Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

622 results about "Pressure reactor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A pressure reactor, sometimes referred to as a pressure tube, or a sealed tube, is a chemical reaction vessel which can conduct a reaction under pressure. A pressure reactor is a special application of a pressure vessel. The pressure can be caused by the reaction itself or created by an external source, like hydrogen in catalytic transfer hydrogenation.

Method for preparing lithium cobaltate by directly using invalid lithium ion battery

InactiveCN102030375AReduce dispersionHigh purityCell electrodesCobalt compoundsElectrical batteryPotassium hydroxide

The invention provides a method for preparing lithium cobaltate by directly using an invalid lithium ion battery. The method comprises the following steps: crushing the invalid lithium ion battery or scraps generated when a lithium cobaltate battery is produced by a mechanical crusher at normal temperature; adding water and one or more of acetic acid, sulfuric acid, hydrochloric acid or nitric acid to produce mixed aqueous solution of the battery scraps and acid; filling the mixed aqueous solution into a hermetic pressure reactor, and controlling the temperature in the reactor to be between 50 and 150 DEG C; introducing or adding one leaching additive of sulfur dioxide or hydrogen, or adding hydrazine hydrate; stirring and leaching, cooling, and filtering; adding one precipitator of sodium carbonate, potassium carbonate and ammonium carbonate, or adding composite precipitator consisting of one of the sodium carbonate, the potassium carbonate and the ammonium carbonate and one of sodium hydroxide and potassium hydroxide to obtain mixture of lithium carbonate, cobalt carbonate and cobalt hydroxide; drying and calcining at high temperature to produce a lithium cobaltate product. The method is particularly suitable for the treatment scale of medium-sized and small enterprises, and is an effective method for directly materializing cobalt secondary resources.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

