Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

621results about How to "Extend heating time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

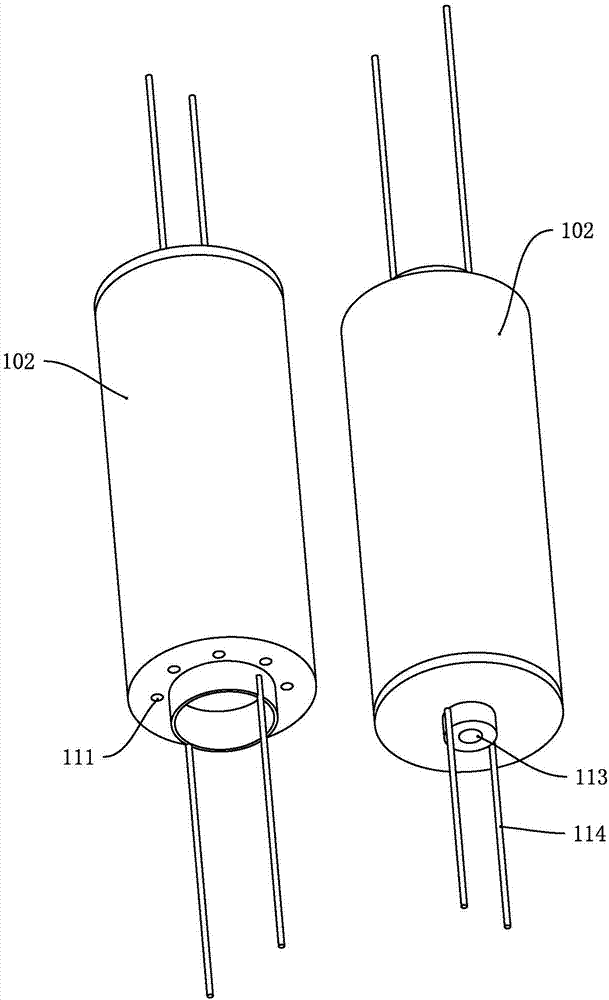

Thermocouple vacuum gauge

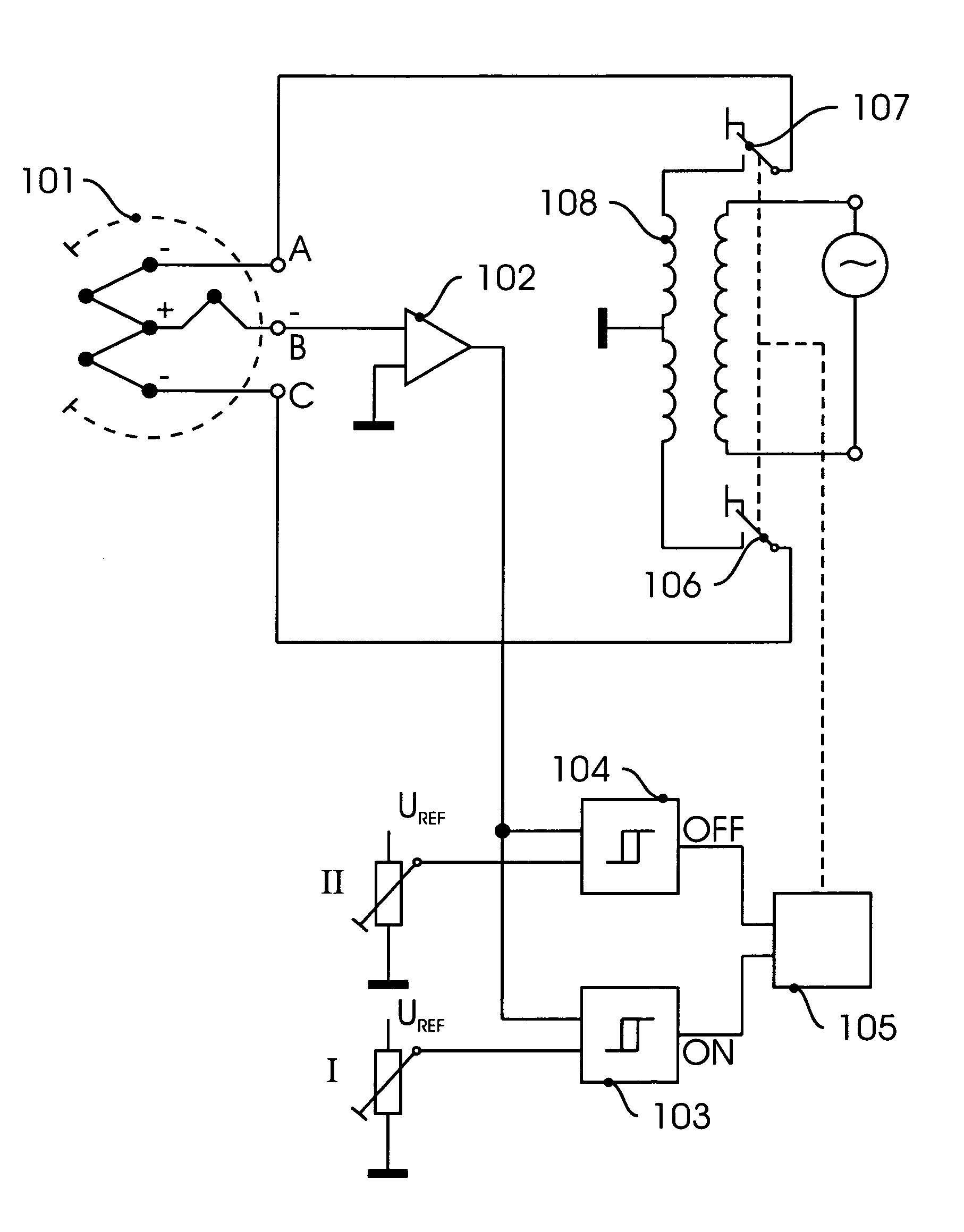

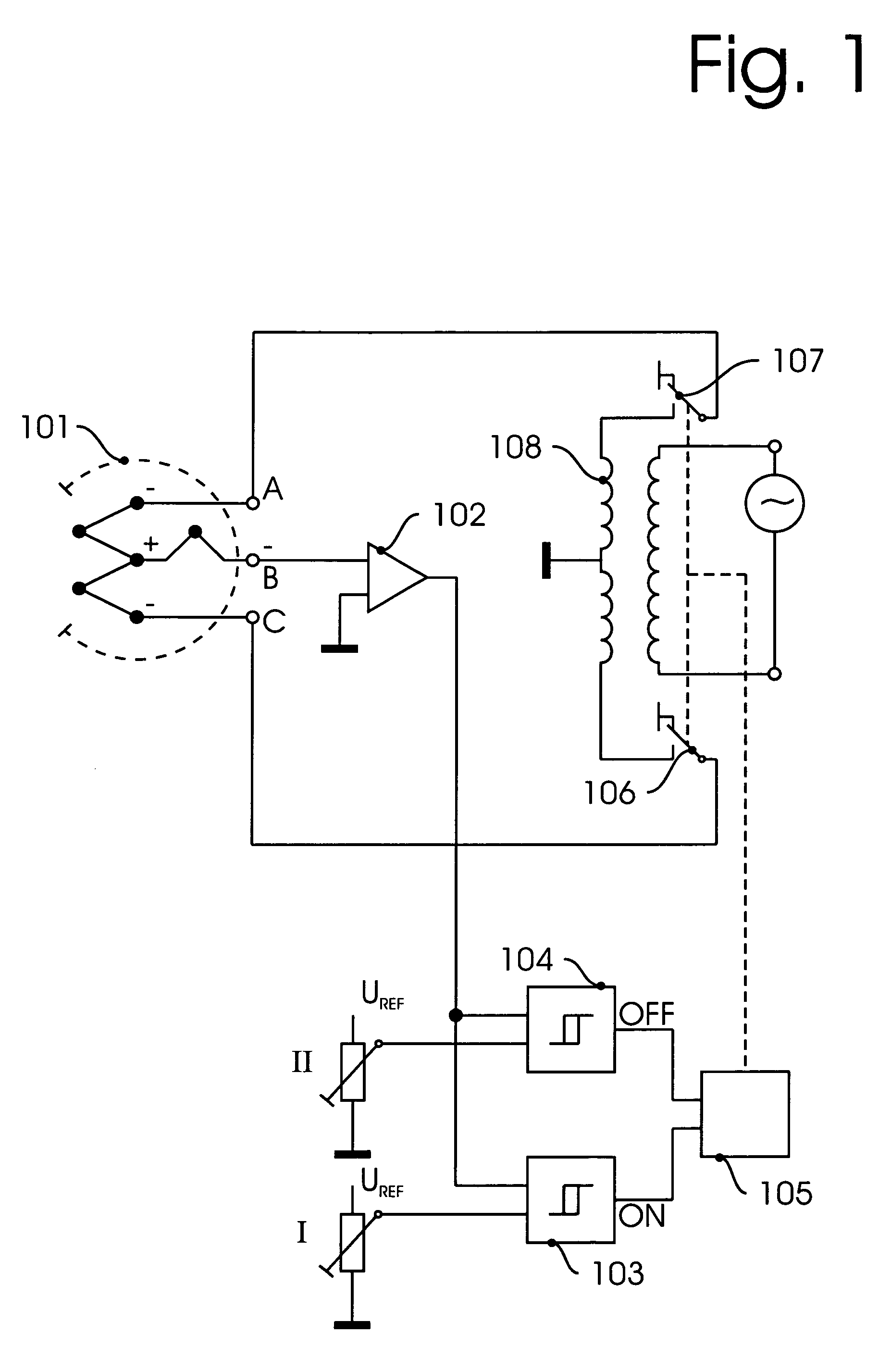

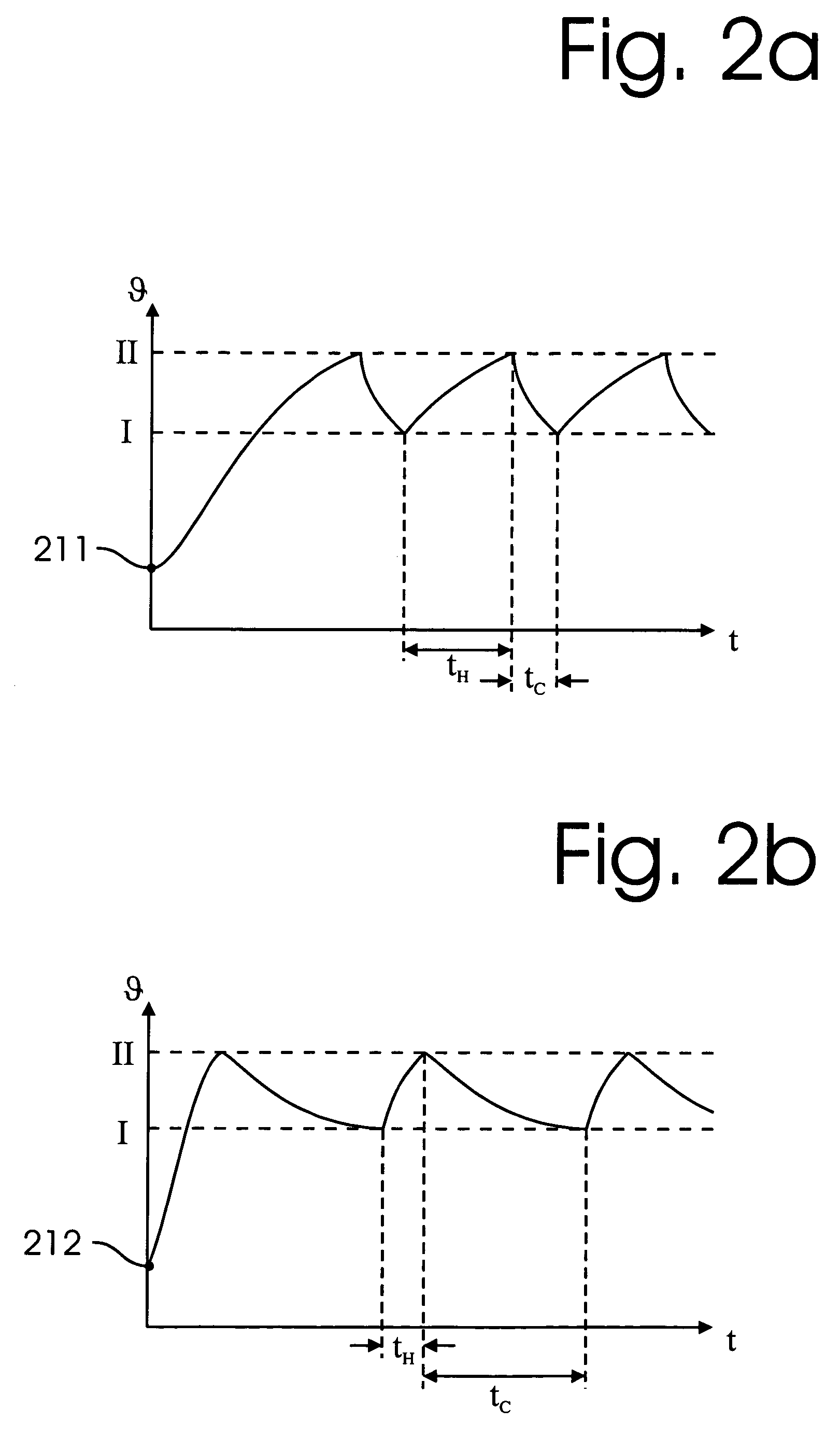

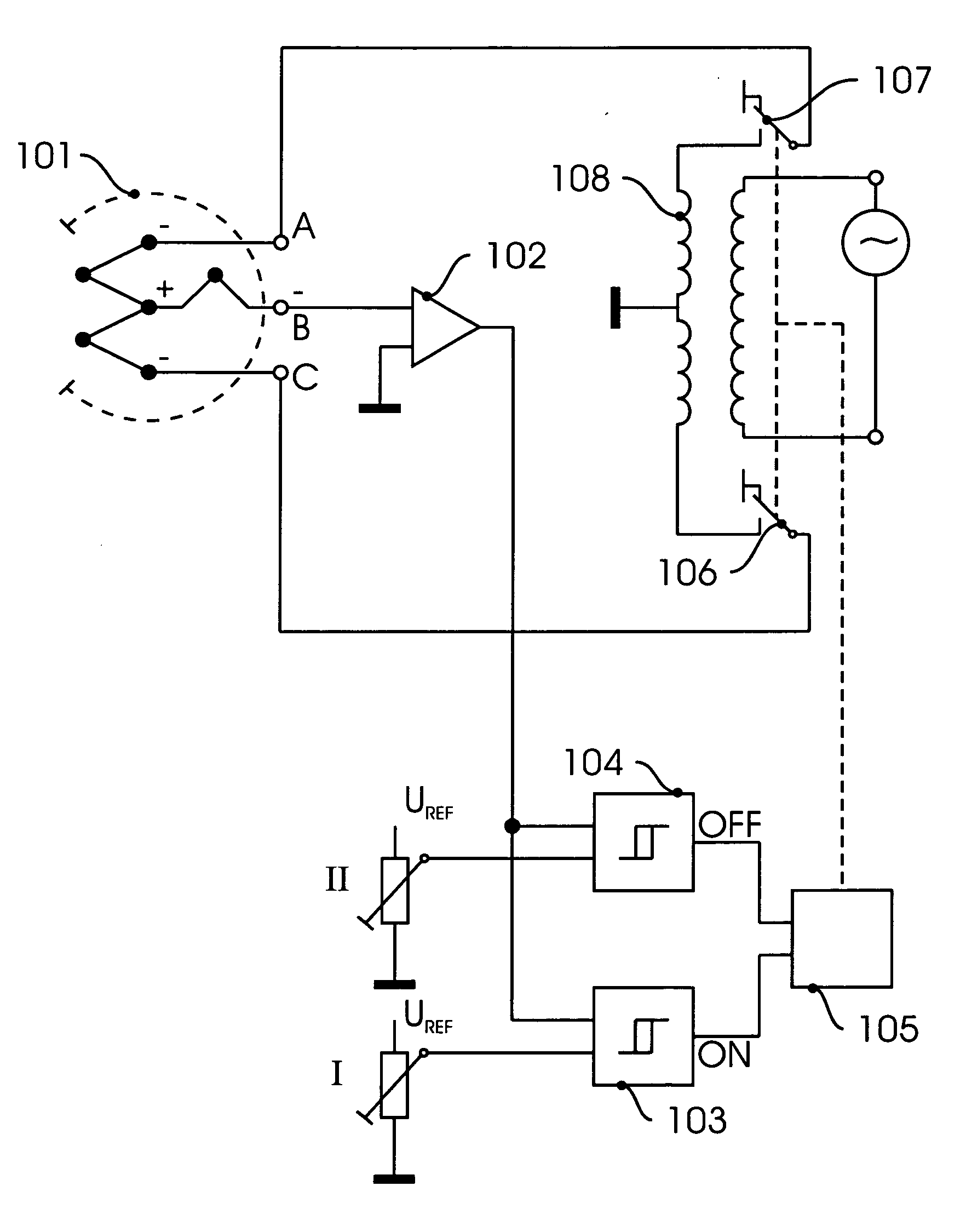

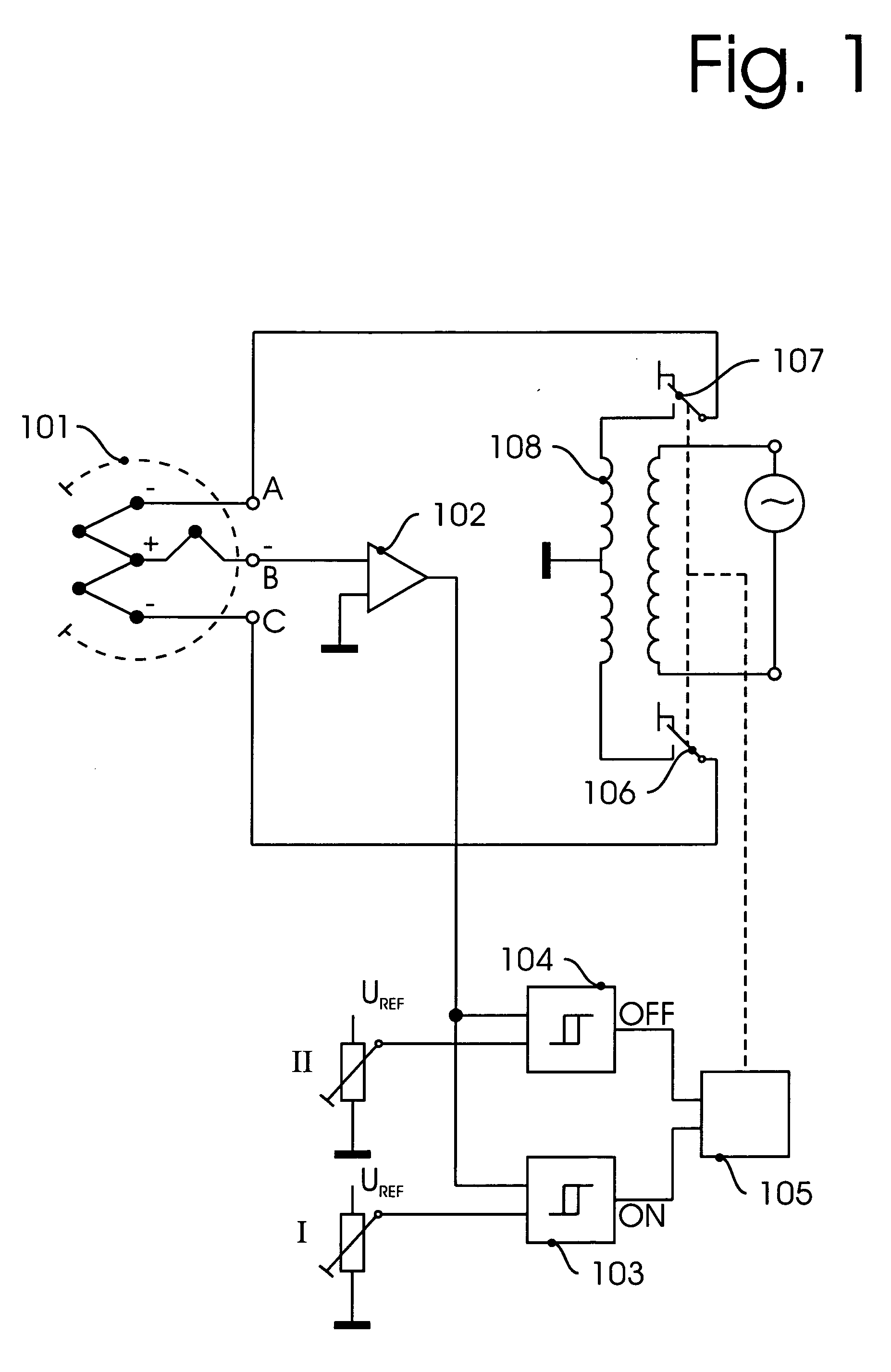

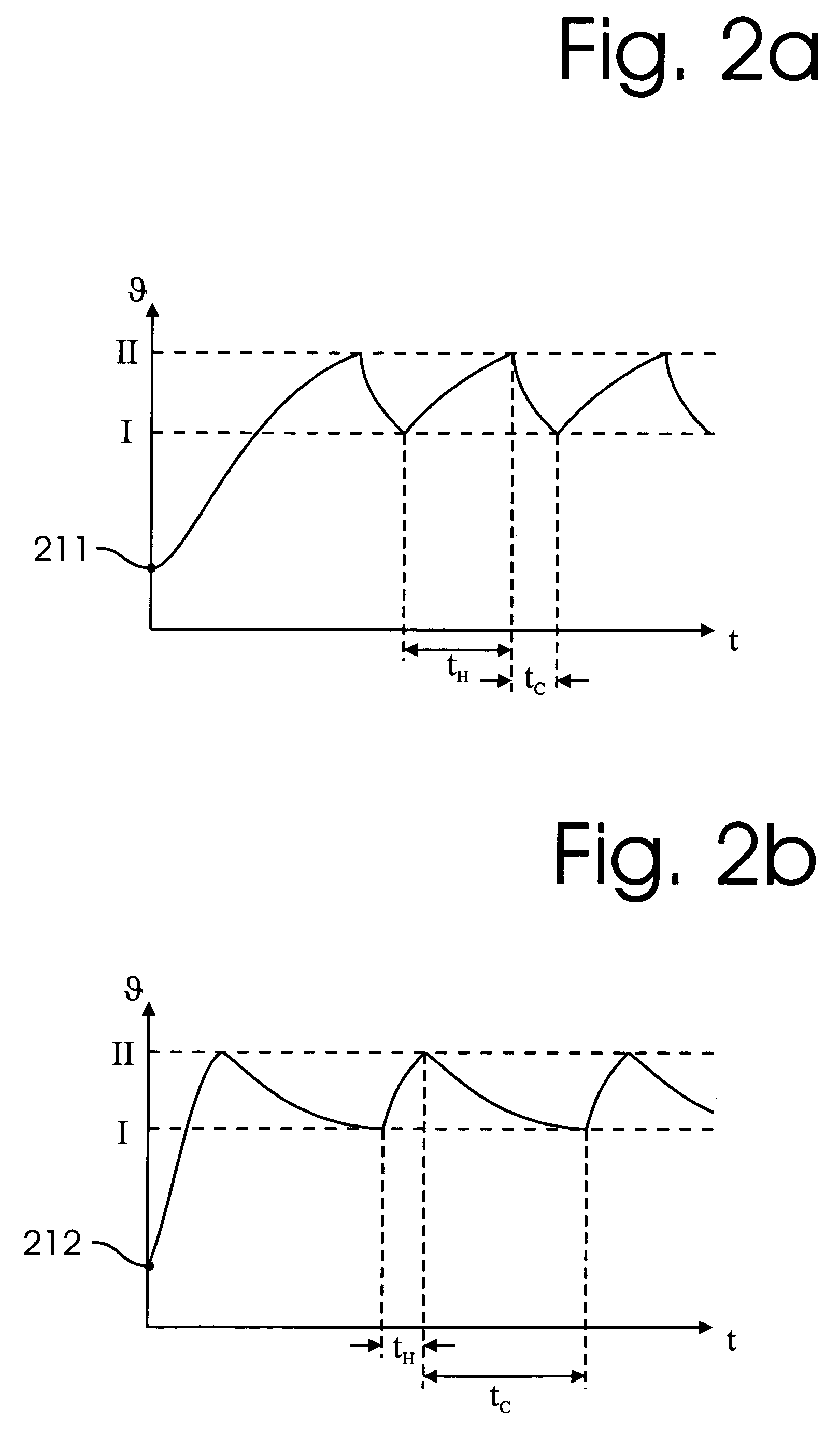

InactiveUS8047711B2Reduce heatLow thermal conductivityThermometer detailsVacuum gauge using heat conductivity variationHeating timeEngineering

A thermocouple vacuum sensor is provided, the thermocouple being surrounded by a gas or mixture of gases the pressure of which is to be measured. Cyclically the thermocouple is heated until its temperature reaches an upper temperature threshold. The thermocouple is subsequently cooled until its temperature reaches a lower temperature threshold. The heating time required to heat the thermocouple from the lower to the upper temperature threshold is measured. The cooling time required to cool the thermocouple from the upper temperature threshold to the lower temperature threshold may also be measured. The pressure surrounding the thermocouple may then be determined as a function of either the heating time, or the cooling time, or both.

