Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3730 results about "Exit surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

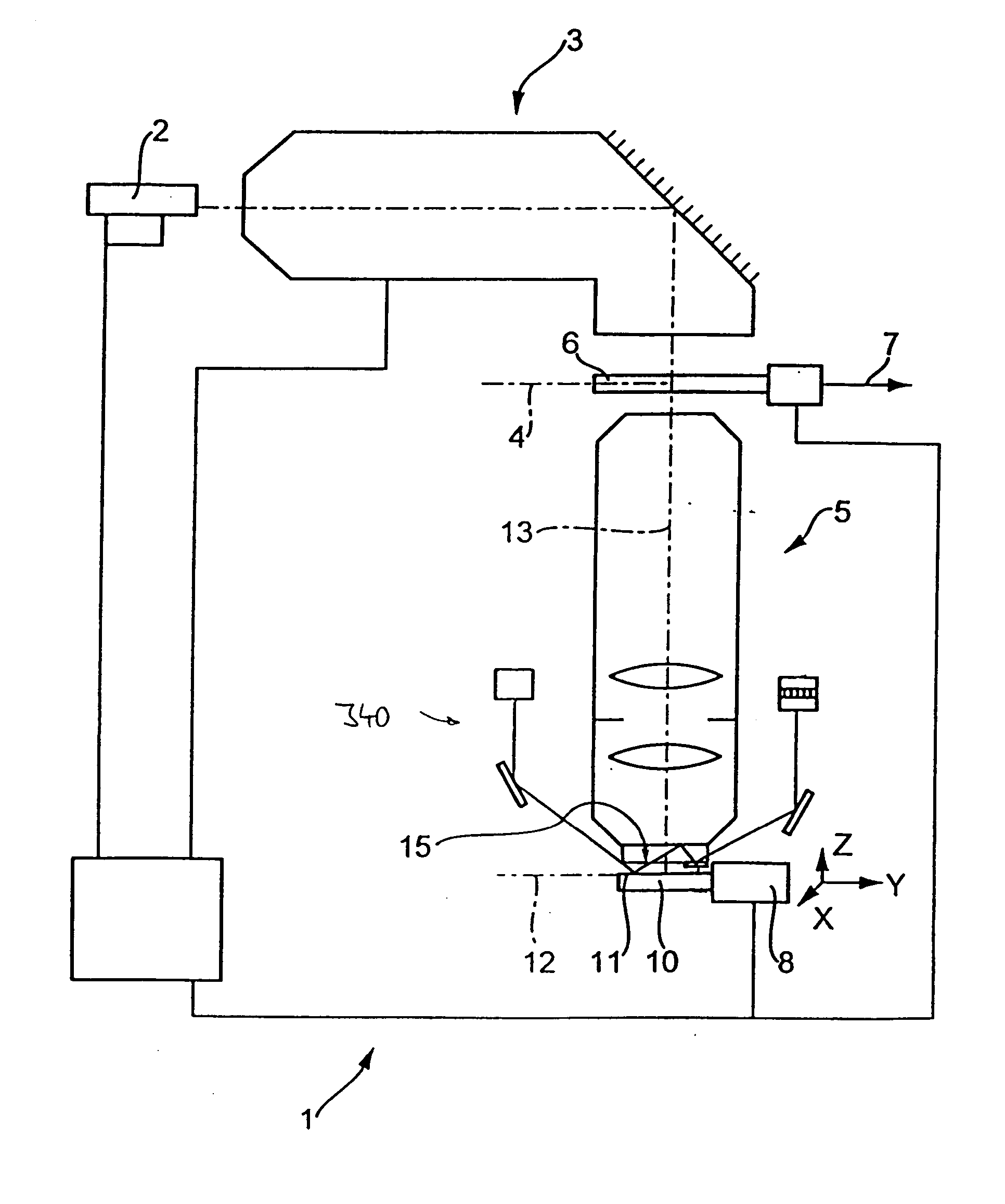

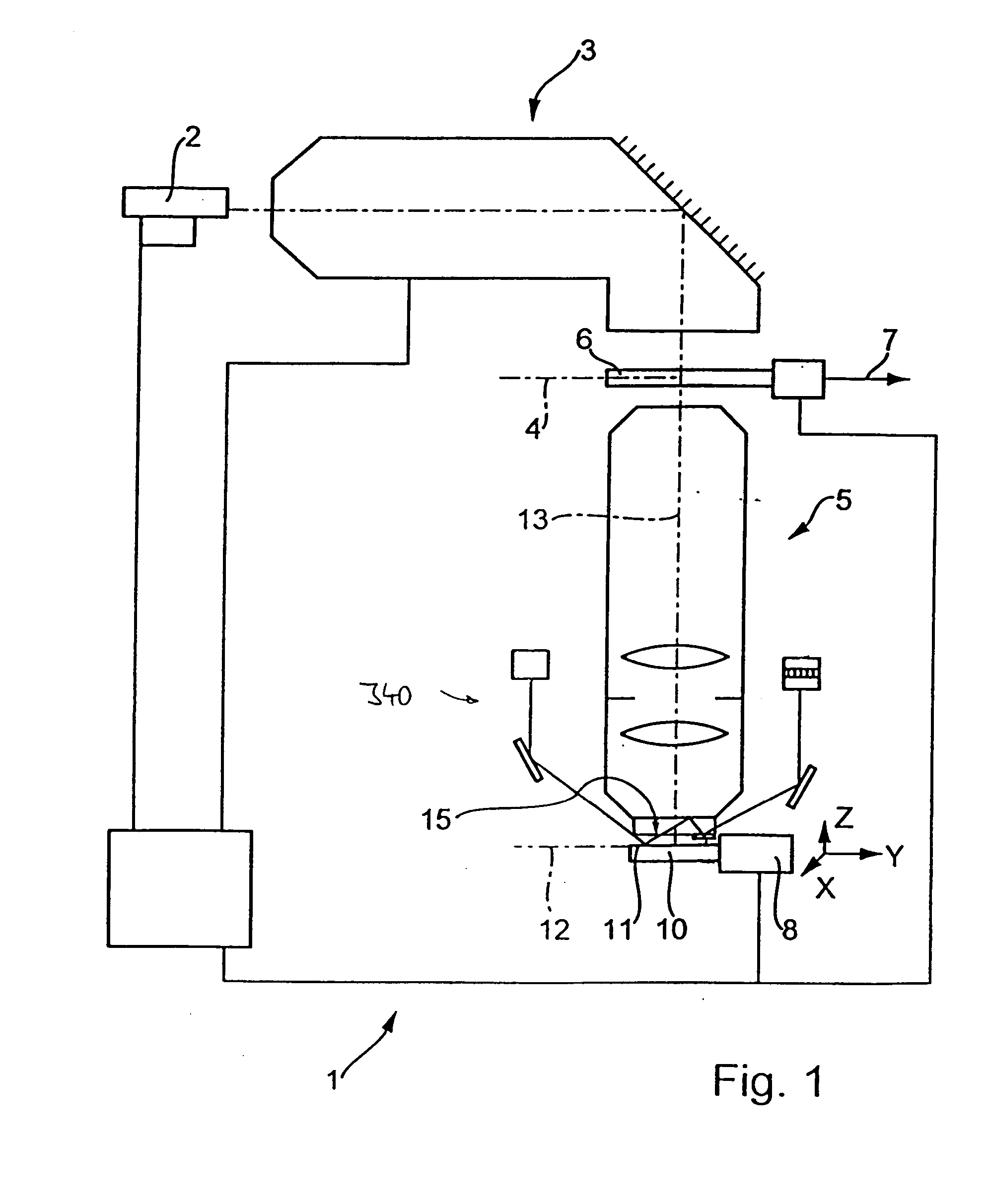

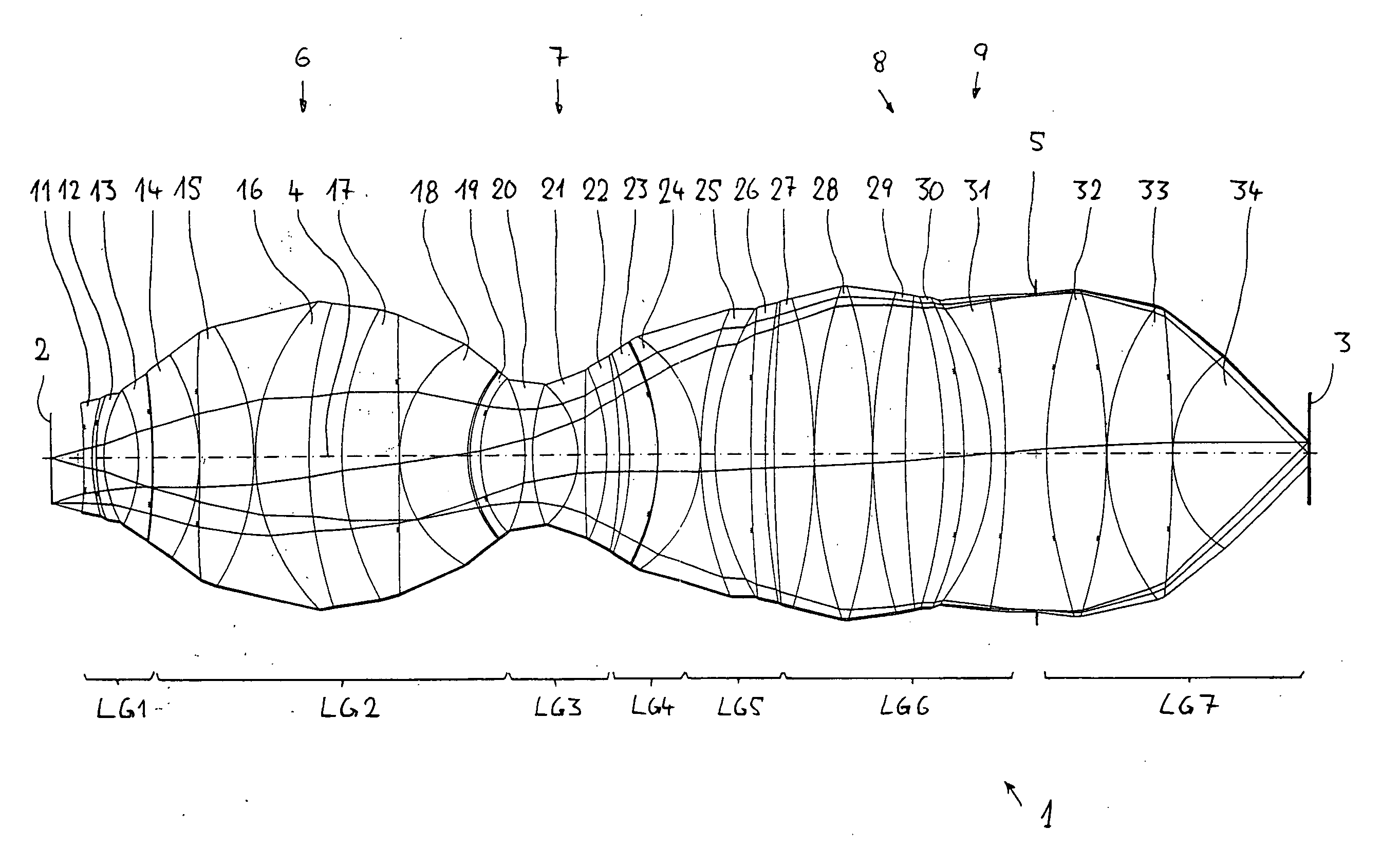

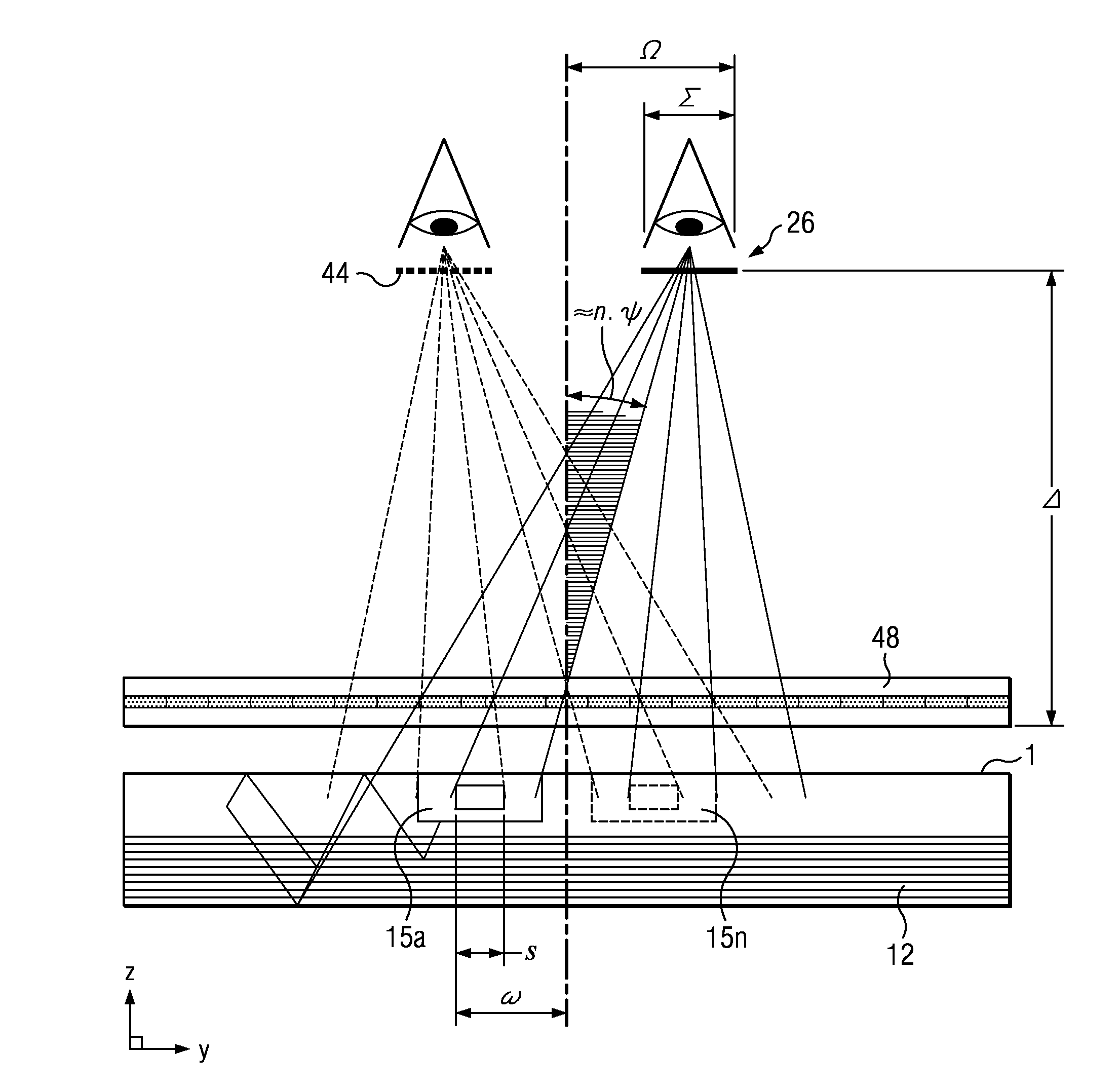

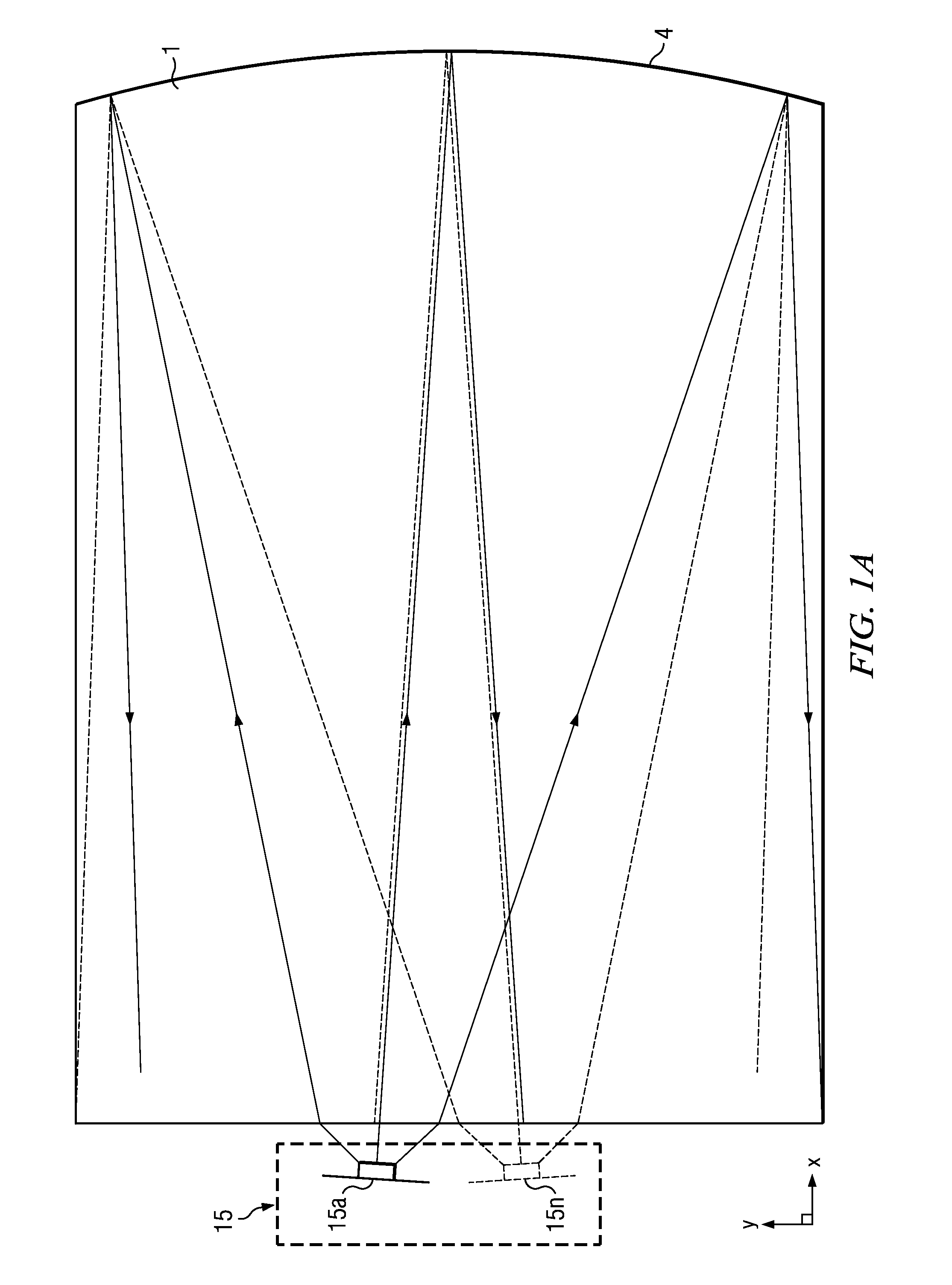

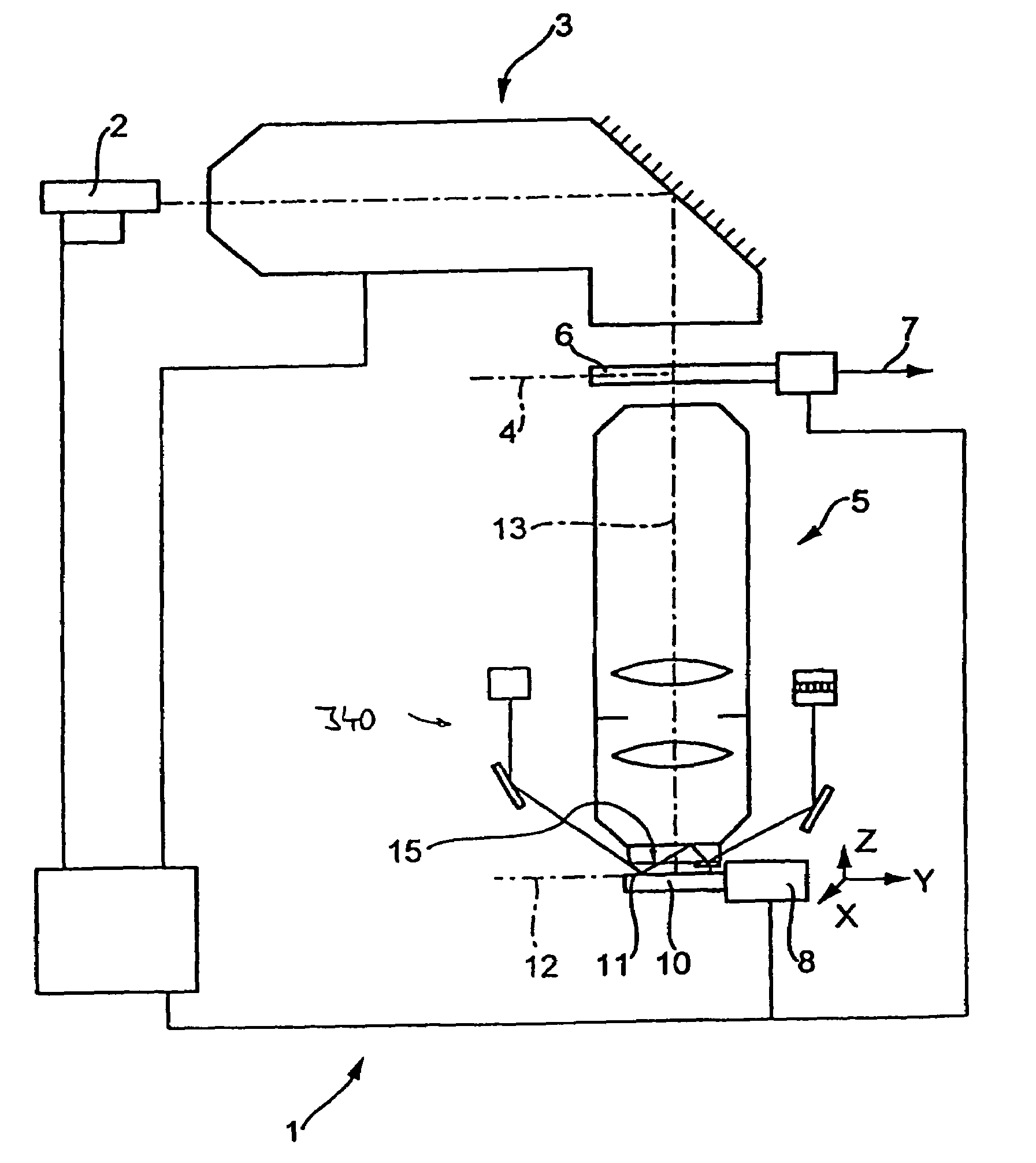

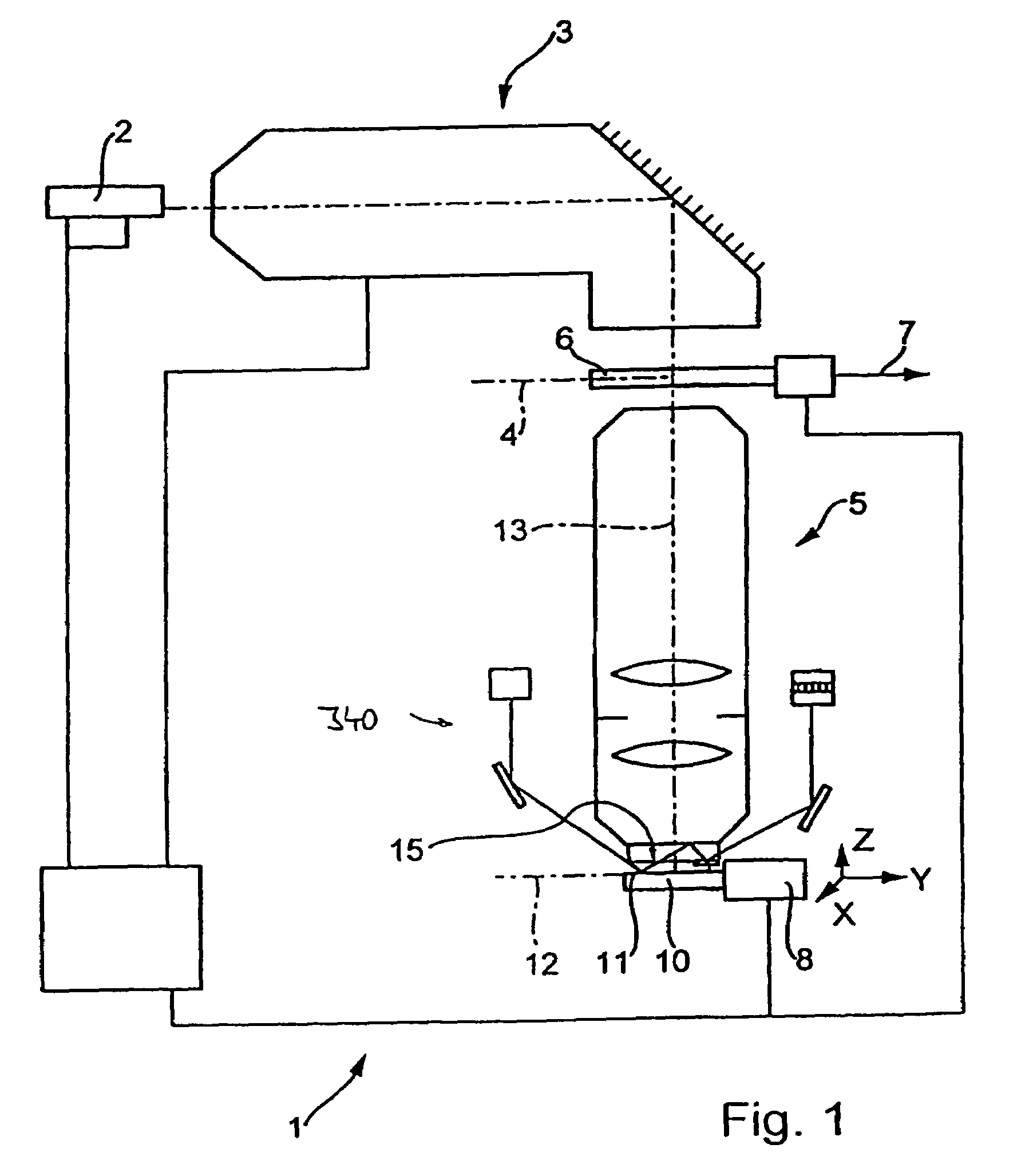

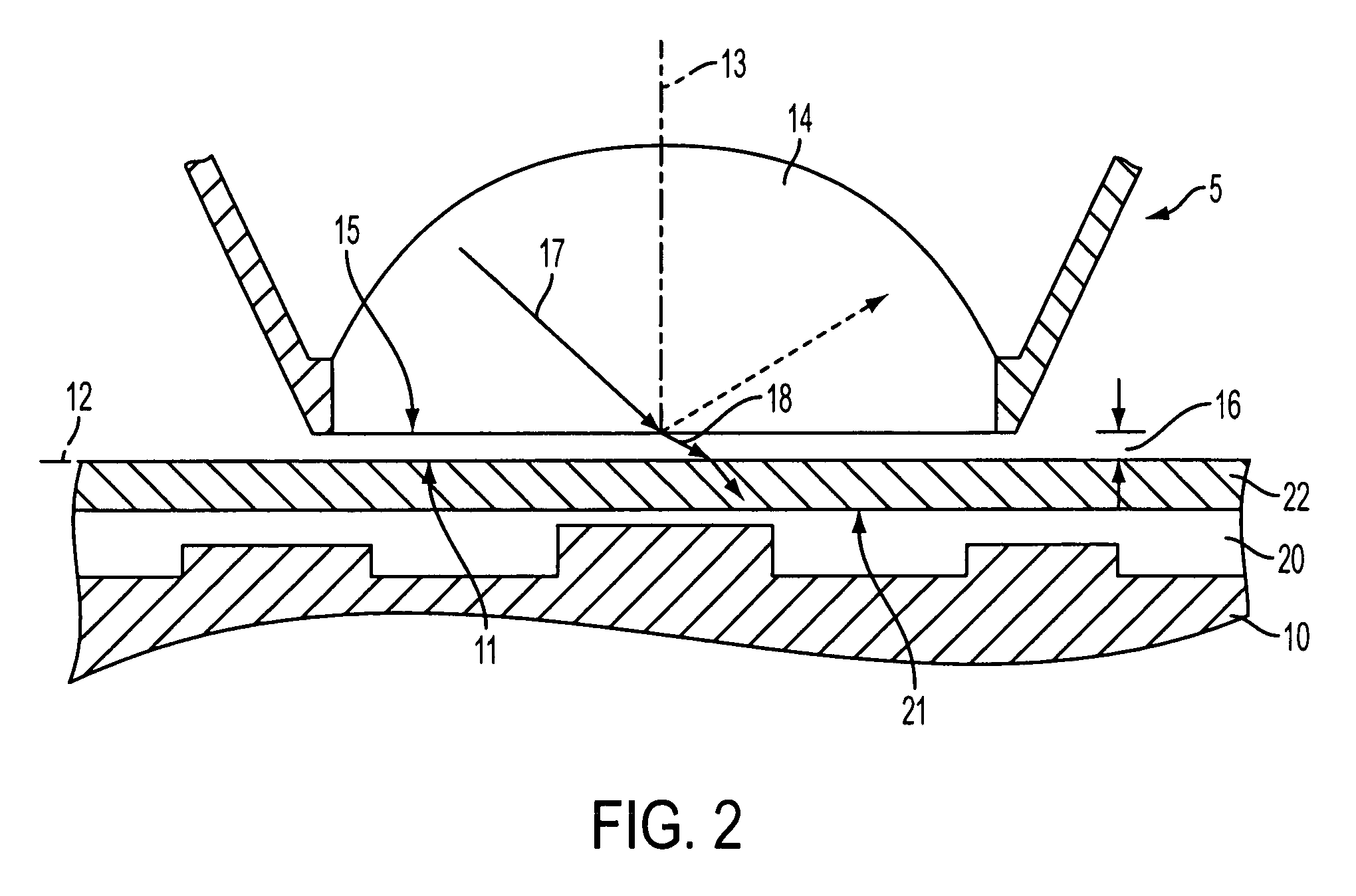

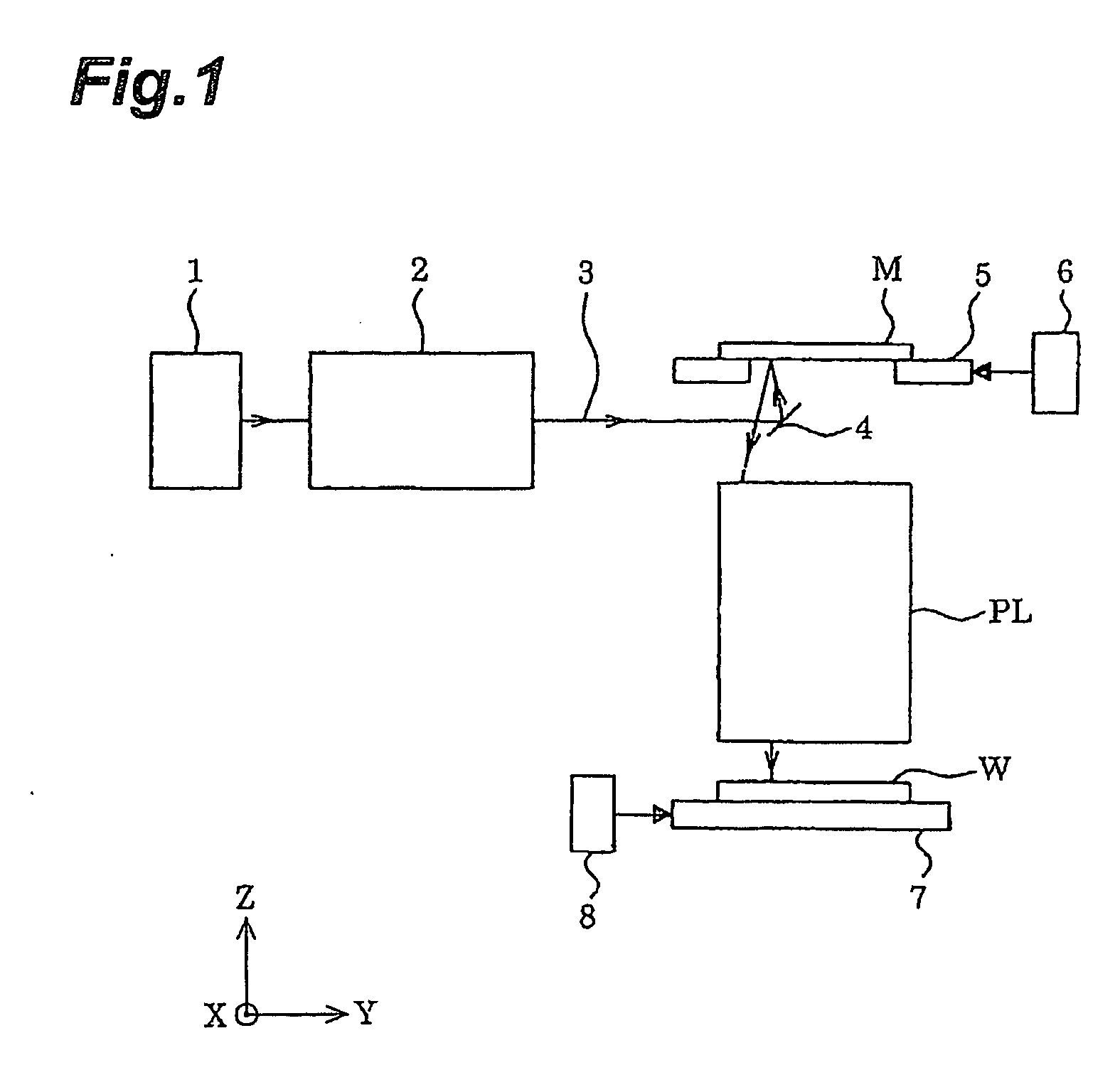

Projection exposure method and projection exposure system

InactiveUS20050030506A1Avoid defocusing errorProvides adequateNanoinformaticsMaterial analysis by optical meansLithographic artistHigh numerical aperture

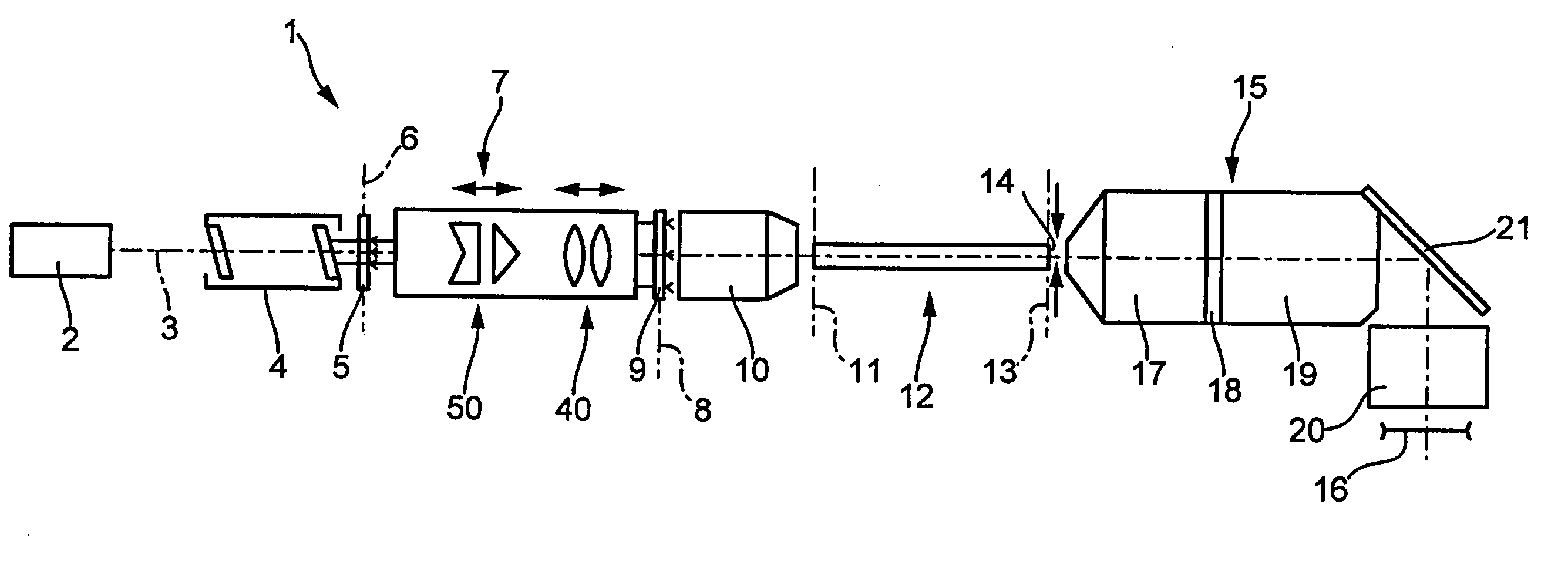

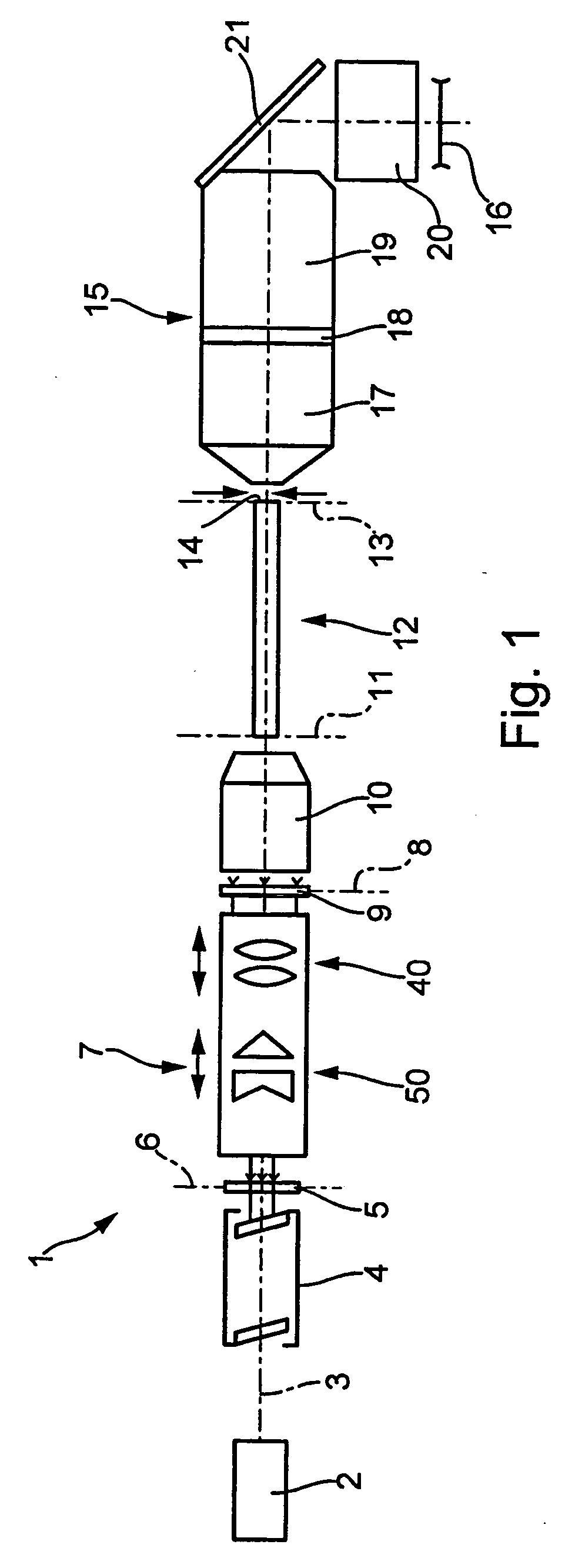

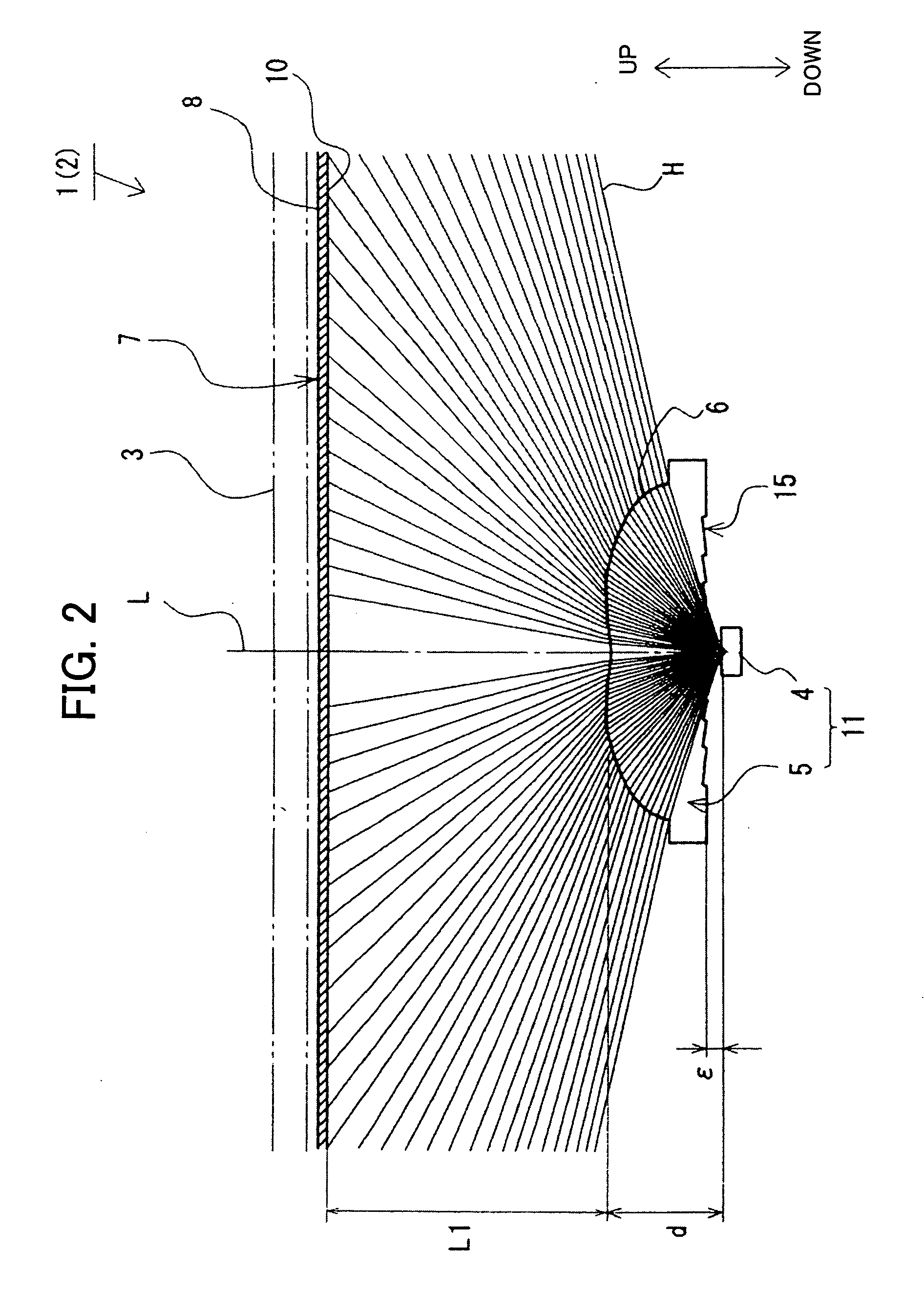

In a method for manufacturing semiconductor devices and other finely structured parts, a projection objective (5) is used in order to project the image of a pattern arranged in the object plane of the projection objective onto a photosensitive substrate which is arranged in the region of the image plane (12) of the projection objective. In this case, there is set between an exit surface (15), assigned to the projection objective, for exposing light and an incoupling surface (11), assigned to the substrate, for exposing light a small finite working distance (16) which is at least temporarily smaller in size and exposure time interval than a maximum extent of an optical near field of the light emerging from the exit surface. As a result, projection objectives with very high numerical apertures in the region of NA>0.8 or more can be rendered useful for contactless projection lithography.

