Method for separating and extracting straw lignin by using eutectic ionic liquid

A technology of straw lignin and ionic liquid, which is applied in the application field of the chemical industry, can solve the problems of no application, etc., and achieve the effects of reducing energy consumption, simple extraction process, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

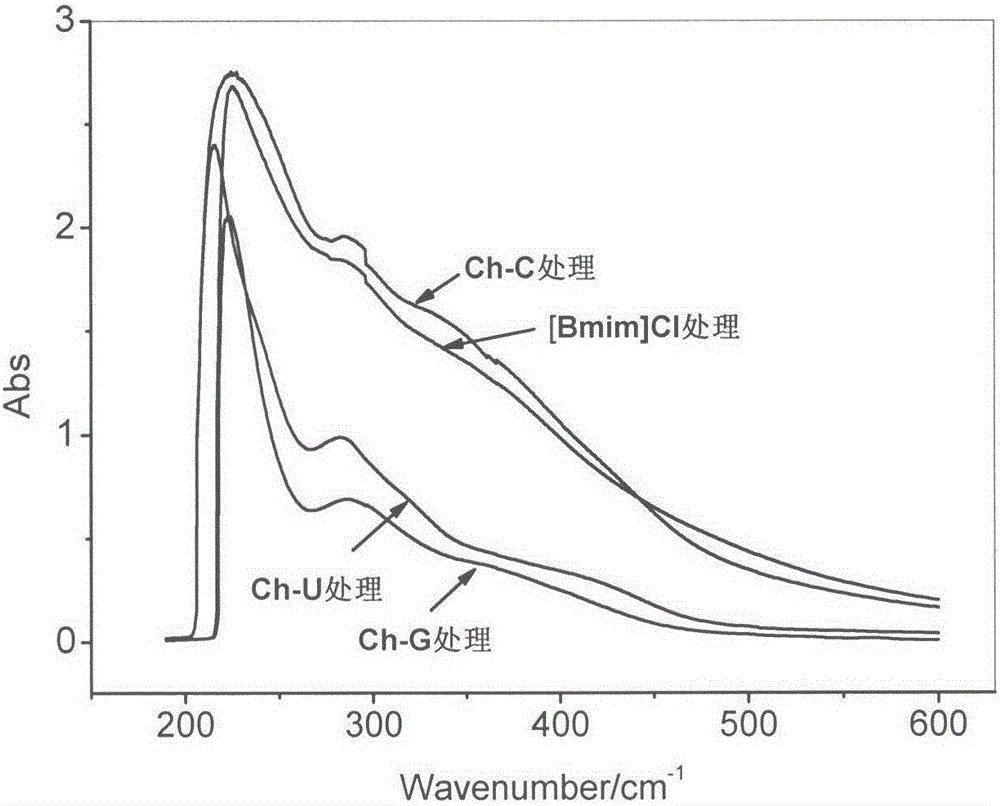

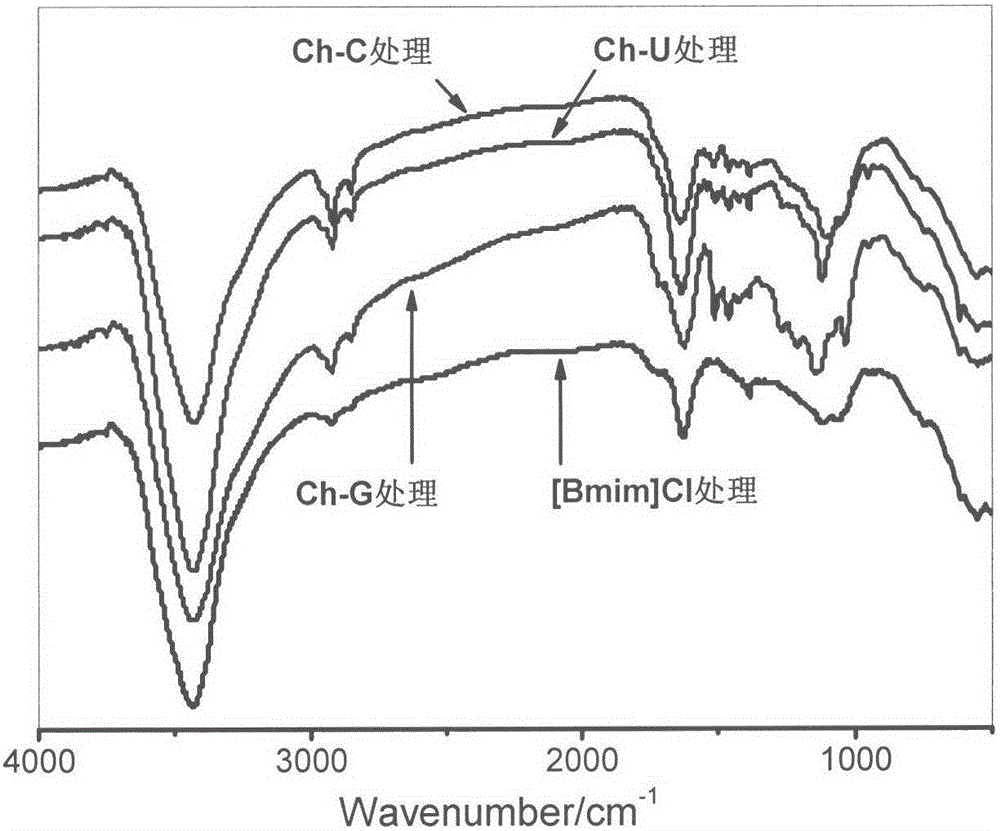

[0016] Weighed 35 g of choline chloride and 30 g of urea, respectively added to a sealed reaction vessel, stirred at 80° C. for 40 min, the reaction liquid was transparent, and Ch-U deep eutectic ionic liquid was obtained. Slowly add 3.25 g of rice straw powder, and when the temperature is raised to about 150° C., the mixture of modified lignin and DES is obtained after heat preservation reaction for 5 hours. Adjust the pH value of the mixture to about 11 with a sodium hydroxide solution with a concentration of about 10%, centrifuge at a high speed, and keep the upper layer solution. Use sulfuric acid with a concentration of about 10% to adjust the pH value of the solution to below 3, and after centrifuging again, wash the precipitate with distilled water several times, centrifuge until the supernatant is neutral, and freeze-dry the final precipitate to obtain lignin 0.195 g.

Embodiment 2

[0018] Weighed 35 g of choline chloride and 46 g of glycerol, respectively added to a sealed reaction vessel, stirred at 80° C. for 40 min, the reaction liquid was transparent, and Ch-G deep eutectic ionic liquid was obtained. Slowly add 4.05 