Owner:HEINZ PLOECHINGER

Remelted ingestible products

ActiveUS20130274296A1Reduce exposureHigh heating temperatureBiocideTobacco preparationSemi solidTemperature sensitive

A method of preparing an orally ingestible hard boiled product, comprising: i) heating a sugar material to a first temperature sufficient to liquefy the sugar material; ii) cooling the liquefied sugar material to provide a cooled sugar material having a solid or semi-solid form; iii) heating the cooled sugar material to a second temperature, which is lower than the first temperature; iv) combining the sugar material with one or more temperature sensitive ingredients before, during, or after said heating step iii), but after said cooling step ii), such that an intimate mixture of the second liquefied sugar material and the one or more temperature sensitive ingredients is provided; and v) cooling the intimate mixture to form an orally ingestible product. Orally ingestible hard boiled products prepared according to this method are also provided.

Owner:R J REYNOLDS TOBACCO COMPANY

Method for preparing seamless titanium alloy tube for aircraft engine

The invention discloses a method for preparing a seamless titanium alloy tube for an aircraft engine. The seamless titanium alloy tube for the aircraft engine which meets corresponding requirements is manufactured by improving the technological plasticity of the titanium alloy tube material. The method comprises the following steps of: firstly, smelting a spongy cast ingot to introduce interstitial elements as little as possible; secondly, cogging and forging heated cast ingot at large deformation and repeatedly upsetting and stretching the cast ingot to ensure that as-cast coarse grains are completely crushed and thinned, thermally processing formed tube billet under vacuum to eliminate residual stress produced during tube billet extrusion so as to improve the plasticity of the tube billet; thirdly, cogging and rolling the tube billet at large deformation and further thinning the grains; and finally, annealing at a low temperature after cold rolling of intermediate rolling and finished product rolling to effectively control the coarsening of the grains. Therefore, full recrystallization can be ensured by prolonging the heating time, and mechanical property and processing property required by material consumption of the aircraft engine can be met under the condition that the tube structure is fully recrystallized.

Owner:WESTERN TITANIUM TECH

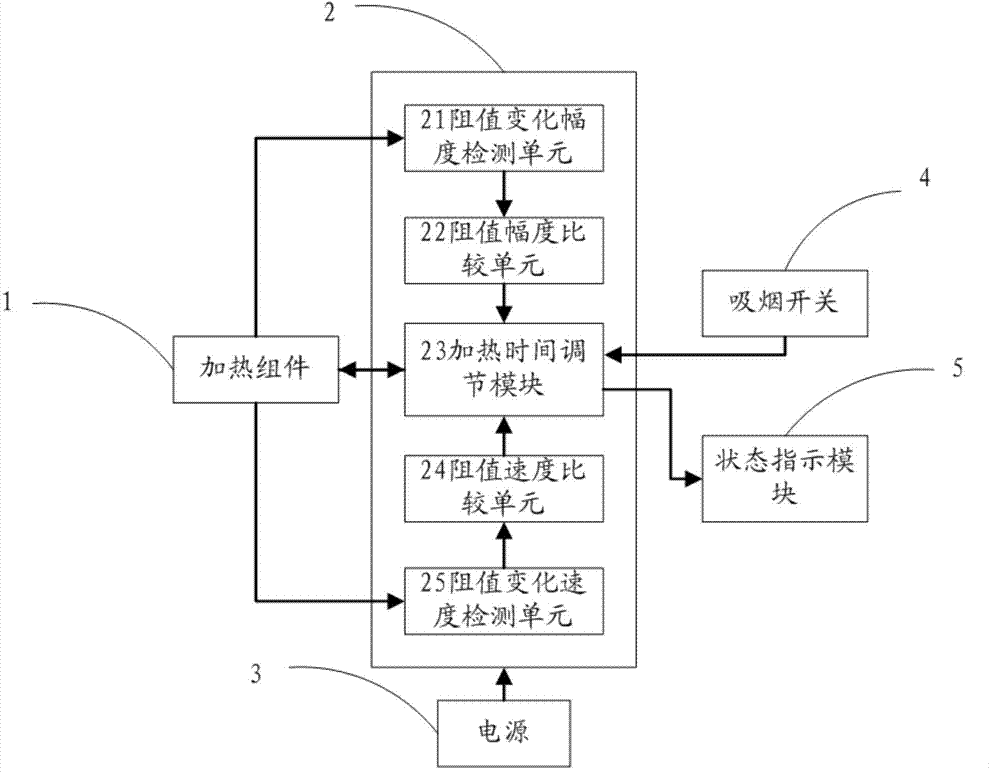

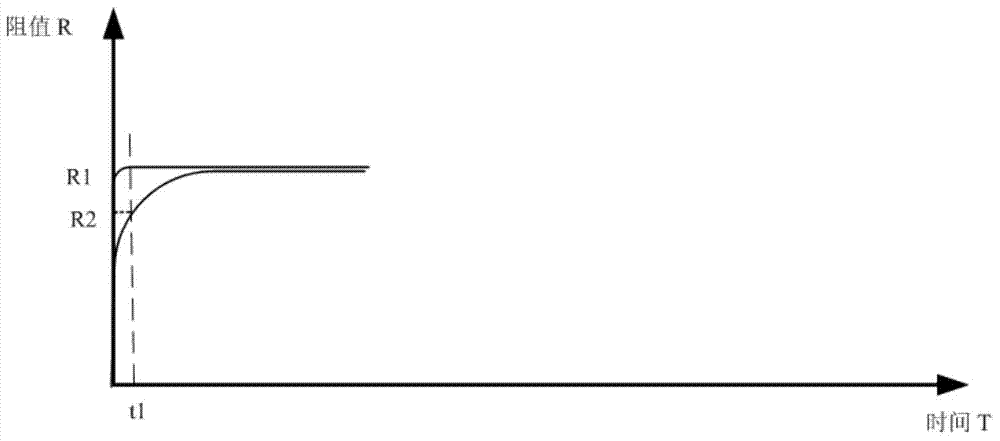

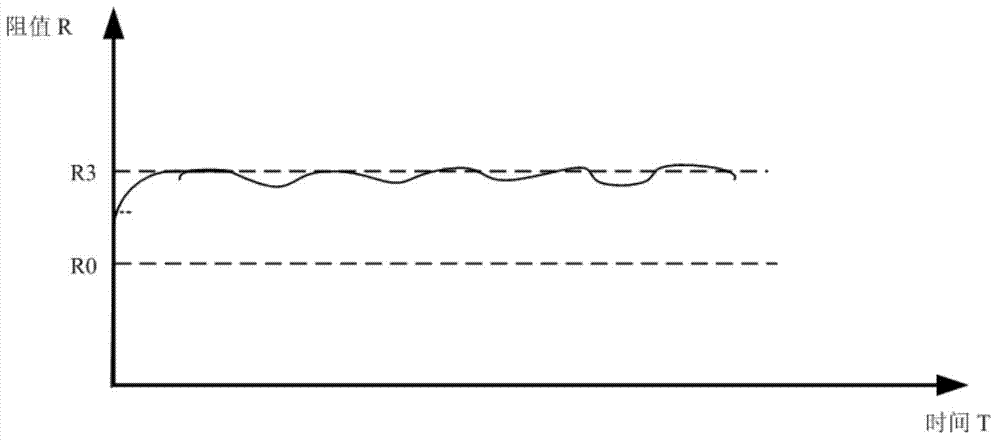

Automatic constant-temperature electronic cigarette and control method thereof

InactiveCN104720119AIncrease temperatureHeavy smokeTemperatue controlTobacco devicesElectricityAuto regulation

The invention discloses an automatic constant-temperature electronic cigarette and a control method thereof. The electronic cigarette comprises an electronic cigarette body, a heating assembly, a controller and a power source are arranged in the electronic cigarette body, the power source supplies power to the heating assembly and the controller, the controller comprises a resistance value detection module, a comparison module and a heating time adjusting module, the resistance value detection module comprises a resistance value change amplitude detection unit, the input end of the resistance value change amplitude detection unit is electrically connected with the heating assembly, the comparison module comprises a resistance value amplitude comparison unit, the input end of the resistance value amplitude comparison unit is electrically connected with the output end of the resistance value change amplitude detection unit, the heating time adjusting module comprises a prolonged heating adjusting unit, a standard heating adjusting unit and a shortened heating adjusting unit, and one of the prolonged heating adjusting unit, the standard heating adjusting unit and the shortened heating adjusting unit is communicated with the heating assembly. The automatic constant-temperature electronic cigarette has the advantages of being capable of automatically adjusting smoke temperature, smoke amount and smoke smoking taste uniformity, saving energy and preventing dry burning.

Owner:董金明

Special poultry meat fine and deep processing method

InactiveCN101961114AImprove sterilization efficiencyExtend heating timeMeat/fish preservationSlaughtering/stunningDeep processingFood item

The invention relates to a food processing method, in particular to a special poultry meat fine and deep processing method. In the invention, high-technology content special duck meat deep processed new products and special convenient and quick poultry meat green products are developed by using technology for preserving raw material duck meat with edible multifunctional preservation films, ultrasonic rapid penetration salting promoting technology, energy-saving, emission-reducing and environmentally-friendly microwave assisted sterilization technology, vacuum cooling technology, vacuum oil frying technology, infrared roasting technology and the like.

Owner:赵保雷

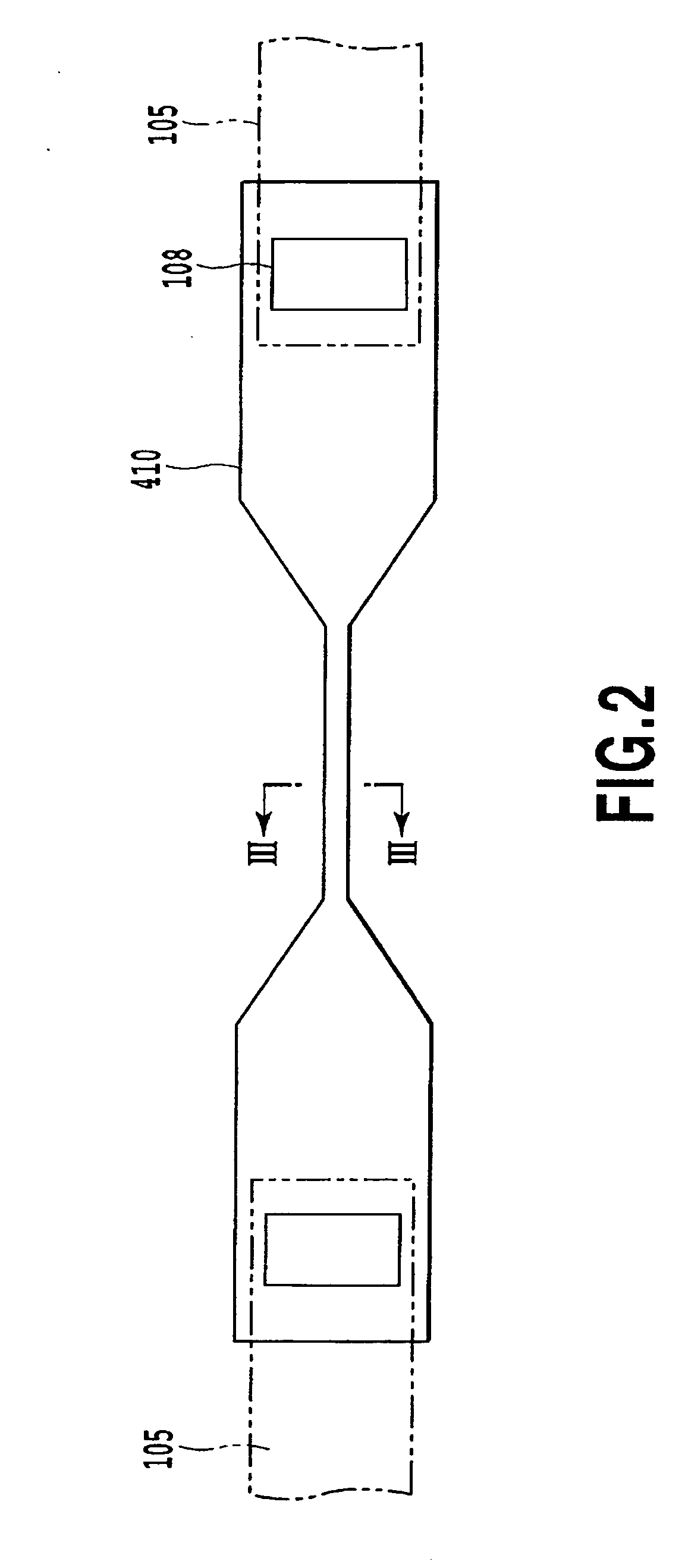

Substrate for ink jet printing head, ink jet printing head, ink jet printing apparatus, and method of blowing fuse element of ink jet printing head

ActiveUS20070008382A1Improve reliabilityAvoid insufficient heatingInking apparatusOther printing apparatusElectrical resistance and conductanceEngineering

The present invention reliably blows a fuse element to store with high reliability data that corresponds to whether or not the fuse element has been blown. For this purpose, a resistor element is provided in a circuit through which an electric current flows to blow the fuse element in the ink jet printing head. The resistor element adjusts the electric current so that, in the process of blowing the fuse element, the current continues to flow for a predetermined duration even after a maximum current has passed through the fuse element. The predetermined duration is longer than a period from a time point when the electric current rises to a time point it reaches the maximum current.