Owner:CARL ZEISS SMT GMBH

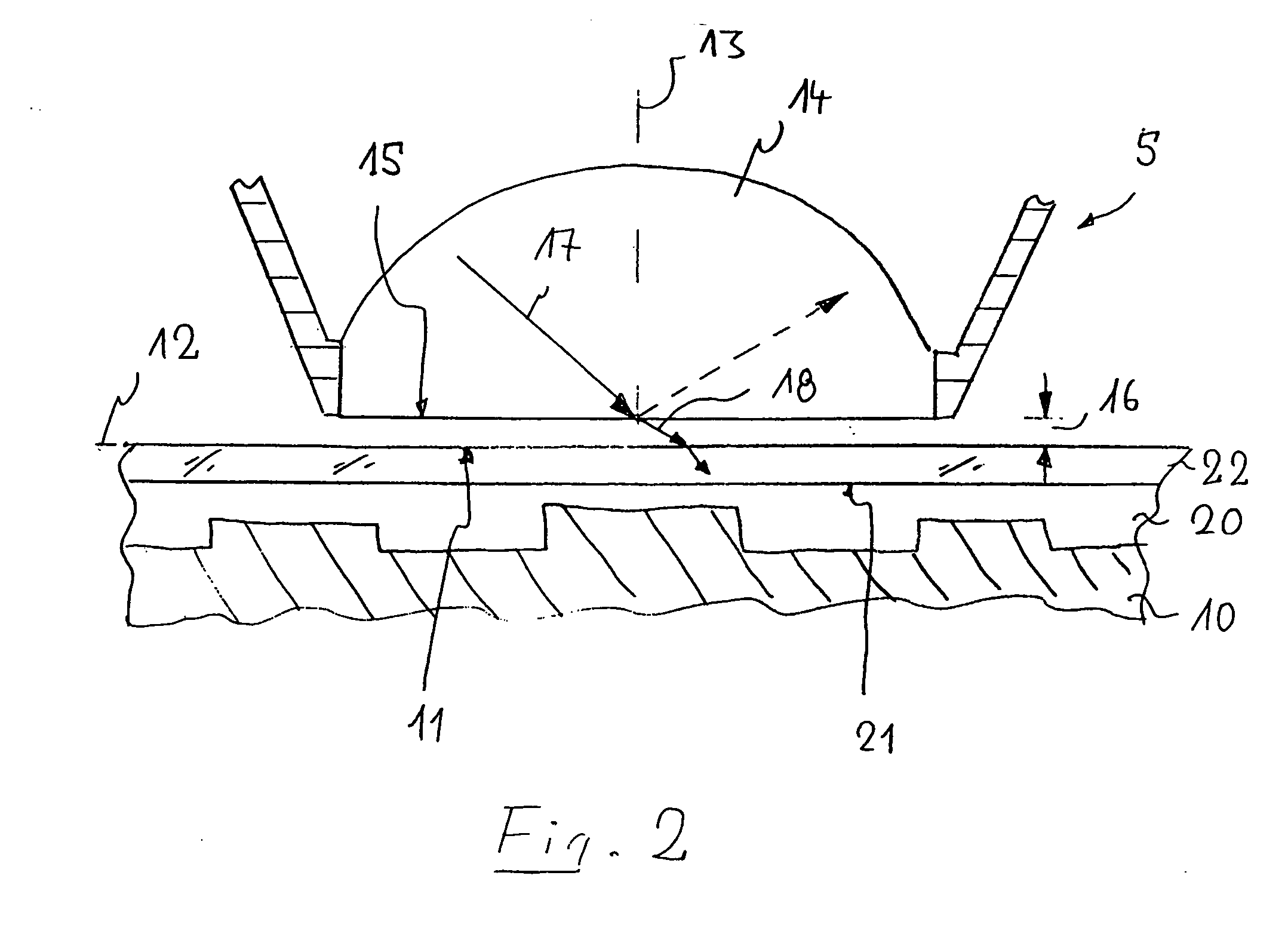

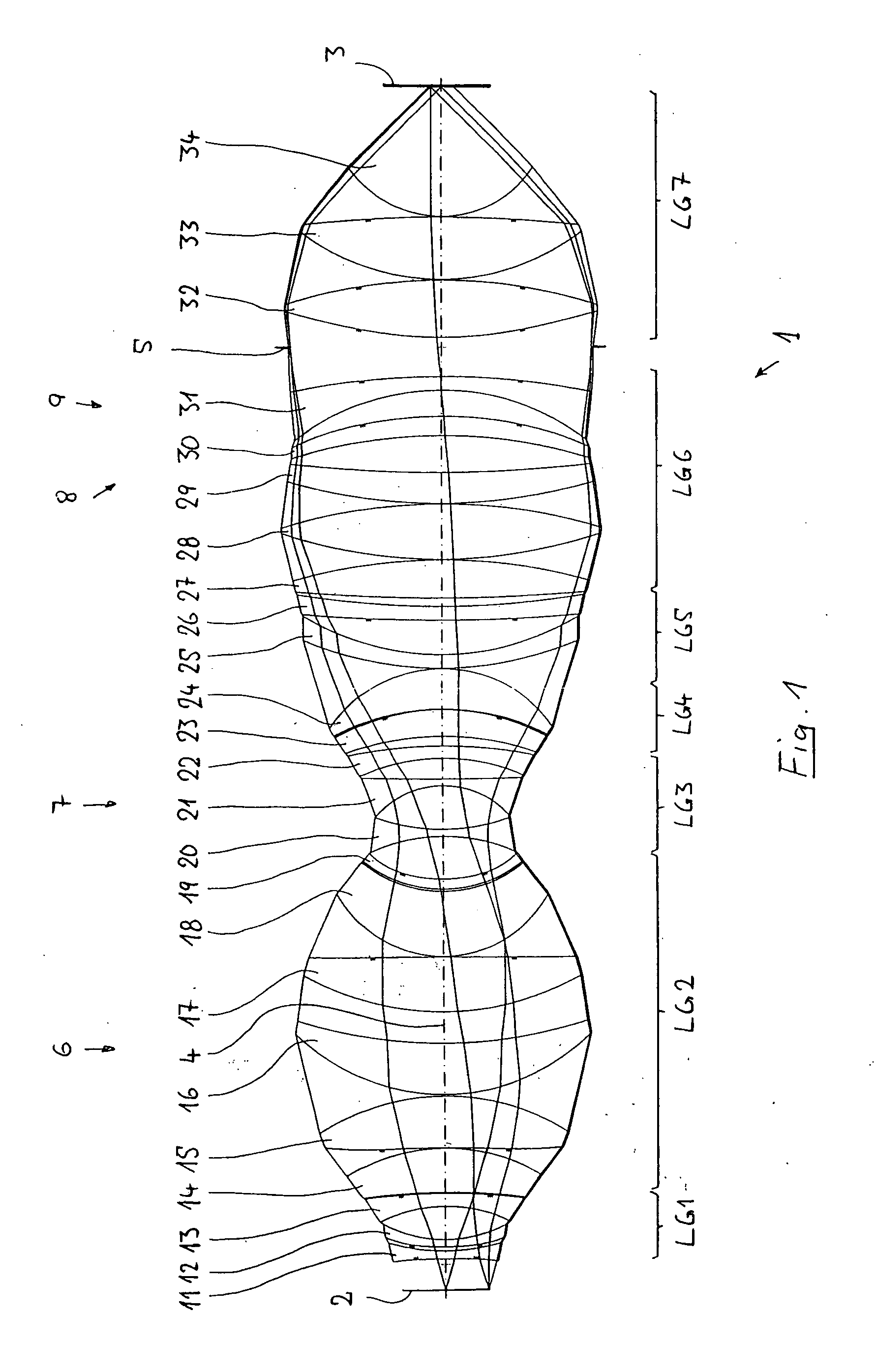

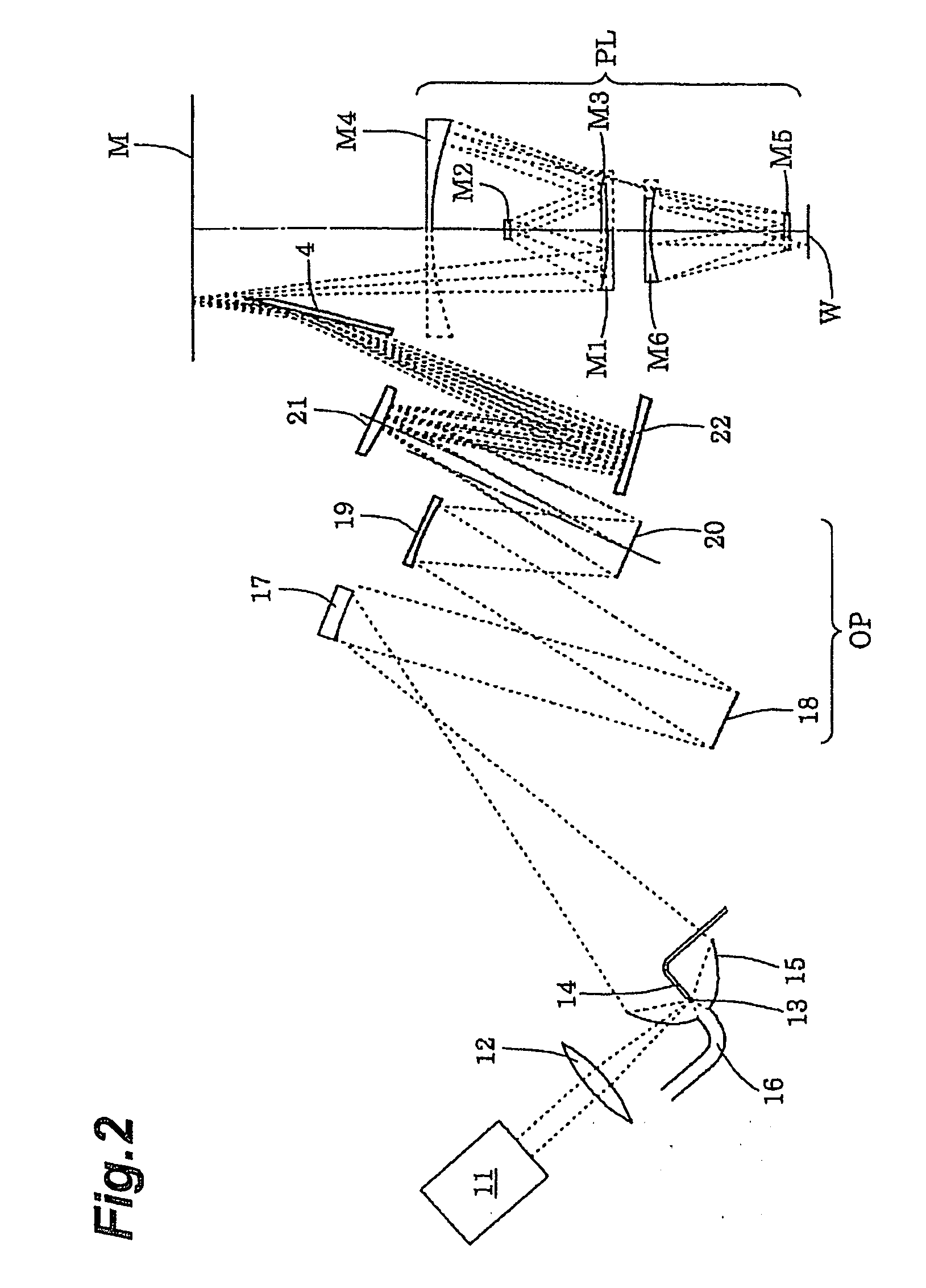

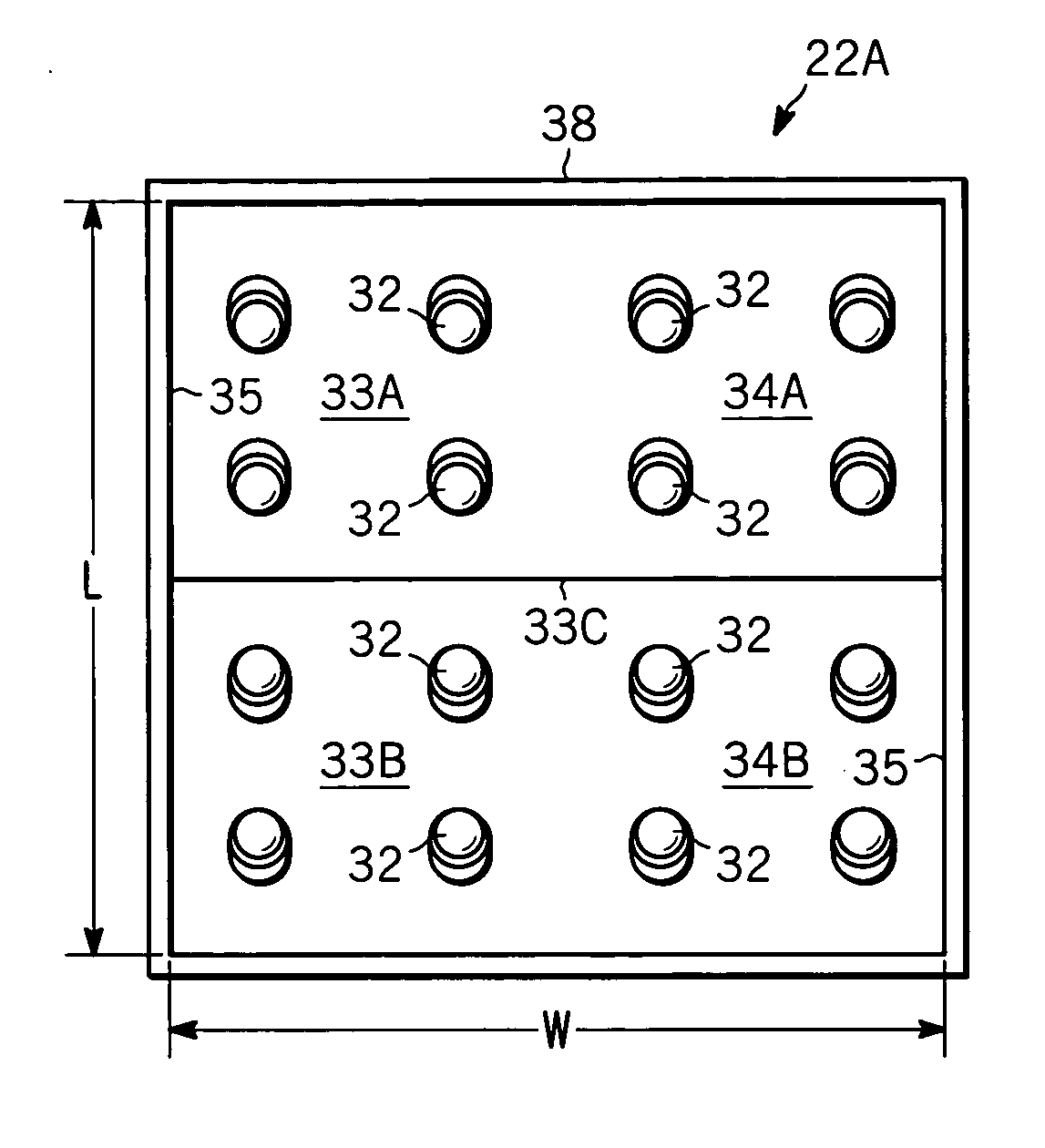

Very high-aperture projection objective

InactiveUS20050141098A1Guaranteed true stateIncrease the number ofSemiconductor/solid-state device manufacturingMicroscopesSpherical shapedOptic system

A very high-aperture, purely refractive projection objective having a multiplicity of optical elements has a system diaphragm (5) arranged at a spacing in front of the image plane. The optical element next to the image plane (3) of the projection objective is a planoconvex lens (34) having a substantially spherical entrance surface and a substantially flat exit surface. The planoconvex lens has a diameter that is at least 50% of the diaphragm diameter of the system diaphragm (5). It is preferred to arrange only positive lenses (32, 33, 34) between the system diaphragm (5) and image plane (3). The optical system permits imaging in the case of very high apertures of NA≧0.85, if appropriate of NA≧1.

Owner:CARL ZEISS SMT GMBH

Semi-continuous feed production of liquid personal care compositions

ActiveUS9174178B2Shorten the timeReduce wasteFlow mixersTransportation and packagingPersonal careEngineering

