Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2402 results about "Draining tube" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

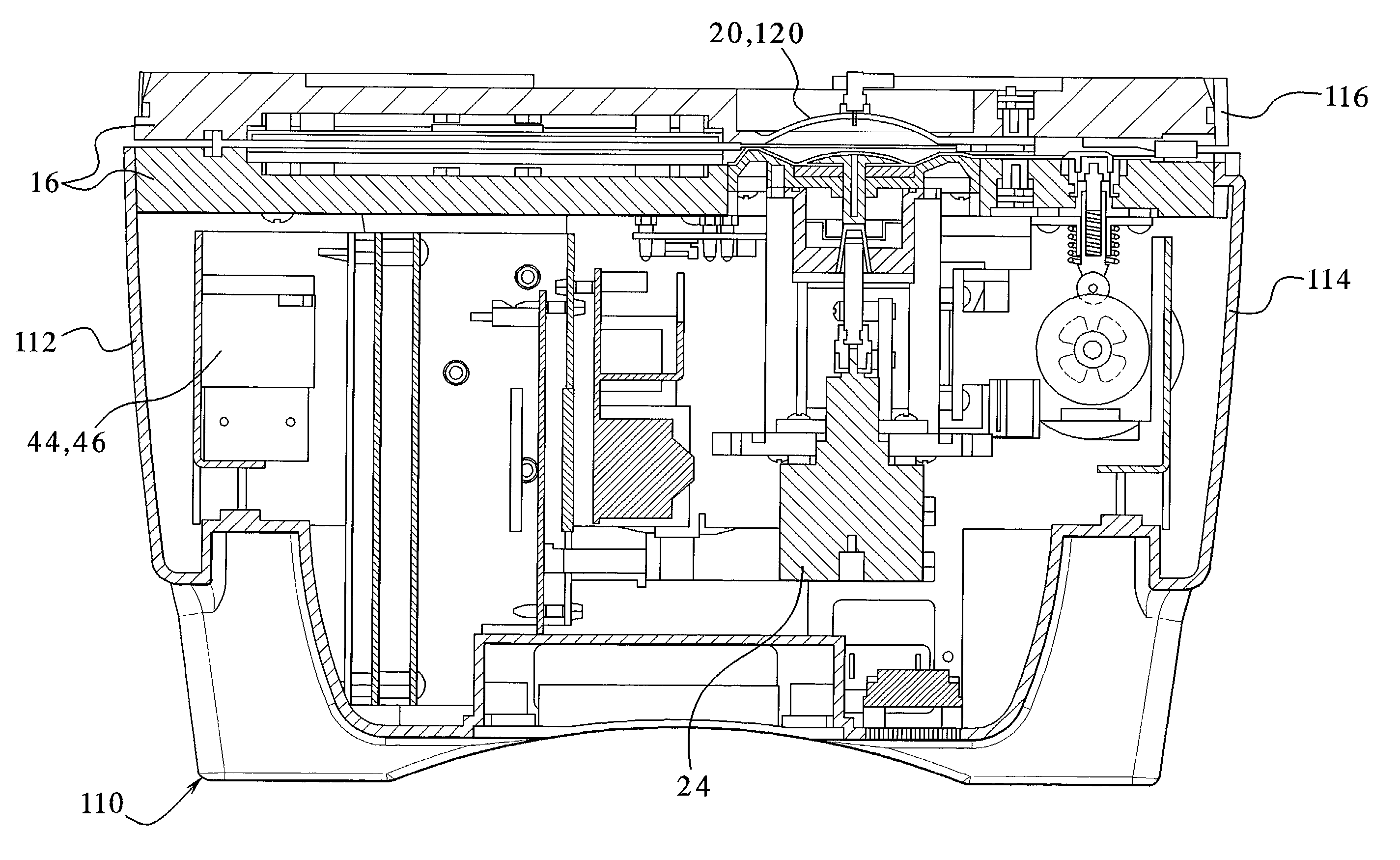

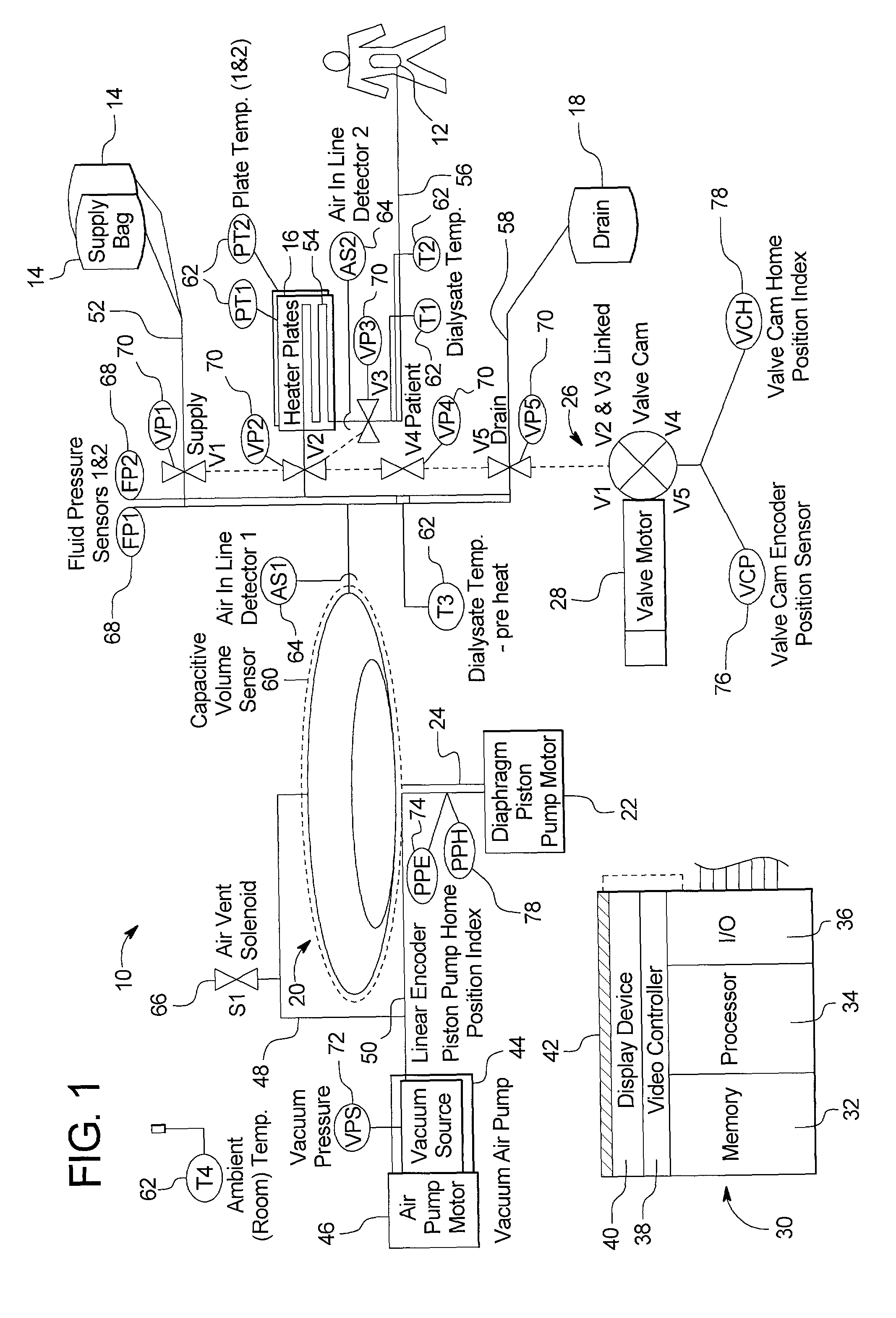

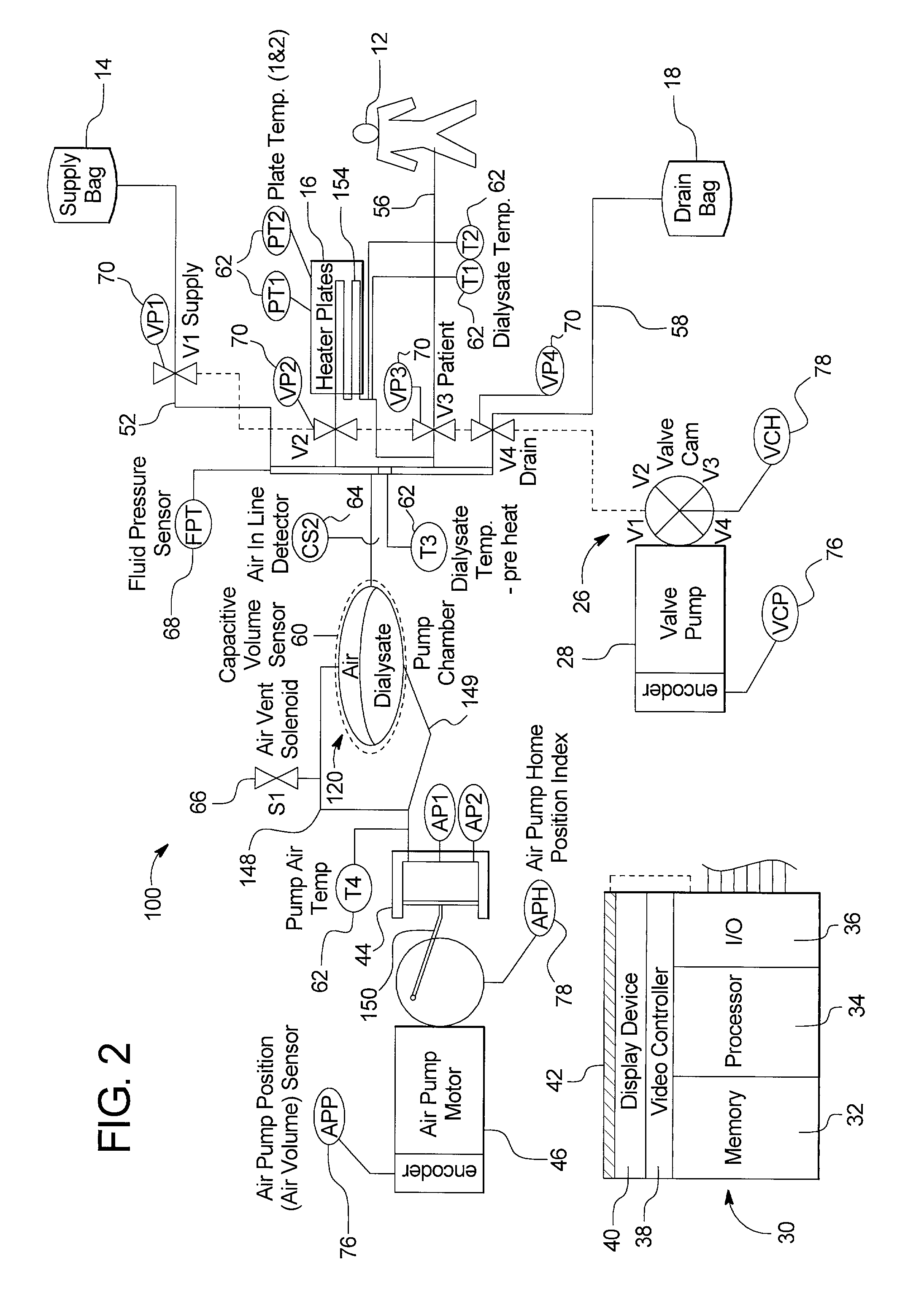

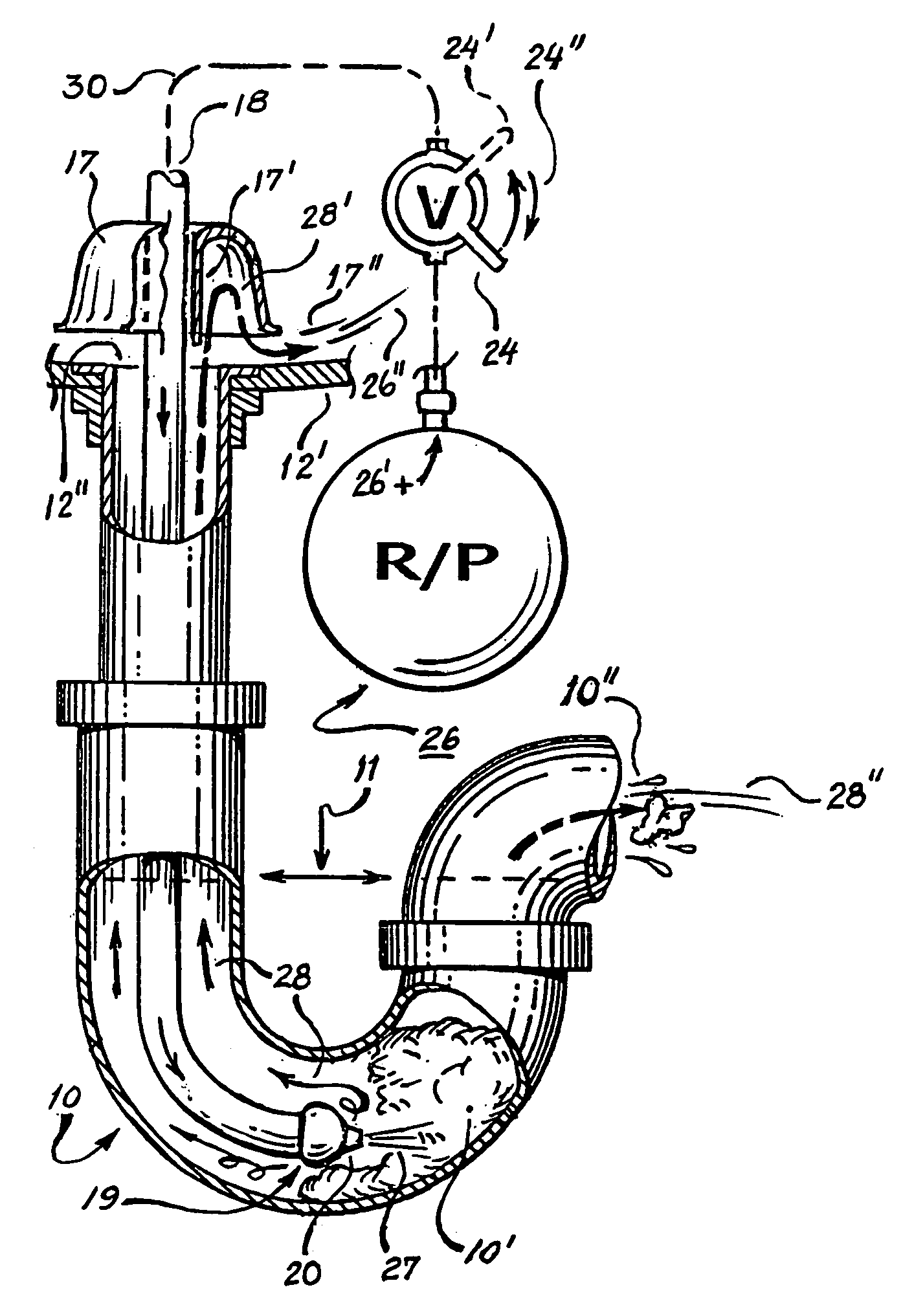

Automated dialysis system

ActiveUS7153286B2Improved system and methodQuality of lifeSemi-permeable membranesSolvent extractionAutomated peritoneal dialysisPeritoneal membrane