Owner:CANON KK

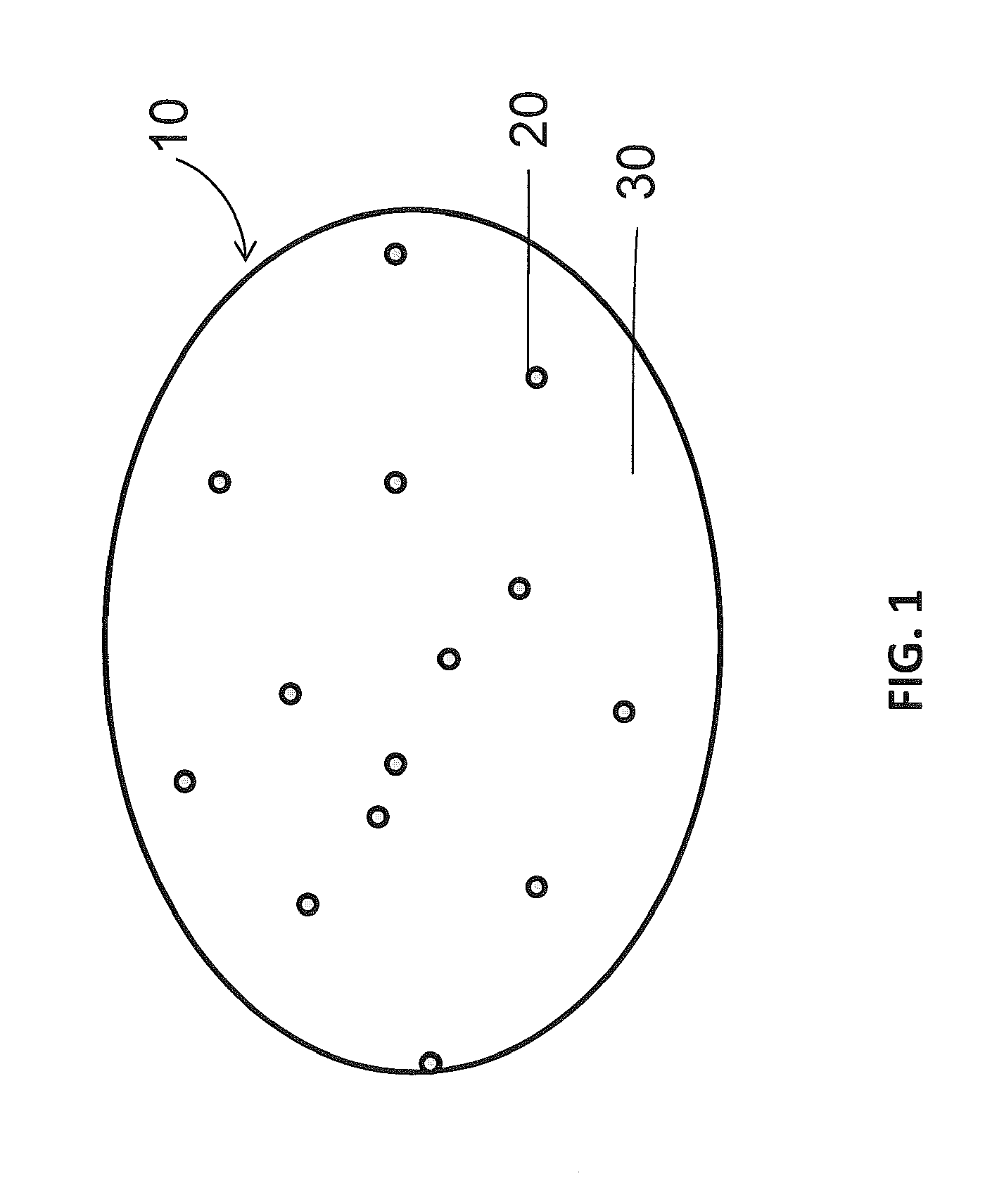

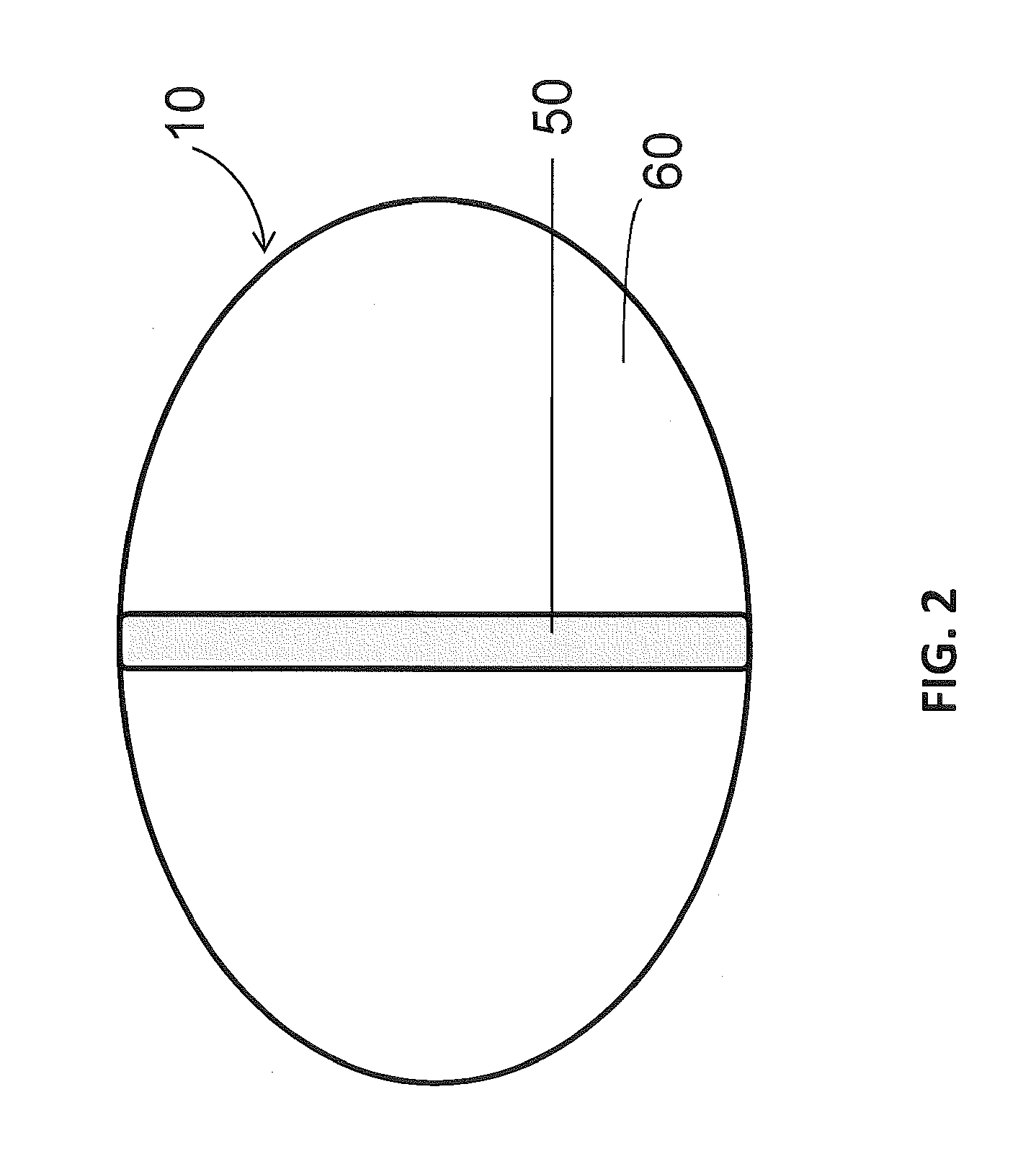

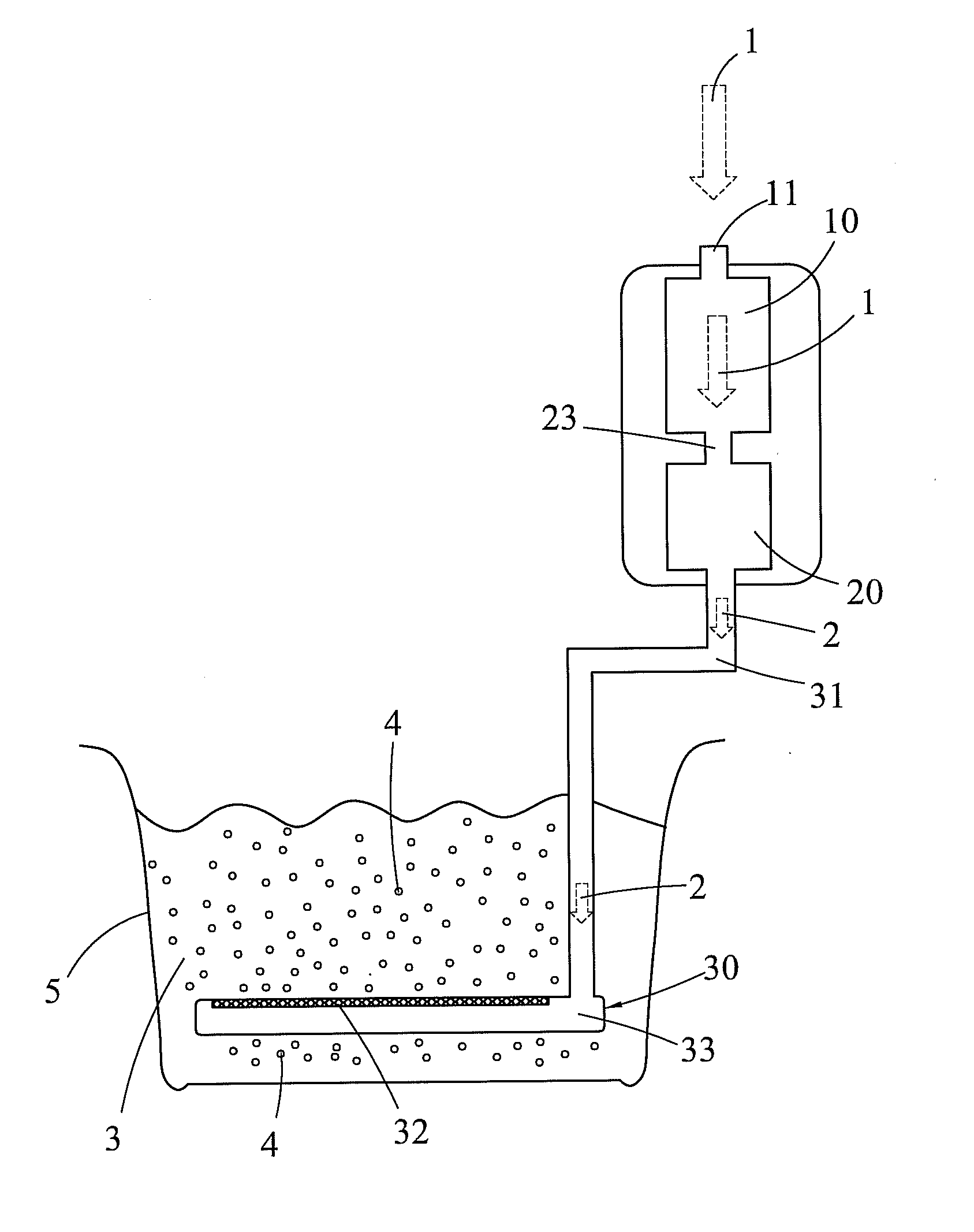

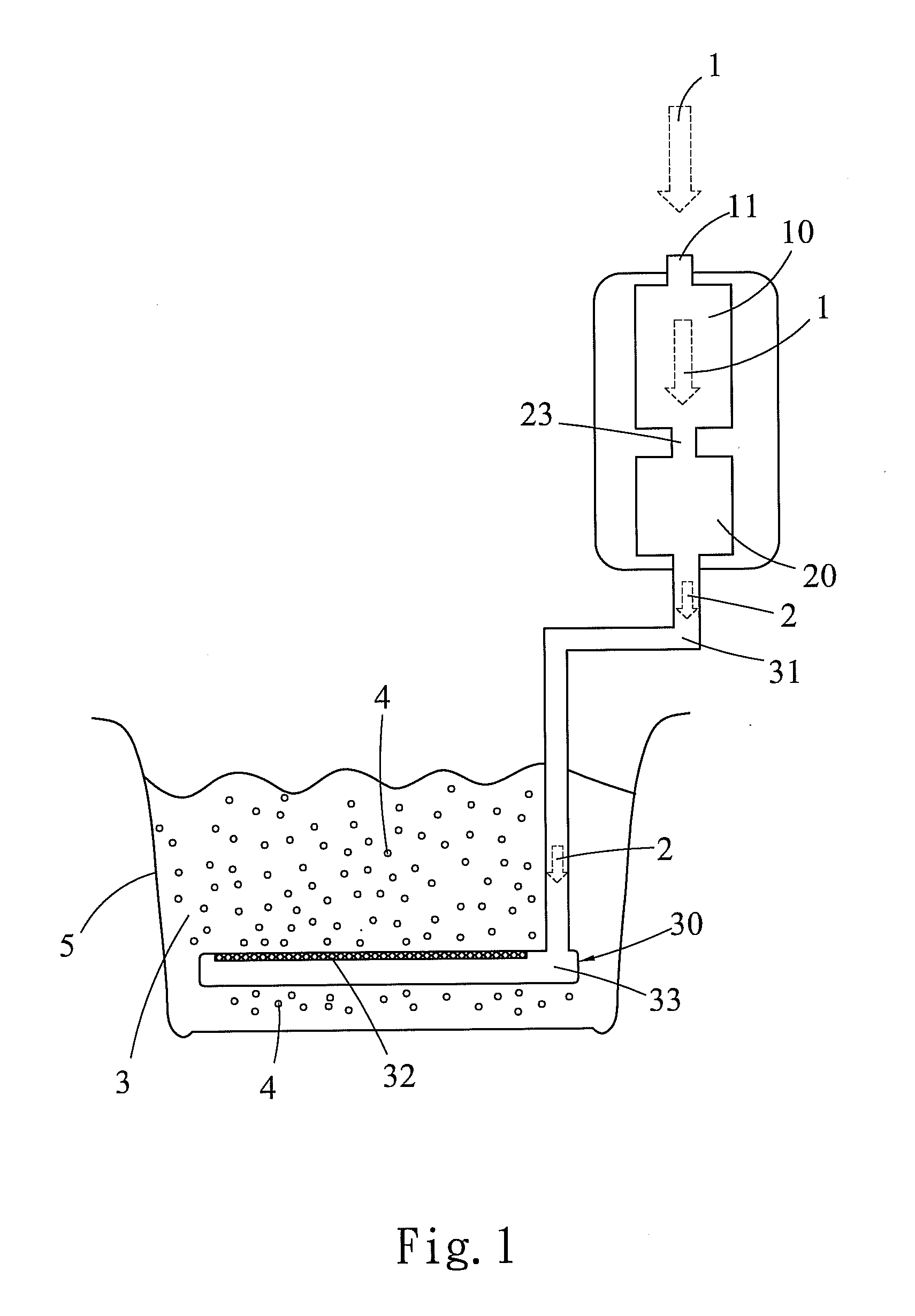

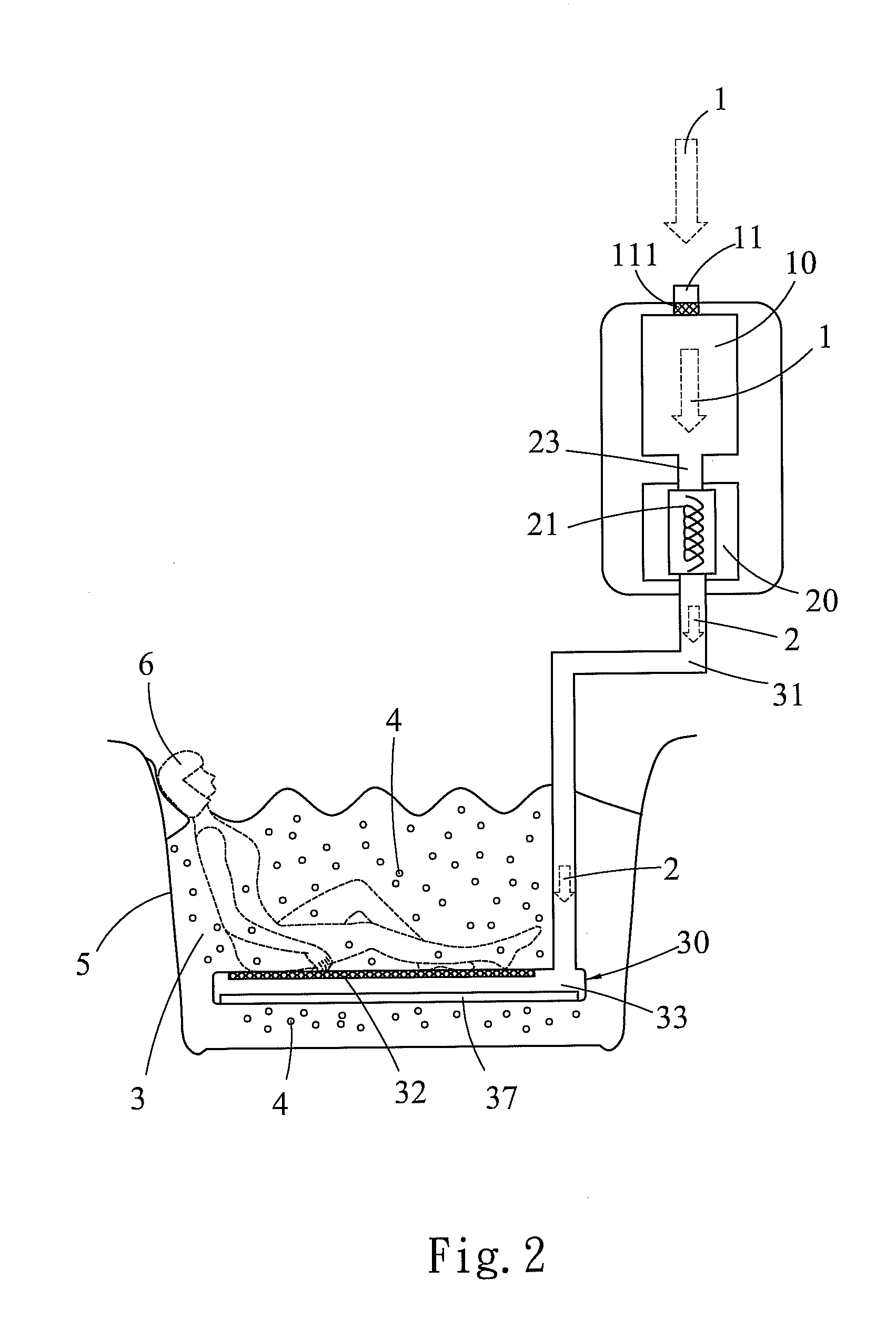

Electrically insulated air-conducting water heater

InactiveUS20120297530A1Force is smallEfficiently conducted to waterBathing devicesHair dryingElectricityEngineering

Electric shock to a user has been a major concern for a conventional electric water heater installed in or near a bathroom. An electrically insulated air-conducting water heater utilizes electrically insulating hot air to indirectly heat water to avoid electric hazard to a user of an electric water heater. The present invention comprises an air pump unit, a heating and temperature control unit, and an air venting unit having a plurality of tiny air nozzles immersed in a water pool. Ambient air is collected by the air pump unit, heated in the heating and temperature control unit, and injected into a water pool through the air venting unit as a form of zillions of small hot bubbles to heat the water. Apart from serving as an electrically safe water heater, the present invention also functions as a hot-bubble sauna machine, bathroom body dryer, and air conditioner.

Owner:NATIONAL TSING HUA UNIVERSITY

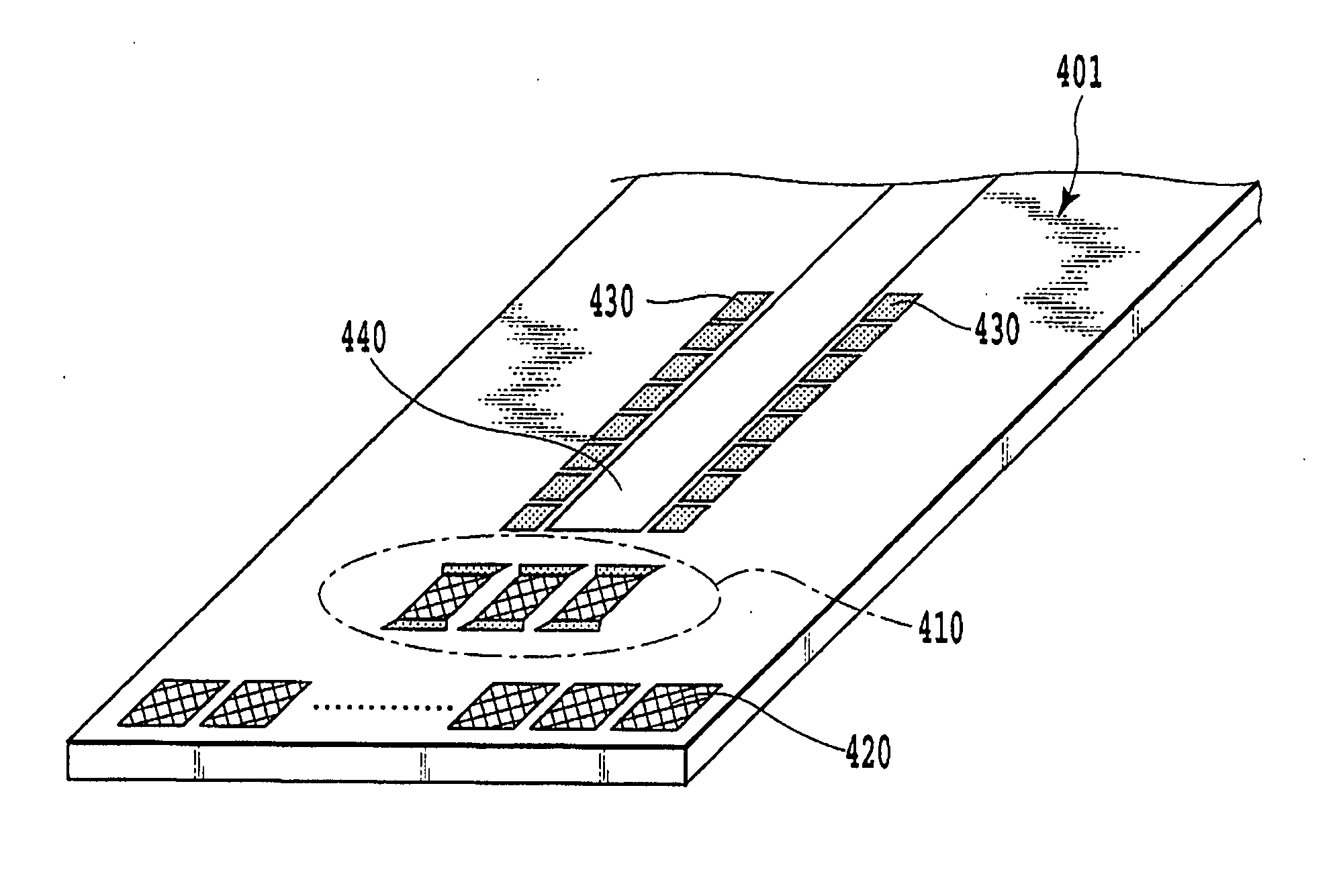

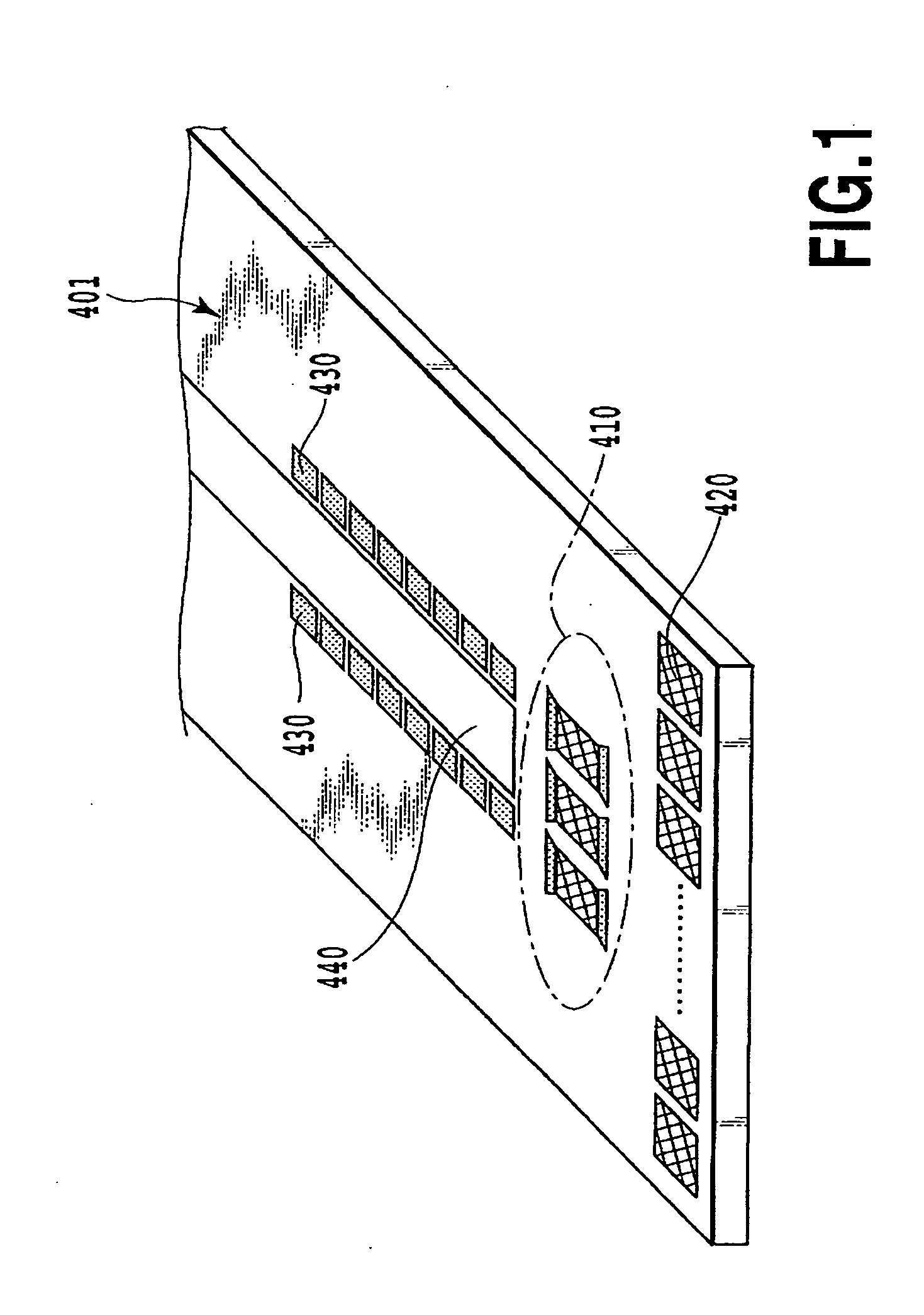

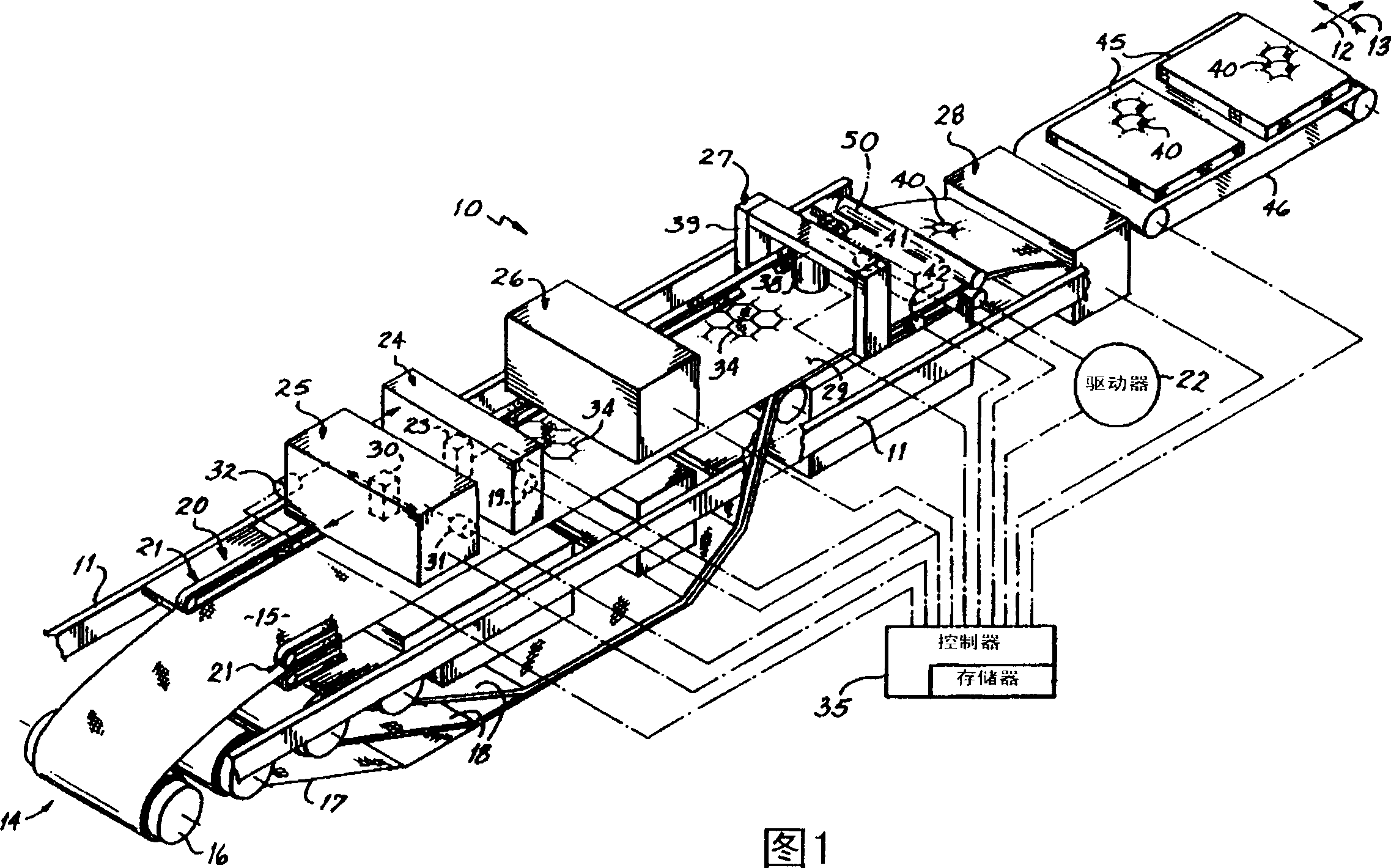

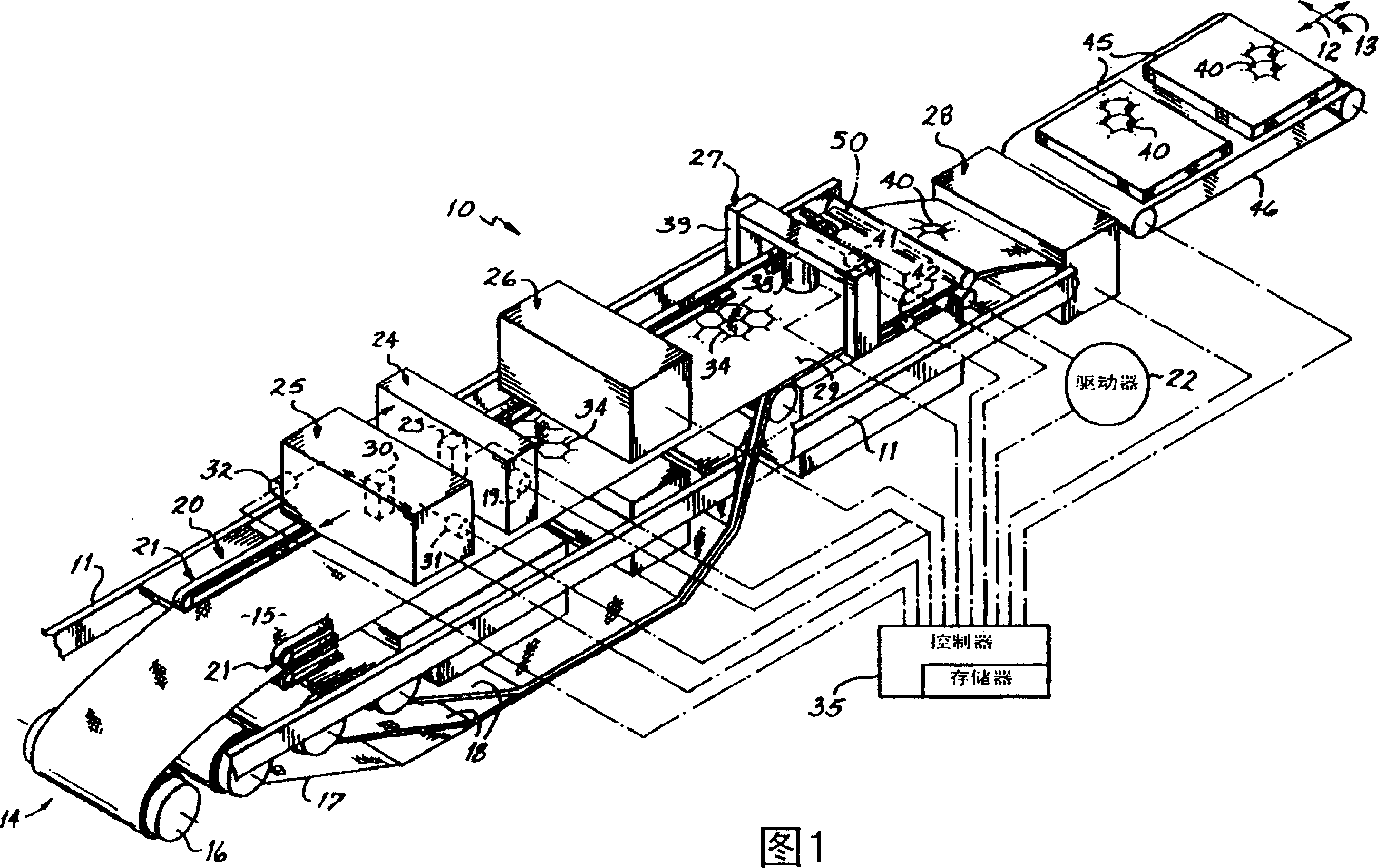

Method nad apparatus for UV ink jet printing on fabric and combination printing and quilting thereby

InactiveCN1377313AChanging the time of exposure to energyIncrease or decrease the time of energy exposureSewing-machine elementsLayered productsUV curingRadiant heater

Ink jet printing is provided on large area substrates such as wide width textile webs. The printheads are driven by linear servo motors across a bridge that extends across the substrate. The timing of the jetting of the ink is coordinated with the motion of the printheads, so that the heads can be rapidly moved and the ink can be jetted while the printheads are accelerating or decelerating as they move on the bridge. Preferably, ultraviolet (UV) light curable ink is jetted and first partially cured with UV light and then subjected to heating to more completely reduce uncured monomers of the ink on the substrate.

Owner:L & P PROPERTY MANAGEMENT CO

Tortuous flow doubleeffect heating solar heat-collector air heat collectors

InactiveCN101178260AStable temperature environmentReduce lossesSolar heating energySolar heat devicesGlass coverCollector device

The invention relates to a flow-bending double-effect heating solar-energy air heat collecting device, comprising an insulation soleplate and a heat collecting device core. The heat collecting device core comprises a heat absorbing board arranged on the insulation soleplate, and a sealed heating air channel is arranged between the heat absorbing board and the insulation soleplate. A horizontal first air-feeding pipeline and a horizontal air-venting pipeline are arranged on the upper part of the heat absorbing board. A horizontal bottom bracket is arranged on the lower part of the heat absorbing board, and a sealed second air-feeding pipeline is arranged in the bottom bracket. Sealed heat collecting tubes are vertically arranged by intervals between the bottom bracket and the air-venting pipeline, and the heat collecting tubes are arranged on the upper part of the face of the heat absorbing board. The upper end and the lower end of the heating air channel are communicated with the corresponding first and second air-feeding pipelines. The upper end and the lower end of the heat collecting tube are communicated with the corresponding air-venting pipeline and the second air-feeding pipeline. A glass cover used for covering the heat collecting device core is arranged on the insulation soleplate. Through two-time heating, the heating distance of the structure is approximately raised by one time. And the heat absorbing efficiency is enhanced and the heating effect is reinforced. One-time circulation temperature rises more quickly.

