Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3792 results about "Selective catalytic reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

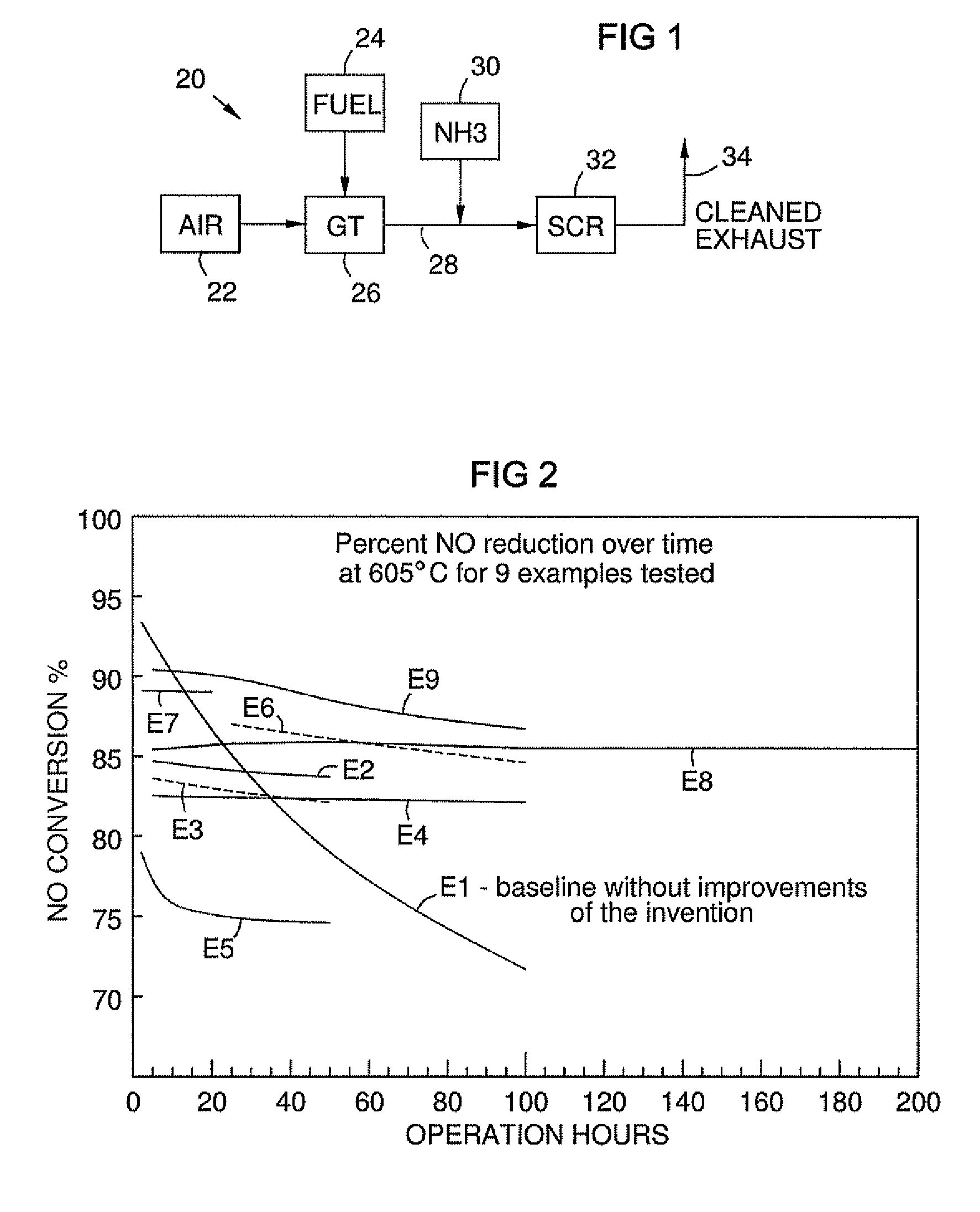

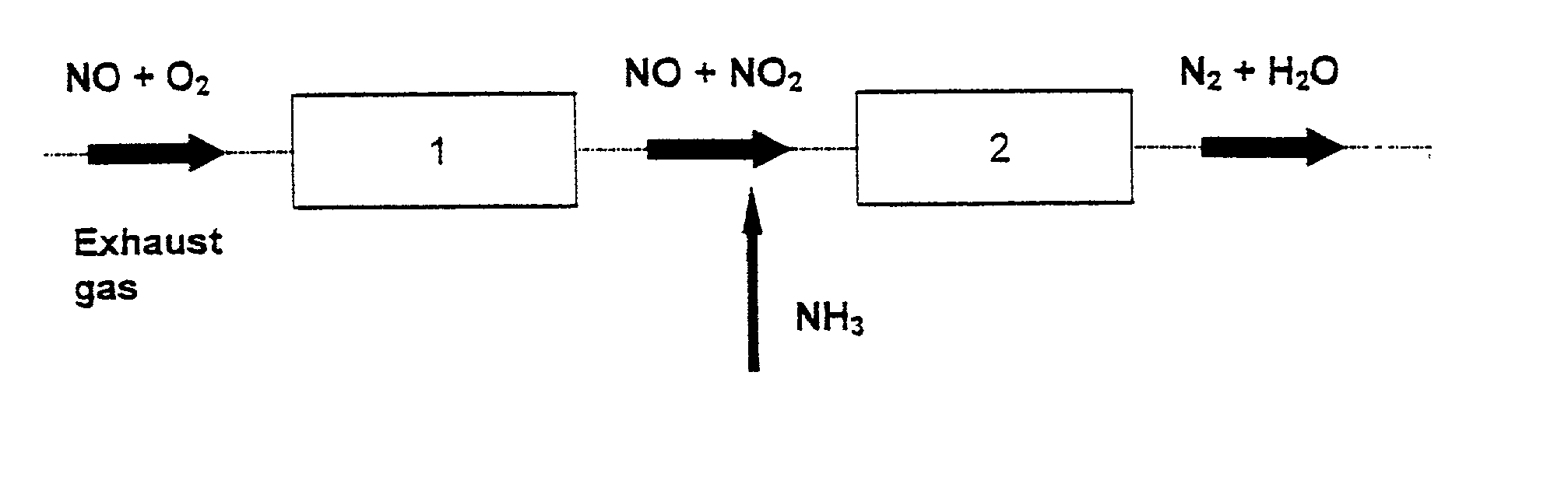

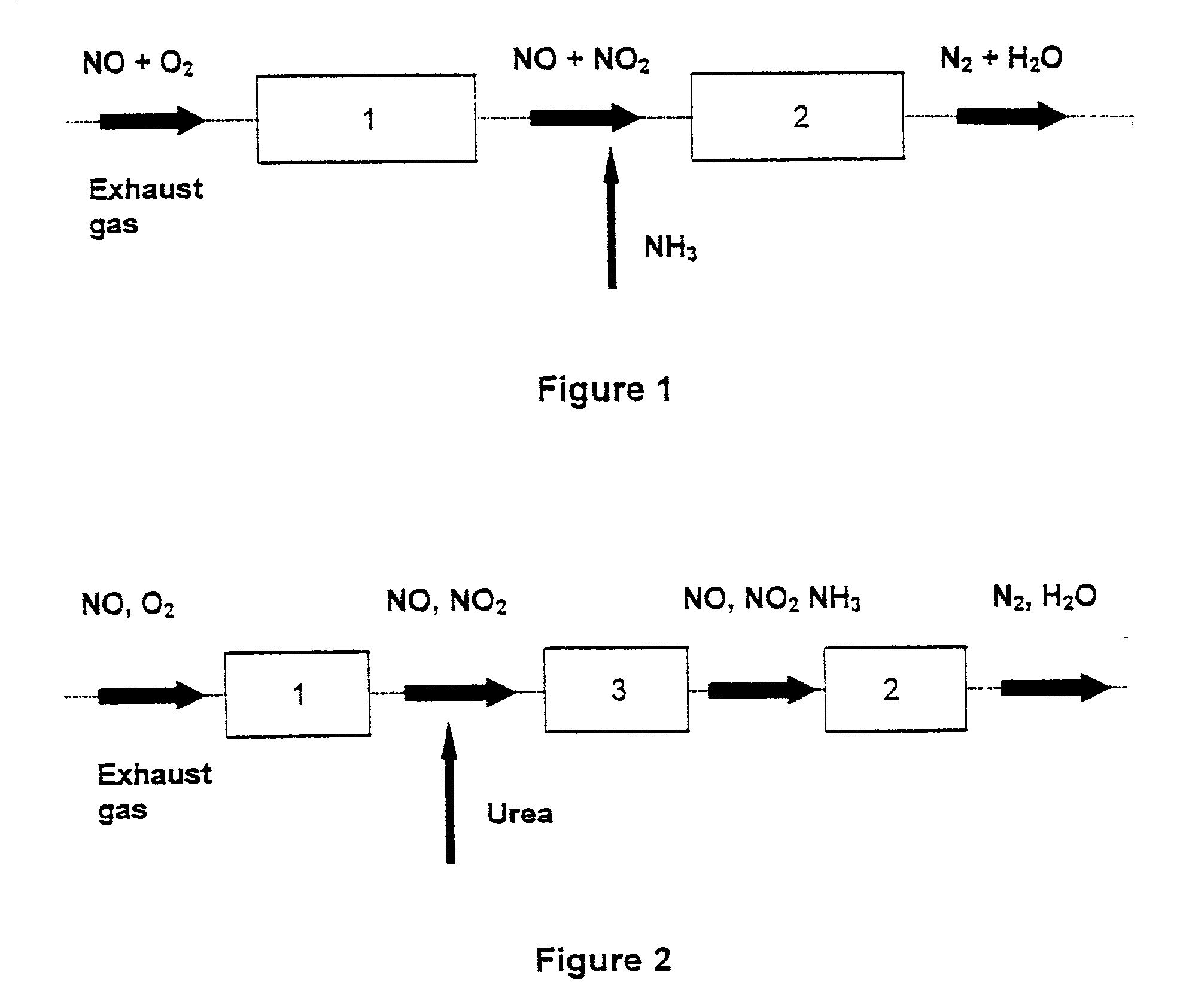

Selective catalytic reduction (SCR) is a means of converting nitrogen oxides, also referred to as NOₓ with the aid of a catalyst into diatomic nitrogen (N₂) , and water (H₂O). A gaseous reductant, typically anhydrous ammonia, aqueous ammonia or urea, is added to a stream of flue or exhaust gas and is adsorbed onto a catalyst. Carbon dioxide, CO₂ is a reaction product when urea is used as the reductant.

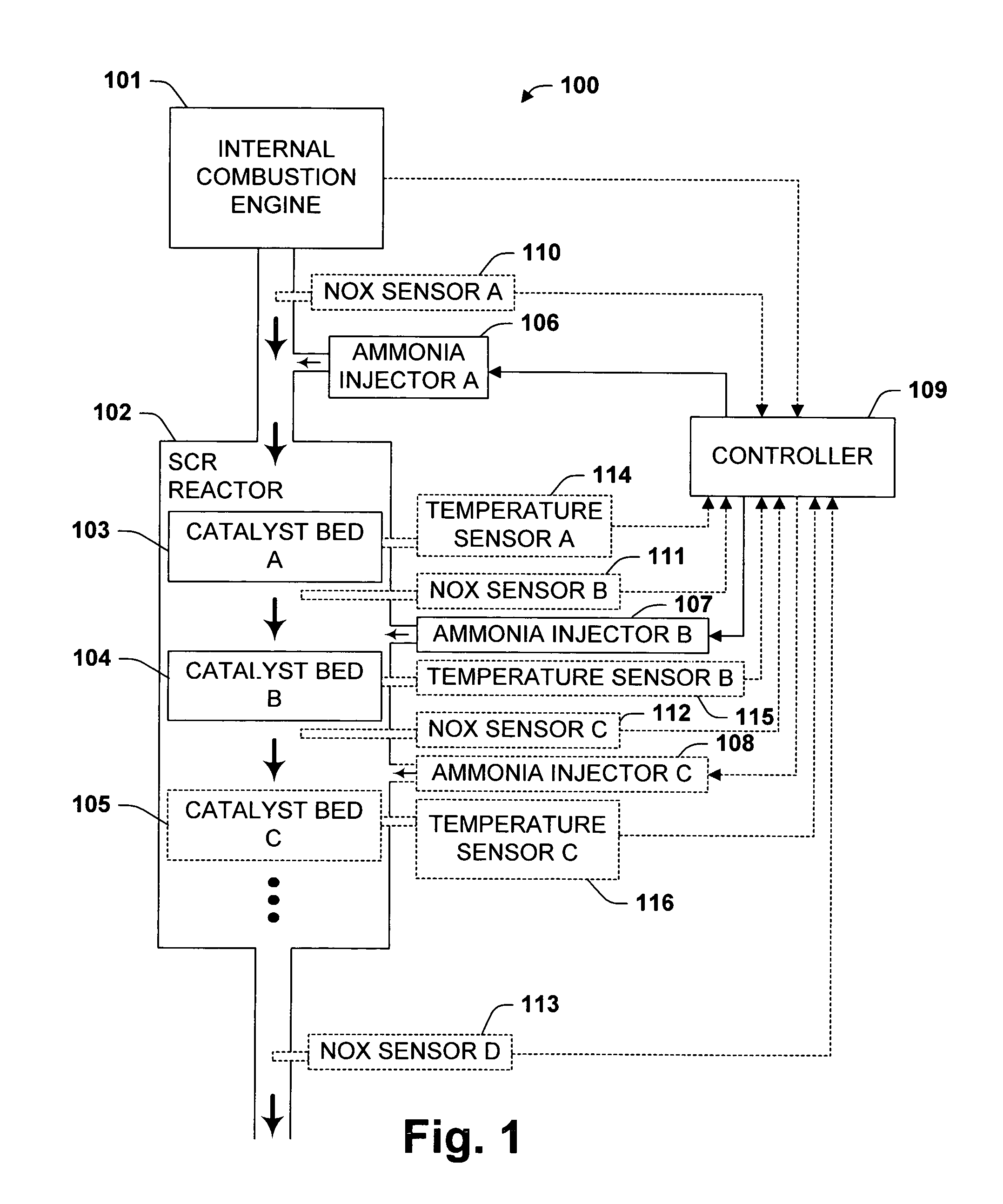

Catalyzed SCR filter and emission treatment system

ActiveUS7229597B2Reduce the temperaturePromote regenerationCombination devicesLiquid degasification with auxillary substancesNitrogen oxideSoot

