Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1179 results about "Tungstic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tungstic acid refers to hydrated forms of tungsten trioxide, WO₃. Both a monohydrate (WO₃·H₂O) and hemihydrate (WO₃·0.5H₂O) are known. Molecular species akin to sulfuric acid, i.e. (HO)₂WO₂ are not observed.

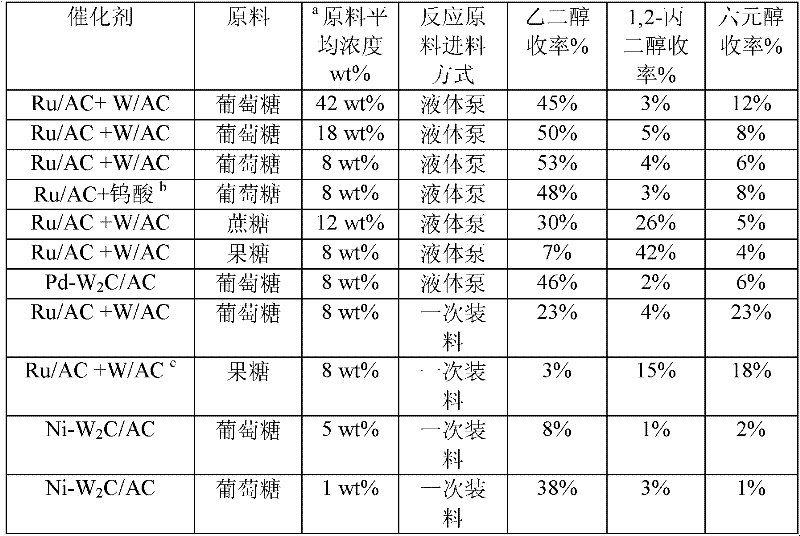

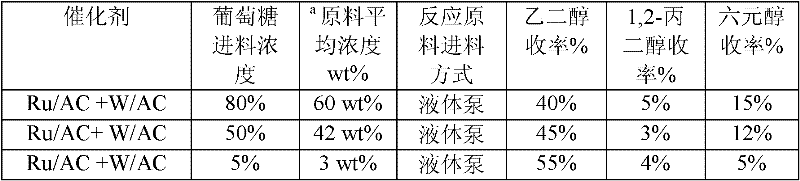

Method for preparing ethylene glycol and 1,2-propylene glycol by using saccharide solution

ActiveCN102675045AIncrease concentrationReduce distillation energy consumptionOrganic compound preparationHydroxy compound preparationHydrogen pressurePolyethylene glycol

The invention provides a method for preparing ethylene glycol and 1,2-propylene glycol by using a high-concentration saccharide solution. Reaction raw materials comprise cane sugar, glucose, fructose, fructosan, xylose, soluble lower polyxylose and soluble starch. According to the method, high-concentration saccharide is used as a reaction raw material, and a high-pressure pump feeding mode is used in a reaction process which is performed in a high-pressure reaction kettle; iron, cobalt, nickel, ruthenium, rhodium, palladium, iridium and platinum which serve as transition metal in eighth, ninth and tenth groups are used as hydrogenation active ingredients; the hydrogenation active ingredients form a composite catalyst together with metal tungsten, tungsten carbide, tungsten nitride, tungsten phosphide, tungsten oxide, tungsten sulfide, tungsten chloride, tungsten hydroxide, tungsten bronze, tungstic acid, tungstate, metatungstic acid, metatungstate, paratungstic acid, paratungstate, peroxotungstic acid, peroxotungstate and tungsten-containing heteropolyacid which serve as catalytic active ingredients; and the high-concentration saccharide solution can be efficiently prepared into the ethylene glycol and the propylene glycol at high selectivity and high yield in a one-step catalytic conversion process under the hydrothermal condition that the temperature is 120 to 300 DEG C and the hydrogen pressure is 1 to 13MPa. By the method, the problem of coking of the high-concentration saccharide in the catalytic conversion process can be effectively solved, and high-concentration ethylene glycol and propylene glycol can be prepared by the high-concentration saccharide.

Owner:中科柏易金(郑州)新能源科技有限责任公司

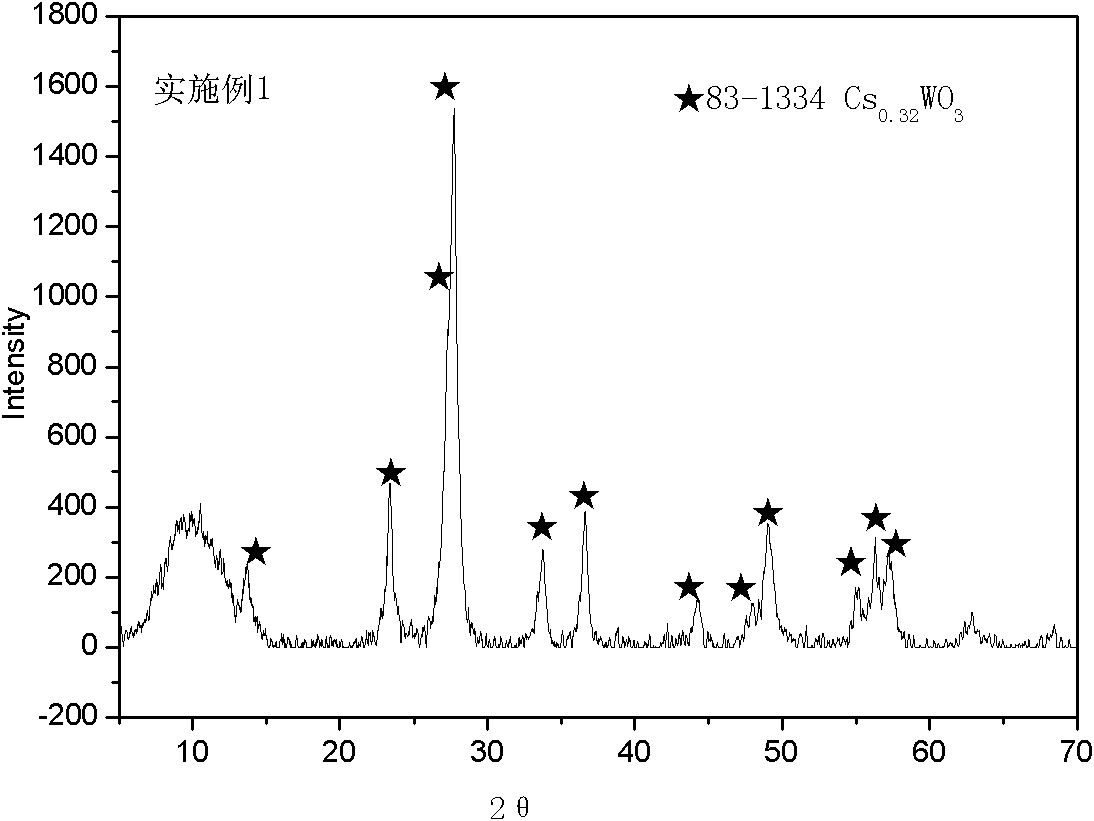

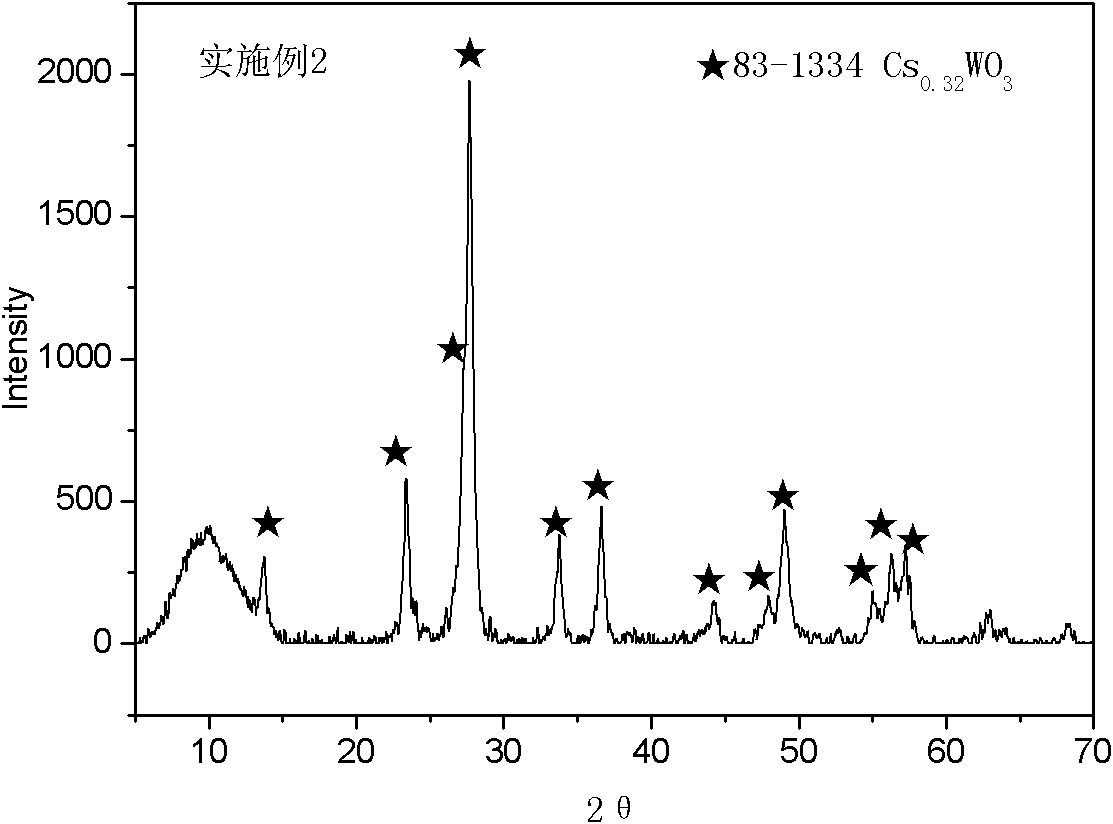

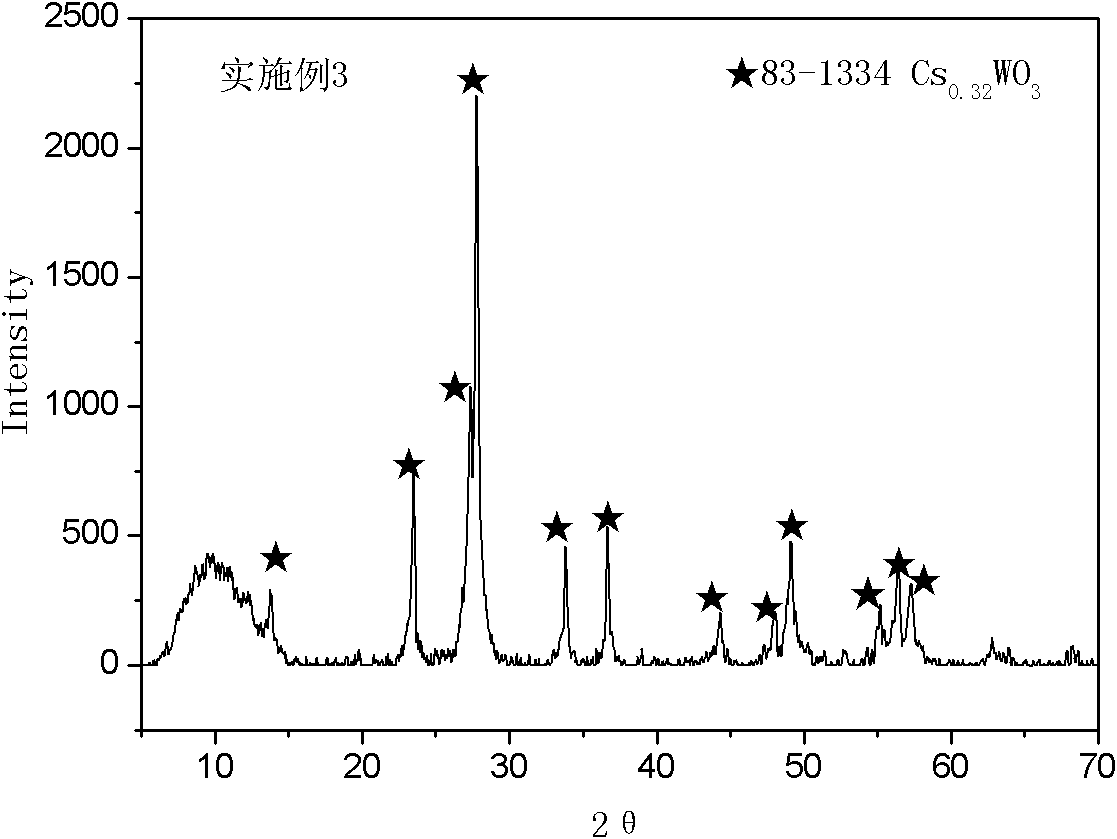

Cesium tungsten bronze powder and preparation method thereof

InactiveCN102320662AOptimal Control StructureReduce manufacturing costTungsten compoundsGranularitySolvent