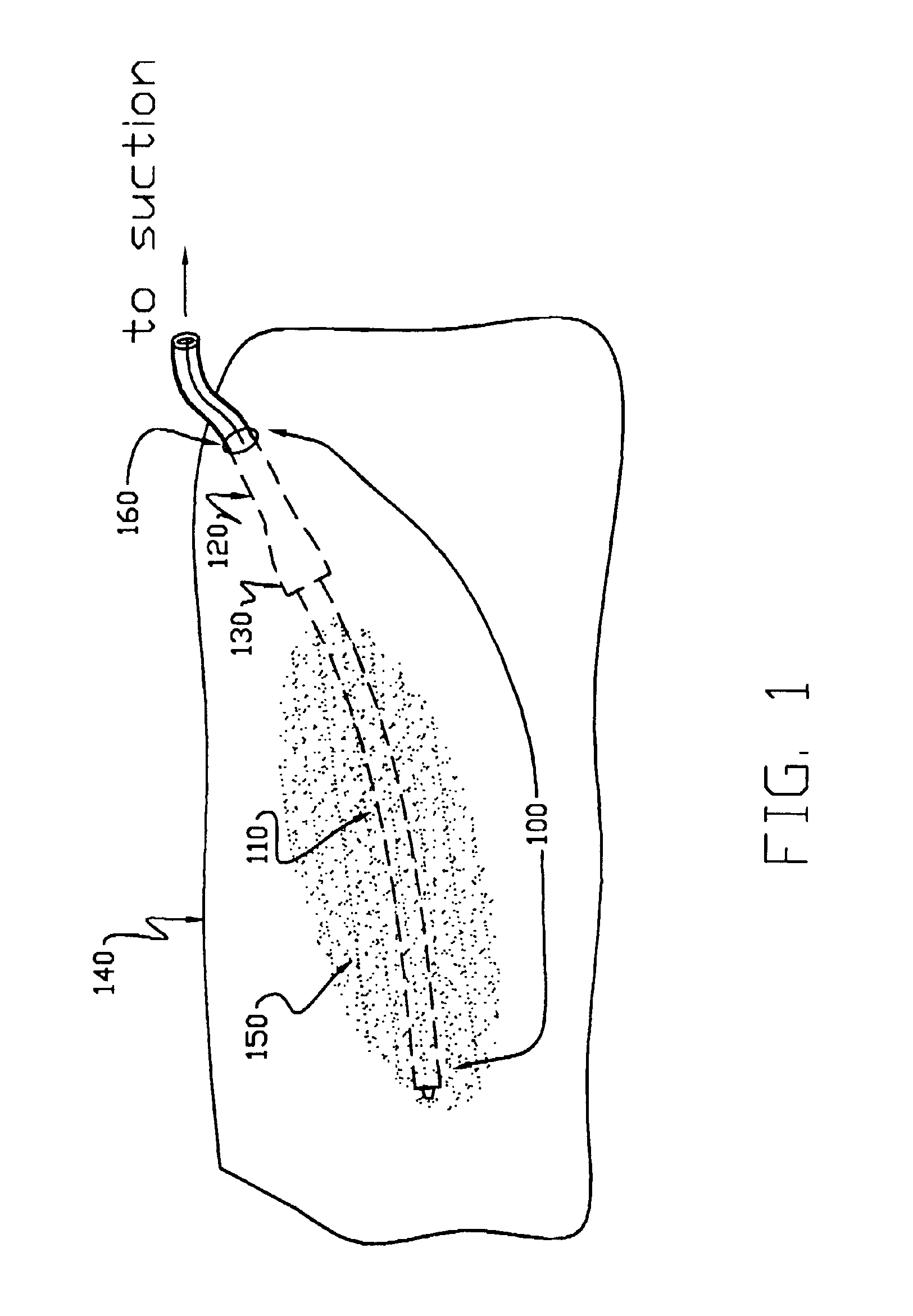

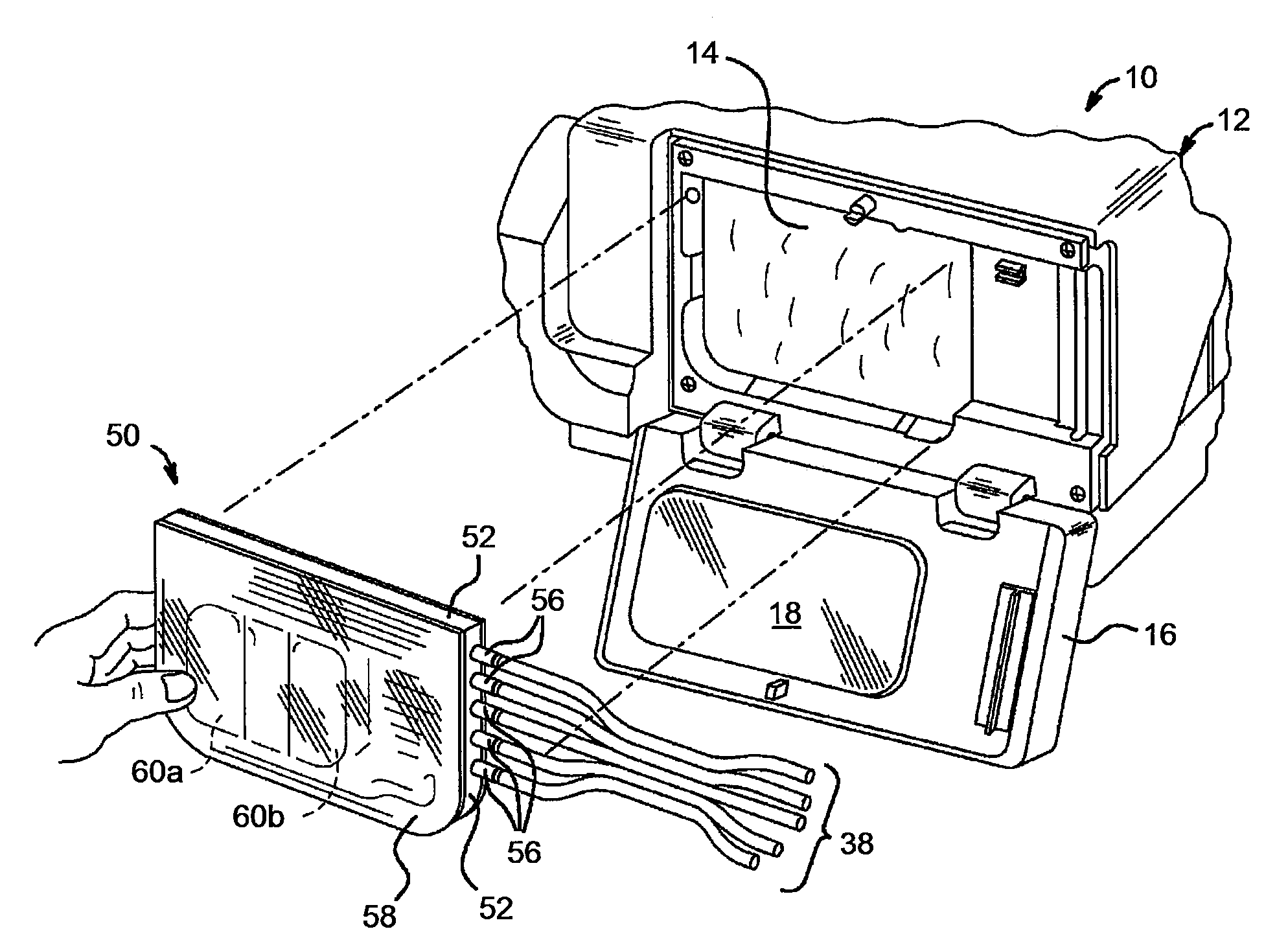

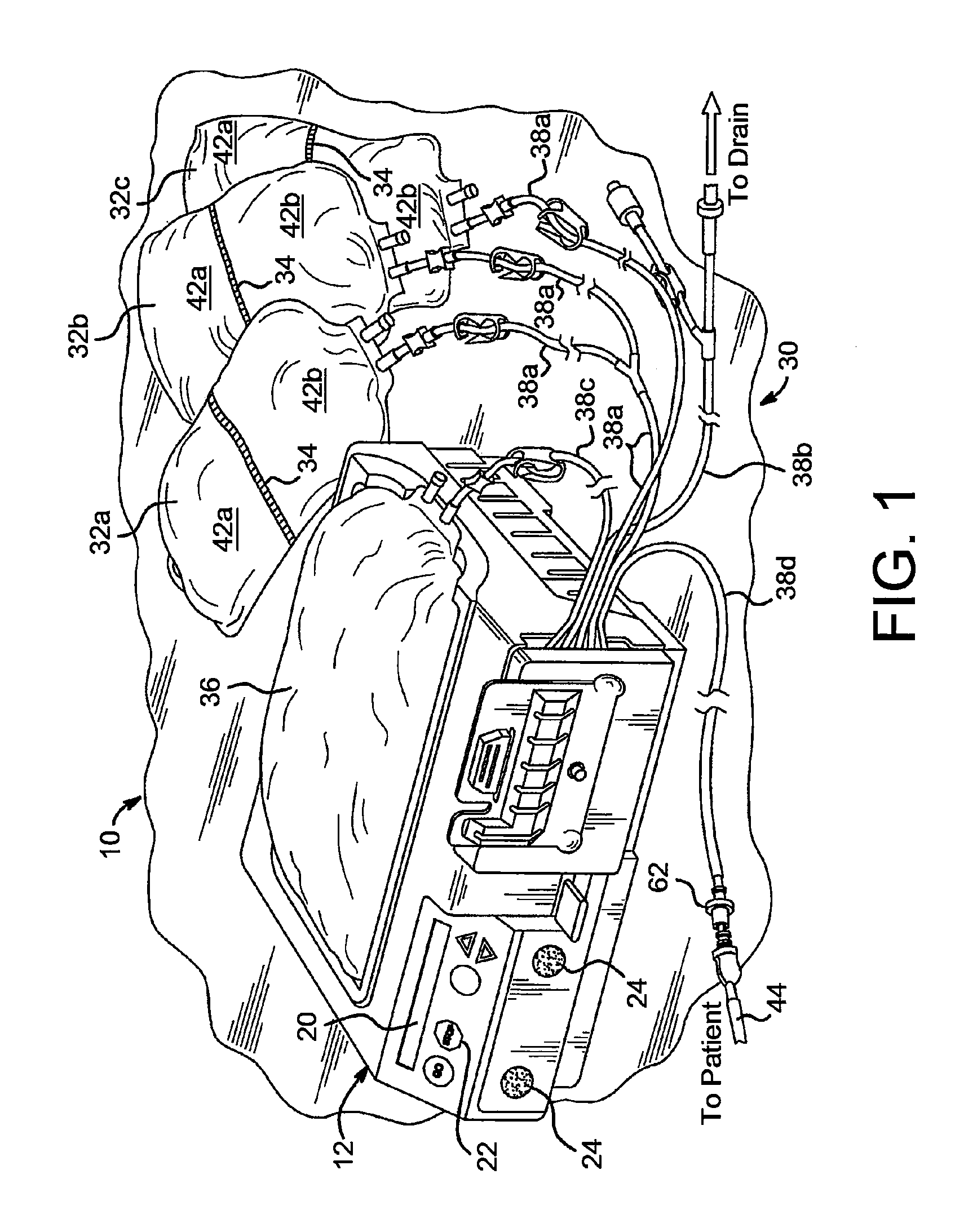

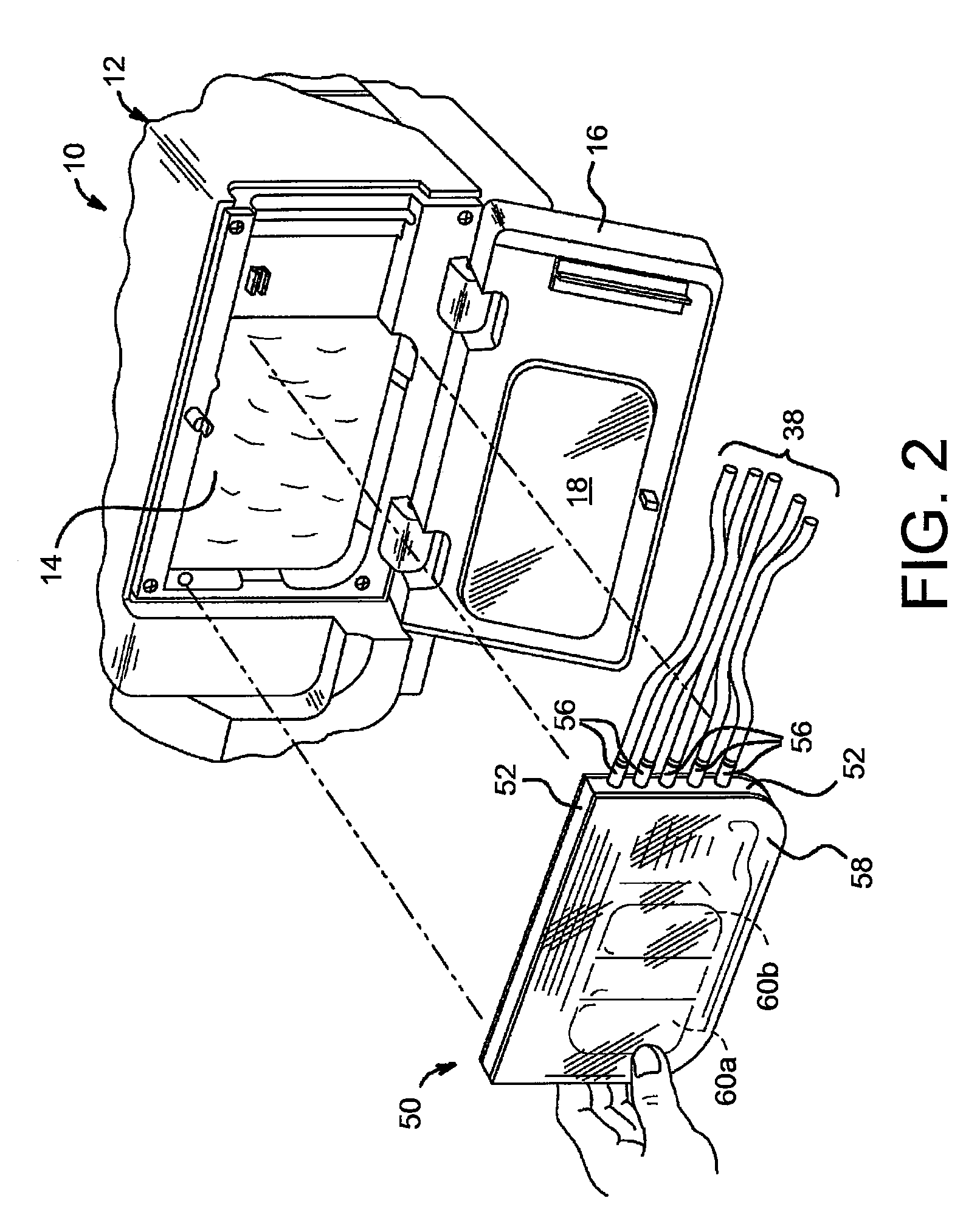

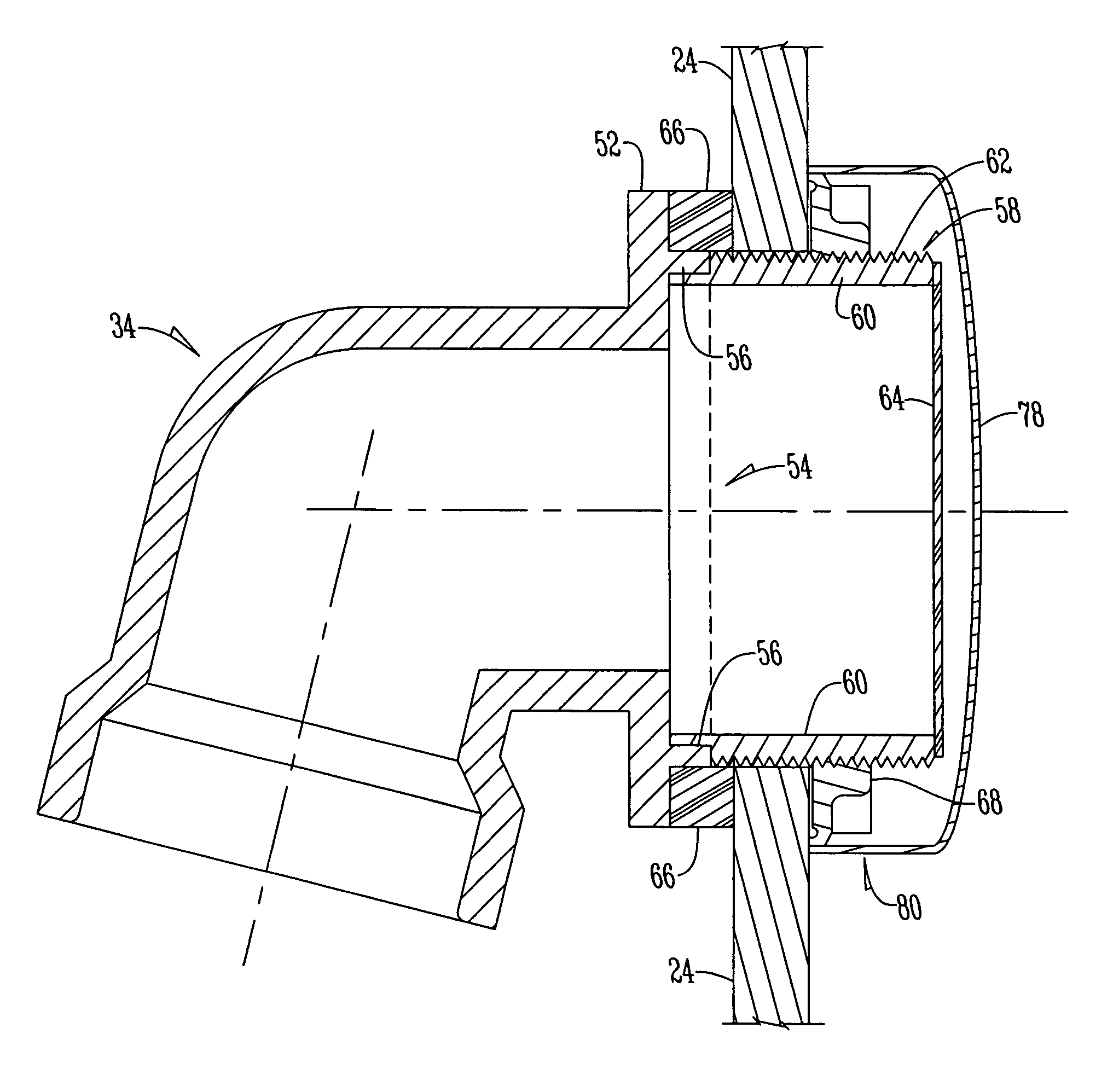

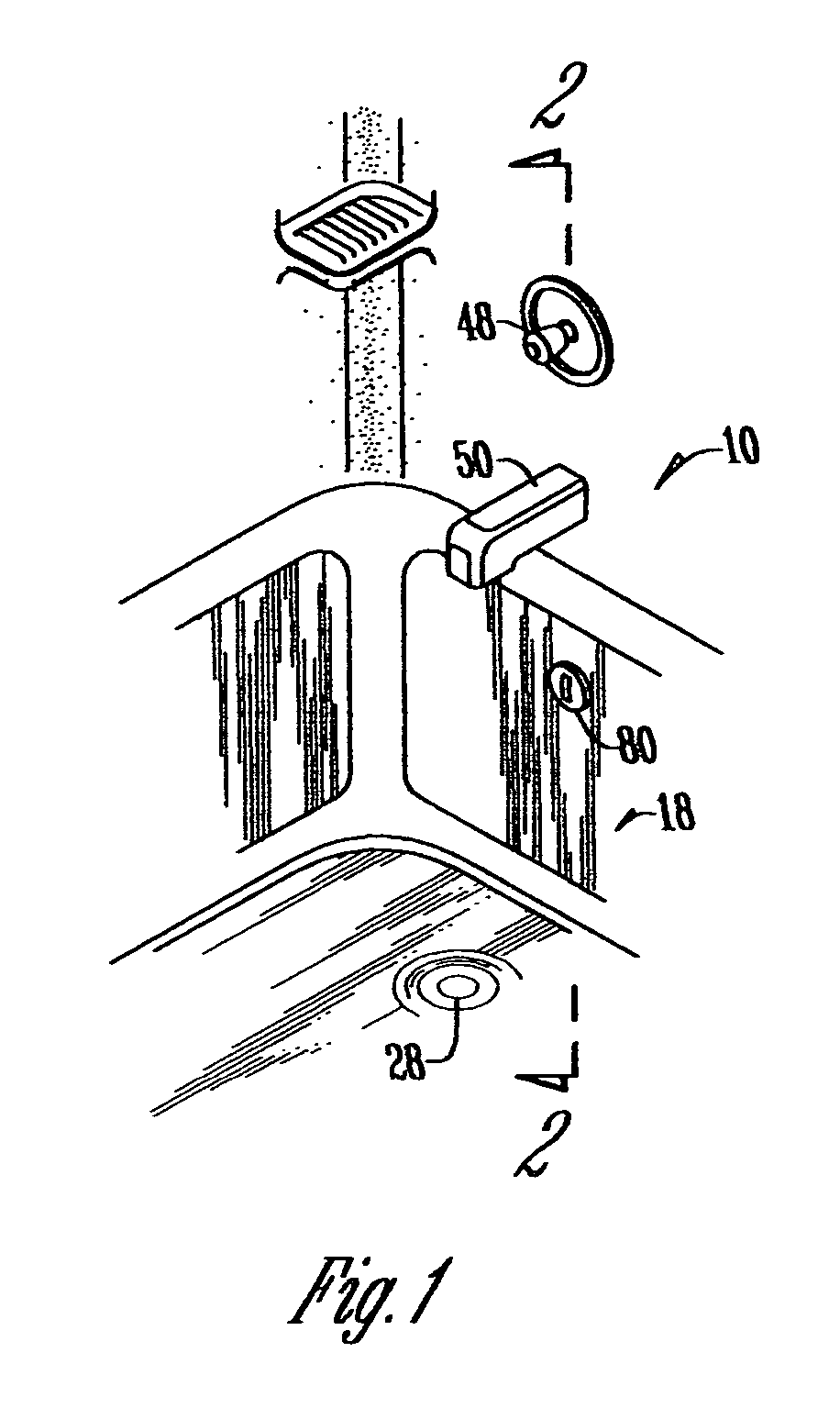

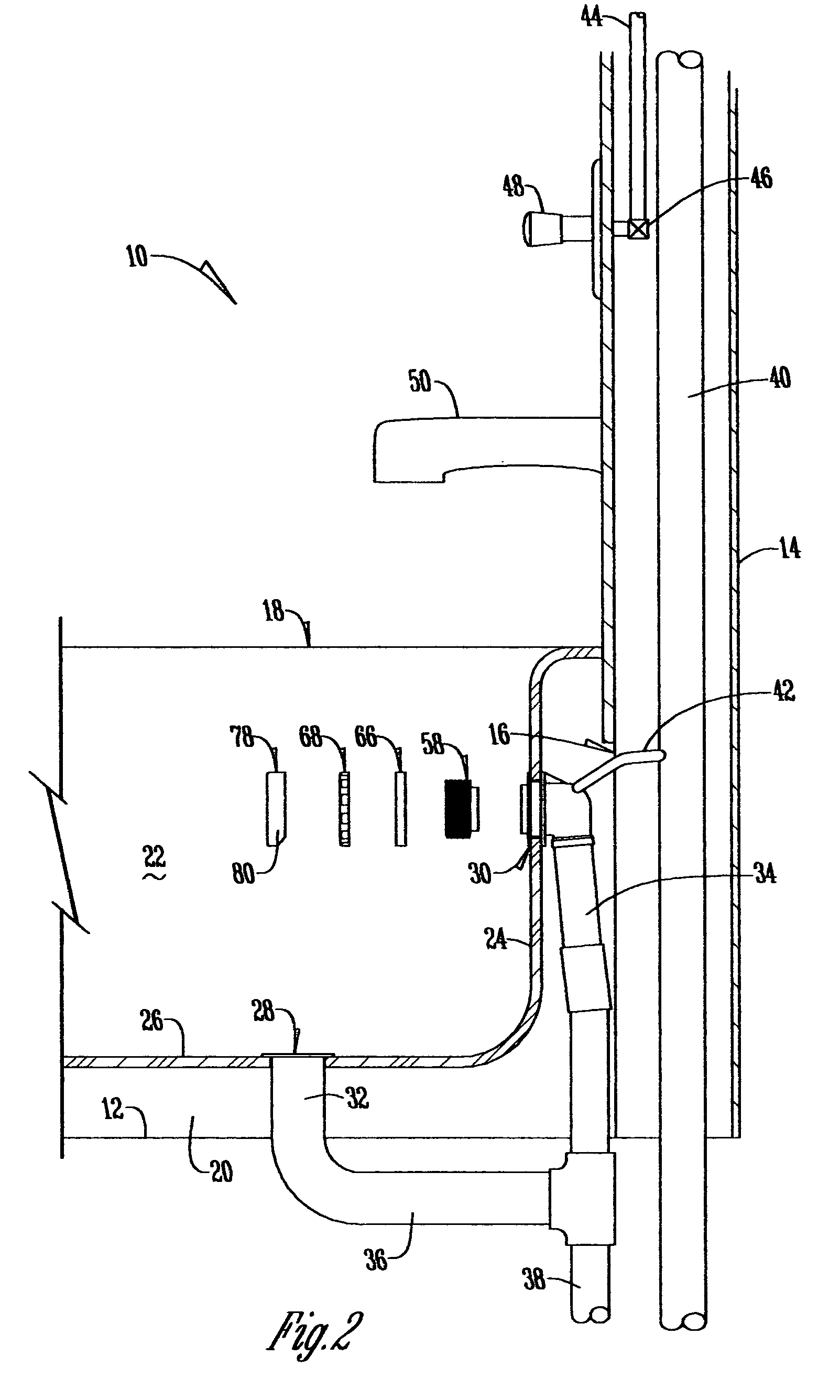

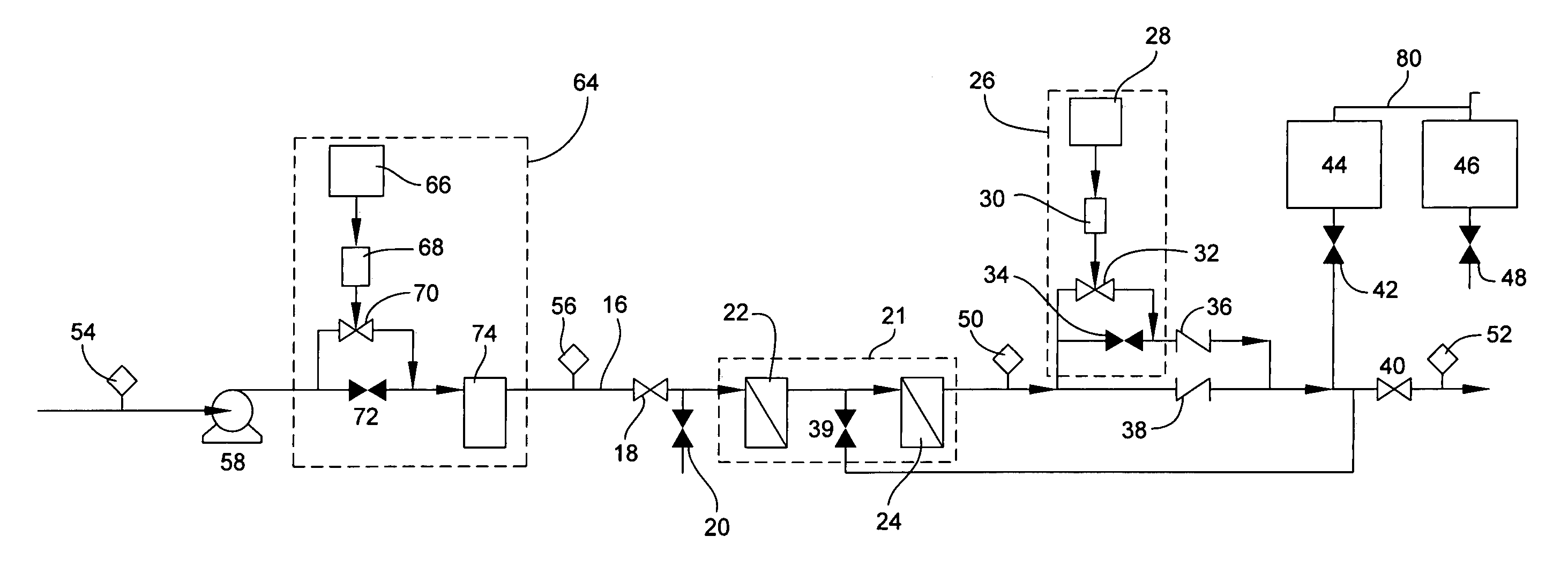

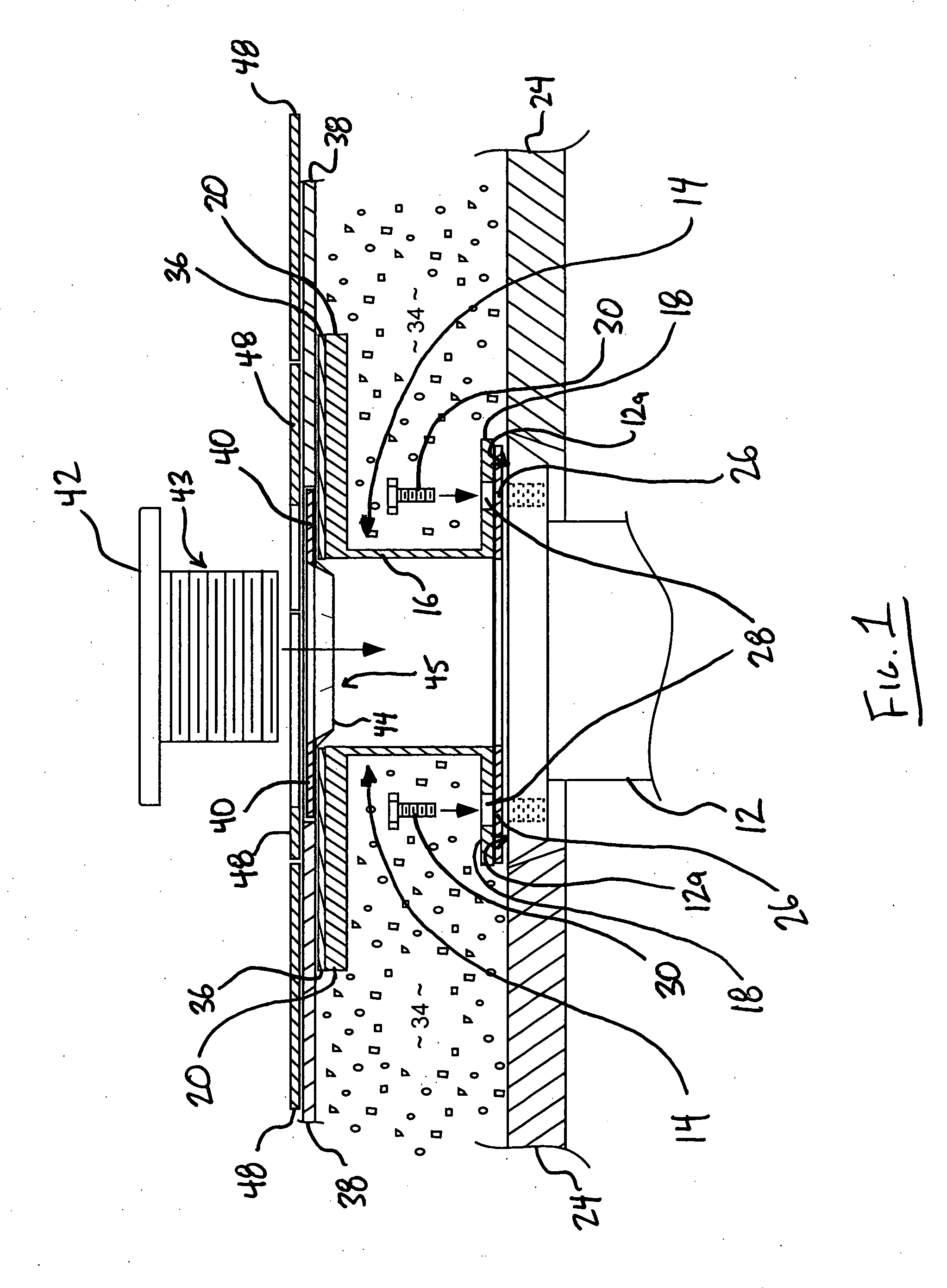

The present invention provides automated peritoneal dialysis systems, methods of operating the systems and devices for performing same. A typical therapy performed by the present invention begins by draining dialysis solution that is already in the patient's peritoneal cavity. The system pumps fresh dialysate from one of a plurality of supply bags, through an in-line heater to the patient's peritoneal cavity. After a dwell period, the spent dialysate in the cavity is pumped out of the patient to a drain or other disposal means. The system then pumps fresh dialysate from the supply bags to the patient and the procedure is repeated as defined in the therapy protocol. The system can pump a last bag of dialysate to the peritoneal cavity for an extended dwell, such as a daytime dwell.