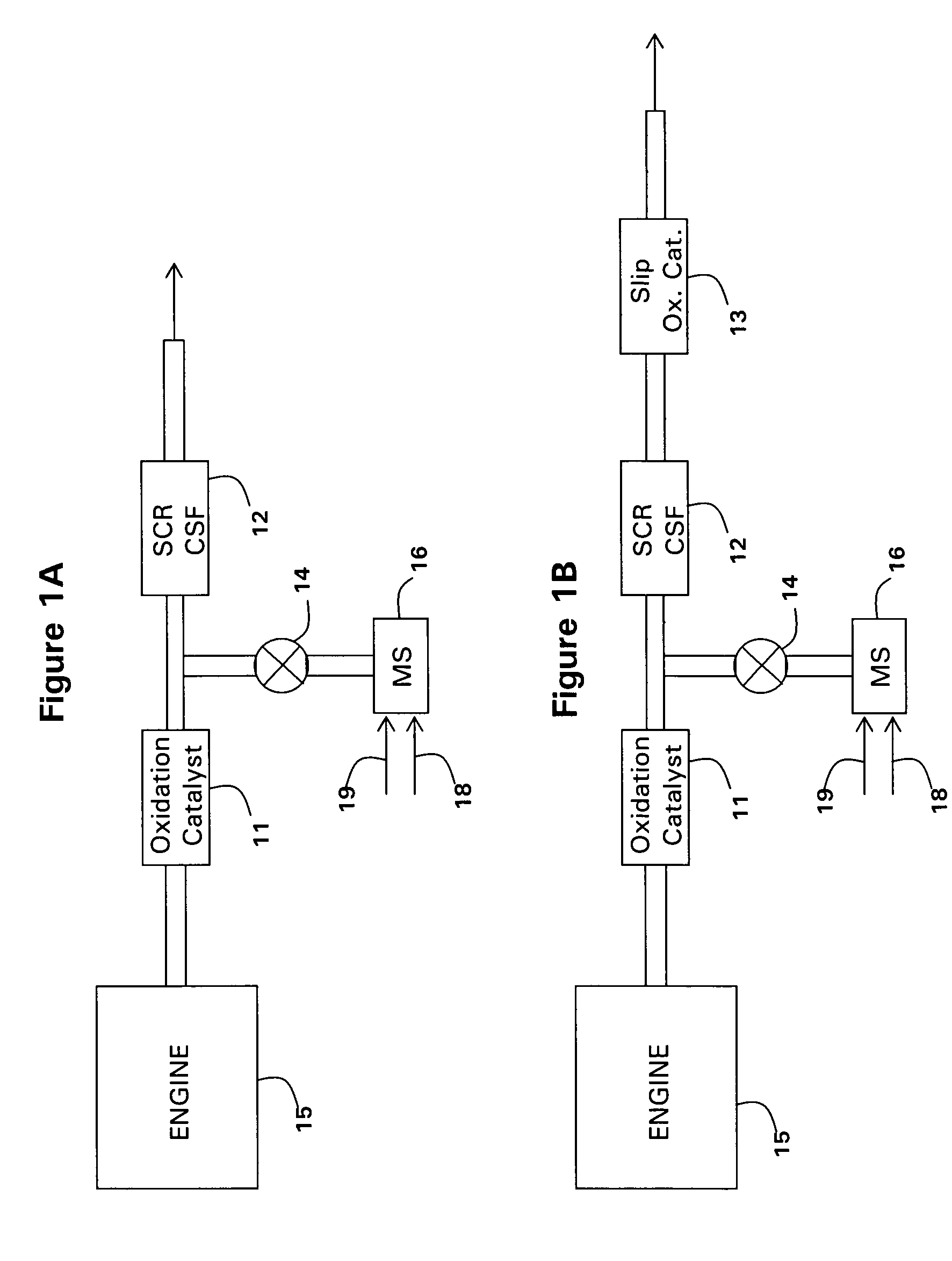

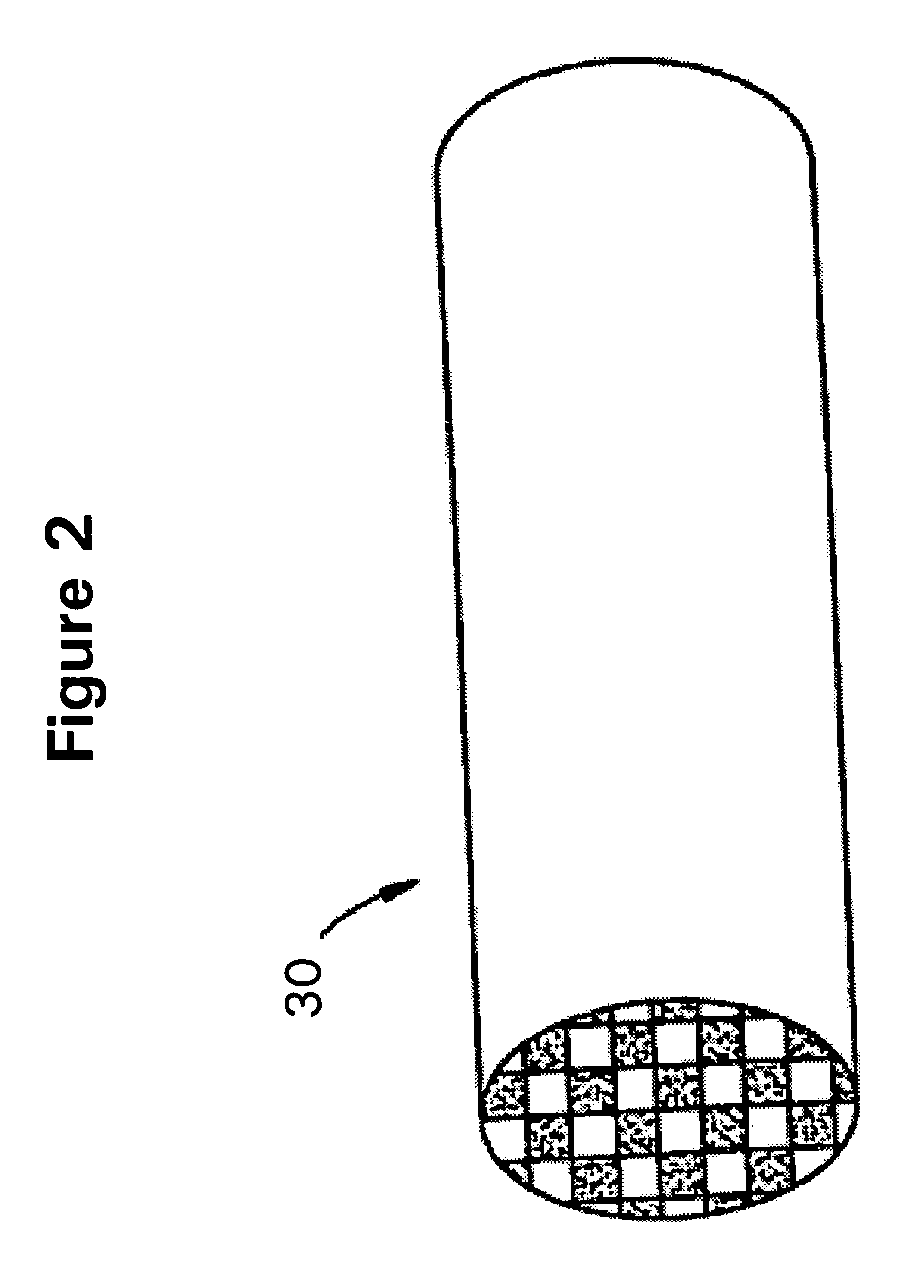

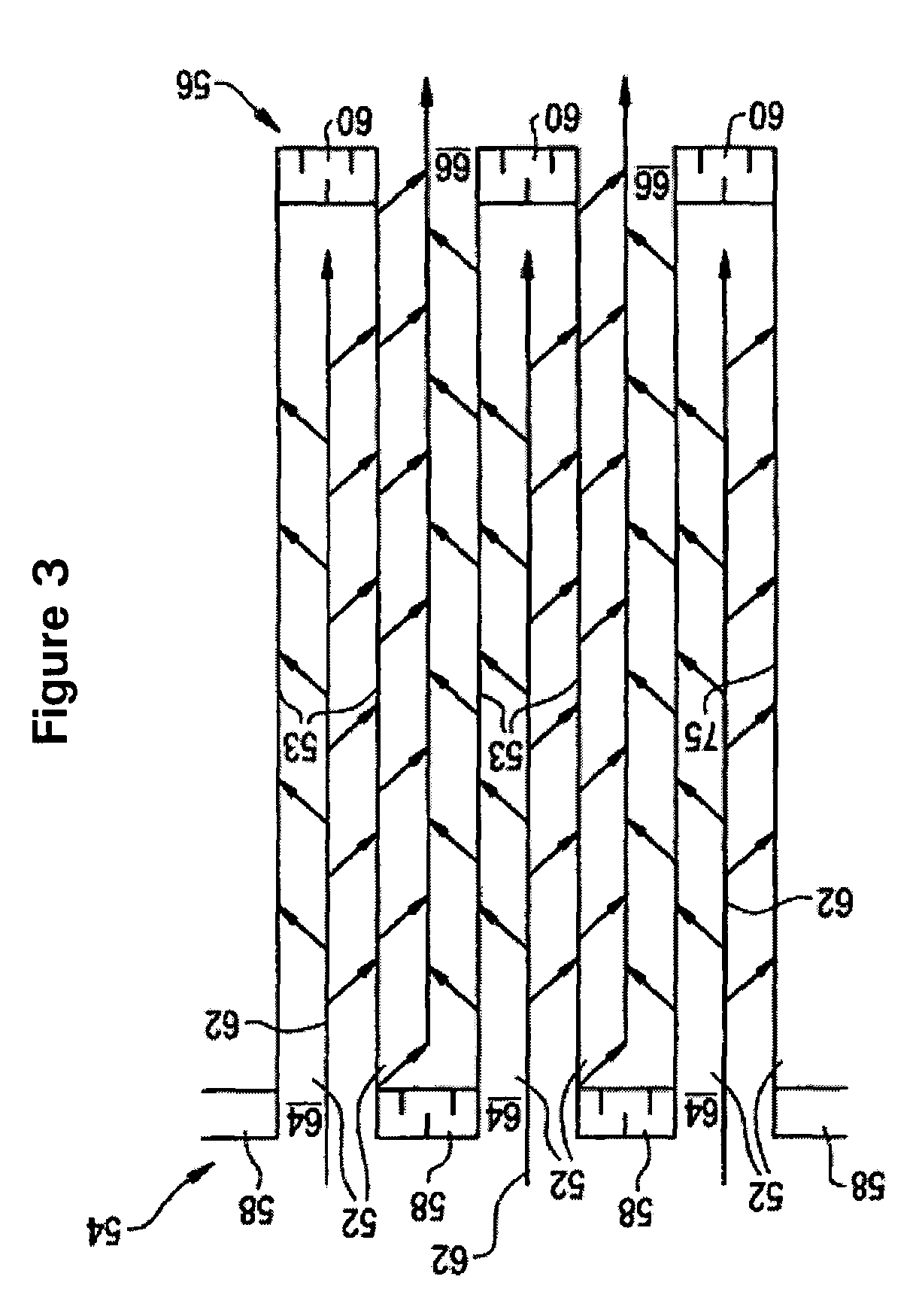

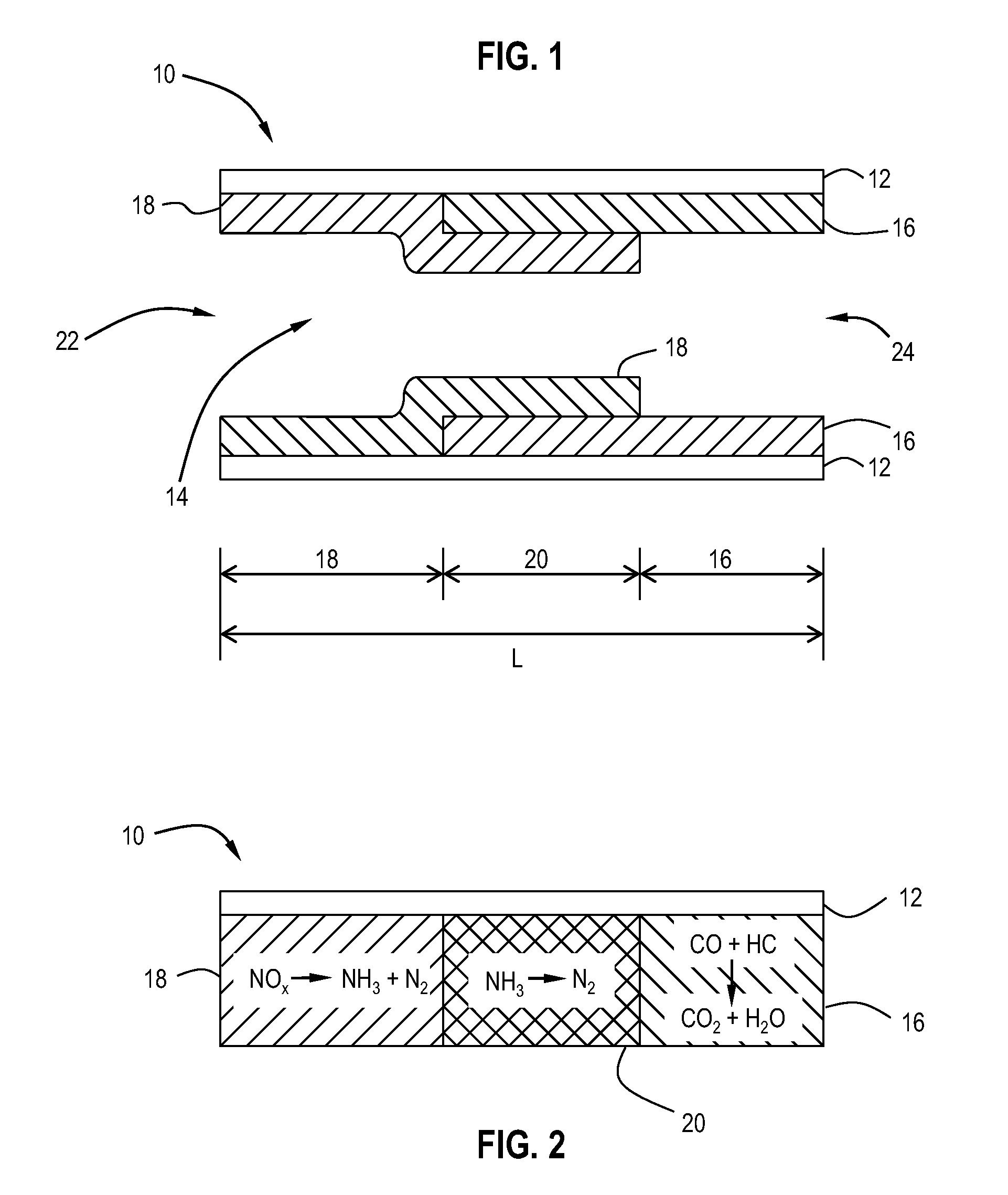

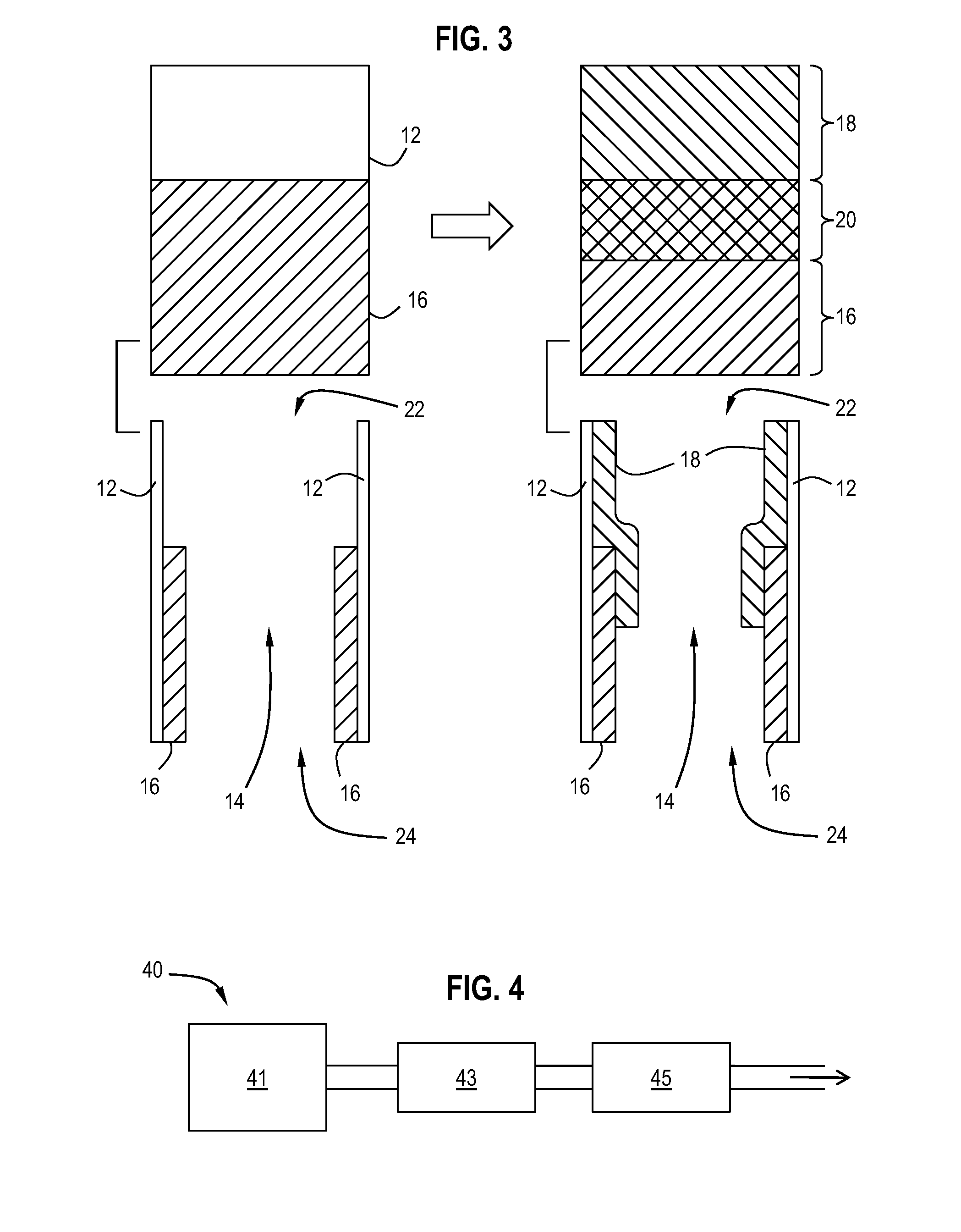

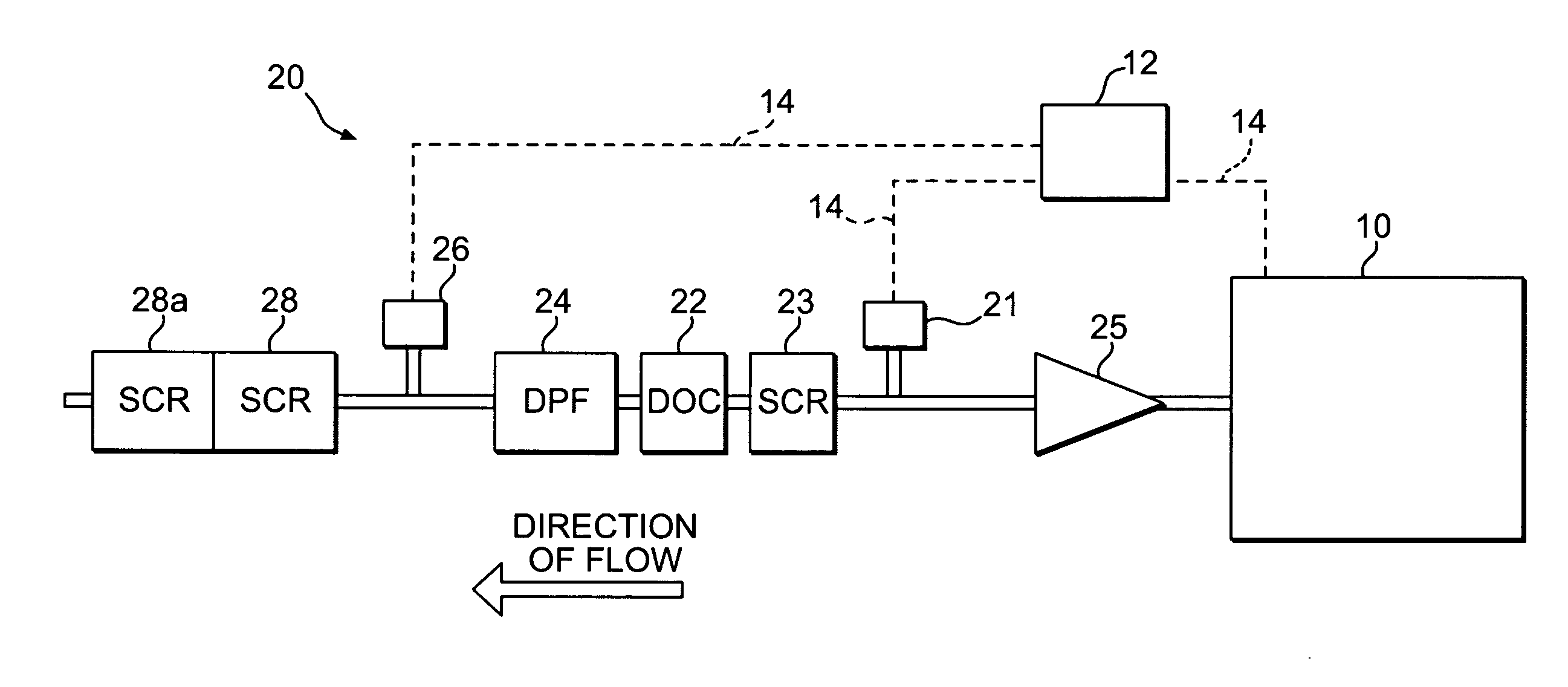

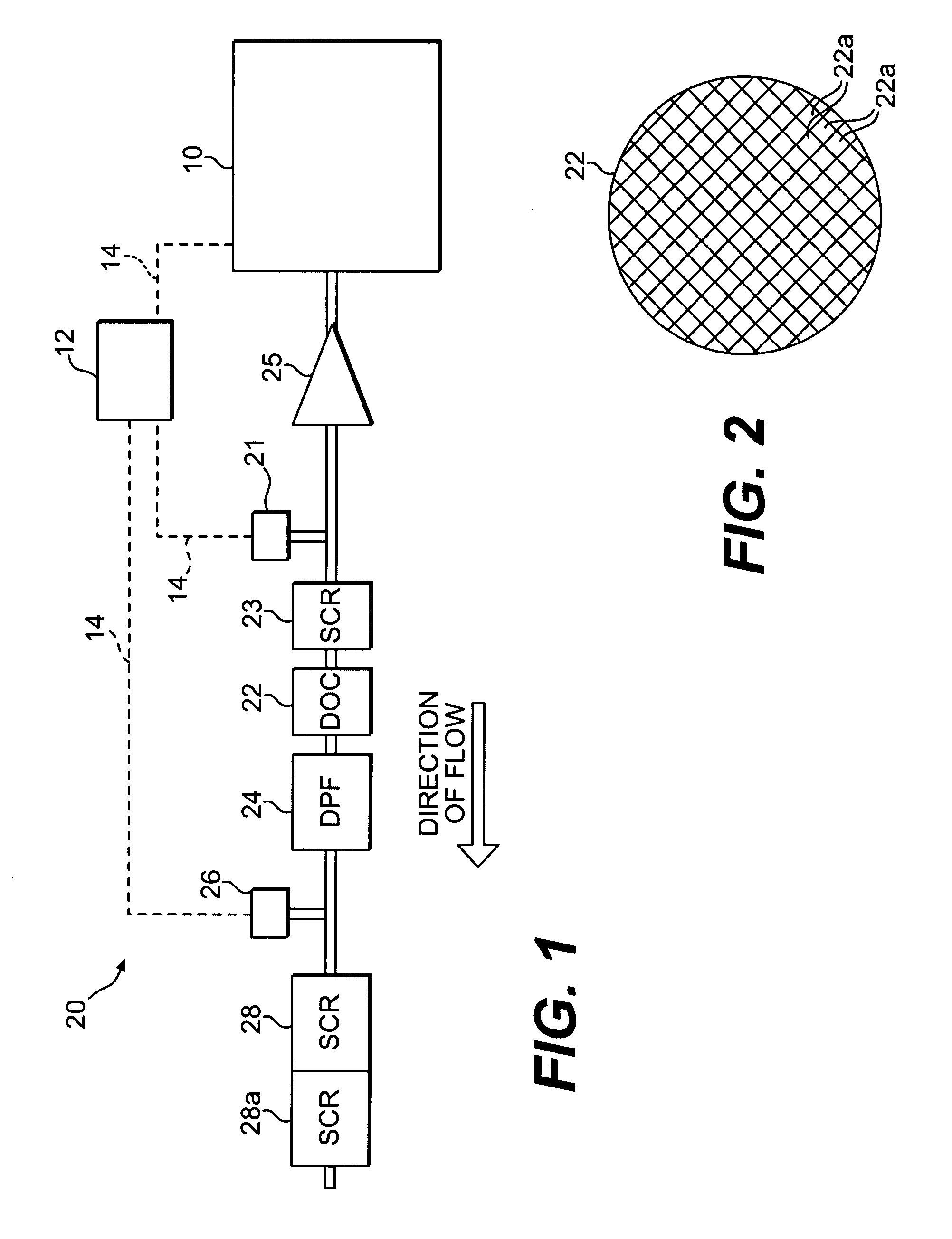

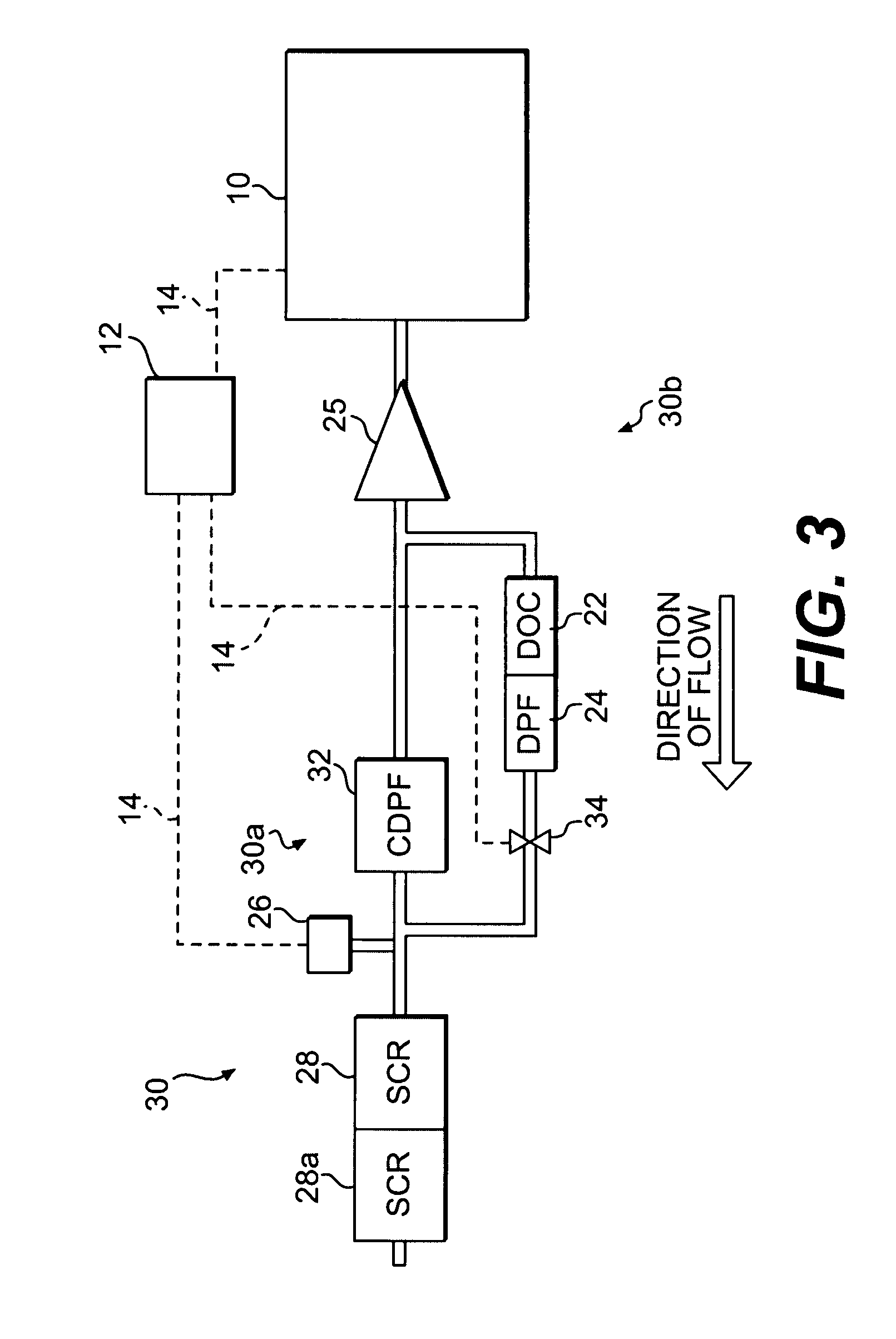

Provided is an emission treatment system and method for simultaneously remediating the nitrogen oxides (NOx), particulate matter, and gaseous hydrocarbons present in diesel engine exhaust streams. The emission treatment system has an oxidation catalyst upstream of a soot filter coated with a material effective in the Selective Catalytic Reduction (SCR) of NOx by a reductant, e.g., ammonia. Also provided is a method for disposing an SCR catalyst composition on a wall flow monolith that provides adequate catalyst loading, but does not result in unsuitable back pressures in the exhaust.

Owner:BASF CORP

Integrated SCR and AMOX Catalyst Systems

Catalysts and catalytic articles for treating exhaust gas streams are described. In one or more embodiments, a catalyst system includes a first zone to abate nitrogen oxides by selective catalytic reduction, a second zone to oxidize ammonia and a third zone to oxidize carbon monoxide and hydrocarbons. Methods for treating the exhaust gas stream are also provided. Methods of making and using such catalysts and catalytic articles are also described.

Owner:BASF CORP

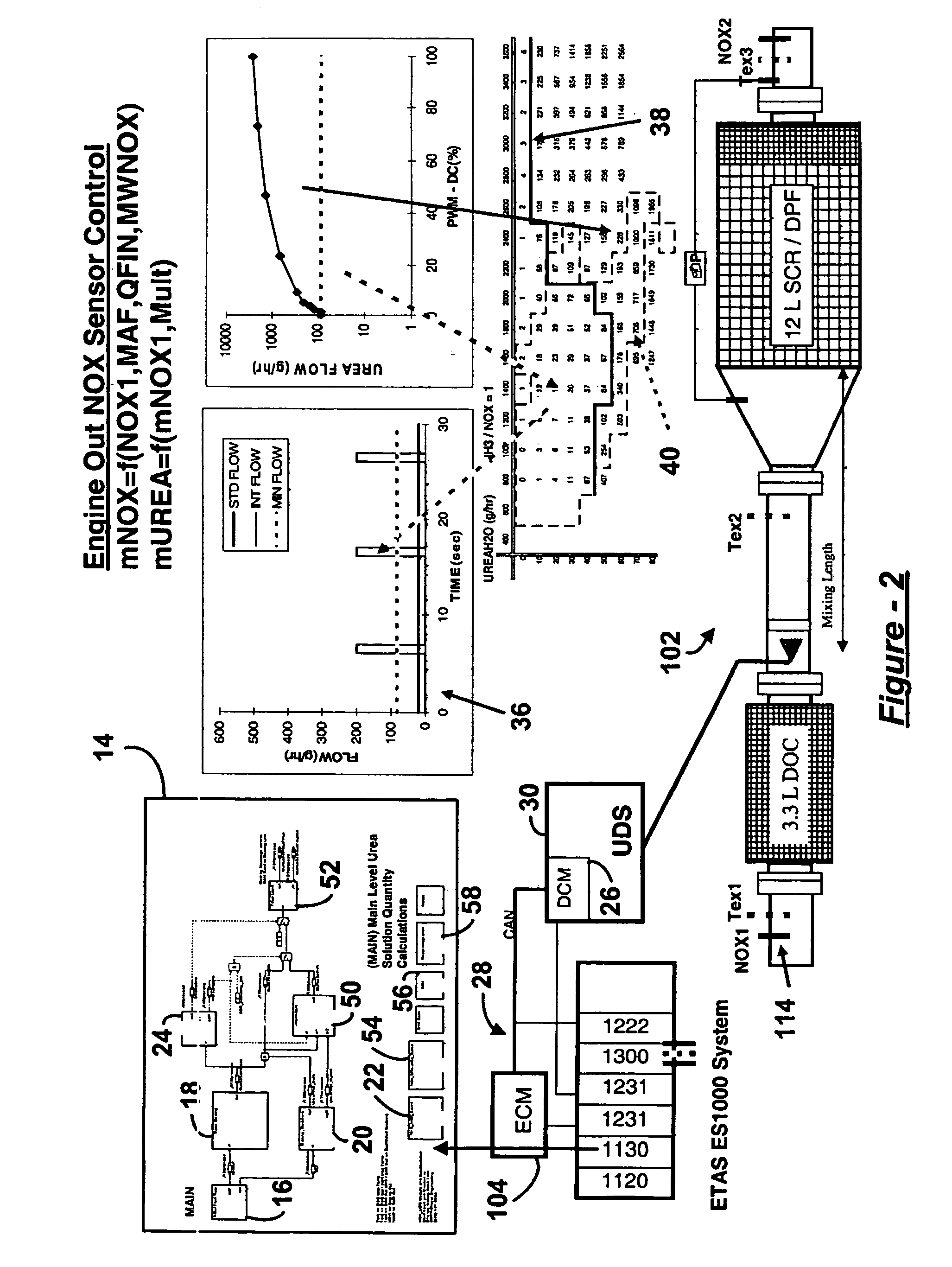

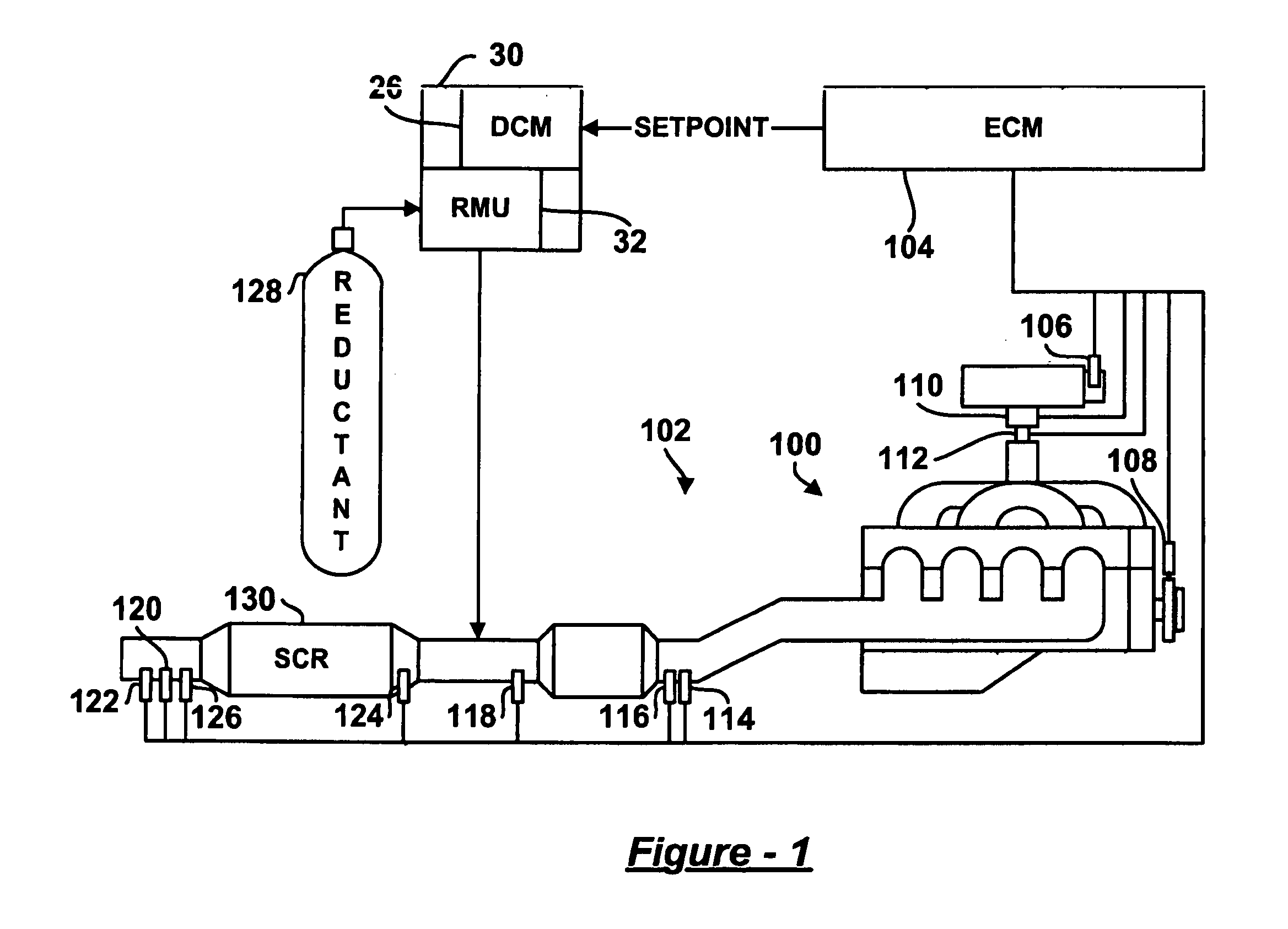

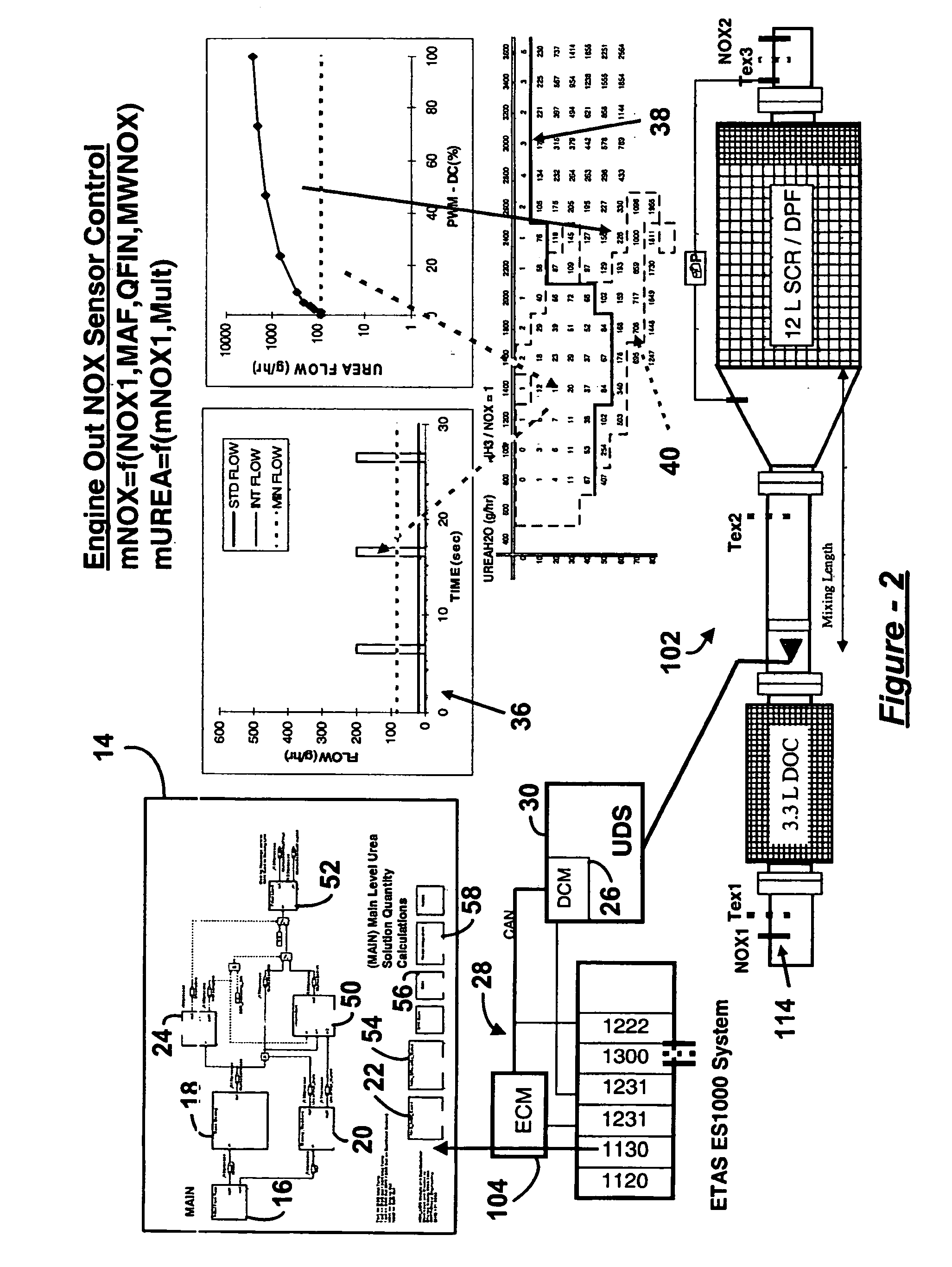

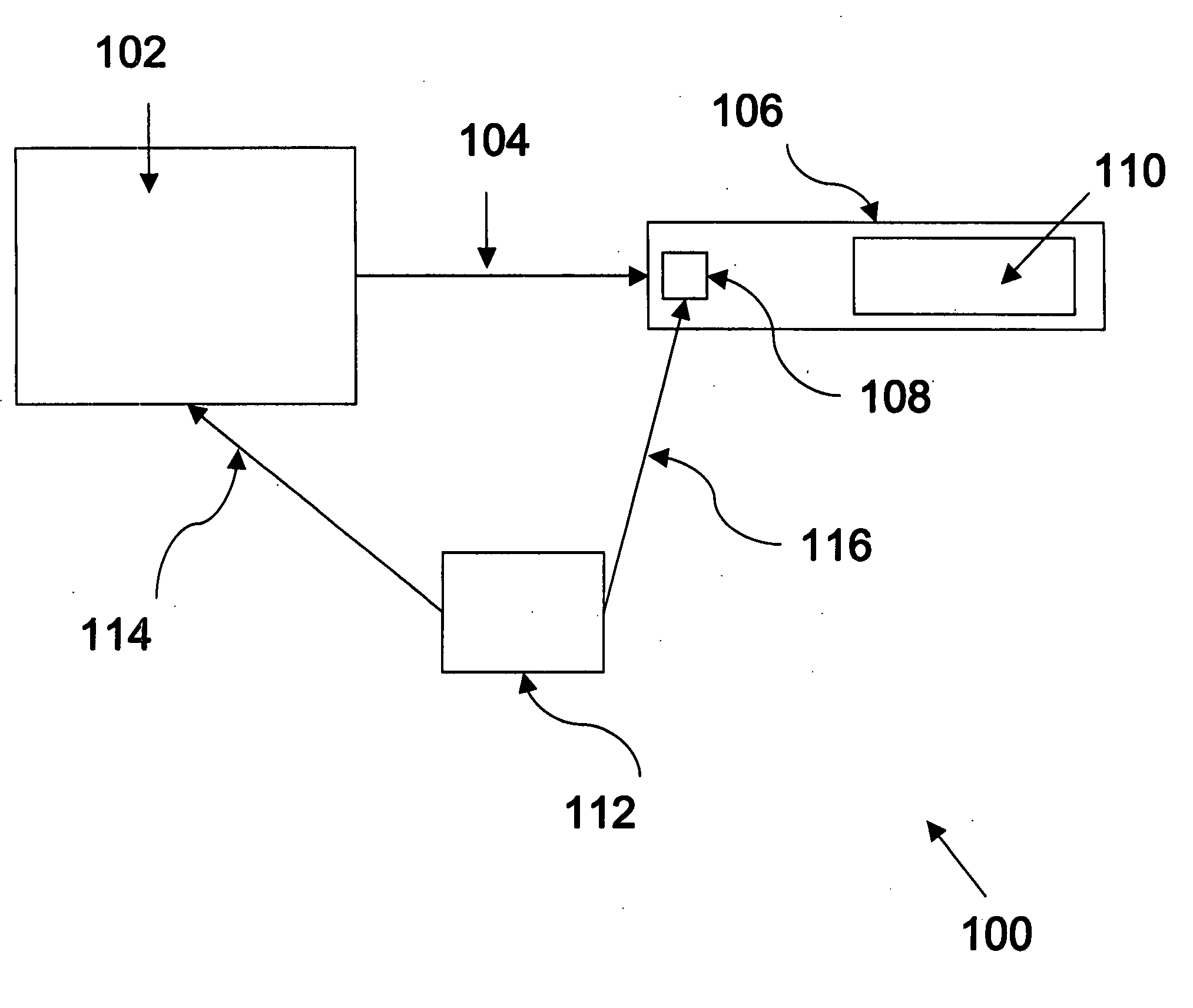

System for controlling the urea supply to SCR catalysts

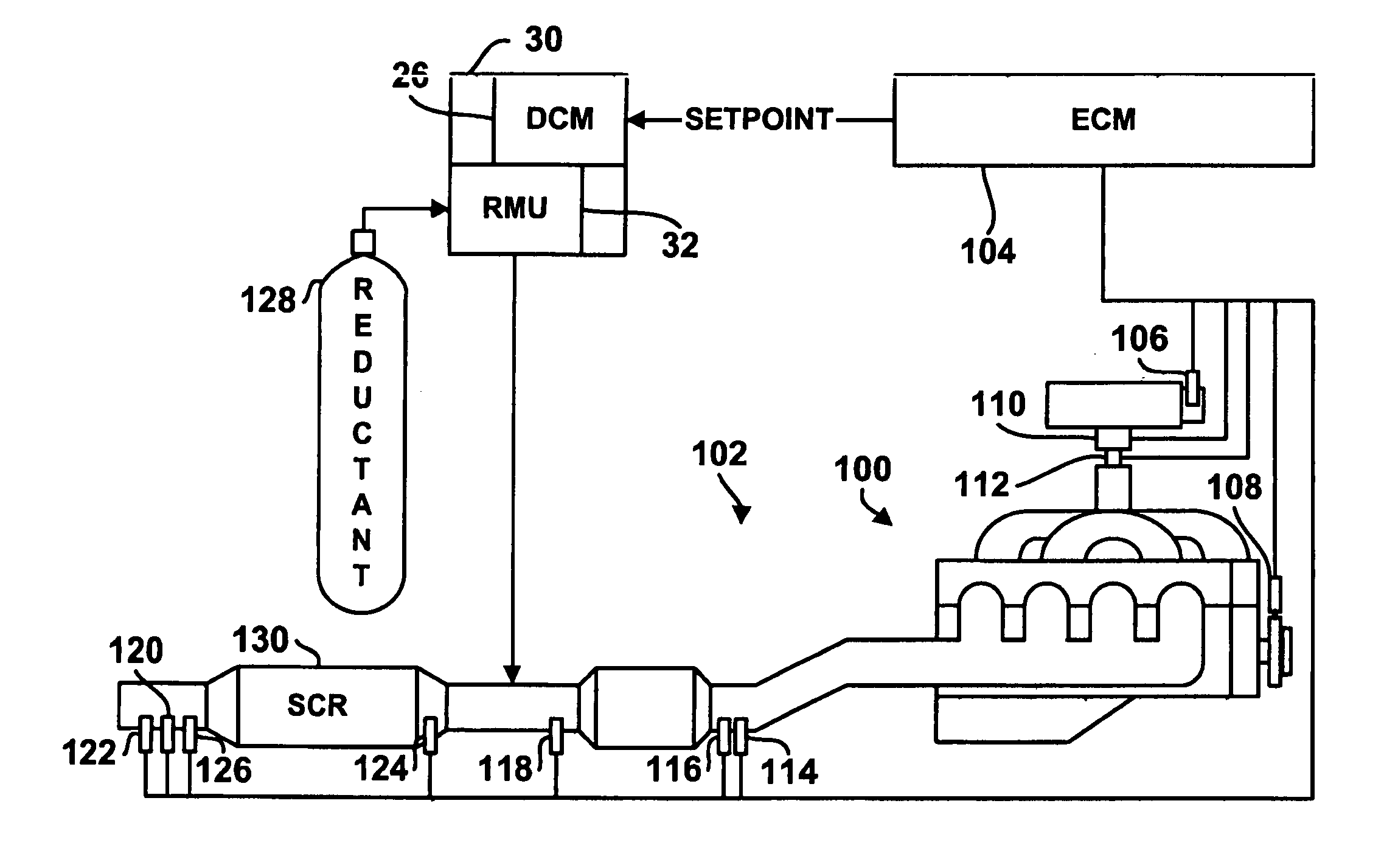

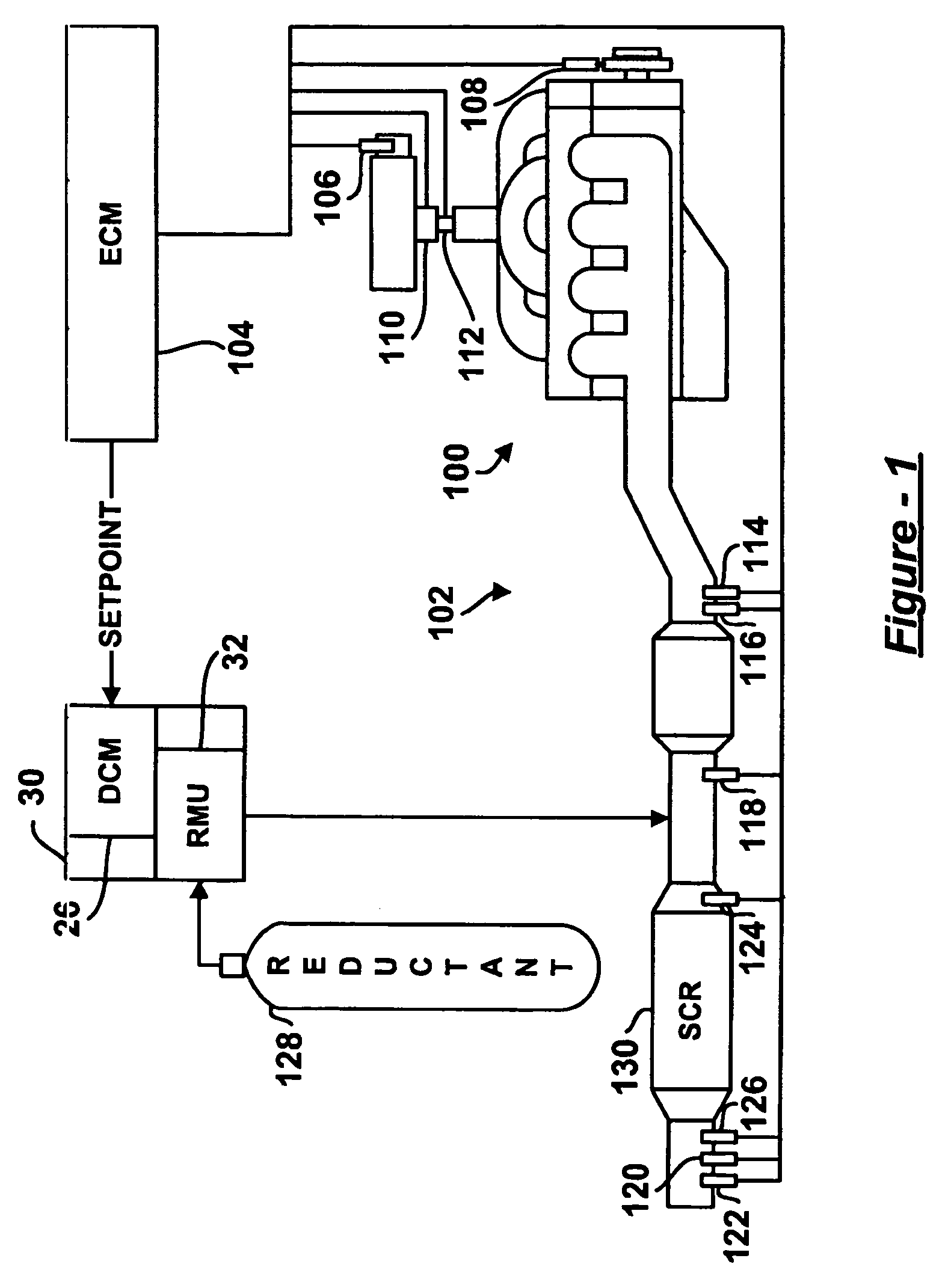

A reductant dosing control system, for use in a Selective Catalytic Reduction (SCR) system of a motor vehicle includes an input receiving a NOx feedback signal from an NOx sensor provided to the SCR system. A base dosing module calculates a required quantity of reductant to inject in front of a SCR catalyst of the SCR system based on the NOx feedback signal. The SCR catalyst has ammonia storage properties. An output signals a reductant metering mechanism to periodically or continuously inject excess reductant based on the required quantity of reductant.

