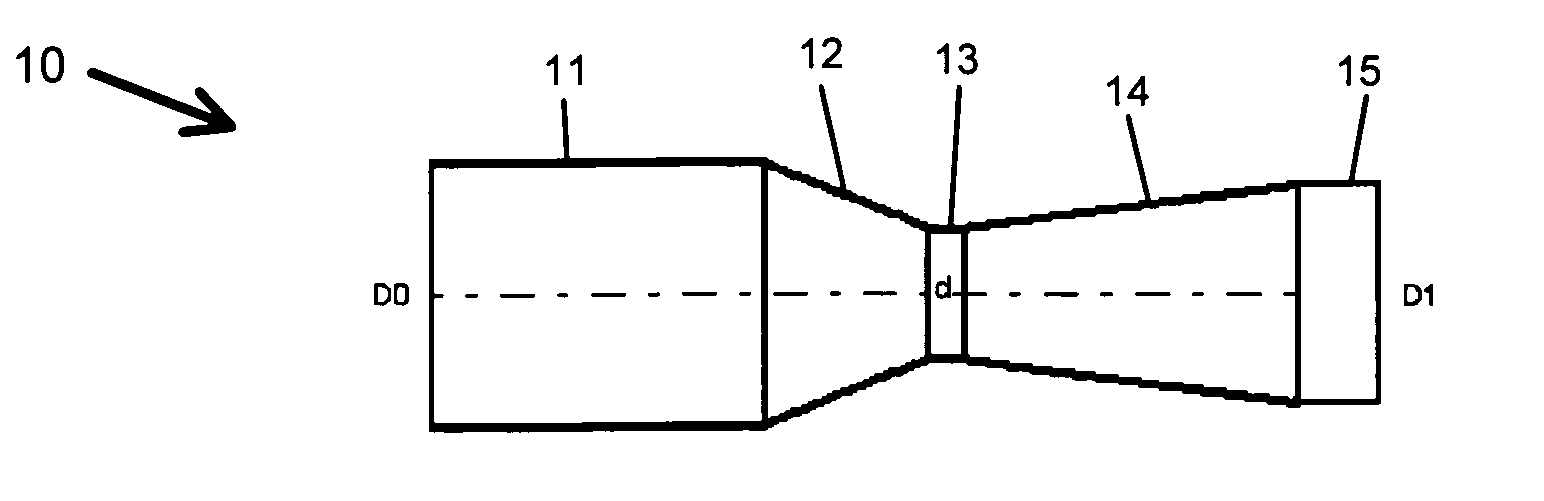

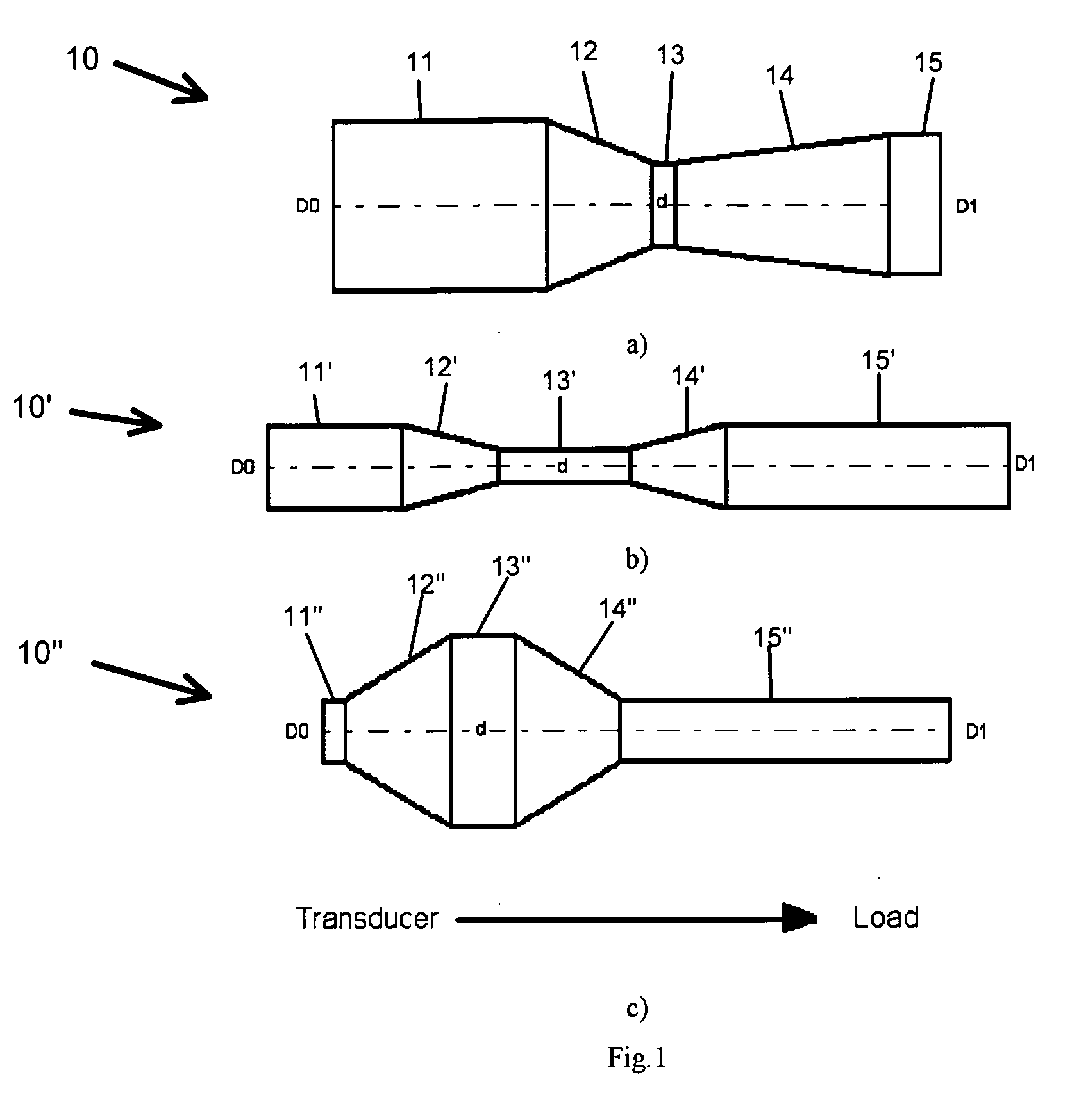

Ultrasonic rod waveguide-radiator

ActiveUS20060090956A1Quality improvementExtended service lifeImpedence networksPiezoelectric/electrostriction/magnetostriction machinesEngineeringWaveguide

The present invention comprises an ultrasonic resonant rod waveguide-radiator with at least three cylindrical sections, one of which is an entrance section having a planar entrance surface and another of which is an exit section having a planar exit surface, and at least two sections having a variable cross-section. The cylindrical sections and sections of variable cross-section are arranged in alternating fashion and connected to each other acoustically rigidly. The dimensions of the cylindrical sections and the sections of variable cross-section are selected so that the gain of the waveguide-radiator is significantly greater than unity and the strain created by passage of ultrasonic waves through the waveguide-radiator is minimized, increasing the operational life of the waveguide-radiator and maximizing the amount of useful energy transmitted by the waveguide-radiator.