Owner:HENAN SENGDA ENERGY ENVIRONMENTAL PROTECTION

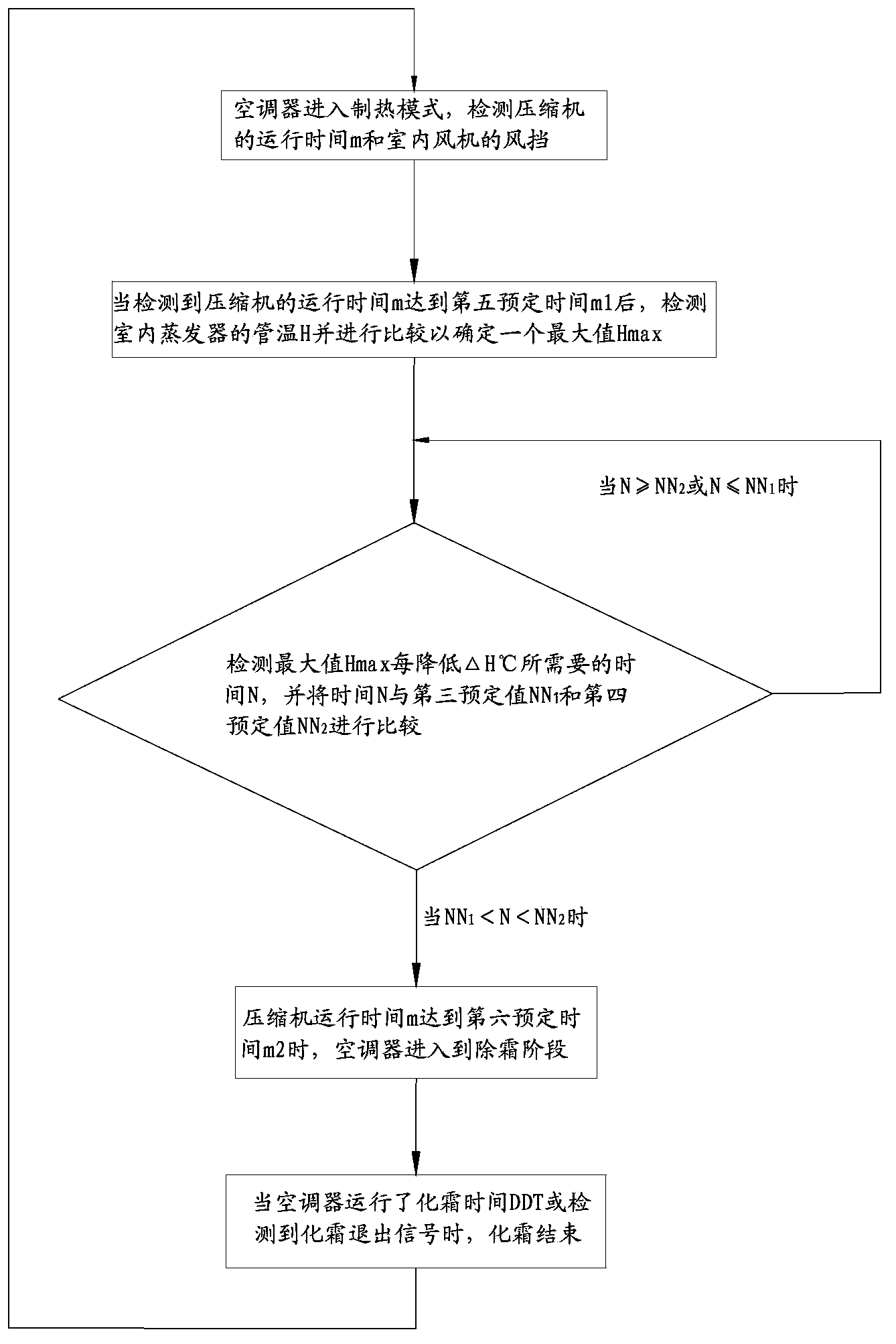

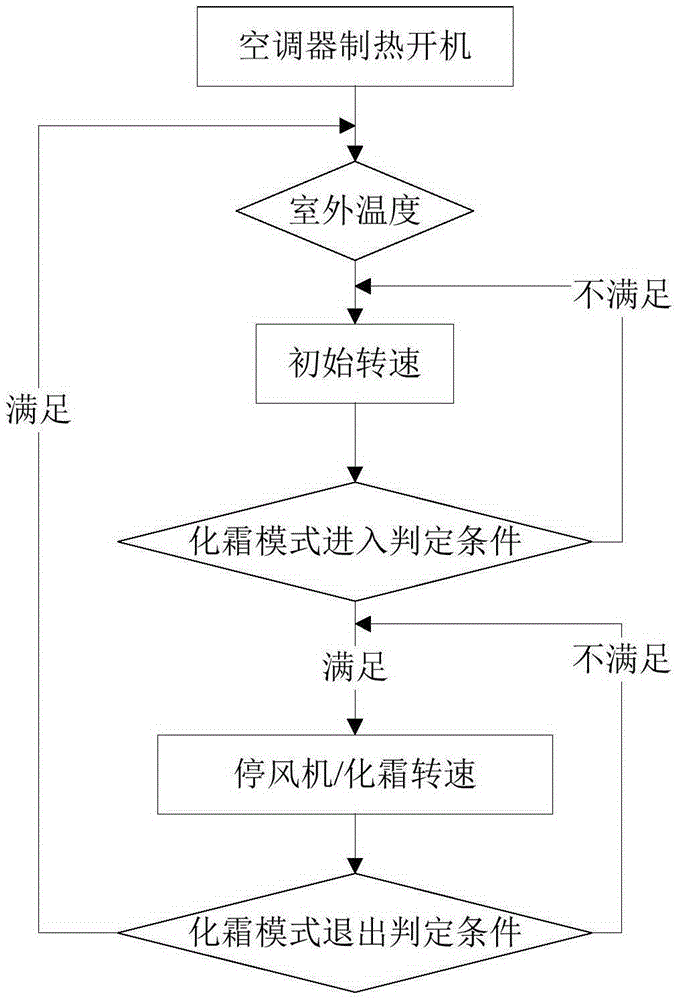

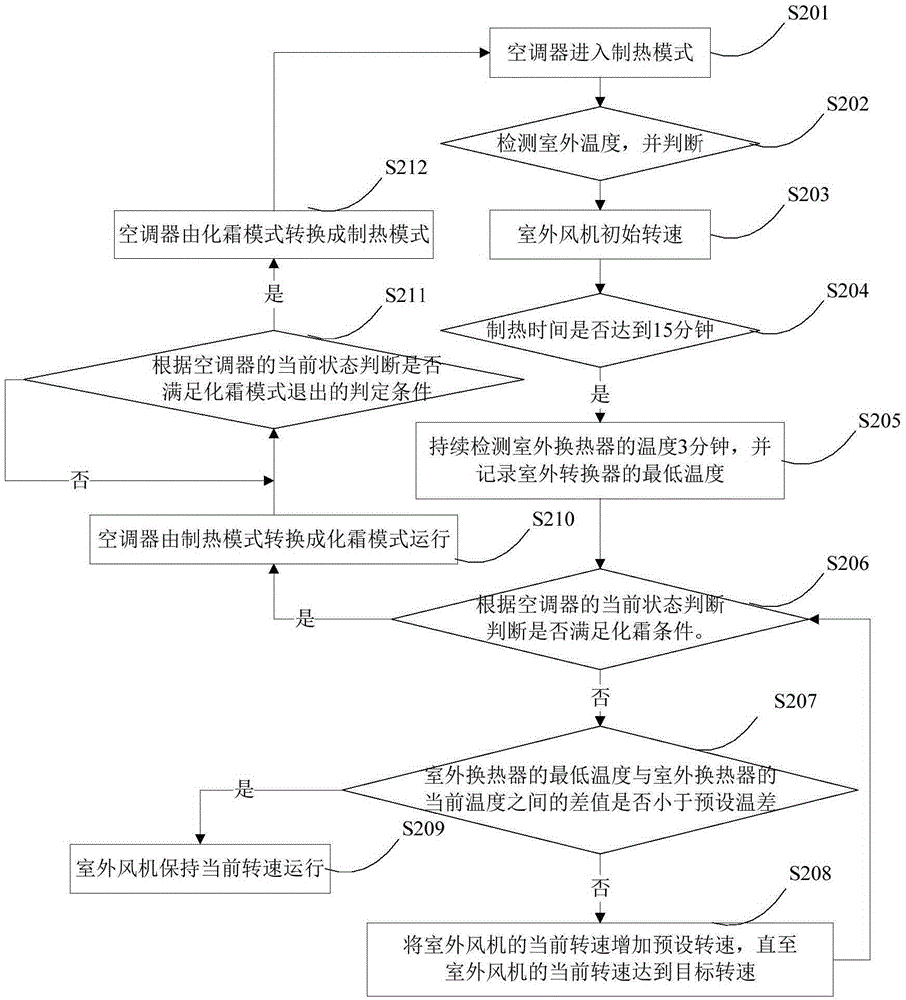

Defrosting method of air conditioner

ActiveCN104165486ADefrost GuaranteeReduce frost-free defrostingSpace heating and ventilation safety systemsSpace heating and ventilation control systemsFrostEngineering

The invention discloses a defrosting method of an air conditioner. The defrosting method comprises the following steps: (S1) the operation time M of a compressor is detector; (S2) when the M is greater than M1, the temperature T of a pipe on an outdoor condenser or an indoor evaporator is detected to determine a maximal value Tmax; (S3) the needed time t of each reduction of the Tmax by delta T DEG C is detected, and is compared with a first predetermined value tt1 and a second predetermined value tt2; (S4) when the t is greater than the tt1 and smaller than the tt2, and the M is not smaller than the M2, the air conditioner enters a defrosting phase; and (S5) in the defrosting phase, when the air conditioner operates by the defrosting time DT or detects a defrosting quit signal, the defrosting is finished, the step S1 is returned to, and the operation is recycled like this. According to the defrosting method of the air conditioner disclosed by the invention, the defrosting of the air conditioner in the frosting state can be guaranteed, so that the no-frost defrosting condition in the heating operation process of the air conditioner is reduced, the effective heating operation time is prolonged, and the heating quantity is increased.

Owner:GUANGDONG MIDEA GRP WUHU REFRIGERATING EQUIP CO LTD +1

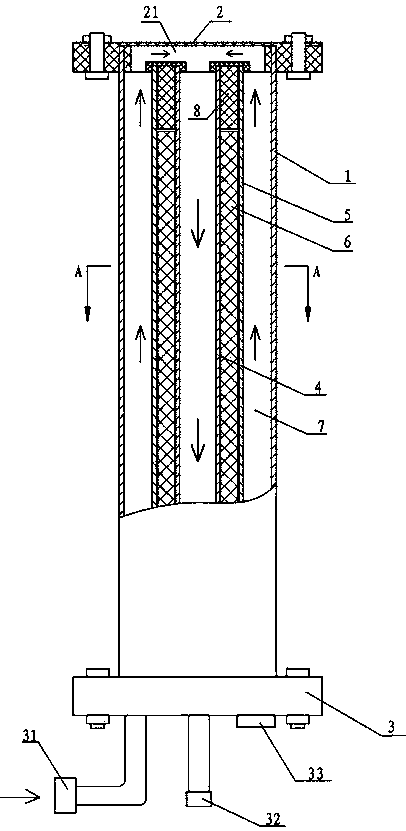

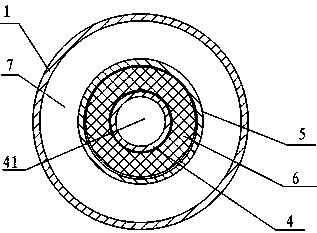

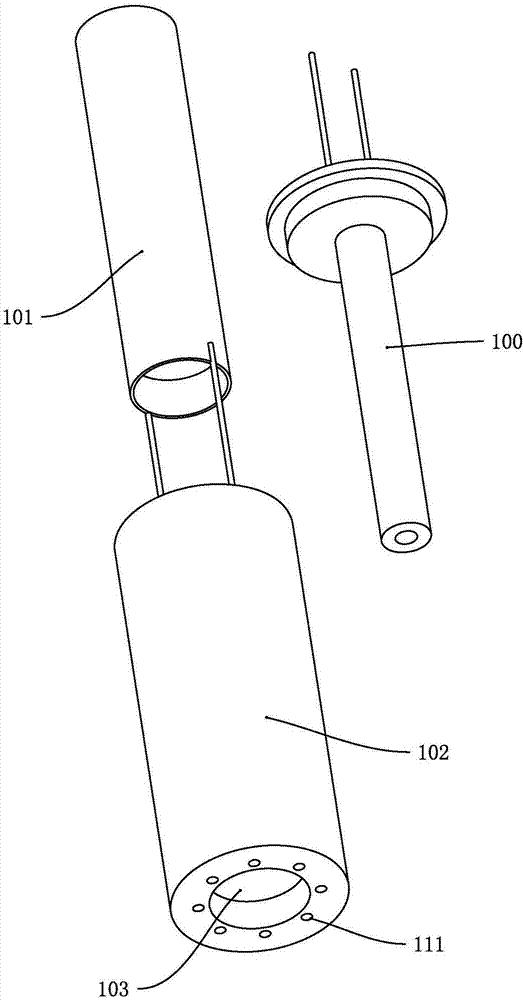

Single-tank, double-pipe and bidirectional electric heating device and air energy instant electric water heater

ActiveCN103759406AIncrease the length of the routeExtend heating timeWater heatersPath lengthWater flow

The invention provides a single-tank, double-pipe and bidirectional electric heating device and an air energy instant electric water heater. The single-tank, double-pipe and bidirectional electric heating device comprises a cylindrical tank body, the two ends of the tank body are connected with an upper end cover and a lower end cover in a sealing mode, the lower end cover is provided with a water inlet, a water outlet and a binding post, the tank body is internally provided with two layers of concentric pipe bodies which are an inner pipe body and an outer pipe body, an electric conduction heating body is arranged on a space layer between the inner pipe body and the outer pipe body, and a communicated water flow channel is formed by the inner channel of the inner pipe body and the annular channel between the tank body and the outer pipe body. The path length of water flow is increased, and the heating area of the water flow pipe bodies is increased by placing pipe bodies into the single tank body to divide the space inside the tank body, the process of obtaining the heating energy directly and bidirectionally transmitted by the heating body is accelerated, the heating and acting heat effect ratio per unit time of the tank body is effectively improved, and the power loss and the heating loss are reduced.

Owner:陈国良

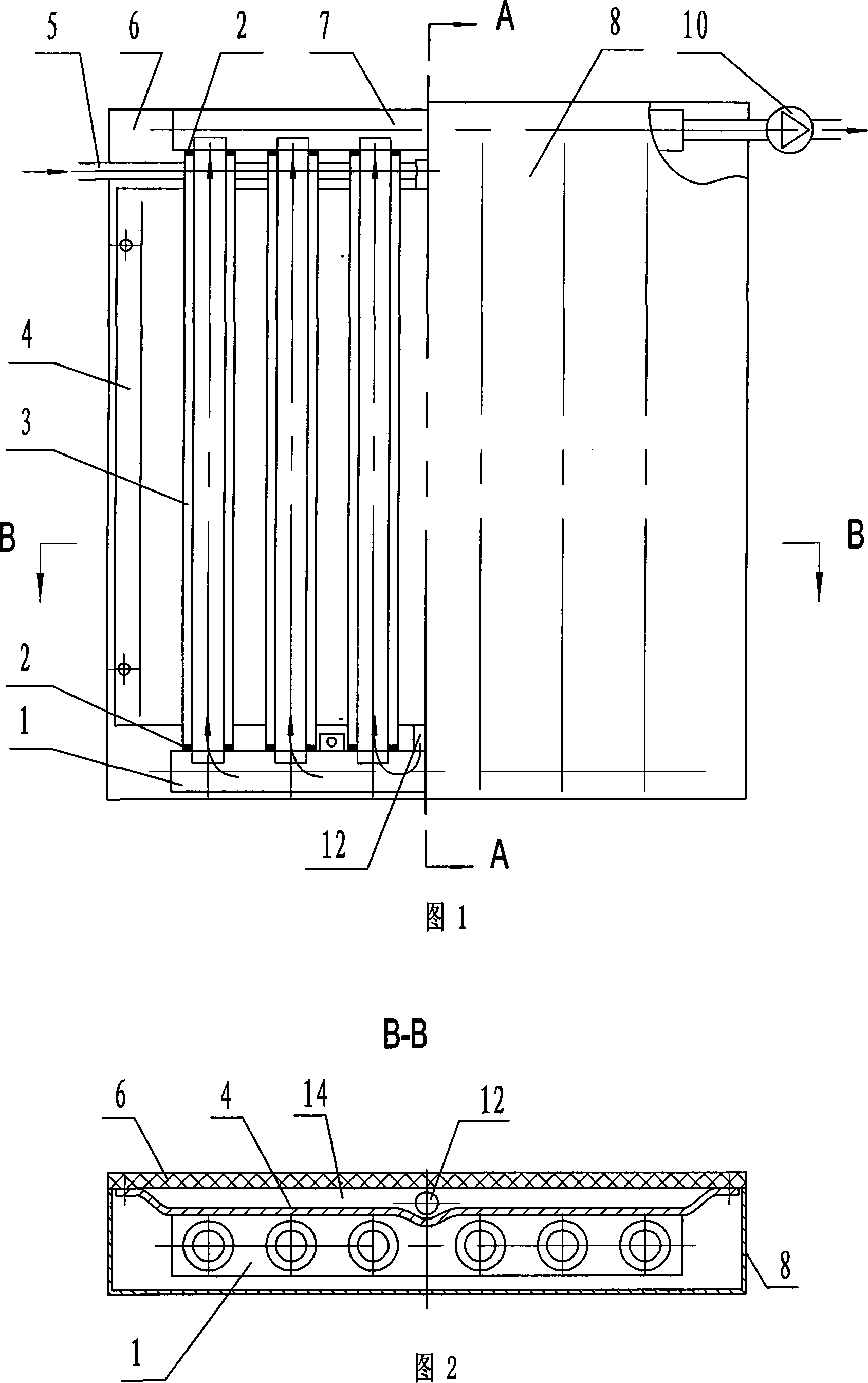

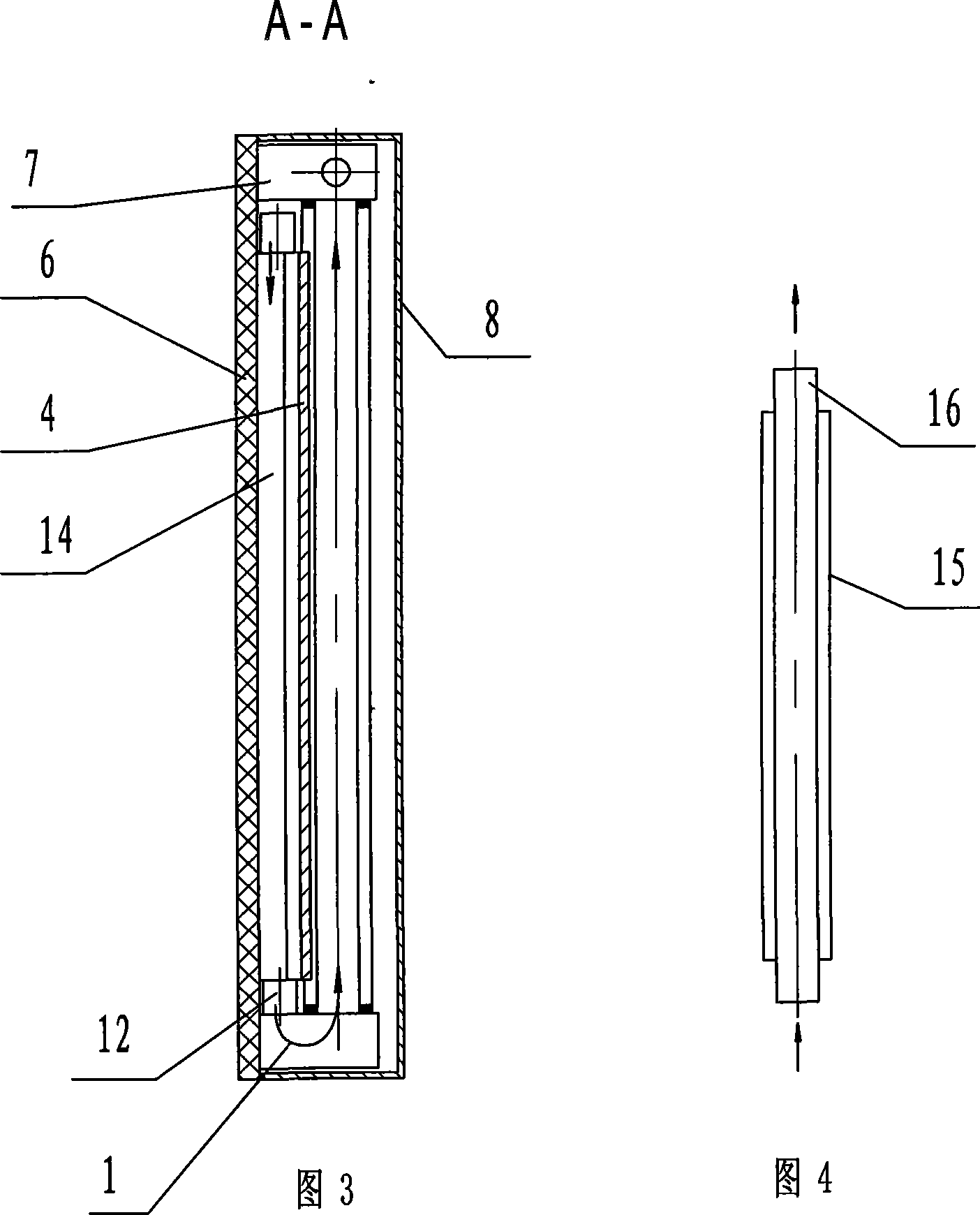

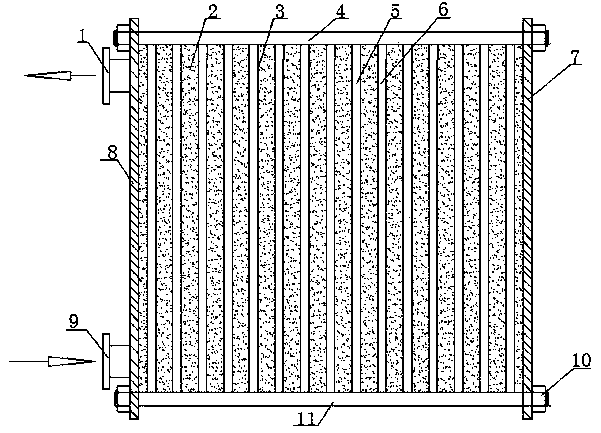

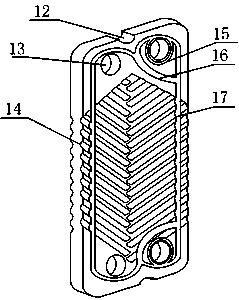

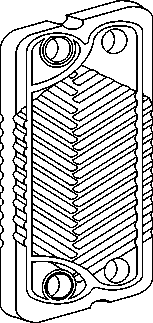

Plate type phase-change thermal storage heat exchanger capable of supplying heat stably

InactiveCN103900404AImprove sealingReduce volumeHeat storage plantsStationary plate conduit assembliesHot workingMechanical engineering

The invention discloses a plate type phase-change thermal storage heat exchanger capable of supplying heat stably. The plate type phase-change thermal storage heat exchanger comprises a plurality of seal boxes arranged in parallel. A phase-change thermal storage body is arranged in each seal box. Corner holes are formed in the four corners of each seal box respectively. A sealing part is arranged between any two adjacent seal boxes, and the two corner holes in the same side end of each seal box are separated through the sealing part. Any two adjacent sealing parts are arranged in parallel at the 180-degree included angle. Hot working medium flowing cavities and cold working medium flowing cavities are defined by the seal boxes through the sealing parts, wherein the hot working medium flowing cavities and the cold working medium flowing cavities are distributed alternately. The plate type phase-change thermal storage heat exchanger further comprises an outer frame. The seal boxes are pressed tightly and sealed by the outer frame. A cold working medium inlet and outlet and a hot working medium inlet and outlet are further formed in the outer frame and are communicated with the corner holes. The plate type phase-change thermal storage heat exchanger is small in size and convenient to assemble, disassemble and maintain; phase-change thermal storage materials are adopted for thermal storage, so the defect that heat supply is not stable is effectively overcome, the heat supply time is prolonged, the stable heat supply temperature can be maintained, the stability is good, and the working media do not influence each other.