Owner:GM GLOBAL TECH OPERATIONS LLC

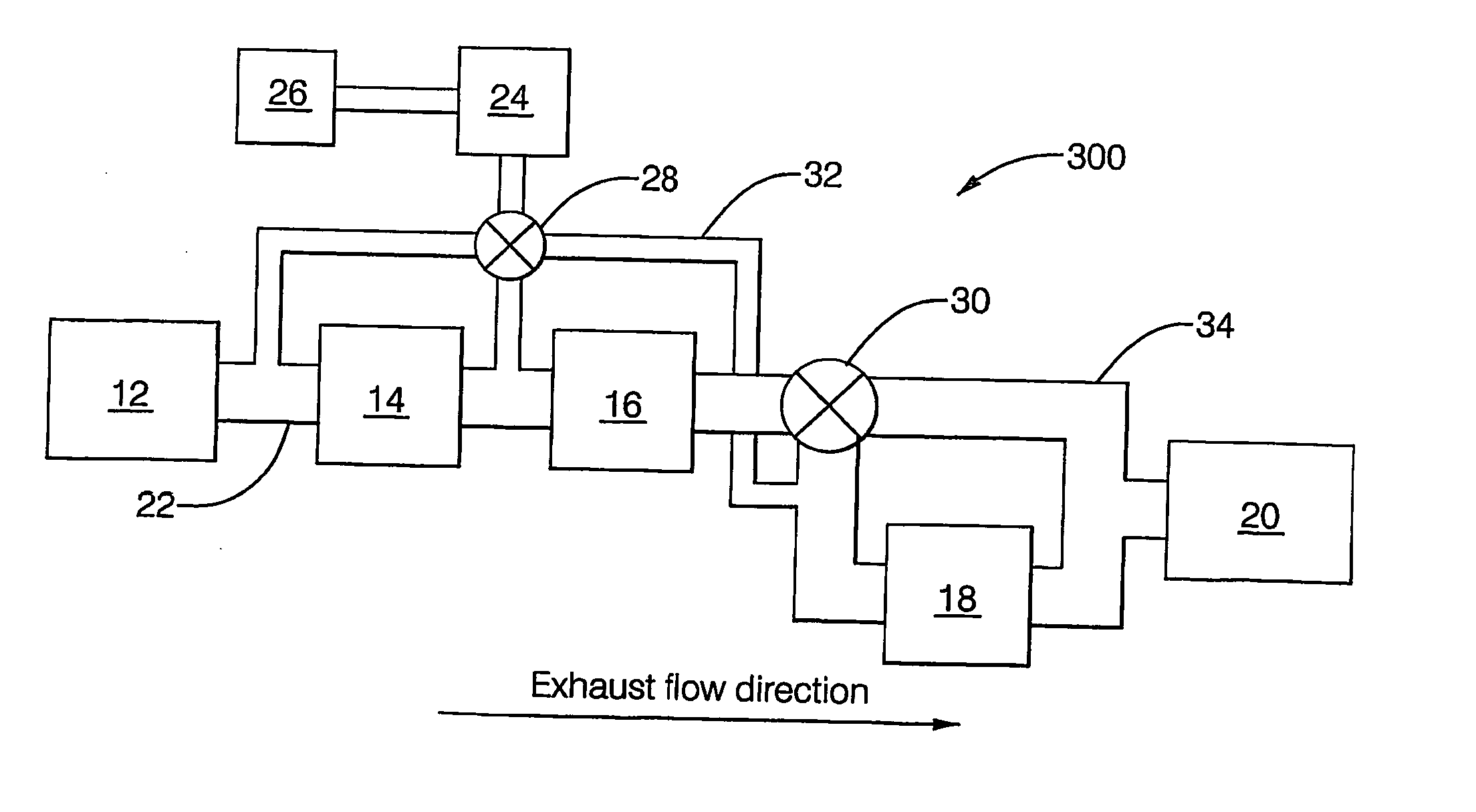

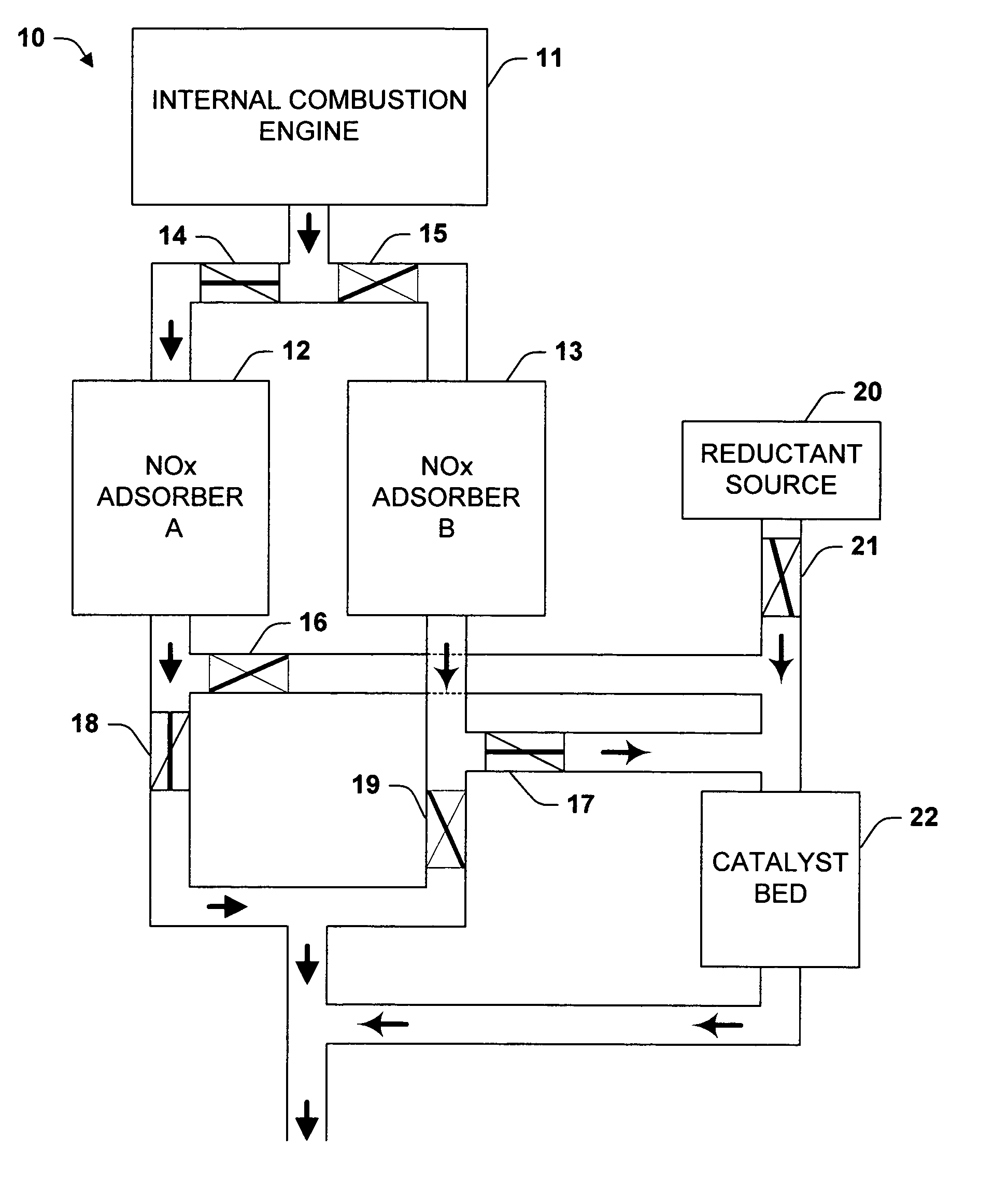

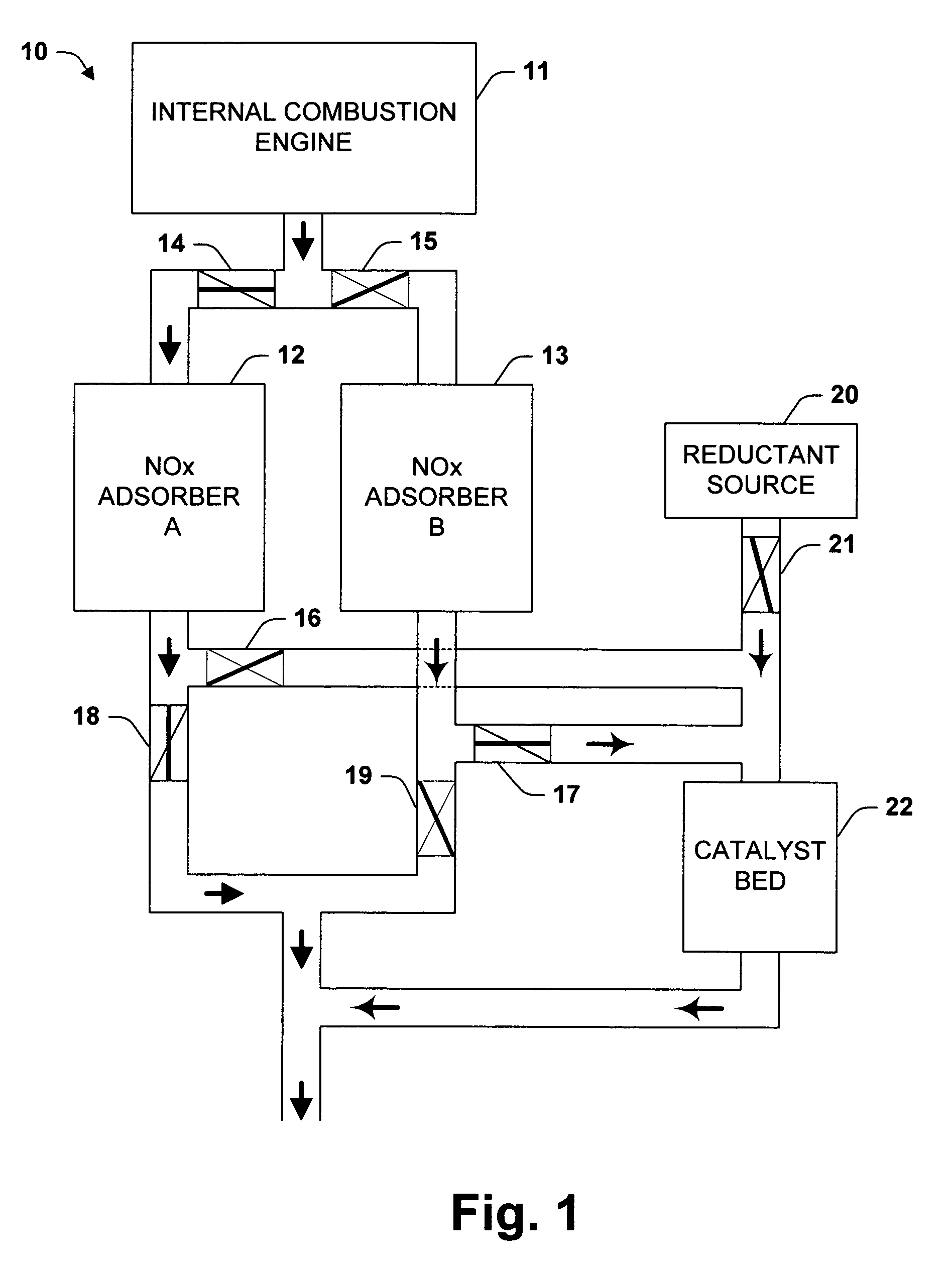

System and method of nox abatement

InactiveUS20060213187A1Internal combustion piston enginesExhaust apparatusHydrogenProcess engineering

A NOx abatement system comprising: a first NOx adsorber (18) capable of being disposed in-line and downstream of and in fluid communication with an engine (12); a selective catalytic reduction catalyst (20) disposed in-line and downstream of and in direct fluid communication with the first NOx adsorber (18), wherein the selective catalytic reduction catalyst (20) is capable of storing ammonia; and an off-line reformer (24) disposed in selective communication with and upstream of the first NOx adsorber (18) and the selective catalytic reduction catalyst (20), wherein the reformer (24) is capable of producing a reformate comprising primarily hydrogen and carbon monoxide.

Owner:DELPHI TECH INC

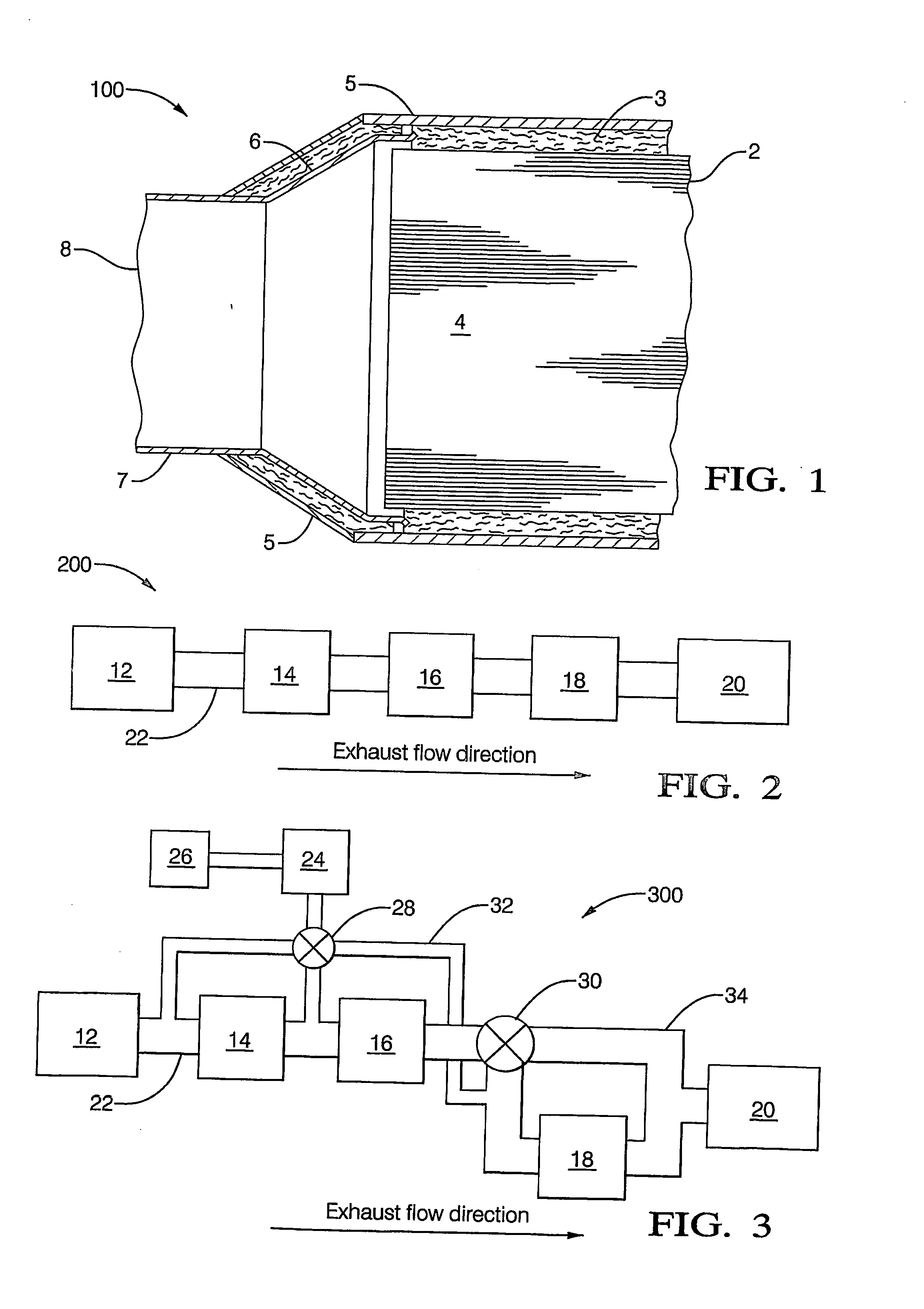

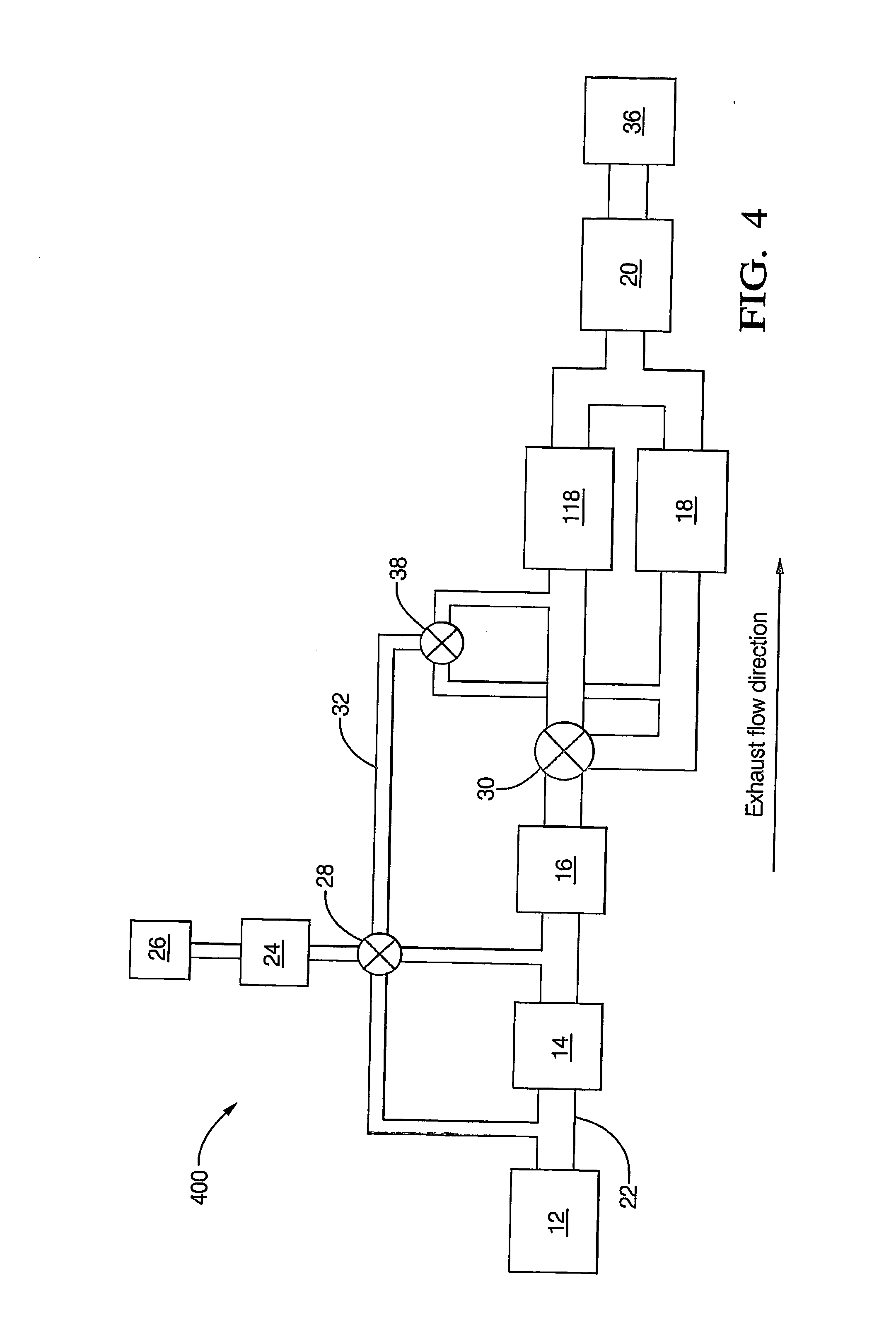

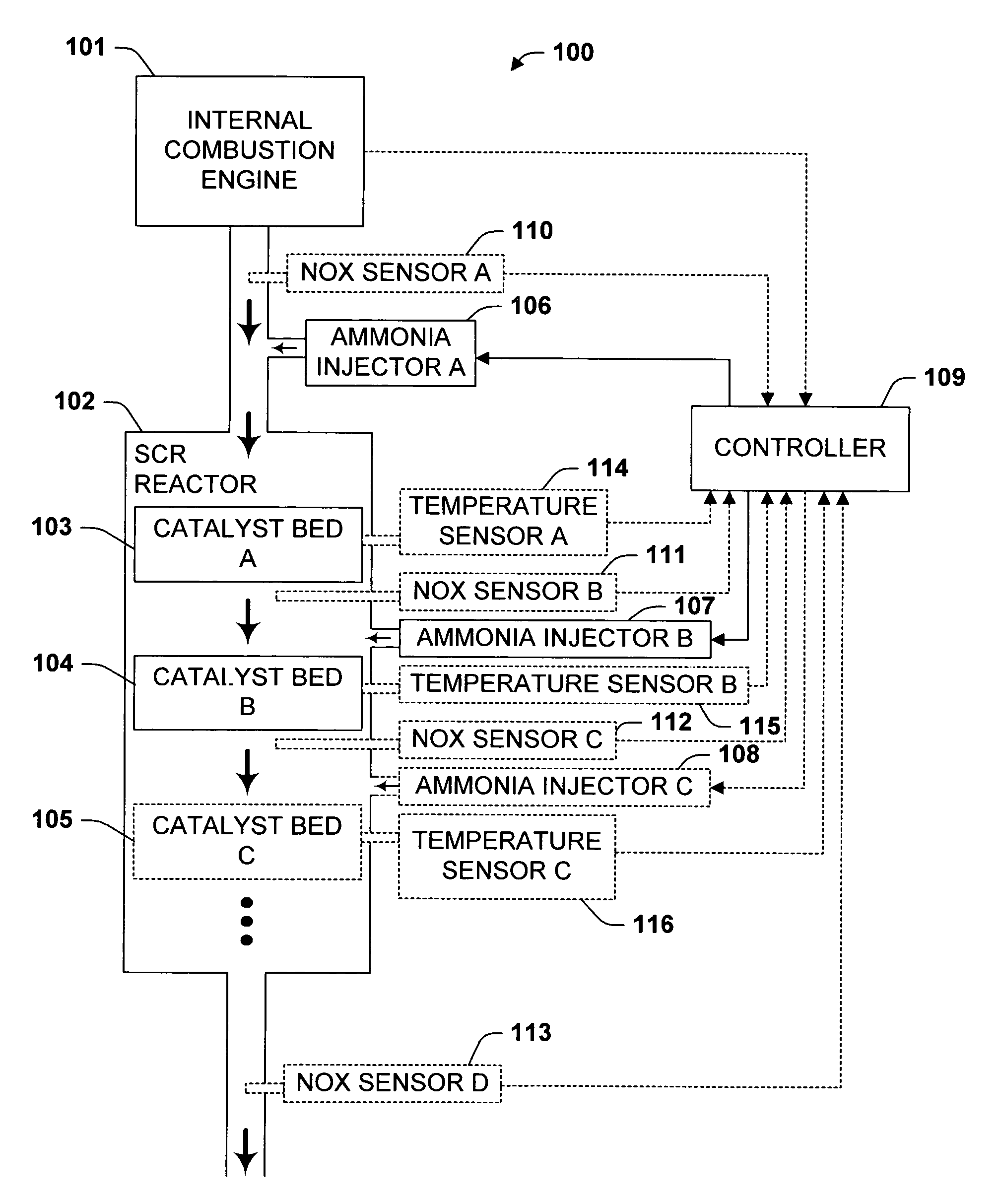

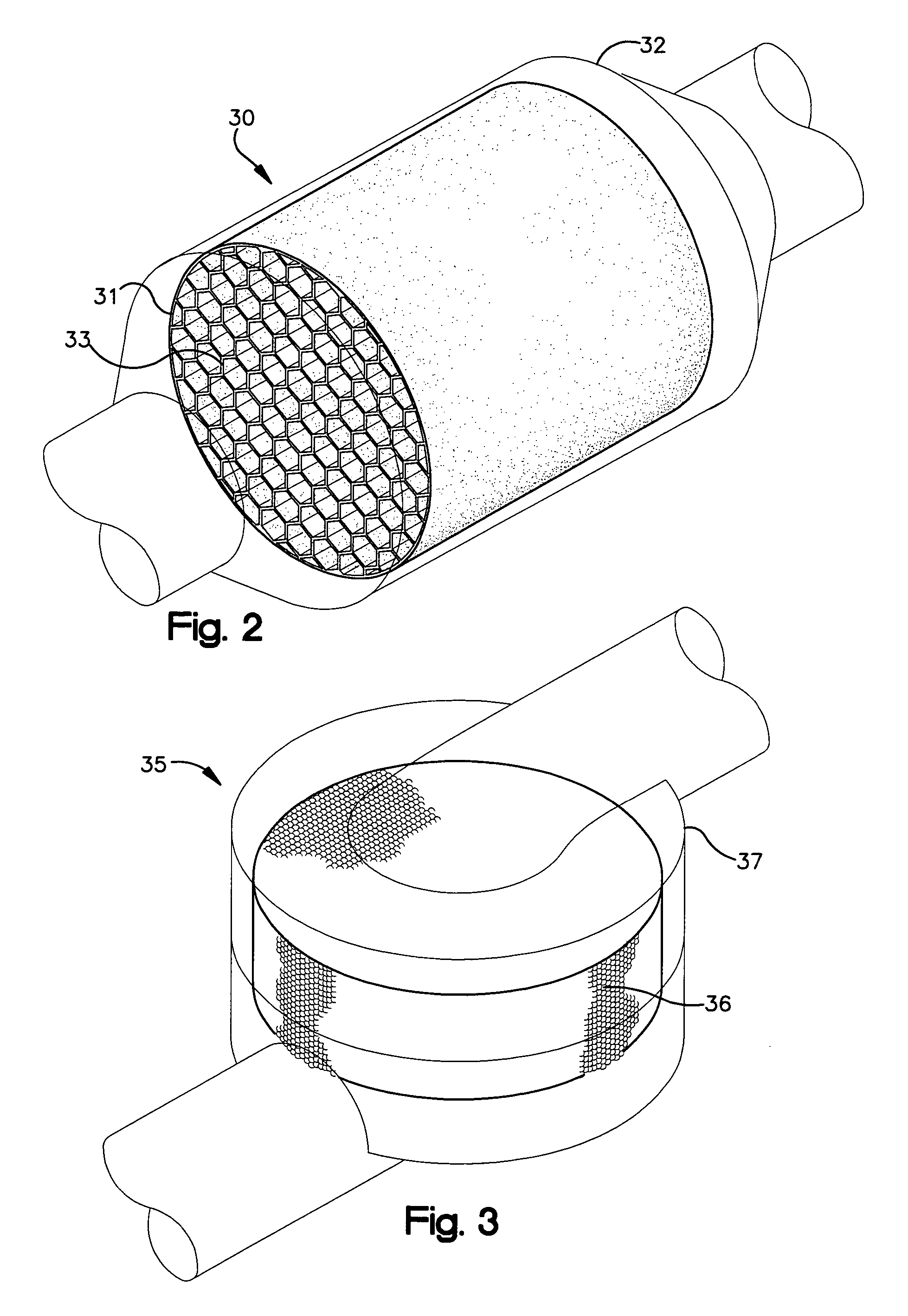

Multistage reductant injection strategy for slipless, high efficiency selective catalytic reduction