Owner:INDAL SONOMECHANICS +1

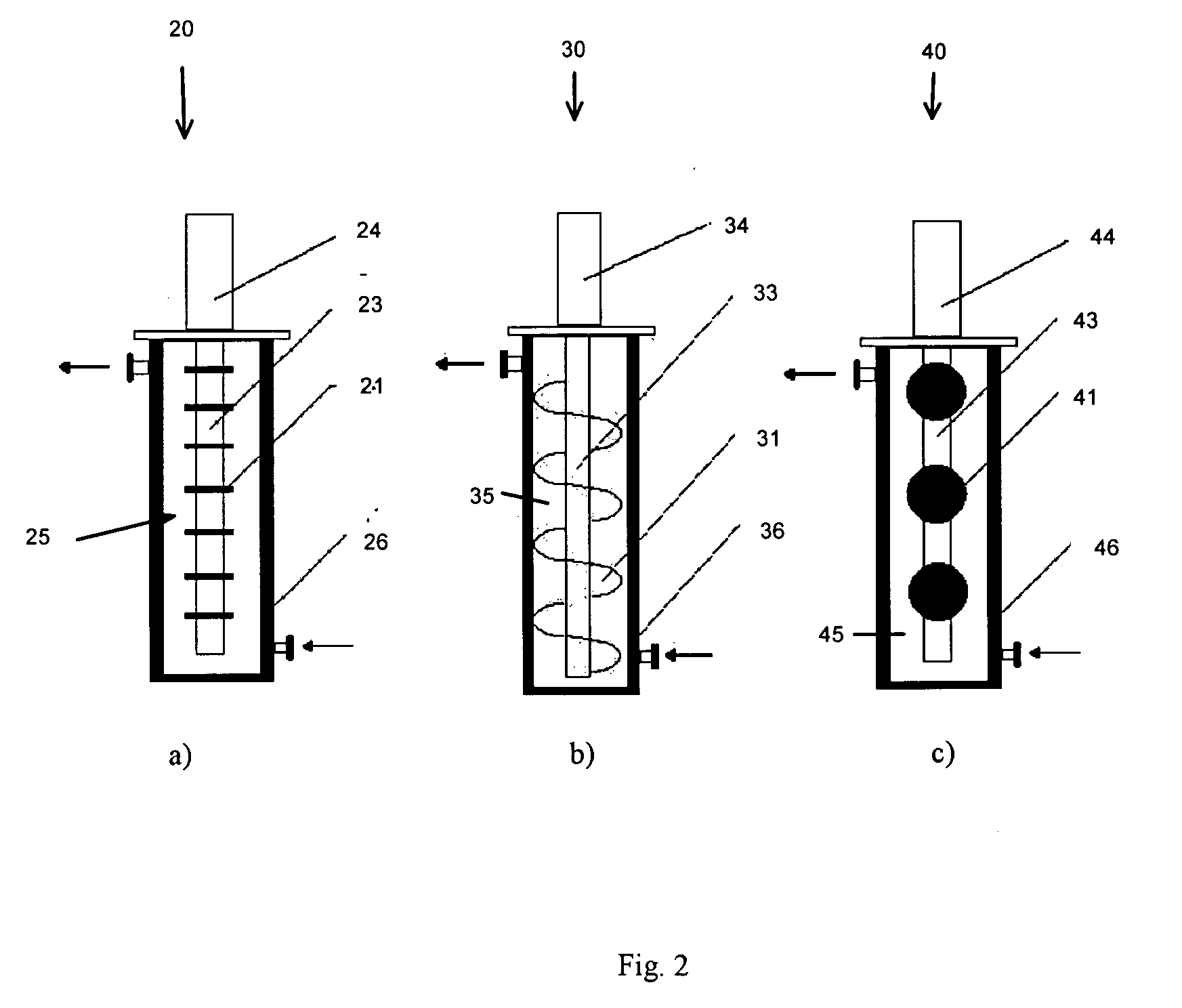

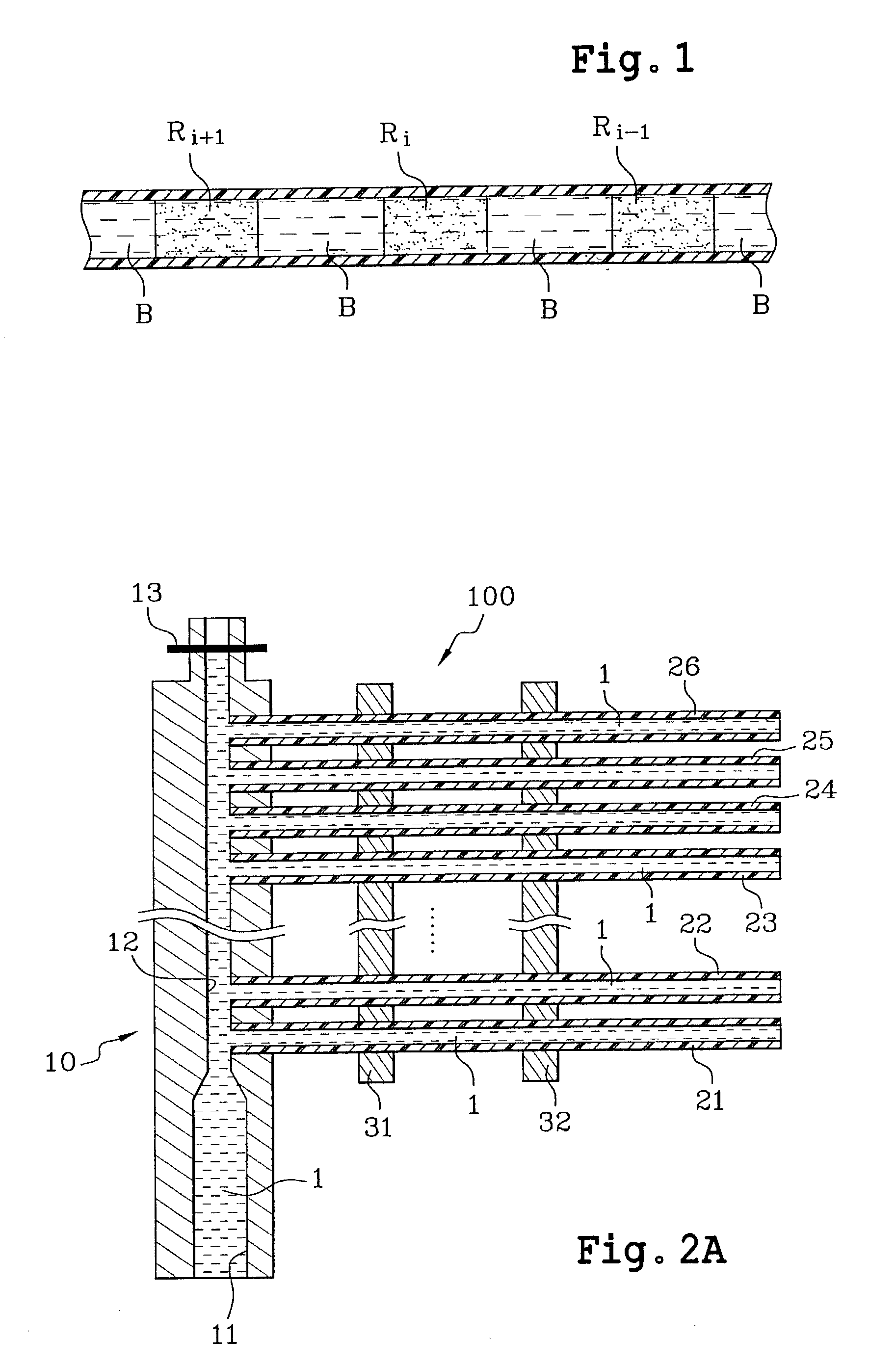

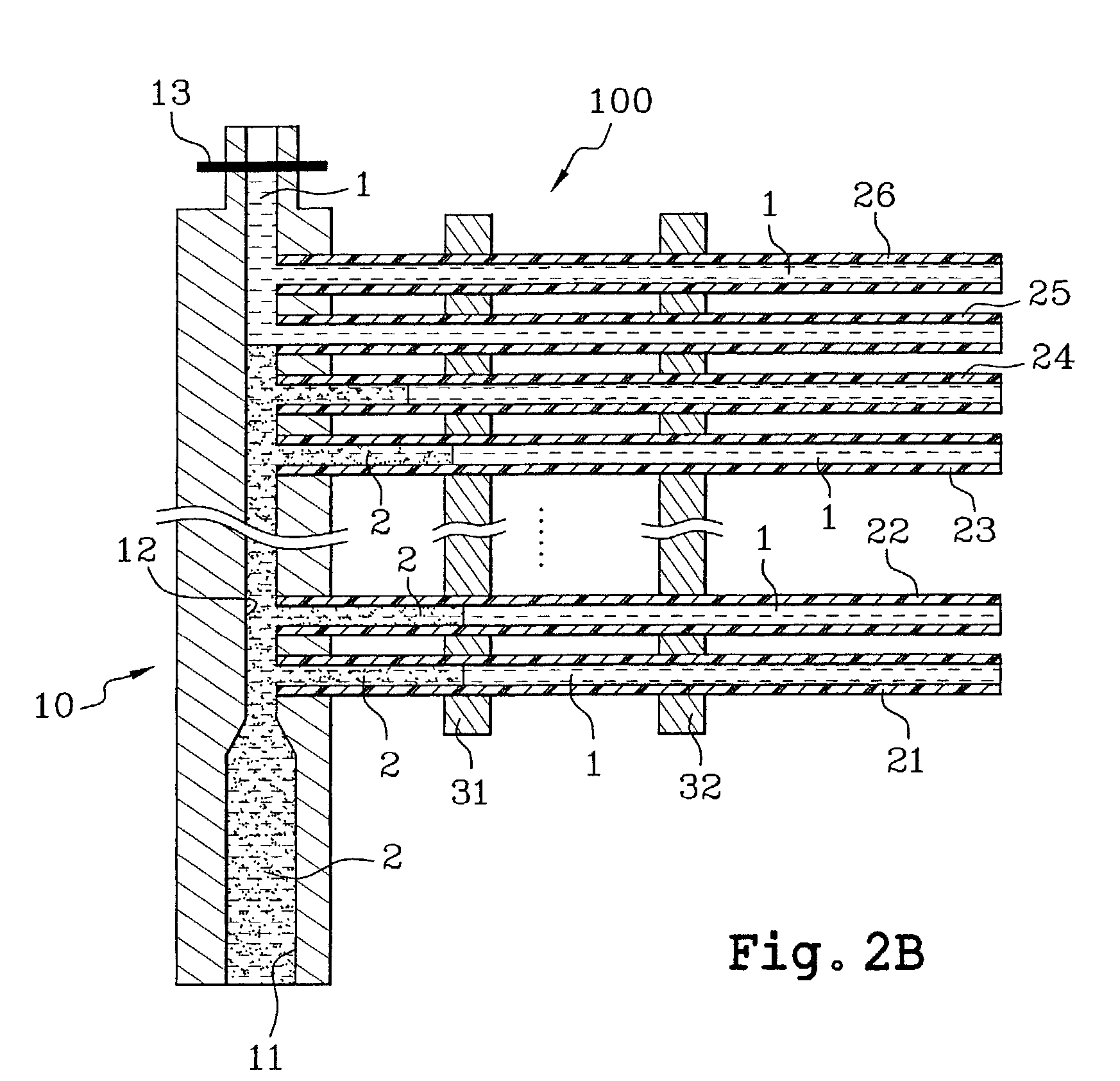

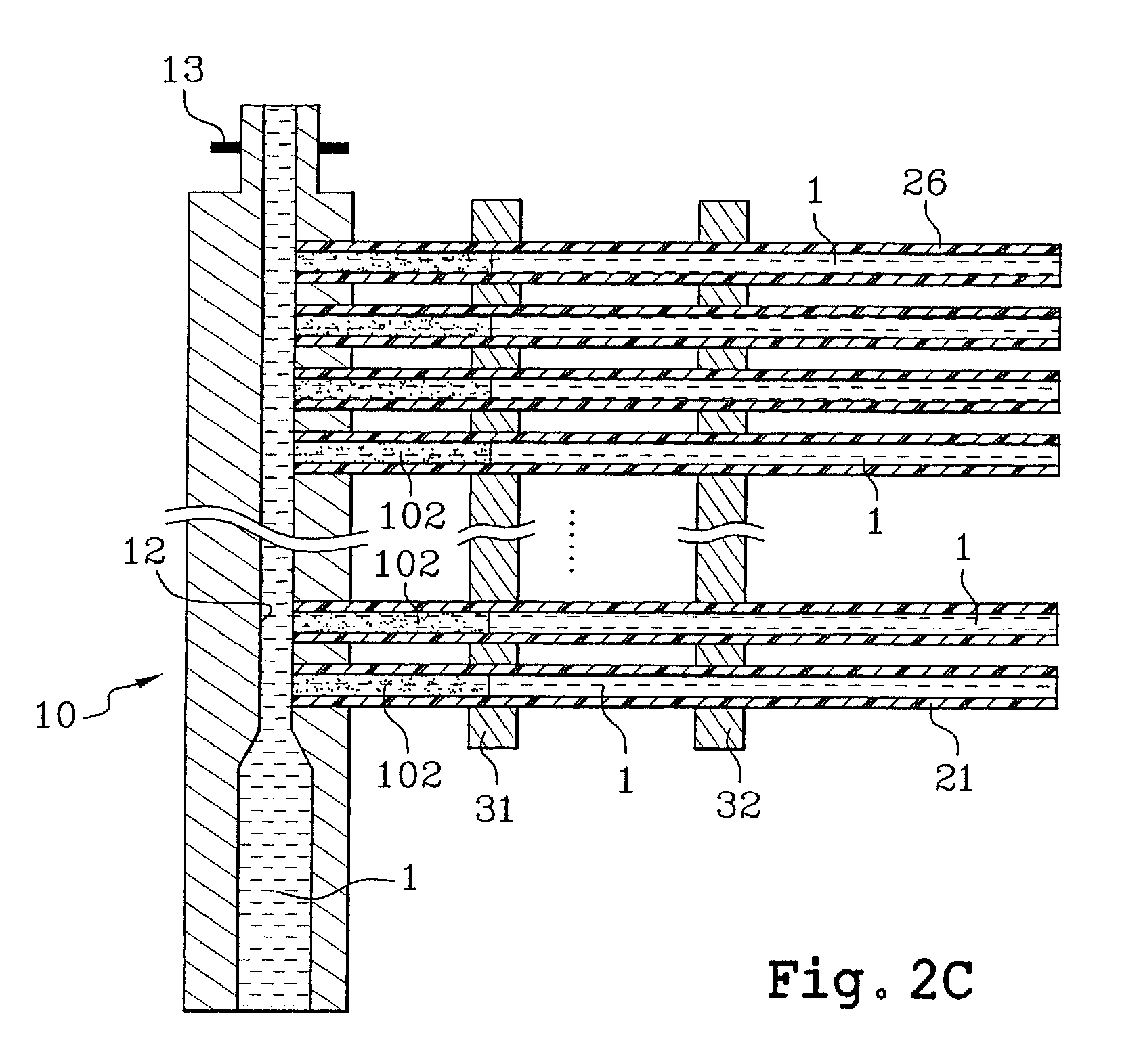

Device for parallel and synchronous injection for sequential injection of different reagents

InactiveUS20030082081A1Exhaust apparatusChemical/physical/physico-chemical microreactorsInjection volumeBiomedical engineering

The invention relates to a microfluidic device for injecting series of mobile reaction chambers (102, 103) having non-miscible segmenters (101) in microchannels (21 to 26), comprising: injection means (10) for injecting into microreaction channels alternatingly and in parallel liquid to form mobile reaction chambers and liquid for forming the segmenters; means for controlling the progression of one of the two liquids, applied to act on one zone (31) of each microchannel delimiting an injection volume of said liquid; the control means being able to cause stopping or slowing of the progression of said liquid over the zone of each microchannel by exerting an action based on a physico-chemical property of the liquid and said action not affecting the other liquid.