Owner:BAXTER INT INC +1

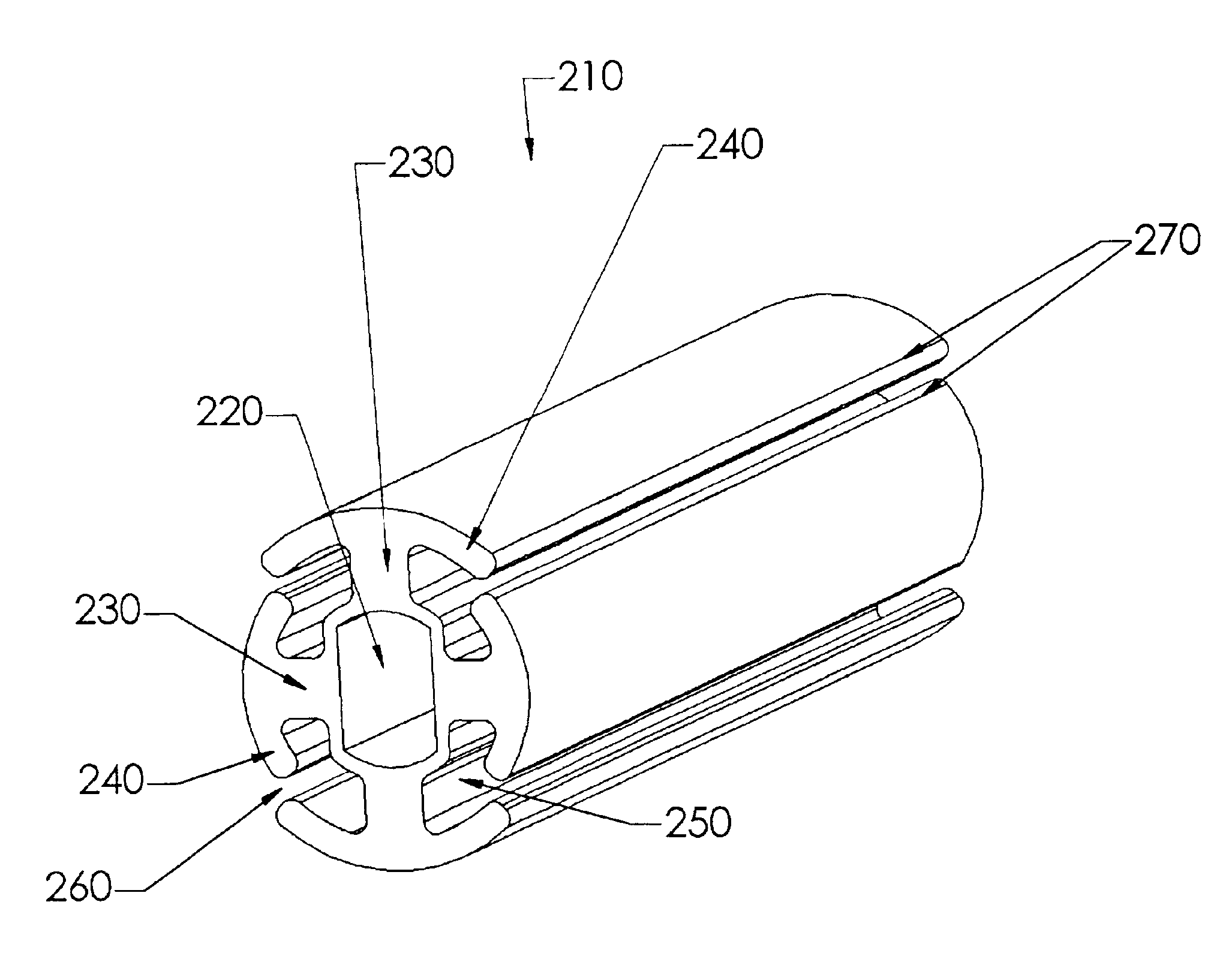

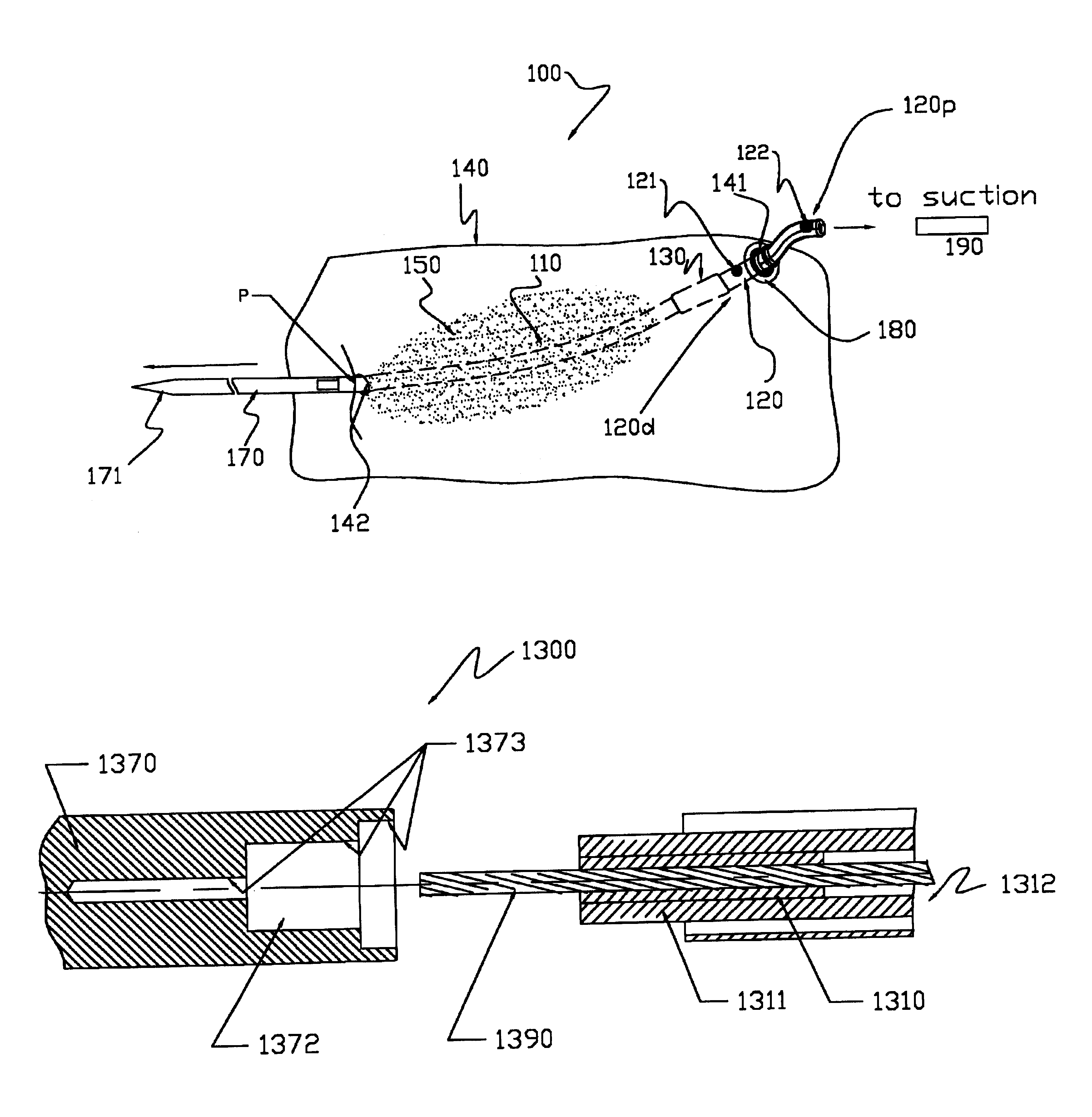

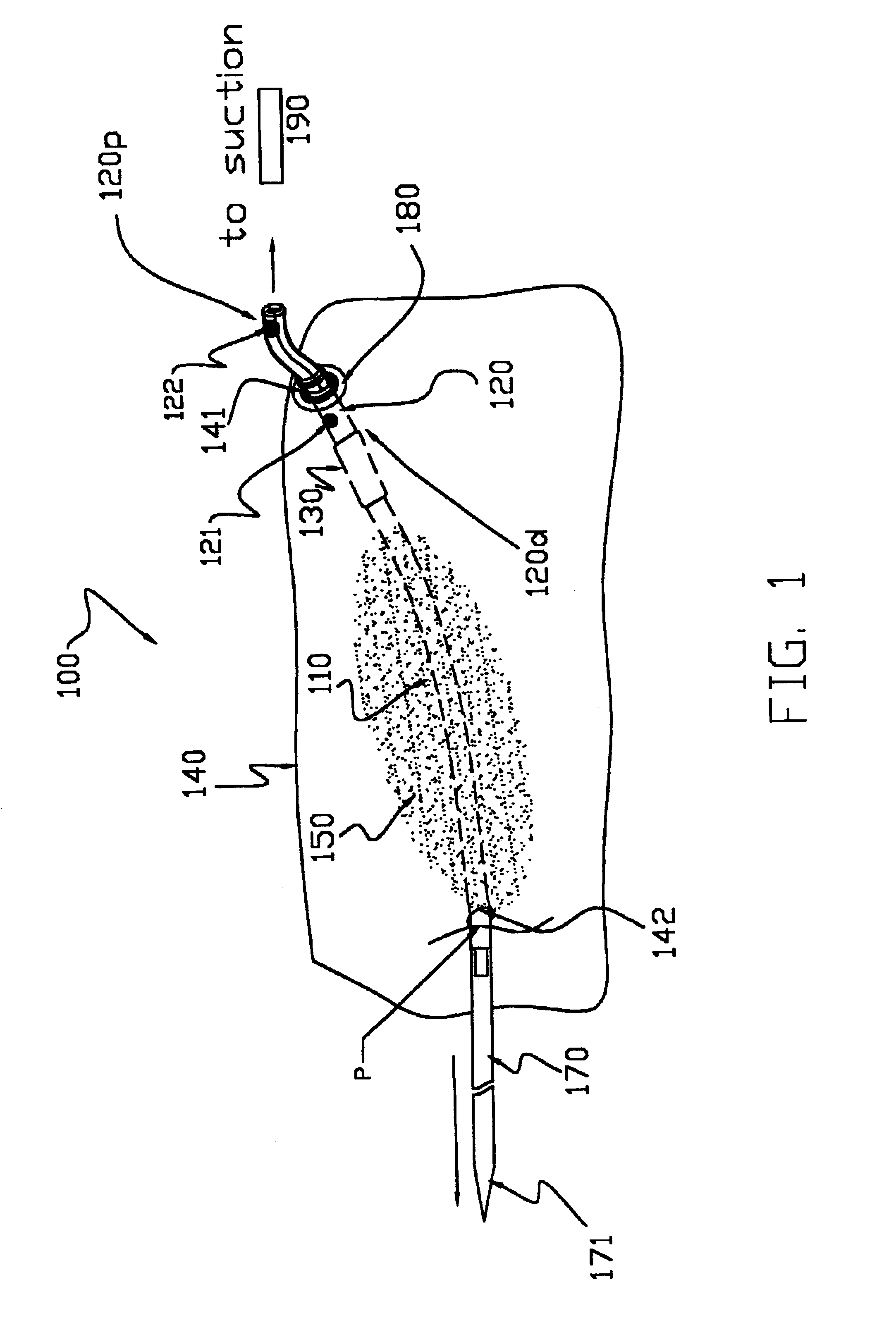

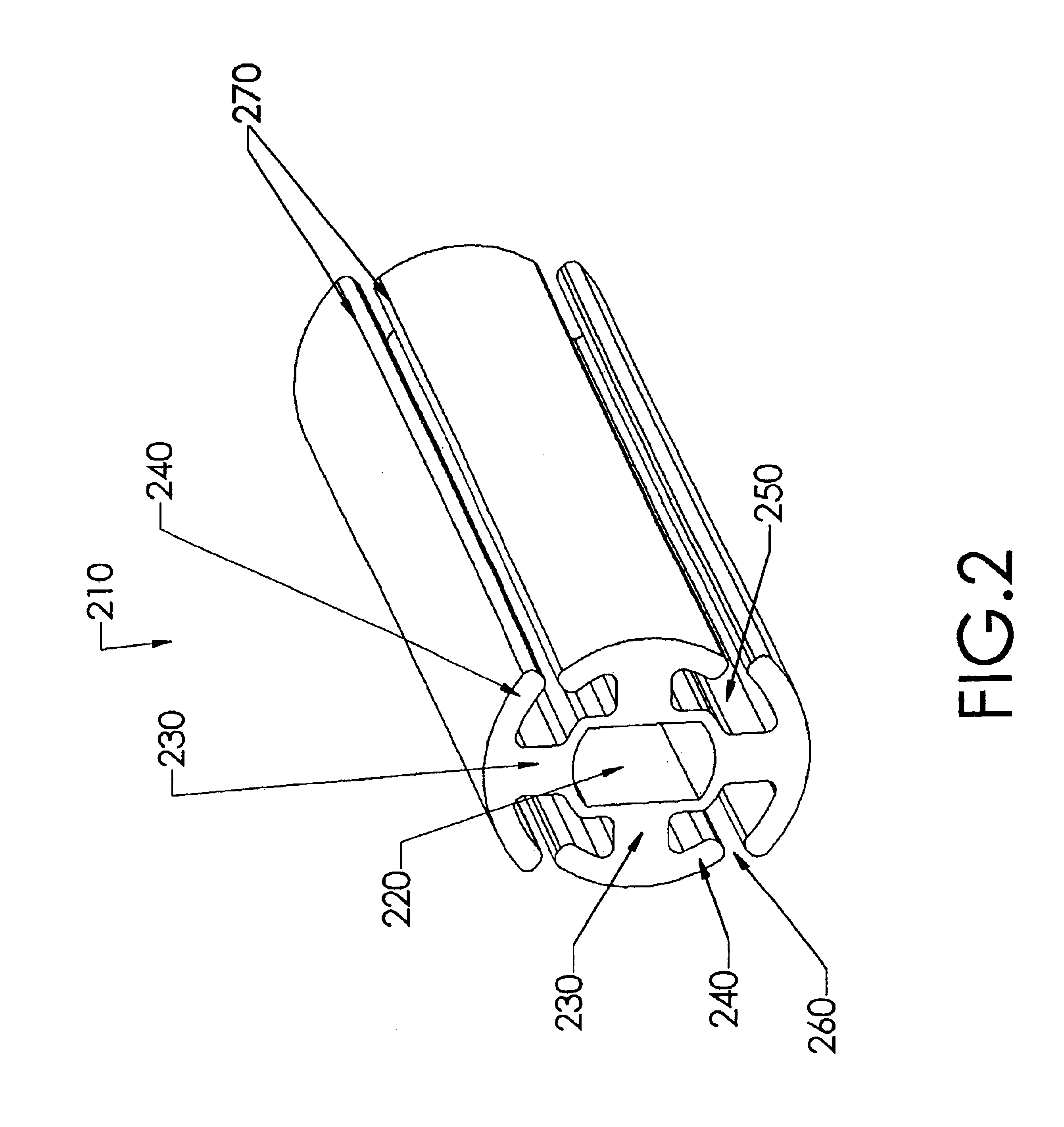

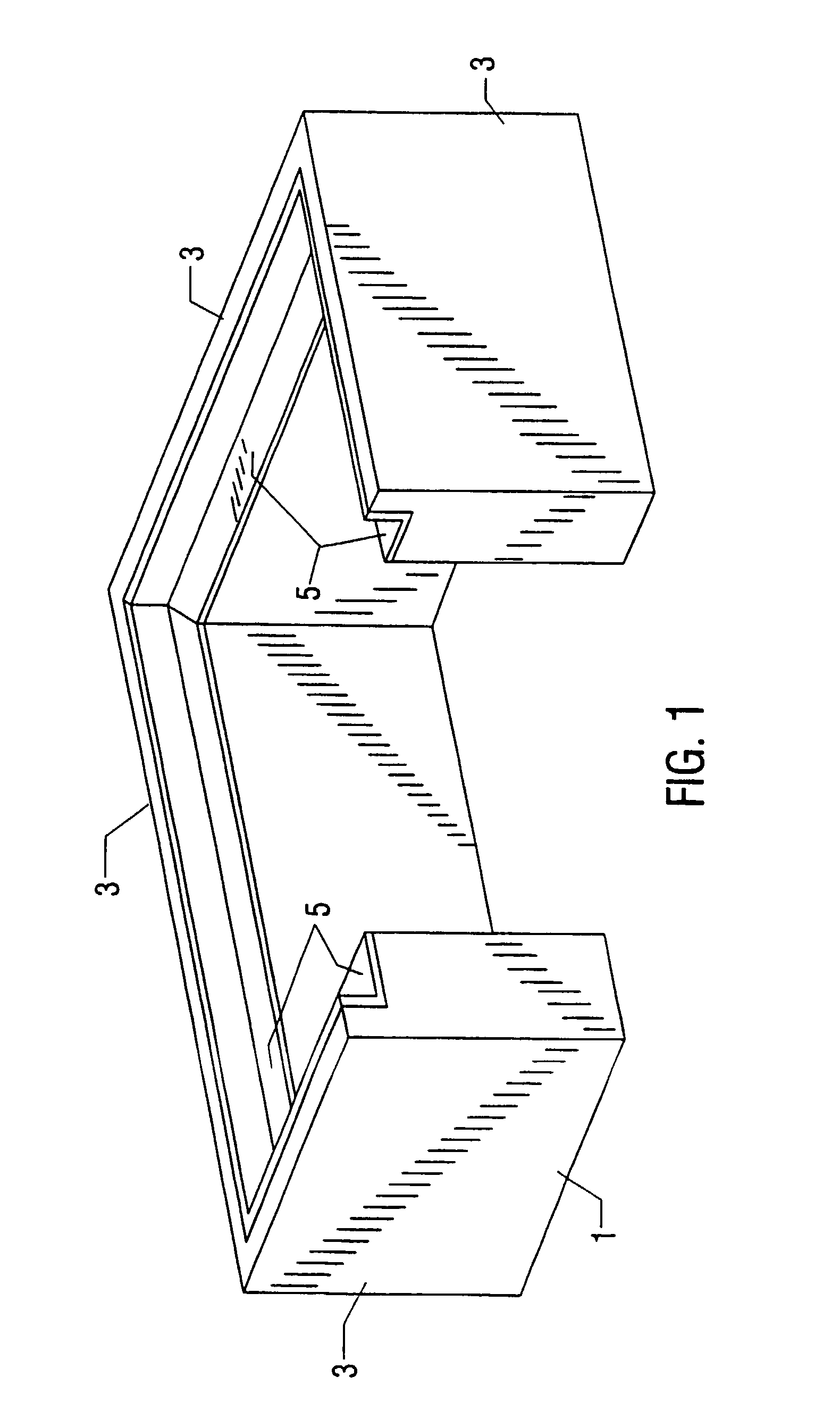

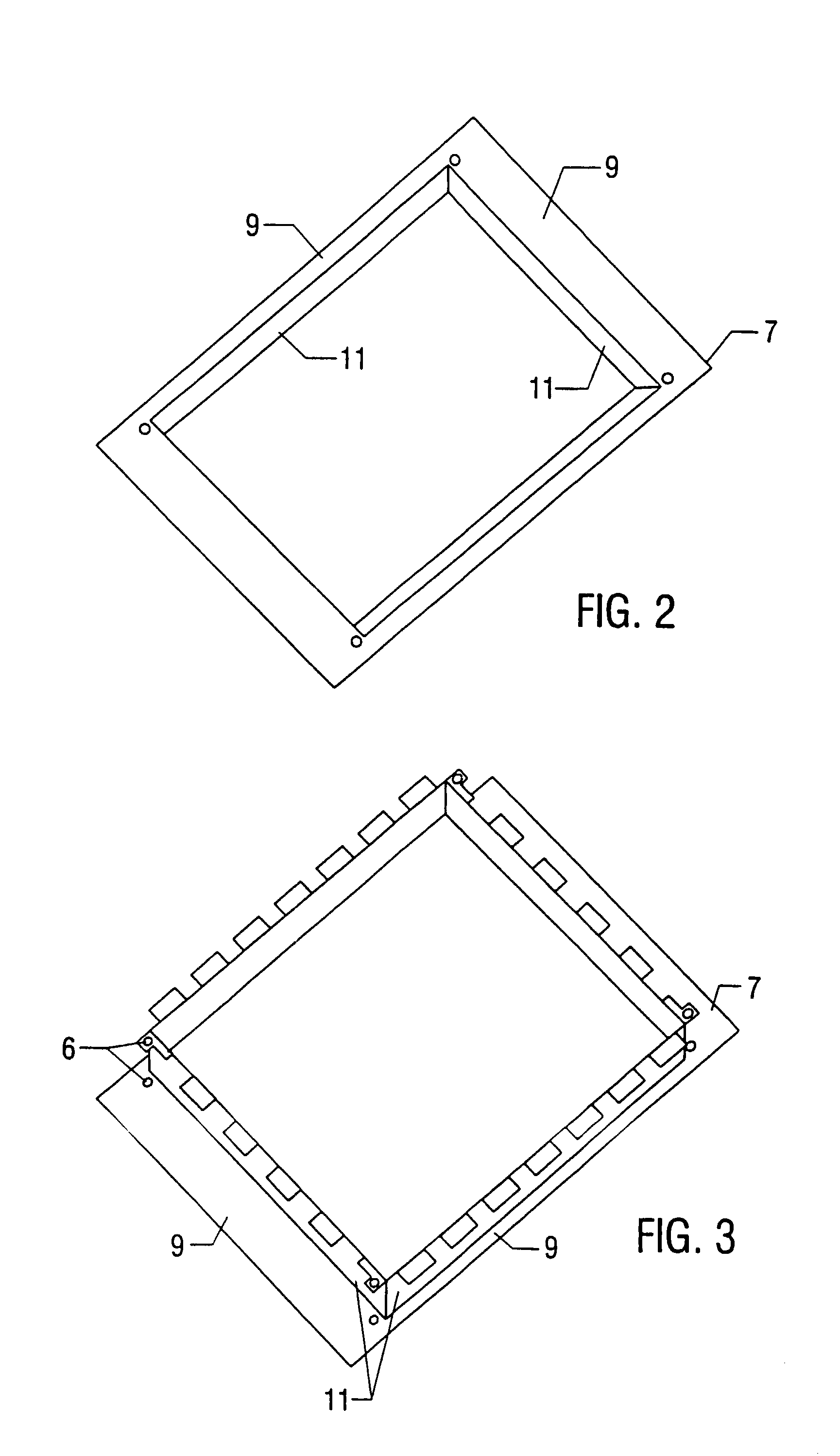

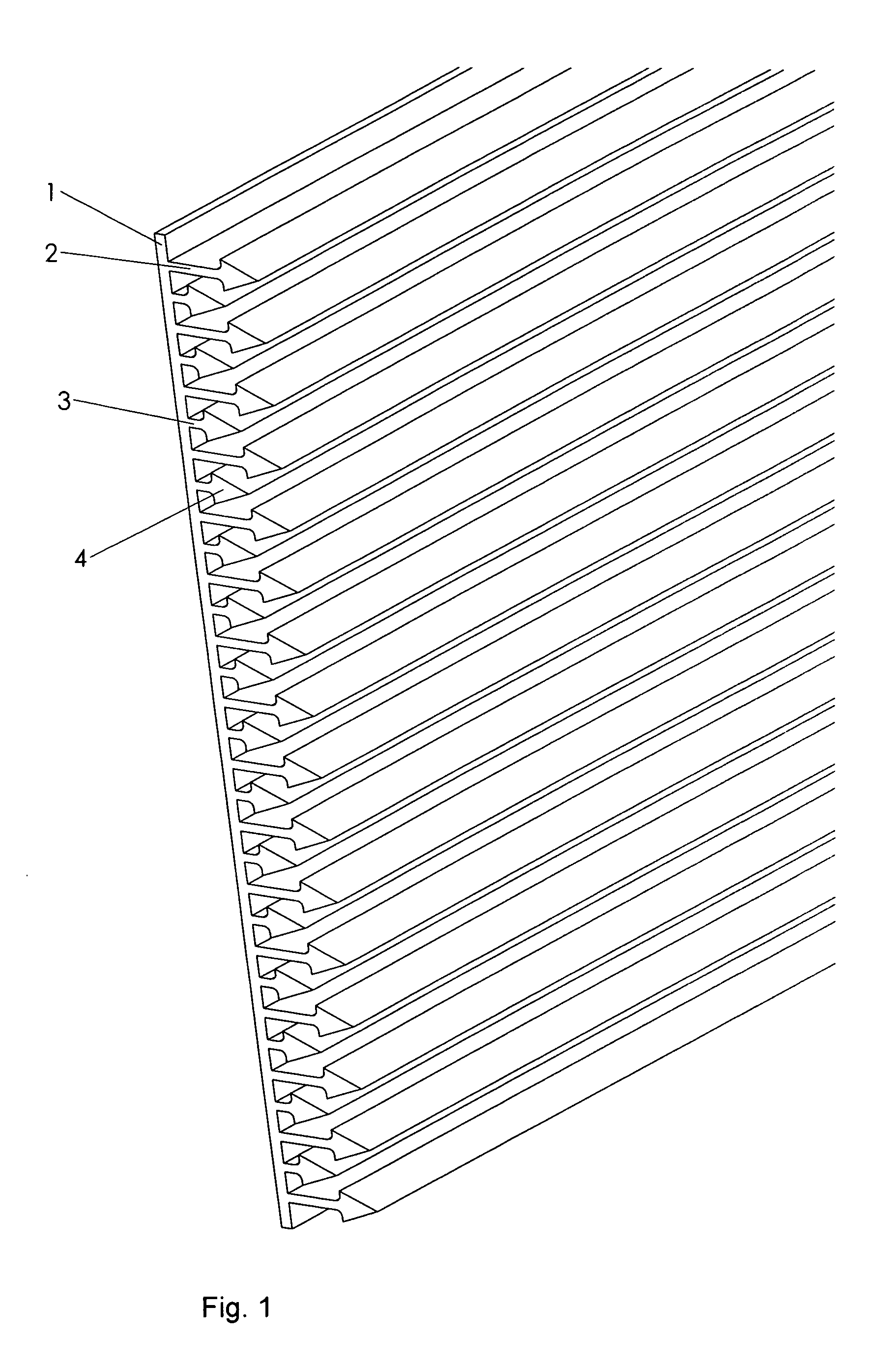

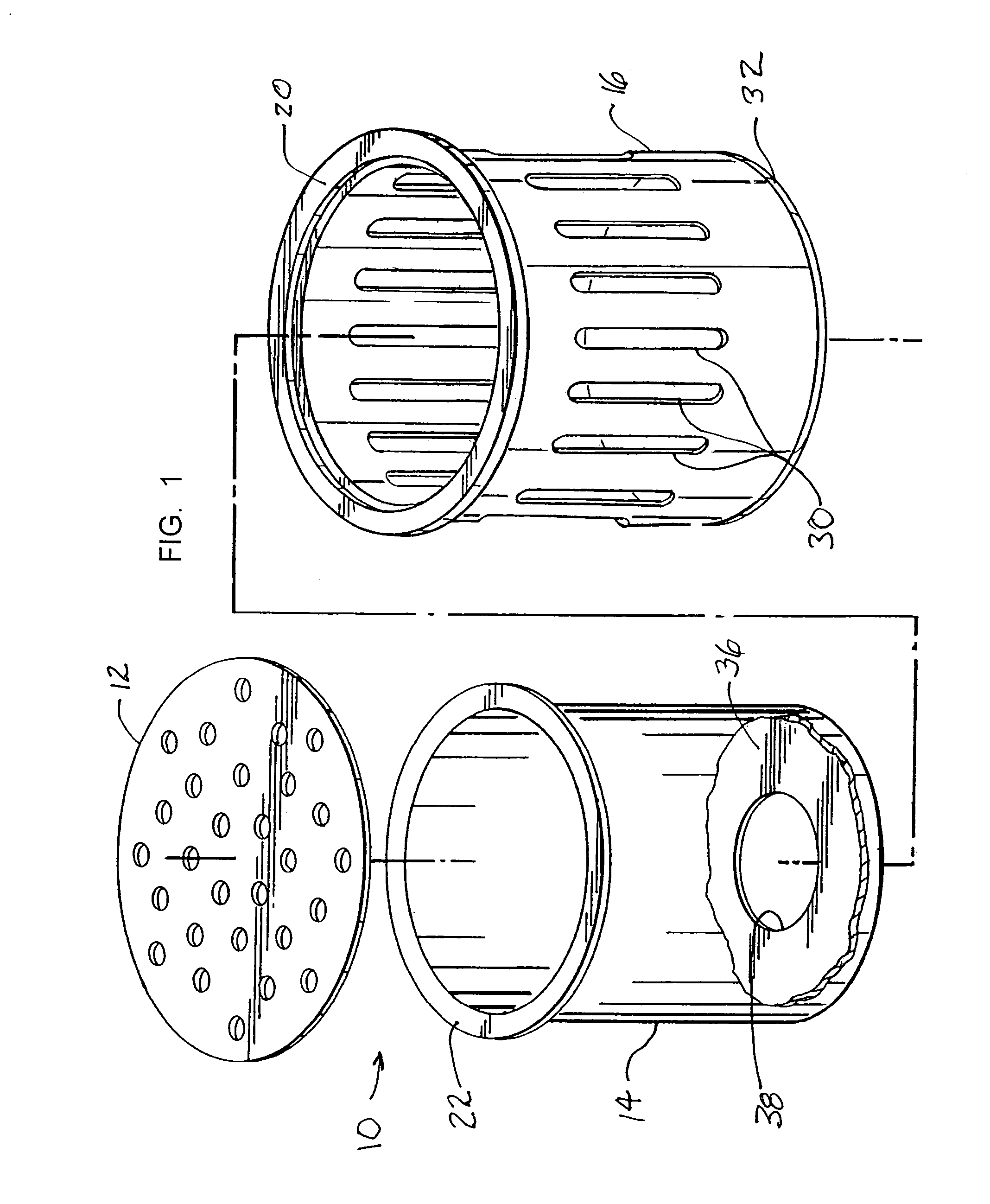

Drain catheters

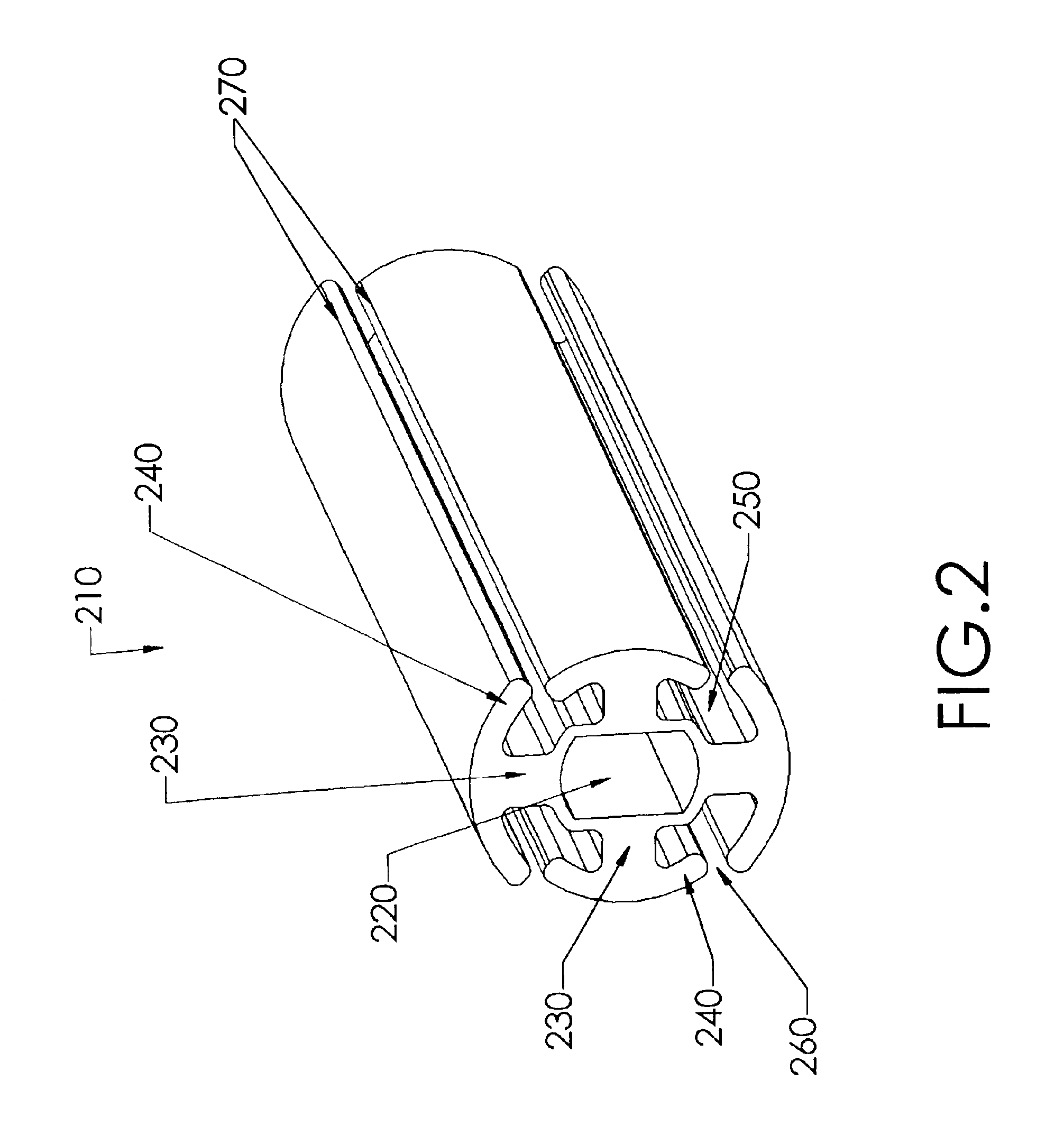

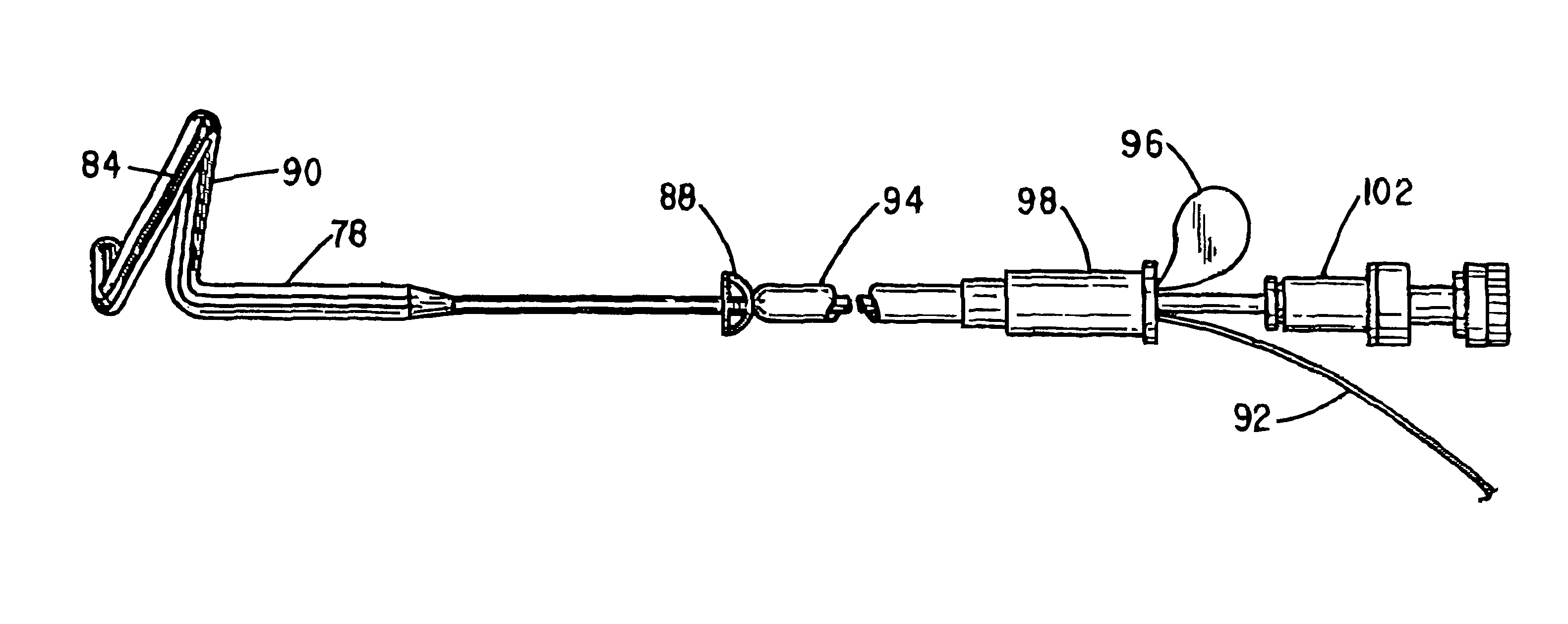

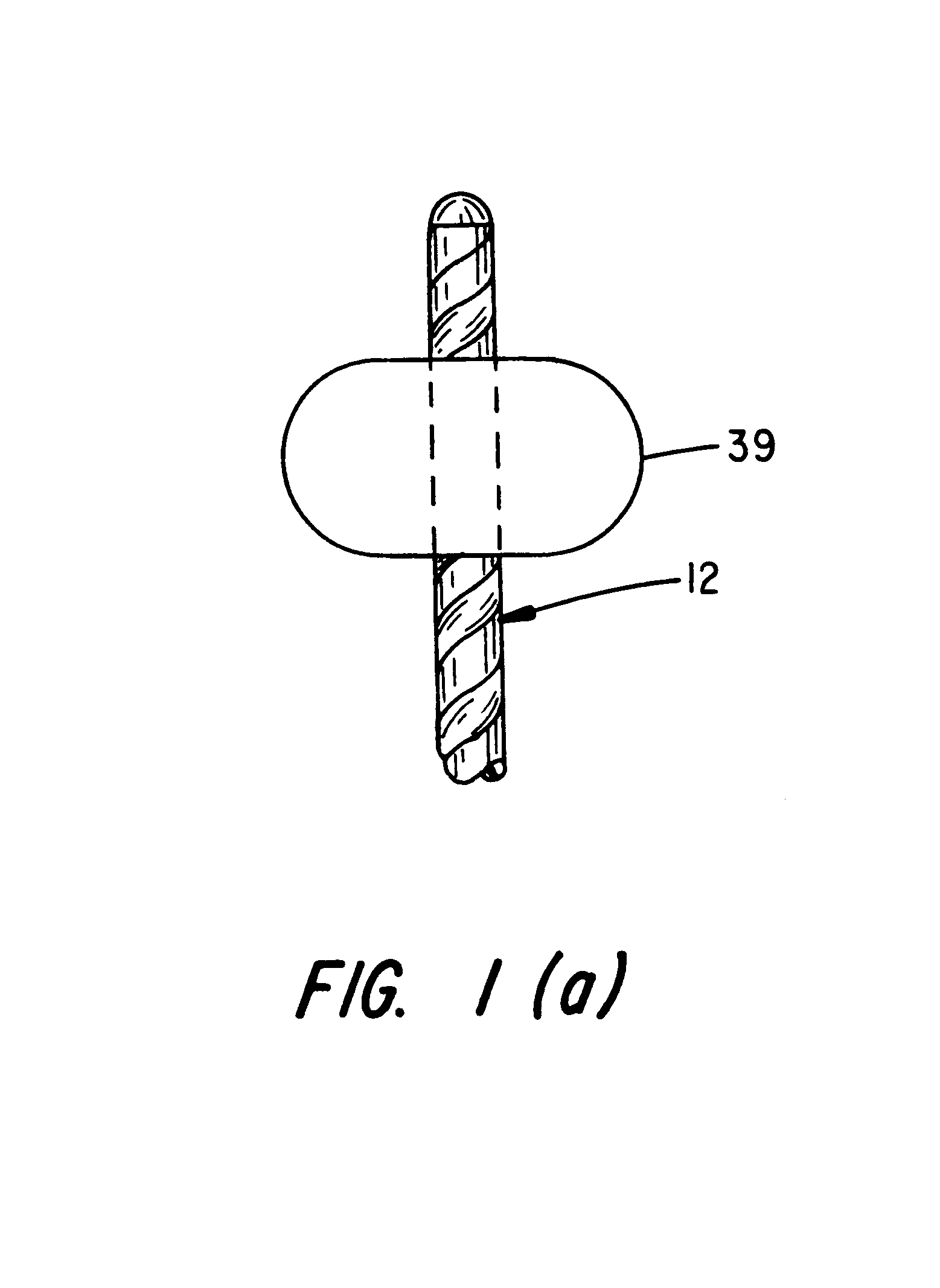

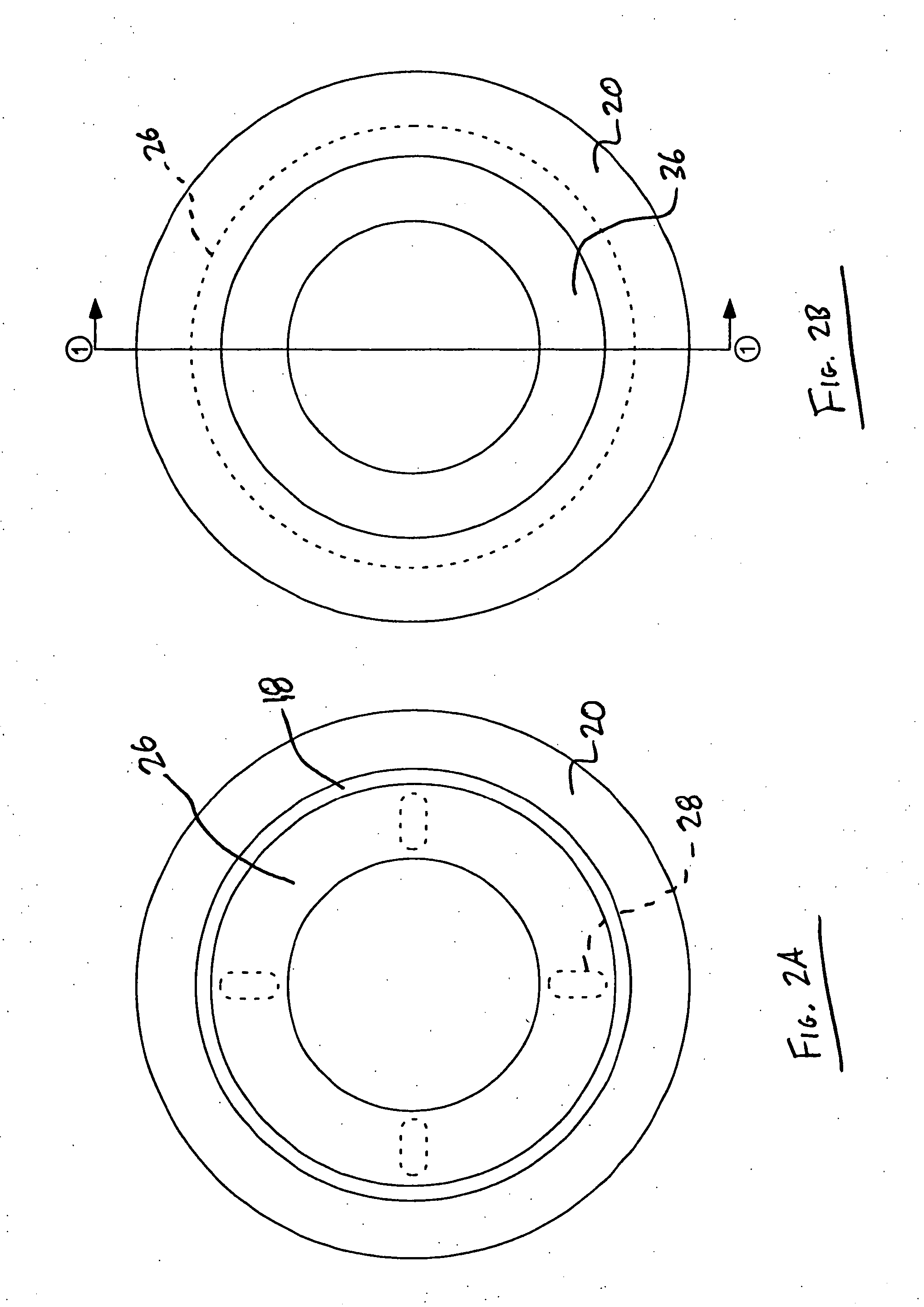

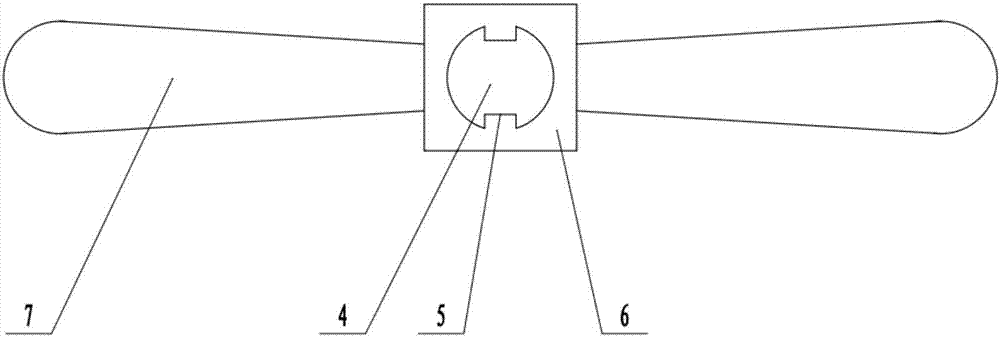

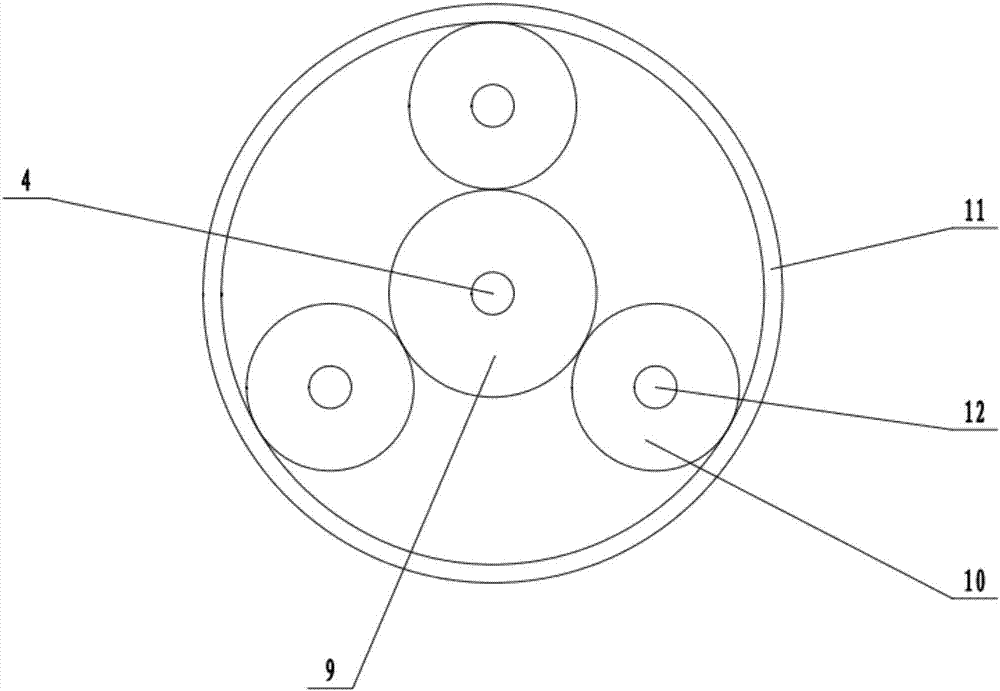

The present invention is directed to a wound drain catheter for draining fluid from, or supplying medication to, a wound in a patient. The wound drain catheter comprises a drain, a flexible outflow tube, and means for connecting the drain to the flexible outflow tube. The drain comprises a hollow core having a longitudinal axis; plural struts extending outwardly from the hollow core and being closed to the hollow core; and plural overhangs connected to the outward ends of the struts, respectively, the overhangs cooperating with the struts to form plural longitudinal lumens, the overhangs cooperating with each other to form, on the outer surface of the drain, segments of a segmented, closed curve with gaps between the segments providing plural longitudinal grooves for fluid communication between the wound and a respective lumen, the grooves sized to inhibit tissue from growing therein and debris from passing therethrough. The present invention also includes a method for draining fluid from, or supplying medication to, a wound in a patient.

Owner:SHCHERVINSKY SEMYON

Self-cleansing bladder drainage device

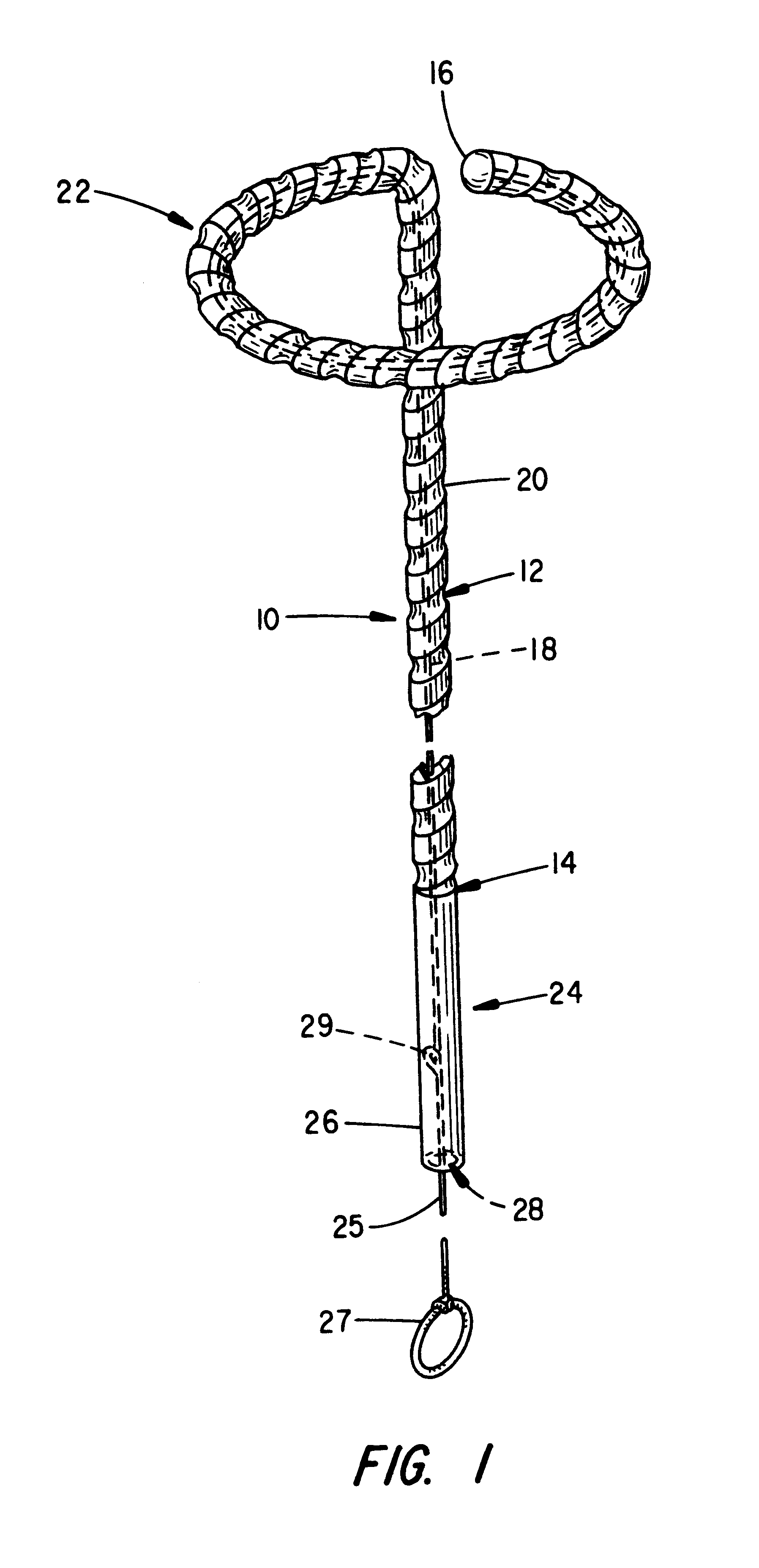

An urethral drain having deep external drainage channels, a low-profiled bladder retention segment, and a reversibly detachable collection segment, facilitates the draining of urine and fluids from the bladder. The low-profiled retention means minimizes bladder irritations and the deep external channels reduce the occurrence of infections. Incorporation of a reduced diameter smooth segment on the catheter, proximate the location of the external urethral sphincter allows the patient to void normally and at will. Modifying the size of this smooth segment aids the function of a defective sphincter in controlling urine leakage. The drain can be worn concealed within the urethra. Flushing action from normal voiding washes out particulate matters in the urethra and the concealed drain further minimizes contamination. Together, these features improve quality of life for patients needing catheterization.

Owner:CONSERT INC

Drain and fill logic for automated peritoneal dialysis

ActiveUS20100191181A1Limit low drain alarmLimitMedical devicesDialysisContinuous cycling peritoneal dialysisDraining tube

A system and method for automatically adjusting a Continuous Cycling Peritoneal Dialysis (“CCPD”) therapy to minimize the potential for excess intra-peritoneal volume. The adjustments are made at the end of the drain, just prior to the next fill. The adjustments short the next fill, if necessary, to limit the intra-peritoneal volume, add a cycle, if necessary, to use all of the available dialysis solution and will average the remaining dwell time to maximize the therapeutic benefit of the therapy in the allotted time. In another embodiment, a tidal therapy using trended patient UF data is provided.

Owner:BAXTER HEALTHCARE SA +1

Intra-abdominal pressure monitoring system

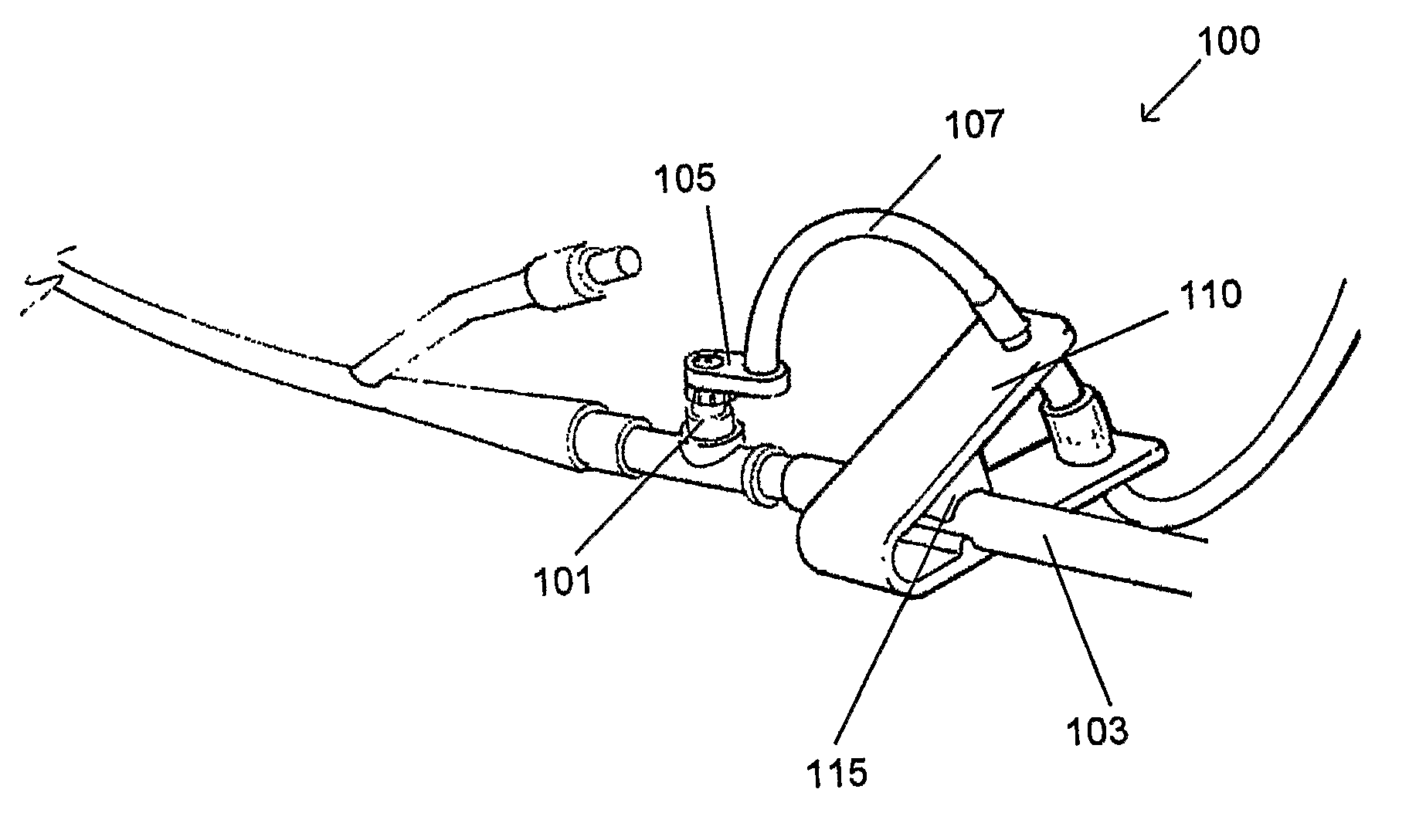

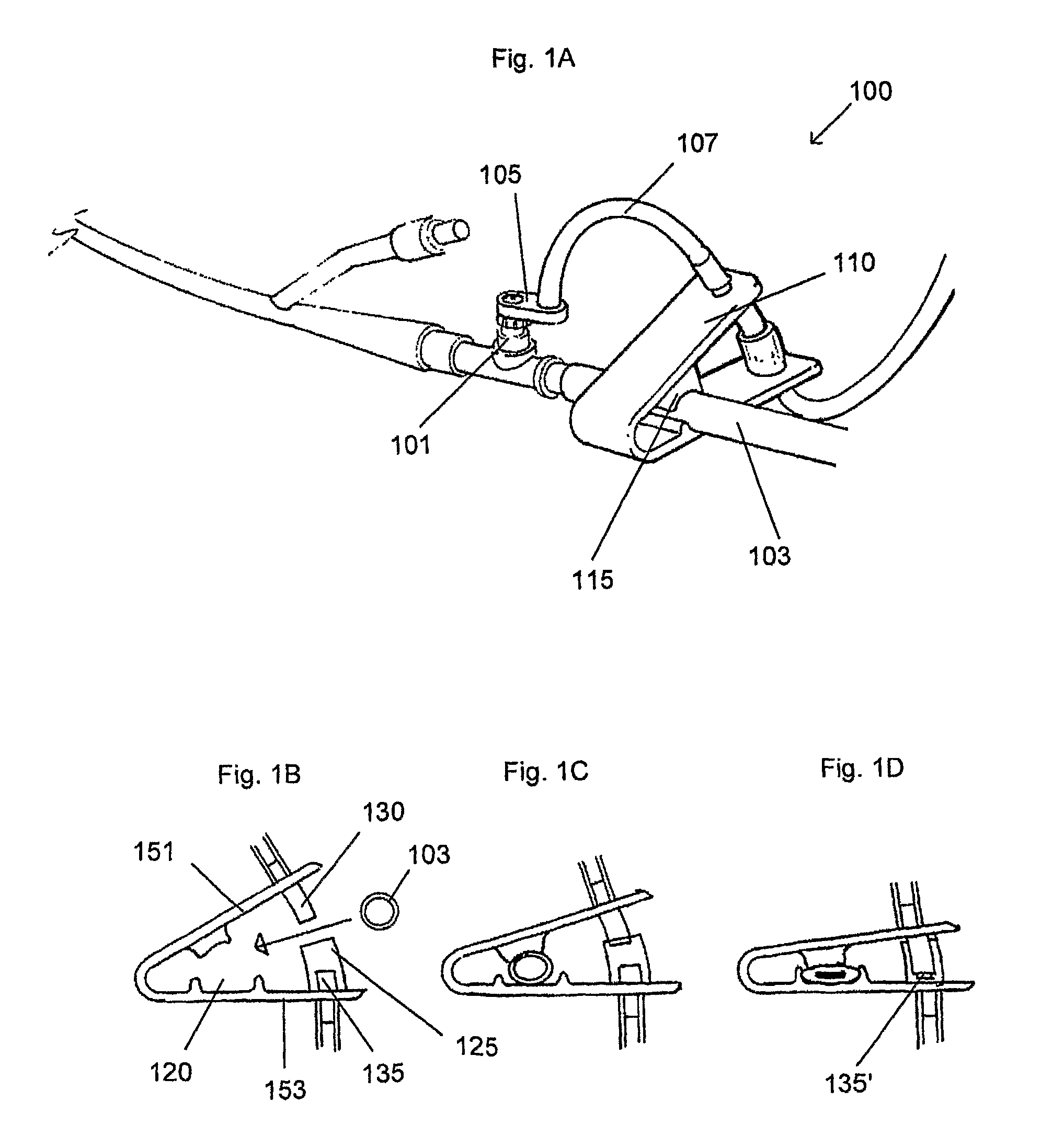

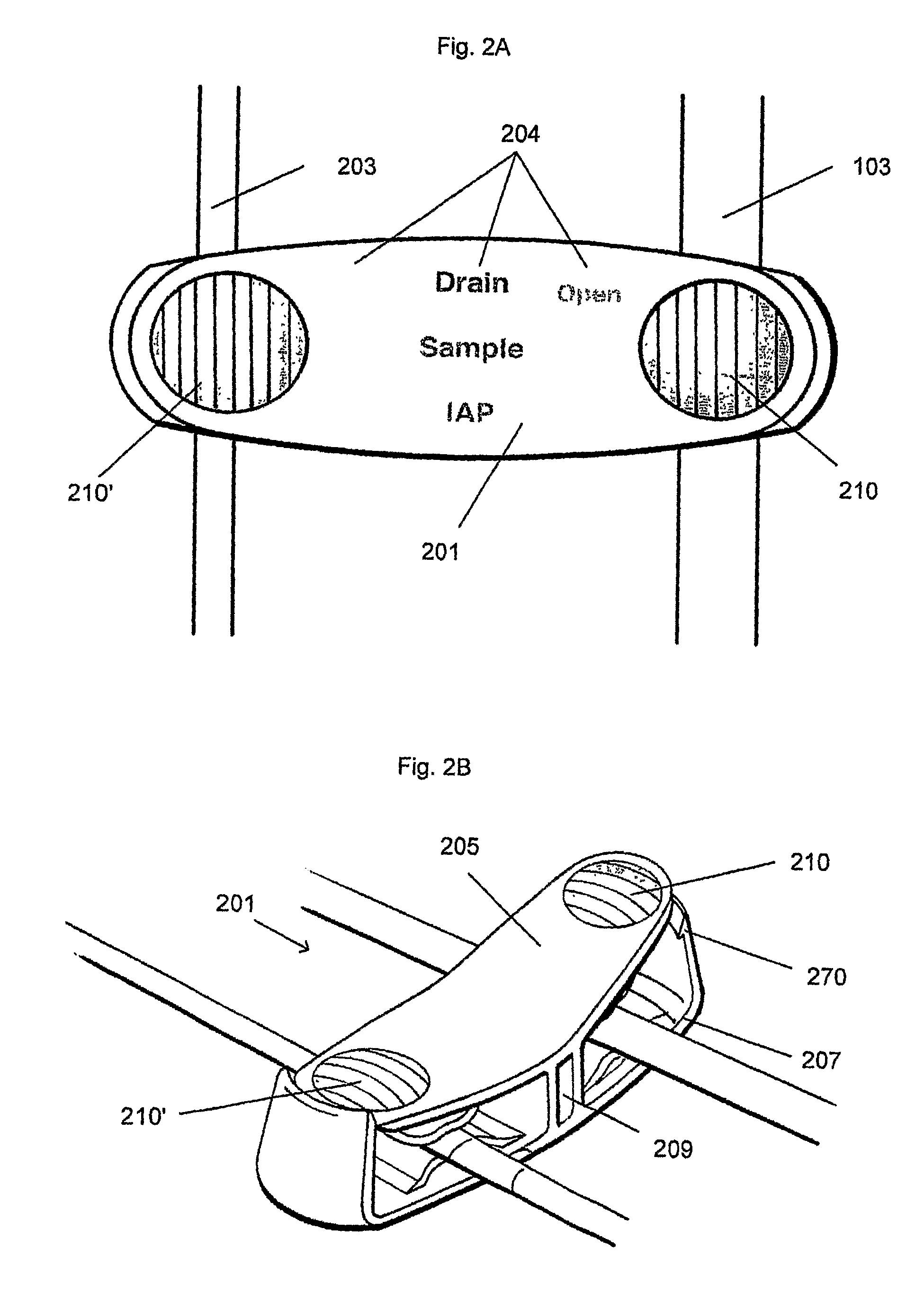

ActiveUS8337411B2Avoid flowMaintaining their functionalityWound drainsBagsUrinary catheterDraining tube

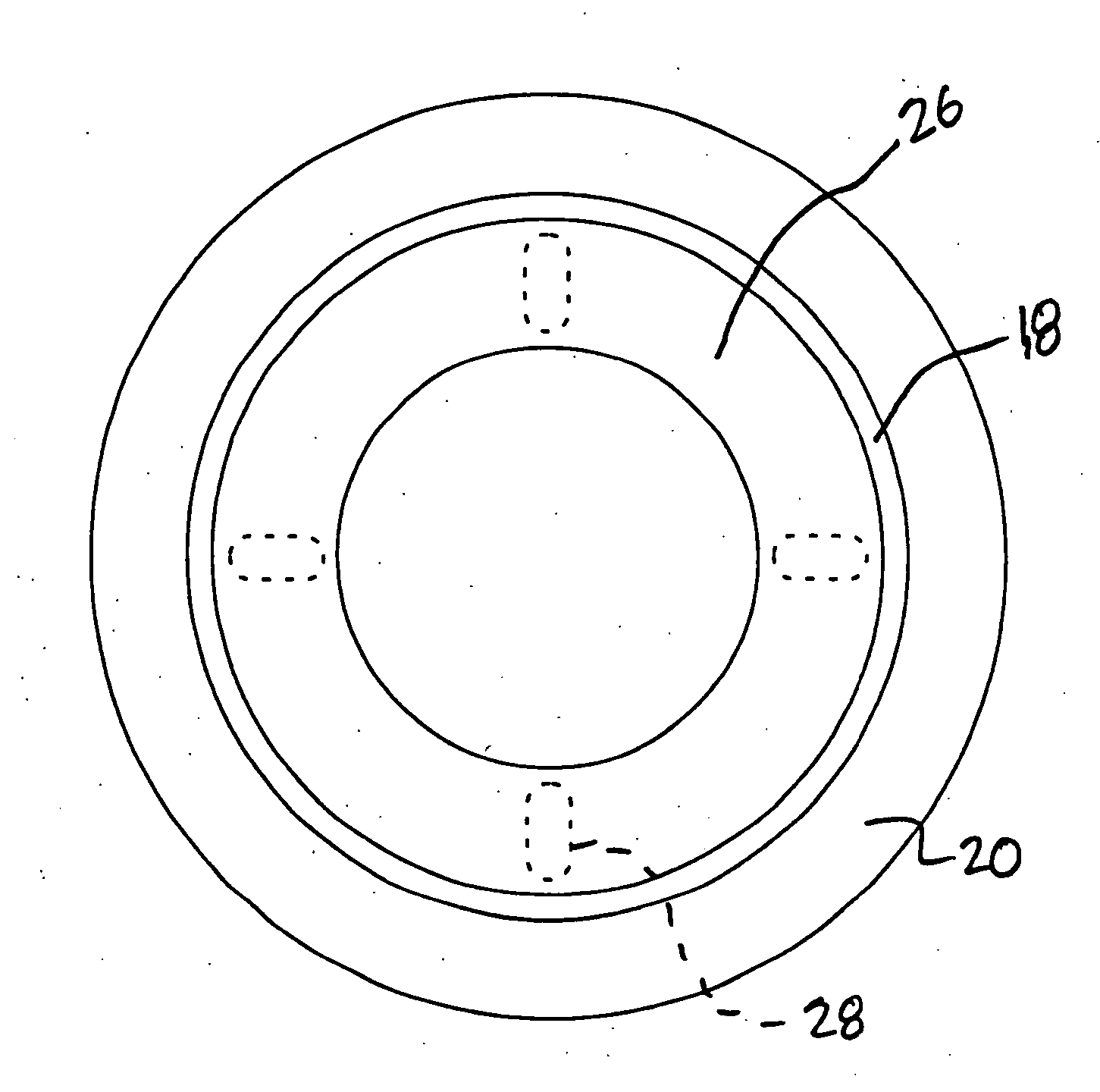

Described herein are devices, systems, kits and methods for measuring intra-abdominal pressure (IAP) from a patient catheterized with a urinary catheter system. Devices may include a bypass lumen configured to connect to a pressure transducer, a sampling port connector connected to the bypass lumen, a drain tube housing configured to at least partially enclose a portion of the drain tube of a urinary catheter system, and a clamp mechanism. The sampling port connector may be configured for removable attachment to the sampling port of the urinary catheter system to form a fluid connection between the urinary catheter system and the bypass lumen of the IAP device. The clamp mechanism may be configured to controllably occlude the lumen of the urinary catheter system drain tube.