The invention relates to cesium tungsten bronze powder and a preparation method thereof. The method comprises the following steps that: 1, precursor solution with tungstic acid, cesium carbonate and reducing substances is prepared according to a Cs / W mole ratio of 0.01 to 0.35 / 1, and the solvents are water or a mixture formed by ethanol and the water according to a volume ratio of 1 / 4 to 4 / 1; and 2, the precursor solution takes reaction for 1 to 3d under the condition of 180 to 200 DEG C in an autoclave, and the cesium tungsten bronze powder is obtained after the obtained precipitates are treated. The powder has the crystalline phase composition of Cs0.2WO3 or Cs0.32WO3, the size of the powder particle is 100 to 1300nm, and the specific surface area is 7 to 50m<2> / g. The synthetic process has the advantages that raw materials are cheap and mild, the operation is easy, the production cost can be reduced, in addition, the low-temperature (lower than or equal to 20 DEG C) synthesis is adopted, and the process is suitable for production and practical application. In addition, the product purposes are wide.

Owner:DALIAN POLYTECHNIC UNIVERSITY

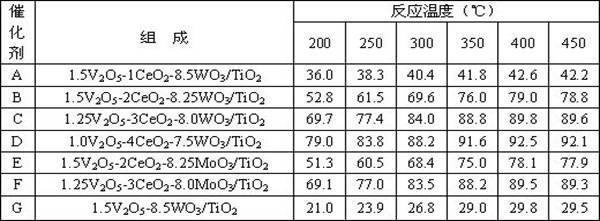

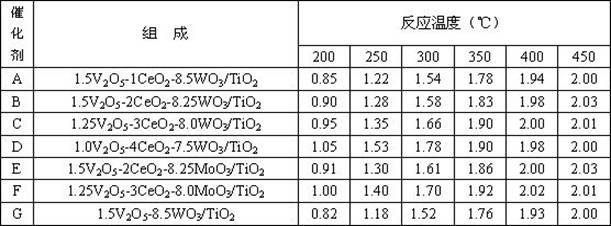

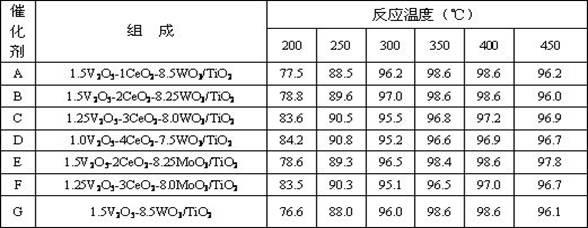

Composite smoke denitration catalyst capable of oxidizing zero-valence mercury

ActiveCN102350340AImprove oxidation capacityRealize collaborative controlDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystVanadate

The invention provides a composite smoke denitration catalyst capable of oxidizing zero-valence mercury. The catalyst is composite oxide V2O5-CeO2-WO3 / TiO2 or V2O5-CeO2-MoO3 / TiO2 based on TiO2 as a carrier, wherein the weight proportion is as follows: the weight percent of TiO2 is 75-100, the weight percent of V is 1-1.5, the weight percent of Ce is 1-5, and the weight percent of W or Mo is 7.5-8.5. The preparation method comprises the following steps: depositing Ce(OH)3 on nano TiO2; dipping ammonium vanadate / ammonium molybdate; and drying and roasting so as to obtain the catalyst; or dipping a commercial SCR (selective catalytic reduction) catalyst in a cerous nitrate aqueous solution, and then drying and roasting. The catalyst provided by the invention maintains the denitraiton efficiency of the original SCR catalyst and simultaneously the oxidation rate of zero-valence mercury is obviously improved, and divalent mercury ions are captured in subsequent dedusting equipment and wet desulphurization system; and the application temperature range of the catalyst is wide, the combination control of emission amounts of nitrogen oxides and mercury in smoke of a fuel coal power plant can be achieved on the promise that the smoke purification facility of the fuel coal power plant is not added.

Owner:GUODIAN SCI & TECH RES INST

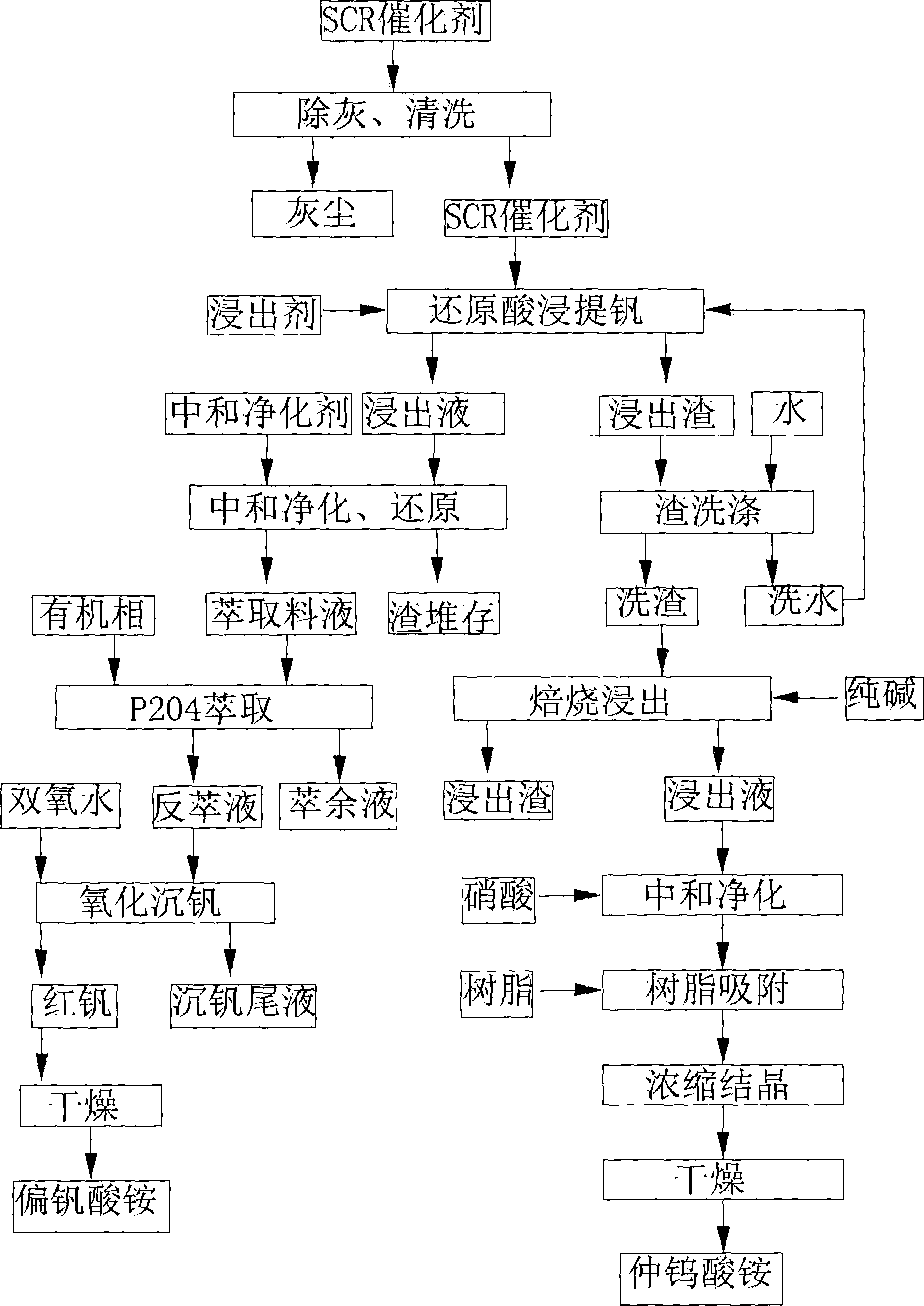

Method for recovering vanadium, tungsten and titanium from waste vanadium-tungsten-titanium-based denitration catalyst

ActiveCN103484678ASimultaneous recoveryLow recovery rateTitanium compoundsVanadium compoundsTungstateAmmonium metavanadate

The invention relates to a method for recovering non-ferrous metals from waste denitration catalysts, particularly relates to a method for recovering vanadium, tungsten and titanium from a waste vanadium-tungsten-titanium-based denitration catalyst, belonging to the field of non-ferrous metal recovery technologies. The method mainly comprises the steps of preparing the catalyst into powder with the grain size being smaller than 100 meshes, and adding concentrated alkali liquor; heating to react vanadium, tungsten and titanium with alkali, so as to produce slightly-soluble titanate, water-soluble vanadate and tungstate; filtrating to obtain a titanate filter cake, wherein titanate or titanic acid can be prepared from the filter cake; adding ammonium salt into a filtrate so as to precipitate ammonium metavanadate, and filtrating to obtain ammonium metavanadate and a new filtrate; adding concentrated acid into the new filtrate, thereby preparing solid tungstic acid. The method has the advantages of simple process, low energy consumption, good solid-liquid reaction contact, high vanadium, tungsten and titanium recovery rate, and the like.

Owner:BEIJING UNIV OF CHEM TECH

Compound nano material of graphene nano slice and WS2 and preparation method thereof

InactiveCN102142550AMild reaction conditionsSimple preparation processMaterial nanotechnologyCell electrodesSynthesis methodsNew energy

The invention discloses a compound nano material of graphene nano slice and tungsten disulfide (WS2), and a synthesis method and a preparation method thereof. The compound material is formed by mixing graphene and a WS2 nano material in a mass ratio of (1 to 1)-(4 to 1). The preparation method comprises the following steps of: preparing an oxidized graphite nano slice from graphite by a chemical oxidization method; then dissolving tungstic acid into deionized water so as to form 0.02 to 0.07M of solution; adding L-cysteine serving as a sulfur source and a reduction agent, wherein the mass ratio of the L-cysteine to the tungstic acid is (5 to 1)-(12 to 1); adding the oxidized graphite nano slice into the solution, and ultrasonically treating so that the oxidized graphite nano slice can be fully dispersed in the hydrothermal reaction solution; transferring the mixture into a hydrothermal reaction kettle and sealing; and synthesizing by a one-step hydrothermal method to obtain the compound nano material of graphene and WS2, wherein the mass ratio of the graphene nano slice to the WS2 is (1 to 1)-(4 to 1). The method has the characteristics of mild reaction condition and simple process. The compound nano material of graphene and WS2 synthesized by the method can be widely used as electrode materials of new energy batteries, high-performance national lubricants, catalyst carriers and the like.