Owner:THE PROCTER & GAMBLE COMPANY

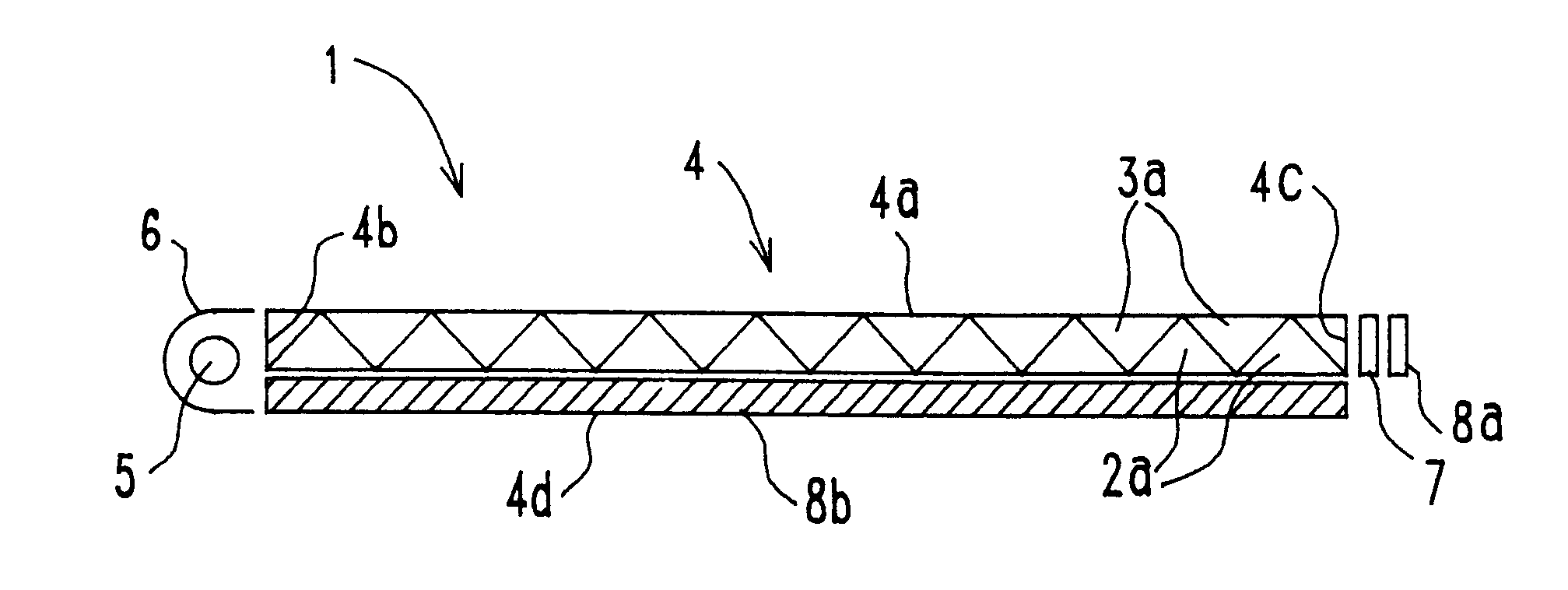

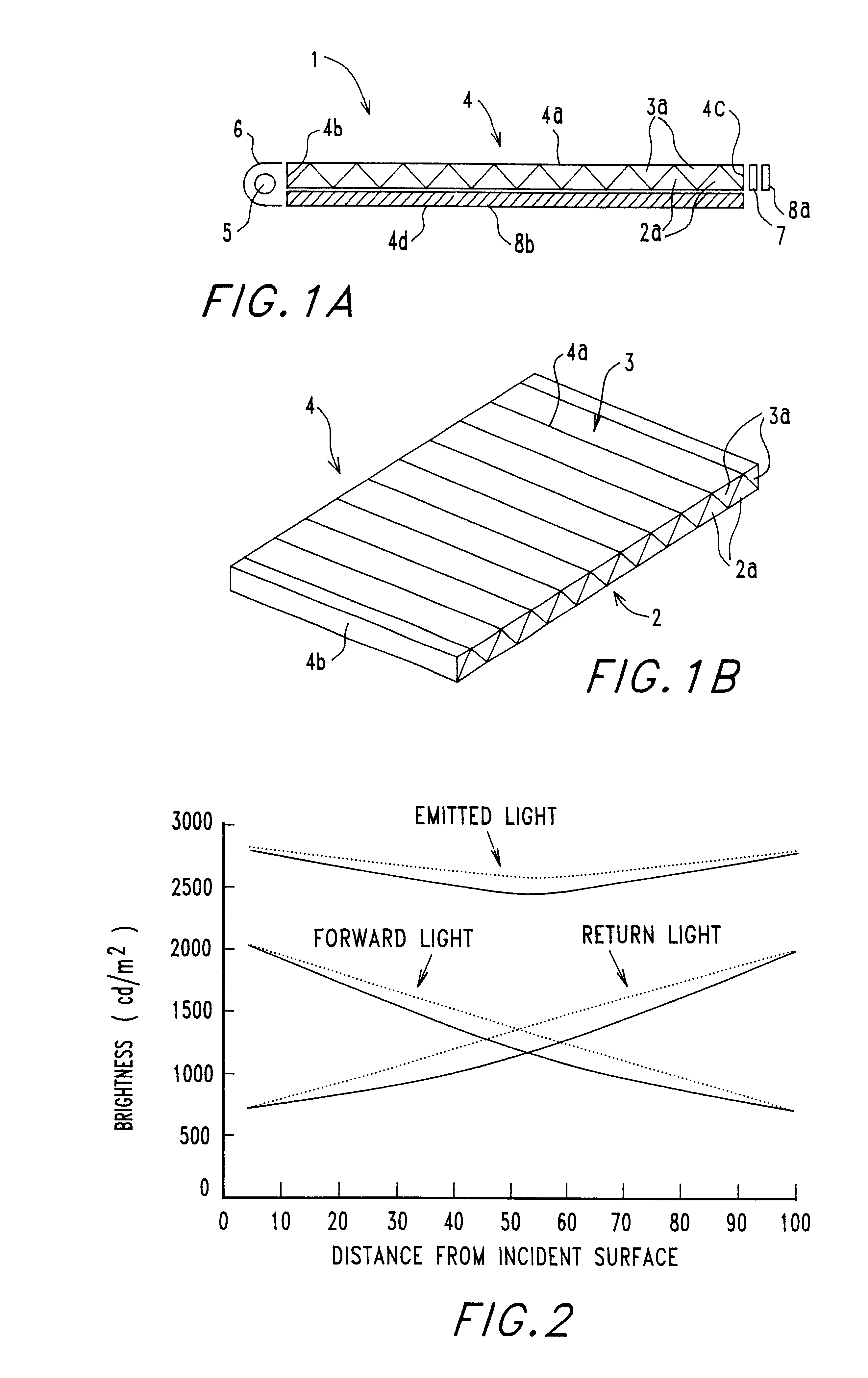

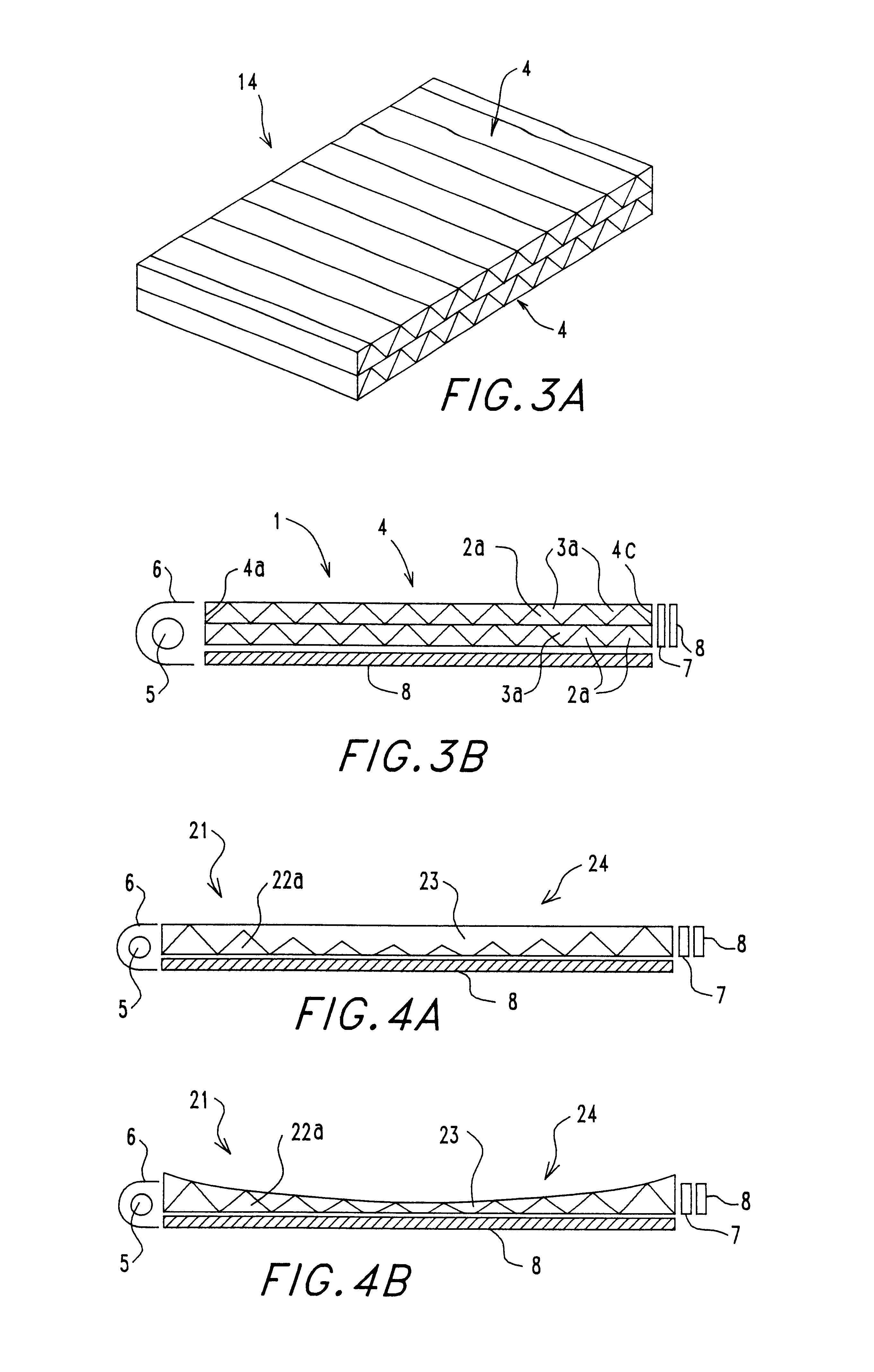

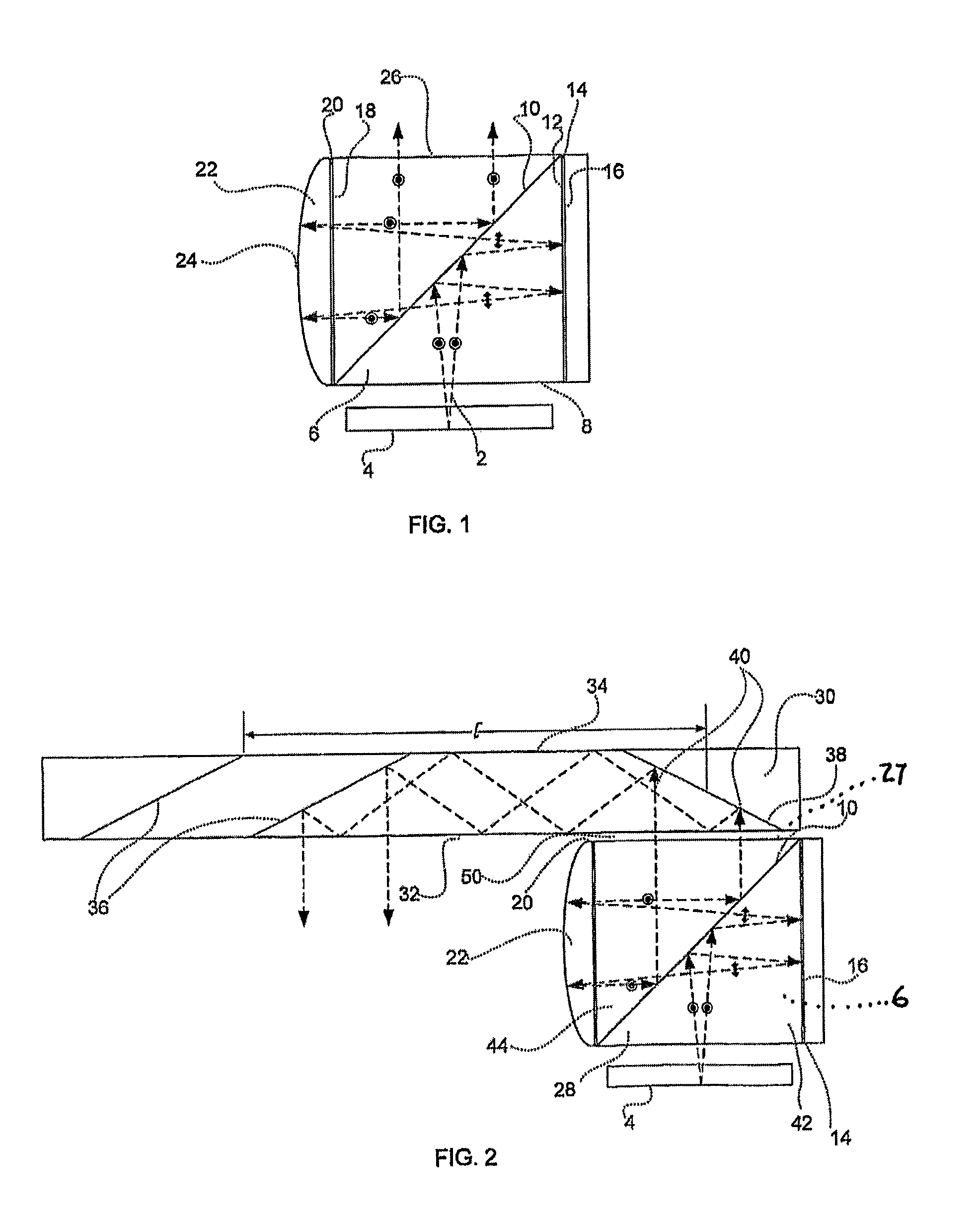

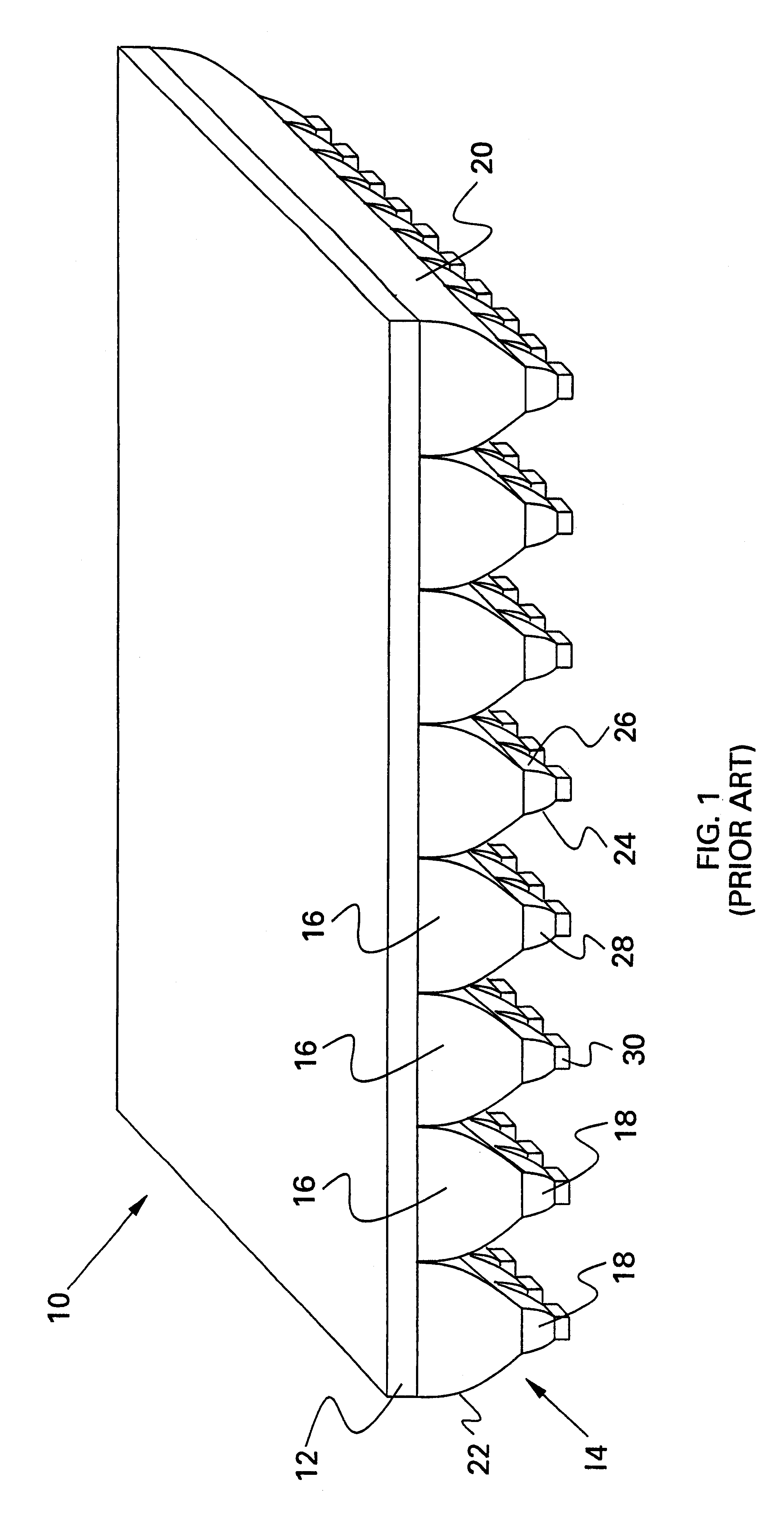

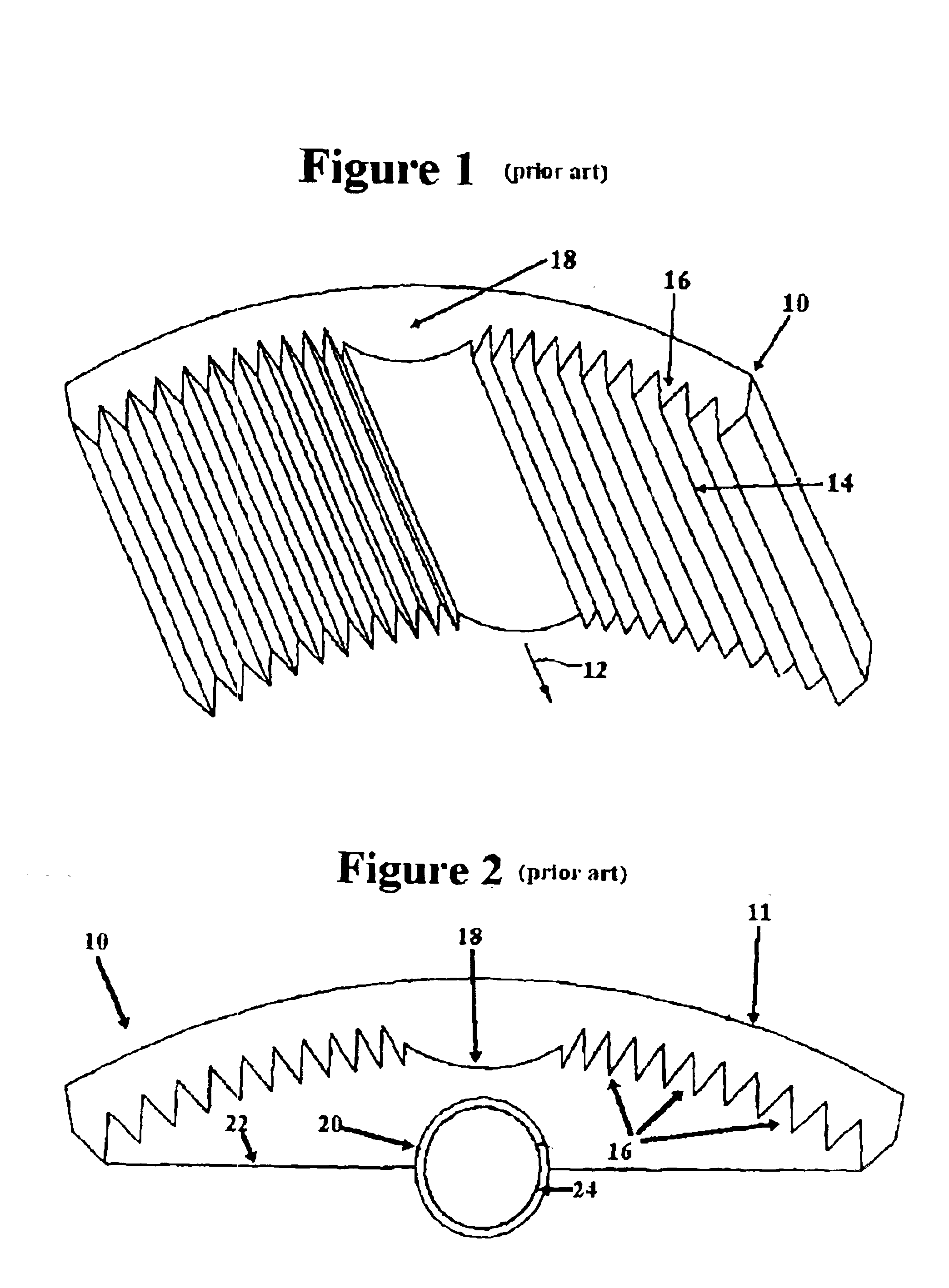

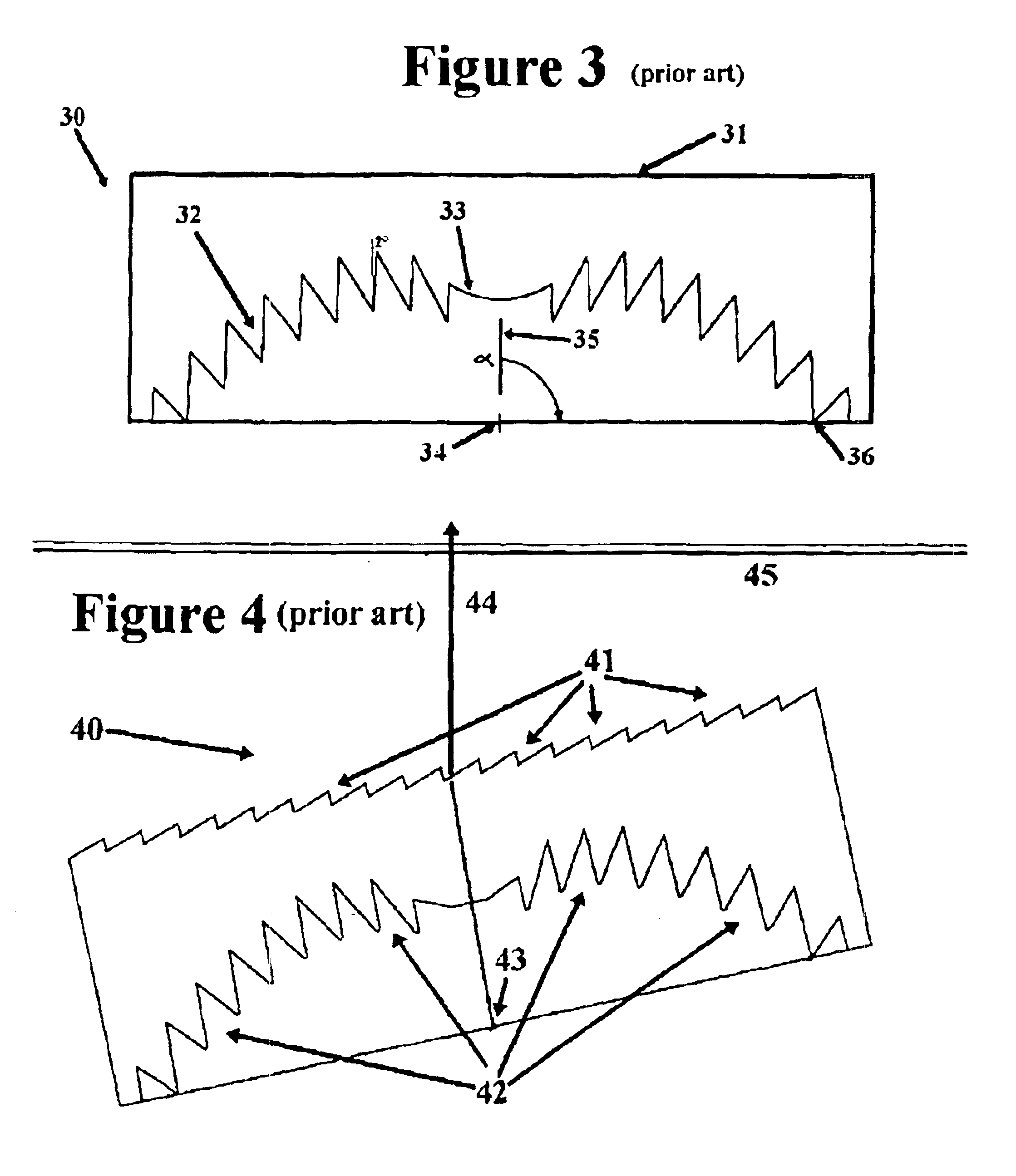

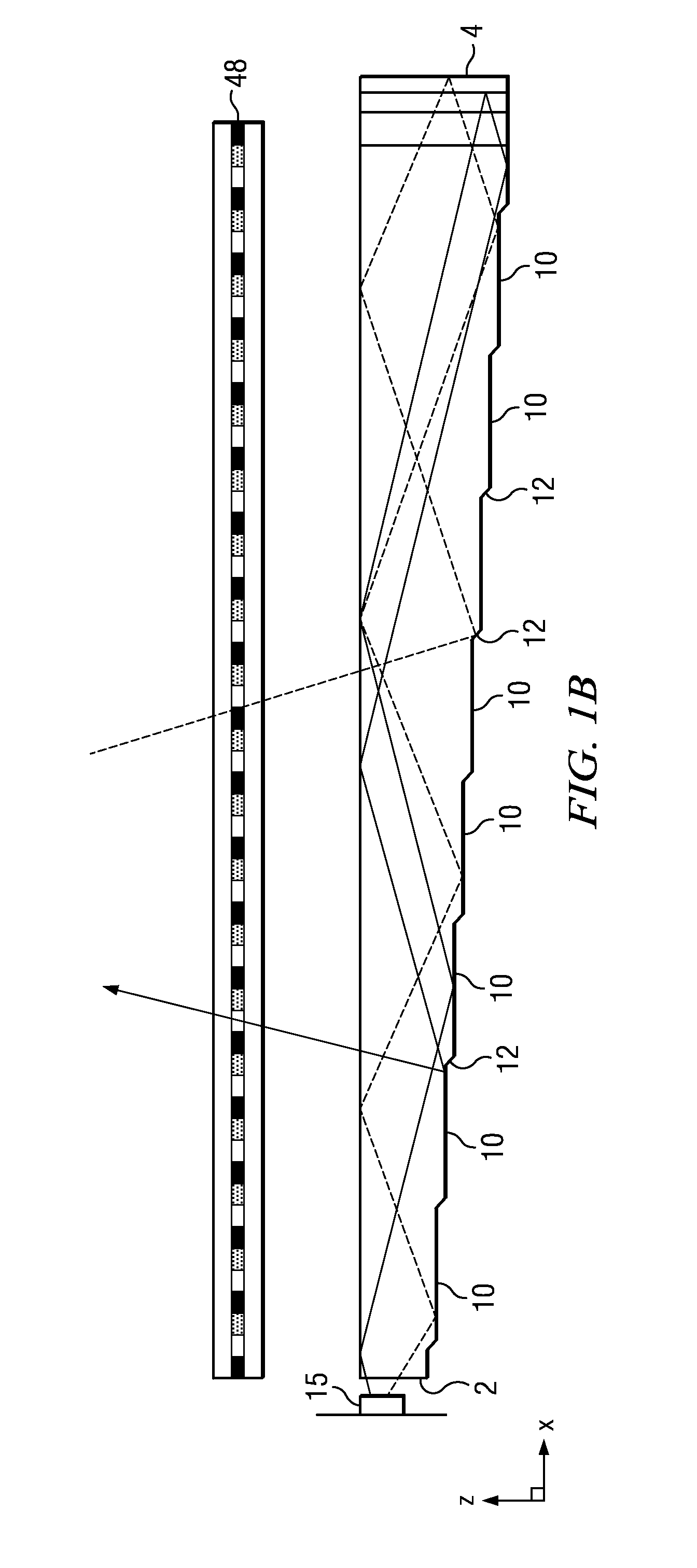

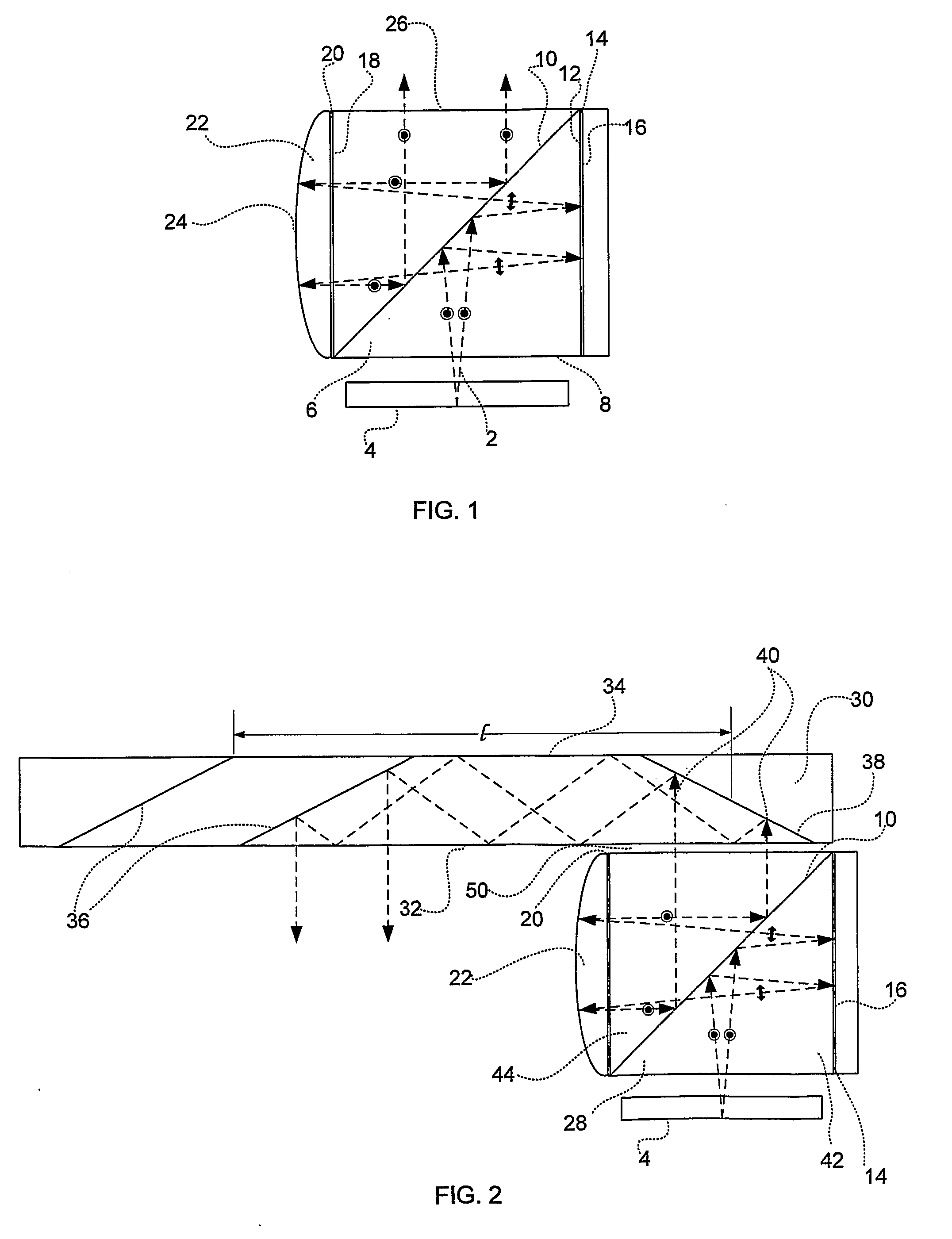

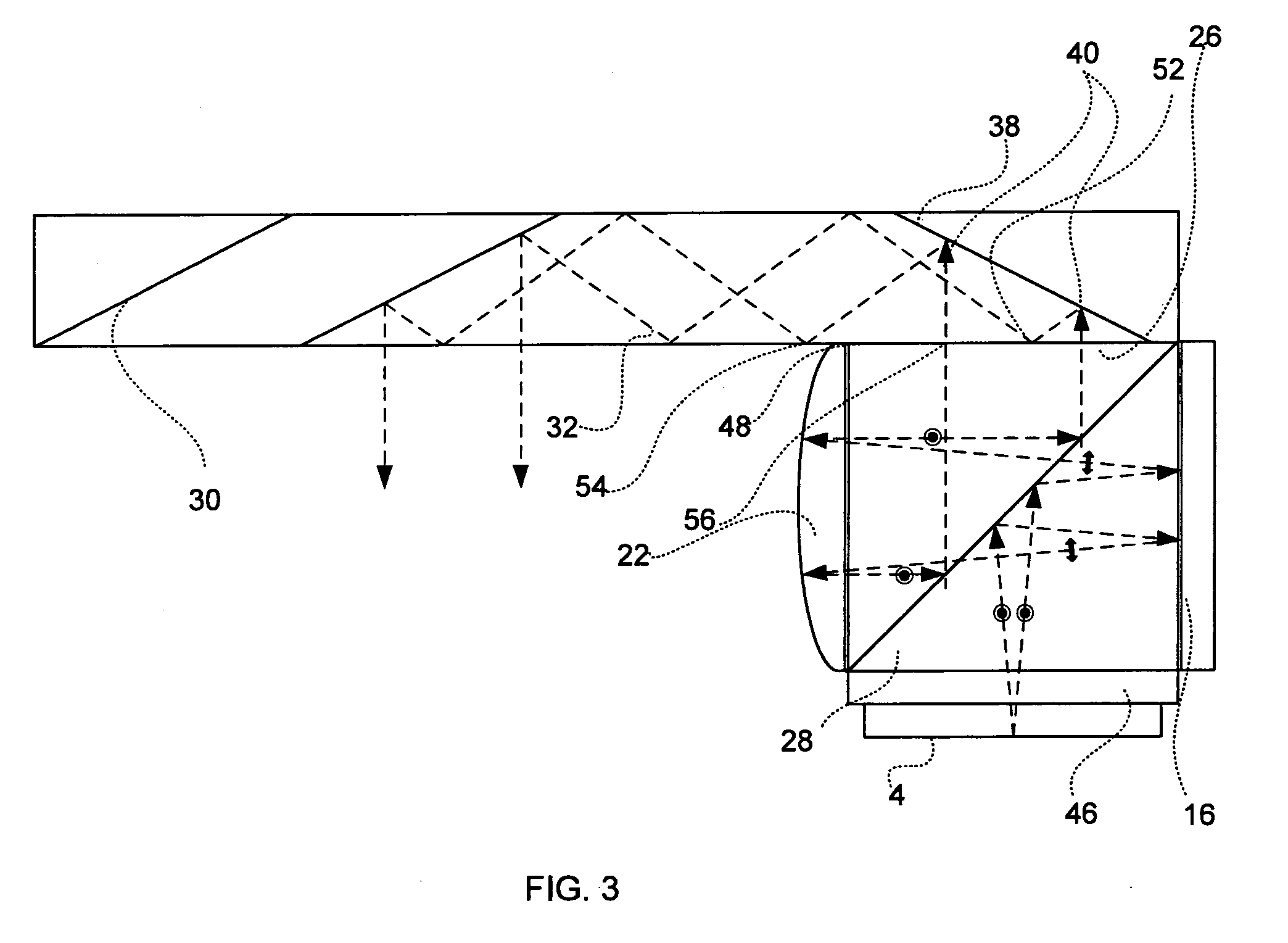

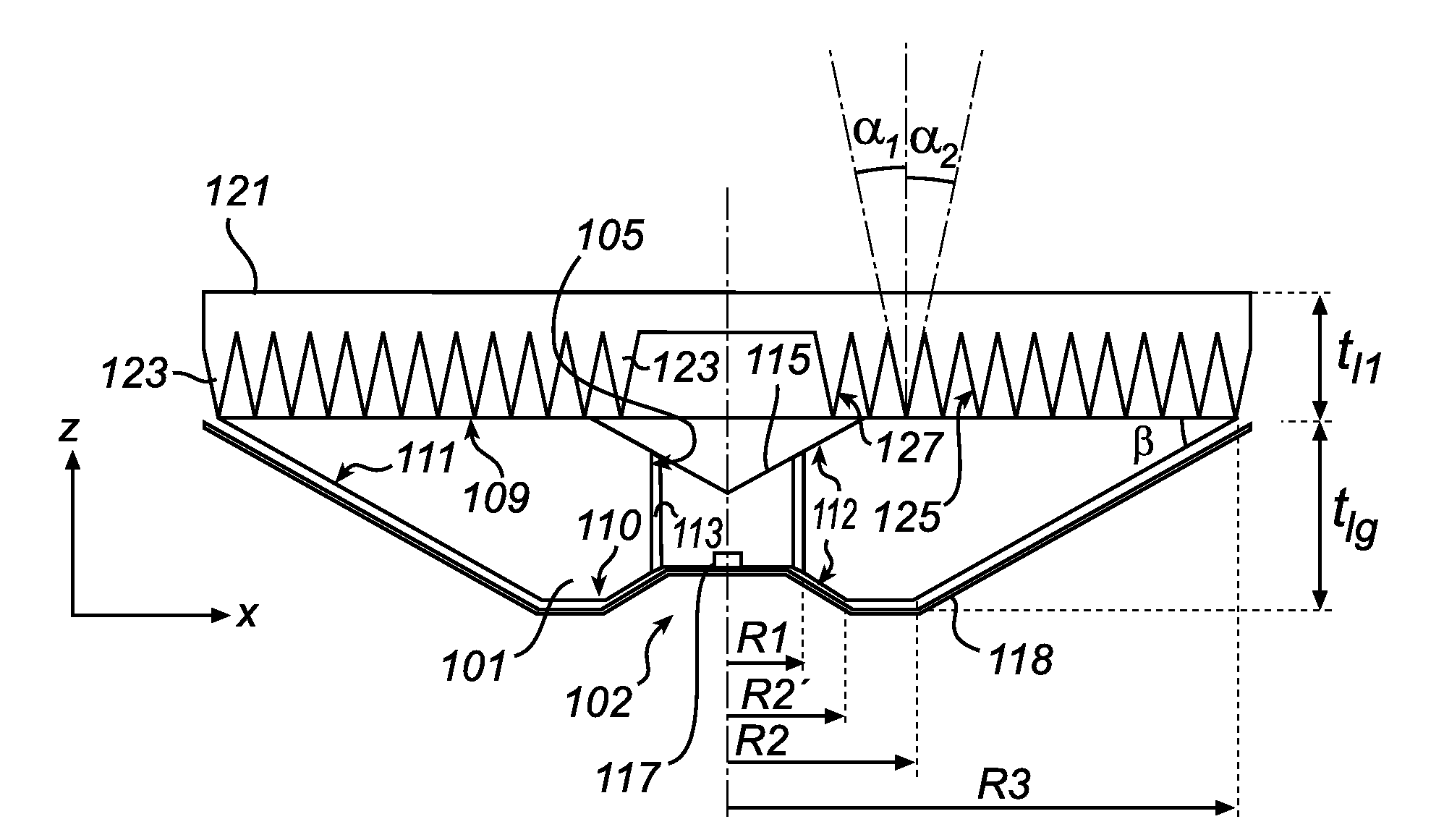

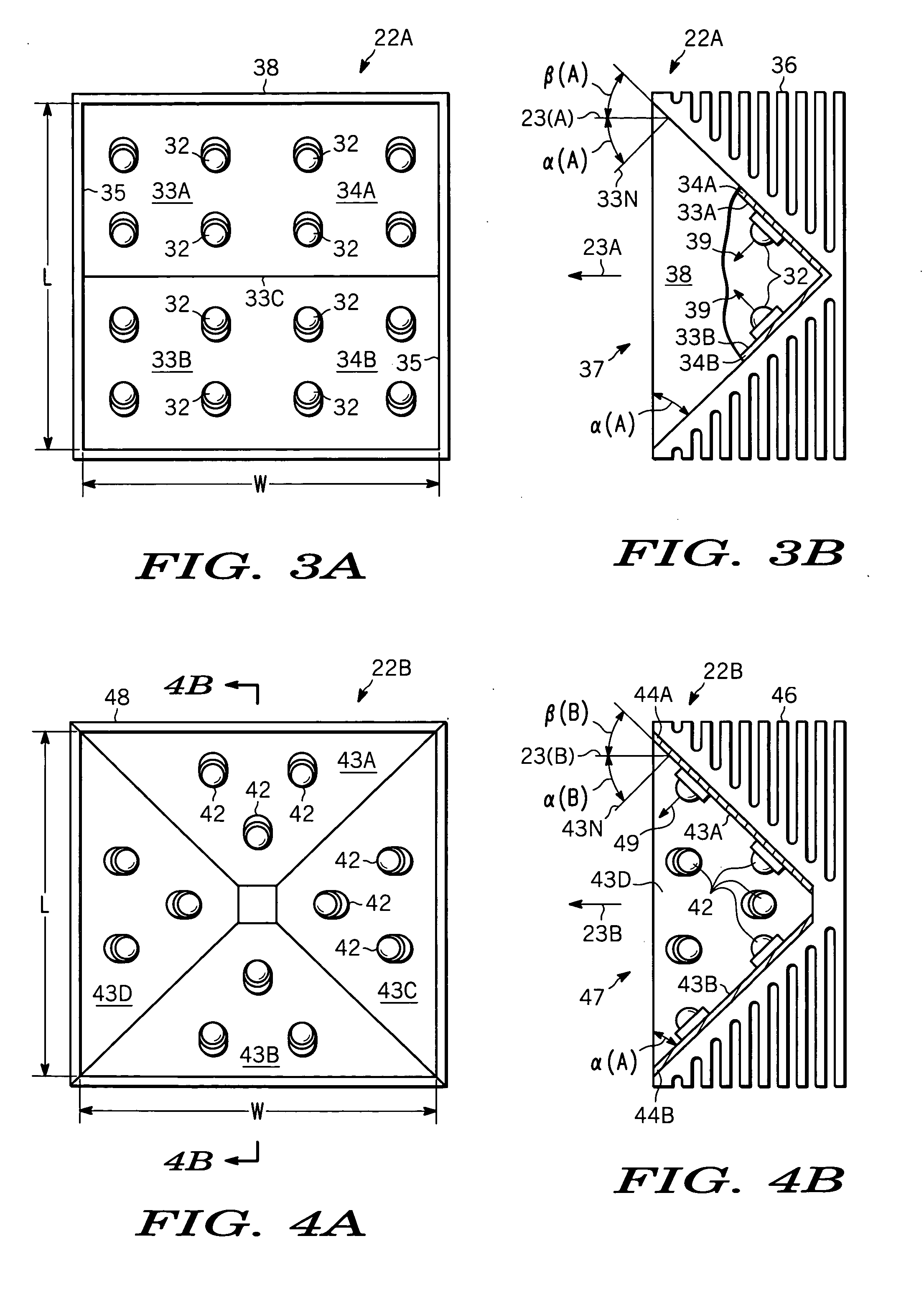

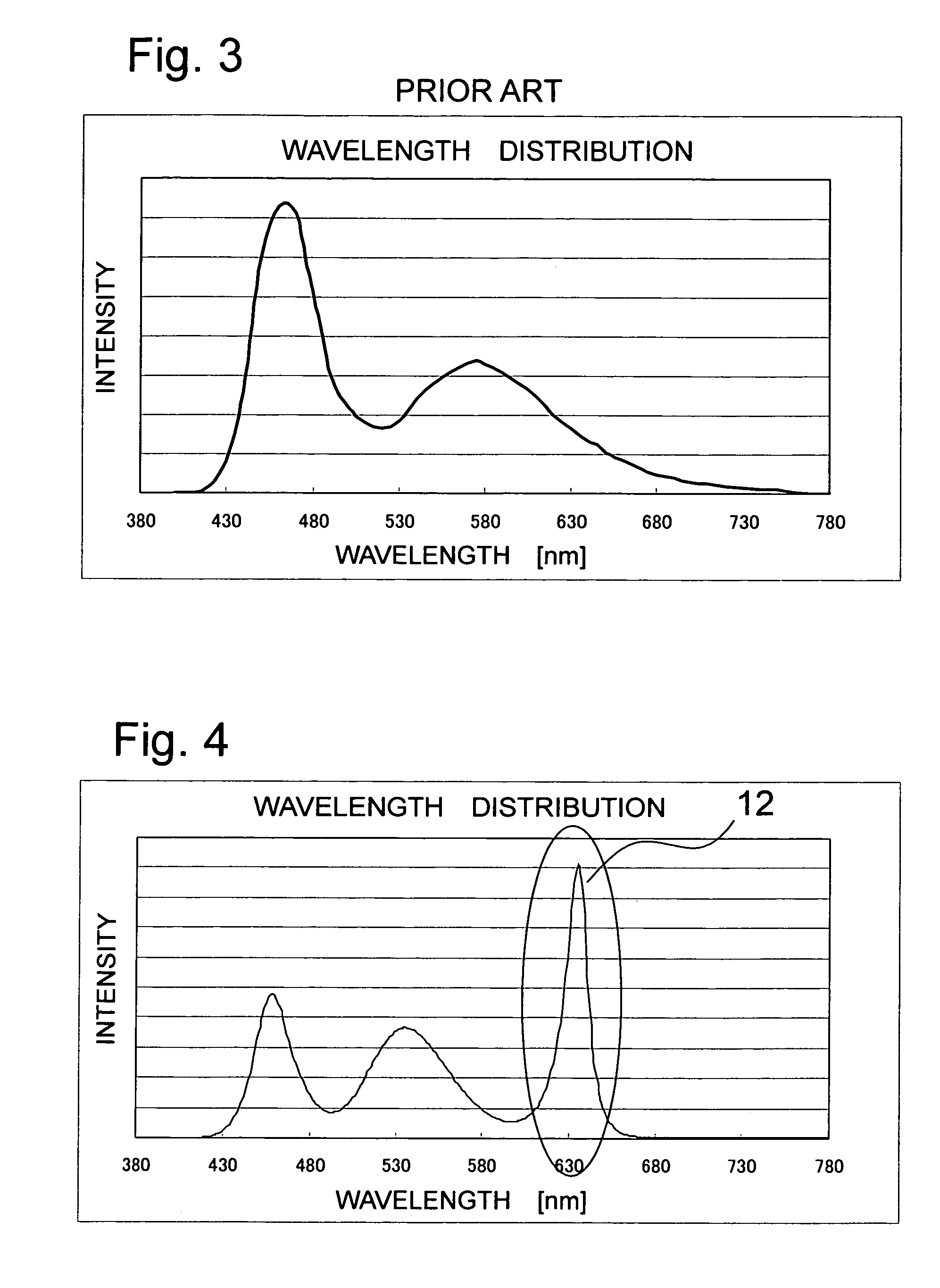

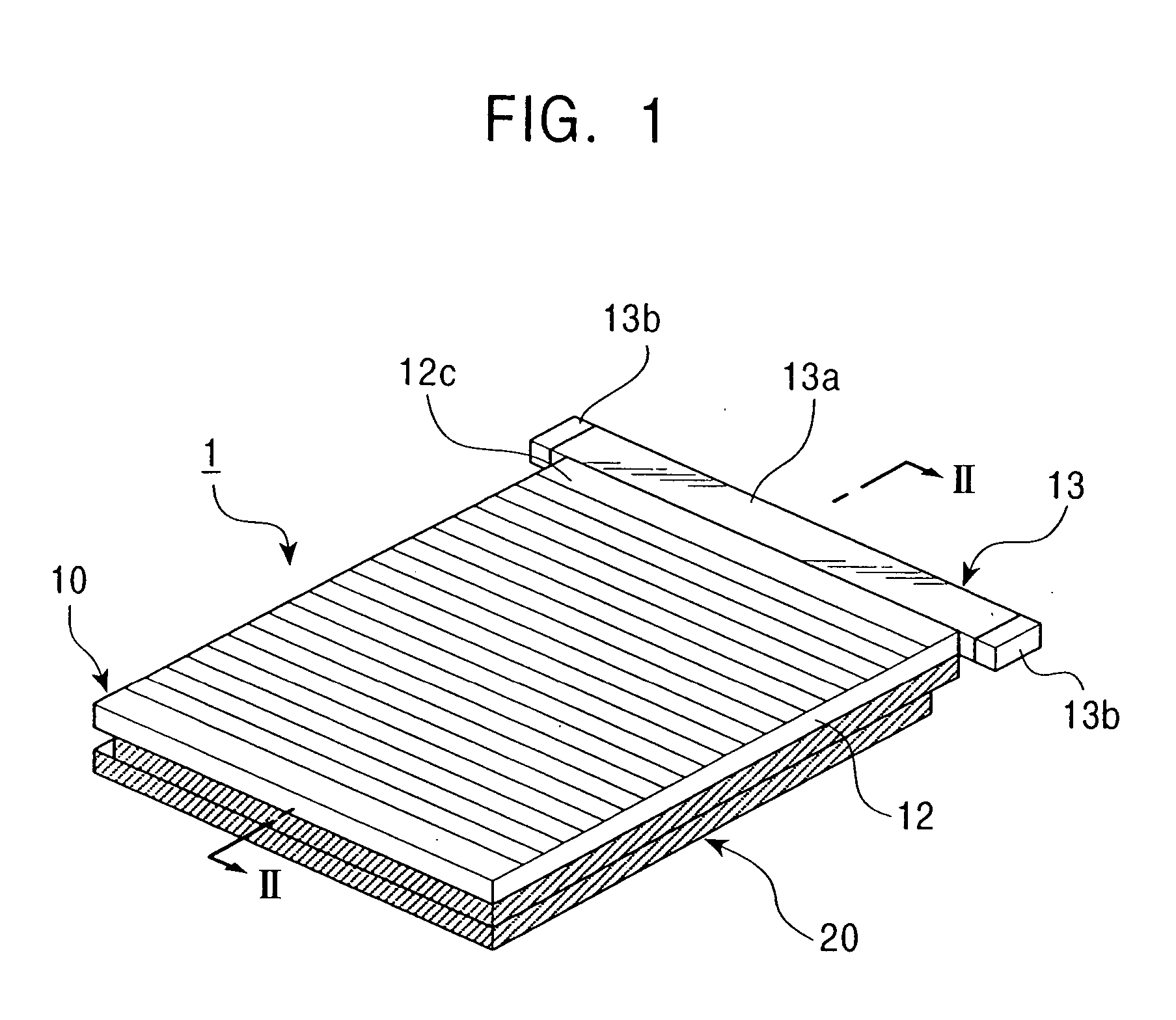

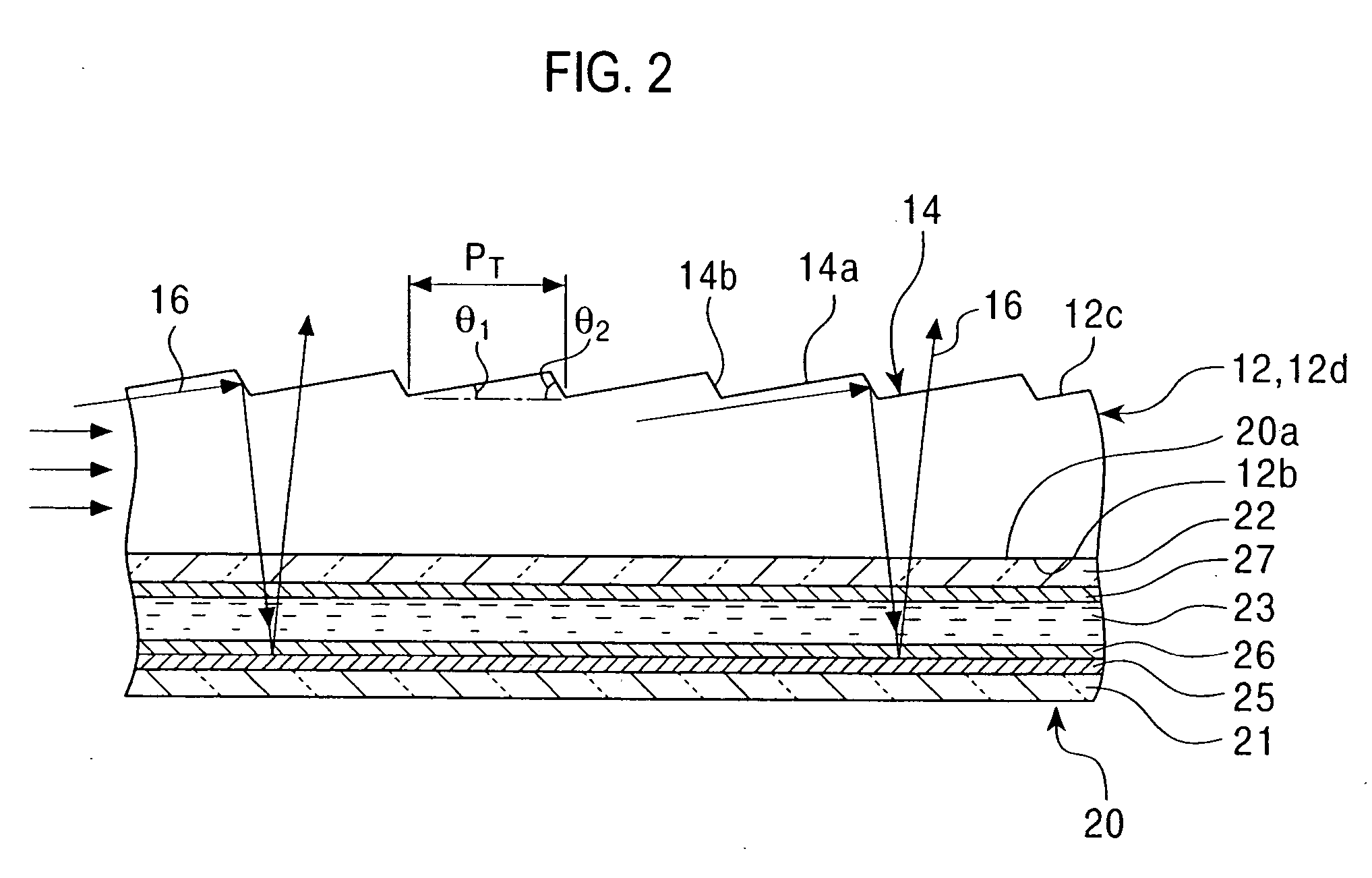

Planar light source device having polarization separator formed of two sheets with mating triangular prisms and different indices of refraction

InactiveUS6239851B1Uniform emitting intensityReduce variationMeasurement apparatus componentsStatic indicating devicesLiquid-crystal displayLight guide

The purpose of the invention is to provide a light guide of a variety of forms having a uniform distribution of brightness in the plane and a planer light source device for a liquid crystal display device which uses such light guide. The light guide comprises a first surface which is a surface to which a natural polarization light is incident and a second surface other than the first surface which is an exit surface of a specific polarization light into which, said natural polarization light is modulated, wherein;said light guide has an interface of two materials of different indices of refraction oriented at an angle of thetaB+ / -alpha degrees relative to the primary propagation direction of said incident light, said thetaB being an angle satisfying Brewster's condition, more than two orientations of said interface exist in a single light guide, and the difference between the indices of refraction of the two materials of different indices of refraction is between 0.001 and 1.0. thetaB is typically about 45 degrees. The light guide comprises a first transparent member having a plurality of upwardly convex right angle isosceles triangles on a first surface thereof and a first index of refraction and a second transparent member having a plurality of downwardly convex right angle isosceles triangles on a second surface thereof and a second index of refraction, and said first surface and said second surface contact each other.