Owner:CR BARD INC

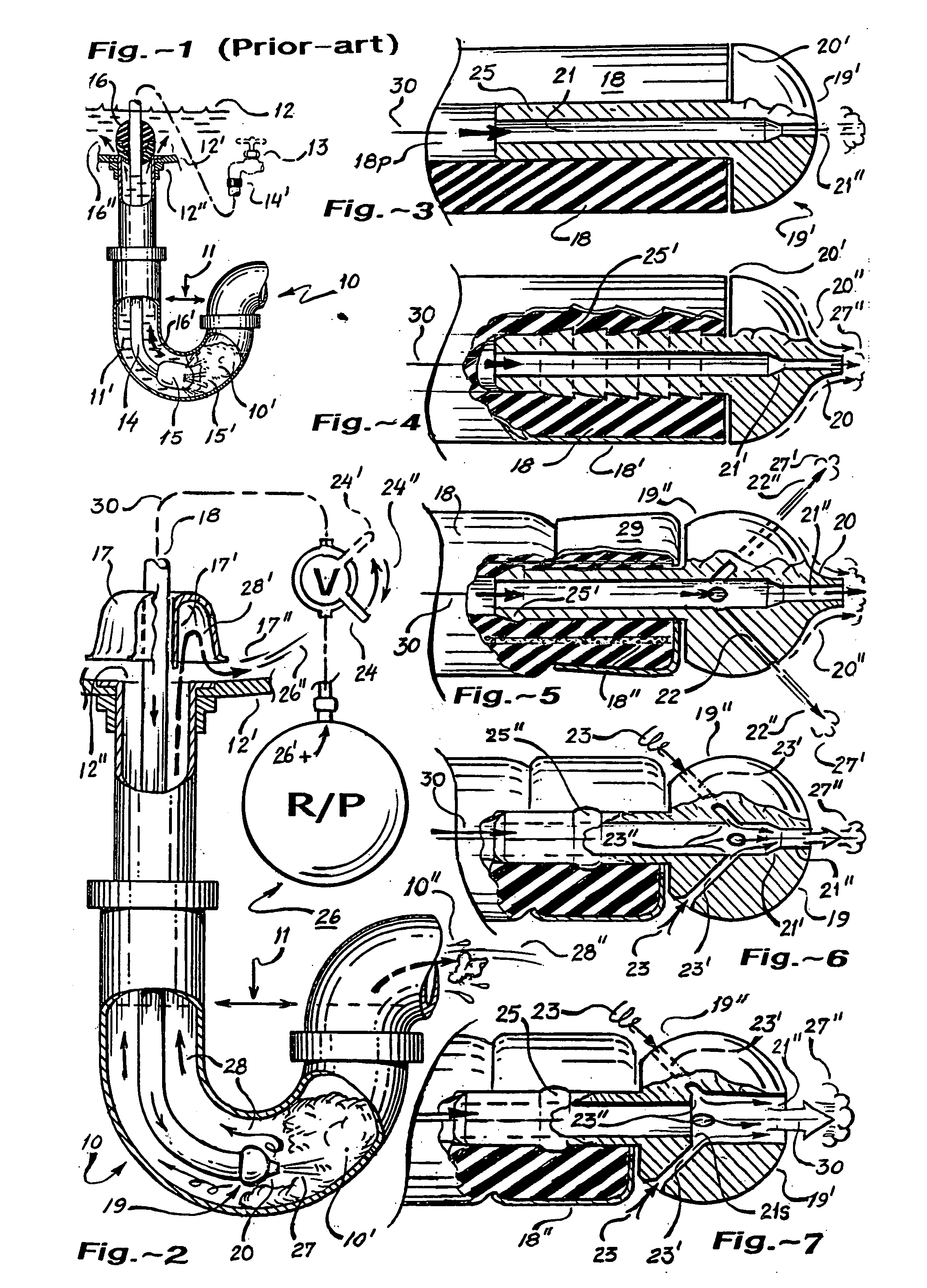

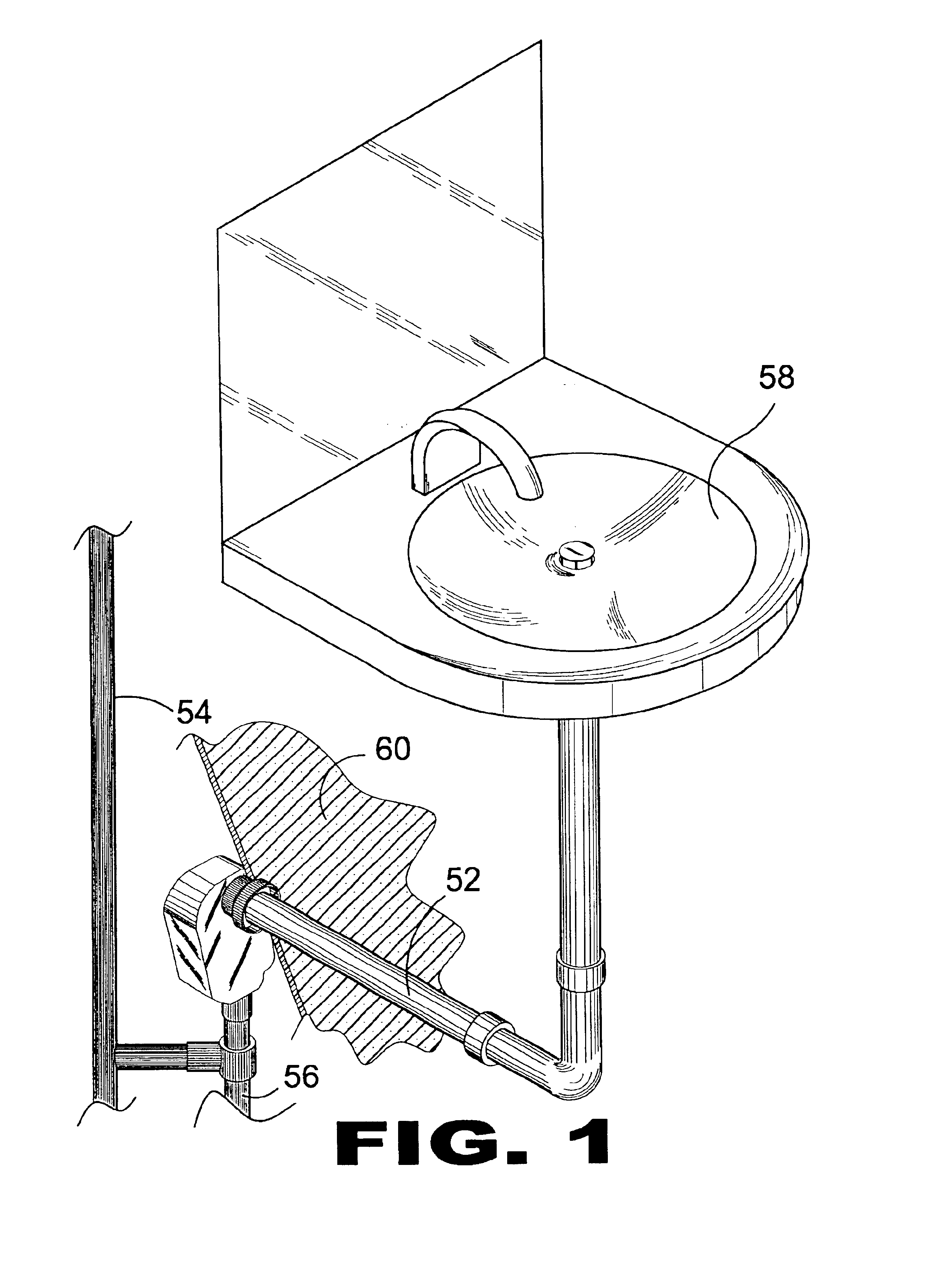

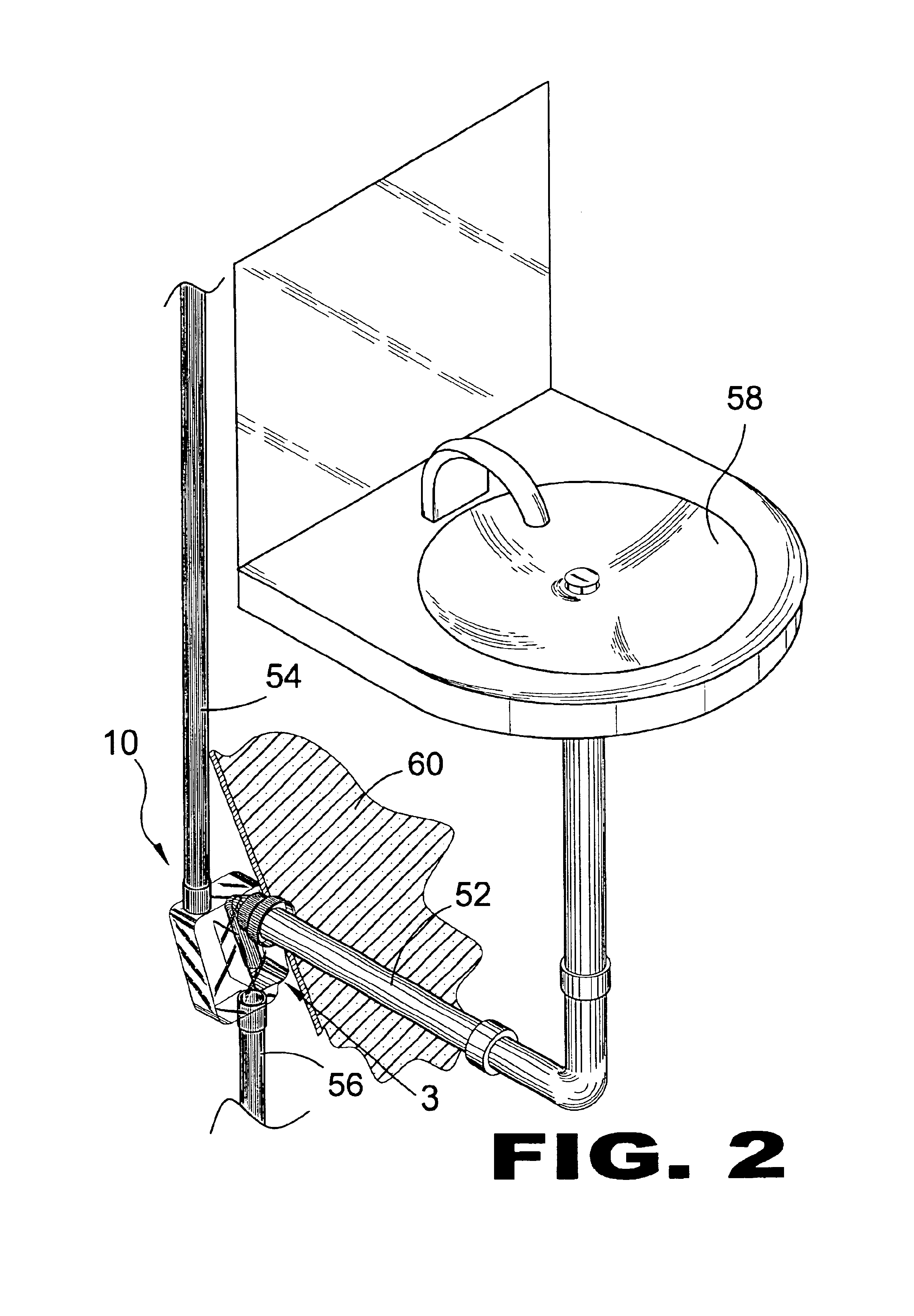

Universal pneumatic-snake apparatus & method

InactiveUS20050050624A1Readily cut throughReadily loosensDomestic plumbingLavatory sanitoryDraining tubeLine tubing

A pneumatic-snake like appratus and method for routine clearing of clogged plumbing-drain lines in buildings and marine installations, employing an air-supply of 80-120 psi at a nozzle-generated velocity sufficient to virtually disintegrate obstructions logged within the plumbing-drain system. Owing to direct-impact infusion of high-velocity air exiting the special ball-shaped fracturing-nozzle positioned at leading-end of the snaking air-hose, the “Pwr / Clogbuster™” is more effective at breaking-up plumbing-line clump-obstructions than conventional mechanical coiled-metal snake devices. Passed-into a drain-line to point of obstruction, the pneumatic-snake operator opens a control-valve positioned between the air-hose and air-supply unit (a conventional portable air-compressor / reservoir rig);—whereupon a few thrusting blasts at point-blank are sufficient to clear an obstruction. An annular drain-cup device is slip-fitted on the air-hose, and held near the drain-entry point, as to provide splash-deflection protection during the procedure;—plus, generic-variant nozzle configurations are also set forth.

Owner:PANGRAMUYEN EUGENIO L

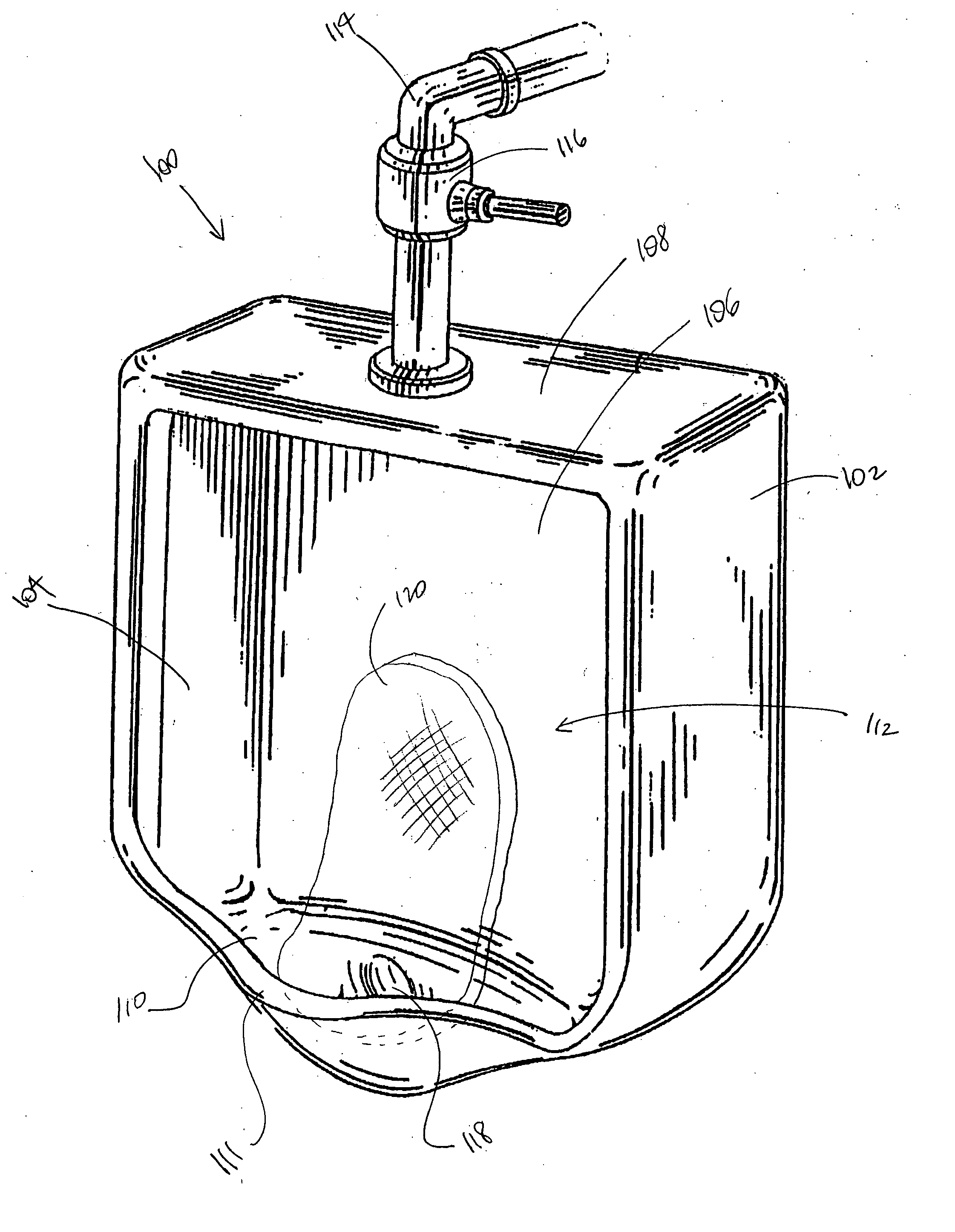

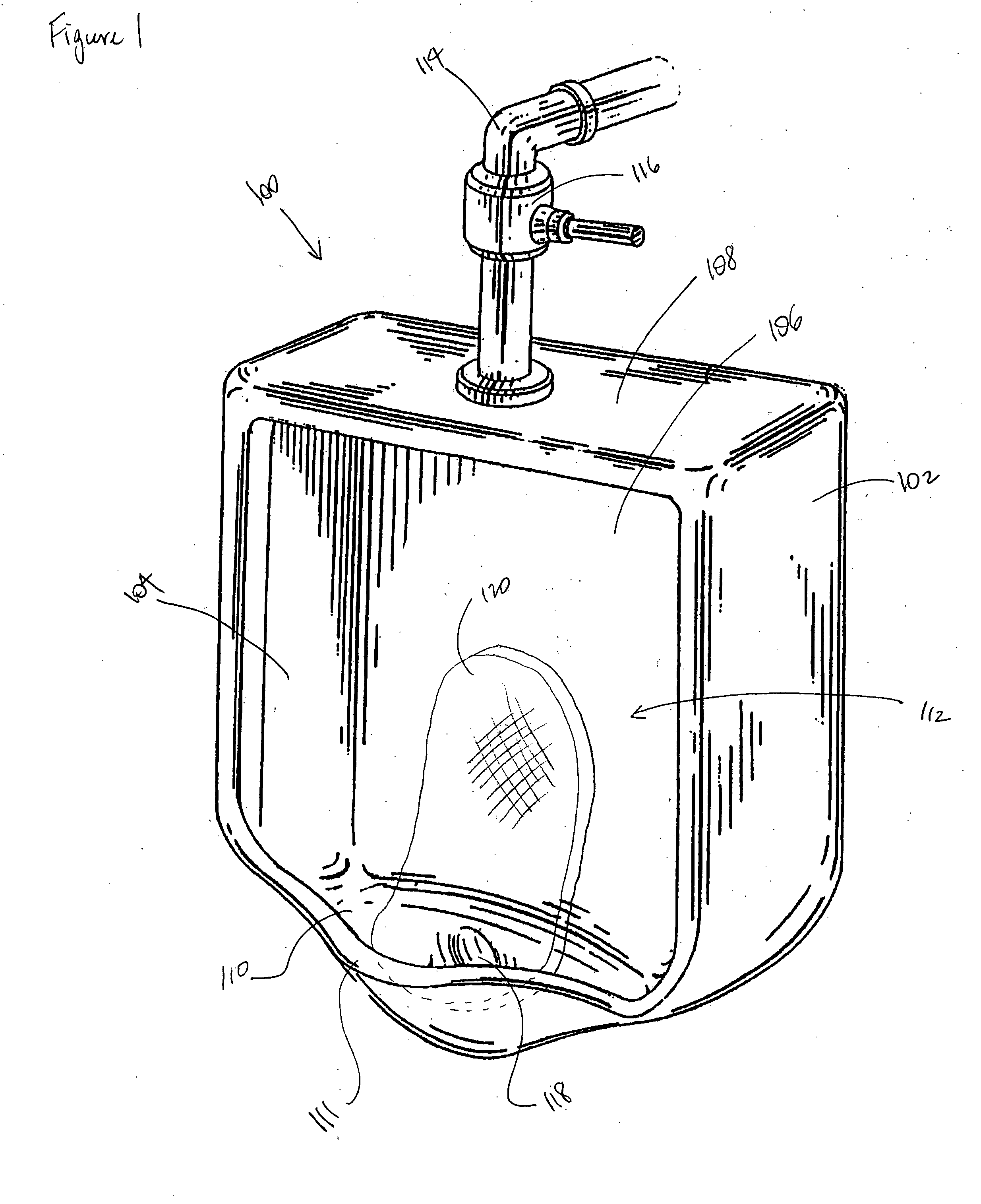

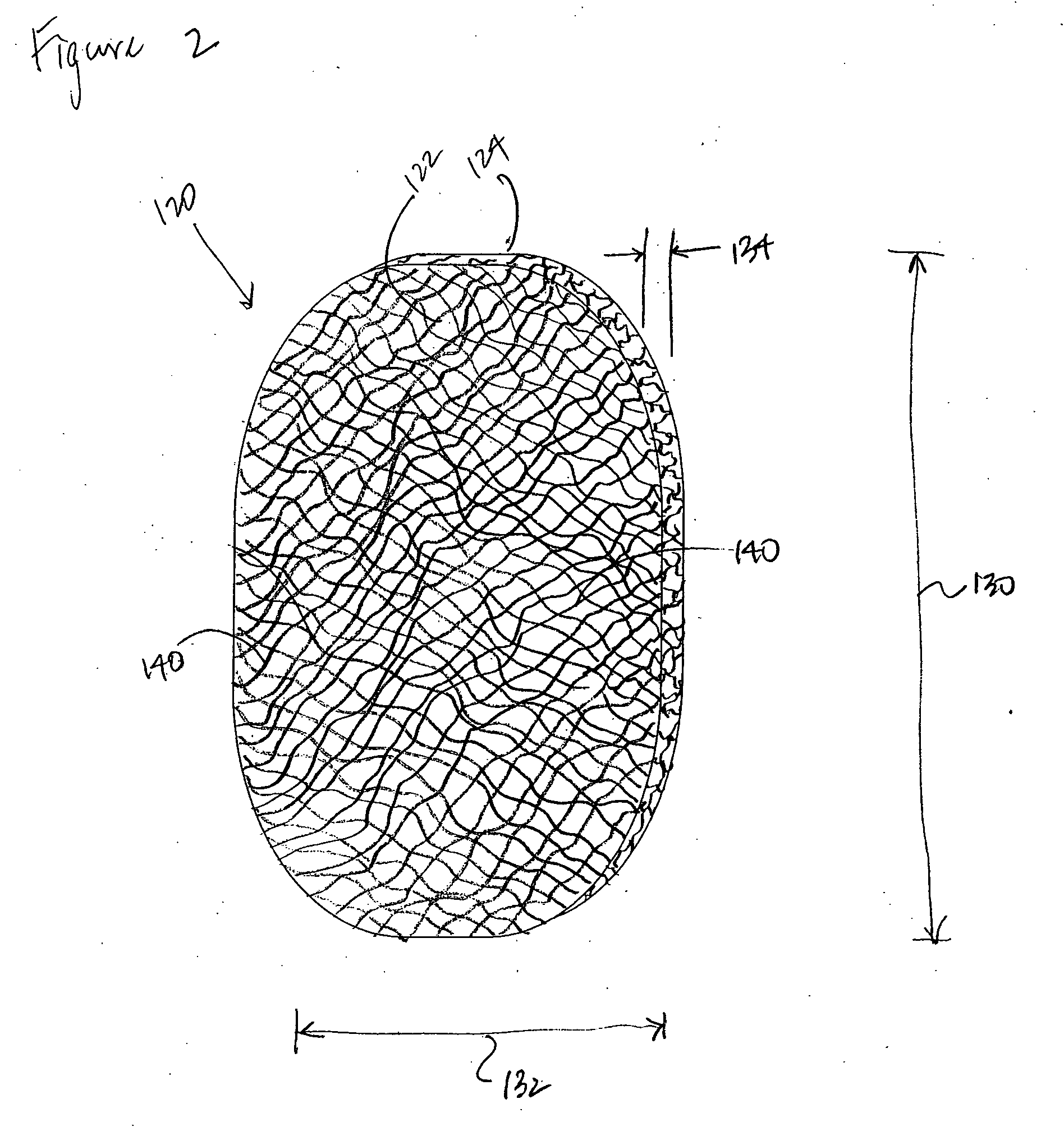

Anti-splash guard and deodorant pouch for urinals

The present teachings describe one embodiment of an anti-splash guard and deodorant pouch adapted for a lavatory device having an interior region for receiving waste fluid. The anti-splash guard may include a fibrous material configured to be positioned in the interior region of the lavatory device so that splash back of fluids contacting the anti-splash guard is reduced. The deodorant pouch advantageously comprises a deodorant material sandwiched between layers of anti-splash material, such as the fibrous material that is used in the anti-splash guard. The deodorant pouch may increased a useful lifespan of the deodorant material held therein by preventing pieces of the deodorant material from falling down the drain of the lavatory device and by reducing the amount of fluid that contacts the deodorant material.

Owner:CONSUMER WORLD PROD DEV

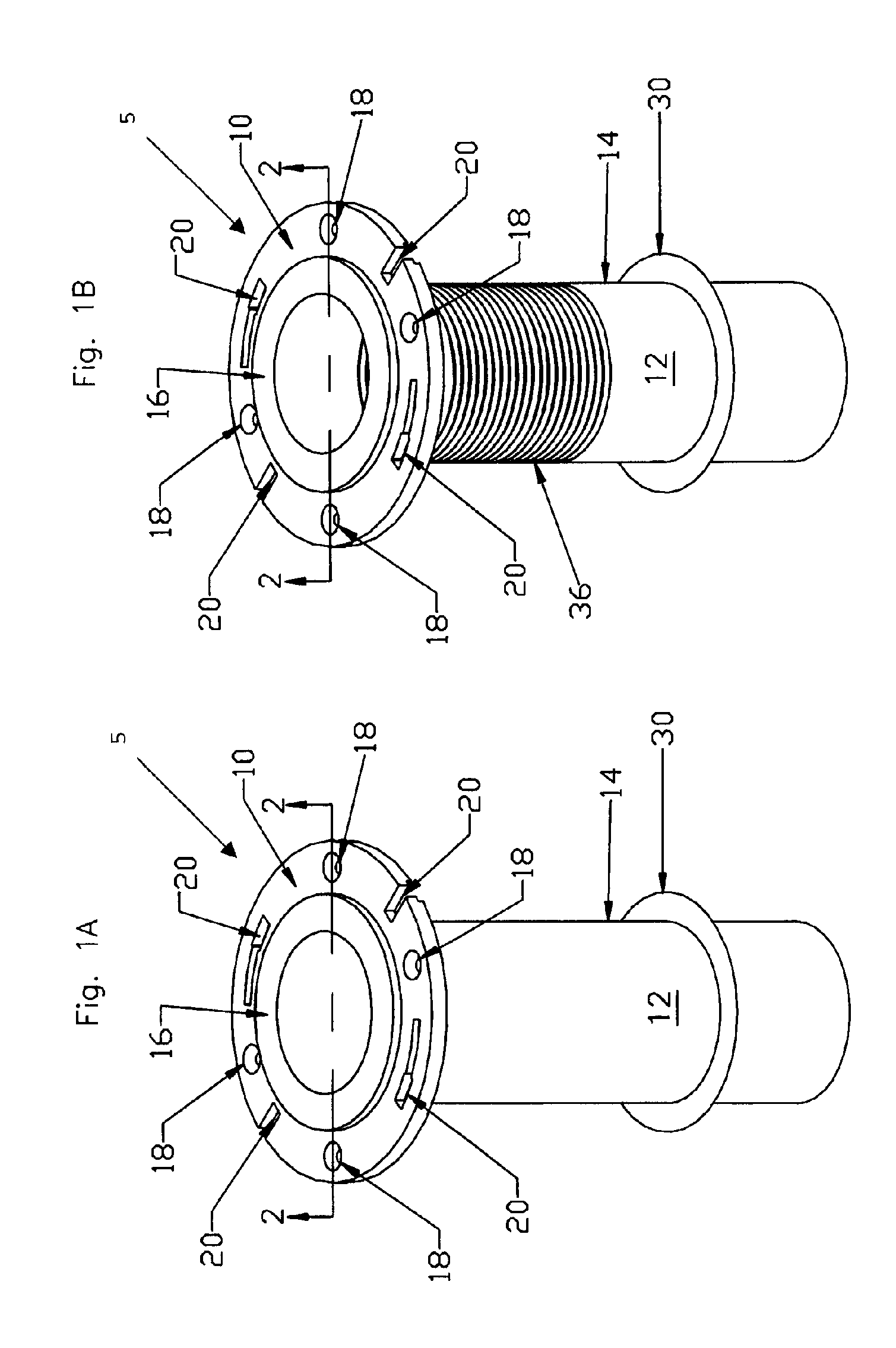

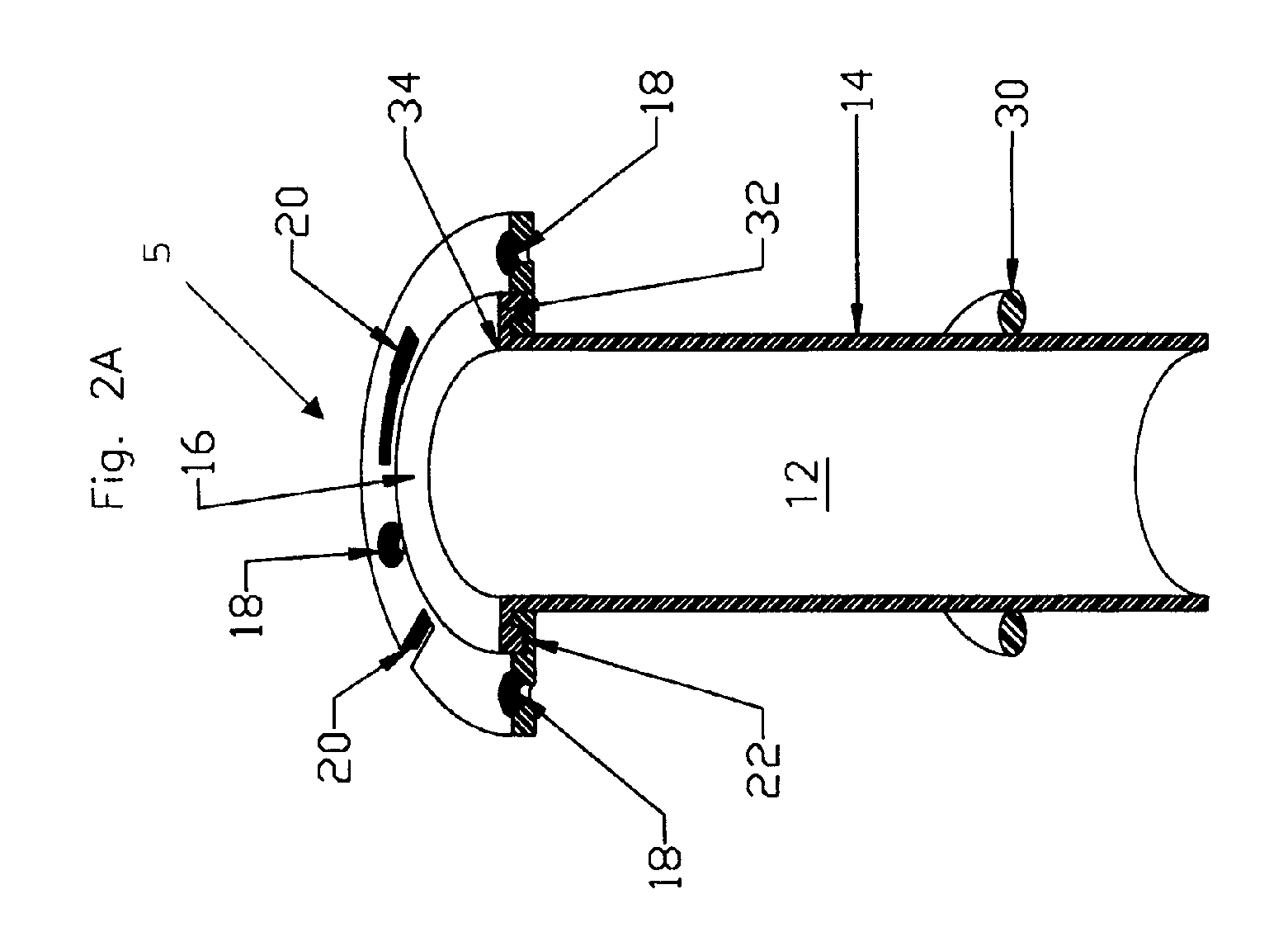

Overflow assembly for bathtubs and the like

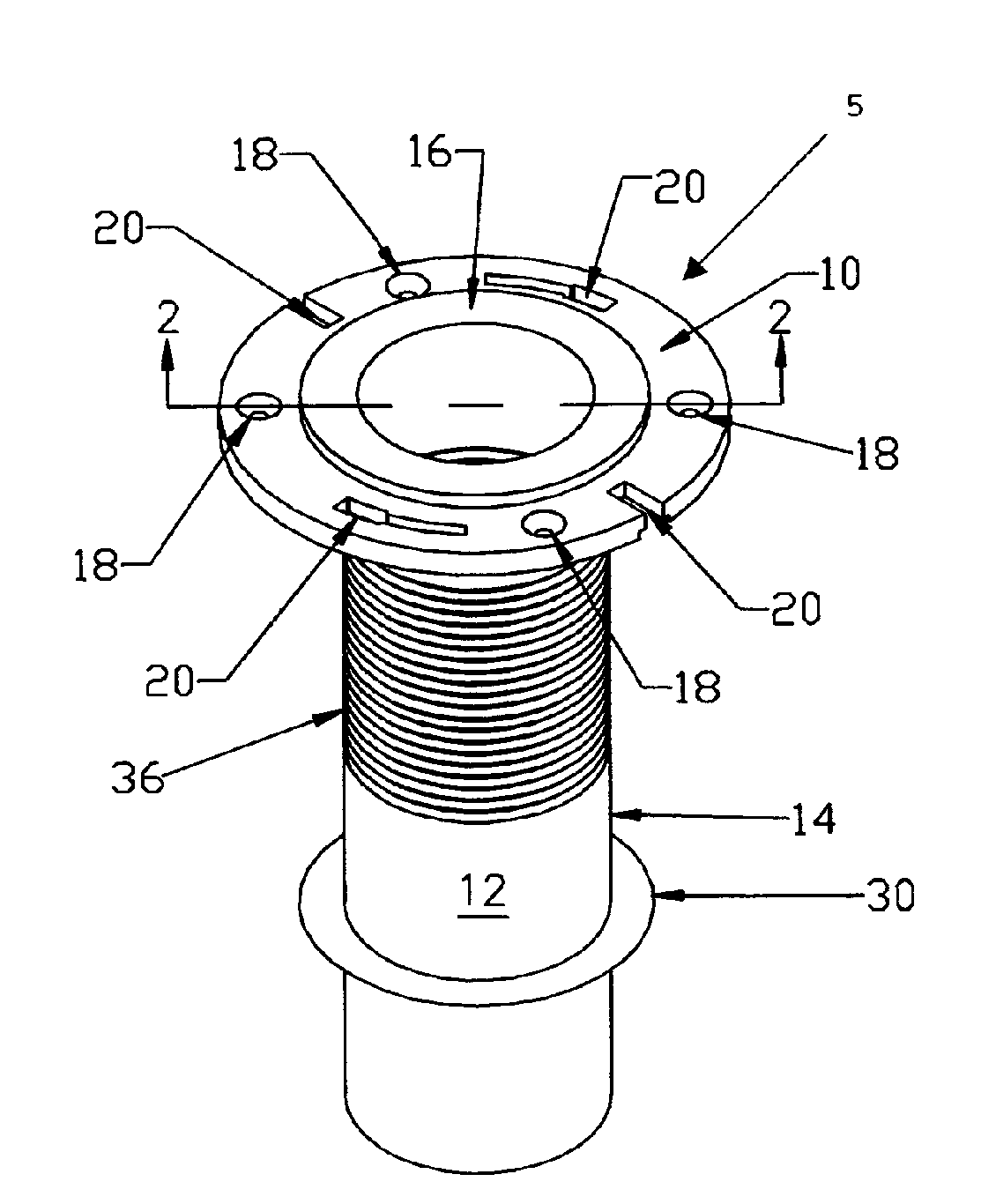

An overflow system in the bathtub has an overflow port and has a drain pipe in connection with the overflow port. A threaded flange has a stub shoulder on one end which is fitted into a circular sleeve on the overflow port. The threaded flange has exterior threads on its outer surface and a thin diaphragm secured to the end thereof opposite to the stub shoulder. A large sealing washer embraces the outside of the circular flange on the overflow port and extends partially over the threads of the threaded flange. A large internally threaded nut is threadably mounted on the outer end of the threaded flange and compresses the sealing washer against a vertical flange on the port to seal the connection between the threaded flange and the port. A decorative cap is frictionally snapped into engagement with protrusions on the outer surface of the nut. The cap can be removed when needed to permit the plumber to gain access to the diaphragm to cut it open for fluid flow after the system has been tested for leaks, or put in place after the cut takes place.

Owner:WCM IND INC

Flexible sleeve for connection to a plumbing fixture

Owner:COFLEX SA DE CV

Drain catheters

The present invention is directed to a wound drain catheter system for draining fluid from, or supplying medication to, a wound in a patient. The system comprises (A) a trocar having (a) a blade portion on a distal end; and (b) a connector portion on a proximal end, the connector portion being a hollow core lying on a longitudinal axis; (B) a drain having (a) a first connector portion on a distal end, the first connector portion being a protrude lying on a longitudinal axis; and (b) a second connector portion on a proximal end; (C) a flexible outflow tube having (a) a proximal end and a distal end; and (b) a smooth exterior for sealing to surface tissue at the point of exit from the body of a patient; and (D) means for connecting the second connector portion of the drain to the distal end of the flexible outflow tube. The protrude of the first connector portion of the drain engages the interior of the hollow core of the connector portion of the trocar. The wound drain catheter system may also include a bioabsorbable transitional part.

