Preparation method of cesium-tungsten bronze powder and function film

A technology of cesium tungsten bronze and powder, which is applied in the field of preparation of cesium tungsten bronze powder, can solve the problems of complex process and high cost of cesium tungsten bronze powder, and achieve the effects of low cost, reduced production cost and excellent shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

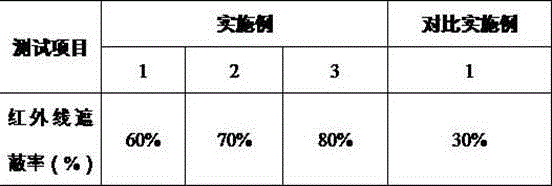

Examples

preparation example Construction

[0015] The embodiment of the present invention provides a method for preparing cesium tungsten bronze powder with simple process and low cost. The method comprises the steps of:

[0016] Step S01: exchange tungstate solution with cationic resin to obtain tungstic acid sol;

[0017] Step S02: adding citric acid solution and cesium carbonate solution to the tungstic acid sol prepared in step S01, and then performing mixing treatment to obtain a hydrothermal reaction precursor;

[0018] Step S03: The hydrothermal reaction precursor solution prepared in step S02 is subjected to a hydrothermal reaction at a temperature of 160-180° C. and a pressure of 0.8-1 MPa. After the reaction is completed, washing and drying are performed to obtain cesium tungsten bronze powder.

[0019] Specifically, in the above step S01, during the exchange process between the tungstate and the cationic resin, the hydrogen ions in the cationic resin are exchanged with the cations in the tungstate. Thus ma...

Embodiment 1

[0037] A preparation method of cesium tungsten bronze powder, comprising the steps of:

[0038] S11: Add 0.5 mol / L sodium tungstate (Na 2 WO 4 ?2H 2 O) The solution is exchanged with a cationic resin to obtain a tungstic acid sol;

[0039] S12: Add citric acid solution and cesium carbonate solution to the tungstic acid sol, and then perform mixing treatment to obtain a hydrothermal reaction precursor solution; wherein, in the hydrothermal reaction precursor solution, ensure that tungstic acid, citric acid and cesium carbonate The molar concentration ratio is 1:0.1:0.1; the concentration of citric acid in the hydrothermal reaction precursor is controlled to be 0.2 mol / L;

[0040] S13: The hydrothermal reaction precursor solution is placed in a high-pressure reactor for hydrothermal reaction. After the reaction is completed, ultrasonic washing, alcohol washing, centrifugation, and spray drying are performed to finally obtain CsxWO 3 Powder. Wherein, the temperature of the hyd...

Embodiment 2

[0042] A preparation method of cesium tungsten bronze powder, comprising the steps of:

[0043] S21: Add 0.5 mol / L sodium tungstate (Na 2 WO 4 ?2H 2 O) The solution is exchanged with a cationic resin to obtain a tungstic acid sol;

[0044] S22: Add citric acid solution and cesium carbonate solution to the tungstic acid sol, and then perform mixing treatment to obtain a hydrothermal reaction precursor solution; wherein, in the hydrothermal reaction precursor solution, ensure tungstic acid, citric acid and cesium carbonate The molar concentration ratio is 1:0.1:0.5; the concentration of citric acid in the hydrothermal reaction precursor is controlled at 0.5mol / L;

[0045] S23: Put the hydrothermal reaction precursor solution in a high-pressure reactor for hydrothermal reaction. After the reaction is completed, it is washed with ultrasonic water, washed with alcohol, centrifuged, and spray-dried to finally obtain CsxWO 3 Powder. Wherein, the temperature of the hydrothermal r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com