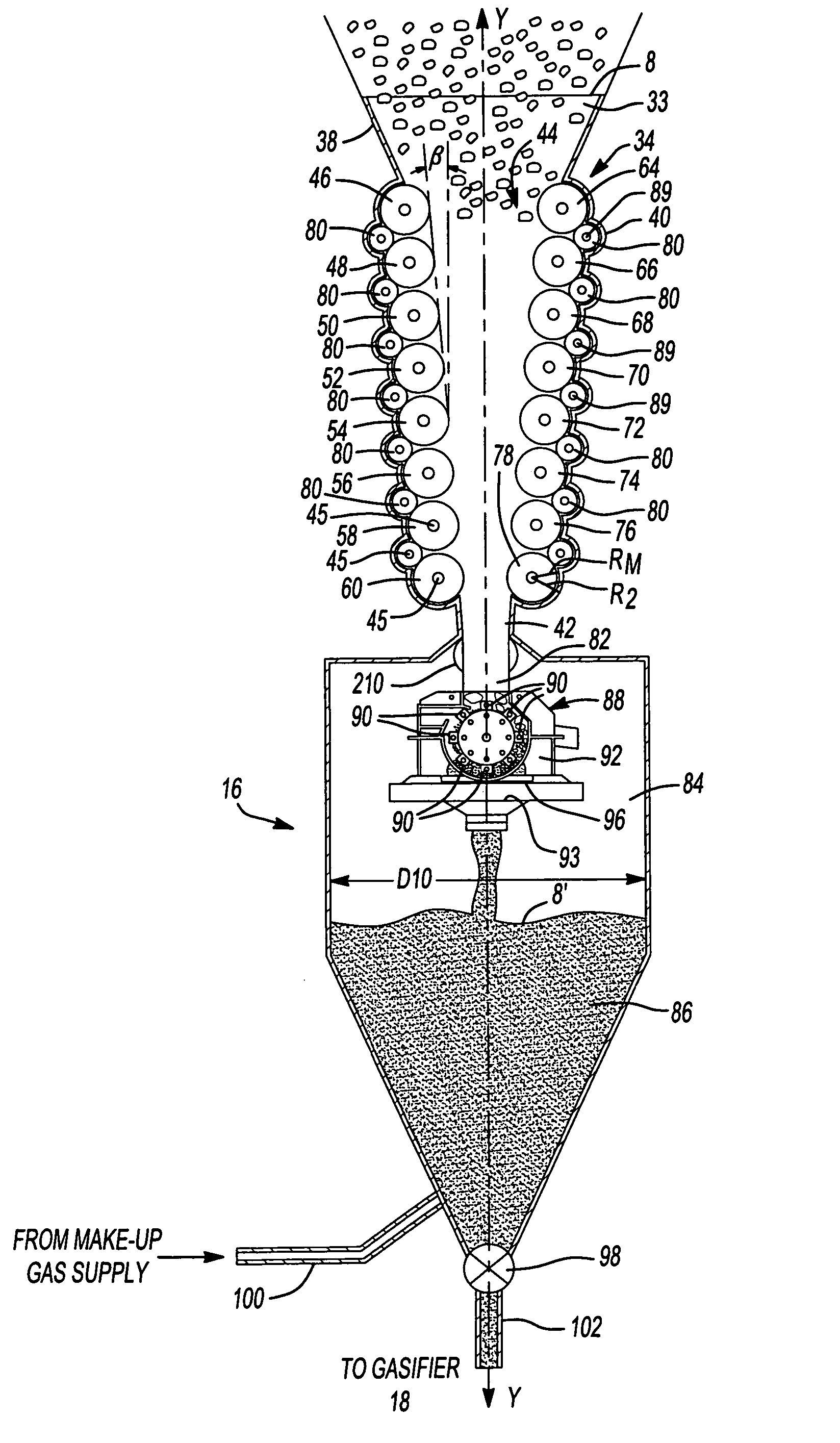

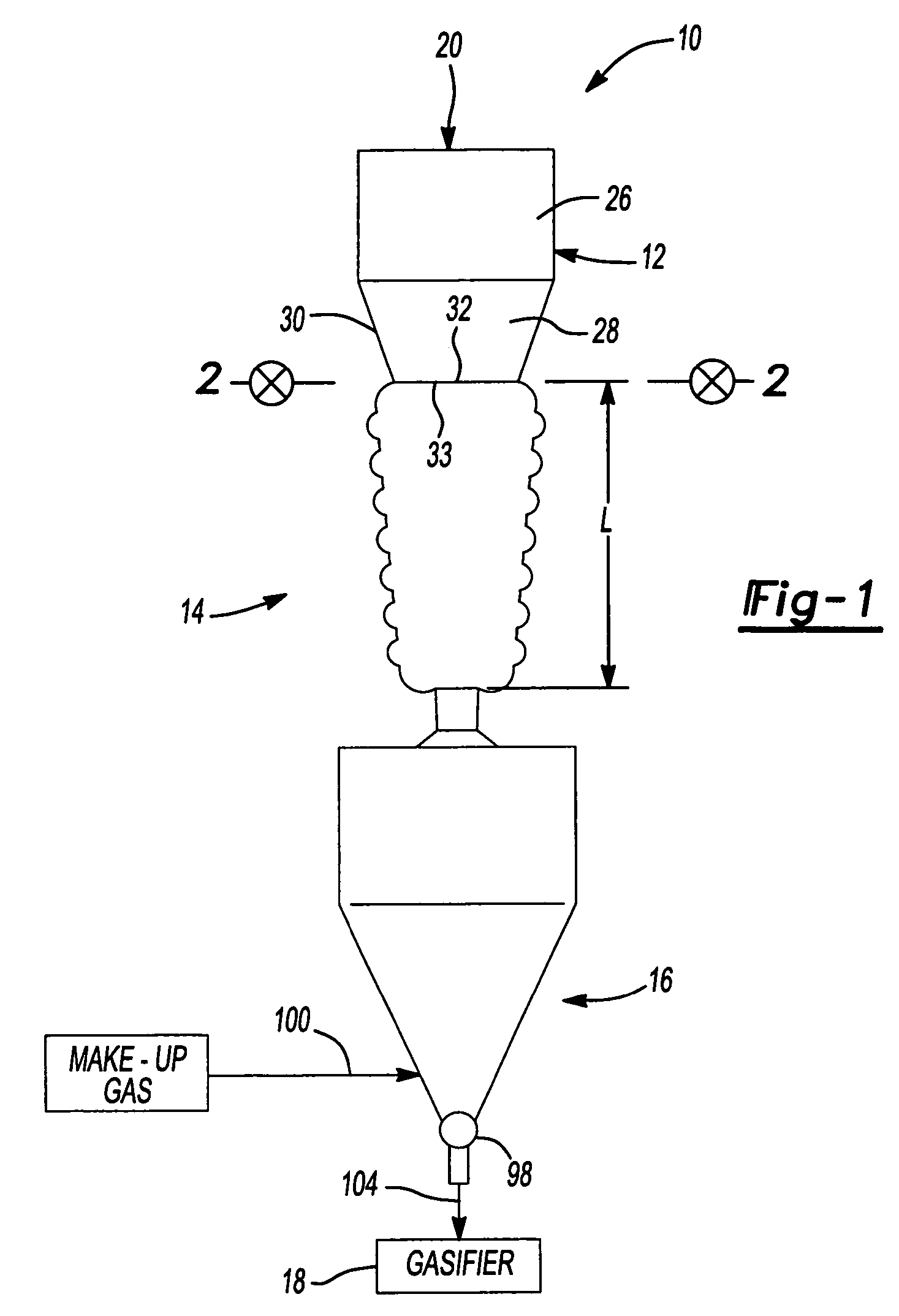

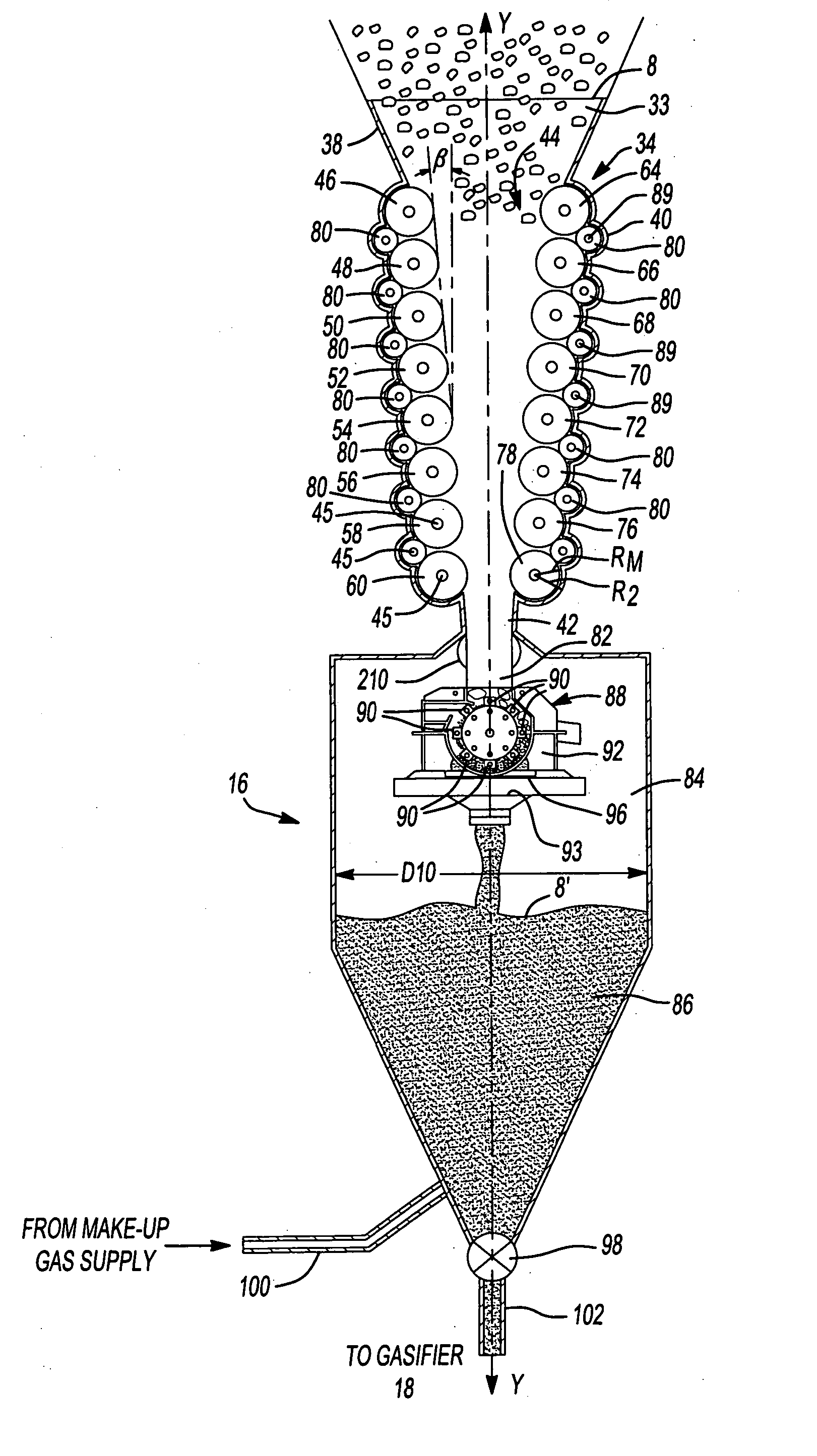

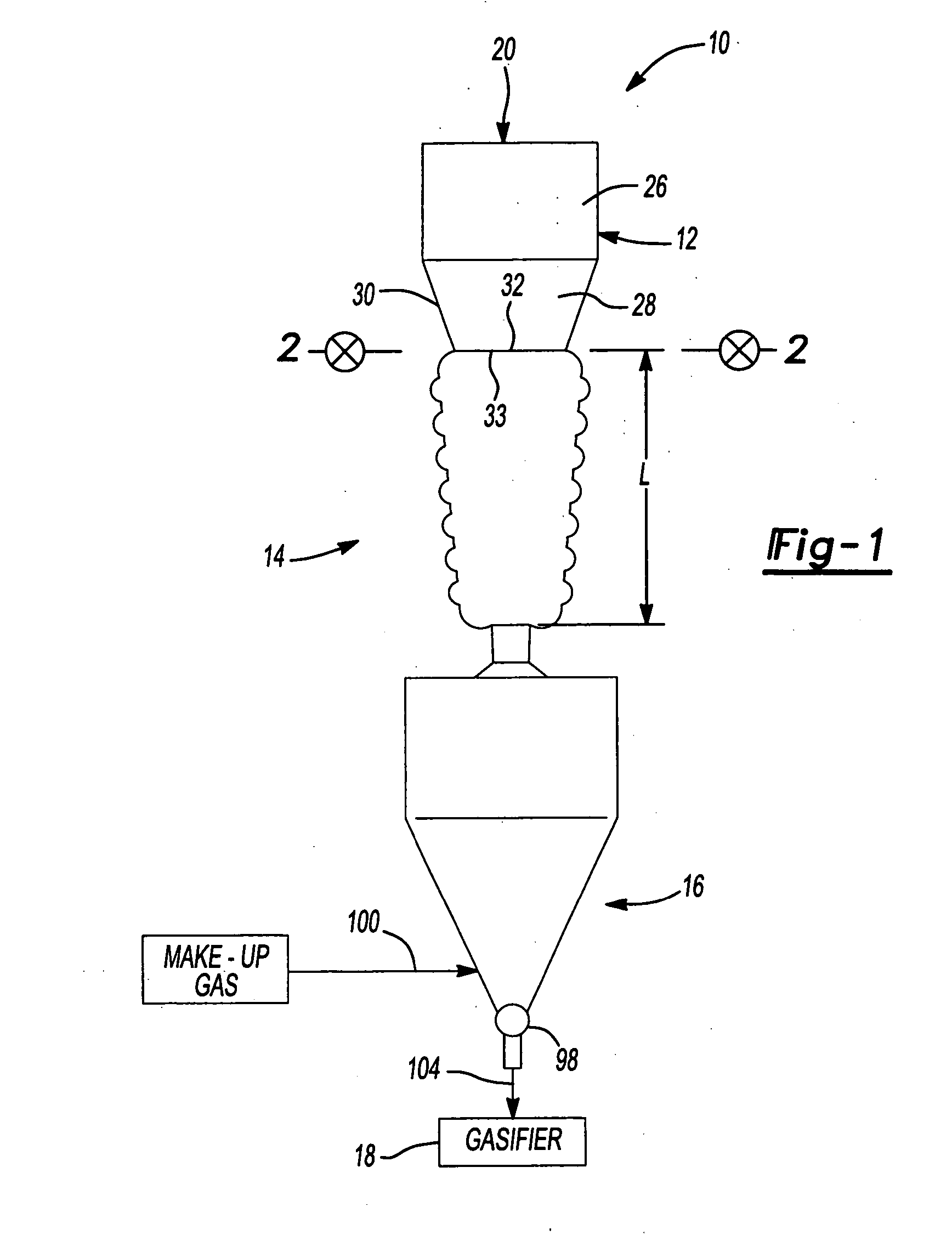

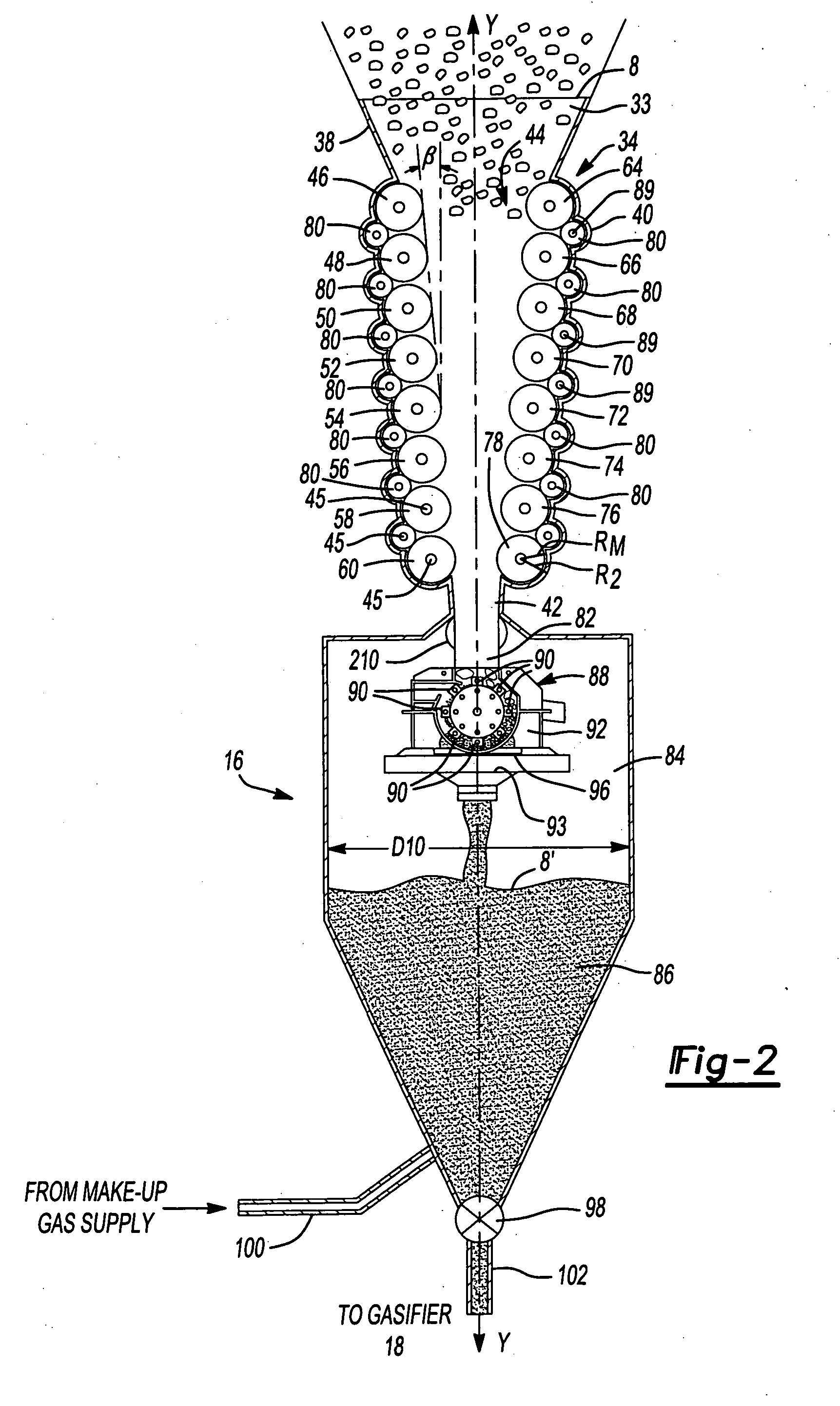

High pressure dry coal slurry extrusion pump

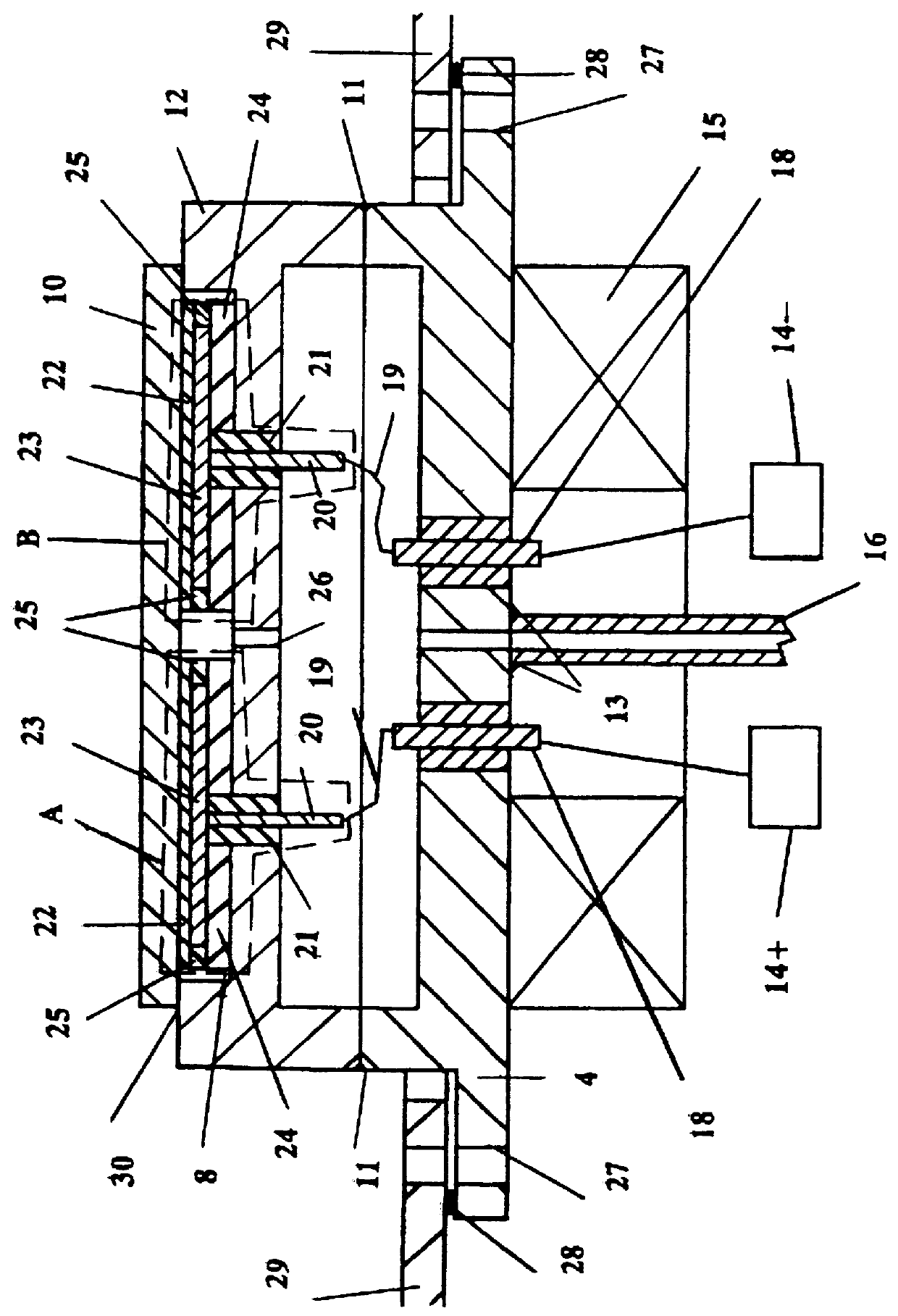

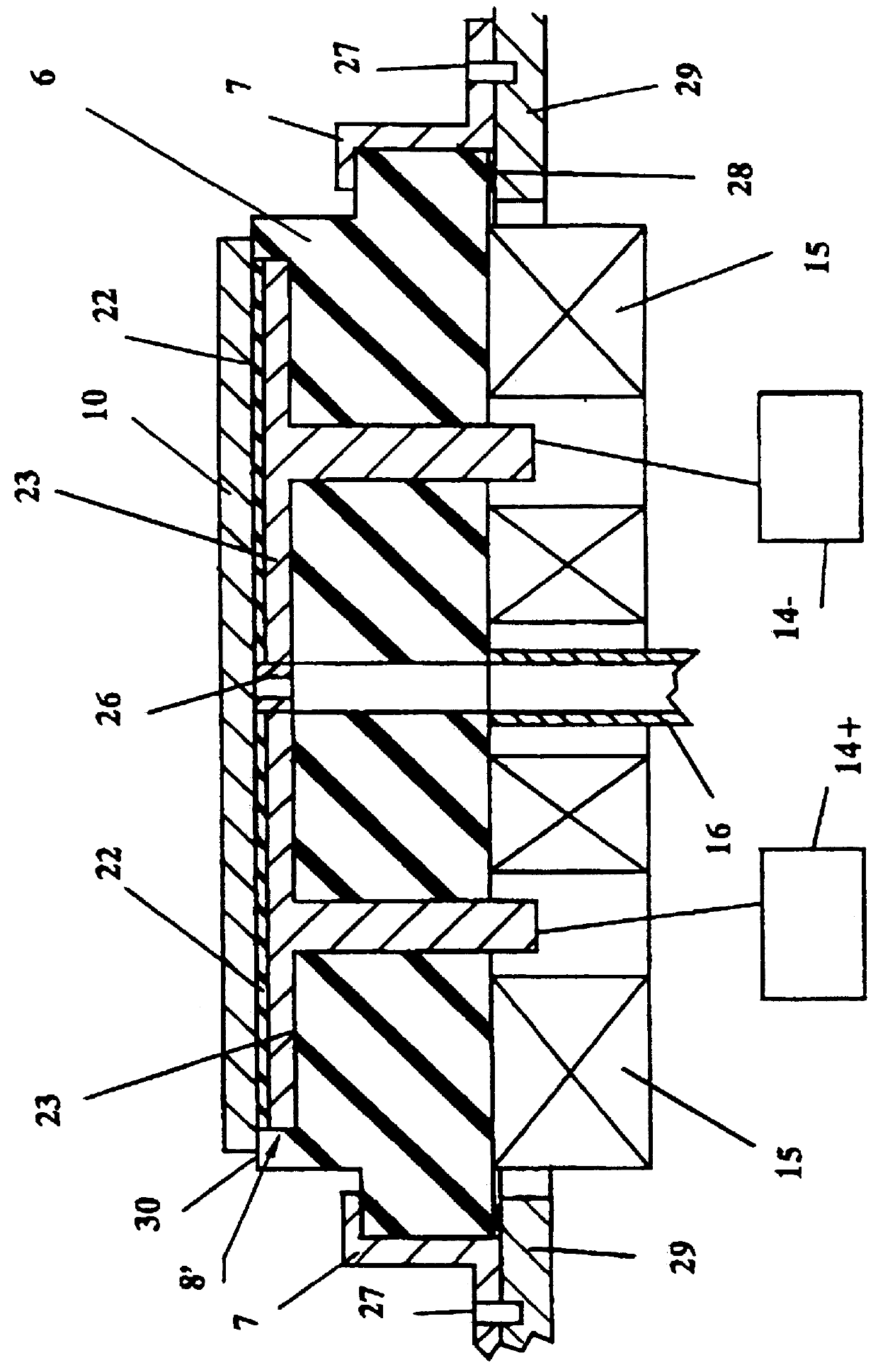

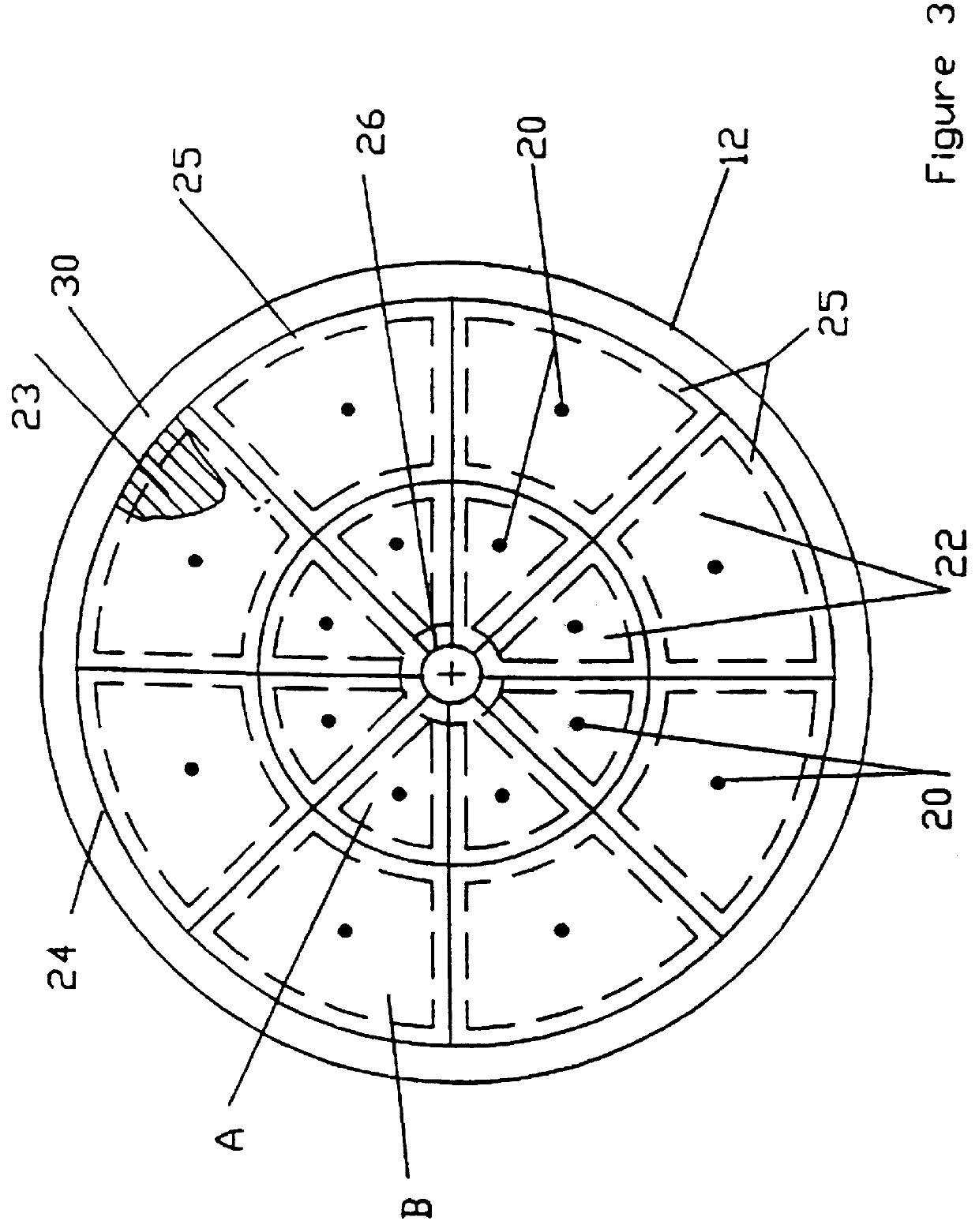

A system for providing highly pressurized raw fuel to a pressure reactor. The system includes an inlet for receiving the raw fuel and a roller system communicating with the inlet. The roller system includes a plurality of independent rollers arranged in two converging planes. The rollers of the roller system successively compress the raw fuel as the raw fuel passes through the roller system between the rollers, such that the fuel is highly pressurized when it reaches an output end of the roller system. An outlet is located adjacent the output end of the roller system to dispense the pressurized raw fuel to the pressure reactor.