Owner:SEKISUI CHEM CO LTD +1

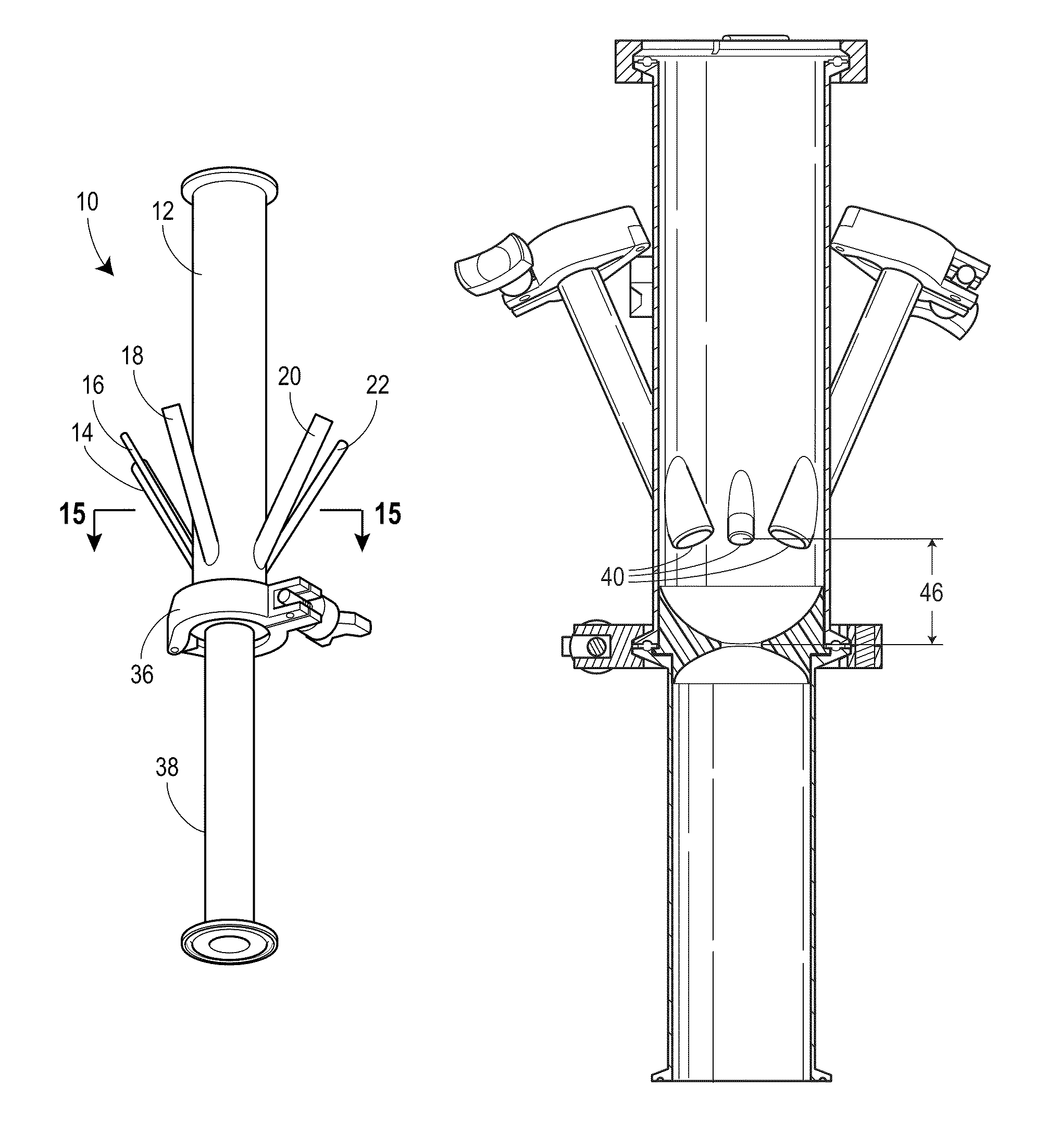

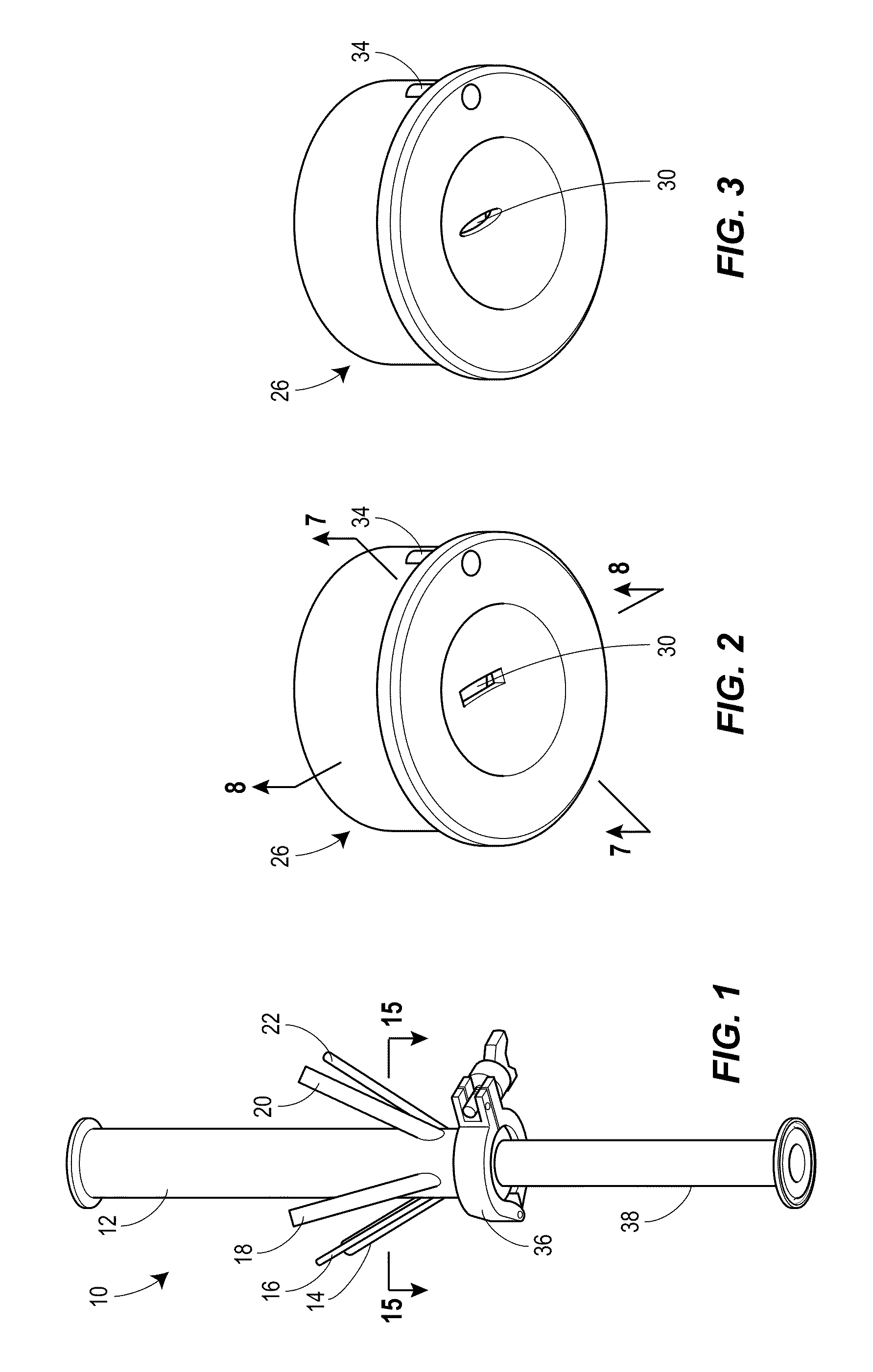

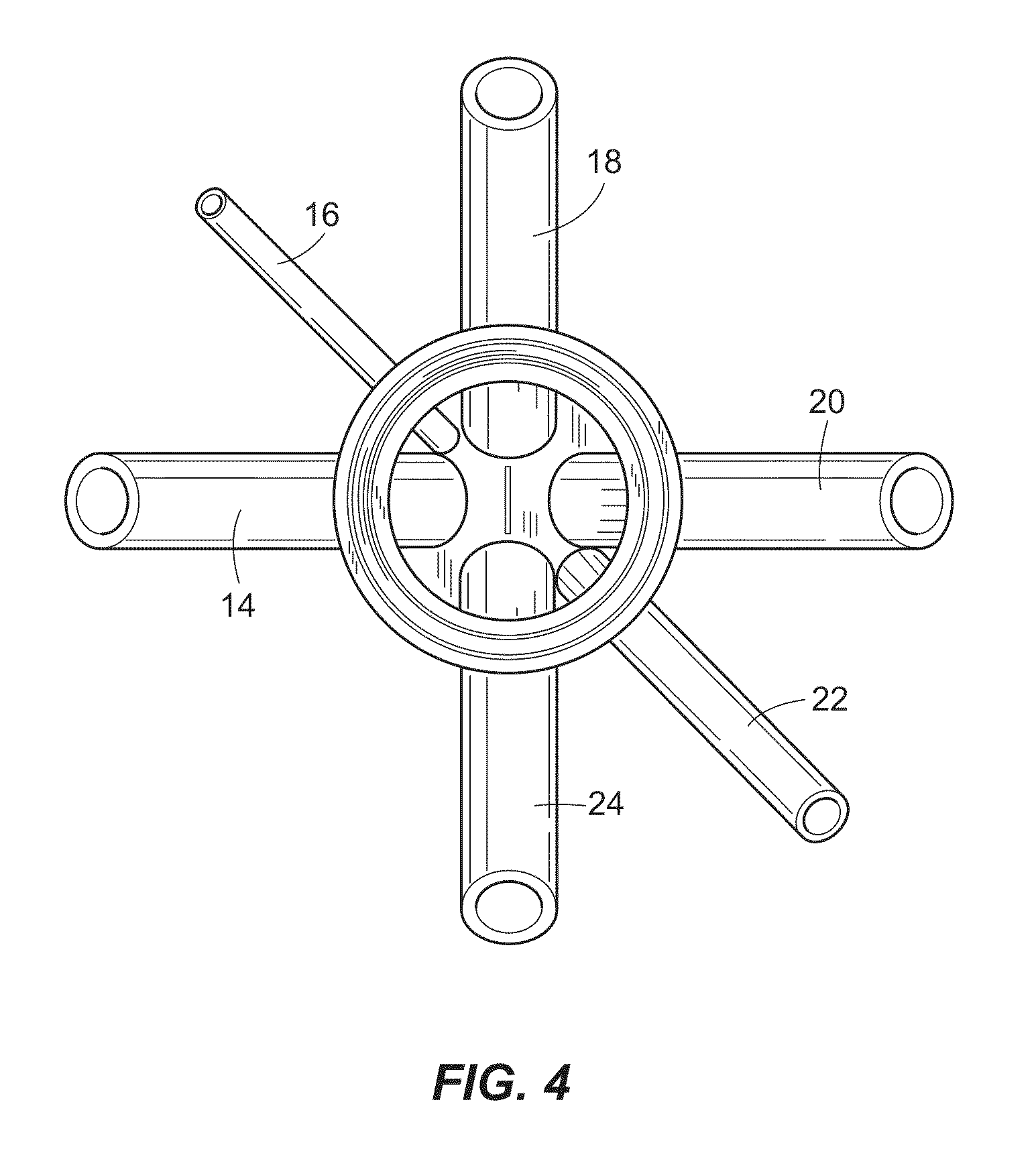

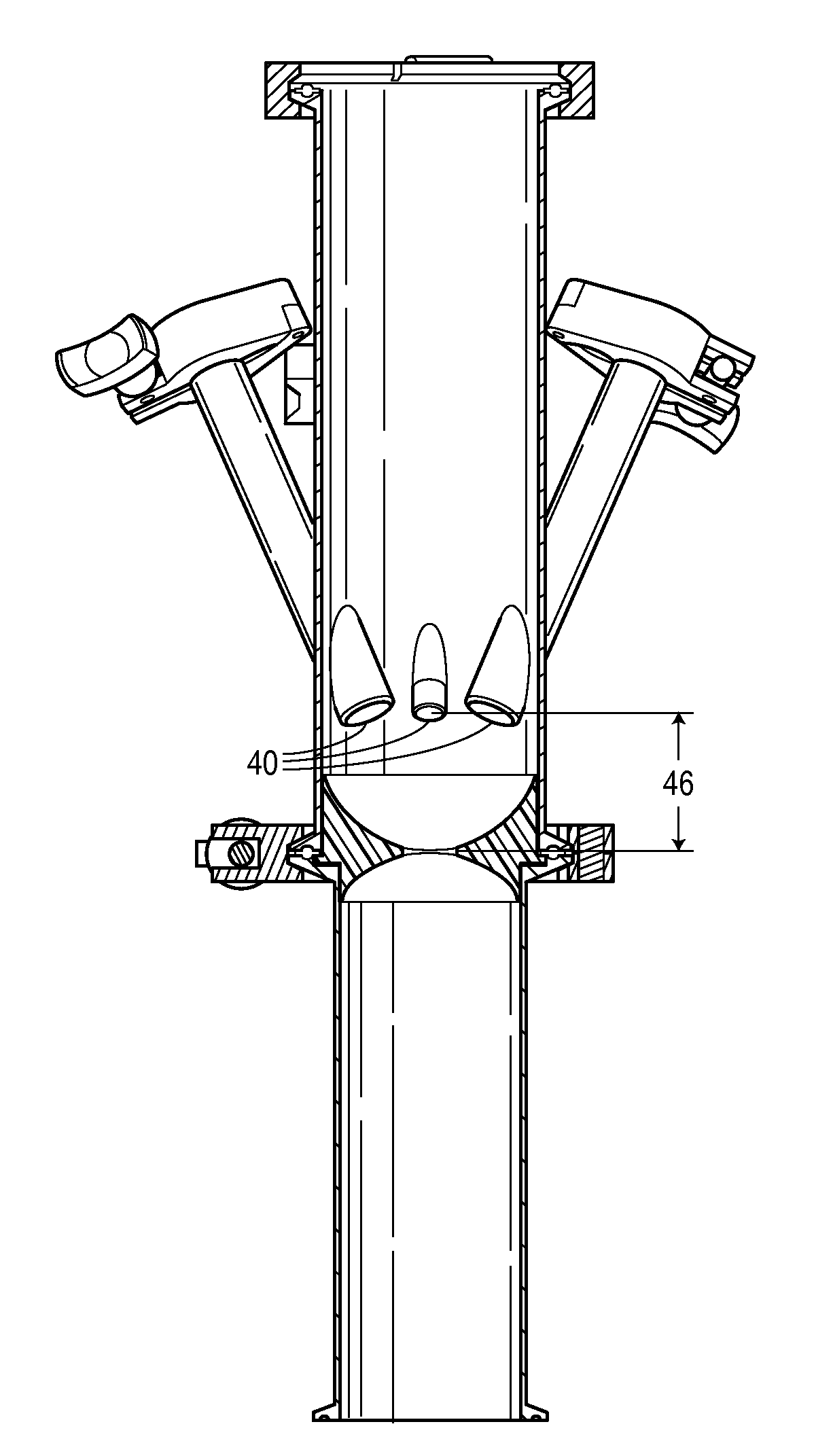

Semi-Continuous Feed Production of Liquid Personal Care Compositions

ActiveUS20110305102A1Shorten the timeReduce wasteFlow mixersTransportation and packagingPersonal careEngineering

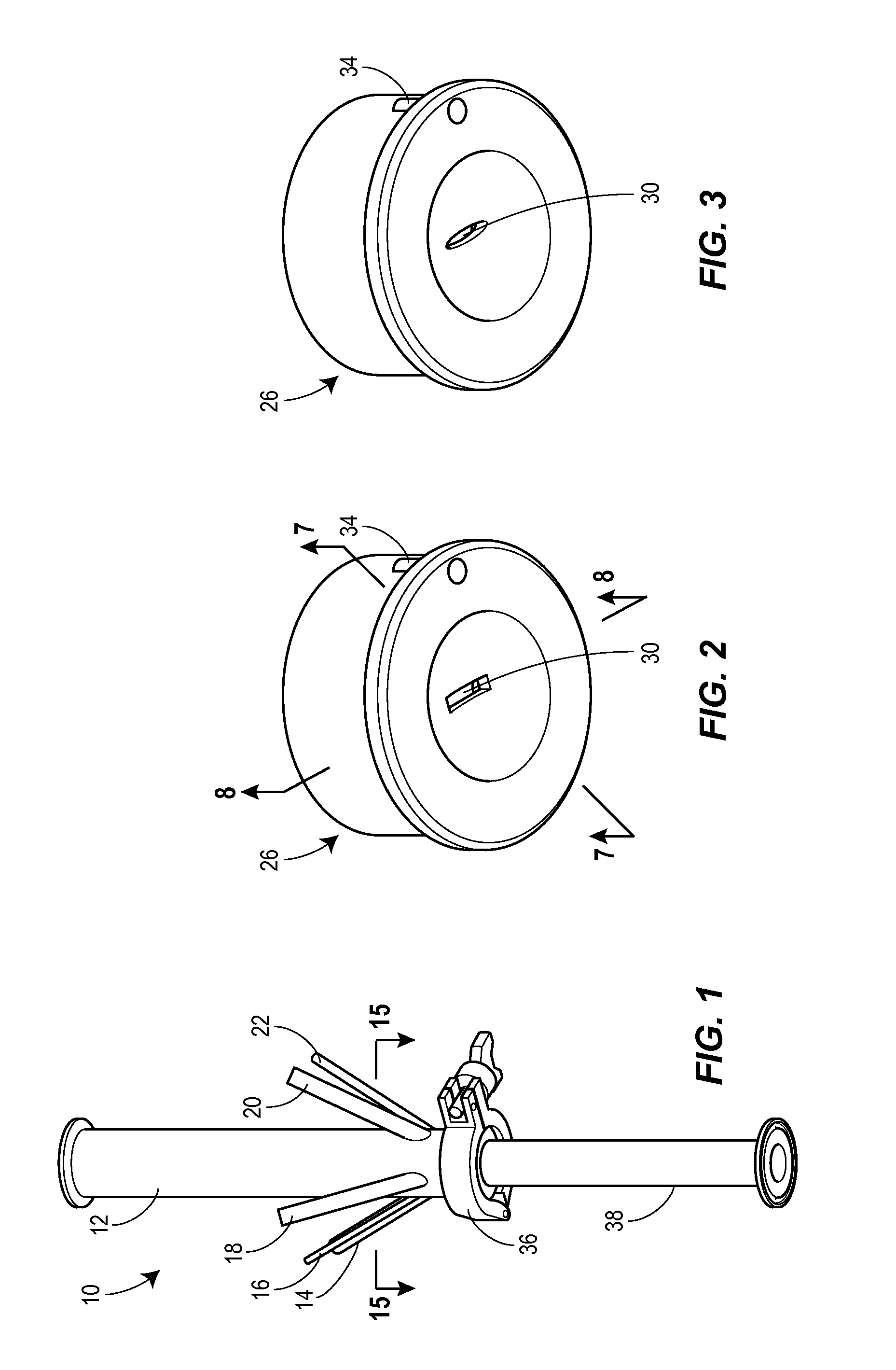

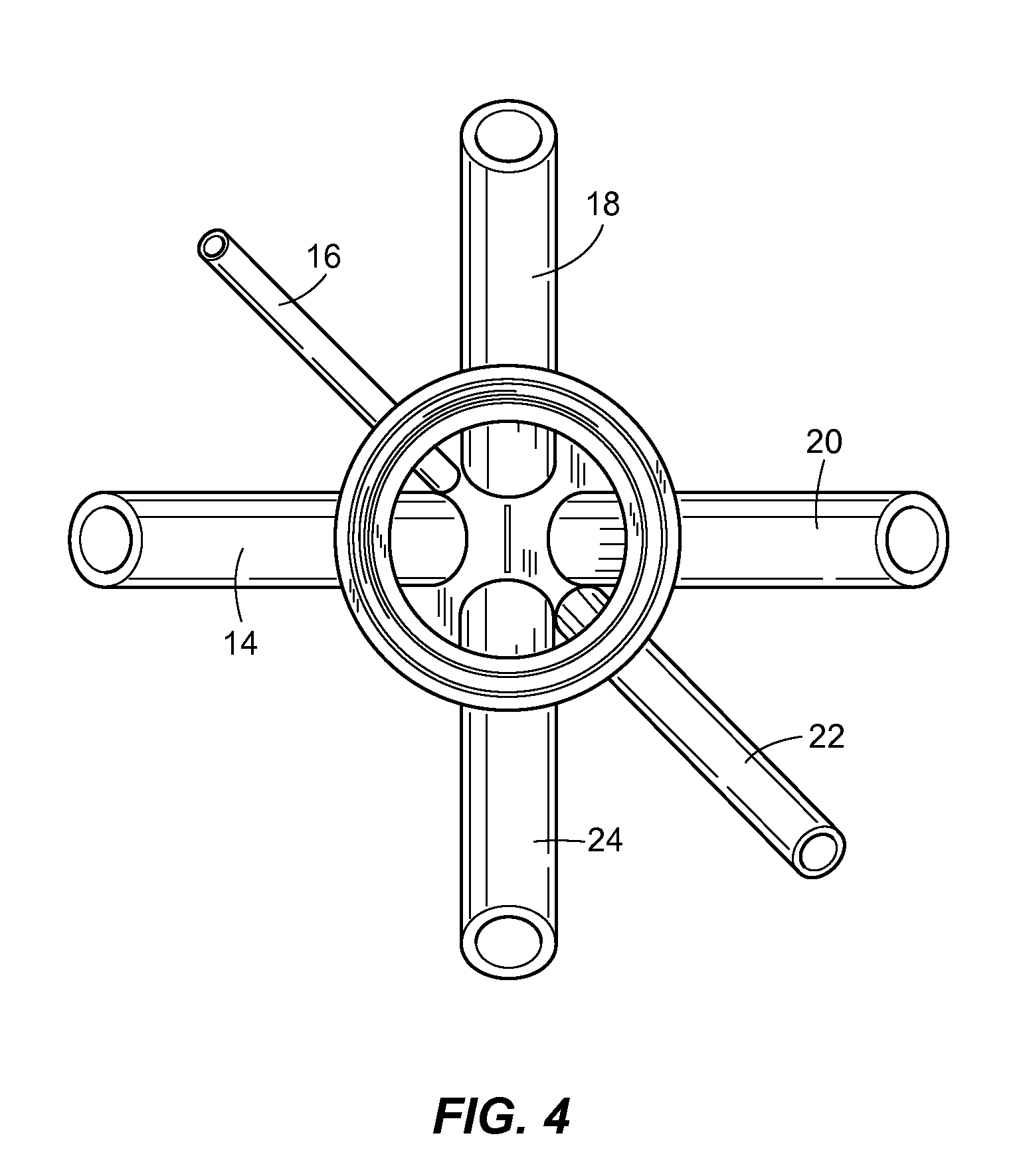

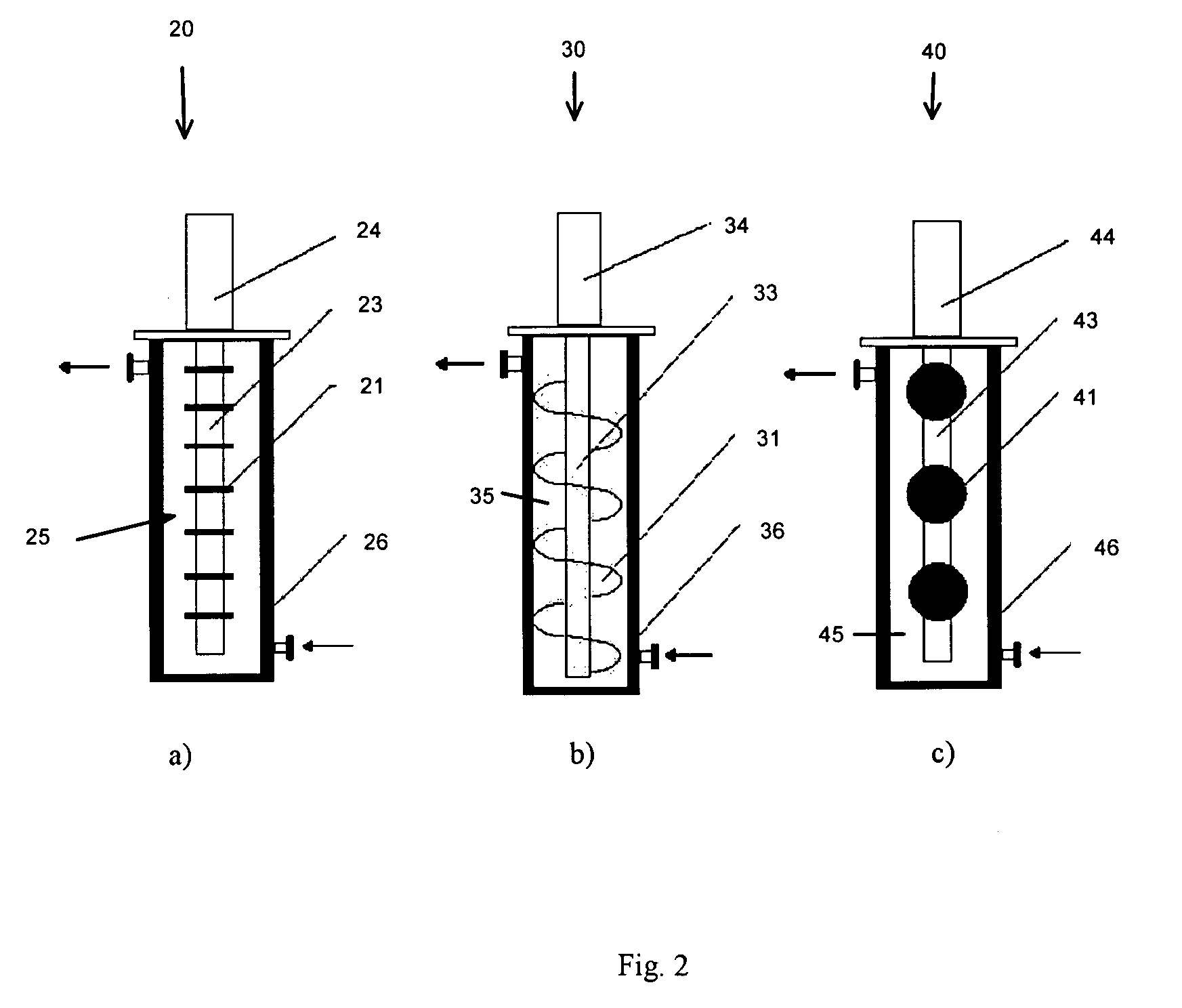

A mixing assembly for use in a semi-continuous process for producing liquid personal care compositions, such as shampoos, includes a main feed tube carrying a base of the composition to be produced, a plurality of injection tubes in selective fluid communication with the main feed tube, and an orifice provided in a wall at an end of the main feed tube downstream of the plurality of injection tubes. The wall in which the orifice is provided includes a curved (e.g., semispherical) entry surface on an upstream or inlet side of an orifice, and a curved (e.g., semi-elliptical) exit surface on a downstream or outlet side of the orifice. The orifice may have a rectangular or elliptical shape. By maintaining symmetry of the injection tubes with respect to the orifice, and leveraging delay between introduction of dosed modules and increased viscosity, effective mixing may be achieved with minimal energy.

Owner:THE PROCTER & GAMBLE COMPANY

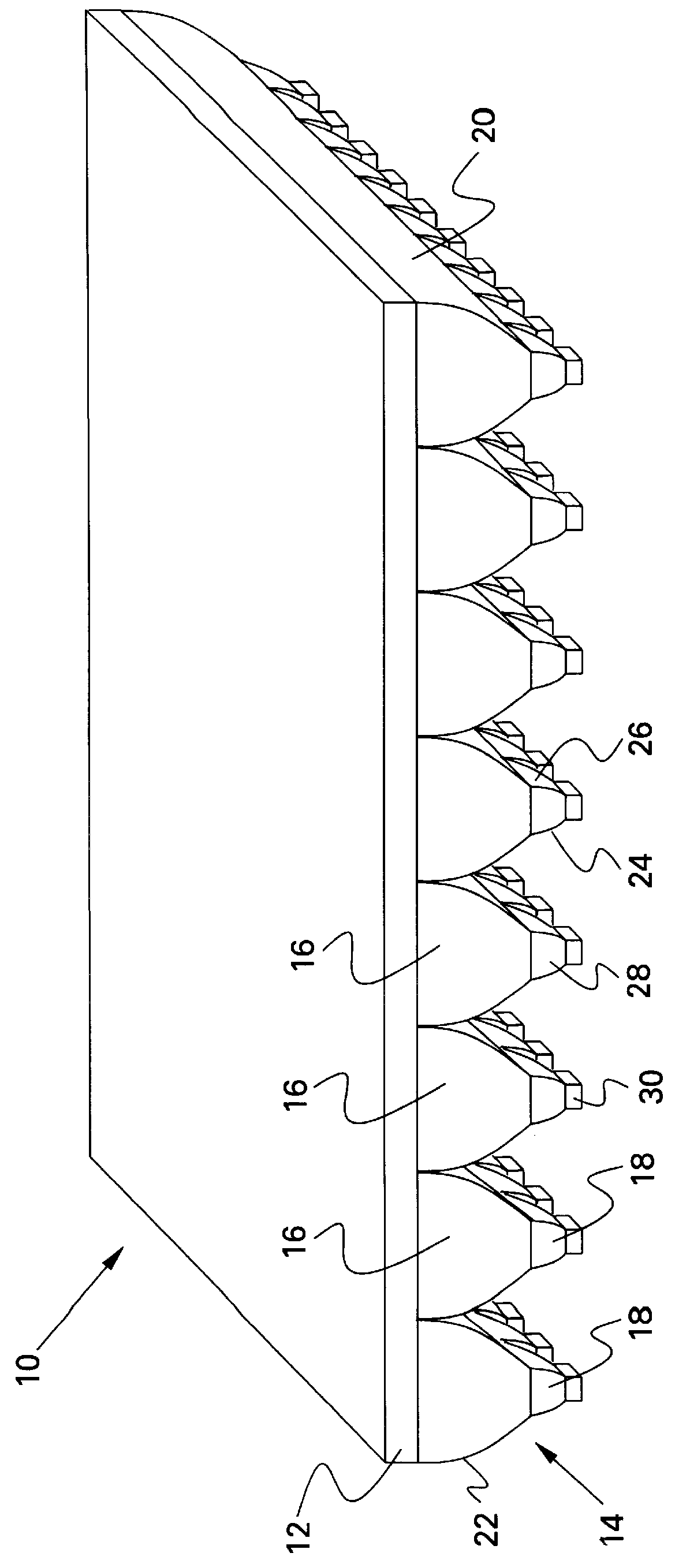

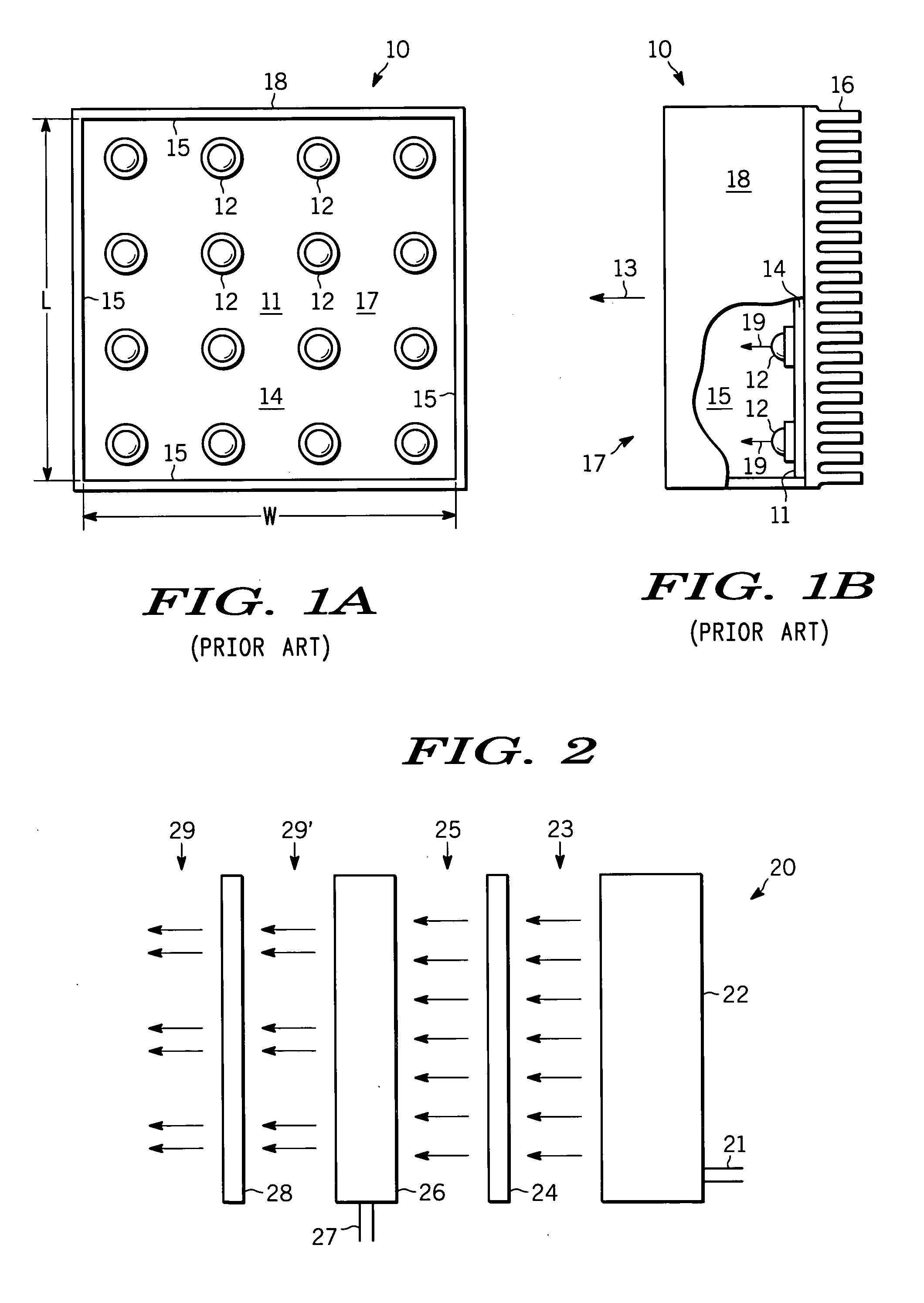

Display with bright backlight

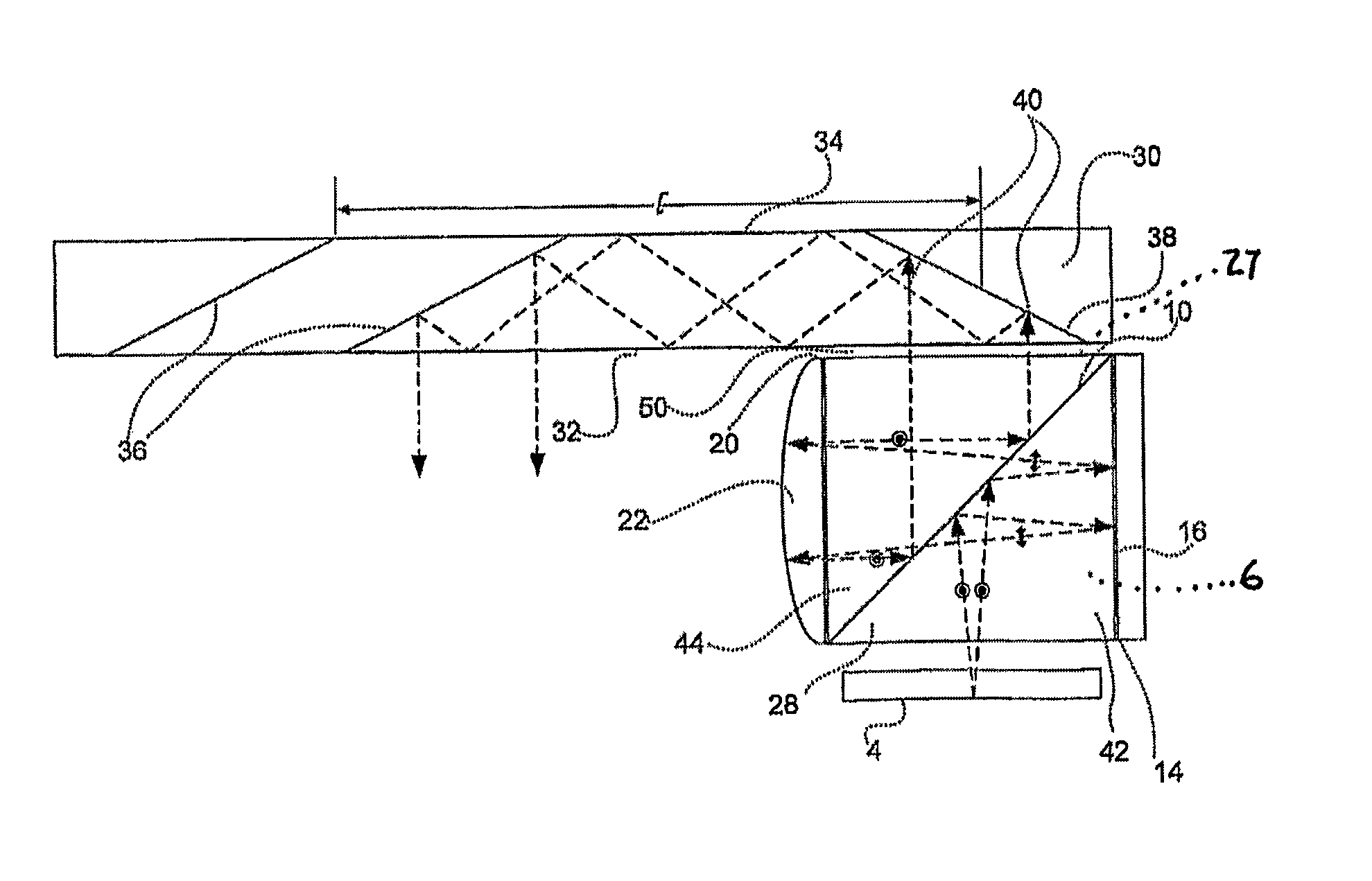

ActiveUS7285903B2Discharge tube luminescnet screensLighting heating/cooling arrangementsTransmittanceExit surface

Methods and apparatus are provided for projecting light carrying a data image. The apparatus comprises a first layer having regions of electrically alterable variable light transmittance adapted to form the data image, and a hollow cavity backlight having a light exiting surface coupled to the first layer and adapted to provide light to the first layer through the light exiting surface from one or more light emitters some of which point in a principal direction other than at right angles to the light exiting surface. In a preferred embodiment, LEDs are used as the light emitters and are preferably mounted on one or more printed circuit boards or other support tilted at non-zero angles with respect to the light exiting surface.