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

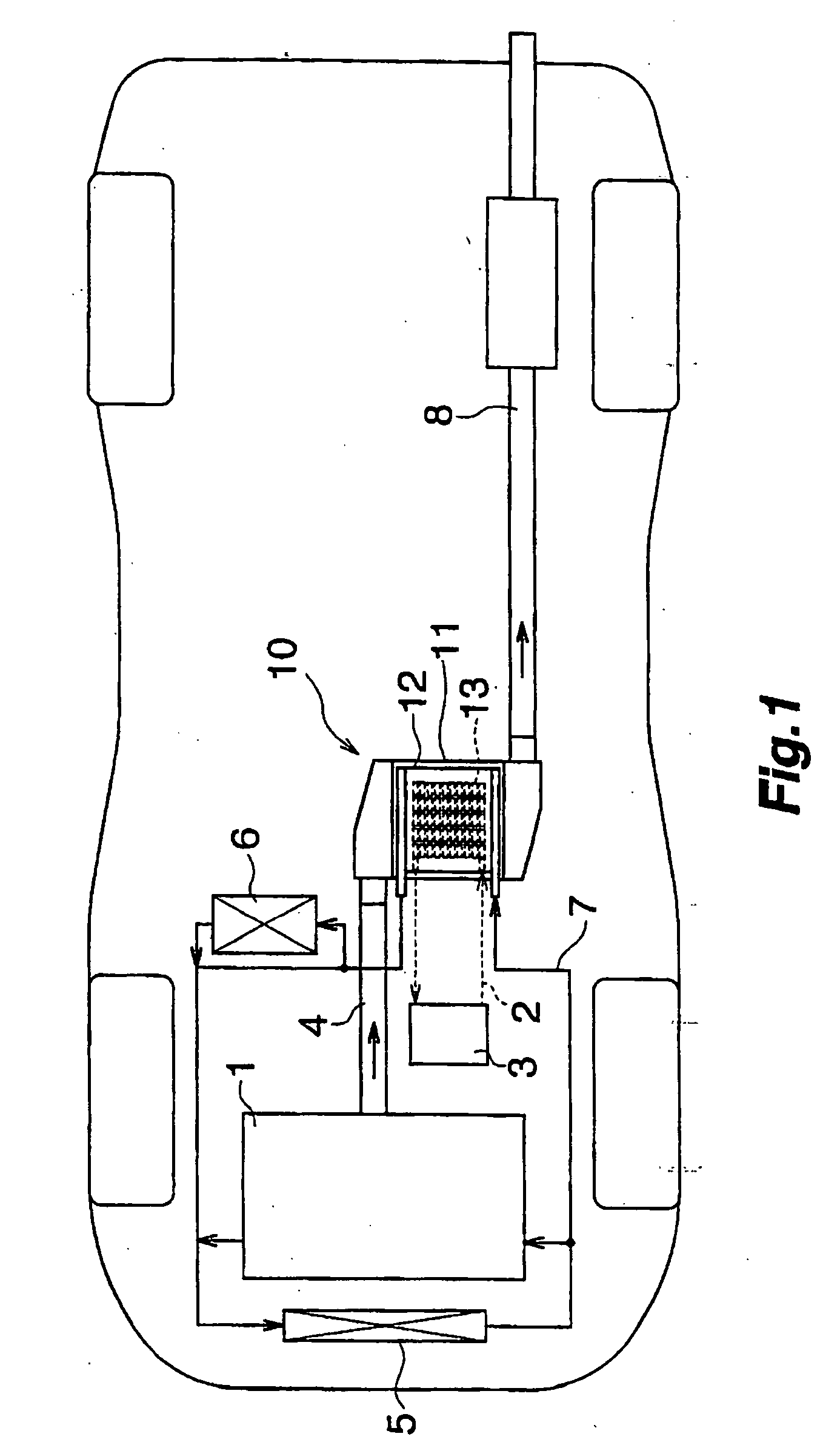

Waste heat recovery system and thermoelectric conversion system

InactiveUS20060157102A1Increase powerImprove efficiencyInternal combustion piston enginesThermoelectric device with peltier/seeback effectWaste heat recovery unitFuel cells

A waste heat recover system includes a mechanism for supplying power by use of a thermoelectric conversion unit, and a mechanism for utilizing heat released from the thermoelectric conversion unit. Heat released from the thermoelectric conversion unit is utilized for, for example, heating, defrosting, defogging, temperature keeping of fuel, temperature keeping of an internal combustion engine, and temperature keeping of a fuel cell. The waste heat recovery system is equipped in, for example, cars, incinerators, fuel cells, and industrial machinery.