Owner:SHCHERVINSKY SEMYON

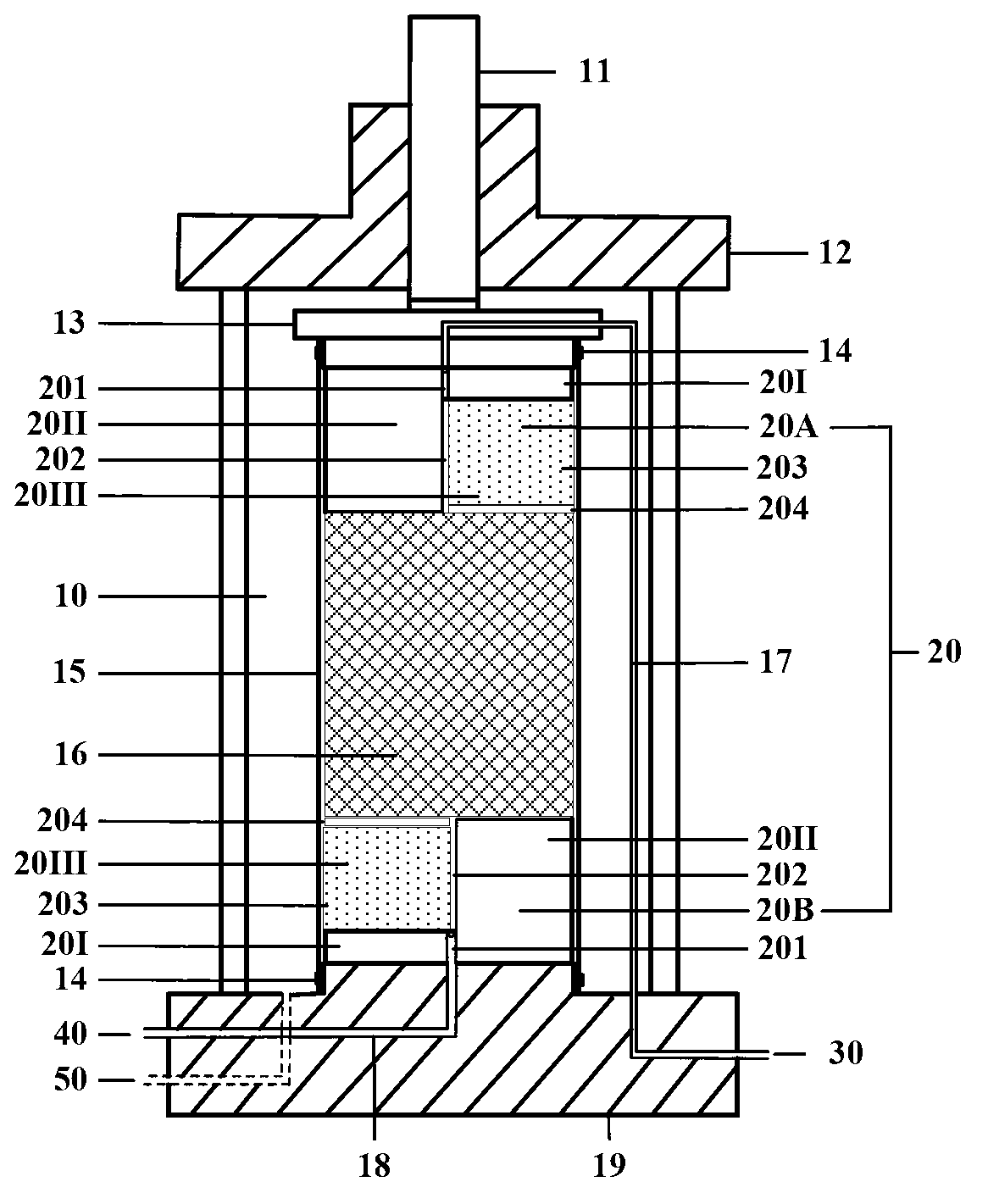

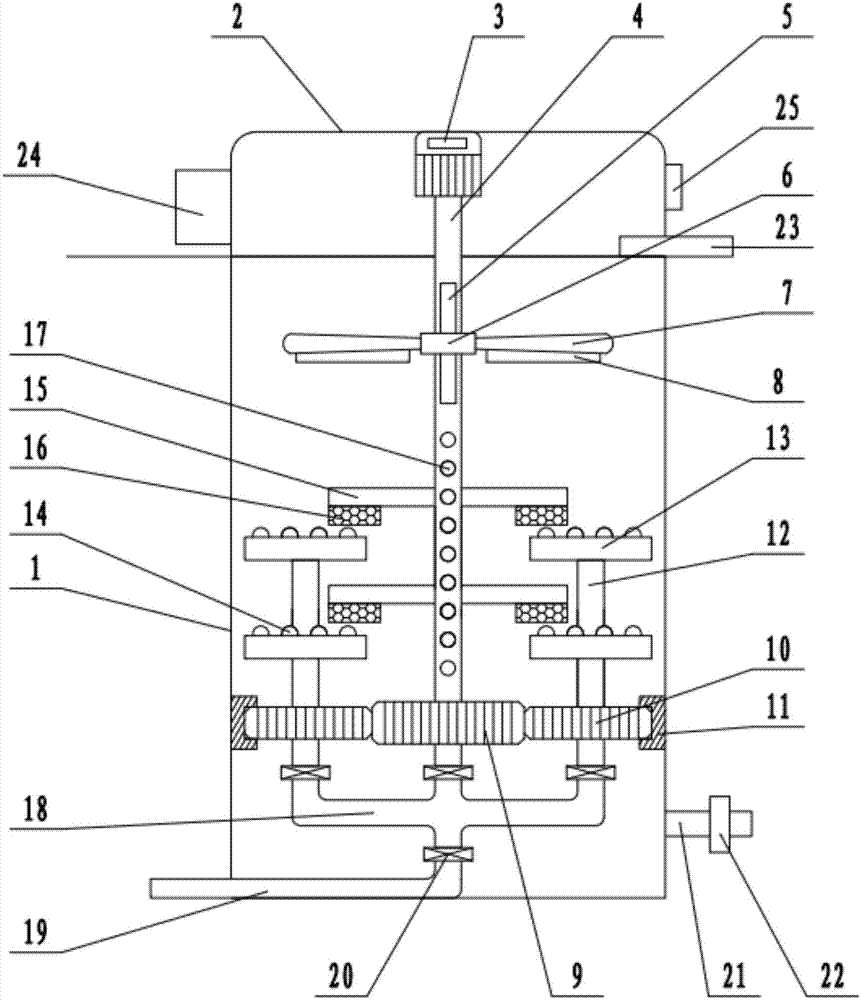

Vertical direct shear test device

InactiveCN102901676ARealize the function of direct shear testOvercome the defect of poor water retentionMaterial strength using steady shearing forcesRubber membraneDraining tube

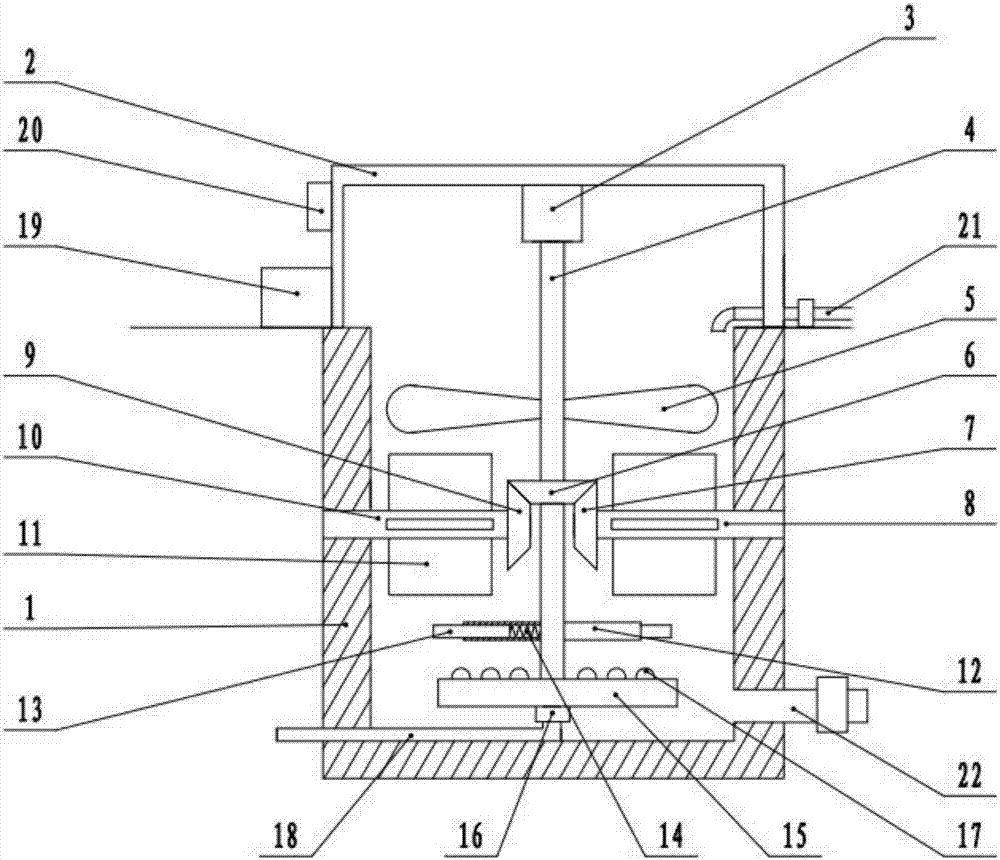

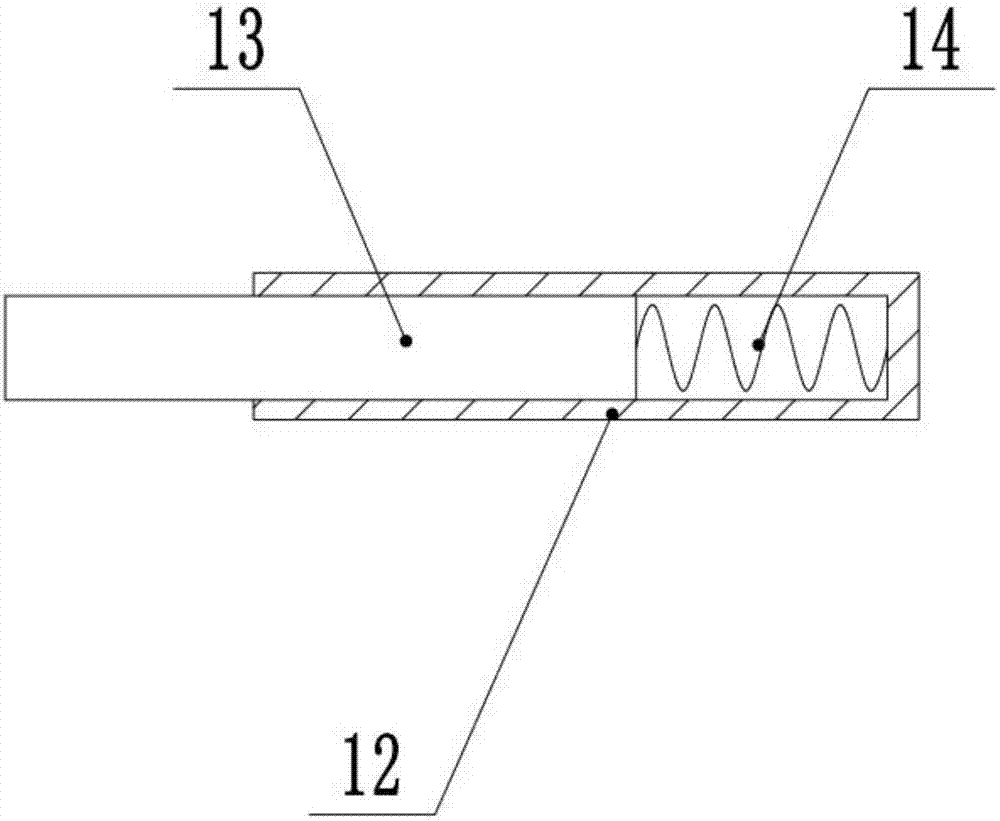

The invention discloses a vertical direct shear test device. The vertical direct shear test device comprises a base, a water injection pipe and a water drainage pipe, wherein a pressure chamber is arranged on the base, an upper cover of a shear chamber is arranged on the pressure chamber, a rubber membrane sleeve is arranged in the pressure chamber, the lower end of the rubber membrane sleeve is arranged on the base, the lower end of the rubber membrane sleeve is hermetically connected with the base, an upper shear box and a lower shear box are arranged in the rubber membrane sleeve, the upper and the lower shear boxes are respectively positioned at the upper end and the lower end of the rubber membrane sleeve, a test sample cavity is surrounded by the rubber membrane sleeve and the upper and the lower shear boxes, the upper and the lower shear boxes adopt shear components, each shear component comprises a substrate, the substrates are respectively provided with a shear block and a deformation block, the opposite planes of the shear block and the deformation block are coplanar with the shear plane of a test sample, water grooves are arranged on the opposite planes of the shear block and the deformation block, the water grooves extend to the substrates and penetrates the substrates, water through holes are formed, the water injection pipe is connected with the water through hole in the upper shear box, the water drainage pipe is connected with the water through hole in the lower shear box, a top cap is arranged on the upper shear box, and the top cap is provided with a vertical loading shaft.

Owner:HOHAI UNIV

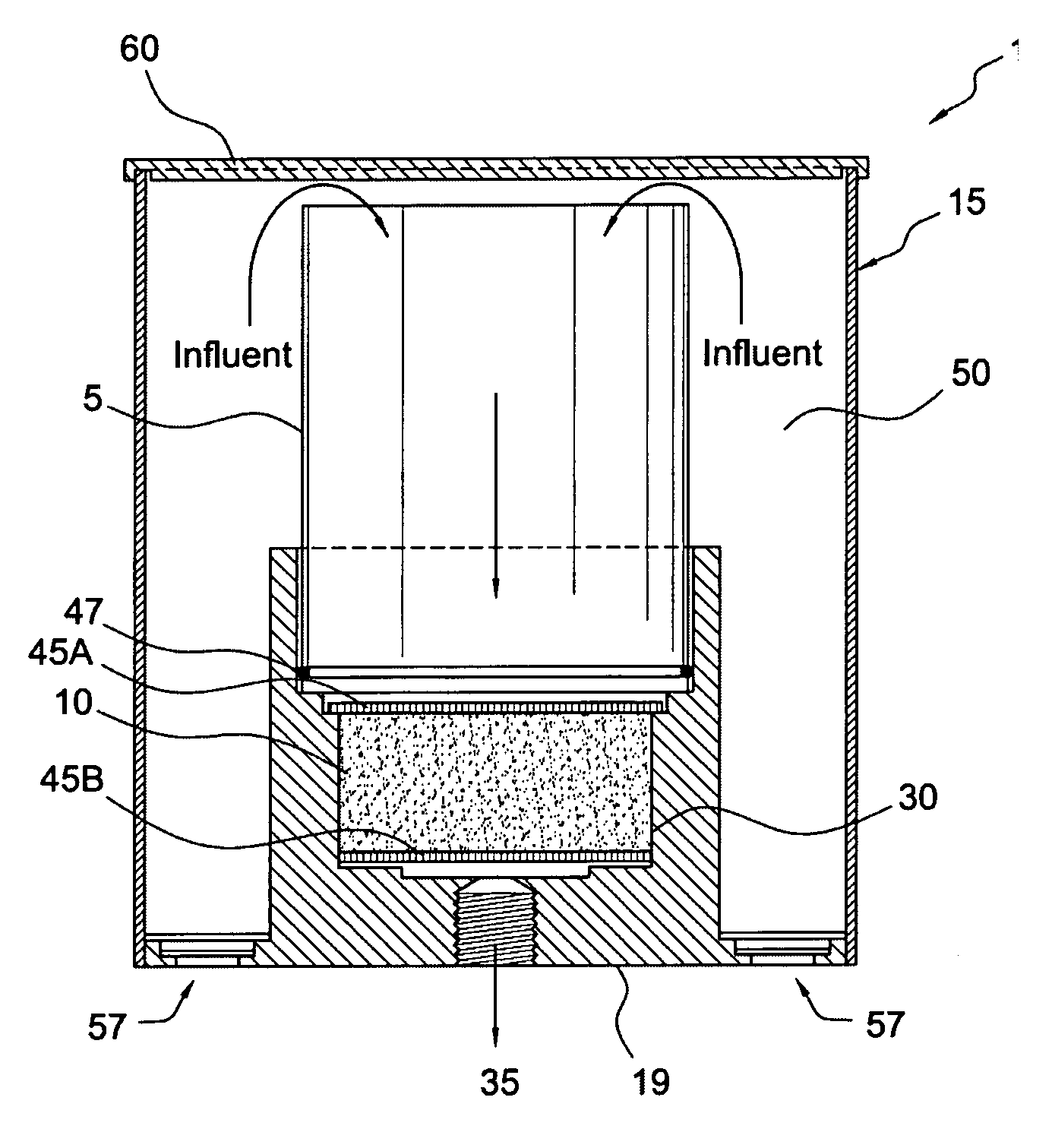

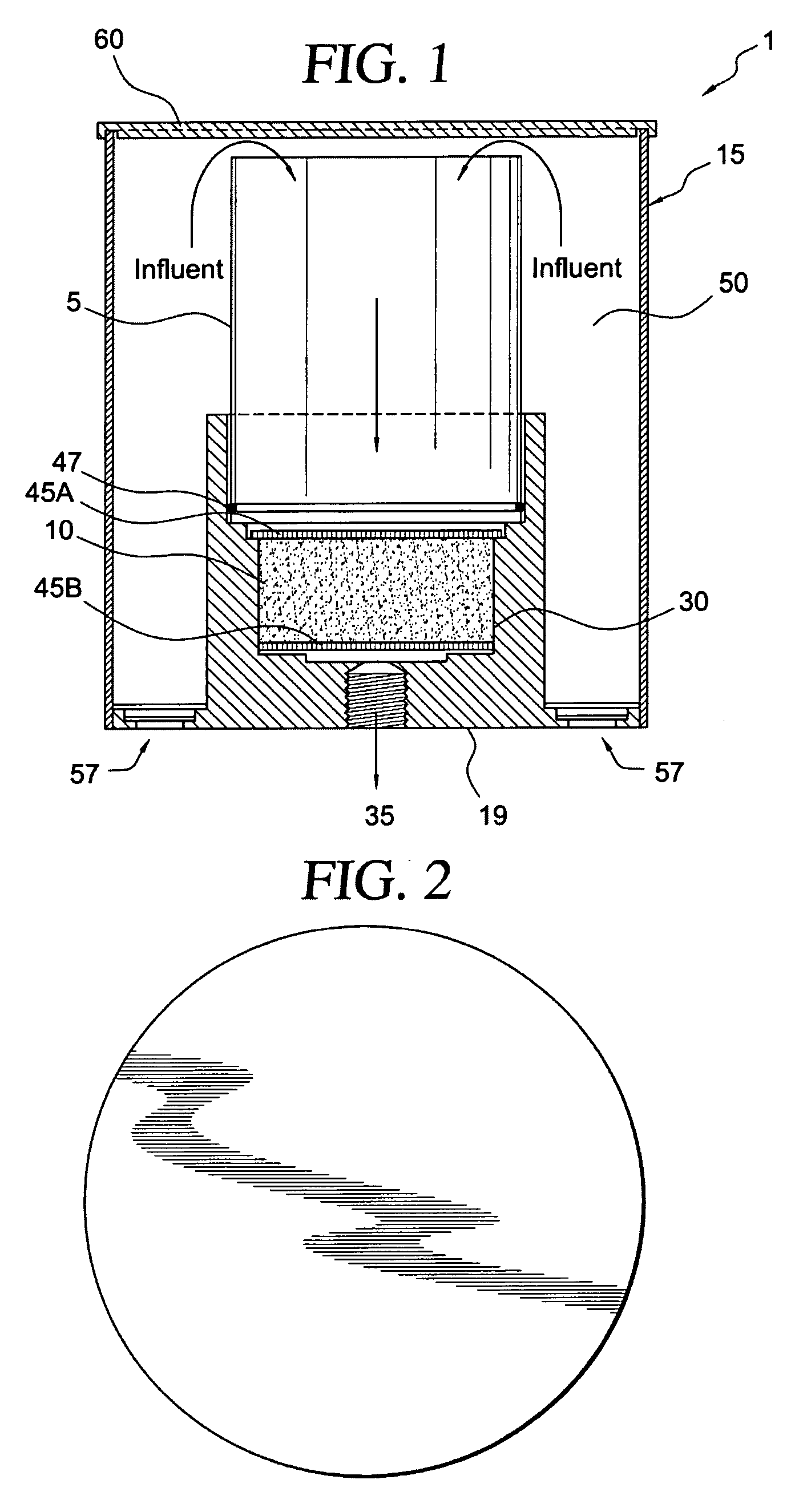

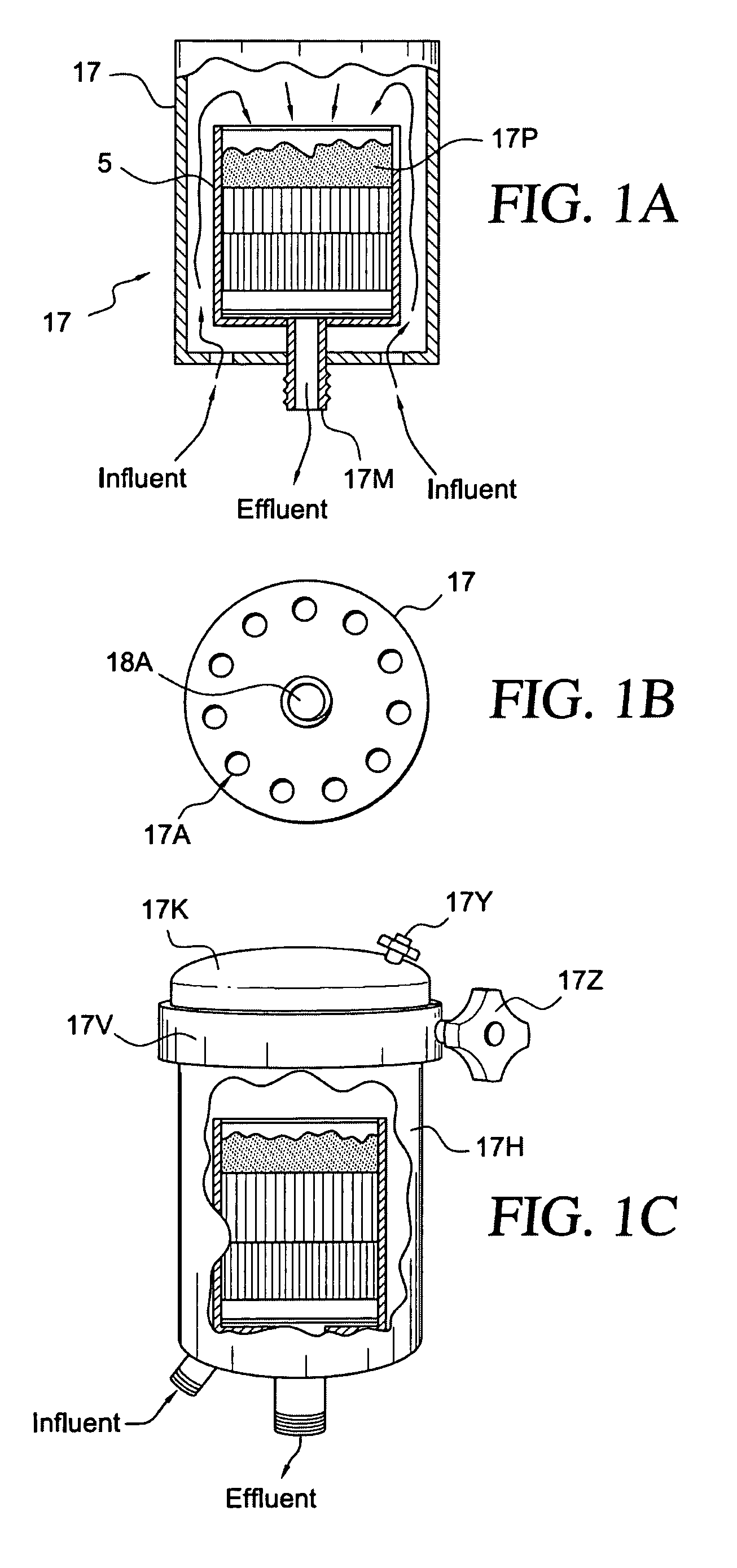

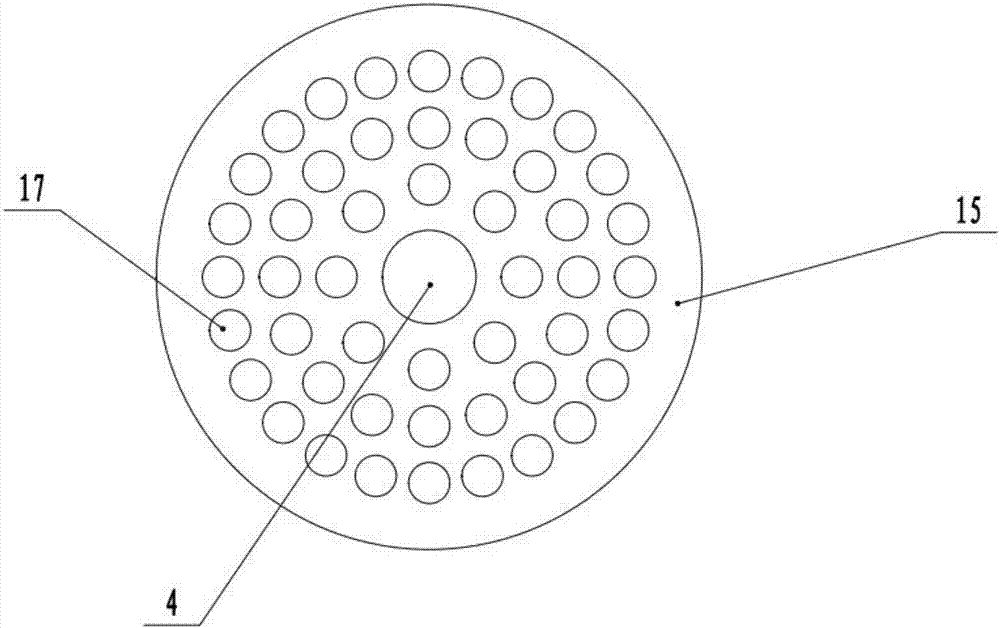

Microfiltration devices

ActiveUS20070062870A1Improve filtering effectImprove performanceSemi-permeable membranesMembranesHollow fibre membraneFiber

A method of treating a hollow fiber membrane microfiltration filter having an influent side and an effluent side to improve performance of the filter is disclosed. The method entails sealing imperfections in surfaces of the filter by flushing the filter with a liquid aqueous suspension of particulates. Filter cartridge devices also are disclosed. The devices may include a bactericidal chamber. A radial flow filter may be included in the devices. The filter cartridges may include a drain tube positioned within the filter for removing of effluent generated by the filter. A plurality of filter cartridges may be positioned on the drain tube.

Owner:STREAMLINE CAPITAL

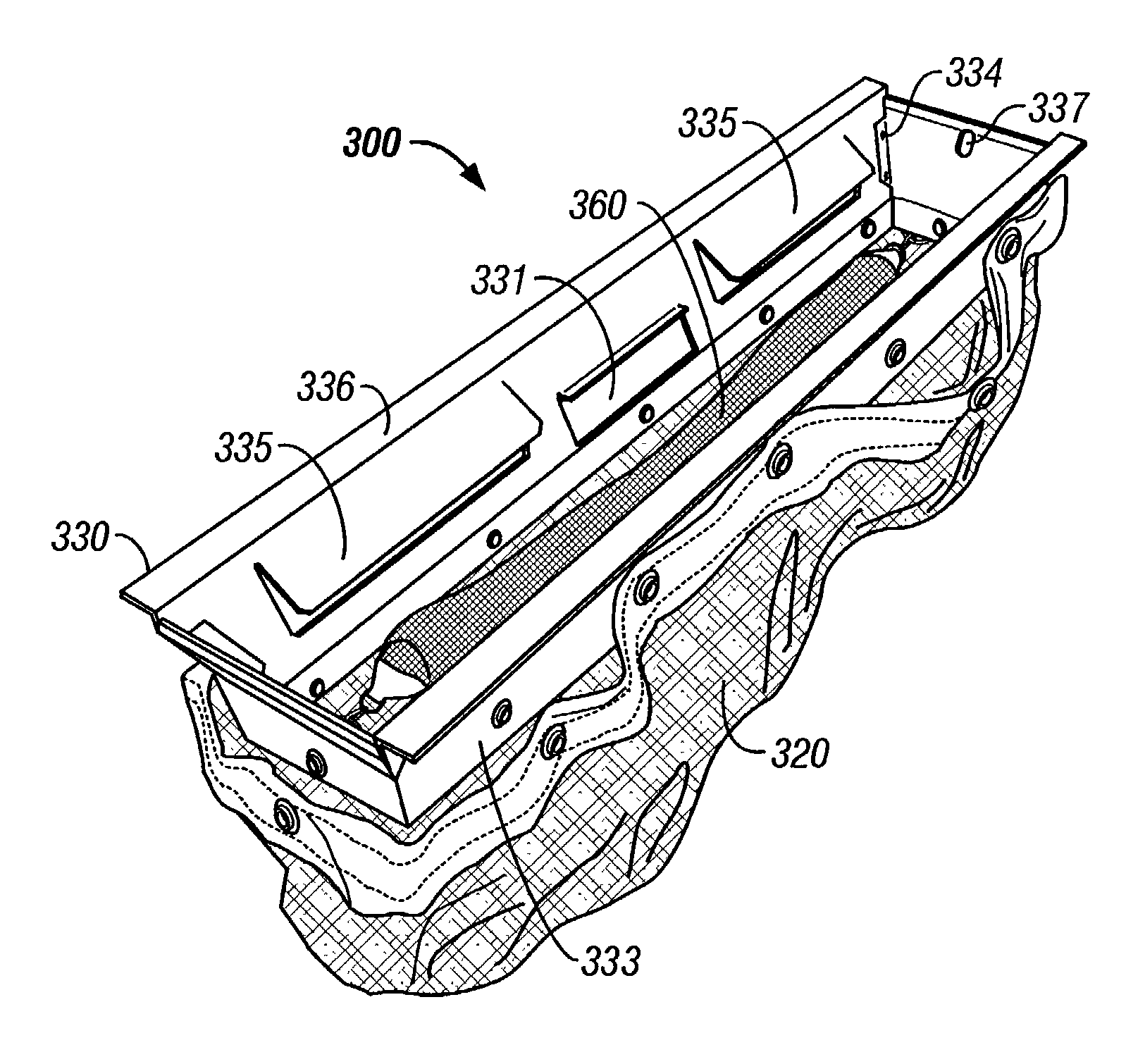

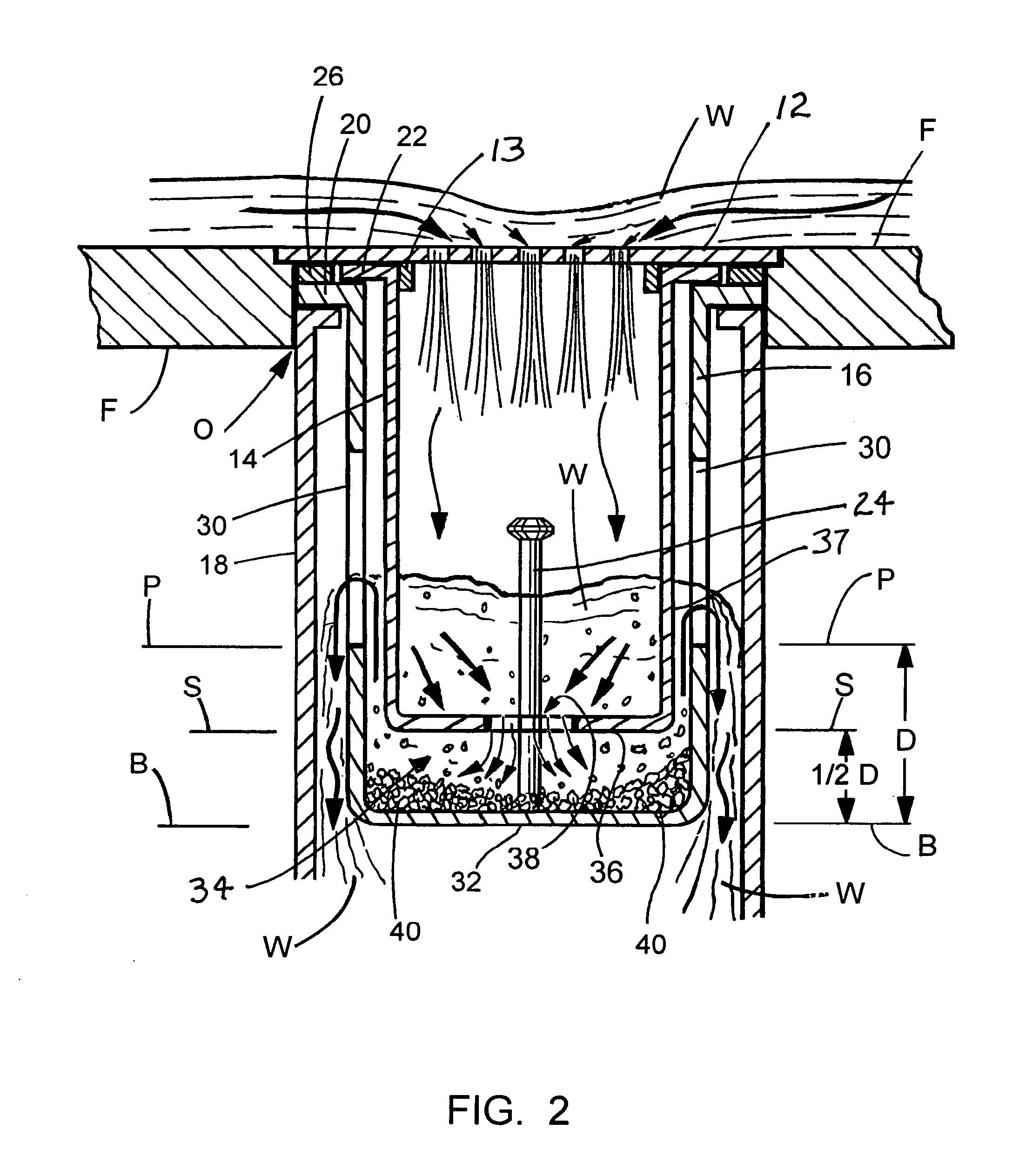

Trench drain filtration system

InactiveUS6986621B2Easy maintenanceEasy to disassembleFatty/oily/floating substances removal devicesGround-workDraining tubeFiltration

A trench drain filtration system having a filter body dimensioned to fit within a trench drain forming a trough or reservoir obstructing at least a portion of the trench drain. The filter body is supported by a filter body support dimensioned to cooperatively engage with the trench drain and with the filter body to substantially maintain said filter body in a pre-selected position within the inlet. One or more connectors removably connect the filter body to the filter body support.

Owner:OLDCASTLE PRECAST

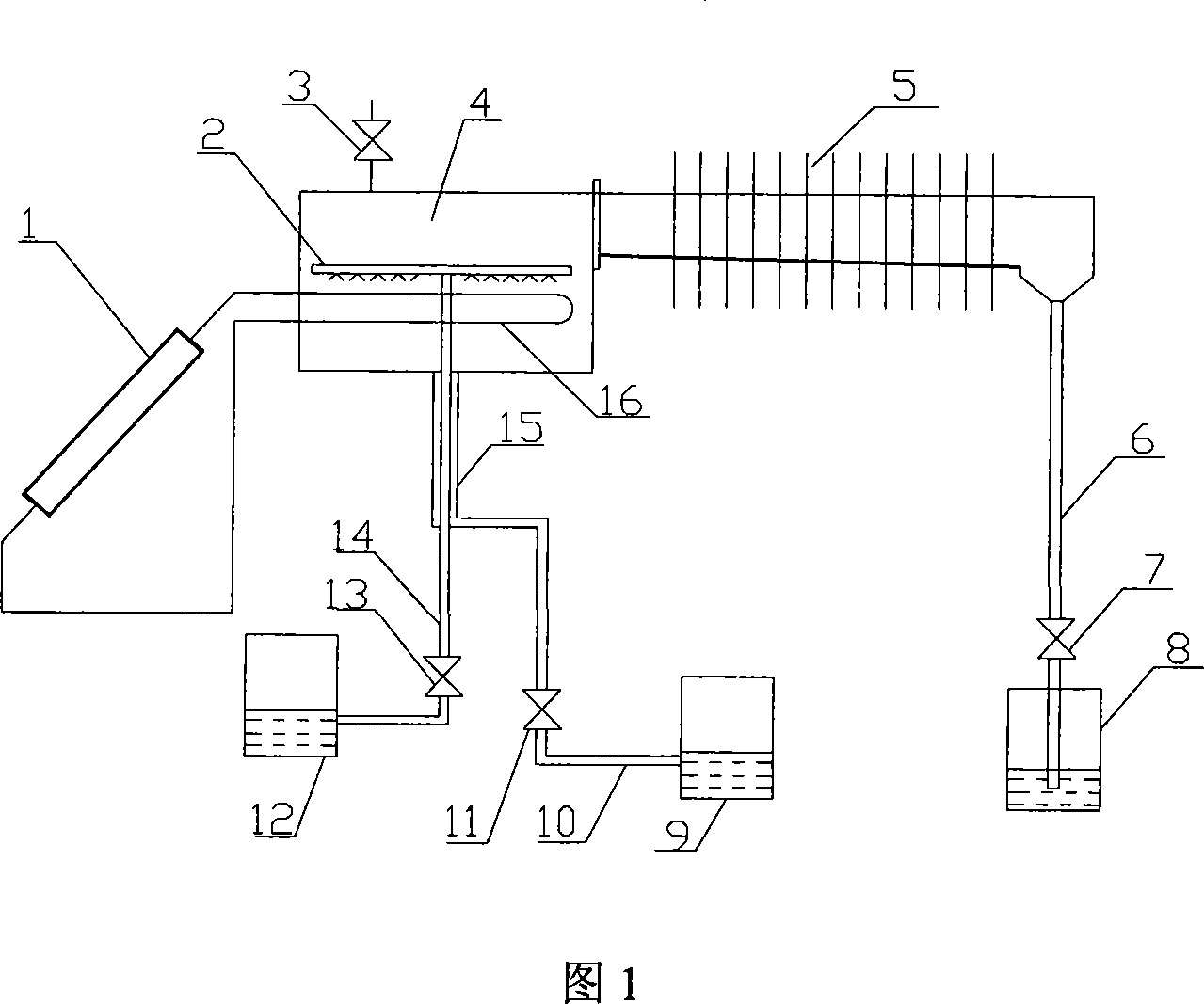

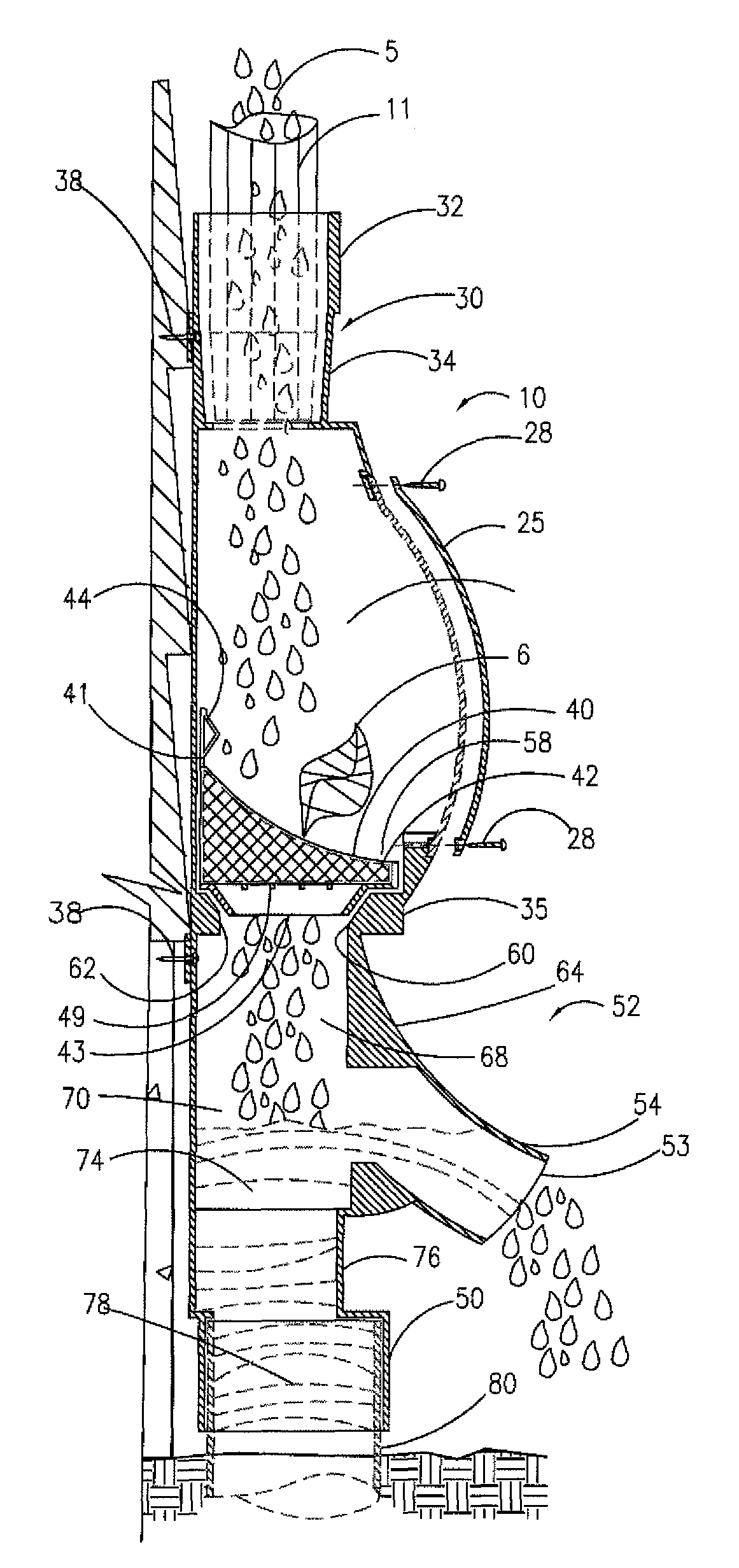

Natural vacuum low temperature distillation sea water desalination method and device

InactiveCN101177308ALower desalination costsEnergy saving effect is obviousGeneral water supply conservationSeawater treatmentWater desalinationWater vapor

The invention relates to a seawater desalination method and device of natural vacuum and low temperature distillation, which is characterized in that the system must be airtight before operation, the water injection valve on the system top is switched on to fill up the system with seawater; the drain valves of all drainage pipes connected with the evaporation chamber are switched on, then the seawater is flowed out under the influence of the gravity; the air in the system is discharged to make the system vacuum; the heat source can be conveyed to the evaporation chamber now; when the temperature of heat source is higher than the condensation temperature, the evaporation pressure of the heated seawater is higher than the condensation temperature of fresh water, the evaporated vapor is condensed by the condenser under the action of pressure difference between the evaporation pressure and the condensing pressure and finally the desalinated water can be obtained. The invention has the advantages that a sleeve regenerator is arranged on the connection section of the water supply pipe of seawater and the evaporation chamber, the heat of the strong brine discharged by the evaporator is partially adopted to preheat the seawater in the evaporator, the liquid in the system can flow freely due to the pressure difference, thus the method can economize energy source and the device can be used to desalinate the seawater on any sea island, water-deficient area or brackish water area.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