Owner:HONEYWELL INT INC

Optical beam transformation system and illumination system comprising an optical beam transformation system

ActiveUS20060146384A1Reduction in polarization-varying effectPhotomechanical apparatusPhotographic printingOptical axisSelective reflection

Owner:CARL ZEISS SMT GMBH

Collimating optical device and system

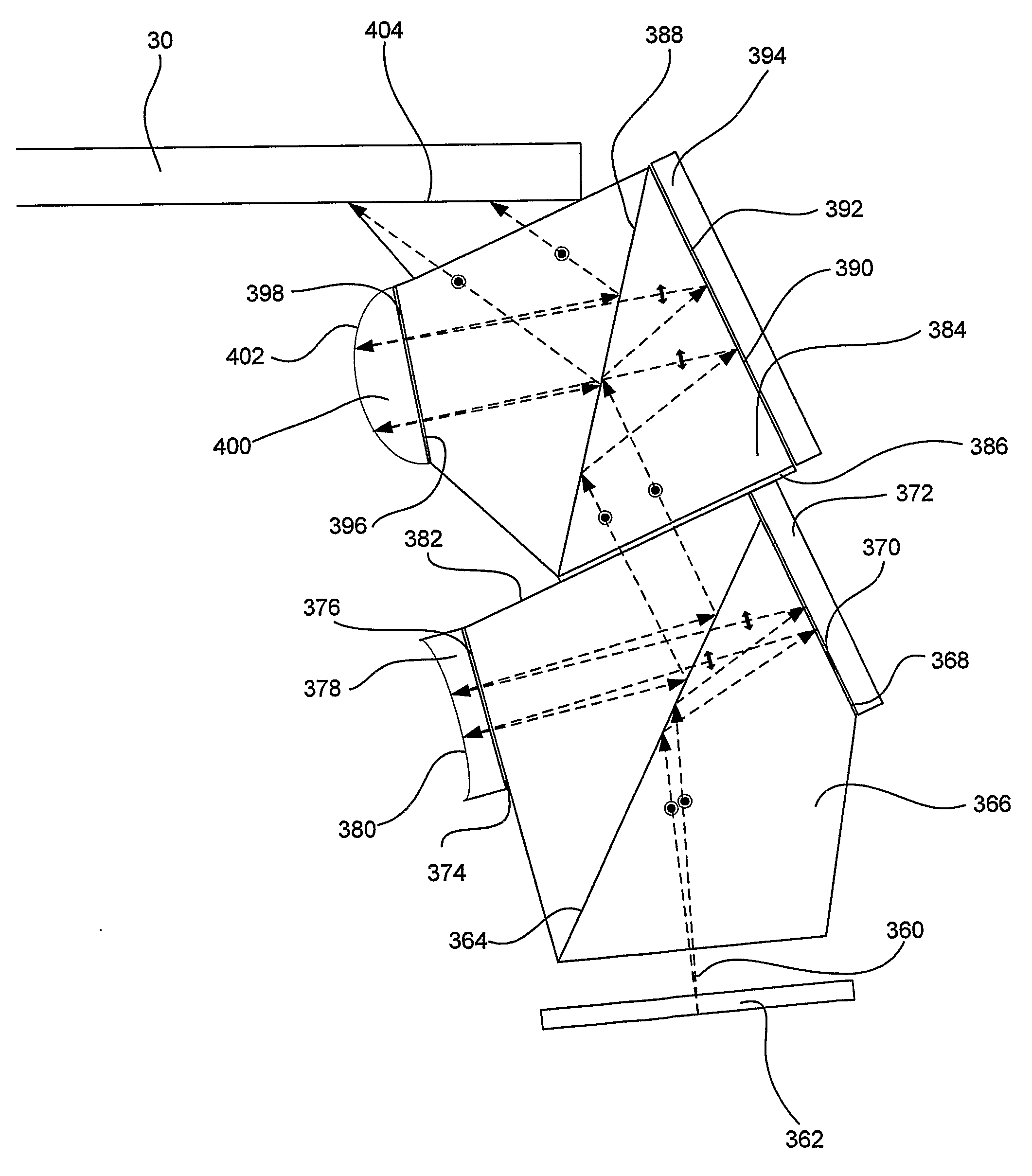

ActiveUS8643948B2Simple designFabrication facilitatedPrismsPolarising elementsLight guidePolarization beam splitter

Owner:LUMUS LTD

Virtual image display apparatus

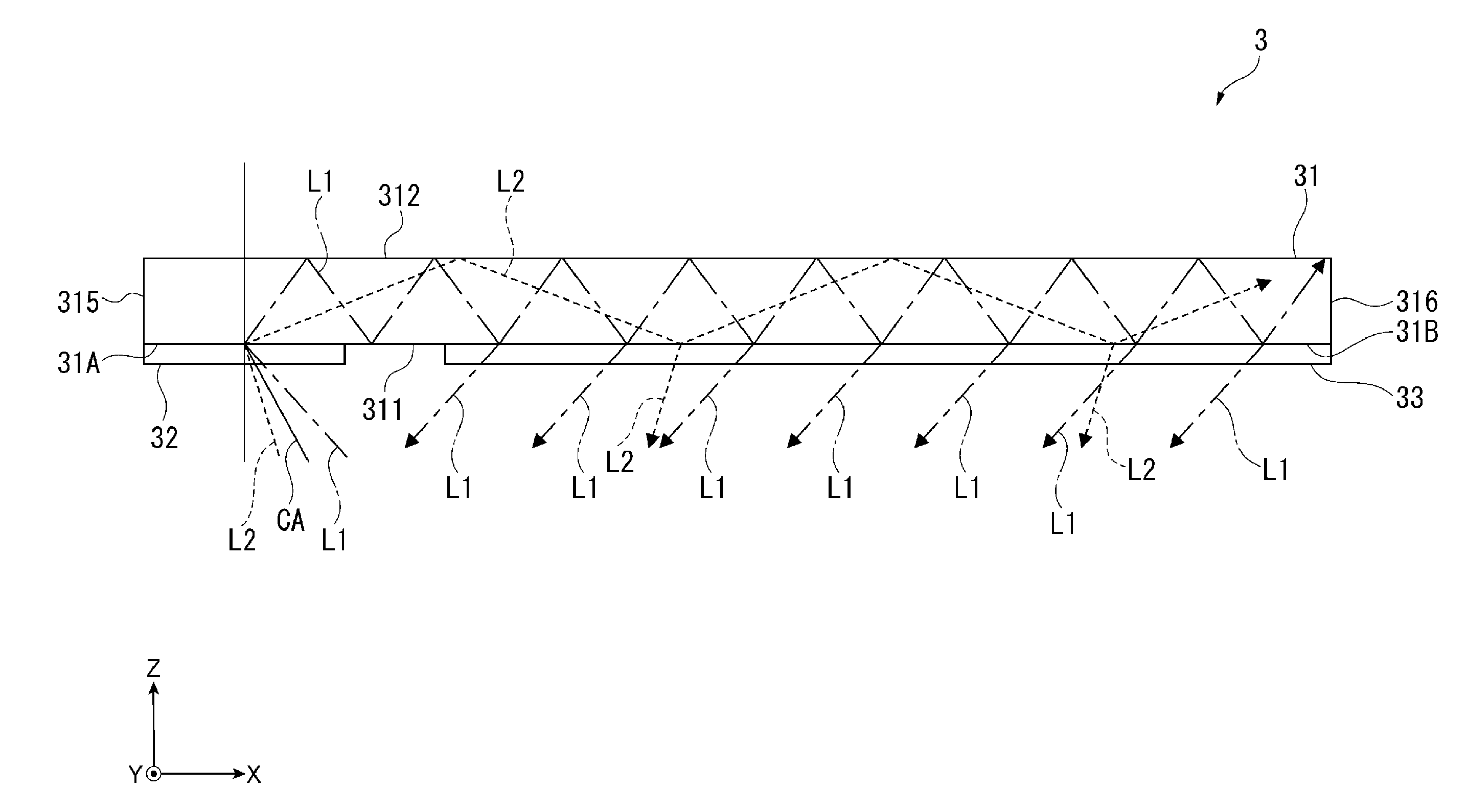

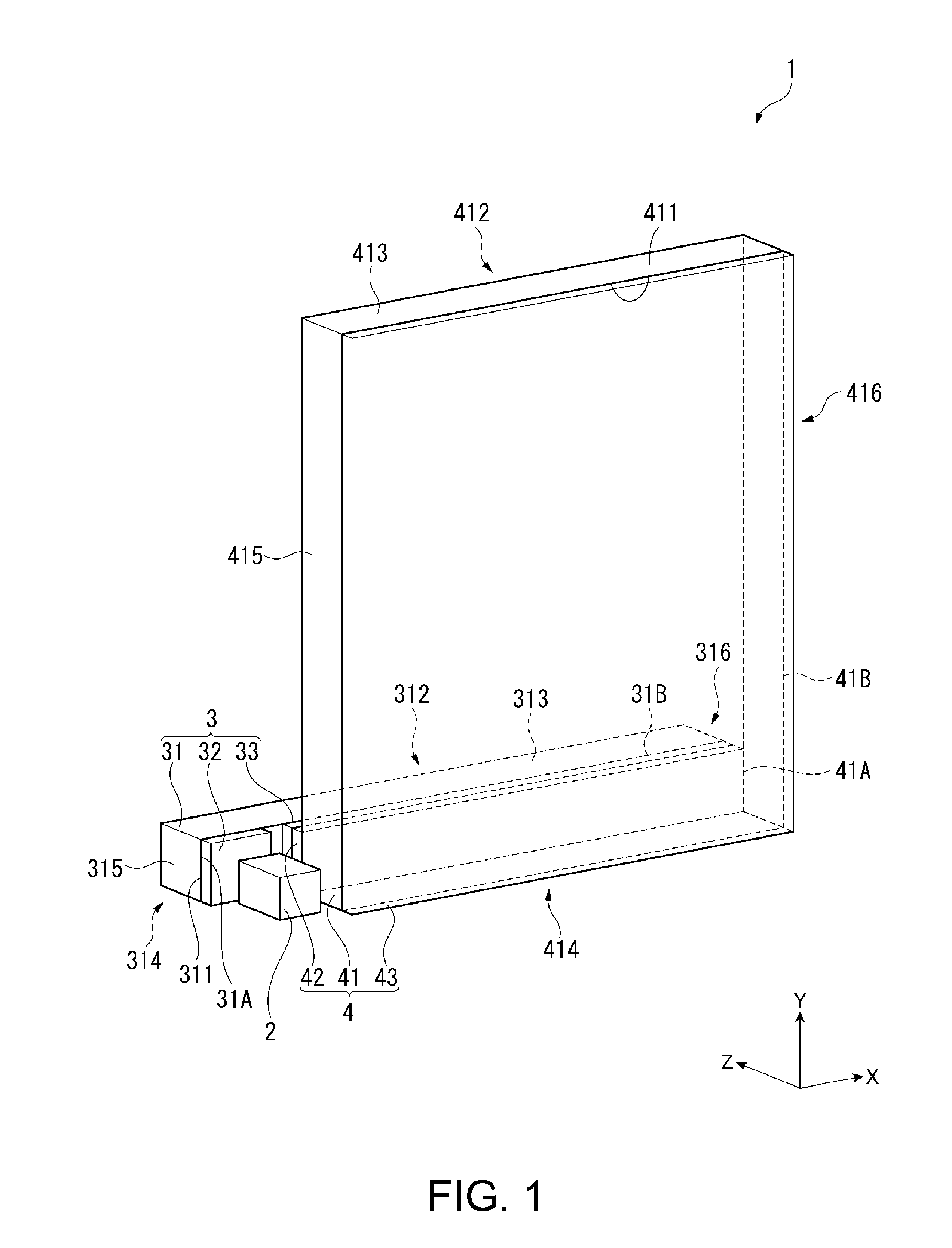

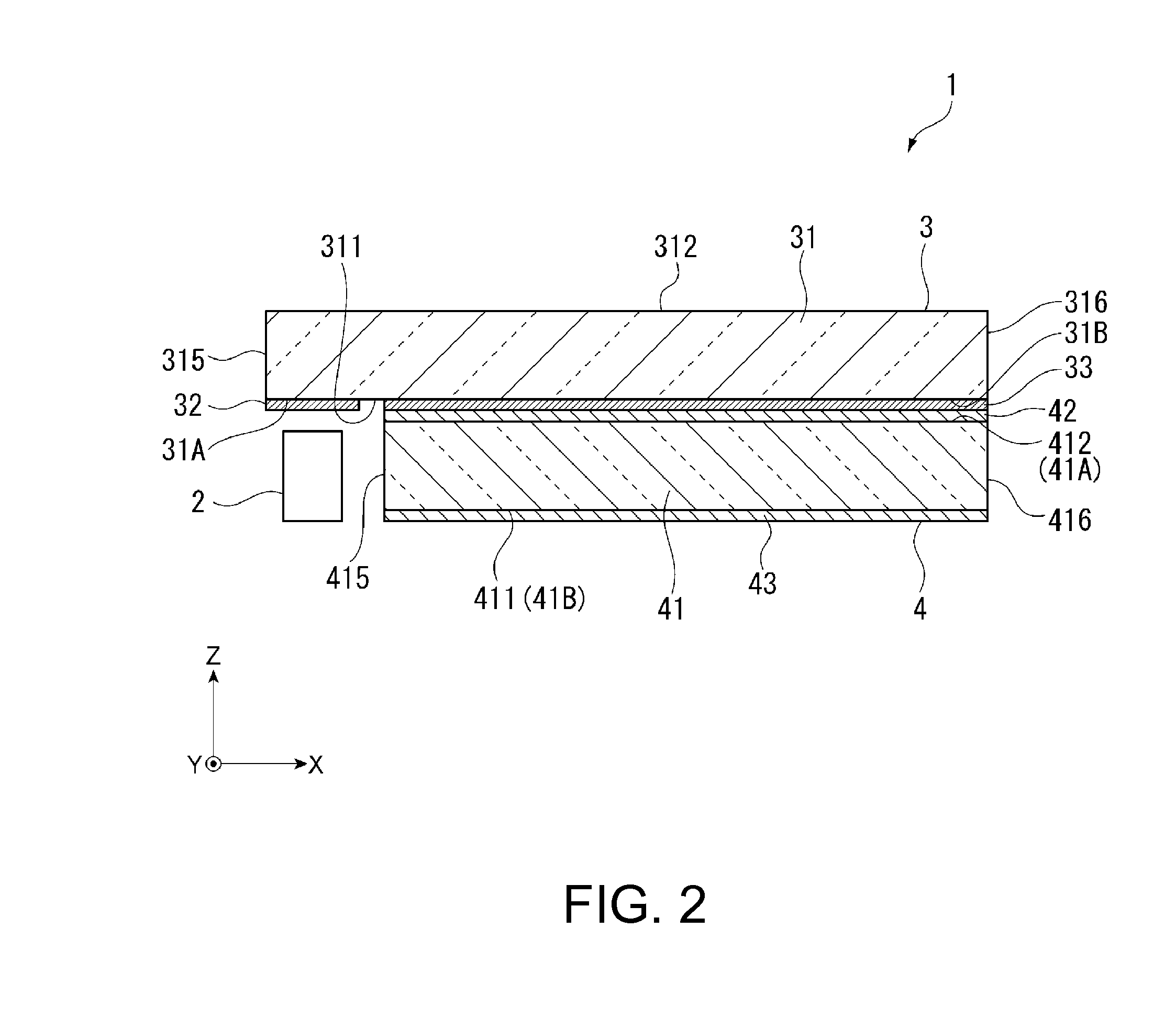

InactiveUS20160124223A1Change in luminanceSuppressing image degradationMechanical apparatusPlanar/plate-like light guidesLight beamDisplay device

A virtual image display apparatus includes a first light guide that not only causes a display light flux incident through a first light incident surface to repeatedly undergo internal reflection to travel in a first direction away from the first light incident surface but also causes part of the display light flux to exit to the outside through areas of a first light exiting surface that is at least one of interfaces with the outside and extends in the first direction, a first light-incident-side diffraction grating that diffracts light incident thereon to cause the diffracted light to enter the first light guide, and a first light-exiting-side diffraction grating that diffracts light incident from the first light guide.

Owner:SEIKO EPSON CORP

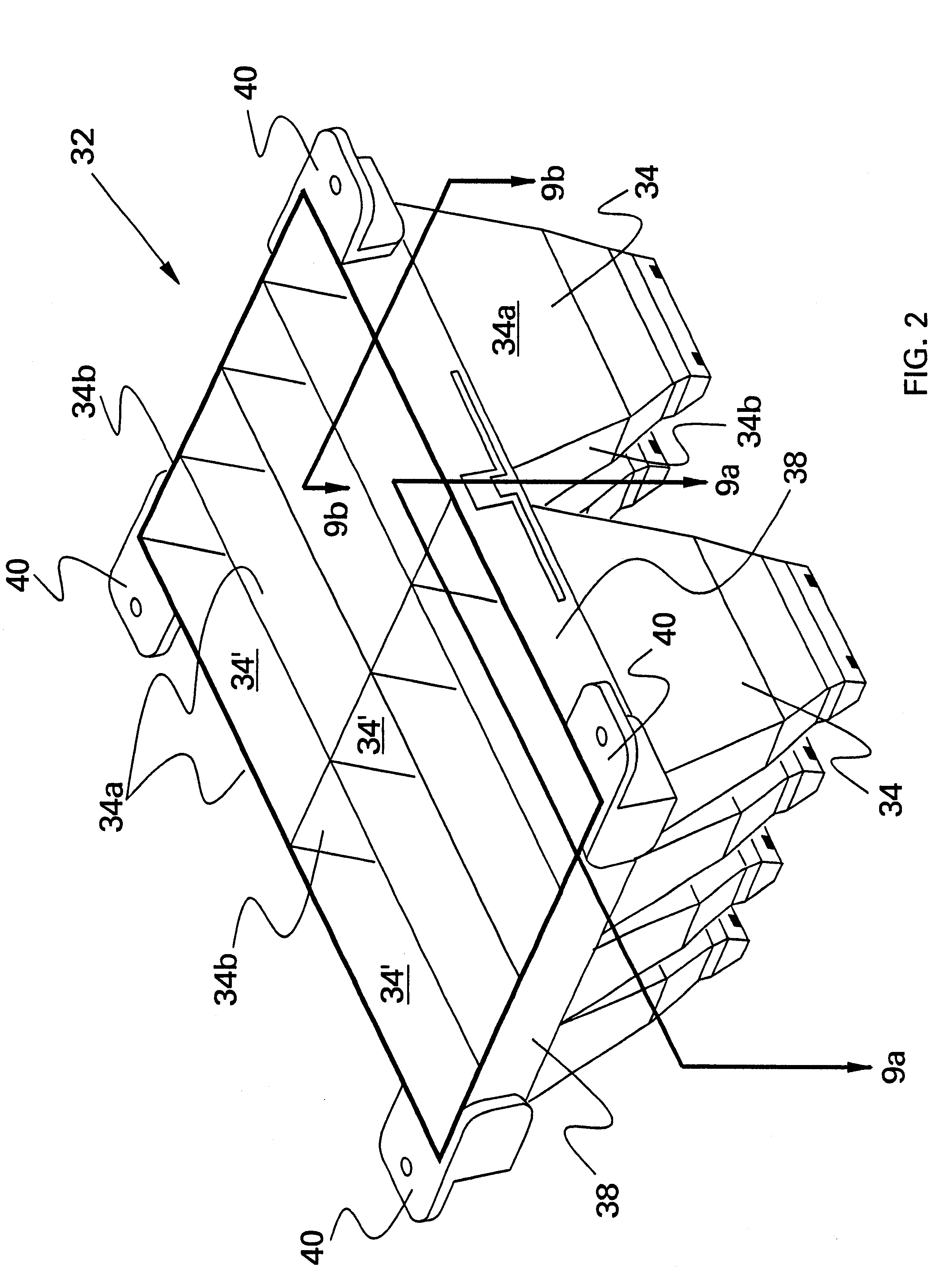

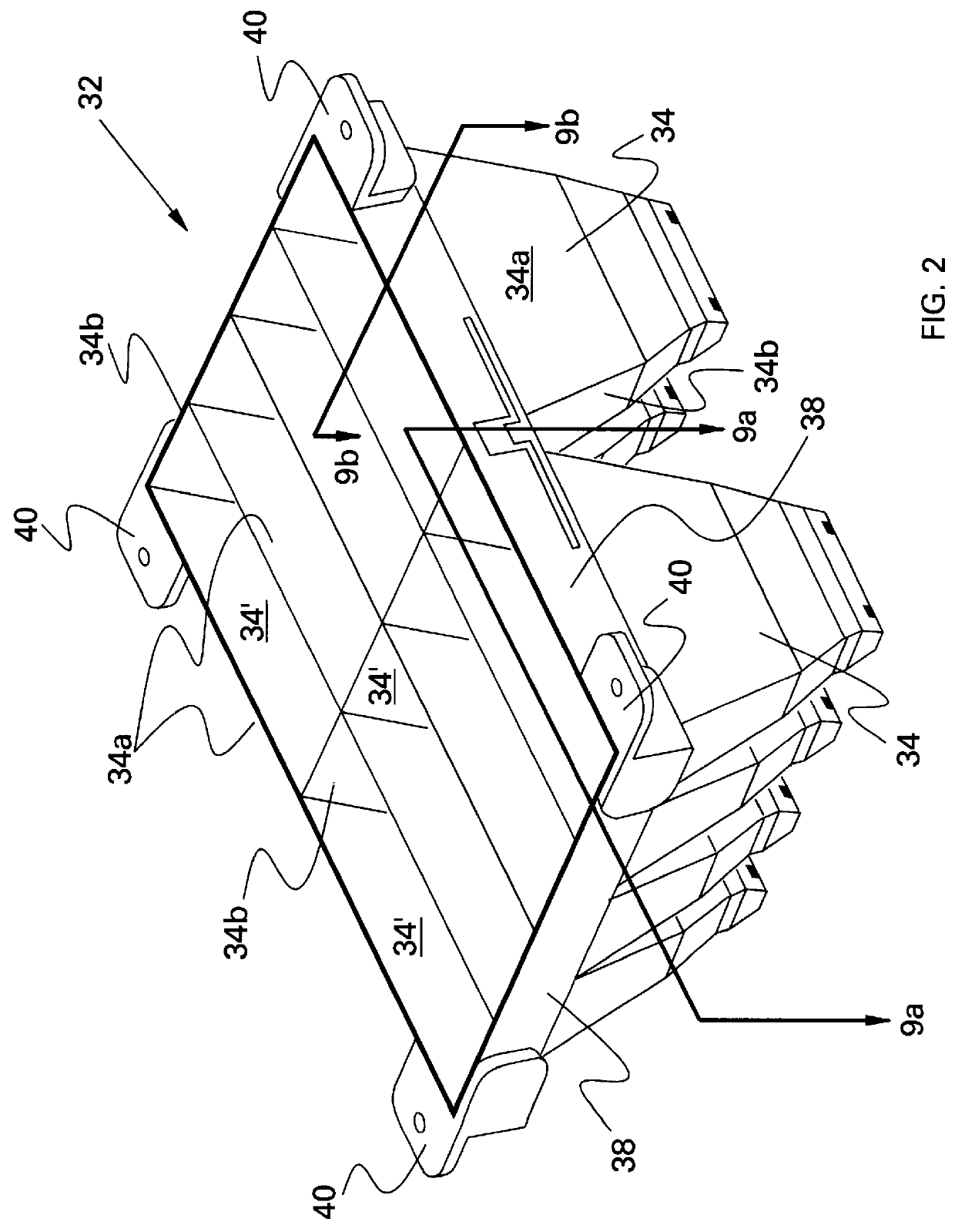

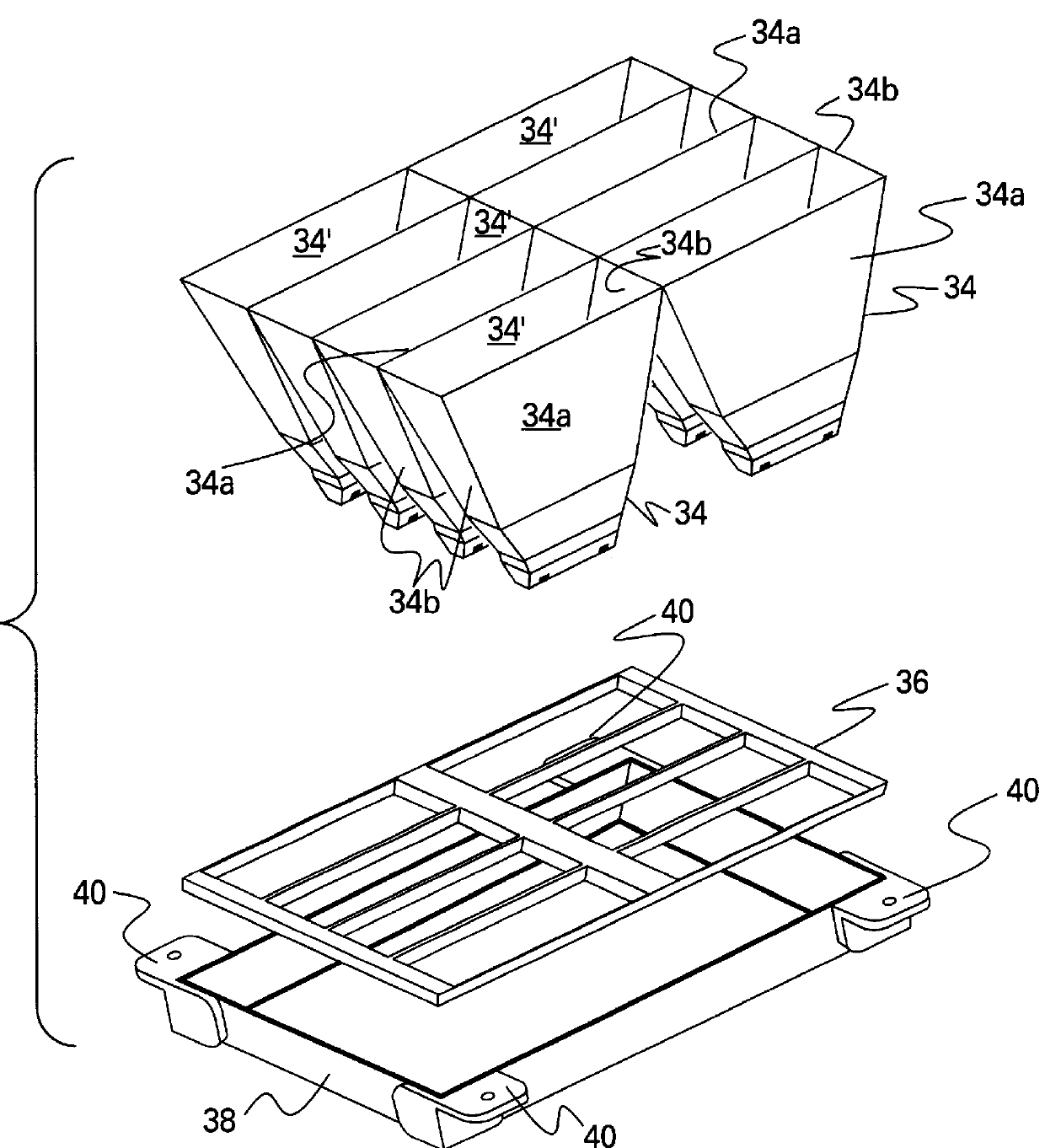

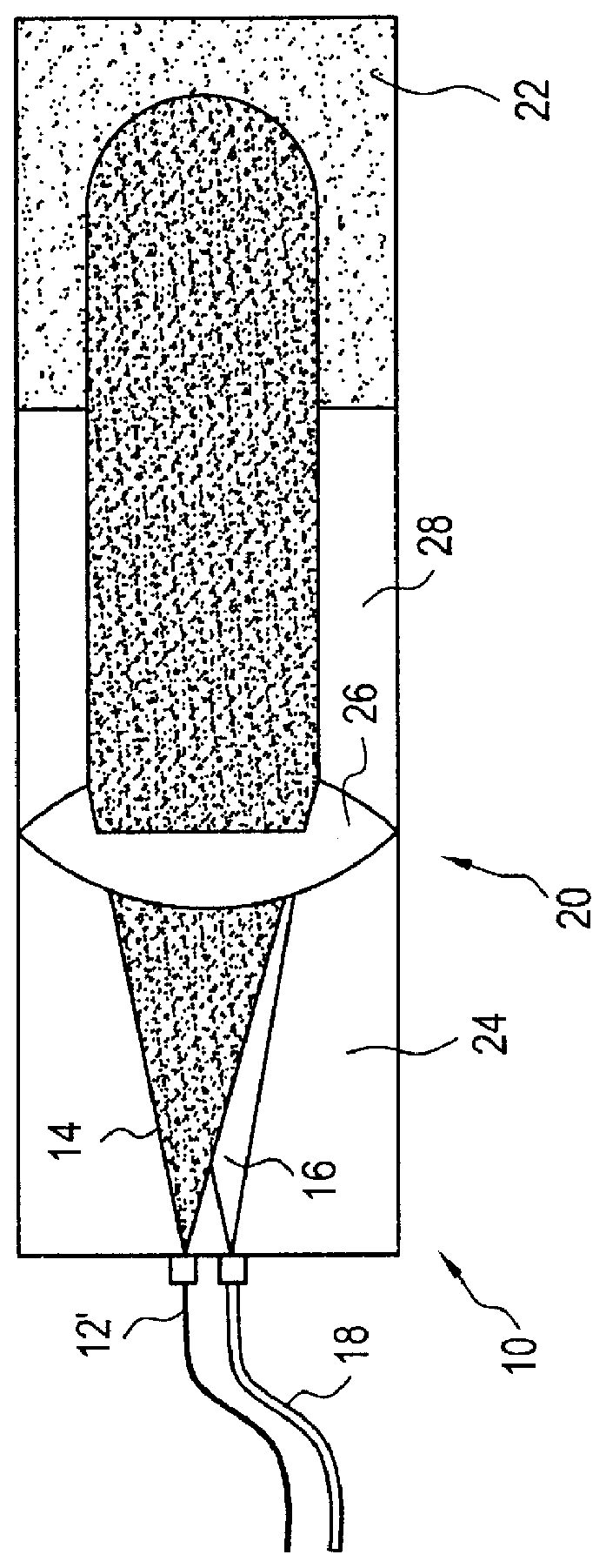

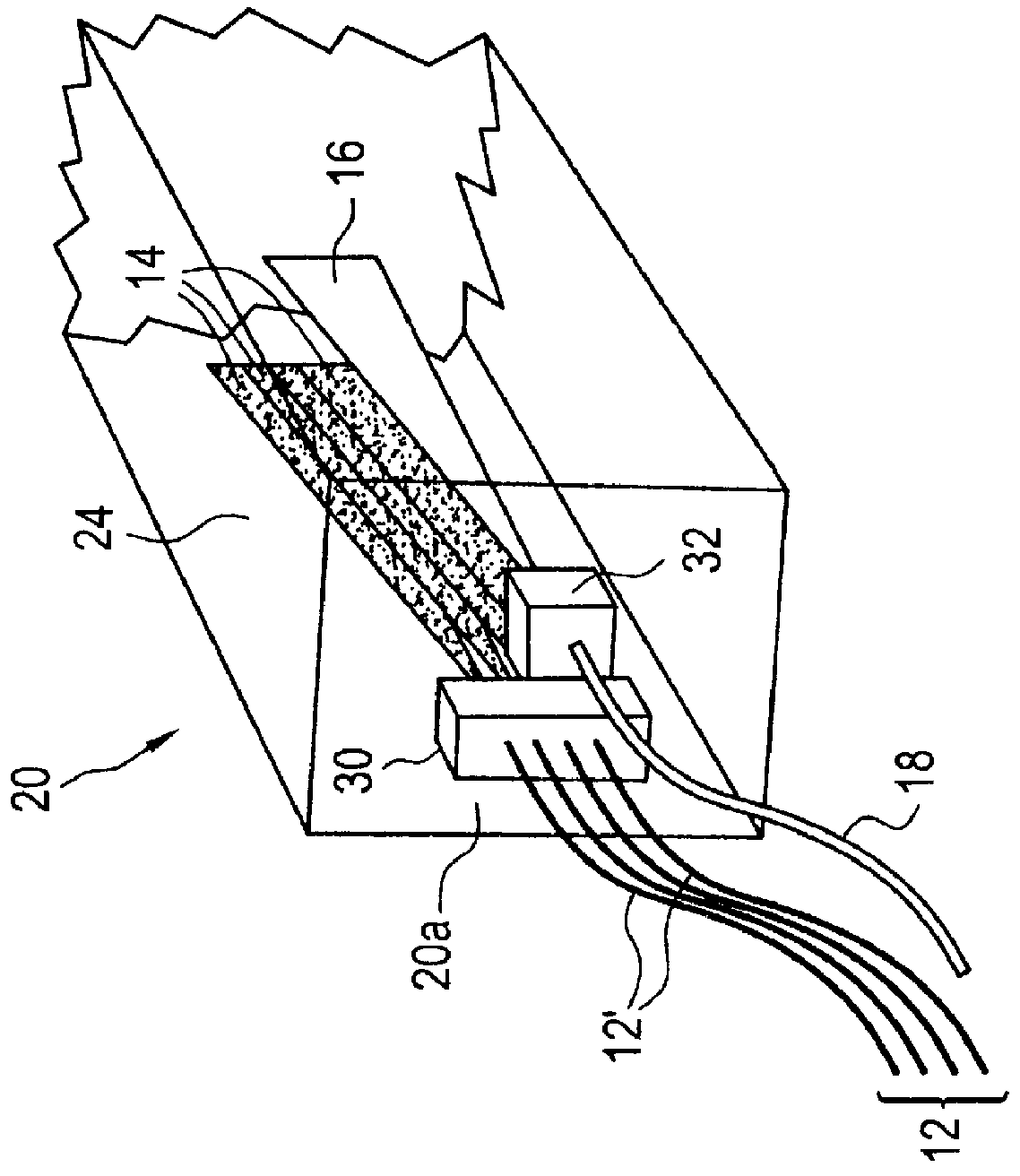

Space concentrator for advanced solar cells

InactiveUS6252155B1Reduce quality problemsImprove efficiencySolar heating energyMirrorsConcentration ratioRefractive index

A solar concentrator is provided that comprises two stages. The first stage comprises either a trough-shaped concentrator cusp unit having two major opposed sides joined by two ends. The inner surfaces of the first stage concentrator are mirrored. Further, the ends have two flat, angled surfaces, while the two sides have a Bezier-generated cylindrical shape that approximate parabolic surfaces followed by a straight section. The second stage comprises a bi-axial gradient refractive index (GRIN) element, in which two gradient refractive index materials, each having a high index surface and a low index surface, are joined together along their high index surfaces. The two ends of the bi-axial element are flat, while the two sides also have a Bezier-generated cylindrical shape that approximate parabolic surfaces followed by a straight section. The top surface of the bi-axial element is provided with a cylindrical surface, while the bottom, or exit, surface is ground flat. The high index boundary is parallel to the side surfaces of the first stage unit. A solar cell is bonded to the flat exit surface of the second stage of the concentrator of the present invention. An array of such concentrators and solar cells, in which the solar cells are electrically interconnected, may then be deployed for converting solar energy into useful electrical energy. The 2-D / 3-D concentrator evidences much lower mass than prior art concentrators. Further, as the array, or panel, of solar cells wobbles in space, the concentrator will continue to operate, even at lower efficiencies, due to the larger acceptance angle. Concentration ratios on the order of 50x are realized with the present concentrator. However, design studies allow concentration ratios in excess of 300x when used with 3-D versions of the same concept. The second stage can comprise mirrored surfaces. Or, the first stage can comprise a conical section and the second stage a radial GRIN element.