Owner:SHOWA DENKO KK

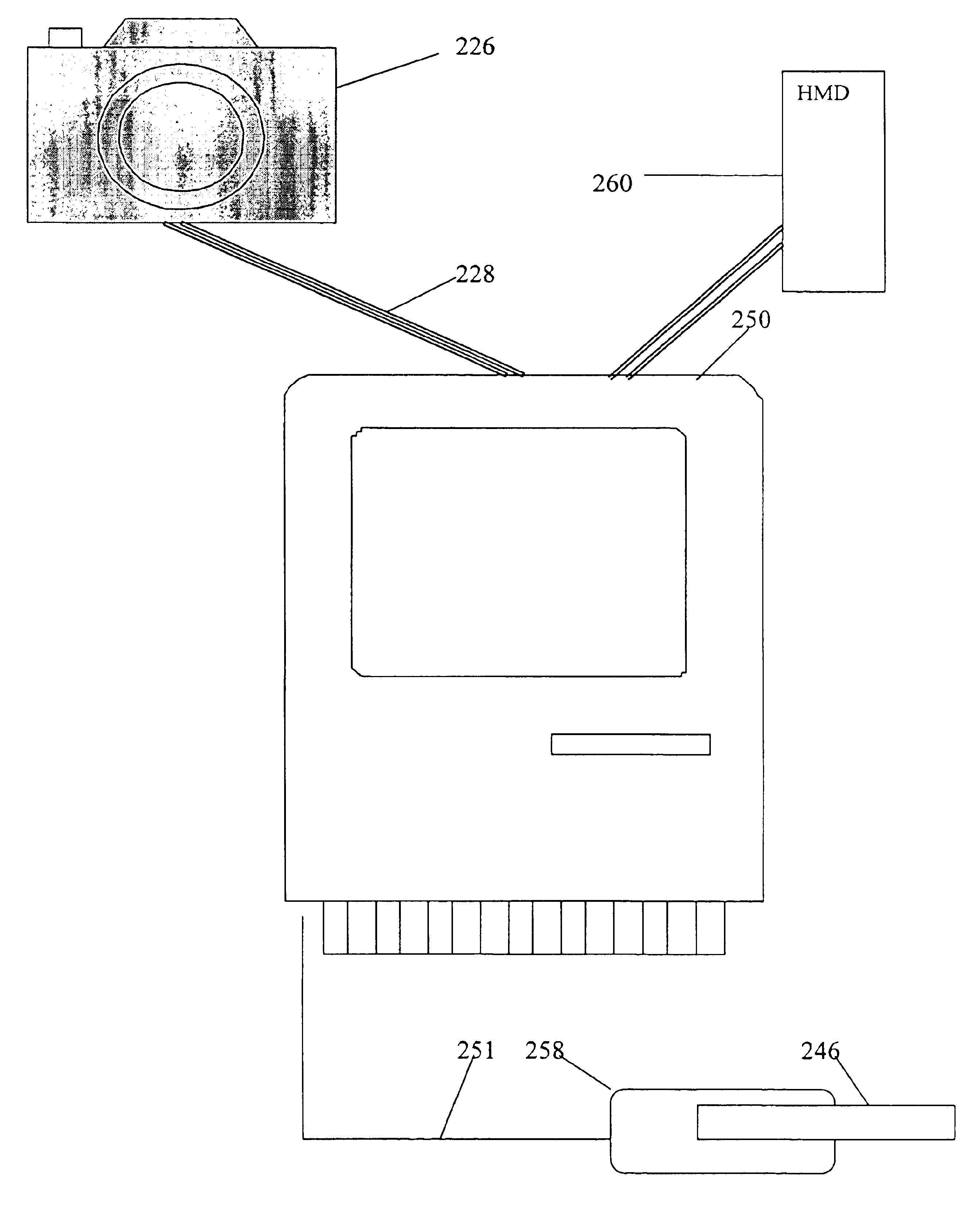

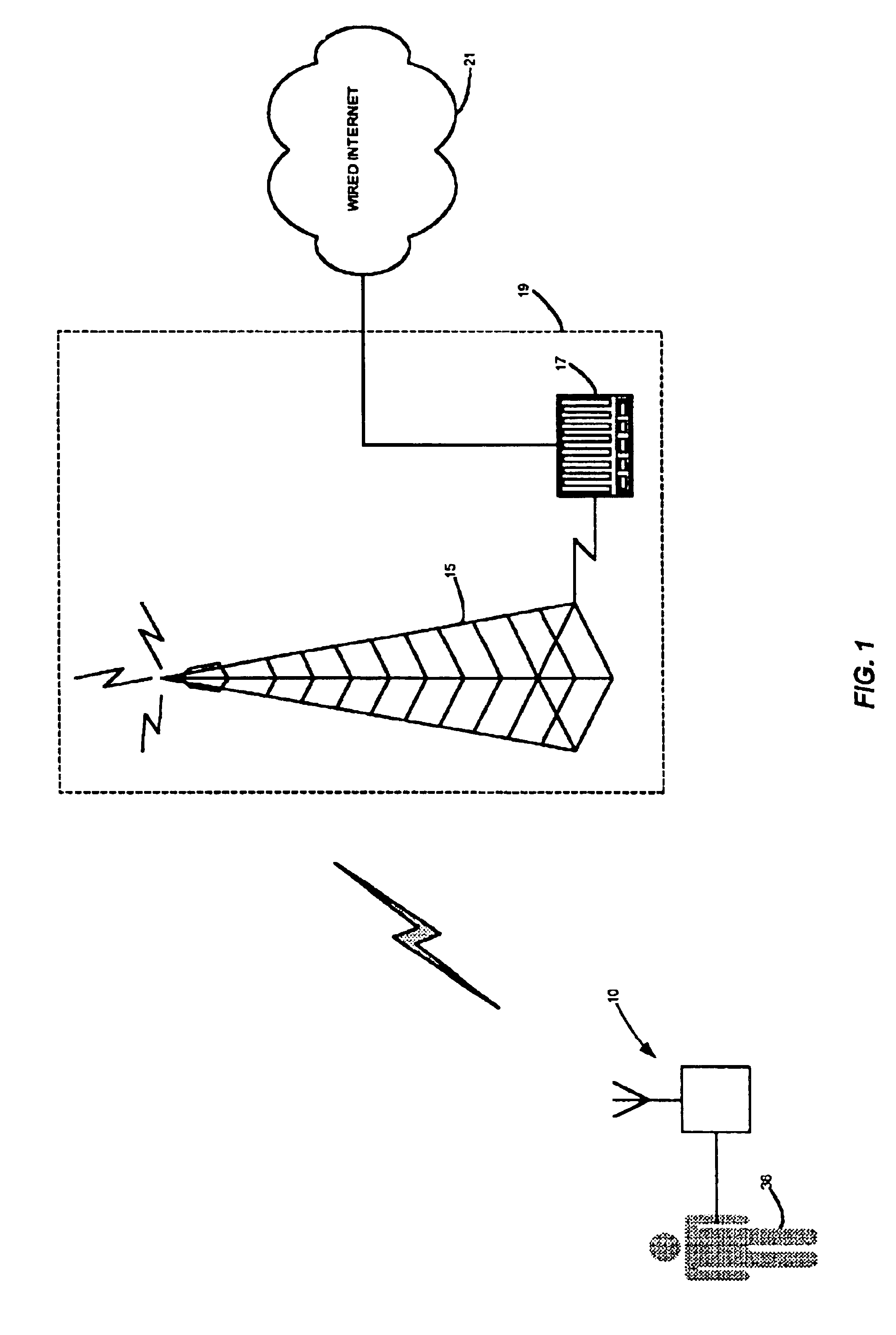

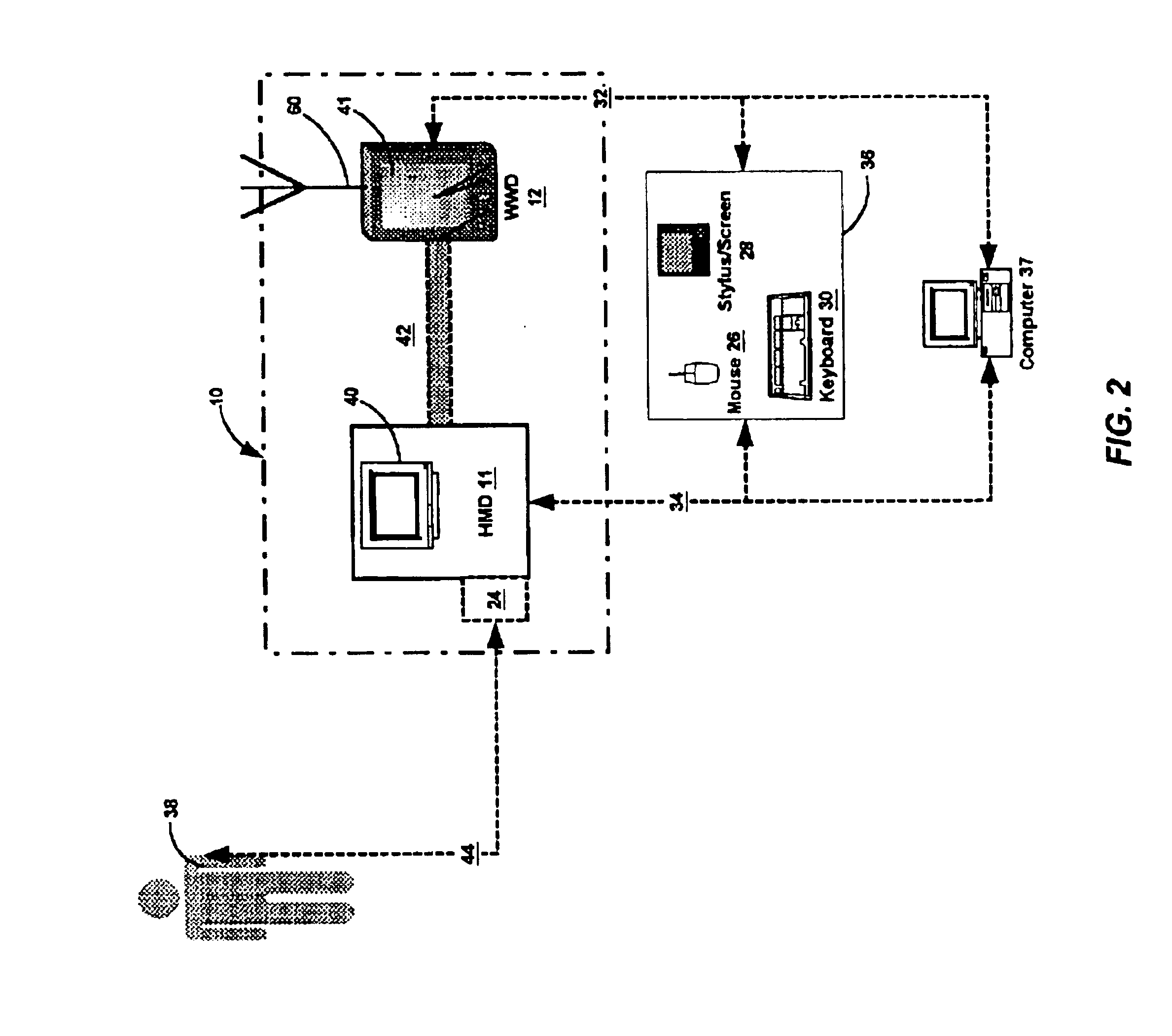

Method and apparatus for health and disease management combining patient data monitoring with wireless internet connectivity

InactiveUS6976958B2Maintain abilityLess memoryTwo-way working systemsMeasuring/recording heart/pulse rateComputer hardwareDisease

Embodiments of the invention provide a method and apparatus for a wireless health monitoring system for interactively monitoring a disease or health condition of a patient by connecting an internet-enabled wireless web device (“WWD”) to a digital camera or other health monitoring device. The WWD may accommodate a memory device for enhanced storage capabilities that may be particularly pertinent to data-intensive tasks such as the handling and storage of images or other visual data. The health related data is transmitted from the WWD to a server using standard internet protocols and may be integrated with various operating systems for handheld or wireless devices, especially those with enhanced capabilities for handing images and visual data.