Owner:THE BOEING CO +1

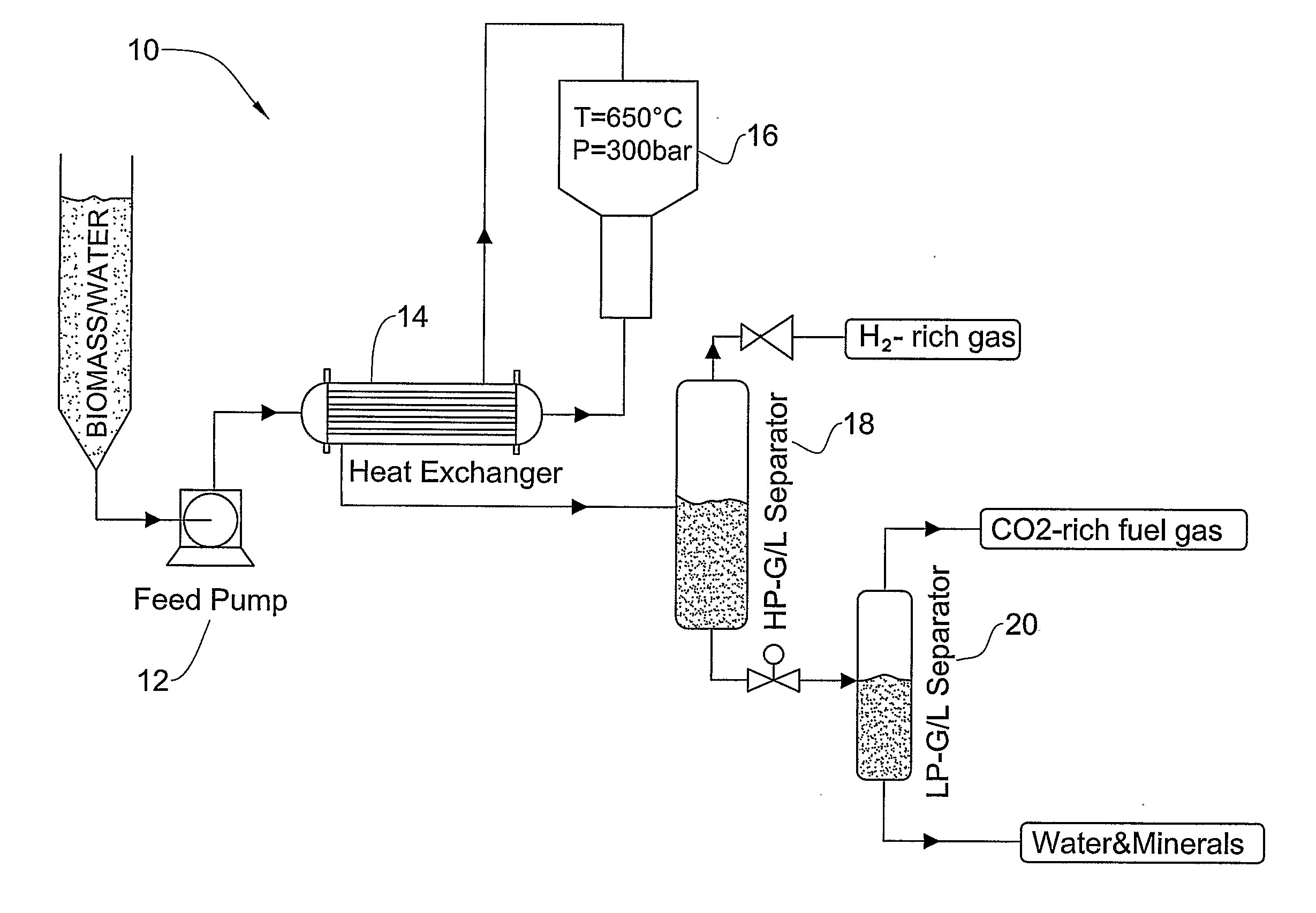

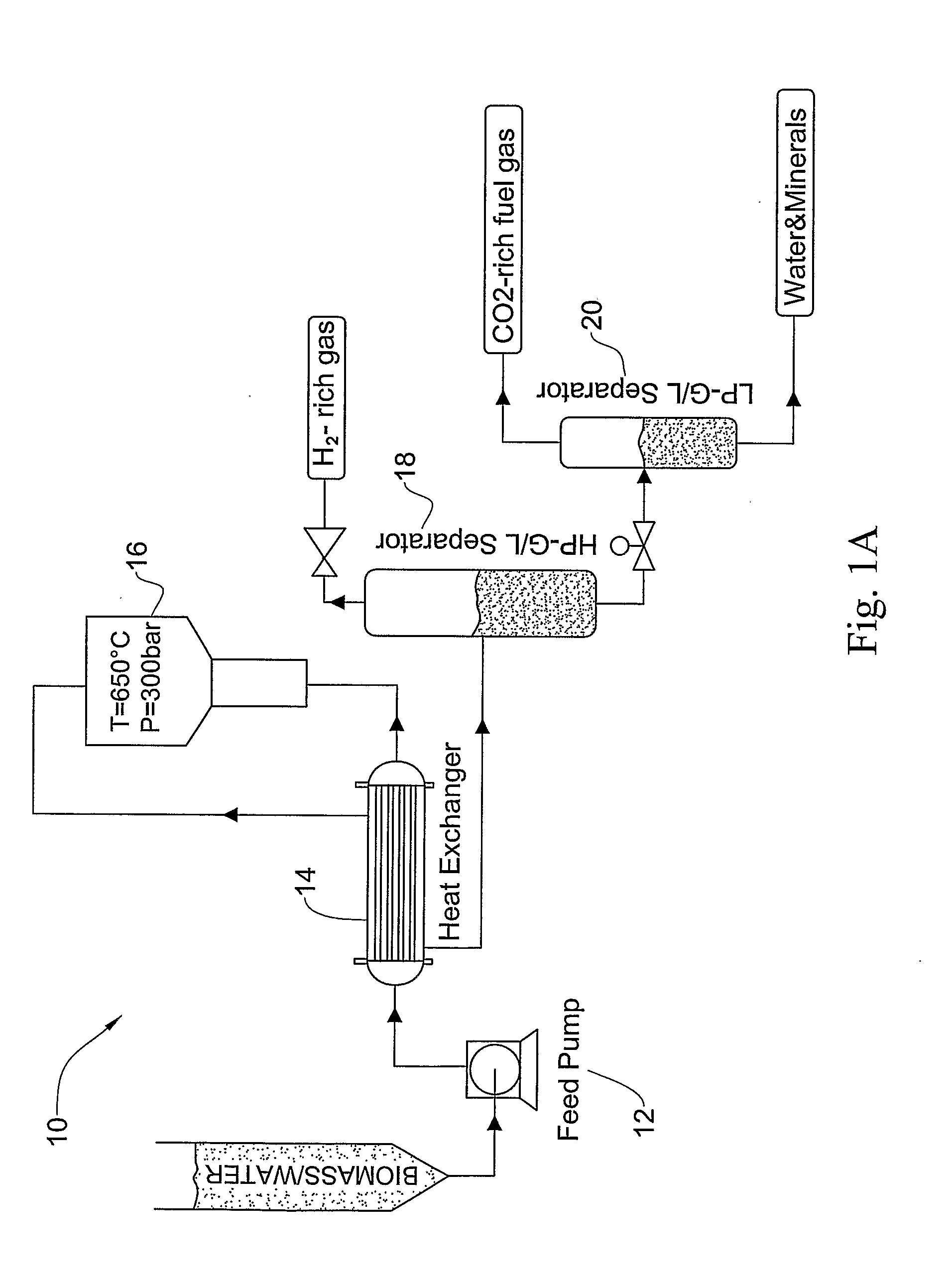

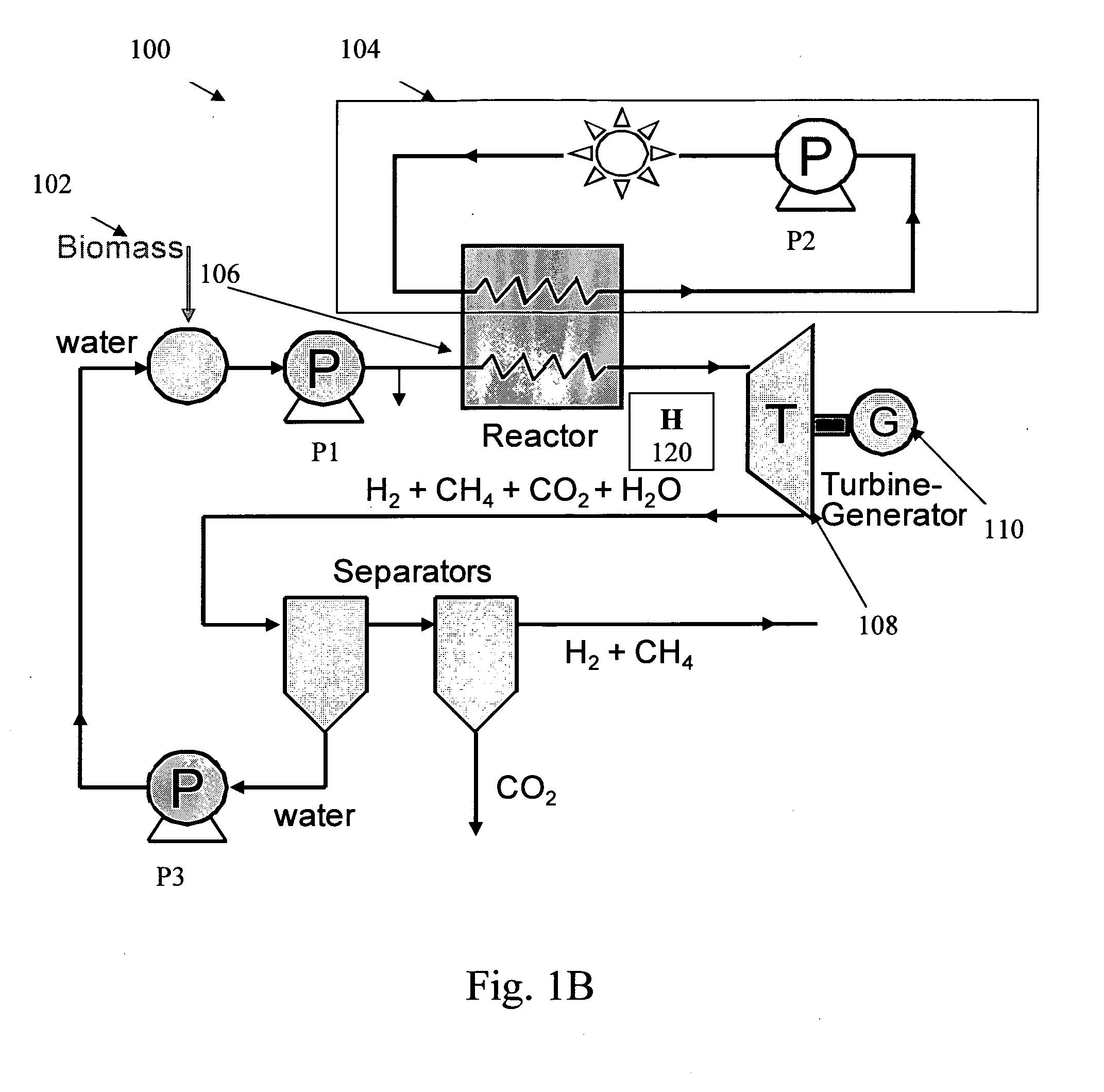

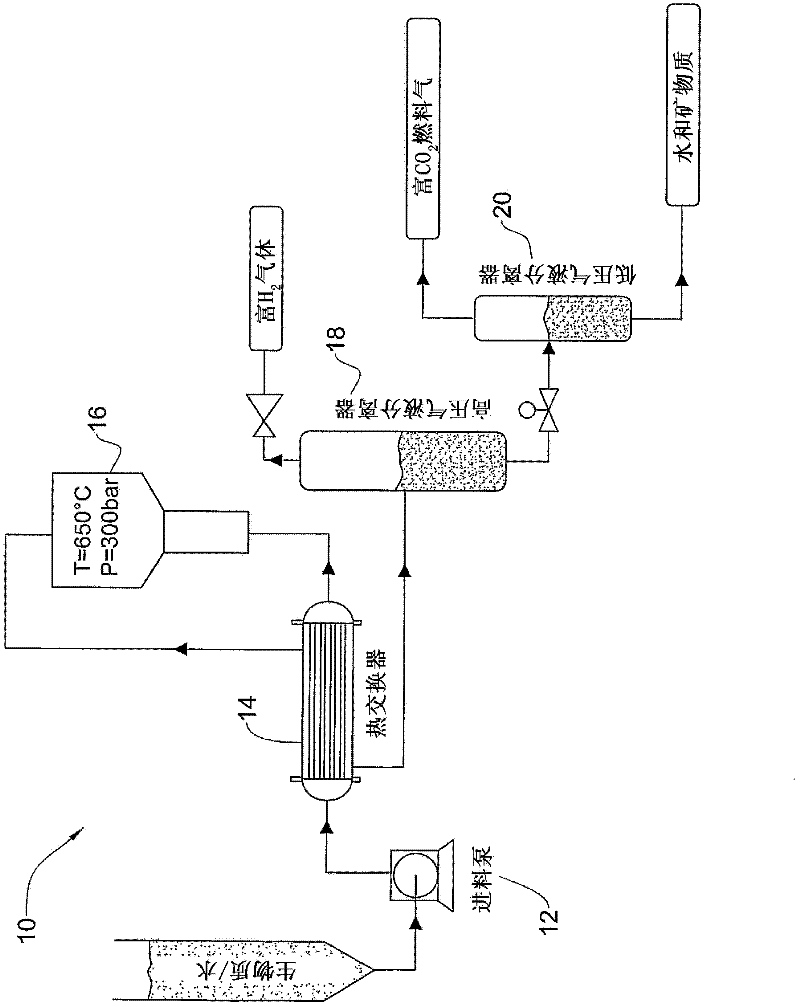

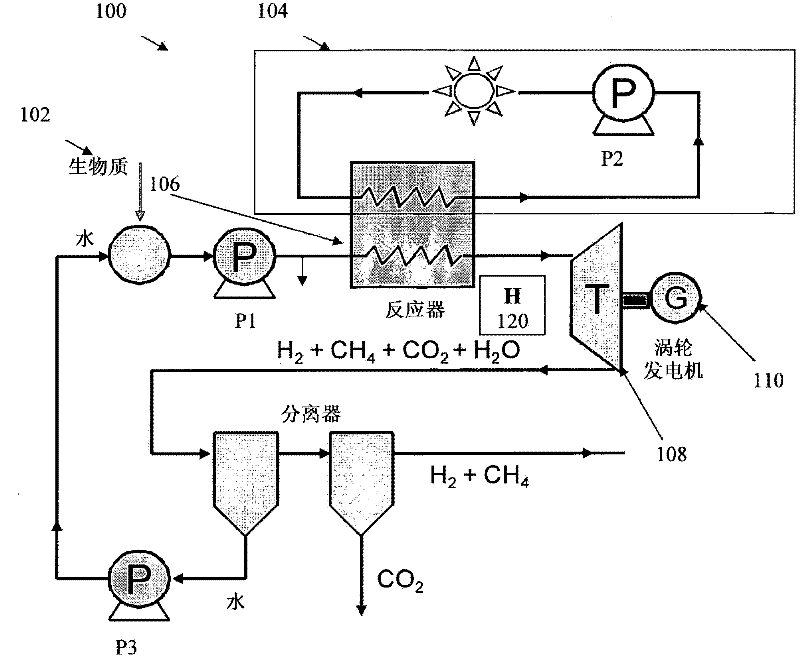

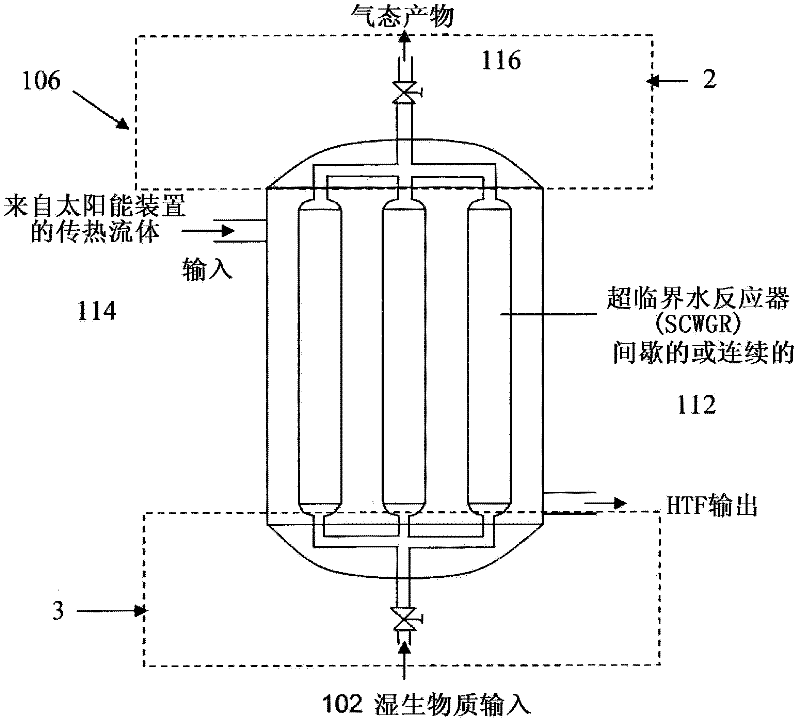

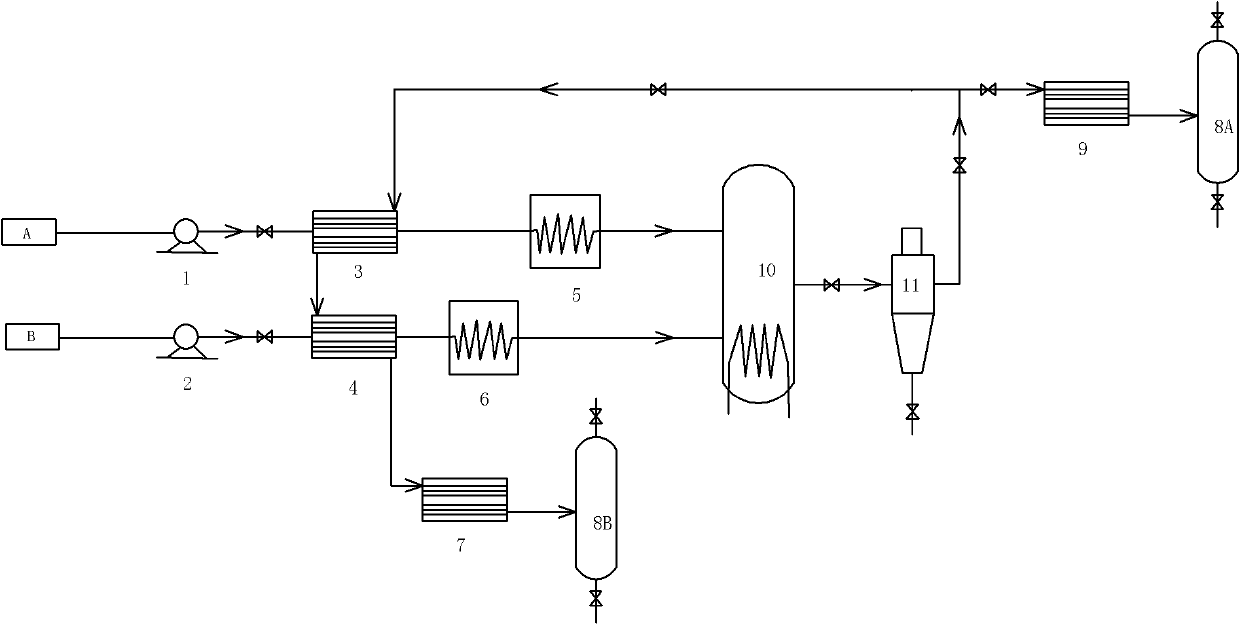

Catalytic gasification of organic matter in supercritical water

InactiveUS20120060418A1Reduce complexity and costReduce the temperatureWaste based fuelHydroxy compound preparationHigh pressureTemperature and pressure

A catalyst system including at least one metal and an oxide support, said oxide support including at least one of Al2O3, MnxOy, MgO, ZrO2, and La2O3, or any mixtures thereof; said catalyst being suitable for catalyzing at least one reaction under supercritical water conditions is disclosed. Additionally, a system for producing a high-pressure product gas under super-critical water conditions is provided. The system includes a pressure reactor accommodating a feed mixture of water and organic matter; a solar radiation concentrating system heating the pressure reactor and elevating the temperature and the pressure of the mixture to about the water critical temperature point and pressure point or higher. The reactor is configured and operable to enable a supercritical water process of the mixture to occur therein for conversion of the organic matter and producing a high-pressure product fuel gas.