Owner:ORTABASI UGUR

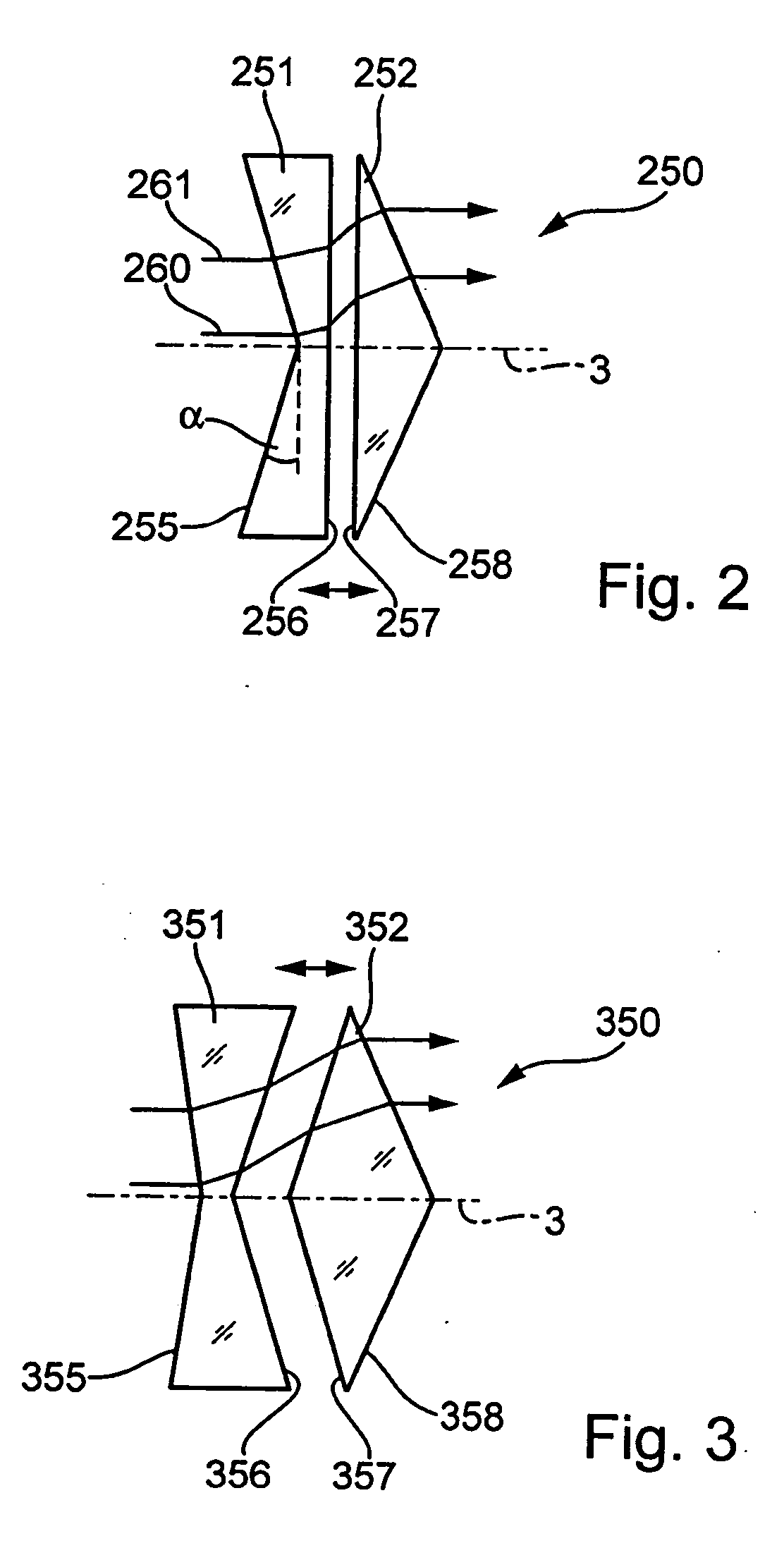

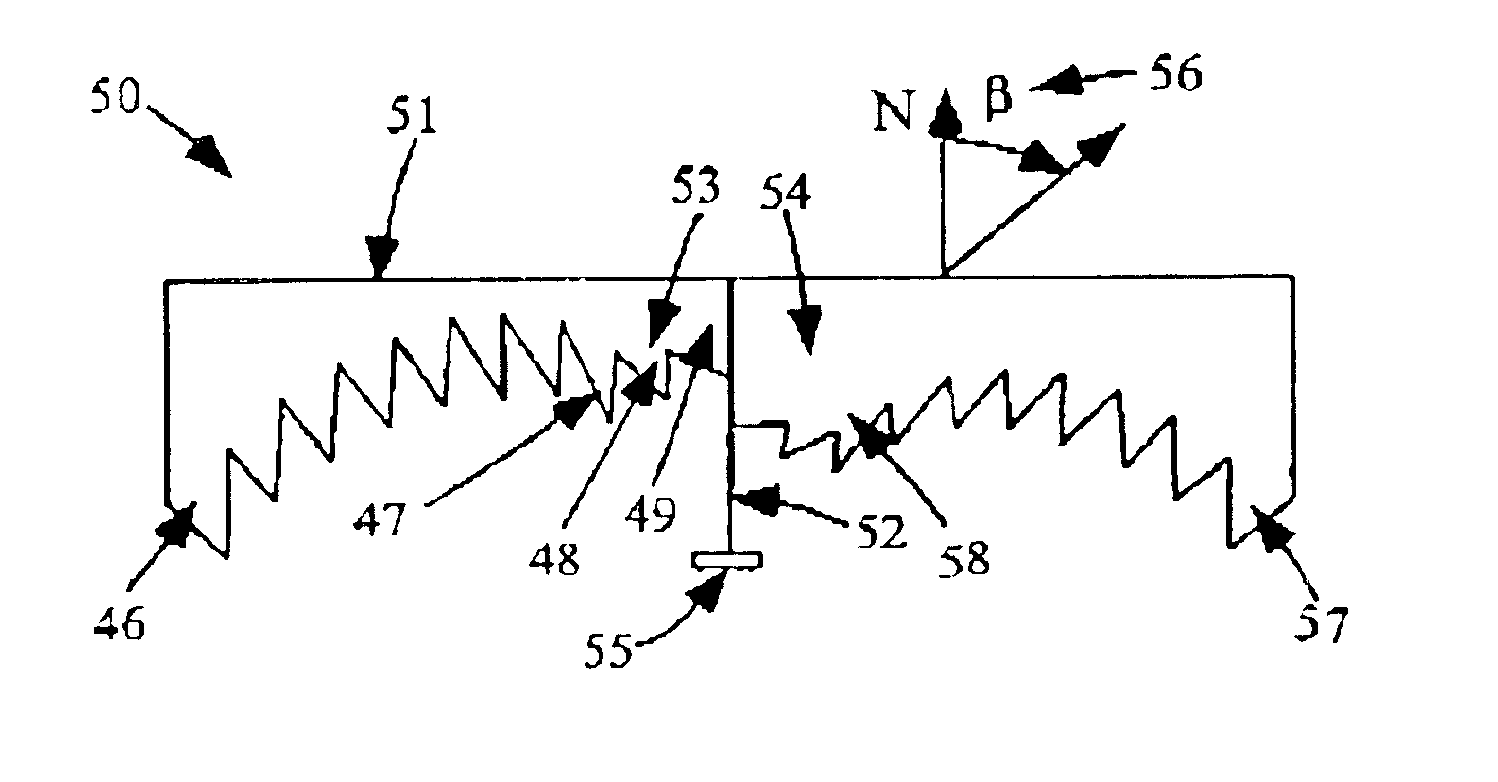

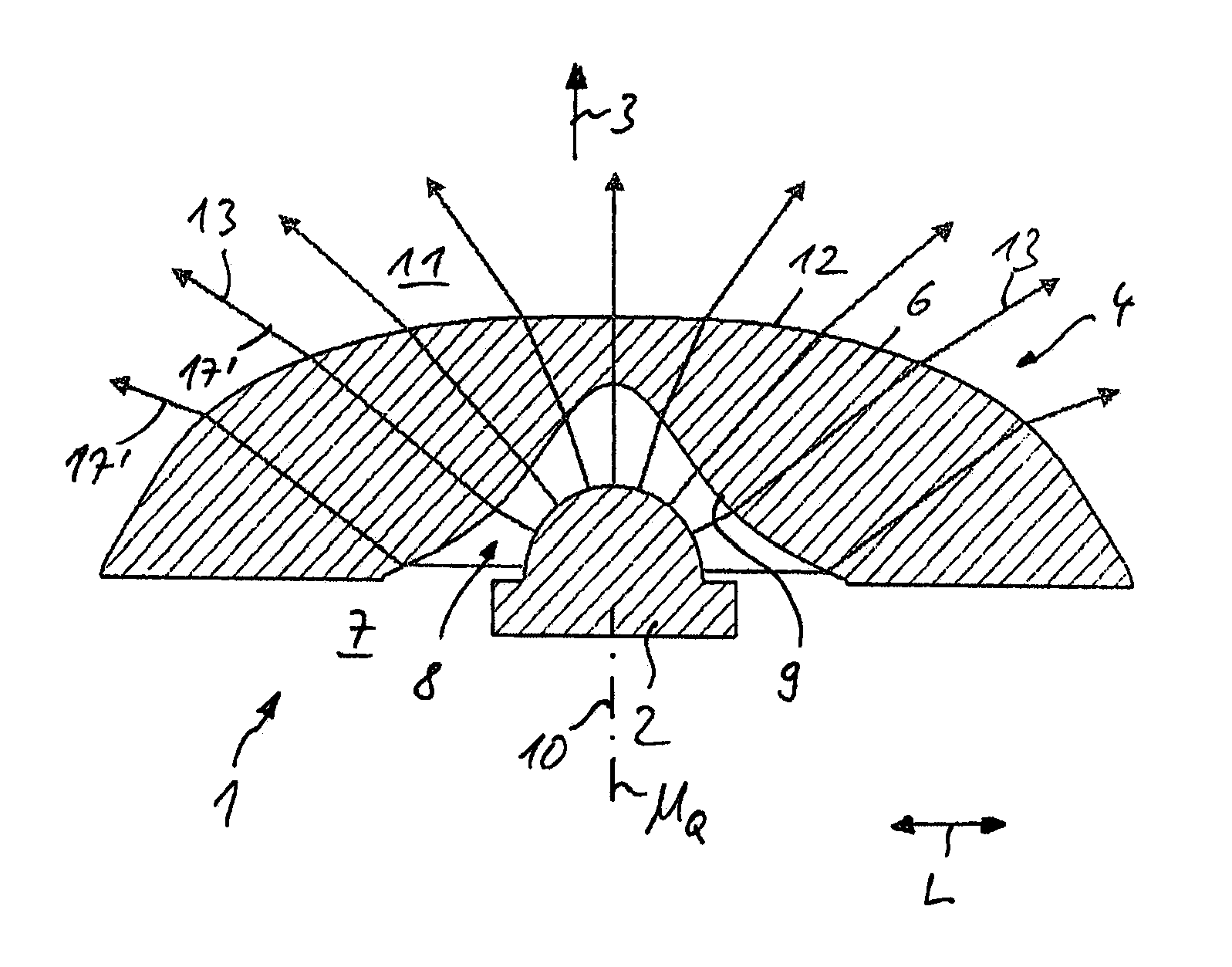

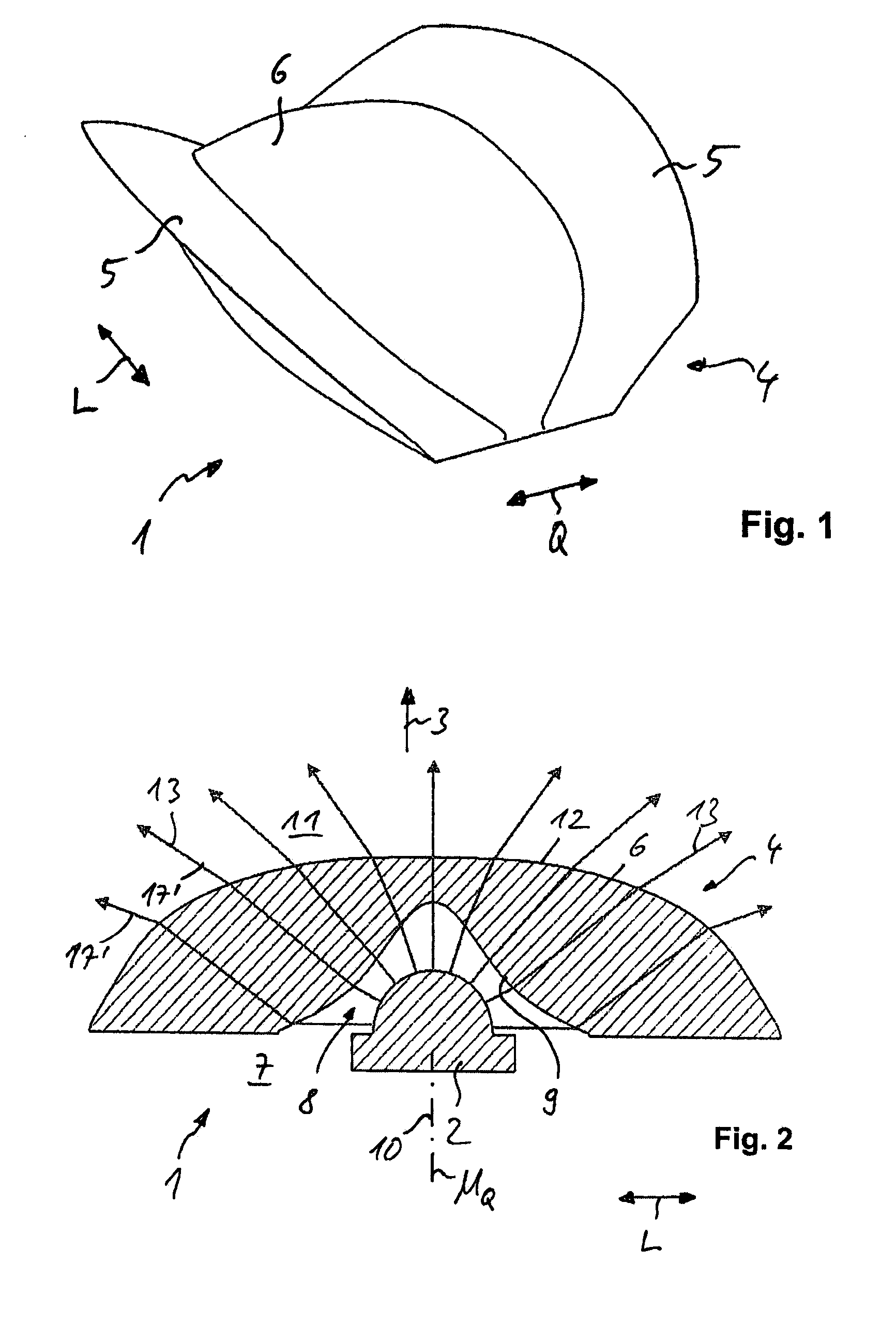

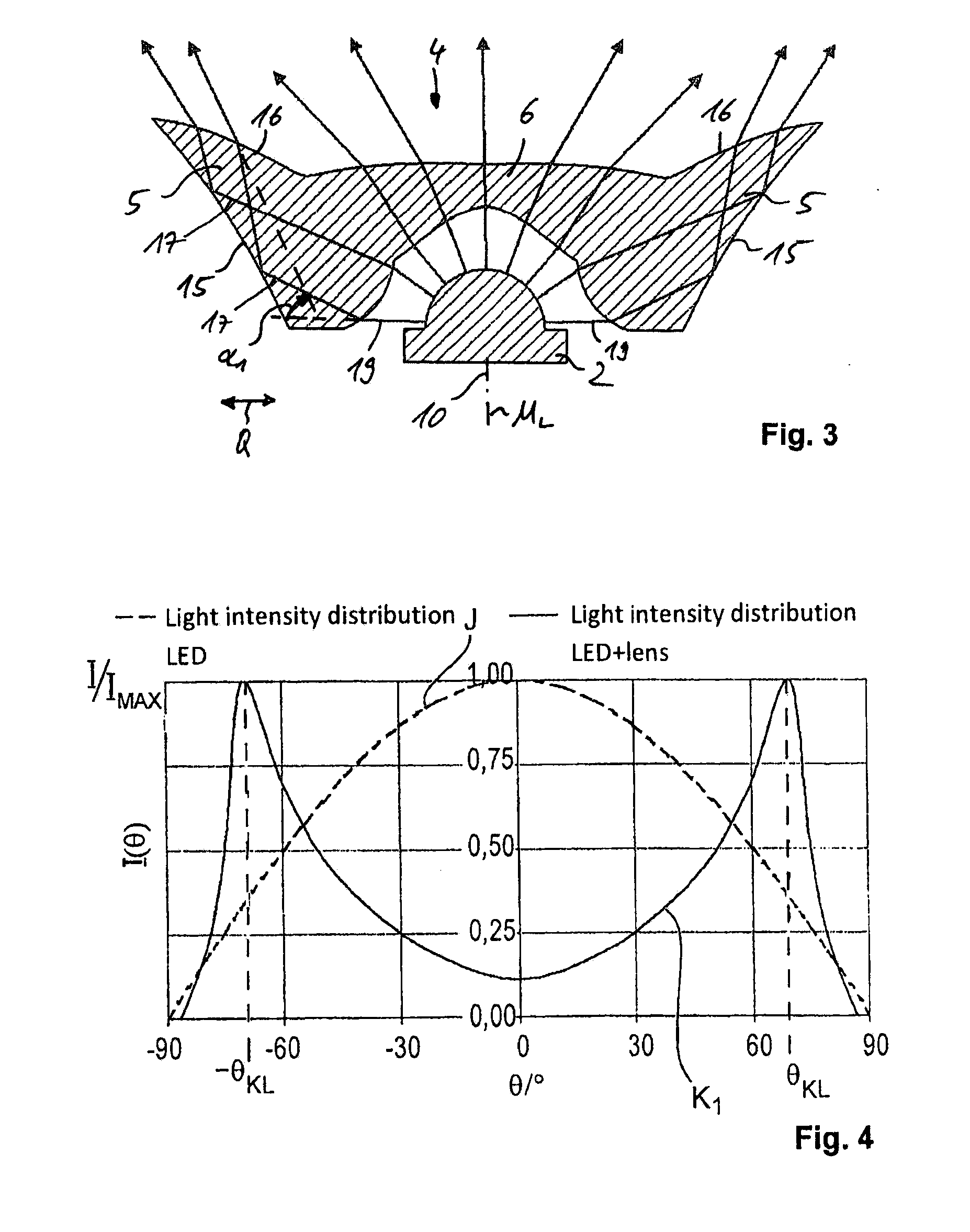

Asymmetric TIR lenses producing off-axis beams

The present invention relates to an improvement of a total internal reflection lens whereby a tilted symmetry axis leads to a net deflection of the output beam away from the surface normal of the exit surface. Linear TIR lenses have a net deflection transverse to their focal strip. Circular TIR lens profiles going beyond 90° are tilted to bring the rim level with the source, the deflected rays exiting the lens to form an off-axis beam.

Owner:LIGHT ENGINE

Space concentrator for advanced solar cells

InactiveUS6057505AReduce weightReduce quality problemsSolar heating energyMirrorsConcentration ratioRefractive index

A solar concentrator is provided that comprises two stages. The first stage comprises either a trough-shaped concentrator cusp unit having two major opposed sides joined by two ends. The inner surfaces of the first stage concentrator are mirrored. Further, the ends have two flat, angled surfaces, while the two sides have a Bezier-generated cylindrical shape that approximate parabolic surfaces followed by a straight section. The second stage comprises a bi-axial gradient refractive index (GRIN) element, in which two gradient refractive index materials, each having a high index surface and a low index surface, are joined together along their high index surfaces. The two ends of the bi-axial element are flat, while the two sides also have a Bezier-generated cylindrical shape that approximate parabolic surfaces followed by a straight section. The top surface of the bi-axial element is provided with a cylindrical surface, while the bottom, or exit, surface is ground flat. The high index boundary is parallel to the side surfaces of the first stage unit. A solar cell is bonded to the flat exit surface of the second stage of the concentrator of the present invention. An array of such concentrators and solar cells, in which the solar cells are electrically interconnected, may then be deployed for converting solar energy into useful electrical energy. The 2-D / 3-D concentrator evidences much lower mass than prior art concentrators. Further, as the array, or panel, of solar cells wobbles in space, the concentrator will continue to operate, even at lower efficiencies, due to the larger acceptance angle. Concentration ratios on the order of 50x are realized with the present concentrator. However, design studies allow concentration ratios in excess of 300x when used with 3-D versions of the same concept. The second stage can comprise mirrored surfaces. Or, the first stage can comprise a conical section and the second stage a radial GRIN element.

Owner:ORTABASI UGUR

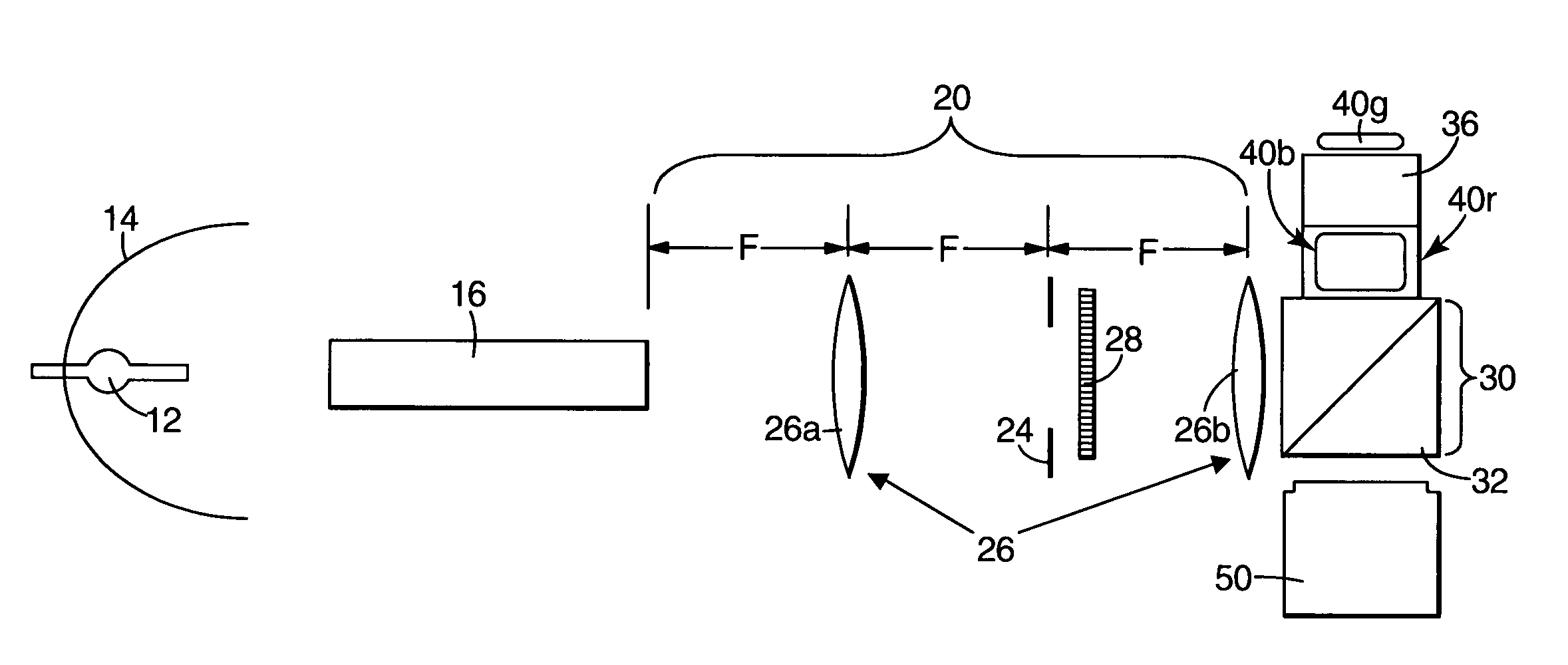

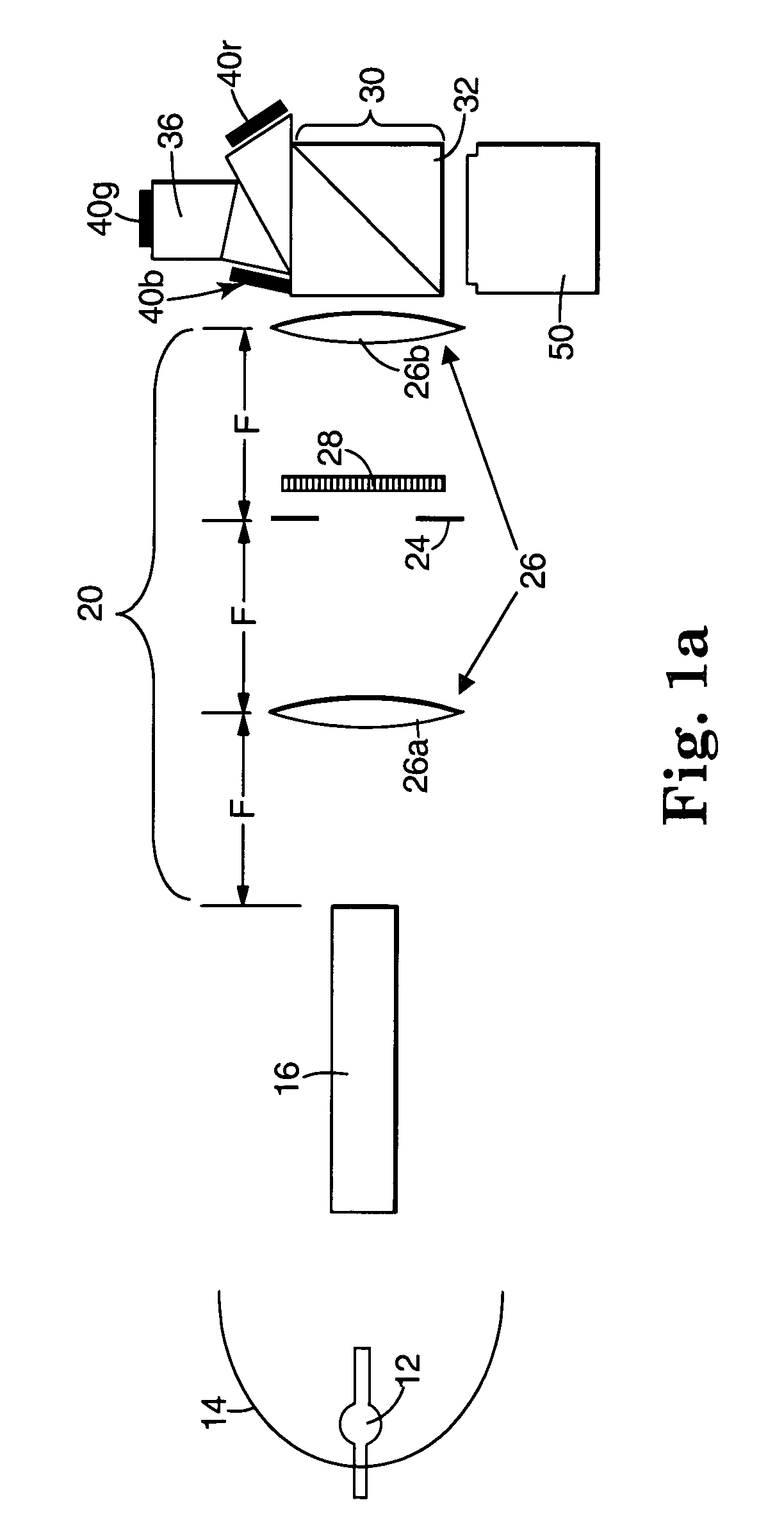

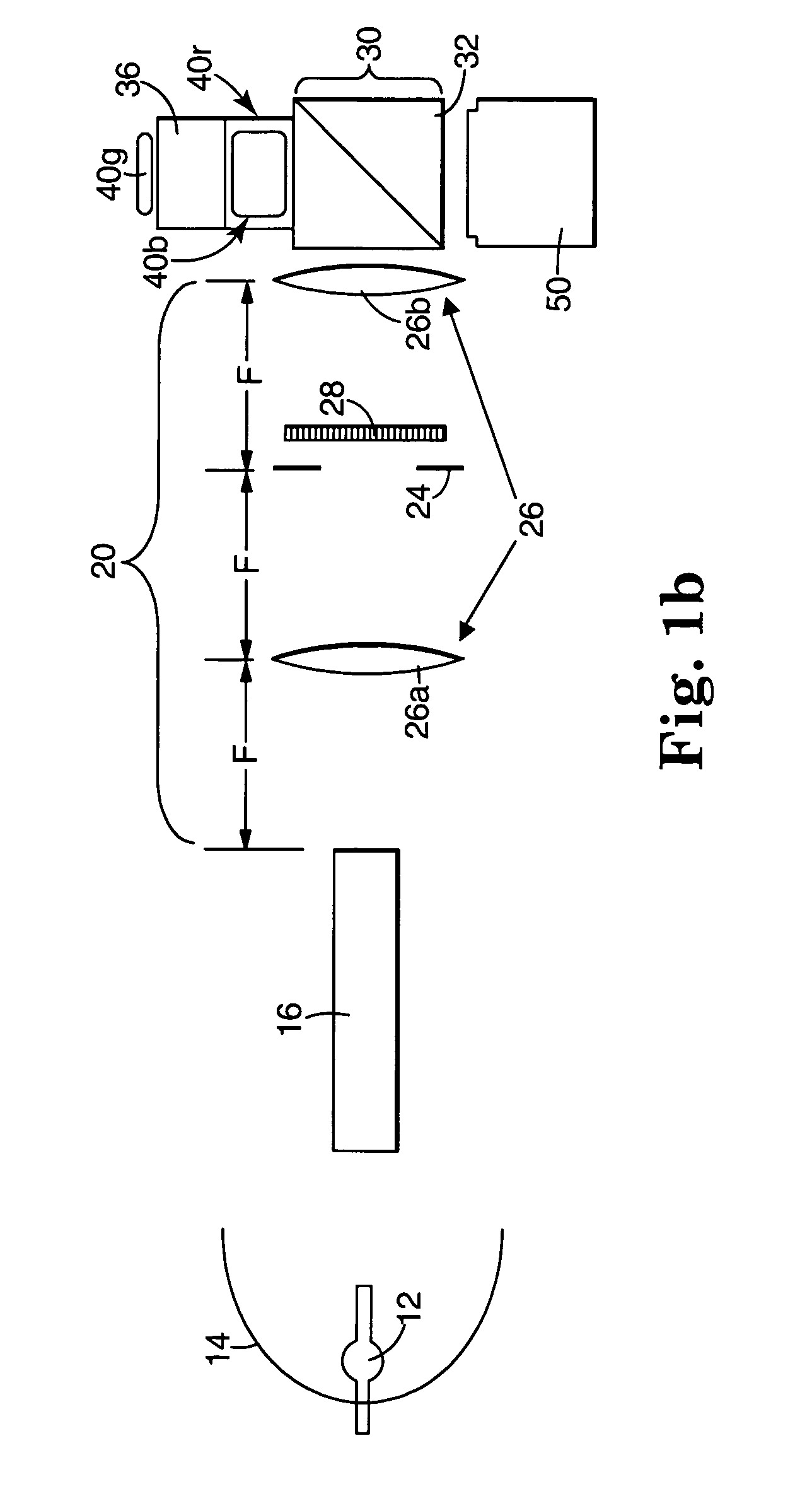

Reflective LCD projection system using wide-angle Cartesian polarizing beam splitter and color separation and recombination prisms

InactiveUS7023602B2Increase contrastImprove light outputProjectorsPolarising elementsBeam splitterBeam polarization

An optical imaging system including an illumination system, a Cartesian PBS, and a prism assembly. The illumination system provides a beam of light, the illumination system having an f / # less than or equal to 2.5. The Cartesian polarizing beam-splitter has a first tilt axis, oriented to receive the beam of light. A first polarized beam of light having one polarization direction is folded by the Cartesian polarizing beam splitter and a second polarized beam of light having a second polarization direction is transmitted by the Cartesian polarizing beam splitter. The Cartesian polarizing beam splitter nominally polarizes the beam of light with respect to the Cartesian beam-splitter to yield the first polarized beam in the first polarization direction. The color separation and recombination prism is optically aligned to receive the first polarized beam. The prism has a second tilt axis, a plurality of color separating surfaces, and a plurality of exit surfaces. The second tilt axis maybe oriented perpendicularly to the first tilt axis of the Cartesian polarizing beam-splitter so that the polarized beam is nominally polarization rotated into the second polarization direction with respect to the color separating surfaces and a respective beam of colored light exits through each of the exit surfaces. Each imager is placed at one of the exit surface of the color separating and recombining prism to receive one of the respective beams of colored light, wherein each imager can separately modulate the polarization state of the beam of colored light.

Owner:3M INNOVATIVE PROPERTIES CO

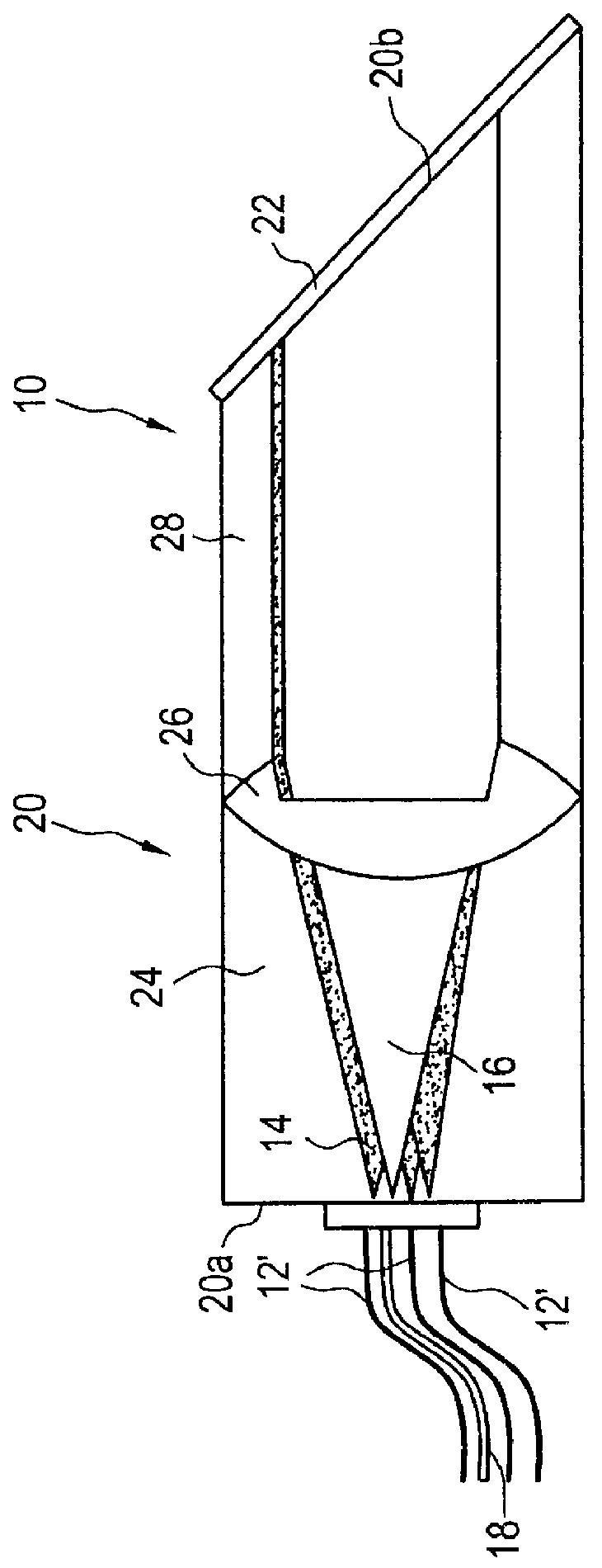

Integrated bi-directional axial gradient refractive index/diffraction grating wavelength division multiplexer

InactiveUS6011884AIncreased durabilityImprove the environmentLaser detailsCoupling light guidesMultiplexingMultiplexer

A wavelength division multiplexer is provided that integrates an axial gradient refractive index element with a diffraction grating to provide efficient coupling from a plurality of input optical sources (each delivering a single wavelength to the device) which are multiplexed to a single polychromatic beam for output to a single output optical receiver. The device comprises: (a) means for accepting optical input from at least one optical source, the means including a planar surface; (b) a coupler element comprising (1) an axial gradient refractive index collimating lens having a planar entrance surface onto which the optical input is incident and (2) a homogeneous index boot lens affixed to the axial gradient refractive index collimating lens and having a planar but tilted exit surface; (c) a diffraction grating, such as a Littrow diffraction grating, on the tilted surface of the homogeneous index boot lens which combines a plurality of spatially separated wavelengths from the optical light; and (d) means to output at least one multiplexed, polychromatic output beam, the means including a planar surface. The device may be operated in the forward direction as a multiplexer or in the reverse direction as a demultiplexer.

Owner:AUXORA

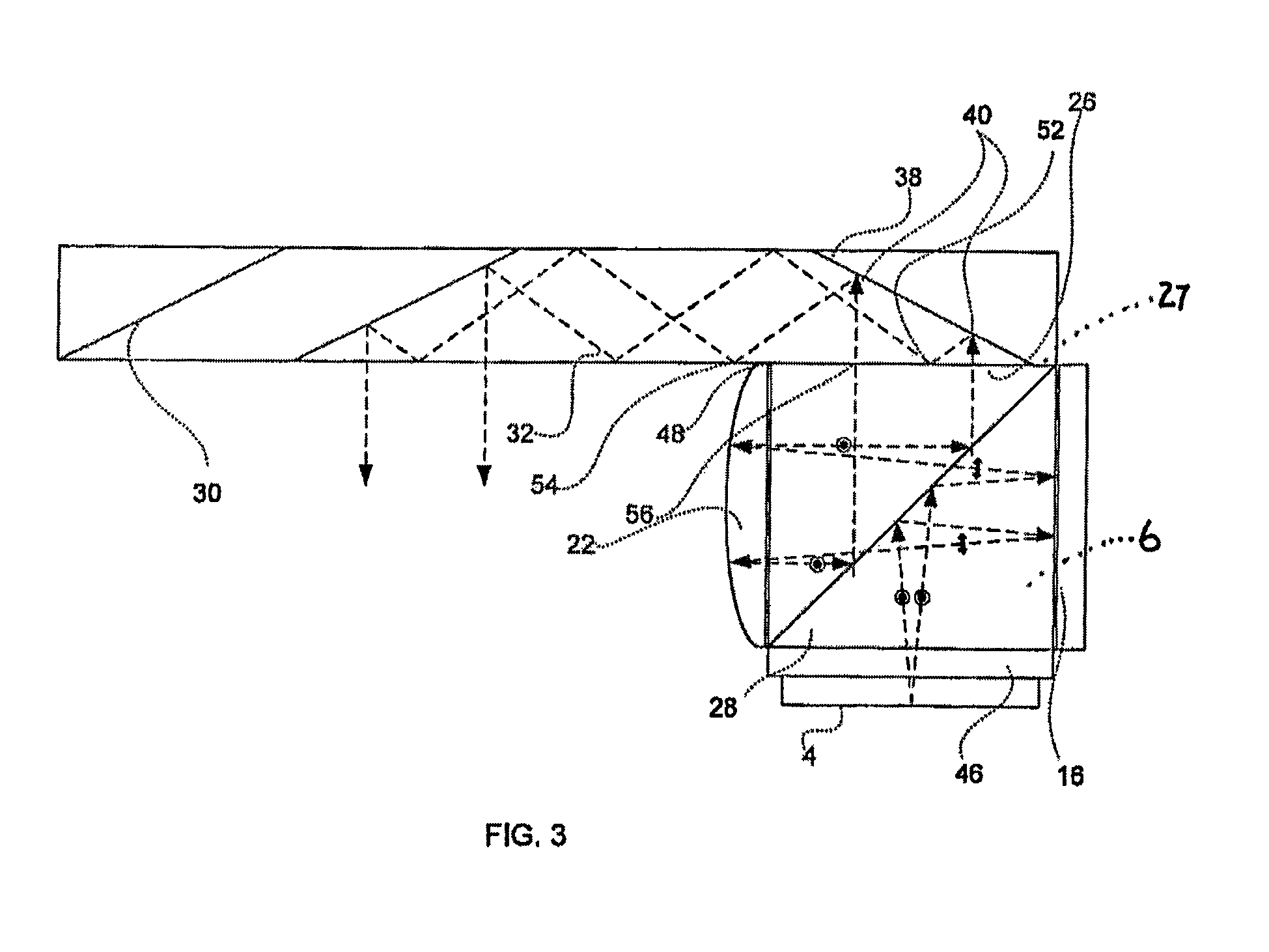

Efficient polarized directional backlight

ActiveUS20120243204A1Improve electricity efficiencyLow costPolarising elementsOptical light guidesRefractive indexWaveguide

By introducing a stack of alternating high and low index dichroic material layers on the exit surface of a waveguide for a wedge type directional backlight, natural reflectivity differences between polarized components can be increased, effectively reflecting the vast proportion of S-polarized light rays, while at the same time transmitting the P-polarized light rays, of light impacting the exit surface of the waveguide at an angle sufficient to exit the waveguide. This recovers polarization in wedge type backlight systems, increasing illumination exiting the waveguide. Also, on the back reflecting surface of the waveguide, a birefringent material can be added to efficiently transform S-polarized reflected light from the dichroic stack, into returning P-polarized light. Because returning rays that are now P-polarized by the birefringent material have already achieved the critical angle for exiting the waveguide, the rays transformed to P-polarization can now also exit the waveguide, increasing waveguide illumination.