Owner:ZHEJIANG UNIV

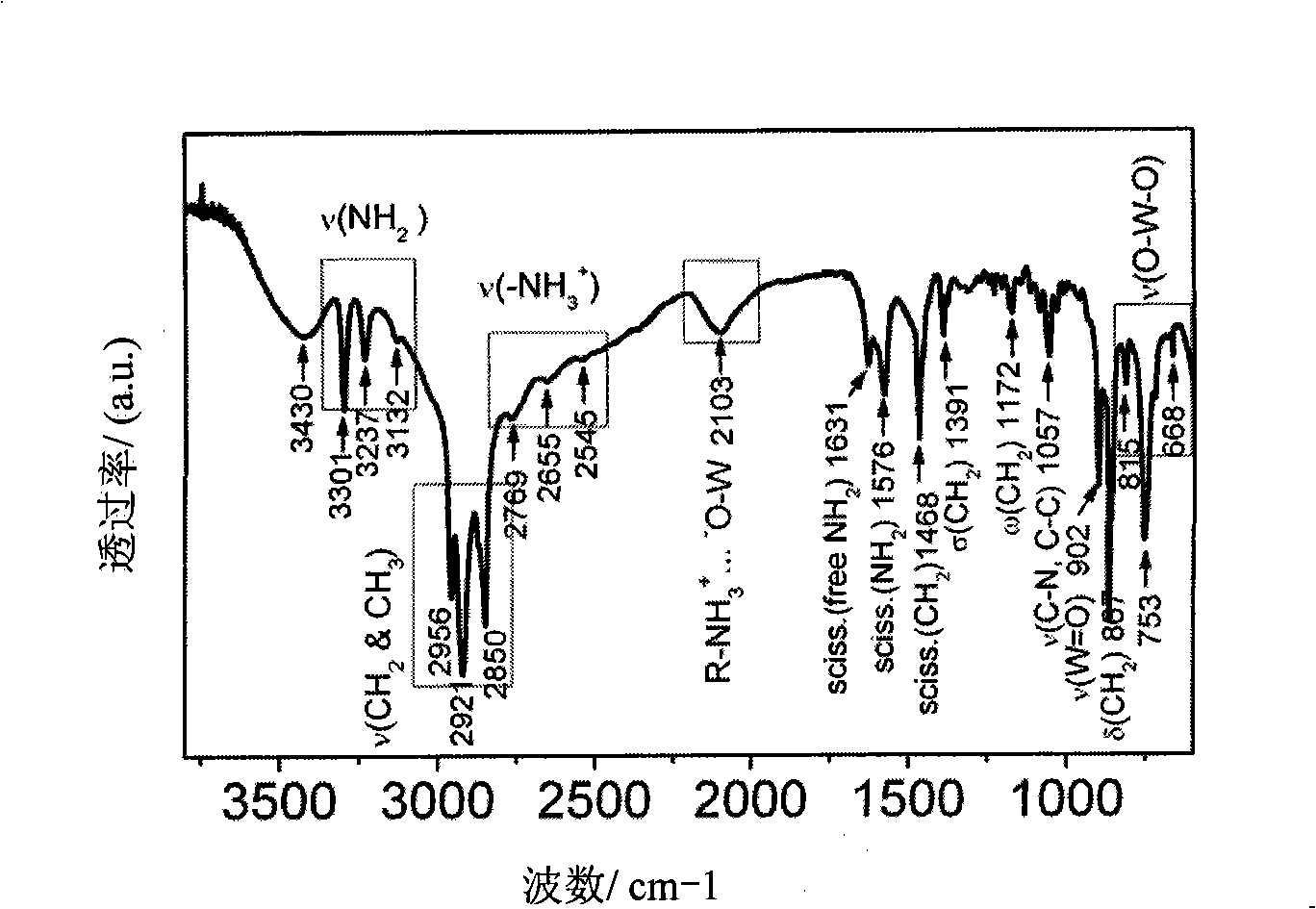

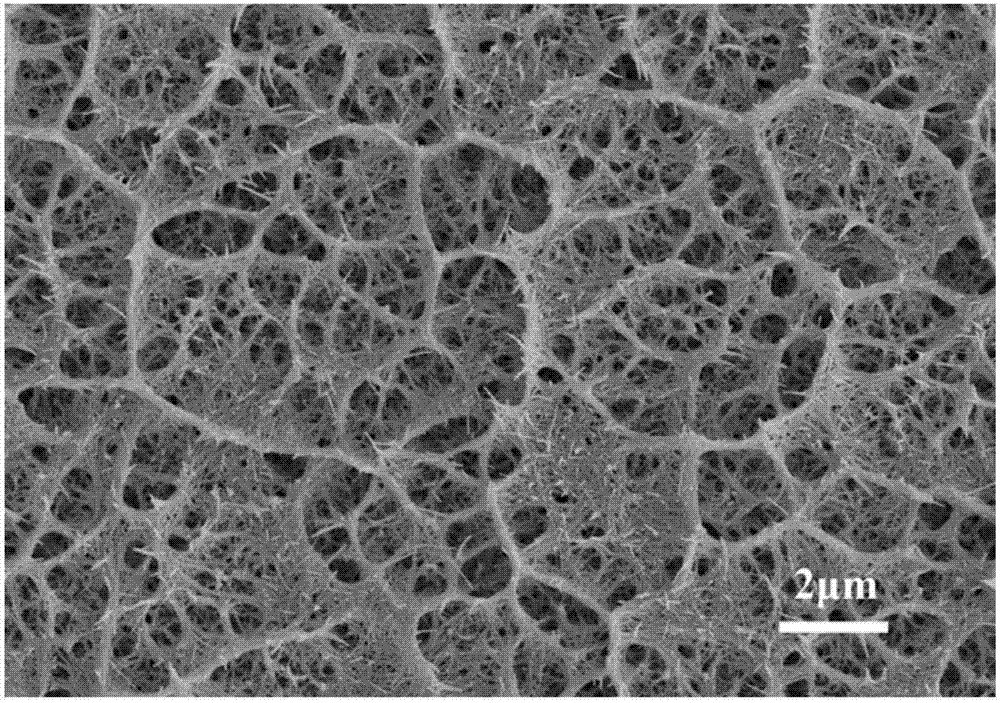

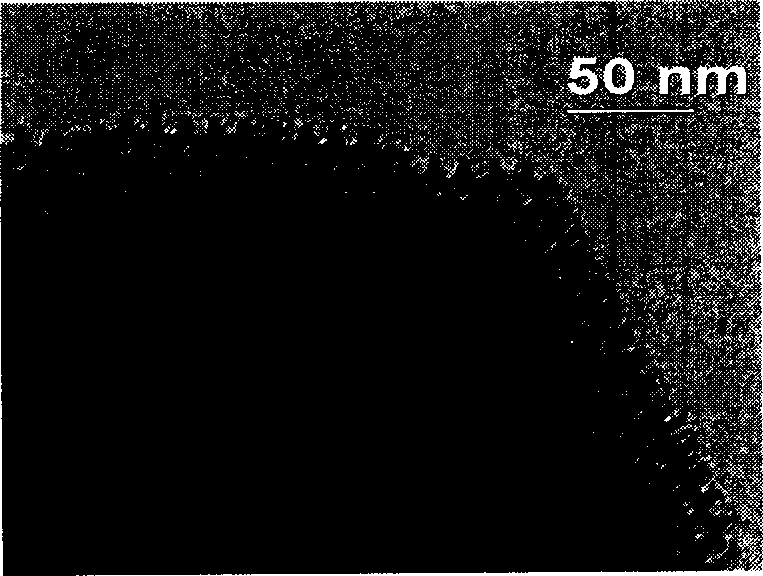

Mesoporous WO[3-x] visible-light-driven photocatalyst with oxygen vacancy as well as preparation method and application thereof

InactiveCN104874389AEasy to adjustEfficient use ofMetal/metal-oxides/metal-hydroxide catalystsOxygen vacancyMesoporous silica

The invention discloses a mesoporous WO[3-x] visible-light-driven photocatalyst with oxygen vacancy and a preparation method thereof. The method comprises the following steps: calcinating at a controlled temperature of 350-600 DEG C in air so as to obtain a mesoporous silica molecular sieve KIT-6 loaded with tungsten trioxide by taking mesoporous silica molecular sieve KIT-6 as a hard template and a silicotungstic acid or phosphotungstic acid hydrate as a tungsten trioxide precursor; then calcinating at a controlled temperature of 450-550 DEG C so as to obtain a mesoporous silica molecular sieve KIT-6 provided with oxygen vacancy and loaded with tungsten trioxide by utilizing H2 as a reducing agent; and finally, removing the mesoporous silica molecular sieve KIT-6 by use of a 10wt% HF aqueous solution, thereby obtaining the mesoporous WO[3-x] visible-light-driven photocatalyst with oxygen vacancy and relatively large specific surface area and pore diameter. The mesoporous WO[3-x] visible-light-driven photocatalyst with oxygen vacancy is capable of effectively utilizing lights to rapidly catalyze CO2 so as to generate methane, and is high in catalysis efficiency, simple in preparation process and needed equipment, environmentally friendly in preparation process and free from pollution.

Owner:SHANGHAI INST OF TECH

Method for separating and extracting tungsten-molybdenum from mixed solution of tungstate-molybdate

InactiveCN101880780AEfficient separationRealize recyclingProcess efficiency improvementMagnesium saltDecomposition

Owner:CENT SOUTH UNIV

Method for preparing rare-earth oxide dispersion strengthened fine-grained tungsten material

ActiveCN105518169AGood compatibilityEvenly distributedTransportation and packagingMetal-working apparatusRare-earth elementTungstate

A method for preparing a rare-earth oxide dispersion strengthened fine-grained tungsten material, comprising: according to a condition that a mass percentage of rare-earth oxide is 0.1-2%, and the remaining composition is W, weighing soluble rare-earth salt and tungstic acid salt, and respectively preparing 50-100 g / L of rare-earth saline solution and 150-300 g / L of tungstic acid saline solution; adding a minor amount of alkali into the rare-earth salt to control the pH to be 7-8, adding an organic dispersing agent, and stirring to enable the rare-earth salt to form uniformly suspending R(OH)3 colloidal particles (R represents a rare-earth element); adding the tungstic acid saline solution into the R(OH)3 colloidal particles, adding a minor amount of acid to control the pH to be 6-7, adding the organic dispersing agent, stirring to enable the tungstic acid salt to form tungstic acid micro-particles, precipitating and coating the R(OH)3 colloidal particles with the R(OH)3 colloidal particles as a core, and forming coprecipitated coated colloidal particles; conducting spray drying on the coprecipitated coated colloidal particles to obtain a composite precursor powder of tungsten and rare-earth oxide; calcining, conducting thermal reduction via hydrogen, and preparing superfine nanometer tungsten powder having a particle size of 50-500 nm; and conducting normal high-temperature sintering after a general pressing forming. The high-performance fine-grained tungsten material dispersed and strengthened by a minor amount of rare-earth oxide prepared by the above method has a density approximate to full density (>=98.5%), and uniform and small tungsten grains having an average size of 5-10 [mu]m; in addition, rare-earth oxide particles having a particle size of 100 nm - 500 nm are uniformly distributed in a tungsten crystal or a crystal boundary.