Owner:RAMOT AT TEL AVIV UNIV LTD +2

Method for preparing oil absorption material by adopting straws as base materials

InactiveCN102344531AEfficient recyclingHigh oil absorptionOther chemical processesChemical recyclingCross-linkOil retention

The invention relates to a method for preparing an oil absorption material by adopting straws as base materials, which comprises the following steps of: grinding crop straws (maize straws, wheat straws, sorghum straws and the like) into block shapes; adding sodium hydroxide solution or dilute sulphuric acid solution; reflowing and stewing for 10min under the action of microwave, or reflowing in anormal pressure reactor for 3h; filtering, rinsing and drying to obtain straw powder; adding the straw powder into water; warning up under the protection of nitrogen; adding an initiating agent, a reaction monomer and a cross-linking agent; stirring and reacting; and filtering and drying to obtain the oil absorption material. According to the invention, the straws of agricultural solid residues are utilized as the base materials, suspension polymerization is adopted, and graft copolymerization is carried out on acrylic ester or styrene and the like, so that the biodegradable oil absorption material is prepared. The oil absorption material not only has the biodegradability of the straws, but also has the high oil absorption performance of long-chain acrylic ester, so that not only can the production cost be greatly reduced and the solid waste be effectively utilized, but also the density is low, and the effects of oil absorption and oil retention are good due to a special porous structure of the raw straw materials.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Electrostatic chuck

InactiveUS6141203AFast heat transferMinimize risk of damageSleeve/socket jointsSemiconductor/solid-state device manufacturingPotential differenceDielectric surface

An electrostatic chuck is provided having a plurality of small electrostatic structures for holding an electrically conductive workpiece forming a plate of a capacitor. Each electrostatic structure includes a first thermally conductive single-crystal dielectric sheet, and a first electrode in sheet form sandwiched between the first dielectric sheet and a second dielectric surface. The workpiece, typically a conductive or semiconductive wafer, is juxtaposed to the first dielectric sheet of each electrostatic structure and forms a second electrode. The second dielectric sheet, if thick, is used as a thermally conducting base plate which can be attached to a low pressure reactor. If the second dielectric is a thin sheet, then it is mounted to a thermally conductive metal base plate through which heat can be controllably conducted. The resultant electrostatic structure may be brazed to the metal base plate if the thermal expansion characteristics of the two elements are sufficiently matched. The first thermally conductive dielectric sheet is preferably formed of sapphire (Al2O3), which is sufficiently thermally conductive to allow for rapid heat transfer between the base plate and the workpiece. The first electrodes of different electrostatic structures are held at different electrical potentials (typically of several thousand volts difference) and a charge is maintained by this potential difference between selected electrostatic structures.

Owner:SHERMAN ARTHUR

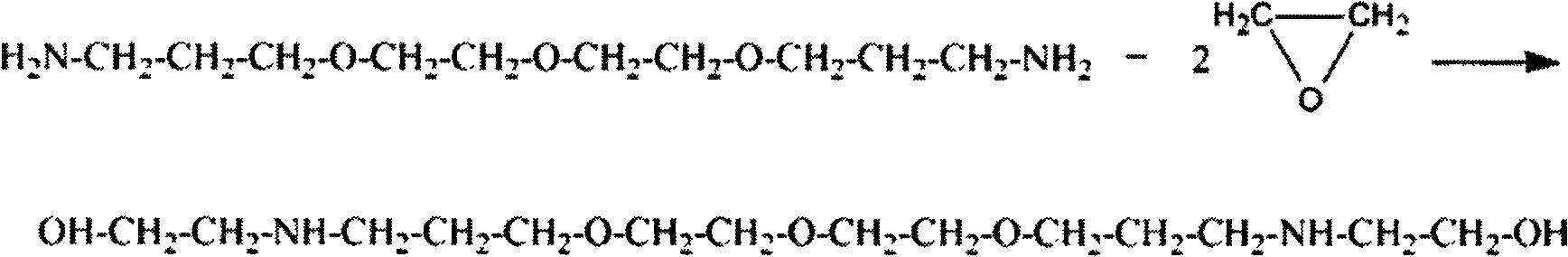

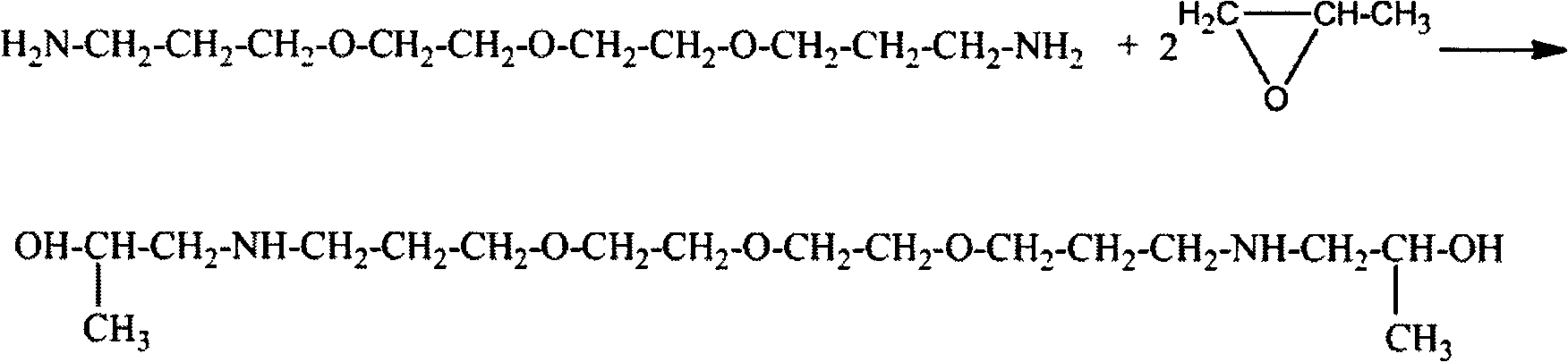

Amine shale stabilizer for drilling fluid

The invention relates to a development for an amine shale stabilizer for a drilling fluid and a preparation method for the same, which is characterized in that the amine shale stabilizer disclosed by the invention is a polymer generated by reacting polyethenoxyamine with epoxide alkane. The polyethenoxyamine is polyoxyethylene diamine or polypropylene diamine or polyoxyethylene propylene diamine, and the molecular weight thereof is less than 1000. The epoxide alkane is one or the mixture composed of two or more of ethylene oxide, propylene epoxide and butylene oxide. During a preparation process, the polyethenoxyamine and the epoxide alkane are poured in a high-temperature and high-pressure reactor according to a molar ratio of 10: 1 to 1: 20, and then reacted at 90-140 DEG C under the function of a catalyst to obtain the amine shale stabilizer for a drilling fluid. The amine shale stabilizer can efficiently prevent shale and clay from being hydrated.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

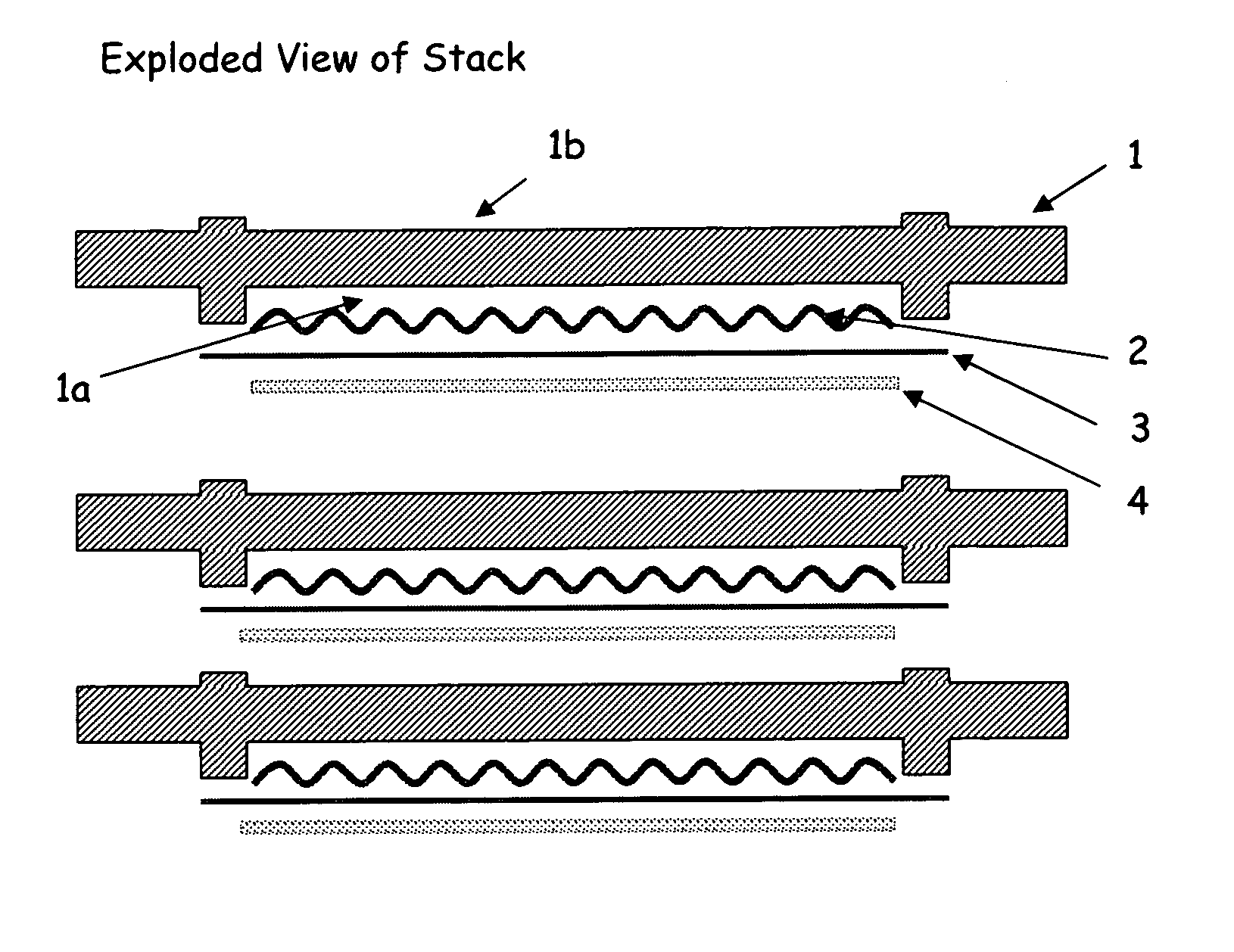

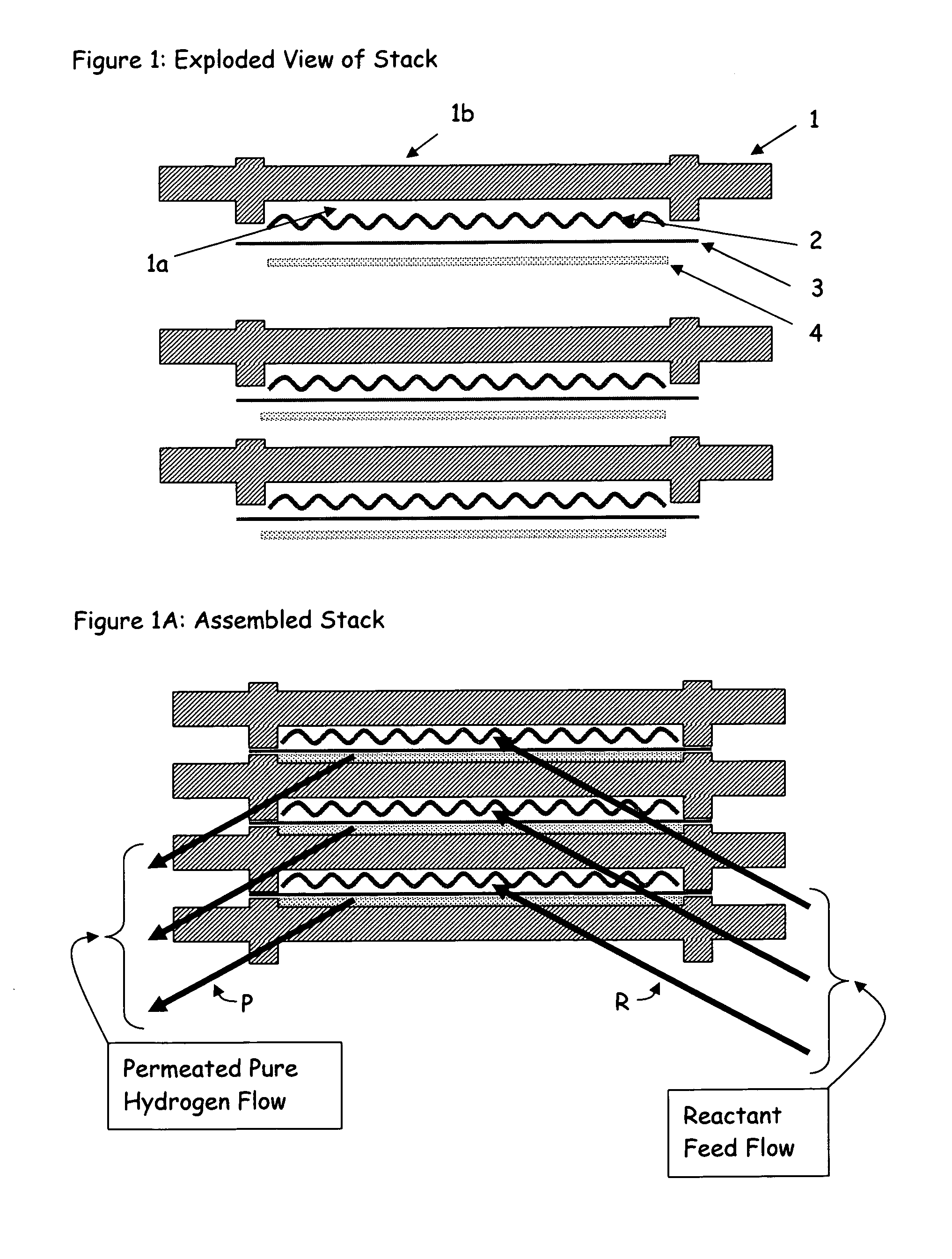

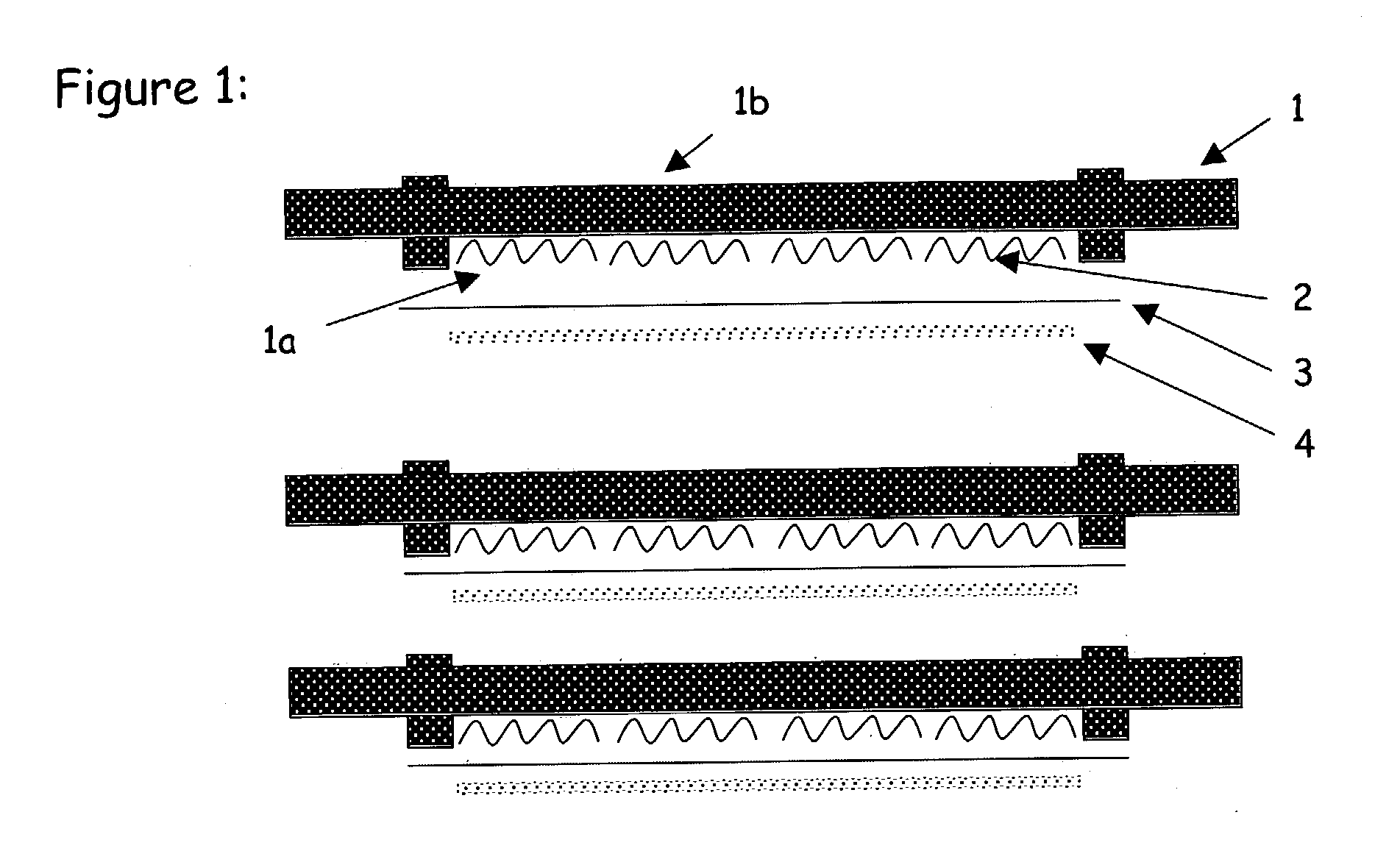

Steam-reforming catalytic structure and pure hydrogen generator comprising the same and method of operation of same

InactiveUS7182917B2Less-expensive structureImproved hydrogen generationIsotope separationHydrogen/synthetic gas productionSteam reformingHeat conducting

A reactor / purifier for generating pure hydrogen in a stack or array of pairs of alternatingly connected high and low pressure reactor chambers wherein a gas-porous turbulence-promoting screen structure washcoated with a steam-reforming catalyst is sandwiched between a planar hydrogen-selective palladium alloy membrane and a planar gas-impermeable heat-conducting metal plate within the high pressure reactor chamber of each high pressure reactor chamber; and wherein the catalyst-coated structure in each high pressure chamber is reacted with steam and hydrocarbon fuel, such as methane or syn / gas, and / or carbon monoxide at an appropriately controlled temperature of between about 200° C. to 650° C. to produce hydrogen and carbon oxides within an isothermal temperature range in each high pressure reactor chamber, while simultaneously permeating pure hydrogen therefrom through the membrane into the corresponding connected low pressure reactor chamber.