Owner:REALD SPARK LLC

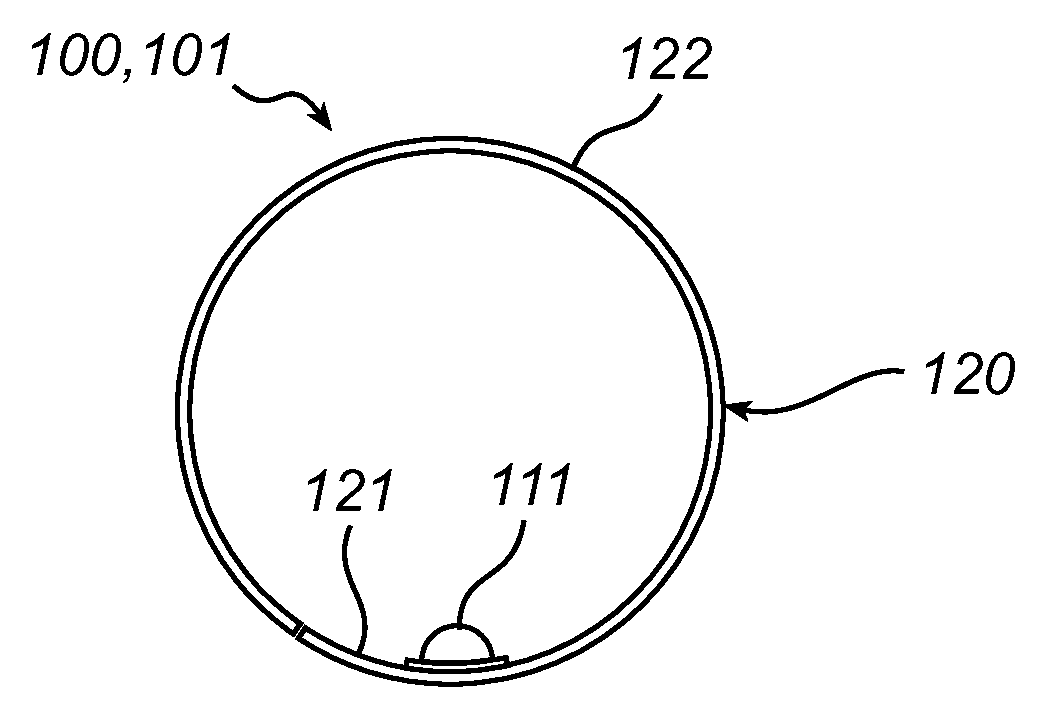

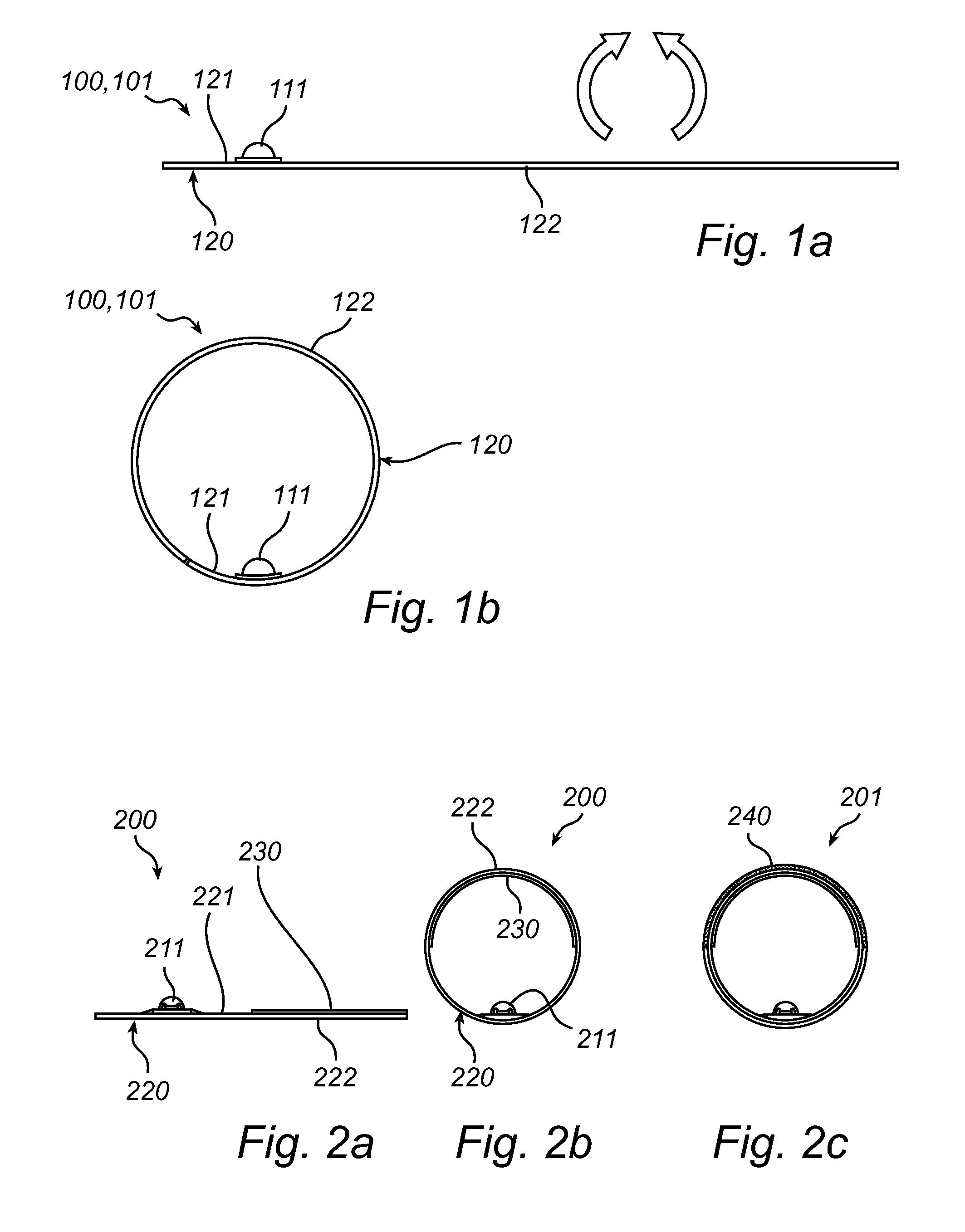

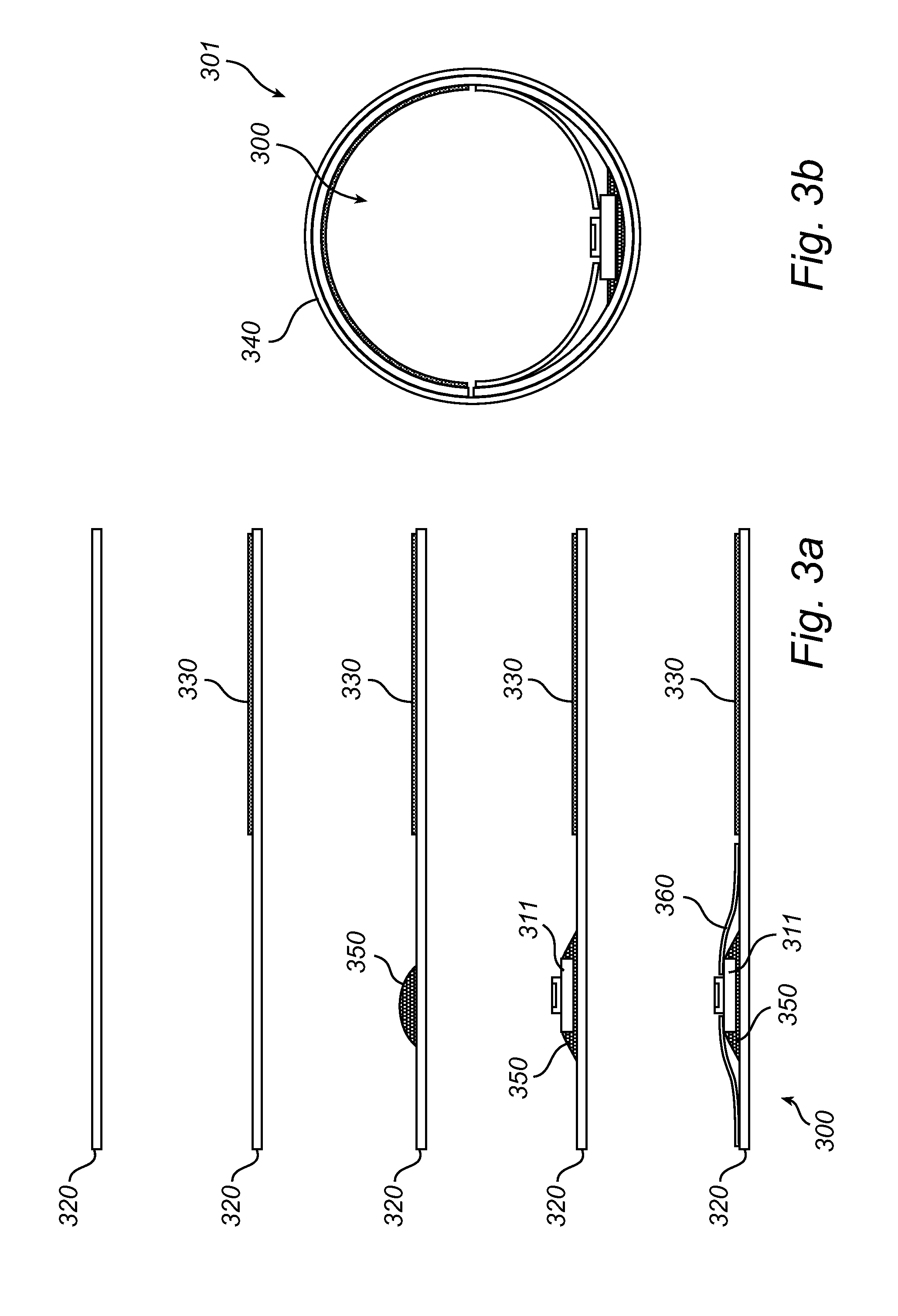

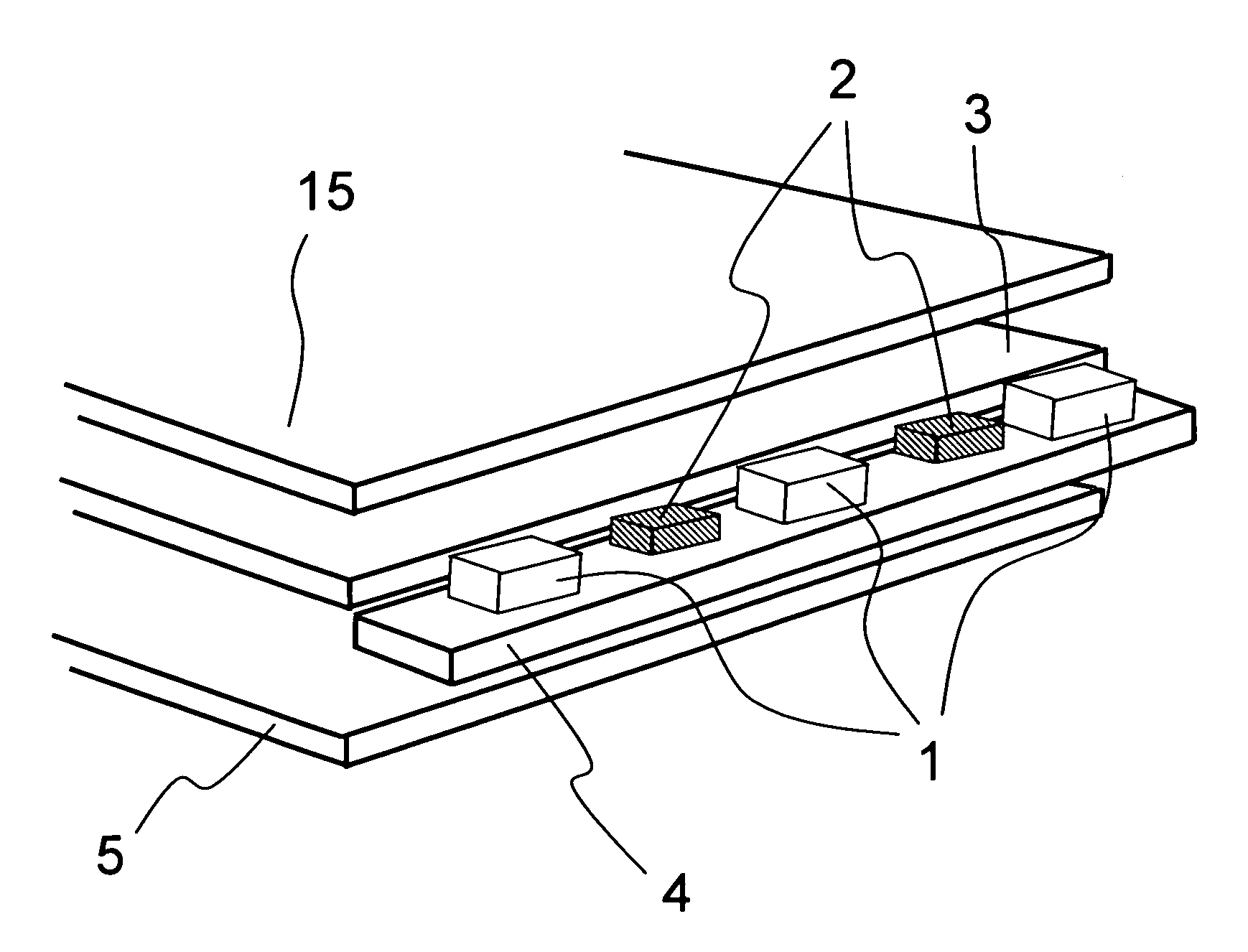

Lighting device

ActiveUS20130033888A1Inexpensive and flexible mannerMechanical apparatusPoint-like light sourceEffect lightExit surface

There is provided a lighting device and a method to manufacture such a lighting device. The inventive concept is based on manufacturing a lighting device on an at least partly flexible sheet assembly which is rolled into a tube, such that the light source of the lighting device is arranged within the tube. The flexible sheet assembly is arranged such that the tube provides a light mixing chamber and light exit surface for the lighting device. Thus, the tube shaped lighting device instantly delivers the necessary optical and mechanical properties for easy assembly and the functionality of a light engine.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

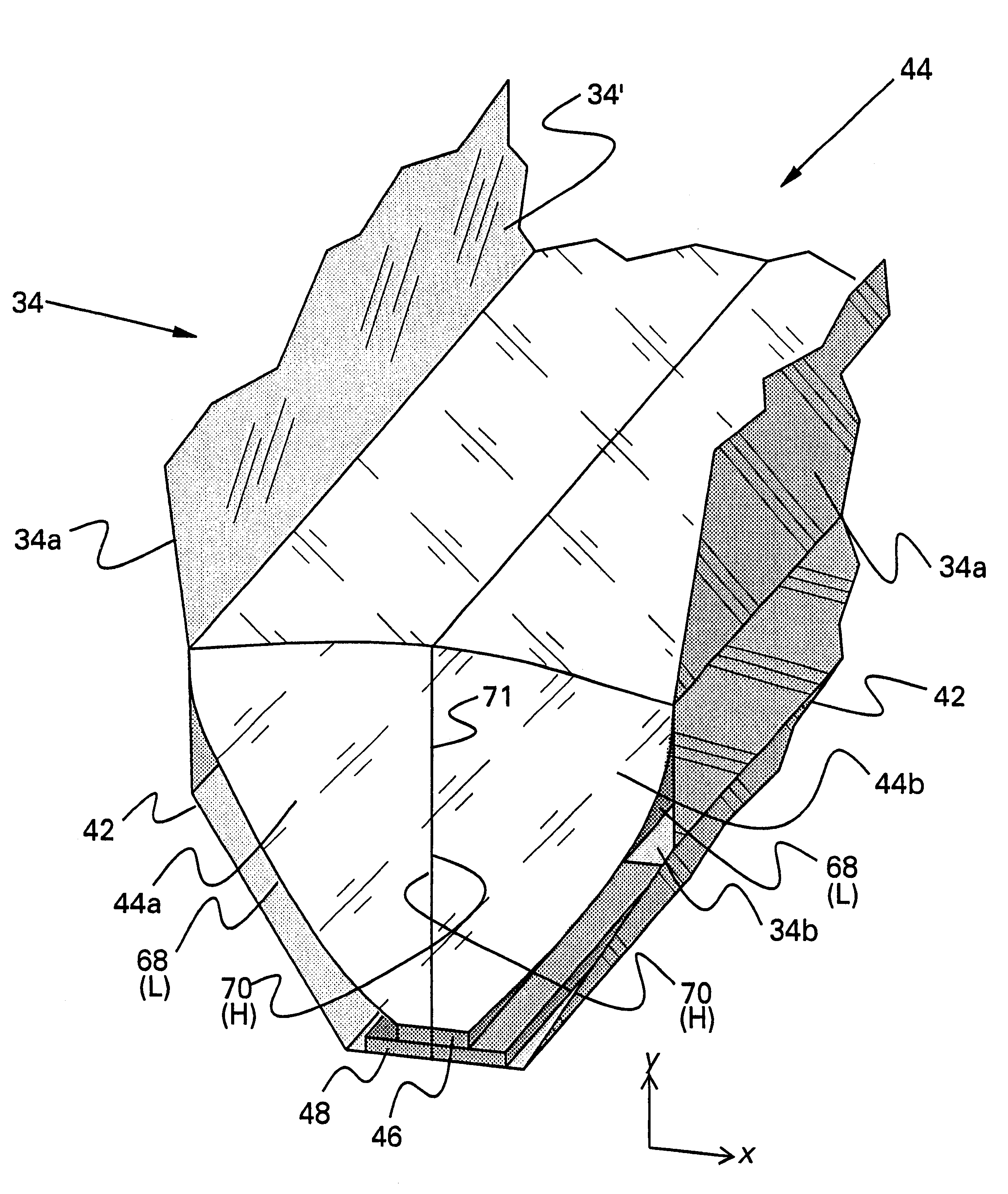

Collimating optical device and system

ActiveUS20100202048A1Simple designFabrication facilitatedPrismsPolarising elementsLight guidePolarization beam splitter

There is provided a light-guide, compact collimating optical device, including a light-guide having a light-waves entrance surface, a light-waves exit surface and a plurality of external surfaces, a light-waves reflecting surface carried by the light-guide at one of the external surfaces, two retardation plates carried by light-guides on a portion of the external surfaces, a light-waves polarizing beamsplitter disposed at an angle to one of the light-waves entrance or exit surfaces, and a light-waves collimating component covering a portion of one of the retardation plates. A system including the optical device and a substrate, is also provided.

Owner:LUMUS LTD

Projection exposure method and projection exposure system

InactiveUS7092069B2Enhanced couplingSharp contrastNanoinformaticsMaterial analysis by optical meansLithographic artistHigh numerical aperture

In a method for manufacturing semiconductor devices and other finely structured parts, a projection objective (5) is used in order to project the image of a pattern arranged in the object plane of the projection objective onto a photosensitive substrate which is arranged in the region of the image plane (12) of the projection objective. In this case, there is set between an exit surface (15), assigned to the projection objective, for exposing light and an incoupling surface (11), assigned to the substrate, for exposing light a small finite working distance (16) which is at least temporarily smaller in size and exposure time interval than a maximum extent of an optical near field of the light emerging from the exit surface. As a result, projection objectives with very high numerical apertures in the region of NA>0.8 or more can be rendered useful for contactless projection lithography.

Owner:CARL ZEISS SMT GMBH

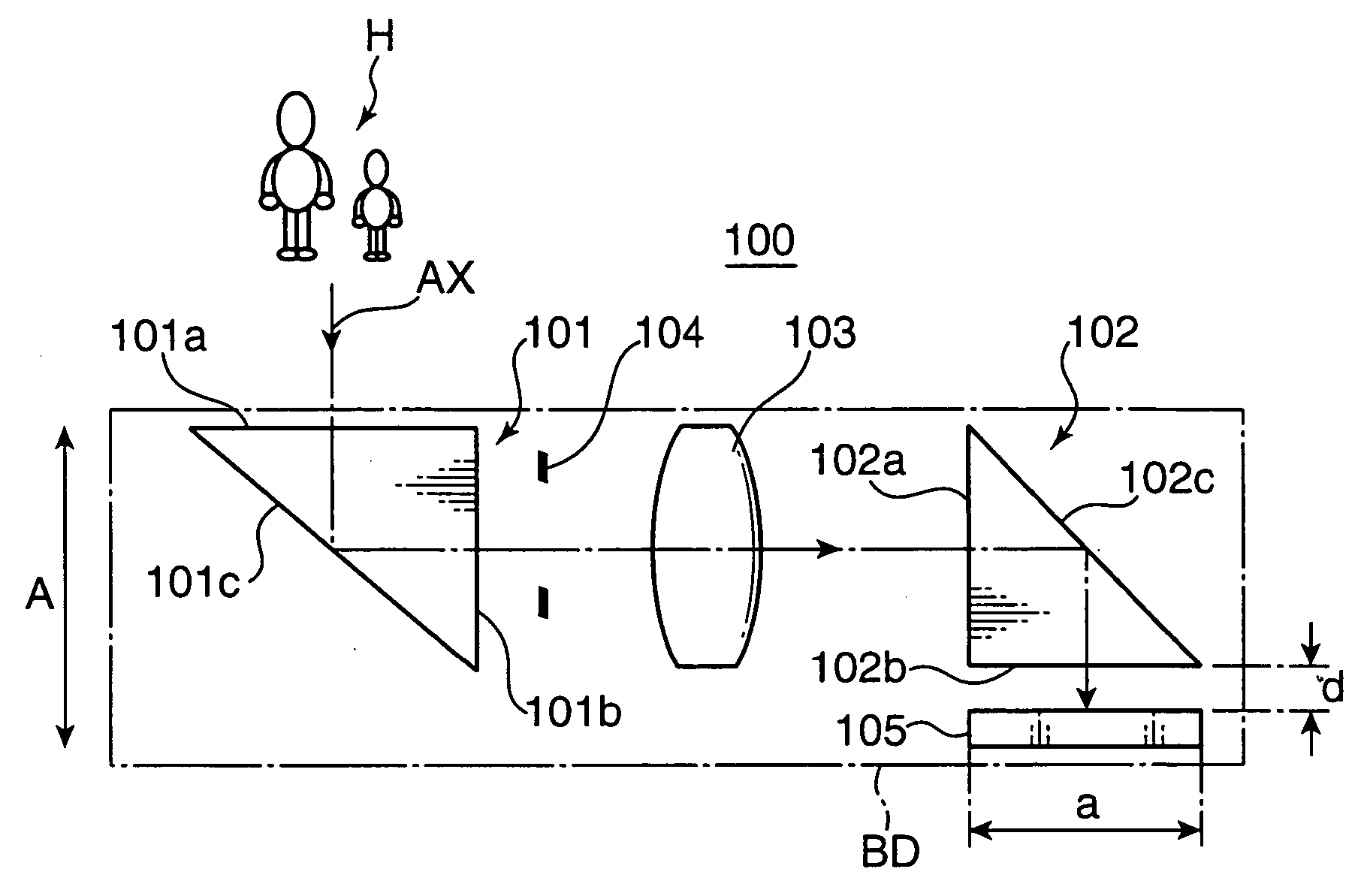

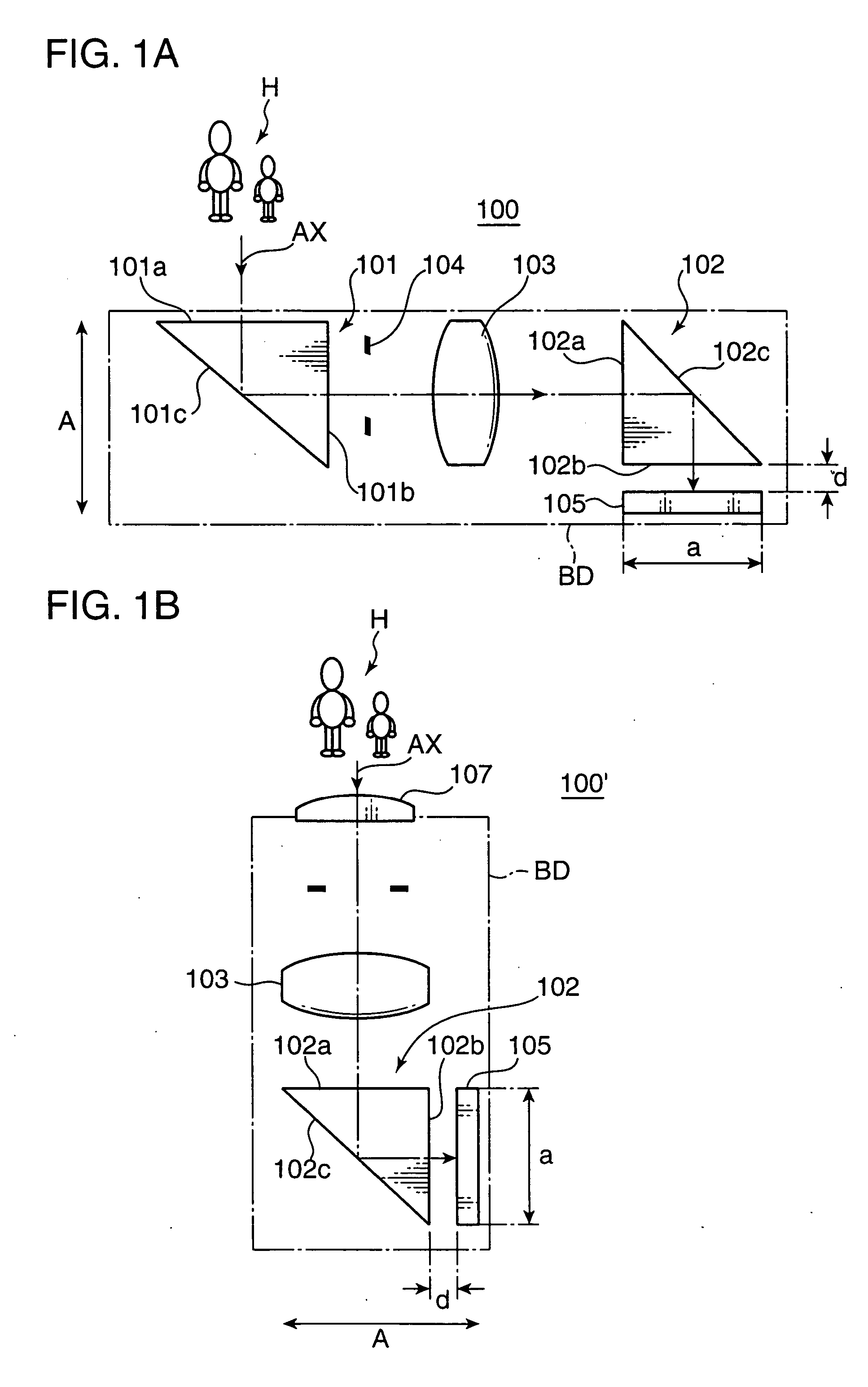

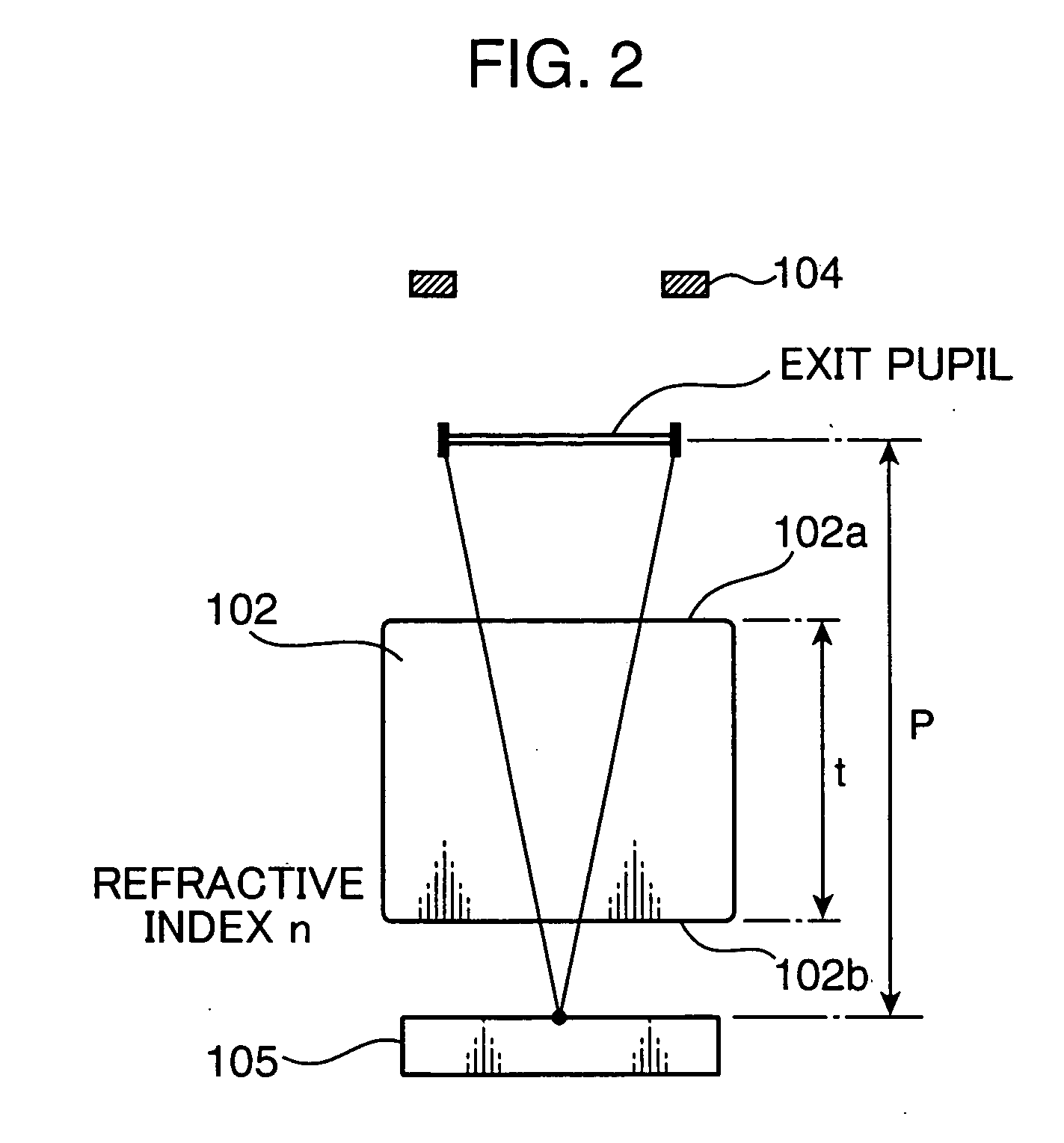

Imaging optical system and imaging lens device

InactiveUS20060017834A1Inexpensive and compactGood optical performanceTelevision system detailsColor television detailsOptical powerImaging lens

An imaging optical system 100 has an imaging side prism 102 for bending incident light at about 90 degrees for reflection, and an image sensor 105 having a light receiving surface opposing to an exit surface 102b of the imaging side prism 102. At least one of an incident surface 101a of an incident side prism 101 and an incident surface 101a of the imaging side prism 102, or at least one of an exit surface 101b of the incident side prism 101 and the exit surface 102b of the imaging side prism 102 has an optical power. An arrangement relation between the exit surface 102b of the imaging side prism 102 and the image sensor 105 is established to satisfy the conditional formula (1): 0.0≦d / a<0.8 (1) where d represents a distance between the exit surface 102b and the light receiving surface of the image sensor 105, and a represents a height of the light receiving surface of the image sensor 105 on a plane where an optical path of the imaging optical system 100 is folded, e.g., the size of the image sensor 105 in the shorter side direction thereof. This arrangement enables to reduce the thickness of an apparatus housing BD for incorporating the imaging optical system 100.

Owner:KONICA MINOLTA OPTO

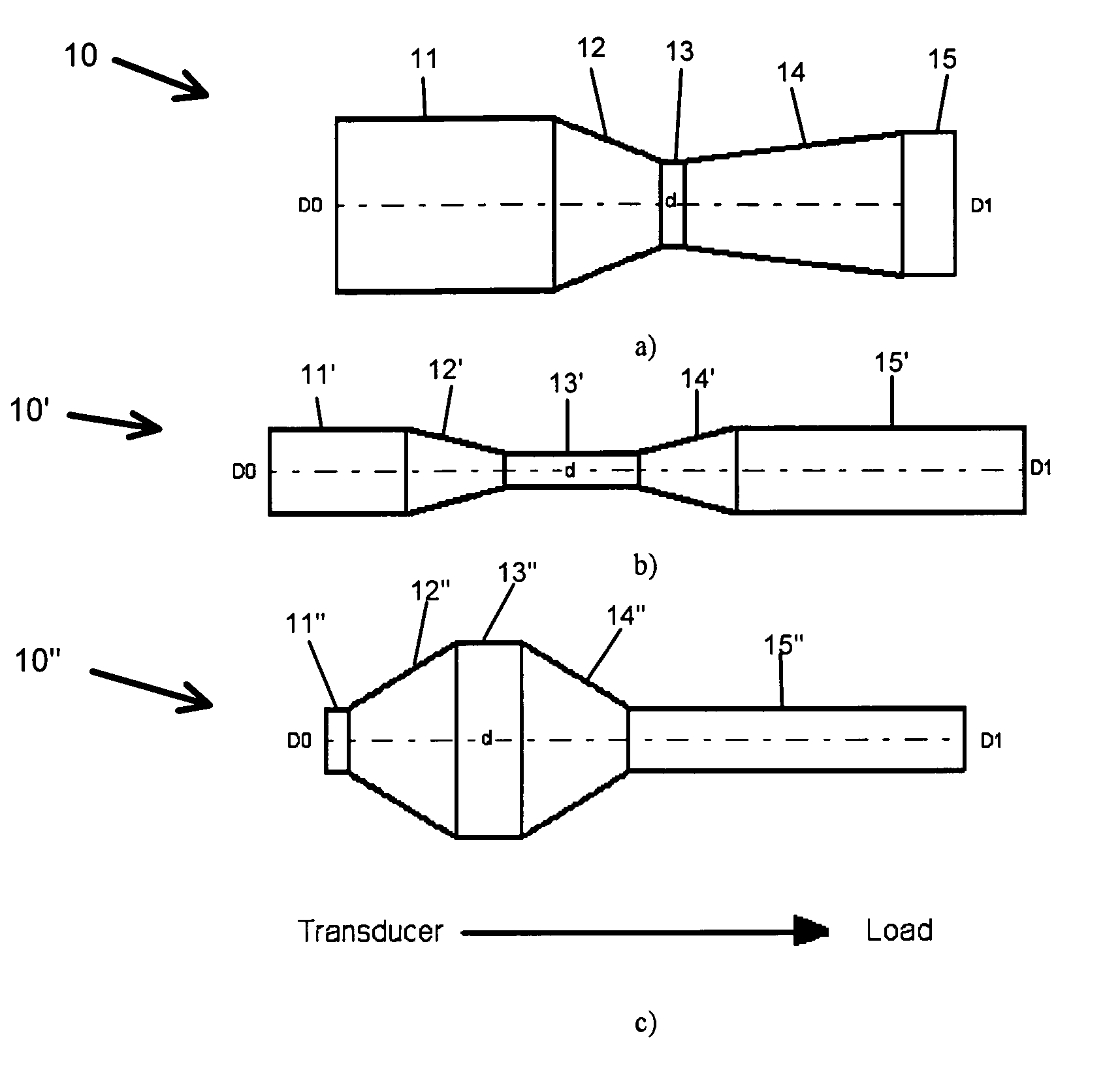

Ultrasonic rod waveguide-radiator

ActiveUS7156201B2Quality improvementExtended service lifePiezoelectric/electrostriction/magnetostriction machinesImpedence networksEngineeringEnergy maximization

The present invention comprises an ultrasonic resonant rod waveguide-radiator with at least three cylindrical sections, one of which is an entrance section having a planar entrance surface and another of which is an exit section having a planar exit surface, and at least two sections having a variable cross-section. The cylindrical sections and sections of variable cross-section are arranged in alternating fashion and connected to each other acoustically rigidly. The dimensions of the cylindrical sections and the sections of variable cross-section are selected so that the gain of the waveguide-radiator is significantly greater than unity and the strain created by passage of ultrasonic waves through the waveguide-radiator is minimized, increasing the operational life of the waveguide-radiator and maximizing the amount of useful energy transmitted by the waveguide-radiator.