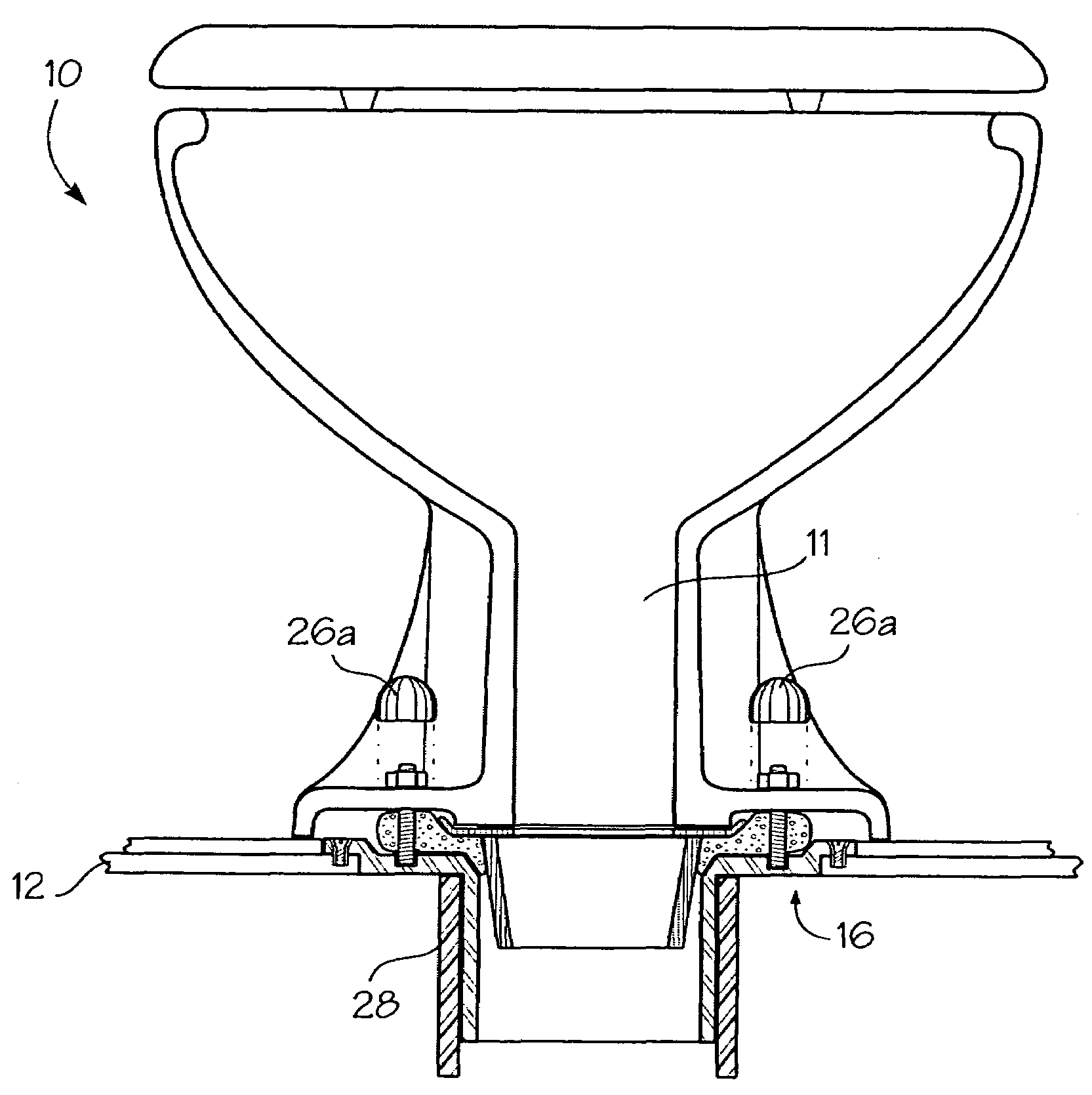

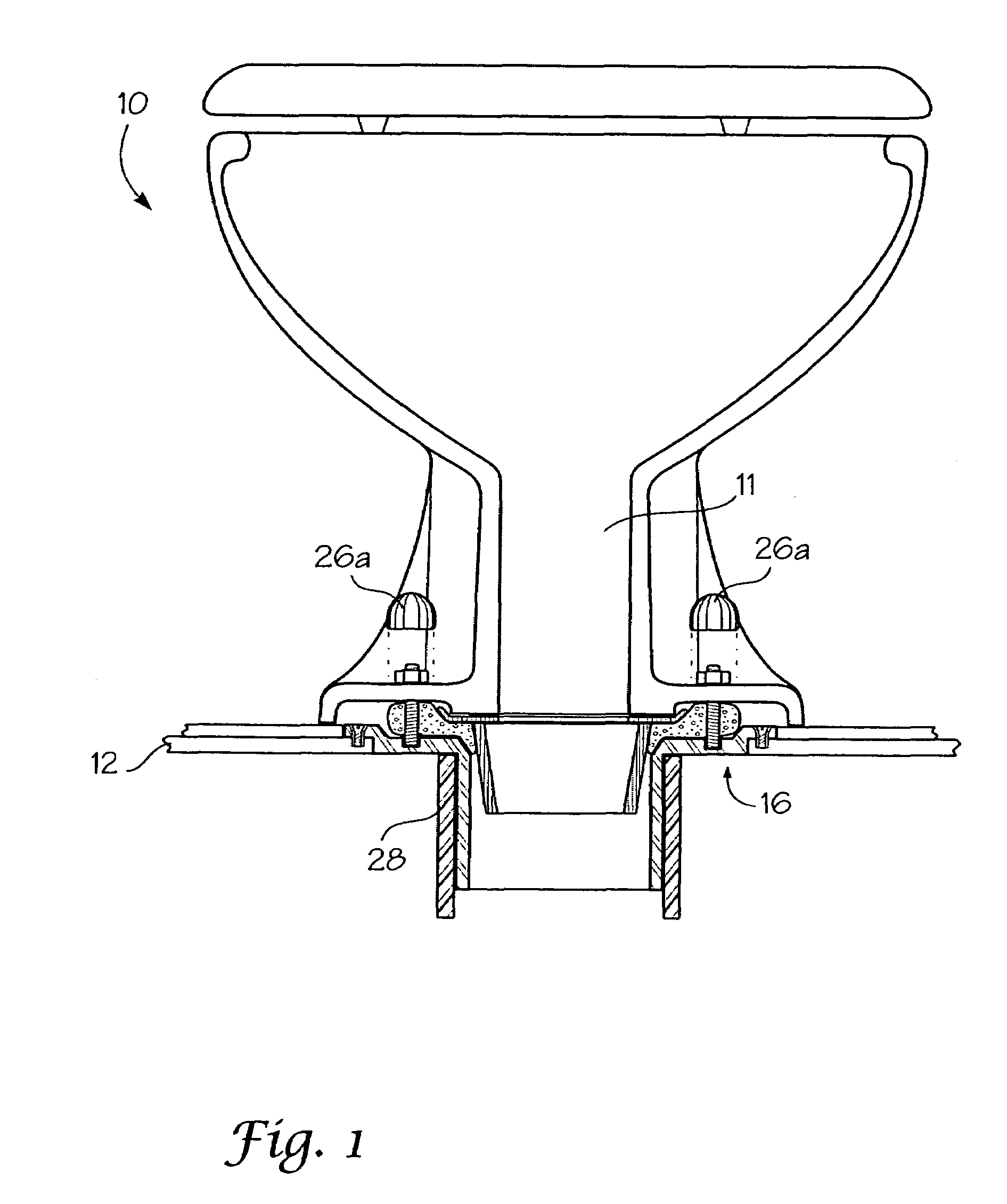

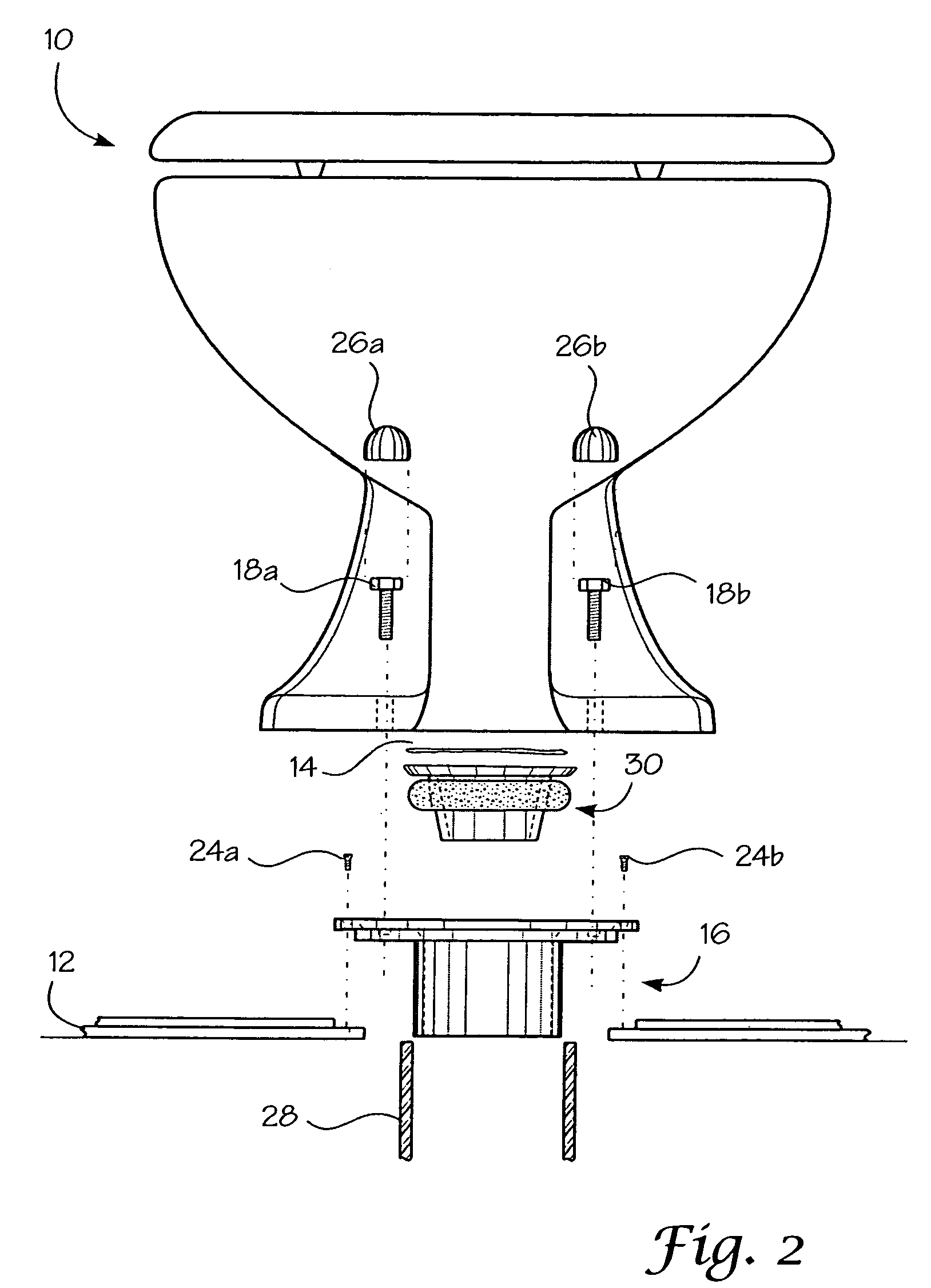

Floor saver toilet flange

A toilet leak containment assembly for preventing water leaks from a toilet during flushing onto the support flooring into which the toilet is attached. The leak containment assembly contains a leak collector for installation between the toilet base and the support flooring for preventing the water leaks onto the support flooring during flushing. The leak collector contains an attachment flange for attaching the leak collector to the support flooring, a collector pan for collecting water leaks during flushing, and an outlet pipe in fluid communication with the collector pan for channeling the leaks into the plumbing drain pipe. It also contains a leak seal assembly for installation and sealing between the toilet base and the leak collector. The leak seal assembly contains a flow channel for channeling water flow into the outlet pipe of the leak collector, and a seal for sealing between the toilet base and the leak collector.

Owner:FLUSHING FLANGE

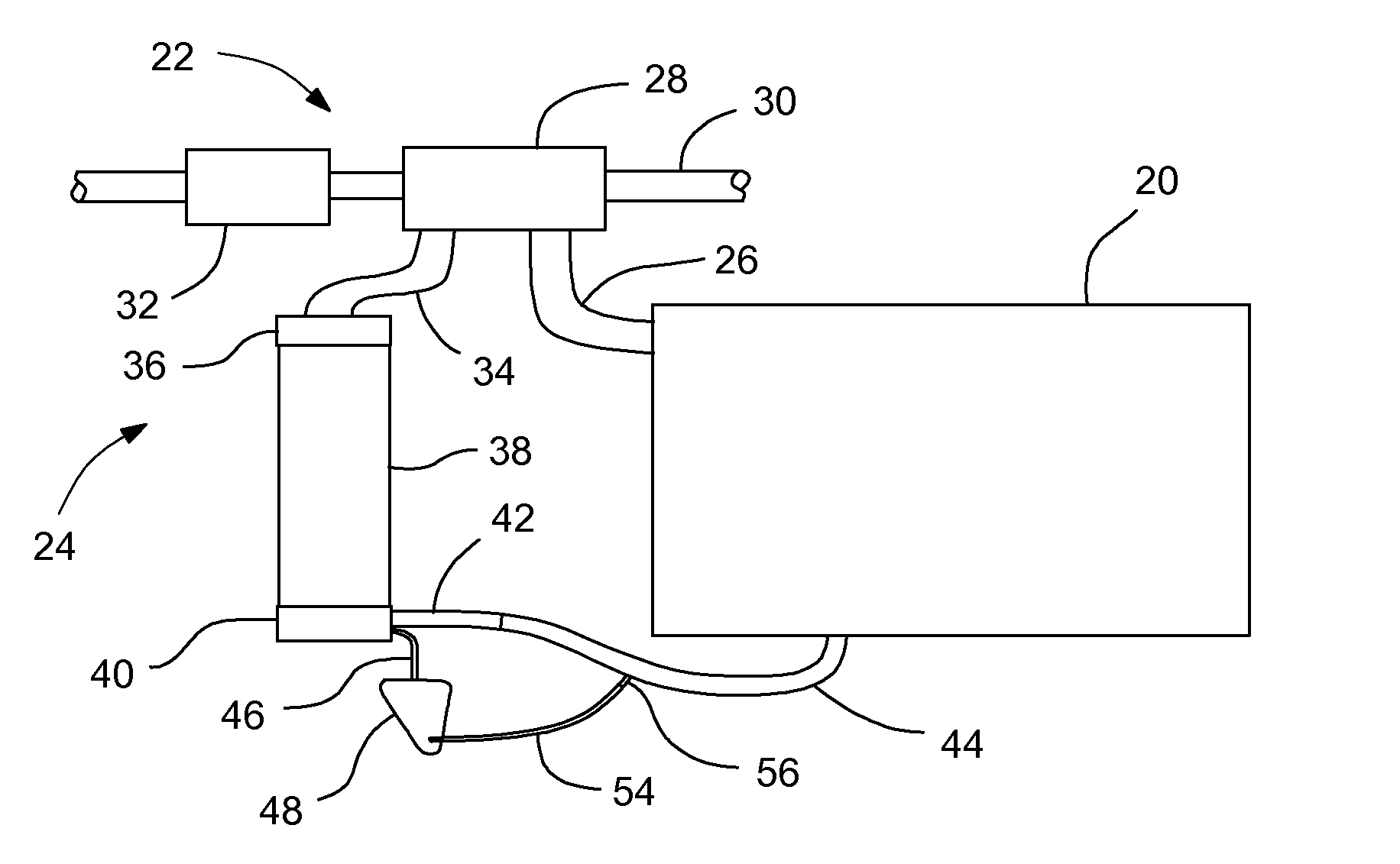

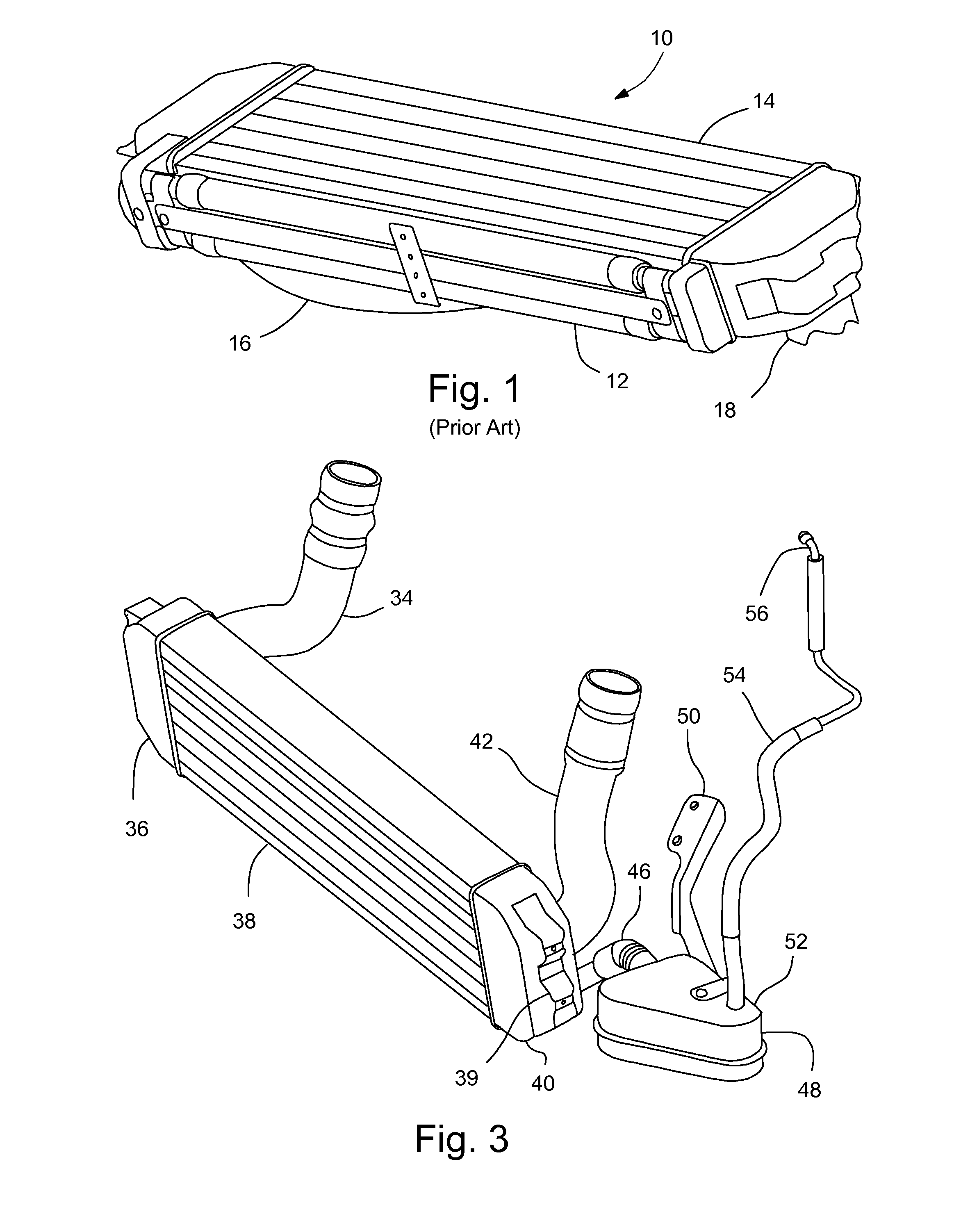

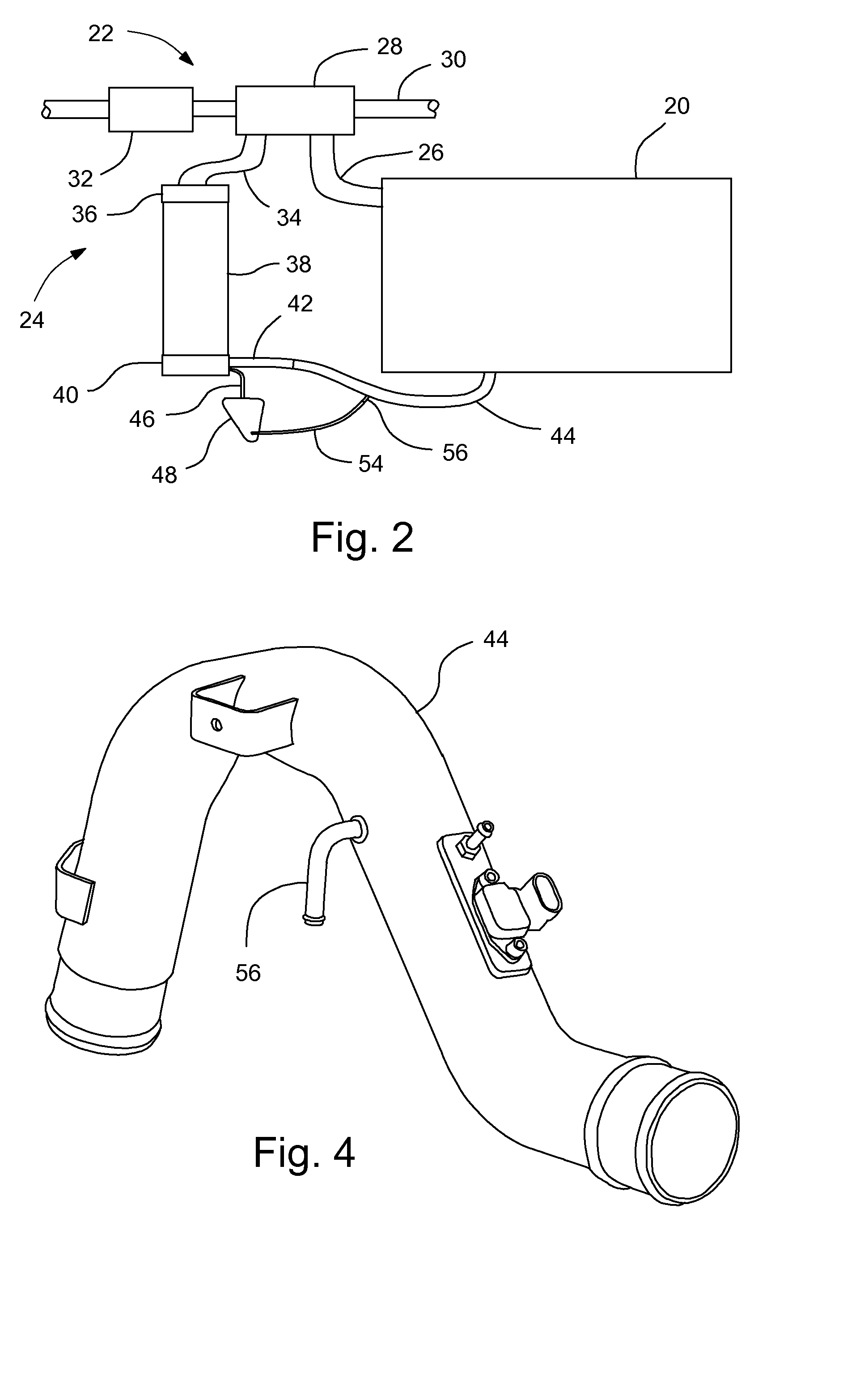

Intercooler Having Condensate Reservoir

InactiveUS20110107760A1Improved intercooler performanceMaximum charge-air-cooler heat exchanger effectivenessNon-fuel substance addition to fuelInternal combustion piston enginesDraining tubeTurbocharger

An engine air intake system for a vehicle having an internal combustion engine may include a turbocharger; a CAC heat exchanger having an inlet end for receiving compressed intake air from the turbocharger and an outlet end; a remote condensate reservoir spaced from the CAC heat exchanger, for storing condensate therein; a condensate drain tube extending from the outlet end to the remote condensate reservoir to allow condensate produced in the CAC heat exchanger to flow into the remote condensate reservoir; an air duct connecting the outlet end to the engine to direct air flow from the outlet end to the engine; and a reservoir outlet hose connected to the remote condensate reservoir at a first end and connected to the air duct at a second end to allow condensate evaporating from the remote condensate reservoir to flow through the reservoir outlet hose into the air duct.

Owner:GM GLOBAL TECH OPERATIONS LLC

Bath drain closure assembly

A drain closure assembly for use with a bathtub, having a drain closure device with a stopper positioned above a lower drain and a plunger device attached to the stopper adapted to bias the stopper in a downward direction. An actuating mechanism received within a housing in communication with a conduit extending from the lower drain, the actuating member having a main body that contacts the drain closure device and moves the drain closure device to an open position when activated and a closed position when deactivated.

Owner:WCM IND INC

Transportable water treatment system

ActiveUS6936176B1Easy to operateEasy maintenanceTreatment involving filtrationSedimentation separationWater treatment systemDraining tube

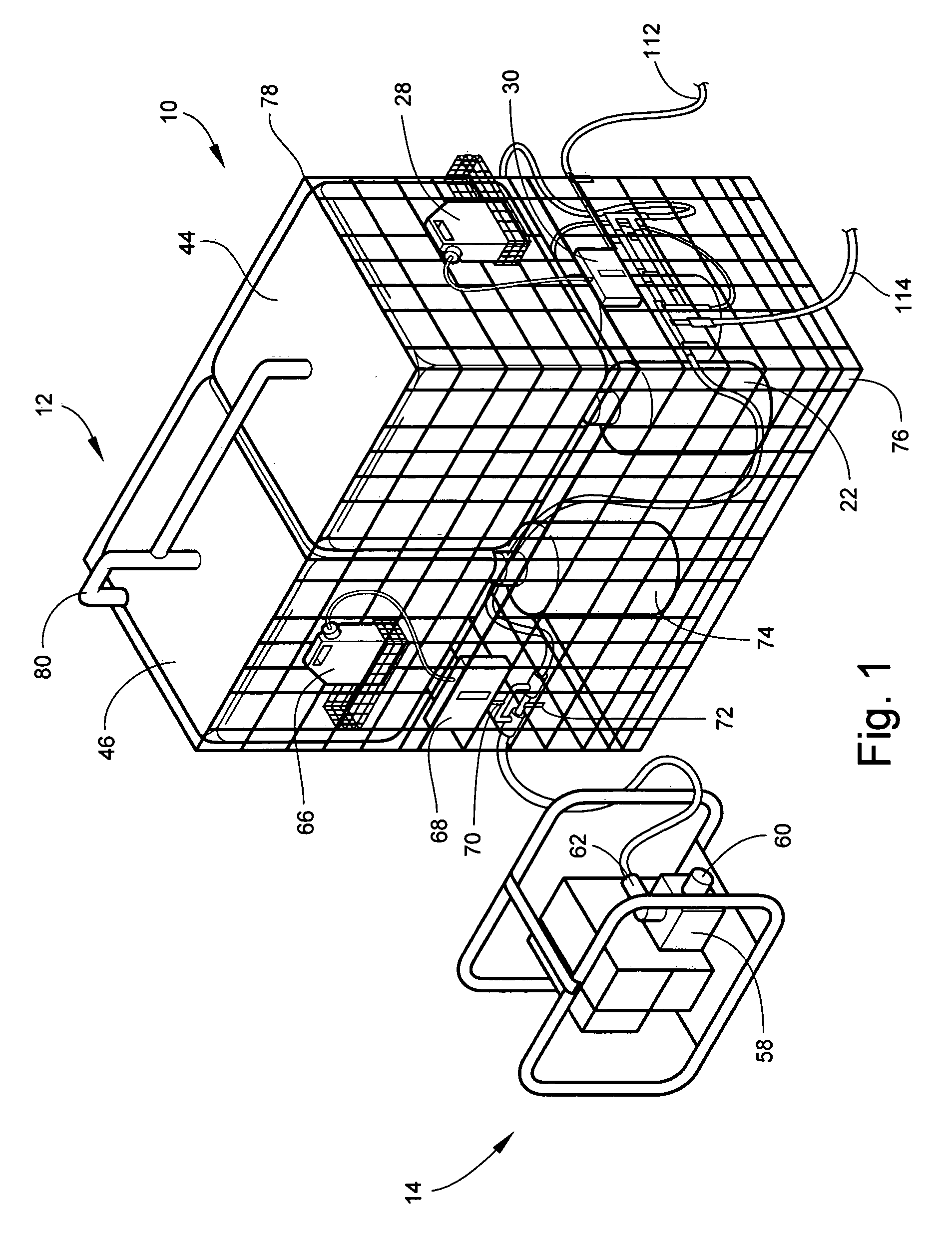

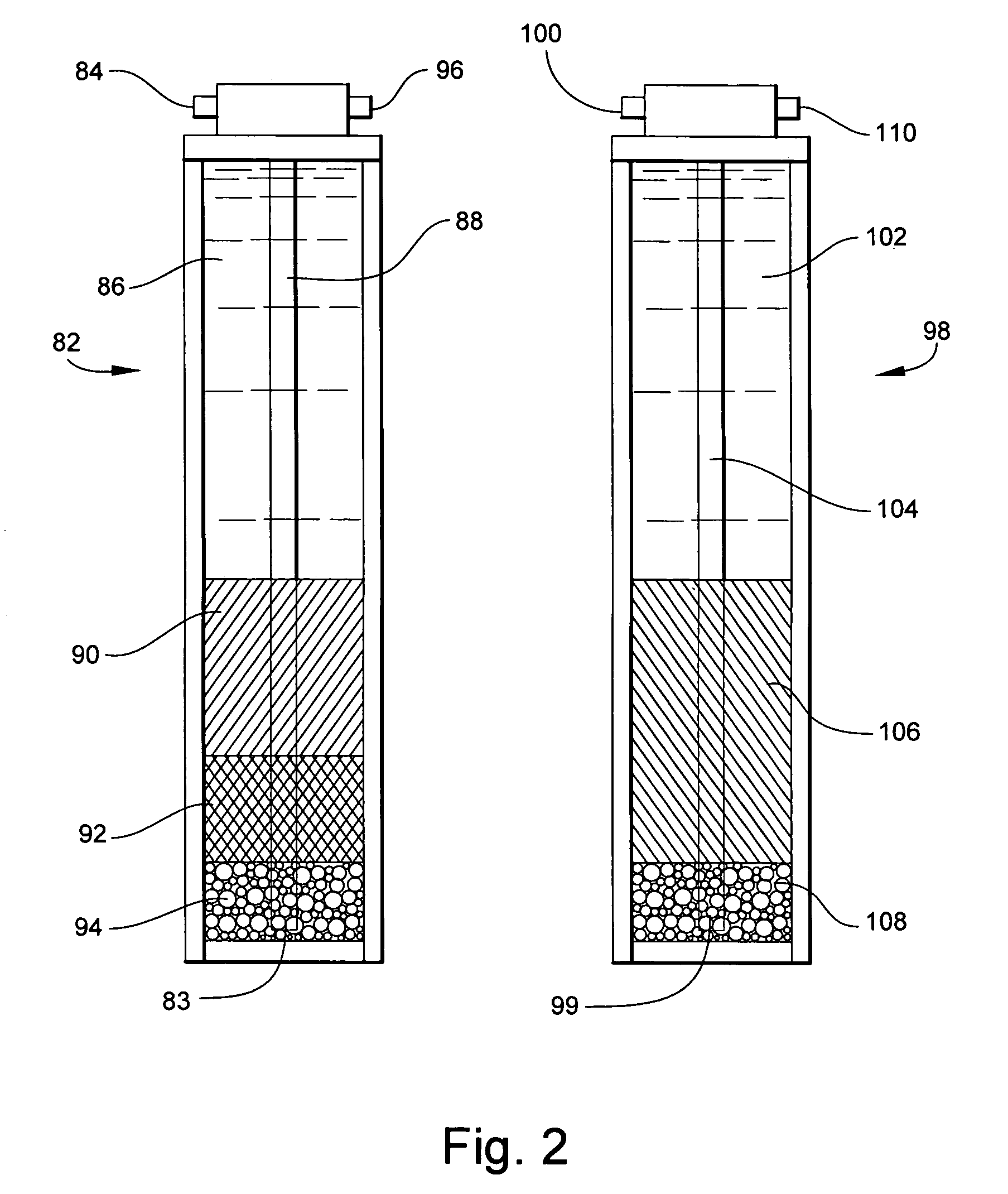

A transportable water treatment system comprising: an inlet adapted to receive water having a pressure of between 10 to 60 psig, a primary regenerable filter connected so as to receive water that has flown through the inlet, the primary regenerable filter configured to separate solids from water flowing therethrough, a secondary regenerable filter, the secondary regenerable filter connected downstream from the primary regenerable filter, and a chemical feed unit connected downstream of said secondary regenerable filter, the chemical feed unit configured to treat water flowing through introduction of chemicals to the water, a water discharge pipe adapted to discharge treated water from the chemical feed unit, where said inlet, the primary regenerable filter, the secondary regenerable filter, the chemical feed unit, and the discharge pipe make up a transportable water treatment and the transportable water treatment is adapted to fit within a bed of a sub-compact pickup truck.

Owner:WATER MISSIONS INT

Shower drain adapter

A shower drain adapter configured to allow use of a bondable waterproof membrane with a shower pan drain system comprises a drain body and a lower mating flange extending from the drain body. The lower mating flange is operable to mate with an upper portion of a body of a shower pan drain installable on a waste pipe. An integrated bonding flange extends from the drain body and is operable to be sealably attached to a bondable waterproof membrane to provide a waterproof seal between the membrane and the adapter.

Owner:SCHLUTER SYST LP

Efficient aeration tank

InactiveCN107010719AWell mixedIncrease contact areaSustainable biological treatmentBiological water/sewage treatmentDraining tubeDrive shaft

The invention discloses an efficient aeration tank which comprises a tank wall, a bracket, a motor, a transmission shaft, an aeration plate, a blower, a water inlet pipe and a drain pipe, wherein the bracket is fixedly connected with the upside of the tank wall; the lower surface of the bracket is fixedly connected with the motor; a shaft extension end of the motor is fixedly connected with the transmission shaft; a right rotating shaft is rotationally connected with an inner wall on the right side of the tank wall; a left rotating shaft is rotationally connected with an inner wall on the left side of the tank wall; stirring plates are fixed on the left rotating shaft and the right rotating shaft; the tail end of the transmission shaft is fixedly connected with the upper surface of the aeration plate; sewage in a middle layer is turned over vertically by the stirring plates; the sewage and air are mixed more uniformly; the aeration plate exhausts the air into the sewage in a rotating process for aeration of the sewage; the aeration plate exhausts the air while rotating; the air and the sewage are mixed more intensively; the stirring rod scatters bubbles exhausted by the aeration plate; the contact area between the air and the sewage is increased; and an aeration effect is further improved.

Owner:HEFEI ZHIHUI LONGTUTENG INTPROP CO LTD

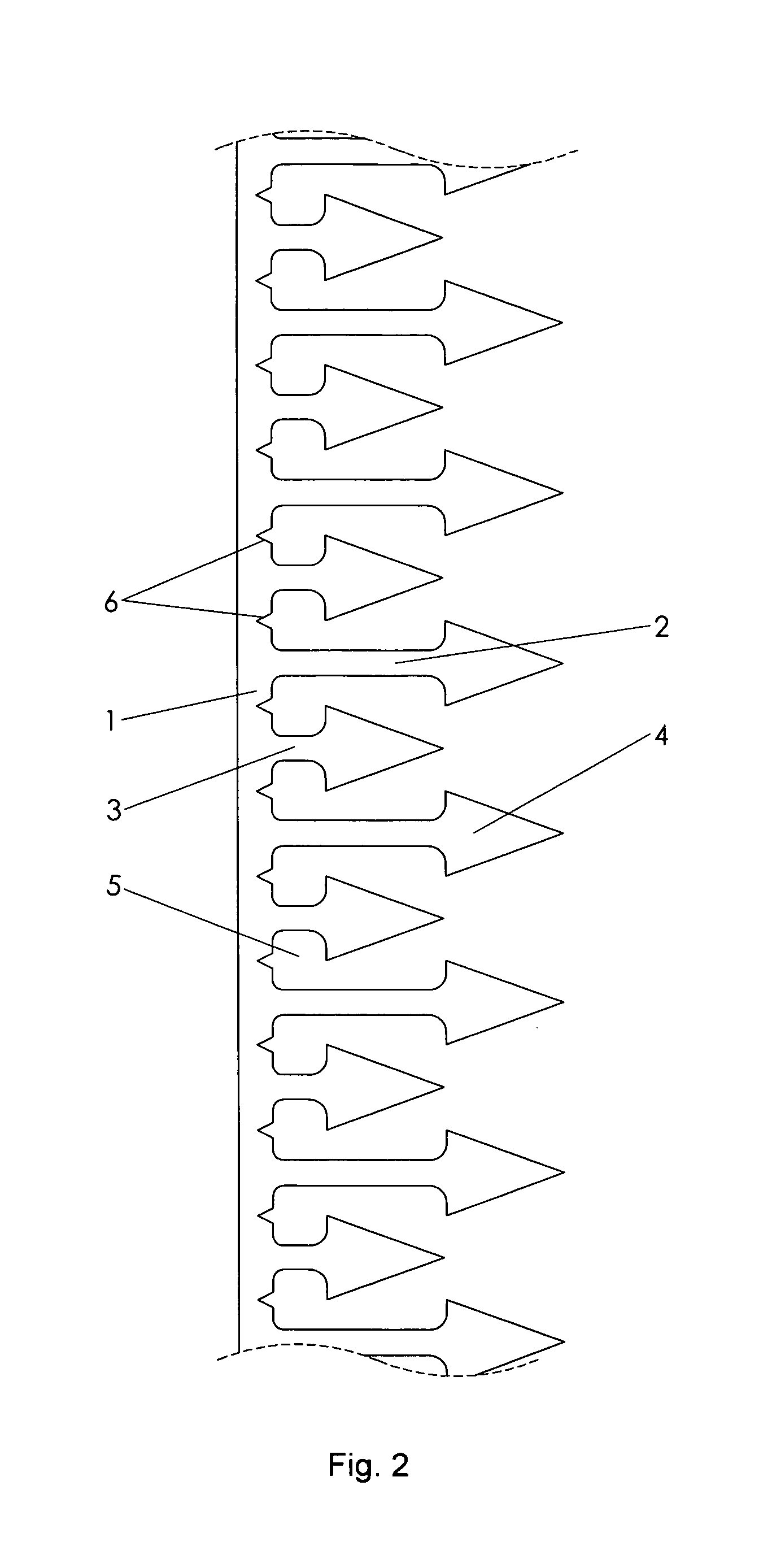

Self-cleaning urinal anti-splash device

A self-cleaning urinal anti-splash device having a series of angled deflectors which send the urine stream ever deeper into a series of channels leading down toward the urinal drain. The angled deflectors not only send the urine stream ever deeper into the channels, but they simultaneously prevent the urine from exiting the channels in any direction other than downward toward the drain. This is accomplished by virtue of the fact that inner faces of the deflectors are adapted to deflect the urine back toward the urinal wall. No plane perpendicular to the direction of the initial urine stream is presented to the user. Gravity then causes it to flow to the drain. The device is also self cleaning because there is nothing to prevent the water of a flush cycle from passing through the vertical channels by gravity feed, thereby removing all the urine on the deflector surfaces. The device can be made of metal, plastic, rubber, or other inexpensive easily moldable substance. It has notches in the channels so the device is easily trimmed to size.