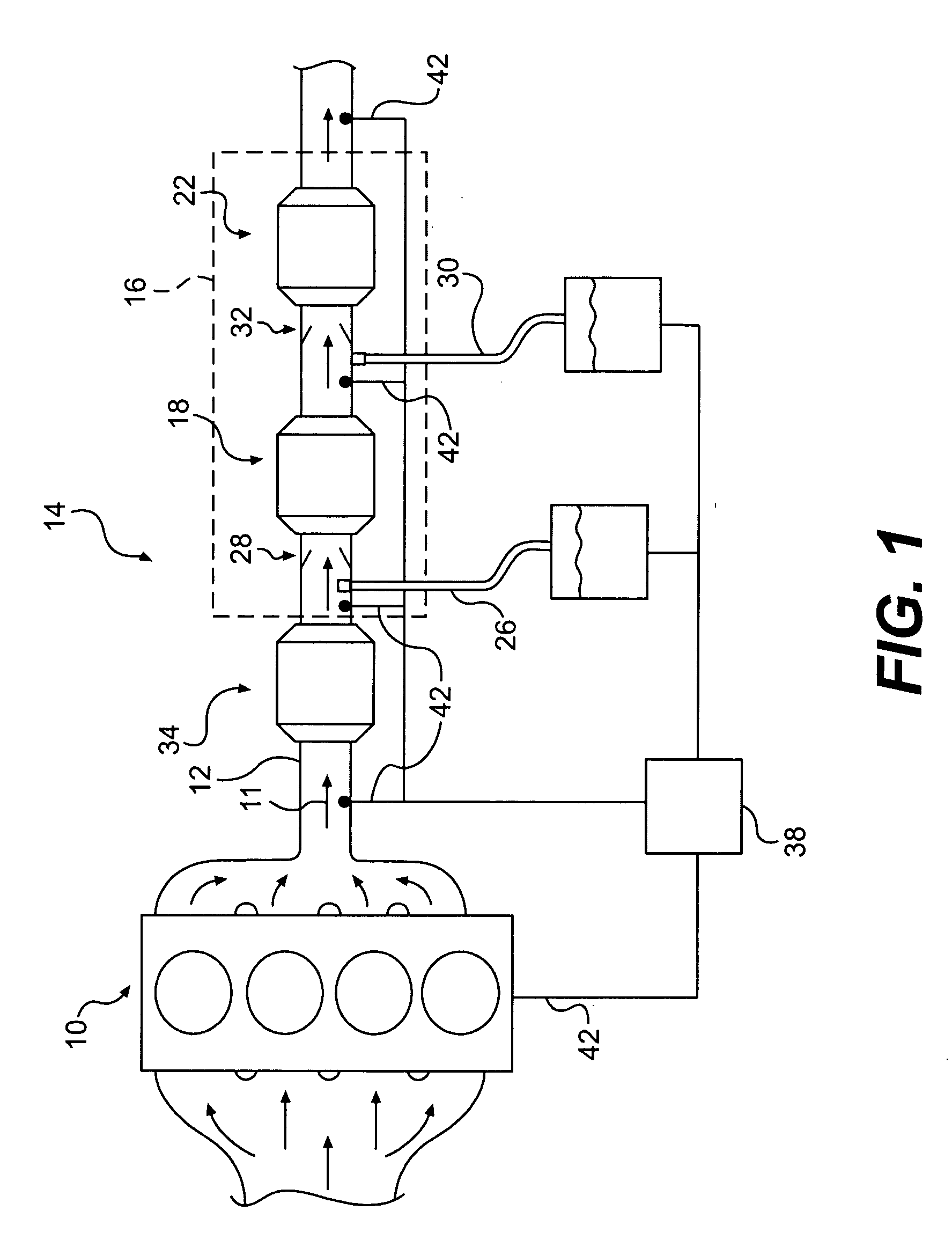

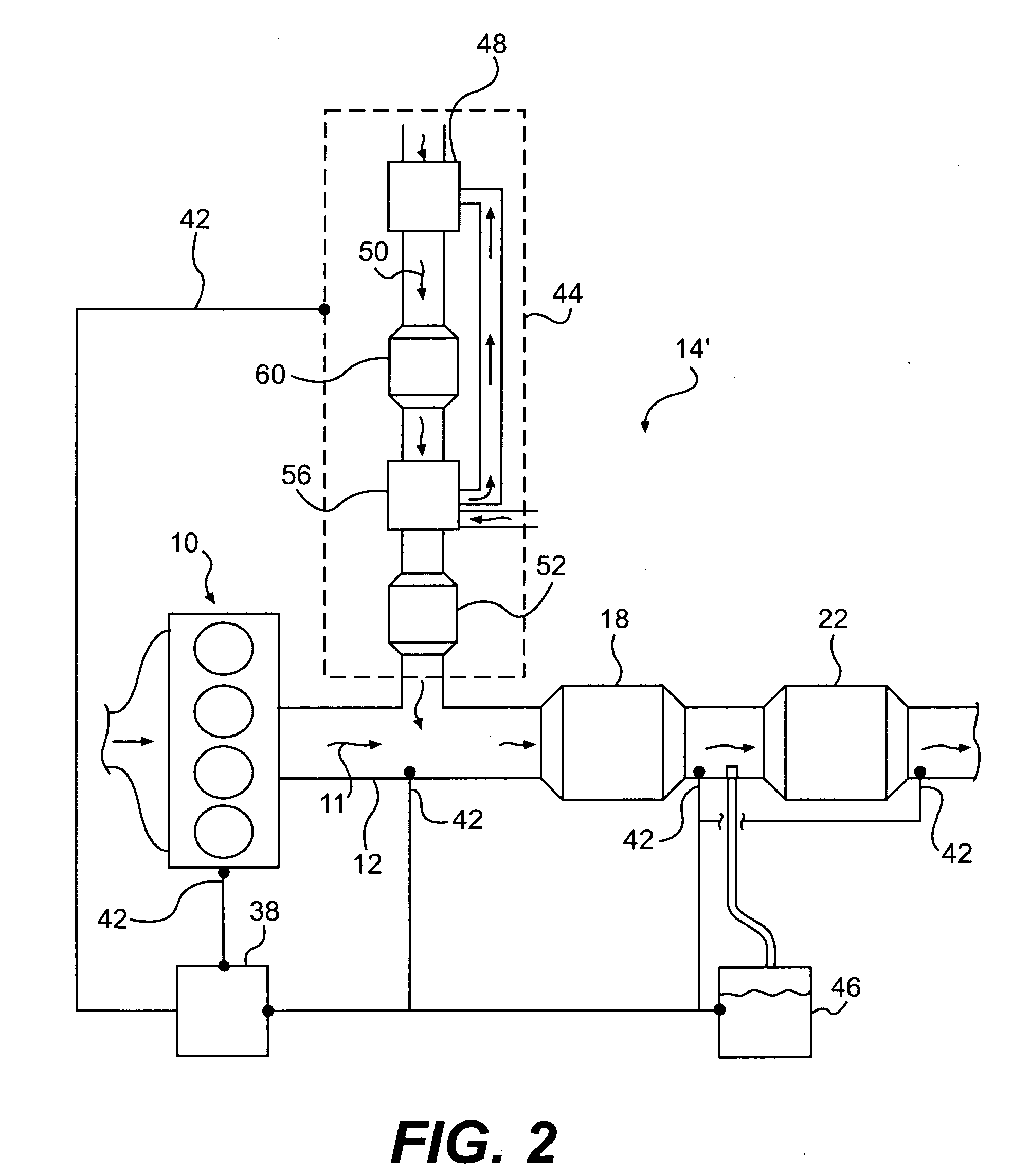

InactiveUS6996975B2Reduce riskReduce controlInternal combustion piston enginesExhaust apparatusInjection portAmmonia

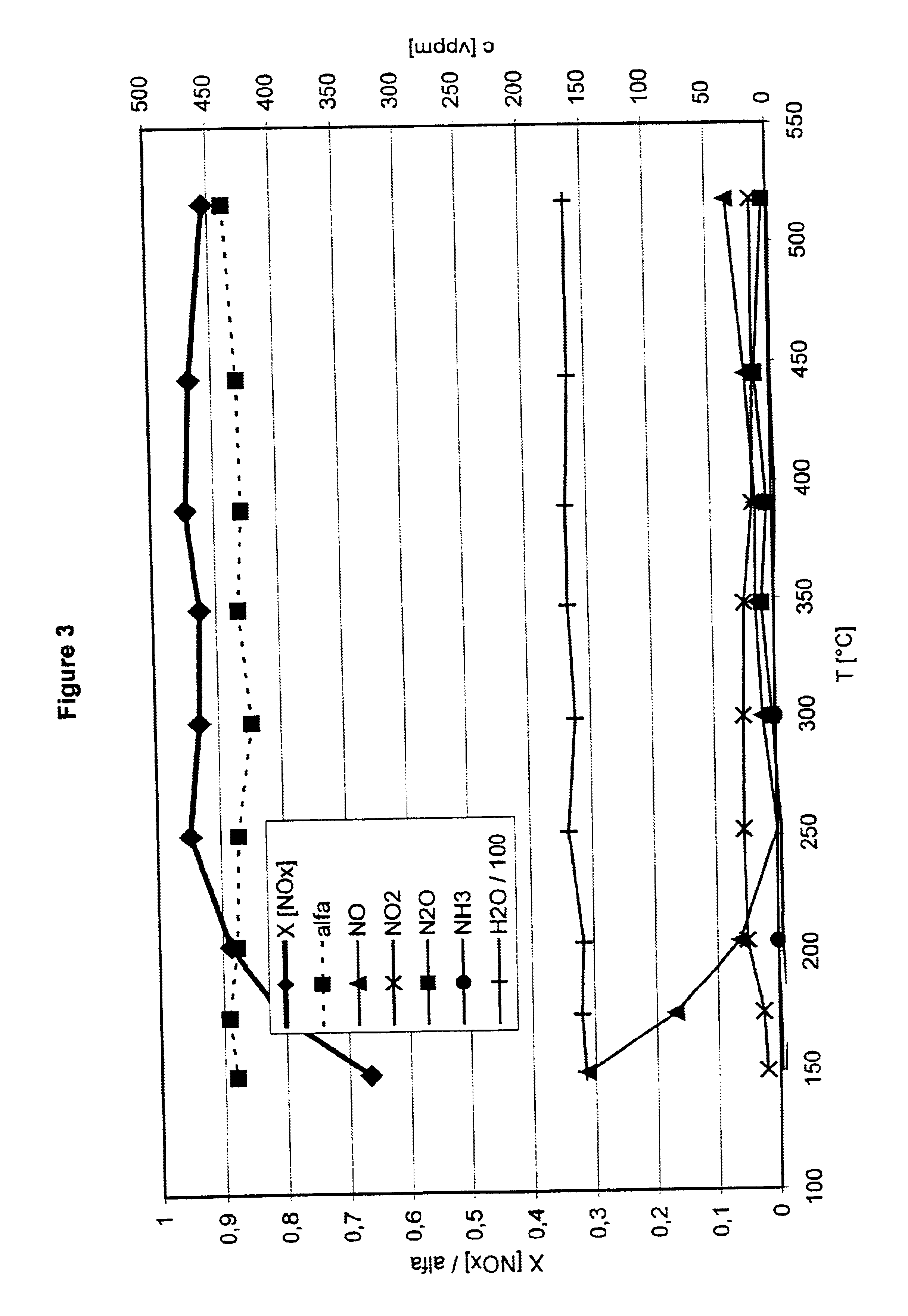

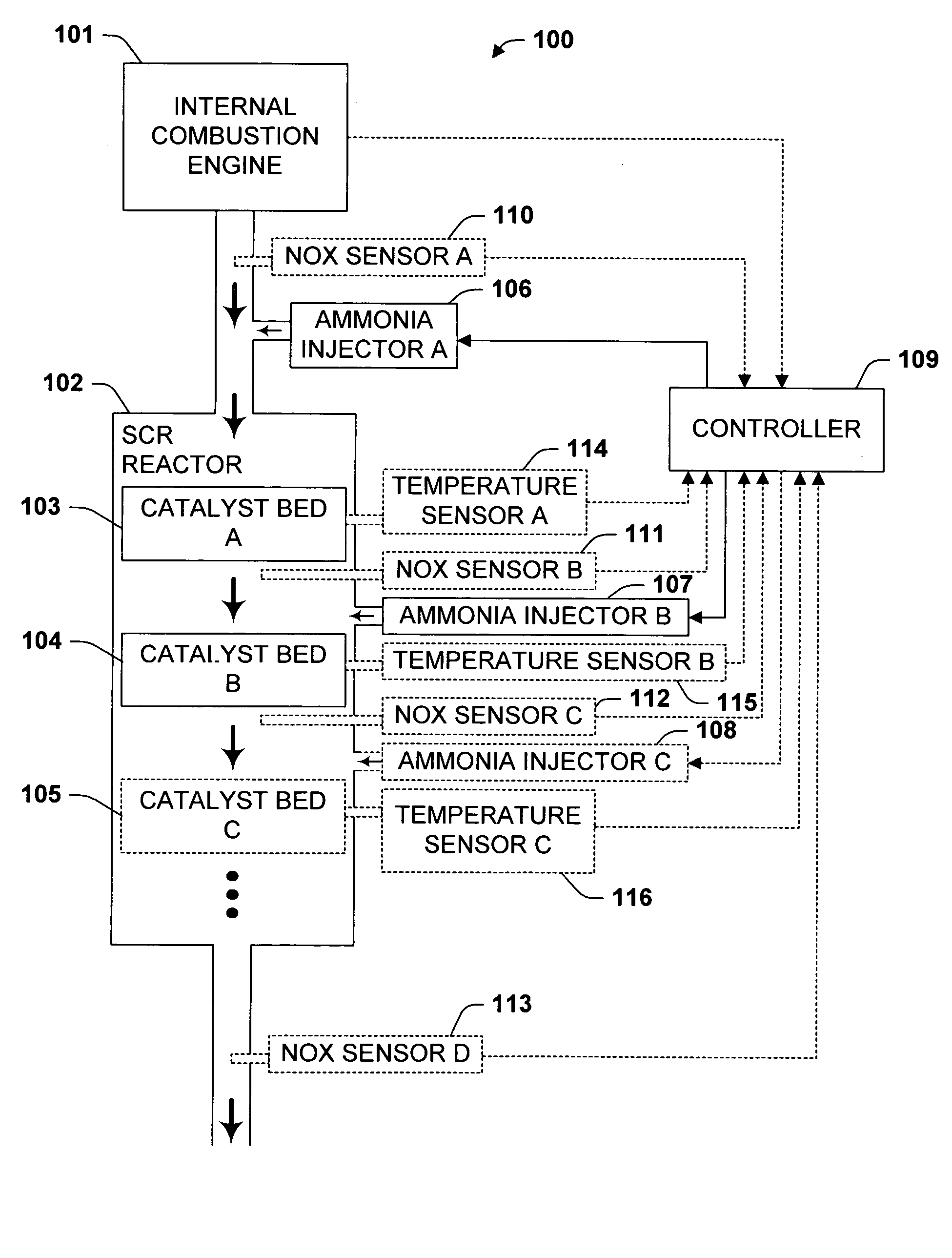

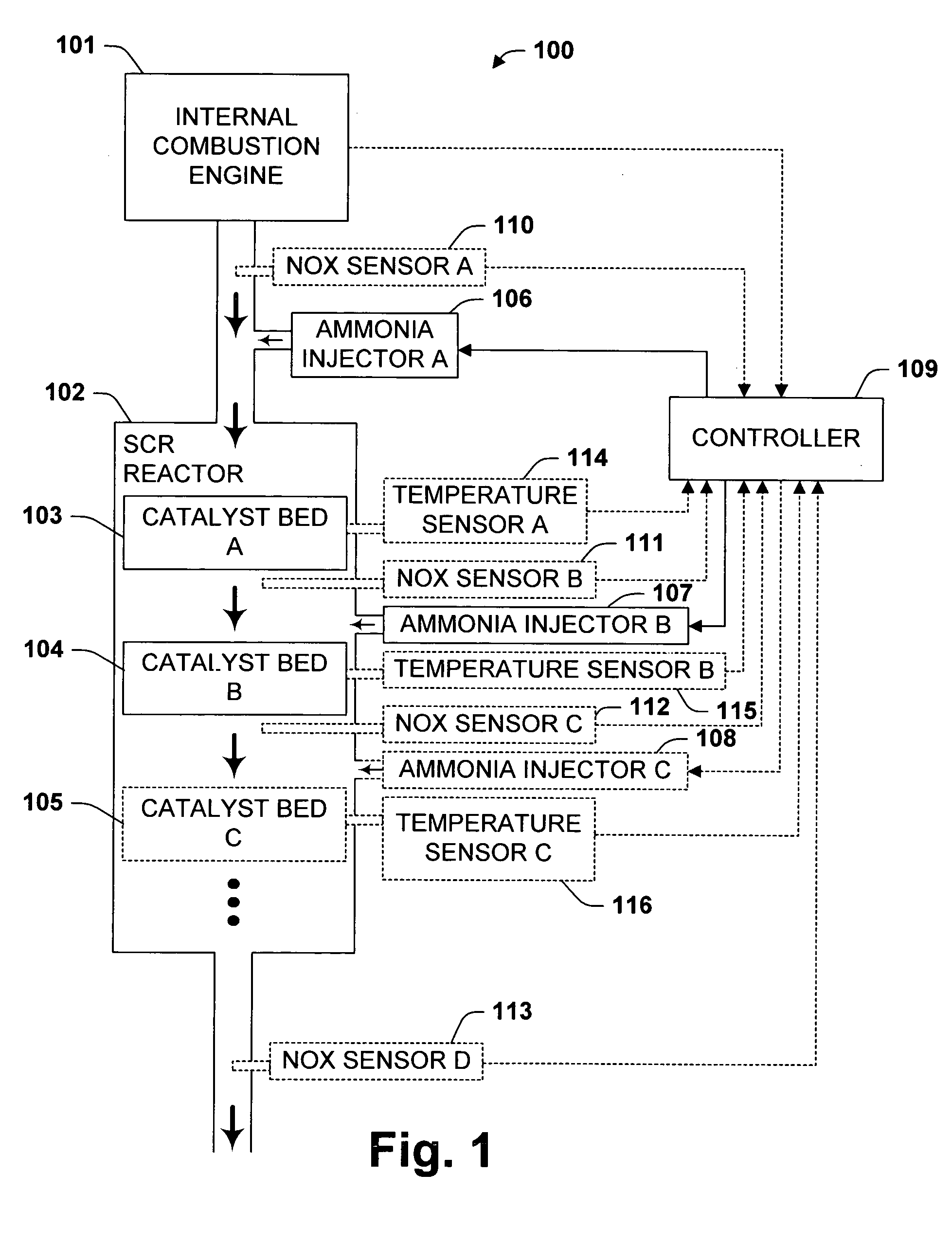

One aspect of the invention relates to an exhaust treatment apparatus having an NOx reduction system comprising first and second catalyst beds in series with associated first and second ammonia injectors. The first catalyst bed with its associated ammonia injector preferably targets removing only about 80 to about 95% percent of the NOx in the vehicle exhaust. The second catalyst bed with its associated injector preferably target removing about 70 to about 100% of the remaining NOx. Staging the reduction system in this manner improves control over NOx reduction and reduces the risk of ammonia slip. Other aspects of the invention relate to methods of treating vehicle exhaust to remove NOx and an SCR reactor comprising a housing having an entrance port, an exit port, and an ammonia injection port, wherein the injection port is configured to inject ammonia in between SCR catalyst beds contained in the housing.

Owner:EATON CORP

Exhaust treatment system with an oxidation device for NO2 control

InactiveUS20090035194A1Combination devicesInternal combustion piston enginesExhaust fumesEnvironmental engineering

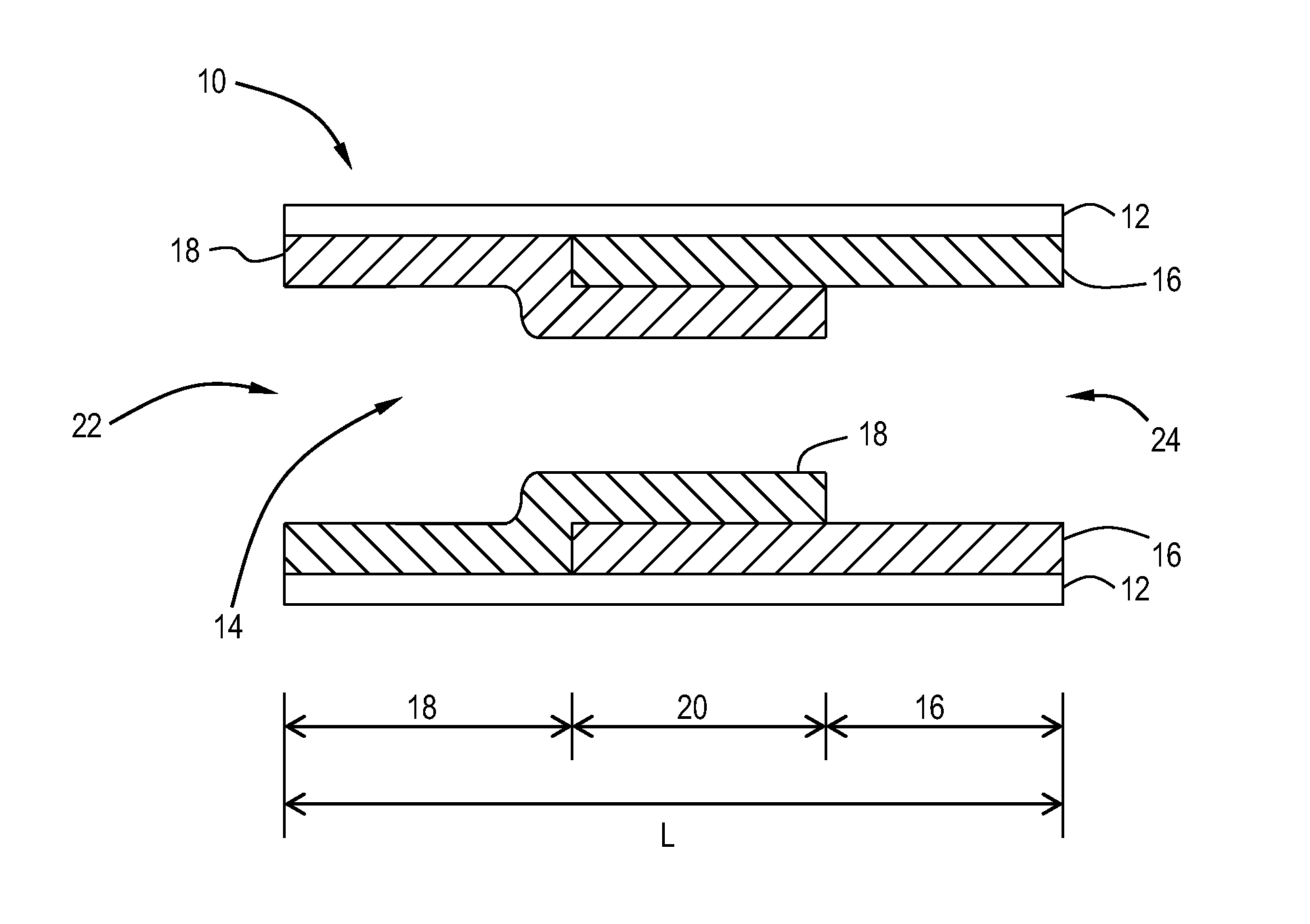

An exhaust treatment system includes an oxidation device having a plurality of channels through which a flow of exhaust flows. A first portion of the channels of the oxidation device are coated with catalytic material for converting NO to NO2 and a second portion of the channels are uncoated with the catalytic material. The exhaust treatment system also includes a selective catalytic reduction device disposed downstream from the oxidation device. The selective catalytic reduction device is configured to receive the flow of exhaust passing through the oxidation device.

Owner:CATERPILLAR INC

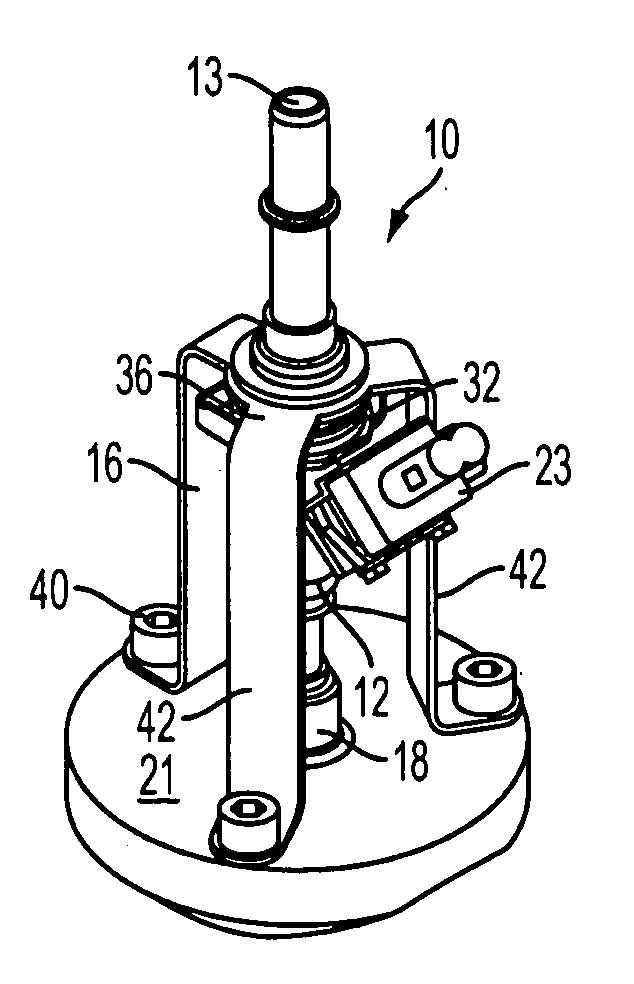

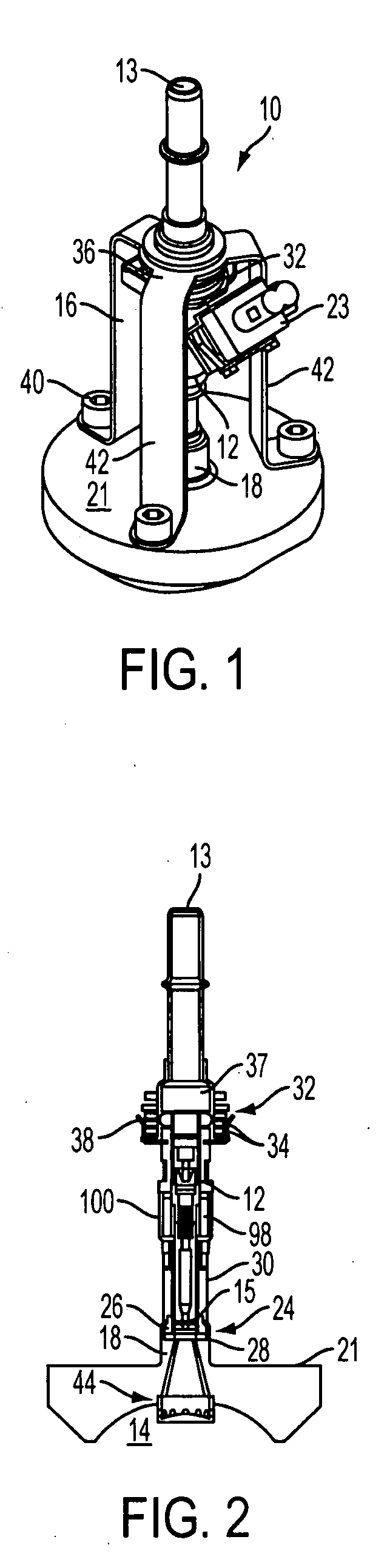

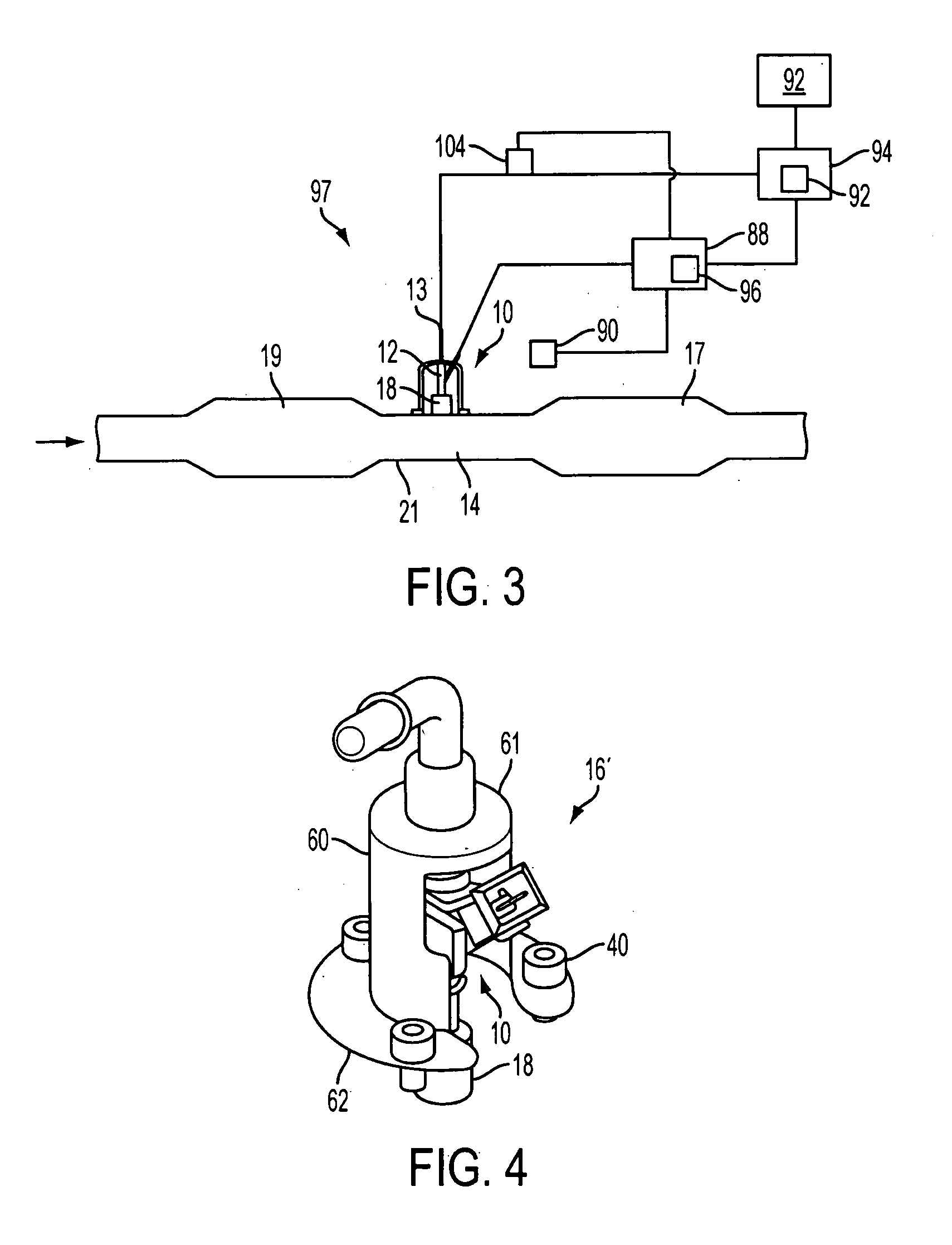

Reductant delivery unit for selective catalytic reduction

ActiveUS20080236147A1Avoid boilingInternal combustion piston enginesExhaust apparatusAfter treatmentExhaust fumes

Owner:CONTINENTAL AUTOMOTIVE SYST INC

System for controlling the urea supply to SCR catalysts

ActiveUS20060130458A1Internal combustion piston enginesExhaust apparatusControl systemAmmonia storage

A reductant dosing control system, for use in a Selective Catalytic Reduction (SCR) system of a motor vehicle includes an input receiving a NOx feedback signal from an NOx sensor provided to the SCR system. A base dosing module calculates a required quantity of reductant to inject in front of a SCR catalyst of the SCR system based on the NOx feedback signal. The SCR catalyst has ammonia storage properties. An output signals a reductant metering mechanism to periodically or continuously inject excess reductant based on the required quantity of reductant.