Owner:HYDRIP LLC

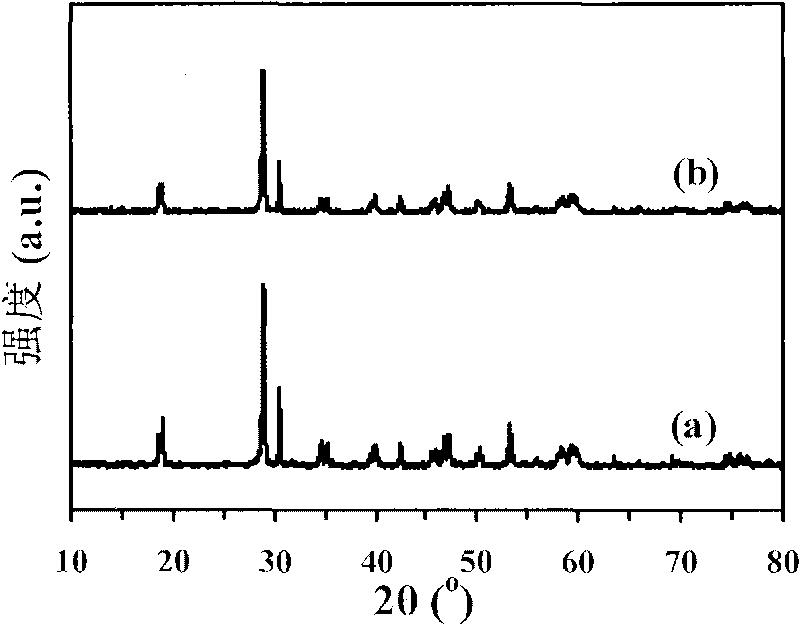

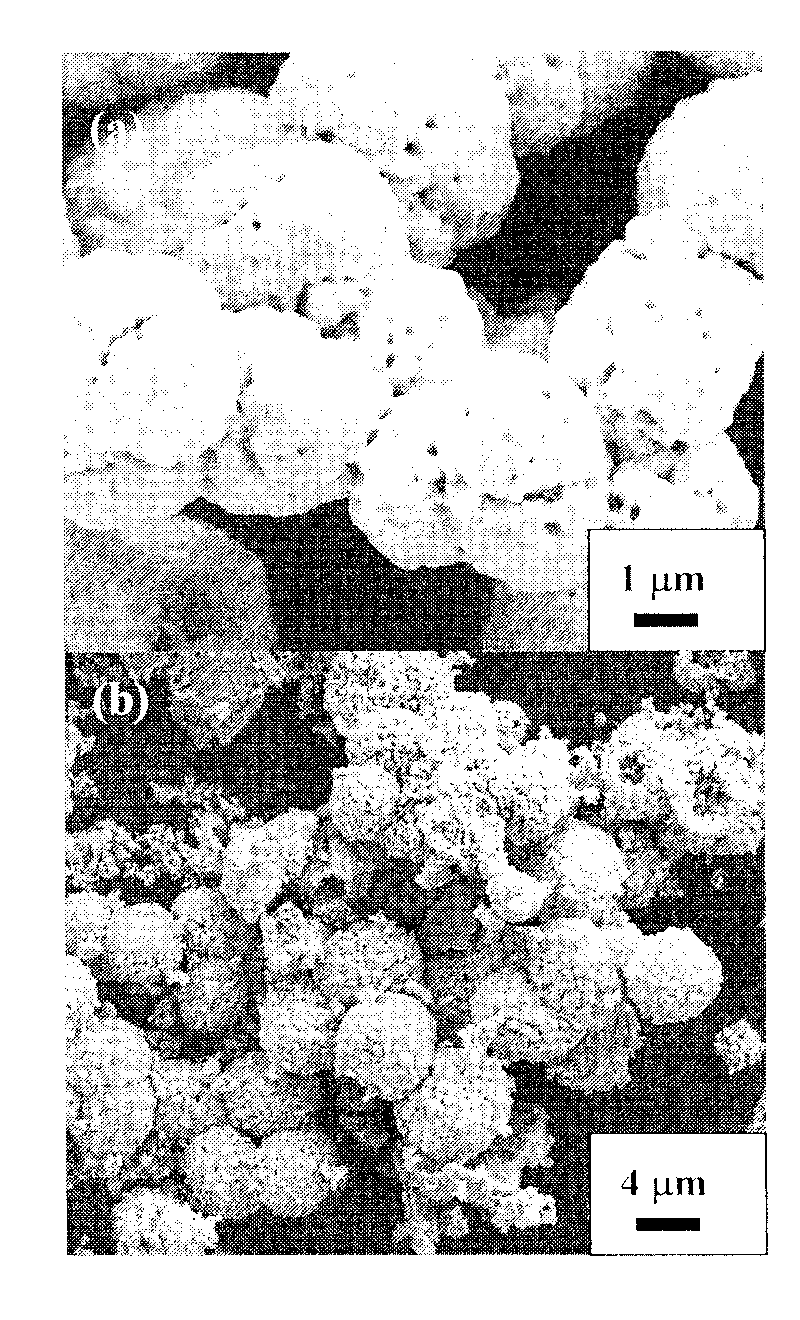

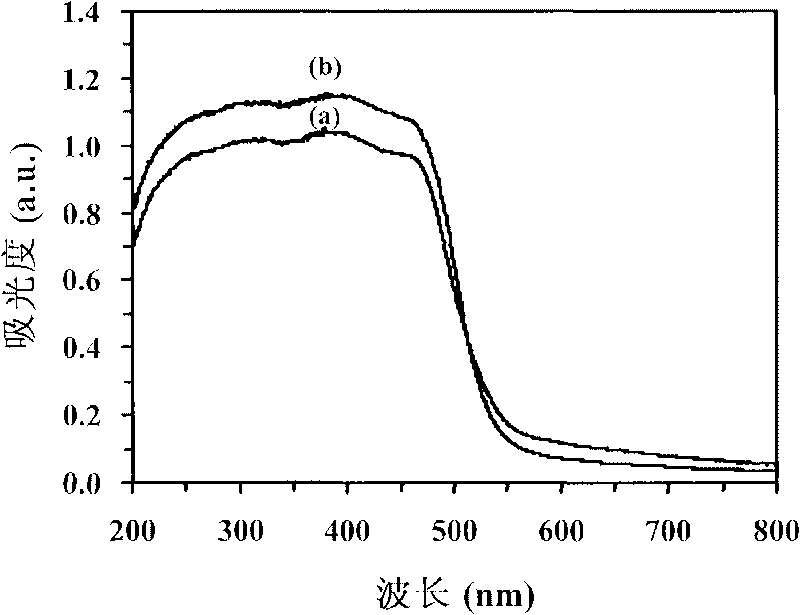

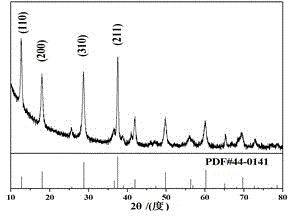

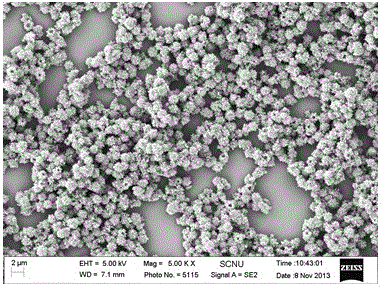

Method for preparing hollow spherical porous BiVO4 with aid of surfactant

The invention discloses a method for preparing hollow spherical porous BiVO4 with the aid of a surfactant, which comprises the following steps of: under a stirring condition, dissolving bismuth nitrate and ammonium meta-vanadate in 2 mol / L solution of nitric acid in a molar ratio of bismuth nitrate to ammonium meta-vanadate to nitric acid of 1:1:10; adding polyvinylpyrrolidone (PVP) and carbamide into the mixed liquid in a molar ratio of bismuth nitrate to PVP to carbamide of 1:0.0075-0.0125:3; transferring the mixed liquid to a stainless steel self-pressure reactor of which the lining is teflon and the volume filling degree is 50 percent, and to a thermostat to perform hydro-thermal treatment for 30 hours at the temperature of 100 DEG C; cool a product naturally to room temperature after the product is taken out; drying the product for 24 hours at the temperature of 60 DEG C; and finally calcining the product in a muffle furnace to obtain hollow spherical porous BiVO4 particles with a monoclinic scheelite structure. The method has the characteristics of cheap raw materials, simple process, controllable appearance and crystalline phase structure of the target product particles and the like.

Owner:BEIJING UNIV OF TECH

High pressure dry coal slurry extrusion pump

A system for providing highly pressurized raw fuel to a pressure reactor. The system includes an inlet for receiving the raw fuel and a roller system communicating with the inlet. The roller system includes a plurality of independent rollers arranged in two converging planes. The rollers of the roller system successively compress the raw fuel as the raw fuel passes through the roller system between the rollers, such that the fuel is highly pressurized when it reaches an output end of the roller system. An outlet is located adjacent the output end of the roller system to dispense the pressurized raw fuel to the pressure reactor.

Owner:THE BOEING CO +1

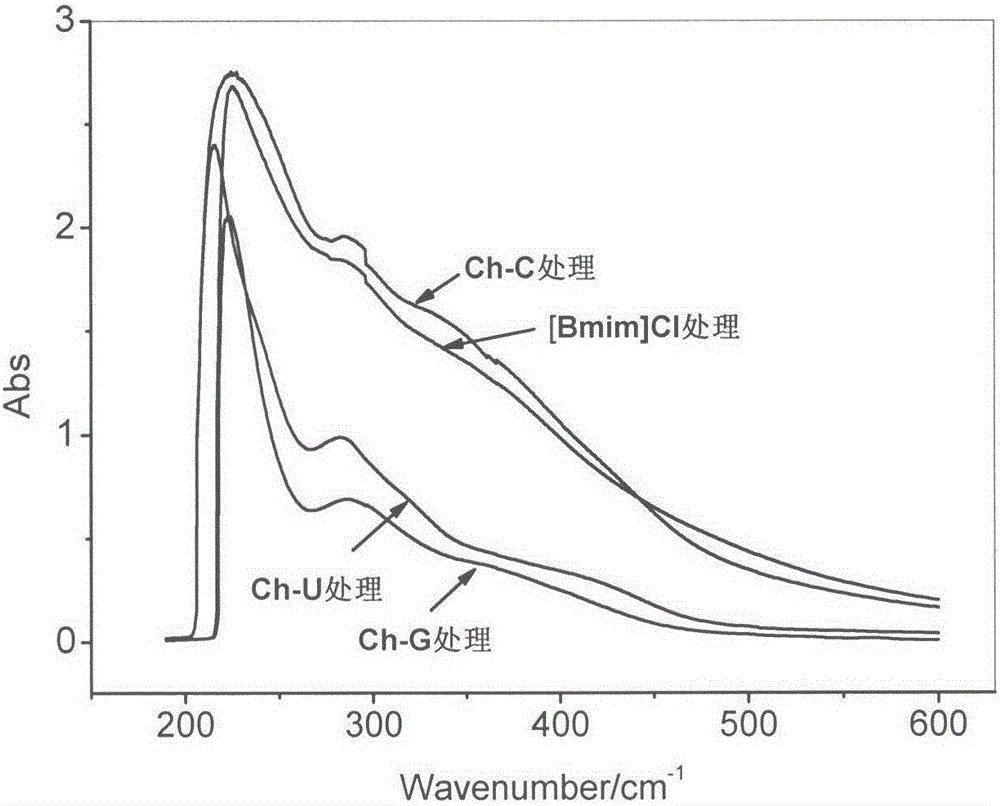

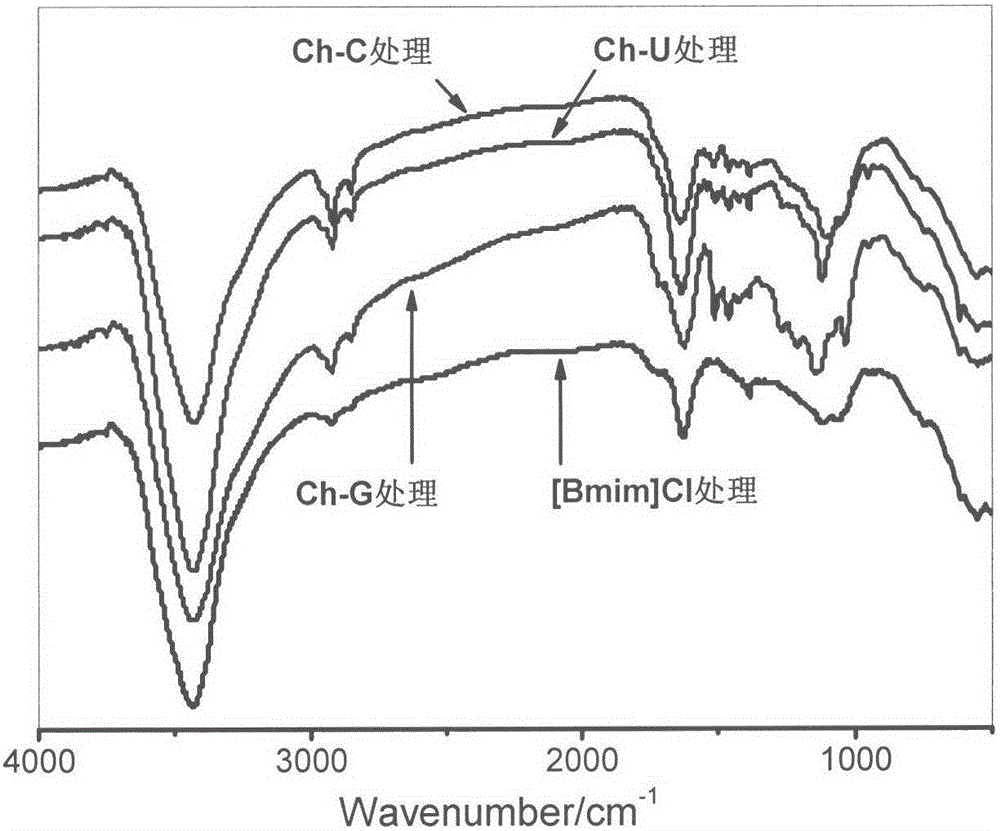

Method for separating and extracting straw lignin by using eutectic ionic liquid

The invention relates to a process method for separating and extracting straw lignin by using eutectic ionic liquid. The method comprises the following steps of: adding a straw powder raw material and eutectic ionic liquid into a normal pressure reactor according to a certain mass ratio, performing mixing and stirring for reaction at 110-160 DEG C for a certain period of time, then regulating the pH value of the mixture to about 11 by using an alkali, performing high-speed centrifugation, and keeping an upper layer solution; and then regulating the pH value of the solution to be less than 3 by using an acid, performing centrifugation again, then washing and centrifuging a deposit by using distilled water until the supernatant is neutral, and performing freeze drying on the final deposit to obtain lignin. The method has the characteristics that the eutectic ionic liquid is prepared under a very mild condition by using low-price and nontoxic choline chloride and an H-bond donor as raw materials, and is used for separating and extracting lignin from rice straws, the raw materials are easy to obtain, the price is low, the process is simple, the condition is mild, the reaction is easy to control, and the energy consumption can be effectively reduced.

Owner:NANJING FORESTRY UNIV

Method for decomposing vanadium slag under normal pressure by adding carbon-containing substance into sodium hydroxide solution

The invention relates to a method for decomposing vanadium slag under normal pressure and extracting vanadium and chromium by adding a carbon-containing substance into a sodium hydroxide solution. The method comprises the following steps of: uniformly mixing the vanadium slag and the carbon-containing substance, and adding the mixture, water and NaOH into a normal pressure reactor; introducing oxidizing gas for oxidization reaction, and diluting reaction slurry obtained by the reaction by using a diluent to obtain mixed slurry containing NaOH, sodium vanadate, sodium chromate, sodium silicate and tailings; and filtering and separating the mixed slurry to obtain the tailings, and an alkaline solution containing the vanadium and the chromium. The operating temperature of the method is below the boiling point of the solution, and the method can be implemented under normal pressure, and is easy to implement and high in safety; and the operating temperature is far lower than the temperature of the traditional vanadium extracting process, the extraction ratio of the vanadium is high, the chromium can be partially extracted synchronously, the total vanadium contained in the tailings is 0.2 to 0.6 weight percent (based on V2O5), and the leaching rate of the chromium is 8-20 percent.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for efficient and comprehensive utilization of high-iron bauxite

ActiveCN102515223AAchieve cycleEffective leachingAluminium oxides/hydroxidesAluminium chlorideAluminium hydroxide

The invention relates to a method for efficient and comprehensive utilization of high-iron bauxite. The method provided by the invention comprises the following steps that 1, high-iron bauxite and hydrochloric acid are mixed, then are added into a hydrochloric acid-resistant medium-pressure reactor and undergo a heating reaction; 2, after cooling, the reaction products are subjected to solid-liquid separation so that high-silicon dregs and a solution containing aluminum chloride and ferric chloride are obtained; 3, the solution containing aluminum chloride and ferric chloride is added with an excess amount of a sodium hydroxide alkaline solution so that a sodium aluminate solution and high-iron dregs are obtained; and the sodium aluminate solution is electrolyzed to produce chlorine, hydrogen, a sodium hydroxide solution and a pure sodium aluminate solution; 4, the pure sodium aluminate solution is introduced into a crystal seed precipitation tank, is subjected to precipitation and then is subjected to solid-liquid separation so that aluminum hydroxide products and a mother liquor are obtained by the precipitation; and 5, the aluminum hydroxide products are graded, wherein the aluminum hydroxide products having small granularity are utilized as crystal seeds for precipitation and the aluminum hydroxide products having big granularity are washed and then are subjected to high-temperature calcination to form metallurgical-grade alumina products. The method provided by the invention can realize effective precipitation of alumina and iron of high-iron bauxite, has low energy consumption in a whole flow, avoids waste production, realizes full green production and is conducive to industrialization.