Owner:SICHUAN PROVINCIAL ARCHITECTURAL DESIGN & RES INST

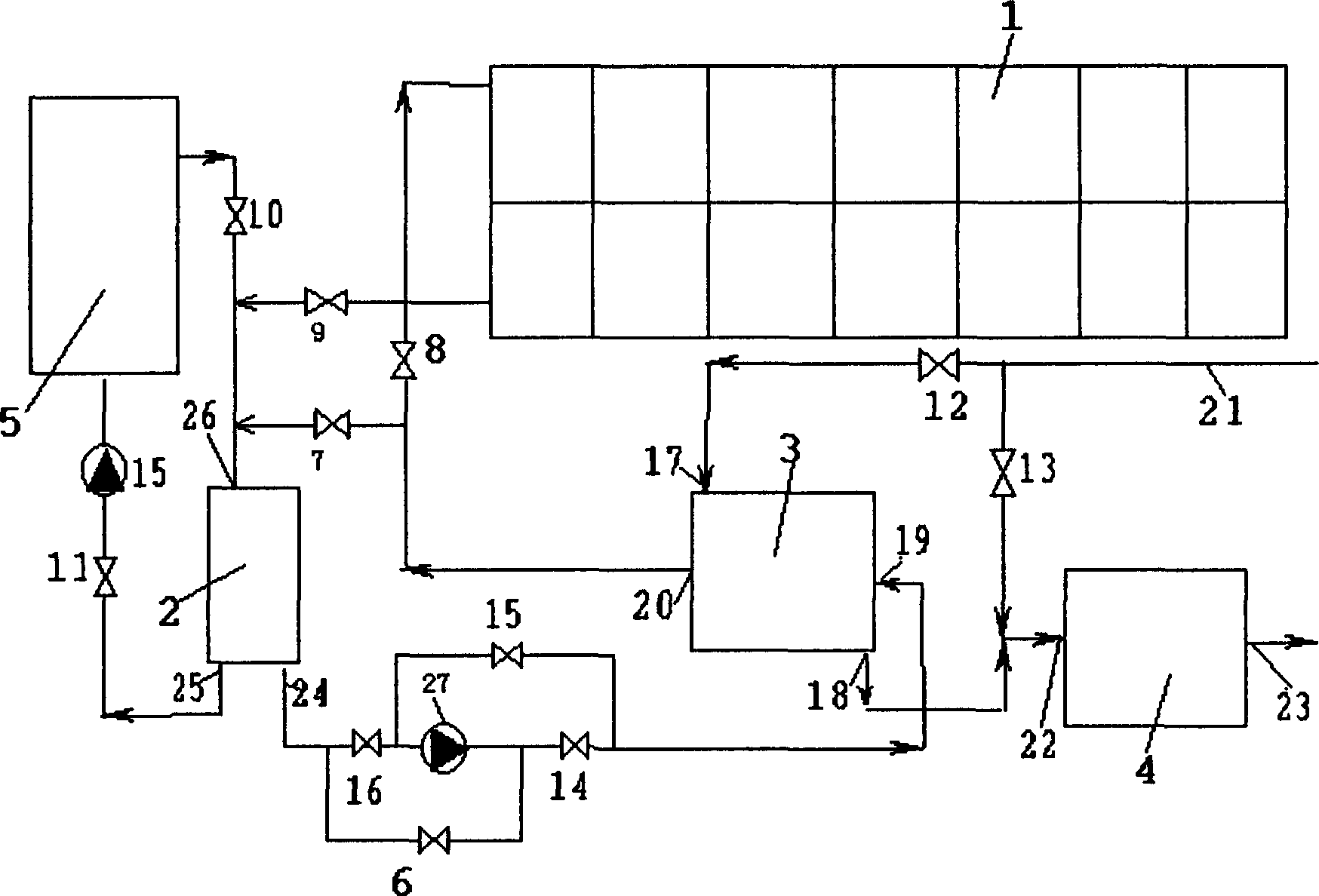

Solar indirect heating crude oil transportation system

InactiveCN1654879AReduce consumptionReduce pollutionSolar heat devicesPipeline systemsWater storagePlate heat exchanger

This invention discloses a solar indirectly heating and transportation crude oil system, which comprises solar heat collection device, small heat storage box, middle heat exchanger and heating furnace, wherein, the crude oil input pipes are separately connected to the input end of the middle heat exchanger and the crude oil entrance of the heating furnace; the said middle heat exchanger output end is connected to the heating furnace oil entrance through pipes; the input end of hot water of the middle heat exchanger is connected to the hot water output end; the hot water output ends are separately connected to the input end of solar heat collection device and the hot water input end of the water storage box; the solar heat collection device output end is connected to the hot water input end.

Owner:EAST CHINA UNIV OF SCI & TECH

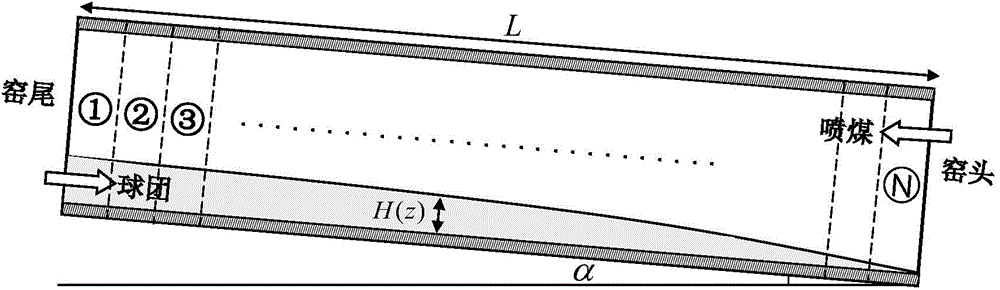

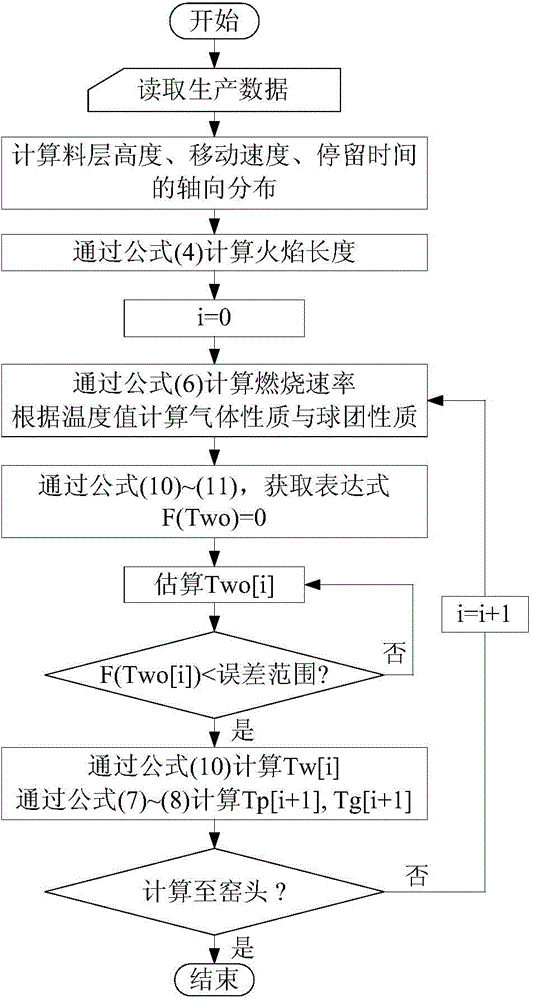

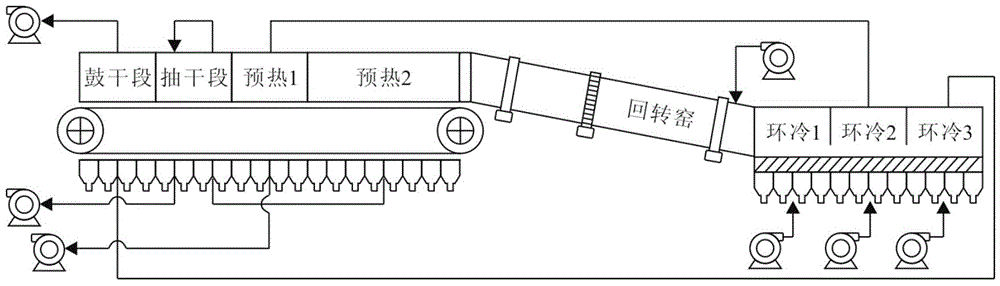

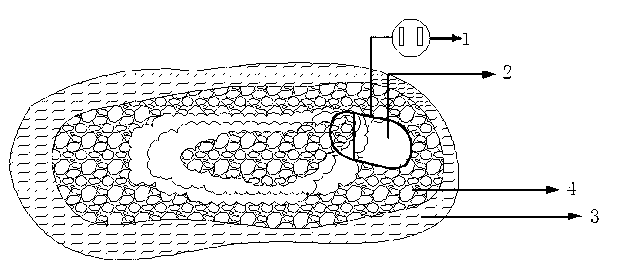

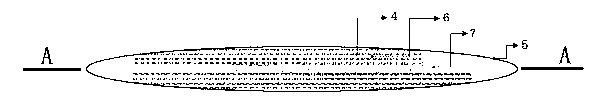

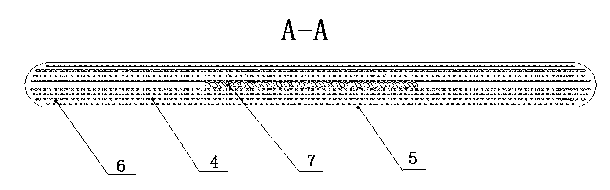

Pellet production method based on prediction of compressive strength of pellets in rotary kiln

ActiveCN104480300AHigh compressive strengthReduce porositySpecial data processing applicationsThermal engineeringHysteresis

The invention discloses a pellet production method based on prediction of compressive strength of pellets in a rotary kiln. The method comprises the following steps: 1) collecting related operation parameters of the rotary kiln; 2) establishing a motion model of the pellets in the rotary kiln; 3) measuring and calculating average residence time T of the pellets in the rotary kiln; 4) measuring flame length FL and the distribution of burning rate Rfuel of fuel in the flame length; 5) measuring the distribution of temperature of the pellets Tp along the kiln length direction z in the rotary kiln; 6) measuring a predicted value of the strength of the pellets; and 7) performing online control on process parameters of the rotary kiln according to the predicted value Qp of the compressive strength of the pellets. By using the method for online prediction of the thermal engineering state and the strength of the pellets in the rotary kiln, the transparency of the production process is increased, the control difficulty caused by information hysteresis is reduced, the risks of low finished product rate, accretion of the rotary kiln and the like caused by insufficient strength of the pellets can be reduced, and the thermal engineering operation of the rotary kiln is optimized in an online manner; and the energy consumption can be reduced and the production benefits can be improved.

Owner:CENT SOUTH UNIV

Electric hot-water bag utilizing phase change latent heat and manufacturing method thereof

InactiveCN103340712AAvoid burnsImprove heating effectHeat-exchange elementsTherapeutic coolingThermodynamicsProcess engineering

The invention discloses an electric hot-water bag utilizing phase change latent heat. An energy storage material layer is arranged inside the electric hot-water bag filled with heat storage liquid, the heat output portion of a heating element is arranged inside the energy storage material layer, the energy storage material layer forms a stable phase composition body system by blending phase change materials and auxiliaries, the composition body system of the energy storage material layer is made to be kept in an even and stable suspended state or an opacifying state or to form a gel state, a heat energy exchange buffering release functional layer is formed, and heat which is output by the heating element and absorbed by the energy storage material layer is slowly and smoothly transferred to the filled heat storage liquid. The invention further provides a manufacturing method of the electric hot-water bag. The method comprises the steps of manufacturing the composition body system of the energy storage material layer, preparing an energy storage material layer unit, manufacturing an energy storage material layer system and forming and manufacturing the electric hot-water bag. The electric hot-water bag utilizing the phase change latent heat can effectively prevent scald, and has the advantages of being longer in warming time, reasonable in structure, environmentally friendly, and good in market prospect.

Owner:SHANGHAI UNIV

Method and apparatus for UV ink jet printing on fabric and combination printing and quilting thereby

InactiveCN1572492AChanging the time of exposure to energyIncrease or decrease the time of energy exposureSewing-machine elementsLayered productsPolymer scienceEngineering

Ink jet printing is provided on large area substrates such as wide width textile webs. The printheads are driven by linear servo motors across a bridge that extends across the substrate. The timing of the jetting of the ink is coordinated with the motion of the printheads, so that the heads can be rapidly moved and the ink can be jetted while the printheads are accelerating or decelerating as they move on the bridge. Preferably, ultraviolet (UV) light curable ink is jetted and first partially cured with UV light and then subjected to heating to more completely reduce uncured monomers of the ink on the substrate.

Owner:L & P PROPERTY MANAGEMENT CO

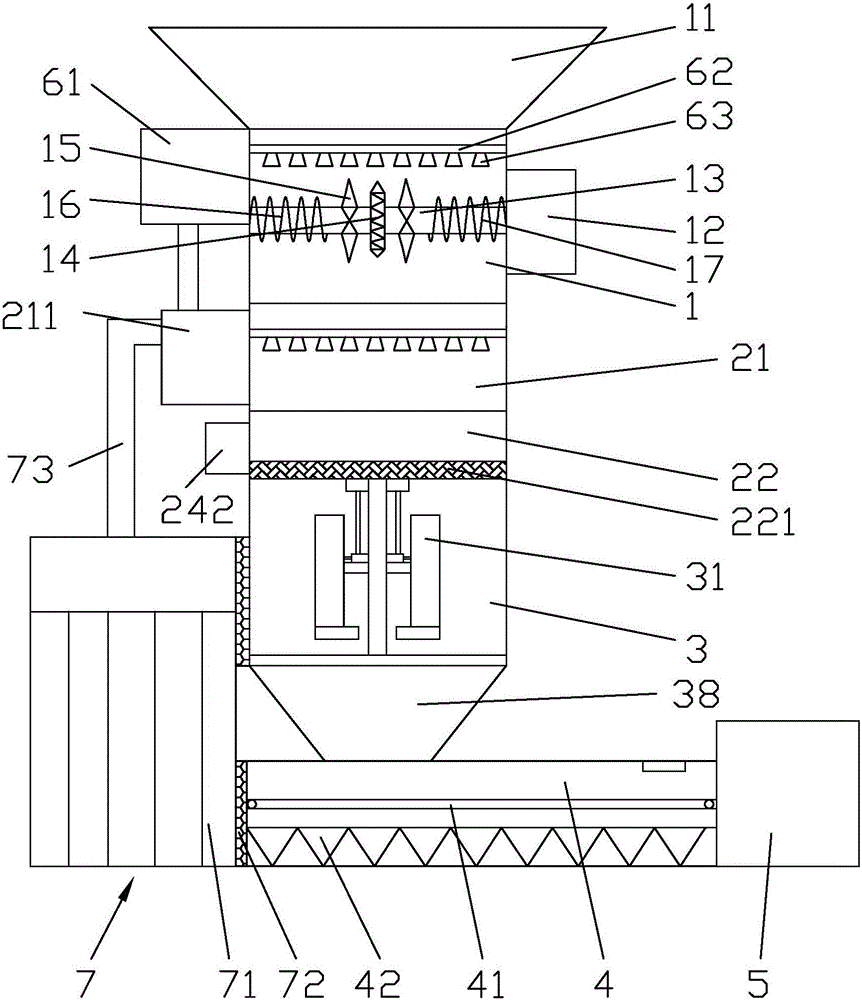

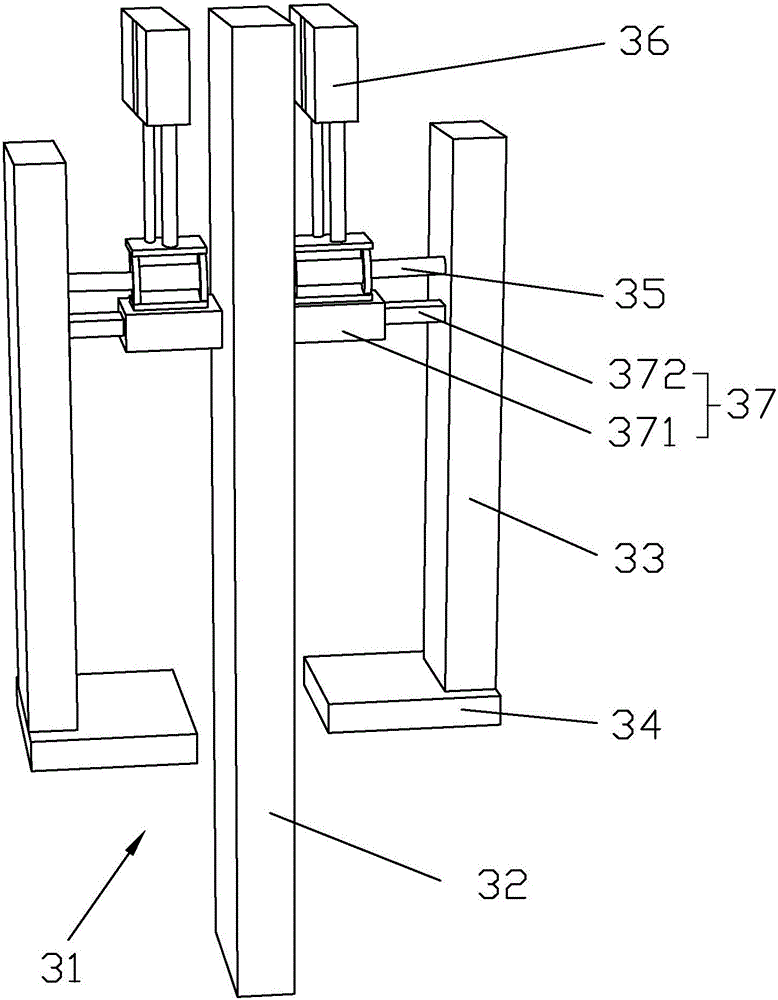

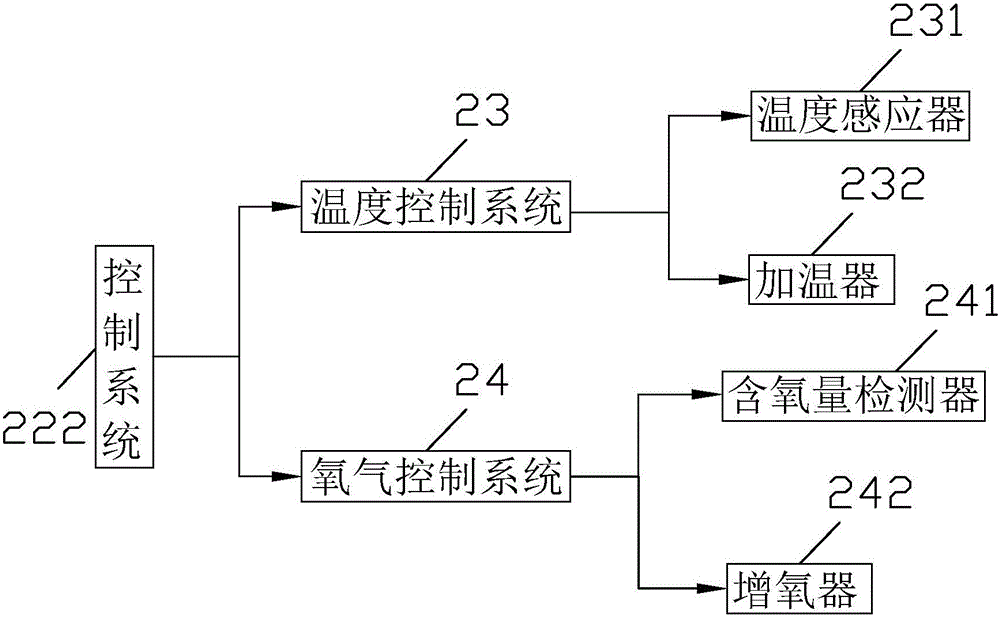

Sludge treating machine applied to ecological river and treating method of sludge treating machine

ActiveCN106082570ASmall particlesEasy to handleSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesChemical treatmentSludge

The invention mainly discloses a sludge treating machine applied to an ecological river and a treating method of the sludge treating machine. The treating machine comprises a pulverizing bin, a treating bin, a water drainage bin, a drying bin and a storage bin, wherein a feeding hopper is arranged above the pulverizing bin; a pulverizing mechanism is arranged in the pulverizing bin; the treating bin comprises a chemical treating bin and a microbial treating bin; a filter pressing device is arranged in the water drainage bin; the water drainage bin is connected with the drying bin through a material guiding plate; a conveying mechanism and a heating mechanism are arranged in the drying bin; and a discharging opening of the conveying mechanism is connected with the storage bin. The treating method comprises the following steps: sludge digging, pulverizing treatment, chemical treatment, microbial treatment, water drainage treatment, drying treatment and storage. The method is simple and effective, convenient to operate, environmentally friendly, and high in treatment efficiency, the quality of the sludge is improved effectively, toxic and harmful substances in the sludge are reduced, meanwhile, water in the sludge is reduced, storage and conveyance of the sludge are facilitated, and purposes of changing harmful substances into beneficial substances, recycling materials and protecting the environment achieved.