Owner:GM GLOBAL TECH OPERATIONS LLC

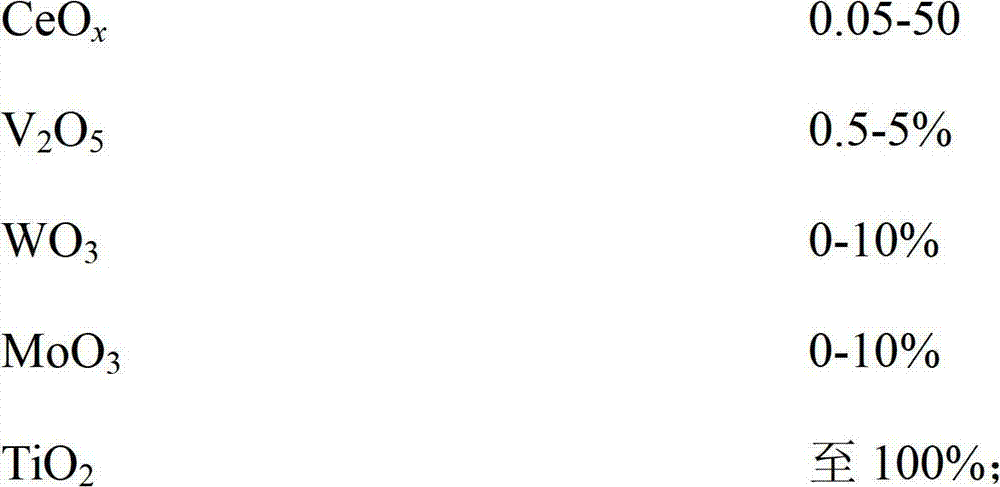

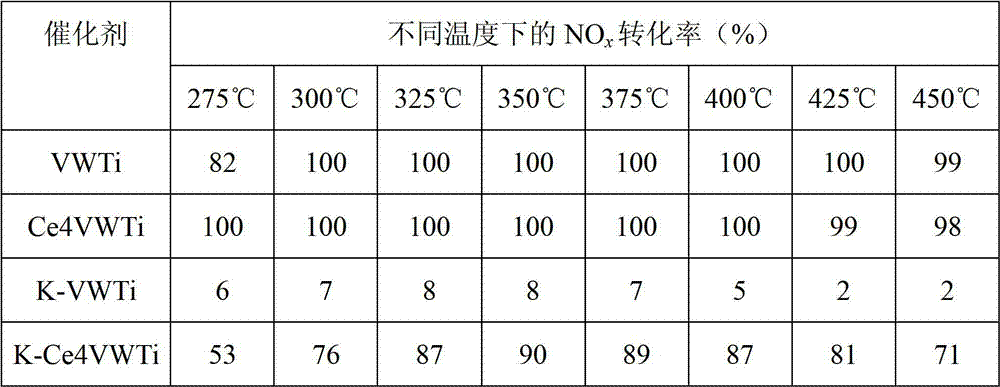

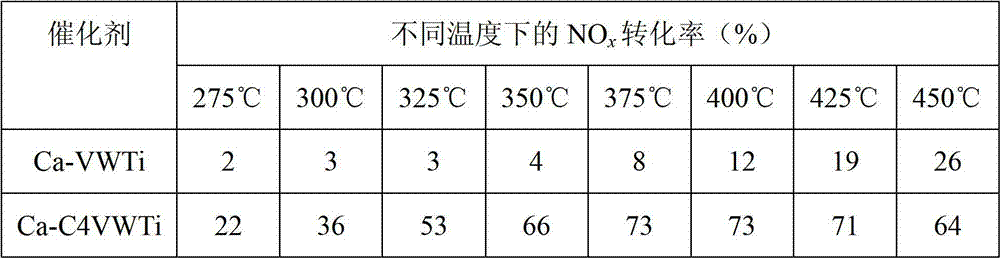

Vanadium-titanium oxide catalyst, and preparation method and application thereof

InactiveCN102764643ANo effect on activityDo not change the production processDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsMetal poisoningAlkaline earth metal

The invention relates to a vanadium-titanium oxide catalyst which can resist alkaline metal and alkaline earth metal poisoning. The catalyst is characterized in that the vanadium-titanium oxide catalyst is doped with an element Ce. The catalyst has fine resistance to alkaline metal poisoning, and above all, the doped cerium component has no influence on the activity of the SCR (selective catalytic reduction) catalyst while improving the resistance of the V2O5 / (MoO3)x(WO3)1-x-TiO2 catalyst to alkaline metal poisoning. The preparation method of the catalyst is simple and easy to implement and has very excellent N2 generation selectivity; and meanwhile, the Ce is a non-poisonous component and can not do harm to human health and ecological environment.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

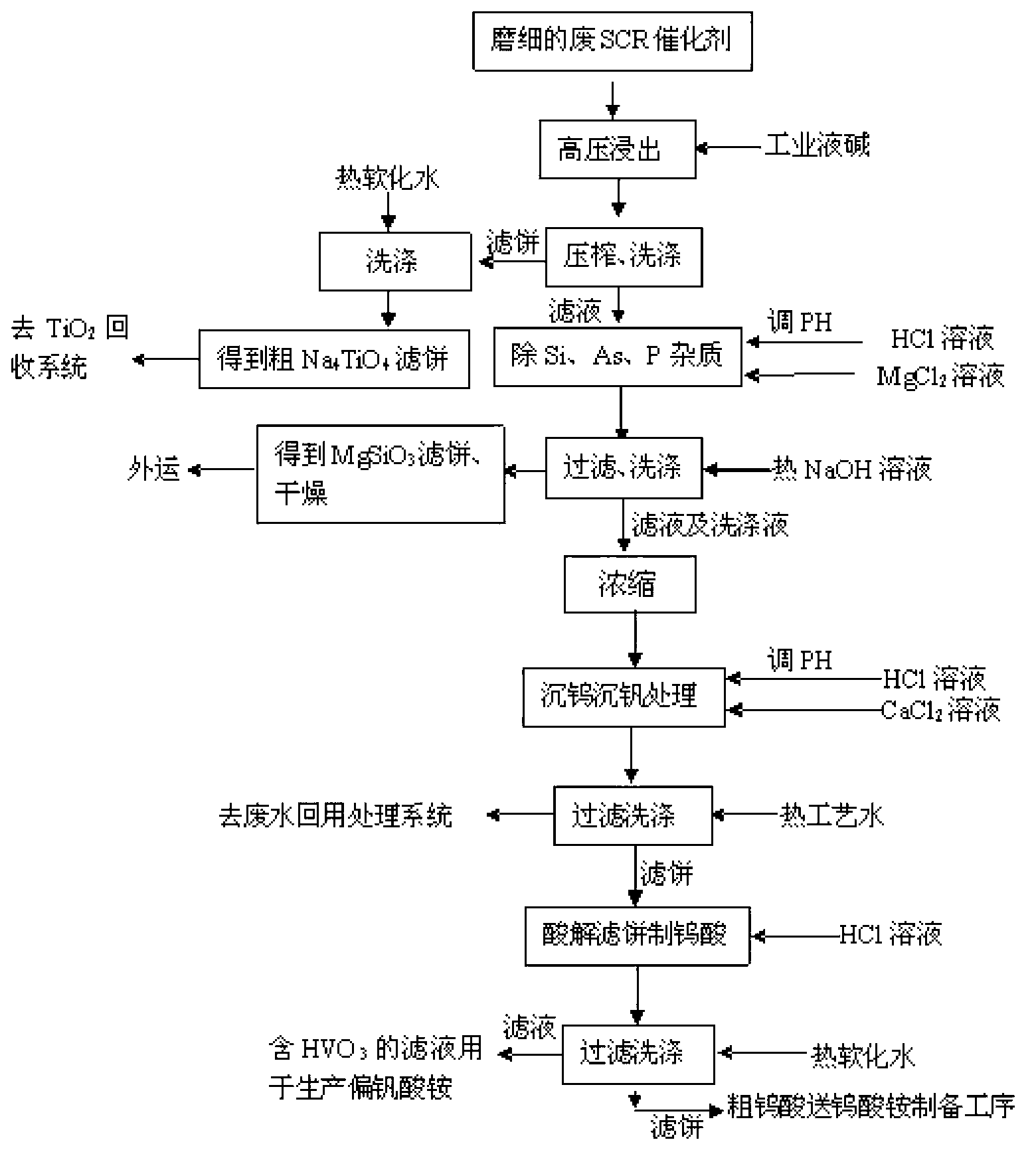

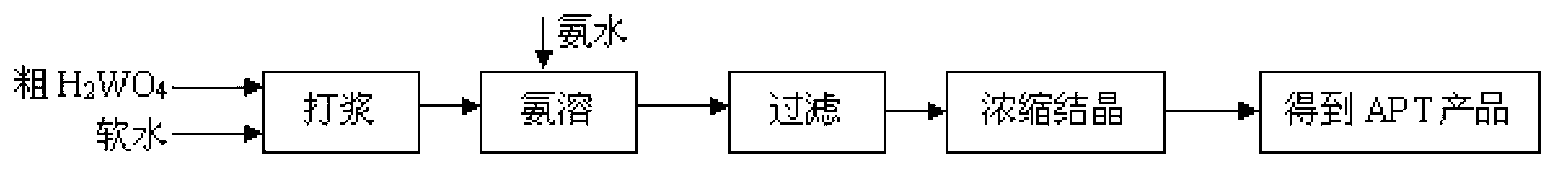

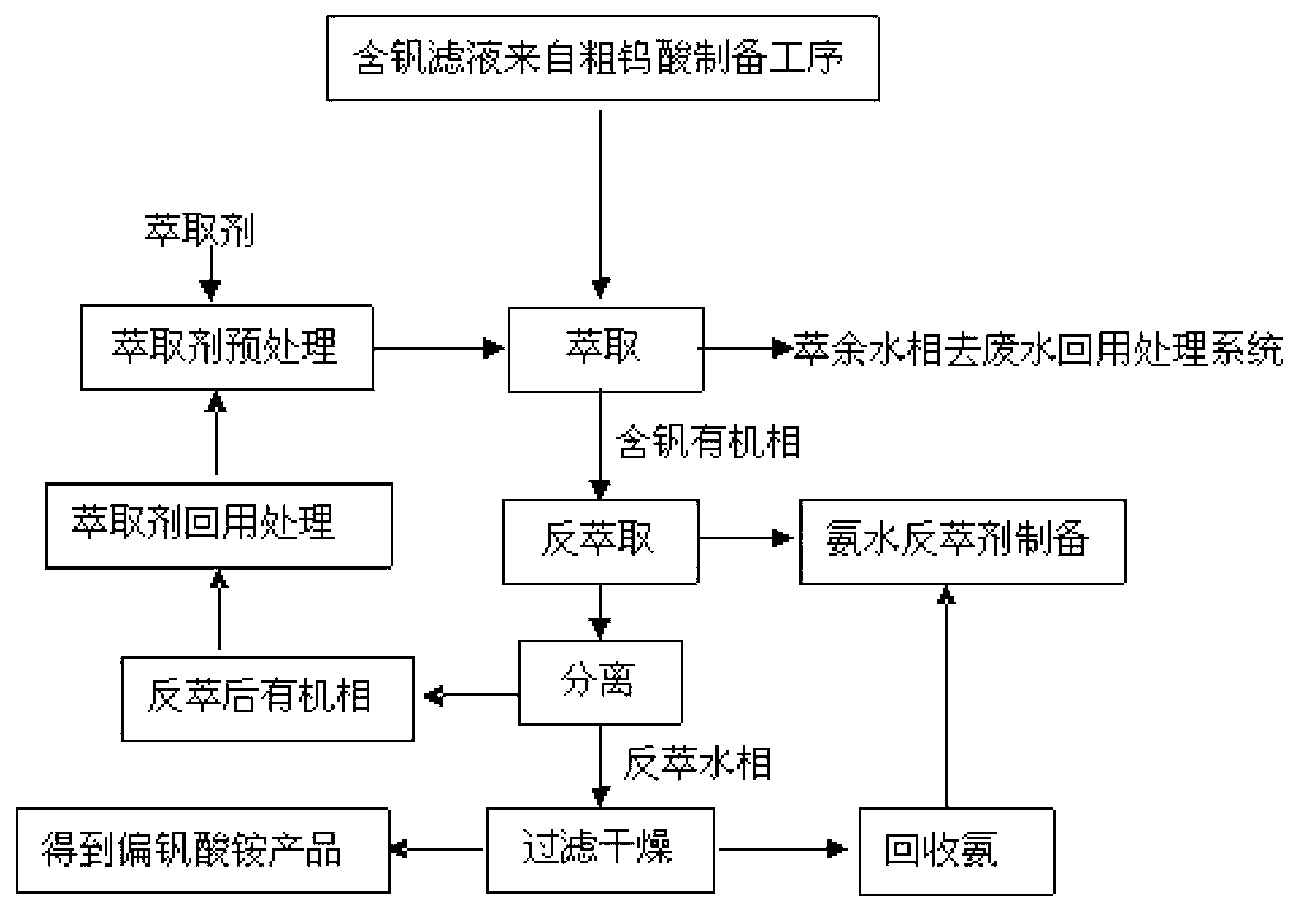

Recovery process of honeycomb type selective catalytic reduction (SCR) waste catalyst containing tungsten, vanadium and titanium

InactiveCN102936039AHigh purityHigh recovery rateTitanium dioxideVanadium compoundsHigh concentrationAmmonium paratungstate

The invention discloses recovery process of honeycomb type selective catalytic reduction (SCR) waste catalyst. The process includes the following steps: a, preprocessing the SCR waste catalyst and leaching at the high temperature and under high pressure; b, adding hydrochloric acid into leaching liquid, adjusting pH, and removing impurities; c, adding hydrochloric acid into the leaching liquid, reacting, calcining and preparing rutile titanium dioxide; d, preparing ammonium paratungstate; e, preparing ammonium metavanadate; and f, recycling and treating waste water. Main products of ammonium paratungstate, ammonium metavanadate and rutile titanium dioxide obtained in the process are high in purity and recovery rate. By-products of silicon magnesium slags, salty mud, high-concentration sodium chloride liquid and barium sulfate dregs are high-purity harmless useful goods. The process is free of harmful secondary pollutant emission, environment-friendly and capable of circulating, has high economical and social benefit and is practicable.

Owner:曾瑞

Temperature swing adsorption and selective catalytic reduction NOx removal system

InactiveUS7117669B2Simpler and more replacedEasy to useMolecular sieve catalystsInternal combustion piston enginesSyngasDesorption

The invention relates to systems for removing NOx from exhaust. In one aspect of the invention, after adsorption, an NOx adsorber is isolated from the main exhaust flow and desorption induced by raising the temperature. The desorbed NOx is combined with a reductant and reduced over a catalyst. Preferably, the reductant is syn gas produced in an on-board reformer. The catalyst need never be exposed to the main exhaust flow, which is particularly advantageous for catalysts sensitive to water, oxygen, or sulfur. In another aspect of the invention, a recirculating flow is induced through an NOx adsorber during a regeneration cycle. Recirculation can induce greater desorption at a given temperature, provide a source of heat for the adsorber, and allow a higher conversion rate with a fixed amount of catalyst. A further aspect of the invention relates to a vehicle-mounted adsorbers with provisions for heating.

Owner:EATON CORP

Multi-stage system for selective catalytic reduction

A first aspect of the present disclosure includes a method of controlling nitric oxides emissions. The method may include producing an exhaust gas stream containing NOx and supplying the exhaust gas stream to an exhaust passage. The method may further comprise supplying ammonia to the exhaust passage at a location upstream of a first selective catalytic reduction catalyst, wherein the amount of ammonia supplied at the first location is less than about 90% of the effective amount of ammonia needed for reduction of all NOx at the first location. Further, ammonia may be supplied to the exhaust passage at a second location downstream of the first selective catalytic reduction catalyst and upstream of a second selective catalytic reduction catalyst.

Owner:CATERPILLAR INC

Composite oxide catalyst for cryogenic selective catalystic reductic oxide nitrogen

InactiveCN101028594AEasy to makeEasy to operateCatalyst carriersDispersed particle separationManganese oxideNitrogen gas

A composite oxide catalyst for removing NOx from the tail gas generated by combustion through low-temp selective catalytic reduction reaction in which ammonia gas or urea is used as reducing agent for reducing the NOx into N2 and H2O is prepared from a composite metallic oxide (whose main component is manganese oxide) and a porous inorganic oxide as carrier through citric acid complexing method.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

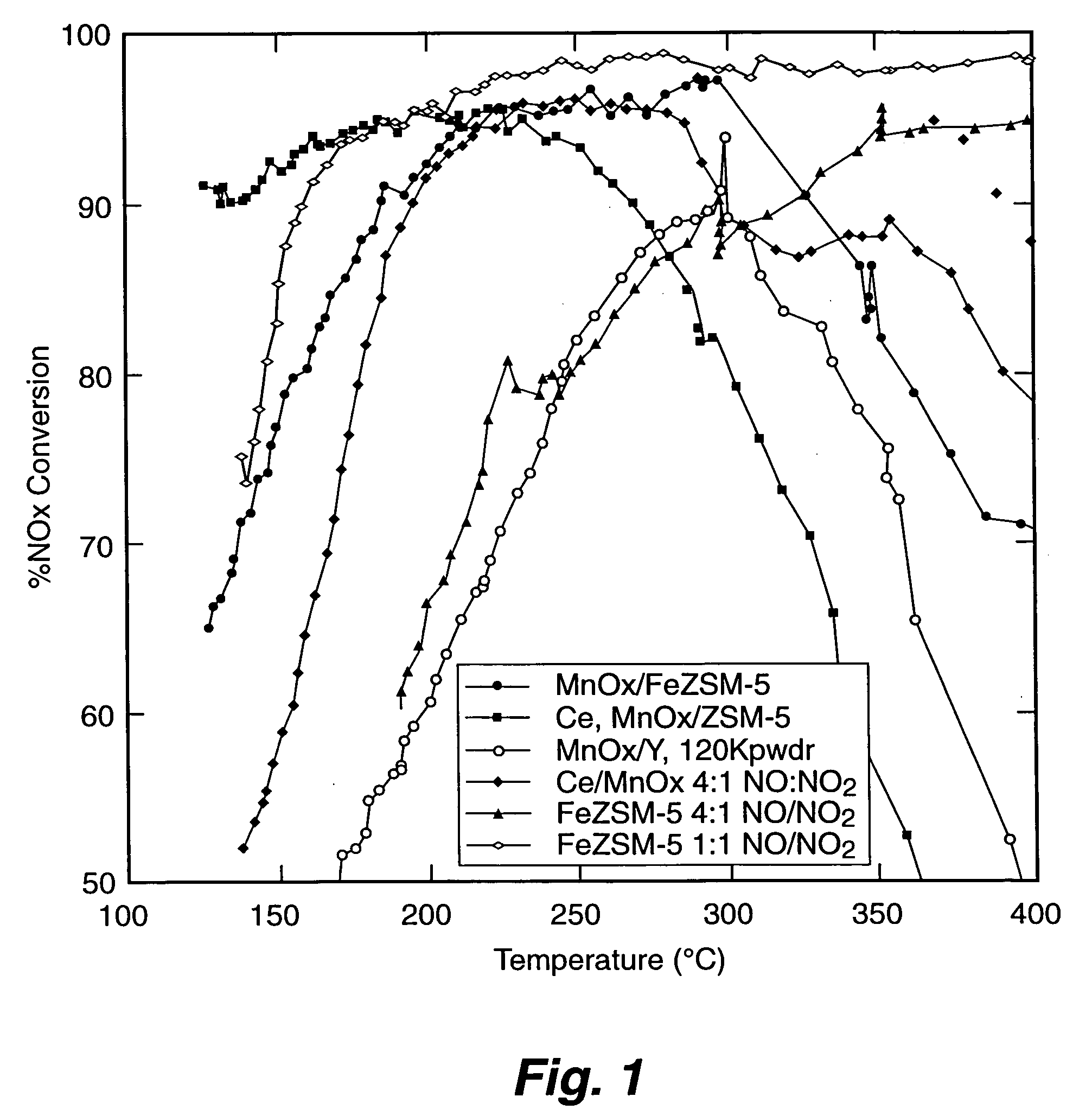

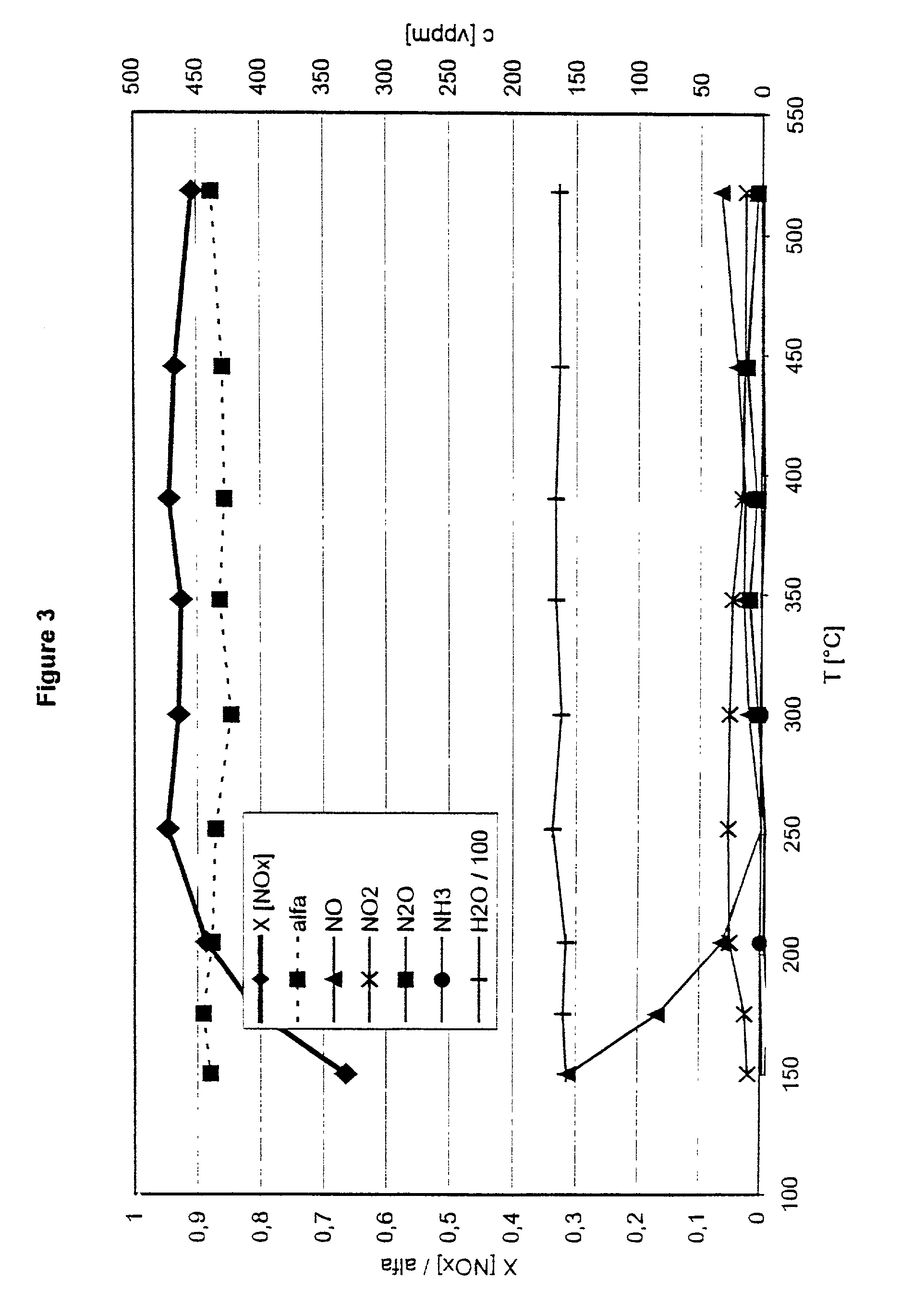

Catalyst and method for reduction of nitrogen oxides

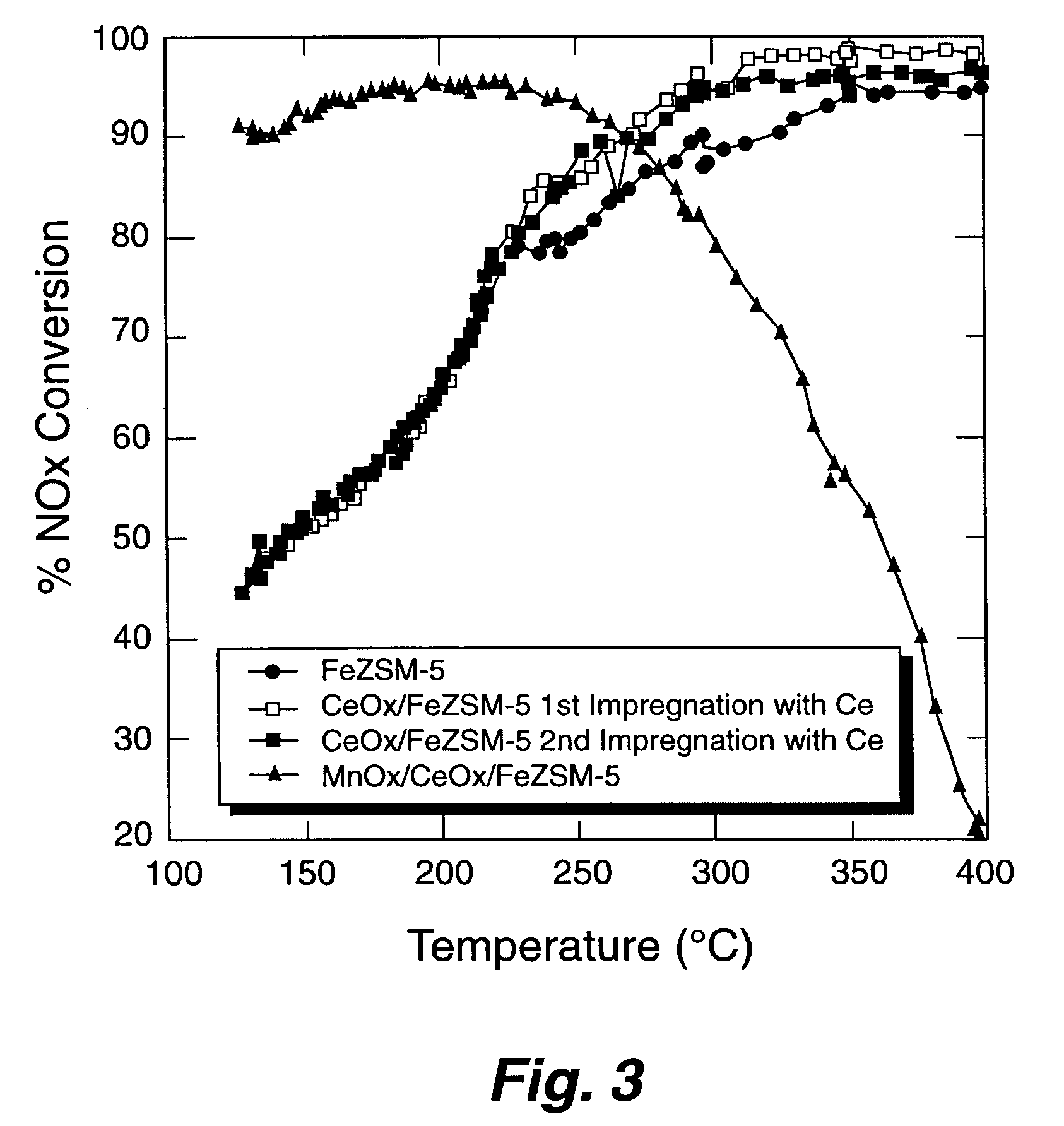

InactiveUS20060029535A1Efficient workSelective catalytic reductionNitrous oxide captureNitrogen compoundsCerium nitrateIron salts

A Selective Catalytic Reduction (SCR) catalyst was prepared by slurry coating ZSM-5 zeolite onto a cordierite monolith, then subliming an iron salt onto the zeolite, calcining the monolith, and then dipping the monolith either into an aqueous solution of manganese nitrate and cerium nitrate and then calcining, or by similar treatment with separate solutions of manganese nitrate and cerium nitrate. The supported catalyst containing iron, manganese, and cerium showed 80 percent conversion at 113 degrees Celsius of a feed gas containing nitrogen oxides having 4 parts NO to one part NO2, about one equivalent ammonia, and excess oxygen; conversion improved to 94 percent at 147 degrees Celsius. N2O was not detected (detection limit: 0.6 percent N2O).