Owner:SHENYANG POLYTECHNIC UNIV

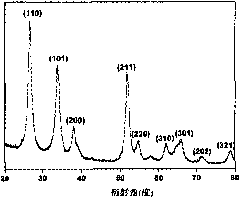

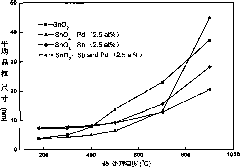

Method for preparing palladium and/or antimony-doping tin oxide nano-powder

InactiveCN101823691ASmall particle sizeImprove thermal stabilityNanostructure manufactureIonTin oxide

The invention discloses a method for preparing palladium and / or antimony-doping tin oxide nano-powder. The method mainly comprises the following steps of: mixing raw materials according to the molar doping ratio of Pd<2+> and / or Sb<3+> to Sn<2+> of 0.5 to 3.5 and dropwise adding at least one of the solution of PdCl2 and the suspension of SbCl3 into the solution of tin salt with stirring to form mixed solution, wherein the raw materials comprise 0.2 to 1 mol / L solution of tin salt, 0.1 to 0.5 mol / L solution of palladium chloride (PbCl2), 0.1 to 0.5 mol / L suspension of antimony chloride (SbCl3)and 0.4 to 1 mol / L solution of alkali source; adding the solution of alkali source dropwise into the mixed solution with stirring until the pH value is between 9 and 13; stirring the solution to formprecursor suspension with a large amount of precipitate; transferring the precursor suspension to a high-pressure reactor to perform reaction for 12 to 36 hours at the temperature of between 100 and 200 DEG C and naturally cooling to room temperature to obtain a hydrothermal product; washing the hydrothermal product for multiple times by using deionized water and ethanol and detecting the productby using silver nitrate until the Cl<-> is removed completely; and drying at the temperature of between 70 and 100 DEG C to obtain the palladium and / or antimony-doping tin oxide nano-powder. The method has the advantages of simple process, environmental friendliness and suitability for industrialized production.

Owner:NINGBO UNIV

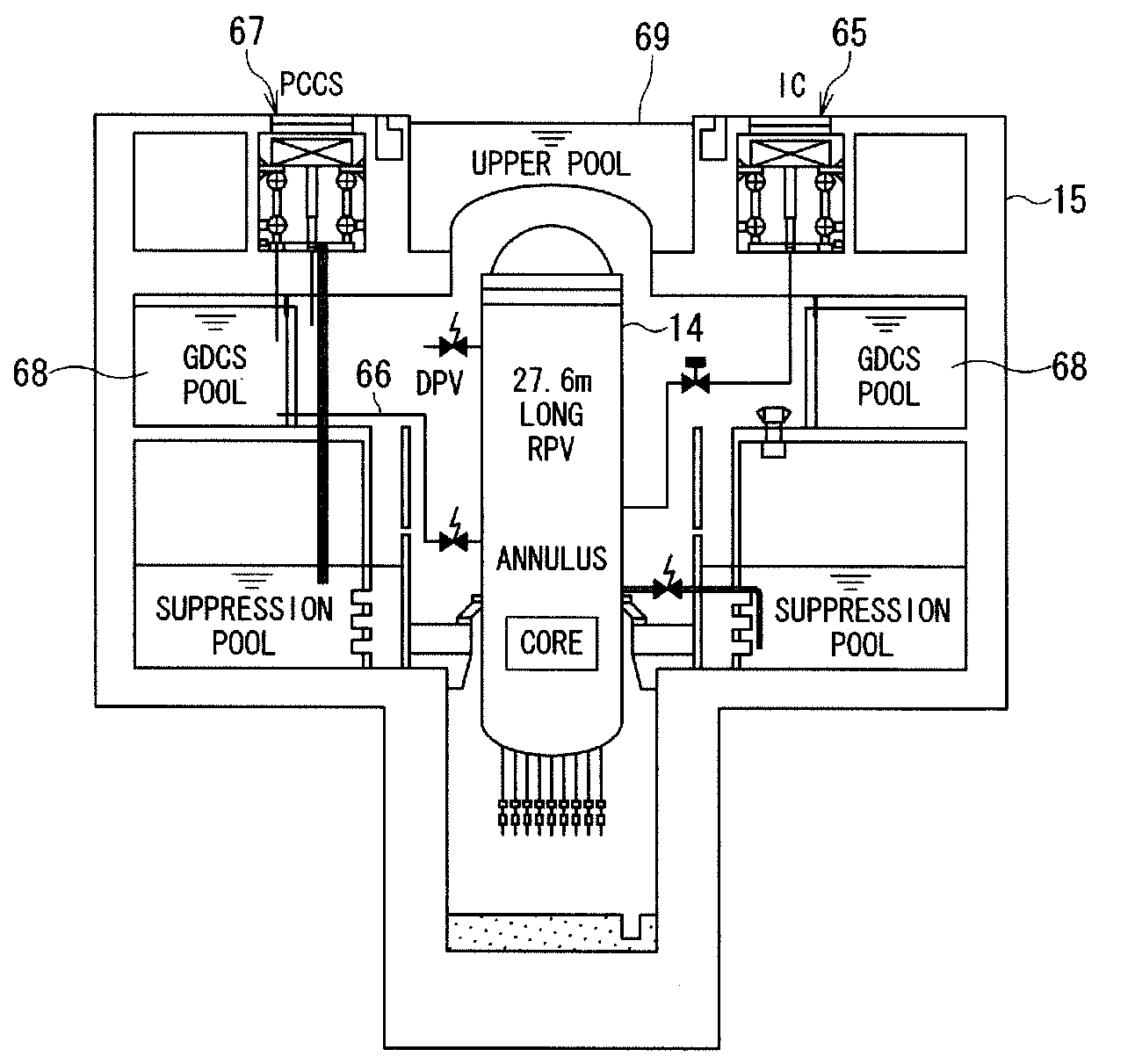

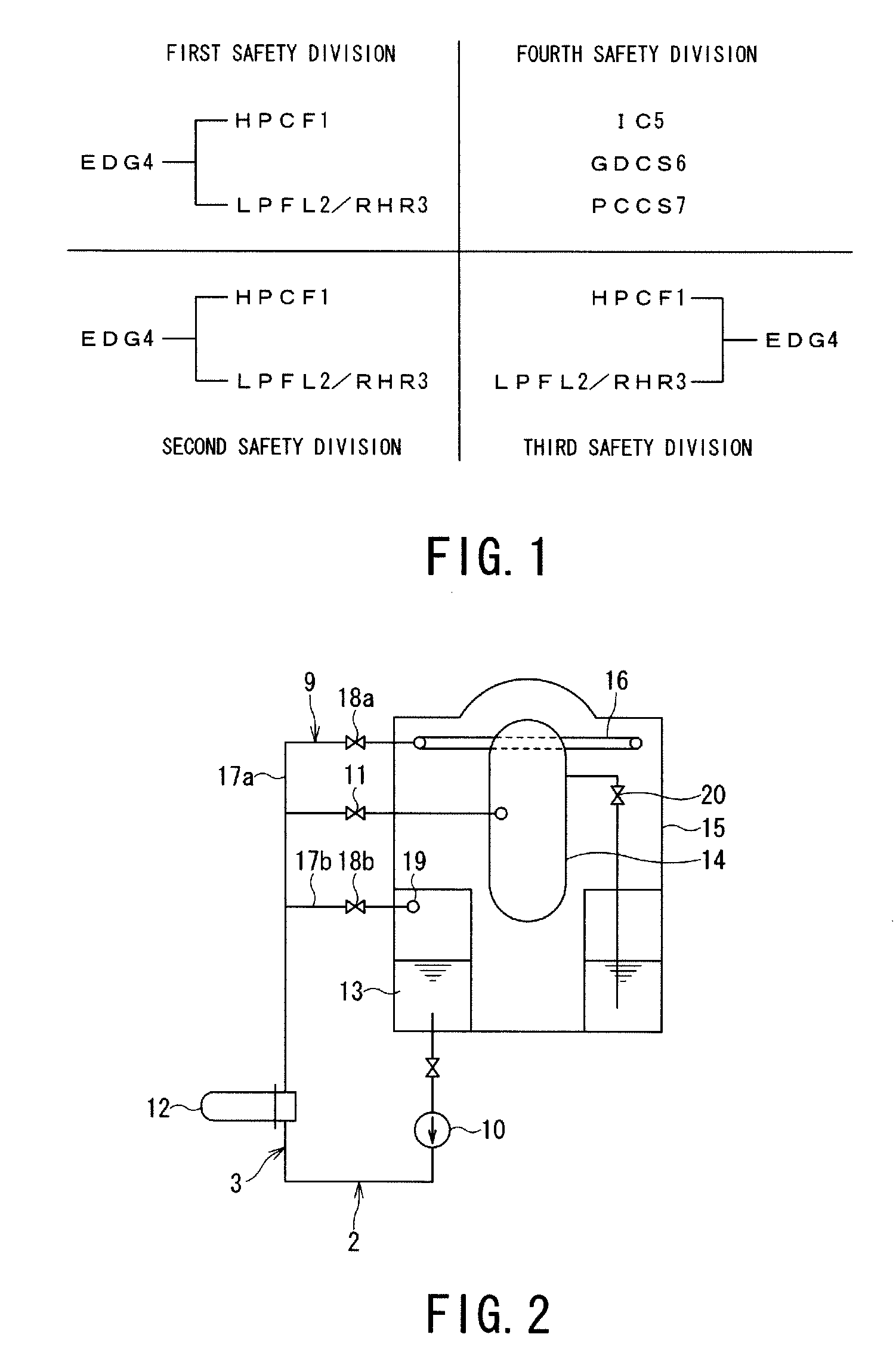

Emergency core cooling system

InactiveUS20080317193A1Improve securityPower plant safety arrangementNuclear energy generationHigh pressureDiesel generator

An emergency core cooling system is provided with a hybrid safety system composed of an active safety system and a static safety system for ensuring the safety against a severe natural phenomenon such as a giant earthquake and a mega hurricane. An emergency core cooling system for a boiling water reactor includes four safety divisions in total: three safety divisions for an active safety system having a high pressure reactor core cooling system, a low pressure reactor core cooling system, a residual heat removal system, and an emergency diesel generator; and one safety division for a static safety system having an isolation condenser, a gravity drop reactor core cooling system, and a static containment vessel cooling system.

Owner:KK TOSHIBA

Steam-reforming catalytic structure and pure hydrogen generator comprising the same and method of operation of same

ActiveUS20030172589A1Less-expensive structureImproved hydrogen generationIsotope separationHydrogen/synthetic gas productionSteam reformingHeat conducting

A reactor / purifier for generating pure hydrogen in a stack or array of pairs of alternatingly connected high and low pressure reactor chambers wherein a gas-porous turbulence-promoting screen structure washcoated with a steam-reforming catalyst is sandwiched between a planar hydrogen-selective palladium alloy membrane and a planar gas-impermeable heat-conducting metal plate within the high pressure reactor chamber of each high pressure reactor chamber; and wherein the catalyst-coated structure in each high pressure chamber is reacted with steam and hydrocarbon fuel, such as methane or syn / gas, and / or carbon monoxide at an appropriately controlled temperature of between about 200° C. to 650° C. to produce hydrogen and carbon oxides within an isothermal temperature range in each high pressure reactor chamber, while simultaneously permeating pure hydrogen therefrom through the membrane into the corresponding connected low pressure reactor chamber, and with the required heat transfer to and from the catalyst being provided in situ predominantly by conduction through the corresponding metal plate.