Owner:浙江景昌建设有限公司

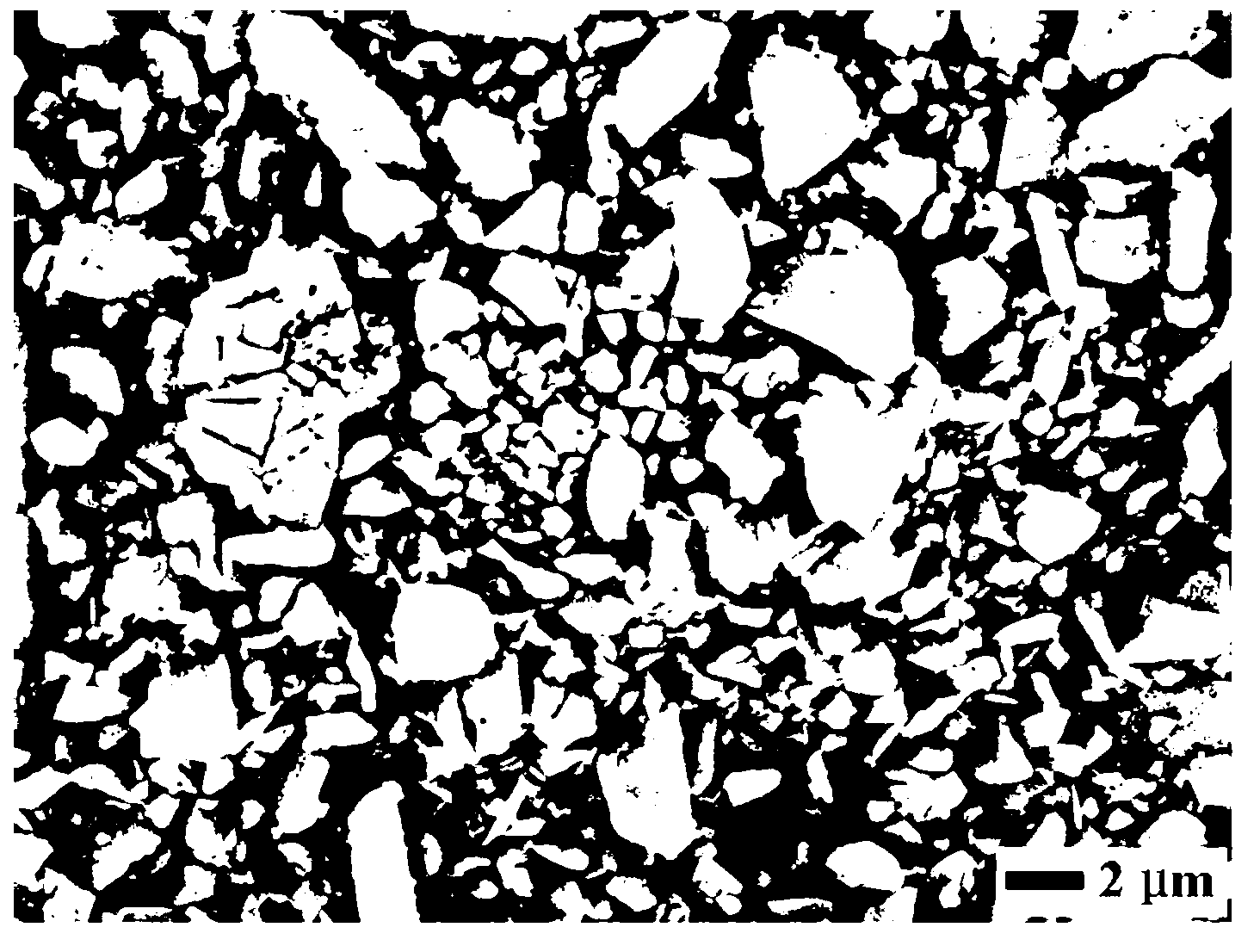

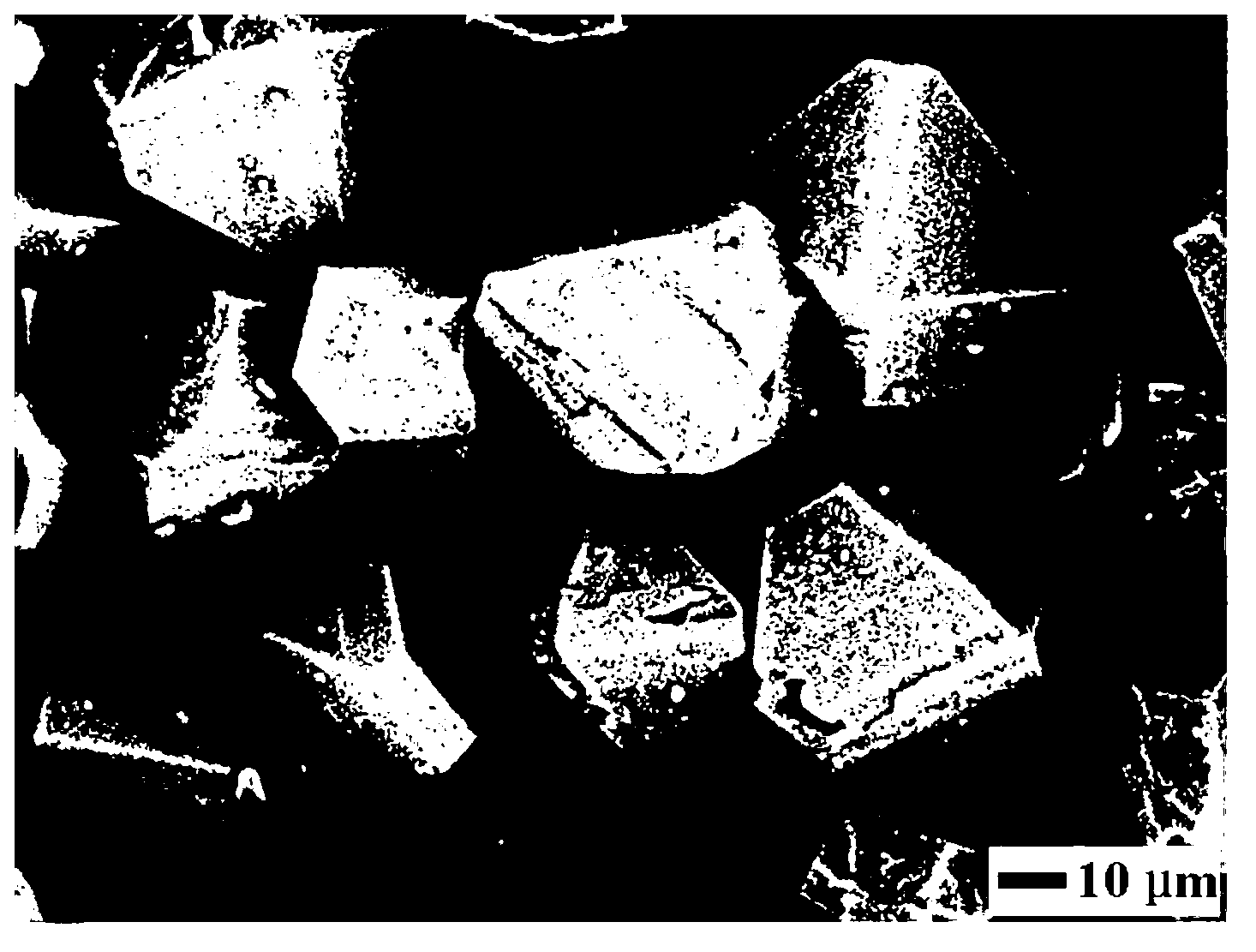

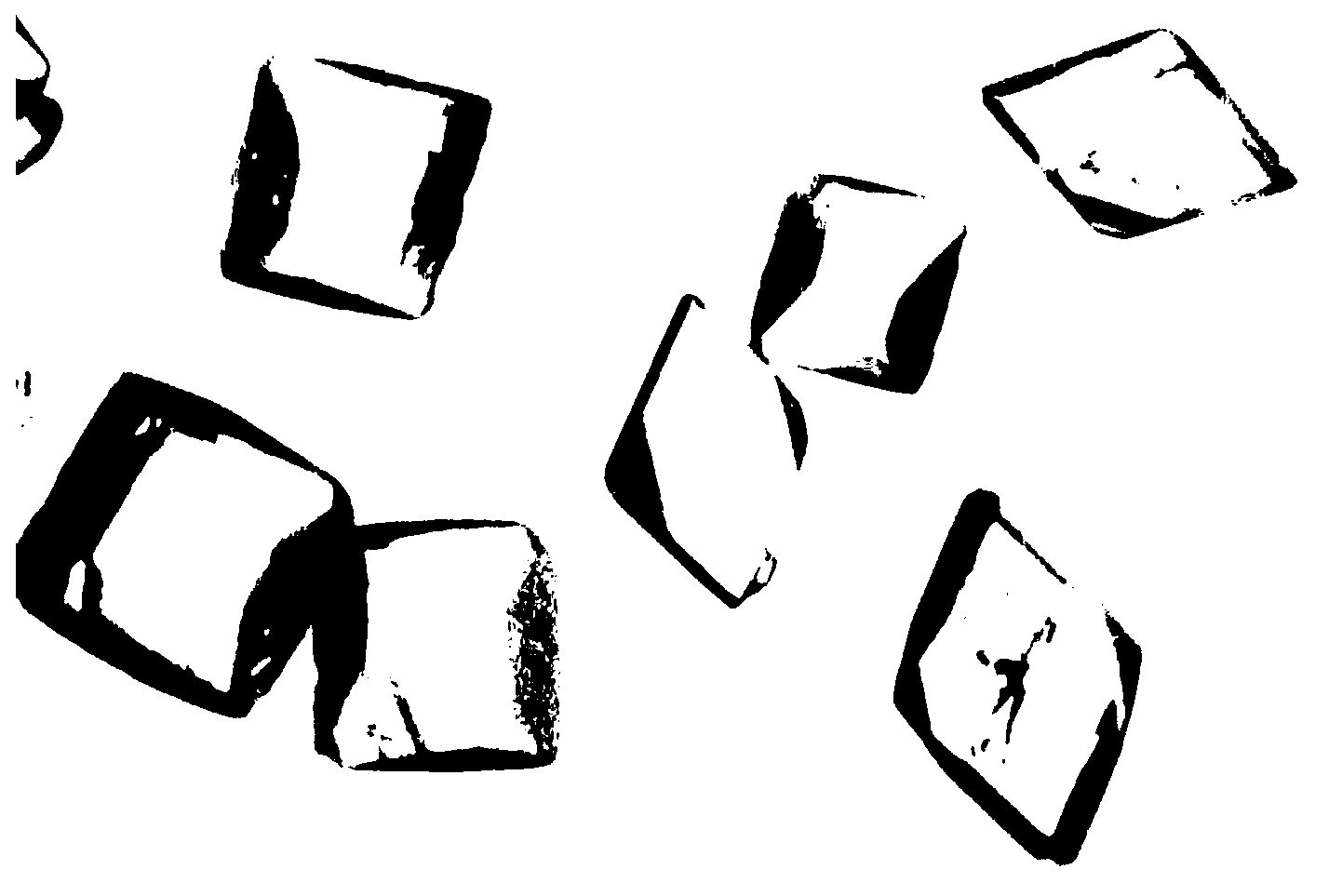

Preparation method of hexaazaisowurtzitane crystal

ActiveCN103214325ARegular particle shapeUniform particlesExplosive working-up apparatusSingle substance explosivesMechanical crushingTwo step

The invention discloses a preparation method of a hexaazaisowurtzitane crystal. The preparation method of the hexaazaisowurtzitane crystal comprises the following steps of: carrying out wet-crushing onto explosives until the particle dimension is 0.1 micron to 5 microns, centrifuging, washing, freezing and drying the crushed materials; placing the material in the step I to a solvent for carrying out ultrasonic treatment, heating, re-filtering, washing and drying under the standing condition or the stirring condition to obtain a hexaazaisowurtzitane explosive crystal. According to the preparation method of the hexaazaisowurtzitane crystal, the high-quality explosive crystal product, which is prepared by a preparation technology adopting a two-step process including mechanical crushing and solvent thermal-induction growing, is regular in particle shape, jewel-shaped, uniform in particle dimension, smooth in surface, less in internal defects of the crystal, and lower in mechanical sensitivity. Besides, the preparation method of the hexaazaisowurtzitane crystal is simple in process, gentle in reaction conditions, good in reproducibility, high in yield and suitable for large-scale industrial production.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

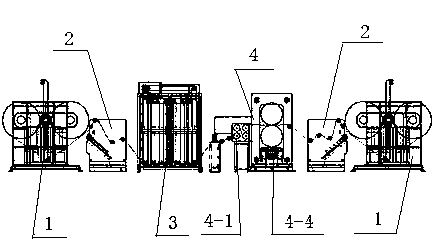

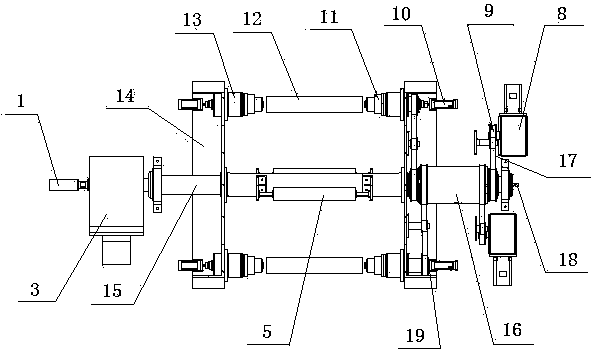

Device used for rolling battery pole piece at high speed

ActiveCN104190708AImprove productivityIncrease productivityElectrode manufacturing processesMetal rolling arrangementsControl systemPole piece

The invention discloses a device used for rolling a battery pole piece at a high speed. The device comprises a control system, two double-station automatic winding and unwinding machines, a band connecting device, a piece storage mechanism and a rolling mechanism. The double-station automatic winding and unwinding machines are arranged at an initial end and a tail end respectively. The band connecting device is arranged on the side face of the output end of a battery pole piece band roll of the double-station automatic winding and unwinding machine arranged at the initial end. The piece storage mechanism and the rolling mechanism are sequentially arranged behind the output end of the band connecting device. The output end of the rolling mechanism is connected with the double-station automatic winding and unwinding machine arranged at the tail end. An automatic roll replacing and band connecting mechanism, the piece storage mechanism and the rolling mechanism are all connected with a control system. According to the device, rolling accuracy can be guaranteed, shutdown is not required in the rolling process, roll replacement and band connection are automatically completed, and therefore automated production is achieved.

Owner:邢台纳科诺尔精轧科技股份有限公司

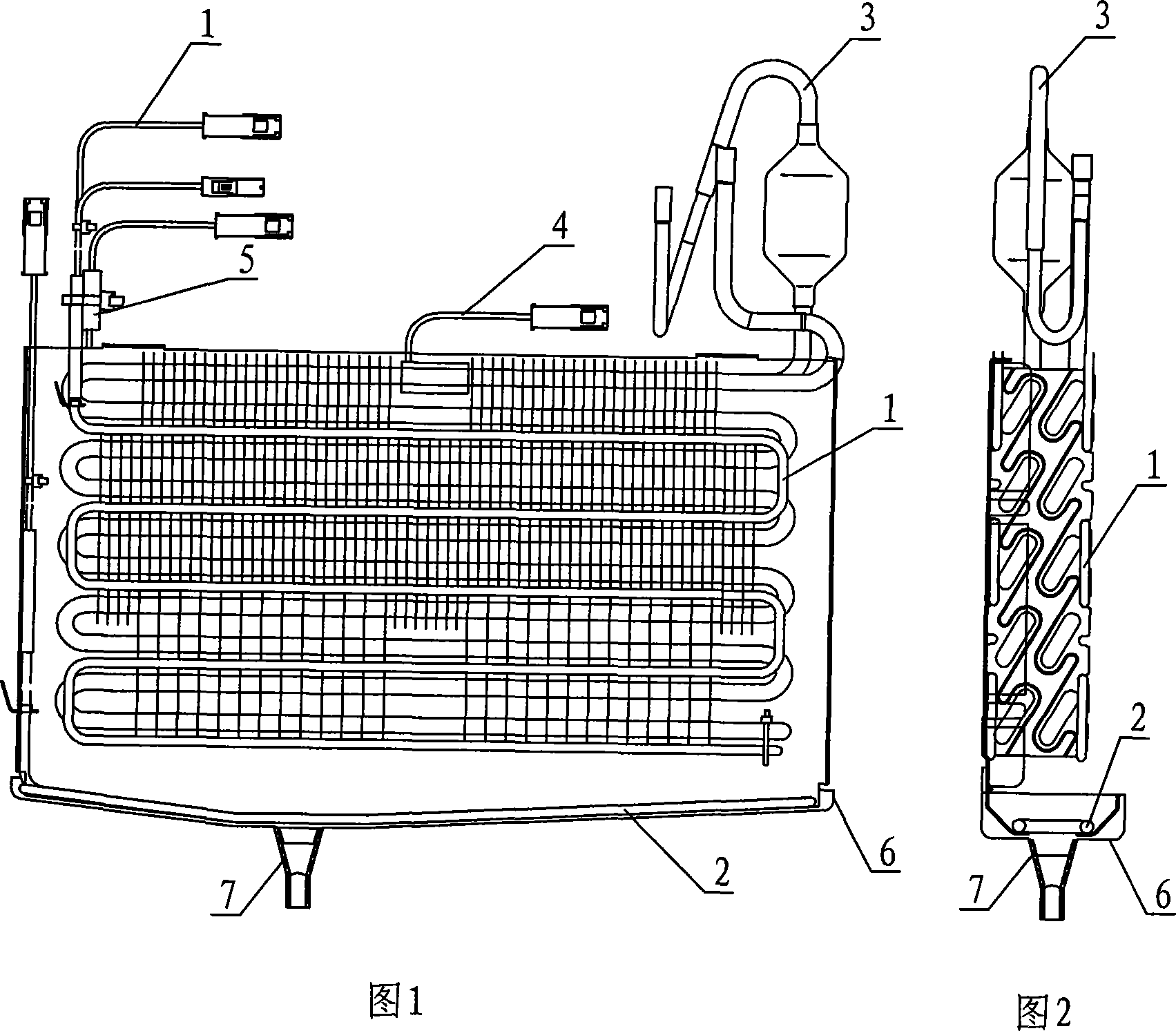

Refrigerator defrosting heater and controlling method thereof

InactiveCN101210761ASave time at workLow powerLighting and heating apparatusDefrostingDraining tubeControl manner

A refrigerator defrosting heater and a control method thereof are provided. The refrigerator defrosting heater is characterized in that a main heater and an auxiliary heater are arranged in group and controlled independently, the main heater is a defrosting heater for an evaporator, and the auxiliary heater is a defrosting heater consisting of a defrosting tray and a drainage pipe. The control method comprises: the main heater and the auxiliary heater are started synchronously to defrost when the defrosting operation is initiated; the main heater is stopped when the evaporator is defrosted completely, while the auxiliary heater continues working; the auxiliary heater is stopped when the defrosting tray and the drainage pipe are defrosted completely; and the whole defrosting process is ended. The invention is particularly suitable for the use in an air-cooling refrigerator and can efficiently prevent the drainage pipe from being blocked by ices and reduce the energy consumption.

Owner:美的集团电冰箱制造(合肥)有限公司

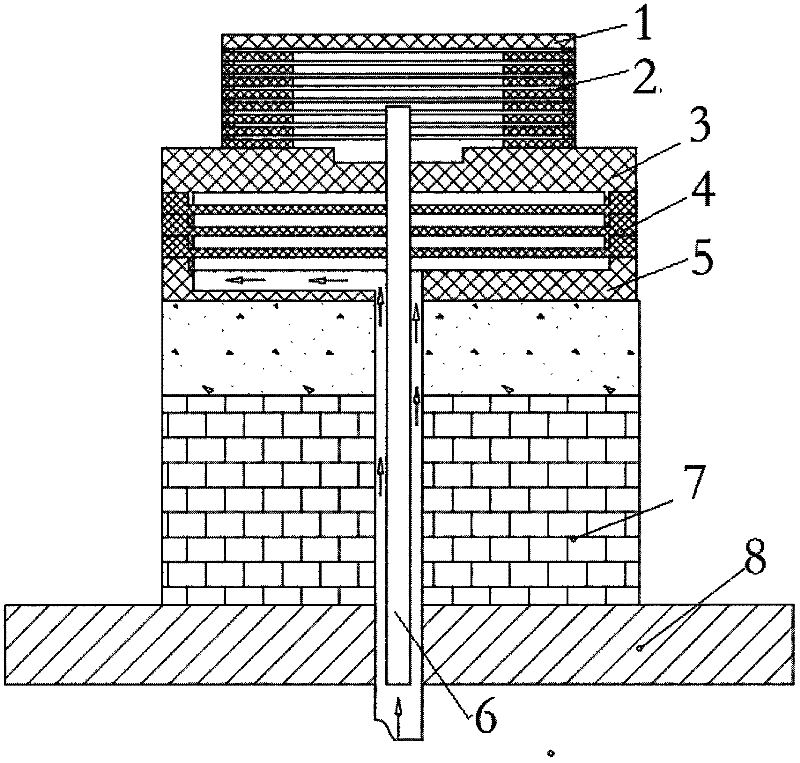

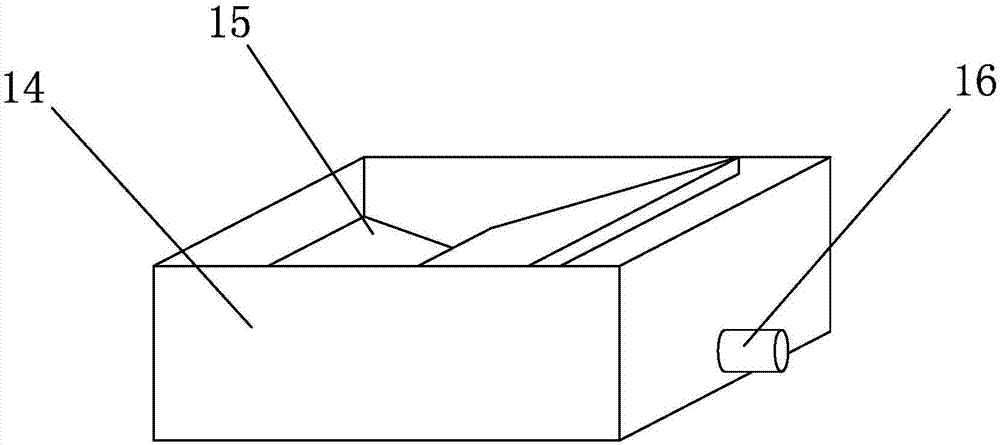

Preheating device for chemical vapor deposition furnace

ActiveCN102363878ASimple processExtend heating timeChemical vapor deposition coatingEngineeringChemical vapor deposition

The invention discloses a preheating device for a chemical vapor deposition furnace. Air flow plates which are arranged in parallel so as to increase air processes and prolong heating time, and beams are arranged simultaneously so as to improve heat radiation capacity; therefore, the aims of fully and uniformly preheating organic air can be fulfilled. An outlet is provided with disturbance holes which are positioned on the same circumference; and a certain included angle is formed between the axial direction of the disturbance holes and a horizontal plane; after preheated air enters the disturbance holes, the preheated air is forced to be sprayed along the axial direction of the disturbance holes to form strong rotation air flow under the collision action of disturbance walls, and organic air which is decomposed in advance forms macromolecules under the actions of centrifugal force and polymerization along with the rising of the rotation air flow; and the macromolecules preferentially enter the bottom of a stock column under the double actions of inertia force and centrifugal force, so axial back mixing probability is reduced, the macromolecules are diffused and deposited in a prefabrication body to achieve the effect of densifying the bottom, the air which is not decomposed rises continuously to ensure that top pressure and air pressure are reduced, and finally the aims of densifying the whole carbon disc stock column can be fulfilled.