Owner:长沙微纳坤宸新材料有限公司

Solution composition and method for electroless deposition of coatings free of alkali metals

InactiveUS6911067B2Low costImprove anti-corrosion performanceAnti-corrosive paintsLiquid/solution decomposition chemical coatingElectroless depositionMaterials science

An electroless deposition solution of the invention for forming an alkali-metal-free coating on a substrate comprises a first-metal ion source for producing first-metal ions, a pH adjuster in the form of a hydroxide for adjusting the pH of the solution, a reducing agent, which reduces the first-metal ions into the first metal on the substrate, a complexing agent for keeping the first-metal ions in the solution, and a source of ions of a second element for generation of second-metal ions that improve the corrosion resistance of the aforementioned coating. The method of the invention consists of the following steps: preparing hydroxides of a metal such as Ni and Co by means of a complexing reaction, in which solutions of hydroxides of Ni and Co are obtained by displacing hydroxyl ions OH− beyond the external boundary of ligands of mono- or polydental complexants; preparing a complex composition based on a tungsten oxide WO3 or a phosphorous tungstic acid, such as H3[P(W3O10)4], as well as on the use of tungsten compounds for improving anti-corrosive properties of the deposited films; mixing the aforementioned solutions of salts of Co, Ni, or W and maintaining under a temperatures within the range of 20° C. to 100° C.; and carrying out deposition from the obtained mixed solution.

Owner:LAM RES CORP

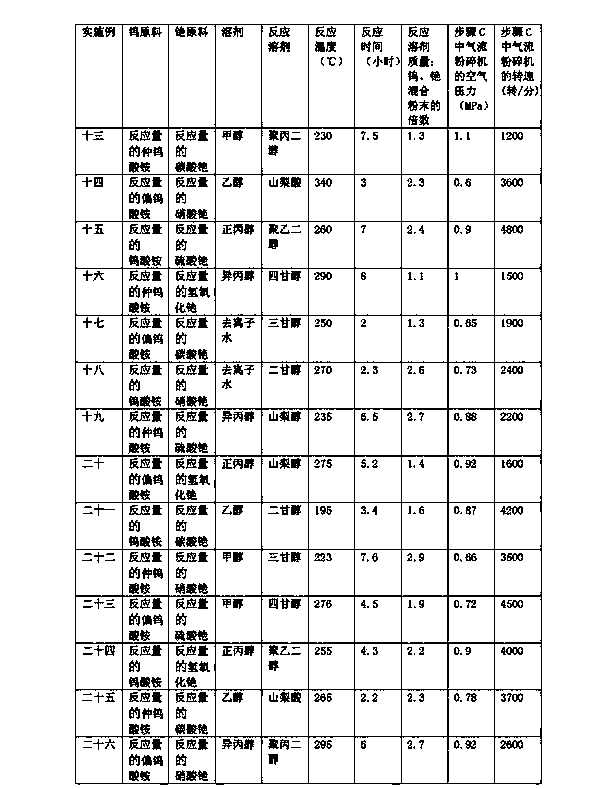

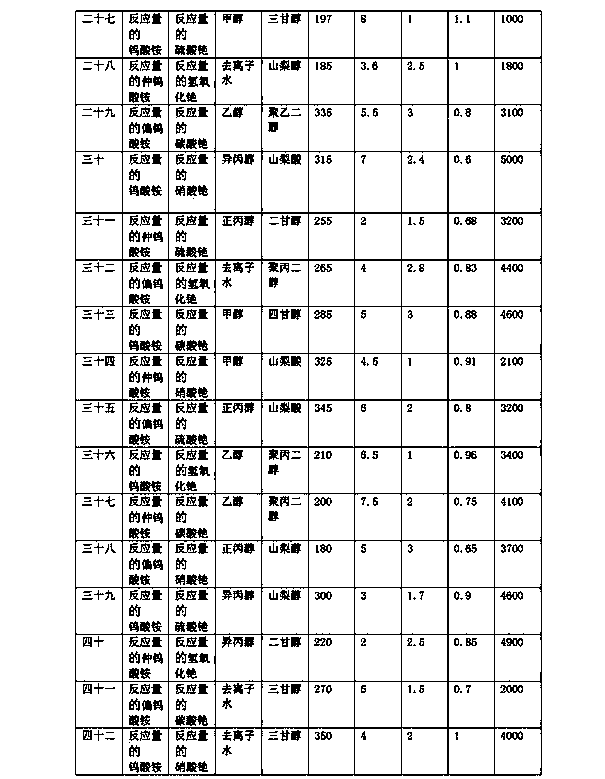

Preparation method of cesium tungstate nanopowder

ActiveCN104192910ALow degree of reunionIncrease productivityMaterial nanotechnologyTungsten compoundsTungstatePhysical chemistry

The invention discloses a preparation method of cesium tungstate nanopowder. The preparation method comprises the following steps of A, dissolving reacting doses of tungsten raw materials and cesium carbonate raw materials into a solvent, drying the solution to obtain particles, and further smashing the obtained particles to obtain tungsten and cesium mixed powder; B, placing the tungsten and cesium mixed powder into a sealed reaction kettle with a stirring function, adding a reaction solvent in the sealed reaction kettle, and reacting at the temperature of 180-350 DEG C for 2-8h while stirring, wherein the mass of the reaction solvent is 1-3 times as mush as that of the tungsten and cesium mixed powder; and C, separating the reaction product obtained in the step B, washing by using deionized water or ethanol, then, drying, and milling by using a jet mill to obtain a target product, namely the cesium tungstate nanopowder. The cesium tungstate nanopowder prepared by using the preparation method is low in agglomeration degree; and the preparation method is high in production efficiency and low in cost.

Owner:宁波今心新材料科技有限公司

Method for preparing denitration catalyst

InactiveCN102357359AImprove conversion rateGood dispersionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystTungstate

The invention discloses a preparation method of a denitration catalyst. The method comprises the following steps: (1) with an intermediate product of metatitanic acid from a titanium dioxide factory as a raw material, washing with dilute nitric acid, weak aqua ammonia, deionized water respectively to remove impurity ions so as to prepare metatitanic acid slurry; (2) orderly adding ammonium tungstate, ammonium molybdate and ammonium metavanadate into the metatitanic acid slurry, beating the mixture by ultrasonic wave, adjusting the pH of the slurry to 4.0-6.5 by an acid; (3) allowing the mixed slurry to stand, drying to obtain the catalyst powder; (4) compacting and molding the catalyst powder into honeycomb by a mold, performing heat treatment at 200-600 DEG C for 4-10 hours to obtain the denitration catalyst of the invention. The method for preparing the denitration catalyst of the invention has low cost and simple process, and the denitration catalyst can increase the conversion rate of NO. The denitration catalyst of the invention can realize a conversion rate of NO in power plant flue gas flue gas components of up to above 97% at a reaction temperature of 350 DEG C.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method of producing tungstic acid by closed type hydrochloric acid decompose tunstite

A process for preparing tungstic acid from scheelite by decomposing it by hydrochloric acid in sealed condition includes such steps as adding hydrochloric acid and powered scheelite to reactor, sealing, thermal decomposing reaction while stirring, filter and washing to obtain H2WO4. Its advantages are high productivity, less consumption of hydrochloric acid and energy, and less environmental pollution.

Owner:ZIGONG CEMENTED CARBIDE CORP

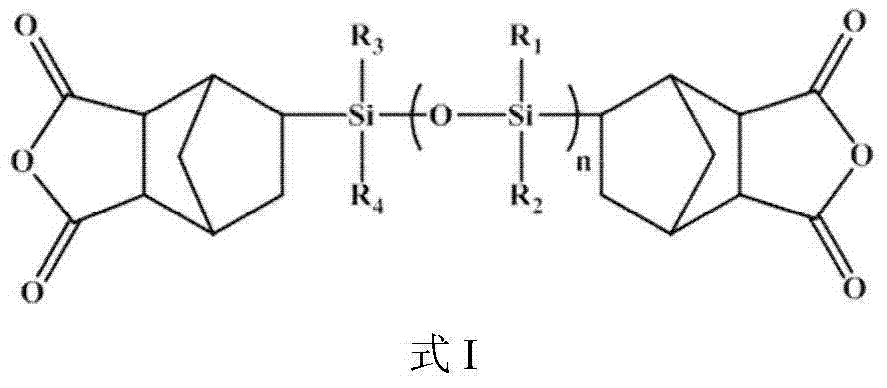

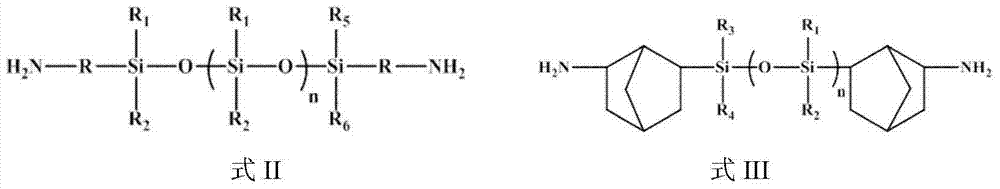

Novel electronic-grade polyimide film with low linear expansion coefficient and manufacturing method thereof

The invention relates to a manufacturing method of an electronic-grade polyimide film with low linear expansion coefficient. The method is characterized by comprising the steps that (1) the step-by-step condensation polymerization technology or the blending compounding technology is used for obtaining two or more polyamide acid glue solutions comprising rigid structures and soft structures at the same time and are different in rigidity and softness; (2) ultrafine inorganic whiskers, like zinc oxide whiskers, silicon carbide whiskers and zirconium tungstate whiskers, which are subjected to surface organic modification already and / or nanoparticle materials are smashed and cavitated through high-energy-density supersonic waves, and then the functional fillers are compounded with polybasic polyamide acid in an in-situ micro-nano mode; (3) the compounded glue solutions are subjected to filtration, vacuum defoamation, extrusion casting filming, chemical amidization or thermal amidization, infrared complete amidization, high-temperature thermal forming processing, corona processing and a reeling process, and therefore the electronic-grade polyimide film with the thickness being 7.5-125 micrometers, the linear expansion coefficient being 5-18ppm / DEG C, and good physical mechanical performance is obtained.

Owner:宏威高新材料有限公司 +1

Modified Powder and Cosmetic Composition Using the Same

ActiveUS20070253989A1Water resistance and cleansabilityUltraviolet protection effect of cosmetic compositions could also be improvedCosmetic preparationsPowder deliveryMass ratioUltraviolet

The present invention provides a modified powder that is obtainable by coating the surface of a base powder with a hydrophobizing agent and a cationic surfactant. In the modified powder described above, it is preferable that the amount of coated hydrophobizing agent and the amount of coated cationic surfactant are 3 to 90% by mass and 0.5 to 10% by mass, respectively, relative to the self weight of the base powder. In the modified powder described above, it is preferable that the mass ratio of the coated hydrophobizing agent and the coated cationic surfactant is from 1:1 to 9:1. In addition, the present invention provides a cosmetic composition comprising the above modified powder wherein the modified powder and the base powder have an ultraviolet scattering effect. In the cosmetic composition described above, it is preferable that the blended amount of the modified powder is from 0.5 to 100% by mass. Furthermore, the present invention provides a sunscreen cosmetic composition comprising the above modified powder with an ultraviolet scattering effect. In the sunscreen cosmetic composition described above, it is preferable that the base powder is one or more selected from the group consisting of titanium oxide, zinc oxide, iron oxide, cerium oxide, bismuth oxide, zirconium oxide, chromium oxide, and tungstic acid. In the sunscreen cosmetic composition described above, it is preferable that the blended amount of the modified powder is from 1 to 40% by mass.