Owner:LOS ALAMOS NATIONAL SECURITY

Selective catalytic reduction of nox enabled by sidestream urea decomposition

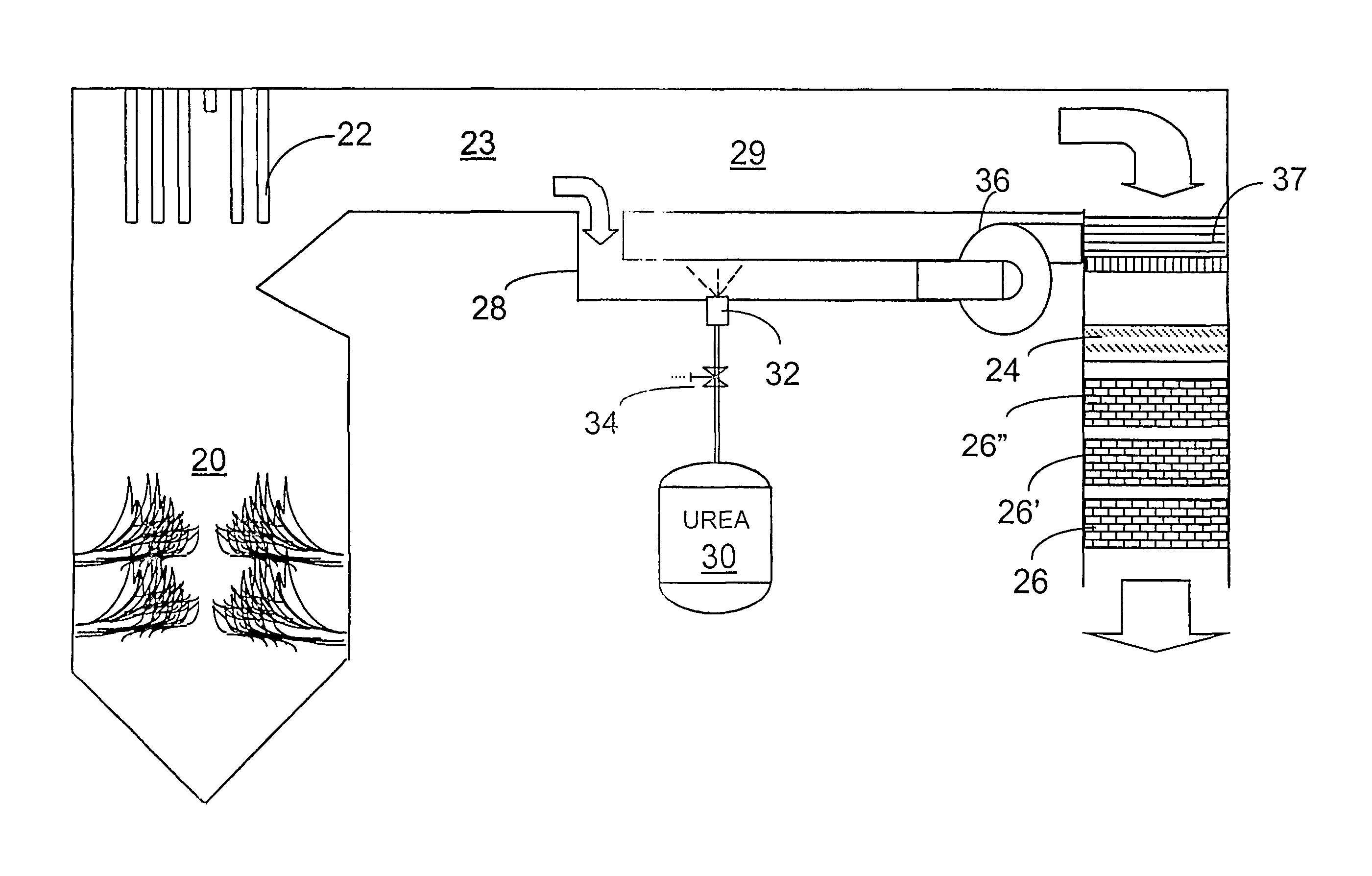

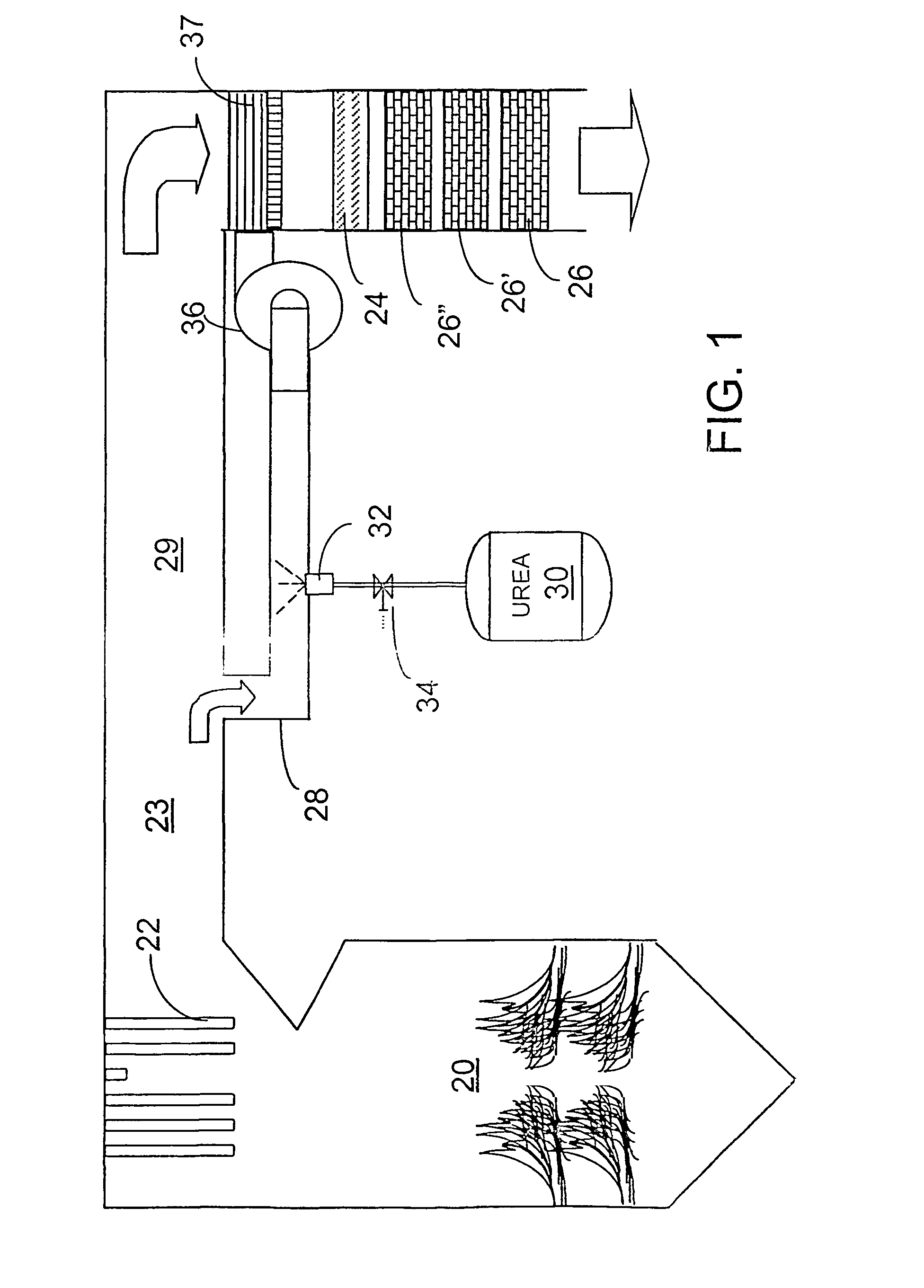

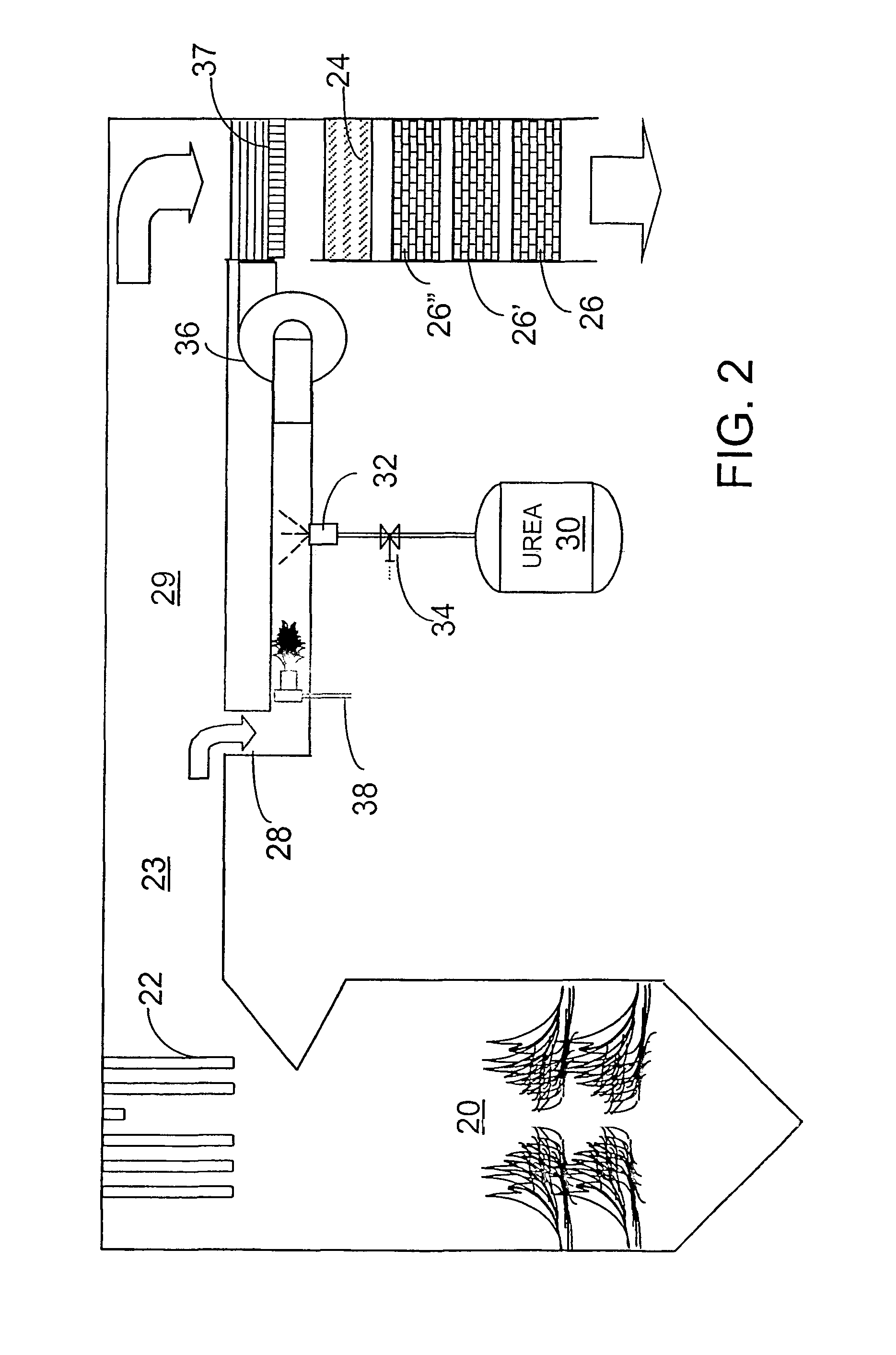

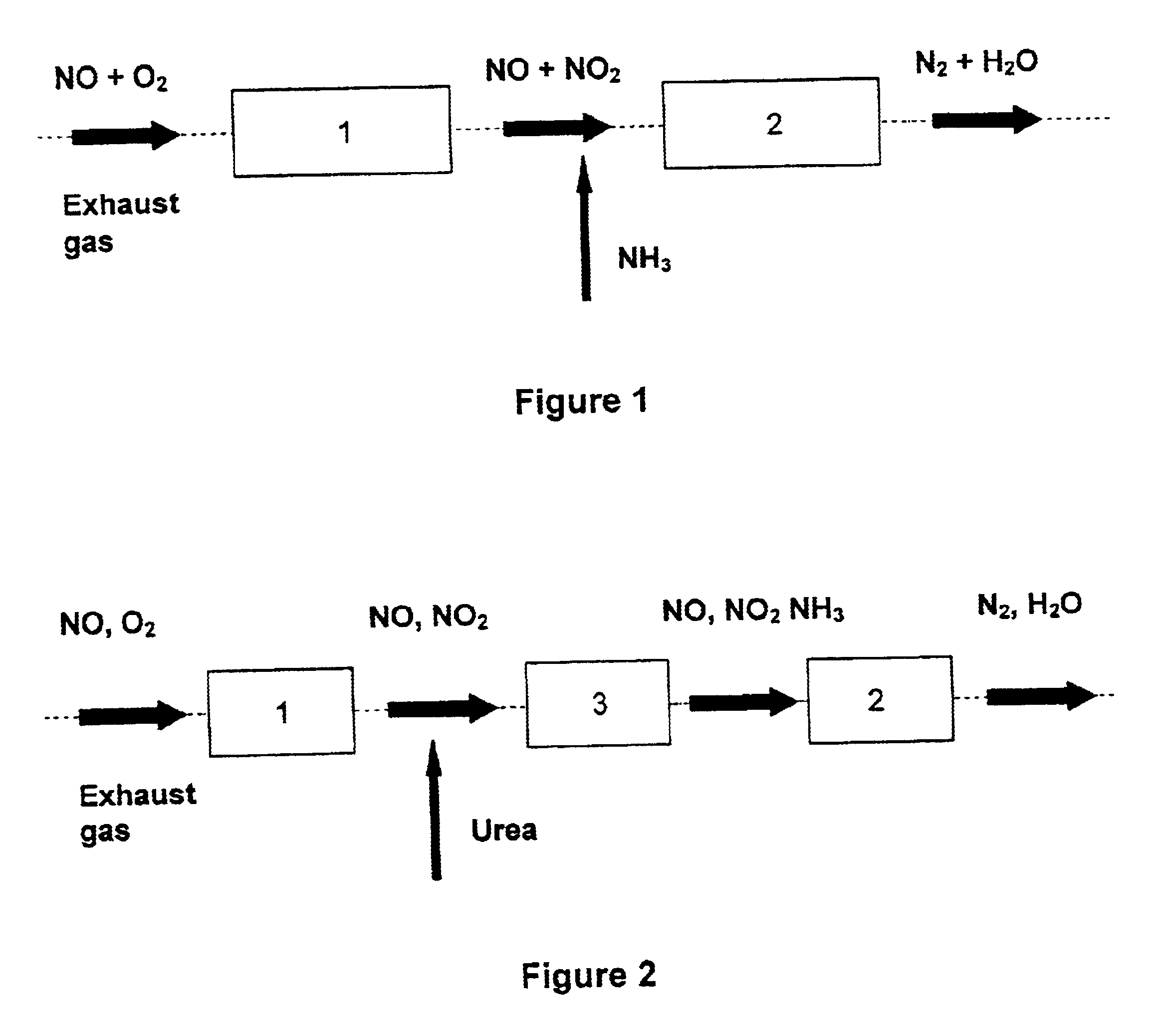

InactiveUS7090810B2Well mixedAccurate temperatureNitrogen compoundsInternal combustion piston enginesParticulatesSuperheater

A preferred process arrangement utilizes the enthalpy of the flue gas, which can be supplemented if need be, to convert urea (30) into ammonia for SCR. Urea (30), which decomposes at temperatures above 140 ° C., is injected (32) into a flue gas stream split off (28) after a heat exchanger (22), such as a primary superheater or an economizer. Ideally, the side stream would gasify the urea without need for further heating; but, when heat is required it is far less than would be needed to heat either the entire effluent (23) or the urea (30). This side stream, typically less than 3% of the flue gas, provides the required temperature and residence time for complete decomposition of urea (30). A cyclonic separator can be used to remove particulates and completely mix the reagent and flue gas. This stream can then be directed to an injection grid (37) ahead of SCR using a blower (36). The mixing with the flue gas is facilitated due to an order of magnitude higher mass of side stream compared to that injected through the AIG in a traditional ammonia-SCR process.

Owner:FUEL TECH

Method for extracting tungsten, titanium and vanadium from waste SCR (selective catalytic reduction) catalyst

InactiveCN102936049ASolve the pollution of the environmentLow equipment requirementsTungsten oxides/hydroxidesTitanium dioxideSlagStrong acids

The invention discloses a method for extracting tungsten, titanium and vanadium from a waste SCR (selective catalytic reduction) catalyst, which comprises the following steps: crushing the waste SCR catalyst, adding a strongly alkaline solution, and reacting; filtering, separating, then adding strong acid into the sodium tungstate and sodium vanadate mixed solution, and reacting to obtain tungstic acid and a sodium salt and vanadic acid mixed solution; regulating the pH value of the sodium salt and vanadic acid mixed solution until precipitate is separated out, thus obtaining ammonium vanadate; then adding sulfuric acid into the tungsten-and-vanadium-removed SCR catalyst, and reacting to obtain a titanyl sulfate solution and solids such as aluminum slag and the like; then adding water into the titanyl sulfate solution, and hydrolyzing to obtain titanic acid and a waste acid solution; and finally, respectively calcining the obtained ammonium vanadate, tungstic acid and titanic acid to obtain vanadium pentoxide, tungsten trioxide and titanium dioxide. According to the invention, tungsten, titanium and vanadium can be extracted from the SCR catalyst through the reaction with strong alkali and strong acid at a low temperature, the equipment requirement is low, the energy consumption is low, some products having added values can be coproduced, and no secondary pollution is generated, thereby facilitating popularization and application.

Owner:成都新智金森环保科技有限公司

Hydrothermally stable metal promoted zeolite beta for NOx reduction

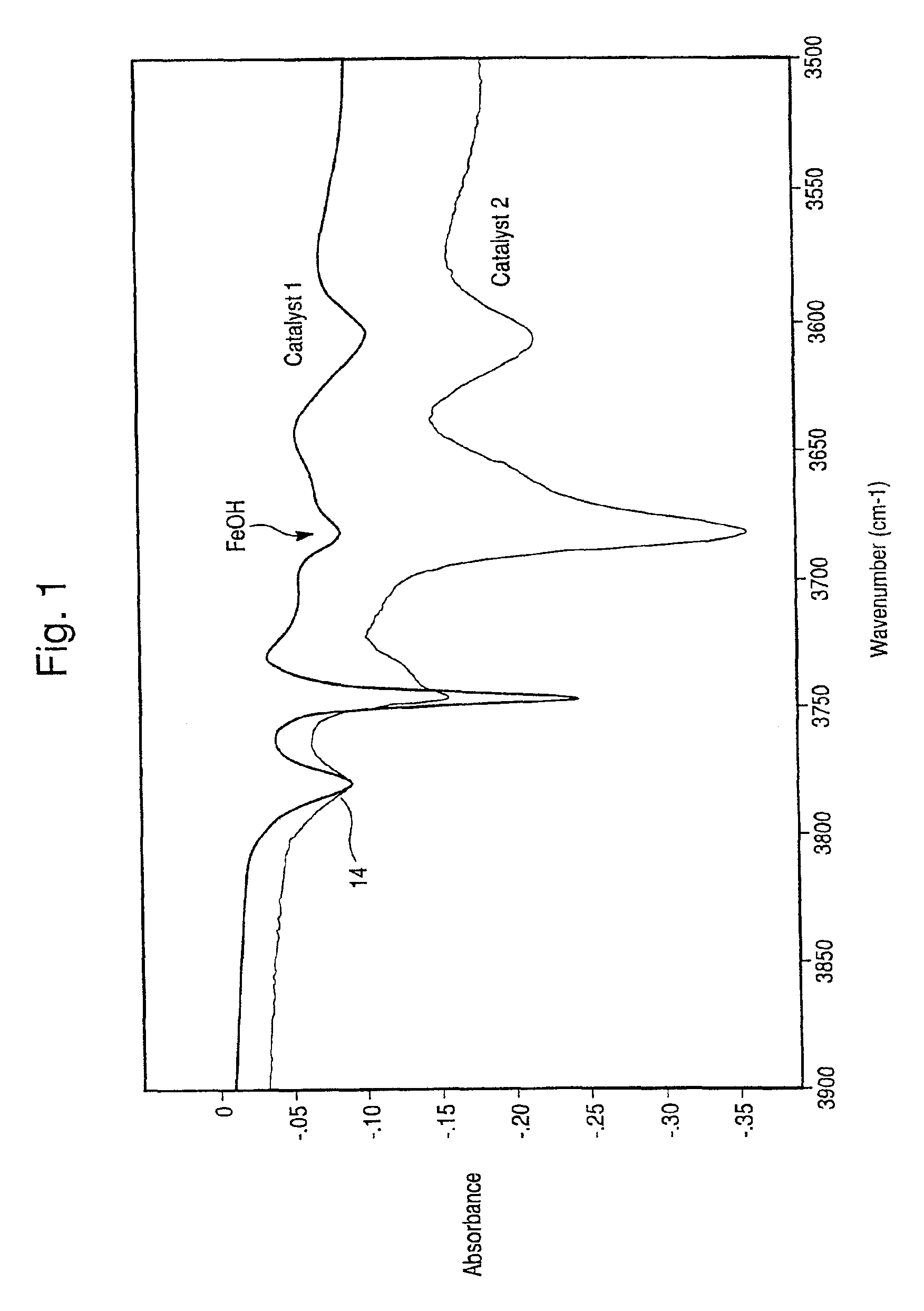

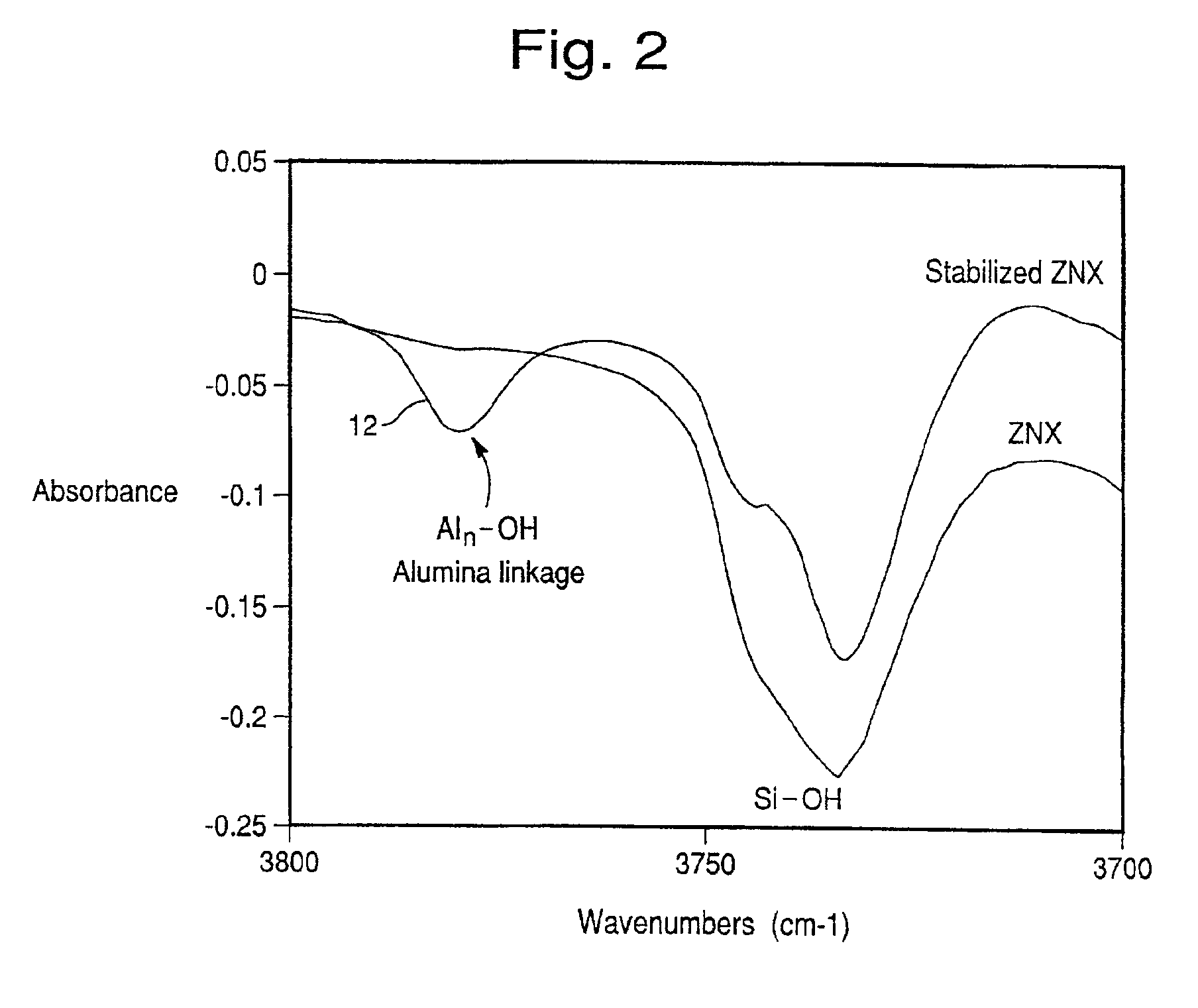

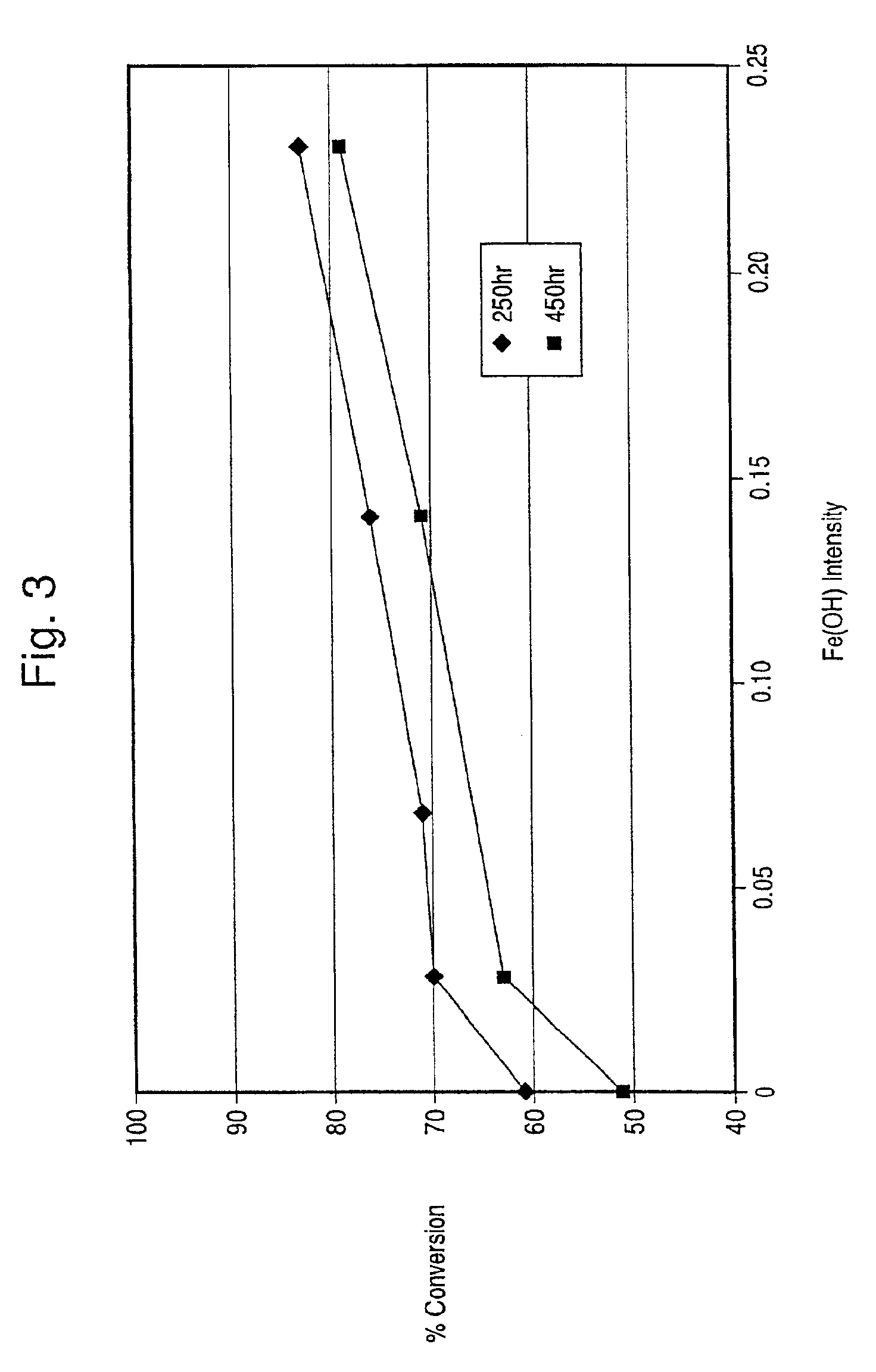

InactiveUS6914026B2Increasing Fe(OH) content of catalystGood hydrothermal stabilityMolecular sieve catalystsDispersed particle separationIron saltsIon exchange

The present invention is directed to an iron-promoted zeolite beta catalyst useful in the selective catalytic reduction of nitrogen oxides with ammonia in which the iron-promoted zeolite beta is treated so as to provide increased amounts of the iron promoter in the form of Fe(OH).The stabilized zeolite is formed by cation exchange of an iron salt into a zeolite beta which has a reduced sodium content such as by exchanging a sodium beta with ammonium or hydrogen cations. A zeolite beta having a reduced carbon content and a Si / Al ratio of no more than 10 also increases the Fe(OH) content of the iron-promoted catalyst. The iron-promoted catalyst which has the iron in the form of Fe(OH) is characterized by a peak at 3680±5 cm−1 in the IR spectra.

Owner:ENGELHARD CORP

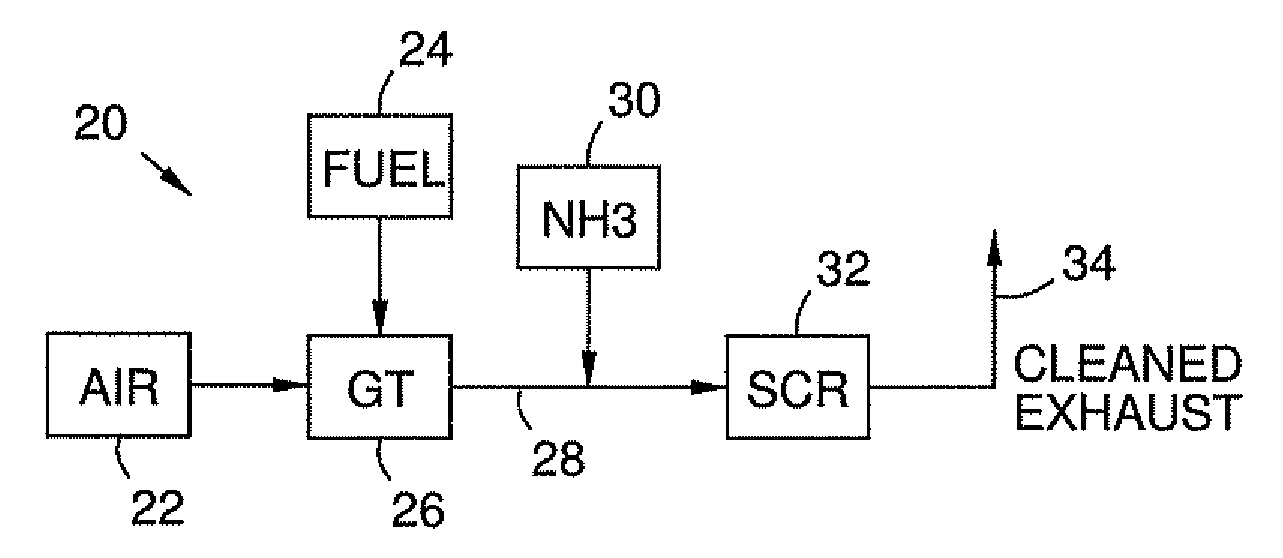

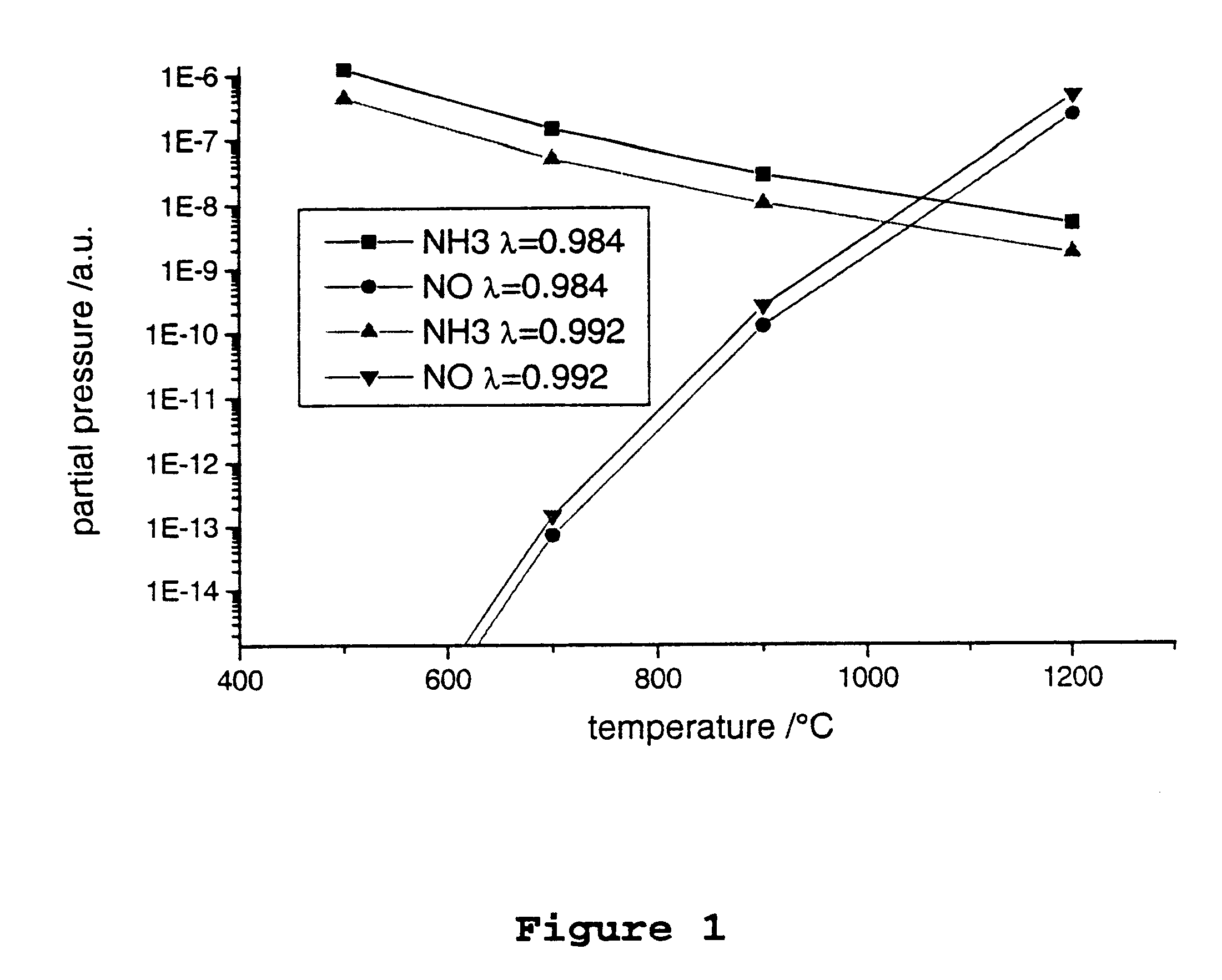

High temperature catalyst and process for selective catalytic reduction of NOx in exhaust gases of fossil fuel combustion

A process for producing a stable high-temperature catalyst for reduction of nitrogen oxides in combustion exhaust gases at operating temperatures from 300° C. to over 700° C. without the need for exhaust dilution. A zeolite material is steam-treated at a temperature and duration sufficient to partially de-aluminize the zeolite to approximately a steady state, but not sufficient to fully collapse its chemical structure. Iron is added to the zeolite material. The zeolite material is calcined at a temperature, humidity, and duration sufficient to stabilize the zeolite material. Examples and specifications for ranges, order, and durations of steaming, calcining, and other steps are provided.