Owner:XIAN AVIATION BRAKE TECH

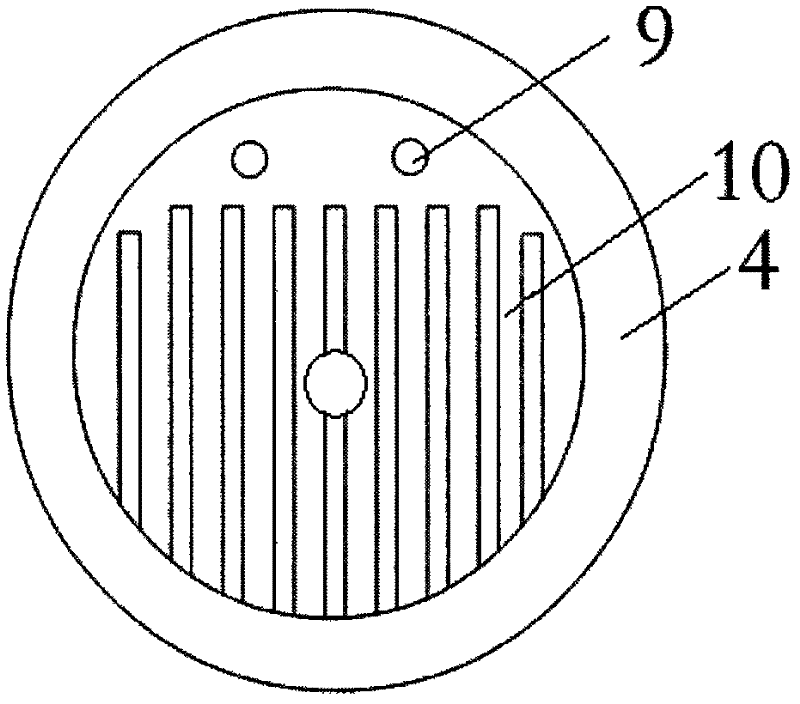

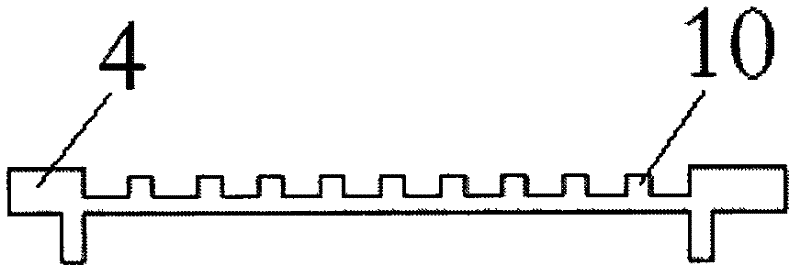

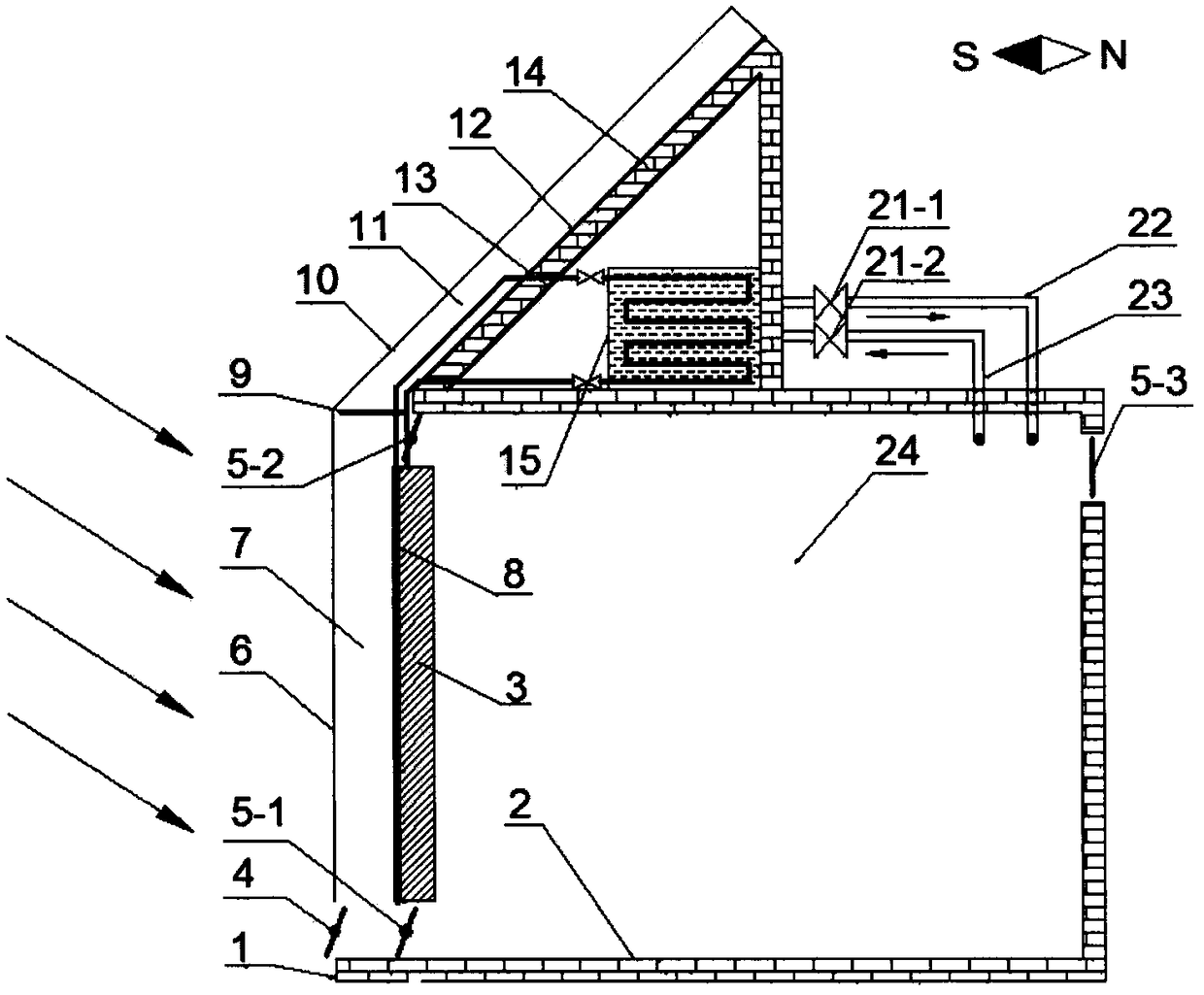

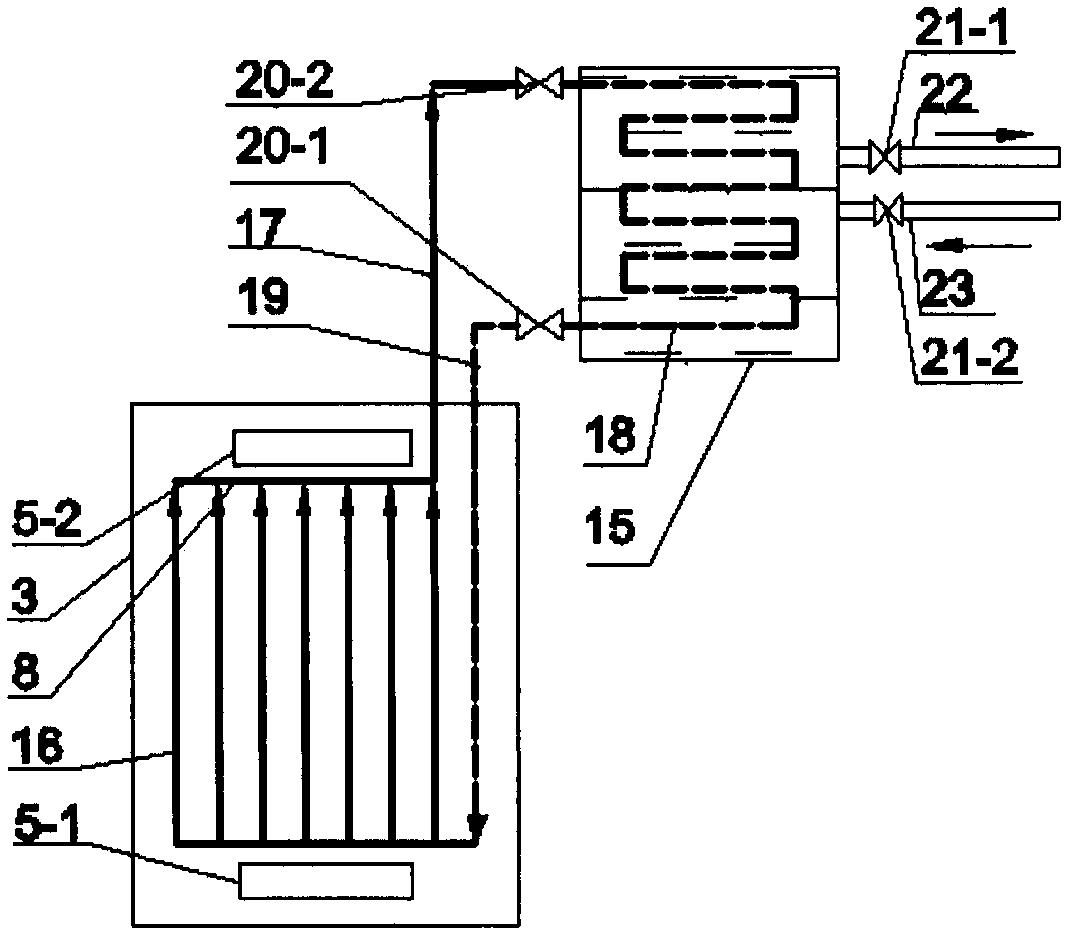

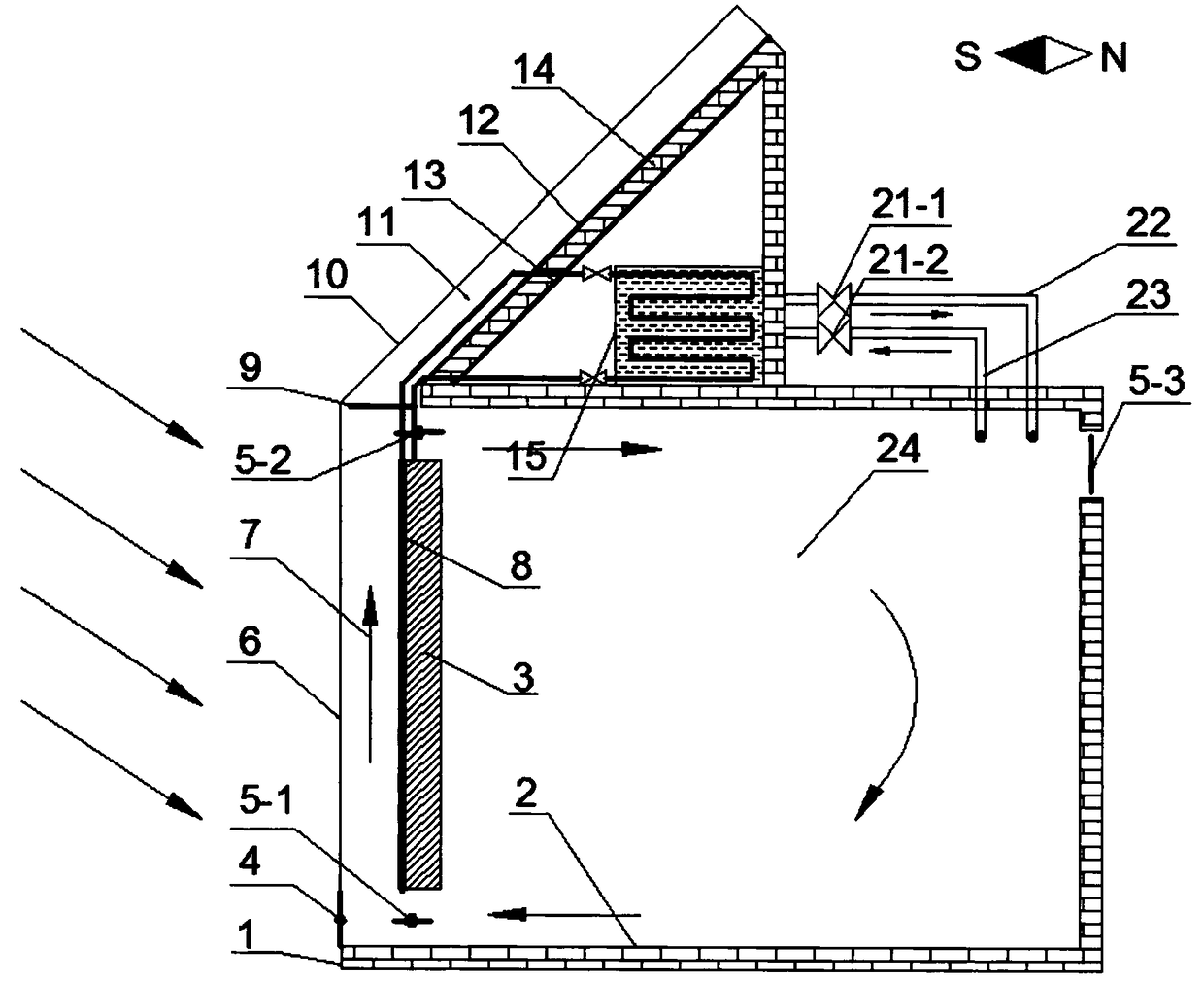

Solar heat collection and ventilation system for passive house

PendingCN108317652ASolve the problem of insufficient natural ventilation powerImprove ventilationSolar heating energyBuilding roofsGlass coverFresh air

The invention discloses a solar heat collection and ventilation system for a passive house. The solar heat collection and ventilation system is composed of a TROMBE wall, a slanting roof solar chimneyand a two-phase closed type thermosiphon, wherein the TROMBE wall comprises a transparent glass cover plate, an air interlayer, a heavy wall, an air valve, a heavy wall upper indoor air inlet and a heavy wall lower indoor air outlet; the slanting roof solar chimney is composed of a transparent cover plate, an air interlayer, a slanting roof, a heat absorption plate and a heat insulation plate. Anair baffle is arranged at the junction between the slanting roof solar chimney and the TROMBE wall; the two-phase closed type thermosiphon is composed of an evaporator, a condenser, a rising air pipe, a downflow liquid pipe and control valves. Through the solar heat collection and ventilation system, the defects that a traditional heat collection and ventilation system is single in function and poor in effect are overcome. The solar heat collection and ventilation system has the advantages of being high in heat collection and ventilation ability, diversified in function and easy to operate and not consuming energy. The solar heat collection and ventilation system is used for conducting natural ventilation and preventing indoor overheat in summer and making domestic hot water and can achieve solar hot air heating and fresh air preheating in winter.

Owner:NANJING UNIV OF TECH

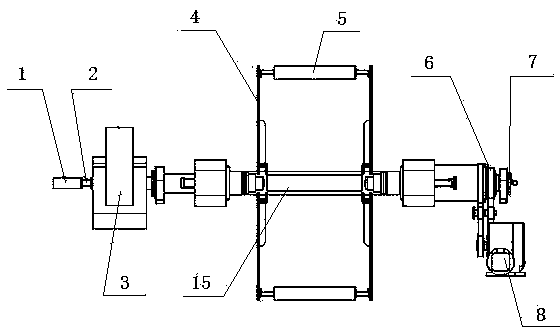

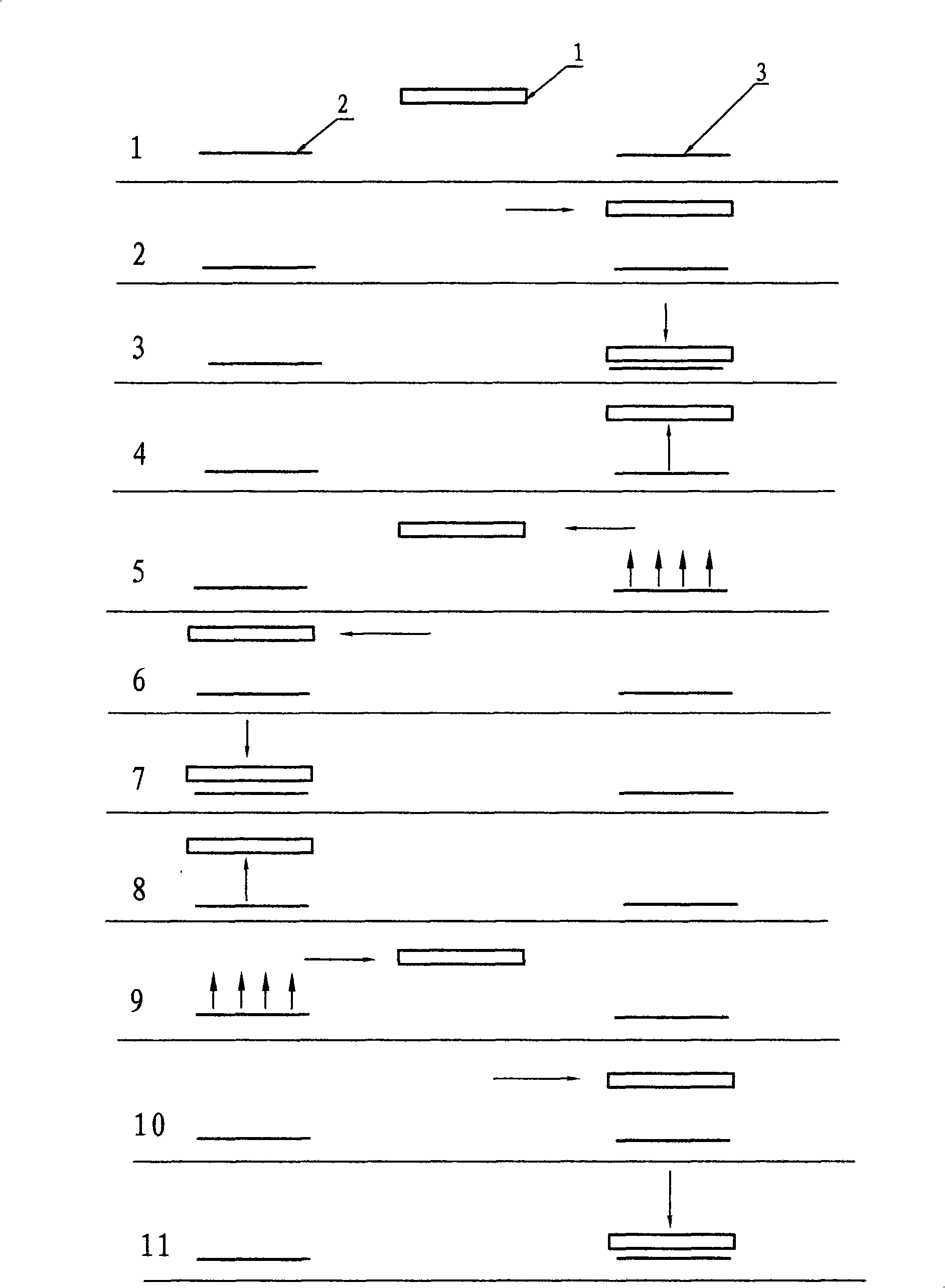

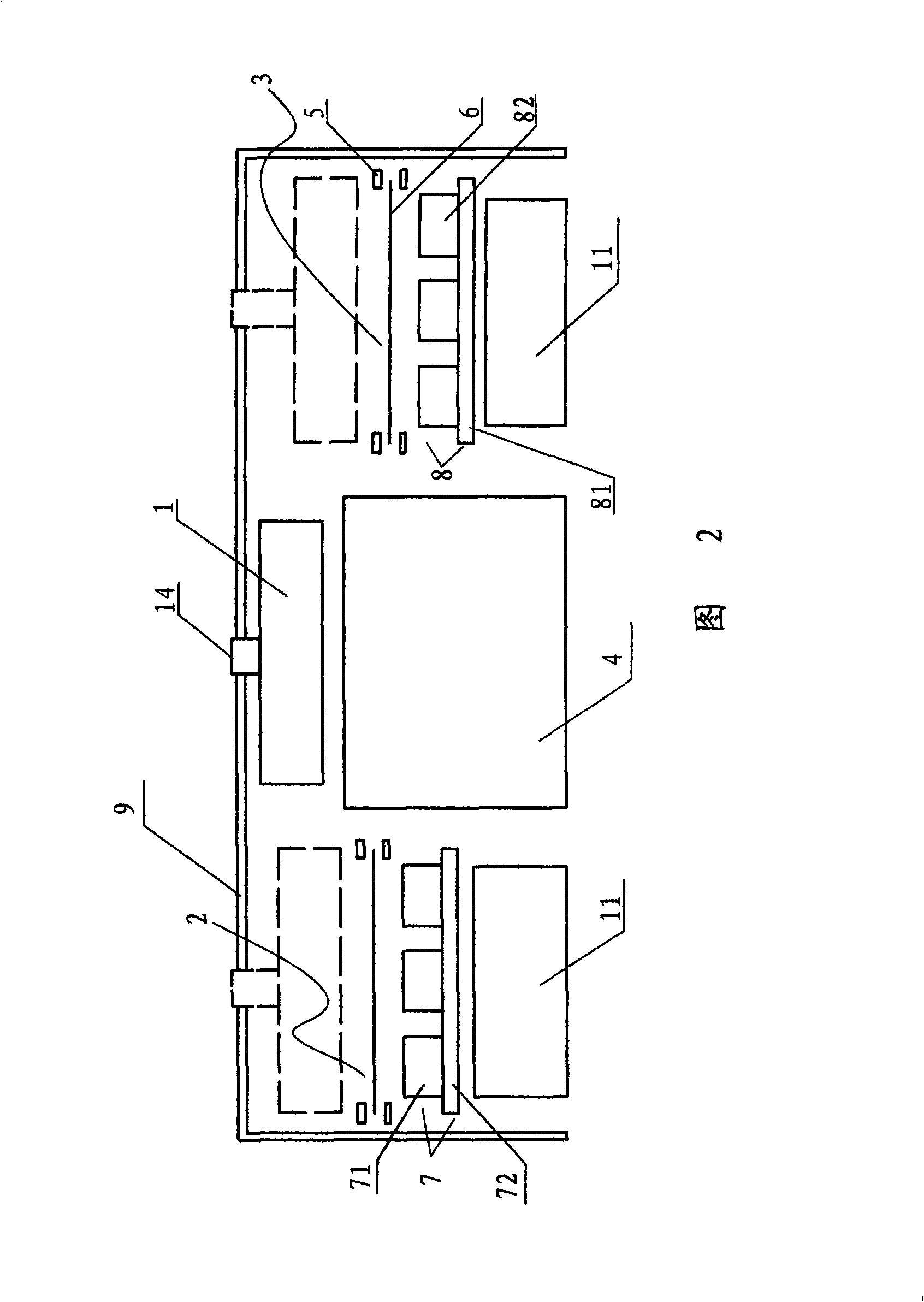

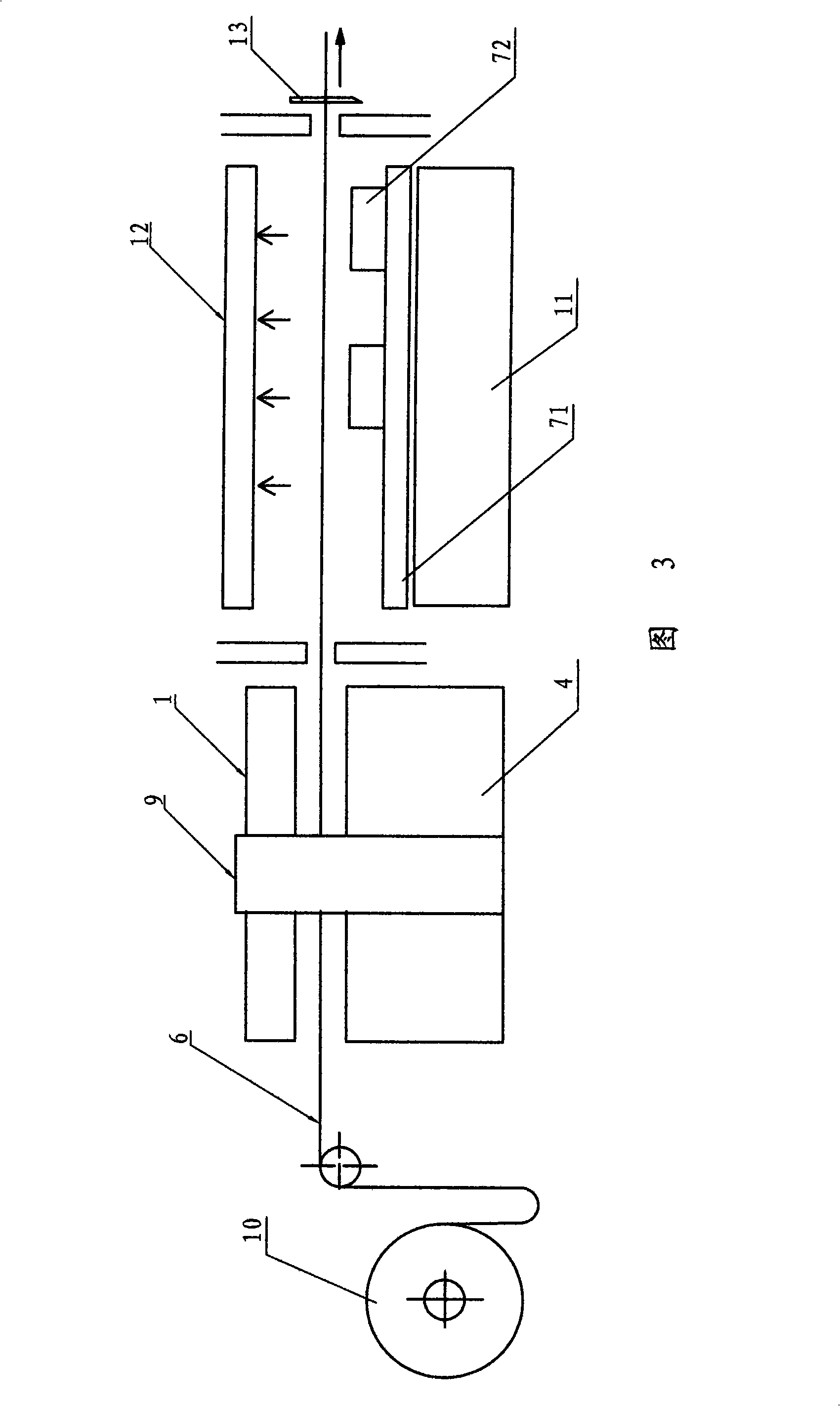

Efficient double-line suction plastic production method and device

The invention provides a high-efficiency dual-line plastic suction production method, comprising the steps as follows: 1) a bidirectional movable plastic suction heating furnace is arranged; the left side and the right side right below the plastic suction heating furnace are respectively provided with a set of vacuum forming processing line; 2) the plastic suction heating furnace is moved to the initial position and electrified to a given temperature, and the temperature is kept; 3) after the plastic suction heating furnace is transversely moved to one side right above the hot forming working position of the vacuum forming processing line, the plastic suction heating furnace vertically runs downwards to a given height H1 and remained for the time t1 so as to heat the material on the side of the processing line hot forming working position; 4) after the prearranged heating time t1 is reached, the plastic suction heating furnace runs upwards vertically and recovers transversely, and stops for a time t3; 5) the plastic suction heating furnace is moved to another processing line, runs downwards vertically by a height H2 and stops for a time t2; 6) the plastic suction heating furnace runs upwards vertically, transversely recovers and stops for a time t4; 7) the step 3) to step 6) are repeated. The invention also discloses a device which realizes the method of the invention.

Owner:DONGGUAN FUCAI PACKAGING PROD

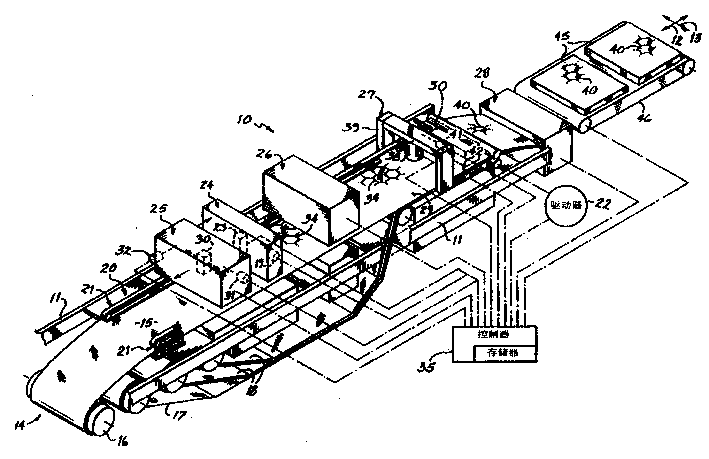

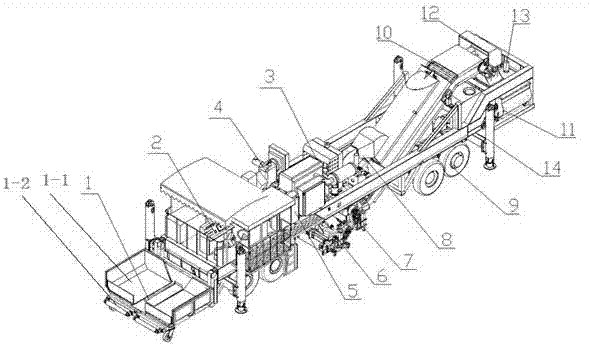

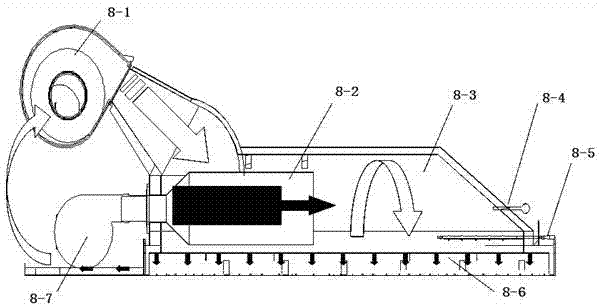

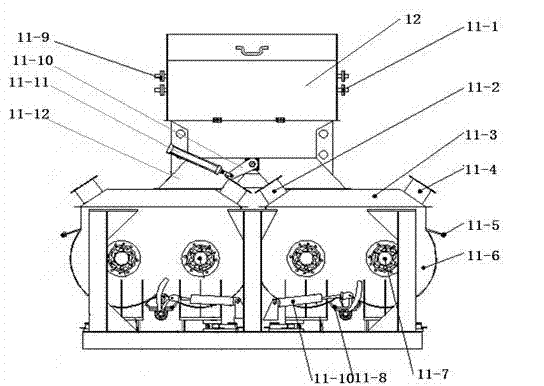

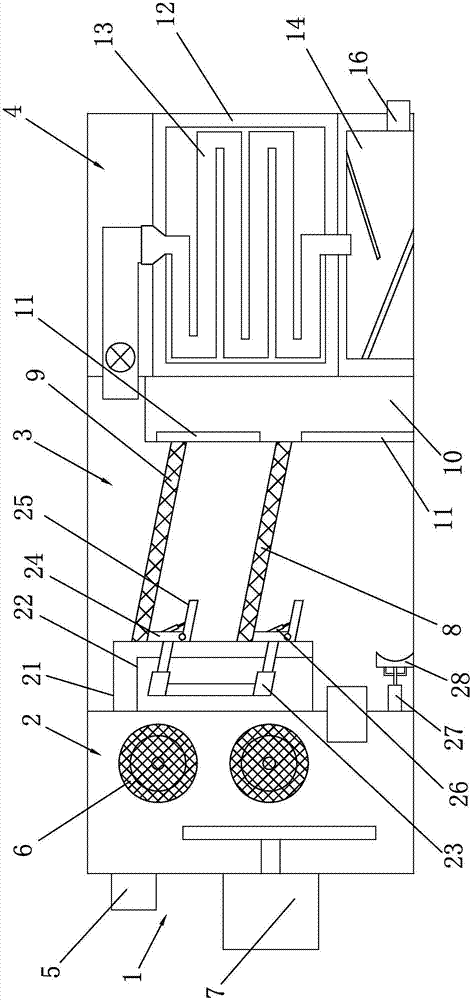

In-place heat regeneration integrated machine for bituminous pavements and control method

ActiveCN104727208AExtend heating timeExtend the mixing timeRoads maintainenceStopped workControl system

The invention provides an in-place heat regeneration integrated machine for bituminous pavements and a control method, wherein the in-place heat regeneration integrated machine for bituminous pavements integrates the functions of pavement milling-planing, bituminous mixture heating, remixing and the like. The regeneration integrated machine comprises a chassis, a milling-planing device, a conveyor, a conveyor heating device, an agitating pan, agitating pan heating devices, and a control system, wherein the conveyor is located behind the milling-planing device, the conveyor heating device is located above the conveyor, the agitating pan heating device is arranged at the top of the agitating pan, and the control system is used for controlling the travelling speed of the chassis, the heating temperature, the mixture metering and the agitating time of the agitating pan. The control method comprises the following steps: starting to accumulate travelling pulses, and if a required travelling distance reaches, switching a material distribution board to the other side; if the material distribution board is overturned, opening an agitating cylinder on the other side, discharging for a period of time, and waiting for the next switching of the material distribution board; and repeating the steps until the machine stops working.