Owner:CHOU MICHAEL C

Closet flange with knockout retainer

A closet flange is provided for coupling the base of a toilet to a drain pipe. A main generally cylindrical body portion is dimensioned for connection to the upper end of a drain pipe and has a through bore for communicating with the interior of the drain pipe. An attachment flange portion extends radially outward from an upper end of the cylindrical body portion and is configured for connecting to the base of a toilet. A knockout temporarily seals the through bore and is removable by breaking away a peripheral edge of the knockout. A retainer extends radially inward from an inner wall of the cylindrical portion below the knockout and is configured to prevent the knockout from falling down the through bore and into the drain pipe when broken away in order to prevent drain clogging.

Owner:IPS

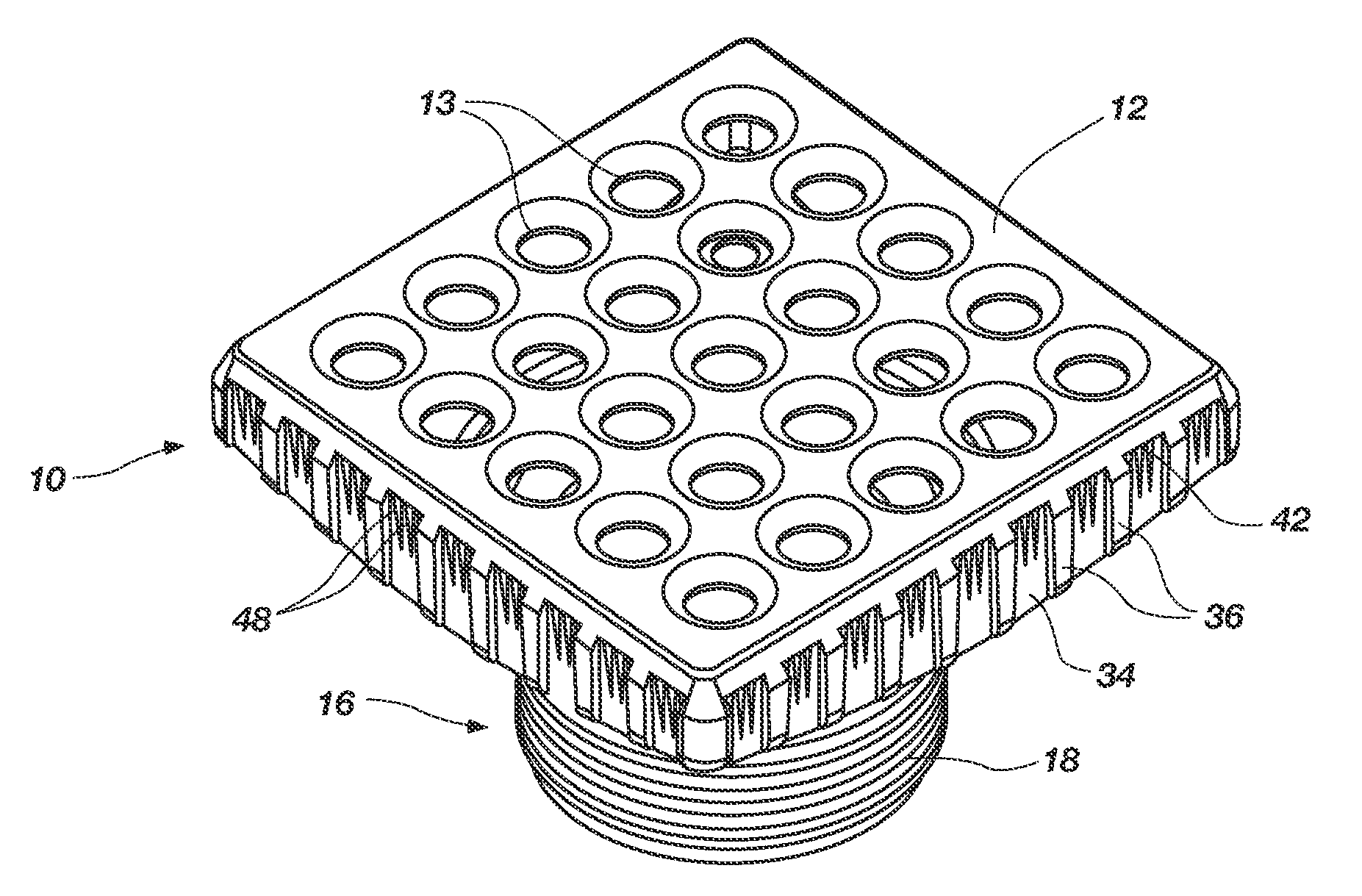

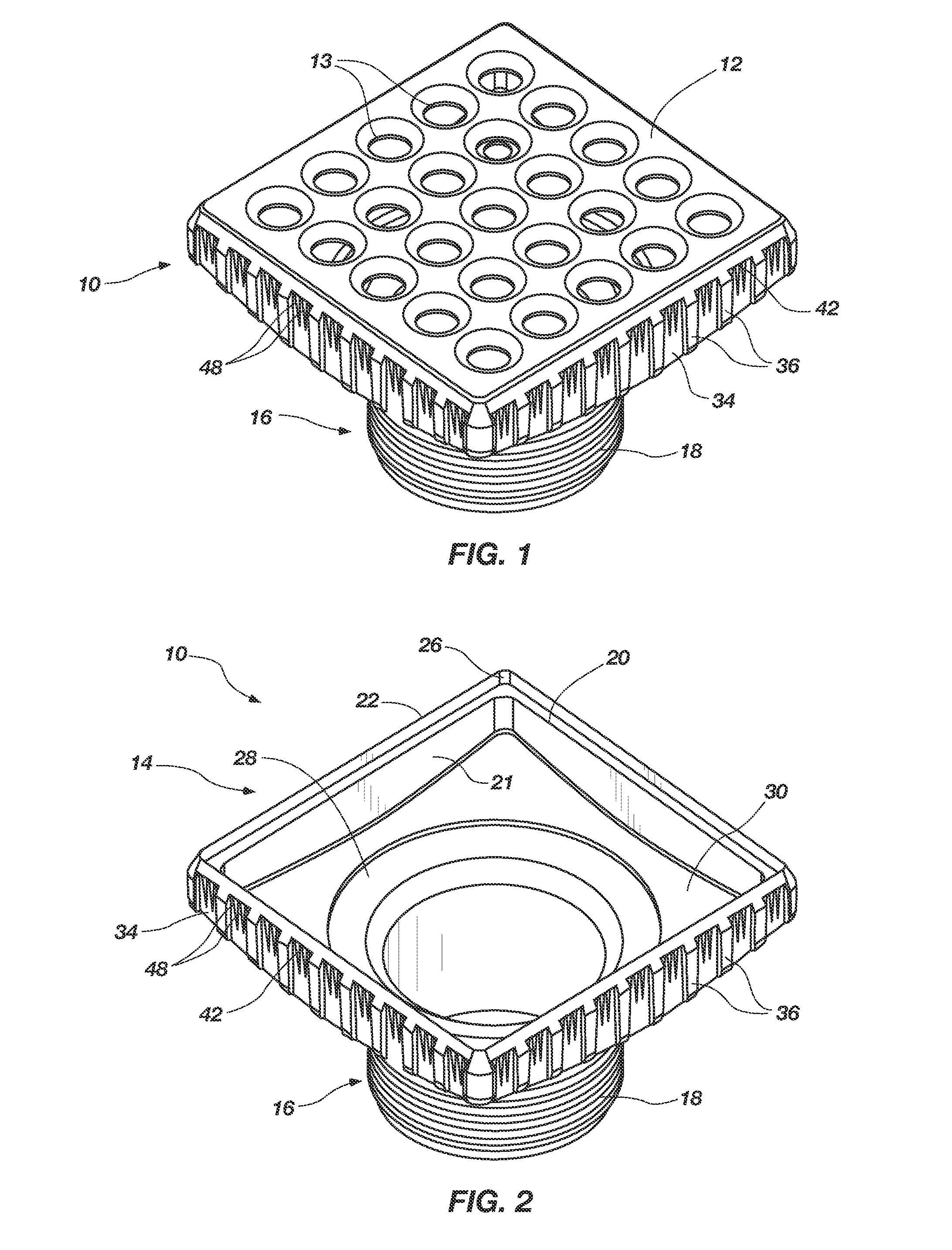

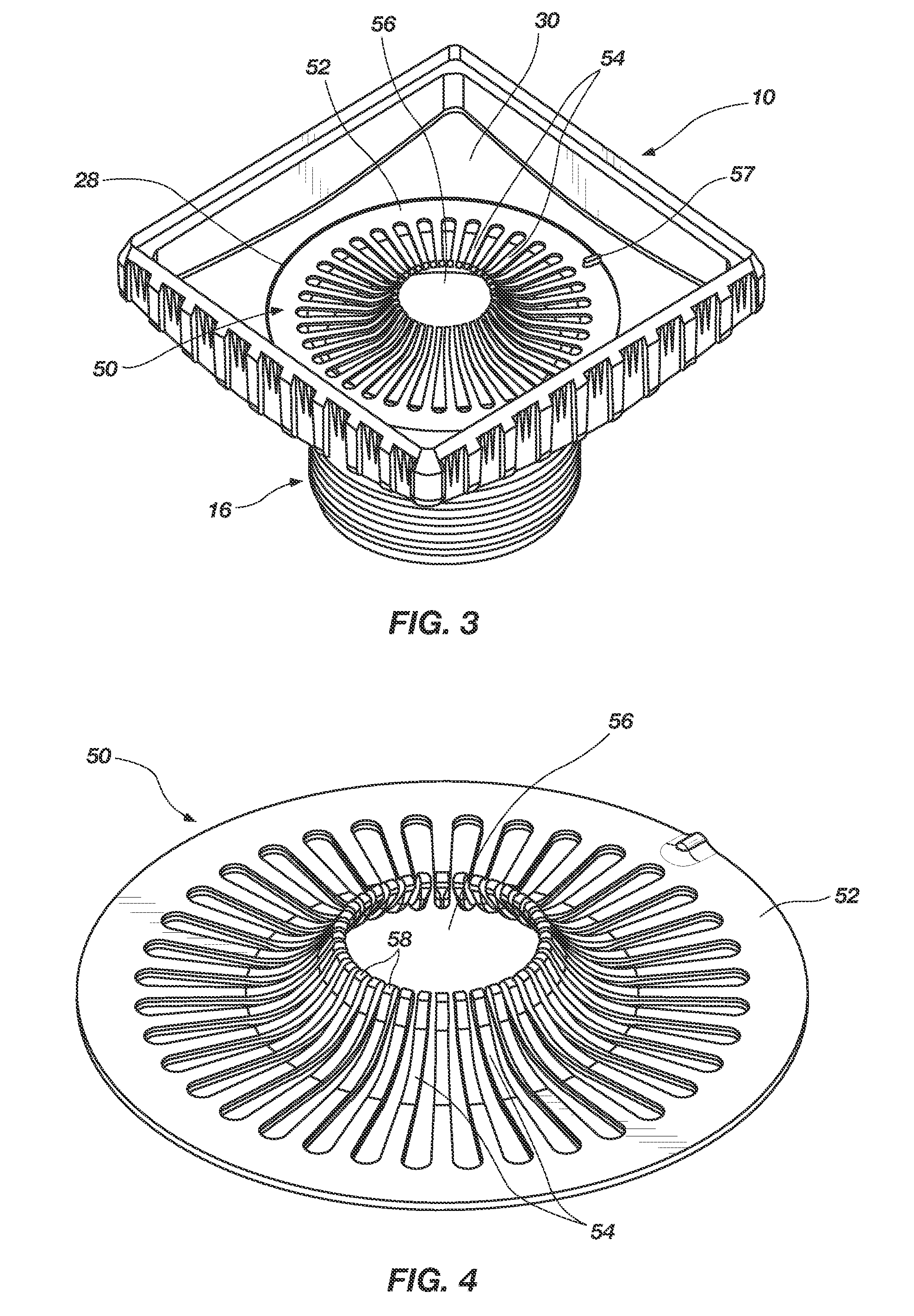

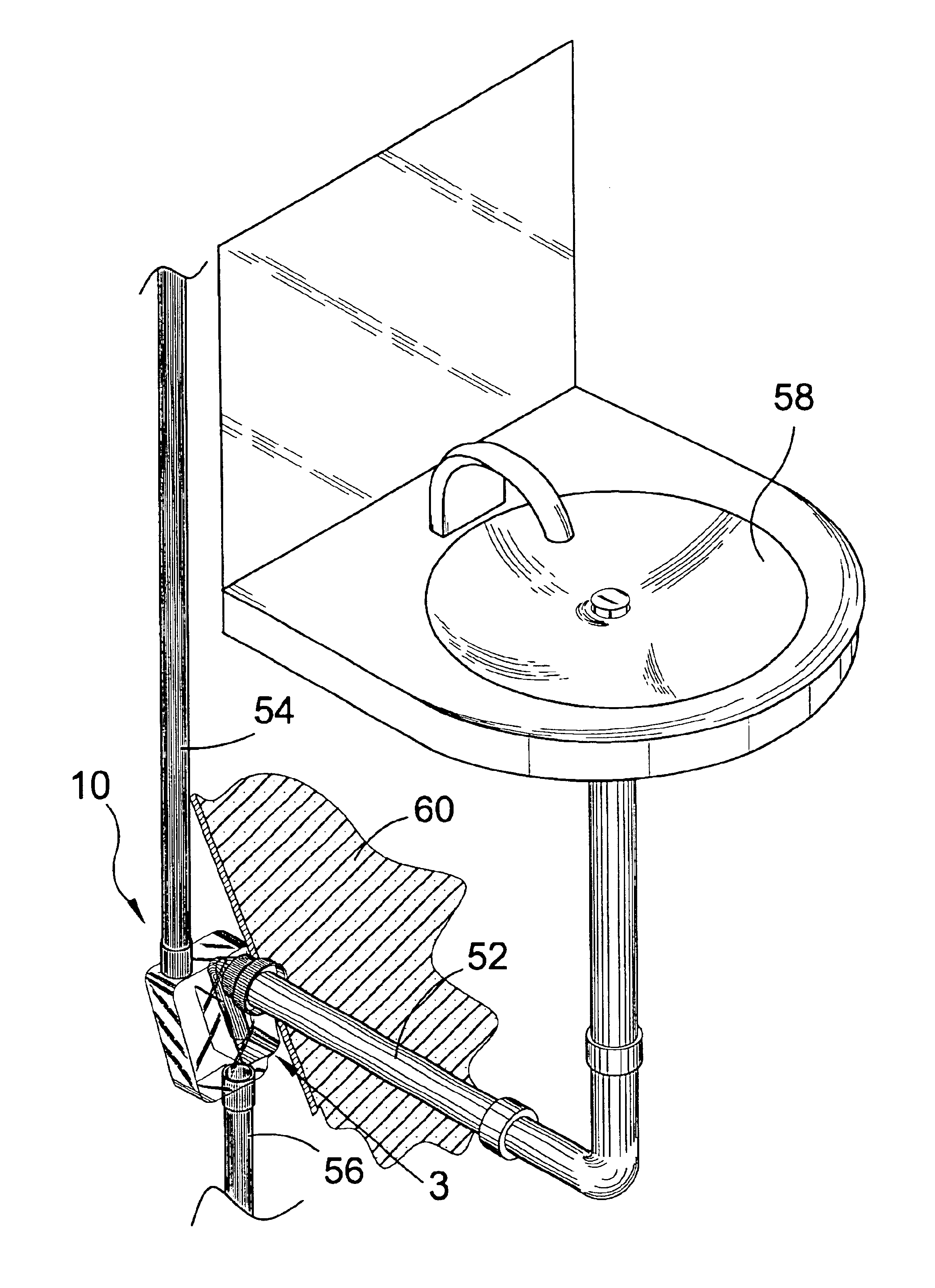

Clog resistant drain

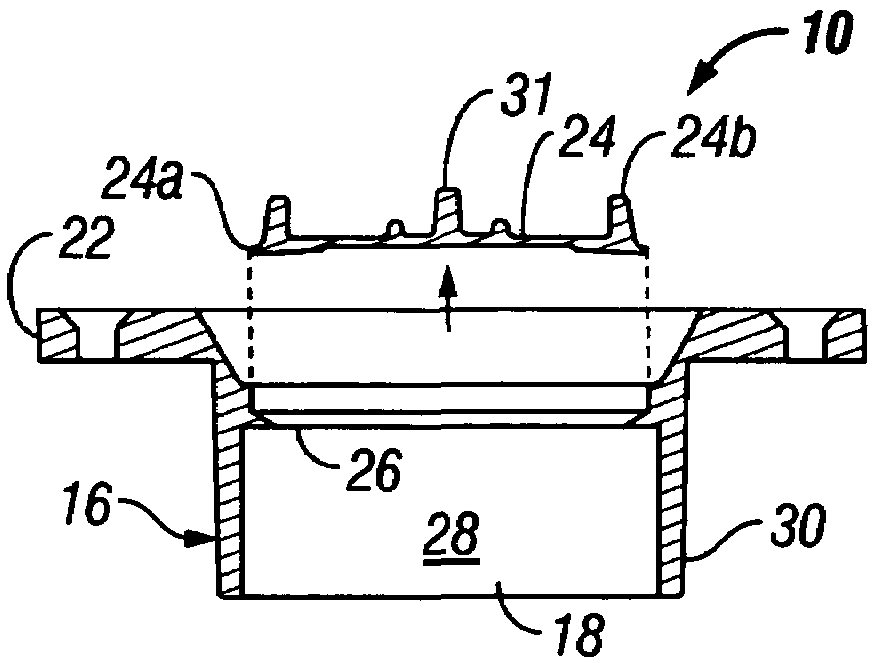

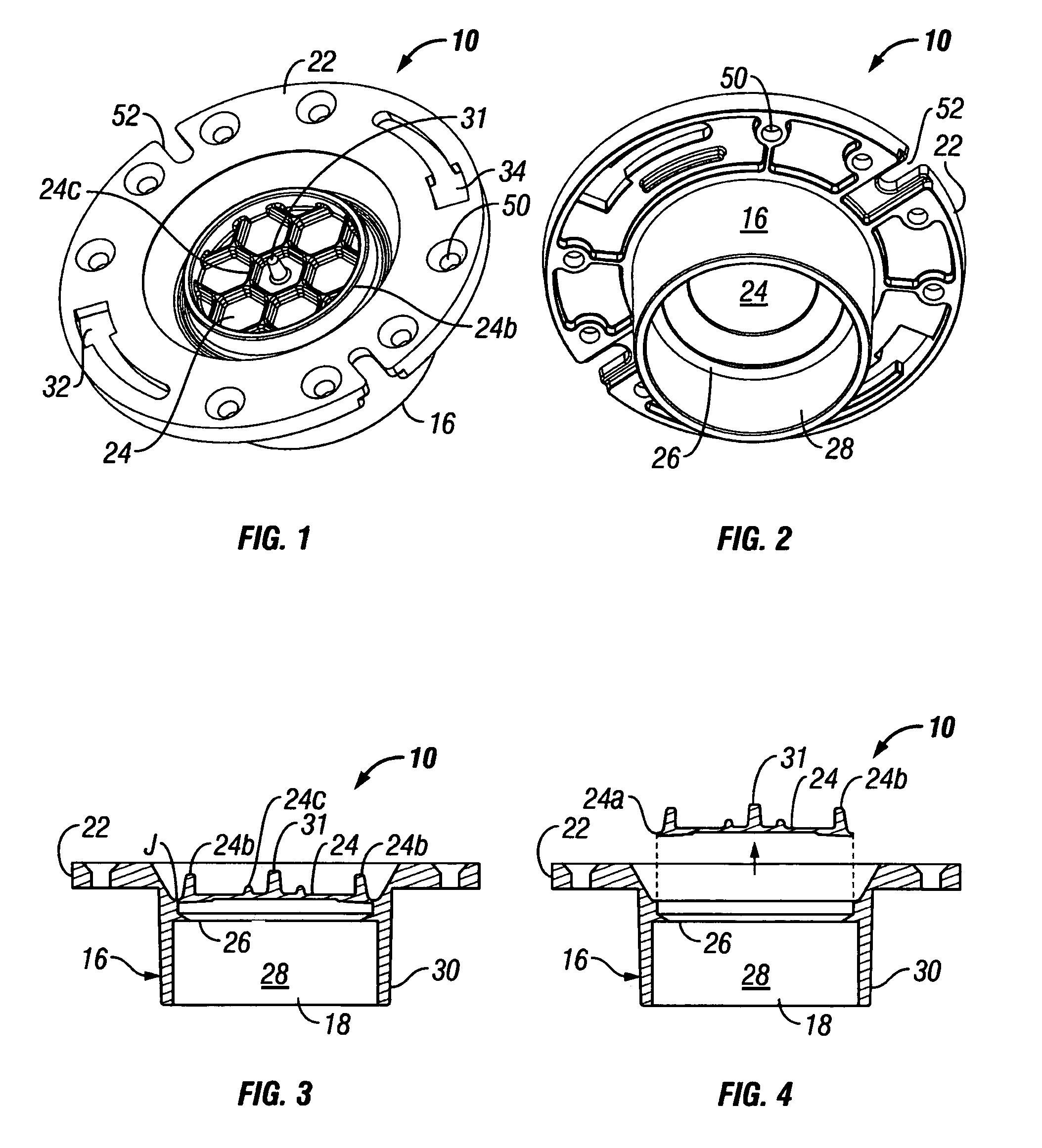

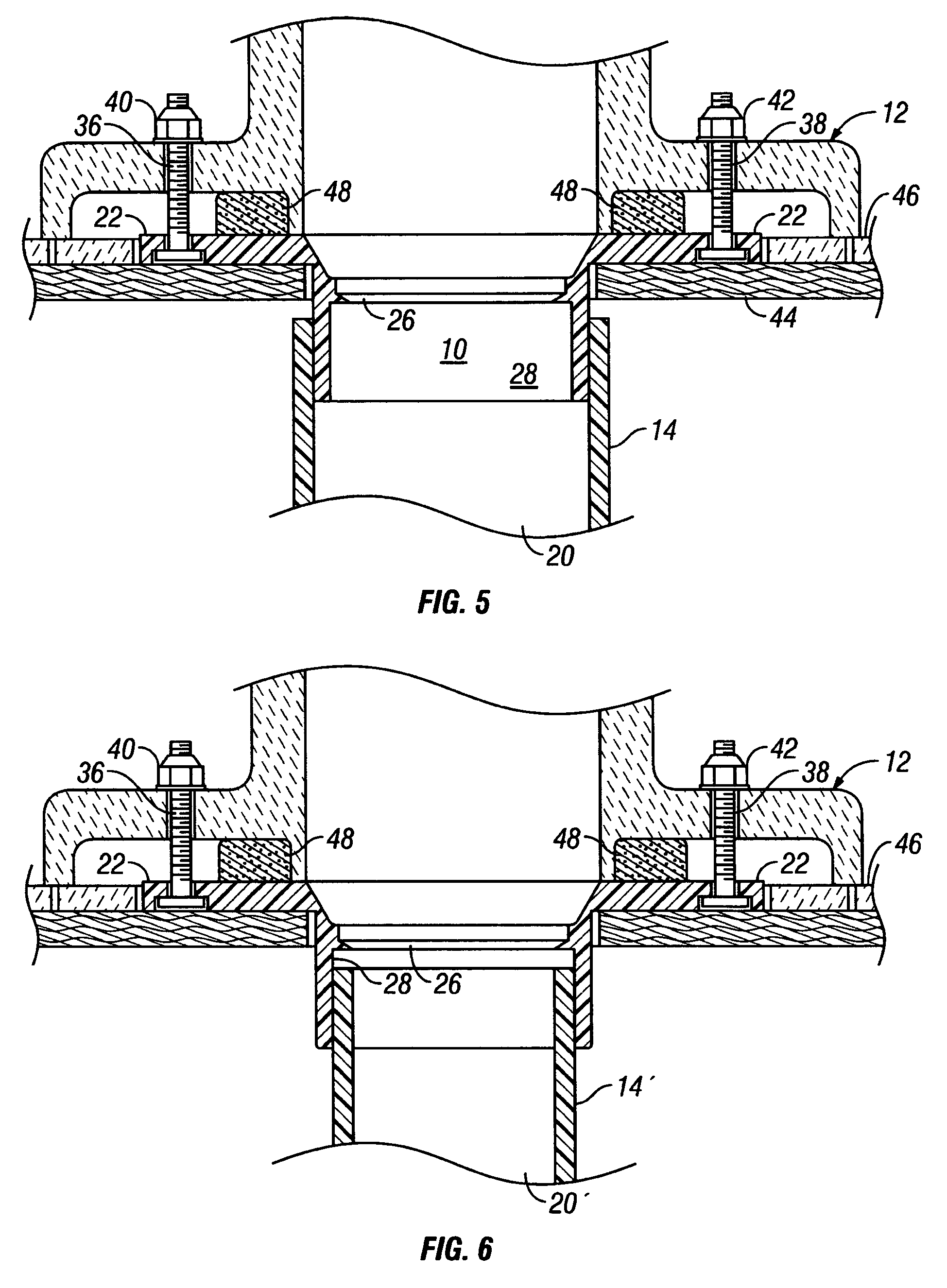

InactiveUS7150576B1Easy constructionLow production costDomestic plumbingNibsSuspended particlesDraining tube

A clog free drain for a surface water drain such as that utilized in a tub or stall shower including a basket having side openings permitting waste water to flow there through and into the drain pipe in which the basket is disposed. Directing waste water into the basket is by a sleeve located coaxially of the basket and the drain pipe and below the drain plate whereby the waste water flows through the sleeve, out an opening in the bottom thereof in to the closed bottom of the basket. The waste water accumulates below and into the sleeve and into the basket to a level of the side openings in the basket where it flows into the drain pipe. Pooling of the waste water in the bottom of the basket allows the debris, hair, soap scum and other suspended particles to accumulate in the bottom of the basket and thus separated from the waste water flowing in to the drain pipe.

Owner:KAMBEYANDA DONA M

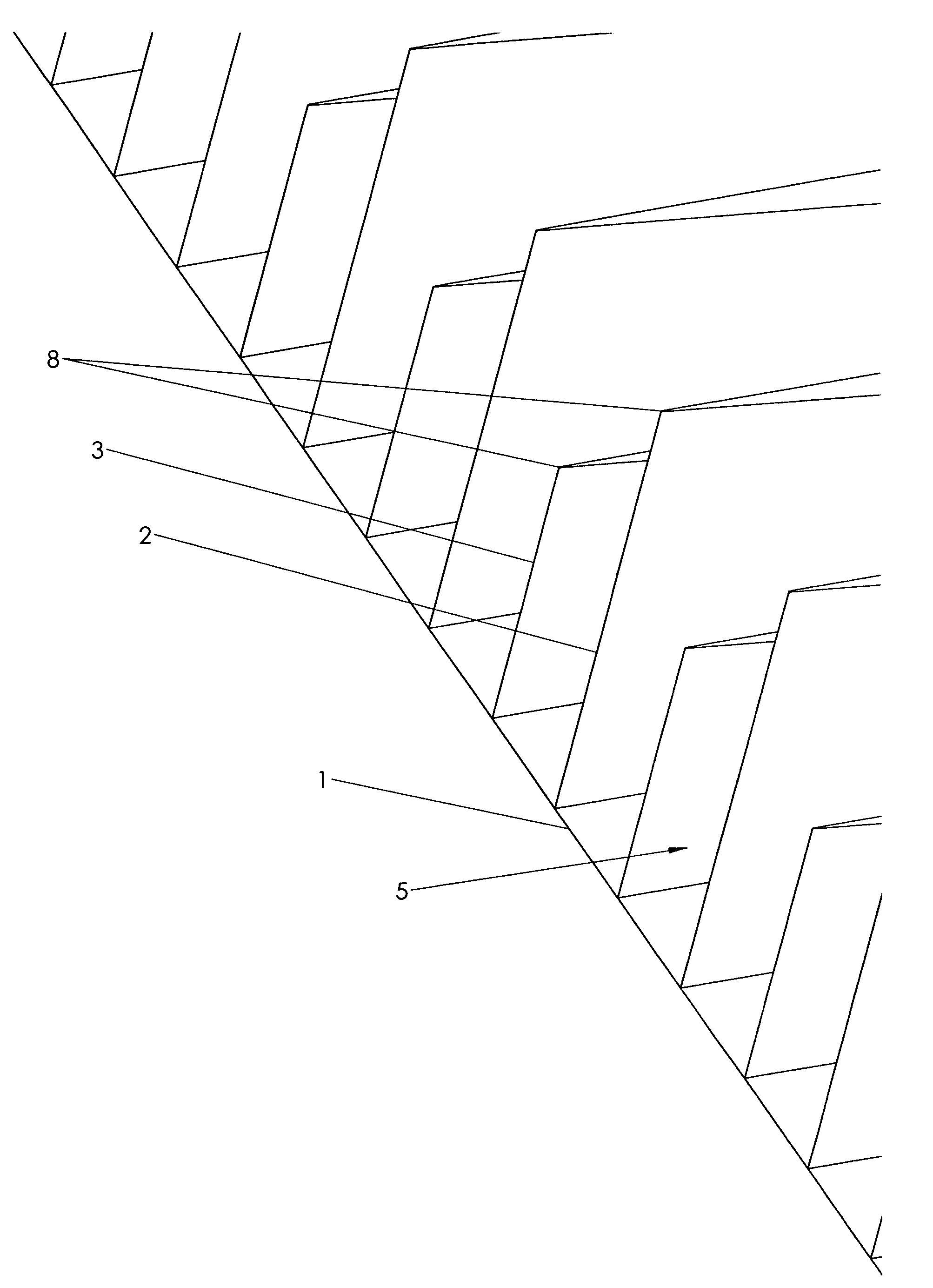

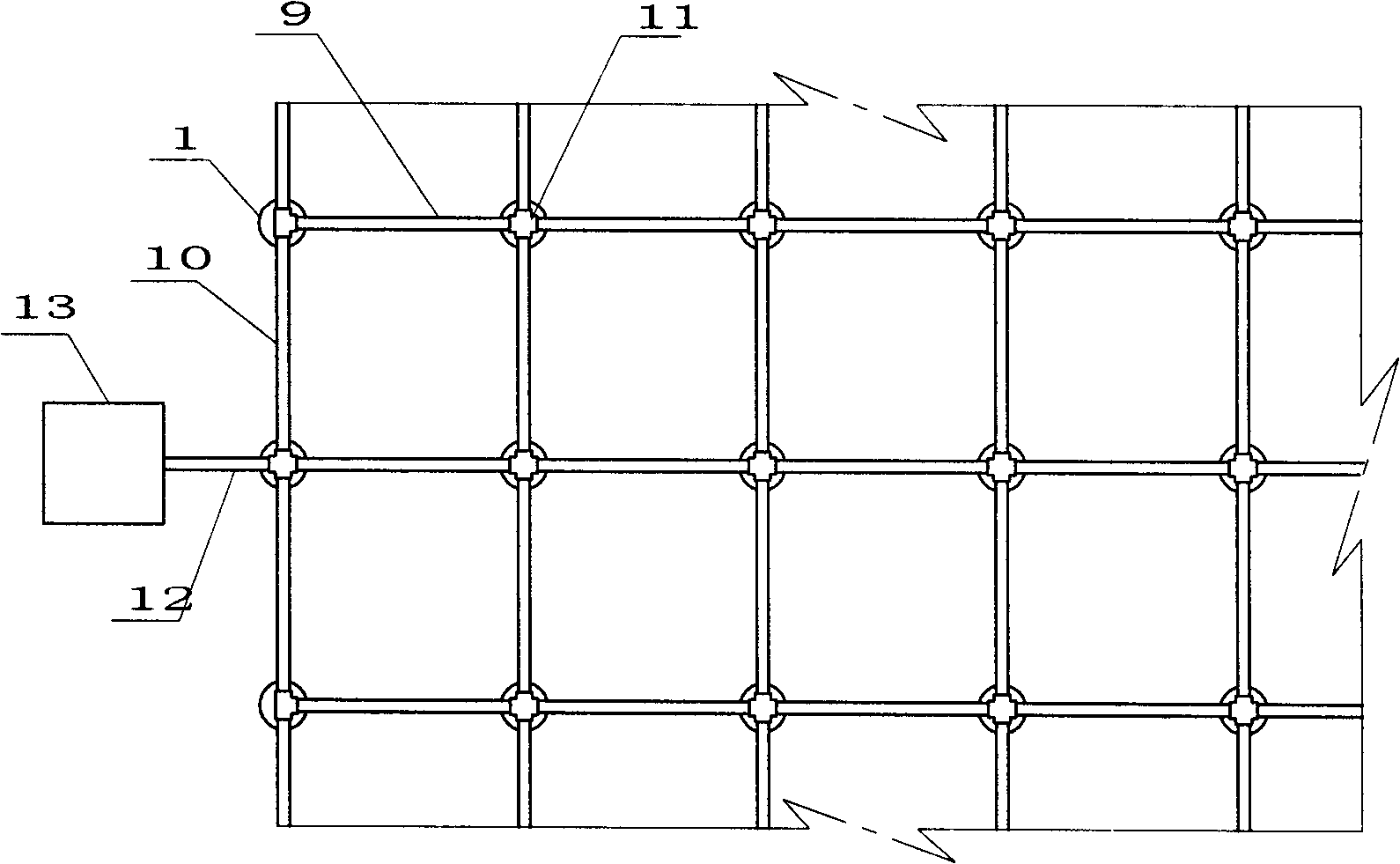

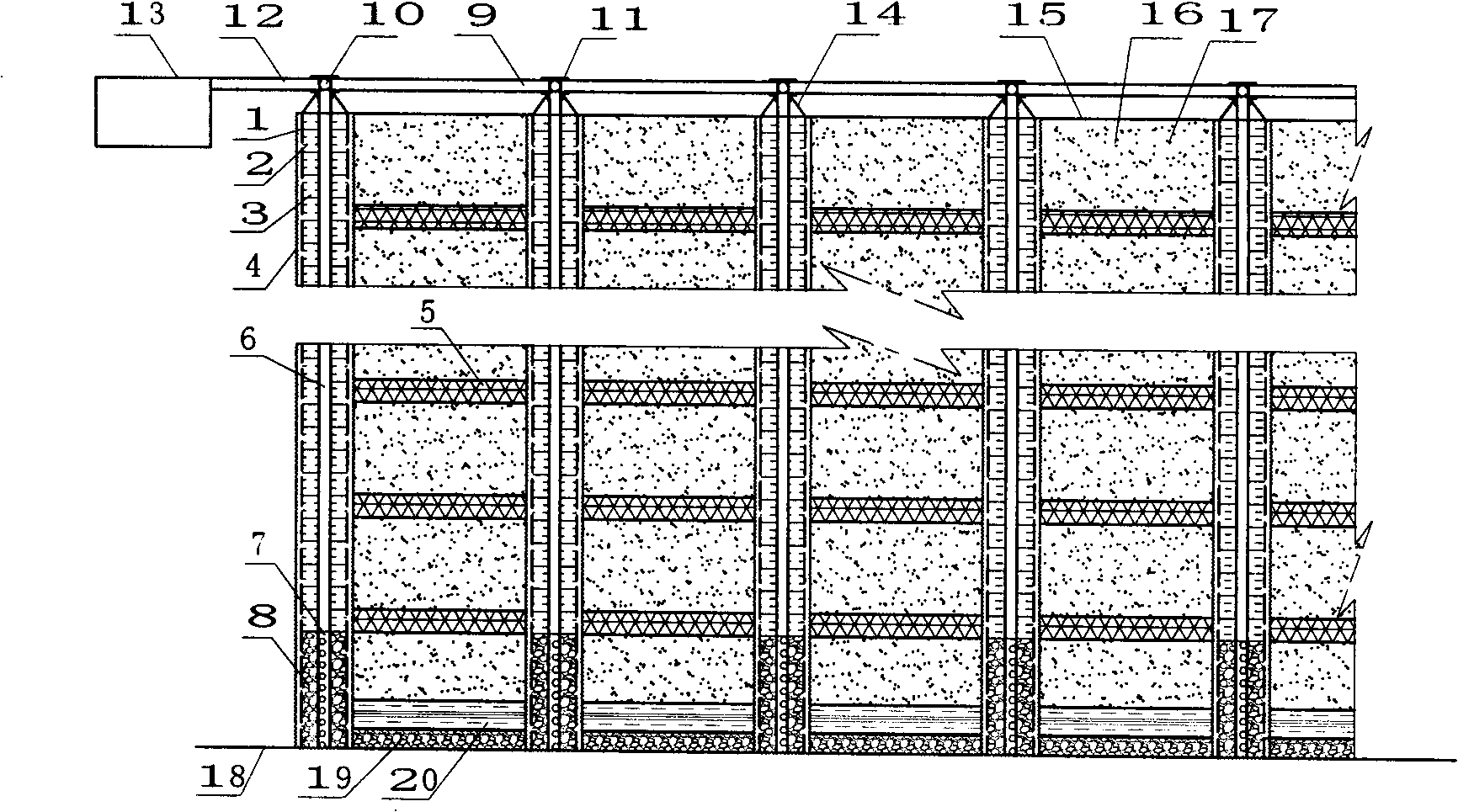

Stereoscopic network drainage for accelerating water drainage consolidation velocity of hydraulic mud fill sludge

InactiveCN101357817ASludge treatment by de-watering/drying/thickeningSolid waste disposalDraining tubeSludge

The invention relates to a three-dimensional network drainage device for accelerating the consolidation speed of the drainage of filled silt. The device is composed of a ripple pipe, a plastic drainage plate and a pumping-drainage pipe, water inlet holes are evenly distributed on the side wall of the ripple pipe, geo-filter cloth is wrapped at the outside thereof, medium-coarse sand with 50cm to 60cm is filled at the bottom part of the ripple pipe, the plastic drainage plate and the ripple plate are connected by adopting the geo-filter cloth for binding, the lower part of the pumping-drainage pipe is processed into a perforated pipe to be inserted in the medium-coarse sand at the bottom part of the ripple pipe, the upper part is connected with an outer pumping-drainage system by a connector to form the three-dimensional network drainage device; a drainage pipe network in the silt filling and the consolidation processes can be connected with an outer pumping-drainage device, thereby realizing the whole process of drainage and improving the drainage efficiency and the speed.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

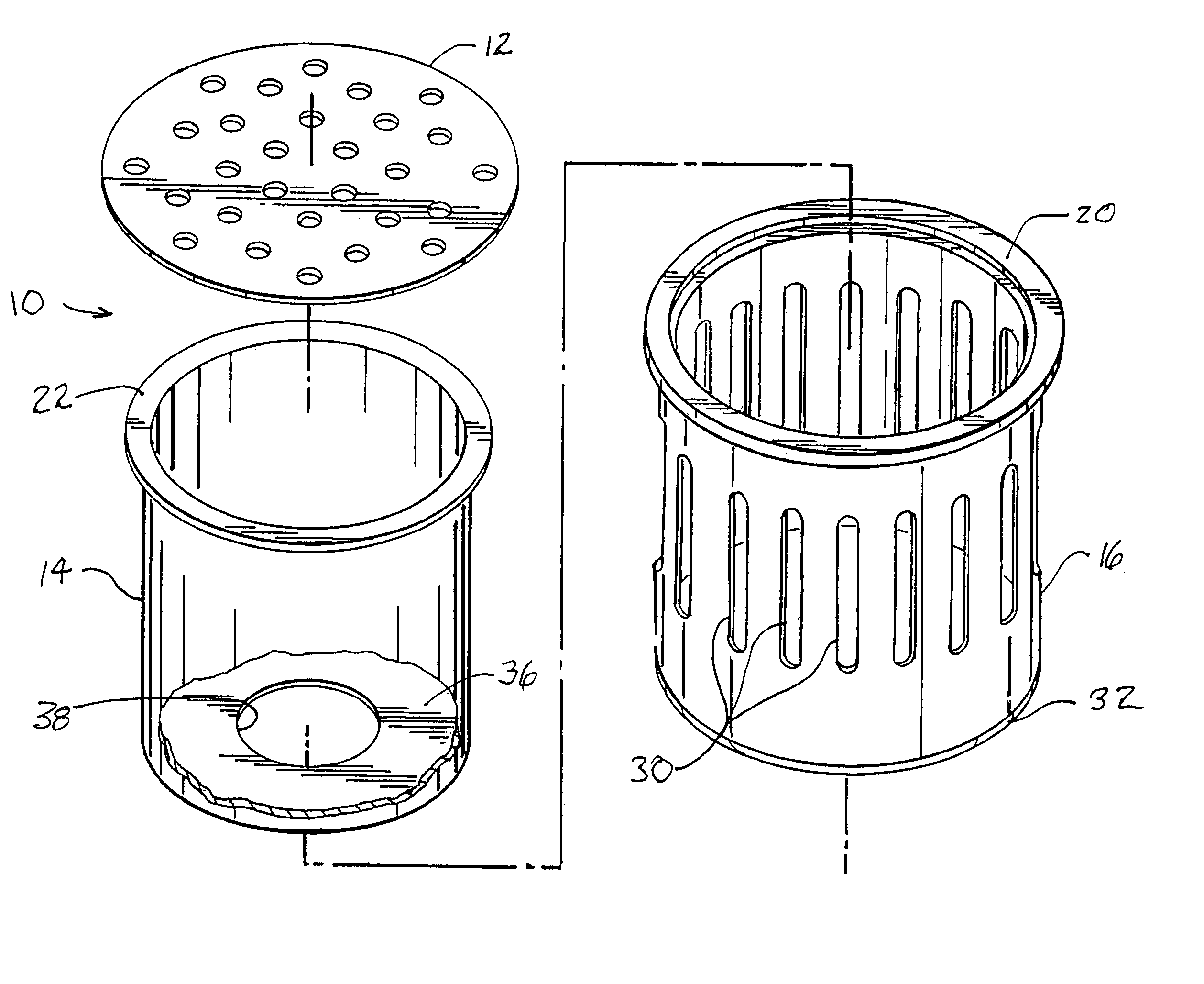

Debris trap for a drain

ActiveUS20120047643A1Easy to removeEasy to cleanSewerage structuresDomestic plumbingDraining tubeEngineering

Owner:MEYERS LAWRENCE G

In-the-wall plumbing trap with integral waste and vent line

InactiveUS6845527B1Avoid back pressurePrevent siphonValve arrangementsDomestic plumbingDraining tubeEffluent

An in-the-wall plumbing trap having integral connections for waste and vent lines wherein in the vent connection is located on the top of the trap housing and the waste connection on the bottom thereof. A substantially vertical wall formed by an overflow member separates the housing interior into two chambers with a liquid seal chamber located beneath a waste intake line and a separation chamber disposed on the other side of the overflow member. Effluent waste entering the liquid seal chamber builds up until reaching the top of the overflow member where it then spills over into the separation chamber and any gases contained therein rise to the top of the housing and escape through the vent line as the fluid flows to the bottom of the separation chamber and exits through the drain pipe.

