Comprehensive recycling method for waste titanium based vanadium SCR catalyst

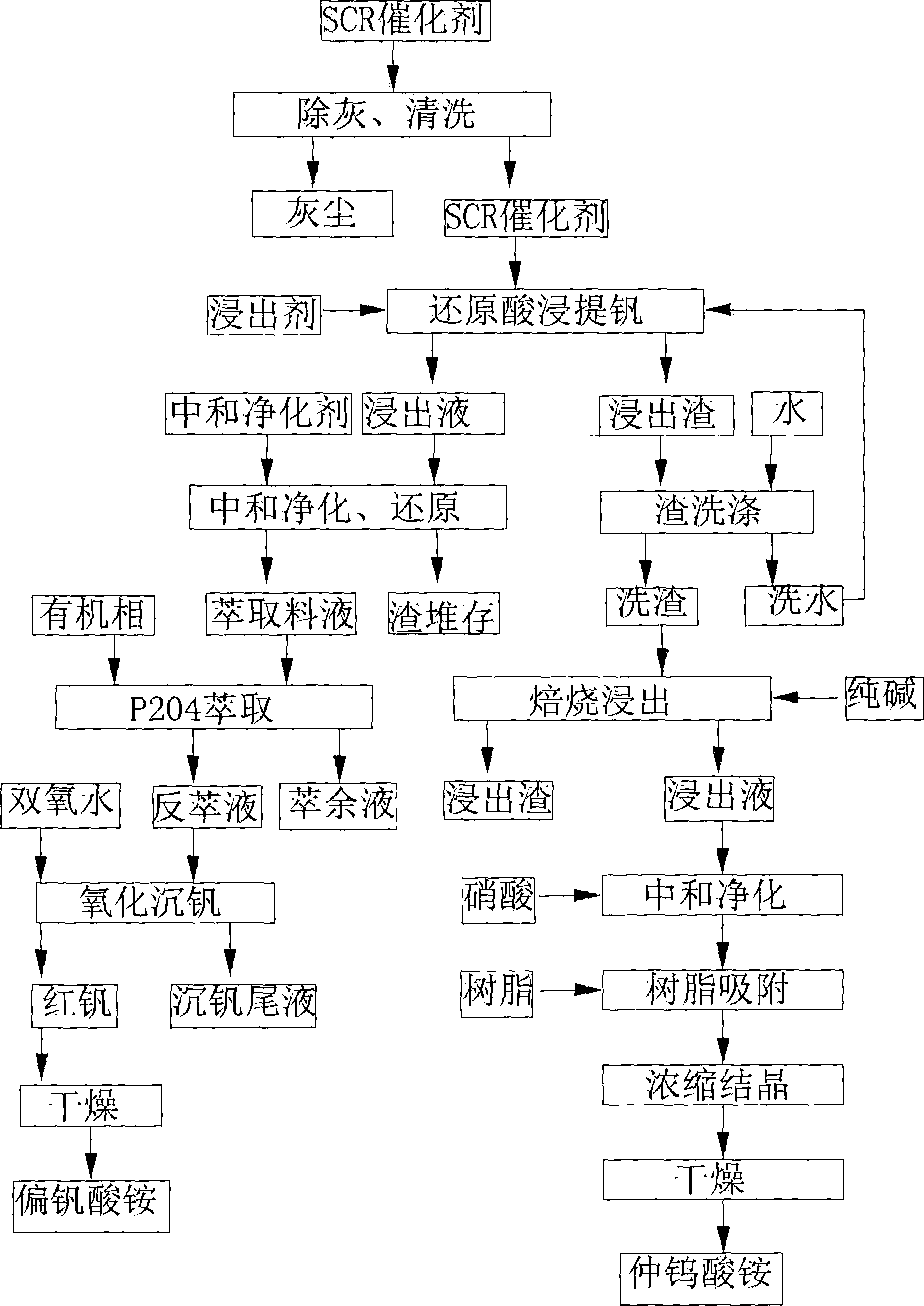

An SCR catalyst and titanium-based vanadium-based technology, which is applied in the field of comprehensive recycling and utilization of waste titanium-based vanadium-based SCR catalysts, can solve the problems of failure to recover valuable metal resources, increase enterprise costs, and waste effective resources, etc. Realize resource utilization, reduce processing costs, and achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Take the discarded honeycomb SCR catalyst (losing strength and cannot be regenerated) from a power plant, crush the block catalyst into flakes, and then sieve. First, use a sieve with a pore size of 1.25mm to sieve for 3 minutes. The sieve with a mass ratio of 92.5% is a catalyst with a small amount of dust attached to the surface, and the undersize is a fine catalyst mixed with dust; then use a sieve with a 0.425mm pore size. After sieving for 3 minutes, the oversieve is all catalyst, and the undersieve is mostly dust. Take the sieved catalyst (with a small amount of dust on the surface), wash it with a high-pressure water gun, adjust the water pressure to 1 MPa, and spray and sweep for 2 minutes, then put the catalyst in a resistance drying oven and dry it to constant weight.

[0028] The dried catalyst is ground by a vibration ball mill, the ball milling time is 4min, and the rotation speed is 700-960r / min. Take 100 powders, leaching with 5% concentration of hydroch...

Embodiment 2

[0033] Take the discarded honeycomb SCR catalyst from a power plant, and use a compressed air gun to blow the surface and pores for about 20 minutes, and the pressure of the compressed air gun is 0.2MPa. The collected dust was sieved with a 0.8mm sieve, and the oversieved material was mixed with the catalyst obtained by purging. The dried catalyst was broken into small pieces, and then put into a vibrating ball mill to grind finely. The ball milling time was 2 minutes, and the rotating speed was 960r / min, and the powder was taken out.

[0034] Put the finely ground powder into a beaker, add 8% hydrochloric acid with a catalyst amount, add 3% sodium sulfite with a catalyst amount, stir it with electric power in a water bath at 90°C for 5 hours, then filter it with a vacuum filter, and use 80°C deionized water After washing for 3 times, the leaching rate of vanadium can reach 88.5%. The liquid vanadium-containing solution is neutralized with lime and soda ash solution to pH 2.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com