Owner:HYDRIP LLC

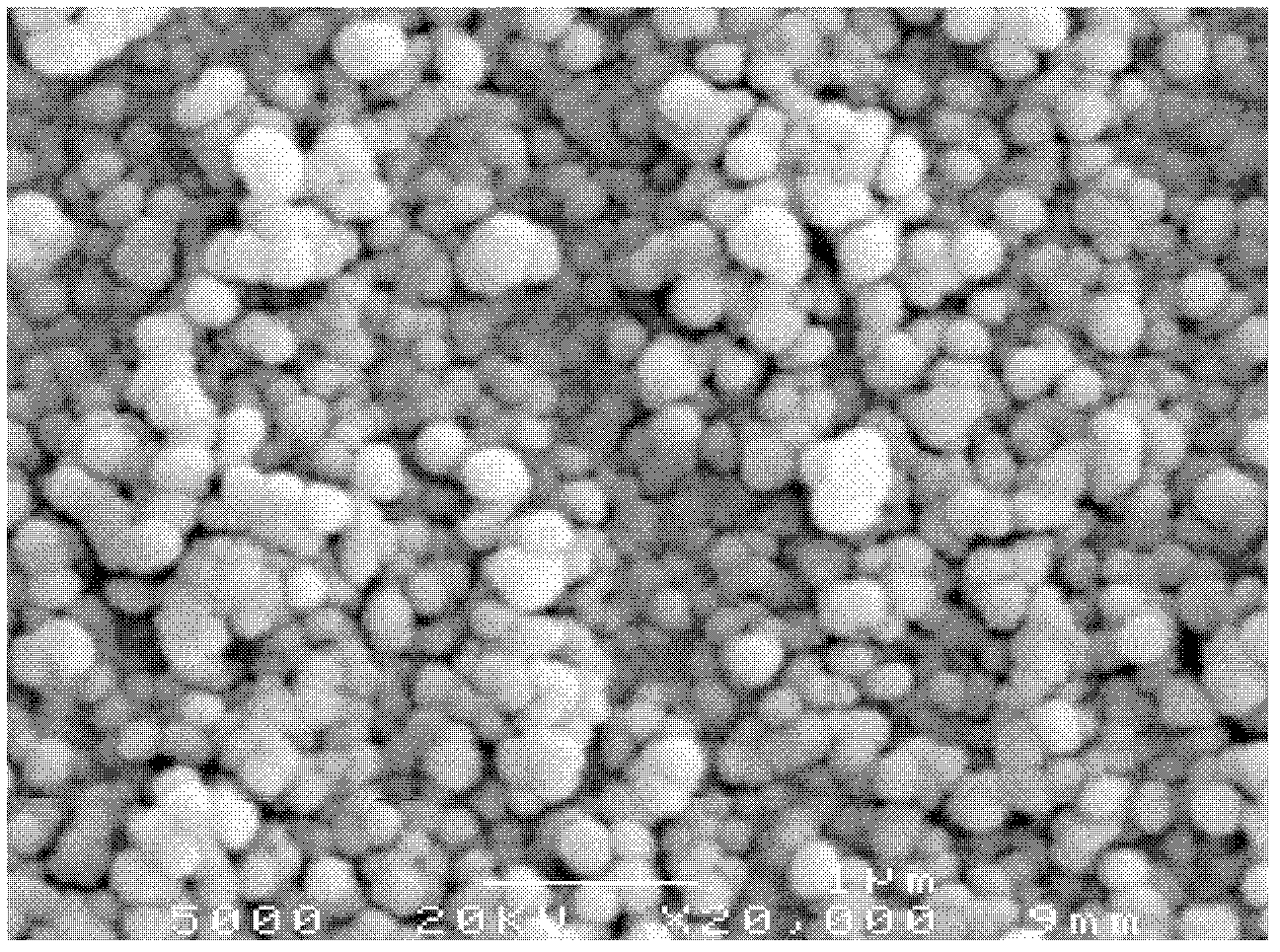

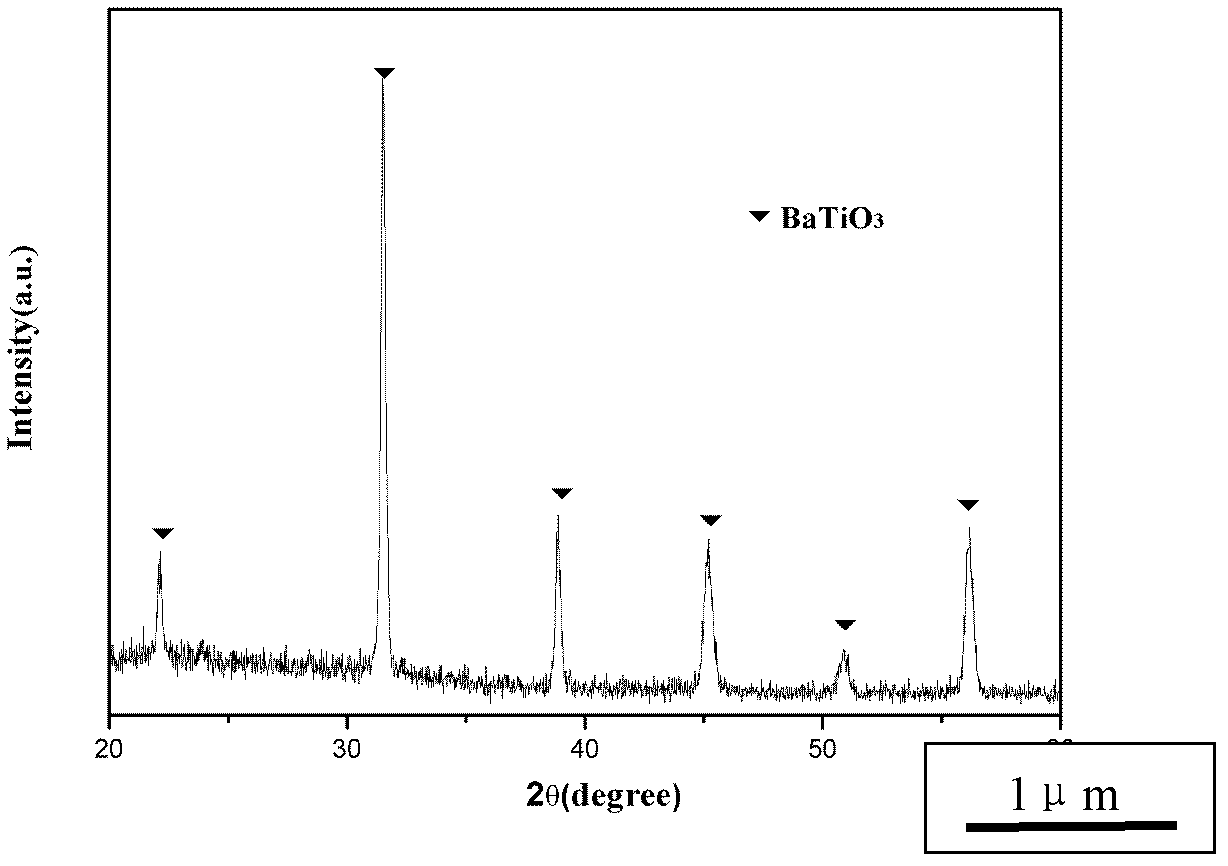

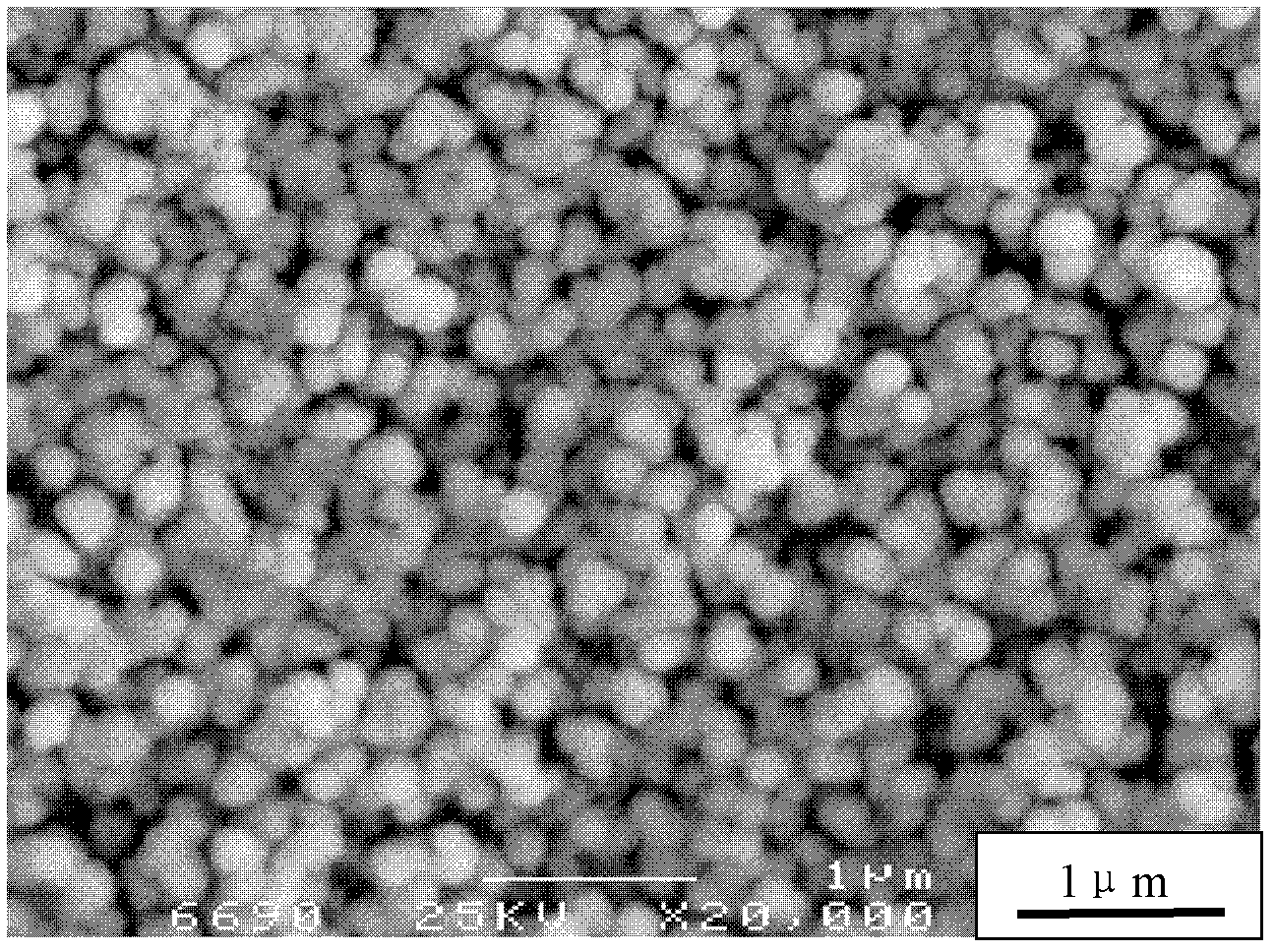

Preparation method for monodisperse barium titanate nanopowder

InactiveCN102502798AAvoid generatingHigh purityNanotechnologyTitanium compoundsHydration reactionBarium titanate

The invention discloses a preparation method for monodisperse barium titanate nanopowder combining with sol-gel method and hydrothermal method, comprising the following steps of: preparing original solution and dripping solution from absolute ethyl alcohol, tetrabutyl titanate, nitric acid and deionized water; mixing the dripping solution with the original solution to obtain TiO2 sol; pouring the TiO2 sol in the liner of a polytetrafluoroethylene high-pressure reactor, adding barium octahydrate precursor solution of different concentrations and then stirring; placing the liner in the step 3 in a stainless steel high-pressure reactor, sealing and then placing in a high-temperature oven to perform hydrothermal reaction; finishing the reaction and cooling, then opening the reactor, filtering and washing the reactants to be neutral by using the deionized water and the absolute ethyl alcohol, and then drying the reactants in the oven , so as to obtain the monodisperse barium titanate nanopowder. The preparation method for monodisperse barium titanate nanopowder disclosed by the invention combines with the advantages of sol-gel method and hydrothermal method for preparing powder, so that the synthesised barium titanate nanoparticles have the advantages of being high in purity, controllable in particle size, complete in crystal particle development etc; and the preparation method for monodisperse barium titanate nanopowder is simple in equipment, practicable in operation and convenient for industrialized batch production.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Catalytic gasification of organic matter in supercritical water

InactiveCN102666808AIncrease pressurePressurized chemical processWaste based fuelProduct gasOrganic matter

The present invention discloses a catalyst system comprising at least one metal and an oxide support, said oxide support comprising at least one of Al2O3, MnxOy, MgO, ZrO2, and La2O3, or any mixtures thereof; said catalyst being suitable for catalyzing at least one reaction under supercritical water conditions. The present invention also provides a system for producing a high-pressure product gas under super-critical water conditions. The system comprises a pressure reactor accommodating a feed mixture of water and organic matter; a solar radiation concentrating system heating the pressure reactor and elevating the temperature and the pressure of the mixture to about the water critical temperature point and pressure point or higher.; The reactor is configured and operable to enable a supercritical water process of the mixture to occur therein for conversion of the organic matter and producing a high-pressure product fuel gas.

Owner:YEDA RES & DEV CO LTD +1

Hydrothermal synthesis method of micro-emulsion of nano lithium titanate

InactiveCN103274454AHigh crystallinityEffective control of particle sizeCell electrodesTitanium compoundsLithium hydroxideHigh pressure

The invention discloses a hydrothermal synthesis method of a micro-emulsion of nano lithium titanate. According to the method disclosed by the invention, the micro-emulsion is prepared from cetyltrimethylammonium bromide, n-hexanol, cyclohexane and a water phase, and tetrabutyl titanate and lithium hydroxide are used as reaction materials. The method comprises the steps of: (1) preparing the 0.02-2.0 mol / L lithium hydroxide micro-emulsion and 0.025-2.5 mol / L titanium tetraisopropoxide micro-emulsion respectively; and (2) mixing the micro-emulsions in two concentrates, stirring for 5-120 minutes at the room temperature, then transferring a mixture into a 50 ml high-pressure reactor which is lined with polytetrafluoroethylene, carrying out hydrothermal reaction at the temperature of 60-240 DEG C for 1-70 hours, and then carrying out centrifugal separation, washing, drying and thermal treatment on a reactant to obtain spinel type lithium titanate. The method has the characteristics of controllable grain size, controllable morphology, simple process, simple equipment and the like.

Owner:JILIN UNIV

Processing method of zinc sulfide concentrate

ActiveCN102417979AExtend effective boot timeEasy to controlSulfur preparation/purificationProcess efficiency improvementSlagOxygen

The invention provides a method used for processing a zinc sulfide concentrate through a first stage pressure acid leaching process and a second stage pressure neutralizing step. The method comprises steps that: (1) oxygen and an acid with a concentration of 110-190g / L are delivered into a zinc sulfide concentrate with a preset particle size; the first stage pressure acid leaching process is carried out, wherein the leaching rate of zinc is no less than 98% and the leaching rate of iron is no more than 10%; (2) an obtained first-stage leaching solution is delivered into a second-stage pressure reactor; oxygen is delivered into the reactor; the zinc sulfide concentrate with a preset particle size is subject to a neutralization reaction, such that free acid in the solution is consumed; with the reduced acidity, iron is oxidized and removed, such that a leaching solution with an acid concentration no more than 5g / L and an iron content no more than 1g / L is obtained. The method provided by the invention is advantaged in simple technology, short technological process, high raw material adaptability, good production capacity, high metal recovery rate, low neutralizer consumption, low production cost, and long machine time. The leaching rate of zinc is no less than 98% and the leaching rate of iron is no more than 10%. 90% of iron is removed with a first-stage leaching slag. A final acid concentration of the leaching solution is no more than 5g / L, and a final iron content is no more than 1g / L.

Owner:YUNNAN METALLURGICAL GROUP +1

Method for preparing H2SnO3 (tin dioxide) powder

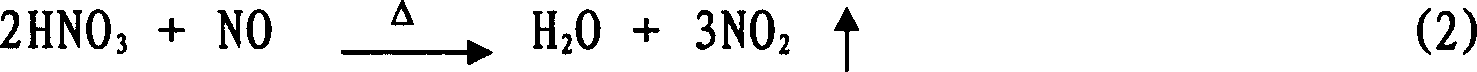

A process for preparing H2SnO3 and SnO2 powder includes such steps as reaction between Sn and nitric acid in sealed pressure reactor containing O2 to obtain the intermediate of H2SnO3, neutralizing, washing, drying to obtain H2SnO3, calcining, and breaking to obtani superfine SnO2 powder.

Owner:云南锡业研究院有限公司研究设计院

Corrosion inhibitor for acidification of oil well, and preparation and application thereof

The invention relates to a preparation method of a corrosion inhibitor for acidification of an oil well. The preparation method comprises the steps of adding formaldehyde, acetophenone, ethene diamine and HCl in a normal pressure reactor according to a molar ratio of 6 :1 :1 : 1 and adding ethanol as a solvent; heating to a temperature of 80-90 DEG C; reacting for 3-4 hours to obtain a condensation compound of aldehyde, ketone and amine; adding propynol with an amount of 5% that of a total mass of the product as a corrosion inhibitor synergistic ingredient and adding methanol with an amount of 30% that of a total mass of the product as a solvent to obtain the corrosion inhibitor for acidification of the oil well; and adding the corrosion inhibitor for acidification of the oil well with an amount of 0.4% that of the mass of the hydrochloric acid medium in a 15% hydrochloric acid medium at a temperature of 90 DEG C, so that corrosion rate of N80 test block can be reduced to 1.32 g / m<2>.h. The corrosion inhibitor for acidification of the oil well solves the corrosion problems of an acidizing fracturing liquid to downhole oil tubes, sleeves and used metal equipment during acidizing and fracturing of the oil well; usability of the corrosion inhibitor for acidification of the oil well is increased; and preparation cost for the corrosion inhibitor for acidification of the oil well is reduced.

Owner:PETROCHINA CO LTD

Method for preparing beef essence

InactiveCN101214042ALower requirementCharacteristic fragranceFood preparationMaillard reactionPreservative

The invention discloses a preparation method of beef flavor, comprising the following steps: A, tallow is put into a reaction container, heated at the temperature of 120 DEG C to 160 DEG C and stirred slowly. When the temperature of the tallow is up to 120 DEG C to 160 DEG C, the air pump works with the air pump adjusting flow of 0.4 to 0.8L / min*100g. After reacting for 2 to 4 hours, the heating is stopped and the temperature is decreased to 45 DEG C to 55 DEG C, the oxidized tallow is prepared. B, the Maillard reaction is adopted, the pro rata raw material is putted into the container, and the pH is adjusted to 6.5 to 7.5, the container is putted into the pressure reactor and heated to 110 DEG C to 130 DEG C; after reacting for 3 hours, the container is taken out and cooled to 48 DEG C to 60 DEG C, antiseptic and thickening agent are added into, to be stirred uniformly to obtain beef flavor paste, or powder is added and stirred uniformly to get beef flavor powder. The beef flavor of the invention has advantages of lifelike characteristic aroma, no need of extraction, less delamination of liquid flavor, large reduction in the manufacture cost.

Owner:SHANGHAI INST OF TECH

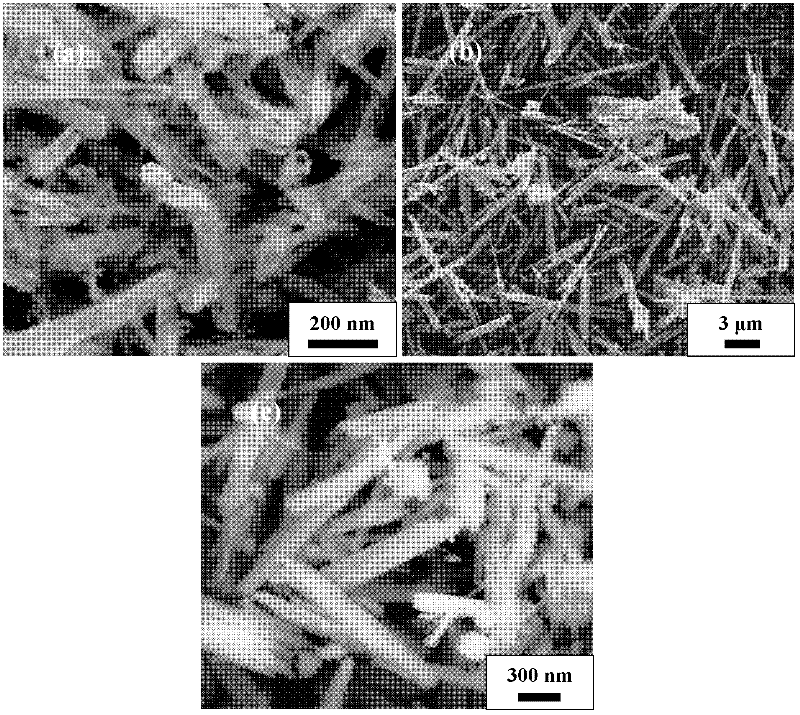

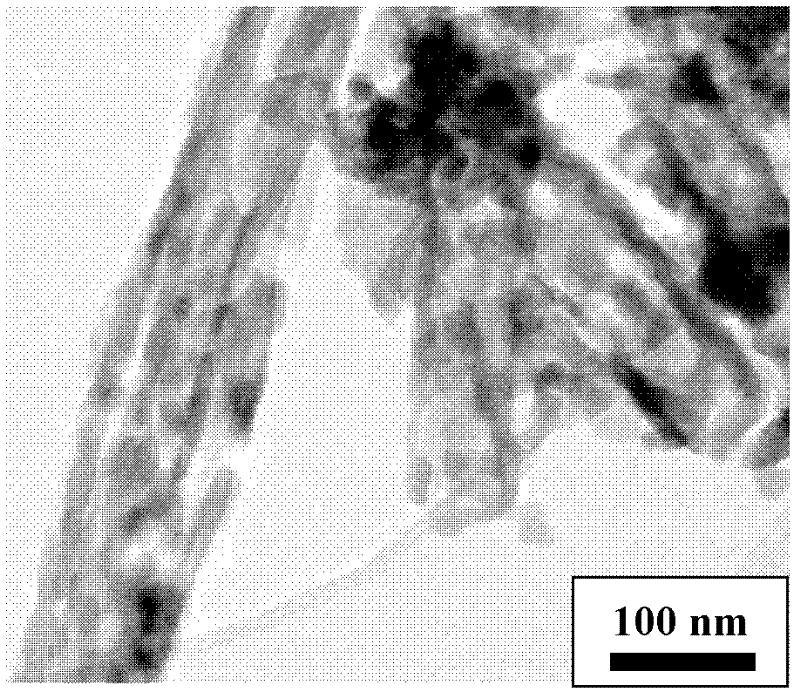

A method for preparing porous nano or submicron rod-shaped manganese oxide

The invention discloses a method for preparing porous nano or submicron rod-like manganese oxide, and belongs to the technical field of functional materials. Ethanediamine, glucose or polyvinylpyrrolidone (PVP) is adopted as an additive, and the porous nano rod-like manganese oxide is prepared. The method mainly comprises the following steps of: dissolving KMnO4 and MnSO4 or KMnO4 and hydrochloric acid in deionized water in a certain molar ratio to obtain a homogeneous solution; adding the ethanediamine, glucose or PVP in a corresponding molar ratio; and fixing the volume of the solution by using deionized water, transferring to a self-pressure reactor, ensuring a liner filling rate is 80 percent, crystallizing at certain temperature for corresponding time, naturally cooling to room temperature, performing suction filtration on the obtained substance, drying at 60DEG C for 12 hours, fully grinding, heating from the room temperature to 400DEG C at a temperature rise rate of 1DEG C / min in the air, keeping the constant temperature for corresponding time to obtain the porous nano rod-like or submicron rod-like manganese oxide, wherein the obtained product contains a small amount of impurity phase.