Owner:SIEMENS ENERGY INC

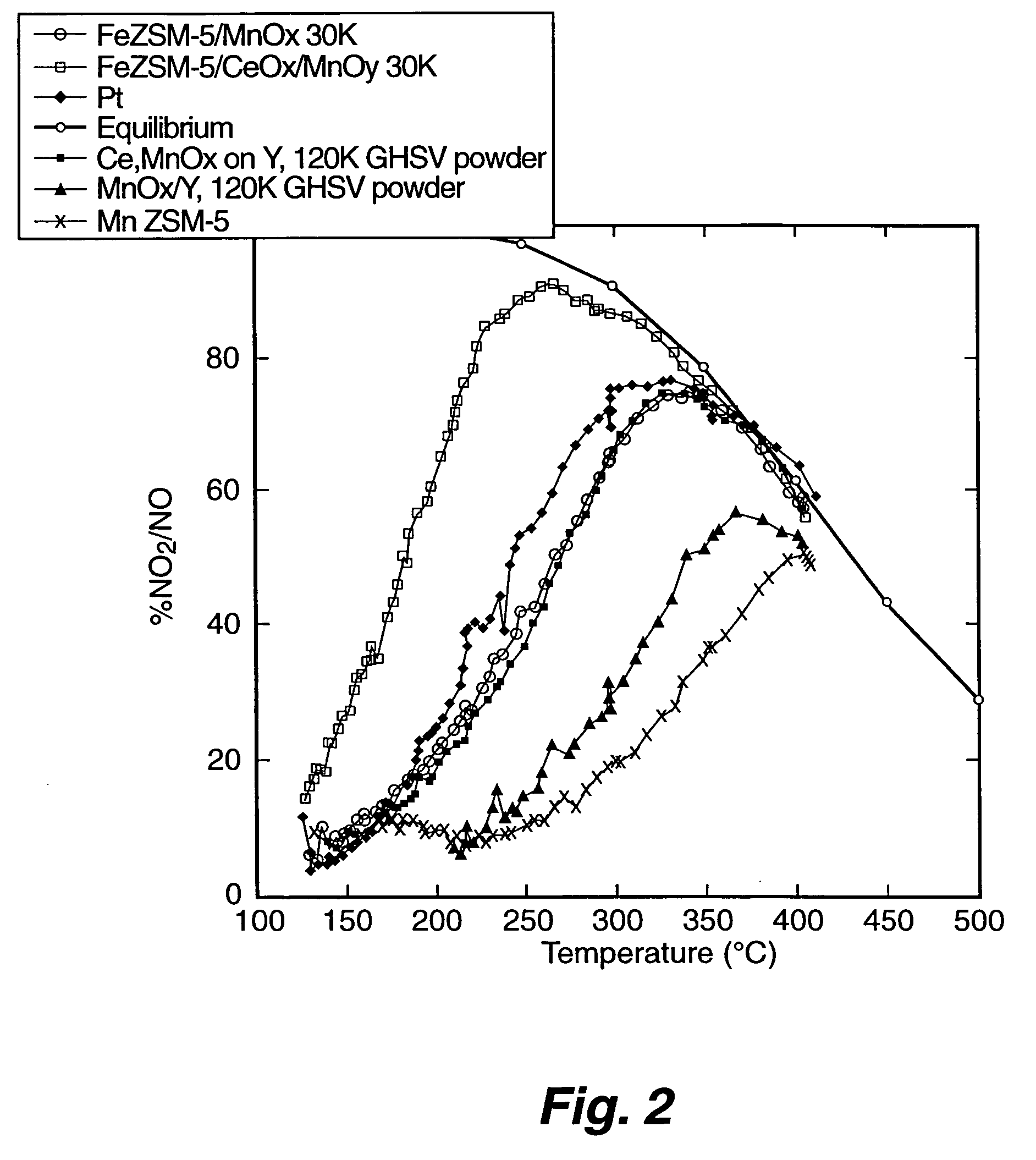

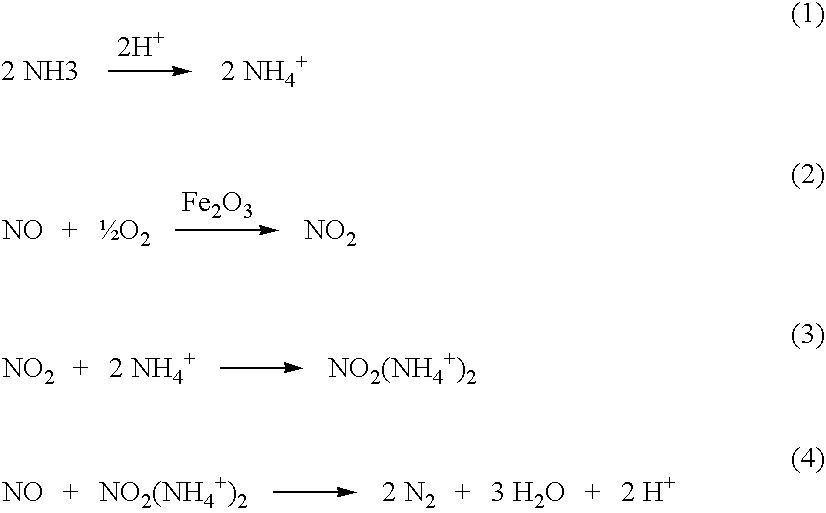

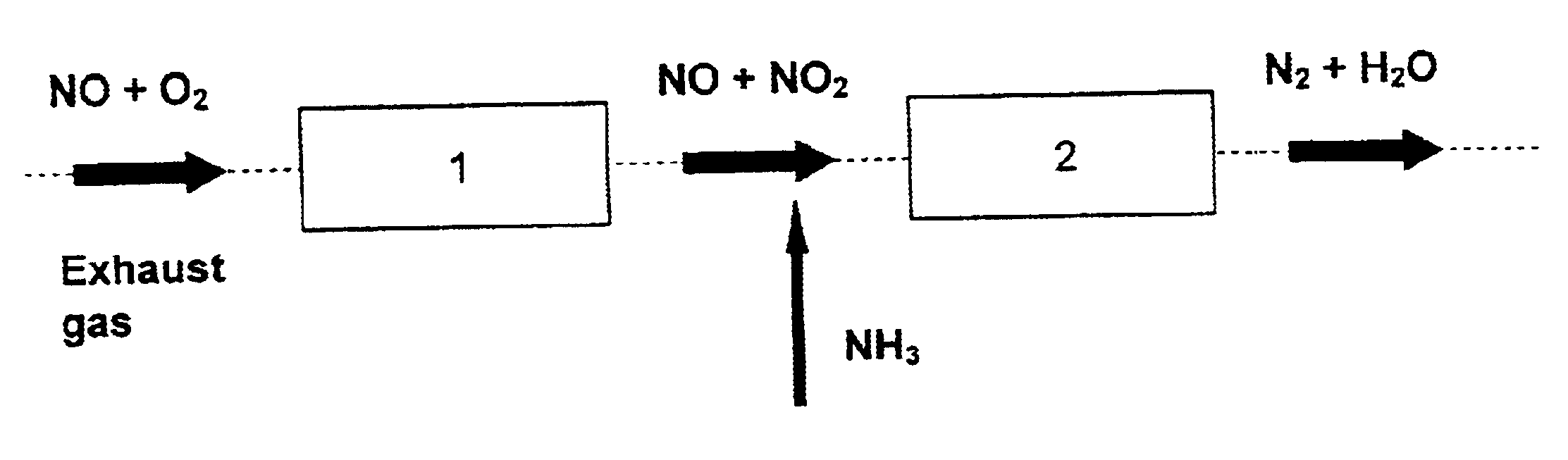

Process and catalyst for reducing nitrogen oxides

InactiveUS6843971B2High activityDelay agingCyanogen compoundsInternal combustion piston enginesInternal combustion engineChemistry

A process for reducing the nitrogen oxides present in a lean exhaust gas from an internal combustion engine by selective catalytic reduction on a reduction catalyst using ammonia, wherein a fraction of the nitrogen monoxide present in the exhaust gas is oxidized to nitrogen dioxide before the exhaust gas, together with ammonia, is passed over the reduction catalyst. The reduction catalyst contains a zeolite exchanged with transition metals and oxidation of the nitrogen monoxide is performed in such a way that the exhaust gas contains 30 to 70 vol. % of nitrogen dioxide before contact with the reduction catalyst.

Owner:UMICORE AG & CO KG

Multistage reductant injection strategy for slipless, high efficiency selective catalytic reduction

InactiveUS20050284134A1Easy to controlReduce riskInternal combustion piston enginesExhaust apparatusInjection portAmmonia

One aspect of the invention relates to an exhaust treatment apparatus having an NOx reduction system comprising first and second catalyst beds in series with associated first and second ammonia injectors. The first catalyst bed with its associated ammonia injector preferably targets removing only about 80 to about 95% percent of the NOx in the vehicle exhaust. The second catalyst bed with its associated injector preferably target removing about 70 to about 100% of the remaining NOx. Staging the reduction system in this manner improves control over NOx reduction and reduces the risk of ammonia slip. Other aspects of the invention relate to methods of treating vehicle exhaust to remove NOx and an SCR reactor comprising a housing having an entrance port, an exit port, and an ammonia injection port, wherein the injection port is configured to inject ammonia in between SCR catalyst beds contained in the housing.

Owner:EATON CORP

Catalyst system for reducing nitrogen oxide emissions

InactiveUS20070149385A1Molecular sieve catalystsDispersed particle separationChemical reactionNitrogen oxide

A multi-functional catalyst composition is provided. The multi-functional catalyst composition comprises a cracking catalyst material capable of enabling the conversion of the primary hydrocarbon into at least one secondary hydrocarbon having a lower molecular weight than the primary hydrocarbon, and a selective catalytic reduction (SCR) material capable of enabling the chemical reduction of NOx species. Further embodiments presented include a catalyst system comprising the catalyst, an apparatus for reducing NOx emissions comprising the catalyst system, and a method for making the catalyst material.

Owner:GENERAL ELECTRIC CO

Process and catalyst for reducing nitrogen oxides

InactiveUS20020039550A1High activityDelay agingInternal combustion piston enginesExhaust apparatusNitric oxideInternal combustion engine

A process for reducing the nitrogen oxides present in a lean exhaust gas from an internal combustion engine by selective catalytic reduction on a reduction catalyst using ammonia, wherein a fraction of the nitrogen monoxide present in the exhaust gas is oxidized to nitrogen dioxide before the exhaust gas, together with ammonia, is passed over the reduction catalyst. The reduction catalyst contains a zeolite exchanged with transition metals and oxidation of the nitrogen monoxide is performed in such a way that the exhaust gas contains 30 to 70 vol. % of nitrogen dioxide before contact with the reduction catalyst.

Owner:UMICORE AG & CO KG

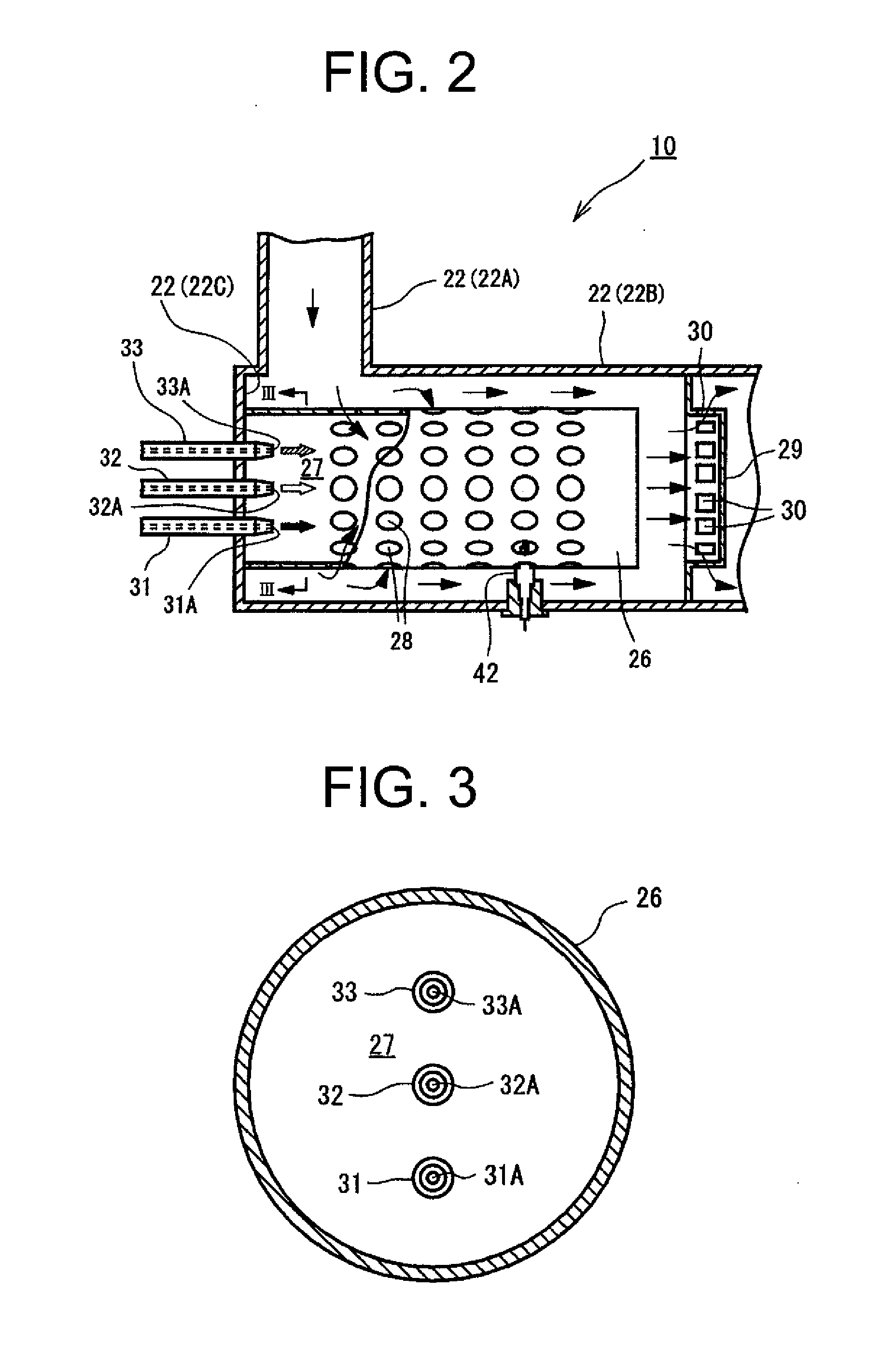

Selective catalytic reduction (SCR) catalyst injection systems

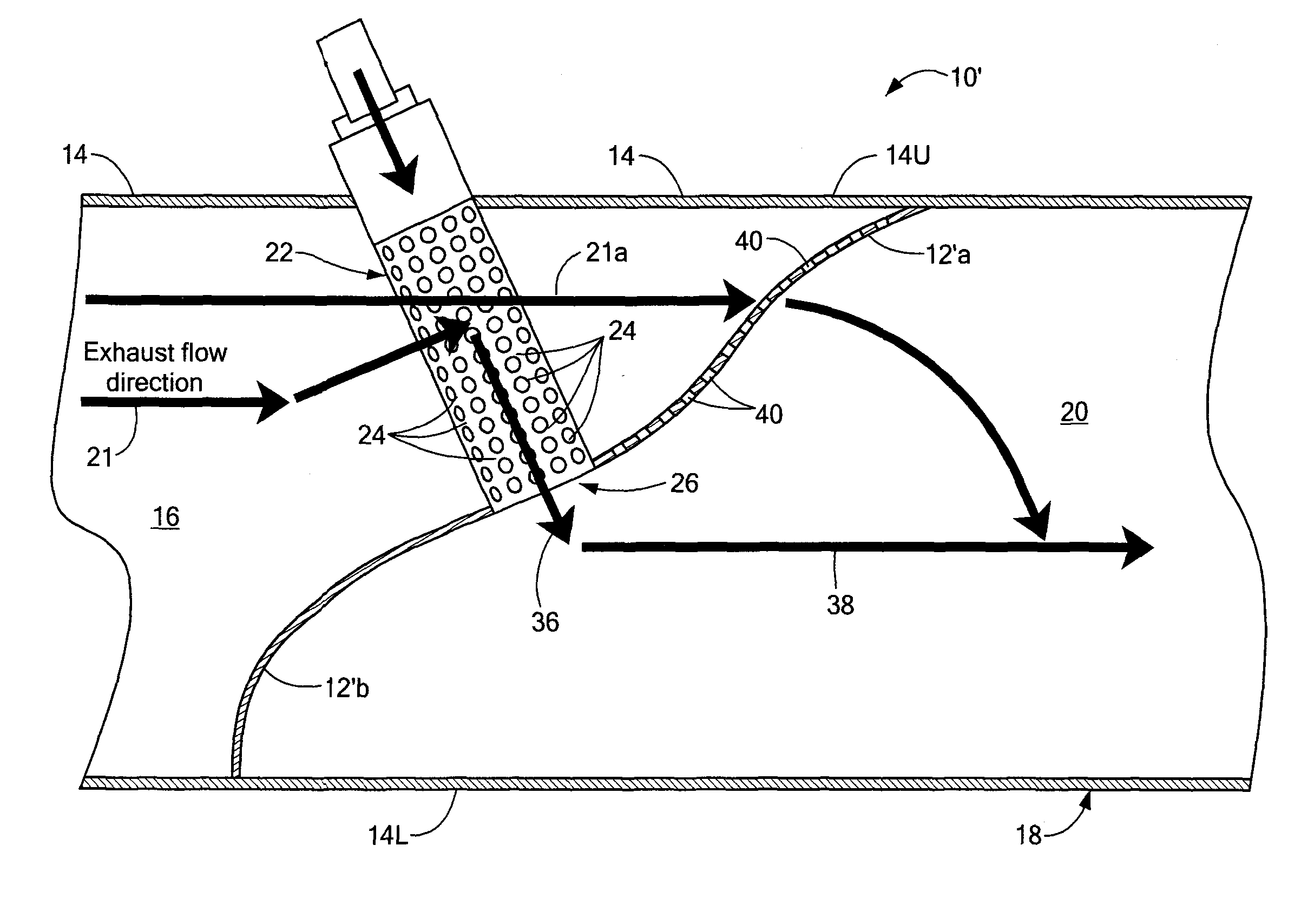

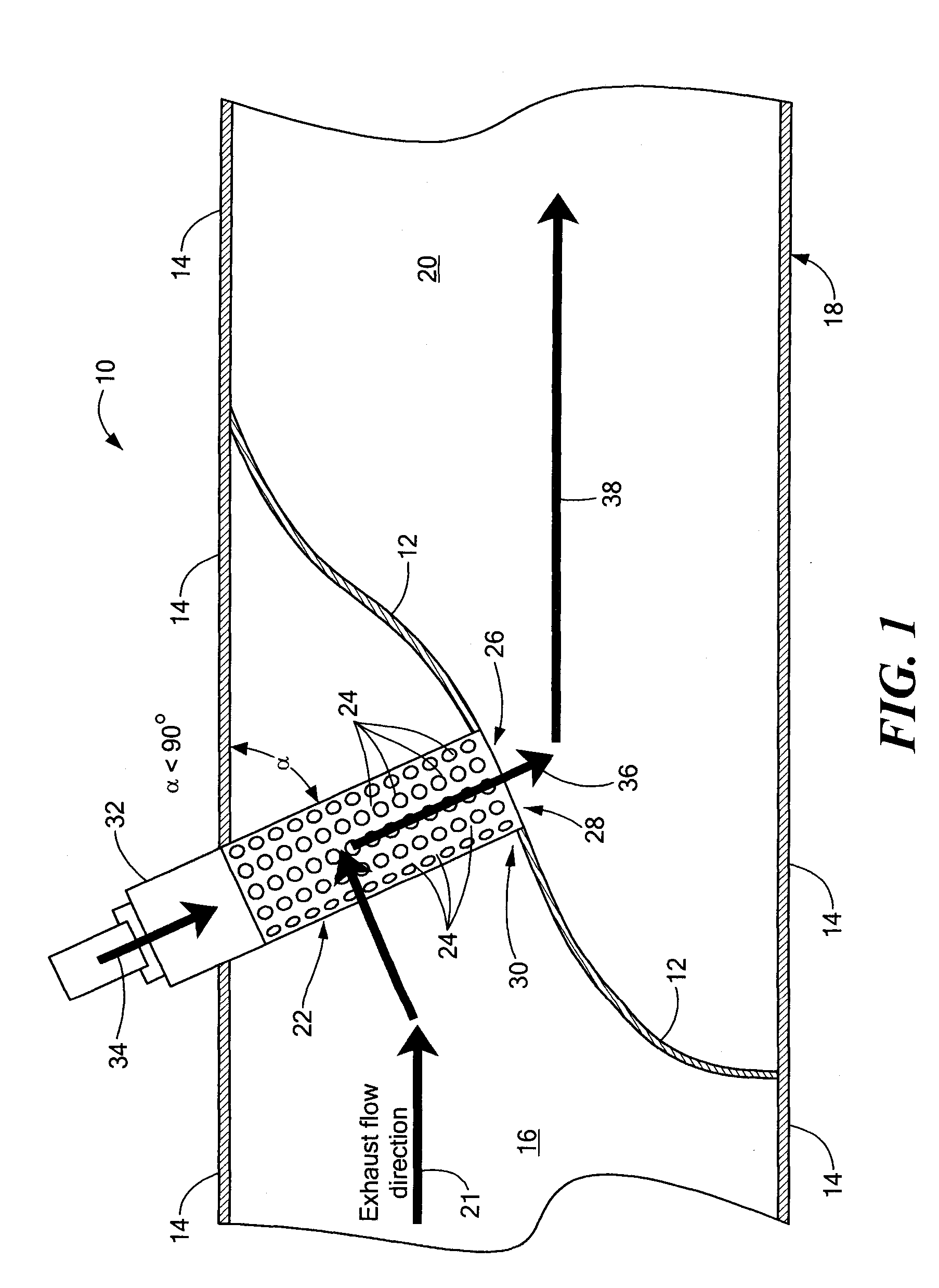

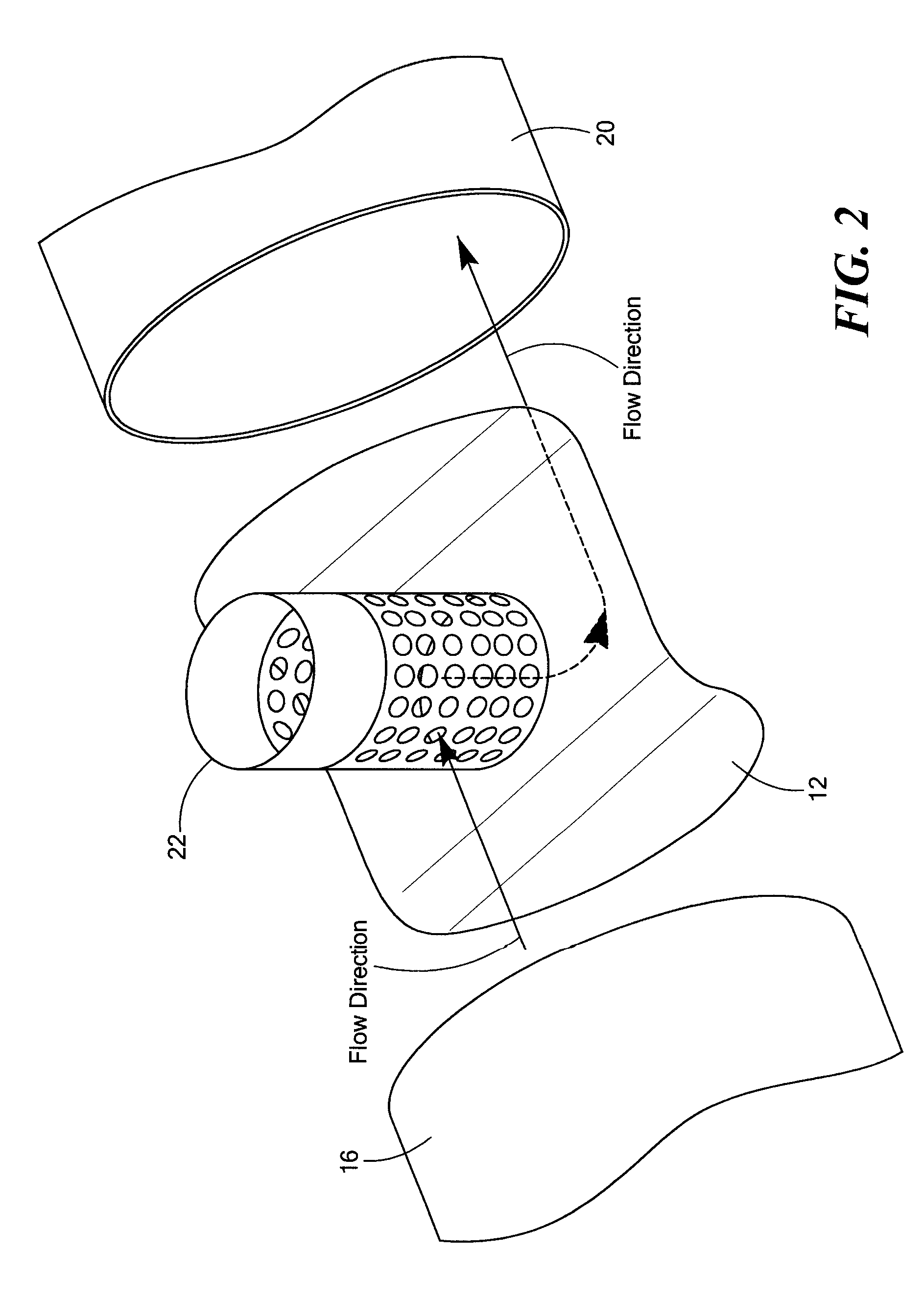

ActiveUS8033104B2Speed up the flowPromote atomizationInternal combustion piston enginesSilencing apparatusExhaust fumesExhaust pipe

A Selective Catalytic Reduction (SCR) injection system for mixing reductant with exhaust gasses. The system includes a plate disposed between walls of an entrance portion and an egress section of the exhaust pipe. The plate intercepts exhaust gasses entering the entrance section of the exhaust pipe and directs such exhaust gasses through apertures in a wall of a reductant-introducing conduit. The conduit has an outlet disposed in the egress section of the exhaust pipe. The wherein dimensions of the apertures in the wall and dimensions in the outlet of the conduit being selected to increase the velocity of the exhaust leaving the outlet of the conduit into the egress section of the exhaust pipe relative to the velocity of the exhaust gases in the entrance section.

Owner:FORD GLOBAL TECH LLC

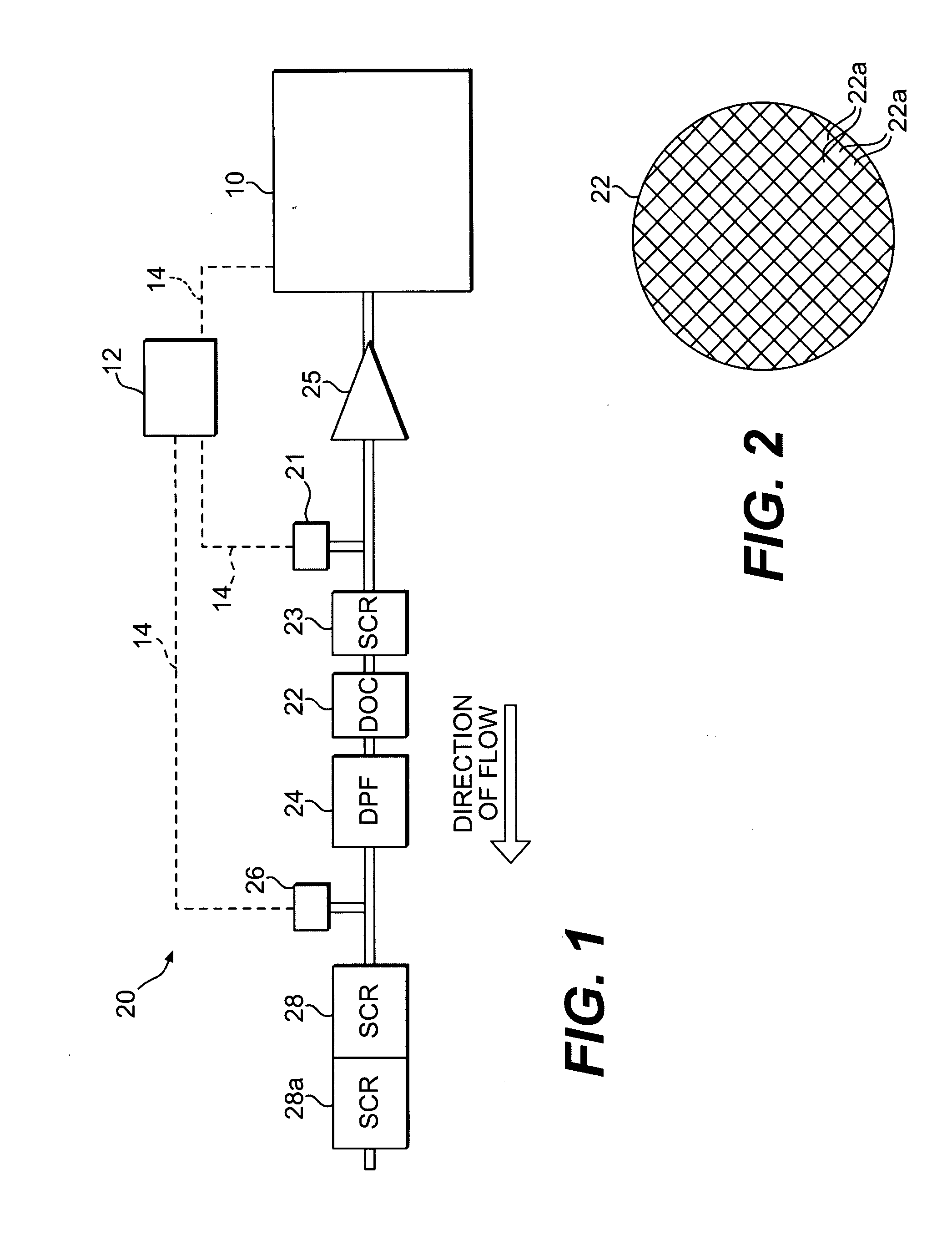

Exhaust treatment system with NO2 control

InactiveUS20090035195A1Combination devicesInternal combustion piston enginesParticulatesExhaust fumes

An exhaust treatment system includes a catalyzed particulate filter disposed in a first passageway and configured to receive a first portion of a flow of exhaust. The catalyzed particulate filter is at least partially coated with a catalytic material for converting NO to NO2. The exhaust treatment system also includes a second passageway configured to direct a second portion of the flow of exhaust around the catalyzed particulate filter and a selective catalytic reduction device disposed downstream from the first passageway and the second passageway. The selective catalytic reduction device is configured to receive a combined flow of exhaust including the first and second portions of the flow of exhaust.

Owner:CATERPILLAR INC

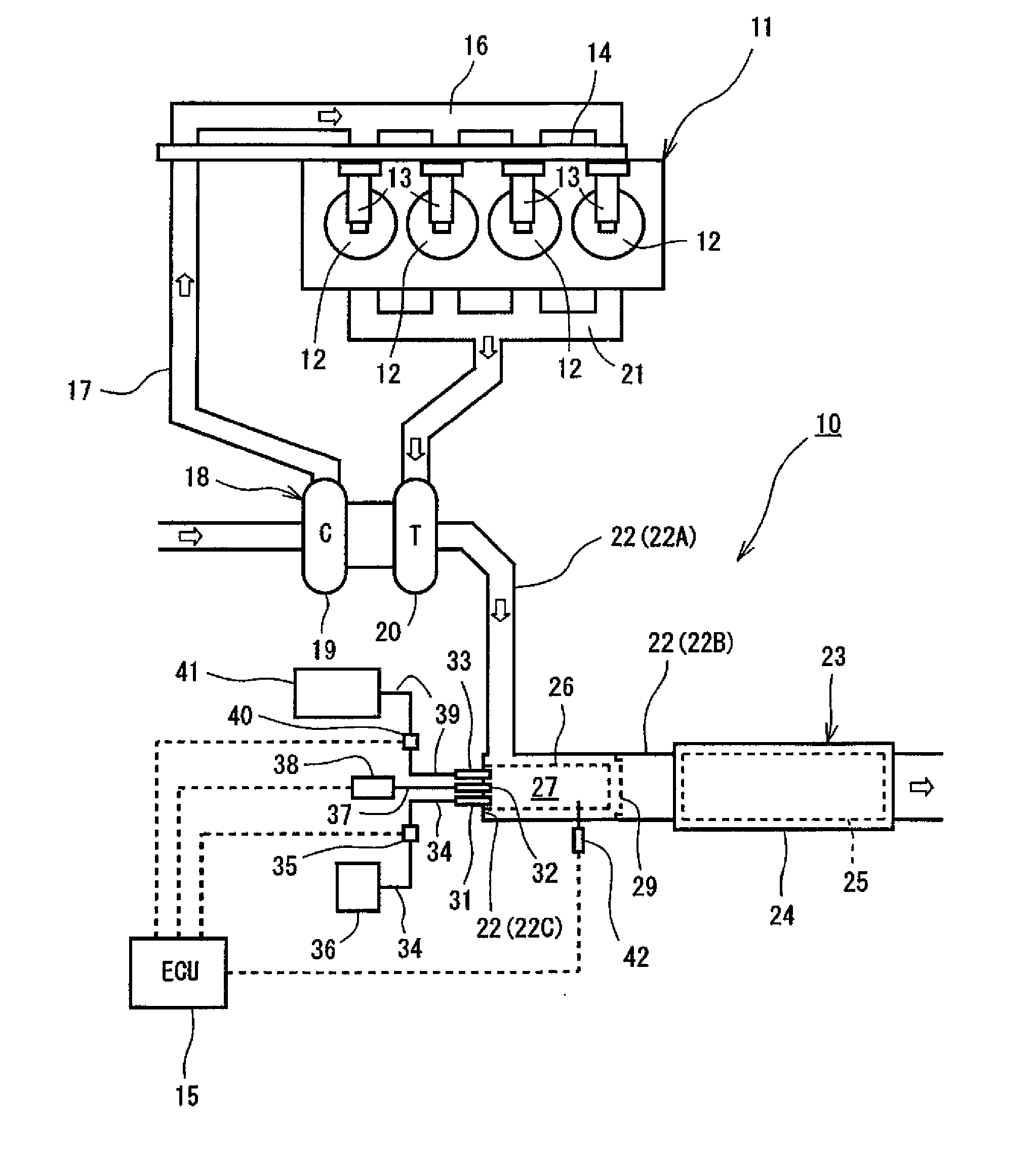

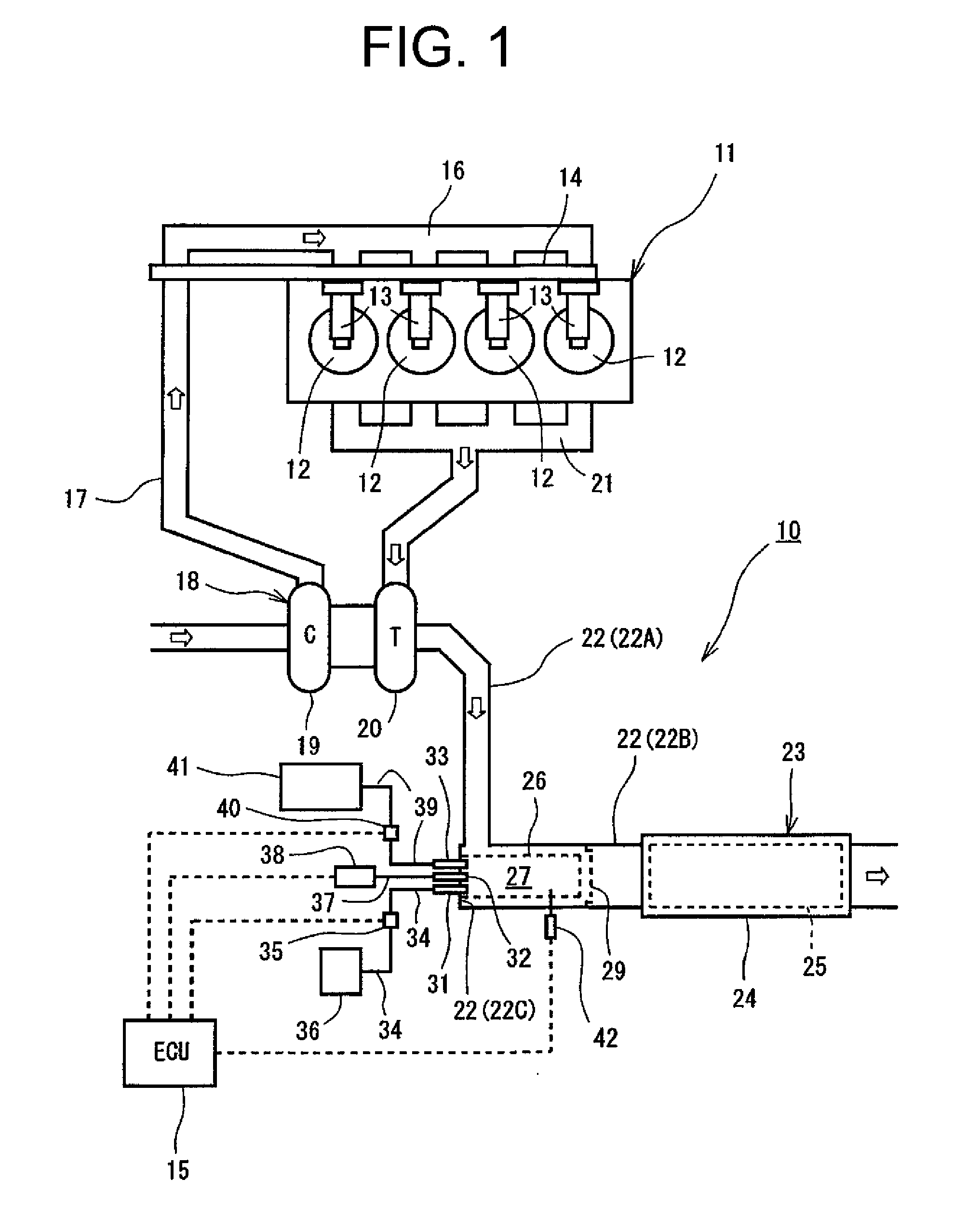

Exhaust gas treatment system

InactiveUS20110061374A1Internal combustion piston enginesSilencing apparatusInjection portExhaust fumes

An exhaust gas treatment system includes an exhaust passage through which exhaust gas from an internal combustion engine is allowed to flow, a selective catalytic reduction catalyst provided in the exhaust passage, a mixing chamber provided upstream of the selective catalytic reduction catalyst in the exhaust passage as viewed in the direction of exhaust gas flow, a fuel injection valve for injection of fuel, an air injection valve for injection of air, and a urea water injection valve for injection of urea water. The fuel injection valve, the air injection valve and the urea water injection valve each has an injection port directed to the mixing chamber.