Owner:Q TEC SYST +1

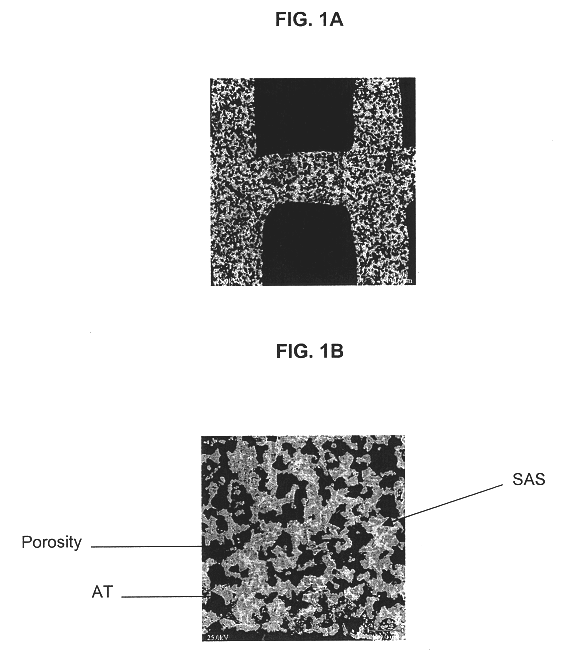

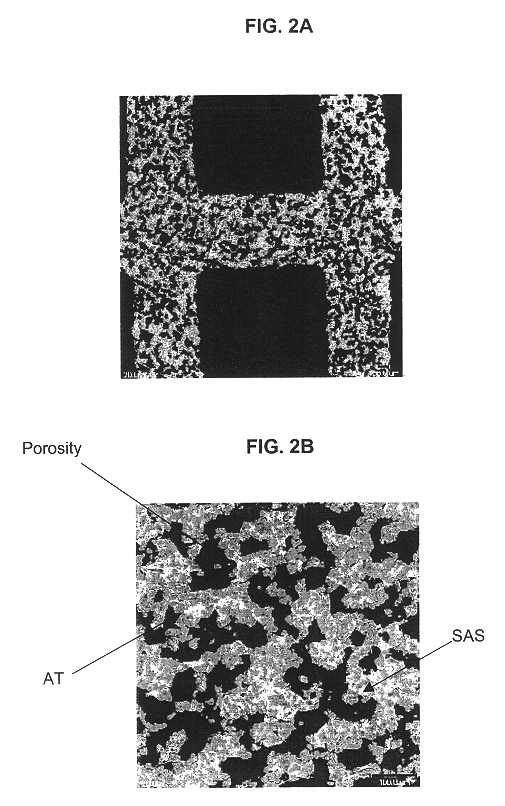

Strontium feldspar aluminum titanate for high temperature applications

InactiveUS6620751B1Improve stabilityReduce bloatInternal combustion piston enginesDispersed particle filtrationMicrometerRoom temperature

A structure for use in high temperature applications and including a porous ceramic material consisting essentially of about 50-90 percent by weight iron or magnesium stabilized aluminum titanate (AlTiO5) and about 10-50 percent by weight strontium feldspar (SrO.Al2O3.2SiO2), and having a coefficient of thermal expansion over a temperature range from room temperature to 1000° C. of about -10x10-7 / ° C. to +15x10-7 / ° C., a heat capacity at 500° C. greater than 3.2 J / cm3K, a porosity of about 15-50 percent by volume, preferably 40-50 percent by volume, and a median pore size of about 5-50 micrometers, preferably 8-15 micrometers. The structure is especially useful as a diesel exhaust particulate filter.