Owner:SHISEIDO CO LTD

Power plant flue-gas SCR denitration catalyst capable of preventing sulfur trioxide poisoning and preparation method thereof

InactiveCN101396656ASimple preparation processEasy to operateDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAmmonium paratungstateSlurry

The invention belongs to the chemical material field, in particular to an SO3 poisoning resisting power plant flue gas SCR denitrification catalyst and a preparation method thereof. Tungsten doped titanium pigment which is synthesized from domestic metatitanic acid slurry and ammonium paratungstate oxalic acid solution is adopted by the catalyst as a carrier. Vanadium is used as a main catalyst, and oxide of germanium or zinc is added as additive for lowering the oxidization of the vanadium on SO2. Through drying, calcining and sieving, the catalyst is obtained. The catalyst comprises 80-95wt percent of TiO2, 3-15wt percent of WO3, 1-8wt percent of V2O5 and 1-8wt percent of GeO2 or ZnO2. The preparation method has the advantages of simple preparation process, easy operation, low cost and good denitrification effect. The SCR catalyst prepared by the method is tested to prove high denitrification efficiency and good SO3 poisoning resistance. Added SO2 has almost no influence on the activity of the catalyst.

Owner:TSINGHUA UNIV +1

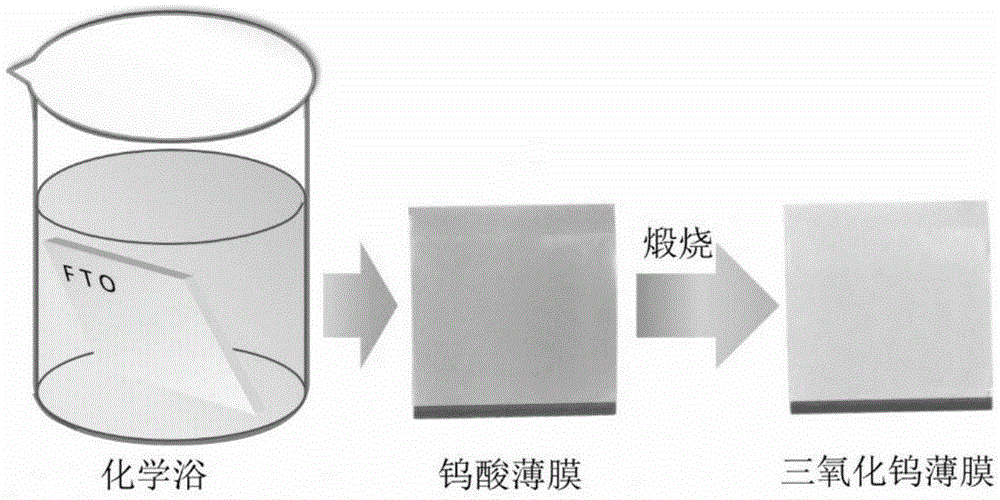

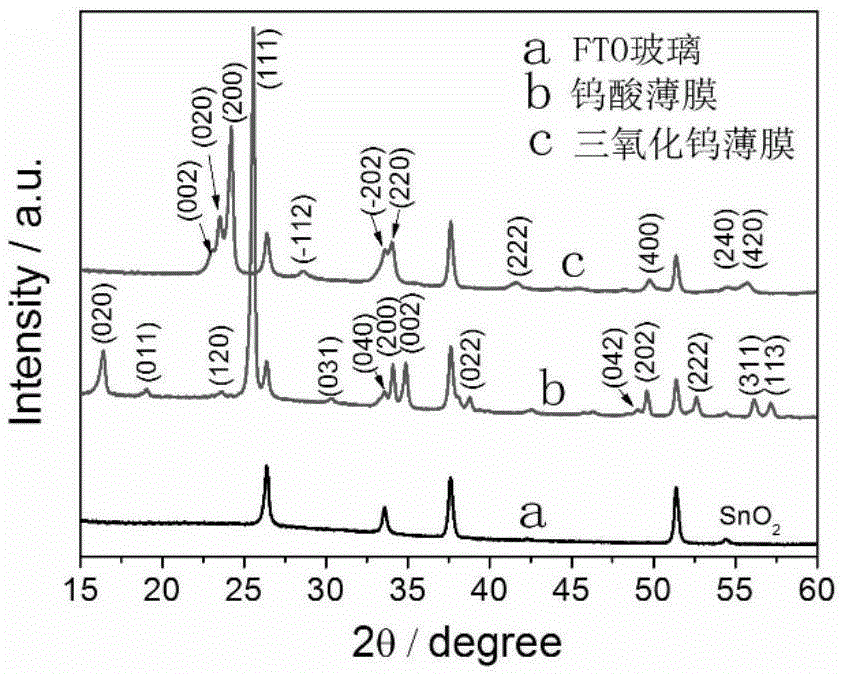

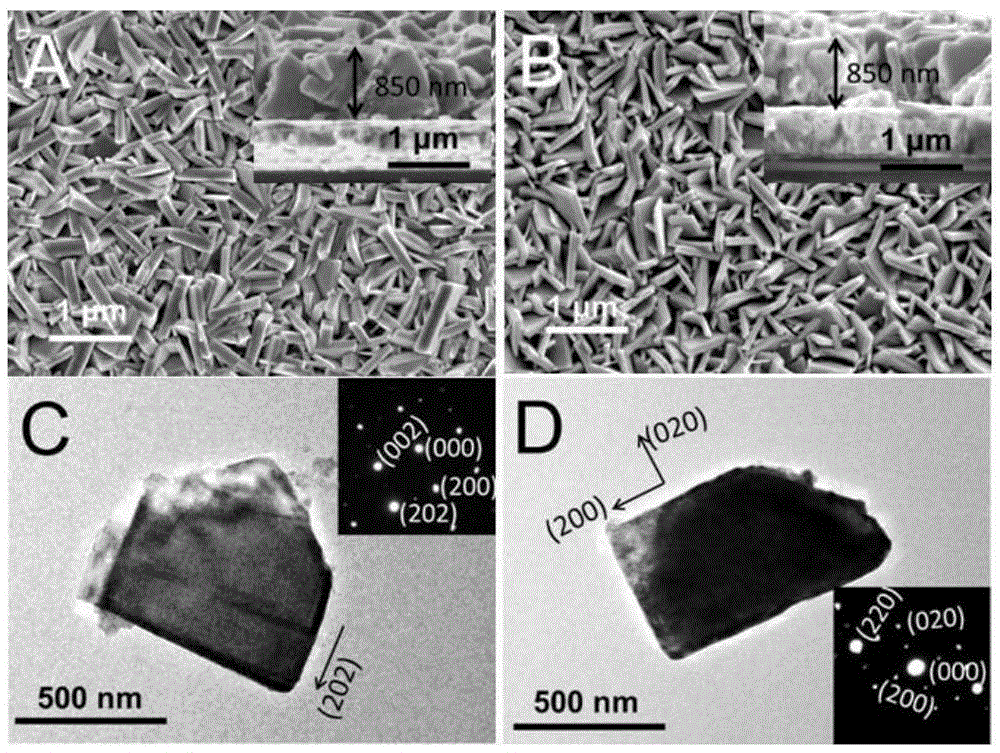

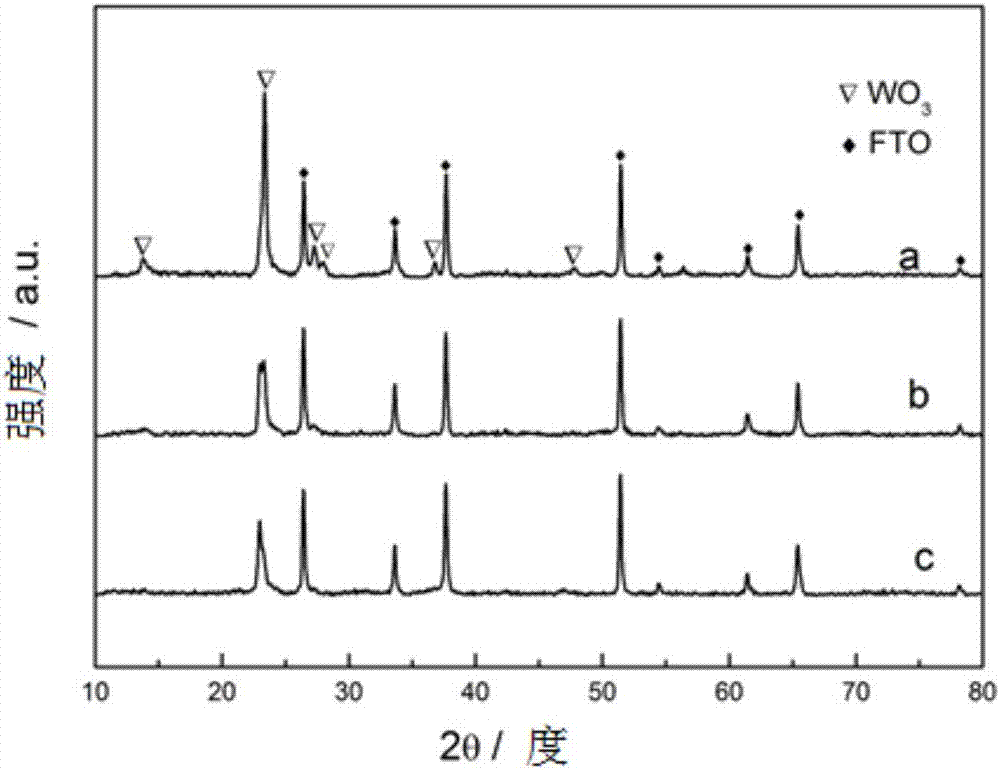

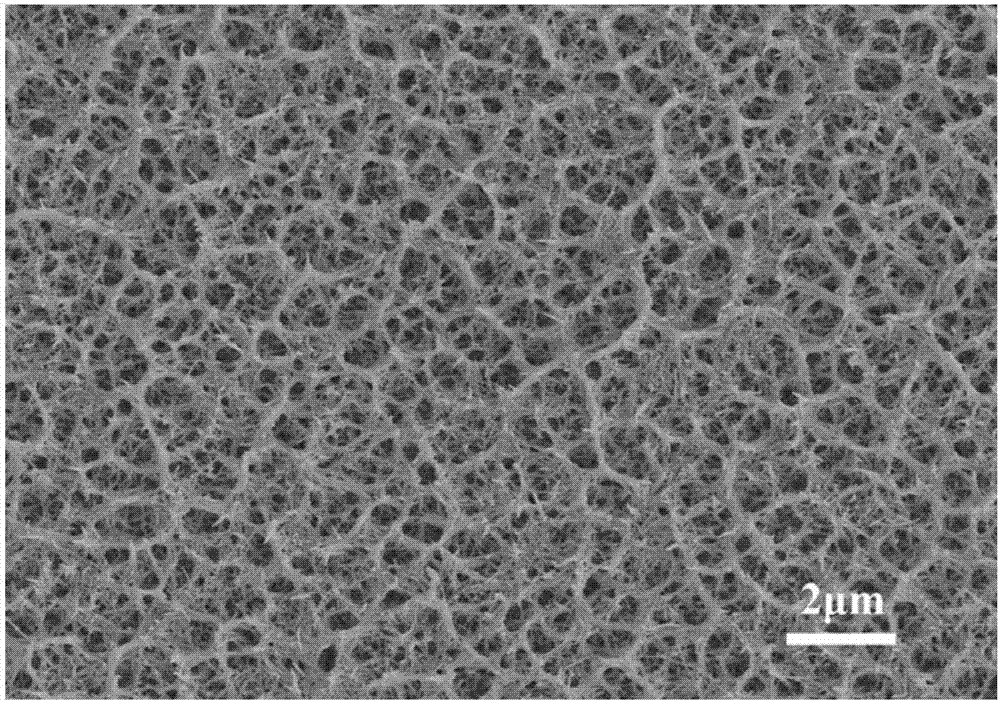

Preparation method and application research of WO3 nanosheet array film

InactiveCN105384358AThe preparation process is simpleThe preparation process is mildCoatingsWater bathsLight response

The invention discloses a preparation technology of a visible-light response WO3 nanosheet array film electrode. The preparation technology comprises the following steps that Na2WO4.2H2O and ammonium oxalate are dissolved in deionized water to react with hydrochloric acid to obtain tungstic acid precipitates, and the tungstic acid precipitates react with H2O2 to obtain a clear peroxotungstic acid solution; an ethyl alcohol reducing agent is added into the peroxotungstic acid solution, fluorine-doped tin oxide (FTO) conducting glass serves as a substrate to be placed in the solution, under the water bath condition, the peroxotungstic acid is slowly reduced into tungstic acid, the tungstic acid is slowly separated out on an FTO film, and then a tungstic acid film is obtained; after being cleaned and dried, the tungstic acid film is calcined to obtain the WO3 nanosheet array film electrode. The preparation technology has the advantages of being simple, convenient, mild, efficient and suitable for large-scale preparation. The prepared WO3 nanosheet array film electrode has the good visible-light absorption property and good stability and is high in photoelectric efficiency, good in photoelectrocatalytic degradation effect on organic matter and capable of being applied to the fields of photoelectrocatalysis hydrogen production and organic matter degradation, and the better effect is achieved.