Owner:KOHN GUY LINDSAY

Debris trap and method of trapping debris

Most commercial & residential buildings have rainwater collection systems that consist of leaders and gutters that collect water coming off the roof. These leaders and gutters are connected to drain pipes that channel the water away from the structure, usually into a dry well or storm drain. A substantial add-on to the leader and gutter system is a debris trap with an overflow port. The debris trap / overflow port may be attached to the leader at waist height (for easy access) to collect leaves, tree droppings, windblown litter and other materials. This debris can be easily discarded by opening an access panel to empty a built-in strainer. When a dry well or storm drain becomes saturated, water will back up through the leader causing seepage and overflow into the building and create erosion that can damage the foundation. The function of the overflow port is to divert water from the drain pipe away from the foundation. The debris trap / overflow port system not only channels water away from the building but also prevents overflow of organic materials that can accumulate along the foundation.

Owner:HURTADO JIM

Rotational living sewage aeration mechanism

InactiveCN107364960ANo cloggingWell mixedSustainable biological treatmentBiological water/sewage treatmentDraining tubeDrive shaft

The invention discloses a rotational living sewage aeration mechanism which comprises a tank body, a fixing rack, a motor, a rotating shaft, aeration blades, an aeration disc, a main air conveying tube, a water discharge tube and a water inlet tube, wherein the fixing rack is fixedly connected with the top of the tank body; the motor is fixedly connected with the lower surface of the fixing rack; the rotating shaft is fixedly connected with a shaft extension end of the motor; a chute is formed in the side wall of the rotating shaft; a sliding block is arranged on the rotating shaft in a sleeved manner; aeration blades are fixedly connected with the left side and the right side of the sliding block; a driving gear is arranged at the lower end of the rotating shaft in a sleeving manner; three driven gears are distributed around the driving gear; an annular tooth groove is fixedly connected with the inner wall of the tank body; the aeration disc is arranged on a driven shaft in the sleeve manner; an air blower is fixedly connected with the left side wall of the fixing rack. Under the action of buoyancy, the aeration blades always float on a water surface, and surface sewage is aerated by using the aeration blades; air is conveyed to the rotating shaft and the driven shaft by using the air blower, and thus sewage at the bottom and in the middle can be aerated simultaneously.

Owner:HUNAN ZHONGBEN INTELLIGENT TECH DEVCO

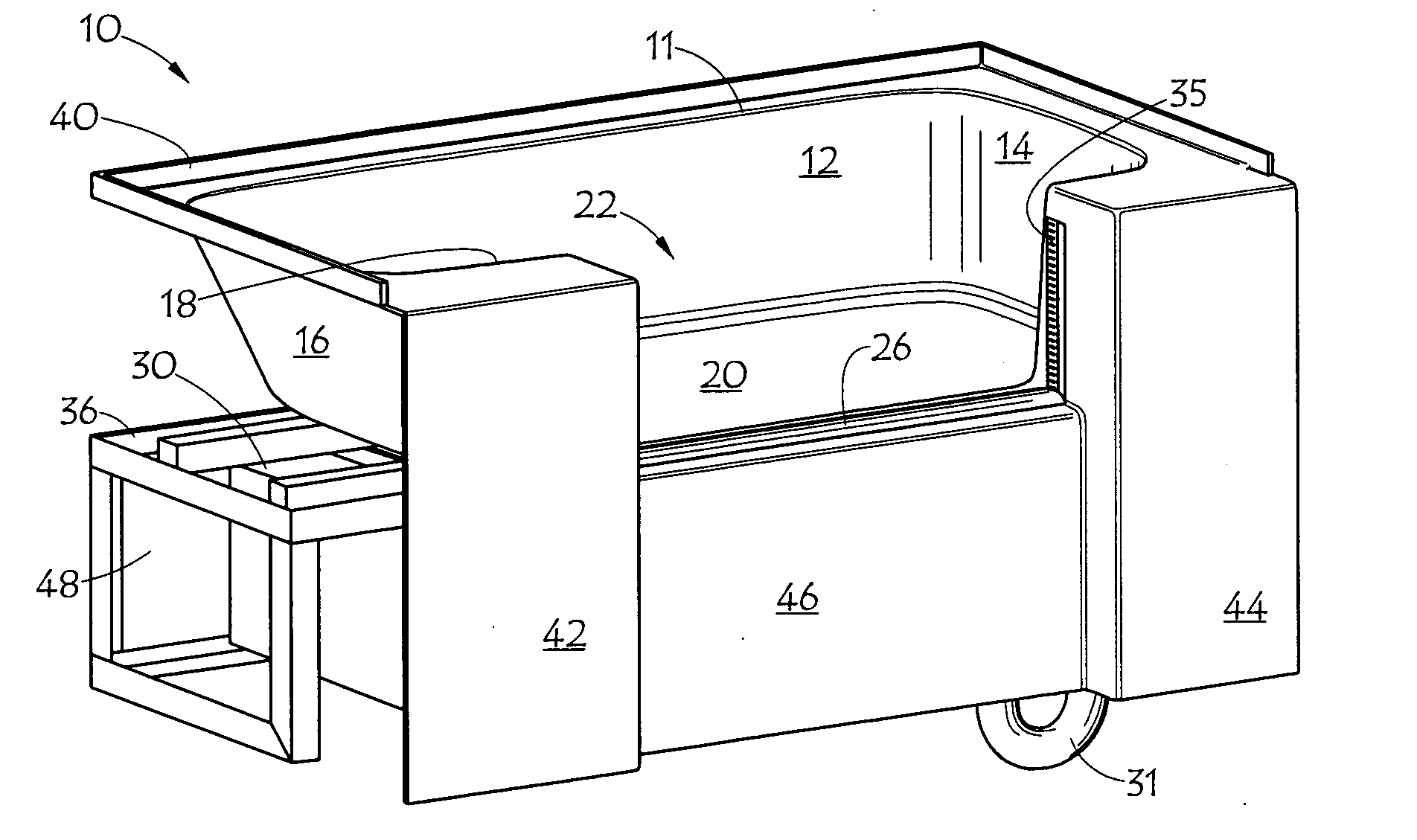

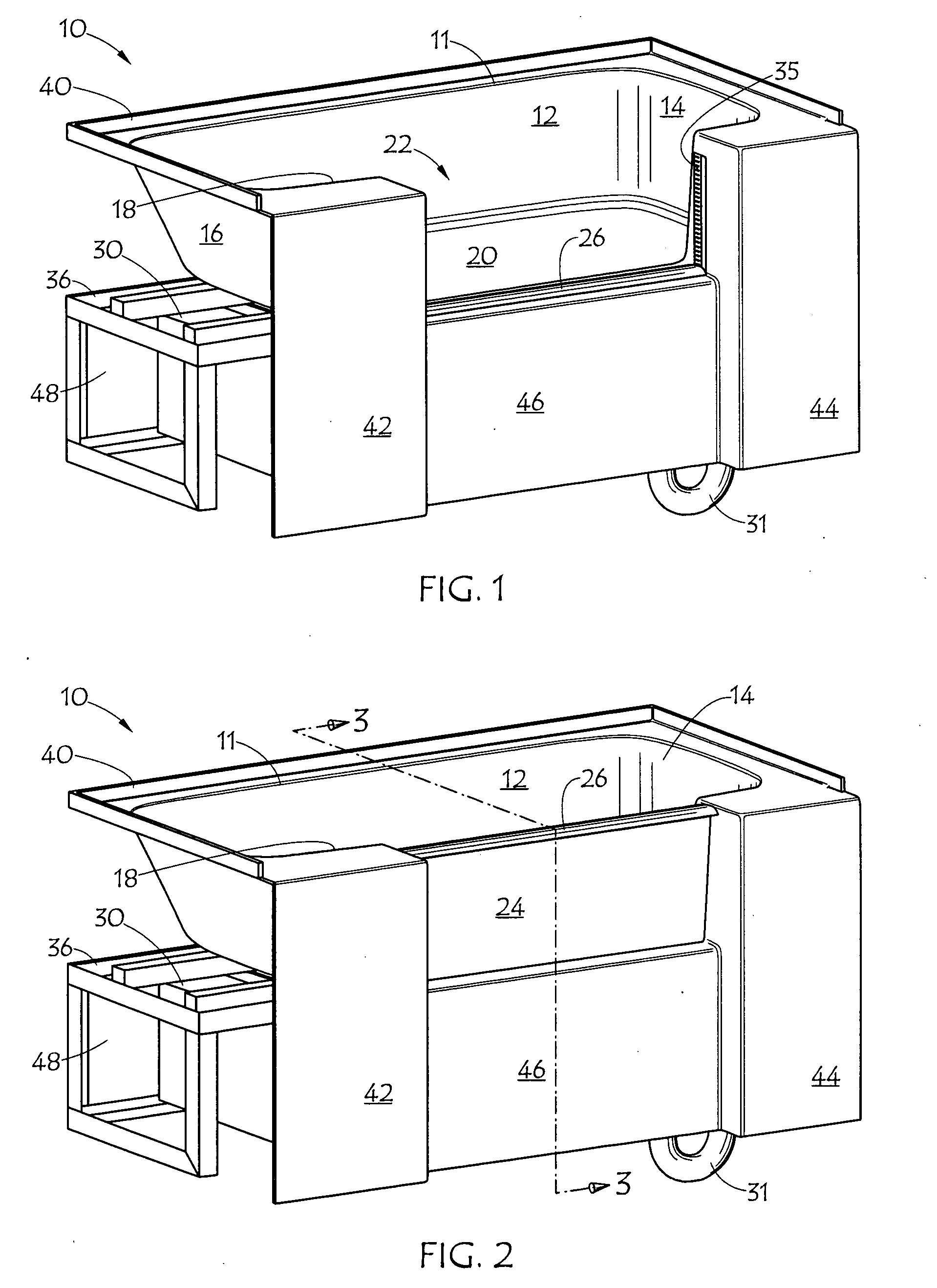

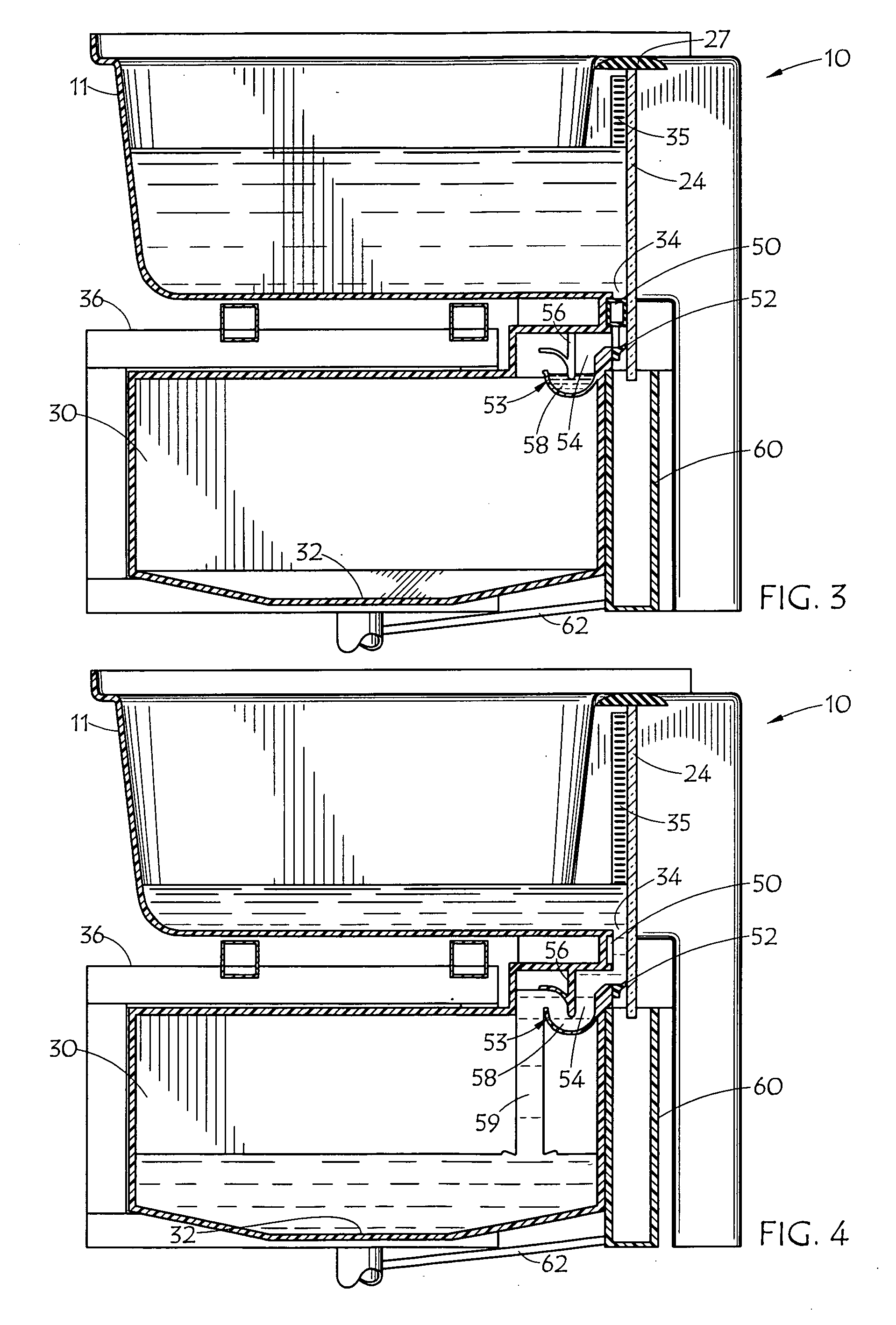

Accessible Bathtub

ActiveUS20100275364A1Minimizes and prevents chillingPrevent escapeGeneral water supply conservationIndustrial water supply conservationDraining tubeEngineering

A bathtub system, including a tub with a bather access opening in one sidewall and a door mounted on that sidewall. In the closed position, the door is adjacent the access opening, and in the open position the door is substantially clear of the access opening. The system includes a gray water reservoir under the tub of approximately the capacity of the tub and which can be connected to a sewer system. A high capacity tub drain conducts water from the tub into the reservoir by gravity alone very quickly.

Owner:AQUATIC CALIFORNIA

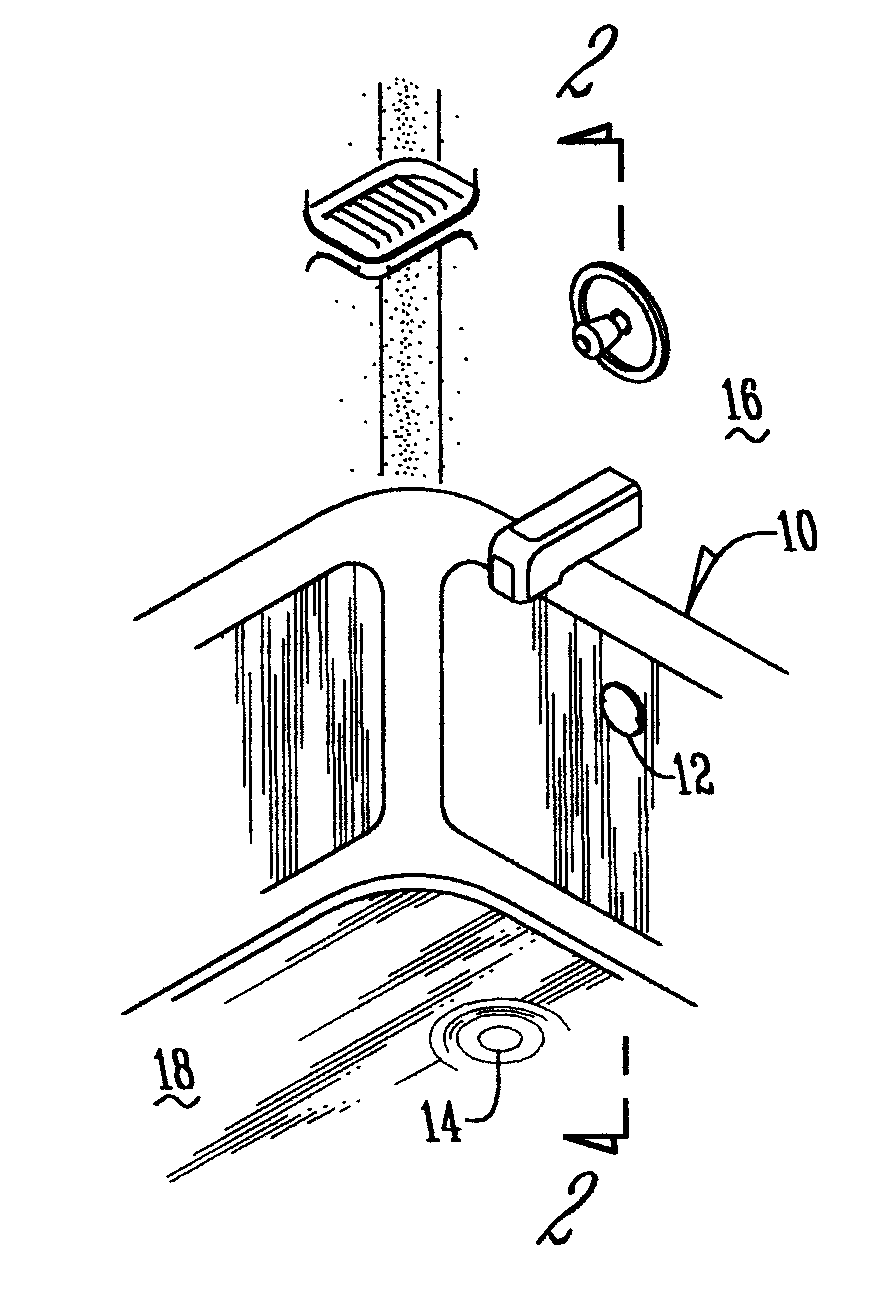

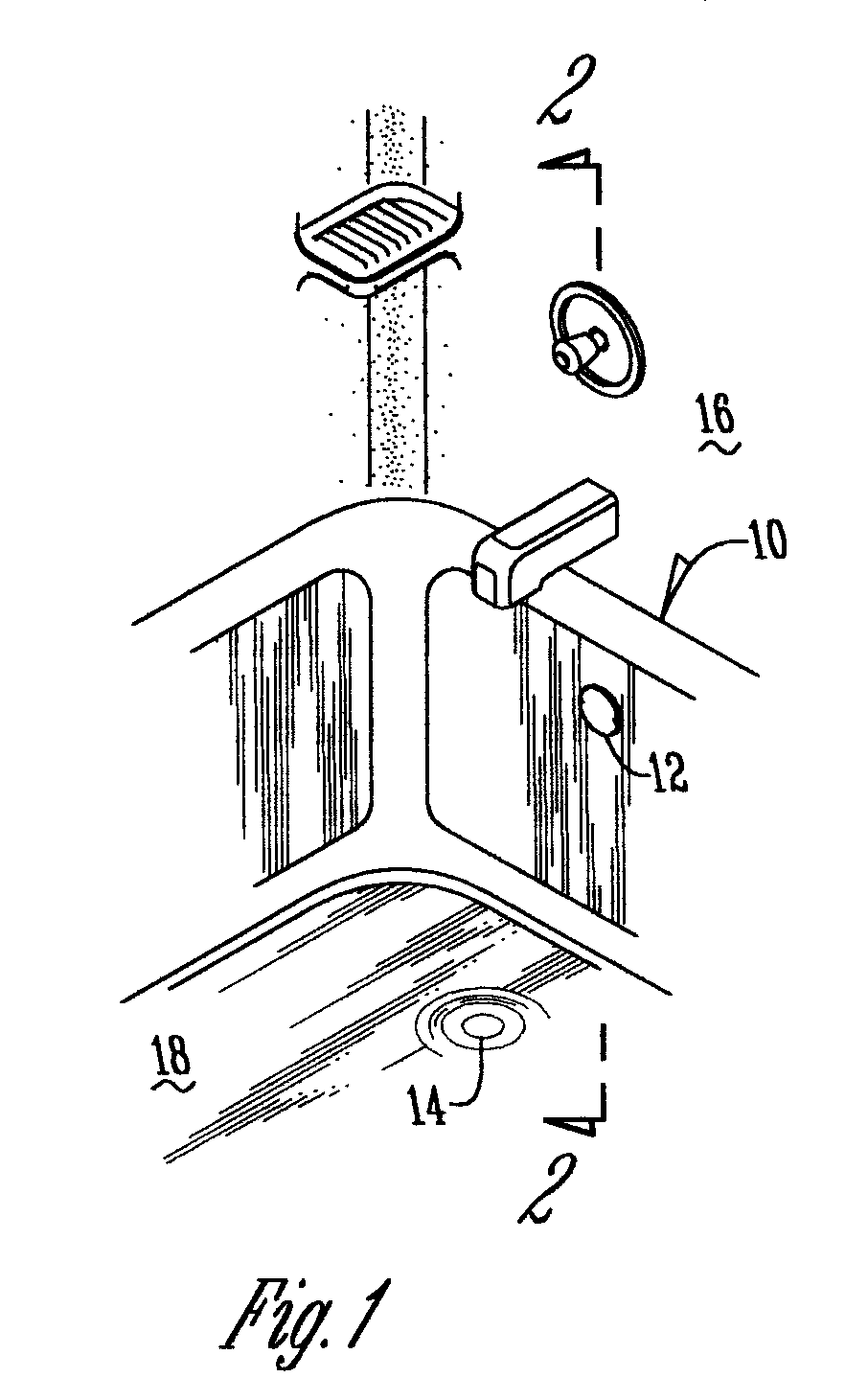

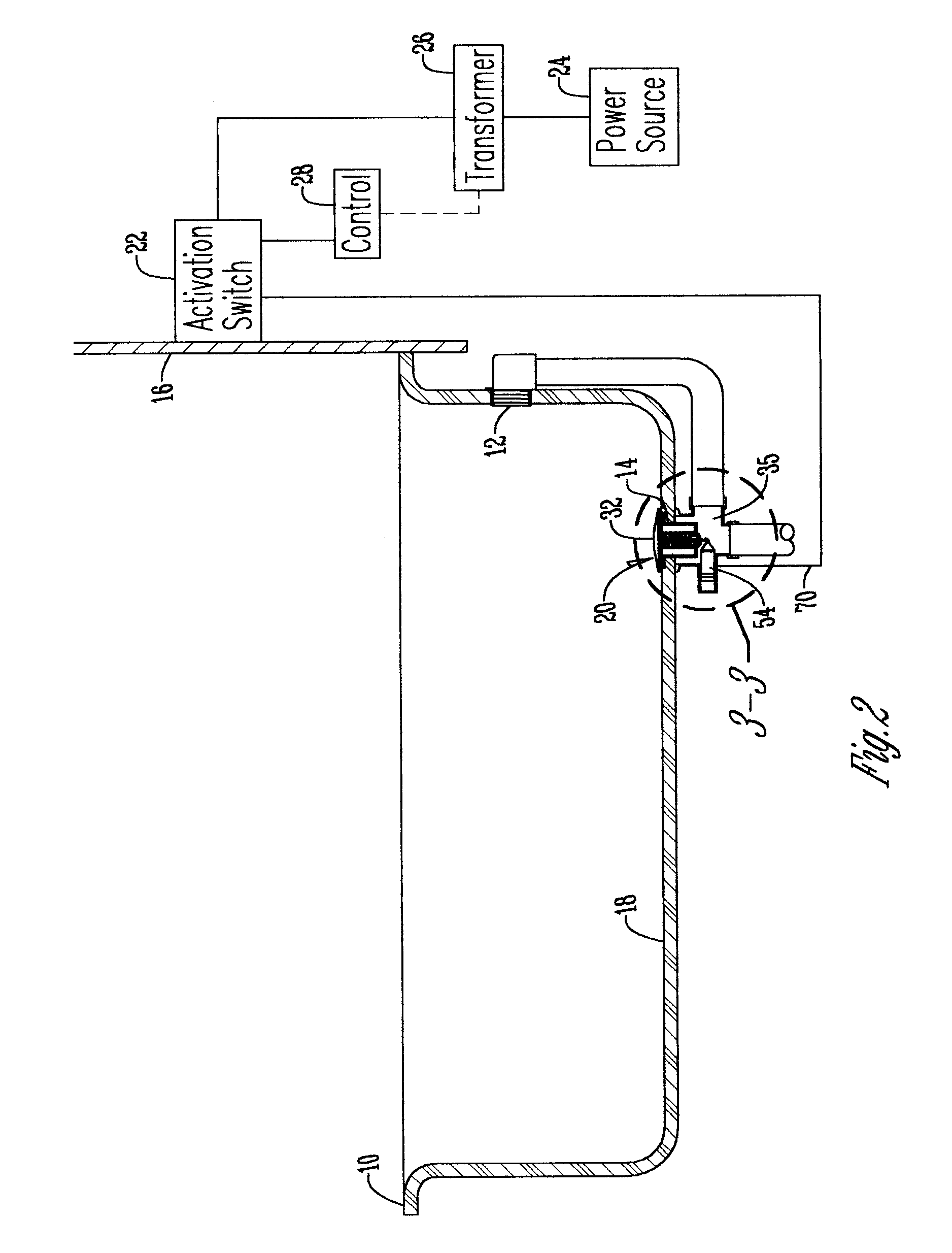

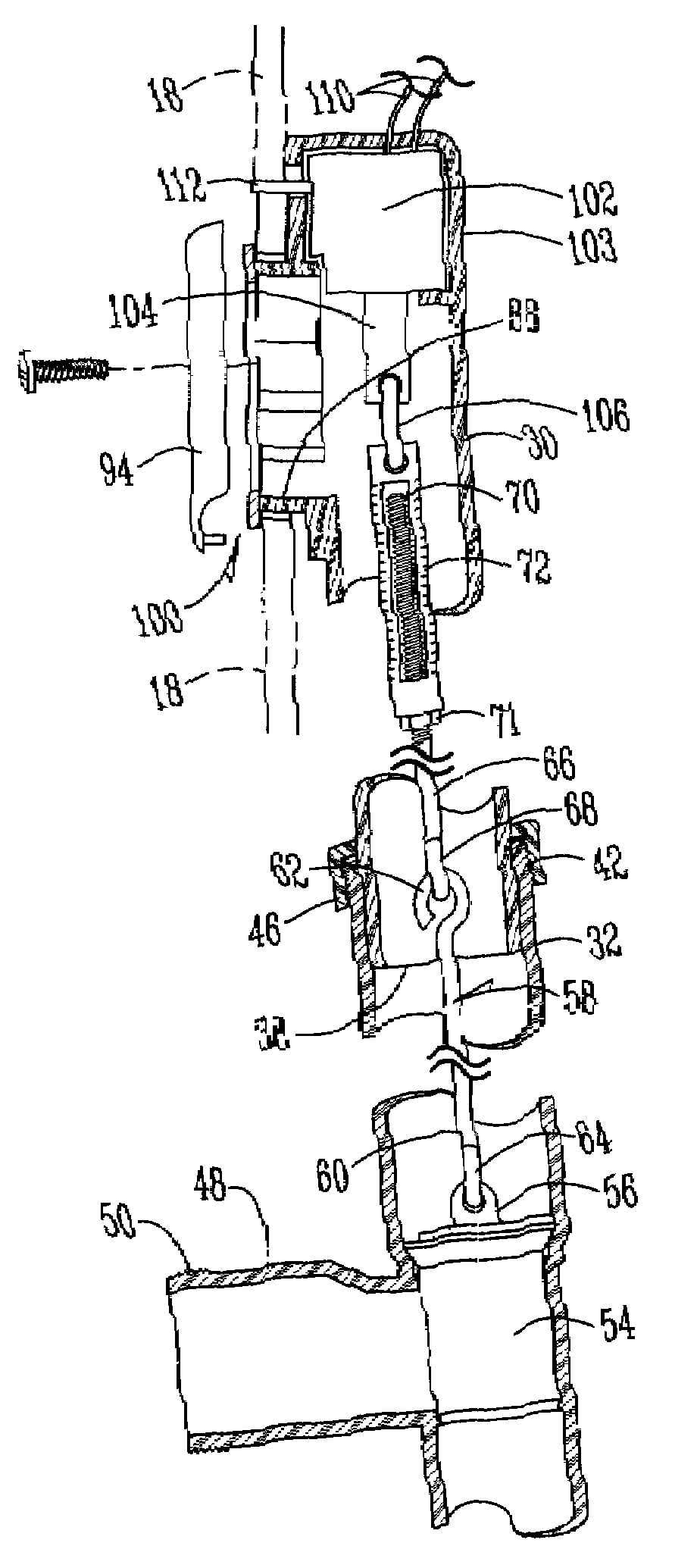

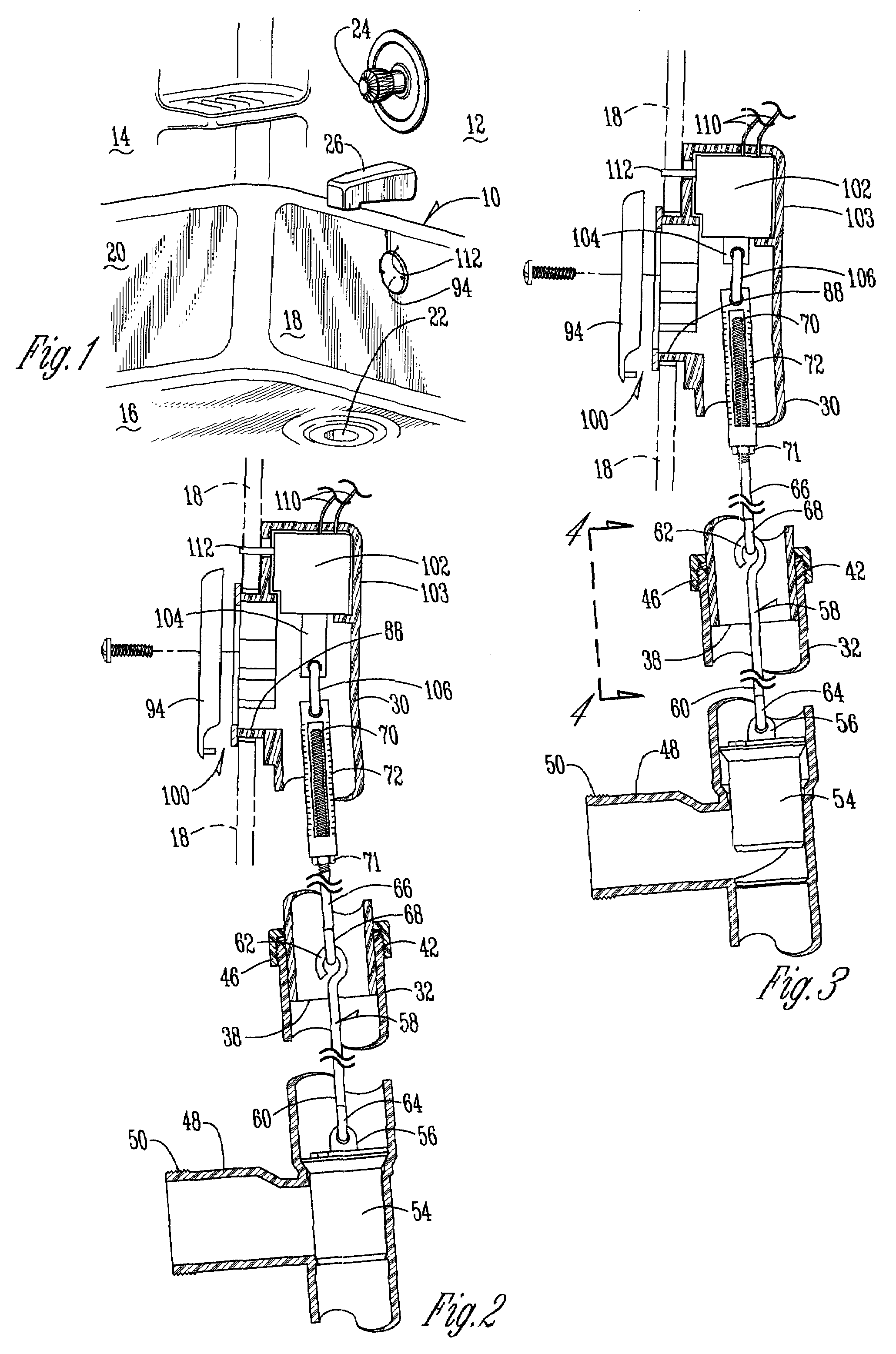

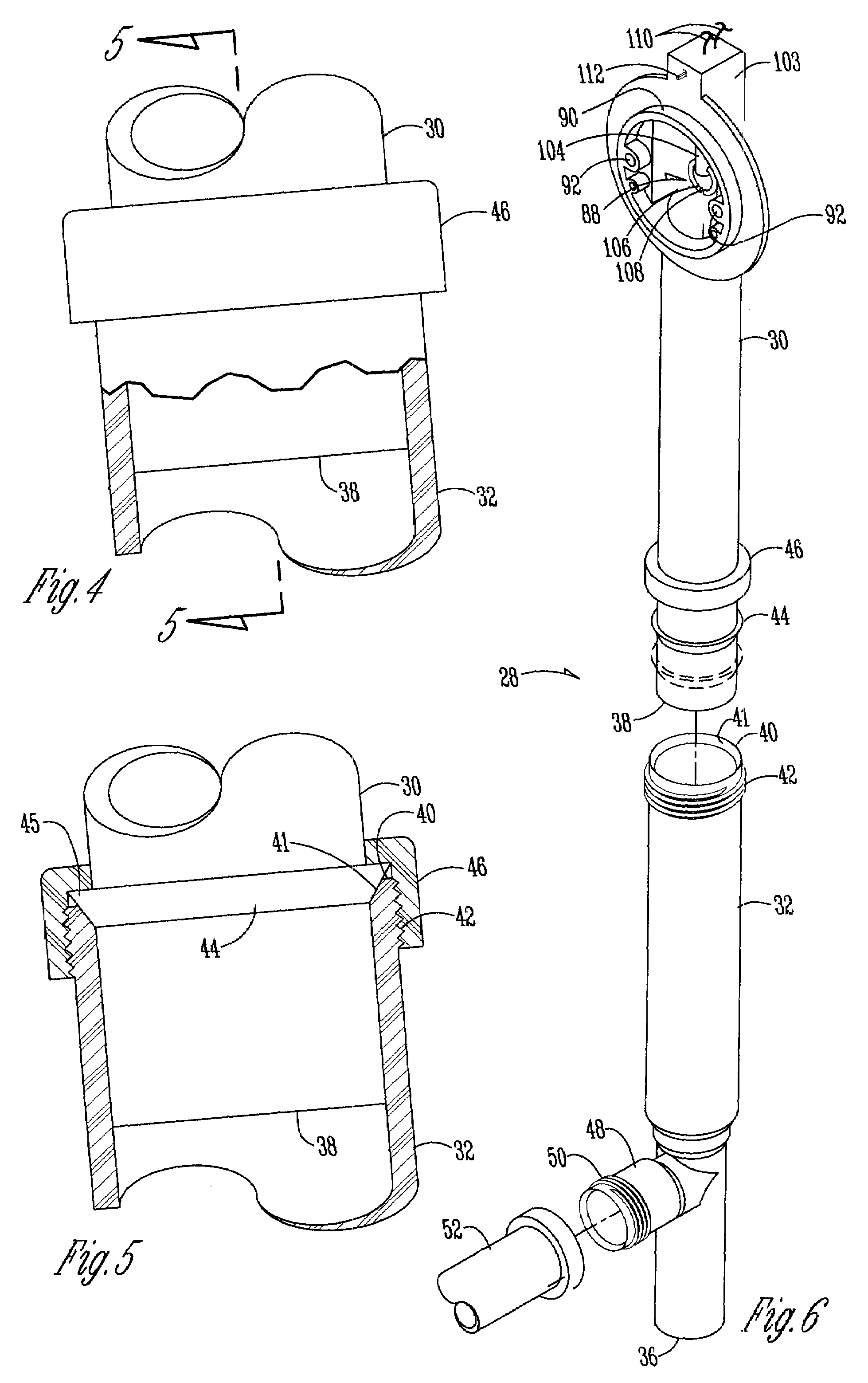

Control for a bathtub waste water drain

A control for a waste water drain in the bottom of a bathtub which has an overflow port above the drain in the end wall of the bathtub has a vertical drain pipe having upper and lower ends. A first fluid port is located at the upper end of the vertical drain pipe and a second fluid port is located below the first fluid port for connection to a bathtub waste water drain. A valve element is slidably mounted in the vertical drain pipe adjacent the second port and is movable between a lower position to close the second port to fluid flow, and an upper position which will open the second fluid port to fluid flow. An electrical motor system is mounted adjacent the first port. An elongated linkage connects the valve element to the motor so that the rotation of the motor will raise and lower the valve element. The vertical drain pipe is length-adjustable.

Owner:WCM IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com