Owner:CORNING INC

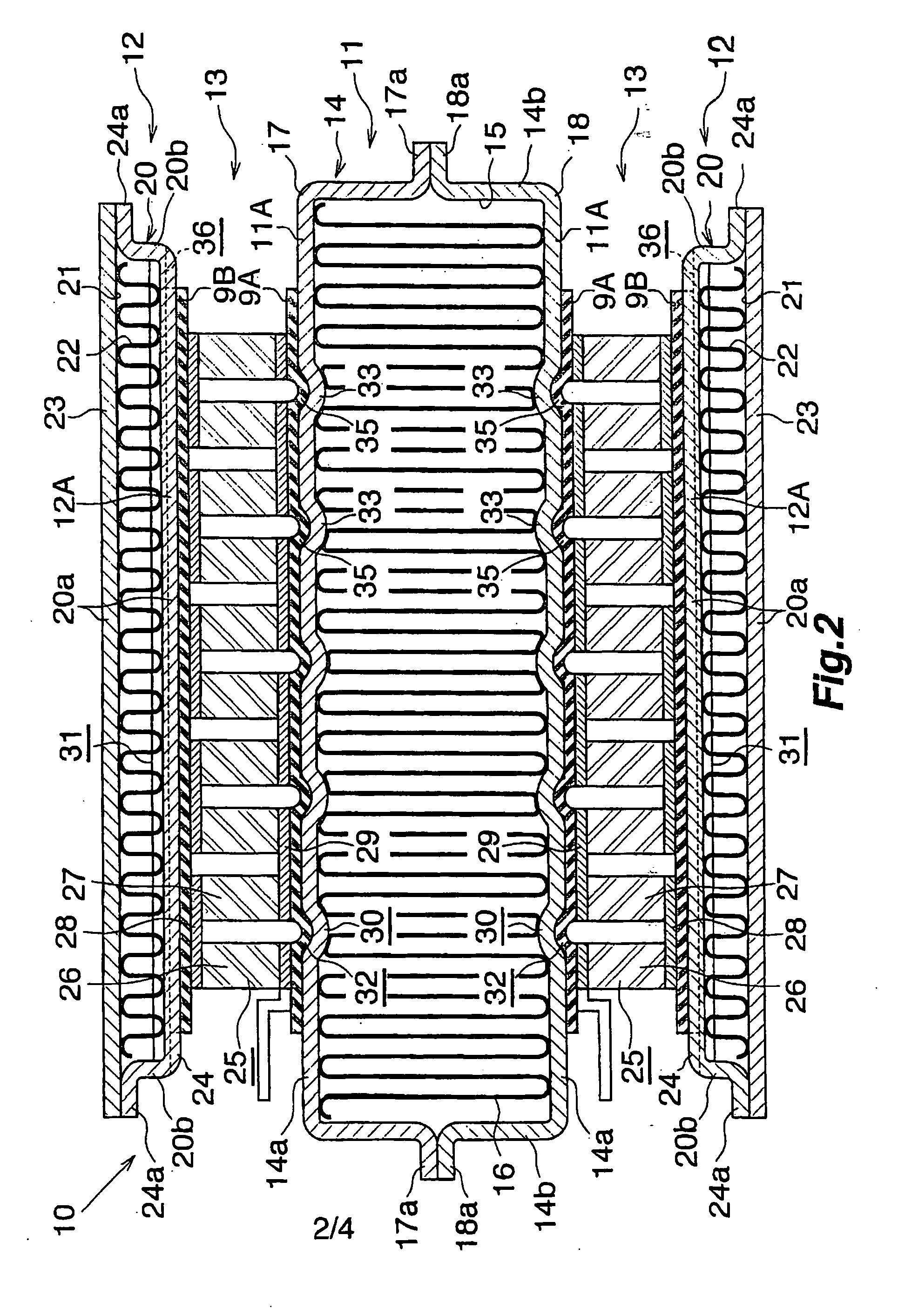

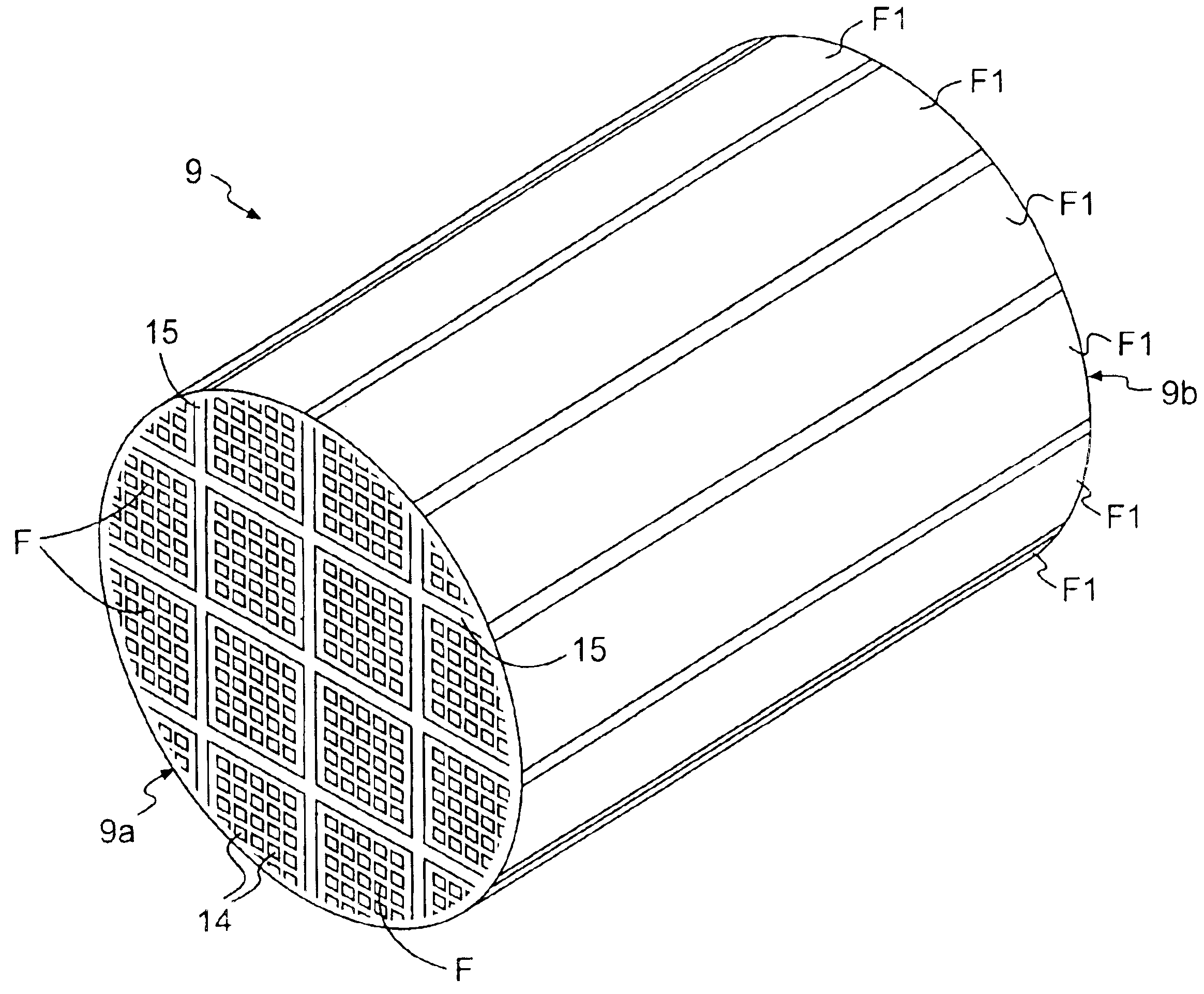

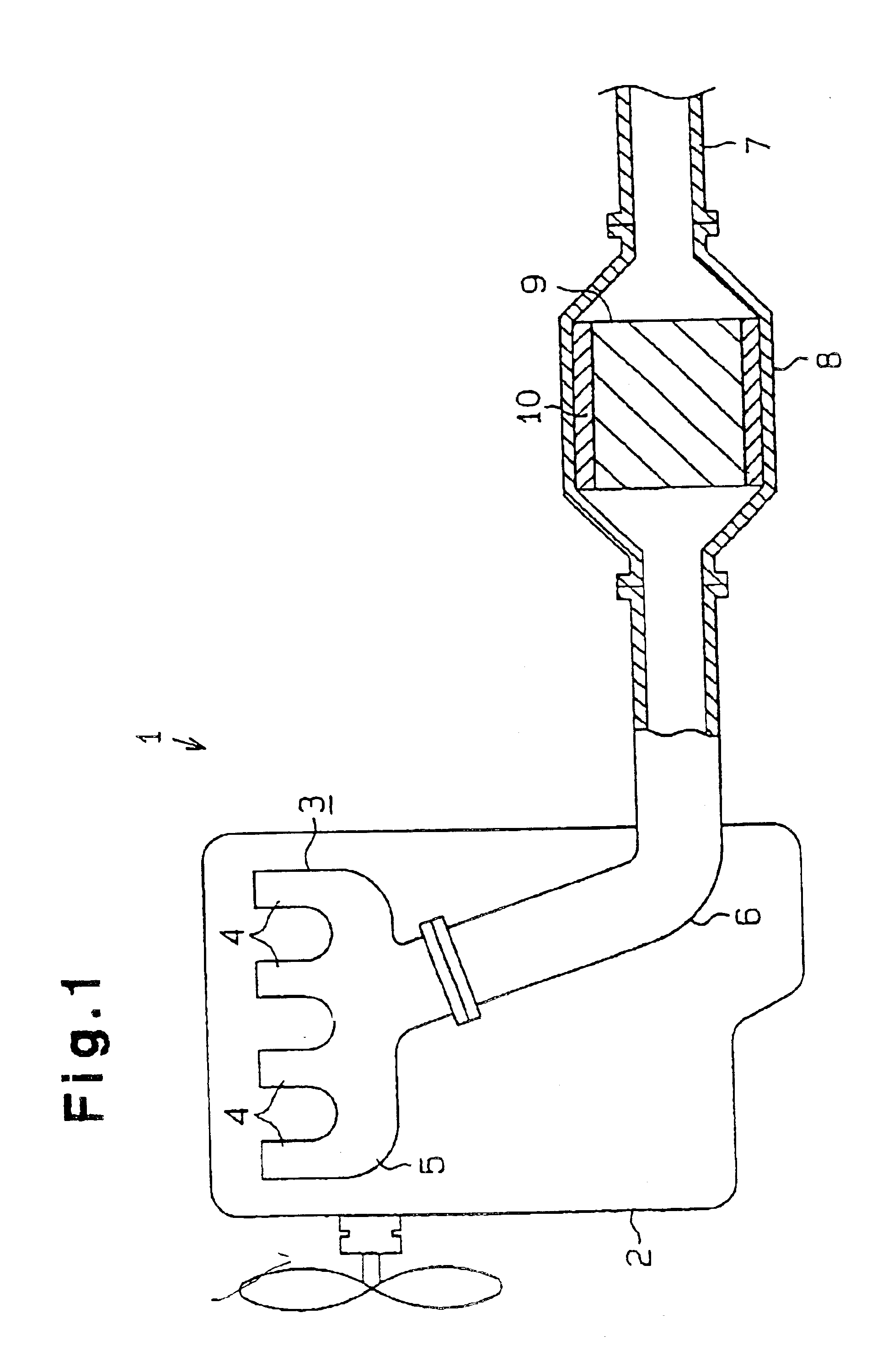

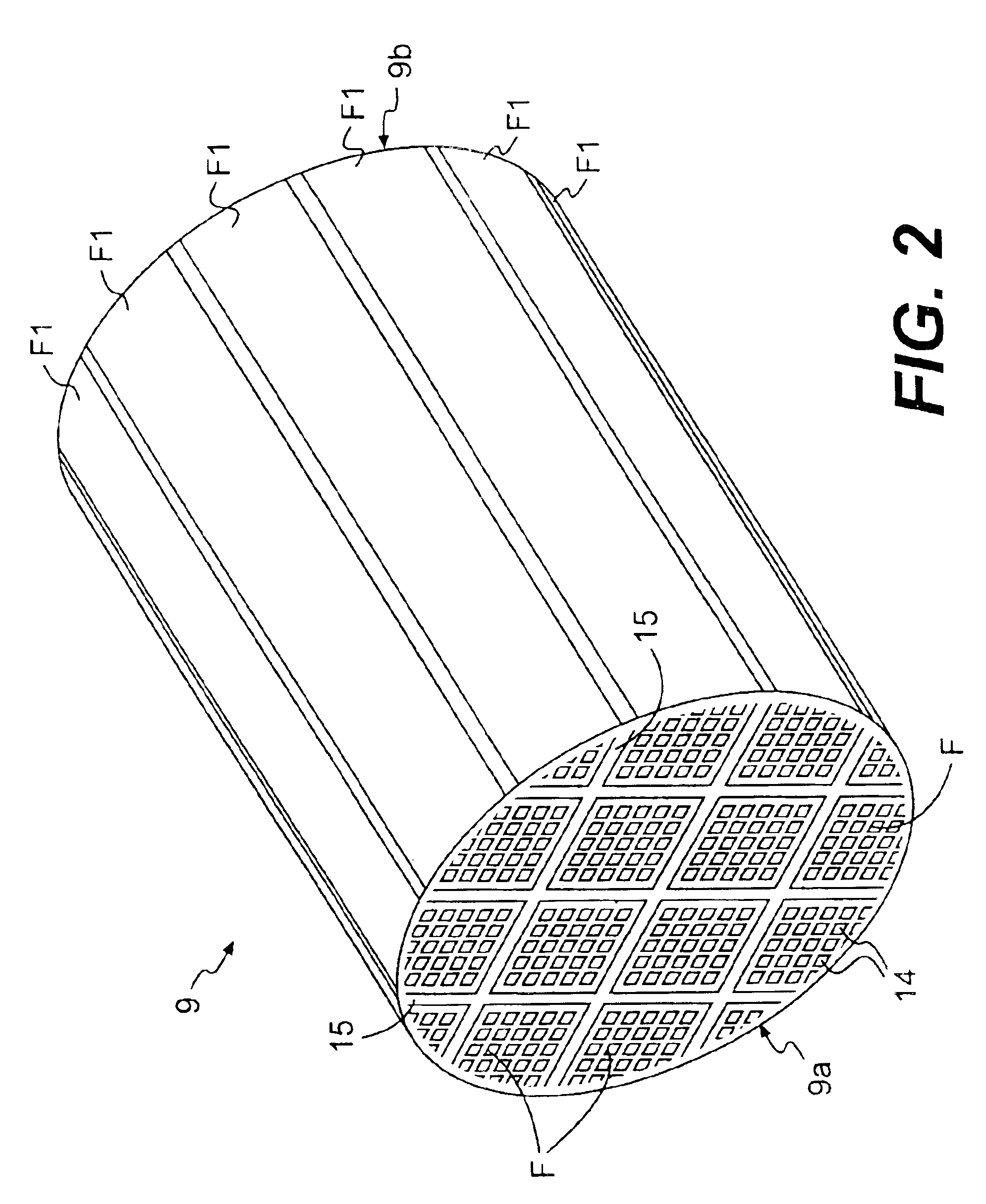

Honeycomb filter and ceramic filter assembly

A ceramic filter assembly having improved exhaust gas processing efficiency. The ceramic filter assembly (9) is produced by adhering with a ceramic seal layer (15) outer surfaces of a plurality of filters (F1), each of which is formed from a sintered porous ceramic body. The seal layer (15) has a thickness of 0.3 mm to 3 mm and a thermal conductance of 0.1 W / mK to 10 W / mk.