Owner:SHANGHAI JIAO TONG UNIV

Recycling method for waste denitration catalyst

InactiveCN104099476AEmission reductionShort production processProcess efficiency improvementMagnesium saltAmmonium paratungstate

A recycling method for waste denitration catalyst is characterized by comprising the following steps: (1) the waste denitration catalyst is smashed into powder of 100 to 200 meshes; (2) the powder reacts with an alkali solution under a heating and stirring condition to obtain a titanium-rich material and a solution containing elements such as vanadium, tungsten, silicon and aluminum; (3) the titanium-rich material reacts with chlorine gas to generate titanium tetrachloride, then the titanium tetrachloride is condensed and reacts with oxygen to generate titanium dioxide, and the titanium dioxide is treated with surface finish and drying to obtain a titanium dioxide finished product; (4) the pH value of the solution obtained in the step (2) is adjusted; a magnesium salt is added into the solution to remove silicate ions and obtain a solution containing vanadium and tungsten; calcium chloride powder is added into the solution containing vanadium and tungsten to generate calcium tungstate; the calcium tungstate reacts with hydrochloric acid to generate tungstic acid; the tungstic acid is treated with ammonia dissolution and evaporative crystallization to obtain ammonium paratungstate crystals; (5) a precipitant ammonium chloride is added, and centrifugal drying is carried out to obtain solid ammonium vanadate. The method has the advantages that the operation is easy; three wastes are reduced; the economic efficiency is improved; the waste denitration catalyst is recycled.

Owner:CECEP L&T ENVIRONMENTAL TECH

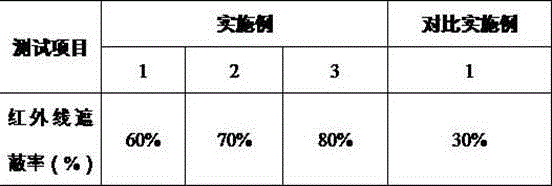

Preparation method of cesium-tungsten bronze powder and function film

InactiveCN104528829AReduce manufacturing costSimple manufacturing processTungsten compoundsInfraredTungstate

The invention discloses a preparation method of cesium-tungsten bronze powder and a function film. The preparation method of the cesium-tungsten bronze powder comprises the following steps: carrying out an exchange treatment on tungstate solution and cationic resin to obtain tungstic acid sol; adding citric acid solution and cesium carbonate solution in the tungstic acid sol and then carrying out a mixing treatment to obtain hydrothermal reaction precursor solution; carrying out a hydrothermal reaction on the hydrothermal reaction precursor solution; after the reaction is finished, carrying out a washing treatment and a drying treatment to obtain the cesium-tungsten bronze powder. The function film disclosed by the invention contains the cesium-tungsten bronze powder prepared by the preparation method of the cesium-tungsten bronze powder disclosed by the invention; according to the preparation method of the cesium-tungsten bronze powder disclosed by the invention, by controlling reactants and carrying out hydrothermal method, the preparation process is effectively simplified and the production cost of the cesium-tungsten bronze powder is reduced; moreover, the cesium-tungsten bronze produced under a specific hydrothermal reaction condition has excellent shielding performance for infrared ray, particularly for near-infrared ray.

Owner:SHENZHEN JIADA HIGH TECH IND DEV

Comprehensive recycling method for waste titanium based vanadium SCR catalyst

ActiveCN104384167ARealize resource utilizationReduce processing costsSolid waste disposalPregnant leach solutionAmmonium paratungstate

The invention relates to a comprehensive recycling method for a waste titanium based vanadium SCR (selective catalytic reduction) catalyst. The method comprises the steps of: removing dust from the waste SCR catalyst; crushing the treated SCR catalyst; subjecting the crushed powder material to acid leaching vanadium extraction in an acid leaching tank, conducting neutralization, reduction and purification on the leachate, then employing P204 to conduct organic extraction, and performing drying to obtain the product ammonium metavanadate; washing the leaching residue generated by vanadium extraction to be close to neutral, adding sodium carbonate to conduct roasting so as to obtain a roasted material, levigating the roasted material and then conducting water leaching, adjusting the obtained leachate with acid to a pH value of 6-9, adsorbing tungsten with weakly basic anions, resolving the loaded resin with a mixed solution of ammonia water and ammonium chloride; heating the resolved solution to boiling and volatilizing ammonia in the solution until the pH value of the ammonia solution is reduced to 7.0-7.7, performing cooling to obtain wet ammonium paratungstate, and finally carrying out drying to obtain the product ammonium paratungstate. The method provided by the invention can effectively recover valuable metals in the waste catalyst.