Owner:SHANDONG LUQIAO GROUP

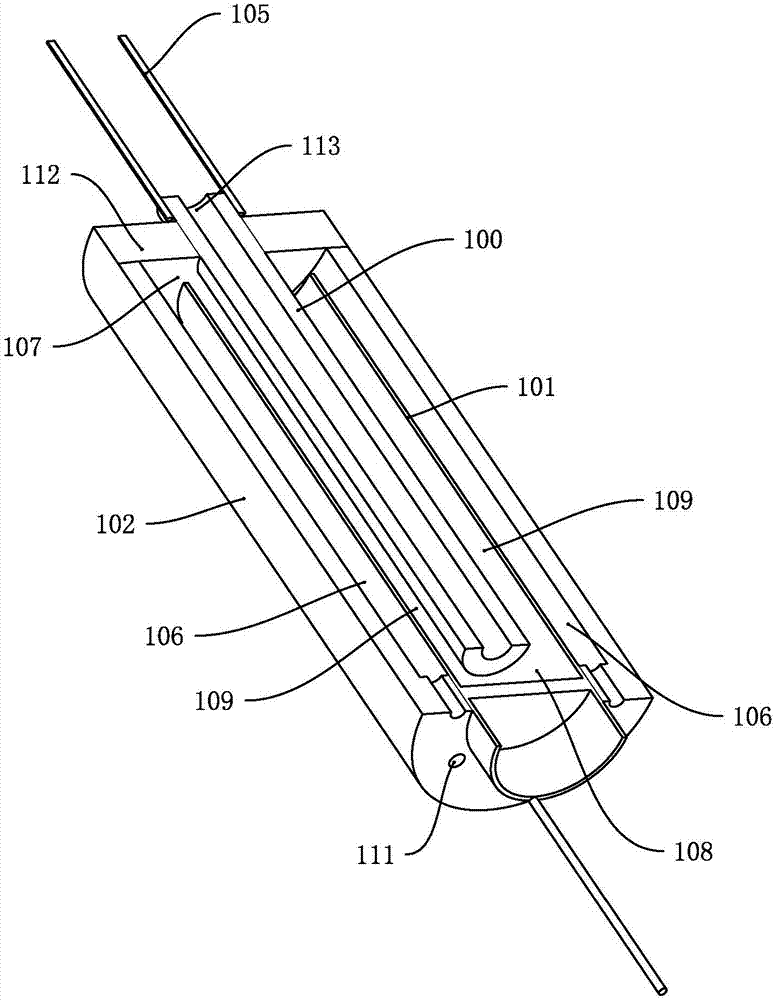

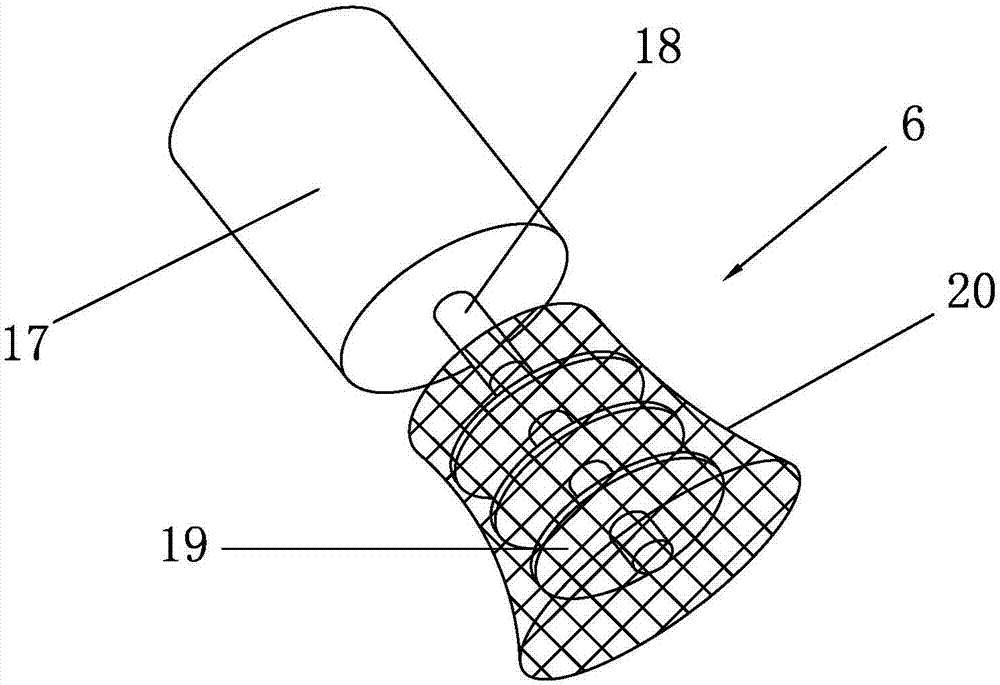

Heater and heating non-combustion electronic cigarette

The invention discloses a heater and a heating non-combustion electronic cigarette. The heater comprises an inner layer heating body, an outer layer heating body and a heat insulation sleeve; the front end of the outer layer heating body is a closed end, and the rear end of the outer layer heating body is an open end; both ends of the inner layer heating body respectively are open ends; a first through hole runs through the front end face of the heat insulation sleeve, and a second through hole runs through the rear end face of the heat insulation sleeve; the outer layer heating body is sleeved with the heat insulation sleeve, and an outer layer gas flow heating passage is formed between the outer layer heating body and the inner wall of the heat insulation sleeve; the front end of the outer layer heating body and the inner wall of the first through hole form sealed connection; the inner layer heating body is sleeved with the outer layer heating body, and an inner layer gas flow heating passage is formed between the inner layer heating body and the inner wall of the outer layer heating body; the rear end of the inner layer heating body and the inner wall of the second through hole form sealed connection; a plurality of gas inlet holes communicated with the outer layer gas flow heating passage run through the front end face of the heat insulation sleeve. The heating non-combustion electronic cigarette comprises the heater and has the advantages that a heating stroke and heating time of air can be increased, the size is small, and a heating temperature is stably increased.

Owner:廖向阳

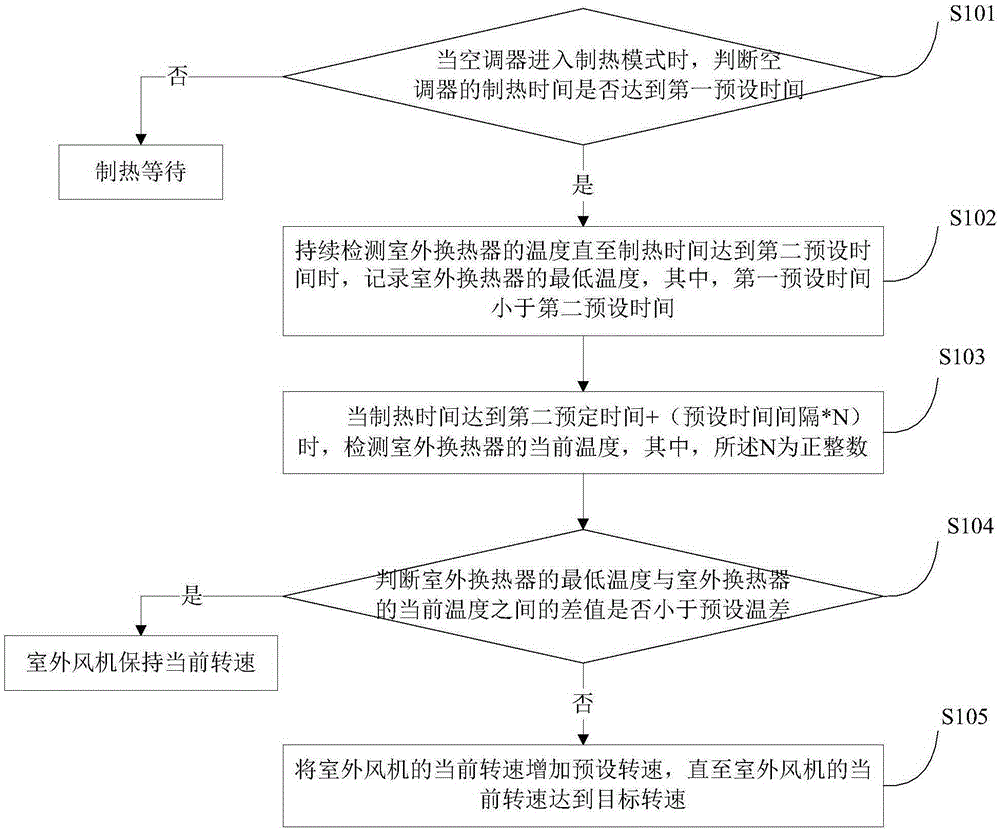

Control method of air conditioner and air conditioner

ActiveCN105423493AExtend heating timeImprove heating effectMechanical apparatusSpace heating and ventilation safety systemsHeating timeEngineering

The invention discloses a control method of an air conditioner and an air conditioner. The air conditioner comprises an indoor unit and an outdoor unit, wherein the outdoor unit comprises an outdoor fan and an outdoor heat exchanger. The control method comprises the steps of when the air conditioner enters the heating mode, judging whether the heating time of the air conditioner reaches the first preset time or not; if the heating time of the air conditioner reaches the first preset time, continuously detecting the temperature of the outdoor heat exchanger, and when the heating time reaches the second preset time, recording the minimum temperature of the outdoor heat exchanger; when the heating time reaches the second preset time+(preset time interval *N), detecting the current temperature of the outdoor heat exchanger; judging whether the difference value of the minimum temperature of the outdoor heat exchanger and the current temperature is smaller than the preset temperature difference or not; and if the difference value of the minimum temperature of the outdoor heat exchanger and the current temperature is larger than the preset temperature difference, increasing the current rotation speed of the outdoor fan by the preset rotation speed till the current rotation speed of the outdoor fan reaches the target rotation speed. According to the control method of the air conditioner provided by the embodiment of the invention, the outdoor heat exchange effect can be improved, and the heating effect during low temperature can be improved.

Owner:WUHU MATY AIR CONDITIONING EQUIP CO LTD

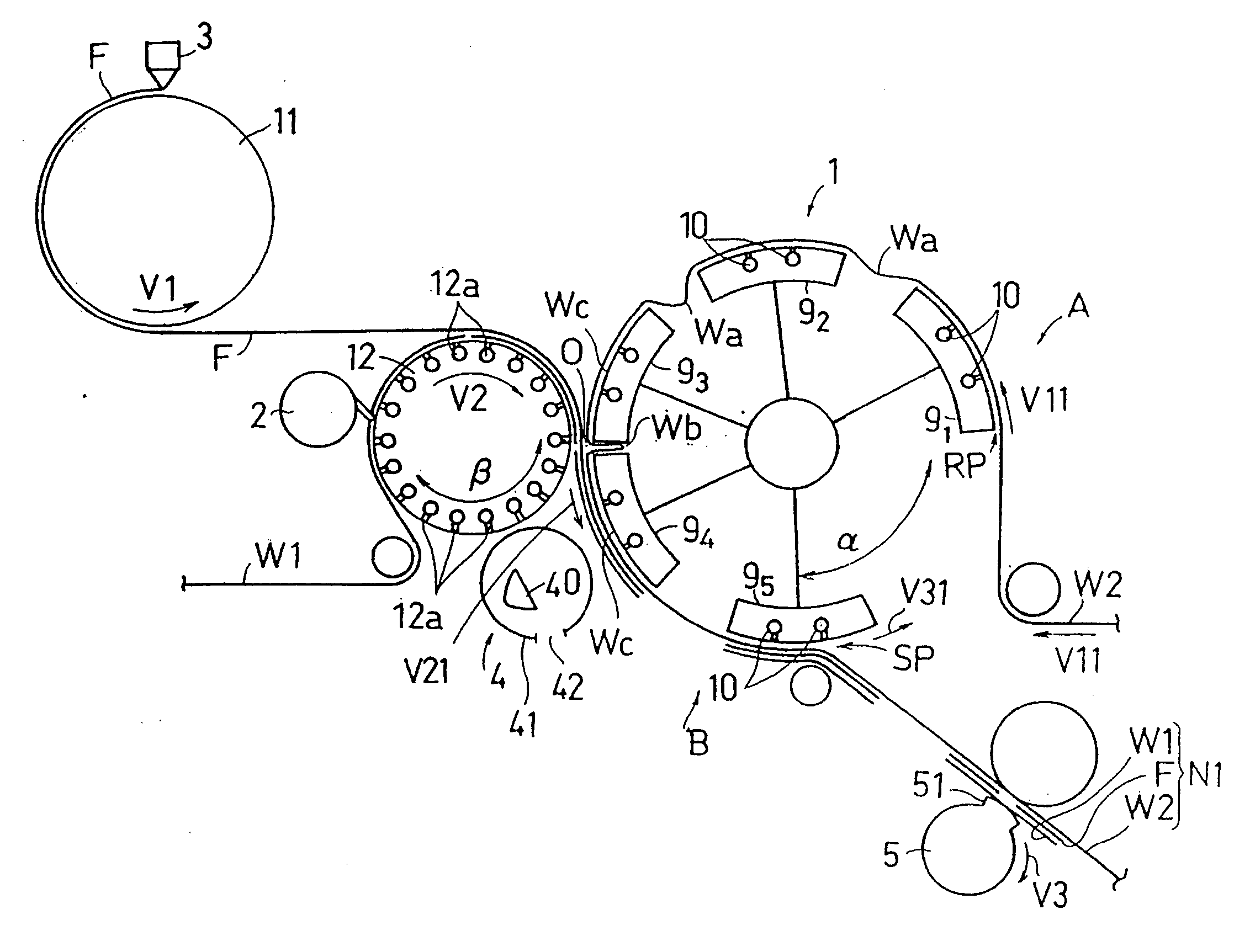

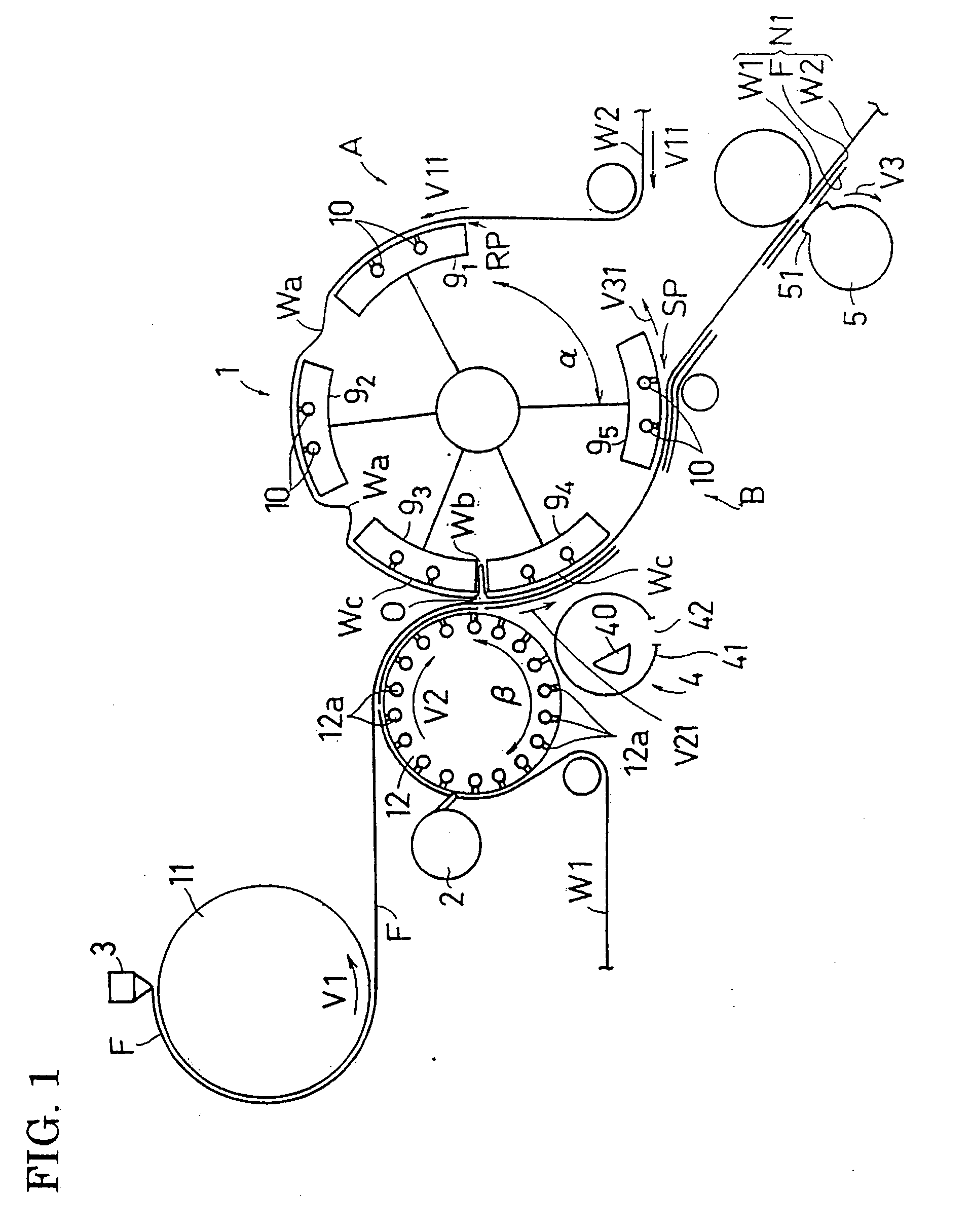

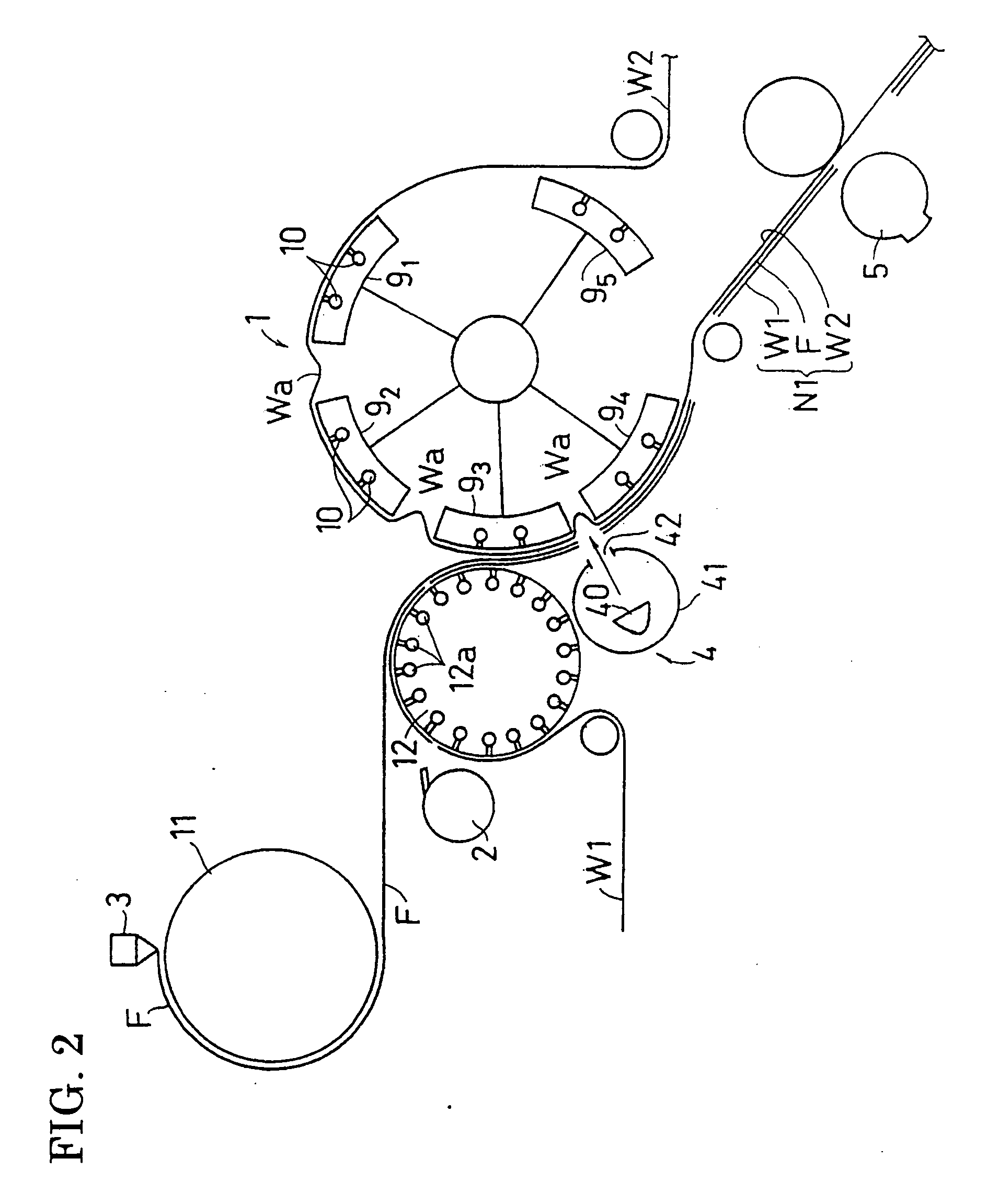

Method and apparatus for producing wearing article

InactiveUS20060032589A1Small heat capacityEasy to transportMechanical working/deformationBox making operationsMechanical engineeringEngineering

An apparatus and method for producing a wearing article of the present invention includes supplying an elastic member; stretching the elastic member; placing the stretched elastic member so that the elastic member spreads across a plurality of first webs divided in a transport direction; making a part of a second web loose in the transport direction while transporting the second web, thereby forming a loose portion; placing the first web, on which the elastic member is disposed, on non-loose portion before and after the loose portion of the second web; and cutting the elastic member between adjacent first webs of the plurality of first webs.

Owner:ZUIKO CORP

Minitype sewage integrated device and method

ActiveCN106865855AStir wellEasy to separateWater treatment parameter controlSpecific water treatment objectivesFlocculationFiltration

The invention discloses a minitype sewage integrated device which comprises a device body, wherein the device body is sequentially provided with a stirring cavity, a separation cavity and a disinfection cavity; a stirring device and a flocculation device are arranged in the stirring cavity; a cleaning device, a filter unit and a sewage accumulation device are arranged in the separation cavity; and a sterilizing device is arranged in the disinfection cavity. The sewage treatment method comprises the following steps: (1) sewage primary filtration; (2) sewage stirring treatment; (3) sewage separation treatment; (4) sewage disinfection treatment; (5) water quality detection; and (6) periodical maintenance. The minitype sewage integrated device has the advantages of simple structure, high practicality, small size and low cost, and is convenient for actual operation and use. After the sewage is sequentially treated by the stirring cavity, separation cavity and disinfection cavity, the treated water has high quality and is clearer.

Owner:ZHEJIANG SHUANGLIN PLASTIC MACHINERY

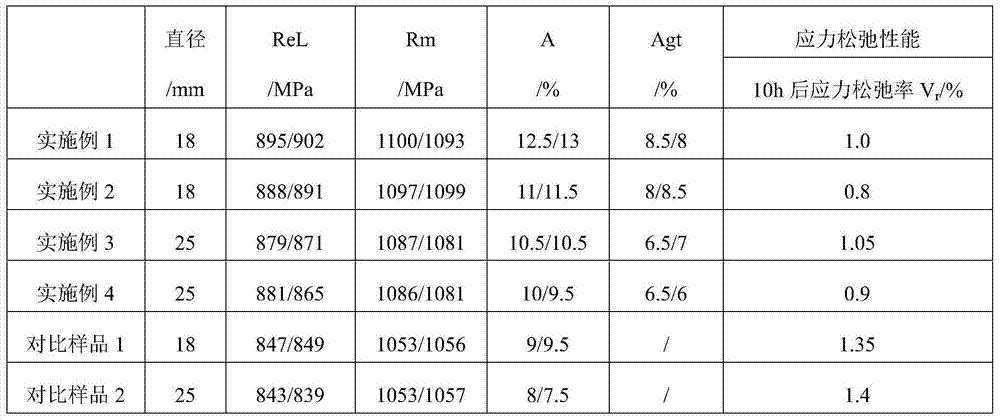

Small-scale finish-rolled twisted steel and production method thereof

ActiveCN104328338AImprove distributionEvenly distributedManufacturing convertersChemical compositionRebar

The invention provides small-scale finish-rolled twisted steel and a production method thereof. The small-scale finish-rolled twisted steel comprises the following chemical components in percentage by mass: 0.40-0.50% of C, 1.5-1.8% of Si, 0.8-1.0% of Mn, less than or equal to 0.035% of P, less than or equal to 0.035% of S, 0.08-0.13% of V, 0.008-0.01% of Als and the balance of Fe and inevitable impurities. The production method comprises the following steps: desulfurizing molten iron, smelting in a converter, blowing argon, performing protective casting into a square blank of 200*200mm<2>, heating the square blank, rolling, performing controlled cooling after rolling, and performing air-cooling in a cooling bed. The finish-rolled twisted steel provided by the invention is stable in property, and the production method is simple and easy to operate.

Owner:武汉钢铁有限公司

Thermocouple vacuum gauge

InactiveUS20100034236A1Reduce heatLow thermal conductivityThermometer detailsVacuum gauge using heat conductivity variationEngineeringThermocouple device

A thermocouple vacuum sensor is provided, the thermocouple being surrounded by a gas or mixture of gases the pressure of which is to be measured. Cyclically the thermocouple is heated until its temperature reaches an upper temperature threshold. The thermocouple is subsequently cooled until its temperature reaches a lower temperature threshold. The heating time required to heat the thermocouple from the lower to the upper temperature threshold is measured. The cooling time required to cool the thermocouple from the upper temperature threshold to the lower temperature threshold may also be measured. The pressure surrounding the thermocouple may then be determined as a function of either the heating time, or the cooling time, or both.

Owner:HEINZ PLOECHINGER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com