Owner:TOYOTA IND CORP

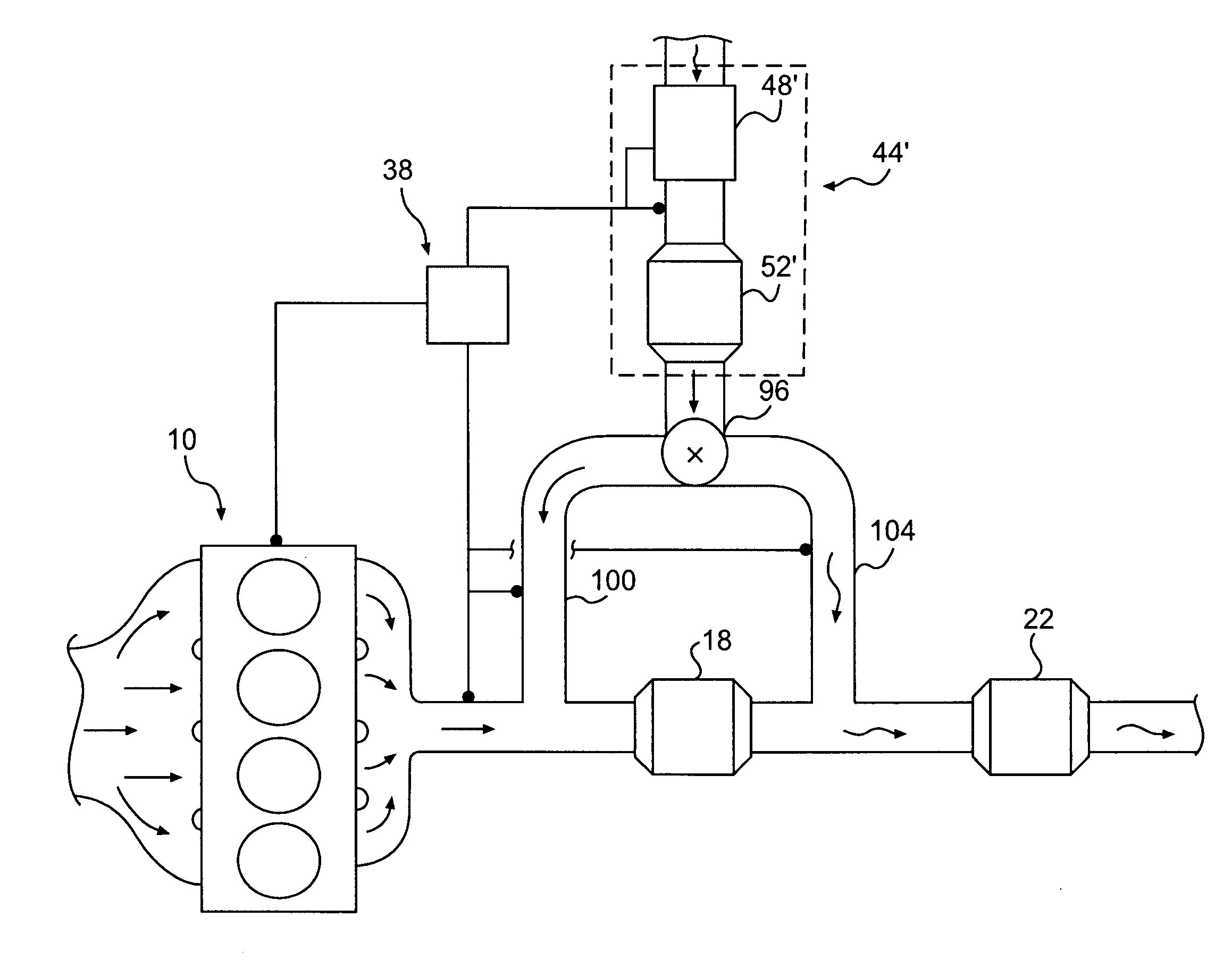

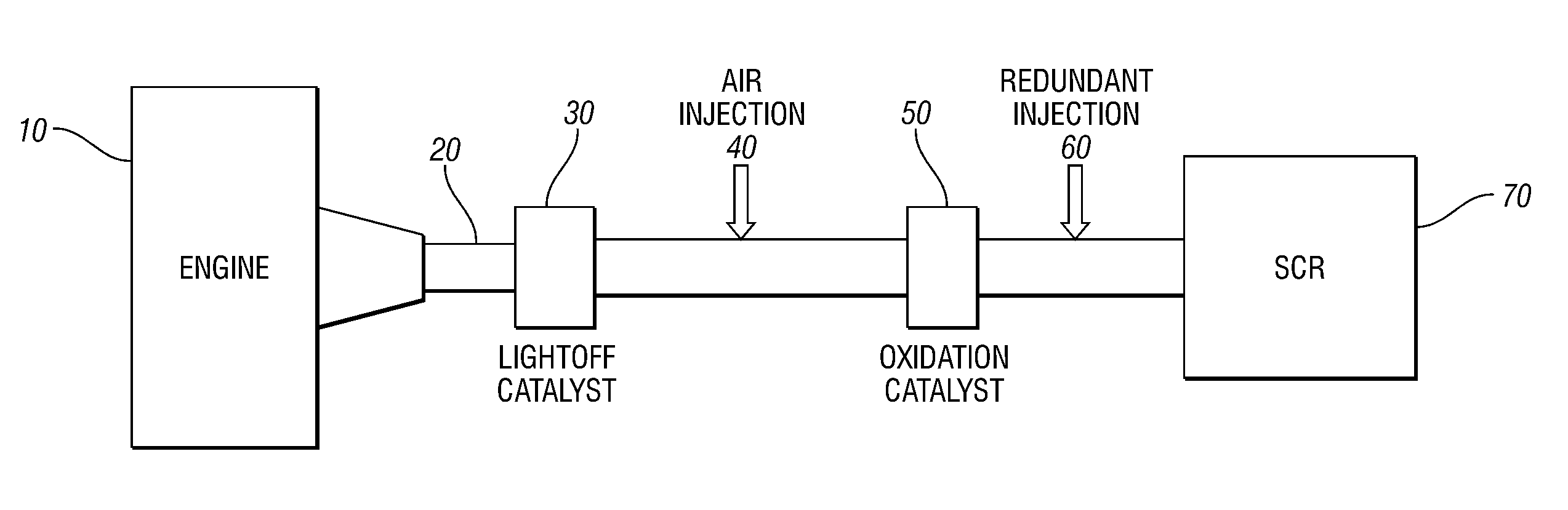

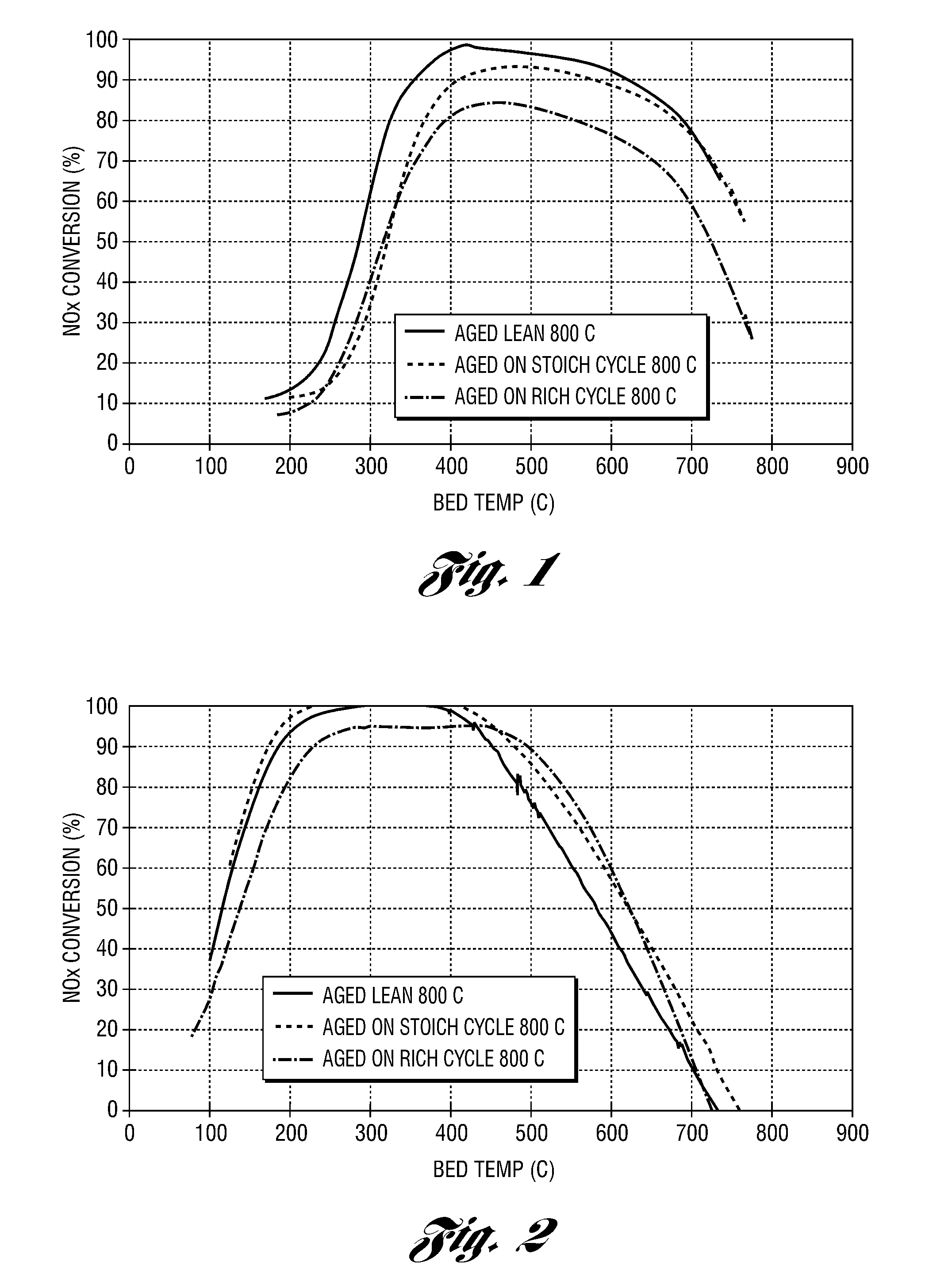

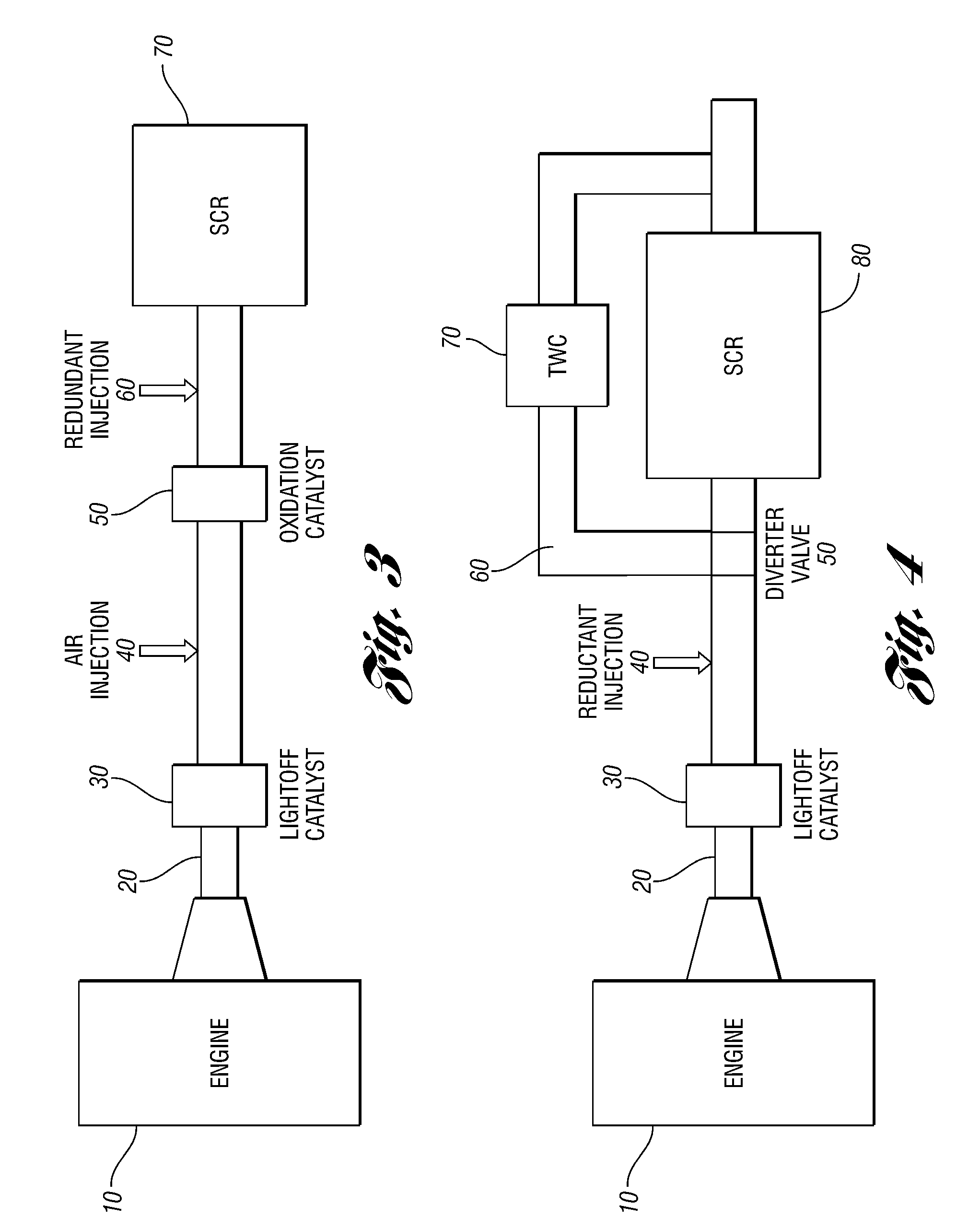

Air-injection system to improve effectiveness of selective catalytic reduction catalyst for gasoline engines

InactiveUS20090260349A1Increased durabilityHarmful emissionGas treatmentInternal combustion piston enginesGasolineEngineering

Embodiments are described to improve the durability of a lean NOx aftertreatment system. According to one embodiment of the present invention an air injection system is used to inject air continuously into the exhaust system between the upstream three-way catalyst and the downstream selective catalytic reduction (SCR) catalyst when the engine is operating at stoichiometric or rich air / fuel ratios and the exhaust temperatures are above a calibratible level (e.g., 700° C.). In another embodiment, an oxidation catalyst is positioned downstream of the air injection point to prevent exothermic reactions from occurring on the SCR. In another embodiment, the reductant for the SCR is generated in-situ. In yet another embodiment, a diverter valve with a reduction catalyst in a bypass arm is utilized to bypass the SCR during high load conditions.

Owner:FORD GLOBAL TECH LLC

Low temp. multiple component capalyst for flue gas denitration and its preparation process

InactiveCN1724149AHigh activityActivity has no effectDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsHigh resistanceReaction temperature

A medium-and low-temp multi-element catalyst for denitrifying fume, that is, using NH4 for selective catalytic reduction (SCR) to Nox is composed of the oxide of Mn as active component, TiO2 as carrier, and the co-catalyst chosen from the oxides of valence-varied Fe, Cu, V, Ce and Cr. Its advantages are high catalytic activity and high resistance to SO2 and H2O poisoning.

Owner:XIANGTAN UNIV

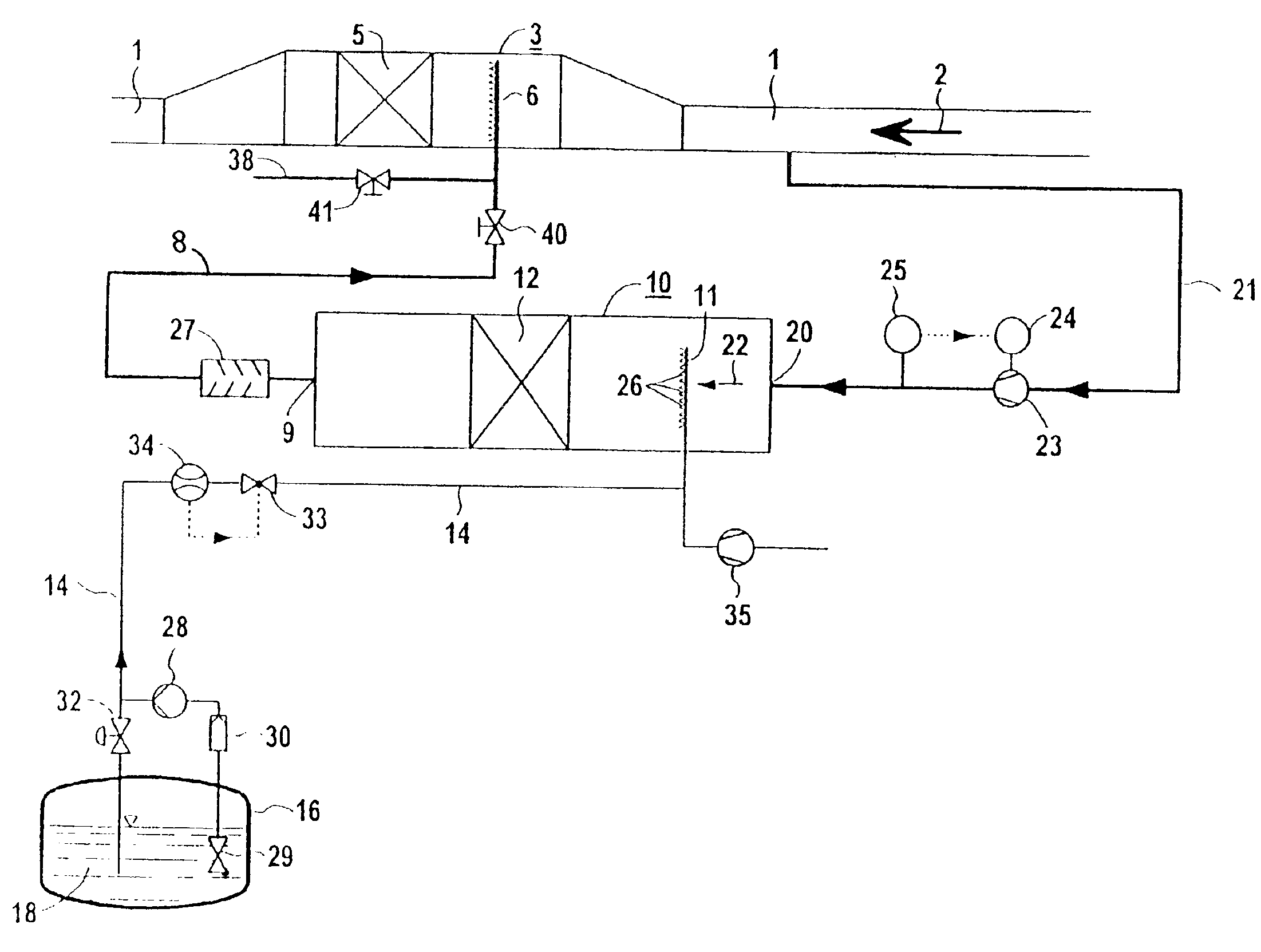

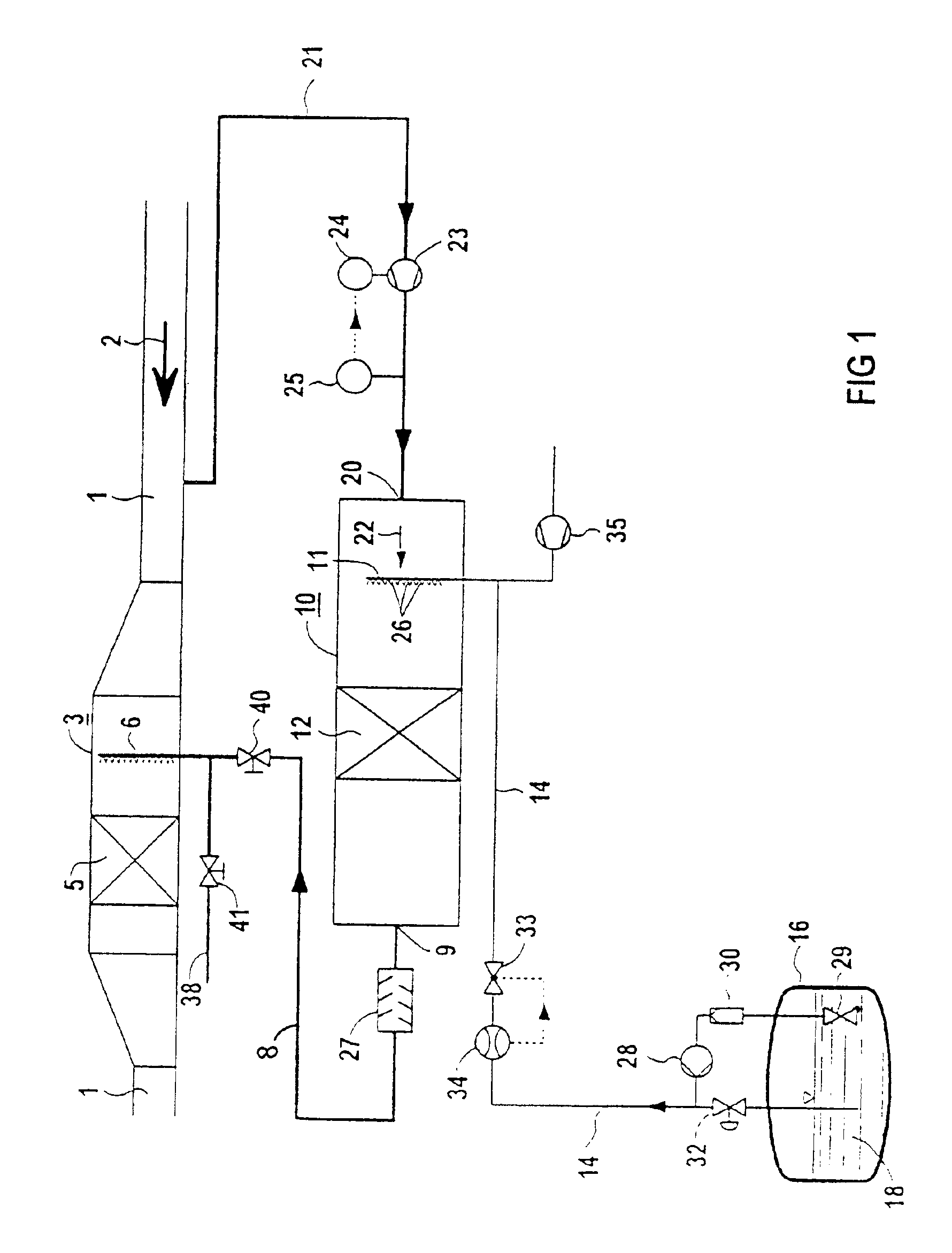

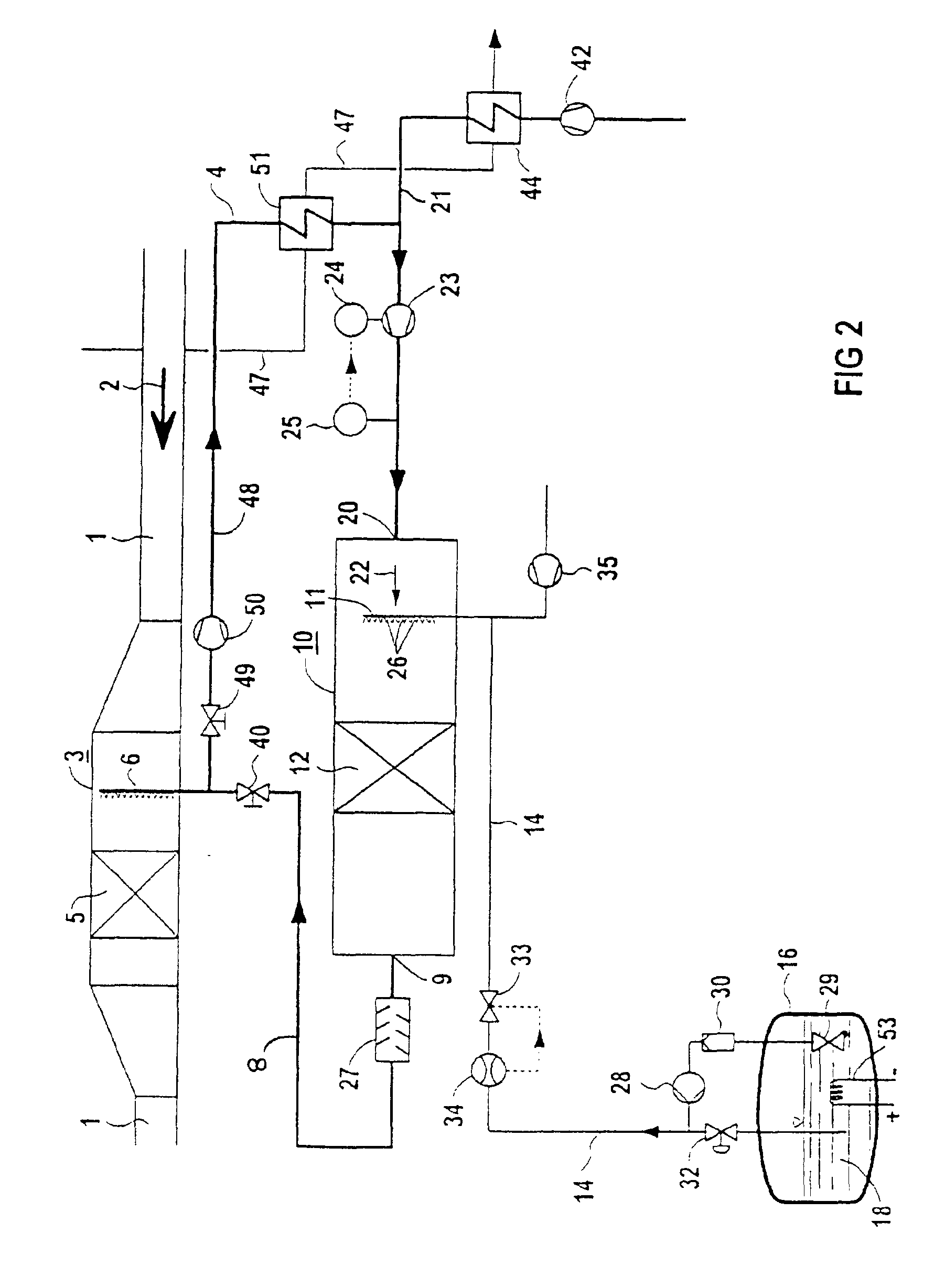

Process and device for the selective catalytic reduction of nitrogen oxides in an oxygen-containing gaseous medium

InactiveUS6878359B1Increase flow rateSimple technical meansNitrogen compoundsExhaust apparatusNitrogen oxideOxygen

The process and the device are provided for the selective catalytic reduction of nitrogen oxides in an oxygen-containing gaseous medium. The reducing agent required for the reaction is prepared in a separate preparation reactor. A substance that can be converted into the reducing agent is introduced into a carrier gas in the preparation reactor and, as a result, is converted by substantially thermal conversion. The energy required for the conversion is provided by the carrier gas.

Owner:CONTINENTAL AUTOMOTIVE GMBH

Process for the selective catalytic reduction of the nitrogen oxides contained in a lean exhaust gas

Owner:DMC2 DEGUSSA METALS +1

Method for recovering tungsten trioxide and ammonium metavanadate from selective catalytic reduction (SCR) denitration catalyst

ActiveCN102557142AEmission reductionTungsten oxides/hydroxidesDispersed particle separationWarm waterAmmonium paratungstate

The invention relates to a method for recovering tungsten trioxide and ammonium metavanadate from a selective catalytic reduction (SCR) denitration catalyst. The method comprises the following steps of: crushing the SCR denitration catalyst, sieving to obtain catalyst powder, mixing with sodium carbonate, and stirring fully and uniformly; putting the mixed powder into a sintering furnace, and sintering to obtain a sintered material; keeping temperature for 1 hour, and sieving to obtain sintered material powder; pouring warm water, so that Na2WO4 and NaVO3 in the sintered material powder are dissolved fully, filtering, and removing precipitates to obtain a mixed solution of Na2WO4 and NaVO3; regulating the pH value to be 6.5-7.5, adding an ammonium bicarbonate solution or an ammonium chloride solution, and precipitating ammonium metavanadate precipitate; filtering, washing by using a diluted ammonium bicarbonate solution for 2 to 3 times, washing by using 30 percent ethanol for 1 to 2 times, and drying to obtain an ammonium metavanadate finished product; and converting the Na2WO4 in the residual solution into ammonium paratungstate, evaporating the residual solution to obtain ammonium paratungstate crystals, and calcining to obtain the tungsten trioxide. By the method, the ammonium metavanadate and the tungsten trioxide can be recovered, and the discharge of pollutants is reduced.

Owner:江苏万德环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com