Owner:HUADIAN HIGH TECH GAOBEIDIAN ENVIRONMENTAL TECH +1

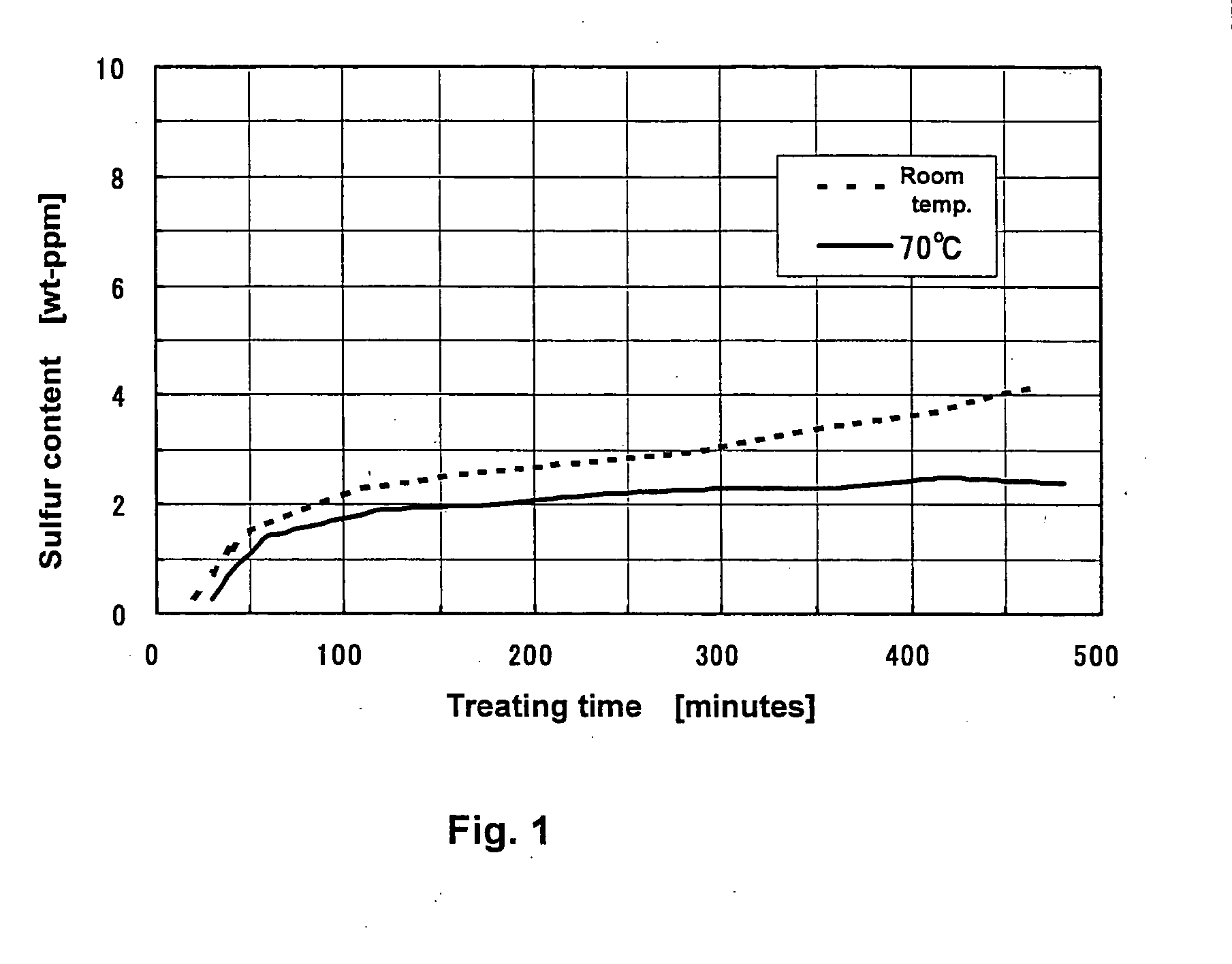

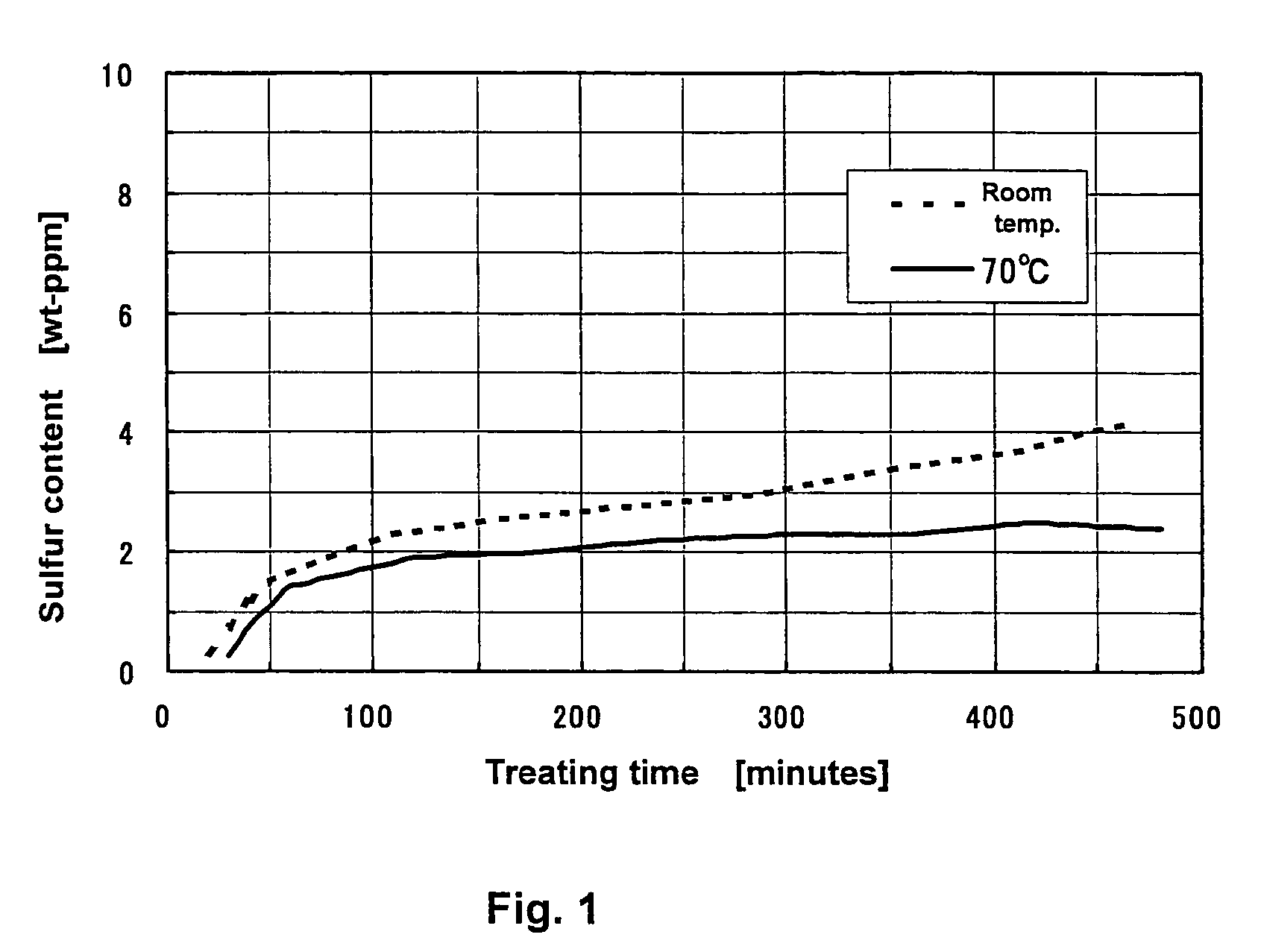

Method of Desulfurizing Hydrocarbon Oil

InactiveUS20090000990A1Suitable for applicationEfficiently and economically removedCatalytic naphtha reformingLiquid carbonaceous fuelsSolid acidTin

A method of desulfurizing / refining a hydrocarbon oil by which sulfur compounds are diminished to an extremely low concentration at a relatively low equipment cost and operating cost. The method of desulfurizing / refining a hydrocarbon oil comprises bringing a hydrocarbon oil containing at least one sulfur compound selected from the group consisting of thiophene compounds, benzothiophene compounds, and dibenzothiophene compounds and optionally further containing aromatic hydrocarbons into contact with a solid acid catalyst and / or an activated carbon having a transition metal oxide supported thereon to thereby desulfurize the oil. The solid acid catalyst preferably is a solid ultrastrong-acid catalyst selected among sulfuric acid radical / zirconia, sulfuric acid radical / alumina, sulfuric acid radical / tin oxide, sulfuric acid radical / iron oxide, tungstic acid / zirconia, and tungstic acid / tin oxide.

Owner:JAPAN ENERGY CORP

Composite catalyst for preparing sec-butyl acetate with direct esterification of ethyl ester and butylene

InactiveCN101293210ASolve the problem of reduced catalytic efficiencyCatalyst carriersOrganic compound preparationHeteropoly acidCordierite

The present invention relates to a composite catalyst for preparing sec-butyl acetate by direct esterification of ethyl ester and butylene, which takes heteropoly acid as the catalyst active component and porous carrier as the dispersant; the weight proportion of the heteropoly acid and the porous carrier is 0.01:1 to 10:1. The heteropoly acid is one with Keggin structure, which consists of phosphotungstic acid, silicotungstic acid, germanium tungstic acid, arsenowolframic acid, phosphomolybdate, germanomolybdate or arsenicomolybdate. The porous carrier comprises porous SiO2, Al2O3, SBA-15, MCM-41, white carbon black, porous SiC, corallite, andalusite, cordierite, meerschaum, Attapulgite or kaolin. The composite catalyst of the present invention solves the problem that the catalysis efficiency is low if the heteropoly acid is separated out from the reaction system.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

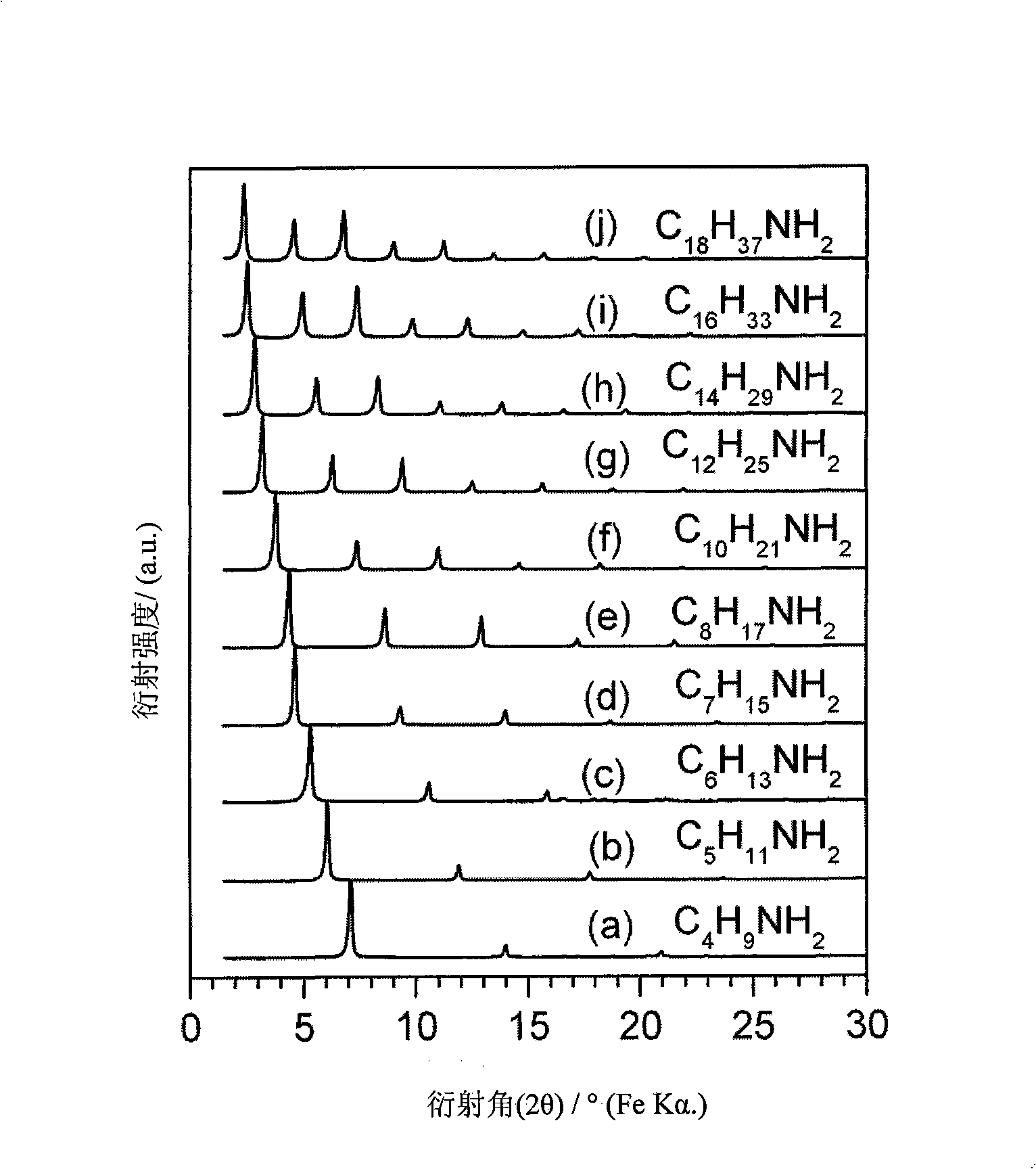

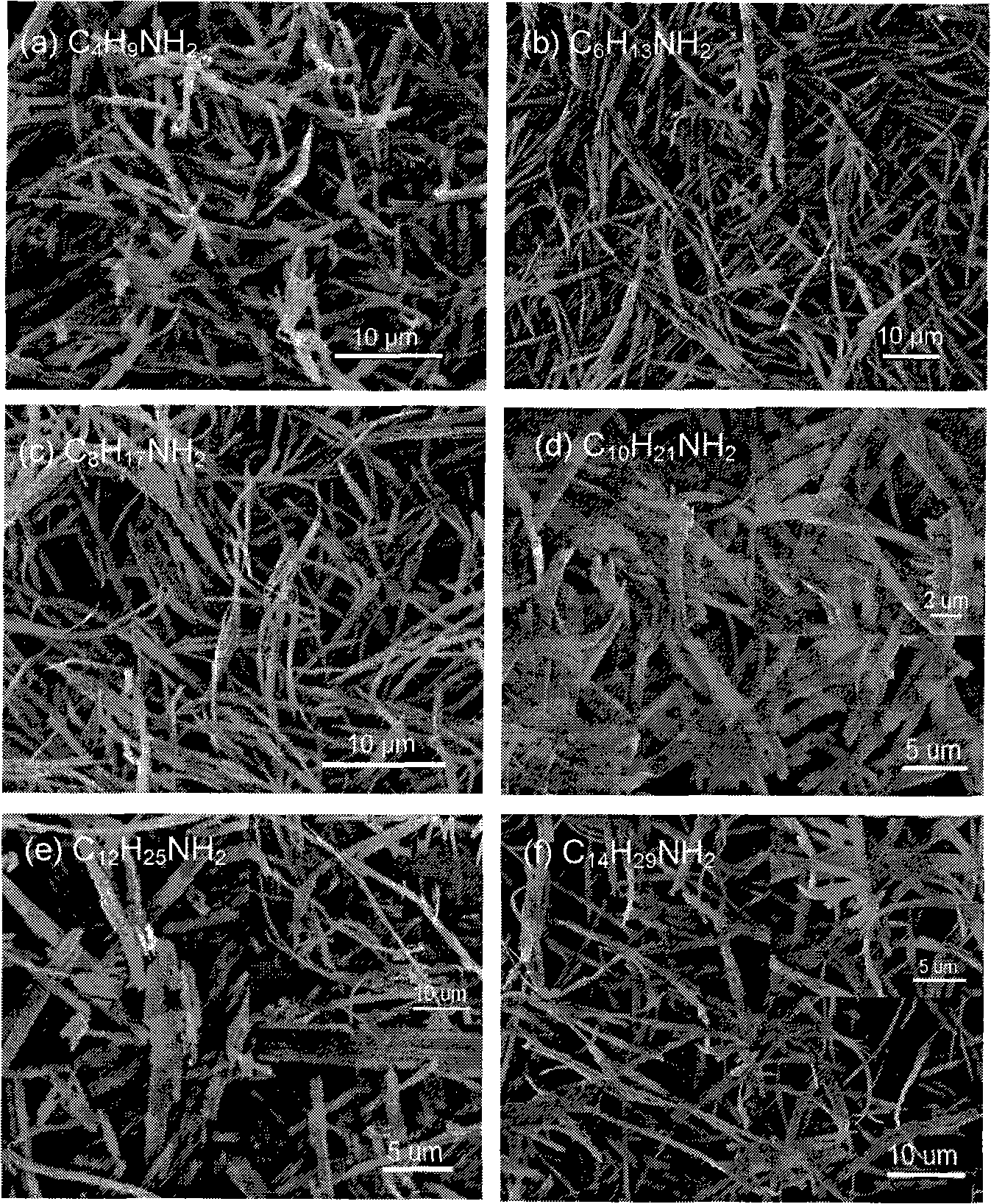

Tungstic trioxide nano-slice and preparation method thereof

InactiveCN101318702AImprove efficiencyPerformance is not affectedNanostructure manufactureTungsten oxides/hydroxidesReaction temperatureSingle crystal

The invention relates to a tungsten trioxide (WO3) nano-plate and a preparation method thereof. The tungsten trioxide (WO3) nano-plate is characterized in that: the tungsten trioxide (WO3) nano-plate is monocrystal and monoclinic phase (JCPDS No.43-1035), and is shaggy and flocculent; the area is (100-800)nmx(100-800)nm; the apparent thickness is between 5 and 40 nanometers; and the BET specific surface area can reach 100-250 square meters per gram. The preparation method for the tungsten trioxide (WO3) nano-plate comprises the following steps that: a tungstenic acid organic or inorganic laminated mixed micron / nano belt (pipe) is taken as a precursor, and organic substances between precursor layers are removed through oxidation by a nitric acid, and then a tungstenic acid (WO3.H2O) nano-plate is prepared; the reaction temperature is between 15 and 50 DEG C, and the reaction time is between 5 and 120 hours; the tungstenic acid (WO3.H2O) nano-plate is heated up to between 250 and 600 DEG C at a heating rate of between 1 and 5 DEG C per minute, undergoes heat insulation for 1 to 5 hours, and finally naturally cooled to the room temperature so as to remove crystal water, and the tungsten trioxide nano-plate is prepared. The method has a simple technological process, a large variation range of operating parameters, strong adaptability, low facility requirement, controllable appearance of products, high repeatability, high efficiency and low cost.