Owner:IBIDEN CO LTD

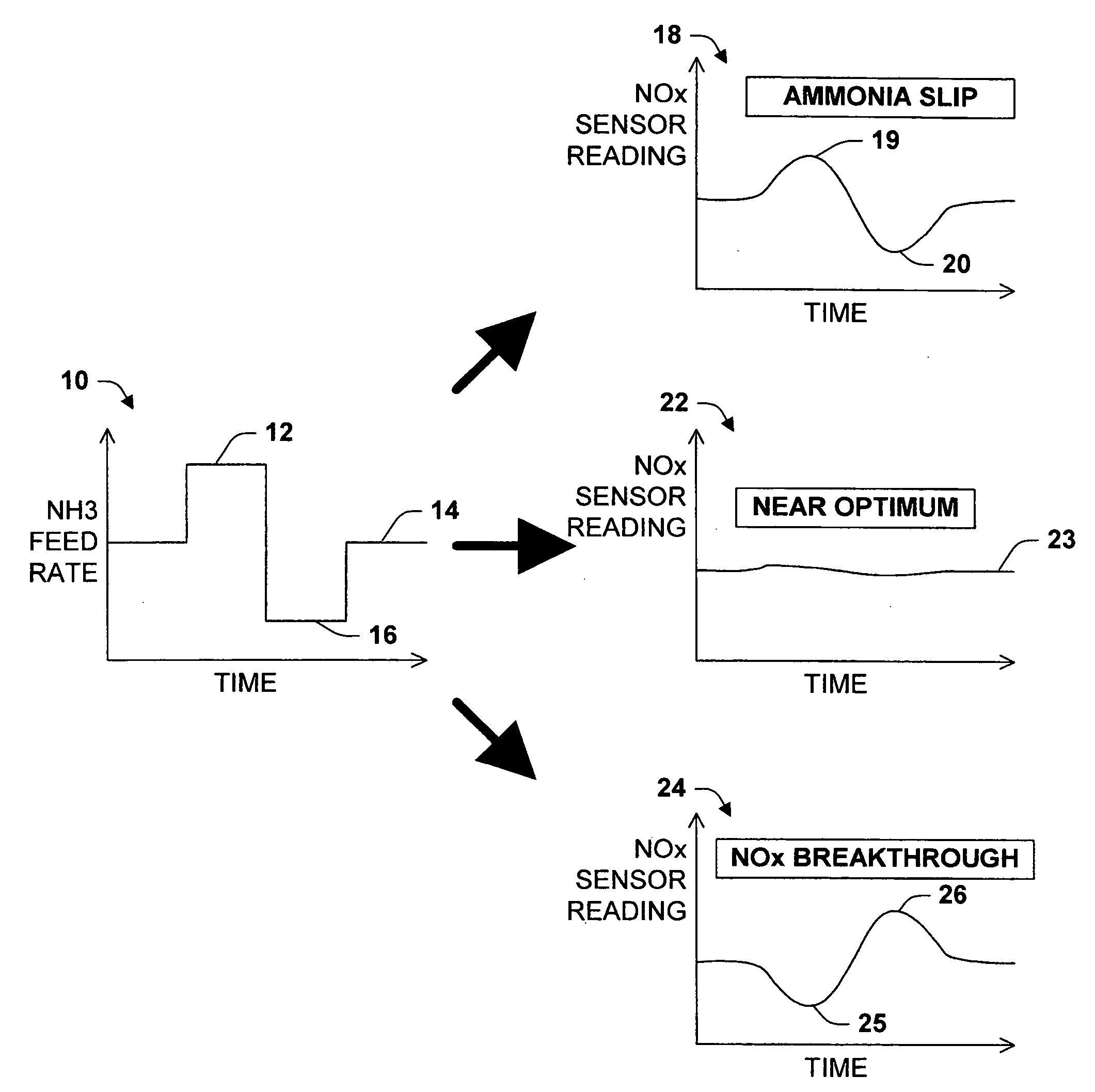

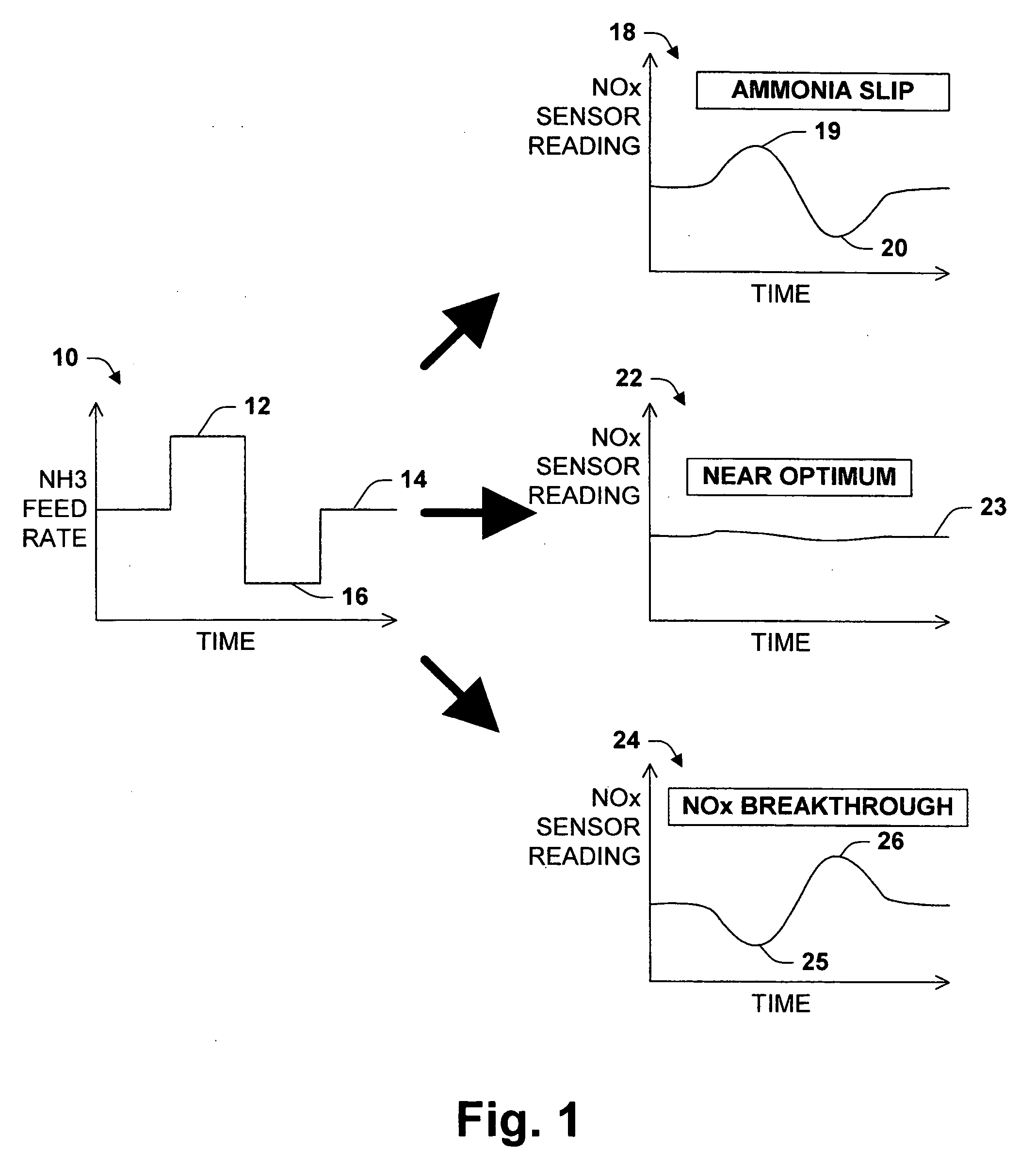

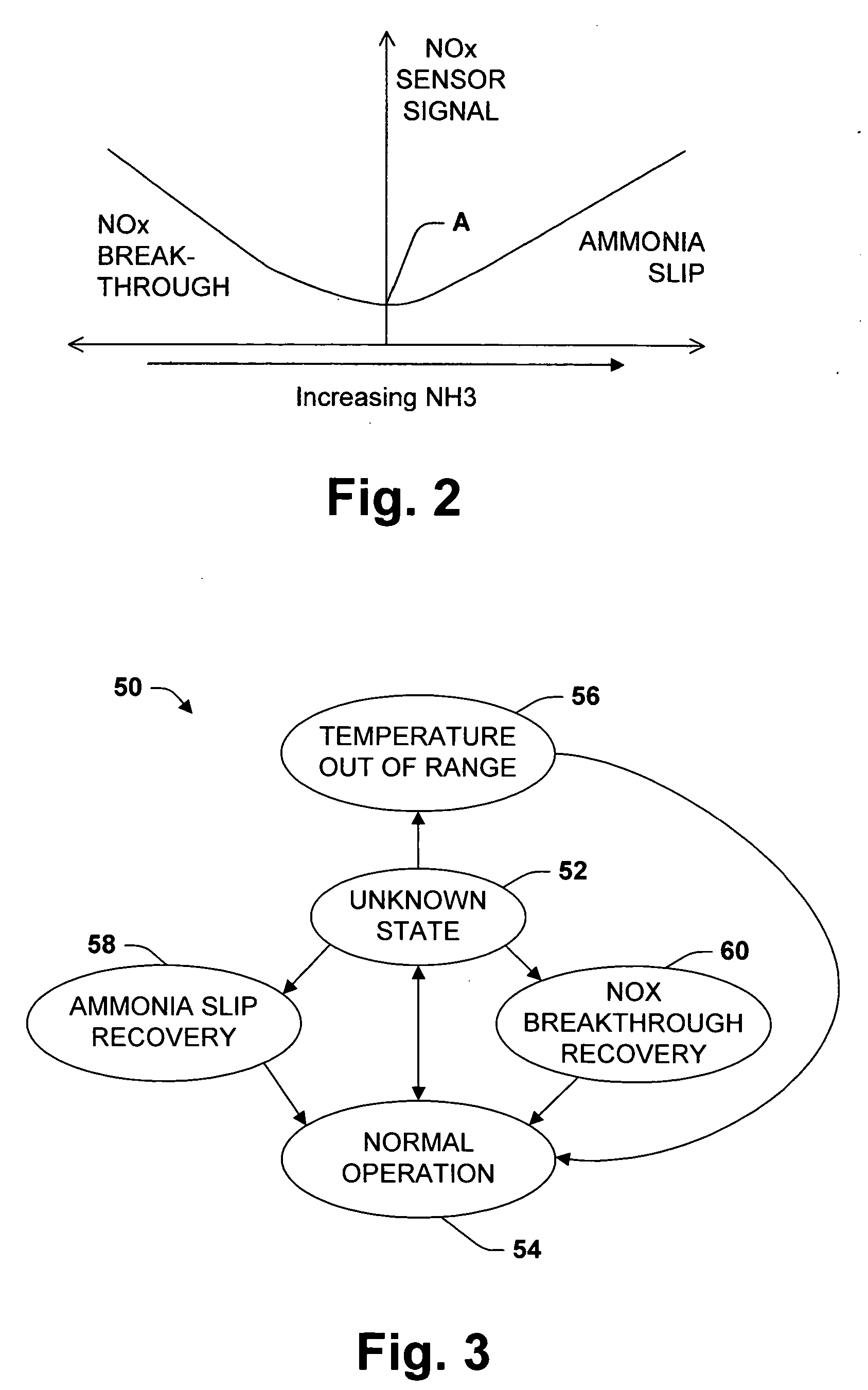

Strategy for controlling NOx emissions and ammonia slip in an SCR system using a nonselective NOx/NH3

InactiveUS20050282285A1Internal combustion piston enginesExhaust apparatusControl objectivePositive response

One aspect of the invention relates to controlling the ammonia feed rate to an SCR reactor using a NOx sensor cross-sensitive to ammonia. The sensor, positioned downstream of the reactor, is interrogated by introducing a pulse in the ammonia feed rate. A positive response to a positive pulse indicates ammonia slip. A negative response to a positive pulse indicates NOx breakthrough. Another aspect of the invention related to a combination of feed-back and feed-forward control. Upon detecting ammonia slip, the controller enters into an ammonia slip recovery mode in which the ammonia feed rate is reduced for a period to restore the reactor's ammonia or NOx buffering capacity. After the recovery period, feed-forward control is restored, optionally with an updated control objective. A further aspect of the invention relates to a learning probabilistic model for feed-forward control trained according to the occurrence or non-occurrence of NOx breakthrough and ammonia slip.