Owner:INDAL SONOMECHANICS +1

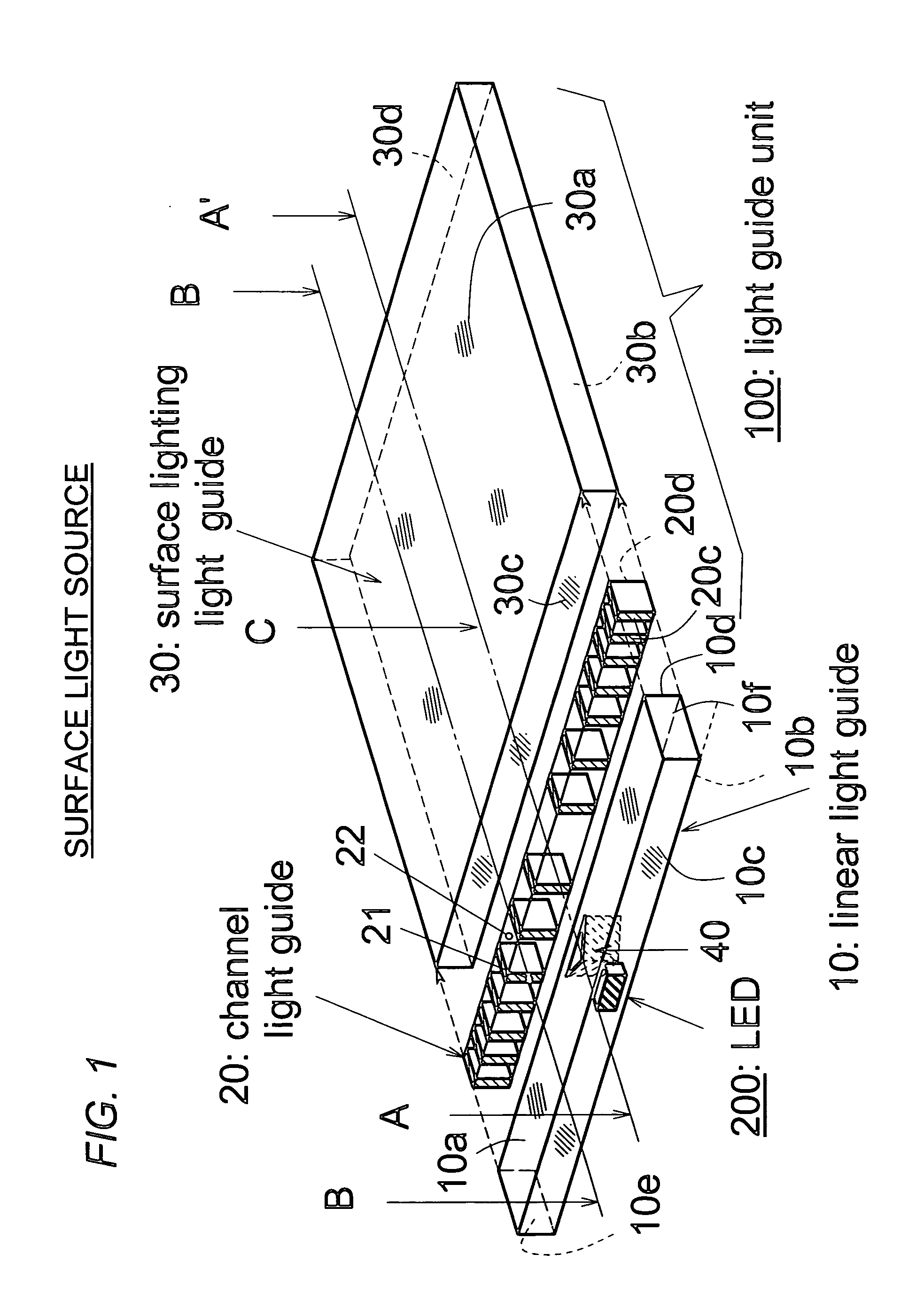

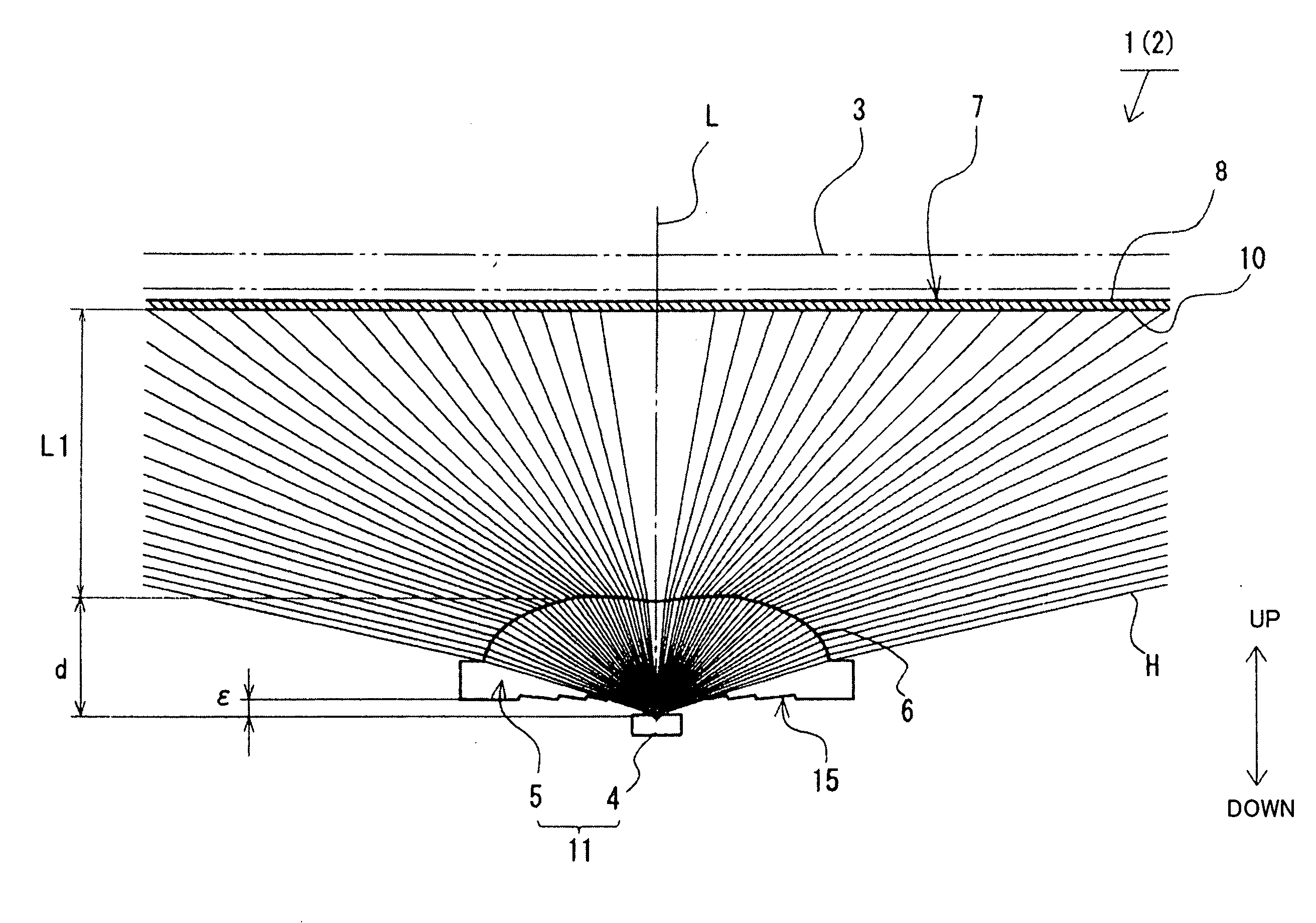

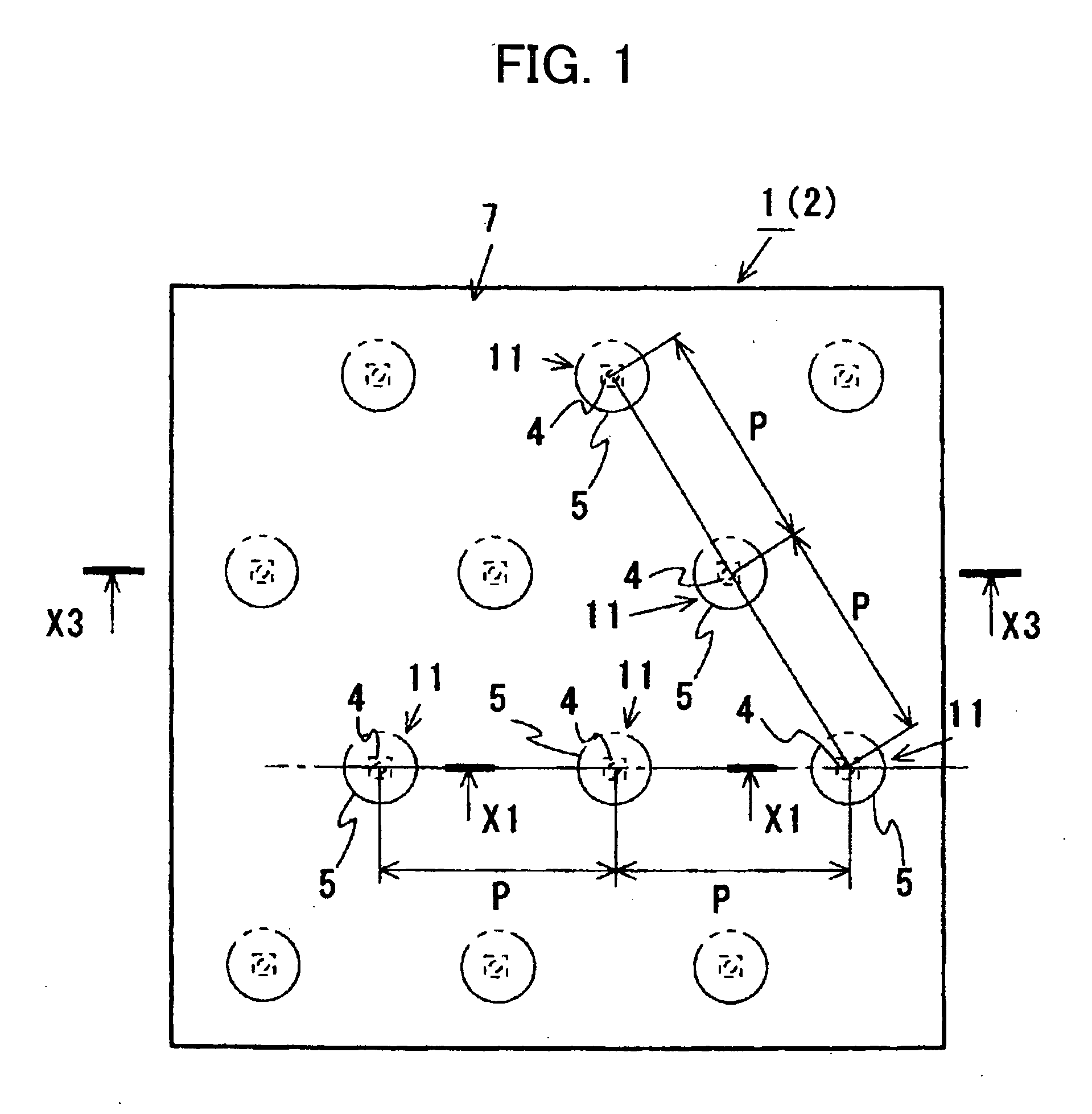

Surface illuminator using point light source

The disclosed apparatus is a surface illuminator i.e. surface light source typically used in lighting for liquid crystal displays (LCDs). The surface illuminator using point light source may comprise a first light guide member for a surface lighting having a first light exiting surface and a first light entering surface; a second light guide member for a light distribution having a second light exiting surface and a second light entering surface; at least one point light source (LED) optically communicated with the second light entering surface; a channel light guide member having a fiber optic channel array having a plurality of light guiding portions optically isolated one another; and wherein the channel light guide member is disposed between the first light guide member and the second light guide member. The second light guide member may be an elongated light guide member having a linear or nonlinear elongated member.

Owner:IIMURA KEIJI

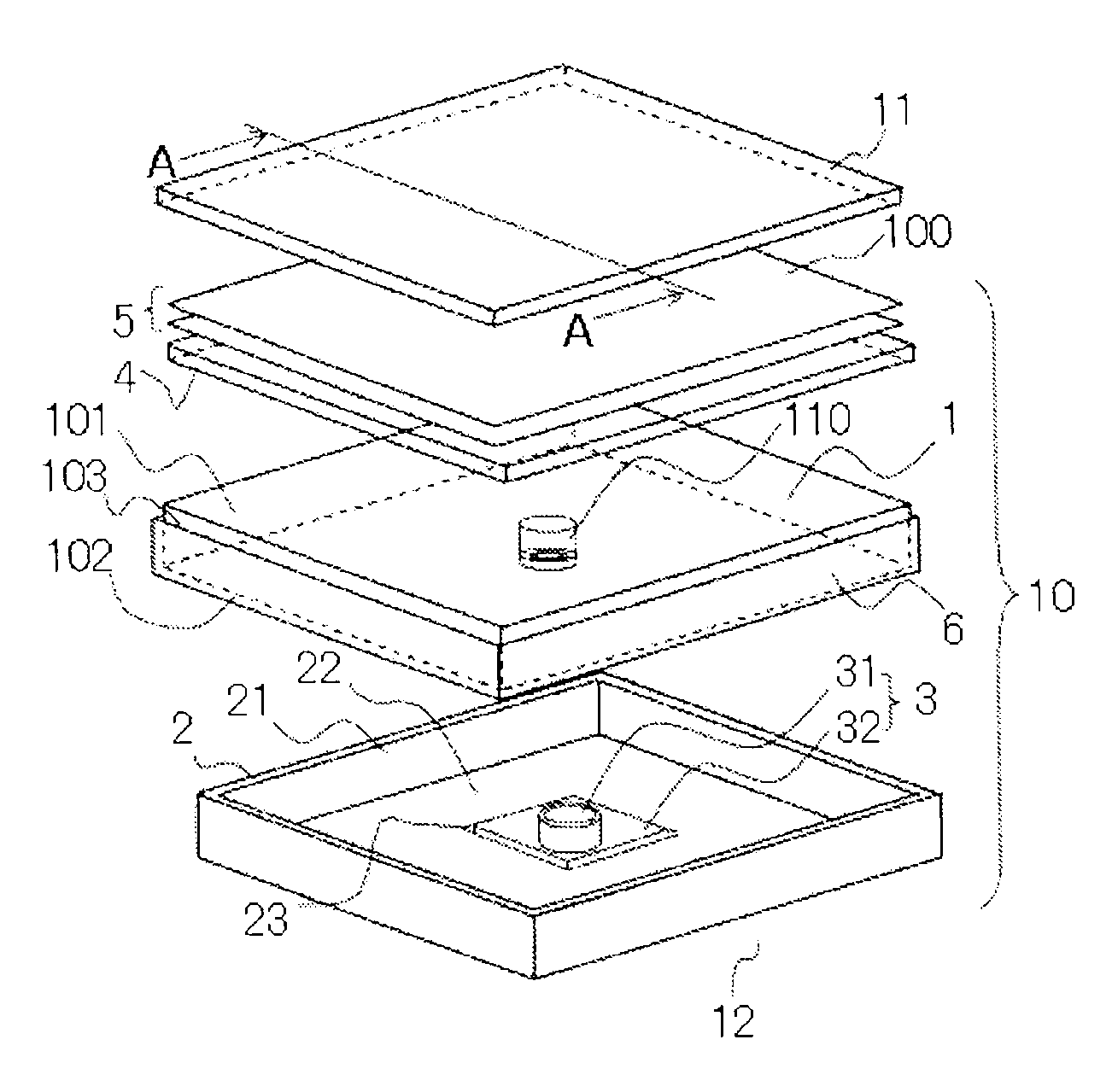

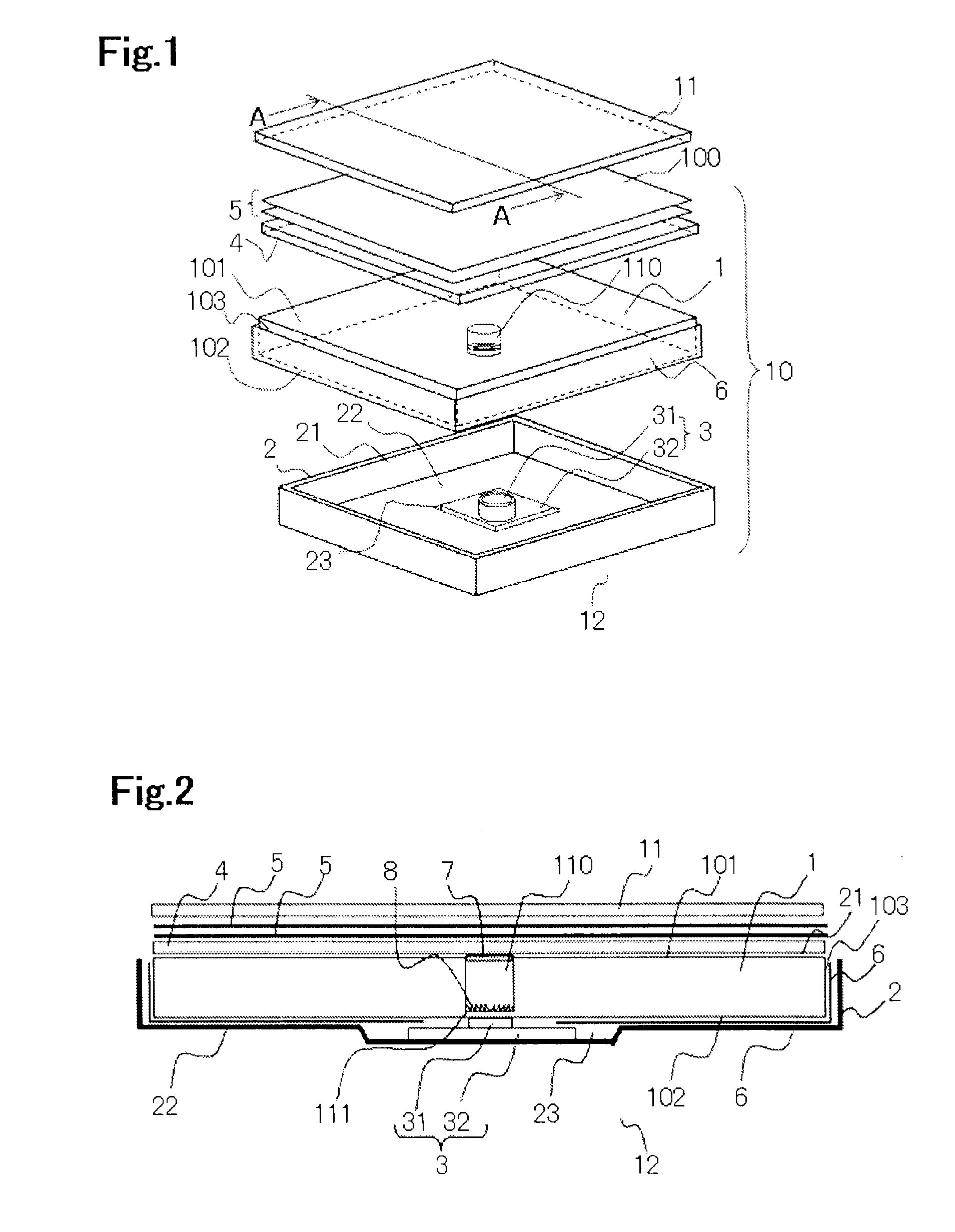

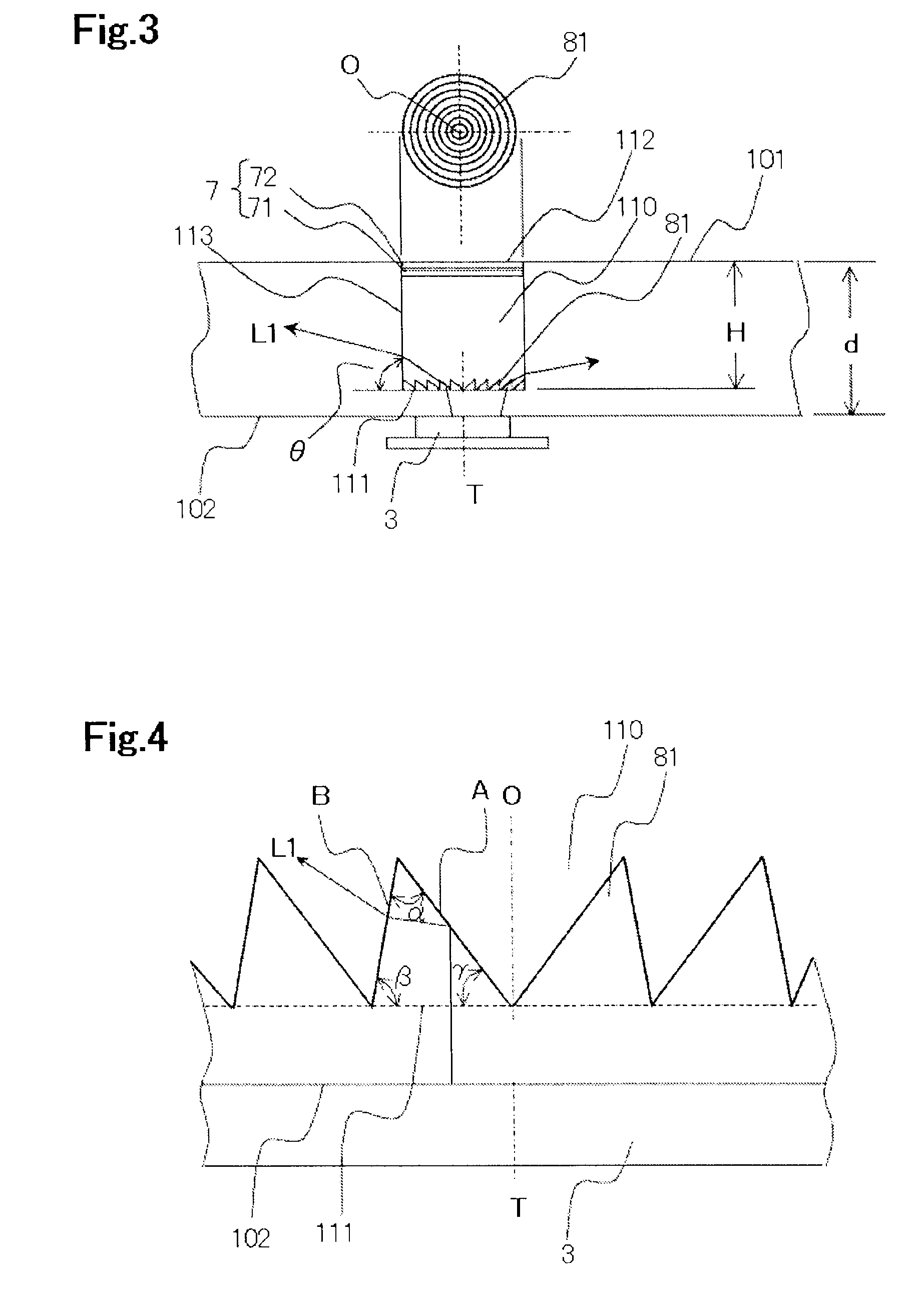

Planar light source device and display apparatus incorporating same

InactiveUS20100079980A1Highly uniform intensityImprove utilization efficiencyPlanar/plate-like light guidesGlobesLight guideOptoelectronics

A planar light source device with highly uniform intensity and high light utilization efficiency, and a display apparatus incorporating the same, are provided. A light guide plate, configured by a material such as plate-shaped and transparent acryl resin, polycarbonate resin, or glass, causes incident light to propagate within the light guide plate and then to exit the light through an exit surface as a surface emitting light. A first recess is formed substantially in the center of the exit surface. The first recess is cylinder-shaped, and on a bottom thereof is provided a lens that refracts incident light from a light source, in a direction away from the center of a circle on the bottom.

Owner:TRIVALE TECH LLC

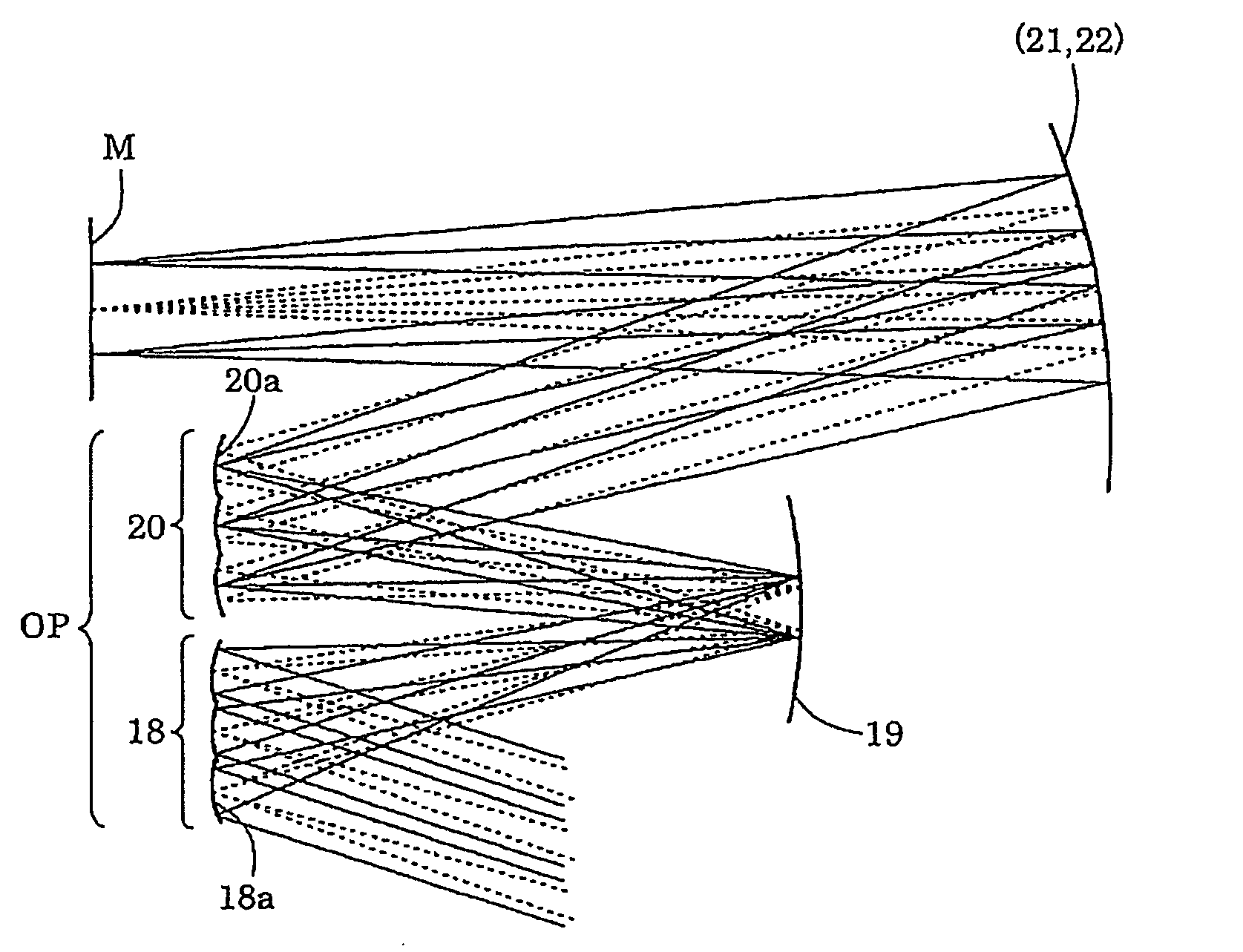

Optical integrator, illumination optical device, exposure device, and exposure method

ActiveUS20070132977A1Easily avoidedInhibit productionMirrorsPhotomechanical apparatusLight beamEngineering

An optical integrator of a wavefront dividing type permits an arbitrary distance to be set between an entrance surface and an exit surface, without production of aberration and without reduction in reflectance on reflecting films. The optical integrator has a plurality of first focusing elements (first concave reflector elements 18a) arranged in parallel, a plurality of second focusing elements (second concave reflector elements 20a) arranged in parallel so as to correspond to the first focusing elements, and a relay optical system (19) disposed in an optical path between the first focusing elements and the second focusing elements. The relay optical system refocuses a light beam focused via one of the first focusing elements, on or near a corresponding second focusing element so as to establish an imaging relation of one-to-one correspondence between one of the first focusing elements and one of the second focusing elements.

Owner:NIKON CORP

Integrated bi-directional dual axial gradient refractive index/diffraction grating wavelength division multiplexer

InactiveUS6137933AIncreased durabilityImprove the environmentCoupling light guidesExit surfaceWavelength-division multiplexing

A wavelength division multiplexer / demultiplexer is provided that integrates axial gradient refractive index elements with a diffraction grating to provide efficient coupling from a plurality of input optical sources (each delivering a single wavelength to the device) which are multiplexed to a single polychromatic beam for output to a single output optical source. The device comprises: (a) means for accepting an optical input from at least one optical source, the means including a planar surface; (b) a first coupler element comprising (1) a first axial gradient refractive index collimating lens having a planar entrance surface onto which the optical input is incident and (2) a first homogeneous index boot lens affixed to the first collimating lens and having a planar exit surface from which optical light exits; (c) a diffraction grating formed on the planar exit surface which combines a plurality of angularly separated diffracted wavelengths from the optical light; (d) a reflecting element for reflecting the plurality of diffracted wavelengths; (e) a second coupler element comprising (1) a second homogeneous index boot lens having a planar entrance surface onto which said plurality of diffracted wavelengths is incident and (2) a second axial gradient refractive index collimating lens affixed to the second homogeneous index boot lens; and (f) means for outputting at least one multiplexed, polychromatic output beam to an optical receiver, the means including a planar back surface. The device may be operated in either the forward or the reverse direction.

Owner:AUXORA

Optical arrangement

InactiveUS20100053959A1Suitable for useNon-electric lightingPoint-like light sourceEdge surfaceLight guide

An optical arrangement comprising a light guide (101) having a light-entry portion (103) with a light-entry surface (105), a tapering portion (107) with a light reflecting surface, and a light-exit surface (109). The light-entry portion (103) is arranged to guide light from the light-entry surface (105) in a first direction (x) towards the light reflecting surface (H I), the light reflecting surface being arranged in relation to the first direction (x) so that incident light from the light-entry portion (103) is reflected towards the light-exit surface (109). A light transmitting layer (113) is adapted to transmit light diffusively and arranged to cover at least a portion of the light-entry edge surface (105) of the light guide (101). The arrangement is e.g. suitable for use in a LED based luminaire and allows for efficiency and forming of a light beam able to fulfill glare requirements. The arrangement may advantageously be used in a downlighting application.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Display with bright backlight

ActiveUS20060012286A1Discharge tube luminescnet screensLighting heating/cooling arrangementsTransmittanceExit surface

Methods and apparatus are provided for projecting light carrying a data image. The apparatus comprises a first layer having regions of electrically alterable variable light transmittance adapted to form the data image, and a hollow cavity backlight having a light exiting surface coupled to the first layer and adapted to provide light to the first layer through the light exiting surface from one or more light emitters some of which point in a principal direction other than at right angles to the light exiting surface. In a preferred embodiment, LEDs are used as the light emitters and are preferably mounted on one or more printed circuit boards or other support tilted at non-zero angles with respect to the light exiting surface.

Owner:HONEYWELL INT INC

Illuminating device and display device including the same

ActiveUS7476016B2Intensity efficiencyAdjust balanceMechanical apparatusPoint-like light sourceLuminous intensityLight guide

Provided is a display device including: a light guide member for mixing light from a blue LED element coated with a translucent resin mixed with phosphor particles which converts blue light into green light with light from a red LED element to make white light exit from a light exit surface; and a non-self light emission display element provided on an irradiating surface side of the light guide member. Therefore, the display element is irradiated with white light whose sufficient wavelength region is 600 nm or more and whose intensity efficiency is high. When the display device further includes a circuit for separately controlling light emission intensities of the red LED element and a blue LED element, chromatic balance can be adjusted even after manufacturing and an intensity of the display device and color reproducibility thereof can be easily set in an optimum range even after assembly.

Owner:HICKORY IP LLC

Light guide plate, surface light-emitting unit, and liquid crystal display device and method for manufacturing the same

InactiveUS20050024890A1Easily brought into tight contactIncrease contrastMechanical apparatusLight guides for lighting systemsLiquid-crystal displayLight guide

A liquid crystal display device includes a liquid crystal display panel having a display surface, and a surface light-emitting unit on the display surface consisting of a light source and a light guide plate for introducing light emitted from the light source into the interior of the light guide plate and emitting the light from an exit surface thereof, wherein at least the exit surface is formed from a resilient material and the exit surface is in tight contact with the display surface of the liquid crystal display panel.

Owner:ALPS ALPINE CO LTD

Street lighting device

InactiveUS20120120666A1Simple fashionMechanical apparatusPoint-like light sourceLuminous intensityLight equipment

A lighting device for streets, paths, and the like, includes a lighting unit containing a lighting element and a lens arranged in front of the lighting element in the main emission direction to produce a specified light distribution characteristic. The lens includes a light entrance surface on a light entrance side facing the lighting element and a light exit surface on a light exit side facing away from the lighting element, at which surfaces the light is refracted. The light entrance surface and / or the light exit surface of the lens is shaped in a direction transverse to the optical axis of the lighting element in such a way that the luminous intensity of the coupled out light, starting from a center plane that intersects with the optical axis, rises with an increasing emission angle from the optical axis at least partially according to a tangent function.

Owner:HELLA KG HUECK & CO

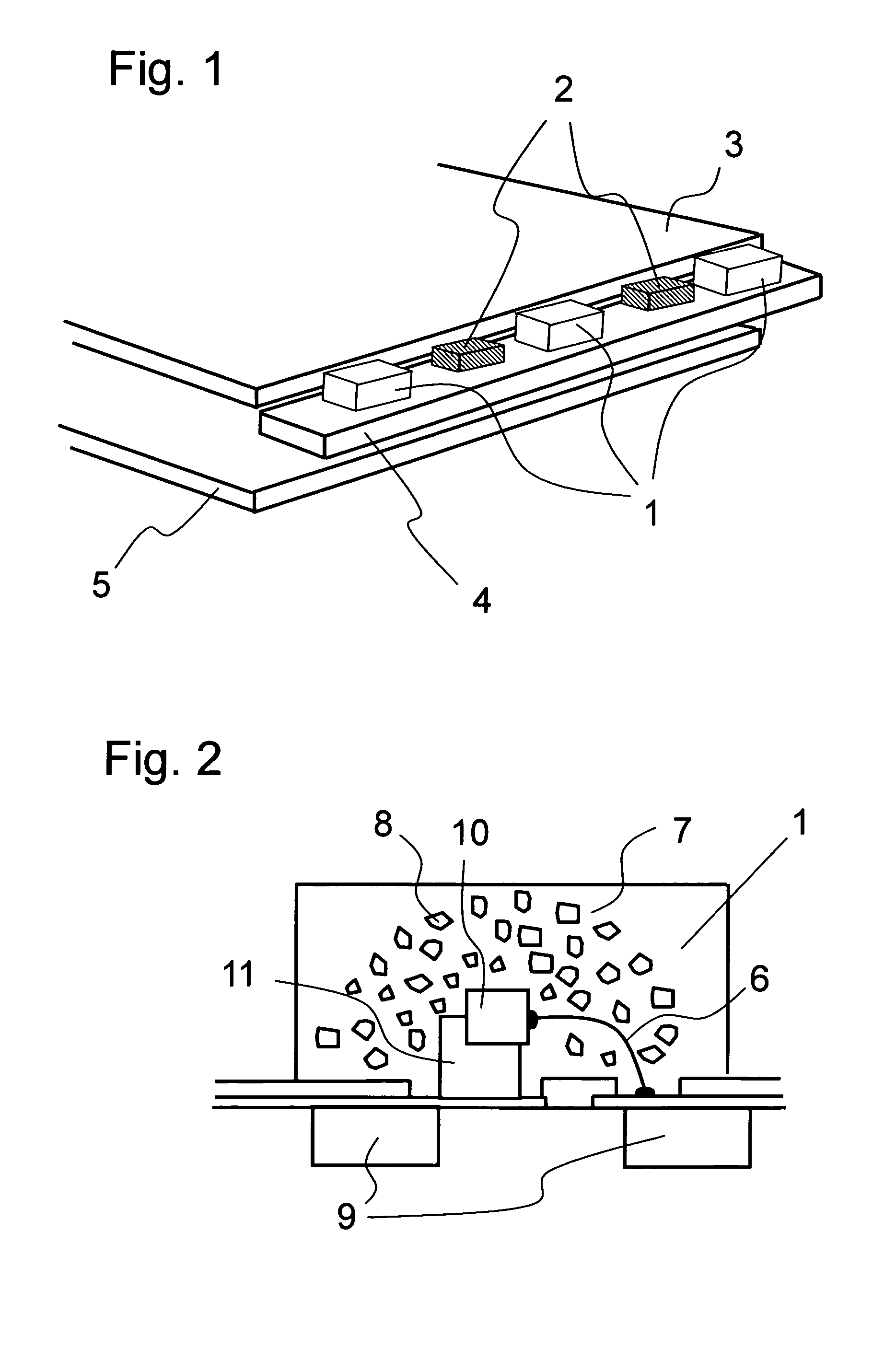

Emission device, surface light source device and display

ActiveUS20090116245A1Reduces illumination qualityHigh qualityPoint-like light sourceElectric lightingLight fluxOptical axis

A light flux control member has a back face provided with a recess and a ring-like-recess-portion surrounding the recess. Output light of a point-like-light-source (light emission element) is incident to the recess and the ring-like-recess-portion. Incident light to the recess is emitted from a light control emission face after inner-propagation. Incident light to the ring-like-recess-portion is refracted as to hardly generate inner-propagation light deflected to directions near to a direction of reference optical axis L, resulting in outgoing from any part of the light control emission face, or, if some outgoing occurs from the light control emission face, such outgoing occurs only at an outer periphery portion of the light control emission face. As a result, illumination light quality is avoided from being reduced by appearance of conspicuous ring-like bright part. In addition, uniform illumination light can be supplied to a broad angle range. Even if a plurality of point-like-light-sources are arranged at intervals, respective light fluxes originated from respective point-like-light-sources are well mixed.

Owner:ENPLAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com