Owner:ZHENGZHOU UNIV

A preparation method of rare earth oxide dispersion strengthened fine grain tungsten materials

InactiveUS20170225234A1Uniform particle sizeFine granularityTransportation and packagingMetal-working apparatusRare-earth elementTungstate

This invention relates to a preparation method of rare earth oxide dispersion strengthened fee grain tungsten materials, the mass percent of the rare earth oxide is of 0.1-2%, and the rest ingredient is W. Weigh soluble rare earth salt and tungstate, dissolve into water to made into 50-100 g / L of rare earth salt solution and 150-300 g / L of tungstate solution, respectively. Firstly, add trace alkali in rare earth salt solution to control pH in 7-8, then add organic dispersant and stir to form evenly suspended R(OH)3 particle colloid (R refers to rare earth element). Secondly pour the tungstate solution into the R(OH)3colloid, add trace acid to control pH in 6-7, then add organic dispersant and stir to form tungstic acid micro particles, which wrap around the colloidal particles, forming coprecipitation coating particle colloid. Thirdly, the coprecipitation coating particle colloidal is spray-dried, forming tungsten and rare earth oxide compound precursor powder. Alter that, ultrafine or nanoscale tungsten powder with particle size of 50˜500 nm is obtained through a process of calcination subsequent with hydrogen thermal reduction. Finally, the tungsten powder is subjected to ordinary compression molding and then conventional high temperature sintering. The trace rare earth oxide dispersion strengthened high performance fine grain tungsten materials prepared by this invention, its density is close to full density (98.5% or higher), its grain size is uniform and very fine (average in 5˜10 microns), and the rare earth oxides particles evenly distribute in tungsten intracrystalline or grain, boundary with particle size of 100˜500 nm.

Owner:CENT SOUTH UNIV

Technique for preparing phase-change temperature controllable tungsten doping nano vanadium dioxide powder

InactiveCN101164900AHigh chemical activityHigh dopingHeat-exchange elementsVanadium oxidesVanadium dioxideNanometre

This invention discloses a method for preparing controllable phase-transformation and tungsten-doped vanadium dioxide powder. In this invention, controlled, strictly, is the pH value (being at 7-9) of the solution for preparing prodecessor; selected is combined reductant containing organic amine and formic acid; protected by inert gas during whole process. By using this inventive method, obtained is high pureness single-phase VO2 nanometer powder. Due to the activity of white tungstic acid is far higher than that of other tungsten compounds, the adulteration of W6+ in VO2 crystal lattice is increased greatly, to achieve the effective adulteration, and then to realize controllable phase transformation temperature.

Owner:SHANGHAI NORMAL UNIVERSITY

Method for preparation of phenolic compound by direct hydrogenolysis of lignin

InactiveCN104276930AHigh yieldSimple processOrganic chemistryOrganic compound preparationFiltration4-propylphenol

The invention relates to a method for preparation of a phenolic compound by lignin direct hydrogenolysis adopting hydrogen produced in situ by a solvent as a hydrogen donor under catalysis effects. The method comprises the following steps of adding lignin, catalysts and a solvent into a pressure-resistant container, carrying out a reaction process at a temperature of 150-350 DEG C for 1-20h and carrying out filtration and extraction separation. The method has a lignin conversion rate of more than 50% and phenol selectivity of more than 85% and can produce main products such as 4-propylguaiacol, 4-propylsyringol, 4-propylphenol, propenylguaiacol, syringol and allylphenol. The catalysts used by the method comprise palladium chloride, ruthenium chloride, cobaltous chloride, phospho-tungstic acid, nickel molybdate, barium molybdate, Pd / TiO2, Ru / TiO2 and Au / TiO2, a mass ratio of lignin to the catalysts is in a range of 1: 0.03 to 1: 1 and a mass ratio of lignin to the hydrogen donor is in a range of 1: 50 to 1: 150. The related lignin hydrogenolysis process has a simple technology and can be used for production of high-added value phenolic compounds by a biomass route.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method of desulfurizing hydrocarbon oil

InactiveUS8021540B2High molecular weightCatalytic naphtha reformingRefining with metal saltsActivated carbonSolid acid

A method of desulfurizing / refining a hydrocarbon oil by which sulfur compounds are diminished to an extremely low concentration at a relatively low equipment cost and operating cost. The method of desulfurizing / refining a hydrocarbon oil comprises bringing a hydrocarbon oil containing at least one sulfur compound selected from the group consisting of thiophene compounds, benzothiophene compounds, and dibenzothiophene compounds and optionally further containing aromatic hydrocarbons into contact with a solid acid catalyst and / or an activated carbon having a transition metal oxide supported thereon to thereby desulfurize the oil. The solid acid catalyst preferably is a solid ultrastrong-acid catalyst selected among sulfuric acid radical / zirconia, sulfuric acid radical / alumina, sulfuric acid radical / tin oxide, sulfuric acid radical / iron oxide, tungstic acid / zirconia, and tungstic acid / tin oxide.

Owner:JAPAN ENERGY CORP

Selective reduction catalyst for nitrogen oxide in smoking gas, its preparation method and application

InactiveCN1443595ALess quantityLow costPhysical/chemical process catalystsDispersed particle separationFlue gasOxide

The present invention provides a selective reduction catalyst of nitrogen oxide in flue gas. It uses iolite cellular ceramics, Al2O3 and TiO2 as carrier, and uses the following metal oxides as activecomponents: (A), V2O5; (B) MoO3; and (C) WO3. The preparation method of said catalyst includes the following steps: preparing compouind catalyst carrier on which Al2O3 and TiO2 are loaded; repeatedlyimpregnating said compound catalyst carrier with ammonium metavanadate, ammonium molybdate and ammonium tungstate mixed aqueous solution, drying until the set load quantity of V2O5, WO3 and MoO3 is reached; finally roasting for 1-5 hr. so as to obtain the invented catalyst. Said catalyst can be used in ammonia reduction method for removing nitrogen oxide from flue gas.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing denitration catalyst carrier TiO2-WO3 composite powder

InactiveCN102327783AImprove performanceEasy to processCatalyst carriersDispersed particle separationPtru catalystAmmonium paratungstate

The invention discloses a method for preparing denitration catalyst carrier TiO2-WO3 composite powder, which comprises the following steps of: pulping and dispersing a metatitanic acid raw material; adjusting until the concentration of the slurry, calculated in terms of the titanium dioxide TiO2, is 15-25% by mass; adding ammonium paratungstate to the slurry according to a proportion, wherein calculated by the mass of tungsten trioxide WO3, the additive proportion of the ammonium paratungstate is 4.0%-10.0% of the sum of the TiO2 and the WO3; adding ammonia water to the slurry to adjust the pH to 6.5-9.0; filtering and dewatering to obtain a blocky filter cake; crushing the filter cake mechanically; drying and roasting the crushed filter cake at 200 DEG C to 580 DEG C for 6 hours; and crushing the roasted material falling in the kiln to obtain a TiO2-WO3 composite powder product serving as the denitration catalyst carrier. The method disclosed by the invention is low in manufacturing cost and simple in process; and the prepared product has the advantages of high specific surface area, high surface chemical activity, high catalytic efficiency and good processability.

Owner:四川华铁钒钛科技股份有限公司

Preparation method for tungsten trioxide nanowire electrochromic film

InactiveCN107216045AIncrease the areaBarrier throughTungsten oxides/hydroxidesNanotechnologyNanowireTungstate

The invention discloses a preparation method for a tungsten trioxide nanowire electrochromic film, which includes the following steps: (Step 1) tungstic acid and hydrogen peroxide solution are mixed, and after water is added for dilution, stirring is carried out for aging, so that sol is obtained; (Step 2) the sol is applied on a conductive glass, and after annealing treatment, a conductive glass with a WO3 seed crystal layer is obtained; (Step 3) tungstate and water are mixed, pH is regulated to strong acidity, ammonium sulfate and alcohol are then added, and after stirring, tungsten precursor solution is obtained; (Step 4) the conductive glass with the WO3 seed crystal layer in the step 2 is immersed in the tungsten precursor solution in step 3 to carry out hydrothermal reaction, and thereby the tungsten trioxide nanowire electrochromic film is obtained. The prepared WO3 nanowire electrochromic film has an supramaximal optical modulation range and a high electrochromic rate; when applied as an electrochromic smart window, the tungsten trioxide nanowire electrochromic film can greatly reduce solar radiation, and can also play the role of saving energy and regulating temperature; moreover, the process is simple and controllable, the cost is low, and the preparation method is suitable for industrialized application.

Owner:ZHEJIANG UNIV

Molecular sieve catalyst containing pores in tungsten media utilized for synthesizing glutaraldehyde and its preparation method

InactiveCN1446631AGood dispersionHigh selectivityMolecular sieve catalystsCarbonyl compound preparation by oxidationDispersityCyclopentene

A novel multi-phase W-contained catalyst for preparing glutaraldehyde by using the aqueous solution of hydrogen peroxide as oxidizing agent to selectively oxidize cyclopentene is prepared through in-situ introducing tungsten oxide in the process for synthesizing SBA-1.5 full-silicon mesoporous molecular sieve. Its advantages are high dispersity of active component, ultrahigh load capacity of tungesten oxide, and high selectivity.

Owner:FUDAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Mesoporous WO[3-x] visible-light-driven photocatalyst with oxygen vacancy as well as preparation method and application thereof Mesoporous WO[3-x] visible-light-driven photocatalyst with oxygen vacancy as well as preparation method and application thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/371f3b02-68c7-41ef-a7cd-a4dfbefe86ed/1505051449421.PNG)

![Mesoporous WO[3-x] visible-light-driven photocatalyst with oxygen vacancy as well as preparation method and application thereof Mesoporous WO[3-x] visible-light-driven photocatalyst with oxygen vacancy as well as preparation method and application thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/371f3b02-68c7-41ef-a7cd-a4dfbefe86ed/1505051449422.PNG)

![Mesoporous WO[3-x] visible-light-driven photocatalyst with oxygen vacancy as well as preparation method and application thereof Mesoporous WO[3-x] visible-light-driven photocatalyst with oxygen vacancy as well as preparation method and application thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/371f3b02-68c7-41ef-a7cd-a4dfbefe86ed/1505051449423.PNG)