Owner:EATON CORP

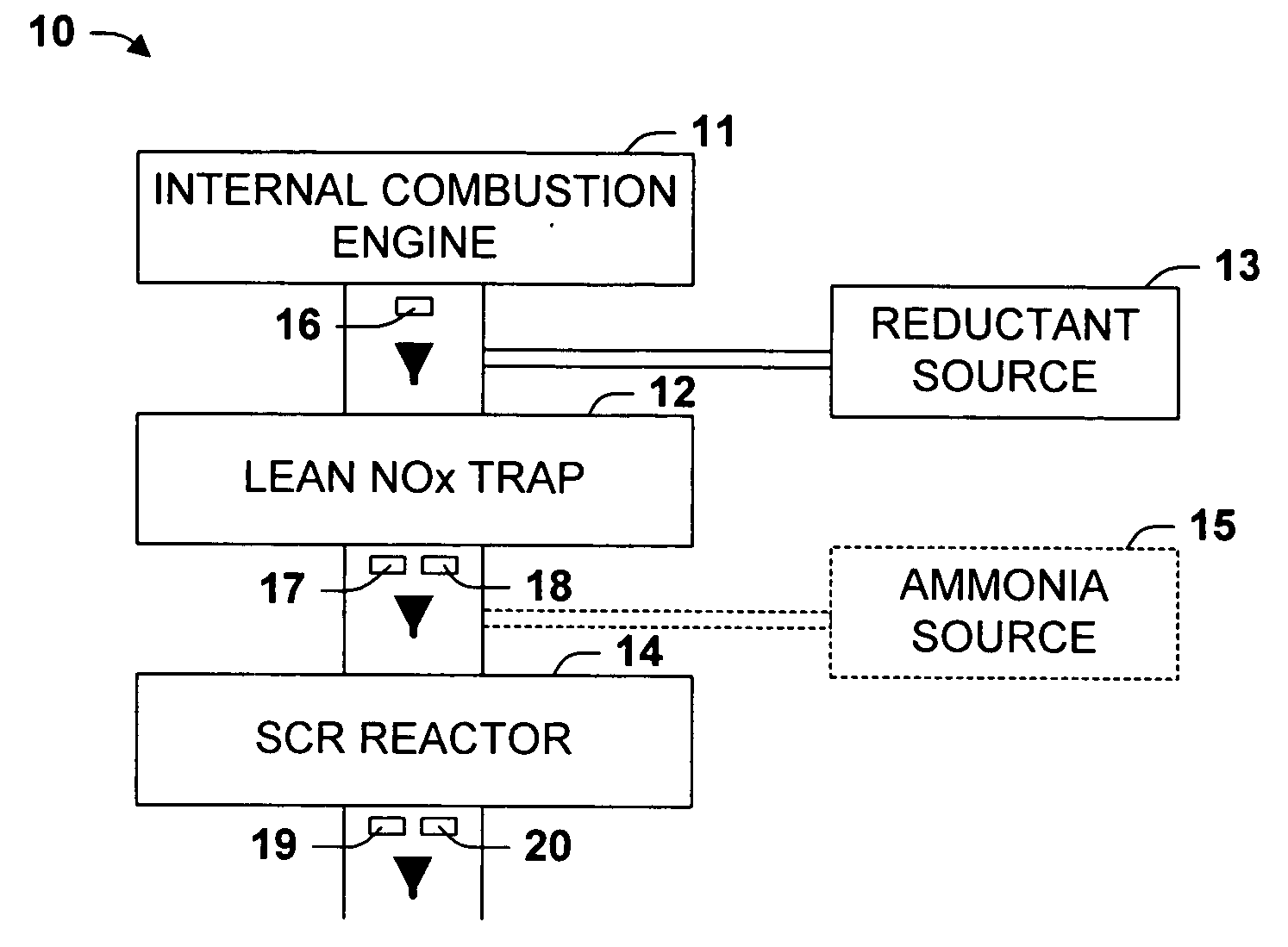

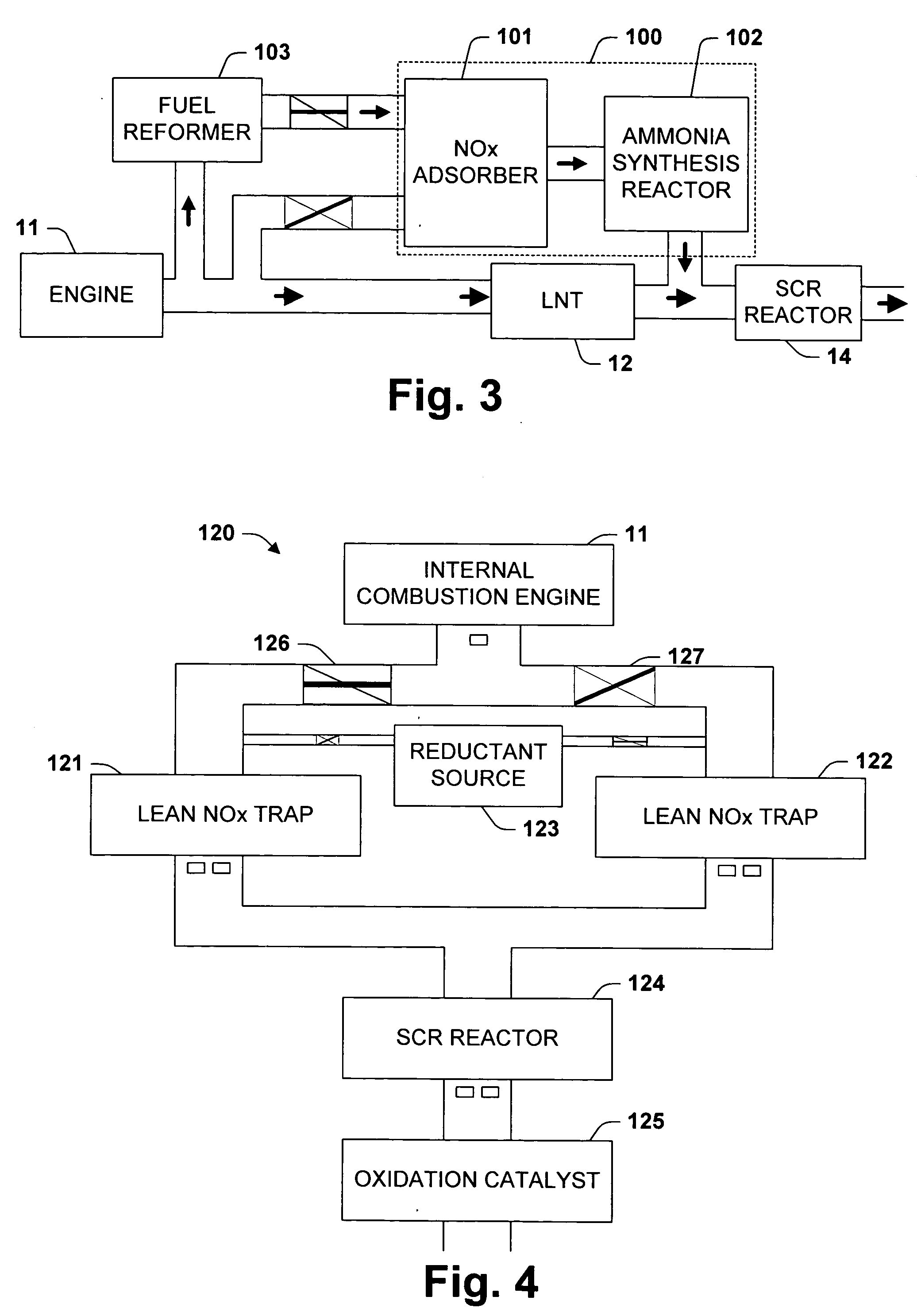

Hybrid catalyst system for exhaust emissions reduction

InactiveUS20060010857A1Improve efficiencySpeed up the conversion processHydrogenGas treatmentExhaust fumesEngineering

One aspect of the invention relates an exhaust treatment system having an SCR reactor following a NOx adsorber. Syn gas is used to regenerate the NOx adsorber. Another aspect relates to an LNT / SCR provided with an ammonia source separate from the LNT. A further aspect relates to a system comprising first and second LNTs and one or more SCRs downstream of the LNTs. A still further aspect relates to a device comprising first and second NOx adsorbers contained in a single housing. Another aspect relates to coating a surface of a moving part in an exhaust system with an oxidation catalyst to mitigate fouling. Additional aspects of the invention relate to strategies for controlling one or more of the time to initiate a regeneration cycle, the time to terminate a regeneration cycle, and the reductant injection rate during regeneration of LNT / SCR exhaust treatment systems.

Owner:INT ENGINE INTPROP CO LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com