g of rice straw powder, and when the temperature is raised to about 150° C., a mixture of modified lignin and DES is obtained after a heat preservation reaction for 5 hours. Adjust the pH value of the mixture to about 11 with a sodium hydroxide solution with a concentration of about 10%, centrifuge at a high speed, and keep the upper layer solution. Use sulfuric acid with a concentration of about 10% to adjust the pH value of the solution to below 3, and after centrifuging again, wash the precipitate with distilled water several times, centrifuge until the supernatant is neutral, and freeze-dry the final precipitate to obtain lignin 0.505 g.

Embodiment 3

[0020] Weighed 35 g of choline chloride and 48 g of citric acid, respectively added to a sealed reaction vessel, stirred at 80° C. for 80 min, the reaction liquid was transparent, and Ch-C eutectic ionic liquid was obtained. Slowly add 4.15 g of rice straw powder, and when the temperature is raised to about 150° C., a mixture of modified lignin and DES is obtained after a heat preservation reaction for 5 hours. Adjust the pH value of the mixture to about 11 with a sodium hydroxide solution with a concentration of about 10%, centrifuge at a high speed, and retain the upper layer solution. Use sulfuric acid with a concentration of about 10% to adjust the pH value of the solution to below 3, and after centrifuging again, wash the precipitate with distilled water several times, centrifuge until the supernatant is neutral, and freeze-dry the final precipitate to obtain lignin 0.65 g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com