Owner:BEIJING UNIV OF TECH

Method for preparing ceria mesoporous hollow ball

InactiveCN103387256AImprove diffusion abilityHollow outRare earth metal compoundsPropanoic acidDissolution

The invention relates to a method for preparing a ceria mesoporous hollow ball. The method comprises the following steps of dissolving a cerium nitrate hexahydrate in deionized water, respectively adding propionic acid and glycol into the solution to obtain a mixed solution, adding the mixed solution into a hot pressure reactor, sealing the hot pressure reactor, wherein a constant temperature reaction undergoes in the hot pressure reactor, applying certain pressure to the reaction system in the constant temperature reaction, wherein constant pressure I of 30-120 MPa is applied in first 100-120min and constant pressure II of 60-150 MPa is applied after first 100-120min and the pressure II is greater than the pressure I, and carrying out forced diffusion of a solvent into ceria mesoporous balls by a pressure difference to obtain the ceria mesoporous hollow balls by dissolution-re-precipitation. The ceria mesoporous hollow ball has the characteristics of controllable inner and outer diameters, high yield, high purity and good dispersibility. The method has simple processes, is environmentally friendly and can be massively prepared.

Owner:SHANDONG UNIV

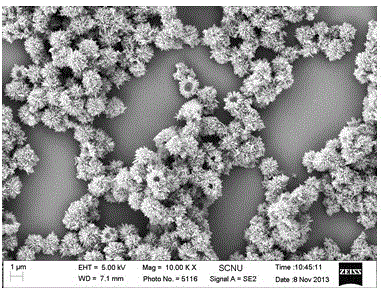

Preparation method and use of manganese dioxide having hollow structure

ActiveCN103910386ALow costThe synthesis process is simpleManganese oxides/hydroxidesPressure reactorToluene

The invention discloses a preparation method and a use of manganese dioxide having a hollow structure. The preparation method of the manganese dioxide having the hollow structure comprises the following steps of dissolving manganese sulfate, potassium persulphate and potassium sulfate in distilled water, carrying out stirring for complete dissolution to obtain a solution A, stirring the solution A, meanwhile, adding concentrated sulfuric acid into the solution A, sequentially carrying out stirring to obtain a uniform mixed solution B, wherein a volume ratio of the concentrated sulfuric acid to the distilled water is 0.8-1: 15, putting the mixed solution B into a high-pressure reactor, putting the high-pressure reactor in an environment having a temperature of 140-180 DEG C, carrying out a reaction process for 6-24h, and carrying out washing and drying to obtain the manganese dioxide having a hollow structure. The preparation method utilizes easily available raw materials and has a low cost, simple and easy synthesis processes. The manganese dioxide product has stable quality and good technology repeatability. The manganese dioxide having a hollow structure can be used as a catalyst and has good catalytic activity to toluene catalytic combustion.

Owner:GUANGDONG UNIV OF TECH

Method for preparing terephthalic acid ester plasticizer with pressurization method

InactiveCN102807491AShort reaction timeImprove performanceOrganic compound preparationCarboxylic acid esters preparationPtru catalystAlcohol

The invention provides a method for preparing terephthalic acid ester plasticizer with a pressurization method. The method comprises the following steps that terephthalic acid, alcohol and a catalyst are mixed to be subjected to esterification reaction to obtain a terephthalic acid ester raw-product, and the terephthalic acid ester raw-product is subjected to neutralization washing and reduced pressure distillation to obtain a terephthalic acid ester finished-product; the esterification reaction is carried out in a high-pressure reactor under pressurization; in the reaction process, the pressure keeps at most 1.6MPa, and the reaction temperature is at most 250 DEG C; when the system pressure is beyond 1.6MPa in reaction, a reducing valve is turned on to exhaust and reduce pressure, and gas is recovered to be condensed; the reaction is carried out for 1-3 hours and then is finished until the acid value of a product is at most 1; and in the reaction, the alcohol is excessive, and the alcohol is C1-10. The method uses the terephthalic acid as a raw material to prepare the terephthalic acid ester plasticizer under the condition of pressurization. The variety of the raw material is not strictly restricted, the reaction time is short, the operation is simple and easy, the used solvents can be efficiently recovered, and the environment is friendly. The method is suitable for industrial production.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY +1

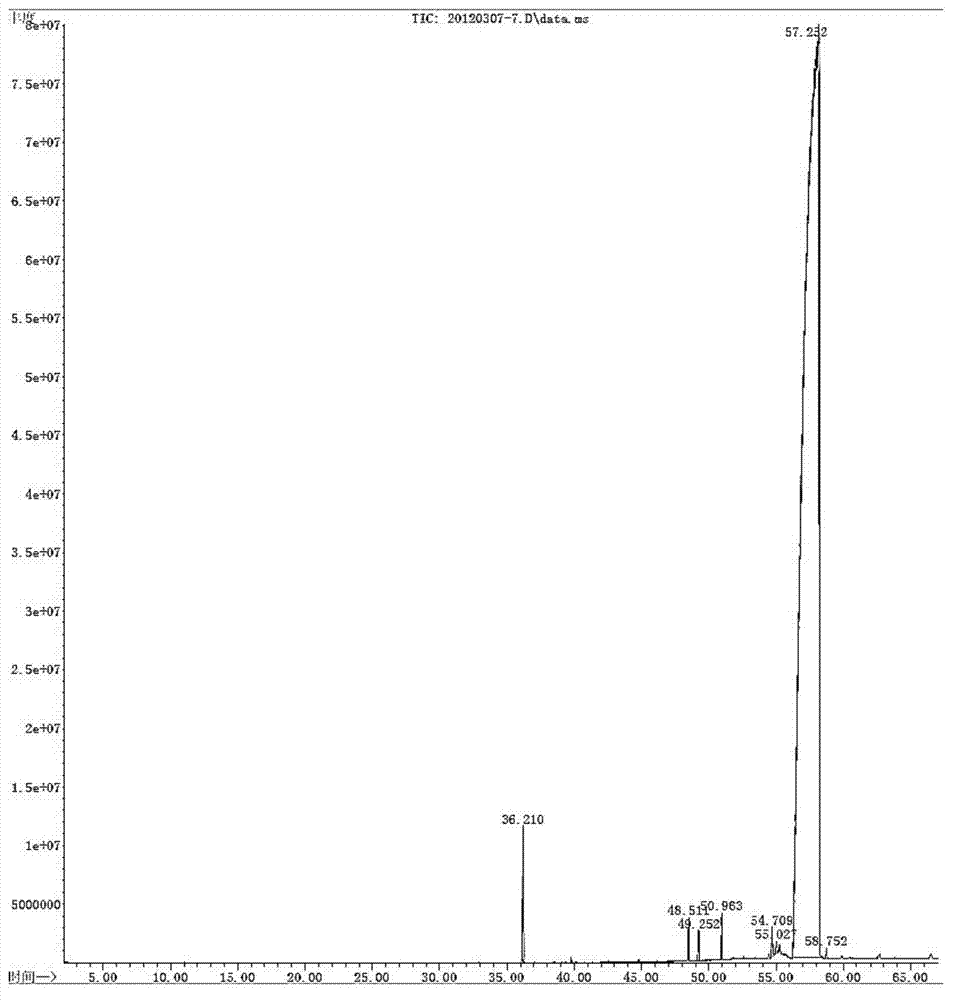

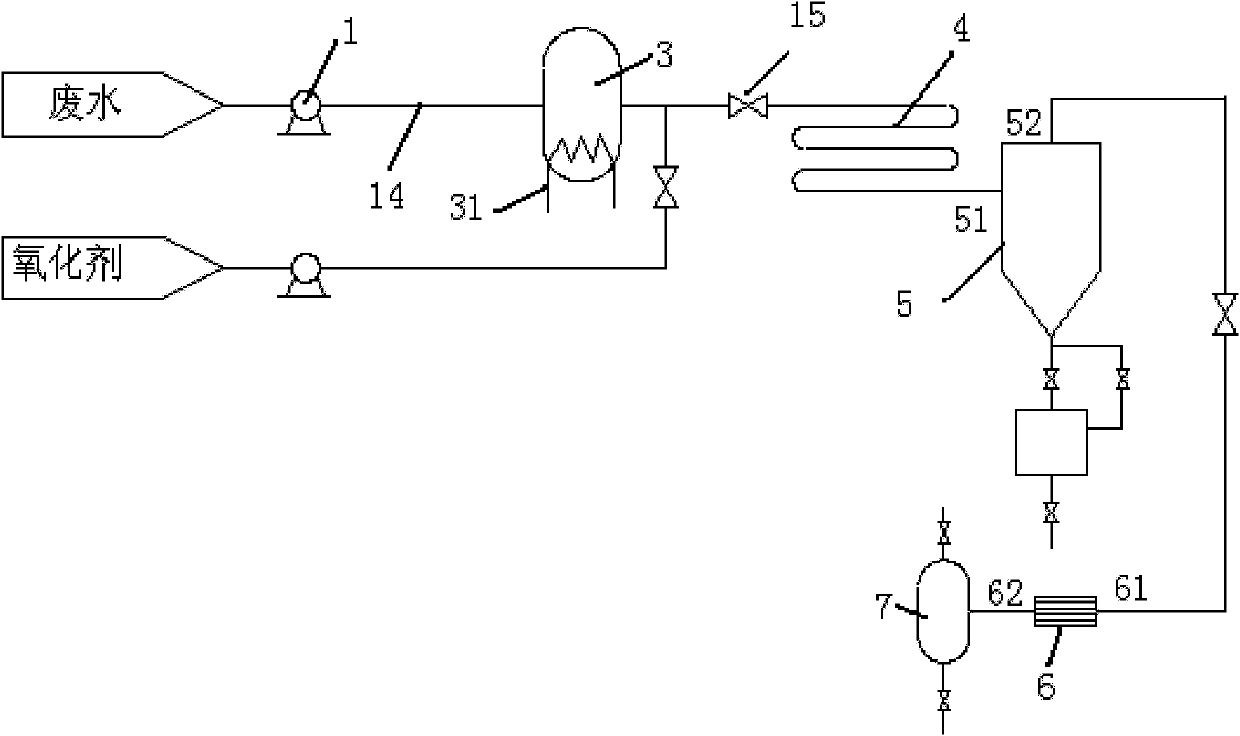

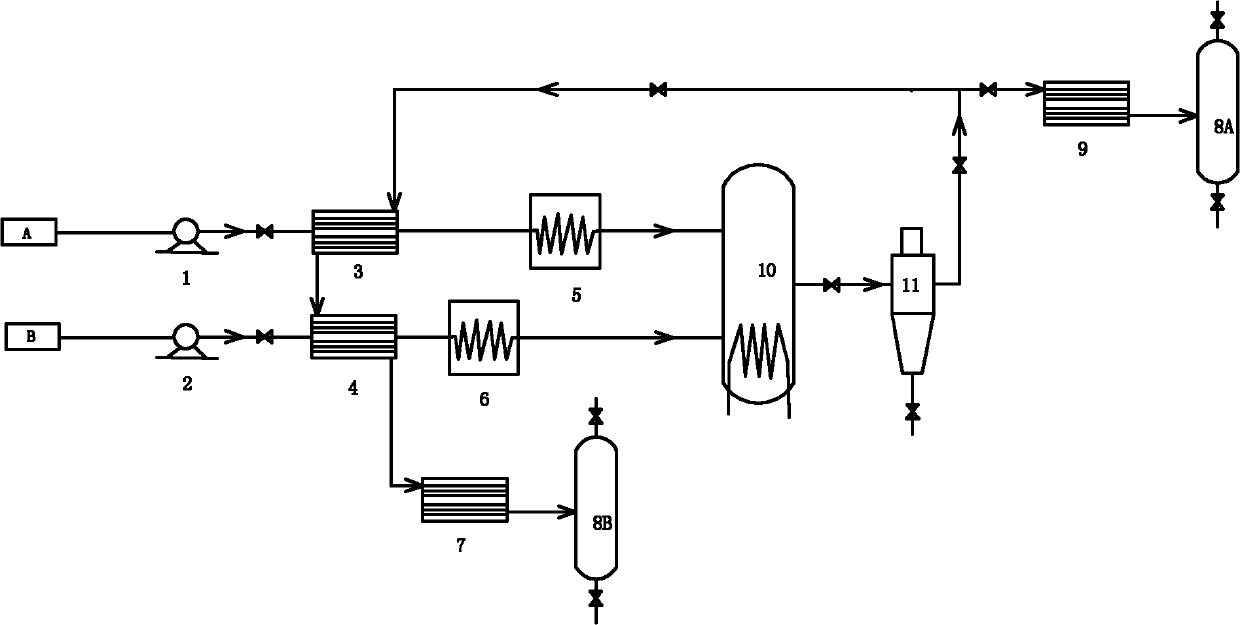

System and method for processing alkaline residue wastewater by utilizing supercritical water oxidation method

InactiveCN101993143AExtend heating timeReduce heating powerWater/sewage treatment by oxidationProcess engineeringSupercritical water oxidation

The invention relates to a system and method for processing alkaline residue wastewater by utilizing a supercritical water oxidation method. The system for processing the alkaline residue wastewater by utilizing the supercritical water oxidation method comprises a wastewater high-pressure plunger pump, a wastewater preheater, a supercritical reactor, an oxidizer high-pressure plunger pump, an oxidizer preheater and an oxidizer pressure pump, wherein the wastewater high-pressure plunger pump, the wastewater preheater and the supercritical reactor are sequentially connected through delivery pipelines; and the oxidizer pressure pump is connected with the supercritical reactor through the oxidizer preheater. The system is characterized in that the supercritical reactor is a high-pressure reactor, and a heater is arranged in the supercritical reactor.

Owner:NANJING UNIV OF TECH

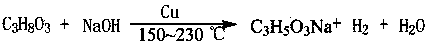

Method for preparing lactic acid through catalyzing glycerol by nano copper

InactiveCN104045543AIncrease concentrationImprove conversion ratePreparation from carboxylic acid saltsCarboxylic acid salt preparationPtru catalystReaction rate

The invention relates to the technical field of lactic acid preparation and particularly relates to a method for preparing lactic acid through catalyzing glycerol by nano copper. According to the method provided by the invention, reaction is carried out on glycerol which serves as a raw material for 0.5-4 hours in a high-pressure reactor at the temperature of 150-230 DEG C under anaerobic alkaline conditions in the presence of nano copper, thereby obtaining lactic acid. The method has the advantages that the reaction temperature and reaction pressure are low, the catalyst activity is high, the selectivity is good, the reaction rate is high, the process flow is safe and environmental-friendly, and the like, so that the industrial prospect is good.

Owner:JIANGSU UNIV

Alkyl phosphinate polymer and preparation method and application thereof

The invention relates to an alkyl phosphinate polymer and a preparation method and application thereof. The method comprises the following steps of: filling a mixture of hypophosphorous acid or phosphinate and water or acetic acid into a pressure reactor with a jacket; when the mixture is heated to between 70 and 110 DEG C, adding alkyne into the pressure reactor through a pressure-reducing valvetill the mixture in the pressure reactor is saturated; uniformly adding aqueous solution of free radical initiator into the obtained mixture with continuous stirring till reaching the required alkynequantity, and then switching the alkyne into olefin; adding the olefin into the pressure reactor through the pressure-reducing valve till the mixture in the pressure reactor is saturated, uniformly adding a catalyst into the mixture, reacting the mixture for 8 to 12 hours, reducing the pressure of the pressure reactor, and cooling the mixture to 80 DEG C; and adding a metal compound into the pressure reactor to perform reaction, centrifuging the obtained solid, washing the solid by using water, and drying the solid in vacuum to obtain the alkyl phosphinate polymer. The invention also relates to the application of the alkyl phosphinate polymer serving as a flame retardant, a flame retardant composition and a flame-retardant polymer molding composition.

Owner:SHANGHAI HUIHAI CHEM TECH

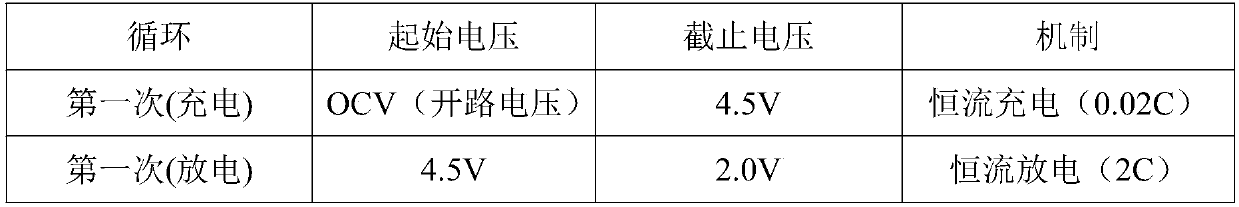

Lithium ion capacitor, and preparation method of Li5FeO4 pre-lithiation agent and lithium ion capacitor

ActiveCN107731560AAchieve pre-lithiationIncrease capacityHybrid capacitor electrodesDouble layer capacitorsLithium hydroxidePole piece

The invention discloses a preparation method of a Li5FeO4 pre-lithiation agent. The preparation method comprises the steps of: (1) dissolving ferric salt and polyvinylpyrrolidone in an organic solvent, uniformly mixing the ferric salt and polyvinylpyrrolidone and then placing the mixture in a high-pressure reactor for reaction, and cooling, washing, filtering and drying a product of the reaction to obtain nanometer Fe2O3; and (2) mixing the nanometer Fe2O3 obtained in the step (1) and lithium hydroxide uniformly, performing ball-milling on the mixture, sintering the mixture after ball-millingin an inert gas atmosphere, and carrying out cooling to obtain Li5FeO4. The invention further provides a preparation method of a lithium ion capacitor adopting L5FeO4 pre-lithiation. The prepared L5FeO4 does not have strict requirement for the environment and can be coated together with a positive electrode material, the operation is simple, the pre-lithiation degree of a negative pole piece is controllable, the effect is obvious, the pre-lithiation can be realized under the existing lithium-ion battery manufacturing condition, and the production cost can be greatly reduced.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com